Patents

Literature

378 results about "Directional well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A directional well is an oil industry term for an oil well with a borehole that deviates from a vertically straight line. This is normally done with the intention of hitting several target sands, for instance.

Method and apparatus for directional well logging with a shield having sloped slots

InactiveUS6297639B1Electric/magnetic detection for well-loggingDetection using electromagnetic wavesUltrasound attenuationDirectional well

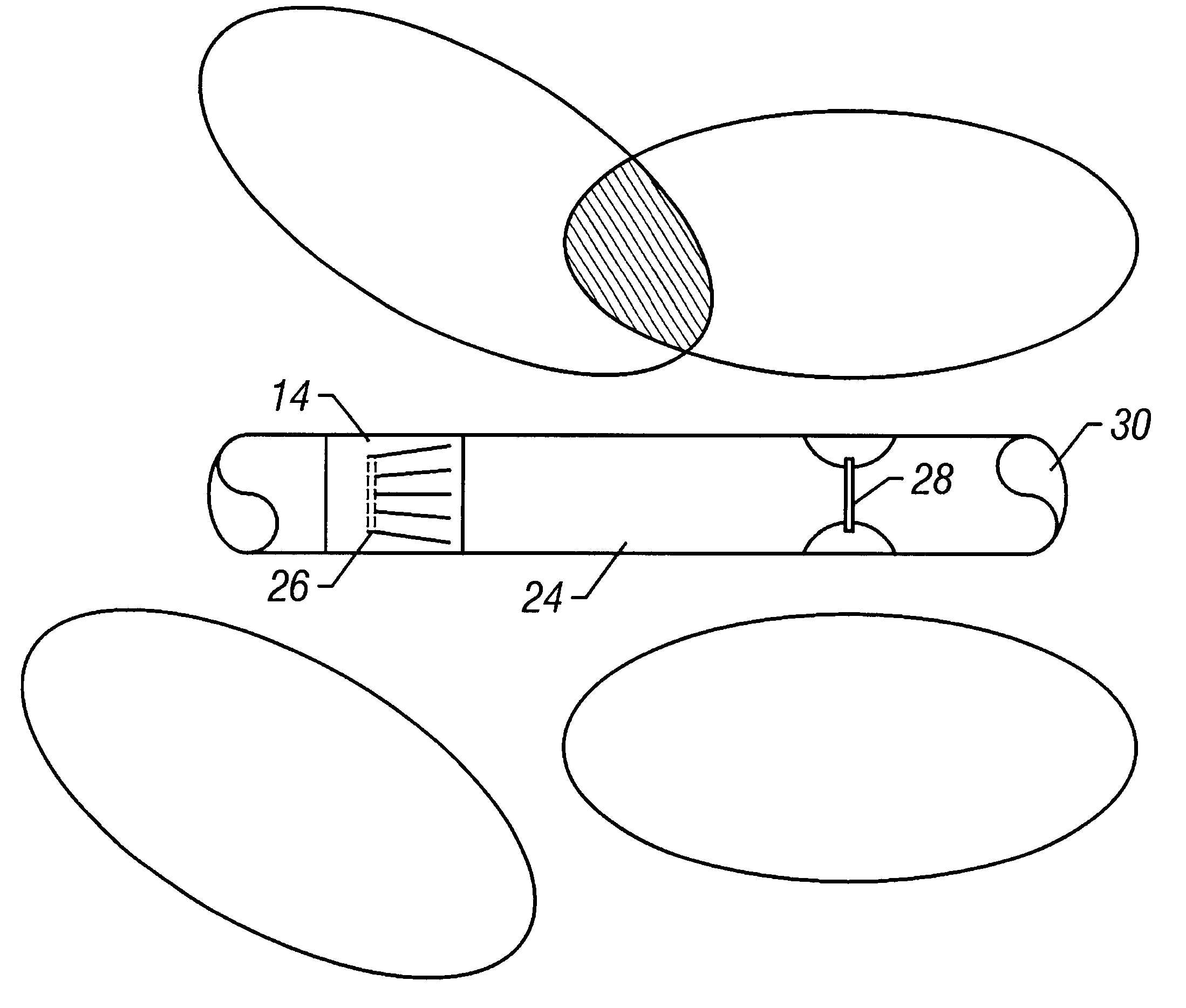

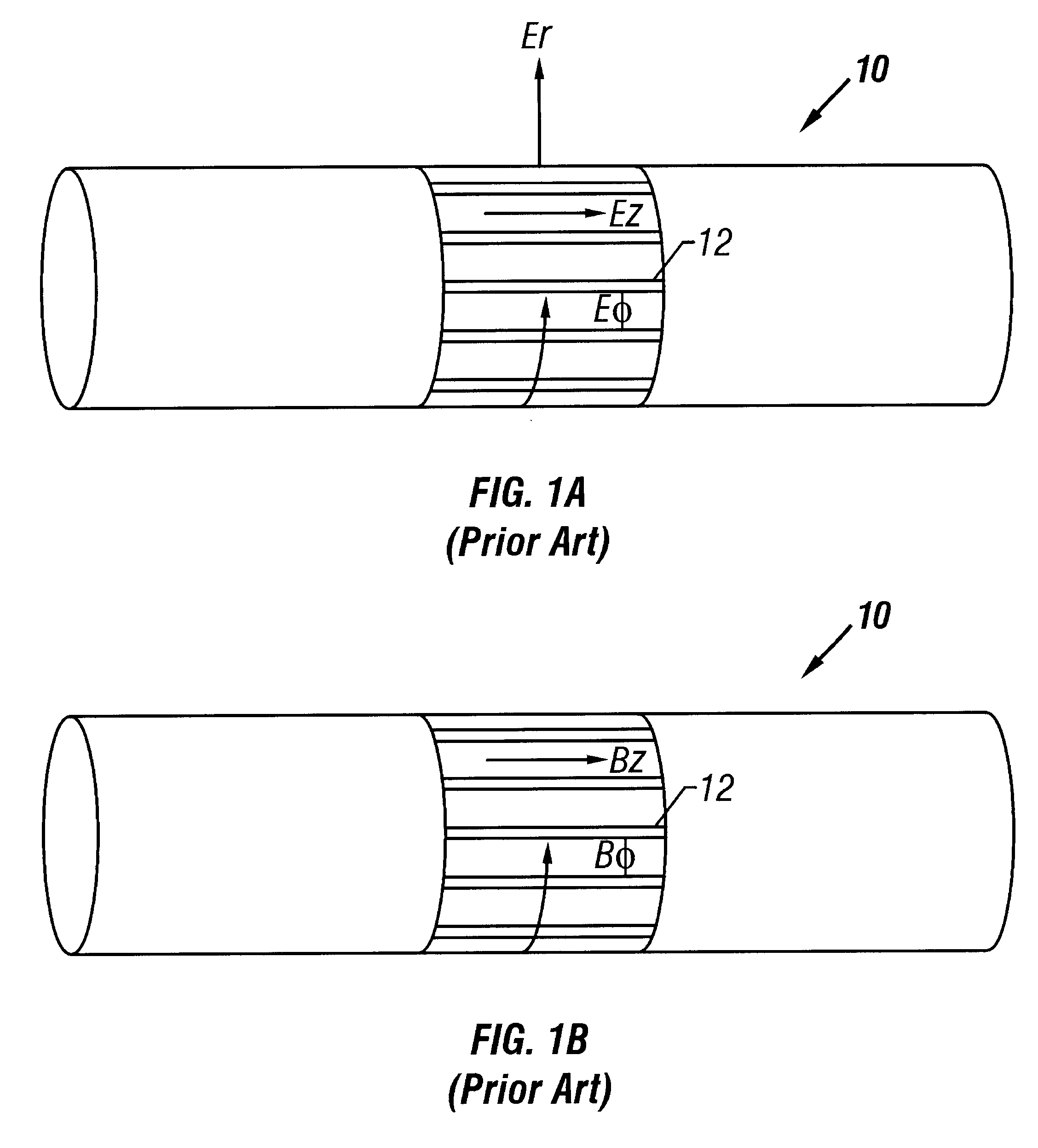

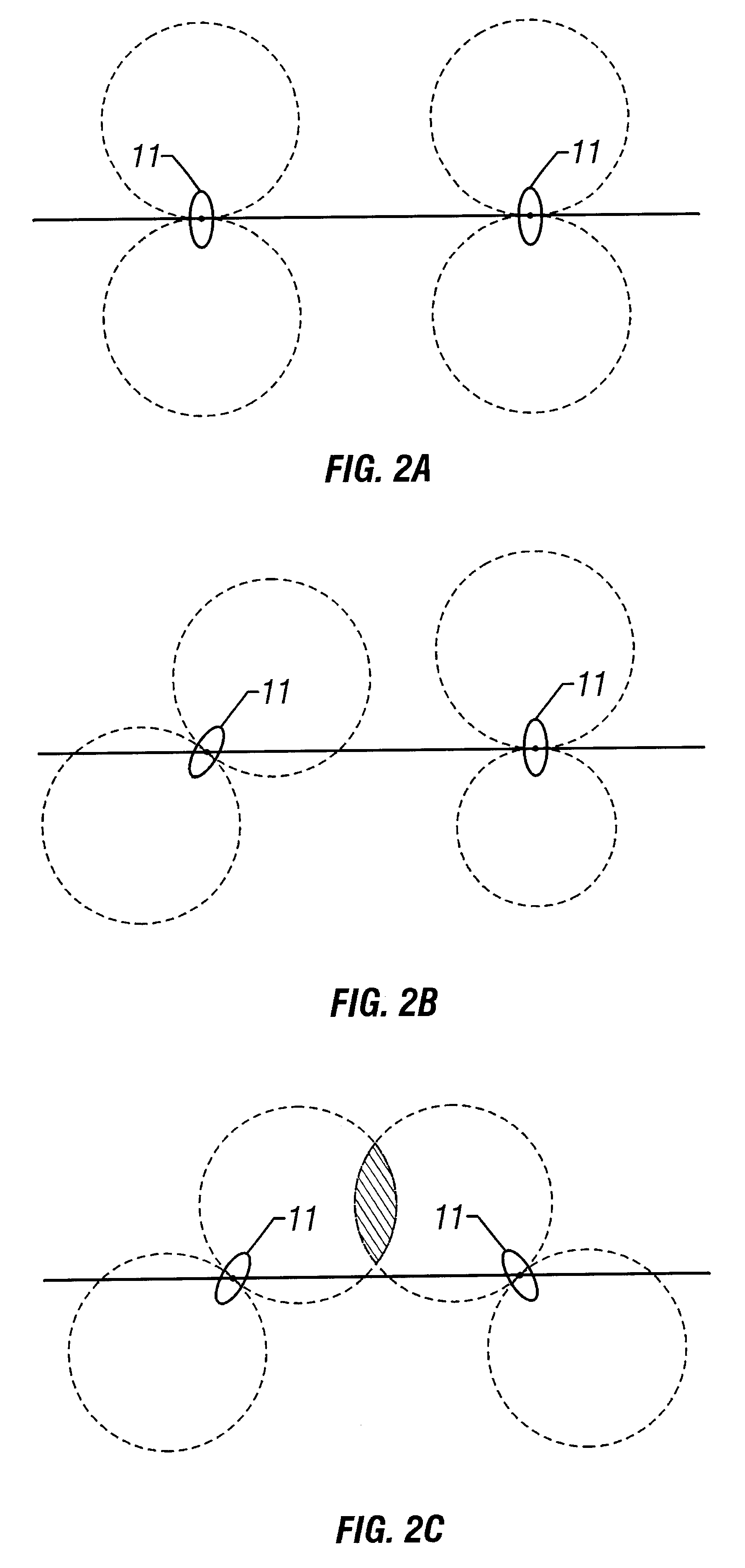

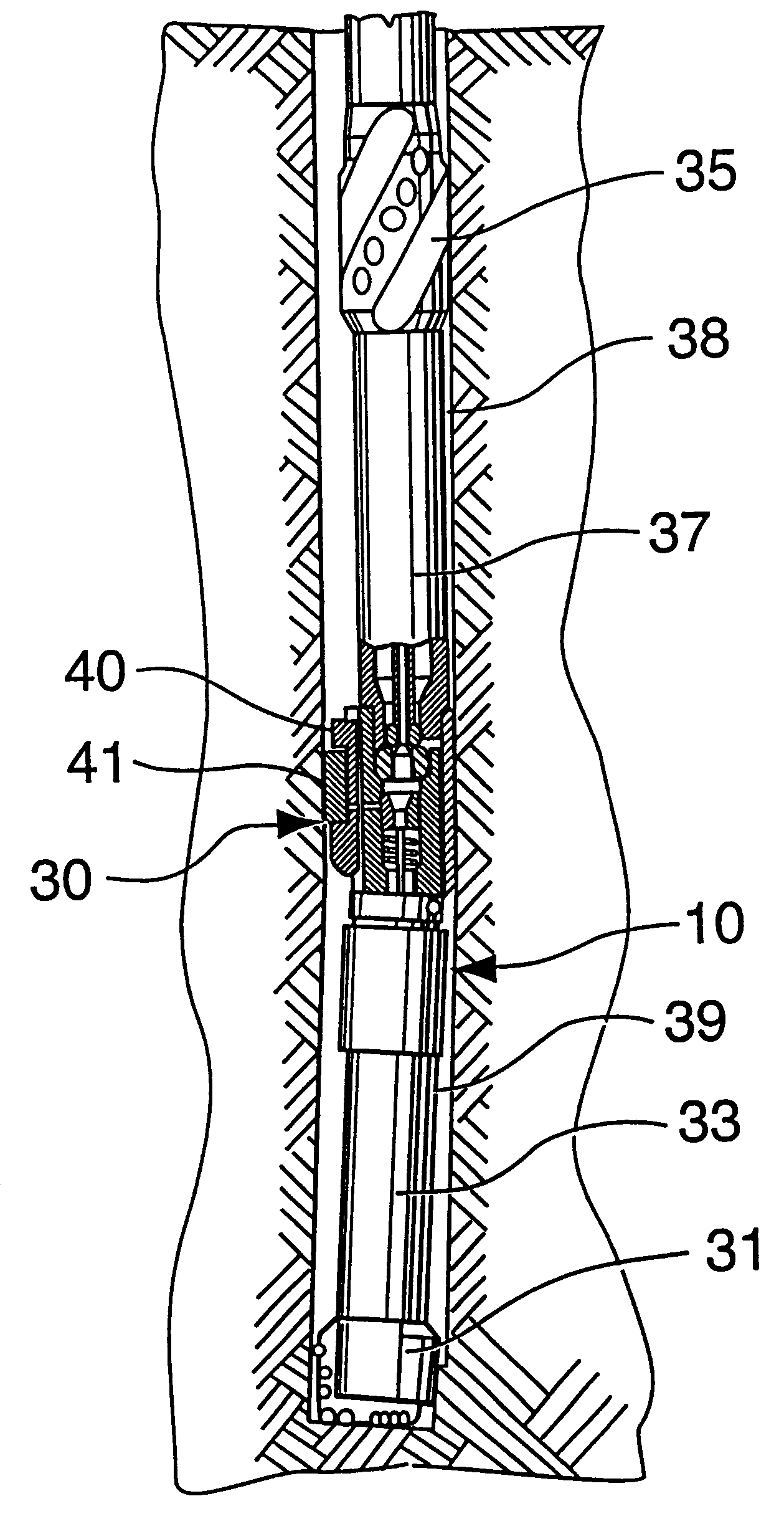

Methods and apparatus for making directional measurements of earth formations surrounding a borehole. New antenna coil shield designs are utilized to provide selective attenuation of at least one electromagnetic energy field component as the component interacts with the shield. The new shields are implemented in several downhole tool configurations to provide azimuthally focused formation measurements. In effect, the new shield filters interacting electromagnetic energy field components to pass those components corresponding to a magnetic dipole oriented at an angle from the tool axis. The shields thereby alter a coil's envelope of influence to electromagnetic energy. The new shields also form part of a system for making directional measurements while drilling.

Owner:SCHLUMBERGER TECH CORP

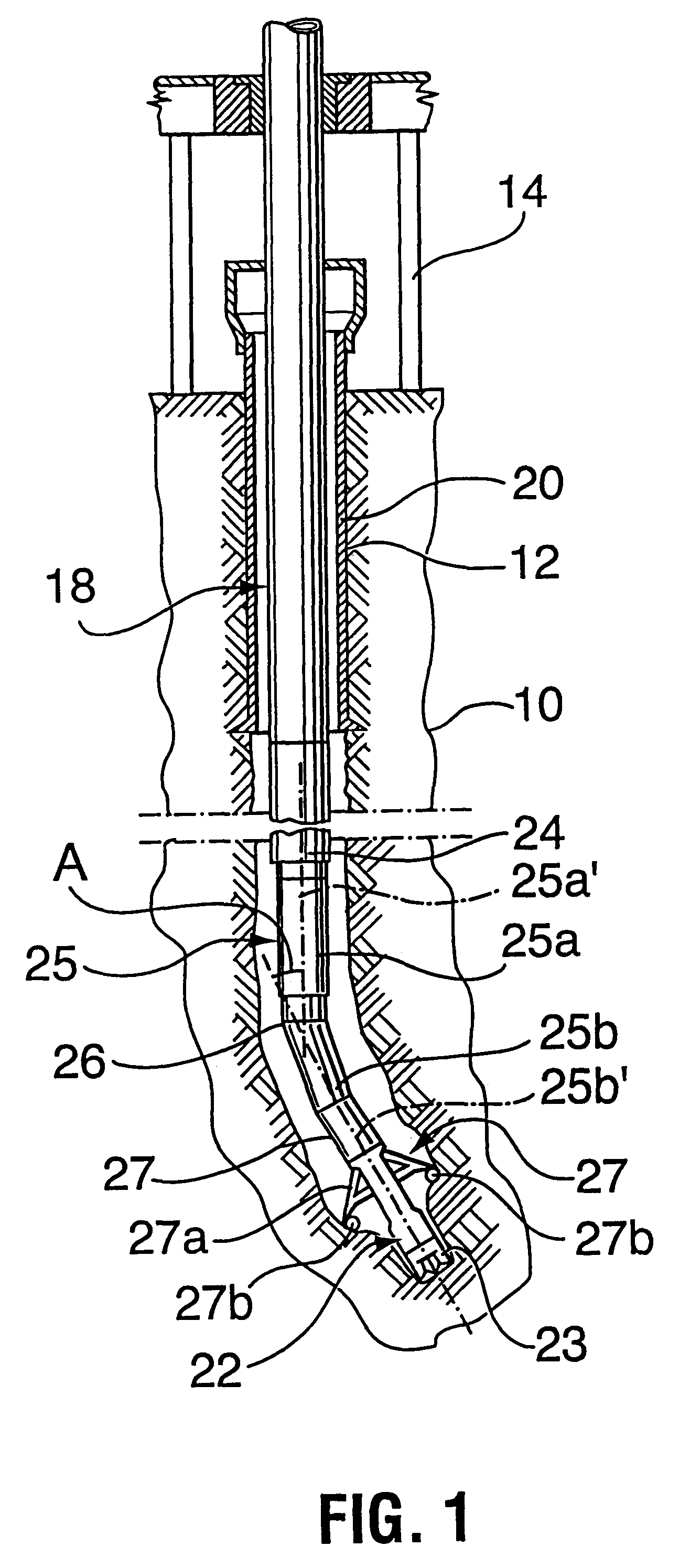

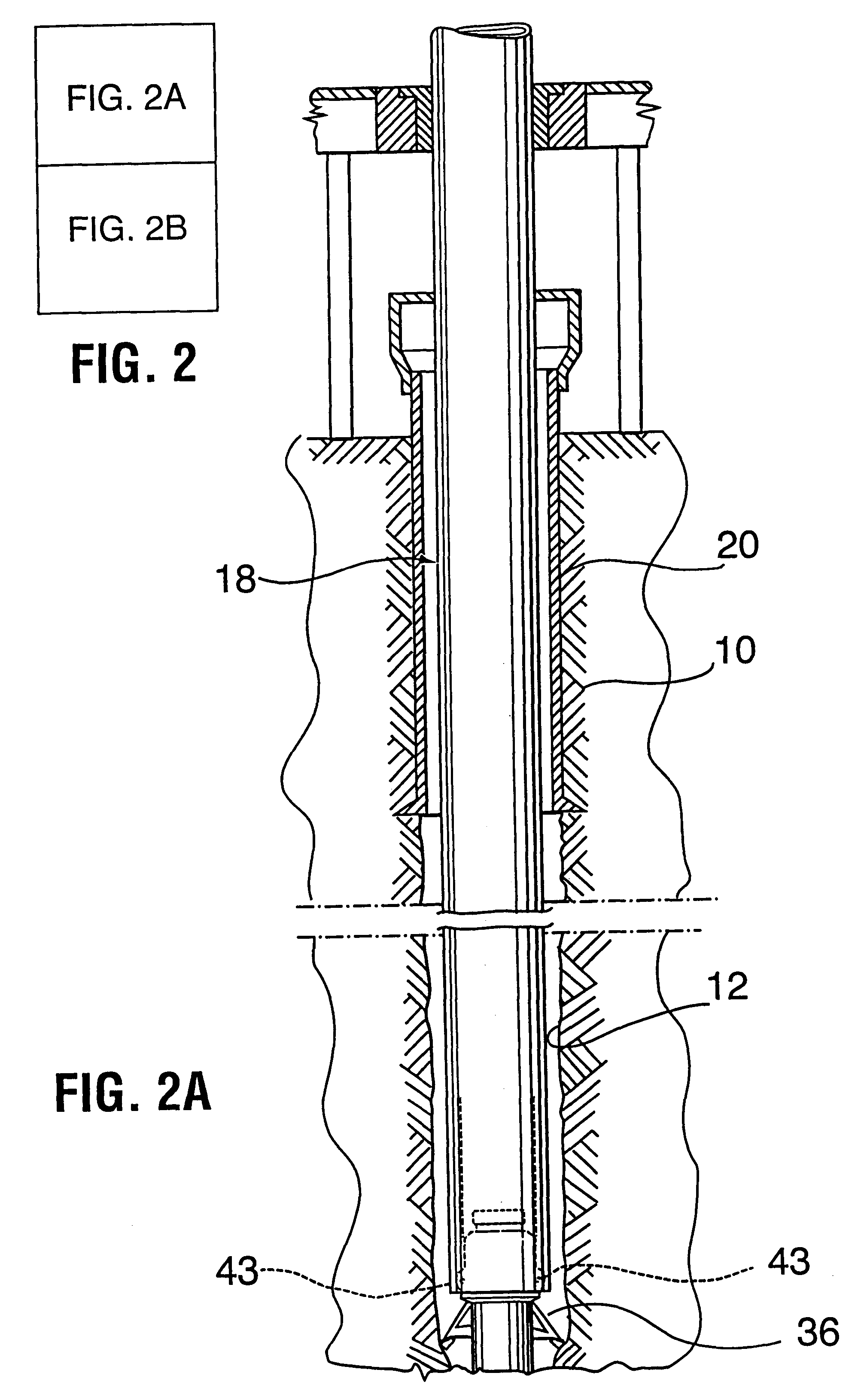

Drilling with casing

A method and apparatus for drilling directional wellbores using a casing string as a drill stem is taught. A retrievable bit is mounted at an end of the casing string and either a mud motor with a bent housing and / or bent sub or a rotary steerable tool is used to direct the bit to drill directionally.

Owner:SCHLUMBERGER TECH CORP

Method and composition for preventing or treating lost circulation

InactiveUS7066285B2Easily hydrolyzedPreventing and alleviatingLiquid/gas jet drillingFlushingDirectional wellWell drilling

An improved composition and method is provided for preventing or alleviating lost circulation during the drilling of wellbores in subterranean formations, and particularly during the drilling of oil and gas wells. The method is suited for horizontal and directional wells as well as more vertical wells. The composition of the invention comprises a synergistic blend of resilient, angular, carbon-based material and a water-swellable, crystalline synthetic polymer. The method employs the composition of the invention in preventing lost circulation.

Owner:HALLIBURTON ENERGY SERVICES INC

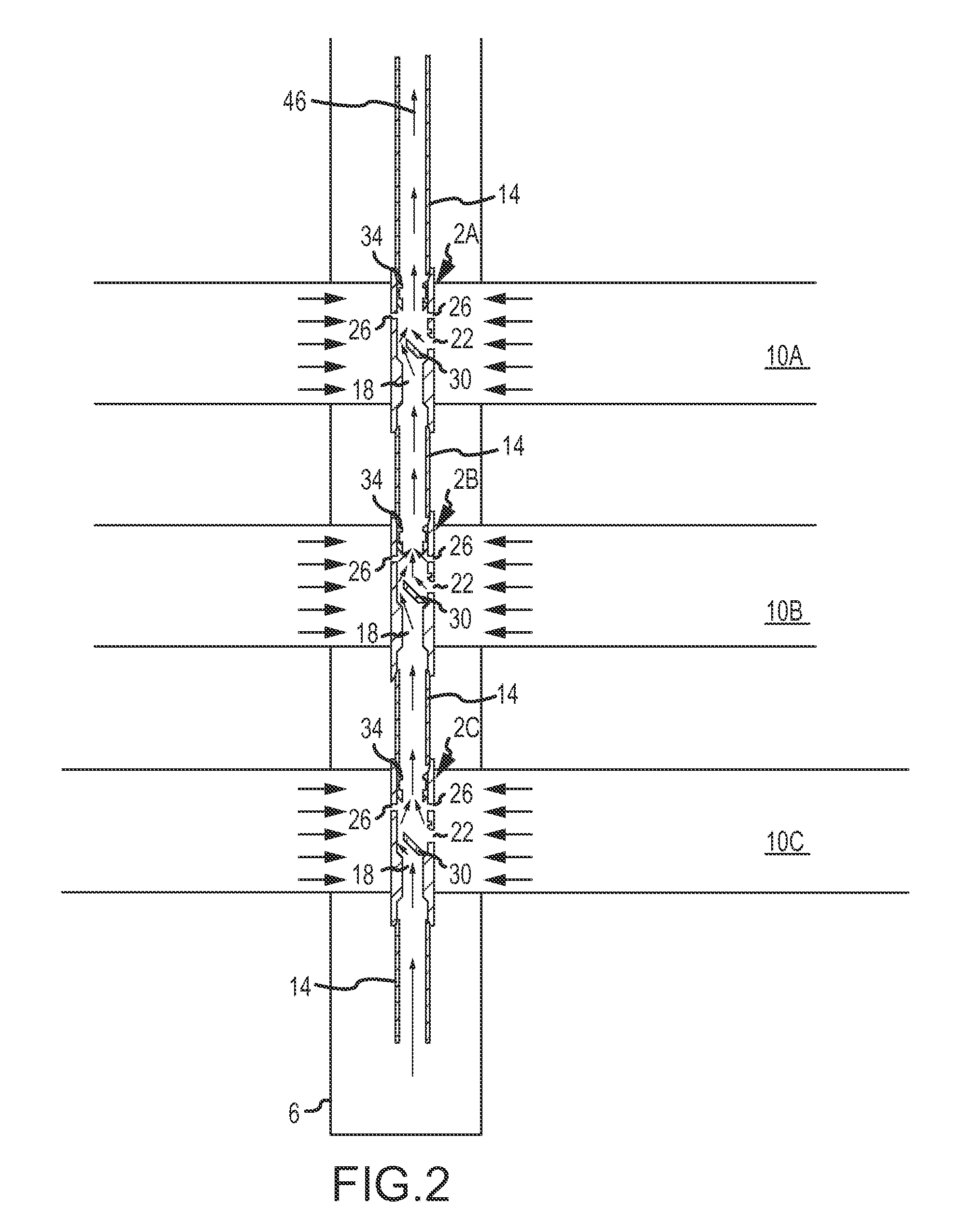

Downhole Tools and Methods for Selectively Accessing a Tubular Annulus of a Wellbore

ActiveUS20140041876A1Quality improvementMinimizing fluid/proppantConstructionsFluid removalDirectional wellWellbore

A downhole tool is provided that selectively opens and closes an axial / lateral bore of a tubular string positioned in a wellbore used to produce hydrocarbons or other fluids. When integrated into a tubular string, the downhole tool allows individual producing zones within a wellbore to be isolated between stimulation stages while simultaneously allowing a selected formation to be accessed. The downhole tools and methods can be used in vertical or directional wells, and additionally in cased or open-hole wellbores.

Owner:COLORADO SCHOOL OF MINES

Highly-efficient lubricant for drilling fluid

InactiveCN101735778AImprove the lubrication effectIncrease the extreme pressure valueDrilling compositionPolyesterPhosphate

The invention discloses a highly-efficient lubricant for a drilling fluid. The highly-efficient lubricant comprises the following components in percentage by weight: 10 to 40 percent of white oil, 30 to 70 percent of fatty acid methyl ester or methyl oleate, 5 to 20 percent of polyester, 2 to 8 percent of organic phosphate, 1 to 6 percent of oilness extreme-pressure additive, 0.5 to 2 percent of emulsifier OP-10 and 0.5 to 2 percent of span-80. The invention also discloses a method and steps for preparing the highly-efficient lubricant for the drilling fluid. The highly-efficient lubricant can enhance the lubricating property of the drilling fluid and increase an extreme pressure value of the drilling fluid, and is suitable for the demand of ordinary drilling and use in a high-difficulty highly deviated directional well and a horizontal well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

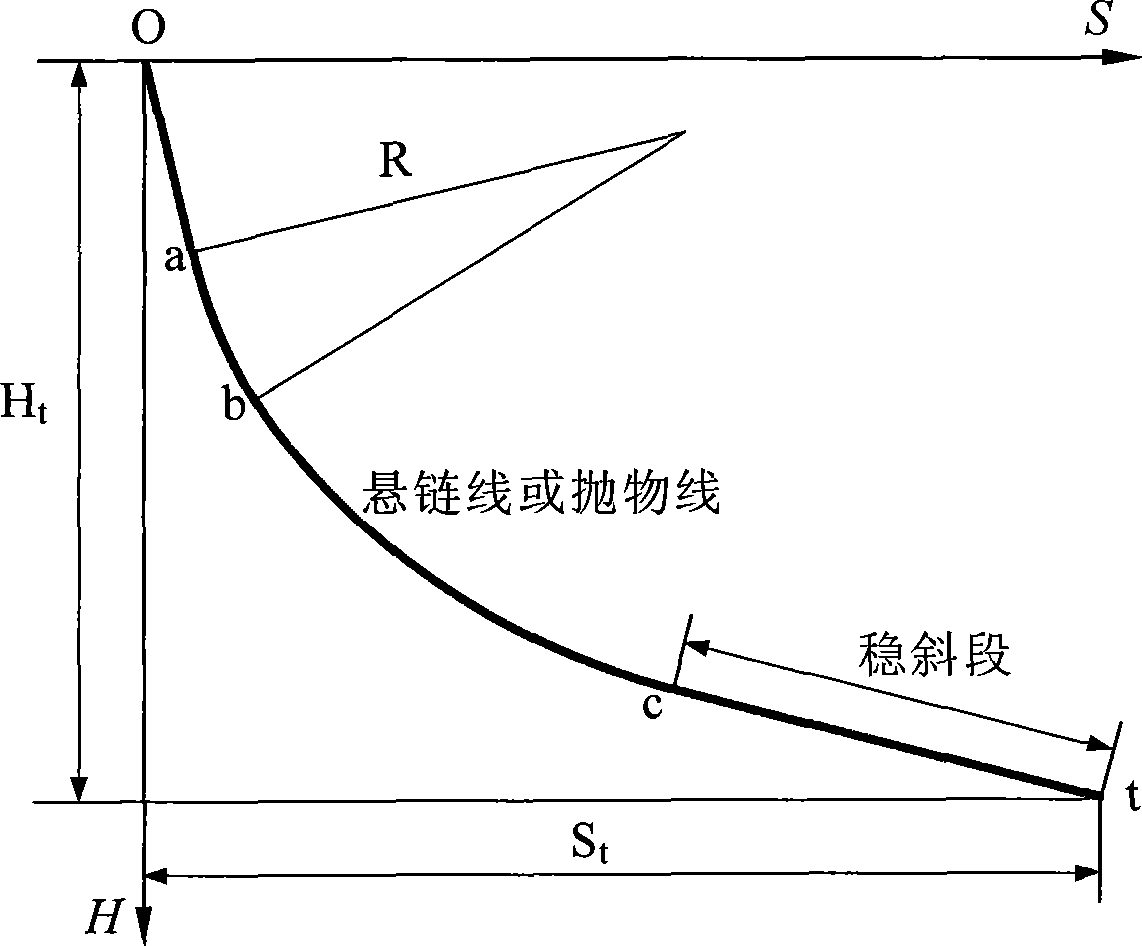

Monitoring method for drilled wellbore trajectories

InactiveCN101387198AIn line with the actual situationImprove monitoring accuracySurveyTracking modelHorizontal wells

The invention relates to a drilling engineering technology in petroleum engineering, in particular to a method for monitoring the track of an actually drilled wellbore. The method comprises the following steps: acquisition of inclination survey data and naturalization treatment; determination of characteristic parameters of a wellbore track model; determination of a hole inclination equation and an azimuth equation; calculation of coordinate increment; calculation of surveying point coordinates; and so on. As for large-displacement wells containing catenary or parabola tracks and various directional wells and horizontal wells, the method can accurately monitor the coordinates of various surveying points, so as to make the monitoring result accord with the practice of the drilling engineering, thereby effectively improving the construction precision and the reliability of catenary drilling and parabola drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

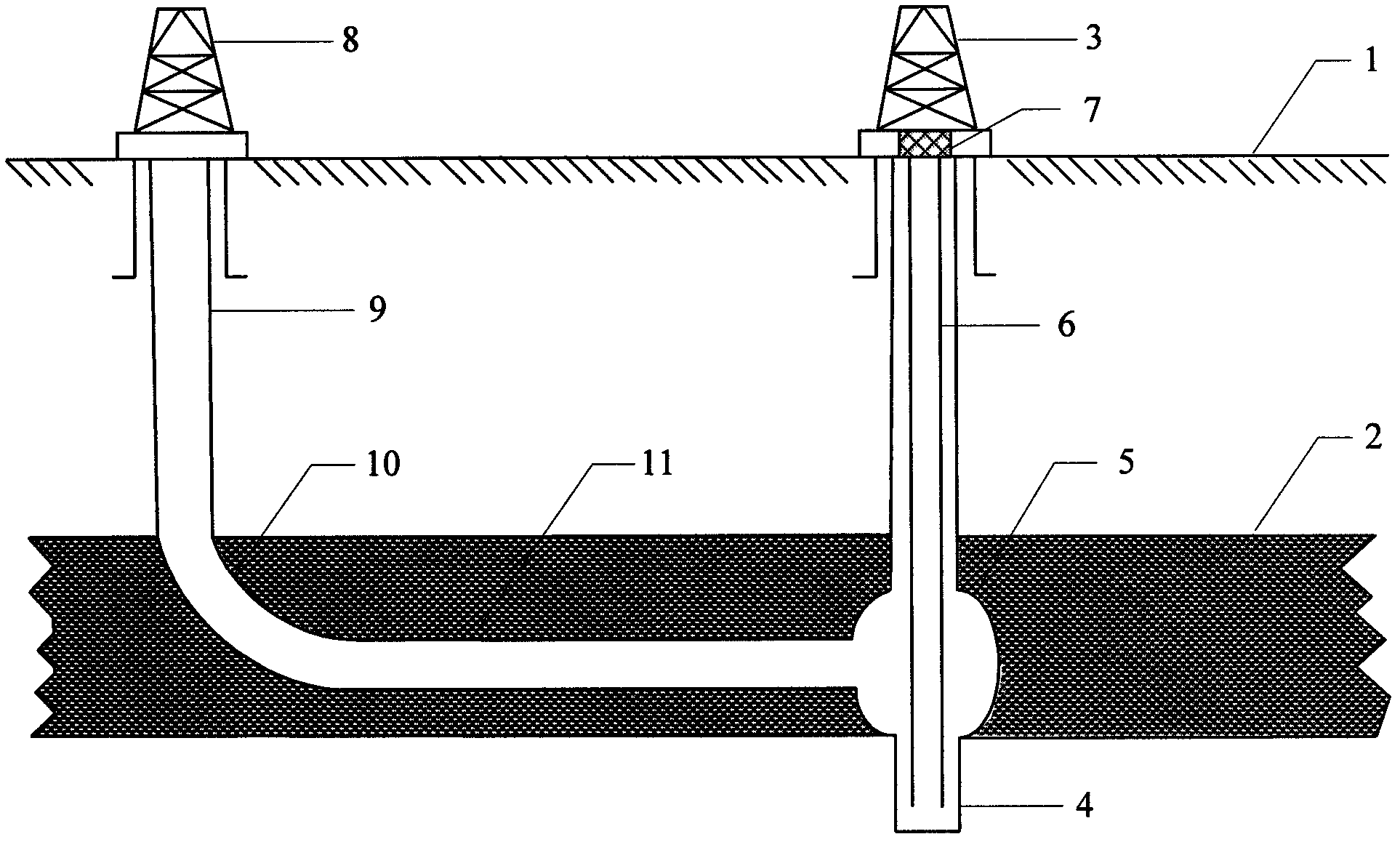

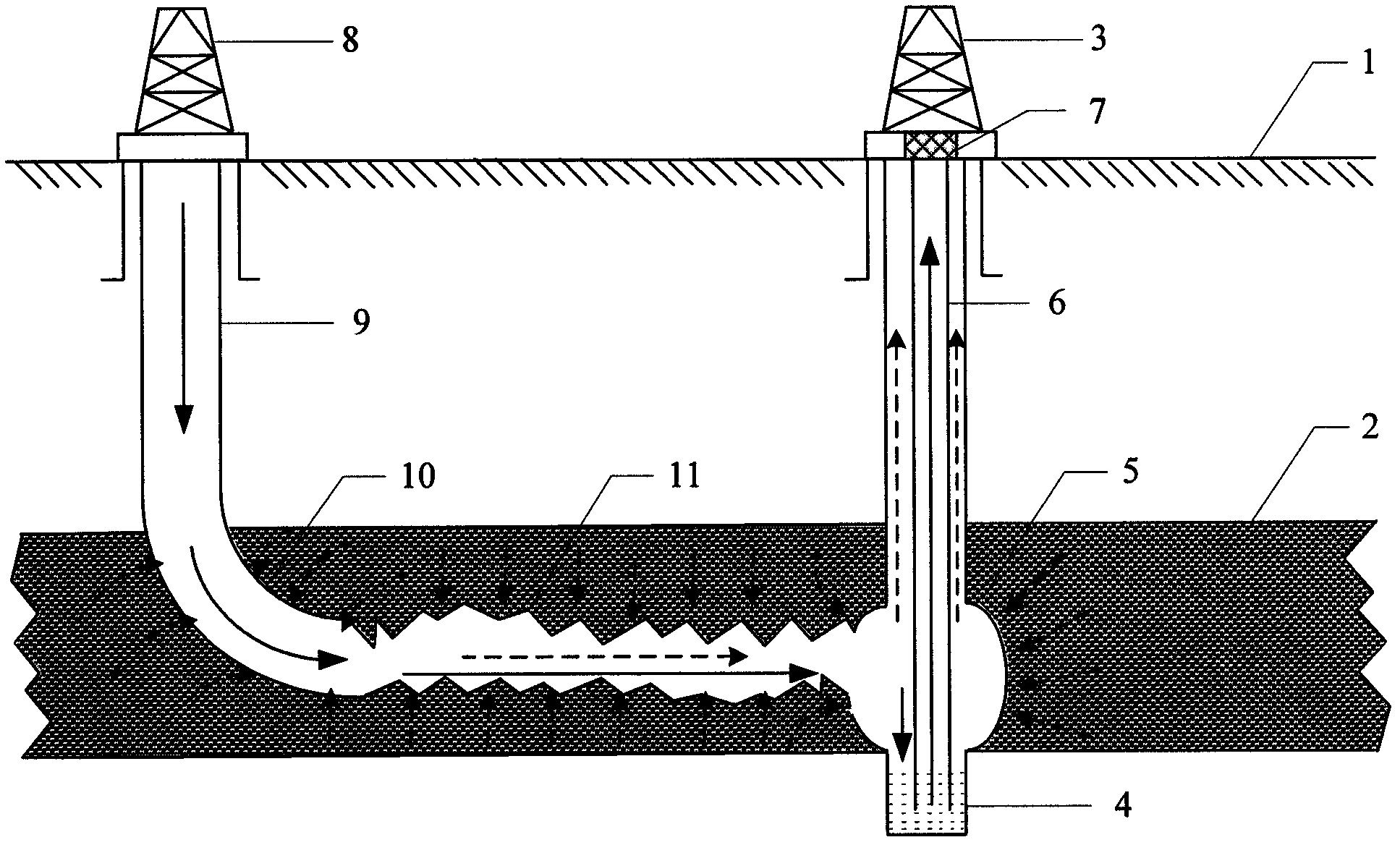

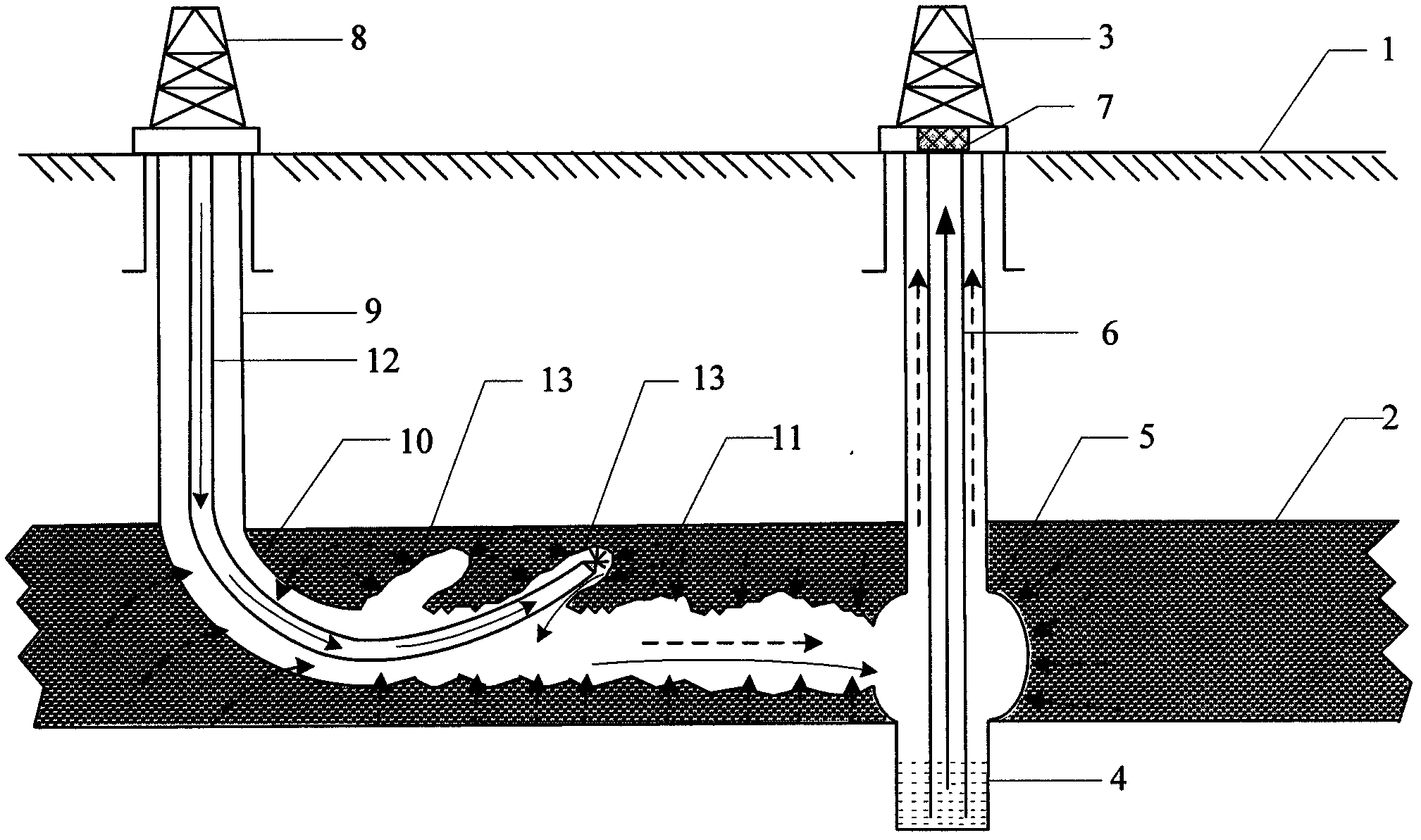

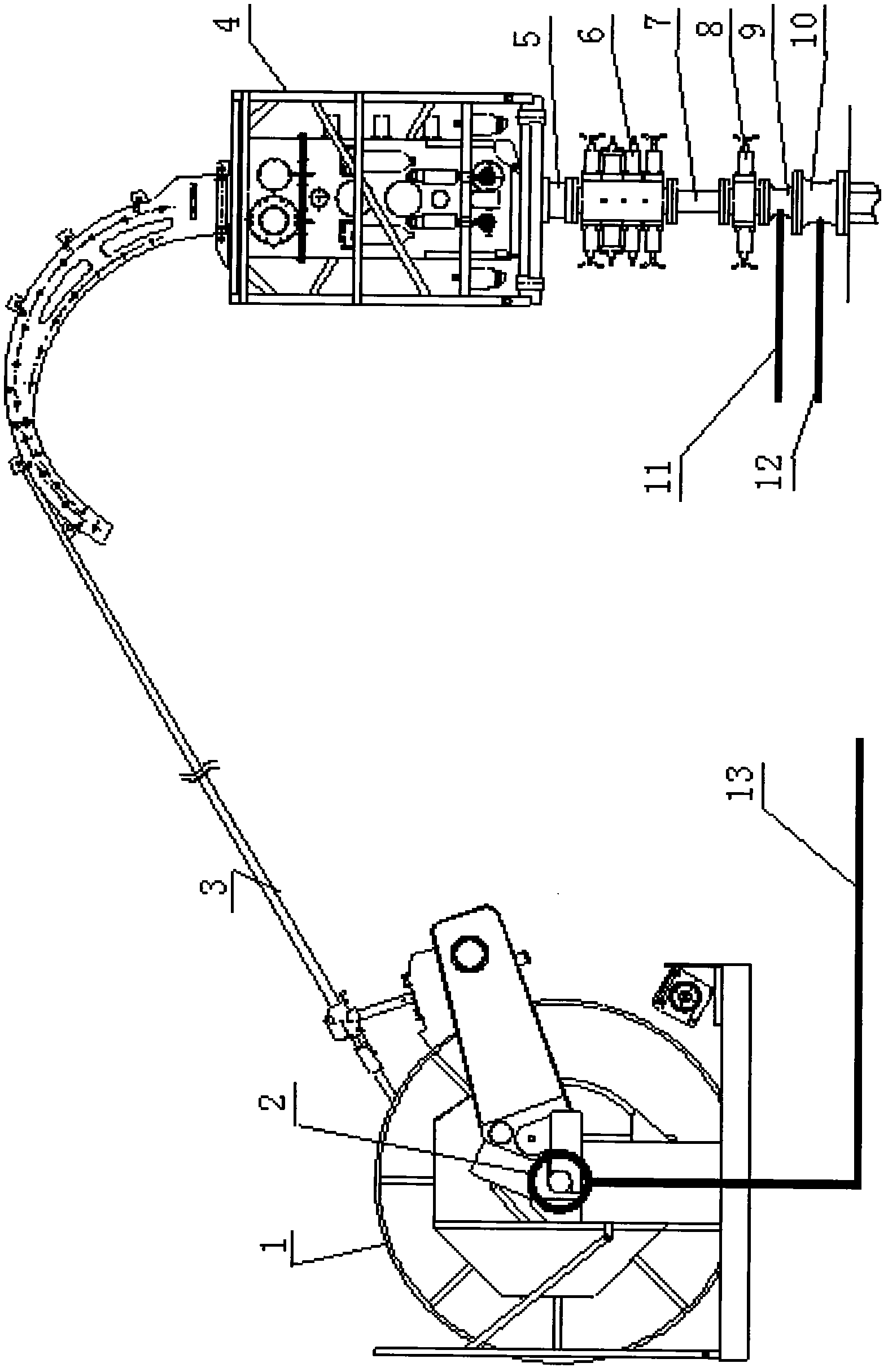

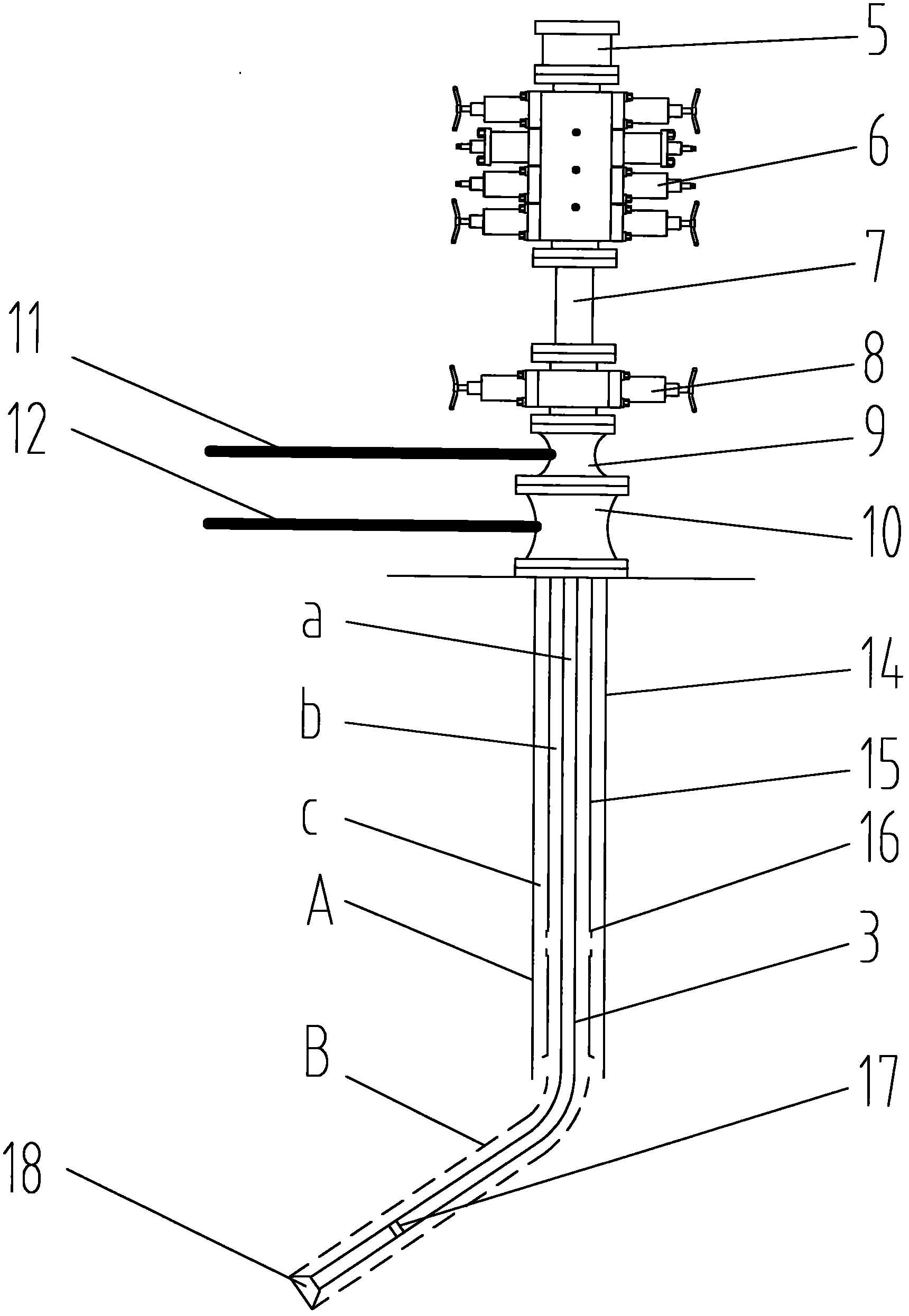

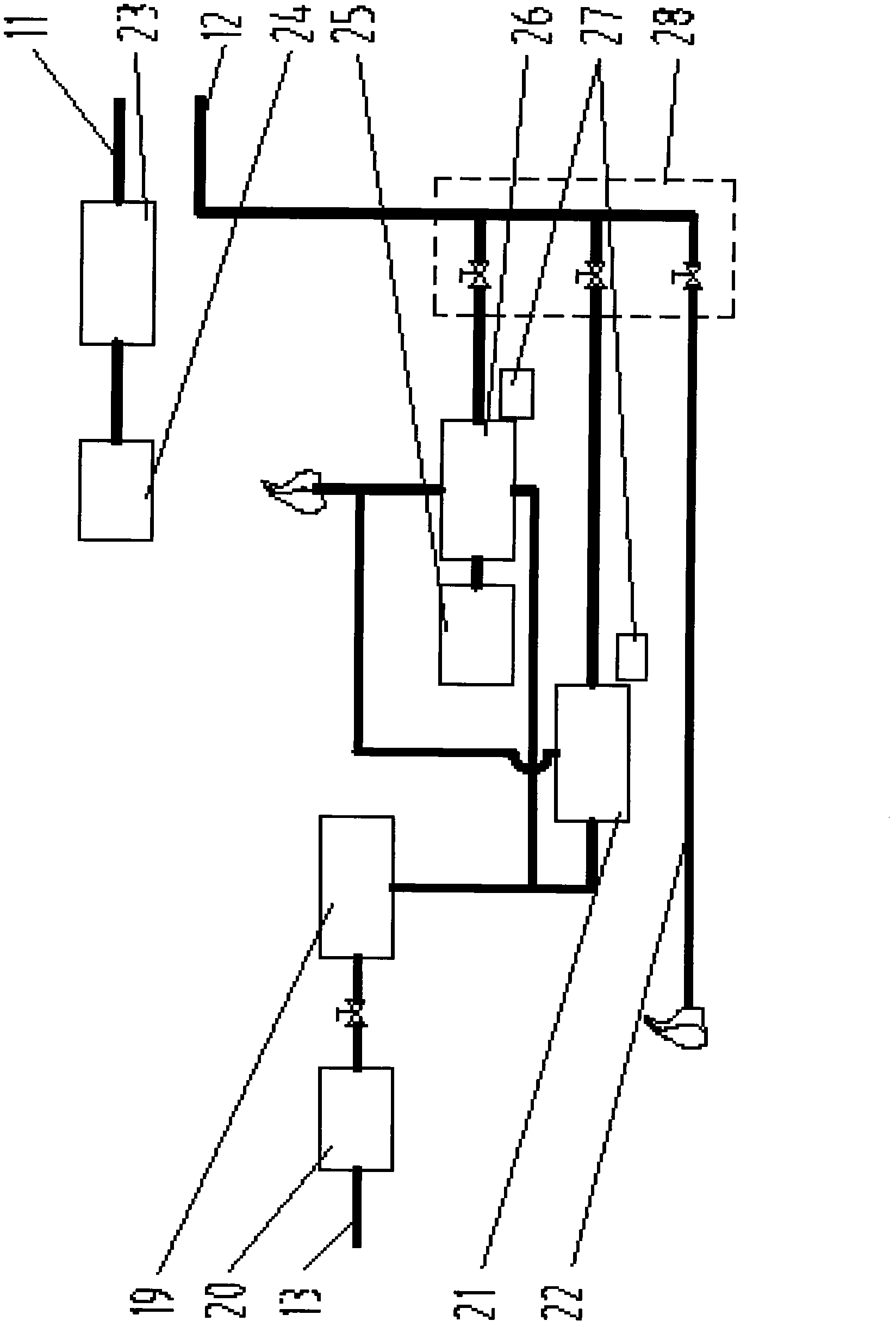

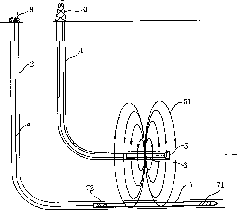

Method for mining coal bed gas by hydraulic washout of butted well in manner of pressure relief

InactiveCN102518411AOvercoming difficult to obtainOvercoming maintenance problemsLiquid/gas jet drillingFluid removalDirectional wellCoal water

The invention discloses a method for mining coal bed gas by hydraulic washout of a butted well in the manner of pressure relief, which comprises the following steps: firstly, drilling a drainage vertical well (3); digging the section of a target coal bed (2); forming a pocket (4) after passing through the coal bed; drilling a vertical well section (9) and a deviating section (10) of a horizontal directional well (8) and laying a casing pipe for well cementation; then, drilling a channel of a horizontal section (11) by using a conventional measure; butting the channel of the horizontal section (11) with the drainage vertical well (3) for barefoot well completion; continuously injecting water into the horizontal directional well (8) to wash the coal bed of the horizontal section (11); gathering coal water into the pocket (4); discharging the coal water through lifting equipment (6); when pulverized coal does not exist in the pocket (4), laying a water spray hose (12); by means of the action of high-pressure water jet, ejecting out a plurality of branch boreholes (13) at the horizontal section (11); continuously injecting the water to wash until the pulverized coal does not exist in the pocket (4) any longer; closing the horizontal directional well (8); and entering a conventional water draining and gas mining stage. The invention provides a new resolution for ground gas mining from soft low-permeability coal beds.

Owner:ZHENGZHOU UNIV

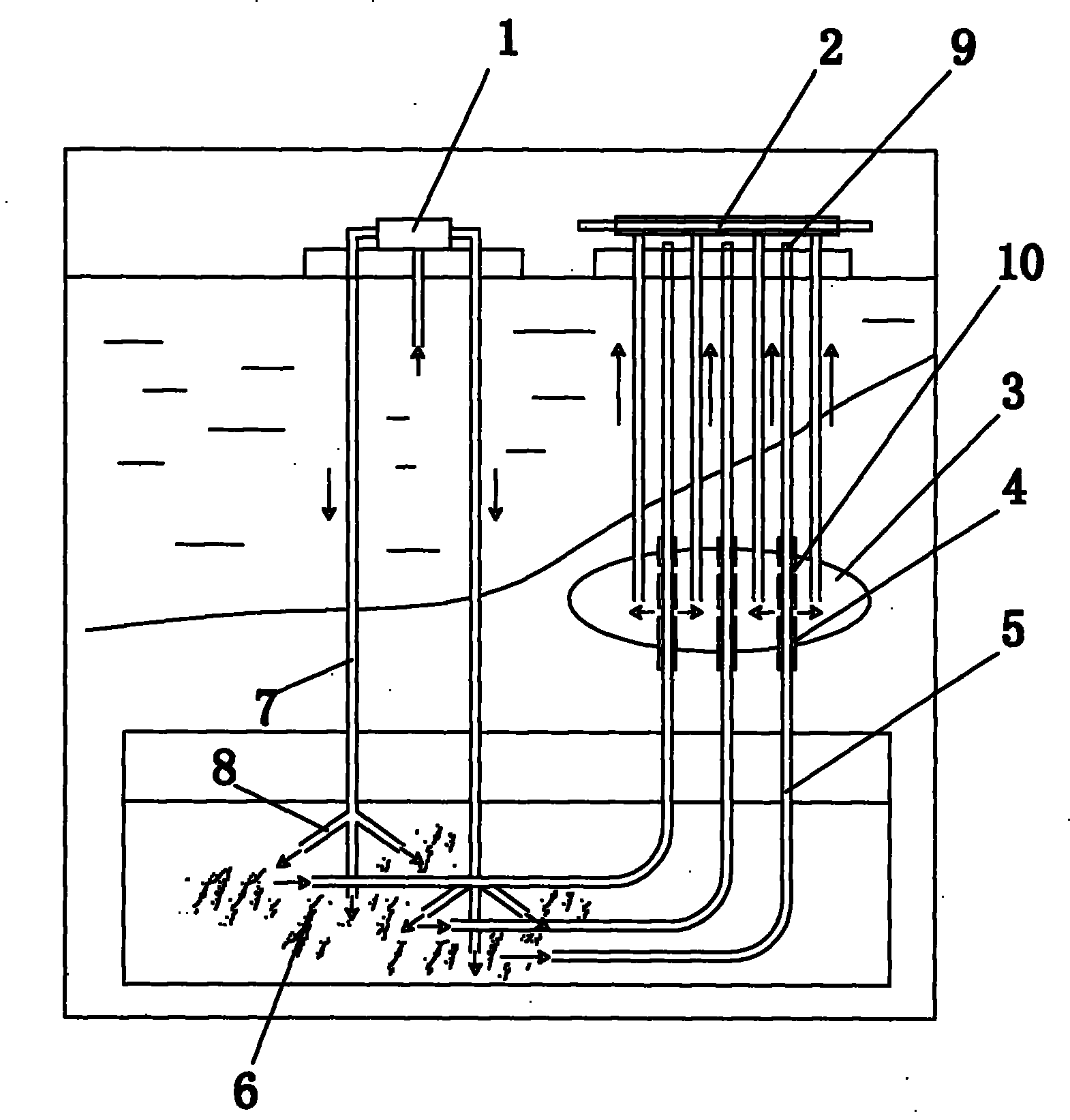

Process for exploiting ocean gas hydrate by utilizing terrestrial heat

The invention relates to a process for exploiting ocean gas hydrate by utilizing terrestrial heat, comprising the following steps: 1) digging a branch well on a target hot rock stratum; 2) utilizing a casing to penetrate through gas hydrate treasure, digging a directional well on the target hot rock stratum, perforating the casing penetrating through the gas hydrate treasure, and sealing the mouth of the well; 3) pressing seawater into the target hot rock stratum by utilizing a pump, pressing the seawater into the directional well after heat exchange heating, leading the seawater into the area of the gas hydrate treasure from the perforation of the casing, and obtaining decomposed gas hydrate and cooled seawater; and 4) transporting the gas hydrate and the cooled seawater to a sea surface by utilizing a gas-liquid recycling tube, separating the gas hydrate from the cooled seawater at an outlet, and collecting natural gas. The invention has the beneficial effect that the invention greatly reduces the heat injection cost in the exploration process, causes the exploration process to continuously develop and has less pollution and damage on environment, and each technical index in the exploration process can refer to the existing petroleum exploration process so as to lower difficulty for realizing the exploration process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Well drilling method of through tubing of gas lift under-balanced coiled tubing

ActiveCN101942962AOvercoming the effect of jacking forcePromote maturityDirectional drillingFlushingDirectional wellSlurry

The invention relates to a well drilling method of a through tubing of a gas lift under-balanced coiled tubing, which is applied in the technical field of petroleum well drilling. The through tubing operation way of the coiled tubing is adopted for carrying out under-balanced well drilling or low-pressure well drilling on target well sections at the lower part in a shaft with a drilled upper borehole, wherein the target well sections are a vertical well, a directional well or a horizontal well. The method has the following effects: the adoption of the through tubing operation of the coiled tubing can form three circulation channels by utilizing the coiled tubing, an oil tube and a sleeve, and a matching pipe column has good universality, does not need a special drilling column or an inner tube and does not need to use a rotary blowout preventer and other special equipment; a gas injection channel and a slurry injection channel are independent mutually, thereby being capable of more conveniently controlling the well bottom pressure and the under-pressure value and using an underground power drilling tool and a slurry pulse measurement system which are applicable to slurry well drilling to carry out well drilling operation and trajectory control; and the method does not need to be connected with a single and can keep the continuous circulation during the tripping process and the drilling process, and realize the full-process controllable under-balanced well drilling operation and the full-process controllable low-pressure well drilling operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

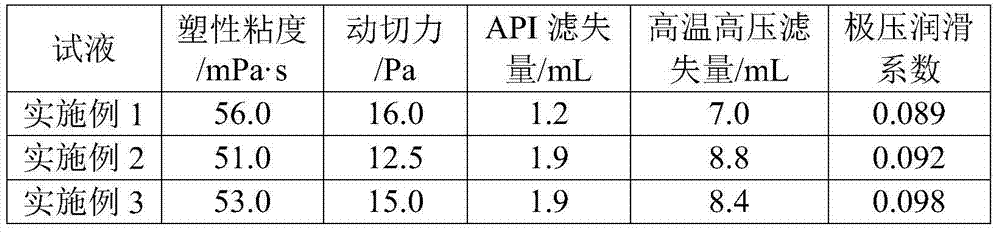

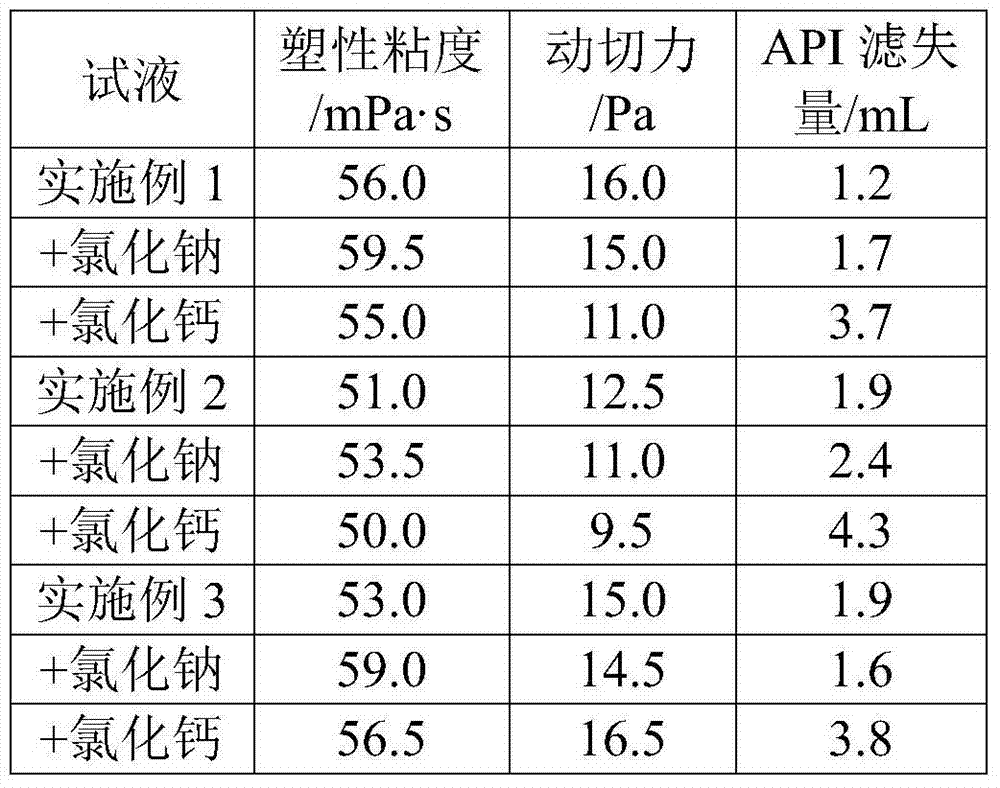

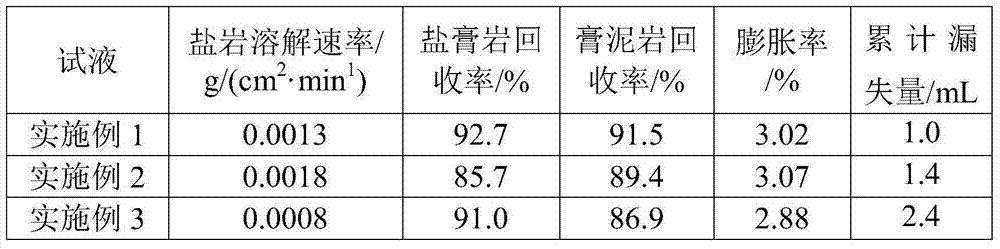

Multielement compound saltwater drilling fluid

InactiveCN103923622AImprove sealingDeterrent invasionDrilling compositionHigh densityDirectional well

The invention relates to a high-density multielement compound saltwater drilling fluid applicable to compound salt bed drilling. The high-density multielement compound saltwater drilling fluid comprises the following components in parts by weight: 100 parts of water, 15-50 parts of multielement compound salt, 1-15 parts of plugging agent, 2-8.2 parts of fluid loss additive, 0.1-0.6 part of pH regulating agent, 1-10 parts of lubricant and 1-270 parts of weighting agent. The multielement compound salt is a mixture of three or more than three of sodium chloride, potassium chloride, calcium chloride, sodium formate, potassium formate, cesium formate and sodium silicate. Due to the synergetic effect of the multielement compound salt and the plugging agent, the drilling fluid can be used for effectively sealing a well wall, meanwhile has favorable microcrack sealing capability, is capable of retarding drilling fluid filtrate transfer, has strong capability of retraining the dissolution of rock salt and gypsum and the expansion of evaporite and mud stock, and can be used for enhancing the well wall stability of an evaporite mud compound salt bed. When the density is up to 2.35g / cm<3>, the drilling fluid still has favorable rheological property and lubricating property, and can meet the requirements of straight well and directional well drilling of an evaporite bed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

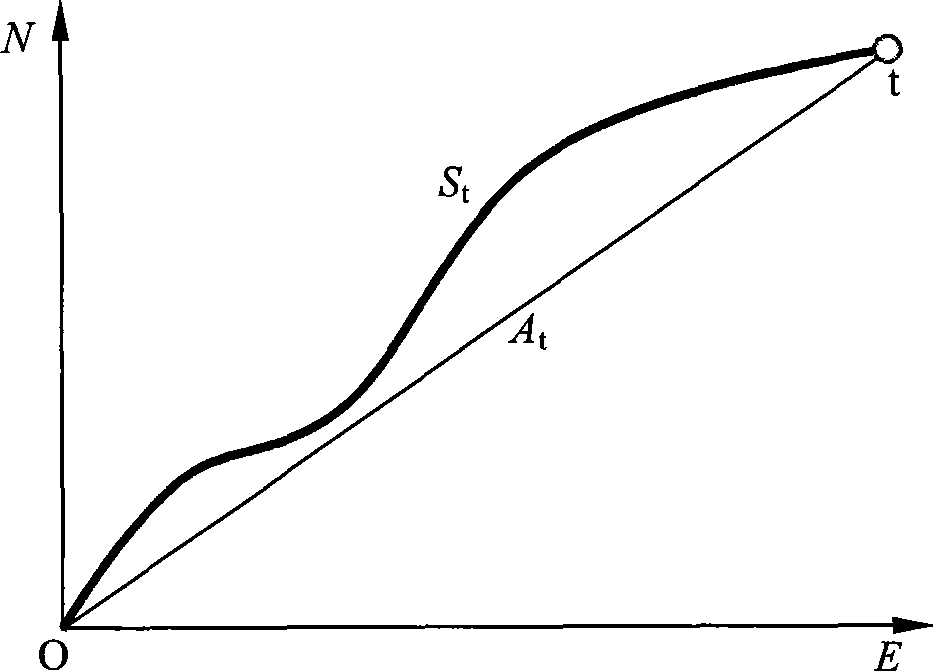

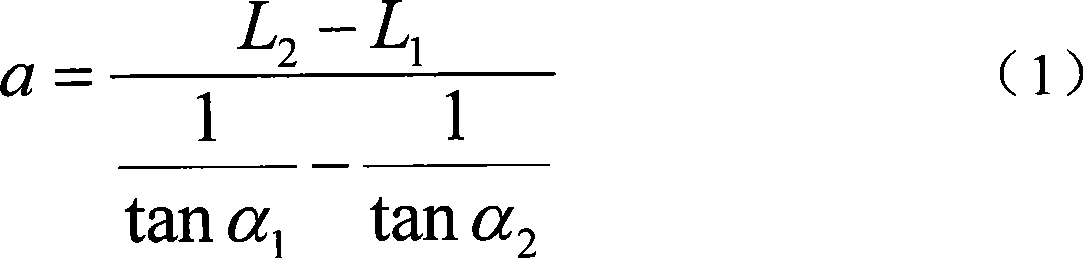

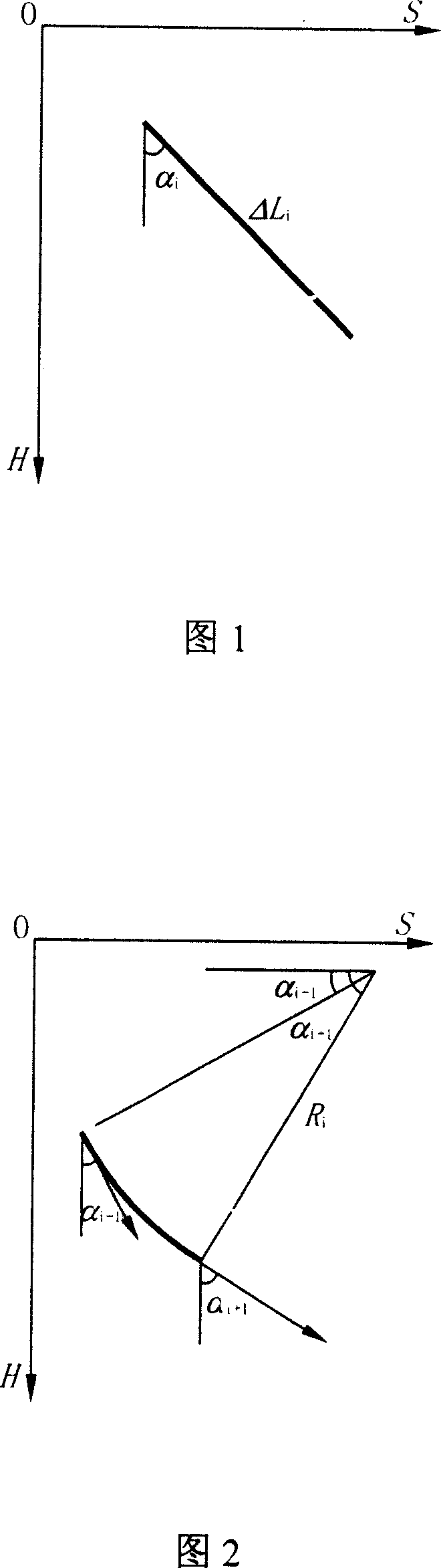

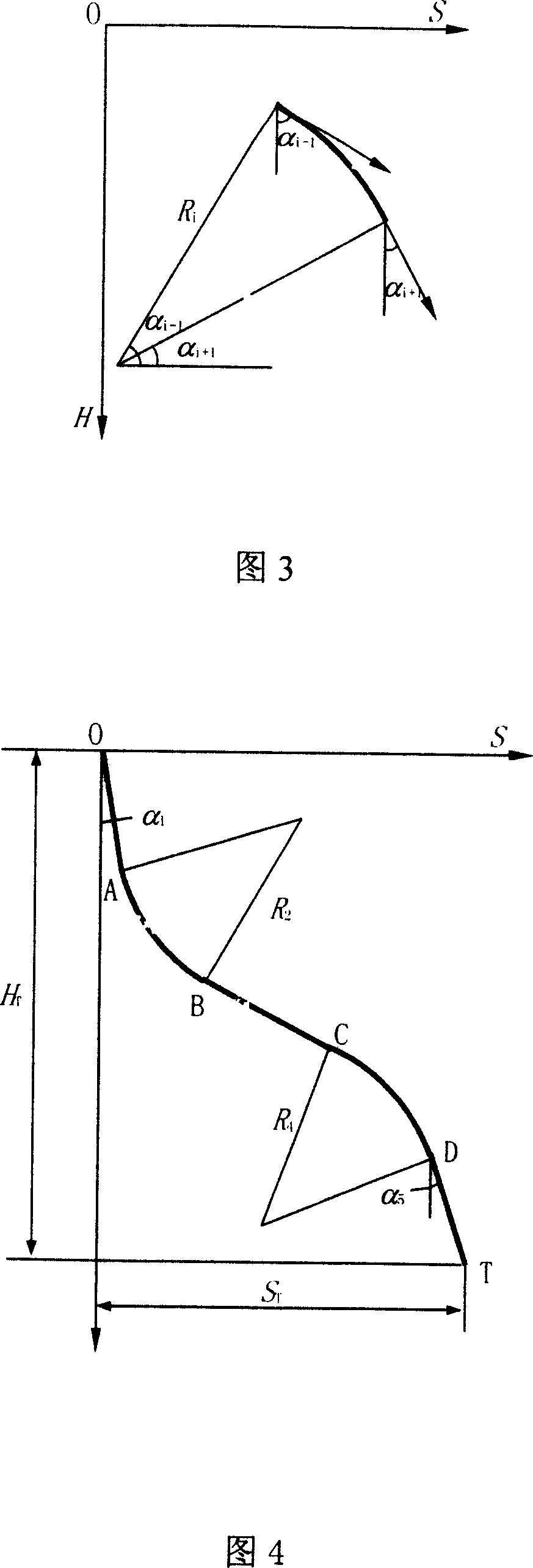

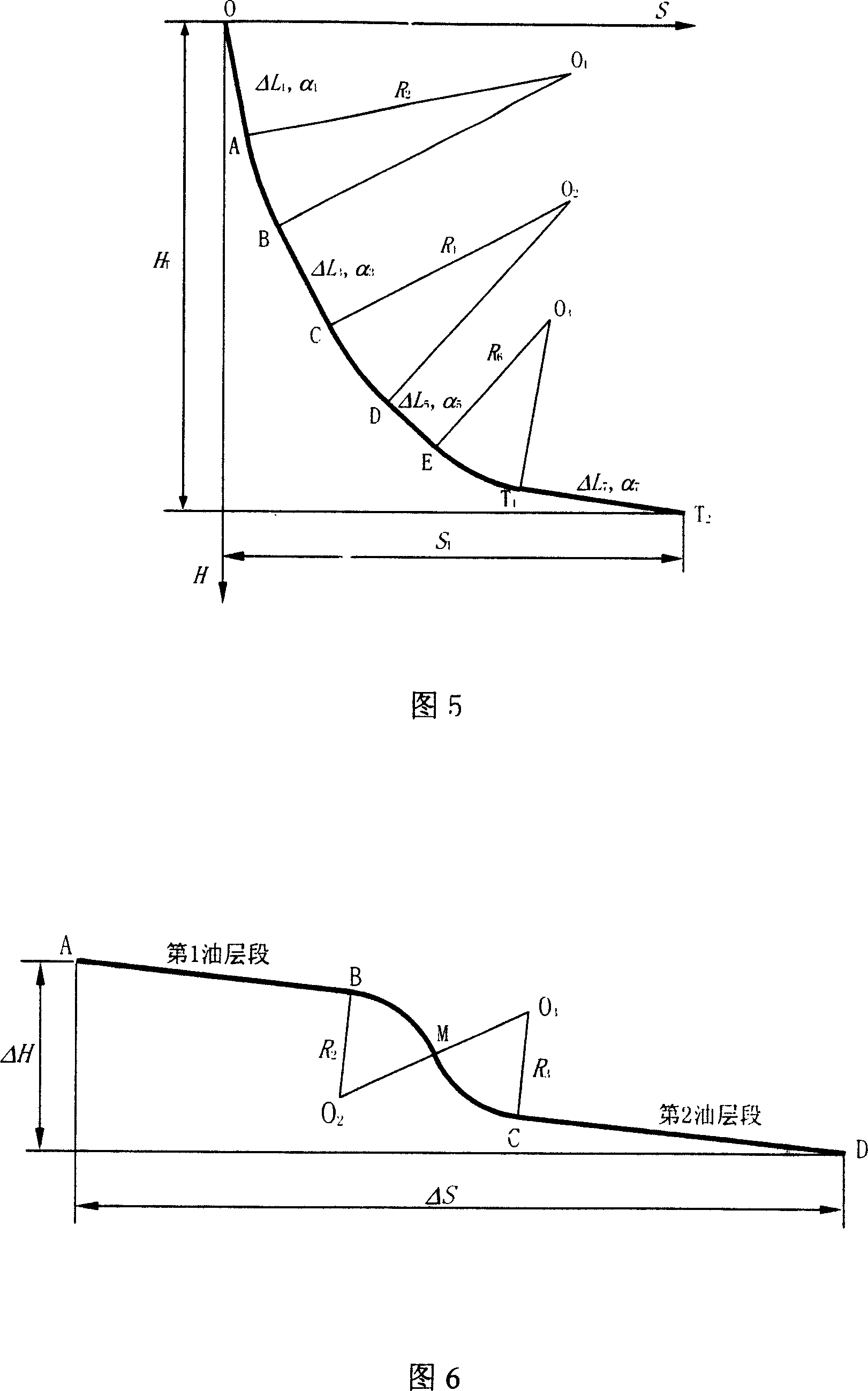

Method for designing well-drilling borehole track

InactiveCN1936264AOptimal design functionImprove scienceSurveyDirectional drillingWell drillingDirectional well

The invention relates to a two dimensional directional well formed by line and arc well section and well bore rail design of horizontal well. It includes the following steps: listing basic equation, expanding equation, giving known parameters, and solving equation. The invention resolves the rail designing problem into unified formalism. Randomly selecting two feature parameters as indeterminate parameter, it includes the taper point location and tool rate of build function. It could be used in the engineering design for drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for underground coal gasification

InactiveCN102287177AEfficient developmentChange areaConstructionsFluid removalMultiple injectionChemical reaction

An underground coal gasification method. The method comprises disposing multiple injection wells (3) and gas collection wells (4) in a gasification operation zone; adding a catalyst and a propping agent into injection wells and gas collection wells by means of a fluid medium; fracturing and reforming the coal layer using a fracturing device to form large areas of fissures and cracks; forming gasification paths in the form of directional wells between the injection wells and gas collection wells; adding a gasification agent, a catalyst, and water through the injection wells to cause coal layer combustions and chemical reactions; collecting at the gas collection wells the gas produced by means of collection devices. The fissure paths between the wells formed by reforming large fractures, and the metal mineral particles used as a propping agent for the paths between wells effectively enable the maintenance of the effective communication in the injection well network for long durations; the metal mineral particles also function as a catalyst and an aggregating agent during gasification, thereby substantially enhancing the coal gasification volume.

Owner:秦勇 +2

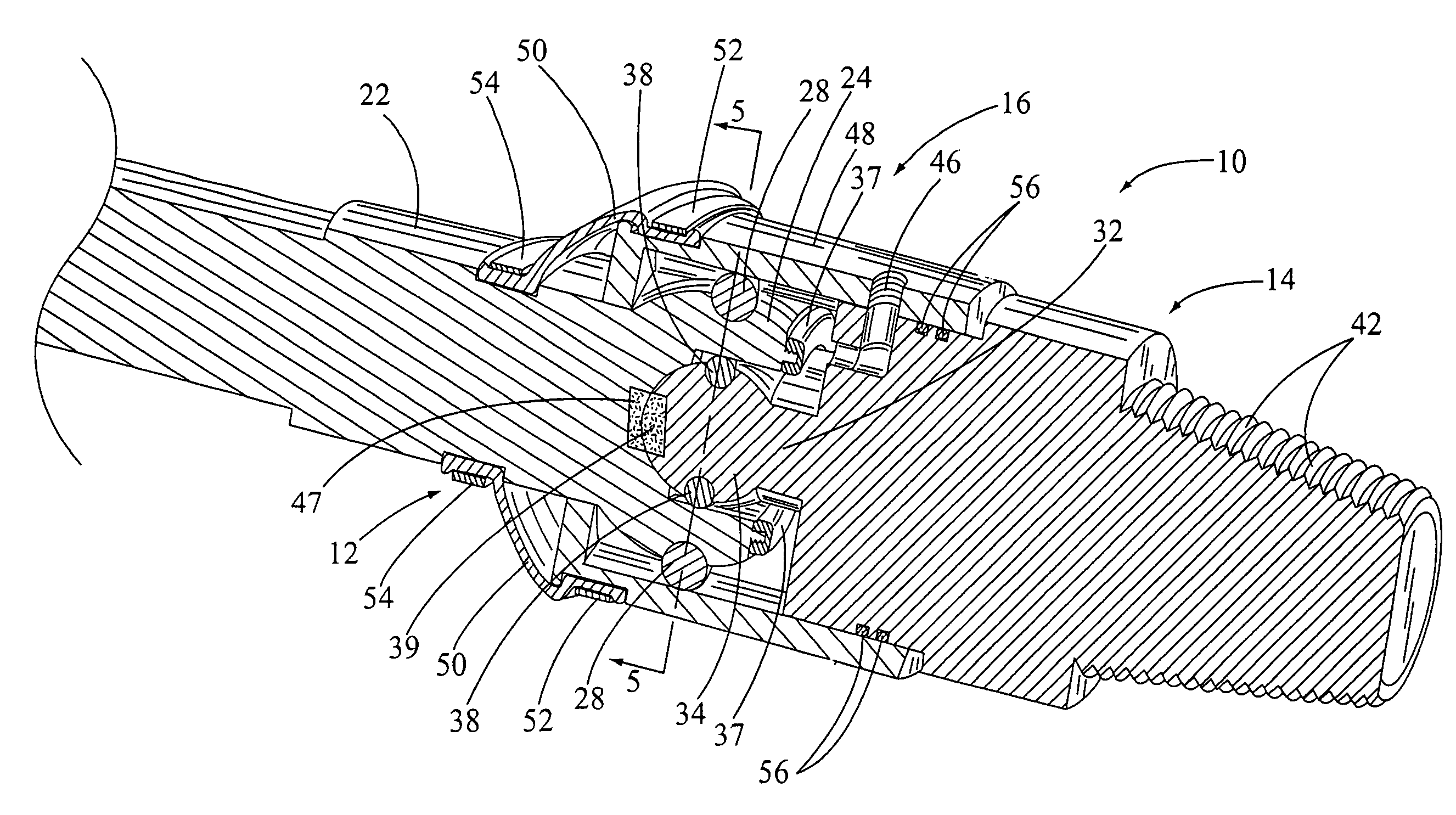

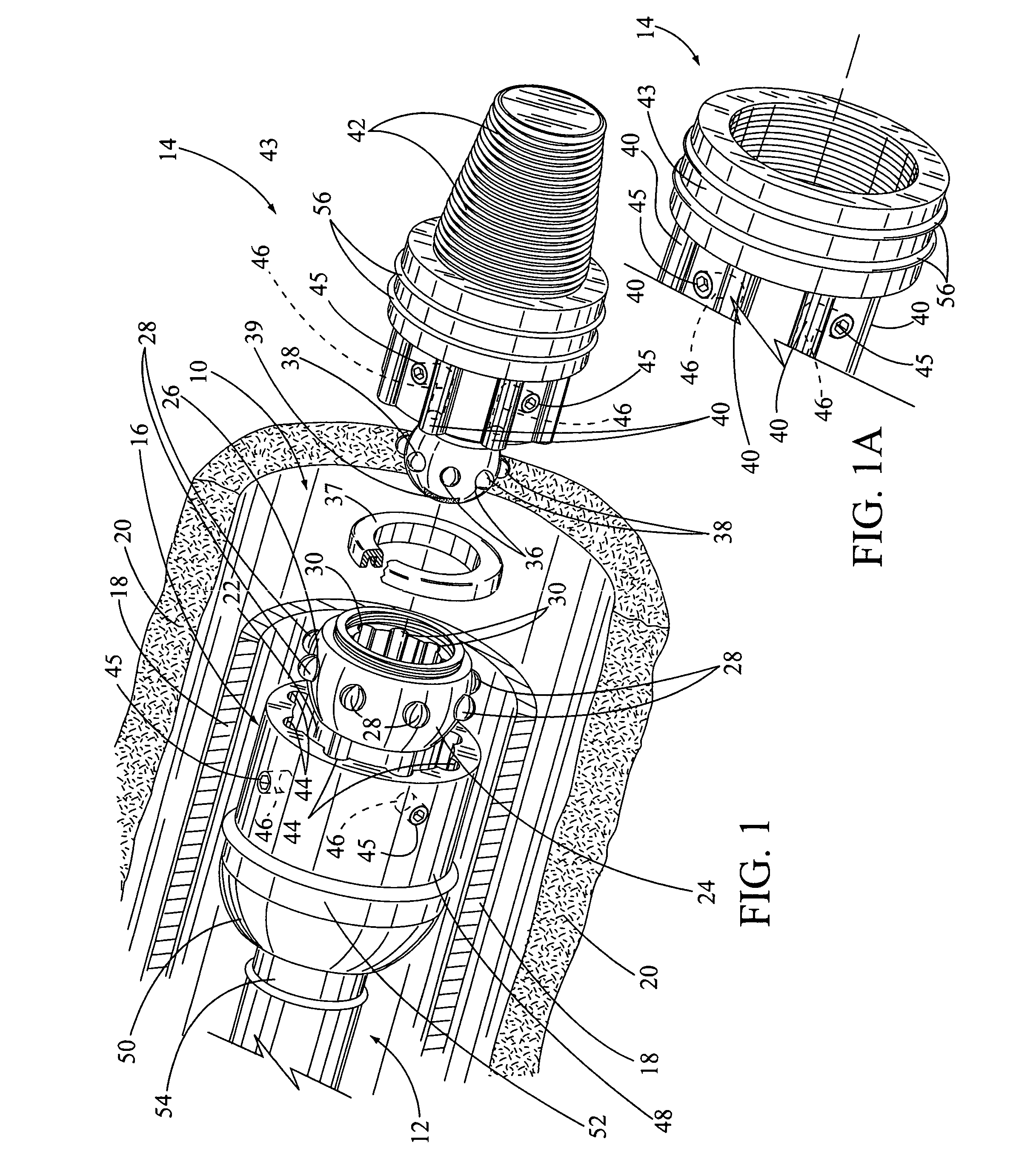

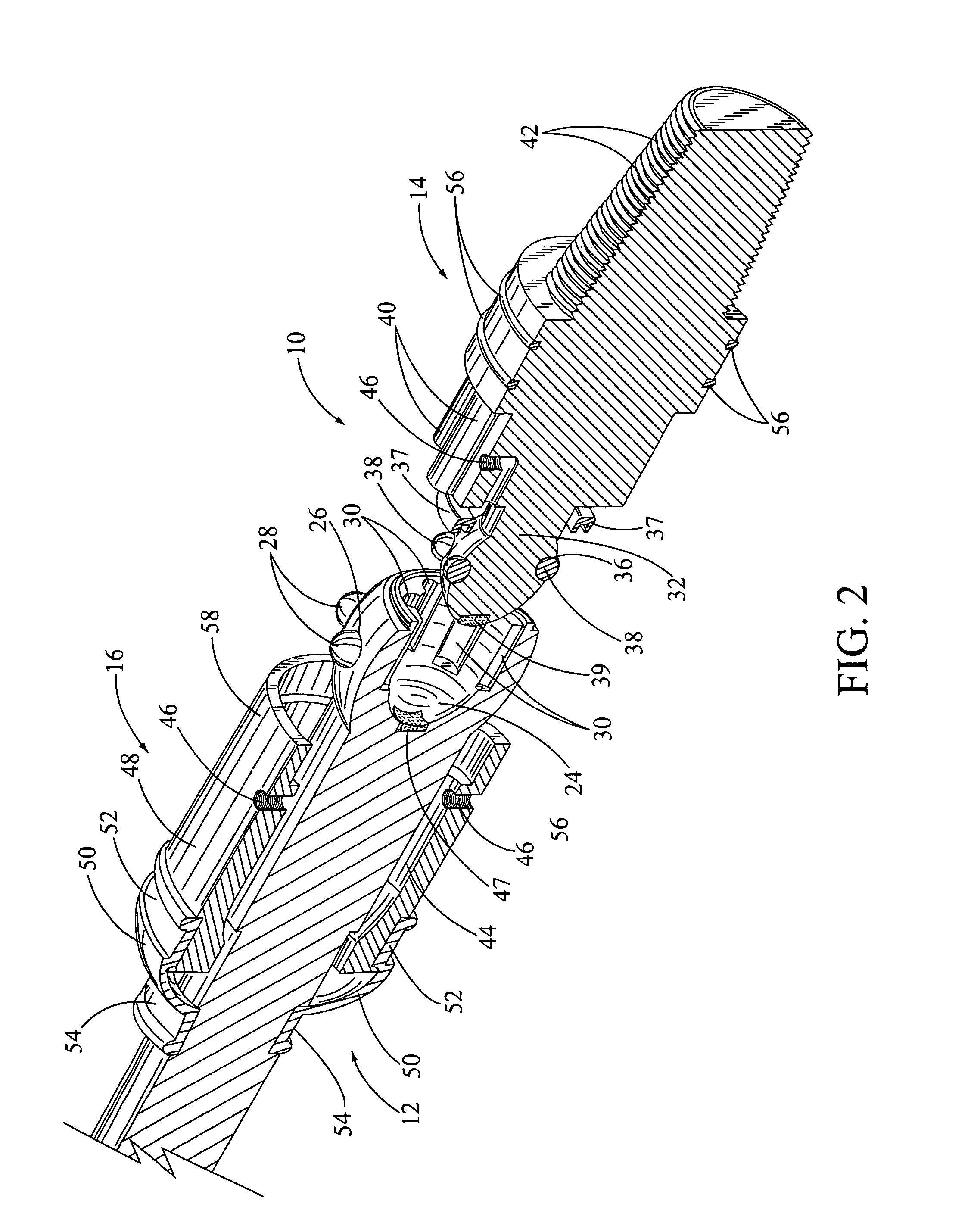

High torque, flexible, dual, constant velocity, ball joint assembly for mud motor used in directional well drilling

A flexible, dual ball joint assembly used for increasing the wear life of a mud motor. The ball joint assembly includes an drive shaft with a drive shaft hollow ball joint. An outer circumference of the hollow ball joint includes a plurality of equally spaced apart drive shaft ball bearings. An inner circumference, inside the hollow ball joint, includes a plurality of equally spaced apart drive shaft grooves. Also, the ball joint assembly includes an annular shaped torque coupler with a torque coupler ball joint. An outer circumference of the torque coupler ball joint includes a plurality of equally spaced apart torque coupler ball bearings. The torque coupler ball bearings are received in the drive shaft grooves for providing lateral movement between the drive shaft and the torque coupler. An outer circumference of the torque coupler next to the torque coupler ball joint includes a plurality of torque coupler lobes equally spaced apart therearound. Further, the ball joint assembly includes a sliding torque sleeve used to secure the drive shaft to the torque coupler during the operation of the ball joint assembly.

Owner:BENSON TODD

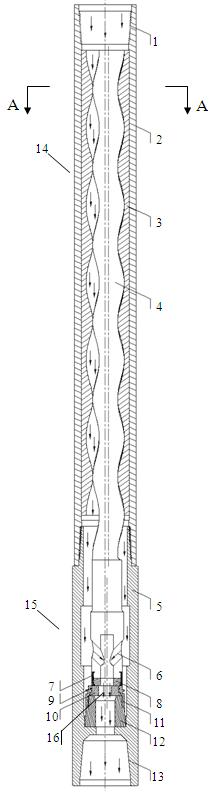

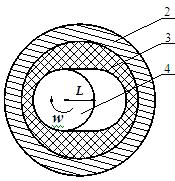

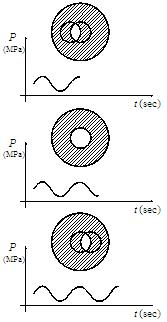

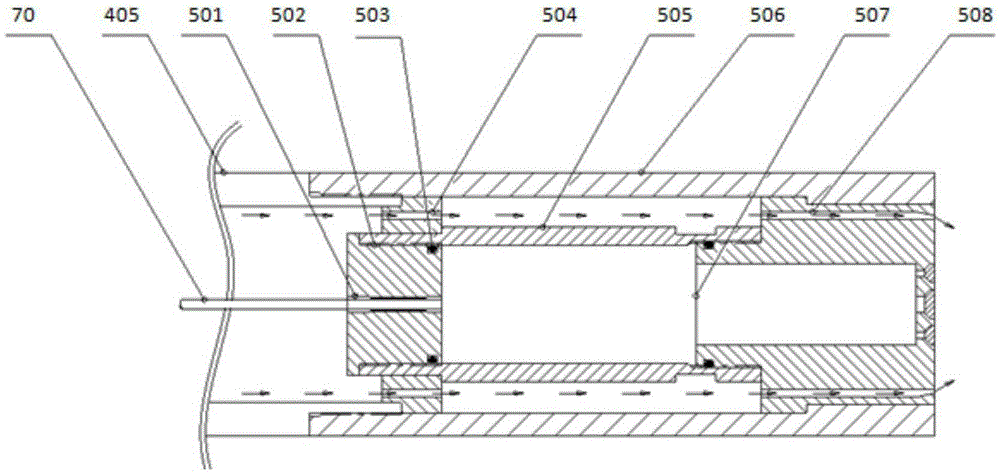

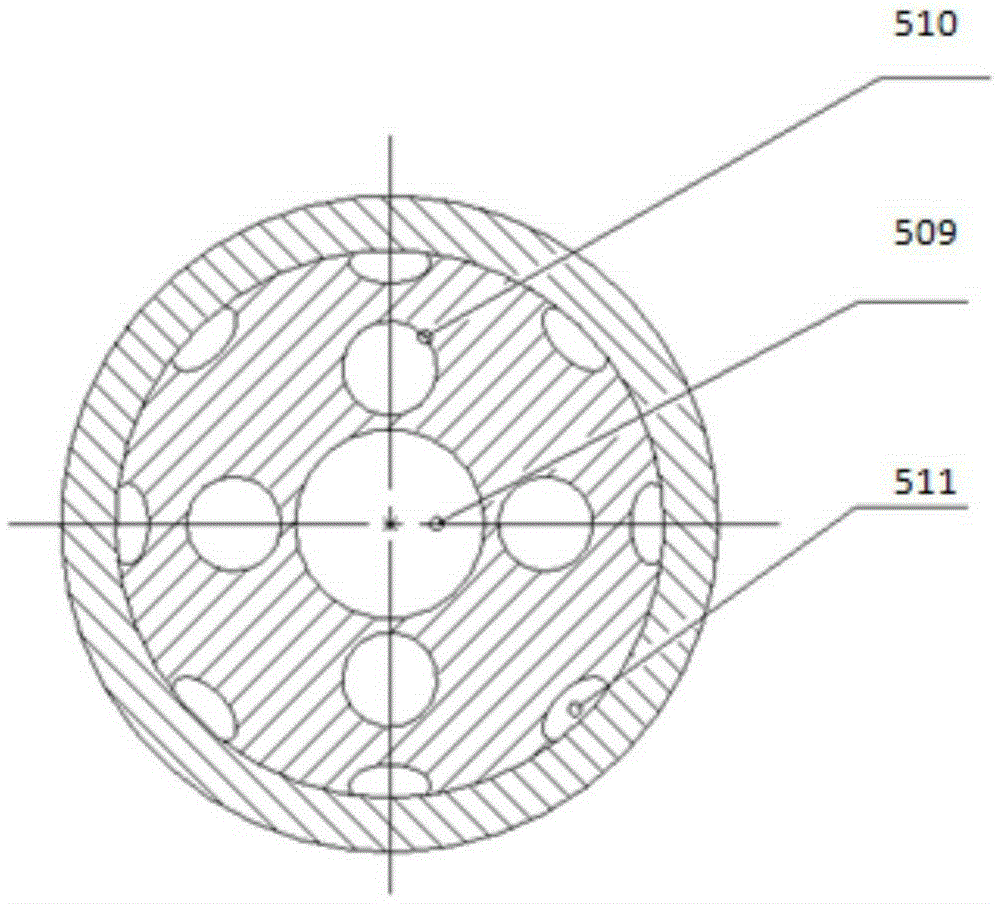

Axial oscillating tool for drill string

InactiveCN102418479AImproved extended drilling capabilityImprove uniform contact timeLiquid/gas jet drillingVibration drillingDirectional wellEngineering

The invention relates to an axial oscillating tool for a drill string, which is used for improving extension and drilling capacities of a horizontal section during drilling of a directional well, a horizontal well and a large-displacement well. The technical scheme is that: the axial oscillating tool for the drill string consists of a stator and rotor unit and a valve unit, wherein an inner wall of a stator is adhered to stator rubber; the stator rubber and a rotor form a sealed chamber; the lower end of the rotor is provided with a flow passage inclined hole; a valve body is fixed to the lower end of the rotor through a valve body nut; a valve seat is connected to a valve seat support body through a valve seat nut; the valve seat support body is arranged in a valve shell through threads; the valve seat is matched with the valve body to form opening and closing of the valve along with movement of the rotor; and the valve shell is in threaded connection with a stator shell. The axial oscillating tool for the drill string has the advantages of high axial oscillation capacity, simple structure, safety and the like; and the extension and drilling capacities of the horizontal section of the directional well, the horizontal well and the large-displacement well can be improved.

Owner:SOUTHWEST PETROLEUM UNIV

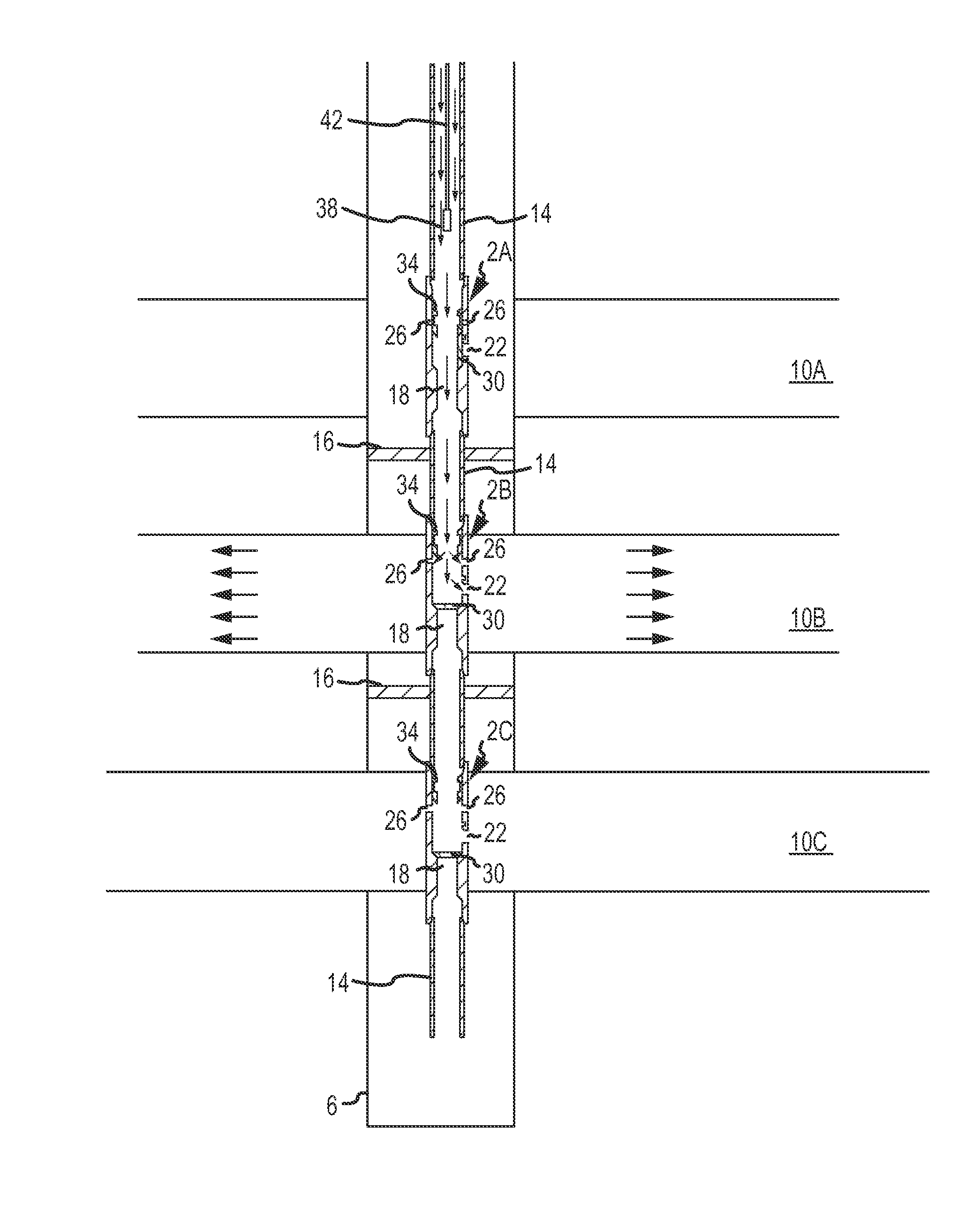

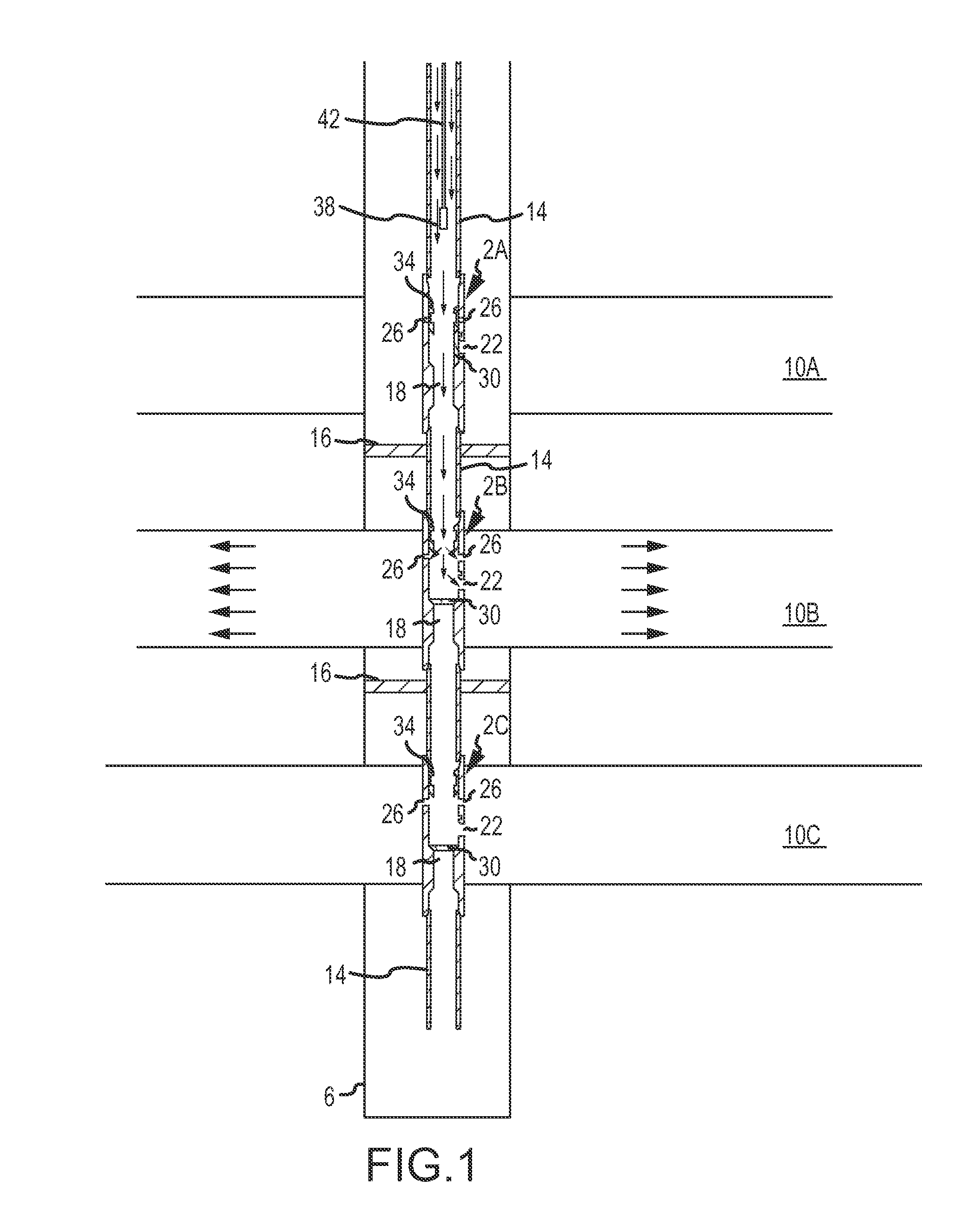

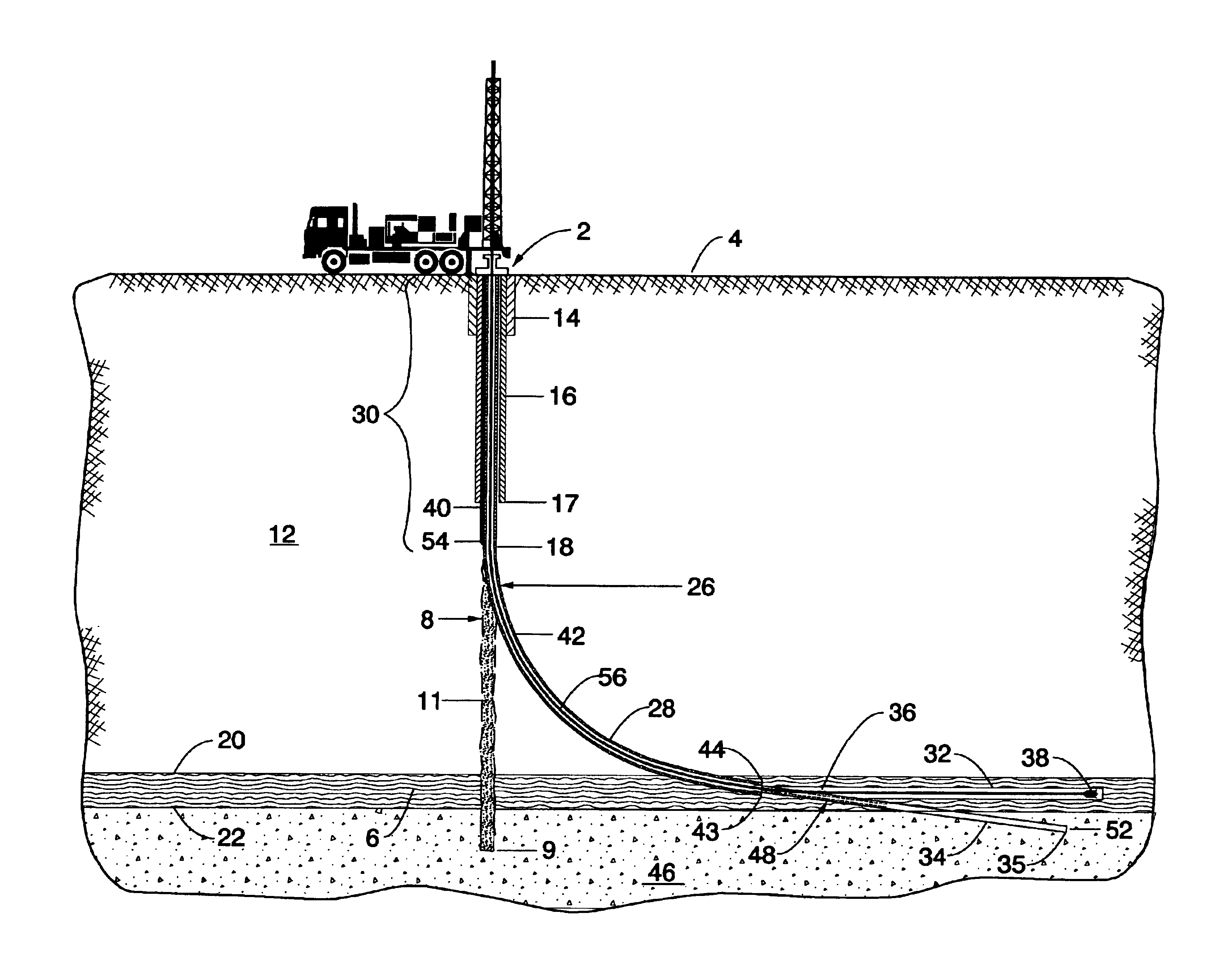

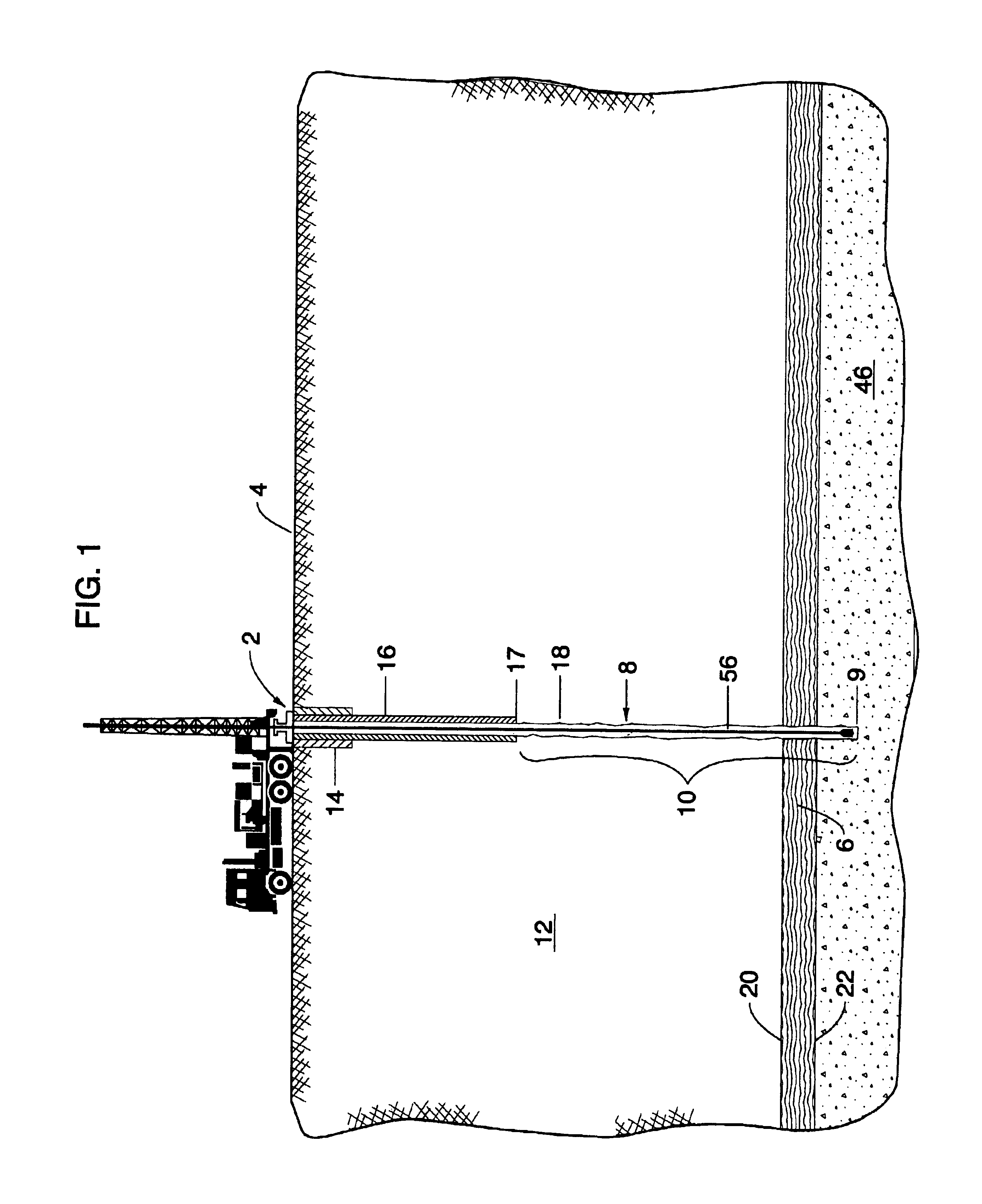

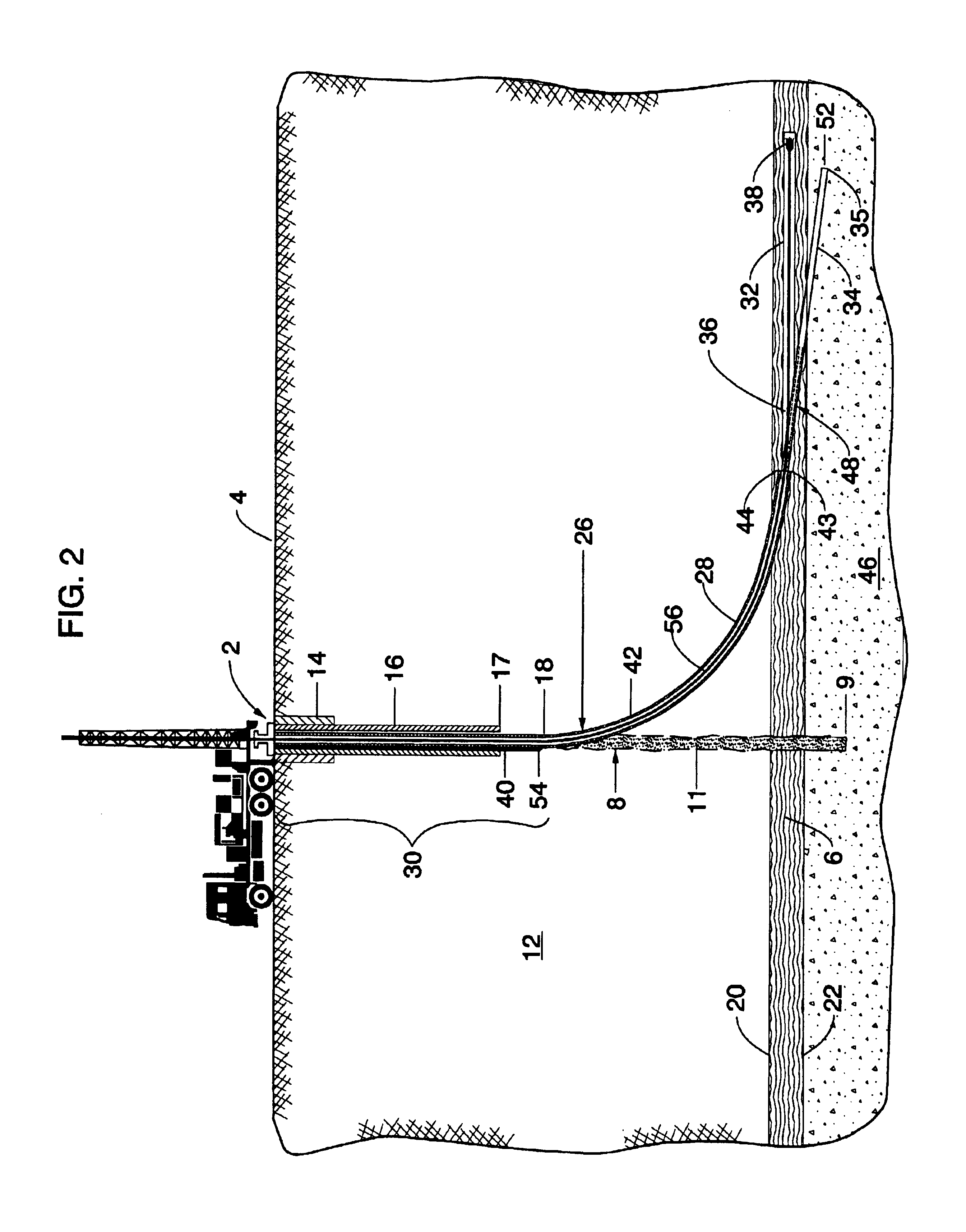

Method for making a well for removing fluid from a desired subterranean formation

InactiveUS6932168B2Easy to disassembleArtificial islandsFluid removalDirectional wellImproved method

An improved method for making a well for removing fluid from a desired subterranean formation. This invention provides for a method for making a well for removing fluid from a desired subterranean formation having an interface zone. The interface zone is coupled to a main directional well bore that extends from a top surface at ground level into the desired subterranean formation. A lateral well bore is also coupled to the interface zone. A directional sump bore is also coupled to the interface zone and the directional sump bore extends from the interface zone to a point below the interface zone. There is also a means for moving fluid from the directional sump bore through the main directional well bore to the top surface.

Owner:CNX GAS +1

Well drilling type oil gas preparing system through gasification and dry distillation of oil shale at normal position and technical method thereof

The invention relates to a well drilling type oil gas preparing system through gasification and dry distillation of oil shale at a normal position and a technical method thereof. At least two parallelly arranged directional wells are arranged in an oil shale layer, the horizontal sections of the directional wells are arranged at the bottom of the oil shale layer, an igniting well is respectively arranged between the tail ends of the horizontal sections of the directional wells and the ground, a plurality of auxiliary gasifying wells are arranged between the horizontal sections of the directional wells and the ground, the horizontal sections of the directional wells are arranged between the vertical sections of the directional wells and the igniting wells, and a plurality of oil gas collecting wells are arranged between the gasifying area and the ground. The technological procedure includes: igniting for reverse fire power penetration and expanding a gasification and dry distillation passage; gasifying and dry-distilling the oil shale layer of the gasifying area in positive, negative or fixed point mode; loosening and heating the oil shale layer in a dry distillation area so as to produce cracks on the dry distillation area and generate oil shale oil gas and combustible gas; collecting the oil shale oil gas through an oil gas collecting well; and condensing and separating the oil shale oil gas on the ground surface, thereby obtaining oil shale oil and combustible gas. The well drilling type oil gas preparing system through gasification and dry distillation of the oil shale at the normal position integrates shaft building, oil shale exploitation and ground surface dry distillation oil preparing technology, shortens the production process, is small in investment, high in efficiency and safe and protects the environment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Self-plugging removal carbonate reservoir drill-in fluid

ActiveCN103834369AReasonable rheologyMeet rheological requirementsDrilling compositionHorizontal wellsDirectional well

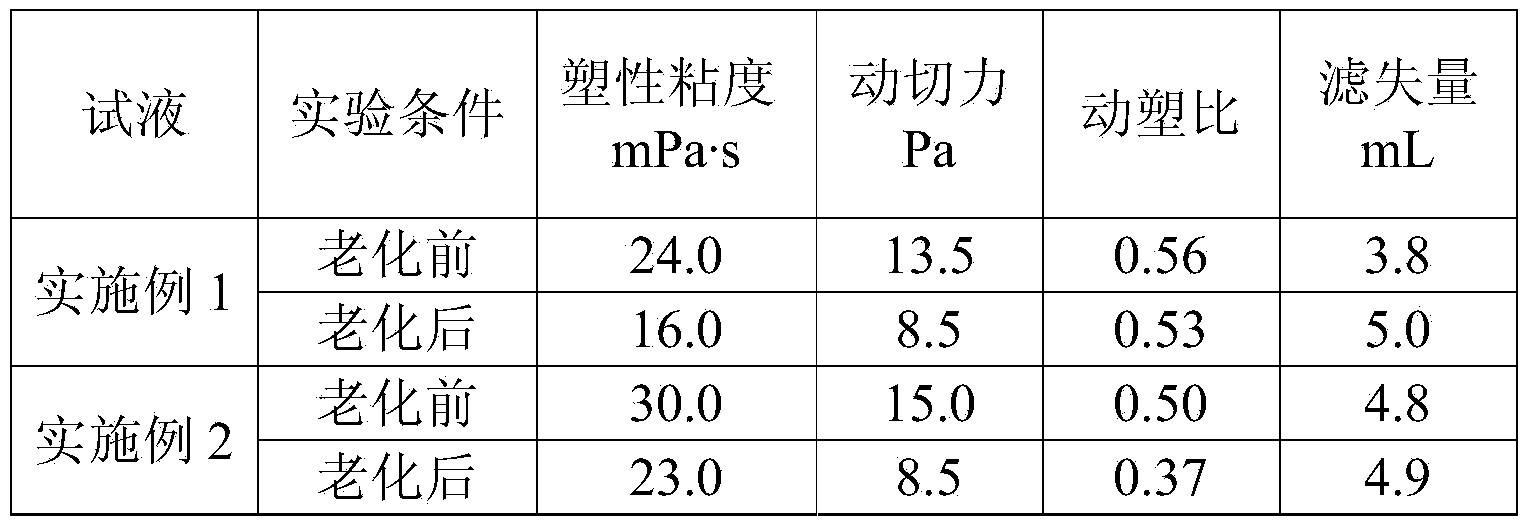

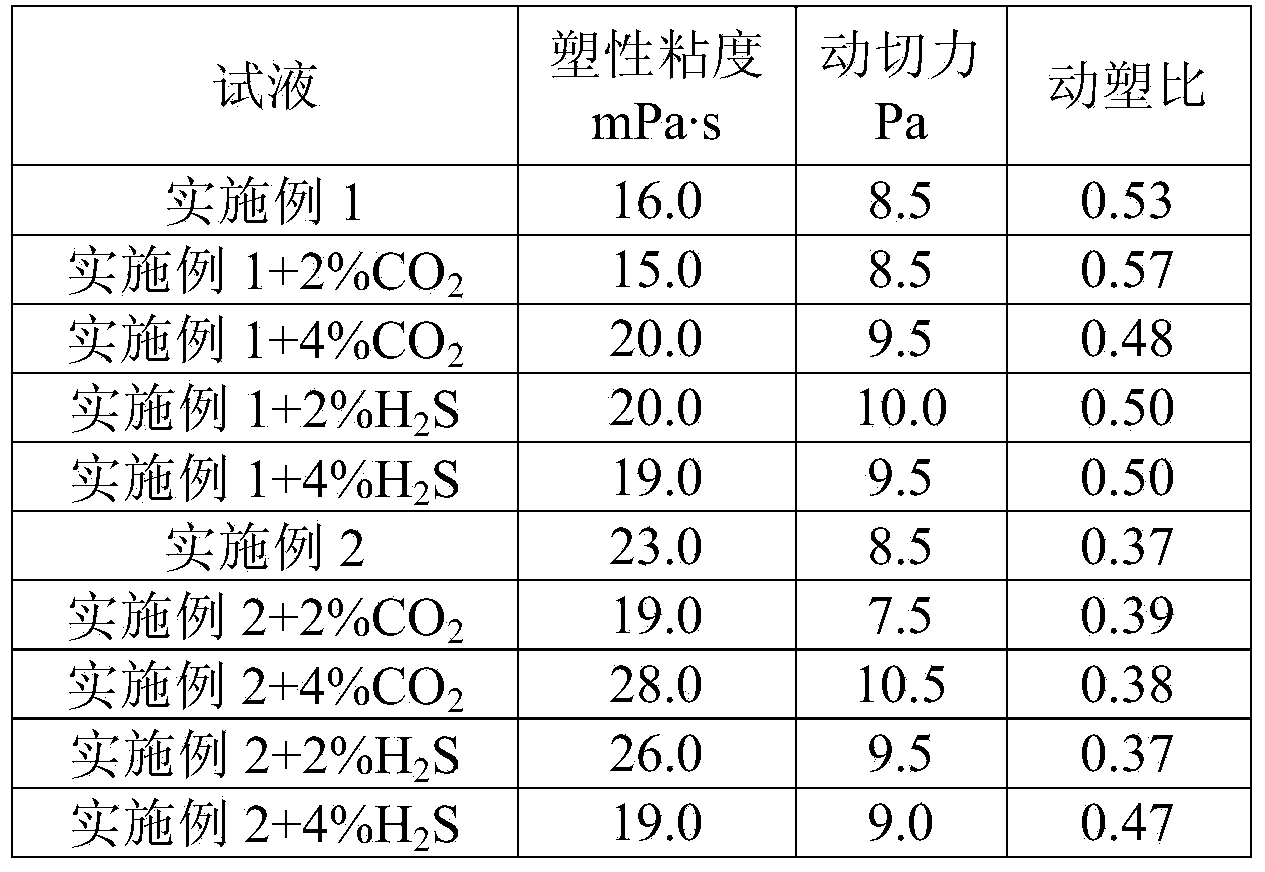

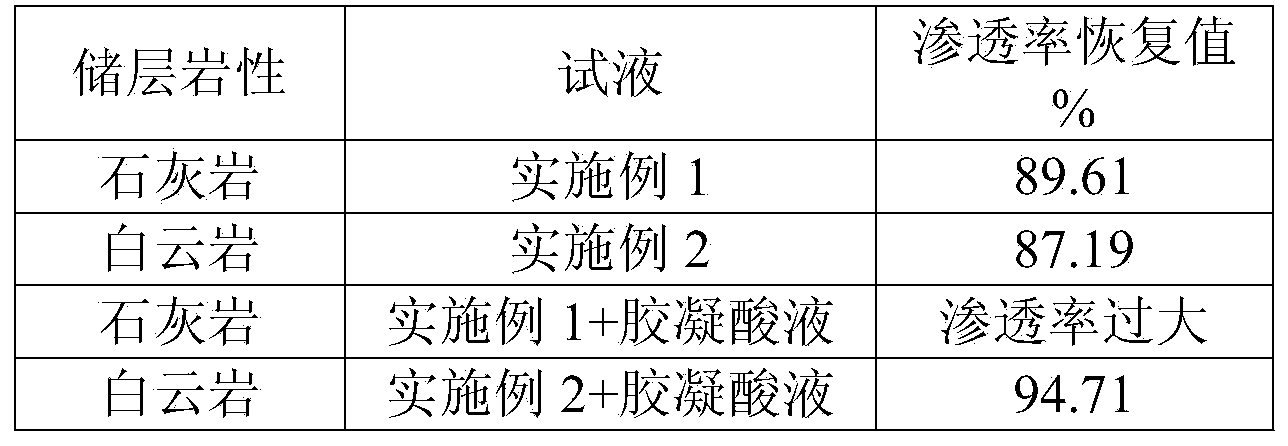

The invention discloses a self-plugging removal carbonate reservoir drill-in fluid. The self-plugging removal carbonate reservoir drill-in fluid comprises the following components in parts by weight: 100 parts of water, 5-16 parts of compound type self-plugging removal temporary plugging agent, 2-6 parts of fluid loss additive, 0.1-0.8 part of tackifier, 0.1-0.5 part of pH regulator, 0.1-0.5 part of waterproof locking agent, 0-7 parts of potassium chloride and 0-230 parts of weighting agent, wherein the addition amount of the weighting agent is greater than zero. The self-plugging removal carbonate reservoir drill-in fluid disclosed by the invention is reasonable in rheological property, can meet the rheological property requirements of drilling reservoirs of vertical shafts, directional wells and horizontal wells and has good fluid loss well building property. The self-plugging removal carbonate reservoir drill-in fluid has strong capacity of resisting pollution of acid gas such as H2S and CO2, excellent reservoir protection performance and good compatibility with a formation fluid, and the carbonate rock core return permeability of the self-plugging removal carbonate reservoir drill-in fluid is greater than 87%; and a gel breaker is not needed, and the self-plugging removal carbonate reservoir drill-in fluid can be used for direct plugging removal through acid pickling and putting into production.

Owner:CHINA NAT OFFSHORE OIL CORP +1

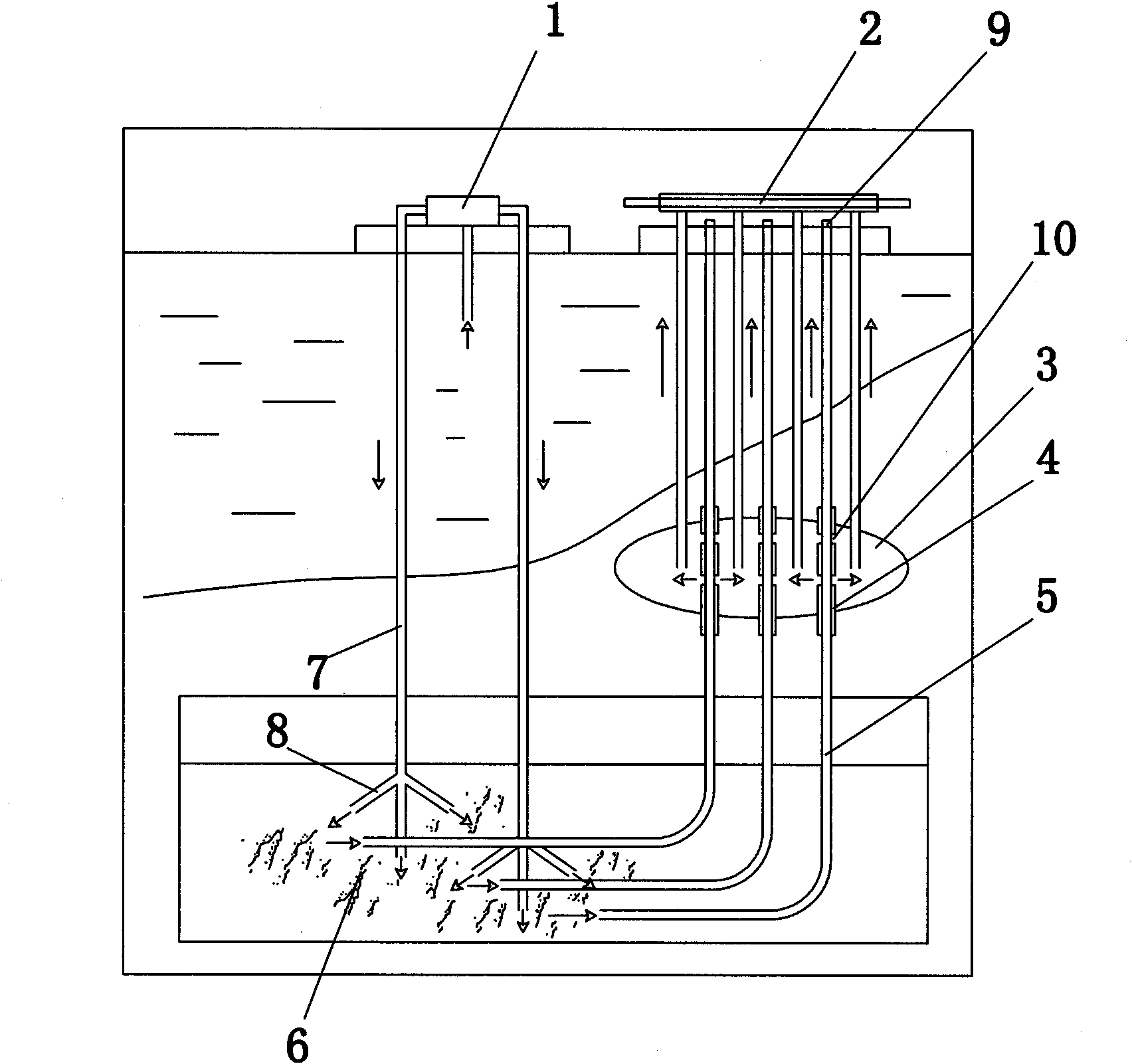

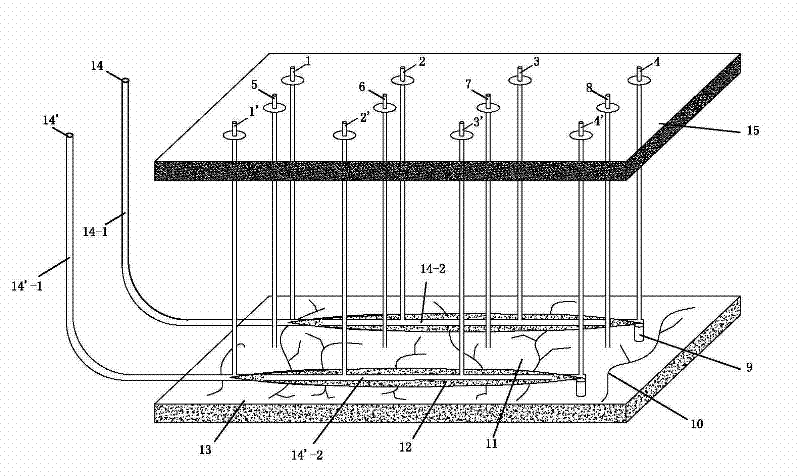

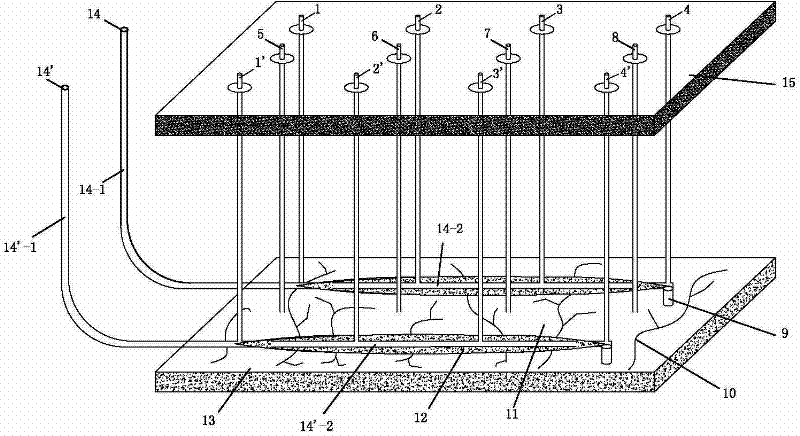

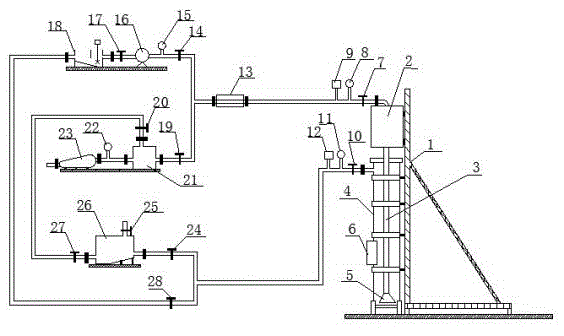

Experimental apparatus and method for simulating circular flowing characteristic of sand-carrying drilling fluid

InactiveCN103558123AMeet the experimental monitoring of circulating flow characteristicsObserve flow patterns in real timeFlow propertiesAir cycleWell drilling

The invention relates to an experimental apparatus and method for simulating the circular flowing characteristic of a sand-carrying drilling fluid. The experimental apparatus is characterized by comprising a simulating drilling system, a slurry recycling system and an air circulating system, and being capable of developing a drilling fluid circular-flowing characteristic experiment under two conditions of using slurry as the drilling fluid and using air as the drilling fluid. A derrick of the experimental apparatus can be regulated to different inclination angles, so as to meet the experimental monitoring on the drilling fluid circular-flowing characteristic under different well deflection working conditions of a vertical well, a directional well, a horizontal well and the like. An arranged toughened glass window is capable of observing the flowing state of the sand-carrying drilling fluid in real time, and an arranged pressure meter and an arranged flow meter are capable of monitoring the pressure change and the flow change of the sand-carrying drilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

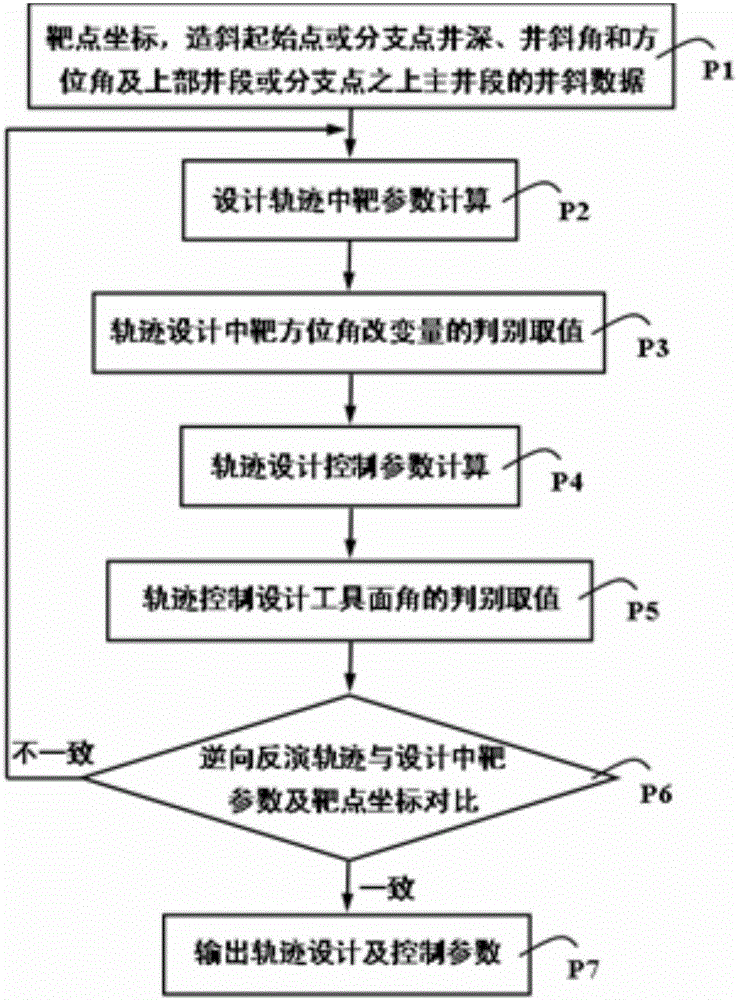

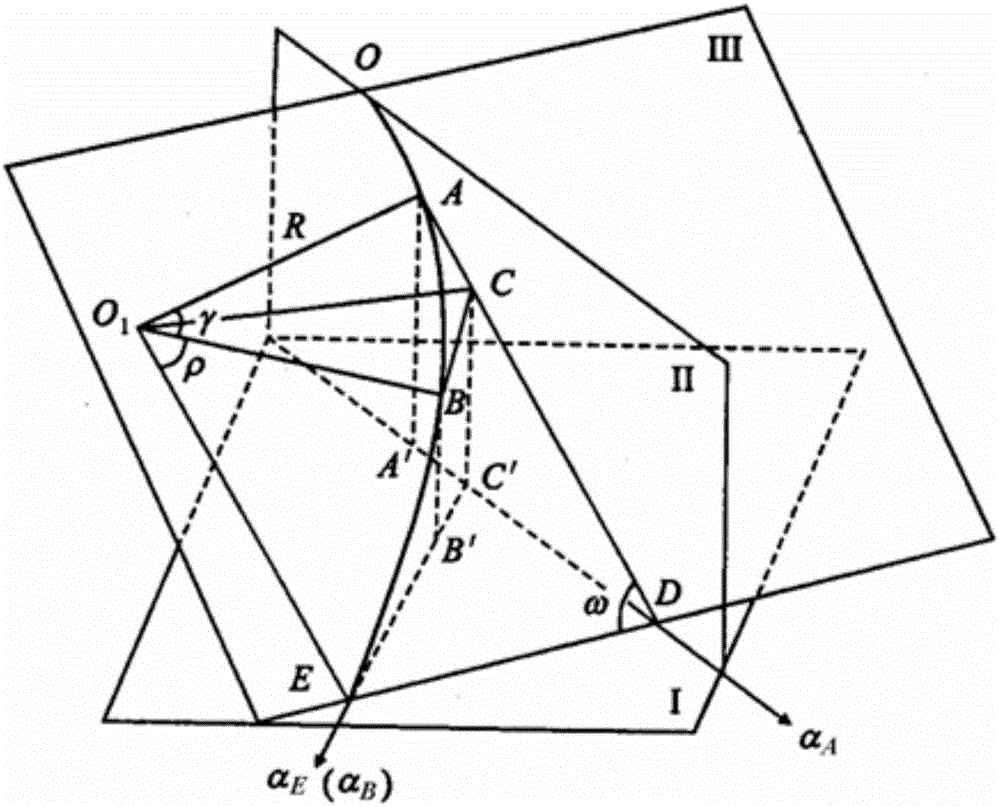

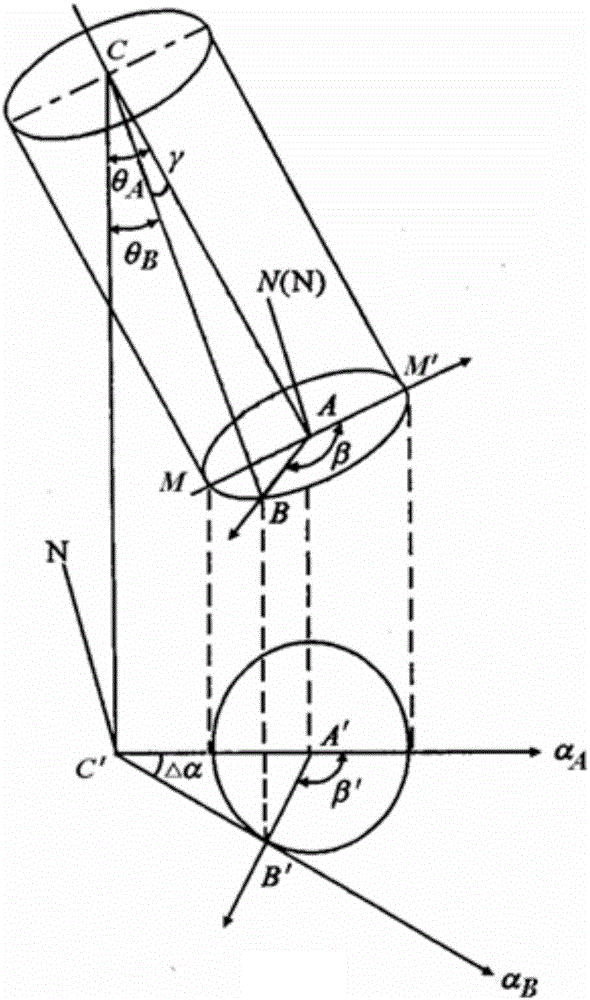

Three-dimensional directional well trajectory design and control parameter discrimination method

InactiveCN105114059AAvoid ambiguitySolve the problem of "incremental angle"SurveyHorizonDirectional well

The invention discloses a three-dimensional directional well trajectory design and control parameter discrimination method. The method includes: via relative coordinates of a target in a target horizon with respect to a tapered plane arc trajectory full-curve tangent midpoint, establishing discrimination criteria, and performing discrimination and valuing on a change amount of a design target hitting azimuth with respect to an azimuth of an arch trajectory start point; discriminating and valuing a design tool face angle via overlap criteria of values obtained by calculating through double formulas of tool face angle; according to the tool face angle obtained by discrimination, verifying targeted design parameters and targeted coordinates via trajectory backward inversion. Compared with traditional target parameter discrimination methods, the method helps prevent the problems that discrimination by directly using target closure azimuth difference causes 0-degree azimuth ambiguity and discrimination of the tool face angle according to functional rules of 0-degree to 360-degree quartering of different tool face angles may has deviations; the method is simple and highly applicable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Plunger tool for gas well drainage and gas recovery

ActiveCN102296943APrevent slippageEfficient removalSurveyFluid removalRelative displacementHorizontal force

The invention discloses a plunger tool for gas recovery by liquid drainage in gas wells. The plunger tool is flexible, more specifically, the plunger tool comprises a flexible plunger assembly, which comprises a flexible central body, a plurality of plunger unit bodies connected in series are sleeved on the periphery of the flexible central body, and each two neighboring plunger unit bodies are in spherical contact with each other; when the flexible plunger assembly passes through a slant hole interval, the flexible central body is bent, each plunger unit body is displaced relatively, and the plunger unit bodies are still kept in spherical contact with each other. When operating in a wide-dogleg degree interval, the flexible plunger tool (12) receives the effect of the horizontal force of the inner wall of a tubing, the length of the flexible central body (13) is changed, the extension and retraction of the flexible central body are compensated by a floating mechanism on the top of the plunger tool (12), and thereby the flexible central body (13) is prevented from being damaged. The plunger tool overcomes the defects of the conventional rigid plunger, and improves the adaptability of the plunger lift technique to highly slanted directional wells.

Owner:PETROCHINA CO LTD

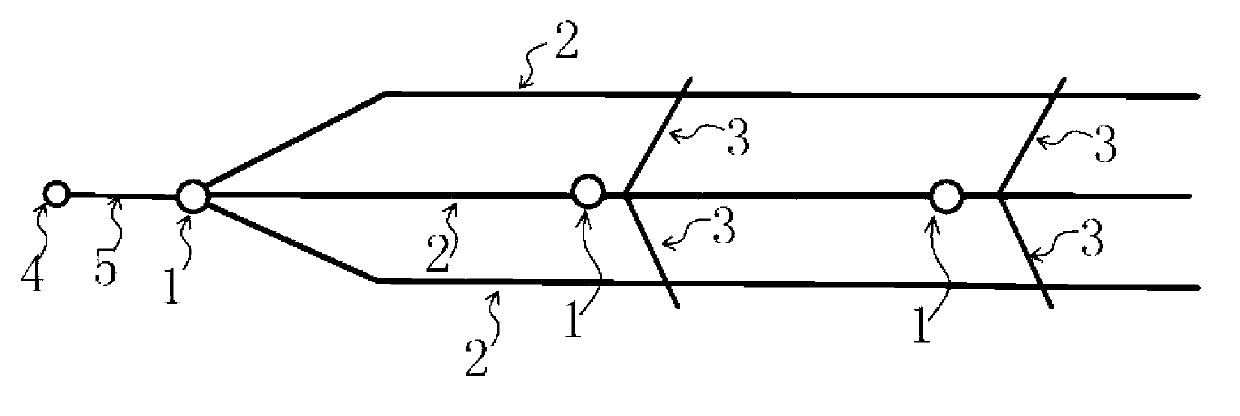

High gas suction and discharge process method for complex well

An embodiment of the invention discloses a high gas suction and discharge process method for a complex well. The process method includes the steps: A, drilling a straight well or a directional well on the ground; B, drilling a branch horizontal well on the ground, wherein the branch horizontal well is communicated with the straight well or the directional well; and C, sucking and discharging gas in the straight well or the directional well. The straight well or the directional well is drilled on the ground, and then the branch horizontal well is drilled on the ground and communicated with the straight well or the directional well, so that an approximately communicated closed-loop complex well network is formed to be communicated with a coal bed fissure system, coal bed gas pressure is quickly reduced, coal bed gas is sucked and discharged, and a foundation is laid for safety production of high gas coal mines.

Owner:BEIJING JIUZUN ENERGY TECH

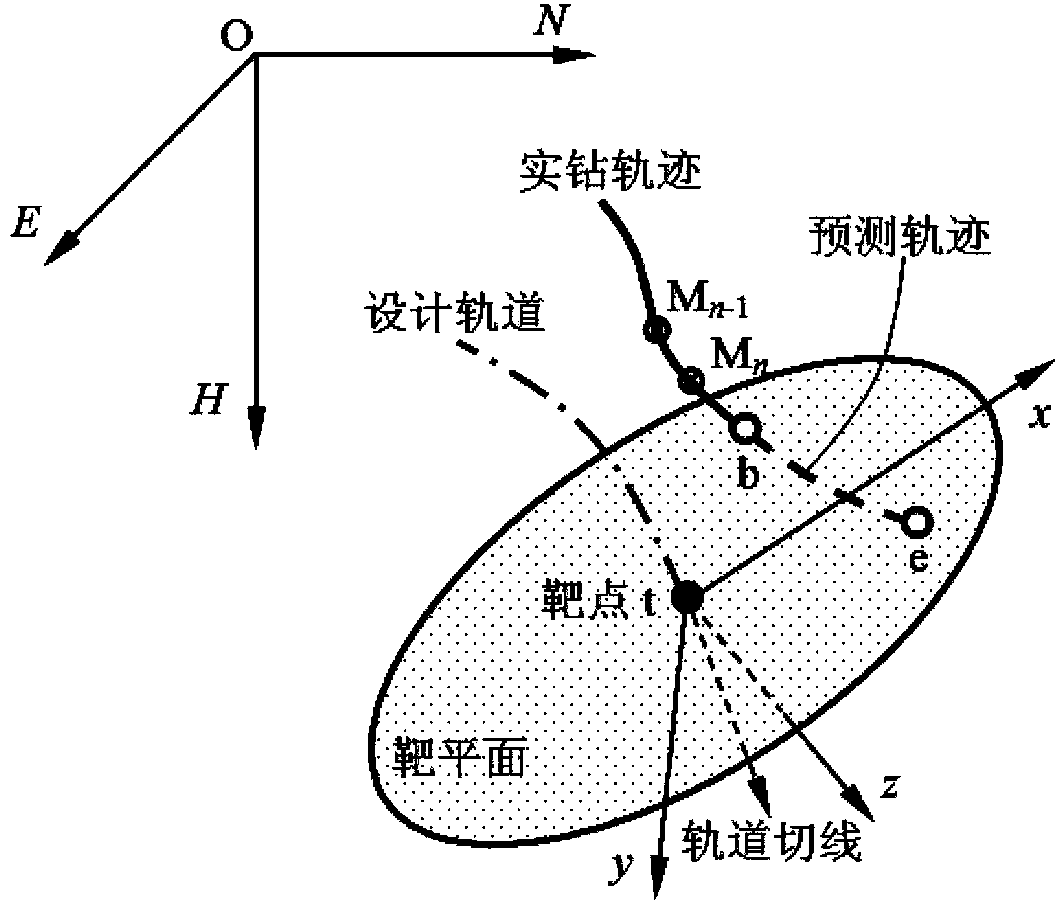

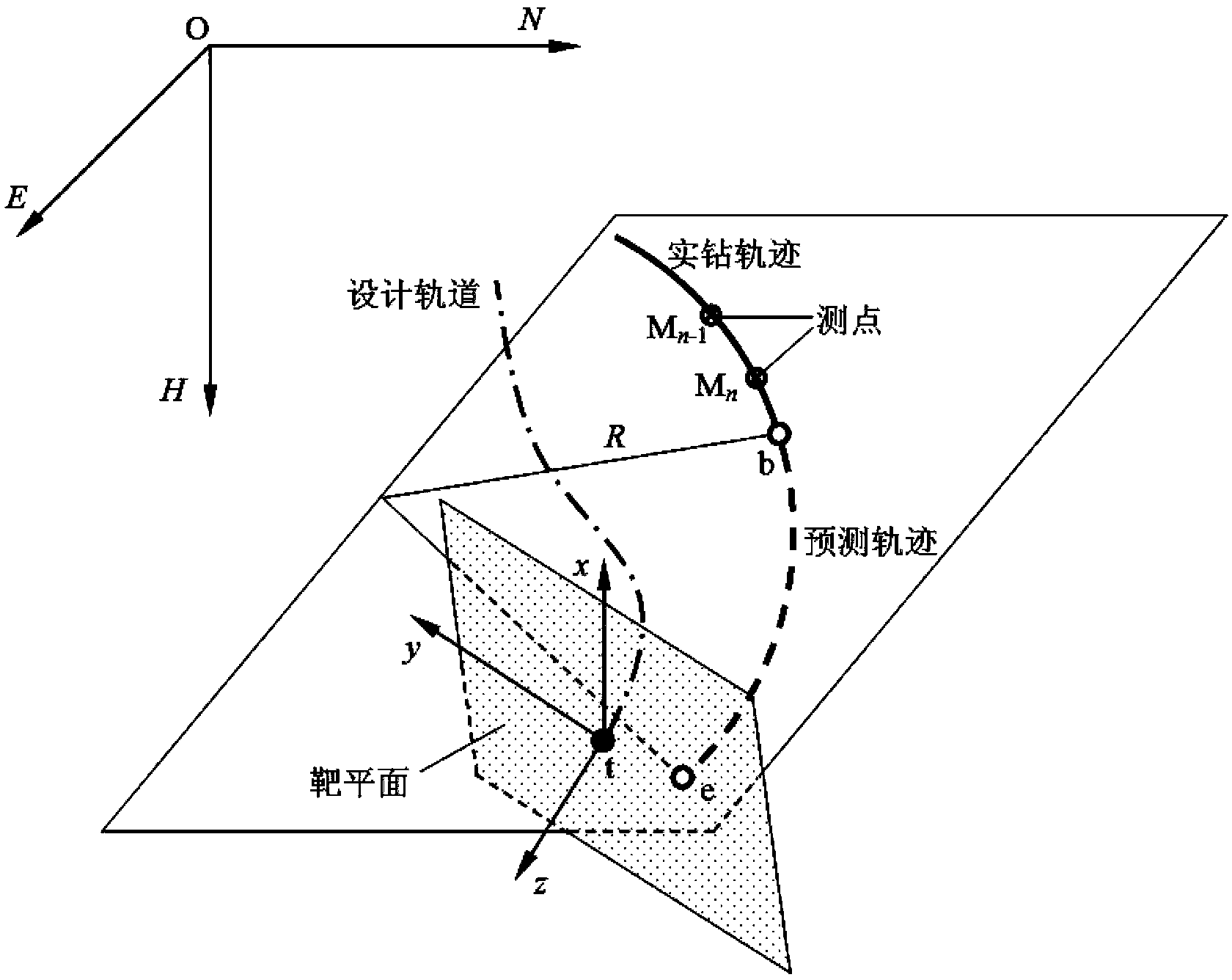

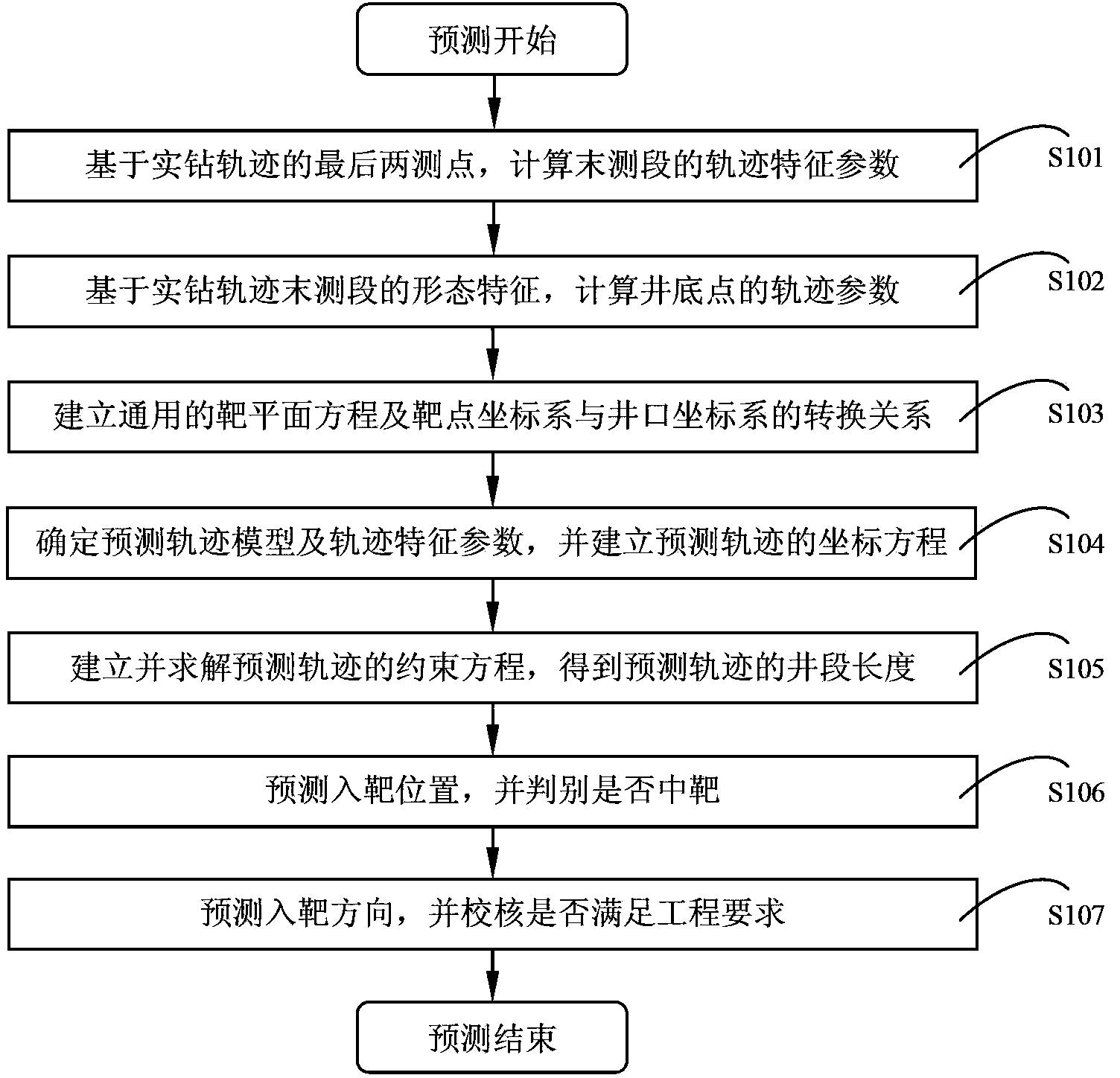

Universal method for forecasting in-target situation of guide drilling

ActiveCN103883312AIncrease the encounter rateIncrease success rateSurveyDirectional wellHorizontal wells

The invention discloses a universal method for forecasting in-target situation of guide drilling. The universal method includes: on the basis of survey data of last two survey points of a real drilling trajectory, calculating trajectory characteristic parameters of unsurveyed sections; calculating trajectory parameters of a well bottom point on the basis of the trajectory characteristic parameters of the unsurveyed sections of the real drilling trajectory; establishing coordinate transformation relations between a general target plane equation as well as a target coordinate system and a wellhead coordinate system; according to a landing-controlled anticipating guide drilling technology, determining a borehole trajectory model and the trajectory characteristic parameters of a forecasting trajectory and establishing a coordinate equation of the forecasting trajectory; establishing and calculating a constraint equation of the forecasting trajectory to acquire well section length of the forecasting trajectory; calculating the in-target location and judging whether a target is in place or not and forecasting the in-target direction. By the universal method, the target-in location and the target-in direction can be forecast, and the universal method is applicable to different well types like directional wells and horizontal wells even to special formed target sections and various drilling modes like sliding guide drilling, rotating guide drilling and composite guide drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

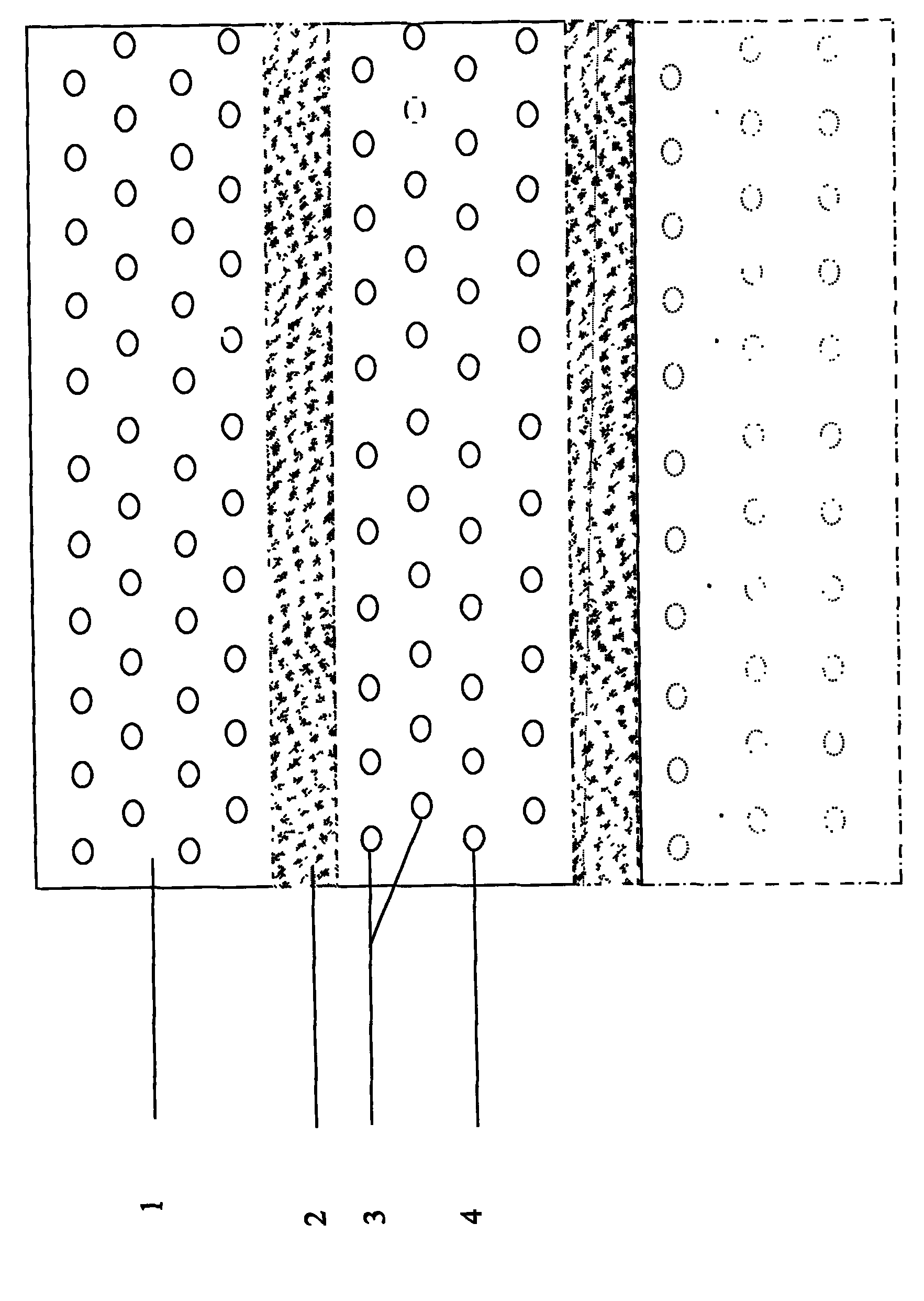

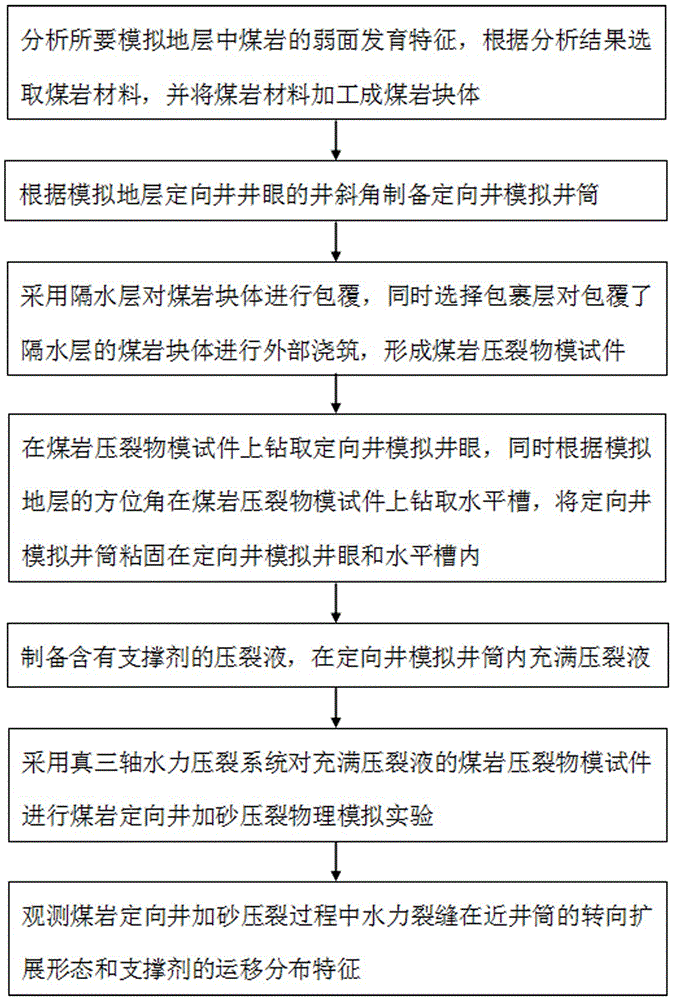

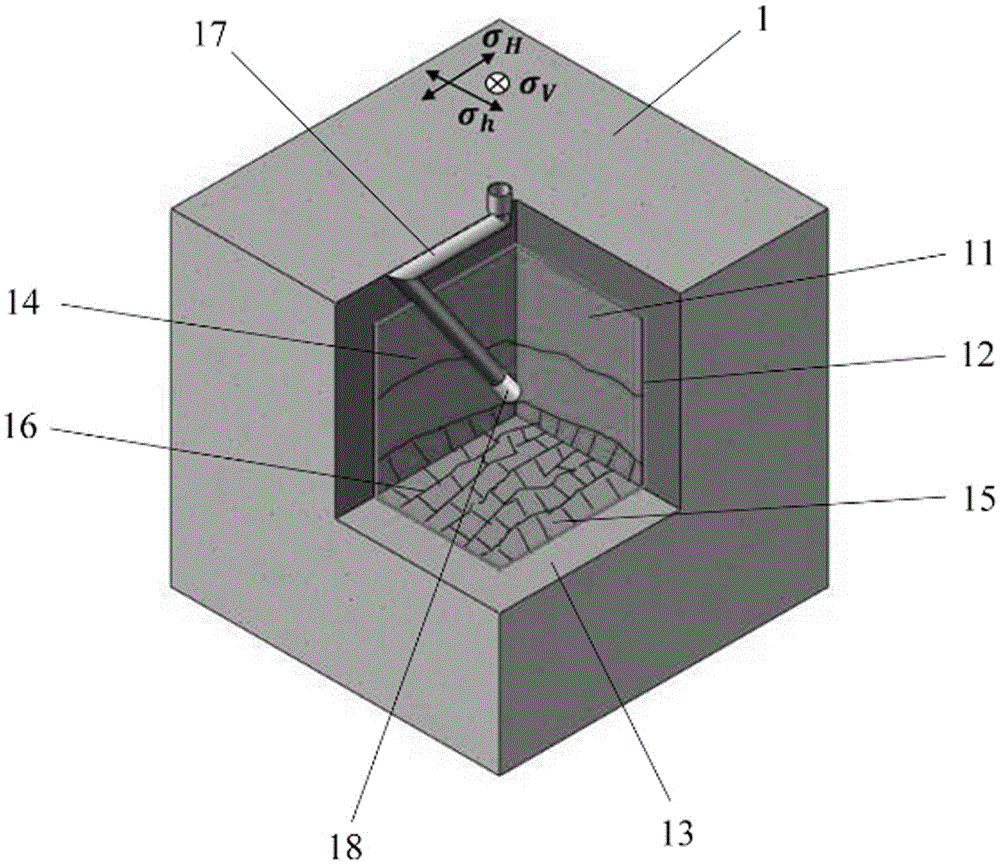

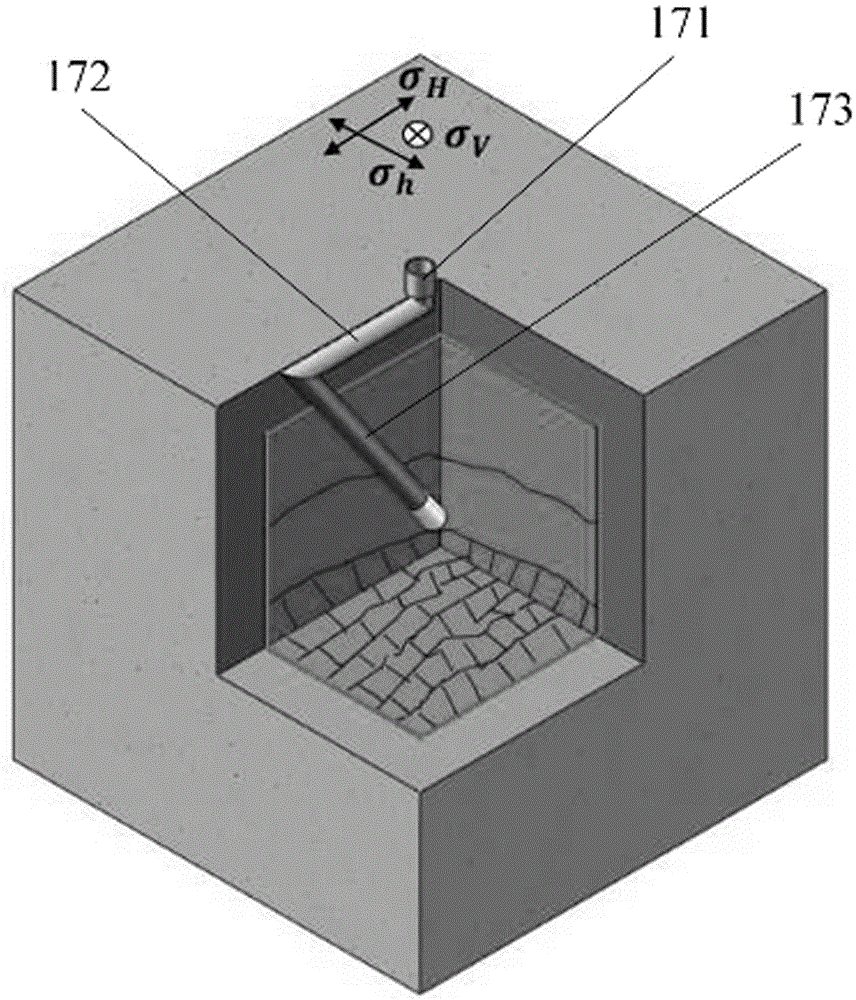

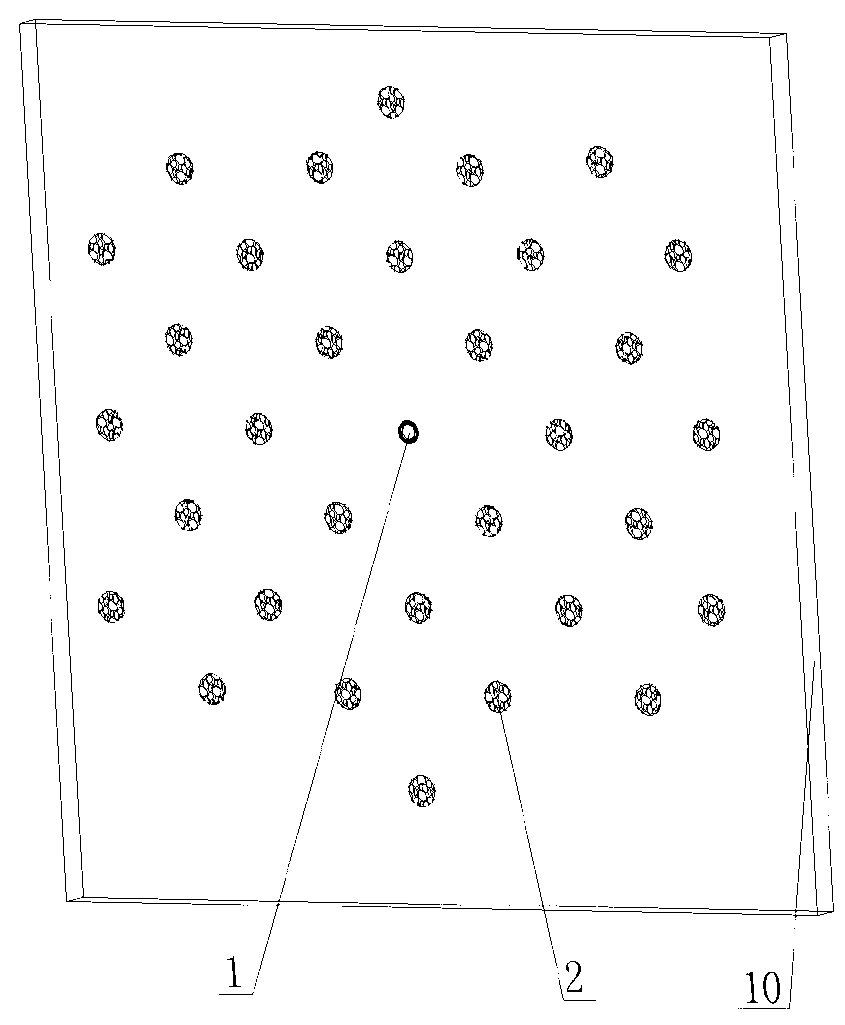

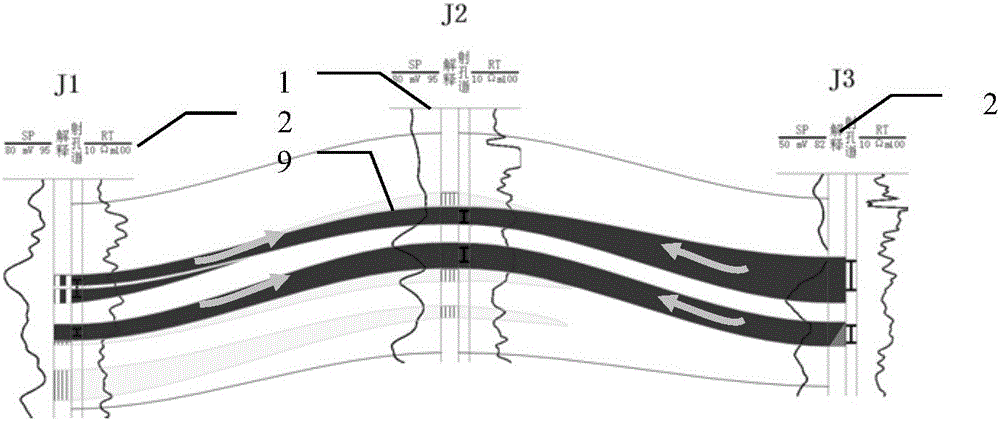

Coal and rock directional well sand fracturing physical simulation method

The invention relates to a coal and rock directional well sand fracturing physical simulation method, which comprises the following steps of selecting coal and rock materials according to the weak face development features of the coal and rock in a simulated stratum, and processing the coal and rock materials into coal and rock block bodies; preparing a wellbore hole simulator of a directional well according to the well deviation angle of a borehole of the directional well of the simulated stratum; covering the coal and rock block bodies with a water-resisting layer, and meanwhile, performing outside pouring on the coal and rock block bodies covered by the water-resisting layer by selecting a covering layer, thus forming a coal and rock fracturing physical model test specimen; drilling a simulated borehole and a horizontal groove of the directional well in the coal and rock fracturing physical model test specimen, and fixedly bonding the wellbore hole simulator of the directional well into the simulated borehole and the horizontal groove of the directional well; preparing fracturing fluid containing supporting agents, and filling the wellbore hole simulator of the directional well with the fracturing fluid; performing simulation experiments on the coal and rock fracturing physical model test specimen by using a true triaxial hydraulic fracturing system; and observing the steering expansion form of the hydraulic fracture in a position near the pit shaft and the conveying distribution features of the supporting agents. The physical simulation method provided by the invention has the advantages that the operation is simple; the accuracy is high; and the physical simulation method conforms to the actual hydraulic fracturing condition.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Mining method for low permeability reservoir of shale gas and the like

InactiveCN103161434ADoes not affect the transformation effectWill not cause scrapFluid removalWater sourceDirectional well

The invention provides a mining method for low permeability reservoir of shale gas and the like. The mining method comprises the steps of arranging a main shaft, forming at least three auxiliary holes in the storage layer on the periphery of the main shaft, performing storage layer transformation in the holes mainly through energizing blasting so as to increase cracks and enable the cracks to be communicated with the main shaft; and maintaining the holes and sealing the shaft after the holes are transformed, and performing production mining and drainage through the main shaft. Completion methods of the holes can be classified into a branch locating shaft, a cluster wall or combination of the branch locating shaft and the cluster wall. The distance between the holes and between the holes and the main shaft is 10-2000m, the diameters of the holes are not smaller than 150mm. The mining method for the low permeability reservoir of the shale gas and the like solves the technical problems that a horizontal shaft must be drilled, multistage fracturing and the like must be performed when the low permeability reservoir is developed, a novel shaft type which is simple to construct, small in occupied area and wide in application range, has low requirements for technical equipment and does not depend on a water source and the novel method are applied to industrialization of low permeability oil gas.

Owner:赵万福

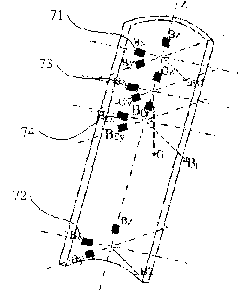

Electromagnetic surveying system while drilling of adjacent-well parallel intervals

ActiveCN101799558AShorten sending timeSimple structureElectric/magnetic detection for well-loggingDetection using electromagnetic wavesDirectional wellHorizontal wells

The invention discloses an electromagnetic surveying system while drilling of adjacent-well parallel intervals, which is capable of providing accurate guiding measurement and calculation for well path control of wells with complicated structures such as double-horizontal wells, directional wells, interspaced wells and the like. The system mainly comprises a magnetic short section, an underground double-magnetic sensor survey meter, a computing system for the adjacent-well parallel intervals, a ground display system and the like. In the invention, the underground double-magnetic sensor survey meter comprises two high-precision alternating magnetic field sensors, can detect two groups of rotating magnetic field signals, and can accurately detect the adjacent-well parallel intervals by a certain drilling footage without a drill bit, thereby being capable of fishing surveying within shorter time; and a data analysis and calculation procedure can be put in the well, and sends few calculated data to the ground, thereby saving the data transmission time. The invention has convenient use, provides an efficient innovative and high technology for the surveying while drilling and the control of the adjacent-well parallel intervals.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

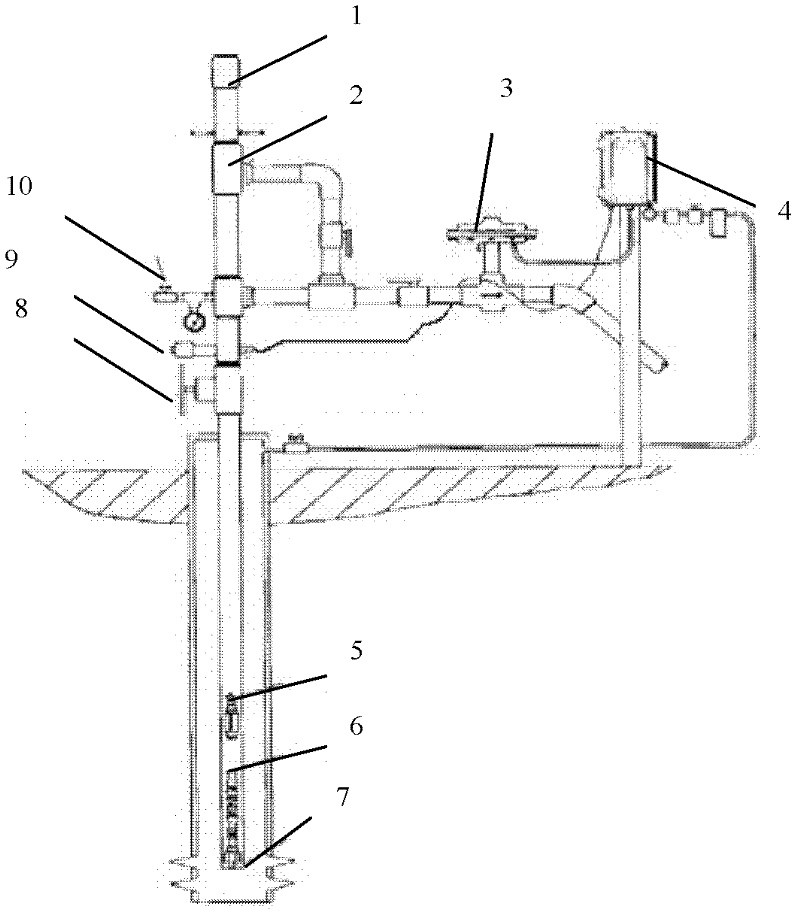

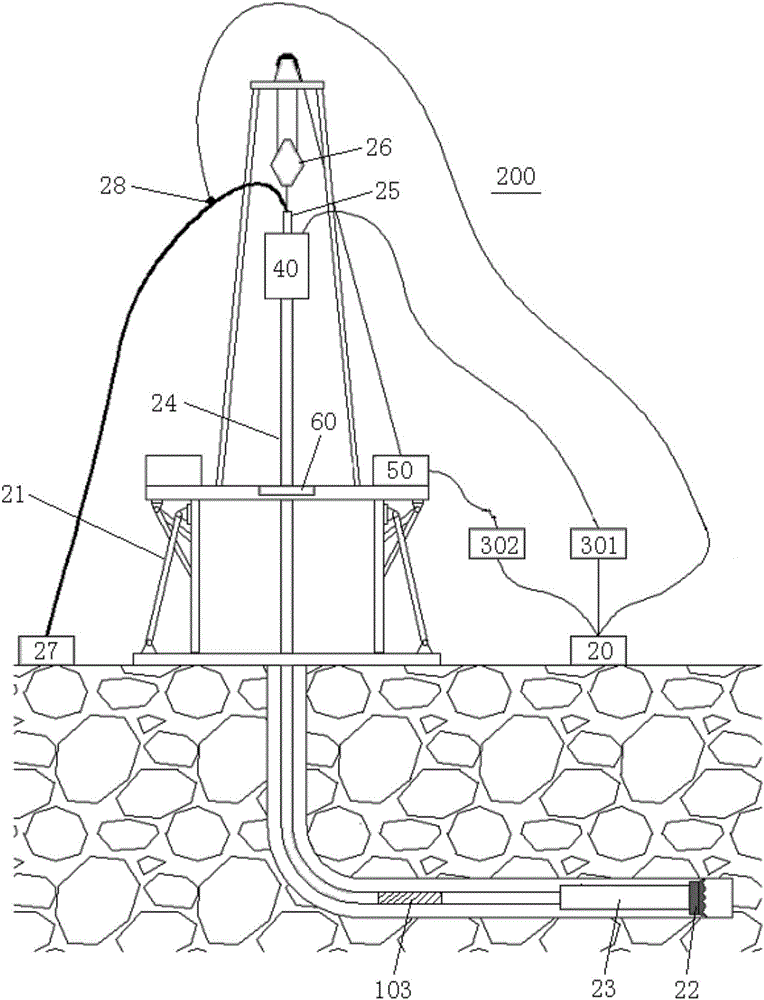

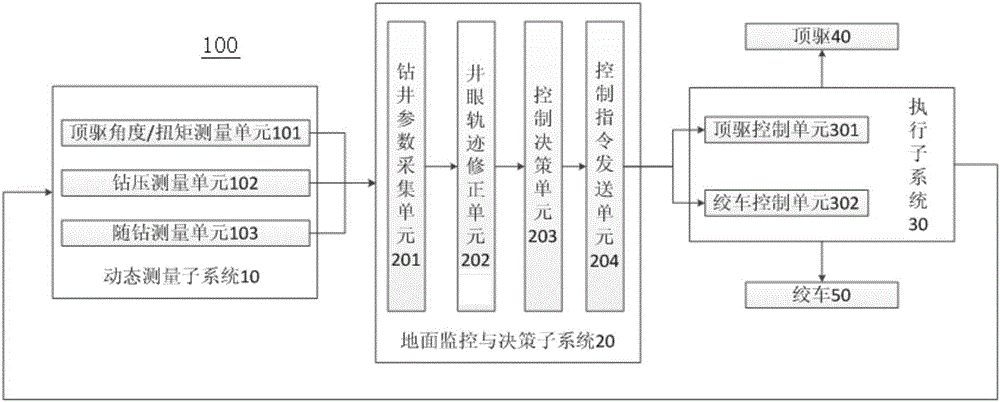

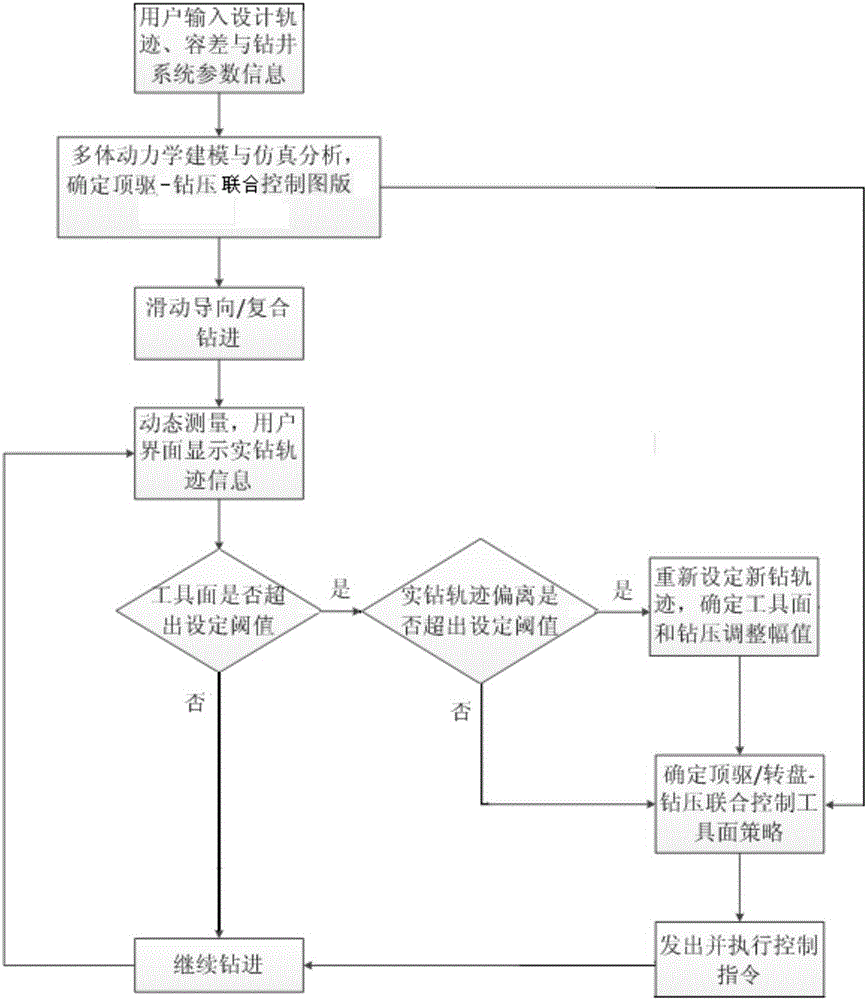

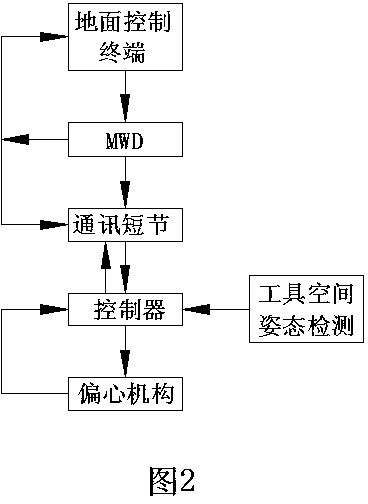

Drilling machine system based on sliding guide drilling closed loop control and drilling method

ActiveCN105041210AQuality improvementImprove work efficiencyDirectional drillingAutomatic control for drillingLoop controlAutomatic control

The invention relates to a drilling machine system based on sliding guide drilling closed loop control and a drilling method. The system comprises a dynamic measuring unit sub system, a ground monitoring sub system, an execution sub system and a guide drilling system, wherein the dynamic measuring unit sub system measures the parameters such as the well deviation, the orientation and the tool surface of an underground power drill tool in real time, and sends the parameters to the ground monitoring sub system; the ground monitoring sub system achieves the goal of re-determining the trace of a borehole to be drilled according to the designed borehole track and the target point when the condition that the borehole track deviates the designed borehole track is found through comparison; the ground monitoring sub system determines the top drive / turntable rotating angle and the drilling pressure regulation strategy through being combined with a top drive / turntable-drilling pressure combined control chart obtained according to the many-body dynamics simulation design analysis, and then dynamically regulates the drilling pressure and the drift of the tool surface of the underground power drilling tool through regulating the rotating angle of a top drive / turntable and the speed of a traveling block by the execution sub system, so that the stability of the underground tool surface and the drilling pressure is maintained; the closed loop automatic control of the sliding guide drilling borehole track is realized; the operation efficiency and the control precision of the directional well borehole track are effectively improved; and the borehole quality is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

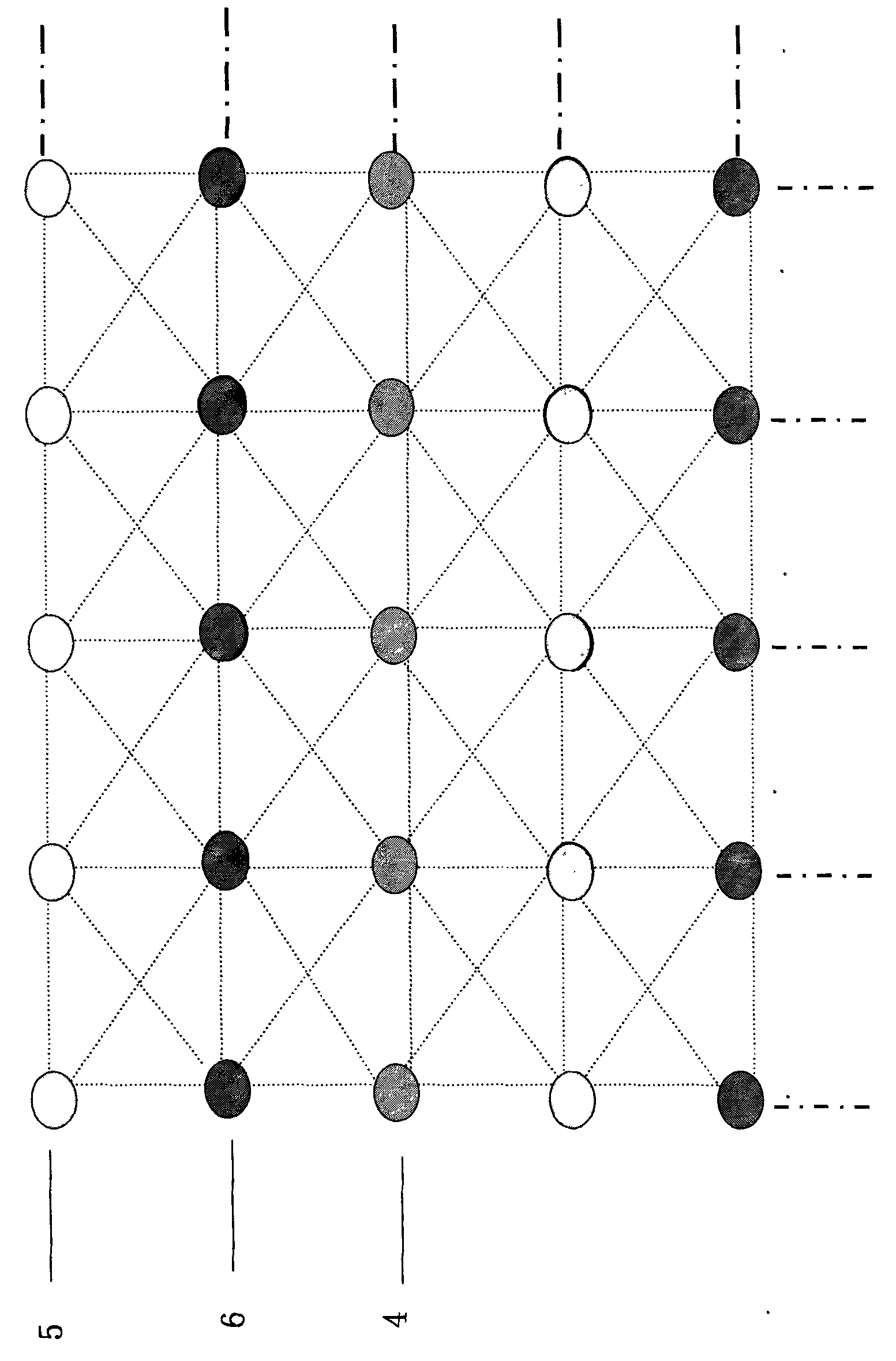

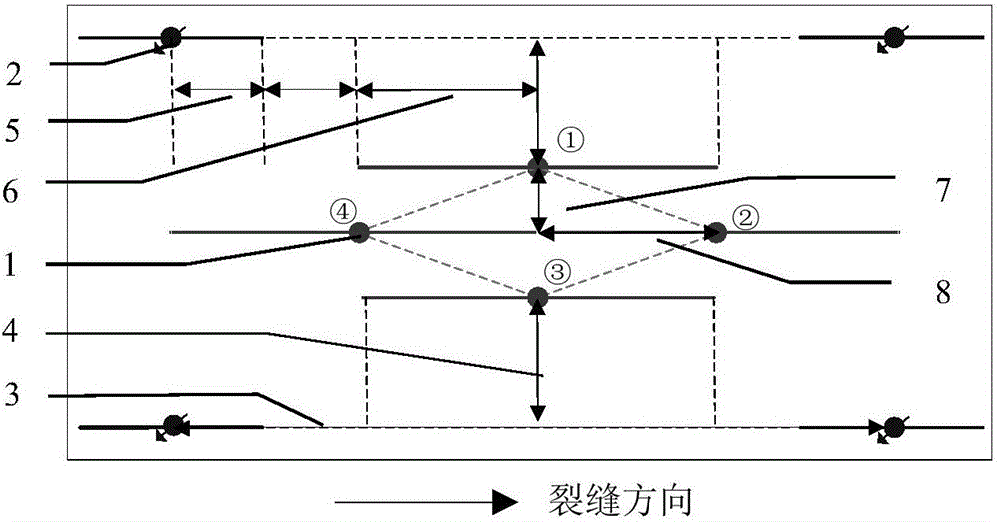

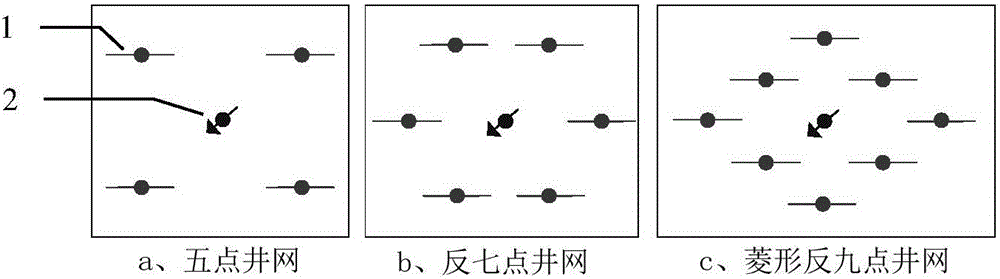

Volume fracturing directional well arranging method for ultra-low permeability dense reservoir

InactiveCN106593400AIncrease productionImprove development efficiencyFluid removalGeomorphologyDirectional well

The invention discloses a volume fracturing directional well arranging method for an ultra-low permeability dense reservoir. By adoption of the well arranging method, the large-scale volume fracturing capability can be achieved, the initial per-well production is greatly increased, and the proportion of oil-water wells is high. The modes of reservoir engineering, numerical simulation, downhole microseismic monitoring, mine field statistics and the like are comprehensively utilized during well pattern optimization, characteristics and transform technologies of different reservoir stratums are fully considered, and fractured flooding is avoided; and meanwhile, the requirement for energy replenishing for long-term stable production and water injection is met, and accordingly the purposes of increasing the per-well production and exploitation benefits of the ultra-low permeability dense reservoir are achieved. The volume fracturing directional well arranging method is suitable for complex geological conditions such as longitudinal reservoir stratum superimposed development and large planar structure variation amplitude of the ultra-low permeability dense reservoir, reasonable, and capable of improving the exploiting effect to the maximum extent.

Owner:PETROCHINA CO LTD

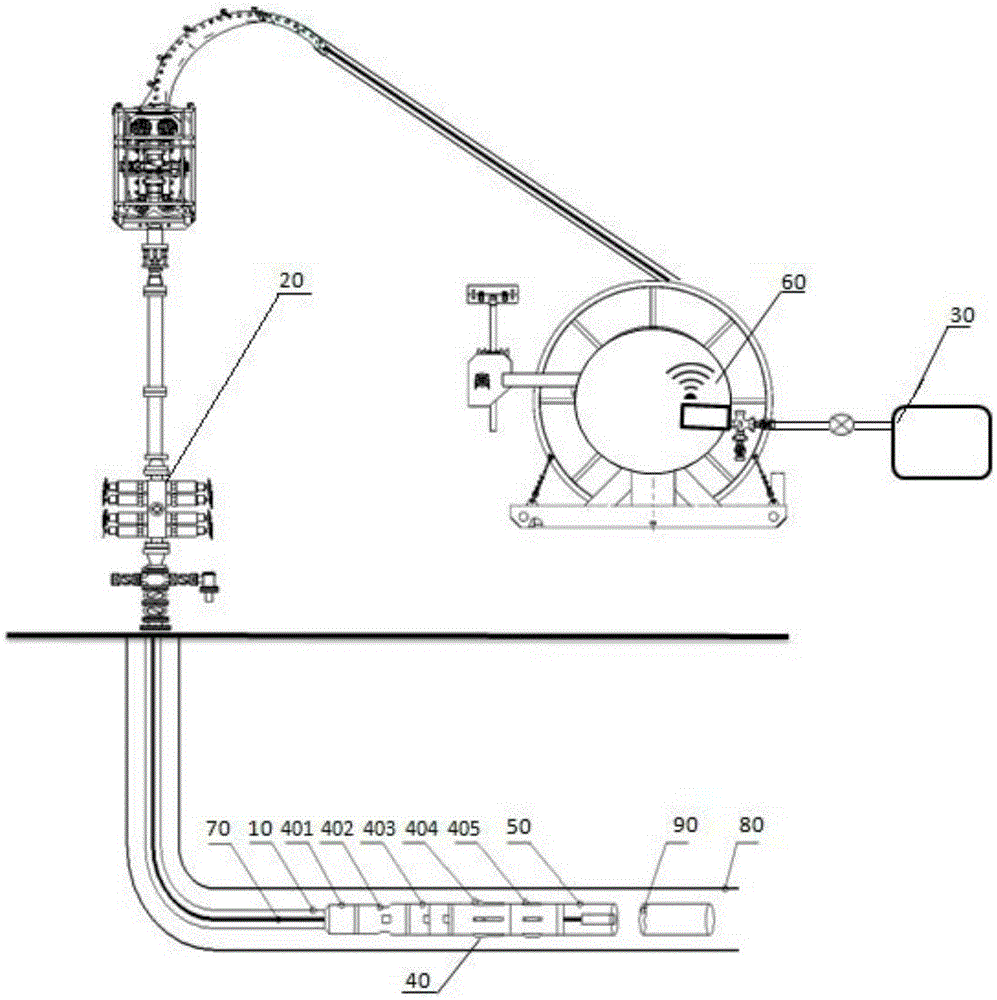

Underground visual probing equipment and method

InactiveCN105317422ARealize whole well detectionConstructionsBorehole/well accessoriesDirectional wellCoiled tubing

The invention provides underground visual probing equipment which comprises a ground pump injection system, a coiled tubing device, a coiled tubing blowout preventing device, a rotating communication device, an underground tubular column string and a cable. The lower portion of the underground tubular column string is connected with a camera supporting barrel, a camera, an overflowing channel and a water spraying hole are arranged in the camera supporting barrel, one end of the overflowing channel is communicated with the coiled tubing, the other end of the overflowing channel is communicated with the water spraying hole, and the cable is arranged in the coiled tubing to connect the camera with the rotating communication device. The invention further provides an underground visual probing method. The underground visual probing equipment can complete whole detection for a directional well and a horizontal well, and can obtain clear image data in the complex environment of turbid liquid and high underground temperature in a well shaft.

Owner:中石化石油工程技术服务有限公司 +1

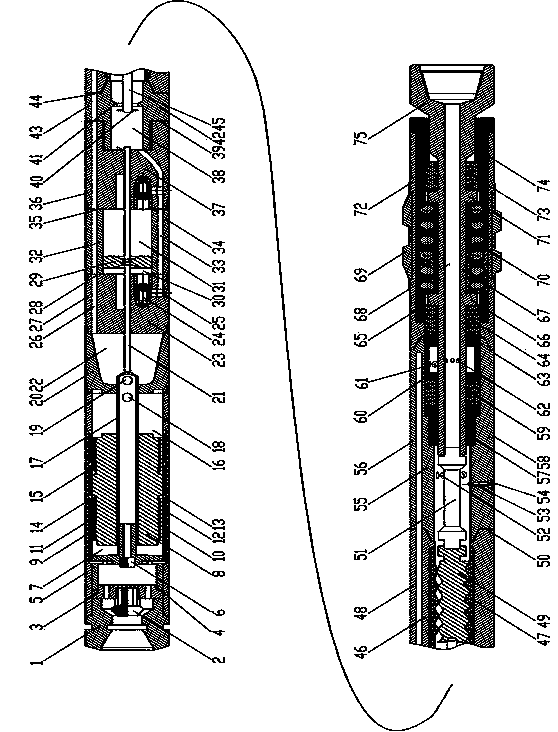

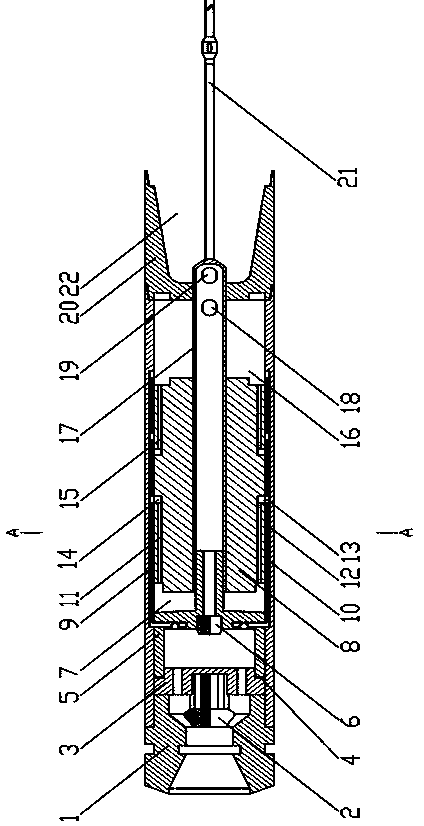

Gas drilling underground motor drilling tool

ActiveCN104213829AAddress lack of motivationMeet drilling needsBorehole drivesHydraulic motorDirectional well

The invention discloses a gas drilling underground motor drilling tool. The gas drilling underground motor drilling tool comprises a double-acting compressed air power short section, a double-acting hydraulic power short section, a closed circulating hydraulic motor and a liquid separation air discharging transmission short section, which are sequentially connected with one another in a threading manner, and a chamber of each part is sealed through a sealing pad after being aligned to one another; a sealing pad d is arranged between the double-acting hydraulic power short section and the closed circulating hydraulic motor. By adopting the gas drilling underground motor drilling tool, the gas energy can be converted to high-pressure hydraulic energy, the rotor is driven to rotate through the closed cycling of hydraulic oil inside a volume-type motor, the power insufficiency caused by the compression when the gas energy is directly used for driving the motor can be overcome, all advantages for adopting the gas as the cycling medium also can be maintained, and the underground power problem of a gas drilling horizontal well, a directional well and a large-displacement well can be effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

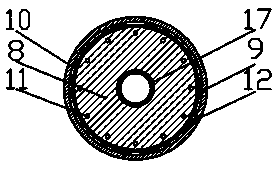

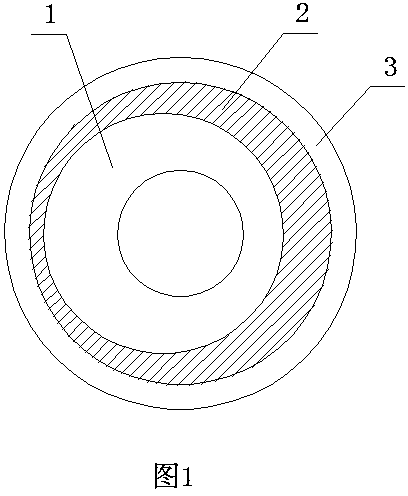

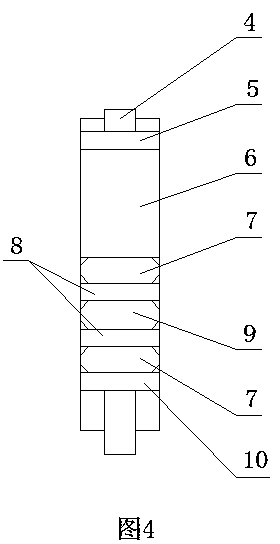

High build-up rate well track control method

InactiveCN103556945AEffective guidanceMeet the requirements of the severe development situationDrilling machines and methodsLithologyElectromagnetic clutch

The invention relates to a high build-up rate well track control method, and belongs to the technical field of well track control methods. The high build-up rate well track control method includes an offset mechanism control method, an offset mechanism is designed by means of combined movement of eccentric rings, power derives from a drill rod, rotational movement of the drill rod is transferred to a speed reducer through an electromagnetic clutch by a coupler, the inner eccentric ring and the outer eccentric ring are respectively driven to rotate after speed is reduced by the speed reducer, so that a spindle is bent to different degrees, a dip angle inconsistent with a well axis is provided for a drill bit, the dip angle of the drill bit is controlled in a stepless manner, and a well track can be controlled. A bias drill bit is not used for guiding, the axis of the drill bit is effectively guided and controlled by controlling bending characteristics of a drill column, and a build-up rate is determined by a tool and cannot be affected by drilling formation lithology. The high build-up rate well track control method can be applied to track control for various wells such as a straight well, a directional well, an ultra-deep well, an extended reach well, an ultra-thin oil layer horizontal well, a long-distance horizontal well and a multi-branch well.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com