A method for underground coal gasification

A technology of coal gasification and gasification agent, applied in coal gasification, underground mining, earthwork drilling and other directions, can solve the problems of large usage and high cost, increase output and combustion value, convert coal resources, and avoid resource waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

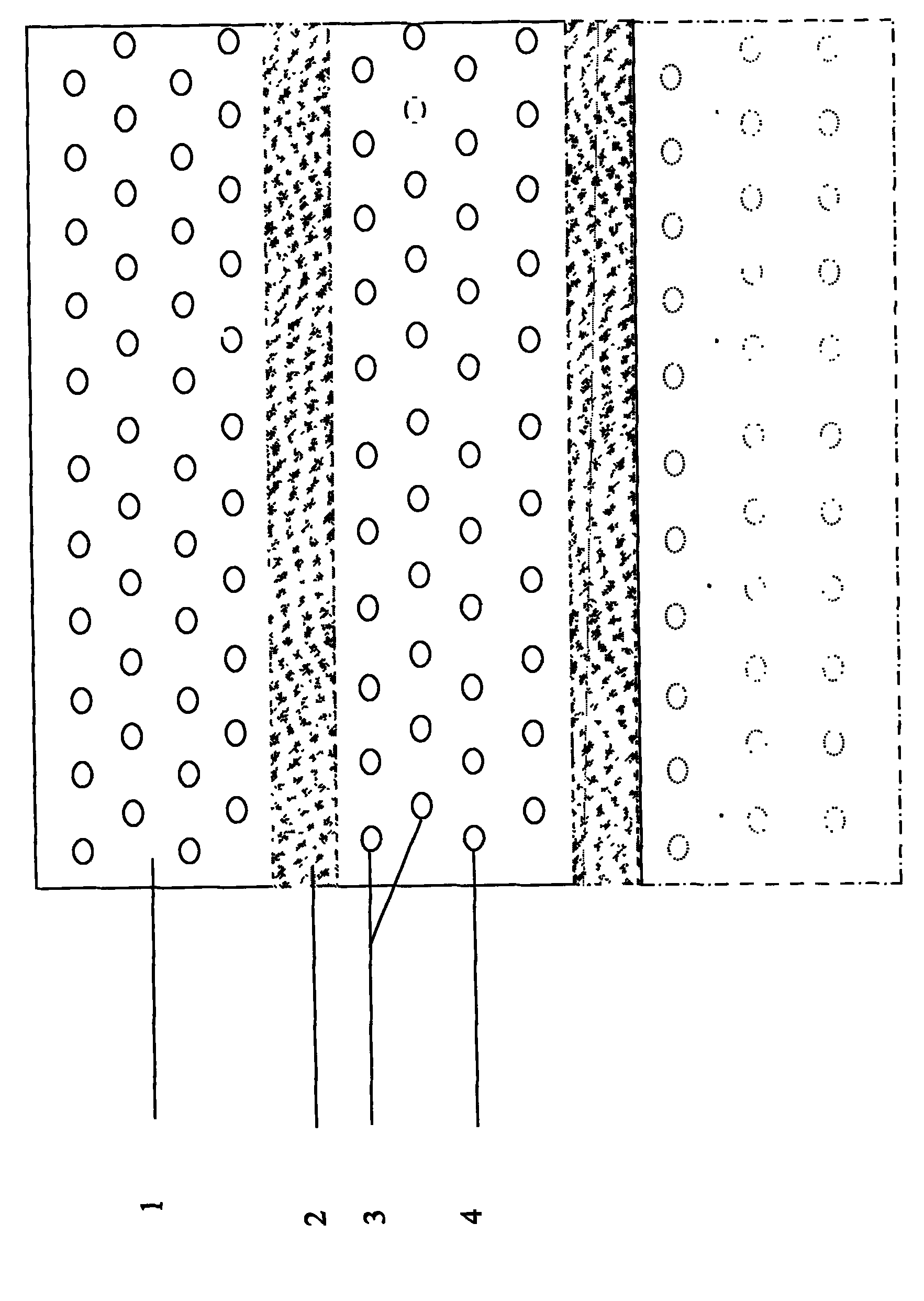

[0042] refer to figure 1 According to the present invention, an isolation zone (2) is arranged between the gasification operation areas (1), and an injection well (3) and a gas production well (4) are arranged in the gasification operation area. The width of the isolated area is more than 500m.

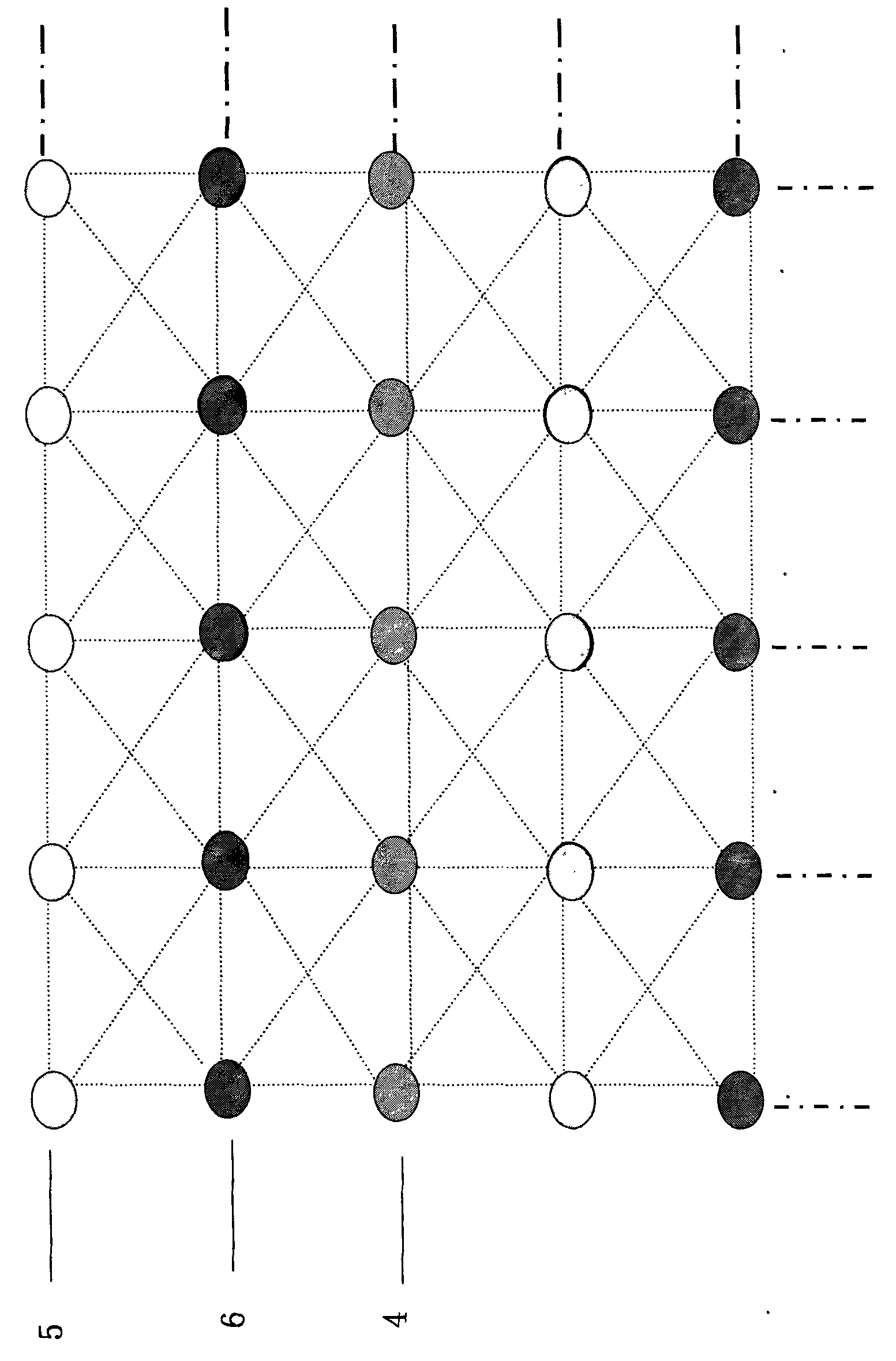

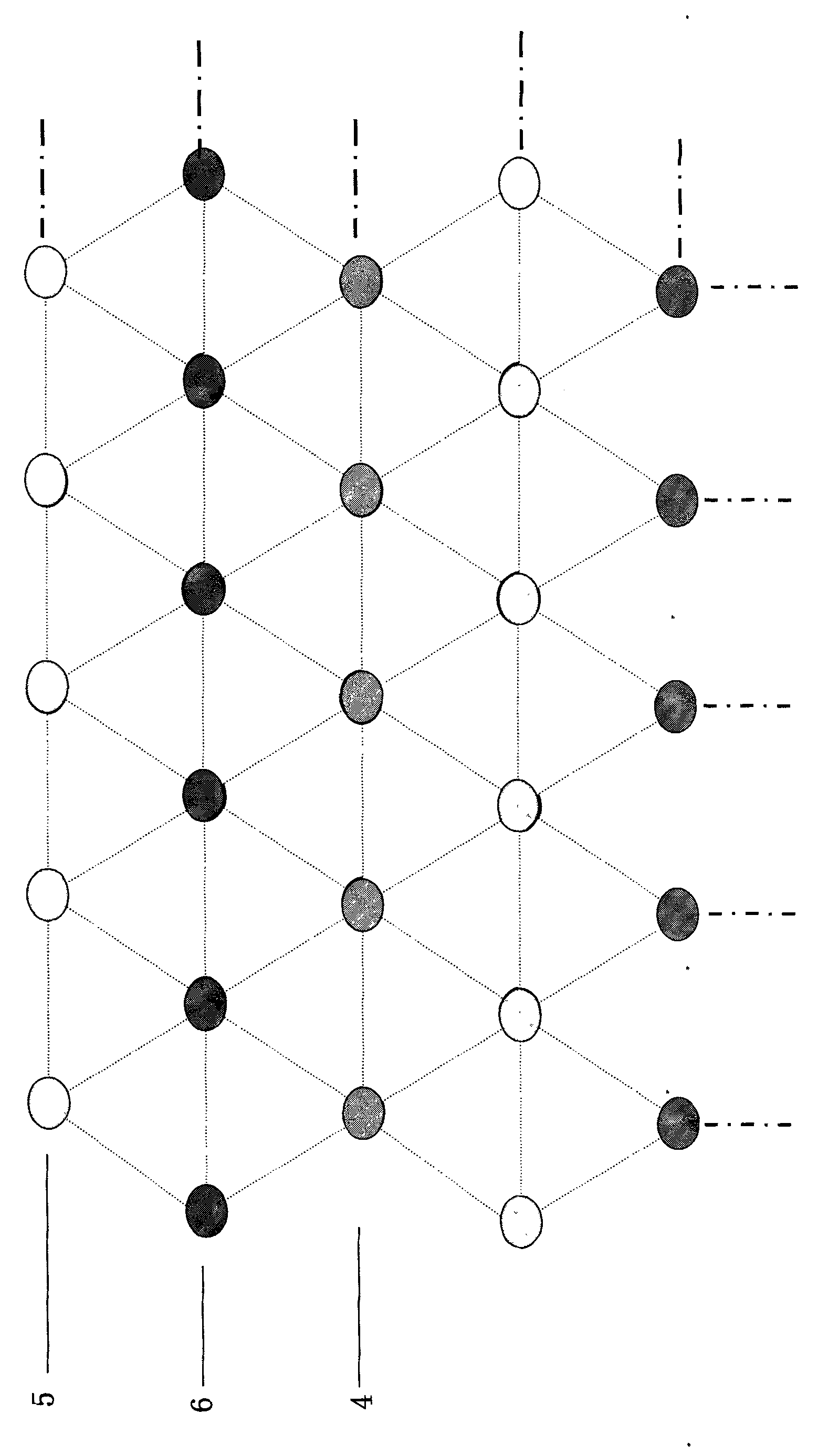

[0043] refer to Figure 2 to Figure 4 , Injection well (3) of the present invention can be set up separately, is respectively gas injection well (5) and water injection well (6), and water injection well (6) is positioned between gas injection well (5) and gas production well (4). Gas injection wells (5), water injection wells (6) and gas production wells (4) can be arranged in a rectangular manner, the gas injection wells (5) at the edge are arranged in turn as water injection wells (6) and gas production wells (4). In the middle, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com