Patents

Literature

228 results about "Underground coal gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Underground coal gasification (UCG) is an industrial process which converts coal into product gas. UCG is an in-situ gasification process, carried out in non-mined coal seams using injection of oxidants and steam. The product gas is brought to the surface through production wells drilled from the surface.

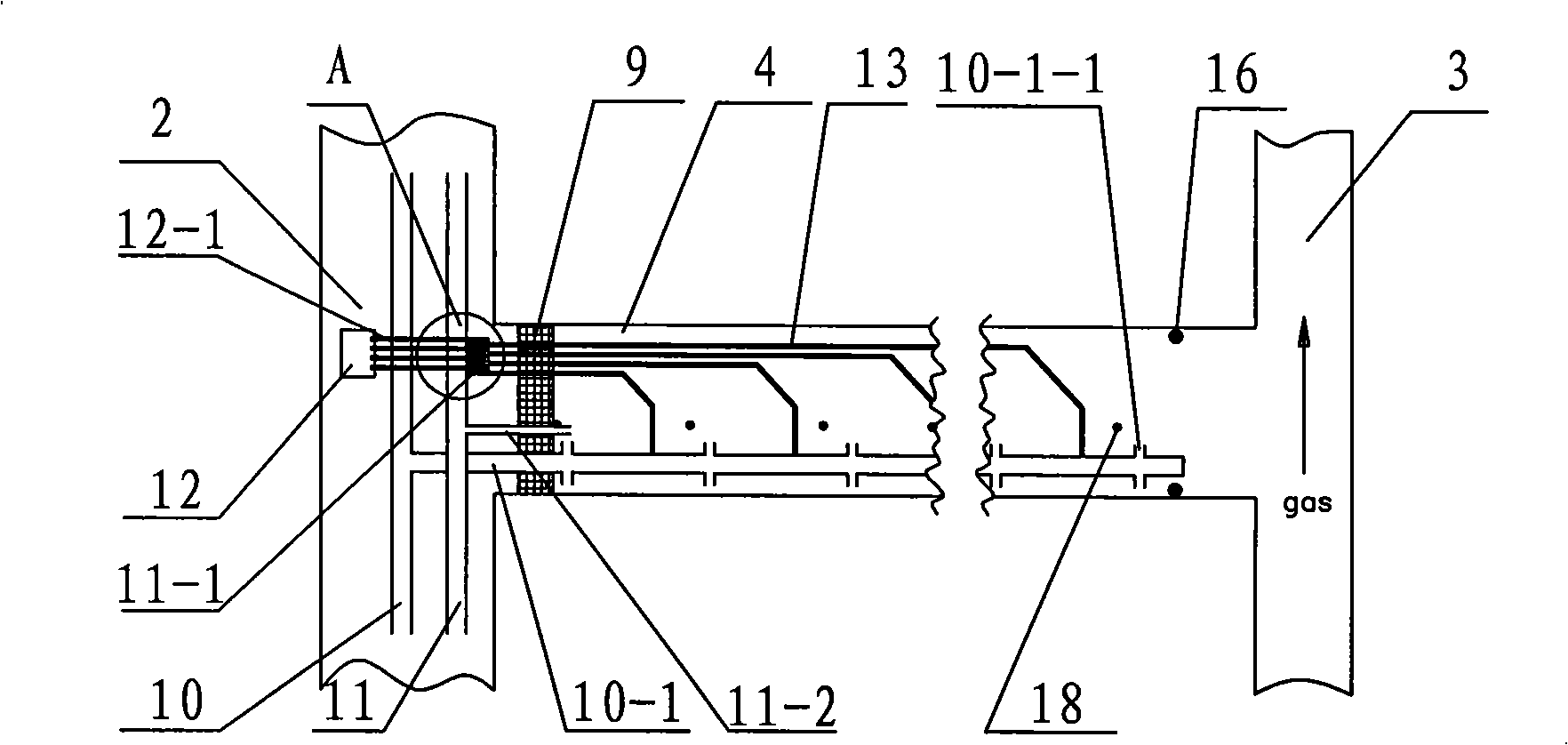

Method for joint-mining of coalbed gas and coal

InactiveUS20150247385A1Increase ratingsImprove breathabilityArtificial islandsFluid removalWell drillingProcess engineering

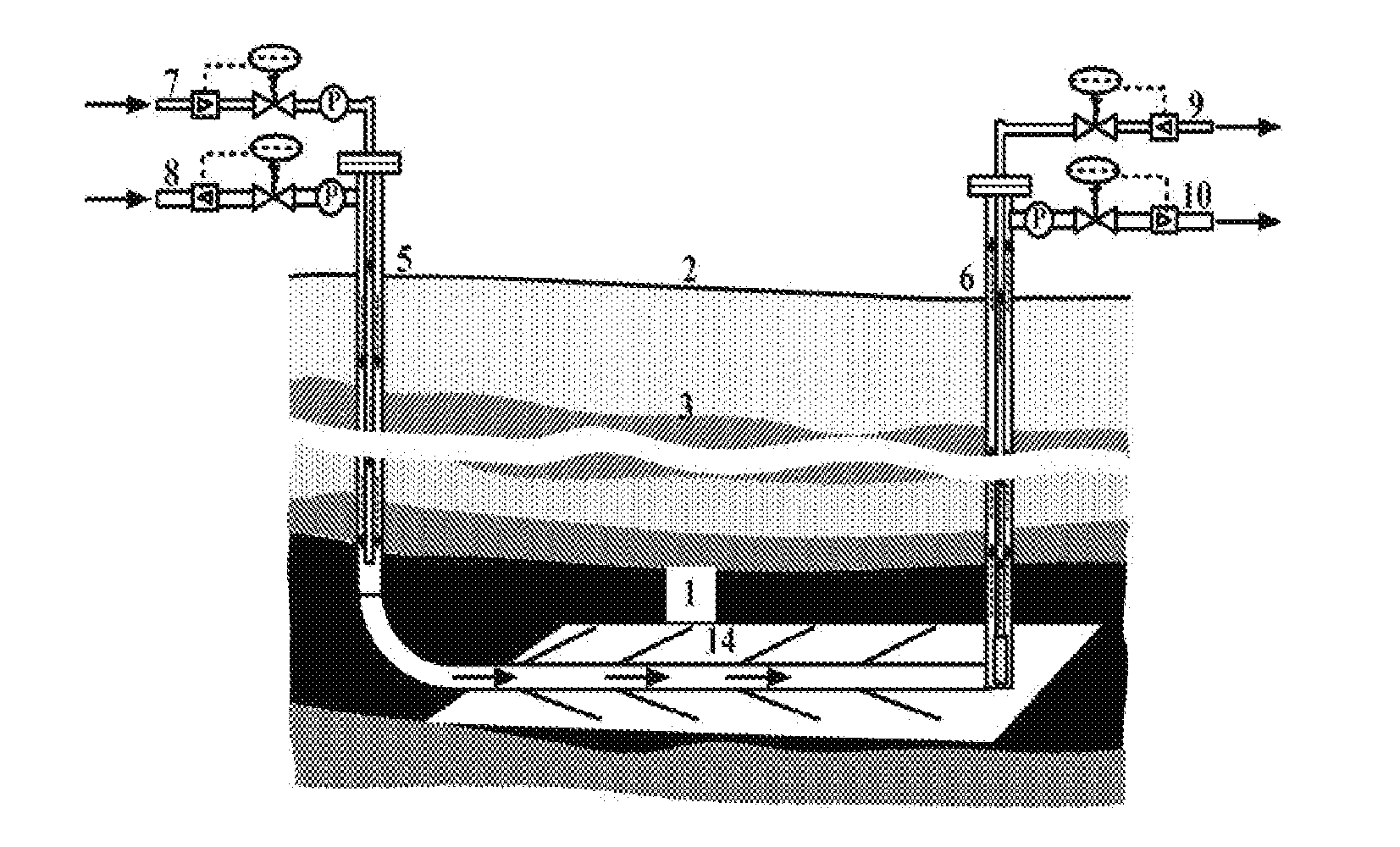

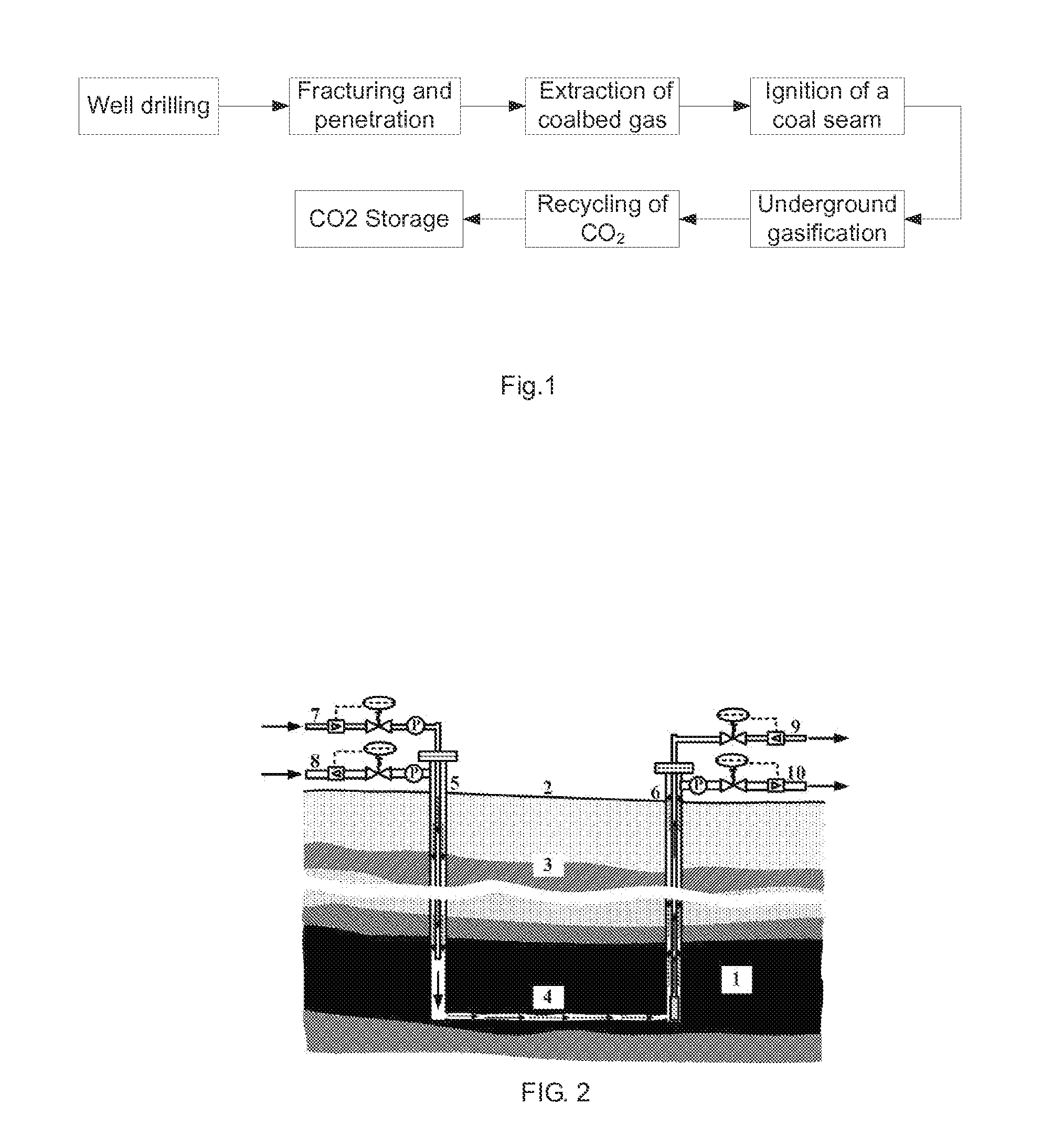

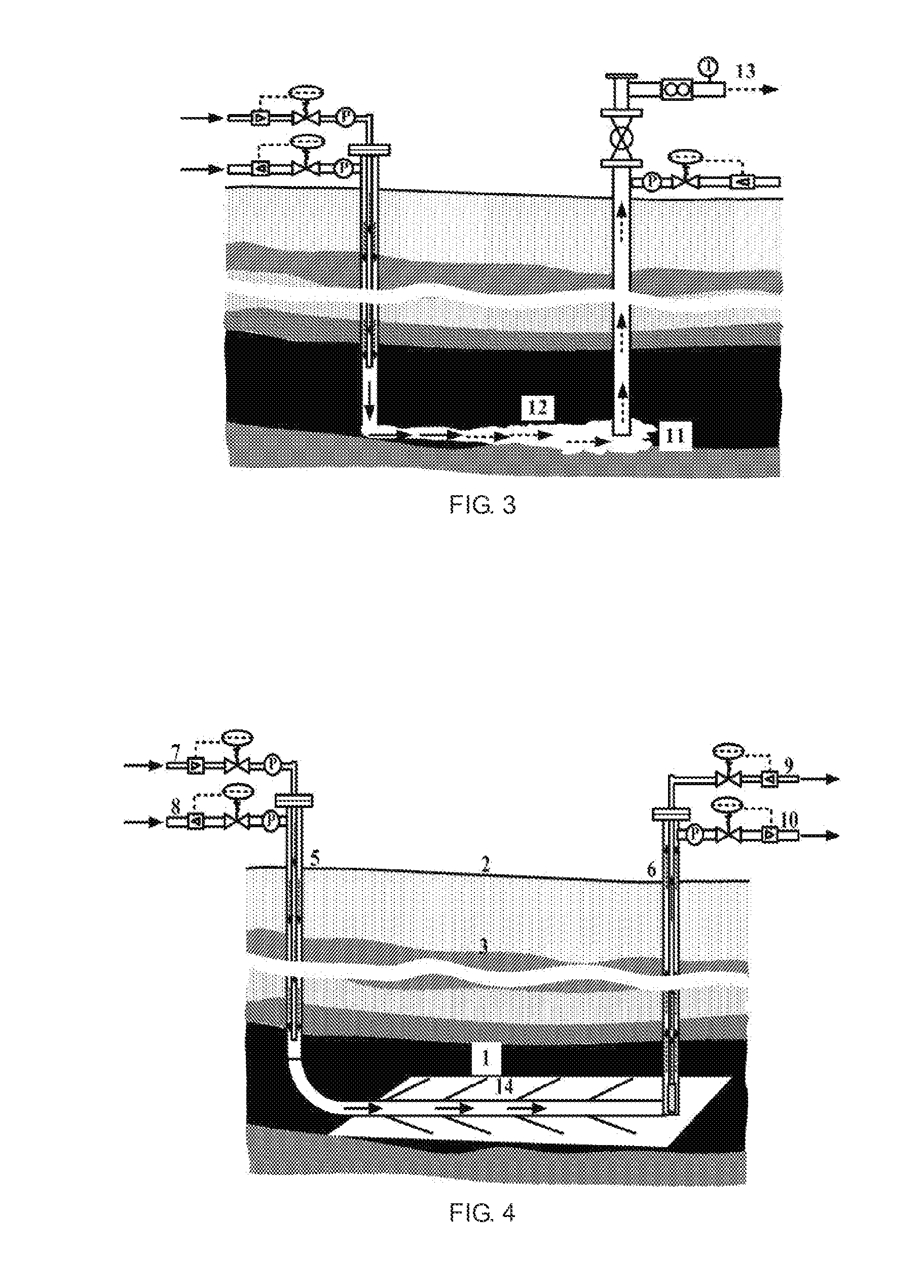

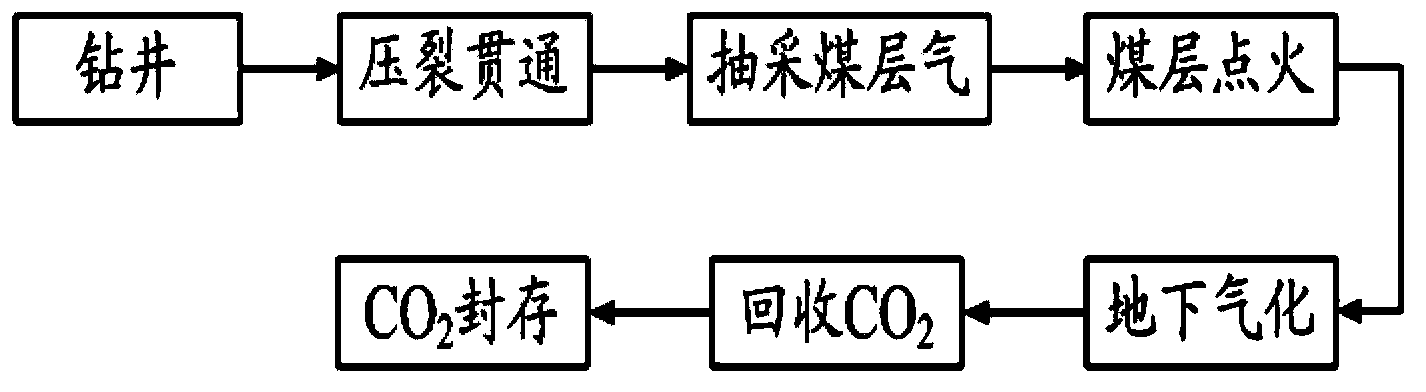

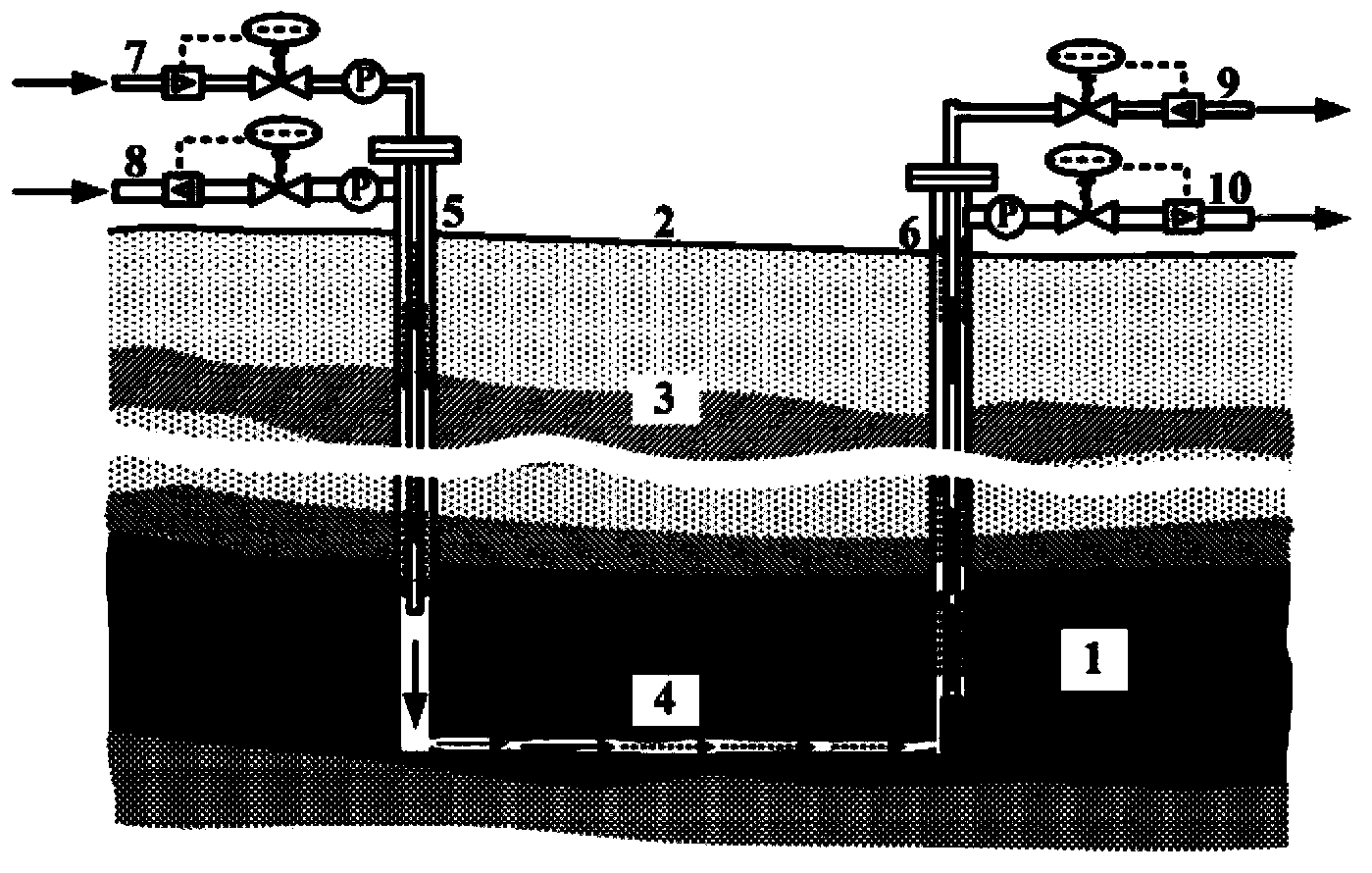

Provided is a method for joint-mining of coalbed gas and coal. The method comprises: a well-drilling step; a fracturing and penetration step; a coalbed gas extraction step: an ignition step, and an underground gasification step. The method combines an underground coal gasification technology and a coalbed gas extraction technology, not only allows for utilization of the high temperature of underground gasification to heat a coalbed. thus increasing the permeability of a coal seam. and increasing the recovery rate of the coalbed gas, but also allows for utilization of the coalbed gas to perform the drilling and the fracturing and penetration processes, thus increasing the efficiency of underground coal gasification for mining.

Owner:ENN COAL GASIFICATION MINING

Method for extracting coalbed methane and coal together

ActiveCN103670338AImprove breathabilityEnhanced overall recoveryConstructionsFluid removalWell drillingCoal

The invention relates to a method for extracting coalbed methane and coal together. The method includes a well drilling step, a pressing crack cut-through step, a coalbed methane extracting step an ignition step and an underground gasification step. According to the method, an underground coal gasification technology and a coalbed methane extracting technology are combined, a coal bed can be heated by high temperature of underground gasification to improve breathability of the coal bed and increase extracting ratio of the coalbed methane, well drilling and pressing crack cut-through processes can be performed by the aid of the coalbed methane, and the underground gasification coal extraction efficiency is increased.

Owner:ENN SCI & TECH DEV

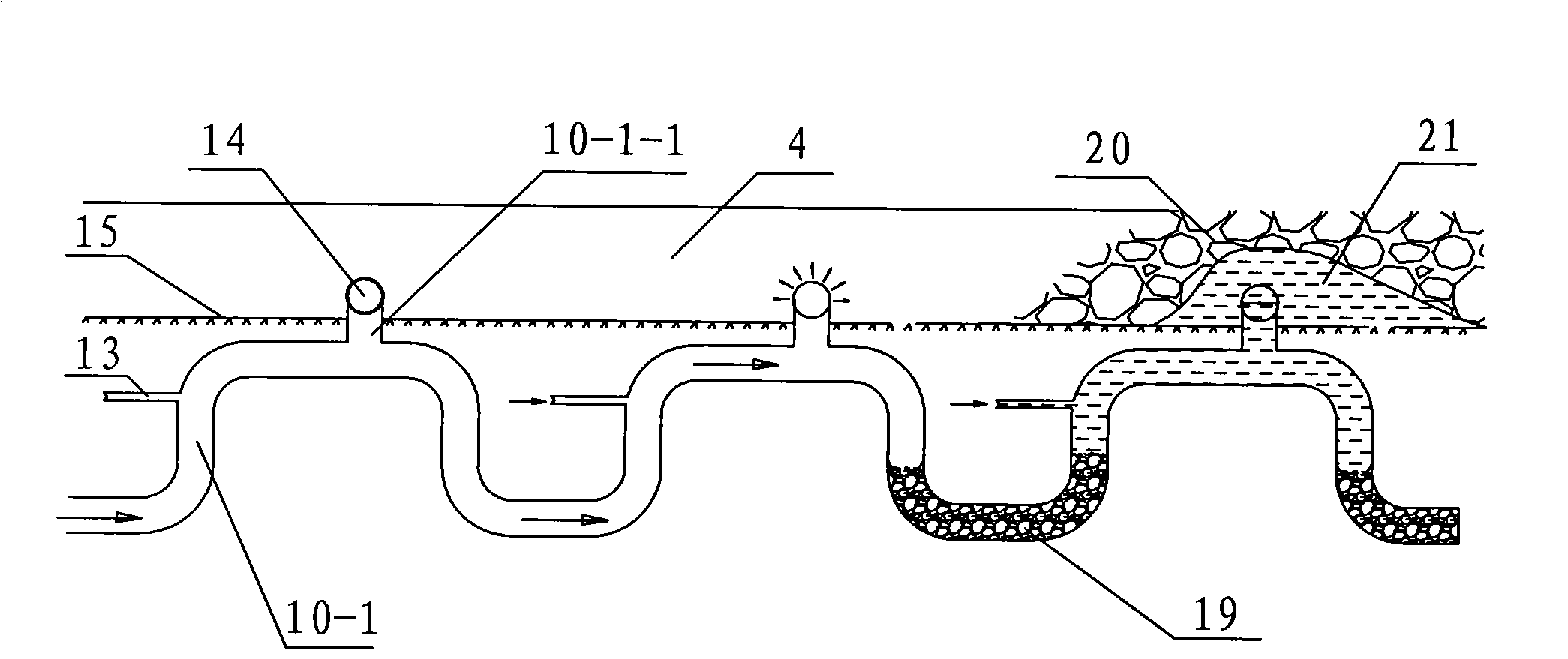

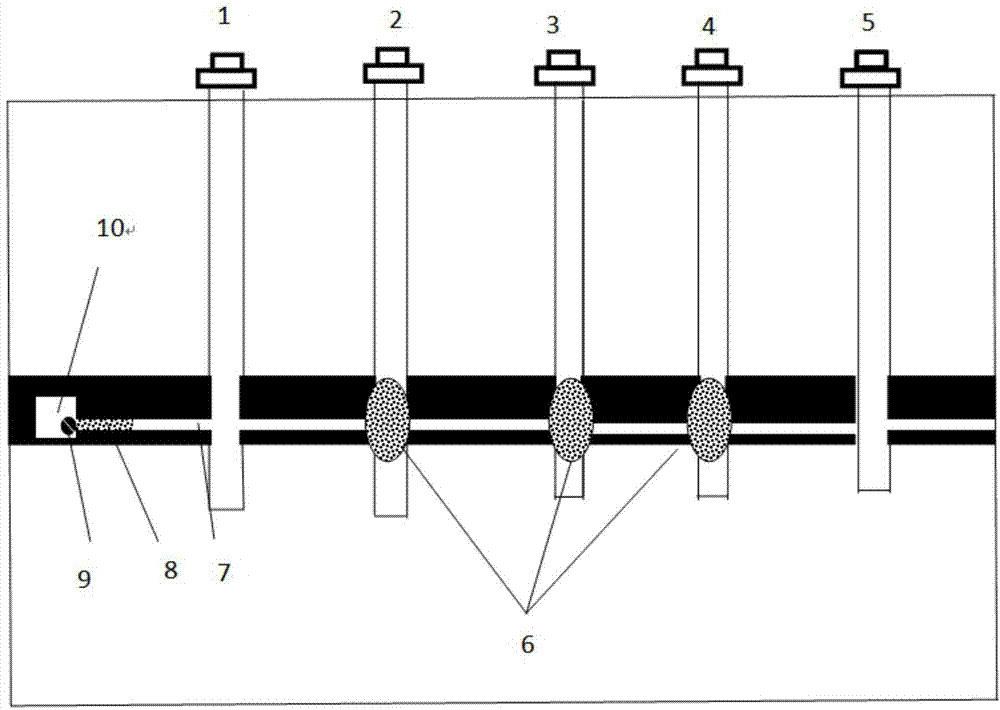

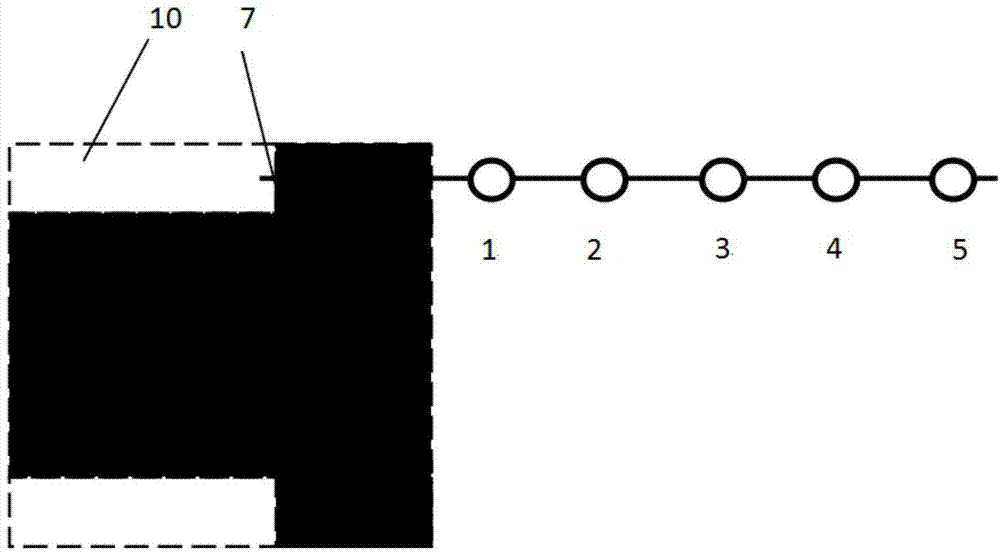

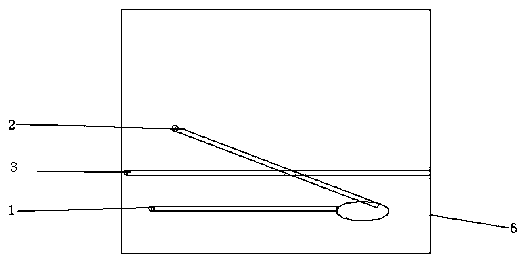

Passage formation method for underground coal gasification

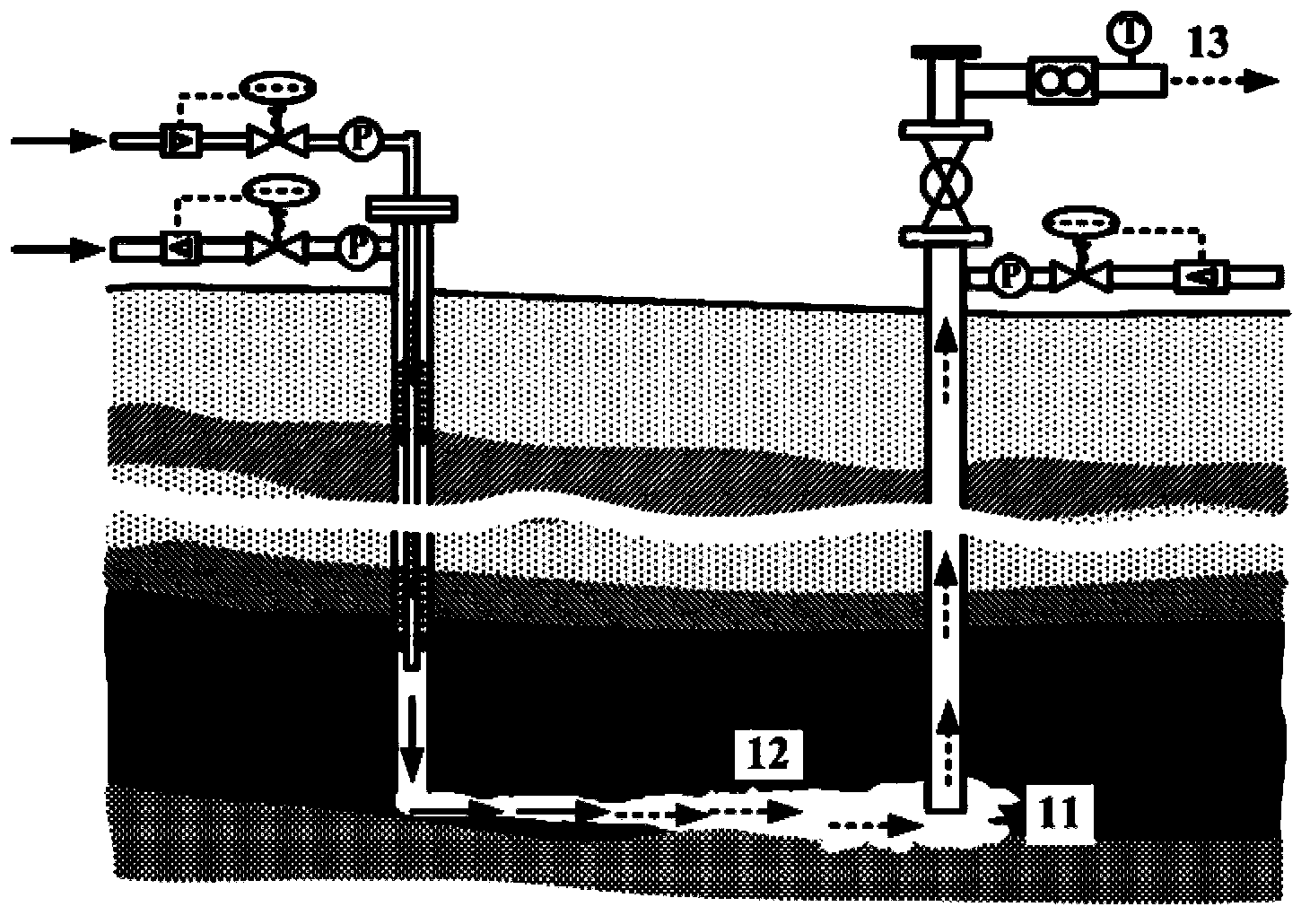

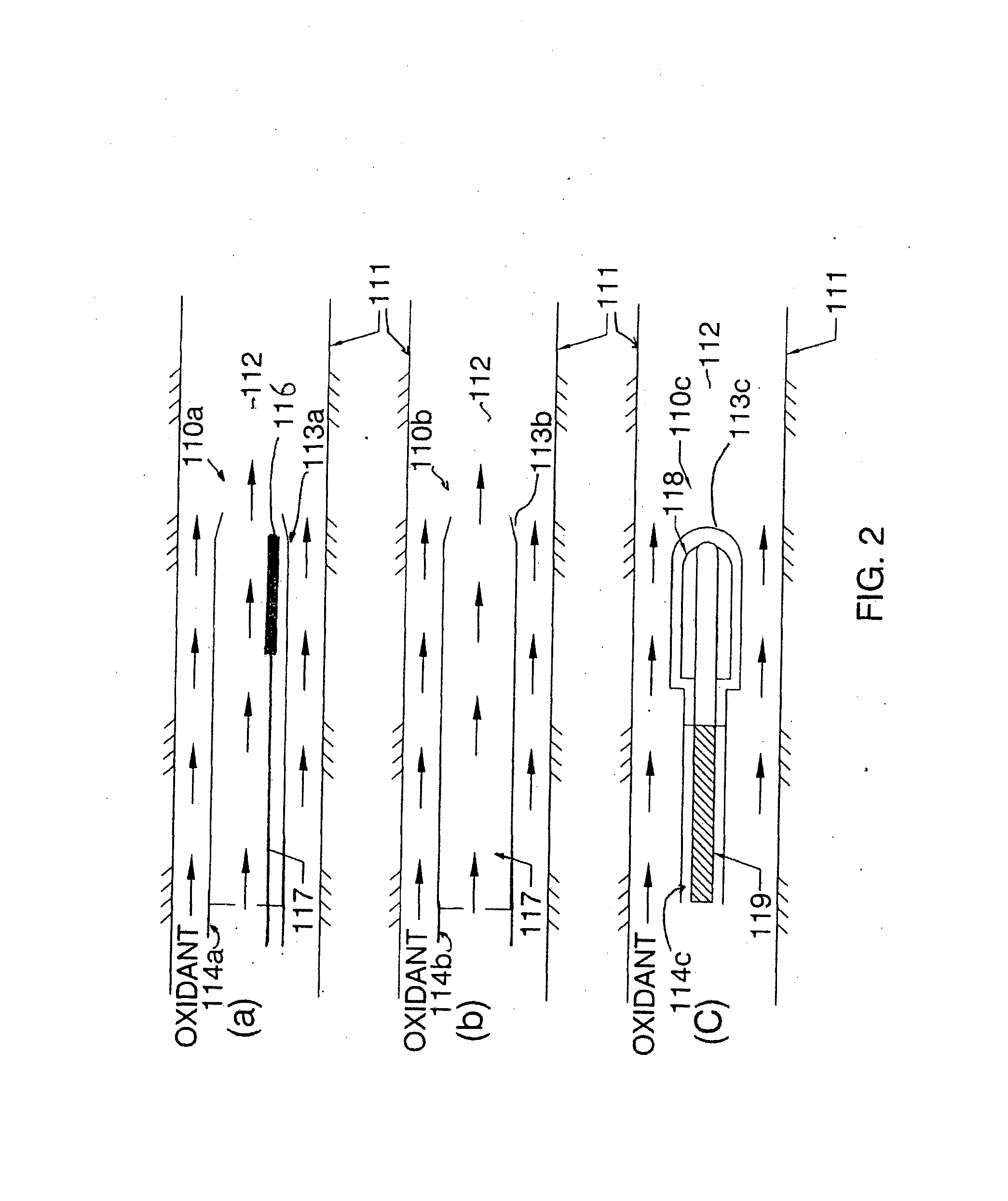

A passage formation method for underground coal gasification is provided. The method comprises the following steps of: (a) building a fire area in the bottom coal bed of a first bore hole; (b) performing mechanical and directional drilling operation in a neighbor coal bed close to the bottom of the first bore hole in the vicinity of the fire area through the lower end of a second bore hole which is another existing bore hole or a newly-drilled bore hole outside the fire area, so as to pre-penetrate the neighbor coal bed and thus to form a directional passage communicated with the fire area in the neighbor coal bed; and (c) delivering an oxygen-containing gas to the fire area through the second bore hole and the directional passage, and thermally processing the directional passage to enlarge the directional passage and thus to form a gasification passage used for a underground coal gasification furnace.

Owner:ENN SCI & TECH DEV

Underground coal gasification

ActiveCN1854459AImprove drainage efficiencyImprove gasification effectConstructionsCoal gasificationProcess engineeringCoal fired

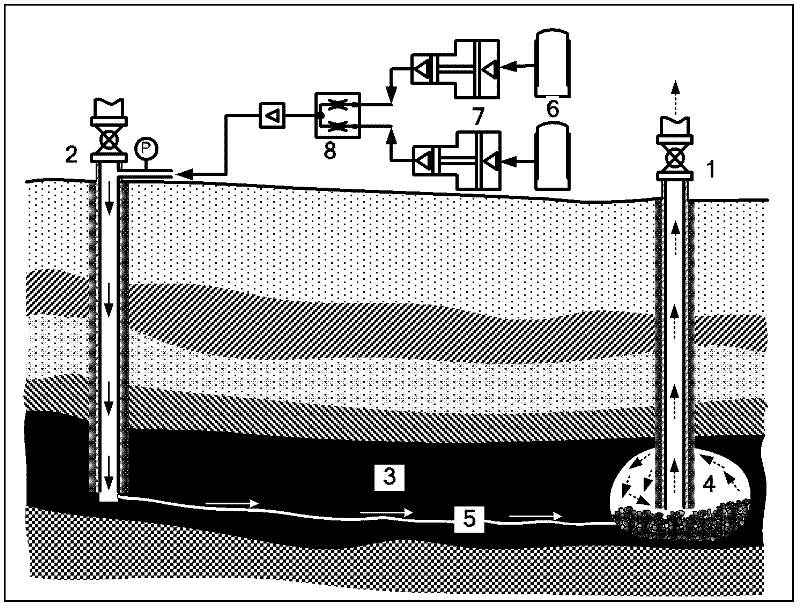

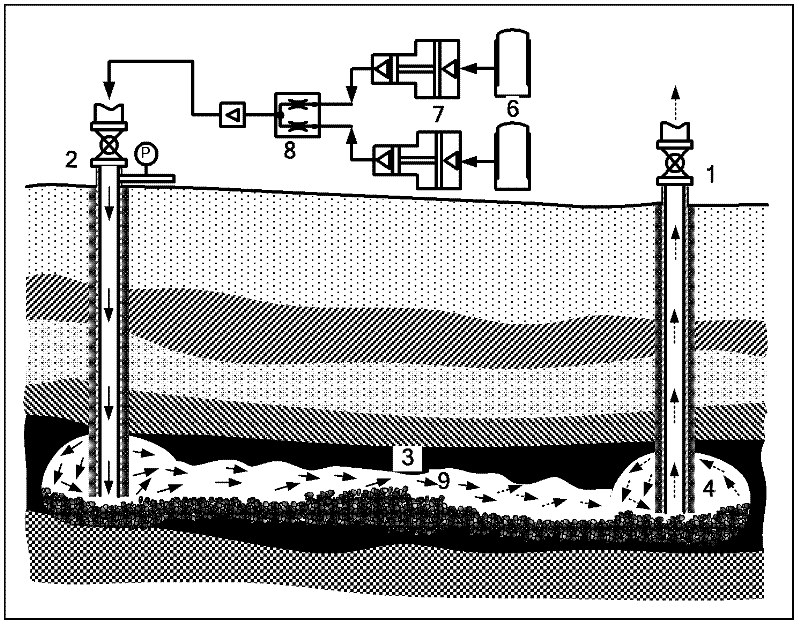

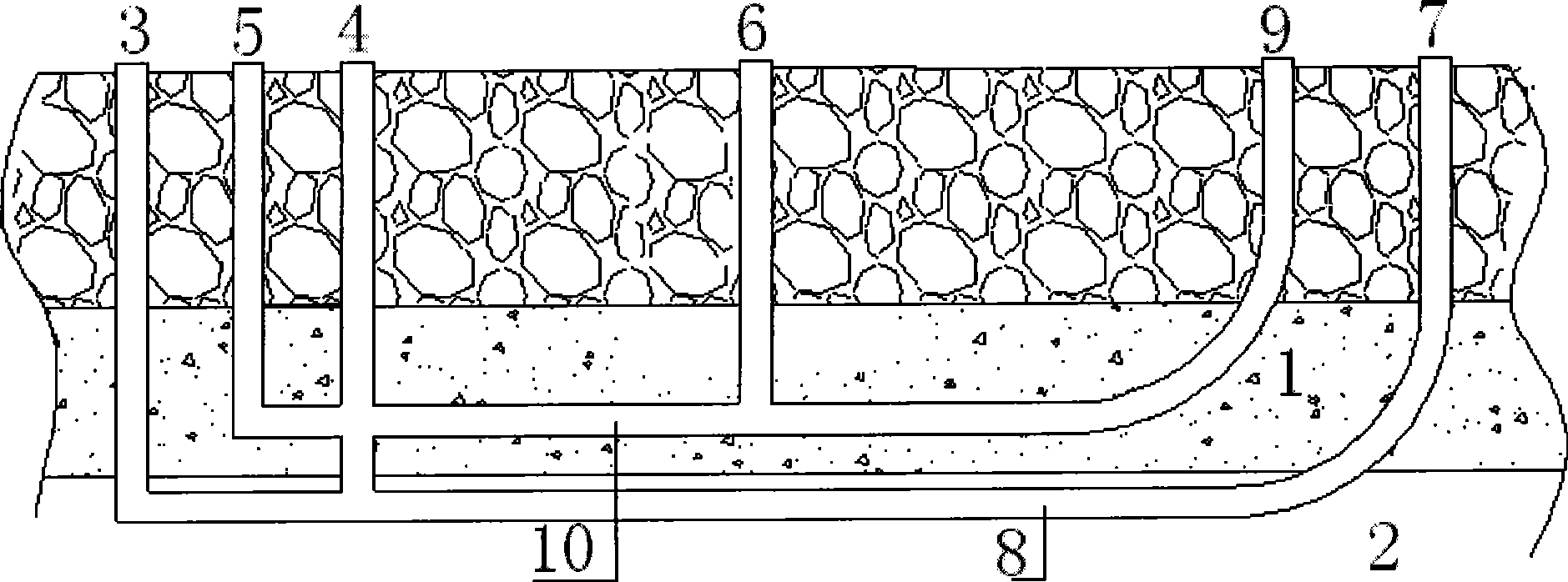

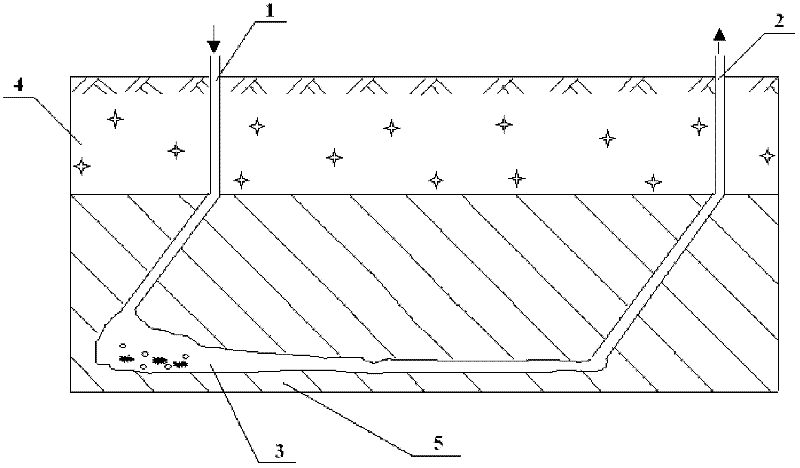

A coal gasification process of coal bed deep underneath includes a gasification furnace in the coal bed, a gas let in canal linking one end of the furnace to ground, a gas let out canal linking the other end of the furnace to ground. Gas generated by coal burning in the furnace is collected. A drain system links a drain outlet over 10 meters below the furnace to the ground.

Owner:ENN SCI & TECH DEV

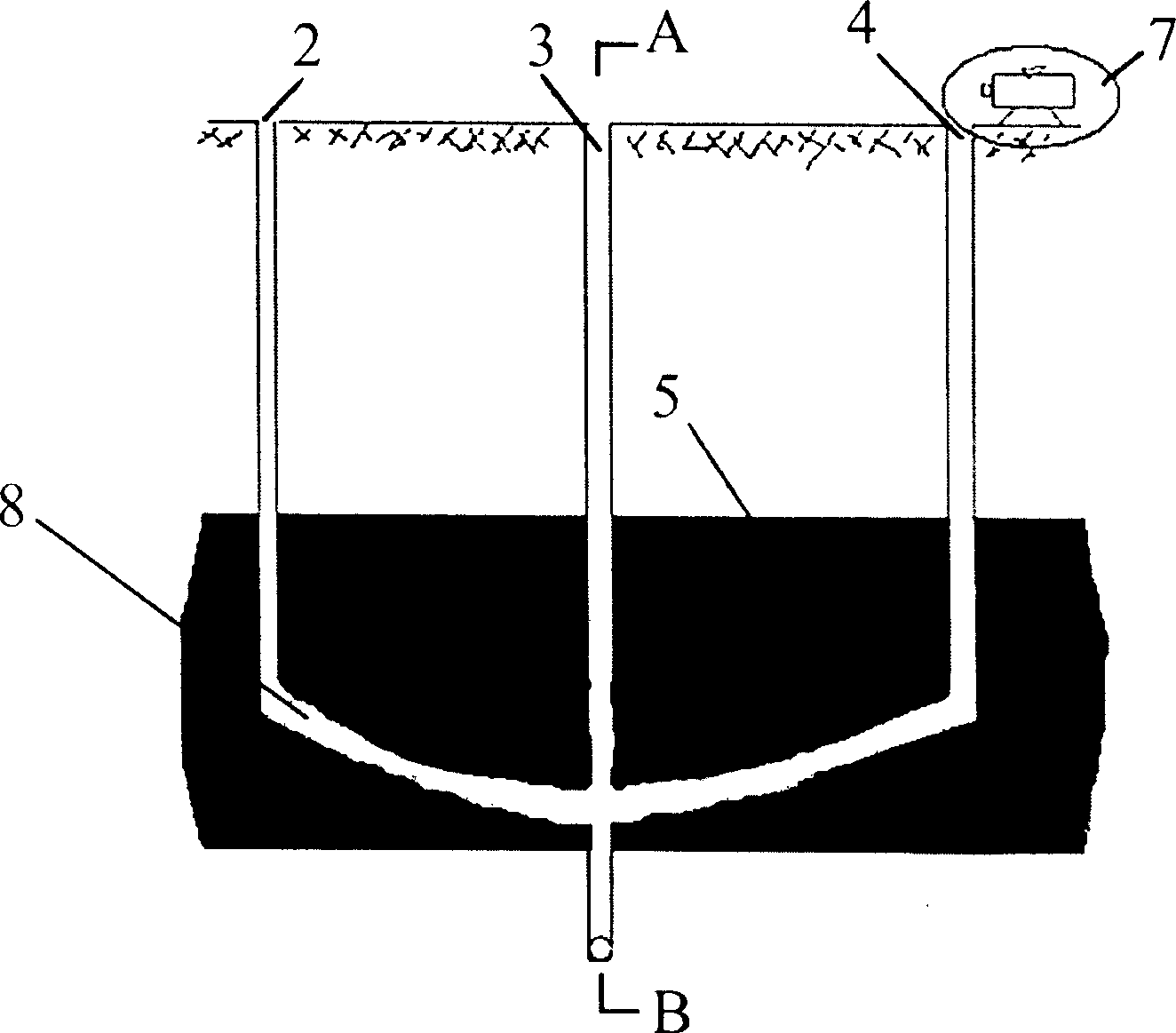

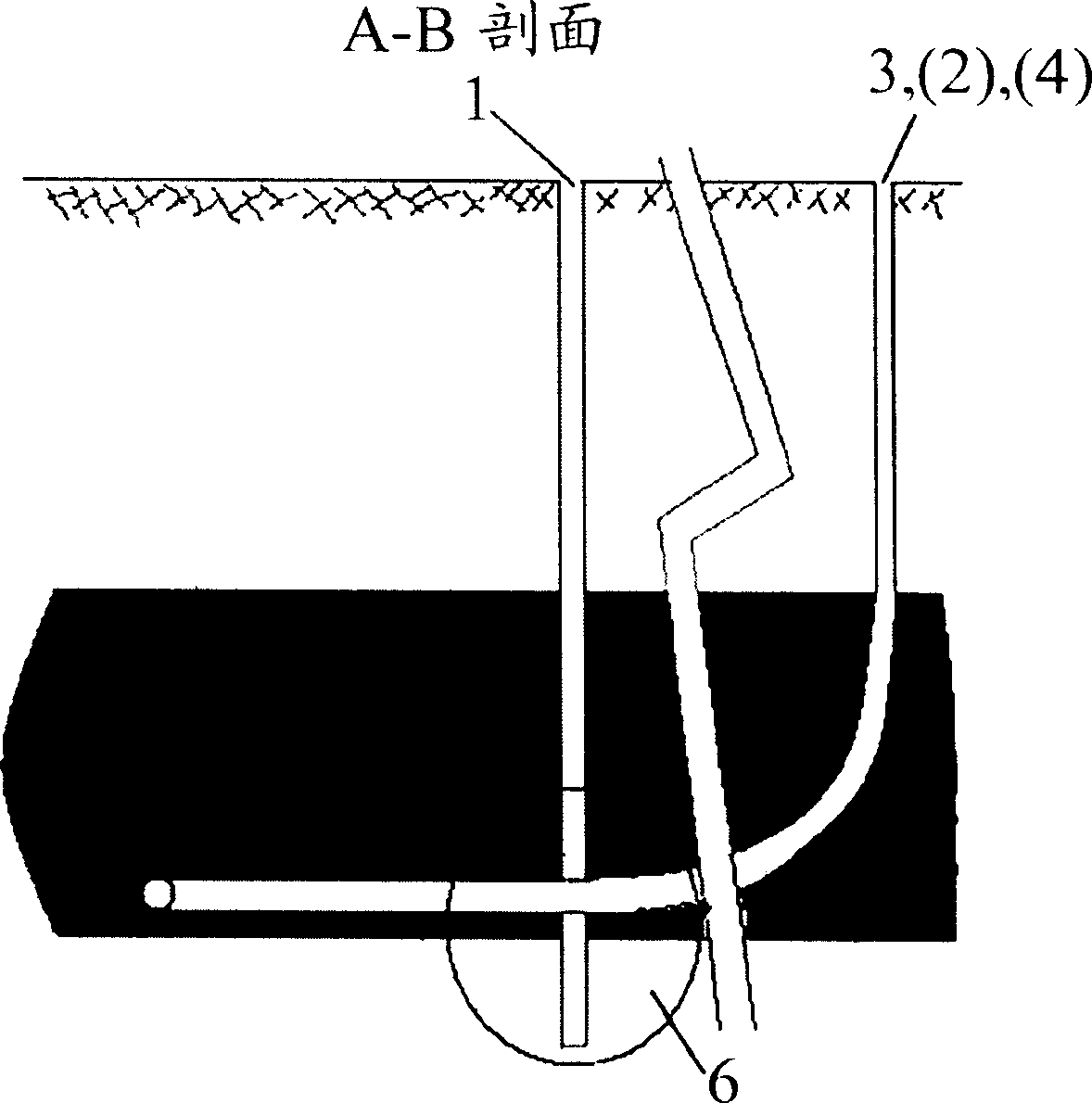

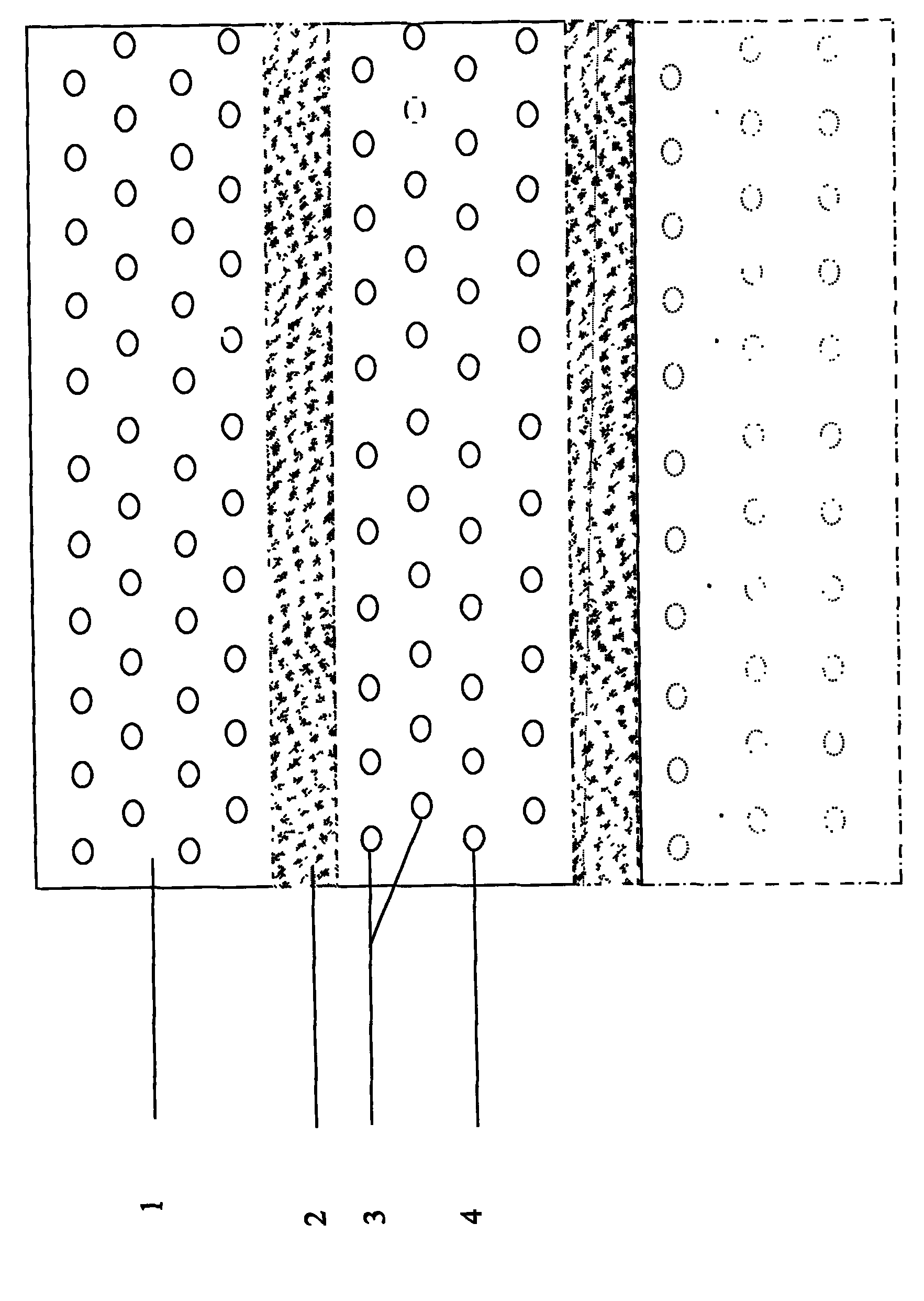

Novel underground coal gasification furnace

InactiveCN101382063AMeet craftFulfil requirementsConstructionsCoal gasificationEngineeringDirectional boring

The invention proposes a novel underground coal gasification furnace which is particularly suitable for the gasification of a coalbed containing water. An underground gasification furnace and a coalbed drainage passage integrated with each other are simultaneously constructed through a coalbed directional drilling process. The coalbed drainage passage can be effectively used for the coalbed drainage before gasification and the furnace body drainage during gasification, thereby ensuring the discharge of the water in the coalbed and consequently realizing the stable gasification of the coalbed containing water. The furnace has the advantages that the composite underground gasification furnace and the drainage passage are simultaneously constructed through the advanced coalbed directional drilling process, thereby bringing about easy execution and short construction period; as the drainage passage is positioned below the gasification passage, the drainage is smooth, and the problem of blockage does not easily happen; and the water in the drainage passage can be pumped out from a plurality of orientations, thereby bringing about rapid drainage. According to the requirements of furnace body drainage, the drainage holes of the gasification passage can be increased flexibly, thereby substantially solving the drainage problem of the coalbed containing water, and avoiding the impact of coalbed water inrush on coalbed gasification.

Owner:ENN COAL GASIFICATION MINING

Underground coal gasification multi-combining production system and method

ActiveCN101509368AReasonable useReduce pollutionConstructionsCoal gasificationGeneration processSyngas

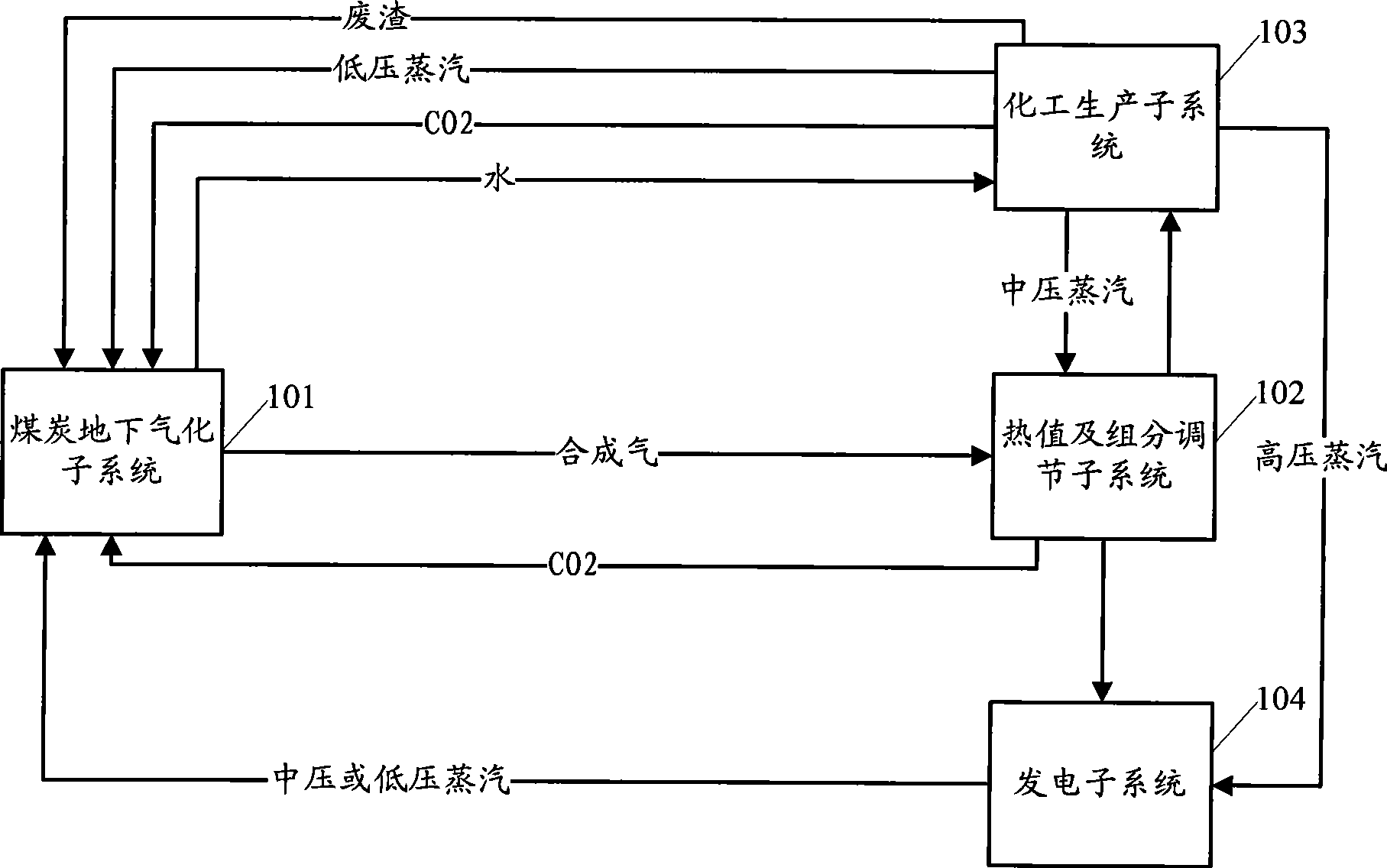

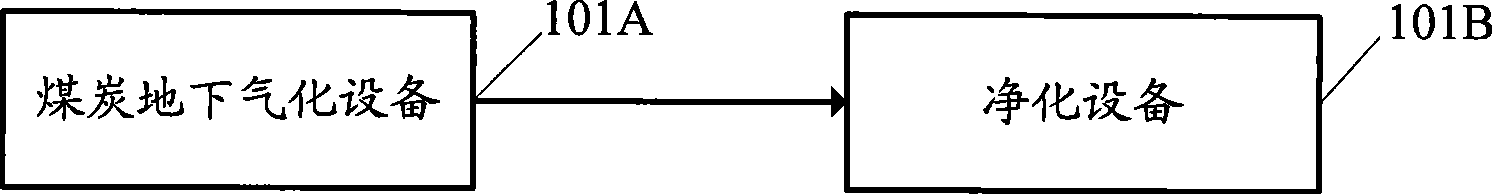

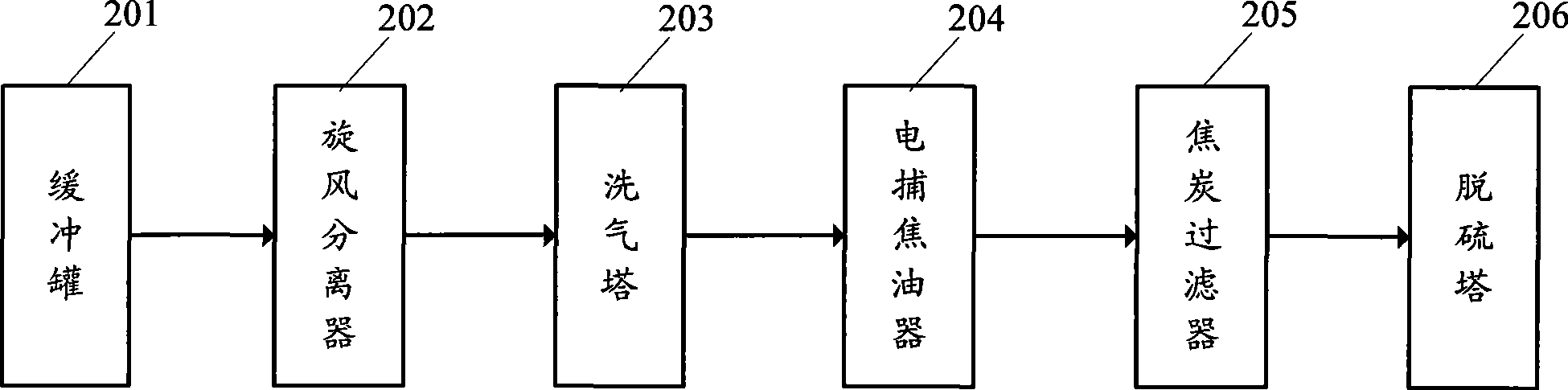

The invention discloses a poly-generation system of underground coal gasification (UCG) and a method thereof. .The system comprises a UCG subsystem, a thermal value and component regulation subsystem and a chemical production system; the UCG subsystem is used for injecting gasification agent into a gasification tunnel after gasification fire so that the gasification agent conducts gasification reaction with a coal bed in the gasification tunnel to generate synthesis gas; crude synthesis gas is led into the thermal value and component regulation subsystem; the thermal value and component regulation subsystem is used for reintegrating the component and thermal value of the synthesis gas and sending the reintegrated synthesis gas into the chemical production system as feed gas; the chemical production system is used for producing chemical products by utilizing the synthesis gas sent by the thermal value and component regulation subsystem. By adopting the method and system provided by the invention, coal gasification poly-generation process can be completed under the condition of energy saving and environmental protection.

Owner:ENN SCI & TECH DEV

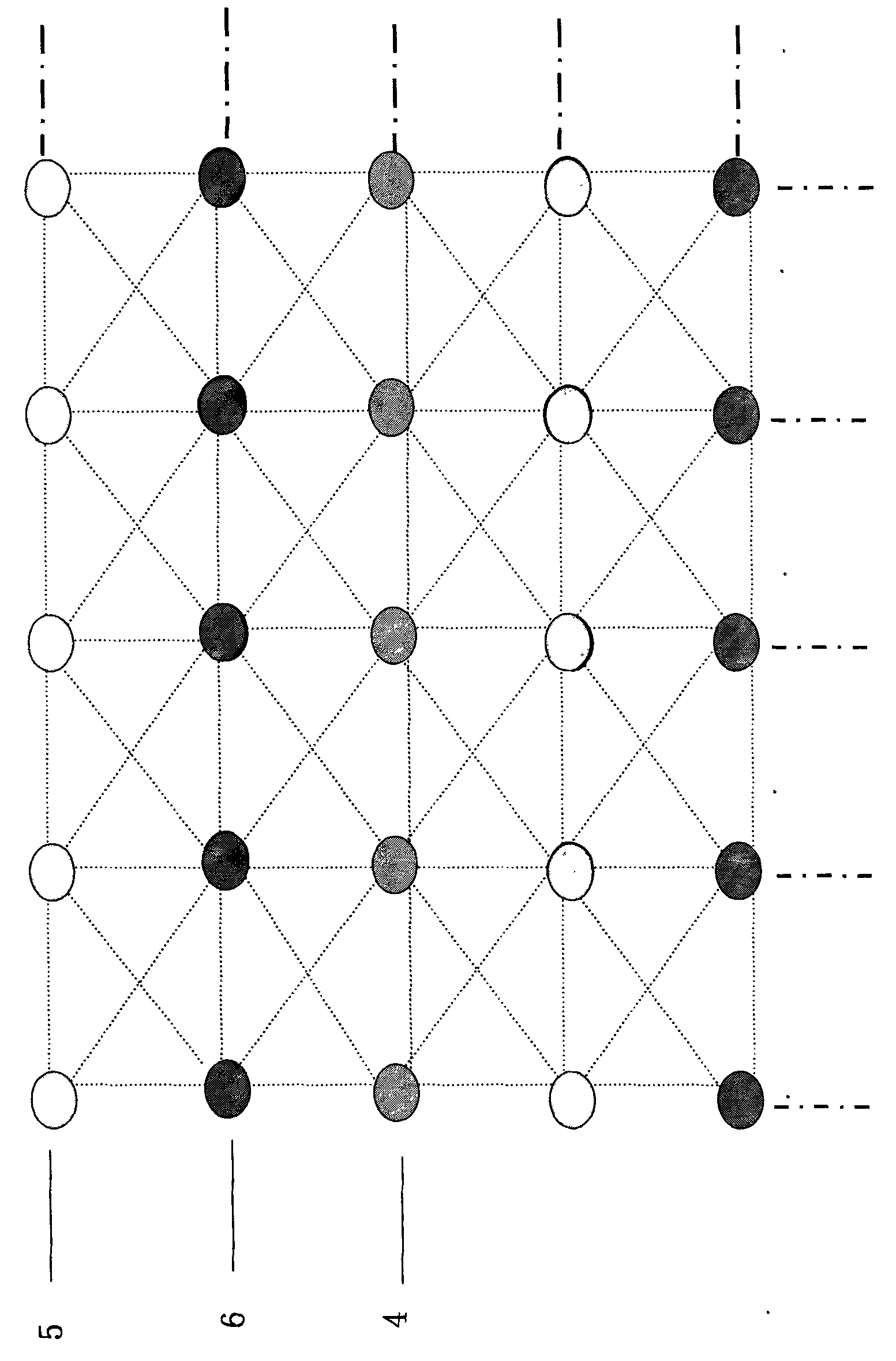

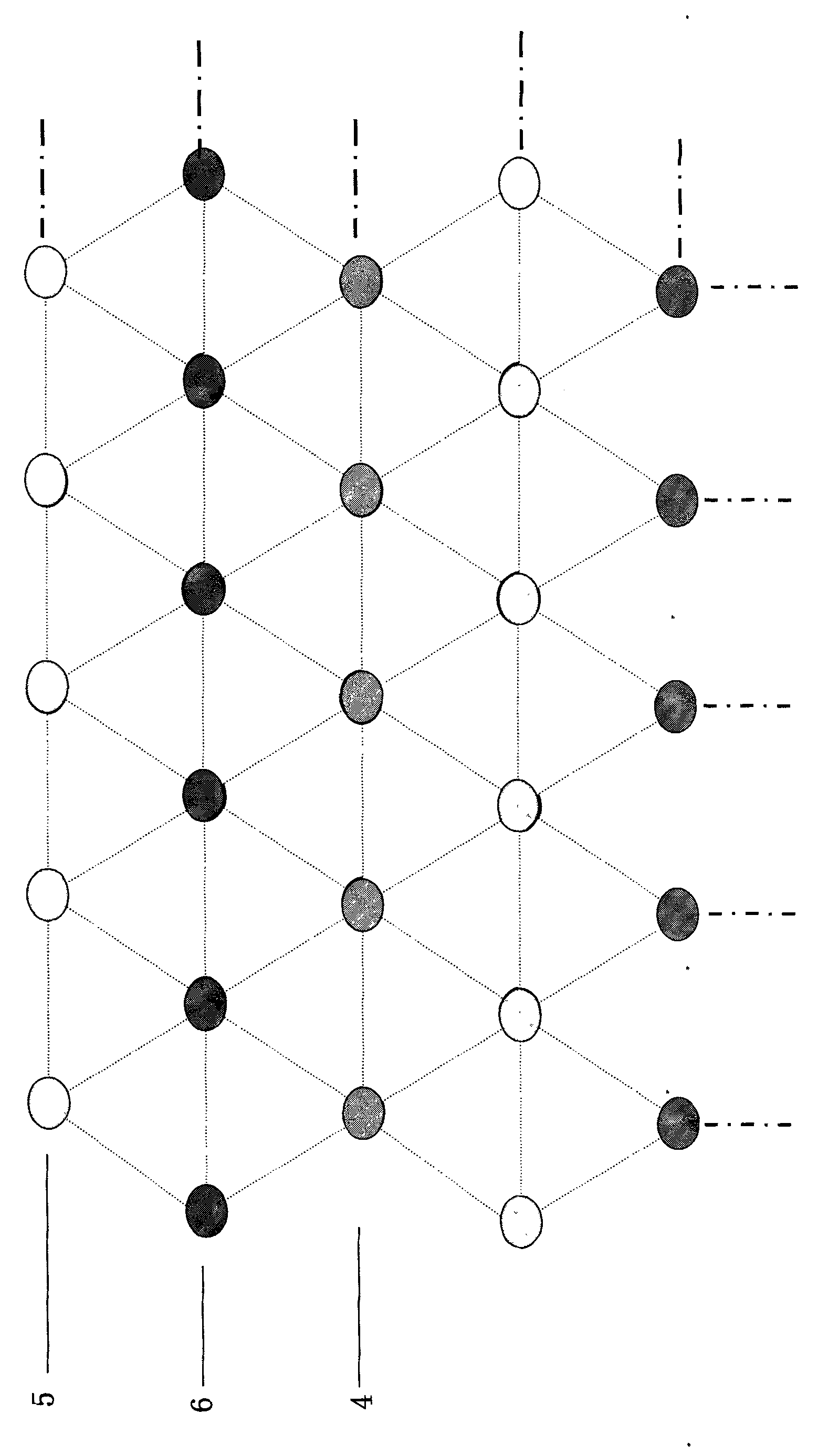

A method for underground coal gasification

InactiveCN102287177AEfficient developmentChange areaConstructionsFluid removalMultiple injectionChemical reaction

An underground coal gasification method. The method comprises disposing multiple injection wells (3) and gas collection wells (4) in a gasification operation zone; adding a catalyst and a propping agent into injection wells and gas collection wells by means of a fluid medium; fracturing and reforming the coal layer using a fracturing device to form large areas of fissures and cracks; forming gasification paths in the form of directional wells between the injection wells and gas collection wells; adding a gasification agent, a catalyst, and water through the injection wells to cause coal layer combustions and chemical reactions; collecting at the gas collection wells the gas produced by means of collection devices. The fissure paths between the wells formed by reforming large fractures, and the metal mineral particles used as a propping agent for the paths between wells effectively enable the maintenance of the effective communication in the injection well network for long durations; the metal mineral particles also function as a catalyst and an aggregating agent during gasification, thereby substantially enhancing the coal gasification volume.

Owner:秦勇 +2

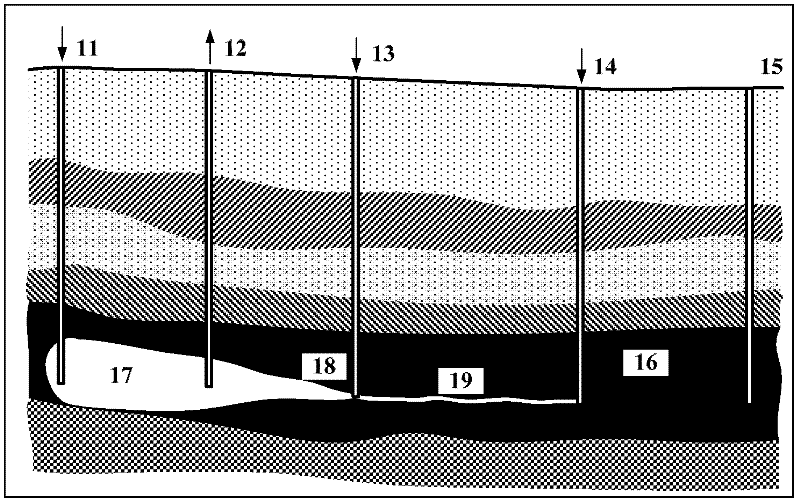

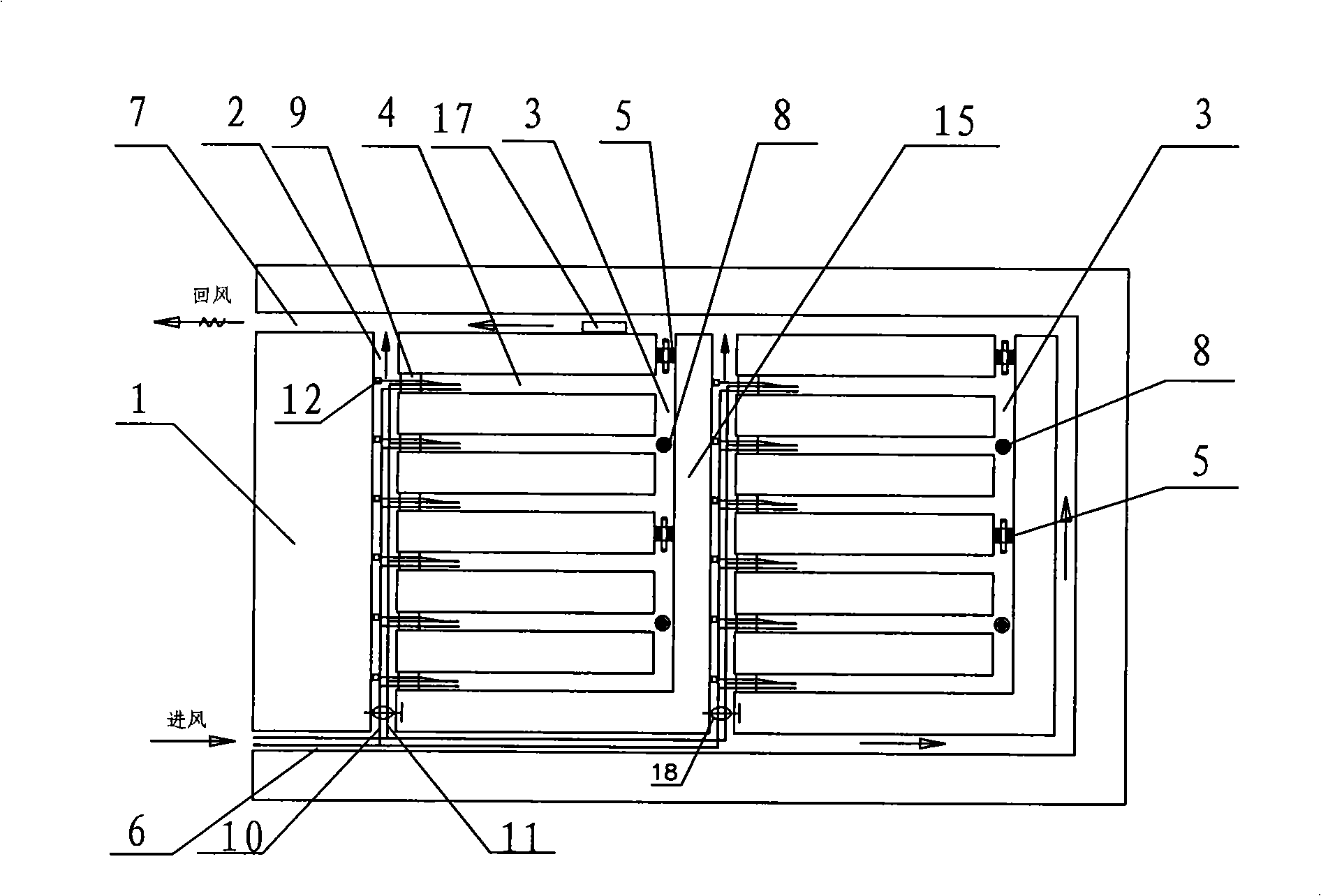

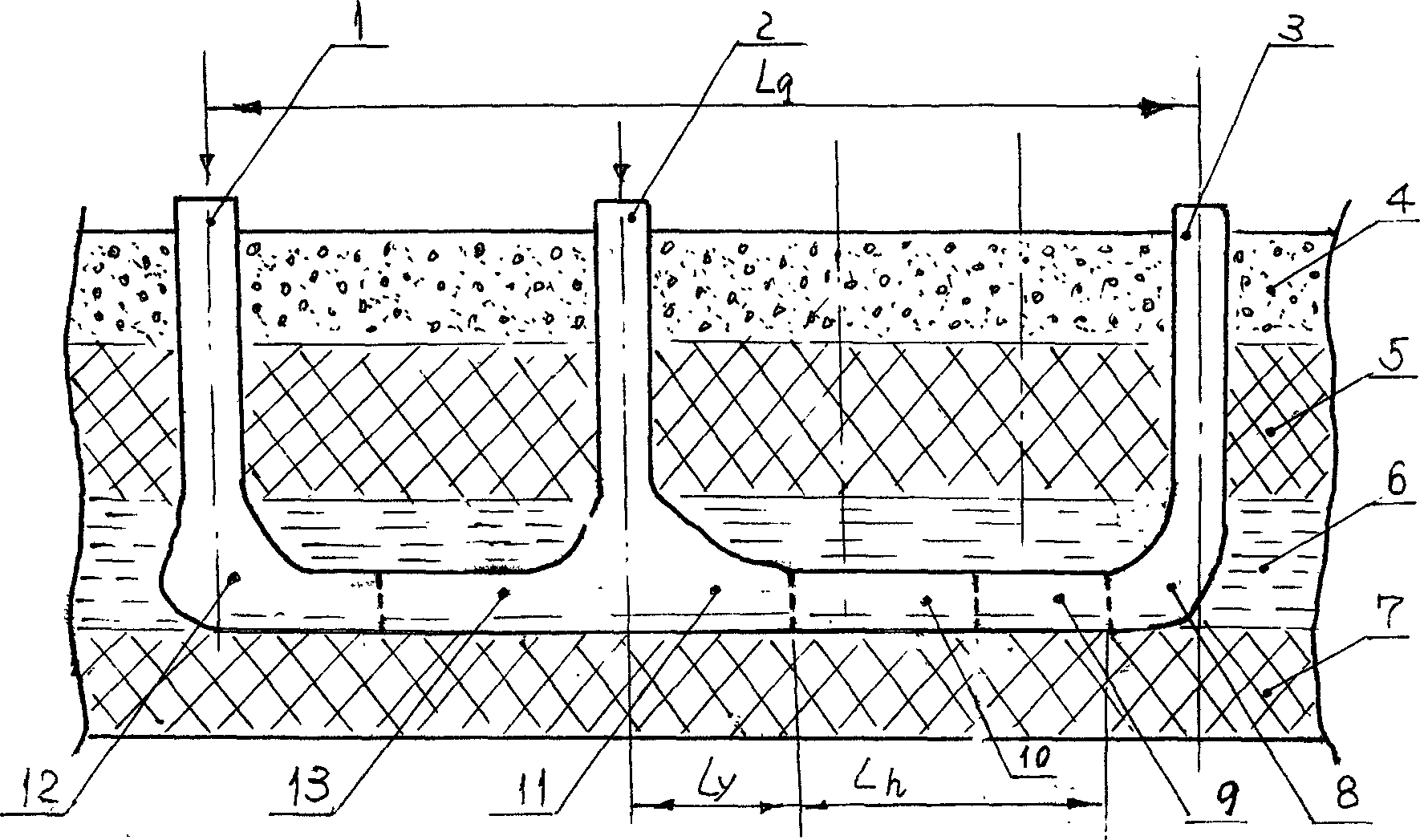

Underground coal gasification system and producing process

InactiveCN101315026AMaximize miningAchieve paddingConstructionsCoal gasificationProcess engineeringControl area

The invention relates to an underground coal gasification system and a production process thereof. The system comprises an air course and a gas transmission course which are arranged in a coal seam, a plurality of gasification channels are arranged in the coal seam, the two mutually parallel ends of each gasification channel respectively communicate with the air course and the gas transmission course, and a water drainage closed wall is arranged in the gas transmission course; and the both ends of the air course are respectively connected with an intake airway and a return airway of a mine system. The gasification process comprises the following steps: igniting; judging whether the burning point is required to be moved forward; moving the burning point of the coal seam backwards; plugging a gas passage of a combustion-supporting gas injection branch pipe which is disabled, and filling a burning control area with paste. The coal underground gasification system and the production process have the advantages that the coal seam can be mined to the utmost extent; the leakage of the combustion-supporting gas to the burning control area can be thoroughly cut off when the secure retraction during the coal underground gasification process is realized; the problem that the gasification agent is short-circuited because a passage is formed due to the collapsing of the coal seam floors in the gasification channel and the earlier period gasification area can be solved in the later period of the underground coal gasification, the gas production is secure and reliable, and the gasification rate is high.

Owner:中矿天晟能源科技有限公司

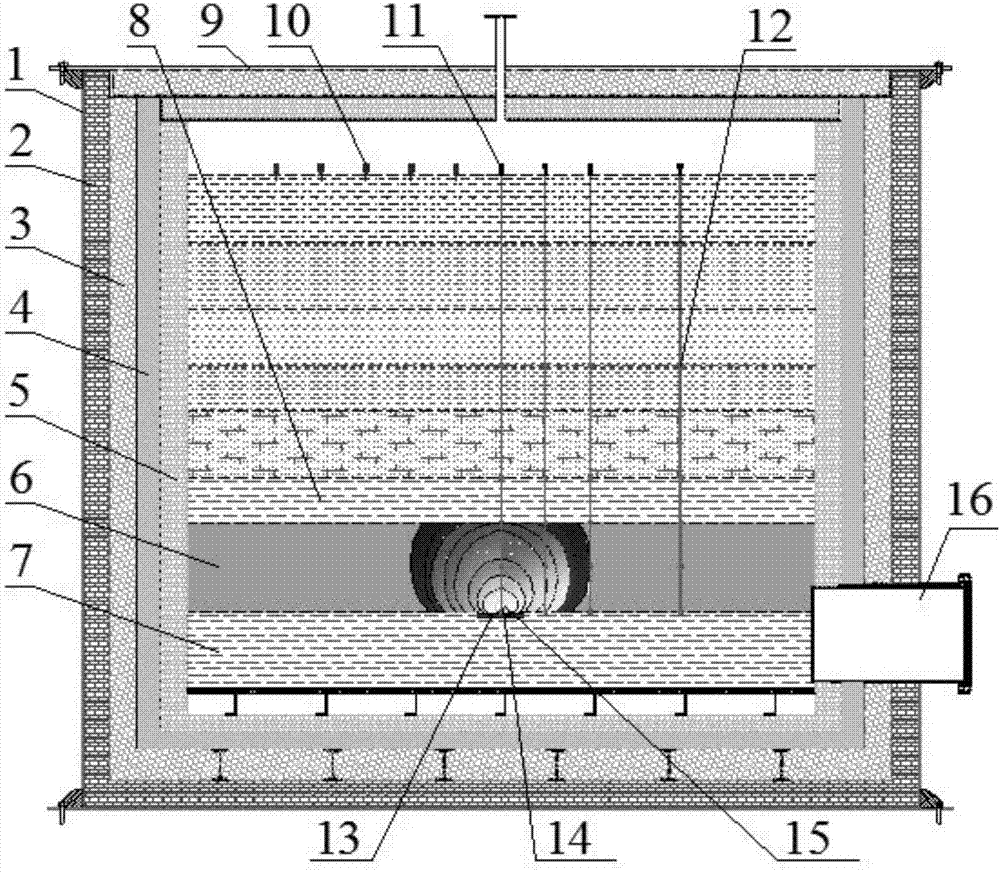

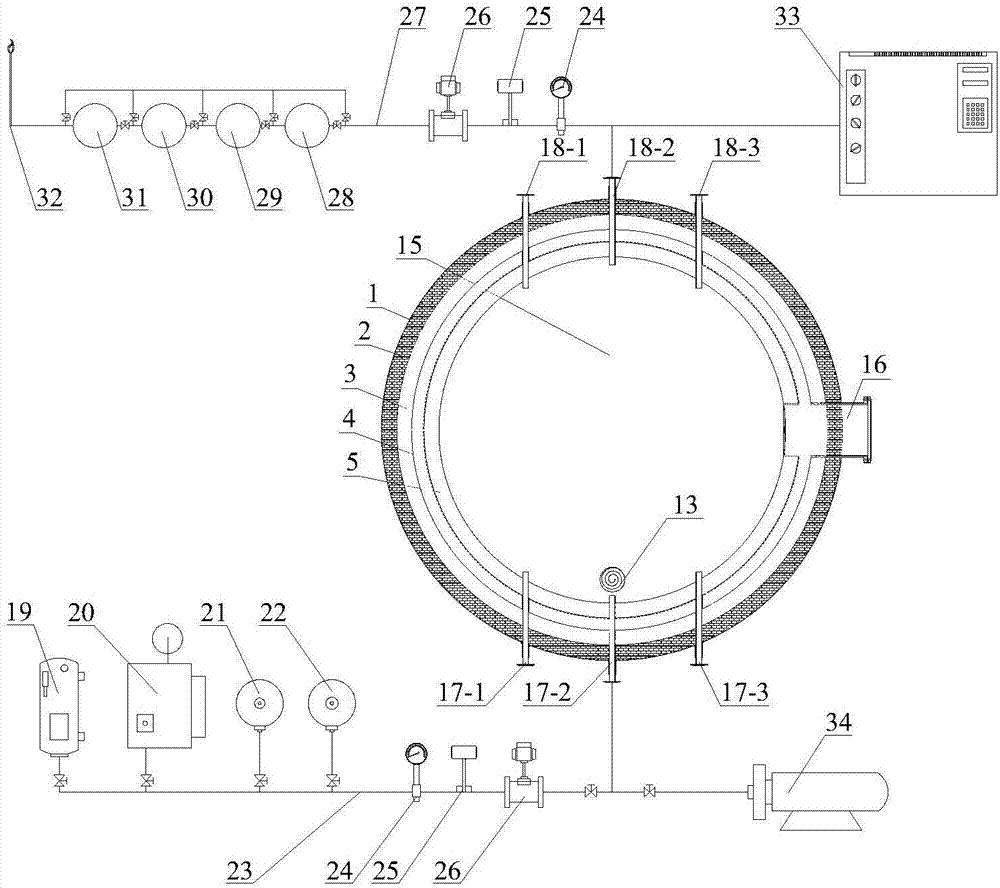

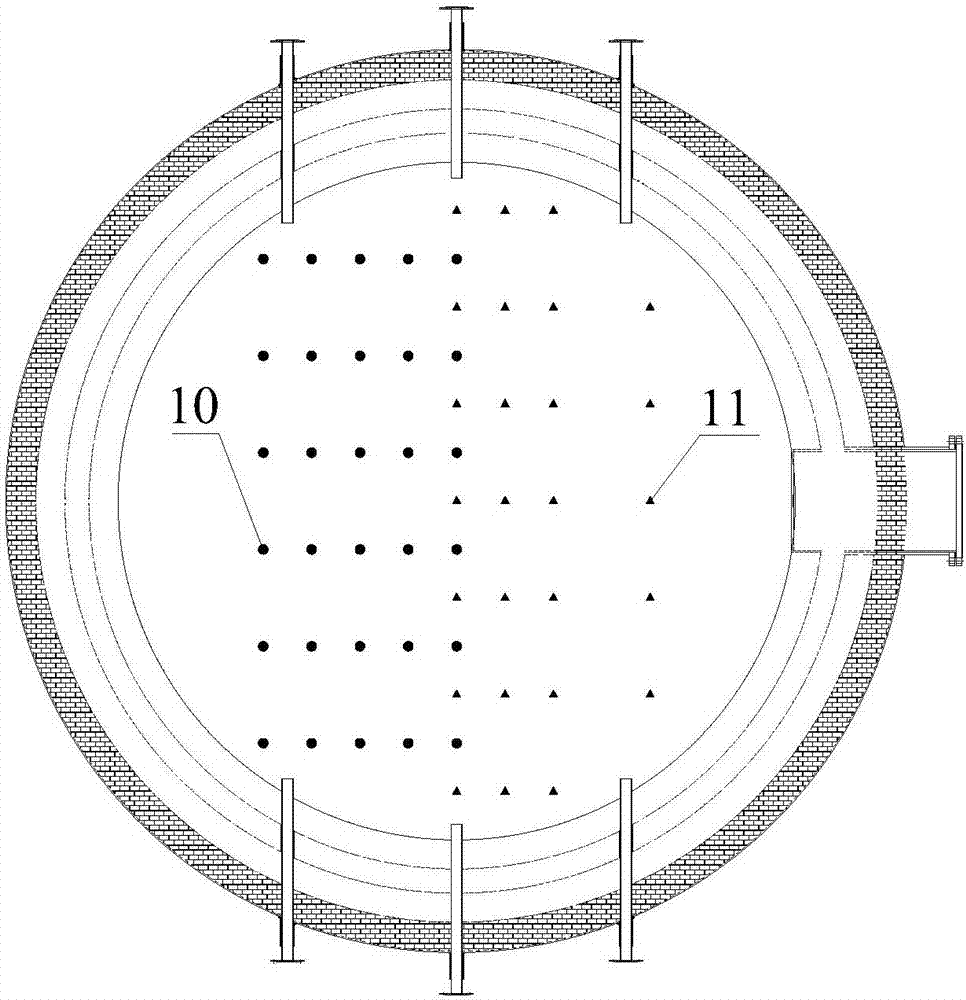

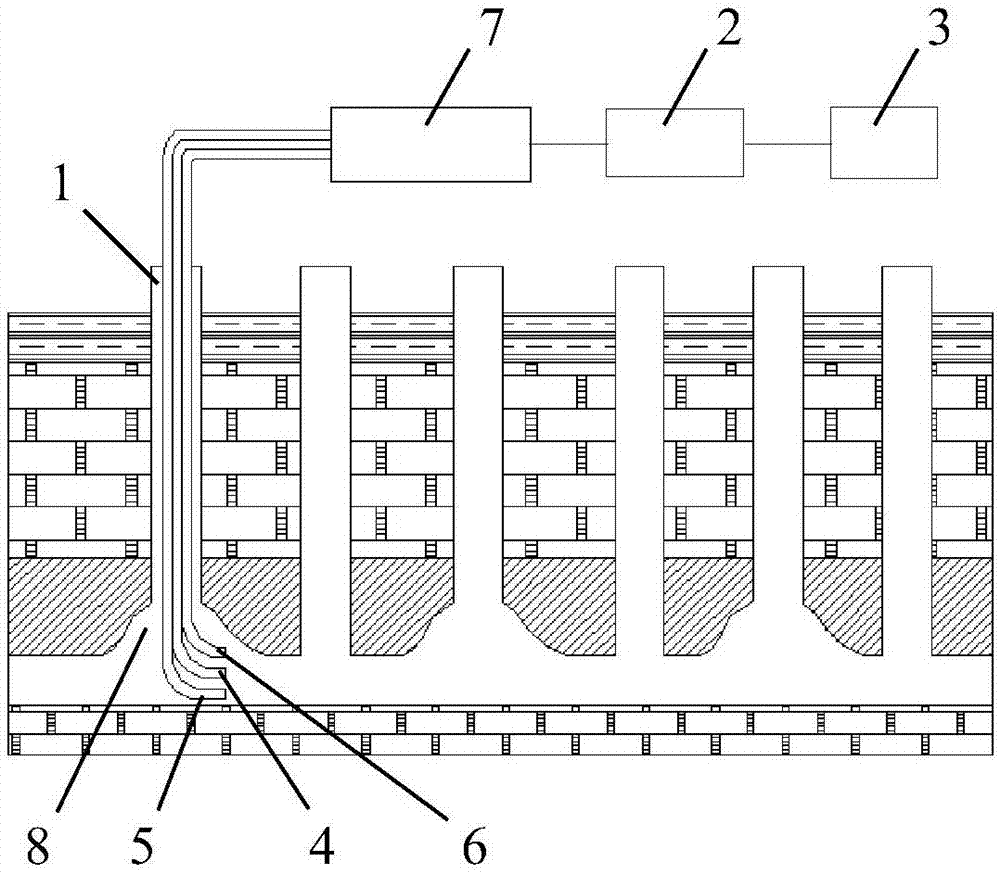

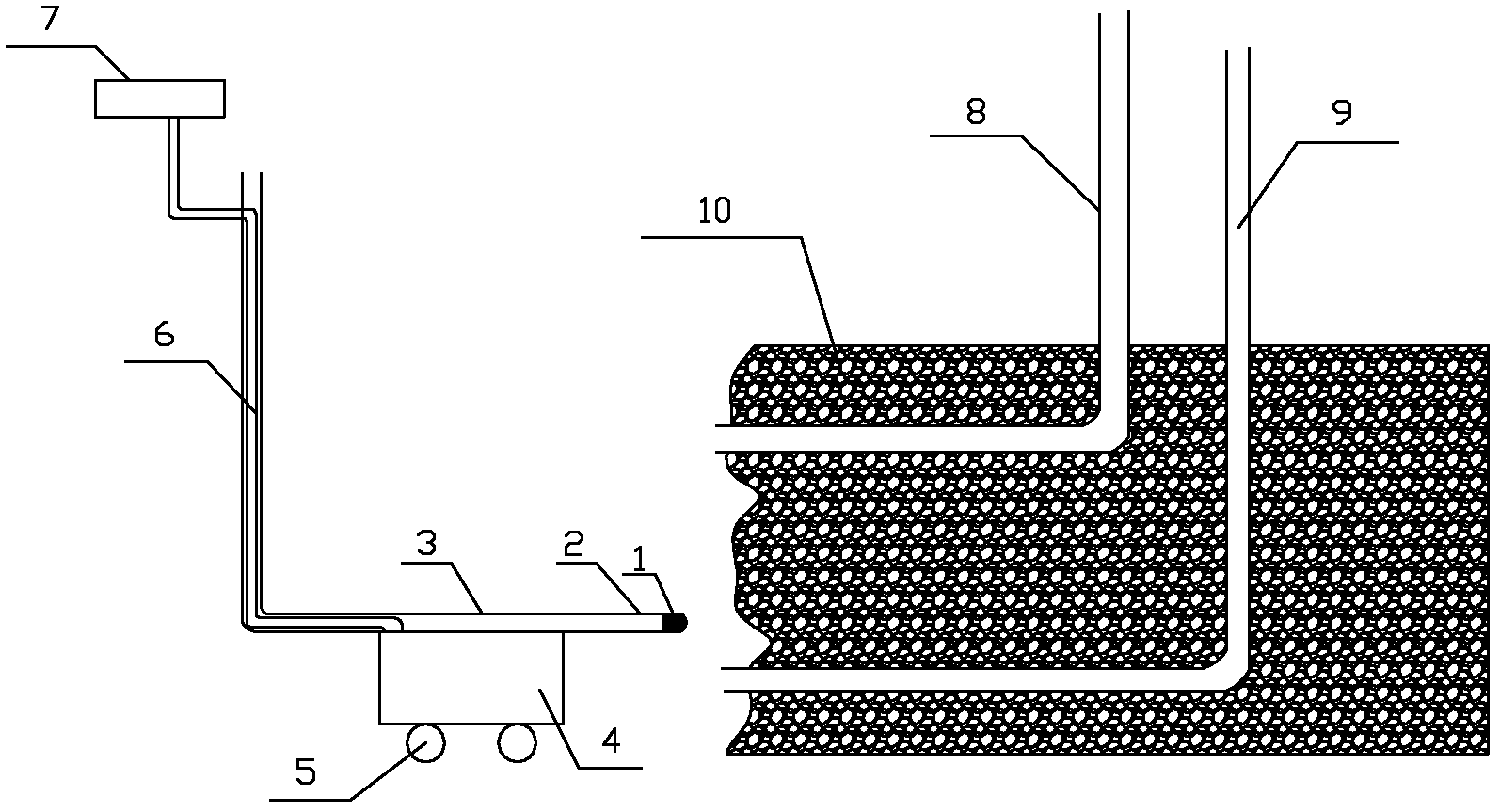

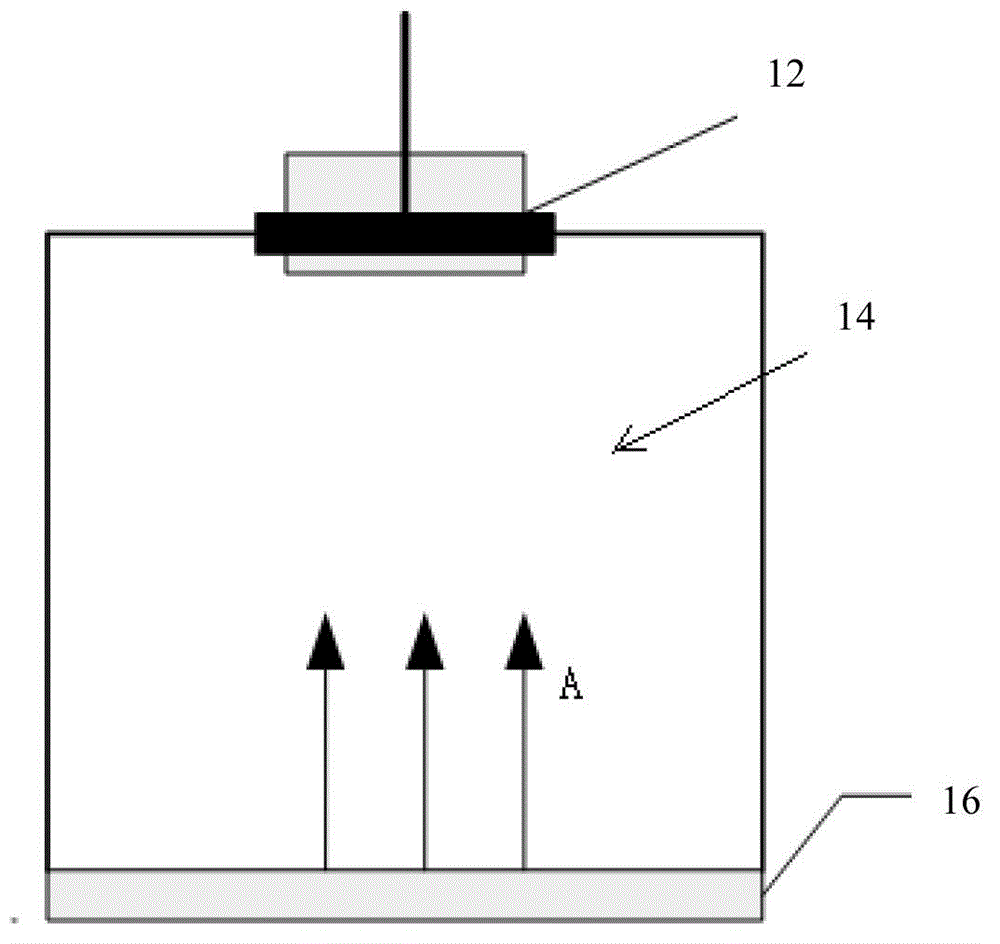

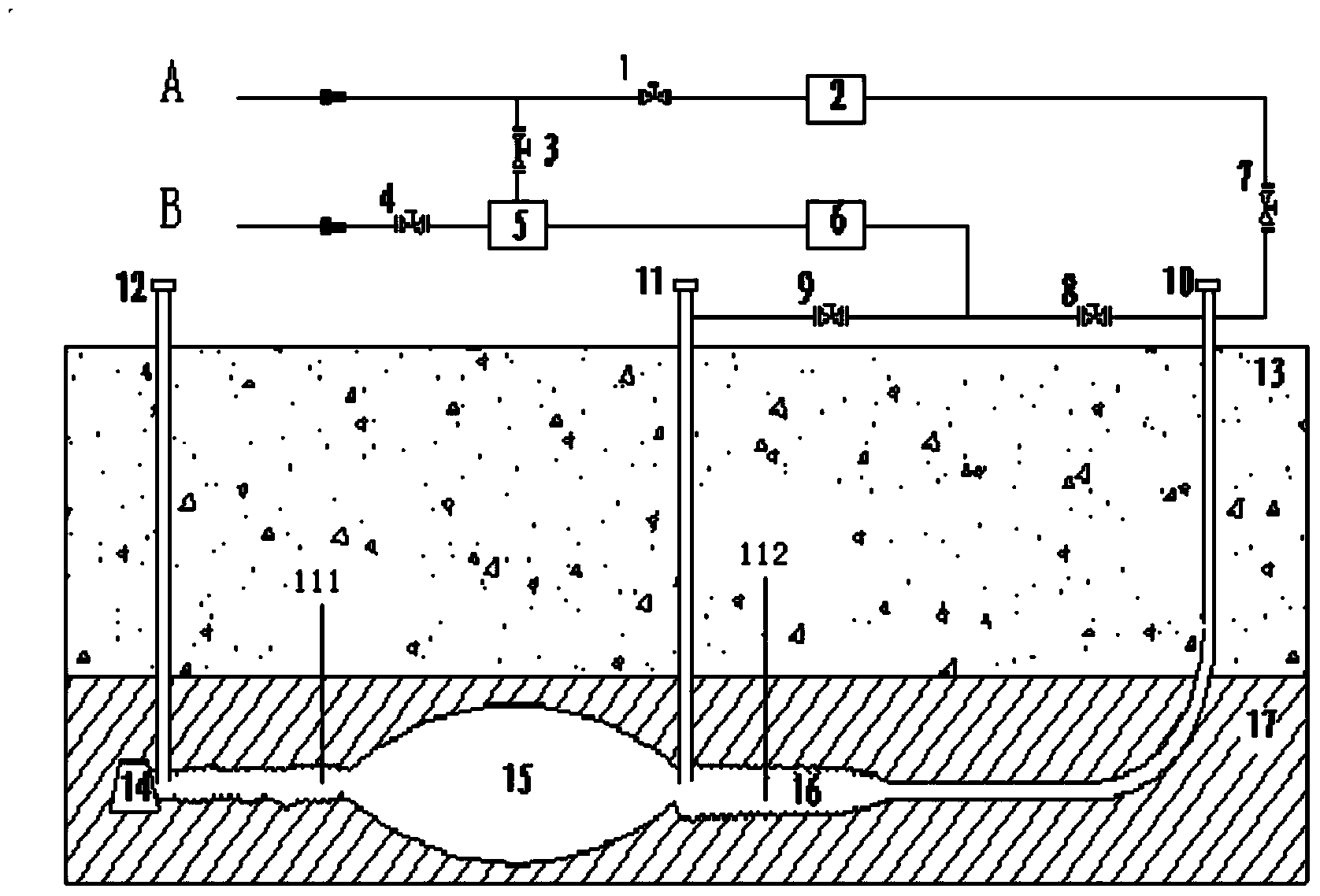

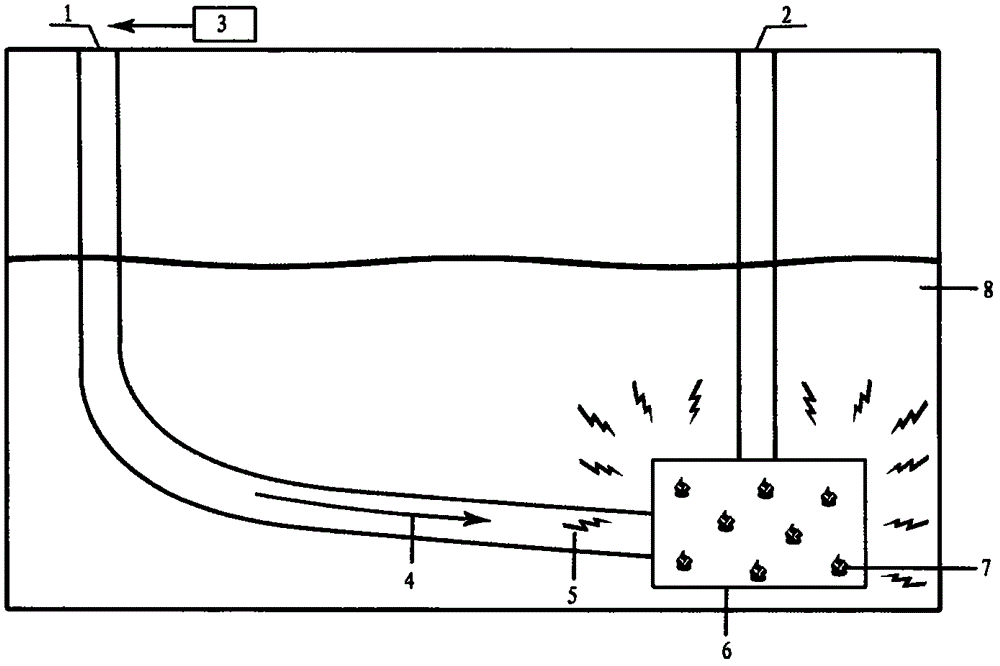

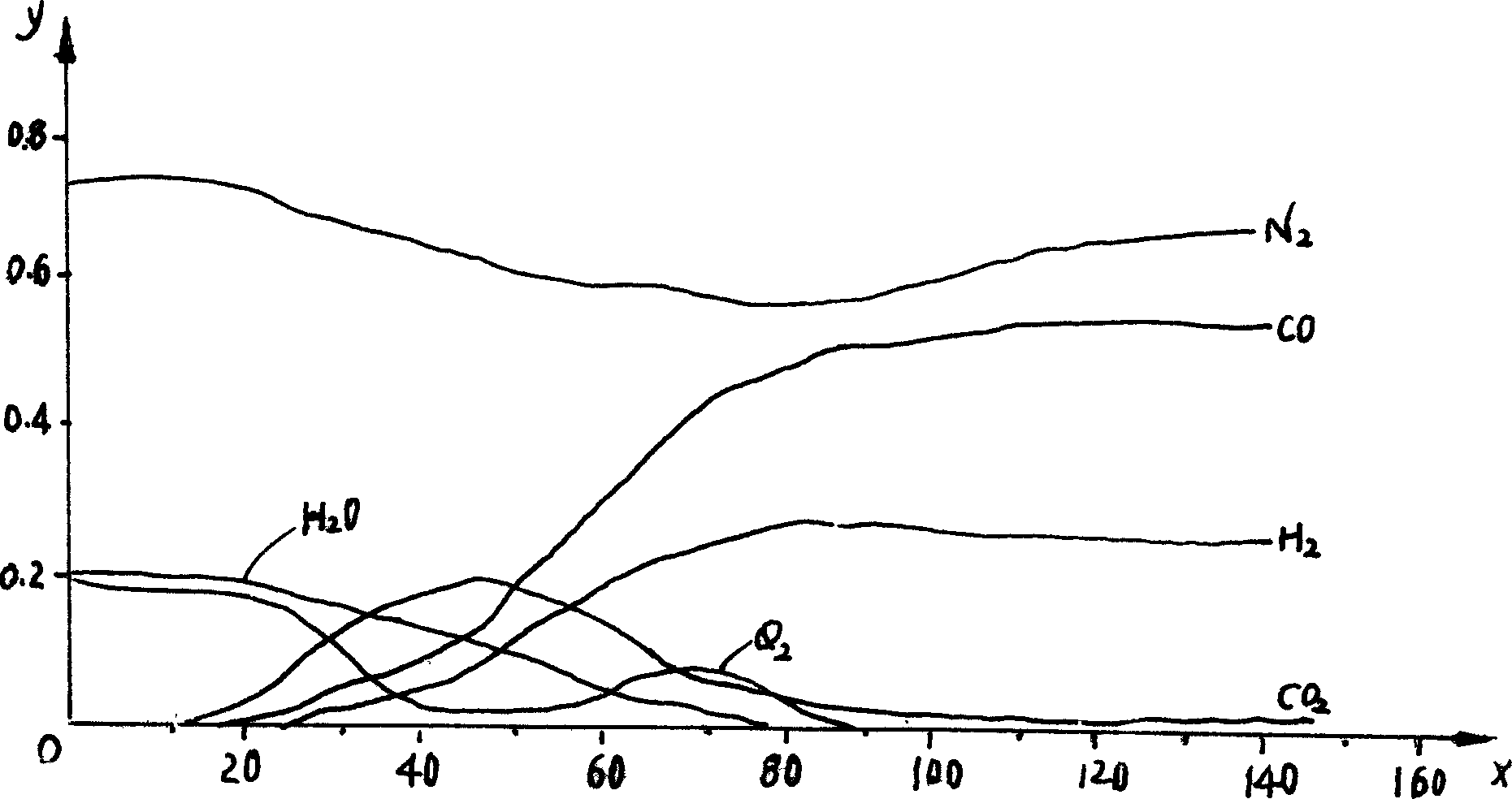

Test device and method for simulating in-situ underground coal gasification

The invention discloses a test device and a test method for simulating in-situ underground coal gasification. The test device comprises a gasifying furnace body, a top cover, a furnace wall injection pipe, a furnace wall exhaust pipe, a gasifying agent preparing unit, an injection pipeline, an exhaust pipeline, a gas flow meter, a gas pressure meter, a gas temperature measuring thermocouple, a gas purifying unit, a gas dispersing unit, an inside-furnace temperature monitoring unit, a gas chromatograph, an igniter, a displacement meter, a filling unit and a computer, wherein the outer shape of the gasifying furnace is cylindrical; the wall of the gasifying furnace comprises a steel plate, a common brick layer, an insulation material, a water jacket layer and a refractory brick layer from outside to inside sequentially, The test device is reasonable in structure and multifunctional, and can utilize instruments to objectively and actually measure temperature fields in a coal seam and a roof rock stratum, gasifying agent ratio and gas production index parameters, overlaying rock movement and ground surface subsidence parameters, and gasifying furnace cavity-growth characteristic parameters, and facilitate research on furnace structure parameters and a gasifying process, so as to determine in-situ underground coal gasification process parameters and an in-situ underground coal gasification production scheme, which are suitable for on-site conditions.

Owner:SHANDONG UNIV OF SCI & TECH

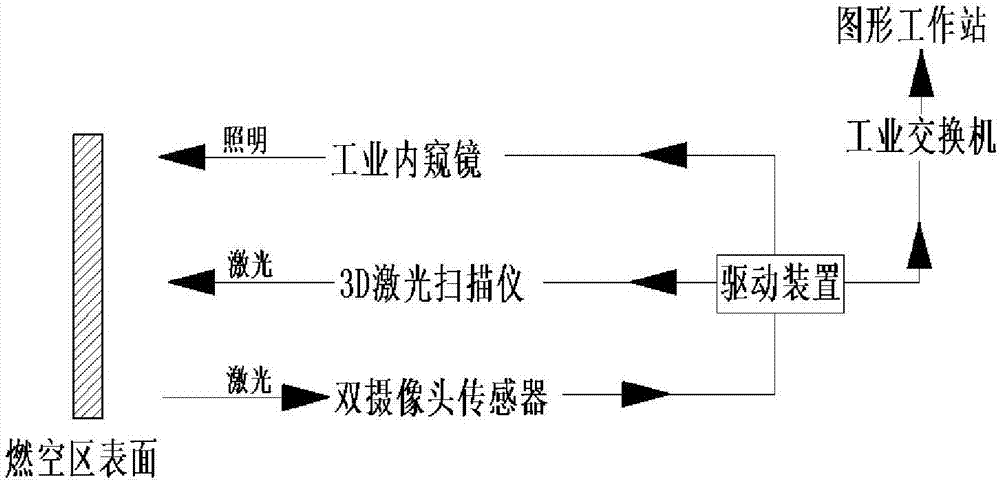

Coal underground gasification combustion space area mapping system and mapping method thereof

PendingCN107462222AKnow the actual shapeSurveyPicture taking arrangementsThermodynamicsGraphics workstation

The invention discloses a coal underground gasification combustion space area mapping system and a mapping method thereof and belongs to the technical field of mine surveying and mapping. According to the coal underground gasification combustion space area mapping system and the mapping method thereof, a driving device is utilized to push a 3D laser scanner, a dual camera sensor and an industrial endoscope into combustion space areas through vertical holes, the combustion space area near each vertical hole are scanned through laser, laser collection, data transmission of an industrial switch and imaging of a graphic workstation are performed through the dual camera sensor, so that the mapping of internal shapes of the combustion space areas is completed, actual shapes of the combustion space areas inside a coal seam are learnt about visually, various technical parameters of a well drilling type underground coal gasification technology are checked, and theoretical support is provided for stability and continuity in the underground coal gasification process.

Owner:XINJIANG GUOLIHENG CLEAN ENERGY TECH CO LTD

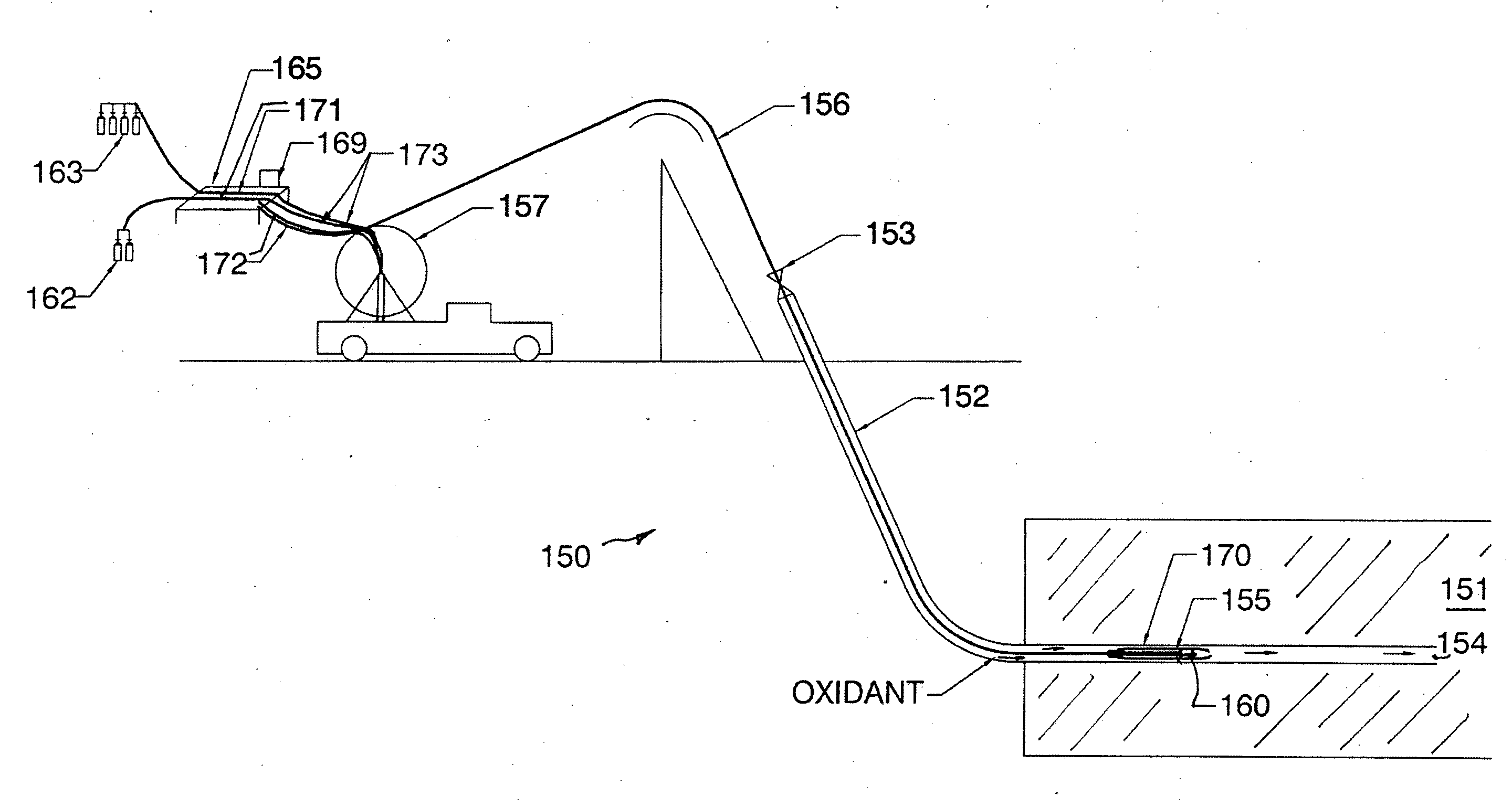

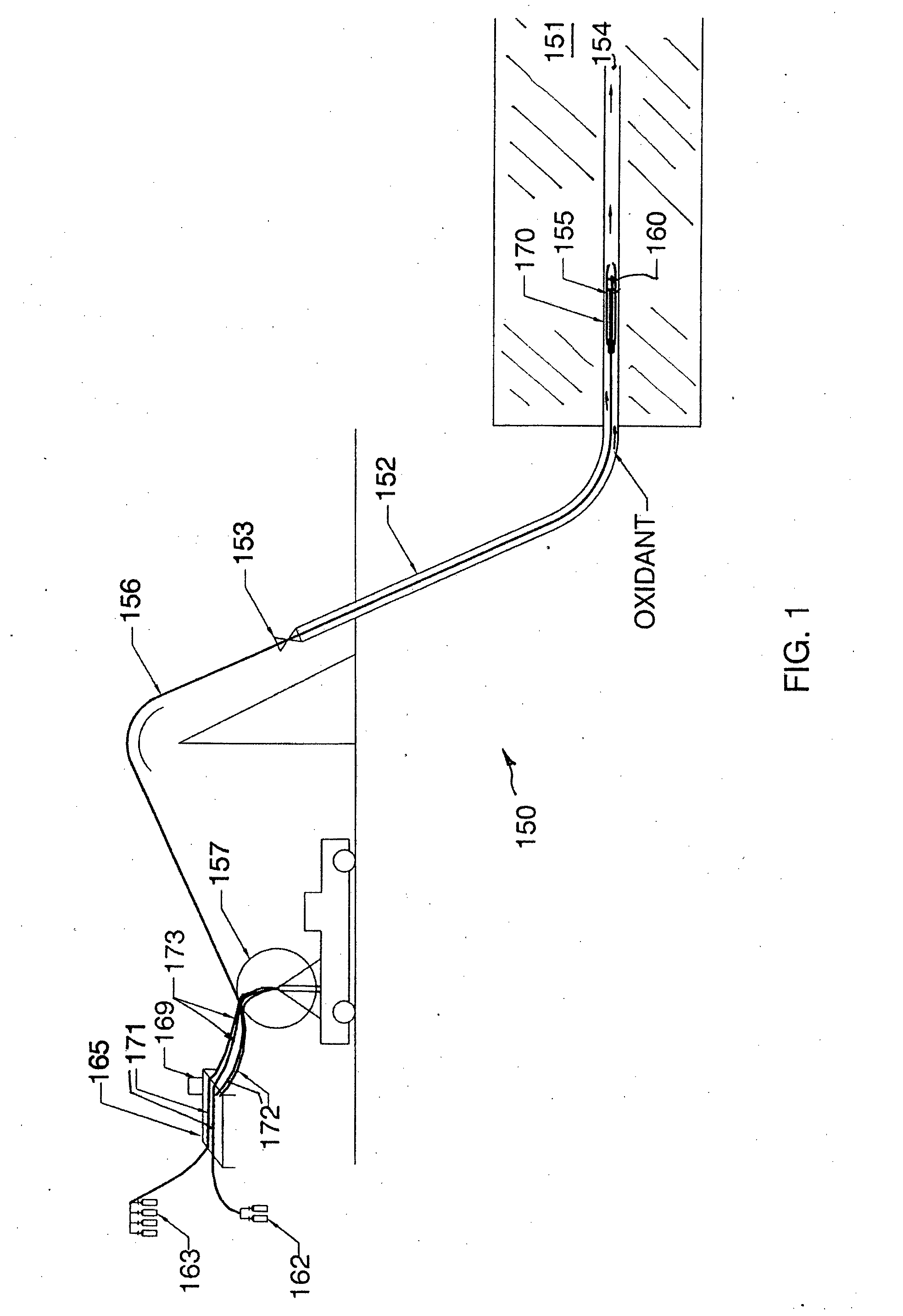

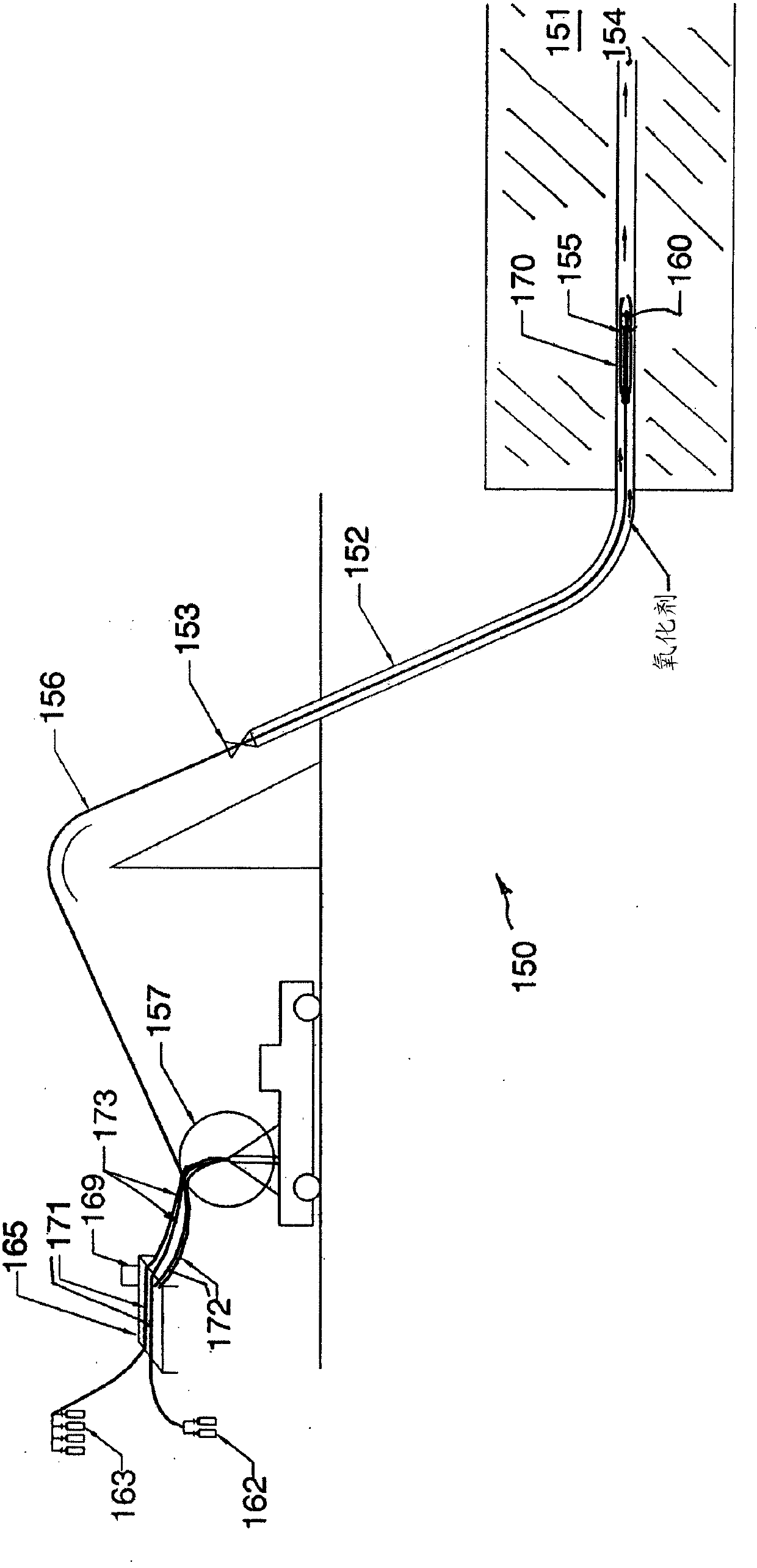

Igniting an underground coal seam in an underground coal gasification process, ucg

An ignition apparatus (150) configured to ignite an underground coal seam (151). The ignition apparatus (150) comprising an ignition system, a positioning system, a sensor (170) and a controller (165). The ignition system comprises ignition means and an ignition tool (155) for igniting the underground coal seam (151) from within the well channel (154) or well liner encasing the well channel (154). The positioning system comprises coiled tubing (156) connected to the ignition tool (155) and extendible through a well head (153) within the well channel (154) to position the ignition tool (155) at a desired location within the well channel (154). The positioning system further comprises a spool (157) for transporting and dispensing the coiled tubing (156).

Owner:LINC ENERGY

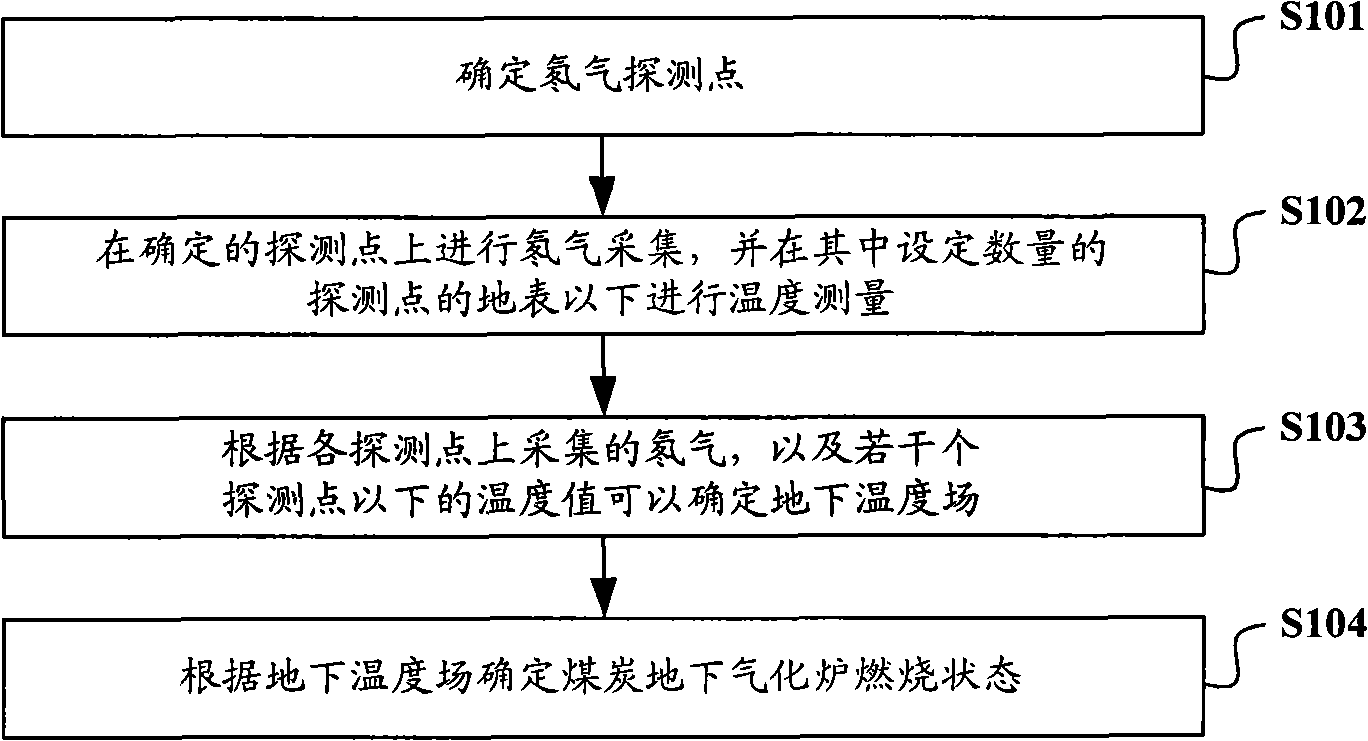

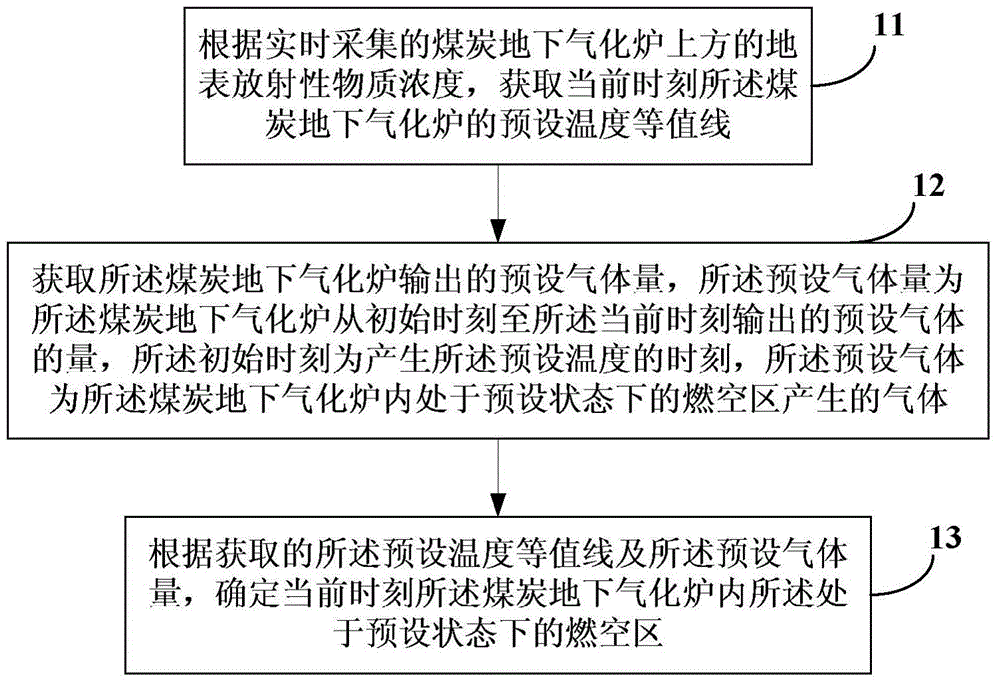

Method, system and device for identifying combustion state of underground coal gasification furnace

ActiveCN101649735ACombustion state estimationIt is more accurate to estimate the combustion state of underground coal gasifiers from the combustion stateConstructionsCoal gasificationSyngasCombustion

The invention relates to the field of underground coal gasification, in particular to a technique for monitoring the combustion state of an underground coal gasification furnace. The invention provides system, device and method for identifying the combustion state of an underground coal gasification furnace. The method comprises the following steps: arranging detection points in the ground surface exploration range of the underground coal gasification furnace; collecting radon gas at the detection points and carrying out temperature measurement at a certain number of determined underground detection points; determining an underground temperature field according to the collected radon gas and the measured temperature so as to identify the combustion state of the underground coal gasification furnace. Because the radon gas is collected at the ground surface of the underground coal gasification furnace, the underground temperature field is identified according to the radon gas collected at the detection points and the underground temperature of at least one detection point, and the underground temperature field directly reflects the combustion state of the underground coal gasification furnace, therefore, the invention is more accurate compared with the prior art which conjectures the combustion state of the underground coal gasification furnace by parameters of syngas.

Owner:ENN SCI & TECH DEV

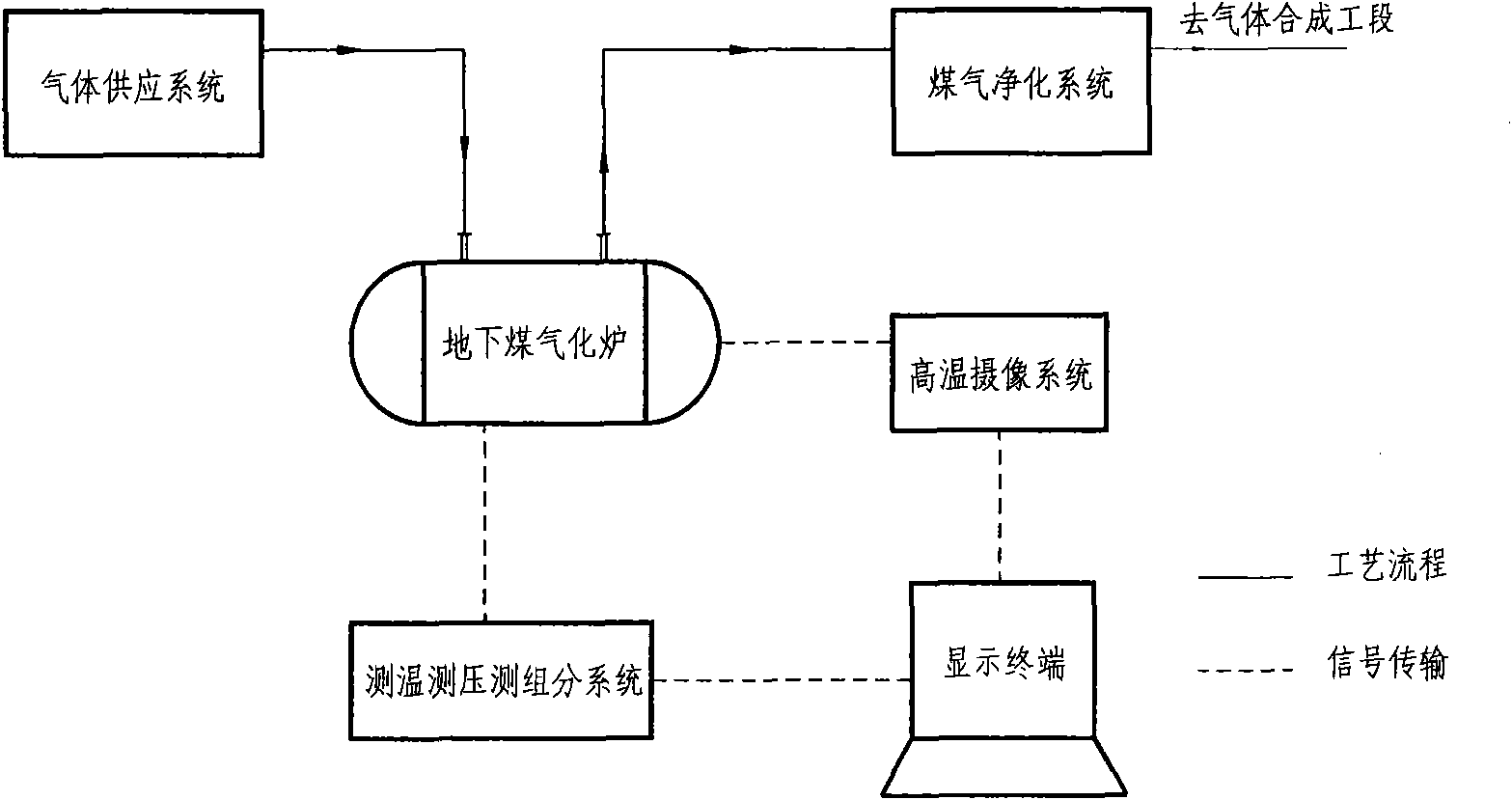

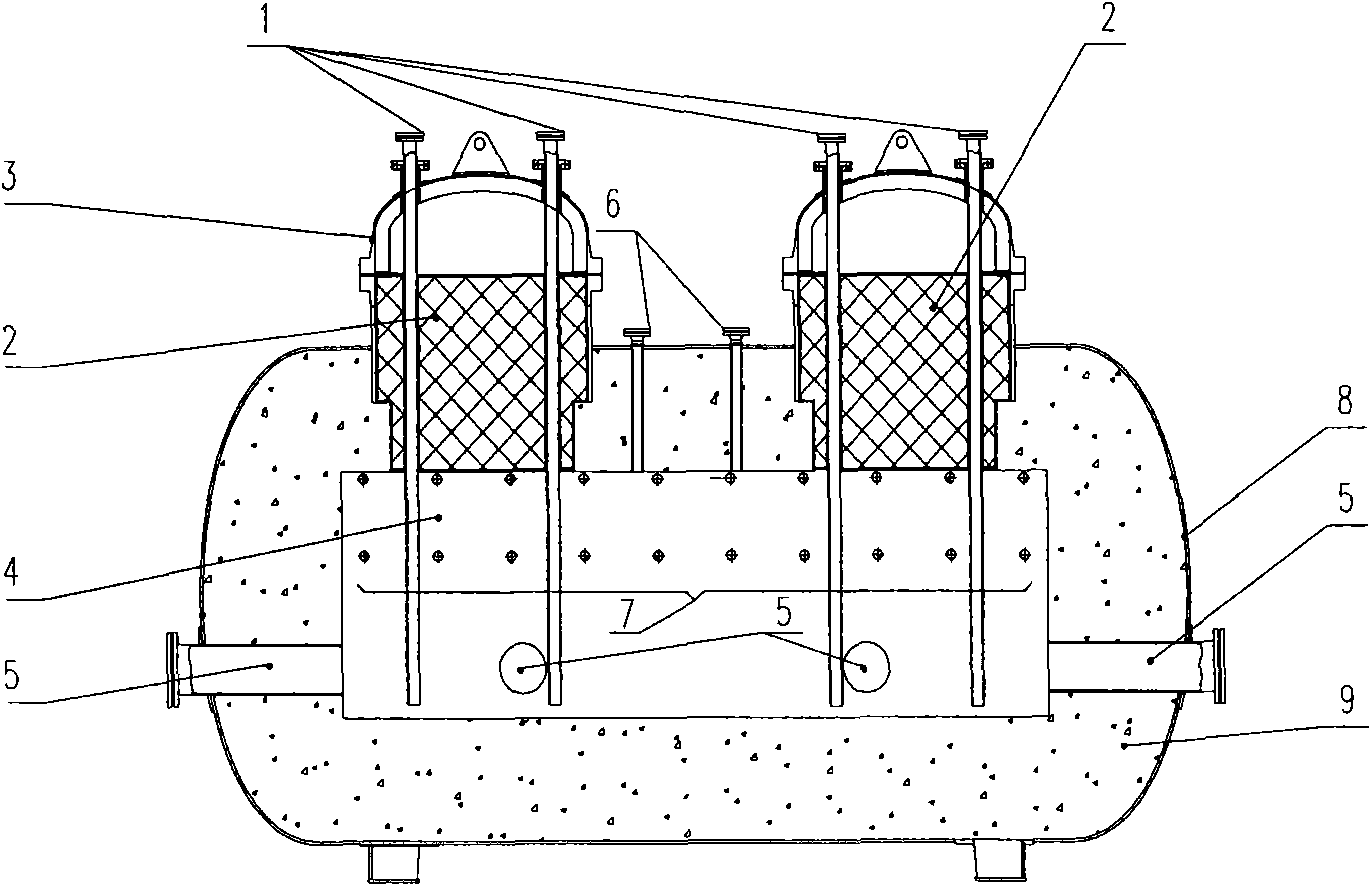

Gasification furnace for the gasification pilot plant test of underground coal and process thereof

Disclosed is a gasification furnace for the gasification pilot plant test of underground coal and the process thereof. The equipment of the process comprises a gas supply system, a gasification furnace, a temperature measuring pressure measuring and ingredient detecting system, a high temperature shooting system and a gas purifying system. The gasification furnace has a refractory material inner liner in the housing, has a grouting hole on the housing for performing seal to the coal bodies inside the furnace, and can perform gasification test in high temperature high pressure condition. The furnace body is formed with a gasifying agents and water-gas input / output hole, a grouting hole, a cooling water input / output hole, a temperature / pressure / ingredient measuring auxiliary hole, a high temperature shooting system viewing hole, a resistor method measuring hole and a manhole. The invention fully considers the pressurized condition in the underground coal gasification process, meets the requirement of gasification pressuring to coal in the pilot plant test, can investigate the technological experiment of normal / high pressure underground coal gasification and combustion point returning. The gasification furnace is equipped with a plurality of temperature measuring, pressure measuring and gas ingredient measuring systems and high temperature visual monitoring systems, can perform on-line monitoring and real time control to various parameters in the pilot plant test process.

Owner:ENN SCI & TECH DEV

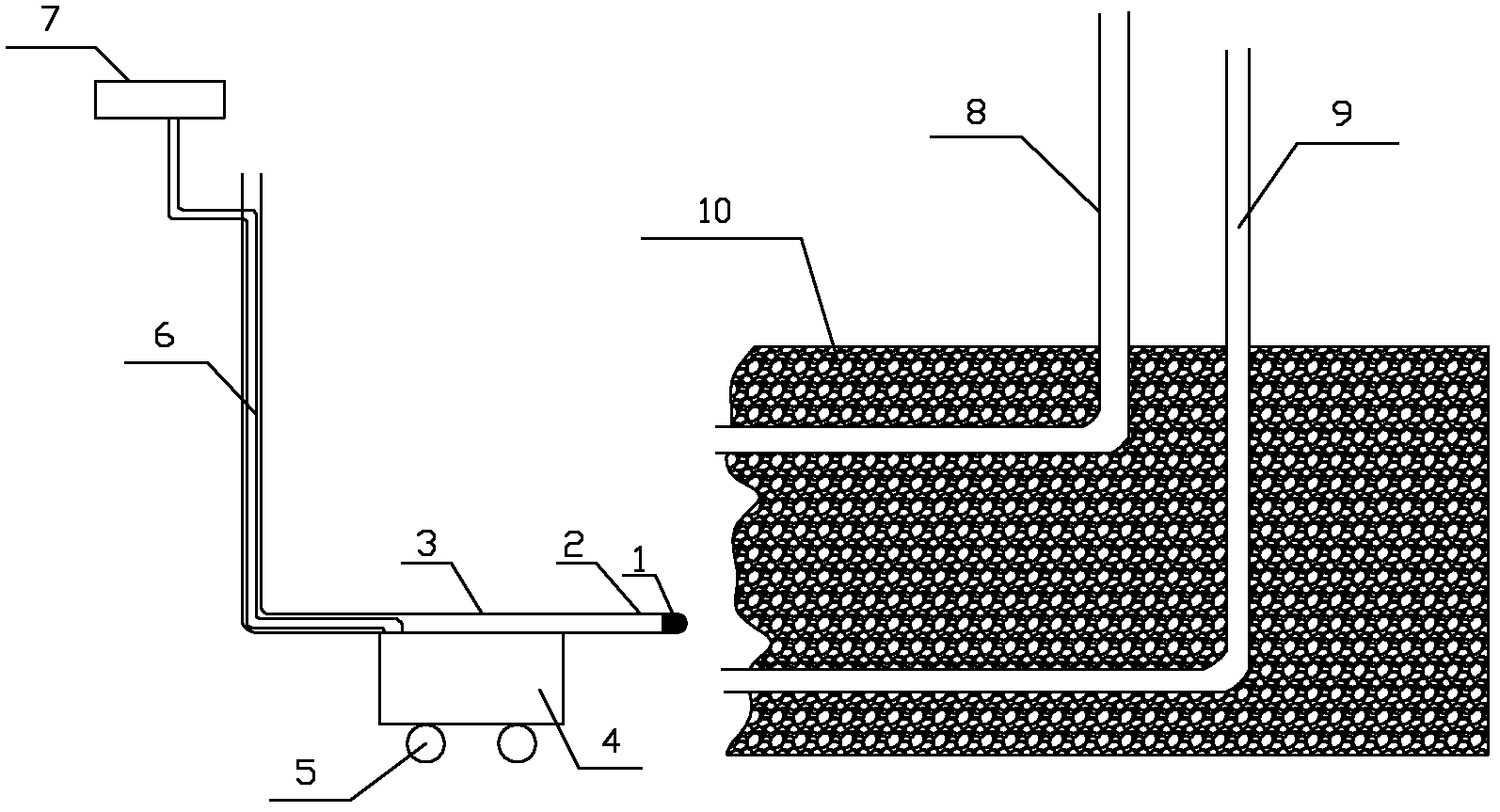

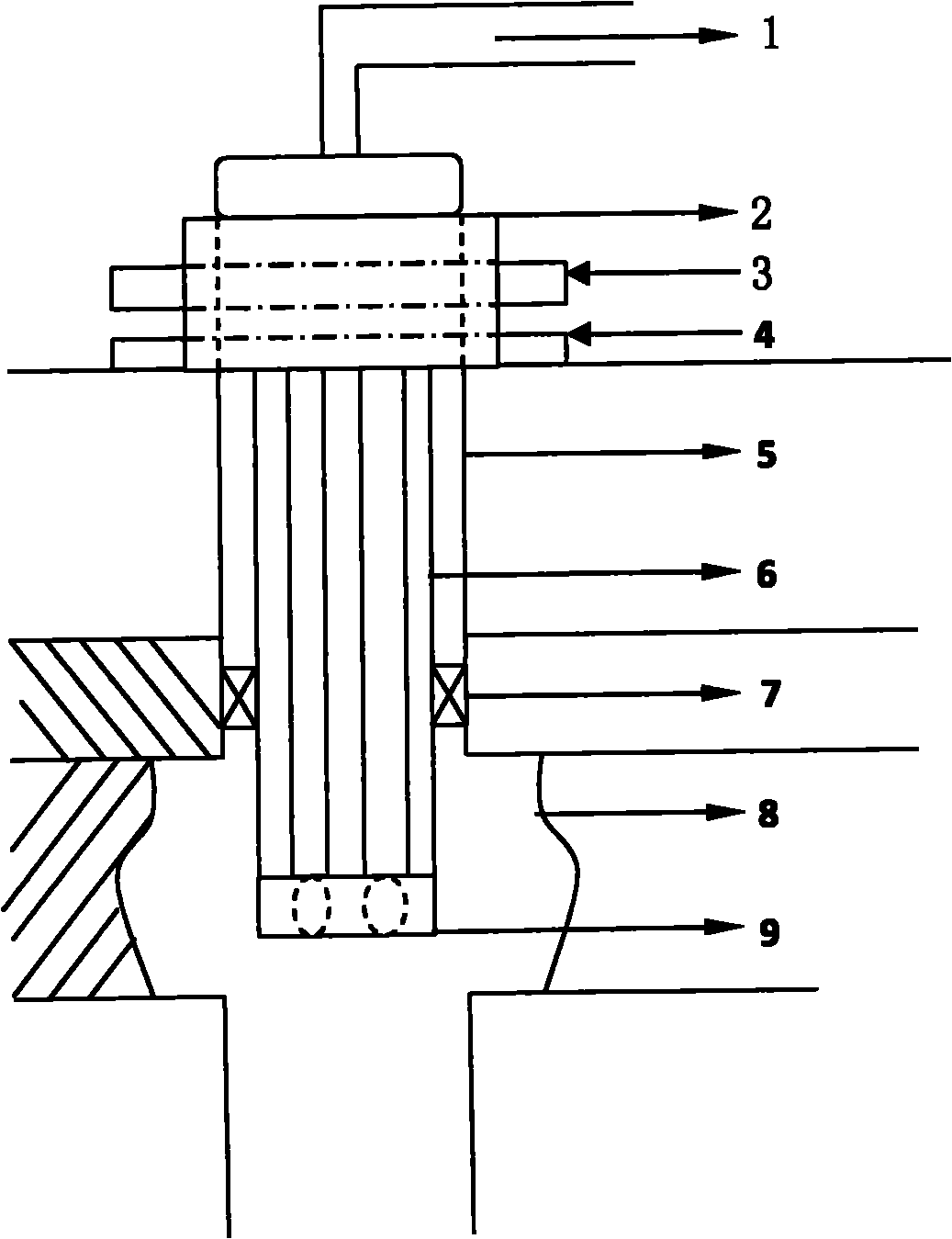

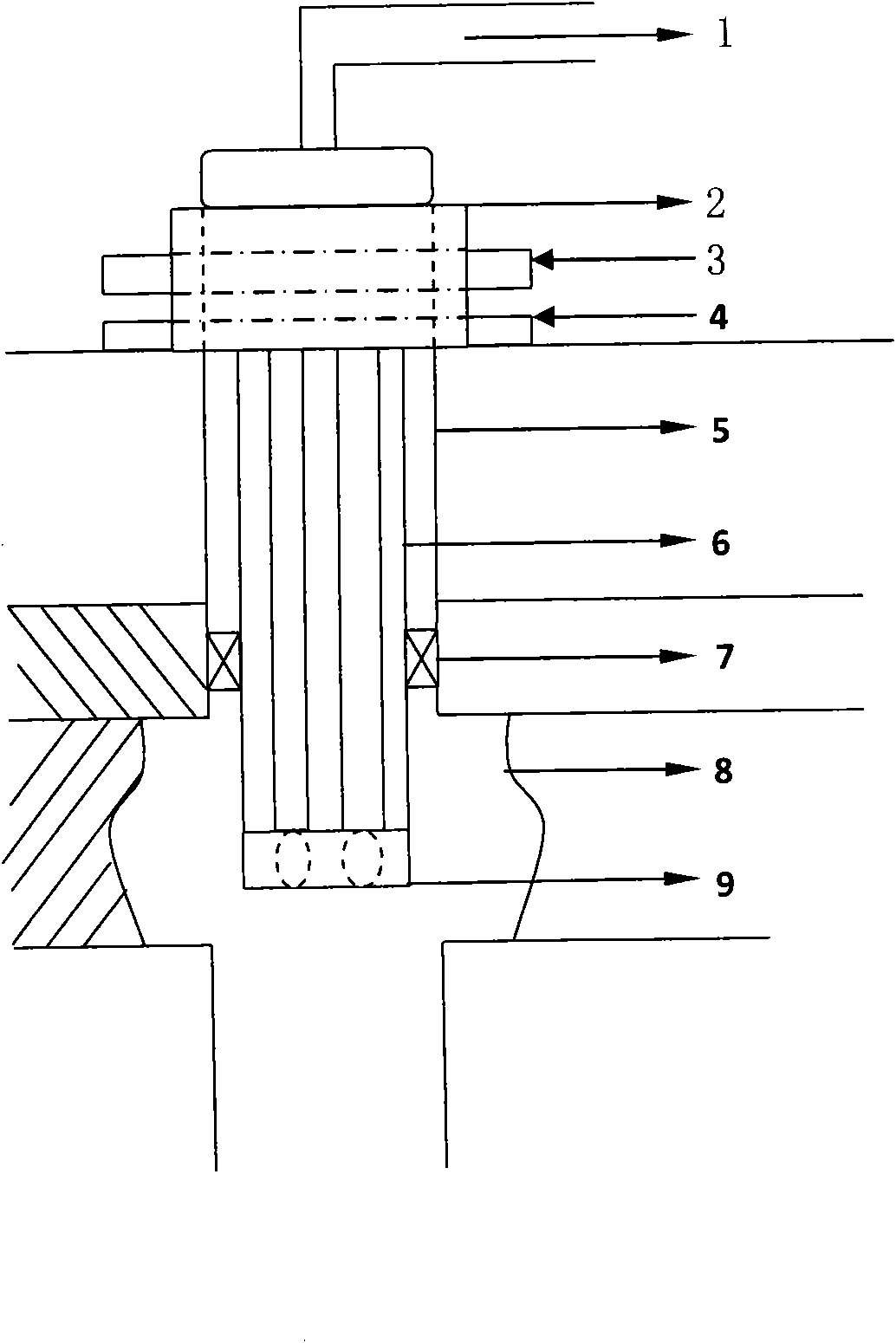

Movable ignition system for UCG (underground coal gasification)

ActiveCN102635346AOvercome the defect that the secondary ignition cannot be performed quicklyScale upConstructionsCoal gasificationProcess engineeringOxygen

The invention discloses a movable ignition system for UCG (underground coal gasification), which comprises a movable ignition device, an overground gas supply system and a gas feeding pipe, wherein the movable ignition device is arranged on underground coal; the overground gas supply system is connected with the ignition device through a gas pipeline, and is used for supplying ignition gas for the ignition device from the ground through the gas pipeline; and the gas feeding pipe passes through a coal bed and communicates the underground coal with the overground coal, and is used for providing ignition air or oxygen for the underground coal from the ground. The ignition system disclosed by the invention can overcome a defect that a traditional igniter can not carry out secondary ignition quickly when a flameout phenomenon occurs in the process of gasification, and can move arbitrarily according to the needs of ignition in the process of gasification, thereby guaranteeing the continuity and timeliness of an ignition process, and saving time and labor; the movable ignition system can enlarge the scale of a gasification furnace, reduce the number of drilled wells, lower the production cost, and improve the production progress; especially for the underground gasification of deep and ultra-deep coal, the ignition system can significantly lower the operation cost; and due to a single gas pipeline design, the ignition process is safer, and the explosion hazard is reduced.

Owner:PEKING UNIV

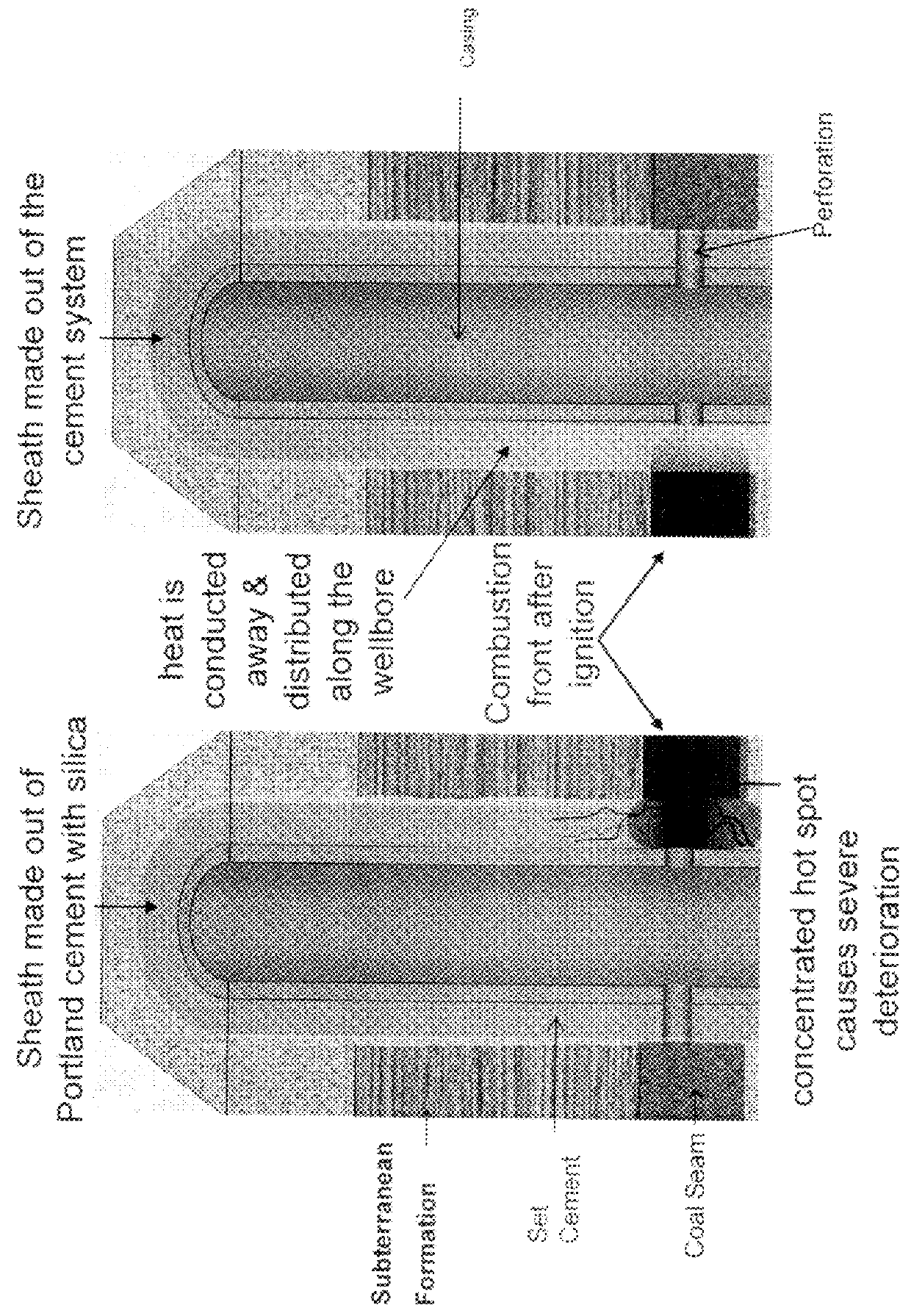

Application of a specialized slurry used for cementing tubulars in wells producing synthesis gas by underground coal gasification

ActiveUS20120103611A1Easy to set upEliminate needFluid removalDrilling compositionAluminum silicateGraphite

Synthesis gas is more effectively produced from the underground gasification of coal from a coal seam when the casing lining is cemented with a cementitious slurry containing a cementitious material, graphite and an aluminum silicate, such as metakaolin. The cementitious slurry of the cement mix sets as a cement sheath at bottomhole static temperatures less than or equal to 65° C. The set cement may withstand extreme dry heat temperatures which are greater than or equal to 800° C.

Owner:BAKER HUGHES INC

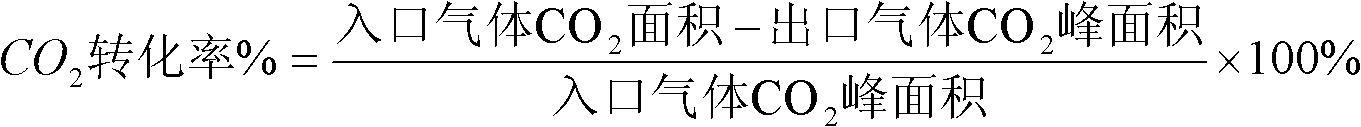

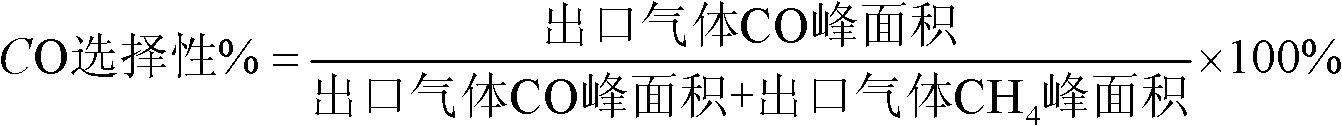

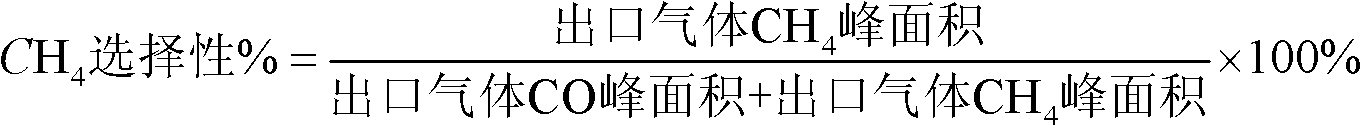

Method for non-thermal plasma and transition metal concerted catalysis CO2 hydrogenation

InactiveCN101880214AReduce energy consumptionStable hydroconversionHydrocarbon from carbon oxidesCarbon monoxideHigh concentrationElectric discharge

The invention belongs to the field of carbon dioxide emission reduction and carbon dioxide conversion, and relates to a method for converting greenhouse gases into high value-added CH4 and CO. The invention is characterized in that media block electric discharge to activate CO2 and H2 molecules and form uniformly distributed nonequilibrium plasmas, hydrogenation is carried out on activated species on a catalyst arranged in a plasma reactor, and CH4, CO, CH4 and CO mixtures are selectively generated; and the proportion of reaction gases of CO2 and H2 is not fixed. The method can convert the greenhouse gas CO2 into high value-added CH4 and CO. The method does not have special requirements or limits on the source and composition of the gas, thereby having universality on CO2 and H2 gases with various components. The technical method can be applied to the hydro-conversion of CO2 with high concentration, and can also be used for the hydro-conversion of CO2 in industrial gasses with low concentration and underground coal gasified gas.

Owner:DALIAN UNIV OF TECH

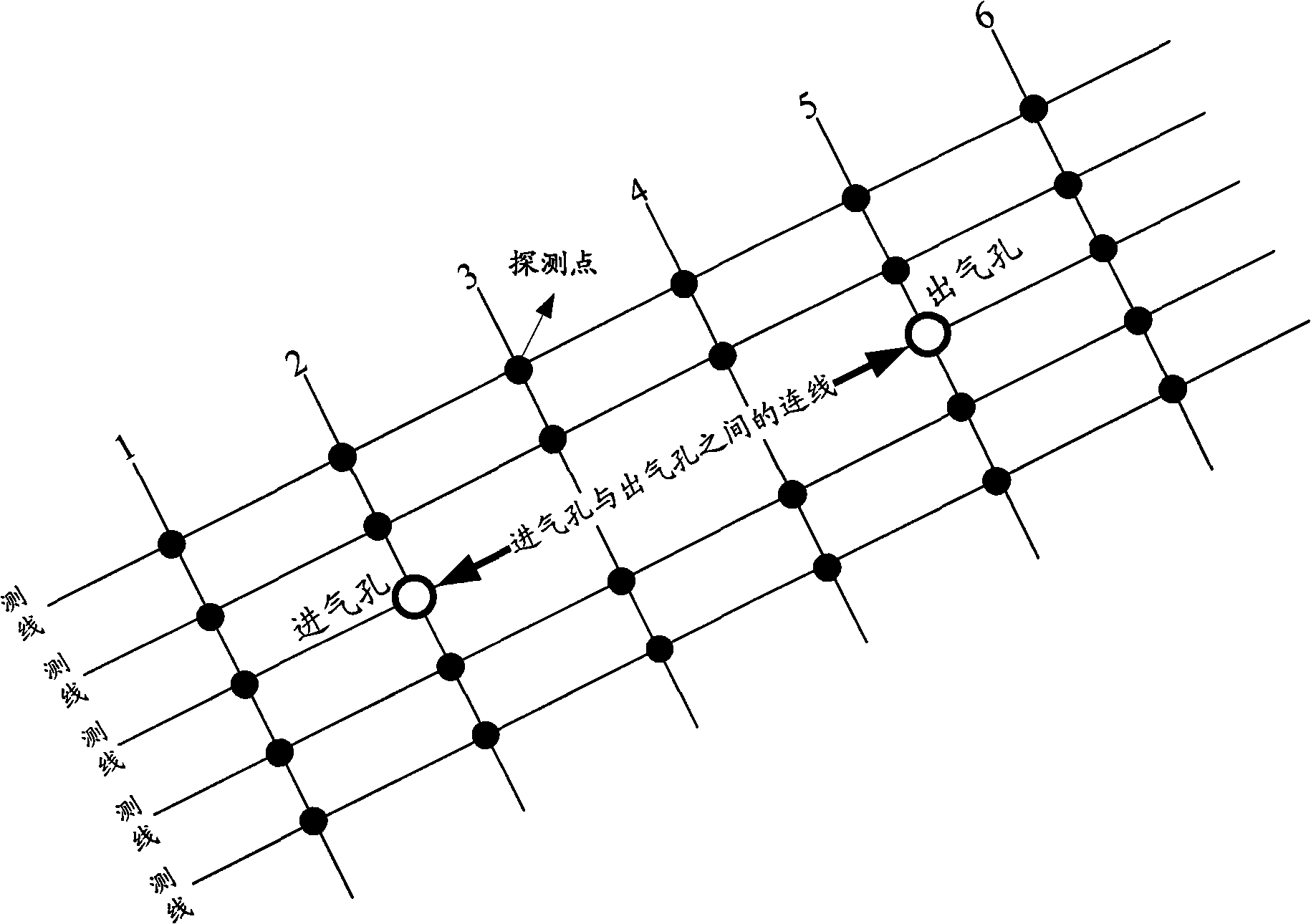

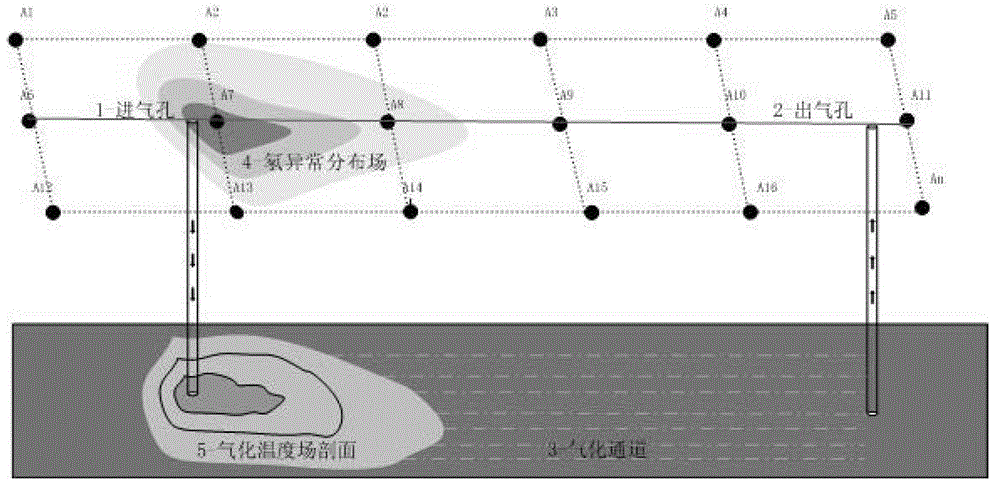

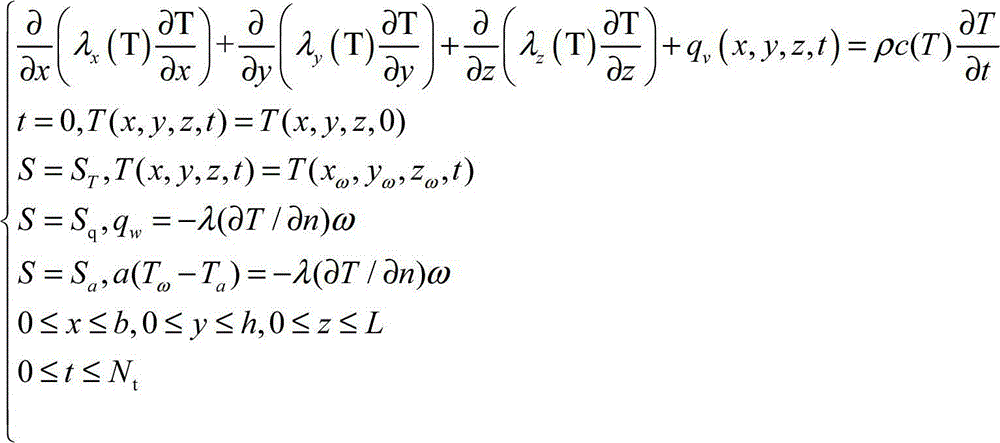

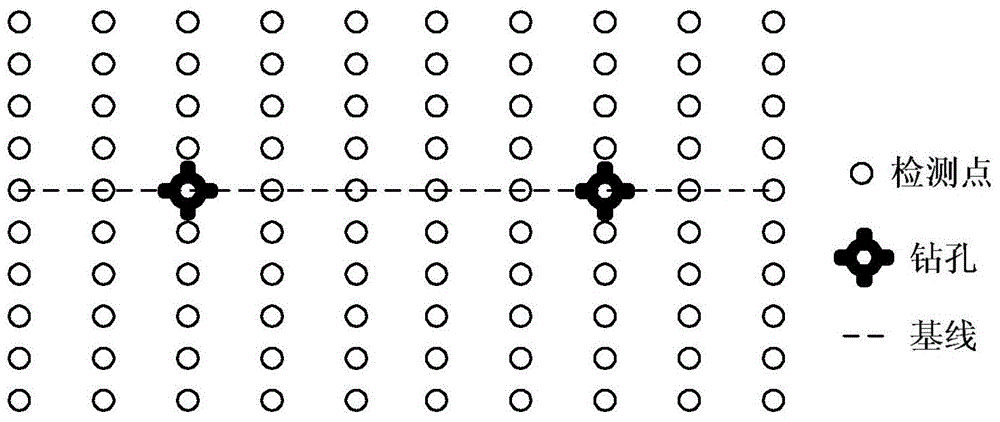

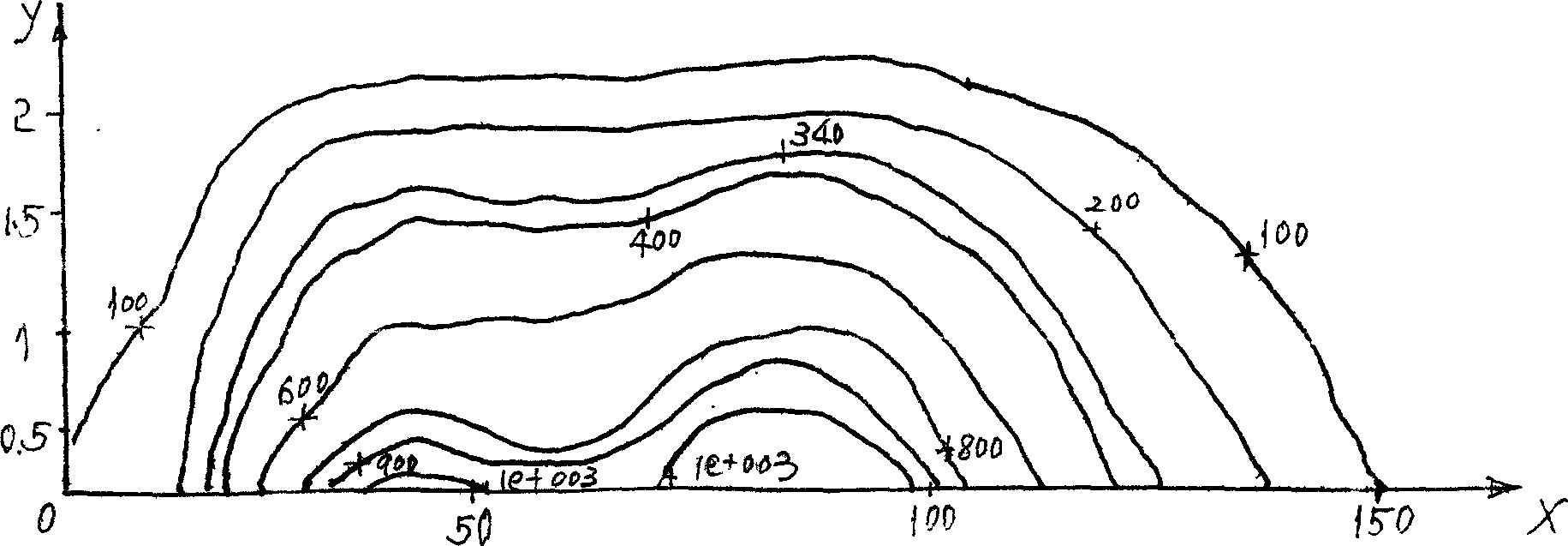

Real-time monitoring method for two-dimensional planar temperature field of underground coal gasification furnace

ActiveCN102721485AAccurately reflectReflect temperature changesThermometers using electric/magnetic elementsUsing electrical meansMathematical modelProcess engineering

The invention provides a real-time monitoring method for a two-dimensional planar temperature field of an underground coal gasification furnace, which comprises the steps of: determining a detecting point array on the ground with the underground coal gasification furnace with the connecting line of a gas inlet and a gas outlet of the underground coal gasification furnace as a reference; and continuously monitoring the radon value in soil with detecting points prior to and after ignition and gasification of the underground gasification furnace to obtain a two-dimensional planar temperature influence field, i.e. a planar geometric model of the temperature field of the gasification furnace according to the variation law of the radon values in the detecting points, and inputting the temperature of gasification agent at the gas inlet and coal gas at the gas outlet of the underground coal gasification furnace and the two-dimensional planar temperature influence field as boundary conditions into a mathematical model of the underground coal gasification temperature field, to obtain the temperature field of the underground coal gasification furnace. The two-dimensional planar temperature field with changes in the temperature of the underground coal gasification furnace can be truly reflected.

Owner:ENN SCI & TECH DEV

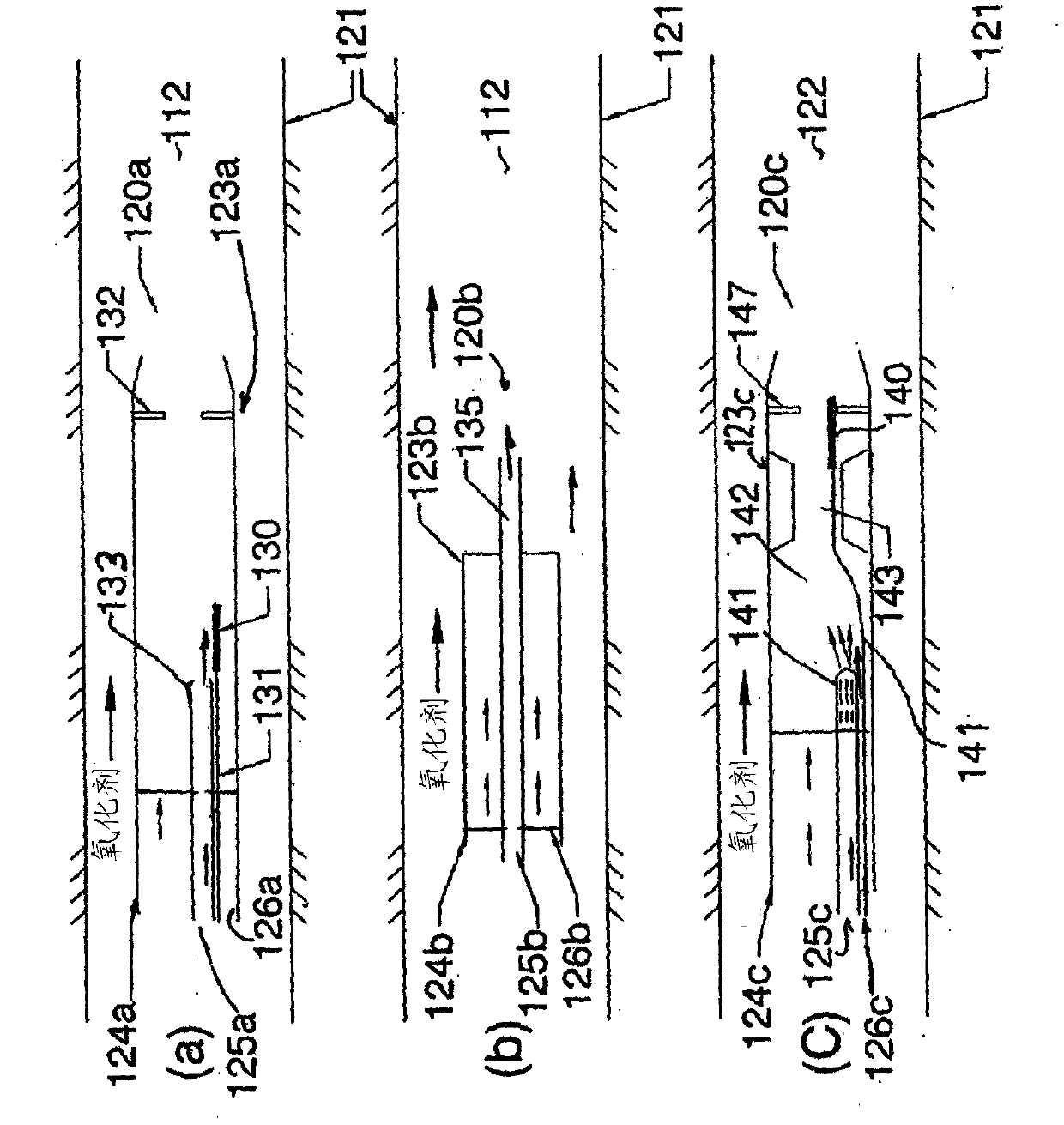

Underground coal gasification system and gasification method

ActiveCN103742122AEasy to control temperatureImprove protectionConstructionsCoal gasificationCombustionEngineering

The invention provides an underground coal gasification system and a gasification method. The underground coal gasification system comprises a first channel located in a coal bed, and a second channel, wherein the two ends of the first channel are communicated with a gas outlet hole and a via hole respectively; the two ends of the second channel are communicated with the via hole and a directional hole respectively; a combustion improver is supplied by the directional hole; the second channel forms a reverse penetration area; a gasification agent is supplied by the via hole; and the first channel forms a forward gasification area. The invention aims at providing the underground coal gasification system and the gasification method which can synchronize a reverse penetration process and a forward gasification process.

Owner:ENN SCI & TECH DEV

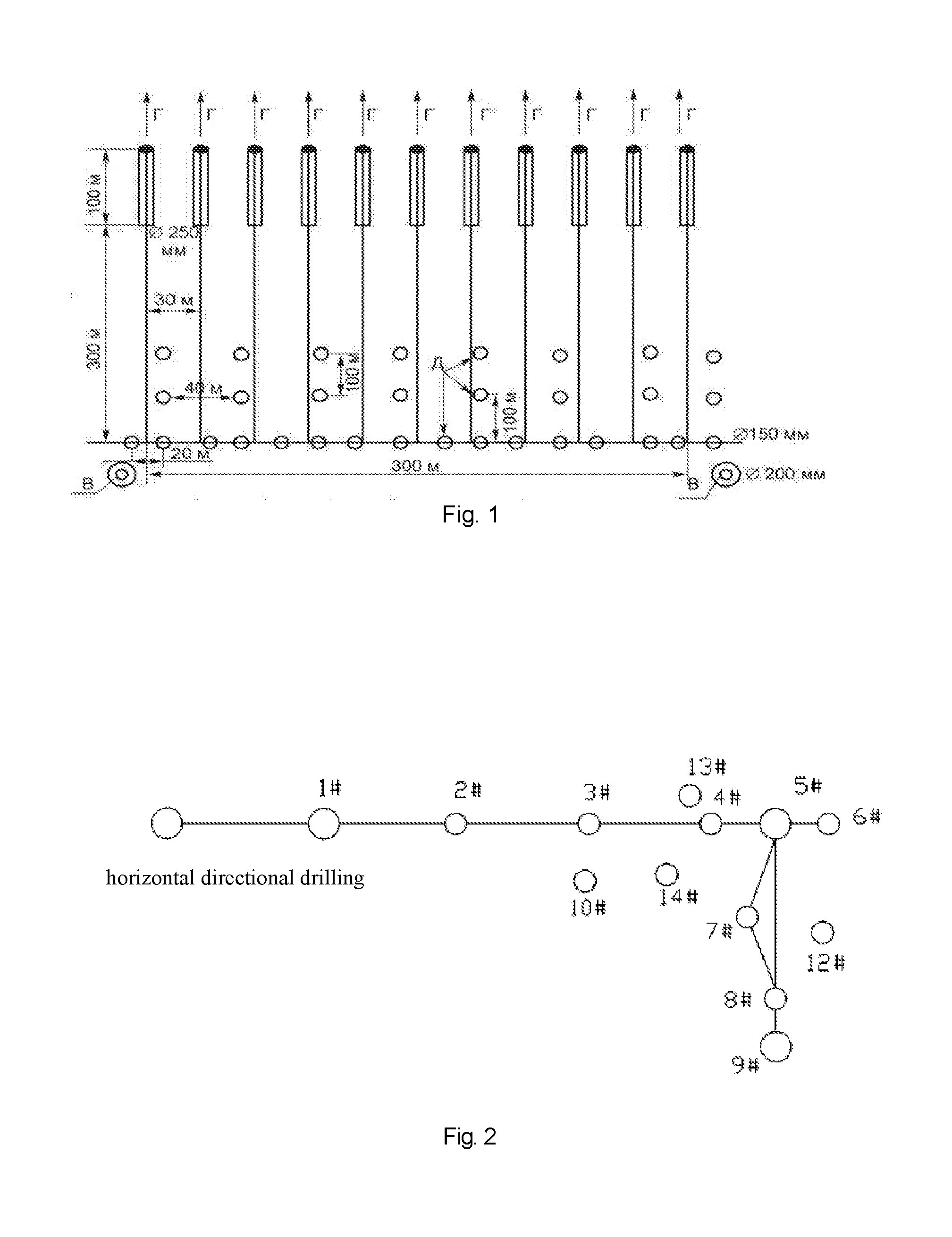

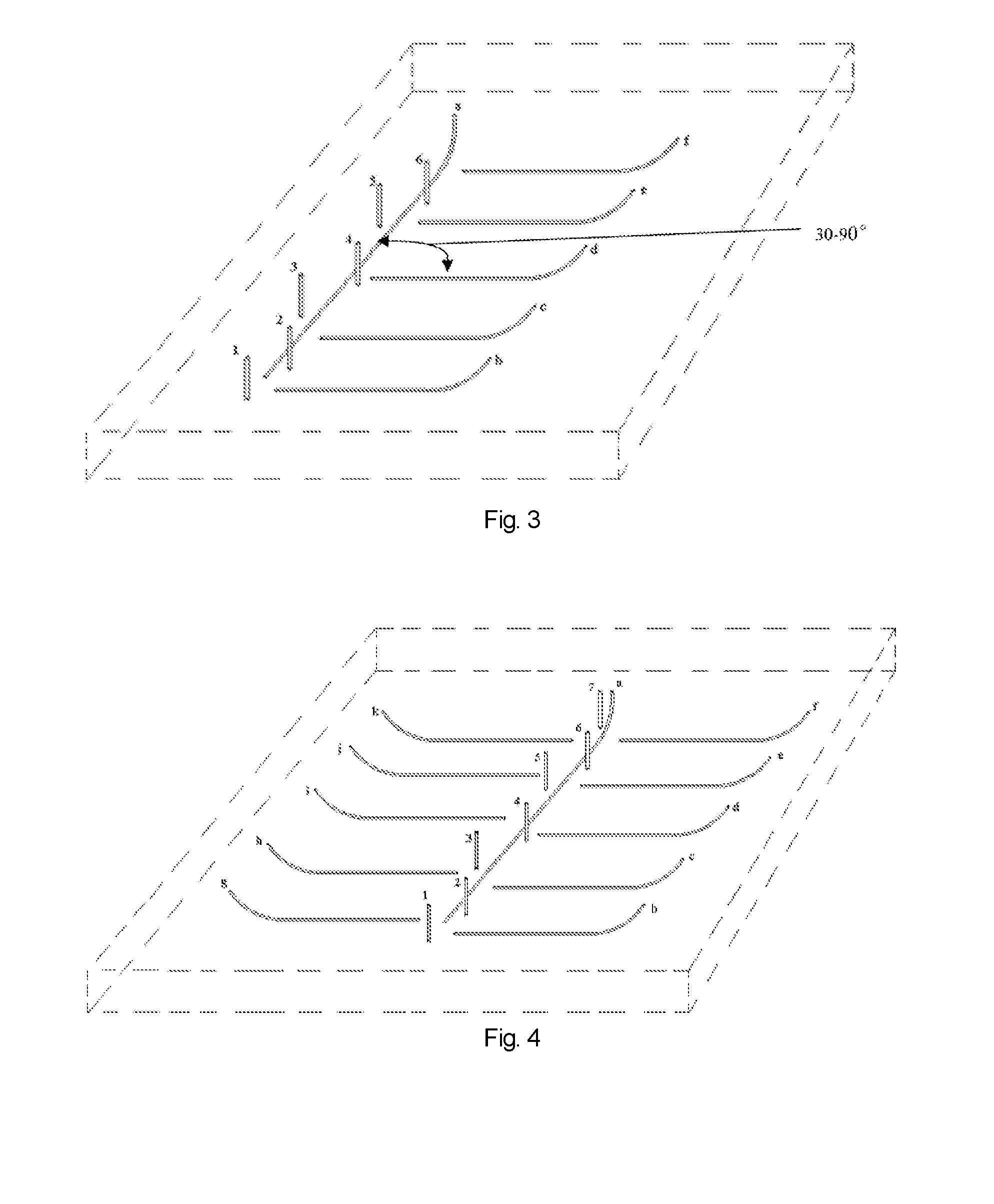

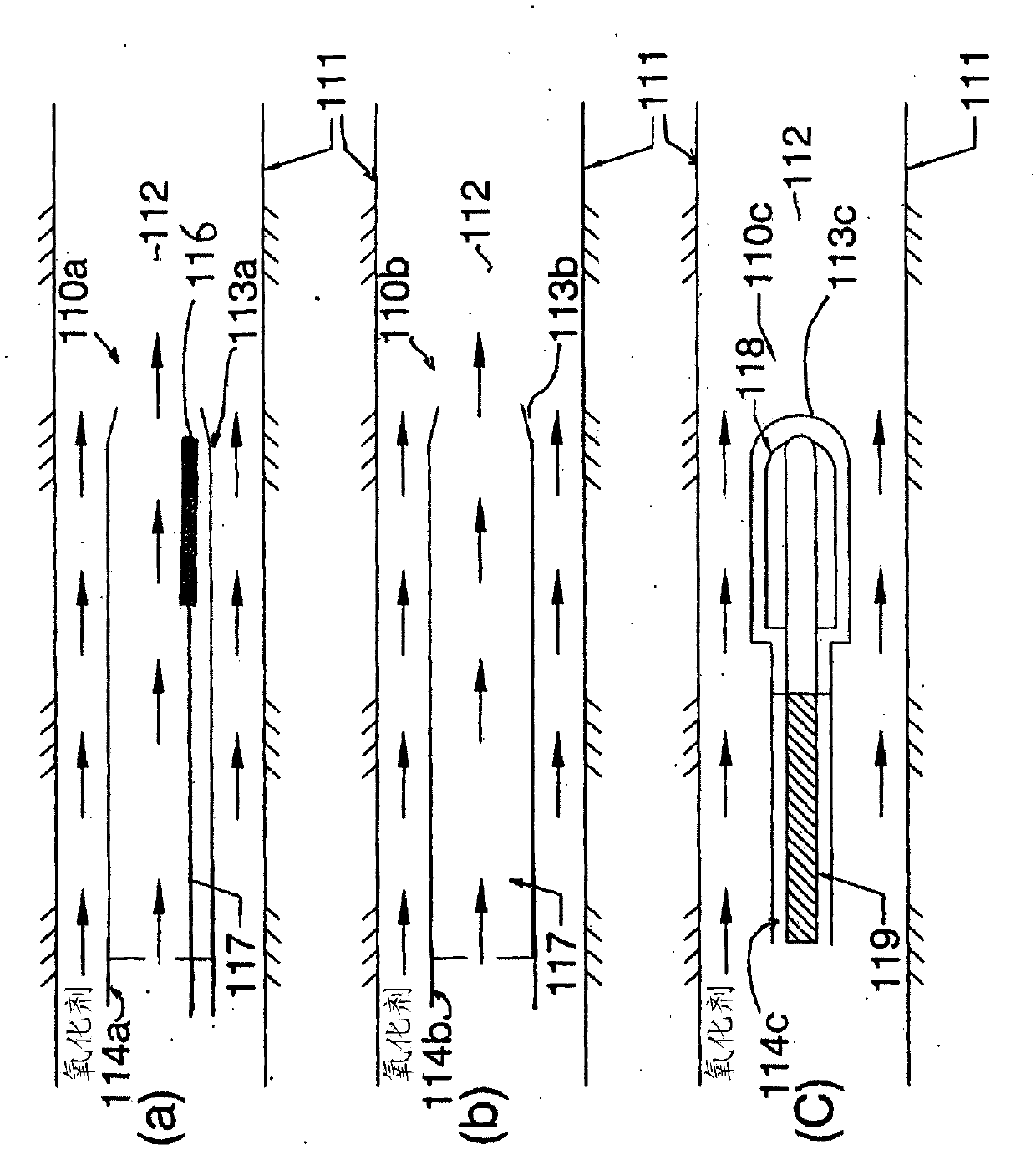

Underground coal gasification furnace and underground coal gasification method

InactiveUS20160194945A1Shorten speedUnstable structureConstructionsFluid removalWell drillingDirectional drilling

An underground coal gasification furnace comprises an ignition system and a gas injection system. The ignition system is provided with a first vertical drilling well and a first horizontal directional drilling well in communication with the first vertical drilling well. The gas injection system is provided with a second drilling well introduced into a coal seam. At least one second horizontal directional drilling wells of a horizontal section in the coal seam serves as the second drilling well. Also provided is an underground coal gasification method. The method comprises: enabling a flaming fire region of a first horizontal directional drilling well to withdraw in a second horizontal directional drilling well until withdraw to near a coal feeding point. The underground coal gasification furnace eliminates the defects of low cut-through speed and unstable structure in a gasification production stage in the prior art.

Owner:ENN COAL GASIFICATION MINING

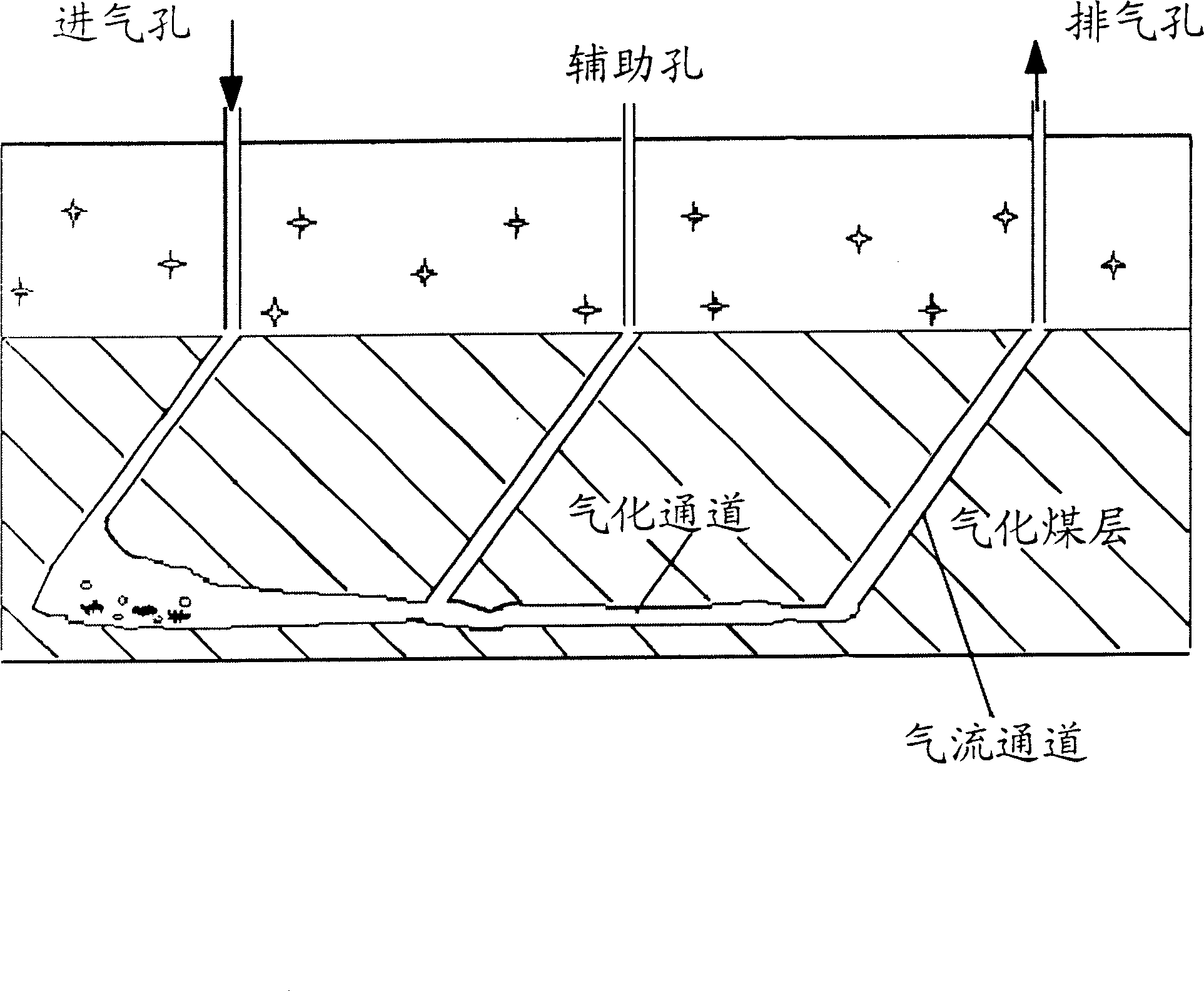

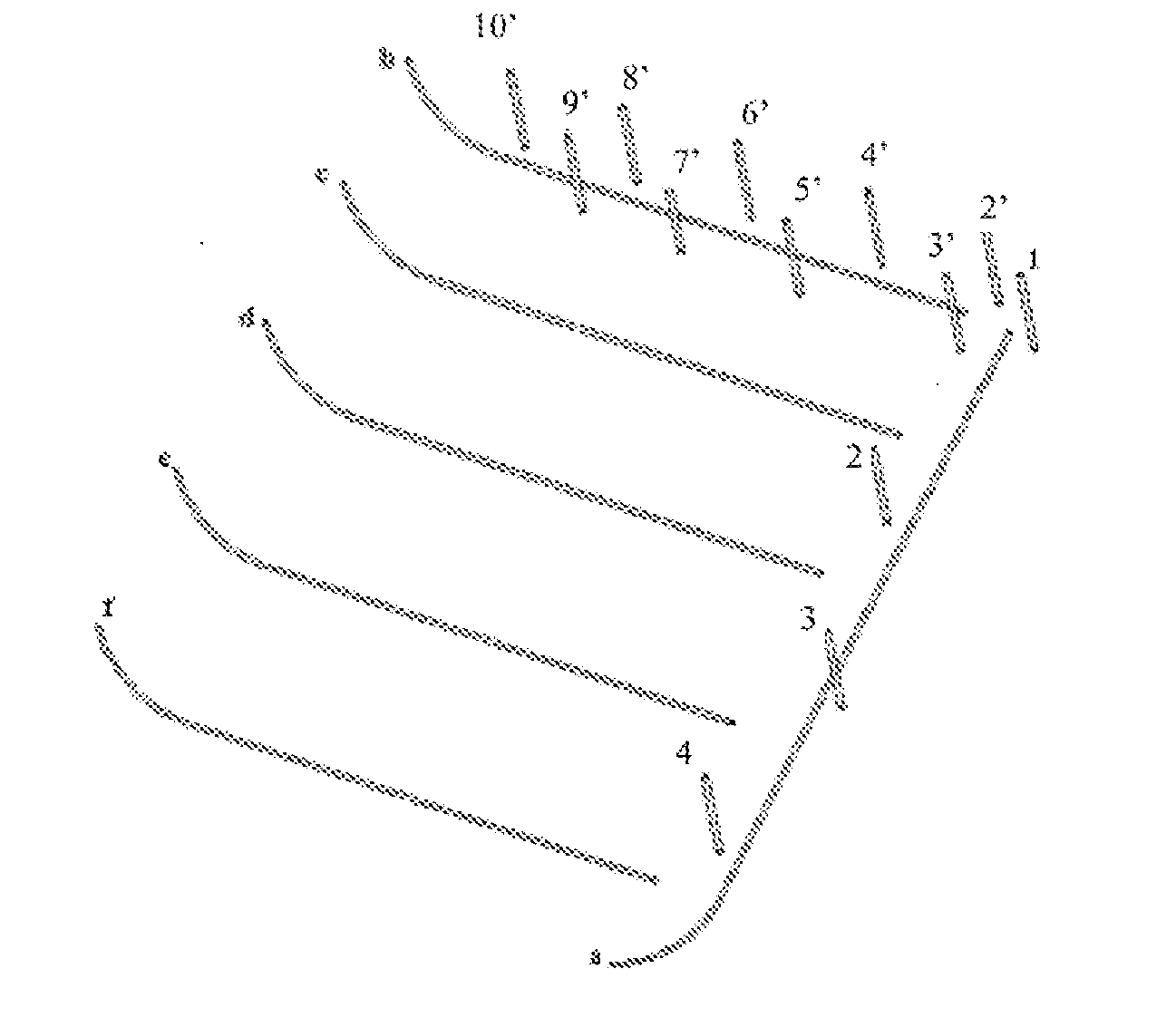

Method for underground coal gasification for gasifier channel establishment

ActiveCN103883304ALow costImprove docking success rateConstructionsCoal gasificationWater dischargeEngineering

The invention belongs to the technical field of underground coal gasification, and particularly relates to a method for underground coal gasification for gasifier channel establishment. A main injection hole, an auxiliary injection hole, a main air outlet, an auxiliary air outlet, a water discharging hole, a crushing zone, horizontal holes, a hole packer and a temperature and pressure monitoring instrument are involved in the method. The ground coal mine face serves as a base point, the injection holes and the air outlets are arranged in a line, and the alignment direction of the injection holes and the air outlets is identical to that of the underground horizontal holes. A gasifier channel is formed through the method that underground drilled holes are in butt joint with the coal bed sections of the ground injection holes. The method has the advantages of being low in cost, high in success rate of butt joint, and particularly suitable for abandoned mines without economic exploitation value.

Owner:GUIZHOU PANJIANG COAL BED GAS DEV UTILIZATION

Coal-bed gas thermal cavity completion method

The invention belongs to the field of coal-bed gas exploration and development, and in particular relates to a coal-bed gas thermal cavity completion method, which comprises the following steps of: (1) performing high temperature resistant cement casing cementation on the top of a coal bed; (2) drilling to a position 50 to 80 meters lower than the coal bed, and performing hole enlargement completion on a coal bed section; (3) removing coal dust from a shaft; (4) descending a thermal completion combination stem to the middle of a cavity; (5) injecting silane and oxygen, beginning combusting on the cavity part, and heating the coal bed; (6) when the temperature is higher than 600DEG C, determining whether to stop supplying the silane according to a component detection result of flow-back gas; and (7) when the temperature is raised to 1,500DEG C, stopping supplying the oxygen. By the method, the cavity completion is performed under the thermal condition, the coal bed around the shaft is stable and difficult to collapse, the ignition is simple and easy to control, and the method can be used for blind hole type underground coal gasification.

Owner:CNPC GREATWALL DRILLING ENG

Vertical shaft and horizontal shaft joint ignition method in underground coal gasification mining

ActiveCN106194147AIncrease the storage volumeImprove ignition success rateConstructionsCoal gasificationCombustionEngineering

The invention relates to a vertical shaft and horizontal shaft joint ignition method in underground coal gasification mining. In order to solve the problems that according to an existing ordinary ignition method, due to the fact that the initial underground space is small, ignition is difficult, and the ignition time is long, perforation and fracturing are conducted on a coal bed, and a mixed combustion improver and oxygen-rich ignition gas are added, so that the fracturing success rate is increased, ignition can be conducted effectively, the time is shortened, and the human cost is reduced.

Owner:中嵘能源科技集团有限公司

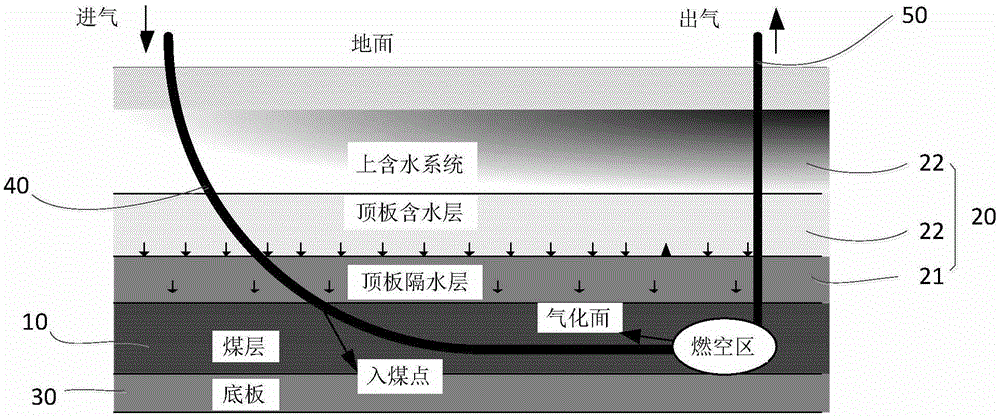

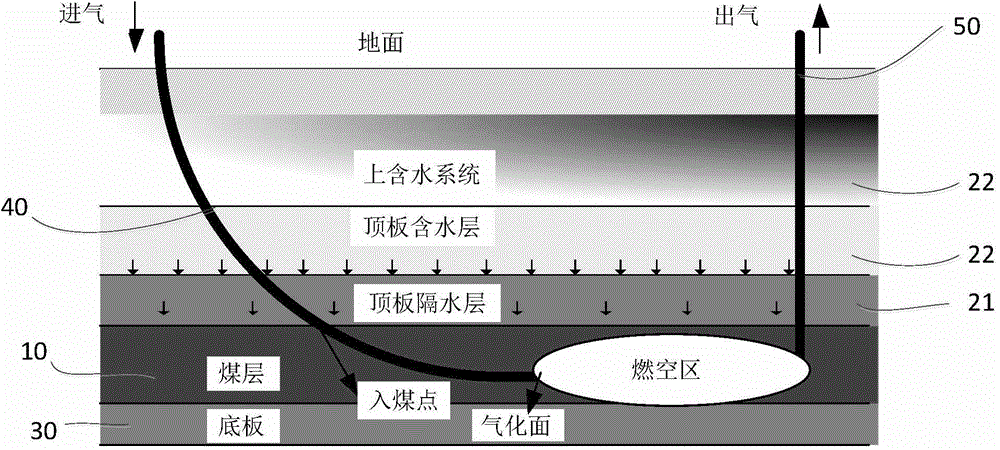

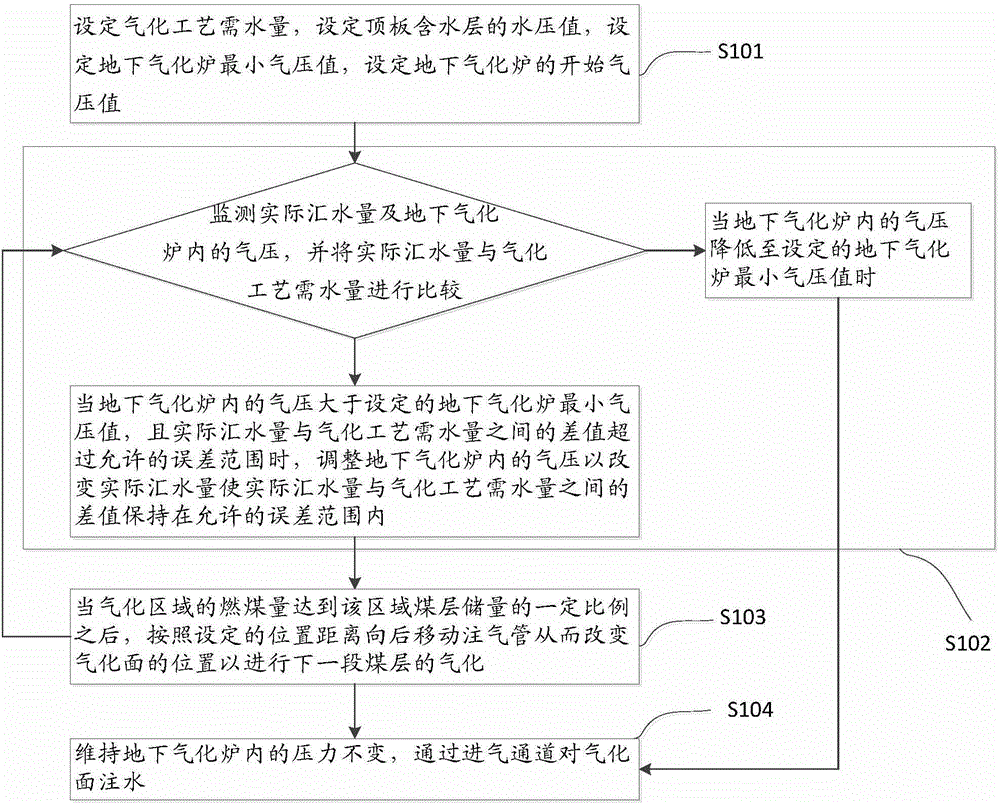

Method for controlling water collection quantity in underground coal gasification process and underground coal gasification method

ActiveCN104653166ACatchment is stableStabilized gasification processConstructionsCoal gasificationThermodynamicsWater collection

The invention provides a method for controlling the water collection quantity in an underground coal gasification process. The method comprises the following steps of: monitoring the actual water collection quantity in the gasification process and the gas pressure in an underground gasification furnace, comparing the actual water collection quantity with a water quantity required by the gasification process, and regulating the gas pressure in the underground gasification furnace so as to change the actual water collection quantity to ensure that the difference value between the actual water collection quantity and the water quantity required by the gasification process is kept in an allowable error range; when the coal consumption in a gasification region reaches a certain proportion of the coal reserve of the region, moving a gas filling pipe backward according to a set position distance so as to change the position of a gasification surface to perform gasification of a next-section coal seam. The invention also provides an underground coal gasification method. According to the underground coal gasification method and the water collection quantity control method, by virtue of the method of regulating the gas pressure in the underground gasification furnace and injecting water through a gas inlet passage in the gasification process, the actual water collection quantity of the gasification surface of the underground gasification furnace is kept stable, and stable execution of the gasification process is facilitated.

Owner:ENN SCI & TECH DEV

Igniting an underground coal seam in an underground coal gasification process, ucg

An ignition apparatus (150) configured to ignite an underground coal seam (151). The ignition apparatus (150) comprising an ignition system, a positioning system, a sensor (170) and a controller (165). The ignition system comprises ignition means and an ignition tool (155) for igniting the underground coal seam (151) from within the well channel (154) or well liner encasing the well channel (154). The positioning system comprises coiled tubing (156) connected to the ignition tool (155) and extendible through a well head (153) within the well channel (154) to position the ignition tool (155) at a desired location within the well channel (154). The positioning system further comprises a spool (157) for transporting and dispensing the coiled tubing (156).

Owner:LINC ENERGY

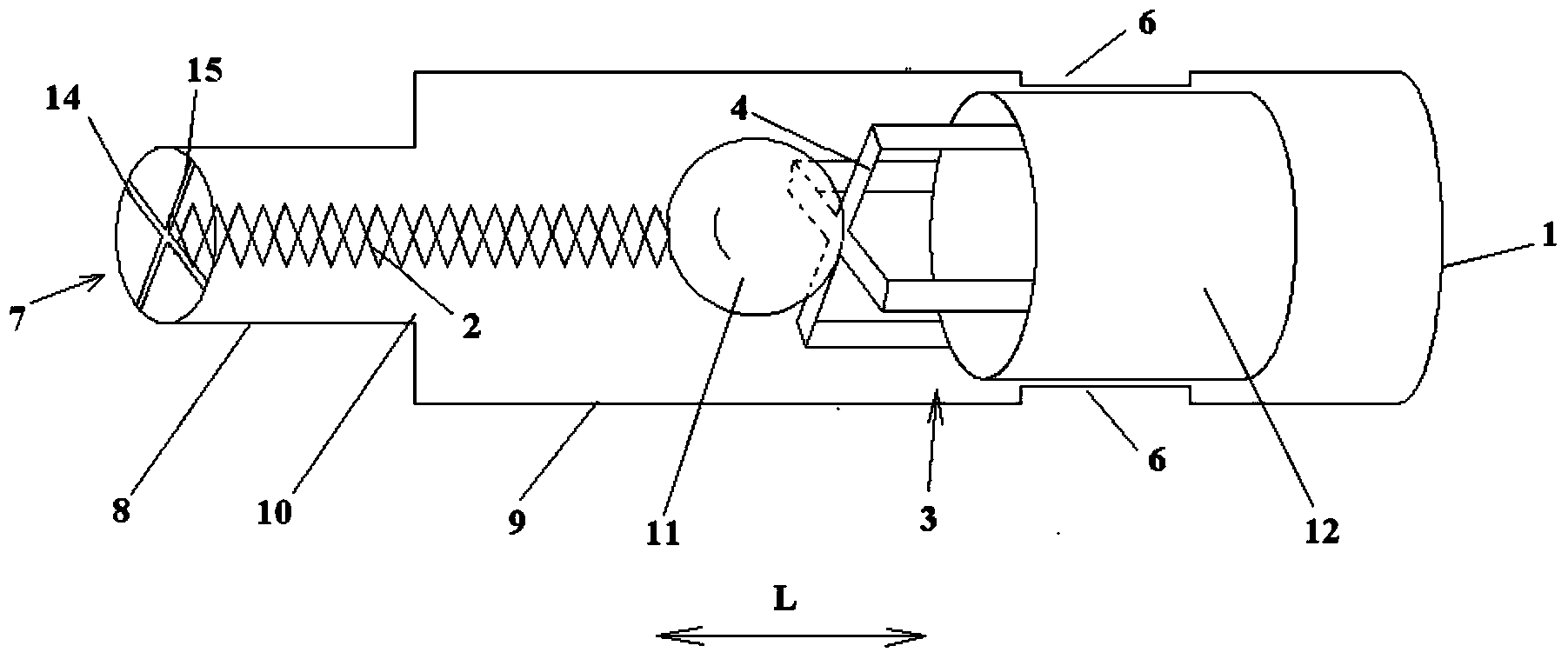

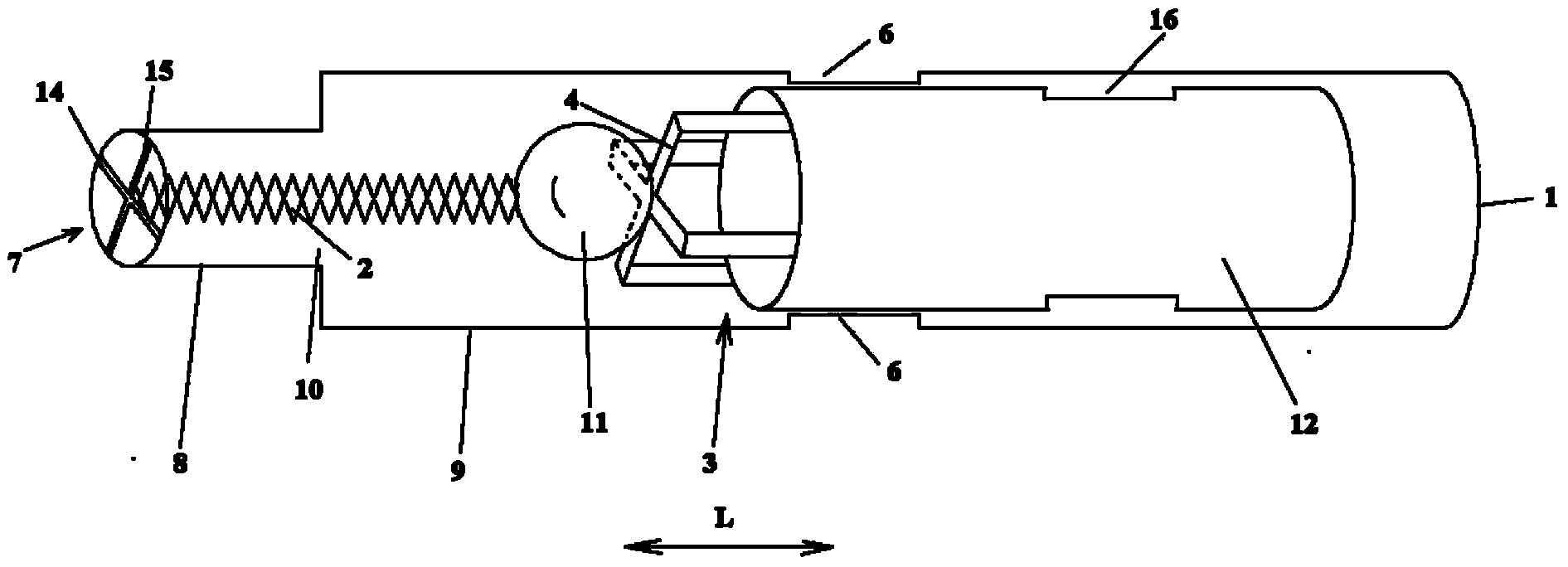

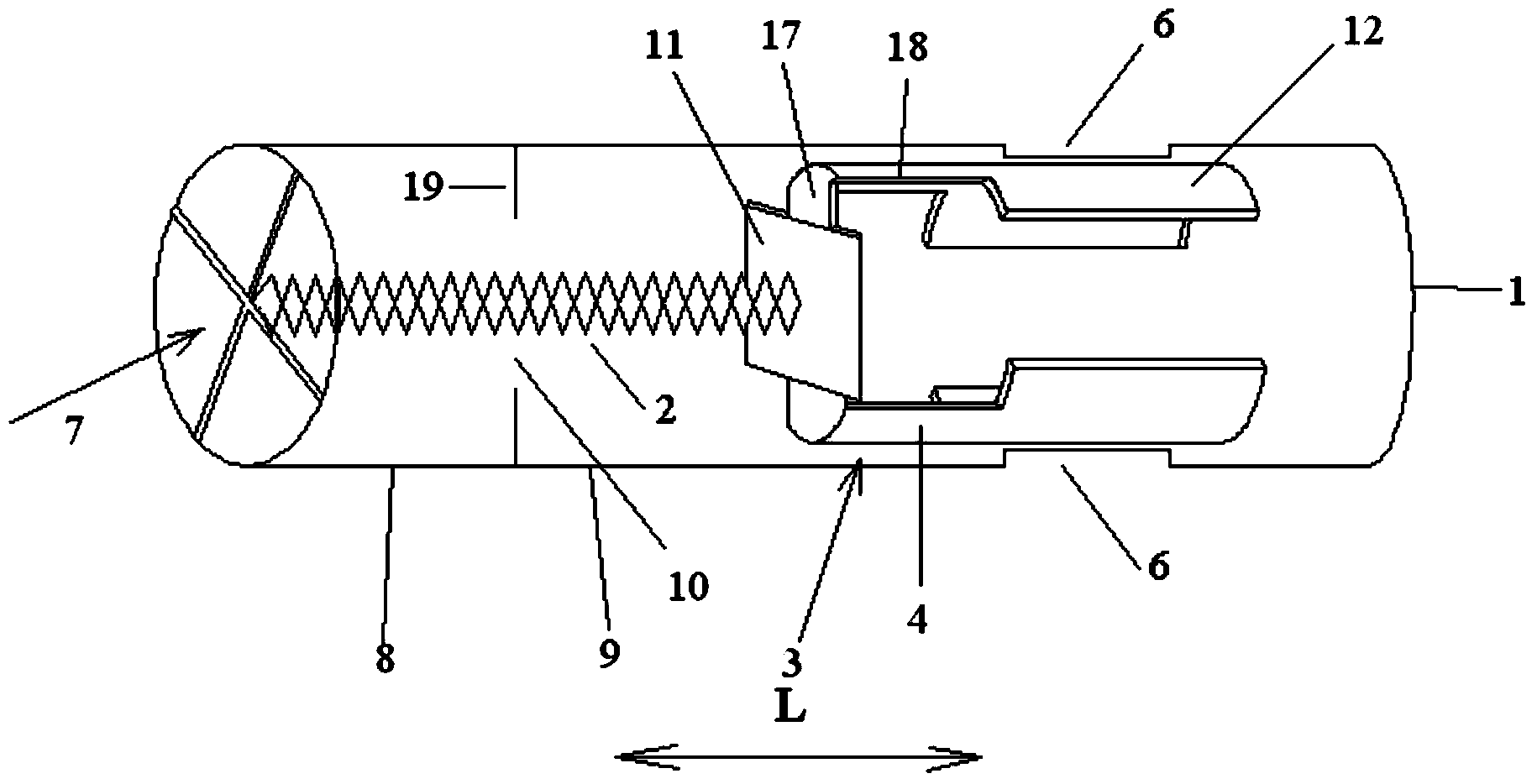

Spray nozzle and underground coal gasification method

ActiveCN103541714AEffectively enhance gasificationImprove recovery rateConstructionsSpray nozzlesInjection pressureSpray nozzle

The invention relates to a spray nozzle. The spray nozzle comprises a casing which comprises a first portion and a second portion; the first portion is in fluid communication with the second portion through a front hole; the side wall of the second portion is provided with a side hole; the spray nozzle also comprises a sealing assembly and a spring; the front hole and the side hole can be opened and closed in the casing in a sliding mode through the sealing assembly; the spring is arranged between the casing and the sealing assembly. The invention also relates to an underground coal gasification method using the spray nozzle. The underground coal gasification method comprises the steps of adjusting the injection flow rate and the injection pressure of a gasification agent and the pressure of the gas outlet channel opening and controlling the opening and closing of the front hole and the side hole of the casing. The front hole and the side hole can be alternately or simultaneously opened selectively without manual operation through the spray nozzle. In the process of underground coal gasification, the gasification working surface can be guided to move through the opening of the front hole of the spraying nozzle, reinforcement gasification can be performed on coal seams which are arranged on the bilateral sides of a gasification channel through the opening of the side hole, and accordingly the extension towards the bilateral sides of the gasification channel can be uniform and the recovery rate of coal resources can be improved.

Owner:ENN SCI & TECH DEV

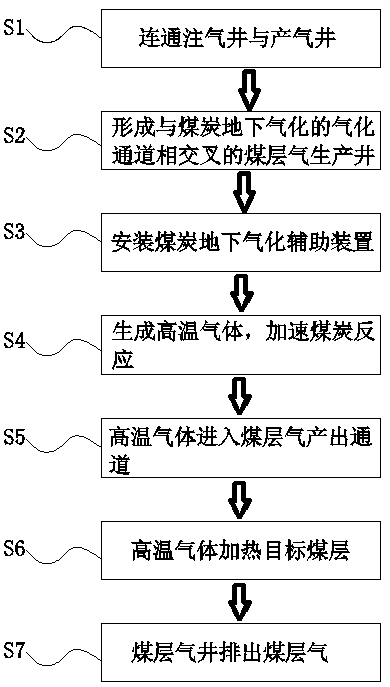

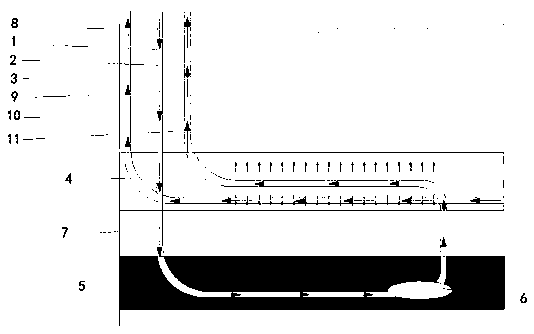

Method for increasing coalbed methane by waste heat in underground coal gasification process

InactiveCN110924919AReduce consumptionIncrease the areaConstructionsFluid removalCombustionHorizontal wells

The invention discloses a method for increasing coalbed methane by waste heat in underground coal gasification process. The method comprises the following steps that S1, a gas injection well and a gasproduction well are driven to a target coal seam of underground coal gasification from the ground, so that a U-shaped well is formed; S2, a horizontal well section of a coalbed methane well and the space of a gasification channel of underground coal gasification form an X-shape intersection; S3, an auxiliary device of underground coal gasification is installed at the tail end of the gas injectionwell; S4, nearby coal can be heated by the high temperature produced by the combustion of the coal; S5, an air pumping device is installed at the ground end of the gas production well; S6, the heat is transferred to a coalbed gas production coal seam for heating by high-temperature airflow in a radiation and heat conduction mode, and the desorption rate of the coalbed gas is improved; and S7, thecoalbed gas is discharged from the coalbed gas well. According to the using method, heat generated in the underground coal gasification process can be reasonably utilized, and a large amount of energy consumption in the coalbed gas heat injection development process is reduced.

Owner:CHINA UNIV OF MINING & TECH

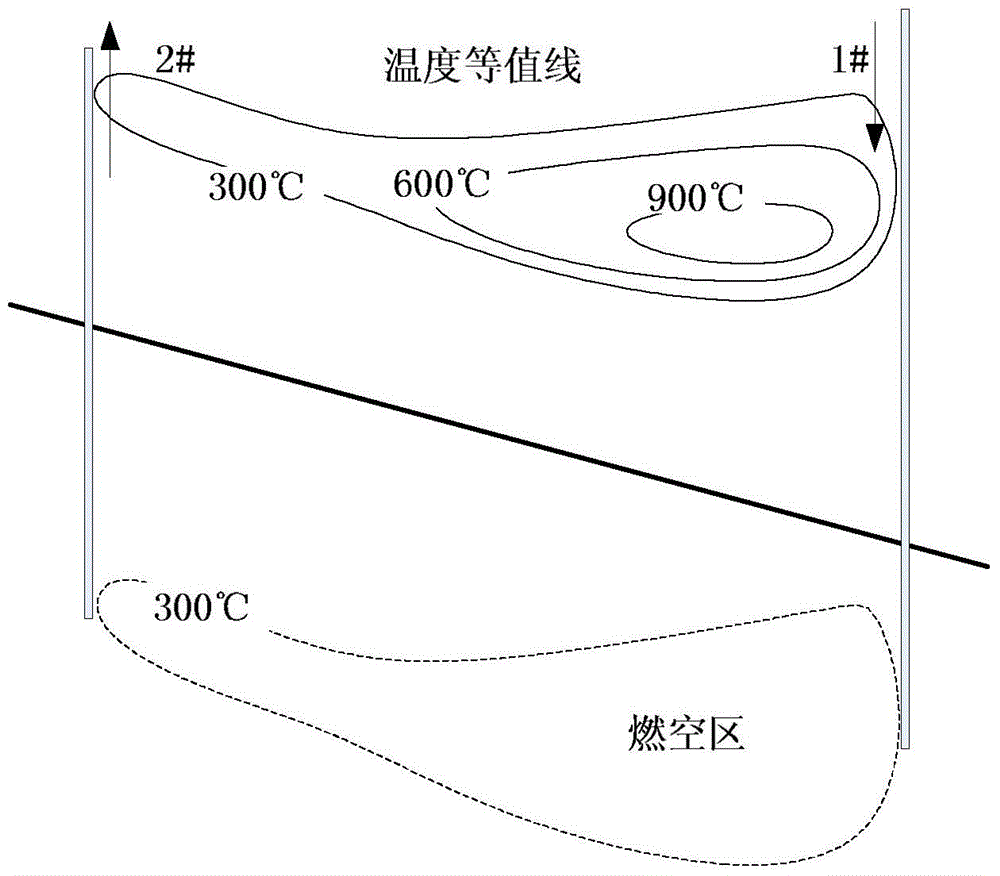

Method, device and system for determining internal combustion mined-out areas of underground coal gasification furnace

ActiveCN103603646ARealize real-time monitoringConstructionsCoal gasificationCombustionProcess engineering

The invention discloses a method, a device and a system for determining internal combustion mined-out areas of an underground coal gasification furnace. The method includes acquiring a preset temperature equivalent line of the underground coal gasification furnace at a current moment according to acquired real-time concentration of earth-surface radioactive substances above the underground coal gasification furnace; acquiring a quantity of preset gas outputted by the underground coal gasification furnace; determining the internal combustion mined-out areas in preset states in the underground coal gasification furnace at the current moment according to the acquired preset temperature equivalent line and the acquired quantity of the preset gas. The quantity of the preset gas refers to the quantity of the preset gas outputted by the underground coal gasification furnace in a period from an initial moment to the current moment, the initial moment is a moment when the requirement of a preset temperature is met, and the preset gas is gas generated by the internal combustion mined-out areas in the preset states in the underground coal gasification furnace. The method, the device and the system have the advantage that the ranges and propagation rules of the internal combustion mined-out areas of the underground coal gasification furnace can be monitored in real time.

Owner:ENN SCI & TECH DEV

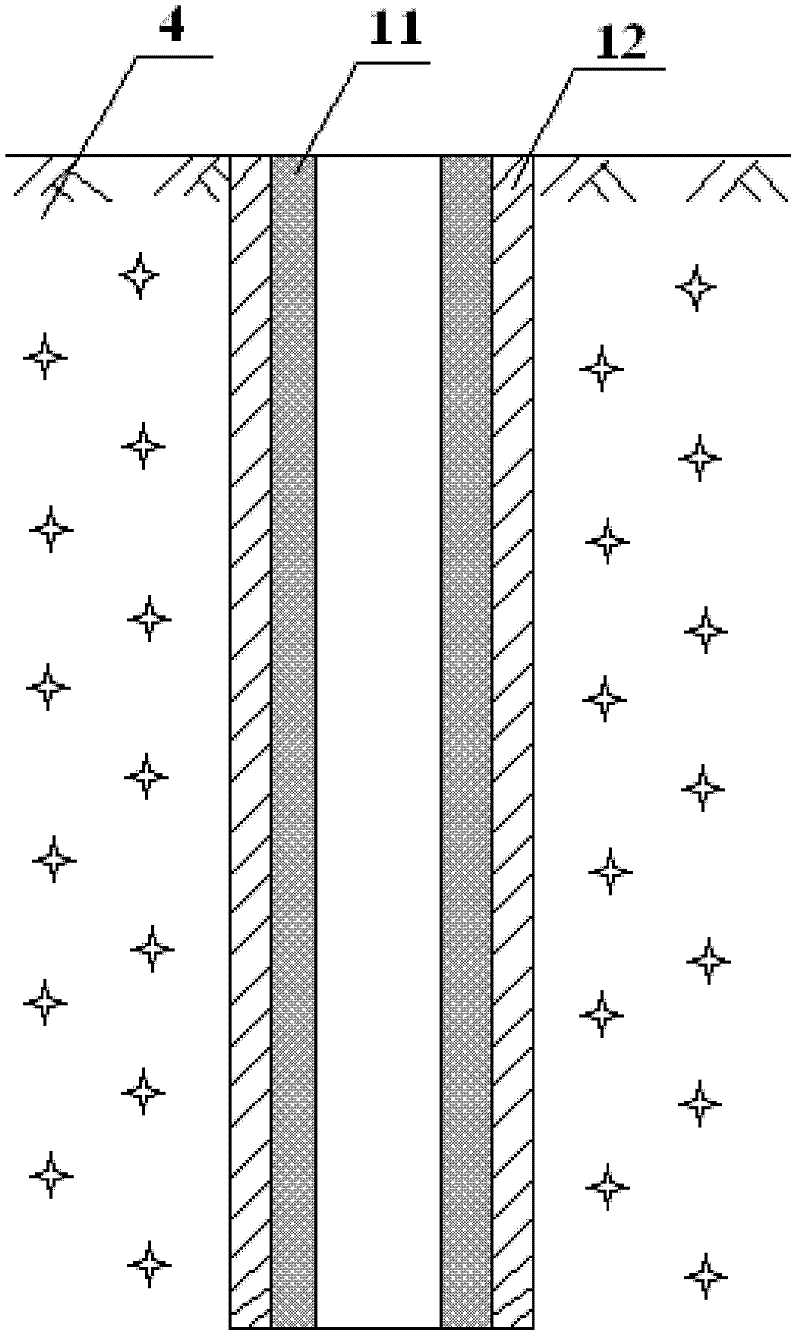

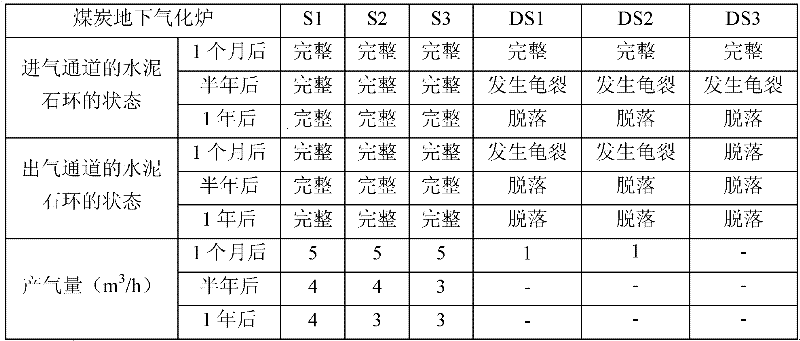

Cement composition and application thereof

ActiveCN102533234AImprove high temperature resistanceHigh strengthConstructionsCoal gasificationQuartzPolymer chemistry

The invention relates to a cement composition, which comprises oil well cement, a heat stabilizer and a lightening agent. Taking the amount of the oil well cement as 100 weight portions, the content of the heat stabilizer is 10-50 weight portions, and the content of the lightening agent is 10-30 weight portions. Based on the total weight of the heat stabilizer, the heat stabilizer comprises 40-60 percent of 100-160-mesh quartz sand by weight and 40-60 percent of 180-250-mesh quartz sand by weight. The invention also relates to an application of the composition in production of an underground coal gasification furnace. The cement stone prepared with the cement composition has good resistance against high temperature. Moreover, the underground coal gasification furnace produced with the cement composition has long service life.

Owner:CHINA SHENHUA ENERGY CO LTD +1

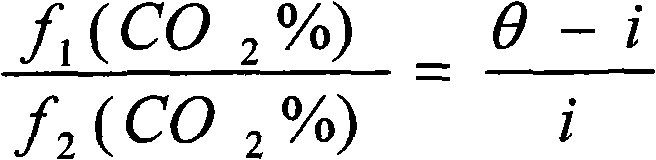

Symbolic gas detecting, regulating and controlling method for underground coal gasification

InactiveCN1667241AHigh calorific valueExtend service hoursSurveyFluid removalProcess engineeringCoal gas

The invention relates to a detecting and controlling method for coal underground gasification indicating gas that belongs to underground coal developing. The invention supplies an enforceable controlling method for coal underground gasification producing. And a new aspect is supplied for the developing of coal industry.

Owner:LIAONING TECHNICAL UNIVERSITY

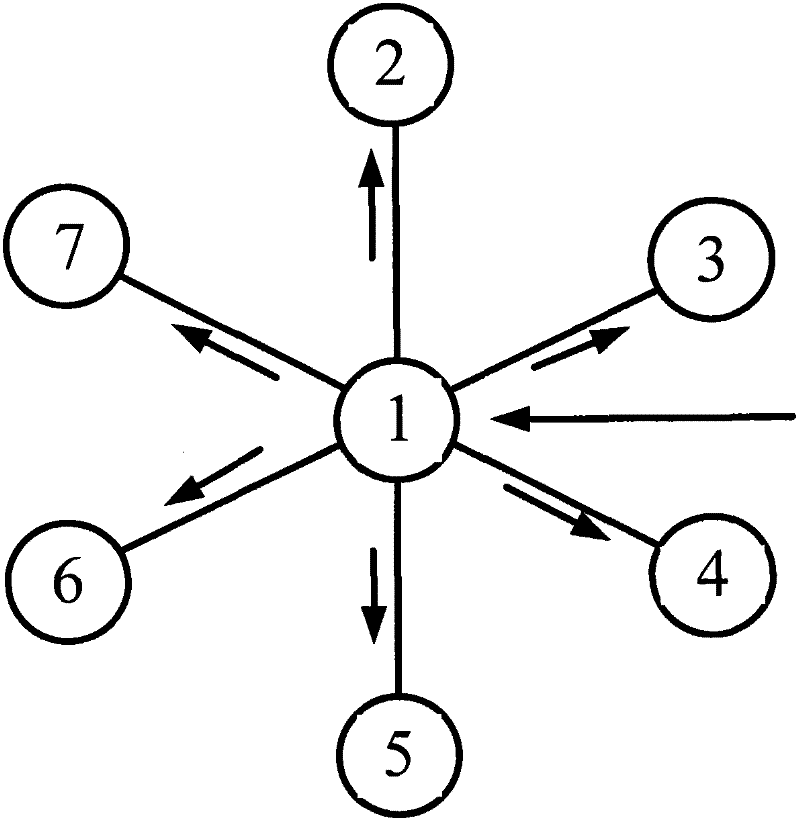

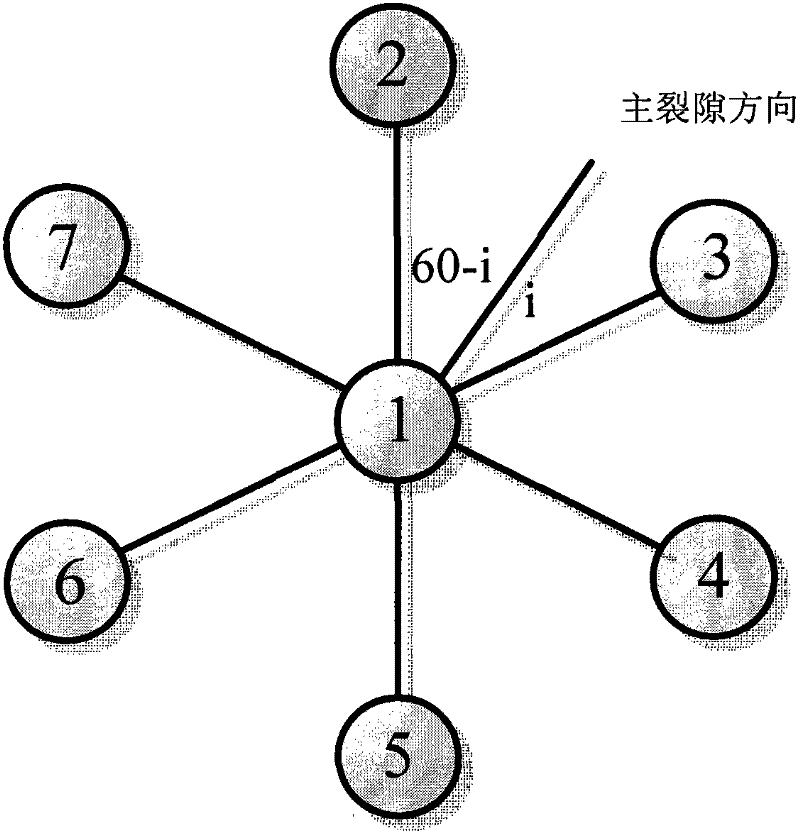

Method for determining coal bed fractures

ActiveCN102477856AReduce difficultyShorten the timeConstructionsFluid removalBreakthrough timeProduct gas

The invention discloses a method for guiding the layout of gasification furnaces for underground coal gasification and determining the directions of main fractures in underground coal beds. The method comprises the following steps: drilling a central hole above the reserving area of an underground coal bed; drilling a plurality of surrounding holes on a circular layout line centering on the central hole; inputting pressurized air from the central hole to the underground coal bed so as to carry out high-pressure air fracturing; monitoring and determining the flow and components of gas discharged from each surrounding hole; carrying out comparison on the determined flow of each discharged gas, determining the position of a first surrounding hole with the largest flow of discharged gas, and determining the position of a second surrounding hole with the second-largest flow of discharged gas; and according to a formula provided by the invention, carrying out calculation on the angles of the main fractures. The practical and economical method provided by the invention can be used for shortening the breakthrough time for underground coal-bed gasification, and reducing the breakthrough difficulty of underground coal-bed gasification.

Owner:ENN SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com