Underground coal gasification system and gasification method

An underground gasification and coal technology, applied in coal gasification, underground mining, construction, etc., can solve the problems of reduced gasification efficiency, water vapor can not be effectively used, and gasifier production time is long, so as to improve the efficiency of gasification. The effect of reducing the production time, shortening the time to production, and reducing the amount of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

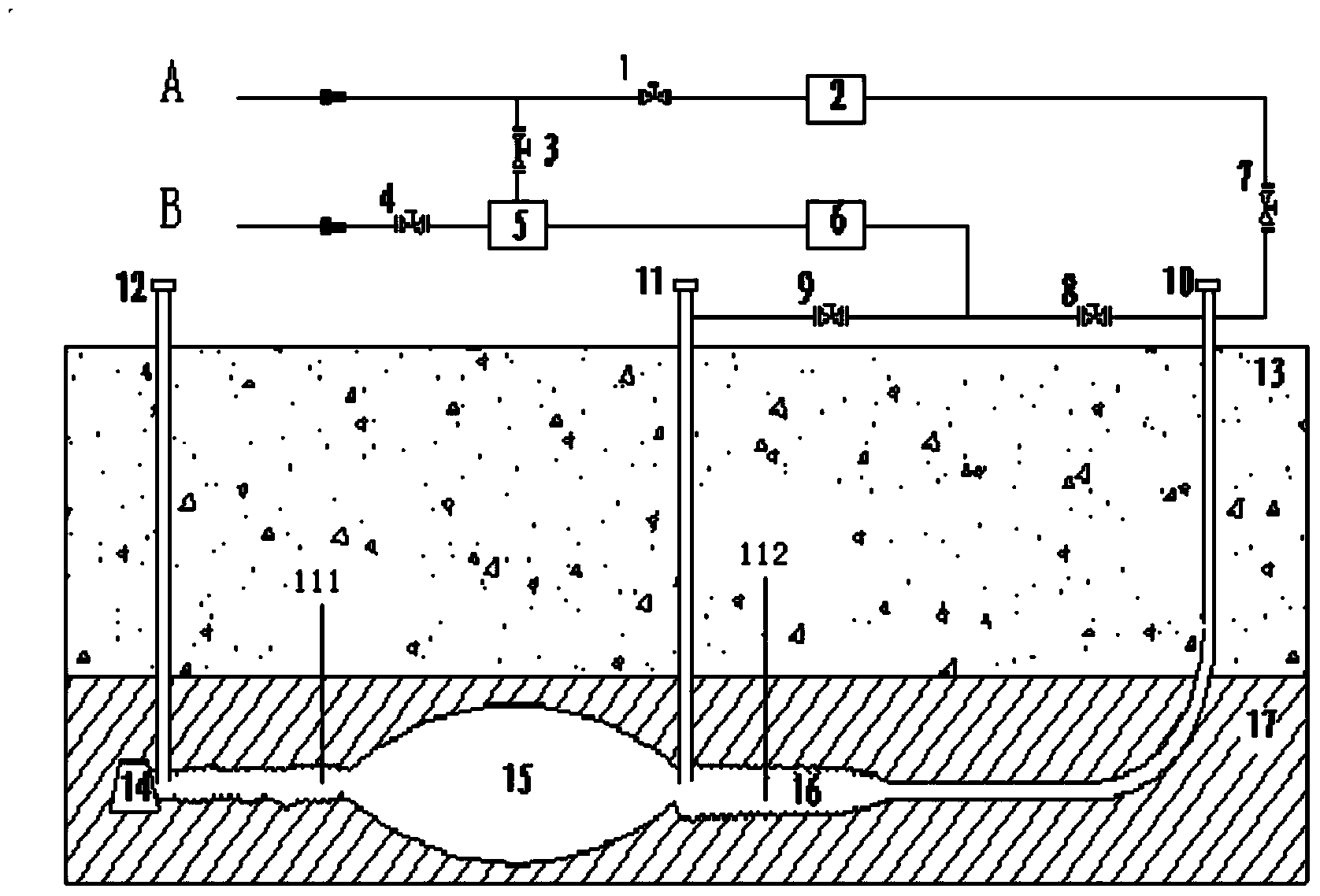

[0019] figure 1 A schematic diagram of an embodiment of the underground coal gasification system of the present invention is shown. As shown in the figure, an underground coal gasification system is shown. The system includes a first channel 111 located in the coal seam 17, the two ends of the first channel 111 are respectively connected to the air outlet hole 12 and the auxiliary hole 11; and a second channel 112 is also included, and the two ends of the second channel 112 are respectively connected to the auxiliary hole 11 and the directional hole 10. The combustion oxidizer is fed through the directional hole 10, so that the second channel 112 forms a reverse through area; the gasification agent is fed through the auxiliary hole 11, so that the first channel 111 forms a forward gasification area.

[0020] The positions of air outlet hole 12, auxiliary hole 11 and orientation hole 10 are according to figure 1 Arrangement shown in positional relationship. Therefore, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com