Cooling substrate of micro heat pipe

A technology of heat dissipation substrate and micro heat pipe, applied in cooling/ventilation/heating transformation, electrical components, electric solid-state devices, etc., can solve the problems of unfavorable integration and miniaturization, increase design complexity, increase extra cost, etc., and achieve no maintenance. , High heat dissipation efficiency, temperature controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

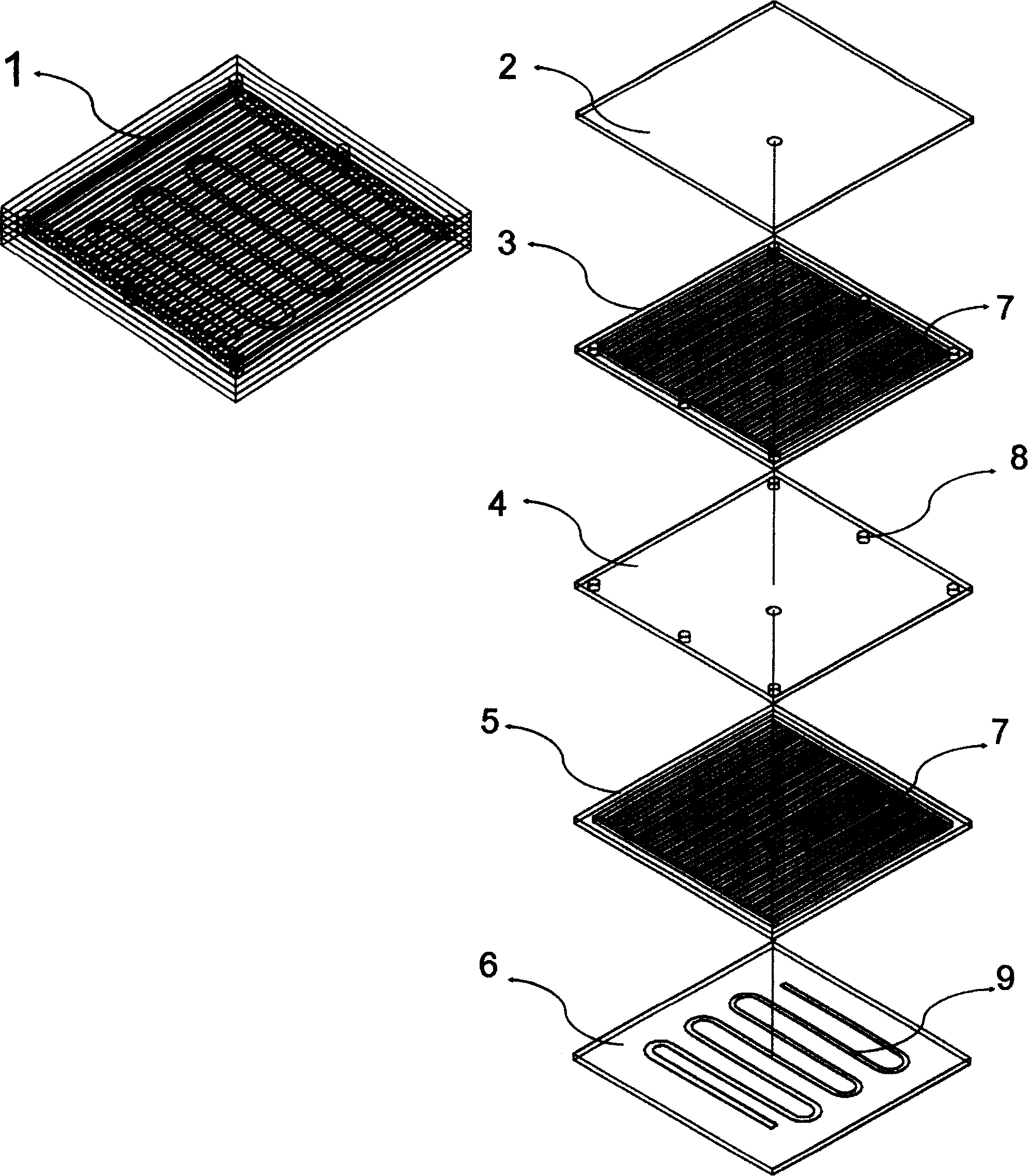

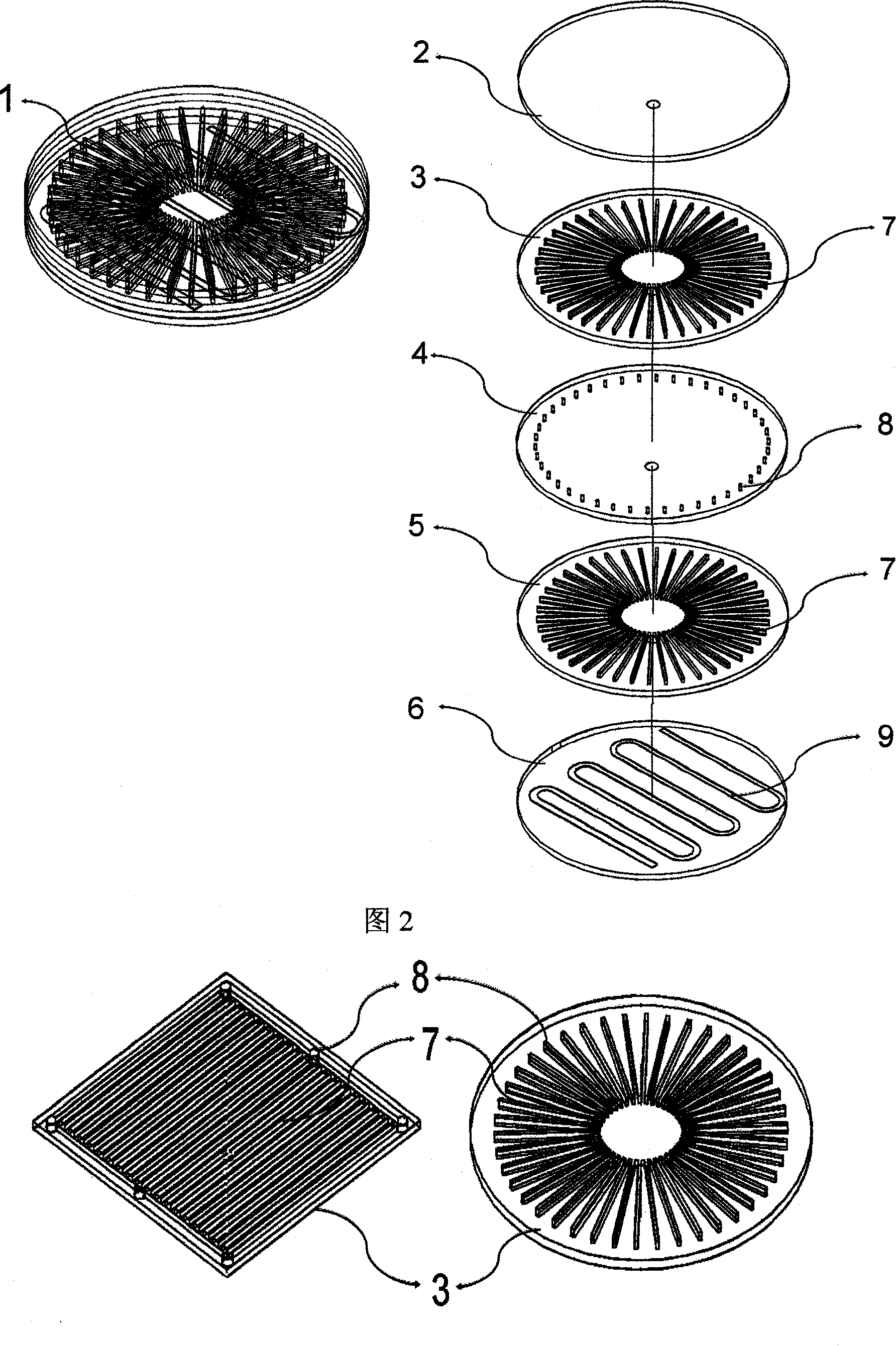

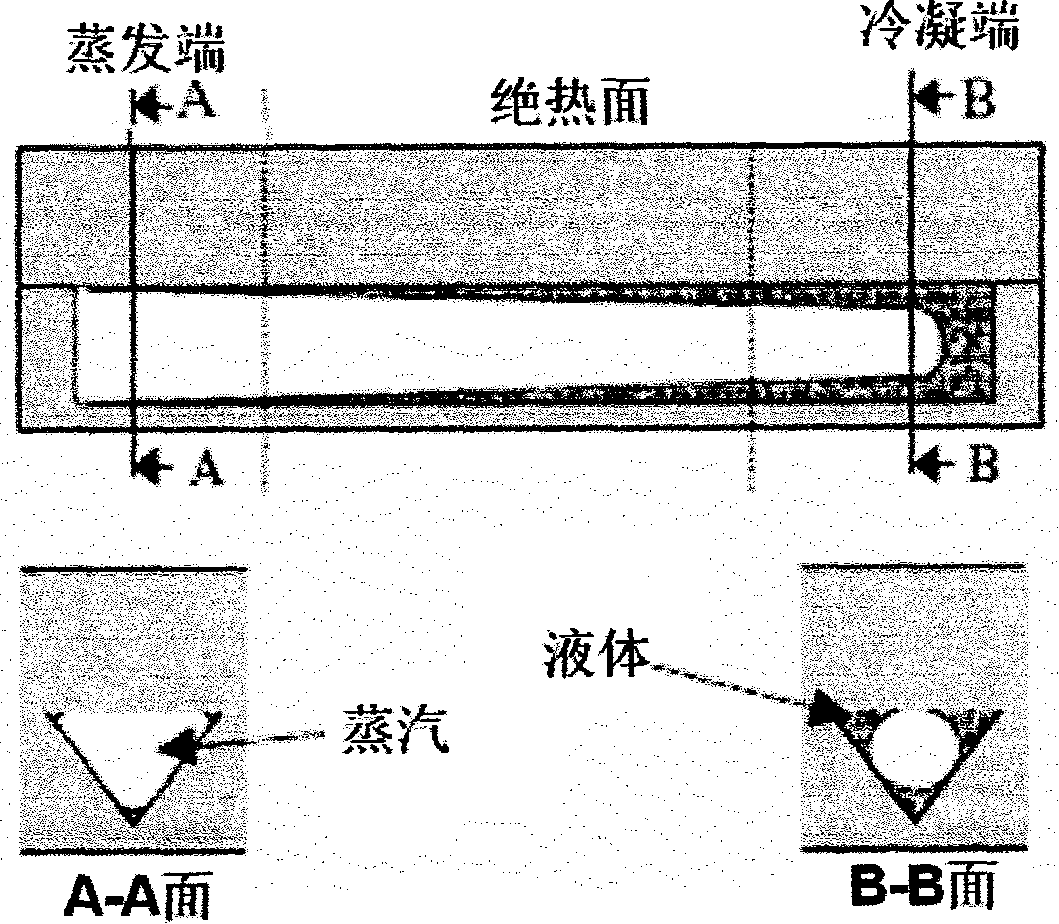

[0023] figure 1 Among them, the left figure is a schematic diagram of the entire micro heat pipe heat dissipation substrate 1 , and the right figure is a structure diagram of each layer of the micro heat pipe heat dissipation substrate 1 . The heat dissipation substrate 1 of the micro heat pipe is composed of 5 layers, and the top ceramic layer 2 is a ceramic sheet with high thermal conductivity, which can be made into a cup and bowl shape required for circuit or LED packaging. The second layer is a ceramic sheet (or metal sheet) heat dissipation layer 3 with a micro-heat pipe structure array, on which there is a rectangular micro-heat pipe 7 structure array, and its edge forms a passage with the lower micro-heat pipe through a communication pipe 8. The third layer is a heat-insulating ceramic layer 4, the purpose of which is to form a hot end and a cold end of the upper and lower layers of micro-heat pipe cooling layers, and its internal communication pipe 8 enables the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com