Patents

Literature

215 results about "Micro-loop heat pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

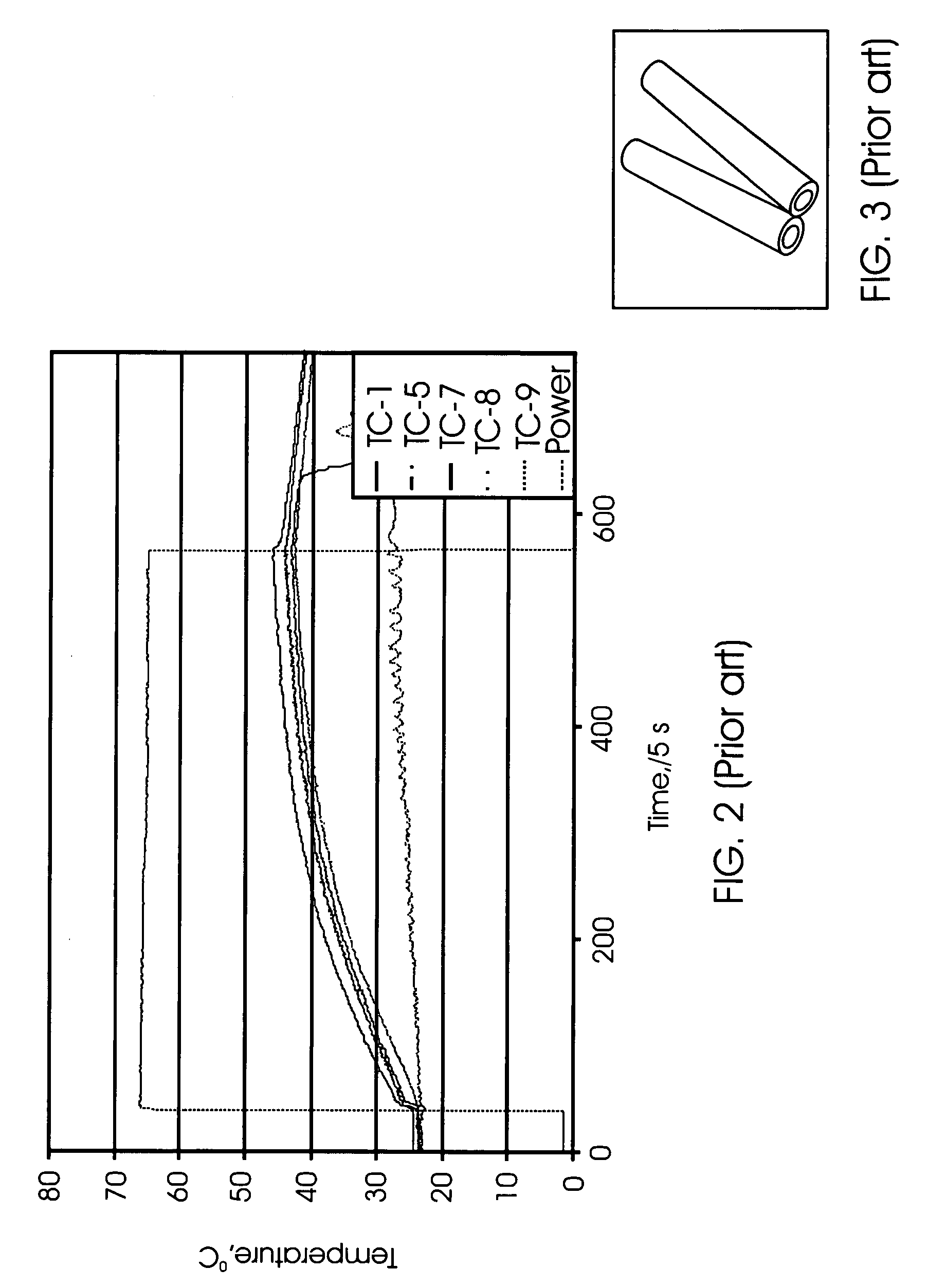

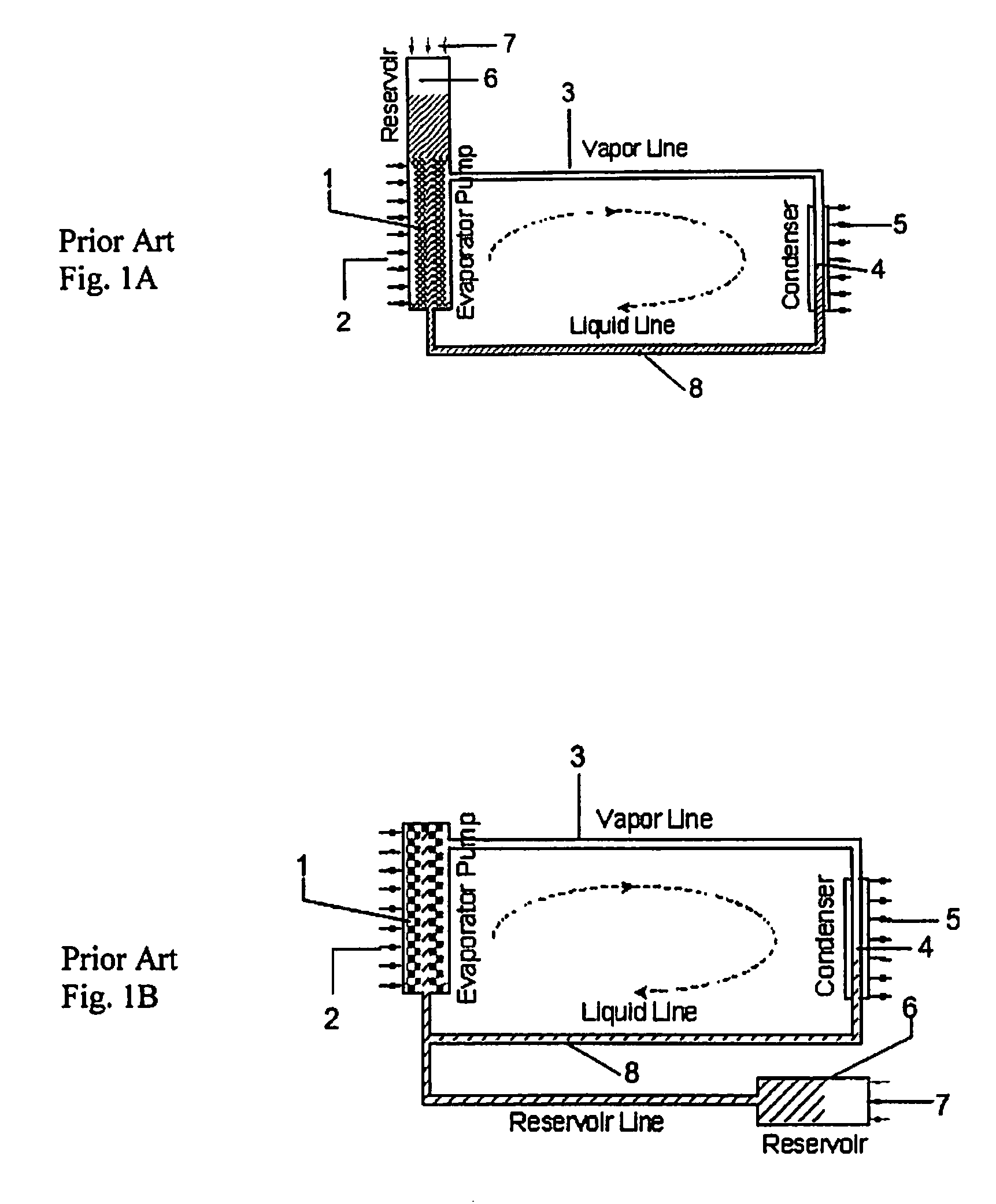

A micro-loop heat pipe or MLHP is a miniature loop heat pipe in which the radius of curvature of the liquid meniscus in the evaporator is in the same order of magnitude of the micro grooves' dimensions; or a miniature loop heat pipe which has been fabricated using microfabrication techniques.

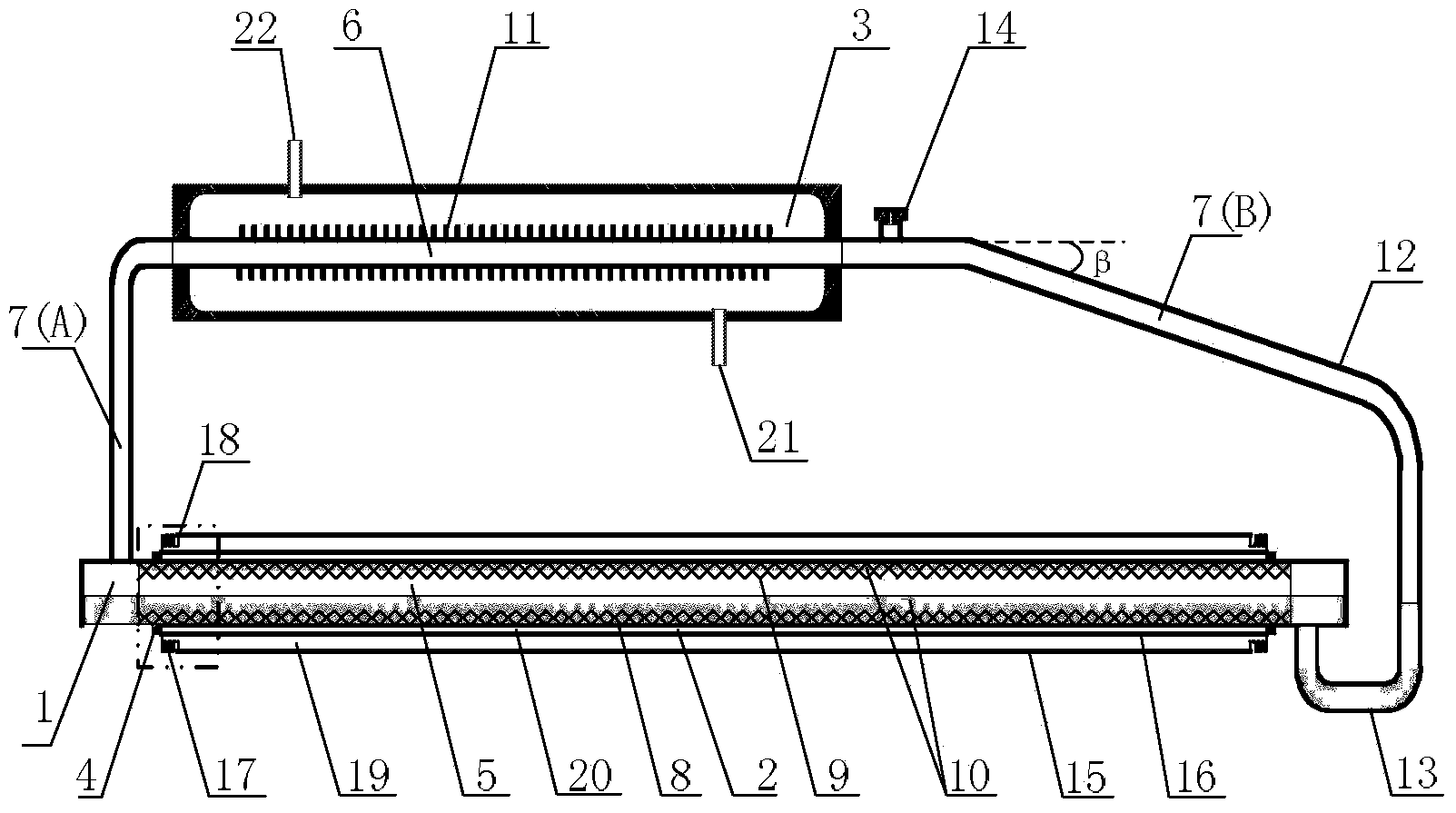

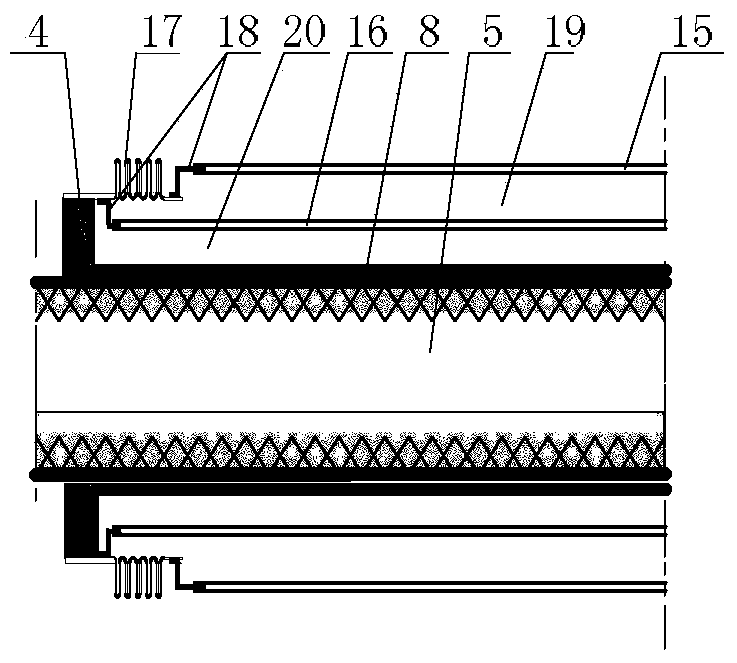

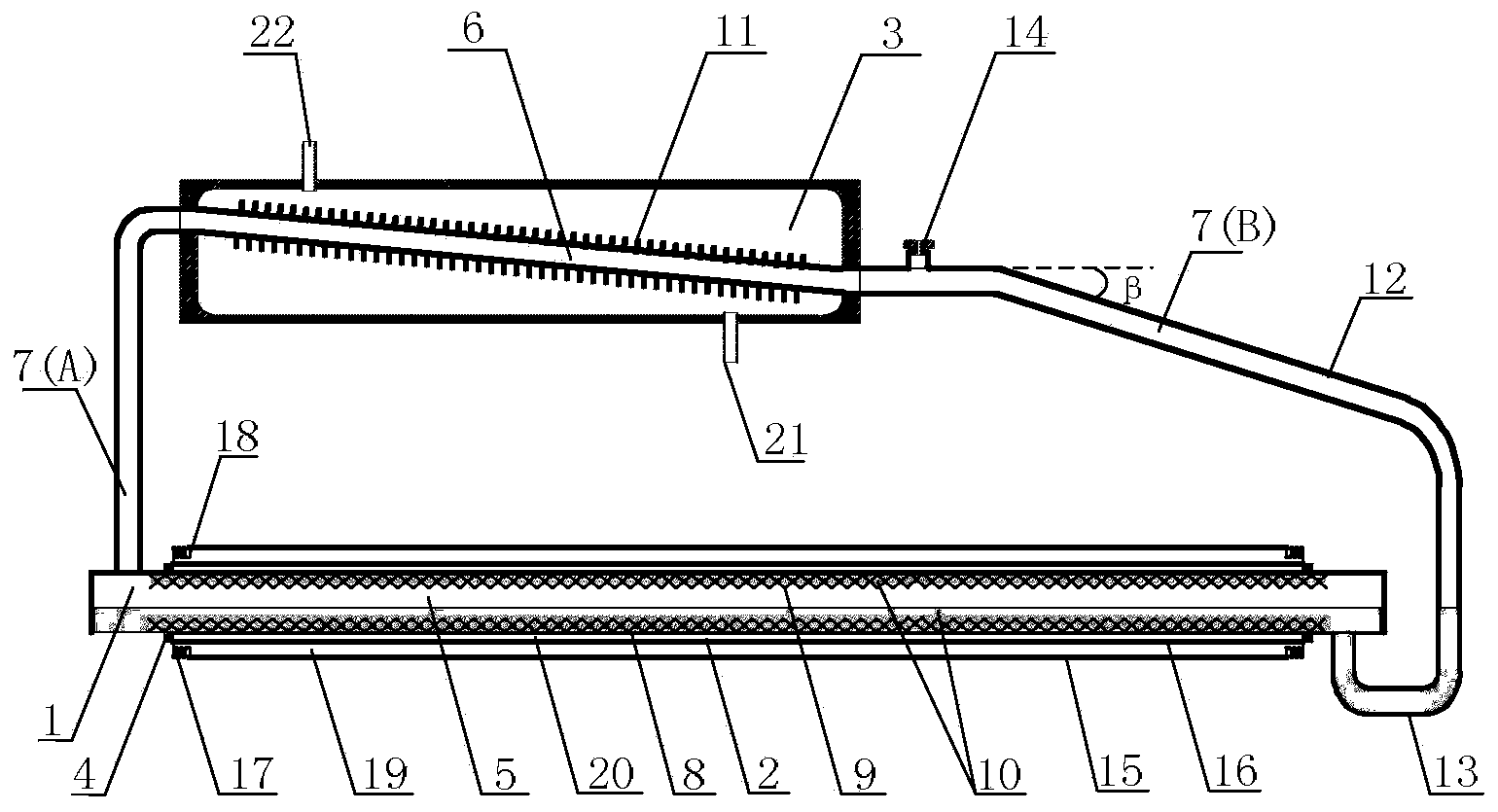

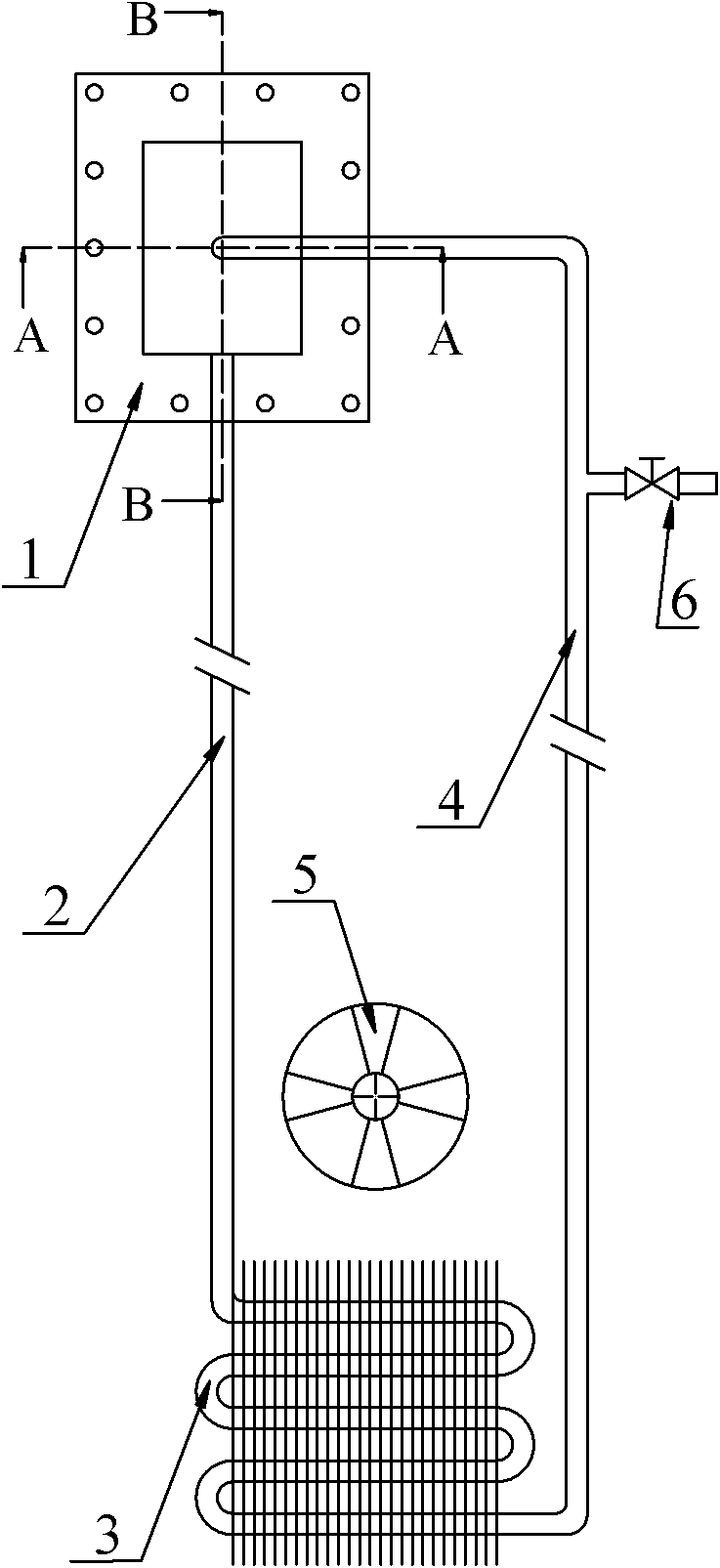

Solar medium-high-temperature loop heat pipe steam generator

ActiveCN104279770ALow costImprove reliabilitySolar heating energySteam generation heating methodsMicro-loop heat pipeEvaporation

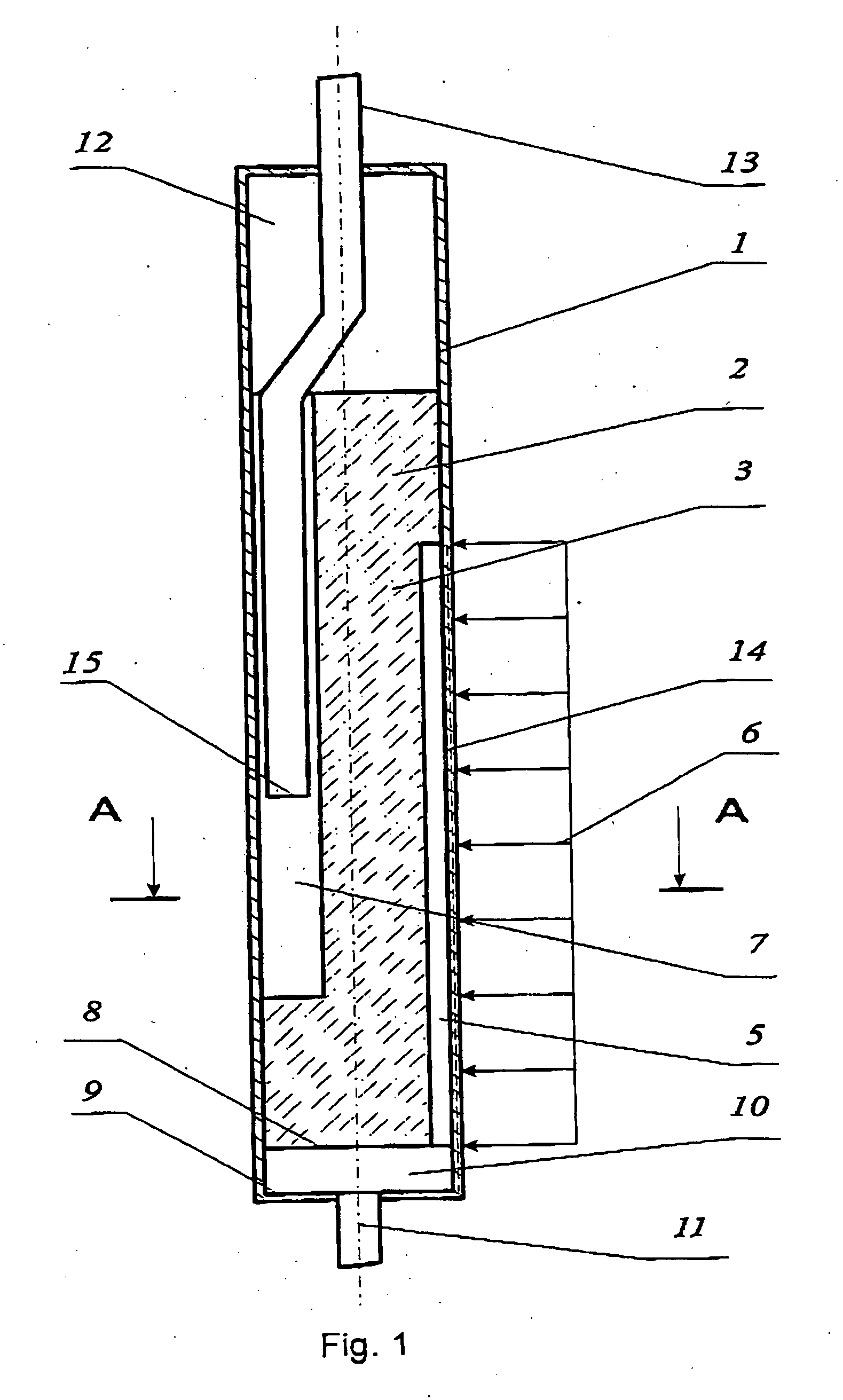

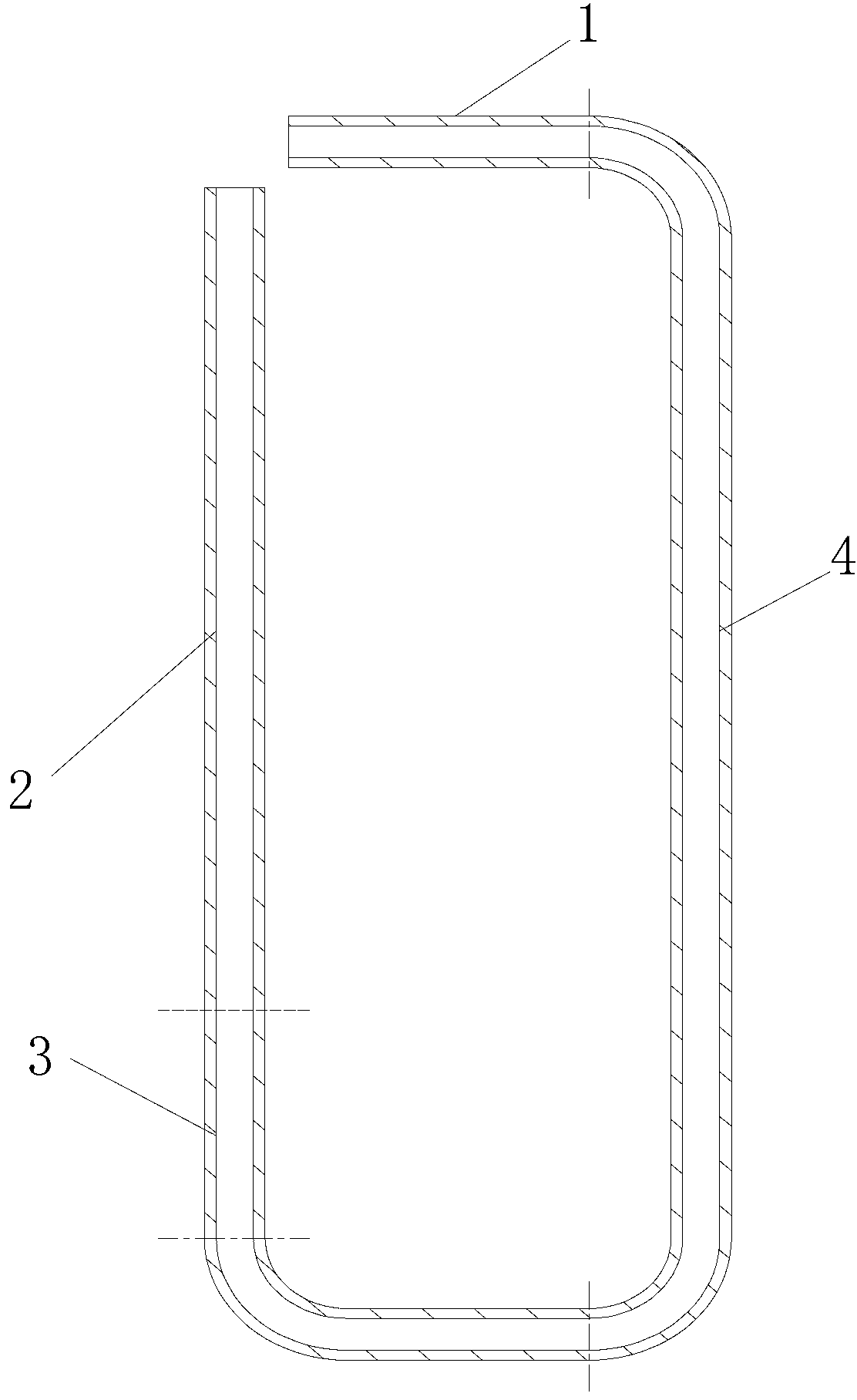

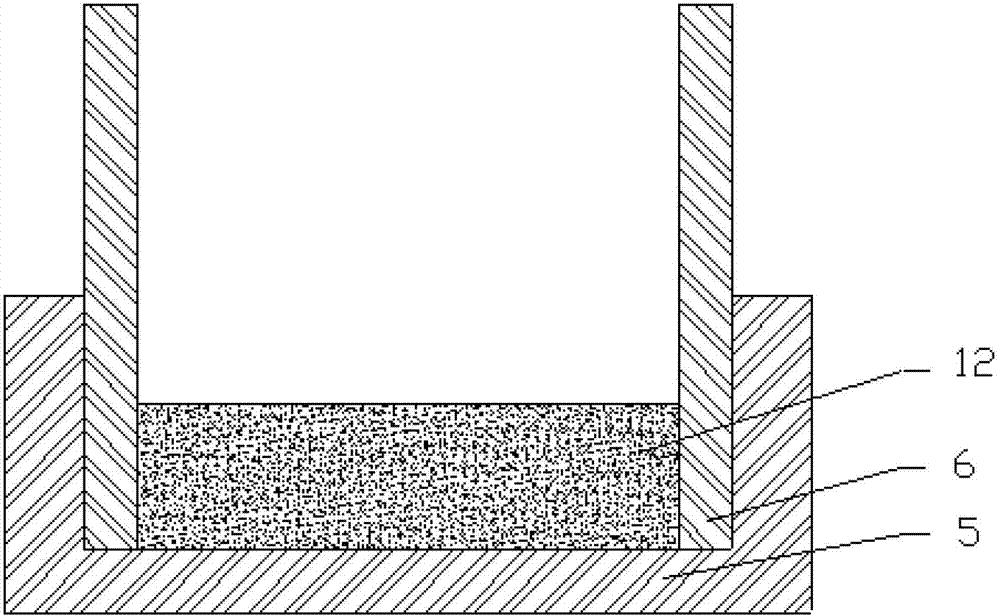

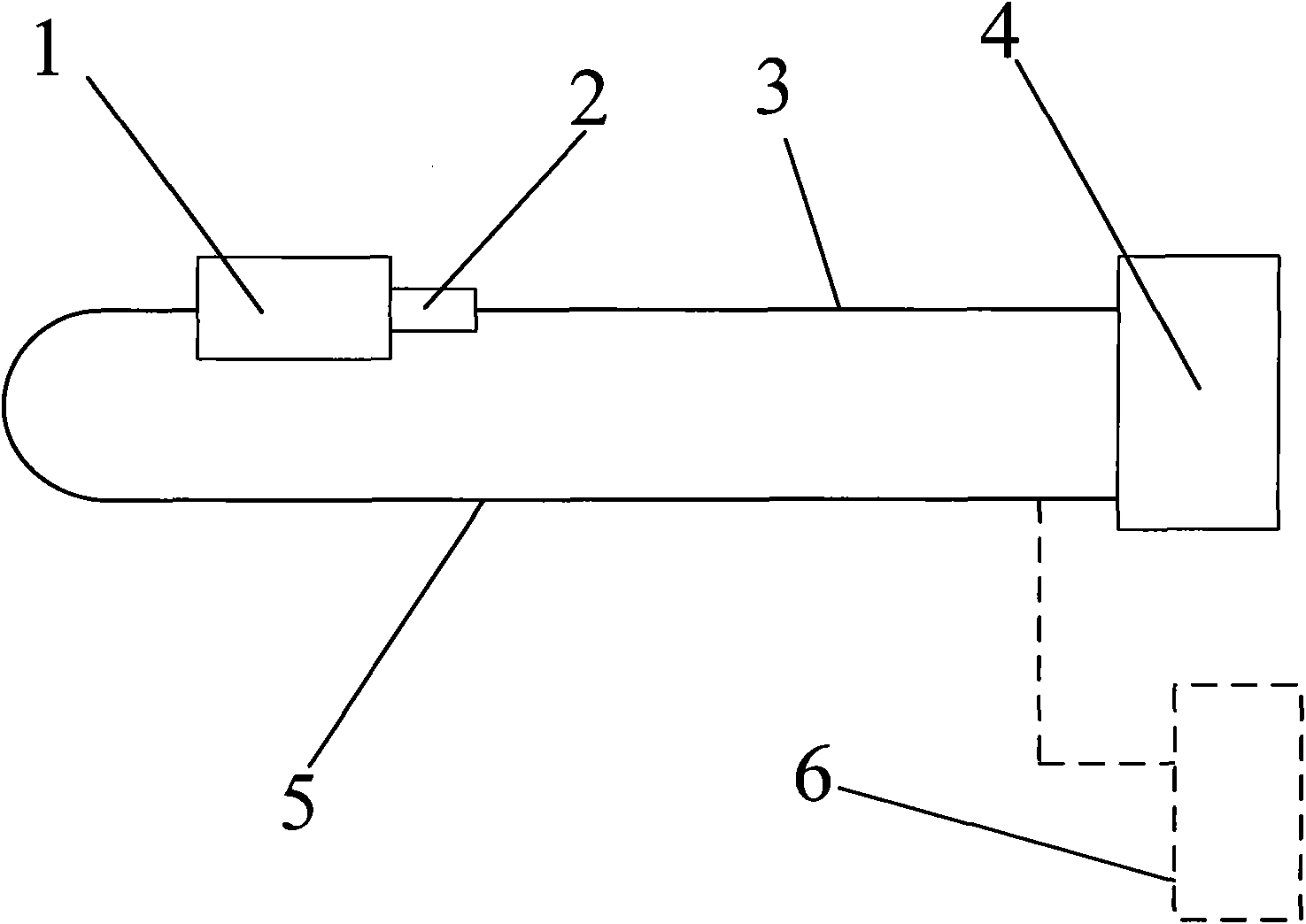

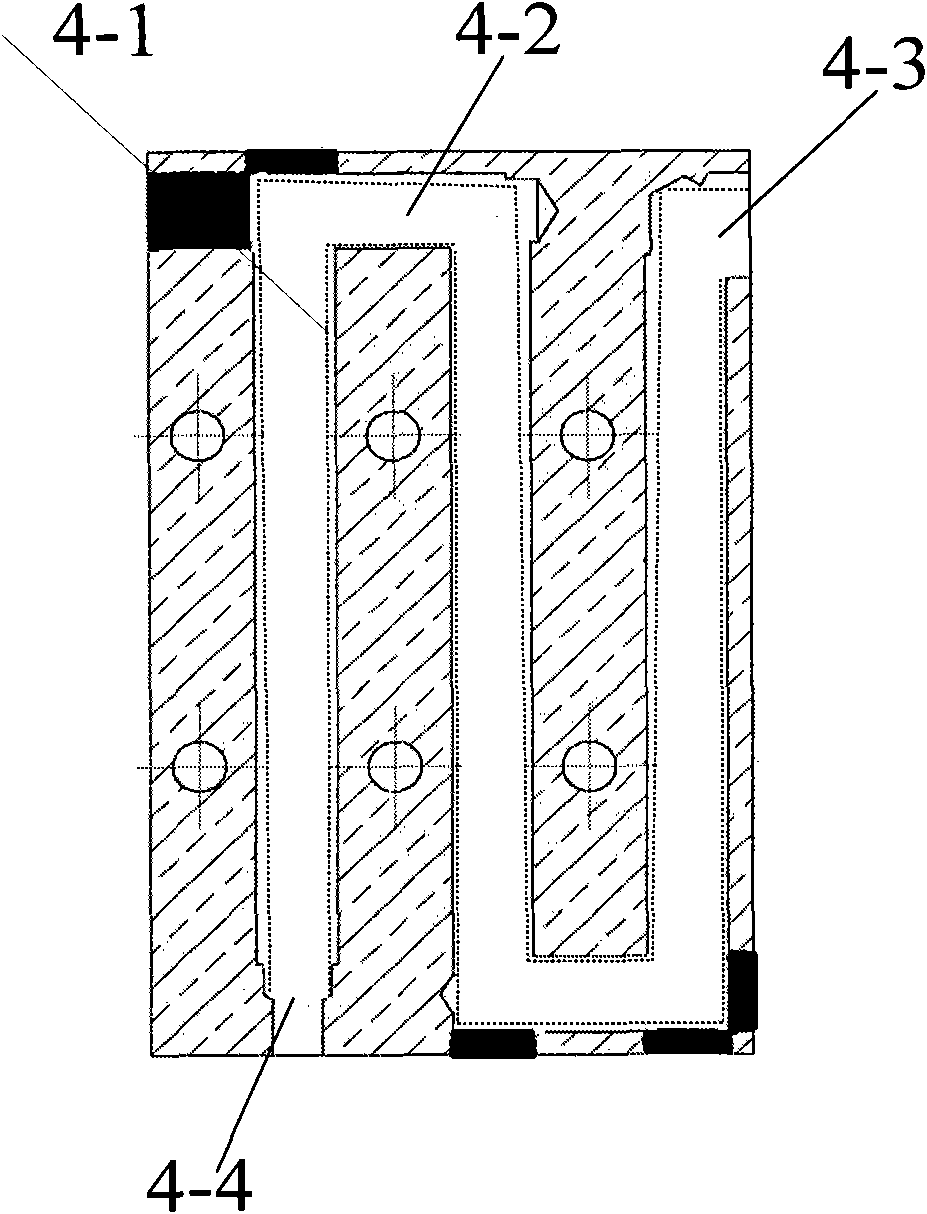

The invention relates to a solar medium-high-temperature loop heat pipe steam generator which is composed of a loop heat pipe (1), a straight-through all-glass vacuum pipe (2), a steam pocket (3) and a sealing ring (4). The loop heat pipe (1) is a closed loop formed by an evaporation section (5), a condensation section (6), a first heat insulation section (7(A)) and a second heat insulation section (7(B)), the first heat insulation section (7(A)) is a steam ascending pipe, the second heat insulation section (7(B)) is formed by a condensing liquid descending pipe (12) and a U-shaped liquid storage pipe (13), the straight-through all-glass vacuum pipe (2) and the evaporation section (5) are placed coaxially to form an annular non-vacuum space (20), two ends of the annular non-vacuum space (20) are sealed by adopting sealing rings (4), and the steam pocket (3) is in sealed connection with the condensation section (6) of the loop heat pipe (1). The solar medium-high-temperature loop heat pipe steam generator is suitable for groove-type solar DSG technology, high-efficiency phase change of the heat pipe is utilized for heat transfer to heat water in the steam generator so as to directly generate high-temperature steam, system cost is lowered, and system running reliability is improved.

Owner:NANJING UNIV OF TECH

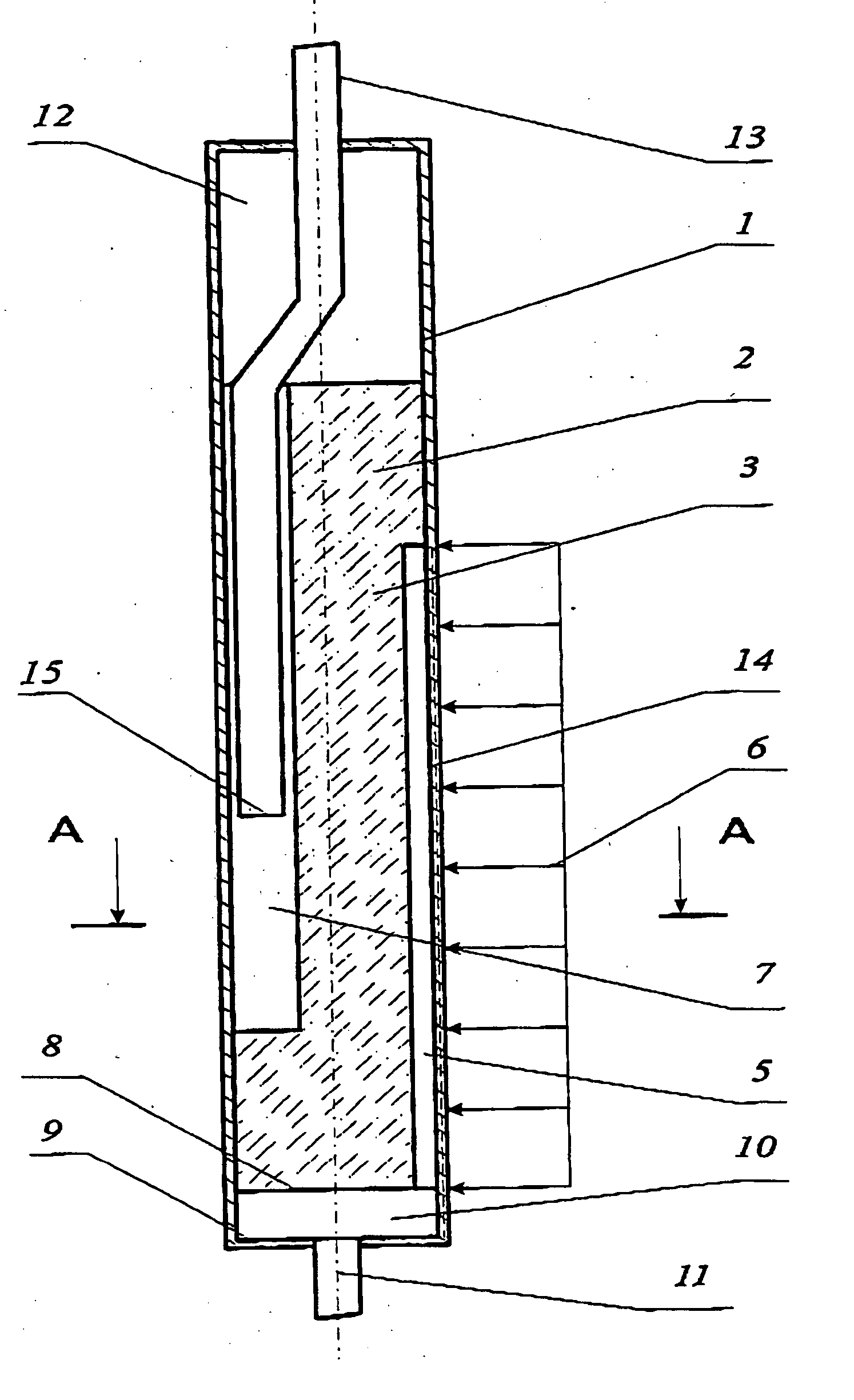

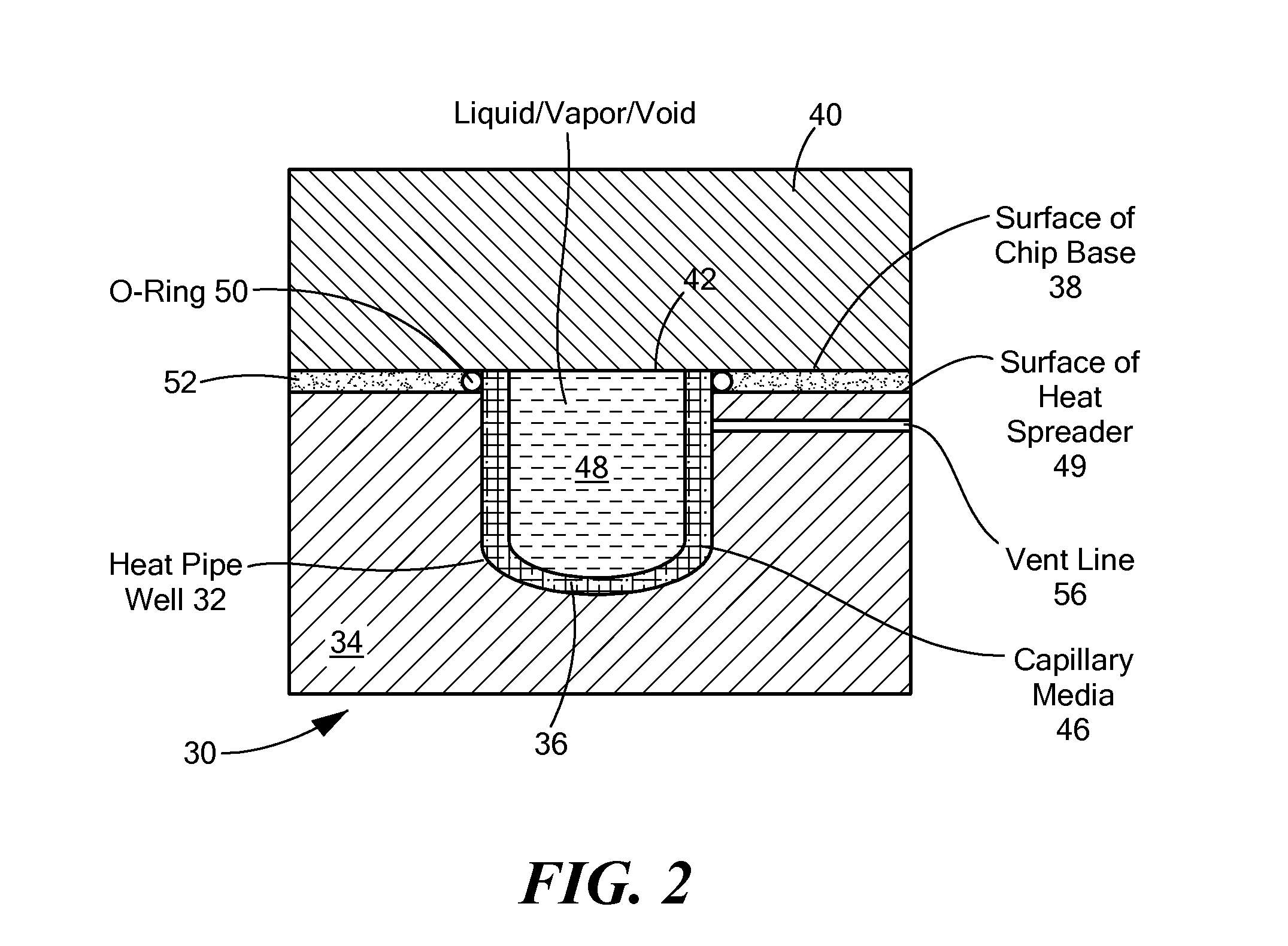

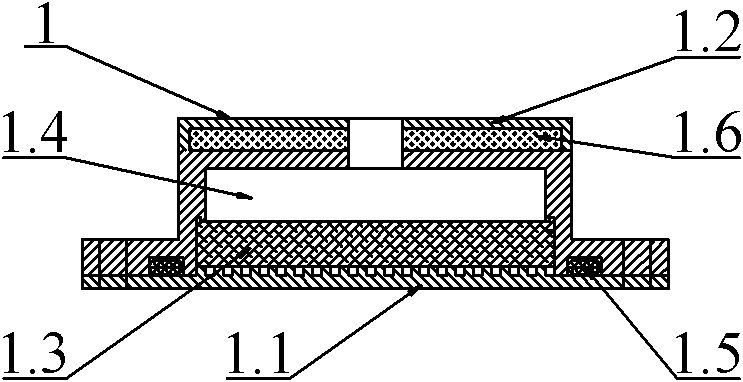

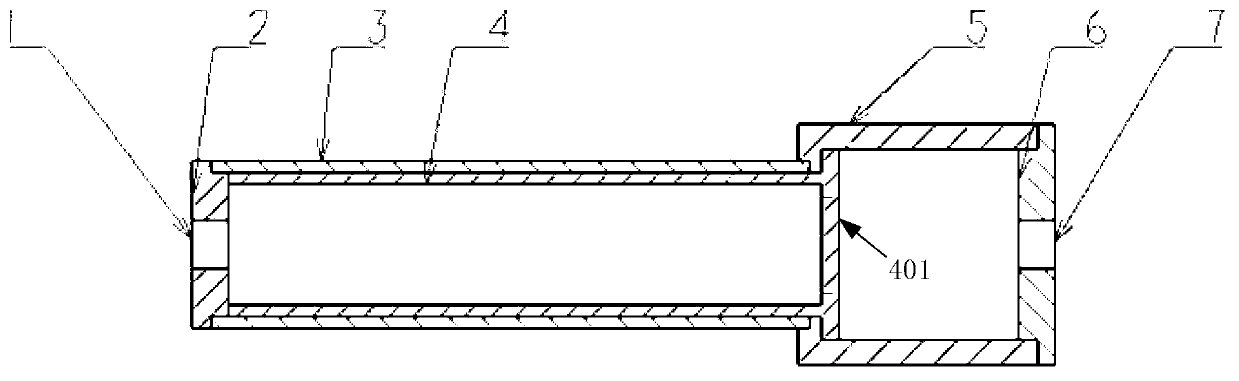

Evaporation chamber for a loop heat pipe

InactiveUS20040206480A1Decrease in parasitic heat leakageIncrease heat loadAir-treating devicesSemiconductor/solid-state device detailsMicro-loop heat pipeCapillary Tubing

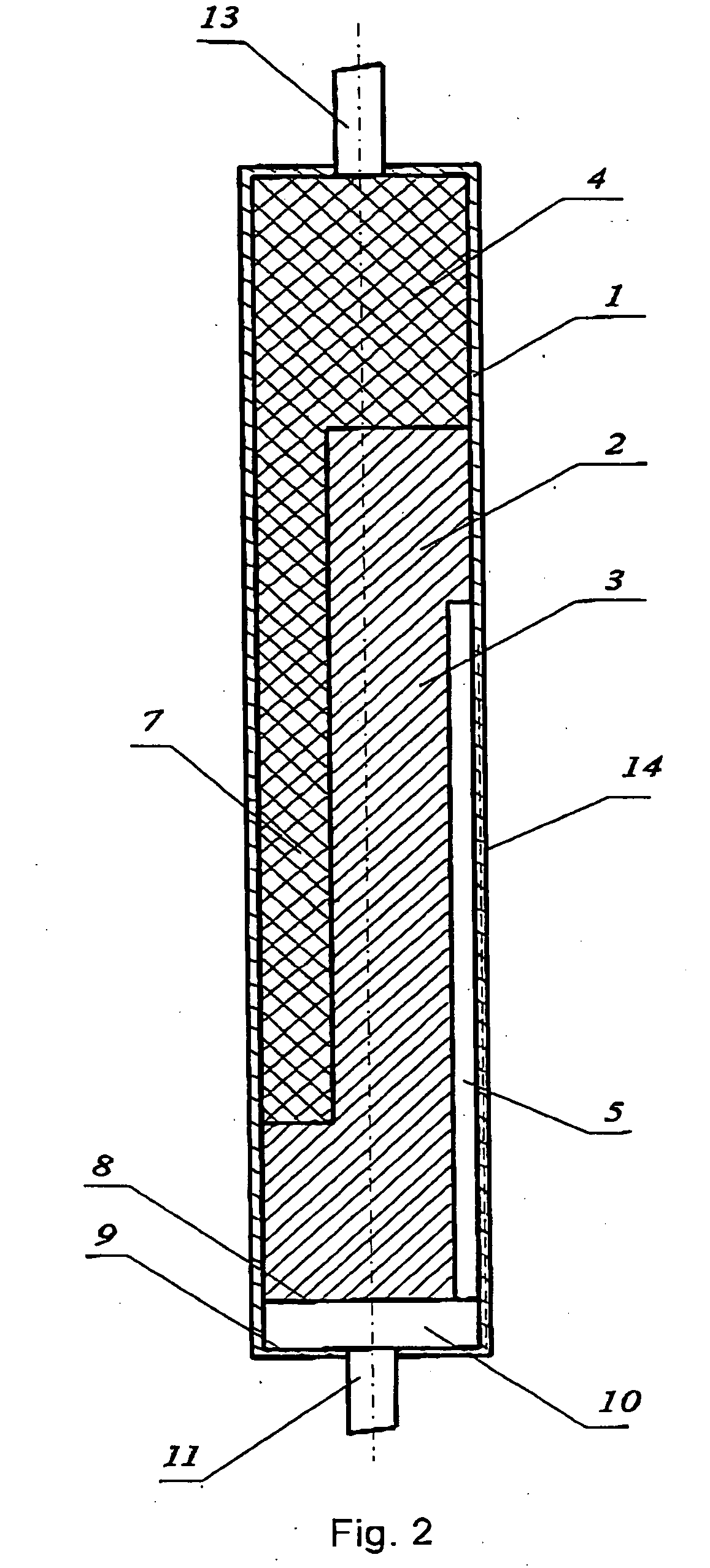

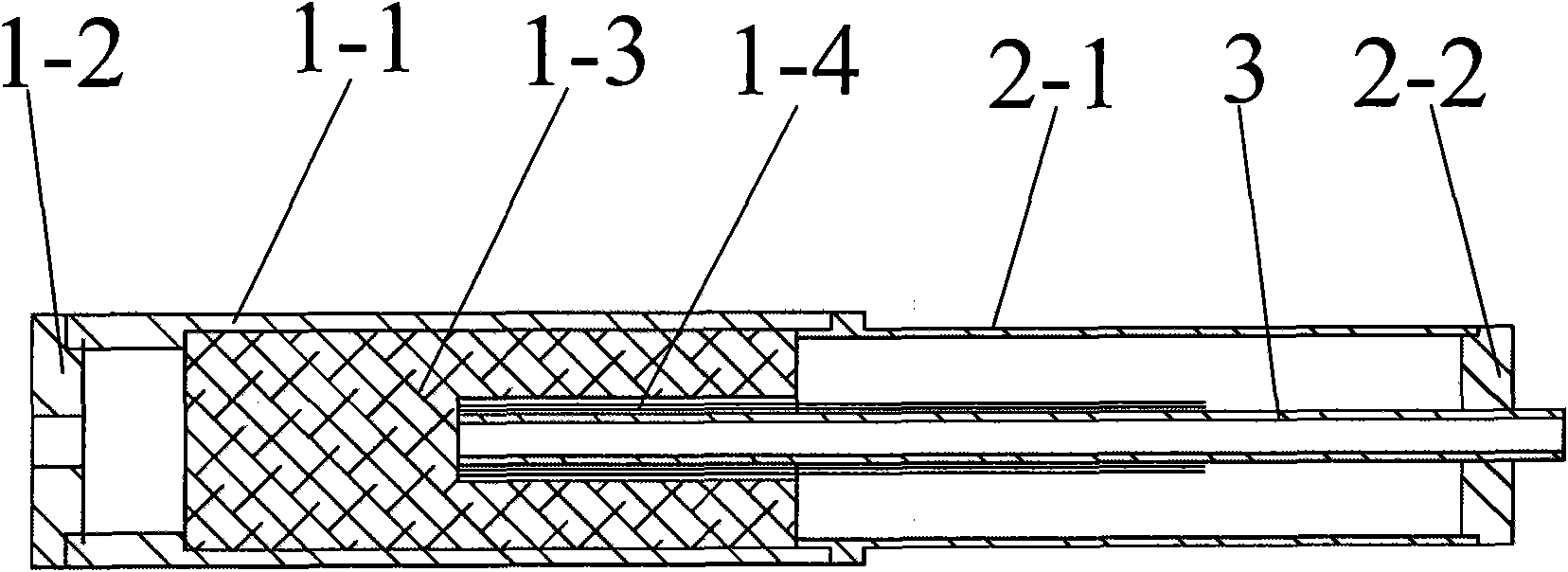

The invention relates to heat engineering, in particular to heat pipes, and may be used for heat removal from miniature heat-tensioned objects, in particular elements of radioelectronic devices and computers requiring effective heat removal within minimum dimensions of a cooling system. The invention is aimed at increasing a heat load of the evaporating chamber at a given operating temperature and reducing its dimensions. For this purpose, in the evaporating chamber of a loop heat pipe comprising a body that includes side and end-face walls and a capillary porous packing accommodated in said body and having vapor-removal channels tied together by a vapor collector, and disposed on a portion of the packing perimeter at the heat-supply side, and having an asymmetrical longitudinal opening shifted in the direction opposite to the heat supply, the end-faces of the vapor-removal channels being blind at one side, the asymmetrical longitudinal opening is also being blind at the side opposite to the blind end-faces of the vapor-removal channels, and the vapor collector is formed by one of the end-face walls of the body and the packing end-face. Besides, on the inner side surface of the body, additional vapor-removal grooves are provided. Cross-section of the asymmetrical longitudinal opening may have the form of a rectangle elongated in the direction of the heat supply and limited at the opposite side by a body wall, or the form of a wedge, whose apex faces the heat supply and whose base is a body wall, or the form of a segment, whose chord is directed towards the heat supply and the arc is a body wall, or the form of a circle limited by a capillary porous packing and whose center is shifted in the direction opposite to the heat supply. Cross-section of the evaporating chamber may be made rectangular, the asymmetrical longitudinal opening, which has the form of a slot gap being shifted in the direction opposite to the heat supply. The capillary porous packing may consist of two interconnected parts. The outlet of the condensate line is positioned in the asymmetrical longitudinal opening of the capillary porous packing.

Owner:MICROWAY

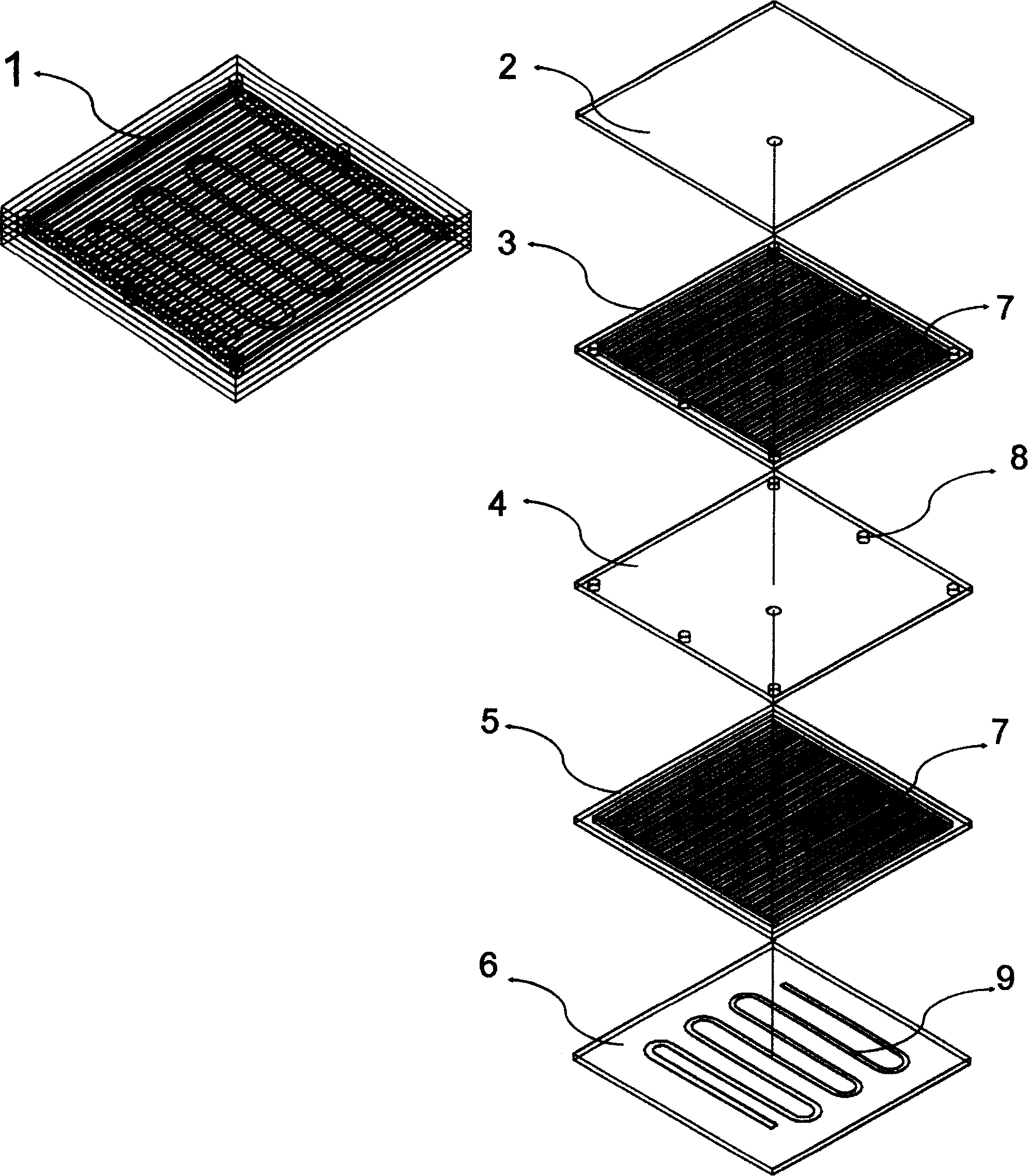

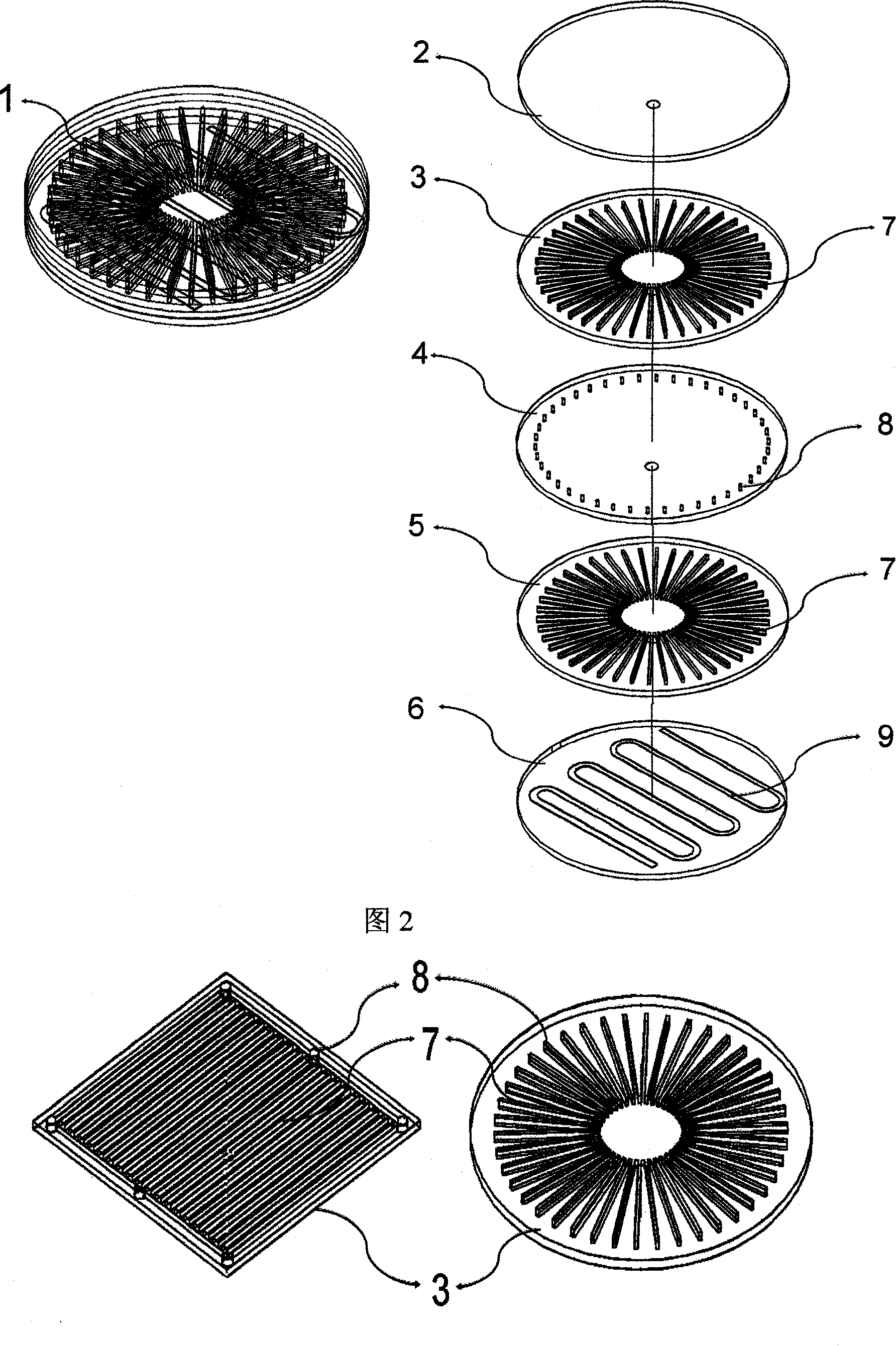

Multi-layer wick in loop heat pipe

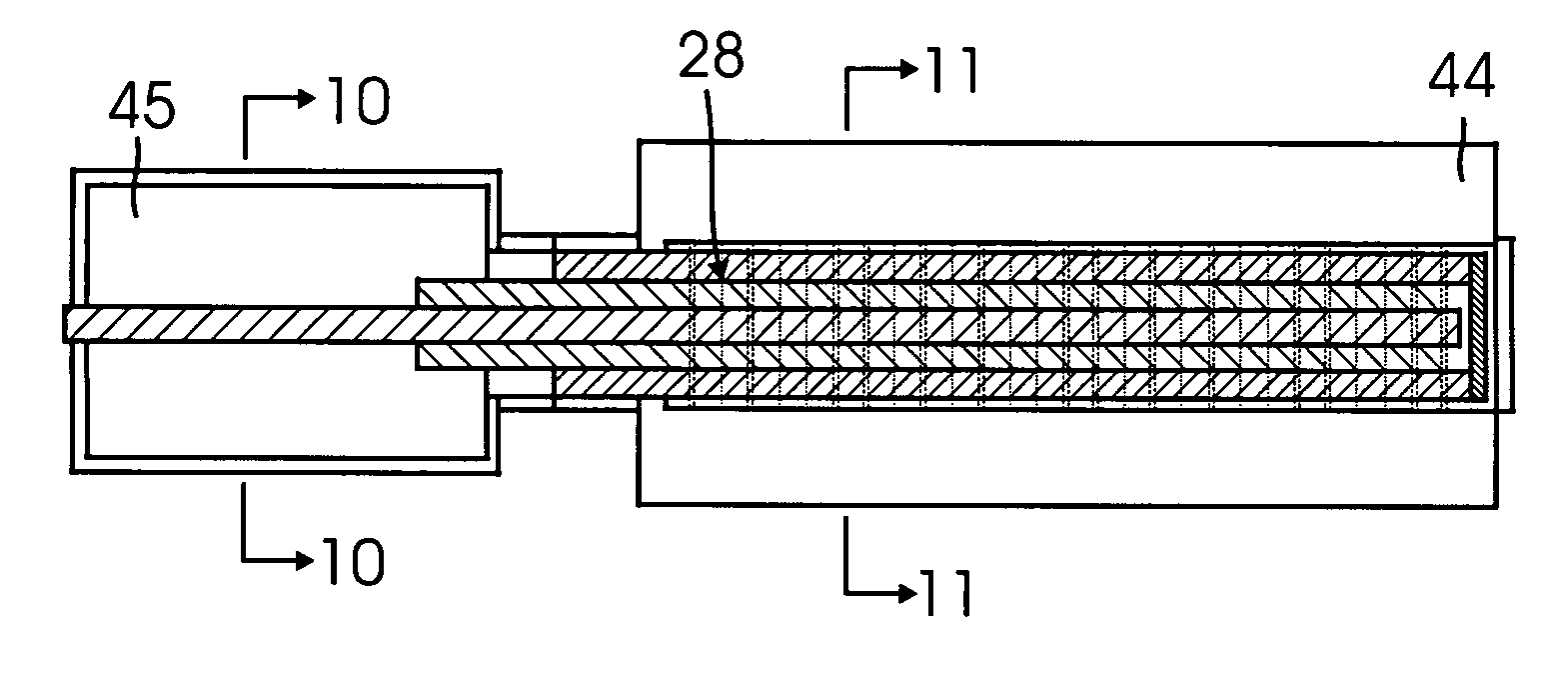

In one aspect of the present invention, a multi-layer wick for a loop heat pipe is provided. The multi-layer wick includes a primary wick, the primary wick comprising: a first layer; and a second layer, wherein the first layer surrounds the second layer; and a secondary wick, wherein the second layer of the primary wick surrounds the secondary wick.In another aspect of the present invention, a method of fabricating a multi-layer wick is provided. The method includes machining the outer diameter of an inner layer larger than the inner diameter of an outer layer; heating the outer layer to enlarge the inner diameter; inserting the inner layer into the outer layer; and cooling the inner layer and the outer layer.

Owner:THE BOEING CO

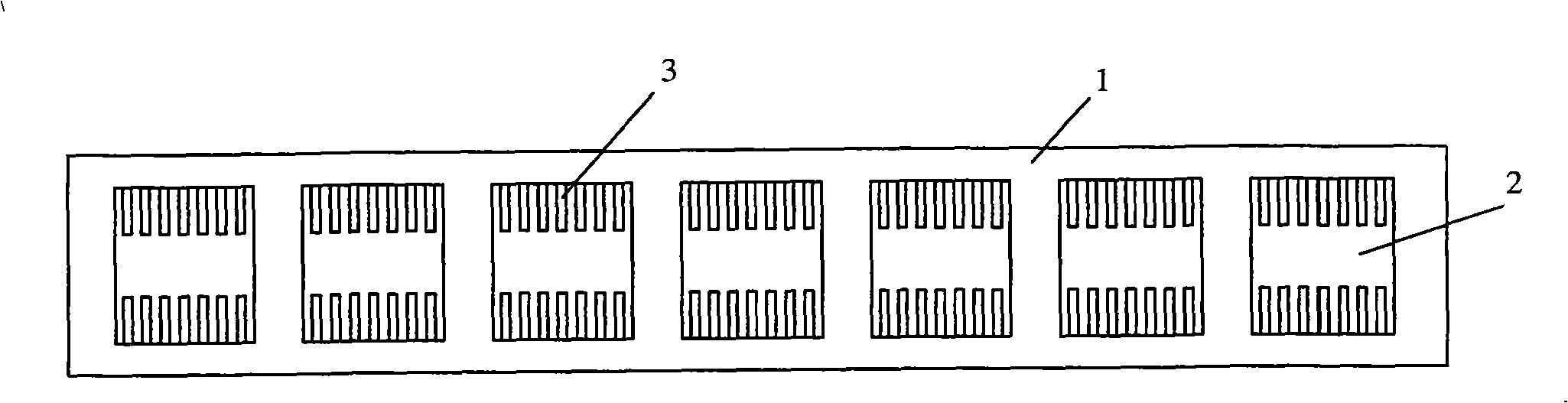

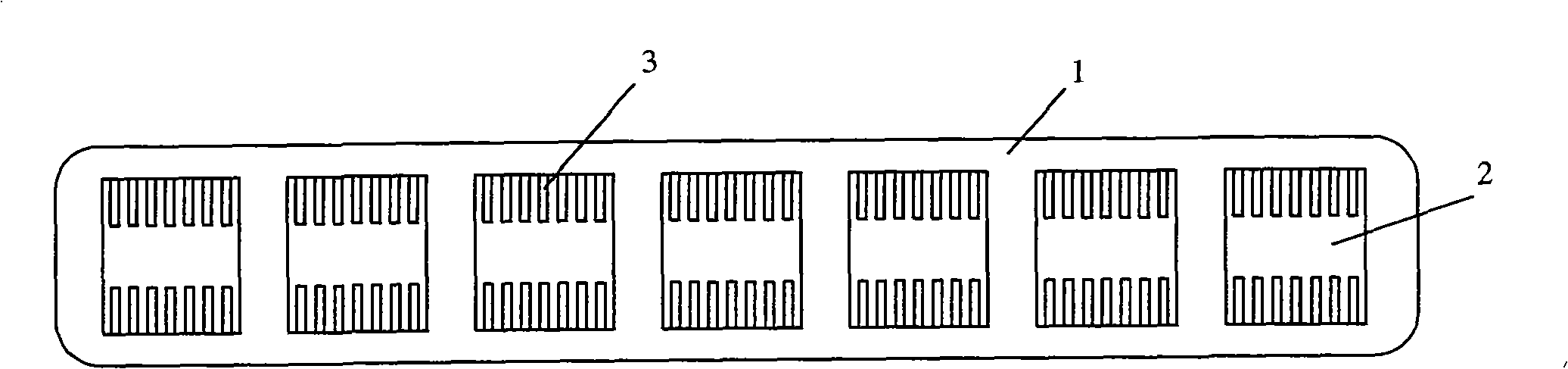

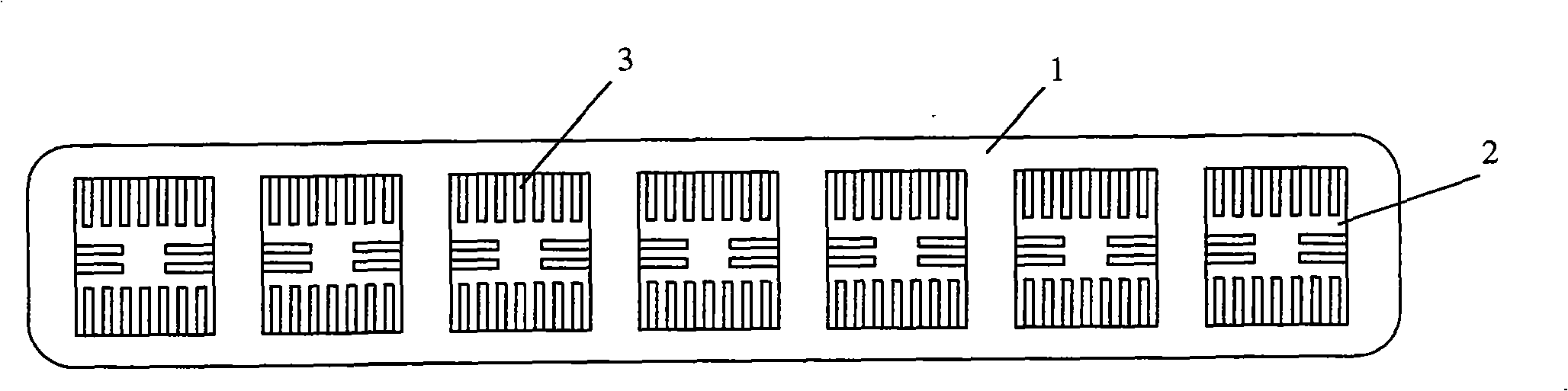

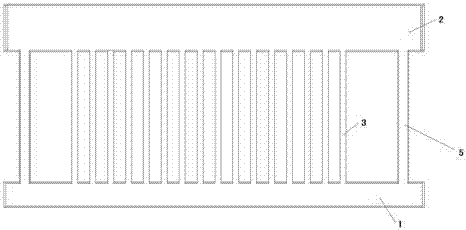

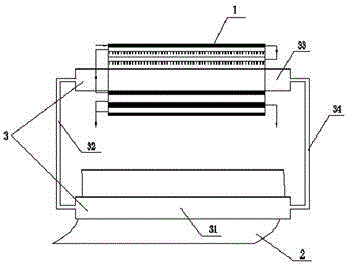

Novel flat-plate heat pipe with stratose microflute subfebrile temperature tube group

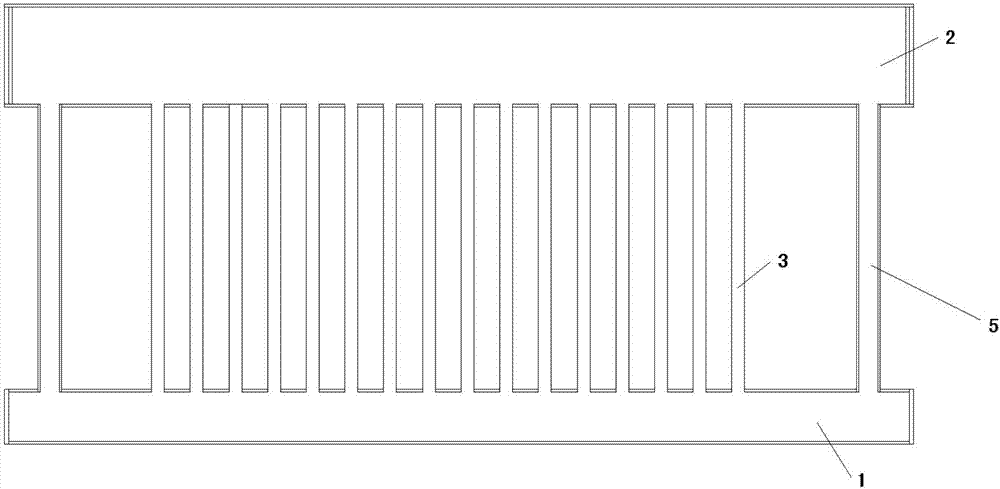

ActiveCN101493296AImprove thermal efficiencyImprove heat transfer efficiencyIndirect heat exchangersTubular elementsMicro-loop heat pipeHeat conducting

The invention relates to the technical filed of heat exchange, in particular to a novel flat thermotube with a stratose microflute micro heat pipe group, comprising a metal flat formed by integral extrusion, more than one array through hole arranged side by side is arranged in the flat thermotube; a plurality of micro-fins made from heat conducting material are arranged at the inner wall of the through hole in sequence; a capillary microflute is formed between adjacent micro-fins; the through hole is filled with working substance to form a micro heat pipe; two ends are enclosed to form the integral flat thermotube. The flat thermotube is completely formed by extrusion; the flat thermotube has both simple structure and high reliability and is capable of remarkably reducing volume and size of a thermotube system to achieve remarkable miniaturization or micromation so as to result in brand new application and popularization of the thermotube technology in the heat exchange field or the cooling field, thereby having high social and economic values. Meanwhile, the flat thermotube of the invention can be applied to other heat exchange fields to replace the existing various heat exchangers.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

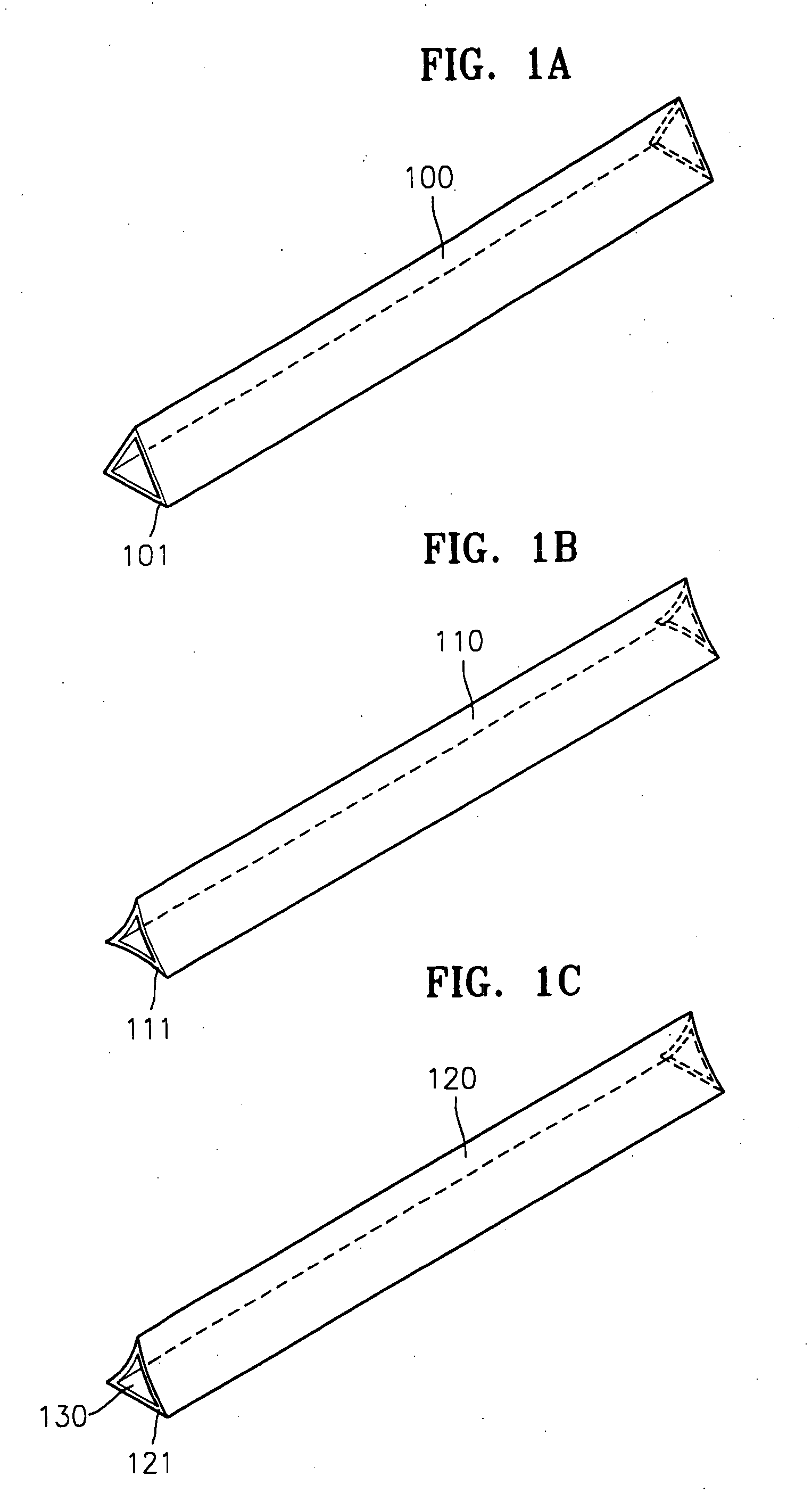

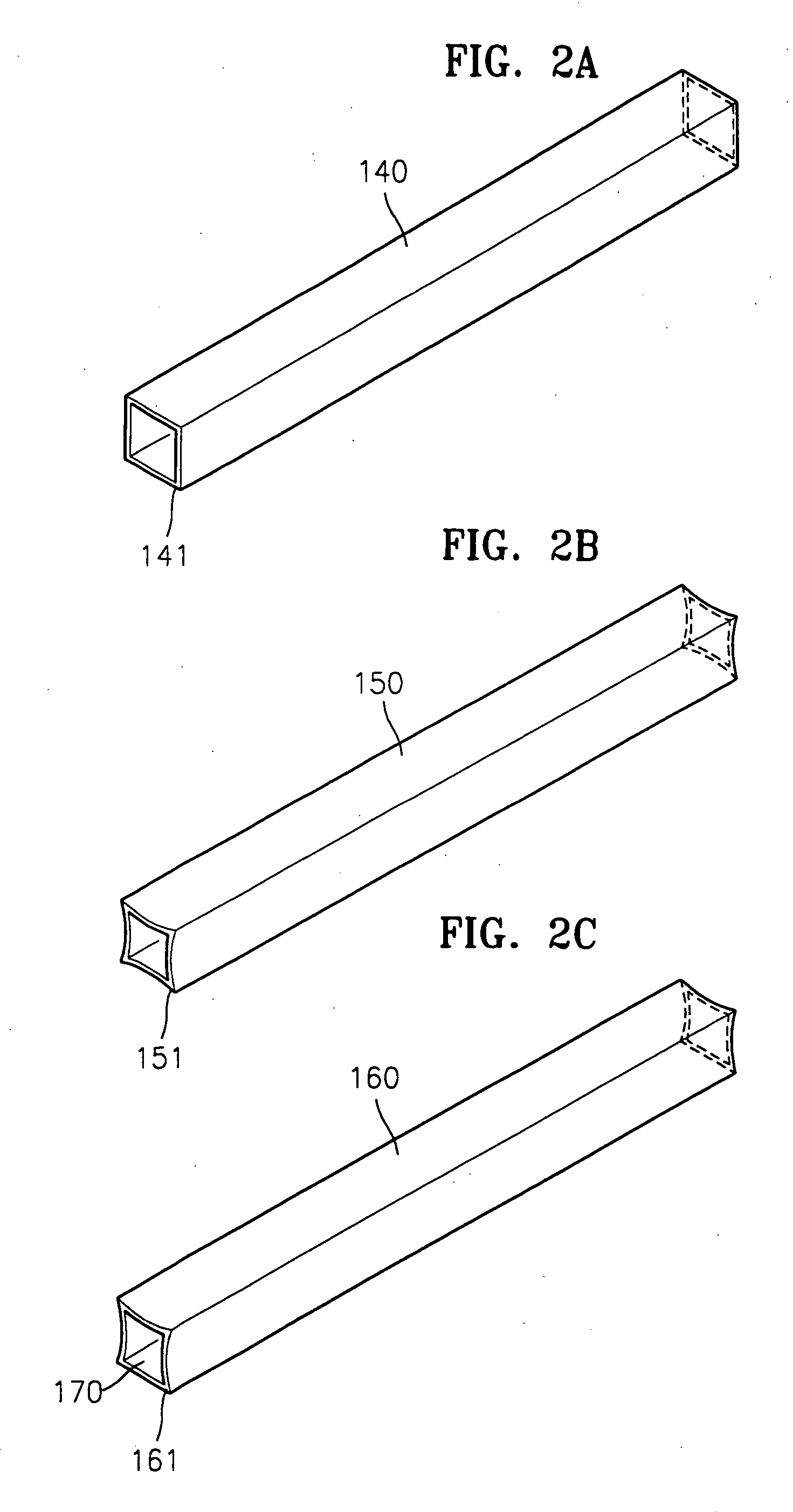

Micro heat pipe with pligonal cross-section manufactured via extrusion or drawing

InactiveUS20070130769A1Easy to manufactureStrong capillary forceSemiconductor/solid-state device detailsSolid-state devicesMicro-loop heat pipeWorking fluid

A method for fabricating a metal micro heat pipe with a polygonal cross-section to allow working fluid to flow by capillary force generated at edges of the polygonal of the micro heat pipe. The polygonal cross-section is formed of a single metal layer via a single drawing process. The micro heat pipe is formed of a single metal plate.

Owner:MOON SEOK HWAN +6

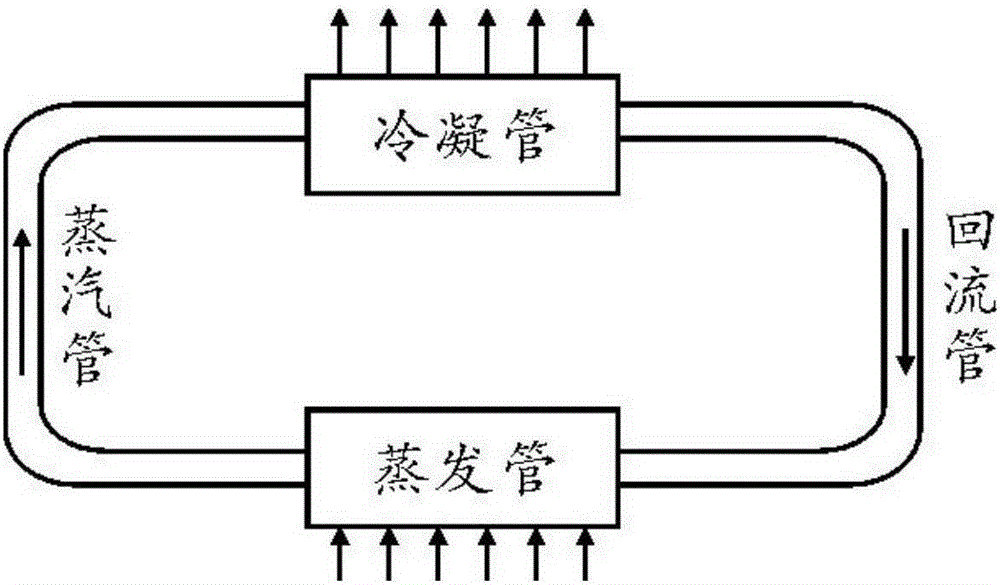

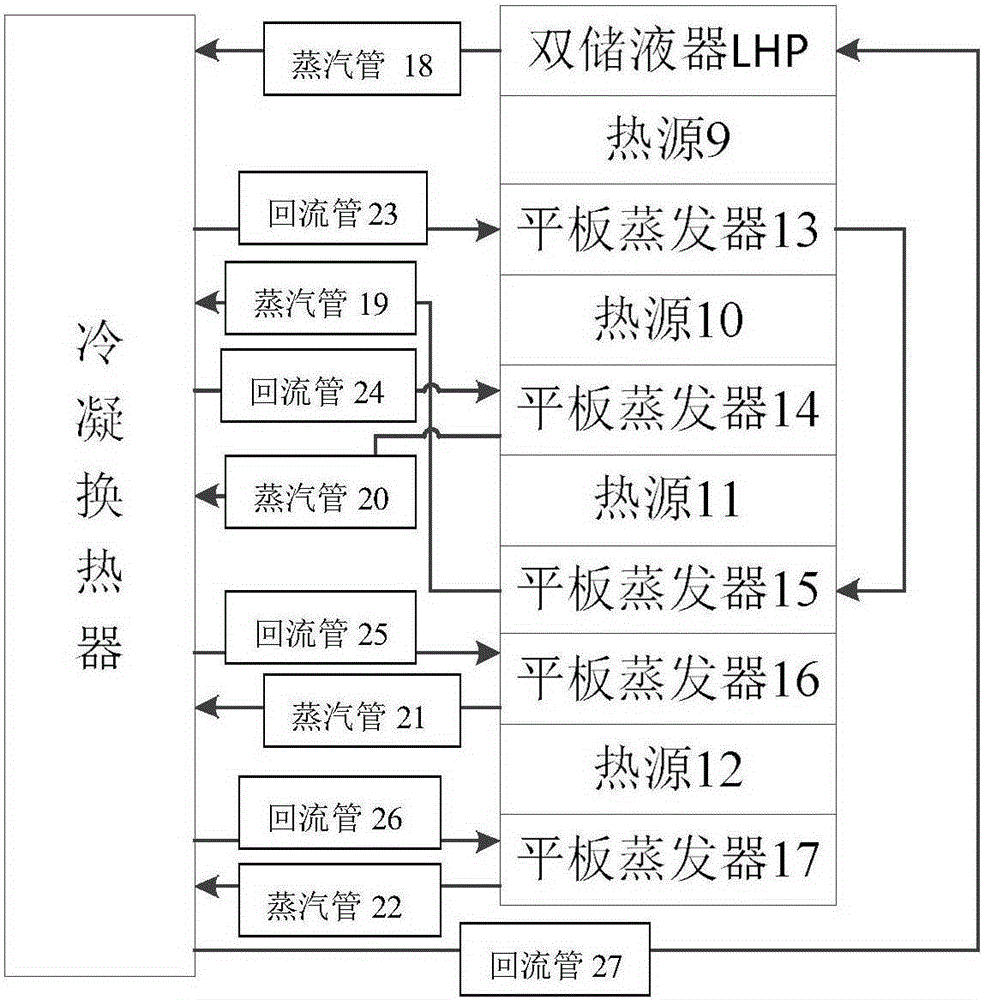

Thermal control loop heat pipe of integrated structure

InactiveCN105277028AImprove temperature uniformityImprove anti-acceleration abilityIndirect heat exchangersMicro-loop heat pipeEvaporation

The invention provides a thermal control loop heat pipe of an integrated structure. The thermal control loop heat pipe comprises a structure thermal control hollow metal pipe body filled with phase change media. The structure thermal control hollow metal pipe body is a loop heat pipe (LHP) formed by connecting a condensation pipe and an evaporator in series, the two sides of the evaporator are connected with liquid accumulators where a steam pipe and a reflux pipe pass, and the liquid accumulators on the two sides are both filled with liquid working media. After heat emitted by a heat source is absorbed by an evaporation pipe, the phase of the liquid working media is changed, the liquid working media enter the condensation pipe through the steam pipe to release heat to be condensed and flows back to the evaporation pipe through the reflux pipe, and then a complete loop heat pipe cycle is completed. According to the thermal control loop heat pipe, integration is adopted, a semiconductor refrigeration manner is used, heat emitted out of the interior of the complex structure can be effectively led out accordingly, and the application range of a heat pipe thermal control system is greatly expanded.

Owner:10TH RES INST OF CETC

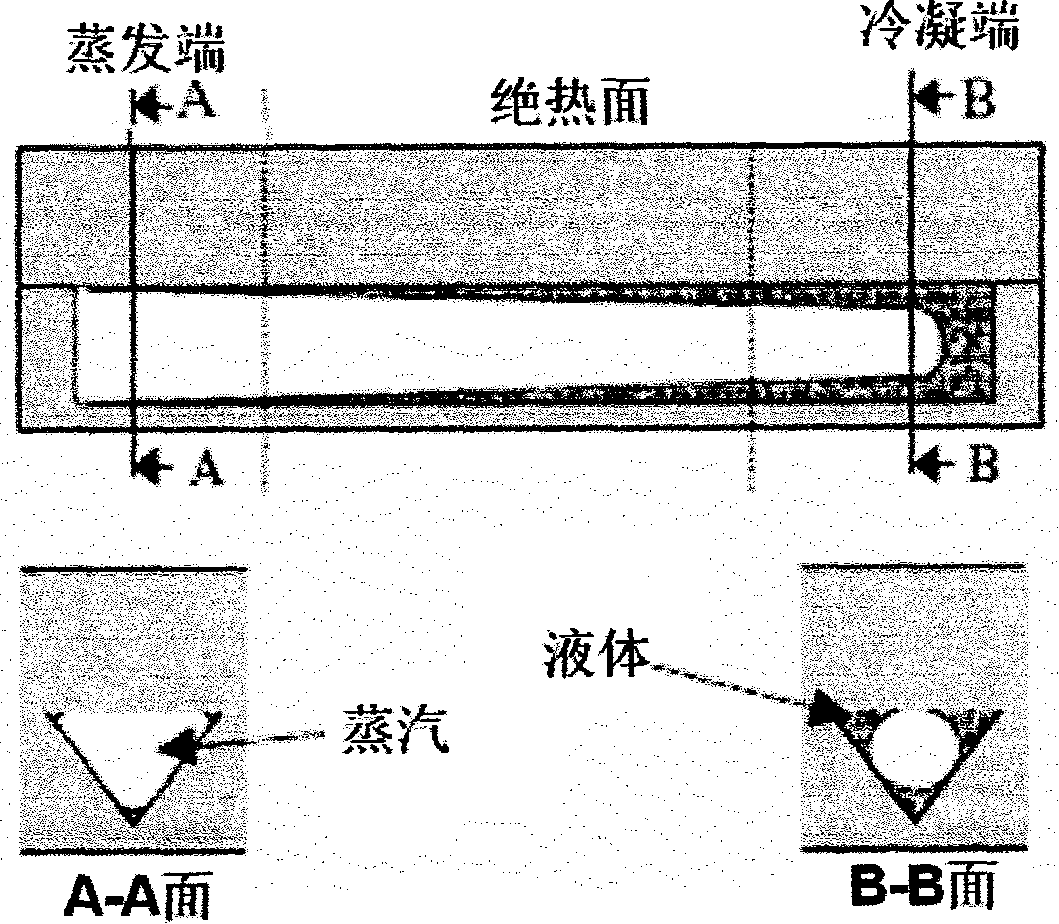

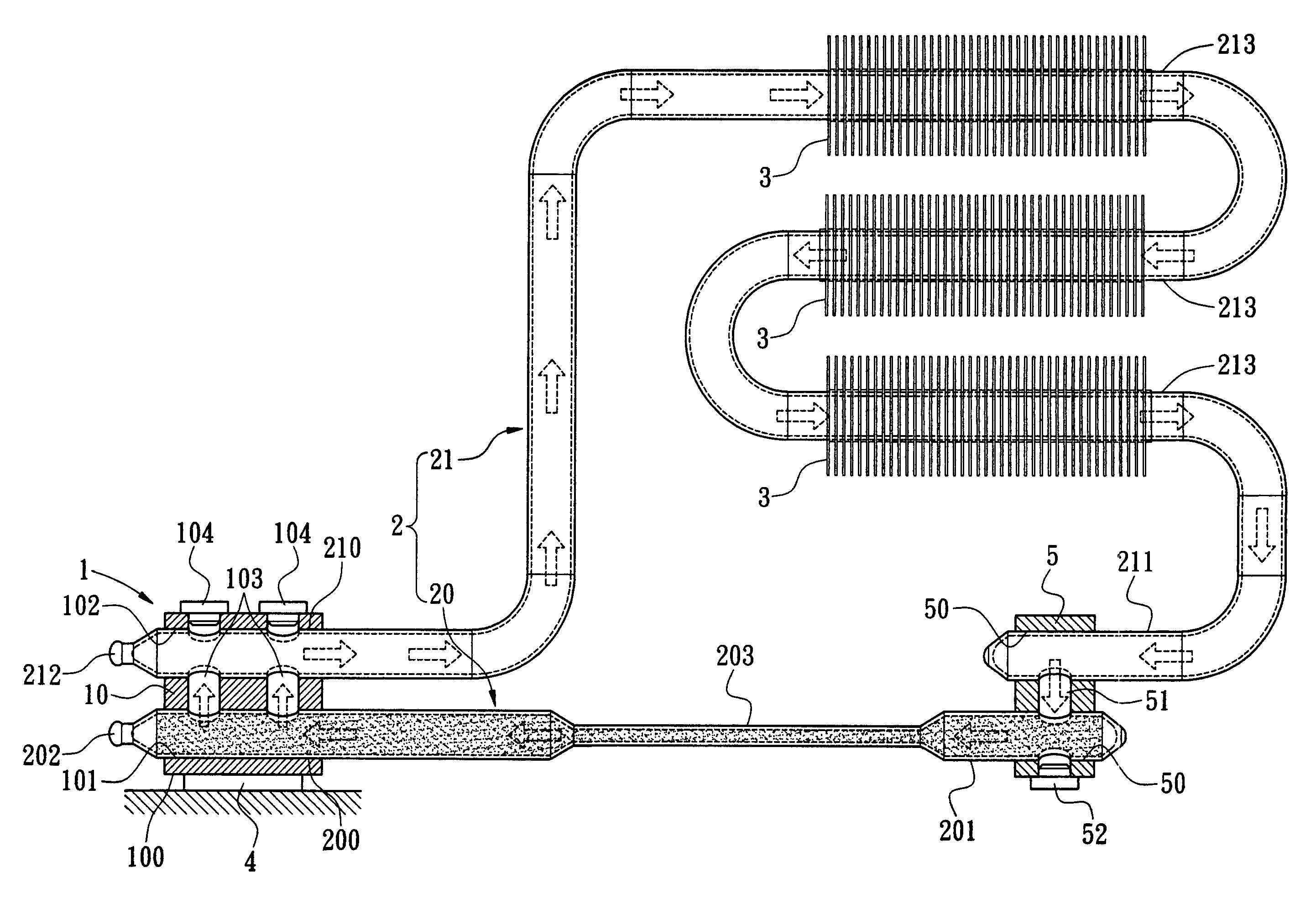

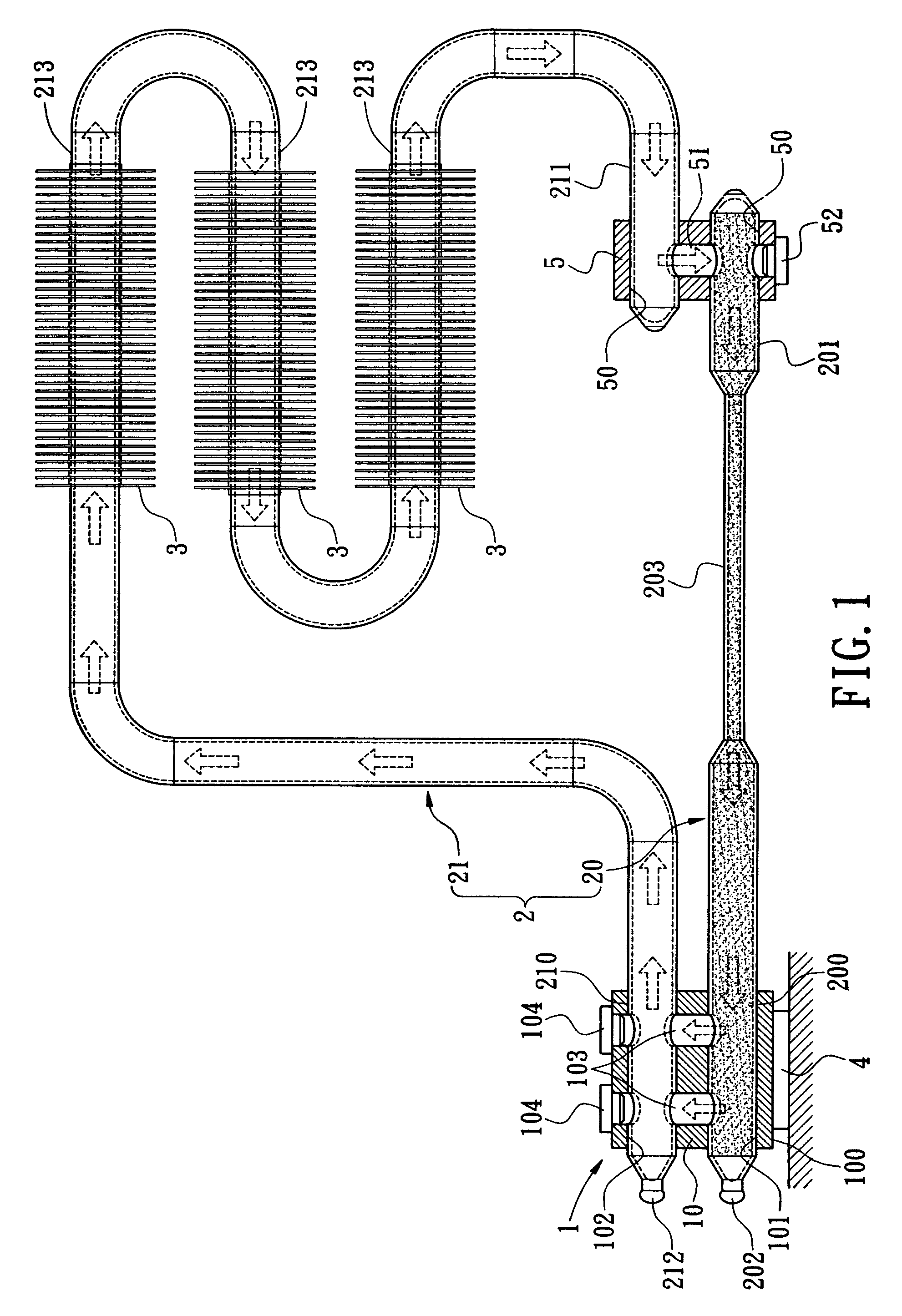

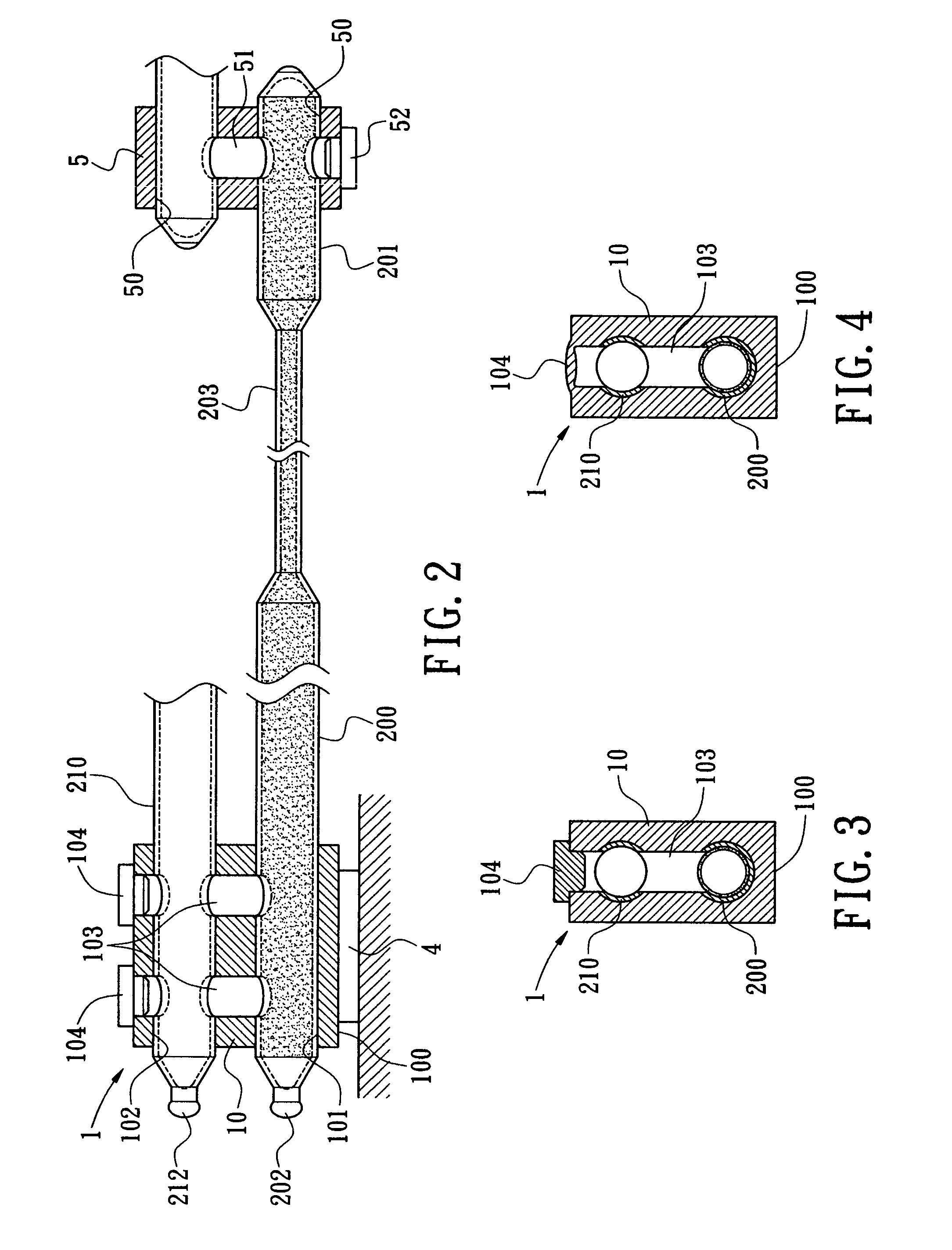

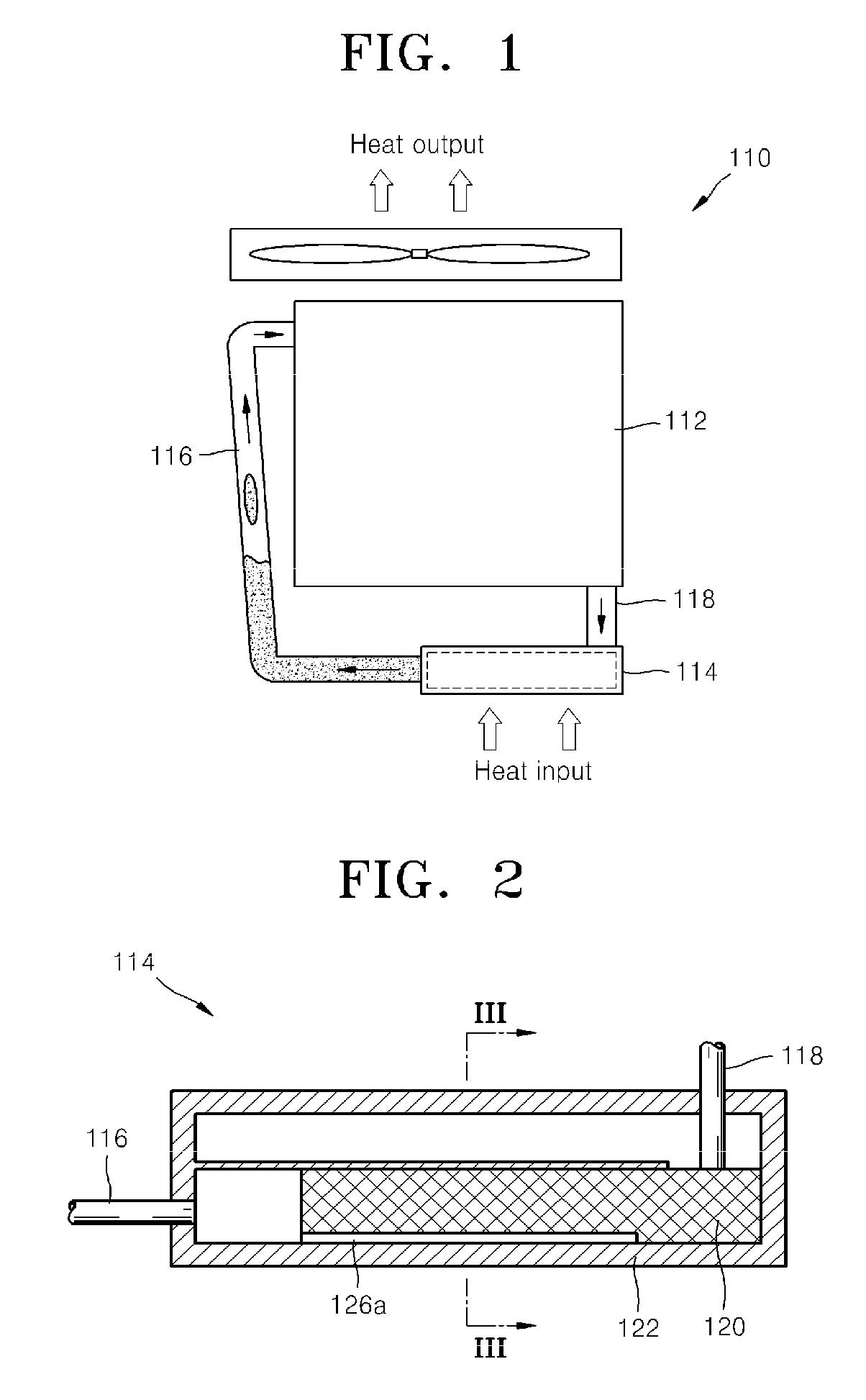

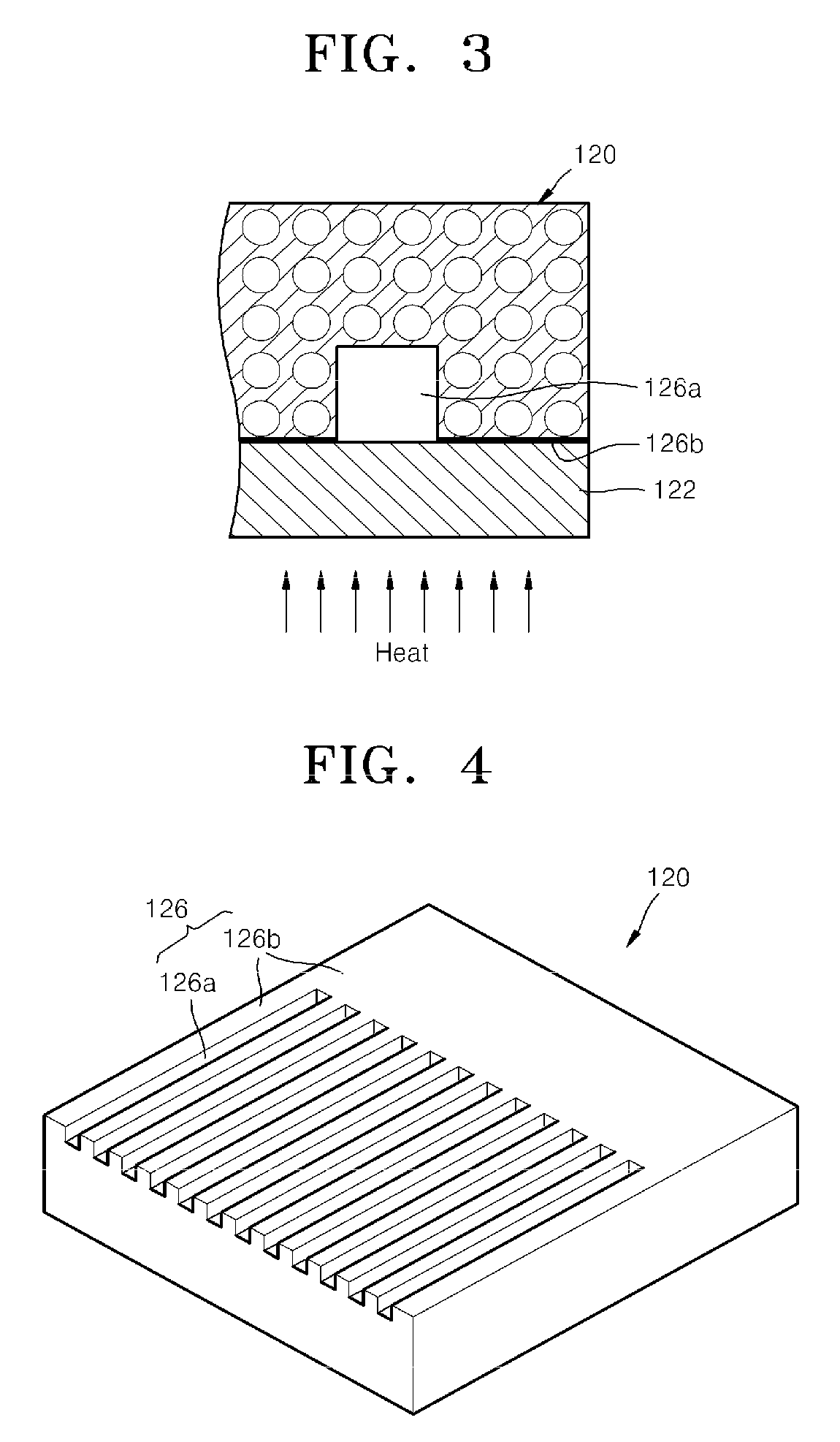

Loop heat pipe with wick passageways and heat transmission method and manufacturing method thereof

ActiveCN103344145AImprove heat transfer effectLower operating temperatureIndirect heat exchangersMicro-loop heat pipeHeat resistance

The invention discloses a loop heat pipe with wick passageways. The loop heat pipe with the wick passageways comprises an evaporation section, a heat insulation section, a condensation section and an infusion section, wherein the evaporation section, the heat insulation section, the condensation section and the infusion section are connected in sequence in an end-to-end mode to form a loop, the pipe body is filled with metal powder at the evaporation section and the infusion section and high sintering is carried out on the metal powder, a first wick passageway is formed by the pipe body at the evaporation section and the metal powder, and a second wick passageway is formed by the pipe body at the infusion section and the metal powder. According to the loop heat pipe with the wick passageways, liquid working media can still move fast under the condition of antigravity through capillary force in the first wick passageway and in the second wick passageway, and therefore heat transmission efficiency is improved, and operating temperature and heat resistance are reduced. The invention further provides a heat transmission method and a manufacturing method of the loop heat pipe with the wick passageways.

Owner:SOUTH CHINA UNIV OF TECH

Loop heat pipe

InactiveCN102374807AImprove performancePrevent drynessSemiconductor/solid-state device detailsSolid-state devicesMicro-loop heat pipeEvaporation

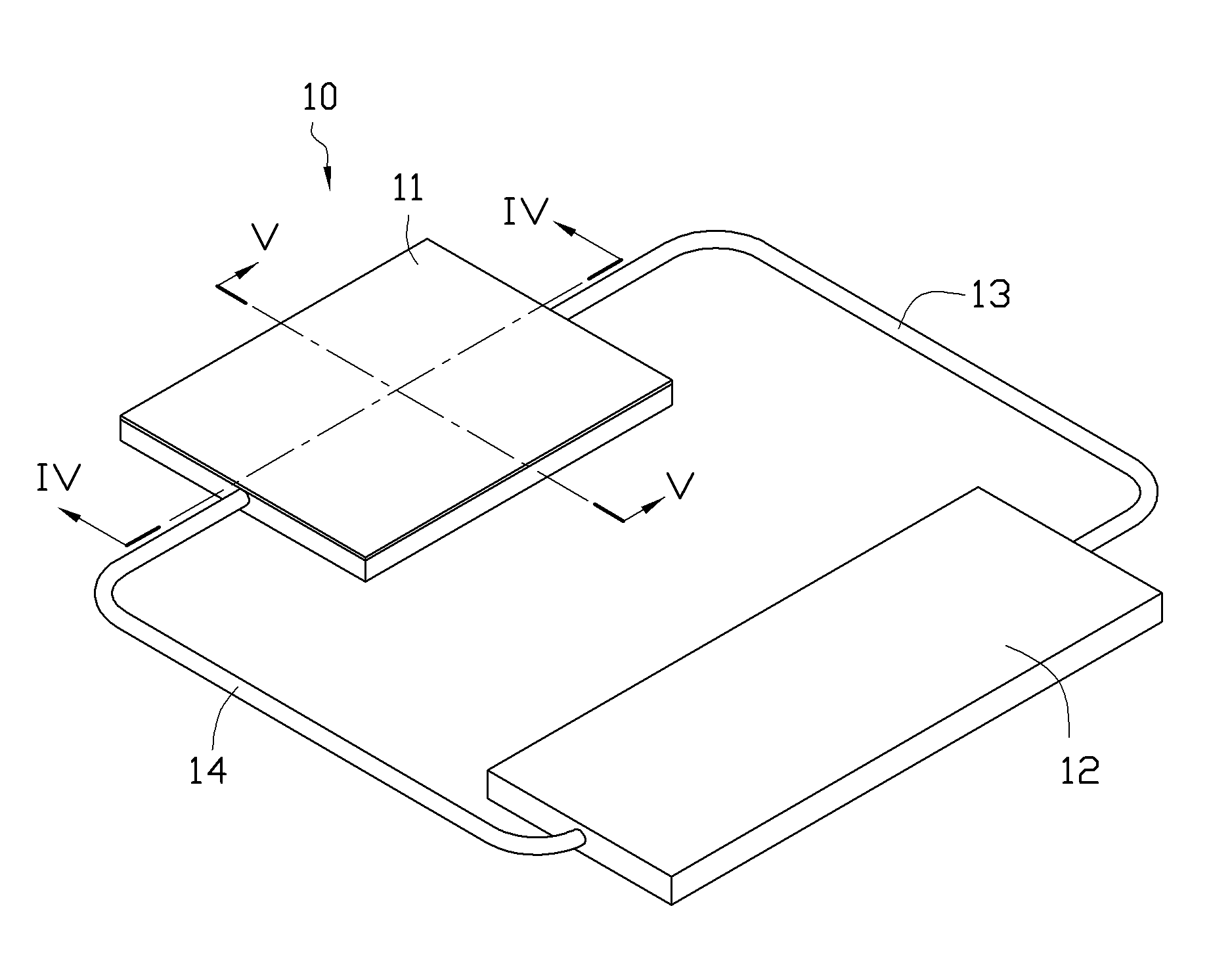

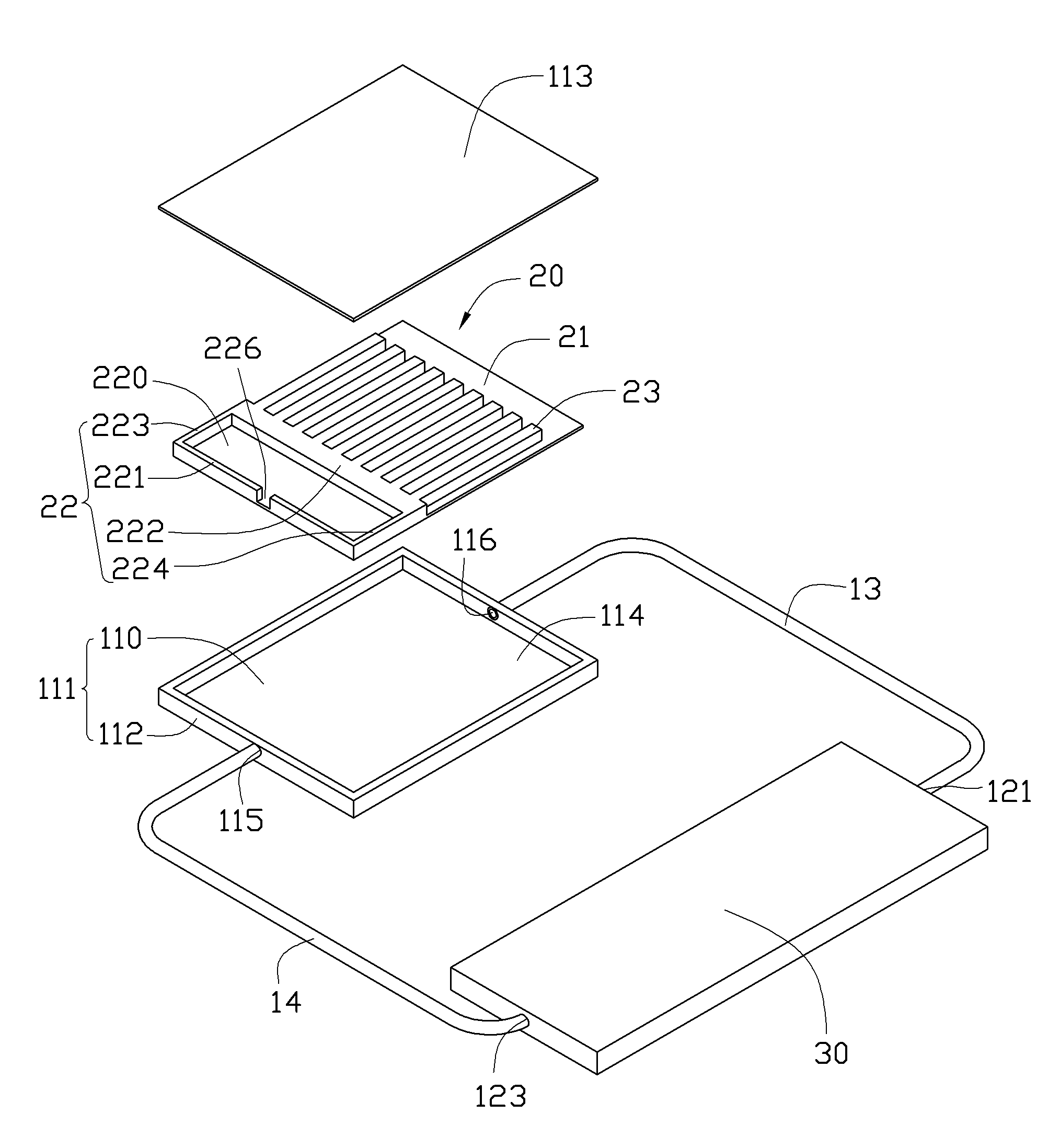

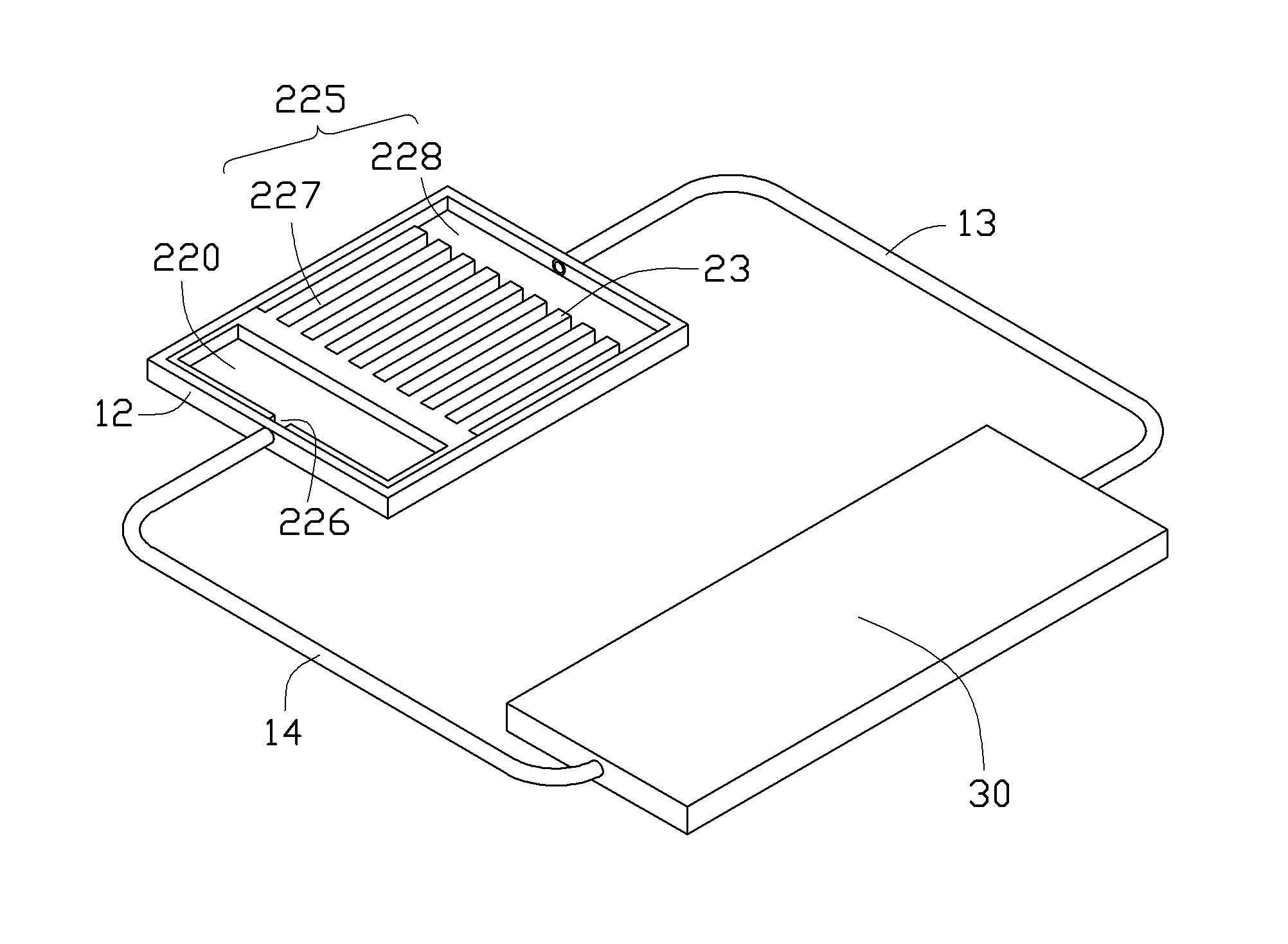

The invention discloses a loop heat pipe. The loop heat pipe comprises an evaporation part, a condensation part, a vapor pipeline and a liquid pipeline, wherein the vapor pipeline and the liquid pipeline are arranged between the evaporation part and the condensation part and connect the evaporation part and the condensation part into a loop; a working medium is filled in the loop; a capillary structure is arranged in the evaporation part, and comprises a flat plate part pasted on the bottom surface of the evaporation part, a supporting wall extending from the flat plate part to the top surface of the evaporation part, and a plurality of bar-shaped parts extending from the side surface of the supporting wall to one side of the vapor pipeline; the supporting wall and the bar-shaped parts separate the space in the evaporation part into a liquid storage chamber communicated with the liquid pipeline, and a vapor chamber communicated with the vapor pipeline; and a vapor groove communicated with the vapor chamber is formed between two adjacent bar-shaped parts.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Cooling substrate of micro heat pipe

InactiveCN101175389AImprove cooling effectEasy to control temperatureSemiconductor/solid-state device detailsSolid-state devicesTemperature controlMicro-loop heat pipe

The present invention relates to an electronic component radiating substrate, in particular to a micro heat pipe radiating substrate. The micro heat pipe radiating substrate is formed by a plurality of layers of flat plate radiating layer. A micro heat pipe structure is manufactured in an upper radiating layer and a lower radiating layer to be provided with a hot end and a cold end in vertical direction. A temperature control ceramic layer at the bottom is used for controlling the temperature of the cold end, so the whole substrate is provide with radiating and temperature control functions. Compared with the traditional metal (or ceramic) substrate, the substrate adopts the design of the micro heat pipe structure and the cold end temperature control. So the present invention not only is characterized by strong heat transport capacity, good radiating and soaking, but also is capable of controlling the temperature of the substrate. The novel substrate is used in the electron field of semiconductor light emitting diode, semiconductor laser device, semiconductor component, integrated circuit and CPU and so on and is of advantages.

Owner:SUN YAT SEN UNIV

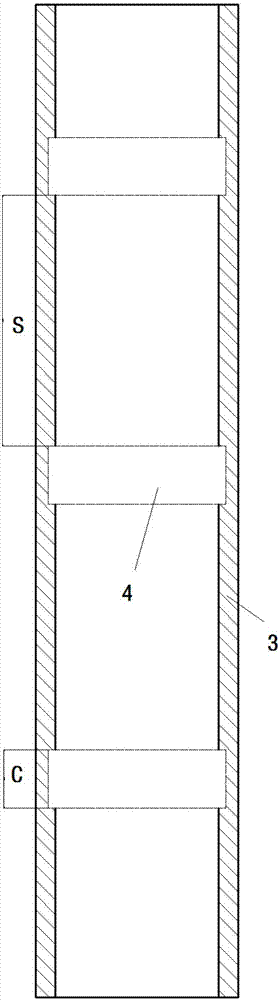

Porous current stabilizing device loop heat pipe

ActiveCN107131783AReduce vibrationImprove heat transfer performanceSafety devices for heat exchange apparatusHeat exhanger conduitsRefluxMicro-loop heat pipe

The invention provides a heat pipe. The heat pipe comprises an evaporation header, a condensation header, an ascending pipe and a reflux pipe; the ascending pipe communicates with the evaporation header and the condensation header; the evaporation header is positioned at the lower part; the condensation header is positioned at the upper part; a fluid absorbs heat for evaporation in the evaporation header, is fed in the condensation header by the ascending pipe, and is condensed in the condensation header after heat exchange; the condensed fluid is returned to the evaporation header through the reflux pipe; current stabilizing devices are arranged in the ascending pipe; multiple current stabilizing devices are arranged in the same ascending pipe; and in the height direction of the ascending pipe, gaps between the adjacent current stabilizing devices are continuously reduced. Through the gap change of the current stabilizing devices, when steam-liquid two-phase flowing exists in the ascending pipe, the heat transfer is intensified, meanwhile, the vibration of the ascending pipe is weakened, and the noise level is lowered.

Owner:西安新港分布式能源有限公司

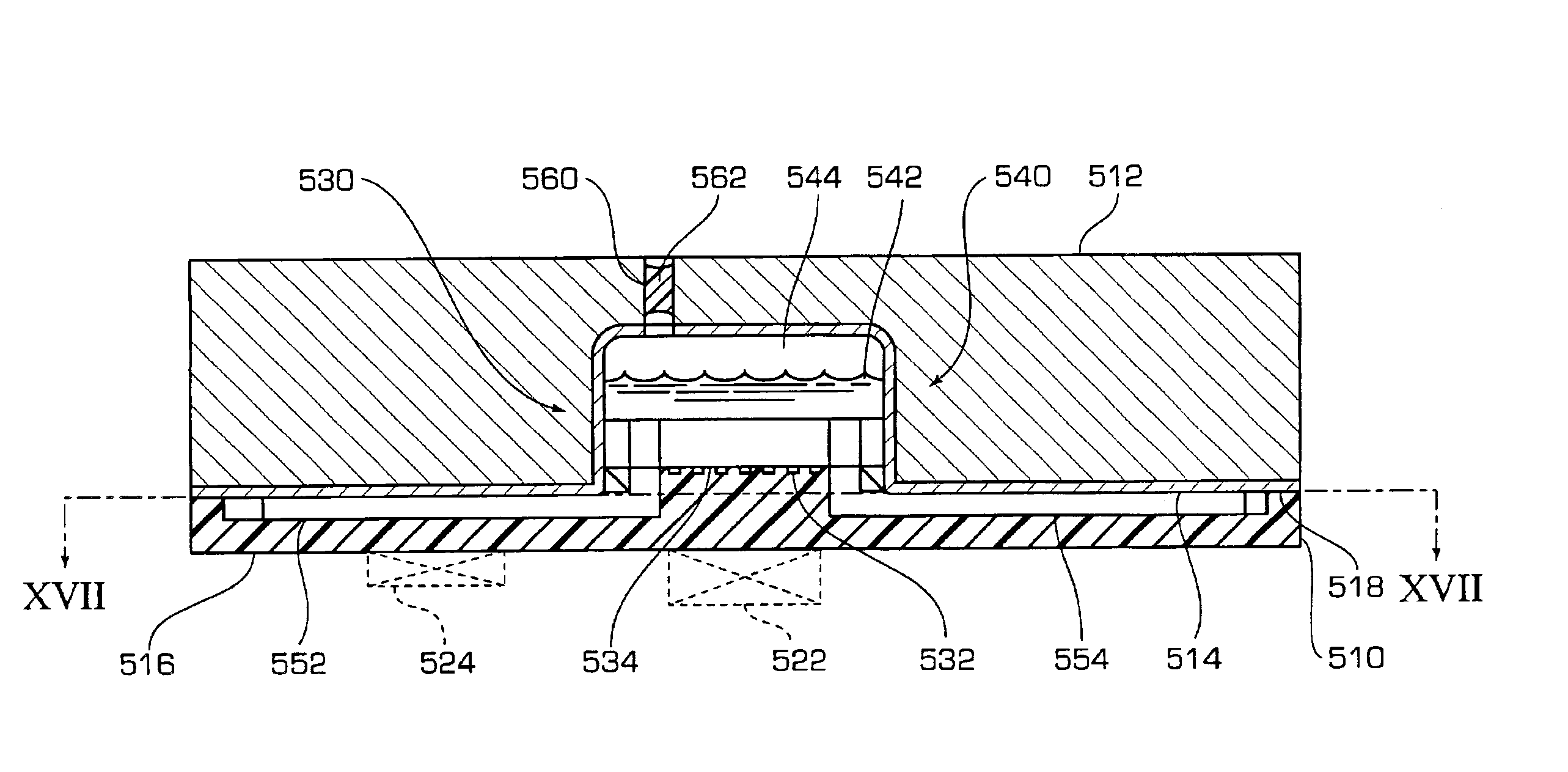

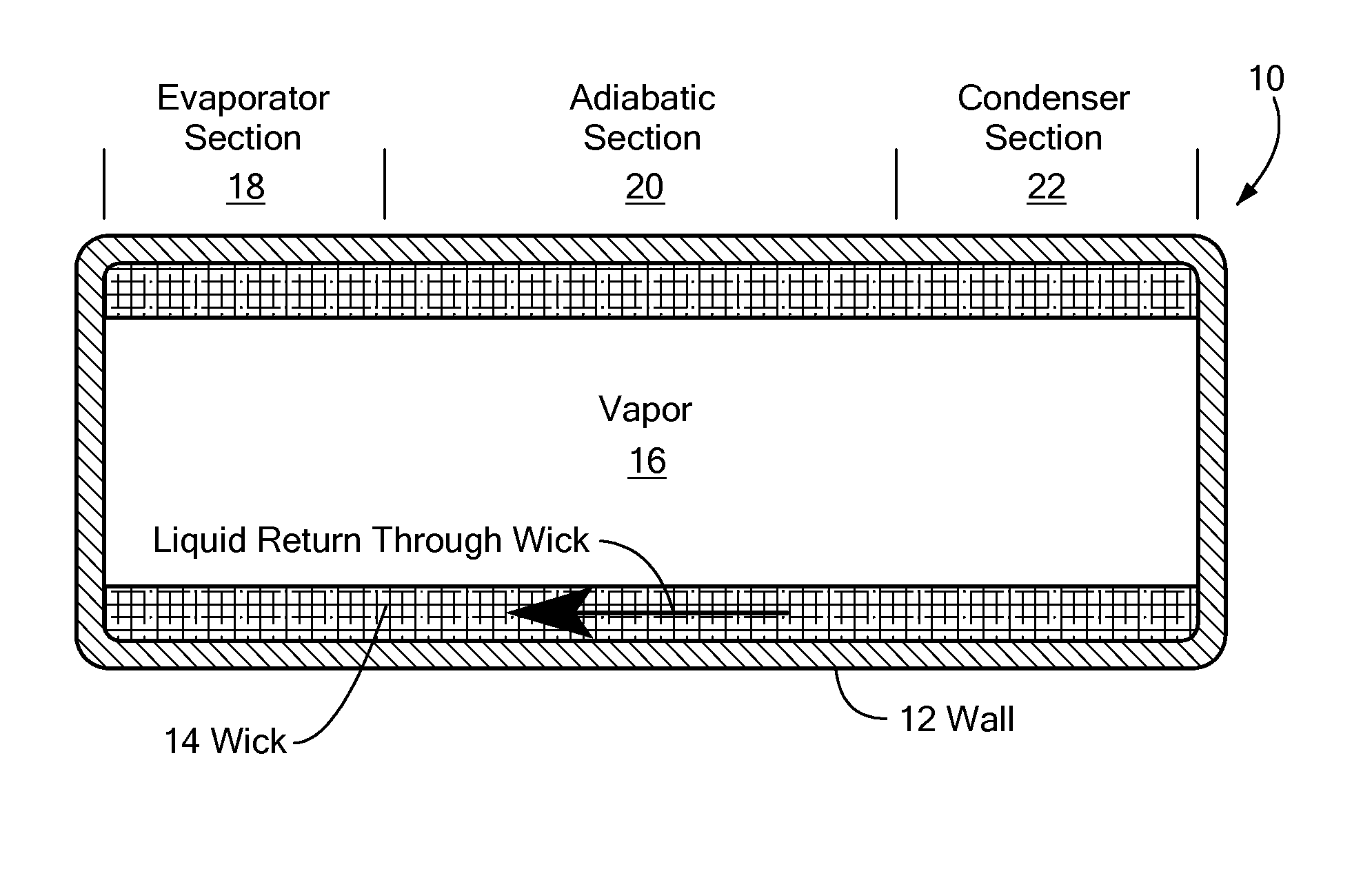

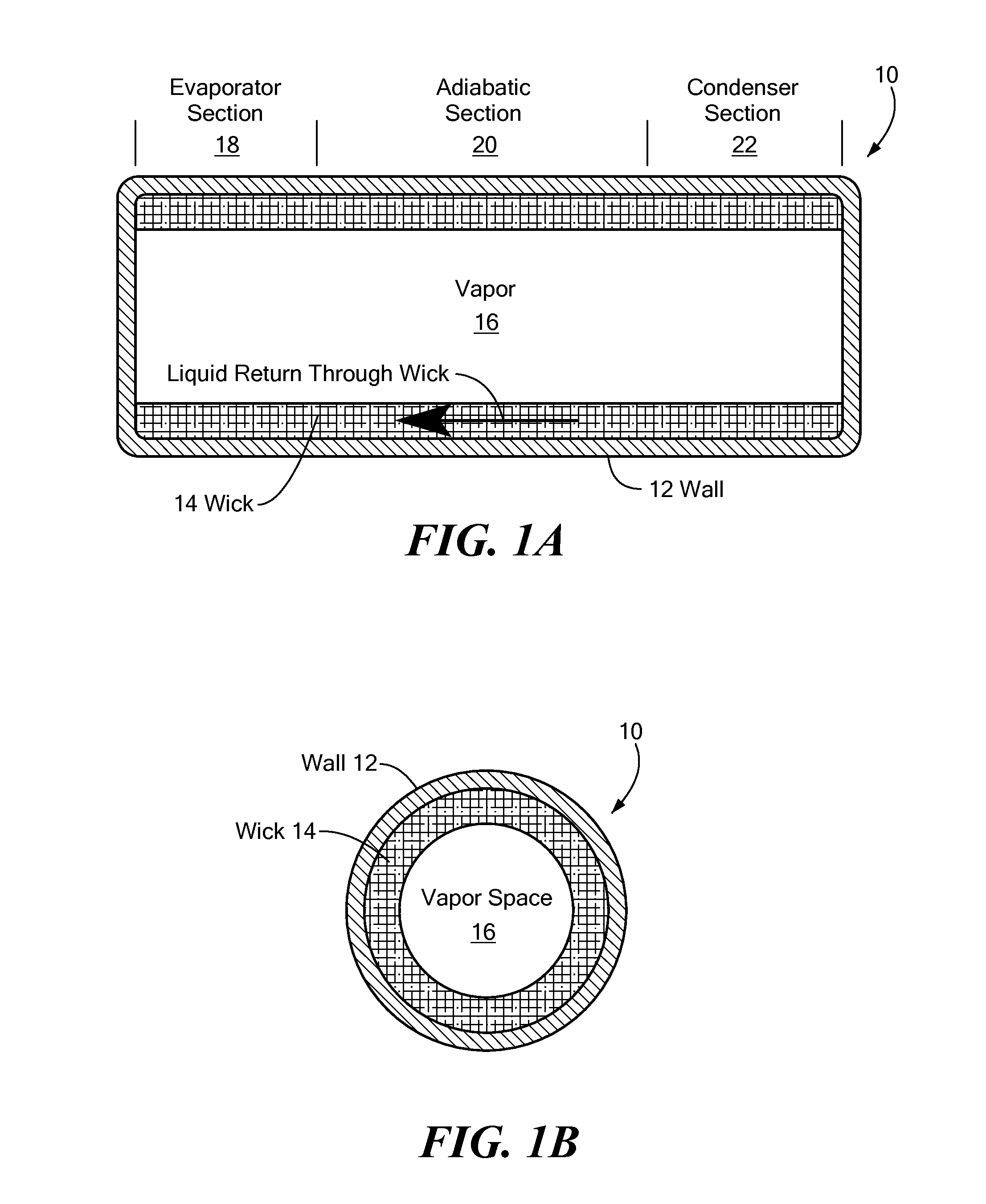

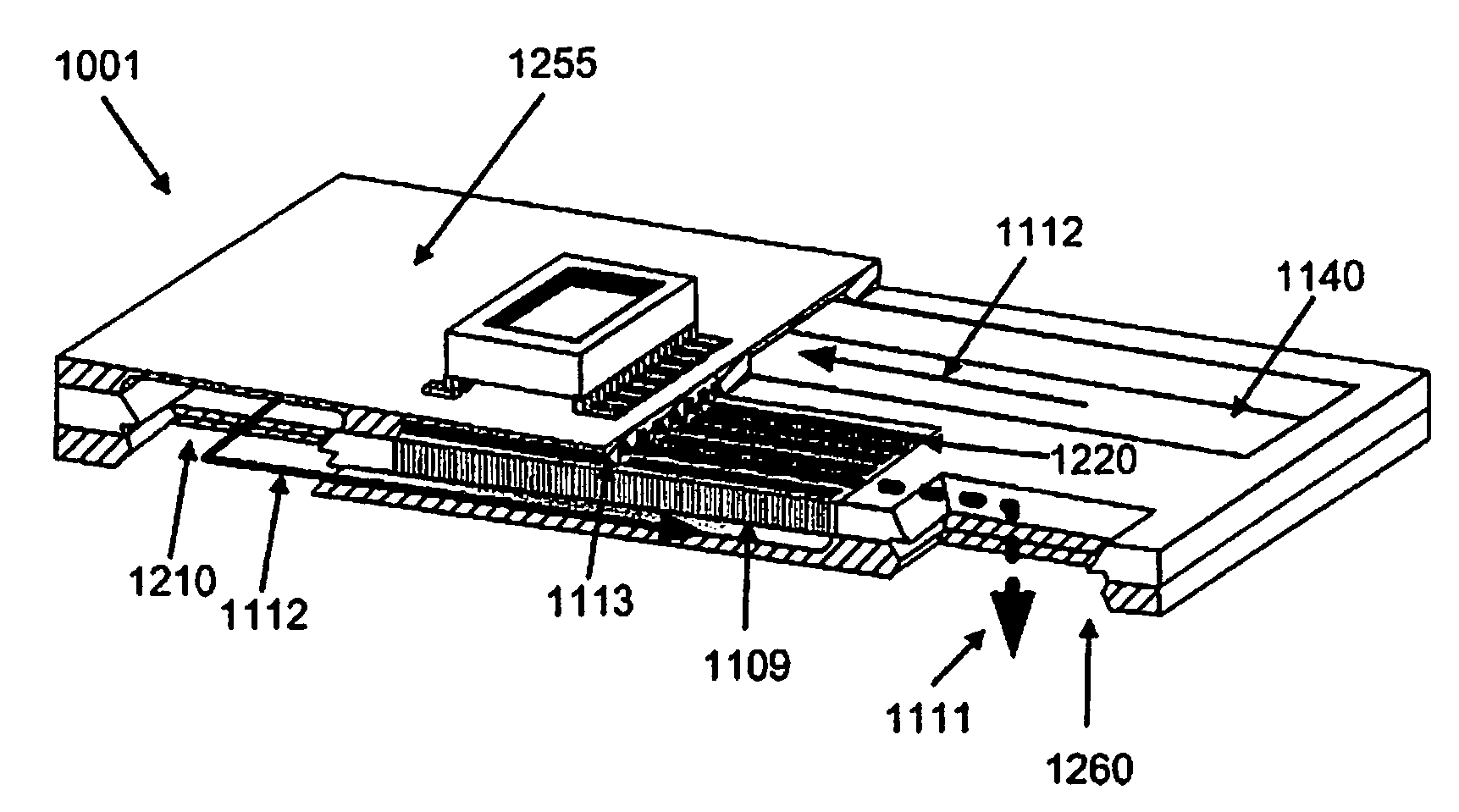

Wick having liquid superheat tolerance and being resistant to back-conduction, evaporator employing a liquid superheat tolerant wick, and loop heat pipe incorporating same

InactiveUS6915843B2Improve performanceReduce back-conductionSemiconductor/solid-state device detailsSolid-state devicesWorking fluidMicro-loop heat pipe

A capillary wick for use in capillary evaporators has properties that prevent nucleation inside the body of the wick, resulting in suppression of back-conduction of heat from vapor channels to the liquid reservoir. Use of a central liquid flow channel in the wick is eliminated, and pore size in the wick is chosen to maximize available pressure for fluid pumping, while preventing nucleation in the wick body. The wick is embodied with different geometries, including cylindrical and flat. A flat capillary evaporator has substantially planar heat input surfaces for convenient mating to planar heat sources. The flat capillary evaporator is capable of being used with working fluids having high vapor pressures (i.e., greater that 10 psia). To contain the pressure of the vaporized working fluid, the opposed planar plates of the evaporator are brazed or sintered to opposing sides of a metal wick. Additionally, a terrestrial loop heat pipe and a loop heat pipe having overall flat geometry are disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

Loop heat pipe

InactiveCN107167010AInhibit refluxSpeed up the flowIndirect heat exchangersVapor liquidMicro-loop heat pipe

The invention provides a loop heat pipe which comprises an evaporation collecting pipe body, a condensation collecting pipe body, ascension pipe bodies and returning pipe bodies. The ascension pipe bodies communicate with the evaporation collecting pipe body and the condensation collecting pipe body; the evaporation collecting pipe body is located on the lower portion, and the condensation collecting pipe body is located on the upper portion; a fluid absorbs heat and is evaporated in the evaporation collecting pipe body, enters the condensation collecting pipe body through the ascension pipe bodies and is condensed after being subjected to heat exchange in the condensation collecting pipe body, and the condensed fluid is returned to the evaporation collecting pipe body through the returning pipe bodies; dividing devices are arranged in the ascension pipe bodies; the dividing devices comprises core bodies and shells; the core bodies are arranged in the shells; the shells are fixedly connected with the inner walls of the ascension pipe bodies; the core bodies comprises a plurality of concentric pipes and rib pieces; and the rib pieces are connected with the adjacent concentric pipes. The loop heat pipe is of a novel structure, when vapor-liquid two-phase flow occurs in the ascension pipe bodies, heat transfer is strengthened, meanwhile, vibration of the ascension pipe bodies is weakened, and the noise level is reduced.

Owner:SHANDONG UNIV

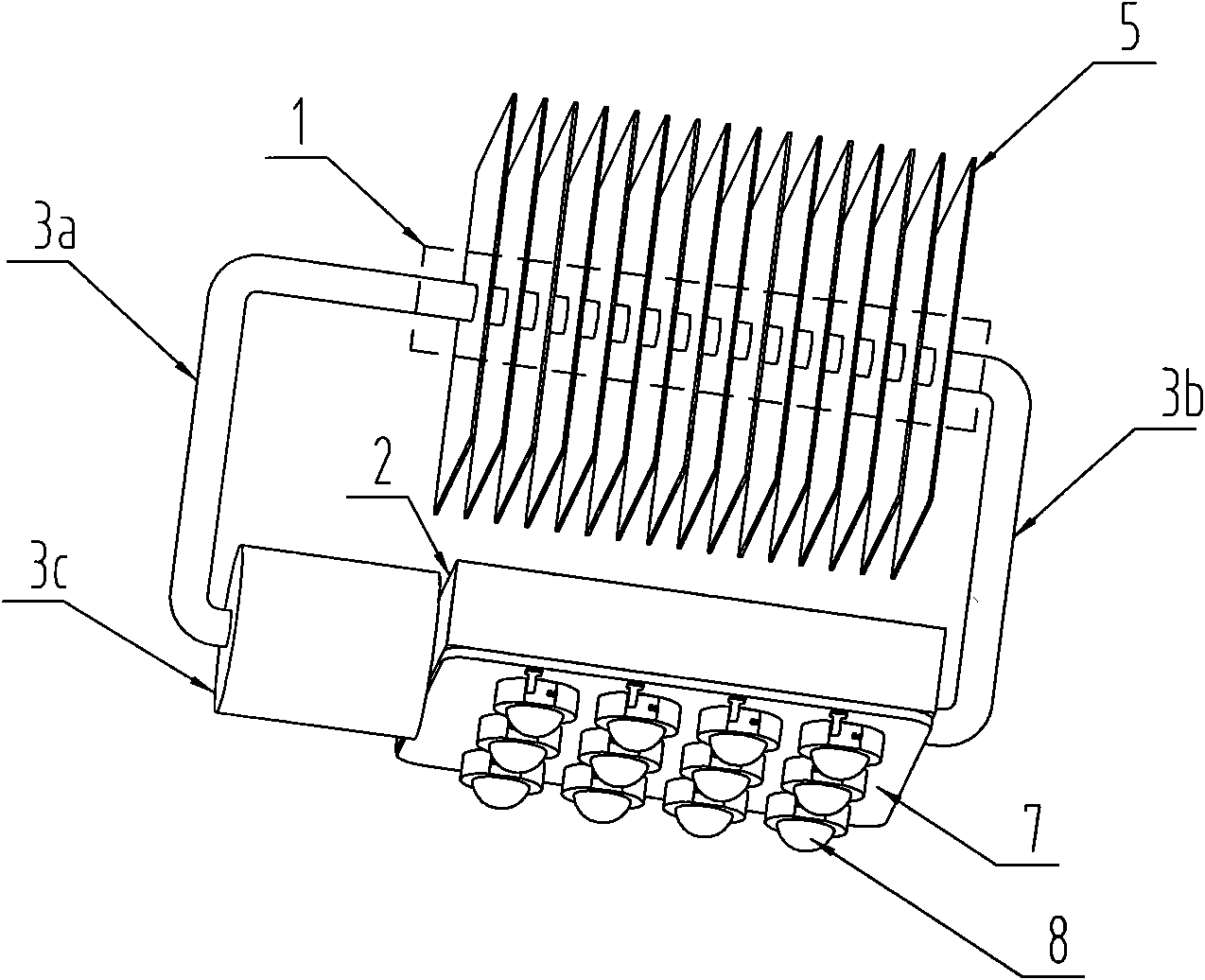

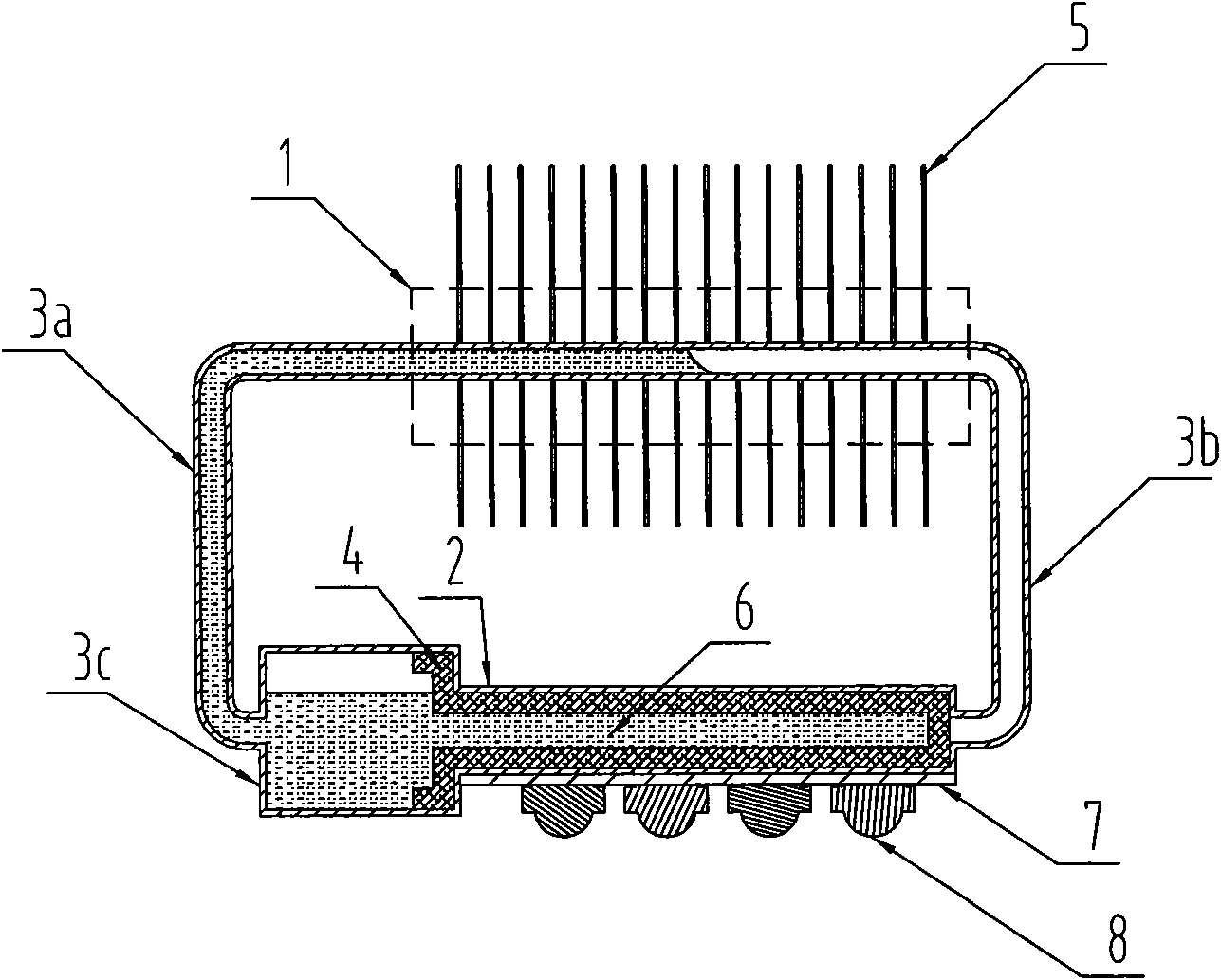

Heat radiation device for loop heat pipe with enhanced evaporation section used in LED lamp

InactiveCN101608788AImprove luminous efficiencyReduce light decay speedPoint-like light sourceSemiconductor/solid-state device detailsRefluxMicro-loop heat pipe

The invention discloses a heat radiation device for a loop heat pipe with an enhanced evaporation section used in an LED lamp. The heat radiation device comprises: a heat pipe, a radiating fin and a working liquid. The heat pipe is a loop pipe with a sealed cavity, comprising: an enhanced evaporation section, a reflux section, a steam section, a compensation chamber and a condensing section; the enhanced evaporation section is arranged at the back of a heat source of the LED lamp; the loop pipe is vacuumed properly, internally provided with a wick structure and filled with a proper amount of working liquid; and the radiating fin is arranged on the condensing section. The heat radiation device has the advantages of reasonable and compact structure, easy production, high heat conduction efficiency and high heat radiation speed. The enhanced evaporation section is contacted with the heat source surface directly and sufficiently, therefore, the heat radiation device can effectively reduce the temperature of the LED modules, solve the heat radiation problem of large-power LEDs, improve the light emitting efficiency of LEDs, reduce the light degradation speed of LEDs and prolong the service life of LEDs. Simultaneously, the heat radiation device can reduce the volume and the weight of LED lamps and improve the adaptability and the use range of the LED lamps.

Owner:史杰

Thermal management system using micro heat pipe for thermal management of electronic components

InactiveUS20100155033A1Semiconductor/solid-state device detailsSolid-state devicesMicro-loop heat pipeWorking fluid

A thermal management system includes a base element and a heat producing element disposed for heat transfer from the heat producing element to the base element. An adherent zone includes an adherent element in physical attachment between the heat producing element and the base element. A heat transfer zone, separate from the adherent zone, includes a heat pipe between the heat producing element and the base element. The heat pipe includes a circulatory flow path between an evaporator section and a condenser section, and a working fluid on the circulatory flow path.

Owner:KAZAK COMPOSITES

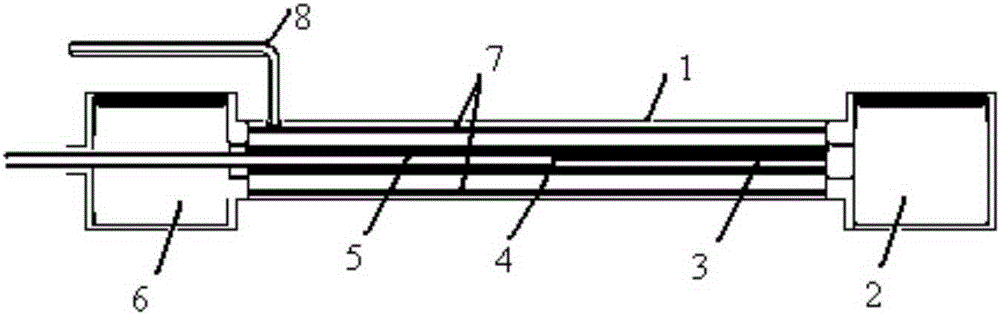

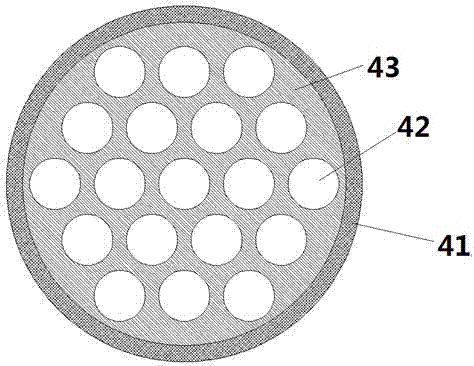

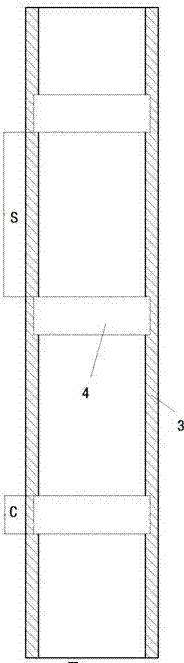

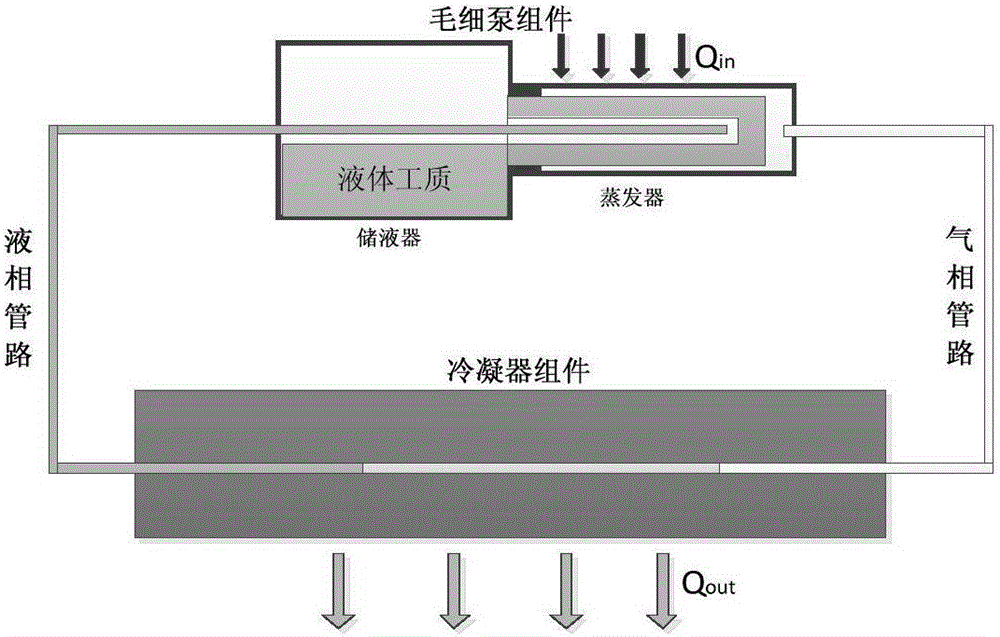

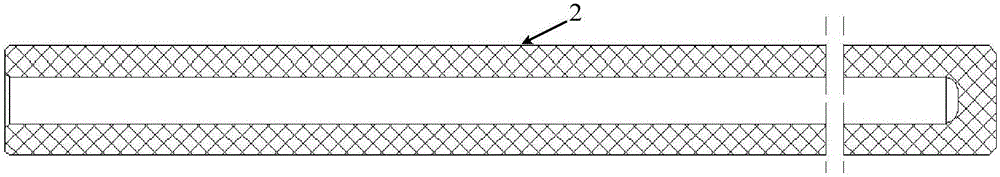

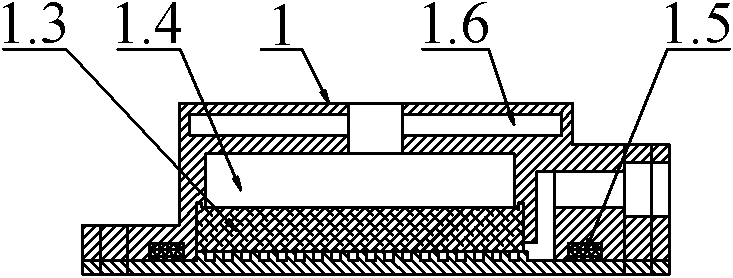

Cylindrical capillary pump assembly of loop heat pipe

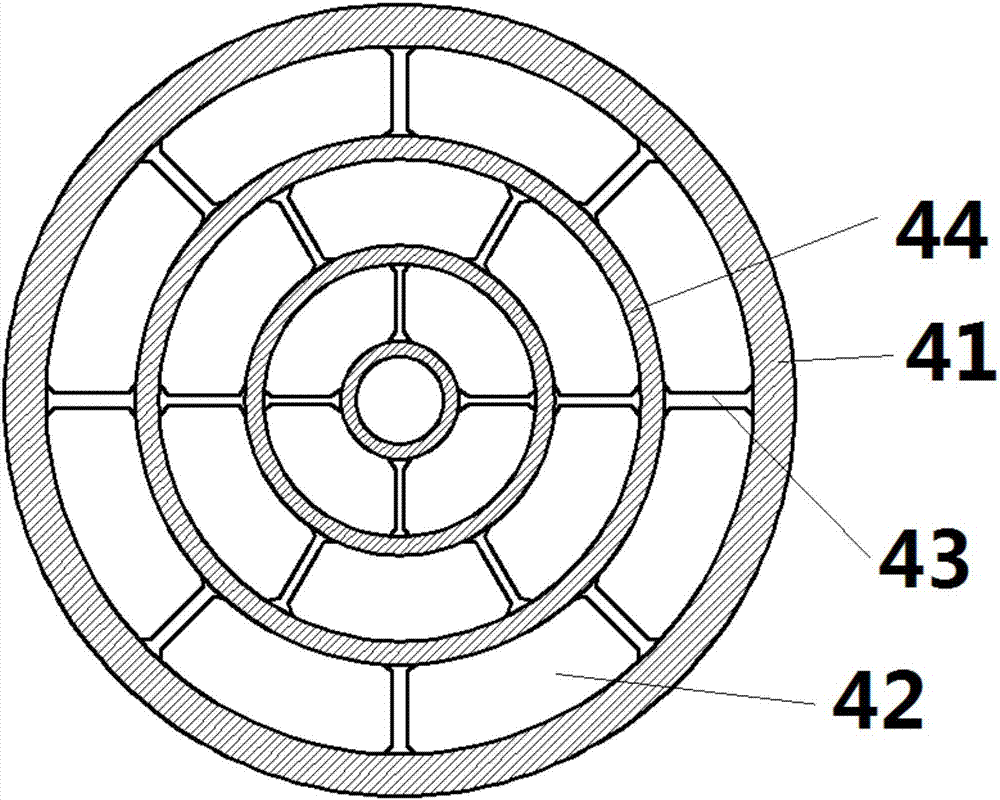

ActiveCN106225535AImprove adaptabilityImprove mechanical propertiesIndirect heat exchangersMicro-loop heat pipeEngineering

A cylindrical capillary pump assembly of a loop heat pipe comprises an evaporator shell (3), a liquid accumulator shell (4) and a capillary core (2). The liquid accumulator shell (3) is connected with the evaporator shell (4). One section of the capillary core (2) is located inside the evaporator shell (3). The other section of the capillary core (2) stretches into the liquid accumulator shell (4). The capillary core (2) is formed by sintering porous silicon nitride, and good porosity, good chemical stability, a low heat conductivity coefficient and a good machining property are achieved. A local part of the junction of the liquid accumulator shell (3) and the evaporator shell (4) is designed to be of an S-shaped structure; and the heat conduction path is long, the heat conductivity coefficient is relatively low, and the probability of leakage of heat from an evaporator to a liquid accumulator can be lowered. According to the cylindrical capillary pump assembly of the loop heat pipe, it can be guaranteed that the loop heat pipe has good starting performance, a good heat transfer property and a long service life, and can well adapt to a spatial microgravity environment and a mechanical environment on a spacecraft launching section at the same time.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Flat type loop heat pipe

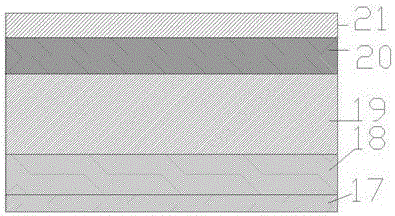

InactiveCN101900504ASuppress generationGrowth inhibitionIndirect heat exchangersLiquid lineSteam line

The invention discloses a flat type loop heat pipe, relates to the radiation of components and is used for solving the problem of dead start resulted from liquid working medium phase change in a liquid compensation cavity of an evaporimeter of the existing loop heat pipe. The flat type loop heat pipe comprises the evaporimeter and a condenser, the working medium outlet of the evaporimeter is communicated with the working medium inlet of the condenser through a steam line, and the working medium outlet of the condenser is communicated with the working medium inlet of the evaporimeter. The evaporimeter comprises a flat type heated wall surface and a shell, wherein the heated wall surface is provided with porous wicks; the shell covers the porous wicks and is provided with the liquid compensation cavity above the porous wicks; the liquid compensation cavity is used for containing working medium and is connected with the liquid line through the working medium inlet; and the wall of the shell is internally provided with a phase-change material layer. Through the phase-change material layer arranged inside the wall of the shell, the invention absorbs back leakage heat and heat conducted by a lateral wall of the evaporimeter through the phase-change heat absorption of the phase change material, thereby effectively inhibiting the generation of bubbles in the liquid compensation cavity and ensuring the smoothly starting of the loop heat pipe.

Owner:WISDRI ENG & RES INC LTD

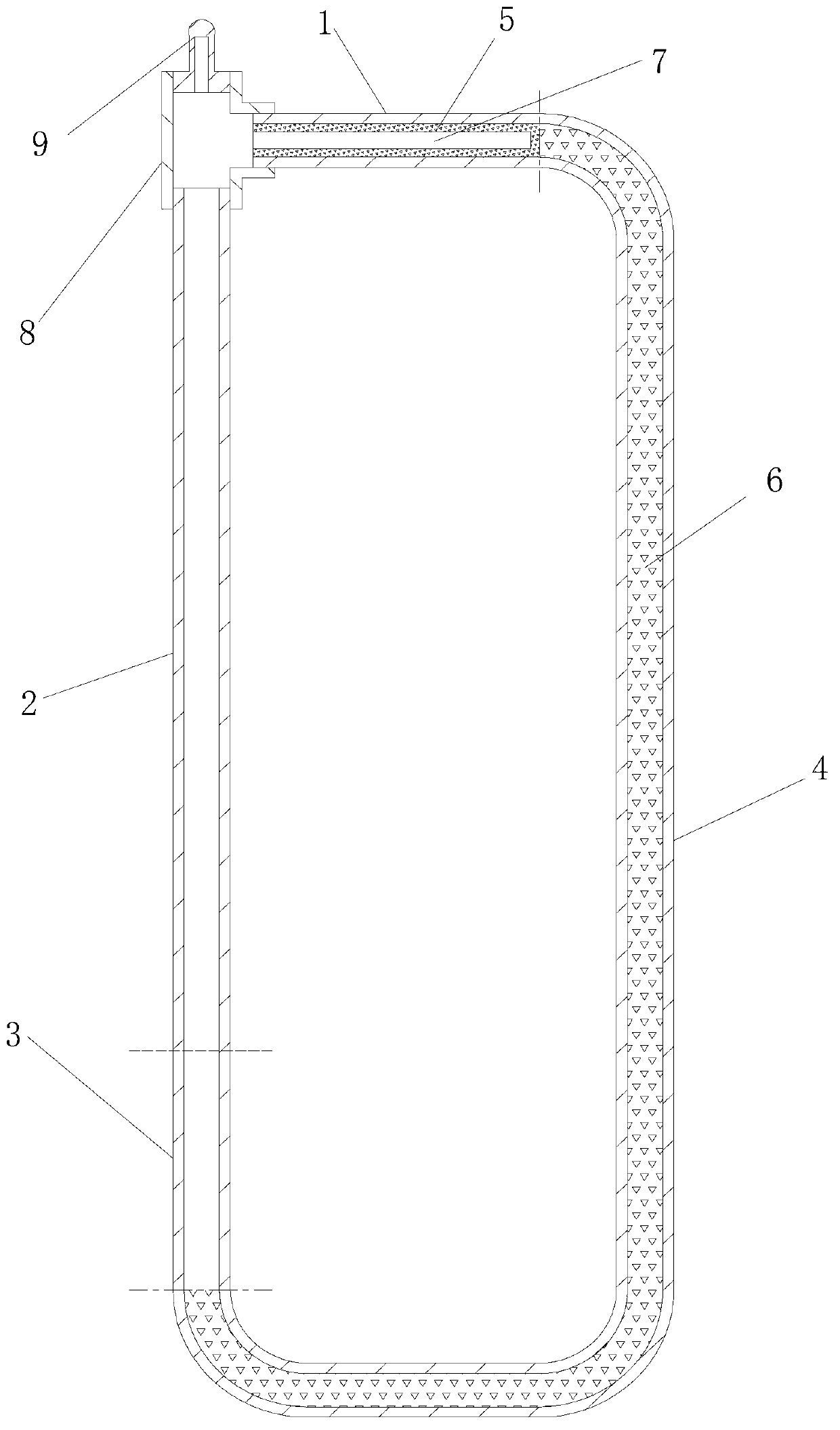

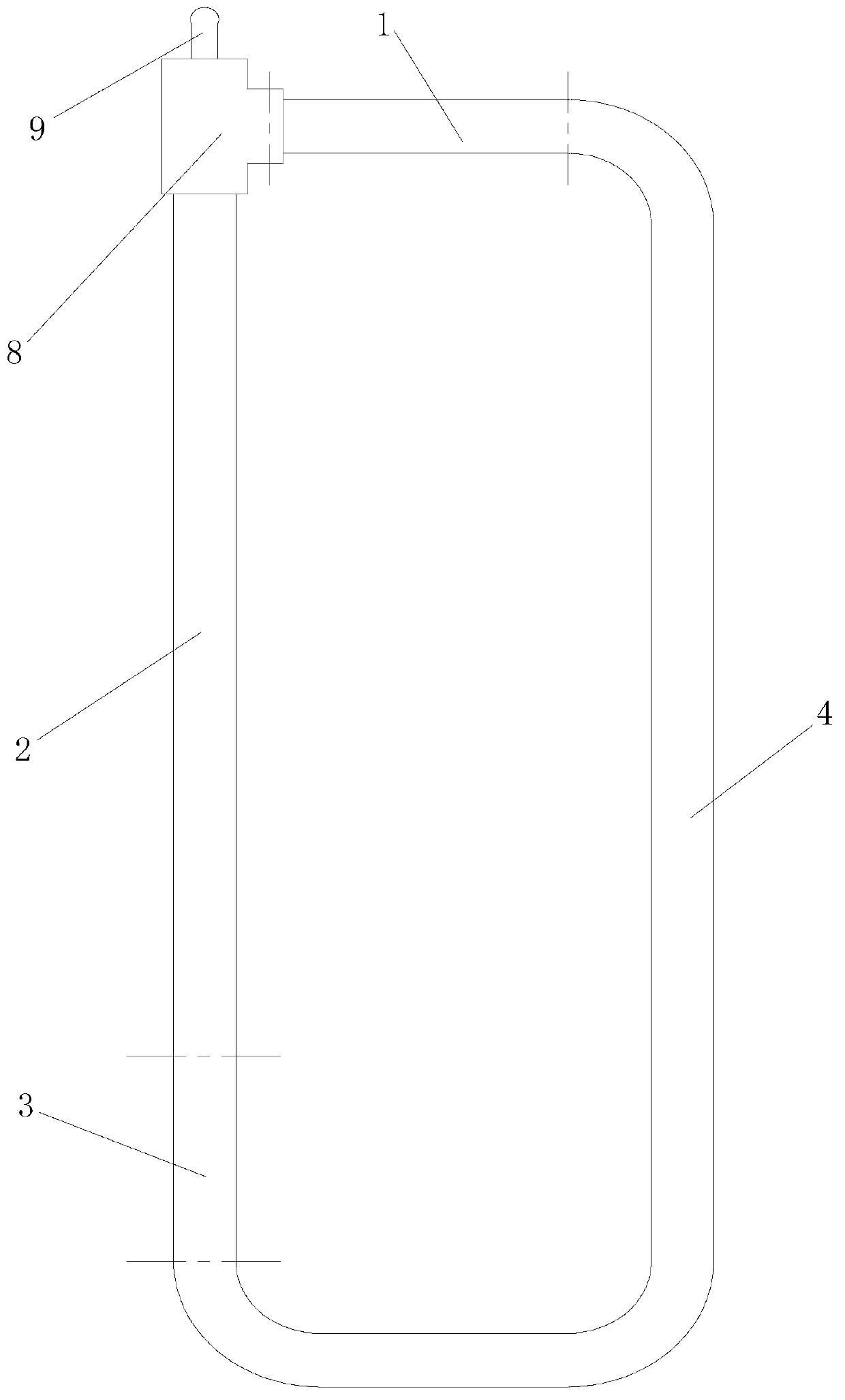

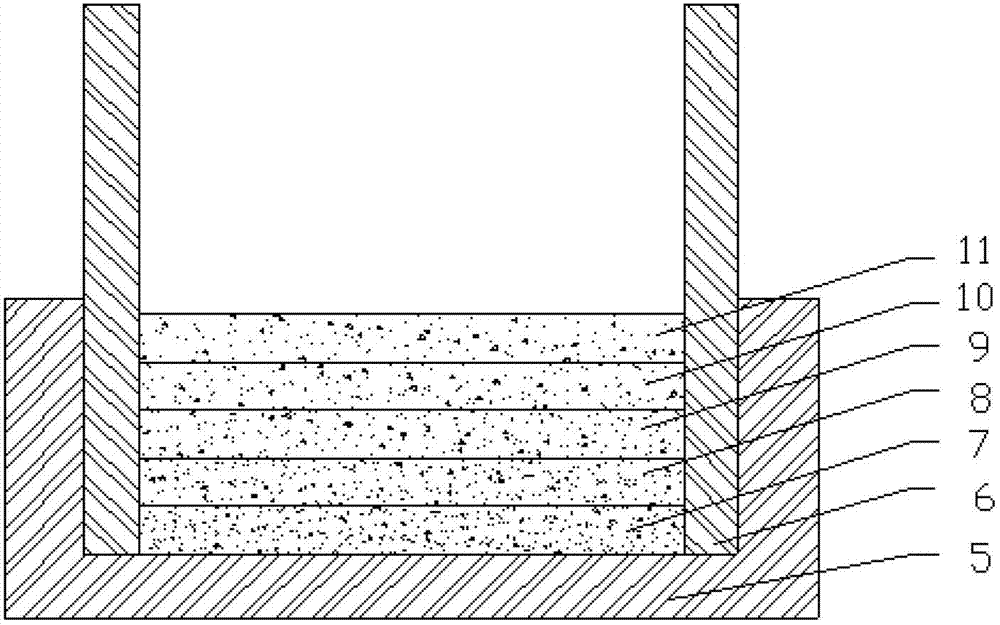

Evaporator and liquid reservoir used for loop heat pipe and application thereof

InactiveCN103344143AReduce heat leakageSimple designIndirect heat exchangersHeat exhanger sealing arrangementMicro-loop heat pipeCapillary pressure

The invention discloses an evaporator and a liquid reservoir used for a loop heat pipe and belongs to the technical field of evaporators. A capillary core structure is adopted for spacing inner spaces of the evaporator and the liquid reservoir, liquid in the liquid reservoir can enter the evaporator through the capillary core, meanwhile the liquid is heated and evaporated to generate steam in the evaporator, and the steam flows out of a steam outlet in an end cover of the evaporator. Due to the fact that the capillary core can generate capillary pressure, the steam in the center of the evaporator can be effectively prevented from entering the liquid reservoir, distribution and flowing of the gas liquid are controlled, and then heat leakage from the evaporator to the liquid reservoir is effectively reduced. The distribution and a flowing route of the gas liquid in the evaporator are adjusted initiatively, therefore the radial heat leakage from the evaporator to the liquid reservoir can be completely eliminated, and the purpose that the heat leakage from the evaporator to the liquid reservoir is effectively reduced is achieved so that starting performance and running stability and reliability of the loop heat pipe can be improved.

Owner:BEIHANG UNIV

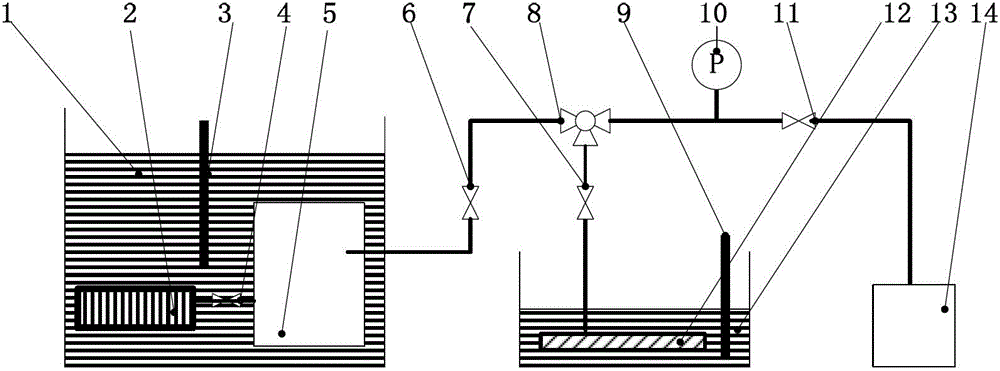

Temperature control gas phase working medium perfusion method for micron heat pipe

InactiveCN103335548APerfusion rate is well controlledImprove performanceIndirect heat exchangersTemperature controlMicro-loop heat pipe

The invention discloses a temperature control gas phase working medium perfusion method for a micron heat pipe, which is applied to heat dissipation of high heating flux devices. The method is characterized in that the temperature of the micron heat pipe and the temperature of a working medium container are respectively controlled; the micron heat pipe and the working medium container are respectively vacuumized; then the working medium container is connected with a working medium source, so that working medium steam can get into the working medium container; the micron heat pipe and the working medium container are communicated, so that perfusion of the gas phase working medium can be realized by utilizing the temperature difference between the micron heat pipe and the working medium container; the perfusion amount of the working medium can be controlled as per time, and after a perfusion port of the micron heat pipe is sealed, working medium perfusion for the micron heat pipe is accomplished. The working medium exists in a perfusion system in gas phase, so the perfusion rate, the repeatability and the controllability are good; the temperature of the micron heat pipe and the temperature of the working medium are respectively controlled, so that the perfusion efficiency of the working medium is improved; the method can improve the performance of the micron heat pipe.

Owner:DALIAN UNIV OF TECH

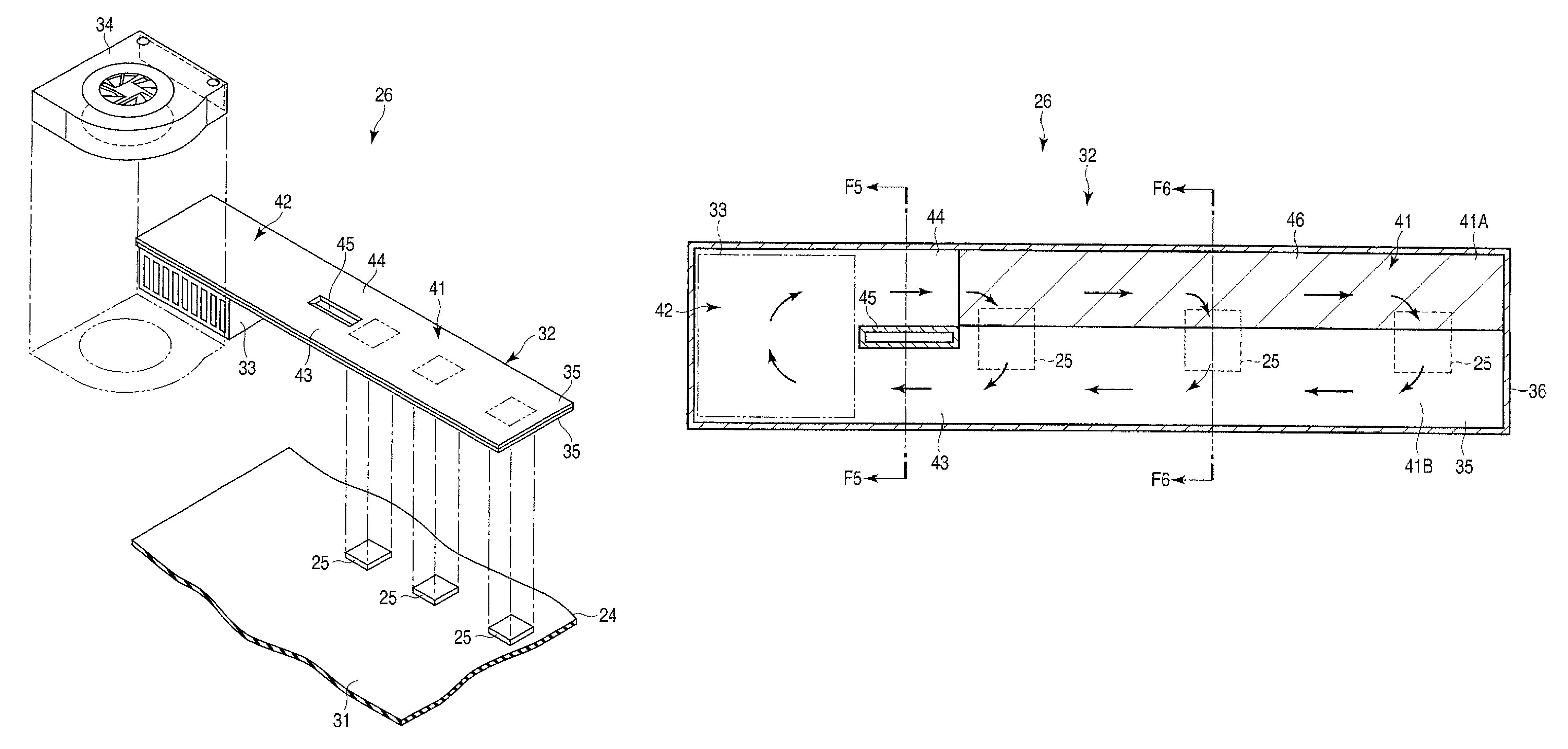

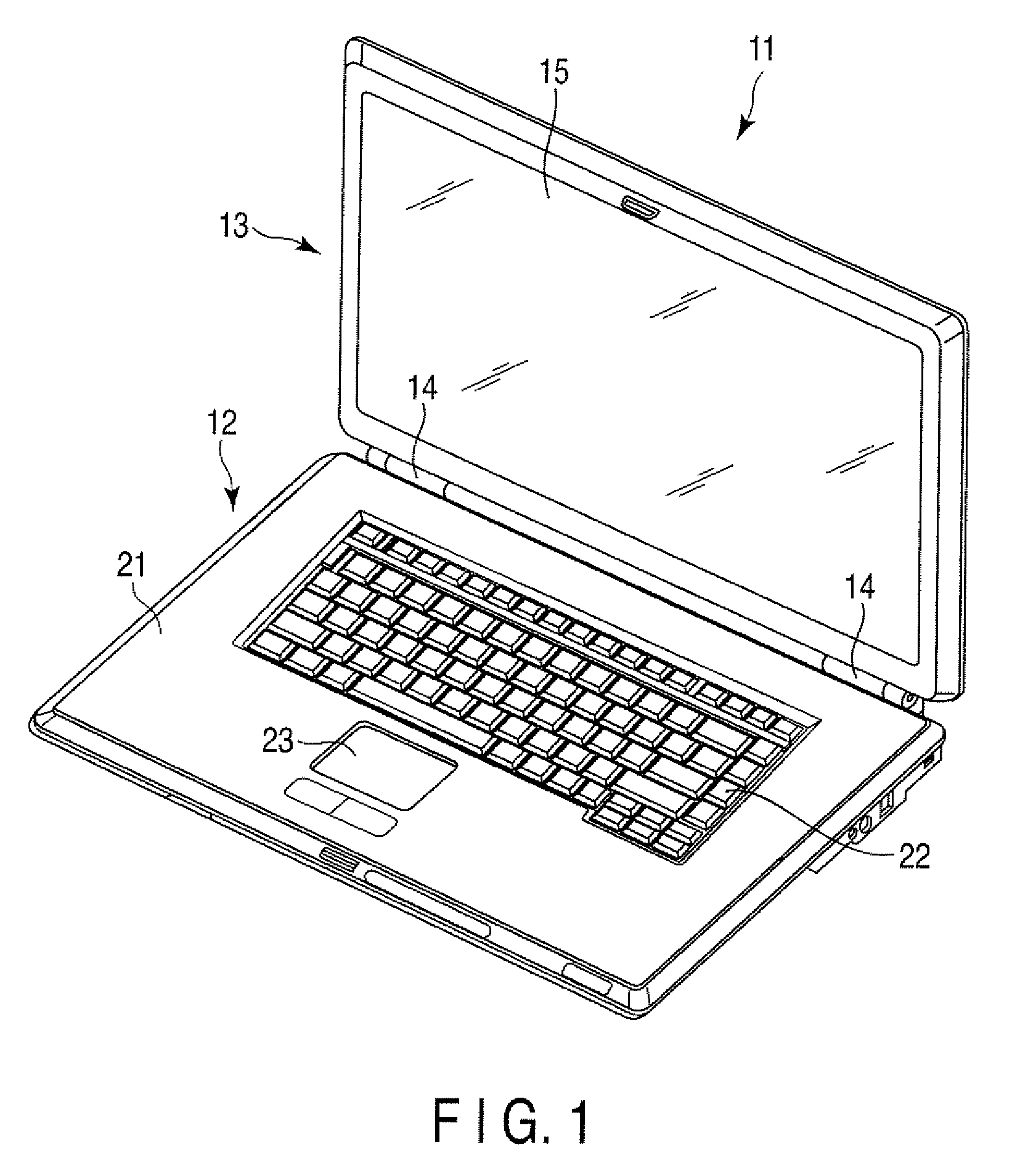

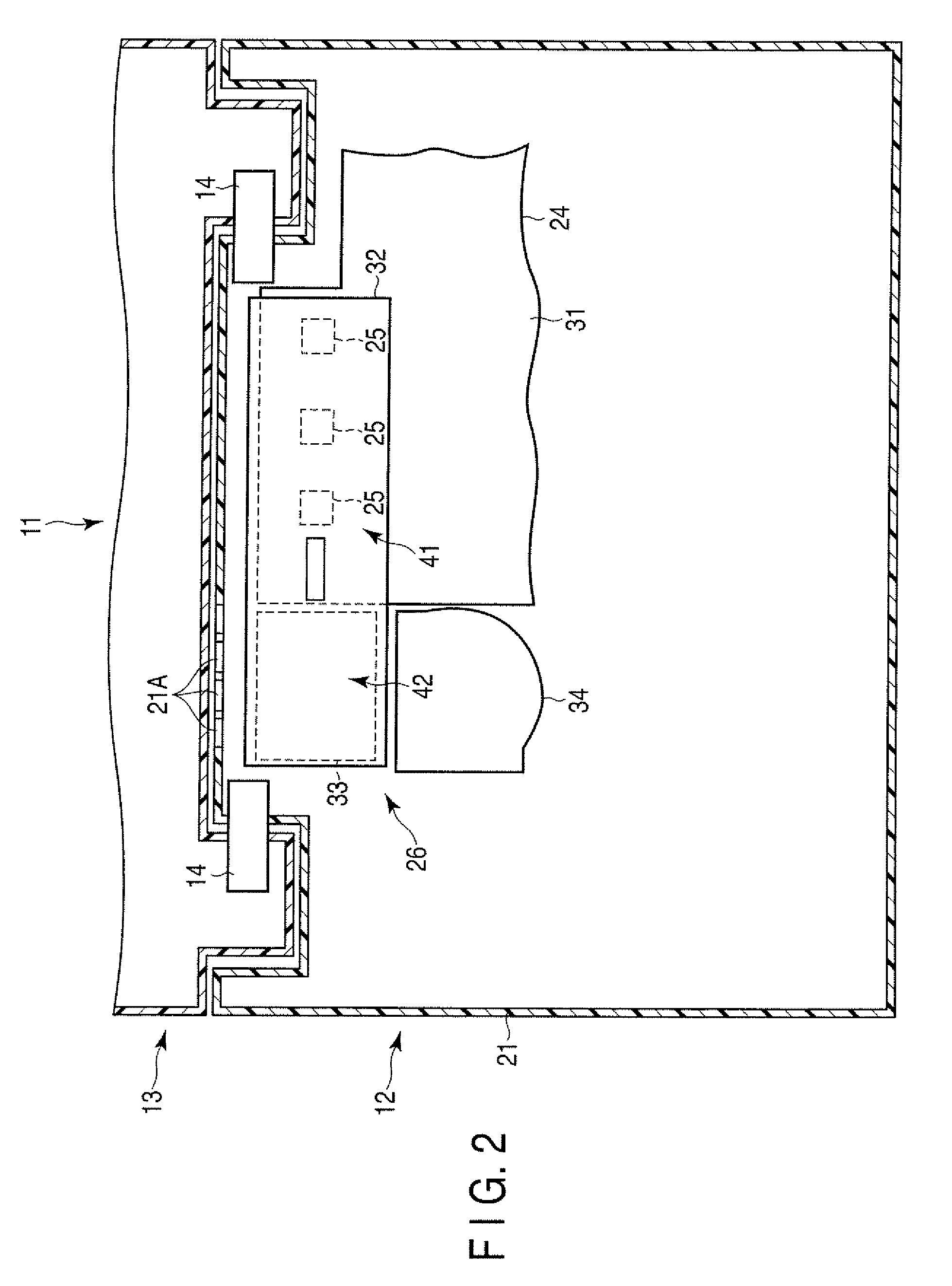

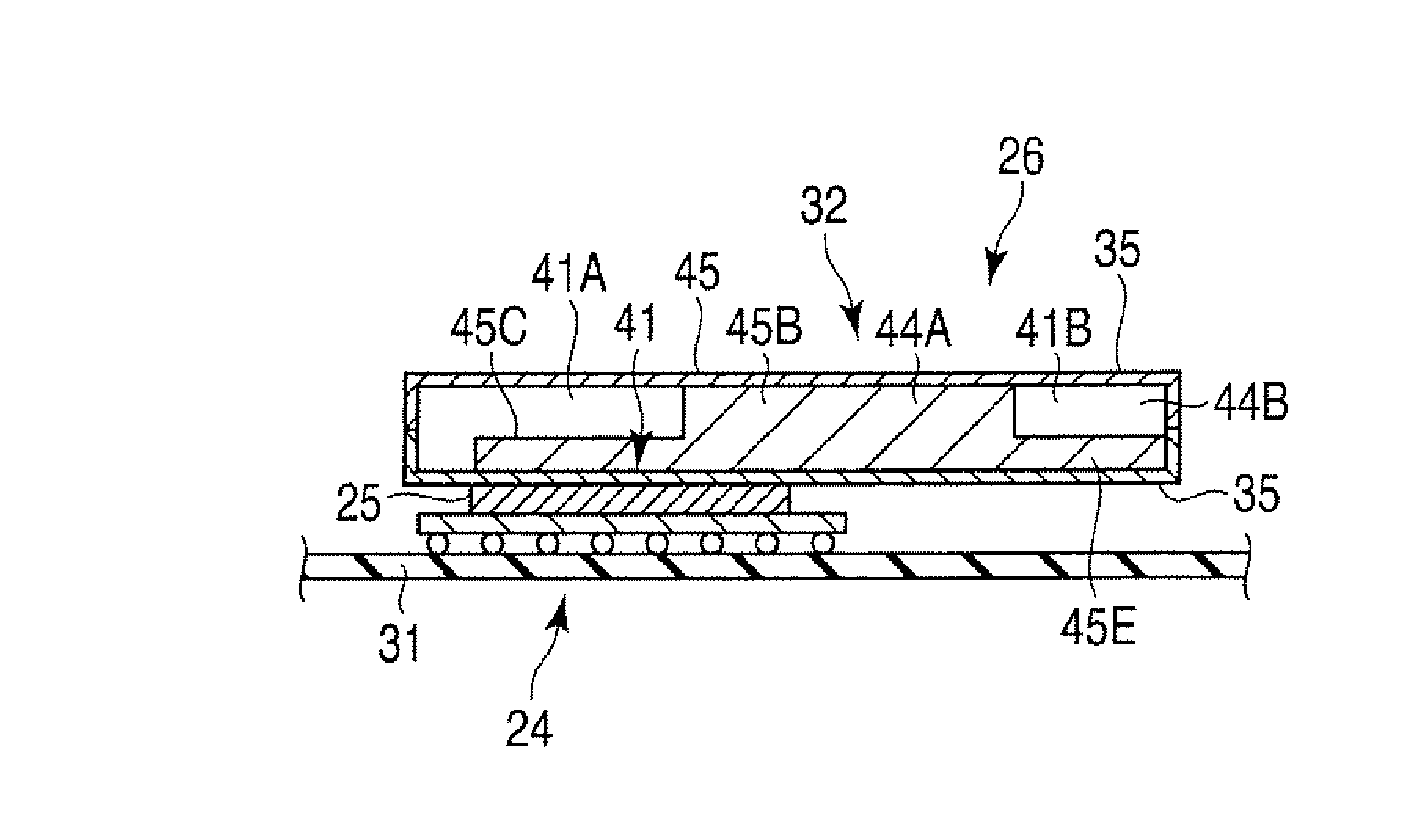

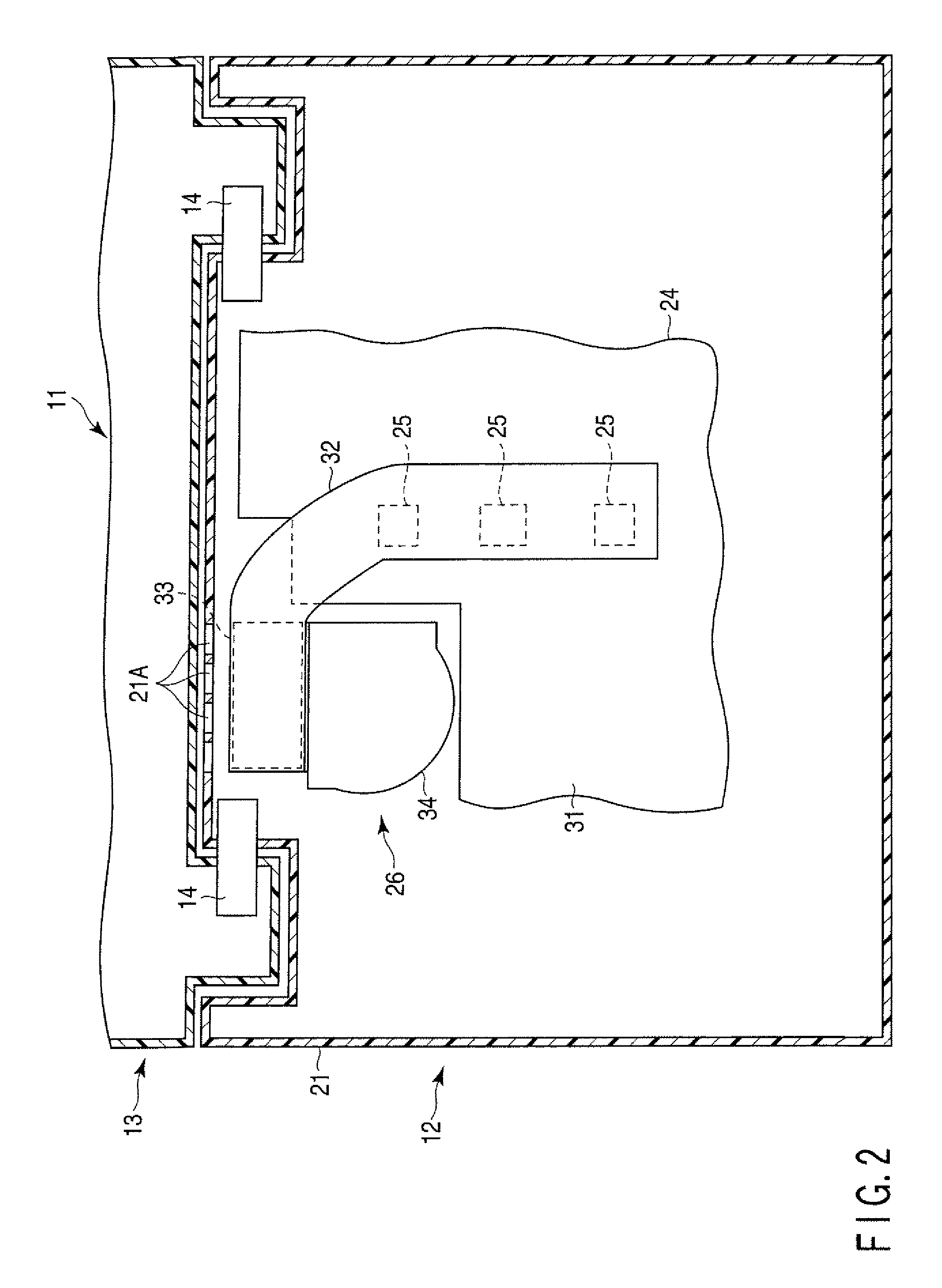

Electronic device, cooling device and loop heat pipe

According to one embodiment, an electronic device includes a housing, a heat generating part contained in the housing, and a loop heat pipe contained in the housing. The loop heat pipe includes a heat receiving portion, a heat radiating portion, a vapor flow path and a liquid return flow path. The heat receiving portion includes a first region connected to the liquid return flow path and provided with a wick, and a second region formed to be hollow, connected to the vapor flow path. The heat receiving portion is thermally connected to the heat generating part at a position across the first region and the second region.

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

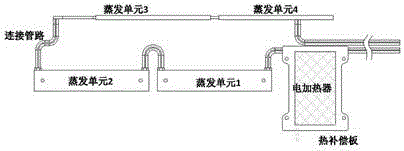

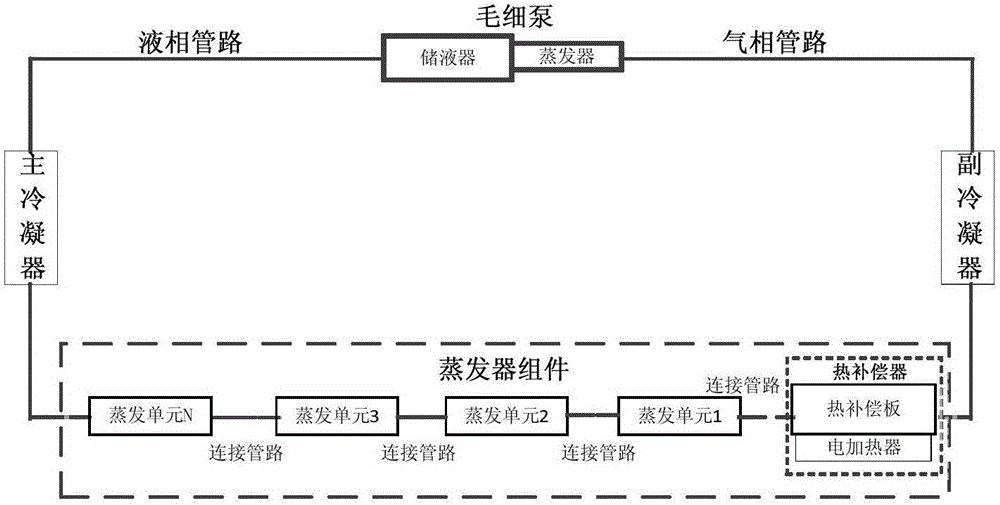

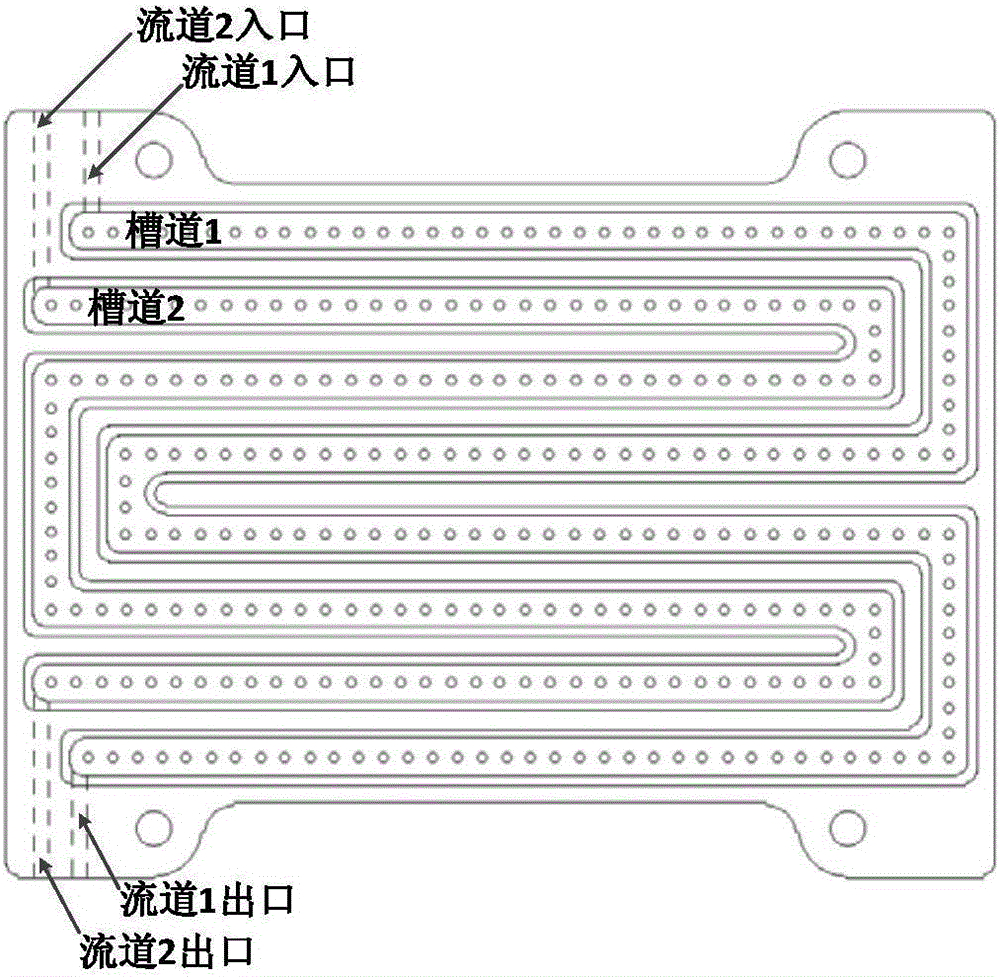

Temperature control type loop heat pipe evaporator assembly

ActiveCN105910479AStable temperatureConsistent temperatureIndirect heat exchangersTemperature controlMicro-loop heat pipe

A temperature control type loop heat pipe evaporator assembly comprises a heat compensator, N evaporation units and a connecting pipeline, wherein the N is a positive integer bigger than or equal to 1; the heat compensator is arranged in the input end so as to heat up the liquid working medium in the loop heat pipe into gas-liquid two-phase state; the N evaporation units are connected by the connecting pipeline so as to form an evaporation network; the input end of the evaporation network is connected with the output end of the heat compensator through the connecting pipeline; the output end of the evaporation network serves as the output end of the evaporator assembly. The evaporator assembly can ensure the working medium entering each evaporation unit in the loop heat pipe operation to be two-phase working medium, thus ensuring constant and consistent temperature of the heat source in working / non working state, and accurately controlling the temperature in the complete cycle.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

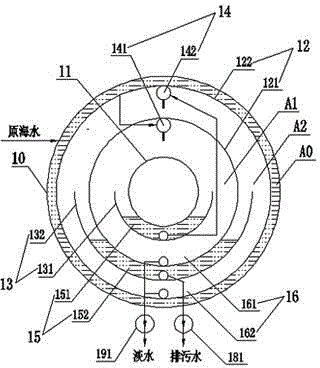

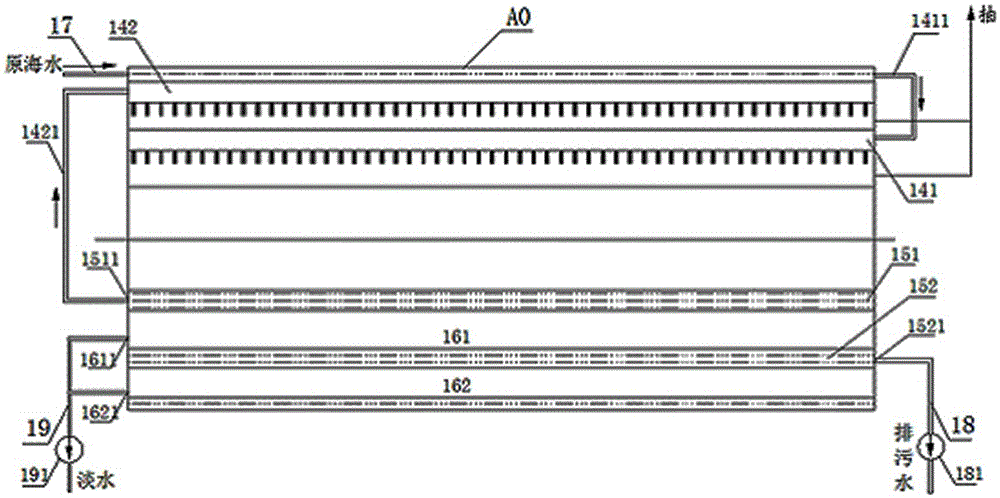

Loop heat pipe-type cylindrical solar seawater desalination device

ActiveCN104591327AIncrease heat transfer distanceHigh heat transferGeneral water supply conservationSeawater treatmentDistillationConcentration ratio

The invention discloses a loop heat pipe-type cylindrical solar seawater desalination device. The device comprises a cylindrical multiple-effect distiller, a light collection groove and a loop heat pipe. An evaporating pipe of the loop heat pipe is used as a solar heat collecting pipe and a condenser pipe of the loop heat pipe is used as a distiller heating pipe so that characteristics of good heat transfer performance and high integral efficiency are obtained. A heating pipe, a heat-transfer pipe, a semi-circular groove and a nozzle unit are tightly arranged in a heat-insulation cylinder inner-cavity so that a pre-heating chamber, a distillation chamber, a seawater tank and a fresh water tank are formed and thus the distiller structure is very compact, can be processed easily and is suitable for standard production. The distiller has the characteristics of repeated use of vaporization latent heat, reinforcement of inner heat and mass transfer processes and improvement of an operation temperature. The heat transfer areas of the distillation chamber are increased from inside to outside so that a small heat transfer temperature difference is kept, the whole distiller effective number is improved and a concentration ratio and a water yield are further improved. The loop heat pipe-type cylindrical solar seawater desalination device is suitable for low-cost modularization production and can be widely used in the field of solar energy seawater desalination.

Owner:JIMEI UNIV

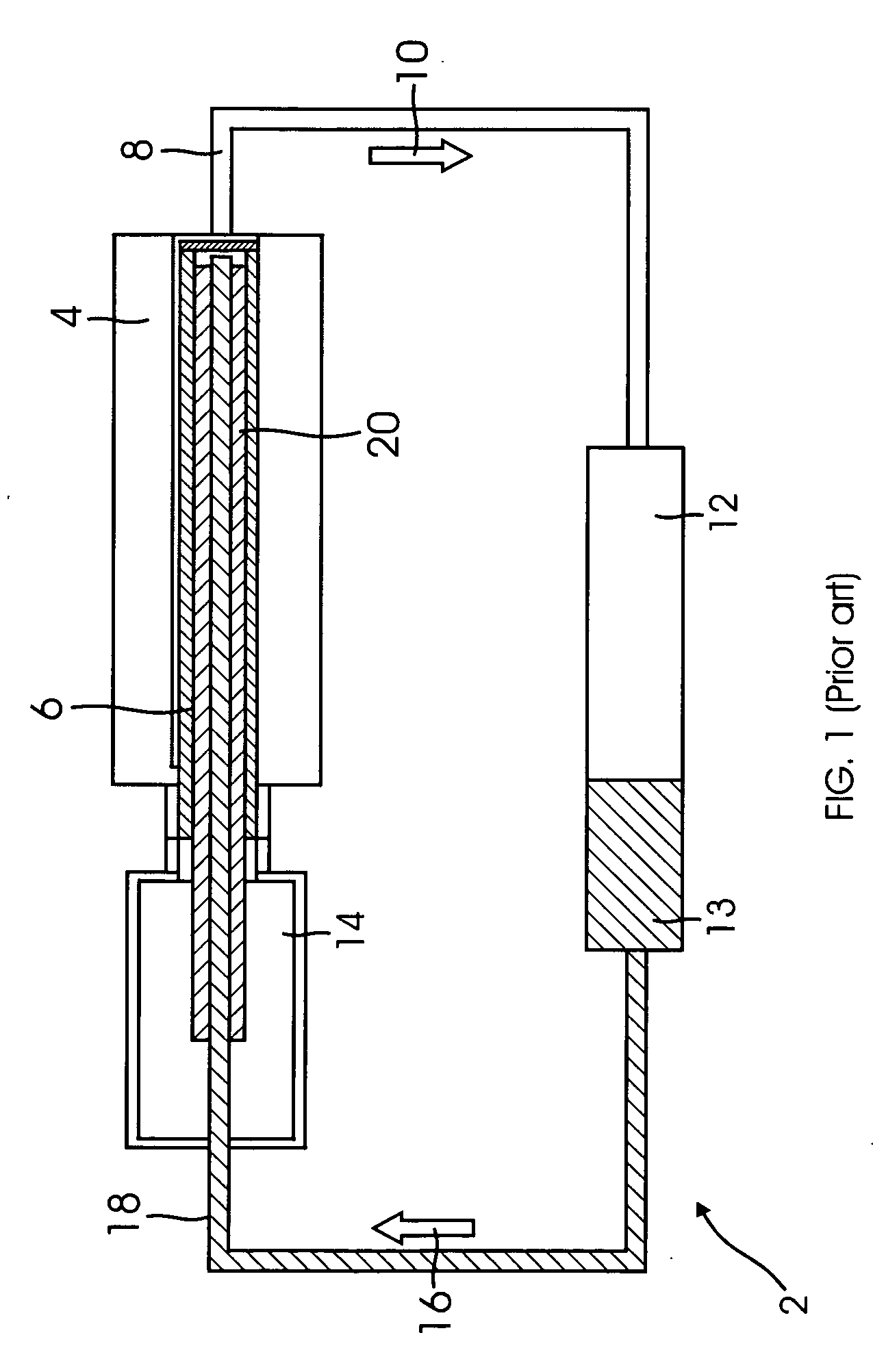

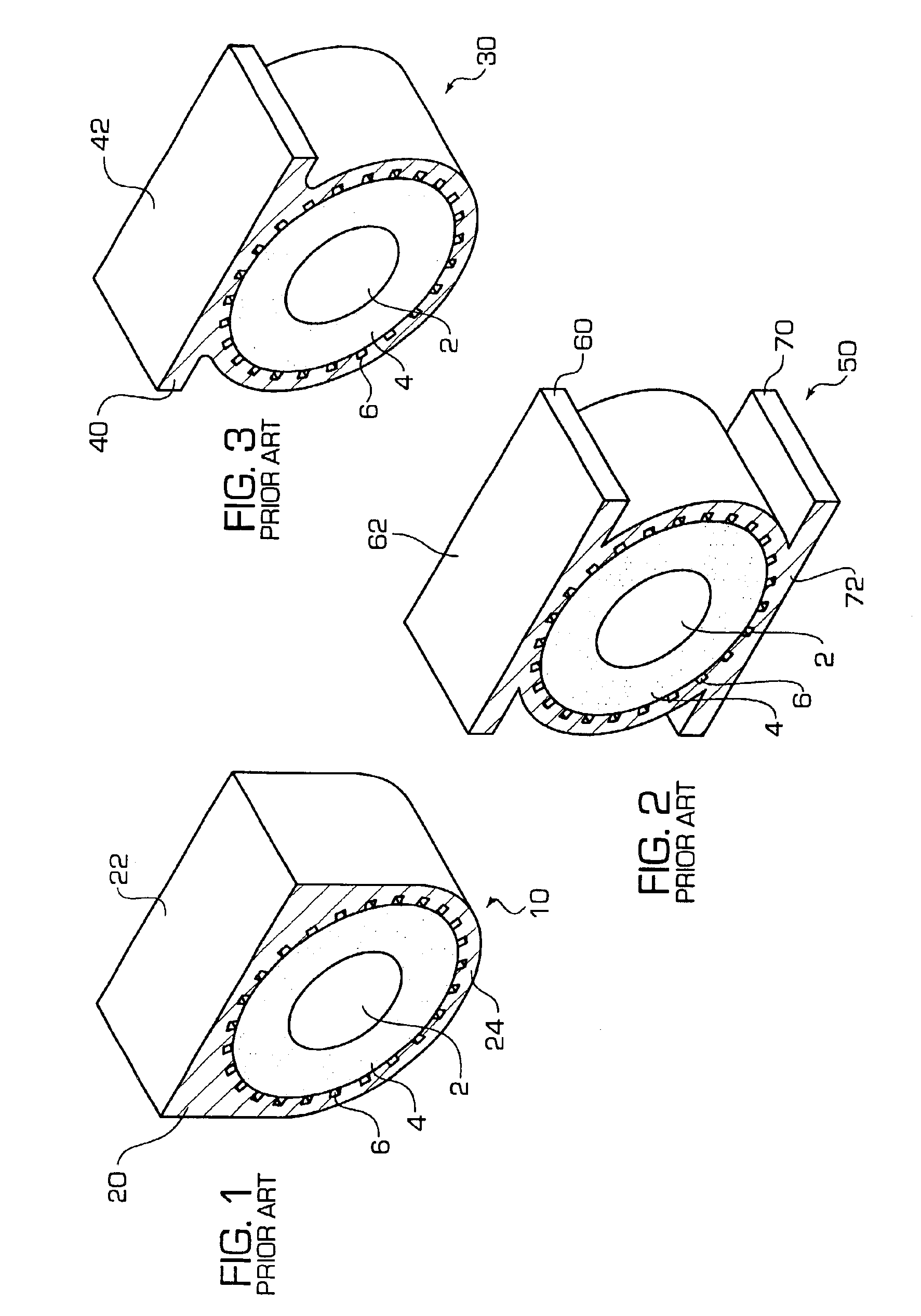

System and method of a heat transfer system and a condensor

InactiveUS20080110598A1Level controlSemiconductor/solid-state device detailsMicron scaleWorking fluid

Owner:UNIVERSITY OF CINCINNATI

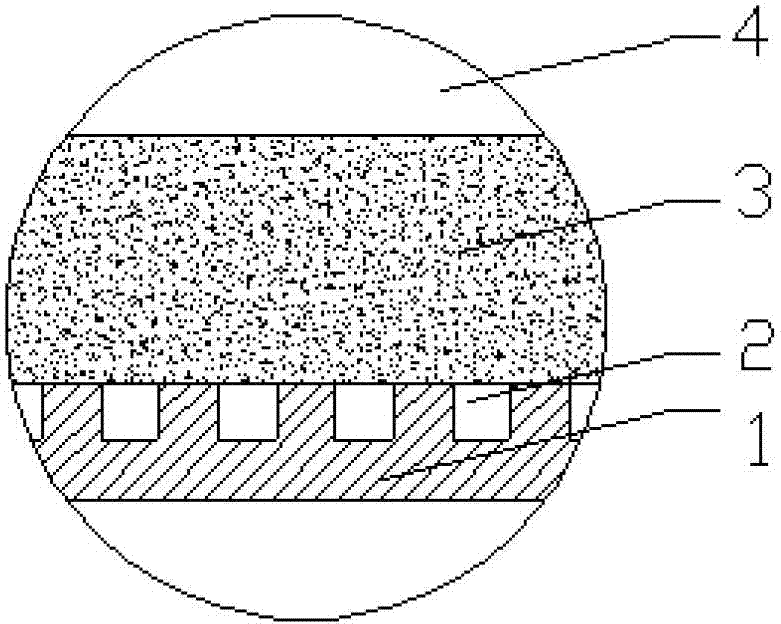

Composite capillary core with differential thermal coefficients for loop heat pipe and preparation method of composite capillary core

ActiveCN102901390AEasy to makeImprove heat transfer performanceIndirect heat exchangersAviationPowder mixture

The invention relates to a composite capillary core with differential thermal coefficients for a loop heat pipe and a preparation method of the composite capillary core. A thermal coefficient of the composite capillary core close to an evaporator side of the loop heat pipe is higher than that of the composite capillary core close to a compensator liquid side of the loop heat pipe. The preparation method of the composite capillary core with differential thermal coefficients comprises the following steps of: selecting sintering material matrix metal powders with an infinite mutual solubility and preparing a powder mixture with different mass proportions; filling the mixed powder mixture with different mass proportions in a mould layer by layer; carrying out cold press moulding on the powder mixture after the powder mixture is filled in the mould to form the shape and size required by a capillary core; and at last, sintering the powder mixture to prepare the composite capillary core with differential thermal coefficients. Since the composite capillary core has differential thermal coefficients, the heat transfer performance of the loop heat pipe can be favorably improved and heat control requirements of the loop heat pipe with performances of large heat transfer power and long-distance transmission can be met; and the composite capillary core with differential thermal coefficients can be used for developing efficient loop heat pipes and can be applied to the fields such as aviation heat control and ground electronic equipment cooling and the like.

Owner:SHANDONG UNIV

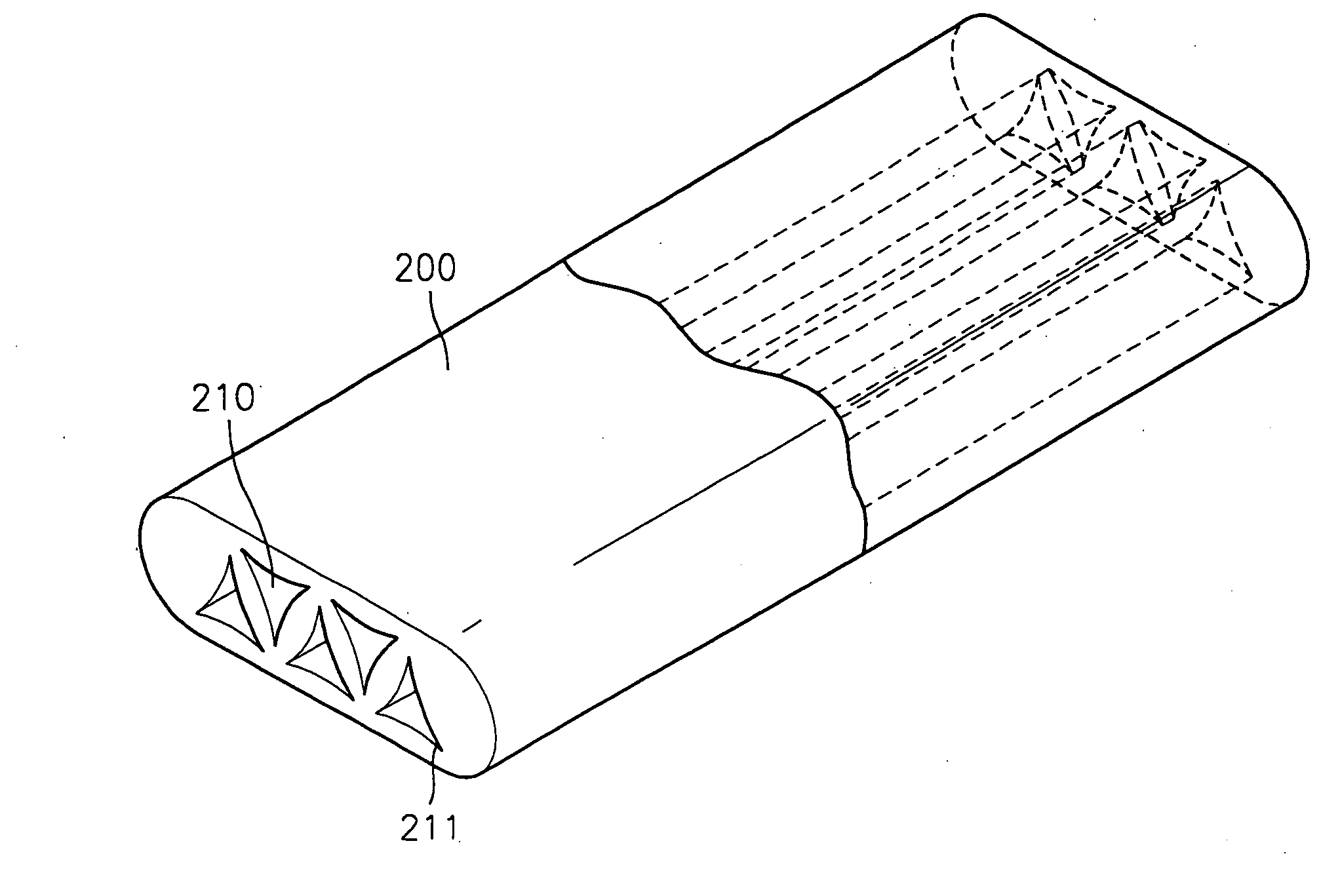

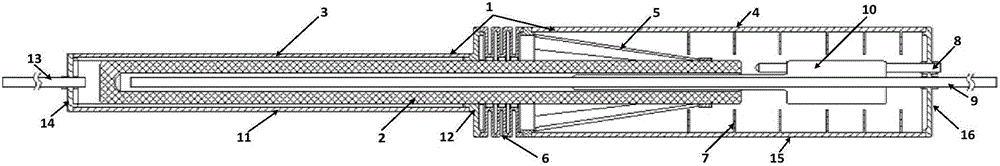

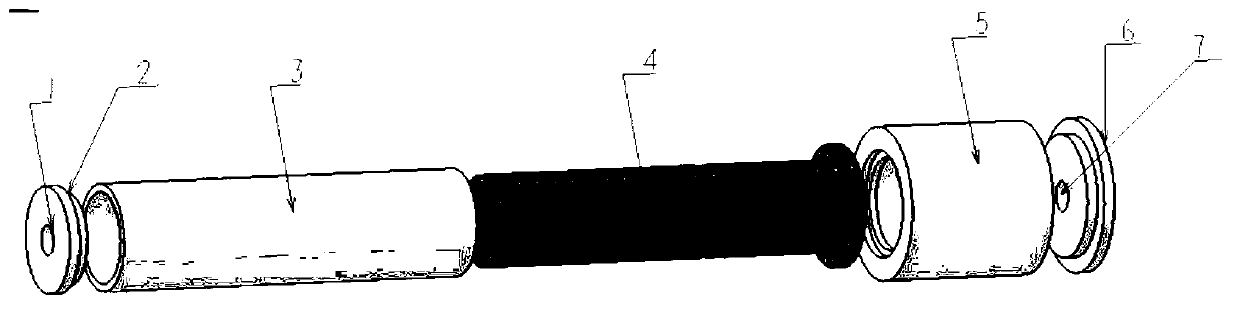

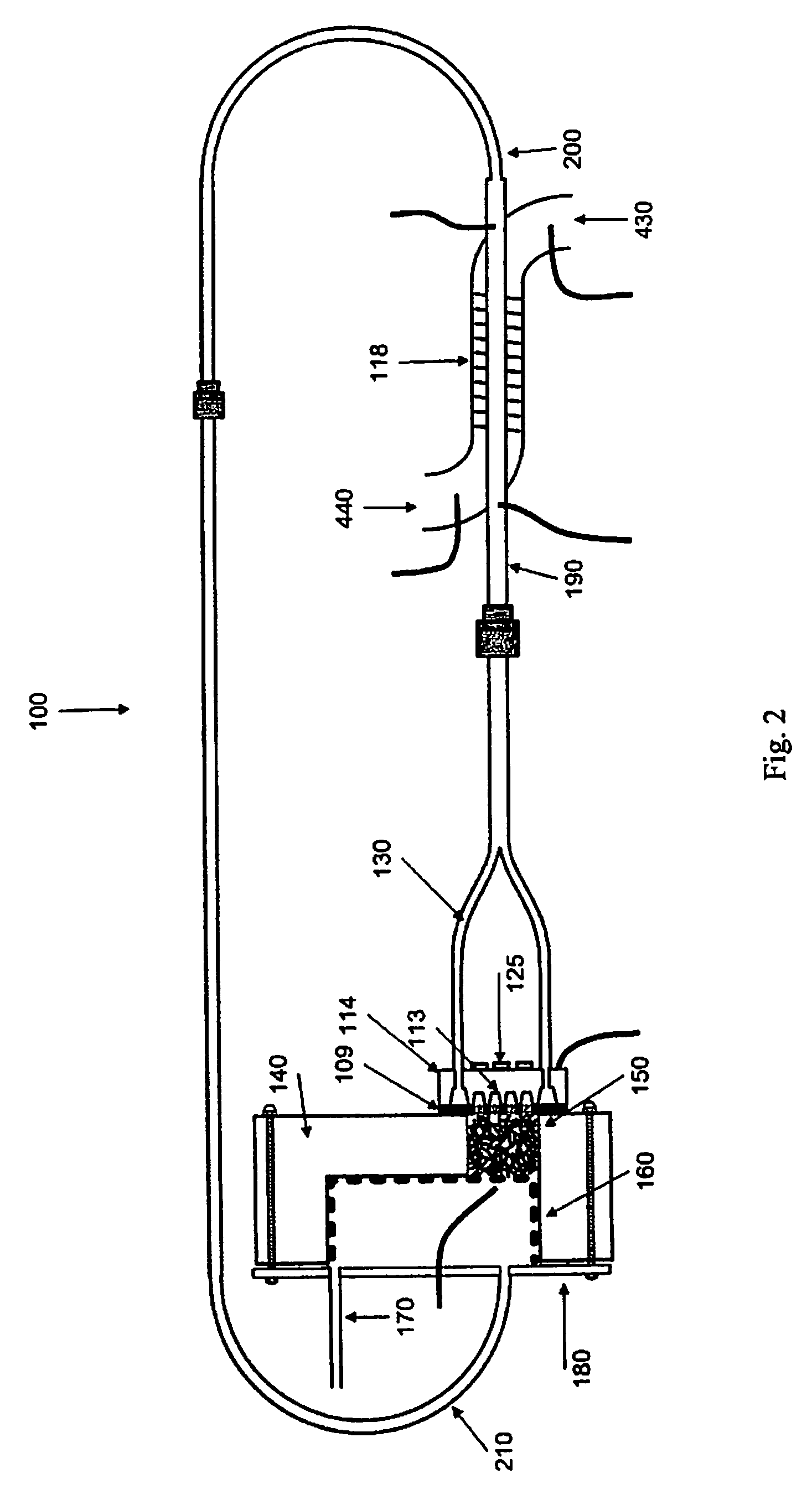

Miniaturized loop heat pipe

ActiveCN101672592AShorten the lengthReduce volumeIndirect heat exchangersHeat exchange apparatusMicro-loop heat pipeMiniaturization

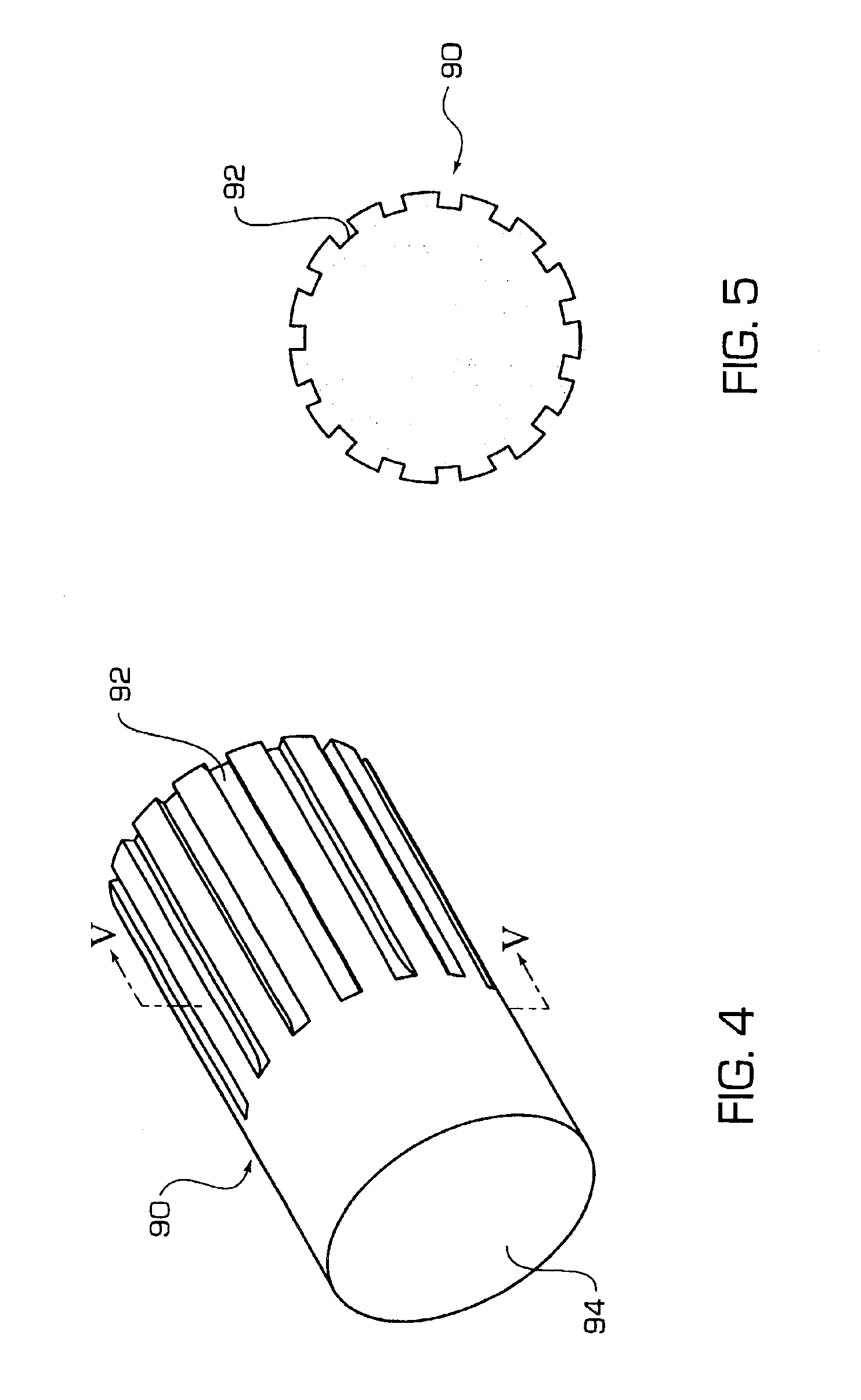

The invention discloses a miniaturized loop heat pipe which comprises an evaporator, a liquid pool and a condenser, wherein the liquid pool and the condenser are connected with the evaporator into anintegral, and the evaporator, the liquid pool and the condenser are connected together through a fine thin wall pipe made of stainless steel to form a loop. When the miniaturized loop heat pipe is applied to the environment lower than 200K, an air reservoir which is connected to a steam pipeline is used for reducing the storage pressure of the miniaturized loop heat pipe in the normal temperatureenvironment. The invention is mainly characterized in that a liquid absorbing core in the evaporator is redesigned; a metal mesh is used as a secondary liquid absorbing core; and a circumferential thread channel is carved on the surface of the main liquid absorbing core to enable the liquid to be distributed uniformly, and an axial rectangular channel is carved to be used as a flow passage of steam. A new condenser is designed, and thread fins, rectangular fins or saw teeth are additionally arranged on the flow passage of working substances to be used as a condensation strengthening measure, thereby improving the condensation efficiency and reducing the size and the weight of the condenser.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Loop heat pipe

InactiveUS7654310B2Easy to operateImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMicro-loop heat pipeClosed loop

Owner:JAFFE

Solar heat storage system of loop heat pipe

InactiveCN105737399AAvoid wastingEven heat absorptionSolar heating energySolar heat devicesMicro-loop heat pipeEvaporation

The invention provides a solar heat storage system of a loop heat pipe. The solar heat storage system comprises a heat collector, a water tank, a heat storage device and the loop heat pipe; the condensation end of the loop heat pipe is arranged in the water tank, and the heat collector absorbs heat of solar energy to heat the evaporation end of the loop heat pipe; working liquid at the evaporation end is circulated to enter the condensation end of the loop heat pipe, and heat releasing is carried out at the condensation end to heat water in the water tank; and after heat releasing is completed at the condensation end, the working liquid is recirculated to enter the evaporation end of the loop heat pipe to conduct heating, and the water tank is connected with the heat storage device. According to the loop heat pipe solar heat storage system, by means of the loop heat pipe, the heat using capacity of solar energy is improved.

Owner:SHANDONG UNIV

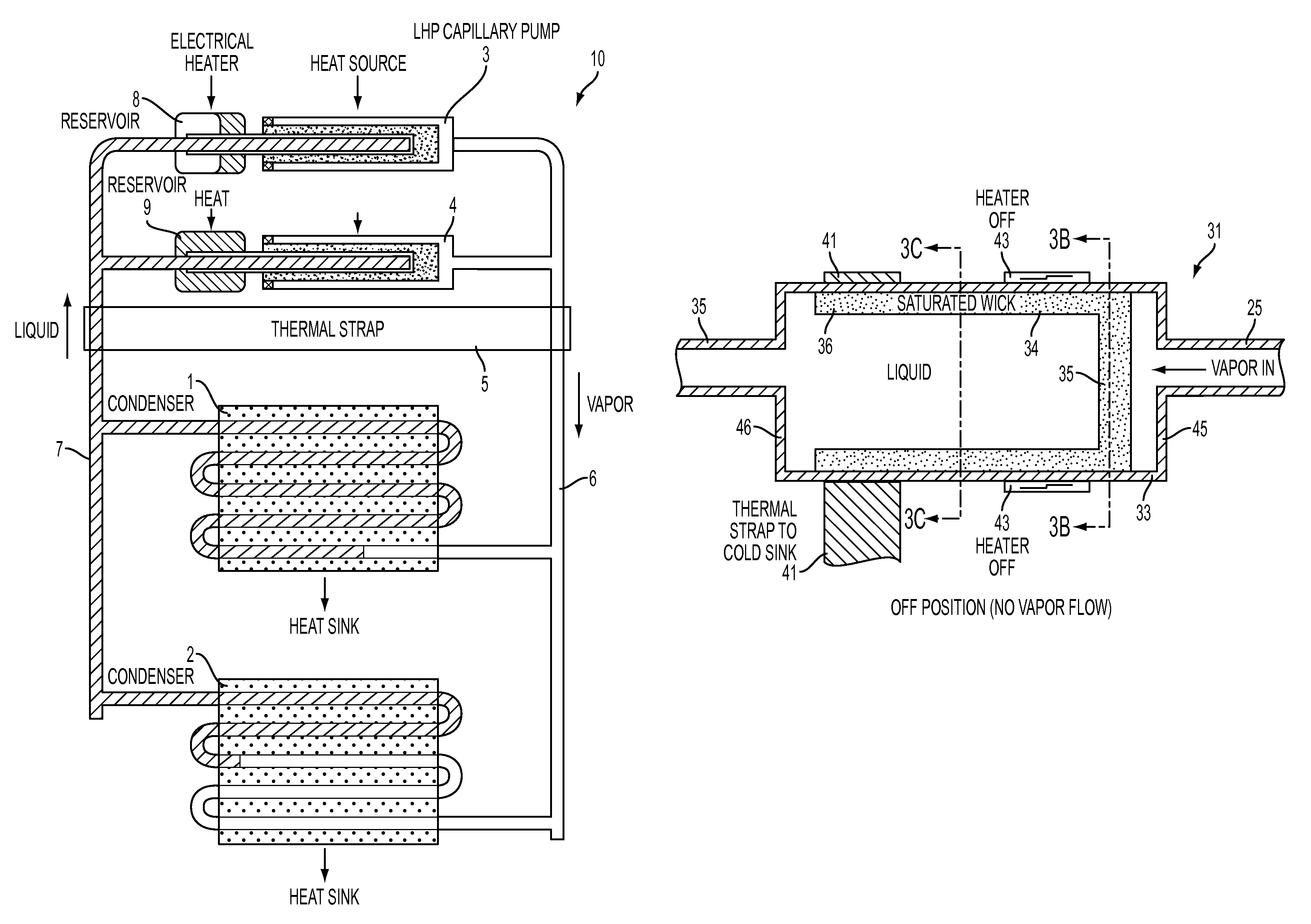

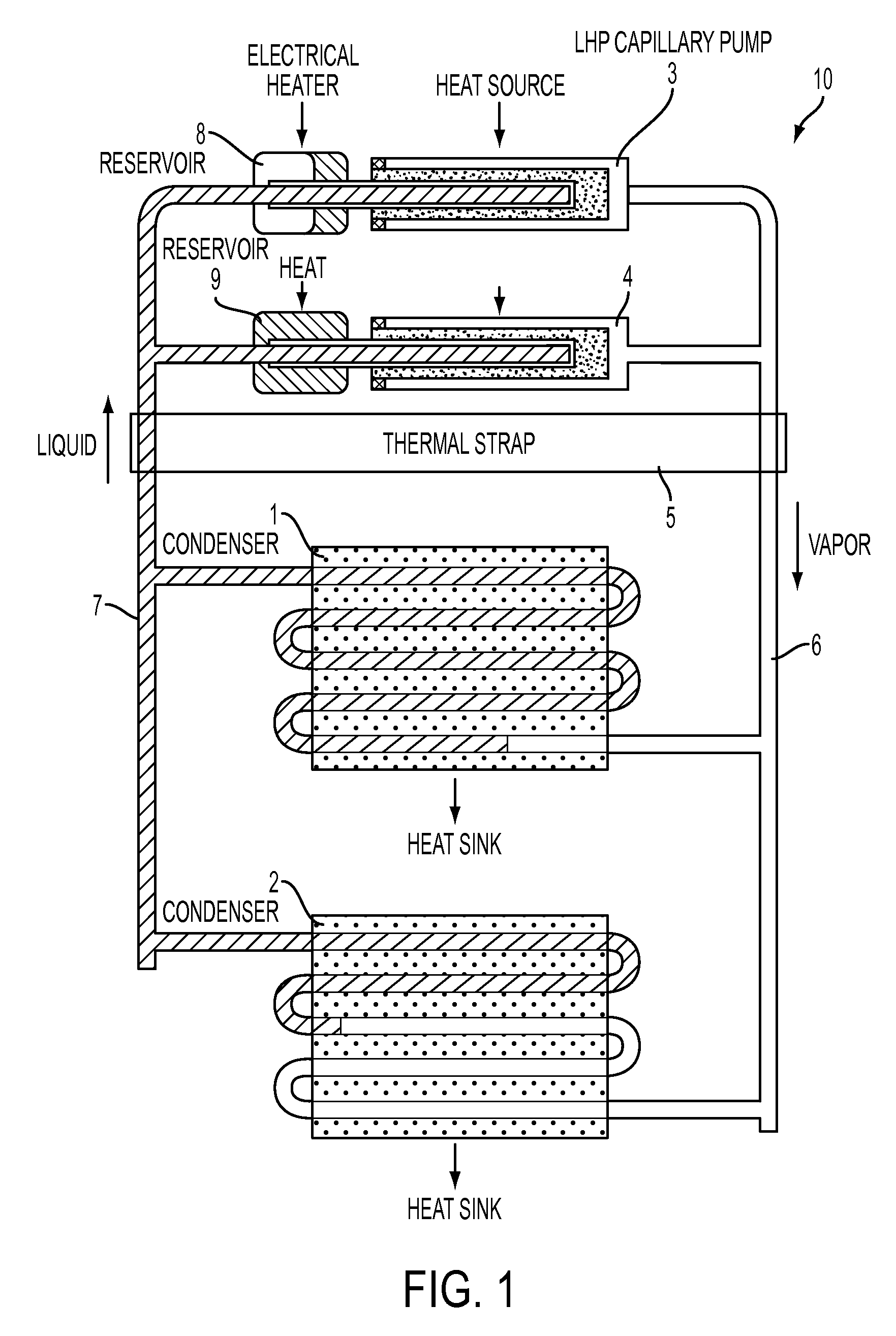

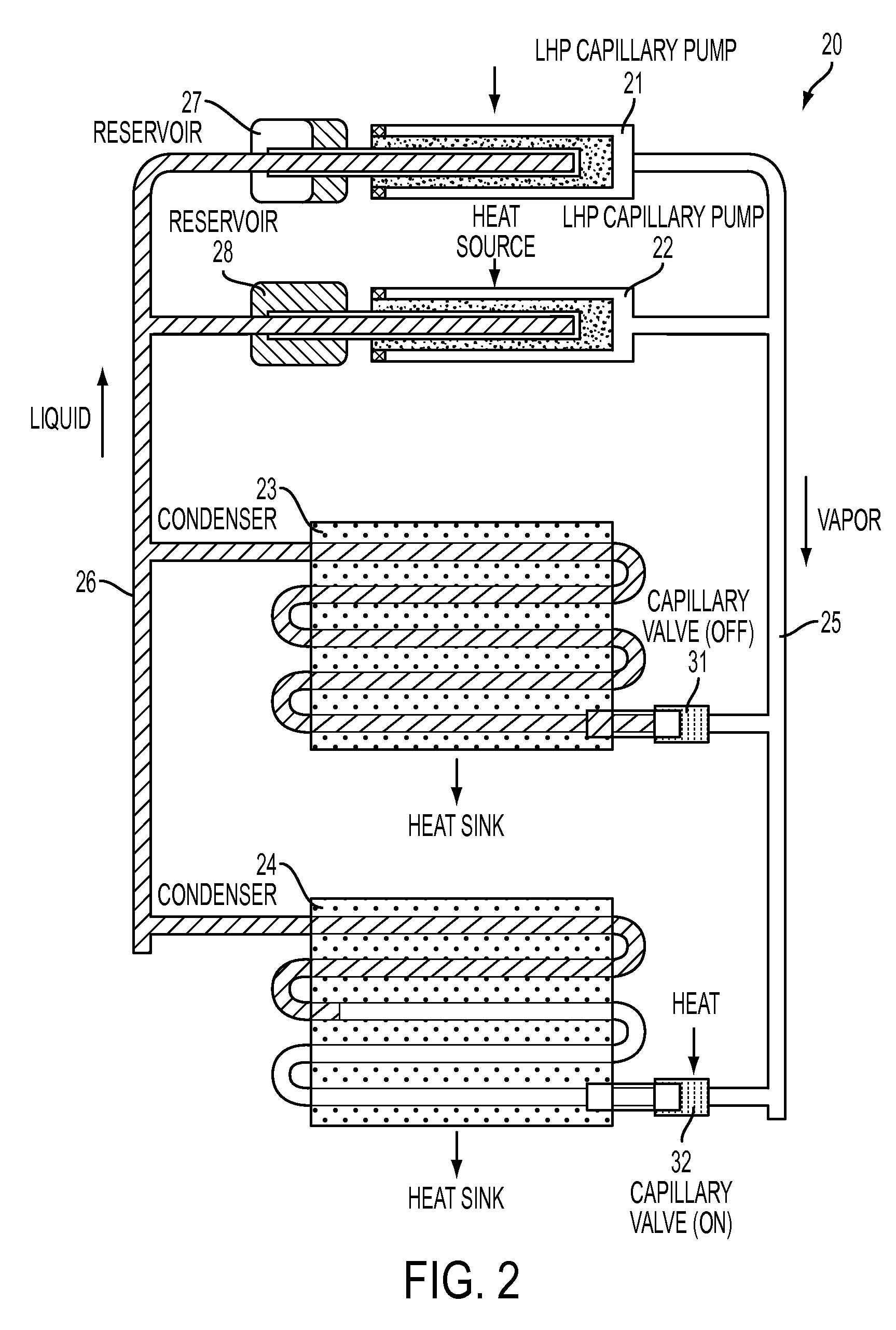

Temperature actuated capillary valve for loop heat pipe system

A capillary flow valve for use in a two phase heat transfer system such as a loop heat pipe, including an inlet port for receiving working fluid in a vapor-phase, an outlet port for outputting working fluid in a vapor-phase, and a porous wick material extending across the interior of the valve. Heating the wick evaporates liquid-phase working fluid from the wick and allows the vapor-phase working fluid to pass through the wick to the outlet port. Removing the heat allows liquid to condense in the wick, preventing flow of the vapor-phase working fluid through the wick to the outlet port.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

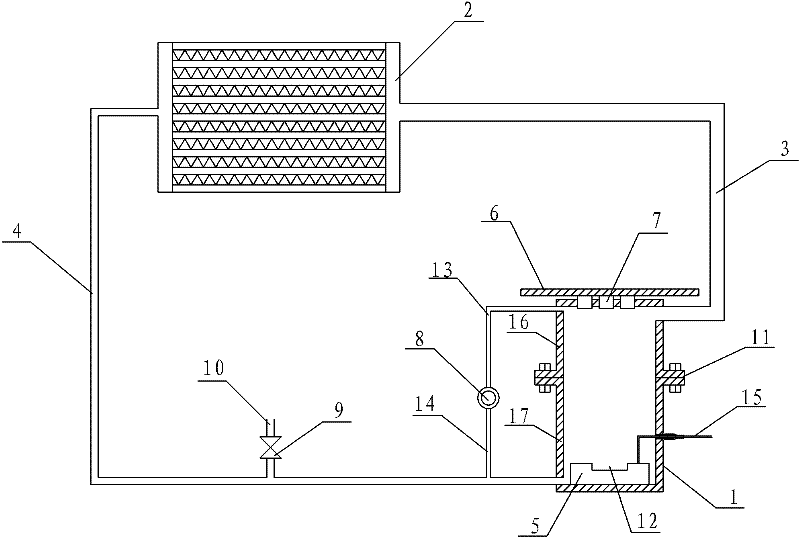

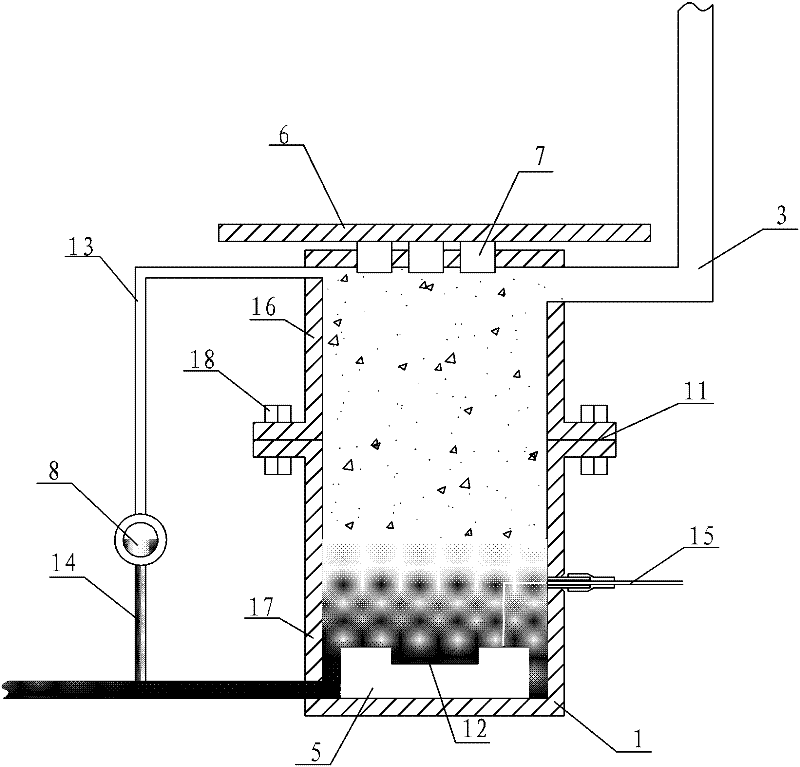

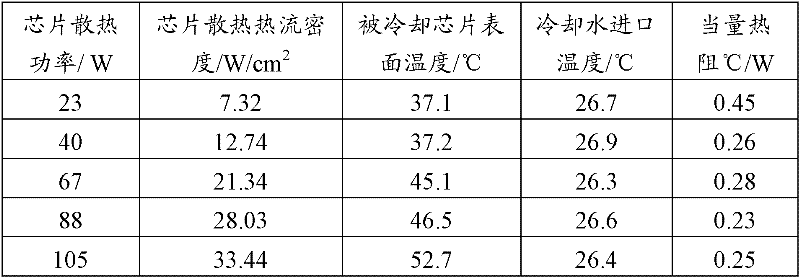

Gravity-assisted loop heat pipe with ultrasonic vibration atomizing device

InactiveCN102506598AIncrease contactImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesGas phaseMature technology

The invention discloses a gravity-assisted loop heat pipe with an ultrasonic vibration atomizing device, which comprises an evaporating cavity, a condensing section, a gas-phase pipe and a liquid-phase pipe. The evaporating cavity and the condensing section are communicated closely to form a circulating loop by the gas-phase pipe and the liquid-phase pipe, the condensing section is arranged above the evaporating cavity, the ultrasonic vibration atomizing device is arranged at the bottom of an inner cavity of the evaporating cavity, and a plurality of slots communicated with the outside are arranged on the top surface of the evaporating cavity. A substrate is arranged above the evaporating cavity, a plurality of cooled chips are fixed on the bottom surface of the substrate, bottom surfaces of the cooled chips penetrate through the corresponding slots on the evaporating cavity, and four sides of each of the cooled chips are respectively connected with each of the slots hermetically. The gravity-assisted loop heat pipe with the ultrasonic vibration atomizing device adopts the mature technology, and the structure of the evaporating cavity can be changed flexibly according to the shapes of the cooled chips and the arrangement position of the substrate, so that the gravity-assisted loop heat pipe can be adaptable to cooling of chip arrays better, particularly has wider application prospect to cooling and heat control of ground high-heat-flux power-consumption electronic chip arrays, such as high-end CPUs (central processing units), high-power LED lamps, communication equipment and the like, and is high in practicability.

Owner:ZHEJIANG COLLEGE OF CONSTR

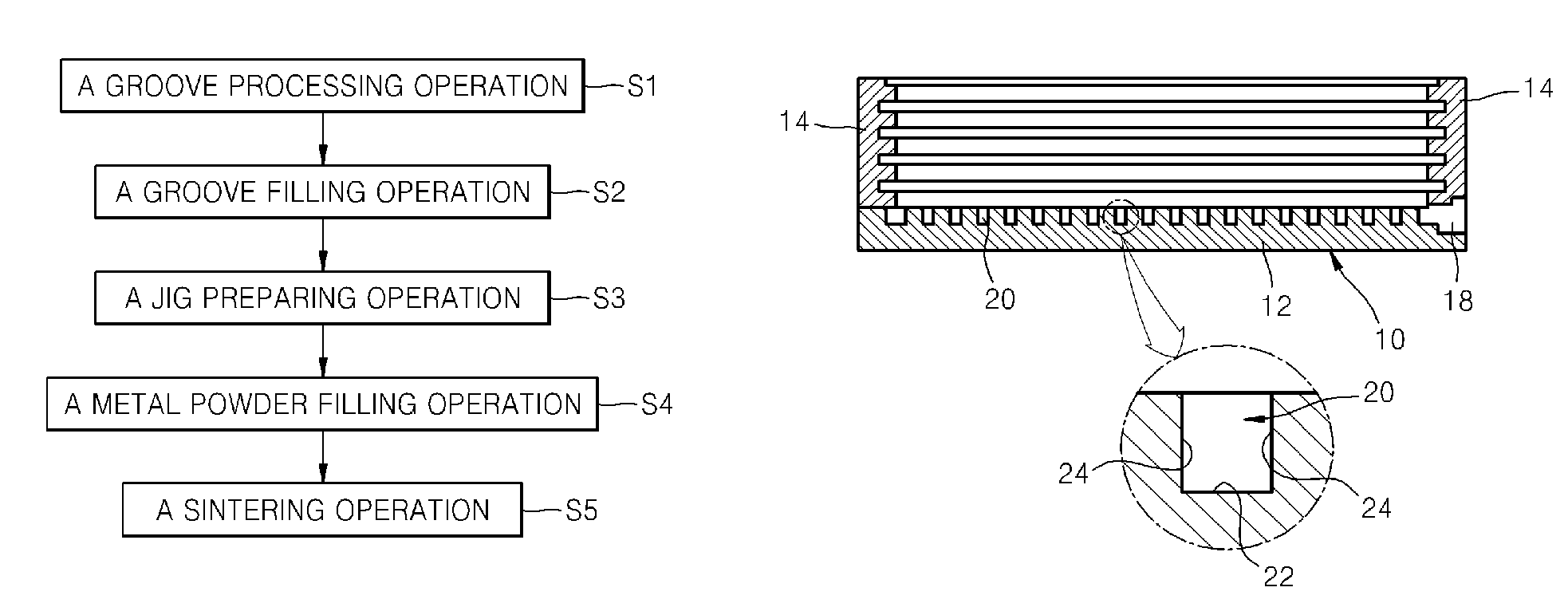

Method for manufacturing evaporator for loop heat pipe system

InactiveUS8033017B2Increase valueSimple manufacturing processSemiconductor/solid-state device detailsMetal-working apparatusMicro-loop heat pipeProcess engineering

Provided is a method of manufacturing an evaporator for a loop heat pipe system including a condenser, a vapor transport line, and a liquid transport line, and more particularly, to a method of manufacturing an evaporator for a loop heat pipe system which provides a simple manufacturing process capable of improving a contact state between a sintered wick and a heating plate.

Owner:ZALMAN TECH CO LTD +1

Electronic device, loop heat pipe and cooling device

InactiveUS7738248B2Digital data processing detailsSemiconductor/solid-state device detailsMicro-loop heat pipeWorking fluid

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com