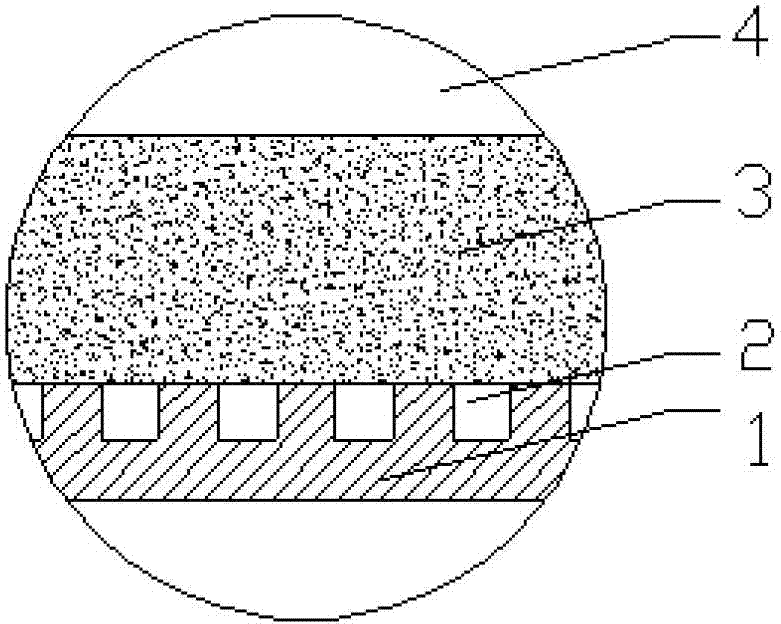

Composite capillary core with differential thermal coefficients for loop heat pipe and preparation method of composite capillary core

A technology of loop heat pipe and thermal conductivity, which is applied in the field of composite capillary core and its preparation, can solve the problems of unfavorable heat leakage, low thermal conductivity, and unfavorable heat transfer of loop heat pipe, so as to improve the overall heat transfer performance and improve the Thermal performance, effect of promoting evaporation heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

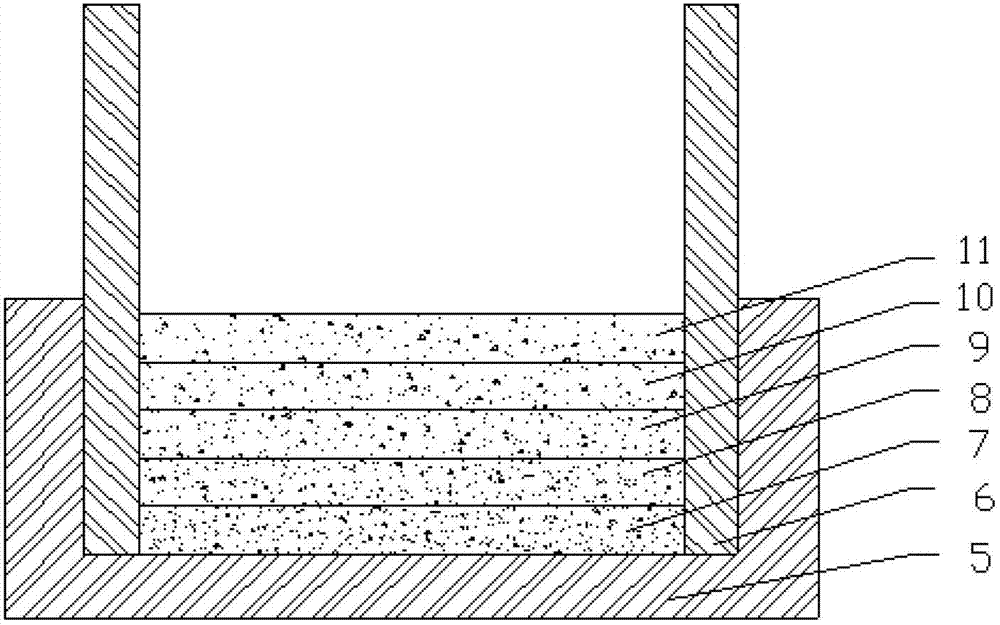

[0031] combine figure 2 , image 3 , the preparation steps of the composite capillary core with differential thermal conductivity used for the loop heat pipe of the present invention are:

[0032] (1) Mix powder. Fine nickel powder with uniform particle size is selected as the base metal powder for sintering, and fine copper powder is used as the subordinate metal powder. A layer of powder mixture 7, a second layer of powder mixture 8, a third layer of powder mixture 9, a fourth layer of powder mixture 10 and a fifth layer of powder mixture 11;

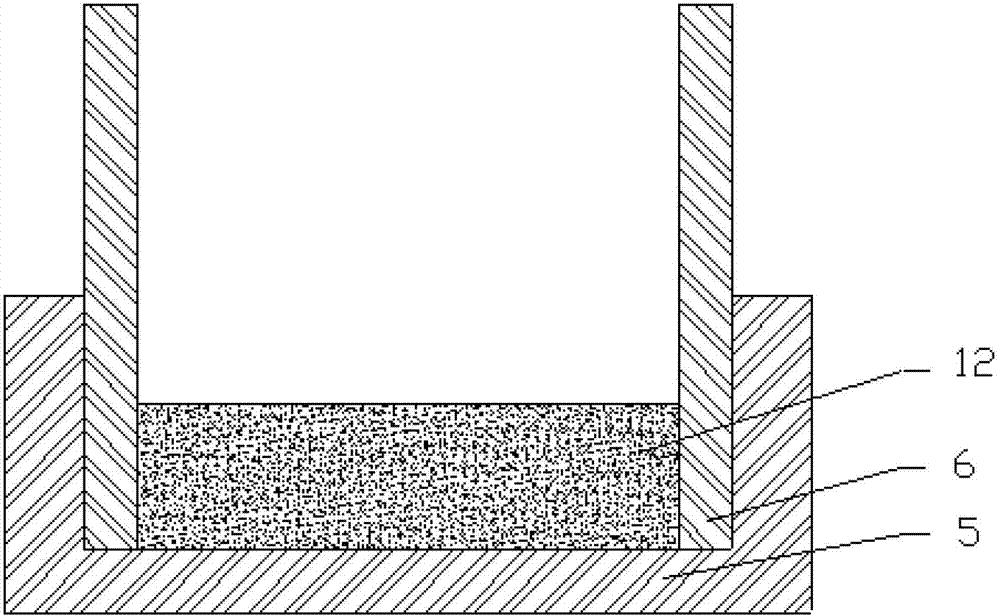

[0033] (2) Make capillary core sintered parison. After placing the cold press mold (base 5, cylinder 6), the quantitative first layer powder mixture 7, the second powder mixture 8, the third layer powder mixture 9, the fourth layer powder mixture 10 and the fifth layer Layers of powder mixture 11 are put in one after another, and then pressurized to press the powder into the required capillary core shape and size to make capillar...

Embodiment 2

[0036] The difference from Example 1 is that when mixing powders, fine copper powder with uniform particle size is selected as the base metal powder for sintering, and fine nickel powder is used as the subordinate metal powder; during sintering, the sintering temperature is 650°C, and the heating rate is controlled at 20°C / min, the holding time is 40min, and the rest are the same, so no more details will be given.

[0037] Implementation 3:

[0038] The difference from Example 1 is that when mixing powders, fine titanium powder with uniform particle size is selected as the base metal powder for sintering, and fine stainless steel powder is used as the subordinate metal powder; during sintering, the sintering temperature is 850°C, and the heating rate is controlled at 30°C / min, the holding time is 60min, and the rest are the same, no more details.

[0039]Combining the above three embodiments, through the control of process parameters, the present invention can be made into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com