Patents

Literature

371results about How to "Reduce heat leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

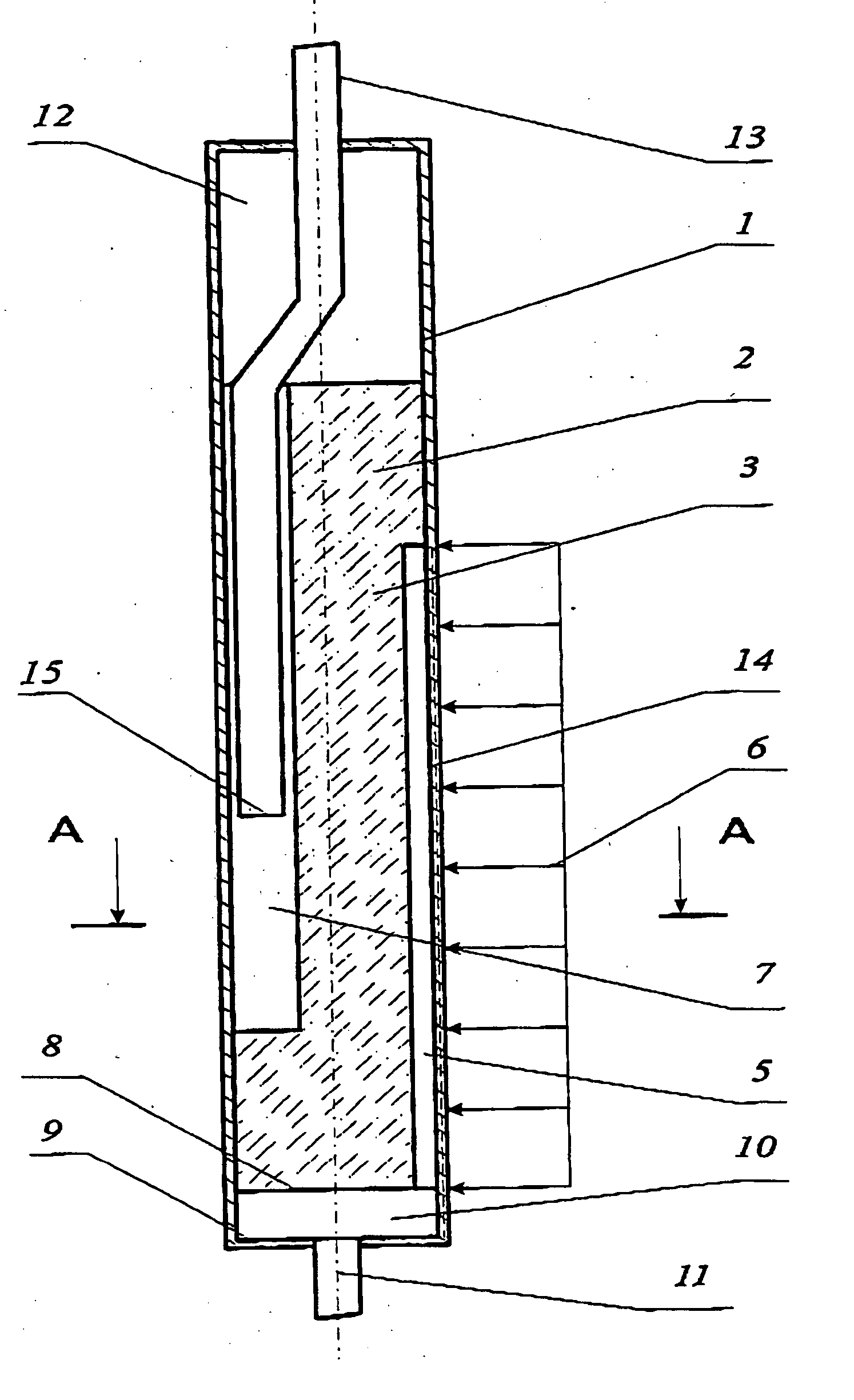

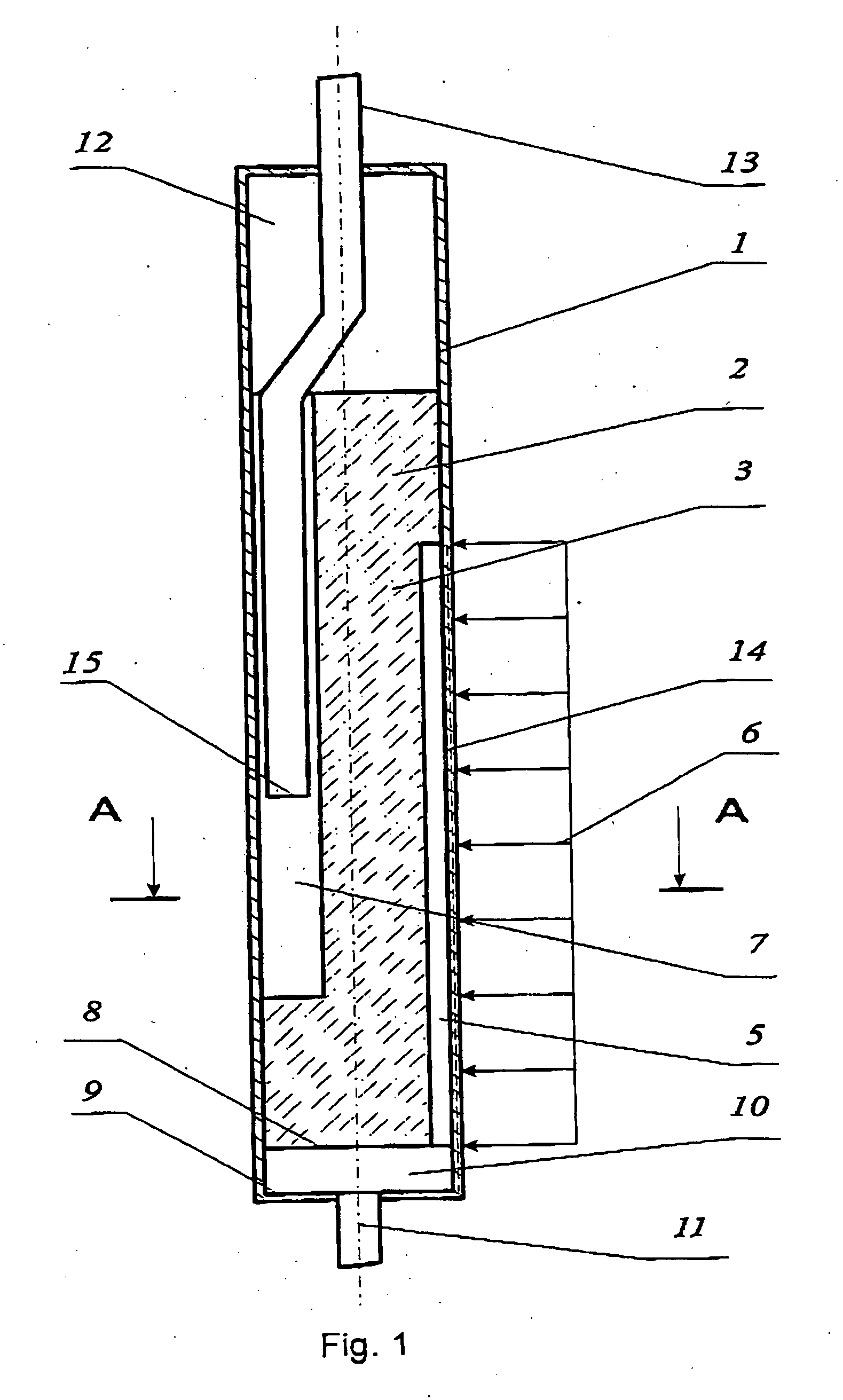

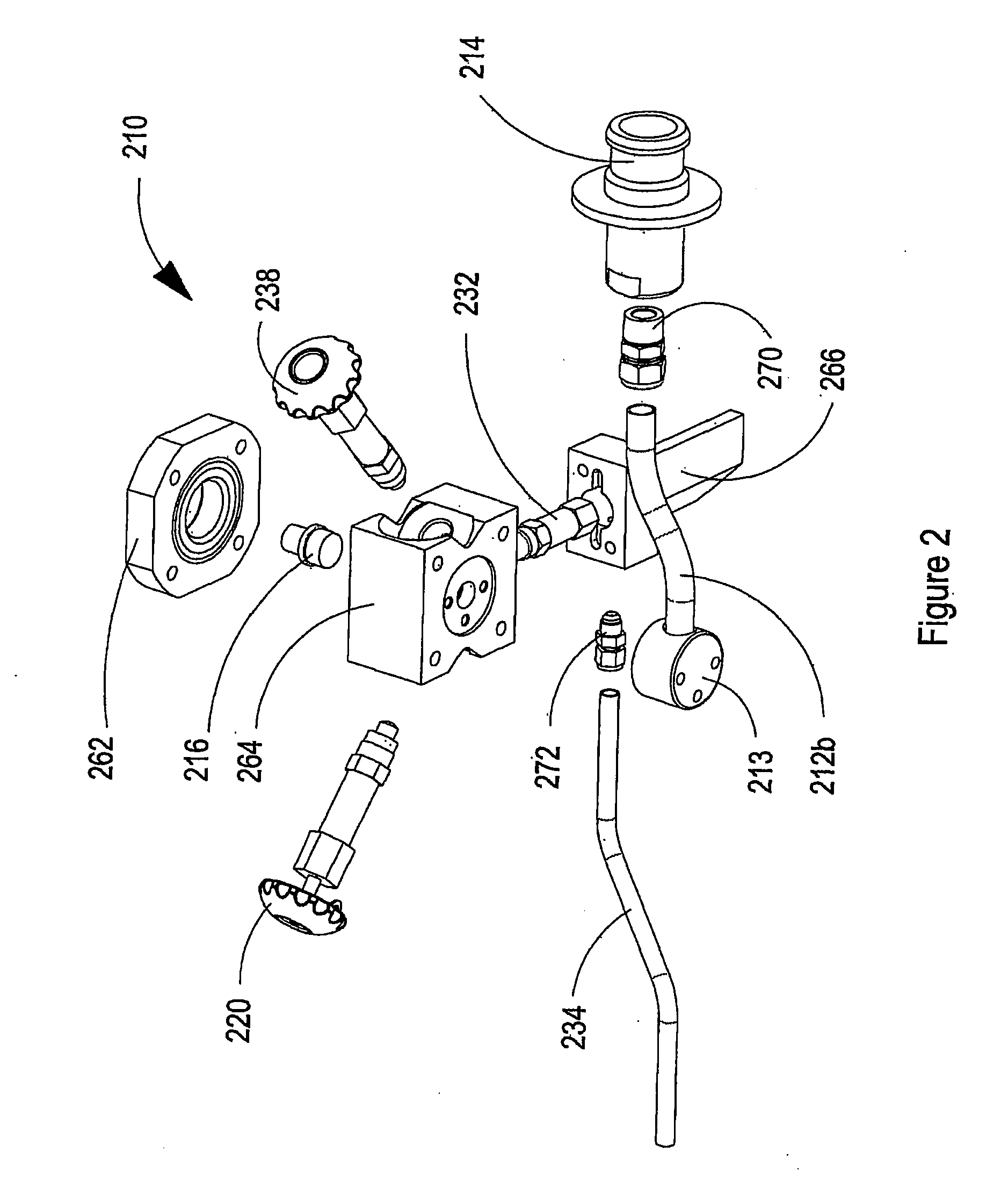

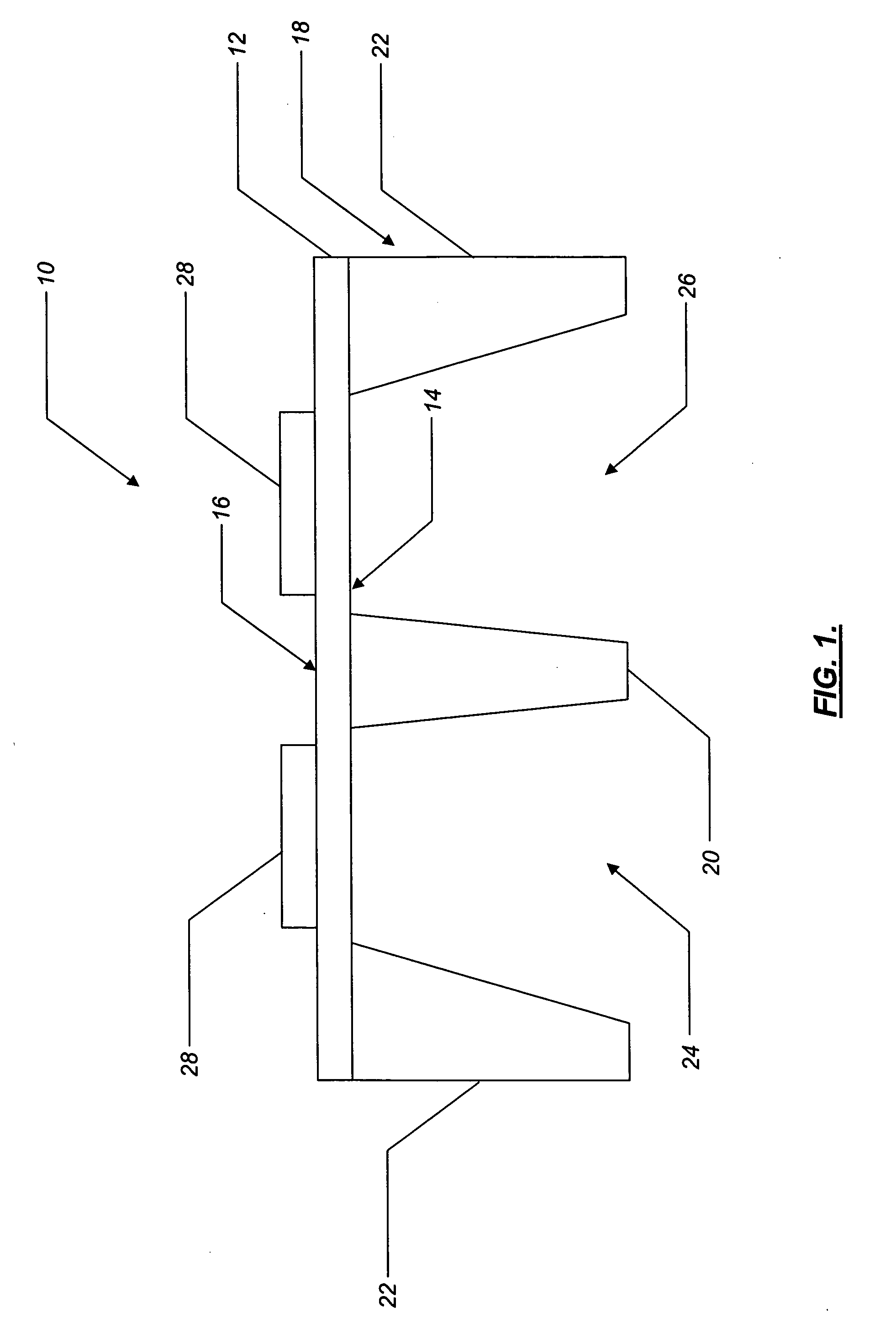

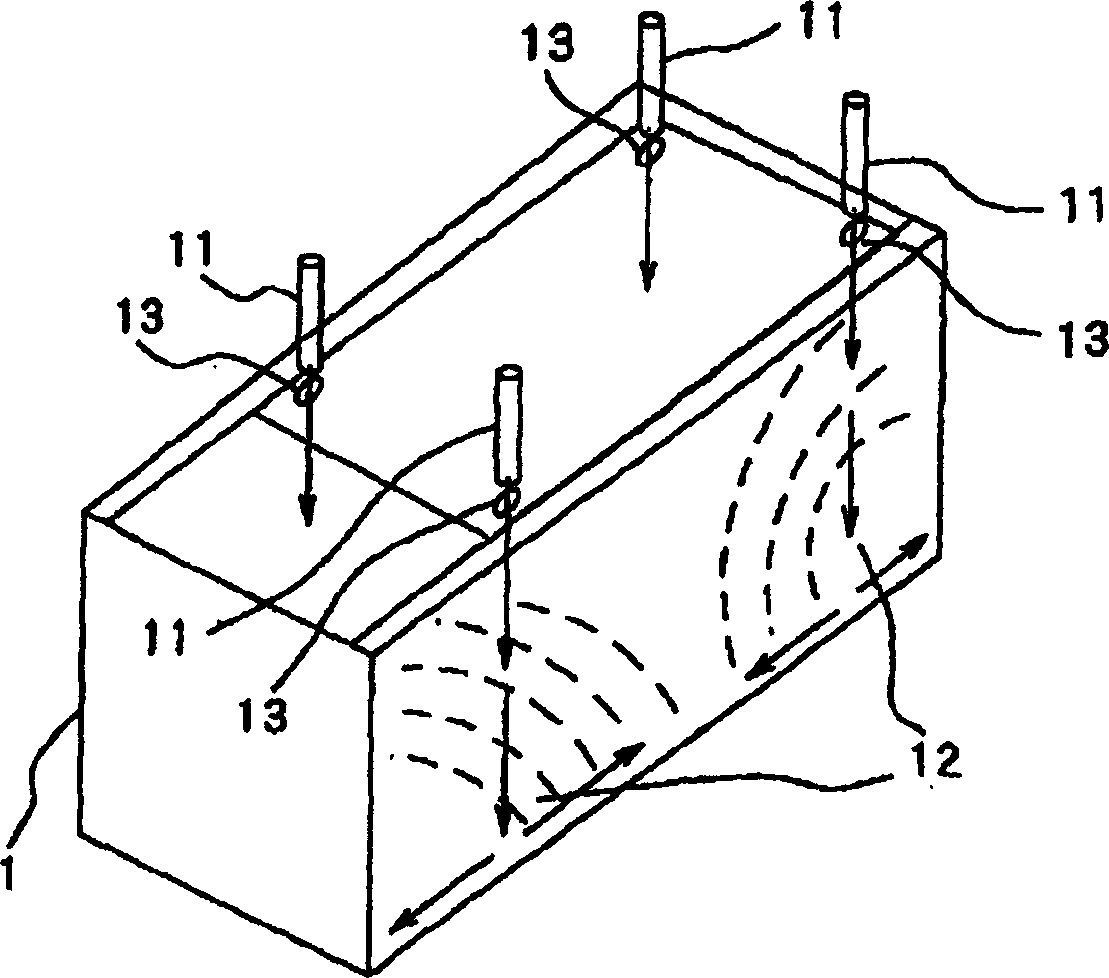

Evaporation chamber for a loop heat pipe

InactiveUS20040206480A1Decrease in parasitic heat leakageIncrease heat loadAir-treating devicesSemiconductor/solid-state device detailsMicro-loop heat pipeCapillary Tubing

The invention relates to heat engineering, in particular to heat pipes, and may be used for heat removal from miniature heat-tensioned objects, in particular elements of radioelectronic devices and computers requiring effective heat removal within minimum dimensions of a cooling system. The invention is aimed at increasing a heat load of the evaporating chamber at a given operating temperature and reducing its dimensions. For this purpose, in the evaporating chamber of a loop heat pipe comprising a body that includes side and end-face walls and a capillary porous packing accommodated in said body and having vapor-removal channels tied together by a vapor collector, and disposed on a portion of the packing perimeter at the heat-supply side, and having an asymmetrical longitudinal opening shifted in the direction opposite to the heat supply, the end-faces of the vapor-removal channels being blind at one side, the asymmetrical longitudinal opening is also being blind at the side opposite to the blind end-faces of the vapor-removal channels, and the vapor collector is formed by one of the end-face walls of the body and the packing end-face. Besides, on the inner side surface of the body, additional vapor-removal grooves are provided. Cross-section of the asymmetrical longitudinal opening may have the form of a rectangle elongated in the direction of the heat supply and limited at the opposite side by a body wall, or the form of a wedge, whose apex faces the heat supply and whose base is a body wall, or the form of a segment, whose chord is directed towards the heat supply and the arc is a body wall, or the form of a circle limited by a capillary porous packing and whose center is shifted in the direction opposite to the heat supply. Cross-section of the evaporating chamber may be made rectangular, the asymmetrical longitudinal opening, which has the form of a slot gap being shifted in the direction opposite to the heat supply. The capillary porous packing may consist of two interconnected parts. The outlet of the condensate line is positioned in the asymmetrical longitudinal opening of the capillary porous packing.

Owner:MICROWAY

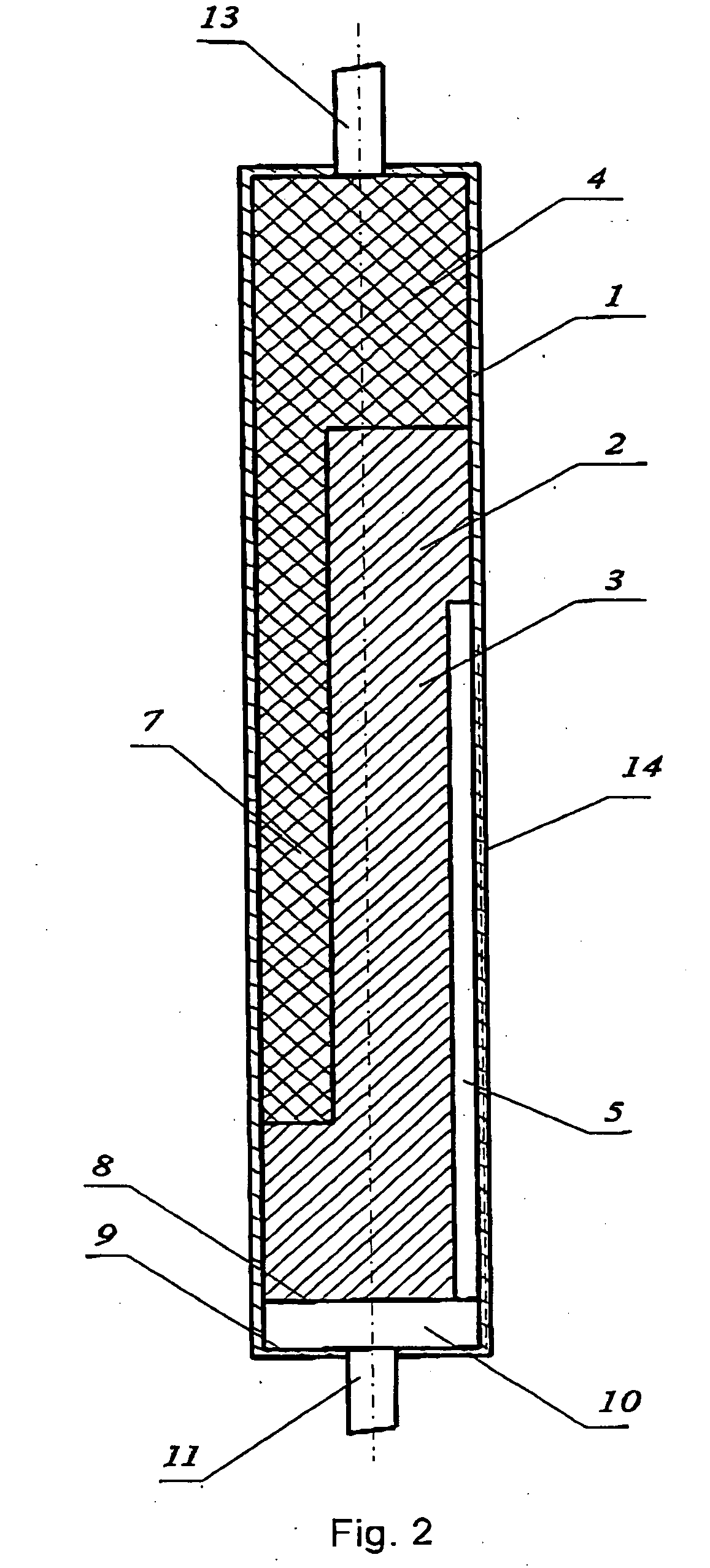

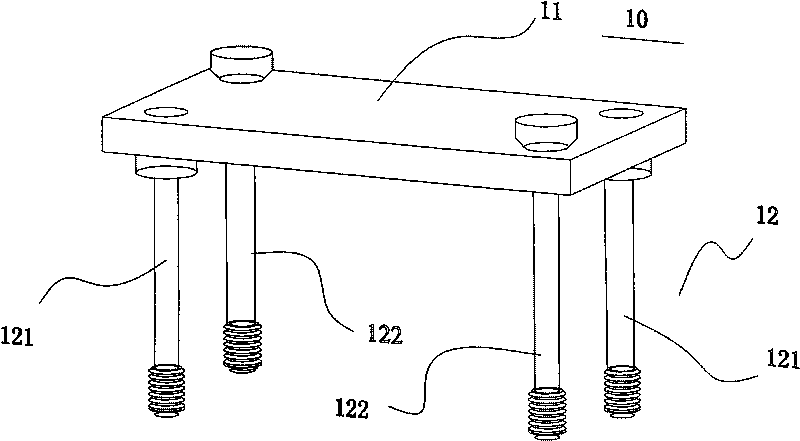

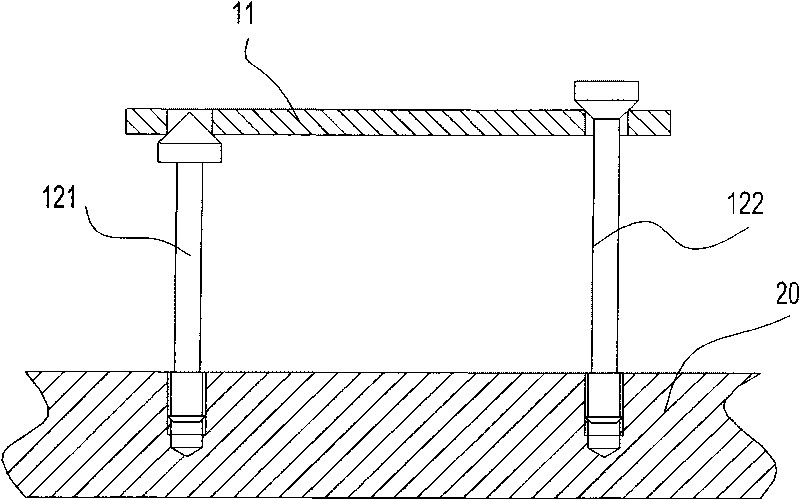

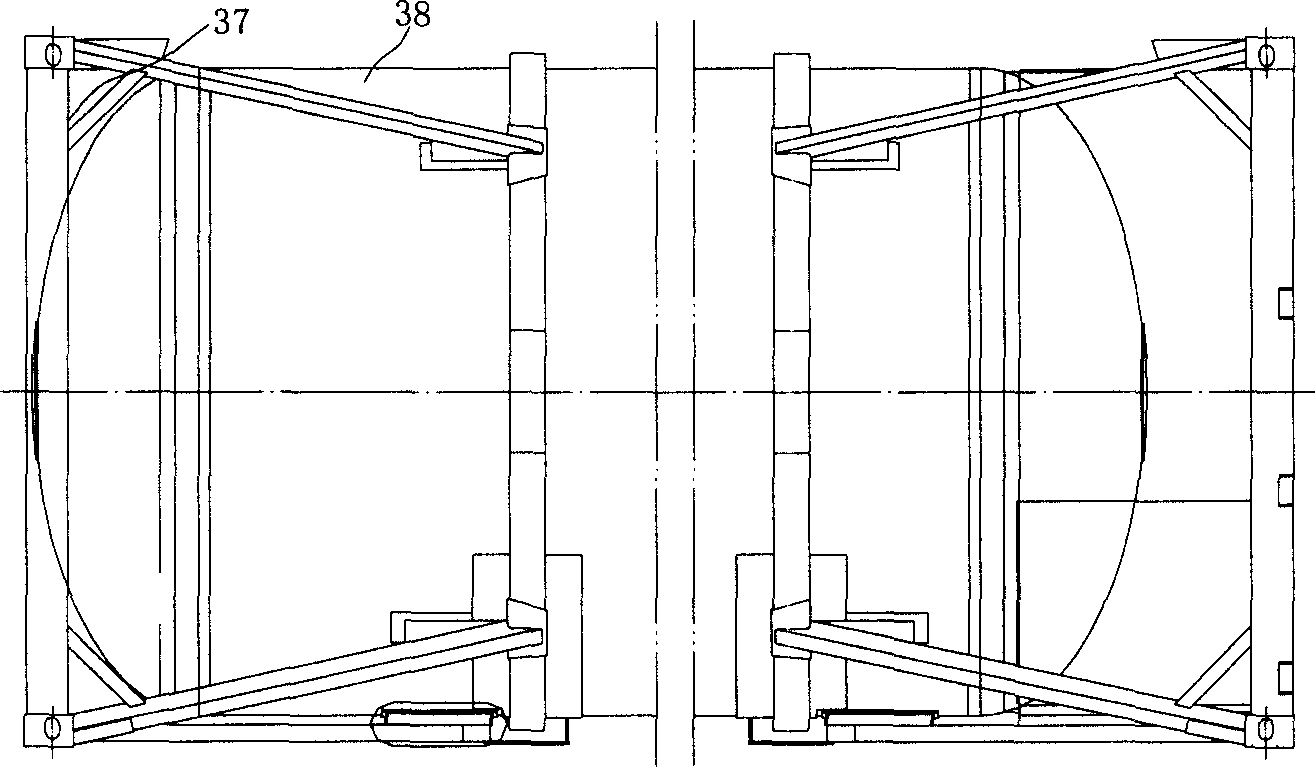

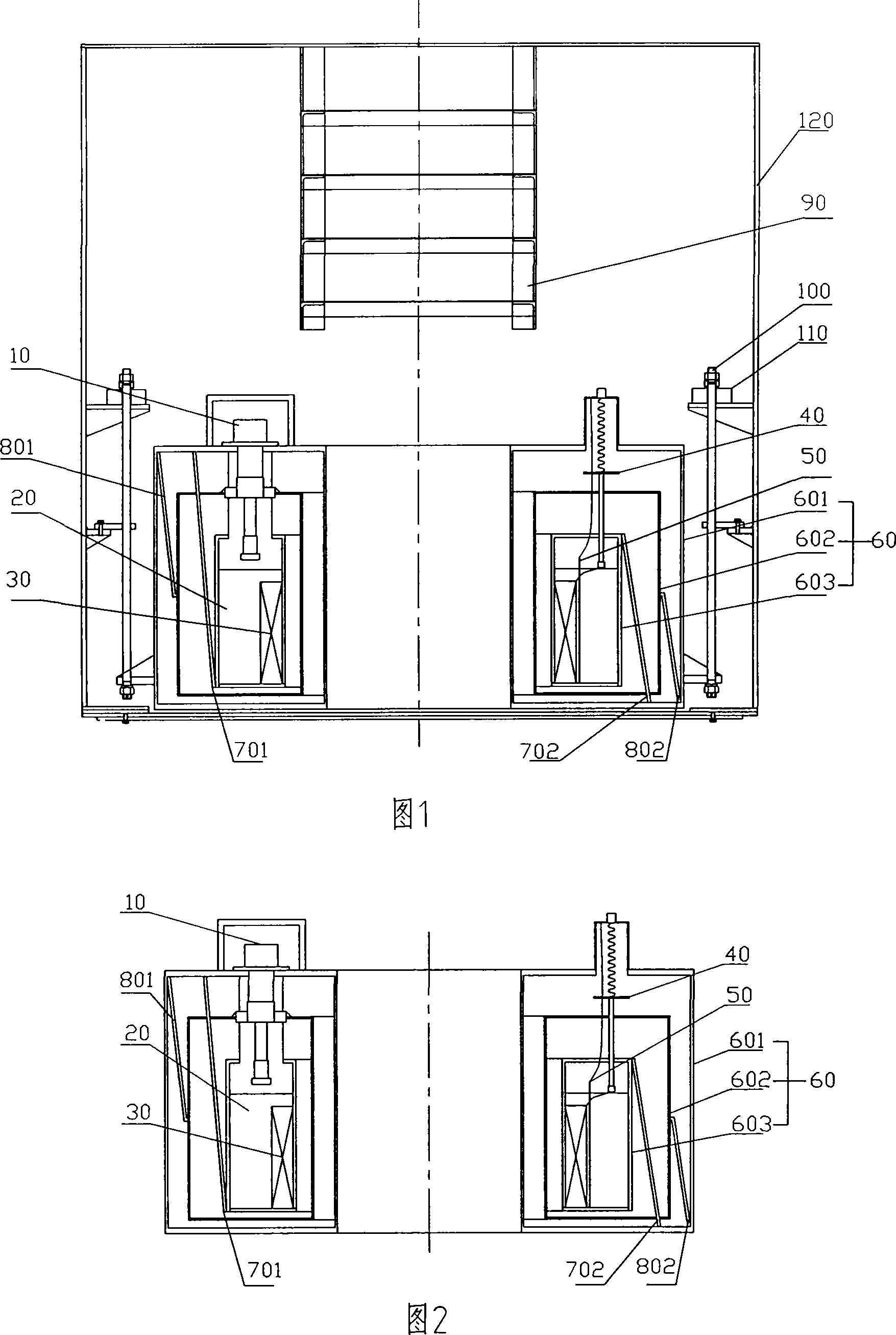

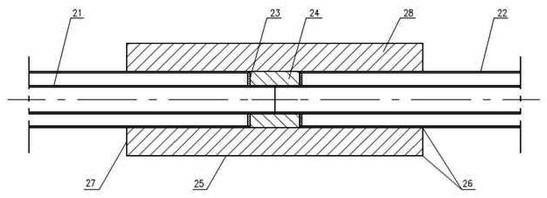

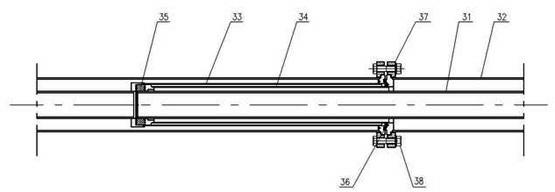

Adiabatic supporting device

ActiveCN101738127AGuaranteed stabilityReduce thermal contact areaHeat exchanger casingsEngineeringVacuum chamber

An adiabatic supporting device is used for supporting low temperature devices in a low temperature vacuum system. The supporting device comprises a cold platform with a plurality of mounting holes and support bars used for supporting the cold platform. The bottoms of the support bars are fixedly connected with a vacuum chamber. The support bars comprise upward ejecting support bars and downward pressing support bars. The upper parts of the upward ejecting support bars are matched with the mounting holes by way of point contact or line contact and the upward ejecting support bars provide upward ejecting force to the cold platform. After the downward pressing support bars pass through the mounting holes, the tops of the downward pressing support bars are matched with the mounting holes by way of point contact or line contact and the downward pressing support bars provide downward pressing force to the cold platform. The upward ejecting force reaches equilibrium with the downward pressing force. The supporting device furthest reduces the heat contact area under the premise of ensuring the stability of the mechanical structure and changes from the original nut surface contact to the current line contact or point contact, thus reducing heat leakage from the vacuum chamber to the cold platform and greatly reducing heat load.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

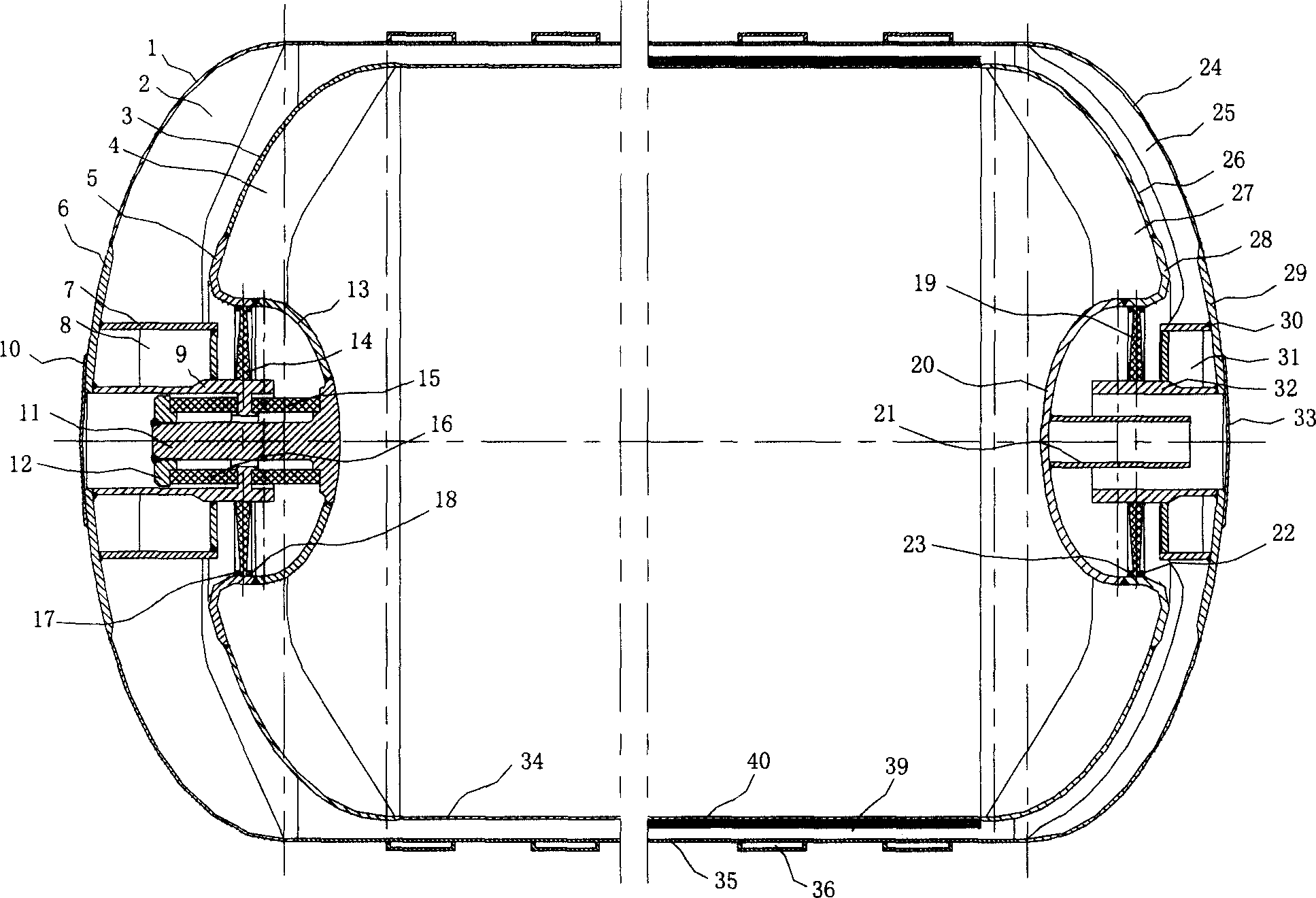

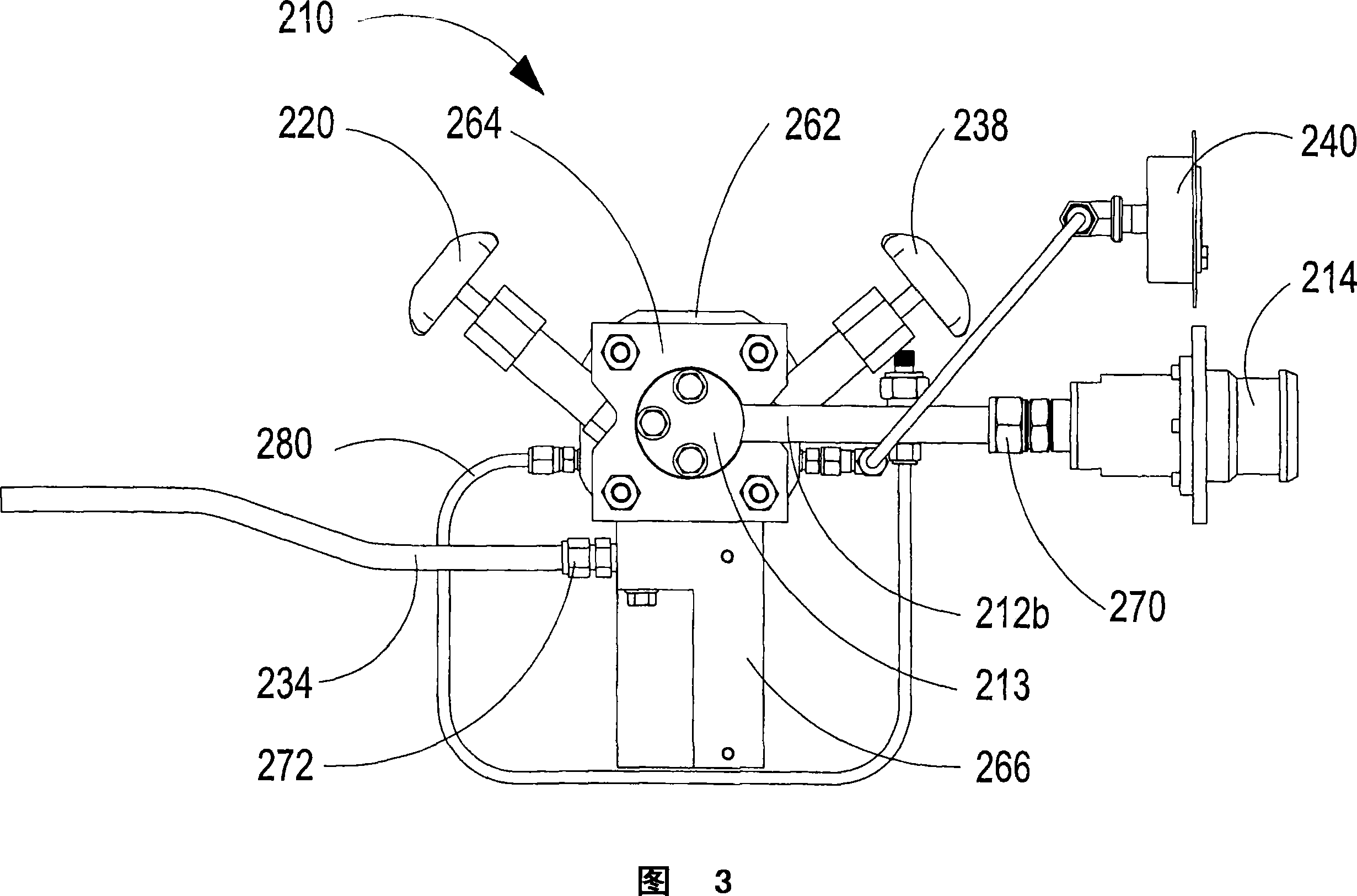

Conduction cooling superconducting magnet dewar convenient for loading and unloading

The invention relates to a conduction-cooled superconducting magnet Dewar with easy loading-unloading, comprising a Dewar cylinder. The conduction-cooled superconducting magnet Dewar is characterized in that the Dewar cylinder is a hollow annular cylinder, the middle of the annular cylinder is provided with a room temperature hole, an annular copper cold shield is arranged in the Dewar cylinder, a refrigerator and a superconducting magnet are arranged in the copper cold shield, a vacuum pumping port is arranged on the Dewar cylinder, a measuring device is arranged on an upper cover of the Dewar cylinder and the Dewar cylinder is in a vacuum state. Compared with the prior Dewar container, the conduction-cooled superconducting magnet Dewar is simpler, has small conduction heat leakage, and has the advantages of easy installation and disassembly; the refrigerator is used for conducting and cooling without a low temperature liquid (such as liquid helium and so on) cooling system; because of simple and safe system, a first-level cold junction of the refrigerator is operated under a temperature of 77K, thereby realizing heat sink of the copper cold shield, an electric lead and a support device; the first-level cold junction of the refrigerator adopts soft connection, thereby reducing temperature increment of the magnet due to vibration of the refrigerator; and the conduction-cooled superconducting magnet Dewar has the advantages of easy operation of manufacture, processing and installation, and is applicable to scale production.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

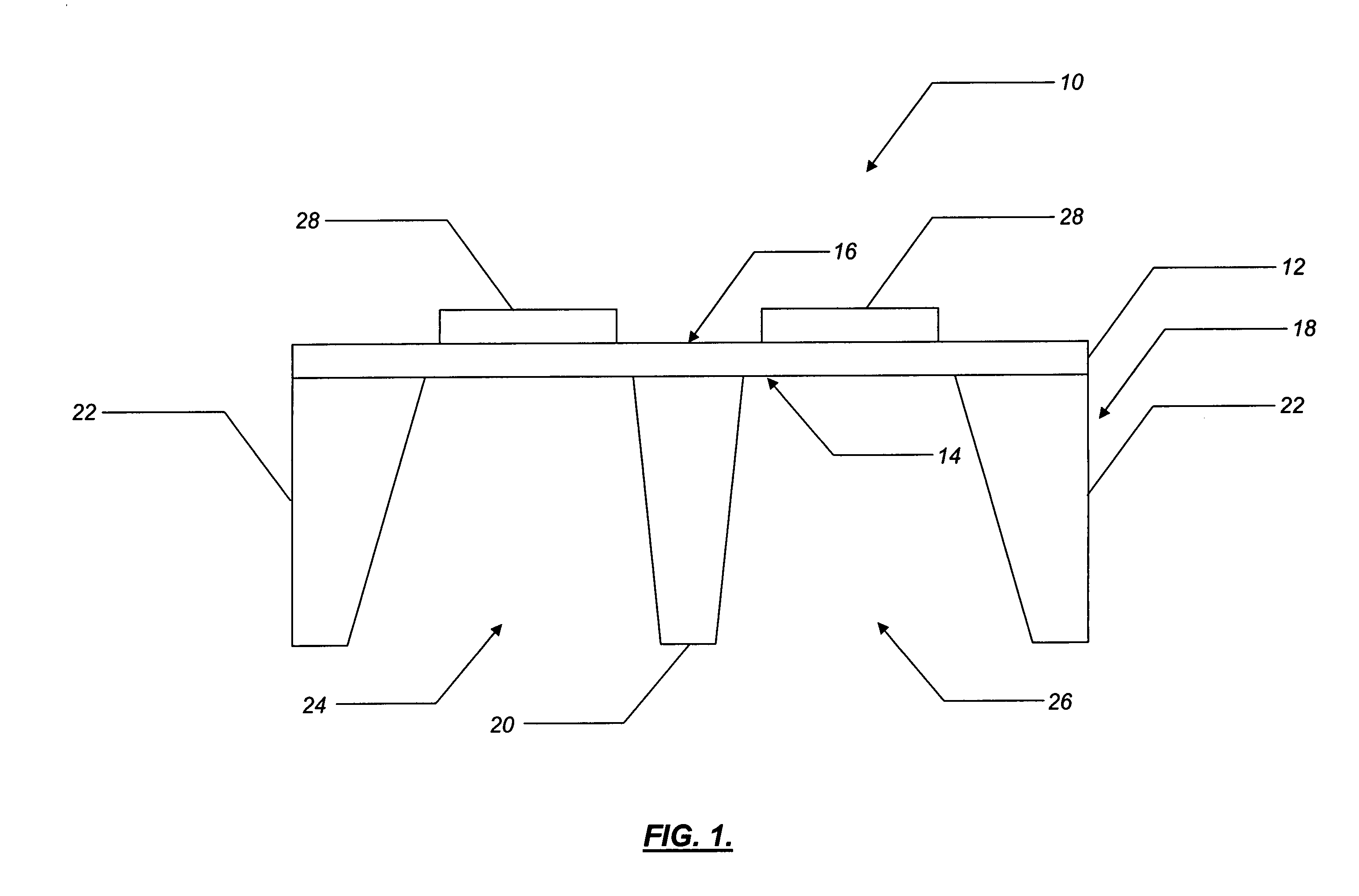

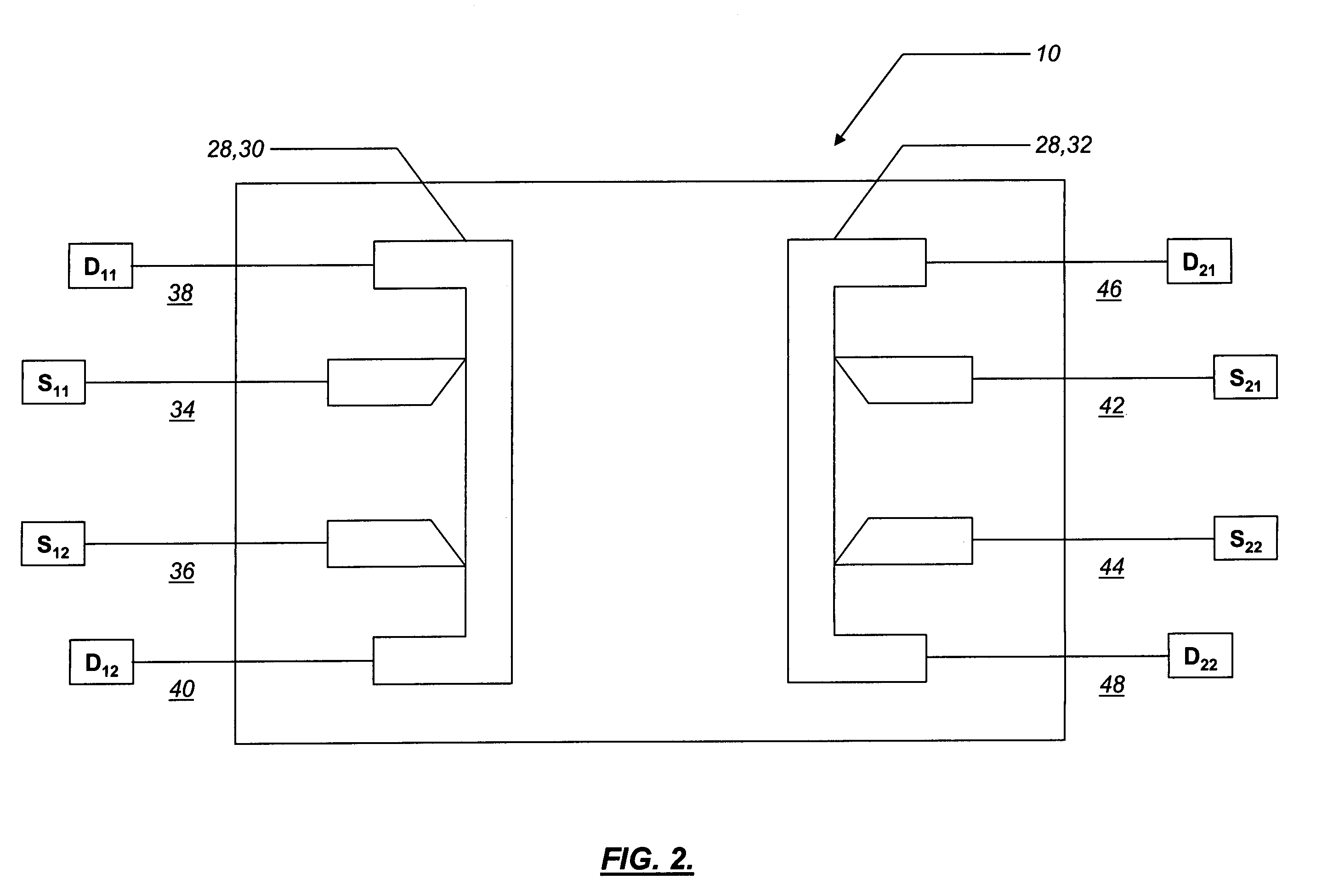

Nano-calorimeter device and associated methods of fabrication and use

InactiveUS6988826B2Reduce capacityReduce conductivityMaterial heat developmentNanosensorsEngineeringThermal contact

Owner:GENERAL ELECTRIC CO

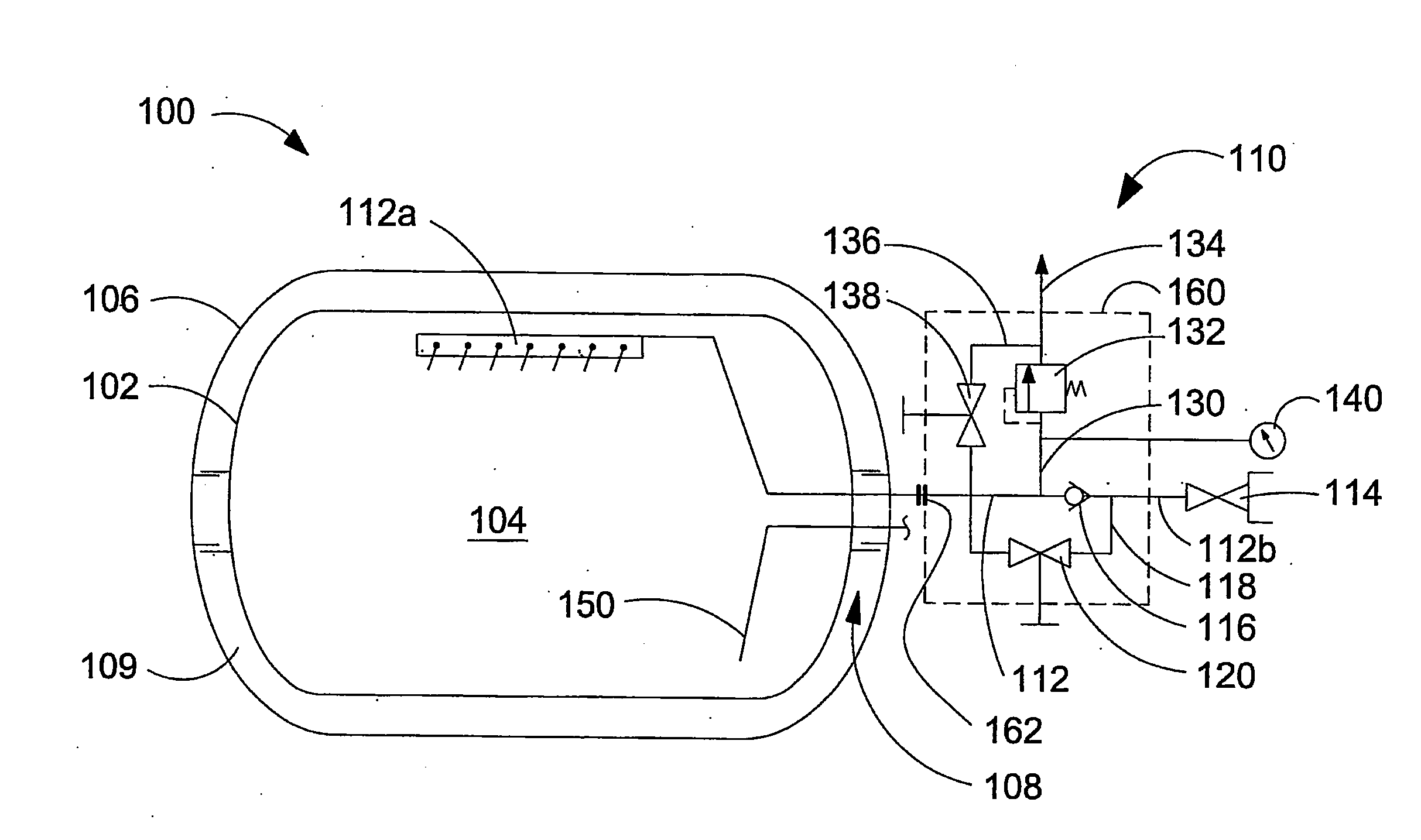

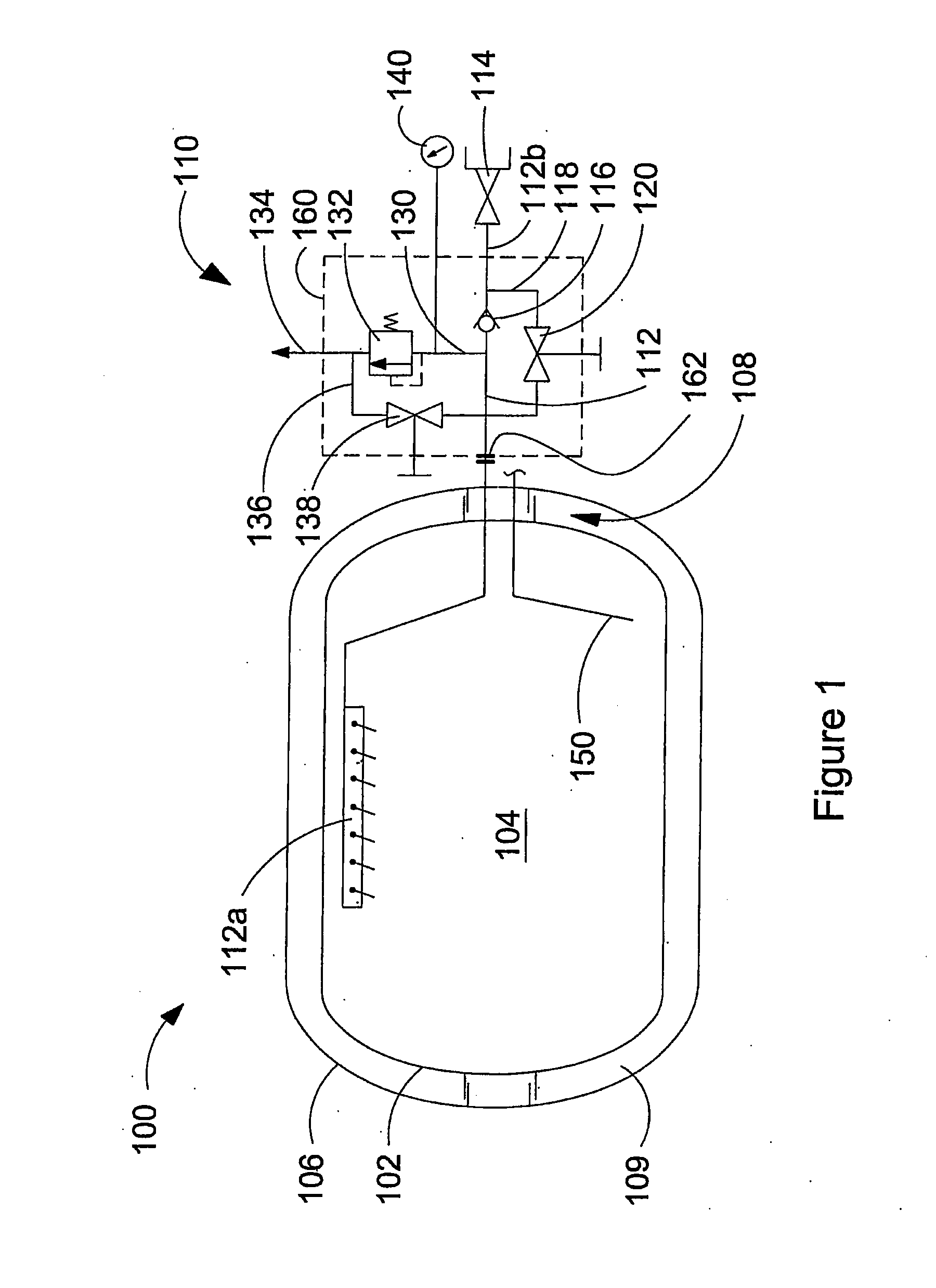

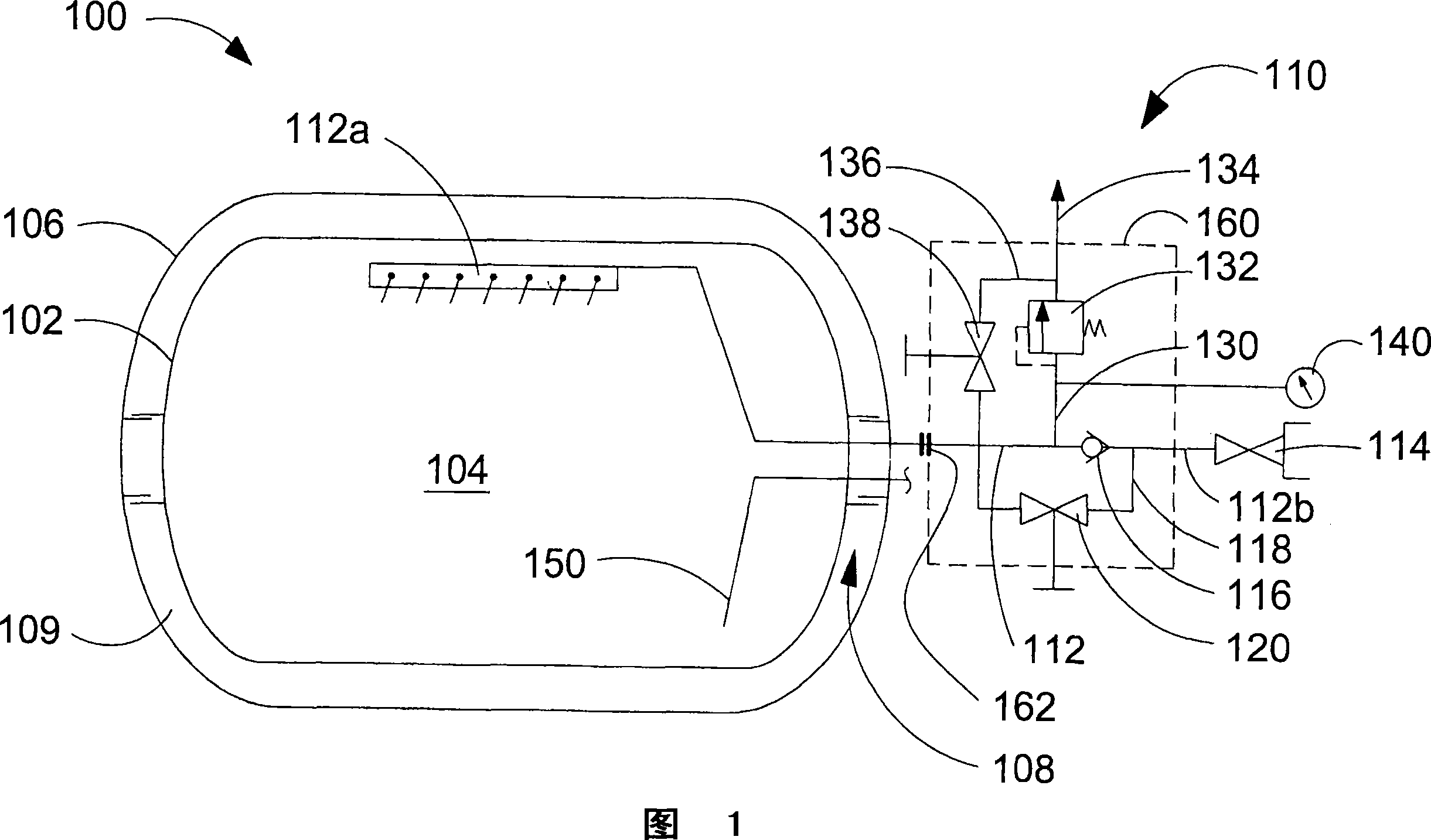

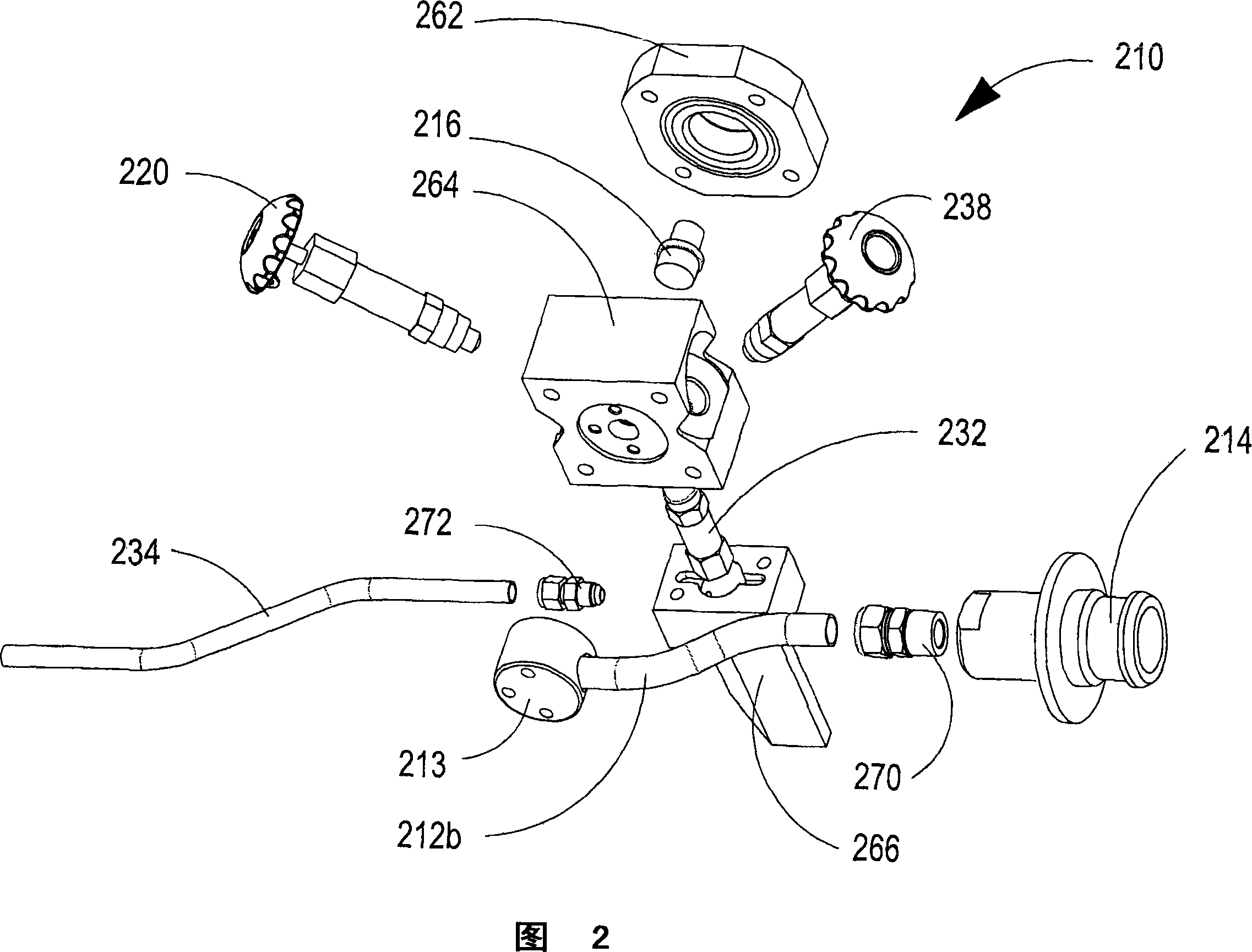

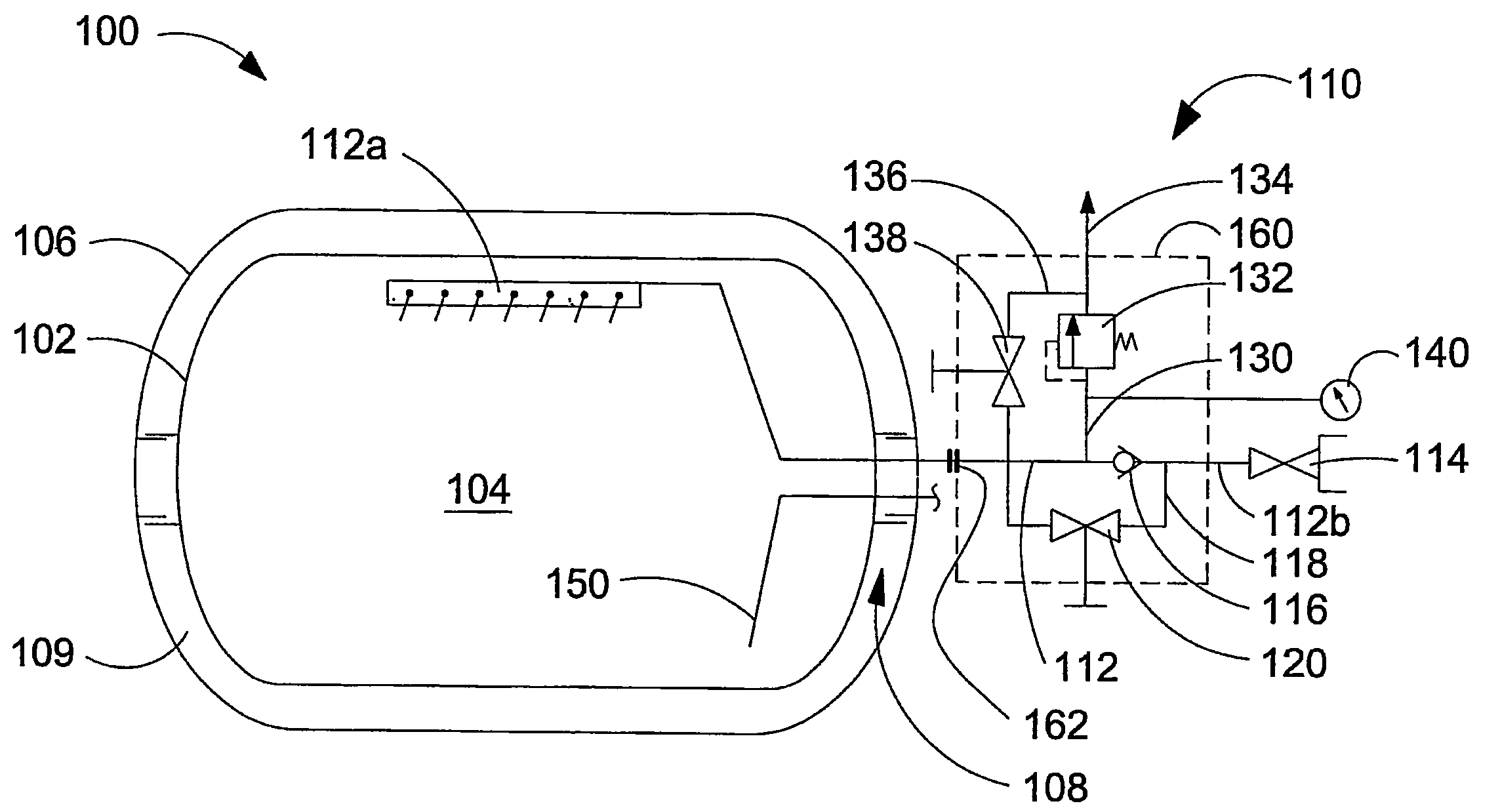

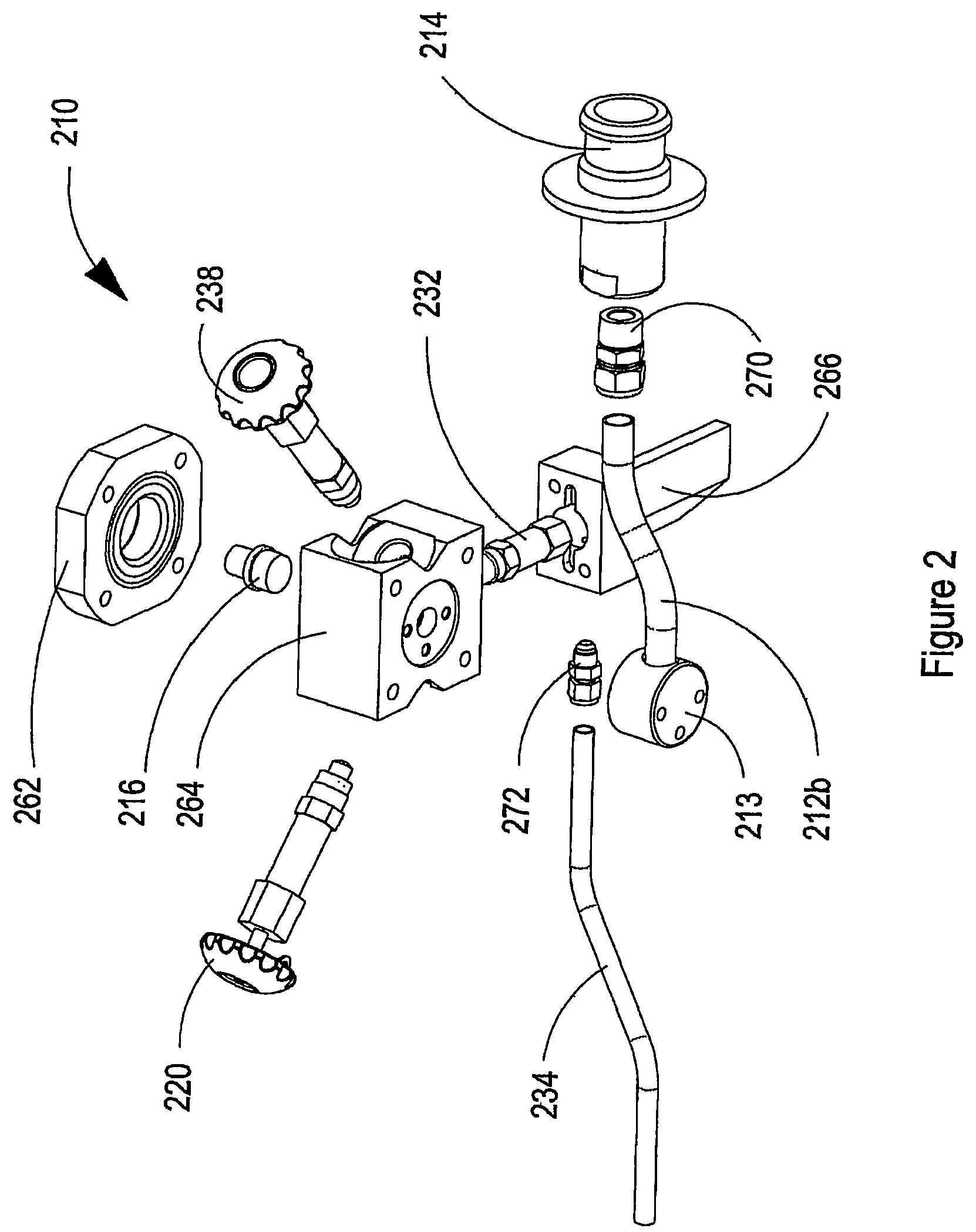

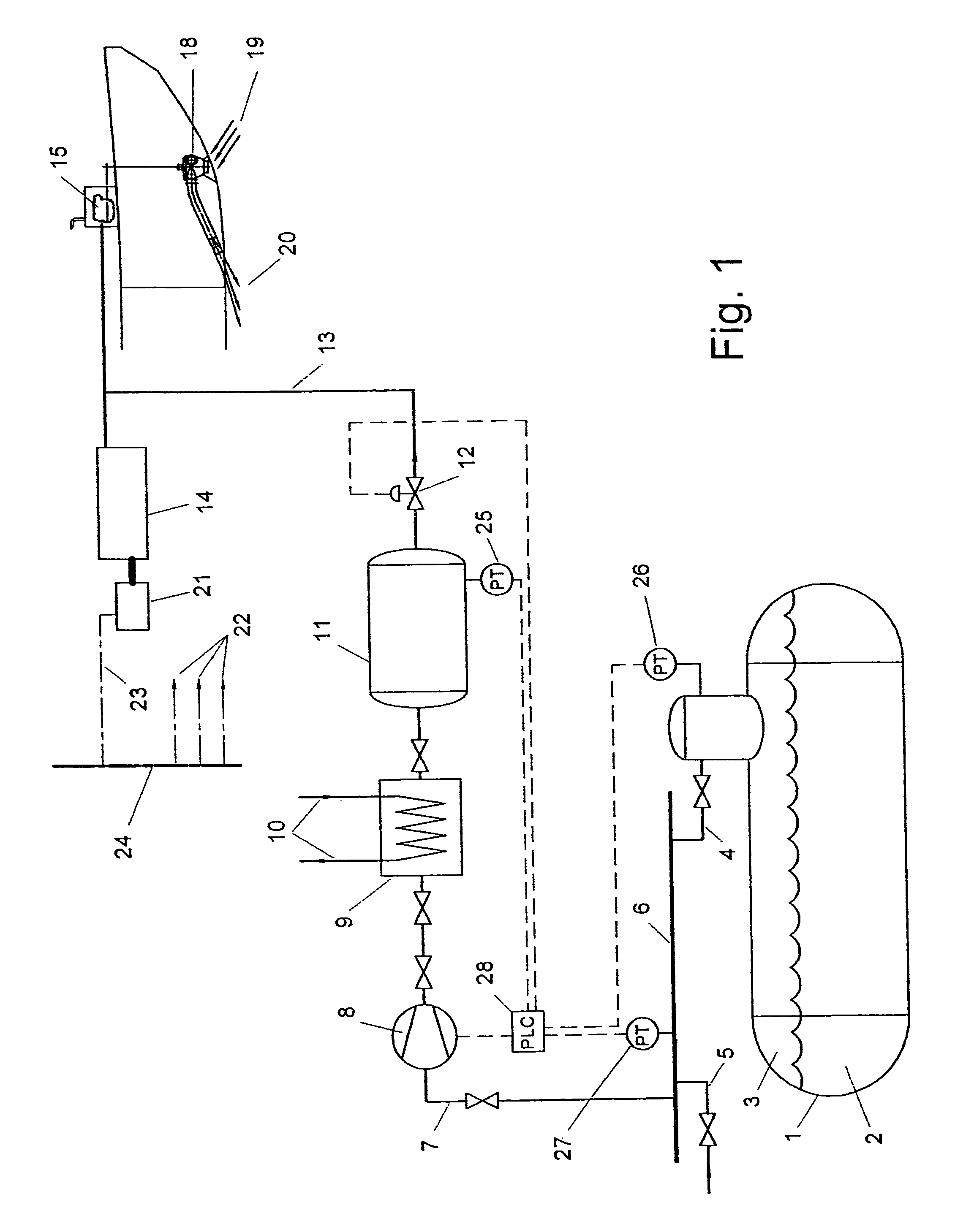

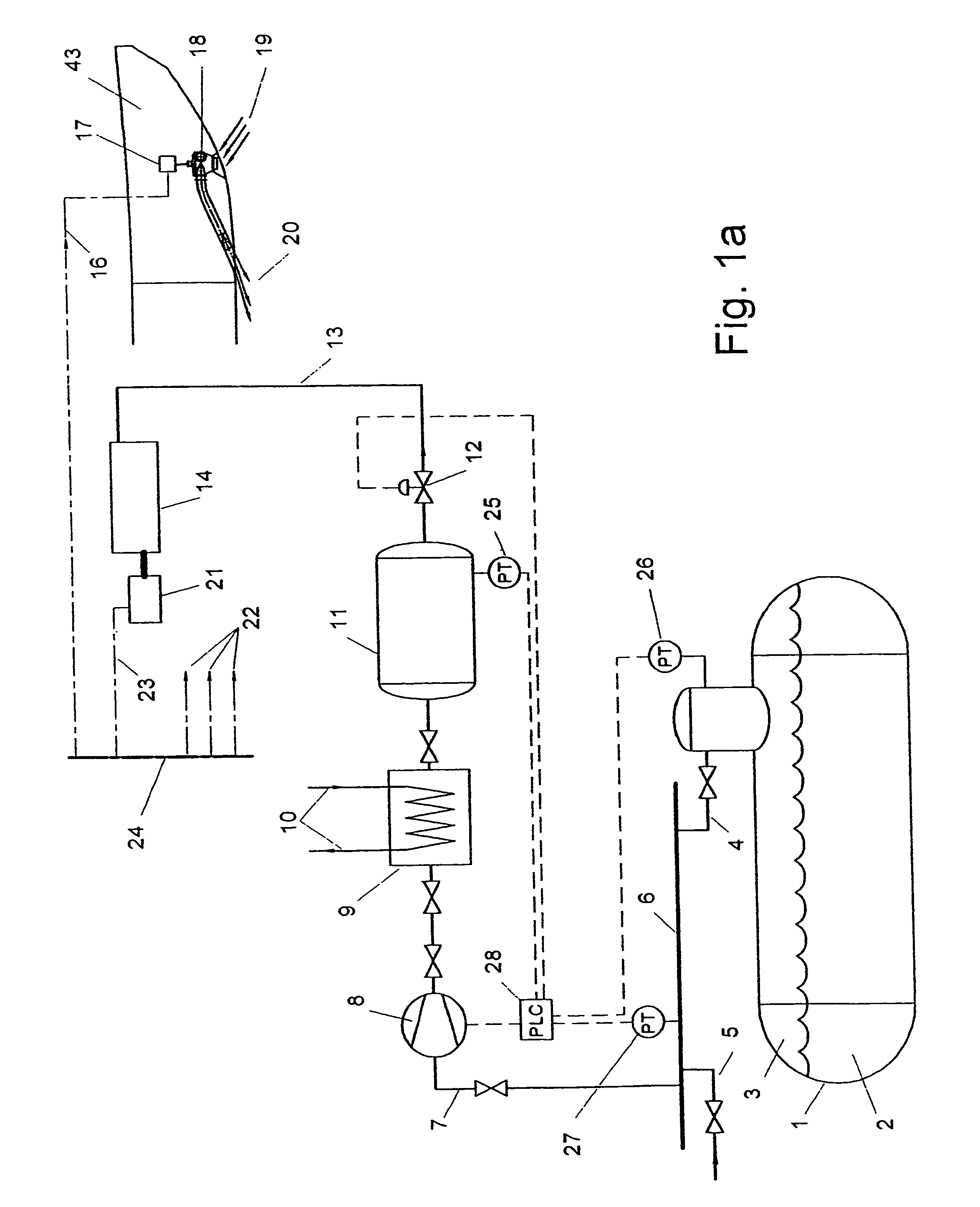

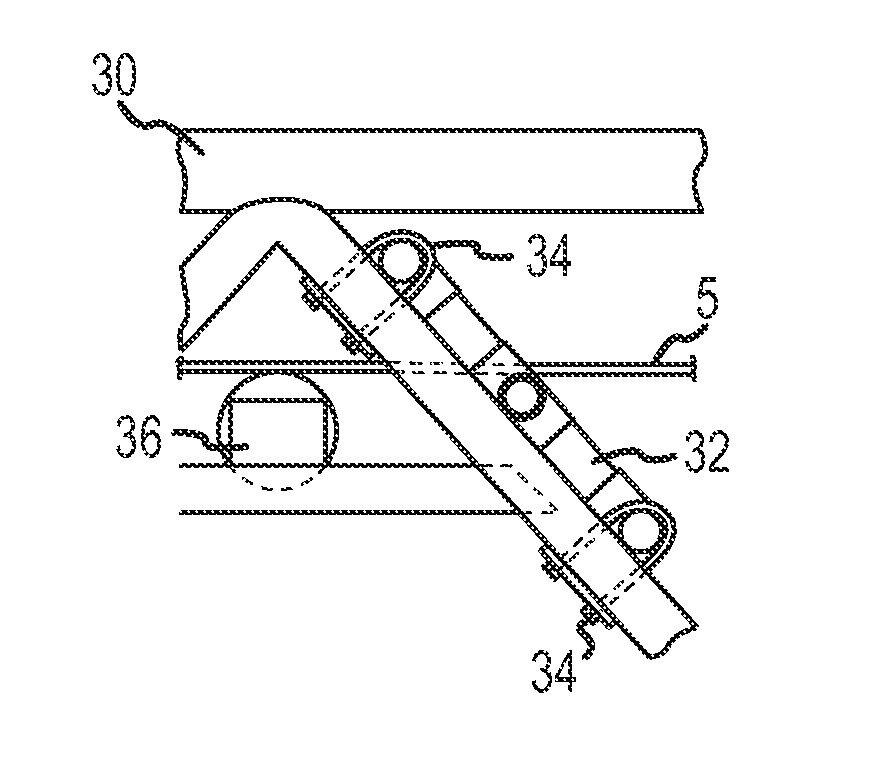

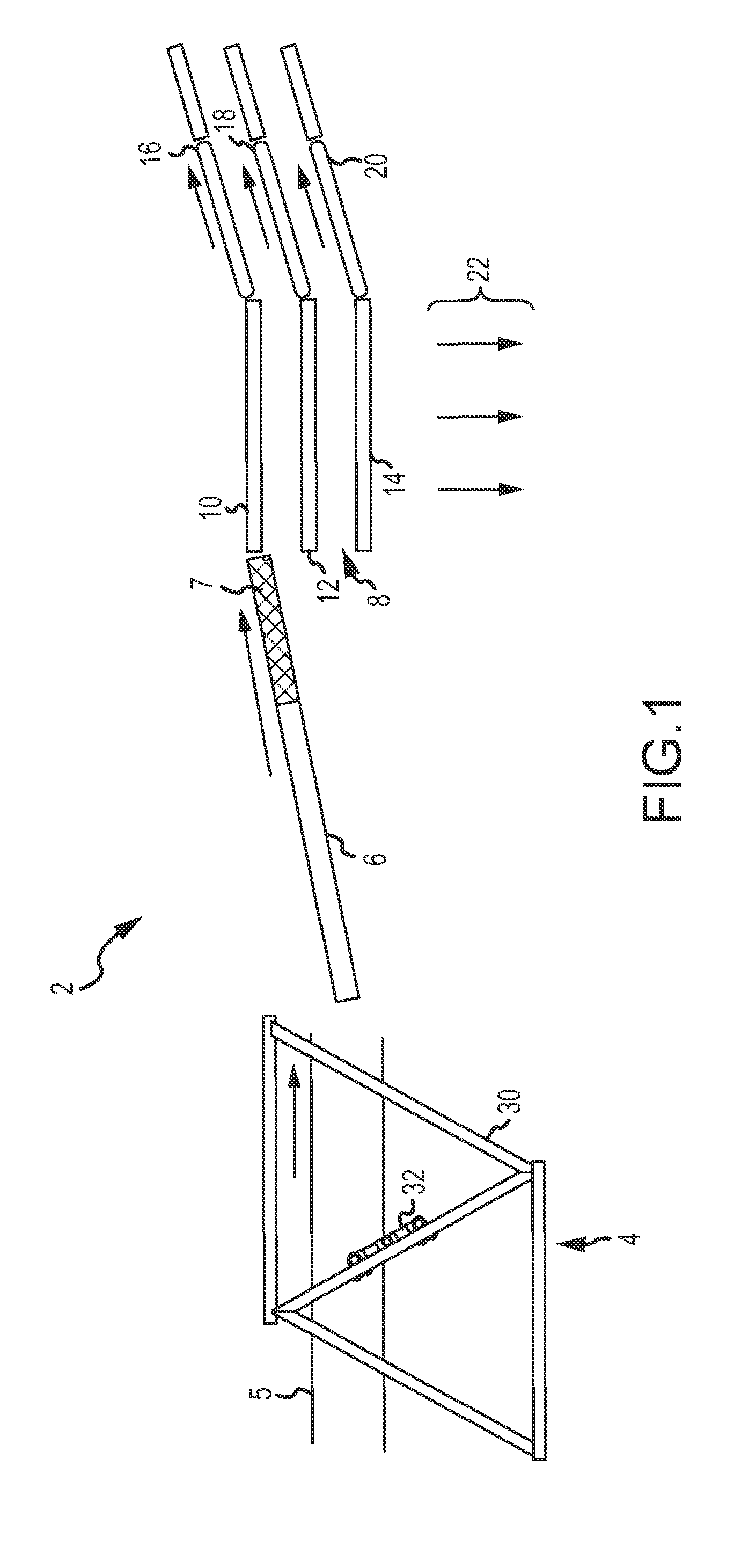

Storage Tank For A Cryogenic Liquid And Method Of Re-Filling Same

ActiveUS20080134693A1Stop the leakReduce in quantityGas handling applicationsPackaging under special atmospheric conditionsLine tubingCheck valve

A storage tank defines a cryogen space for storing a cryogenic liquid. The storage tank comprises a combined fill and vent assembly, which comprises a conduit having a first end with an opening disposed within an upper part of the cryogen space, and a second end outside of the cryogen space that is connected to a receptacle, to which a re-filling nozzle can be attached. A check valve disposed in the conduit allows flow only in the direction of filling the cryogen space with cryogenic liquid from the receptacle. A by-pass line is provided around the check valve with a valve disposed in the by-pass line that is operable to open or close to control flow through the by-pass line. The method comprises attaching a re-filling nozzle to the receptacle and opening the by-pass valve to vent vapor from the cryogen space to reduce vapor pressure therein and to cool the conduit, receptacle, re-filling nozzle, and fill line. After venting the storage tank, the by-pass valve is closed, and the storage tank can be re-filled through the receptacle and conduit.

Owner:OLYMPUS CORP +1

High vacuum heat insulation low temperature liquefied gas storage tank

ActiveCN1683816AIncrease effective volumeReduce heat transfer areaVessel mounting detailsVessel manufacturingEngineeringHeat conducting

The high vacuum heat insulating low temperature liquefied gas storing tank includes frame and tank body. The tank body consists of outer casing, inner container and combined support structures connecting the outer casing and the inner container. The combined support structures are set between the inner sealing head and outer sealing head on two ends of the tank to bear the radial load and the axial load with great bearing force. The heat conducting area between the inner container and the outer casing is small, and the inner container has great effective loading volume.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Temperature controlled focal plane detector mechanism

InactiveCN101813951ATo achieve different working temperature requirementsFulfill cooling needsTemperatue controlHeat conductingHeat leak

The invention discloses a temperature controlled focal plane detector mechanism, which mainly solves the problem that the conventional focal plane detector mechanism cannot work under different temperature conditions. The temperature controlled focal plane detector mechanism comprises a shell, a cabinet, a detector and a detector mounting base, wherein the detector mounting base comprises a detector support plate and a cold plate; the detector support plate is fixedly connected with the cabinet; the detector is arranged on one side of the cold plate, and is provided with a temperature test sensor; the other side of the cold plate is provided with a refrigerator of which the side far from the cold plate is provided with a heat conducting device; and the heat conducting device and the cold plate isolate and seal the refrigerator. The temperature controlled focal plane detector mechanism can meet the requirements of different working temperatures of the detector; and the detector is not influenced by frosting and pollution when working in various environments (laboratories or space environments), and the environmental heat leak is effectively reduced.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

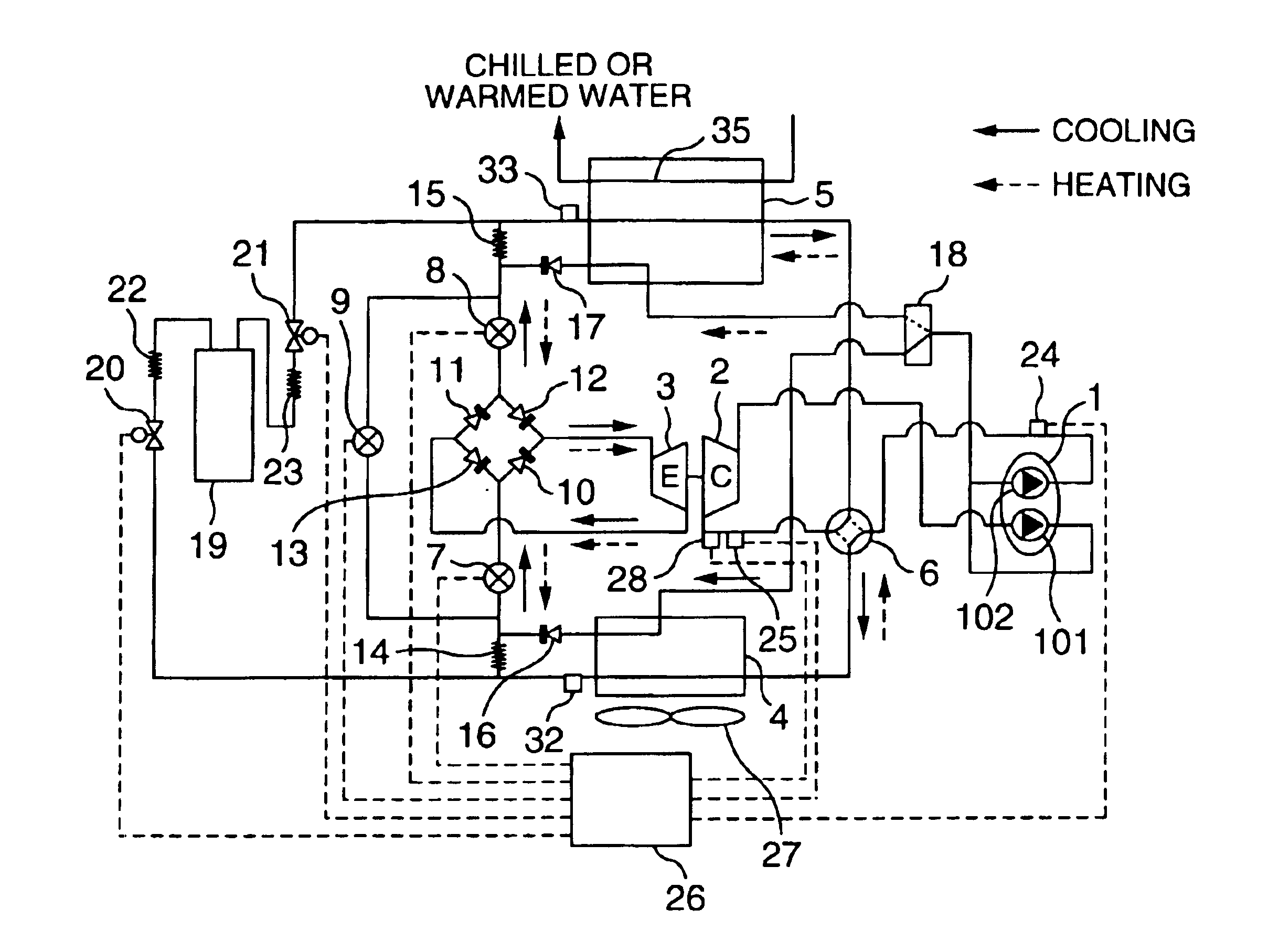

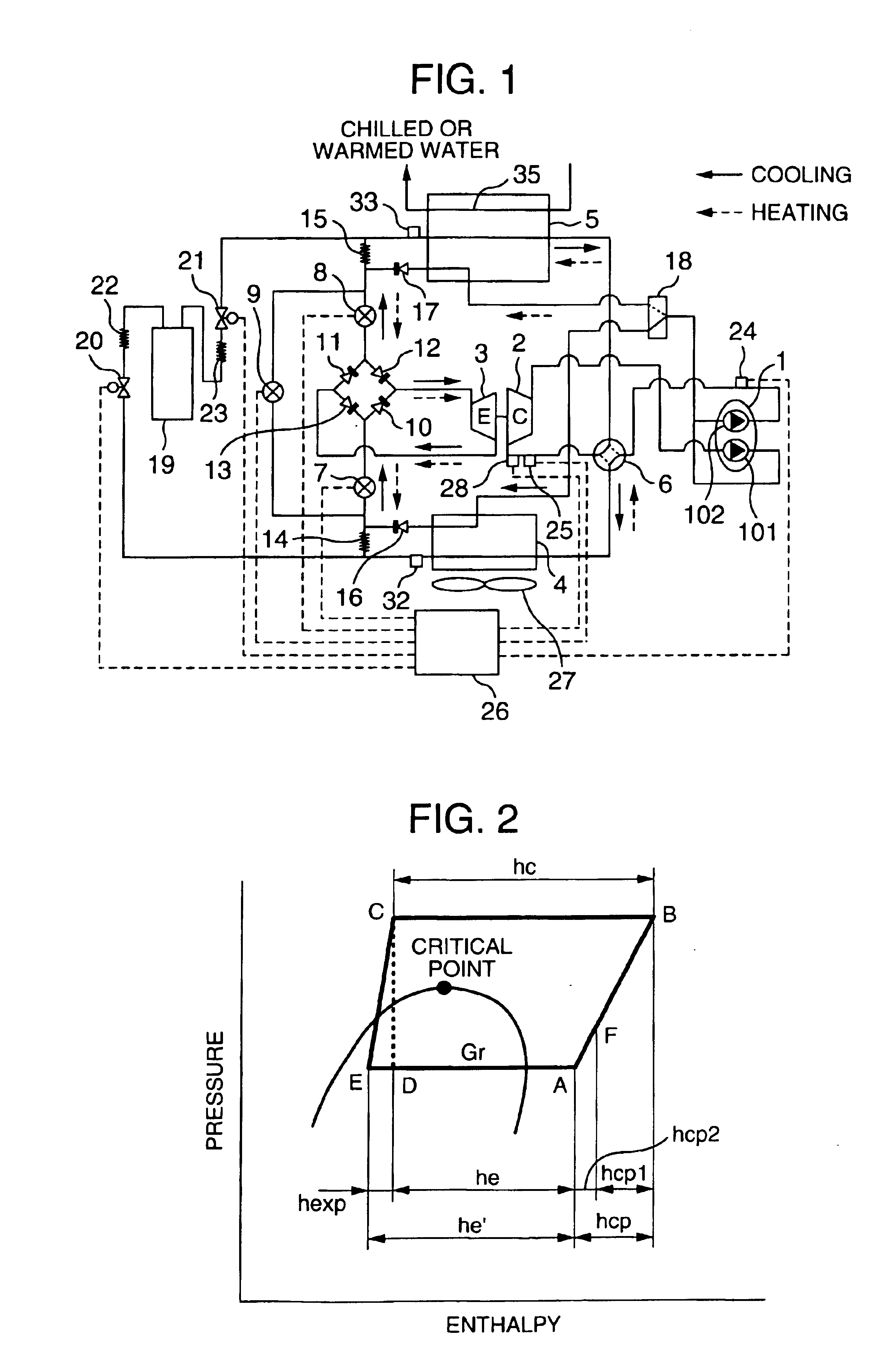

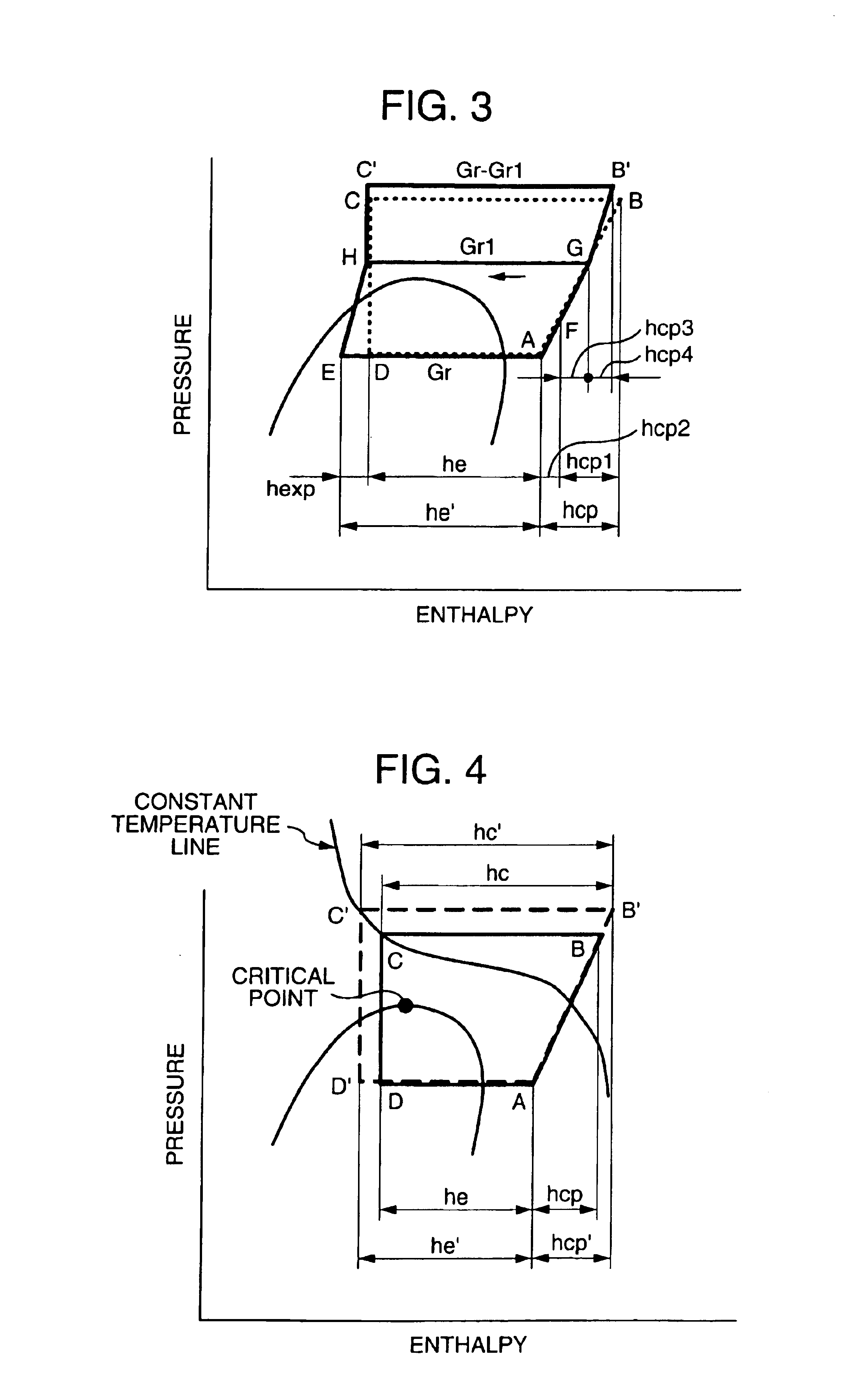

Refrigeration cycle apparatus

InactiveUS6923016B2Improve efficiencyIncrease amount of energy recoveredSolidificationMechanical apparatusProcess engineeringRefrigerant

In a refrigerant cycle apparatus, an energy-saving operation is performed by using a refrigerant which is used in a supercritical state. A refrigeration cycle apparatus is constituted by a main compressor, an expander, a sub compressor independently placed in an upstream side of the main compressor, a use side heat exchanger, a heat source side heat exchanger and the like. A refrigerant such as a carbon dioxide or the like which is used in a supercritical state is employed as the refrigerant. The sub compressor is driven by utilizing a recovered energy by the expanding device. Further, a refrigerant tank is provided, and properly controls an amount of the refrigerant circulating in the refrigerant cycle.

Owner:HITACHI AIR CONDITIONING SYST

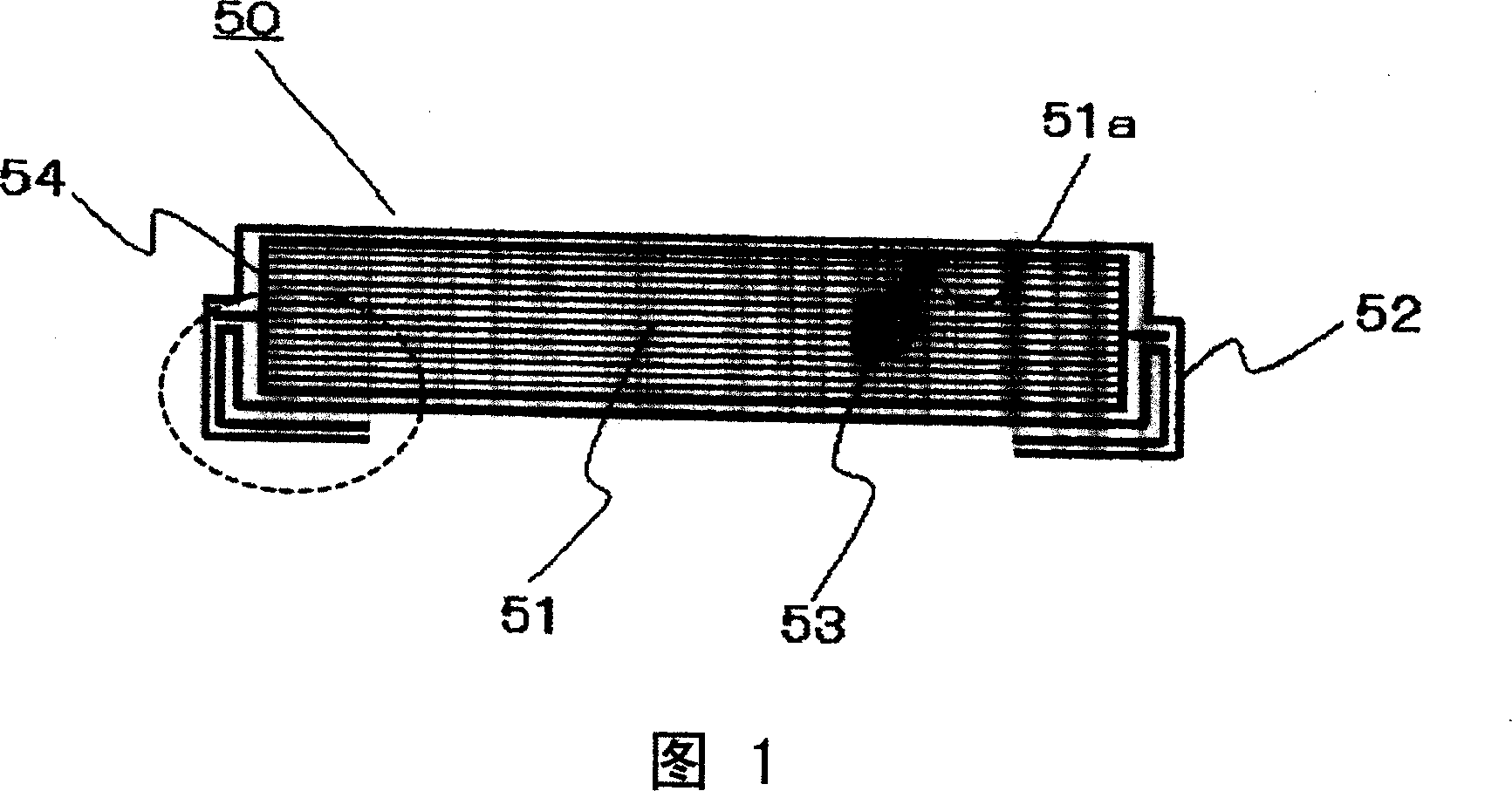

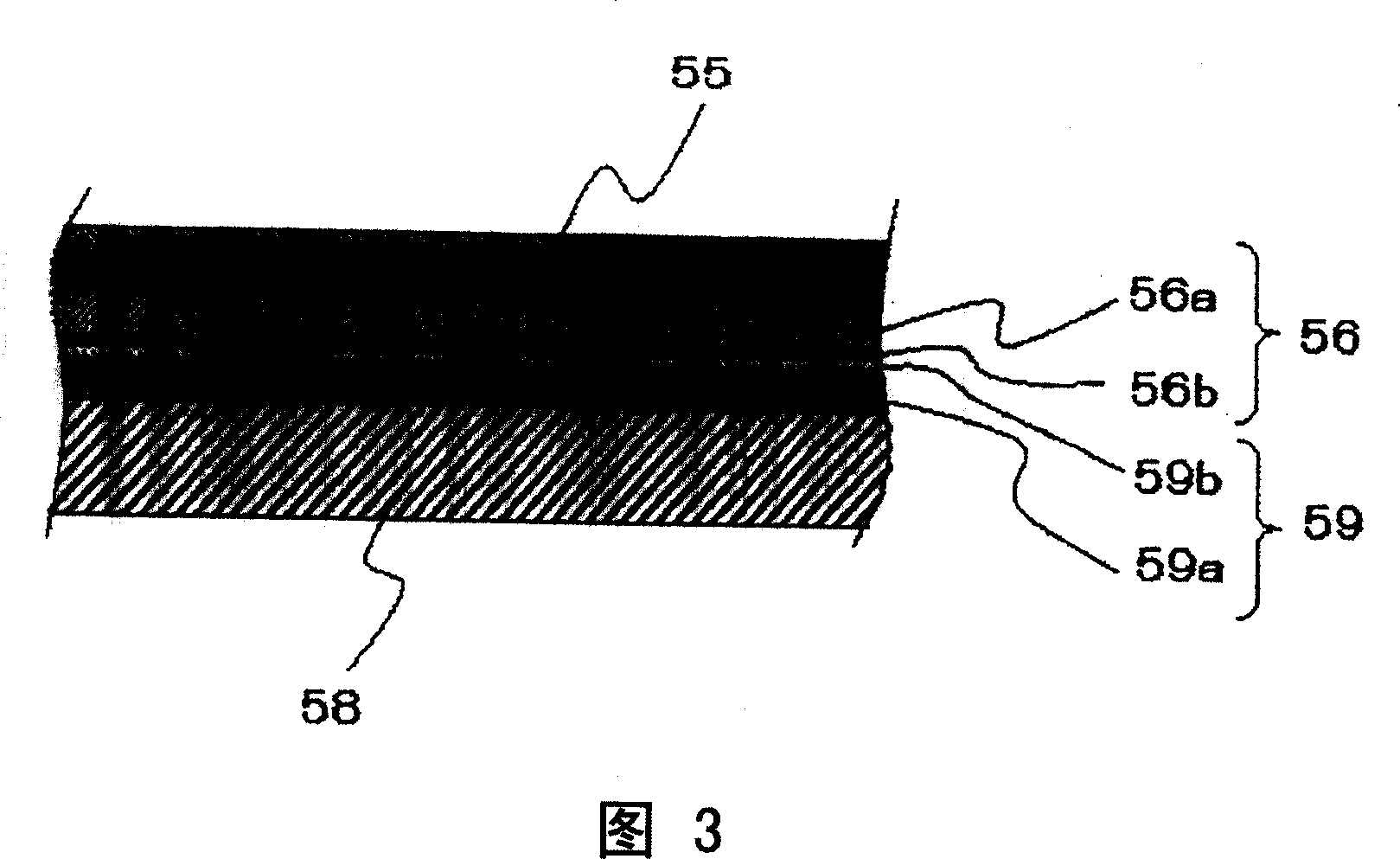

Vacuum insulating material, hot water supplying device using the same and electric drive type hot water device

InactiveCN101046271ASuppresses deterioration of thermal insulation performanceInhibit entryCooking-vessel materialsThermal insulationFiberSorbent

The present invention provides a vacuum heat insulation material capable of maintaining high heat insulation capacity even in high temperature circumstance, and provides a hot water supply device having high heat insulation capacity. In the vacuum heat insulation material comprising core material (51) composing of inorganic fiber polymer, a housing material (52) having surface protection layer and aerospace sealing layer and heat melting coating layer, and sorbent (53) absorbing the moisture and air component of core material (51) and the housing material (52), the heat insulation capacity can be maintained in long time in condition of high temperature by laminating the aerospace sealing layer of the housing material (52) with a first aerospace sealing layer and the second aerospace sealing layer in terms of opposite metal surface of at least tow layers of metal layer, and using resin film with melting point more than 150 DEG C as heat melting coating layer.

Owner:HITACHI APPLIANCES INC

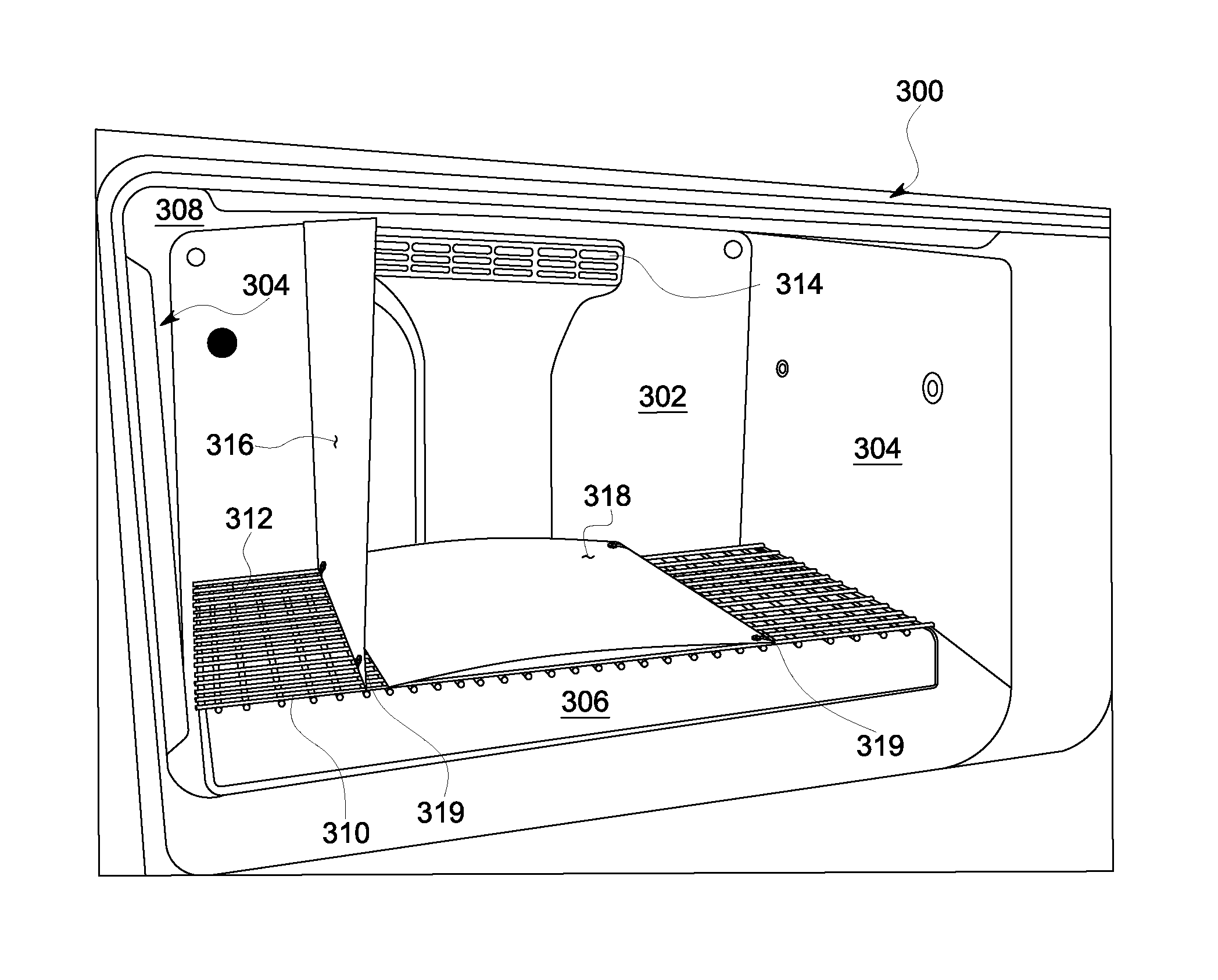

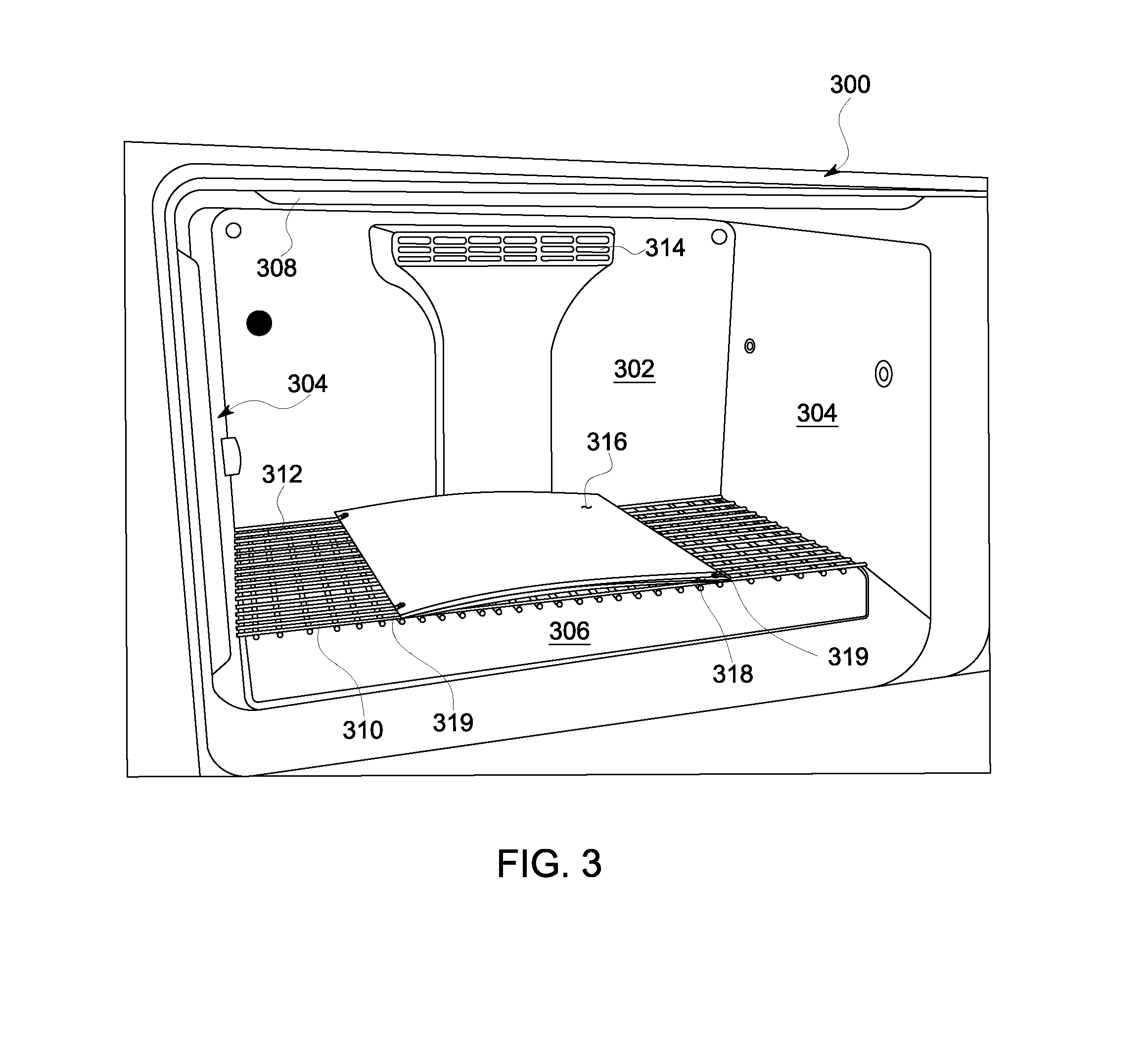

Refrigerator appliance with freezer compartment position-adjustable partitions

ActiveUS8359881B2Increase air temperatureReduce energy useLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

A refrigerator appliance includes a freezer compartment and at least one position-adjustable partition located in the freezer compartment. The at least one position-adjustable partition is configured to be selectively deployed in a first position such that a space is defined in the freezer compartment that causes a reduction in an amount of inlet airflow that contacts one or more portions of the freezer compartment that are outside the defined space.

Owner:HAIER US APPLIANCE SOLUTIONS INC

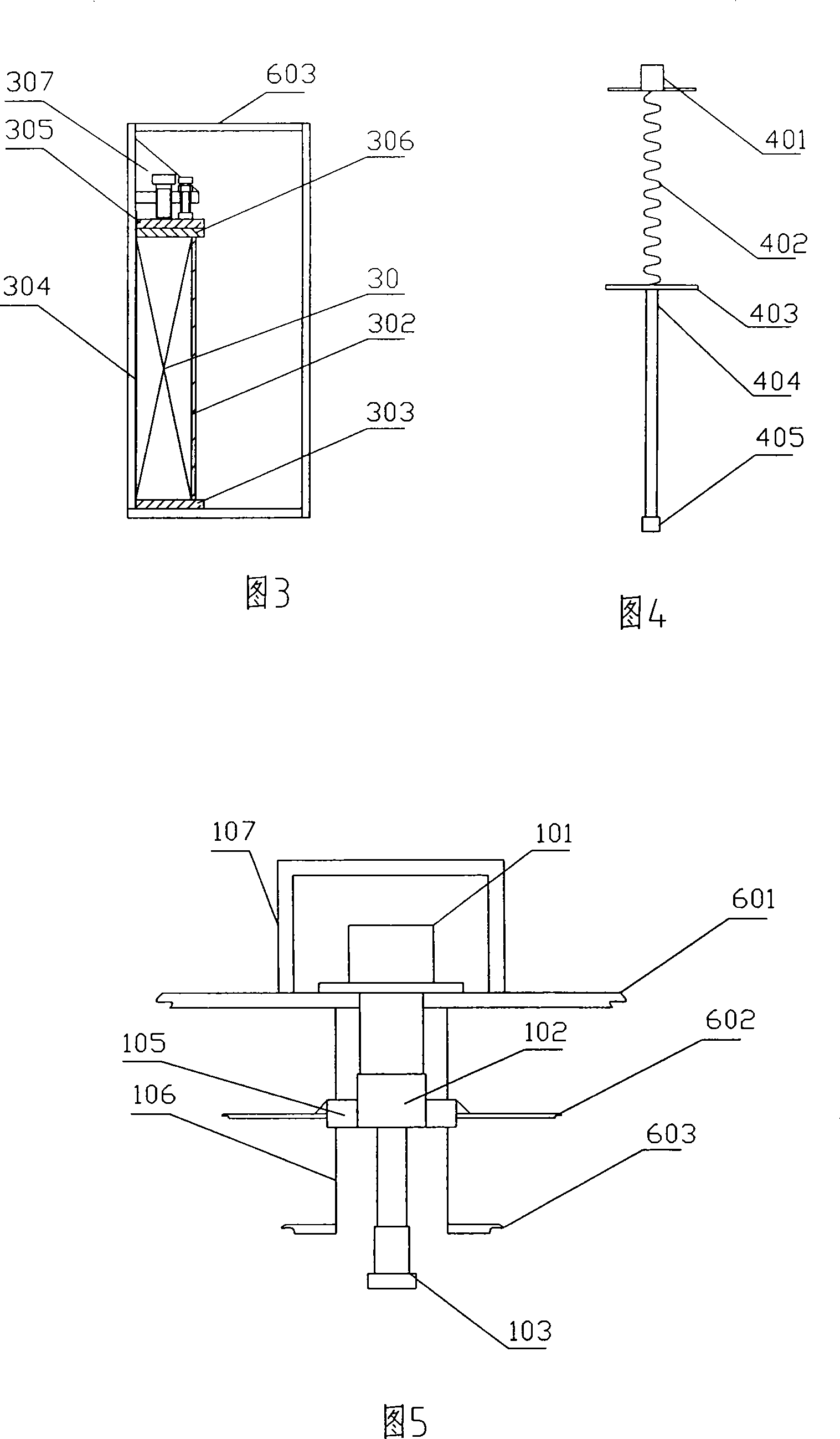

Low temperature superconductivity ferromagnetic deironing device

ActiveCN101195108AReduce heat leakageImprove stabilityOpen gradient mangetic separatorsSuperconducting magnets/coilsSuperconducting CoilsSuperconductivity

The invention discloses a strong magnetic iron remover with low temperature superconductivity, a cryostat is arranged on an outer cover of the invention, and the cryostat is hoisted on an inner wall of the outer cover through a pull-rod. The cryostat is provided with an indoor temperature Dewar, a 4.2K Dewar is arranged in the indoor temperature Dewar, a heat radiation screen is arranged between the indoor temperature Dewar and the 4.2K Dewar, gaps are arranged in perimeters between the indoor temperature Dewar and the heat radiation screen and between the heat radiation screen and the 4.2K Dewar, a superconducting coil can be coiled in insulation on an inner cylinder of the 4.2K Dewar, and power can be provided for the superconducting coil by a pair of two-dimensional electric currents lead-in wires. A vacuum state is between the indoor temperature Dewar and the 4.2K Dewar, and the 4.2K Dewar is filled with liquid helium20. The invention has great magnetic induction intensity, and can suck out tiny iron magnetic substances from materials, and has high working stability.

Owner:SHANDONG HUATE MAGNET TECH +1

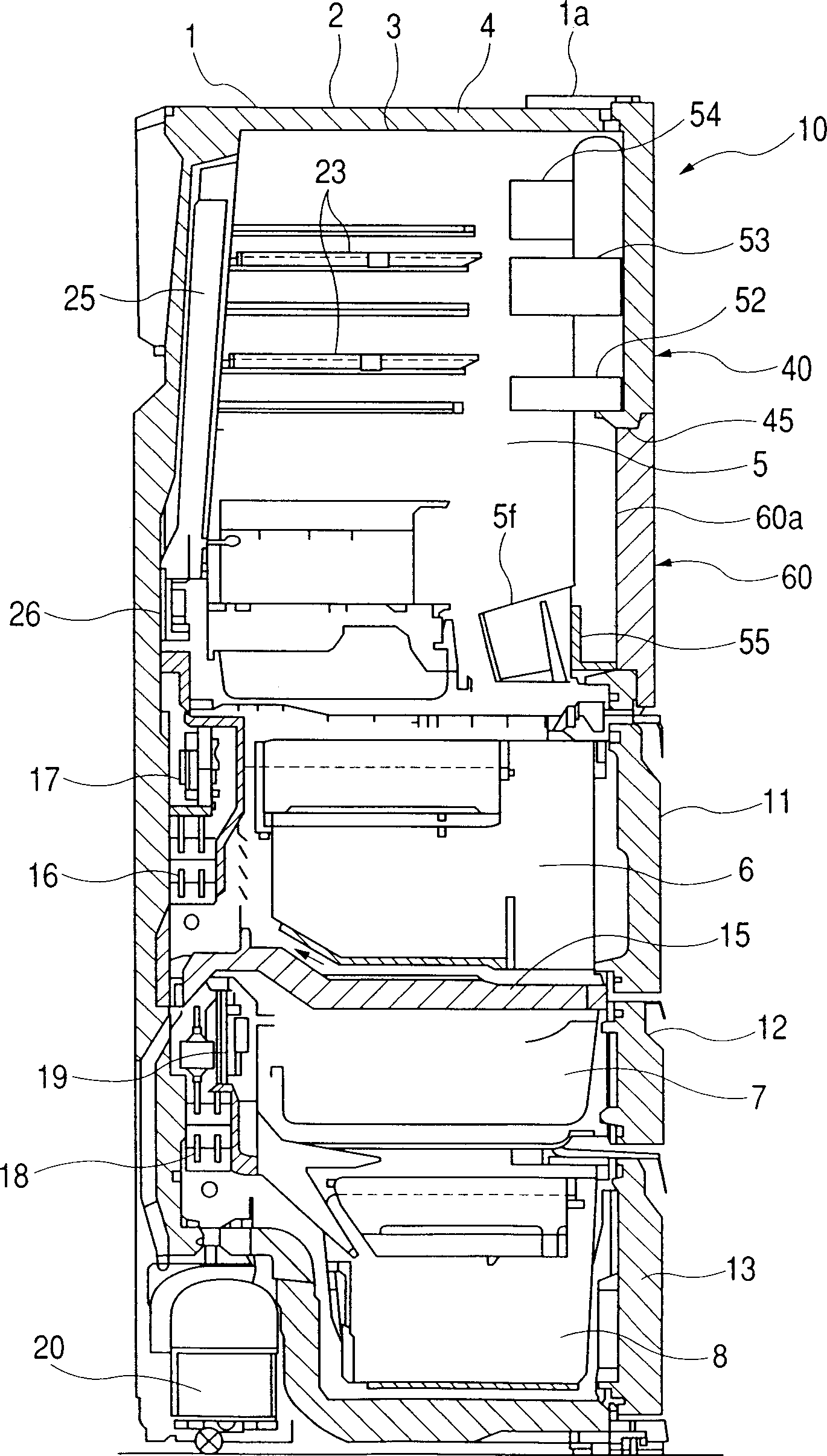

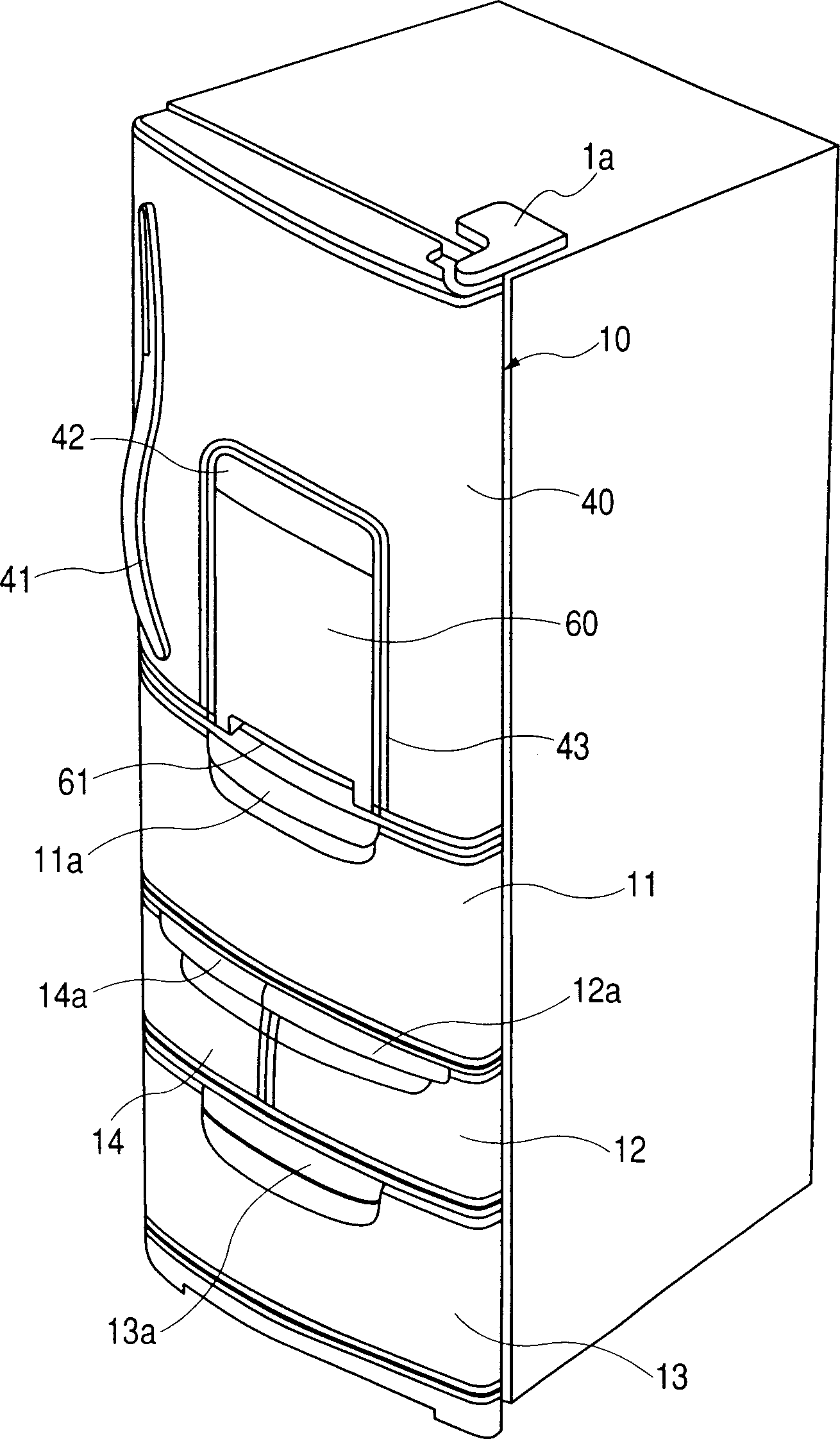

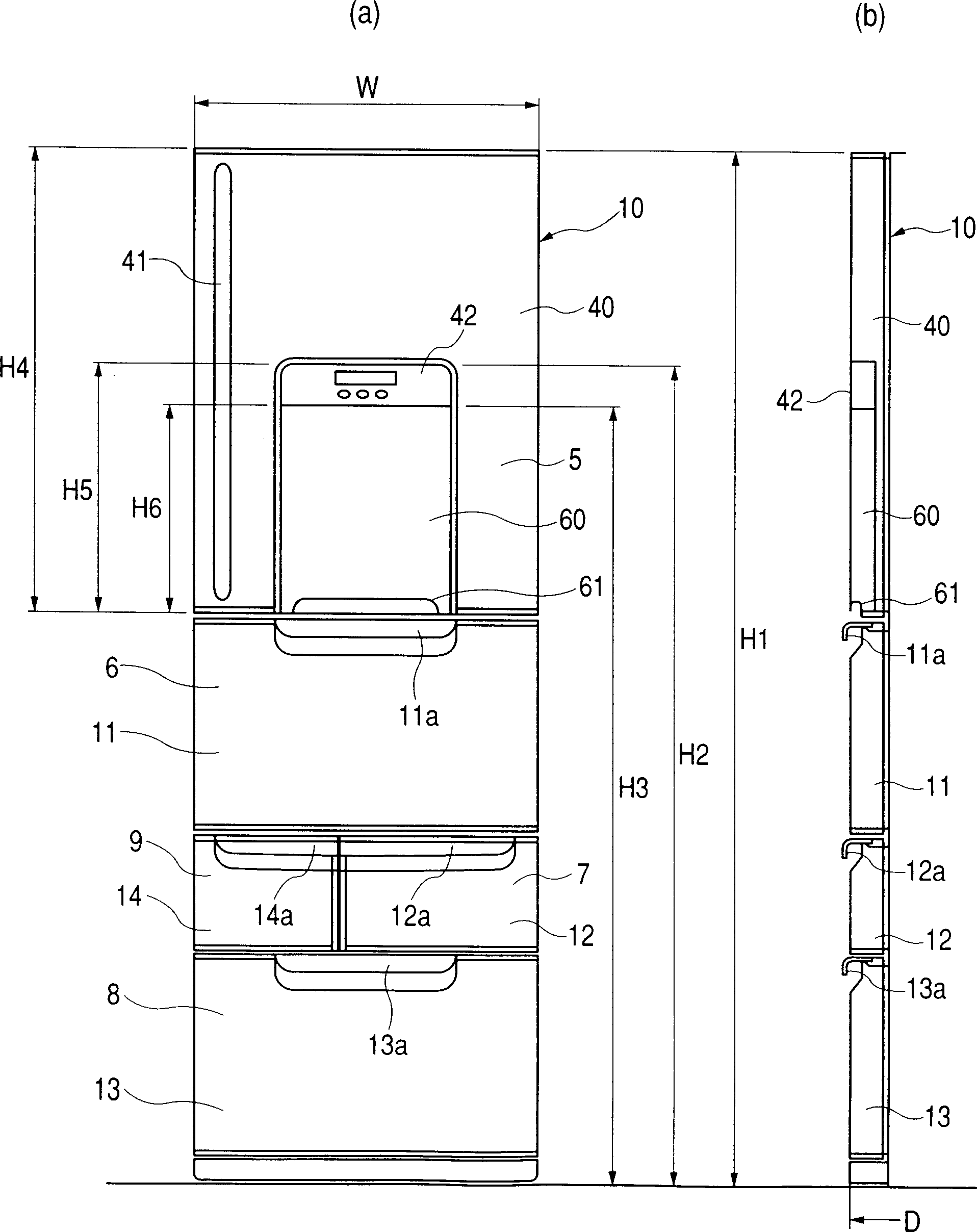

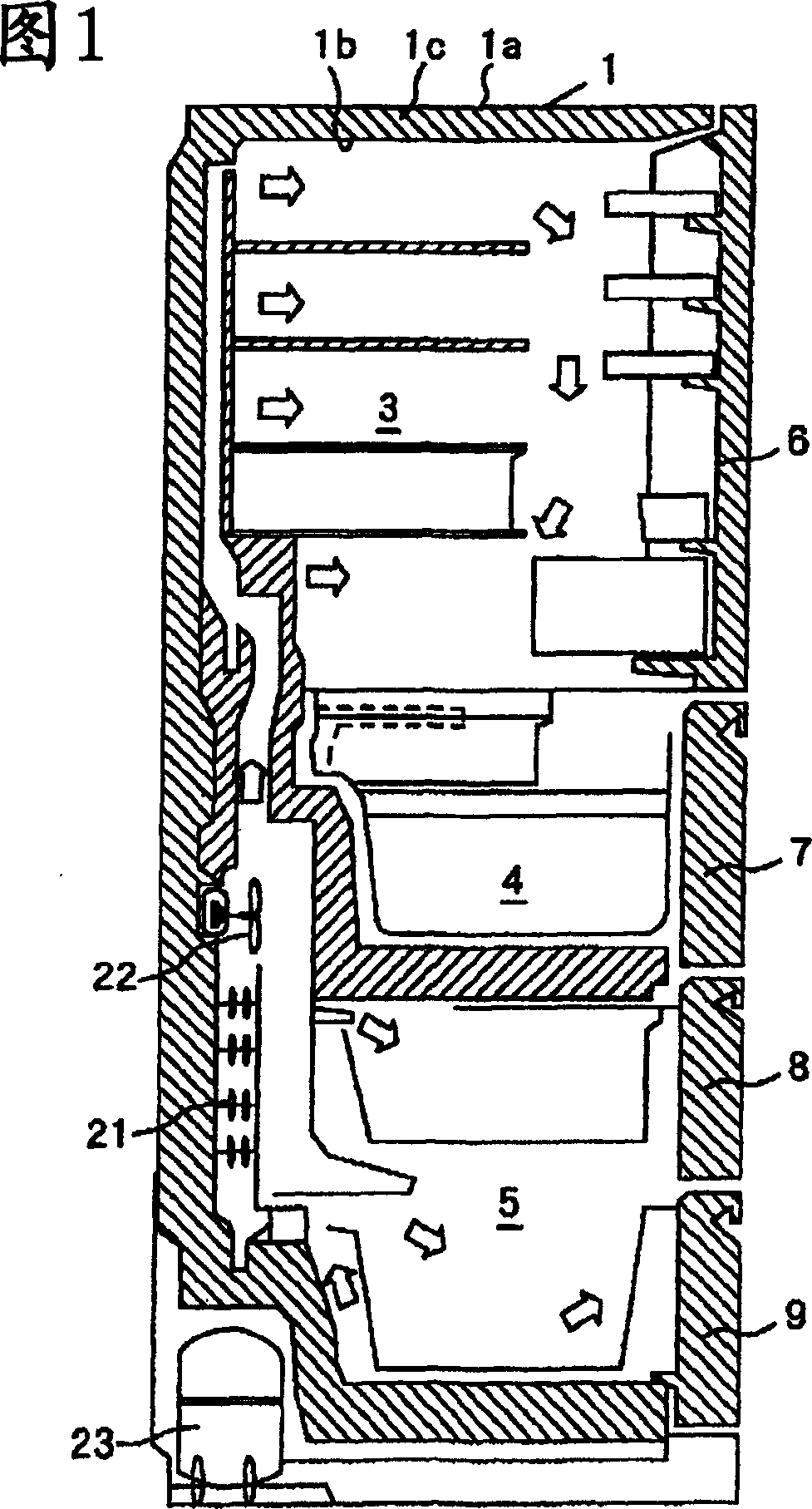

Refrigerator

InactiveCN1382950AEasy accessReduce outflowLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The utility model relates to a refrigerator, which enables storage to be easily entered and exited through the door of the refrigerator compartment, can reduce the outflow of cold air and heat leakage in the refrigerator chamber, facilitates the generalization of refrigerator doors with opposite opening and closing directions on the left and right, and simultaneously improves the accommodation performance of the groove. In a refrigerator having a multi-stage storage compartment with the uppermost section as the refrigerator compartment 5, the refrigerator compartment door 10 has a main door 40 that opens and closes the entire refrigerator compartment 5, and an auxiliary opening 45 that is symmetrically disposed at the center of the lower part of the main door 40. The main door 40 has main door grooves formed on the left and right sides of the auxiliary opening 45 for placing storage items, and the auxiliary door 60 is supported so as to be rotatable in the horizontal direction.

Owner:HITACHI APPLIANCES INC

Storage tank for a cryogenic liquid and method of re-filling same

ActiveCN101189469AReduce the numberReduce heat leakageVessel mounting detailsVessel geometry/arrangement/sizeEngineeringCheck valve

A storage tank defines a cryogen space for storing a cryogenic liquid. The storage tank comprises a combined fill and vent assembly, which comprises a conduit having a first end with an opening disposed within an upper part of the cryogen space, and a second end outside of the cryogen space that is connected to a receptacle, to which a re-filling nozzle can be attached. A check valve disposed in the conduit allows flow only in the direction of filling the cryogen space with cryogenic liquid from the receptacle. A by-pass line is provided around the check valve with a valve disposed in the by-pass line that is operable to open or close to control flow through the by-pass line. The method comprises attaching a re-filling nozzle to the receptacle and opening the by-pass valve to vent vapor from the cryogen space to reduce vapor pressure therein and to cool the conduit, receptacle, re-filling nozzle, and fill line. After venting the storage tank, the by-pass valve is closed, and the storage tank can be re-filled through the receptacle and conduit.

Owner:WESTPORT POWER

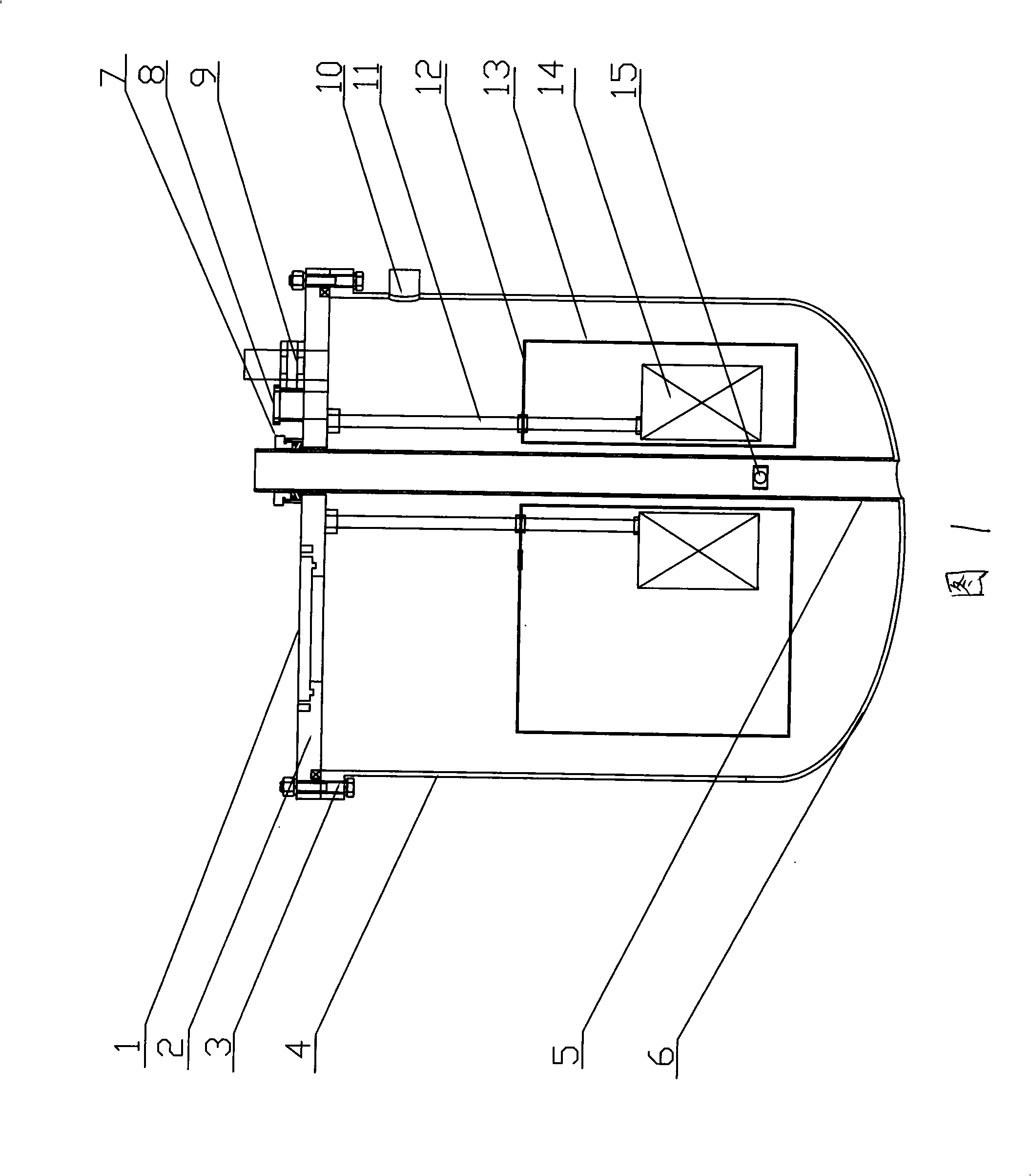

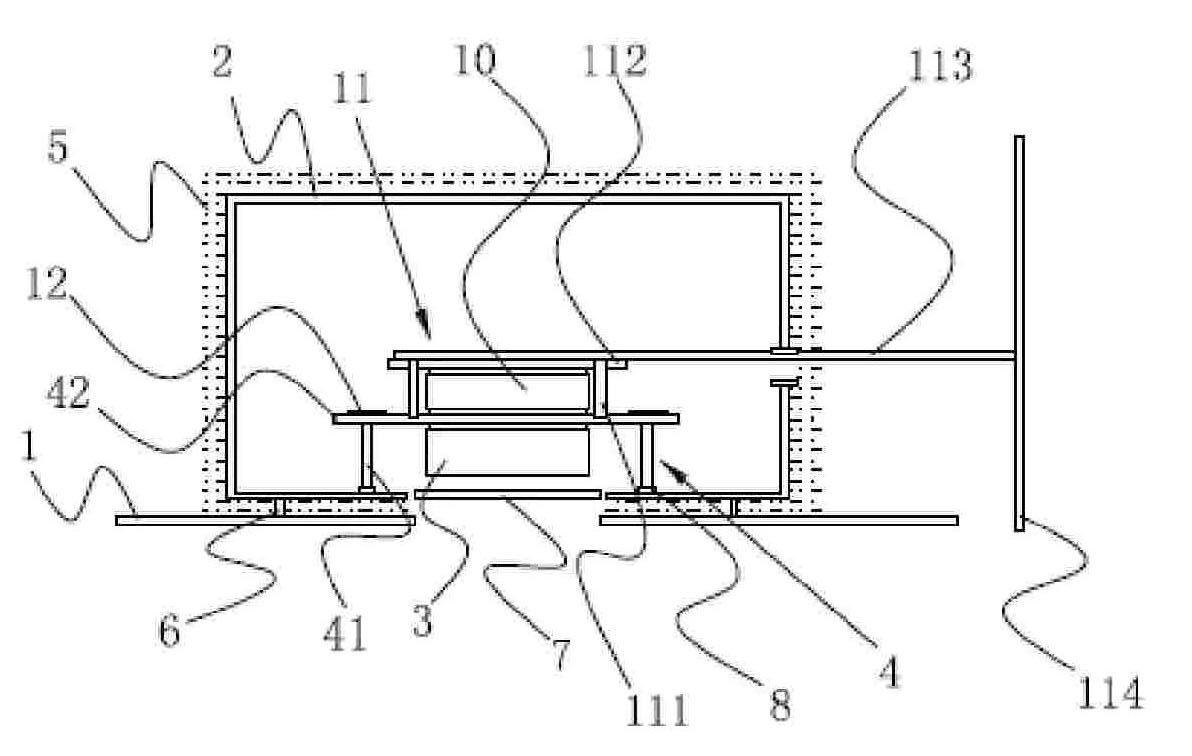

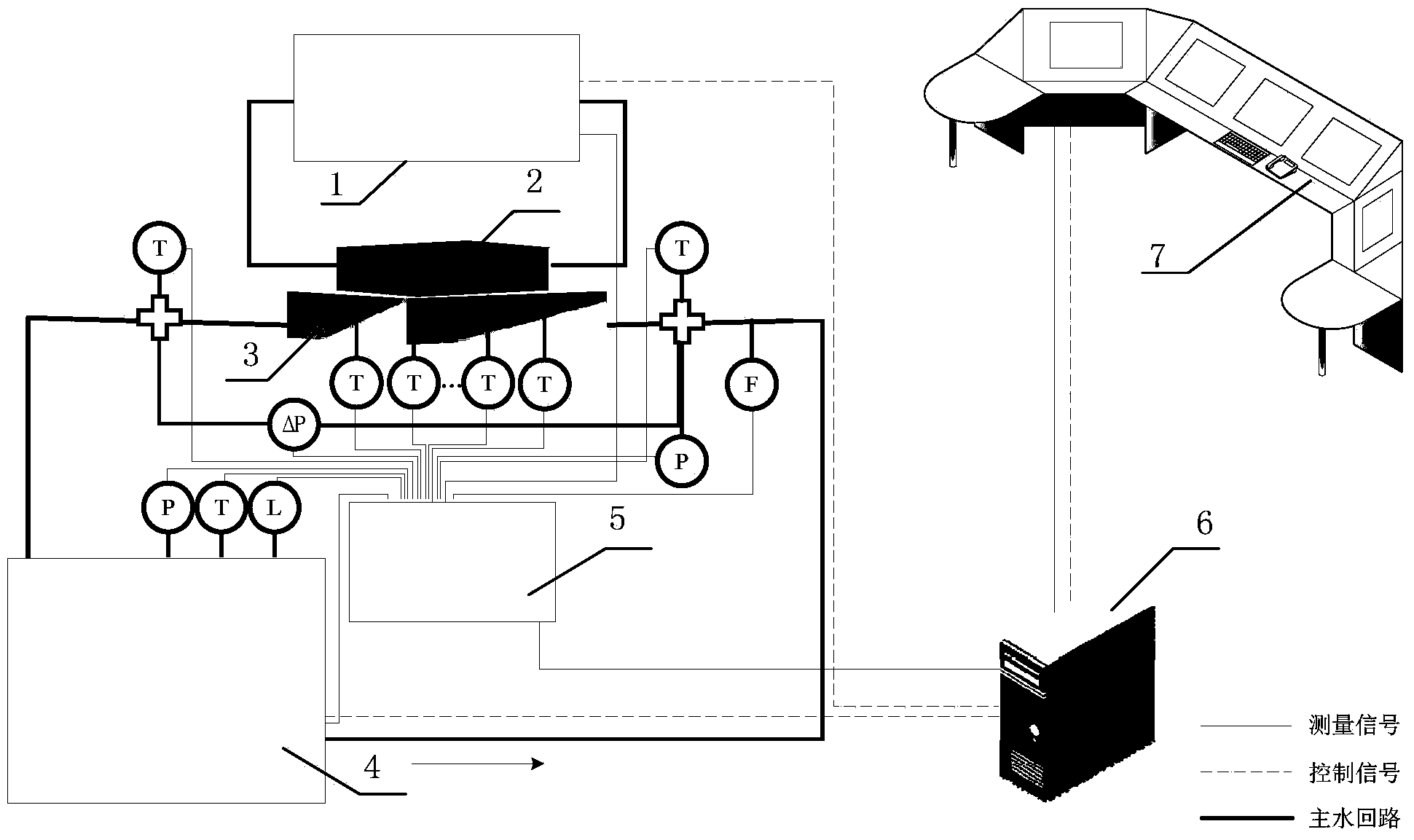

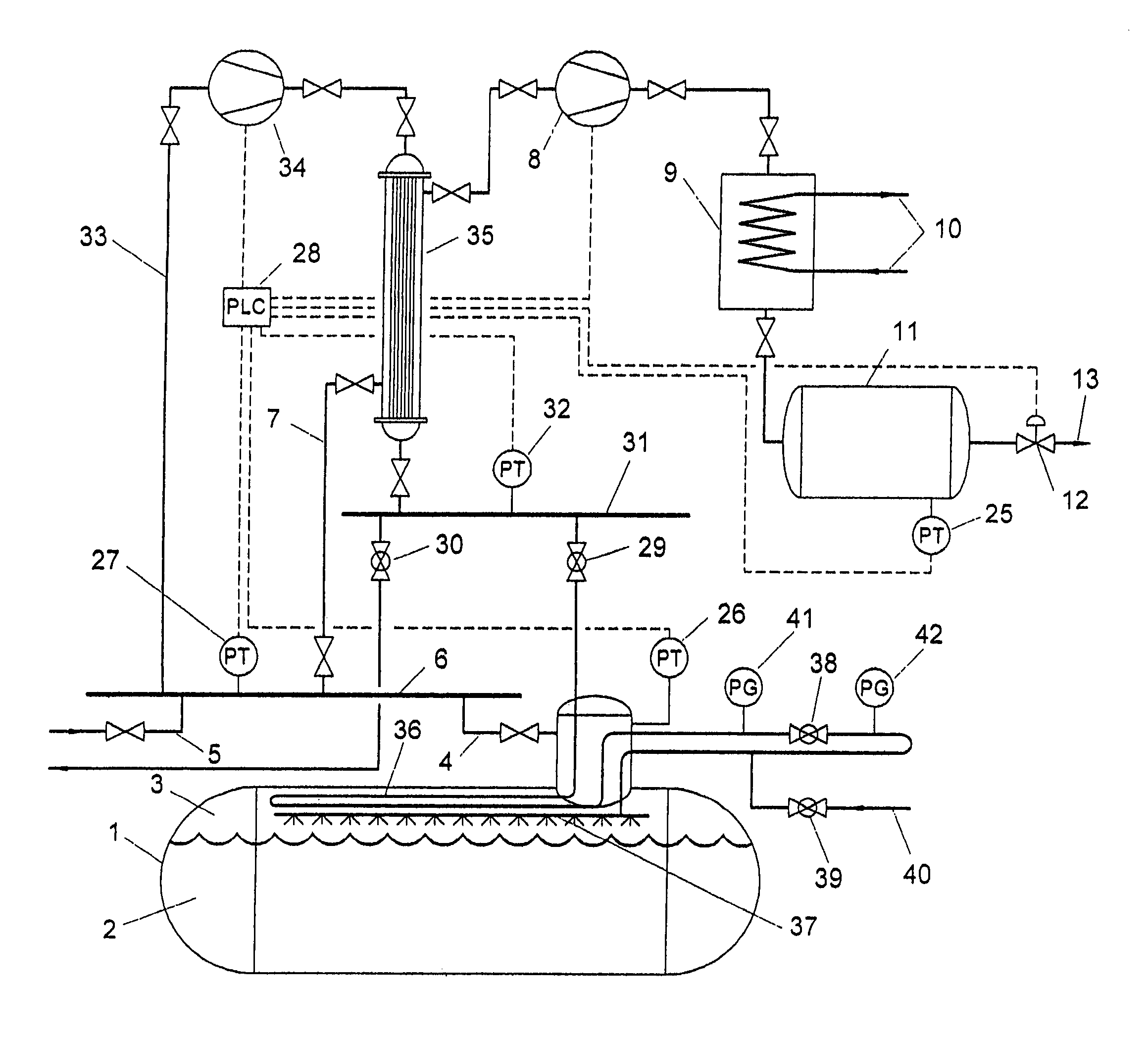

Heat dissipation performance test system and method of water-cooling heat sink

ActiveCN103630415AAccurately Measure Heat Dissipation CapabilityReduce heat leakageStructural/machines measurementDifferential pressureEngineering

The invention provides a heat dissipation performance test system. A power supply unit is in circuit connected with a heating device to form a loop, the heating device is arranged on the tested water-cooling heat sink, a water supply unit is in waterway connection with the tested water-cooling heat sink to form another loop, and a control unit controls switches of the power supply unit and the water supply unit respectively through an industrial personal computer. In the waterway loop of the water supply unit and the tested water-cooling heat sink, a pipeline of a water inlet end of the tested water-cooling heat sink is provided with a flow controller, a pressure sensor and a temperature sensor. A pipeline of a water outlet end of the tested water-cooling heat sink is provided with the temperature sensors. The water inlet end and the water outlet end of the tested water-cooling heat sink are in parallel connection with a bypass which is provided with a differential pressure sensor. Compared with the prior art, the heat dissipation performance test system and method are capable of rapidly and accurately measuring heat dissipation performance of the tested water-cooling heat sink.

Owner:STATE GRID CORP OF CHINA +3

Storage tank for a cryogenic liquid and method of re-filling same

ActiveUS7546744B2Stop the leakReduce in quantityGas handling applicationsPackaging under special atmospheric conditionsLine tubingCheck valve

A storage tank defines a cryogen space for storing a cryogenic liquid. The storage tank comprises a combined fill and vent assembly, which comprises a conduit having a first end with an opening disposed within an upper part of the cryogen space, and a second end outside of the cryogen space that is connected to a receptacle, to which a re-filling nozzle can be attached. A check valve disposed in the conduit allows flow only in the direction of filling the cryogen space with cryogenic liquid from the receptacle. A by-pass line is provided around the check valve with a valve disposed in the by-pass line that is operable to open or close to control flow through the by-pass line. The method comprises attaching a re-filling nozzle to the receptacle and opening the by-pass valve to vent vapor from the cryogen space to reduce vapor pressure therein and to cool the conduit, receptacle, re-filling nozzle, and fill line. After venting the storage tank, the by-pass valve is closed, and the storage tank can be re-filled through the receptacle and conduit.

Owner:OLYMPUS CORP +1

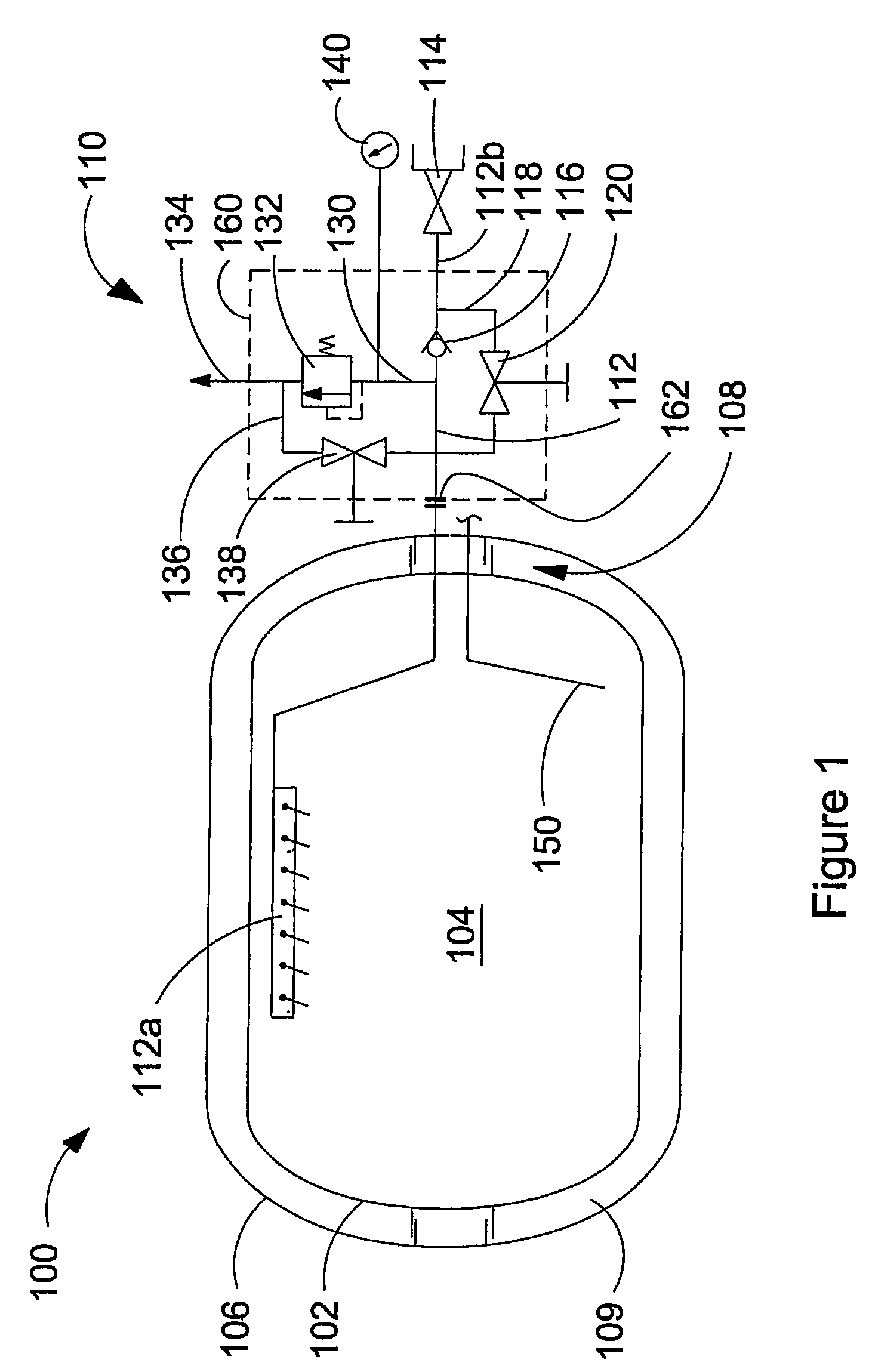

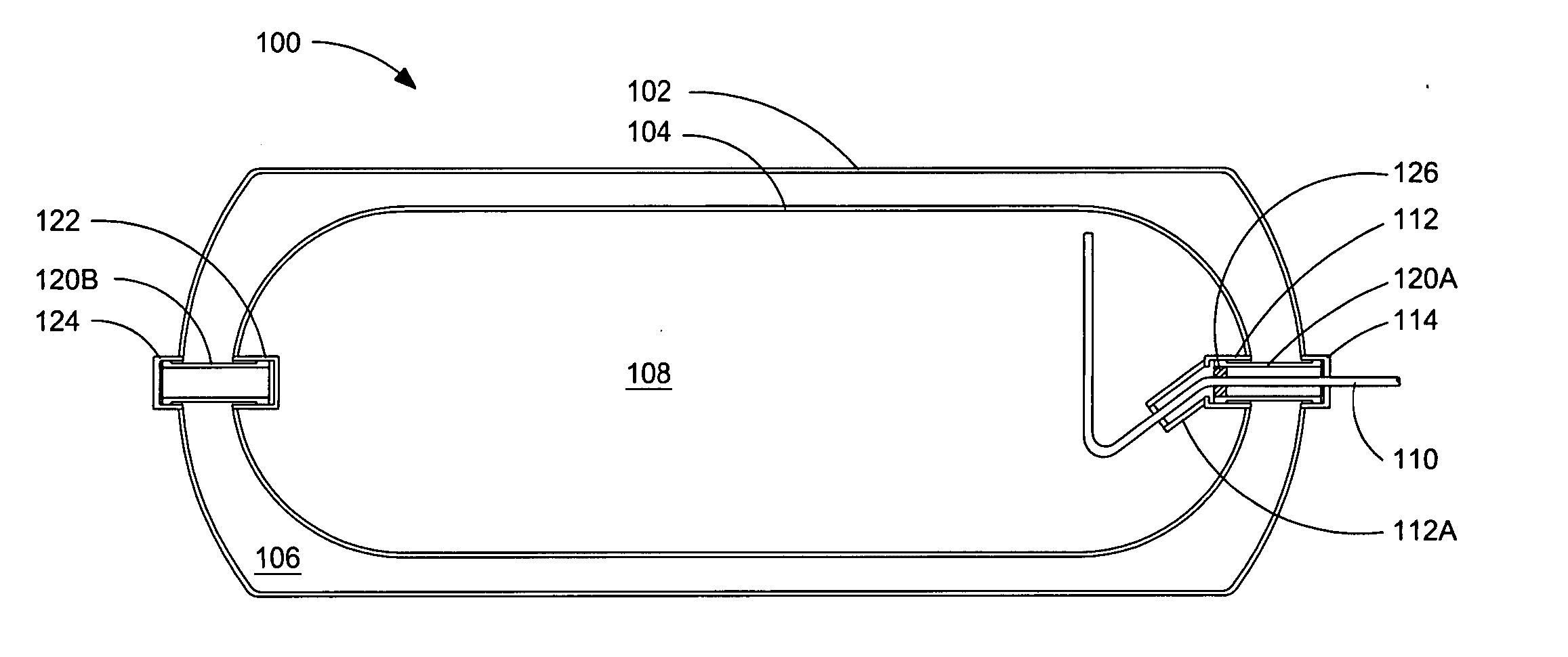

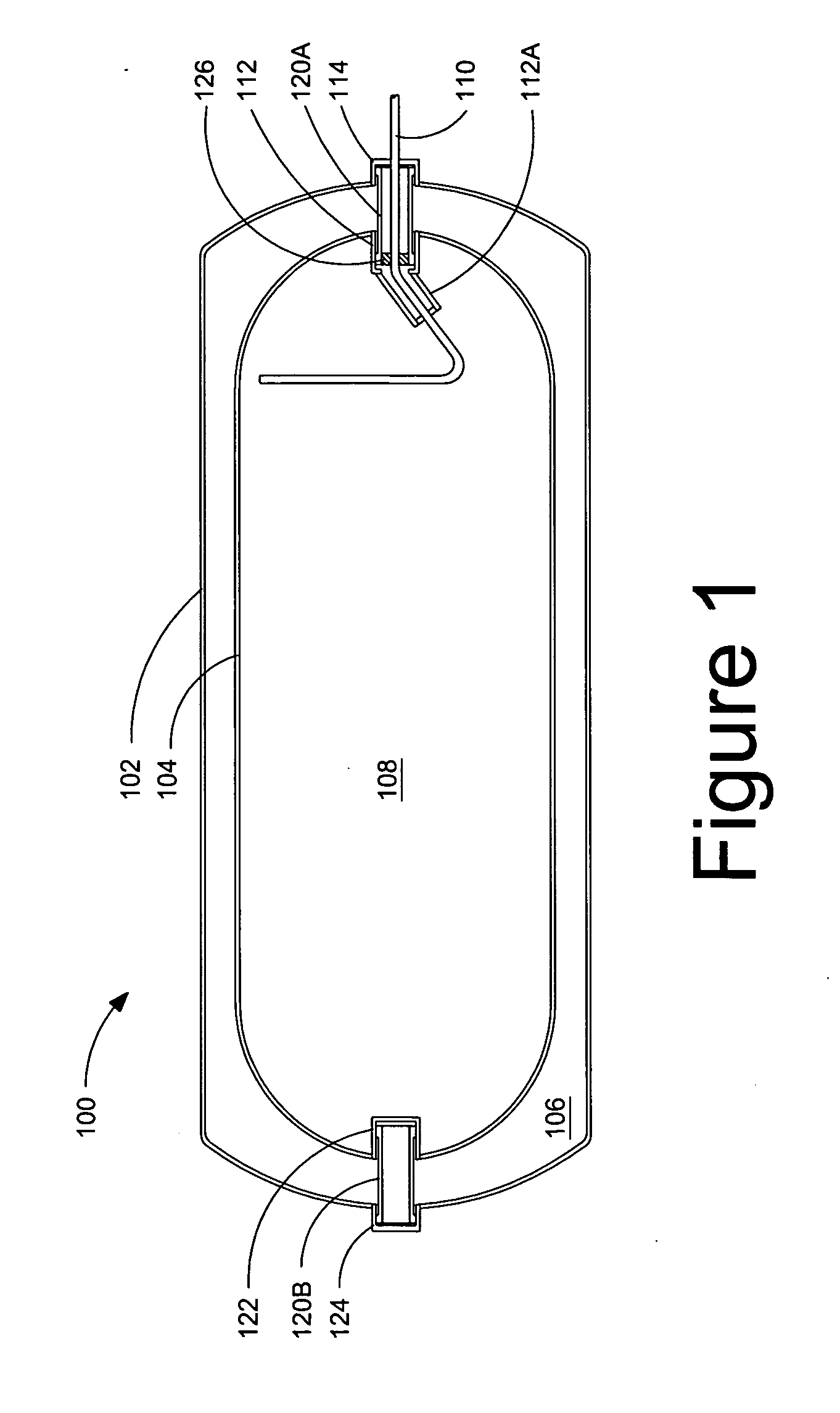

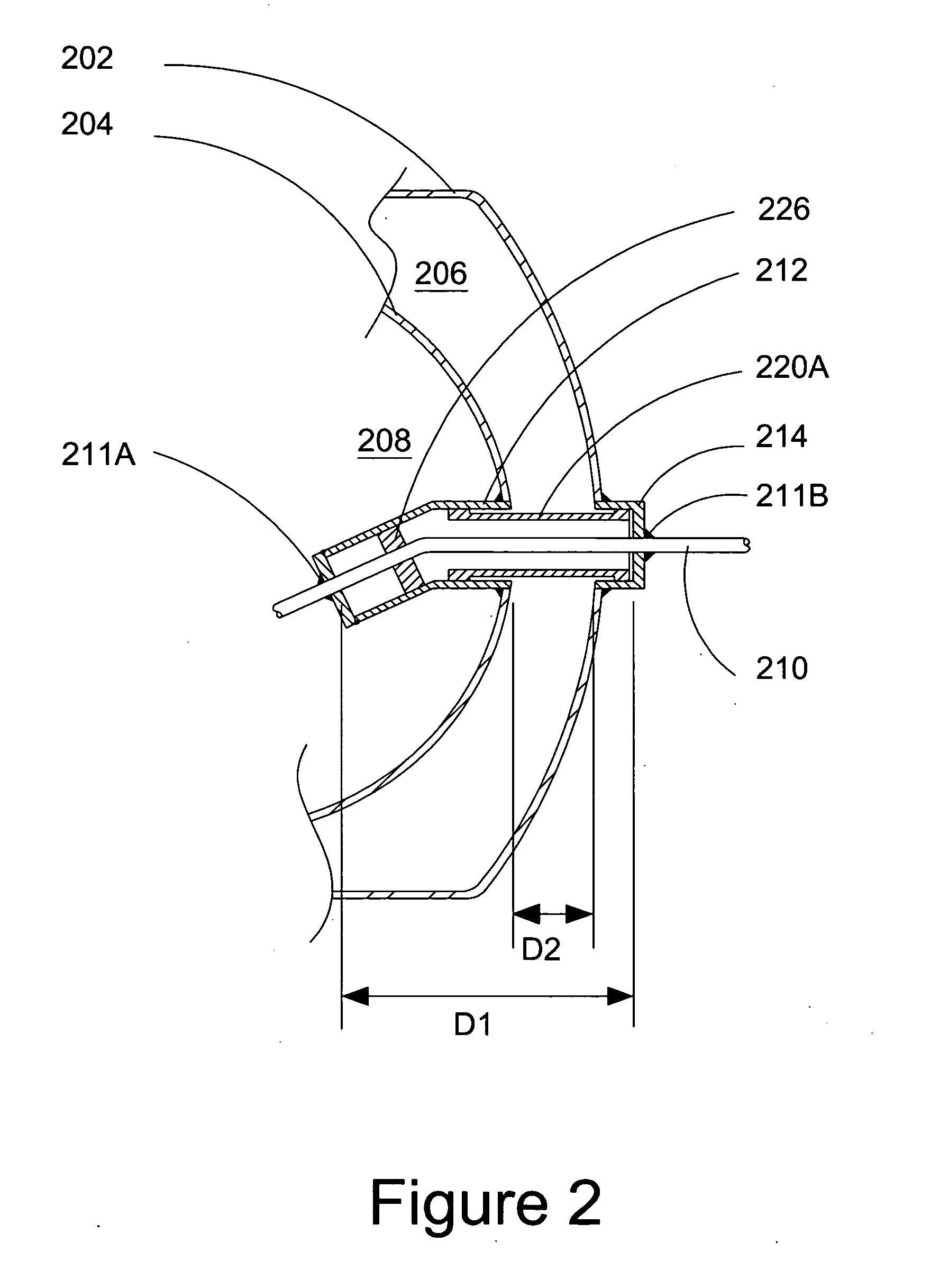

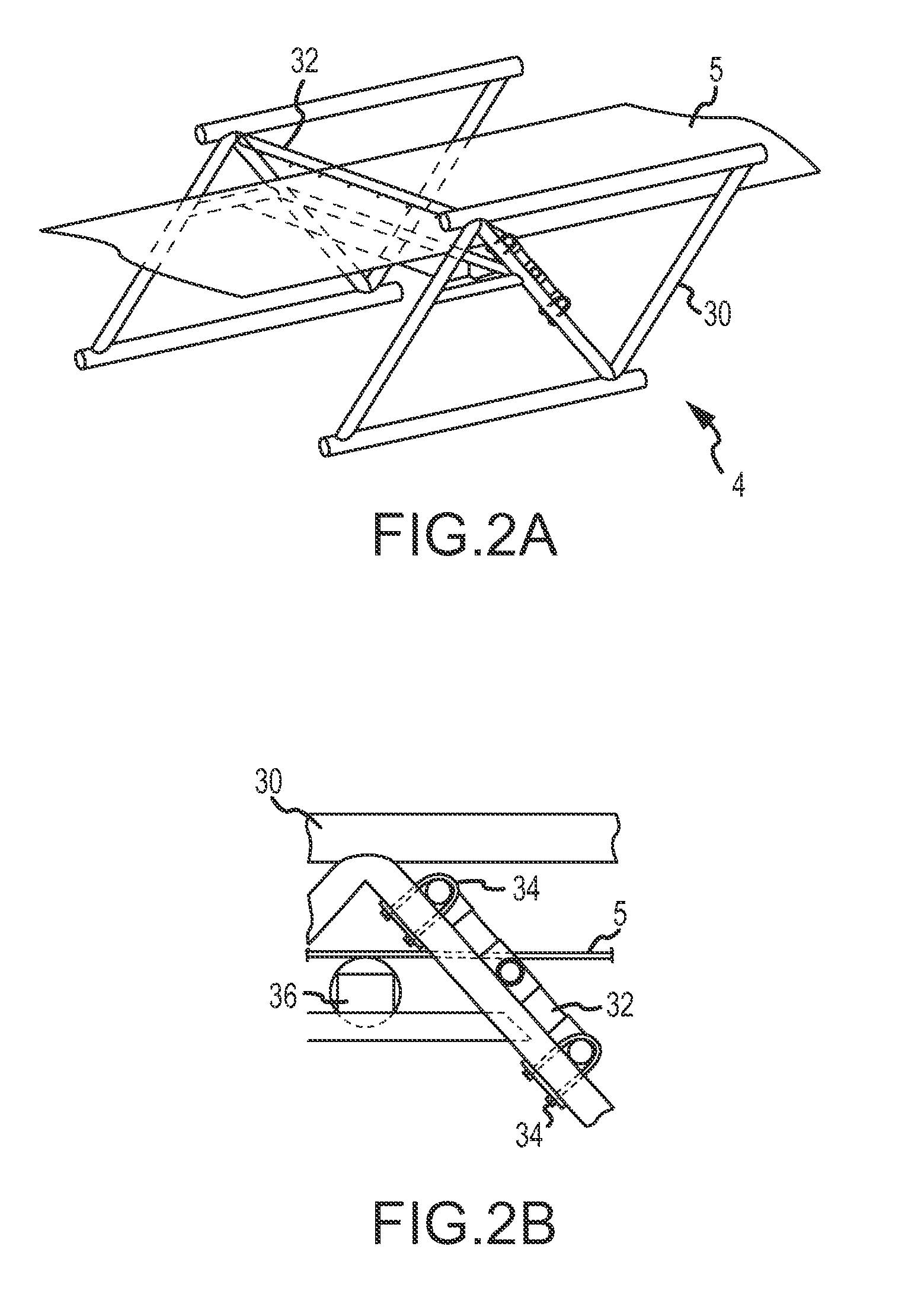

Container for holding a cryogenic fluid

ActiveUS20050139600A1Reduce heat leakageLow thermal conductivityContainer filling methodsSurgeryHorizontal axisDouble wall

A double-walled vacuum-insulated container for holding a cryogenic fluid comprises a support structure for supporting an inner vessel within an outer vessel. The container has an elongated horizontal axis. A conduit extending between the inner and outer vessels has a wall thickness that allows the conduit to carry a substantial portion of axial loads acting on the inner vessel in a direction parallel to the horizontal axis. The support structure further comprises a non-metallic support spanning between the inner and outer vessels, with the non-metallic support capable of transferring substantially all radial loads transverse to said horizontal axis. The non-metallic support is also fixedly attached to the inner and outer vessels so that it is capable of supporting a substantial portion of the axial loads so that the non-metallic support and the conduit cooperate to provide support in the axial direction.

Owner:WESTPORT FUEL SYST CANADA INC

System and process for transporting LNG by non-self-propelled marine LNG carrier

Marine LNG carrier and method of operating the marine LNG carrier. The LNG carrier carries LNG in at least one tank. Gas composed of evaporated LNG within the at least one tank is removed. The gas is fed to at least one gas consuming prime mover of the LNG carrier. Power is provided with the at least one gas consuming prime mover. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:ARGENT MARINE MANAGEMENT

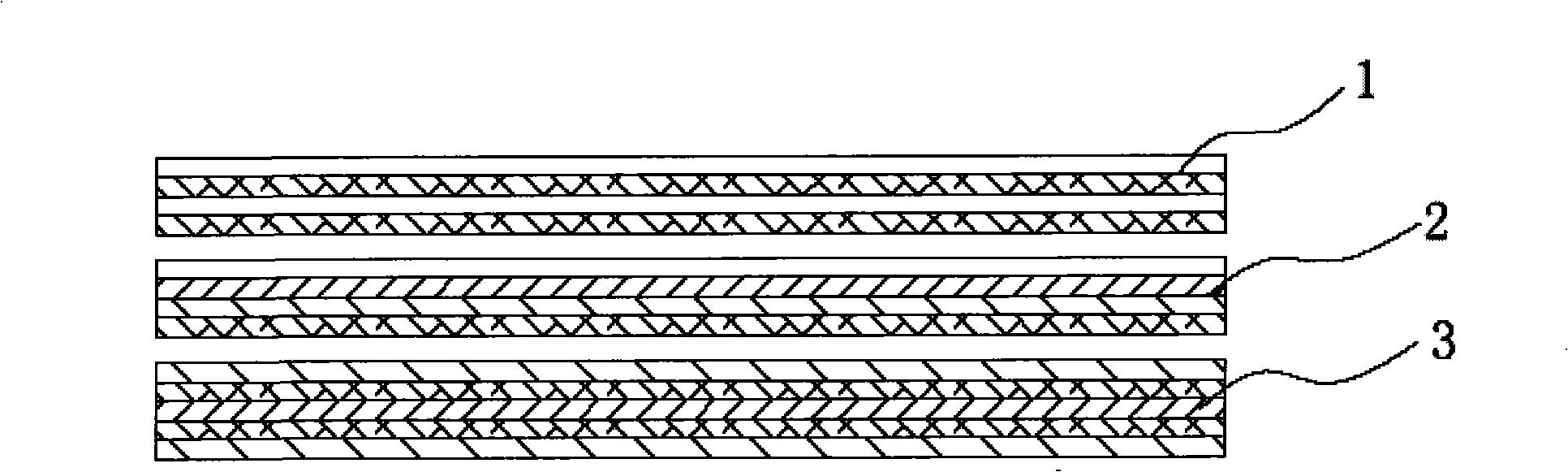

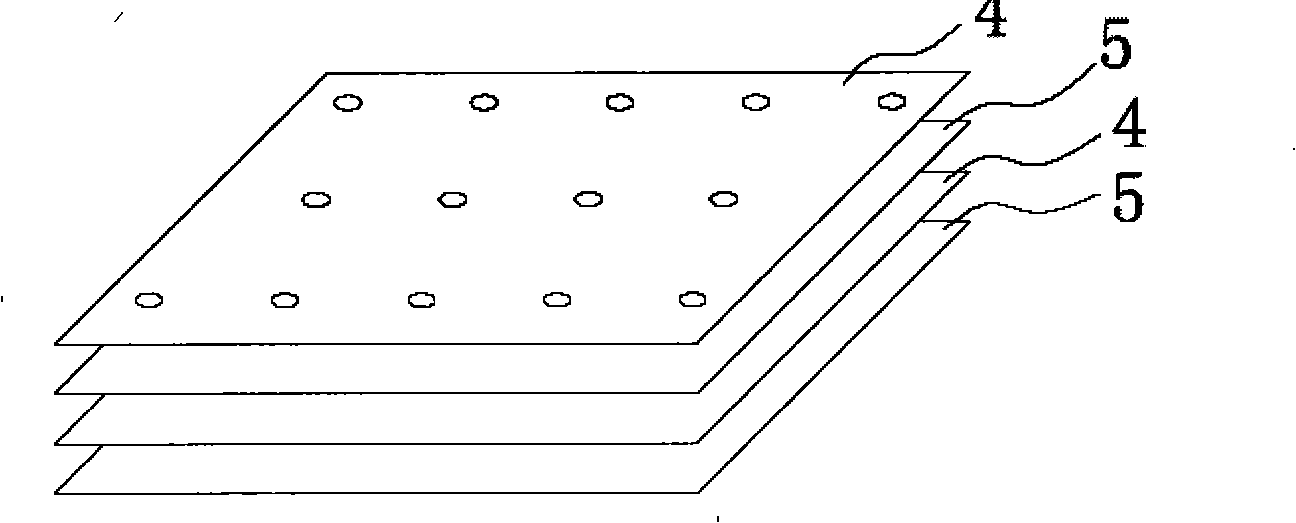

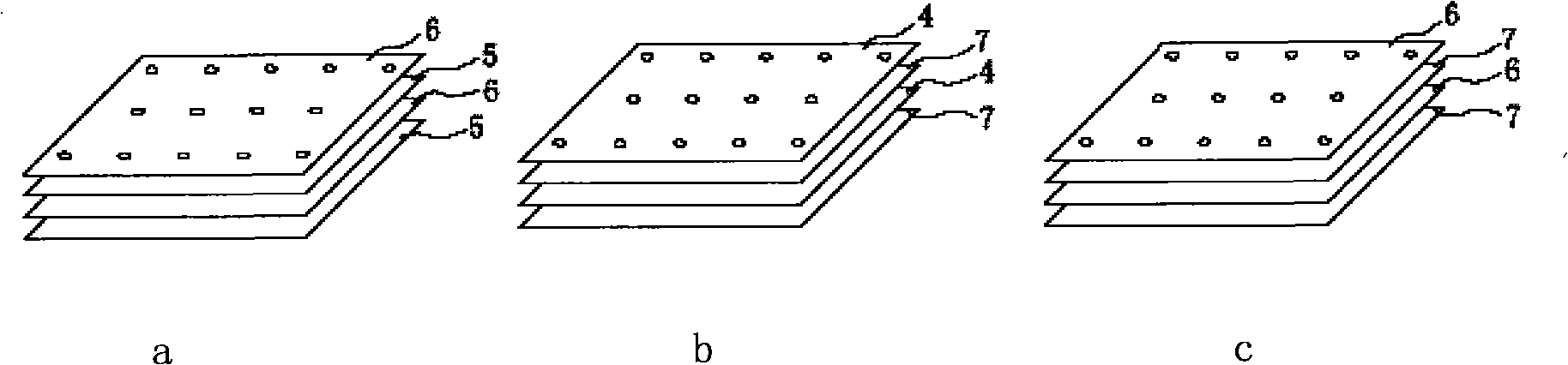

Various material composite fire retardant -type high vacuum multiple layer heat insulation structure

InactiveCN101307857AGuaranteed flame retardant performanceGuaranteed CompatibilityThermal insulationPipe protection by thermal insulationFiberGlass fiber

The invention relates to an inflaming retarding type high vacuum multilayer heat insulation structure combined with multiple materials, which belongs to the cryogenic engineering and cryogenic technical field. The invention comprises a high temperature side combination, a transition combination and a low temperature side combination, wherein the high temperature side combination adopts an alternating combination of the aluminum foil and the glass fiber paper; the transition combination adopts an alternating combination of the double-sided aluminum coated sheet and the glass fiber paper or the aluminum foil and the chemical fiber paper or the double-sided aluminum coated sheet and the chemical fiber paper; and the low temperature side combination adopts a mixed combination of the aluminum foil, the glass fiber paper and the chemical fiber paper. The insulation structure of the invention is characterized in that the whole structure can retard inflaming without exterior inflaming and the low temperature heat-insulating performance is superior to that of the traditional inflaming retarding type heat insulation structure, thereby decreasing the use of the heat insulating materials, lowering the cost of the heat insulating materials, shortening the intervals of the vacuum interlayers, increasing the inner effective volume of the low temperature vessel when the outside dimensions are the same, and contributing to the light weight and the volume maximization of the mobile low temperature accumulating conveyers.The inflaming retarding type high vacuum multilayer heat insulation structure combined with multiple materials has more obvious economic benefit and social benefit in the cryogenic engineering.

Owner:SHANGHAI JIAO TONG UNIV

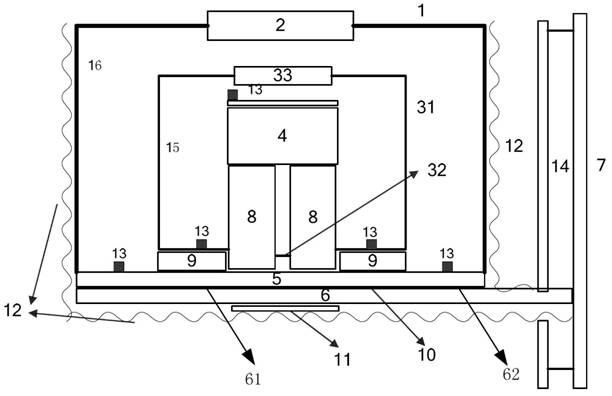

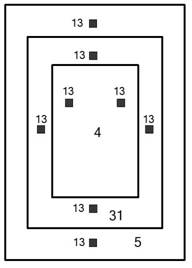

Precise thermal control mechanism of focal plane detector

InactiveCN102681568ATo achieve different working temperature requirementsFulfill heating needsTemperatue controlTemperature controlPhotovoltaic detectors

The invention relates to a precise thermal control mechanism of a focal plane detector, and the precise thermal control mechanism comprises a vacuum box body, a refrigerating assembly, a cold screen assembly, a heating assembly and a temperature collecting unit, and the precise thermal control mechanism also comprises a heat insulating layer which is arranged at the outer side of the vacuum box body and the outer side of the heating assembly, the refrigerating assembly comprises a refrigerator substrate, at least one detector refrigerator, at least one cold screen refrigerator, a heat tube assembly and a heat radiation plate. Due to the adoption of the precise thermal control mechanism, the technical problems that the quick variation of the temperature under the same working mode is difficult to realize because the temperature control of the traditional photoelectric detector thermal control mechanism mainly depends on the passive heat radiation way can be solved, a way combining the initiative refrigeration and the initiative heating is adopted, by the reasonable design of a thermal control system structure, not only is the quick variation of the temperature of the detector realized to meet the temperature requirement under different working modes, but also the temperature range can be precisely controlled, and the working reliability of the system is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

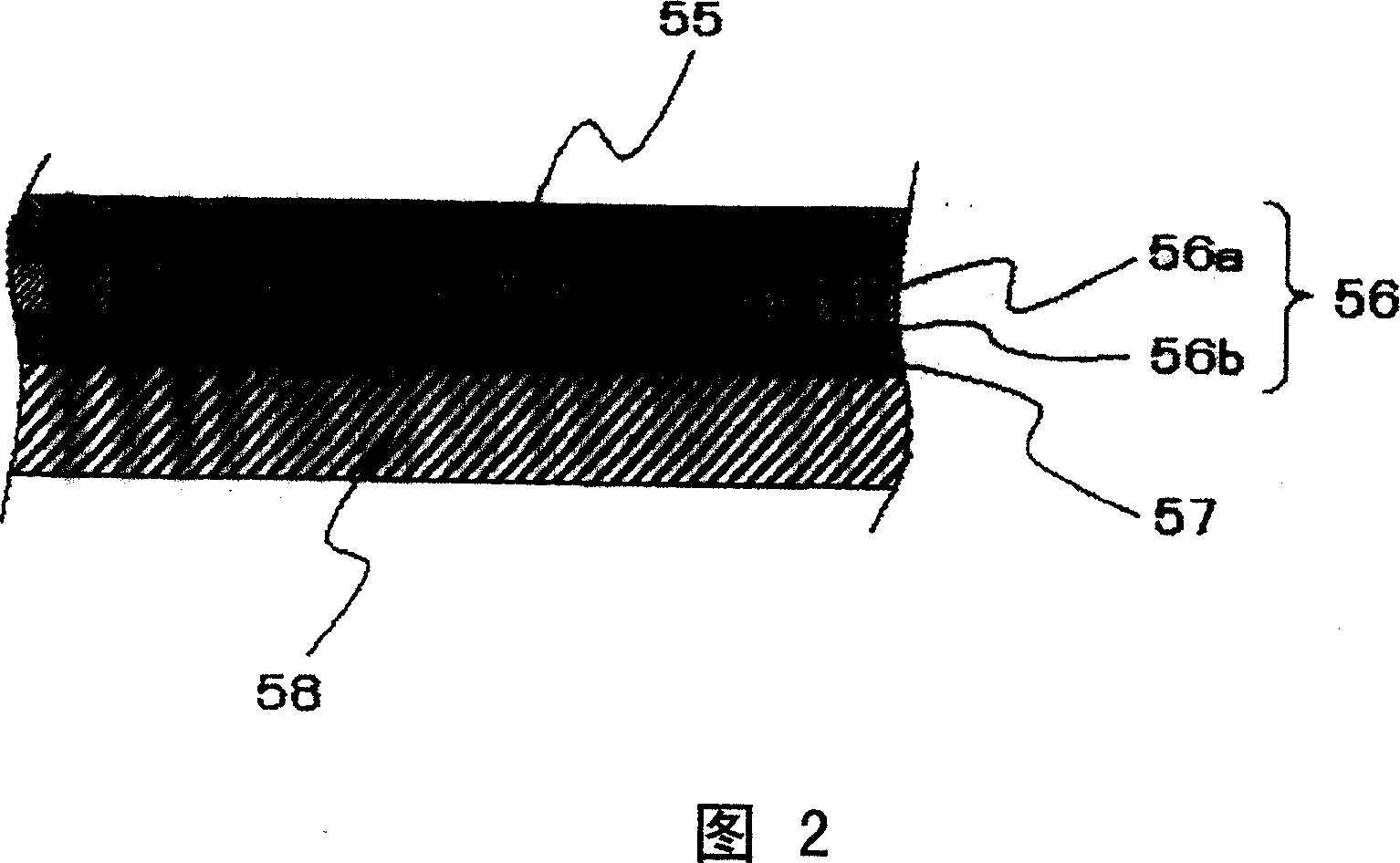

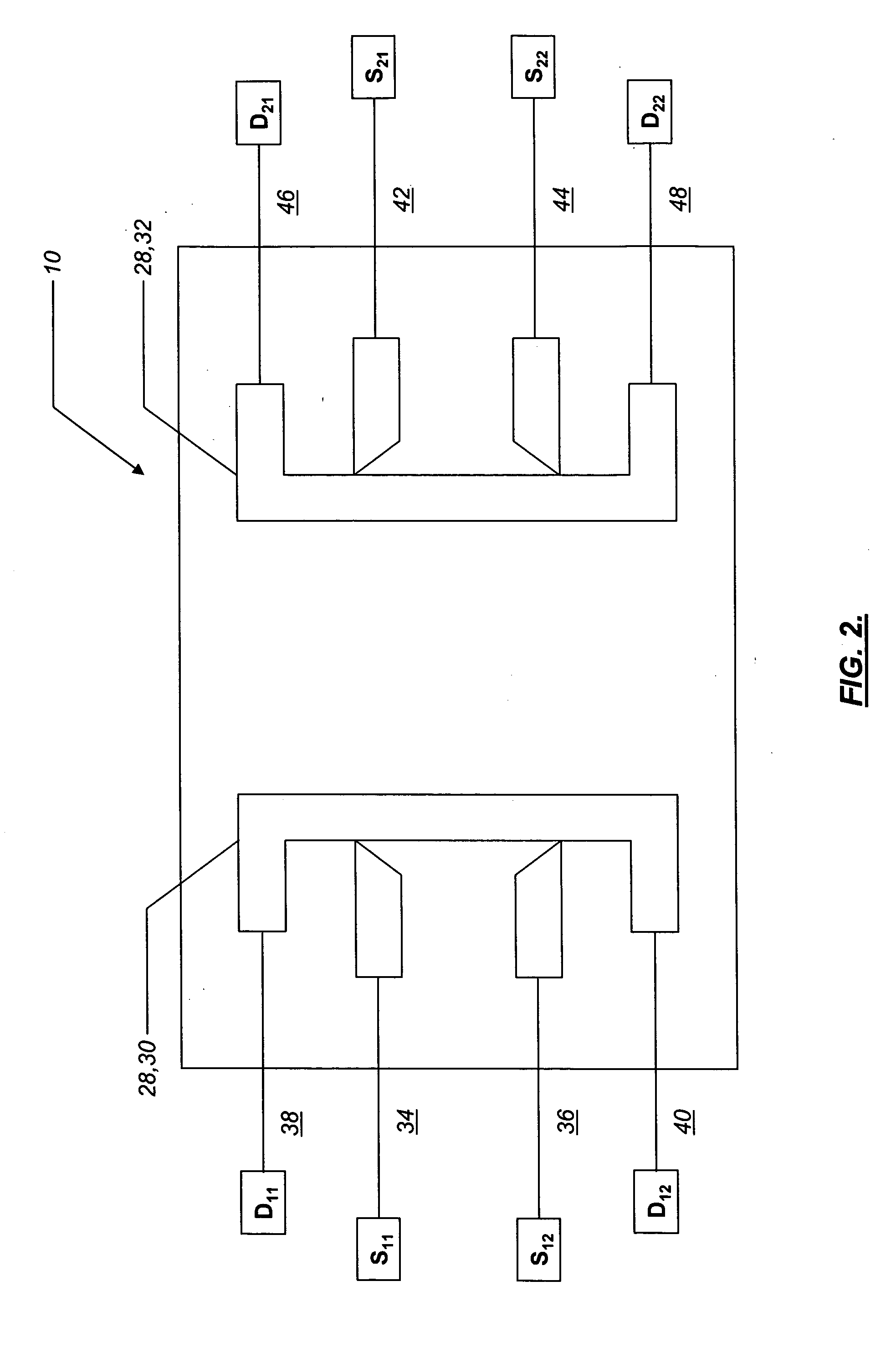

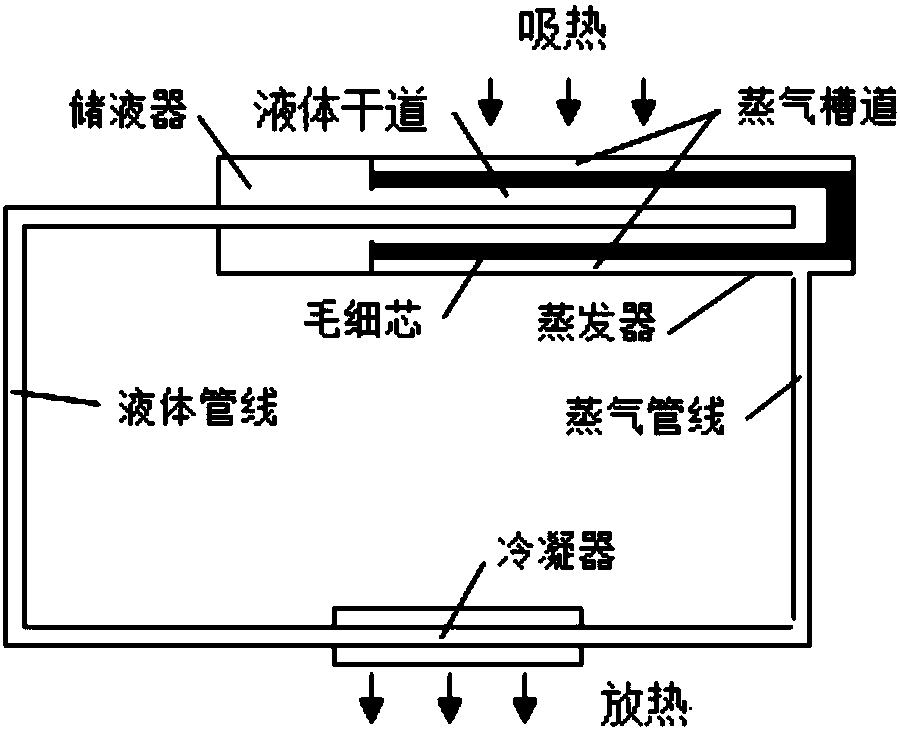

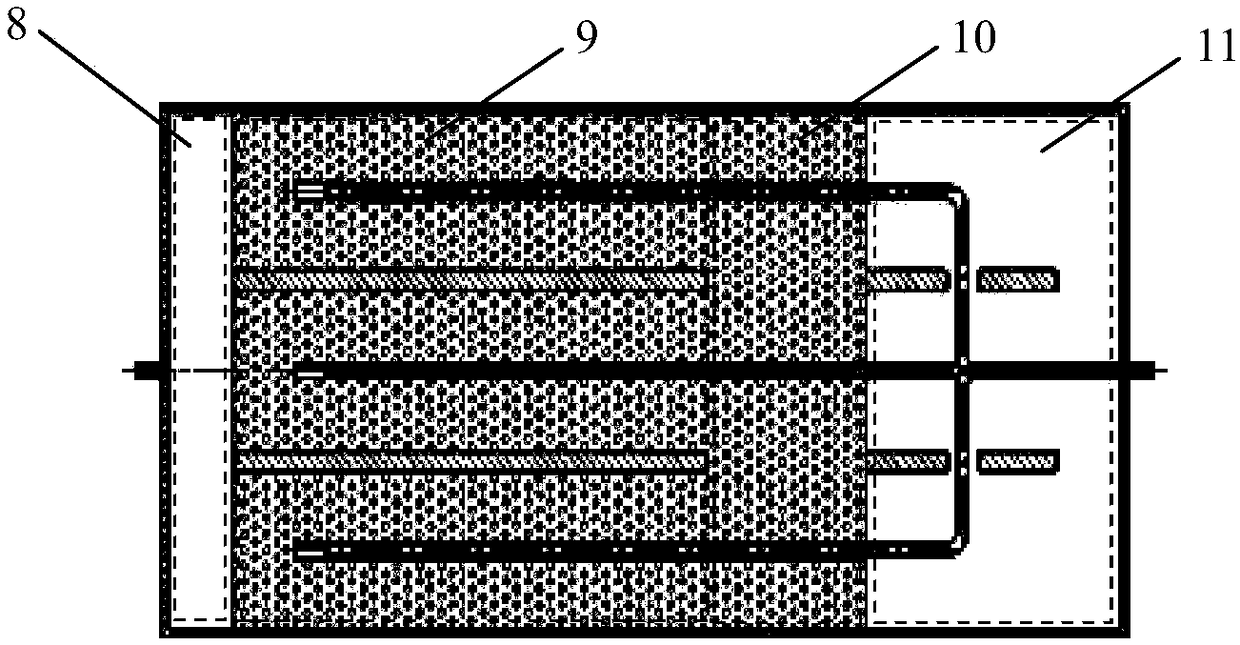

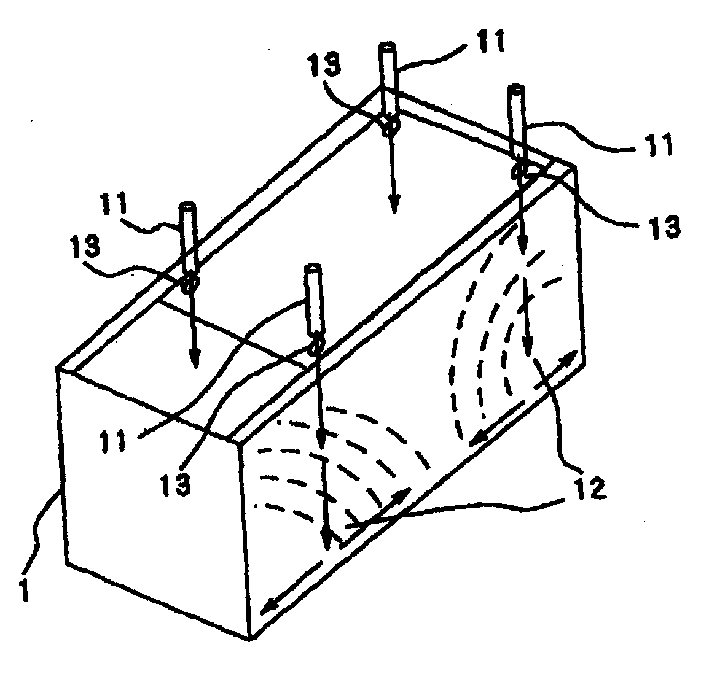

Evaporator and liquid reservoir used for loop heat pipe and application thereof

InactiveCN103344143AReduce heat leakageSimple designIndirect heat exchangersHeat exhanger sealing arrangementMicro-loop heat pipeCapillary pressure

The invention discloses an evaporator and a liquid reservoir used for a loop heat pipe and belongs to the technical field of evaporators. A capillary core structure is adopted for spacing inner spaces of the evaporator and the liquid reservoir, liquid in the liquid reservoir can enter the evaporator through the capillary core, meanwhile the liquid is heated and evaporated to generate steam in the evaporator, and the steam flows out of a steam outlet in an end cover of the evaporator. Due to the fact that the capillary core can generate capillary pressure, the steam in the center of the evaporator can be effectively prevented from entering the liquid reservoir, distribution and flowing of the gas liquid are controlled, and then heat leakage from the evaporator to the liquid reservoir is effectively reduced. The distribution and a flowing route of the gas liquid in the evaporator are adjusted initiatively, therefore the radial heat leakage from the evaporator to the liquid reservoir can be completely eliminated, and the purpose that the heat leakage from the evaporator to the liquid reservoir is effectively reduced is achieved so that starting performance and running stability and reliability of the loop heat pipe can be improved.

Owner:BEIHANG UNIV

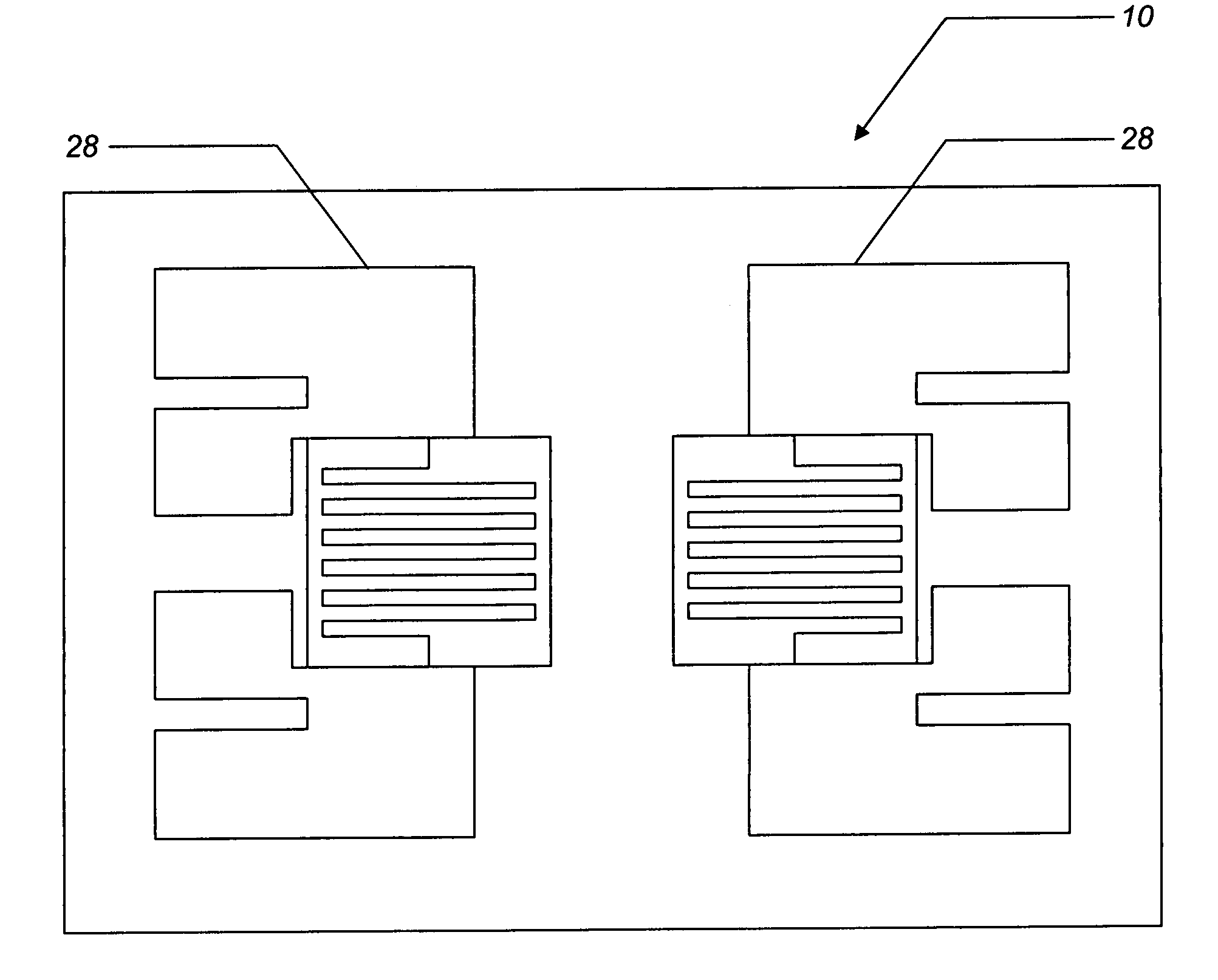

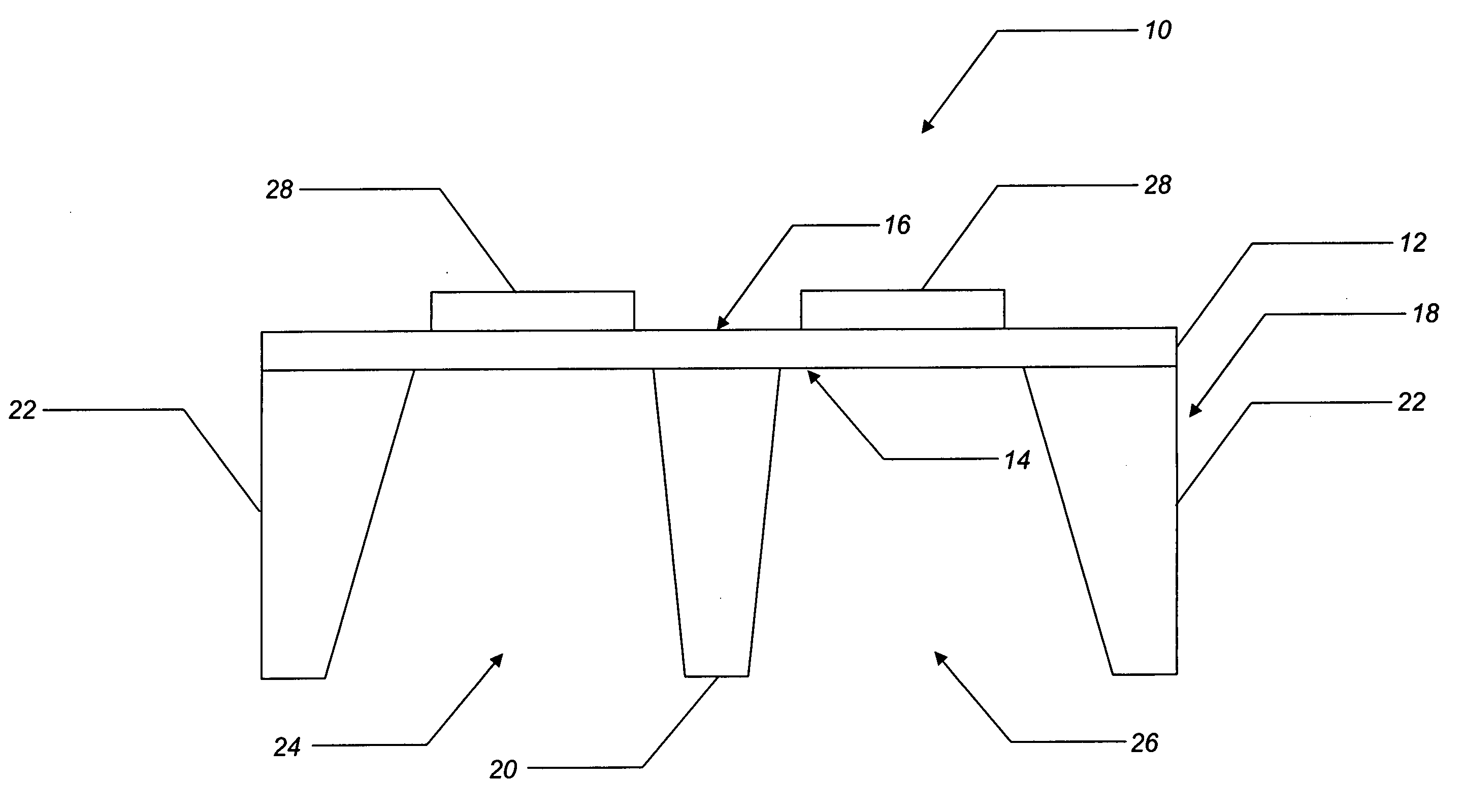

Nano-calorimeter device and associated methods of fabrication and use

InactiveUS20050254547A1Low thermal conductivity and heat capacityAdequate temperature controlMaterial heat developmentNanosensorsNanometreMembrane configuration

The present invention provides a nano-calorimeter device operable for measuring and characterizing the thermodynamic and other physical properties of materials that are confined to essentially nano-scale dimensions. The nano-calorimeter device including a thin film membrane having a first surface and a second surface. The nano-calorimeter device also including a frame structure disposed adjacent to and in thermal contact with the first surface of the thin film membrane, the frame structure defining a plurality of hollow cells adjacent to and in thermal contact with the first surface of the thin film membrane. The nano-calorimeter device further including one or more micro-heating elements disposed adjacent to and in thermal contact with the second surface of the thin film membrane, the location of the one or more micro-heating elements disposed adjacent to the second surface of the thin film membrane substantially corresponding to the location of the plurality of hollow cells defined adjacent to the first surface of the thin film membrane.

Owner:GENERAL ELECTRIC CO

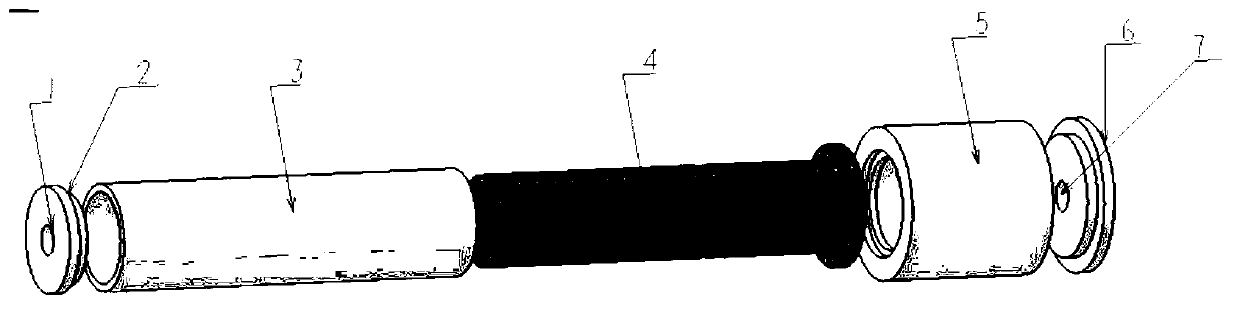

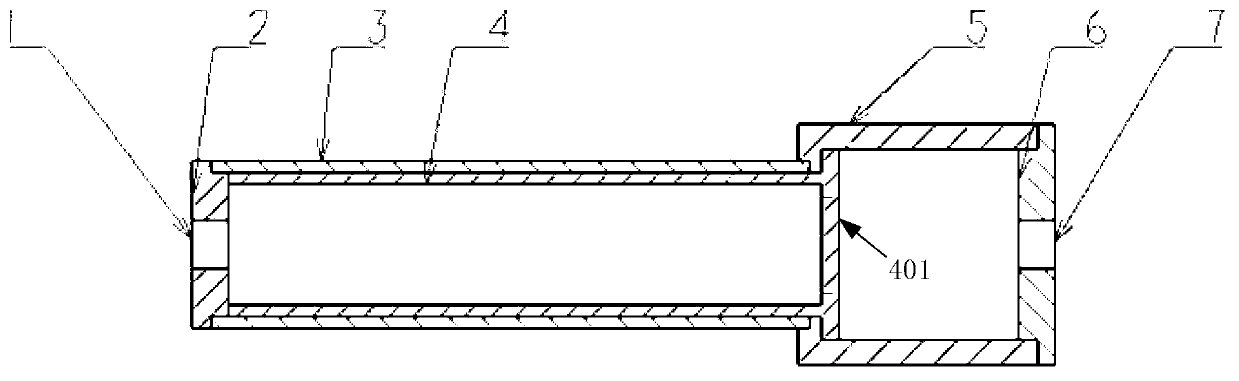

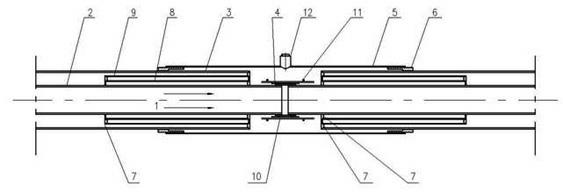

Vacuum heat insulating low-temperature pipe joint

ActiveCN102352940AEasy to installReduce heat leakageThermal insulationPipe protection by thermal insulationEngineeringMulti-layer insulation

The invention discloses a vacuum heat insulating low-temperature pipe joint, which comprises inner pipes for low-temperature liquid to flow through and outer pipes sleeved outside the inner pipes and connected with the inner pipes, wherein a vacuum space is formed between each inner pipe and each outer pipe; spliced positions of the two inner pipes are welded together through a bushing; heat preserving barrels are sleeved on the joints of the two outer pipes; the two end parts of each heat preserving barrel are provided with a welded loop which is welded with the outer walls of the outer pipes respectively; a section of internal heat isolating pipe and a section of external heat isolating pipe which are sleeved together and extend towards the two outer sides are arranged between the end parts of the joints and the inner pipe walls of the two outer pipes respectively to constitute a vacuum interlayer enclosed space between the inner pipe and the outer pipe; a plurality of vacuum heat insulating layers are formed outside the bushing at the spliced position of each inner pipe; a steel wire is arranged outside the heat insulating layers for fixing; and the heat preserving barrel at the joint of each outer pipe is provided with a vacuumizing valve. The vacuum heat insulating low-temperature pipe joint has the characteristics of low heat leakage, simple and attractive appearance andthe like.

Owner:杭州杭氧低温液化设备有限公司

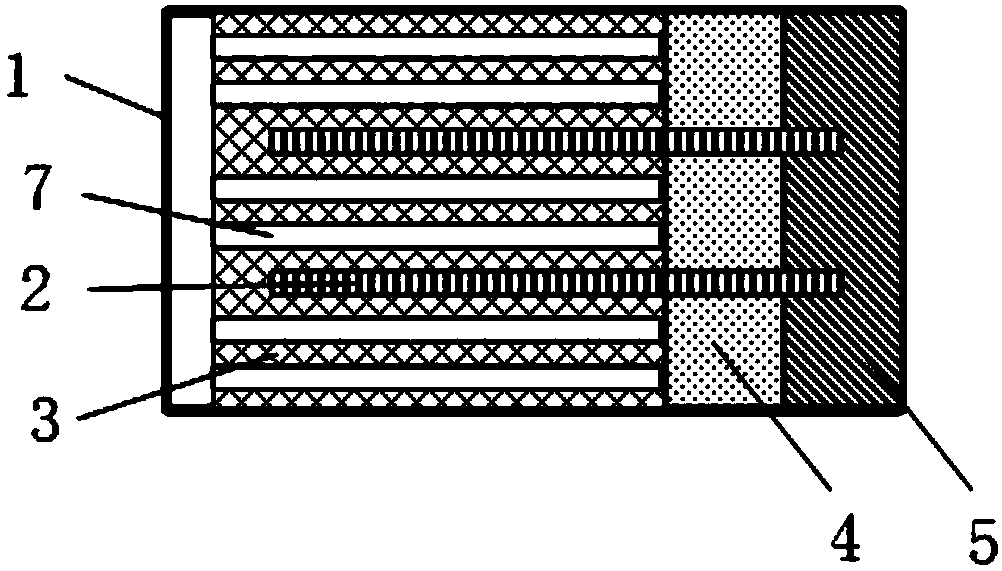

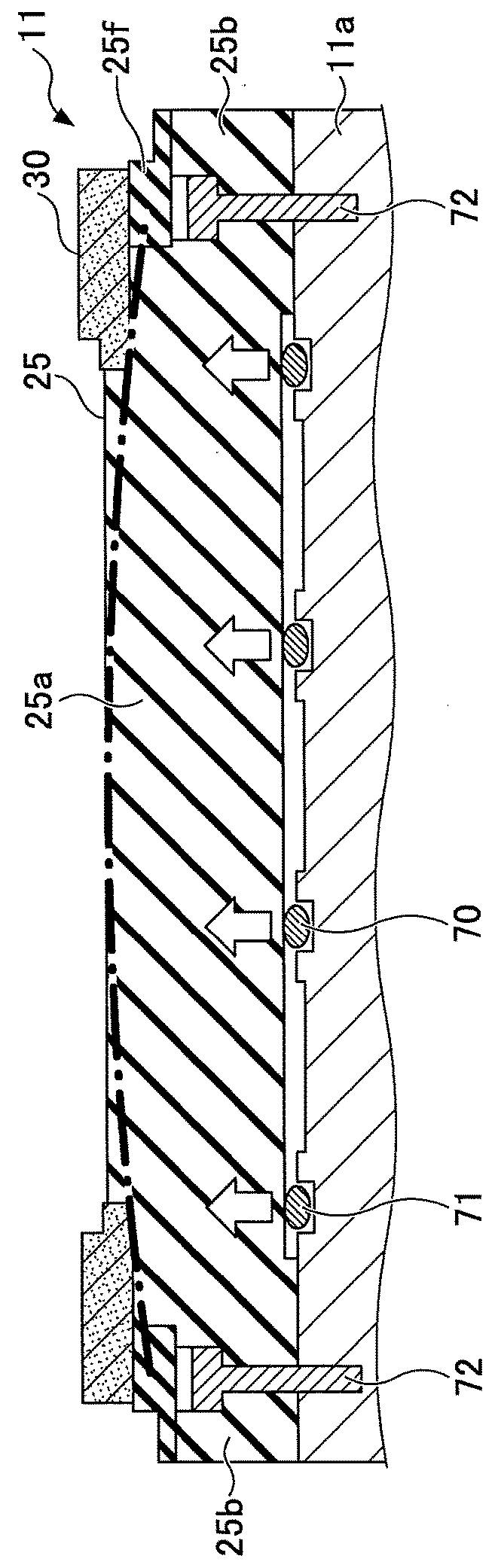

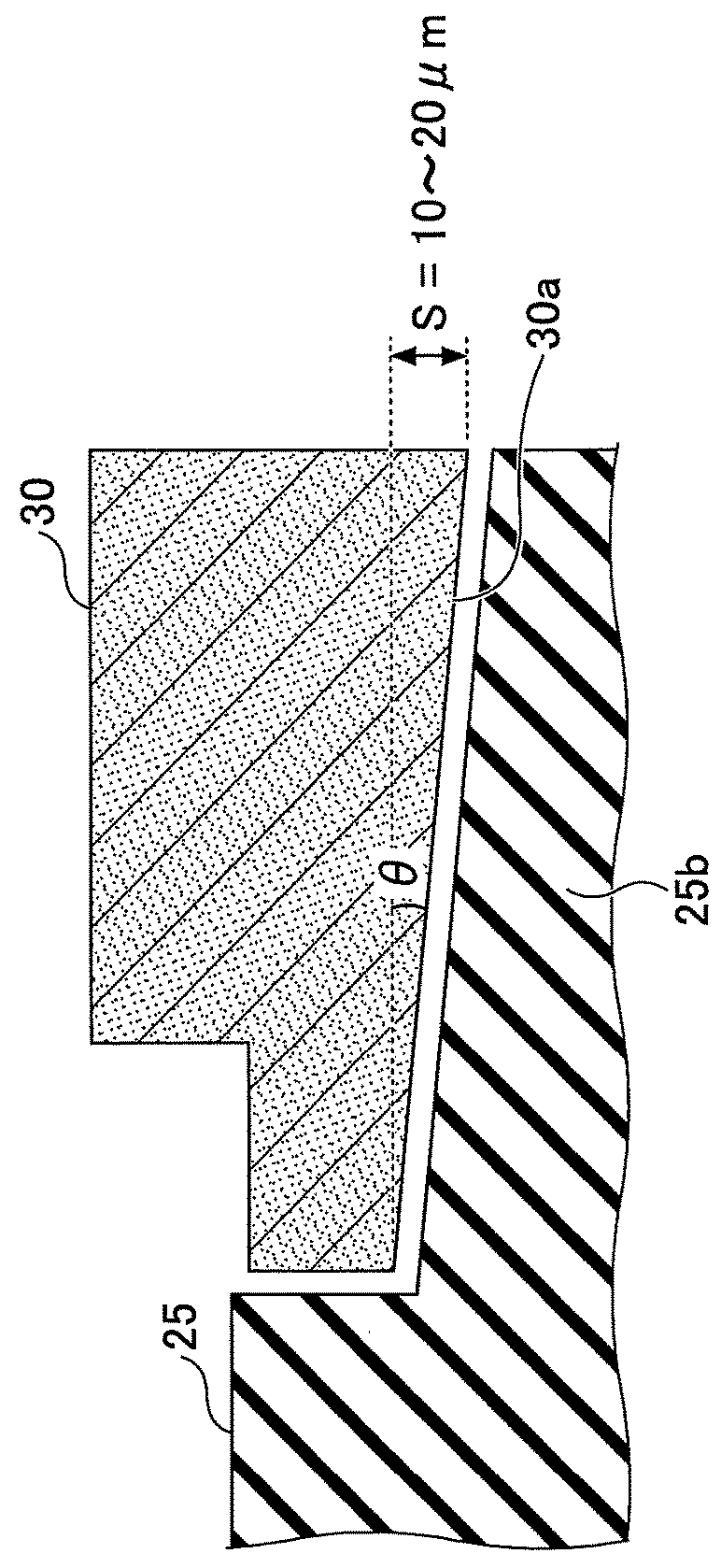

High-power flat evaporator resistant to positive pressure, processing method of flat evaporator and flat-plate loop heat pipe based on evaporator

ActiveCN107782189AHigh compressive strengthSuitable for positive pressure working mediumIndirect heat exchangersThermal insulationPositive pressure

The invention provides a high-power flat evaporator resistant to positive pressure, a processing method of the flat evaporator and a flat-plate loop heat pipe based on the evaporator and belongs to the technical field of spacecraft structures. The evaporator comprises a casing, reinforcing ribs and a capillary core, wherein the reinforcing ribs and the capillary core are located in the casing, andthe strength of the whole evaporator can meet the requirement of positive pressure resistance by means of arrangement of the reinforcing ribs; the capillary core is formed by combining an evaporationcore, a thermal insulation core, a sealing core and a transmission core, liquid supply with low flow resistance can be realized on the basis of high permeability of the transmission core, heat-transfer capability of the loop heat pipe is improved substantially, and the problems of long liquid supply path and high flow resistance of a large-area evaporator are solved; with adoption of the transmission core and the thermal insulation core with low thermal conductivity, the phenomenon of heat leakage from the evaporator to a liquid accumulator can be reduced, meanwhile, good permeability is achieved, flow resistance in the capillary core is reduced, and operating stability of a product is improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

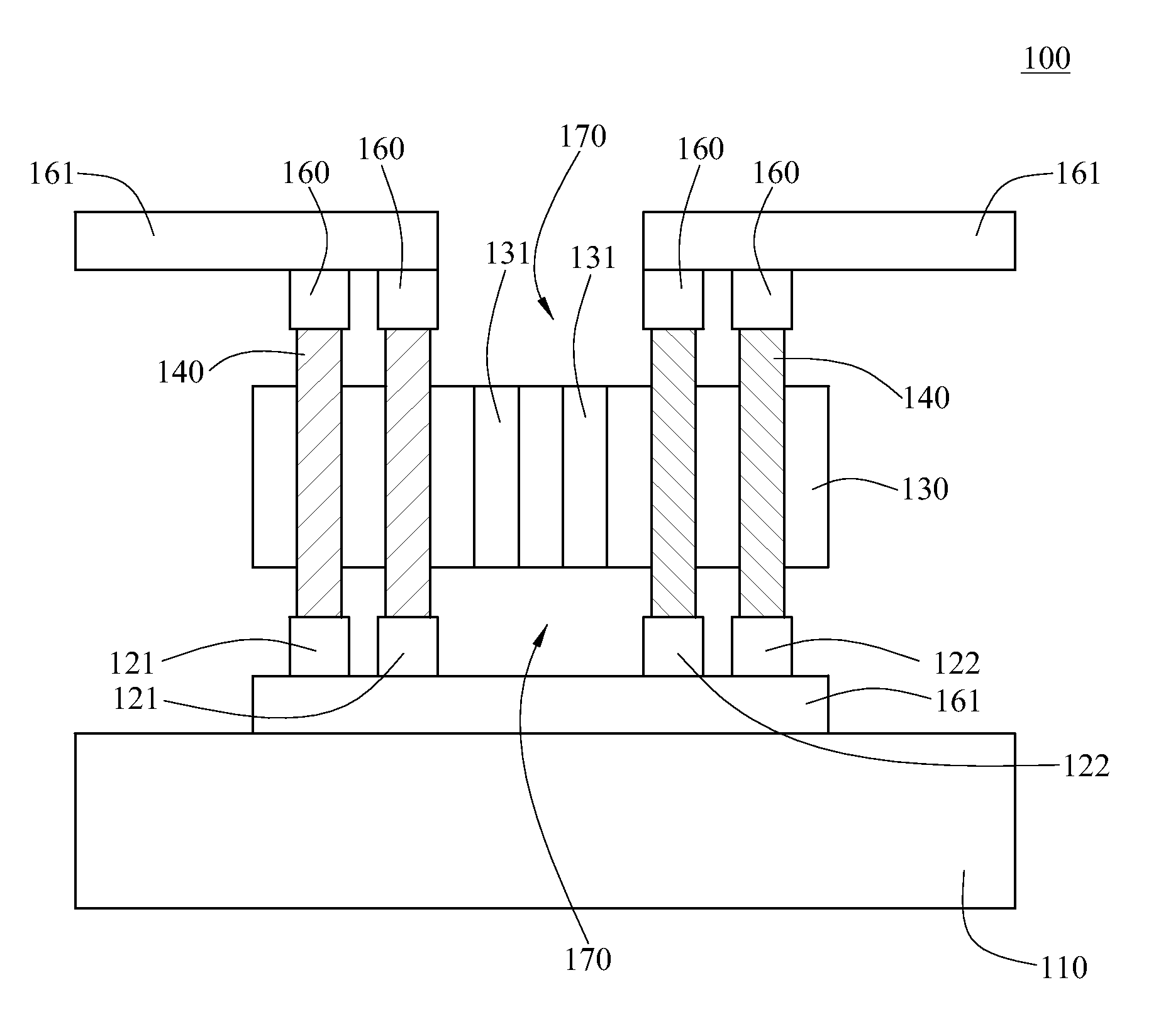

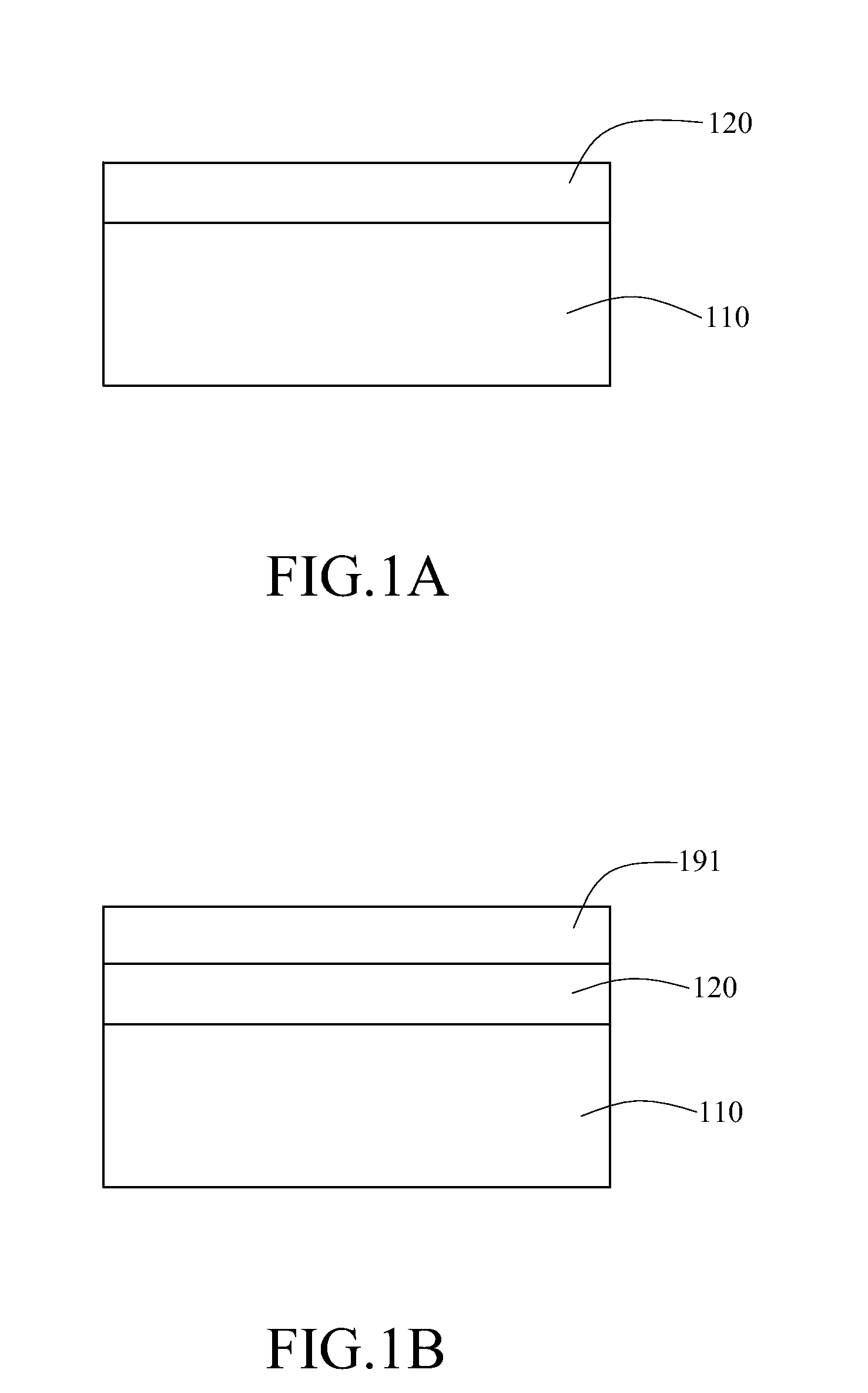

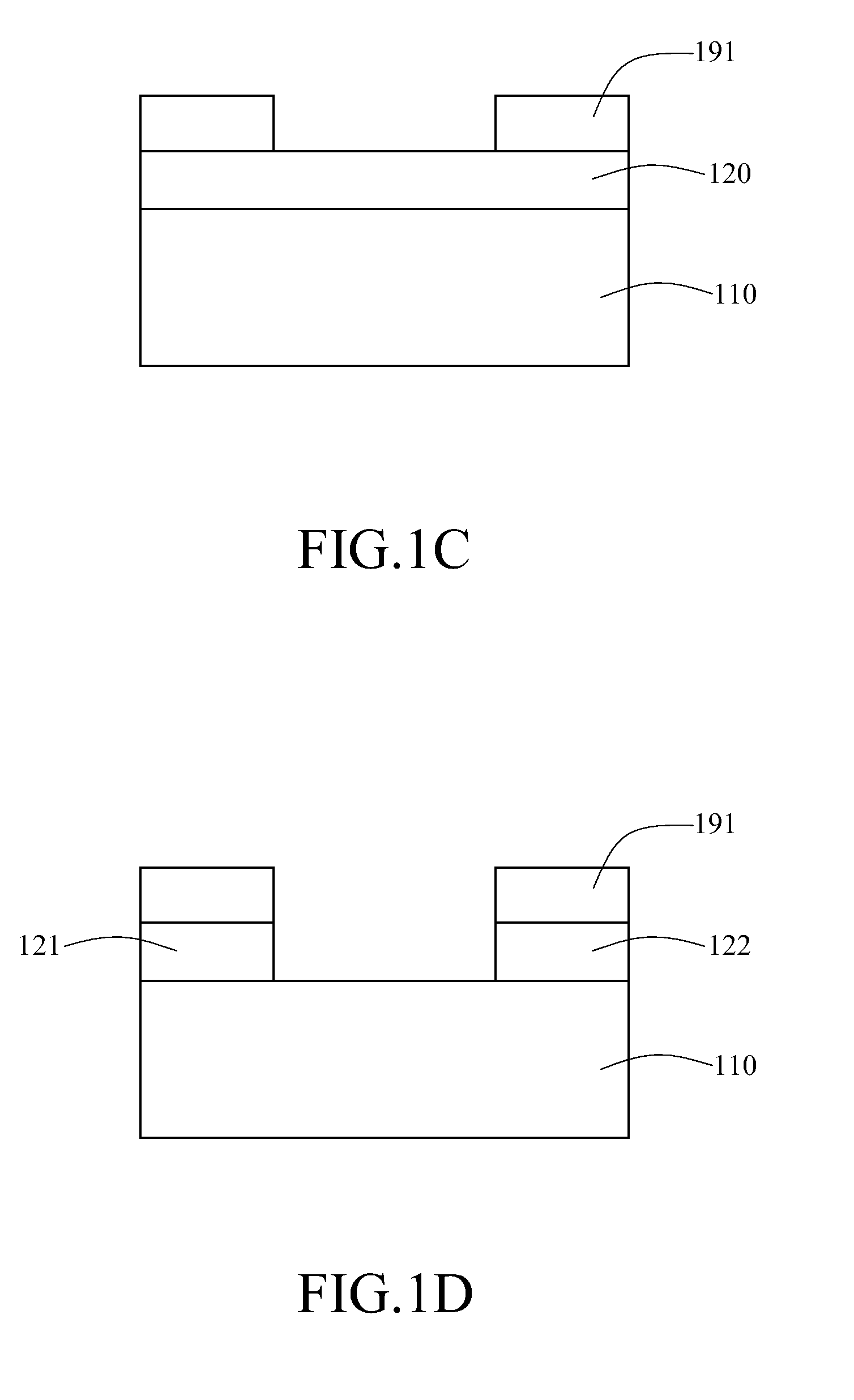

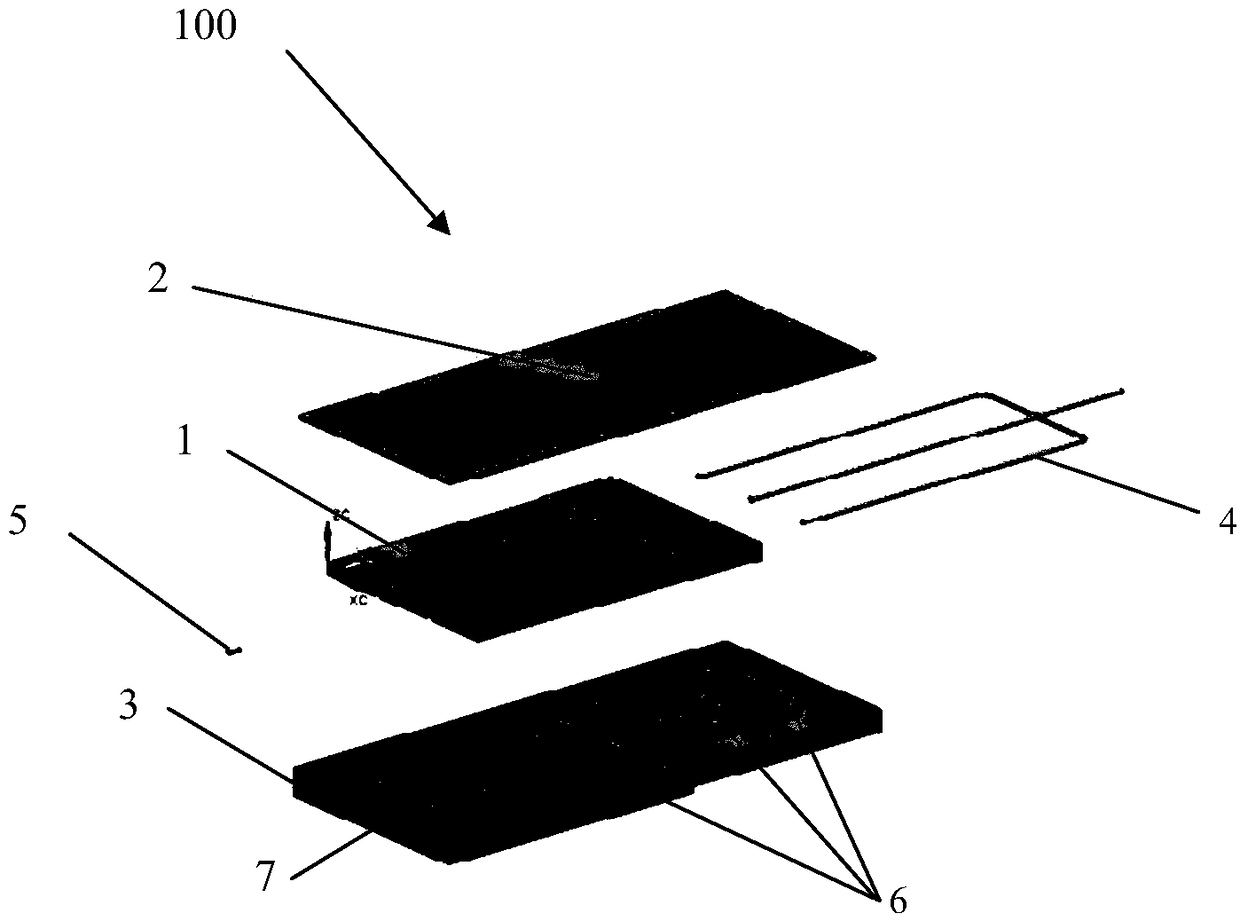

Thermoelectric nanowire array with low heat leakage and manufacturing method thereof

InactiveUS20100162728A1Low thermal conductivityImprove performanceLiquid/solution decomposition chemical coatingMachines using electric/magnetic effectsNanowire arrayThermal dissipation

A thermoelectric nanowire array with a low heat leakage and a manufacturing method thereof are described. Nanowire array units separated from each other are formed on a substrate, and an air wall is formed at a region on the substrate free of the nanowire array units. Or, a polymeric material having a low thermal conductivity is combined with a template material so as to form a composite template structure for nanowires to deposit therein. With the design of the air wall or the composite template structure, the thermal reflow phenomenon of the thermoelectric nanowire array is avoided, thereby greatly improving a thermal dissipation efficiency of the thermoelectric nanowire array.

Owner:IND TECH RES INST

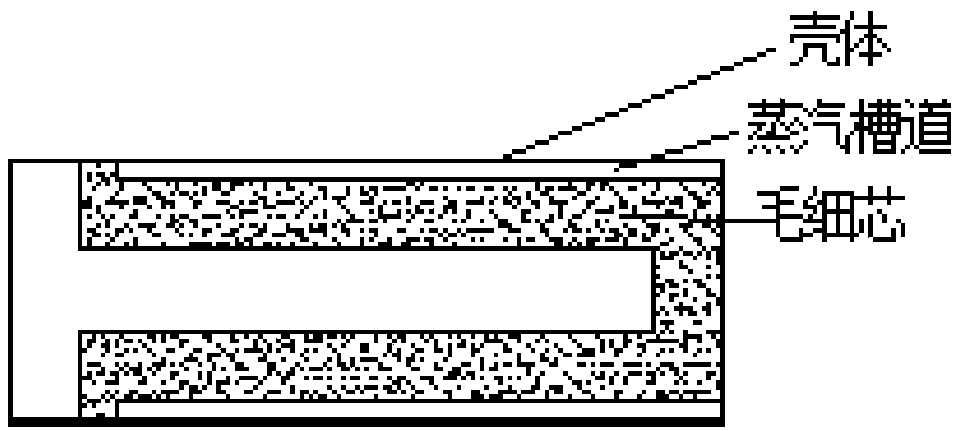

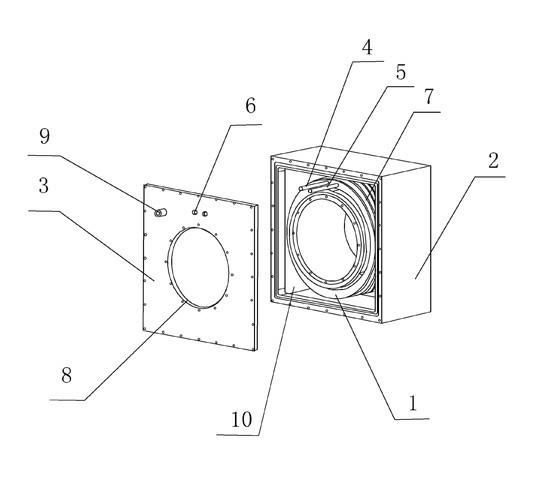

Plate type loop heat pipe evaporator

ActiveCN108278916ASolve the wetting is not timelySolve the problem of temperature differenceIndirect heat exchangersInternal cavityEvaporator

The invention relates to a plate type loop heat pipe evaporator. The plate type loop heat pipe evaporator comprises an evaporator shell, a capillary core, a liquid guide pipe and a steam pipe. The evaporator is provided with a plate type structure, and an internal cavity is formed in the evaporator shell. The internal cavity comprises an air collecting cavity, an evaporation area, a buffering areaand a liquid storage cavity. The capillary core is arranged in the internal cavity and occupies the evaporation area and the buffering area. The air colleting cavity and the liquid storage cavity areseparated through the capillary core. The liquid guide pipe is used for guiding incoming flow liquid into the capillary core. Steam in the air collecting cavity flows out through the steam pipe. According to the plate type loop heat pipe evaporator, a slab structure is adopted, and the defects that a cylindrical evaporator is poorly attached to a wall face, and a saddle causes additional temperature differences and heat resistance are overcome.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Eliminating screens using a perforated wet belt and system and method for cement cooling

InactiveUS8584864B2Lower cost of capitalImprove efficiency and longevitySievingScreeningEngineeringDelivery system

The present disclosure involves a system and methods for eliminating rinse and dewatering rescreens while cooling coarse aggregates, including in one embodiment a perforated wet belt conveyance system. According to another embodiment disclosed herein, a system and method for cooling cement is also provided.

Owner:COLDCRETE

Nonmetal magnetism-free liquid nitrogen dewar

ActiveCN102661482AGuaranteed sealing performanceGuaranteed inflowContainer filling methodsNon-pressured vesselsVacuum pumpingInsulation layer

The invention discloses a nonmetal magnetism-free liquid nitrogen dewar which is composed of a vacuum cover and a dewar liner (1). The vacuum cover comprises an outer casing (2) and a cover plate (3), the dewar liner (1) is arranged inside the outer casing (2), at least one liquid inlet tube (4) or liquid outlet tube (5) is arranged on the dewar liner (1), at least one circular hole (6) is arranged on the cover plate (3), the circular hole (6) is matched with the liquid inlet tube (4) or the liquid outlet tube (5), a heat insulation layer (7) is arranged at the periphery of the dewar liner (1), a through hole (8) is arranged in the middle of the cover plate (3), the diameter of the through hole (8) is matched with the inner diameter of the dewar liner (1), and a vacuum pumping port (9) is further arranged on the cover plate (3). By means of the structure, the nonmetal magnetism-free liquid nitrogen dewar can be used for installing a high temperature superconducting radio frequency coil, simultaneously has the effects of containing liquid nitrogen and cooling the high temperature superconducting radio frequency coil.

Owner:TIME MEDICAL JIANGSU

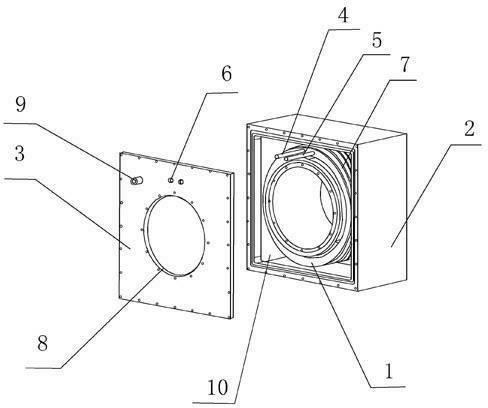

Air conditioner with temperature regulated based on indoor relative humidity and control method thereof

InactiveCN103836770AReduce loadImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusThermal comfortEngineering

The invention relates to an air conditioner, in particular to an air conditioner with the temperature regulated based on indoor relative humidity and a control method of the air conditioner. The air conditioner is used for solving the problem that the indoor relative humidity is not combined with the requirement for human body comfort in the process of regulating the temperature of an existing air conditioner. According to the technical scheme, when the air conditioner is used for refrigeration in summer, a correlation between the decrease of the indoor relative humidity and the change of a set temperature is established to carry out comfort energy saving control, and the real-time relative humidity detected by a relative humidity sensor is input into an air conditioner processor to undergo correlation calculation and is then output for specific control over the set temperature; in this way, the set temperature of the air conditioner can be intelligently changed along with the change of the relative humidity, and a user feels the same thermal comfort. The control method is suitable for air conditioners.

Owner:四川长虹空调有限公司

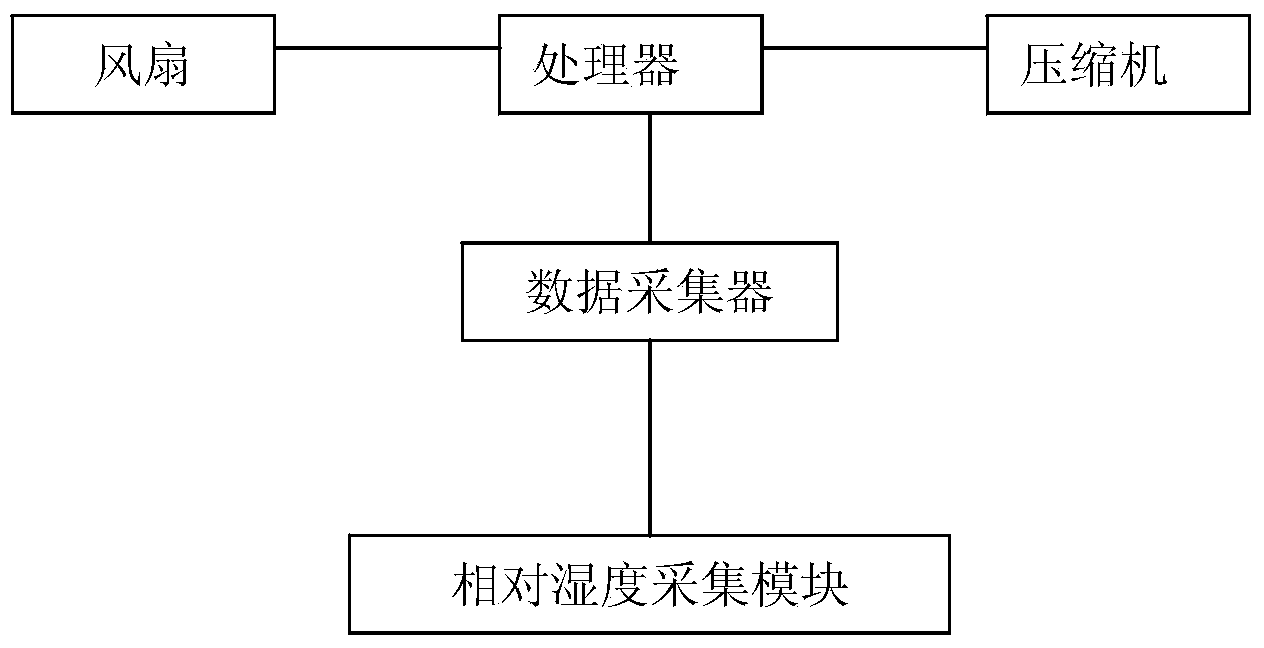

Focus ring and substrate processing apparatus

InactiveUS20180182635A1Reduce heat leakageElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A focus ring that surrounds a periphery of a substrate placed on a stage in a processing chamber of a substrate processing apparatus includes a lower surface to contact a peripheral portion of the stage, the lower surface being inclined such that an outer peripheral side becomes lower than an inner peripheral side in a radial direction.

Owner:TOKYO ELECTRON LTD

Hard polyurethane foam material and insulator

Provided is a rigid polyurethane foam that achieves combination of a low heat conductivity and a low density and has a reduced deterioration with time of heat conductivity and a high dimensional stability. The rigid polyurethane foam is formed by using a polyol, an isocyanate, a mixed foaming agent of cyclopentane and water, a catalyst and a foam stabilizer. The polyol contains a polyether polyol component in which propylene oxide is added to tolylenediamines as a first polyol component, a polyether polyol component in which propylene oxide is added to triethanolamines as a second polyol component, and an aromatic polyester polyol as a third polyol component. The polyol contains the first and the second polyol components each >=6 times of the third polyol component.

Owner:HITACHI APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com