Patents

Literature

52 results about "Heat leak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

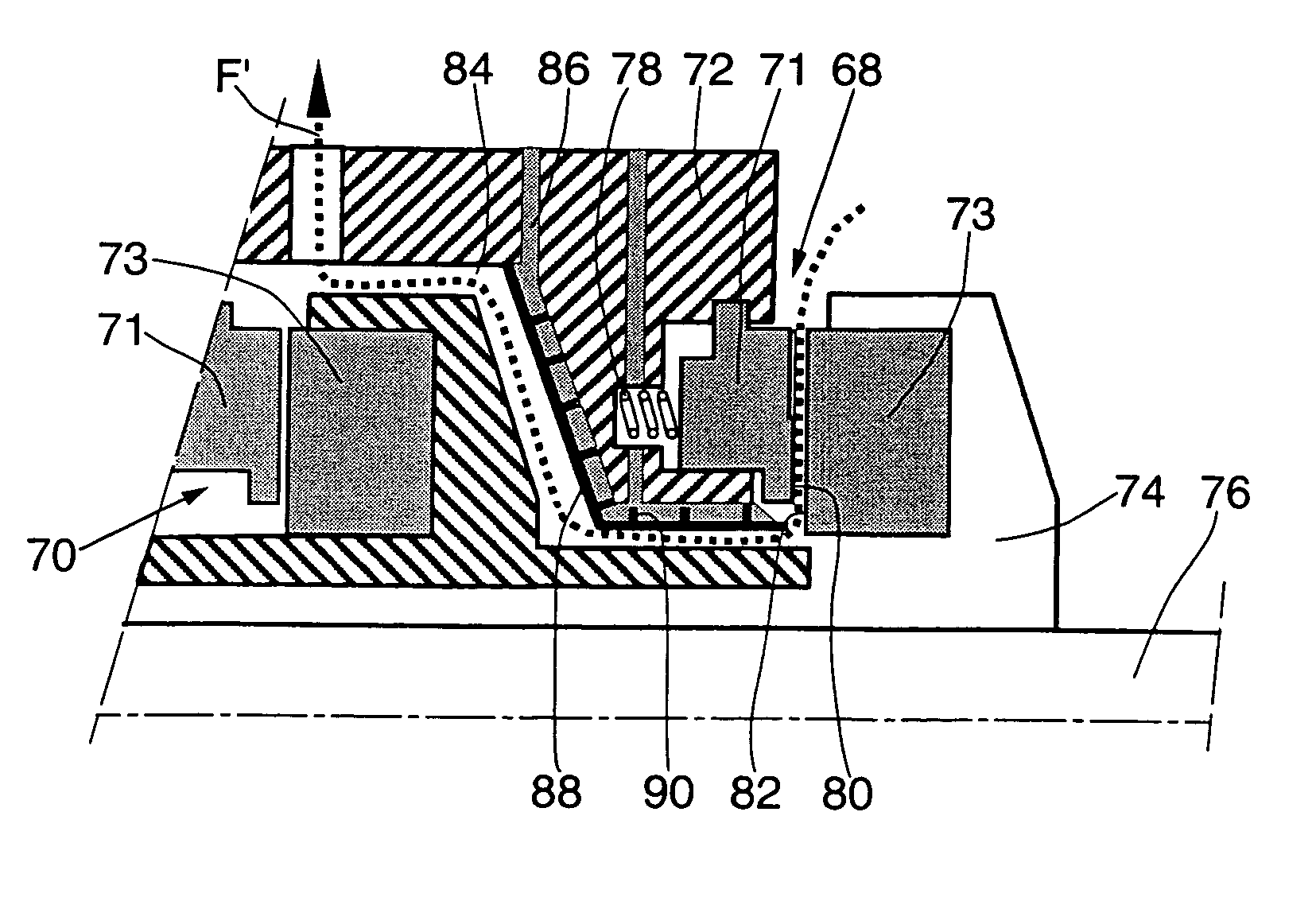

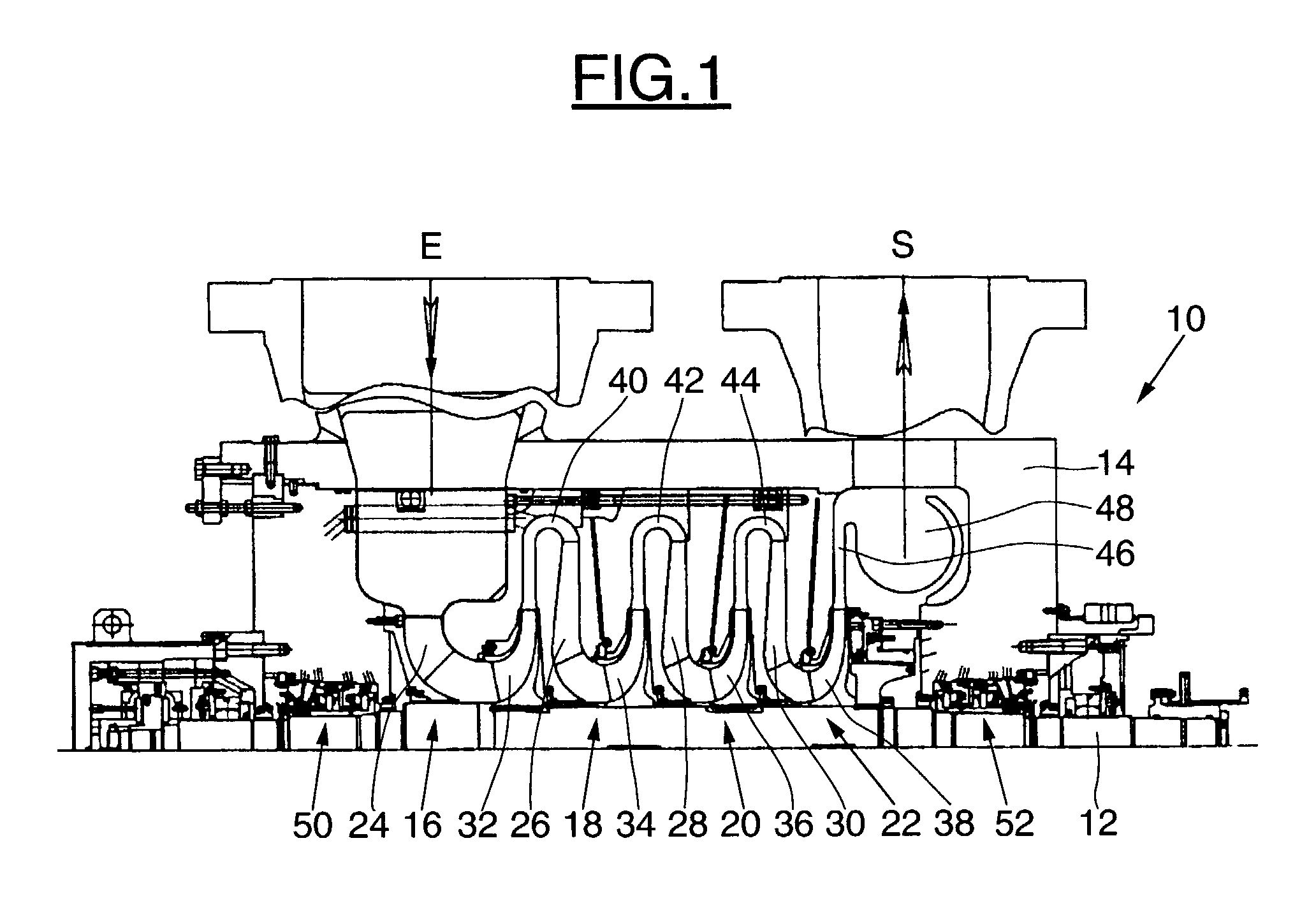

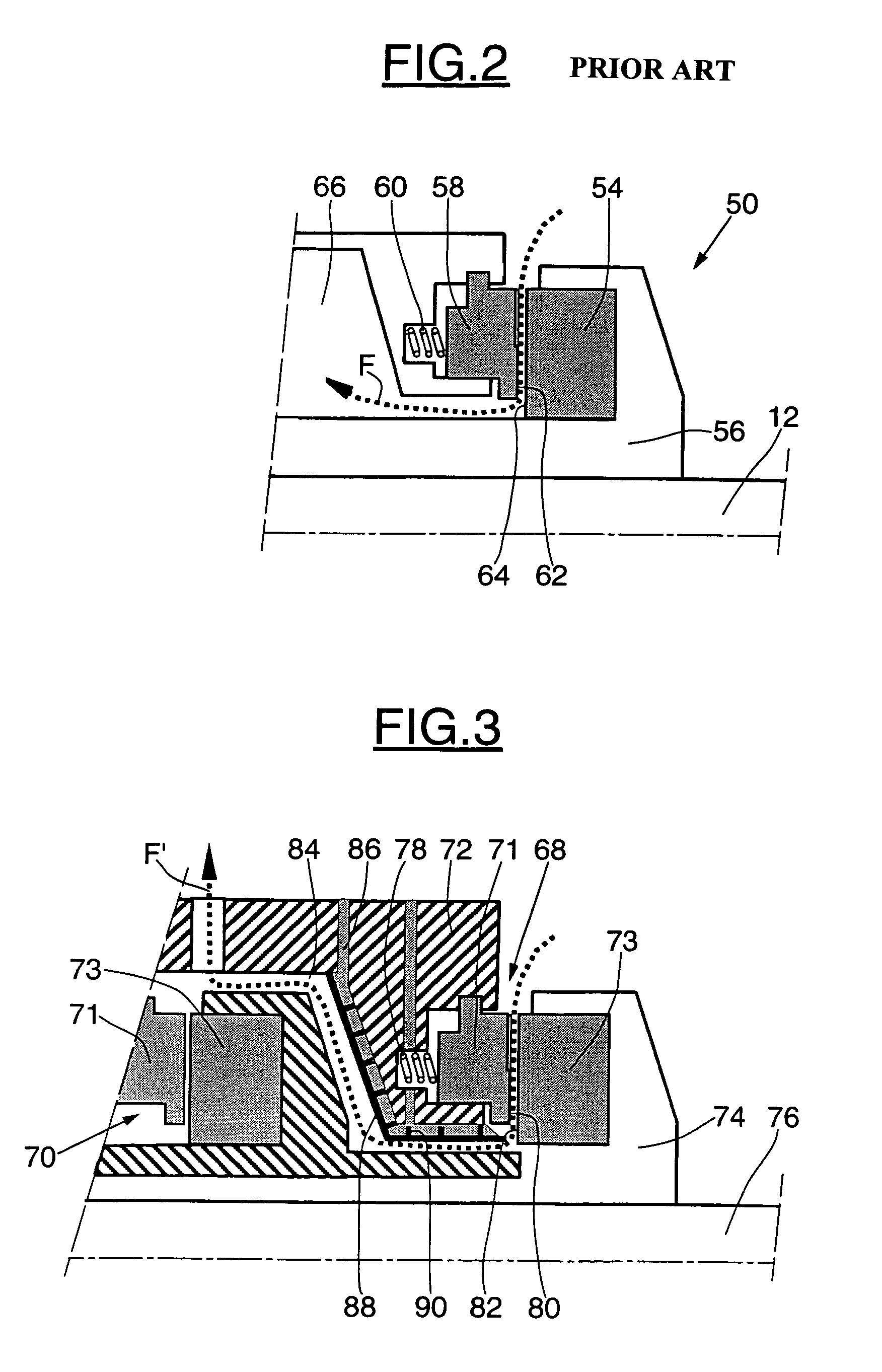

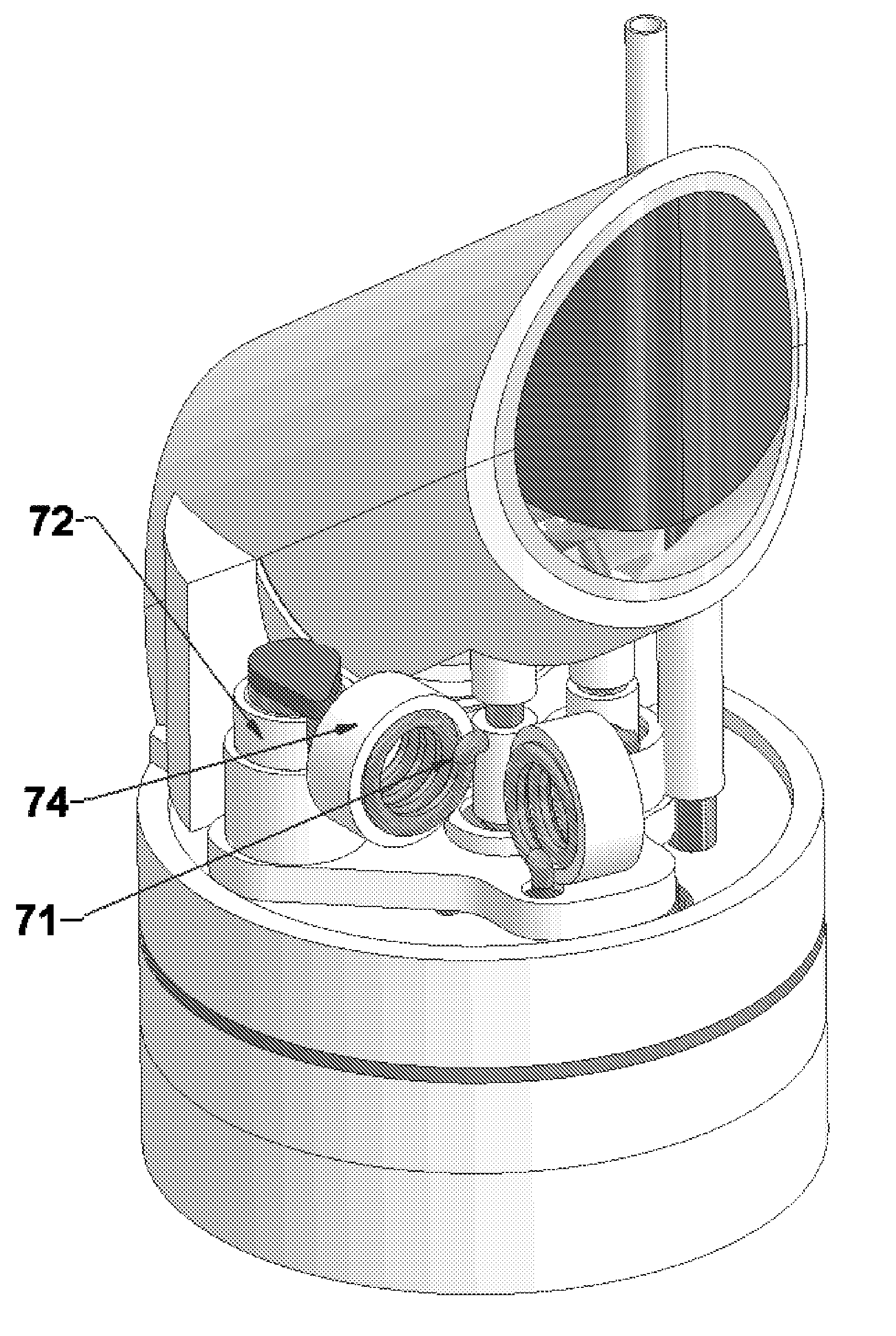

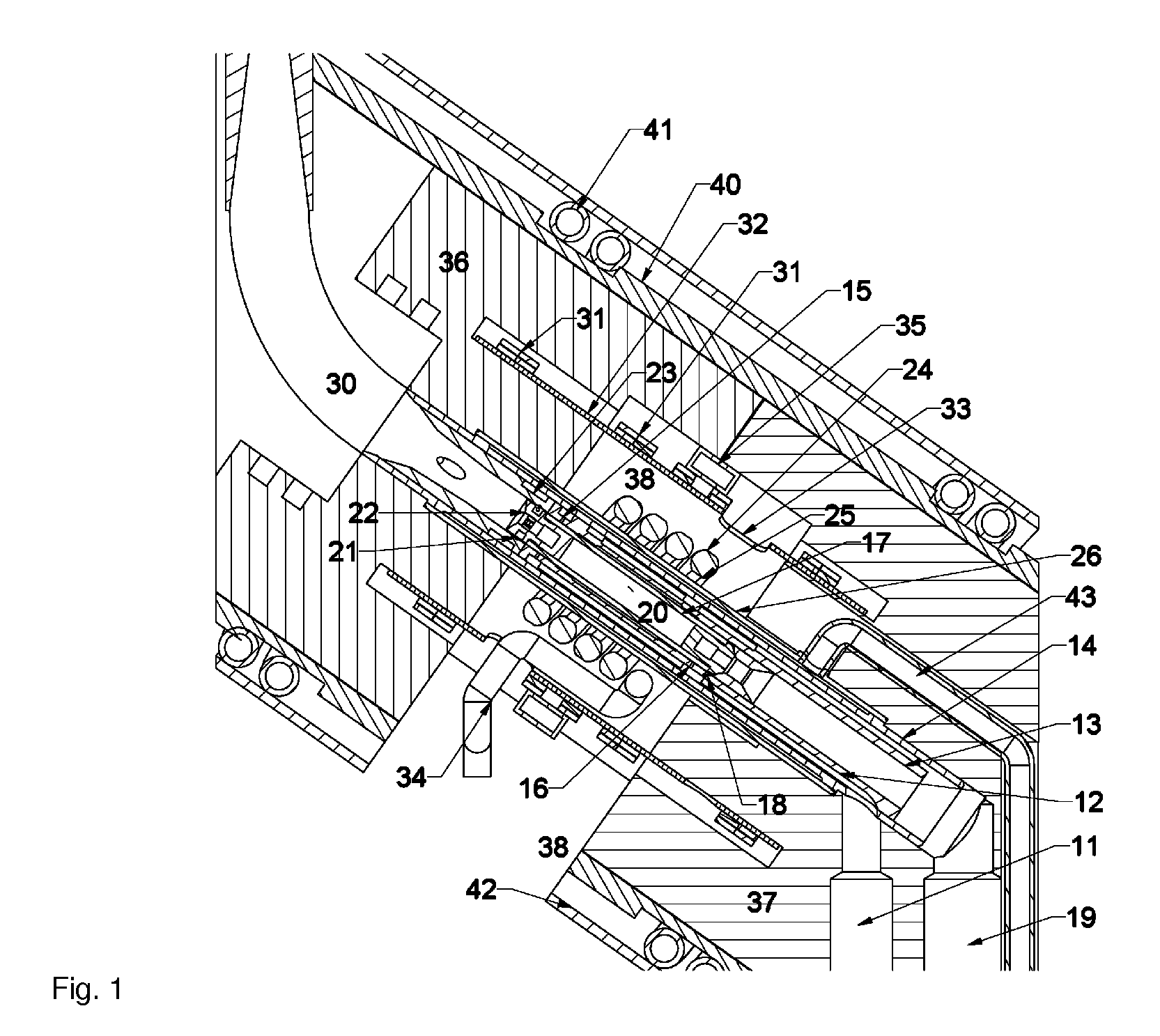

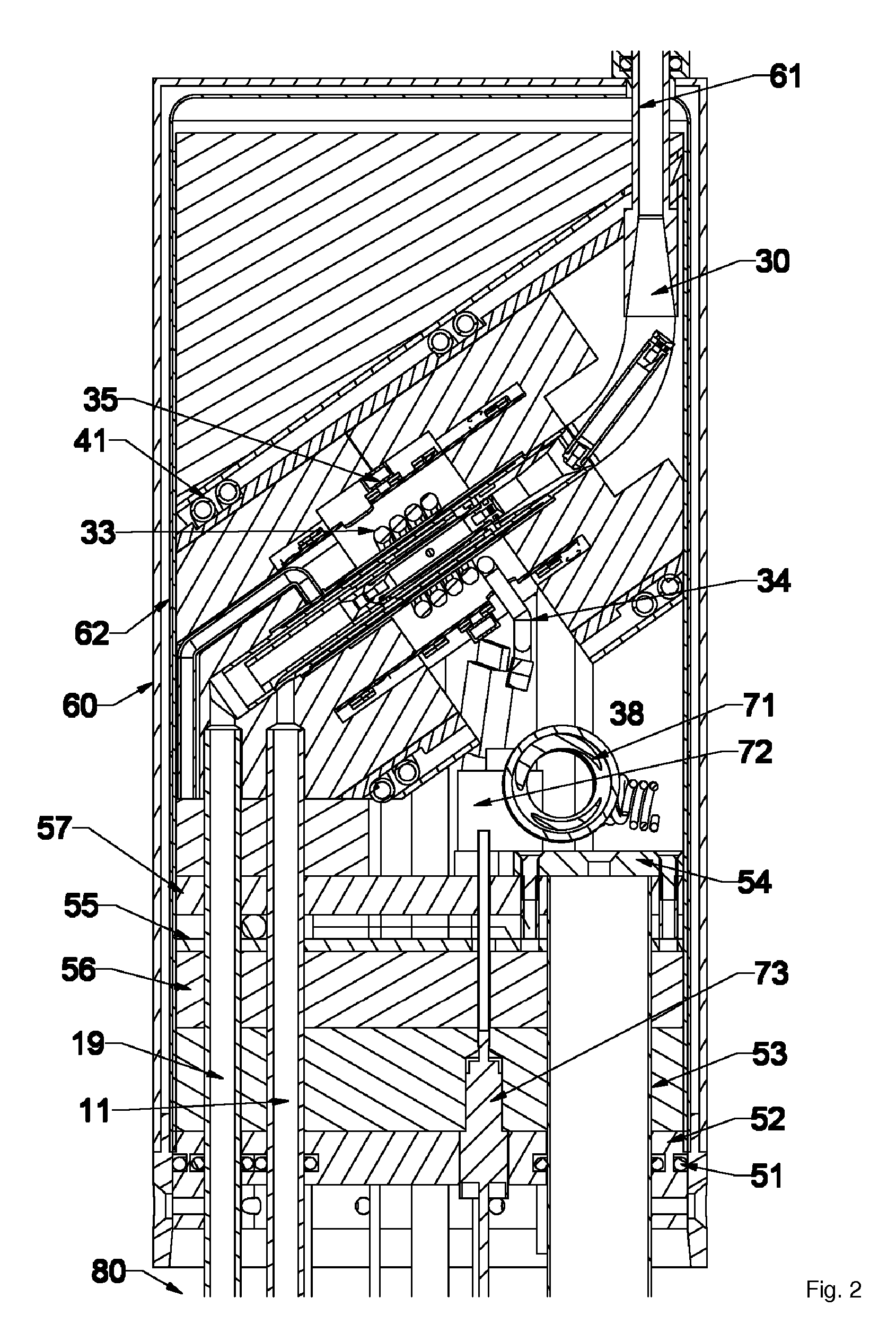

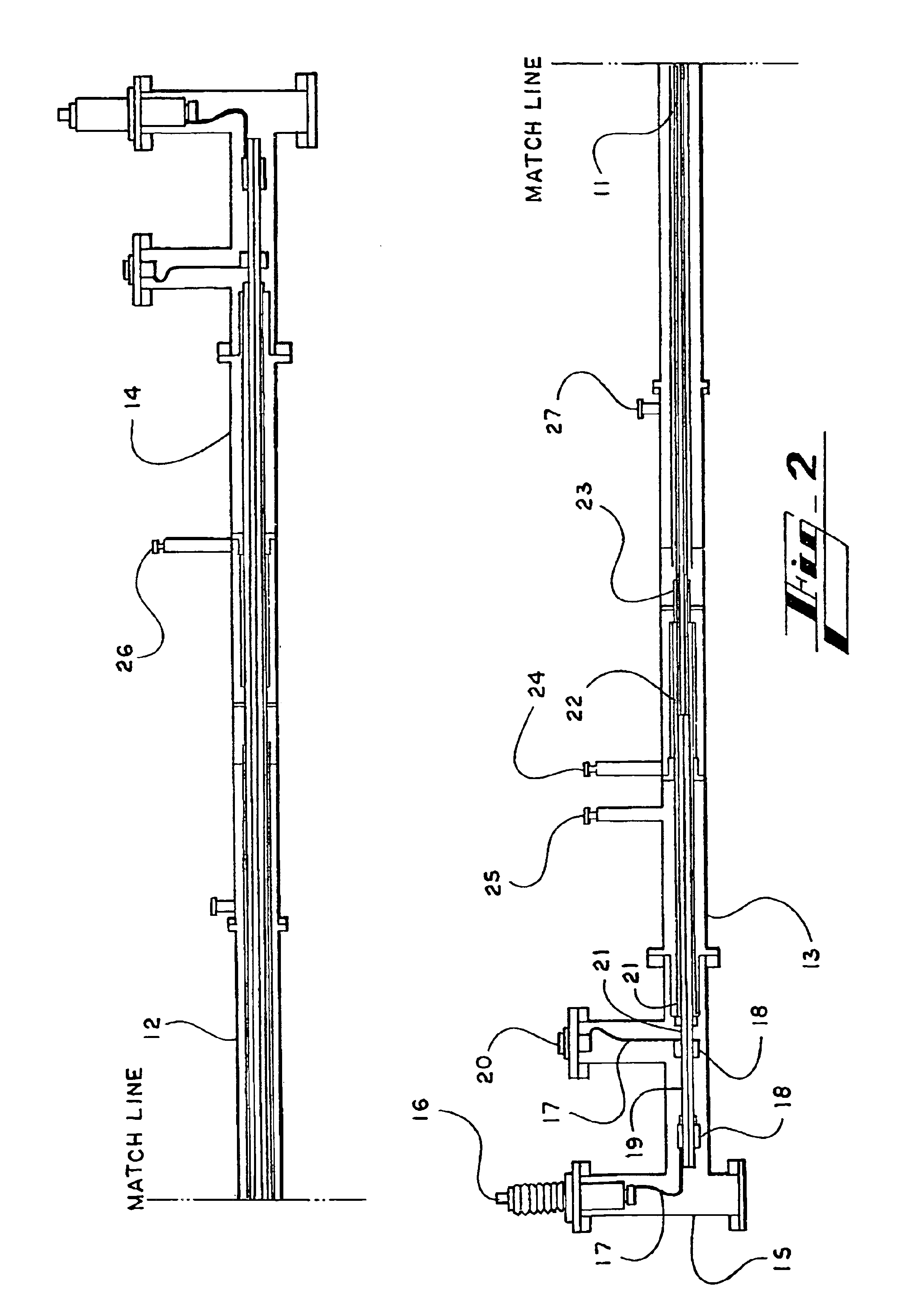

Seal for a compressor and centrifugal compressor equipped with such a seal

A seal for a rotary compressor comprises a casing, at least one assembly having a rotating seal face ring which rotates as one with a sleeve intended to be mounted on a shaft of the compressor and of a stationary seal face ring mounted on the casing, the seal face rings being urged to press against one another via their rubbing face. The seal design further incorporates fluid circulation for heating leaks of compressible fluid conveyed by the compressor that occur between the seal face rings, this fluid circulation being formed in the casing and extending at least partially downstream of the seal face rings with respect to the direction of flow of the fluid stream.

Owner:THERMODYN

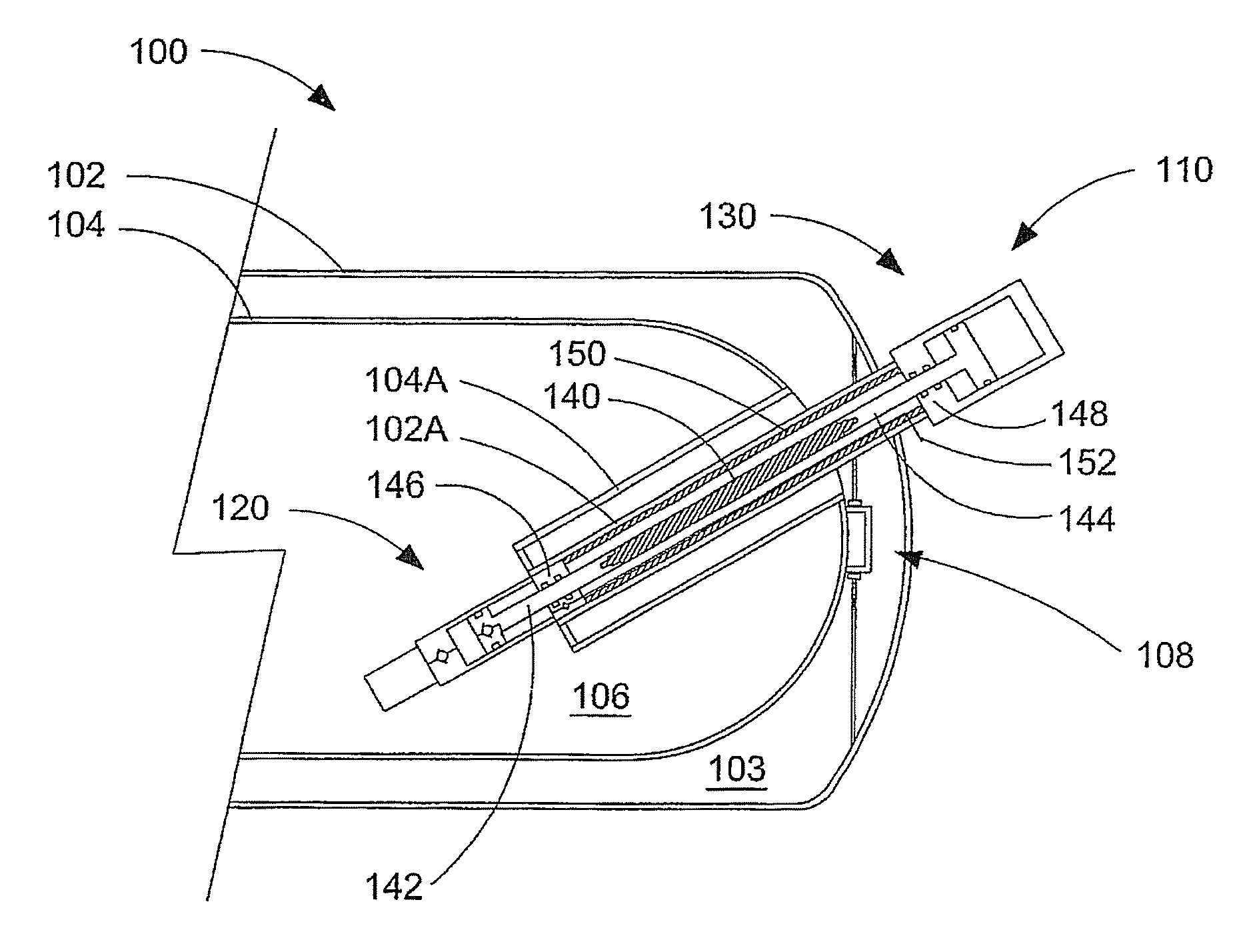

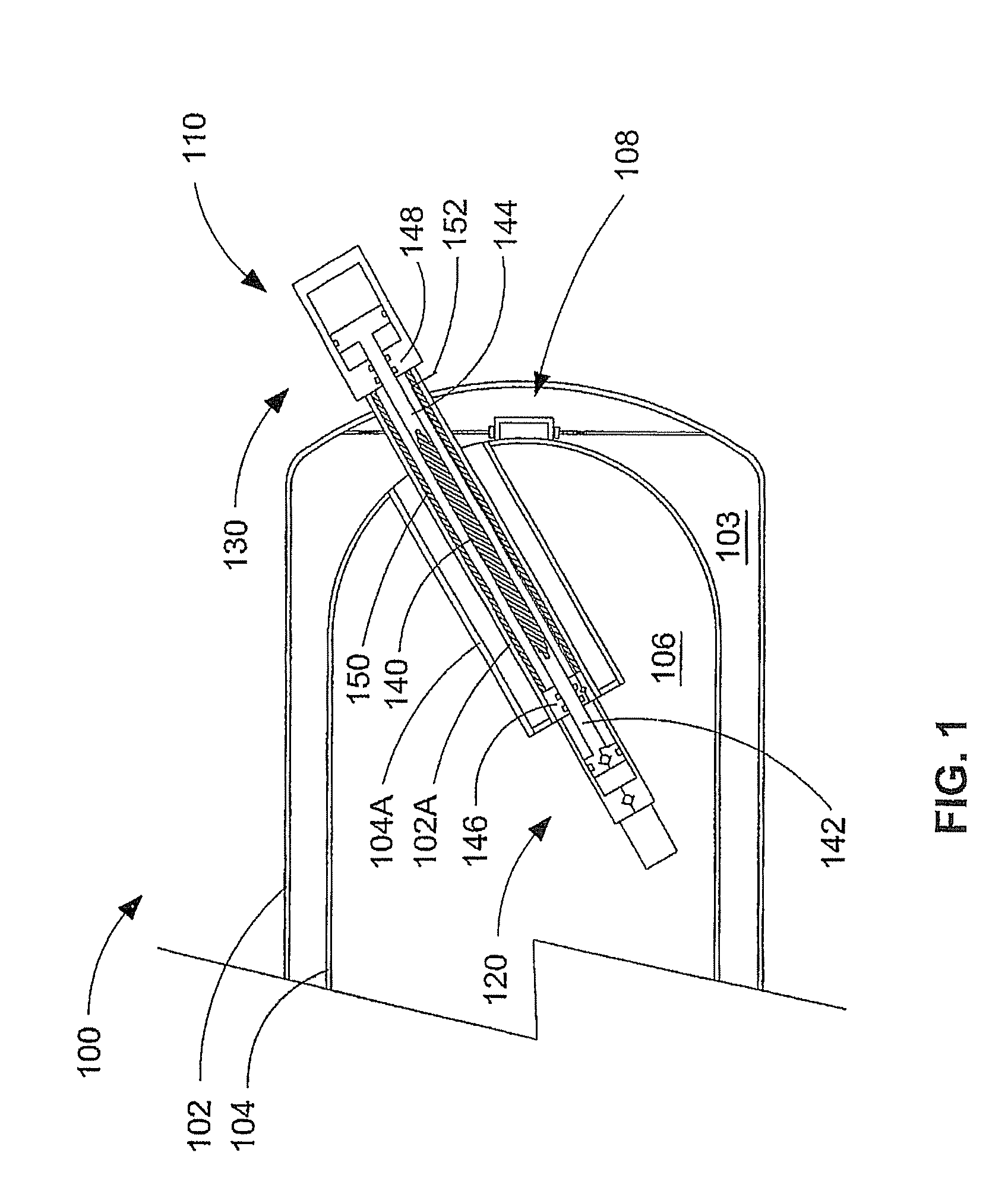

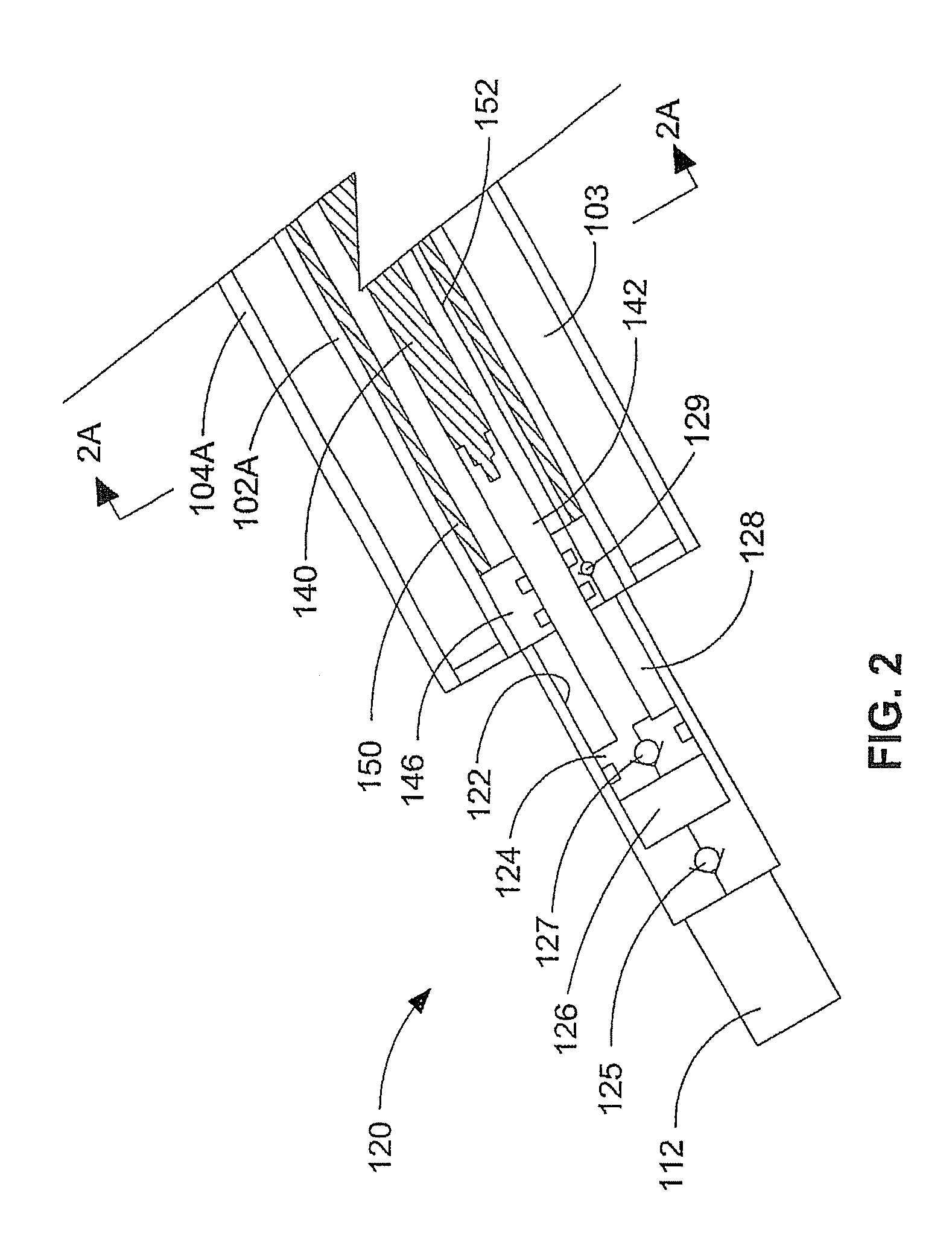

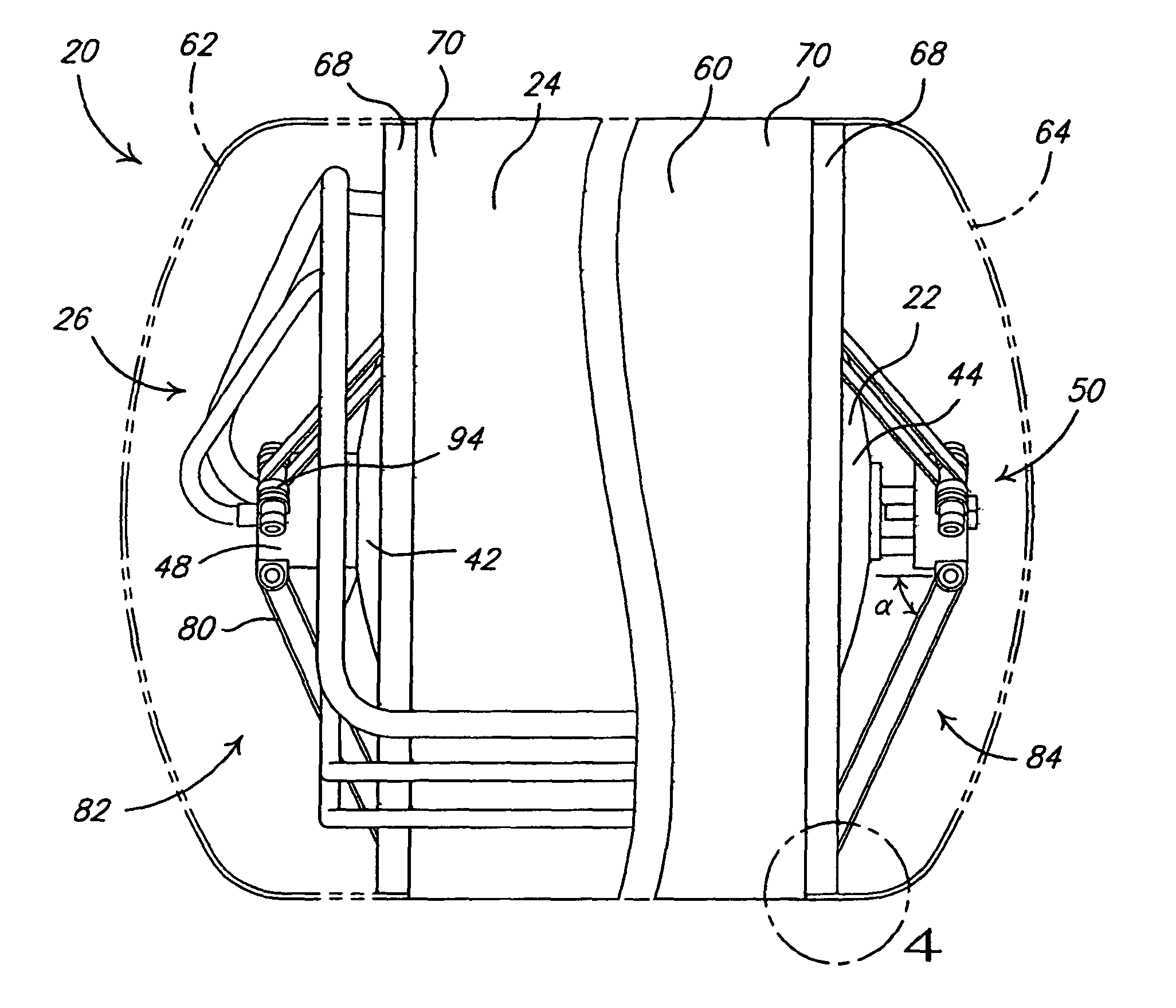

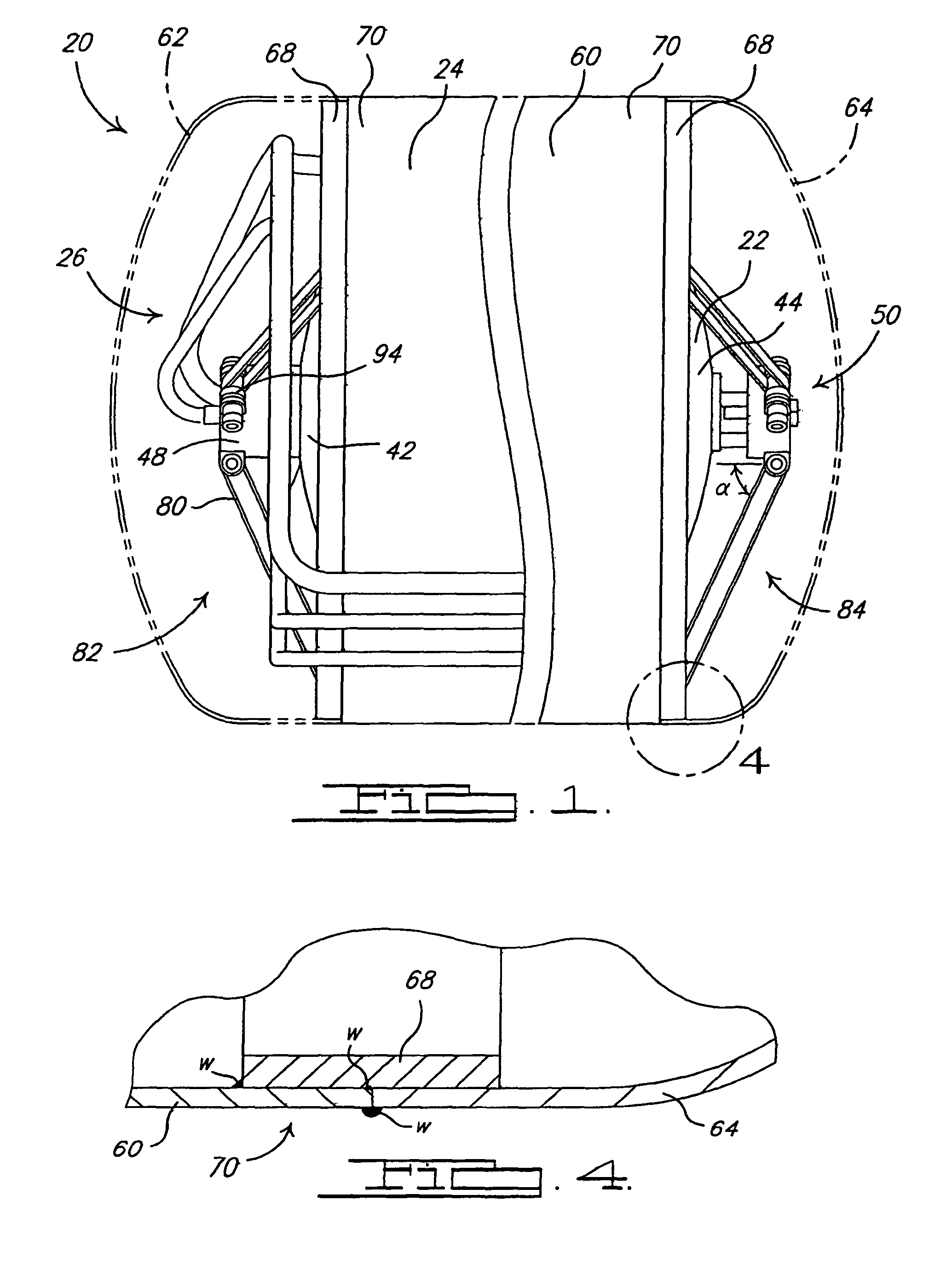

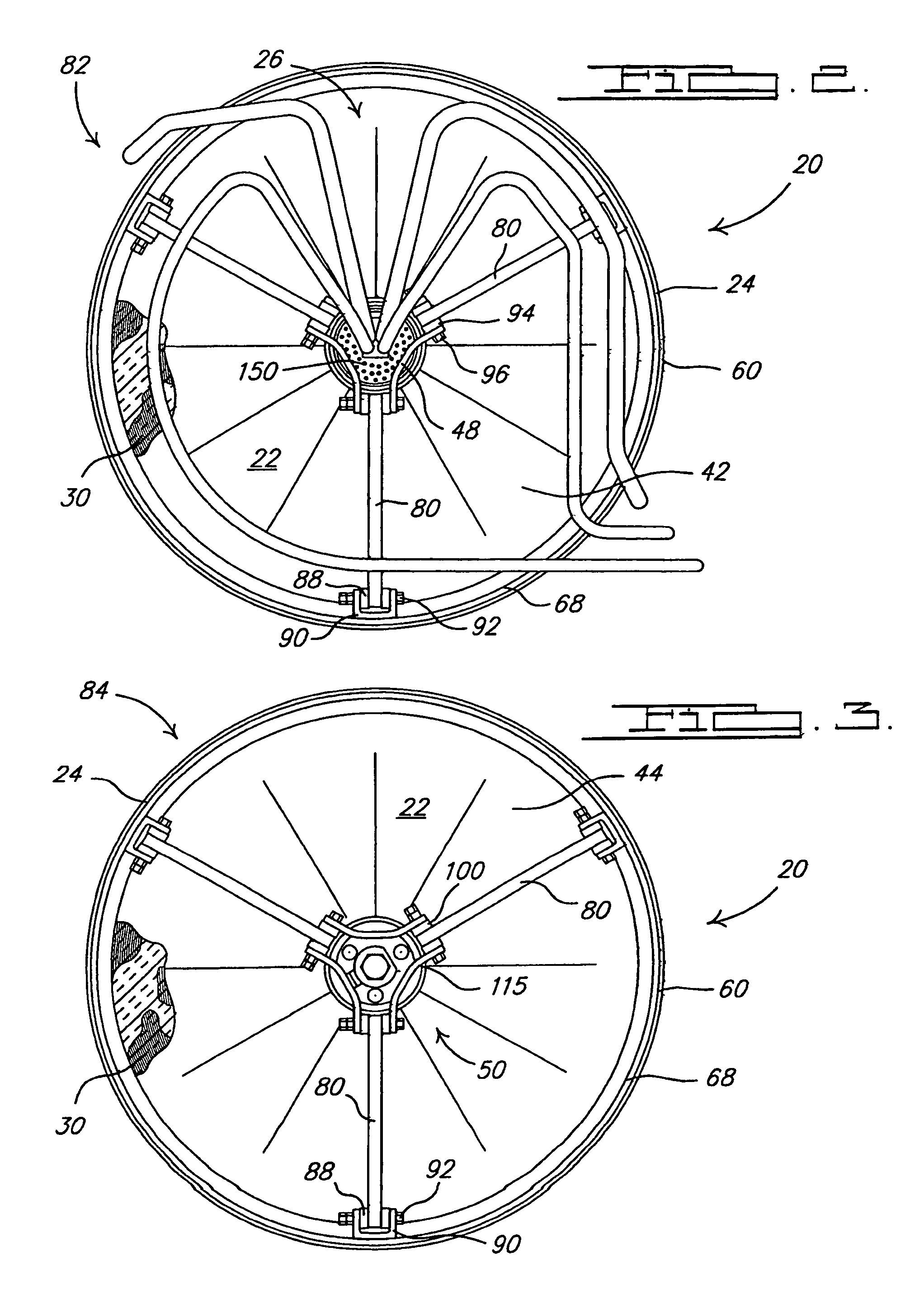

NMR CryoMAS Probe for High-field Wide-bore Magnets

InactiveUS20060176056A1Reduce riskImprovement factorElectric/magnetic detectionMeasurements using magnetic resonancePartial solutionNitrogen gas

An MAS probe is disclosed for obtaining a substantial improvement in signal to noise (S / N) in triple-resonance high-resolution (HR) magic-angle-spinning (MAS) NMR of samples near room temperature (RT) in high-field magnets where the magnet's RT shim bore is greater than 60 mm. All critical circuit components, including the sample coils, are located along with the spinner assembly in a thermally insulated cold zone pressurized with helium gas. The spinner assembly attaches to a sealed, curved, rotor-loading tube to permit automatic sample change, and it is surrounded by a partially insulated jacket cooled with a cryogenic fluid, generally nitrogen gas. The MAS probe is also compatible with magic angle gradients, variable temperature operation, field locking, and commonly available closed-cycle cold fingers. One major challenge in implementing CryoMAS is solving the problem of gas leakage from the spinner bearing, drive, and exhaust nitrogen into the cold zone, as some components will necessarily be ceramic, some plastic, and some metal. It is not desirable to use helium for the spinner bearing and drive gases for cost reasons and to prevent risk of degradation of o-ring-sealed magnet cryostats. A pressurized helium atmosphere in the cold zone may be utilized to prevent nitrogen flow from the spinner exhaust streams or atmosphere into the cold zone. The drawback to a pressurized cold zone is that the heat transfer coefficient in dense helium at low temperatures is very high, making it challenging to cool the sample coils and all the large, critical, circuit components in a practical manner. Part of the solution here is to use a first-stage cooling-jacket around the major heat leaks near the spinner exhaust flows. The critical components may be insulated with fine glass wool or teflon foam and conduction cooled without cooling much of the cold zone below the temperature of the first-stage cooling. The use of coaxial sapphire capacitors allows the noise contributions from the most critical capacitors to be reduced to a minor fraction of the total.

Owner:DOTY SCI

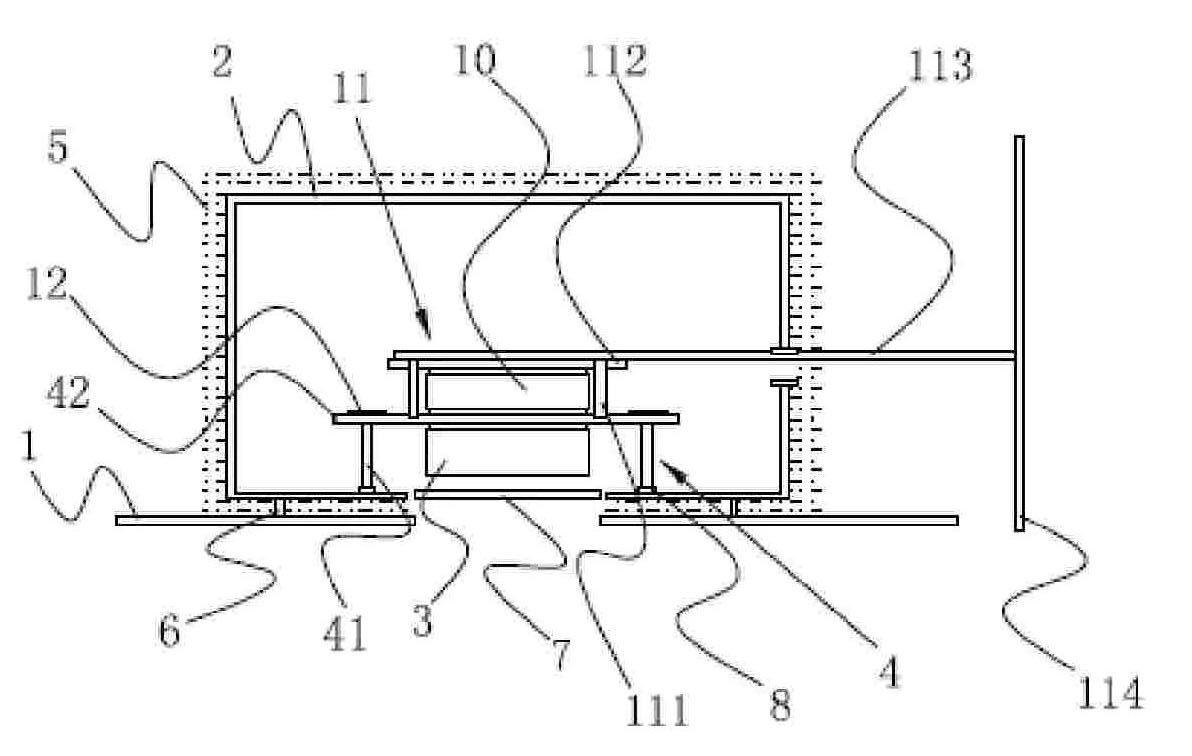

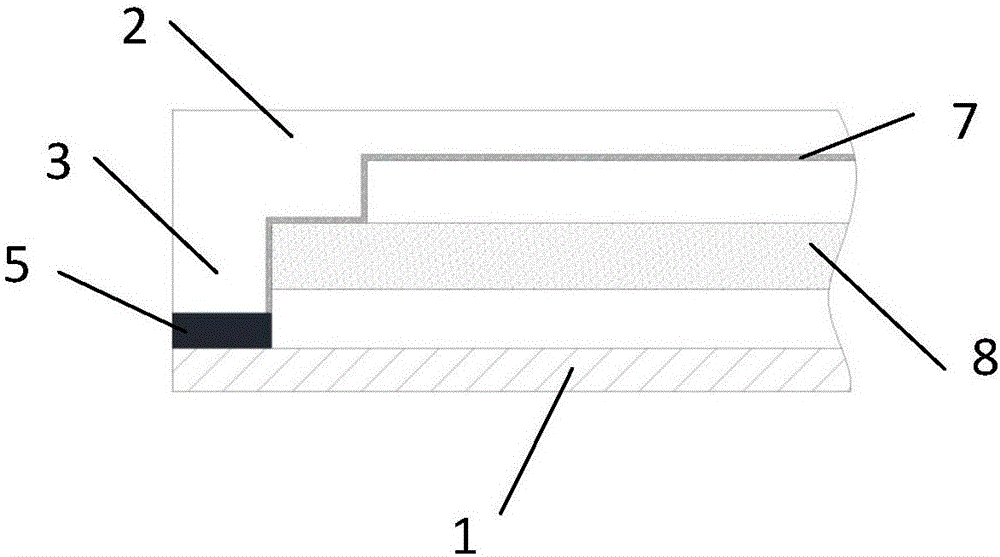

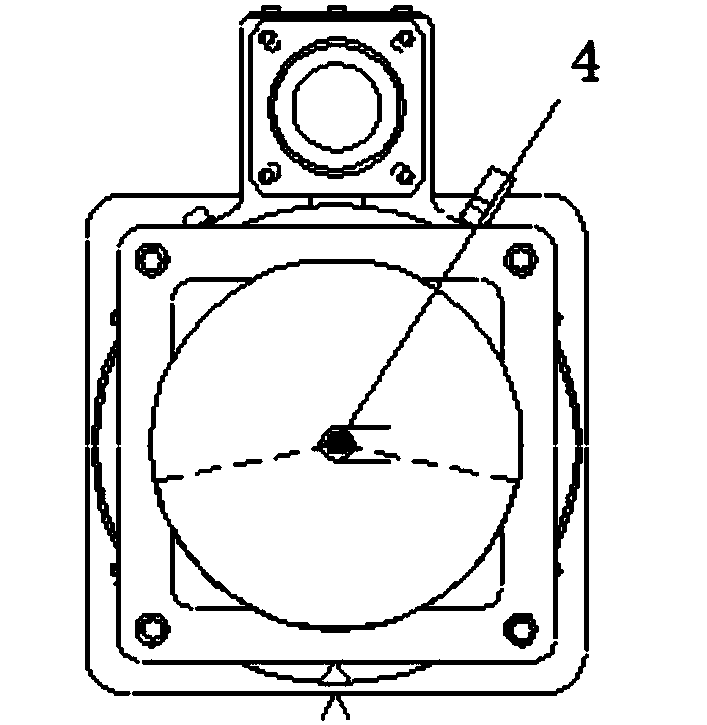

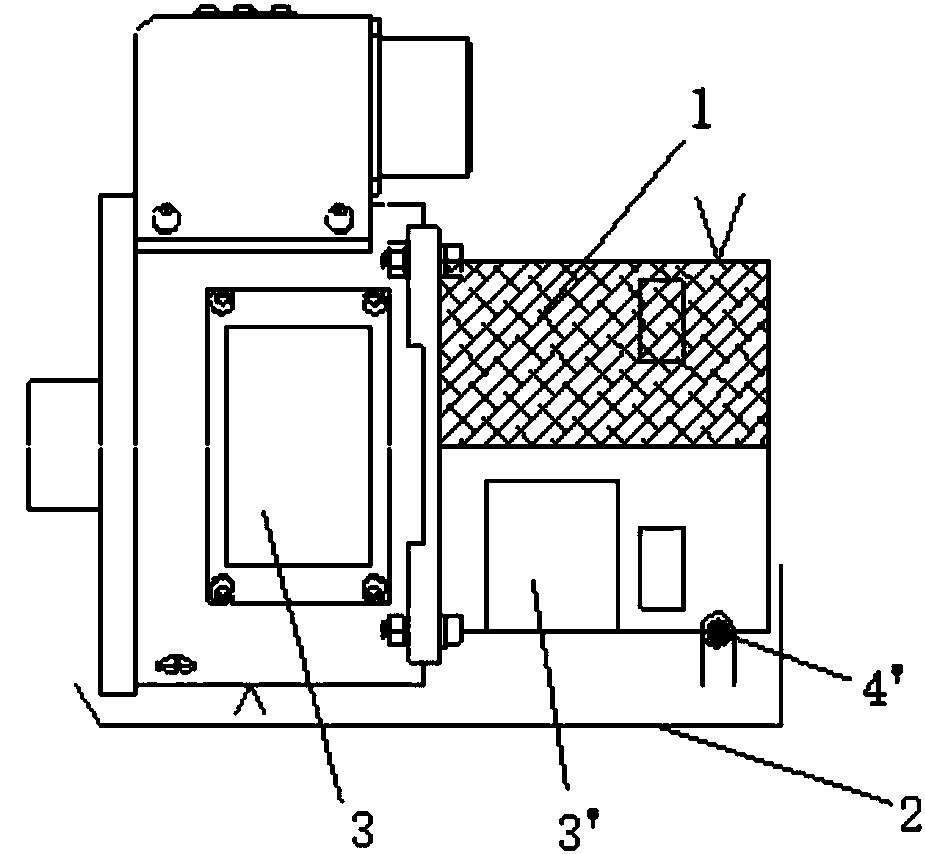

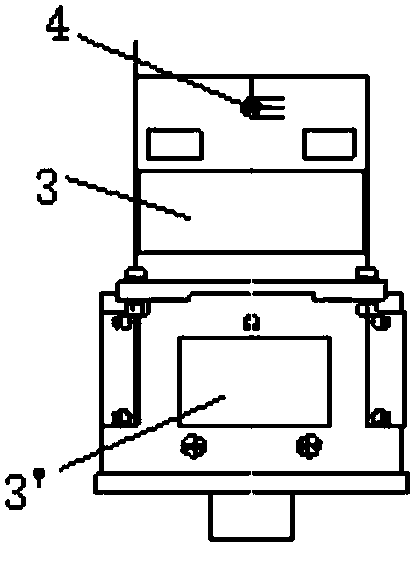

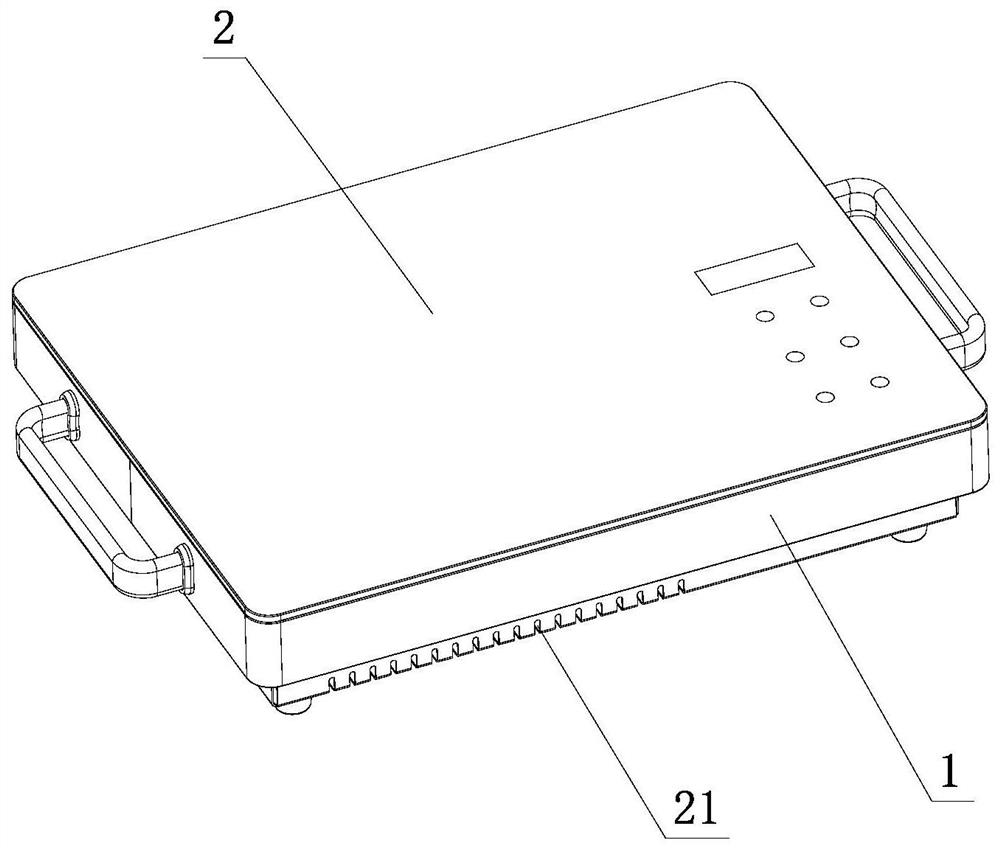

Temperature controlled focal plane detector mechanism

InactiveCN101813951ATo achieve different working temperature requirementsFulfill cooling needsTemperatue controlHeat conductingHeat leak

The invention discloses a temperature controlled focal plane detector mechanism, which mainly solves the problem that the conventional focal plane detector mechanism cannot work under different temperature conditions. The temperature controlled focal plane detector mechanism comprises a shell, a cabinet, a detector and a detector mounting base, wherein the detector mounting base comprises a detector support plate and a cold plate; the detector support plate is fixedly connected with the cabinet; the detector is arranged on one side of the cold plate, and is provided with a temperature test sensor; the other side of the cold plate is provided with a refrigerator of which the side far from the cold plate is provided with a heat conducting device; and the heat conducting device and the cold plate isolate and seal the refrigerator. The temperature controlled focal plane detector mechanism can meet the requirements of different working temperatures of the detector; and the detector is not influenced by frosting and pollution when working in various environments (laboratories or space environments), and the environmental heat leak is effectively reduced.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Energy-saving instantaneously heated type electric heater unit

The invention relates to an energy-saving instant heating electric-heat device, comprising a non-metal water pipe, an electric-heat wire twisted on the non-metal water pipe and a water leg could absorb heat. When the device is operated, the normal temperature water firstly flows inside the water leg, the water is gradually preheated by the heat leaked via the electric-heat wire, the water preheated go to the water pipe, the water is gradually reheated by the electrical-heat wire when the water is flowing, when the water flows to the outlet of the heat device, the water temperature reaches the needed temperature. The distinctive character is that the heat speed is high, energy-saving, and safe and deposition would not be easy to form. The device is mainly applied in the instant heating drinking machine, to heat the water flows inside. The invention can be used in the devices that need to instantaneously heat the flowing liquids.

Owner:黄樟焱

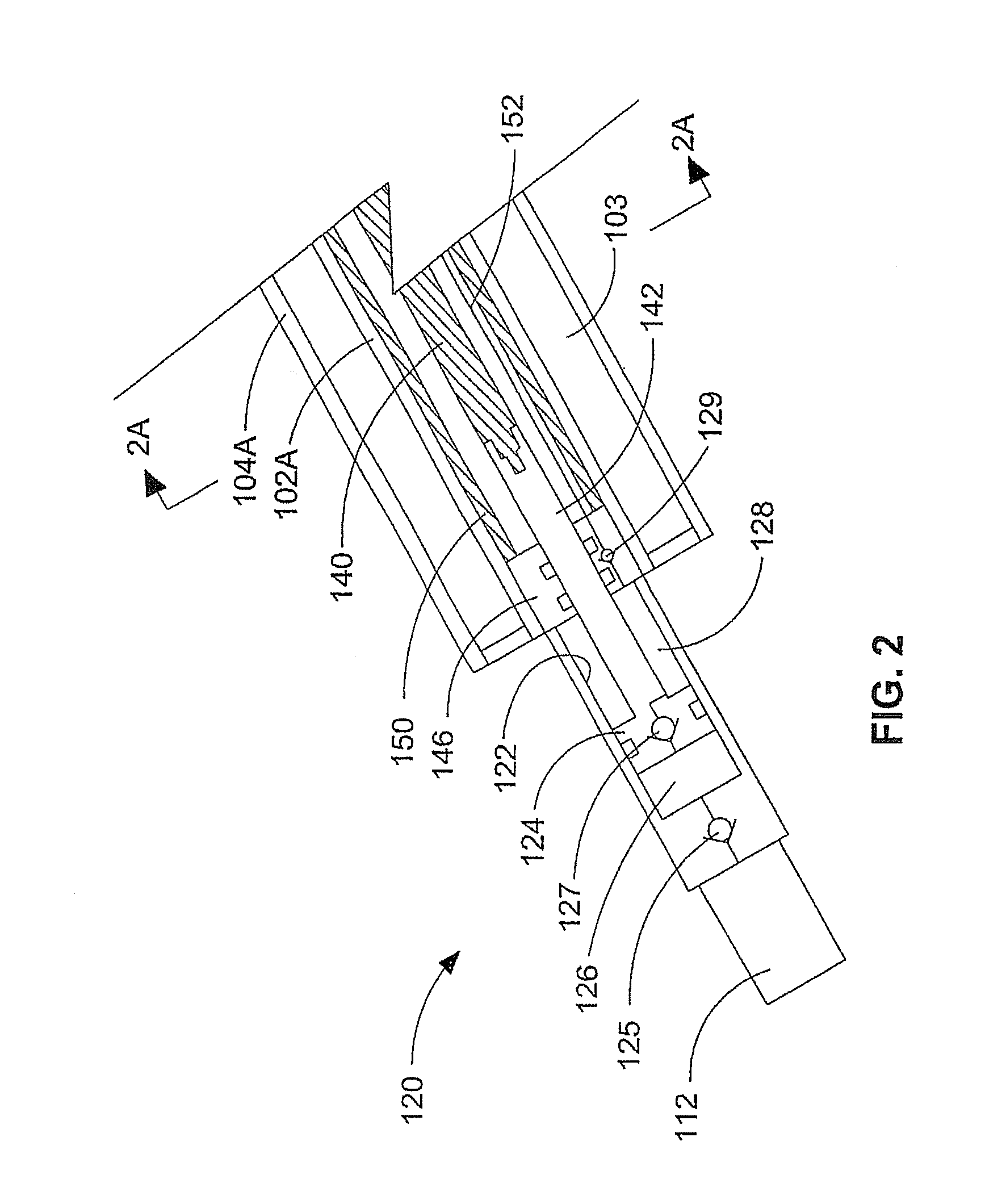

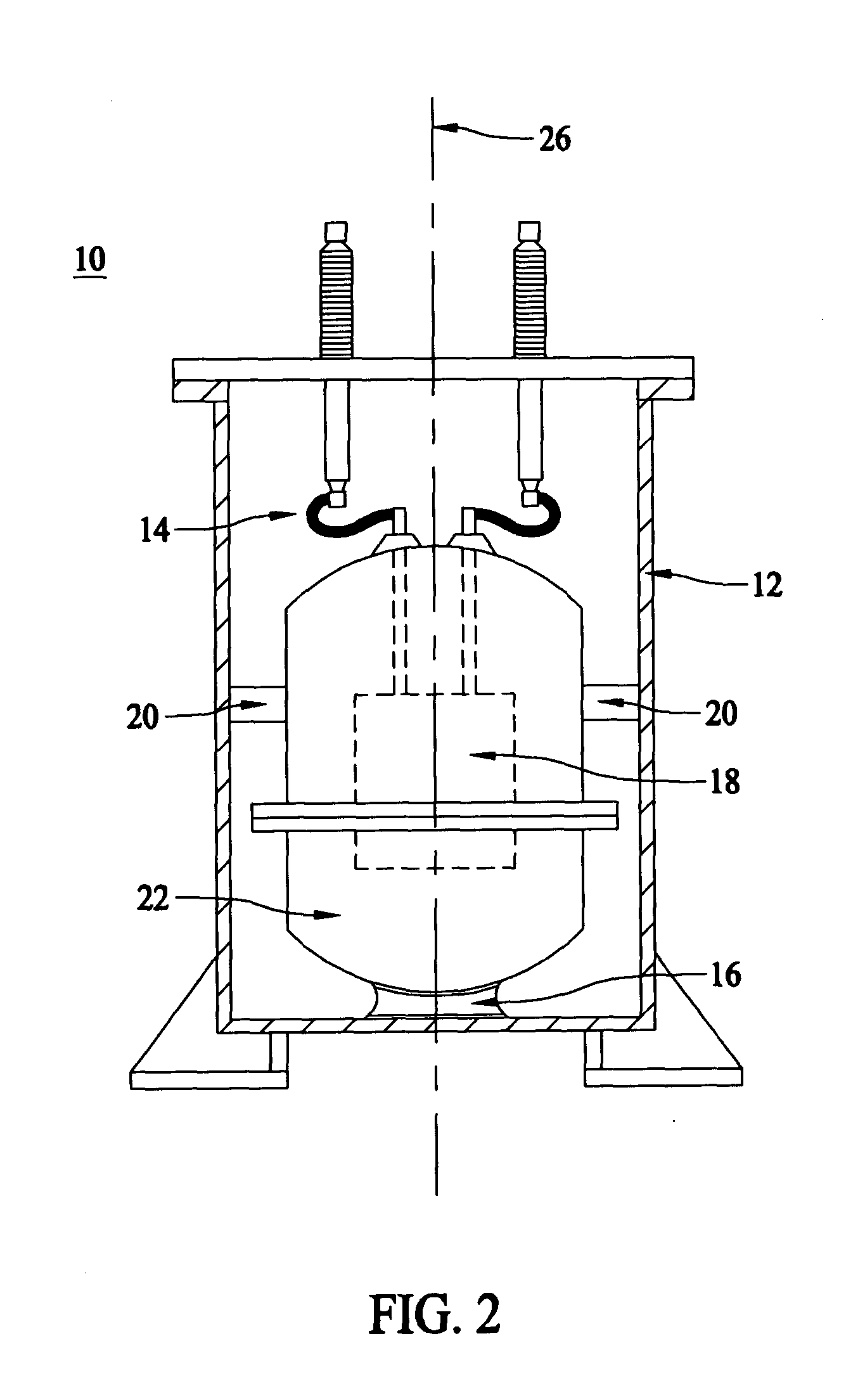

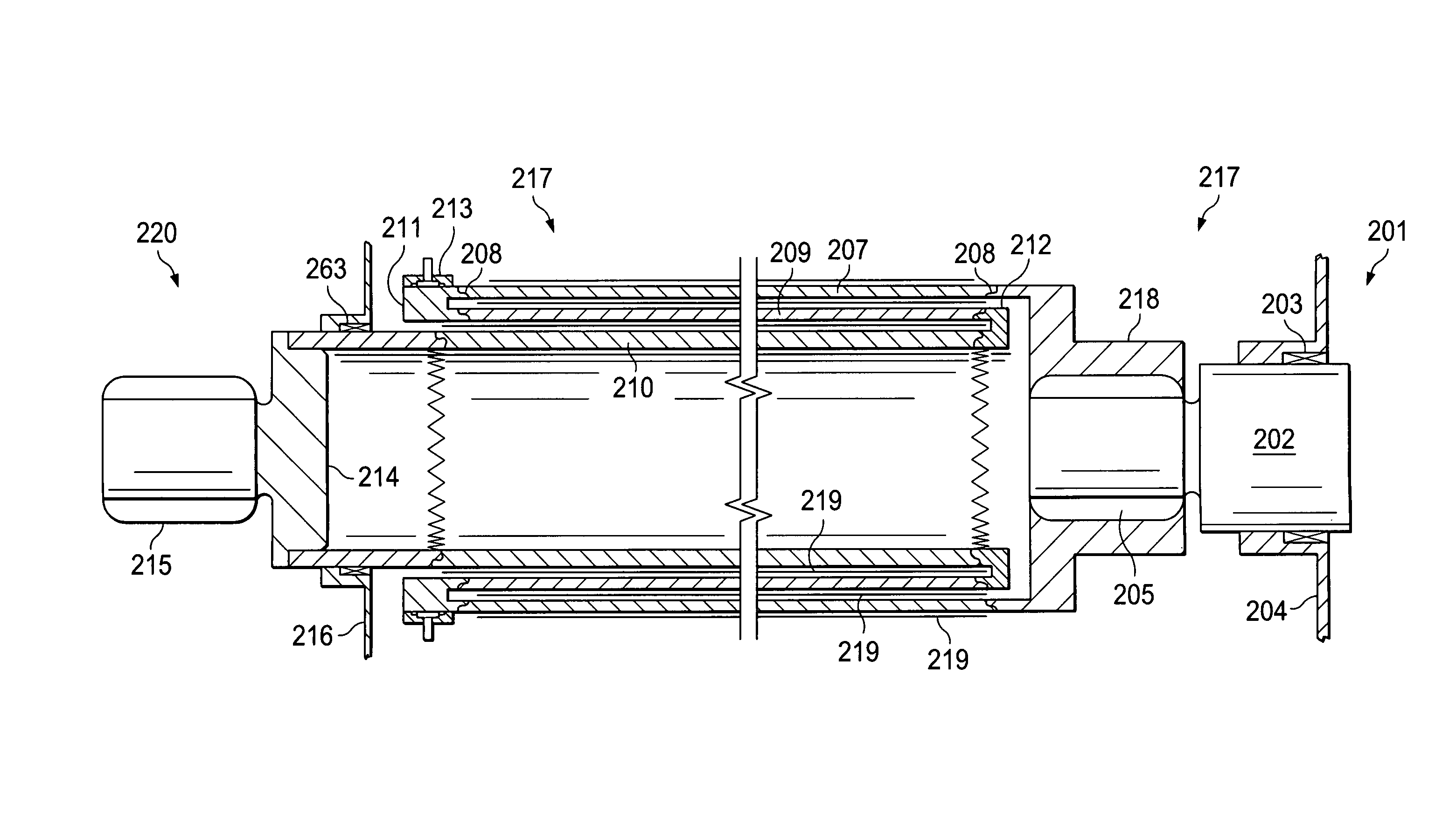

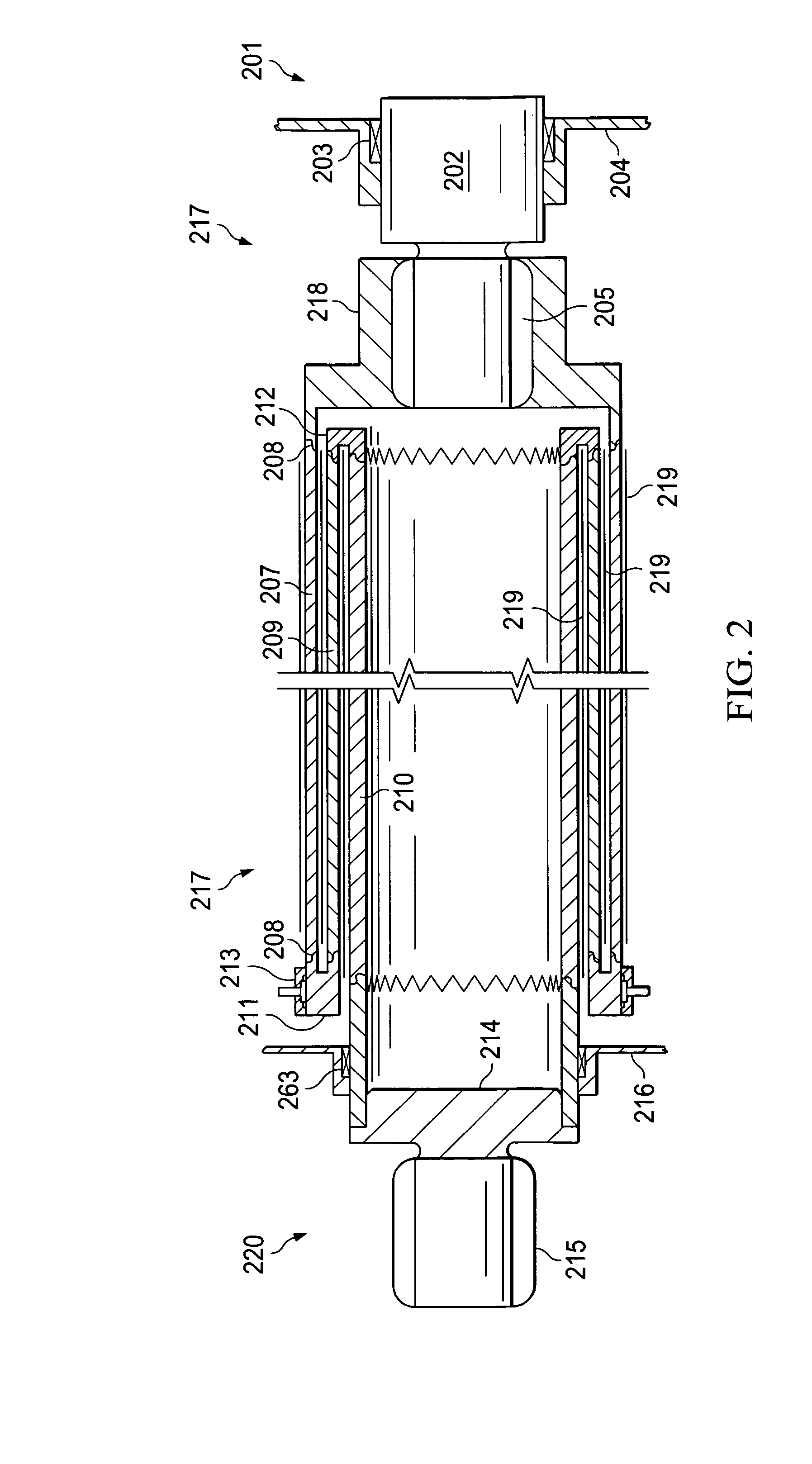

Apparatus And Method For Holding A Cryogenic Fluid And Removing Cryogenic Fluid Therefrom With Reduced Heat Leak

ActiveUS20070000259A1Reduce heat leakageExtended hold timeInternal combustion piston enginesFuel supply apparatusDrive shaftHeat leak

The apparatus comprises a double walled vacuum insulated vessel defining a cryogen space for holding a cryogenic fluid, a pump assembly comprising a pump with a suction inlet disposed within the cryogen space, and at least one elongated member extending from the pump to a drive unit disposed outside the cryogen space. The elongated member comprises an elongated non-metallic section that has a thermal conductivity that is less than that of a structurally equivalent elongated stainless steel member of the same length. In preferred embodiments, the elongated member can be one or both of a drive shaft or a rigid structural member for supporting the pump and holding it in a fixed relationship to the drive unit. The method employs the apparatus to increase hold times for holding cryogenic fluids by reducing heat leak into the cryogen space.

Owner:WESTPORT FUEL SYST CANADA INC

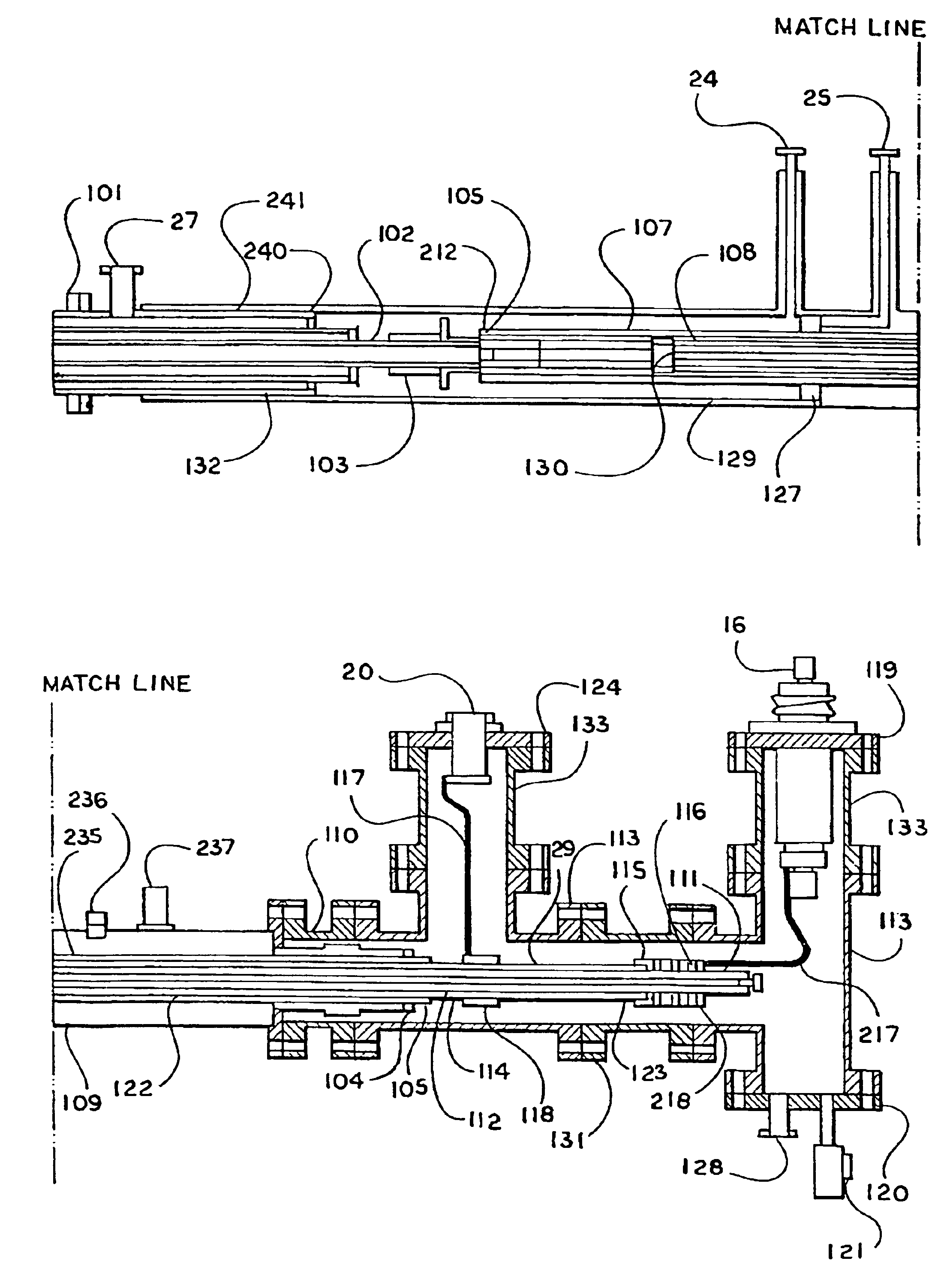

Superconducting cable termination

InactiveUS6936771B2Minimize flow of heatControl flowSuperconductors/hyperconductorsTransit-time tubesElectrical conductorHeat leak

Disclosed is a termination that connects high temperature superconducting (HTS) cable immersed in pressurized liquid nitrogen to high voltage and neutral (shield) external bushings at ambient temperature and pressure. The termination consists of a splice between the HTS power (inner) and shield (outer) conductors and concentric copper pipes which are the conductors in the termination. There is also a transition from the dielectric tape insulator used in the HTS cable to the insulators used between and around the copper pipe conductors in the termination. At the warm end of the termination the copper pipes are connected via copper braided straps to the conventional warm external bushings which have low thermal stresses. This termination allows for a natural temperature gradient in the copper pipe conductors inside the termination which enables the controlled flashing of the pressurized liquid coolant (nitrogen) to the gaseous state. Thus the entire termination is near the coolant supply pressure and the high voltage and shield cold bushings, a highly stressed component used in most HTS cables, are eliminated. A sliding seal allows for cable contraction as it is cooled from room temperature to ˜72-82 K. Seals, static vacuum, and multi-layer superinsulation minimize radial heat leak to the environment.

Owner:SOUTHWIRE CO LLC

Container for holding a cryogenic fluid

InactiveCN1856679ADomestic cooling apparatusLighting and heating apparatusSupporting systemThermal insulation

A double-walled vacuum insulated container for holding a cryogenic fluid comprises a support system for the inner vessel that comprises at least one elongated metallic conduit that penetrates the walls of the outer vessel and the inner vessel. The conduit itself provides support in an axial direction parallel to a horizontal axis and at least two non-metallic members provide support in a radial direction from the horizontal axis. By requiring the conduit to support only axial loads, its wall thickness can be reduced, thereby reducing heat transfer through the conduit. The non-metallic members that provide support in the radial direction can be made from composite materials selected for structural strength as well as low thermal conductivity, resulting in a container with improved overall thermal insulation to reduce heat leak and allow longer holding times.

Owner:WESTPORT FUEL SYST CANADA INC

Apparatus and method for holding a cryogenic fluid and removing cryogenic fluid therefrom with reduced heat leak

ActiveUS7356996B2Extended hold timeReduce heat leakageInternal combustion piston enginesFuel supply apparatusDrive shaftHeat leak

Owner:WESTPORT FUEL SYST CANADA INC

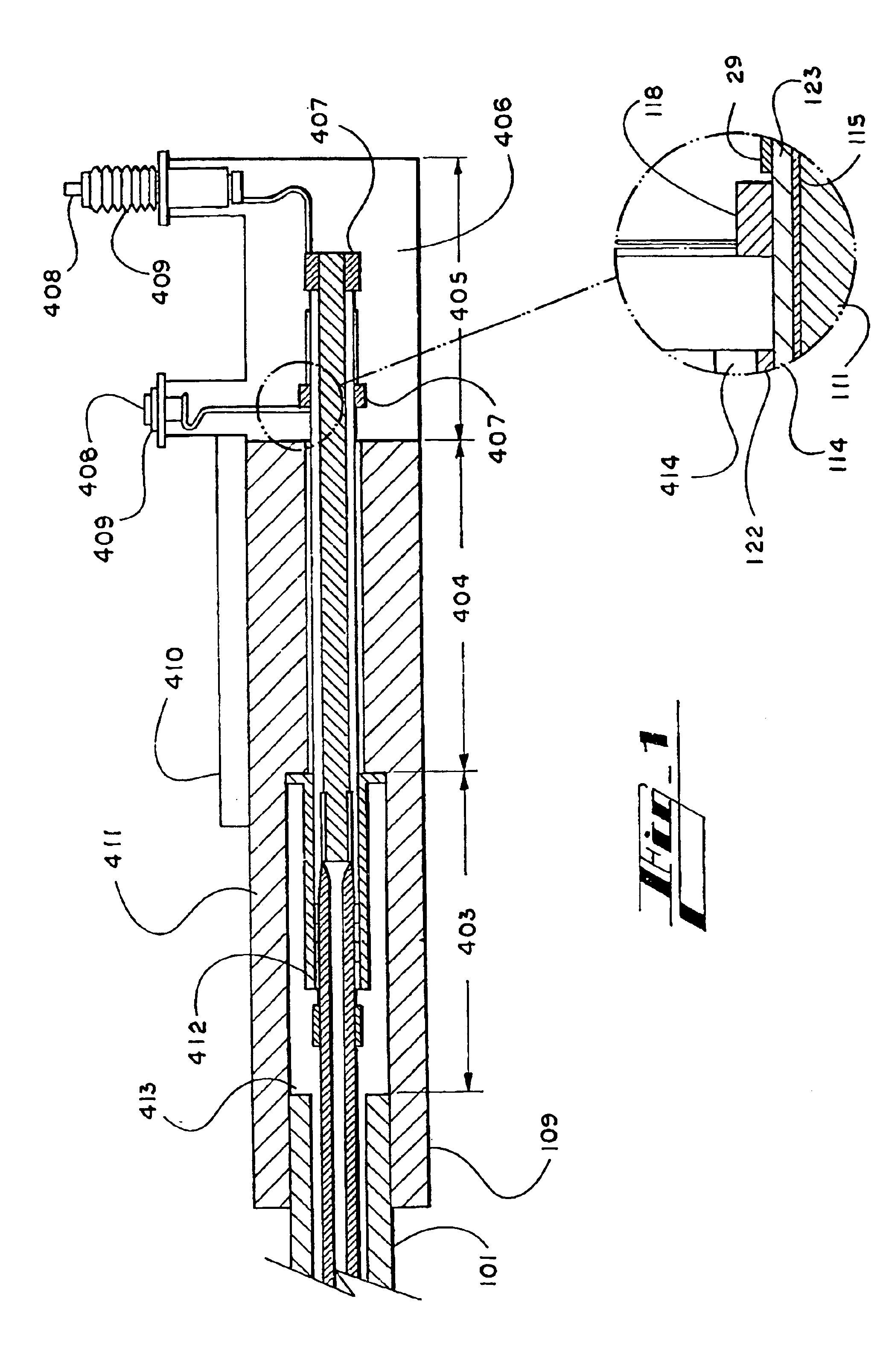

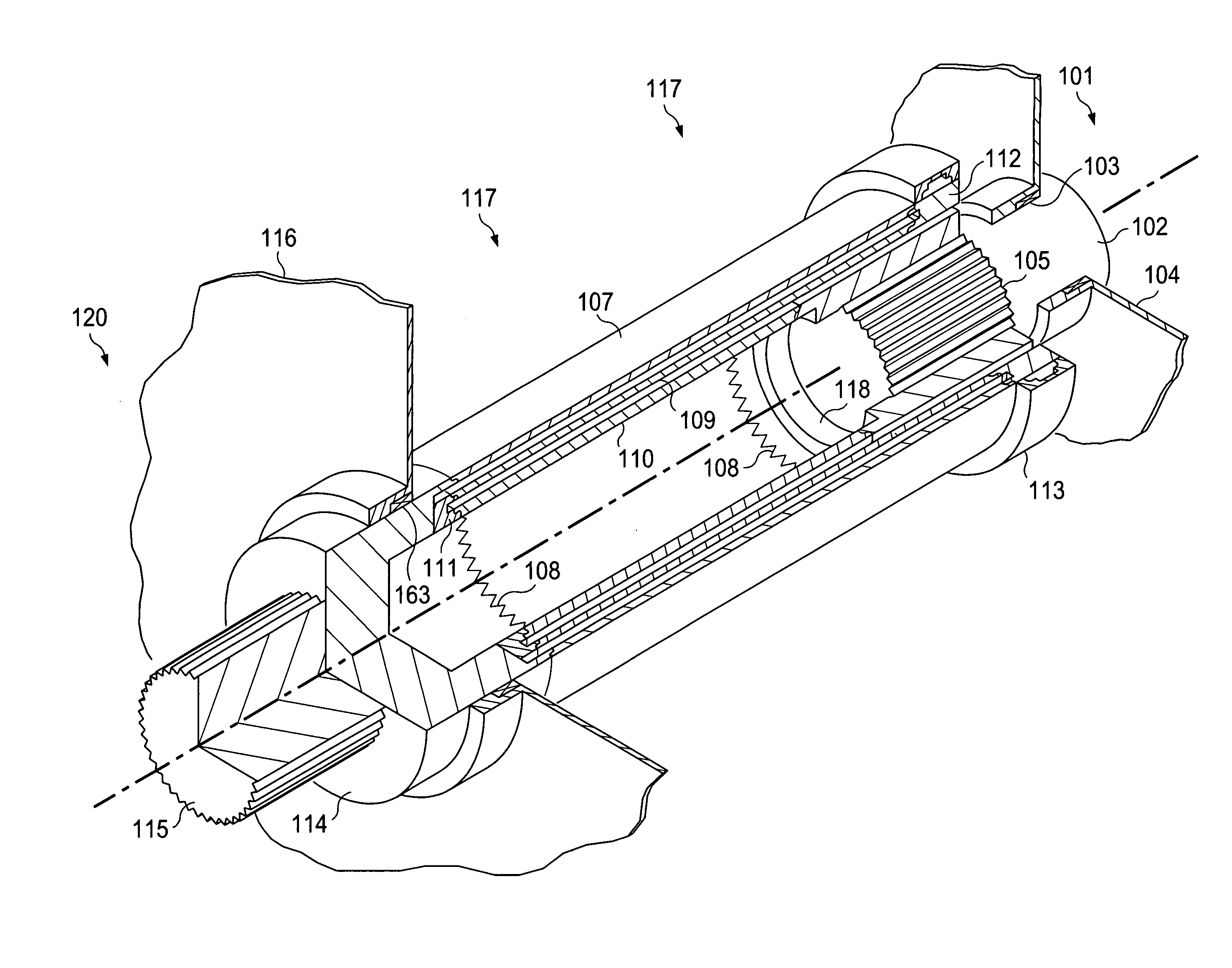

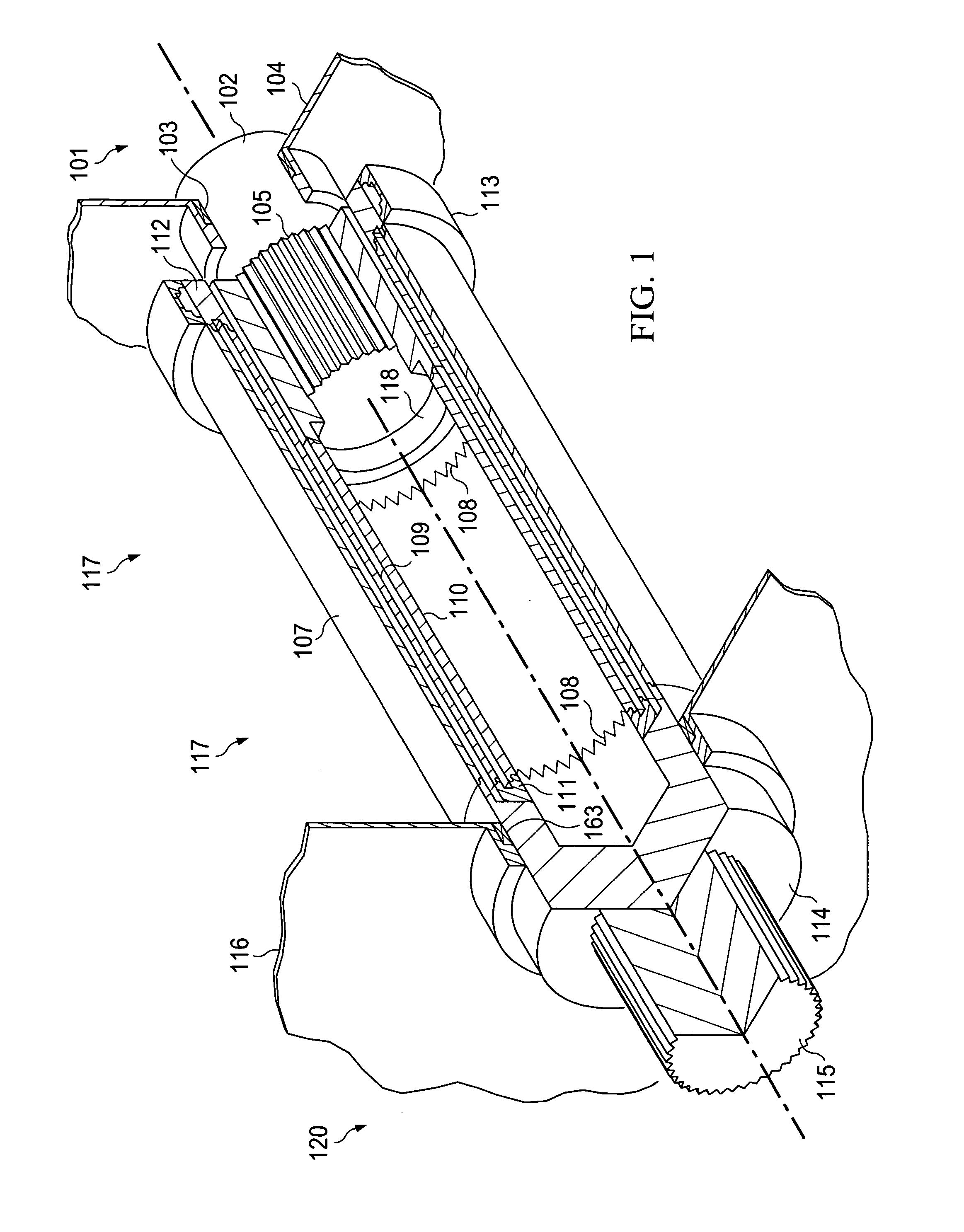

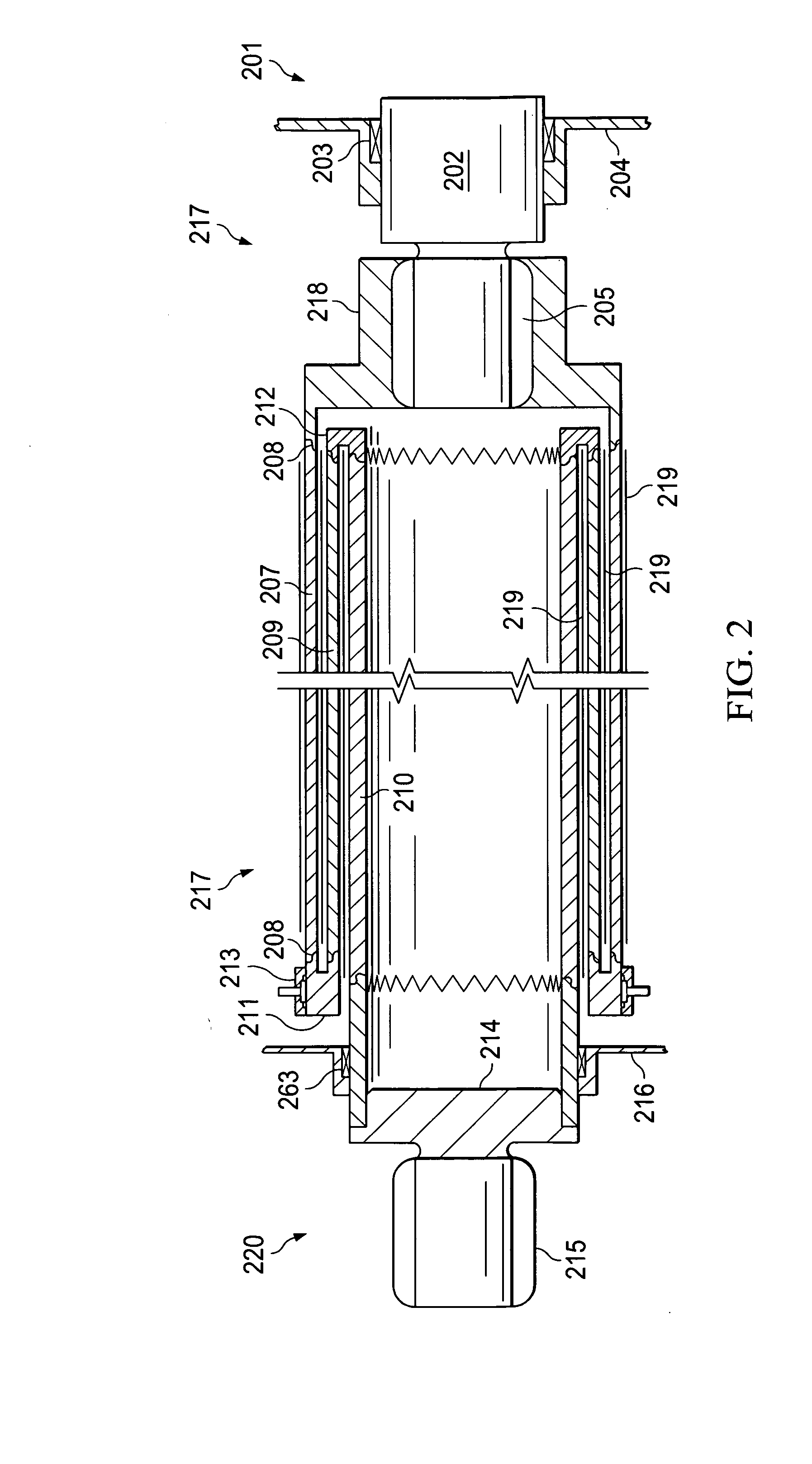

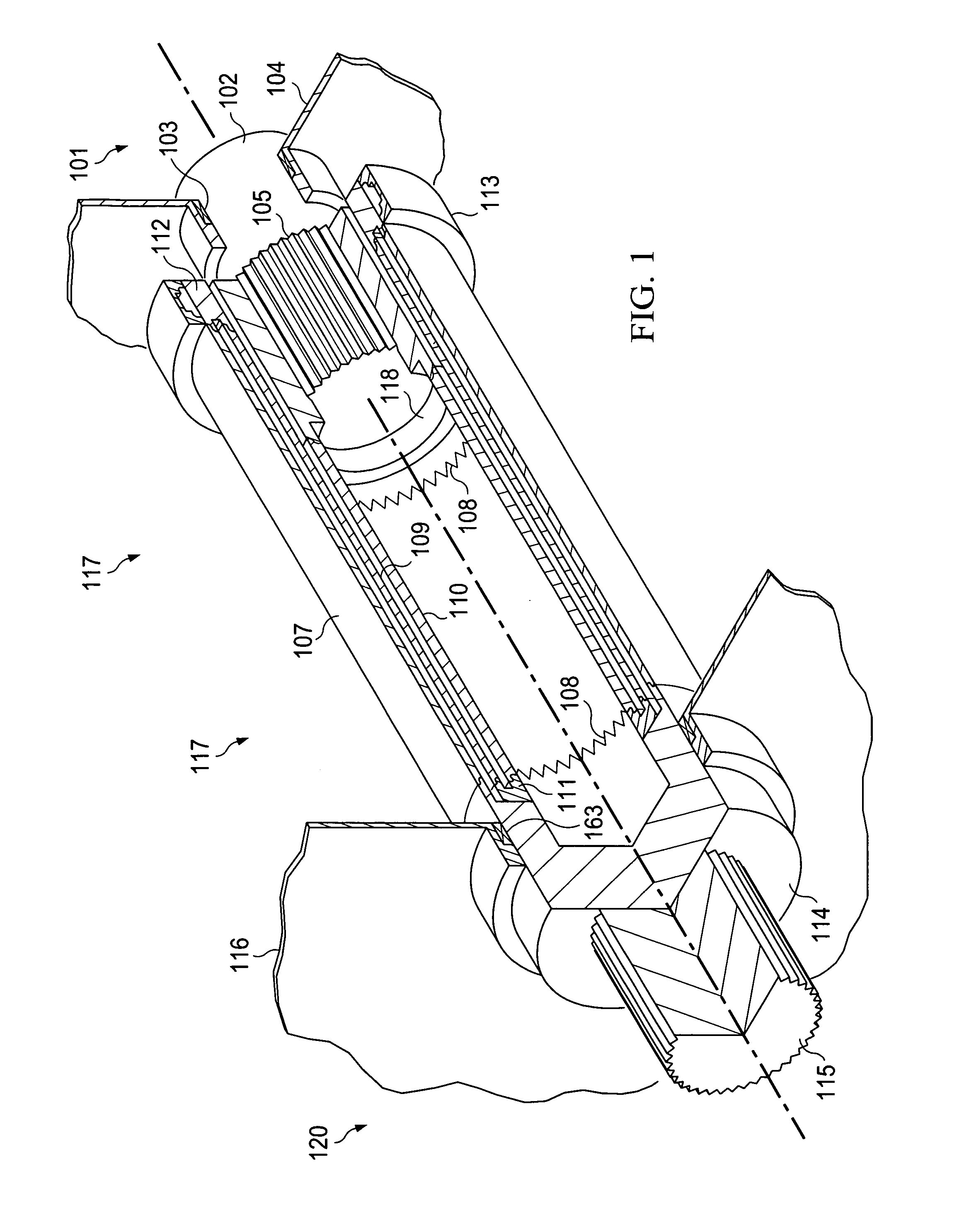

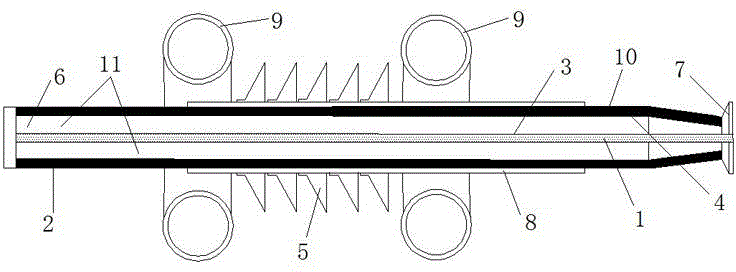

Low heat leak, high torque power shaft for cryogenic machines

InactiveUS20090251014A1Reduce heat leakageReduce heat transferMechanical energy handlingCooling/ventillation arrangementFree rotationSuperconducting electric machine

A shaft assembly and method for reducing the heat leak into the cryogenic region of a superconducting electrical machine comprising a rotor shaft extension assembly capable of transmitting large amounts of torque with substantially increased thermal impedance. The shaft assembly contains a plurality of concentric structural cylinders composed of high strength, low thermal conductivity structural materials. The structural cylinders are connected in series by means of welded joints or strong interlocking “finger” connections, in such a way that the coldest cylinder is connected to the cryogenic machine. An optional intermediate heat sink that allows the shaft extension member to rotate freely within the confines of the heat sink further reduces the heat leak into the cryogenic environment. Splined adapter hubs are typically used to connect the cylinder assembly to the rotor of the superconducting machine and the external device.

Owner:GOODZEIT CARL L

Mechanical support system for devices operating at cryogenic temperature

InactiveUS20050006392A1Prevent movementAvoid vertical movementVessel mounting detailsSuperconductors/hyperconductorsSupporting systemHeat leak

A mechanical support mechanism for a device operating at cryogenic temperature where the cryogenic container vessel is situated within another larger container vessel. The apparatus provides means to secure the inner vessel to the outer vessel through a bottom-support component and a side-support component. These components consist of mating structures of different configurations that provide inner vessel with constraints for horizontal, lateral, vertical and rotational degrees of freedom while at the same time achieving minimal physical contacts between the inner and outer container vessels to reduce heat leak into the inner cryogenic container.

Owner:SUPERPOWER INC

Hot riveting connection method of thermoplastic material and light alloy

The invention provides a hot riveting connection method of a thermoplastic material and a light alloy. A hole is preformed in the light alloy, and a light alloy / thermoplastic material high-efficiencyheterogeneous joint is formed by using the light alloy with the hole, a thermoplastic fiber prepreg, a heating element, the thermoplastic material and the like through an electric heating melting bonding process; due to the introduction of the preformed hole, the interface bonding strength of the thermoplastic resin adhesive layer and the light alloy is improved; and due to the introduction of thethermoplastic fiber prepreg, the situation that the current of the heating element and the generated heat leak through the light alloy is avoided. The method disclosed by the invention is simple, quick and extremely low in cost, and has a wide application prospect in the fields of metal and non-metal material connection of aviation, aerospace, automobiles and the like.

Owner:SHENYANG AEROSPACE UNIVERSITY

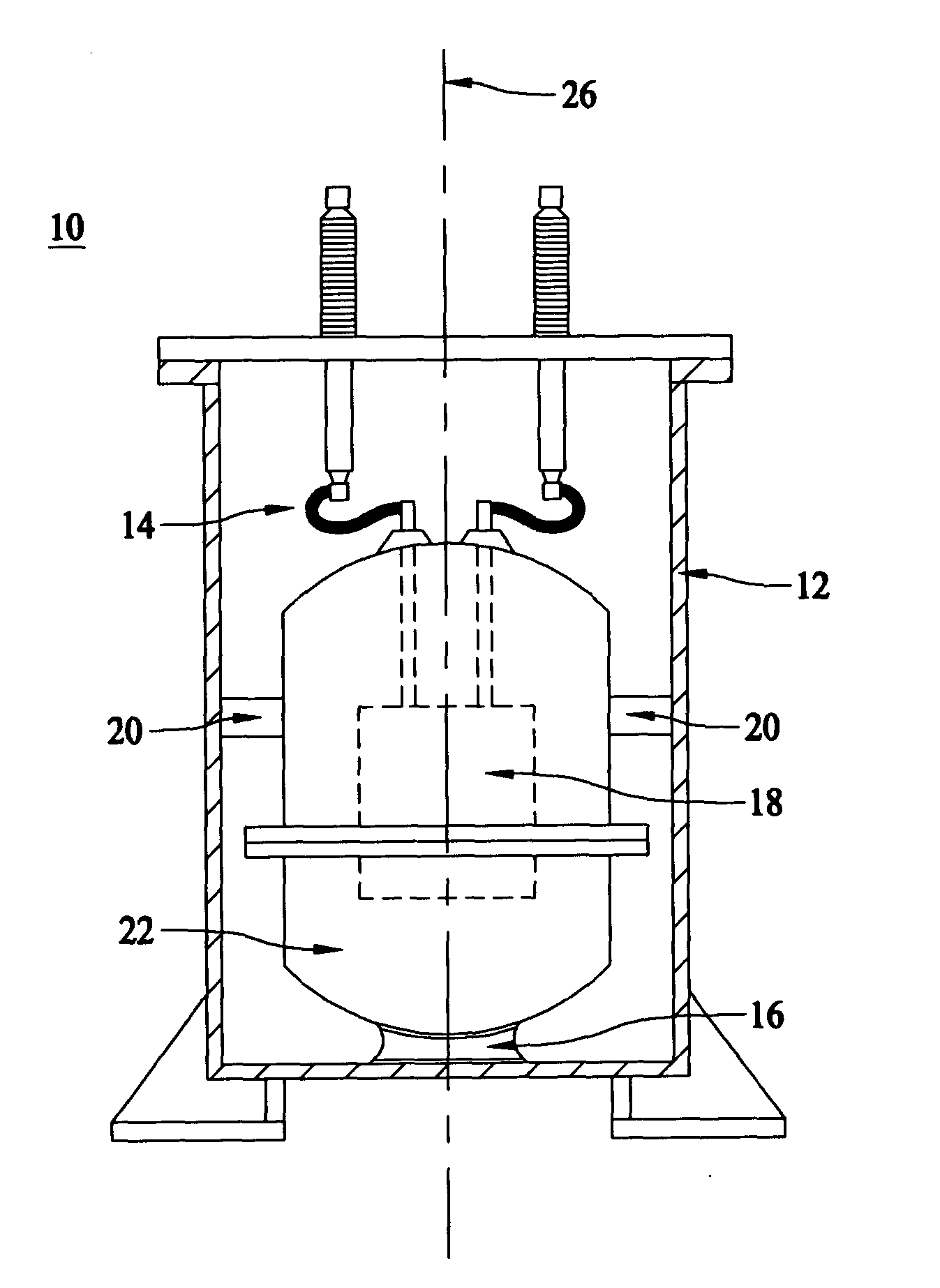

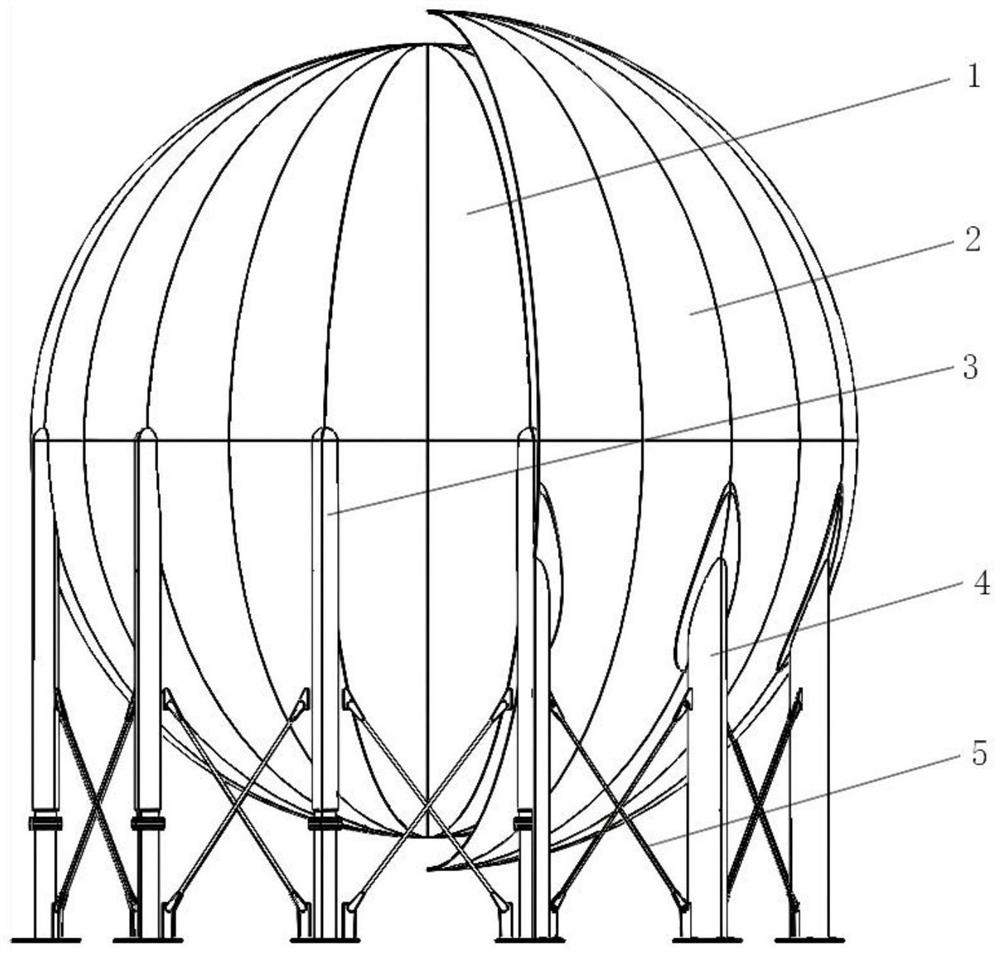

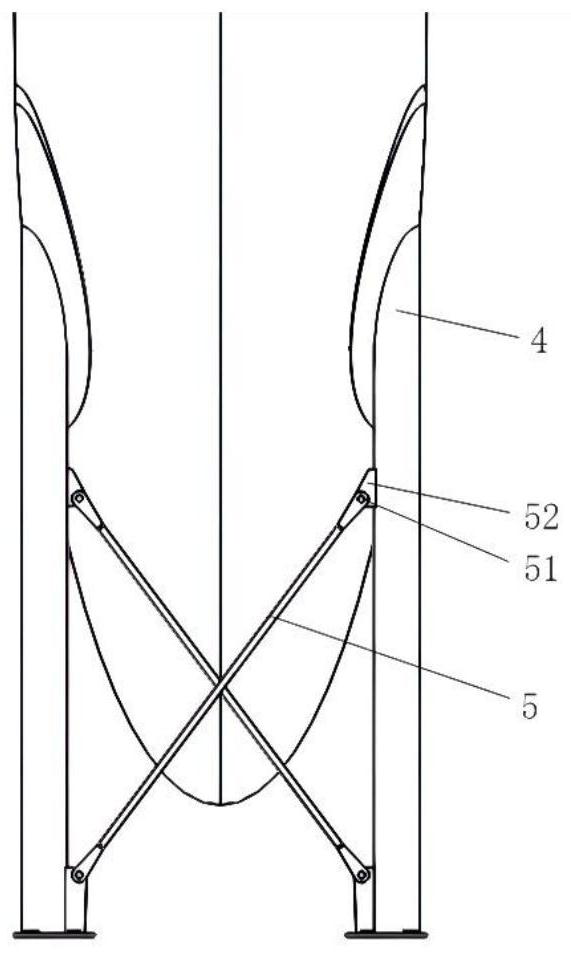

Suspended liquid hydrogen storage tank

InactiveUS7757882B2Facilitates preloadingLimit parasitic heat leakDomestic cooling apparatusLighting and heating apparatusLiquid stateHeat leak

An apparatus and method for suspending an inner tank within an outer tank to form a cryogenic storage tank. Opposing ends of the inner tank are suspended from the outer tank by suspension members. A preloading device facilitates the preloading of the suspension members to suspend the inner tank within the outer tank. The suspension members constrain the inner tank in a statically determinable manner so that a desired preloading and loading can be imparted upon the suspension members. The suspension members advantageously limit the parasitic heat leaks between the inner and outer tanks.

Owner:GM GLOBAL TECH OPERATIONS LLC

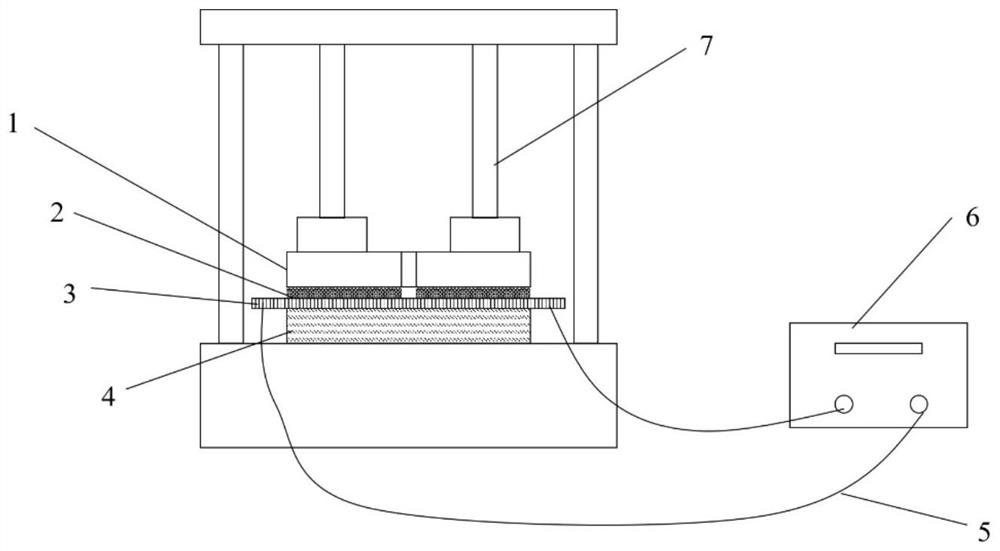

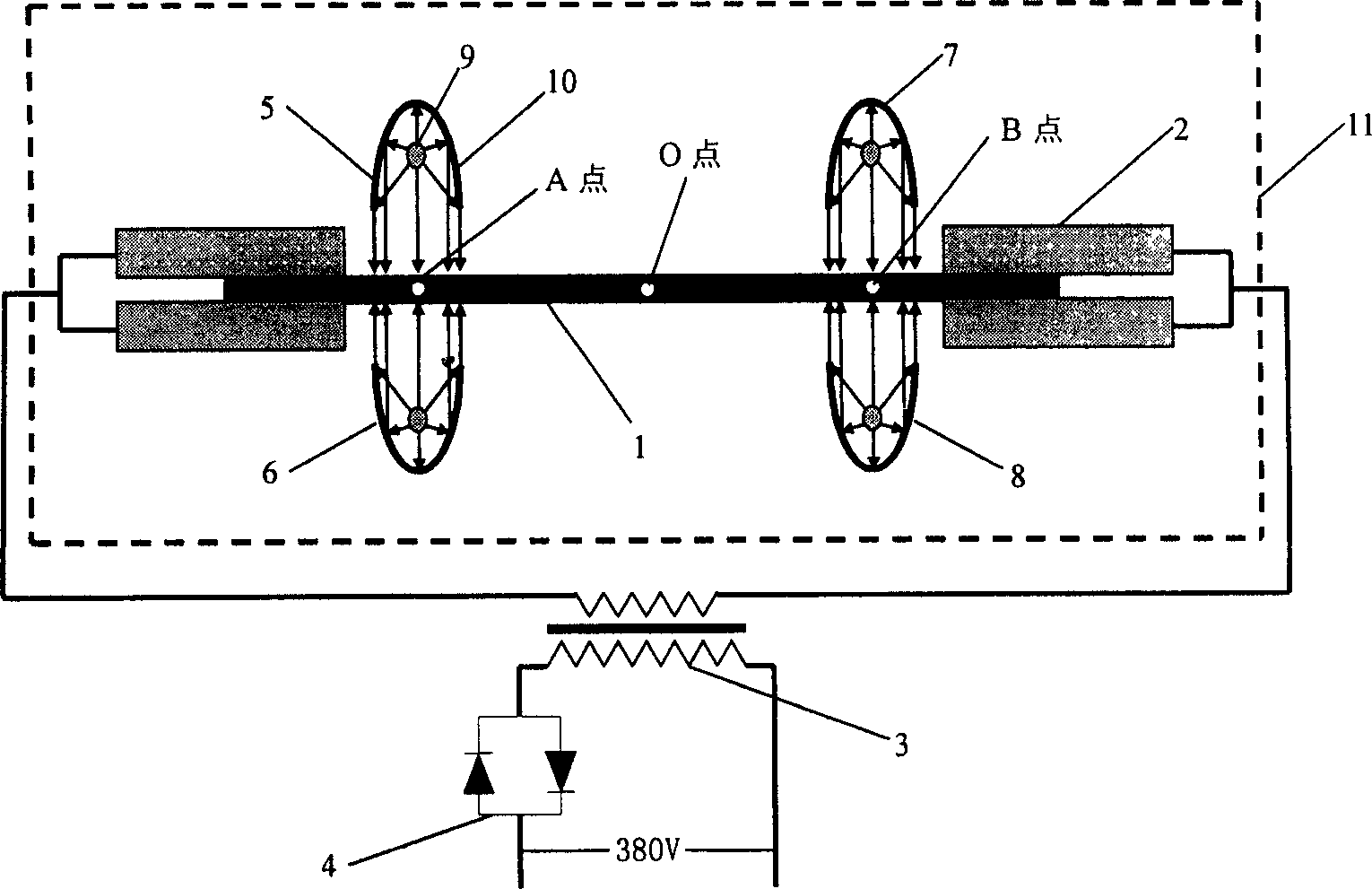

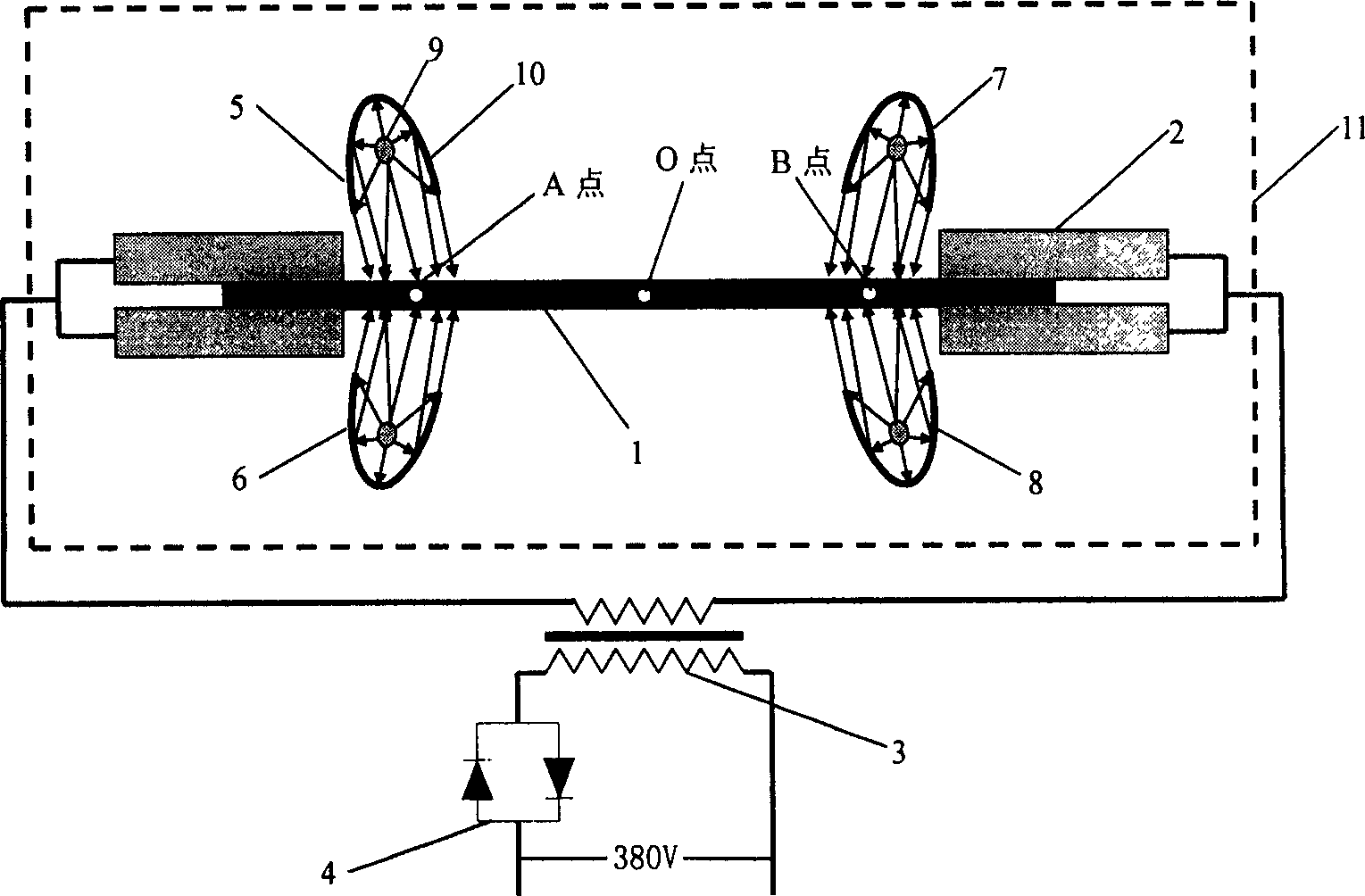

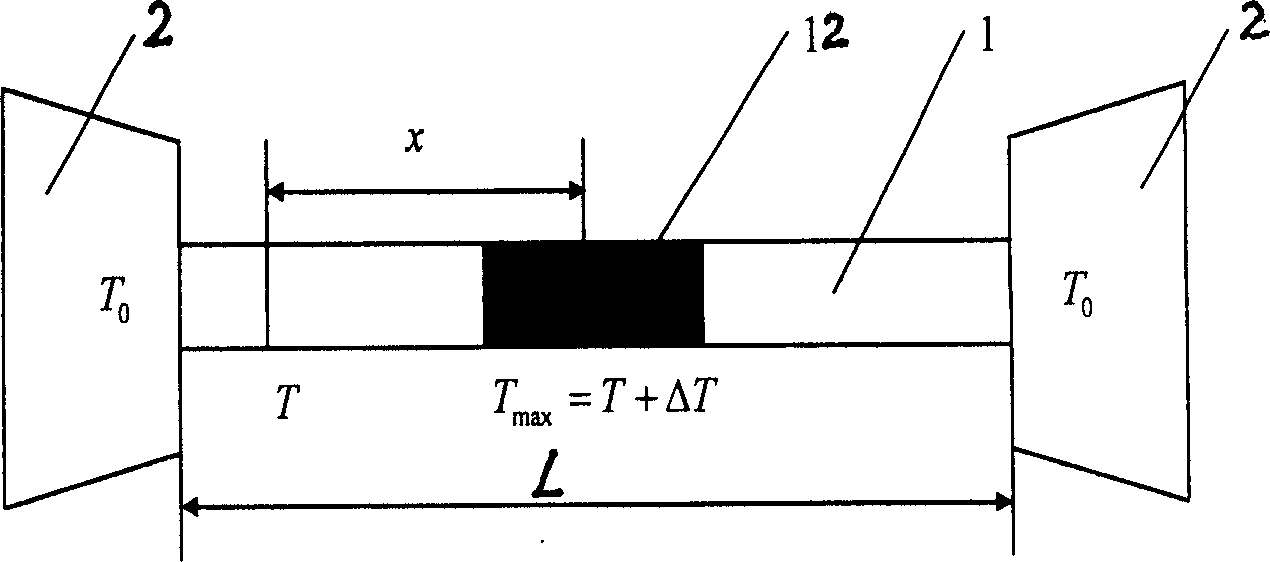

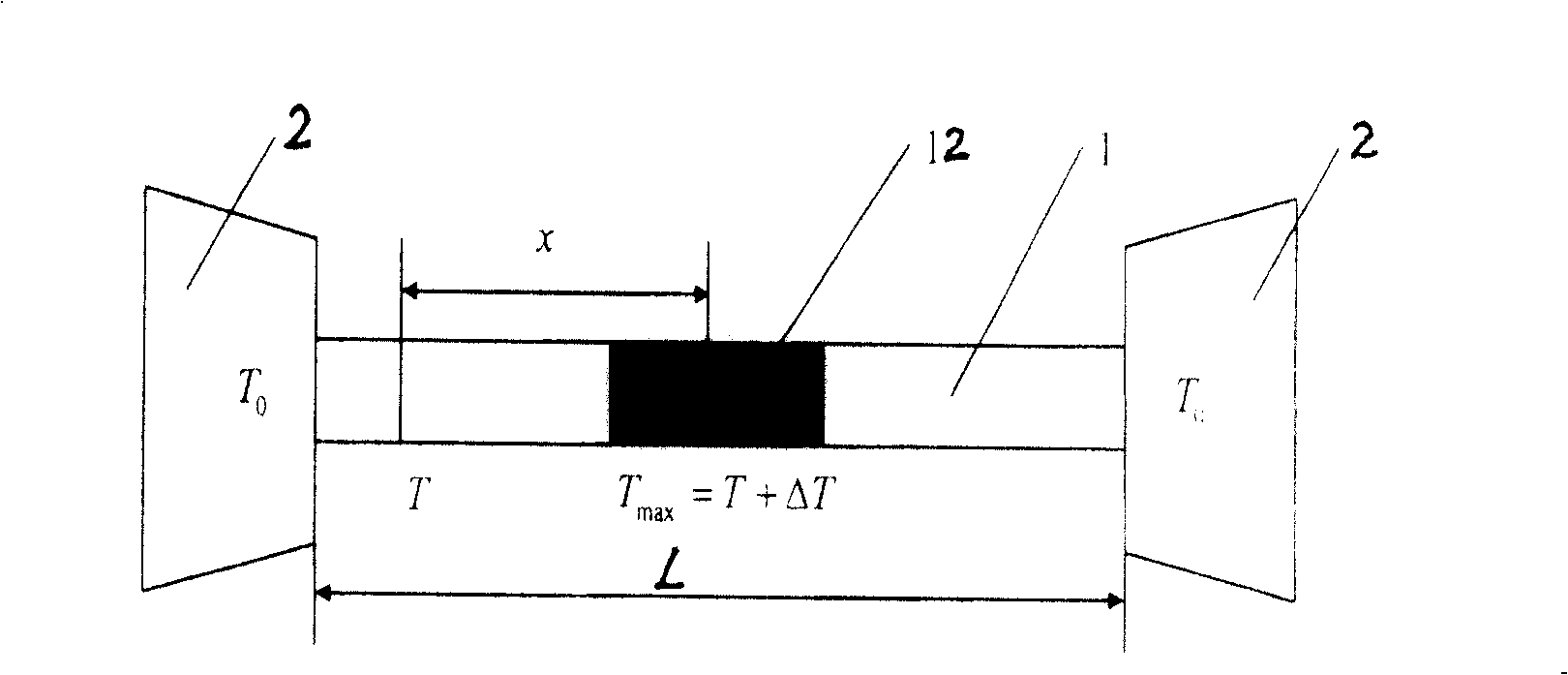

Method for eliminating temperature gradient in metal strip sample heat treatment test

InactiveCN1731132AIncrease the lengthEliminates or reduces temperature gradientsPreparing sample for investigationElectrical resistance and conductanceThermodynamics

The invention relates to a method for erasing temperature gradient in mental plate with sample heat treating experiment, which is characterized in that it adds infrared radiation heating means based on the mode of directly using the resistance to heat; it fixes infrared heating apparatus on the two sides of the sample near the clamp, and uses the infrared radiation energy of the infrared heating apparatus to compensate the heat leaked by heat transmitting; it separately controls the directly resistance heating and the infrared radiation heating.

Owner:NORTHEASTERN UNIV LIAONING

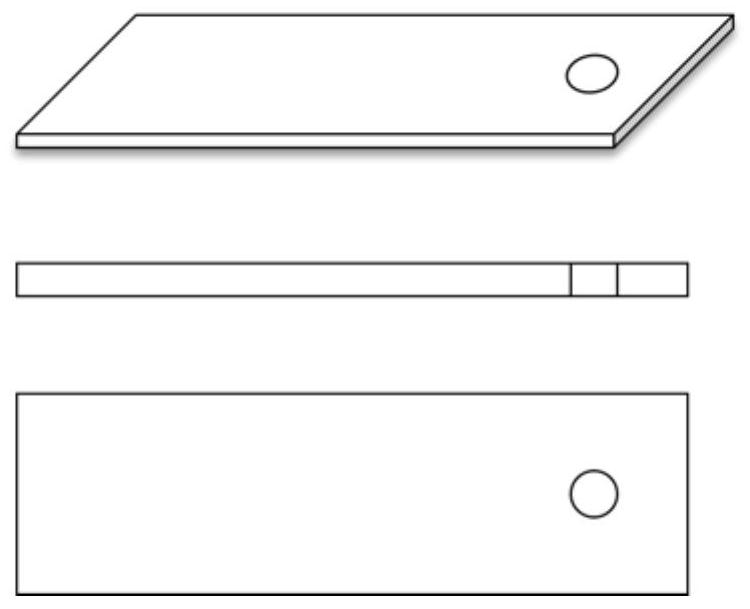

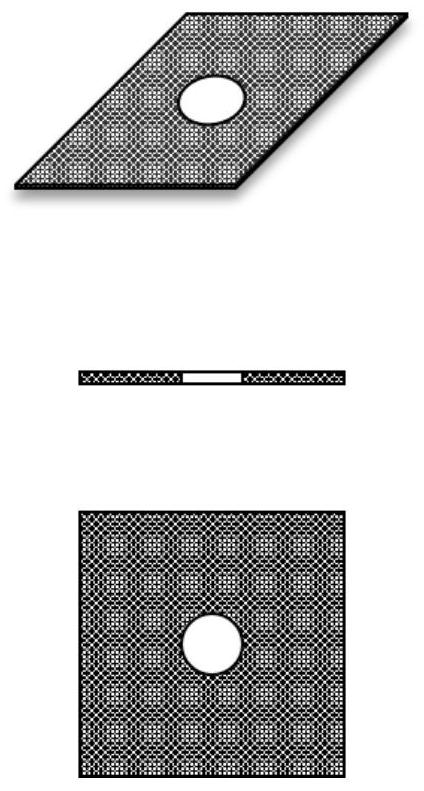

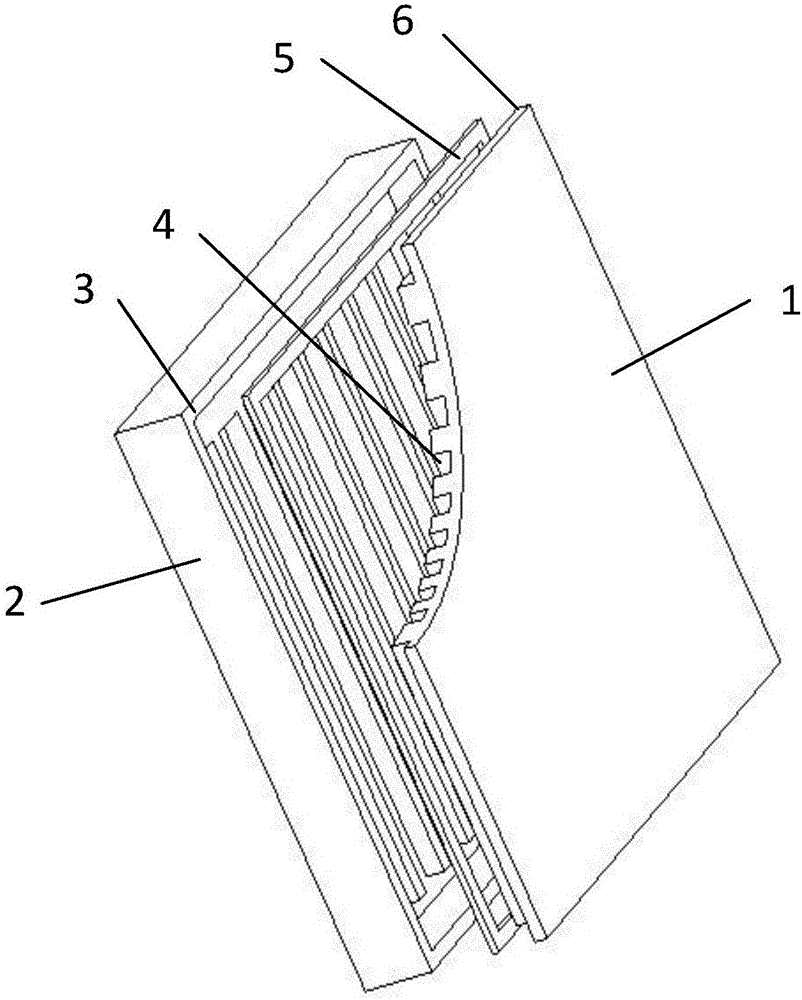

Flat plate type loop heat pipe evaporator and loop heat pipe

InactiveCN106767070AReduce the risk of operational failureEasy to startIndirect heat exchangersInsulation layerMicro-loop heat pipe

The invention discloses a flat plate type loop heat pipe evaporator and a loop heat pipe. The flat pipe type loop heat pipe evaporator comprises an evaporation chamber, a capillary core and a liquid storage chamber. The evaporation chamber communicates with the liquid storage chamber through the capillary core. The inner wall of the liquid storage chamber is covered with a heat insulation layer. The surface of the heat insulation layer is coarsely arranged. By means of the heat insulation layer, the heat transfer resistance produced when heat is transferred from the wall face of the liquid storage chamber to a working medium in the liquid storage chamber is increased, heat leaked to the working medium in the liquid storage chamber through the wall face and the side wall is reduced, the reverse heat conduction effect of the evaporator is reduced, the temperature difference of the two sides of the capillary core is ensured, the start speed of the evaporator is increased, and operation failure of the flat plate type loop heat pipe is avoided; and meanwhile, due to the fact that the surface of the heat insulation layer is coarsely arranged, the capillary effect is formed on the surface of the heat insulation layer, and liquid obtained through condensation can flow back into the liquid storage chamber.

Owner:SHANDONG UNIV

Low heat leak, high torque power shaft for cryogenic machines

InactiveUS7791229B2Reduce heat leakageReduce heat transferMechanical energy handlingCooling/ventillation arrangementFree rotationSuperconducting electric machine

A shaft assembly and method for reducing the heat leak into the cryogenic region of a superconducting electrical machine comprising a rotor shaft extension assembly capable of transmitting large amounts of torque with substantially increased thermal impedance. The shaft assembly contains a plurality of concentric structural cylinders composed of high strength, low thermal conductivity structural materials. The structural cylinders are connected in series by means of welded joints or strong interlocking “finger” connections, in such a way that the coldest cylinder is connected to the cryogenic machine. An optional intermediate heat sink that allows the shaft extension member to rotate freely within the confines of the heat sink further reduces the heat leak into the cryogenic environment. Splined adapter hubs are typically used to connect the cylinder assembly to the rotor of the superconducting machine and the external device.

Owner:GOODZEIT CARL L

Heat leakage test device and usage method thereof

The present invention discloses a heat leakage test device and a usage method thereof. The device concretely comprises a first heat insulation container, a second heat insulation container, a liquid medium source, a gaseous medium source, a liquidometer and a flowmeter. The first heat insulation container is arranged in the second heat insulation container, a valve cover assembly of a low-temperature valve is placed in the second heat insulation container, and the liquid medium source provides a liquid medium to the first heat insulation container; the gaseous medium source provides a gaseousmedium to the first heat insulation container, and the flowmeter is communicated with the first heat insulation container. The heat leakage test device also comprises a temperature sensor used for measuring the temperature of the fluid flowing from the first heat insulation container to the flowmeter and a pressure sensor used for measuring the pressure of the fluid flowing from the first heat insulation container to the flowmeter, and the temperature sensor and the pressure transducer are both connected with a processor and are used for transmitting the detected temperature and pressure signals to the processor for the exchange calculation. The heat leakage test device and the usage method thereof provided by the present invention can effectively test the heat leakage amount of the low-temperature valves.

Owner:JIANGSU CRYOTE CRYOGENIC TECH

Method for eliminating temperature gradient in metal strip sample heat treatment test

InactiveCN100437076CIncrease the lengthEliminates or reduces temperature gradientsPreparing sample for investigationElectrical resistance and conductanceThermodynamics

The invention relates to a method for erasing temperature gradient in mental plate with sample heat treating experiment, which is characterized in that it adds infrared radiation heating means based on the mode of directly using the resistance to heat; it fixes infrared heating apparatus on the two sides of the sample near the clamp, and uses the infrared radiation energy of the infrared heating apparatus to compensate the heat leaked by heat transmitting; it separately controls the directly resistance heating and the infrared radiation heating.

Owner:NORTHEASTERN UNIV LIAONING

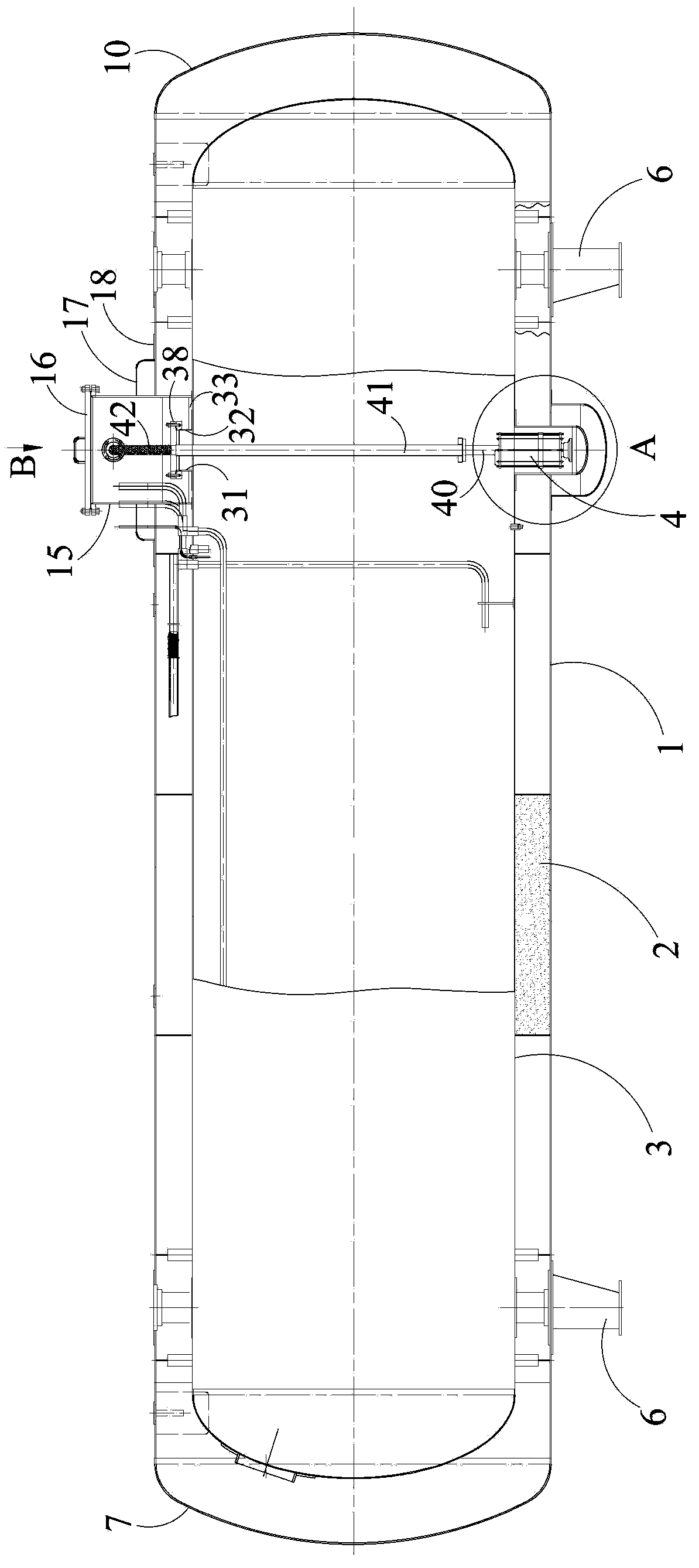

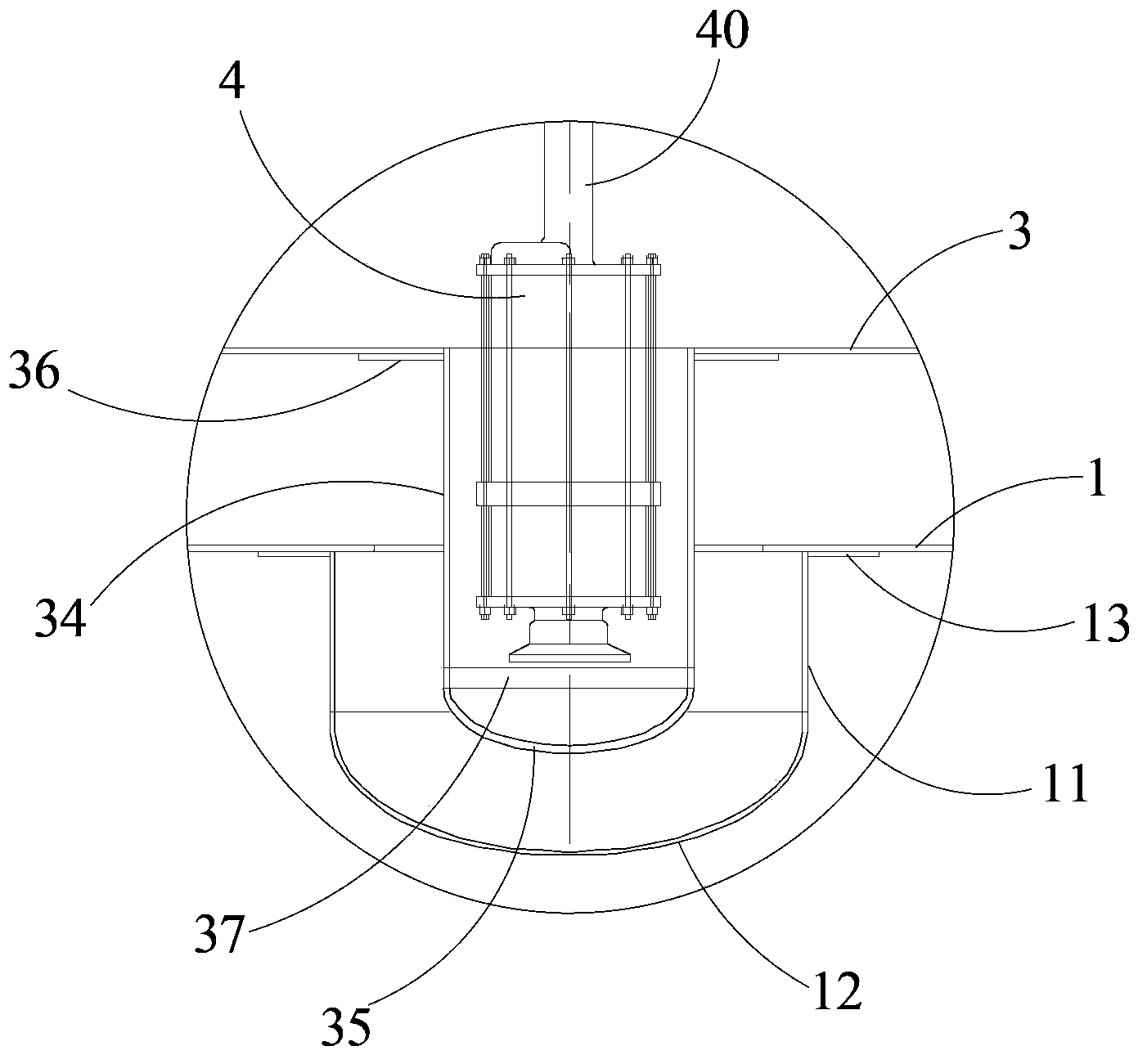

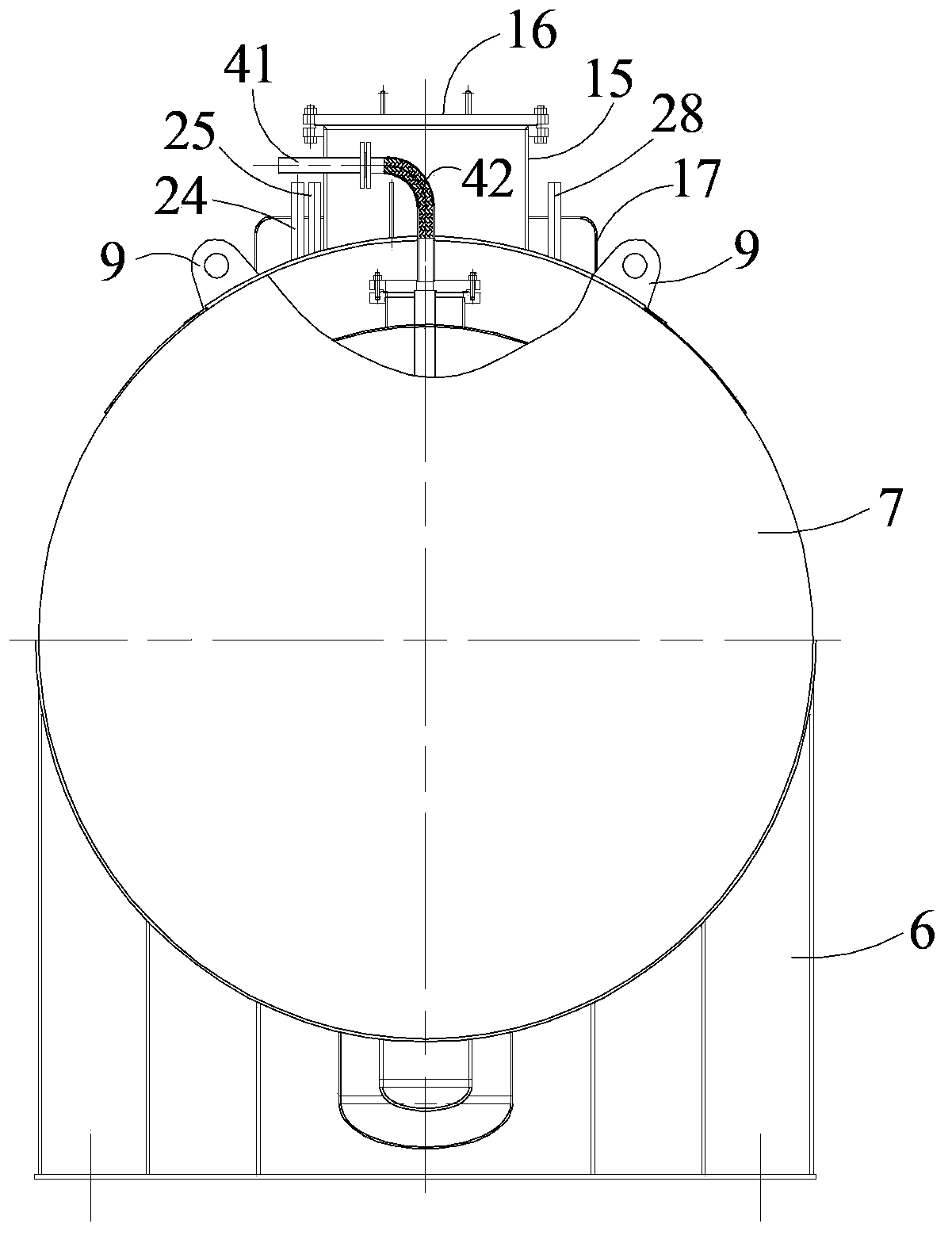

Horizontal double-layer buried storage tank

ActiveCN104235595AImprove low temperature performanceReduce daily evaporation ratePressure vesselsThermal insulationWhole body

The invention provides a horizontal double-layer buried storage tank which comprises an outer container, an inner container, an immersed pump and a drain pipe. The outer container can completely be buried underground; the inner container is arranged inside the outer container; the immersed pump is disposed at the bottom inside the inner container; and one end of the drain pipe is connected with a liquid outlet of the immersed pump and the other end of the drain pipe extends out of the outer container. According to the invention, the outer container can completely be buried underground and the immersed pump is arranged inside the inner container. Thus, the pump and the tank are integrated as a whole and the whole body is buried underground. There is no need to specially build thermal insulation facilities such as a cryogenic pump sump and the like. Therefore, a lot of manpower, material and financial resources are saved. In addition, it is guaranteed that the immersed pump is always in a low-temperature state; heat leak of the cryogenic pump sump is minimized; overall cryogenic property of the storage tank is enhanced; and daily evaporation rate of the storage tank is reduced effectively. Accordingly, it is energy saving and environmentally friendly to use the horizontal double-layer buried storage tank.

Owner:ZHANGJIAGANG CIMC SANCTUM CRYOGENIC EQUIP +2

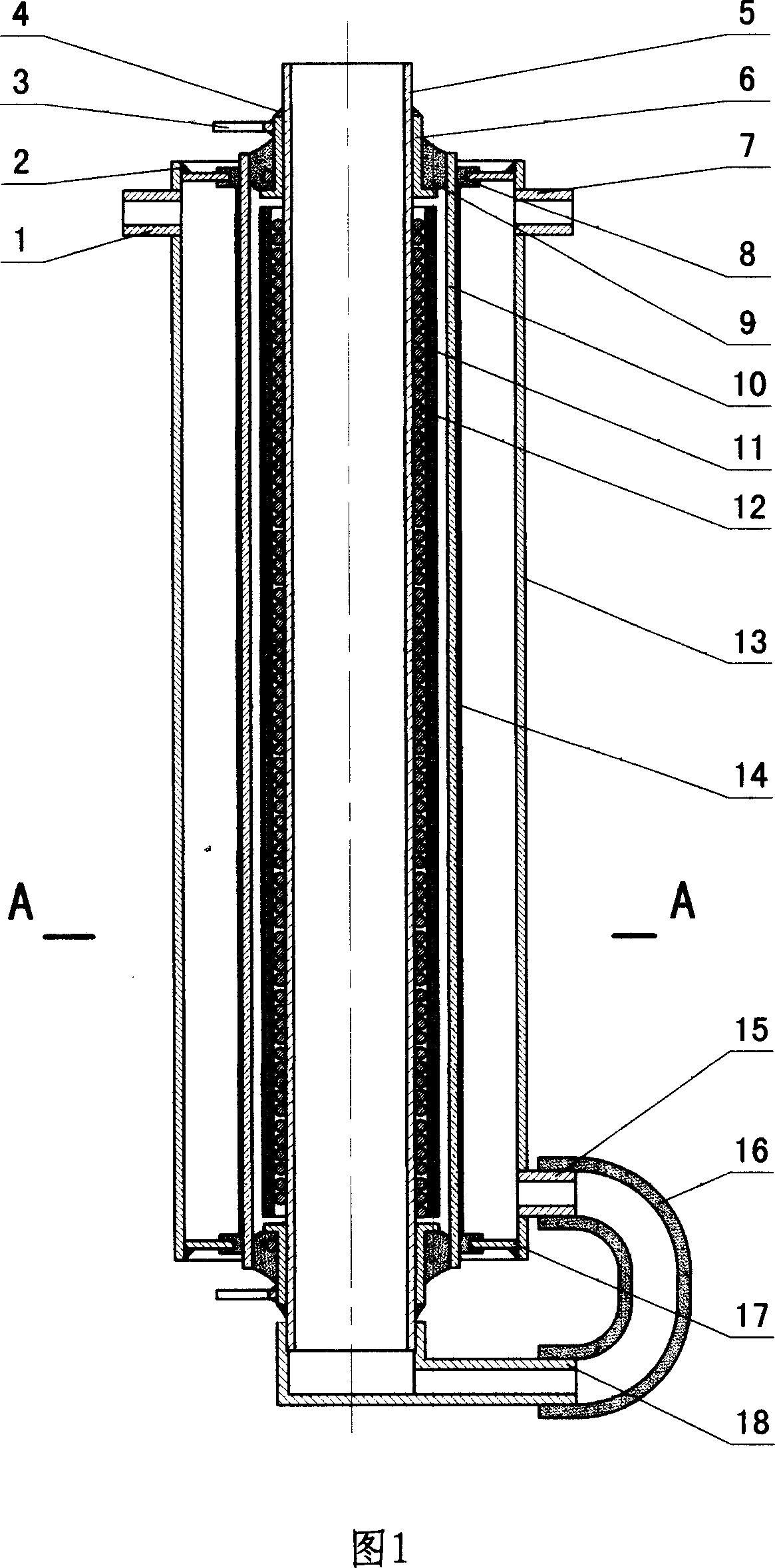

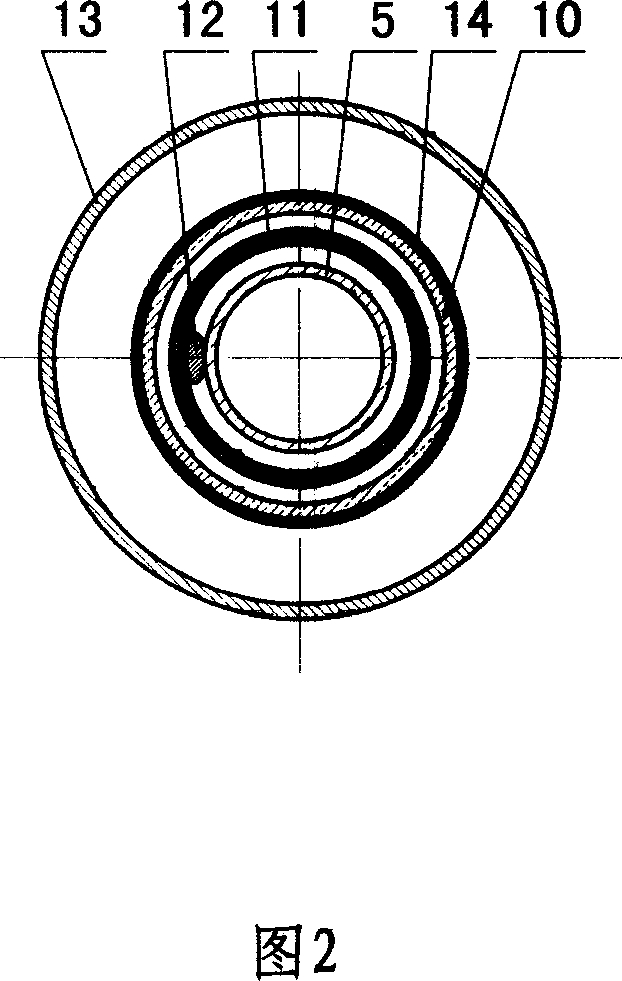

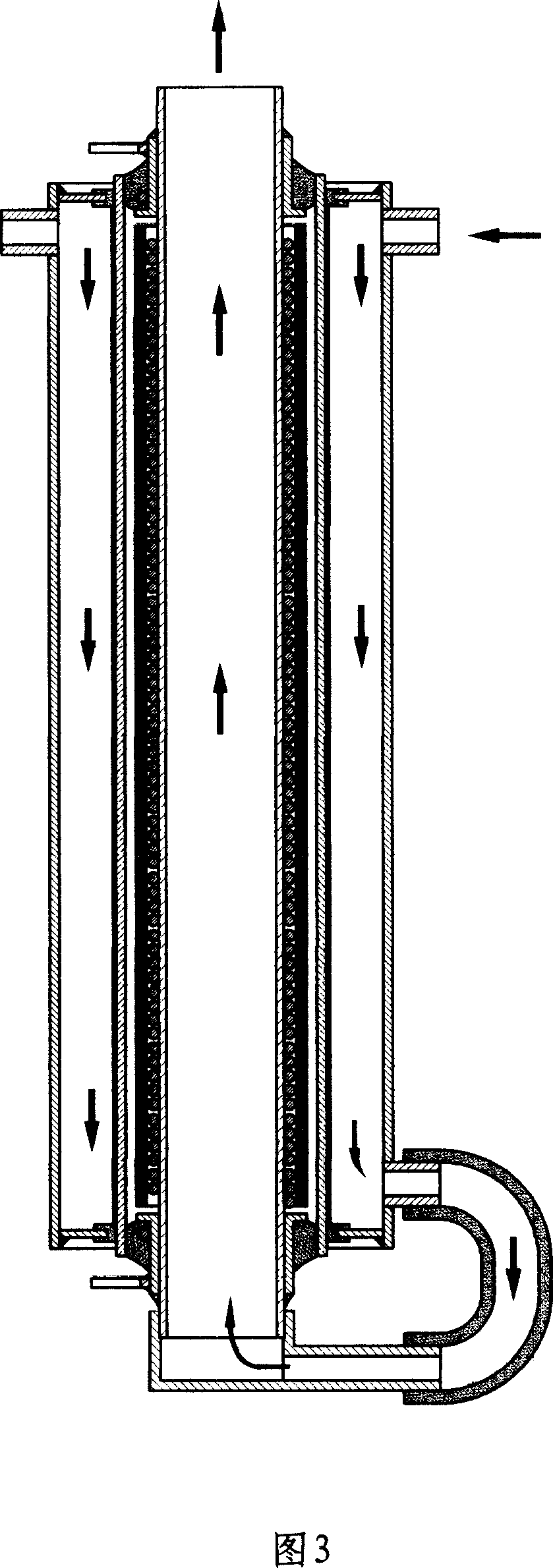

Superconducting cable insulating connecting pipe

InactiveCN103986115AHigh breakdown strengthReduce heat leakageCable fittings for cryogenic cablesCalcium silicateEpoxy

The invention discloses a superconducting cable insulating connecting pipe which comprises an inner core cylindrical liquid nitrogen circulating pipeline. A vacuum layer is arranged outside the liquid nitrogen circulating pipeline. An epoxy resin glass fiber reinforced plastic pipe is arranged outside the vacuum layer. A metal pipe is arranged outside the epoxy resin glass fiber reinforced plastic pipe. One end of the metal pipe is provided with a pipeline interface. A thermal-shrinkage high-pressure busbar insulating bush is arranged outside the metal pipe and evenly provided with a plurality of thermal-shrinkage umbrella shirts. High-potential grading rings are arranged on the two sides of each thermal-shrinkage umbrella shirt. The superconducting cable insulating connecting pipe is characterized in that the vacuum layer is filled with silica aerogel or foam glass plates, and a calcium silicate heat insulating layer is further arranged between the epoxy resin glass fiber reinforced plastic pipe and the metal pipe. It is ensured that less heat leaks when low-temperature cooling medium liquid nitrogen passes through the pipe; furthermore, overall use performance is improved.

Owner:KUNSHAN DAGONG ELECTRONICS

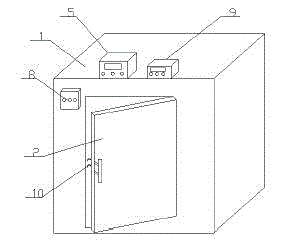

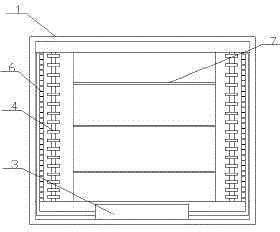

Novel industrial oven

InactiveCN104457148ASave internal spaceEvenly heatedDrying gas arrangementsDrying chambers/containersHeat leakEngineering

The invention discloses a novel industrial oven and relates to the field of machinery. The novel industrial oven comprises an oven body, an oven door, a circulating fan, electric heating components and a temperature controller, wherein the oven door is movably connected with the oven body, the circulating fan is arranged at the bottom of the oven body, the electric heating components are electrically connected with the temperature controller and are arranged on the inner wall of two sides of the oven body, the inner walls of two sides of the oven body are provided with airflow pipelines in the diameter of 1-2mm, and the oven door is provided with a two-point lock catch. The novel industrial oven can effectively transfer heat to materials to be heated uniformly, uniform heating of the materials can be ensured, and the oven door and the oven body are locked in a two-point locking way, so that the oven door and the oven body more firmly contact, and heat leak caused by deformation due to high temperature is avoided.

Owner:上海伟阳纸业有限公司

Engine servo mechanism with heat proof and heat radiation integrated thermal control

InactiveCN108052143AAchieve heat protectionImprove cooling effectTemperatue controlHeat leakEngineering

The invention provides an engine servo mechanism with heat proof and heat radiation integrated thermal control; the engine servo mechanism comprises a thermal control coating, a multilayer, heaters and thermistors; one side, far away from the engine, of a servo mechanism is a heat radiation surface, and the heat radiation surface employs the thermal control coating; one side, facing the engine, ofthe servo mechanism is wrapped by the multilayer so as to provide heat leak and thermal protection functions; a main heater and a backup heater are bonded on the surface of the servo mechanism so asto make temperature compensating control, and a main thermistor and a backup thermistor are bonded to serve as temperature measurement and control points; the servo mechanism and the engine mounting surface are installed in a heat insulation manner. The engine servo mechanism thermal protection and heat radiation integrated thermal control can be realized, thus providing temperature compensating control in on-orbit long term storage, realizing massive heat diffusion in short term working, providing high temperature thermal protection in engine working, and solving the multiple difficult thermal control problems that the servo mechanism faces under different work modes and thermal environments, such as long term standby, short time working and engine high temperature influences.

Owner:SHANGHAI SATELLITE ENG INST

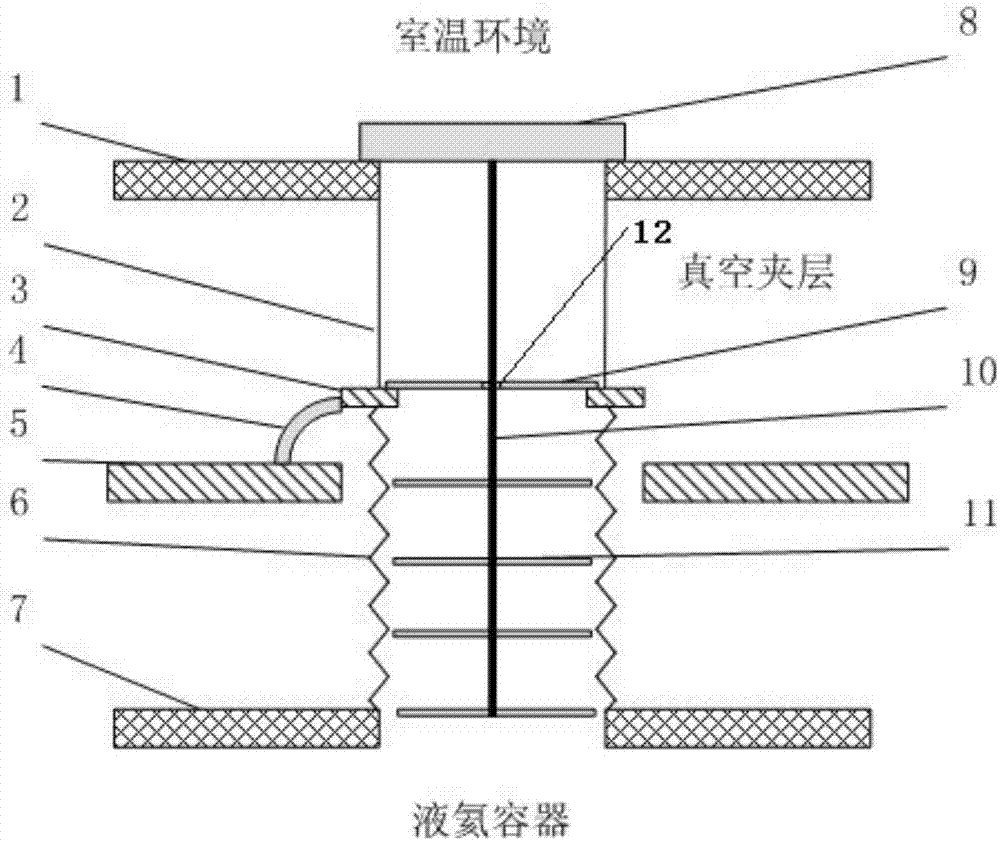

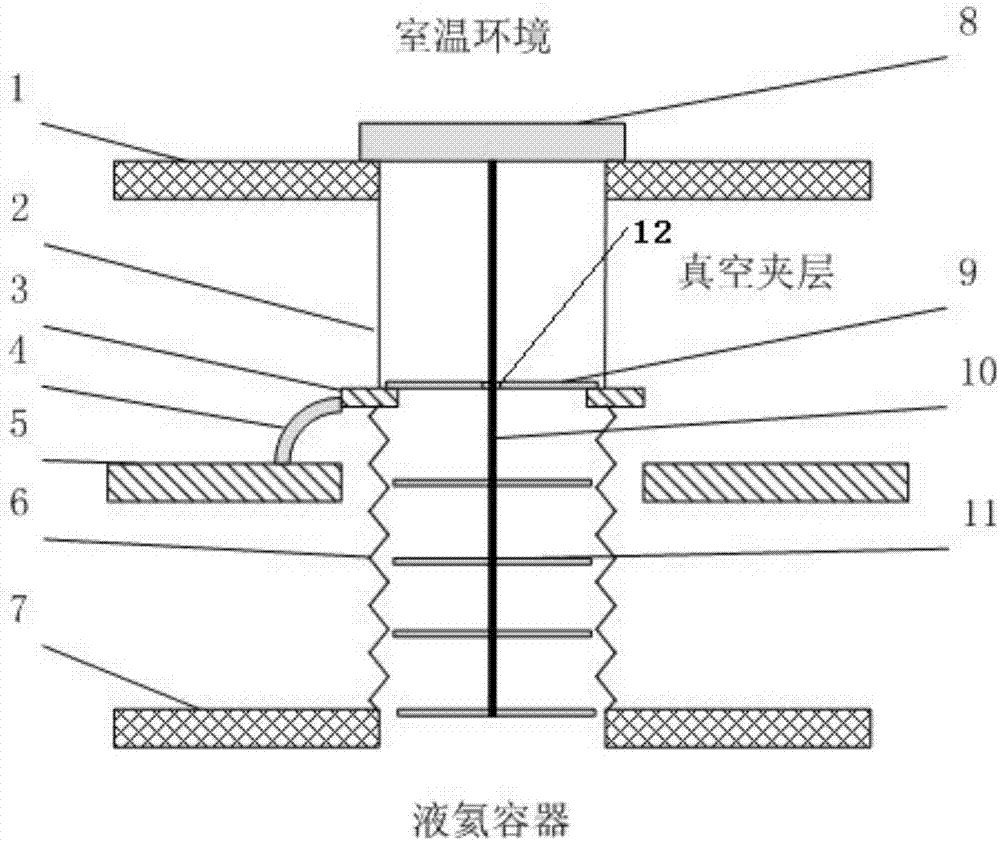

Helium channel structure used for connecting liquid nitrogen temperature region and normal temperature region

PendingCN107978414AReduce heat leakageAvoid direct conductionDomestic cooling apparatusLighting and heating apparatusLiquid nitrogen containerHeat conducting

The invention discloses a helium channel structure used for connecting a liquid nitrogen temperature region and a normal temperature region. The helium channel structure comprises a helium channel component and a channel interior thermal insulation component, and a heat conducting path from a normal temperature end to a low temperature end is transferred onto a cold shield, so that heat leakage ofa liquid nitrogen container is reduced; a solid conducts leaked heat, namely heat is conducted onto a heat sink from a room temperature end, and the heat sink conducts the heat to the cold shield ofa low temperature superconducting magnetic system by virtue of a heat conducting connecting piece; the leaked heat is radiated, wherein a heat cut-off light barrier in the channel interior thermal insulation component is contacted with the heat sink in a helium channel, and a high temperature surface of the leaked heat radiated by liquid helium can turn into the heat cut-off light barrier from a room temperature flange surface and is above a light barrier, so that the leaked heat radiated in the channel is greatly reduced; and a gas conducts the leaked heat, namely a high temperature end of heat leaked by helium gas also becomes the heat cut-off light barrier from a room temperature surface, so that the heat leaked by the gas in the channel is greatly reduced.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

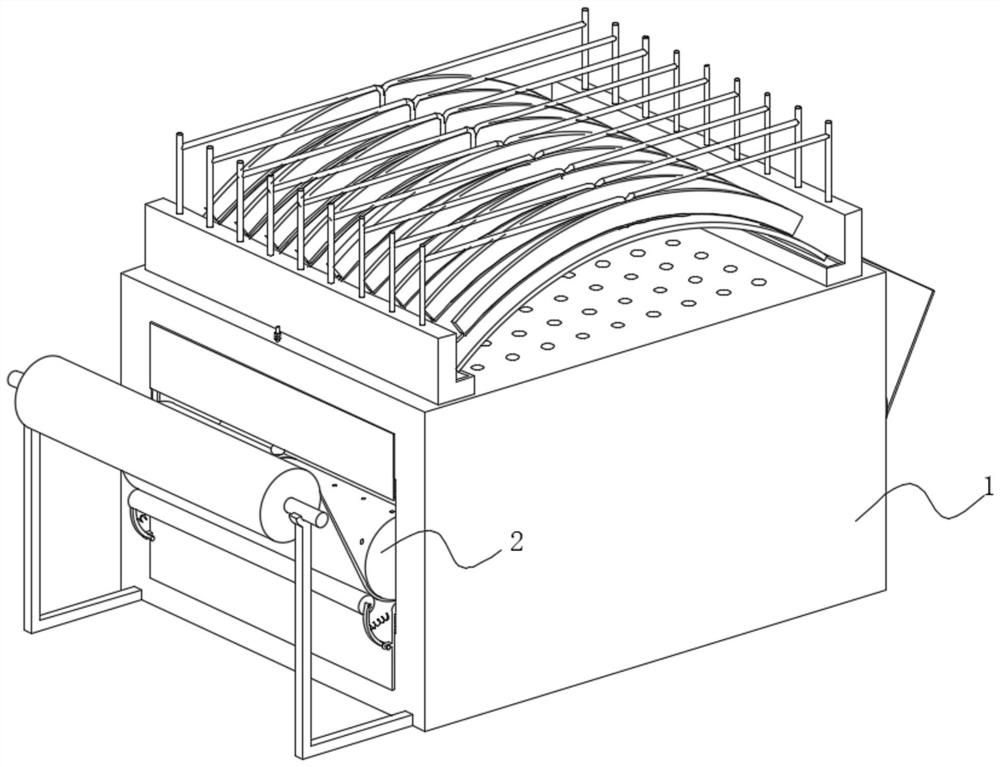

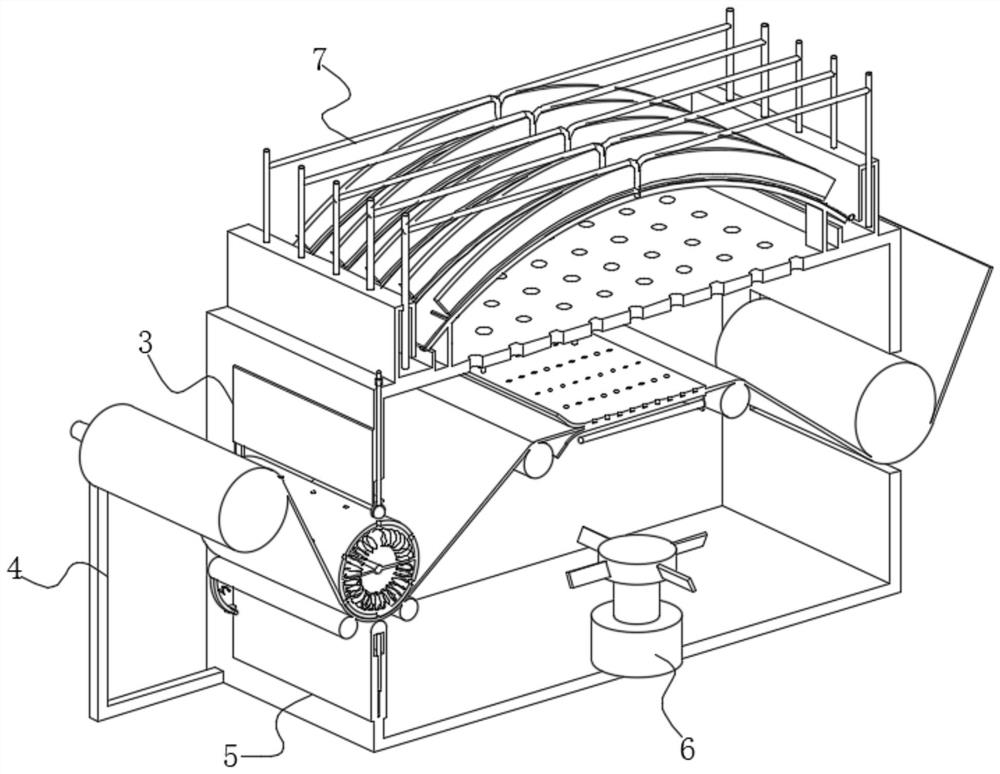

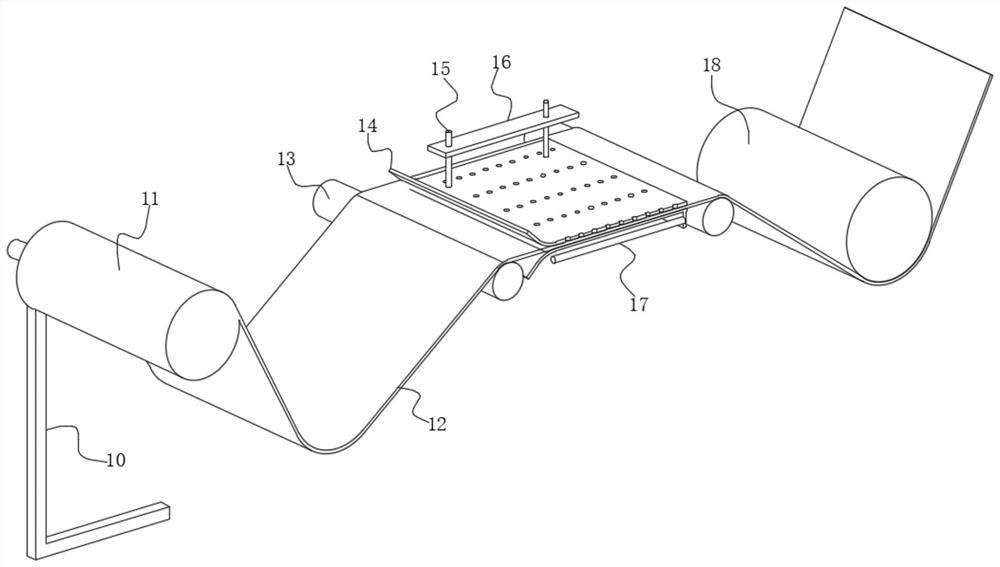

Drying and dehumidifying device for chemical fiber spinning

ActiveCN114279195AEvenly dispersedImprove drying effectTextile/flexible product manufactureDrying machines with progressive movementsChemical fiber clothHeat leak

The drying and dehumidifying device for chemical fiber spinning comprises a machine body, the inner surface of the machine body is rotationally connected with a preheating device, the top of the preheating device is provided with a top sealing device, the lower surface of the preheating device is rotationally connected with a feeding device, and the bottom of the feeding device is movably connected with a bottom sealing device. The invention relates to the technical field of chemical fibers. According to the drying and dehumidifying device for chemical fiber spinning, by arranging the top sealing device, when the device is used, the tightness degree of chemical fiber cloth can be adjusted by adjusting the position of a preheating device up and down, at the moment, a screw rotates, a sealing plate moves along with movement of the screw, and a ball head clamps a ball to prevent falling; the lower surfaces of the balls are always kept in contact with the upper surface of the preheating device, the balls and the preheating device rotate relatively, under the influence of the sealing plate, a gap generated at the top is effectively reduced when the preheating device is adjusted up and down, and the problem that internal heat leaks easily when traditional drying equipment is adjusted is solved.

Owner:宿迁至诚纺织品股份有限公司

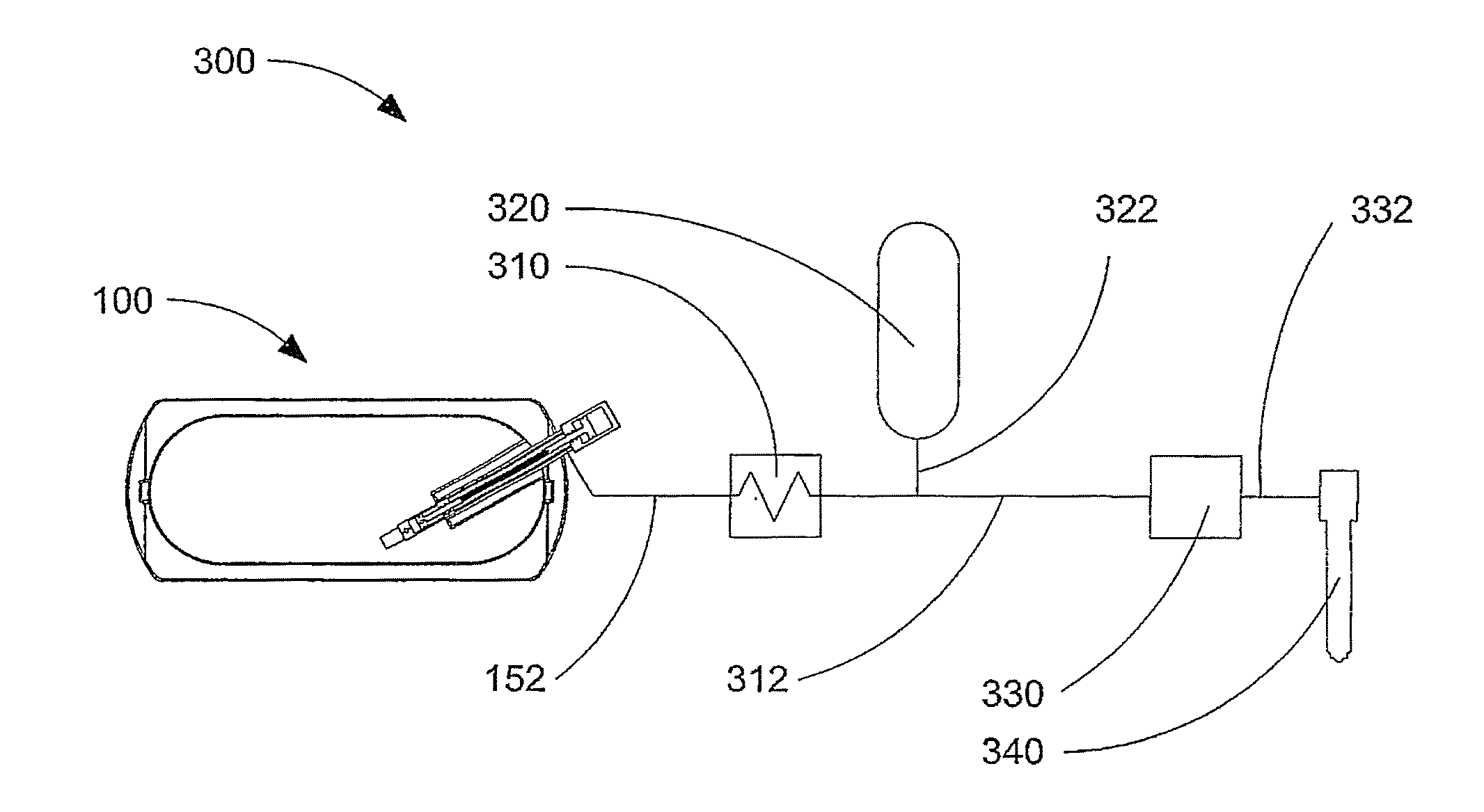

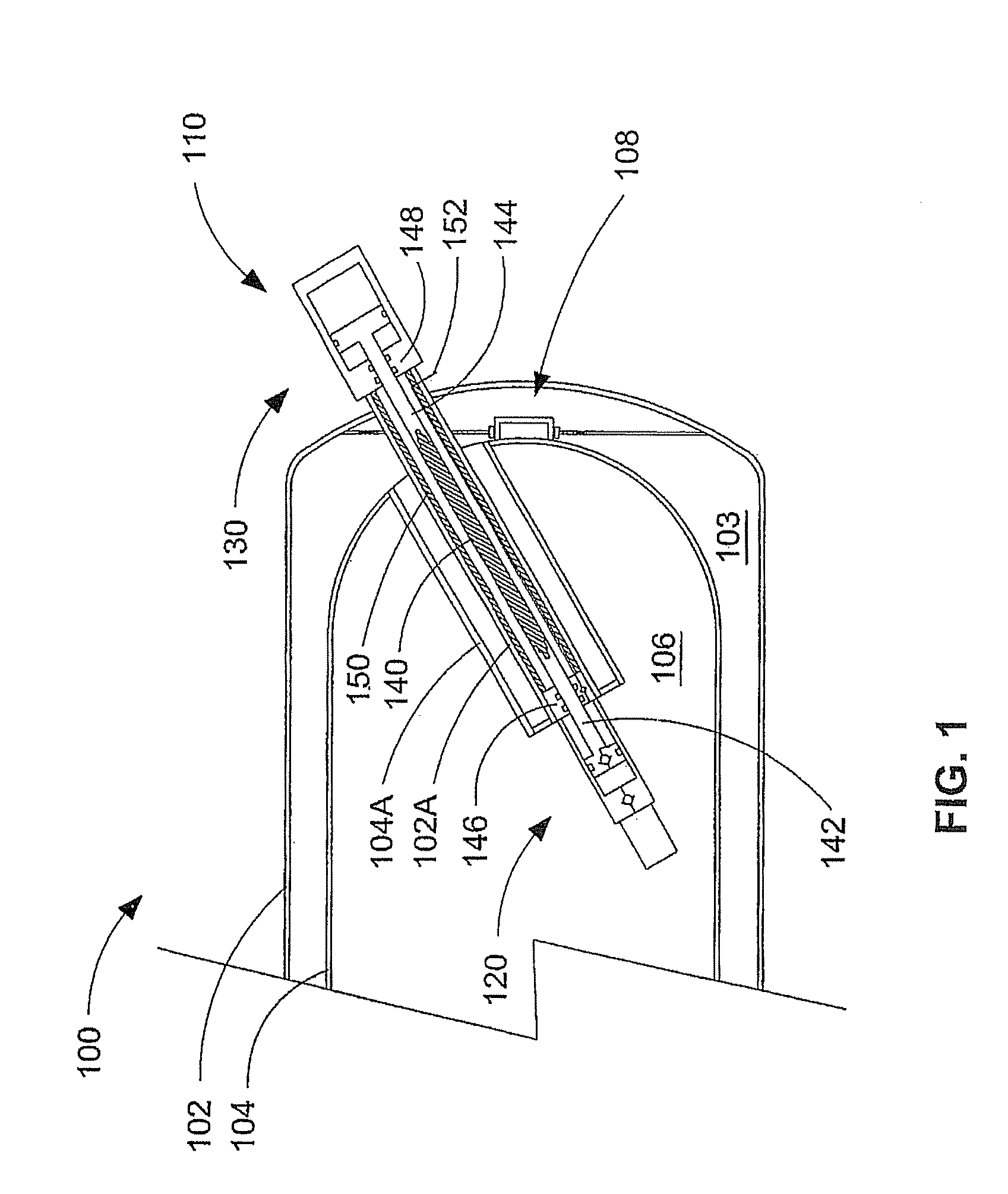

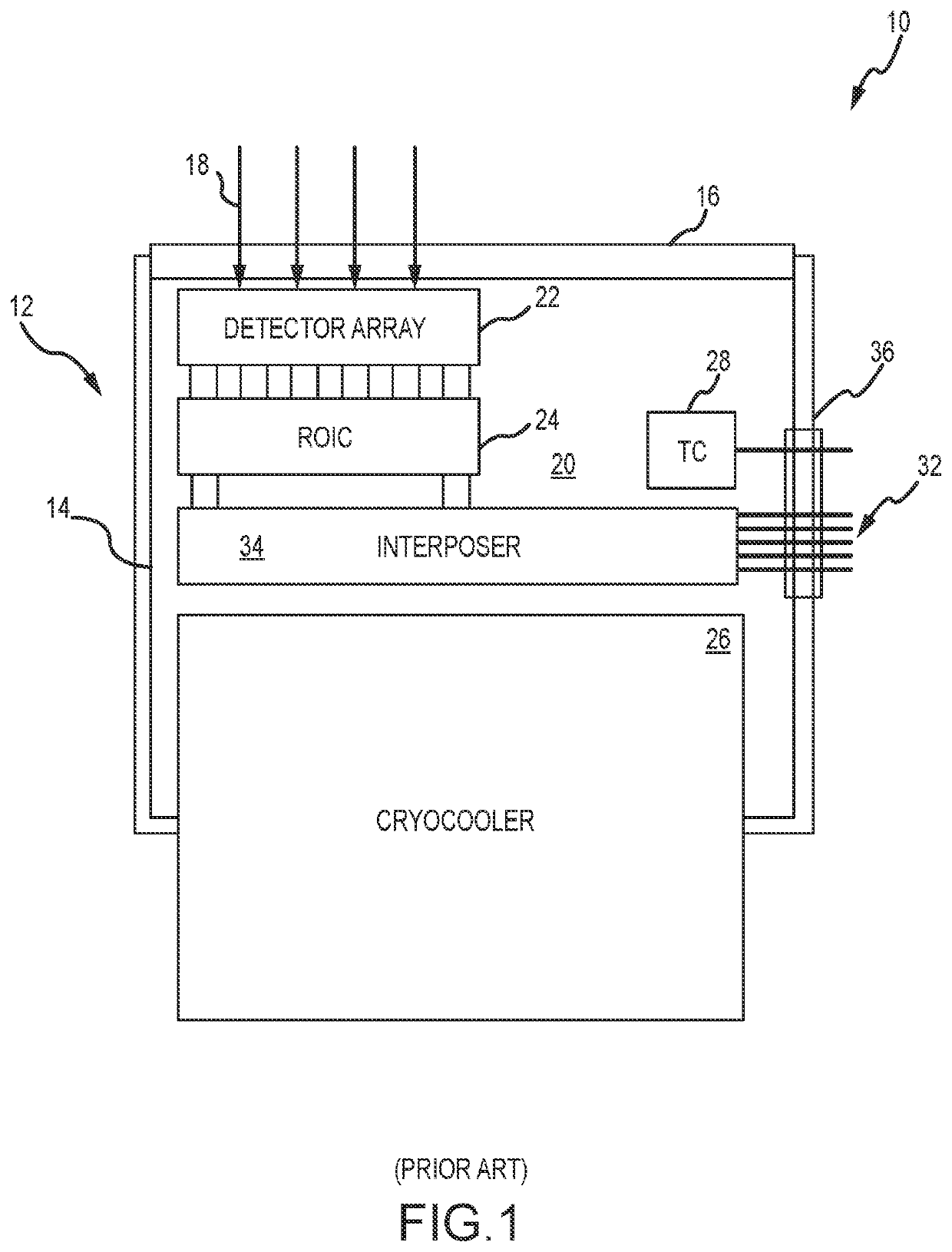

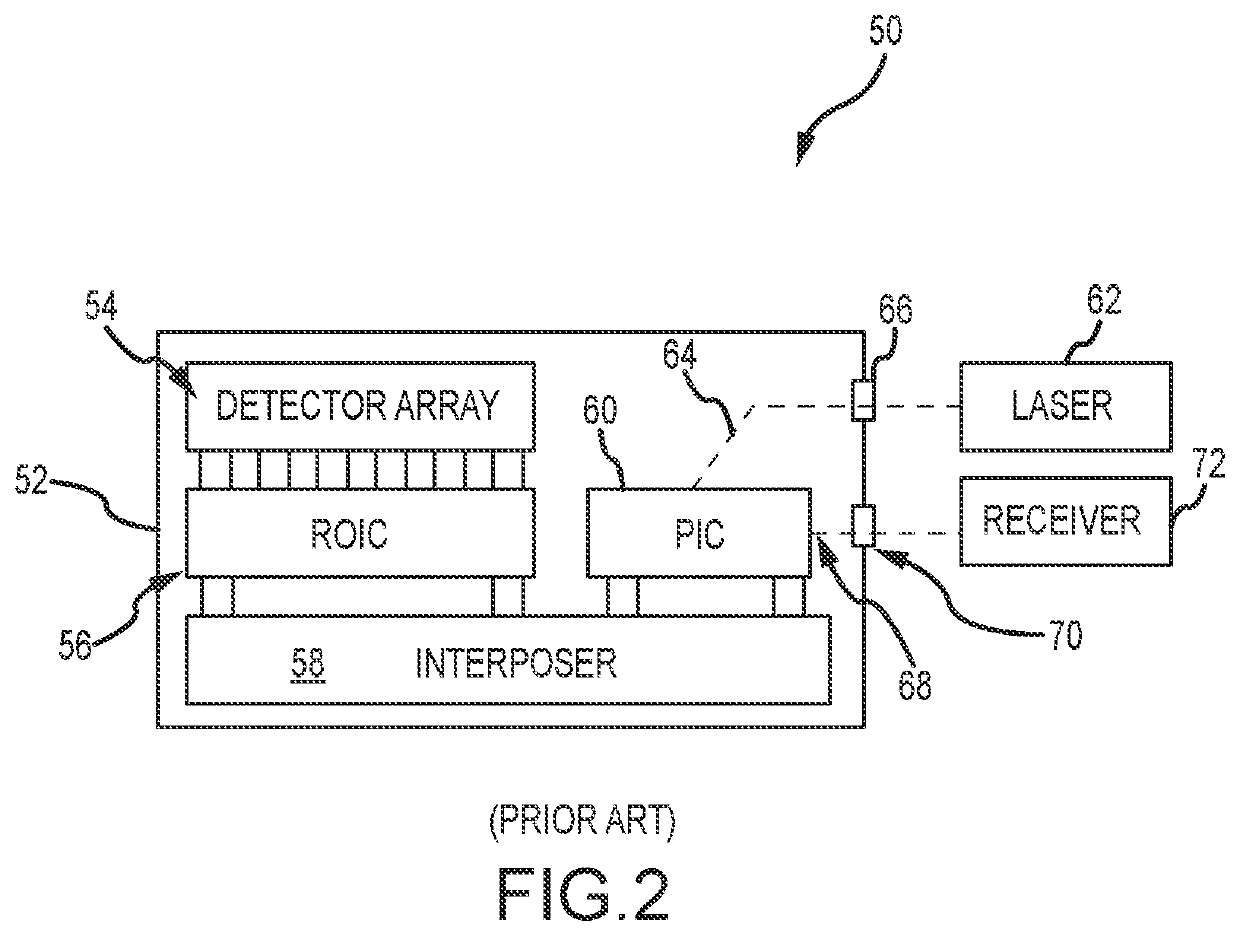

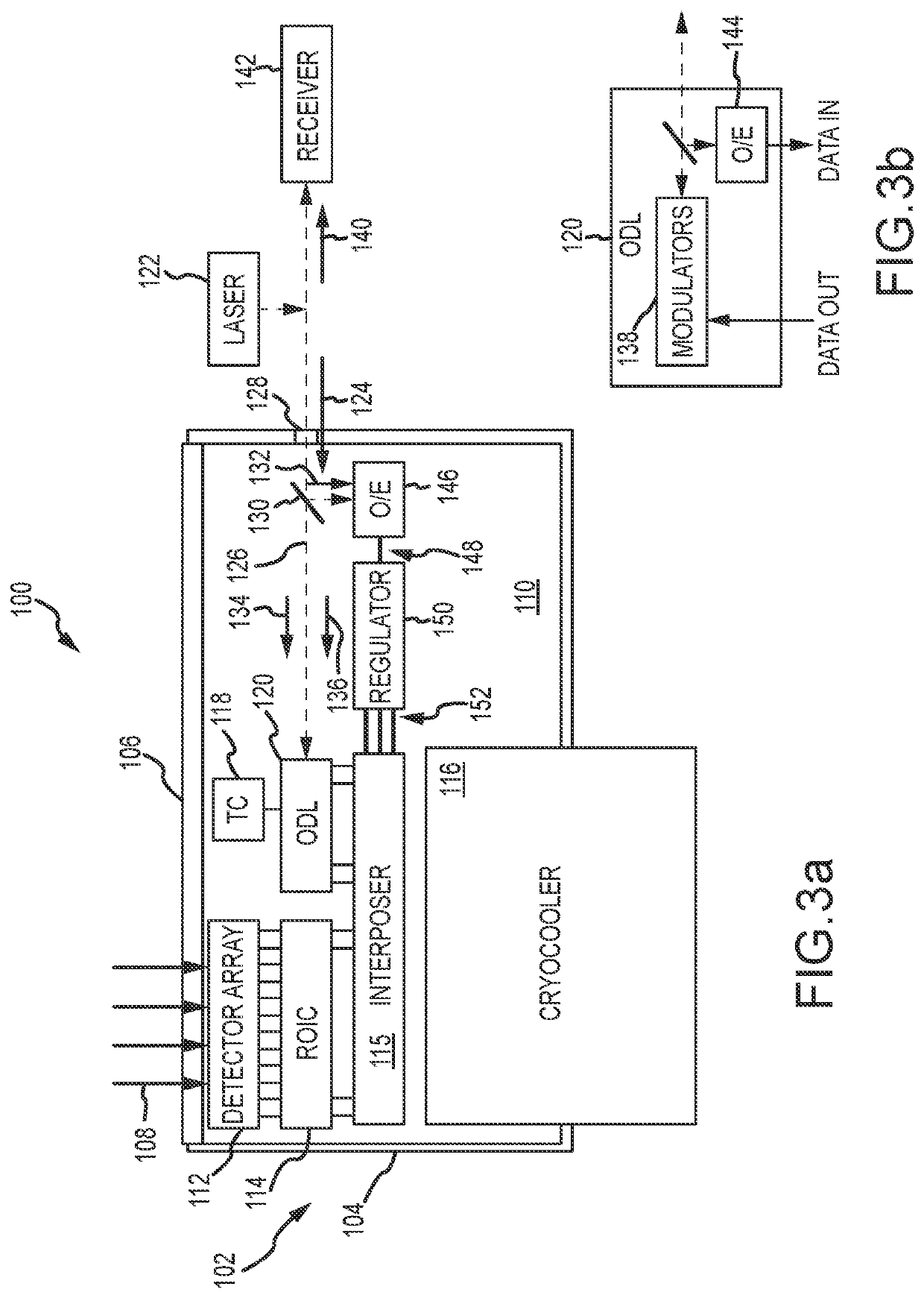

Optically powered cryogenic focal plane array (FPA) with an optical data link

ActiveUS11333557B2Eliminating electrical penetrationReduce heat leakageCompression machinesElectromagnetic transmission optical aspectsConvertersCopper wire

An optically powered cryogenic FPA with an optical data link eliminates electrical penetrations of the cryogenic chamber for power delivery thereby reducing heat leaks into the cold volume by copper wires and EMI. An optical splitter receives and separates an optical input signal into an optical carrier signal, an optical Data IN signal and an optical power signal. An optical-to-electrical (O / E) converter converts the optical power signal into an electrical power signal, which is converted into a plurality of DC voltage signals to supply power within the chamber. An optical data link modulates the optical carrier signal with electrical signals from the ROIC to form and output an optical Data OUT signal.

Owner:RAYTHEON CO

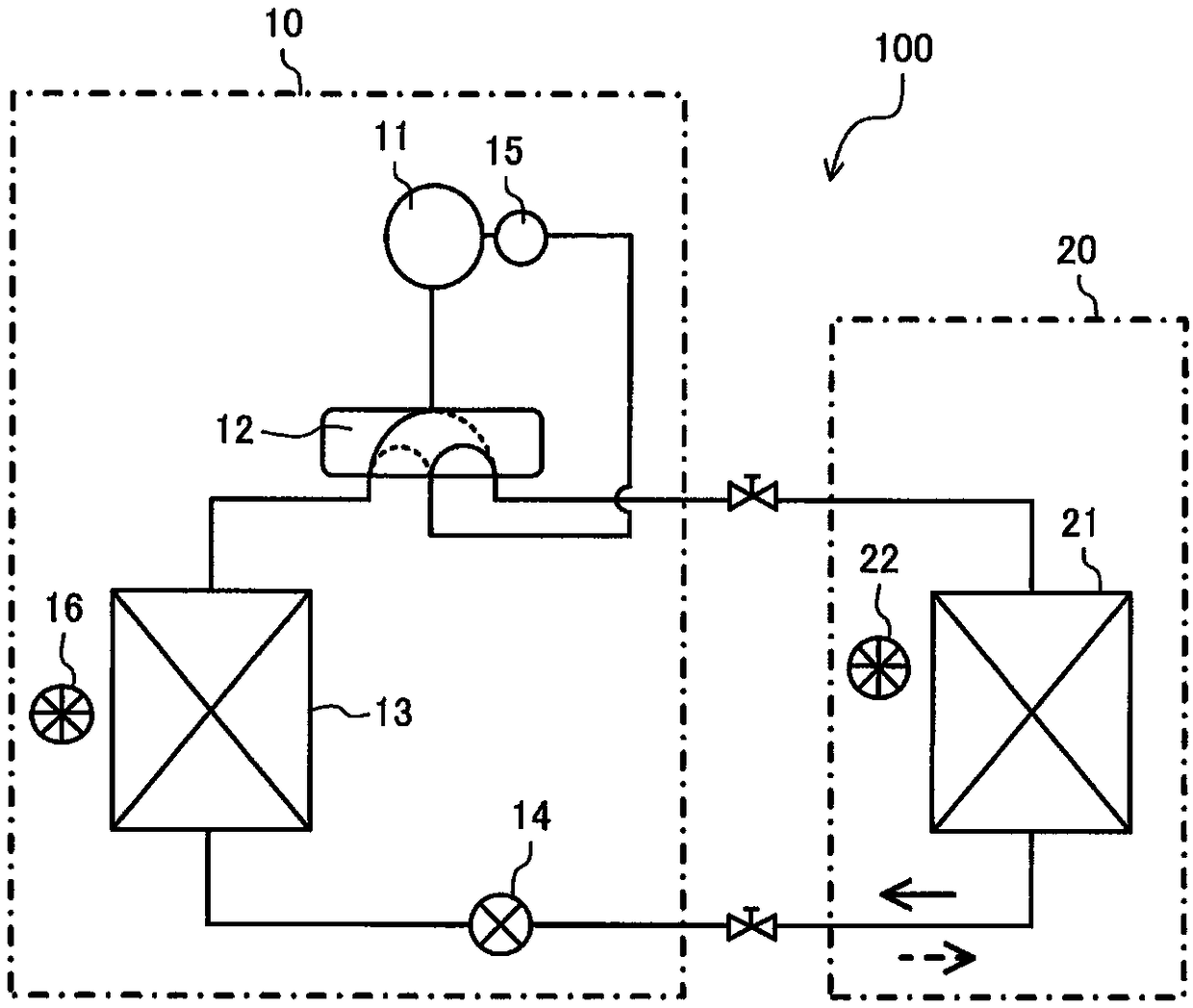

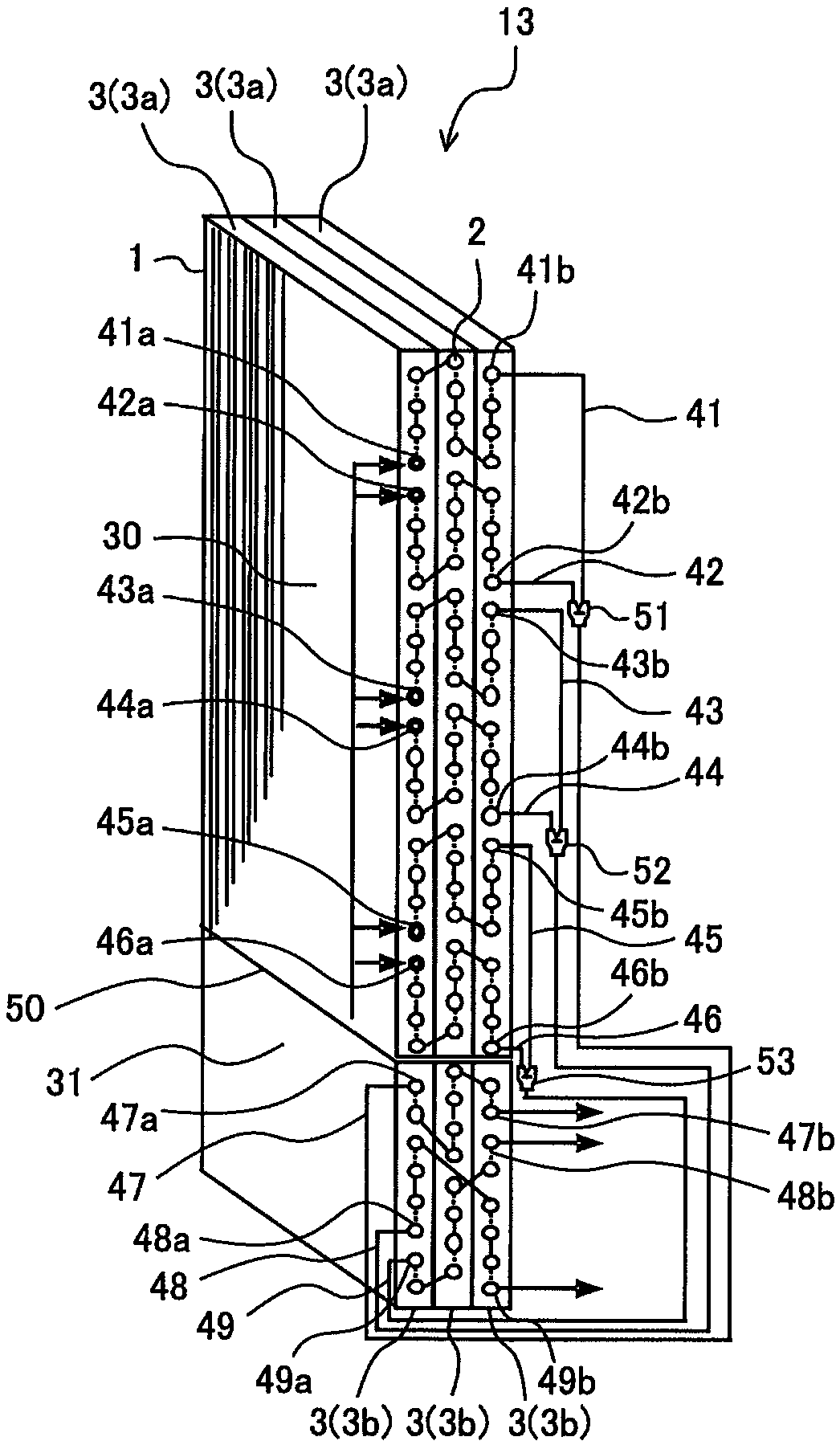

Heat exchanger and refrigeration cycle device provided with heat exchanger

ActiveCN109477669AReduce heat leakageEvaporators/condensersCompression machines with several condensersHeat leakEngineering

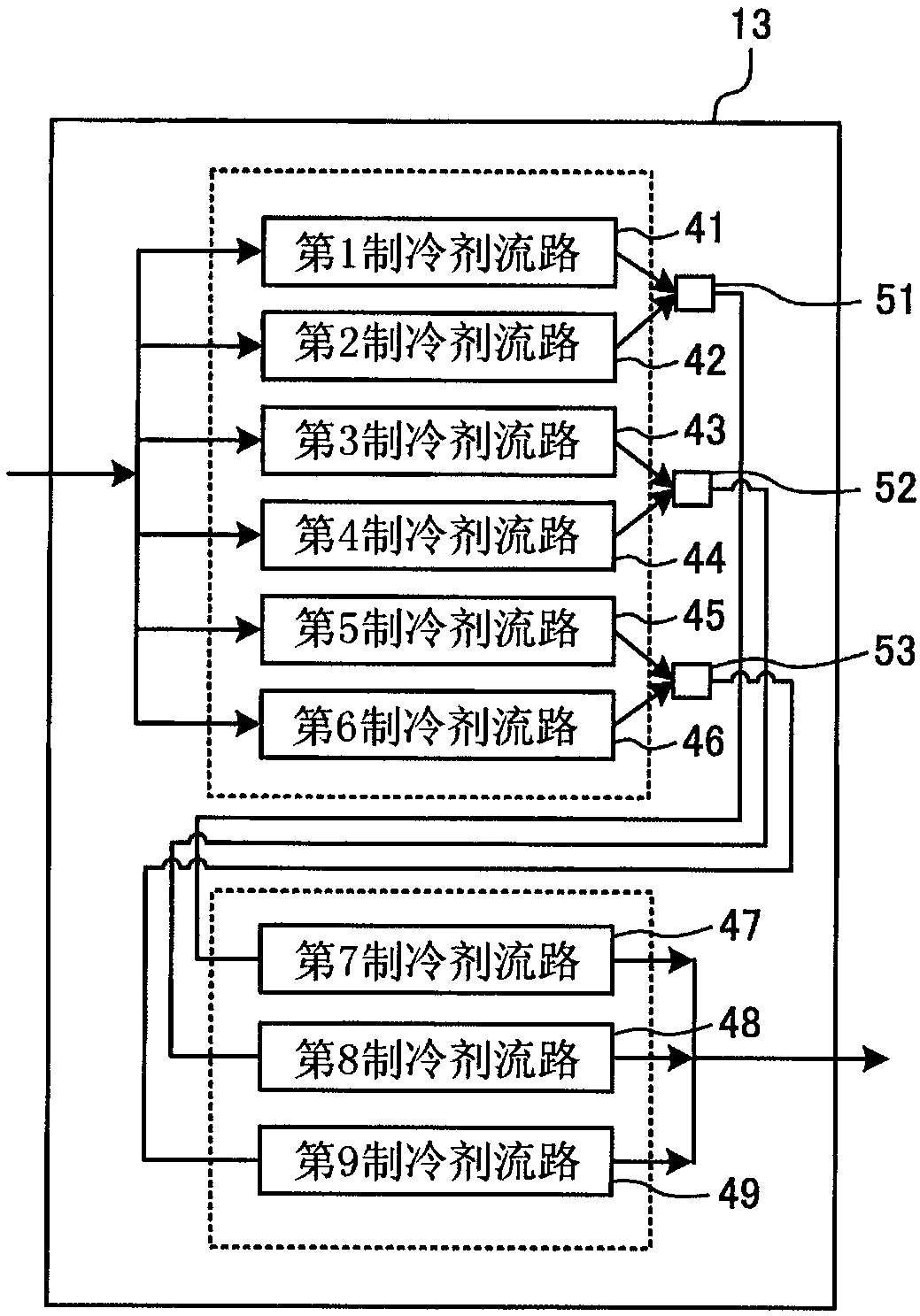

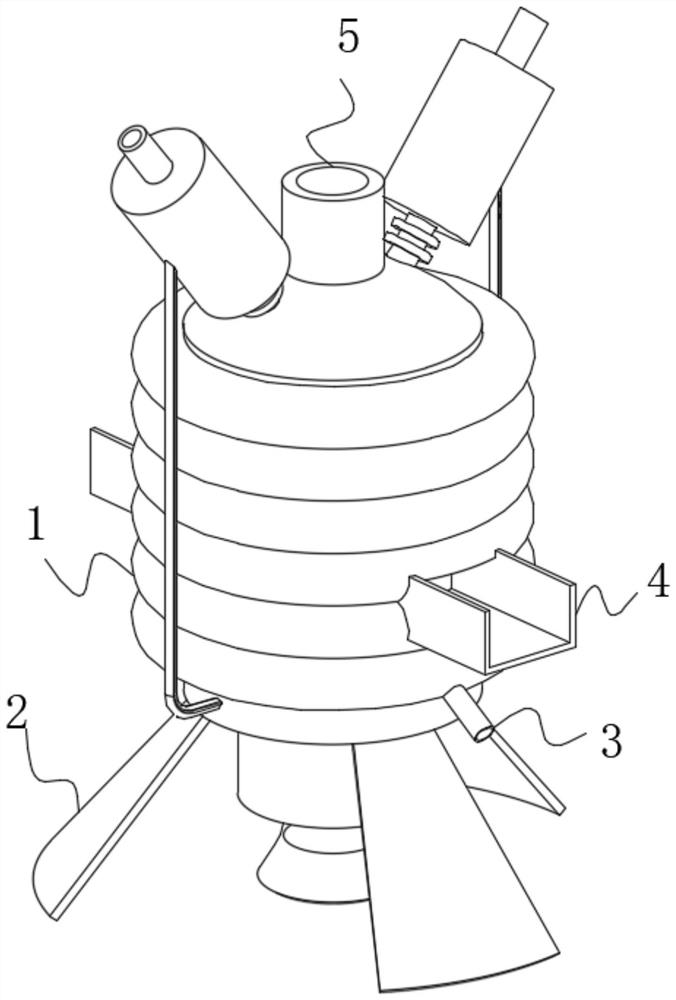

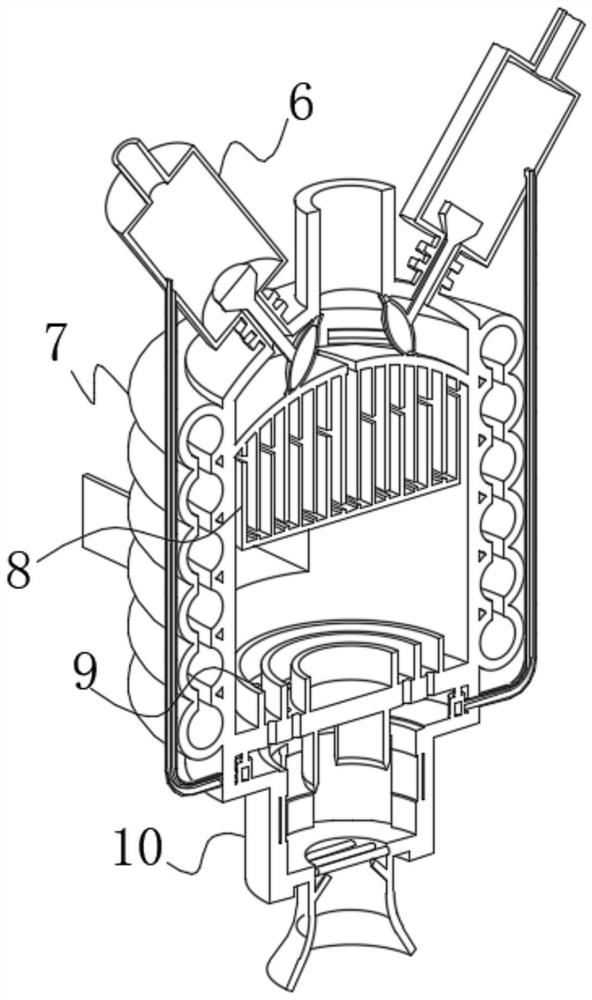

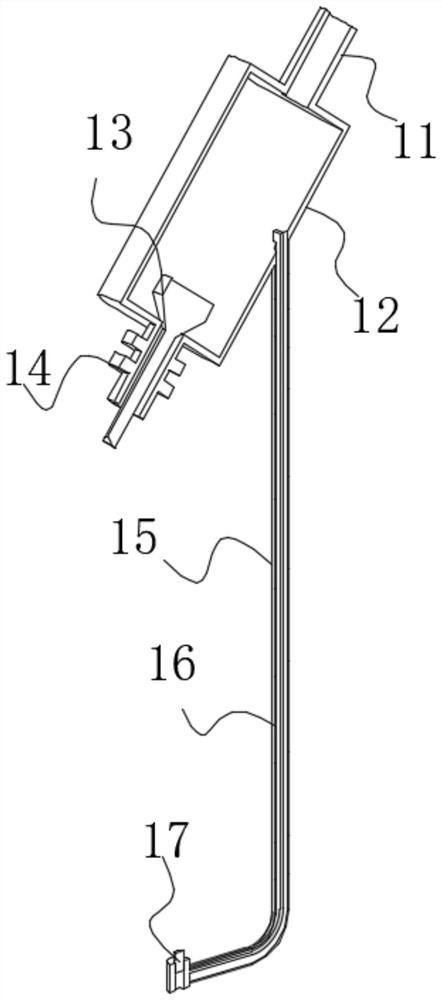

The purpose of the invention is to provide a heat exchanger and a refrigeration cycle device provided with the heat exchanger that can reduce heat leaks inside a condenser when the heat exchanger functions as a condenser. Provided is a heat exchanger (13) having a plurality of refrigerant channels, wherein each of the plurality of refrigerant channels is a channel from which a refrigerant that flowed in as a gas flows out as a liquid, and each has an upstream-side channel (41-46) through which a gas refrigerant and a gas-liquid two-phase refrigerant pass and a downstream-side channel (47-49) through which a gas-liquid two-phase refrigerant and a liquid refrigerant pass. In addition, the heat exchanger comprises an upstream-side heat exchanger (30) having the upstream-side channel, a downstream-side heat exchanger (31) having the downstream-side channel, and one or more merging devices (51-53) that merge refrigerant flowing out of each upstream-side channel and causes same to flow intothe downstream-side channel, wherein the upstream-side heat exchanger and the downstream-side heat exchanger are configured to be separate from each other, and the number of downstream-side channels is less than the number of upstream-side channels.

Owner:MITSUBISHI ELECTRIC CORP

Waste heat utilization energy-saving smelting furnace

InactiveCN113624007ASolve resource problemsSolve environmental pollutionIncreasing energy efficiencyCrucible furnacesHeat leakWater circulation

The invention belongs to the field of energy conservation of smelting furnaces, and particularly relates to a waste heat utilization energy-saving smelting furnace, which comprises a furnace body; and base is fixedly connected to the lower surface of the furnace body, and a blow-off pipe is arranged at the top of the base. According to the waste heat utilization energy-saving smelting furnace provided by the invention, by arranging a water circulation mechanism, when equipment is used, cooling water is injected into a water tank through a water injection pipe, a heat absorption mechanism ejects open a one-way valve along with rising of the temperature in the equipment, and the cooling water flows into a heat absorption mechanism from a ceramic heat insulation pipe and flows into a heat preservation pipe through the heat absorption mechanism, the other part of cooling water downwards flows to the top end of a telescopic rod along a backflow pipe, the telescopic rod extends, the expansion density of hot water in the telescopic rod is reduced and the hot water upwards flows along with the rising of the water temperature, and the cold water downwards flows on the contrary, the movement of the telescopic rod is controlled through residual heat leaked by the device according to the principle of thermal expansion and cold contraction, and then the work of a supporting mechanism is controlled, the problems that waste heat of a traditional smelting furnace is directly discharged outwards, and resource waste and environmental pollution are easily caused are solved.

Owner:王超

Construction method of heat pipeline

InactiveCN111550606AStable deliveryAvoid lostPipe supportsThermal insulationHeat transmissionHeat Avoidance

The invention provides a construction method of a heat pipeline. The construction method includes the specific steps that S1, multiple groups of pipeline supports are arranged along the two sides of the to-be-erected heat pipeline at intervals, and a pipeline bracket for supporting the heat pipeline is fixed between each group of pipeline supports; S2, the to-be-erected heat pipeline is subjectedto heat insulating pretreatment; S3, the heat pipeline is hoisted to the pipeline brackets of the pipeline supports through hoisting equipment and is mounted; and S4, after being mounted, the heat pipeline is subjected to pressure water testing, the heat pipeline is subjected to leakage detection, if it is detected that heat leaks, leakage portions need to be overhauled again, and if it is detected that no heat leaks, construction of the whole heat pipeline is completed. The measure of heat insulating pretreatment is carried out before the pipeline is laid, the heat pipeline can be subjected to heat insulating and heat replenishing, heat transmission of the heat pipeline is guaranteed, leakage of the heat pipeline can be detected in time, and heat losses are avoided from the source.

Owner:TIANJIN ZHENJIN ENG GRP

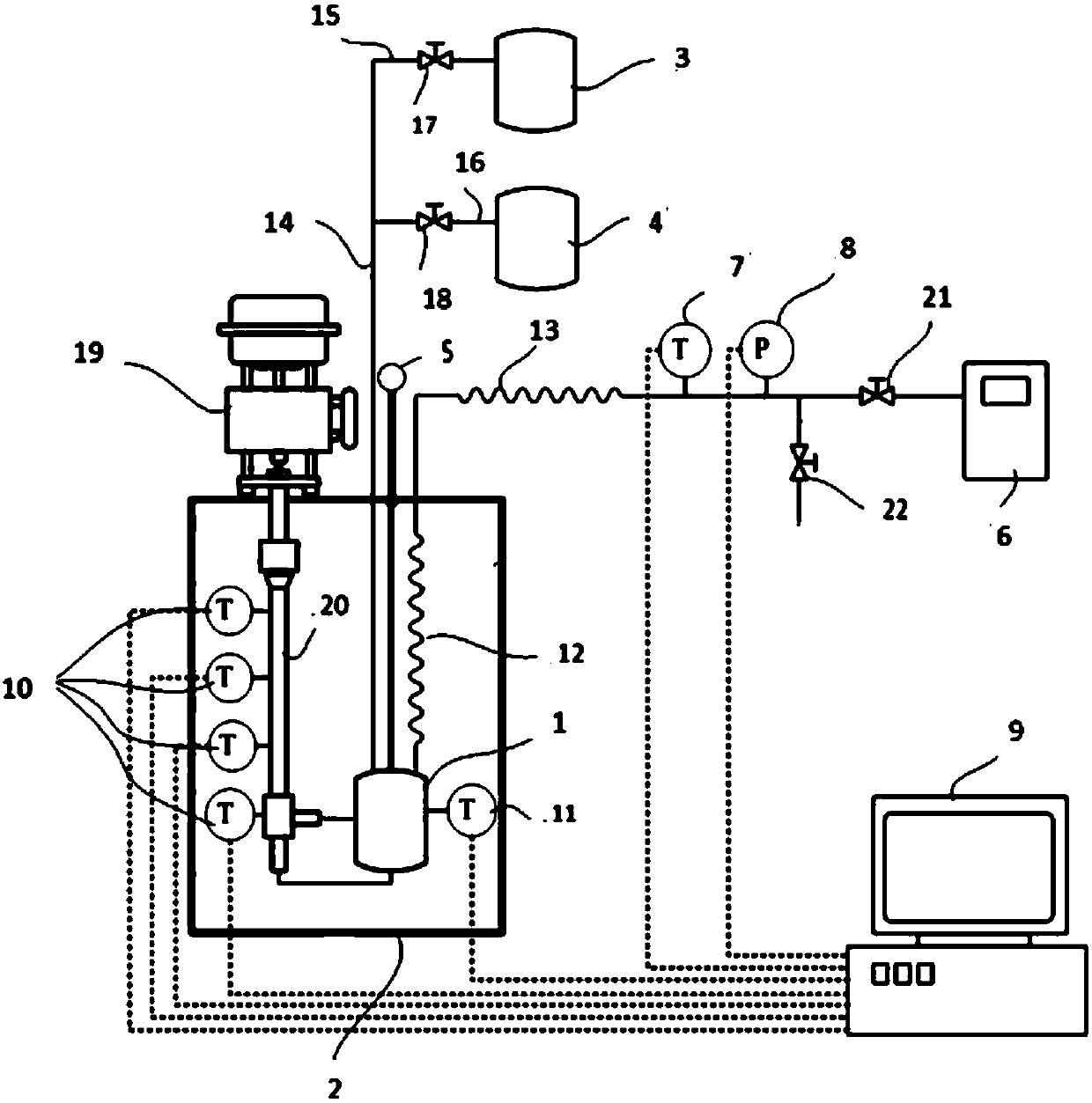

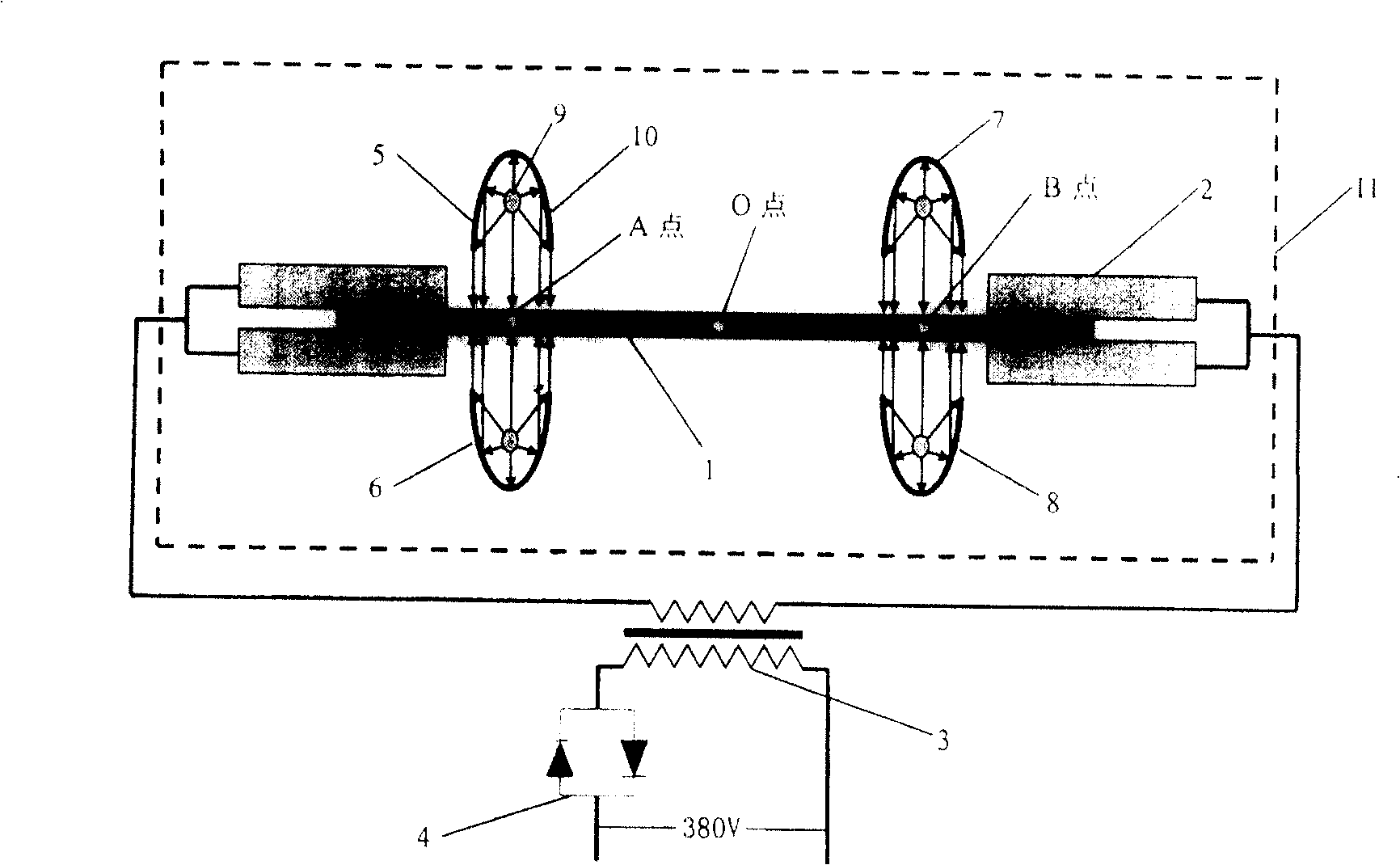

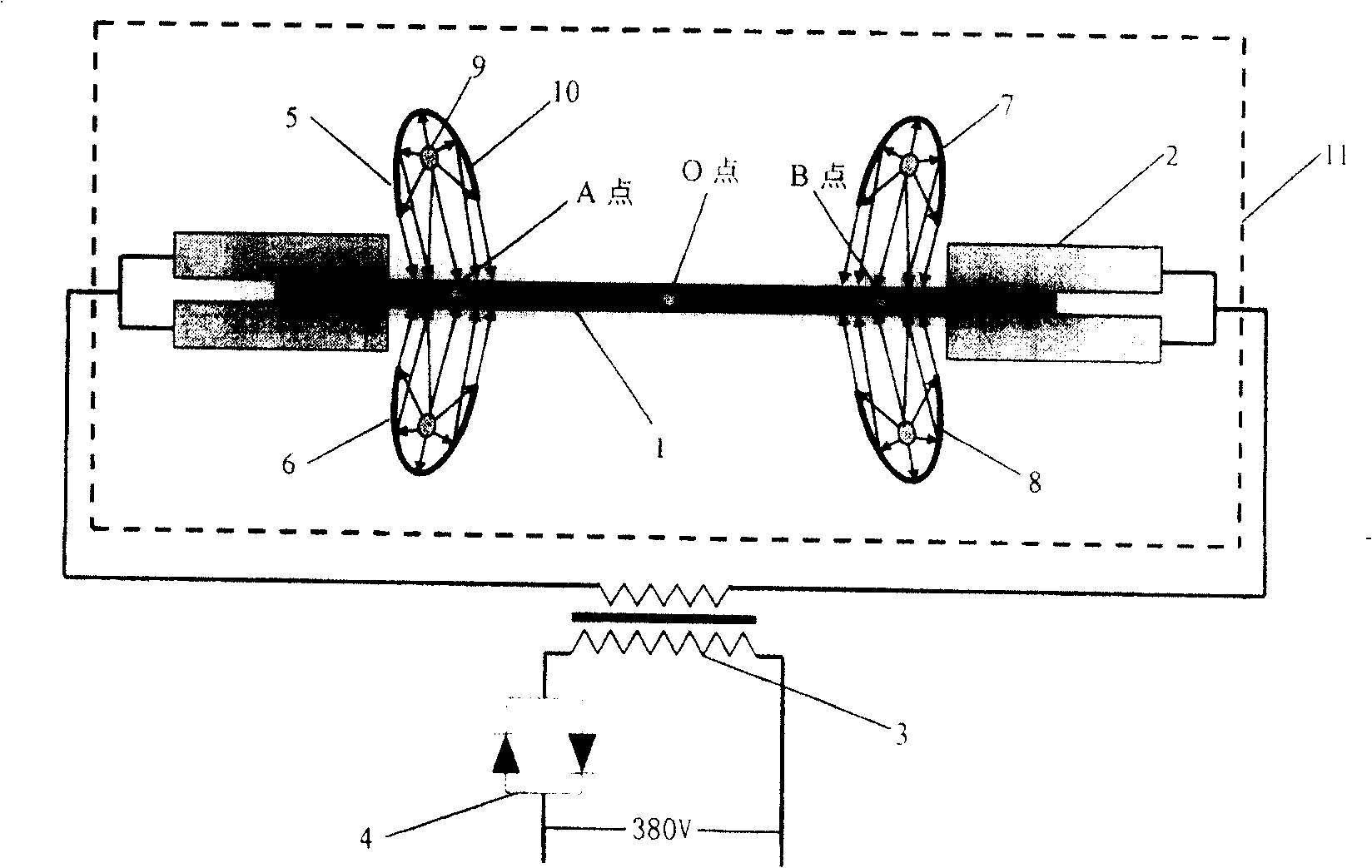

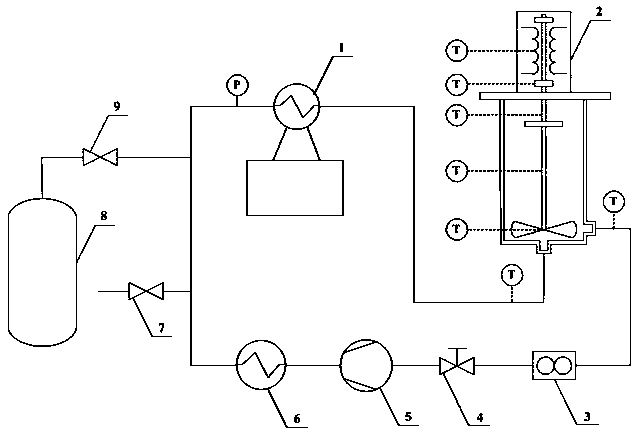

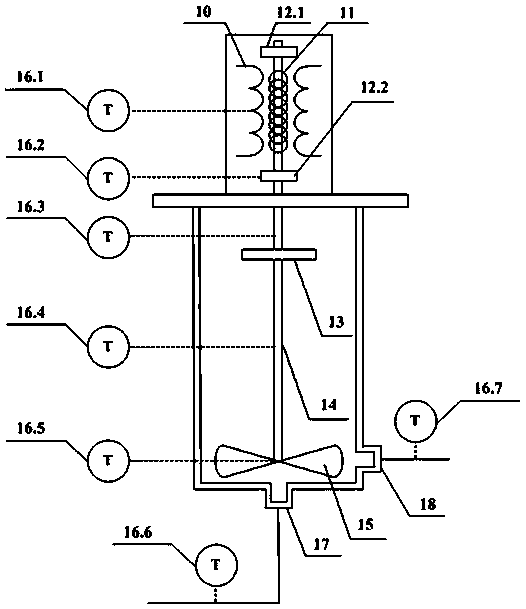

Rotor temperature measurement simulated system and method for low-temperature centrifugal type fluid machine

ActiveCN110095206AConvenient temperature measurementFacilitate thermal insulation designCryogenic temperature measurementTemperature measurement of moving solidsHeat leakEngineering

The invention discloses a rotor temperature measurement simulated system and method for a low-temperature centrifugal type fluid machine. The system comprises a refrigerator, the centrifugal type fluid machine to be measured, a flowmeter, a flow control valve, a dynamic fluid machine and a heater connected via pipes. The refrigerator serves as a cold source, the dynamic fluid machine provides circulating power for a medium in the system, and a rotor of the centrifugal type fluid machine to be measured is kept static. The system can measure the rotor temperature when the centrifugal type fluidmachine transmits the low-temperature working medium, the complete internal temperature field and an axial heat leak can be obtained, and help is provided for design of a heat insulation structure ofthe whole machine.

Owner:ZHEJIANG UNIV

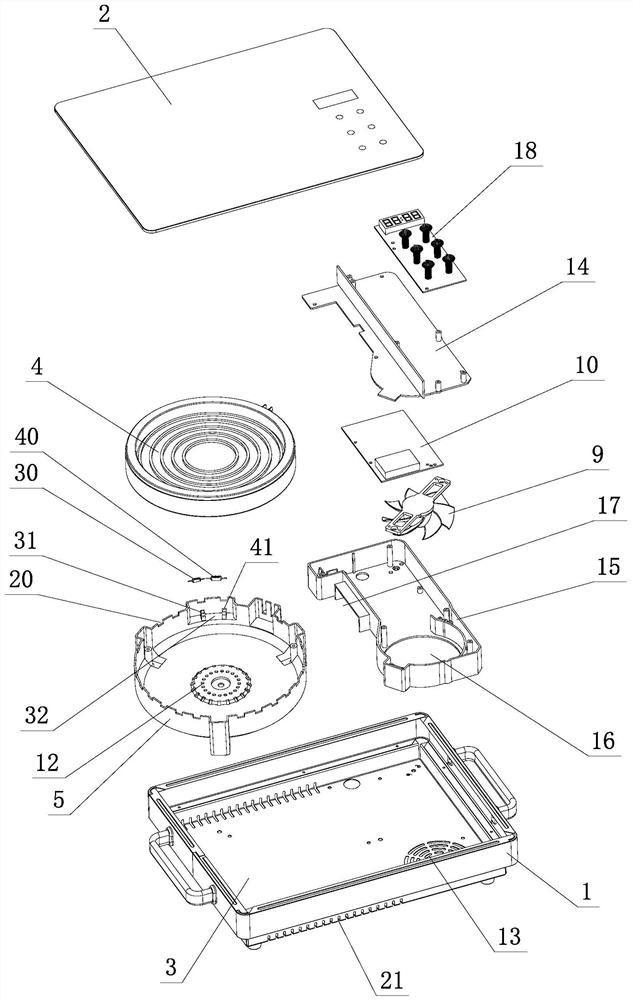

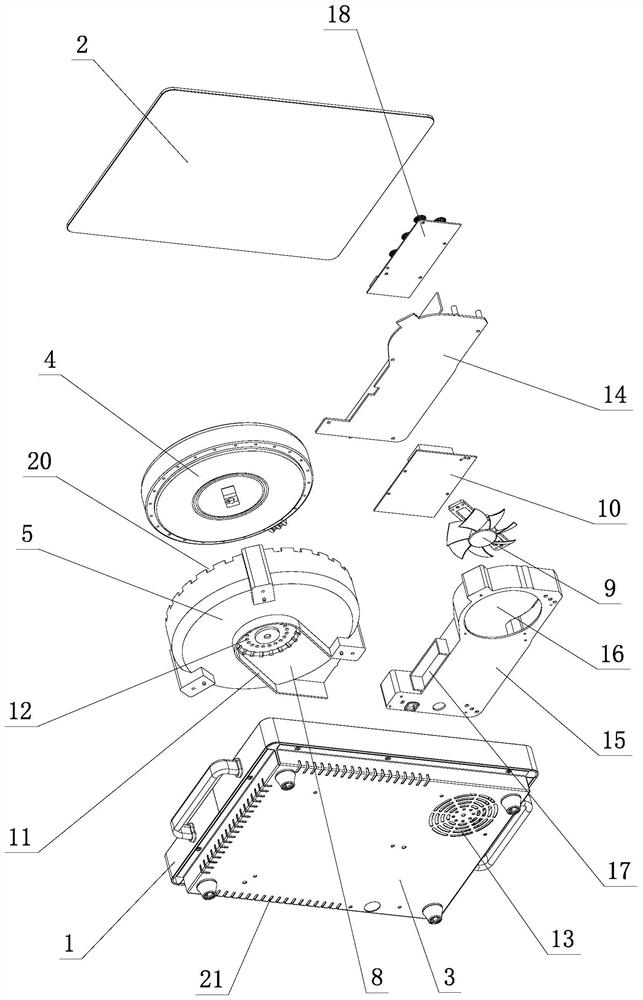

Electric heating furnace

ActiveCN112146138AAvoid damageAvoid security issuesStoves/ranges foundationsDomestic stoves or rangesThermodynamicsHeat leak

The invention relates to an electric heating furnace. The electric heating furnace comprises a furnace body, a cooling fan, a main control panel, a panel and a bottom plate, wherein the panel and thebottom plate are arranged at the upper part and the lower part of the furnace body respectively; a heating piece and a heat energy recovery cover are arranged in the furnace body; the heating piece ispositioned below the panel; an opening is formed in the top of the heat energy recovery cover, and a heat insulation cavity is formed to cover the periphery of the heating piece; an air flowing channel is formed among the heat energy recovery cover, the furnace body and the bottom plate and communicates with the heat insulation cavity; and the cooling fan is used for pumping air outside the furnace body into the air flowing channel, then guiding the air into the heat insulation cavity, dissipating heat of the heating piece and guiding and transferring heat leaked outwards by the heating pieceto the panel. Through the improvement, the air flow direction can be more reasonable and more accurate, the influence of heat on all members except the panel is reduced, heat leaked and lost by a heating body can be transmitted to the panel to the maximum extent and acts on a heated body, heat loss is reduced, and the heat utilization efficiency is improved.

Owner:佛山市顺德区普发特电器实业有限公司

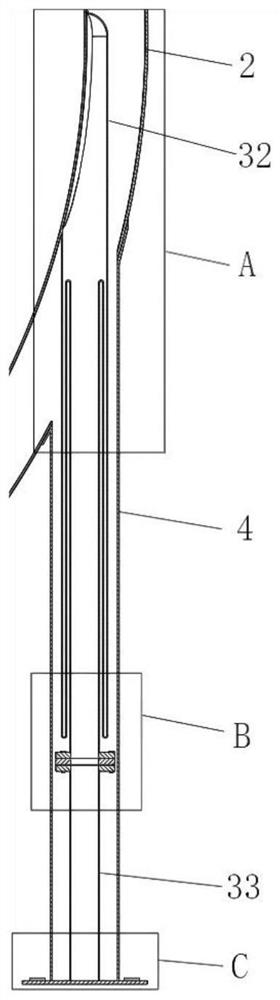

Sleeve supporting structure of large liquid hydrogen vacuum double-layer spherical tank

PendingCN114738658AExtended thermal pathIncrease thermal resistanceVessel mounting detailsVessel geometry/arrangement/sizeHeat leakEngineering

A sleeve supporting structure of a large liquid hydrogen vacuum double-layer spherical tank comprises a supporting structure composed of an inner supporting column and an outer supporting structure, an inner tank is supported and suspended in a cavity of an outer tank through the inner supporting column, and the outer tank is supported through the outer supporting structure; a plurality of groups of supporting structures for supporting the inner tank and the outer tank are arranged on the inner tank and the outer tank, and each group of supporting structure consists of an inner supporting column and an outer supporting structure; the inner supporting column comprises a top cover, an inner upper supporting column, an inner lower supporting column and an up-down connecting structure, the top cover is connected to the top of the inner upper supporting column, and the inner upper supporting column and the inner lower supporting column are connected through the up-down connecting structure; the inner upper supporting column is of a three-sleeve structure and comprises an inner upper supporting column outer pipe, an inner upper supporting column middle pipe and an inner upper supporting column inner pipe from outside to inside. The length of the heat conduction section of the pillar is effectively prolonged; meanwhile, convective heat transfer and radiative heat transfer of the supporting structure are effectively reduced, heat leaking into the spherical tank from the supporting structure is remarkably reduced, and therefore the heat insulation performance of the large liquid hydrogen spherical tank is greatly improved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com