Hot riveting connection method of thermoplastic material and light alloy

A thermoplastic material and lightweight alloy technology, applied in the field of metal and composite material connection, can solve the problems of inability to fully meet the performance requirements, limited joint performance improvement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

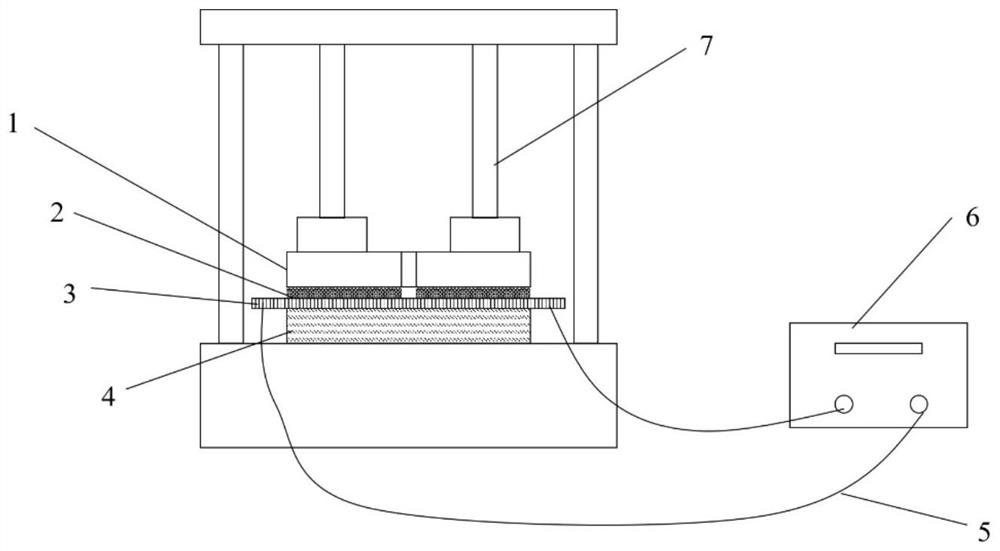

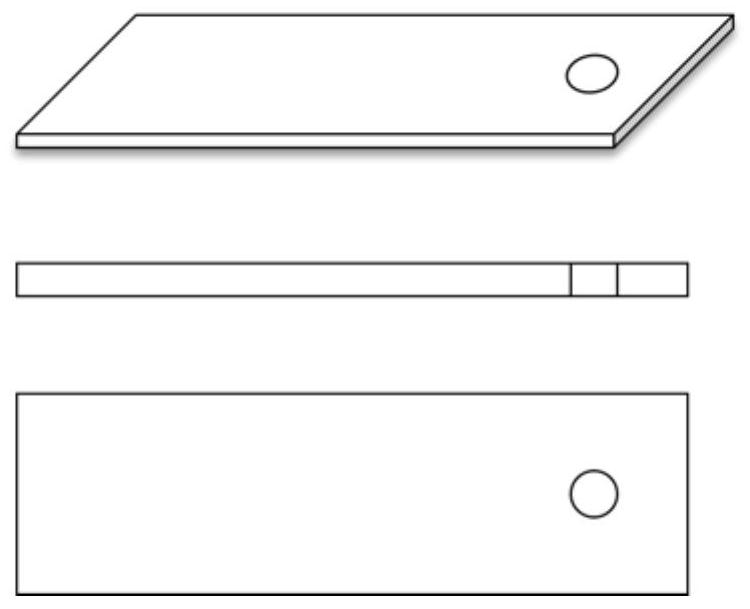

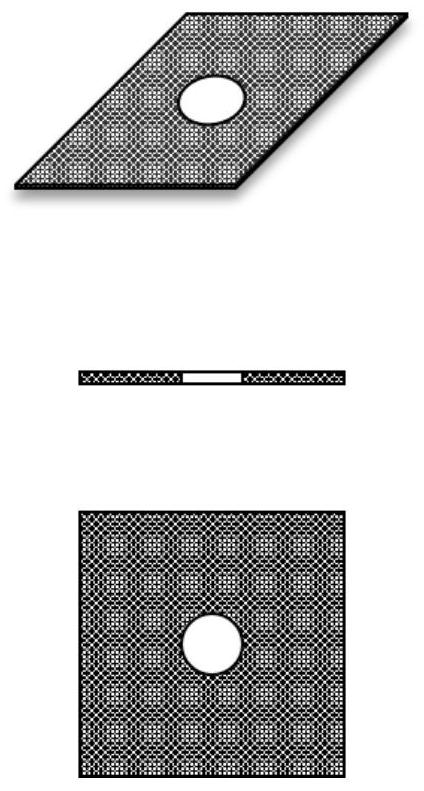

Embodiment 1

[0039]Grind the aluminum alloy sample with 400-grit sandpaper, and then use a laser drilling machine to prefabricate a through hole in the center of the aluminum alloy sample to be welded, and make holes in the corresponding position of the glass fiber / PEI prepreg; implant the stainless steel mesh into the body , glass fiber / PEI (glass fiber composite PEI) prepreg according to the order of joint structure design ( Figure 4 ) placed on the overlapping area to be welded between aluminum alloy and GF / PEI (chopped glass fiber reinforced PEI) laminates; apply an initial pressure of 0.3MPa, turn on the power supply, adjust the voltage and current so that the maximum temperature of the welding area reaches 360°C, and the welding time After cooling for 120s, an aluminum alloy-GF / PEI laminate hot riveted piece is obtained, and its joint strength is 12MPa.

Embodiment 2

[0041] Grind the aluminum alloy sample with 400-grit sandpaper, and then use a laser drilling machine to prefabricate a through hole in the center of the aluminum alloy sample to be welded, and make holes in the corresponding position of the glass fiber / PEEK prepreg; implant the stainless steel mesh into the body , glass fiber / PEEK prepreg according to the order of joint structure design ( Figure 4 ) placed on the overlapping area to be welded between the aluminum alloy and the GF / PEEK laminate; apply an initial pressure of 0.3 MPa, turn on the power supply, adjust the voltage and current so that the maximum temperature of the welding area reaches 380°C, and the welding time is 180s. After cooling, the aluminum alloy is obtained -GF / PEEK laminate heat riveting parts, the strength is 26Mpa.

Embodiment 3

[0043] Grind the aluminum alloy sample with 400-grit sandpaper, and then use a laser drilling machine to prefabricate a through hole in the center of the aluminum alloy sample to be welded, and make holes in the corresponding position of the glass fiber / PPS prepreg; implant the stainless steel mesh into the body , glass fiber / PPS prepreg according to the order of joint structure design ( Figure 4 ) placed in the overlapping area to be welded between the aluminum alloy and the PPS sample; apply an initial pressure of 0.3MPa, turn on the power supply, adjust the voltage and current so that the maximum temperature of the welding area reaches 300°C, and the welding time is 180s. After cooling, the aluminum alloy-PPS is obtained. For hot riveted parts, the joint strength is 21MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com