HT 960 steel plate with excellent plasticity and toughness and manufacture method thereof

A manufacturing method and plastic toughness technology, applied in the field of high plastic toughness HT960 steel plate and its manufacturing, can solve the problems of damage to the weldability of steel plate, long manufacturing cycle, inability to fully exert the hardenability and hardenability potential of alloy elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with embodiment.

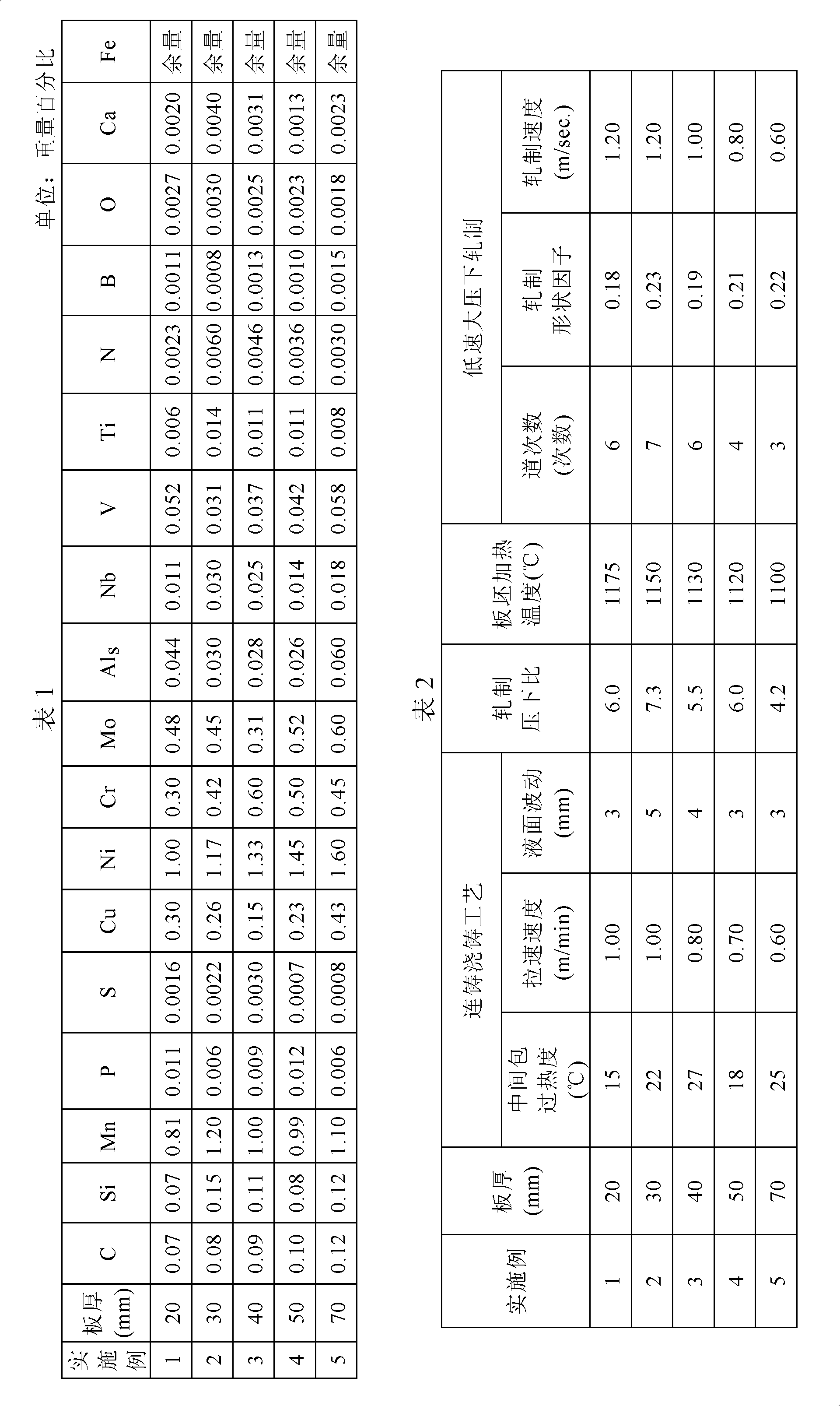

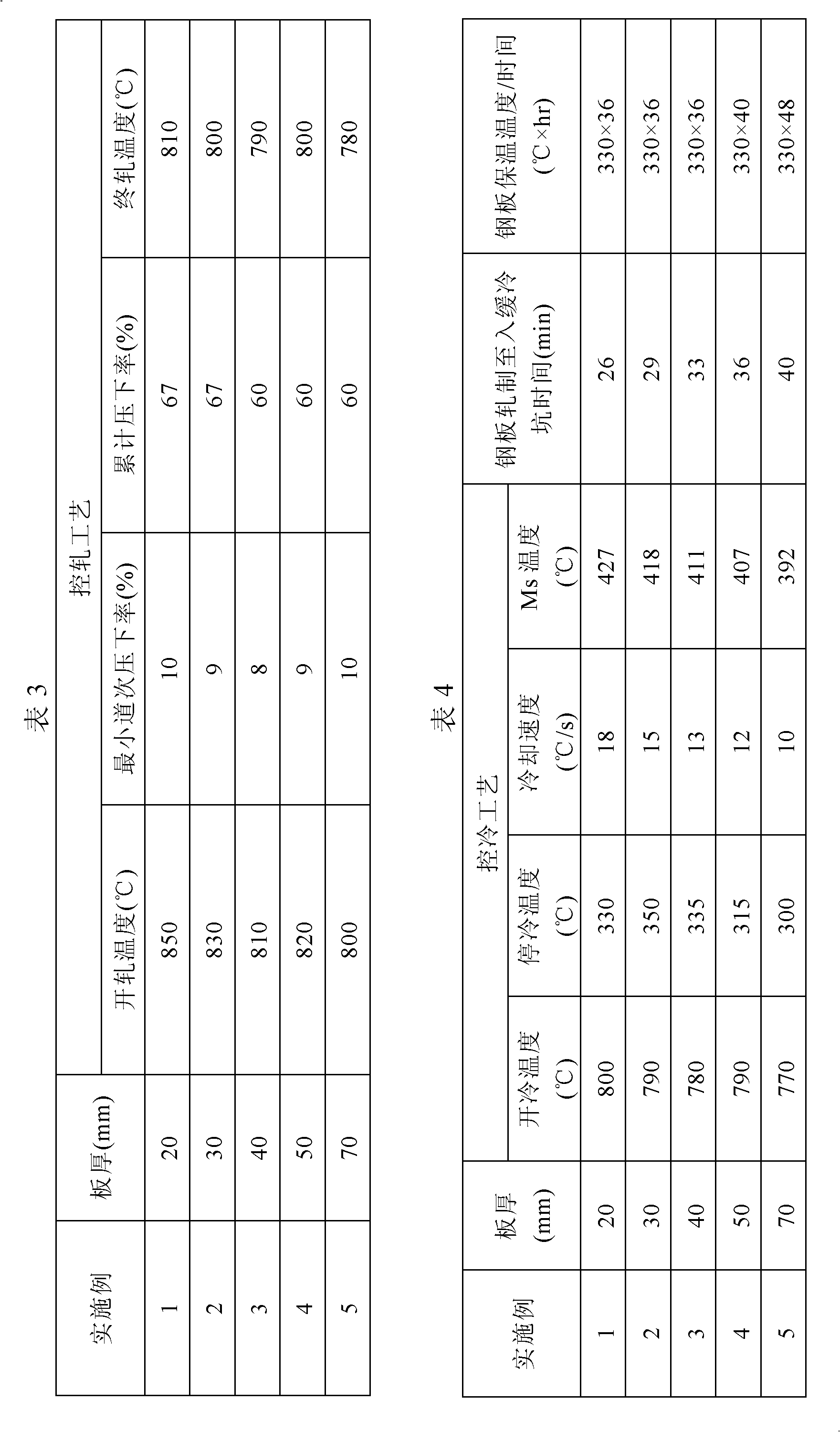

[0092] Table 1 is an example of the composition of the present invention. Table 2 to Table 5 are the manufacturing process of the embodiment of the present invention.

[0093] Table 6 is the performance parameter of the embodiment of the present invention.

[0094] Depend on figure 1 It can be seen that the steel structure of the present invention is a mixed structure of fine, low-carbon tempered martensite structure and a small amount of low-carbon tempered lower bainite structure.

[0095]

[0096]

[0097]

[0098] The present invention combines the combined design of steel plate alloy elements with the TMCP+T process. While obtaining an excellent 960MPa ultra-high-strength steel plate, the plastic toughness and welding processability of the steel plate are also excellent, and the strength of the ultra-high-strength steel plate is successfully solved. , plasticity, low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com