Patents

Literature

653results about "Combing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

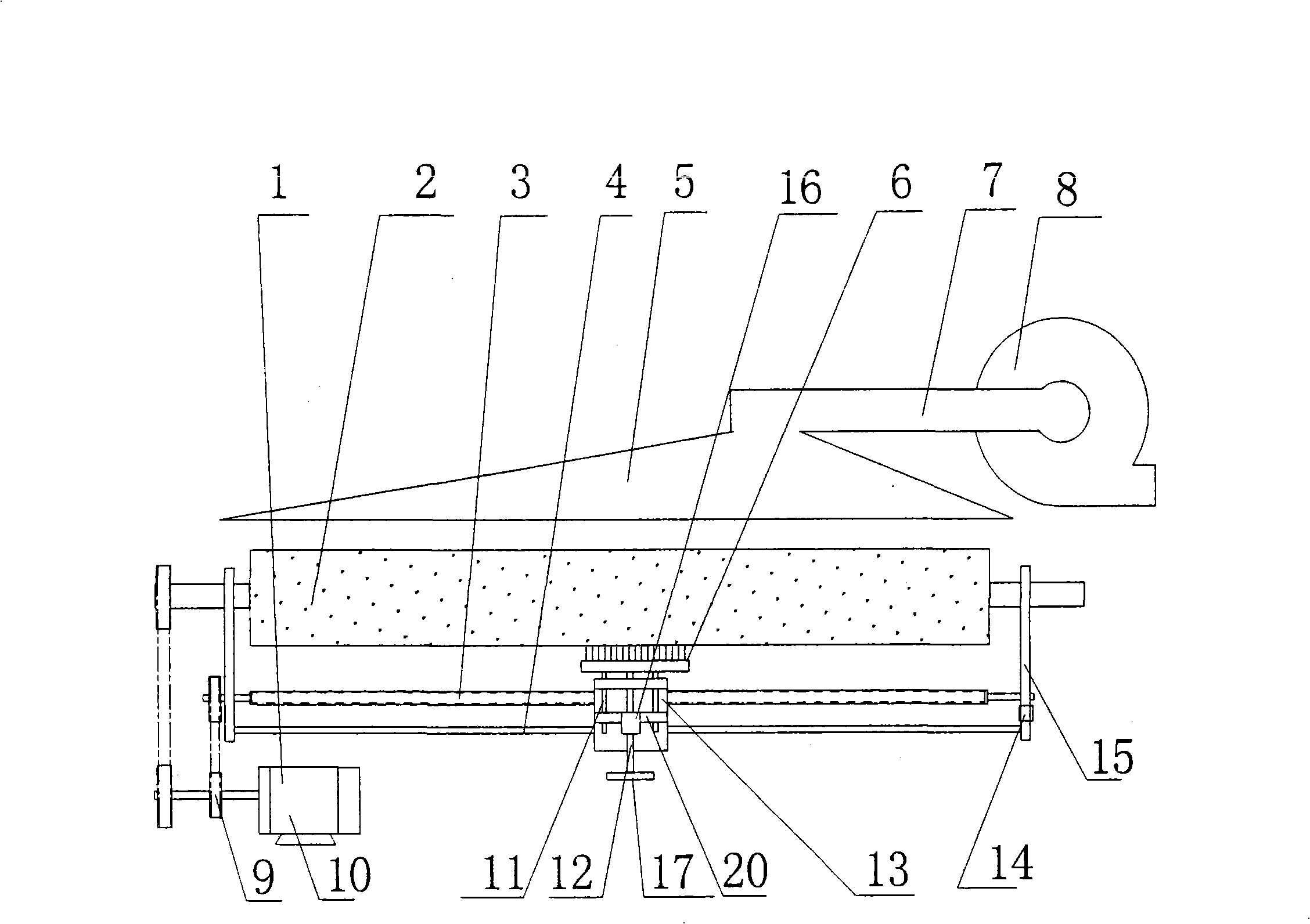

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

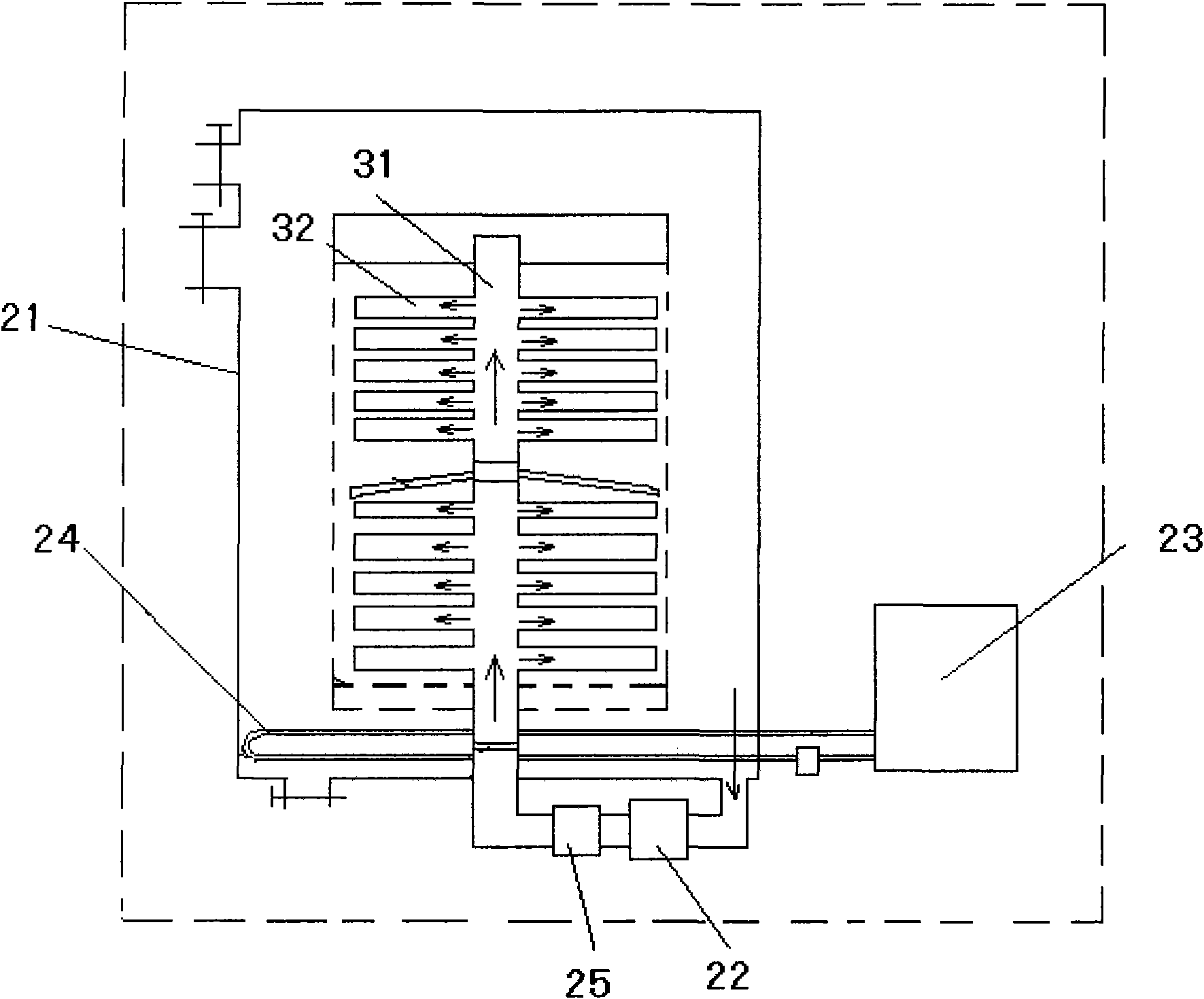

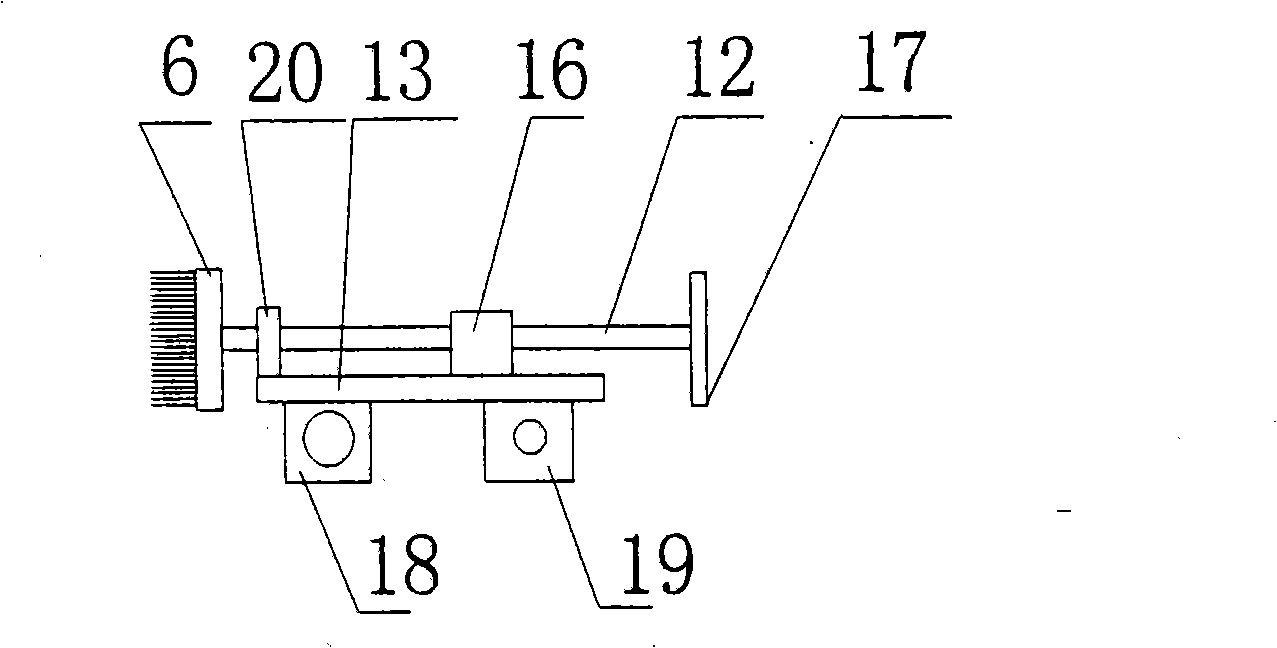

Automatic cleaning device for bristle roll of combing machine and cleaning method thereof

InactiveCN101285222AReduce damageImprove self-cleanlinessCombing machinesCleaning using toolsBristleEngineering

The invention provides an automatic cleaning device of a brush roller of a combing machine and a method for cleaning the same. The method comprises the following steps that: the upper side of the brush roller of the combing machine is provided with a dust hood which is connected with a draft fan through an air duct; the front part of the brush roller of the combing machine is provided with a brush roller cleaning mechanism; sundries which are attached on the brush roller of the combing machine are cleaned by contacting the brush roller cleaning mechanism with the surface of the brush roller of the combing machine. The automatic cleaning device of the brush roller of the combing machine and the method for cleaning the same are designed based on the principles of automation, cleaning and actual effect, which improve greatly work efficiency of an equipment maintainer so that the work must be done originally by two persons, but now the work can be done by one person after the brush automatic cleaner is used. Compared with the brush which is cleaned by persons, the brush which is cleaned by the brush automatic cleaner is cleaner, and the brush hair is straighter; and after the brush is operating, the state of cleaning the circular comb by the brush is improved greatly.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD +1

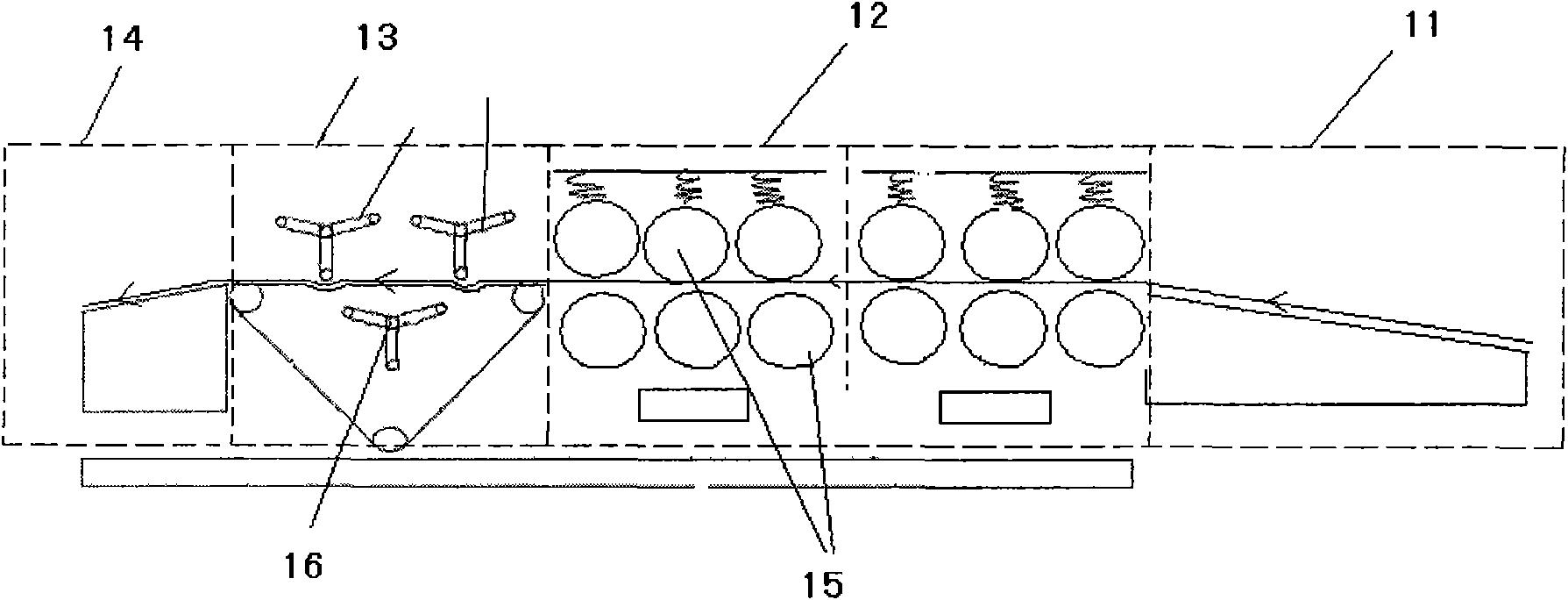

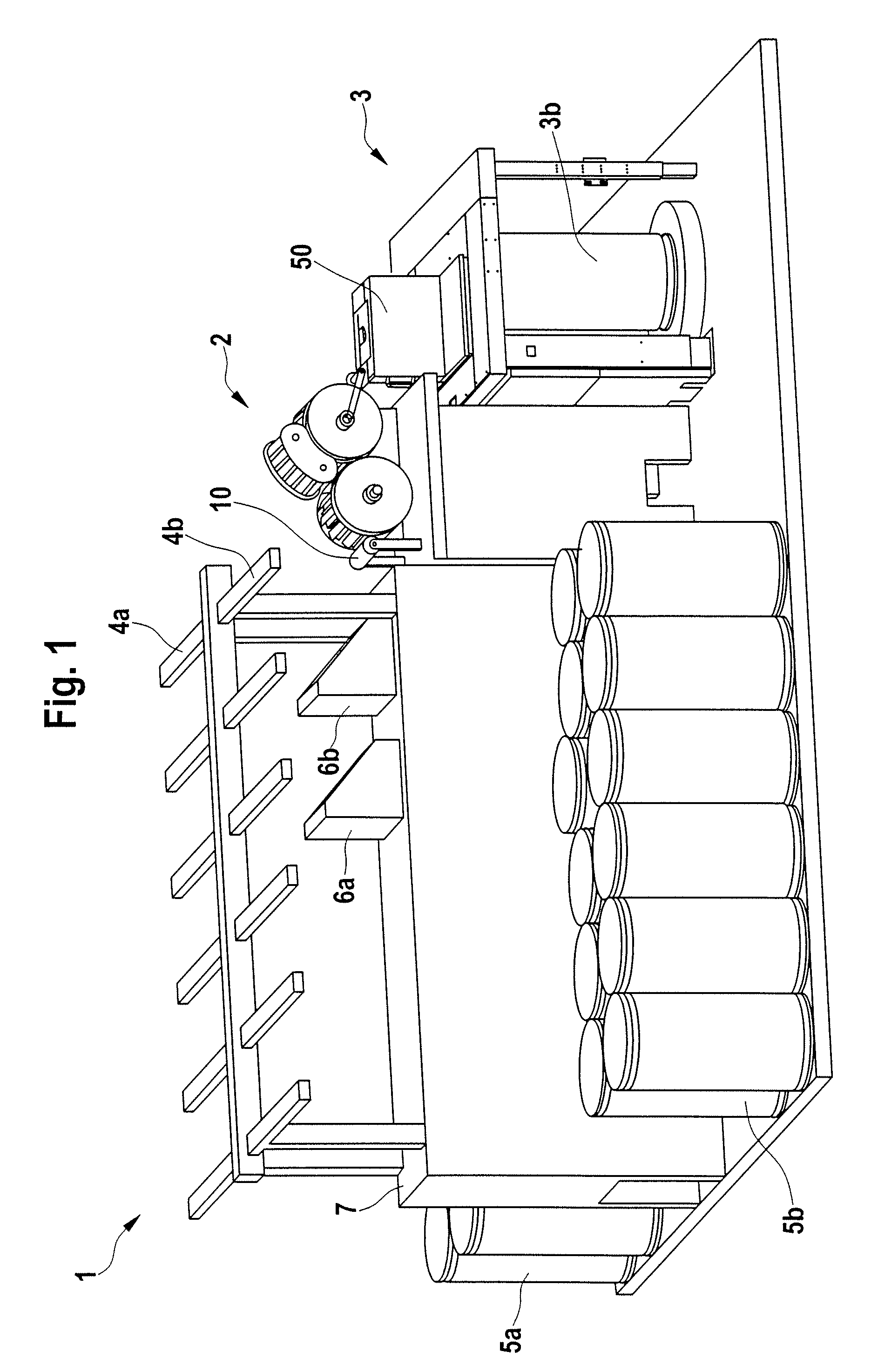

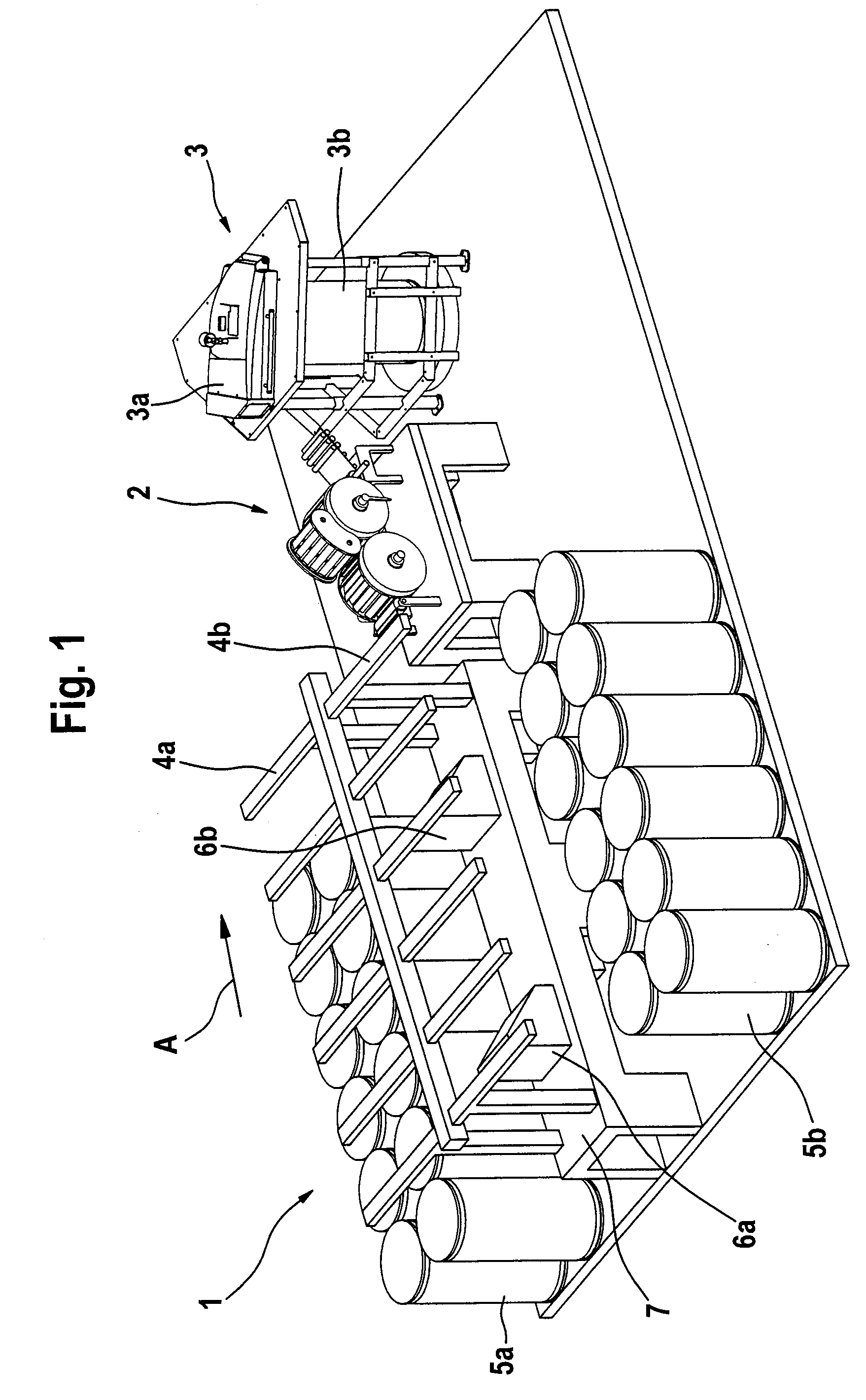

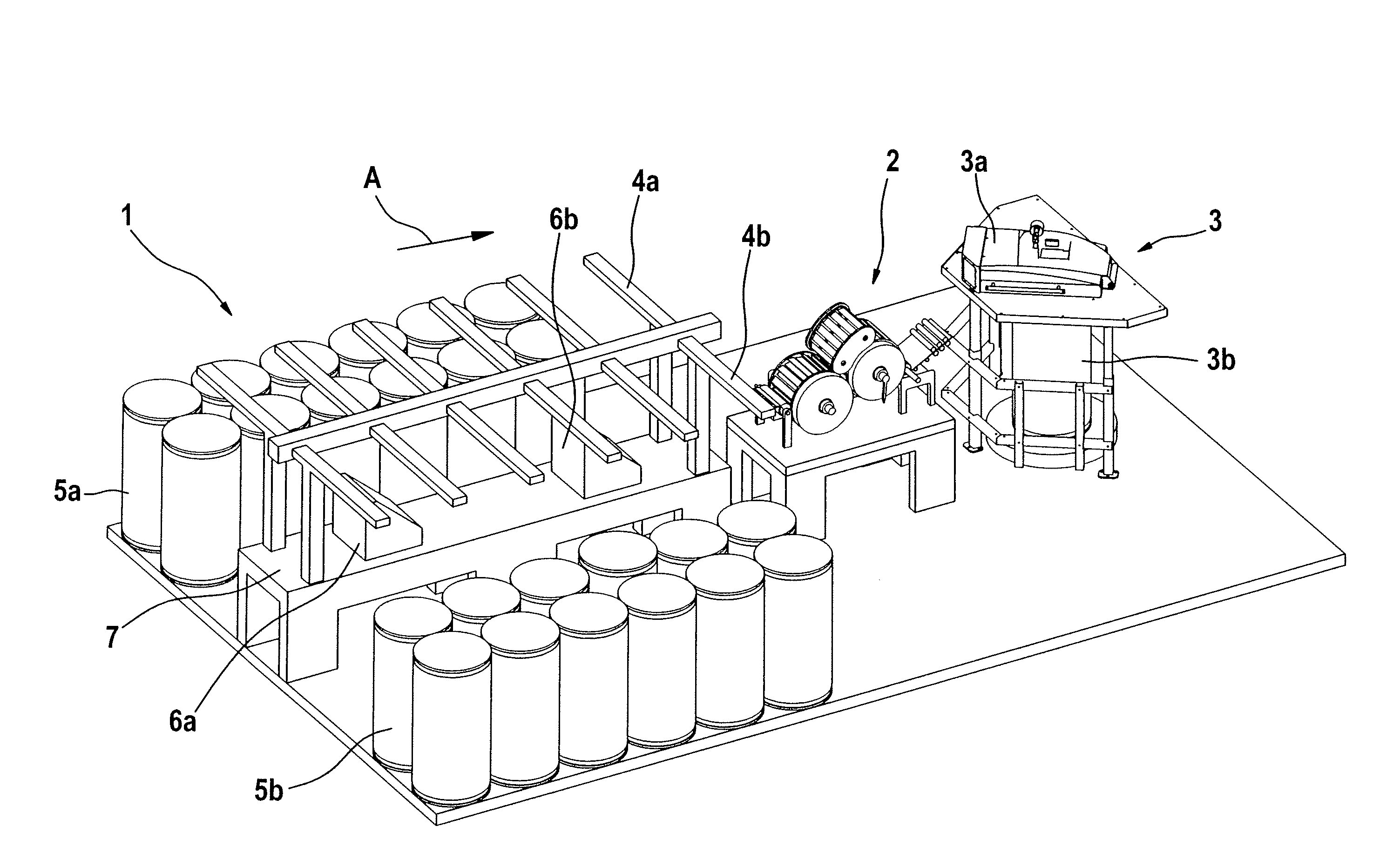

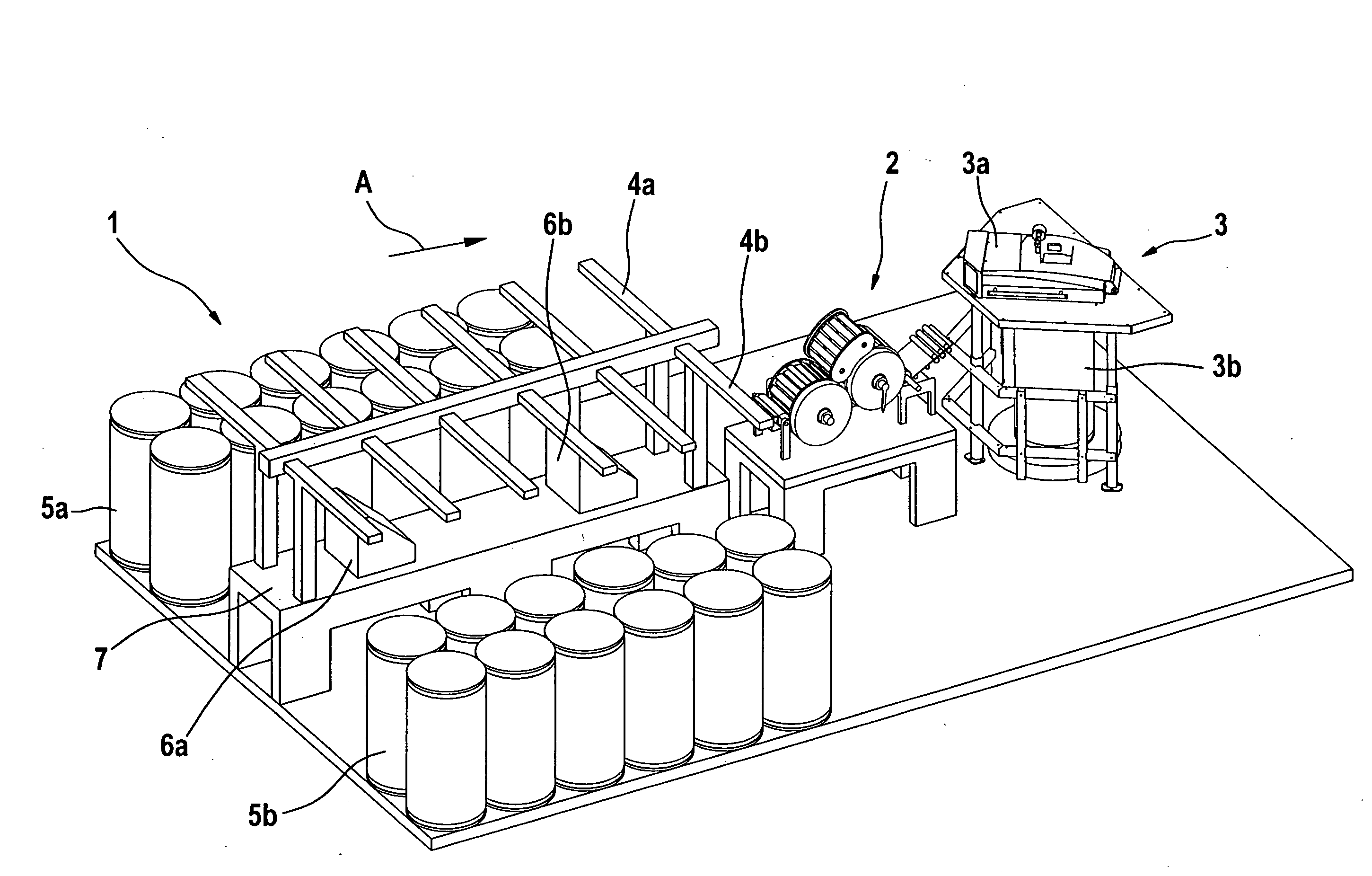

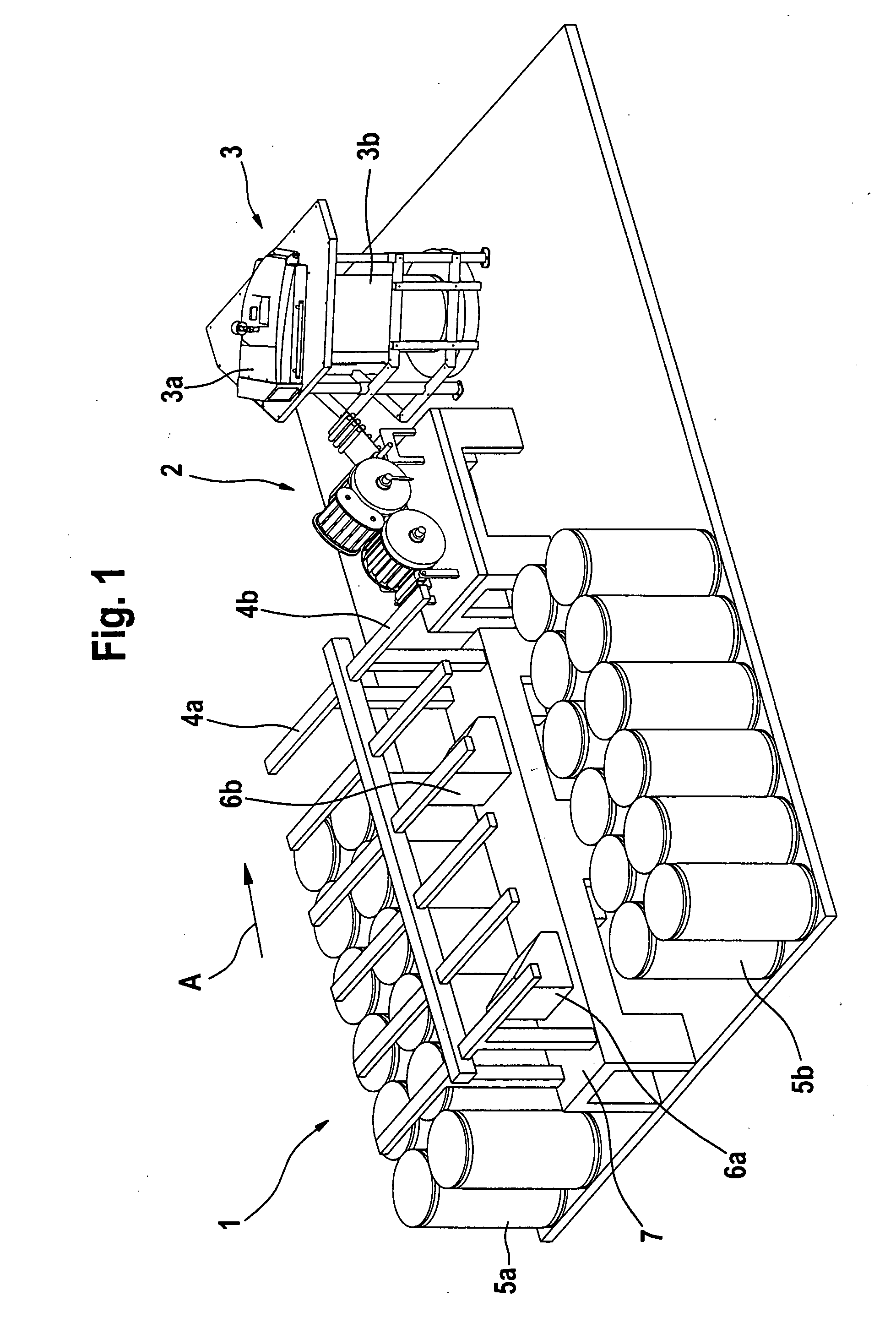

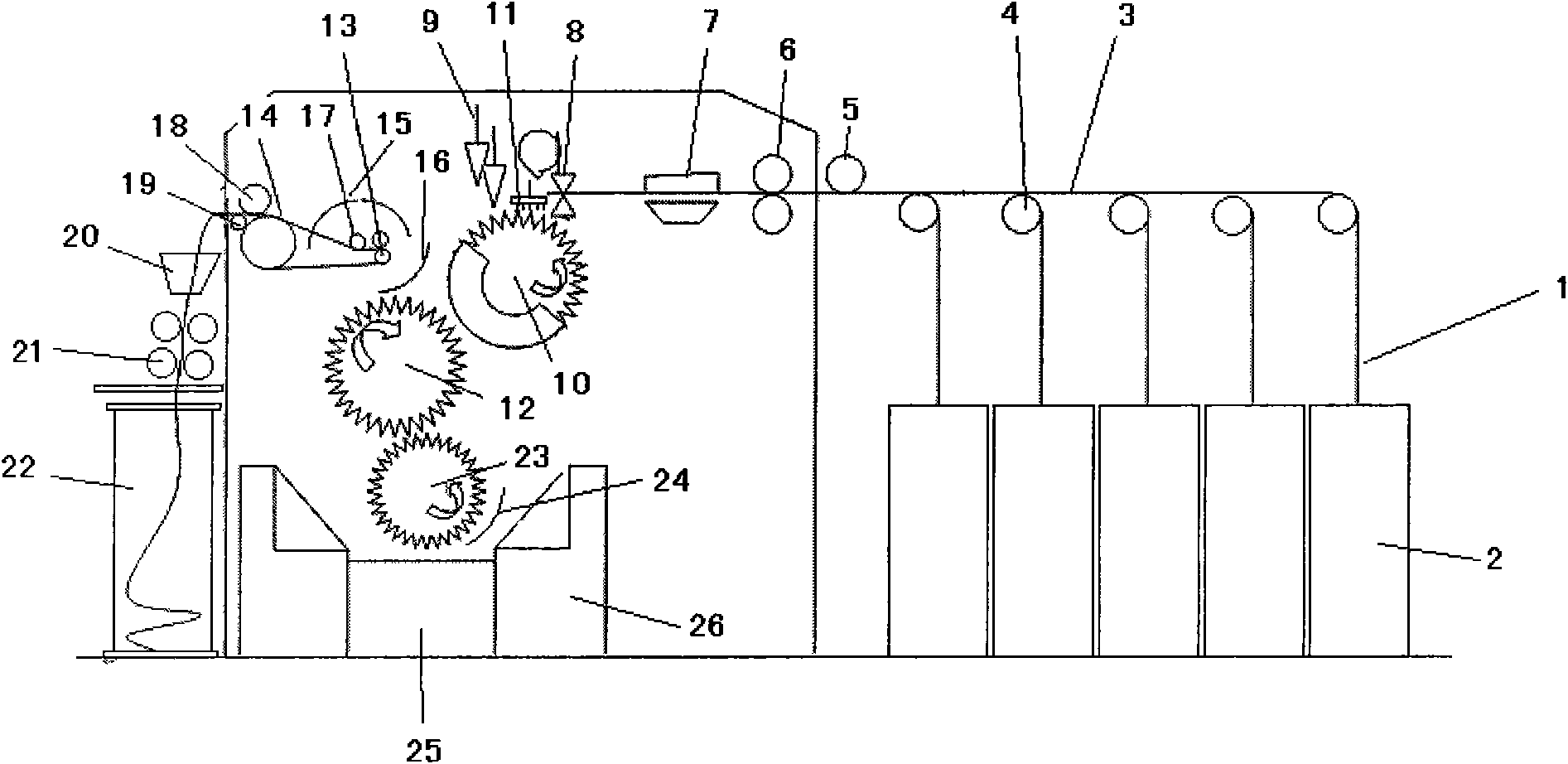

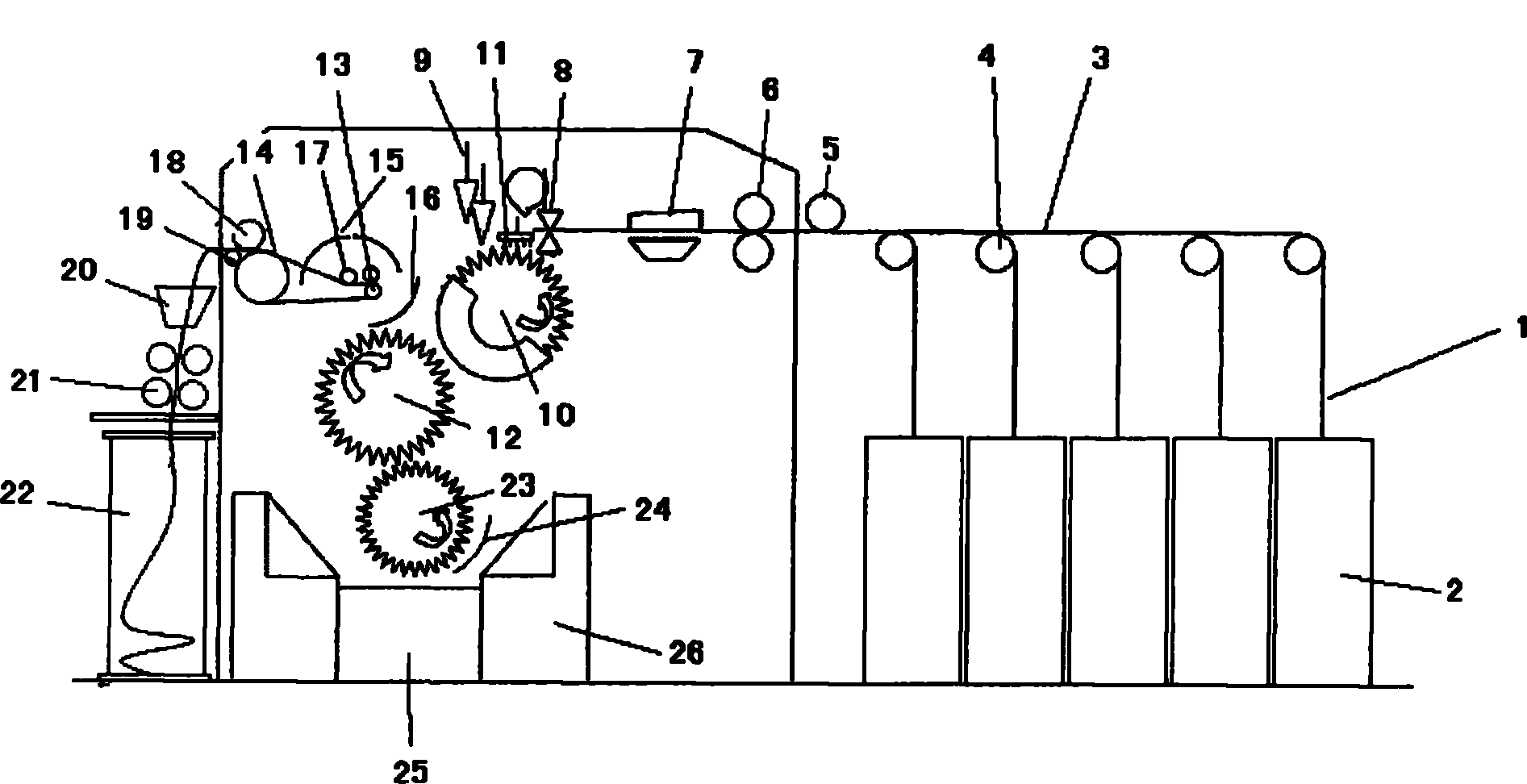

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

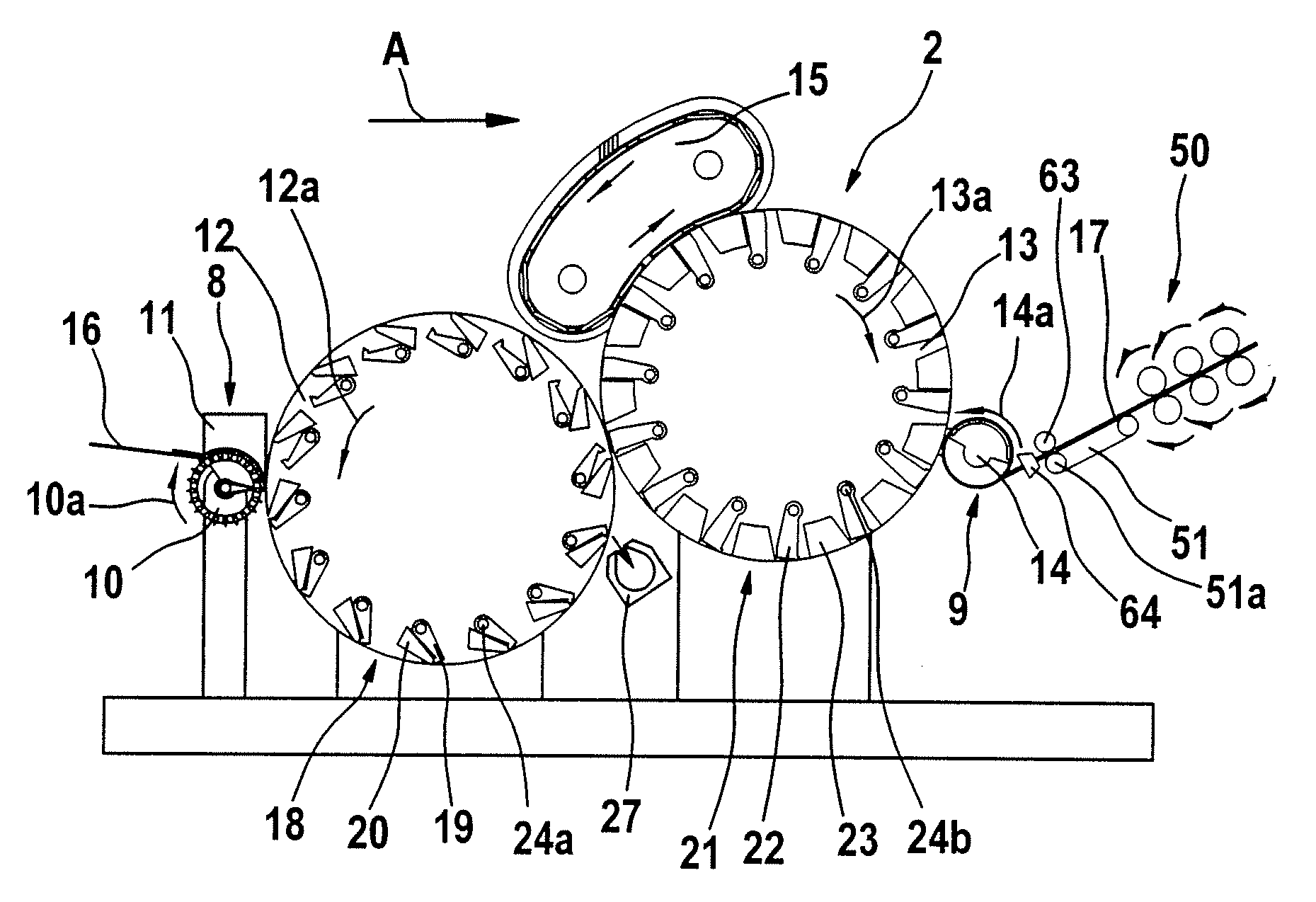

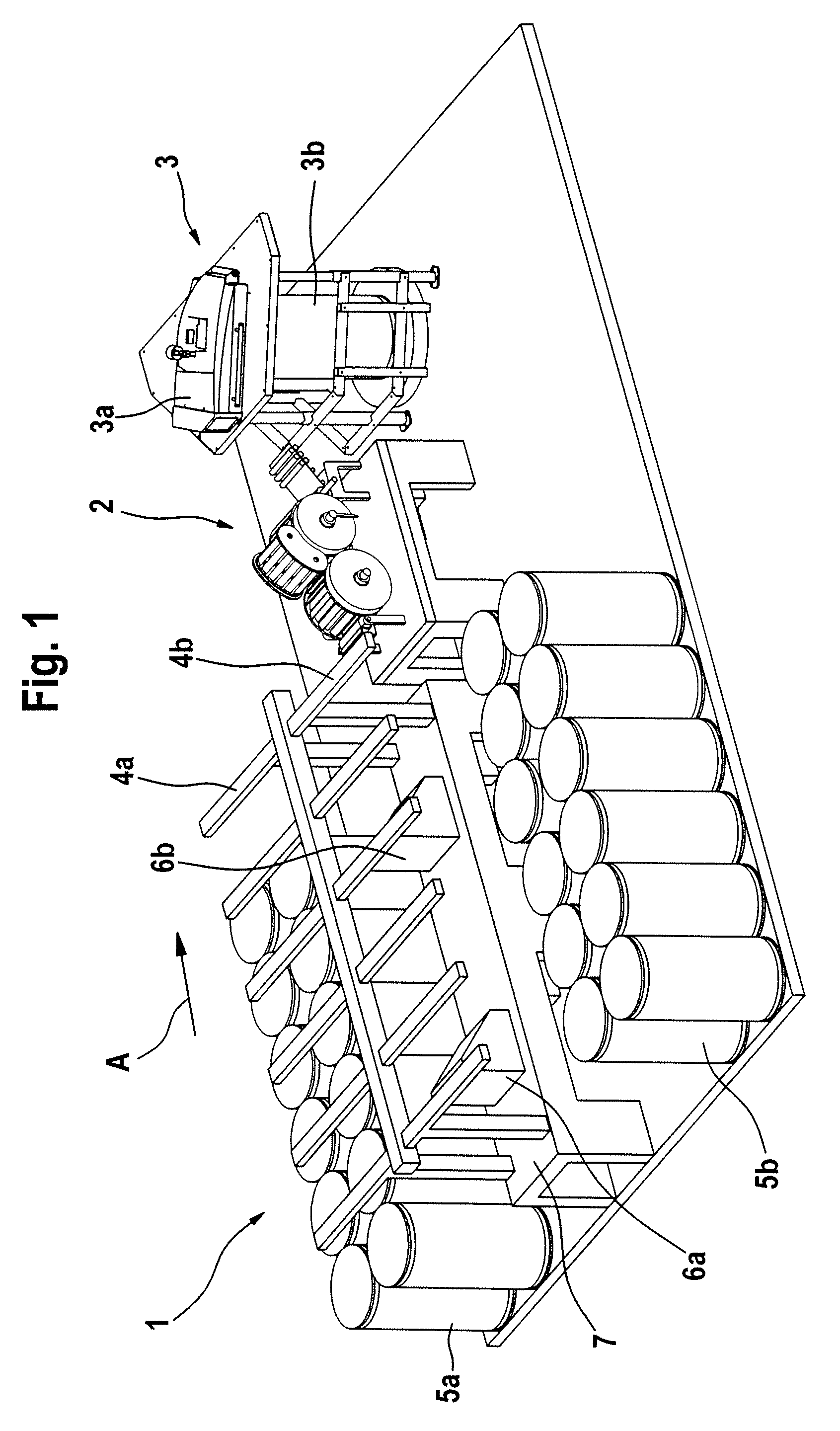

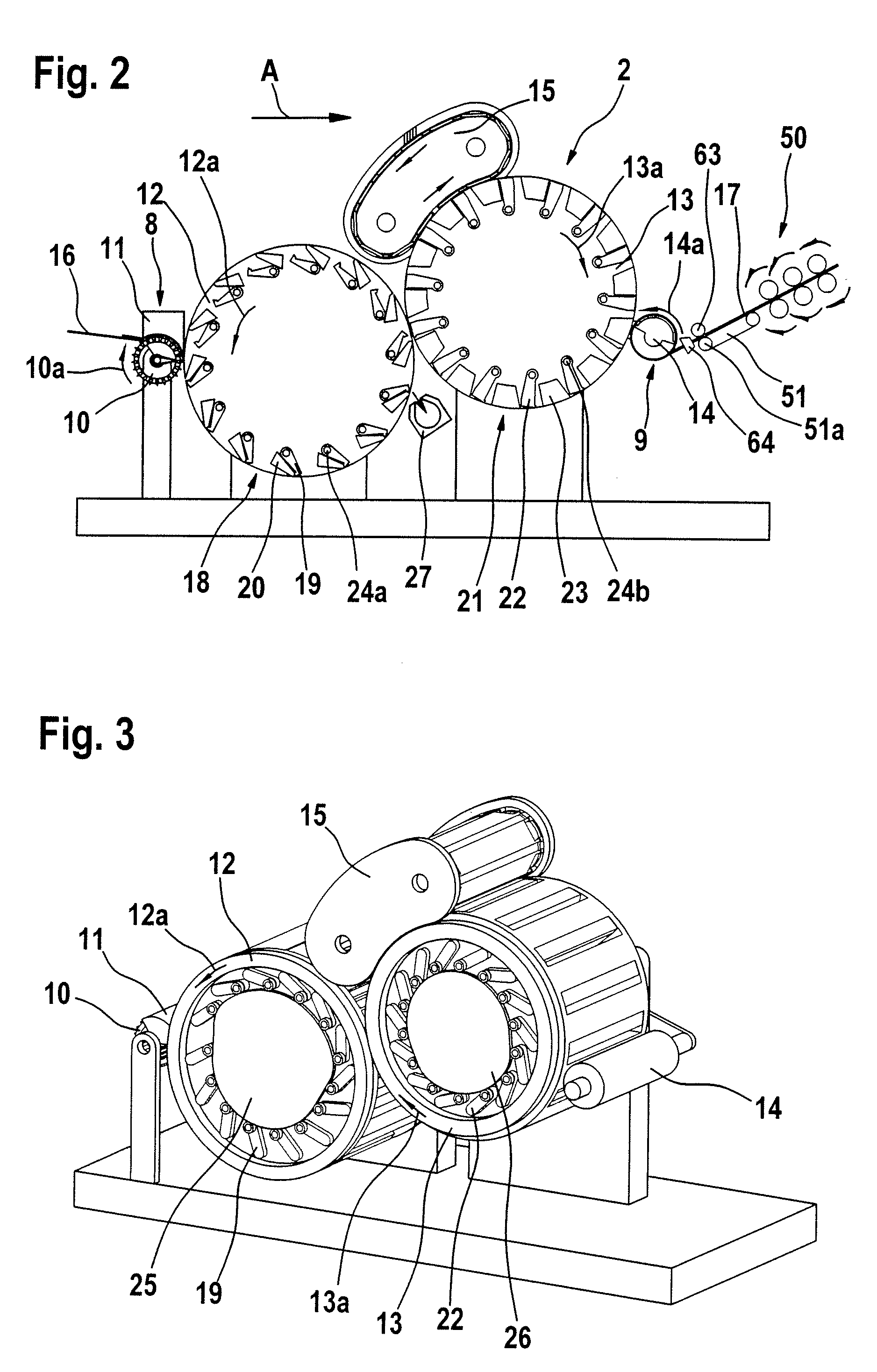

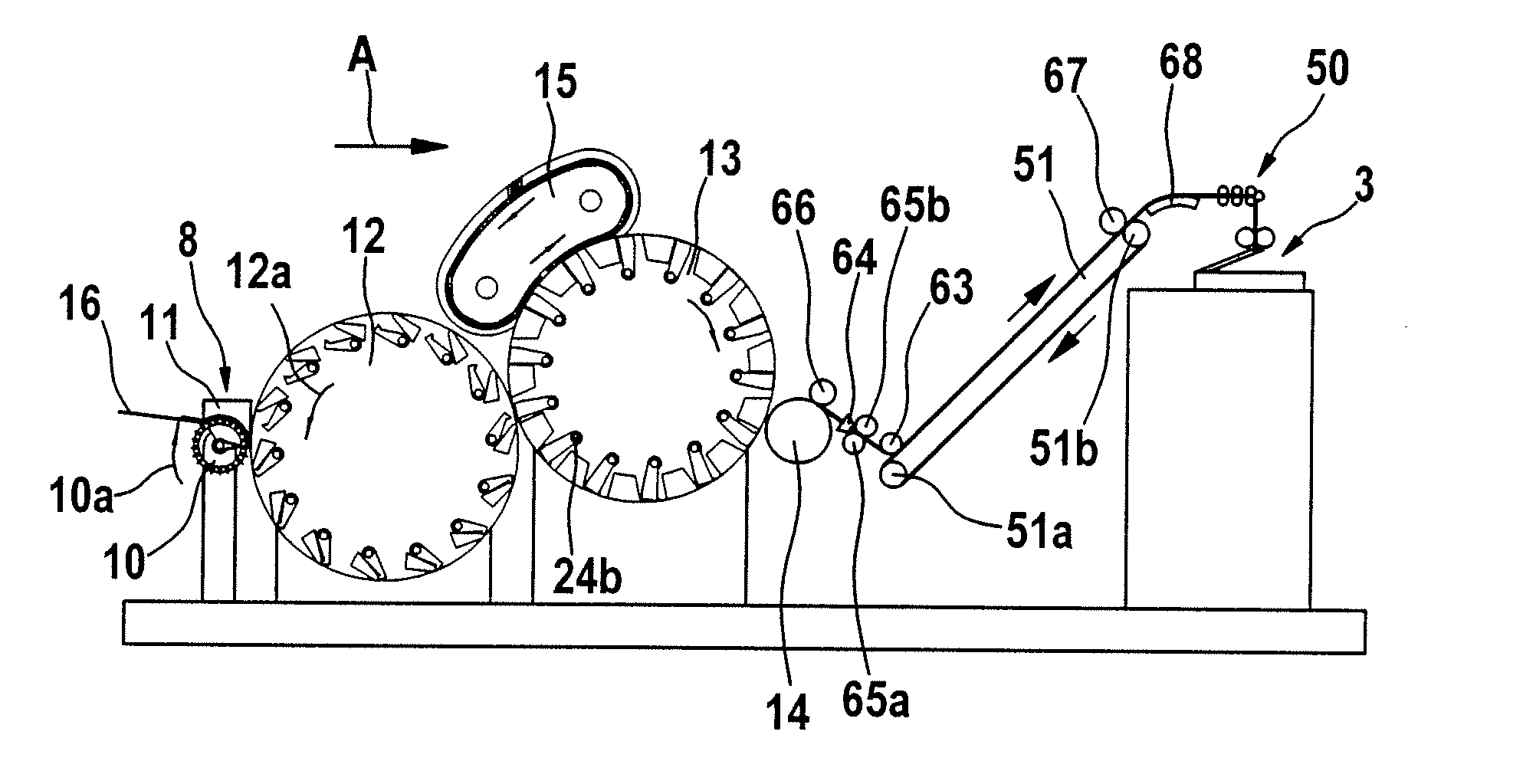

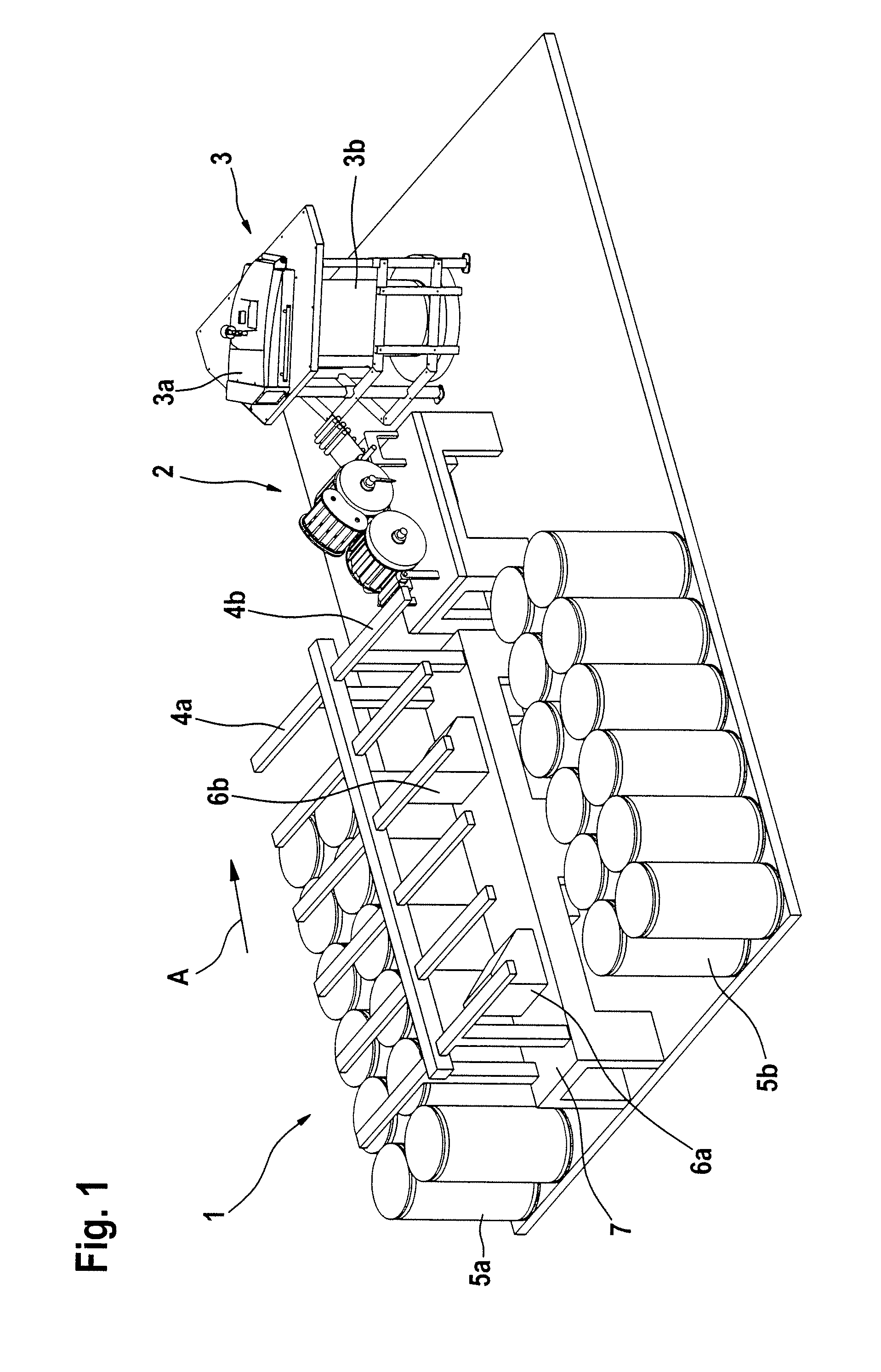

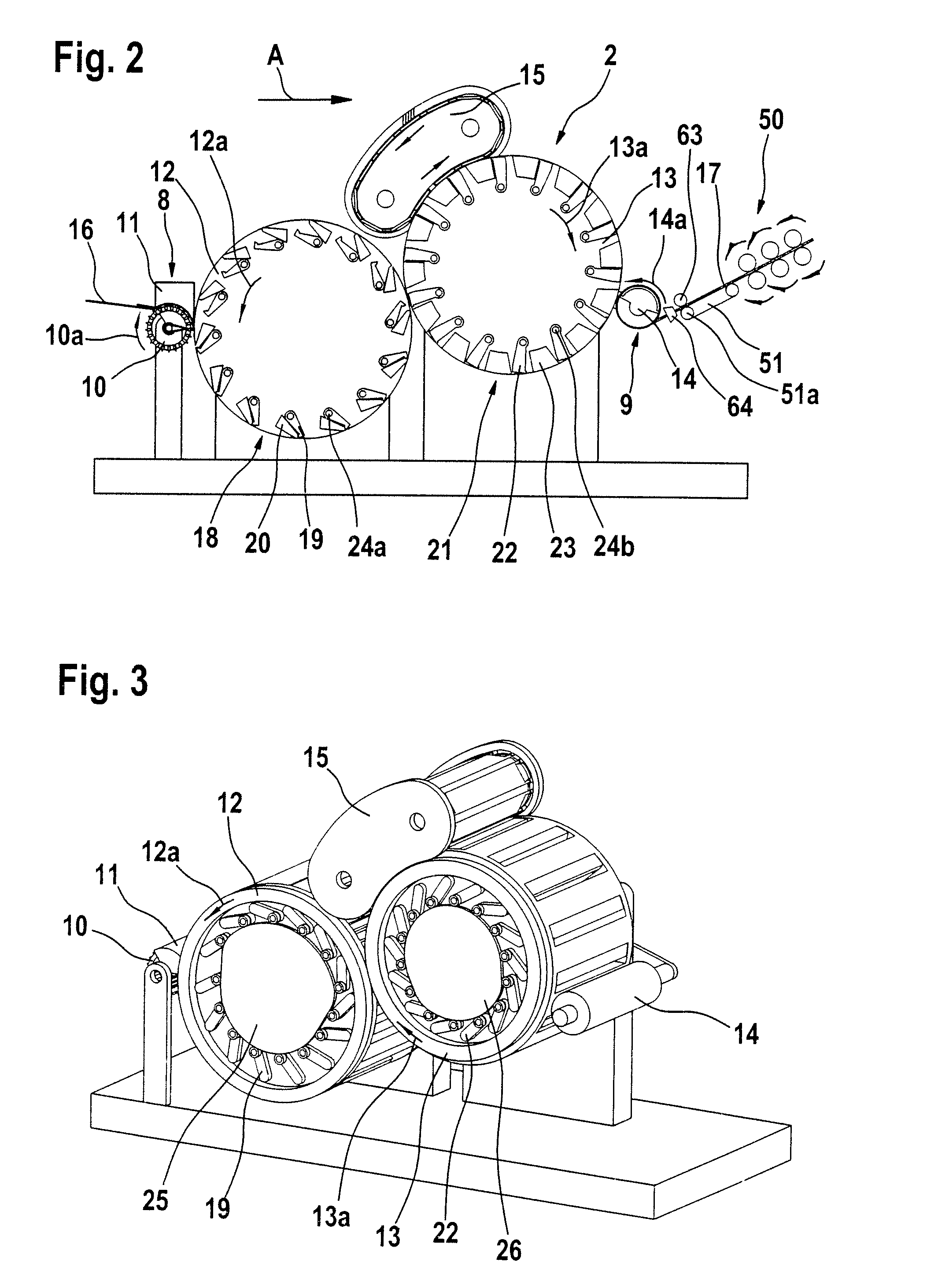

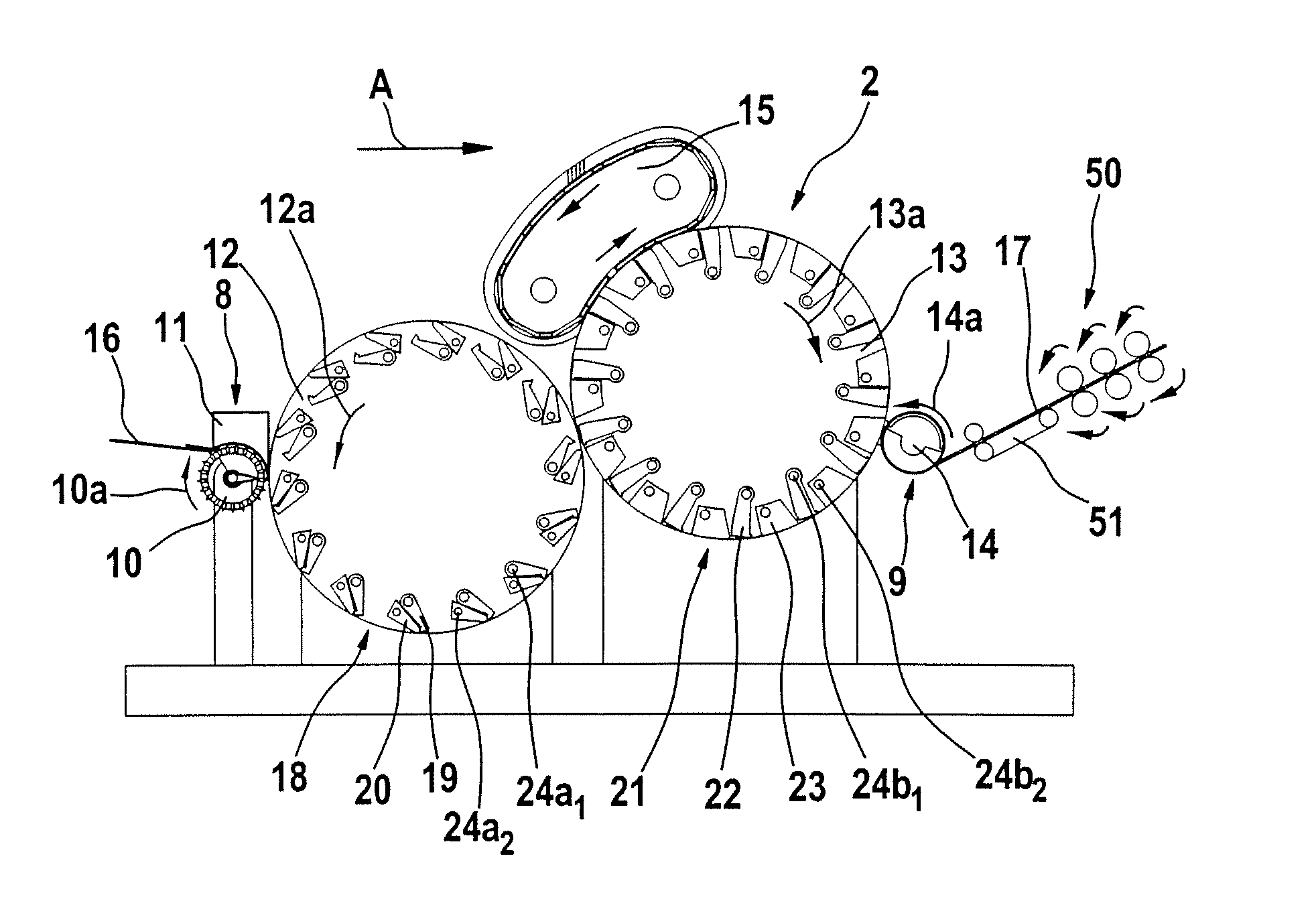

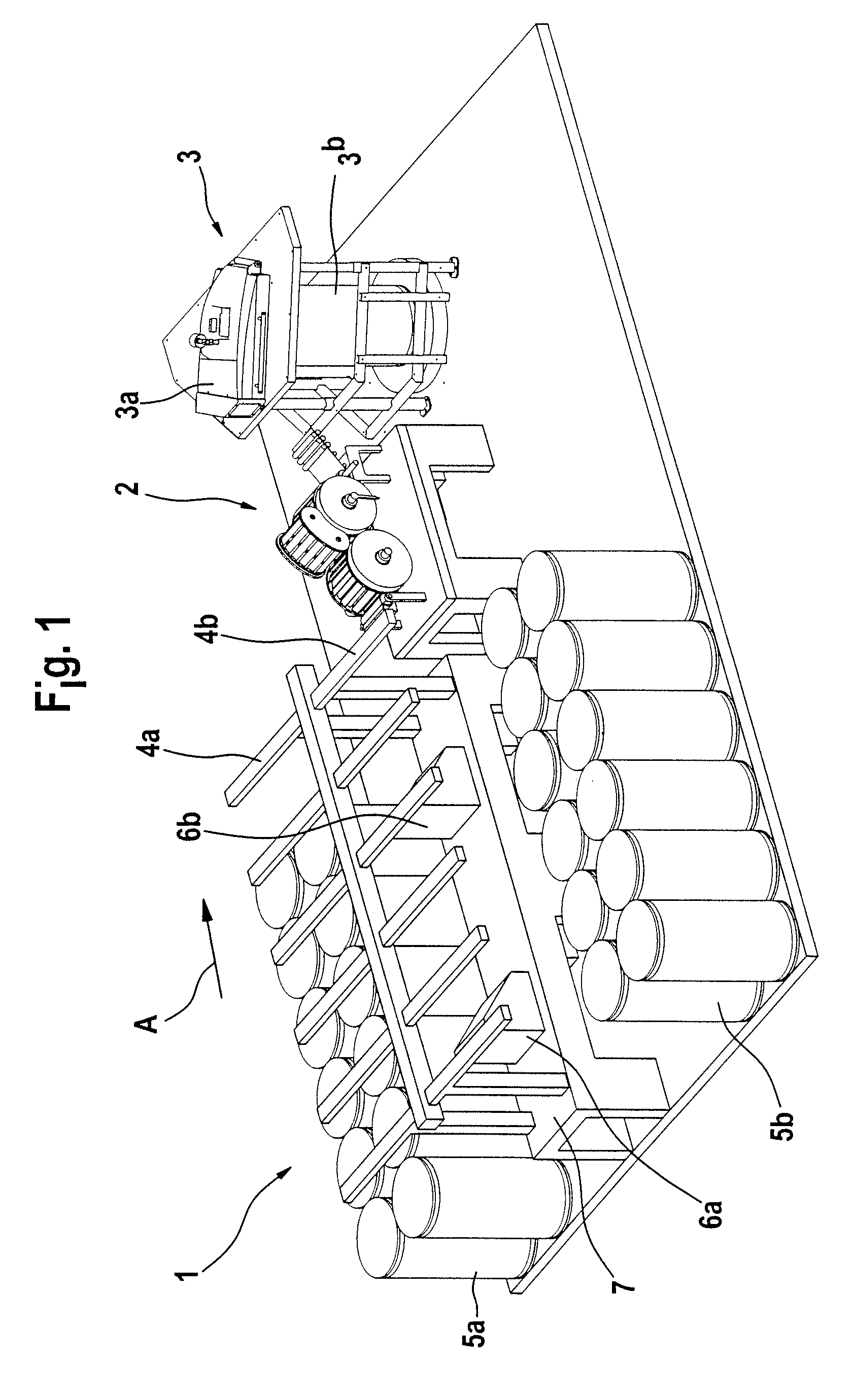

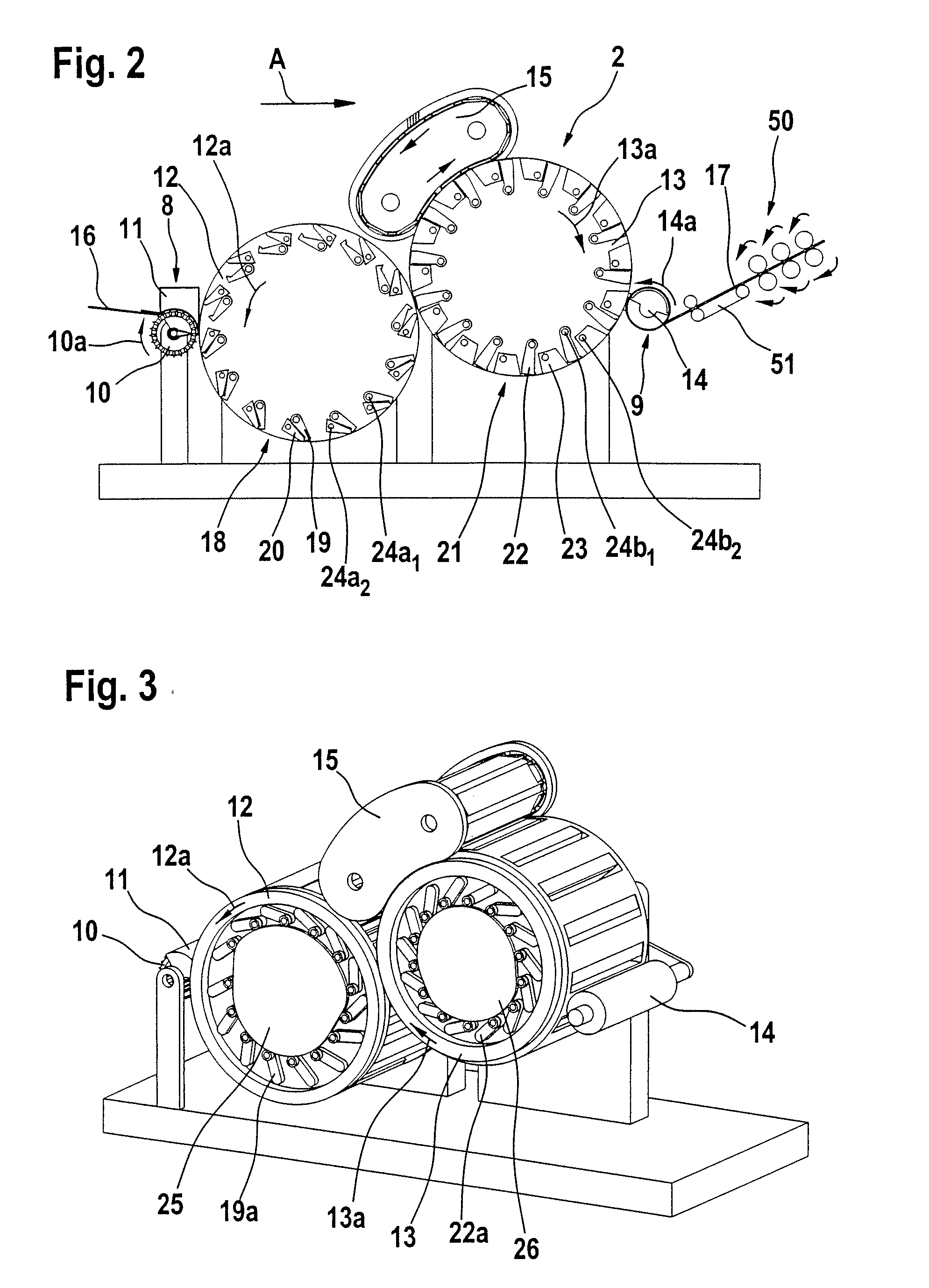

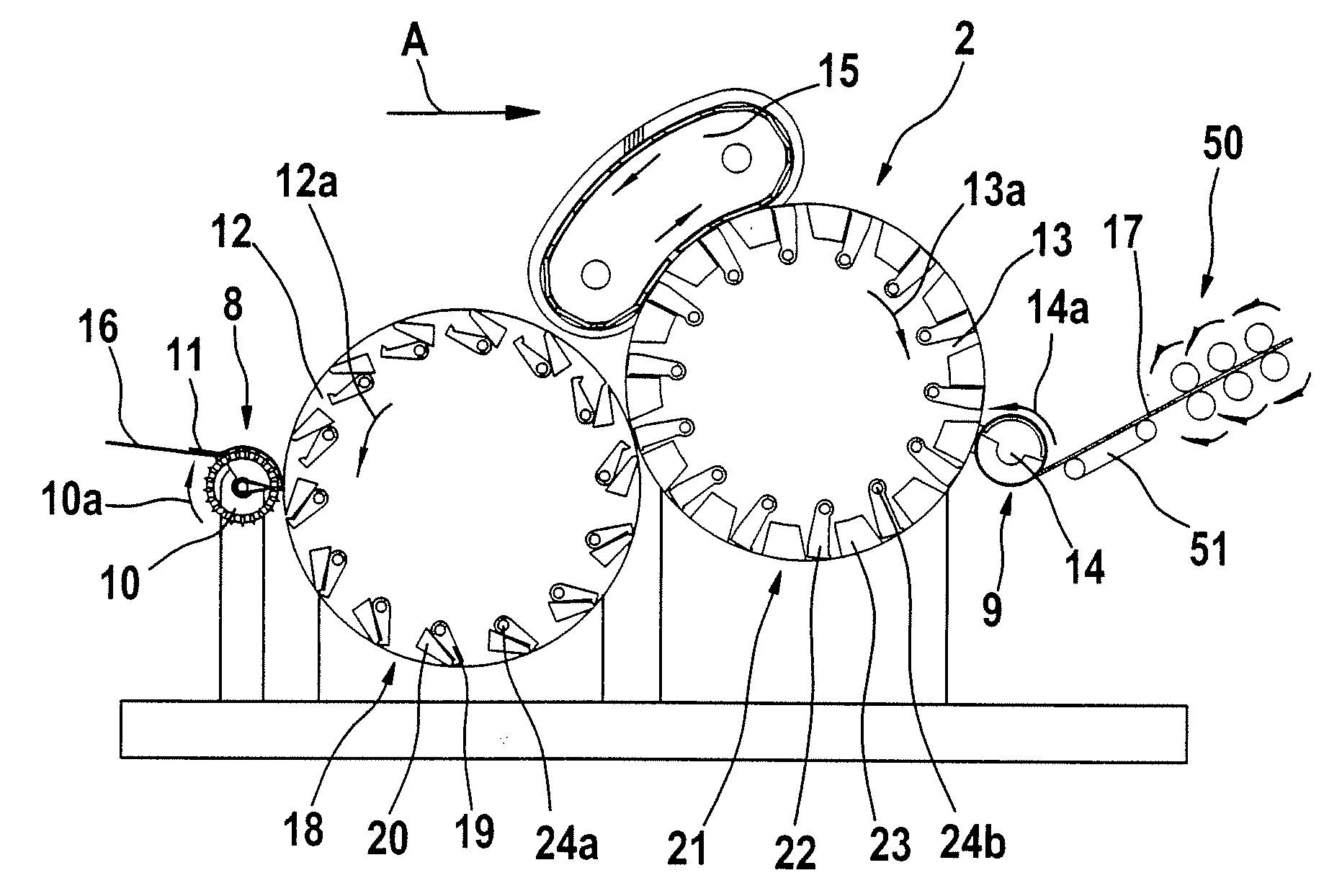

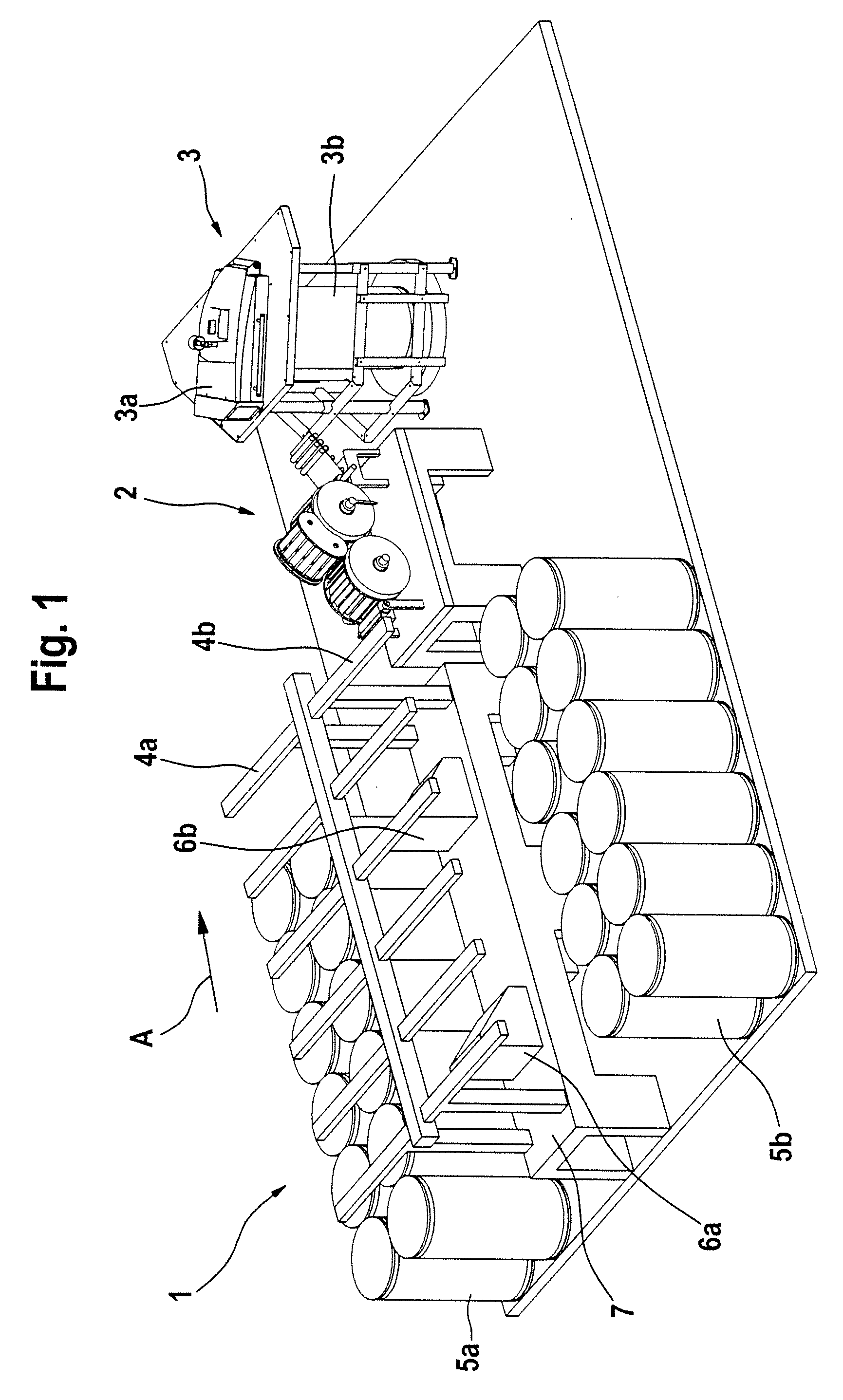

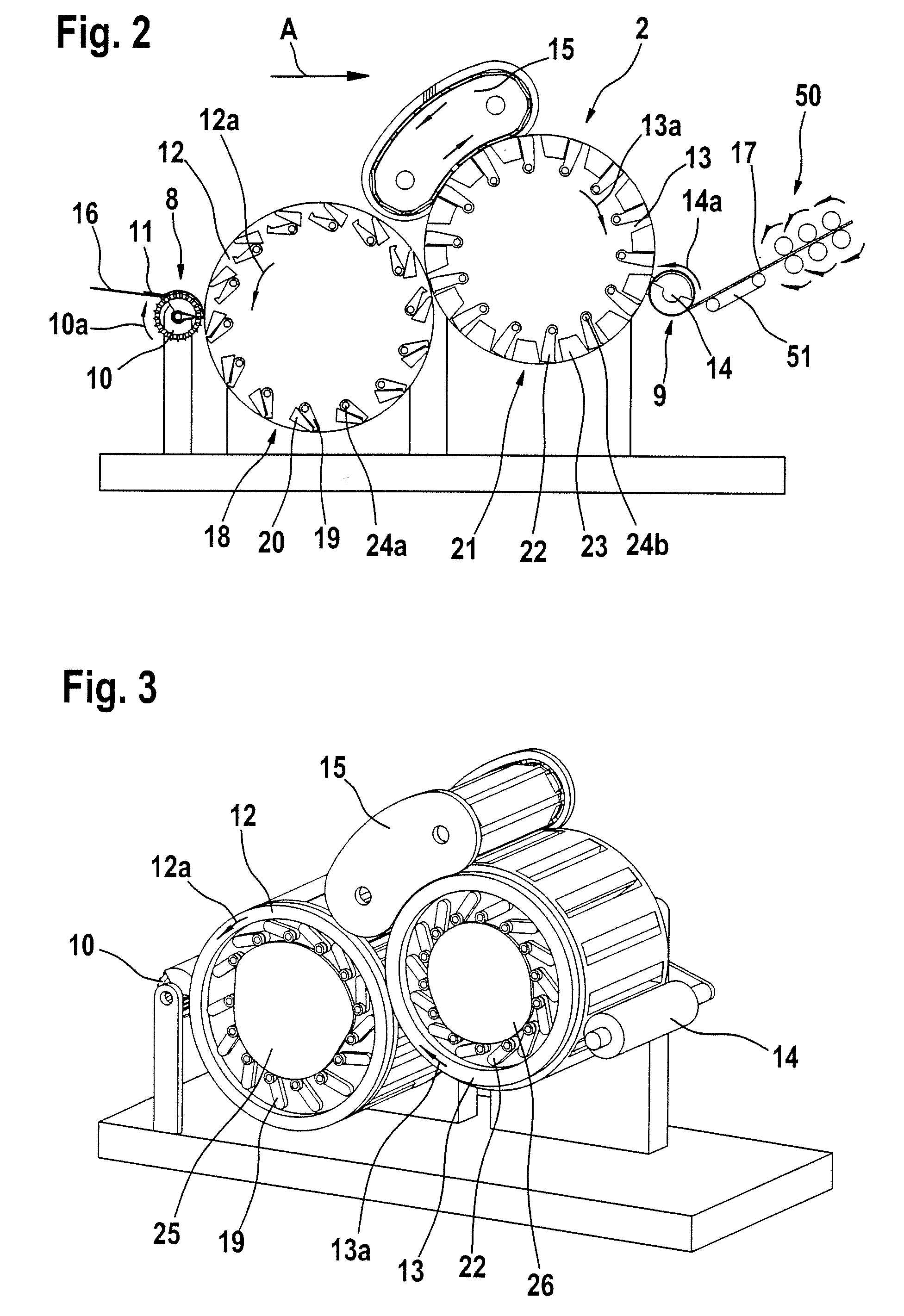

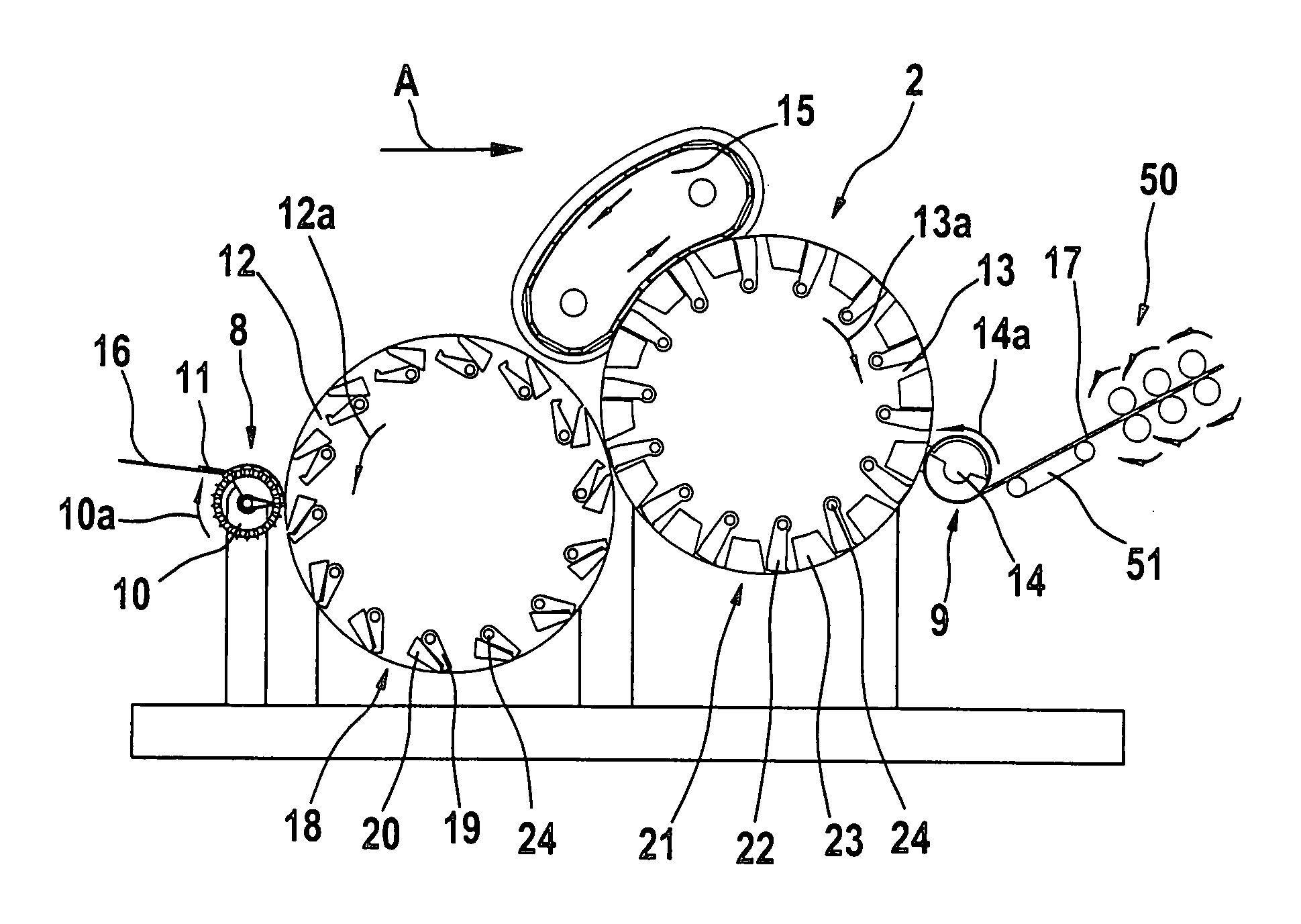

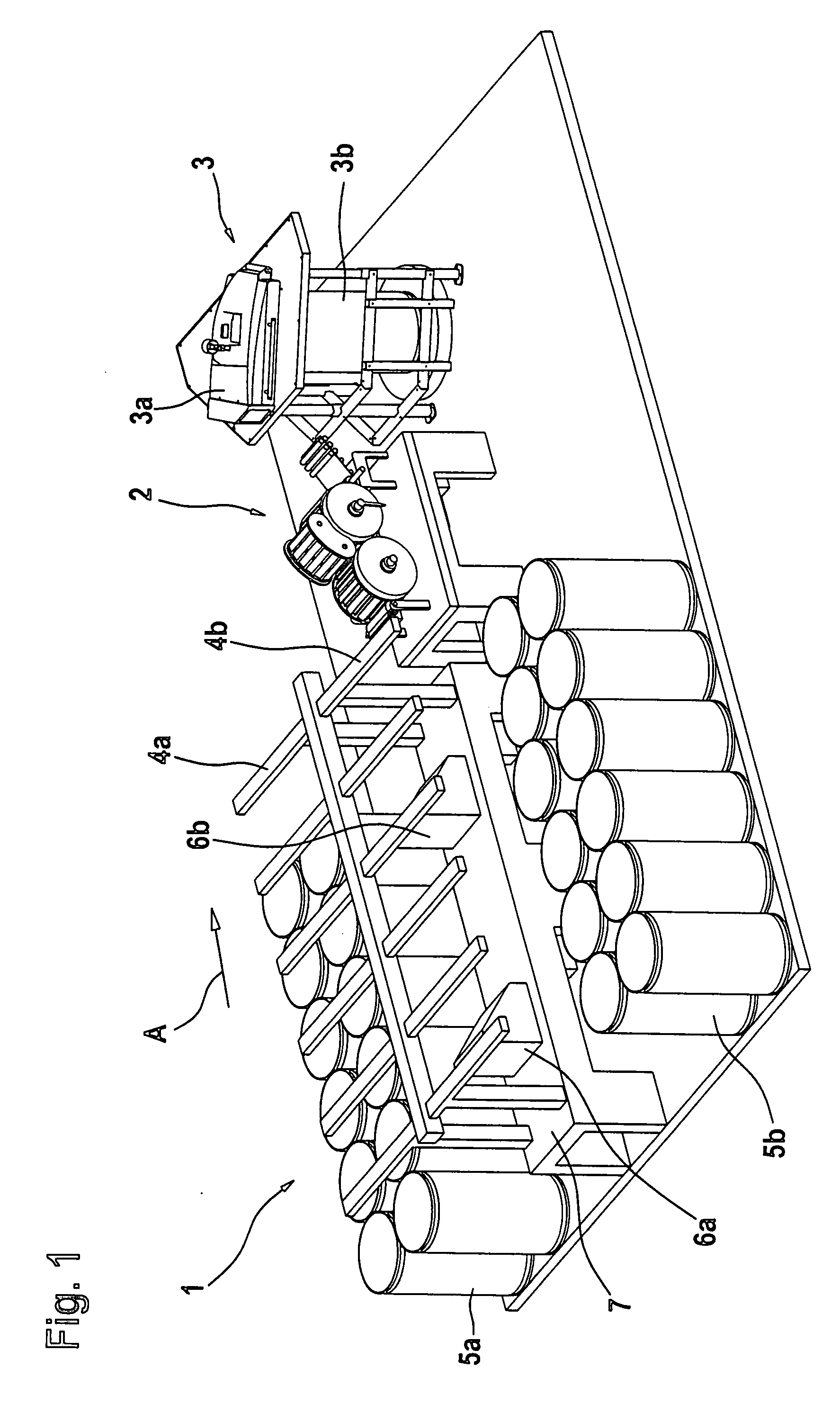

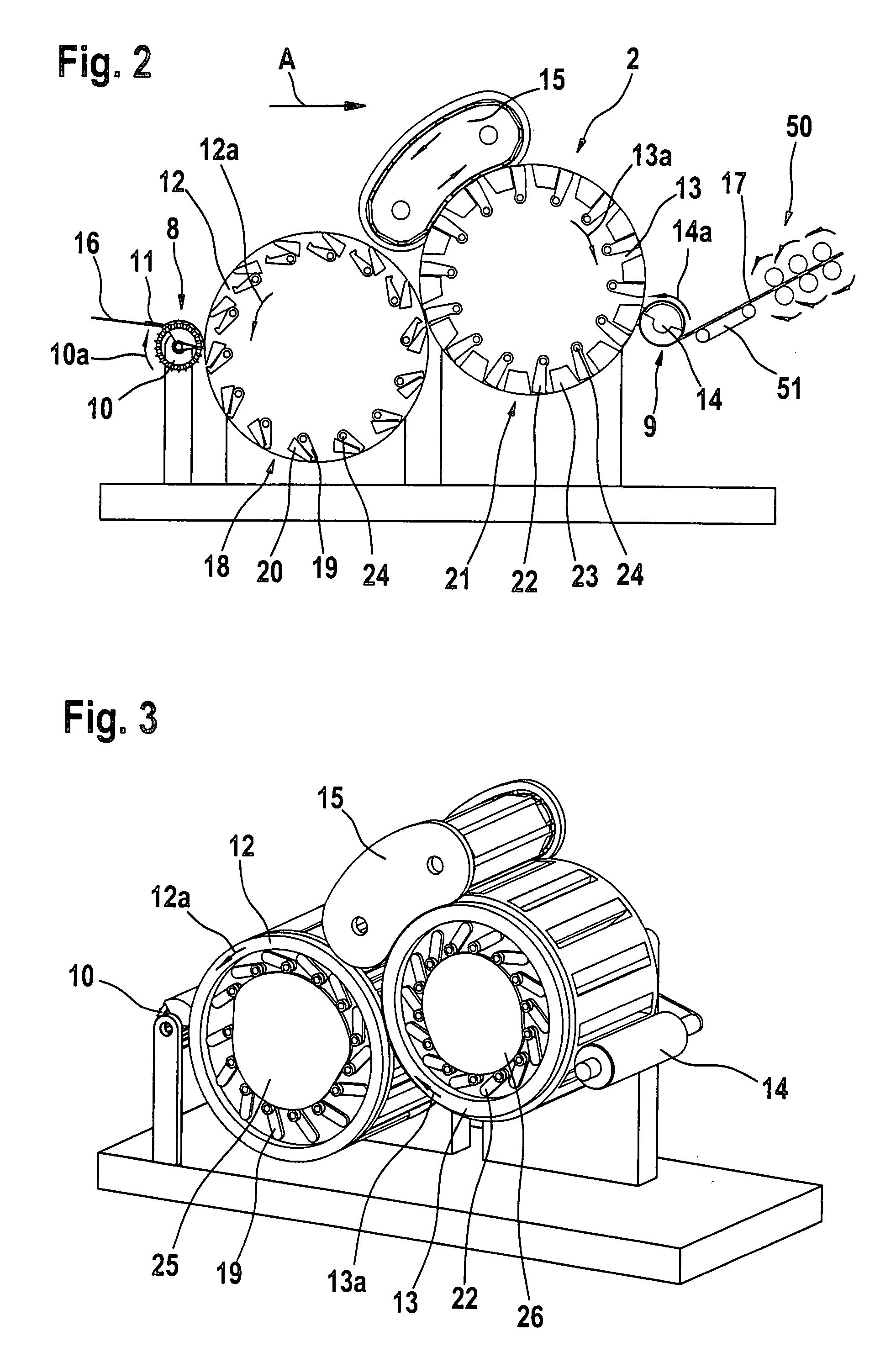

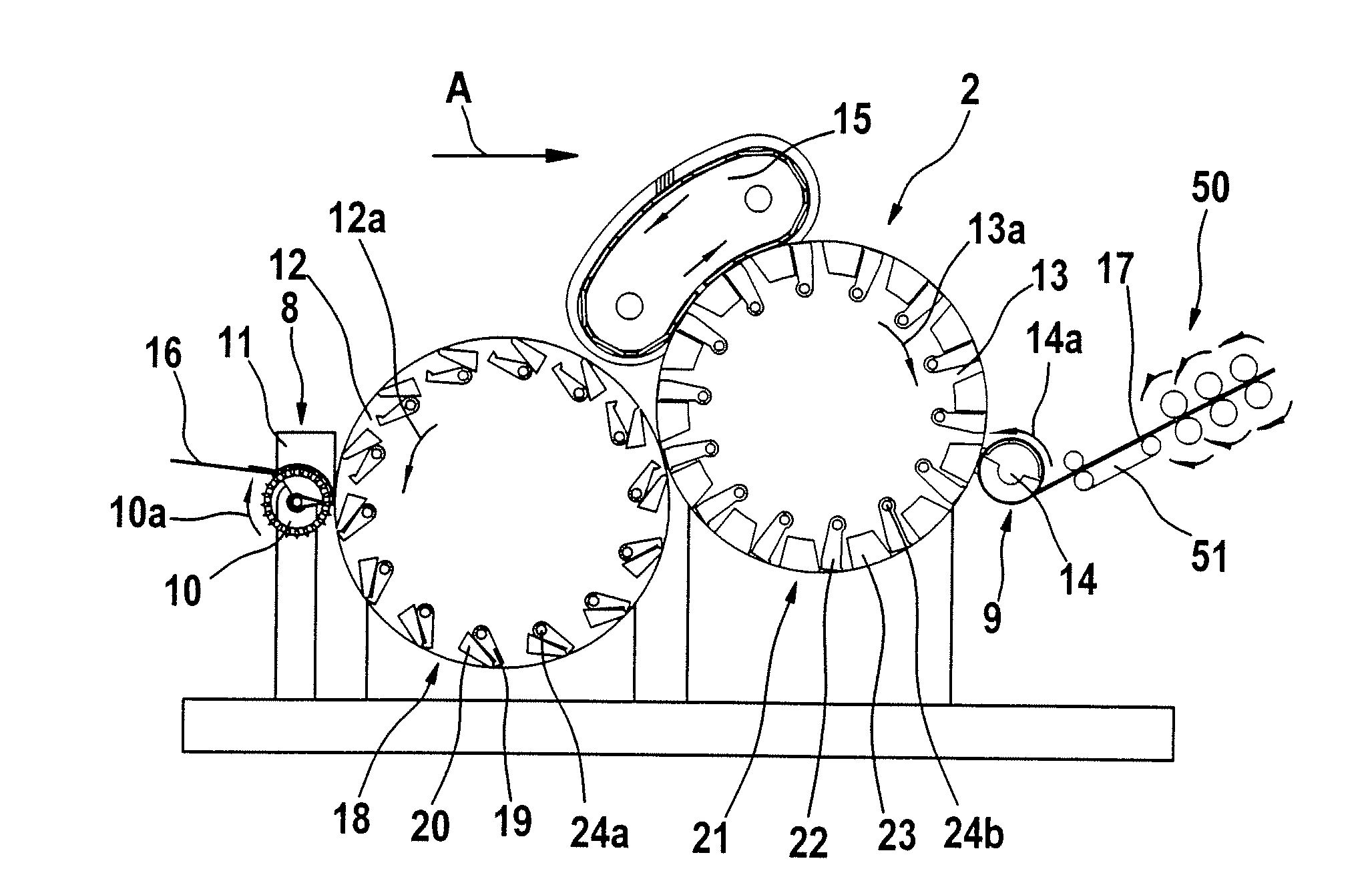

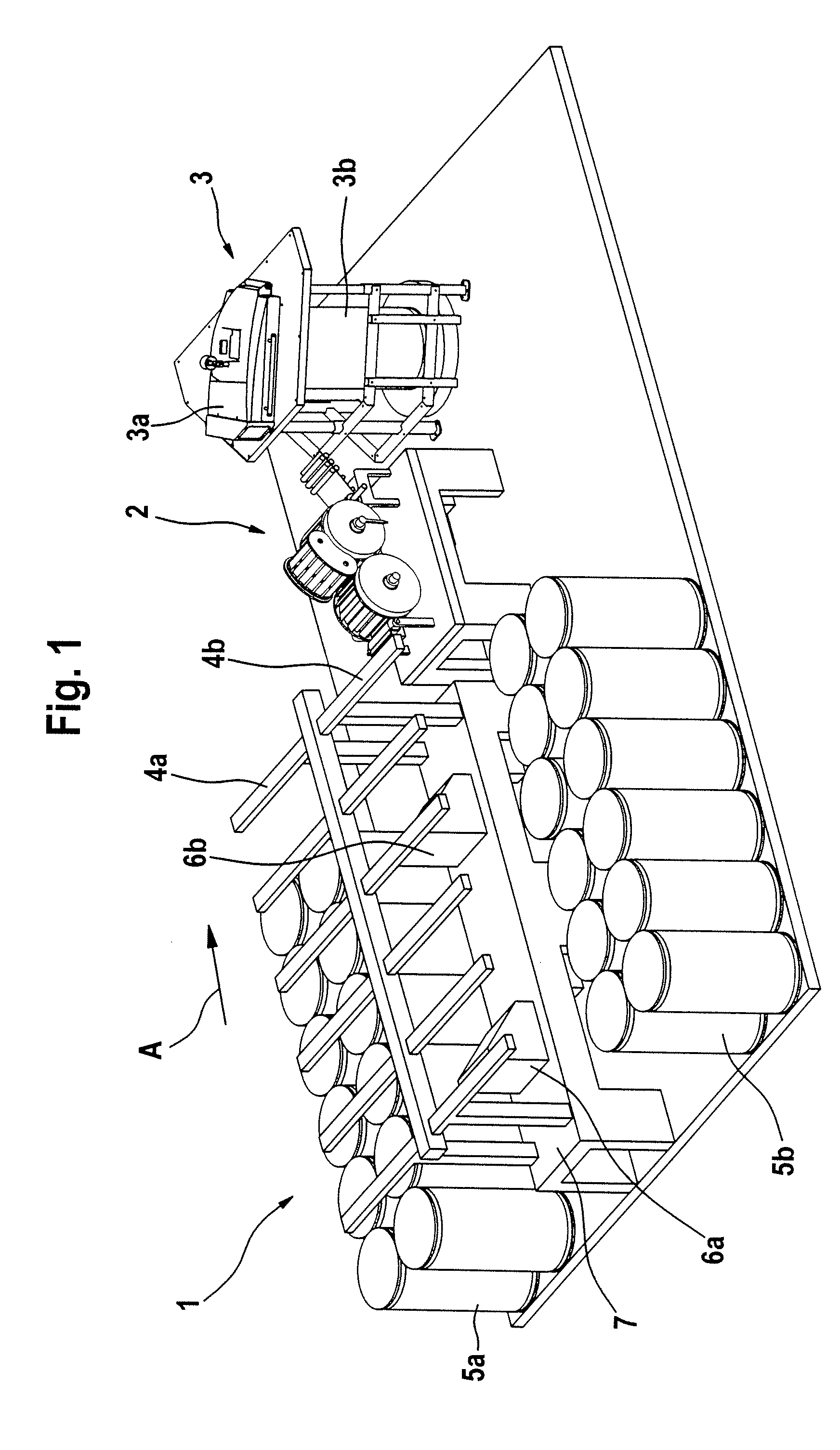

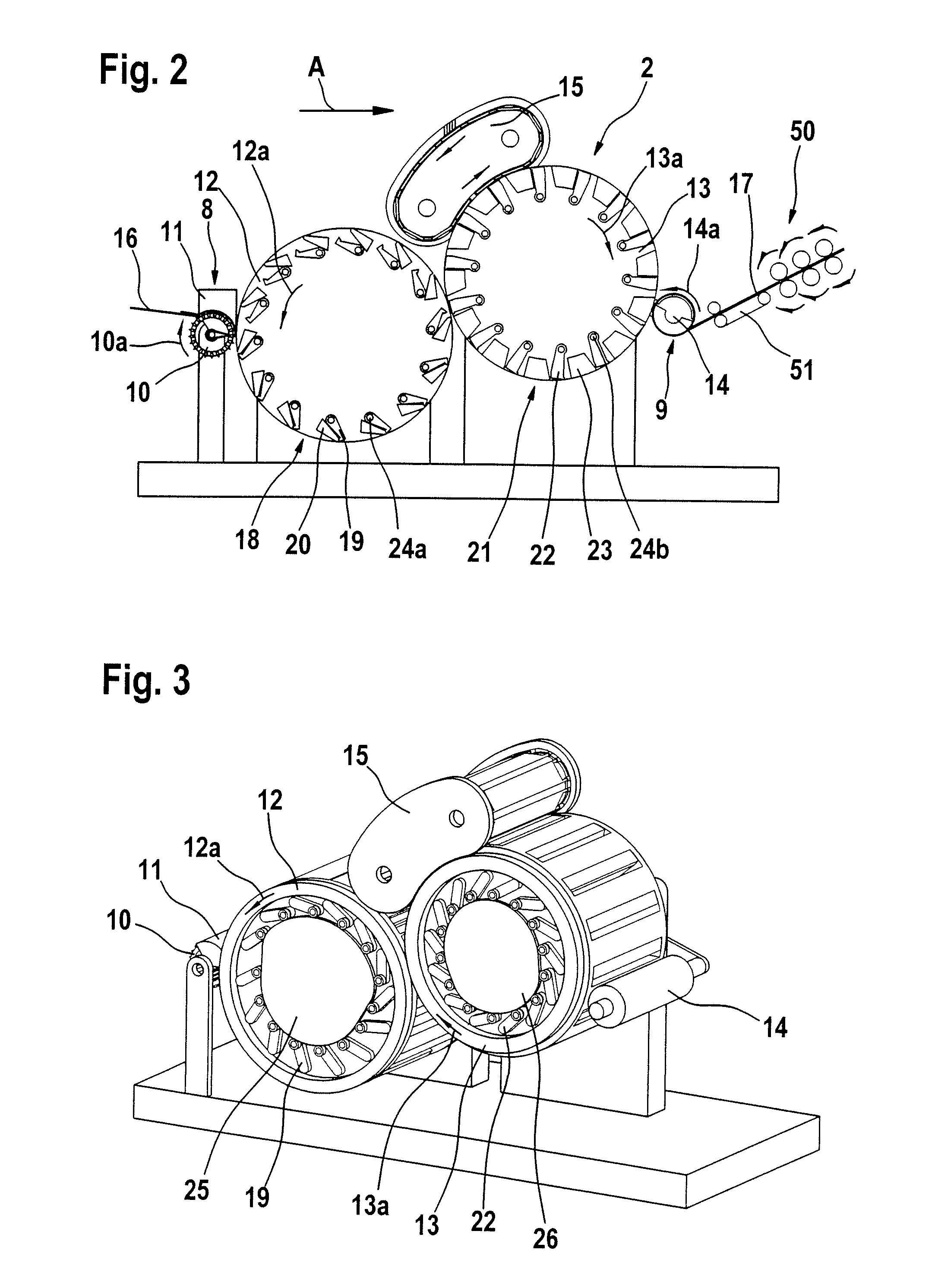

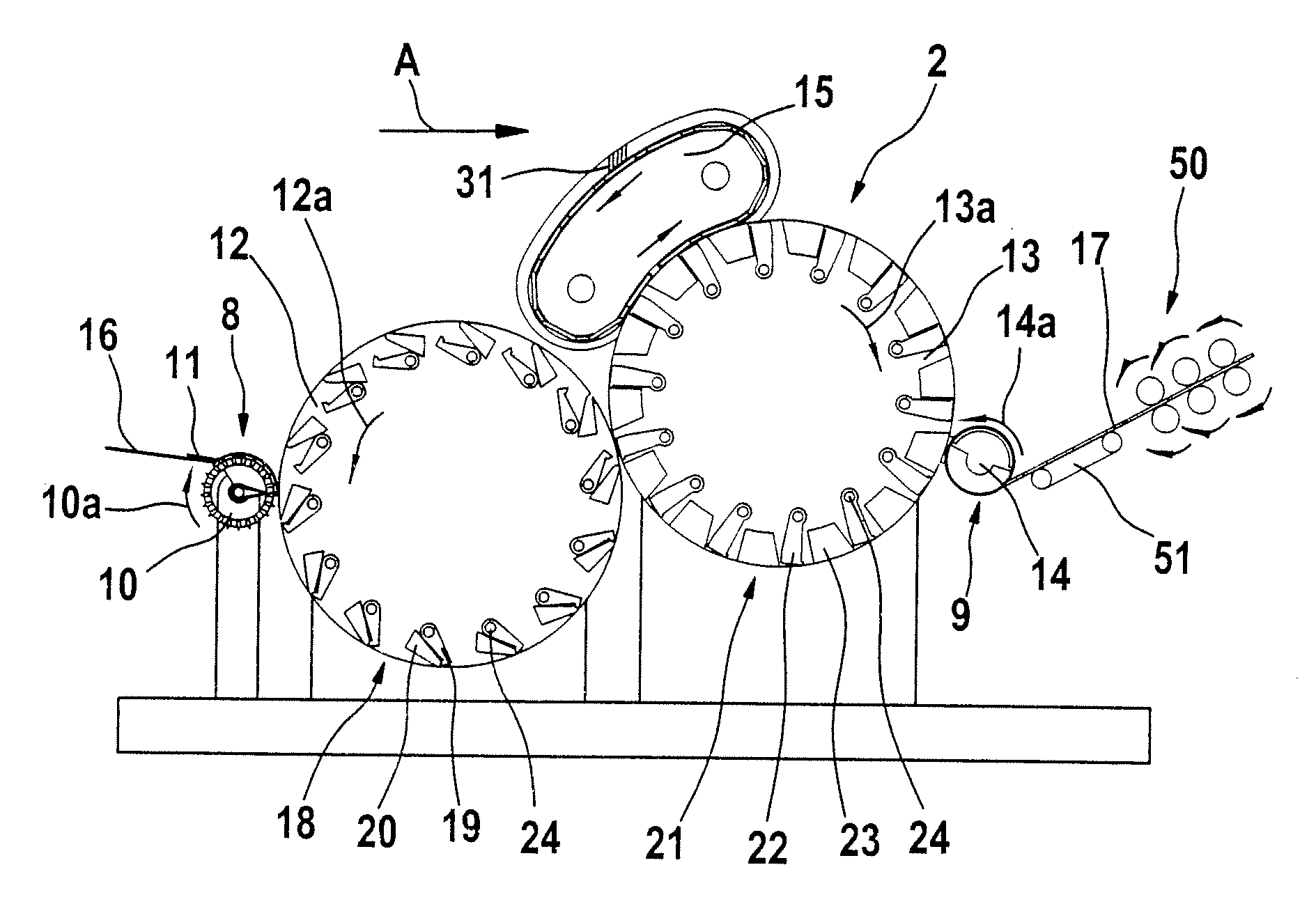

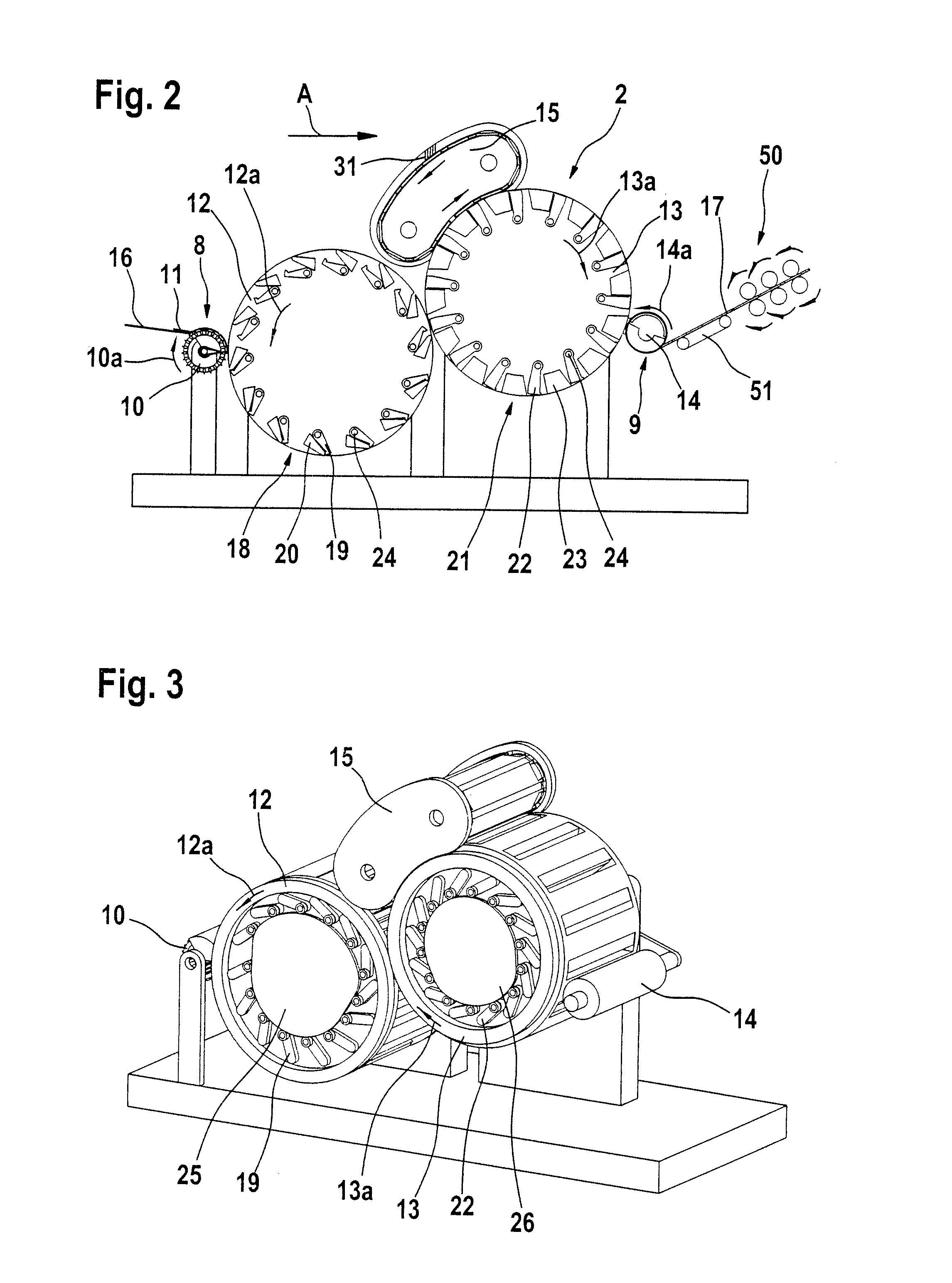

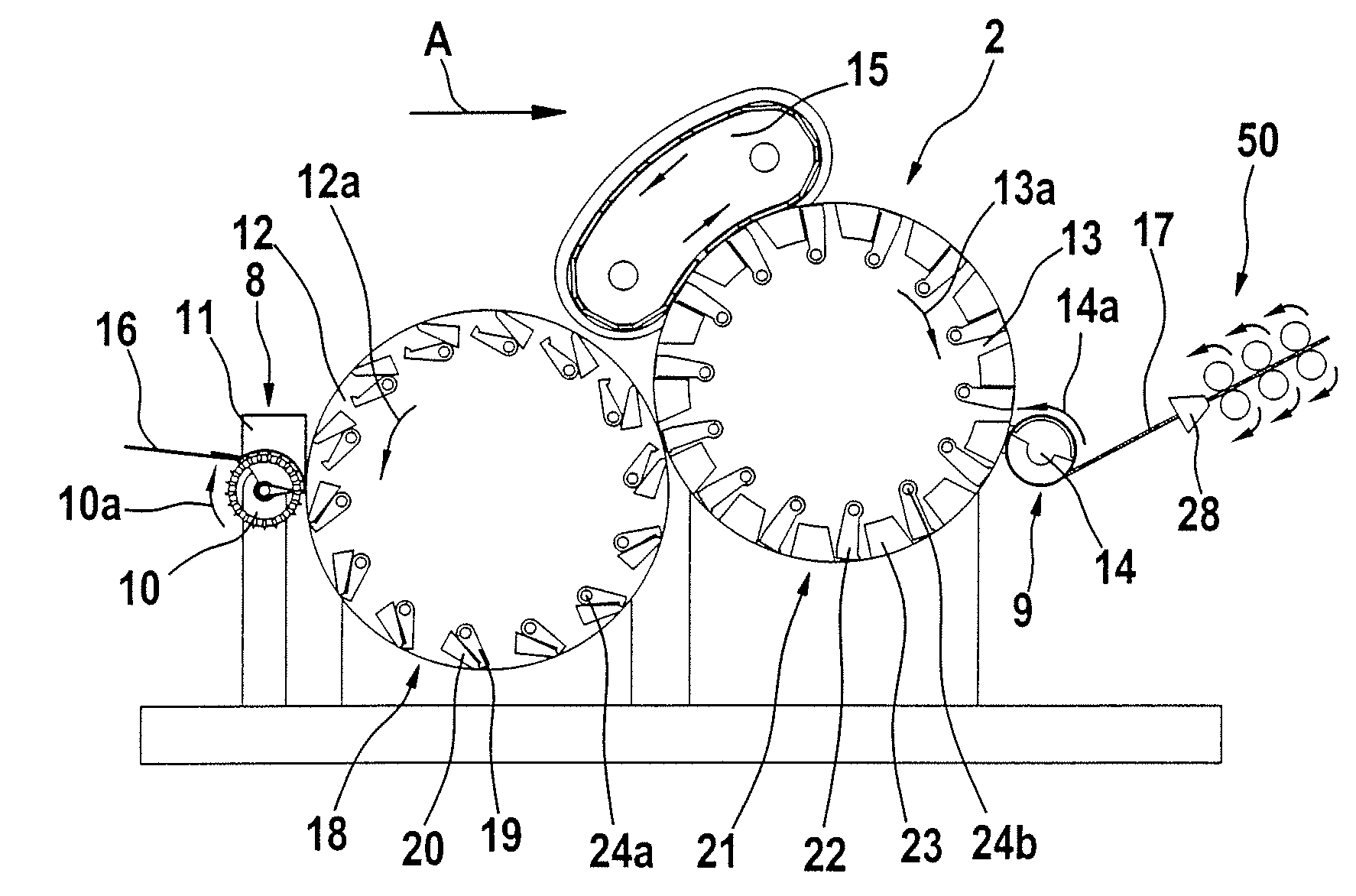

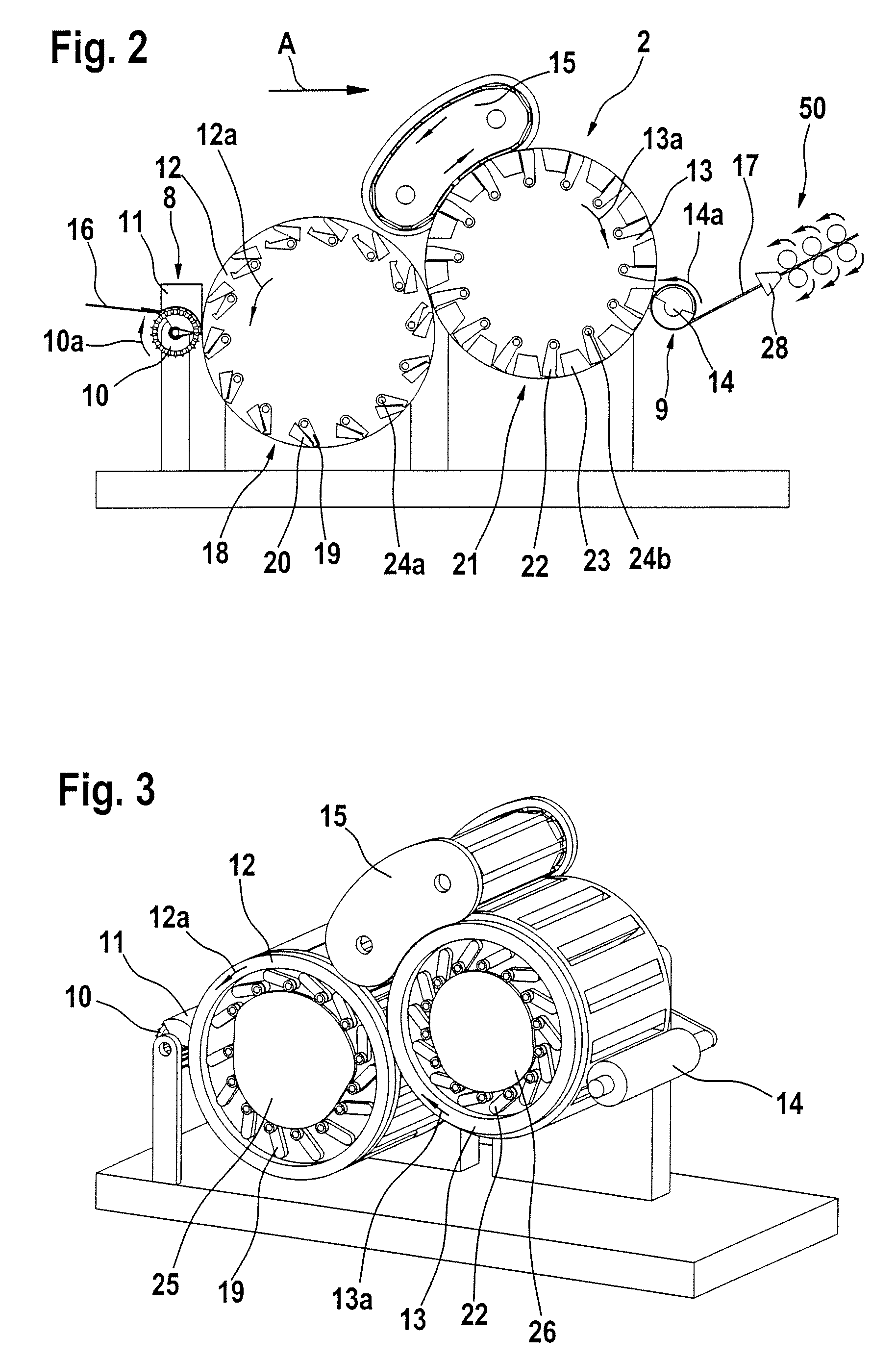

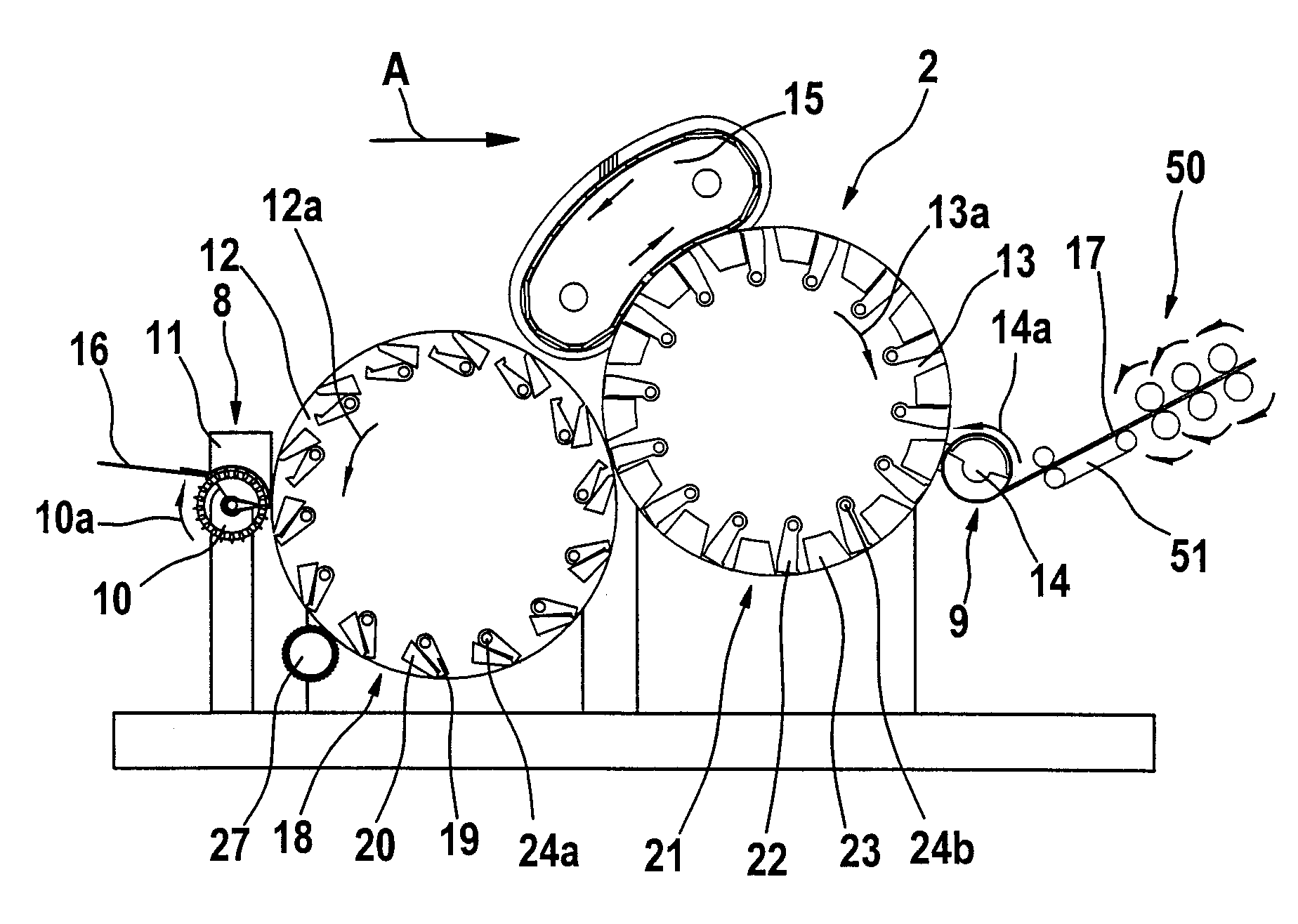

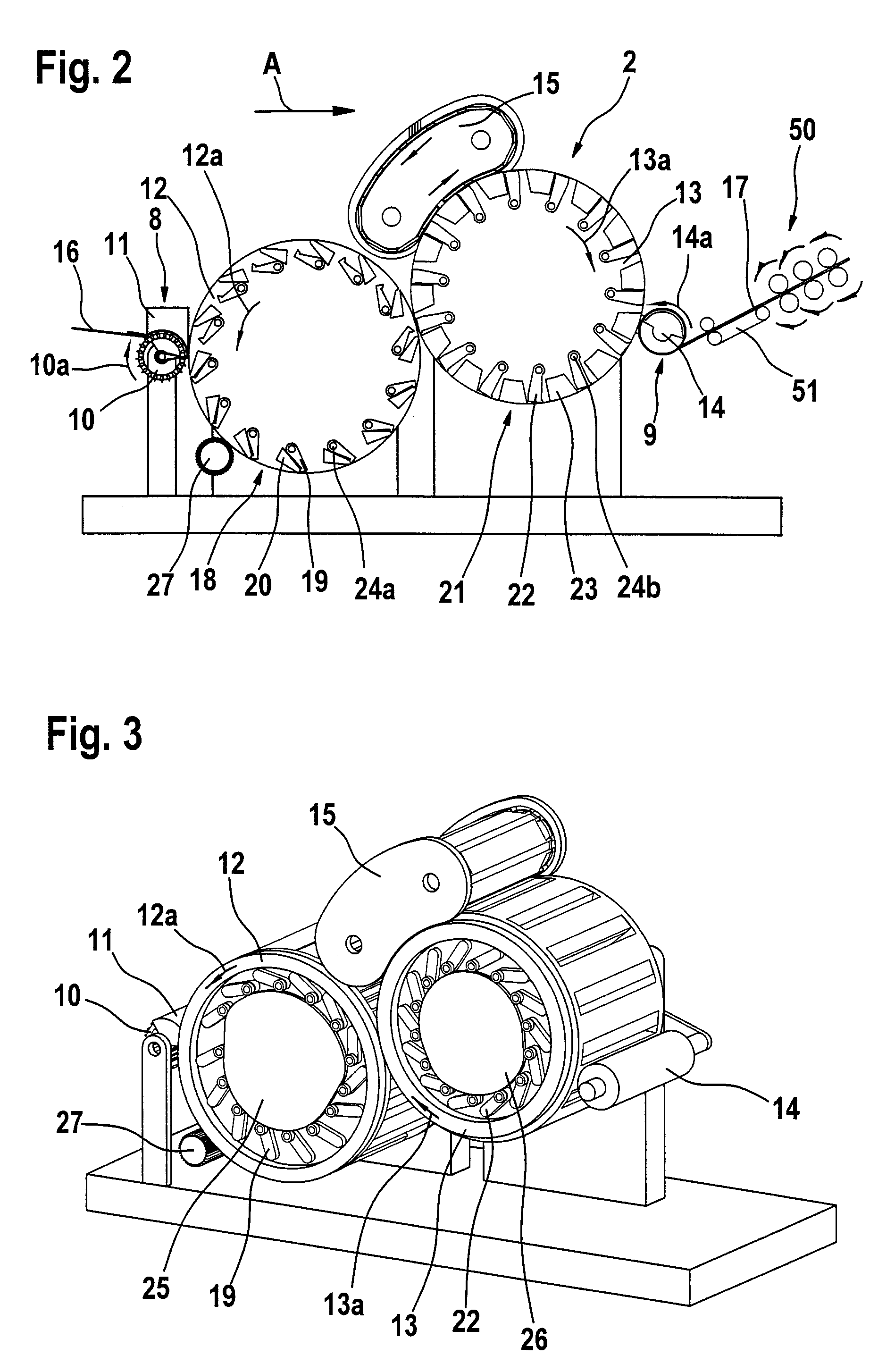

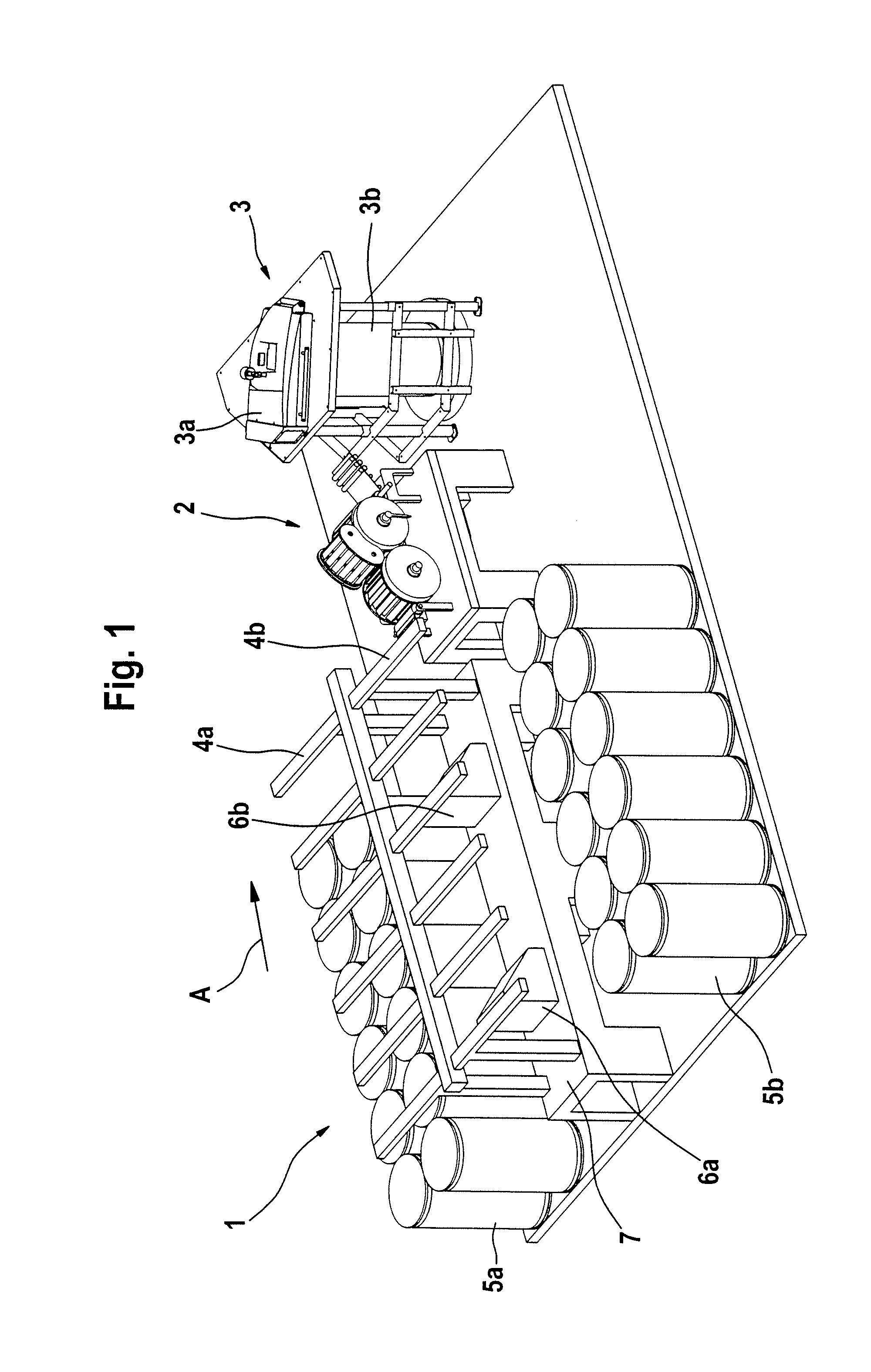

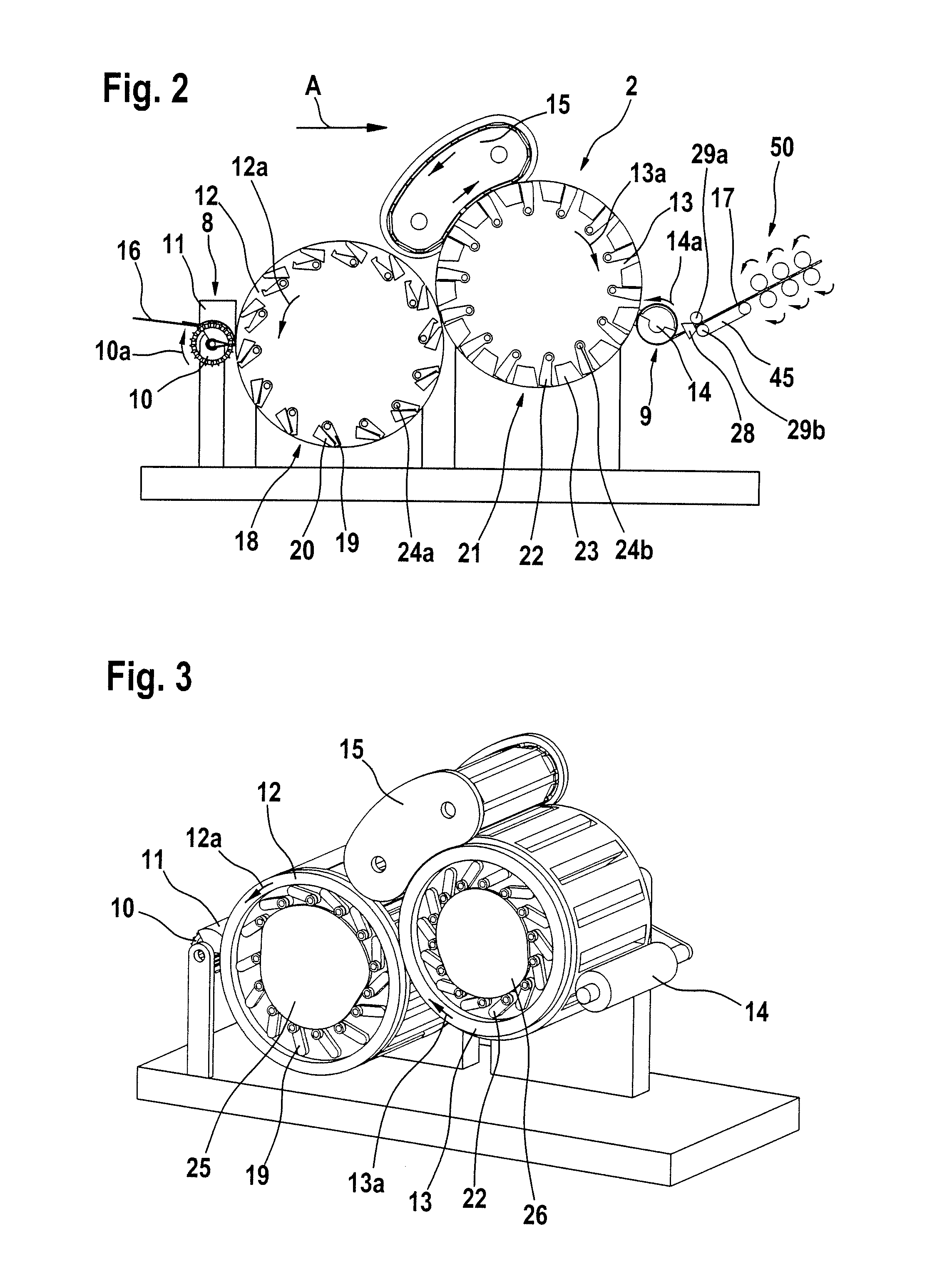

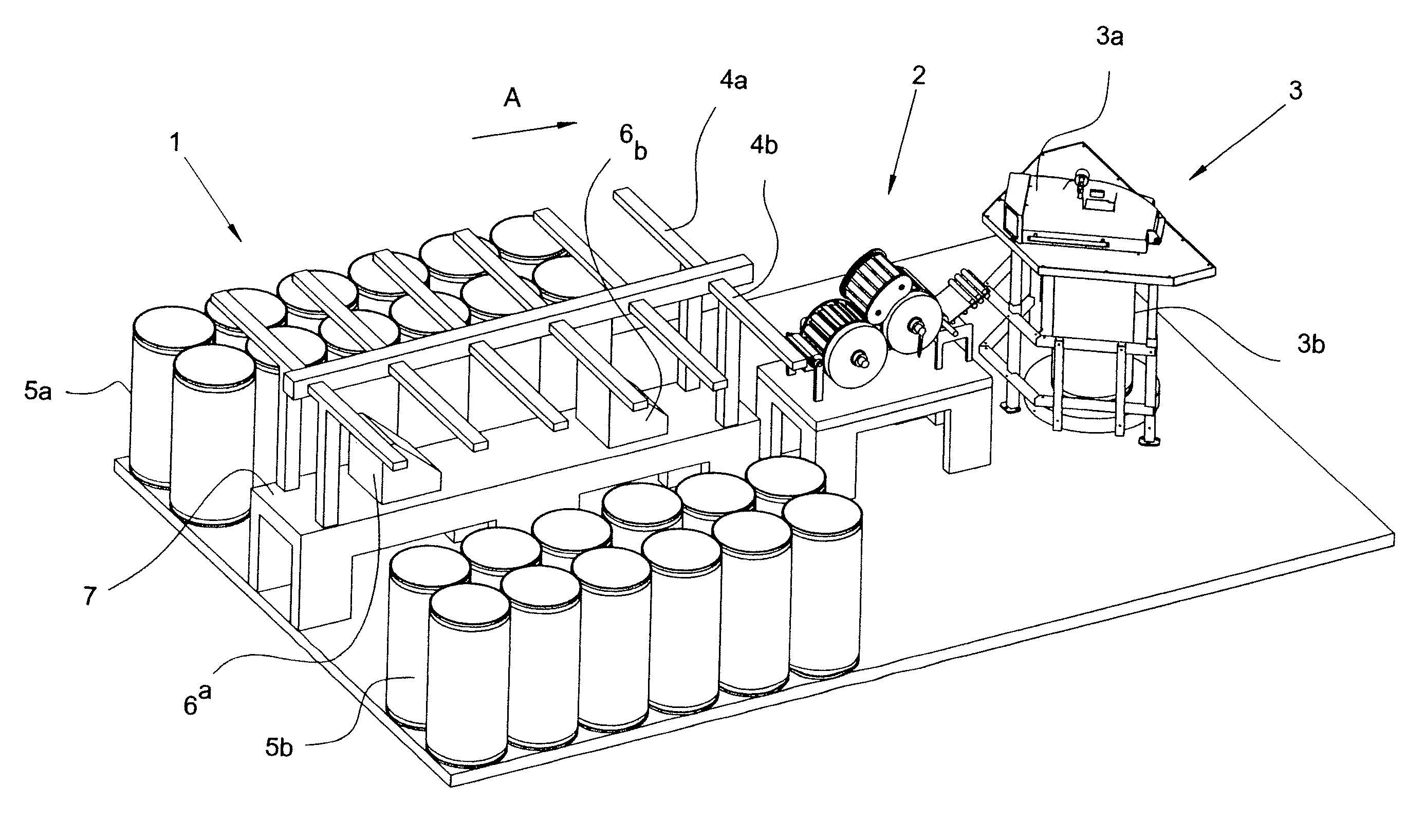

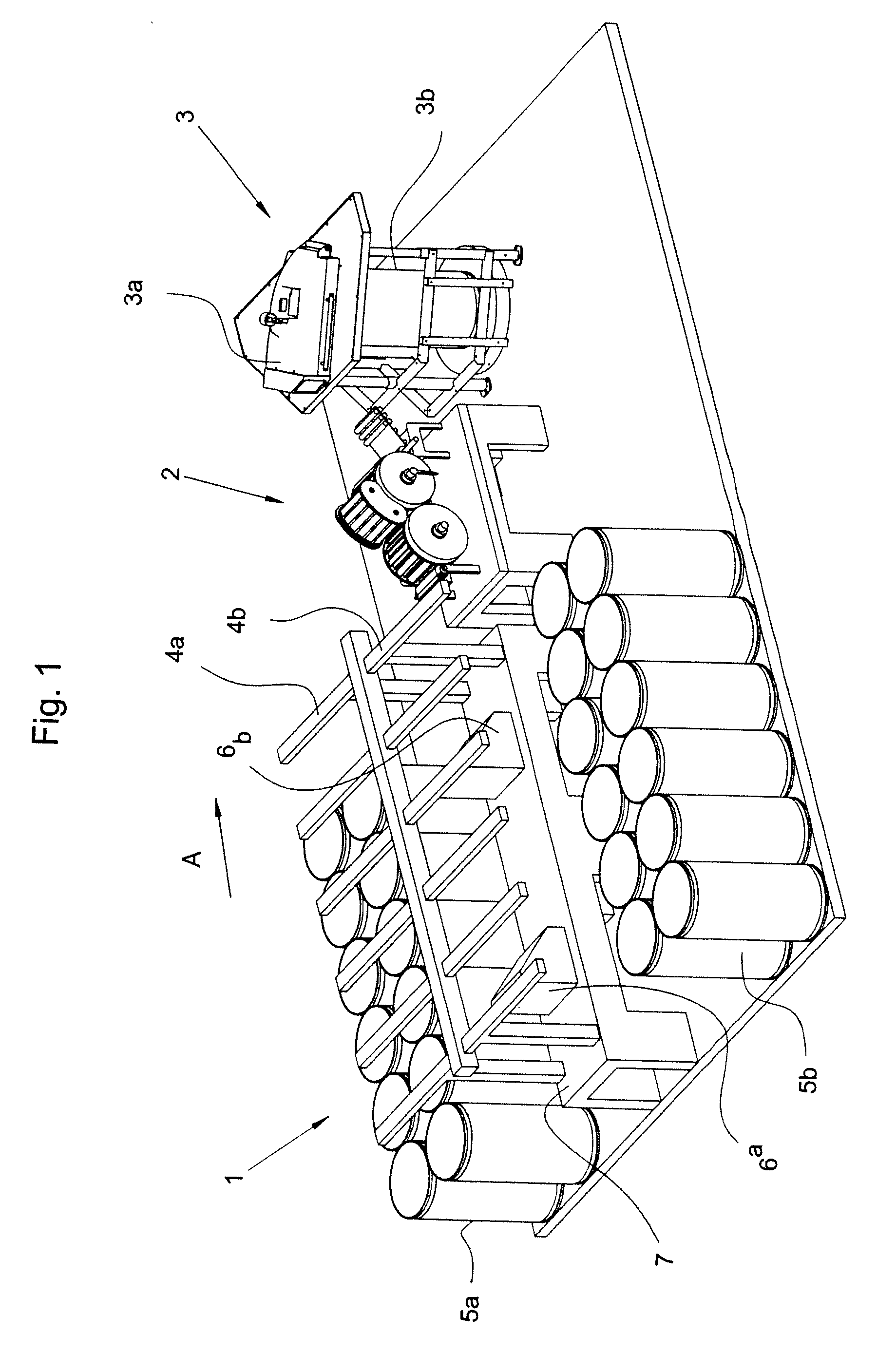

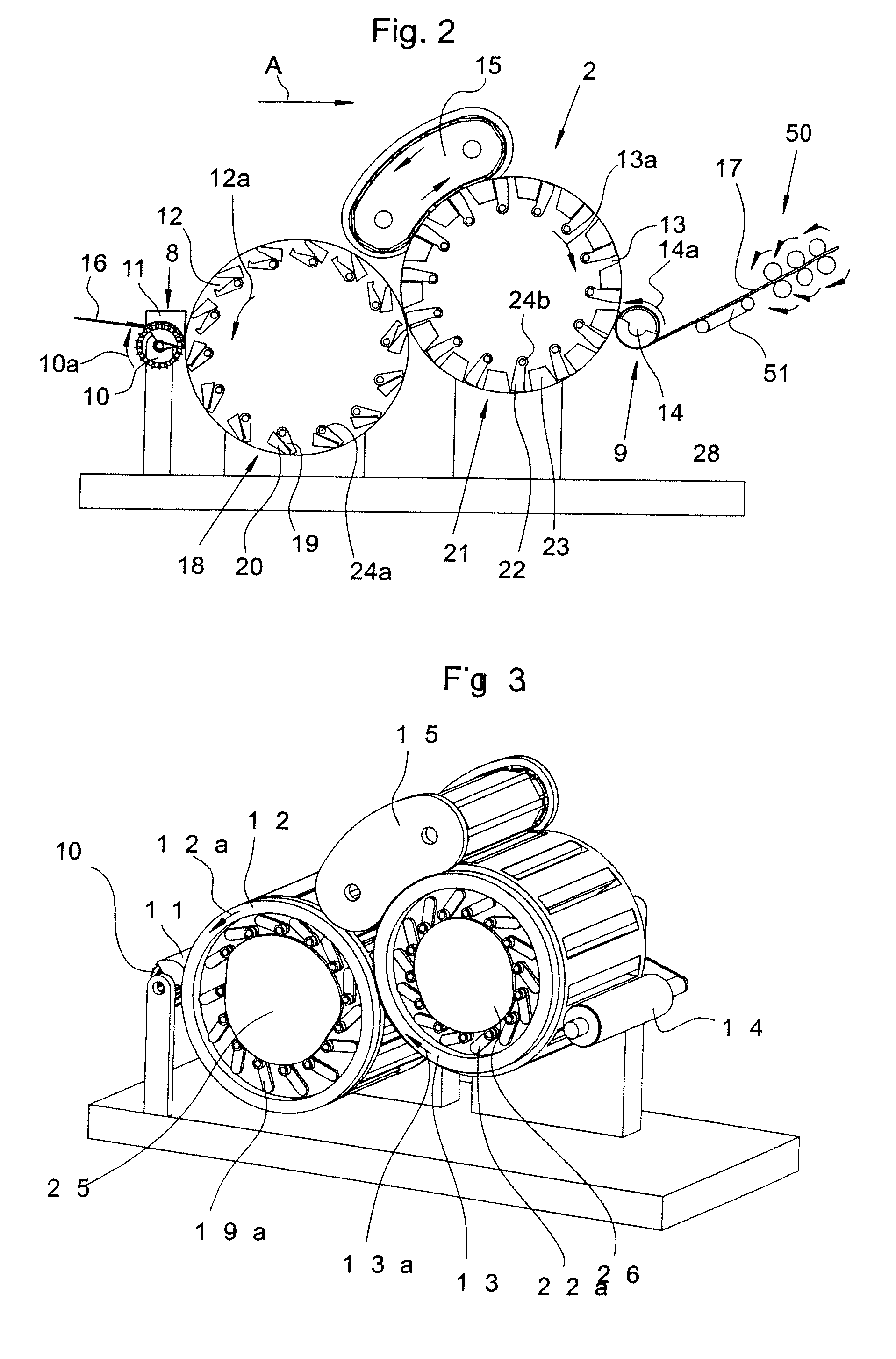

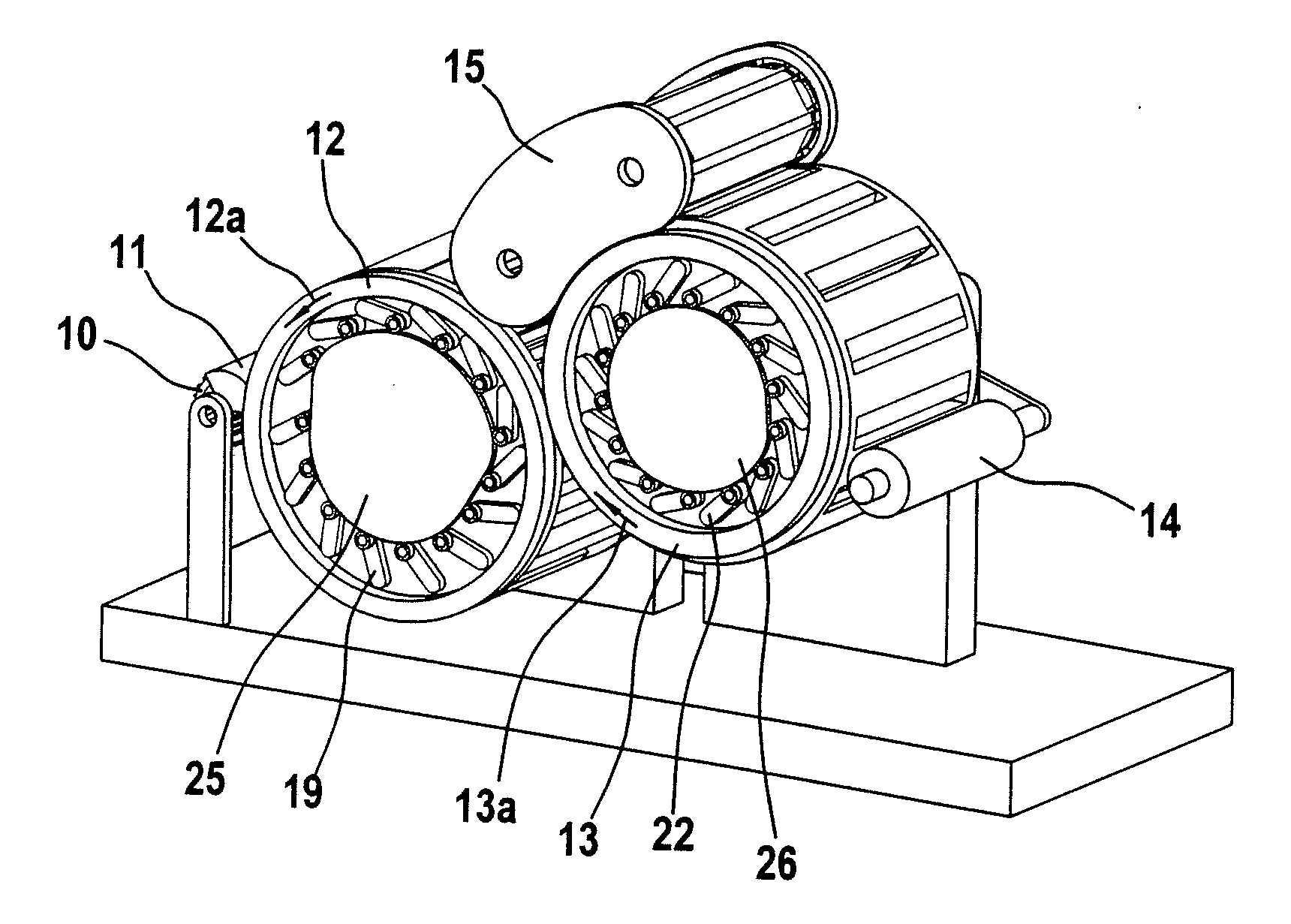

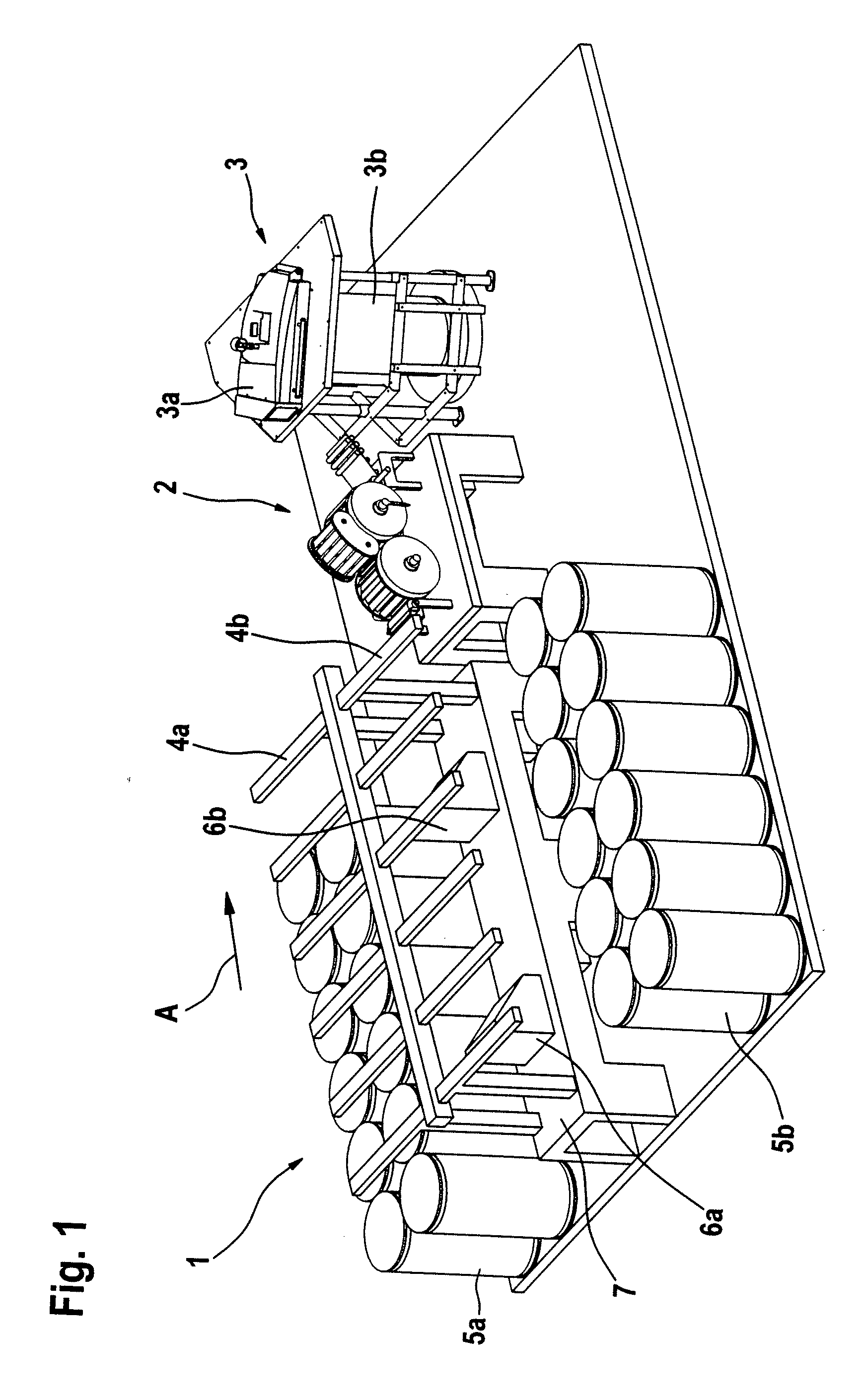

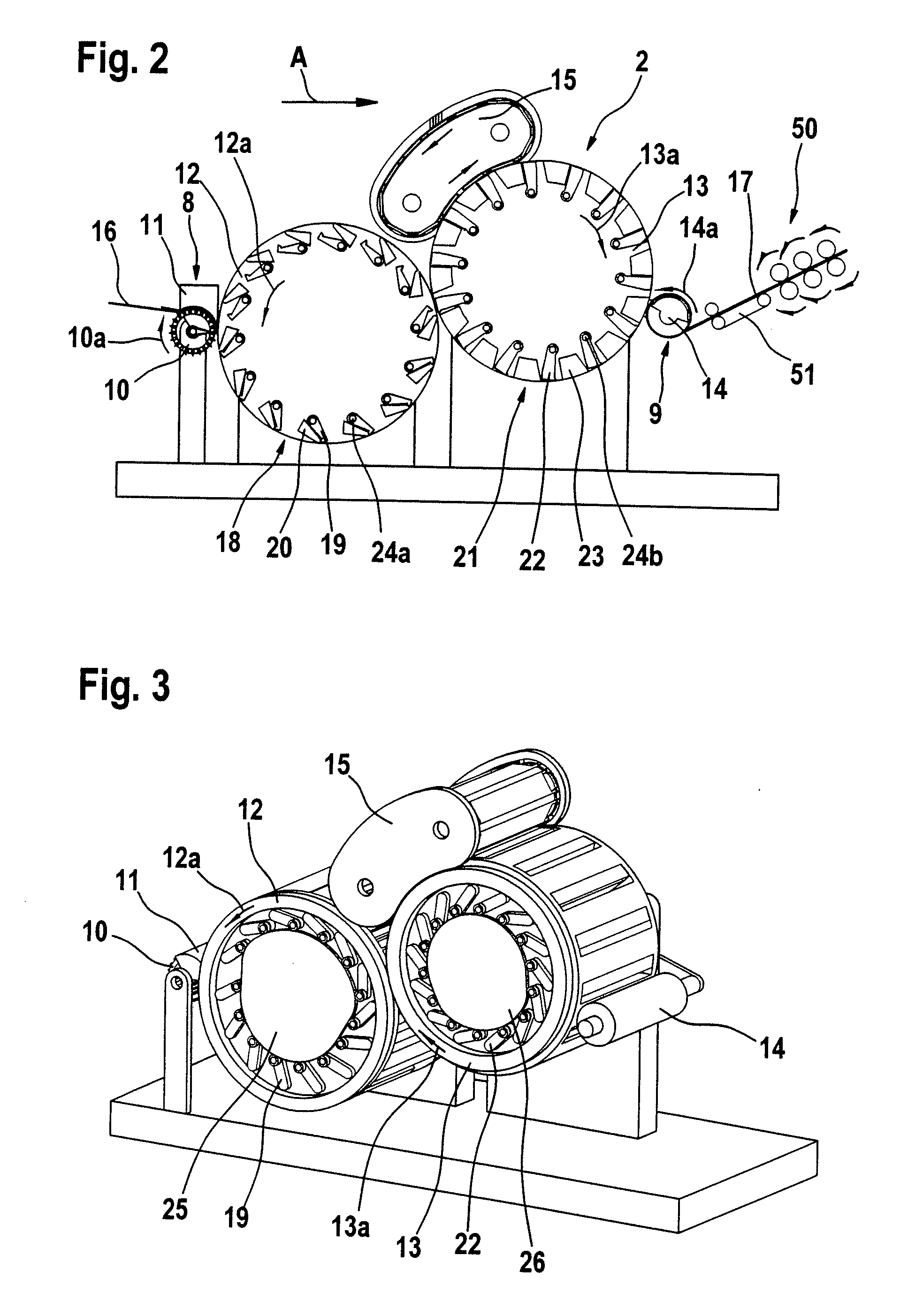

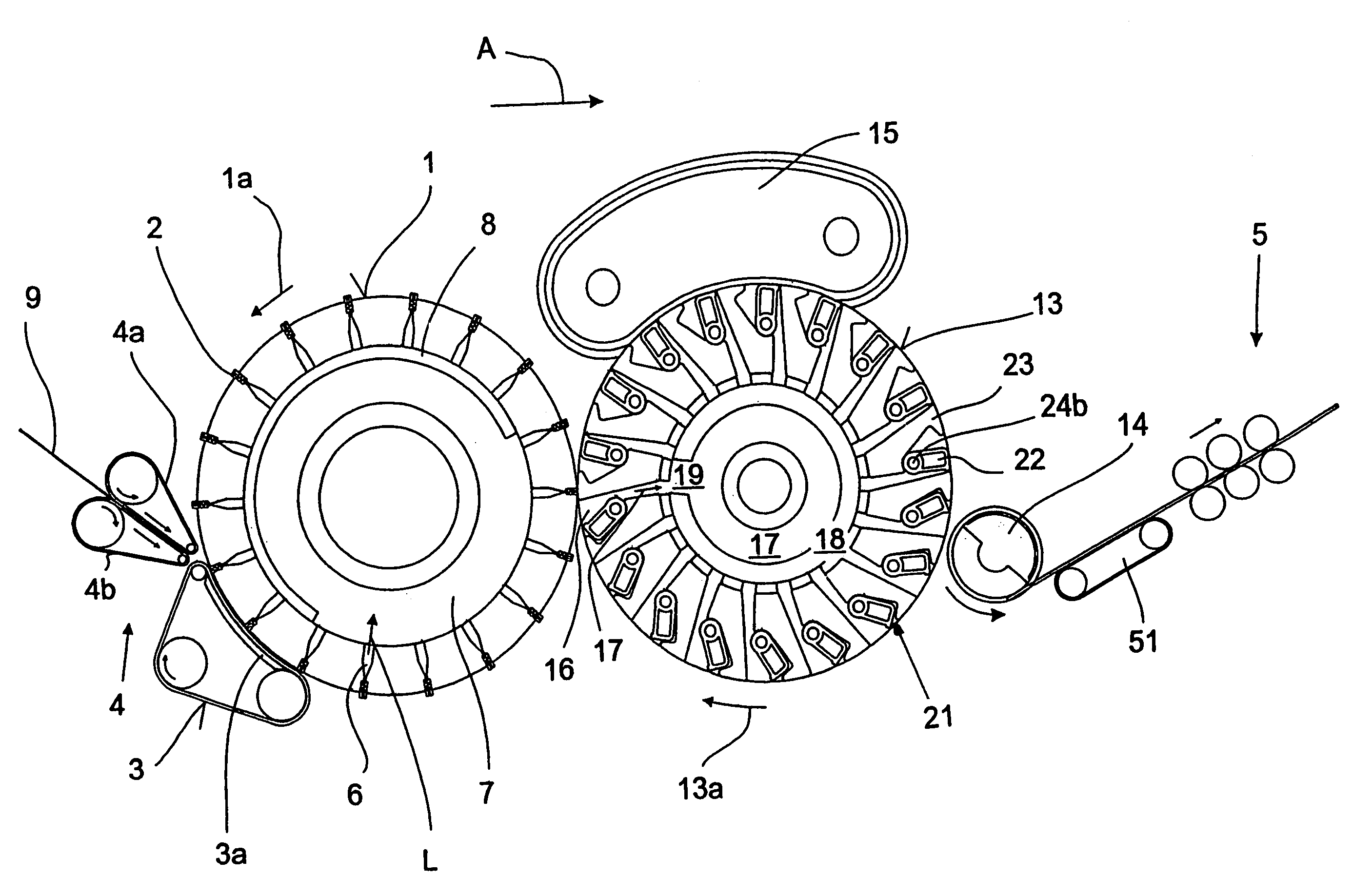

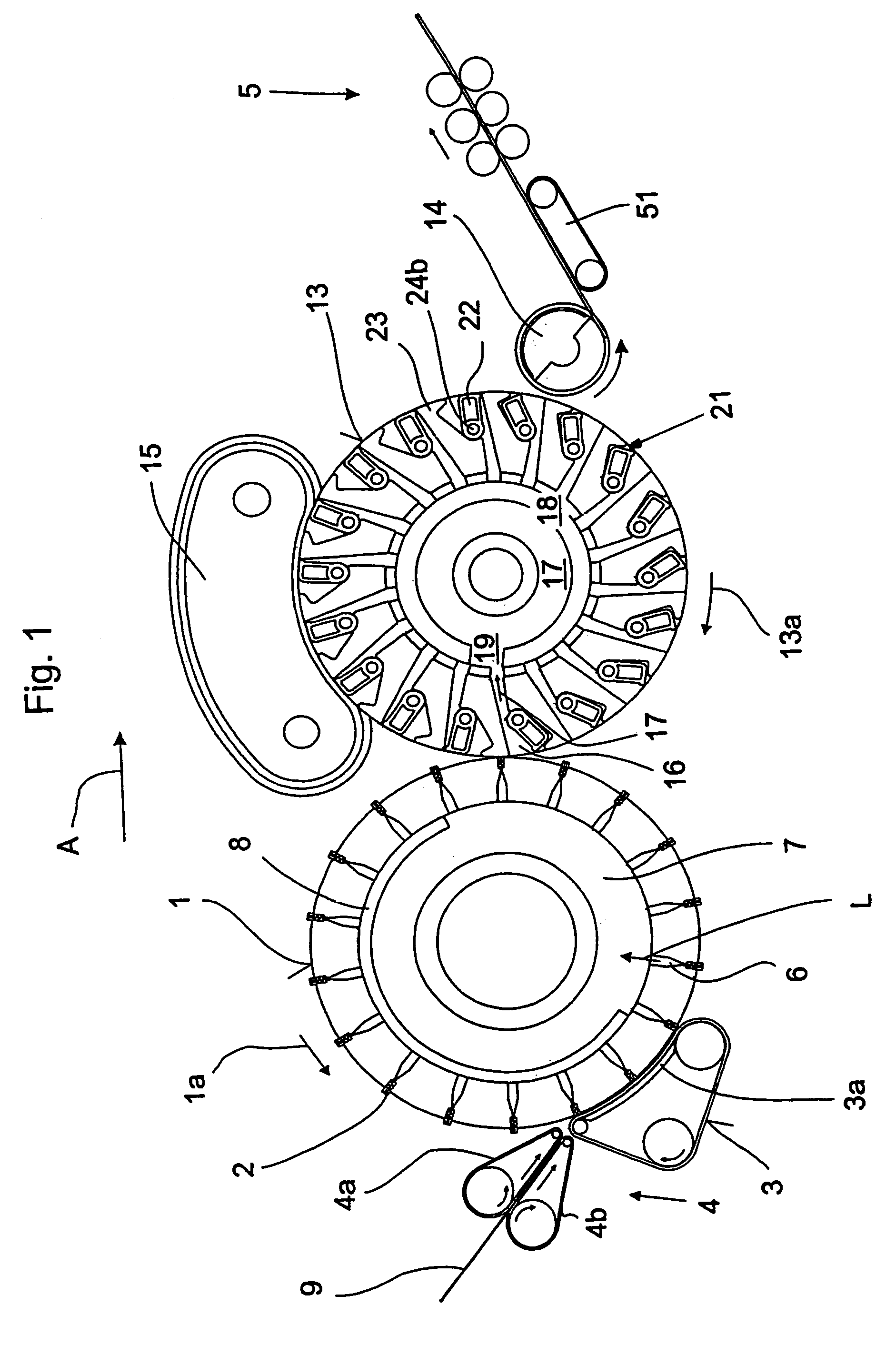

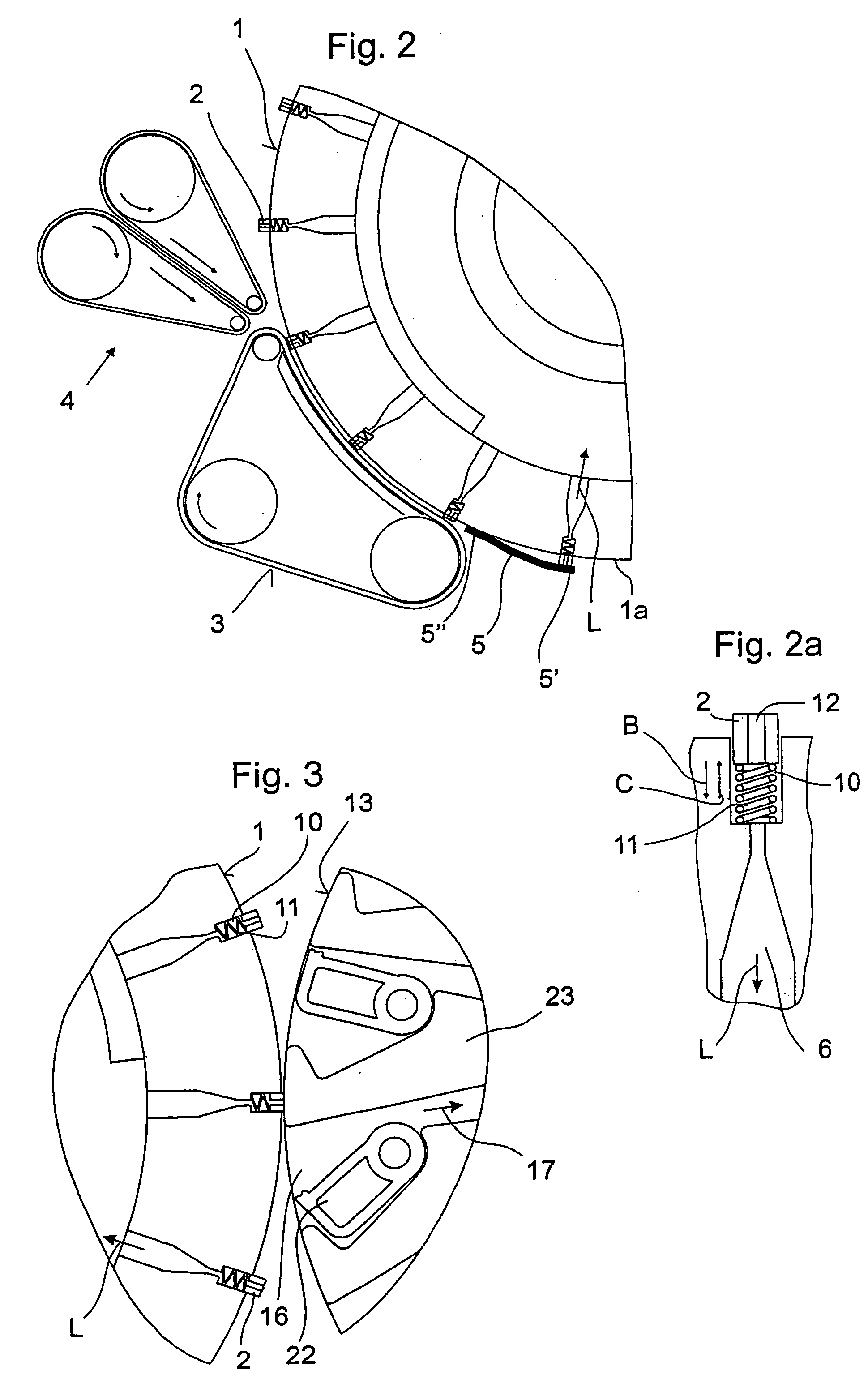

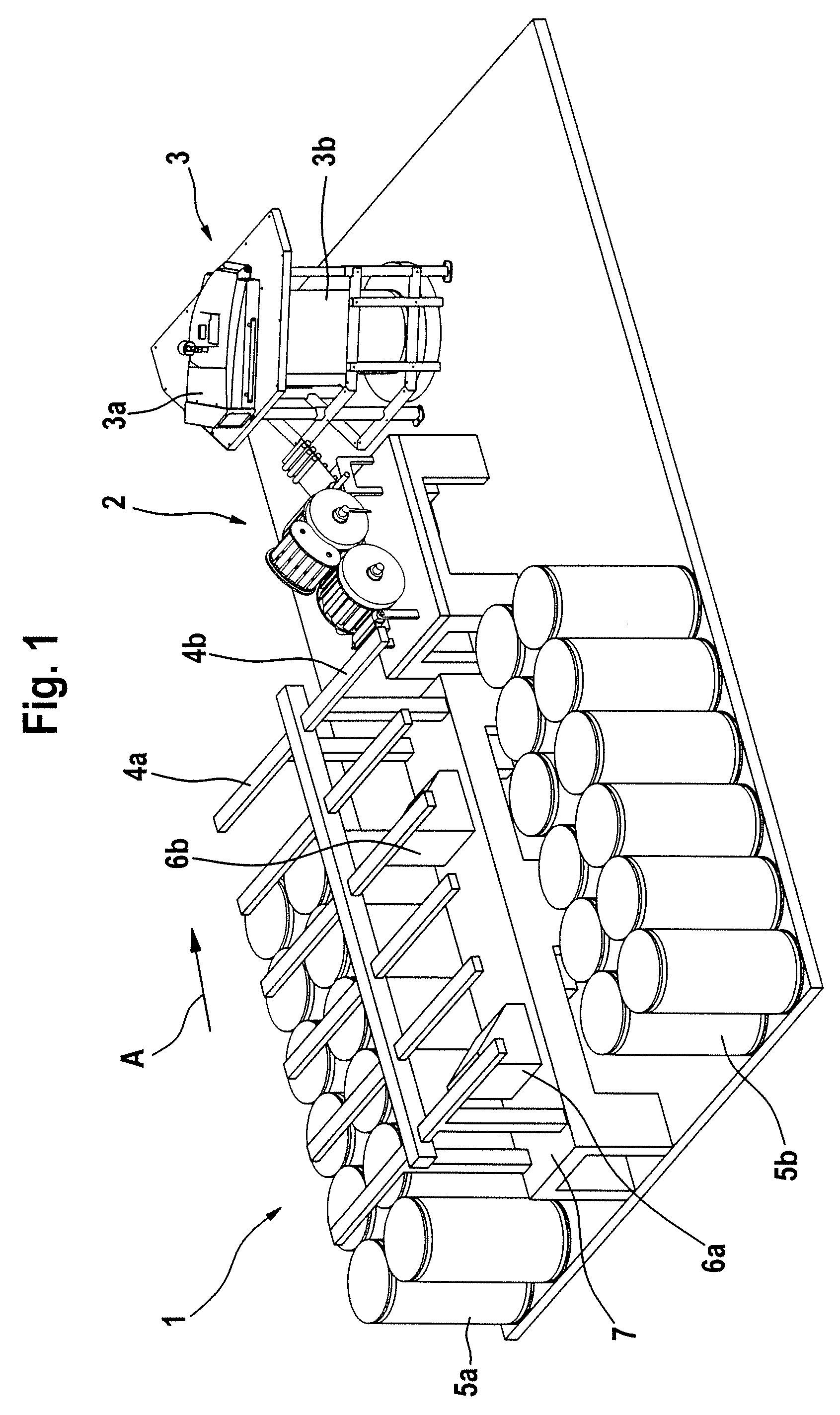

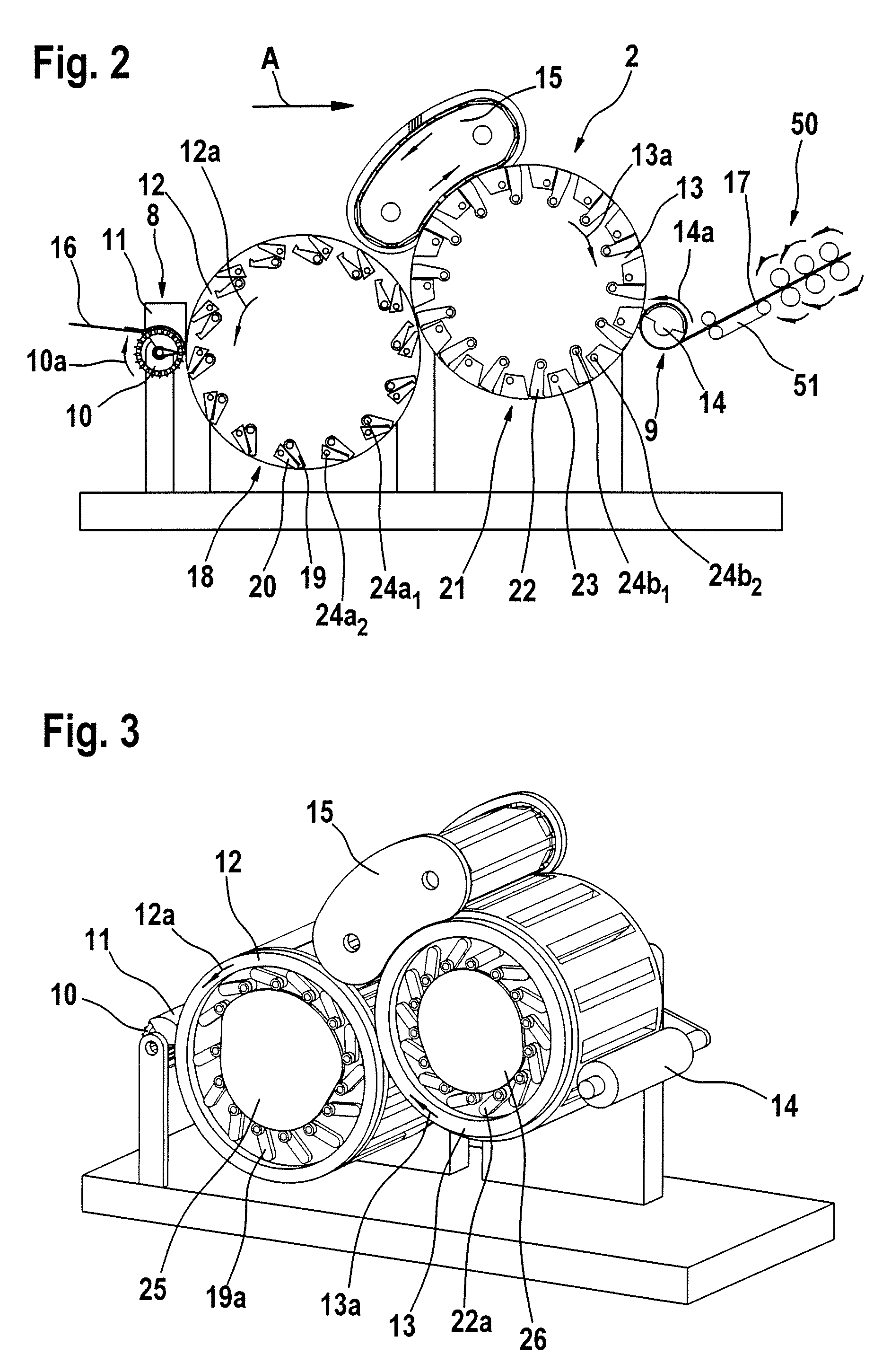

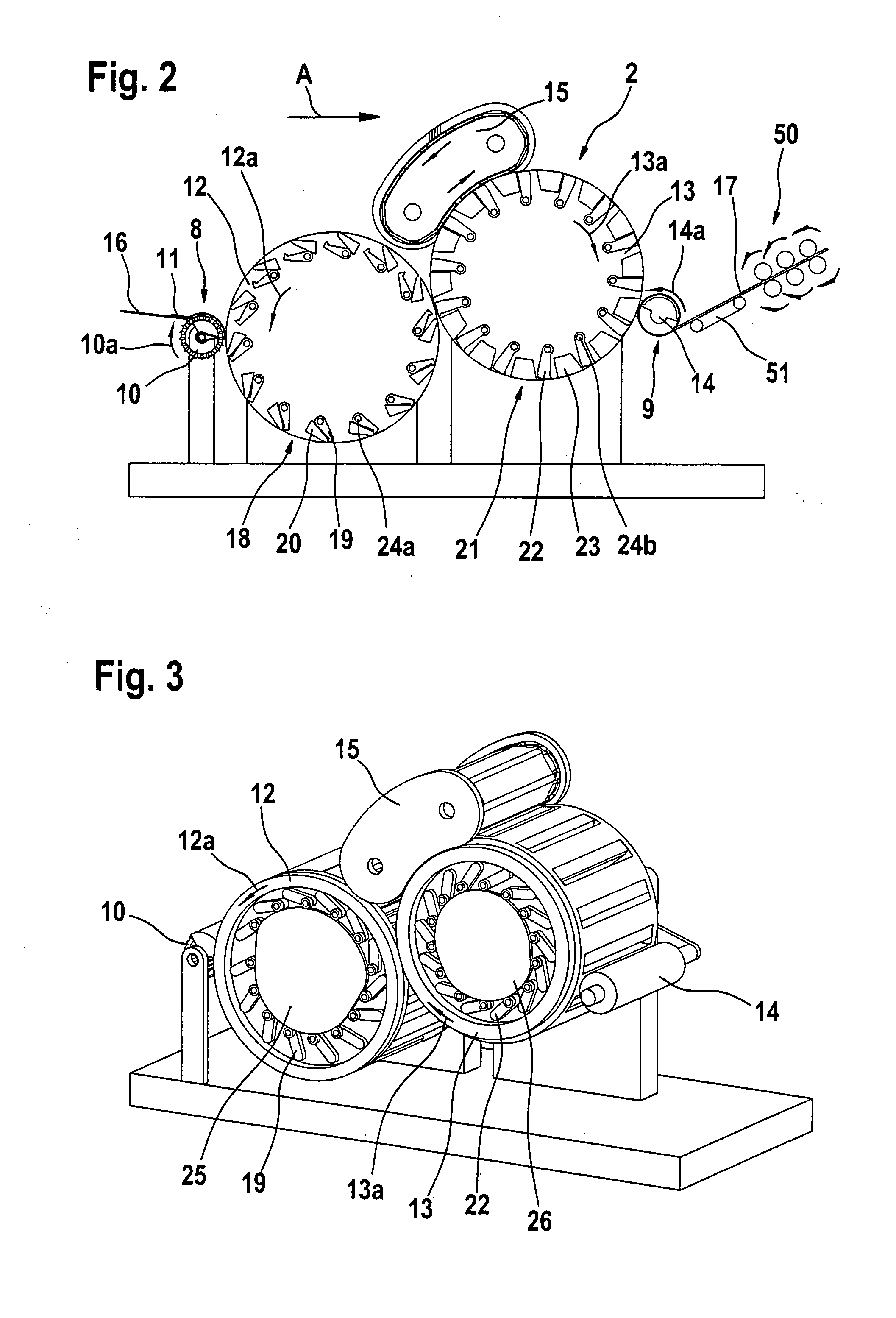

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000071A1Increase volumeImproved combed sliverCombing machinesTextile fiberFiber bundle

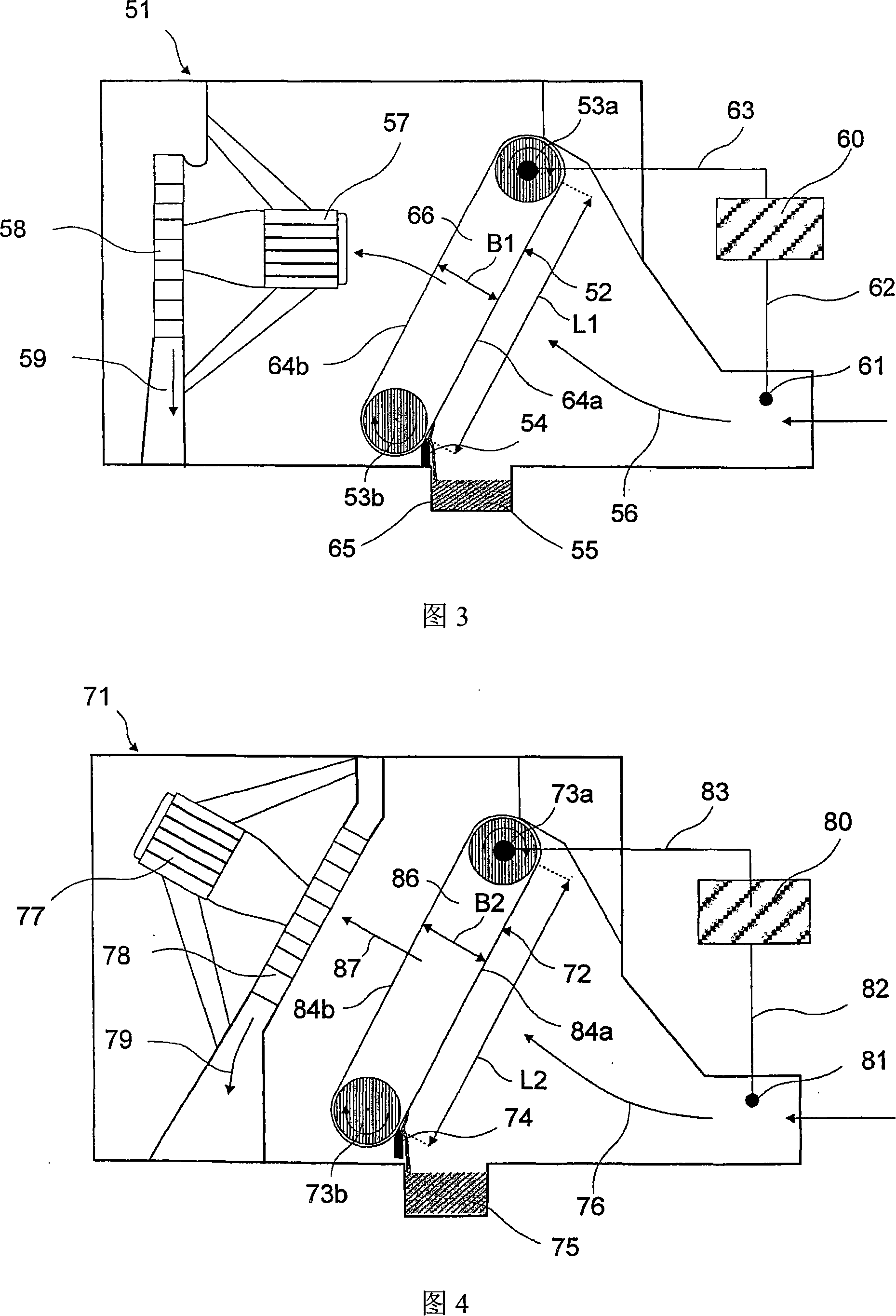

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action in order to loosen and remove non-clamped constituents from the fibre bundle, and a take-off device is present to remove the combed fibre material. To enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, which clamping devices are distributed around the periphery of the rollers, wherein in the region between the rollers, devices are present which provide an optimum feed of the fibre material and / or provide optimum positioning of the fibre material for transfer and take-up from the first roller to the second roller.

Owner:TRUETZSCHLER GMBH & CO KG

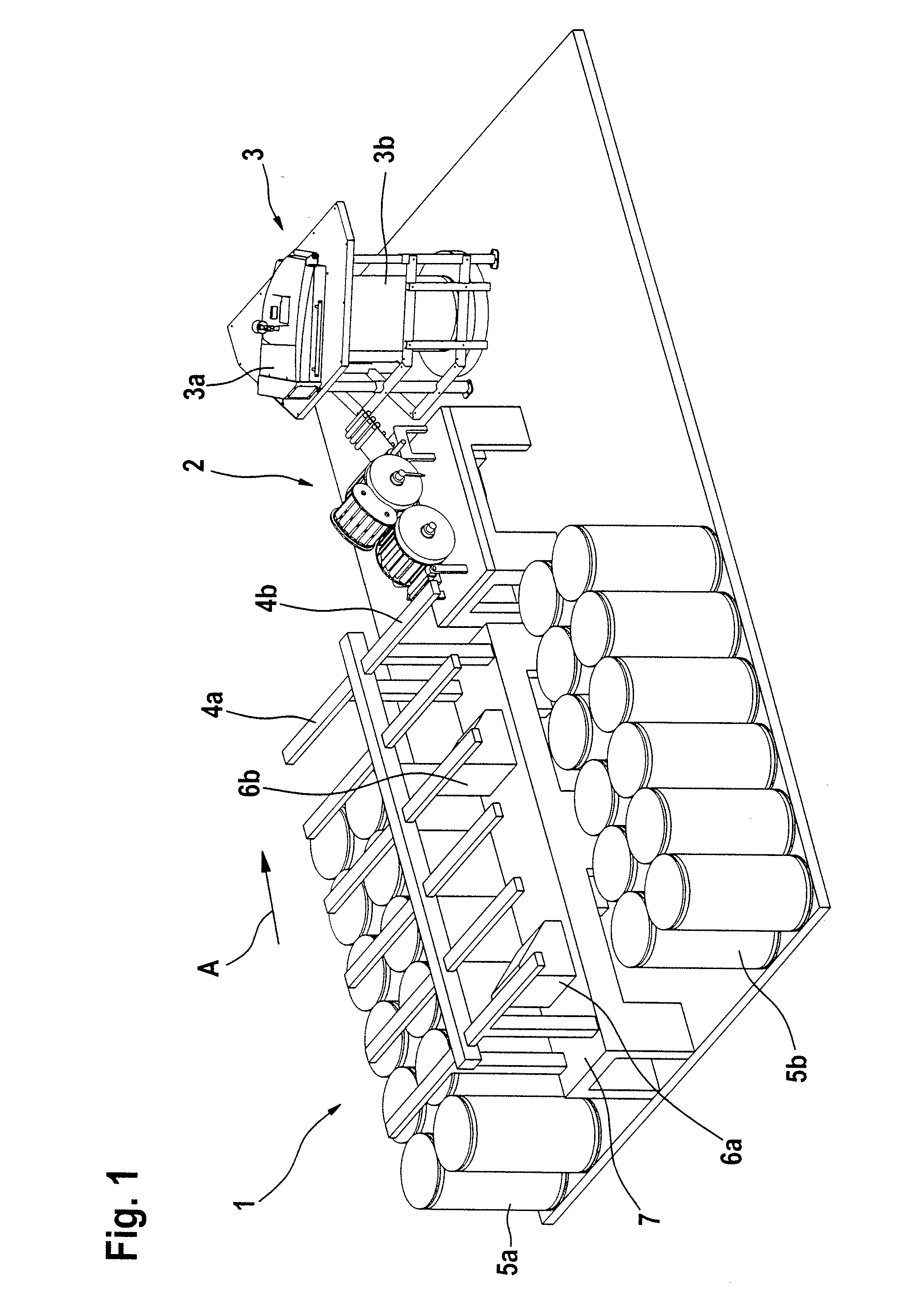

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000067A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of a supply device to a fibre-sorting device, especially a combing device, for removal of the combed fibre material at least one take-off device with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices for the fibre bundle, and between the sliver-forming element and the drafting system at least one conveyor element for a formed combed sliver is present.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000077A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part at least partially of a lightweight material. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000072A1Increase volumeImproved combed sliverCombing machinesProduction rateFiber bundle

In an apparatus for fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, the fibre bundle is supplied to a fibre-sorting device, clamping devices are provided, which clamp the fibre bundle at a distance from its free end, and mechanical device is present, which generates a combing action from the clamping site to the free end of the fibre bundle. To increase productivity in a simple manner and obtain an improved combed sliver downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, the combing device are associated with a said roller, and an arrangement for optimum feed and / or positioning of the fibre material to be combed is associated with the combing device.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the sorting or selection of a fibre sliver comprising textile fibres, especially for combing

An apparatus for the sorting or selection of fibre, especially for combing, is supplied by supply device to a sorting device. Clamping devices are provided which clamp the fibre sliver at a distance from its free end, for combing in order to loosen and remove non-clamped constituents, such as, for example, short fibres, neps, dust and the like from the free end. To enable productivity to be increased and an improved combed sliver to be obtained, downstream of the supply there is arranged at least one rotatably mounted roller which is provided with clamping devices for the fibre sliver, which clamping devices are distributed spaced apart around the periphery of the roller, and combing elements are associated with the periphery of the roller.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000066A1Improved sliverIncrease volumeCombing machinesCarding machinesFiber bundleEngineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action to remove non-clamped constituents such as short fibres. Downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, and the supply device comprises a feed unit, which feed unit comprises a feed roller and at least one feed tray defining a nip between said feed roller and said feed tray, and the retaining force in the nip optimally retains the short fibres completely or substantially completely in the nip during separation of a fibre bundle by said clamping devices.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

In an apparatus for the fibre-sorting or fibre-selection a fibre bundle which is supplied by means of a supply device to a fibre-sorting device in which clamping devices are provided which clamp the fibre bundle at a distance from its free end, and in which a mechanical device is present which generates a combing action, for removal of the combed fibre material a revolving element is present. To enable the amount produced per hour (productivity) to be substantially increased in a simple manner and to permit a reliable removal and piecing at high production speed, downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre, which clamping devices are distributed around the periphery of at least one of the rollers and the device for generating a combing action is associated with a said roller, wherein after take-up of the free regions of the combed fibre bundles by the revolving element, the clamping of the ends of the combed fibre bundles is terminated.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000065A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device for removal of the combed fibre material at least one take-off means with a sliver-forming element is present, downstream of which is a drafting system to enable productivity to be substantially increased and an improved combed sliver to be obtained, downstream of the supply device there is arranged at least one rotatably mounted roller rotating rapidly without interruption, which is provided with clamping devices for the fibre bundle, which clamping devices are distributed spaced apart in the region of the periphery of the roller and the combed sliver formed is arranged to be supplied directly to the drafting system.

Owner:TRUETZSCHLER GMBH & CO KG

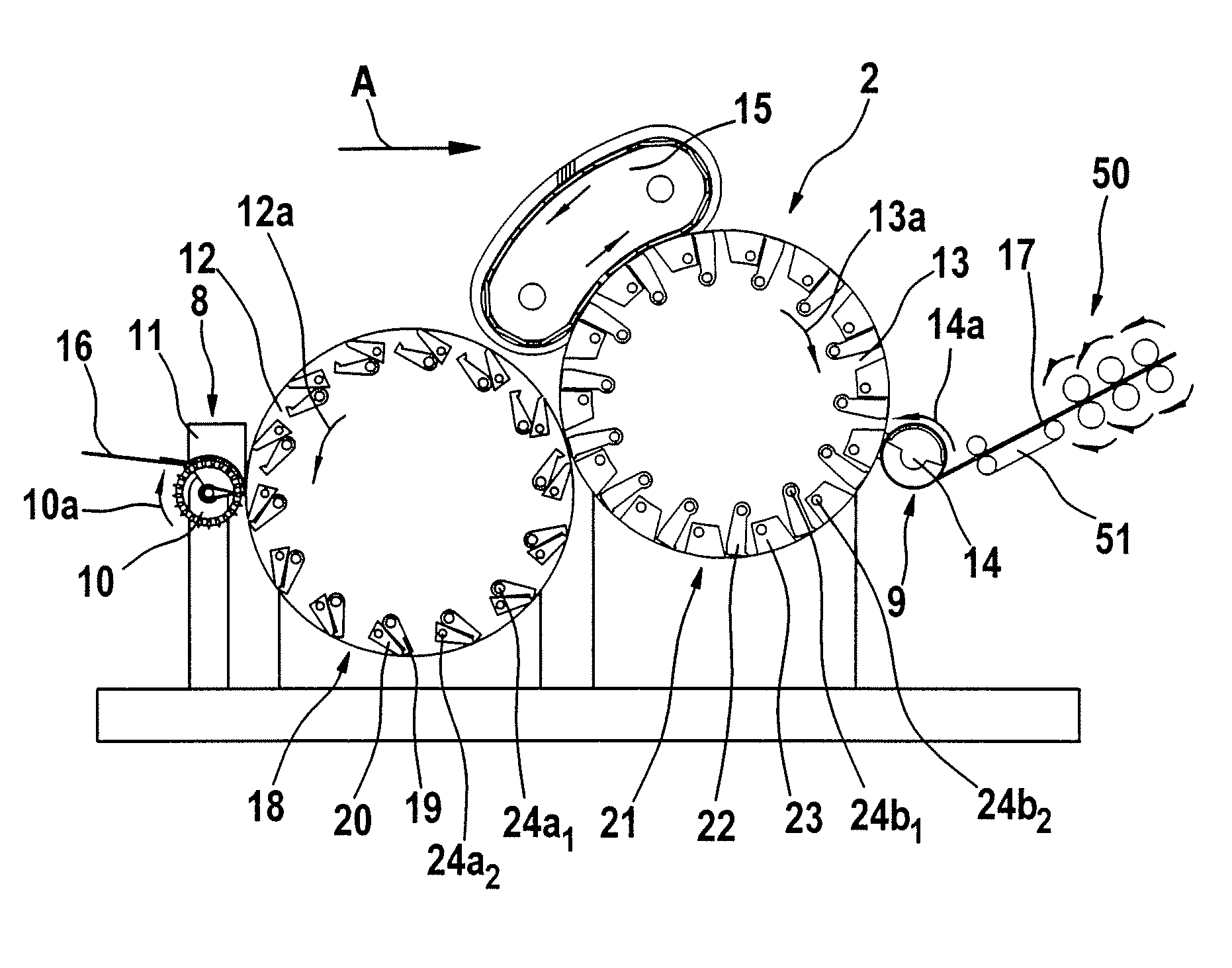

Apparatus for the Fibre-Sorting or Fibre-Selection of a Fibre Bundle Comprising Textile Fibres, Especially For Combing

InactiveUS20090000070A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateMechanical engineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of supply means to a fibre-sorting device, at least one mechanical device is present which generate a combing action to remove non-clamped constituents such as short fibres. To enable productivity to be substantially increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged at least first and second rotatably mounted rollers with clamping devices for the fibre bundles, and the apparatus further comprises at least two supply devices and / or at least one further high-speed roller and / or at least two take-off devices.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000075A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by a supply device to a fibre-sorting device, especially a combing device, having clamping devices, which clamp the fibre bundle at a distance from its free end, for combing to remove non-clamped constituents, at least one take-off device 14 with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and improve the combed sliver, the fibre-sorting device has at least two rotatably mounted rollers rotating rapidly without interruption, having the clamping devices and between the sliver-forming element and the drafting system the at least one fibre sliver is present in the form of a fibre structure having a width greater than its height, for example, following spreading by a web-spreader.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000064A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part which is at least partially resilient. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000068A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, fibre is supplied by a supply device to a fibre-sorting device, especially a combing device. Clamping devices clamp the fibre bundle at a distance from its free end, and a mechanical device combs the free end to loosen and remove non-clamped constituents, for example, short fibres, neps, dust and the like. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices, and measured value sensors for detecting values relating to the fibres or machine settings are connected to a control and regulation device, which is arranged to effect actions in dependence on the measured values.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000079A1Improved sliverIncrease volumeCombing machinesFibre separationProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device, in which a mechanical device is present which generates a combing action to loosen and remove non-clamped constituents, and a clamping element is present for transfer of the supplied fibre material. To enable productivity to be increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged two rotatably mounted rollers, which are provided with clamping devices for the fibre material having clamping elements that are distributed spaced apart in the region of the roller periphery and co-operate with counter-elements, the counter-elements in the case of the first roller being arranged opposite the roller periphery and in the case of the second roller on or in the roller.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000069A1Increase volumeImproved combed sliverCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is suppled by a supply device to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and the clamping jaws of the each clamping device are arranged to be movable in relation to one another and separately drivable.

Owner:TRUETZSCHLER GMBH & CO KG

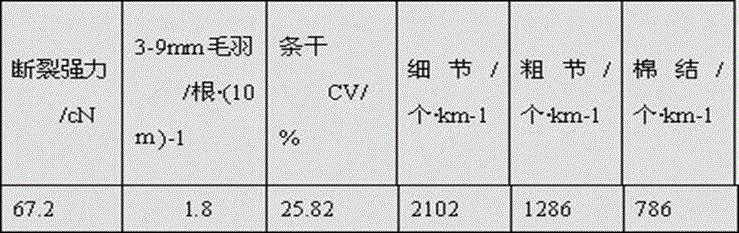

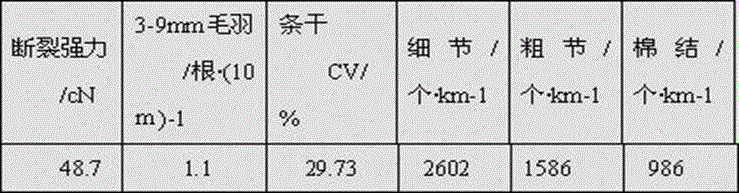

Ultra-high-count pure cotton combing yarn and spinning technology of ultra-high-count pure cotton combing yarn

ActiveCN103334190APromote maturityAmerican cotton has high strengthContinuous processingCombing machinesYarnFiber

The invention discloses ultra-high-count pure cotton combing yarn and a spinning technology of the ultra-high-count pure cotton combing yarn. Raw cotton comprises, by weight, 15%-25% of Egypt cotton, 25%-35% of American cotton and 40%-50% of Xinjiang long stapled cotton, wherein the Egypt cotton, the American cotton and the Xinjiang long stapled cotton are blended to spin 200S to 300S pure cotton yarn. The spinning technology includes the following steps that the first procedure of blowing-carding, the second procedure of combing, the third procedure of drawing, the fourth procedure of roving yarn, the fifth procedure of spun yarn and the sixth procedure of spooling. With the blending scheme, the raw cotton can integrate the advantages of high fineness and good maturity of the Egypt cotton, the advantages of high strength and non-existing abnormal fibers of the American cotton, the advantage of large length of the Xinjiang long stapled cotton and the like. The raw cotton reaches the requirements for the fiber length, the length CV value, the Micronaire value, the fineness, the strength and other performance indexes of raw cotton in producing ultra-high-count yarn. According to the spinning technology of the ultra-high-count pure cotton combing yarn, the ultra-high-count yarn can be produced under a large ration of roving yarn, the spinning efficiency is improved and meanwhile, quality of resultant yarn is ensured.

Owner:傲丝生态(中国)有限公司

Apparatus for the fibre-sorting or fibre-selection of fibre bundle comprising textile fibres, especially for combing

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of a supply device to a fibre-sorting device, and a mechanical device is present which generates a combing action to remove non-clamped constituents such as short fibres, a clamping element is present. Downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, and the device for generating a combing action is associated with a said roller, wherein for the suction of the supplied fibre bundles, at least one suction device is associated with the clamping devices in the region of the transfer of the fibre bundle from the supply device to the first roller and / or in the region of the transfer of the fibre material from the first roller to the second roller.

Owner:TRUETZSCHLER GMBH & CO KG

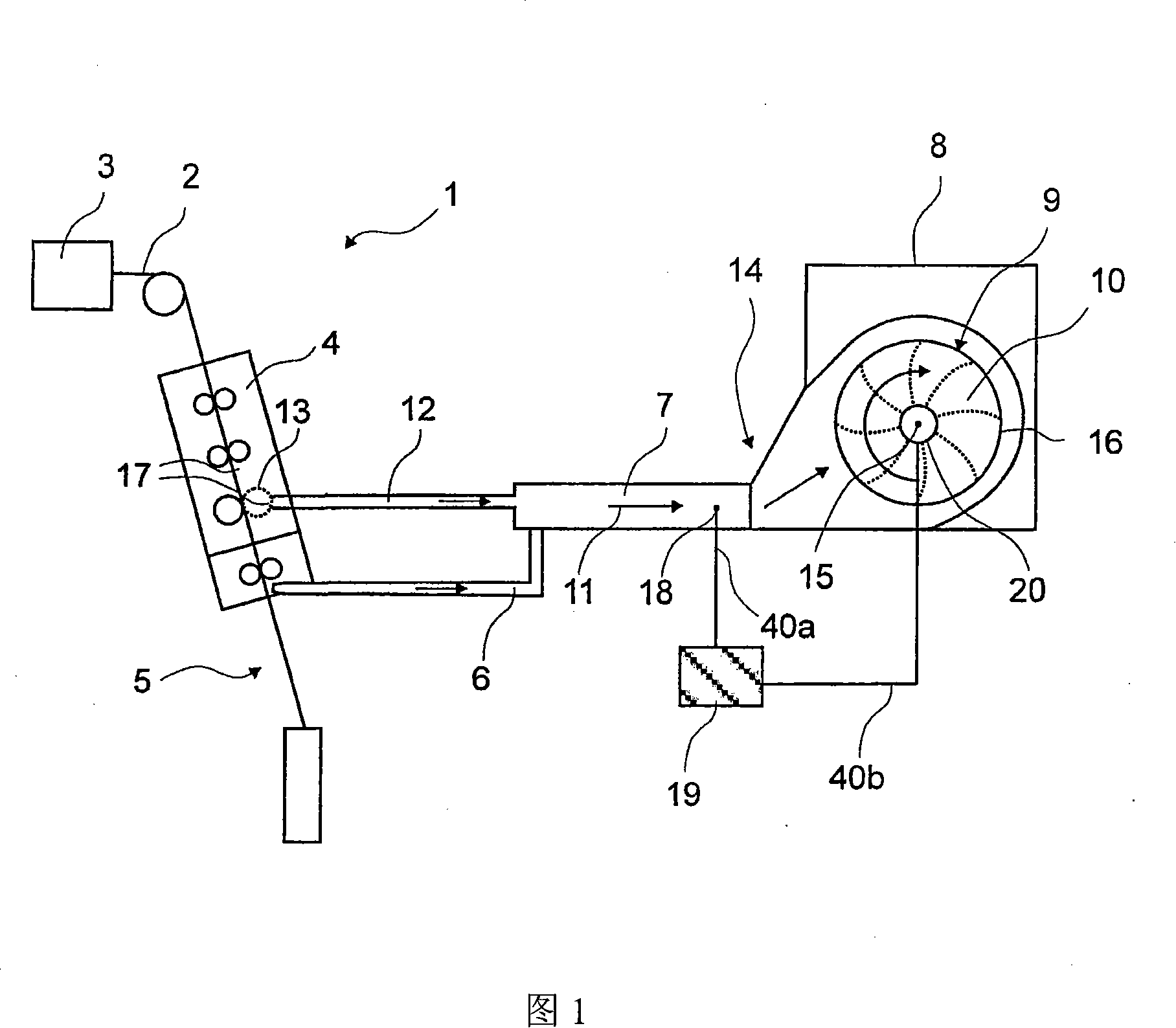

Device and method for pumping and filtering air containing dust and/or fibre on the spinning machine

InactiveCN101113537AEasy to storeEffectively fixedDispersed particle filtrationTransportation and packagingFiberMotor drive

The device for the suction and filtration of dust- and / or fiber loaded air on spinning machines (1), comprises working places consisting of a suction channel (7), a filtering device (8) with a filter forming a filtering surface (16), a system for removing the filter outflow from the filtering surface, a vacuum source (10) for generating an induced draft, an operating means for carrying out a filter cleaning process using a removal system, and a vacuum sensor arranged in the main suction channel for measuring the vacuum in a vacuum zone before and / or after the filtering. The device for the suction and filtration of dust- and / or fiber loaded air on spinning machines (1), comprises working places consisting of a suction channel (7), a filtering device (8) with a filter forming a filtering surface (16), a system for removing the filter outflow from the filtering surface, a vacuum source (10) for generating an induced draft, an operating means for carrying out a filter cleaning process by a removal system, and a vacuum sensor arranged in the main suction channel for measuring the vacuum in a vacuum zone before and / or after the filtering. The device contains a controller or regulator for vacuum in the vacuum zone before and / or after the filtering surface based on the vacuum values, vacuum target values or vacuum target value areas, which are measured by the vacuum sensor. The controller or regulator is connected with a driving mechanism for filter cleaning. The controlling or regulating of the vacuum takes places by the operation of the driving mechanism. The spinning place contains suction places (17), over which polluted air is sucked out and supplied over a central suction channel or -channel of the filter arrangement. The vacuum source contains an axial- or radial ventilator. The filter outflow is liftable or removable from the filtering surface using removal- or a lifting device and is fed to a collecting- or disposing device. The controller contains a signal converter and a control device, by which the measured values received by the vacuum sensor in the form of vacuum values are compared with the vacuum target values and vacuum target value areas. Controlling or regulating signals are generated for correcting the variation of actual value from the target value for operating on an actuator and / or a final control element containing driving means. The filtering device contains a filter drum with a cylinder shaped, fixed or flexible filter surface, which is arranged on the removal system. The driving mechanism comprises a drive system for turning the filter drum around the drum axis. The filter cleaning is carried out by a continuous or sequential turning of the filter drum, by which the filter surface is directed to the removal device and the filter outflow is removed. The driving mechanism contains a hydraulic or pneumatic piston drive, and a linear motor or electric cylinder, which is connected with a gear between the driving mechanism and the filter. A control is intended for thread count and / or equipment parameters of the pressure ratio in the channels and / or pipes are adjustable. The control consists of a means for changing the vacuum over the filter device and / or over the ventilator output. The filter device contains a continuous filter band forming a space, and electro motor driving mechanism for a circulatory movement of the filter band, which forms a layered filter surface. Independent claims are included for: (1) a spinning machine; and (2) a method for the suction and filtration of dust- and / or fiber loaded air on spinning machines.

Owner:MASCHINENFABRIK RIETER AG

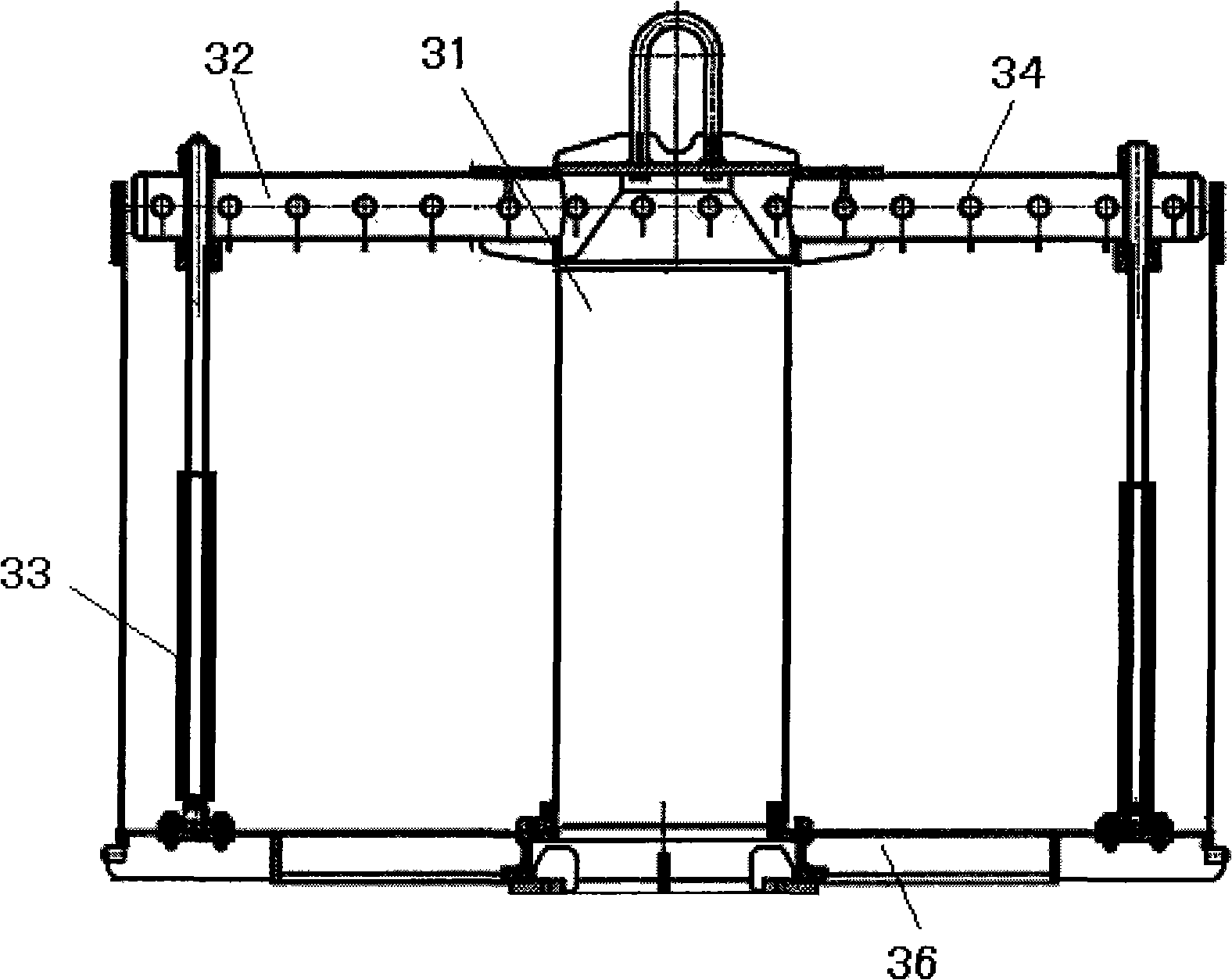

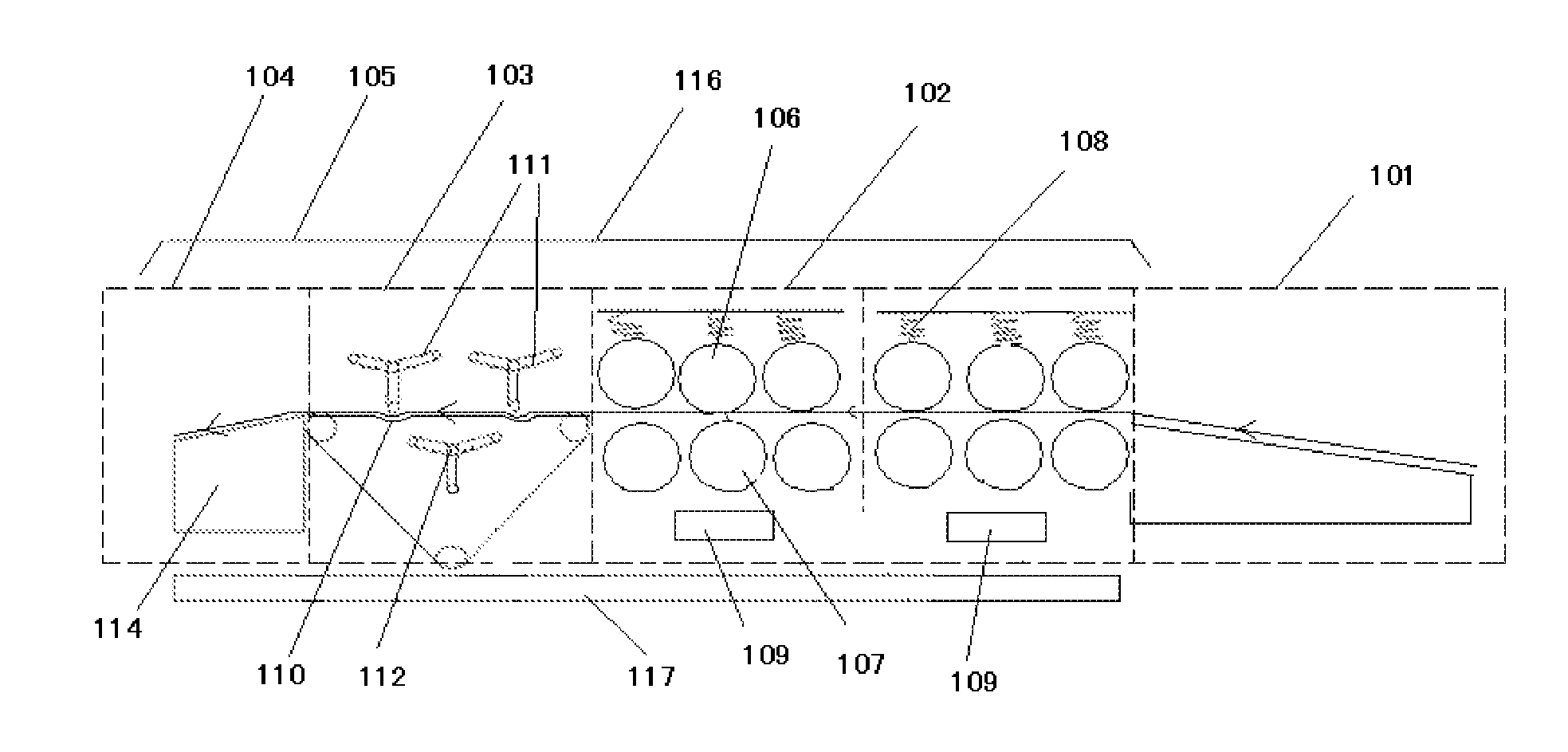

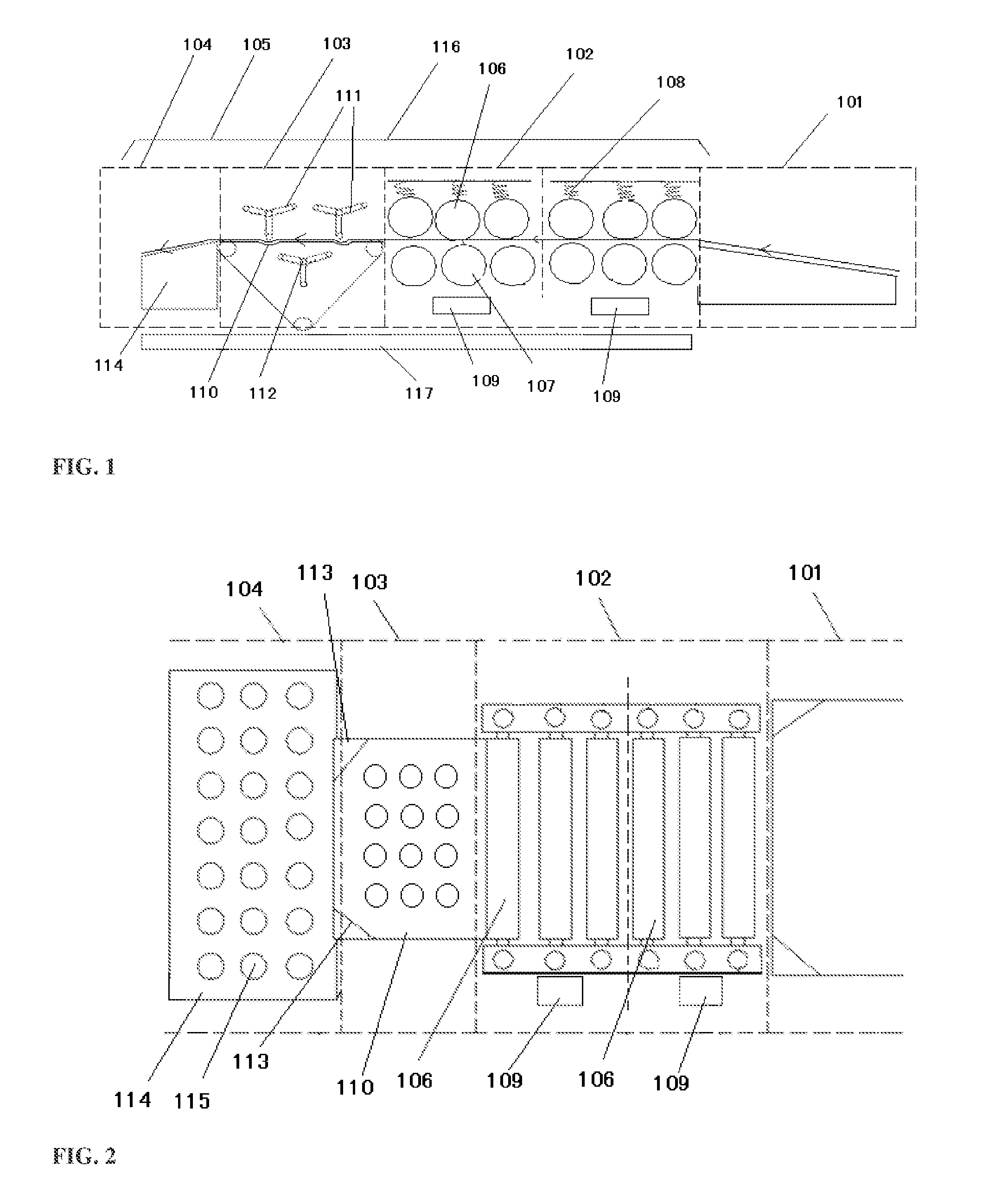

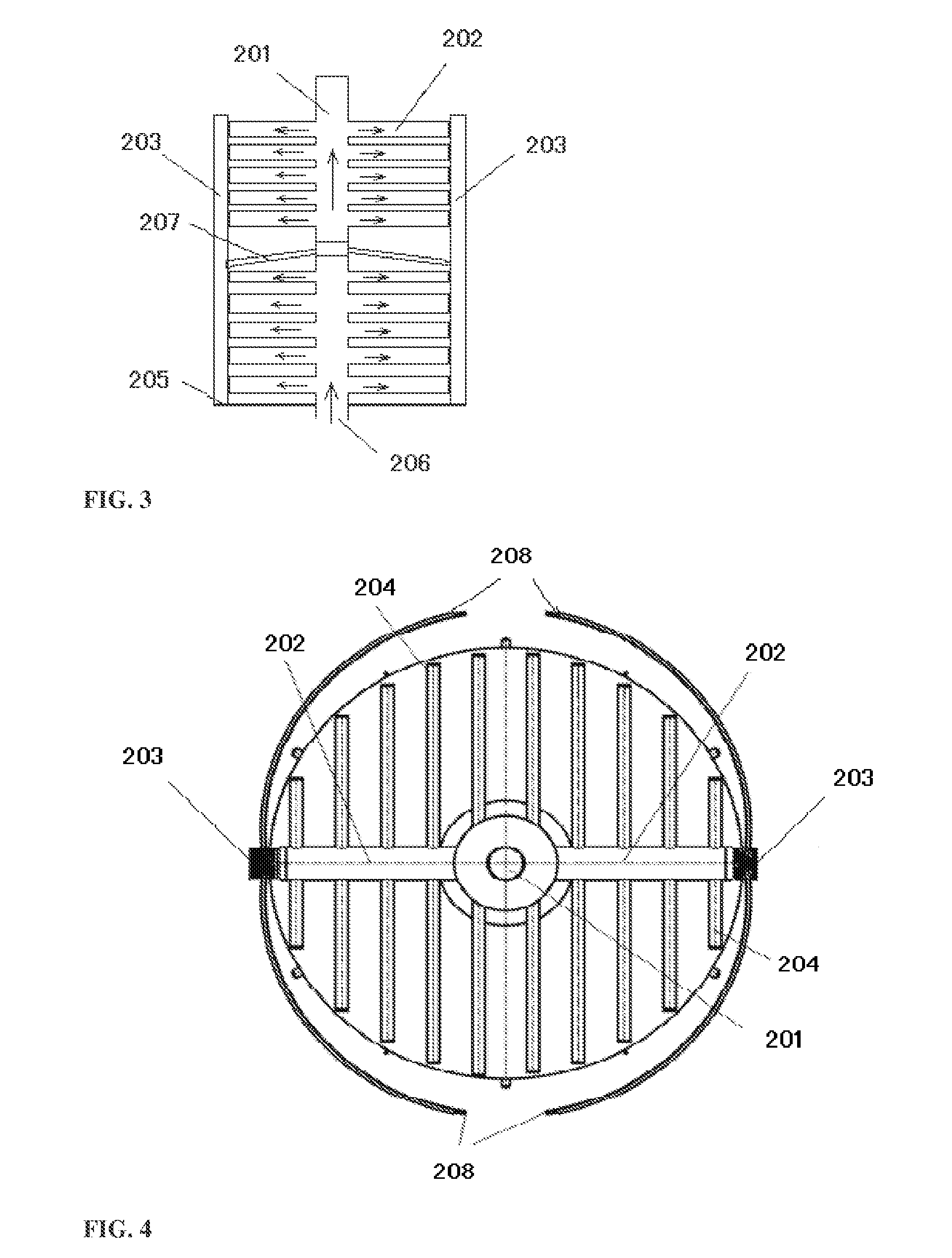

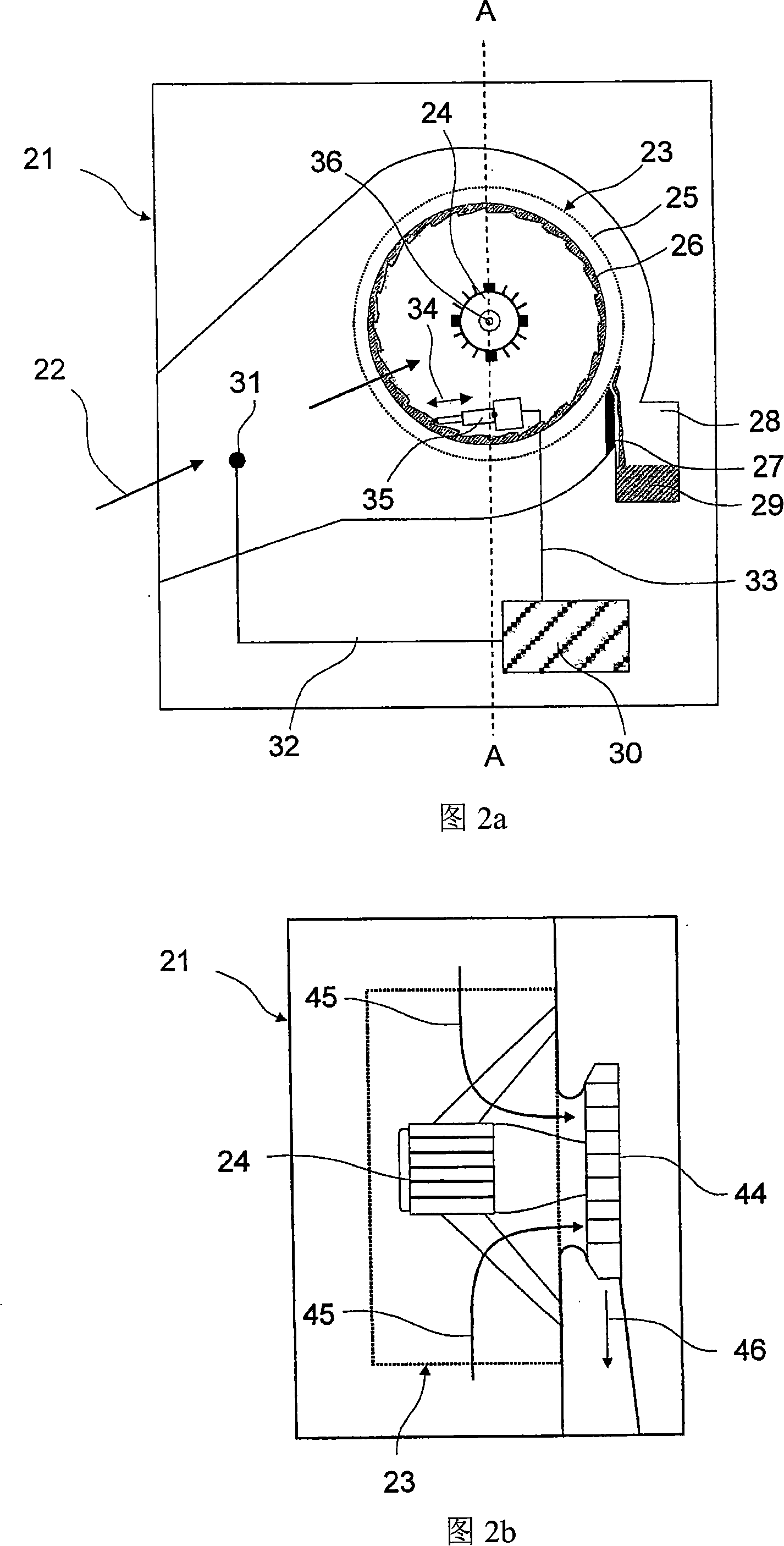

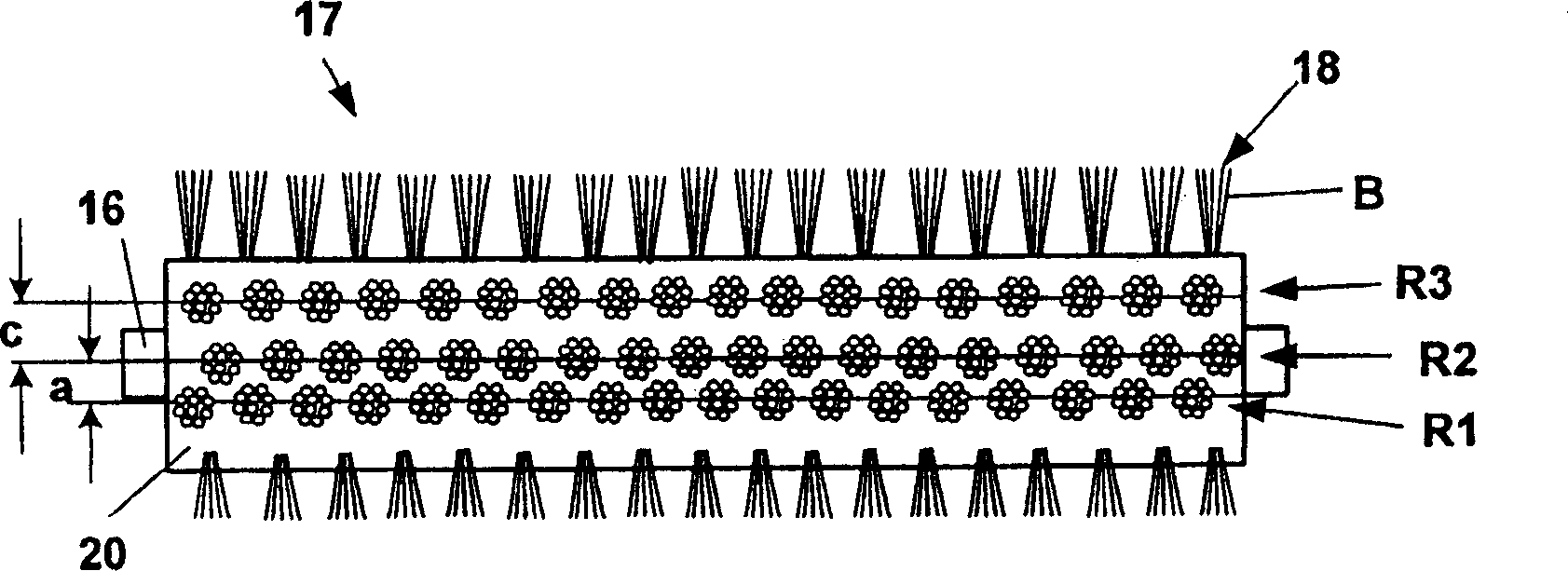

Sesaron combing and sorting method and device

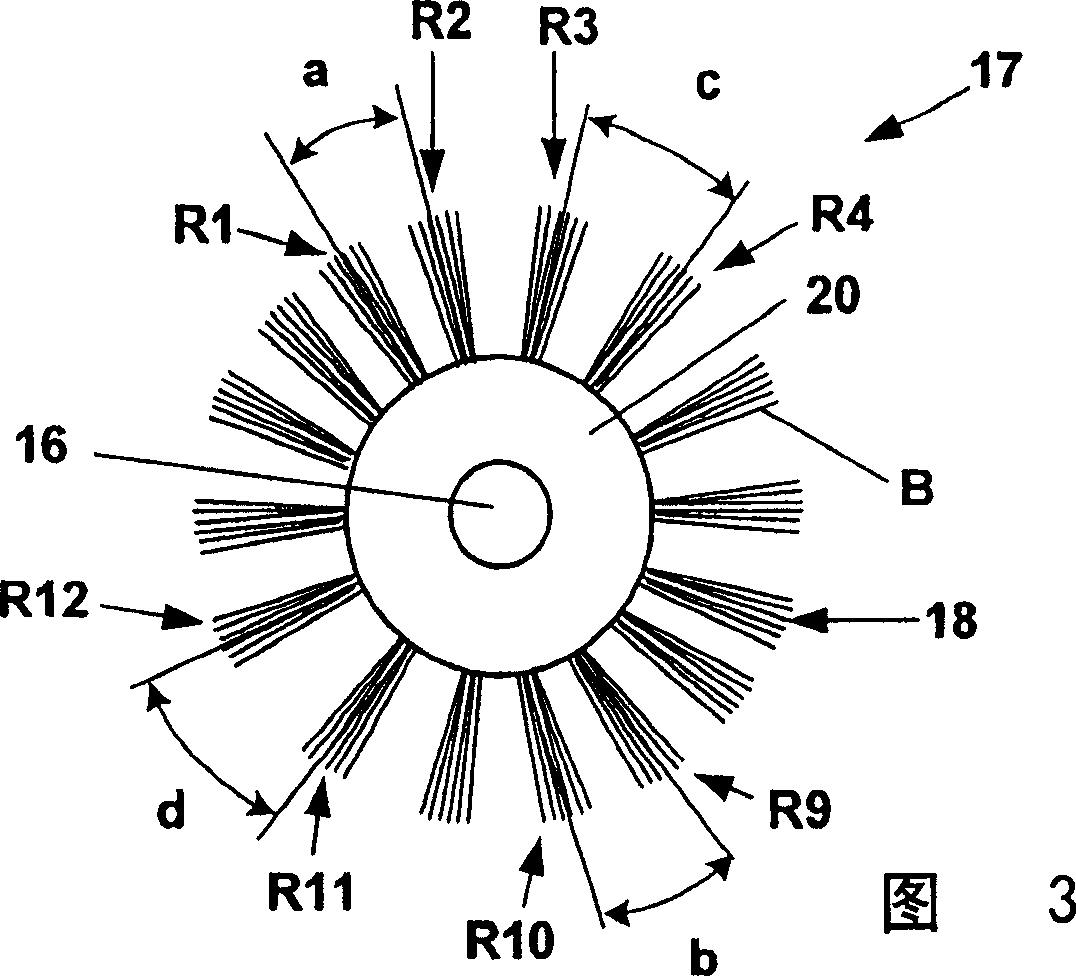

ActiveCN101824676AEfficient removalIncrease the degree of splittingSafety devices for fibre treatmentCombing machinesCombingEngineering

The invention relates to a sesaron combing and sorting method and a device; combed ramie stripes with different specifications and lengths are obtained through a plurality of layers of combing; the split degree of the ramie stripes is decided by comb needle models used in all the layers of combing; and the lengths of the ramie stripes are changed by adjusting a pulling vehicle. In a combing and sorting mechanism of the device, circular comb needle strips are lined in a circumference of 0 to 270 degrees respectively through a rack method and a rack and needle row combined method, and top combs are in a single row or a plurality of rows. A pulling separation mechanism comprises the pulling vehicle, the pulling vehicle is arranged on a regulation frame, the regulation frame is provided with a rod and a circular arc-shaped chute, a bolt is inserted into the circular arc-shaped chute, the bolt is fastened on a frame, the bolt is loosened, and the regulation frame can slide along the circular arc-shaped chute by triggering the rod. At least two pairs of curl rollers are arranged in a strip discharge mechanism. The ramie stripe fibers processed by the method and the device are even and uniform, have short fiber rate, uniform fiber length and low ultra-long length fiber content, so that the fibers are more parallel and straighter, the operation is convenient, the efficiency is high, and the labor intensity is low.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

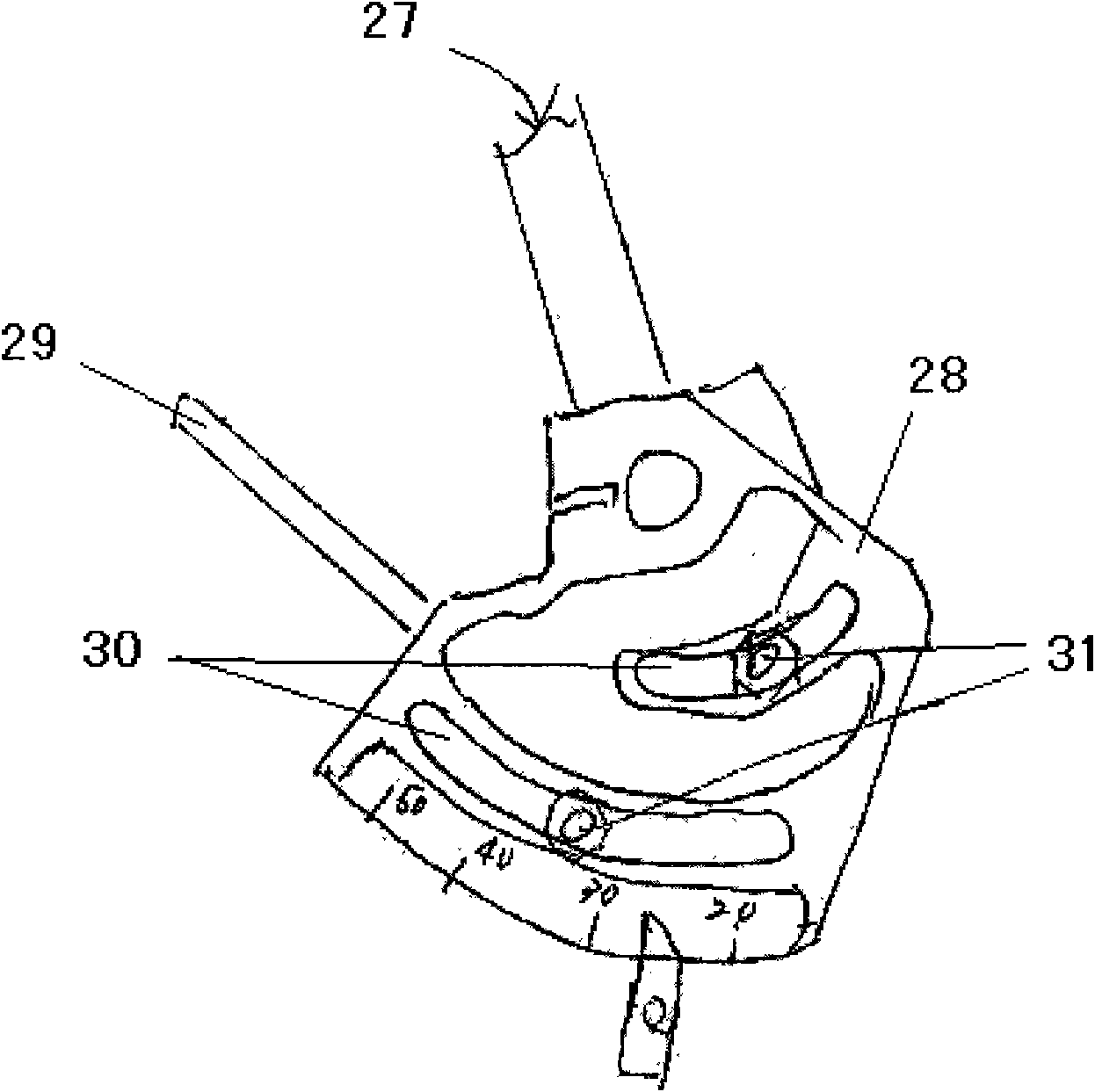

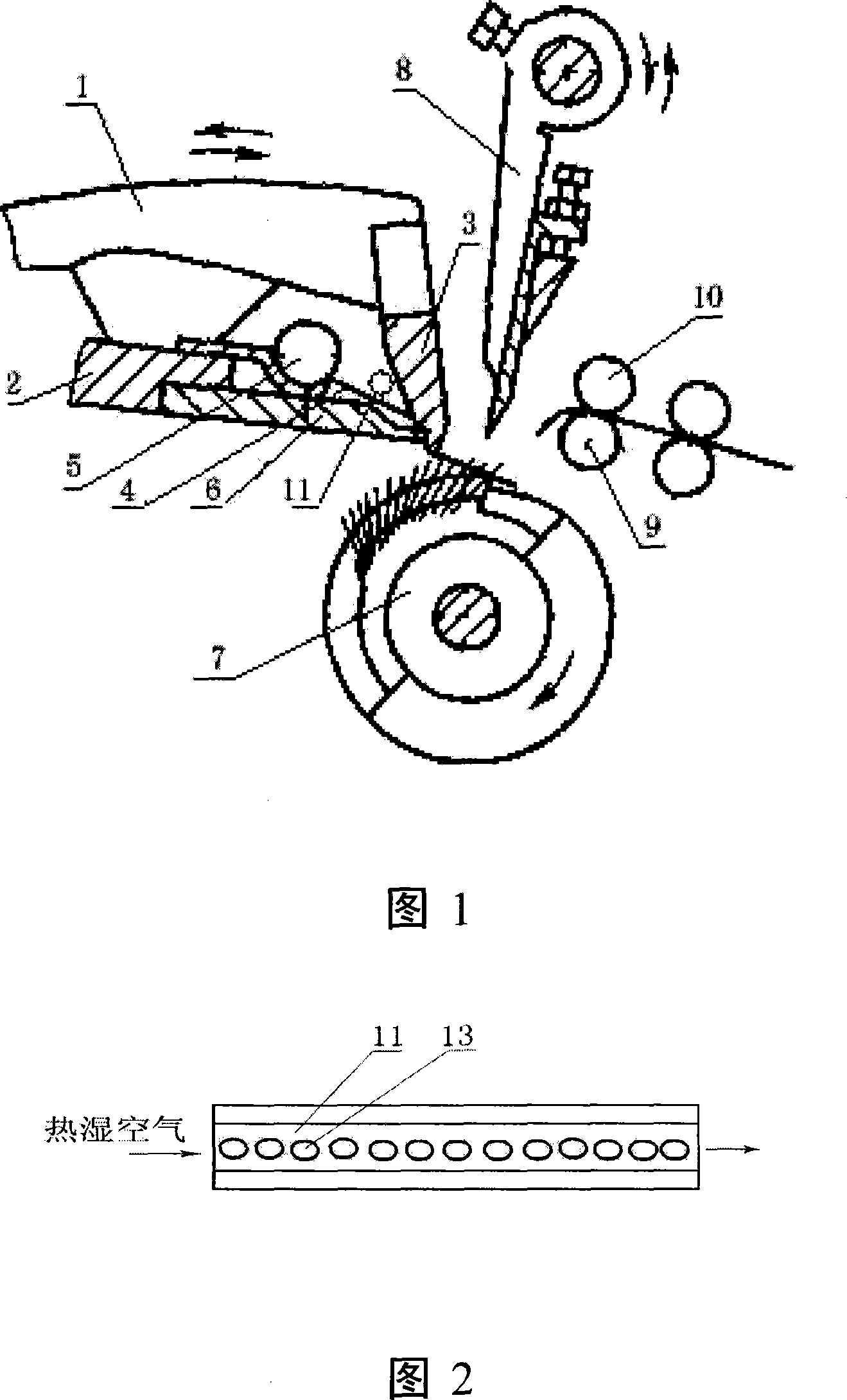

Combing machine heat moist treatment nipper plate mechanism

InactiveCN101215738ANot easy to damageReduce long fiber contentLubricating devicesCombing machinesFiberCavity wall

The invention provides a nipper mechanism which is applied in a combing machine, which belongs to the textile processing technical field. The nipper mechanism of the combing machine comprises a nipper frame which is provided with a lower nipper, an upper nipper arm which is provided with an upper nipper, a feed roller, a feed table and a heat-wet processing device, the heat-wet processing device is a hollow circular pipe element, a row of air discharging holes which are evenly arrayed are opened on the cavity wall, the circular pipe element is fixedly installed on the lower nipper or the upper nipper, the axial cord of the heat-wet processing device and the axial cord of the feed roller are in parallel, the heat-wet processing device is externally connected with a heat-wet air generating device, the feed roller and the feed table are externally connected with a heating device. The flexibility of fiber is improved through heat-wet process of the heat-wet processing device and heating process of the feed roller and the feed table, the frictional force between fibers is reduced, and impurities removing and fiber straightening and paralleling effect of a combing machine is distinctively increased, and fiber damage is reduced.

Owner:WUHAN TEXTILE UNIV

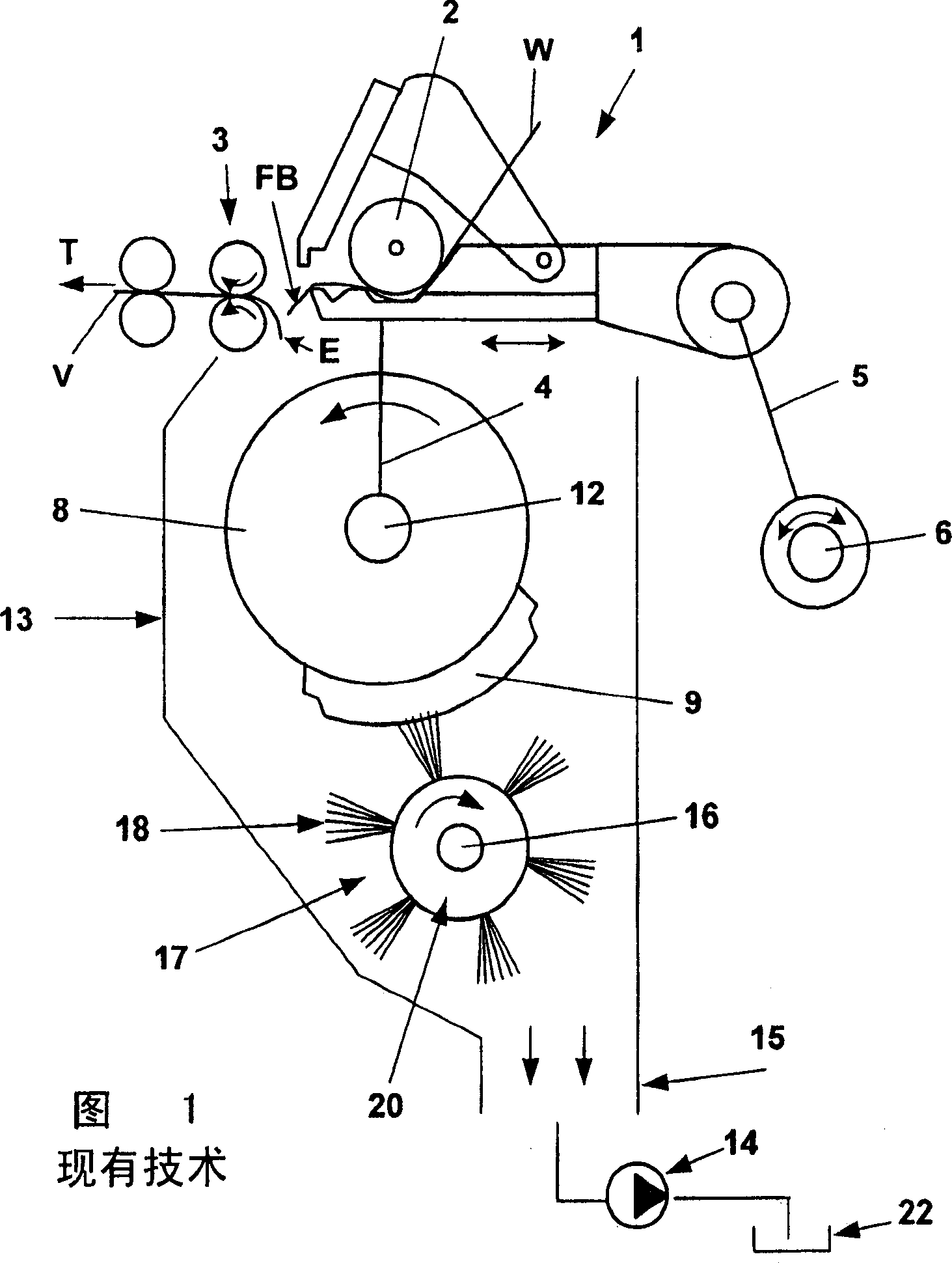

Device for cleaning a combing segment in a combing machine

InactiveCN1884648AImprove bending strengthHigh or low flexural strengthCombing machinesMechanical engineeringEngineering

In apparatus for cleaning the comb segments of a circular comb in a combing machine, comprising a cleaning roller (17) parallel to and spaced from the round comb and with peripheral cleaning elements (18) temporarily contacting the segments during rotation of the roller, some of the cleaning elements differ from the other cleaning elements in geometrical location, geometrical pattern and / or material.

Owner:MASCHINENFABRIK RIETER AG

Method for manufacturing towels of low-twist yarns

InactiveUS20110192488A1Reduce post-processing costsSoft texturePattern makingCombing machinesPulp and paper industryWater soluble

The present invention discloses a method for manufacturing low-twist towels, wherein pure cotton yarns produced from long-staple cotton are used as terry warps to manufacture low-twist towel by the processes comprising warping, weaving and greige post treatment, and the terry warp has a yarn twist multiplier of 240-270. The method eliminates the step of removing water-soluble filaments during post treatment, thereby reducing post treatment costs, relieving the pressure on sewage treatment and attaining environmental friendly effects. The resulting products have standing loops and a fluffy and soft texture.

Owner:SUN YONG

Rear separating rolling mechanism of servo motor drived comber

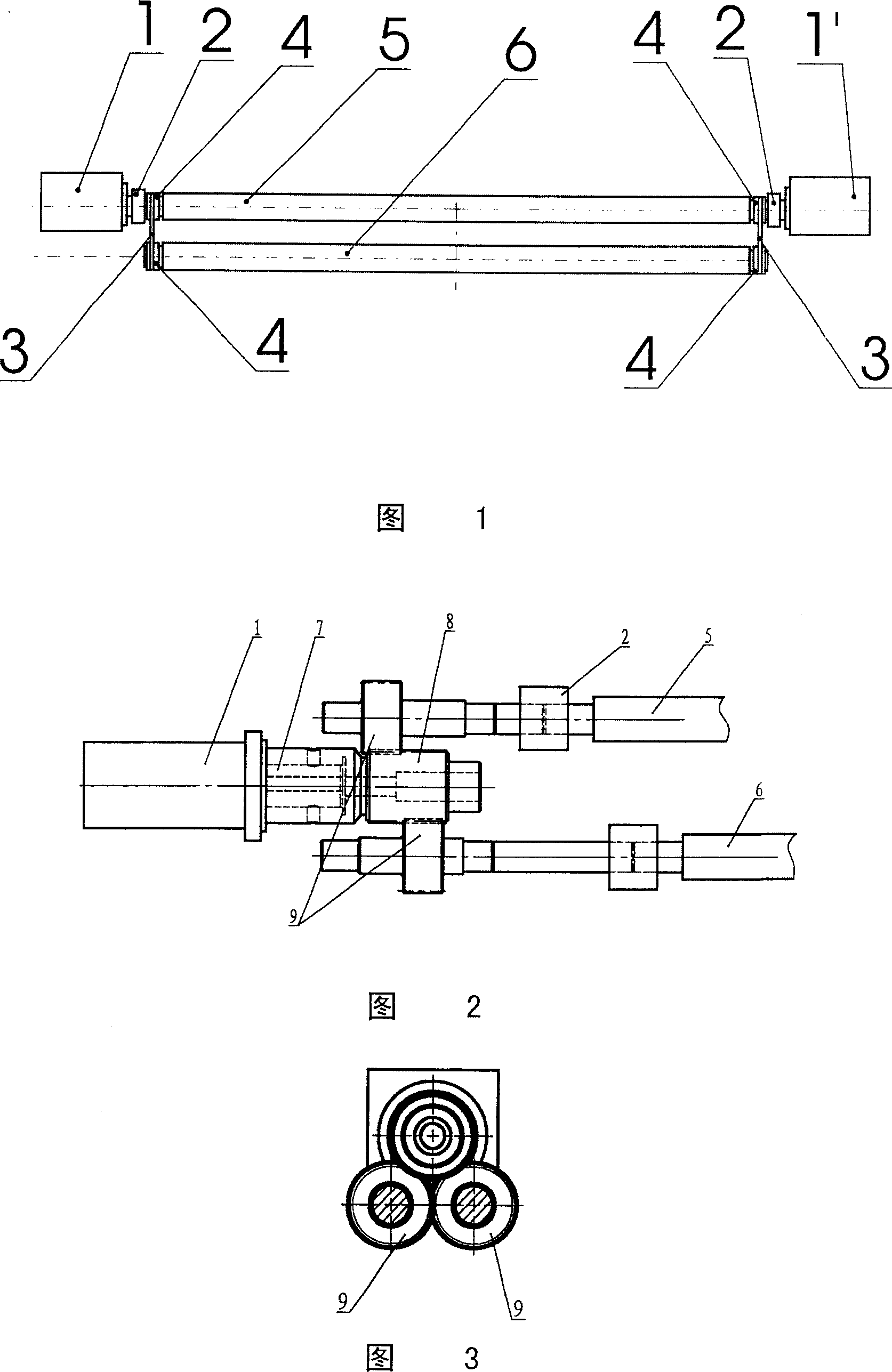

InactiveCN100999837AReduce stand-alone powerReduce distortionCombing machinesMotor driveElectric machinery

The servo motor driven back separating roller mechanism for combing machine consists of servo motors, a back separating roller and a front separating roller. Each of the back separating roller and the front separating roller is one continuous integral. Two servo motors controlled with the same driving controller are set separately on two ends of the back separating roller to drive the back separating roller while driving the front separating roller through sync belt wheels and sync belt. The servo motor driven back separating roller mechanism has lowered single motor power, raised response speed of the servo motors and thus raised motion precision of the separating rollers in combing machine.

Owner:SHANGHAI TEXTILE MACHINERY COMPLEX

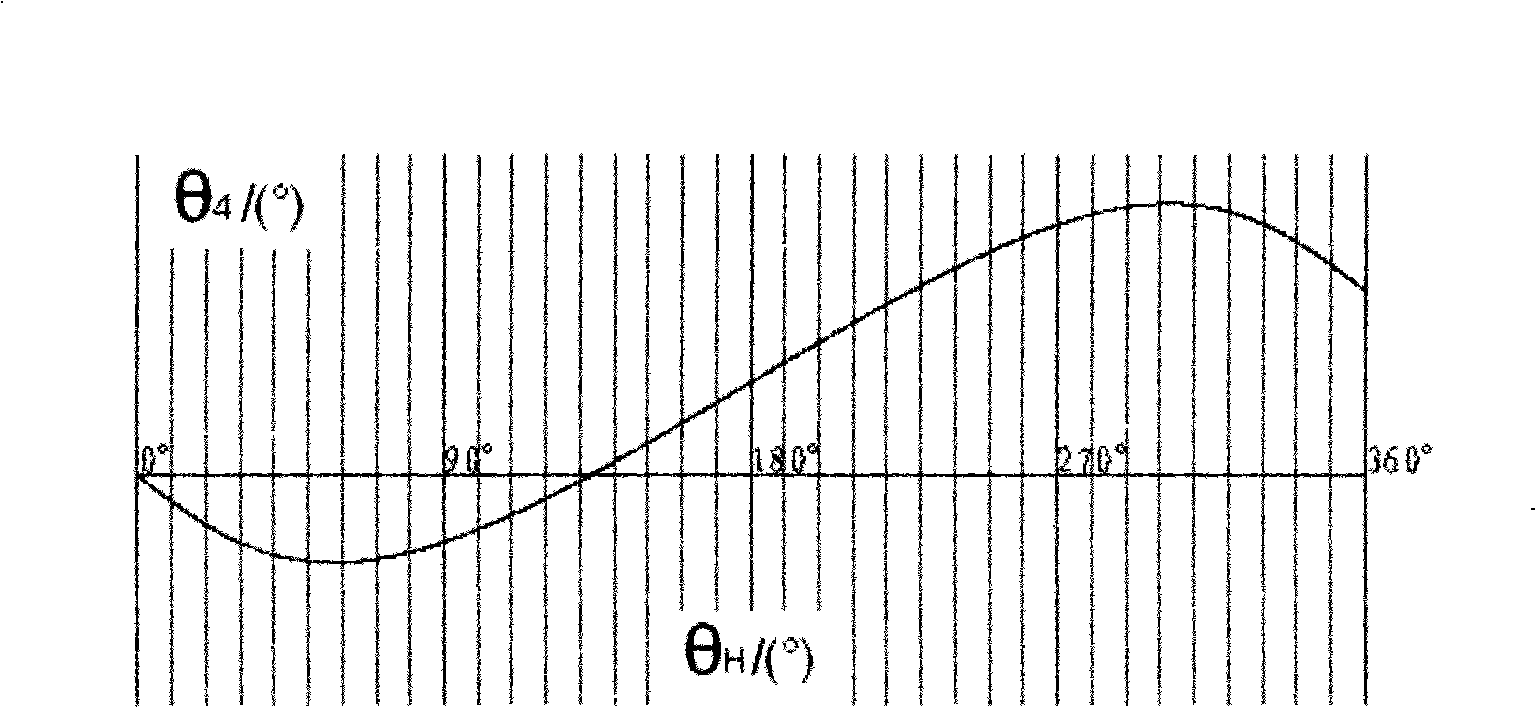

Transmission mechanism of combing machine detaching roller

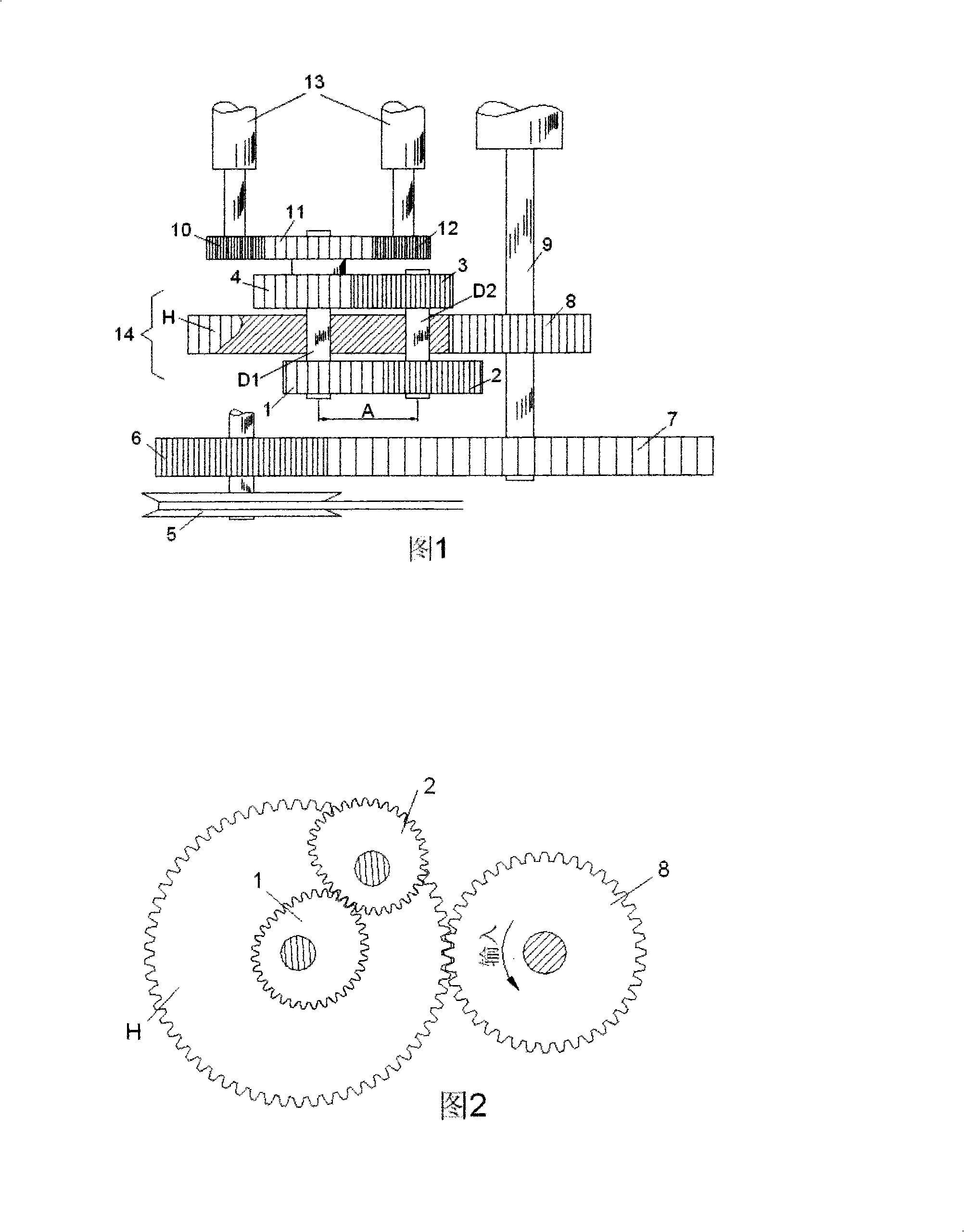

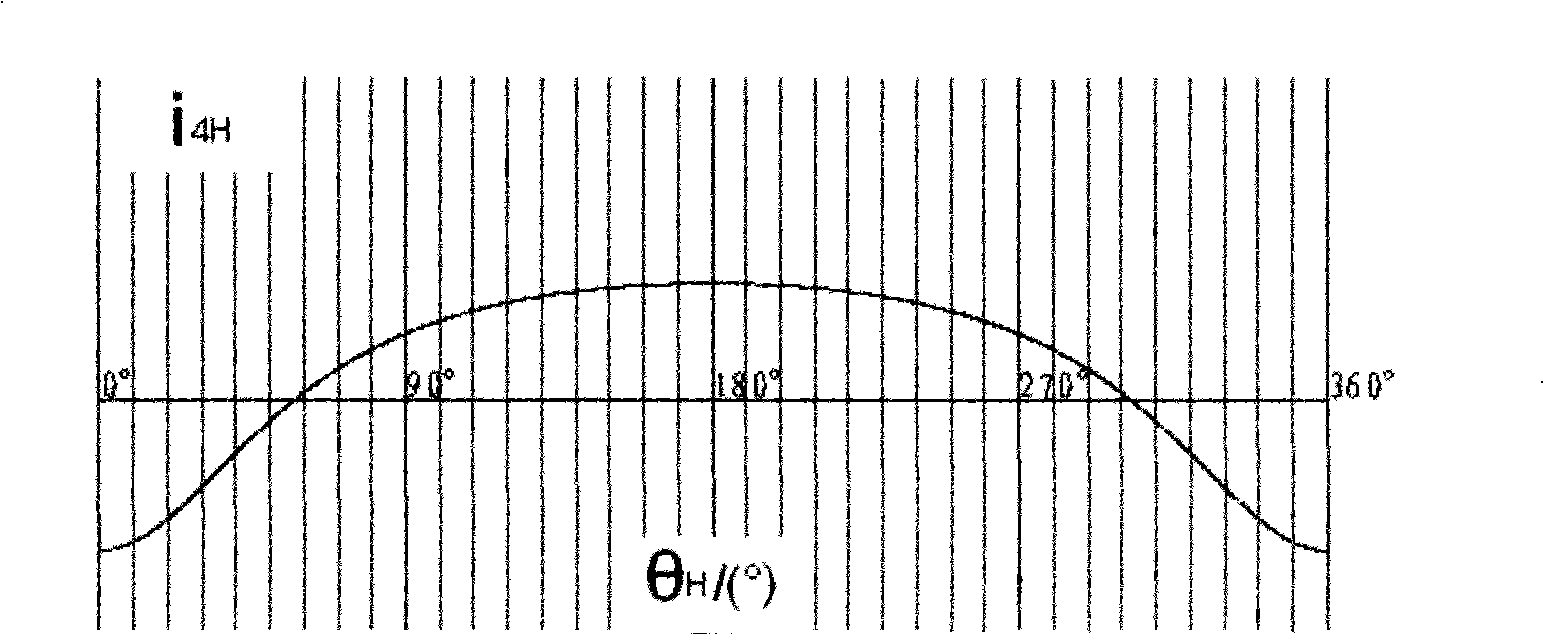

InactiveCN101311393AImprove transmission control precisionWork fasterToothed gearingsCombing machinesEngineeringGear train

The invention relates to a transmission mechanism of a detaching roller on a combing machine which is provided with a non-circular planetary gear train. The mechanism comprises two sun gears, a tie bar and an even number of planetary gears. The transmission mechanism outputs variable motions including natural rotation, stop and reversion in every working circle (which means the 360 degree rotation of a cylinder), drives the detaching roller to change the speed and the direction of the rotation in accordance with the requirements of the process when the tie bar is rotating at the constant speed driven by a single power source by constructing a pitch curve of the non-circular gear.

Owner:胡平 +1

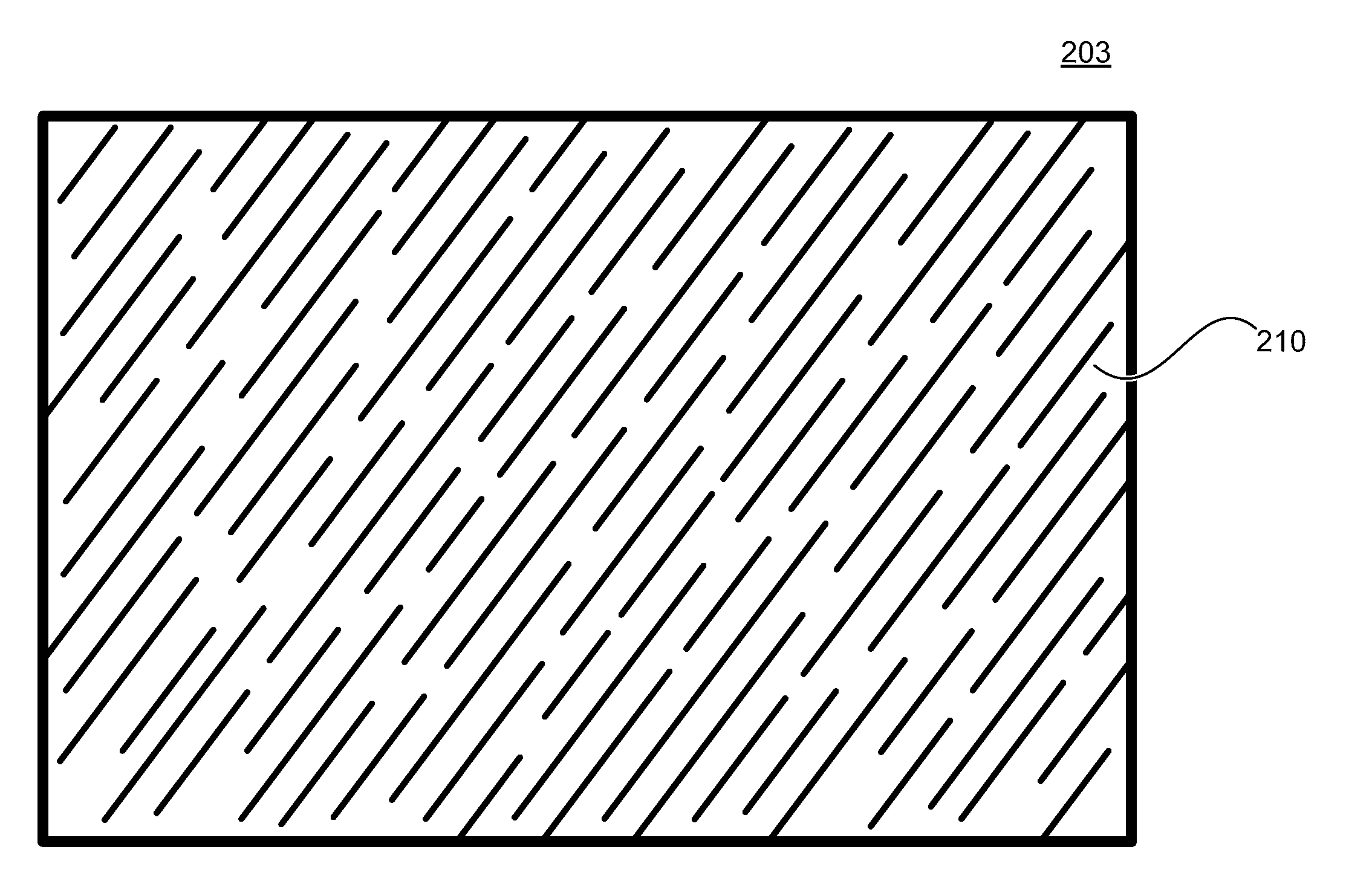

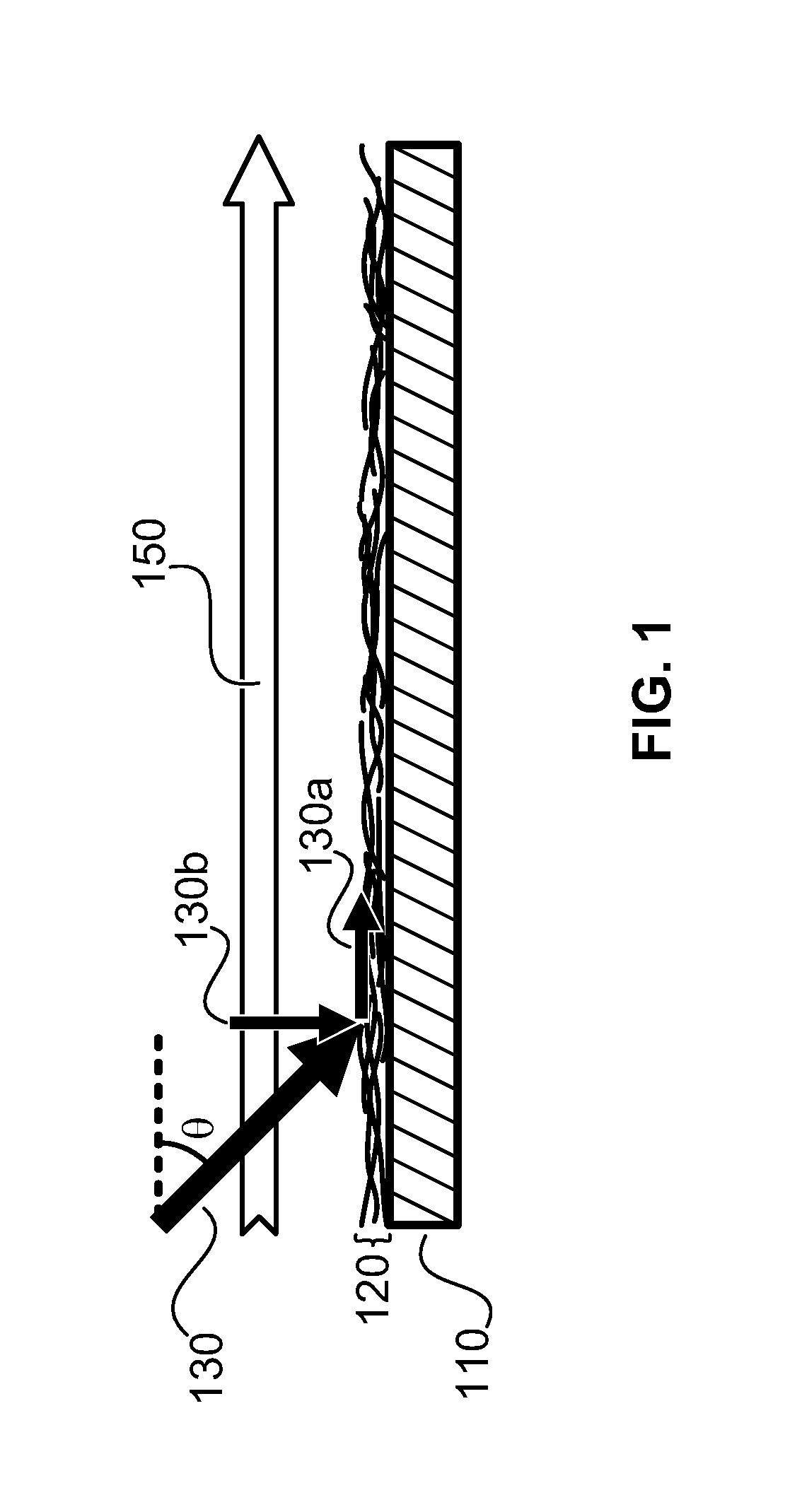

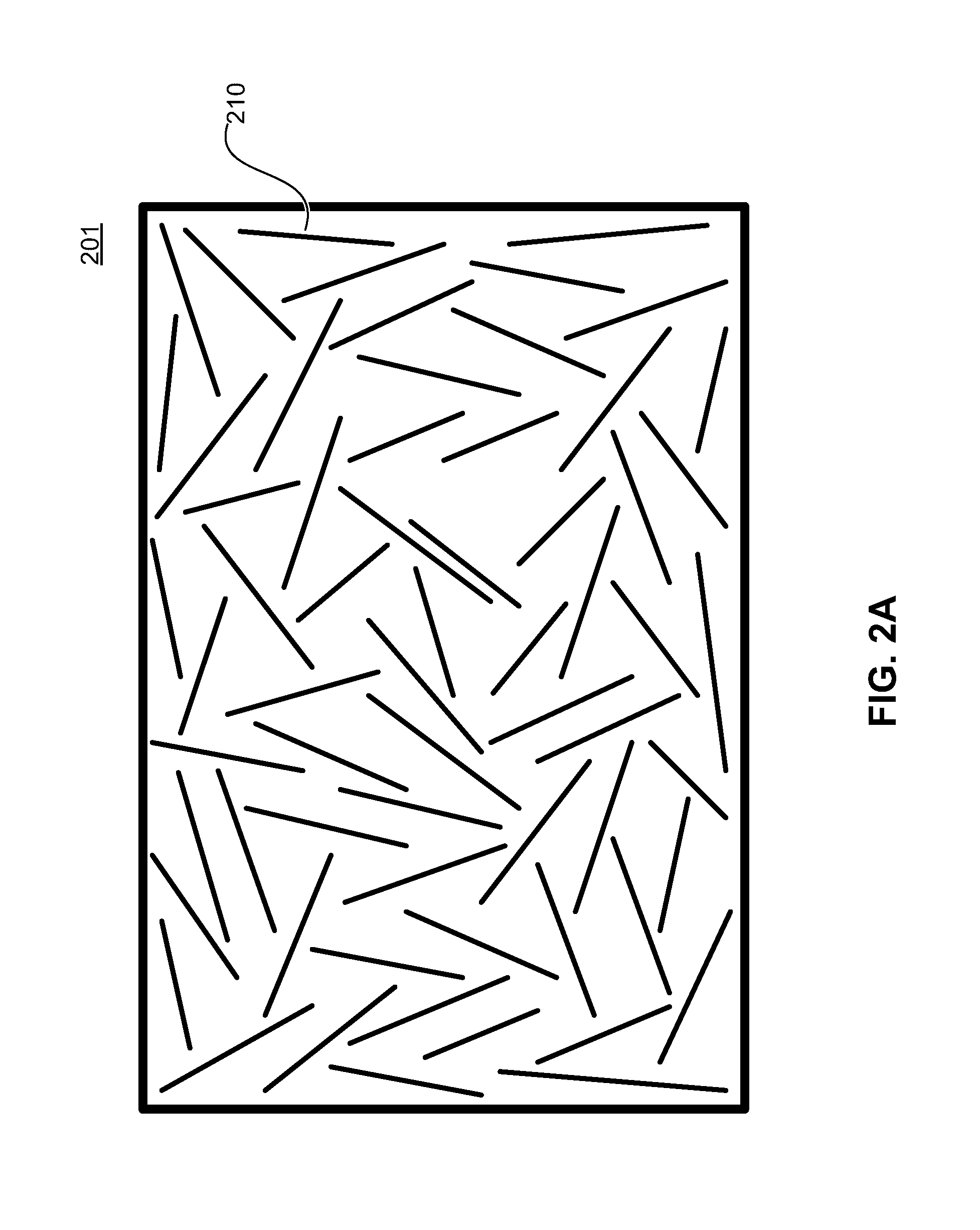

Methods for arranging nanoscopic elements within networks, fabrics, and films

ActiveUS20110291315A1Gap minimizationMaterial nanotechnologyLiquid surface applicatorsEngineeringRubbing

A method for arranging nanotube elements within nanotube fabric layers and films is disclosed. A directional force is applied over a nanotube fabric layer to render the fabric layer into an ordered network of nanotube elements. That is, a network of nanotube elements drawn together along their sidewalls and substantially oriented in a uniform direction. In some embodiments this directional force is applied by rolling a cylindrical element over the fabric layer. In other embodiments this directional force is applied by passing a rubbing material over the surface of a nanotube fabric layer. In other embodiments this directional force is applied by running a polishing material over the nanotube fabric layer for a predetermined time. Exemplary rolling, rubbing, and polishing apparatuses are also disclosed.

Owner:ZEON CORP

Method To Process Oilseed Flax Fiber For Use In Biocomposite Materials

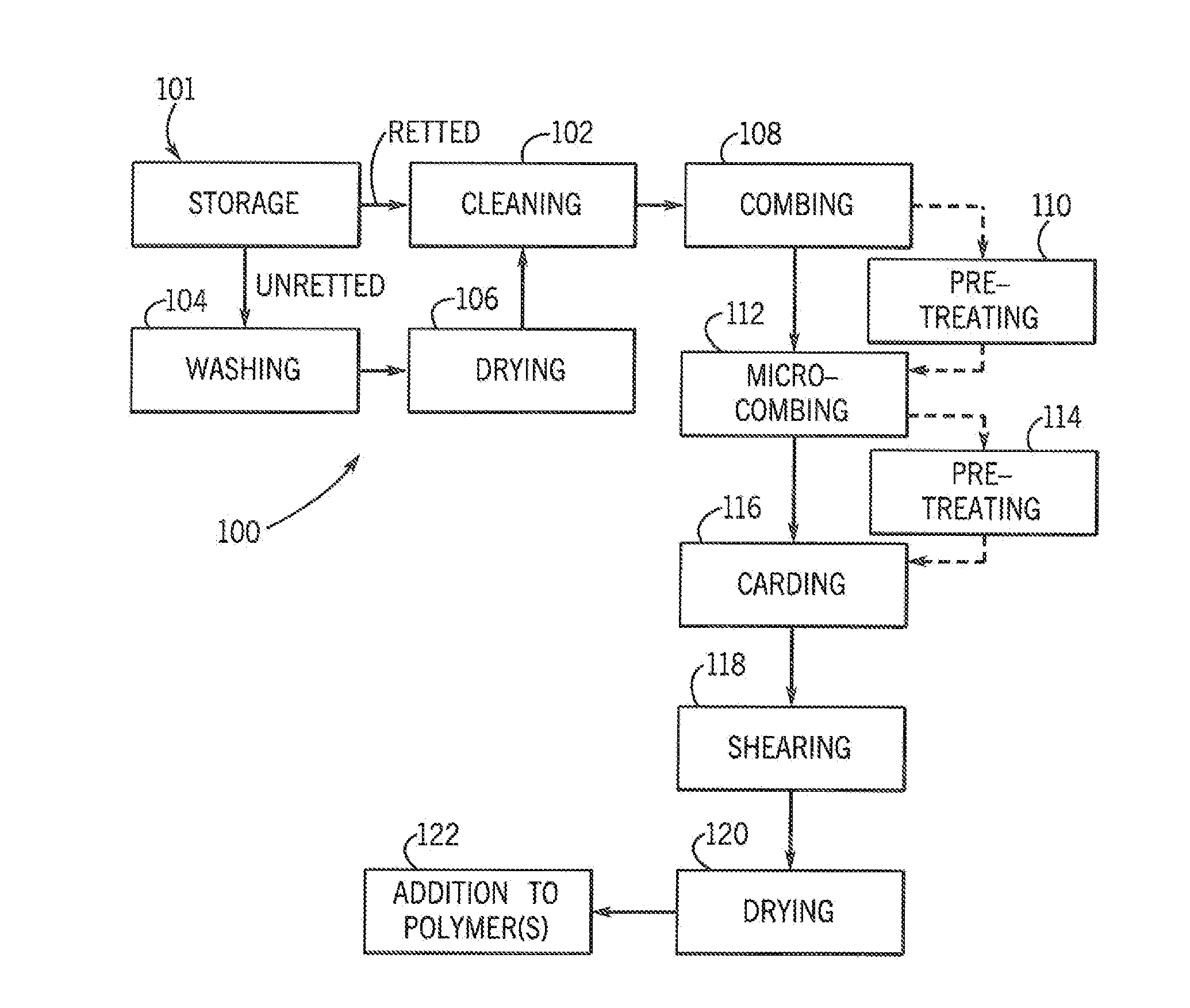

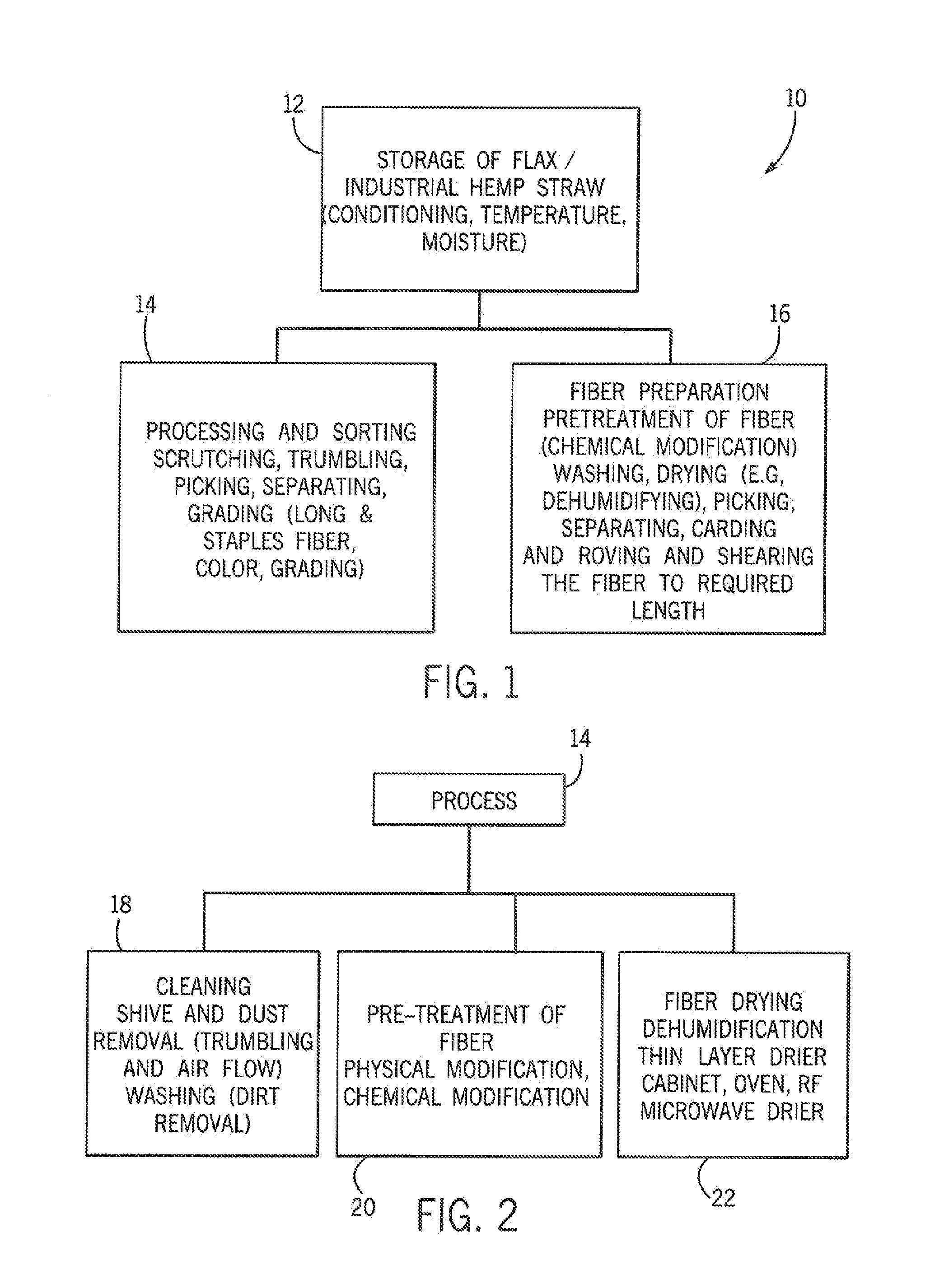

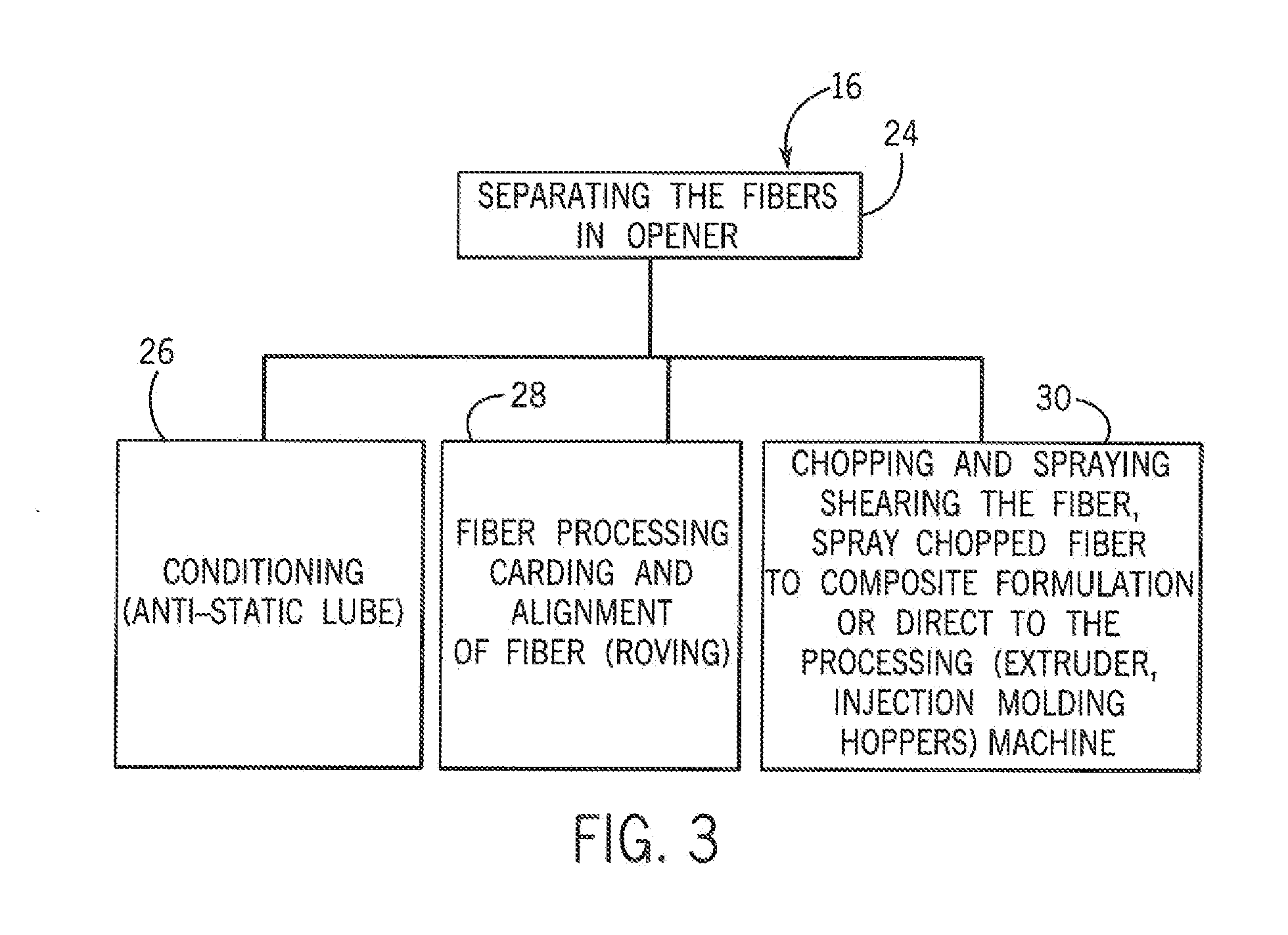

ActiveUS20150166745A1Retention strengthOptimizationMechanical impurity removalFibre cleaning/opening by air draught arrangementsFlax fiberSISAL

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

Method for producing ramie cotton blended yarn by using cotton-spinning equipment

This invention discloses a method for producing gunny-cotton blend yarn with a cotton spinning device including the following steps: pretreatment of fine dry gunny, cleaning cotton, combing cotton, fine combing, merging slivers, roving, spinning and winding process, which is advantaged that hemp yarn number is high reaching to 60-80 British yarn with 55-80% hemps, dry yarn is increased greatly and faults are reduced greatly.

Owner:CHANGSHANZHAOZHOU TEXTILE

Special yarn for thermal underwear and producing method thereof

InactiveCN101403151AMeet the needs of cohesionImprove yarn strengthDrafting machinesCombing machinesYarnCarding

The invention discloses muslin dedicated for thermal underwear, and a manufacturing method thereof, wherein, long stapled mutton and viscose fiber are adopted as raw materials; a combing technology is adopted for the long stapled mutton to manufacture combed sliver; a carded cotton carding technology is adopted for viscose fiber to manufacture viscose fiber stripe; after drawing, roving and spun yarn are carried out to the combed sliver and the viscose fiber, high-woven yarn dedicated for the thermal underwear with the weight blend ratio of 68-72 percent of the long stapled mutton and 28-32 percent of the viscose fiber is manufactured. With the adoption of current spinning equipment, the manufacturing method can manufacture the high-woven yarn used for manufacturing high range clothing fabric or knitwear such as thermal underwear, and the like; besides, the number of fibrogen inside the cross section of the manufactured high-woven yarn can fully satisfy the need of cohesive force between fiber and fiber; the yarn strength is improved, thus being entirely capable of adapting to the requirements for manufacturing high range clothing fabric or knitwear such as thermal underwear, and the like.

Owner:丁宏利

Popular searches

Liquid/gas/vapor treatment of definite length materials Textile treatment by spraying/projecting Mechanical fibre separation Liquid/gas/vapor fibres/slivers/rovings treatment Bacteriological retting Fibre treatment to obtain bast fibre Tows to slivers/yarns Dry-cleaning apparatus for textiles Continuous wound-up machines Open-end spinning machines

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com