Patents

Literature

325 results about "Biocomposite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

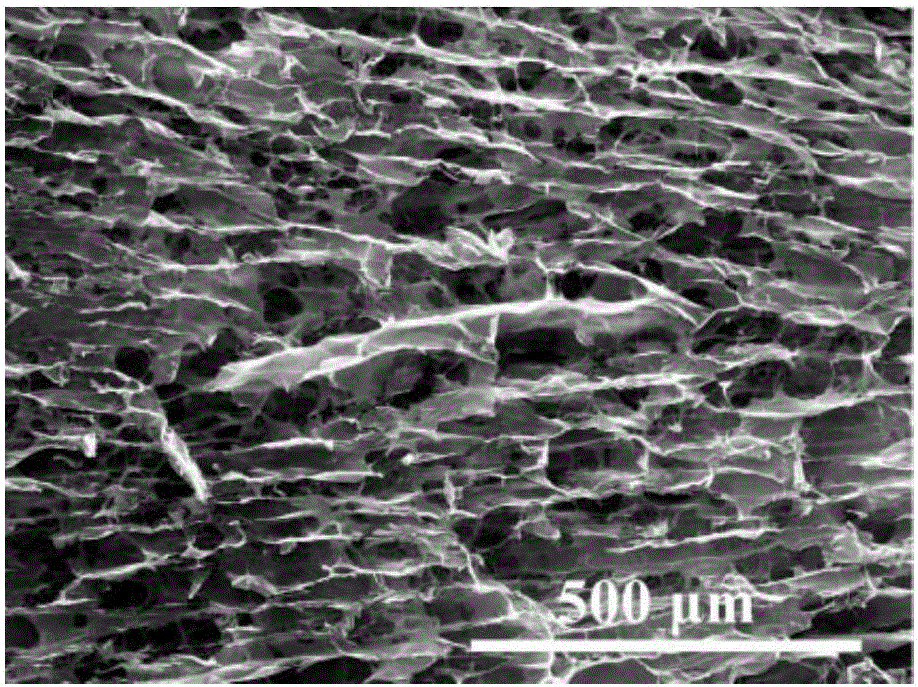

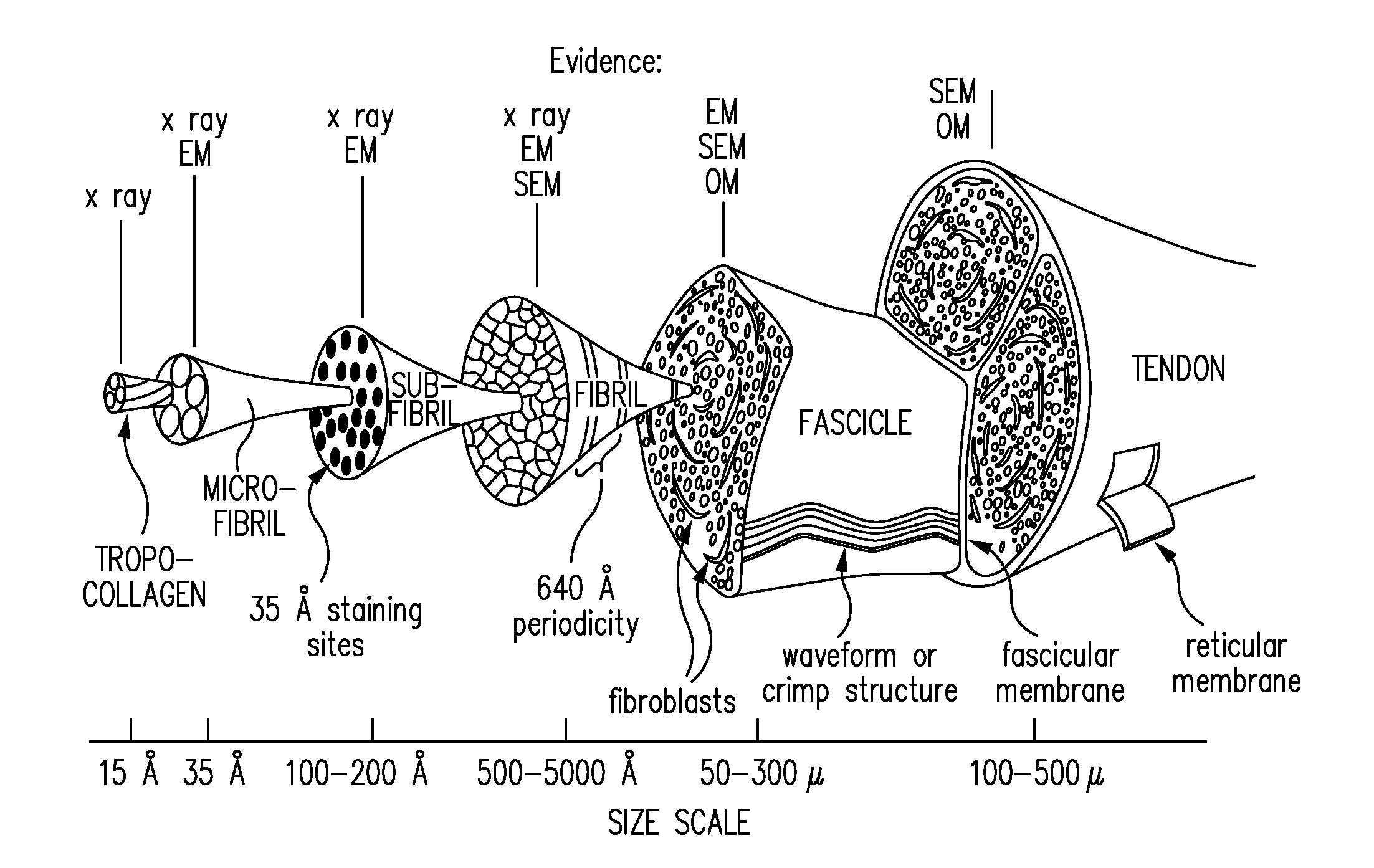

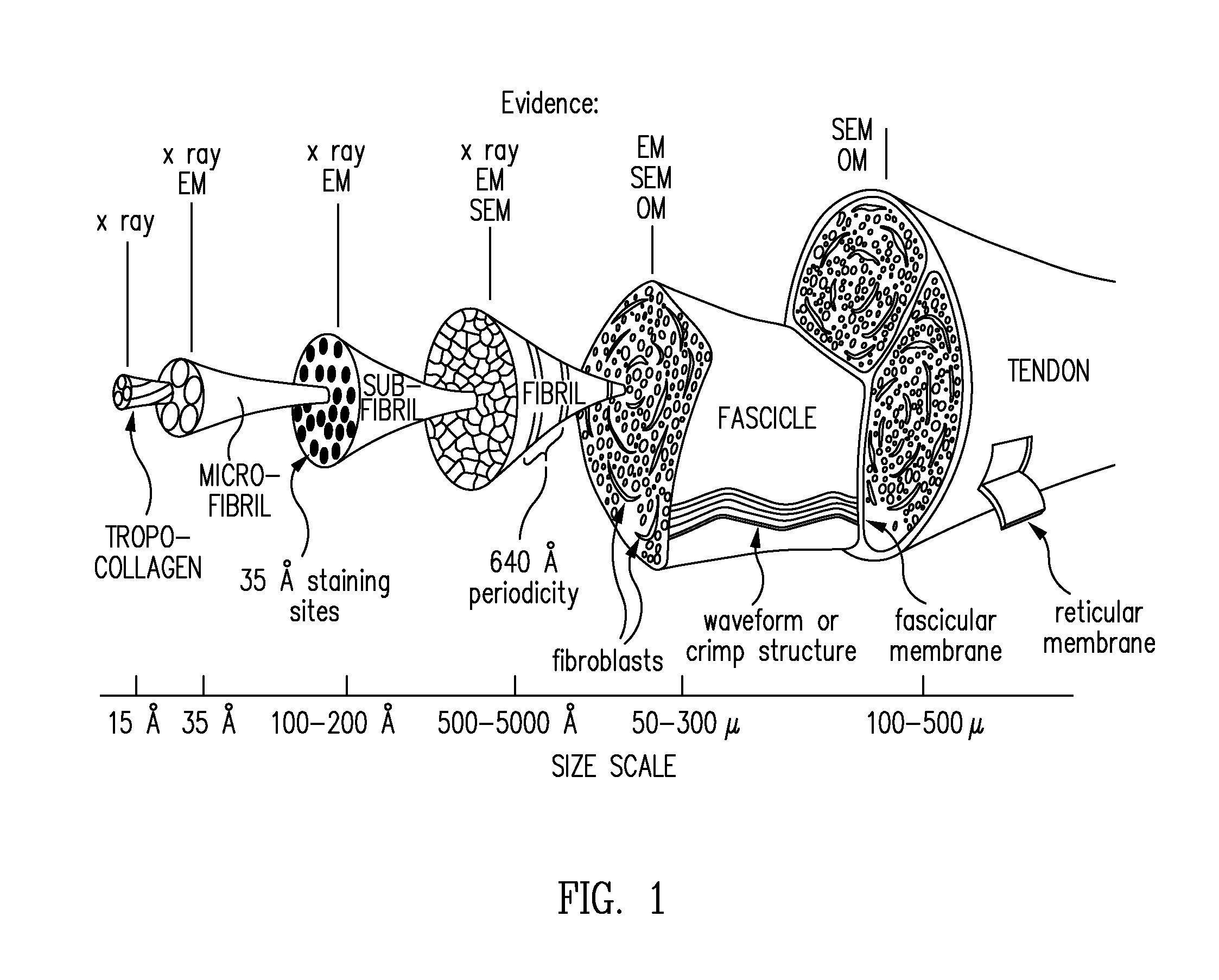

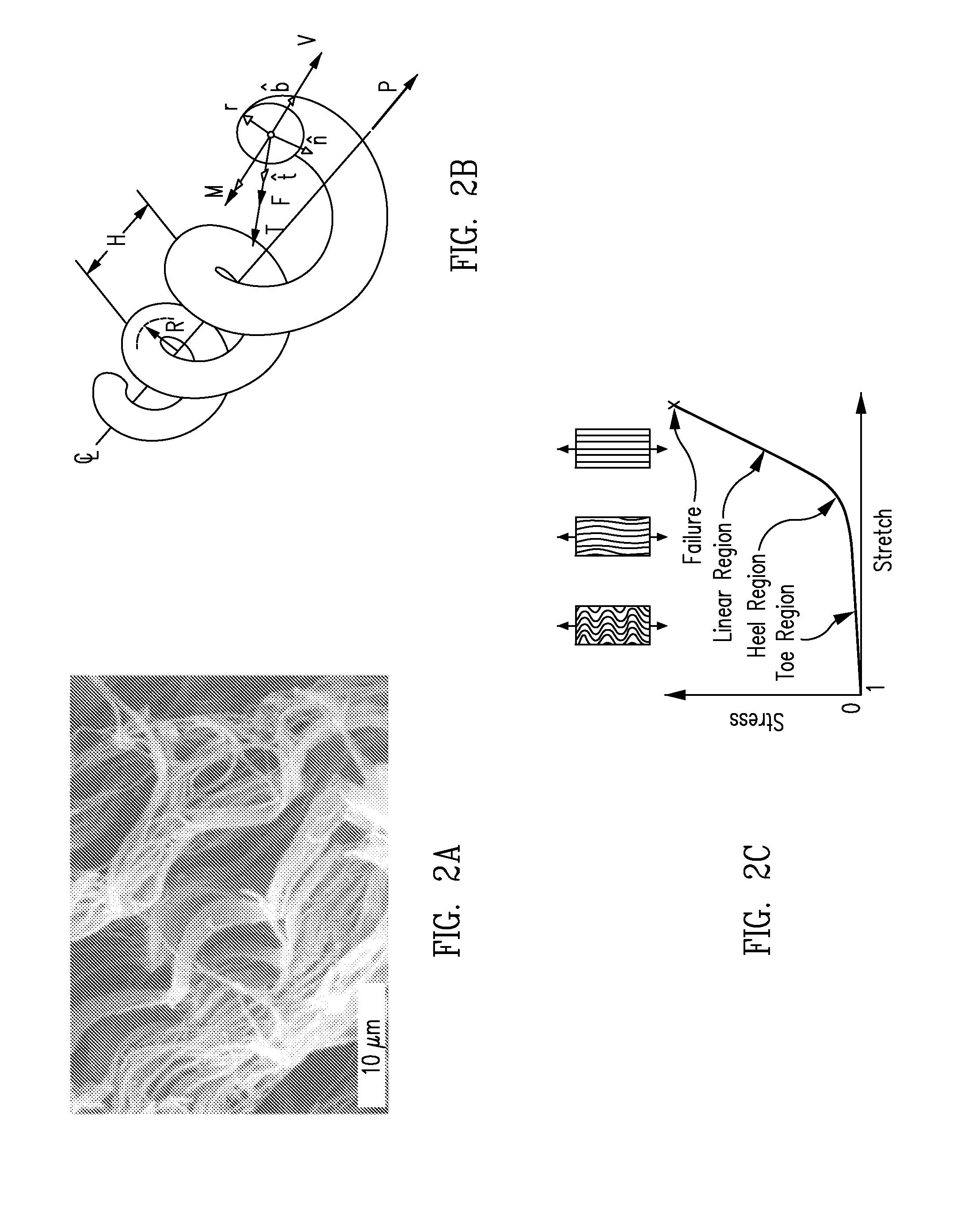

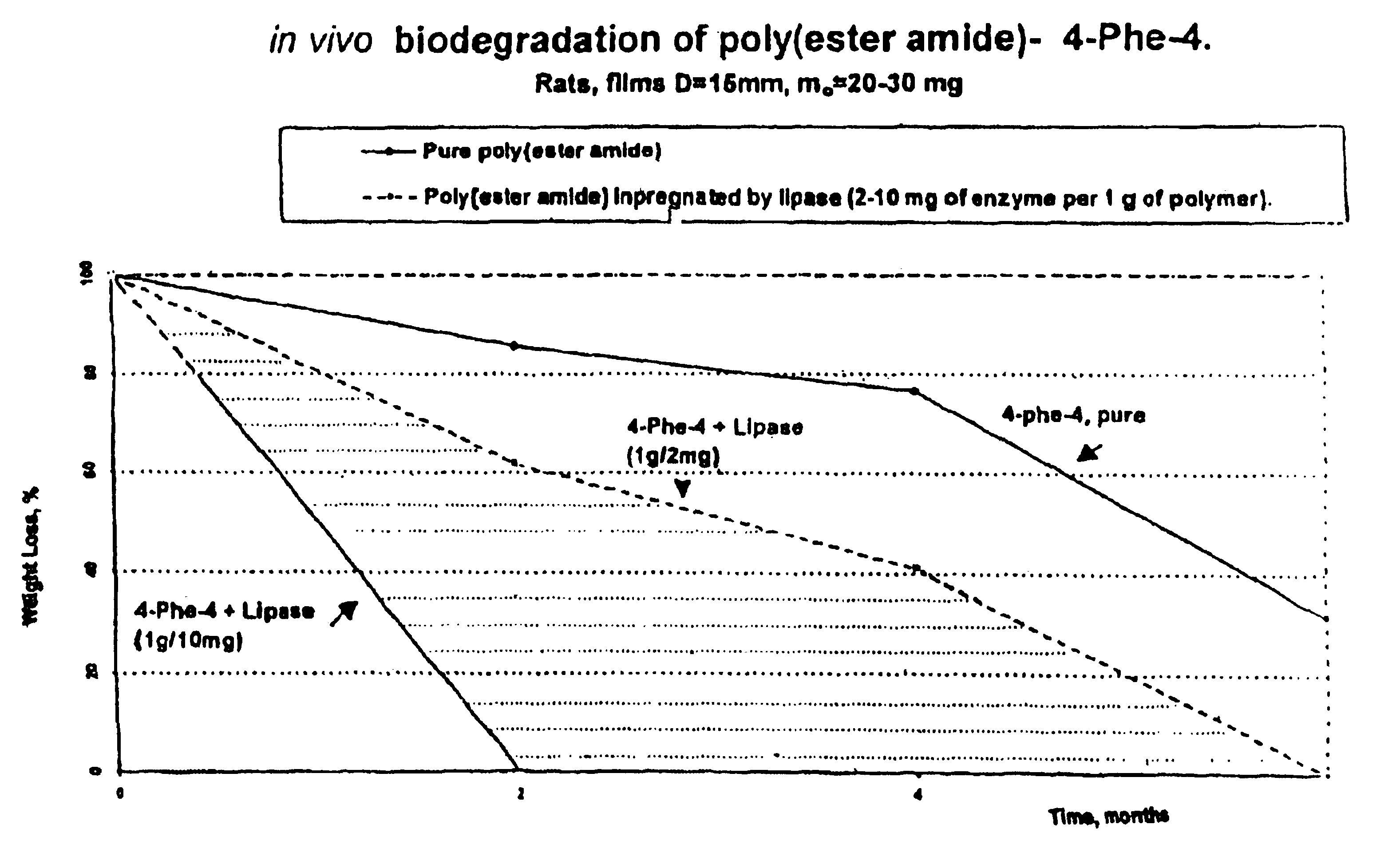

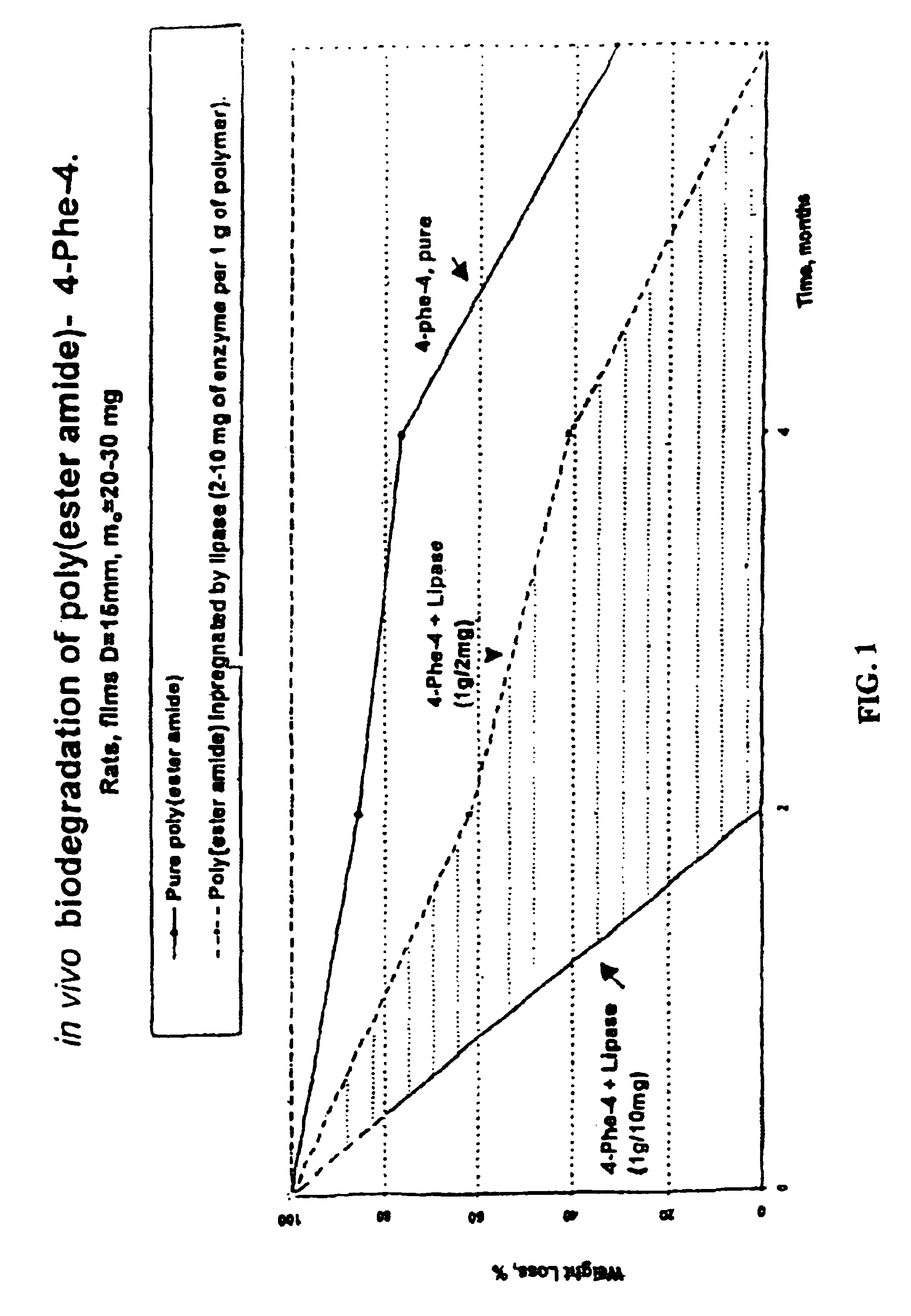

A biocomposite is a composite material formed by a matrix (resin) and a reinforcement of natural fibers. These kind of materials often mimic the structure of the living materials involved in the process keeping the strengthening properties of the matrix that was used, but always providing biocompatibility. The matrix phase is formed by polymers derived from renewable and nonrenewable resources. The matrix is important to protect the fibers from environmental degradation and mechanical damage, to hold the fibers together and to transfer the loads on it. In addition, biofibers are the principal components of biocomposites, which are derived from biological origins, for example fibers from crops (cotton, flax or hemp), recycled wood, waste paper, crop processing byproducts or regenerated cellulose fiber (viscose/rayon). The interest in biocomposites is rapidly growing in terms of industrial applications (automobiles, railway coach, aerospace, military applications, construction, and packaging) and fundamental research, due to its great benefits (renewable, cheap, recyclable, and biodegradable). Biocomposites can be used alone, or as a complement to standard materials, such as carbon fiber. Advocates of biocomposites state that use of these materials improve health and safety in their production, are lighter in weight, have a visual appeal similar to that of wood, and are environmentally superior.

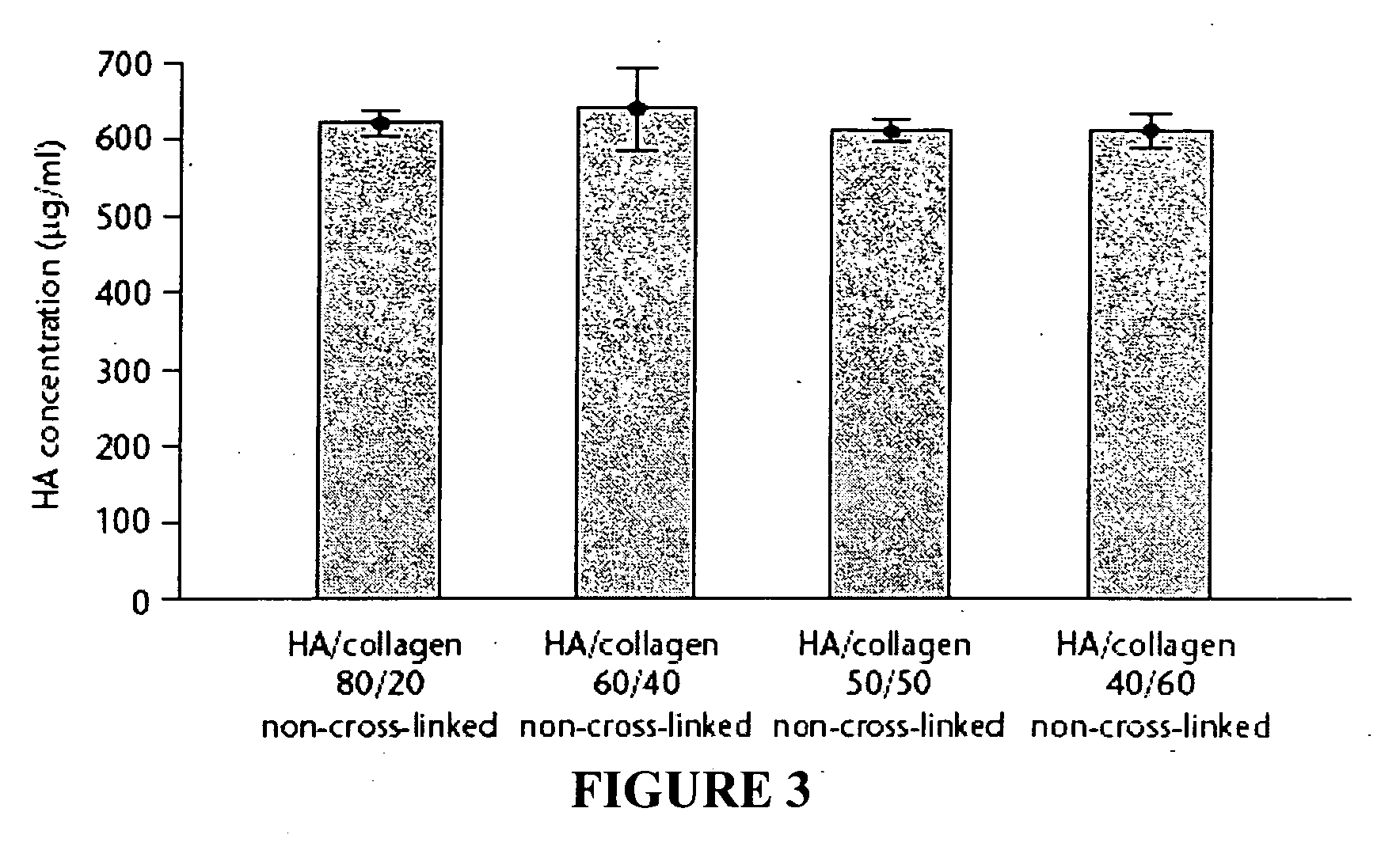

Method for producing cross-linked hyaluronic acid-protein bio-composites

InactiveUS20060189516A1Uniform densityUniform porosityPeptide/protein ingredientsSkeletal disorderCross-linkFiber

This invention is concerned with a new method for producing cross-linked hyaluronic acid—protein bio-composites in various shapes. In the present process, a polysaccharide solution and a protein solution are mixed under moderate pH values in presence of salts to form a homogenous solution, which can be processed into various shapes, such as membrane, sponge, fiber, tube or micro-granular and so on. After then, the homogenous solution is subjected to a cross-linking reaction in organic solvent containing weak acid to produce an implantable bio composite material having excellent bio-compatibility, biodegradability, prolonged enzymatic degradation time, and good physical properties.

Owner:IND TECH RES INST

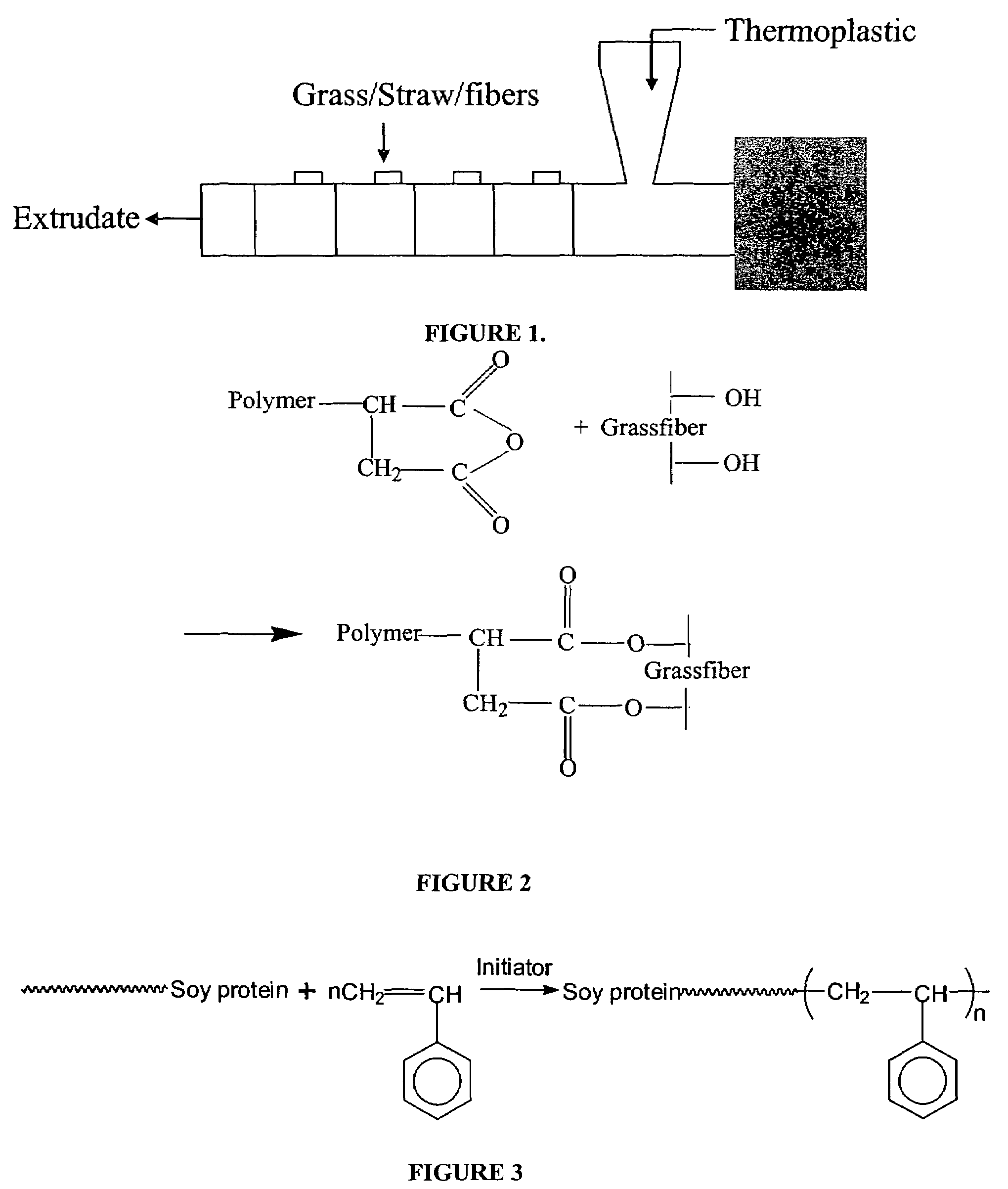

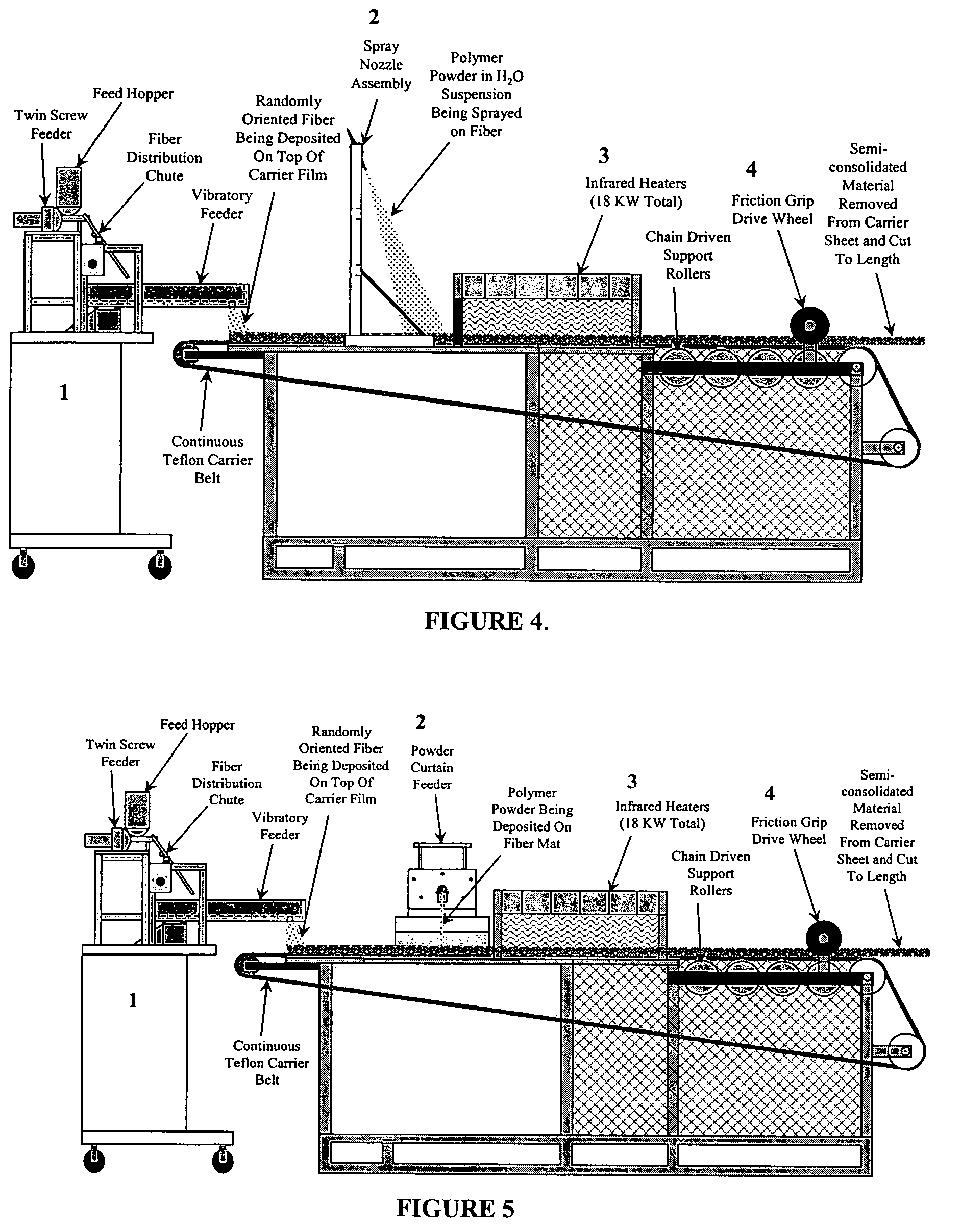

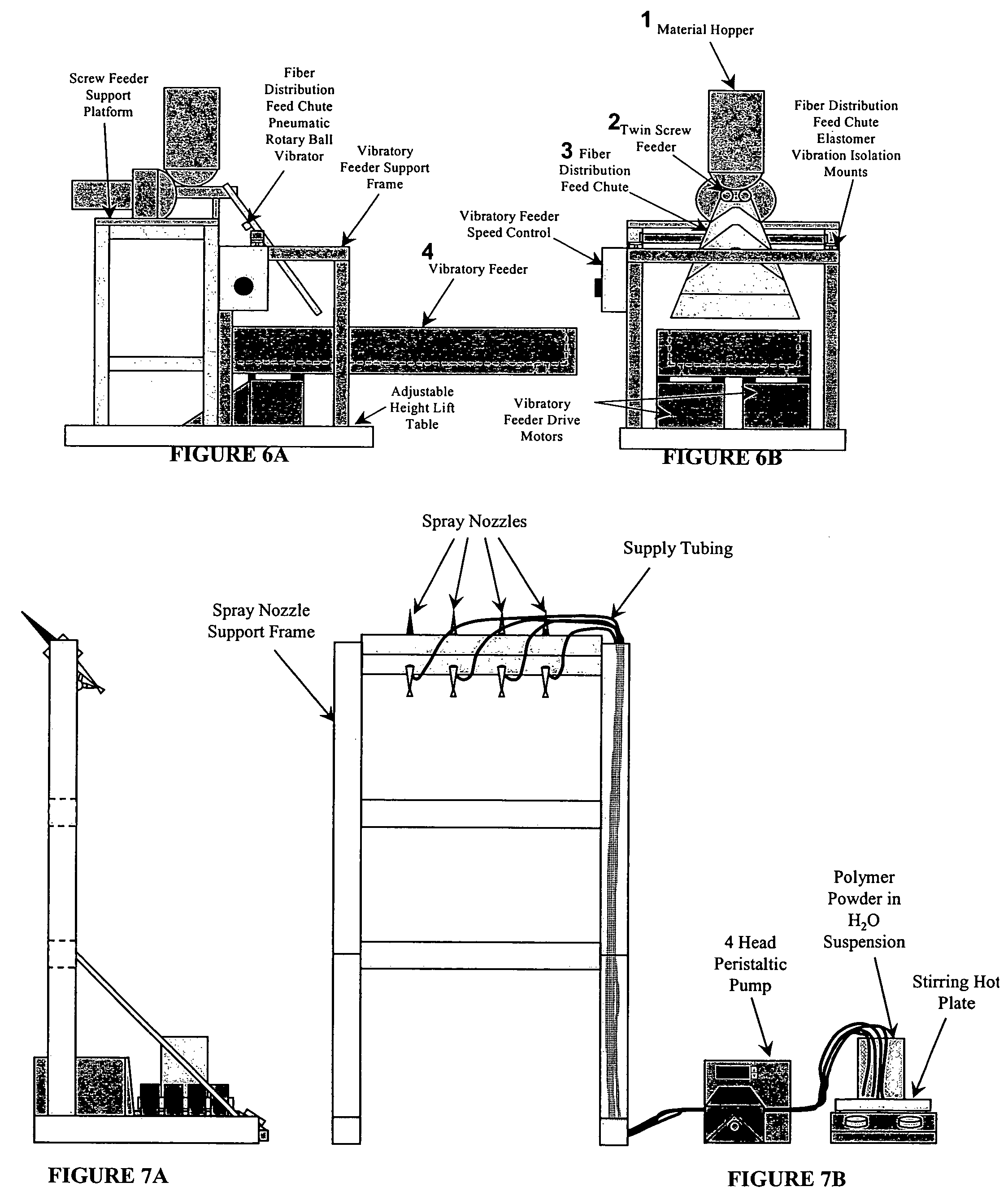

Cellulosic biomass soy flour based biocomposites and process for manufacturing thereof

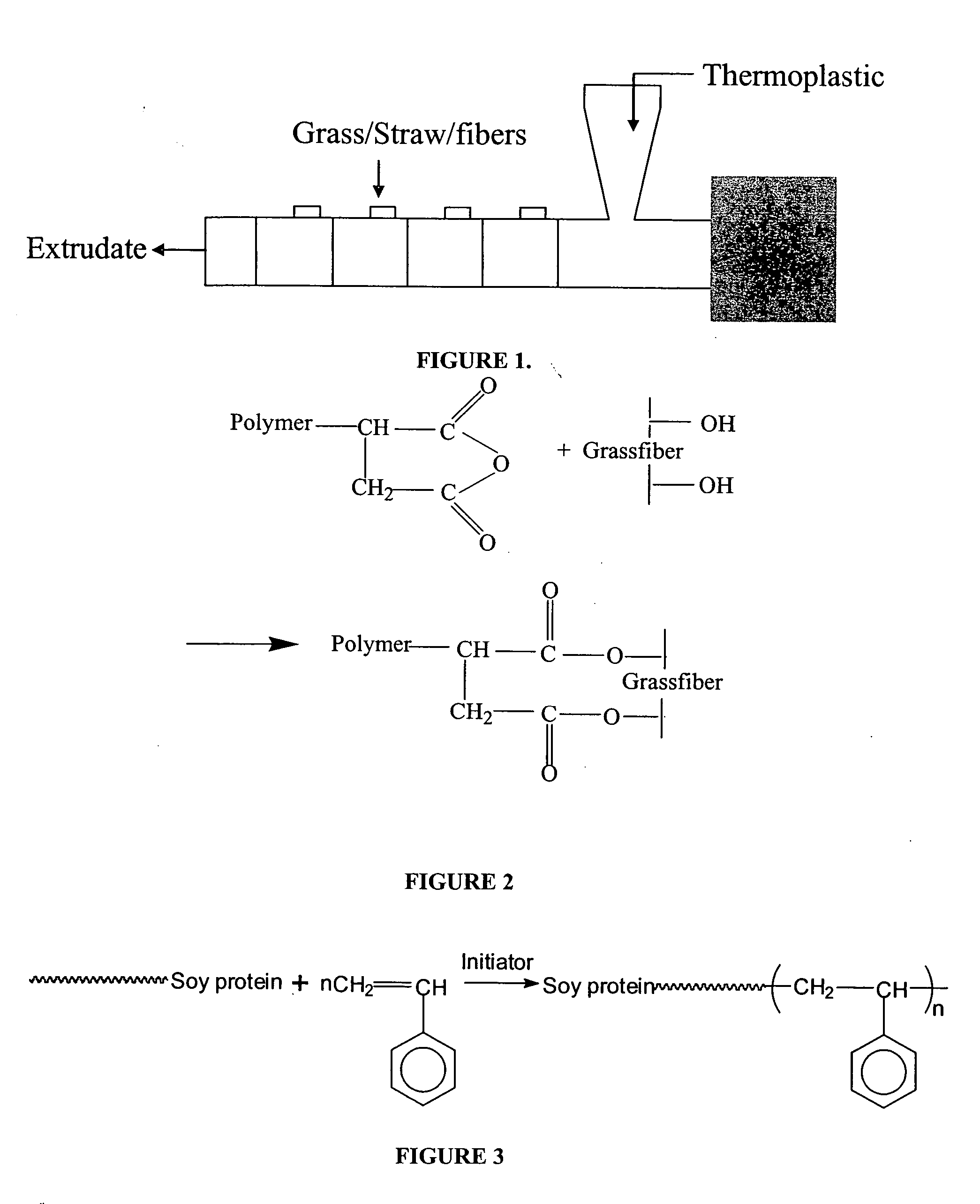

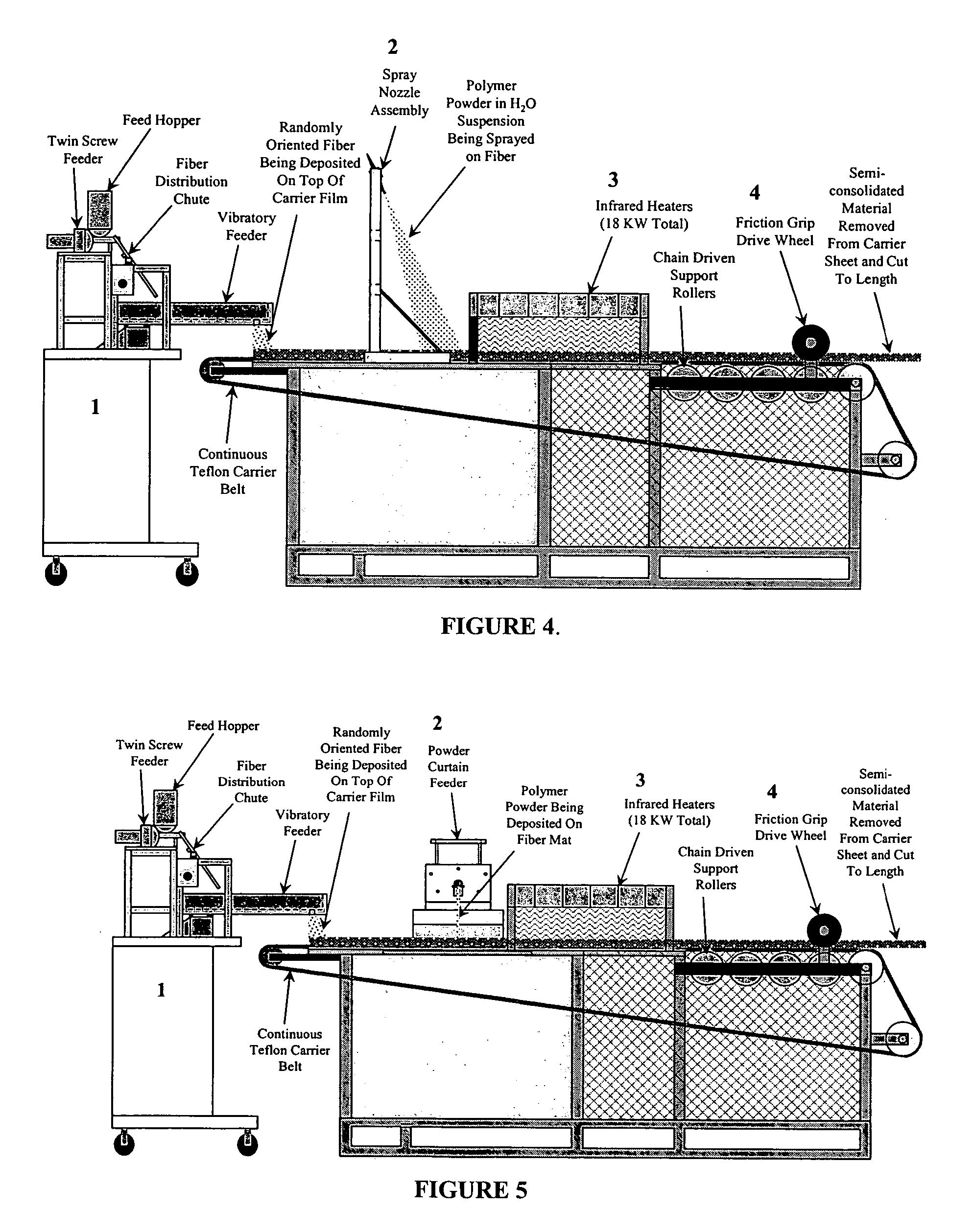

A process for the manufacture of natural fiber and polymer composites is described. Thermoplastically processed plasticized soy flour based plastics are used with thermoplastic polymers. Polymers of soy flour and an in situ polymerized polyvinyl polymer which links proteins and carbohydrates in the flour to form the polymer are used. The composites are useful in engineering materials.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Tissue substitutes comprising stem cells and reduced ceria

InactiveUS7888119B2Promote healingGood adhesionBiocideIn-vivo radioactive preparationsProgenitorBiology

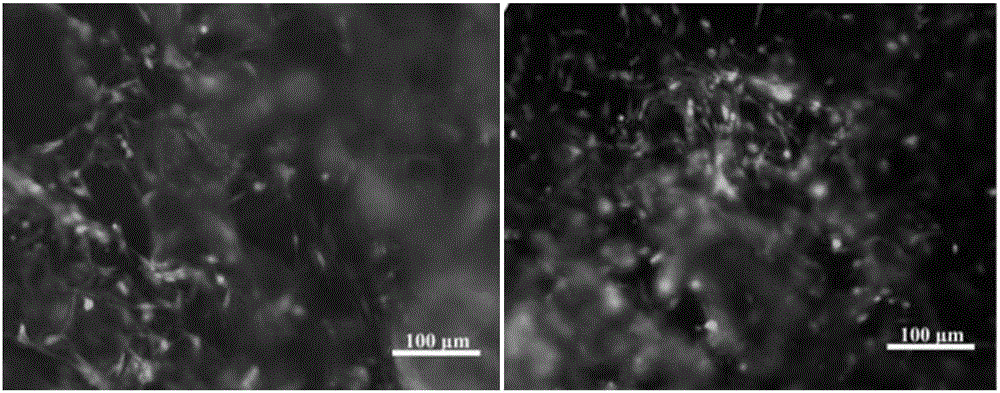

A biocompatible composite includes a solid biocompatible material and a plurality of living human progenitor or living stem cells attached thereto. The biocomposite provides a stable interface with endogenous tissue and the implanted composition resulting in accelerated repair to damaged bones and tissues.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

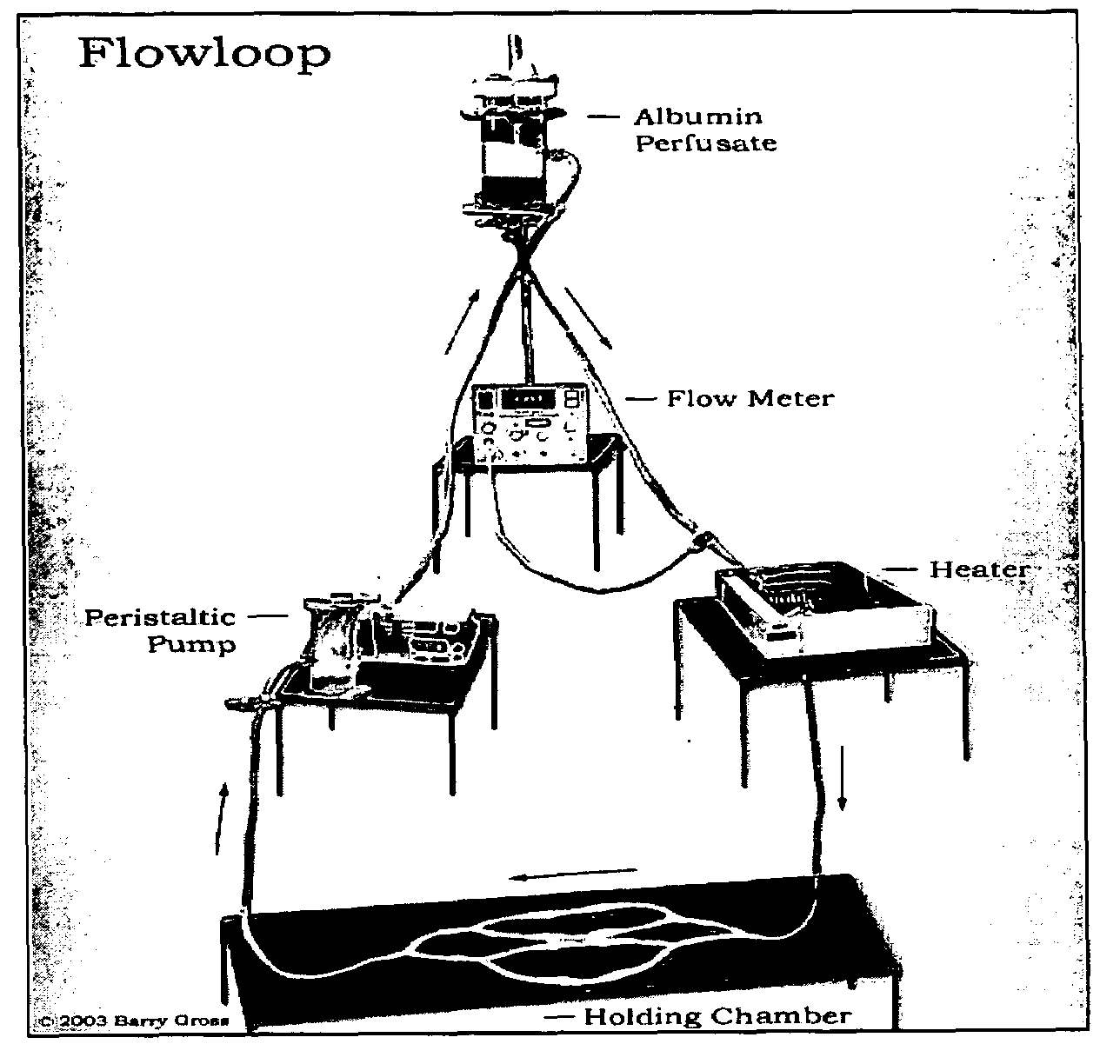

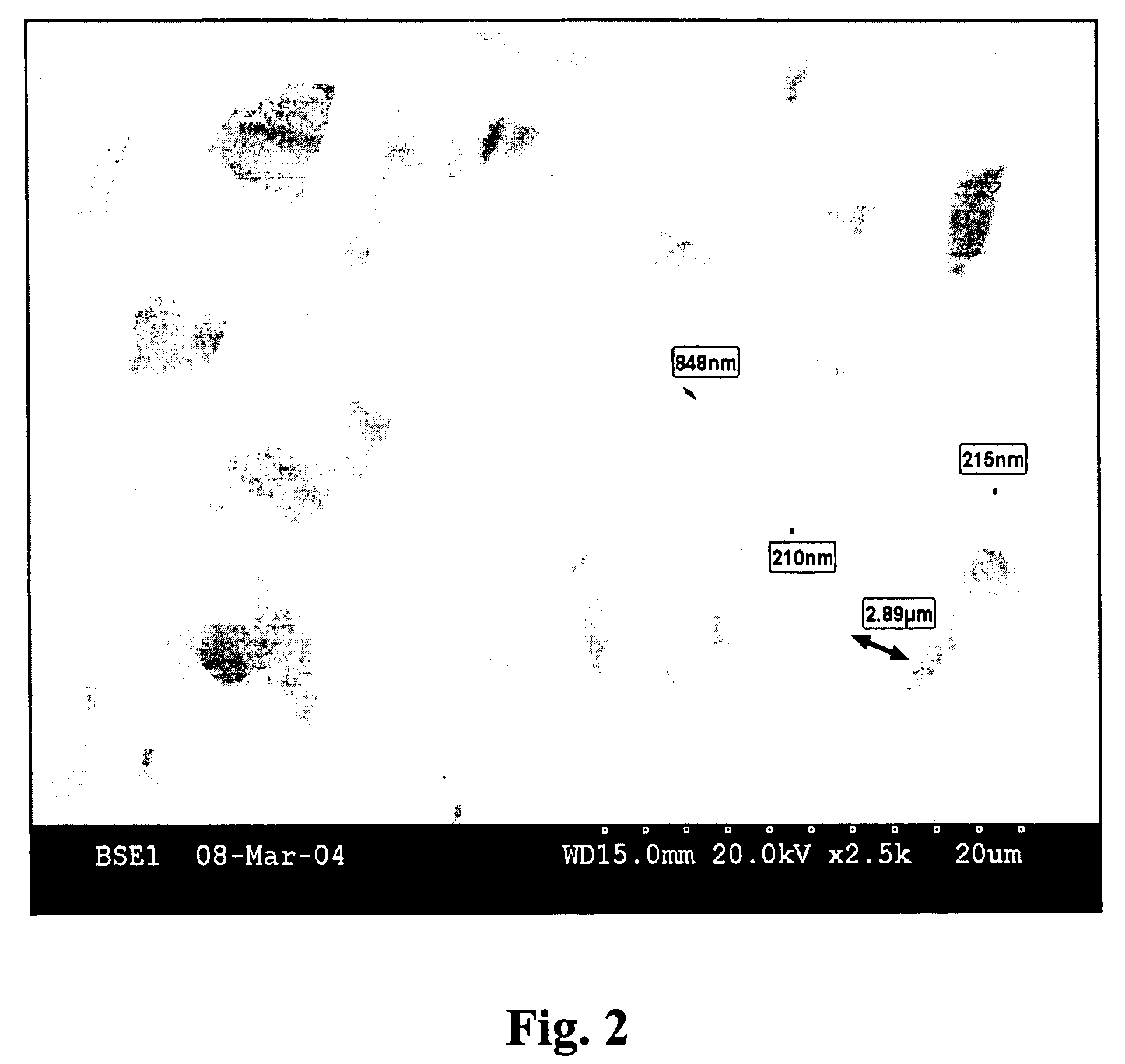

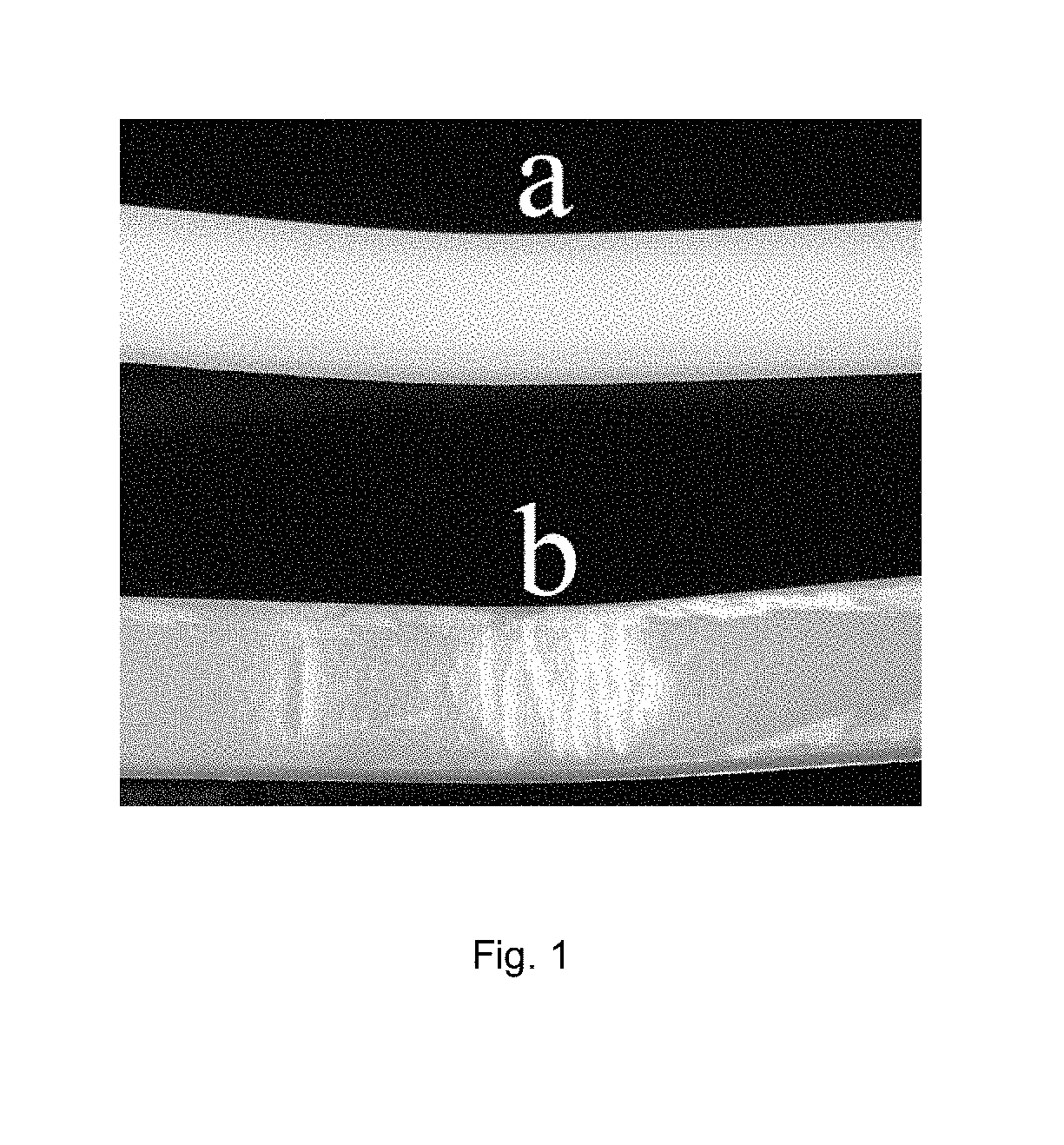

Nanofibrous biocomposite prosthetic vascular graft

The present invention provides a bioactive, small-diameter (typically less than 6 mm in internal diameter) vascular graft prosthesis, and is a textile conduit preferably manufactured using a novel electrospinning perfusion methodology. One preferred embodiment is a nanofibrous biocomposite textile conduit which comprises a prepared liquid admixture of polyester (Dacron), a biodurable implantable synthetic polymer, and Type IV collagen, an extracellular matrix protein. This prepared admixture and blending of diverse fibrous matter is utilized in a novel electrospinning perfusion process to form a small-diameter (less than 6 mm) fabricated textile conduit, a discrete article of manufacture, which then serves as an antecedent tangible workpiece for a subsequently-made prosthetic vascular graft construct.

Owner:BIOSURFACES +2

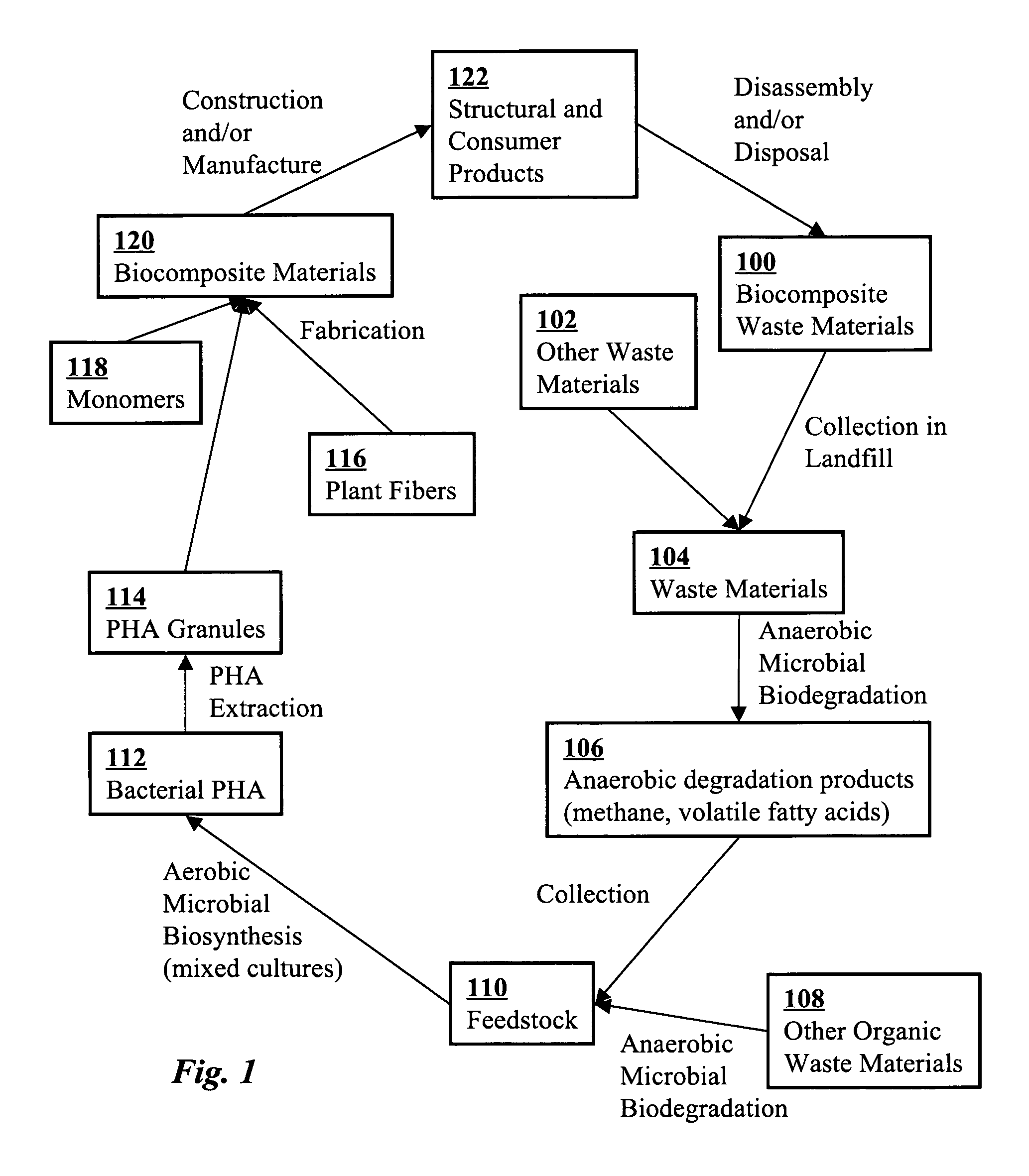

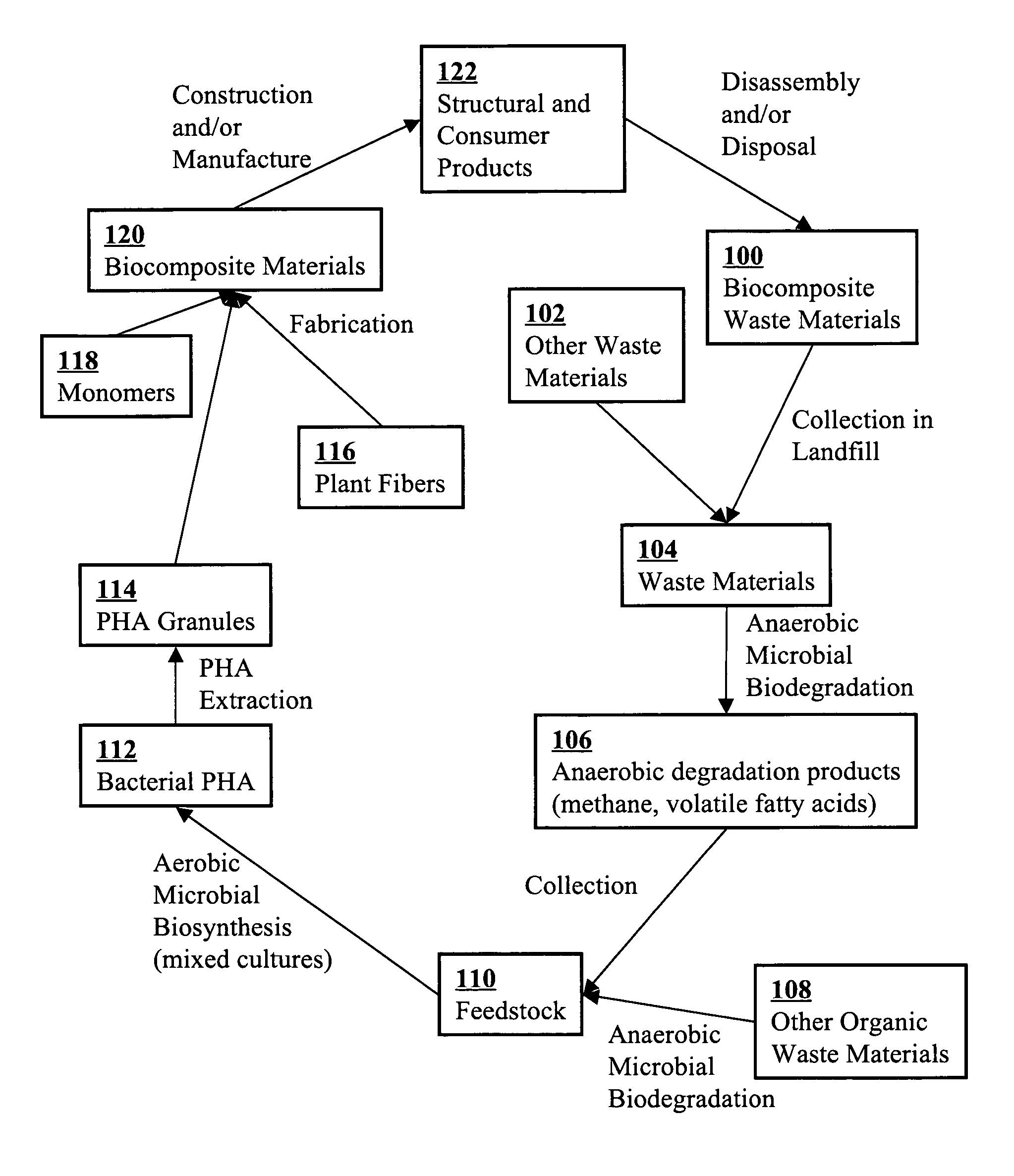

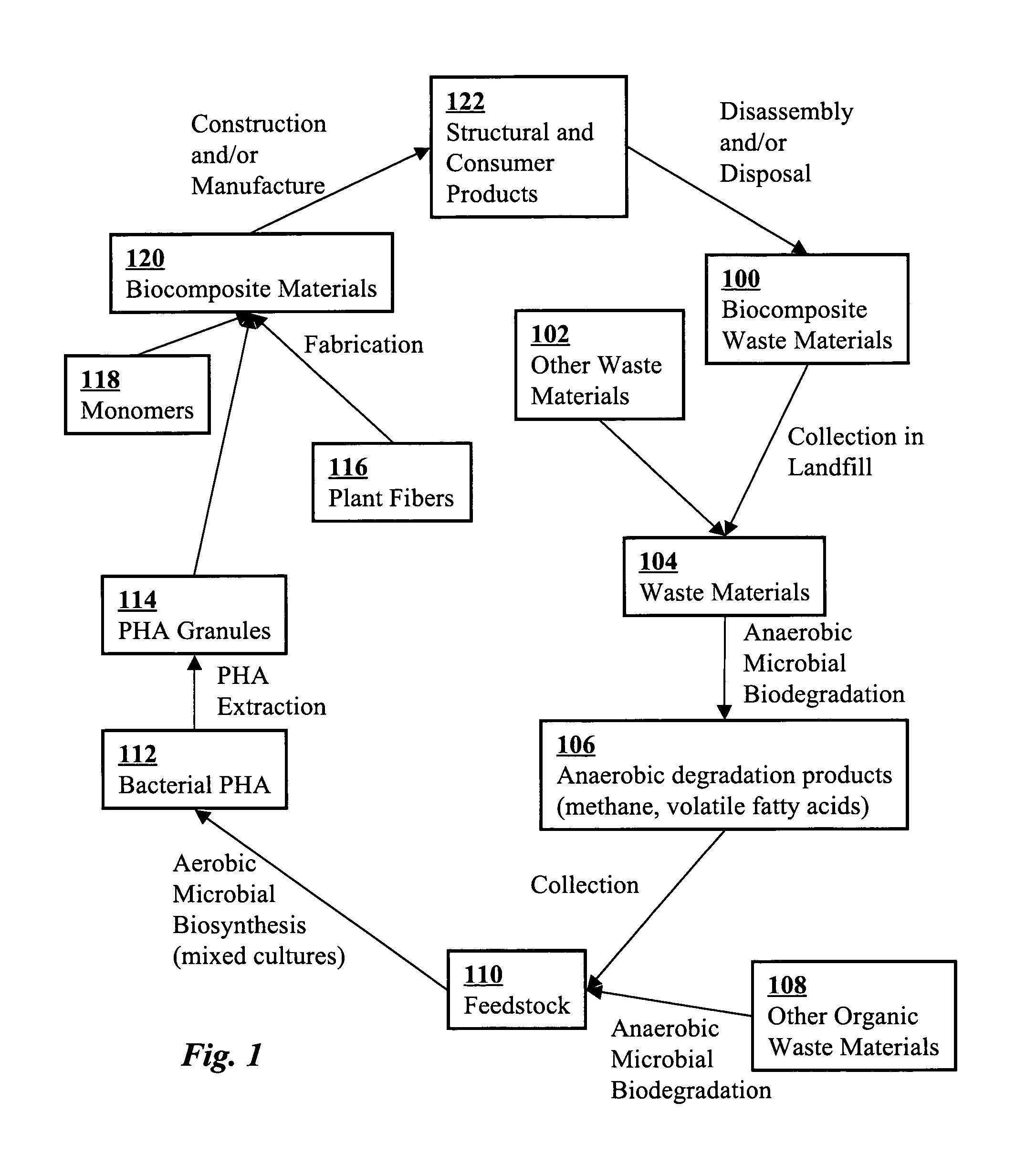

Bacterial poly(hydroxy alkanoate) polymer and natural fiber composites

ActiveUS7887893B2Improve bindingImprove performanceLayered productsPedestrian/occupant safety arrangementVolatile fatty acidsResin matrix

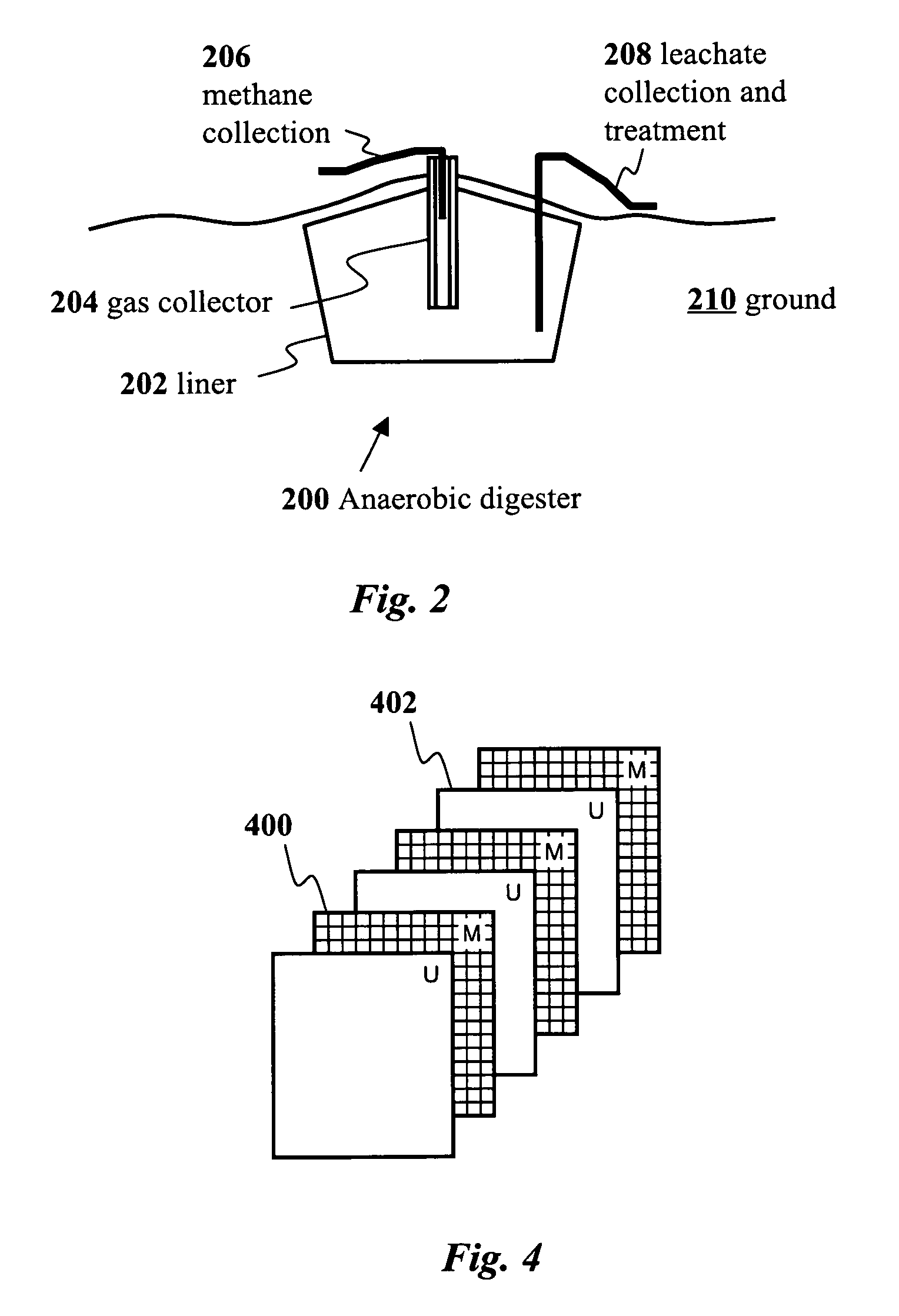

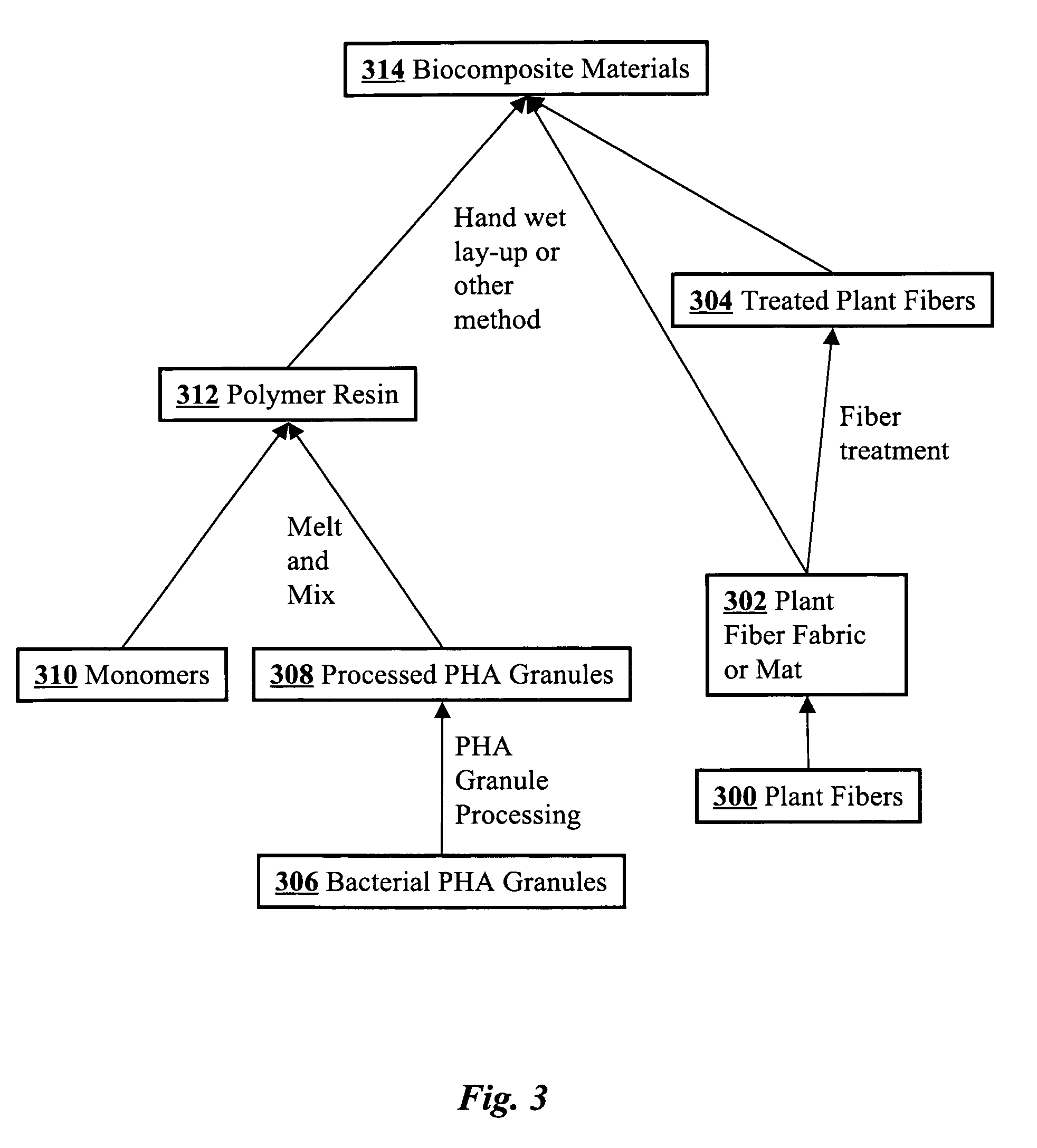

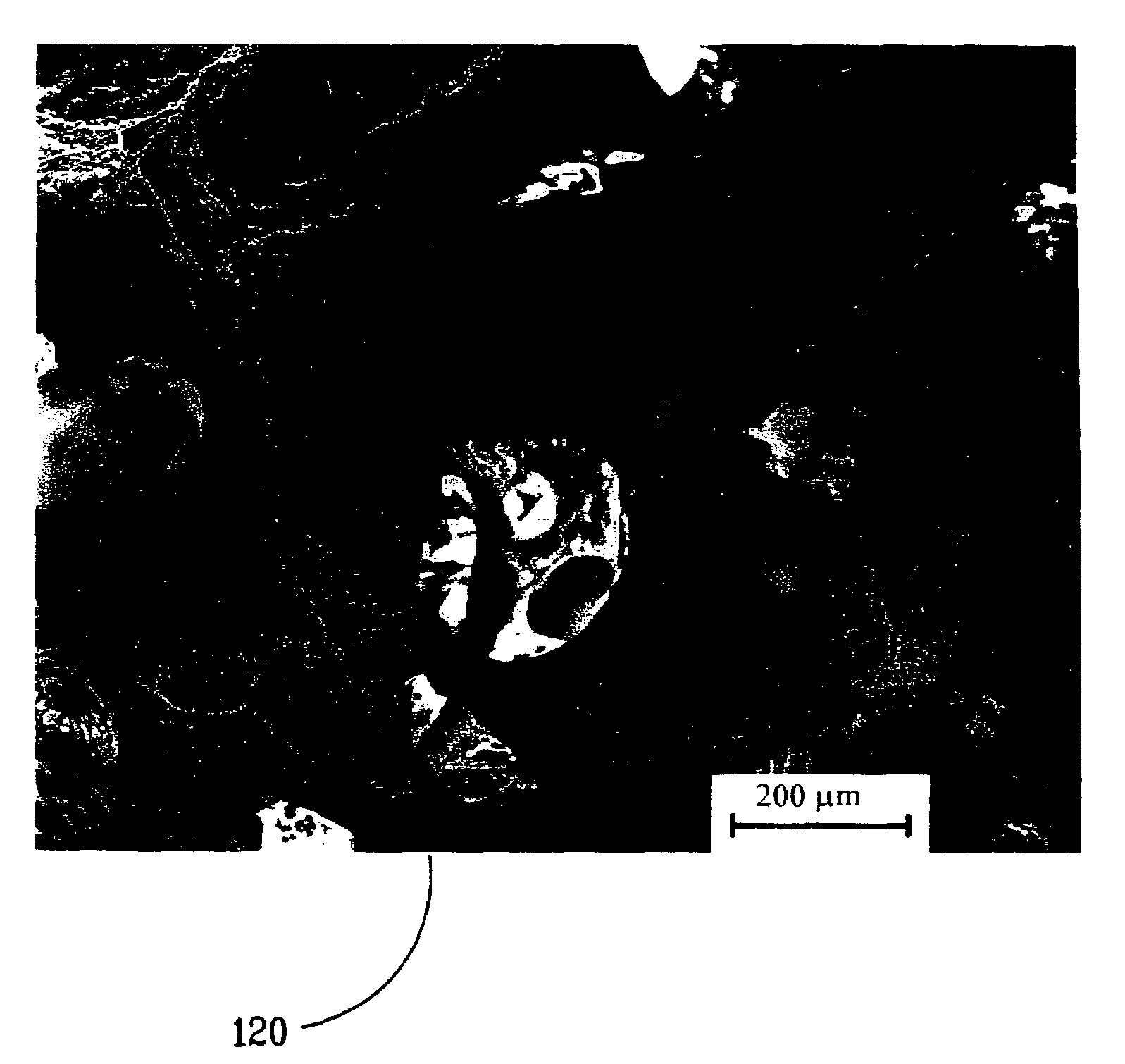

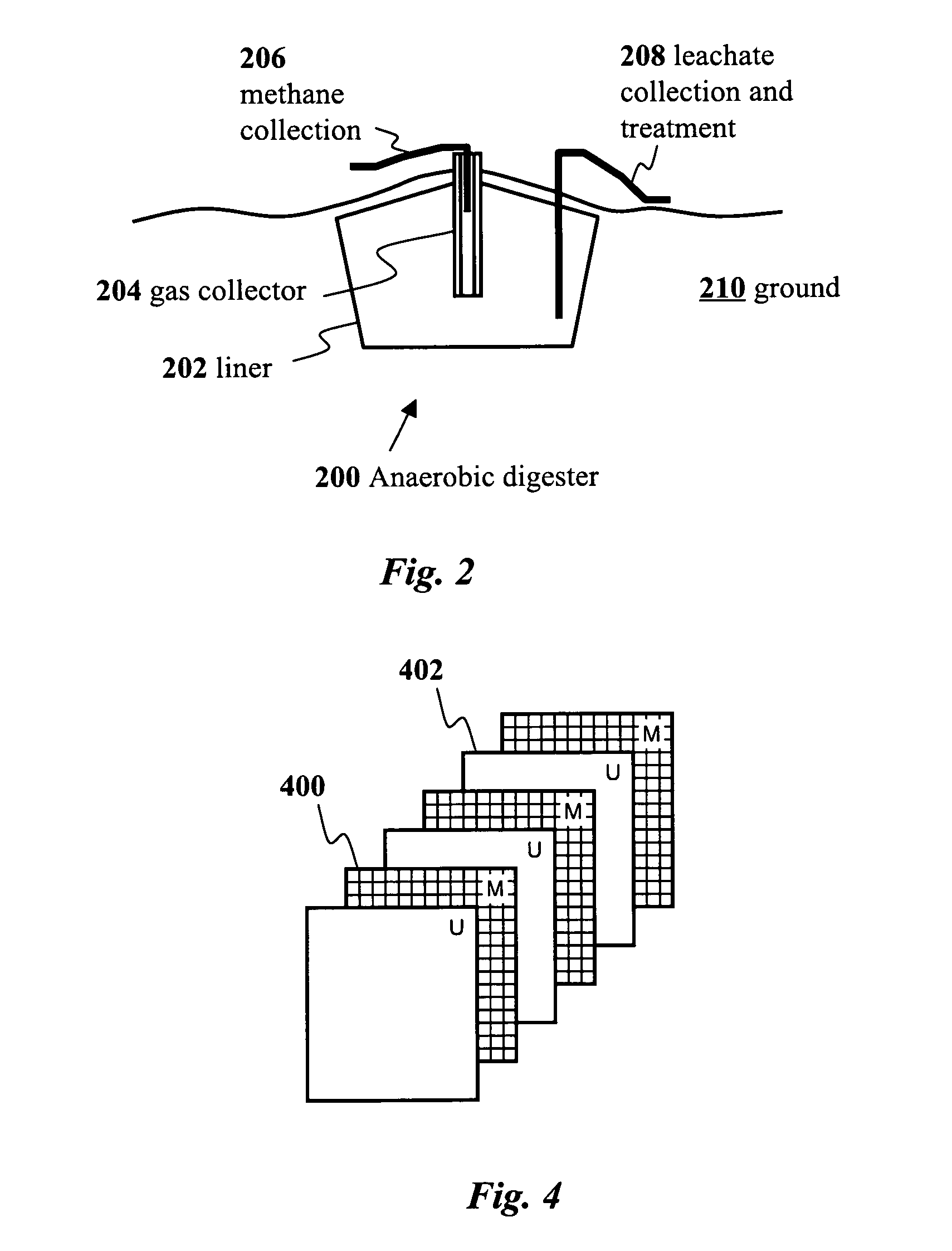

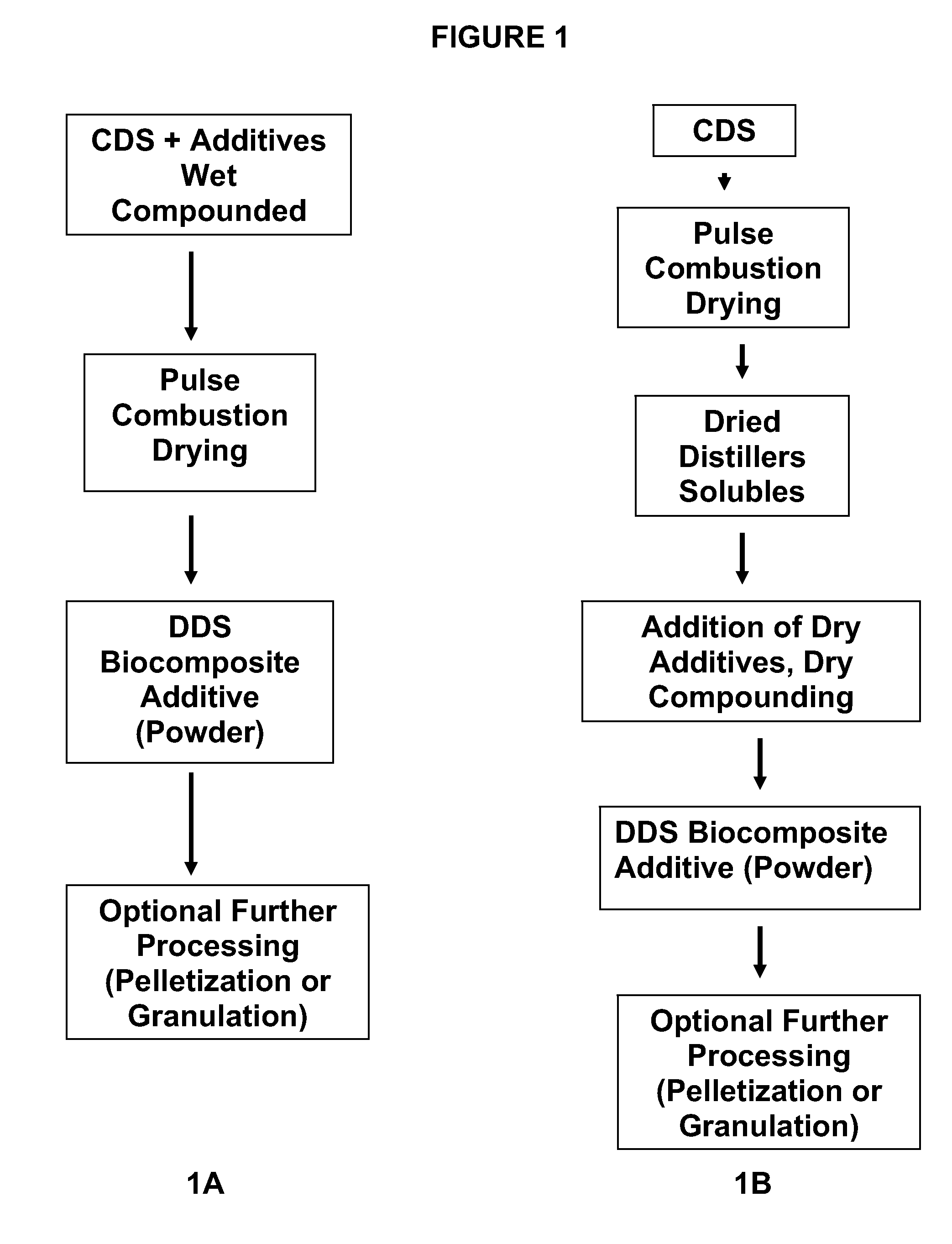

A biocomposite is produced from natural fiber fabrics embedded in a matrix of biosynthetic polyhydroxy-alkanoate (PHA) polymers. The PHA is synthesized using aerobic microbial biosynthesis using mixed bacterial cultures and a feedstock containing anaerobic degradation products such as methane and volatile fatty acids derived from microbial biodegradation of organic waste materials, which may include waste biocomposites. Monomers may be added to the synthesized PHA polymer to control mechanical properties of the resulting biocomposite. The natural fibers and / or PHA may be pretreated using various techniques to improve the bond between the fibers and the PHA resin matrix and water absorption resistance of the fibers. The composite may be a laminate of treated and untreated fabric layers, or differently treated layers, to achieve good in-service performance as well as rapid and / or optimal biogas production when taken out of service and put in an anaerobic environment to degrade.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

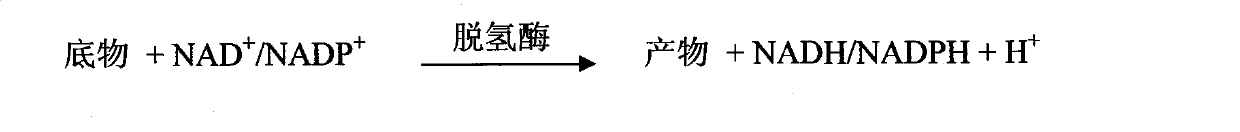

Preparation method of dehydrogenase-electrochemical biosensor

InactiveCN102998348ASimple manufacturing processRealize low potential detectionMaterial electrochemical variablesElectrochemical biosensorCarbon nanomaterials

The invention relates to a preparation method of an electrochemical biosensor, and particularly relates to a preparation method of a dehydrogenase-electrochemical biosensor. The method comprises the following steps of: preparing nano biocomposite from all components (including a carbon nanomaterial, an electronic mediator, a high-molecular polymer, dehydrogenase, coenzyme and buffer solution) required for modifying electrodes in a preparation process of the sensor; and modifying the composite material to the surface of a screen-printed electrode by a simple one-step dispensing method, so as to prepare the dehydrogenase-electrochemical biosensor. By adopting the method, the preparation process of the dehydrogenase-electrochemical biosensor is simplified, and the method is suitable for mass production; an inter-batch difference and the difference between batches are reduced; and the detection sensitivity and accuracy and the storage stability are improved.

Owner:CHONGQING MEDICAL UNIVERSITY

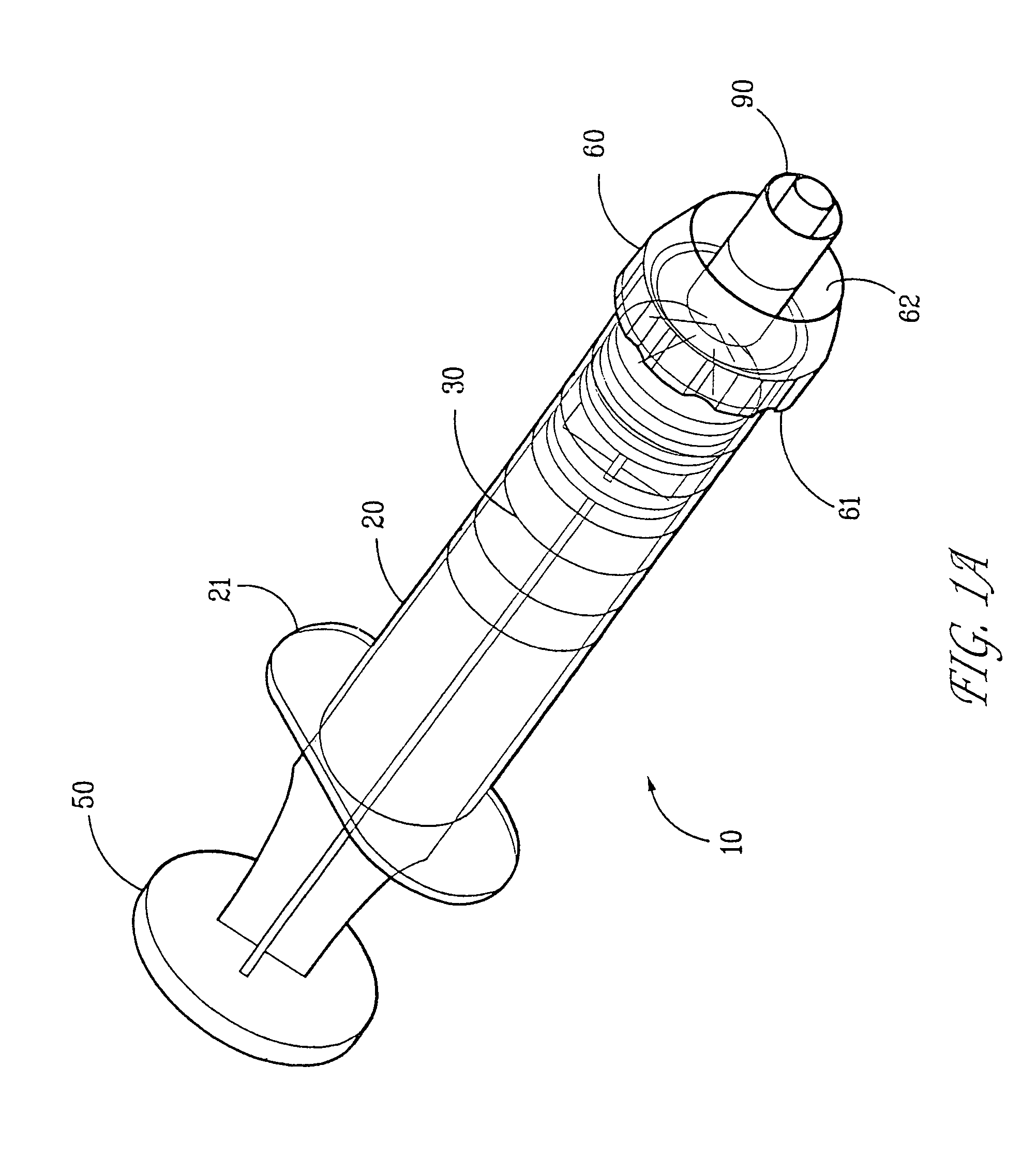

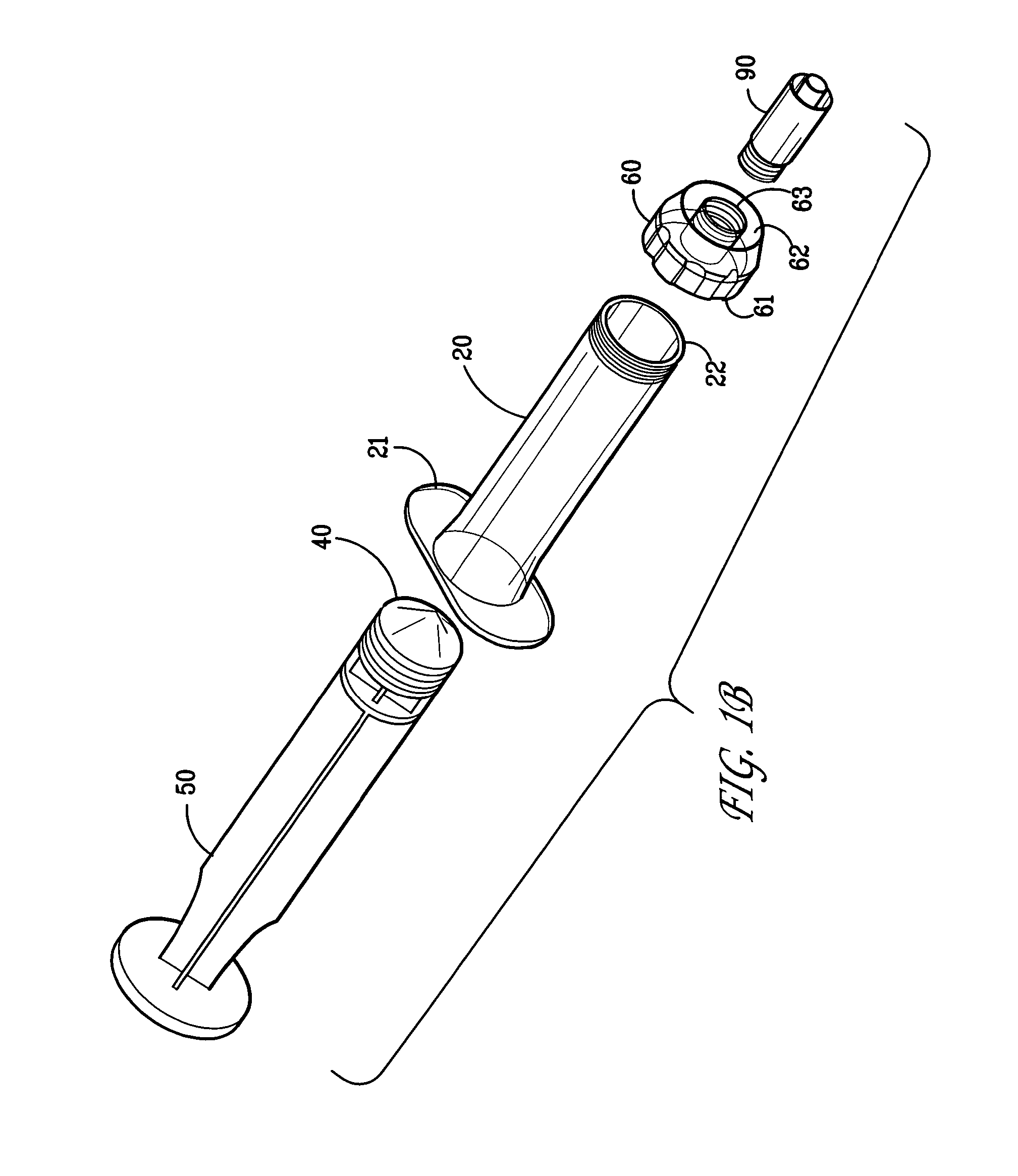

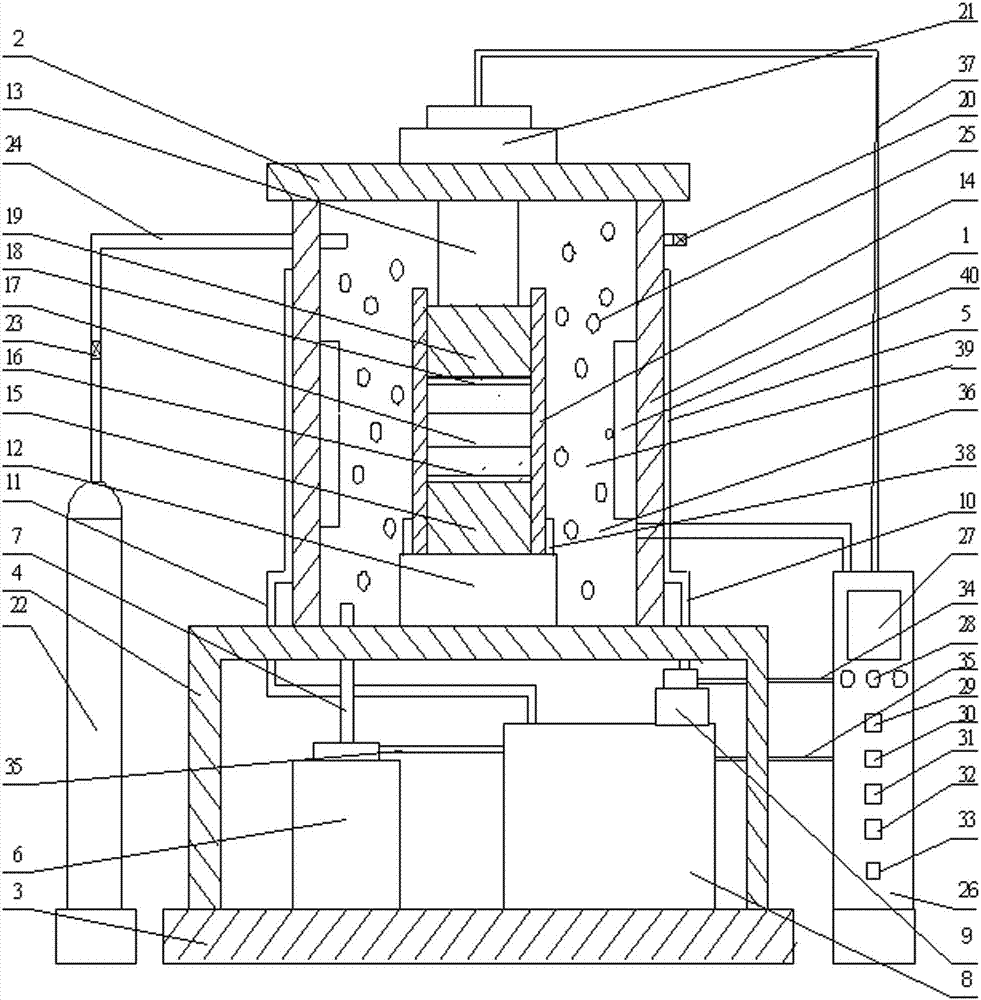

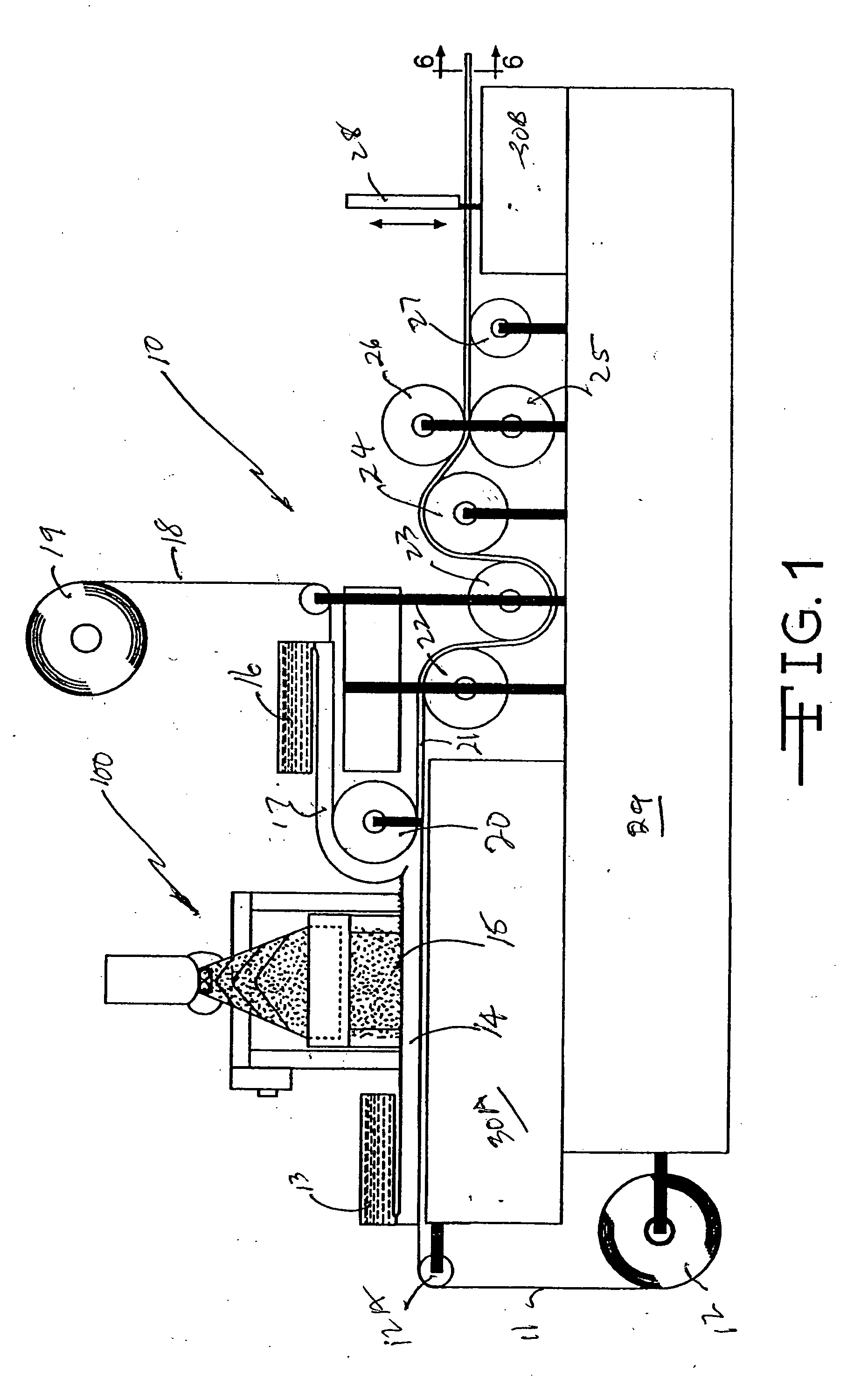

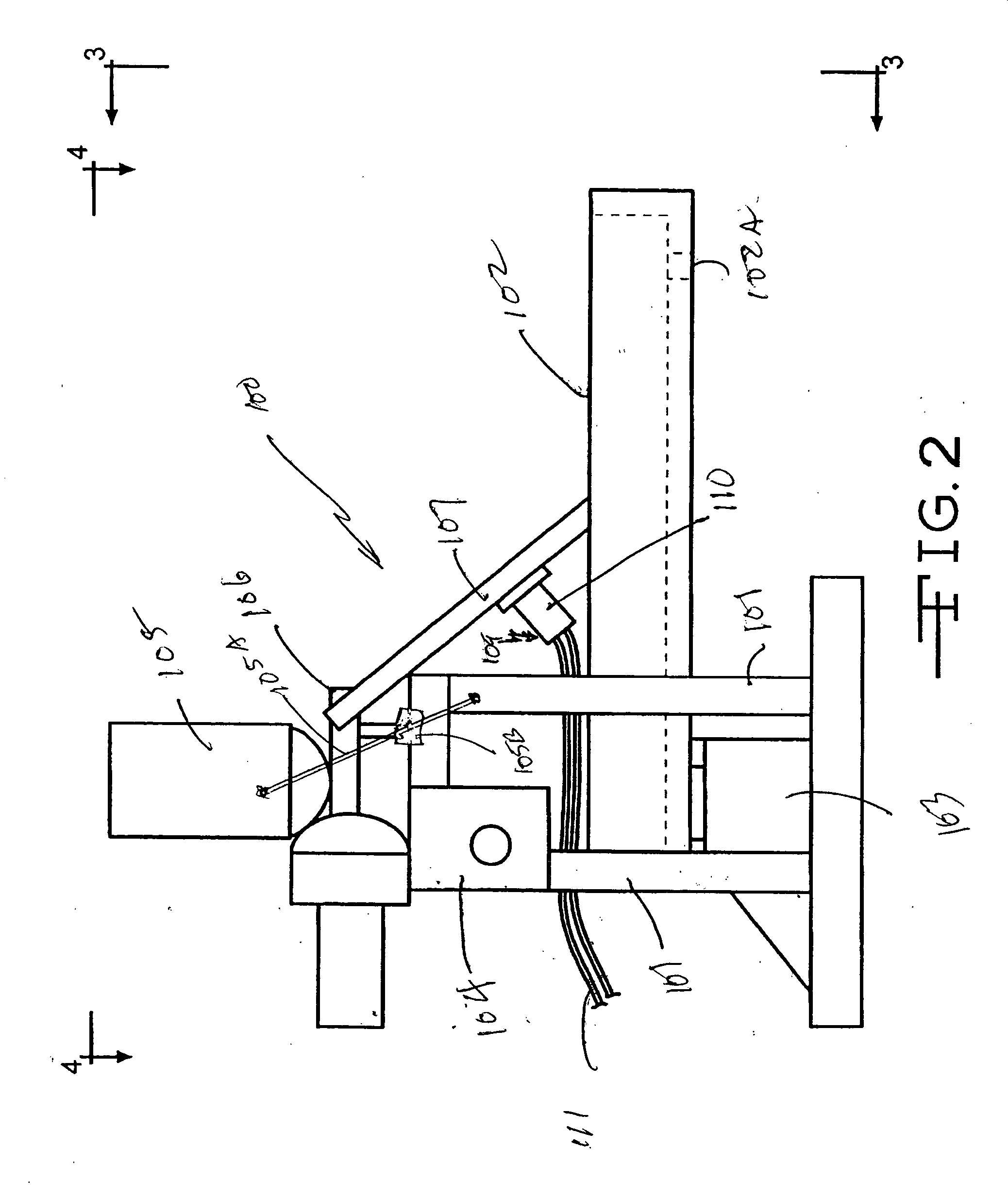

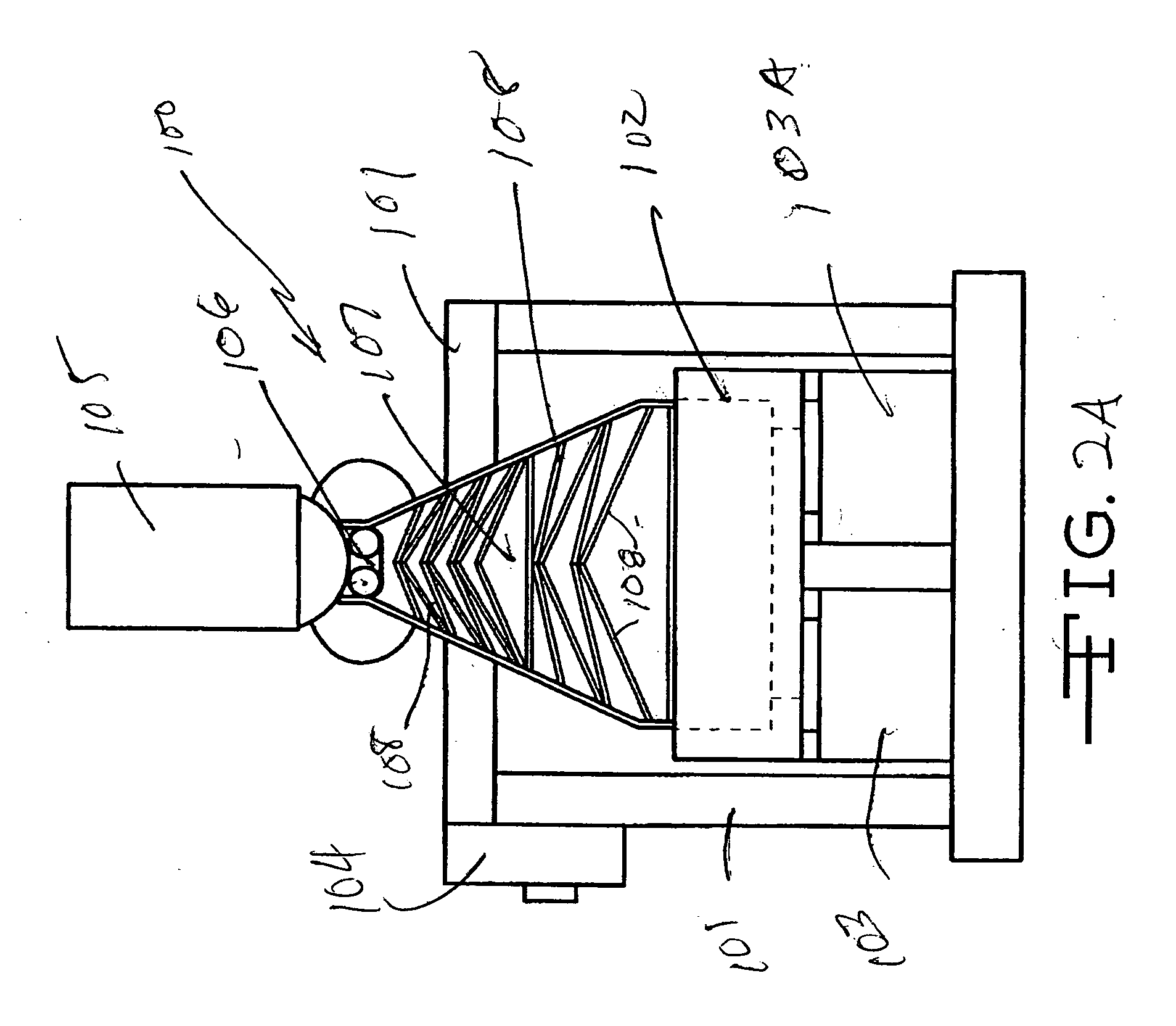

Delivery device for biological composites and method of preparation thereof

An apparatus for the delivery of a biological composite and a method, kit, and system for preparing a biological composite is described herein. The biological composite includes both inorganic and biological materials.

Owner:ORTHOVITA INC

Bacterial poly(hydroxy alkanoate) polymer and natural fiber composites

ActiveUS20080160567A1Improve bindingGood in-service performanceLayered productsPedestrian/occupant safety arrangementVolatile fatty acidsResin matrix

A biocomposite is produced from natural fiber fabrics embedded in a matrix of biosynthetic polyhydroxy-alkanoate (PHA) polymers. The PHA is synthesized using aerobic microbial biosynthesis using mixed bacterial cultures and a feedstock containing anaerobic degradation products such as methane and volatile fatty acids derived from microbial biodegradation of organic waste materials, which may include waste biocomposites. Monomers may be added to the synthesized PHA polymer to control mechanical properties of the resulting biocomposite. The natural fibers and / or PHA may be pretreated using various techniques to improve the bond between the fibers and the PHA resin matrix and water absorption resistance of the fibers. The composite may be a laminate of treated and untreated fabric layers, or differently treated layers, to achieve good in-service performance as well as rapid and / or optimal biogas production when taken out of service and put in an anaerobic environment to degrade.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

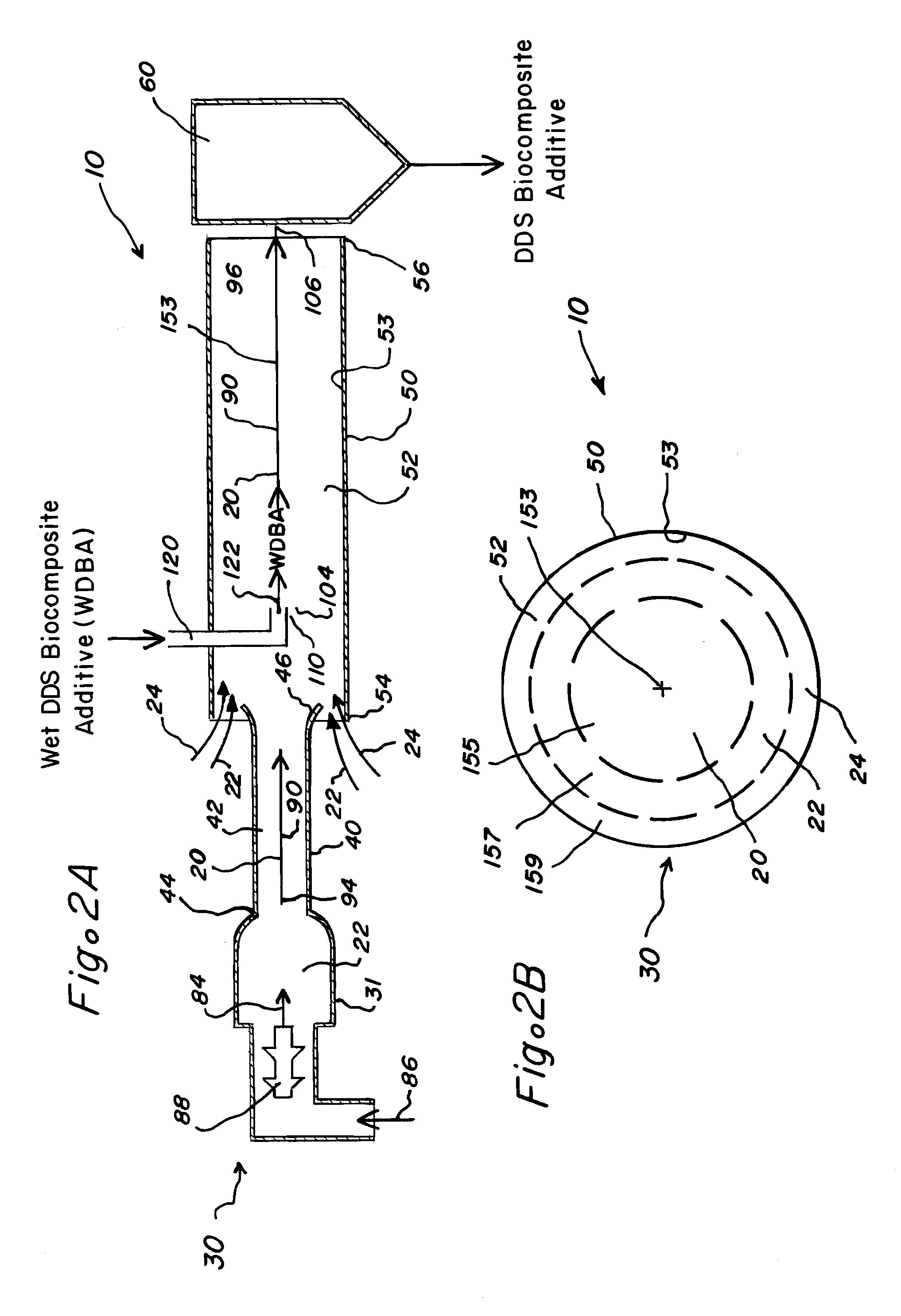

Multifunctional biocomposite additive compositions and methods

Biocomposite compositions and compositions, which include dried distillers solubles, and which can be used in making biocomposite compositions are described. Methods for preparing the compositions are also described.

Owner:GENAREX FD LLC

Nanofibrous biocomposite prosthetic vascular graft

The present invention provides a bioactive, small-diameter (typically less than 6 mm in internal diameter) vascular graft prosthesis, and is a textile conduit preferably manufactured using a novel electrospinning perfusion methodology. One preferred embodiment is a nanofibrous biocomposite textile conduit which comprises a prepared liquid admixture of polyester (Dacron), a biodurable implantable synthetic polymer, and Type IV collagen, an extracellular matrix protein. This prepared admixture and blending of diverse fibrous matter is utilized in a novel electrospinning perfusion process to form a small-diameter (less than 6 mm) fabricated textile conduit, a discrete article of manufacture, which then serves as an antecedent tangible workpiece for a subsequently-made prosthetic vascular graft construct. In this manner, after the biocomposite textile conduit has been fabricated as a tangible article, one or more pre-chosen biologically-active compounds are then subsequently permanently bound (covalently or ionically) via a bifunctional linking agent to the wall surface(s) of the textile conduit. These permanently bound compounds retain their characteristic biological activity after becoming permanently immobilized to the textile wall surface; and, via such immobilization, provide the textile conduit wall with many of the highly desired attributes and properties characteristic of naturally occurring blood vessels. Accordingly, after the immobilization of one or more biologically active compounds to the wall surfaces, the completely prepared article is then suitable for use in-vivo as a prosthetic vascular graft construct.

Owner:BIOSURFACES +2

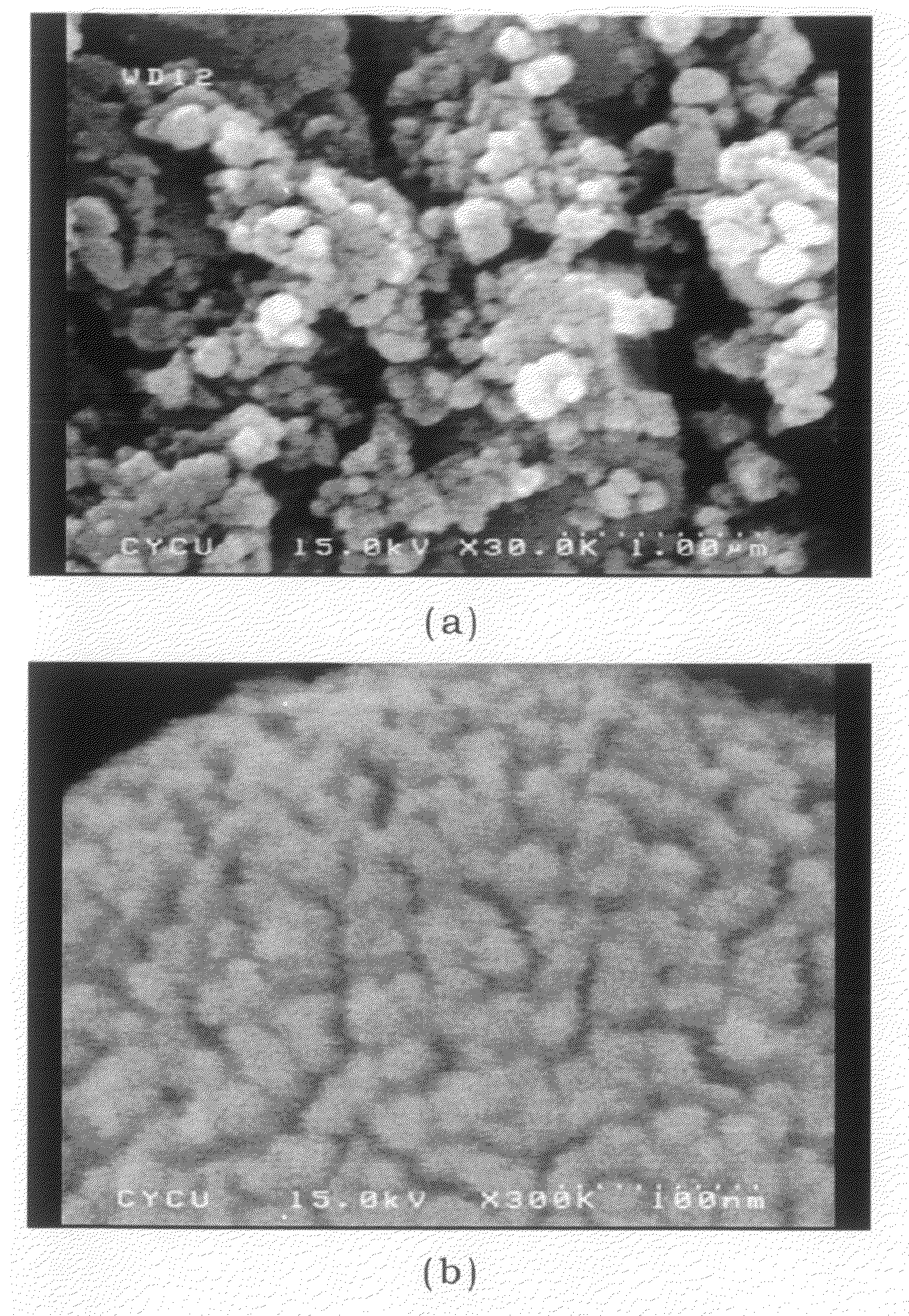

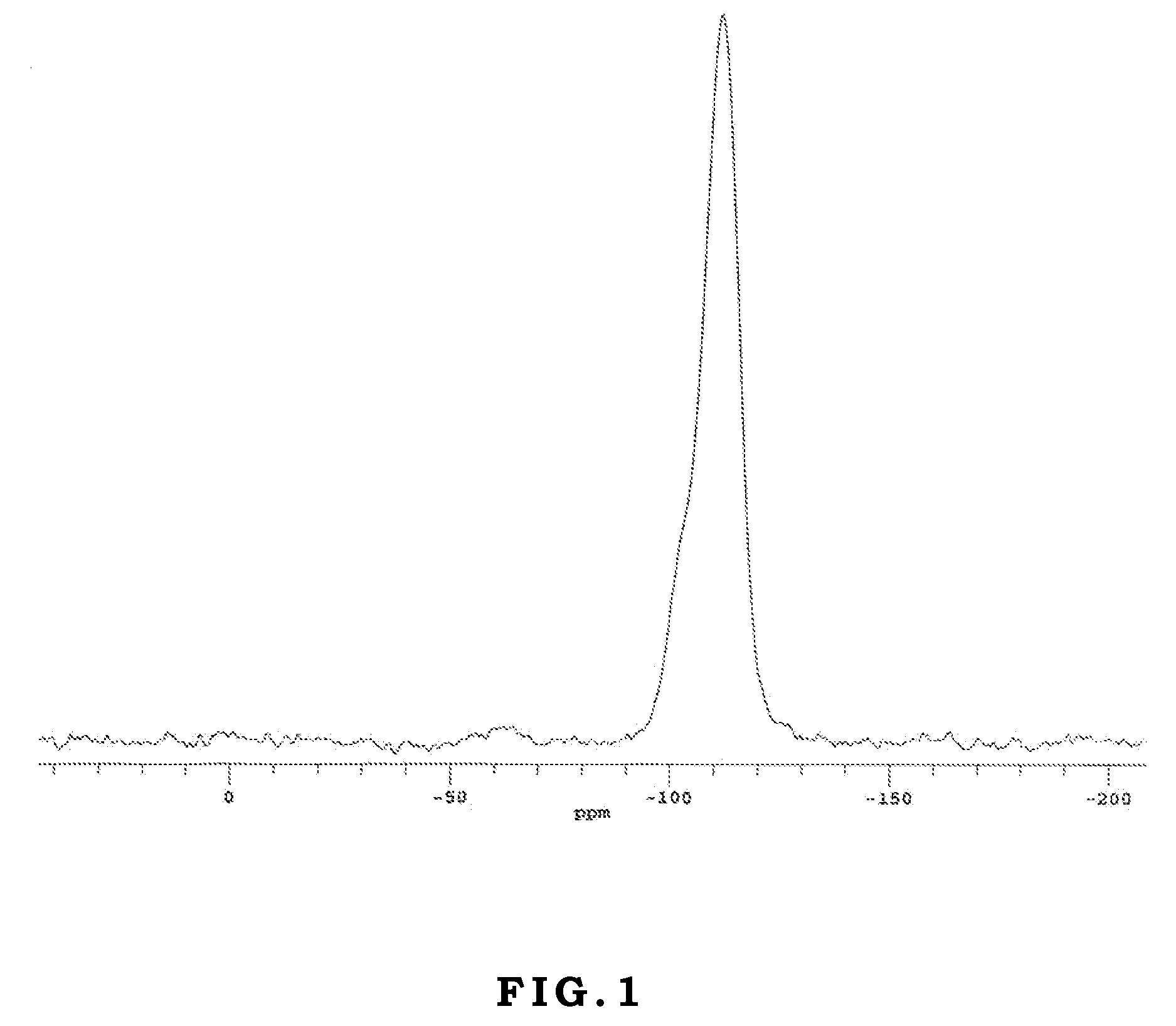

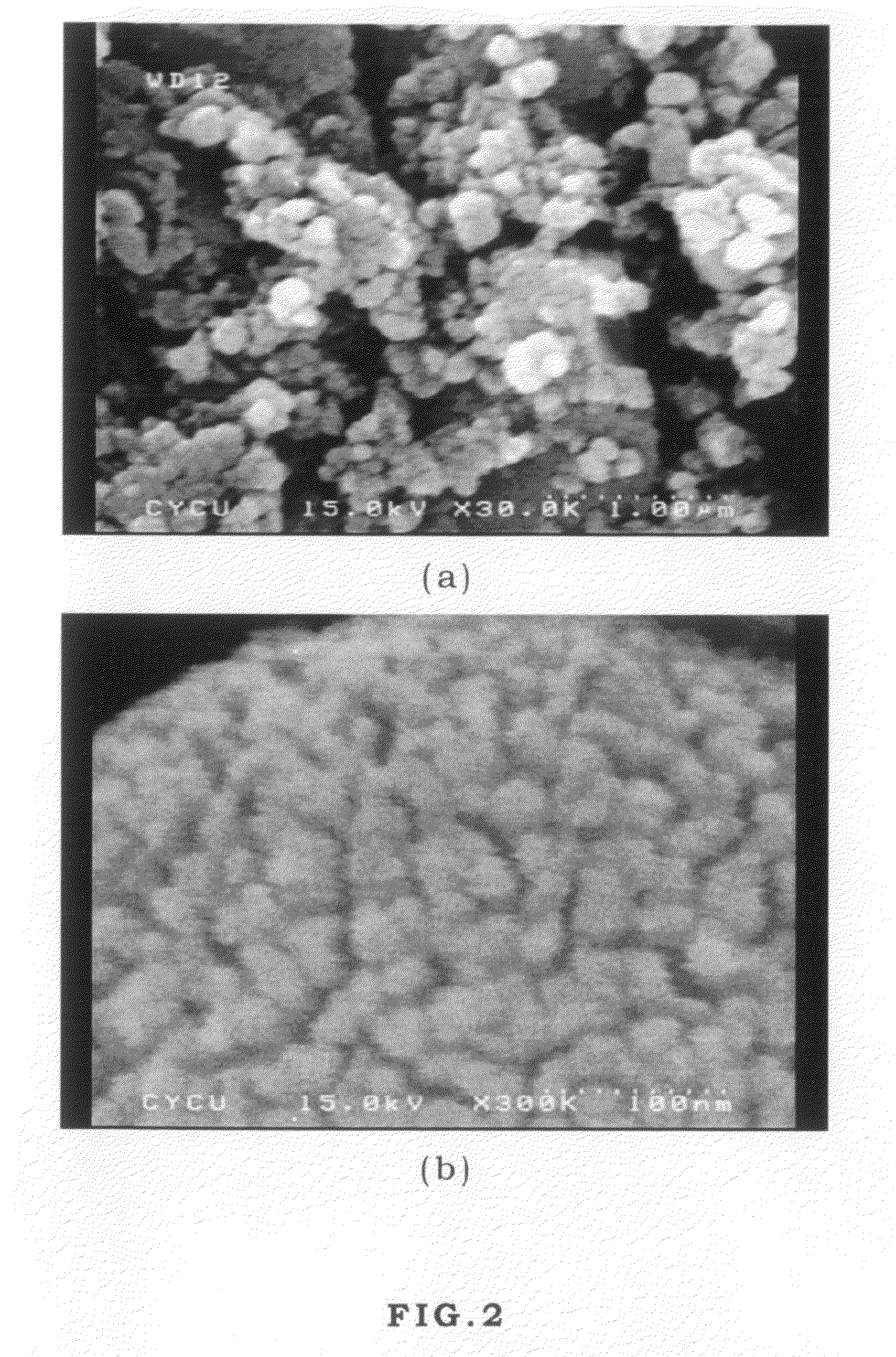

Method for fabricating aerogels and their application in biocomposites

InactiveUS20090123985A1Easy to prepareEasy to separateSugar derivativesPeptide preparation methodsSolventHydrolysis

The present invention discloses a method for fabricating aerogels, a method for fabricating surface-modified aerogels, and a method for fabricating biocomposites. Take the fabricating method of biocomposites for example, first, a precursor solution is provided and the precursor solution comprises a hydrophilic ionic liquid, a catalyzed hydrolysis and / or condensation reagent, at least one biomolecule. Next, a curing process is performed for the precursor solution to hydrolyze and polymerize the at least one alkoxide monomer and / or aryloxide monomer to wrap at least one biomolecule and thus form biocomposite. Afterwards, an extracting process is performed by a solvent for the biocomposite to substitute the ionic liquid in the biocomposite. Finally, a drying process for the biocomposite is carried out after the extracting process so as to remove the solvent in the biocomposite. Therefore, the biocomposite is formed.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

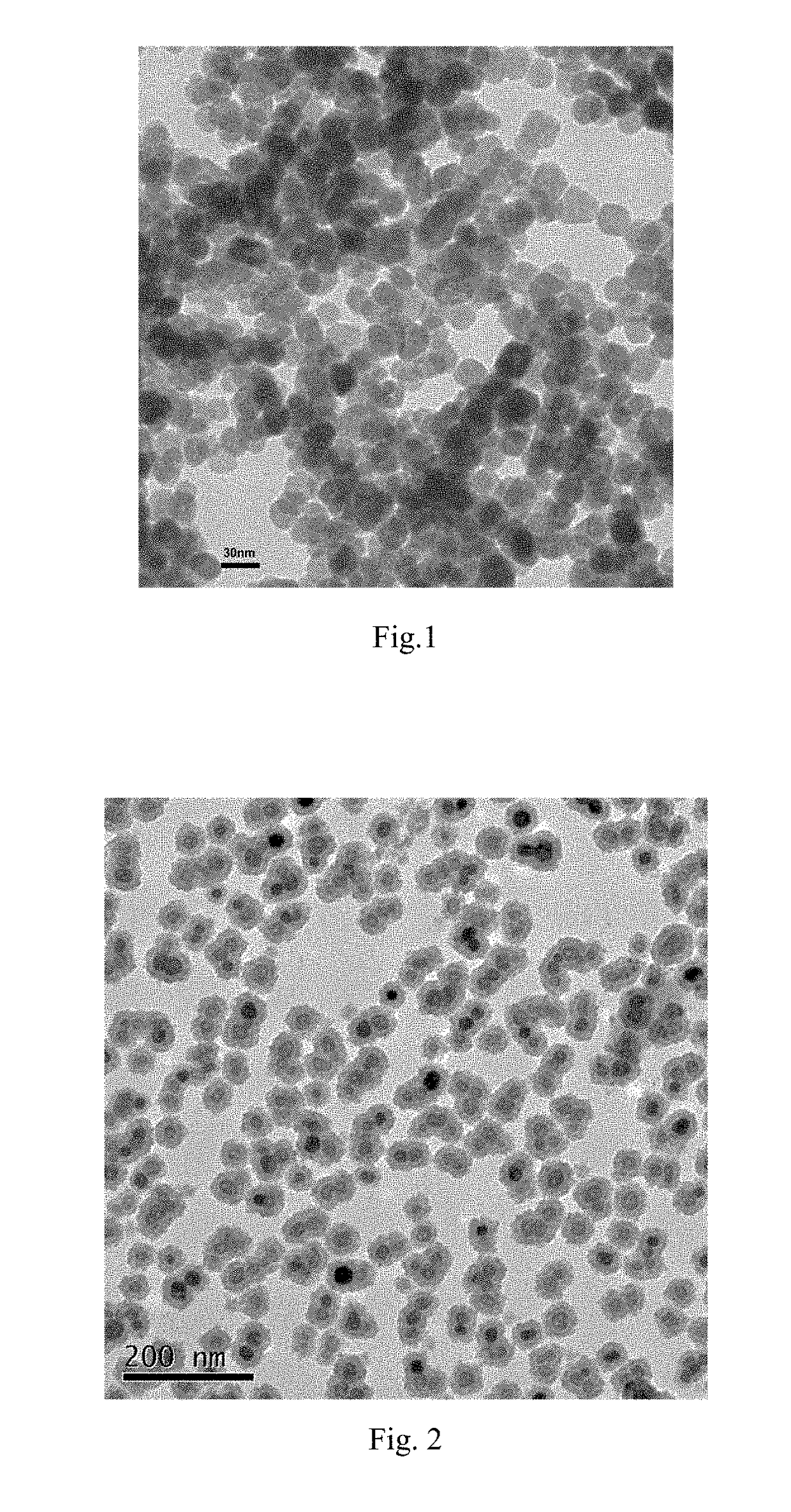

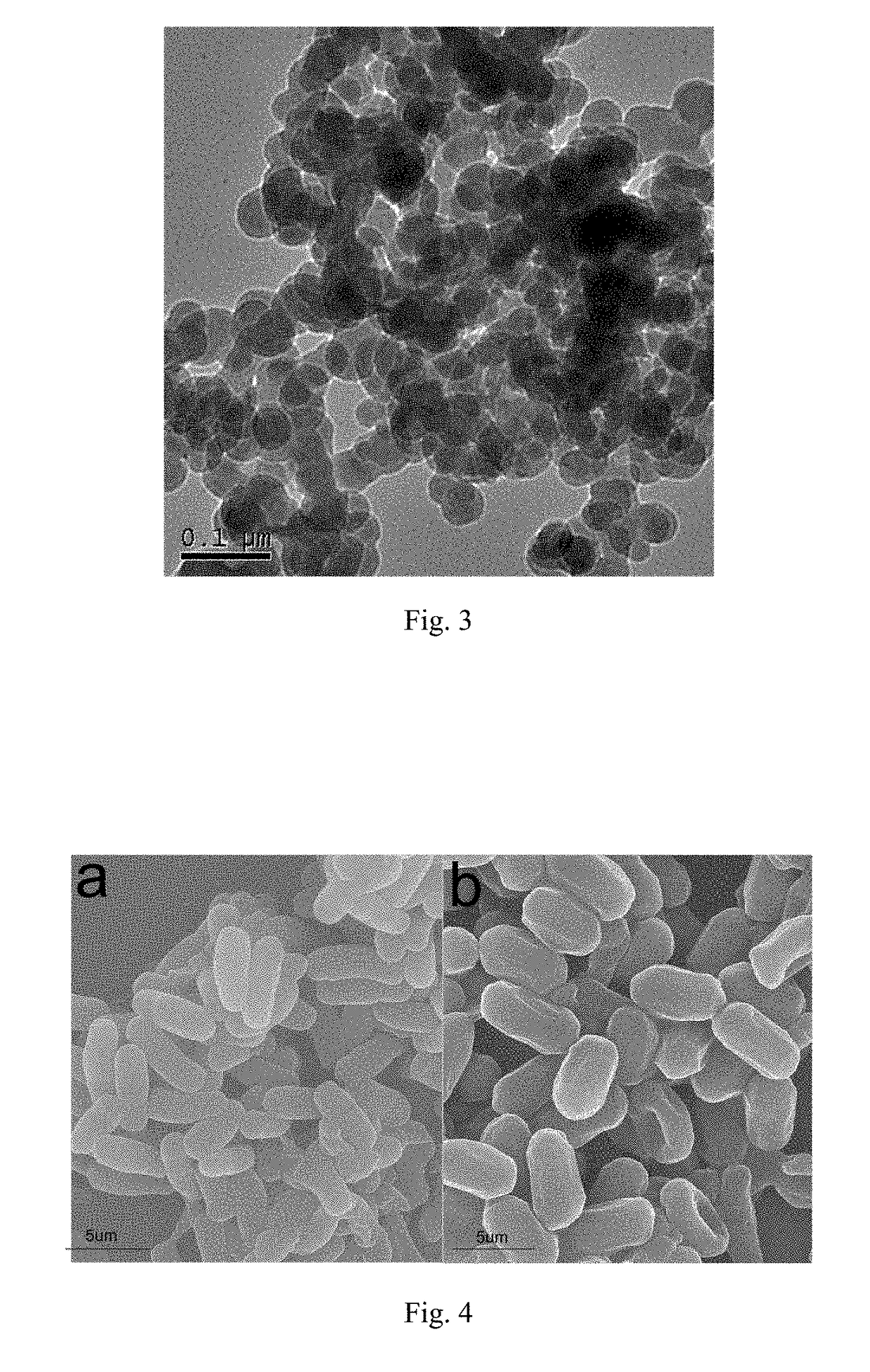

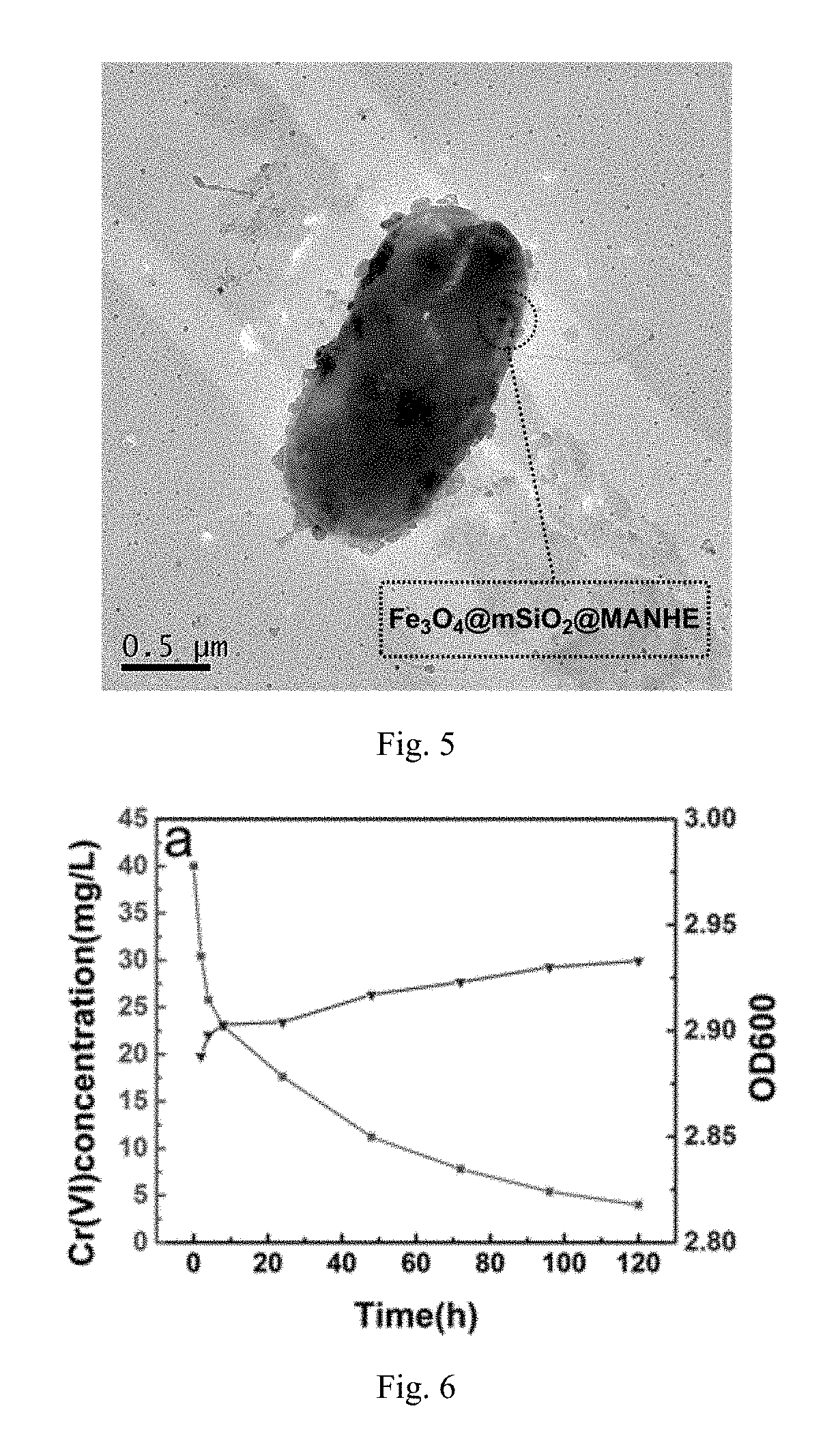

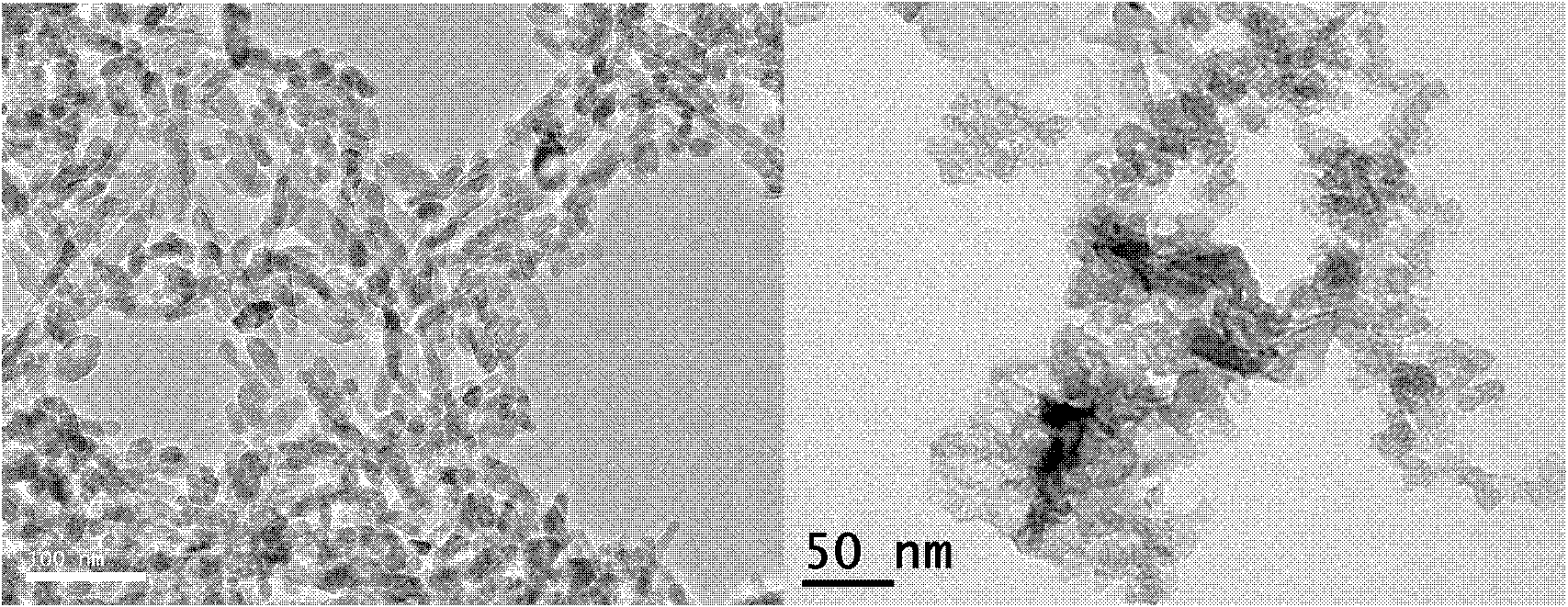

Biological composite material loaded with magnetic nanoparticles with core-shell structure, the preparation therefore and the application

ActiveUS20170174542A1Rapidly enrichedPromote degradationBacteriaWater treatment compoundsMagnetite NanoparticlesBacillus subtilis

A preparation method of Bacillus subtilis biological composite material loaded with Fe3O4 magnetic nanoparticles with core-shell structure includes the following steps: 1) preparation of Fe3O4 nanoparticles, 2) preparation of Fe3O4@mSiO2 nanoparticles, 3) preparation of Fe3O4@mSiO2@MANHE nanoparticles; and 4) preparation of Bacillus subtilis@Fe3O4@mSiO2@MANHE composite.

Owner:SUZHOU UNIV

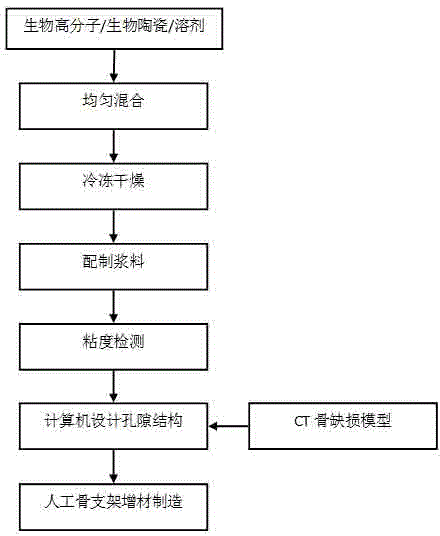

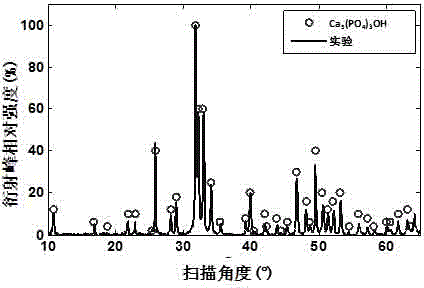

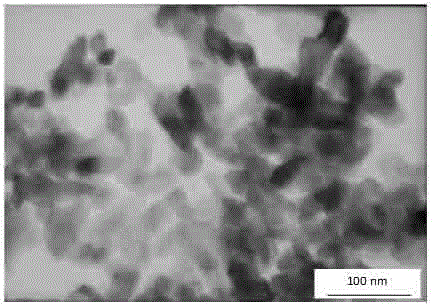

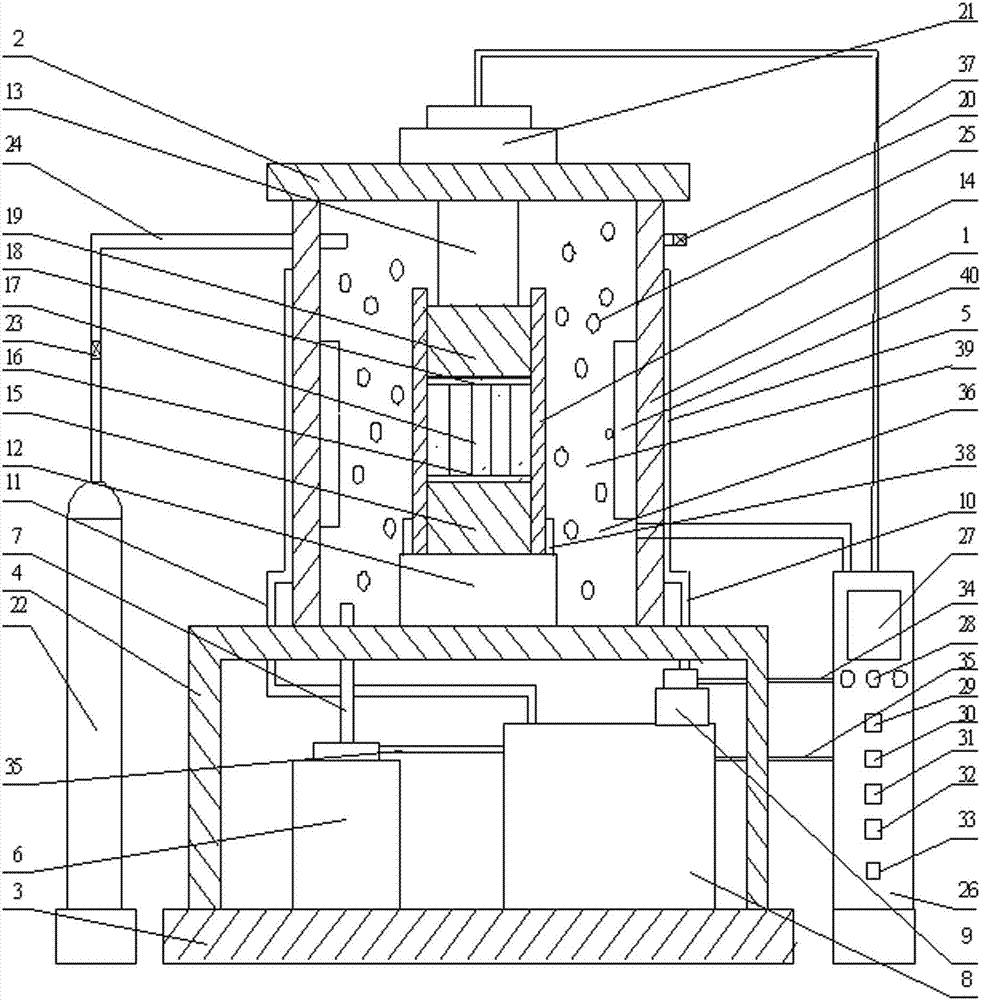

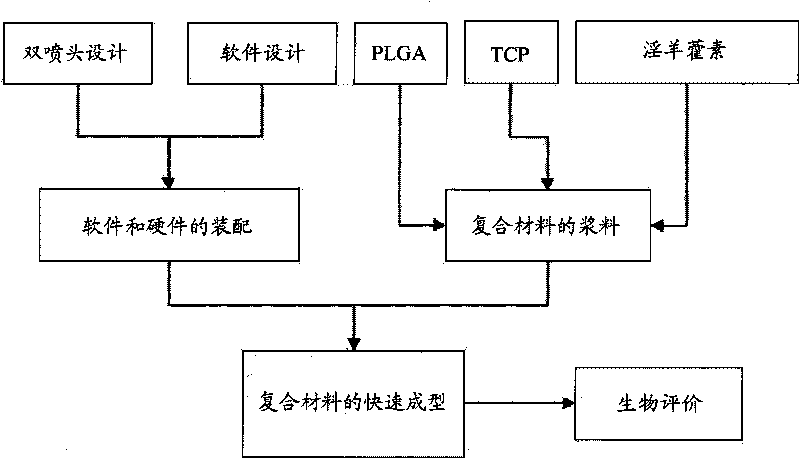

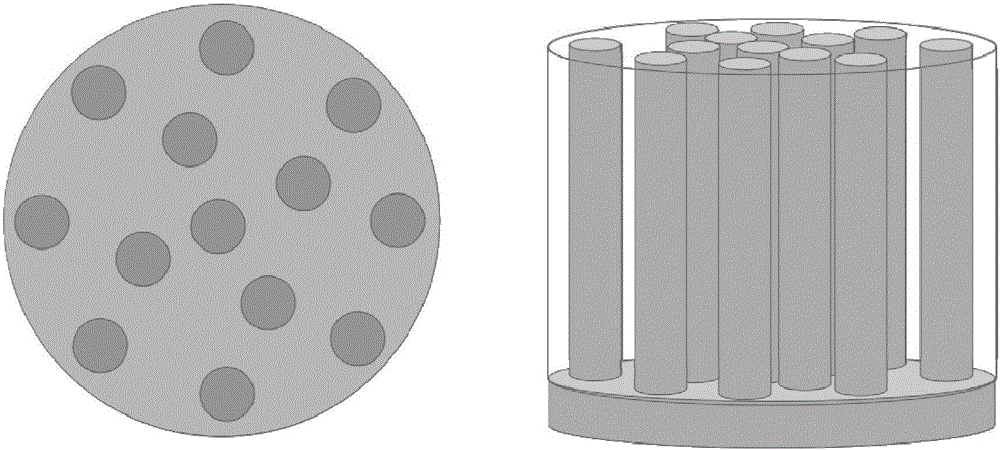

Material increase manufacturing method of multi-scale biomimetic artificial bone support

ActiveCN104826171AReduce the cost of clinical applicationMeet lifelong growth requirementsProsthesisPorosityAutologous tissue

The invention discloses a material increase manufacturing method of a multi-scale biomimetic artificial bone support. The material increase manufacturing method comprises blending a biopolymer material and a bioceramic material, blending the mixture and deionized water or an organic solvent to obtain uniform slurry, carrying out freeze drying to obtain uniform powder, blending the uniform powder and deionized water or an organic solvent, carrying out vacuum exhaust, carrying out quantitative extrusion by a screw pump, by a XYZ motion device, designing internal aperture shapes, sizes and porosity of a geometric model by computer program according to a bone defect 3D geometric model obtained by CT scanning, and carrying out material increase manufacture under control of an extruded material motion locus. Through use of a degradable biological compound material, human autologous tissue finally replaces bone defect positions so that human lifelong growth requirements are satisfied. The needed biomaterial is quantificationally extruded by the screw pump so that use amount can be accurately controlled and an artificial bone clinical application cost is substantially reduced. The material increase manufacturing method has the advantages of accurate printing material use amount, wide material application range, accurate and controllable aperture structure, and free formation of a macroscopic geometric shape.

Owner:西安点云生物科技有限公司

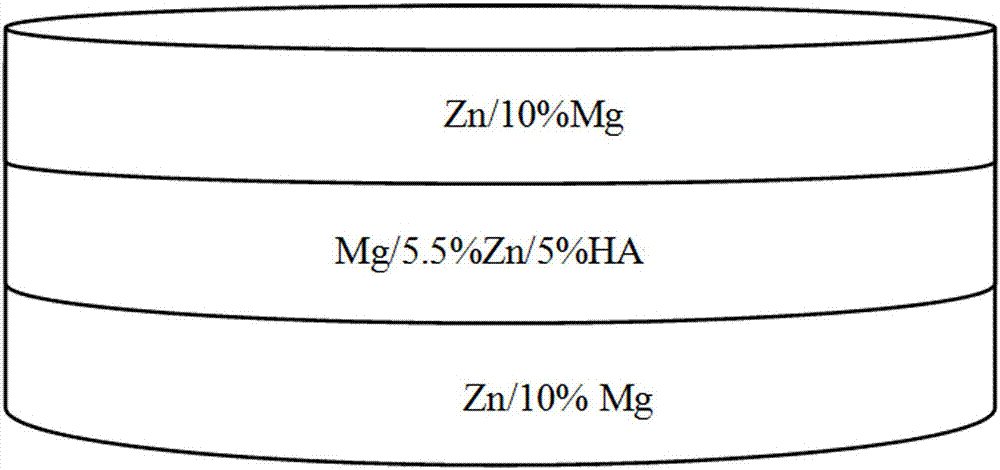

Preparing method of zinc magnesium function gradient biological composite

ActiveCN107385251AImprove the bonding strength of the interfaceNo debondingGradient materialStress shielding

The invention relates to a preparing method of a zinc magnesium function gradient biological composite. Magnesium powder, zinc powder and HA powder are adopted to serve as raw materials, ball milling powder mixing, die filling and vacuum discharge plasma sintering are carried out, and a zinc magnesium composite of two gradient structures is prepared. The preparing method is advanced in technology, data are full and accurate, a prepared zinc magnesium gradient material is high in combination strength on the interface, the debinding phenomenon is avoided, wear resistance and mechanical properties(the crush resistance strength is 293.66MPa, the elasticity modulus is 8.0 GPa, and breaking tenacity is 9.327 MPa.mm<1 / 2>) of all gradient layers are matched with the natural bone, the stress shielding effect is effectively avoided, and the preparing method is an ideal preparing method for a degradable biomedical metal gradient material.

Owner:TAIYUAN UNIV OF TECH

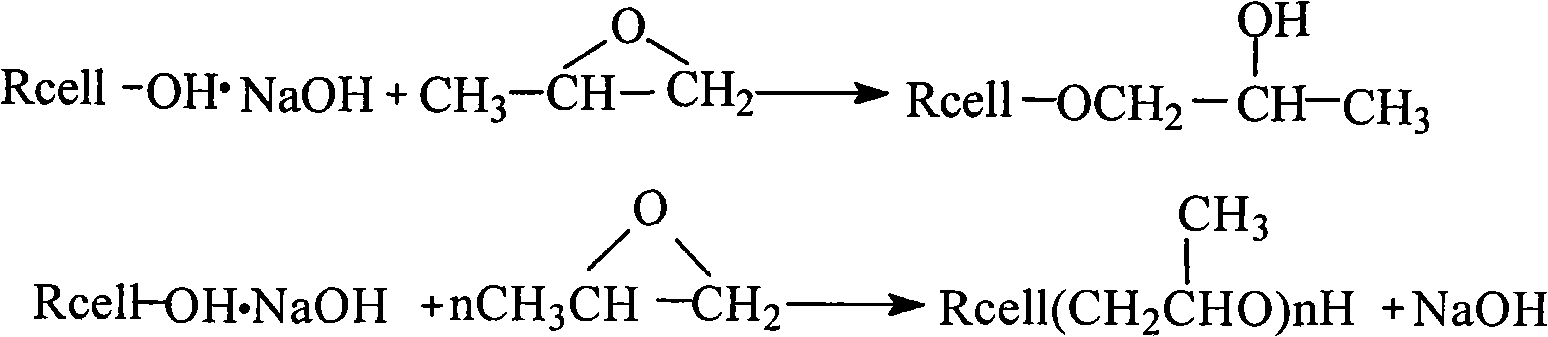

Method for preparing bacterial cellulose membrane with high rehydration

The invention relates to a method for preparing a bacterial cellulose membrane with high rehydration, which comprises the following steps: (1) performing alkaline treatment on bacterial cellulose hydrogel membrane of which bacteria and culture medium are removed; (2) performing etherification treatment on the processed membrane; (3) performing neutralization reaction on the etherified membrane to obtain a bacterial cellulose membrane subjected to hydroxypropylation; and (4) drying the bacterial cellulose membrane subjected to hydroxypropylation to obtain the bacterial cellulose membrane with high rehydration. The method aims at the defect of low rehydration performance of the prior bacterial cellulose membrane, uses a method of hydroxypropylation modification of the bacterial cellulose surface to destroy a part of hydrogen bonds in cellulose; a rehydration rate test finds that the dried bacterial cellulose membrane subjected to hydroxypropylation has high rehydration and reswelling capability; and the bacterial cellulose membrane subjected to hydroxypropylation can be used for preparing biologic composite materials, and has importance significance on biomedical materials and the like.

Owner:TIANJIN UNIV OF SCI & TECH

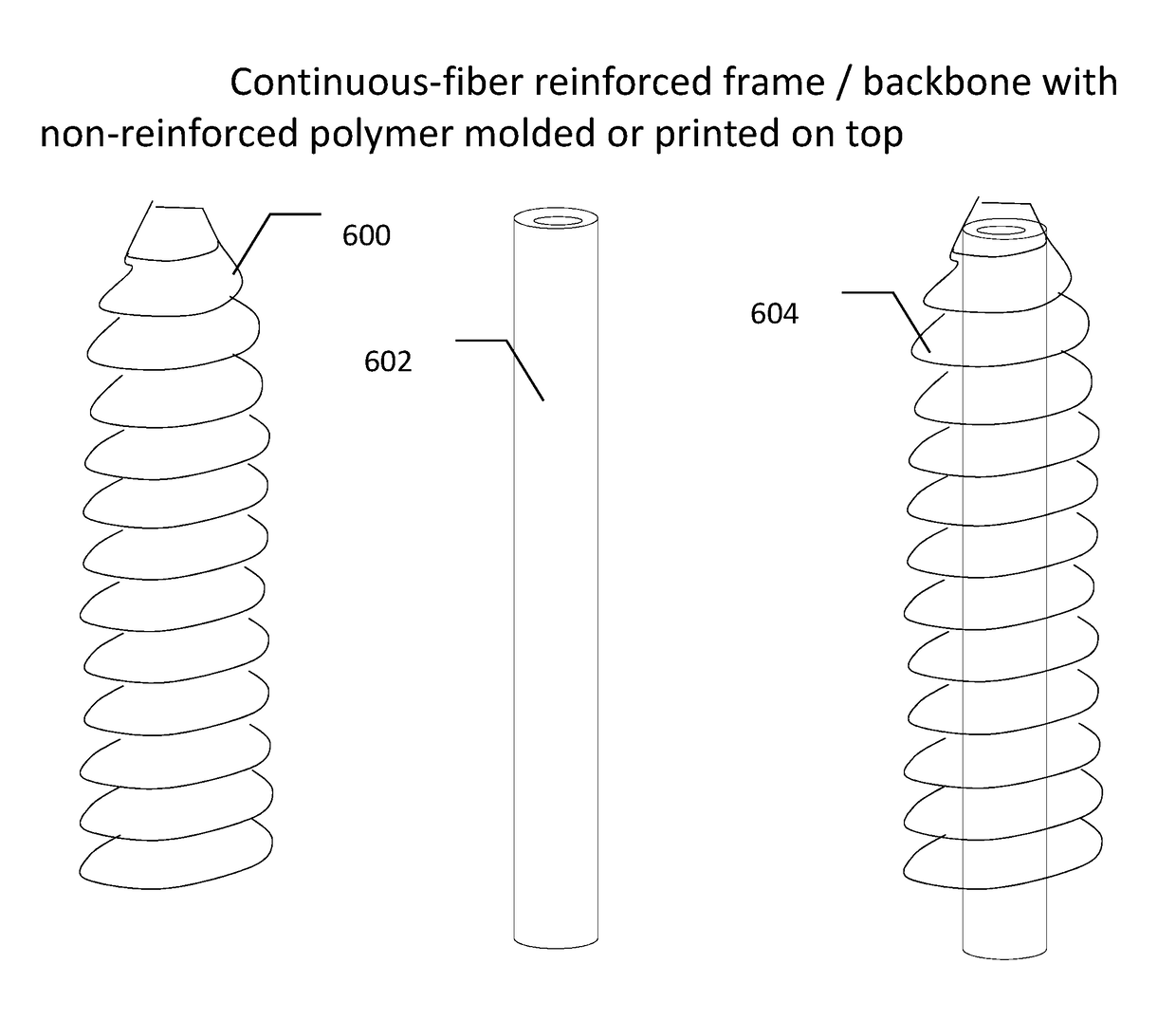

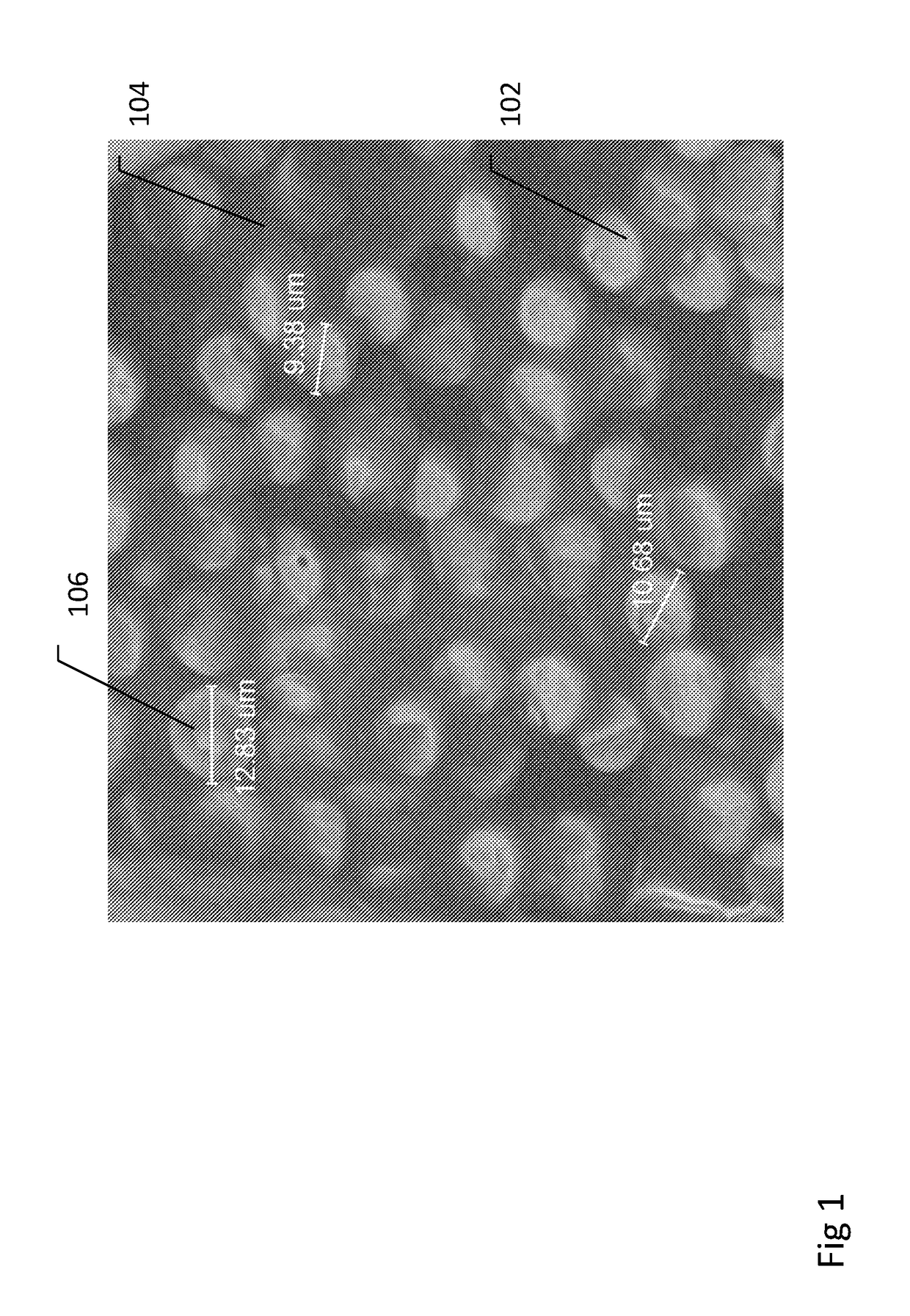

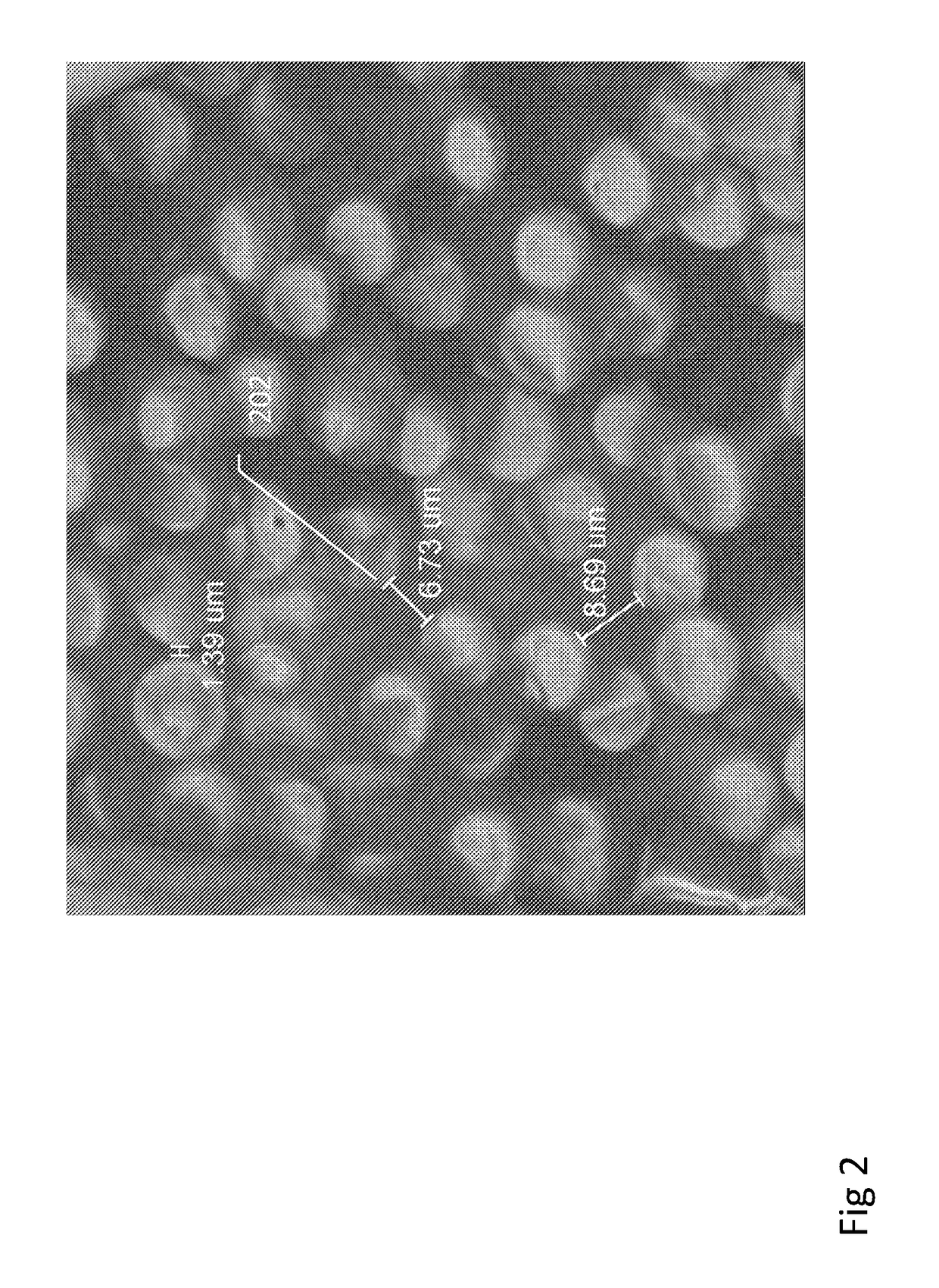

Continuous-fiber reinforced biocomposite medical implants

ActiveUS20170246356A1Improve mechanical propertiesHigh stiffnessSpinal implantsTissue regenerationBiomedical engineeringPolymer

Owner:OSSIO LTD

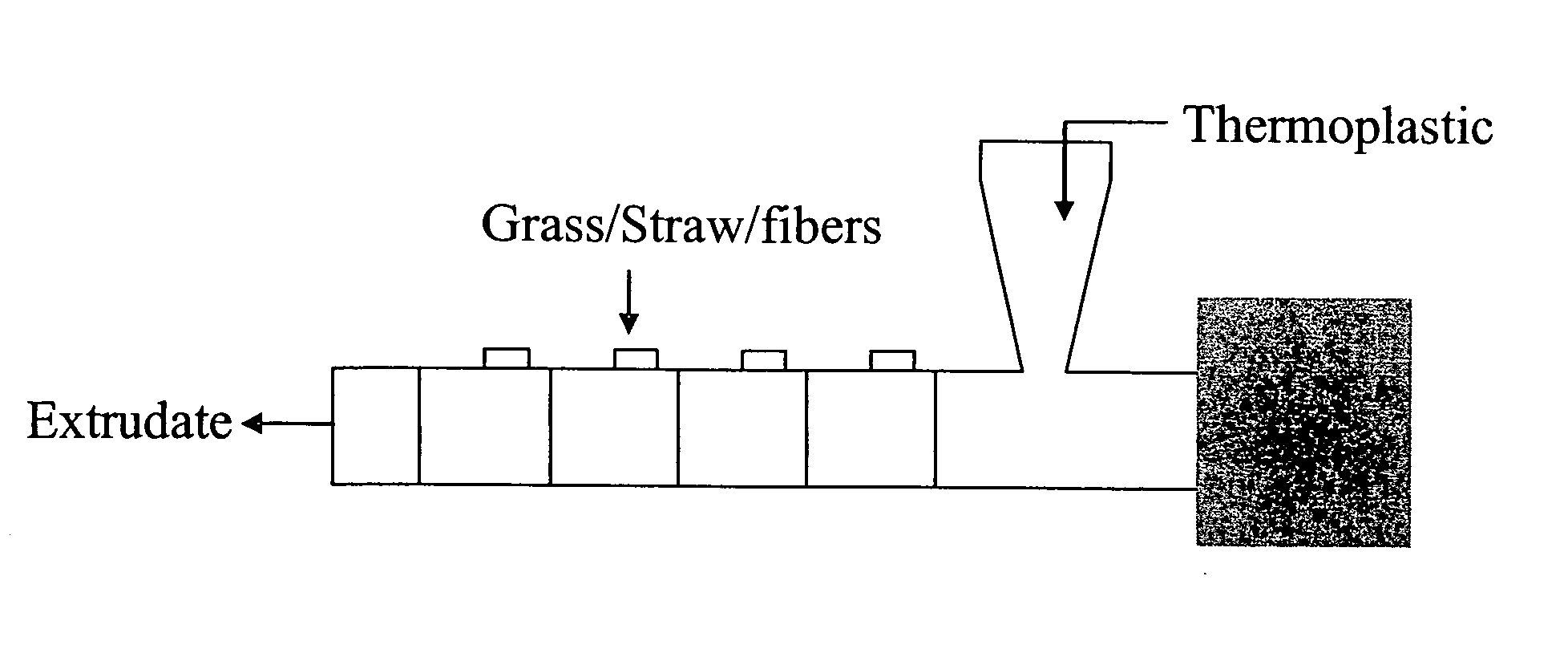

Cellulosic biomass soy flour based biocomposites and process for manufacturing thereof

A process for the manufacture of natural fiber and polymer composites is described. Thermoplastically processed plasticized soy flour based plastics are used with thermoplastic polymers. Polymers of soy flour and an in situ polymerized polyvinyl polymer which links proteins and carbohydrates in the flour to form the polymer are used. The composites are useful in engineering materials.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Preparation method of bionic human bone biologic material

InactiveCN101507839AGood biocompatibilityAchieve osseointegrationProsthesisHuman bodyBiocompatibility Testing

The invention provides a method for preparing a bionic human bone biomaterial. The method comprises the steps of utilizing a direct laser selective sintering technique to prepare a human bone bionic micropore bracket, injecting a material with the function of inducing bone growth into the bionic micropore bracket, drying and curing the obtained product and obtaining the bionic human bone biomaterial. The method combines the advantages of metal biomaterials and non-metal biological ceramic materials (hydroxyapatite), and utilizes the direct laser selective sintering technique, a vacuum impregnation technique and the like to prepare a novel bionic human bone biological composite material. The material has the advantages of biomechanical properties similar to natural bones, good biocompatibility, capability of realizing the synostosis of implanted bones and human tissue after the material is implanted into human bodies, safety and reliability. The bionic human bone biomaterial prepared by the preparation method has ultimate tensile strength more than 300 MPa, elongation between 10 and 12 percent, tension-compression elastic modulus less than 50 GPa and good biocompatibility.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing bionic laminar articular cartilage/bone compound implant

InactiveCN1961975AMeet the mechanicsSatisfy physiological functionJoint implantsPolyvinyl alcoholBiomechanics

The invention relates to a method for preparing bionic laminated cartilage / bone element, wherein it comprises preparing porous same heterogenous bone or different bone elements; preparing artificial cartilage and laminated cartilage / bone composite. The invention processes the bone into needed size and shape, to be washed and immunity treatment, to be put at the bottom of mould; then at positive and passive pressures, pouring the polyvinyl alcohol / biological active component preformed element and polyvinyl alcohol / lubricant molecule preformed element into mould; flattening the surface and compressing; freezing and fusing, shaping. The inventive product has surface layer as abrasion-resistant lubricant layer, middle layer as force layer, and bottom layer as biological active cartilage / bone combine layer, to meet biological physica property and physiological function.

Owner:UNIV OF SCI & TECH BEIJING

Polyether-ether-ketone composite material containing fluorapatite and titanium dioxide and preparation method thereof

InactiveCN101879332AReinforcement and toughnessEnhanced mechanical compatibilityProsthesisCalcium fluorophosphateMechanical property

The invention discloses a polyether-ether-ketone composite material containing fluorapatite and titanium dioxide and a preparation method thereof, belonging to the technical field of biomedical composite materials. The composite material is a bone restoration material prepared from a polyether-ether-ketone composite material with enhanced fluorapatite and titanium dioxide and is prepared by blending fluorapatite, titanium dioxide and polyether-ether-ketone in a fusion way, wherein the fluorapatite and the titanium dioxide are respectively 10-30 percent of the total weight of the composite material, and the balance is the components of the polyether-ether-ketone. The composite material prepared from the fluorapatite, the titanium dioxide and the polyether-ether-ketone in the invention realizes good strength and toughness and consistent elastic modulus with a human bone, has bone-substitute material with bioactivity, and can overcome the defect that the traditional metal and ceramic bone-substitute material has the mechanical property which is not matched with the human bone.

Owner:PEKING UNIV

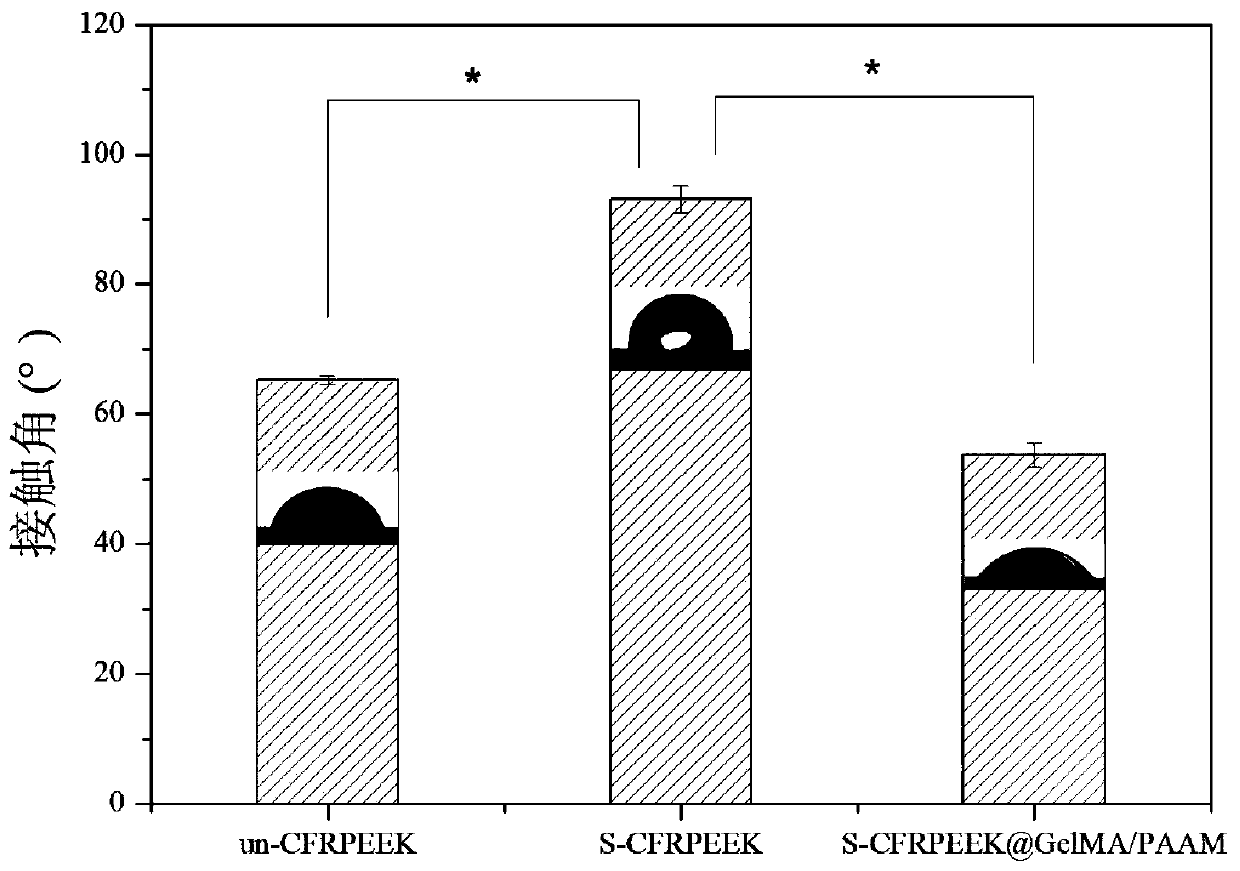

Method for improving surface biological activity of carbon fiber reinforced polyether-ether-ketone composite material

InactiveCN110511419APromote ingrowthImprove biological activityTissue regenerationProsthesisFiberMethacrylate

The invention relates to a medical biological composite material, particularly to a method for improving the surface biological activity of a carbon fiber reinforced polyether-ether-ketone composite material. According to the invention, the photosensitive polymer methacrylic acid esterified gelatin with good biocompatibility and the photosensitive monomer acrylamide are loaded onto the surface ofsulfonated porous carbon fiber reinforced polyether-ether-ketone by using an ultraviolet grafting method, so the biological activity and osteogenesis integration capability of the composite material are enhanced. A double-network structure is formed on the surface of the sulfonated and grafted carbon fiber reinforced polyether-ether-ketone; one layer of the double-network structure is a porous polyether-ether-ketone structure layer, and the other layer of the double-network structure is a methacrylic acid esterified gelatin / polyacrylamide composite hydrogel layer. The carbon fiber reinforced polyether-ether-ketone composite material is beneficial for ingrowth of cells, greatly improved in biological activity, conductive to bone conduction and body fluid conveying, and enhanced in surface osteogenesis integration capacity.

Owner:JILIN UNIV

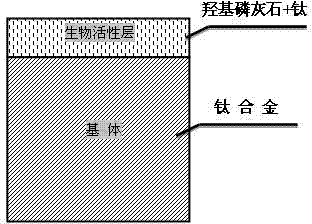

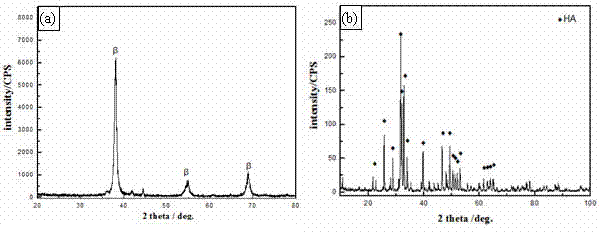

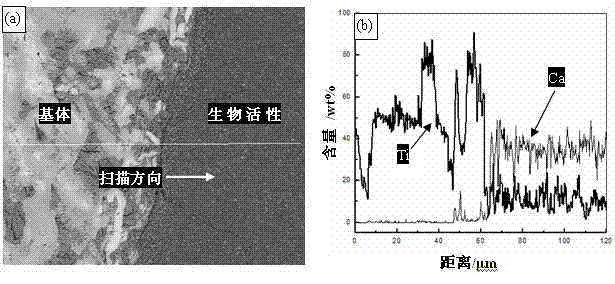

Hydroxyapatite activated titanium alloy surface-layer biological composite material and preparation method thereof

ActiveCN104841009AGood mechanical propertiesImprove biological activityProsthesisThermal insulationAxial pressure

The invention discloses a hydroxyapatite activated titanium alloy surface-layer biological composite material and its preparation method and belongs to the field of biomedical material preparation. The surface-layer biological composite material is characterized in that titanium alloy is used as a matrix, and hydroxyapatite + titanium is a biological active layer. Technological steps are as follows: respectively carrying out mechanical alloying, ball-milling, powder-blending and drying on the titanium alloy matrix powder and the biological active layer powder, respectively placing the dried matrix mixed powder and the dried biological active layer mixed powder to a lower layer and an upper layer of a graphite mould (as shown in the specification), sintering in a spark plasma sintering furnace, and cooling to room temperature to obtain the surface-layer biological composite material. During the sintering process, axial pressure is 30-40 MPa, sintering temperature is 1100-1250 DEG C, and thermal insulation lasts for 10-15 min. In the prepared surface-layer composite material, the composite layer and the matrix are chemically and metallurgically bonded. The interface bonding strength is high, and the problem that a biological ceramic coating is easy to fall off can be solved. The preparation process is clean. The technology is simple and low-cost, and is easy to realize industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing chitosan reinforced bars

InactiveCN101225192AImprove performanceHigh mechanical strengthInternal osteosythesisProsthesisFiberDistilled water

Owner:XIAMEN UNIV

Biocomposites sheet molding and methods of making those

InactiveUS20060046042A1Minimal deteriorationPrevent vibrational attenuationButtonsRecord carriersFiberGlass fiber

A Sheet Molding Compound (SMC) as prepregs and cured compositions with naturally derived fibers which have been dried for at least three hours is described. The SMC process combines polyester polymer or resin with the fibers preferably continuously. The molded products are useful for a variety a purposes where glass fiber filled polyester polymers are conventionally used.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

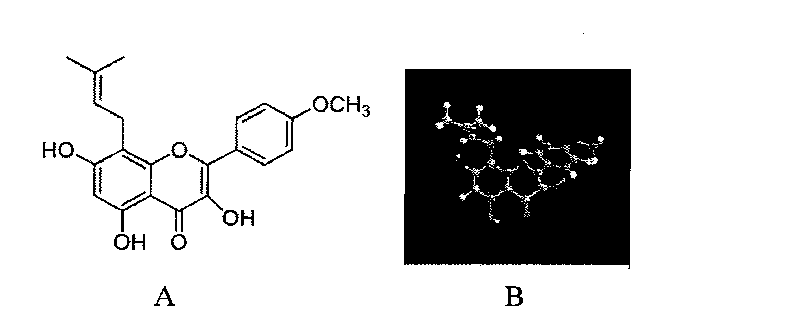

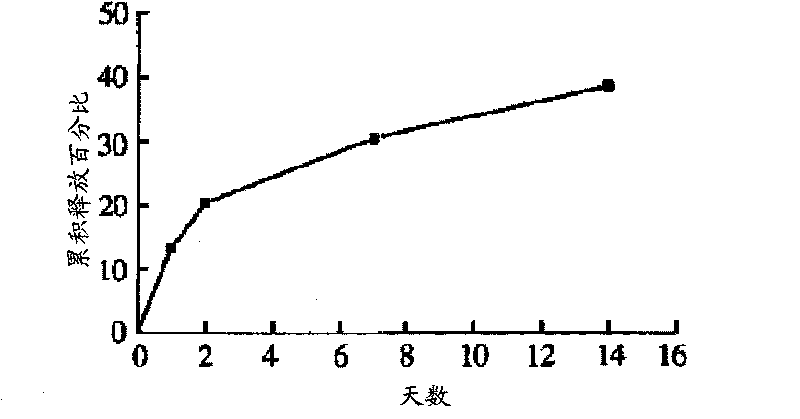

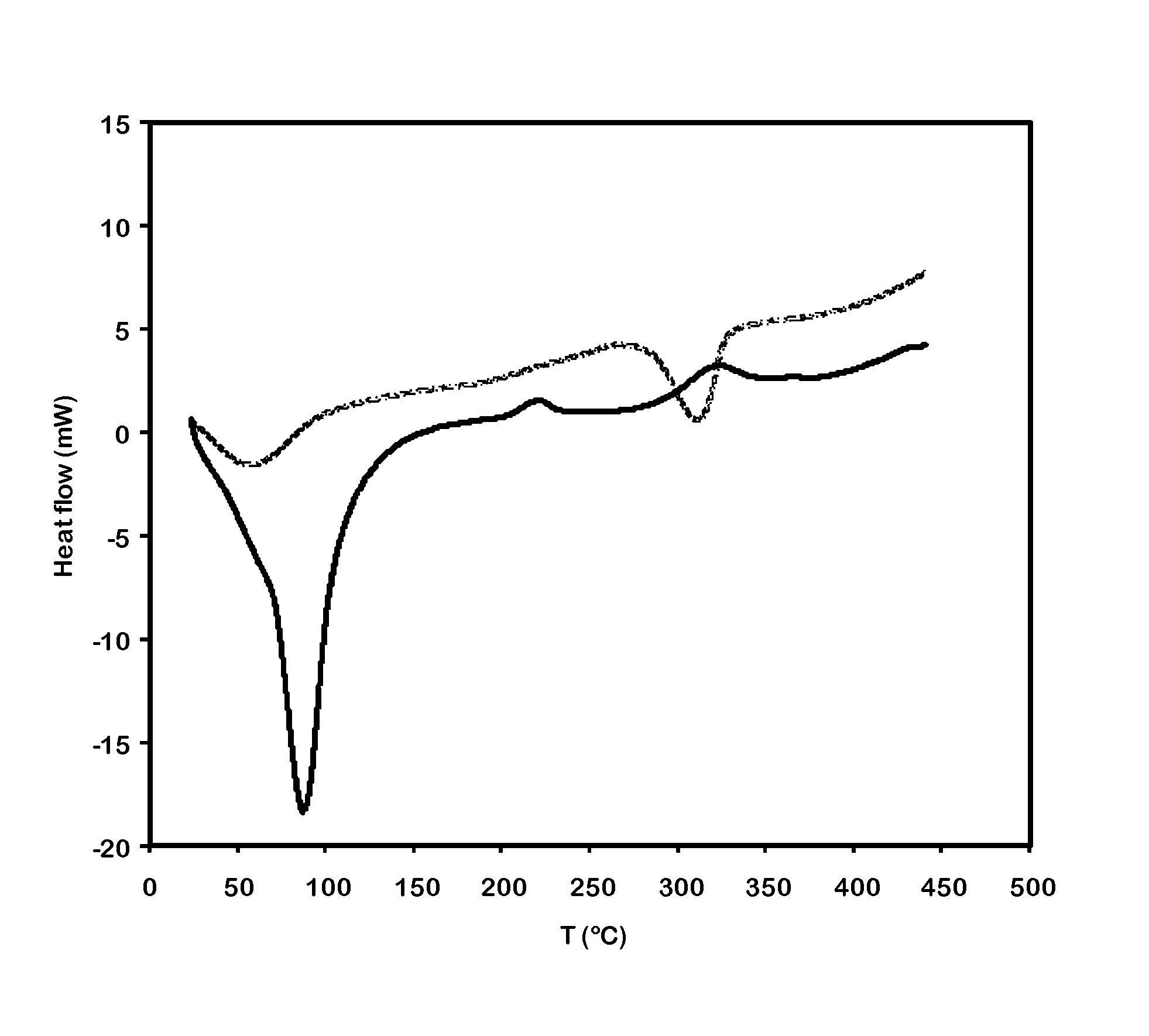

Biocomposite material, preparing method and use thereof

The present invention relates to a biocomposite material which comprises biodegradable polylactic acid / glycolic acid copolymer, tricalcium phosphate and effective amount of icaritin. The invention also relates to a preparing method of the biocomposite material and an artificial bone support prepared by the biocomposite material. Furthermore, the invention also relates to the use of the biocomposite material in treating tissue defect, particularly in preparing bone defect.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

Natural biocomposite powder prepared from pichia pastoris biomass, method of preparation and its use as excipient

ActiveUS20130251806A1Easy to processReduce shearPowder deliveryCosmetic preparationsPichia pastorisChitin-glucan complex

The present invention concerns a natural biocomposite powder prepared from the biomass of yeast Pichia pastoris, comprising chitin-glucan complex (CGC) and mannose-containing polysaccharides. In a second aspect, the invention concerns the method of preparation of the natural biocomposite powder. The invention also concerns the method to obtain Pichia pastoris biomass with increased CGC content, as well as increased chitin to glucan content in the CGC. Finally, the invention concerns the use of the natural biocomposite powder, prepared from the cell wall of yeast Pichia pastoris by the method according to the invention, as excipient in the pharmaceutical, cosmetics or food industries.

Owner:PHARMA73

Preparation method of novel neural restoration tissue engineering scaffold

ActiveCN105854077AIncrease moisture contentImprove mechanical propertiesPharmaceutical delivery mechanismTissue regenerationSomatic cellBiology

The invention relates to the technical field of biological composite materials, and discloses a preparation method of a novel neural restoration tissue engineering scaffold. The preparation method comprises the following steps: modifying bacterial cellulose; preparing a living cell derived material; uniformly mixing the modified bacterial cellulose with the living cell derived material to obtain a mixture, injecting the mixture into a mold, and preparing the neural restoration tissue engineering scaffold by an ice crystals directional solidification method and a freeze vacuum drying method. The preparation method has the benefits that due to dual bionic design of a structure and a component, the living cell derived material, modified nano fibers and a conductive nano material are combined, so that the obtained scaffold is high in moisture content, good in comprehensive mechanical property and high in stability, and has bioactivity and electroactivity; meanwhile, growth and increment of blood cells can be promoted favorably, and a function of axonal regeneration can be guided; the preparation method is simple, and the shape and the size of a prepared product are easy to control; various requirements of the neural restoration tissue engineering scaffold can be met, and the application prospect is wide.

Owner:UNIV OF SCI & TECH BEIJING

Biocarbon and nylon based hybrid carbonaceous biocomposites and methods of making those and using thereof

A polymer blend comprising polyamide, polypropylene (PP) and at least one of poly (lactic acid) (PLA) and a multi-phase compatibilizer comprising PA11-co-PP-maleic anhydride (MA). The polymer blend can be reinforced with hybrid fillers including biocarbon, glass fiber, carbon fiber and nano-clay to create composites useful in the creation of products of manufacture such as auto parts.

Owner:UNIVERSITY OF GUELPH

Biocomposites and methods of making the same

ActiveUS20100036098A1High strengthImprove abilitiesConnective tissue peptidesPeptide/protein ingredientsPolymerMaterials science

In general, the present invention is related to biopolymer and biocomposite materials and structures, and methods of making and using the same. In some embodiments, the present invention is directed to oriented collagen based biocomposite materials and structures, and methods of making.

Owner:FIBRALIGN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com