Patents

Literature

296results about "By-product recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

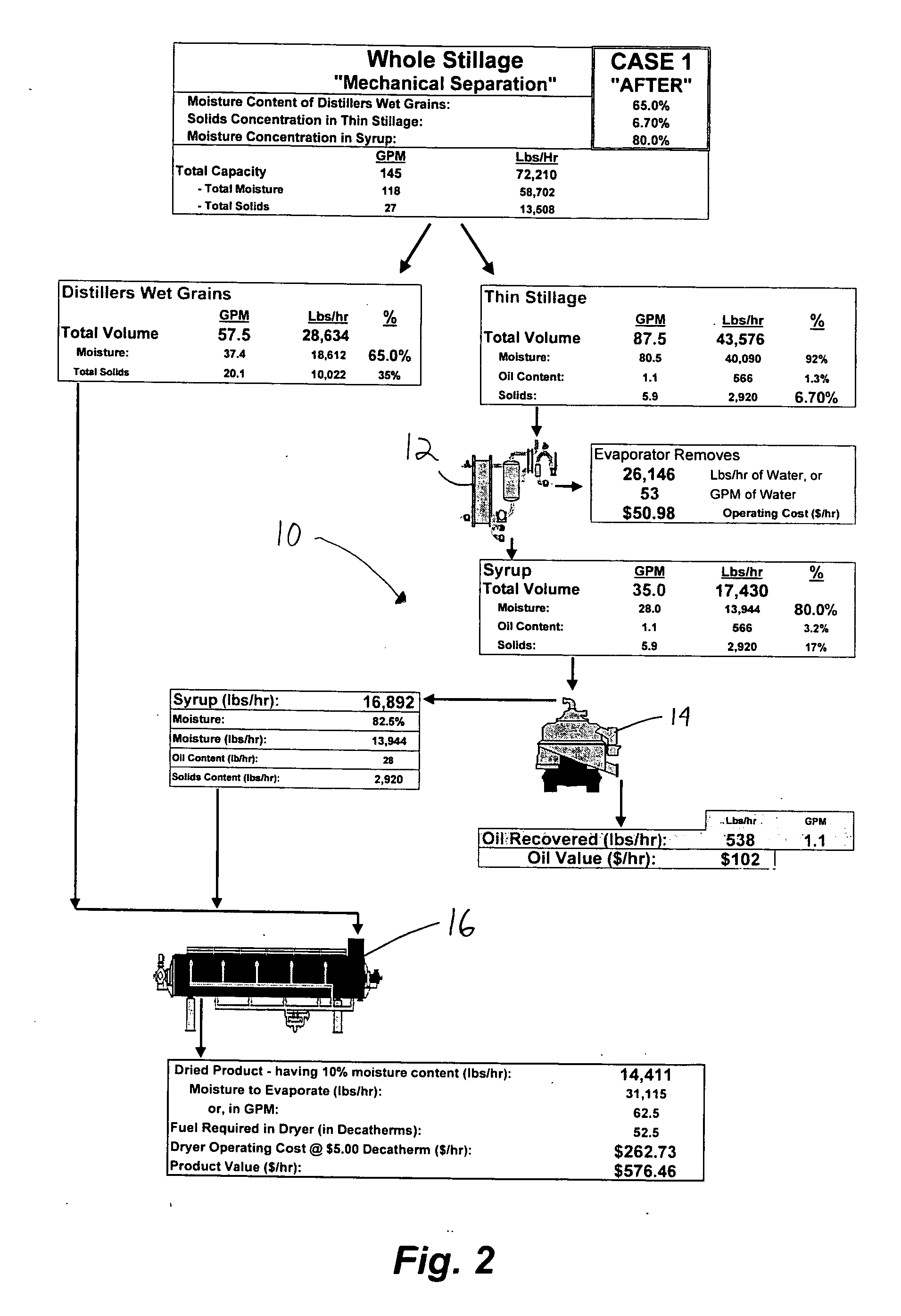

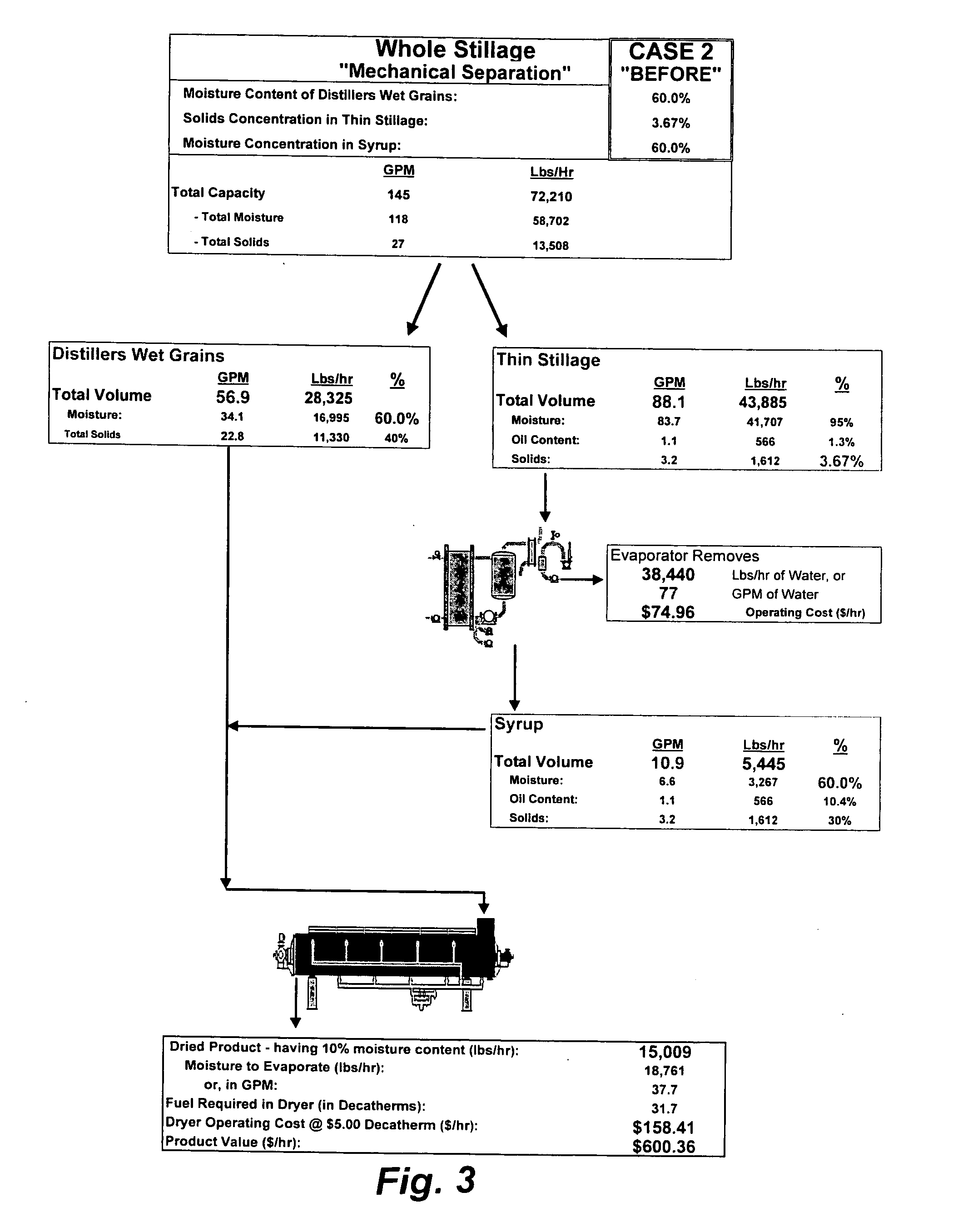

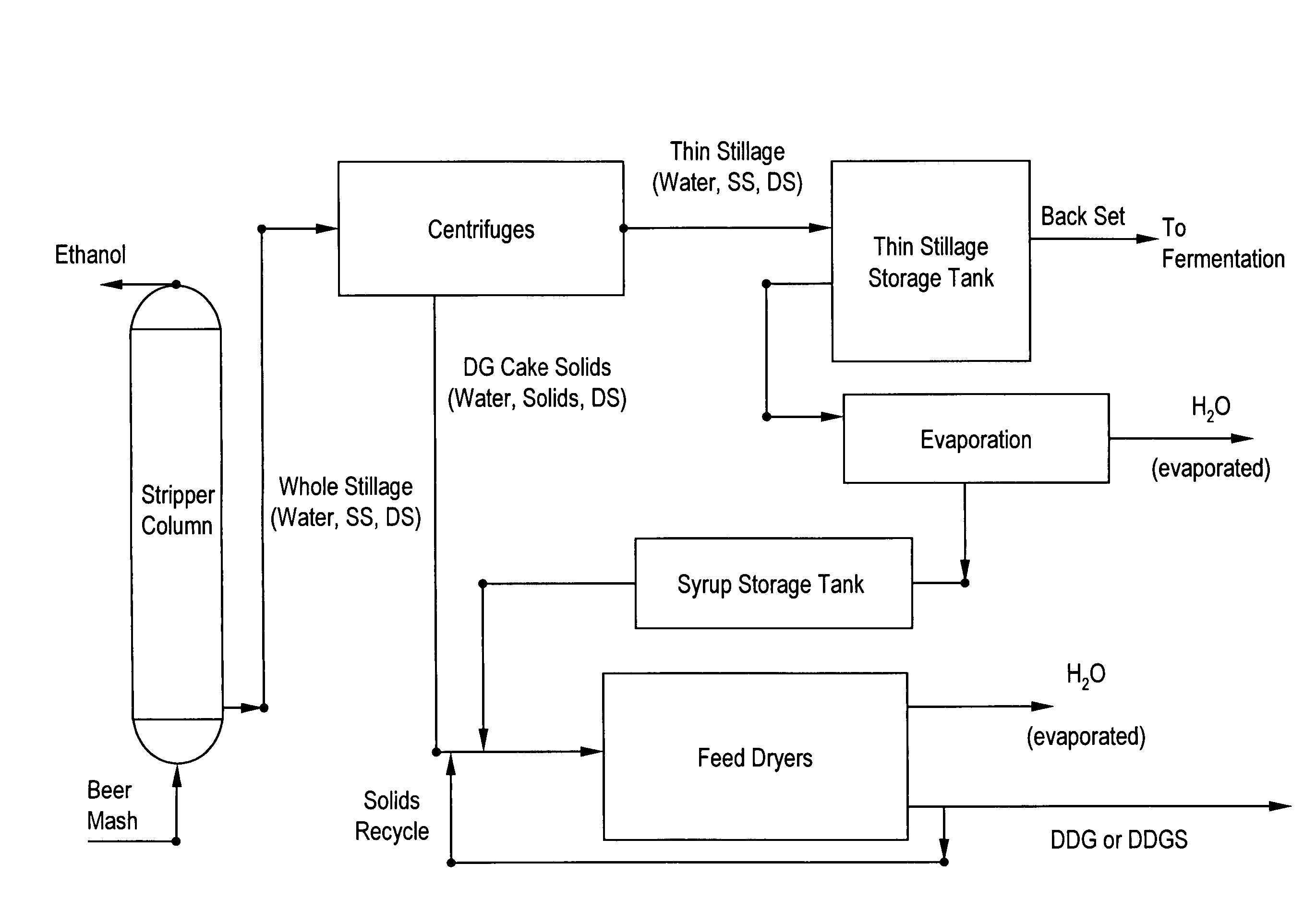

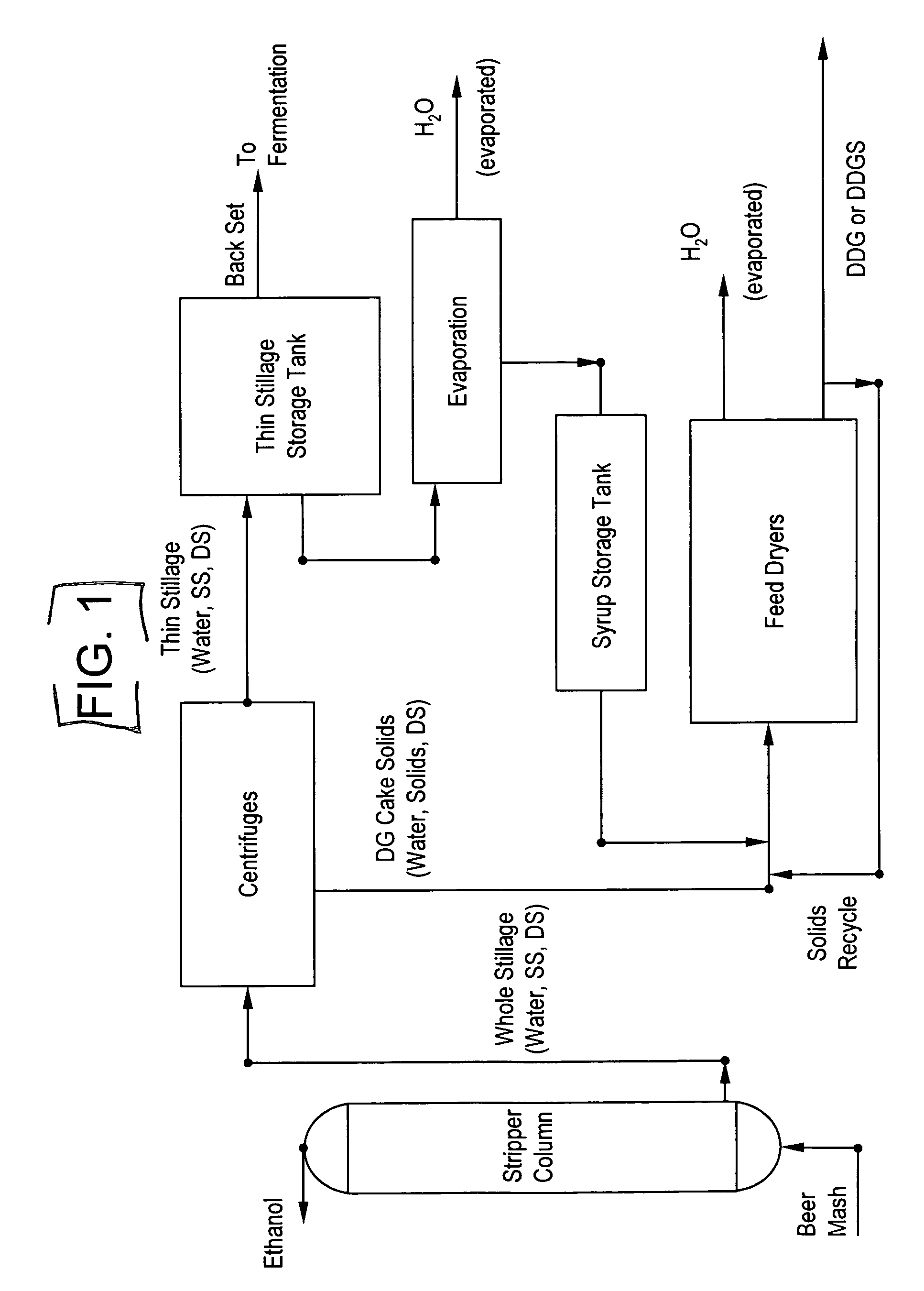

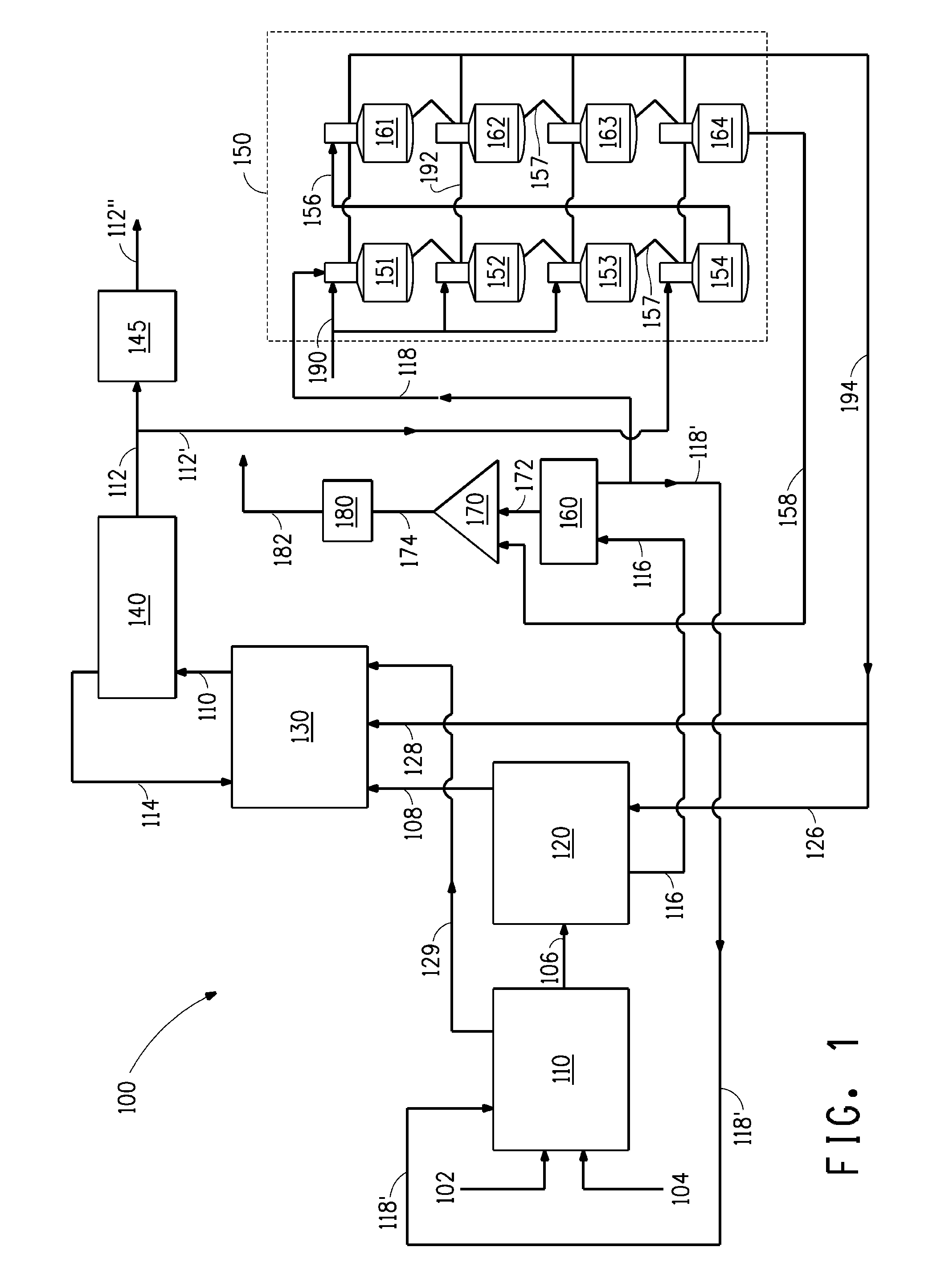

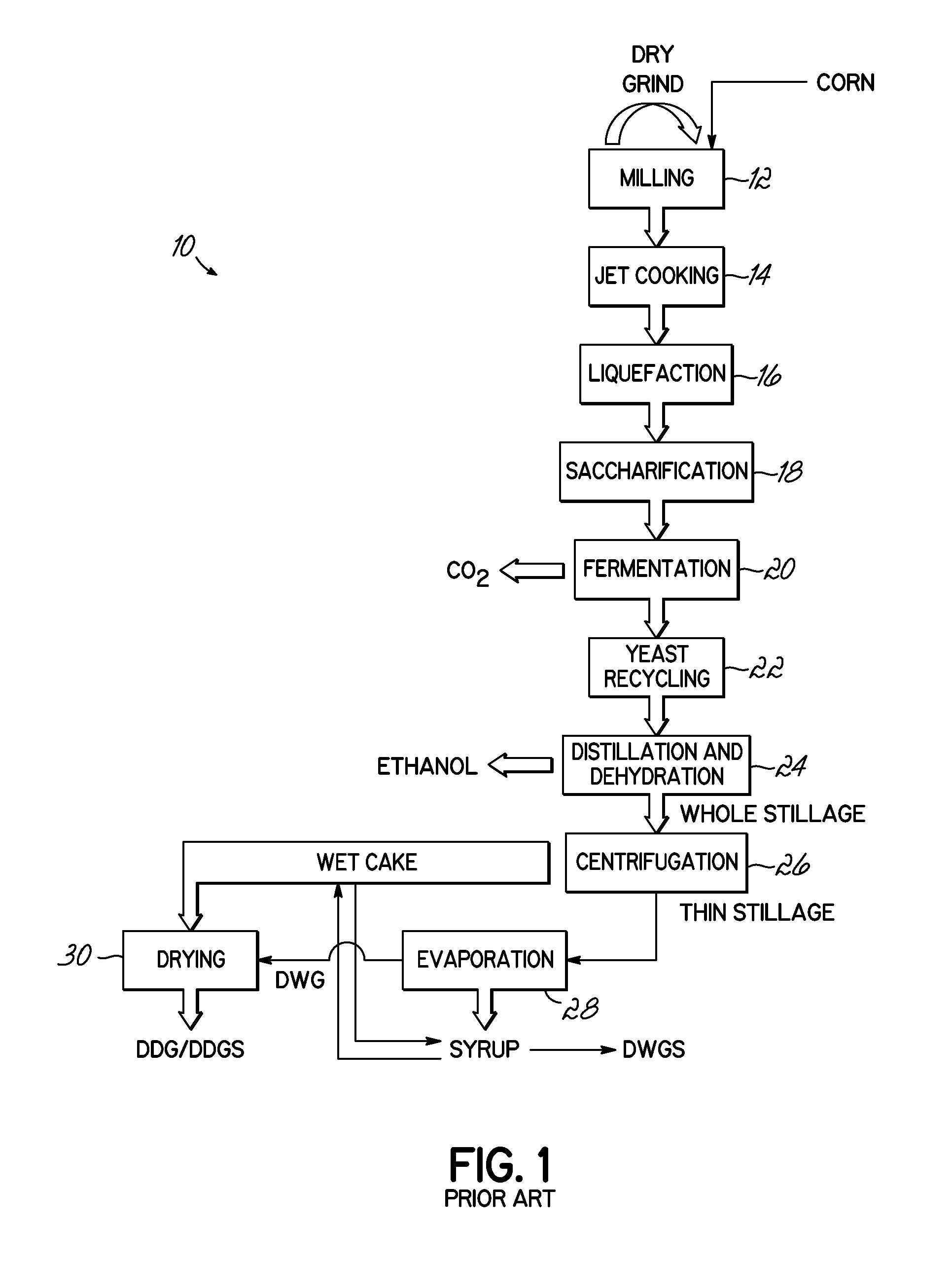

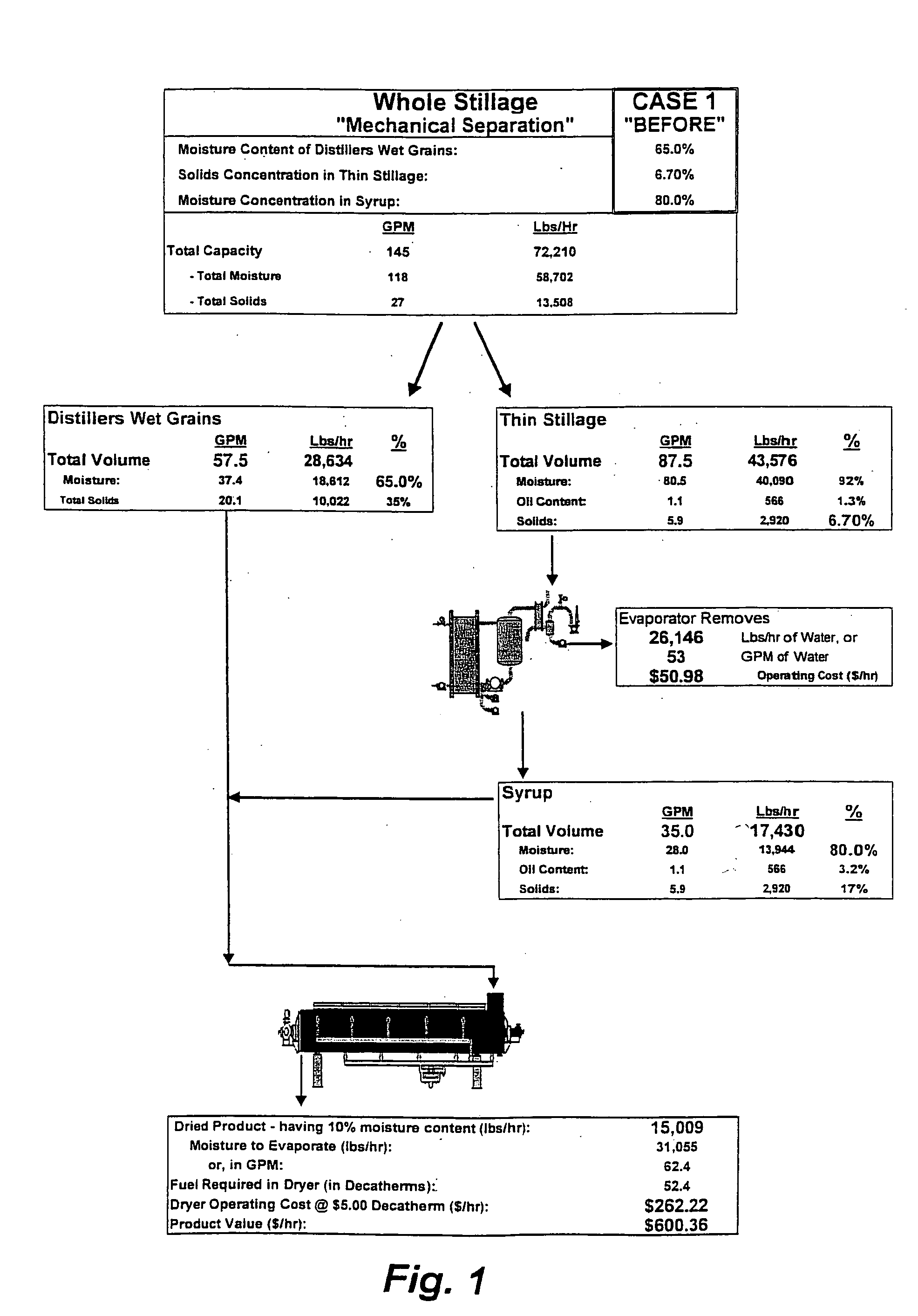

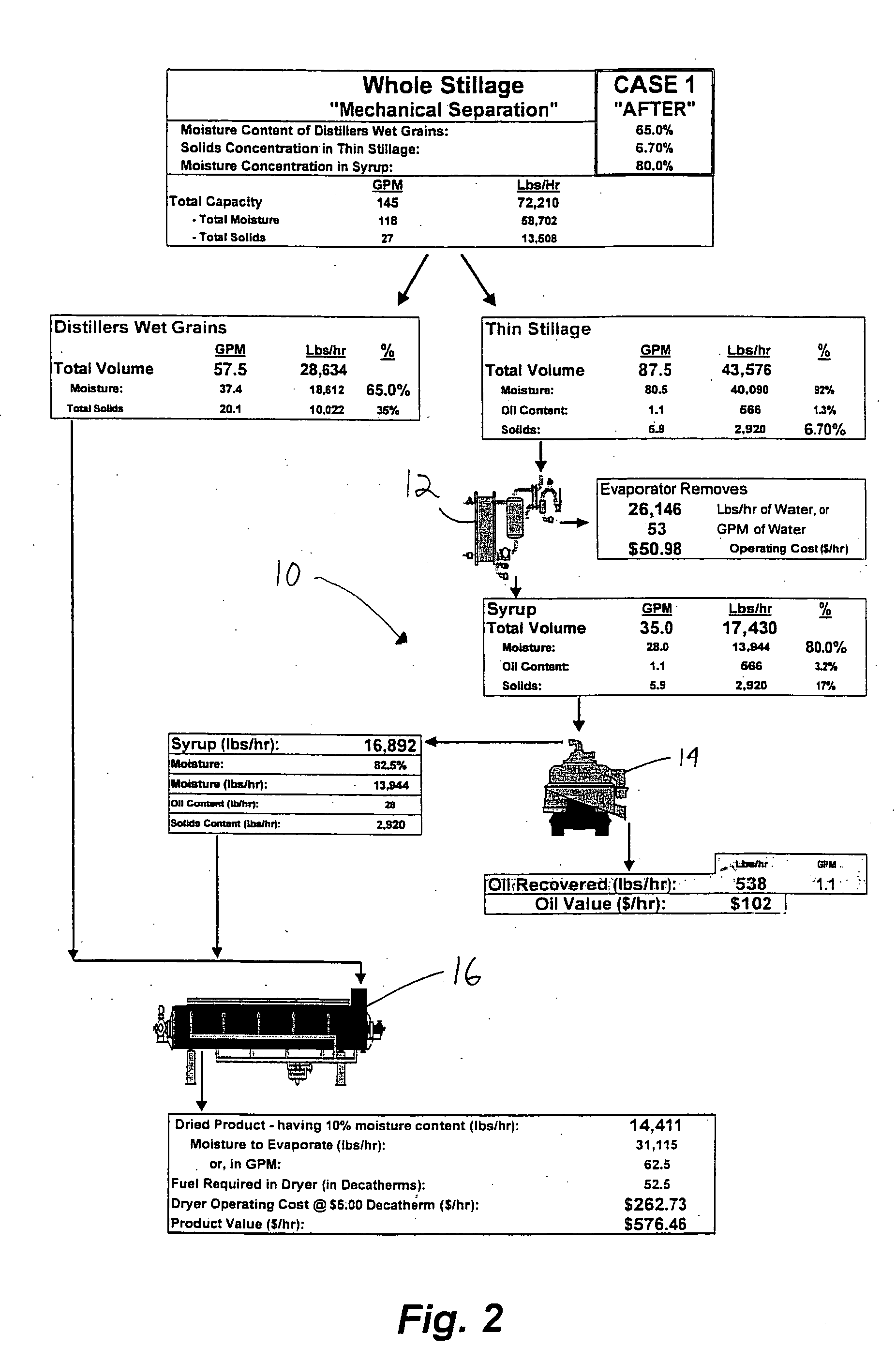

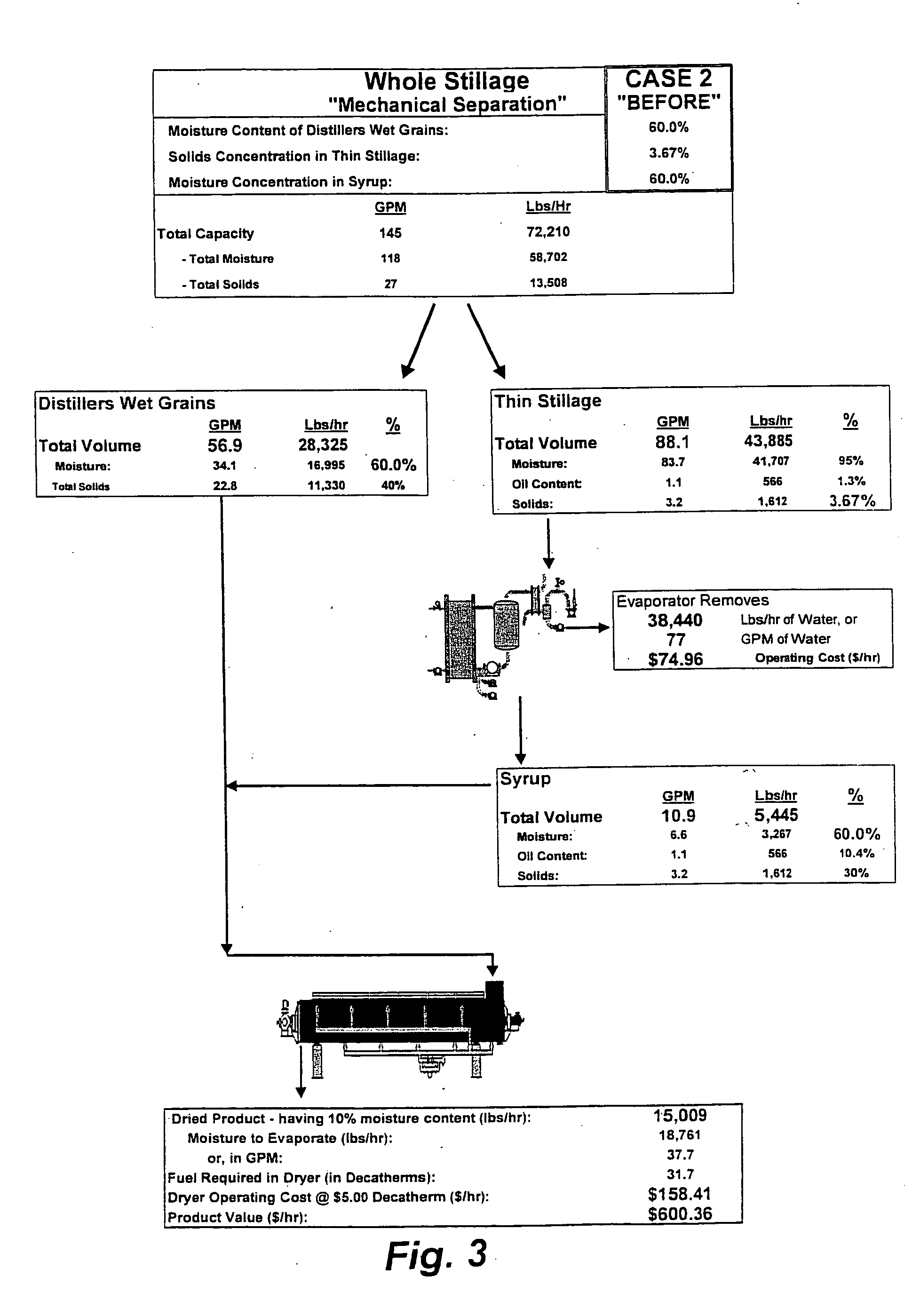

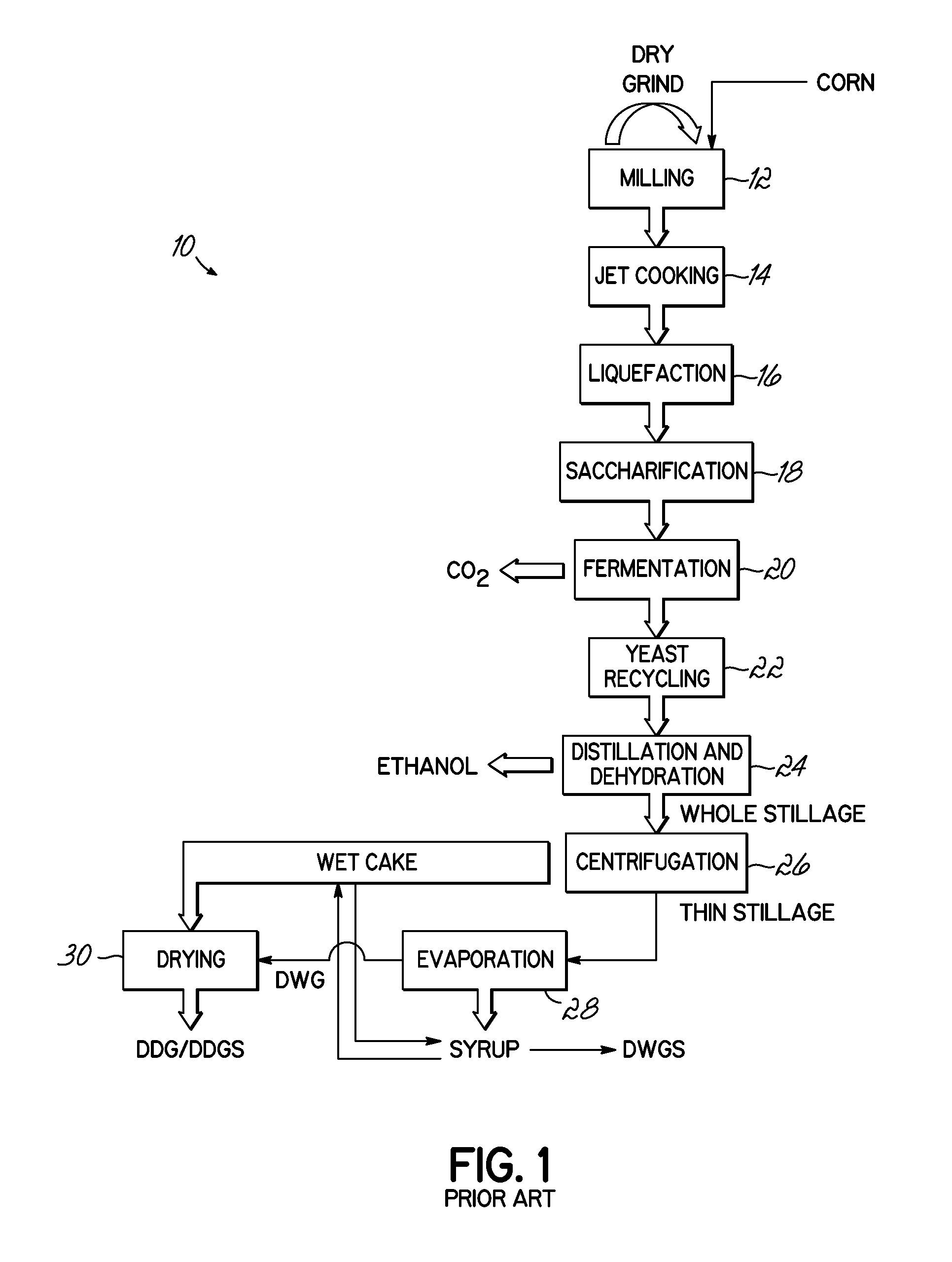

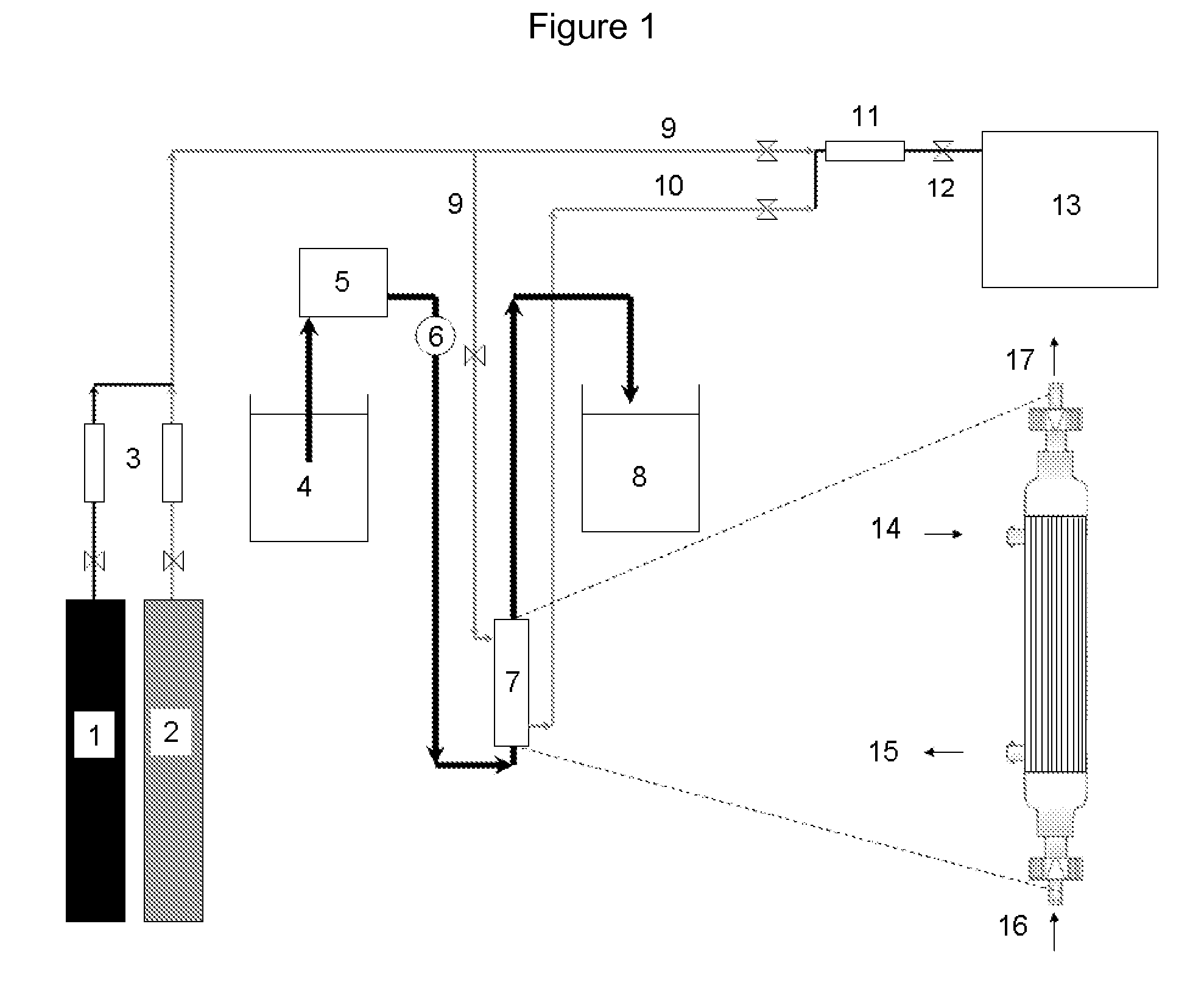

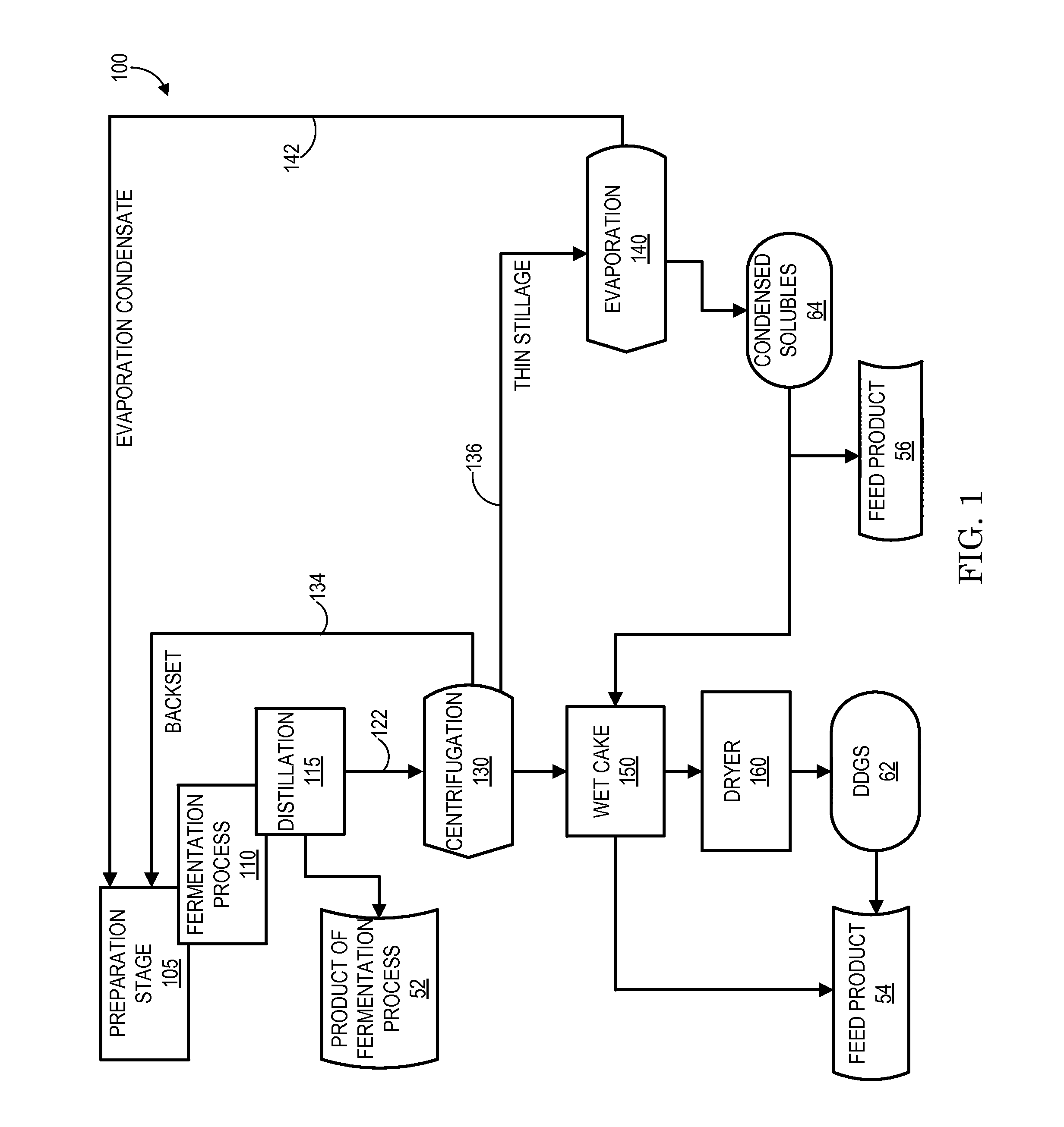

Method of processing ethanol byproducts and related subsystems

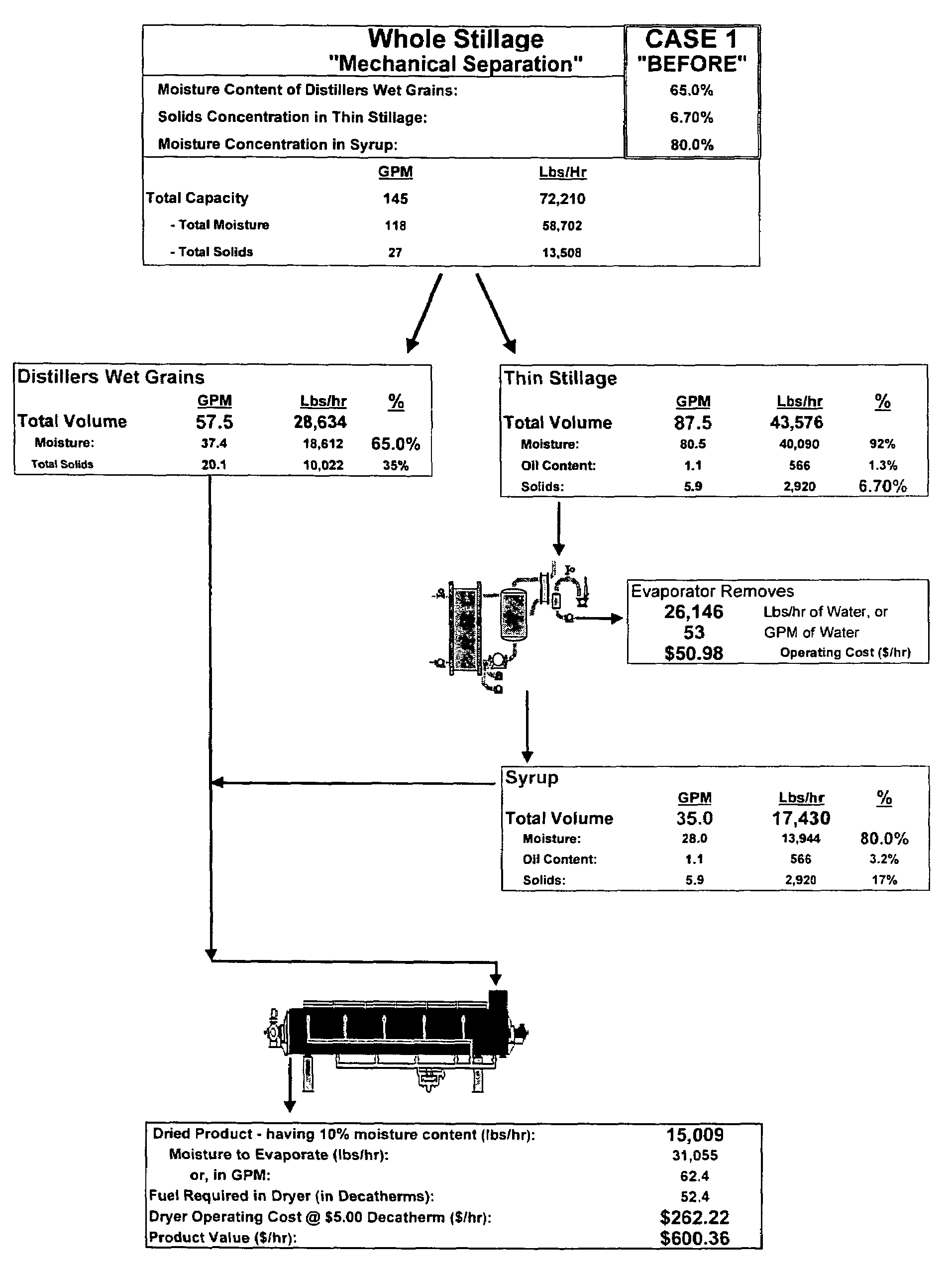

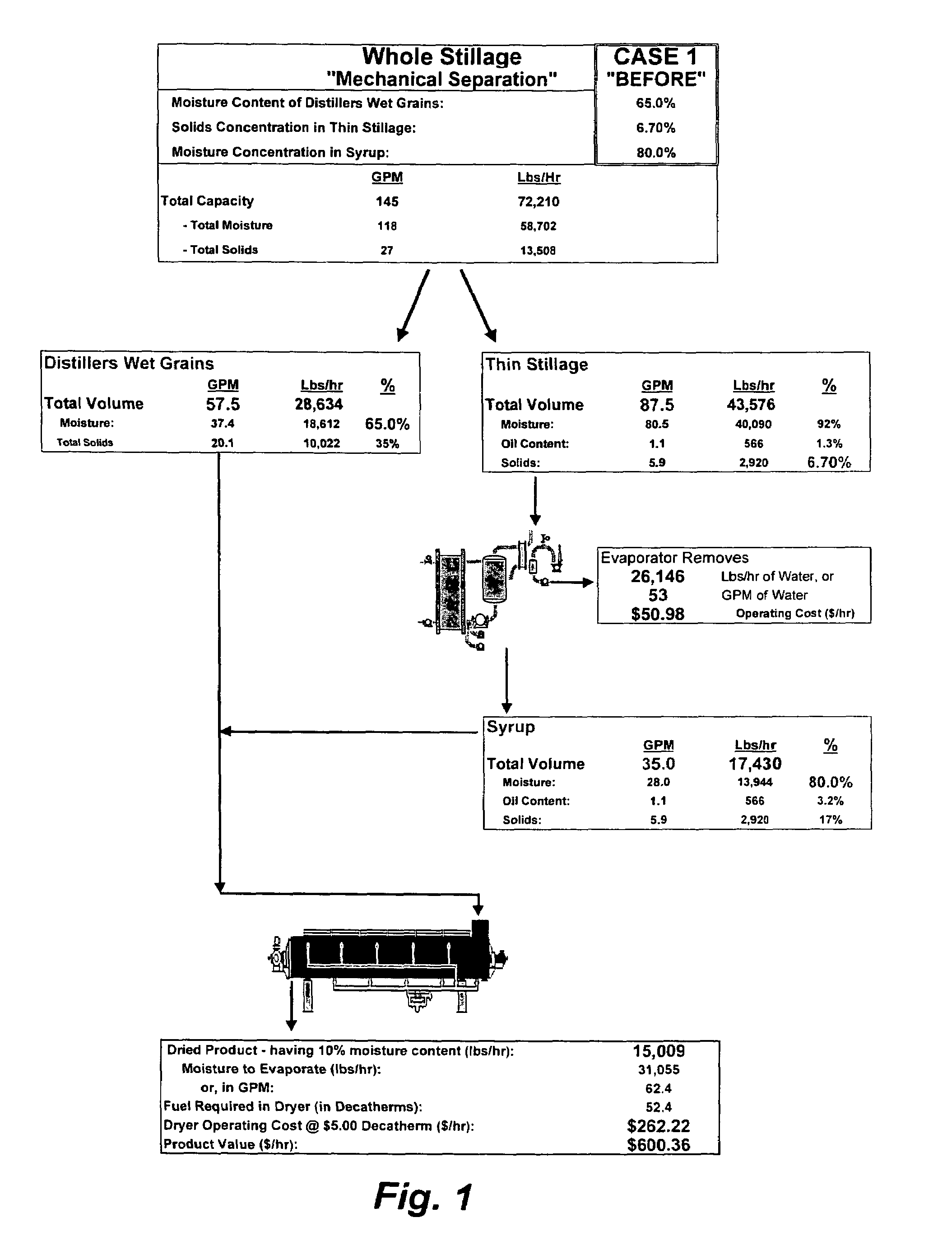

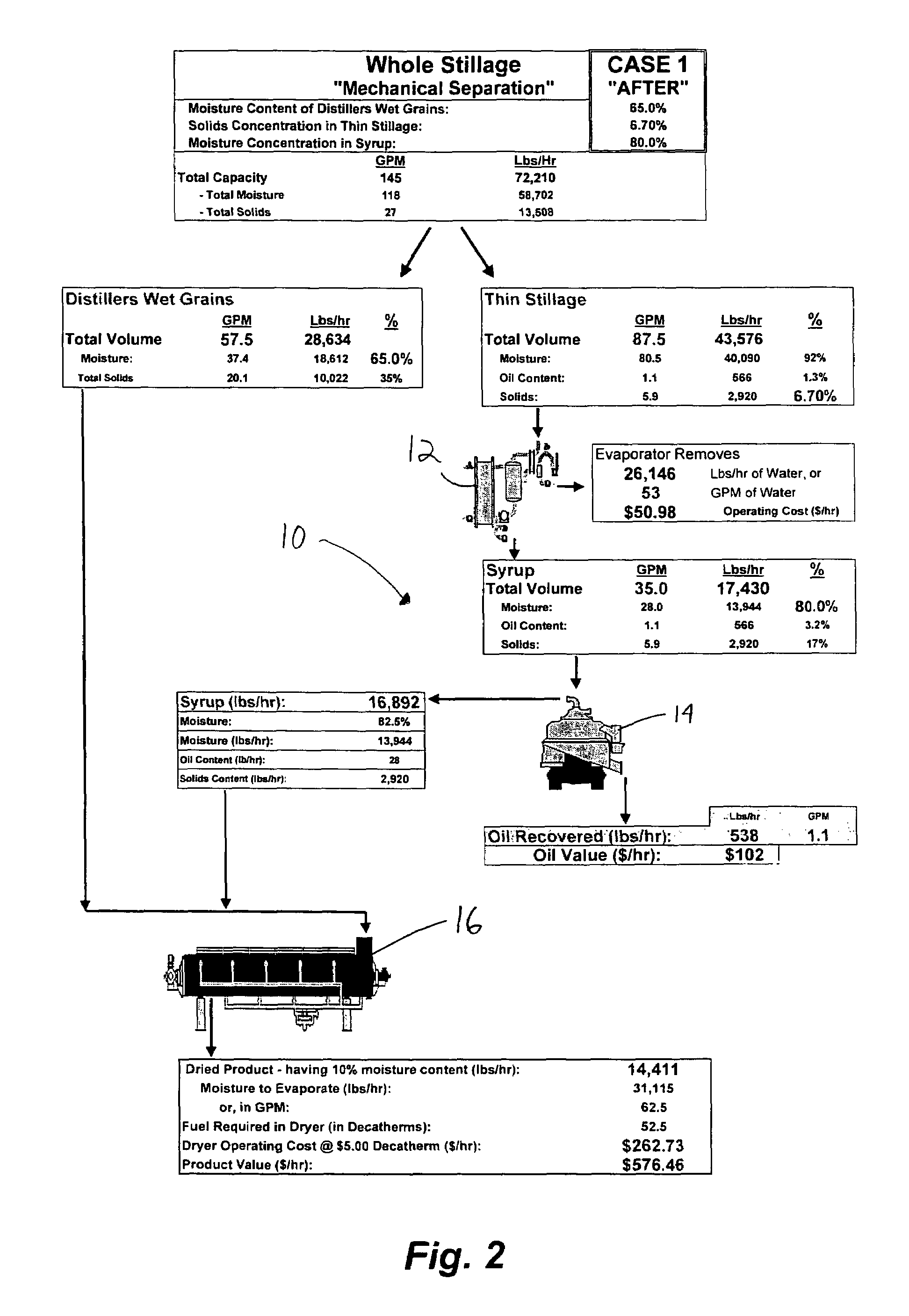

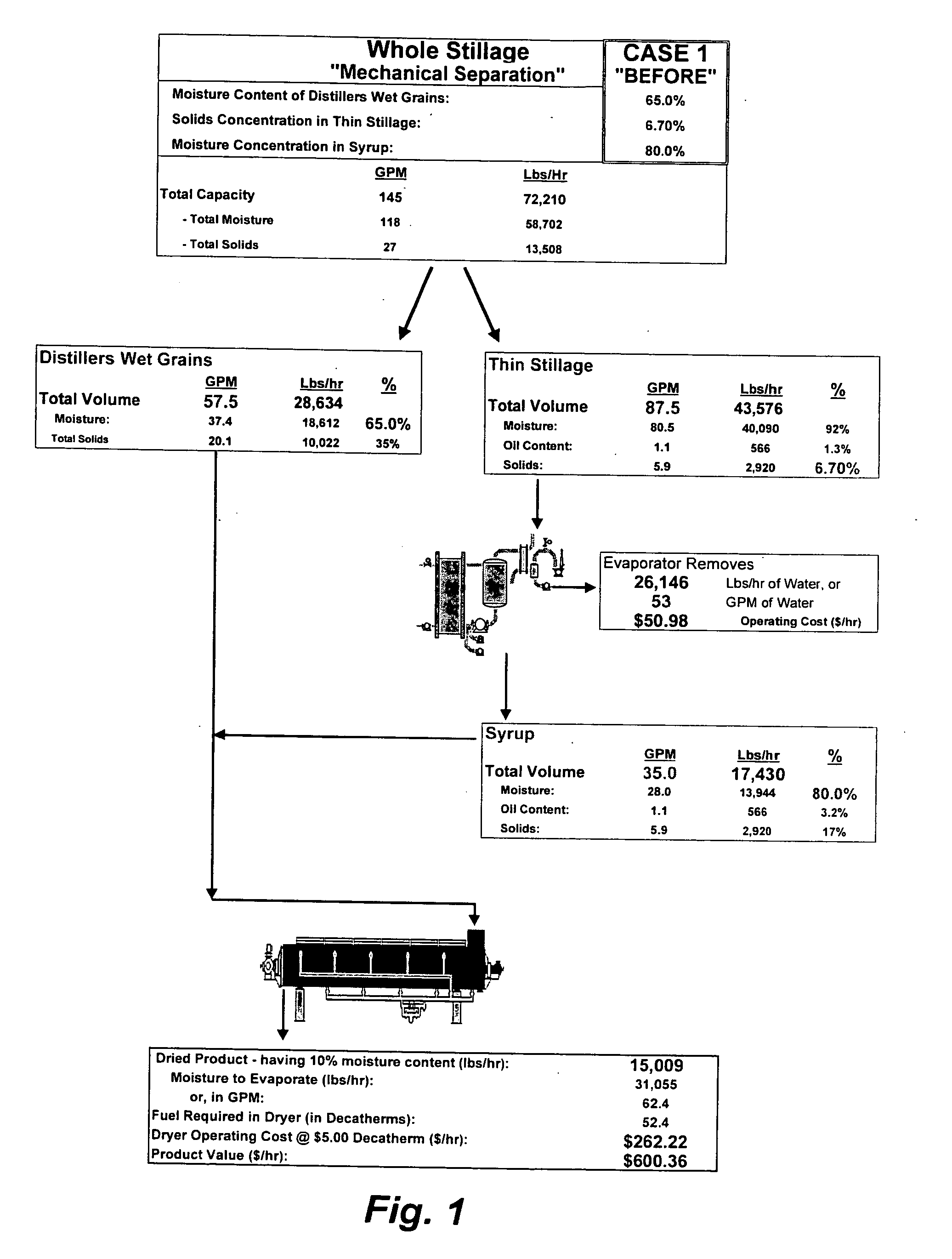

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

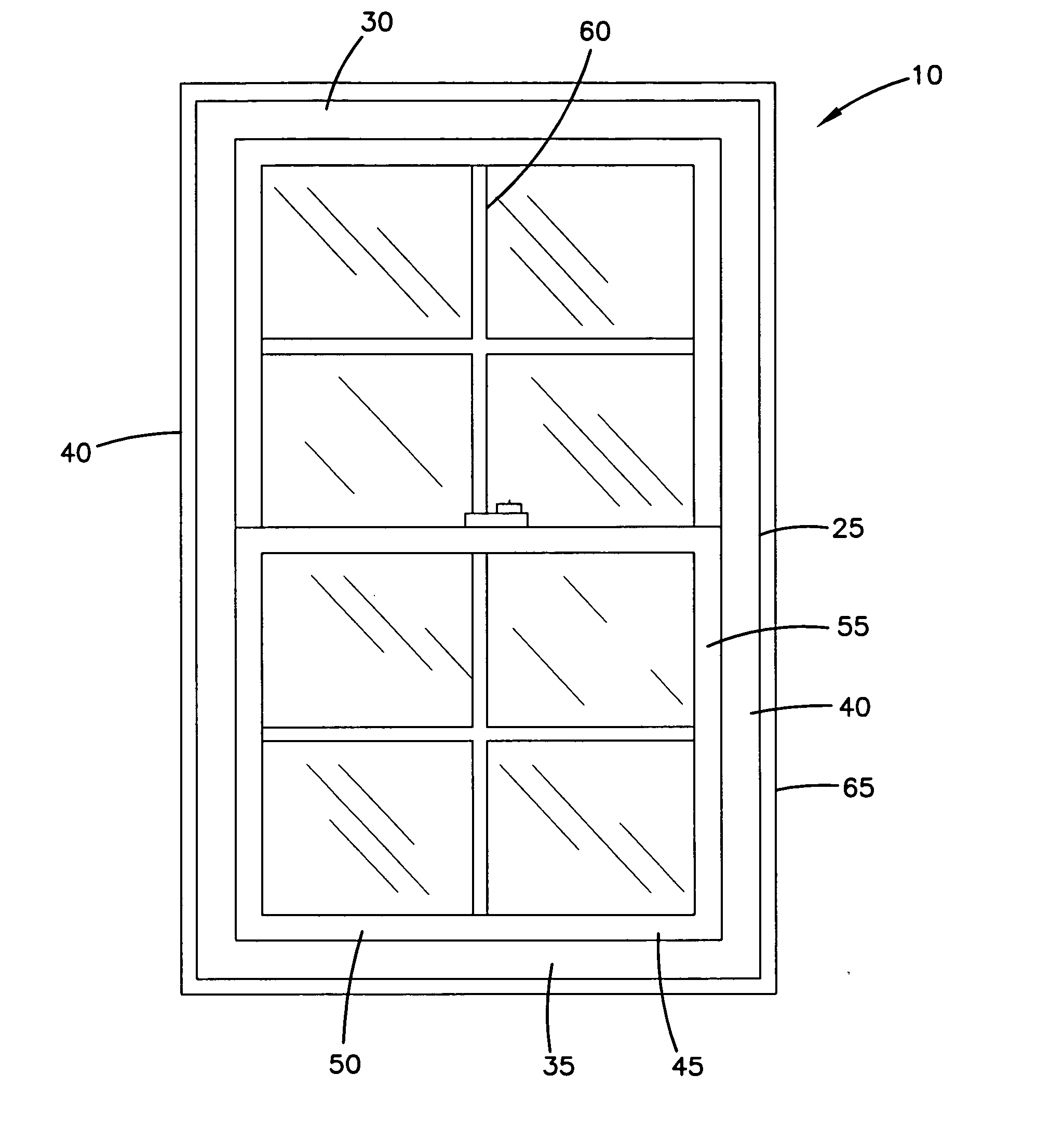

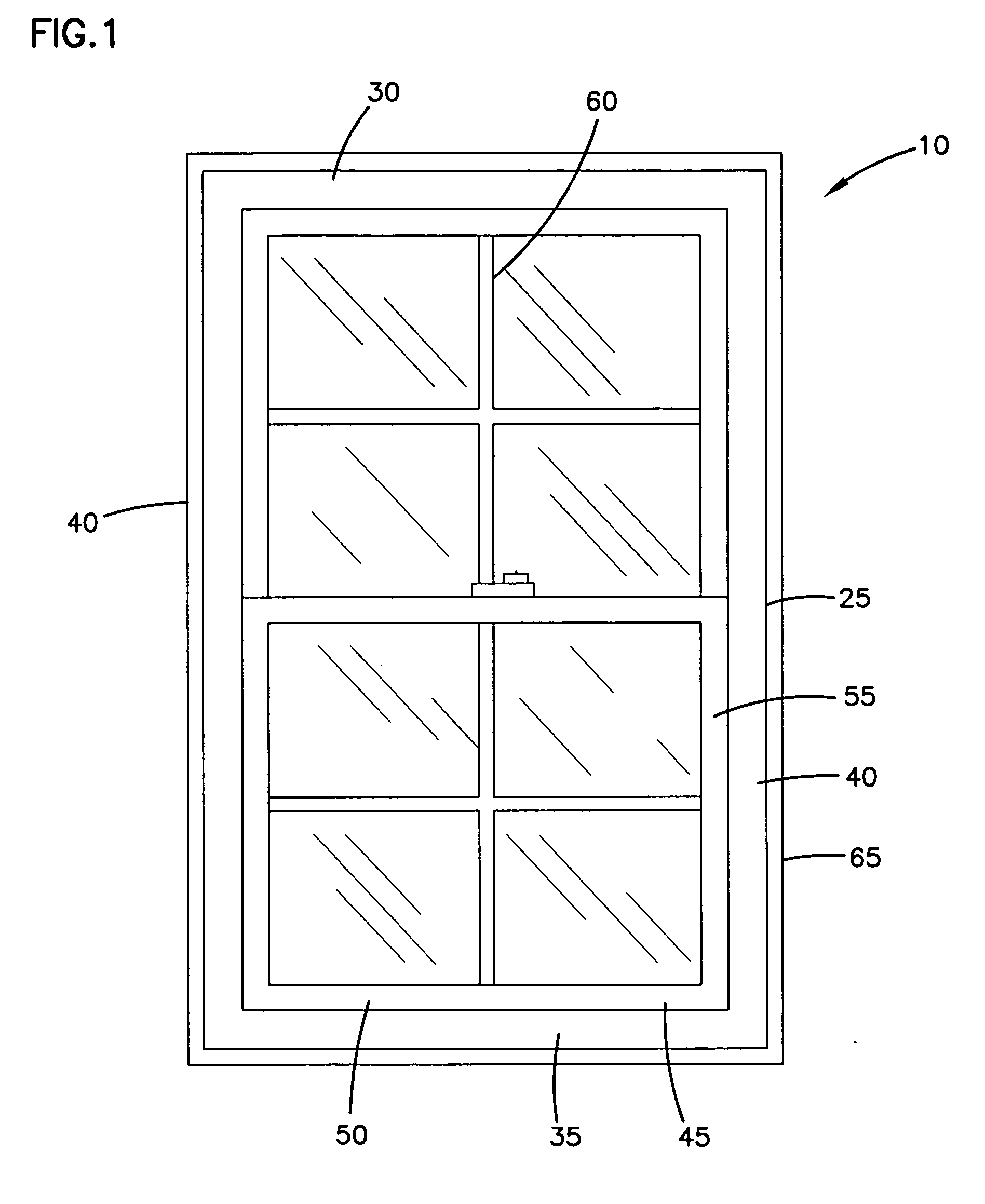

Biopolymer structures and components

InactiveUS20050019545A1Keep shapeIncrease valueVehicle arrangementsAlcoholic beverage preparationBiopolymerEngineering

Structures can be formed from a composition, which can be referred to as a biopolymer, that includes fermentation solids and thermoactive material. Methods of making biopolymer products include for example extruding, injection molding, or compounding fermentation solid and thermoactive material. Structures formed from biopolymer can include lumber replacements, window components, door components, siding assemblies, and other structures.

Owner:POET RES INC

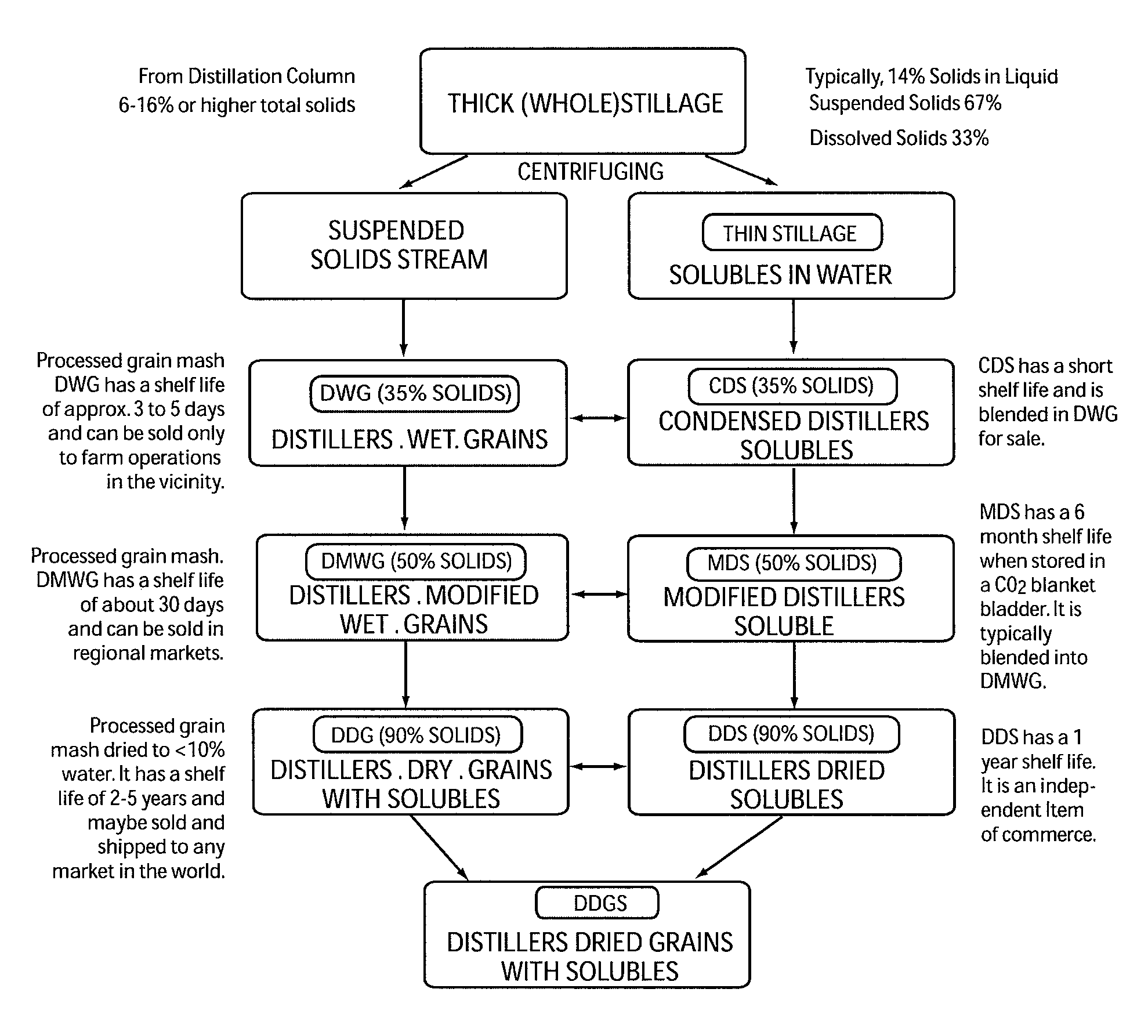

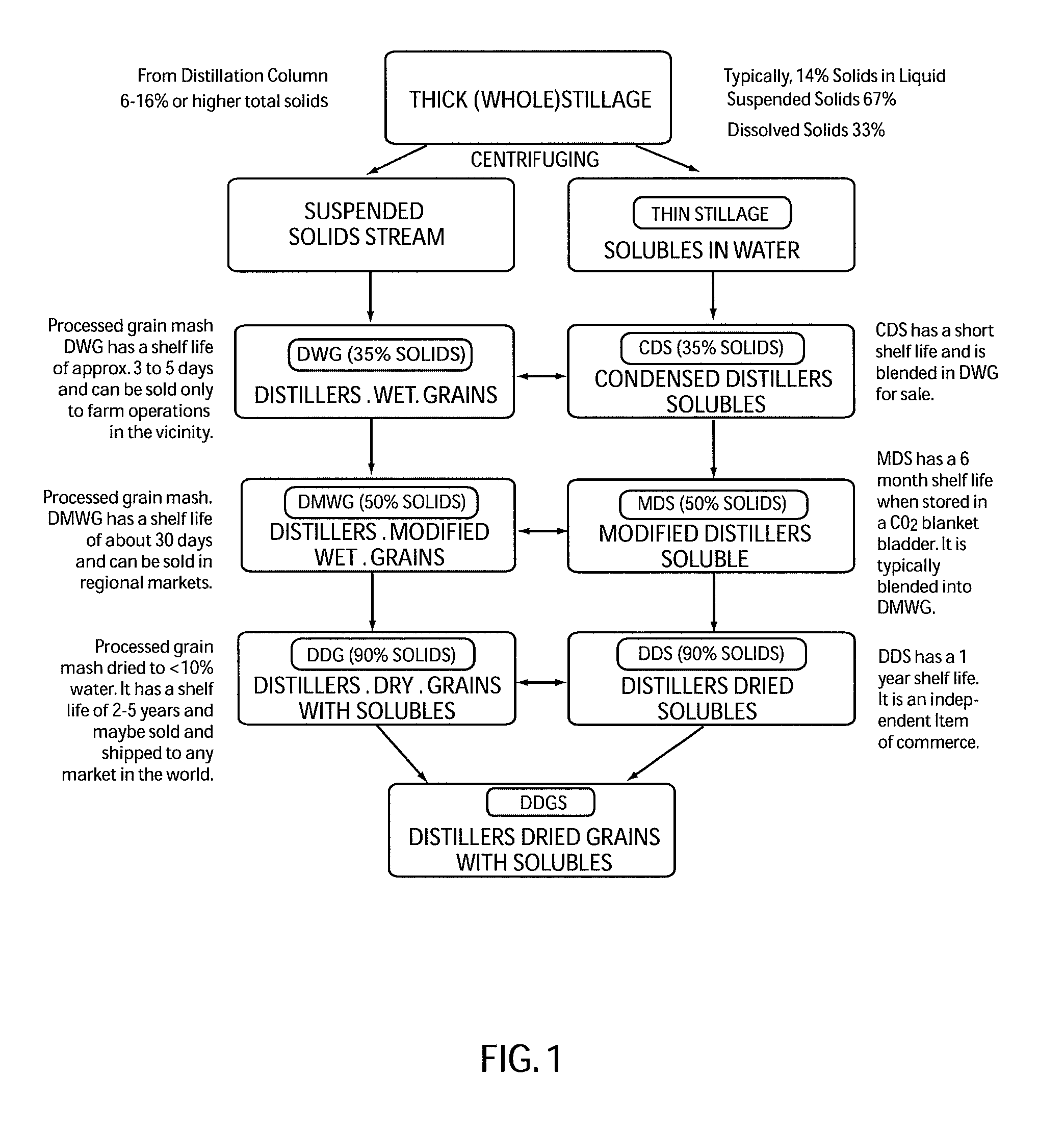

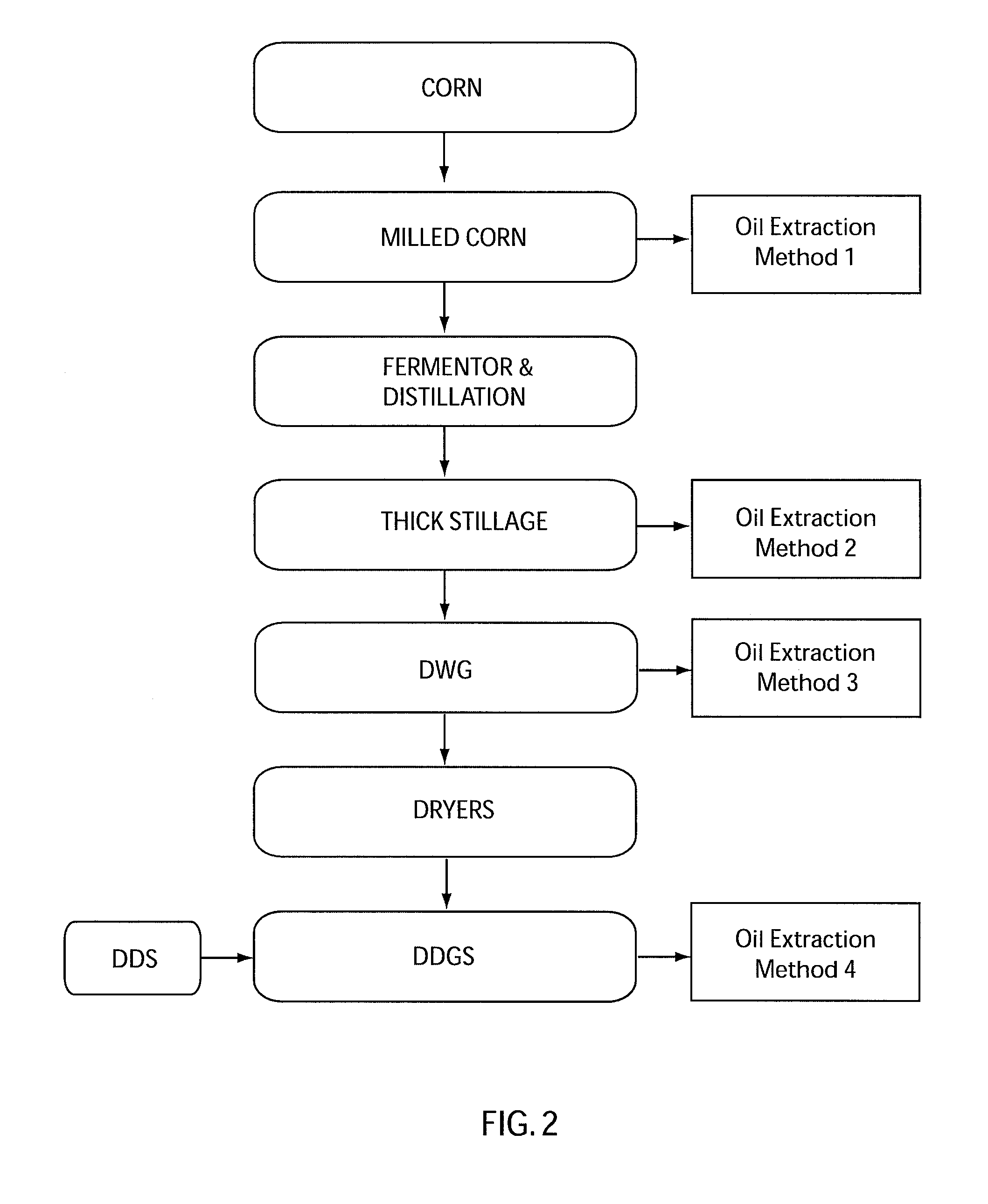

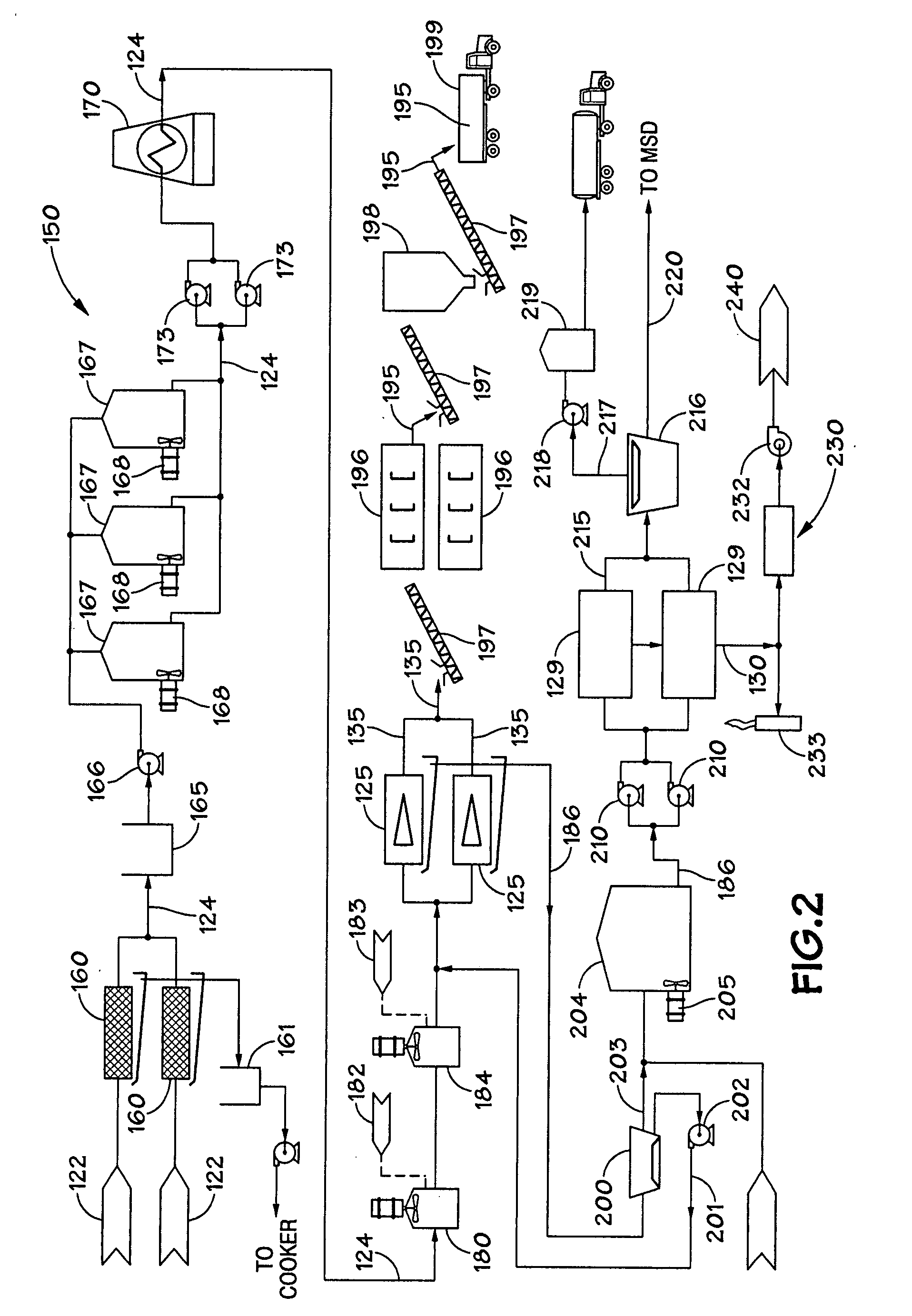

Oil recovery from dry corn milling ethanol production processes

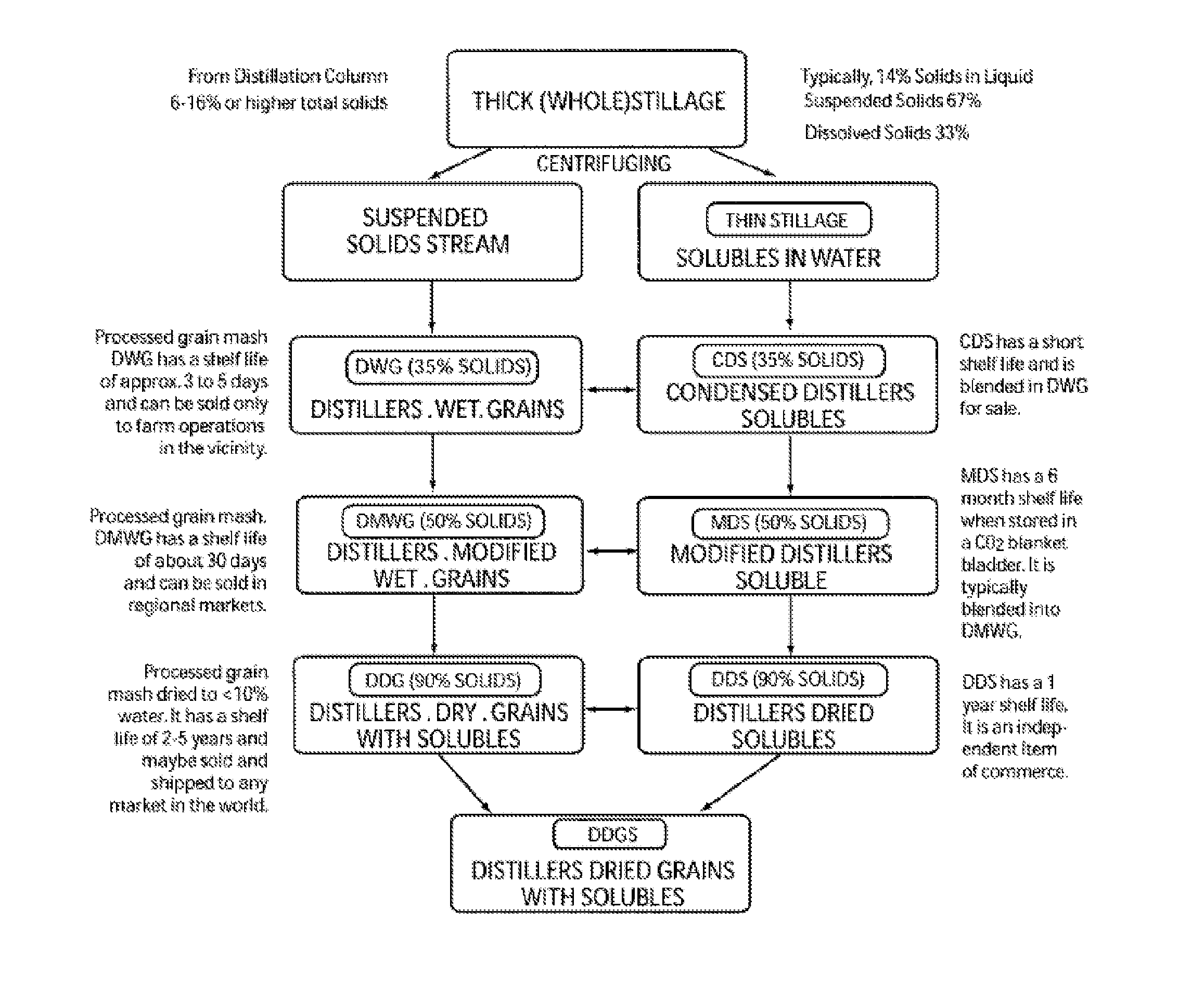

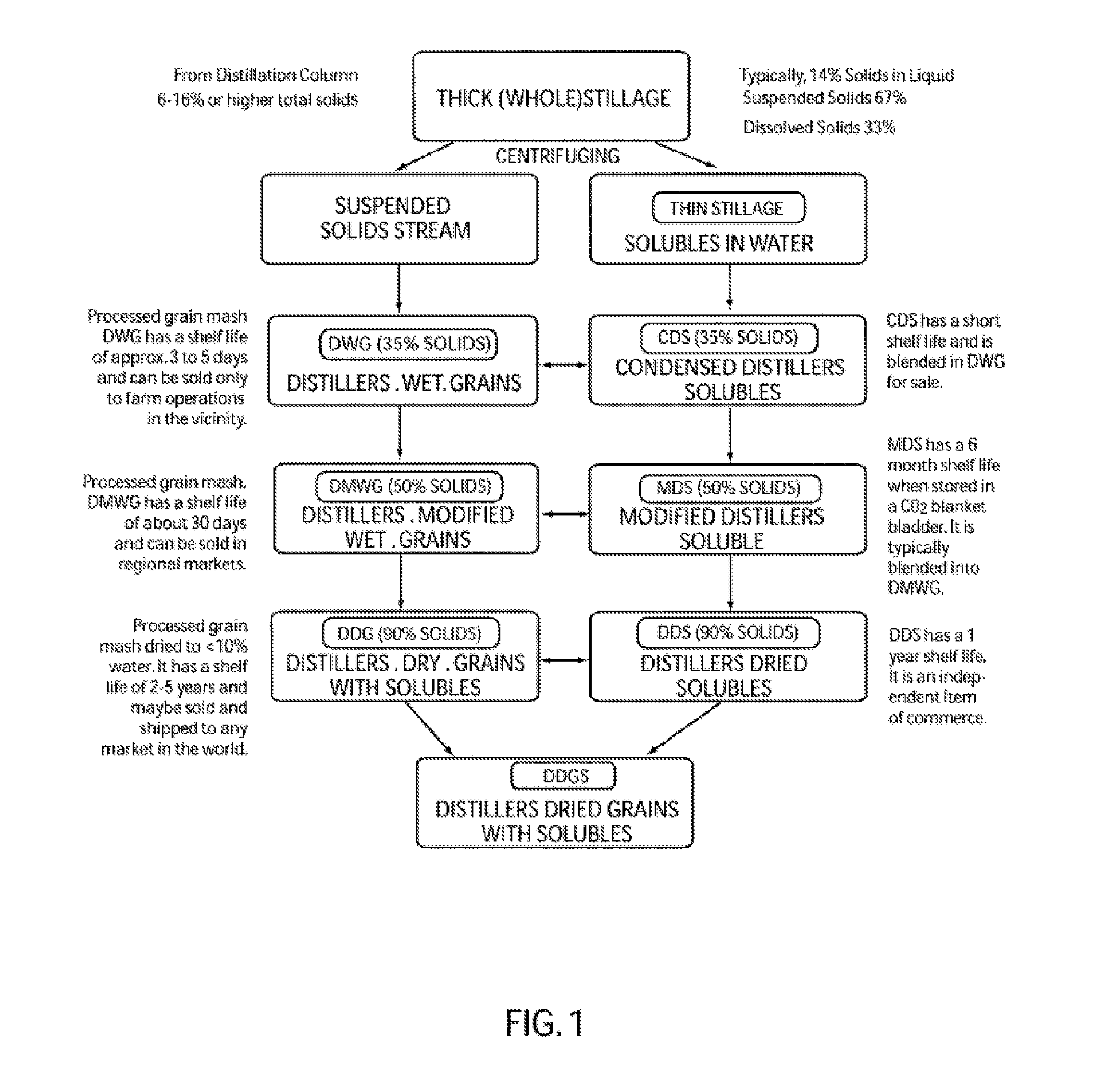

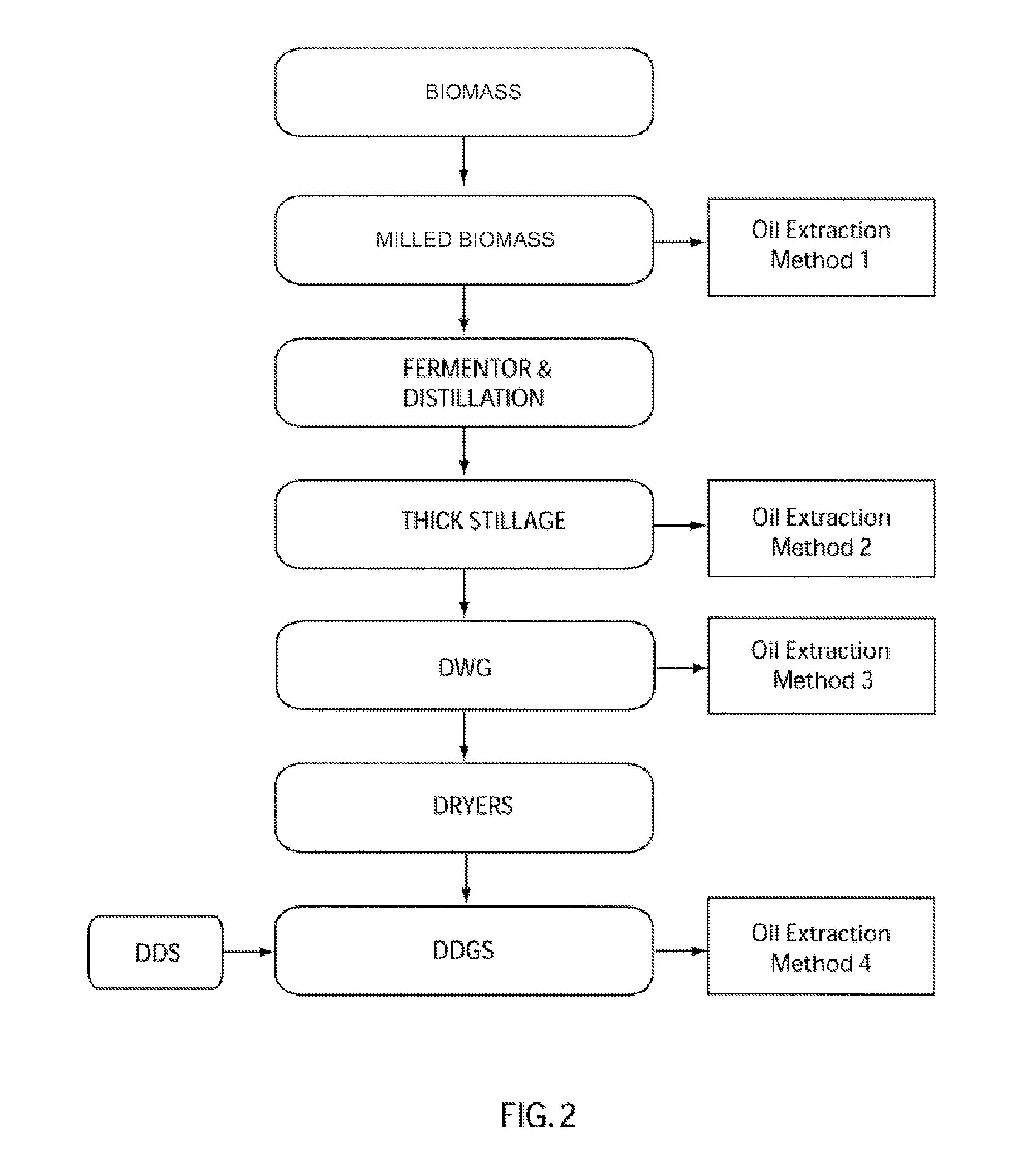

A corn oil extraction process is disclosed. The process includes the recovery of corn oil and other co-products, including but not limited to steam, electric power and chemicals, from an ethanol production process and in particular, a process that involves dry corn milling methods. The process involves extraction of oil from milled corn and residues from the fermentation step, including thick stillage, distillers wet grain, distillers dry grain and distillers dry grains with solubles, by the application of an alkyl acetate, phase separation and recovery of the separated matter. A process of drying wet co-product using ethanol and carbon dioxide from the production facility is also disclosed.

Owner:GROWMARK

Biopolymer and methods of making it

The present invention relates to a composition, which can be referred to as a biopolymer, including fermentation solid and thermoactive material. The present invention also includes methods of making the biopolymer, which can include compounding fermentation solid and thermoactive material. The present biopolymer can be formed into an article of manufacture.

Owner:POET RES INC

Method of dewatering thin stillage processing streams

InactiveUS20060006116A1Improve agglomerationAbility to withstandBy-product recoveryWater treatment parameter controlAcryditeSodium methacrylate

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:NALCO CO

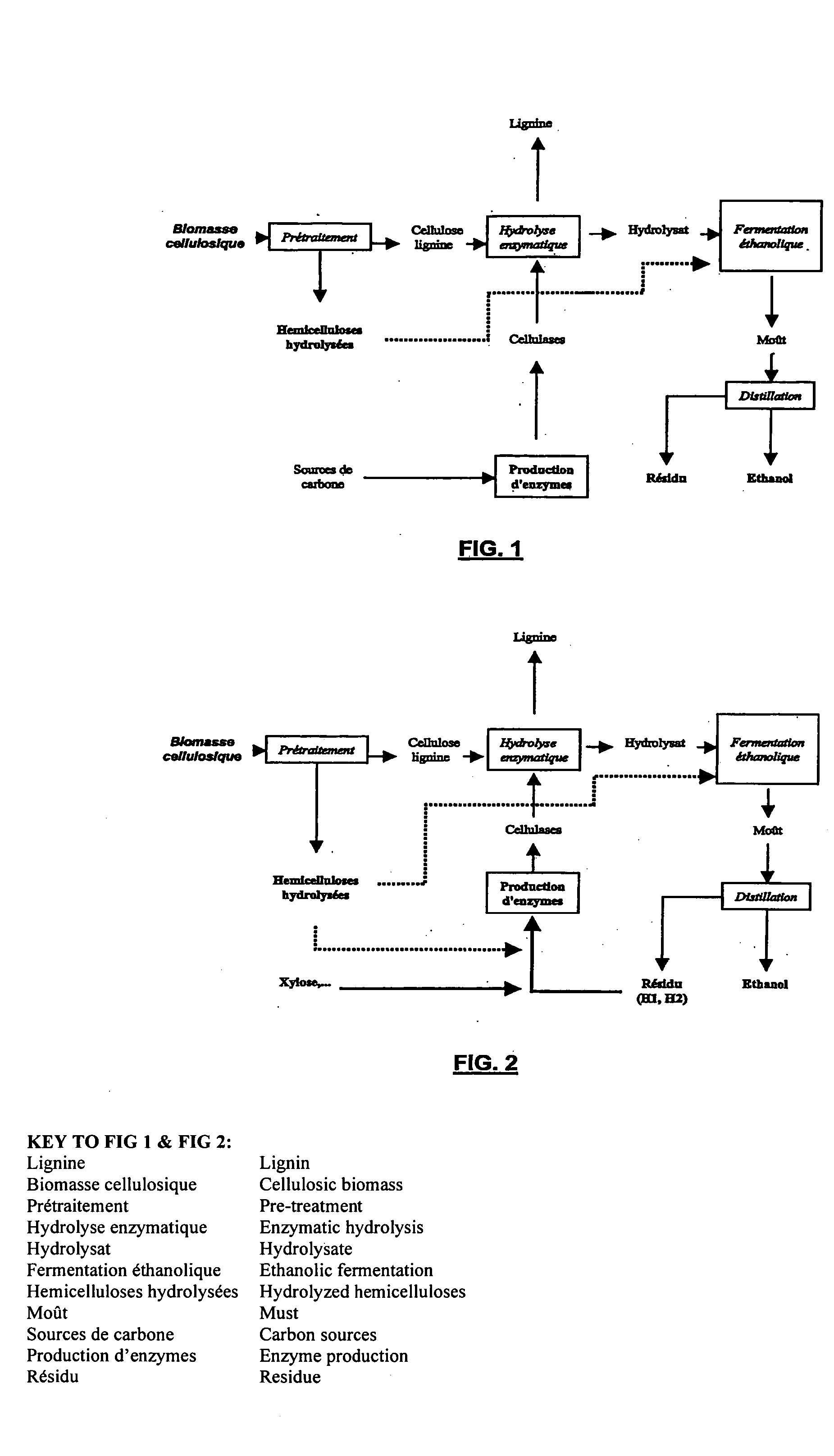

Process for the production of cellulolytic and hemicellulolytic enzymes using distillation residues from the ethanolic fermentation of enzymatic hydrolyzates of (ligno)cellulosic materials

A process for producing cellulolytic and / or hemicellulolytic enzymes uses the residue from the ethanolic fermentation of enzymatic hydrolyzates of cellulosic or ligno-cellulosic materials. This process may be integrated into a process for the production of ethanol from cellulosic or ligno-cellulosic materials which comprises the following steps: 1) chemical and / or physical pre-treatment of a cellulosic or ligno-cellulosic substrate; 2) enzymatic hydrolysis of the pre-treated substrate using cellulolytic and / or hemicellulolytic enzymes; 3) ethanolic fermentation, by a suitable alcohologenic microorganism, of the hydrolyzate from step (2) and production of a fermentation must; and 4) separation of the alcohologenic microorganism used in step (3), separation / purification of the ethanol and production of an aqueous phase constituting a residue; and in which said residue serves for the production of the cellulolytic and / or hemicellulolytic enzymes used in step 2).

Owner:INST FR DU PETROLE

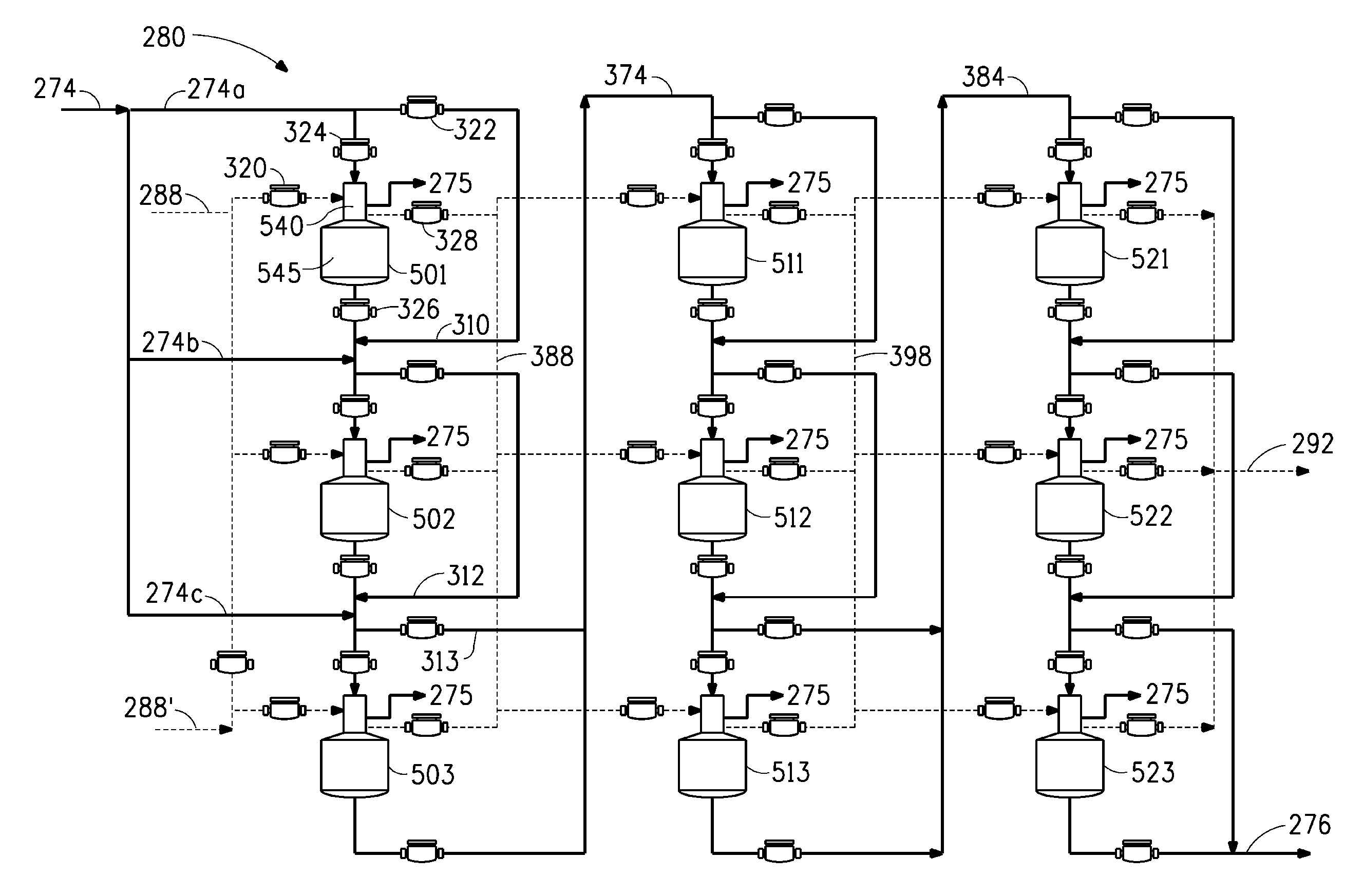

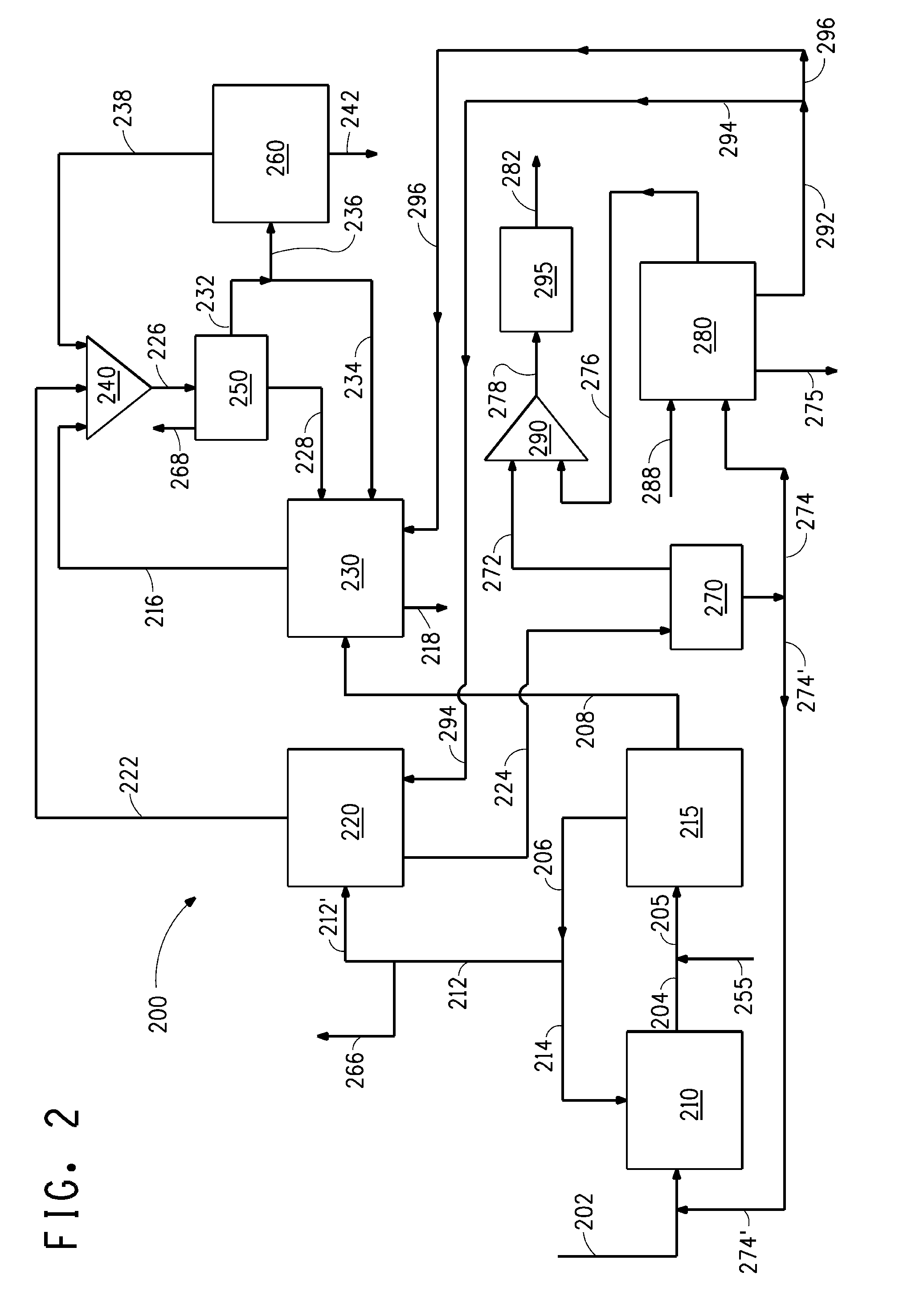

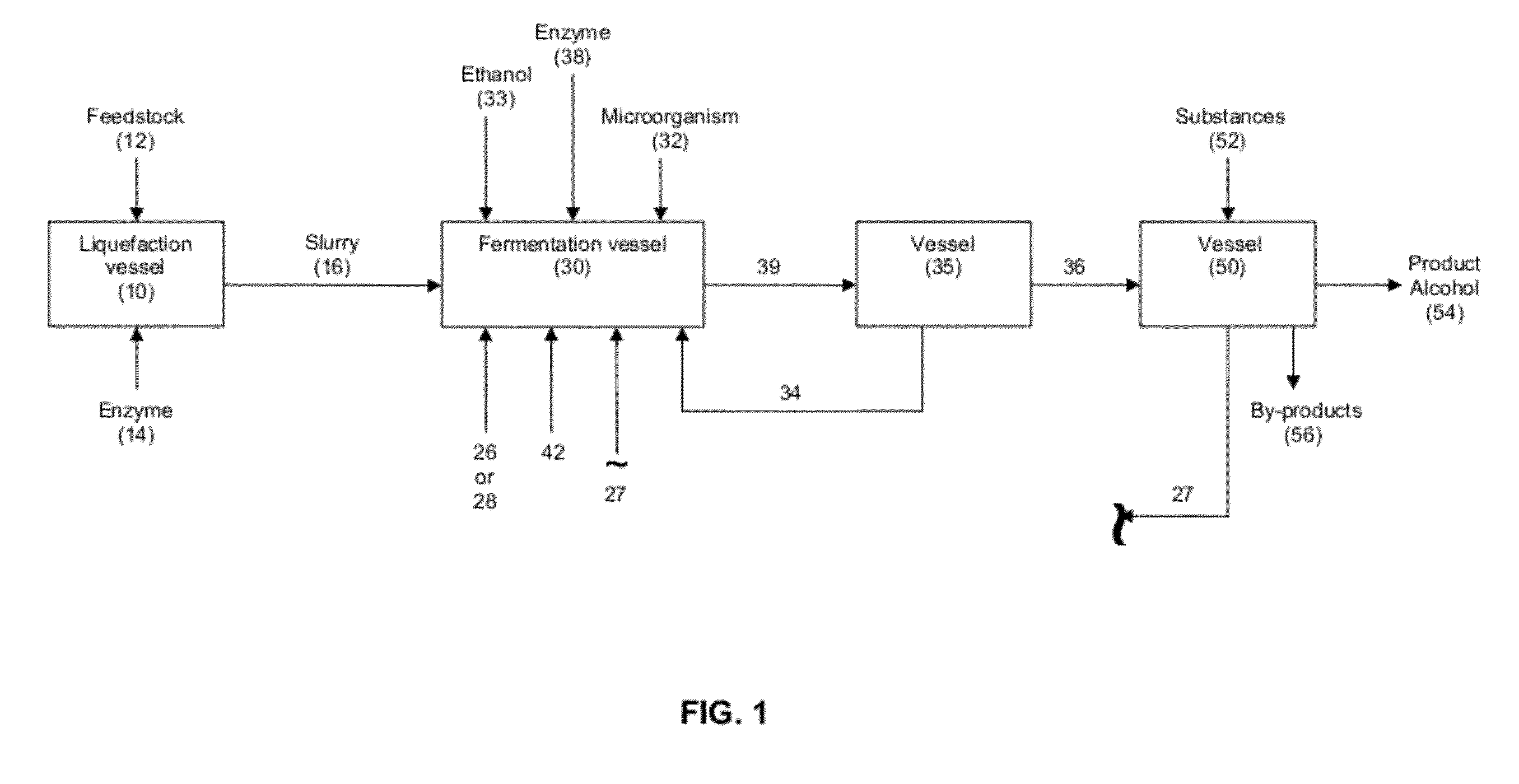

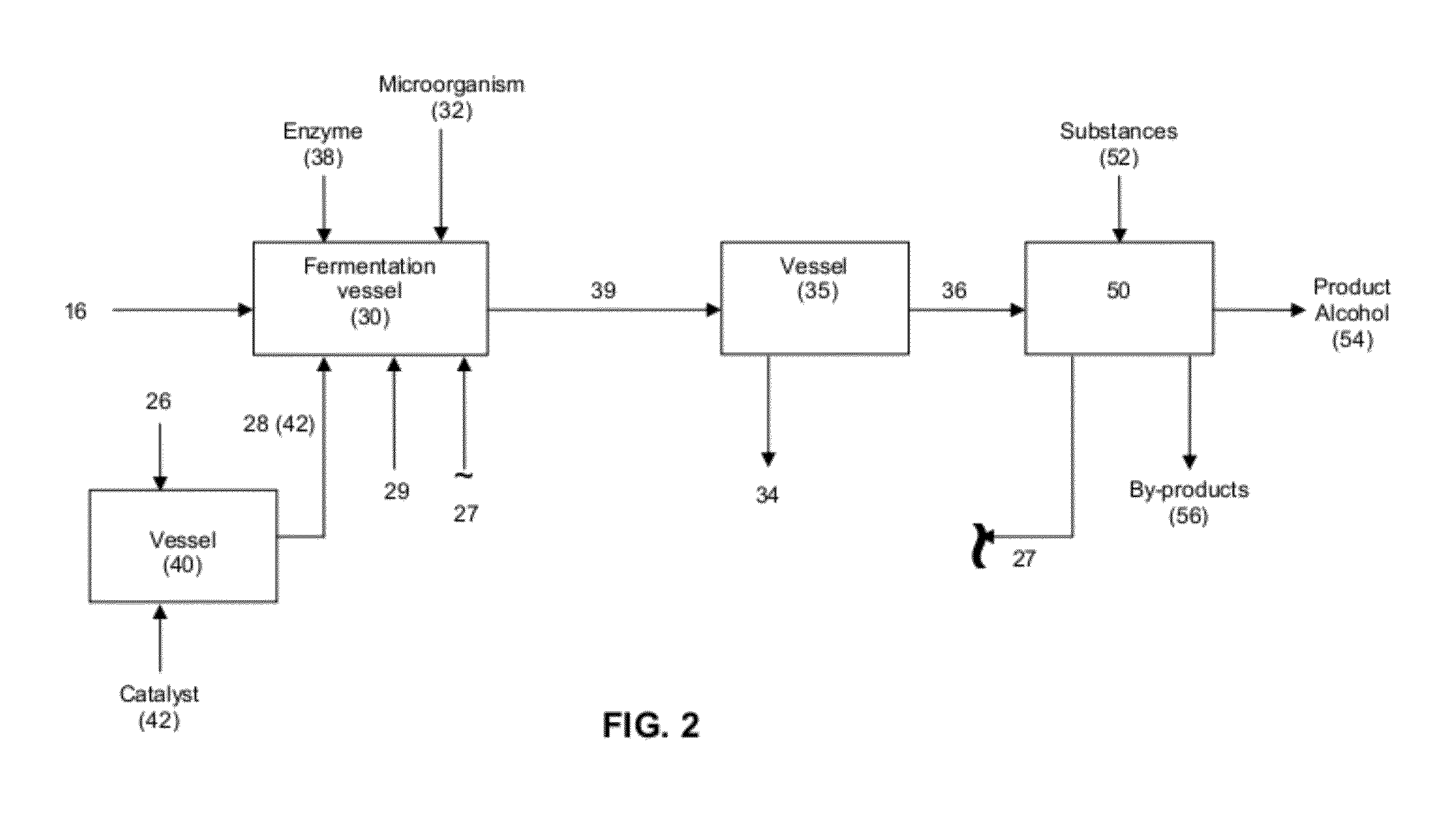

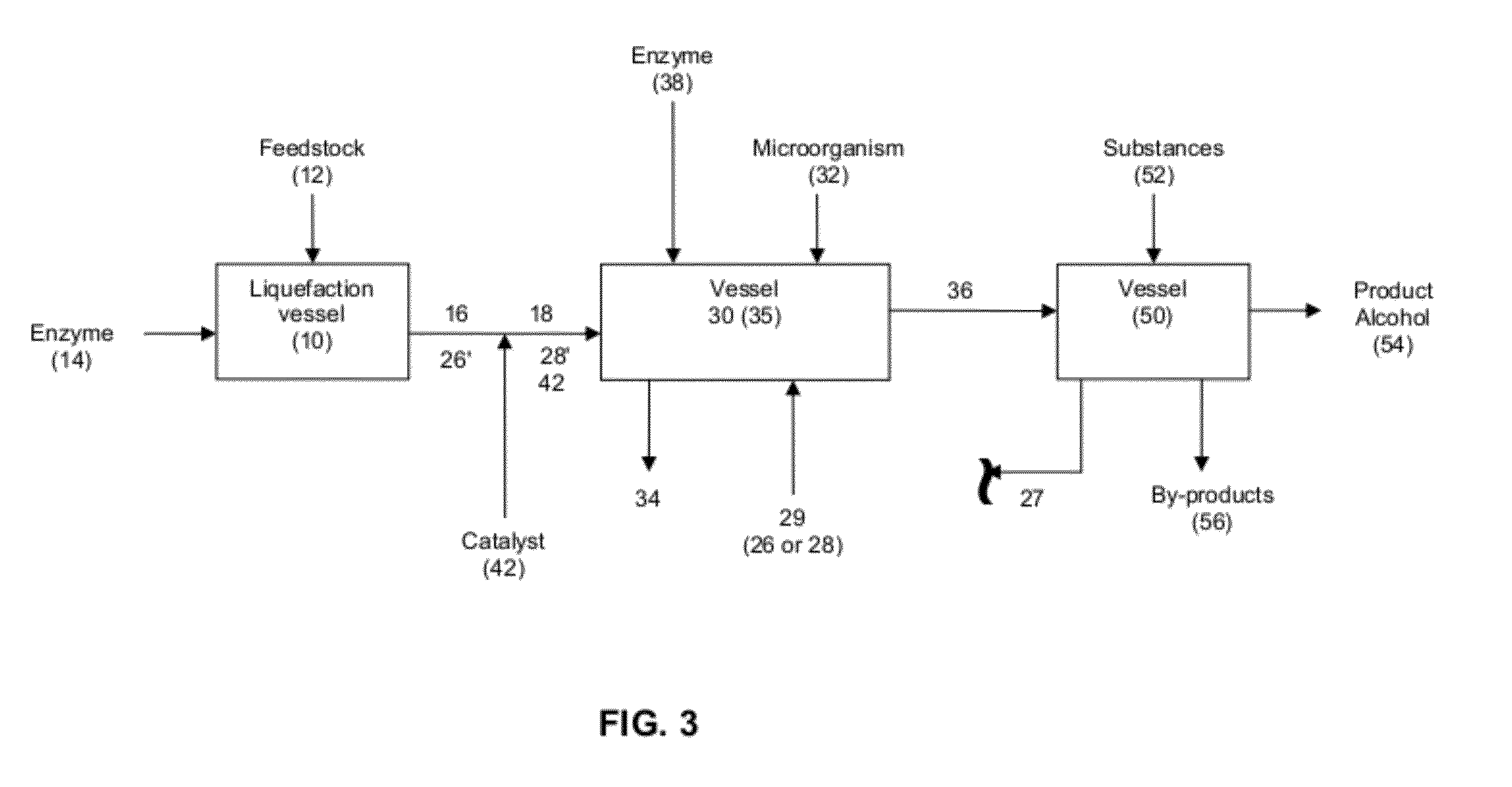

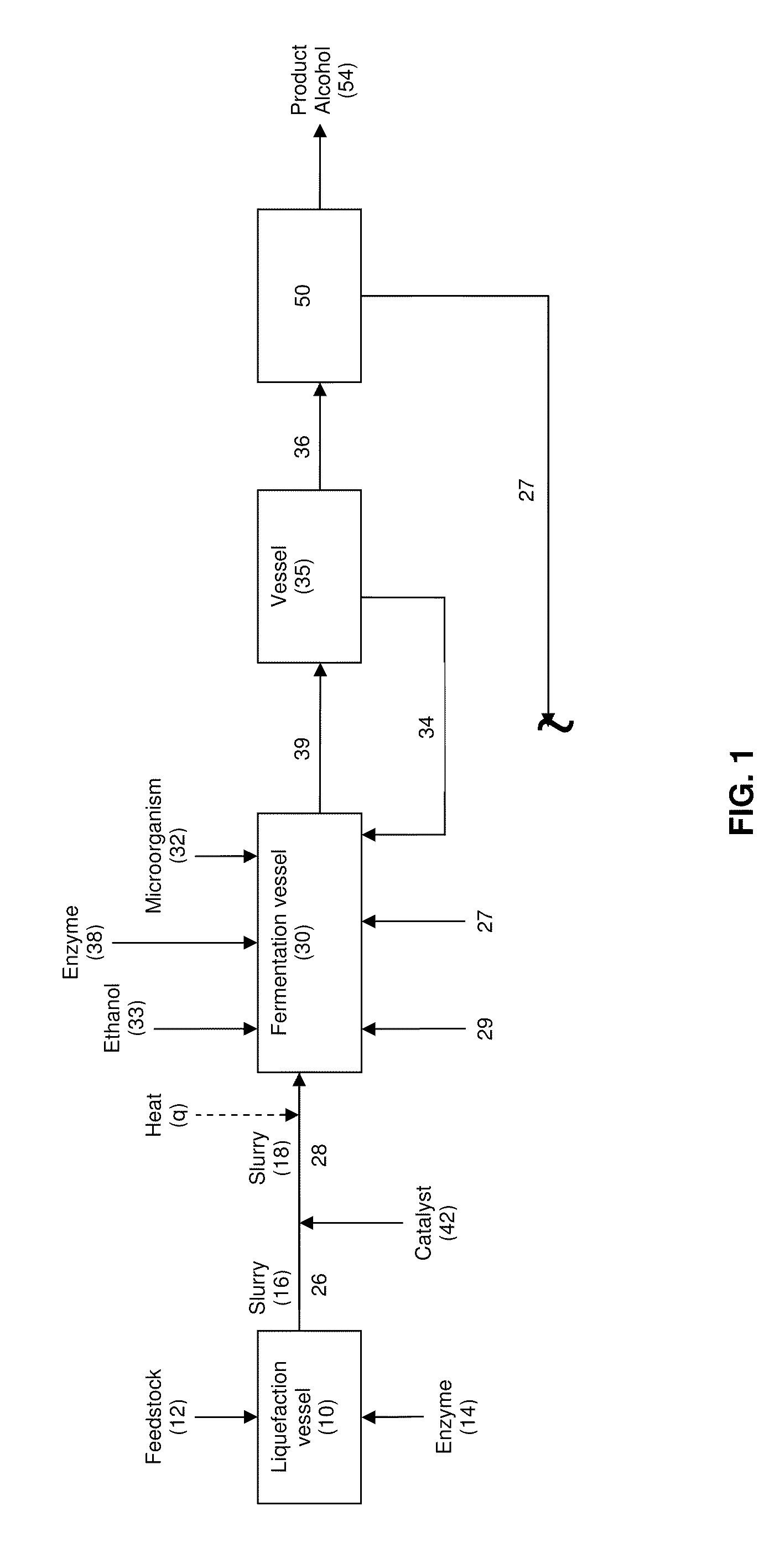

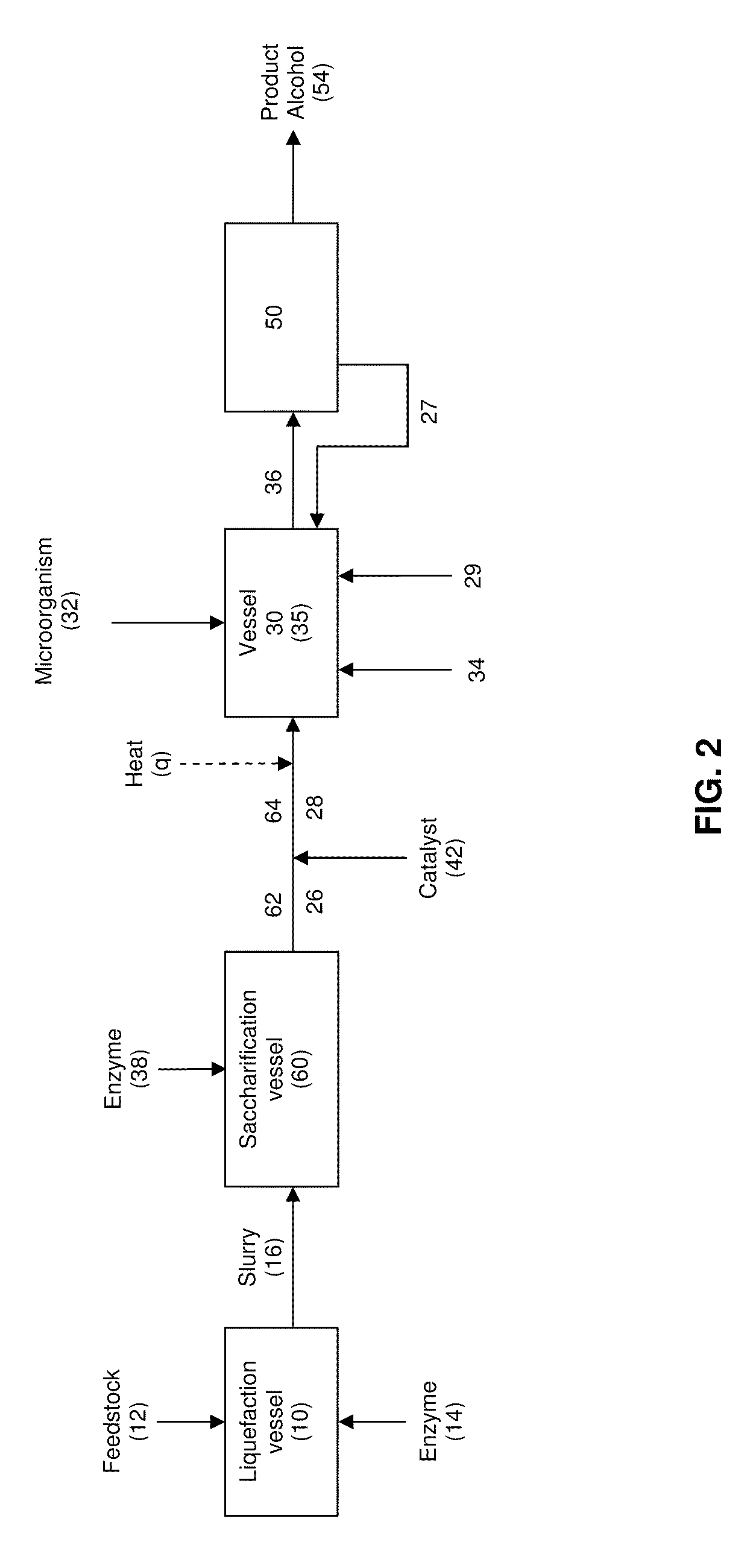

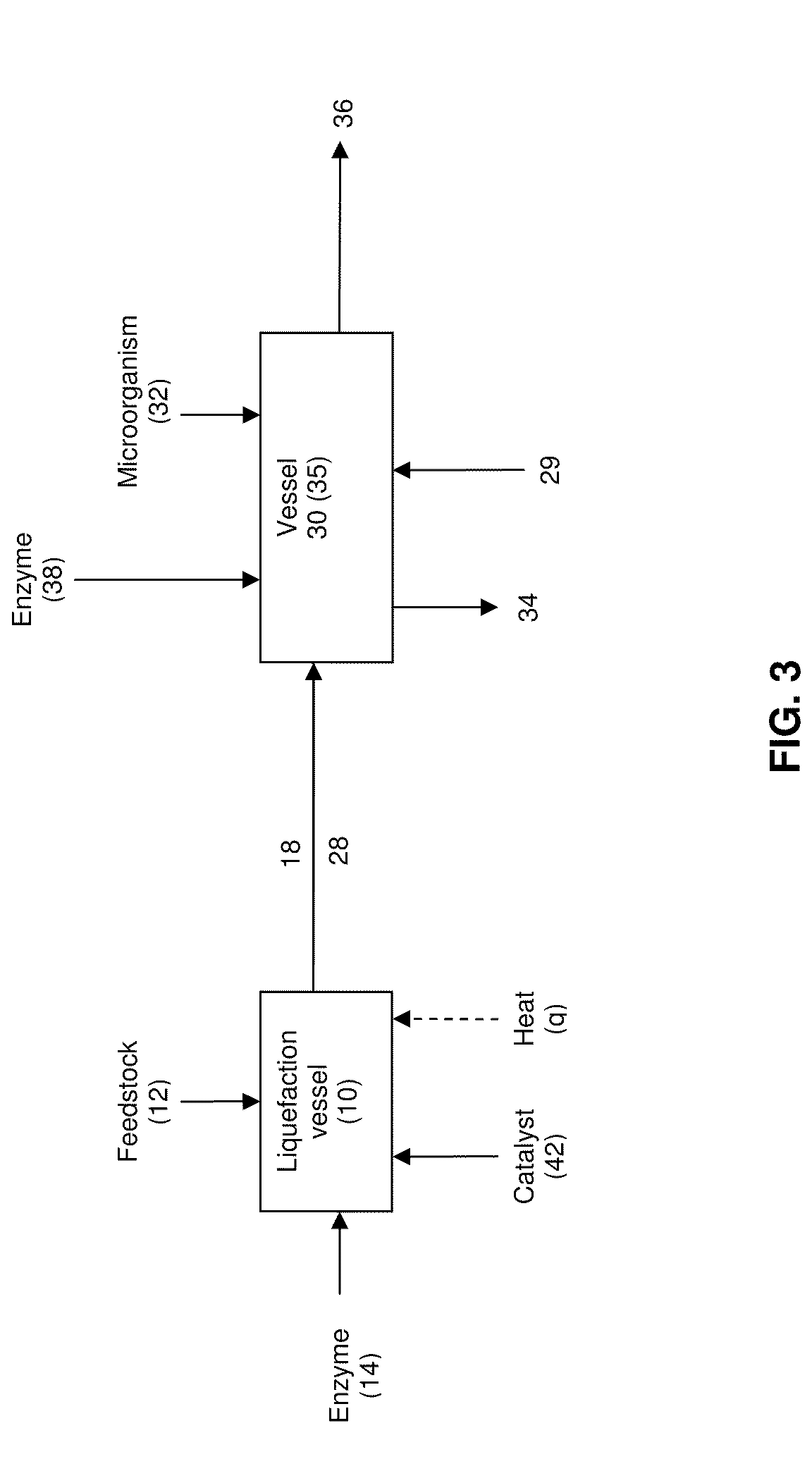

Systems and methods for alcohol recovery and concentration of stillage by-products

ActiveUS20110315541A1Efficient use ofHydrocarbon purification/separationHydroxy compound preparationAlcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

Method and system for processing a biomass for producing biofuels and other products

InactiveUS20120122164A1High production costEfficient and cost-effectiveFatty oils/acids recovery from wasteCarbon compoundsMicroorganismBiofuel

The present invention provides methods of processing a biomass, e.g., for producing lipid and non-lipid materials, by inducing autolysis of a biomass. The biomass may be generated using any species of microorganism and any available biodegradable substrate, including waste materials. The lipid and non-lipid materials are present in two separate layers of the autolysate, and they can be used to generate valuable products such as biofuels and nutritional supplements. The present invention further provides a processing apparatus useful for practicing the methods of the present invention.

Owner:EL SHAFIE MOUSTAFA AHMED

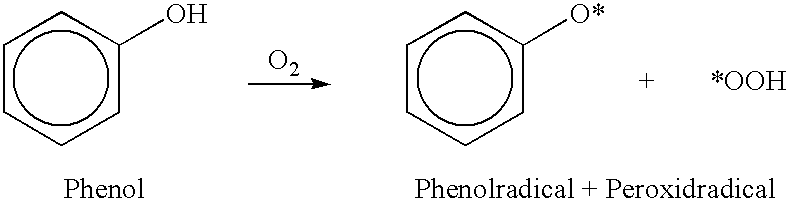

Extraction solvents derived from oil for alcohol removal in extractive fermentation

ActiveUS20110312044A1Reduce the amount requiredReduce decreaseFatty oils/acids recovery from wasteOxygen-containing compound preparationSolventFatty alcohol

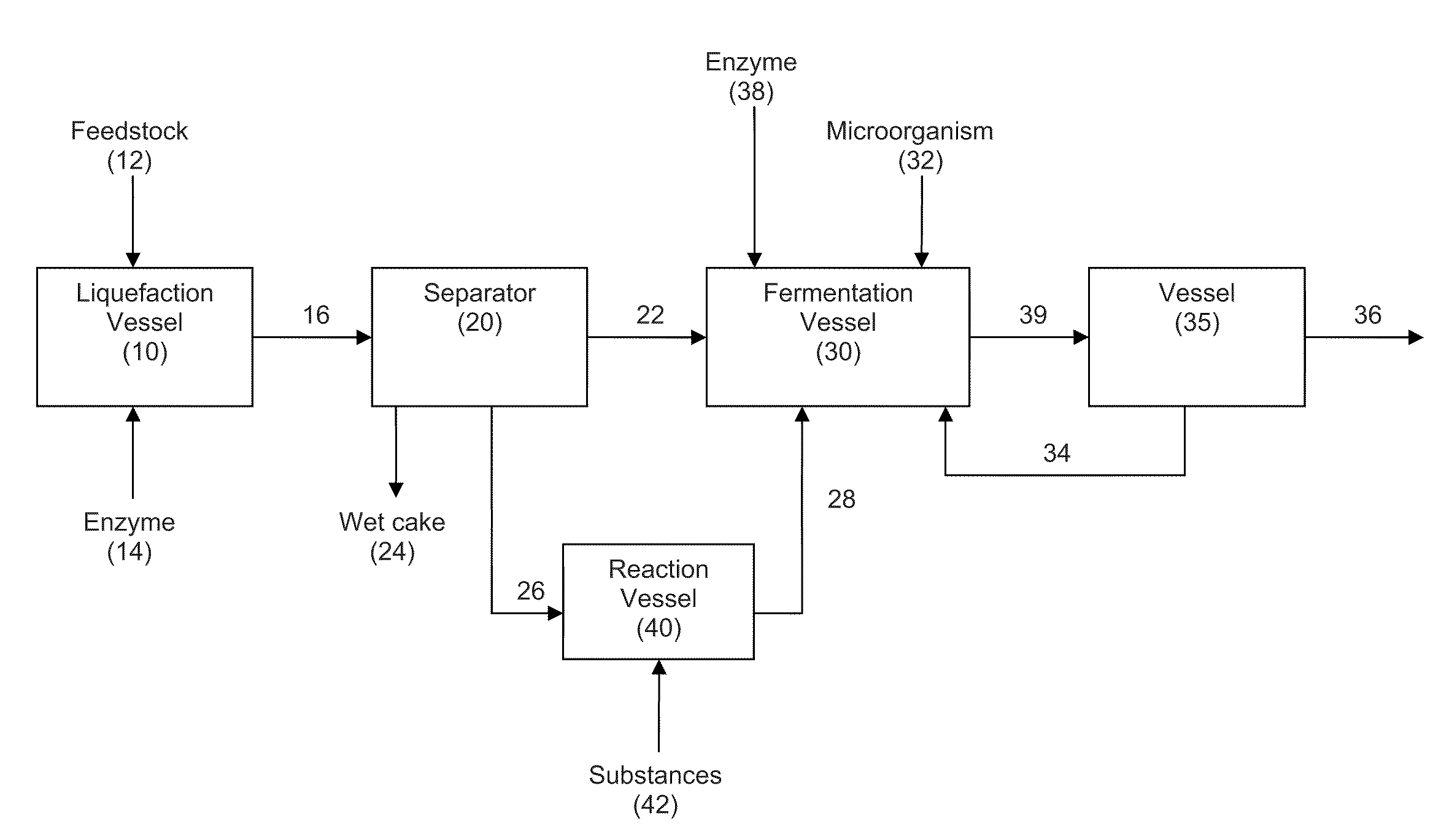

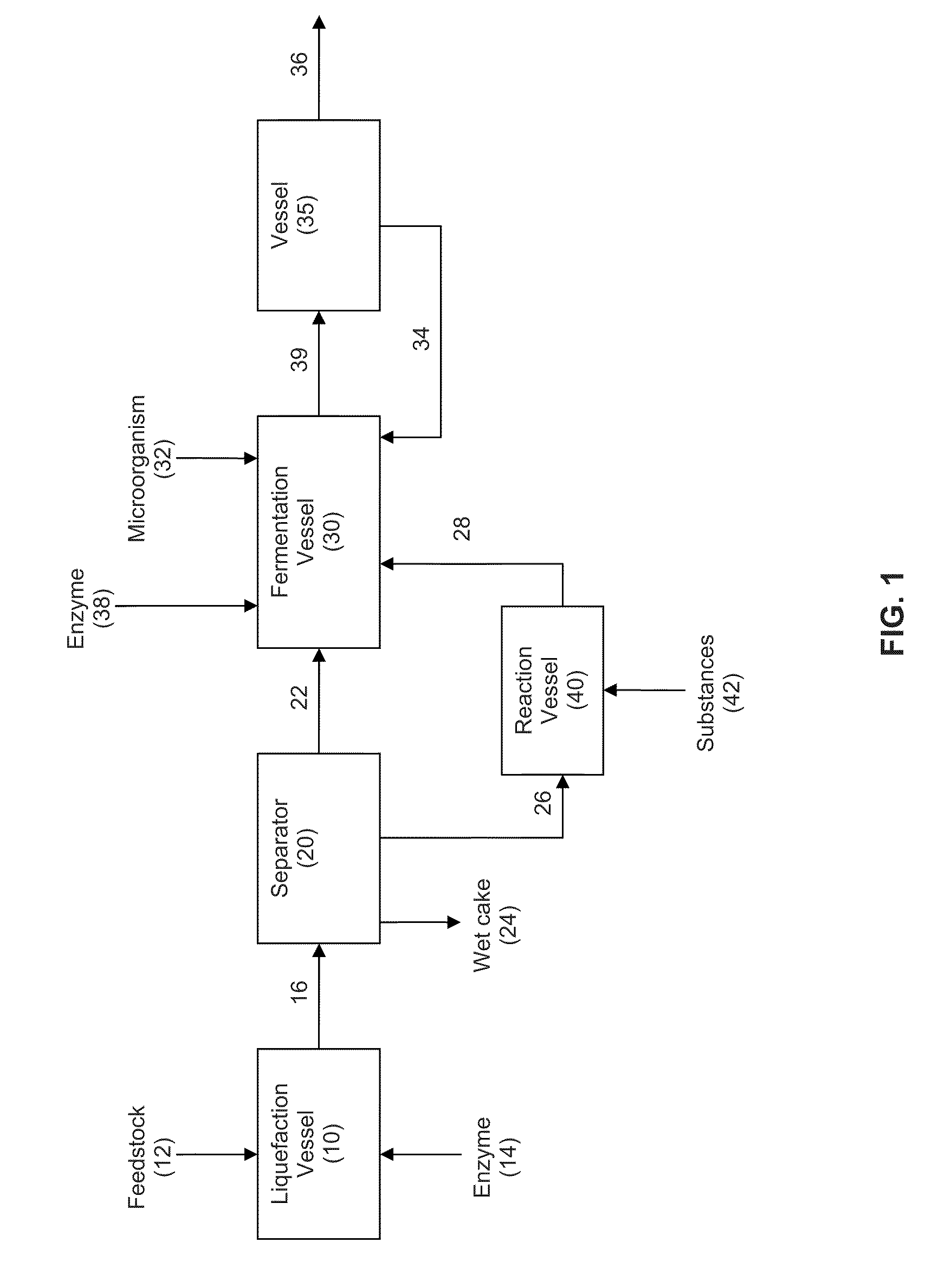

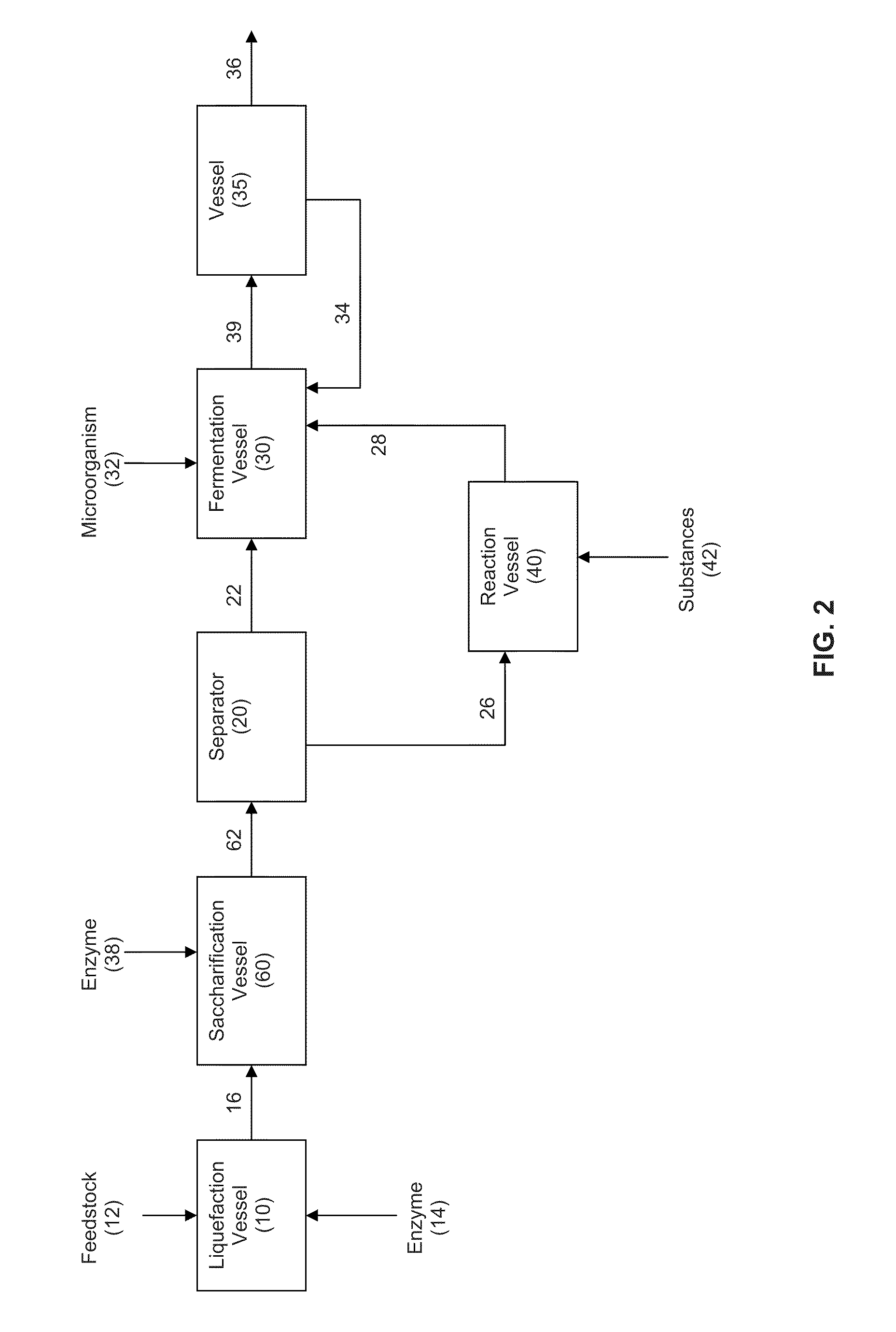

In an alcohol fermentation process, oil derived from biomass is chemically converted into an extractant available for in situ removal of a product alcohol such as butanol from a fermentation broth. The glycerides in the oil can be chemically converted into a reaction product, such as fatty acids, fatty alcohols, fatty amides, fatty acid methyl esters, fatty acid glycol esters, and hydroxylated triglycerides, and mixtures thereof, which forms a fermentation product extractant having a partition coefficient for a product alcohol greater than a partition coefficient of the oil of the biomass for the product alcohol. Oil derived from a feedstock of an alcohol fermentation process can be chemically converting into the fermentation product extractant. The oil can be separated from the feedstock prior to the feedstock being fed to a fermentation vessel, and the separated oil can be chemically converted to a fermentation product extractant, which can then contacted with a fermentation product comprising a product alcohol, whereby the product alcohol is separated from the fermentation product.

Owner:GEVO INC

Oil recovery and syngas production from biomass-based processes

InactiveUS20100331580A1Small sizeSolvent extractionCombustible gas catalytic treatmentSyngasCompound (substance)

A biomass-based oil extraction process is disclosed. The process includes the recovery of biomass-based oil and other co-products, including but not limited to steam, electric power and chemicals, from various biomass processes and in particular, a process that involves dry biomass milling methods. The process involves extraction of oil from milled biomass-based products and residues from the fermentation step, including thick stillage, distillers wet grain, distillers dry grain and distillers dry grains with solubles, by the application of an alkyl acetate, phase separation and recovery of the separated matter. A process of drying wet co-product using ethanol and carbon dioxide from the production facility is also disclosed. Also a process for the production of syngas from oil containing or deoiled biomass-based products in a pressurized gasifier is disclosed.

Owner:FS FINANCIAL SERVICES

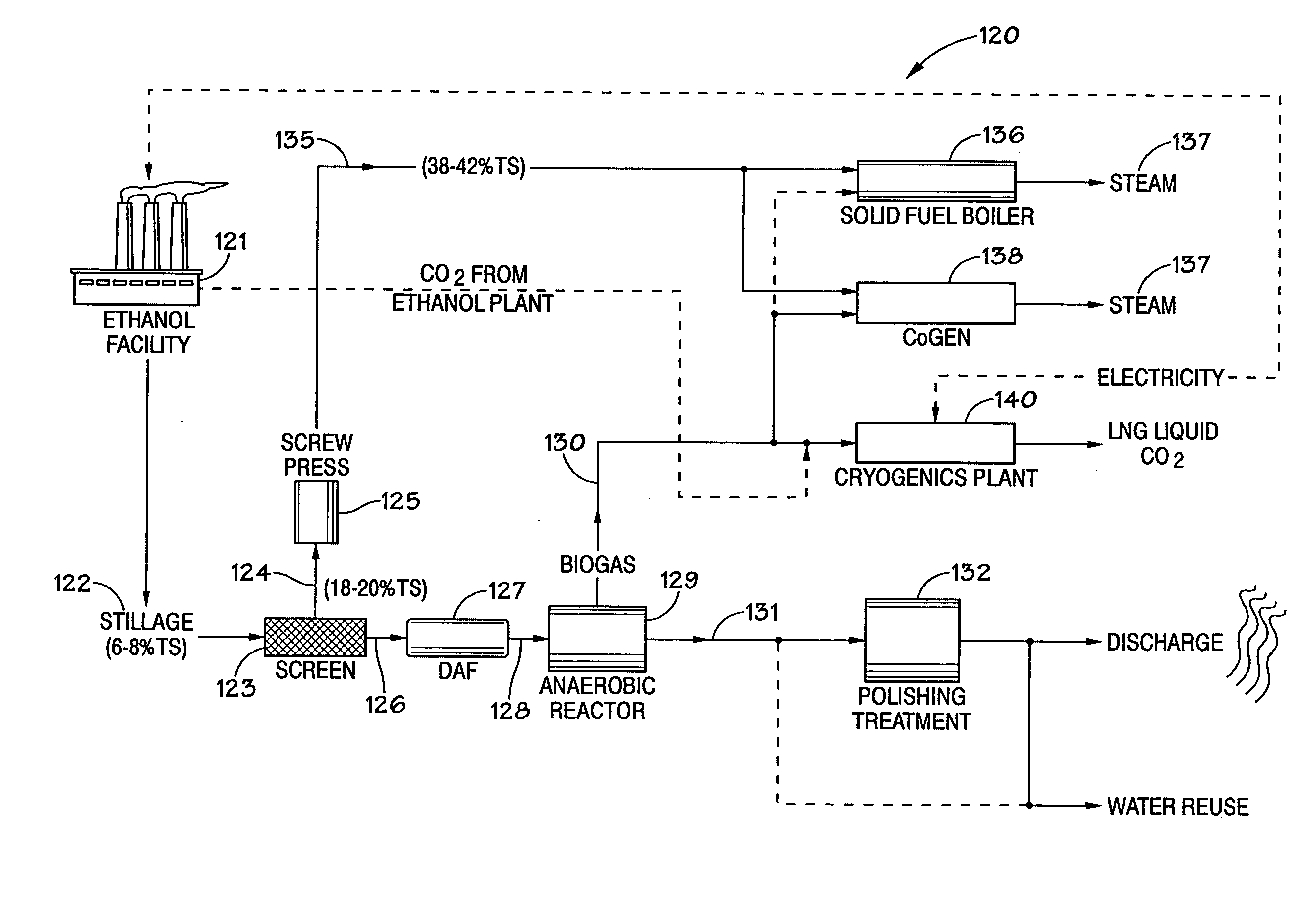

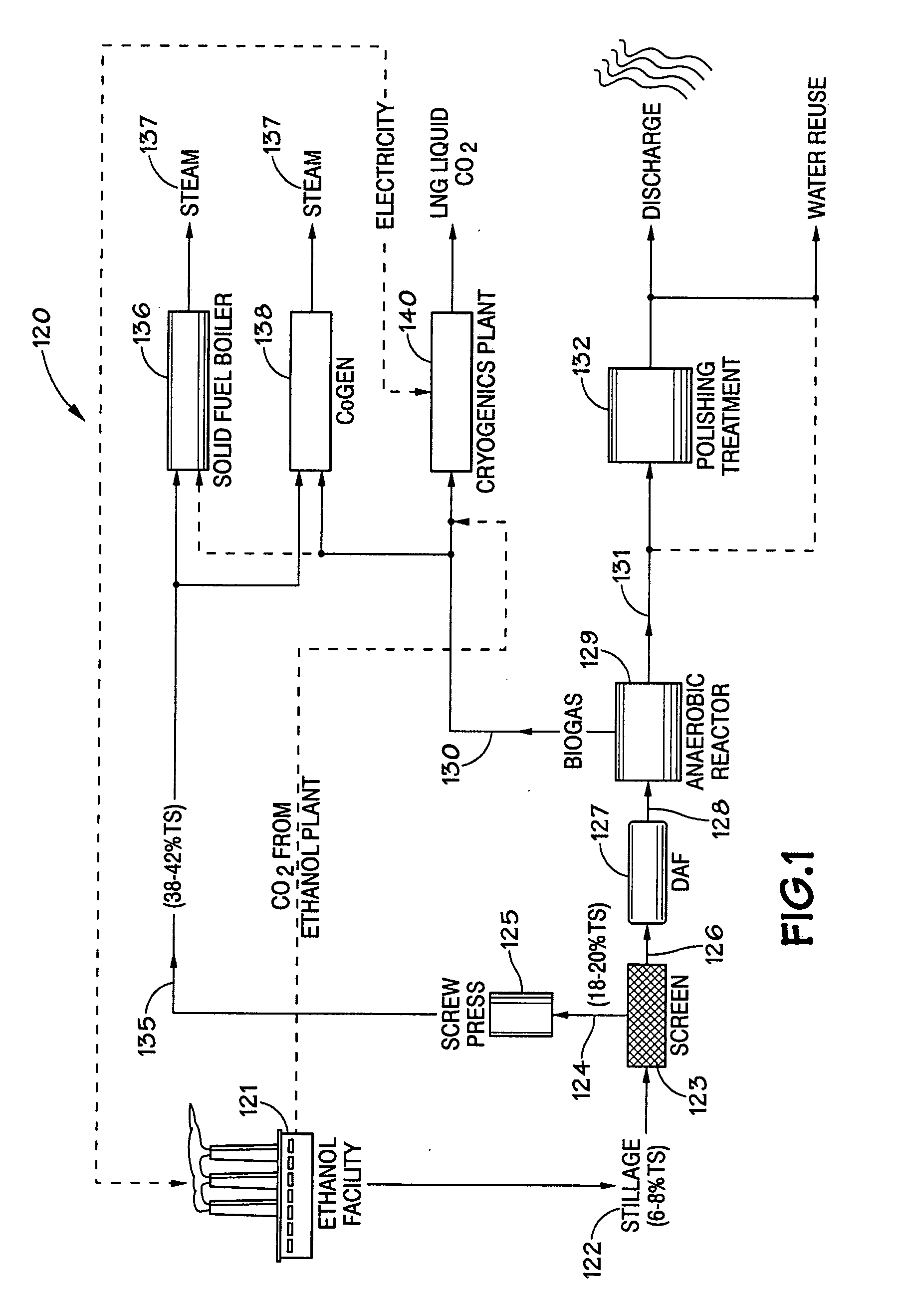

Method and apparatus for the treatment of byproducts from ethanol and spirits production

A method and system for the treatment of byproducts from the production of ethanol or alcohol spirits may include: a screw press to dewater the byproducts to produce a wet cake product and a filtrate product; and an anaerobic reactor to treat to filtrate product.

Owner:ECOVATION

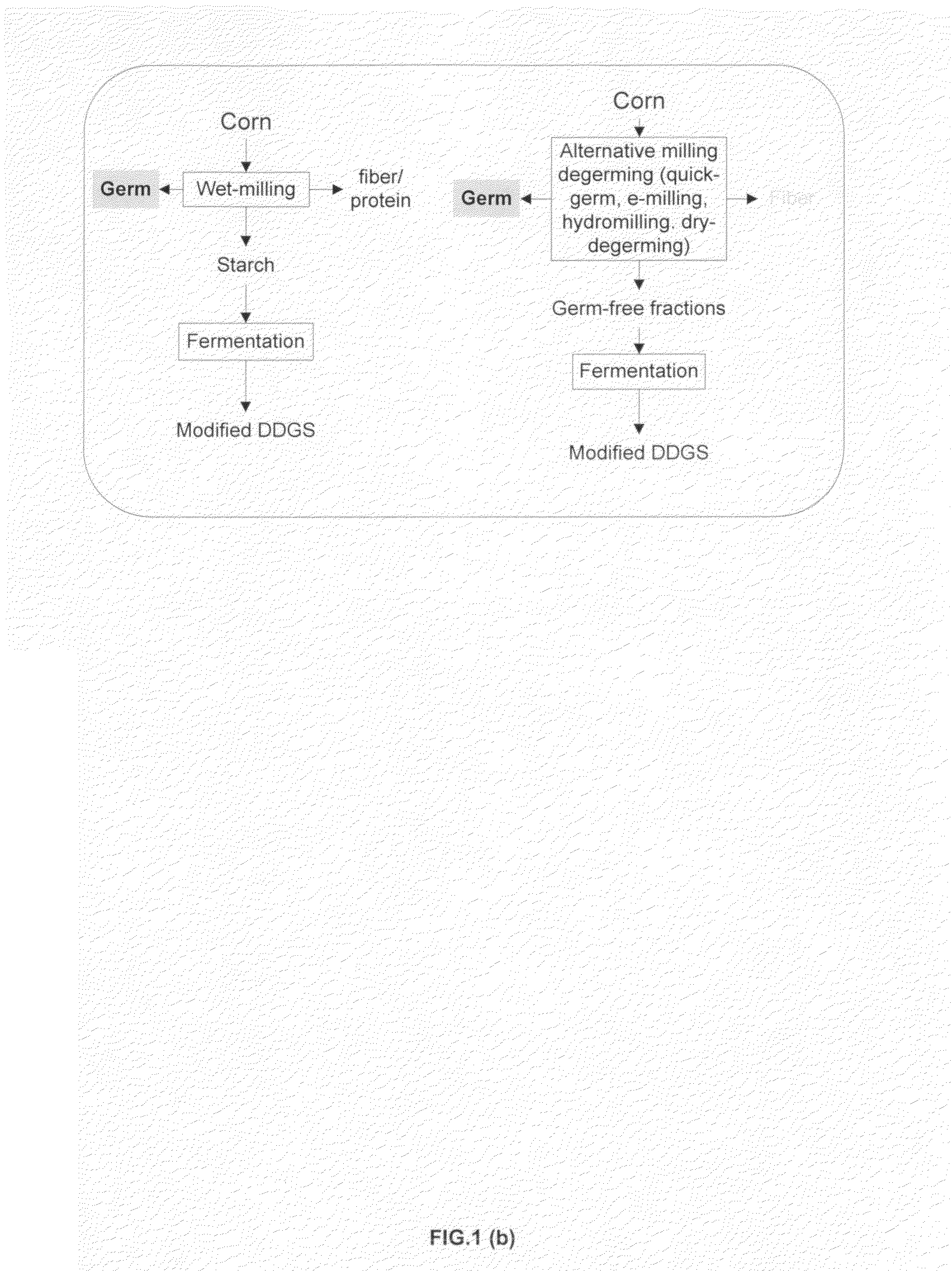

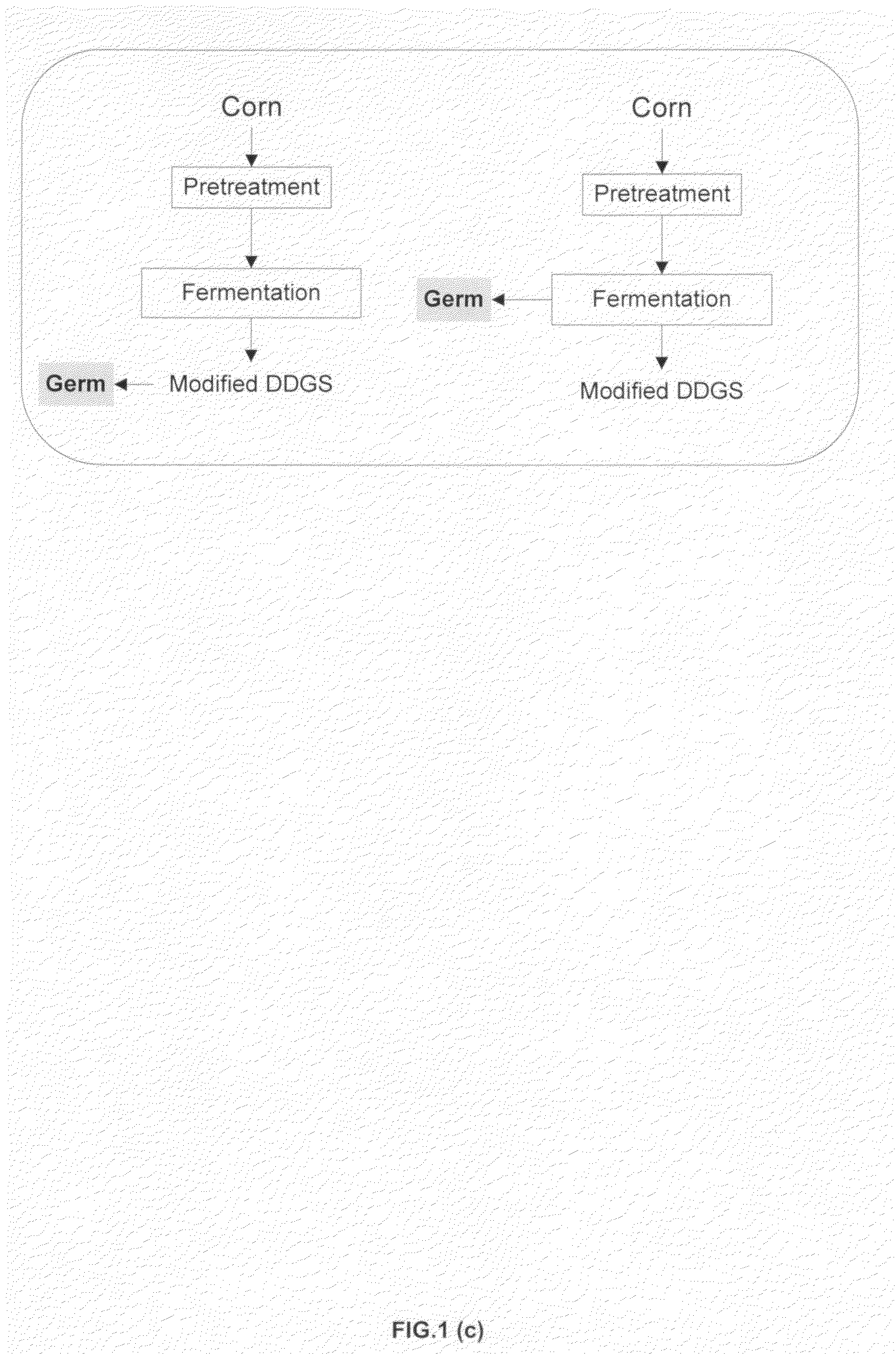

Novel corn degerming Ethanol fermentation processes

The invention presents novel corn fermentation processes that remove the oil-rich fraction either during or after fermentation instead of before fermentation as usual. Besides recovery of high value oil-rich fraction of the corn, the processes also produce other value-added co-products such as that with high fiber or high protein but low oil contents.

Owner:WANG HUI

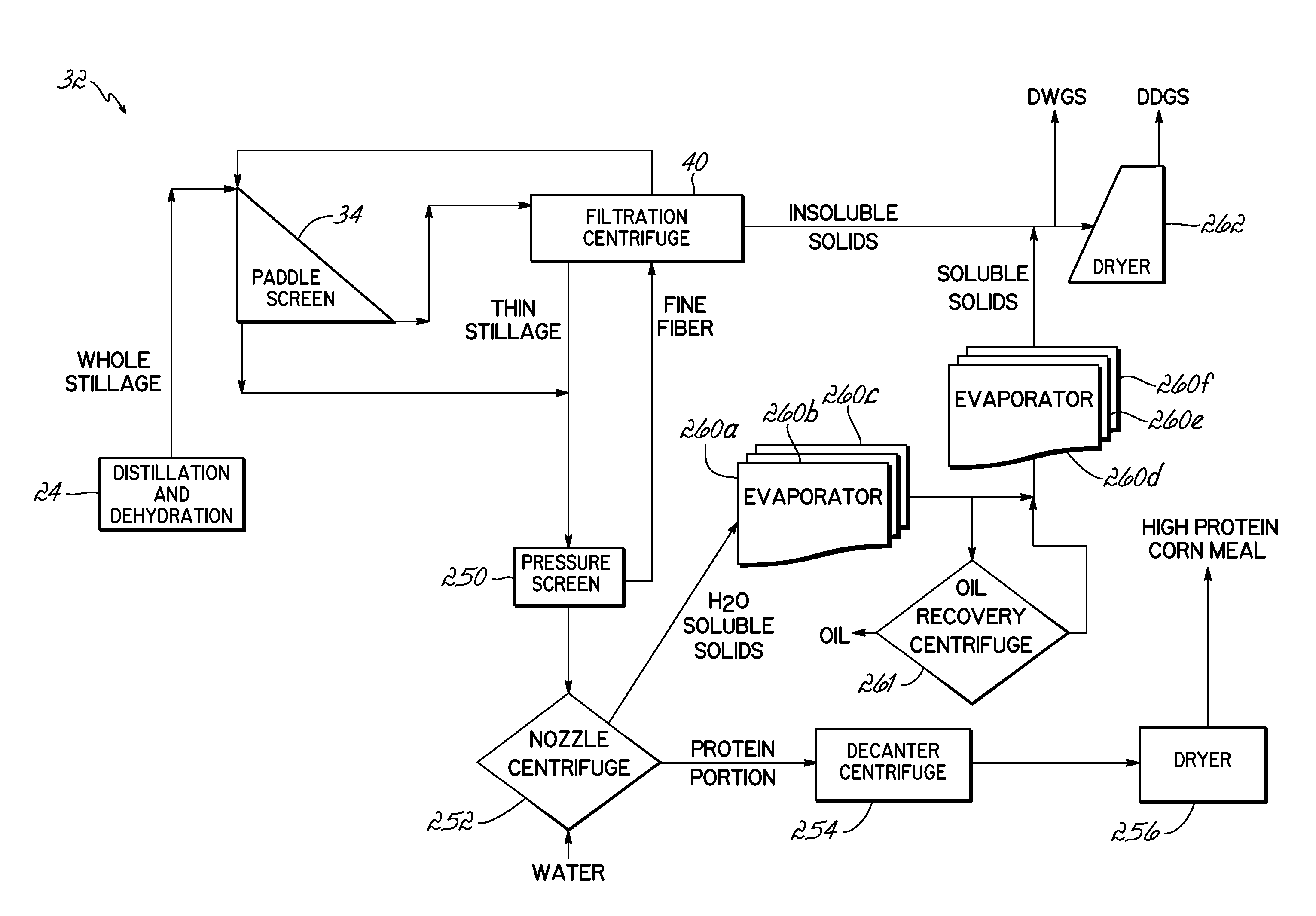

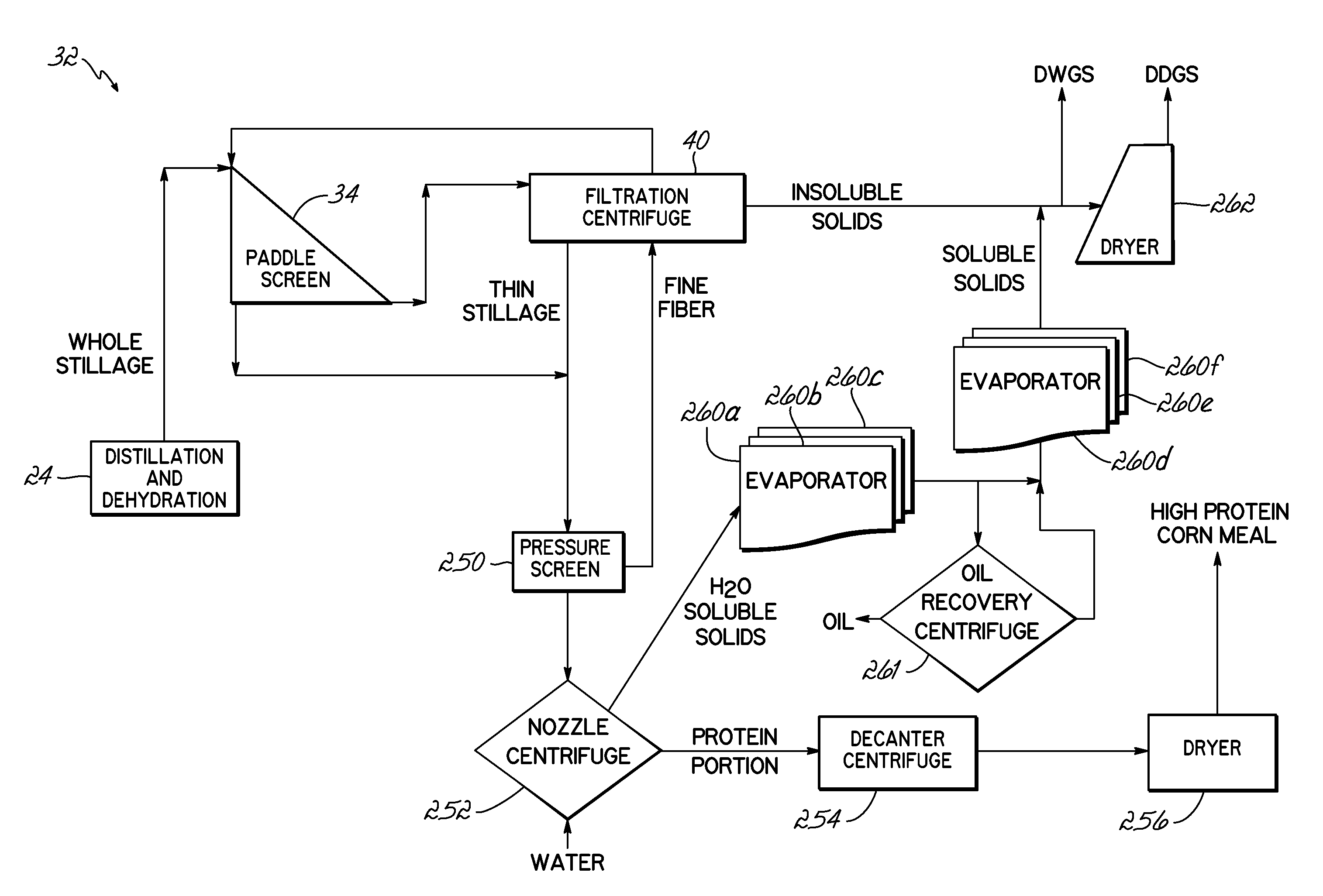

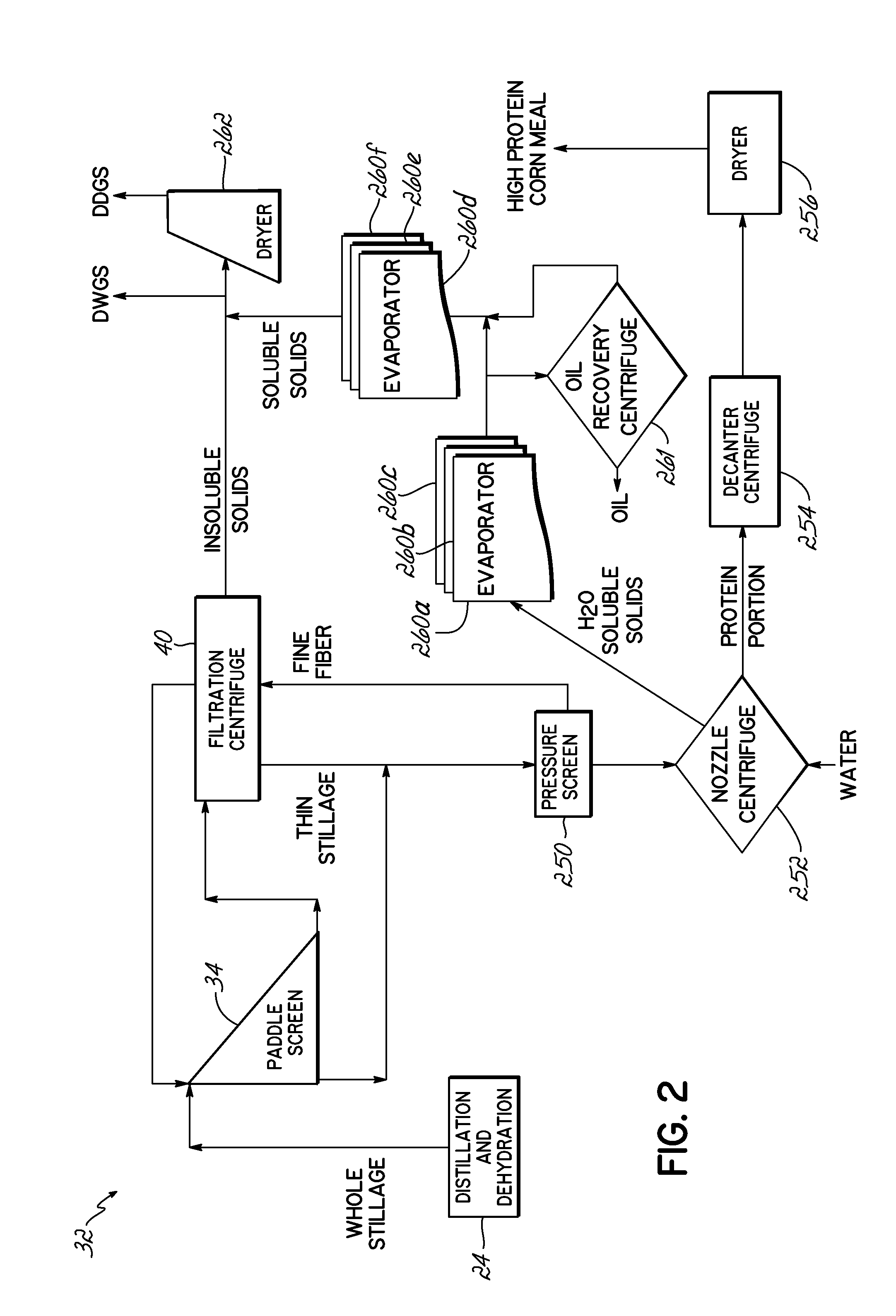

Methods for producing a high protein corn meal from a whole stillage byproduct

The present invention relates generally to corn dry-milling, and more specifically, to methods for producing a high protein corn meal from a whole stillage byproduct produced in a corn dry-milling process for making ethanol and a system therefore. In one embodiment, a method for producing a high protein corn meal from a whole stillage byproduct includes, in a corn dry-milling process for making ethanol, separating the whole stillage byproduct into an insoluble solids portion and a thin stillage portion. The thin stillage portion is separated into a protein portion and a water soluble solids portion. Next, the protein portion is dewatered then dried to define a high protein corn meal that includes at least 40 wt % protein on a dry basis.

Owner:FLUID QUIP TECH LLC

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

Production of alcohol esters and in situ product removal during alcohol fermentation

ActiveUS20120156738A1Increase productionDecreasing rate of build-upFatty oils/acids recovery from wasteFungiAlcoholCarboxylic acid

An alcohol fermentation process and composition that includes production of alcohol esters by esterification of product alcohol in a fermentation medium with a carboxylic acid (e.g., fatty acid) and a catalyst (e.g., lipase) capable of esterifying the product alcohol, such as butanol, with the carboxylic acid to form the alcohol esters. The alcohol esters can be extracted from the fermentation medium, and the product alcohol recovered from the alcohol esters. The carboxylic acid can also serve as an extractant for removal of the alcohol esters from the fermentation medium.

Owner:GEVO INC

Extracts from residues left in the production of wine

InactiveUS20030108493A1Stimulating regulating healing regenerating effectCosmetic preparationsBiocideMedicineCosmetics

The invention relates to extracts from residues left in the production of wine, and to the use thereof as active substance combinations for producing cosmetic and / or pharmaceutical compositions.

Owner:COGNIS FRANCE SA

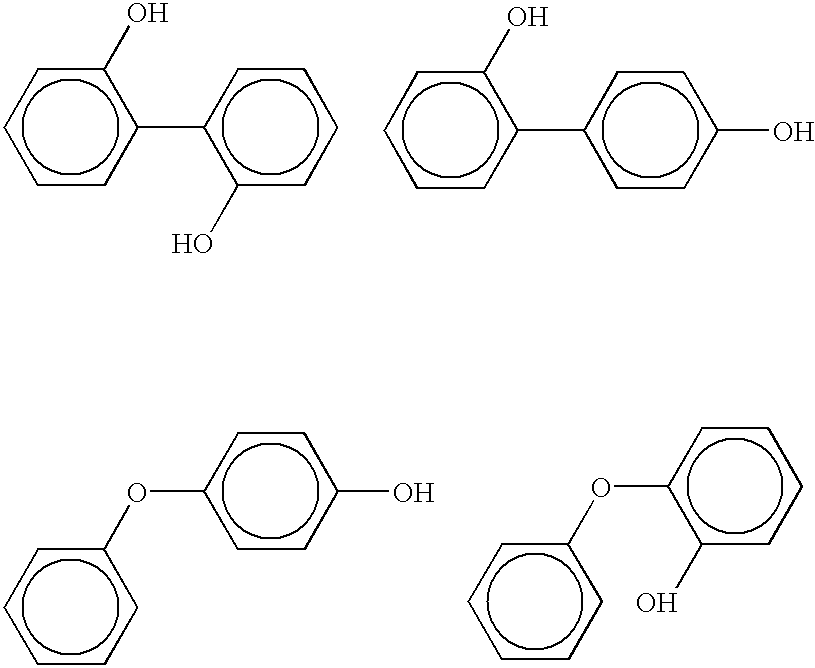

Extraction solvents derived from oil for alcohol removal in extractive fermentation

ActiveUS20110312043A1Reduce capacityPreventing lowering of partition coefficientFatty oils/acids recovery from wasteFungiAlcoholSolvent

In an alcohol fermentation process, oil derived from biomass is hydrolyzed into an extractant available for in situ removal of a product alcohol such as butanol from a fermentation broth. The glycerides in the oil can be catalytically (e.g., enzymatically) hydrolyzed into free fatty acids, which form a fermentation product extractant having a partition coefficient for a product alcohol greater than a partition coefficient of the oil of the biomass for the product alcohol. Oil derived from a feedstock of an alcohol fermentation process can be hydrolyzed by contacting the feedstock including the oil with one or more enzymes whereby at least a portion of the oil is hydrolyzed into free fatty acids forming a fermentation product extractant, or the oil can be separated from the feedstock prior to the feedstock being fed to a fermentation vessel, and the separated oil can be contacted with the enzymes to form the fermentation product extractant. The fermentation product extractant can be contacted with a fermentation broth for in situ removal of a product alcohol.

Owner:GEVO INC

Method of dewatering grain stillage solids

ActiveUS20050079270A1Improve throughputShorten the timeBy-product recoveryFood processingAcryditeSodium methacrylate

A method of dewatering corn stillage solids comprising adding to the solids an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

Methods for improving the nutritional quality of residues of the fuel, beverage alcohol, food and feed industries

InactiveUS20060233864A1Improve nutritional qualityIncreased rate of weight gainBy-product recoveryFood processingBeet pulpIngested food

A method is provided for improving the nutritional quality of a fibrous by-product or residue of a food manufacturing process, wherein the fibrous by-product or residue is inoculated with at least one filamentous fungus, and the fibrous by-product or residue is fermented thereby to decrease dry matter content, increase protein content, and decrease fat content of the by-product or residue. Suitable byproducts or residues include spent brewer's grains, dried distiller's grains, dried distiller's solubles, distiller's dried grains with solubles, residues of the cereal processing industry, wheat bran, soybean hulls, citrus pulp, beet pulp, rice husks or hulls, bagasse, apple pommace, and combinations thereof. Enzymes produced during the fermentation may also be used as valuable coproducts such as animal feed supplements, or may be used in primary fermentations for the brewing and distilling industry.

Owner:ALLTECH CO LTD

Polyphenol-and protein-containing extracts of winemaking residues, and methods of using the same

Extracts from the residues left in the production of wine, wherein the extracts contain a polyphenol and a protein, are disclosed along with their uses in cosmetic and pharmaceutical applications. The polyphenols are present in the extracts in an amount of from 0.4 to 6% by weight and the proteins are present in an amount of from 15 to 40% by weight, based on the dry weight of the extract.

Owner:HENRY FLORENCE +2

Biopolymer and methods of making it

The present invention relates to a composition, which can be referred to as a biopolymer, including fermentation solid and thermoactive material. The present invention also includes methods of making the biopolymer, which can include compounding fermentation solid and thermoactive material. The present biopolymer can be formed into an article of manufacture.

Owner:POET RES INC

Method of dewatering grain stillage solids

ActiveUS7566469B2Improve dehydration effectSmall apertureBy-product recoveryFood processingSodium methacrylateSodium salt

A method of dewatering corn stillage solids comprising adding to the solids an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

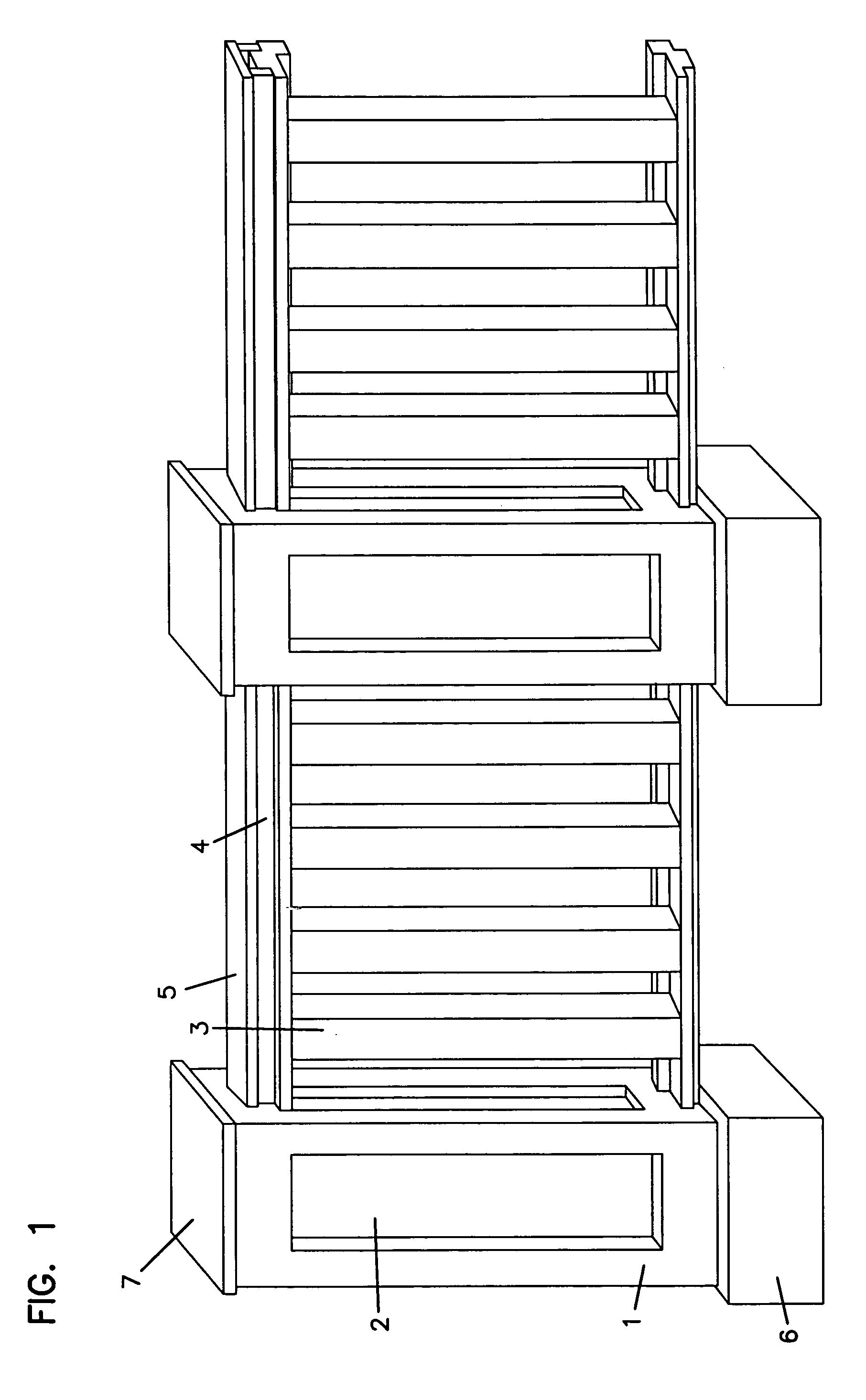

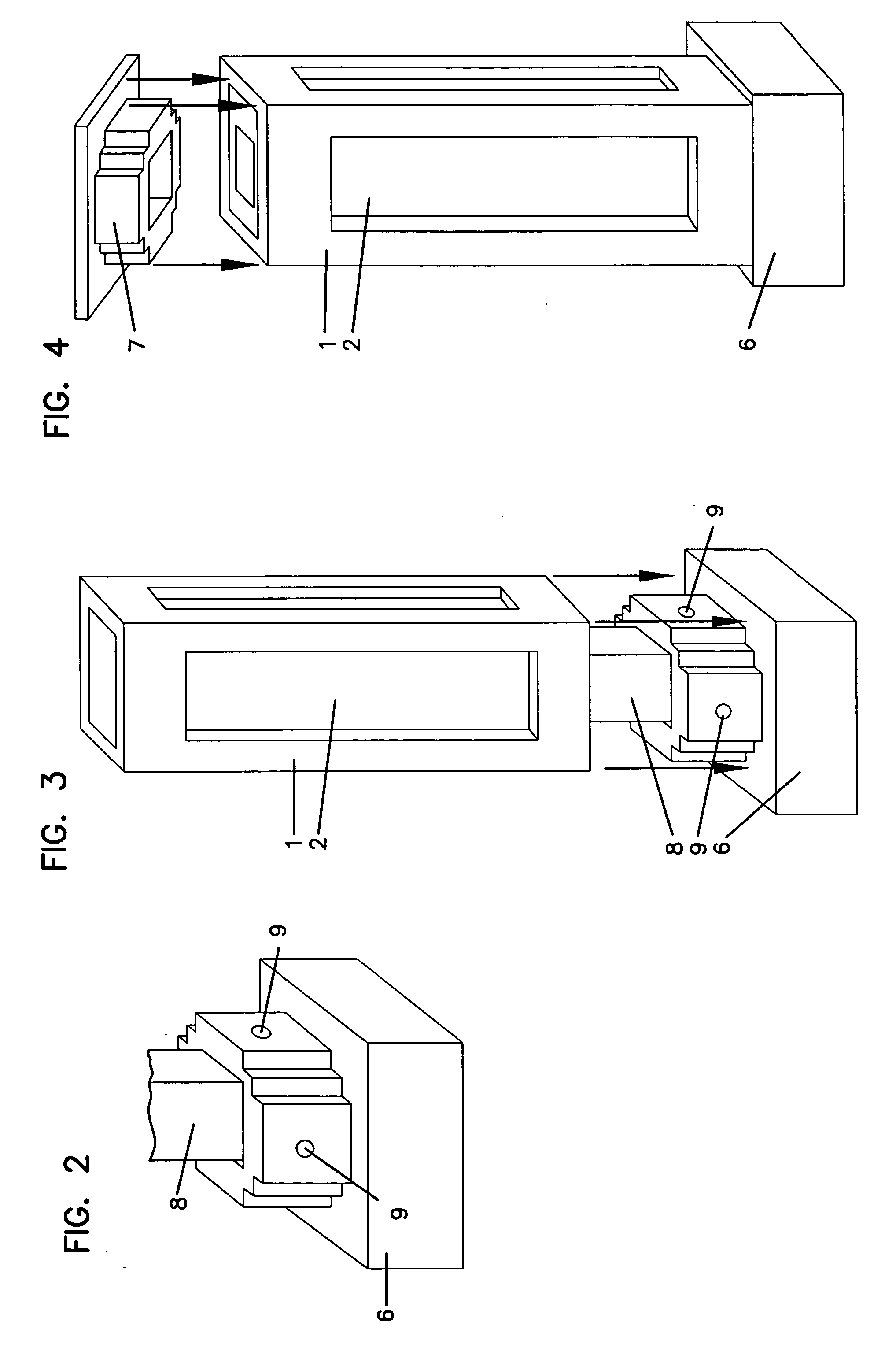

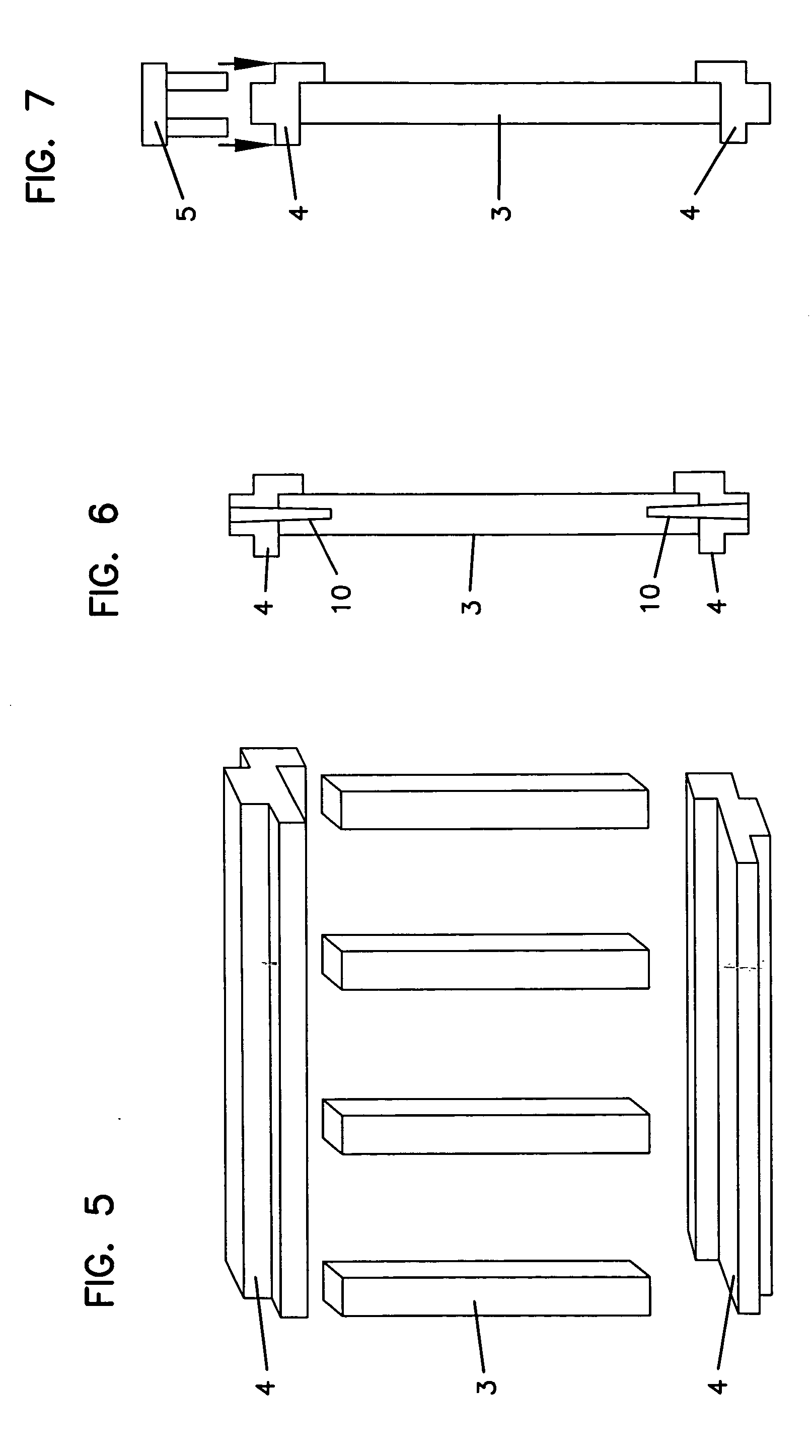

Biopolymer structures and components including column and rail system

The present invention relates generally to structures formed from a biopolymer. The present invention more particularly relates to biopolymer structures and components formed from fermentation solids and thermoactive materials, including a column and rail system and the component parts of this system.

Owner:AGRI POLYMERIX LLC

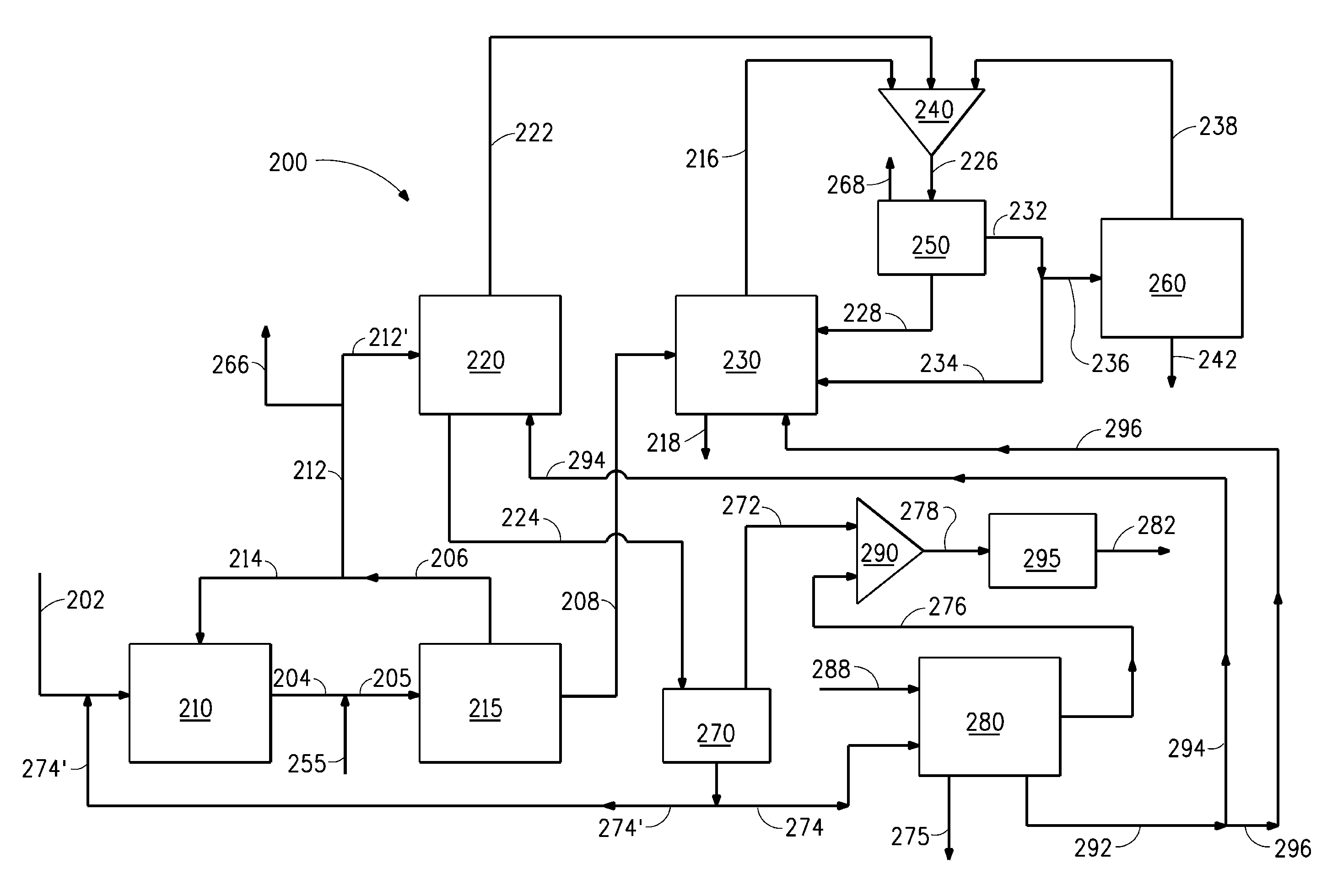

Methods for alcohol recovery and concentration of stillage by-products

ActiveUS8906204B2Efficient use ofHydrocarbon purification/separationAlcoholic beverage preparationAqueous alcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

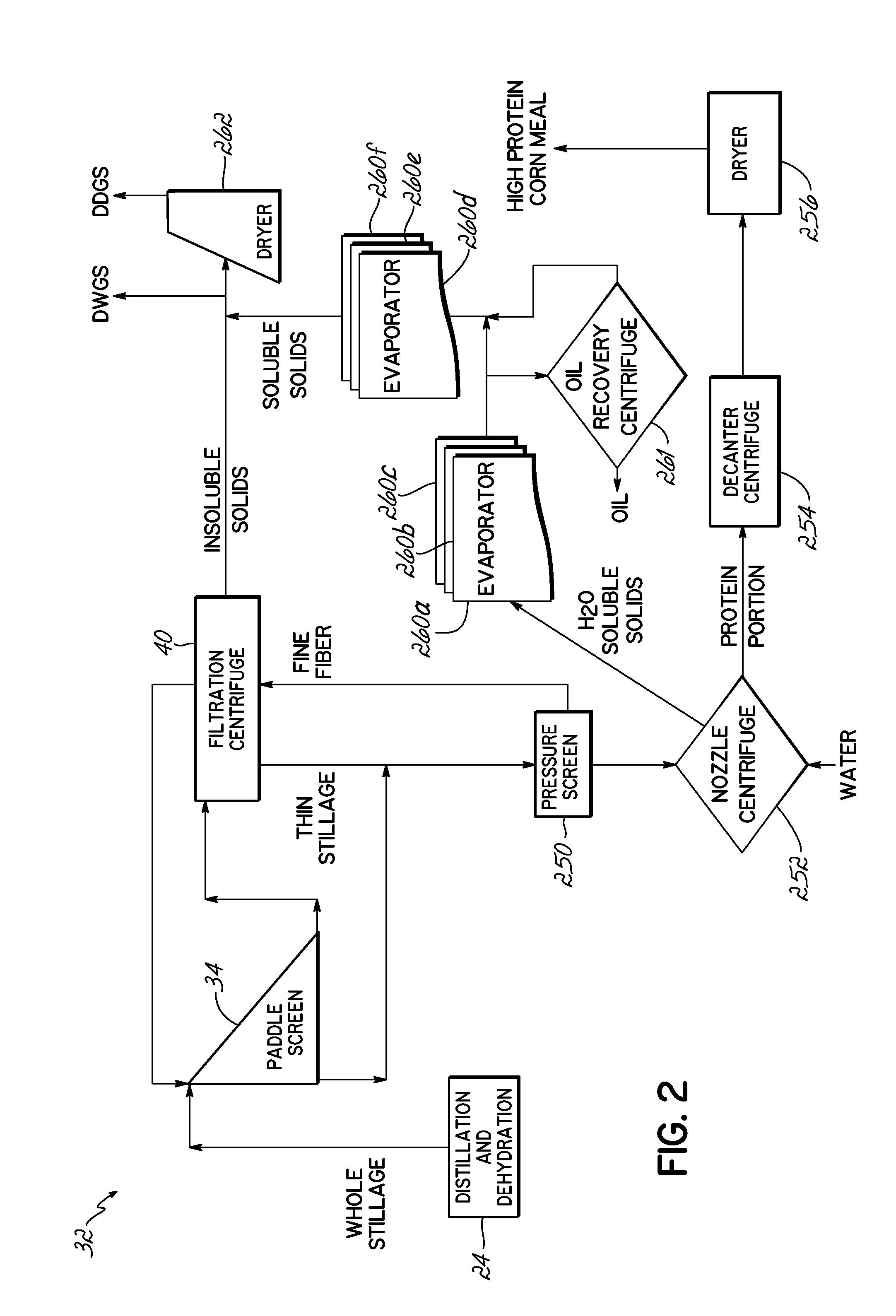

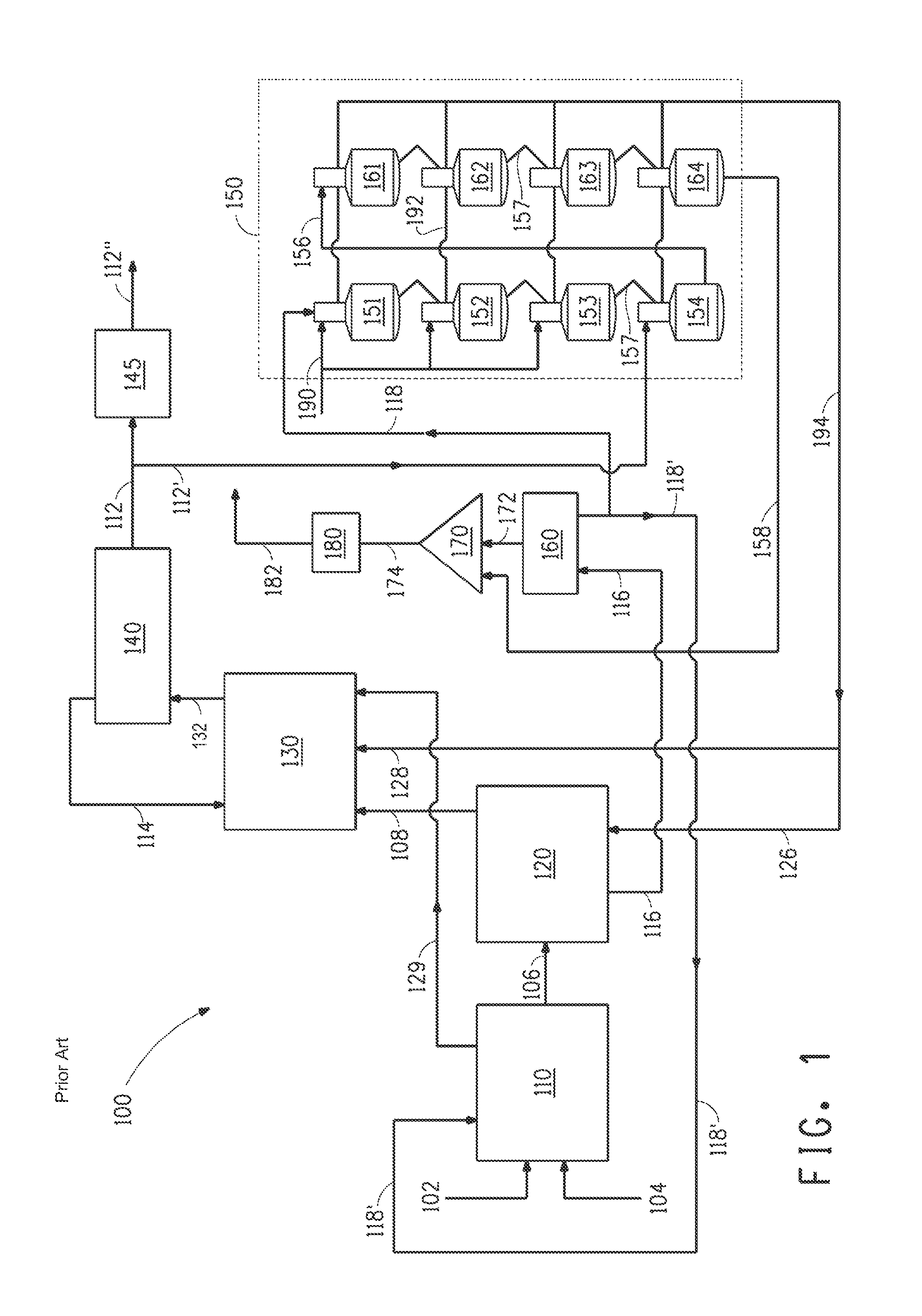

Methods for producing a high protein corn meal from a whole stillage byproduct and system therefore

ActiveUS20120064213A1High in proteinFatty oils/acids recovery from wasteBy-product recoveryWater solubleCorn meal

The present invention relates generally to corn dry-milling, and more specifically, to methods for producing a high protein corn meal from a whole stillage byproduct produced in a corn dry-milling process for making ethanol and a system therefore. In one embodiment, a method for producing a high protein corn meal from a whole stillage byproduct includes, in a corn dry-milling process for making ethanol, separating the whole stillage byproduct into an insoluble solids portion and a thin stillage portion. The thin stillage portion is separated into a protein portion and a water soluble solids portion. Next, the protein portion is dewatered then dried to define a high protein corn meal that includes at least 40 wt % protein on a dry basis.

Owner:FLUID QUIP TECH LLC

Heat-Stable Carbonic Anhydrases and Their Use

The present invention relates to use of heat-stable carbonic anhydrase in CO2 extraction, e.g., from flue gas, natural gas or biogas. Furthermore, the invention relates to isolated polypeptides having carbonic anhydrase activity at elevated temperatures and isolated polynucleotides encoding the polypeptides. The invention also relates to nucleic acid constructs, vectors, and host cells comprising the polynucleotides.

Owner:NOVOZYMES AS

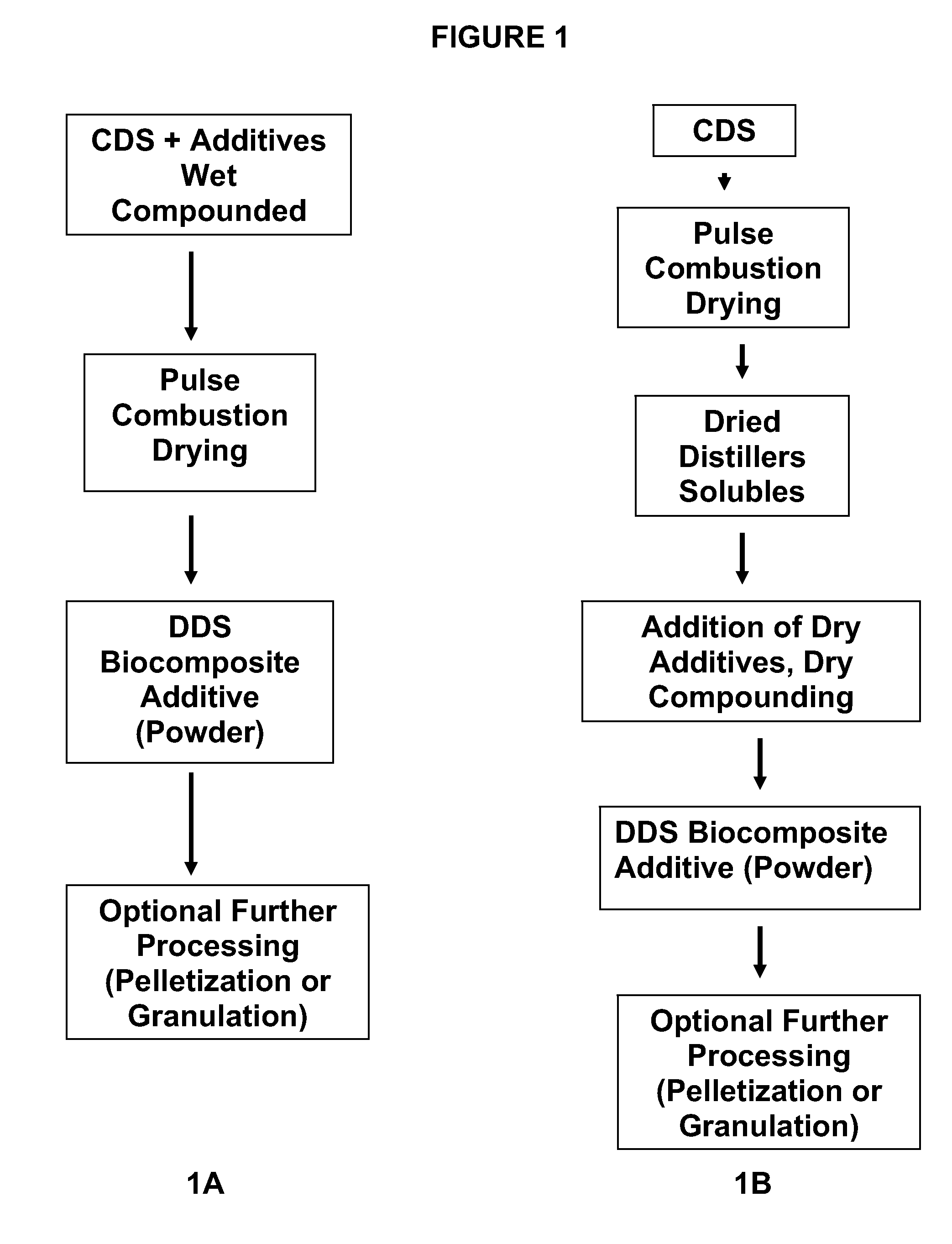

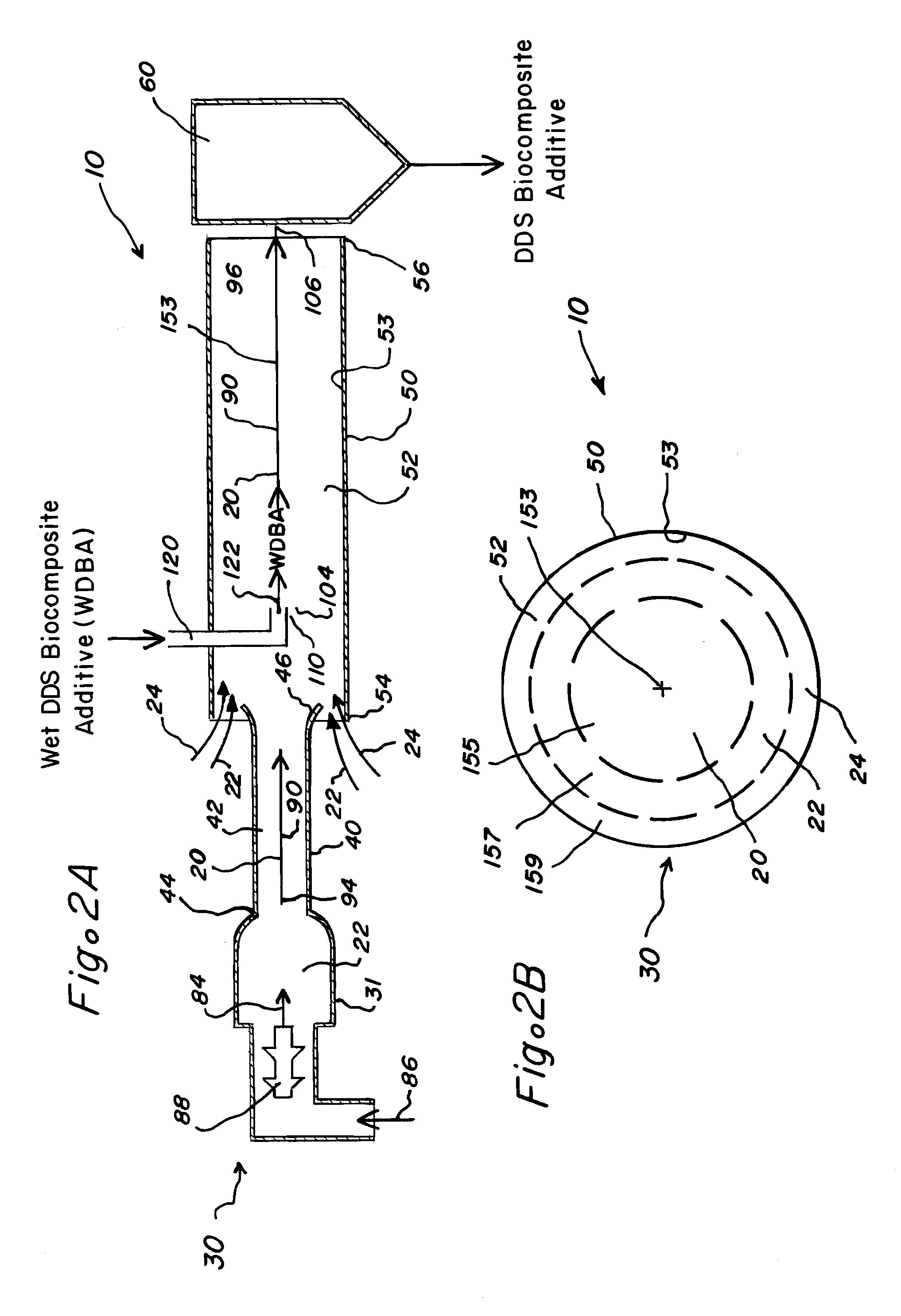

Multifunctional biocomposite additive compositions and methods

Biocomposite compositions and compositions, which include dried distillers solubles, and which can be used in making biocomposite compositions are described. Methods for preparing the compositions are also described.

Owner:GENAREX FD LLC

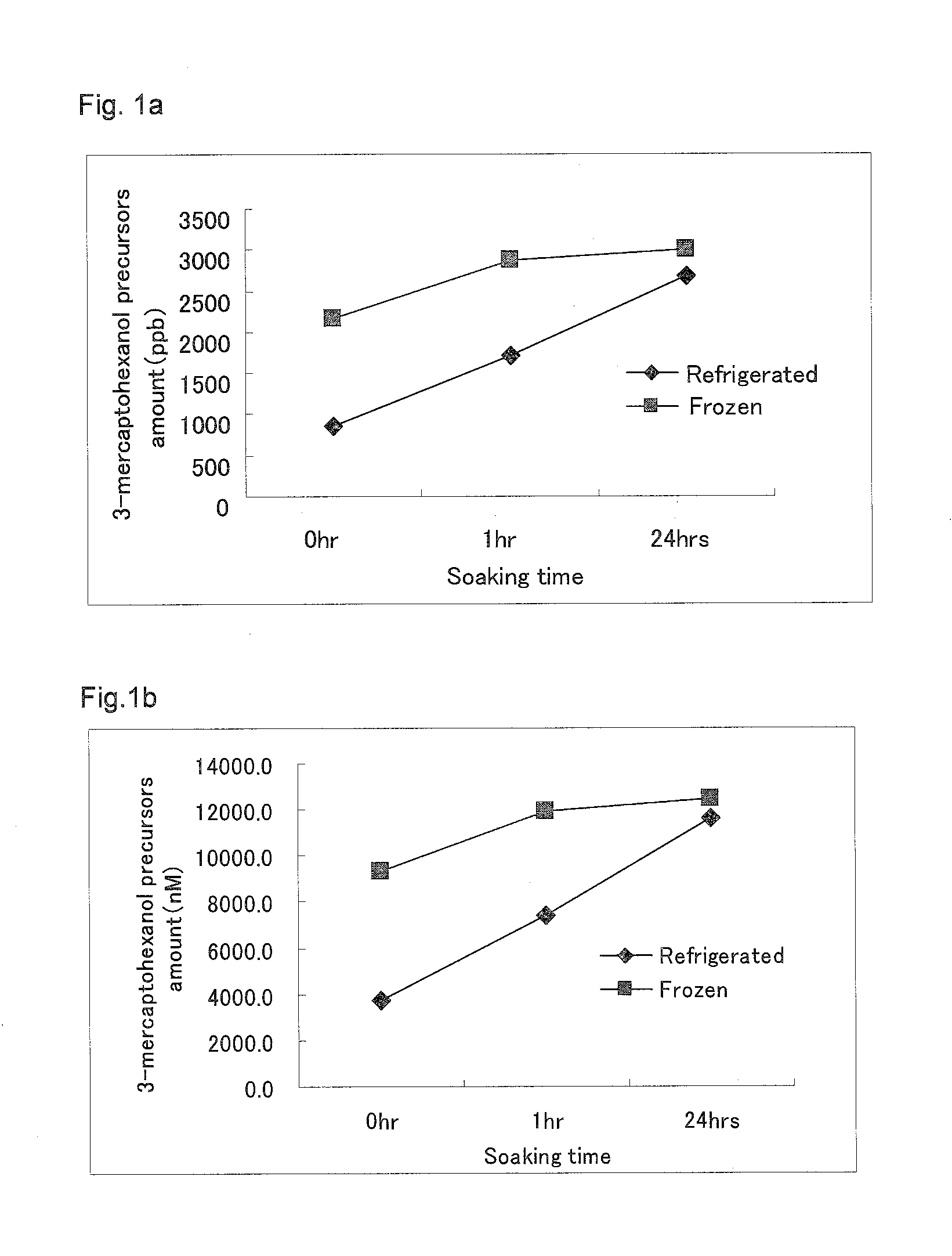

Soft drink, grape skin extract, and methods of preparation of same

InactiveUS20110311680A1Reliable manufacturingIncrease aromaBy-product recoverySolid waste disposalMedicineSoft drink

The disclosed are a soft drink having both an excellent fruity aroma and a fruity afteraroma once swallowed, and a method for manufacturing the same. The further disclosed are a grape skin extract, rich in precursors of 3-mercaptohexan-1-ol having good aroma, for use in manufacturing the soft drink, and to a method of preparation of the same.

Owner:MERCIAN CORP

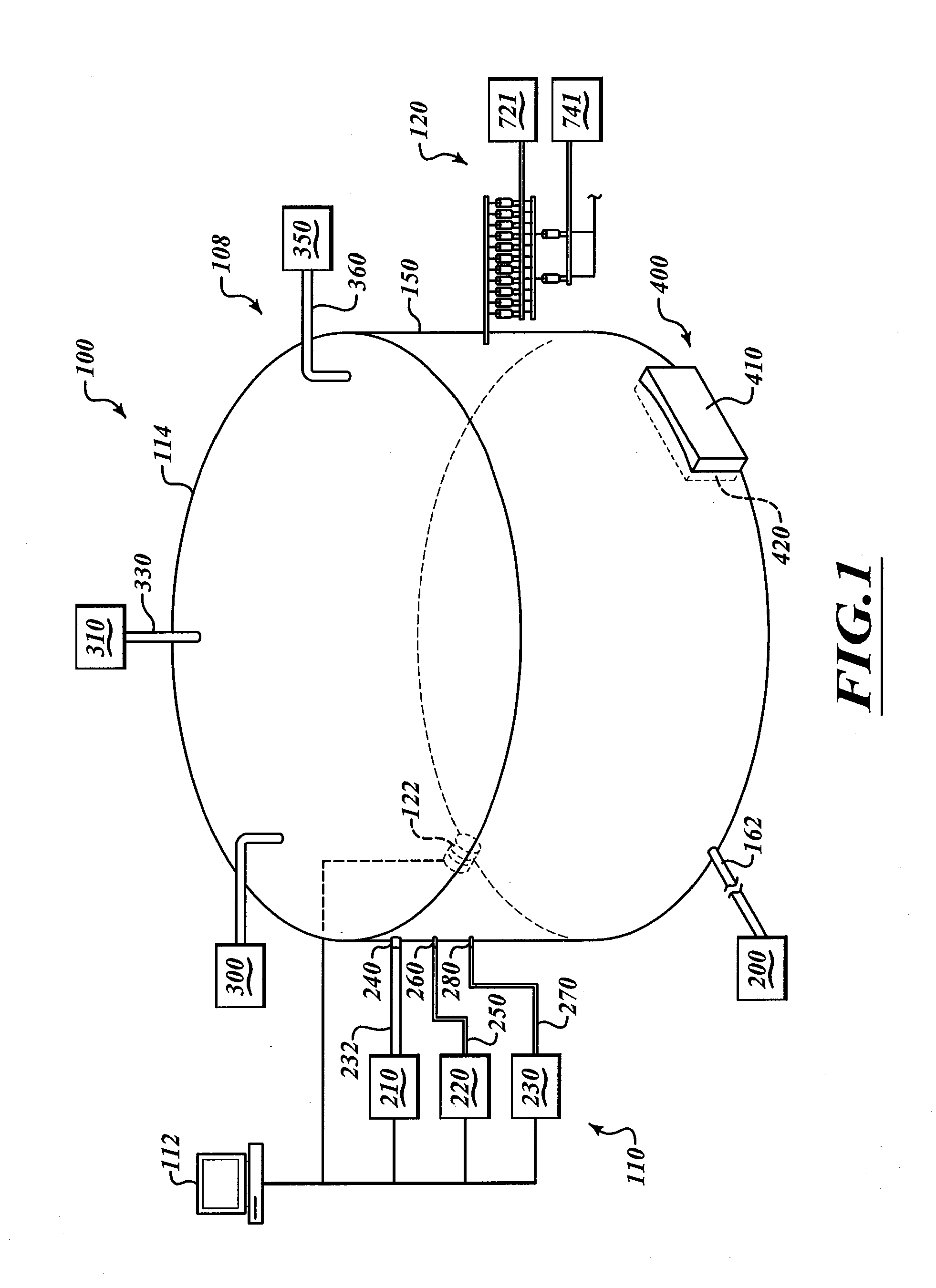

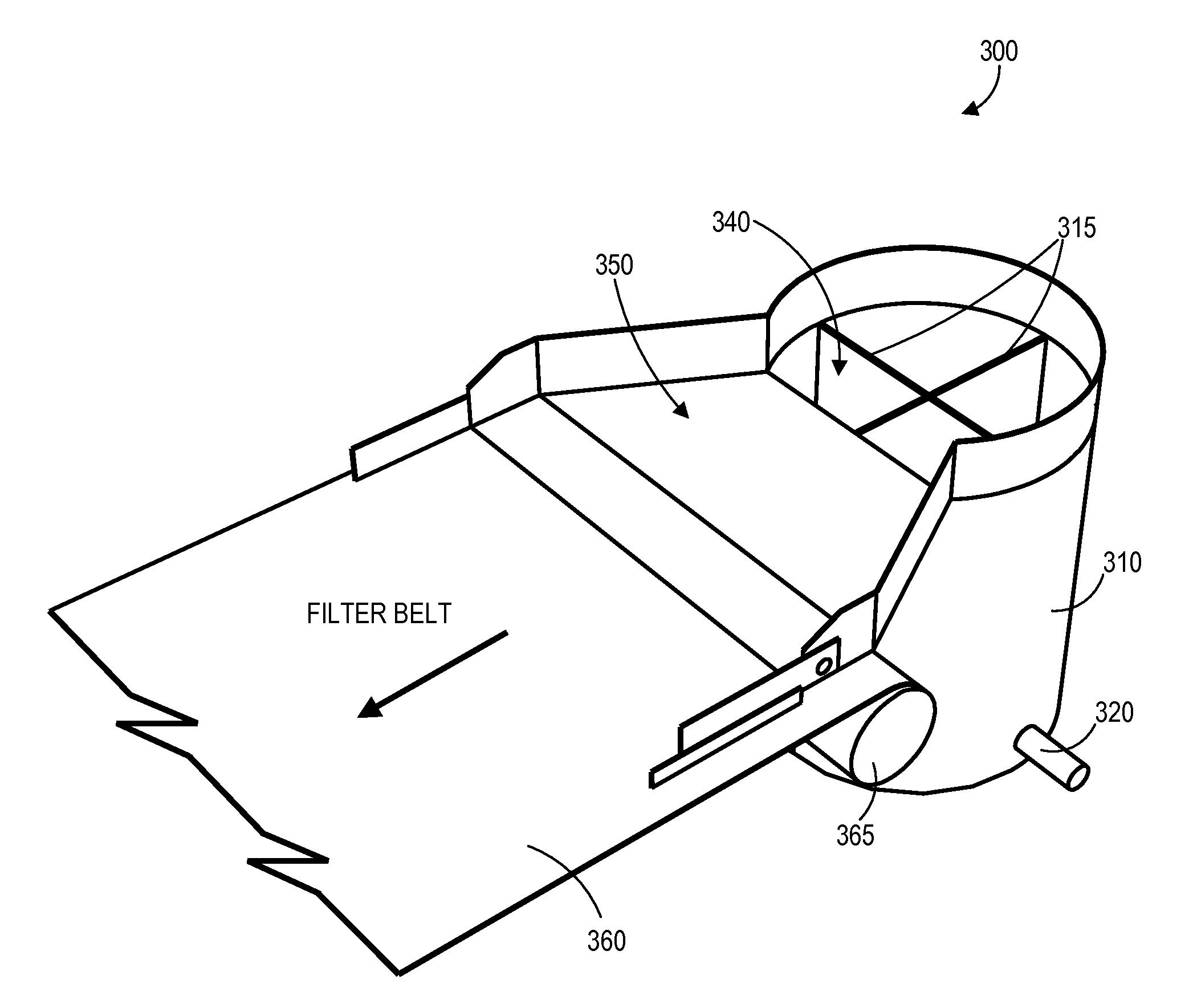

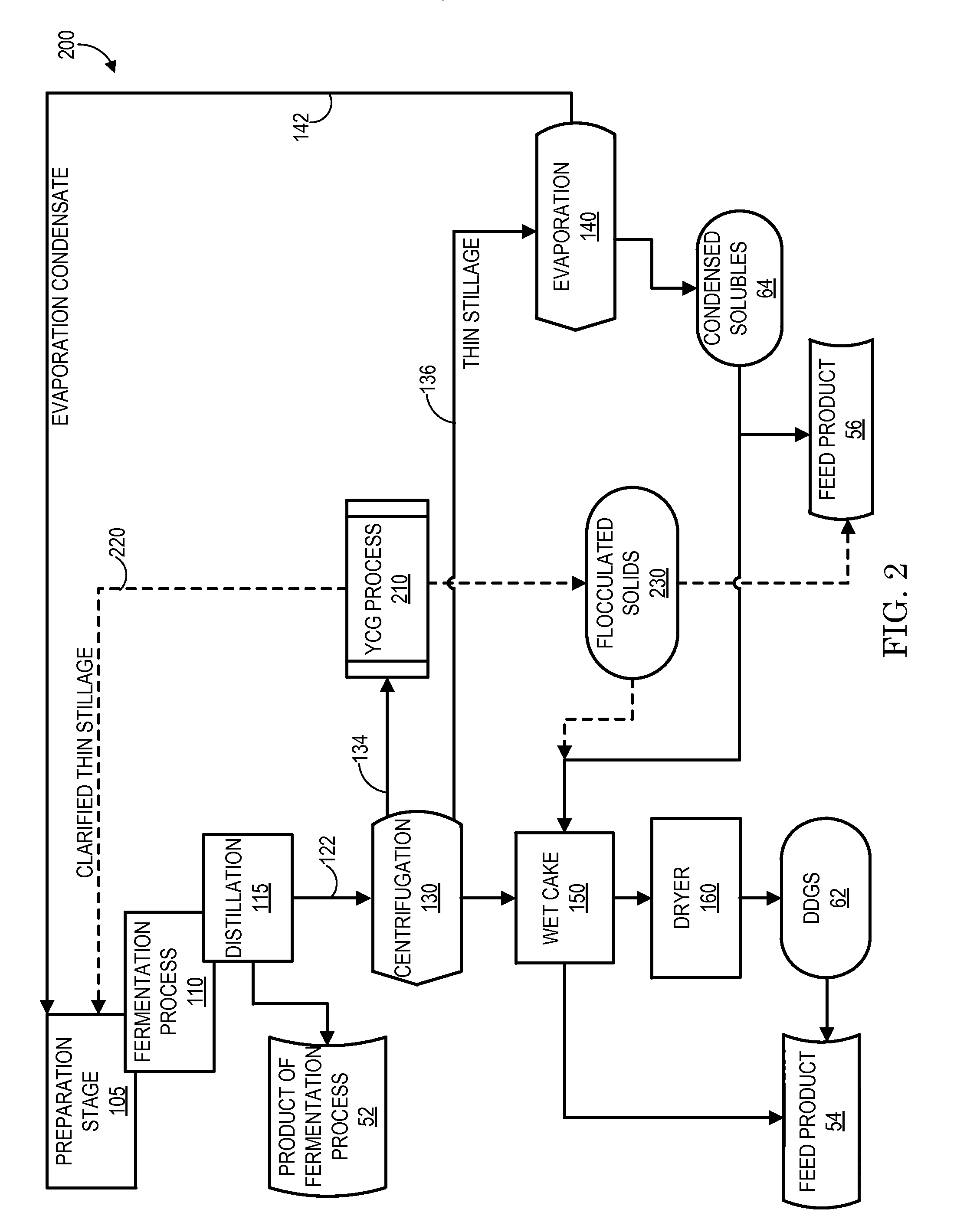

Thin Stillage Clarification

InactiveUS20140319066A1Efficiently processing and recoveringQuality improvementBy-product recoveryWater/sewage treatment by centrifugal separationEvaporationFatty acid

Systems and methods for improving the quality of solids and liquids recovered at atmospheric pressure and temperature from a stillage stream generated as a by-product of an ethanol production process, the recovered solids having higher bio-available amino and fatty acids than evaporation-produced condensed solubles, the recovered liquids having less total solids and total suspended solids than evaporation-produced condensate. A static mixer includes an input for receiving the stillage stream combined with a GRAS anionic polymer, a cylindrical mixing chamber that controllably mixes the stillage stream and the polymer to generate wet flocculated solids and liquid co-product, and a discharge chute that outputs the wet flocculated solids and liquid co-products onto a moving, gravity filter belt having a membrane surface that separates the output from the static mixer into recovered liquids in the form of clarified, thin stillage and recovered solids in the form of dry flocculated solids.

Owner:YIELD & CAPACITY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com