Patents

Literature

505results about How to "Reliable manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

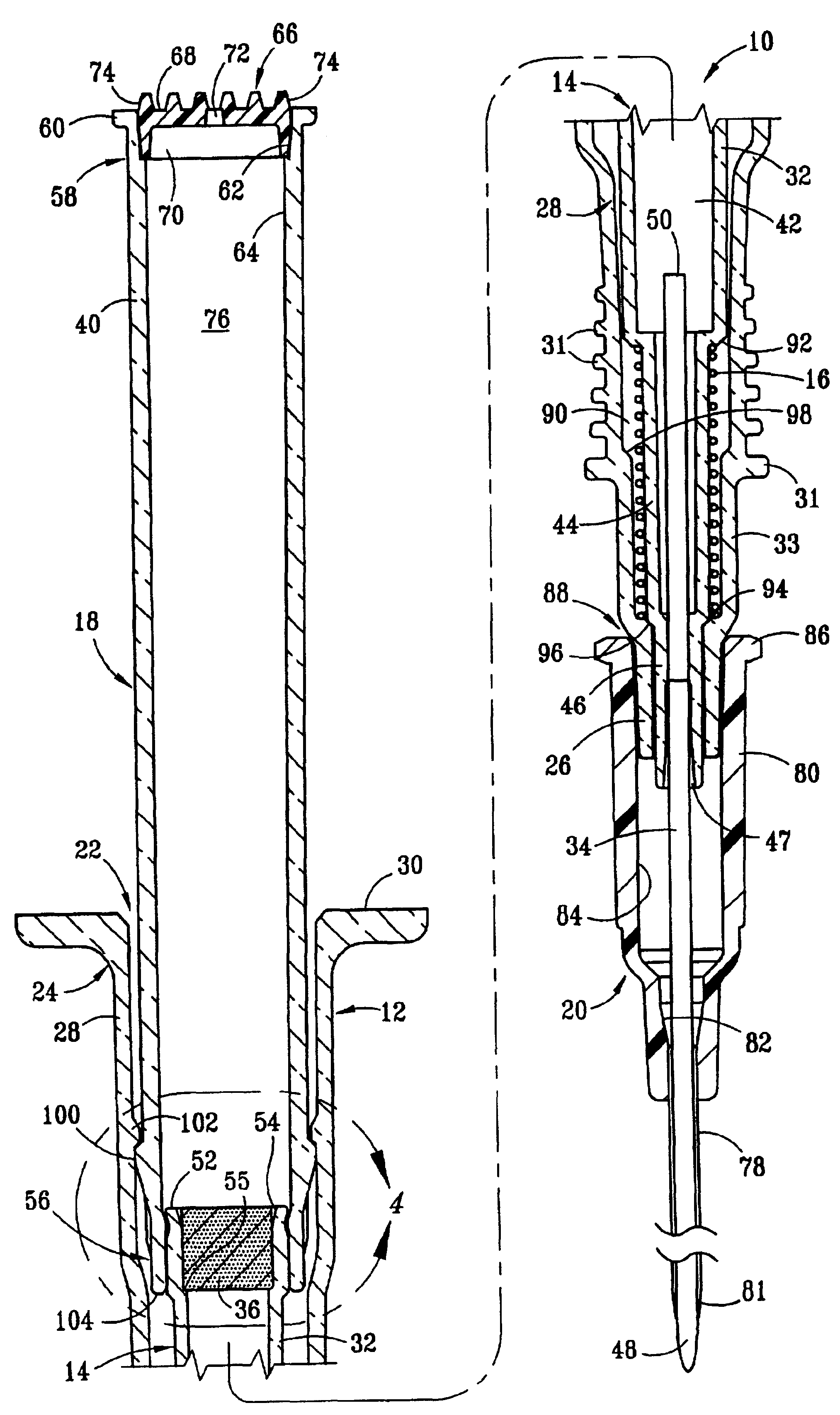

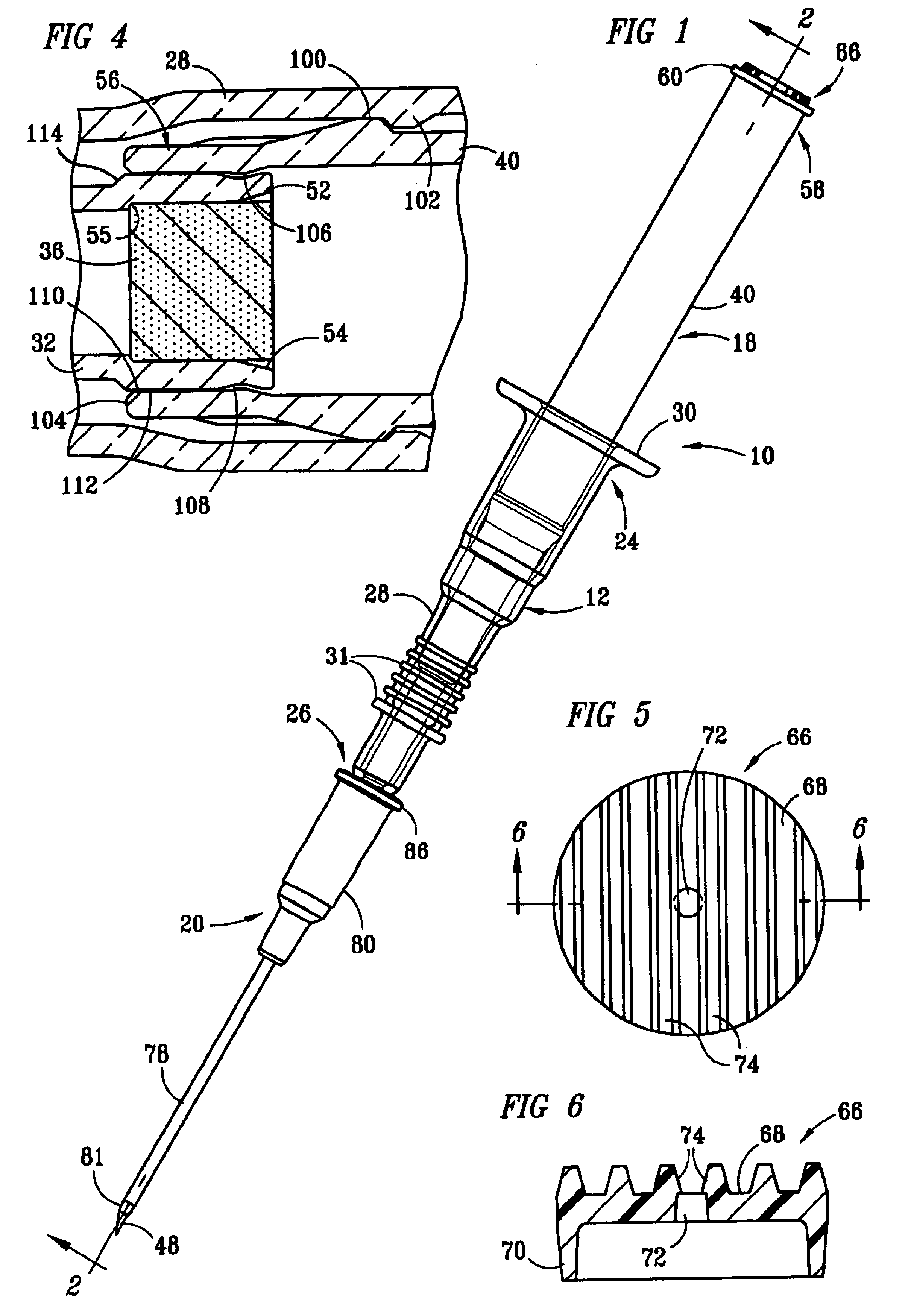

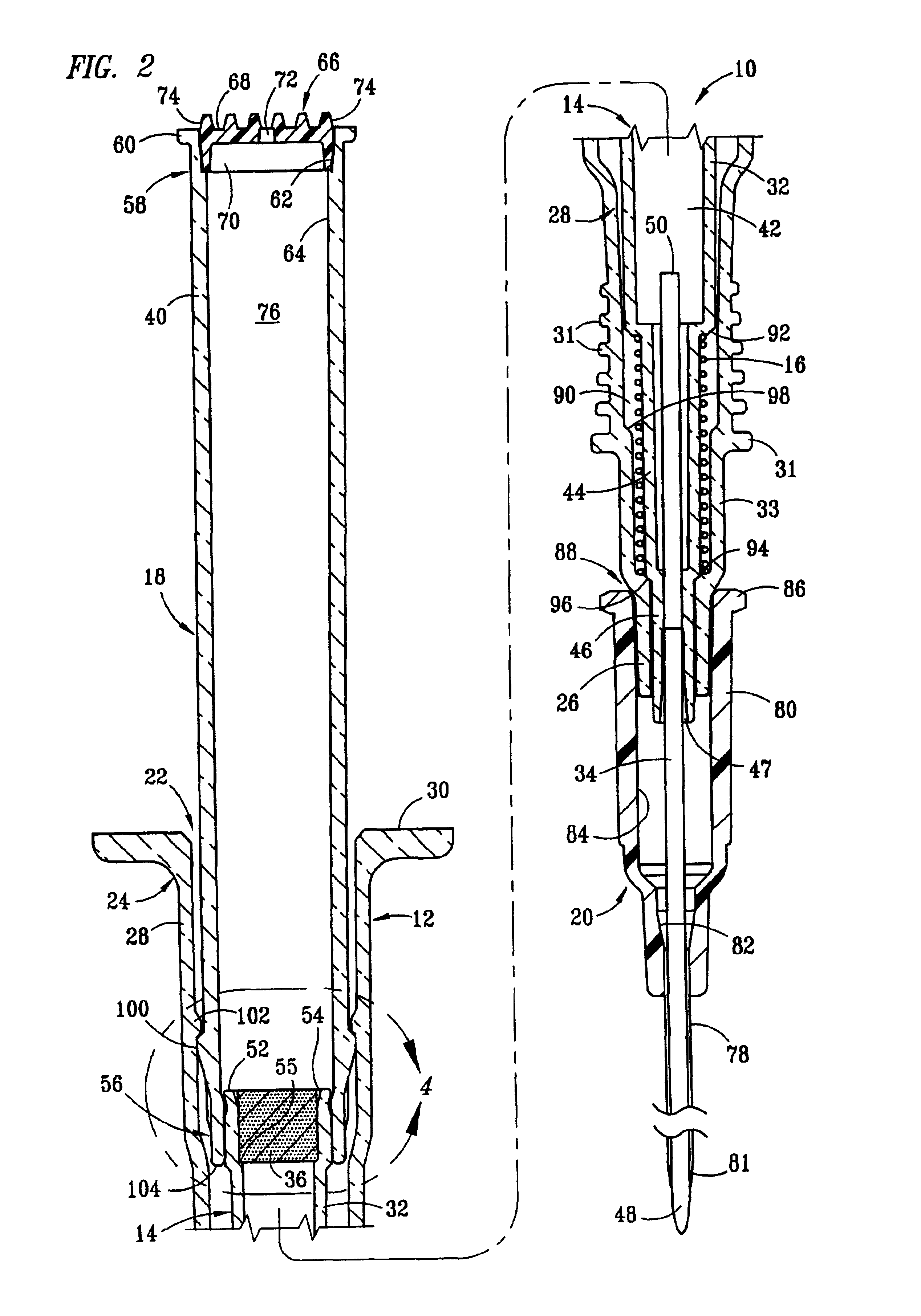

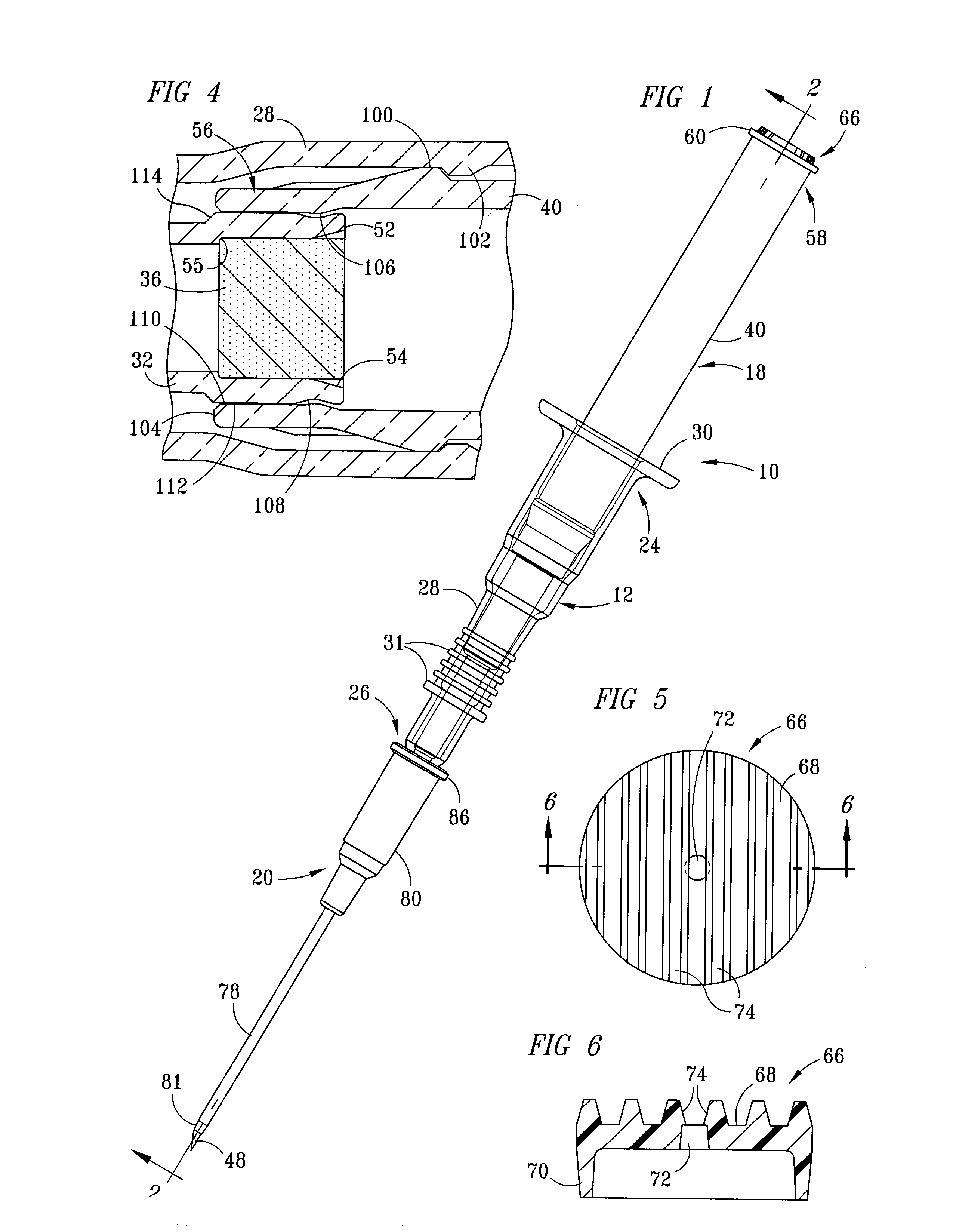

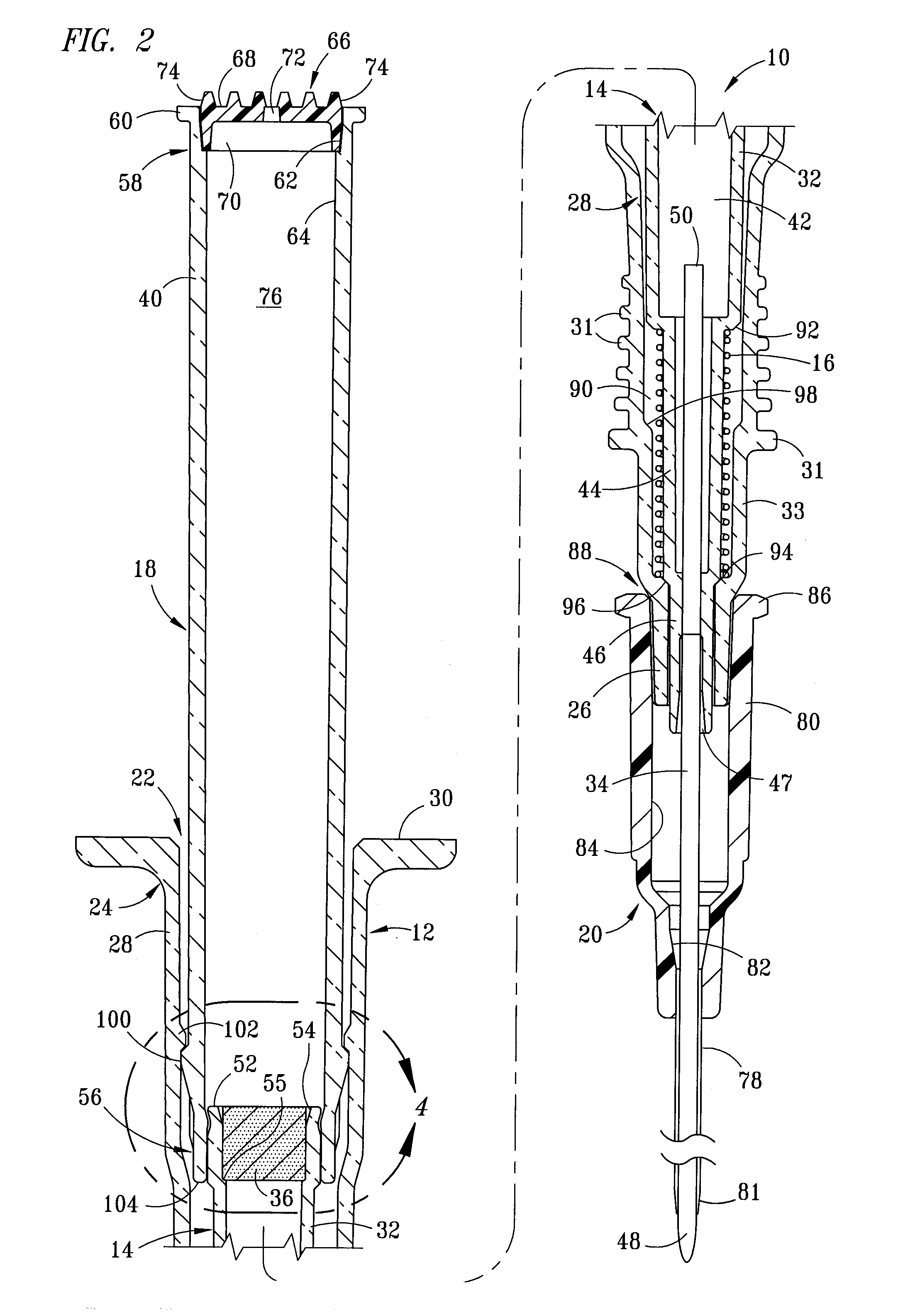

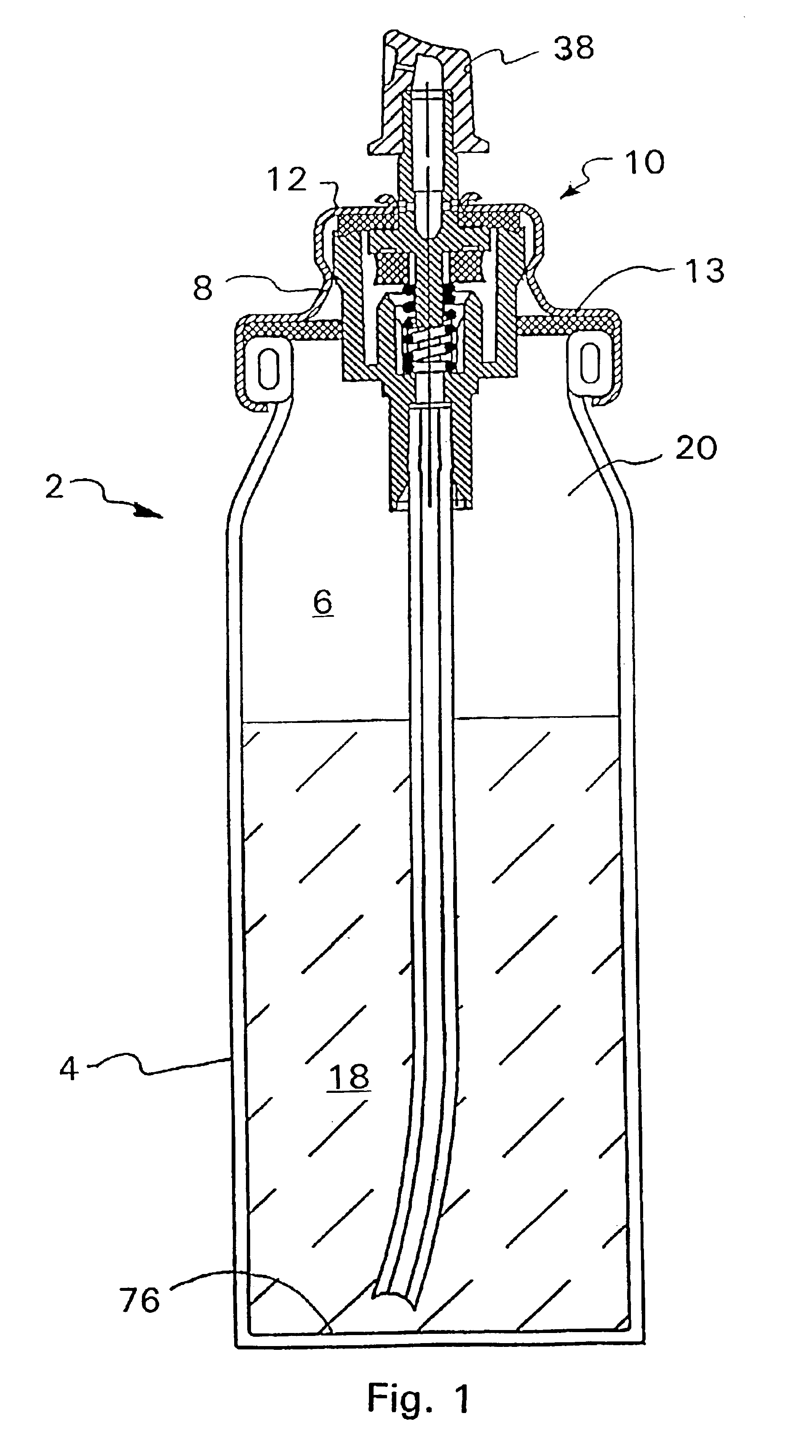

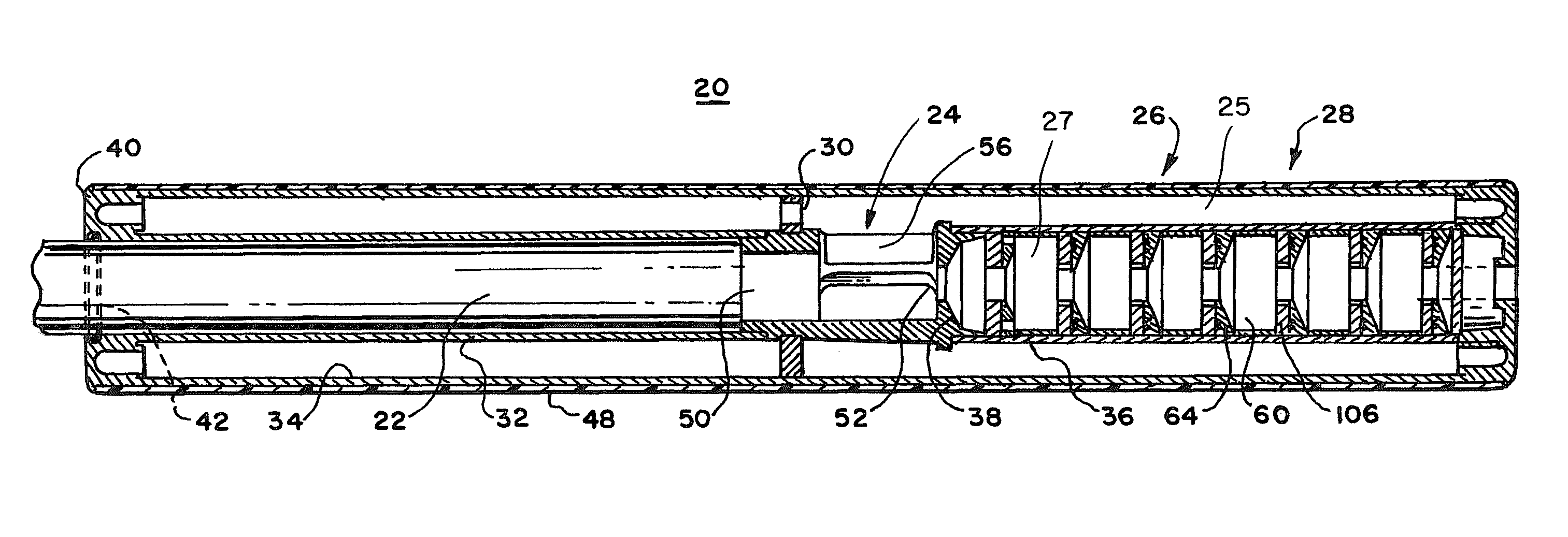

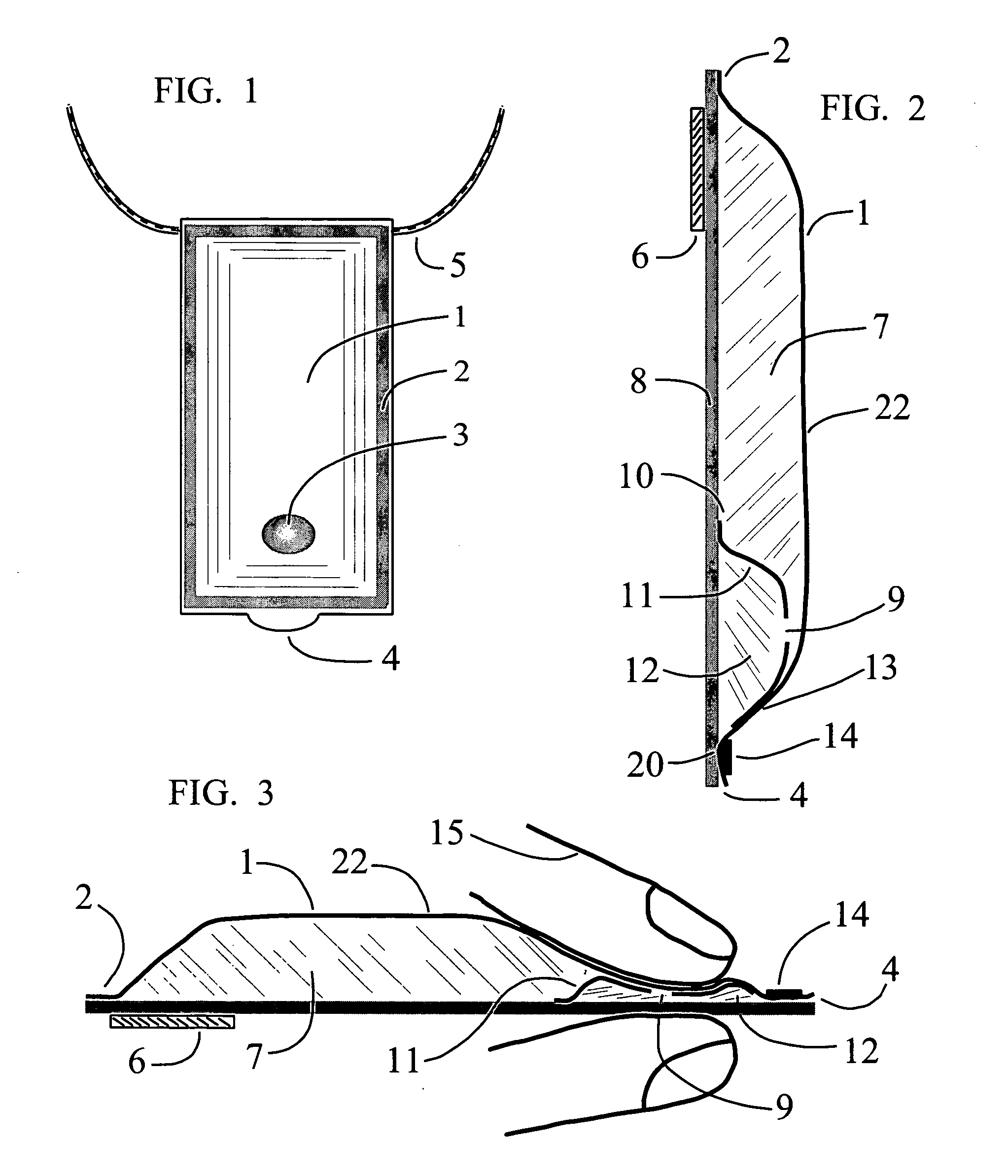

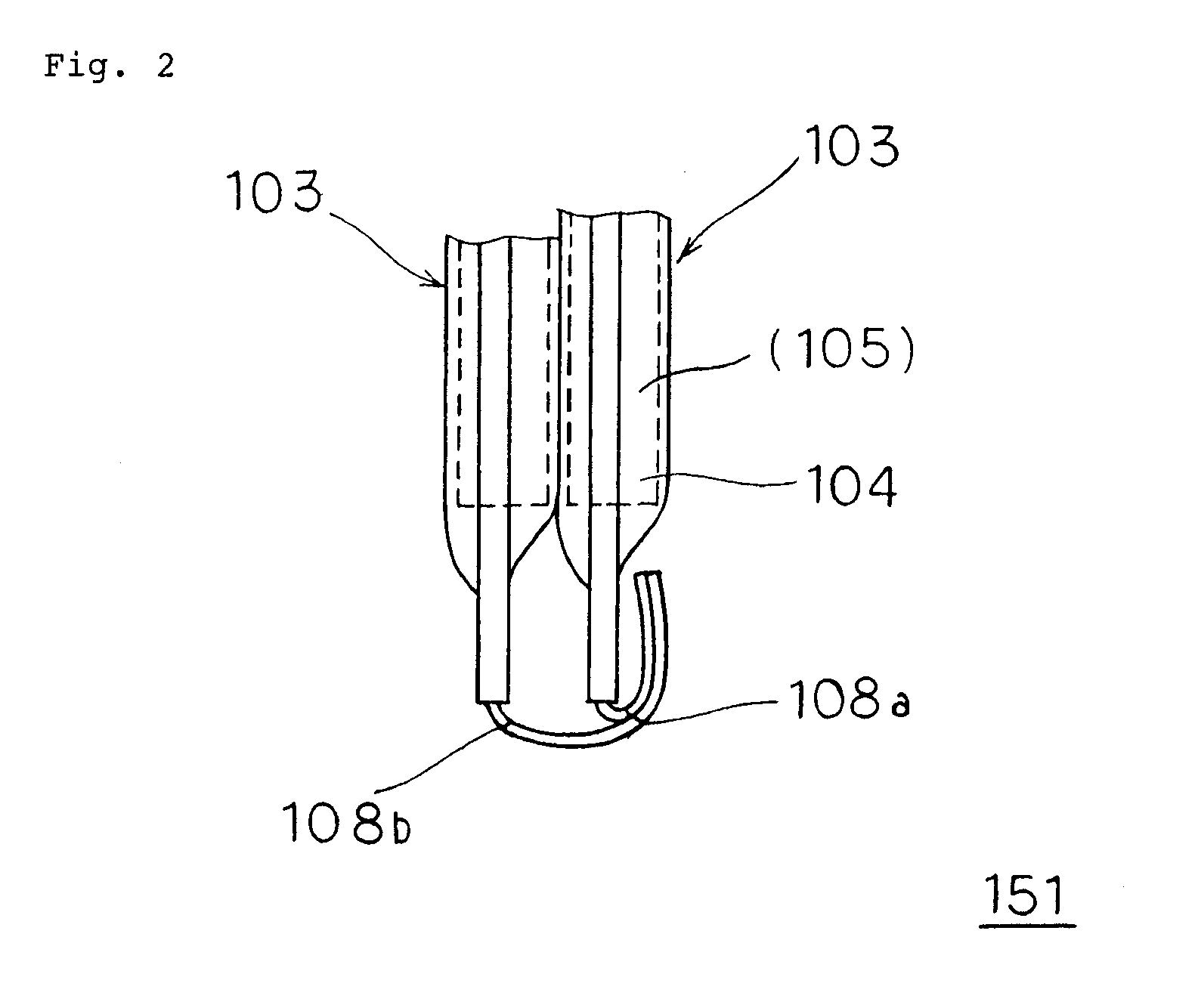

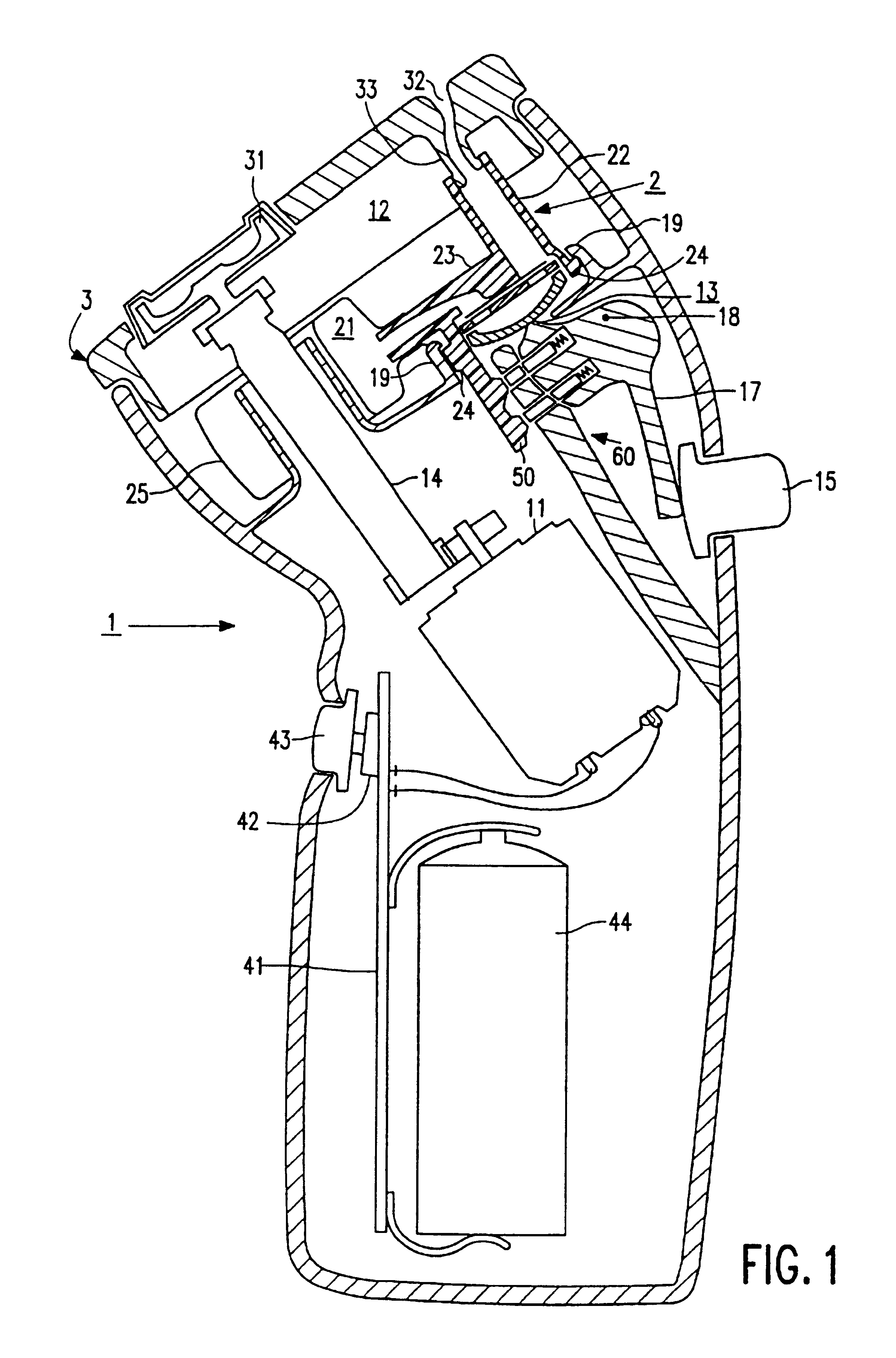

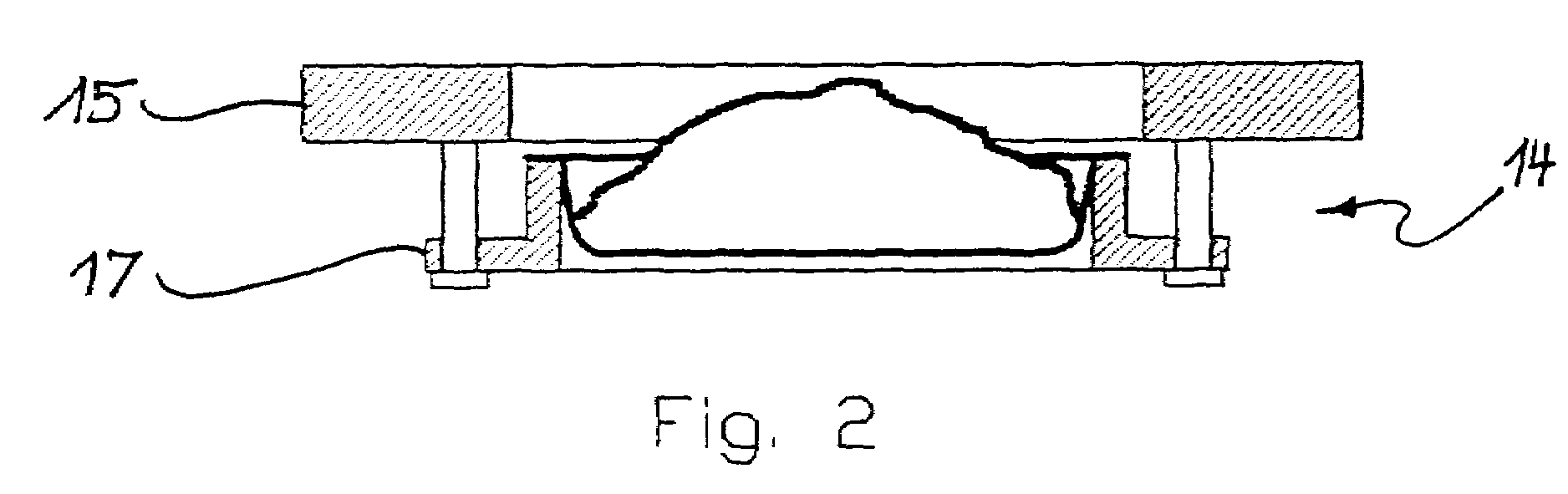

IV catheter introducer with retractable needle

InactiveUS6872193B2Reliable and reliableEasy to use with one handGuide needlesInfusion syringesDetentCatheter introducer

An IV catheter introducer having a retractable needle holder and a tubular plunger that are held by a detent structure in a preferred positional relationship prior to and during insertion of the catheter. Following insertion, the plunger is pushed past the detent structure, permitting a compressed spring to force the needle holder upwardly into the plunger. A vented end cap in the plunger permits rapid venting of air displaced during retraction of the needle holder. The needle holder includes a flash chamber that is easily viewable through a clear plastic housing. Wings are provided on the housing to facililate one-handed operation of the device. A method for assembling the subject catheter introducer is also disclosed.

Owner:RETRACTABLE TECH INC

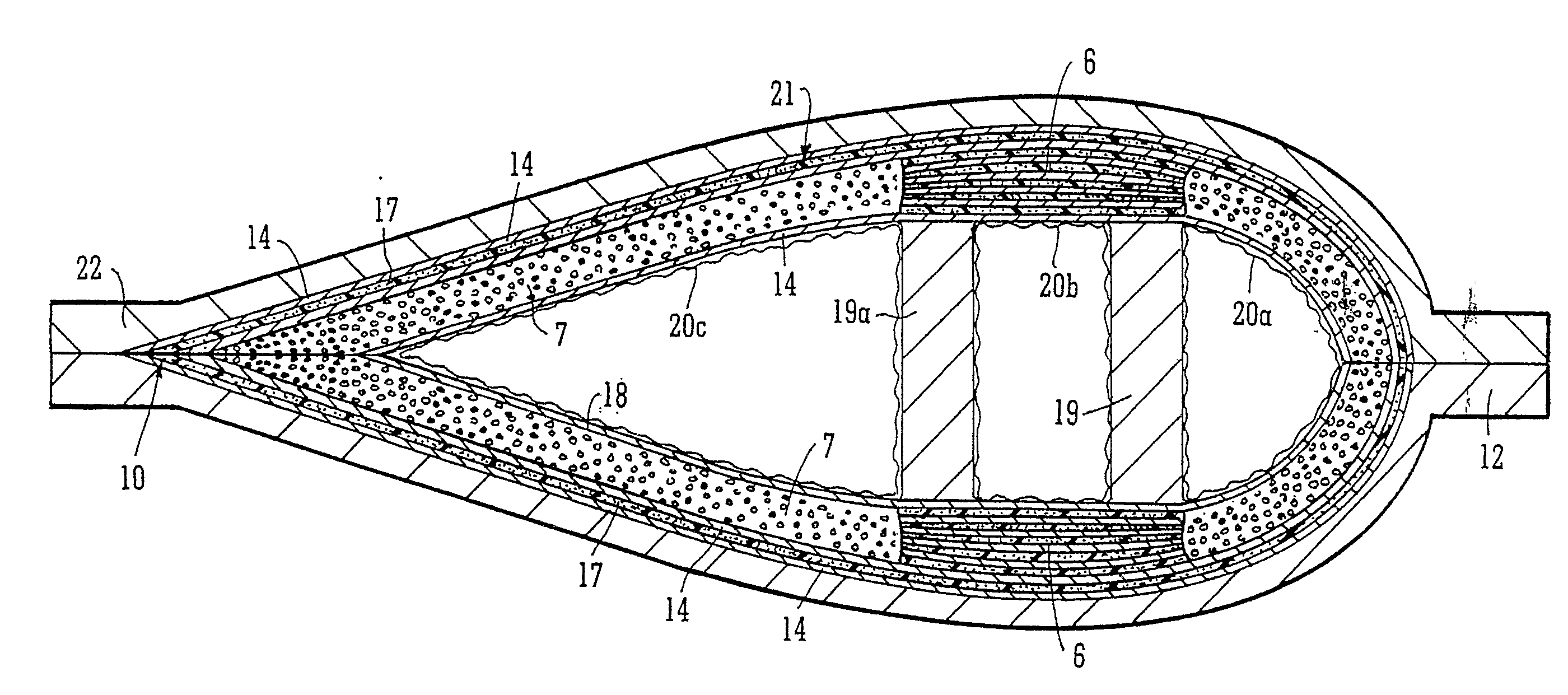

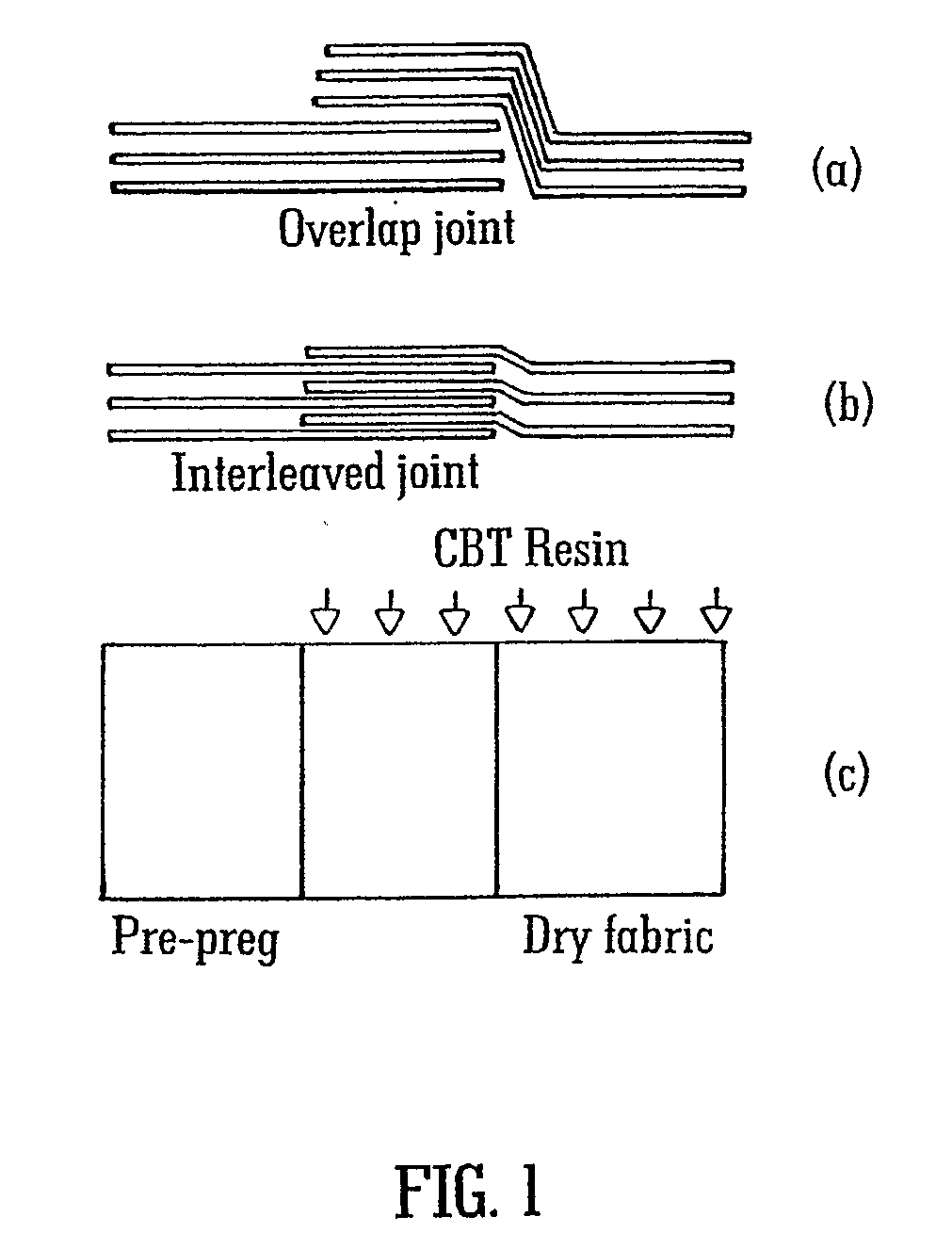

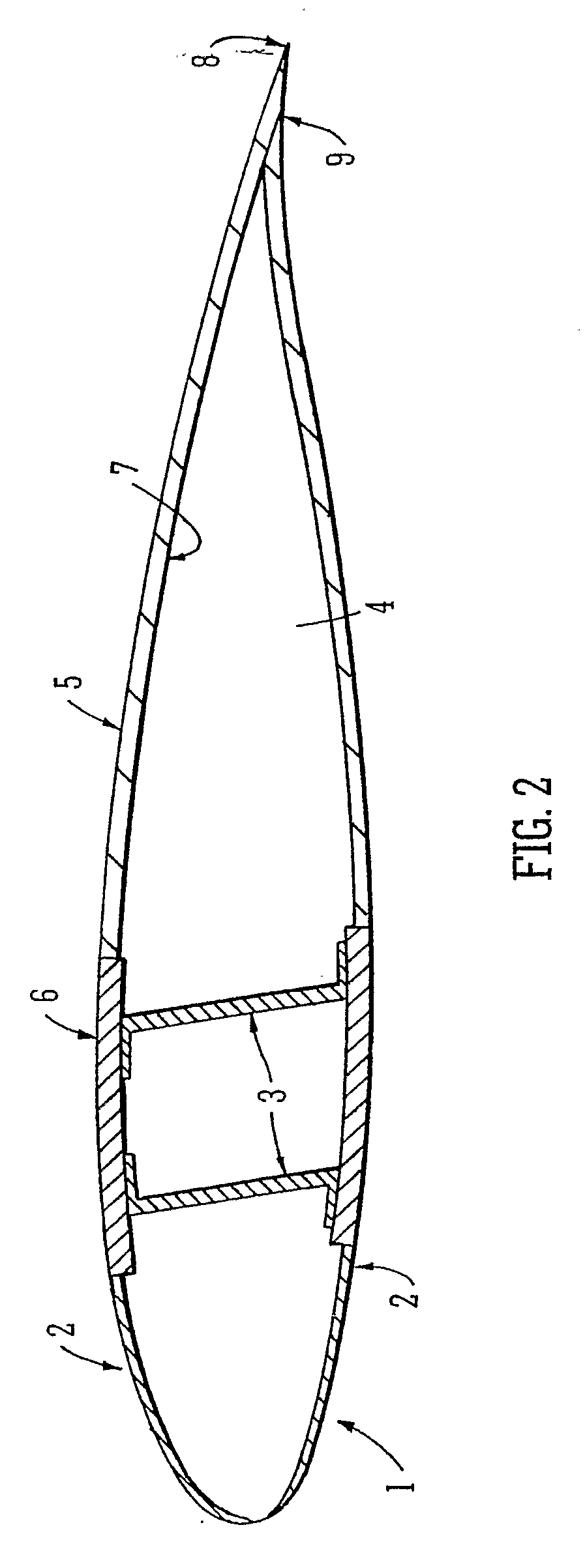

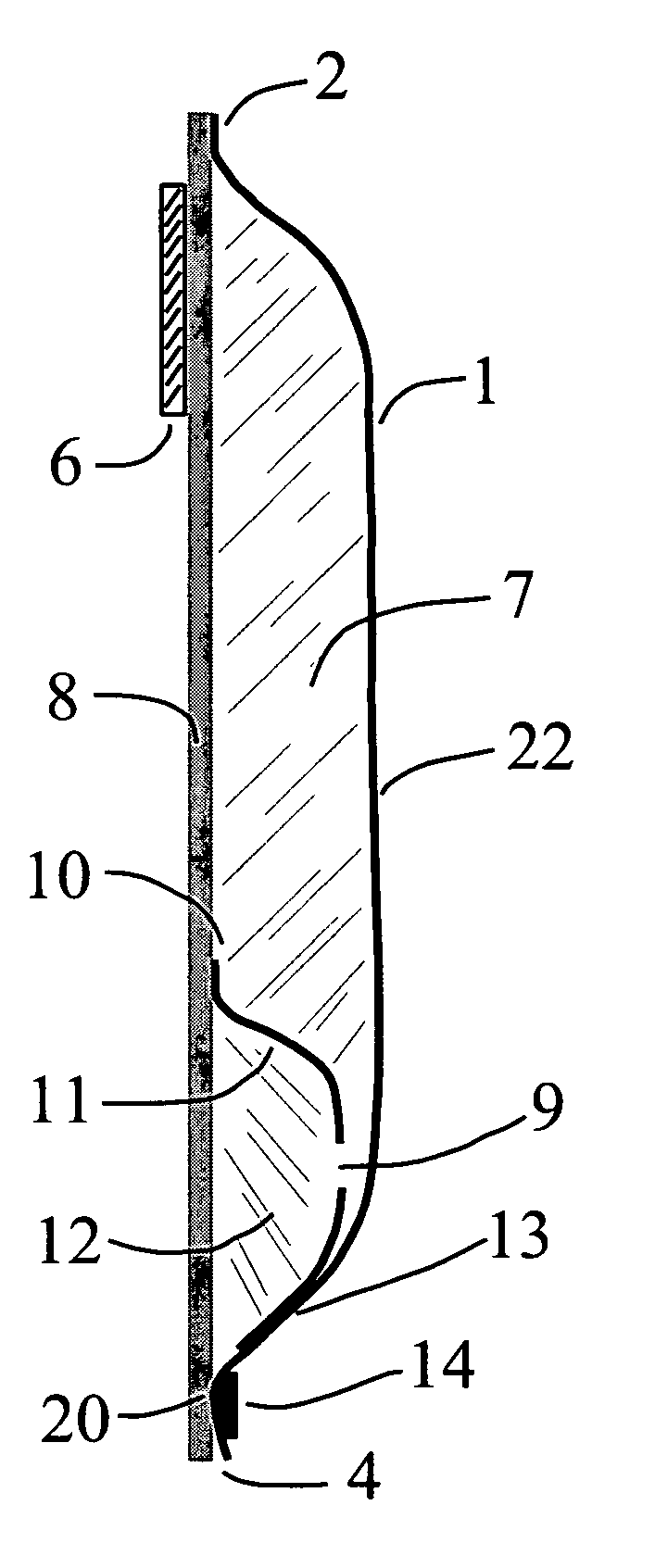

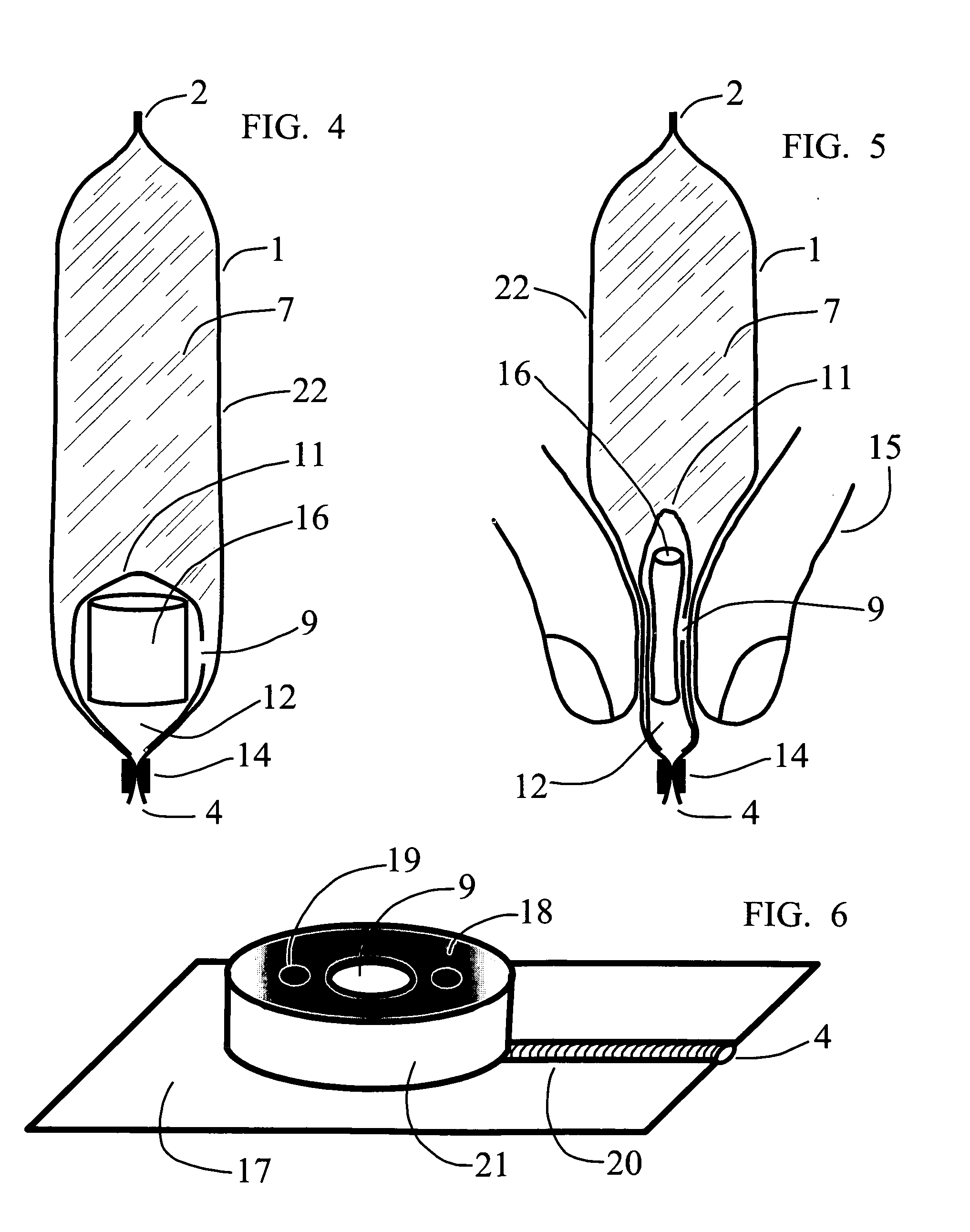

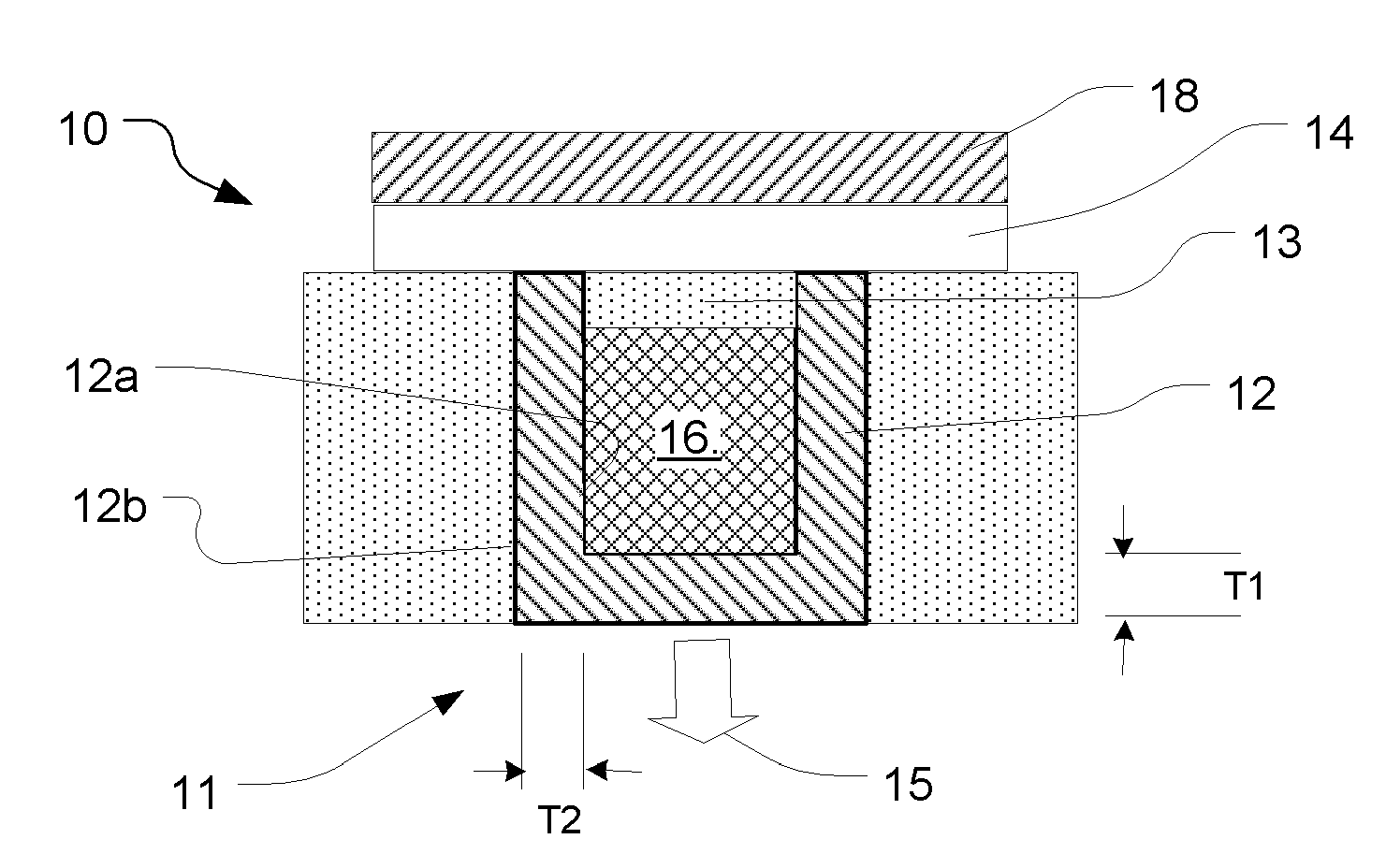

Composite Articles Comprising In-Situ-Polymerisable Thermoplastic Material and Processes for their Construction

InactiveUS20100062238A1Reliable constructionLow costFinal product manufacturePretreated surfacesTurbine bladeIn situ polymerization

A process for the manufacture of a composite article is described wherein the process comprises the steps of (i) providing on a tool (22) a fibrous material (14) having associated therewith in at least one region thereof an in-situ polymerisable non-fibrous form of a thermoplastic material; (ii) applying heat and a vacuum to said material; and additionally (iii) drawing into the fibrous material, from a source external to the tool, additional thermoplastic pre-polymer material. The process described is particularly useful for the manufacture of a large composite structure such as thermoplastic composite wind turbine blade, for example.

Owner:UNIVERSITY OF LIMERICK +2

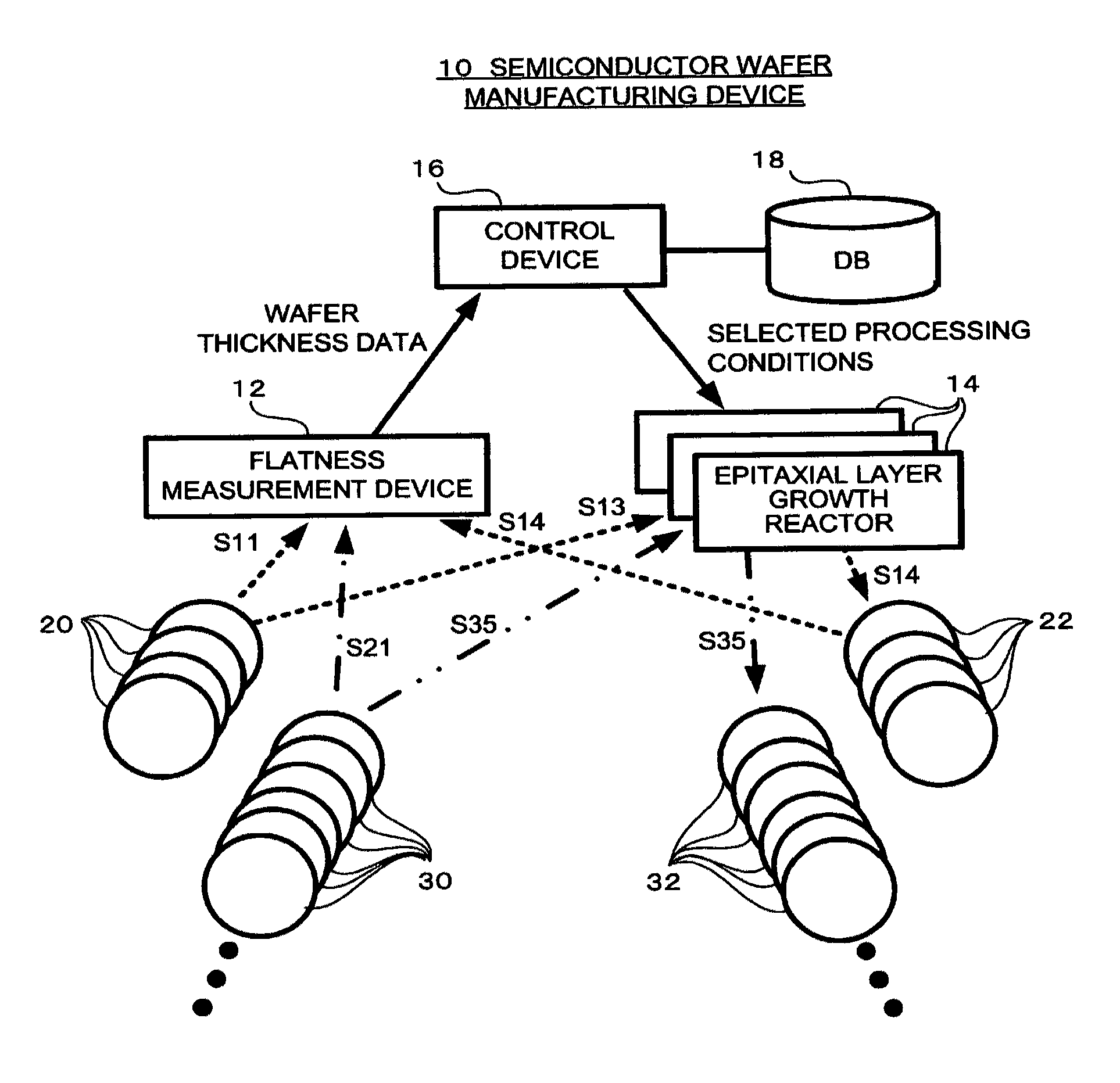

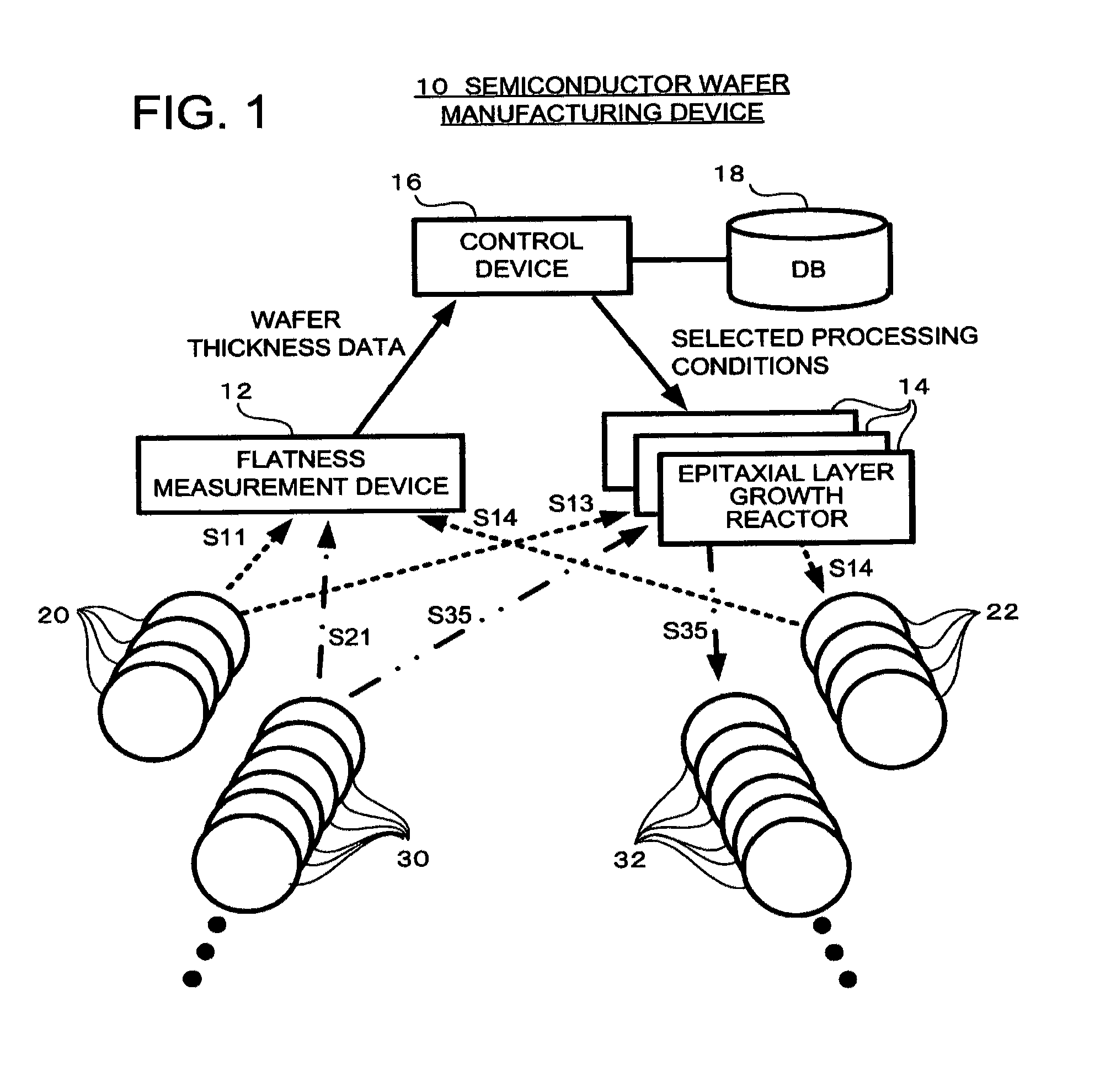

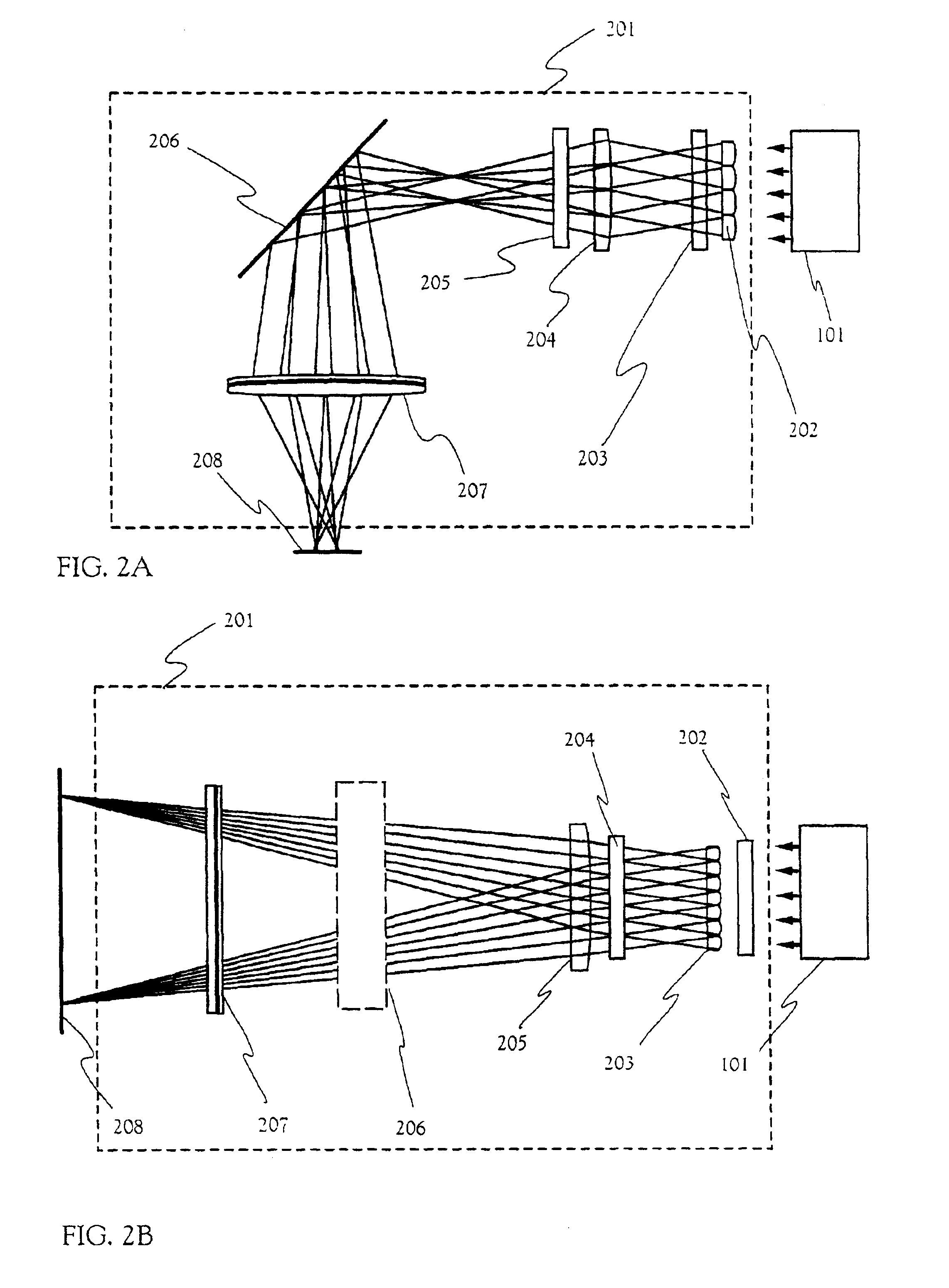

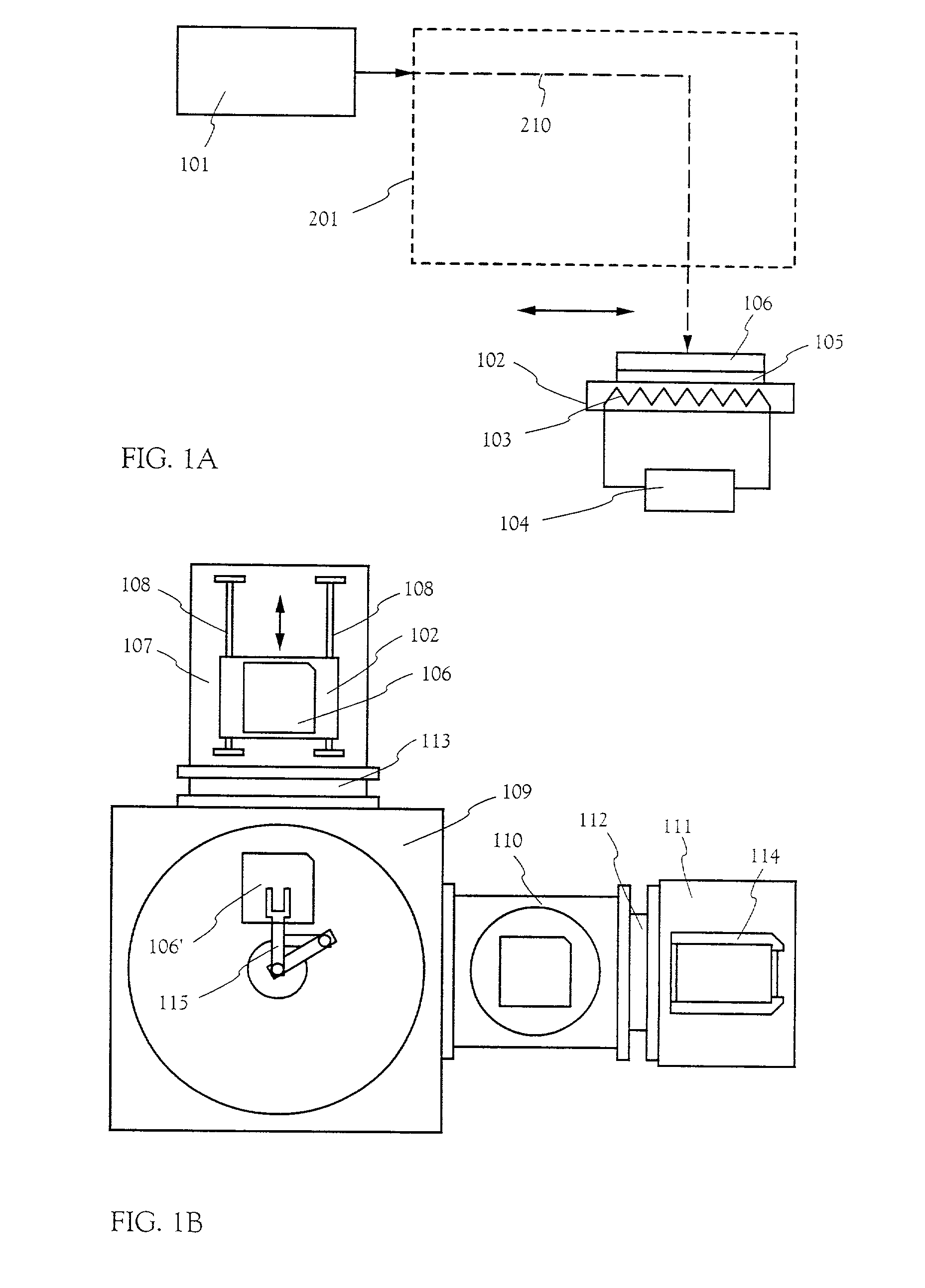

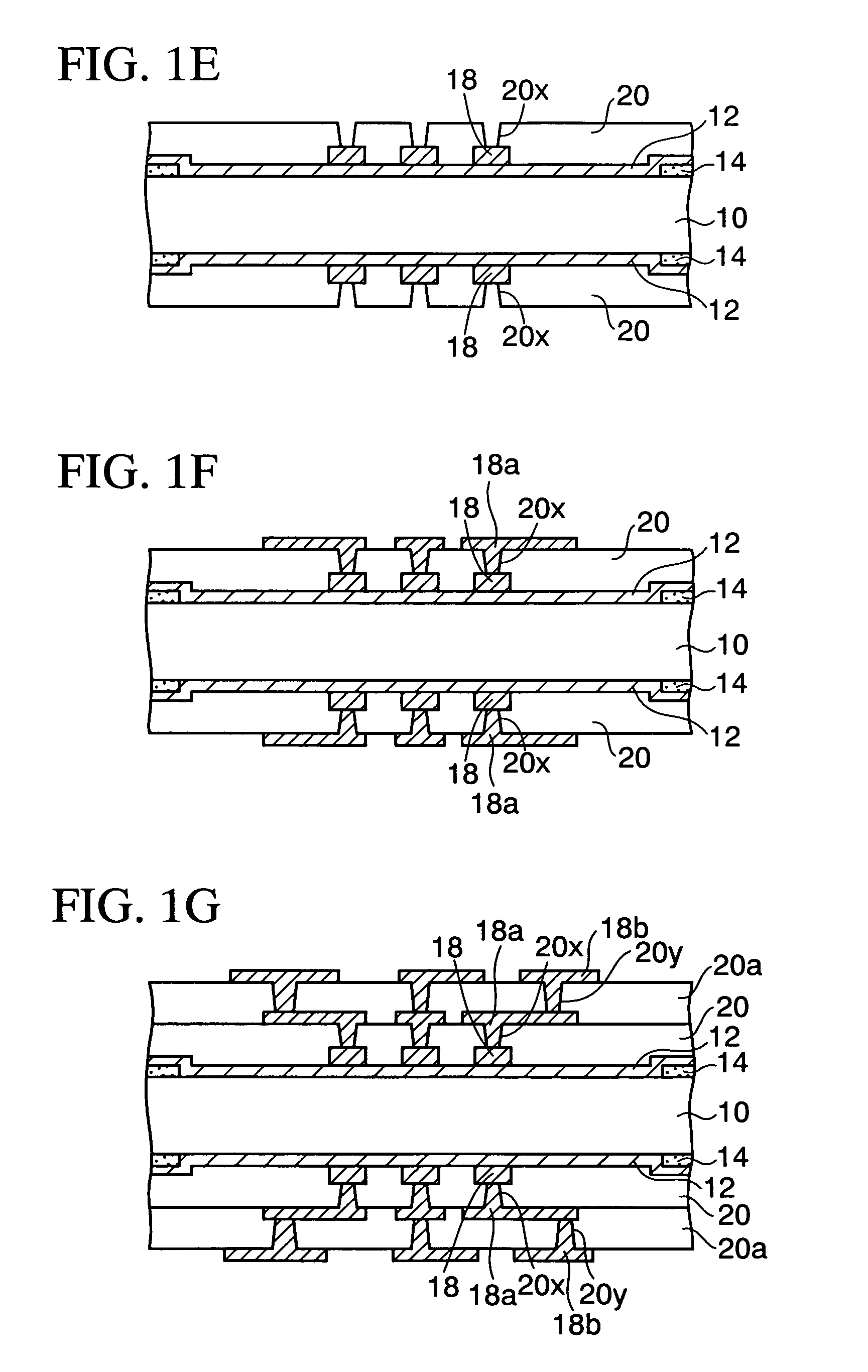

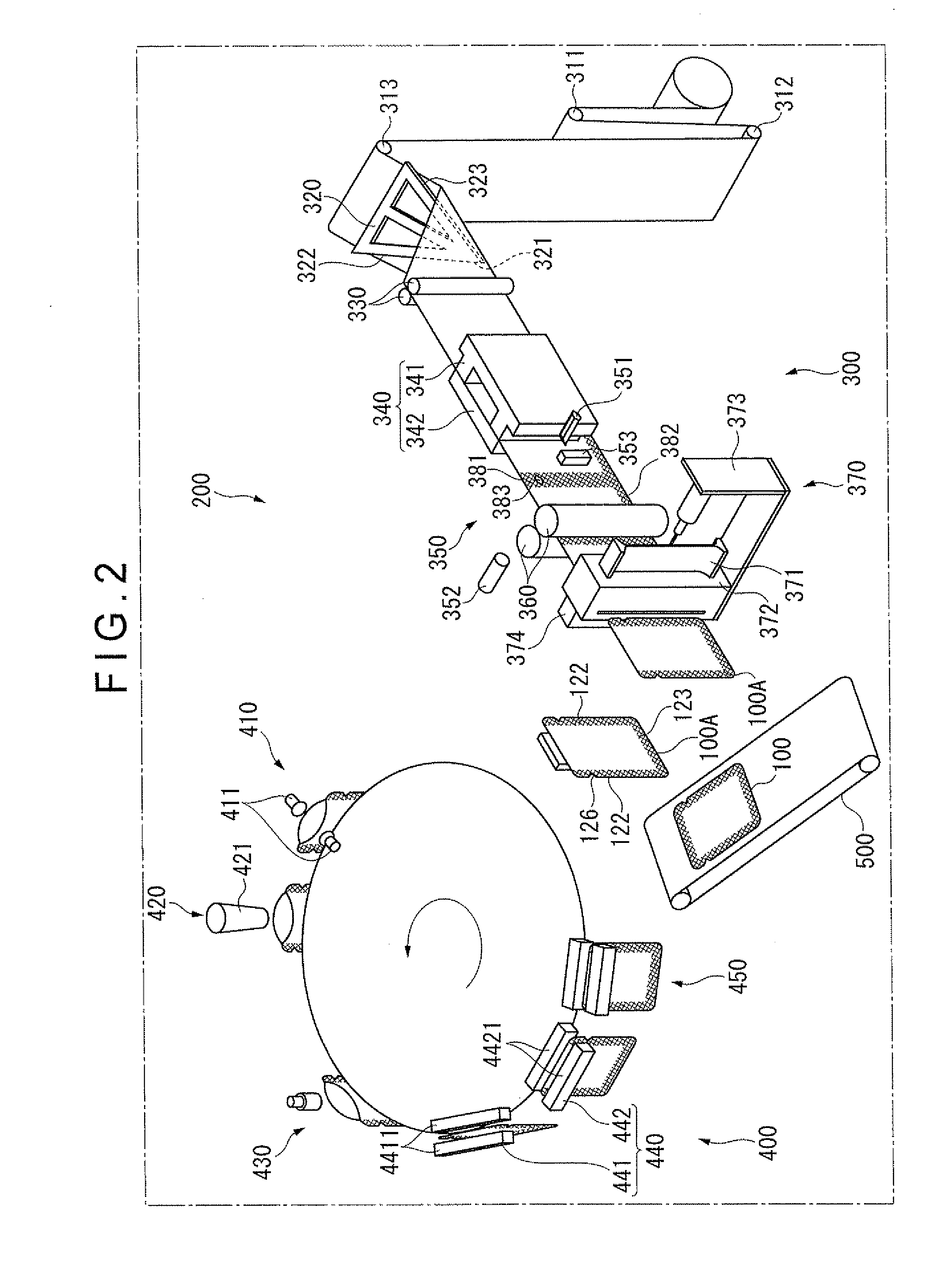

Device and method for manufacturing a semiconductor wafer

ActiveUS8196545B2Reliable manufacturingEnhance the imageProgramme controlLiquid surface applicatorsEngineeringLayer thickness

Owner:SUMCO TECHXIV

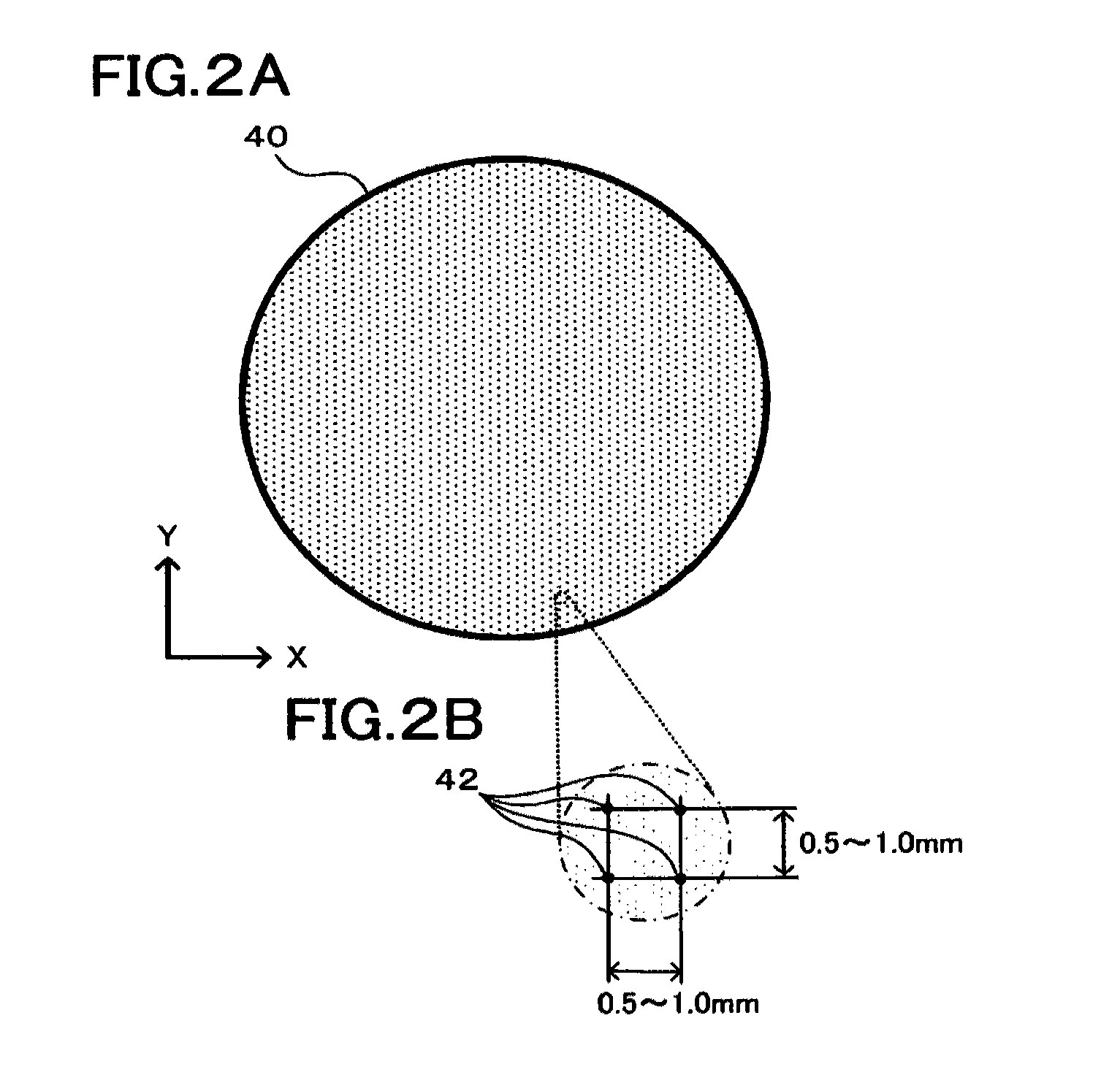

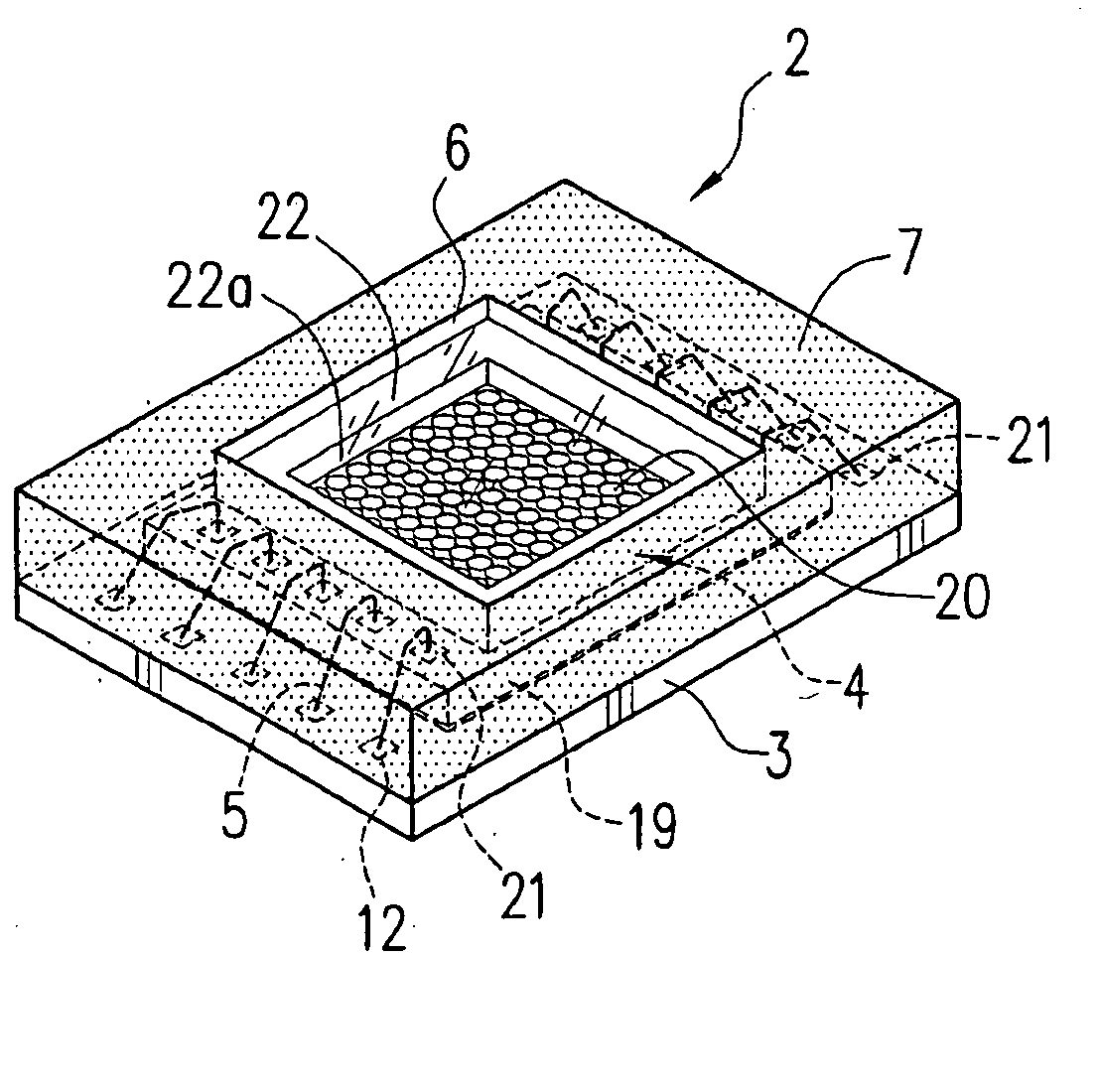

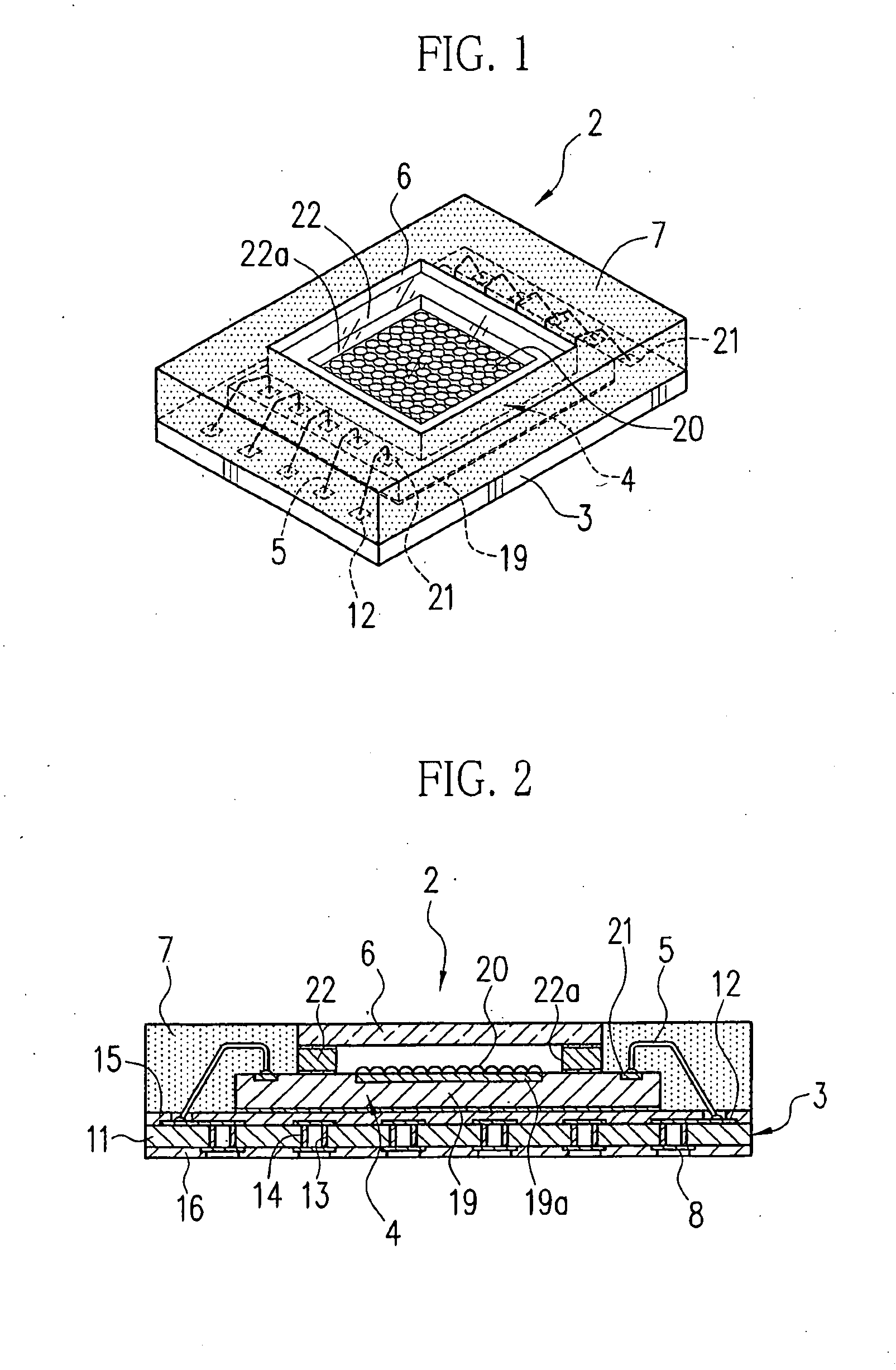

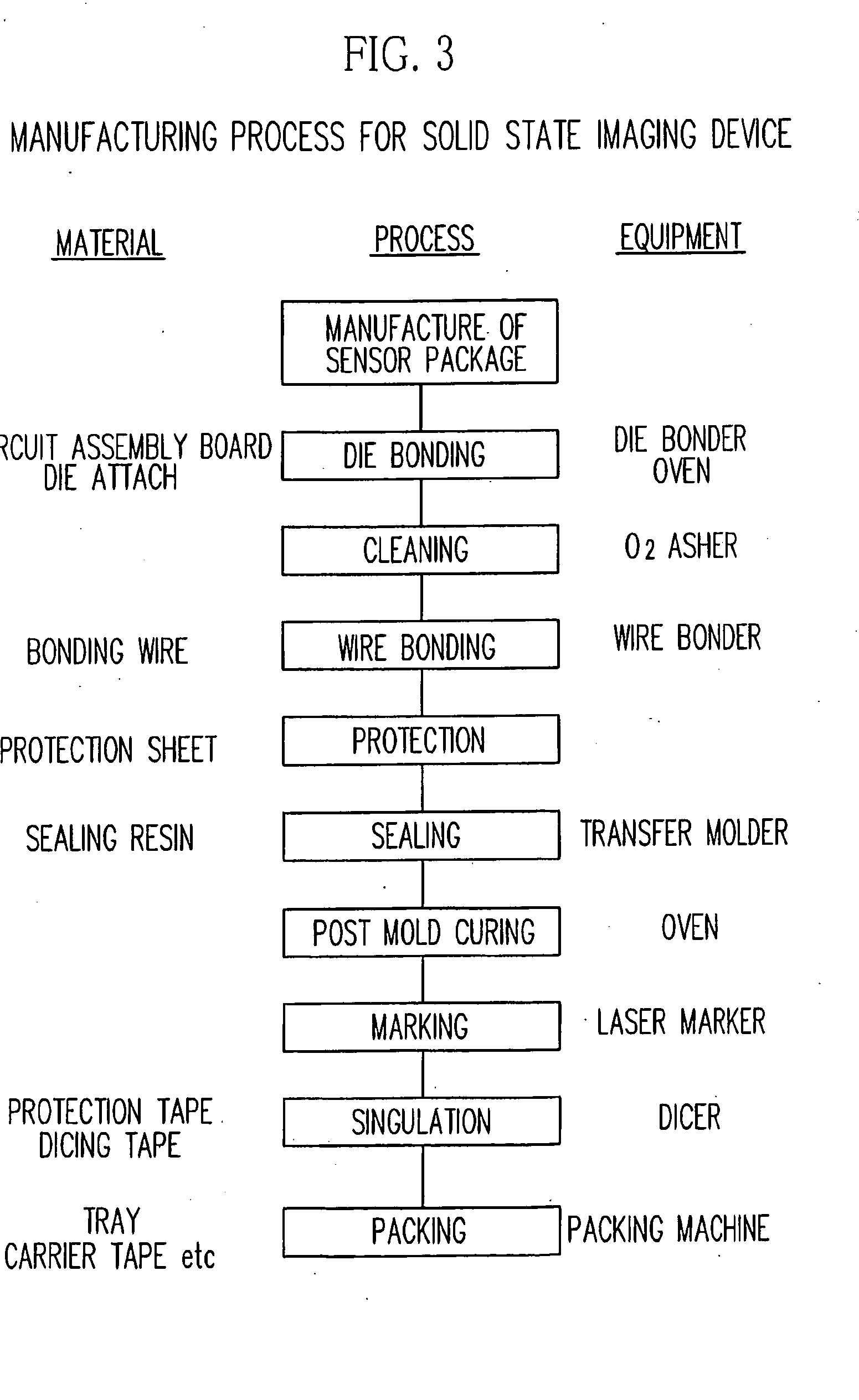

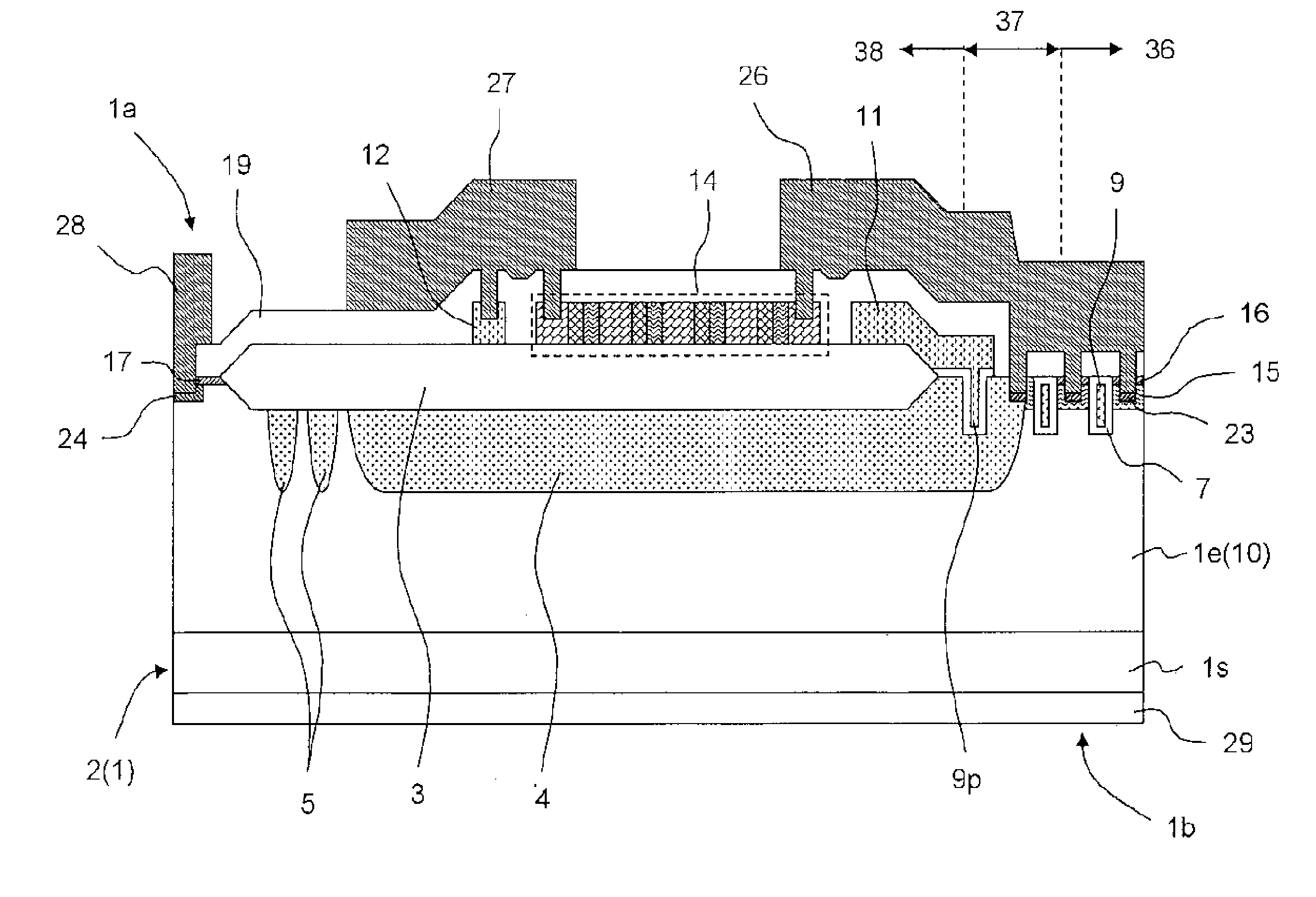

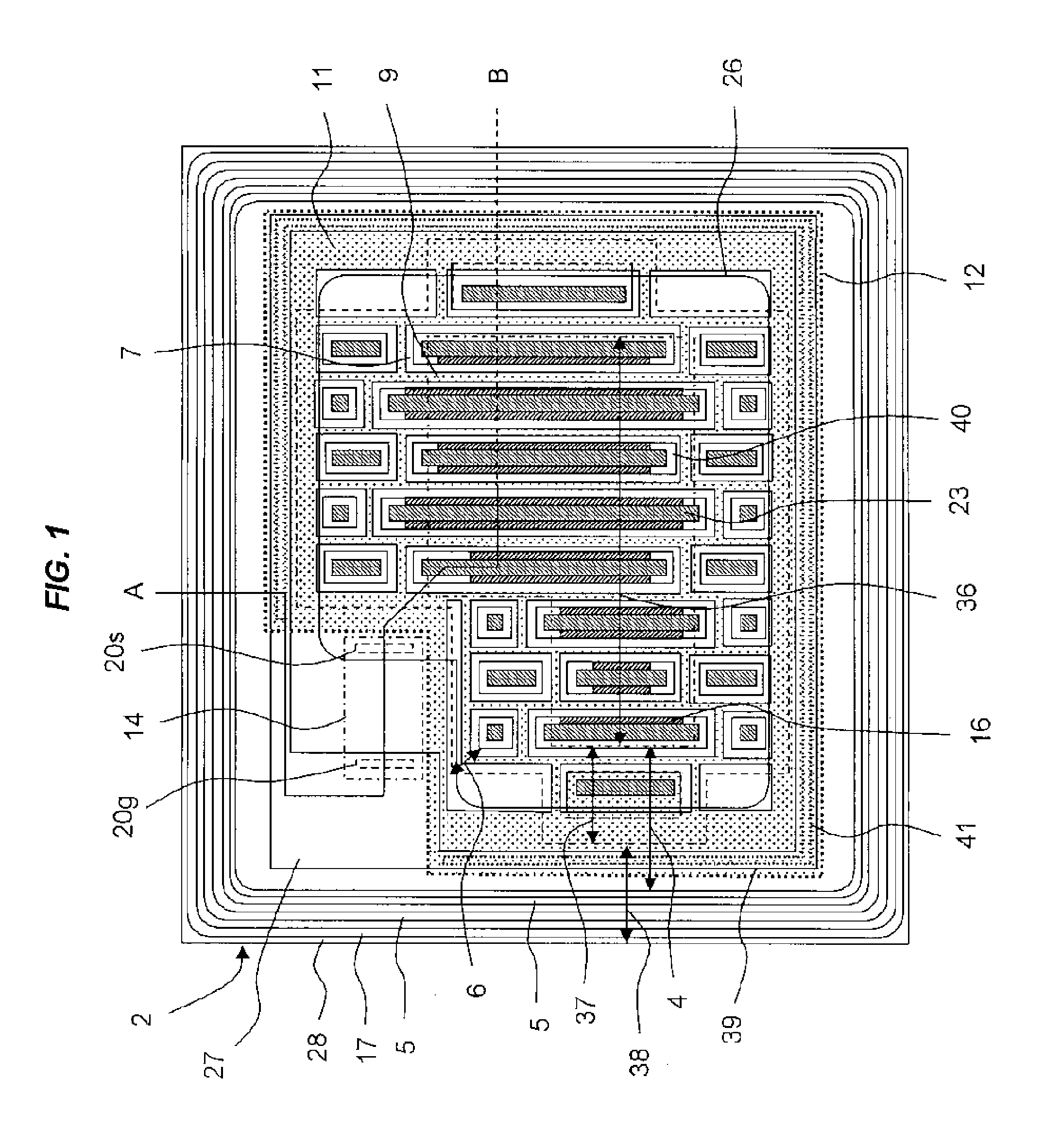

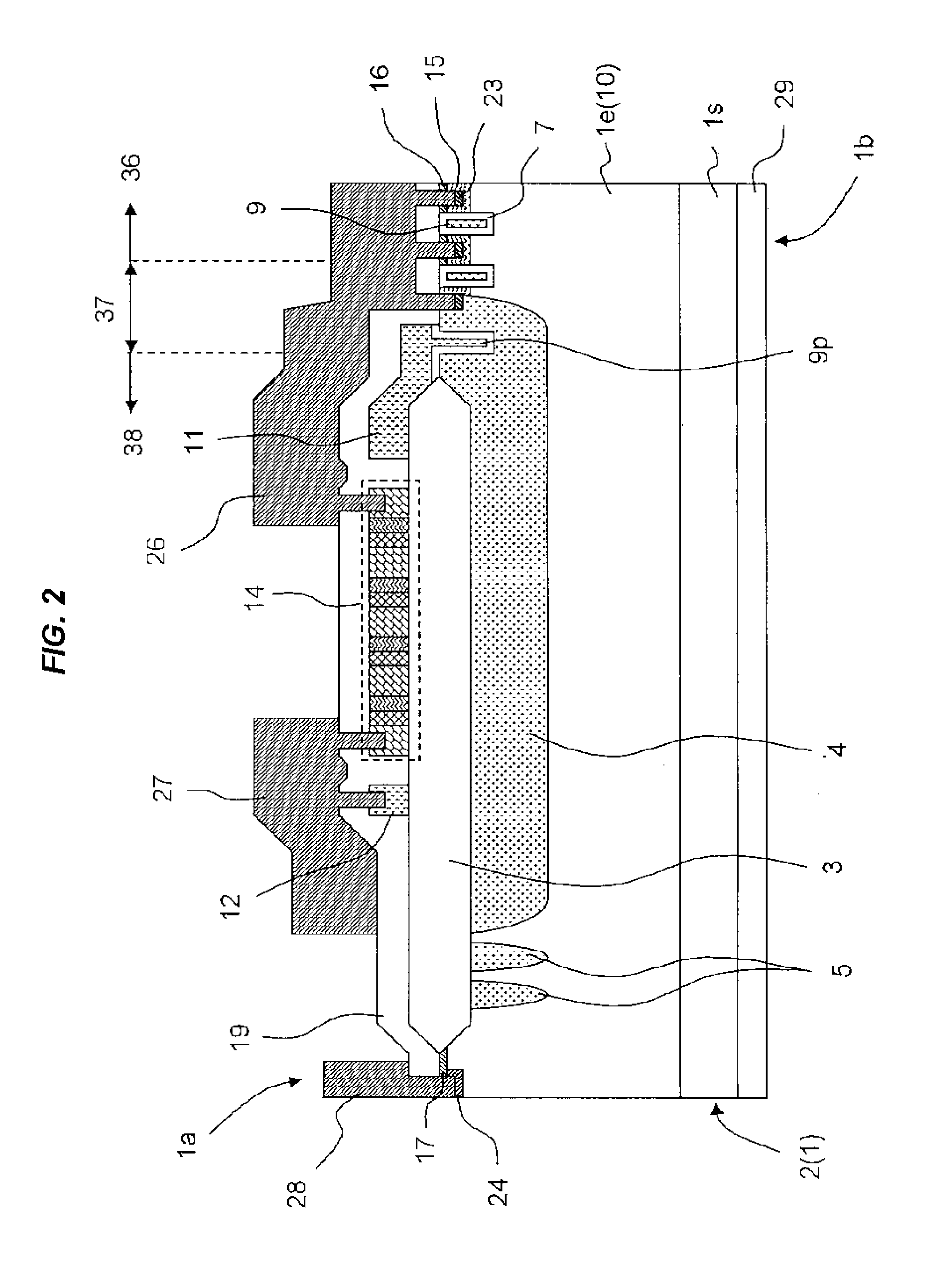

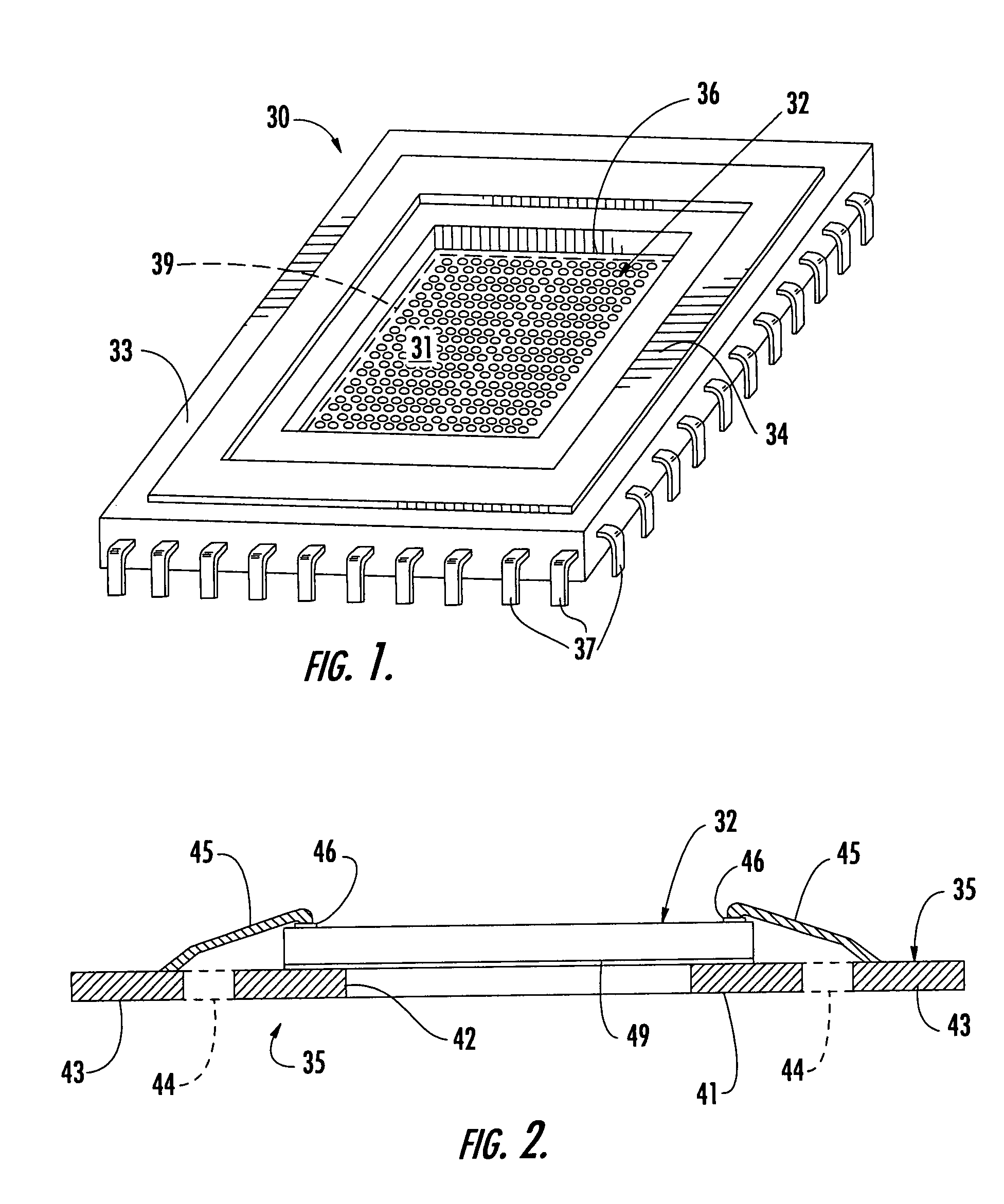

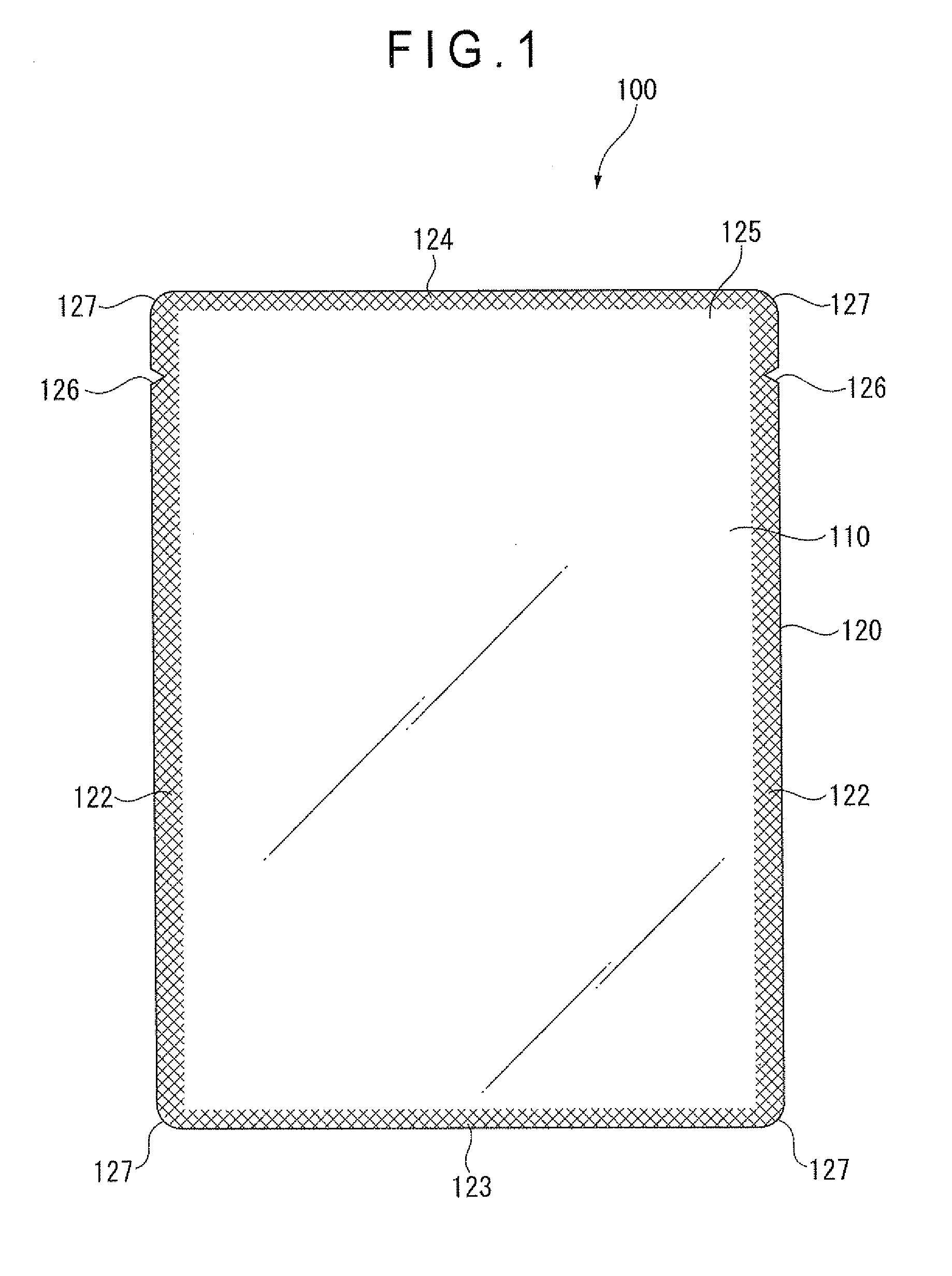

Solid state imaging device and manufacturing method thereof

InactiveUS20090046183A1Increase contact areaSufficient adhesion forceTelevision system detailsTelevision system scanning detailsSolid-stateEngineering

A plurality of sensor packages (4) are fixed to a circuit assembly board (47) and placed on a lower mold die (56) of a transfer molding apparatus (54). Attached inside a cavity (58a) of an upper mold die (58) is a protection sheet (65), which will make contact with the upper face of a cover glass (6) of each sensor package (4). When the upper mold die (58) meshes with the lower mold die (56), the upper face of the cover glass (6) is tightly covered with the protection sheet (65). A plunger (62) is activated to fill the cavities (56a, 58a) with sealing resin (7). The upper face of the cover glass (6) is not stained or damaged when the peripheries of the sensor packages (4) are sealed.

Owner:FUJIFILM CORP

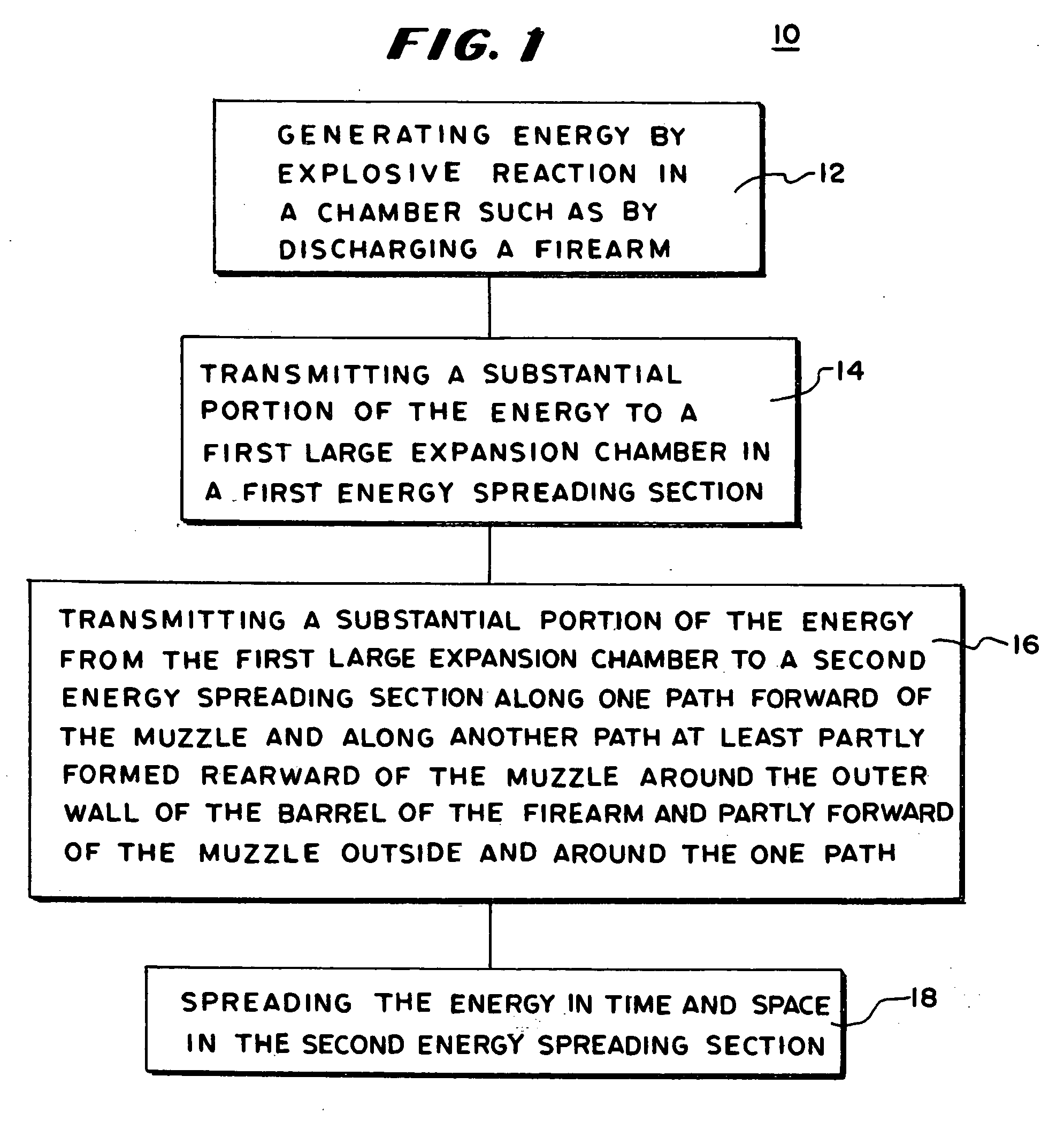

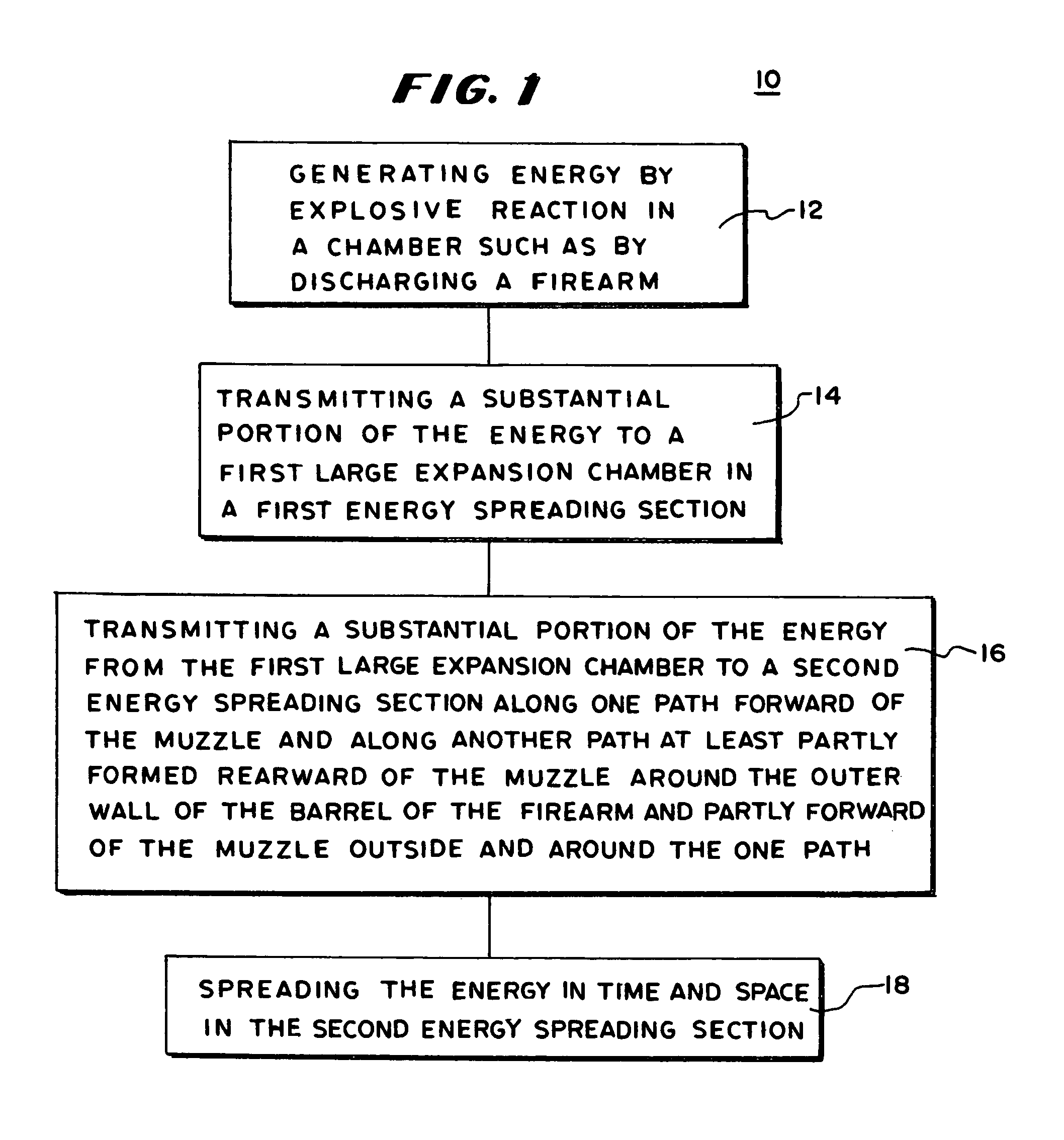

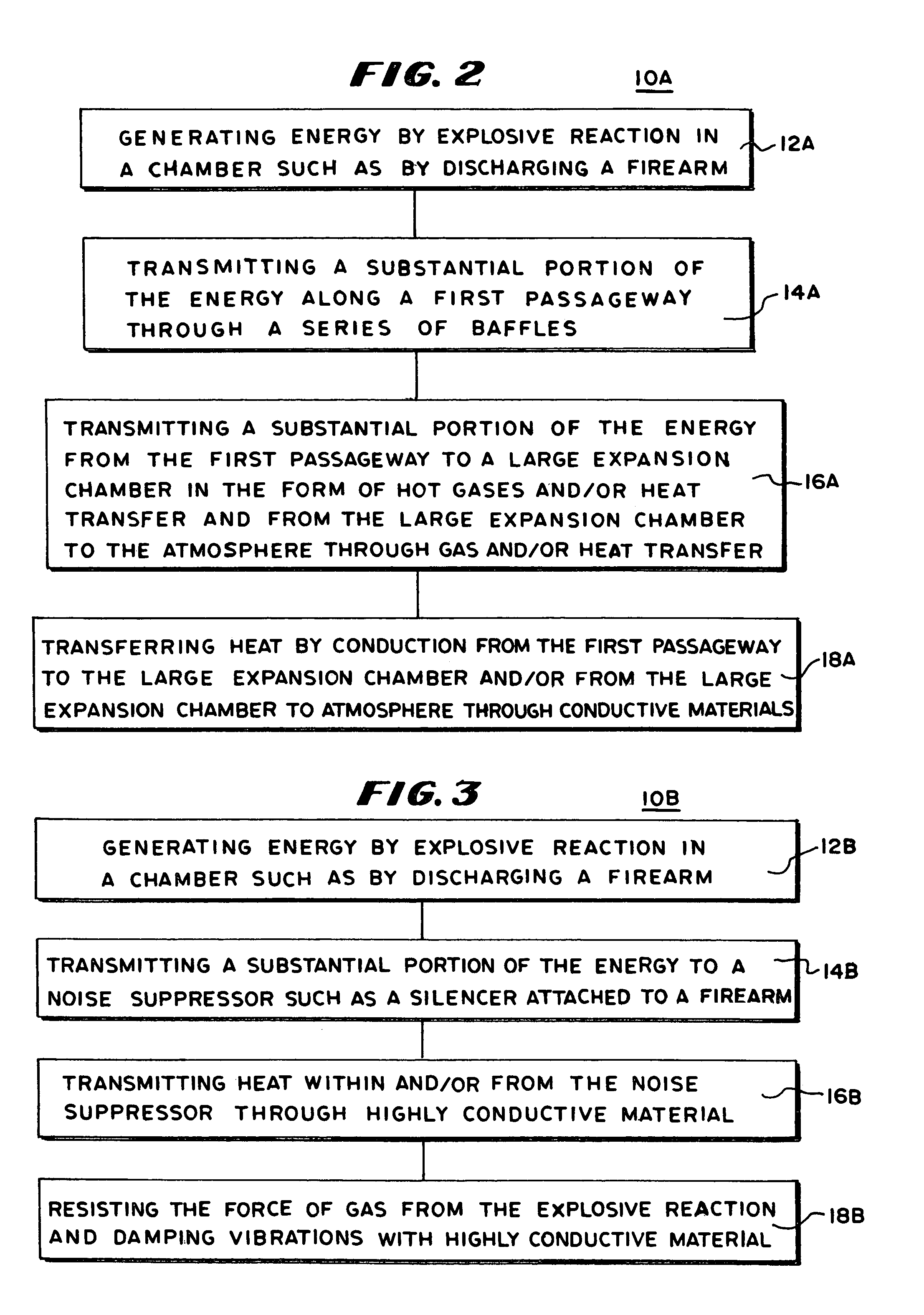

Energy suppressors

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

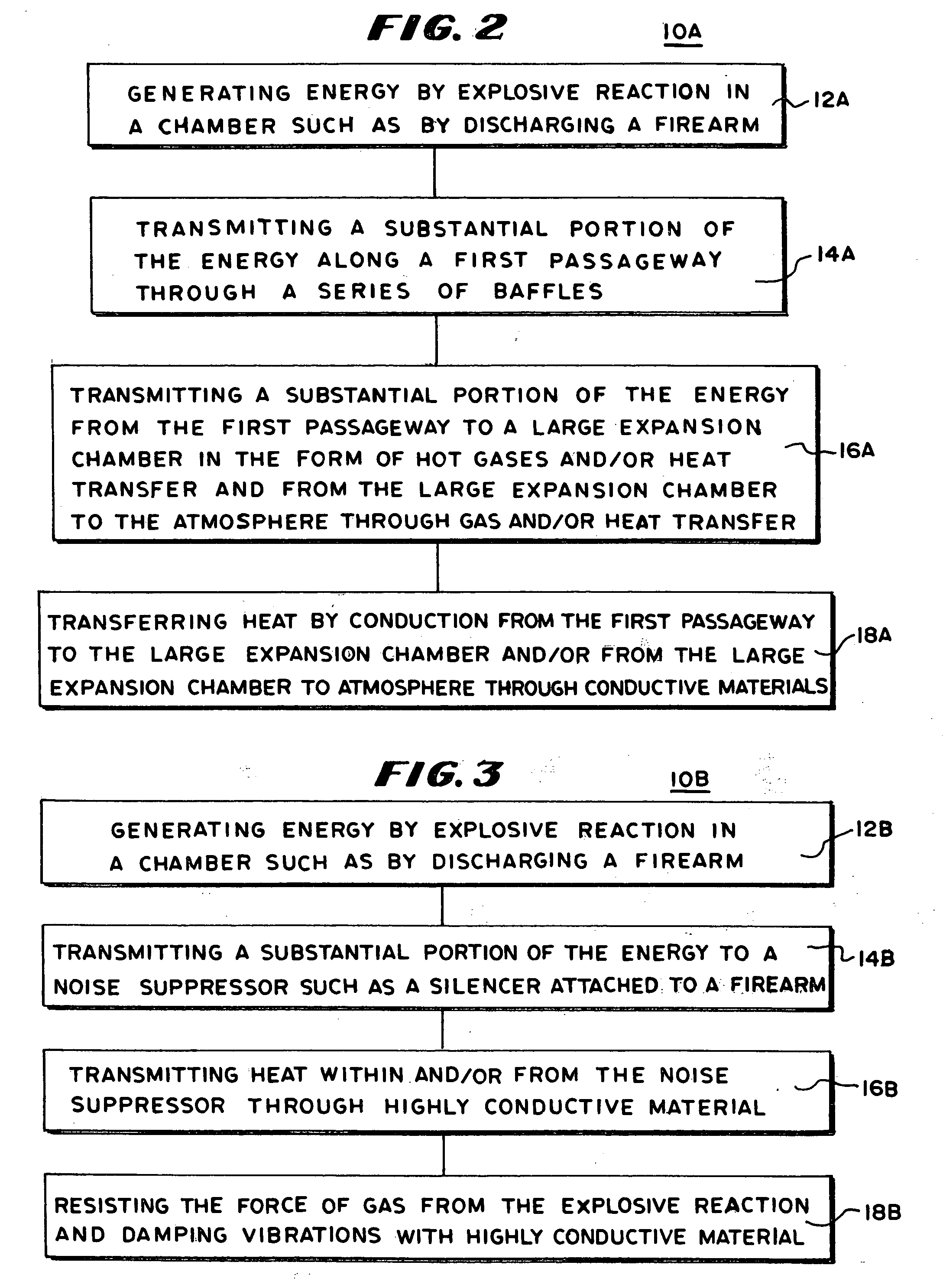

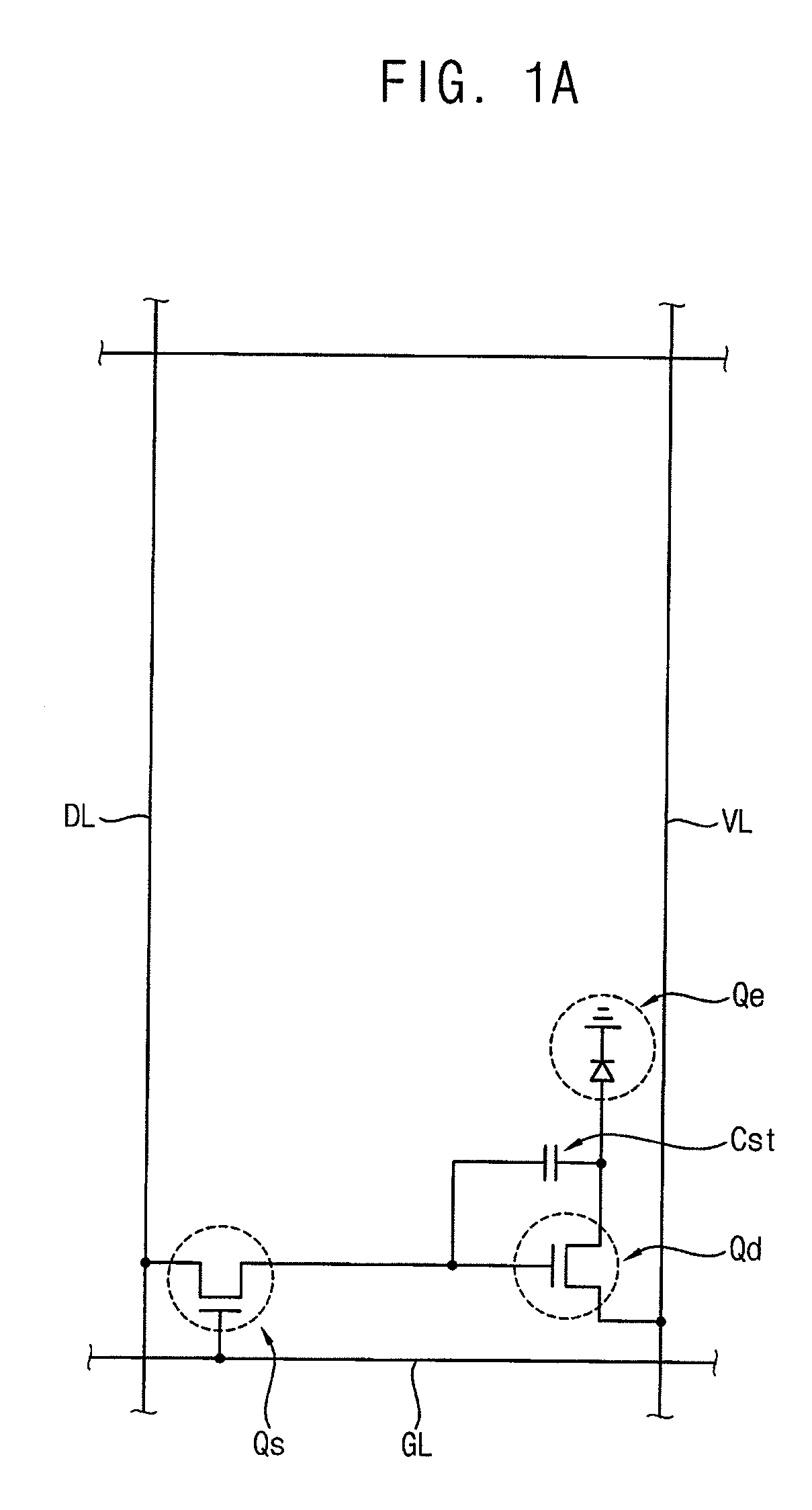

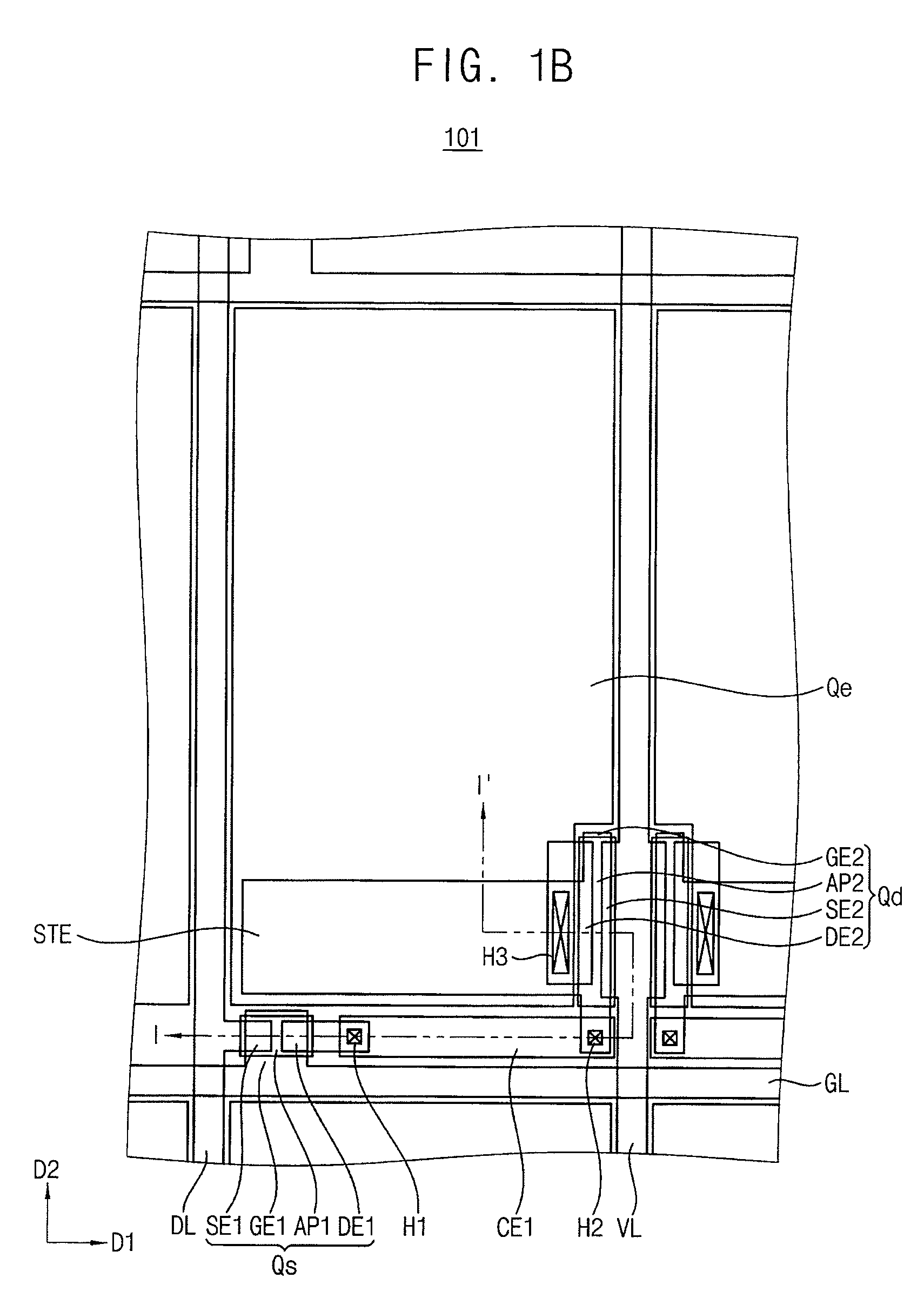

Display substrate and method of manufacturing the same

ActiveUS20100019996A1High resolutionImprove featuresStatic indicating devicesSolid-state devicesAmorphous siliconEngineering

A display substrate includes a switching transistor electrically connected to a gate line and a data line, the data line extending in a first direction substantially perpendicular to the gate line extending in a second direction, the switching transistor including a switching active pattern comprising amorphous silicon, a driving transistor electrically connected to a driving voltage line and the switching transistor, the driving voltage line extended in the first direction, the driving transistor including a driving active pattern comprising a metal oxide; and a light-emitting element electrically connected to the driving transistor.

Owner:SAMSUNG DISPLAY CO LTD

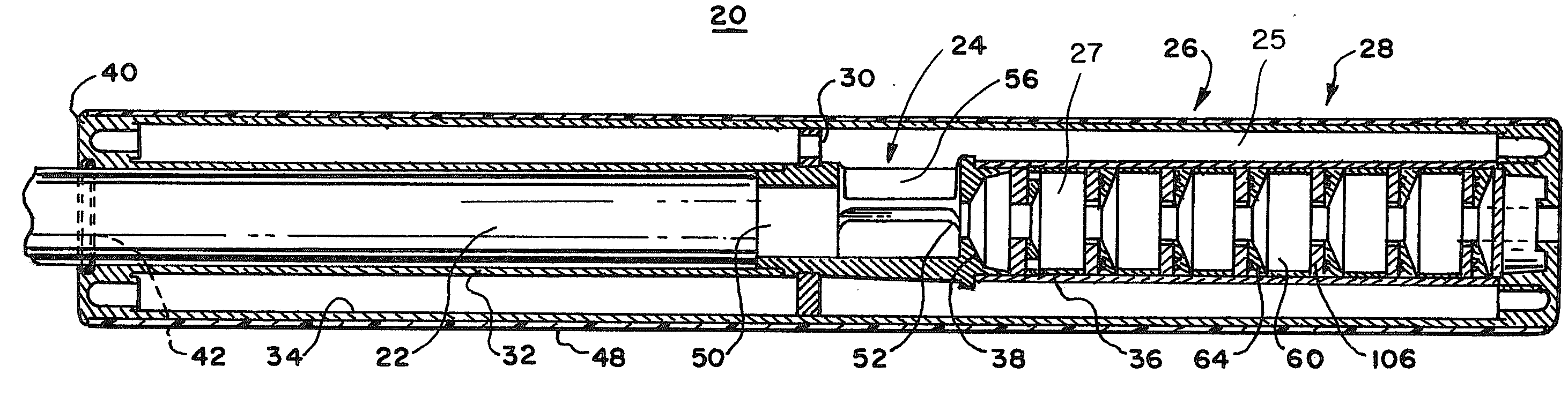

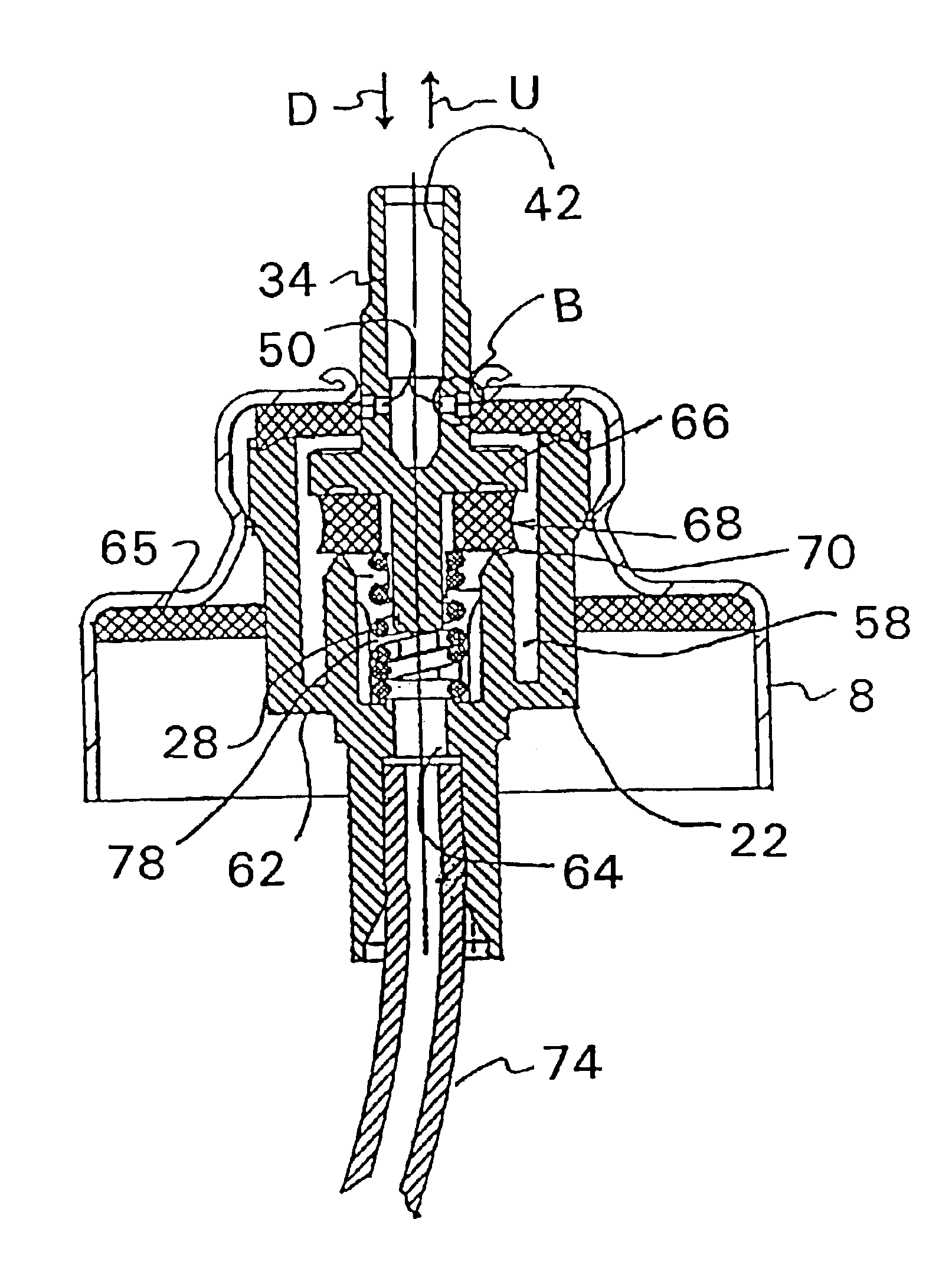

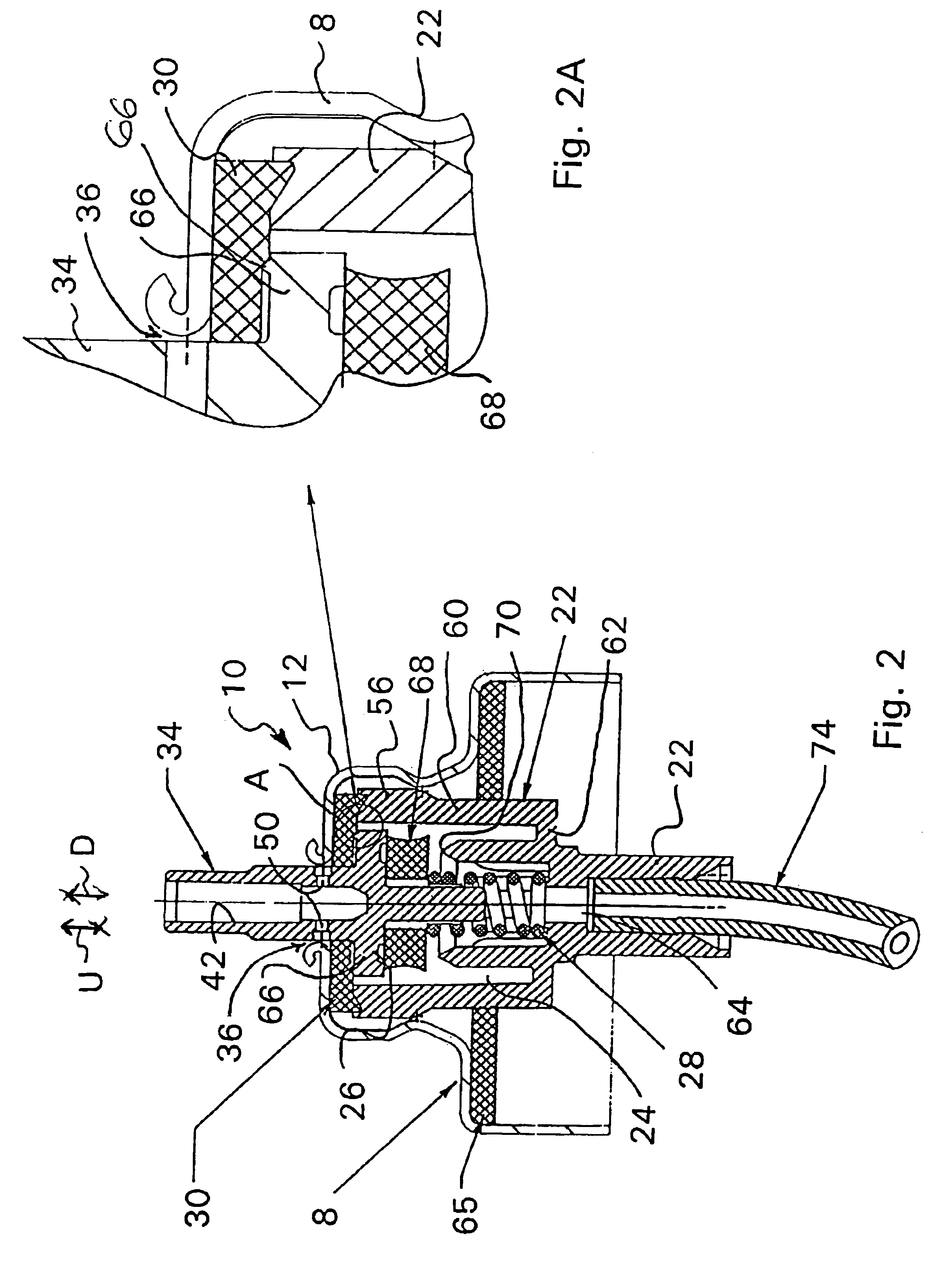

IV Catheter Introducer

ActiveUS20100168674A1Reduce the possibilityEasy to useInfusion syringesInfusion devicesCatheter hubCatheter introducer

An IV catheter introducer having an elastomeric grommet disposed between the housing and the IV catheter assembly that helps avoid unintentional separation of IV catheter assembly from the housing during shipping and handling prior to use, that acts as a needle guide, that helps align the housing and IV catheter assembly coaxially, that indicates that top side of the catheter introducer, that provides proper rotational alignment between the grommet and housing, that wipes blood off the needle during withdrawal of the needle from the catheter assembly and grommet, that impedes blood flow out of the catheter hub after needle withdrawal, and that assists the user in separating the housing from the IV catheter assembly following insertion of the catheter and withdrawal of the needle.

Owner:RETRACTABLE TECH INC

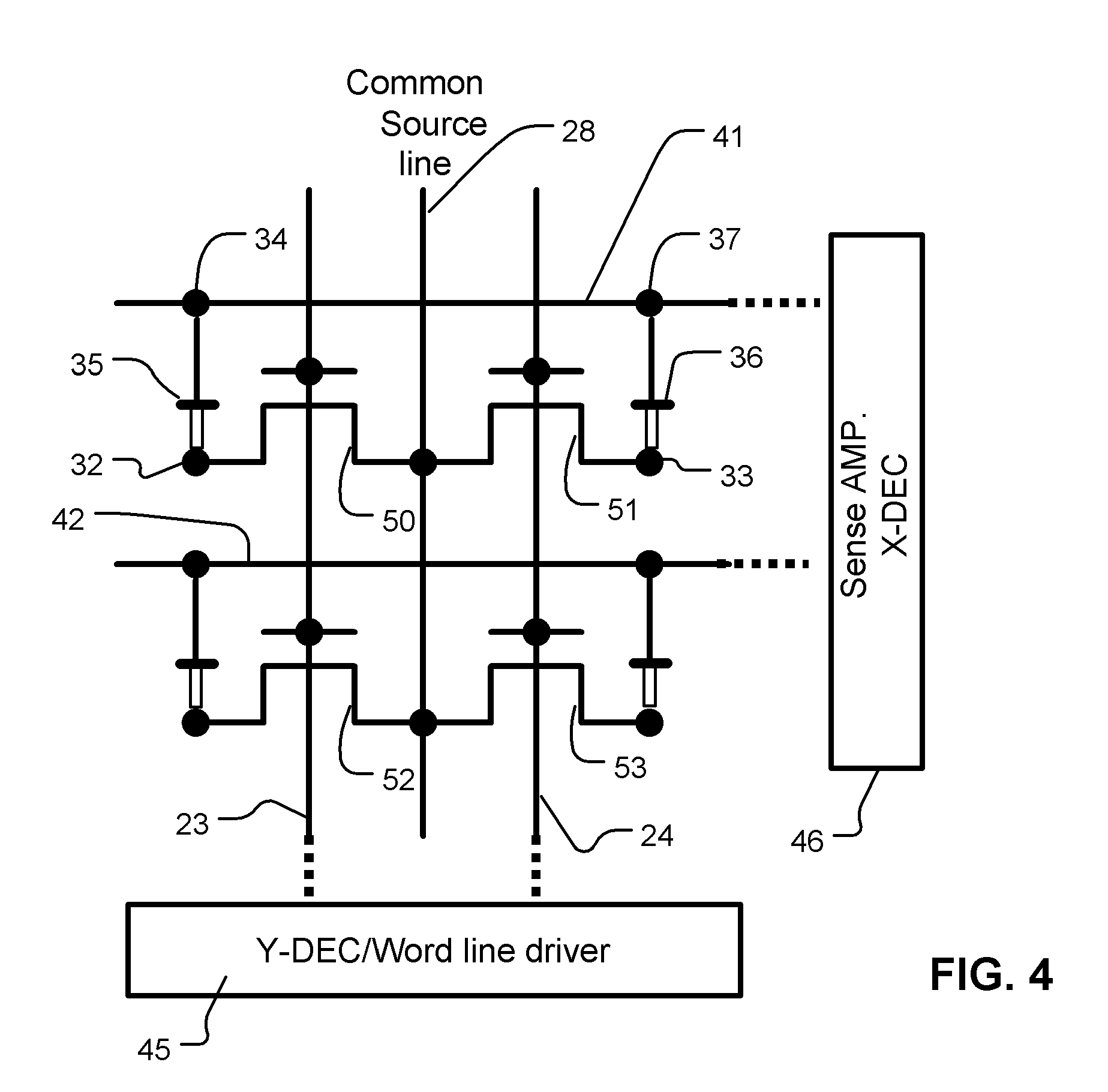

Semiconductor device

InactiveUS20120049187A1Reliable manufacturingEffectively prevent deteriorationSolid-state devicesDiodeZener diodeMiniaturization

Accompanying the miniaturization of a gate electrode of a trench gate power MOSFET, the curvature of the bottom part of the trench increases, and thereby, electric fields concentrate on the part and deterioration of a gate oxide film (insulating film) occurs. The deterioration of the gate insulating film is more likely to occur when the gate side bias is negative in the case of an N-channel type power MOSFET and when the gate side bias is positive in the case of a P-channel type power MOSFET.The present invention is a semiconductor device including an insulating gate power transistor etc. in a chip, wherein a gate protection element includes a bidirectional Zener diode and the bidirectional Zener diode has a plurality of P-type impurity regions (or a P-type impurity region) having different concentrations so that the withstand voltage with its gate side negatively biased and the withstand voltage with the gate side positively biased are different from each other.

Owner:RENESAS ELECTRONICS CORP

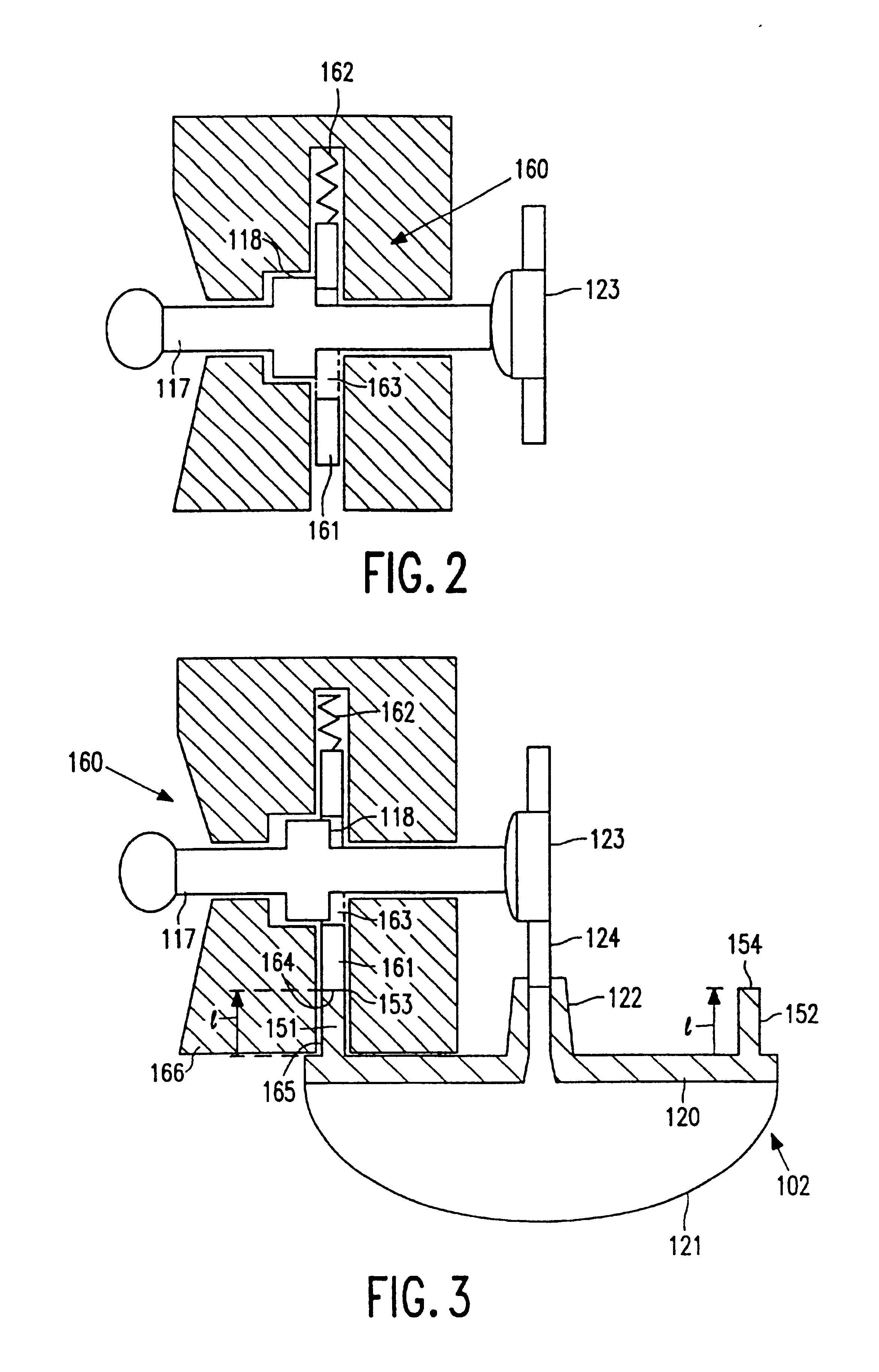

Metering valve for aerosol container

InactiveUS6978916B2Improve easy of assemblyMinimize amountPowdered material dispensingSolid materialInternal cavityValve stem

A metering valve assembly comprising a ferrule and a valve housing defining an internal cavity. The valve housing accommodates an annular flange and a compression spring therein with a valve gasket closing the internal cavity. The valve housing is attached to the ferrule such that a stem portion of the valve stem protrudes through apertures provided in both the valve gasket and the ferrule. A stem portion has a discharge passageway which is normally closed by the valve gasket. Either an undersurface of the annular flange or a mating surface of the valve housing is provided with a compressible sealing member while the other is provided with an annular edge. The compressible sealing member and the annular edge form a seal therebetween, when the valve stem is sufficiently depressed, to partition the interior cavity into a metering chamber and a separate filling chamber whereby product may only be dispensed solely from the metering chamber when a product flow path is established.

Owner:SUMMIT PACKAGING SYST

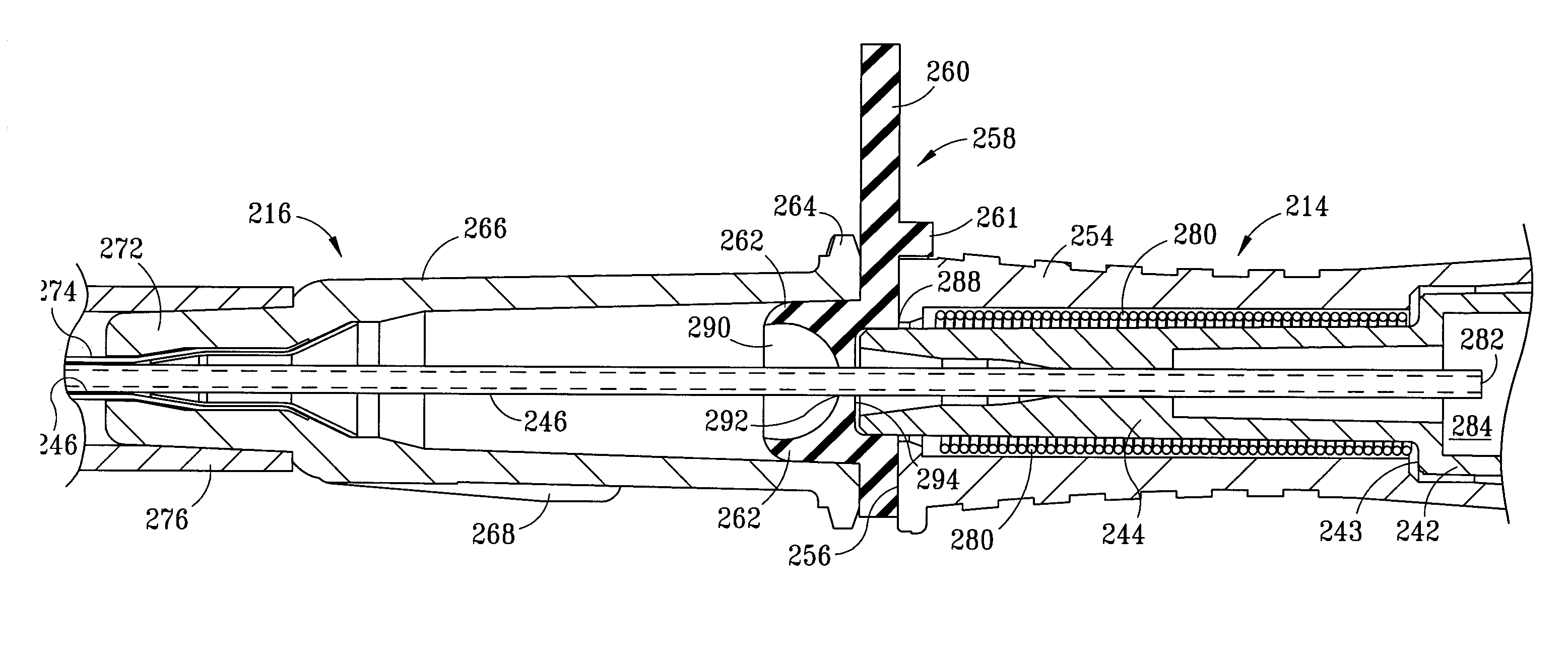

Energy suppressors

ActiveUS7789008B2Good noise suppression characteristicsReduce the amplitudeWeapon componentsBursting strengthFiber

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

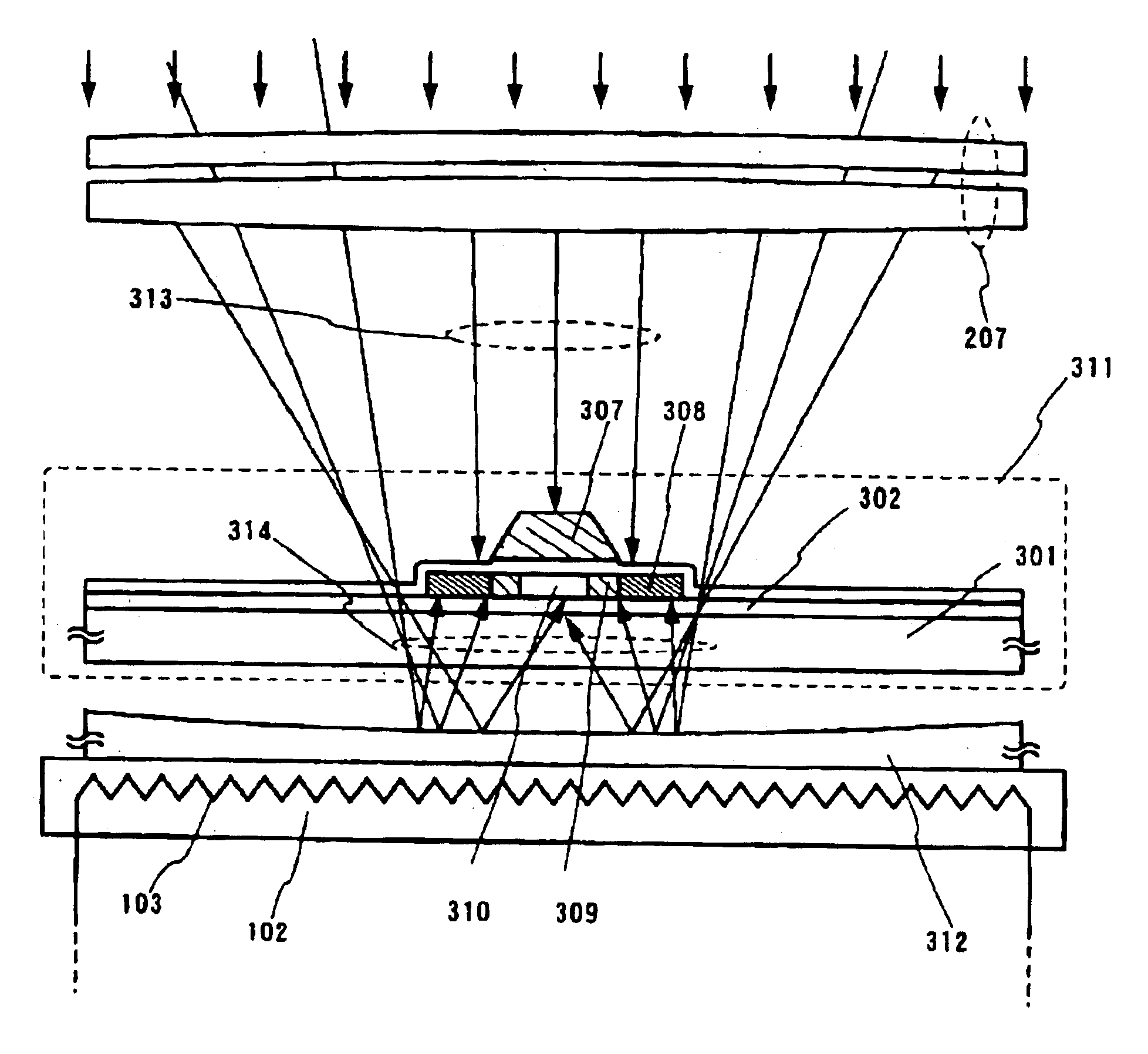

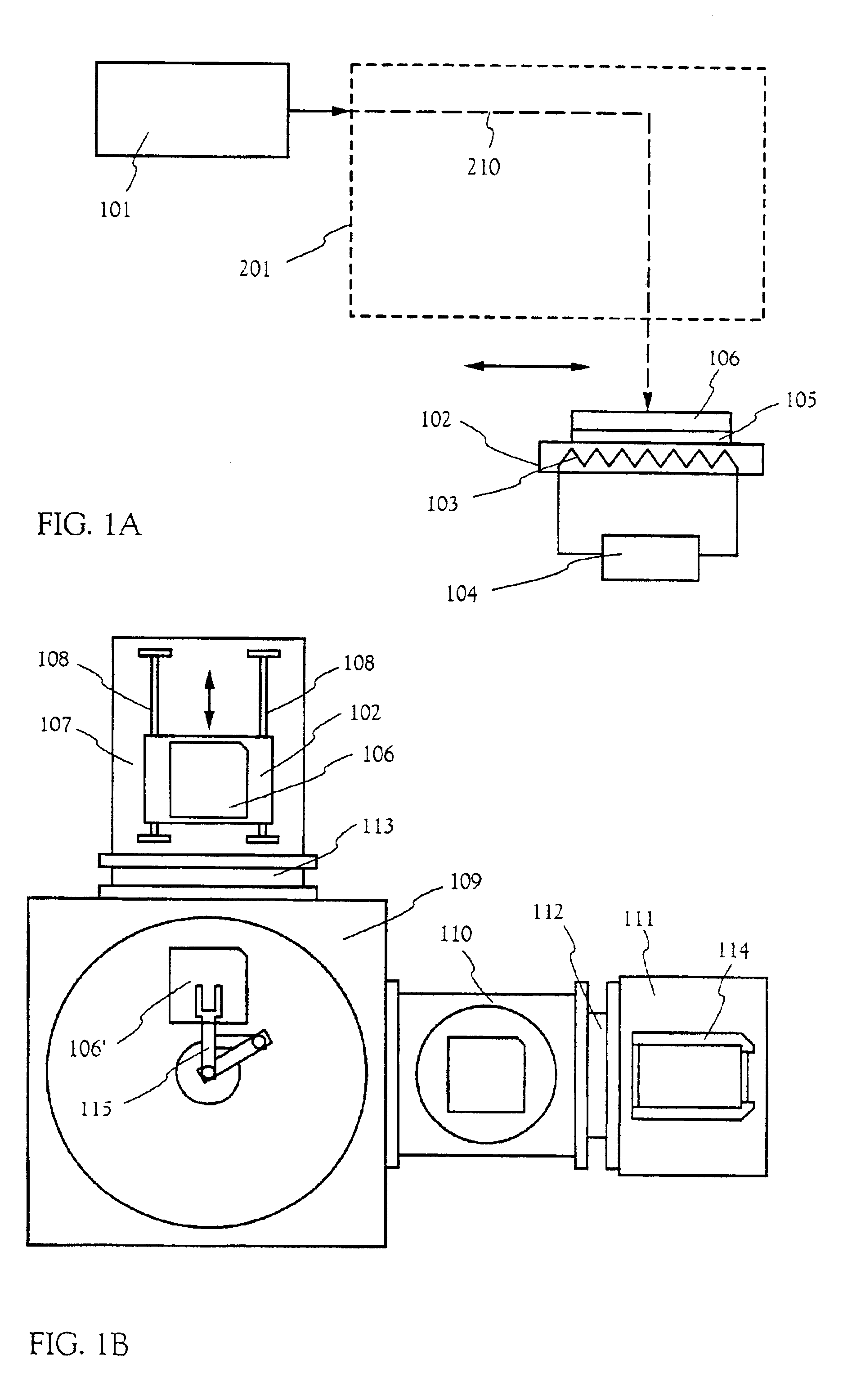

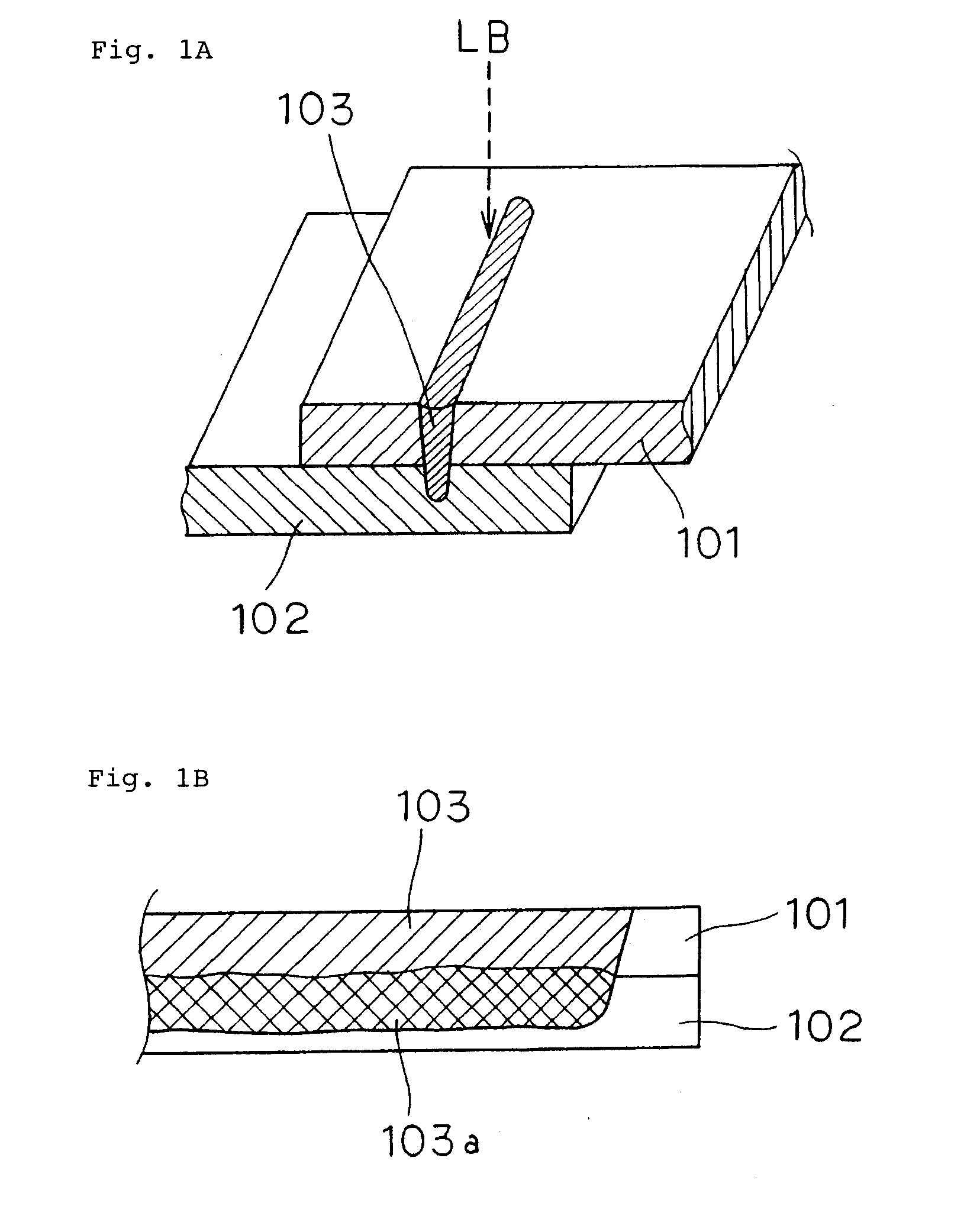

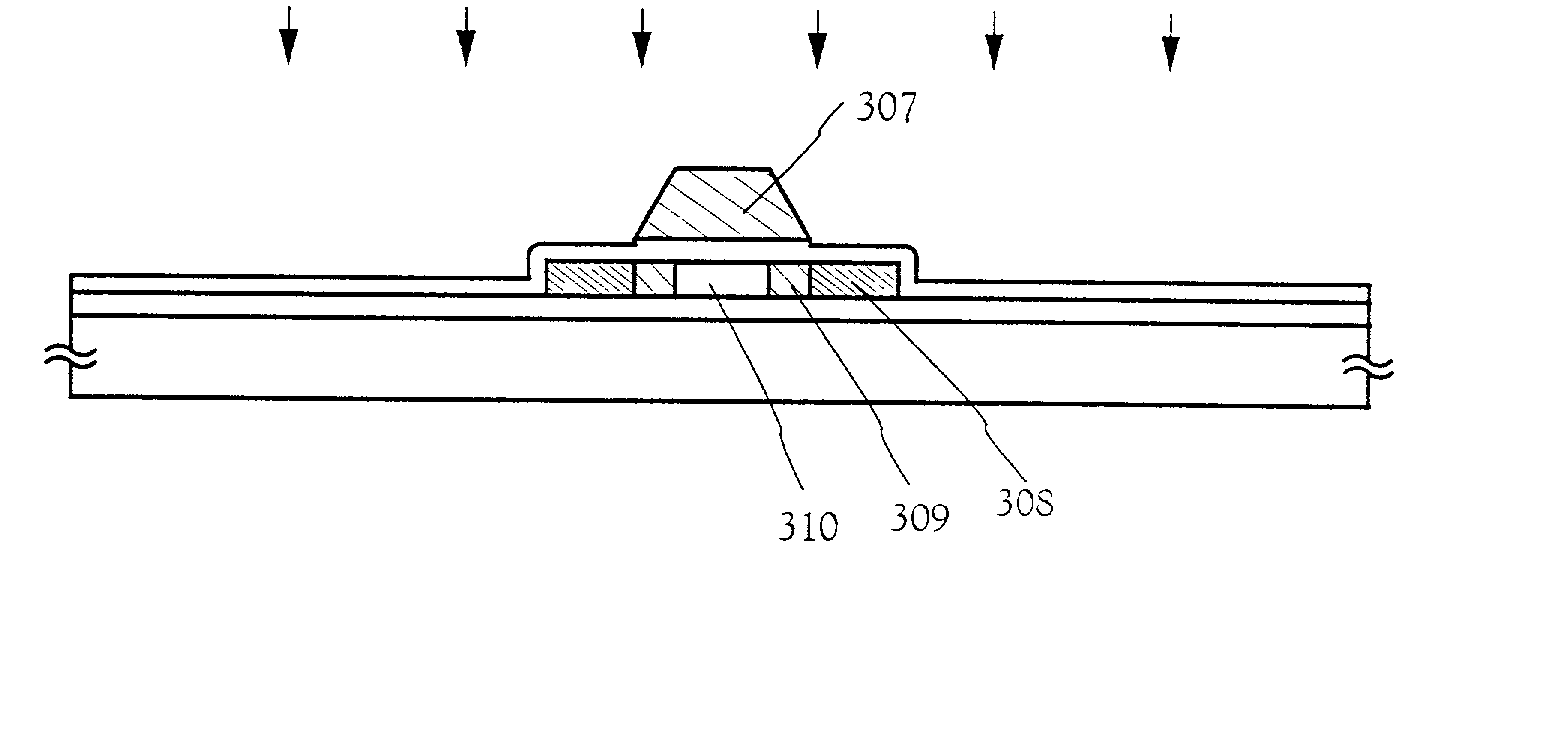

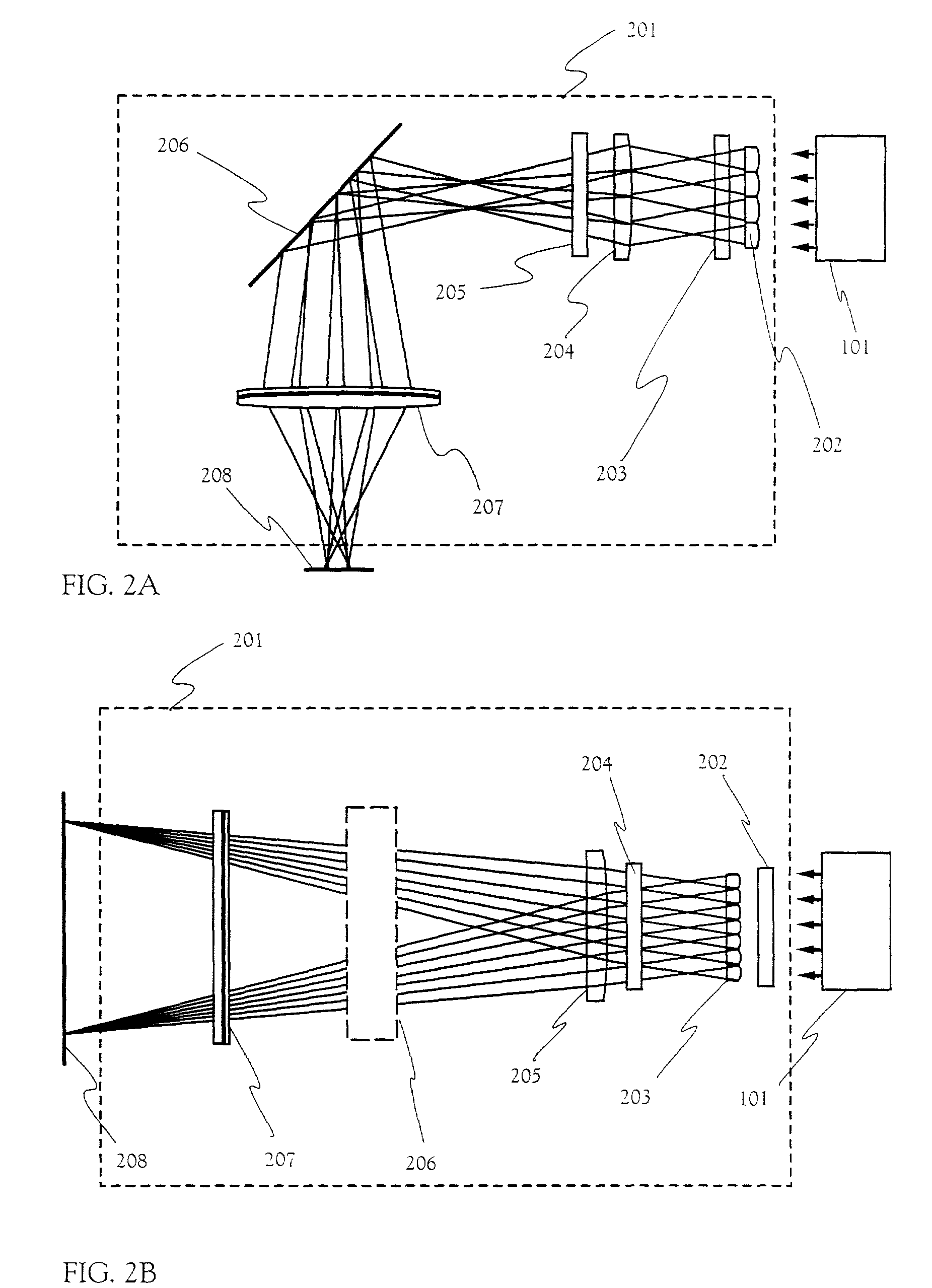

Method of making a thin film transistor using laser annealing

InactiveUS6809012B2Activation can be moreRecovery can be moreTransistorSolid-state devicesNoble gasLaser light

The present invention is characterized in that gettering is performed such that impurity regions to which a noble gas element is added are formed in a semiconductor film and the metallic element included in the semiconductor film is segregated into the impurity regions by laser annealing. Also, a reflector is provided under a substrate on which a semiconductor film is formed. When laser light transmitted through the semiconductor film substrate is irradiated from the front side of the substrate, the laser beam is reflected by the reflector and thus the laser light can be irradiated to the semiconductor film from the read side thereof. Laser light can be also irradiated to low concentration impurity regions overlapped with a portion the gate electrode. Thus, an effective energy density in the semiconductor film is increased to thereby effect recovery of crystallinity and activation of the impurity element.

Owner:SEMICON ENERGY LAB CO LTD

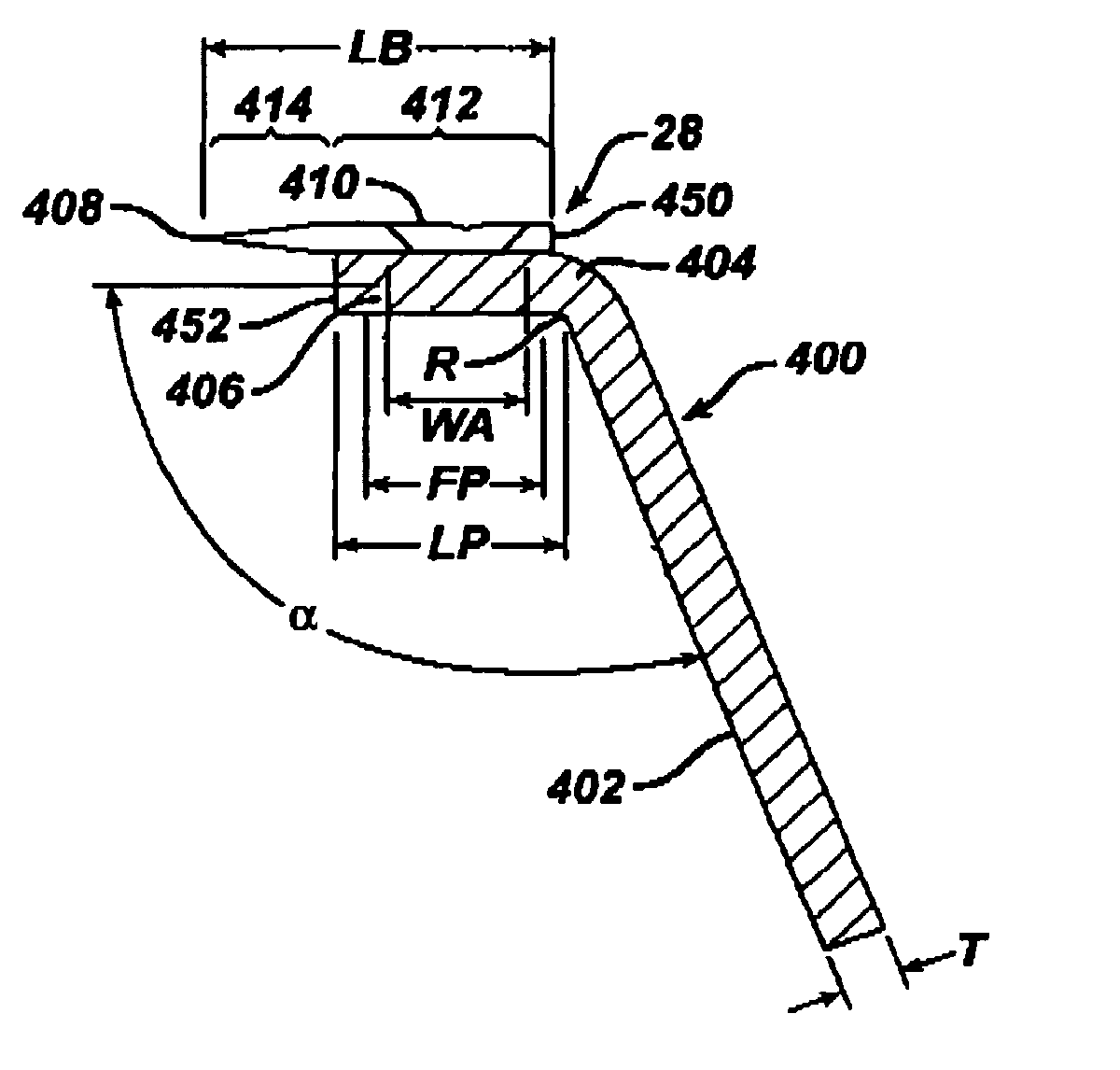

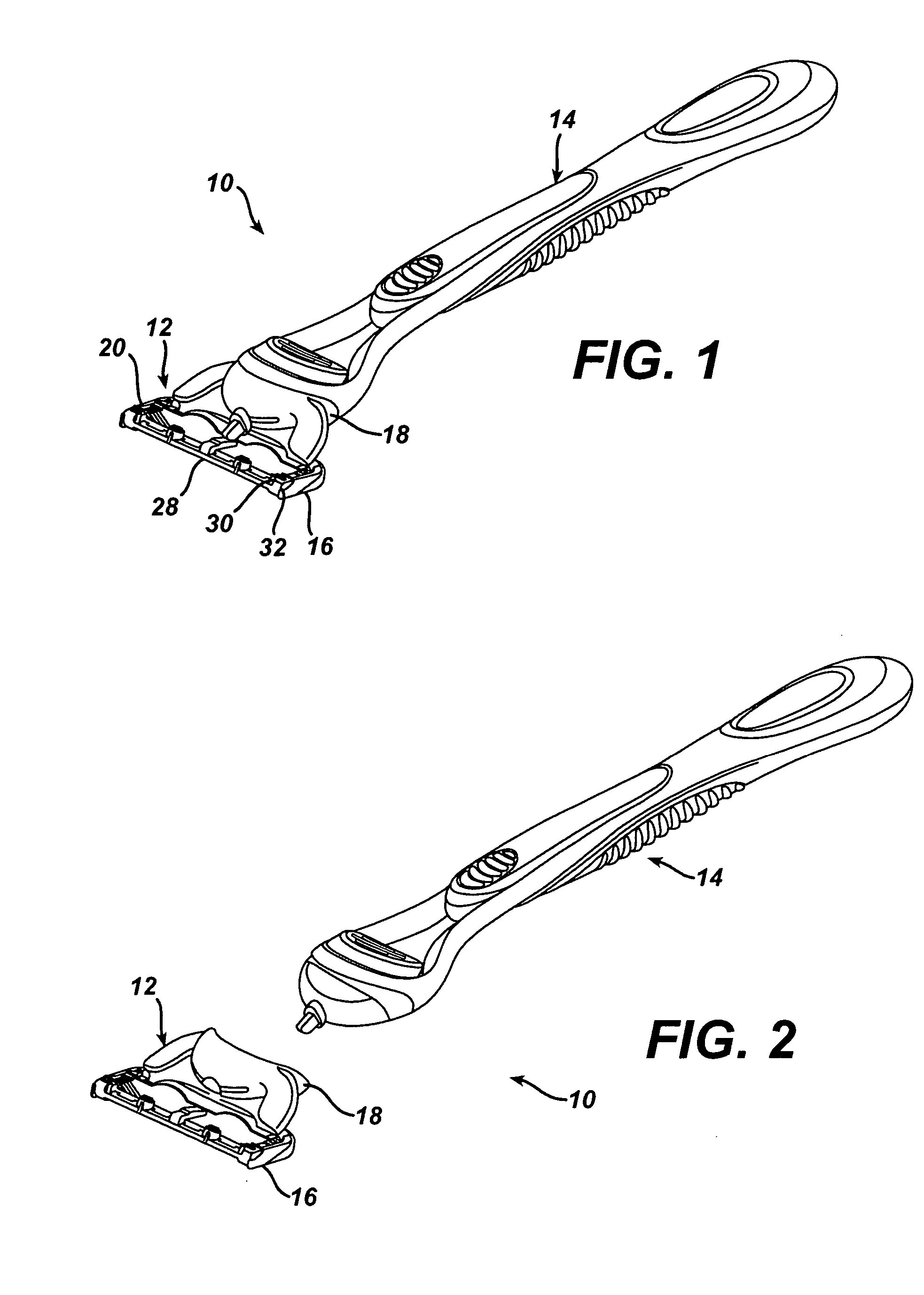

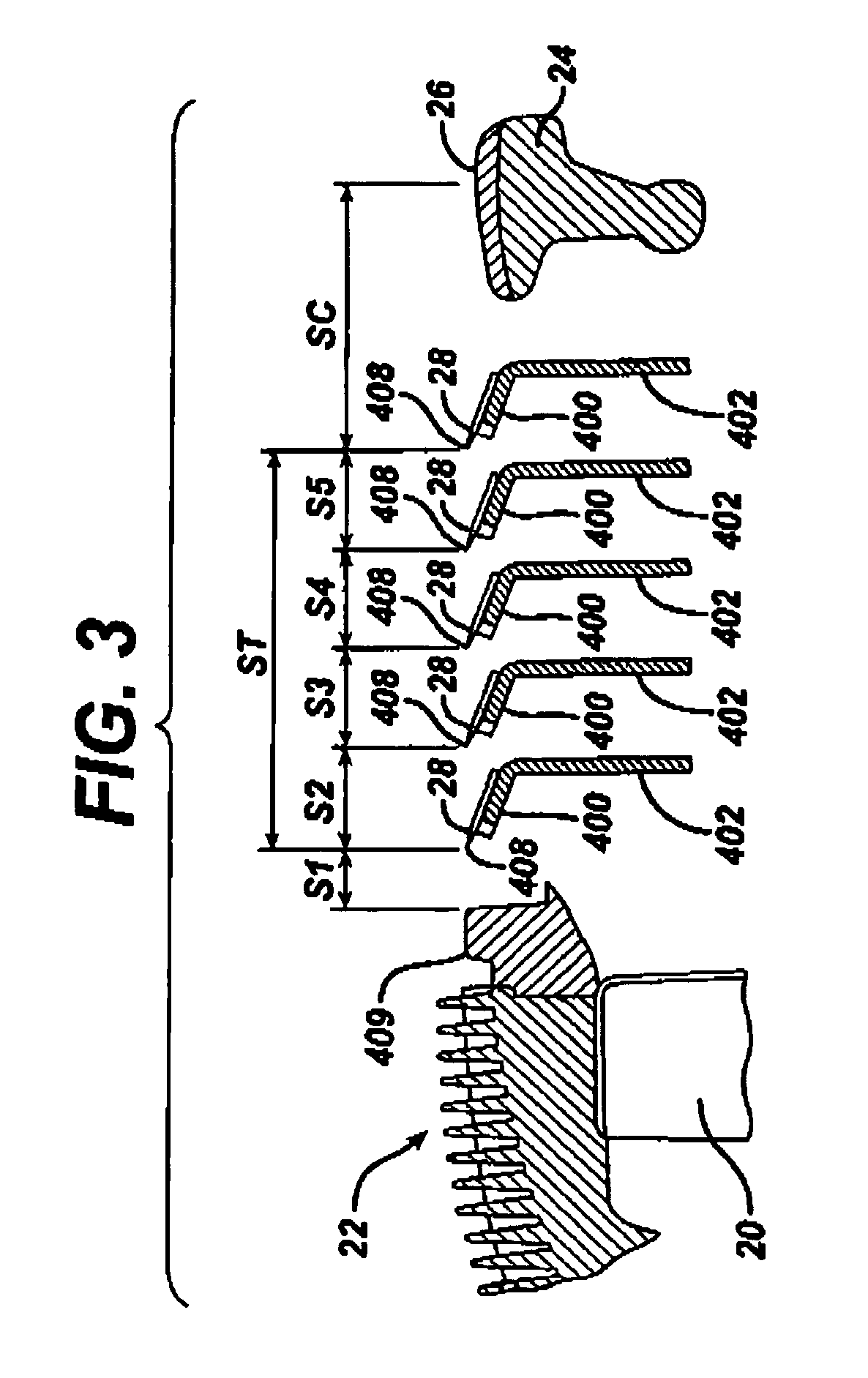

Cutting members for shaving razors with multiple blades

ActiveUS7131202B2Reliable manufacturingSufficiently compactMetal working apparatusRazor stropEngineering

A cutting member for a shaving razor includes an elongated metal blade having a cutting edge, a blade end, a tapered portion near the blade end and a uniform thickness portion extending from the blade end to the tapered portion, and an elongated bent metal support that has a platform portion, a bent portion and a base portion extending downward from the bent potion. The platform portion extends forward from the bent portion to a front end. The platform portion includes an attachment area that is spaced from the front end and the bent portion, and a flat portion that includes and extends beyond the attachment area. The uniform thickness portion of the blade is supported on the platform portion and secured thereto at the attachment area, the tapered portion extending forward beyond the front end of the platform portion.

Owner:THE GILLETTE CO

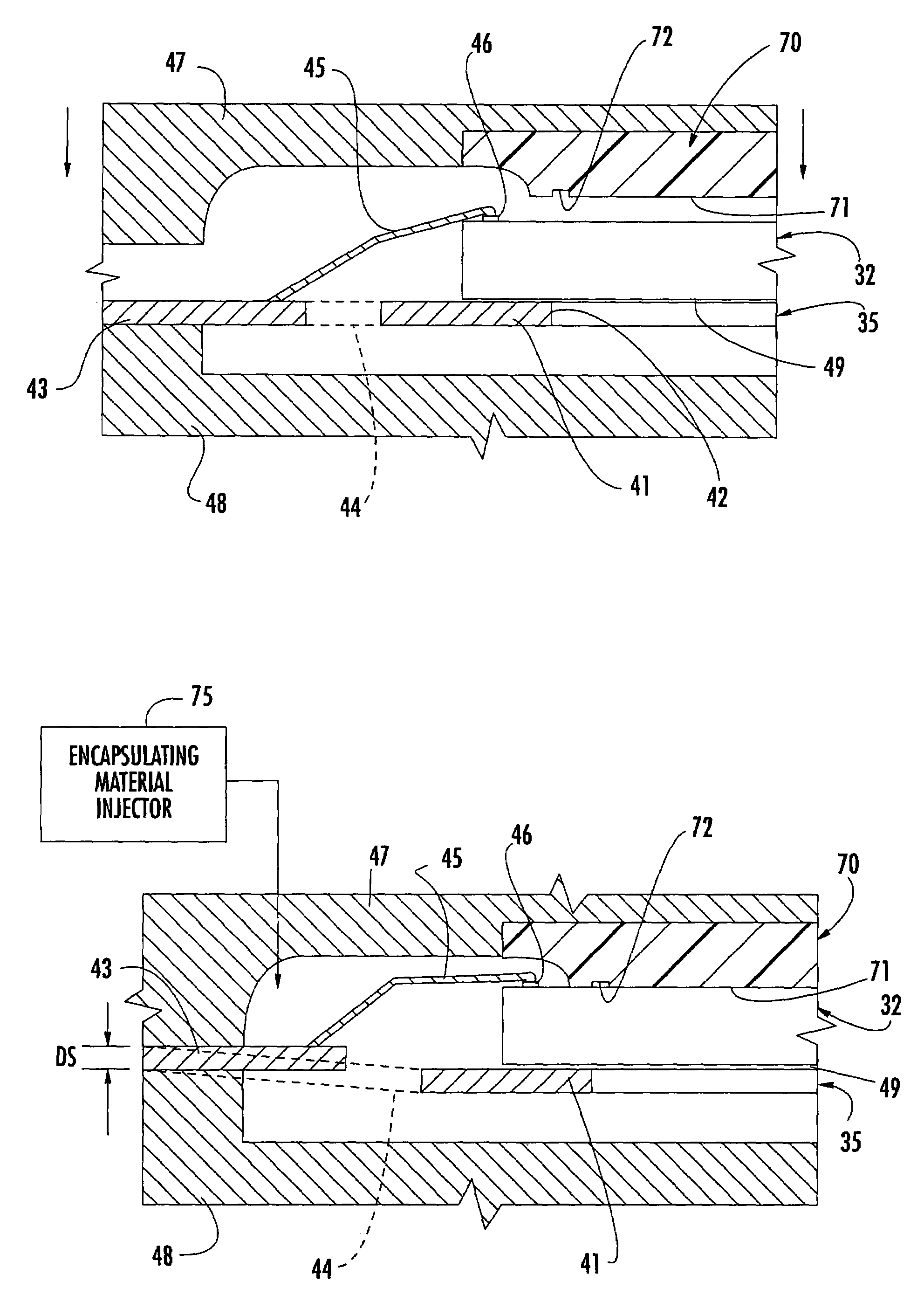

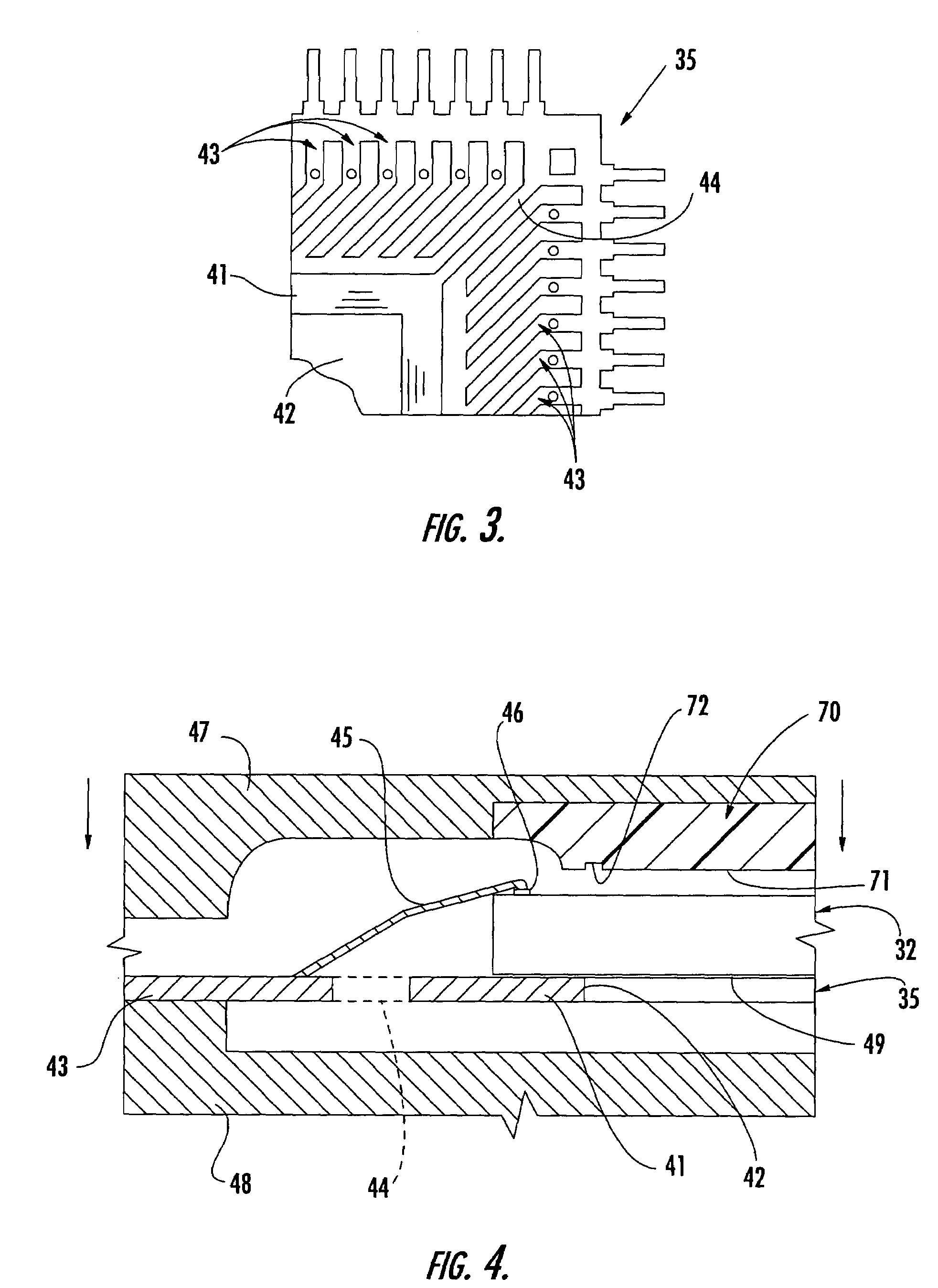

Methods and apparatus for making integrated circuit package including opening exposing portion of the IC

InactiveUS7049166B2Low costHigh manufacturing reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit packaging

A method for making an IC package preferably includes providing a mold including first and second mold portions, and wherein the first mold portion carries a mold protrusion defining an IC-contact surface with peripheral edges and a bleed-through retention channel positioned inwardly from the peripheral edges. The method also preferably includes closing the first and second mold portions around the IC and injecting encapsulating material into the mold to encapsulate the IC and make the IC package having an exposed portion of the IC adjacent the mold protrusion. Morever, the bleed-through retention channel retains any encapsulating material bleeding beneath the peripheral edges of the IC contact surface, and prevents the encapsulating material from reaching further onto the exposed portion of the IC. The method may also include releasing the IC package with the exposed portion from the mold.

Owner:INTERCONNECT SYST GROUP +1

Fluid dispenser with internal pump

A hand operated fluid dispensers comprised of a sealed flexible reservoir chamber containing a fluid, a flexible pump chamber encased by and drawing fluid from the reservoir, and a pump cycled by external pressure applied through a reservoir wall. This class of simple, inexpensive, disposable dispensers is particularly useful in packaging cosmetics, foodstuffs, and healthcare products. As pocketable dispensers they are popular for dispensing small amounts of stored viscous liquids easily damaged when exposure to the atmosphere, a condition where sealed reservoirs coupled with airless pumps working together successfully prevent such product contamination and deterioration. A method of improved healthcare employing such pump dispensers containing a hand sanitizing fluid is also discussed.

Owner:PENNCREEK

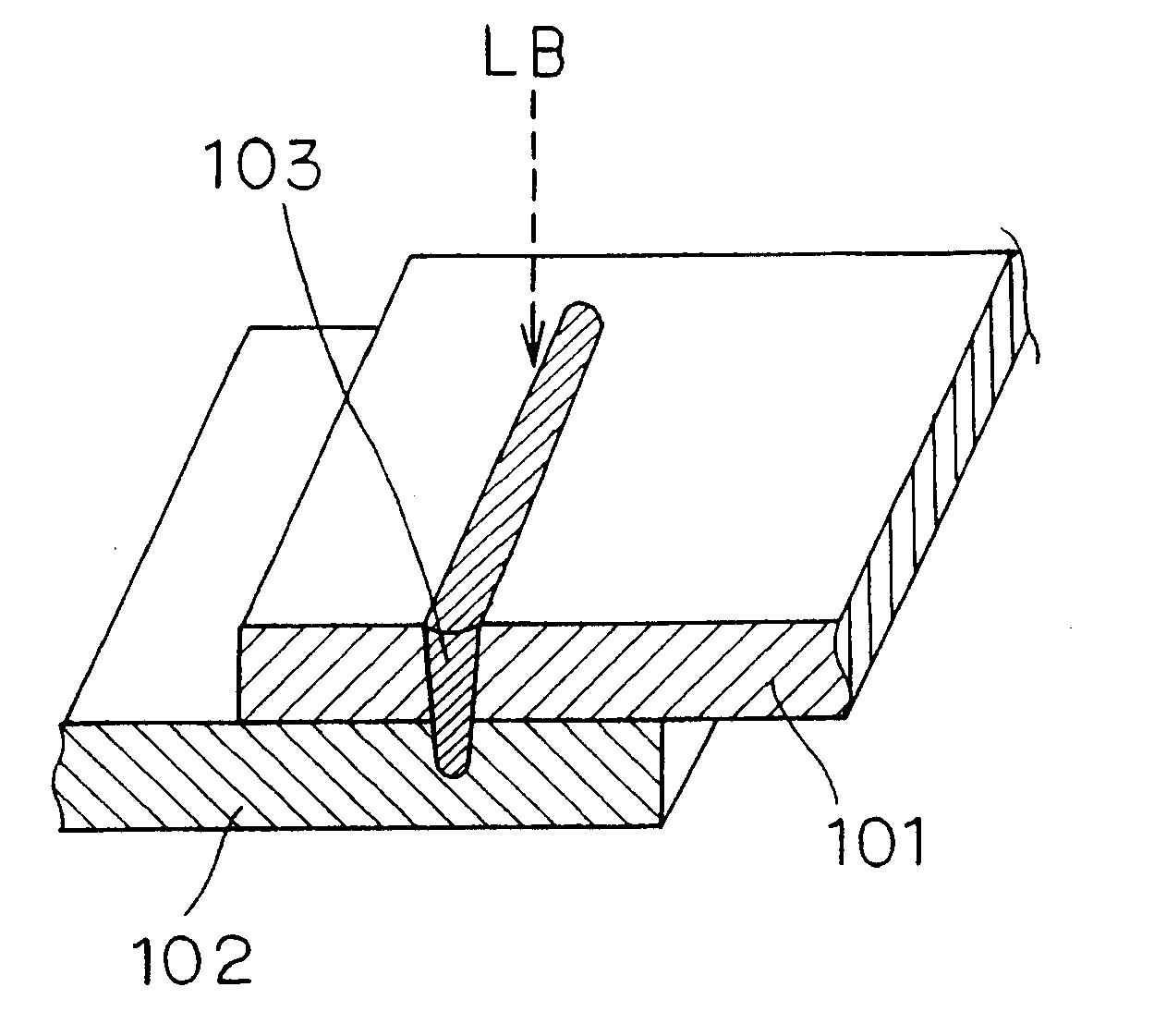

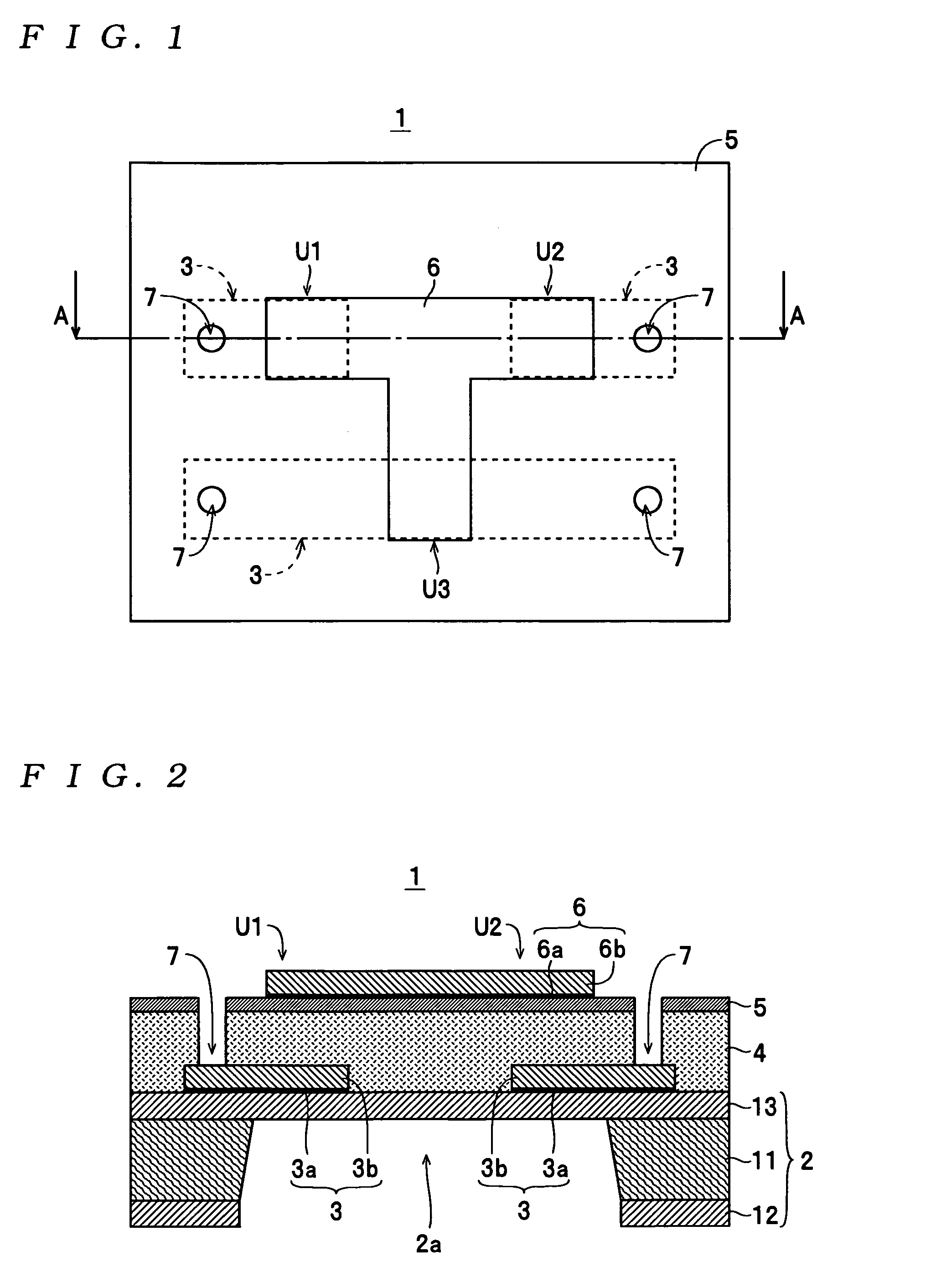

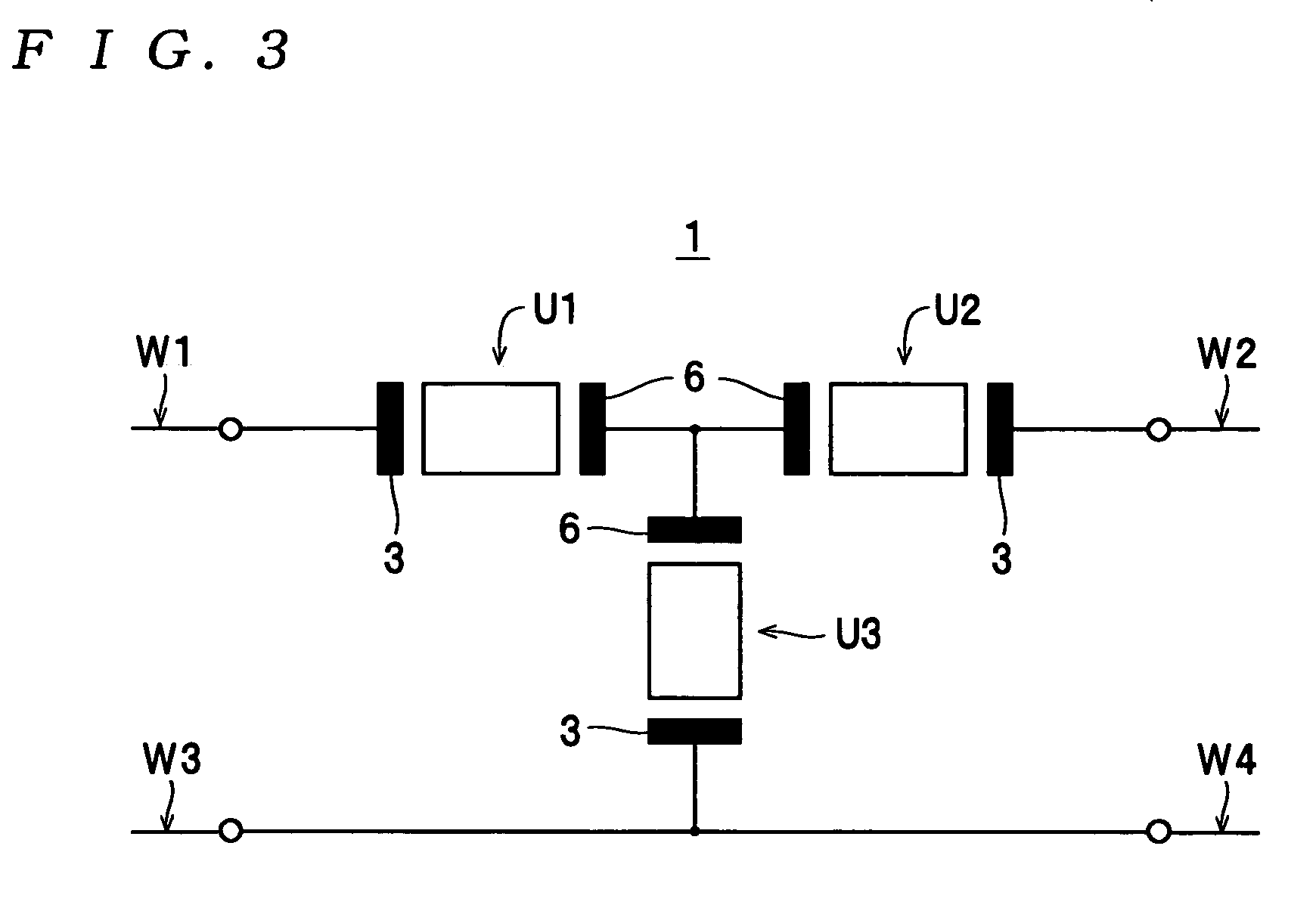

Different metallic thin plates welding method, bimetallic thin plates jointing element, electric device, and electric device assembly

InactiveUS20090223940A1Increase resistanceIncrease blockingLine/current collector detailsElectrically conductive connectionsMetal sheetLaser beams

A bimetallic thin plate jointing element that is jointed, such that a good electric characteristics are maintained, is provided. Thin plate jointing element (10) is formed by welding and jointing positive-electrode terminal (1) and negative-electrode terminal (2) having different melting points, and having flexibility. A plurality of spot-like welding areas (3) formed, for example, by laser welding are provided at overlaid portion (9) of positive-electrode terminal (1) and negative-electrode terminal (2). Welding areas (3) are formed by irradiating laser beams from the side of positive-electrode terminal (1) having a relatively low melting point, and have a cross sectional shape that is tapered from the side of positive-electrode terminal (1) side toward negative-electrode terminal (2).

Owner:NEC CORP +1

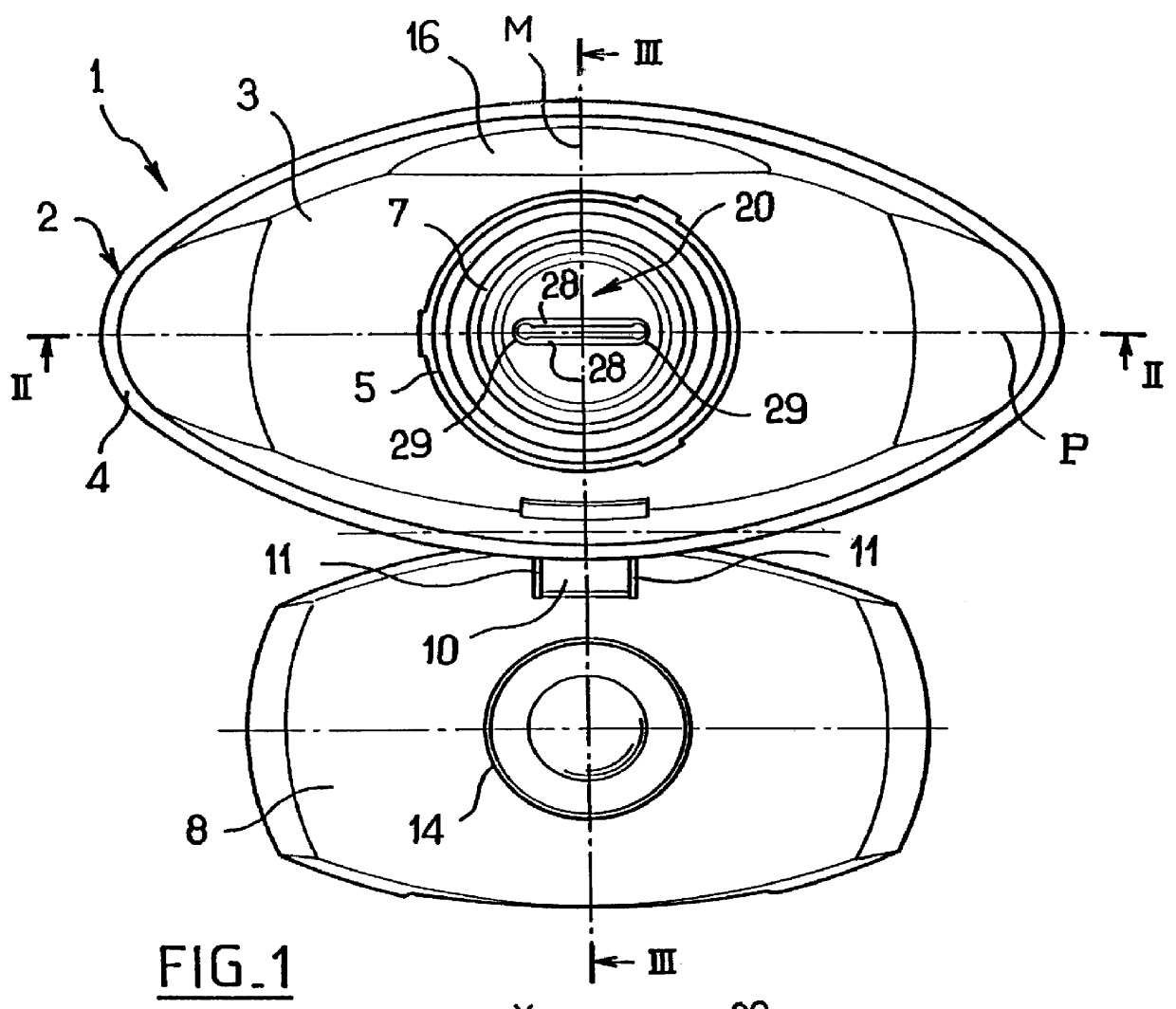

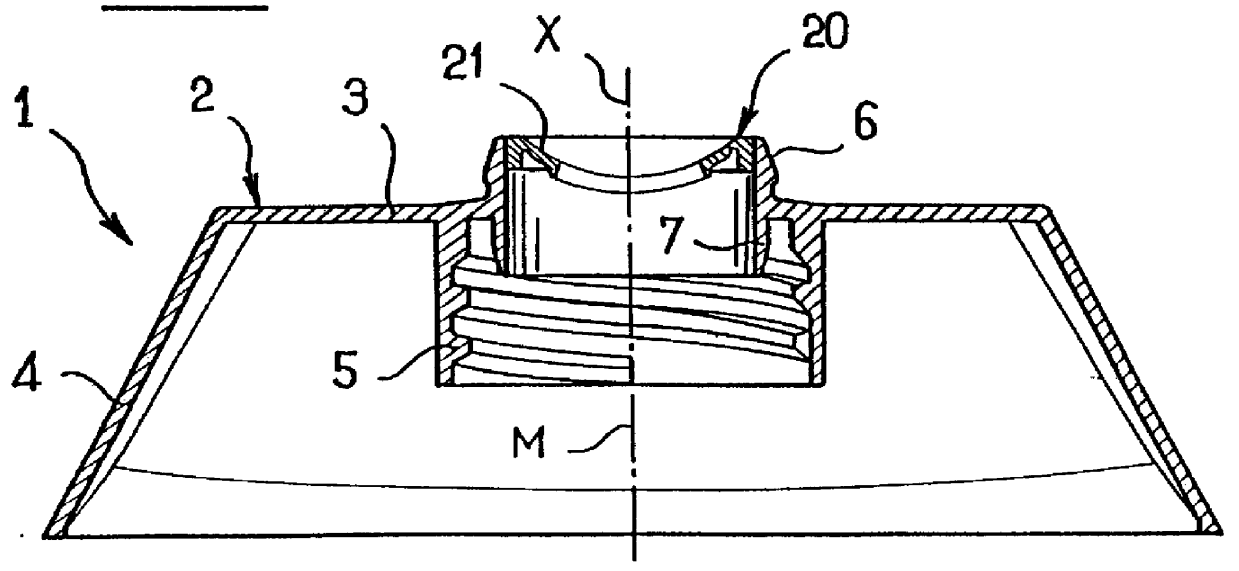

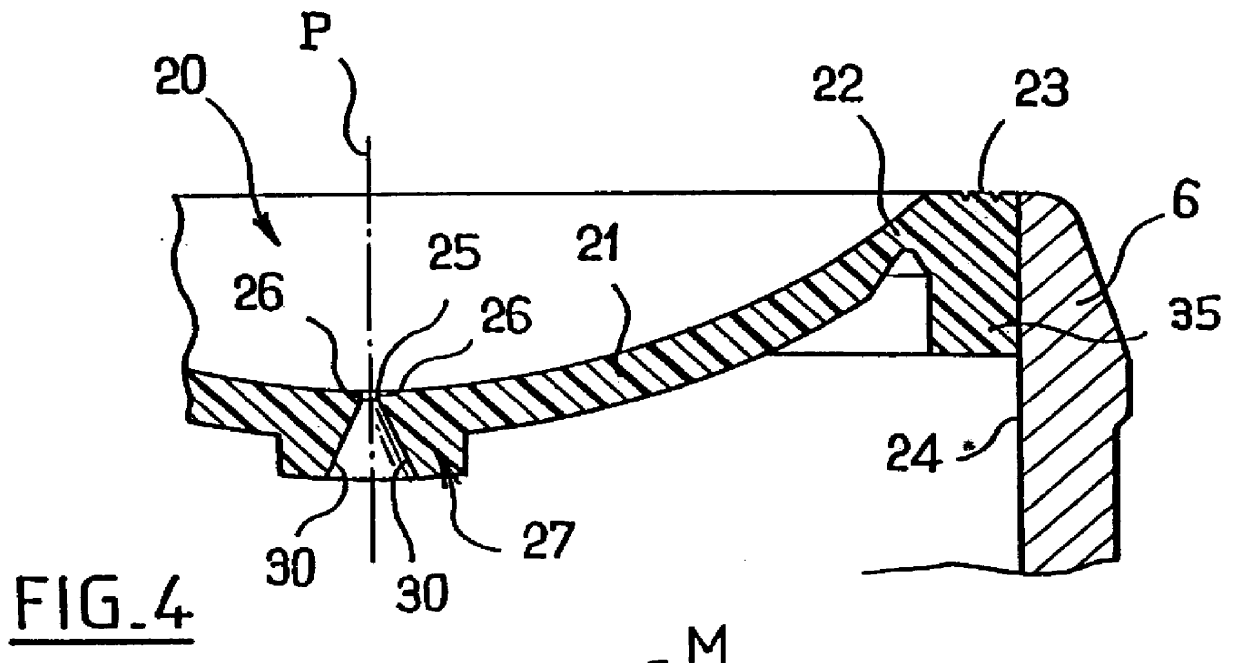

Flow reducer member, in particular for a receptacle containing a cosmetic, and a method of manufacture

InactiveUS6152324ALow costReliable manufacturingPower operated devicesMouldsInjection pointEngineering

A dispenser head for dispensing a fluid includes a dispenser endpiece of rigid or semi-rigid thermoplastic material and a flow reducer member of elastically deformable thermoplastic material secured to the endpiece. The member includes at least one slot whose edges are suitable for moving apart under the effect of thrust from the fluid while it is being dispensed. A method of making the dispenser head includes making the flow reducer member by injection molding from one or more injection points situated on one or both sides of the slot.

Owner:LOREAL SA

Method of manufacturing semiconductor device

InactiveUS20020094613A1Activation can be moreRecovery can be moreTransistorSolid-state devicesLaser lightLaser annealing

The present invention is characterized in that gettering is performed such that impurity regions to which a noble gas element is added are formed in a semiconductor film and the metallic element included in the semiconductor film is segregated into the impurity regions by laser annealing. Also, a reflector is provided under a substrate on which a semiconductor film is formed. When laser light transmitted through the semiconductor film substrate is irradiated from the front side of the substrate, the laser beam is reflected by the reflector and thus the laser light can be irradiated to the semiconductor film from the read side thereof. Laser light can be also irradiated to low concentration impurity regions overlapped with a portion the gate electrode. Thus, an effective energy density in the semiconductor film is increased to thereby effect recovery of crystallinity and activation of the impurity element.

Owner:SEMICON ENERGY LAB CO LTD

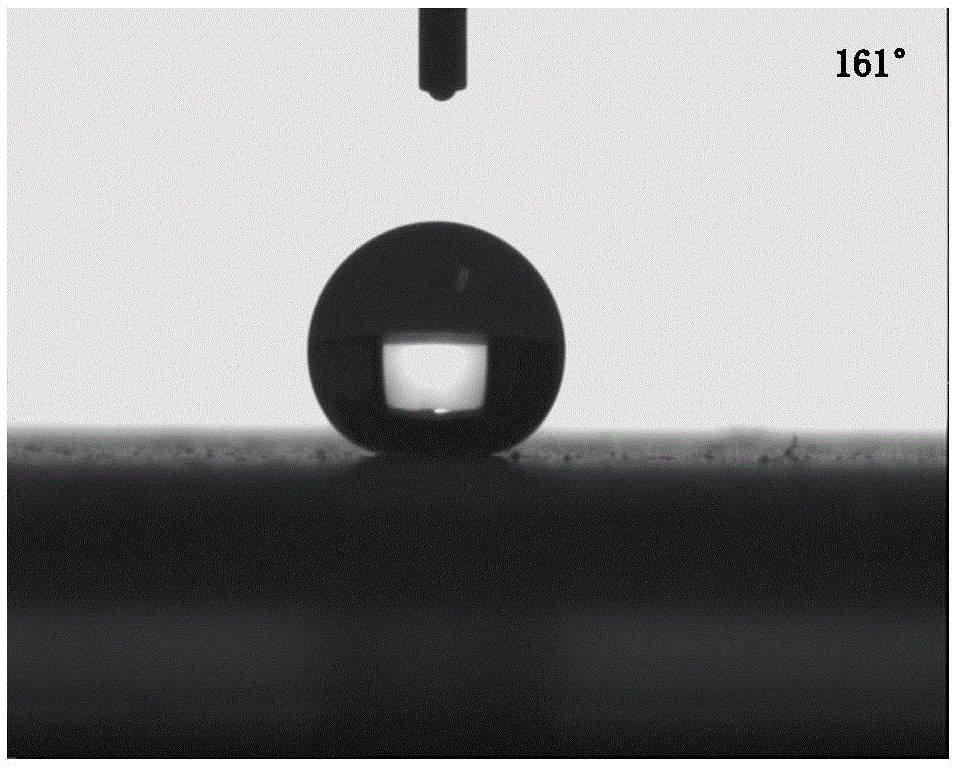

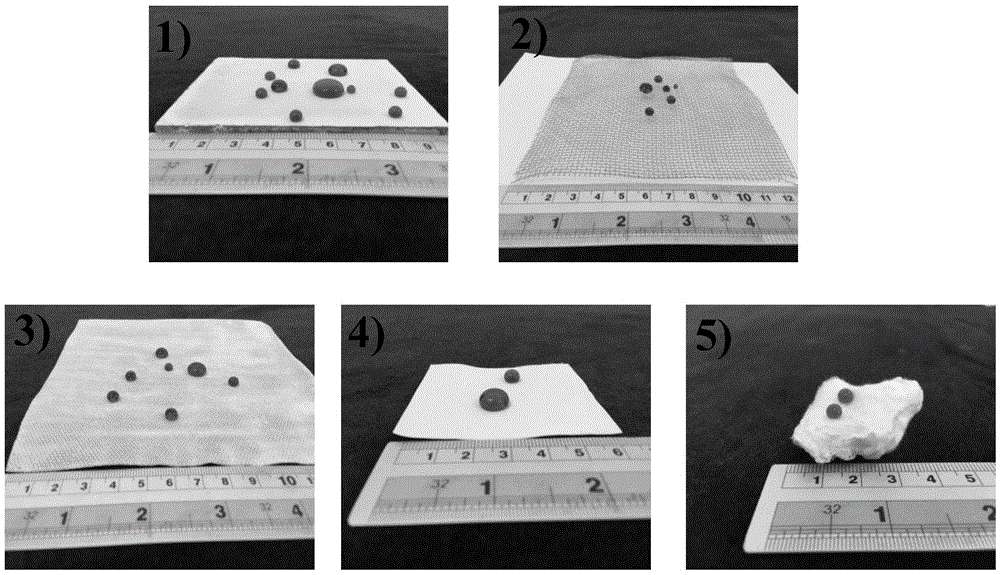

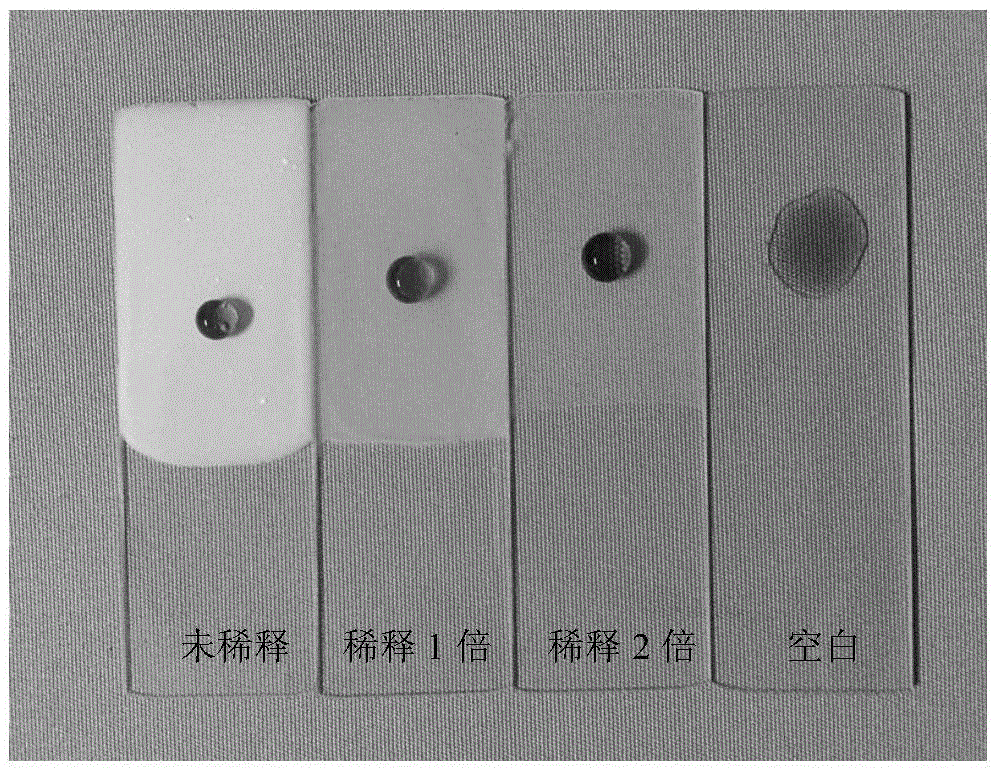

Method for preparing superhydrophobic coating layer through composite of inorganic nano-particles with different average particle sizes

InactiveCN105602297ASimplify production industry and production costsGood application prospectCoatings with pigmentsFibre treatmentRolling angleMulti material

The invention discloses a method for preparing a superhydrophobic coating layer through composite of inorganic nano-particles with different average particle sizes, belongs to the field of novel materials, and in particular, belongs to the field of self cleaning materials. The inorganic nano-particles with different average particle sizes are composited to form a mixed dispersion liquid, then a silane coupling agent is added for hydrophobic modification of the composite nanoparticles in the mixed dispersion liquid under the action of a catalyst, and a composite nanoparticle dispersion liquid having a superhydrophobic property is obtained and acts on various soft or hard substrates through extraction, spraying, drop-coating, spin-coating and other methods to form the superhydrophobic coating layer; the superhydrophobic composite nanoparticle dispersion liquid is gradually diluted according to the proportion and then acts on a transparent material substrate, and the superhydrophobic coating layer having adjustable transparency can be obtained; the superhydrophobic coating layer has the contact angle greater than 160 degrees and the rolling angle of less than 5 degrees. The method is simple in process and is applicable to surface hydrophobic modification of various materials, and the transparency of the superhydrophobic coating layer can be adjusted according to different uses.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

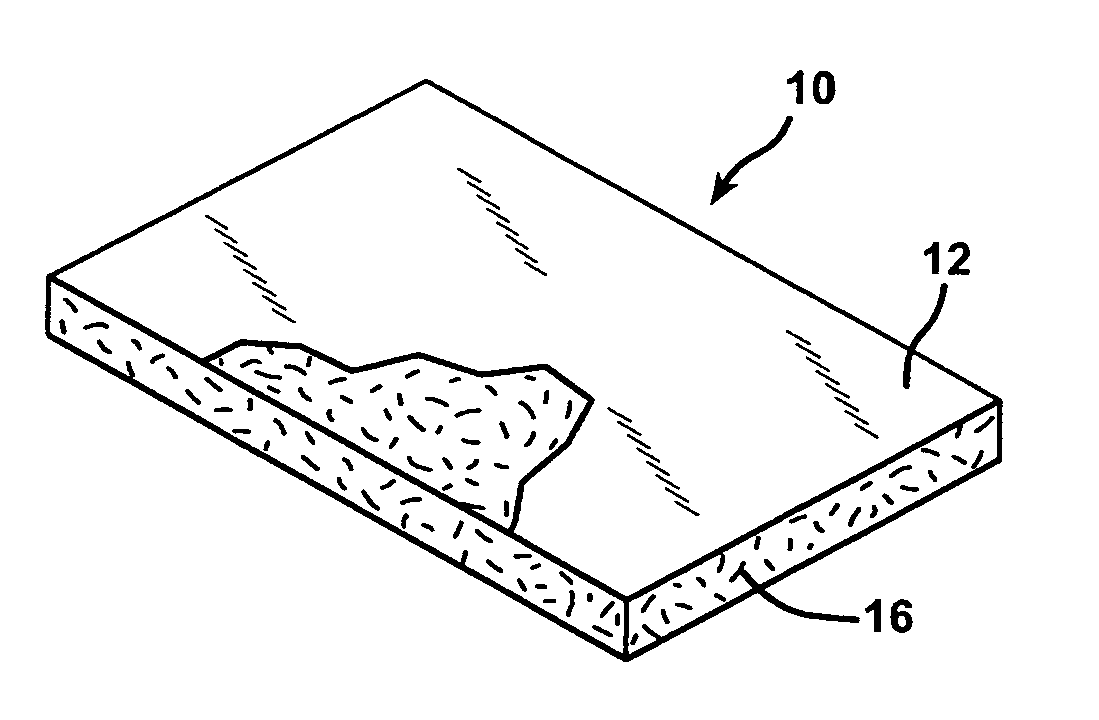

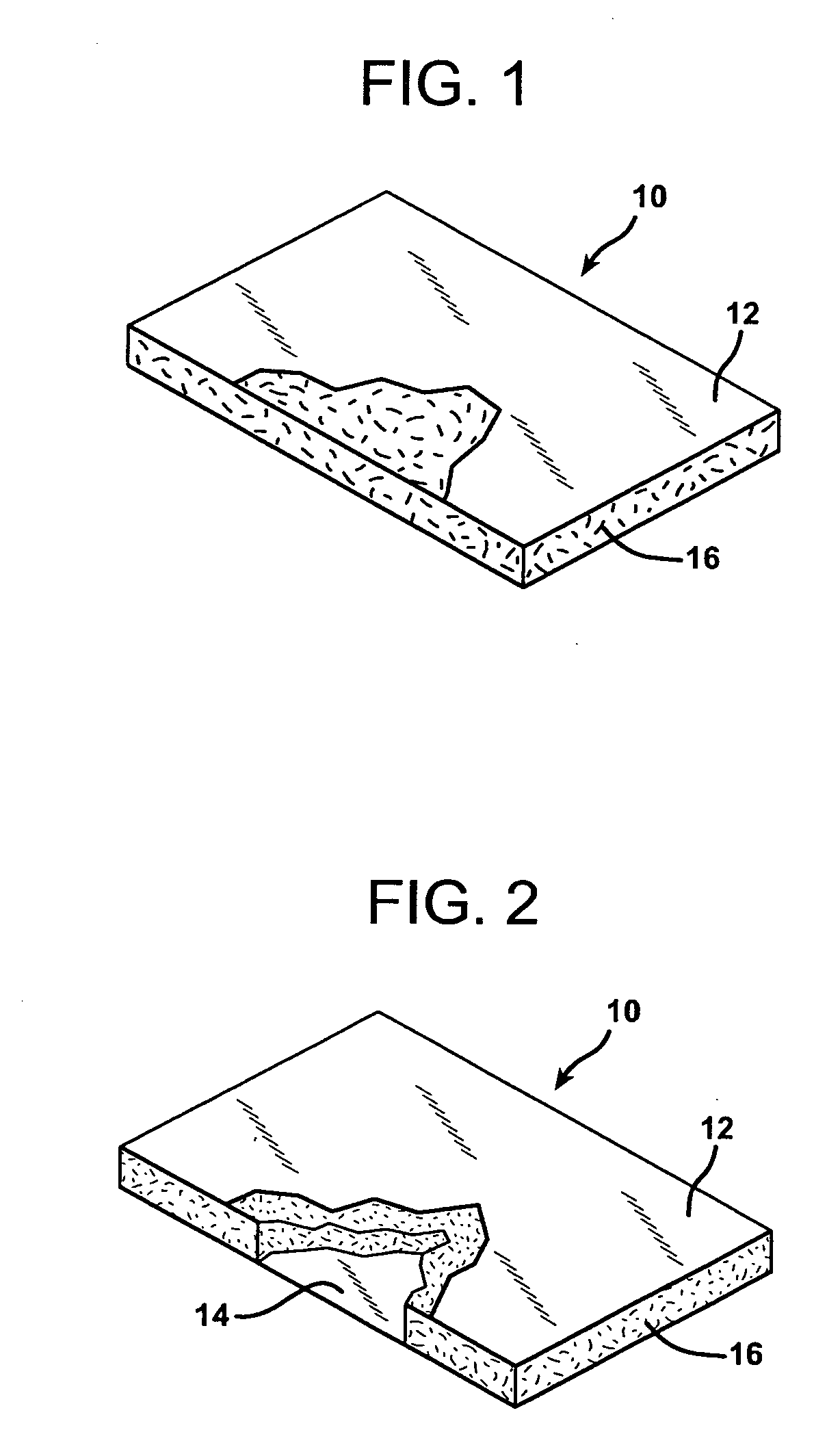

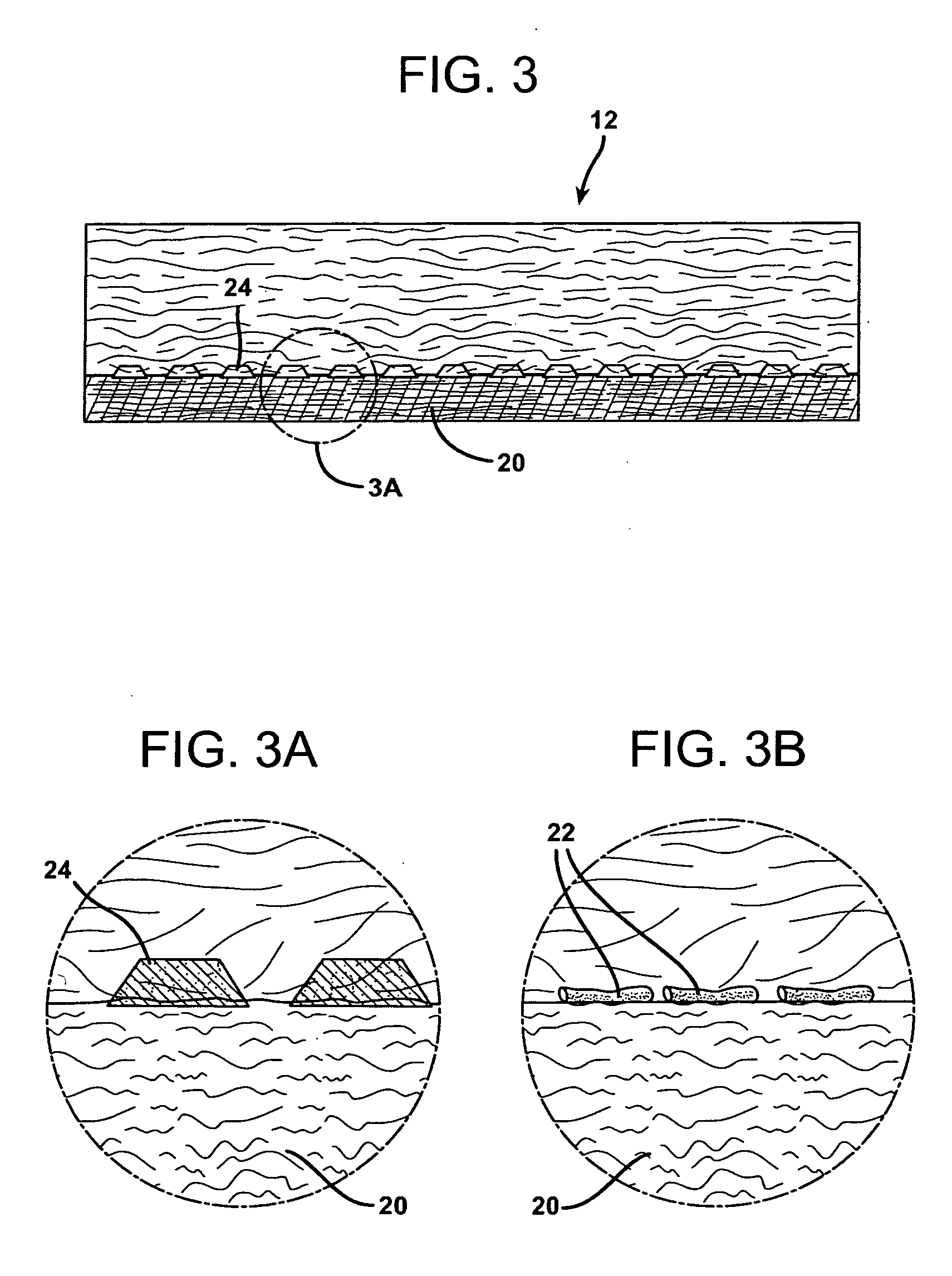

Faced fibrous insulation

InactiveUS20050284065A1Improve surface qualityHigh and controlled adhesionThermal insulationLayered productsVapor barrierFiber

A faced fibrous insulation having a facing on one or more surfaces of a fibrous insulation material is provided. The facing provides improved surface quality, high and controlled adhesion, and is easily manufactured. The facing of the present invention includes a pre-applied adhesive that is heat activated to provide adhesion to the fibrous insulation. The facing may be input into the glass fiber forming section of a fibrous insulation production line. Alternatively, the facing may be applied to the uncured pack prior to curing or applied to the cured fibrous insulation. As another alternative, a vapor barrier layer may be attached on a surface of the insulation opposite the facing.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

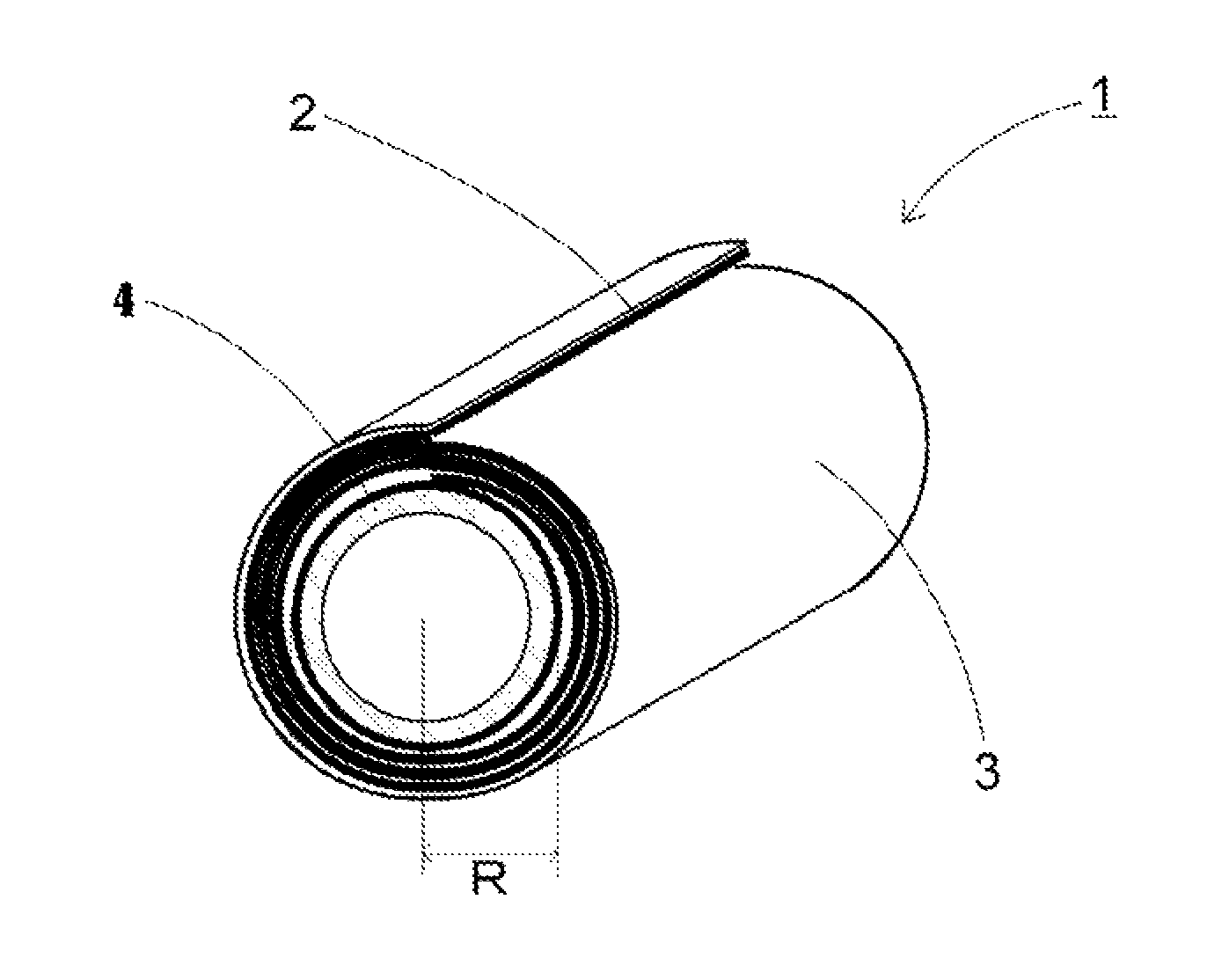

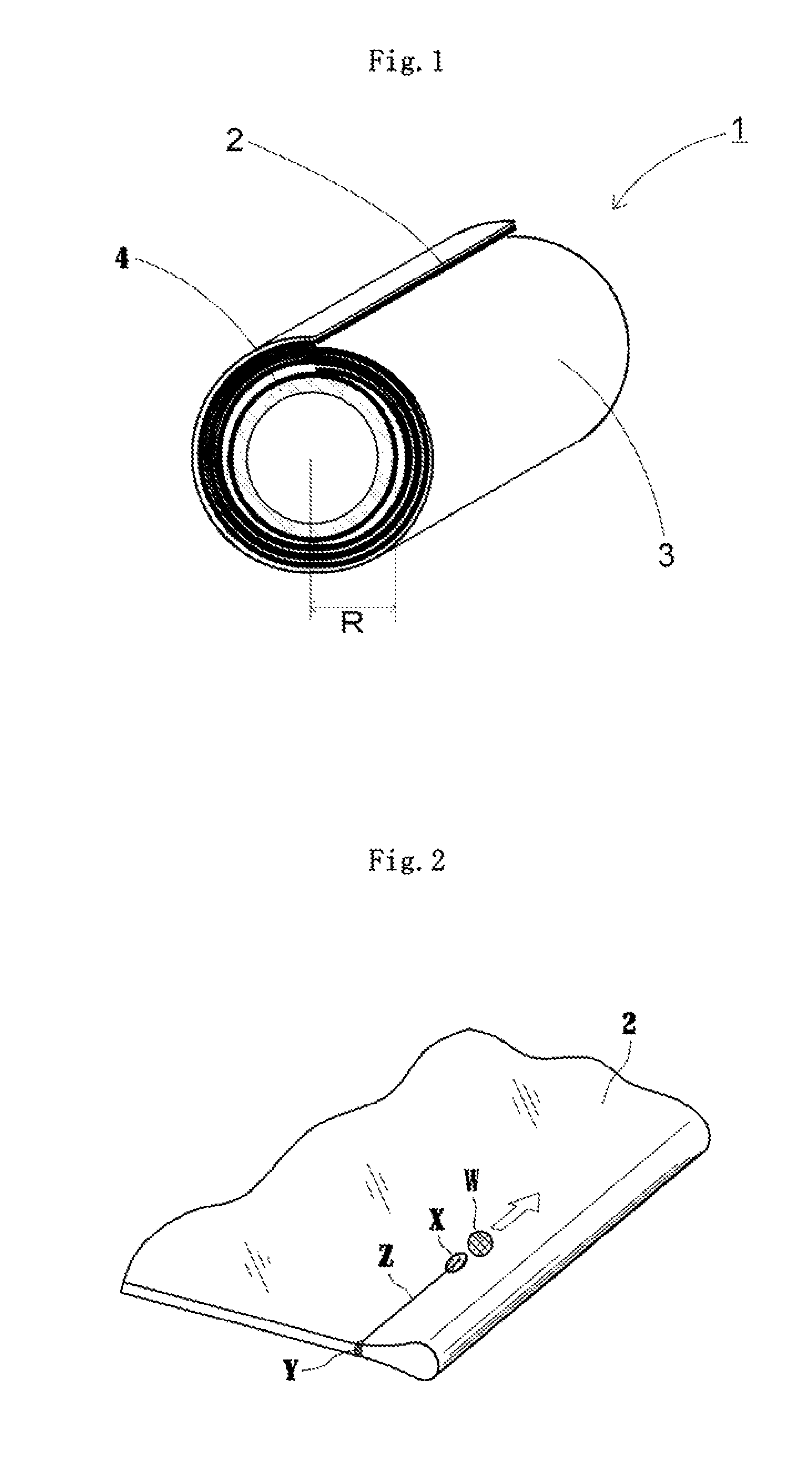

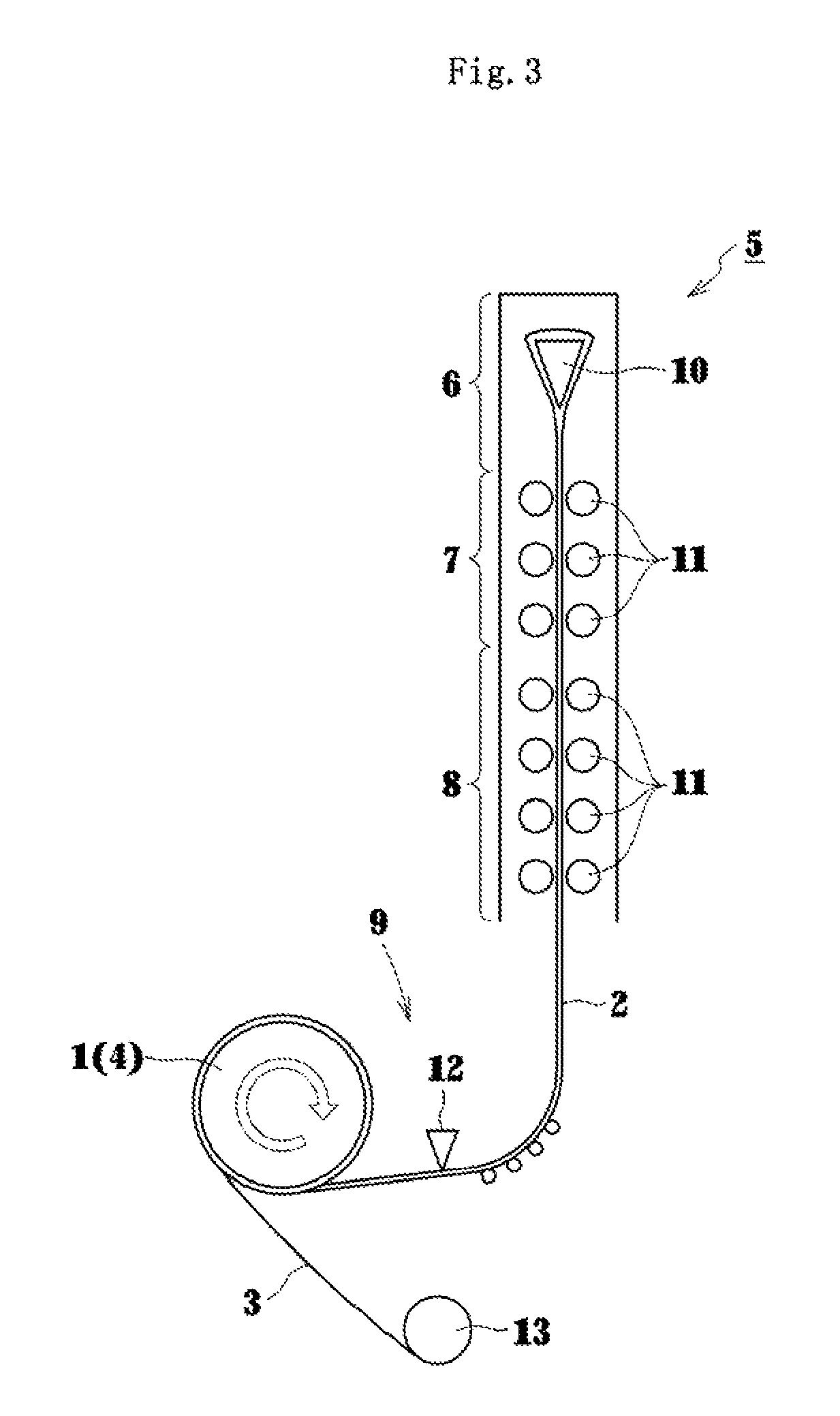

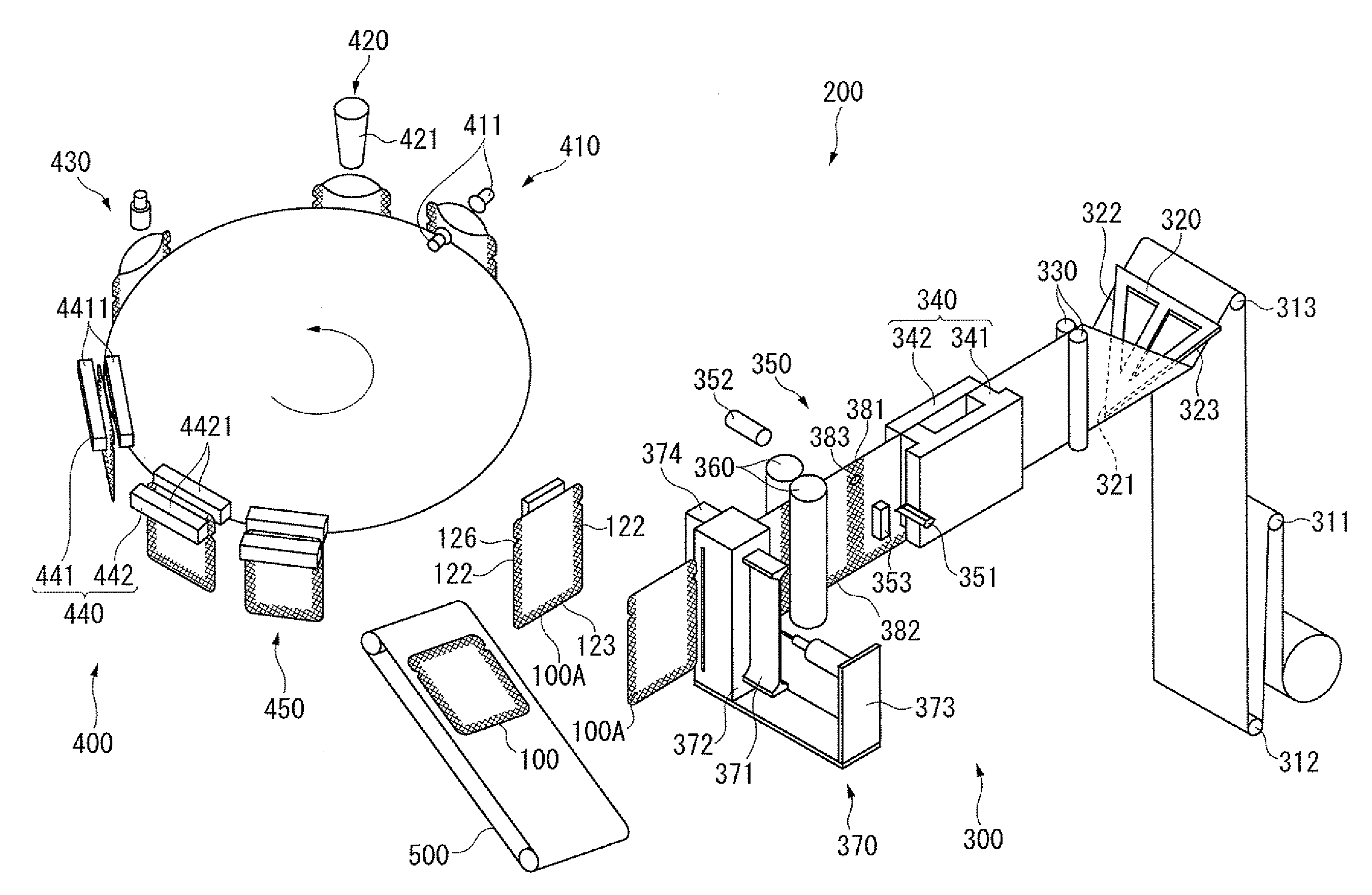

Glass roll and process for producing glass roll

ActiveUS8241751B2Suppress situationReliable manufacturingShaft and bearingsGlass drawing apparatus3 point bendingFlexural strength

Provided is a glass roll formed by winding a glass film into a roll, in which a minimum winding radius of the glass film is optimized. Thus, the glass film is reliably prevented from breaking due to static fatigue, and is able to be stored for long periods. A glass roll (1), which is formed by winding a glass film (2) into a roll, has a configuration in which the glass film has a minimum winding radius (R) satisfying the following relation: R≧(T / 2)[(2.3 / σ)×E−1], where σ represents flexural strength of the glass film (2) obtained by a 3-point bending test, T represents a thickness of the glass film, and E represents a Young's modulus of the glass film.

Owner:NIPPON ELECTRIC GLASS CO LTD

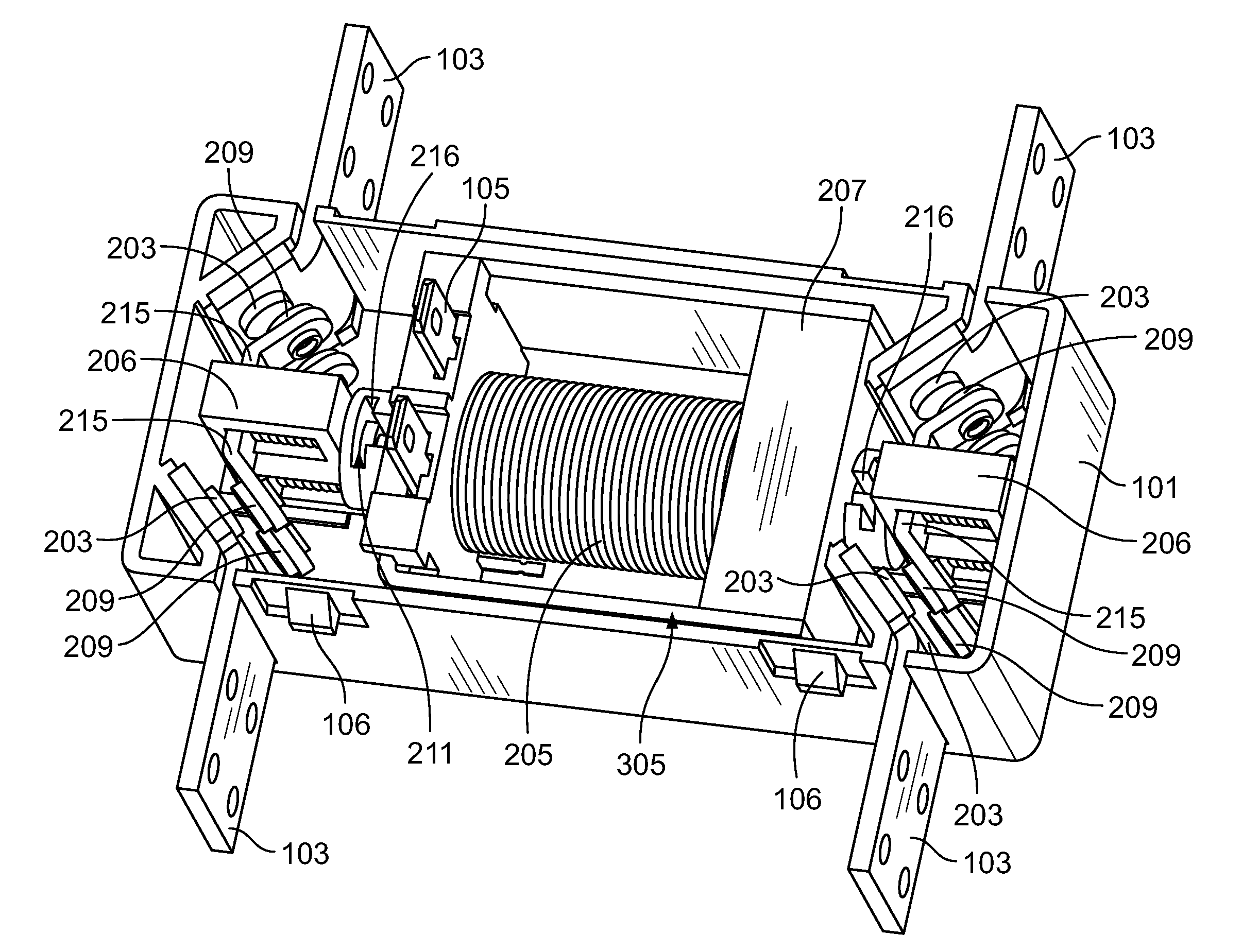

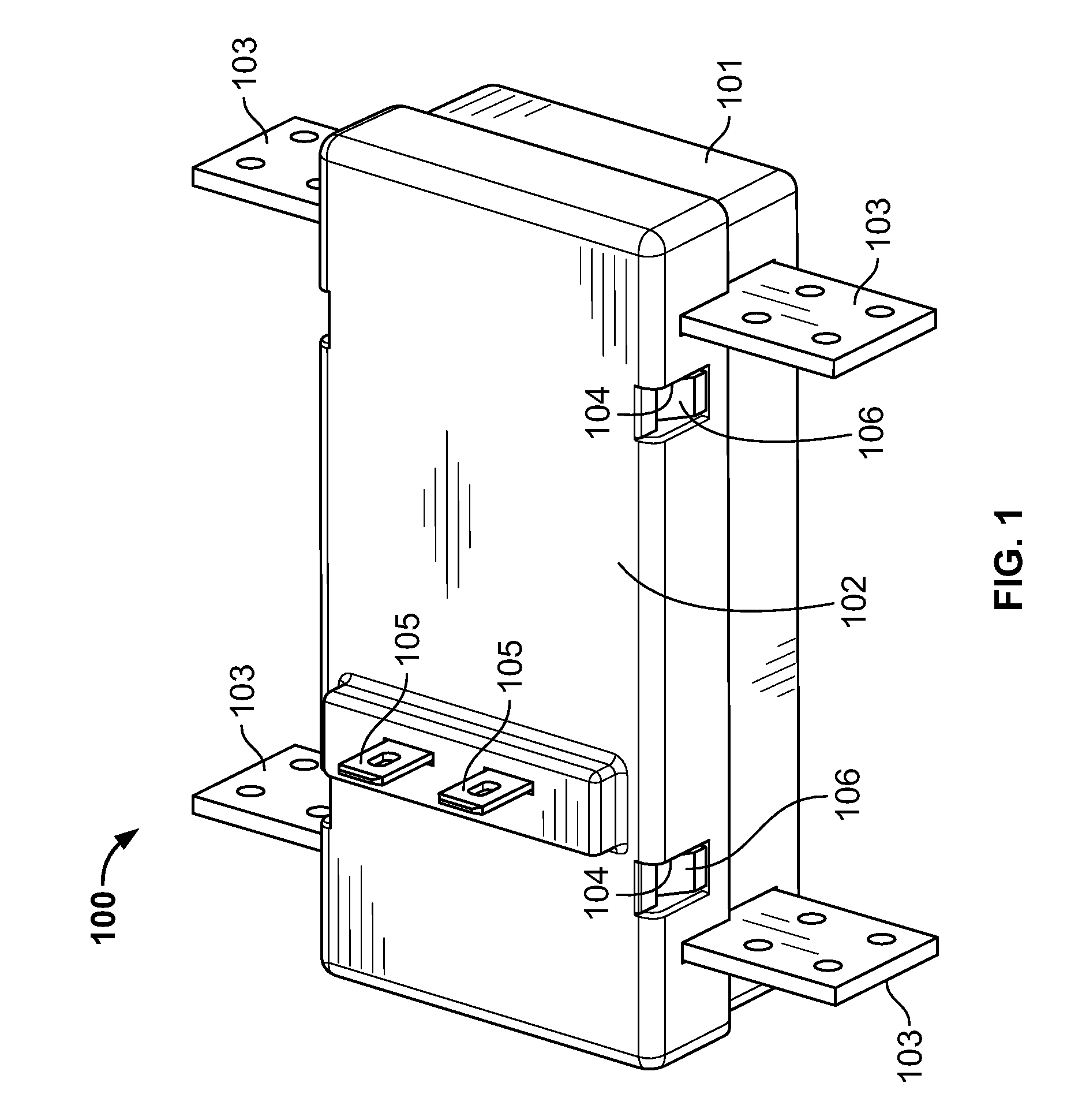

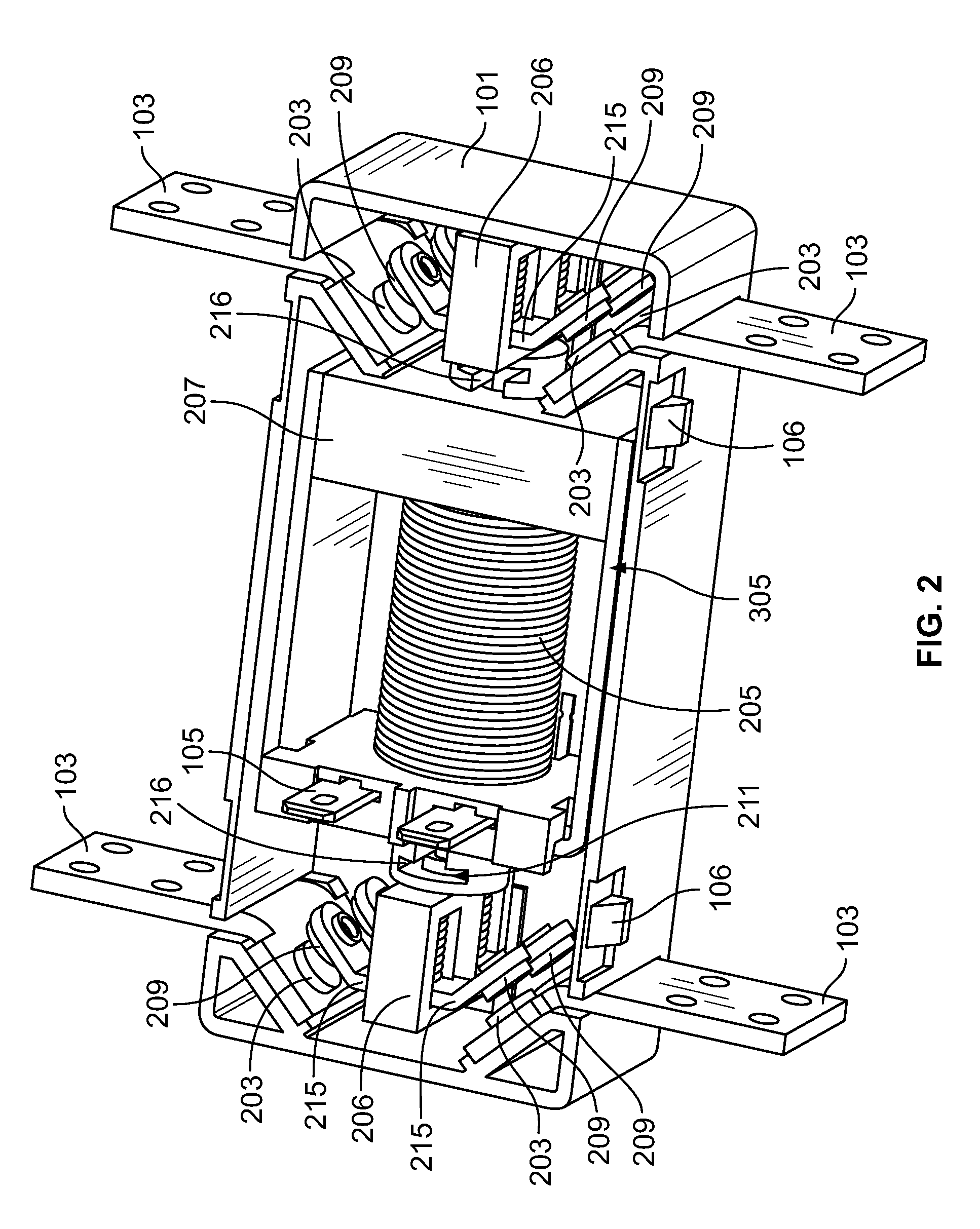

Switching device

ActiveUS20100026427A1Low costEasy to produceContact mechanismsElectromagnetic relay detailsLinear motionMotor drive

The invention is directed to a switch assembly which can be used in situation in which the switch accommodates the flow of high voltage current. An actuator assembly with moveable contacts is moved by a motor driven armature. The moveable contacts are in electrical engagement with the stationary contacts when the armature is in the first position, and the moveable contacts are spaced from the stationary contacts when the armature is in the second position. By angling the stationary contacts and moveable contacts, the linear motion of the armature causes the moveable contacts to move across the surface of the stationary contacts as the armature approaches the first position. As all of the movements of the assembly are in a direction parallel to the axis of the armature, the assembly can be manufactured and operated reliably in a relatively small space. In addition, the linear movement on the angled contact provides for a positive electrical connection even in adverse environments.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Spring steel and preparation method thereof

InactiveCN101671792AImprove fatigueOvercome the disadvantage of low fatigue strengthSpring steelQuenching

The invention discloses spring steel. Based on the total weigh of the spring steel, the spring steel comprises 0.56 to 0.64 weight percent of C, 1.6 to 2 weight percent of Si, 0.6 to 0.9 weight percent of Mn, 0 to 0.015 weight percent of Ti, 0.0055 to 0.03 weight percent of S, 0.01 to 0.02 weight percent of Als and the balance of Fe and inevitable impurities, wherein the weight ratio of the S to the Als is 0.55 to 3; and the Als is acid soluble aluminum. The invention also provides a preparation method of the spring steel, which comprises: subjecting the raw material of the spring steel to primarily smelting, refining, cold forming, rolling, quenching and tempering, wherein the composition of the raw material of the spring steel ensures the composition of the spring steel obtained is the same as the composition of the spring steel of the invention. The spring steel is high in fatigue resistance. The production method is simple and reduces cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

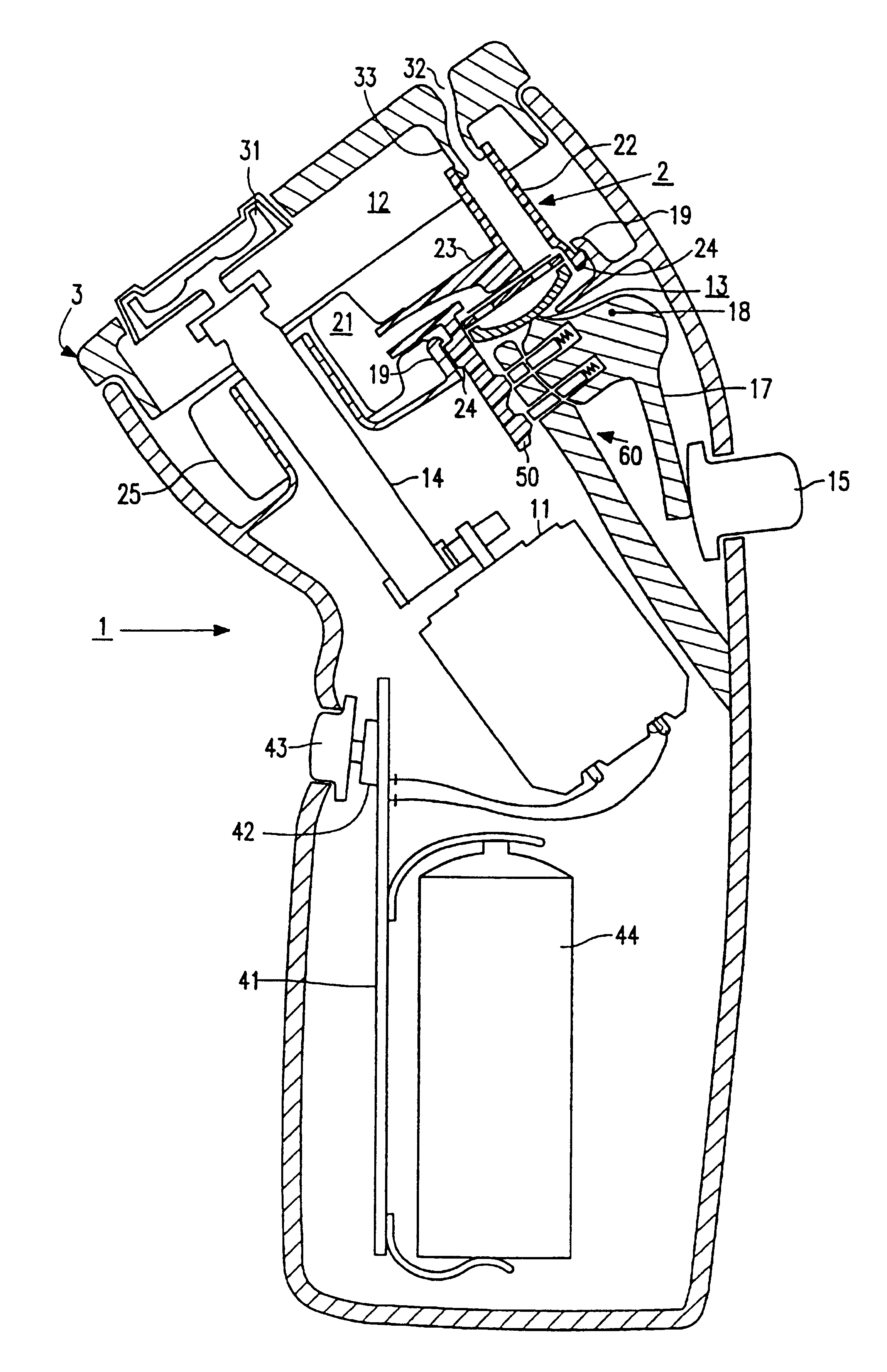

System appliance and cartridge for personal body care

InactiveUSRE38634E1Simplify mountingEasily replaceMetal working apparatusTooth cleaningPersonal careEngineering

The system comprises, for example, an electric shaver (1) and a cartridge (2) mounted in a chamber (12) of the shaver (1). The shaver (1) comprises a shaving head (3) having drivable cutters (31) and an electric motor (11) for driving the cutters (31) via a coupling pin (14). The cartridge (2) comprises a reservoir (25) for holding an auxiliary fluid. This auxiliary fluid may, for example, serve to reduce the friction between the shaving head (3) and the skin of a user. The cartridge (2) has an outlet channel (22) and a diaphragm pump (23) for feeding the auxiliary fluid from the reservoir (21) to the outlet channel (22). For the actuation of the diaphragm pump (23) the shaver (1) comprises a button (15) and a lever (17) which is pivotable about a pivot (18). When the button (15) is pressed the diaphragm pump (23) is actuated and a small amount of the auxiliary fluid is applied to the skin of a user via an outlet opening (32). The cartridge (2) has a key (50) which cooperates with a blocking device (60), which is adapted to block the lever (17) by means of pins. The key (50) has projections for positioning the pins of the blocking device (60). In the absence of the correct key the lever (17) is blocked and thus prevents the auxiliary fluid in the cartridge from being pumped to the outlet opening (32).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

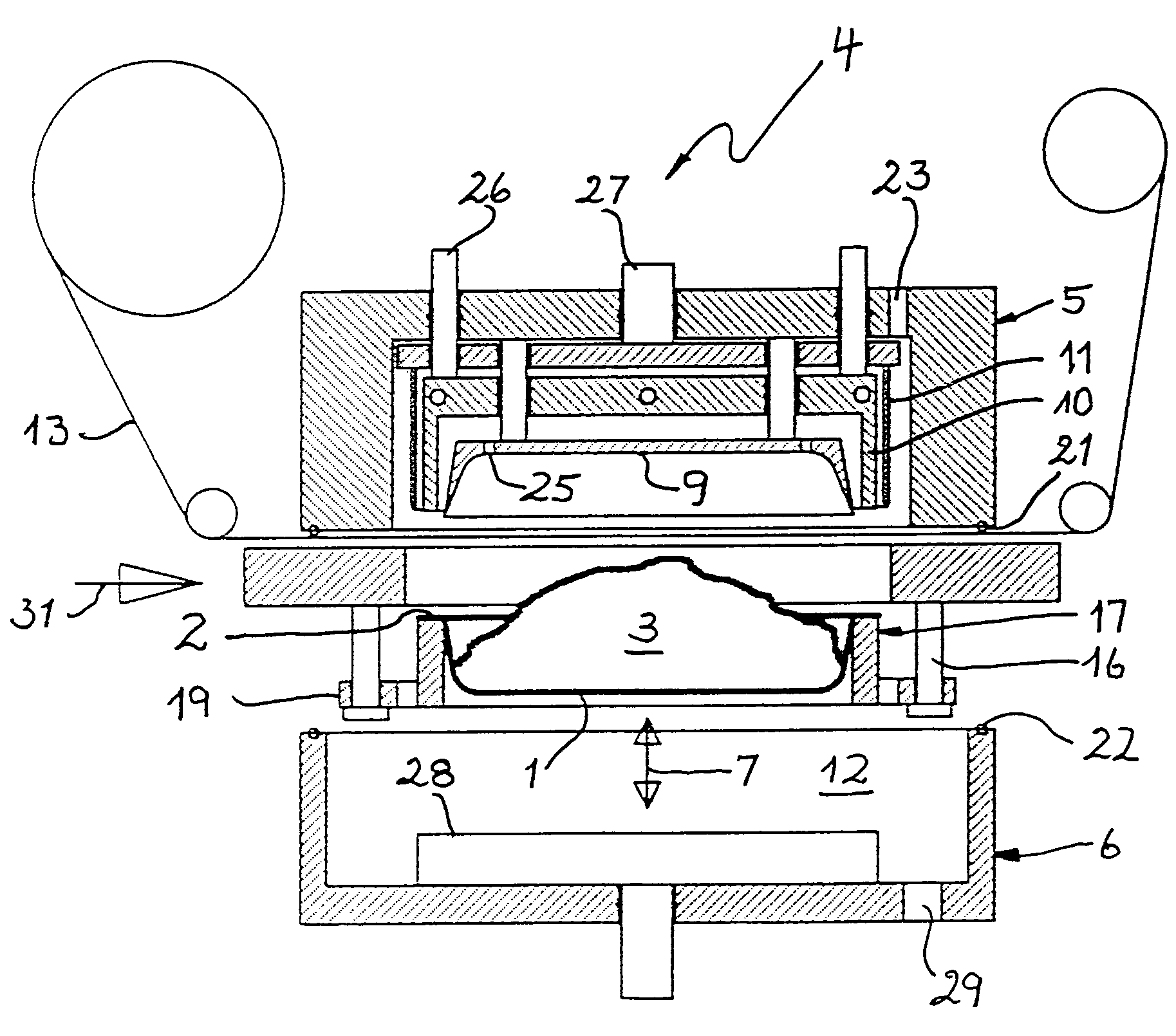

Method and packaging machine for packaging a product arranged in a tray

InactiveUS7600358B2Adversely affectedReliable manufacturingPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringPackaging machine

A method for packaging a product arranged in a tray is provided. An upper film located in a distance above the product is clamped along an edge surrounding the tray and is deformed in a direction extending away from the product. Subsequently, evacuating of the space surrounding the product is performed, then a raising of the tray towards the upper film and finally a sealing of the film and of the edge of the tray. In this way, the seam of the upper film and the edge of the tray is attained to be free from creases such that a long-living and good looking package is produced. Additionally, a packaging machine for performing the method is provided.

Owner:CREAVIS GES FUER TECH +1

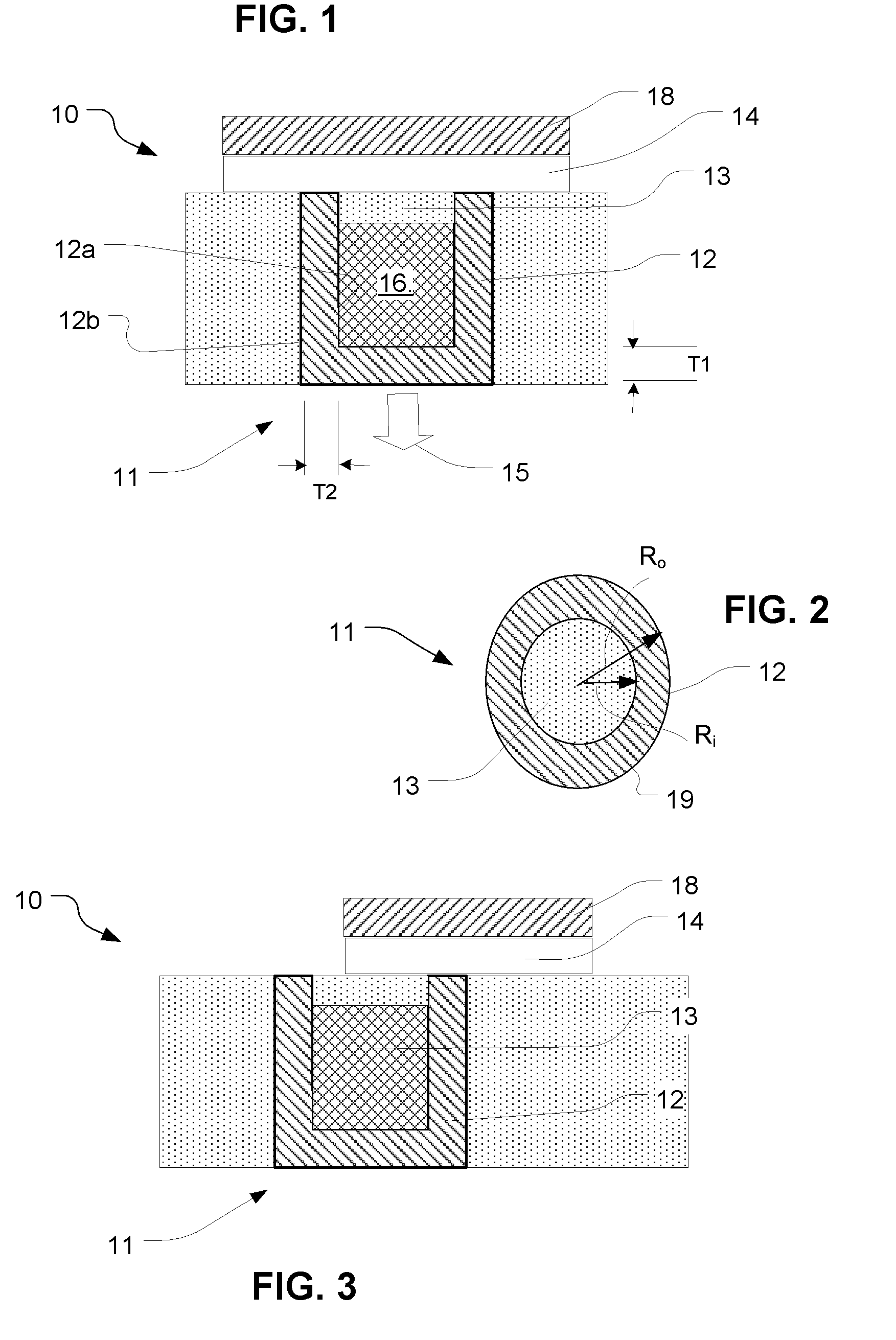

Ring-shaped electrode and manufacturing method for same

ActiveUS20100264396A1Lower resistanceHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingConductive materialsEngineering

An electrode structure and a method for manufacturing an integrated circuit electrode includes forming a bottom electrode comprising a pipe-shaped member, filled with a conductive material such as n-doped silicon, and having a ring-shaped top surface. A disc-shaped insulating member is formed on the top of the pipe-shaped member by oxidizing the conductive fill. A layer of programmable resistance material, such as a phase change material, is deposited in contact with the top surface of the pipe-shaped member. A top electrode in contact with the layer of programmable resistance material.

Owner:MACRONIX INT CO LTD +1

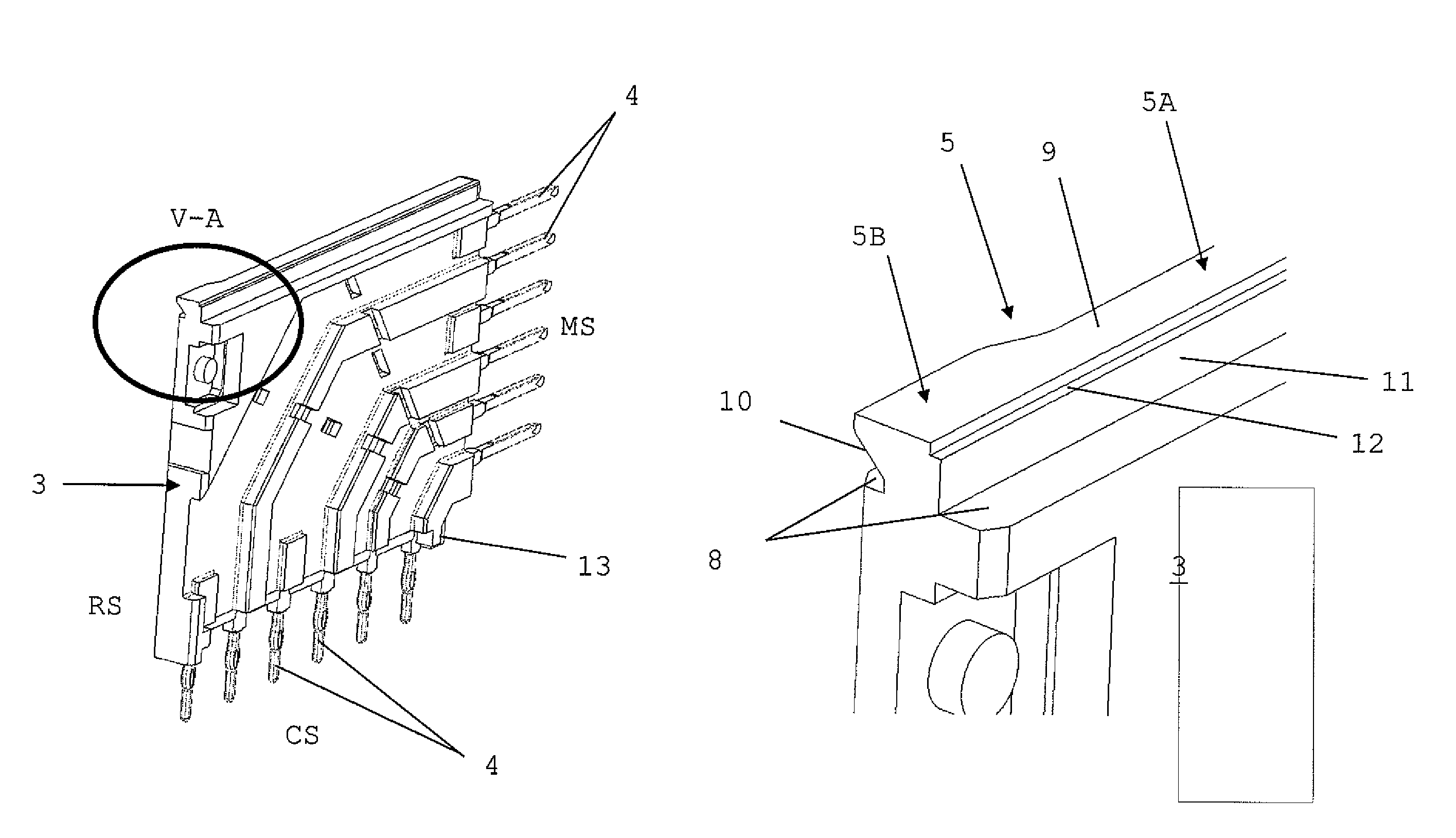

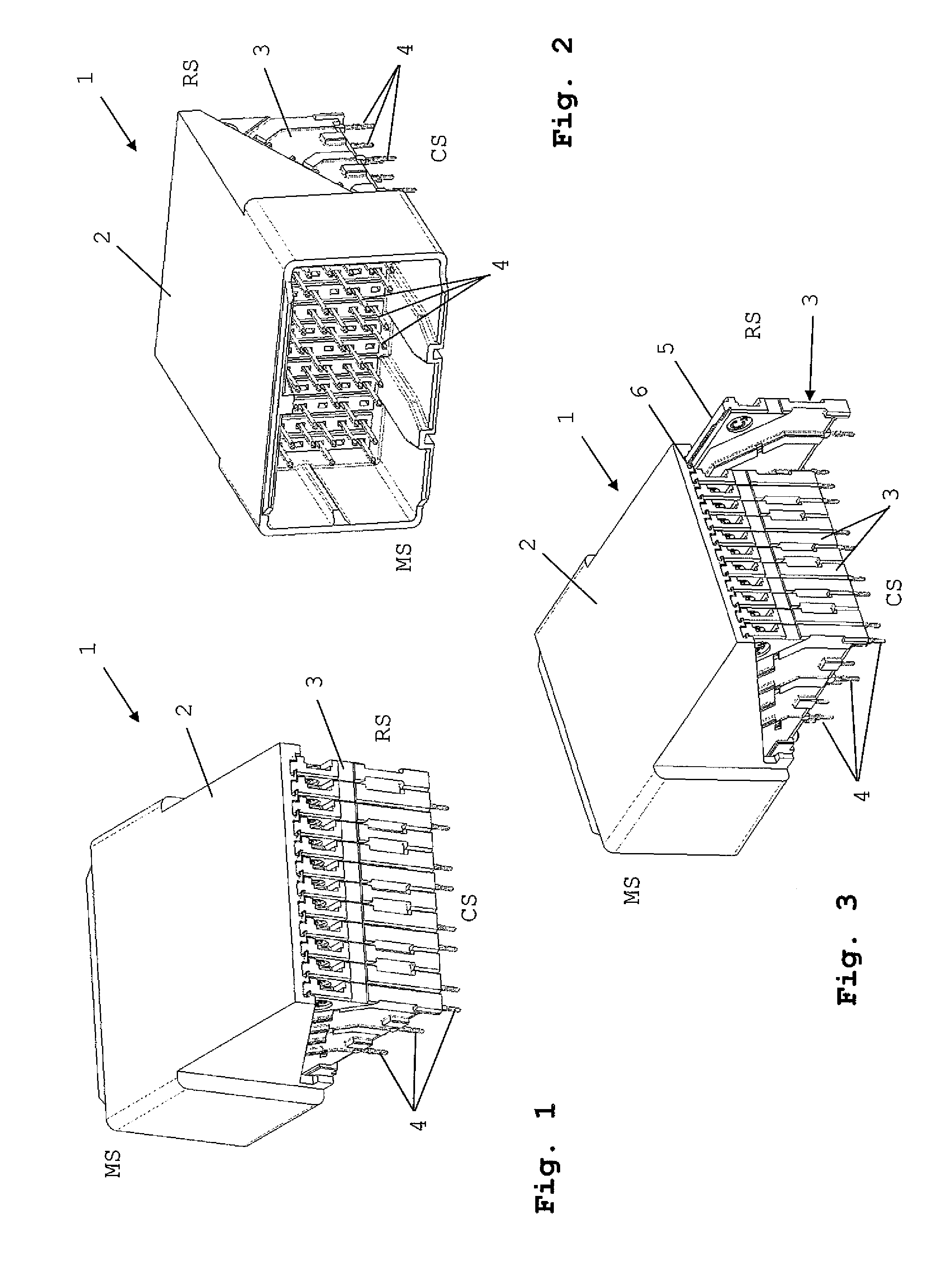

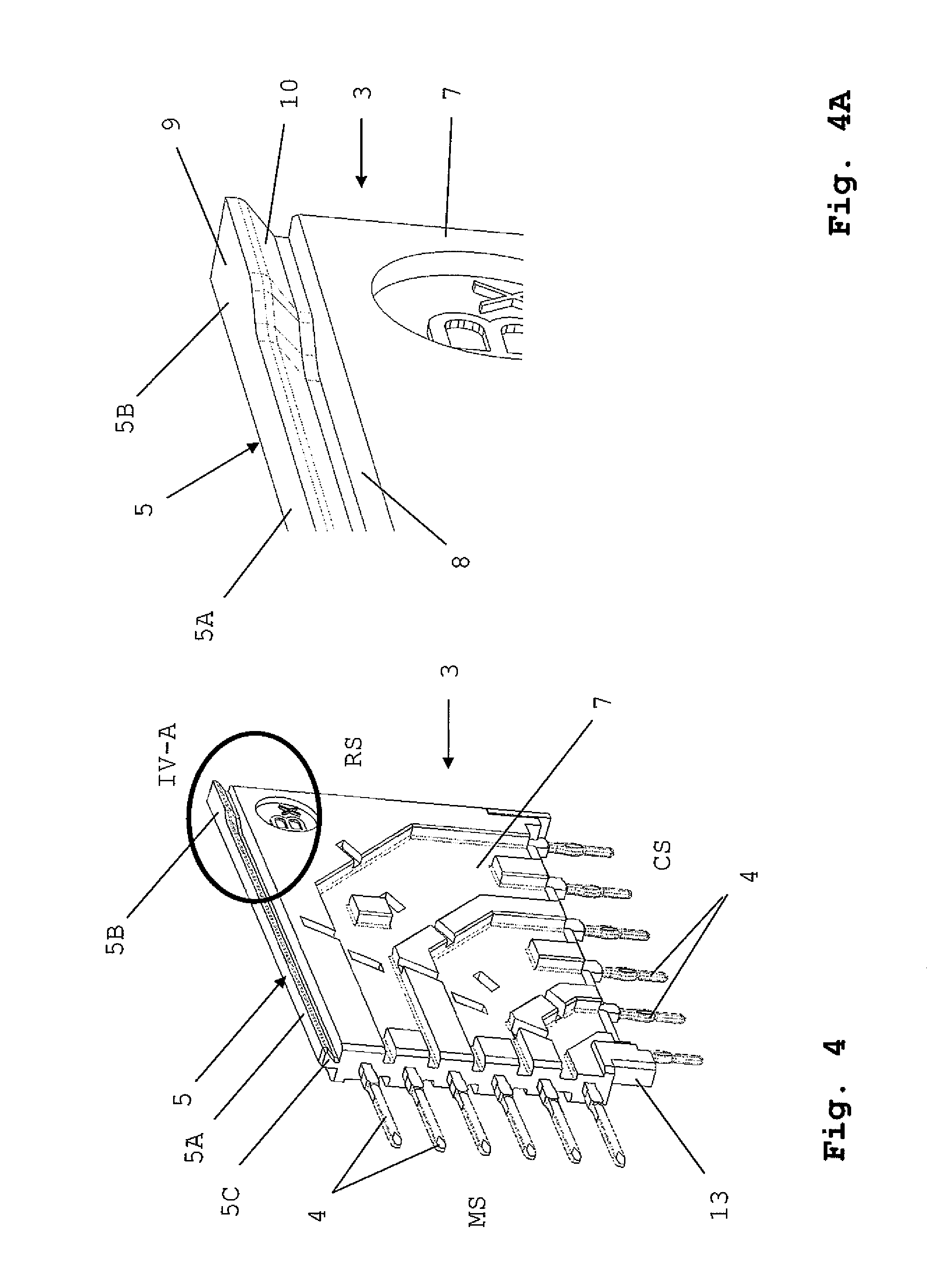

Modular connector

ActiveUS8210877B2Improves localisation and mounting accuracy of partReliable manufacturingIncorrect coupling preventionCoupling protective earth/shielding arrangementsModularityElectrical connector

An electrical connector includes at least two parts: a housing having a mating side (MS) and a rear side (RS) and a terminal module having a mating side and a rear side. One part includes a mounting structure and the other part includes a corresponding receiving structure for receiving the mounting structure of the other part. The mounting structure extends in a direction from the mating side to the rear side of the part and includes a cross-section perpendicular to that direction, which cross-section has an asymmetric profile.

Owner:FCI ASIA PTE LTD

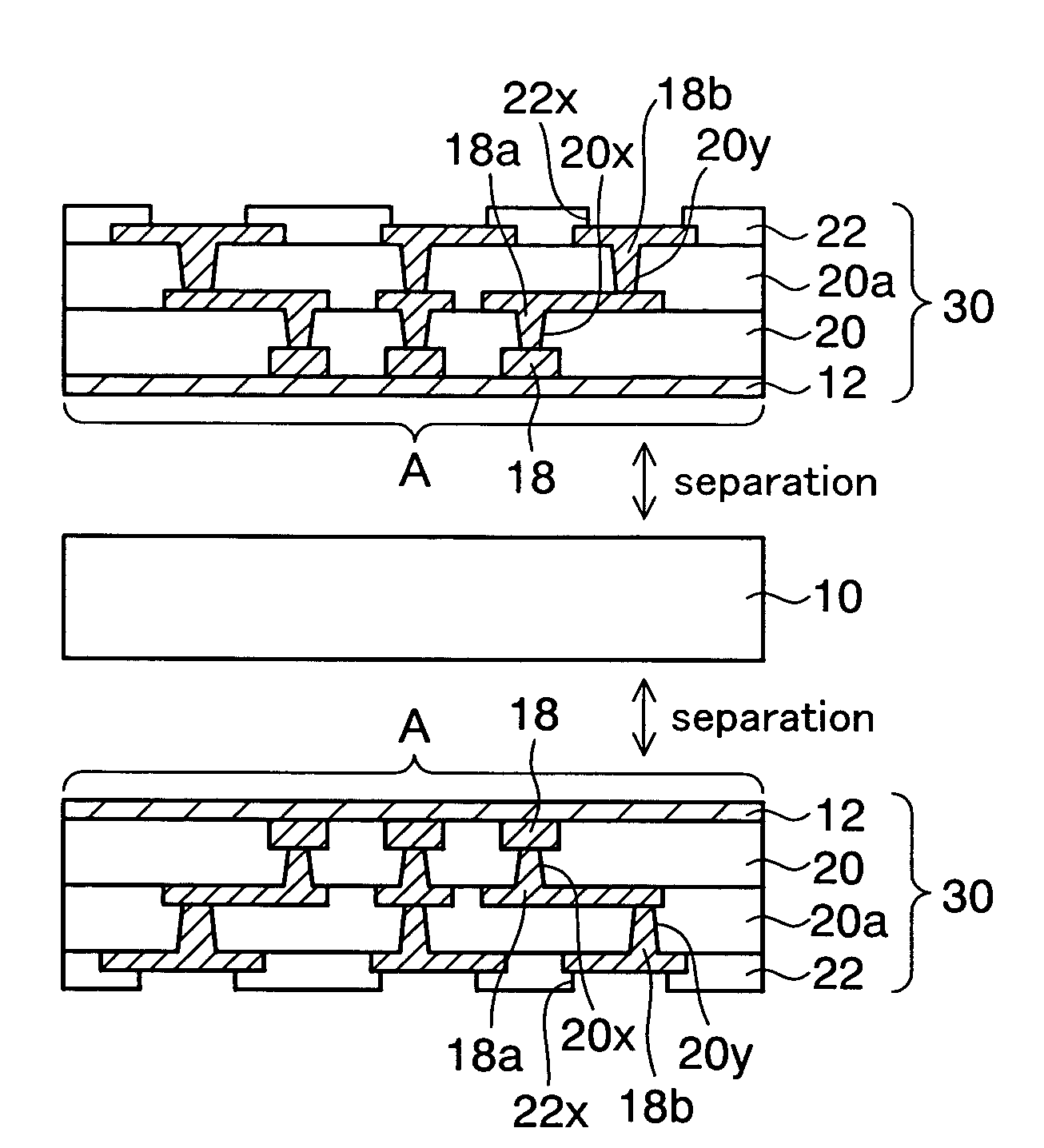

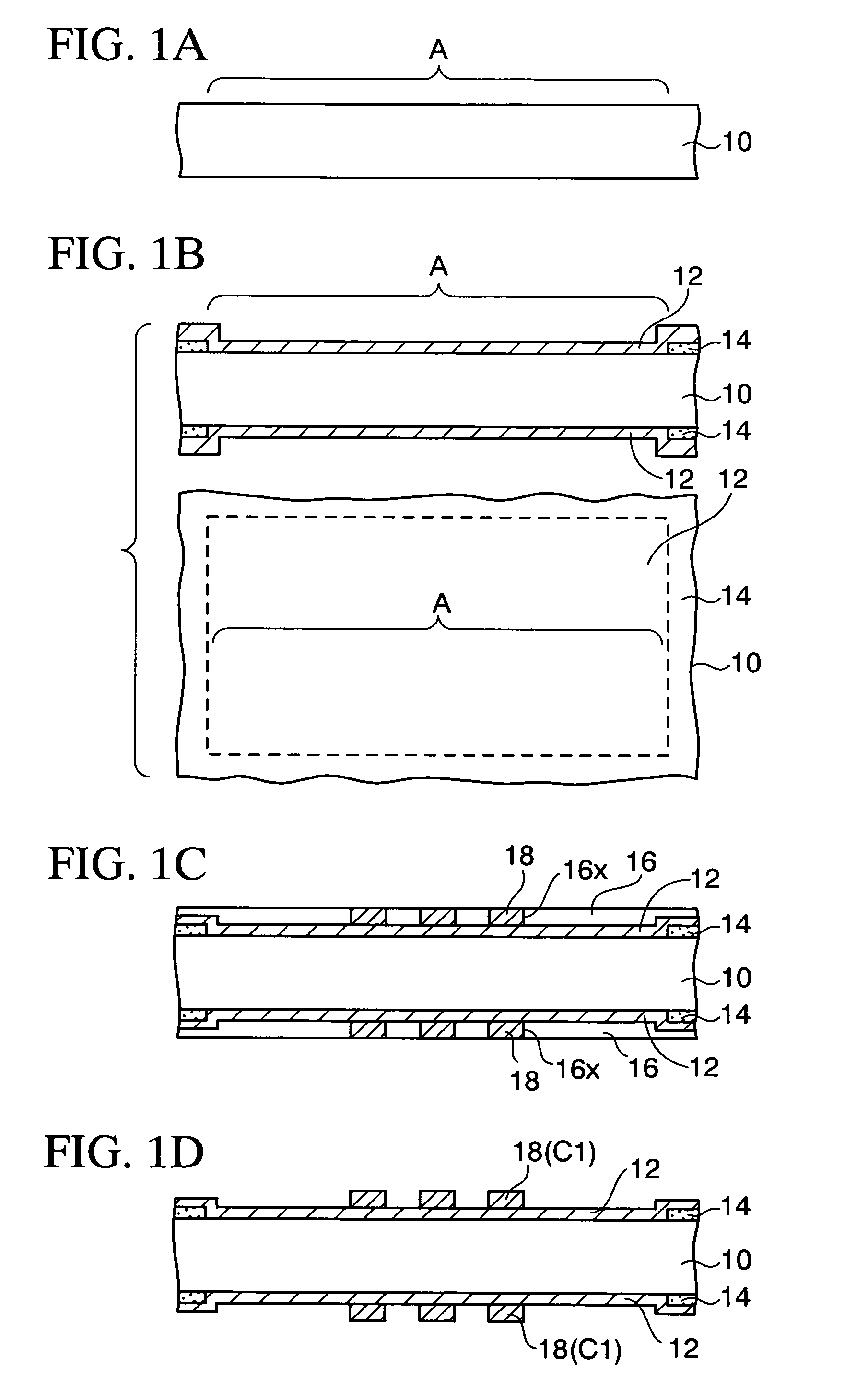

Method of manufacturing wiring substrate and method of manufacturing electronic component mounting structure

ActiveUS20070124925A1Reliable manufacturingLow costPrinted circuit assemblingLine/current collector detailsMetal foilEngineering

In a method of manufacturing a wiring substrate according to the present invention, a metal foil is tentatively fixed onto a temporary substrate, which is made of a nonwoven fabric impregnated with resin, by selectively attaching a peripheral side of the metal foil to an outer peripheral portion of a wiring formation region of the temporary substrate, thereafter, a build-up wiring layer is formed on the metal foil, and the metal foil is separated from the temporary substrate by cutting out an inside portion of a structure, the portion being inward from the adhesive layer, in this way, a wiring member including the build-up wiring layer formed on the metal foil is obtained.

Owner:SHINKO ELECTRIC IND CO LTD

Device for cutting packing bag, device for producing packing bag and method for producing packing bag

InactiveUS20100210439A1Low costLow equipment costEnvelopes/bags making machineryMechanical working/deformationEngineeringMechanical engineering

A cutter includes a male blade, a female blade, an advancement and retraction controller and a suction device. The male blade includes: a linear cutting portion linearly shaped with a predetermined thickness in a center part; a rounded cutting portion where a radius having a substantially arc shape in planar view is continuously formed from the linear cutting portion; and an end provided adjacent to the rounded cutting portion. The female blade has a fitting portion that is a hole conforming to the profile of the male blade in planar view and to which the male blade is fitted. On a lateral side of the female blade, an elongated hole for inserting a base film from one lateral side to the other lateral side is formed as an insertion portion.

Owner:IDEMITSU UNITECH CO LTD

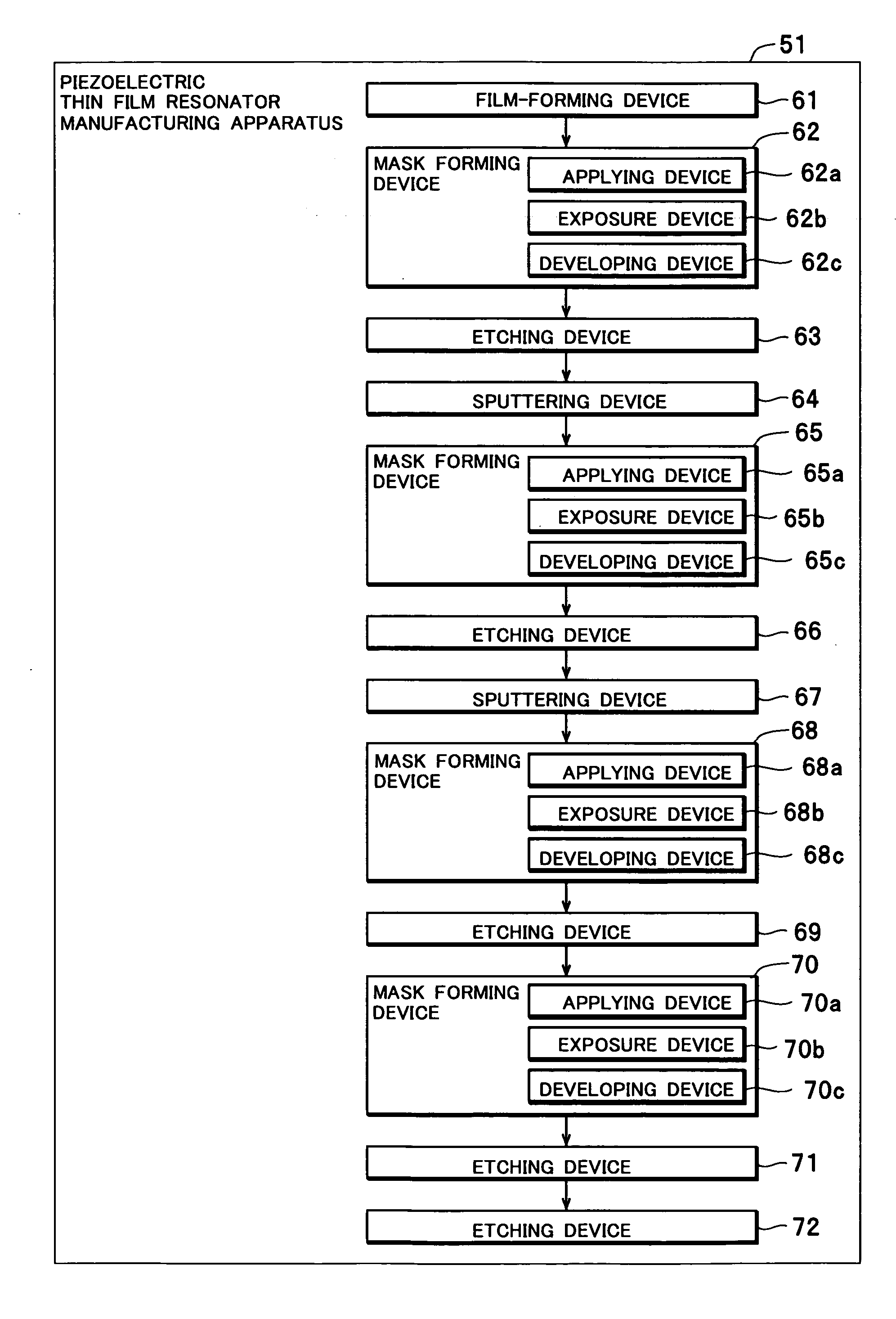

Method of manufacturing a piezoelectric thin film resonator, manufacturing apparatus for a piezoelectric thin film resonator, piezoelectric thin film resonator, and electronic component

ActiveUS7239067B2Avoid unnecessary etchingReliable and easy to manufacturePiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectronic componentPiezoelectric thin films

A method of manufacturing a piezoelectric thin film resonator forms, after forming a piezoelectric film on a substrate so as to cover a lower electrode formed on the substrate, an electrode material layer for forming an upper electrode above the piezoelectric film, forms a mask of a predetermined form on the electrode material layer, and then etches the electrode material layer to form the upper electrode. Before a step of forming the electrode material layer, a protective layer for protecting the piezoelectric film during etching of the electrode material layer is formed so as to cover at least a part of the piezoelectric film where the upper electrode is not formed, and the electrode material layer is then formed so as to cover the protective layer.

Owner:SNAPTRACK

Process for preparing a semiconductor wafer

InactiveUS6297076B1Reliable manufacturingImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesFluenceWafer dicing

Disclosed is a process for preparing a semiconductor device comprising the steps of adhering a back surface of a wafer, a front surface of which has been formed a circuit, onto the radiation curable adhesive layer, dicing the wafer into chips, rinsing, drying, irradiating the adhesive layer with radiation to cure said adhesive layer, expanding the adhesive sheet if necessary to make the chips apart from each other, then picking up the chips, mounting the picked chips on a lead frame, bonding, and molding to give such a structure that the back surfaces of the chips are partially or wholly in contact with a package molding resin, wherein the radiation curable adhesive layer comprises 100 parts by weight of an acrylic adhesive composed of a copolymer of an acrylic ester and an OH group-containing polymerizable monomer and 50-200 parts by weight of a radiation polymerizable compound having two or more unsaturated bonds, and the radiation curable adhesive layer has an elastic modulus of not less than 1x109 dyn / cm2 after curing by irradiation with radiation.

Owner:LINTEC CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com