Patents

Literature

887 results about "Cold forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold forming is the process of forging metals at near room temperatures. In cold forming metal is formed at high speed and high pressure into tool steel or carbide dies.

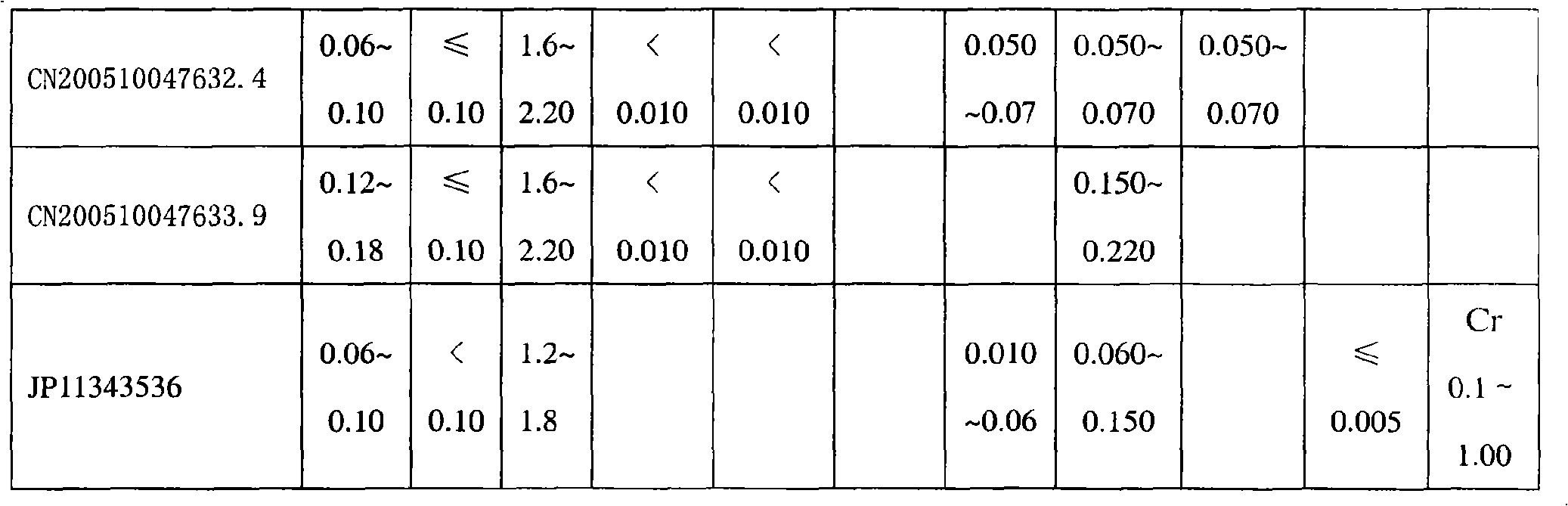

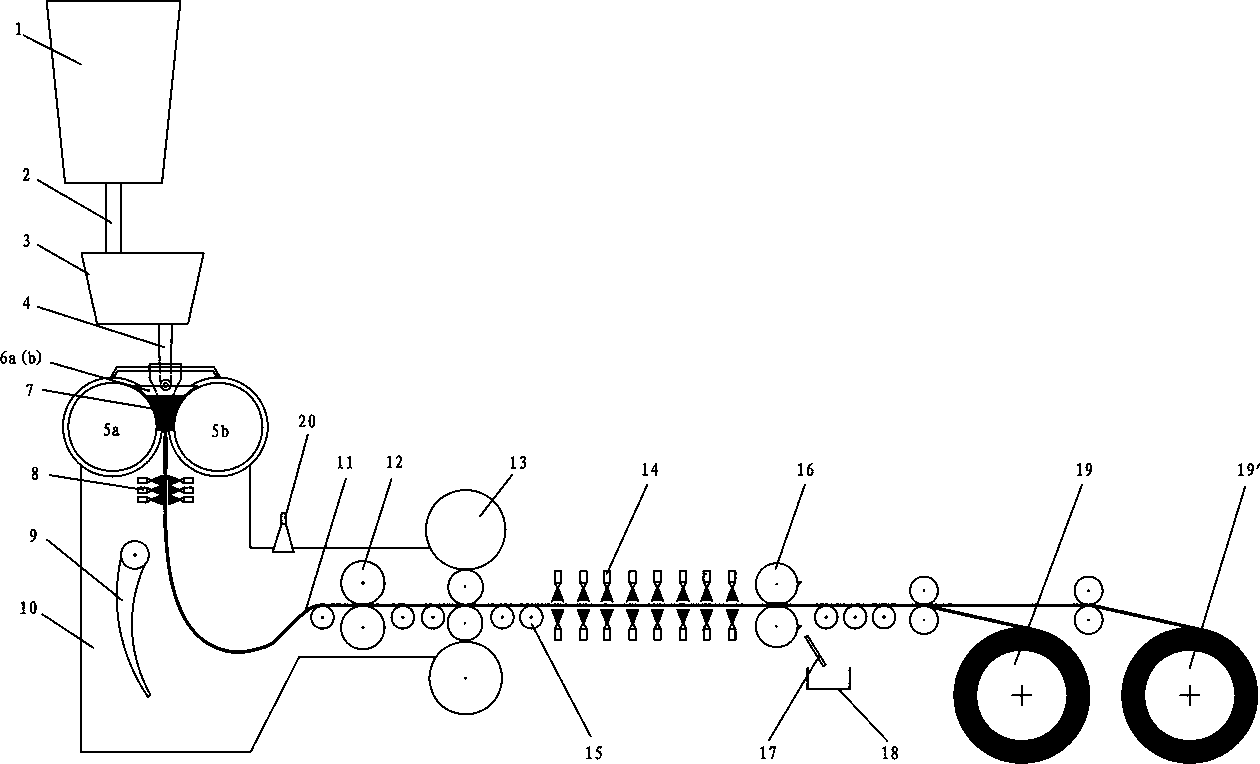

Production method of ultrahigh strength steel plate for cold forming and steel plate

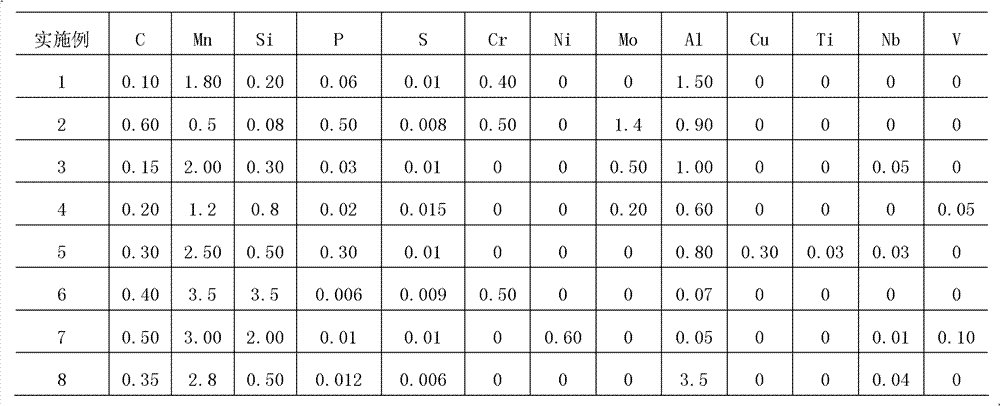

The invention provides a production method of an ultrahigh strength steel plate for cold forming and the steel plate. The method comprises the steps of smelting, casting, hot rolling, cold rolling, heating the cold-rolled steel plate through a continuous annealing production line with rapid cooling treatment to the austenite temperature, holding the temperature for a certain time, carrying out quenching treatment, obtaining a steel plate with the main structure of M+A and carrying out distribution treatment in a bell type annealing furnace. The steel plate comprises the following components in percentage by mass: 0.02-0.60% of C, 0.05-3.5% of Si, 0.20-3.50% of Mn, P more than or equal to 0.005 but less than or equal to 0.50%, S not more than 0.05%, 0.02-3.00% of Al, Cr not more than 0.50%, Ni not more than 3.00%, Cu not more than 0.50%, Mo not more than 1.50%, V not more than 0.50%, Ti not more than 0.20%, Nb not more than 0.20% and the balance of Fe and unavoidable impurities. The steel plate produced by adopting the method provided by the invention has the advantages of high strength and capability of cold forming and the process route of Q&P steel industrial production is effectively solved.

Owner:ANGANG STEEL CO LTD

Steel sheet for hot press forming having low-temperature heat treatment property, method of manufacturing the same, method of manufacturing parts using the same, and parts manufactured by the same

ActiveUS20090238715A1Reduced strengthHigh yield strengthMetal rolling stand detailsFurnace typesManganeseHeat treated

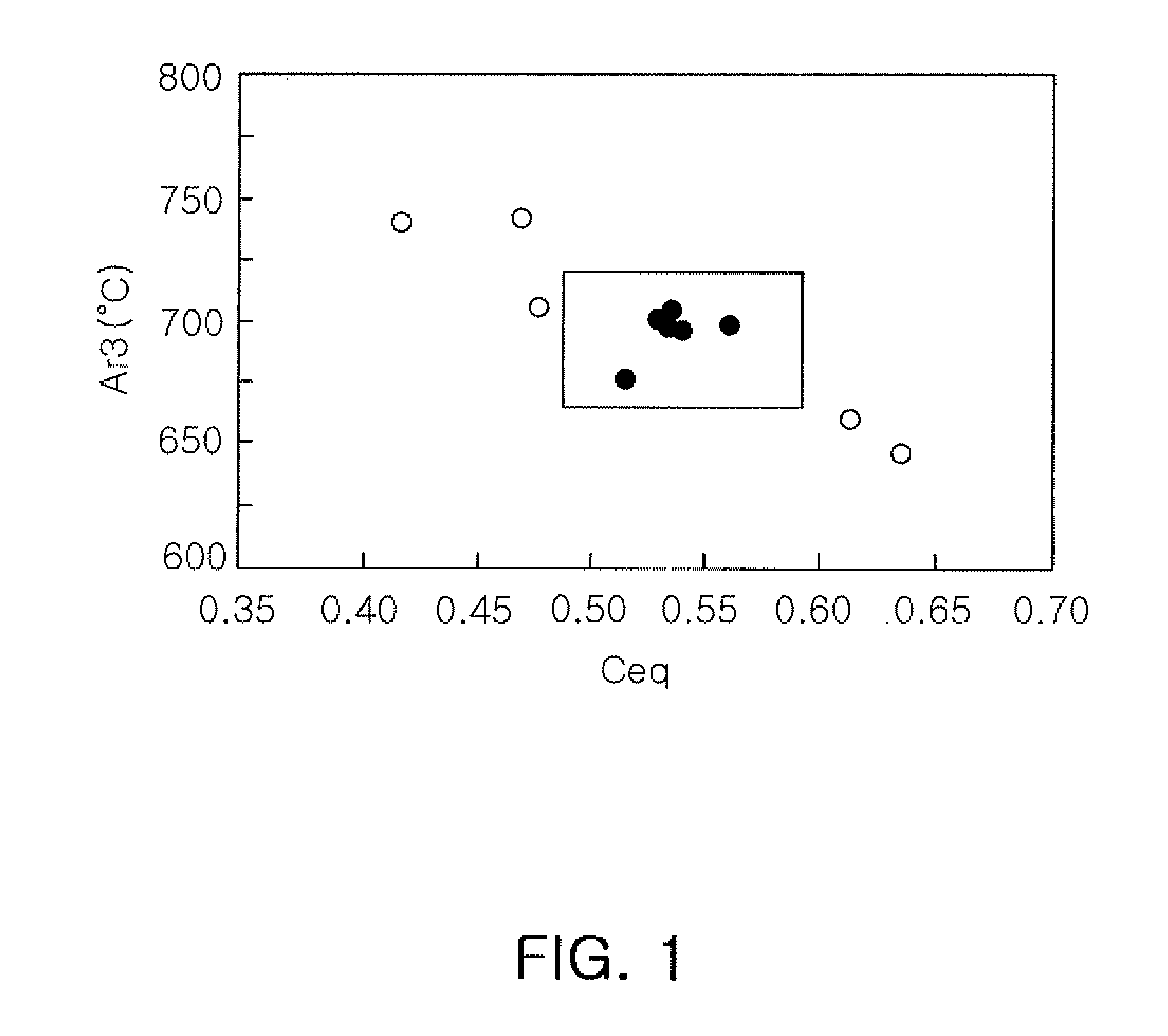

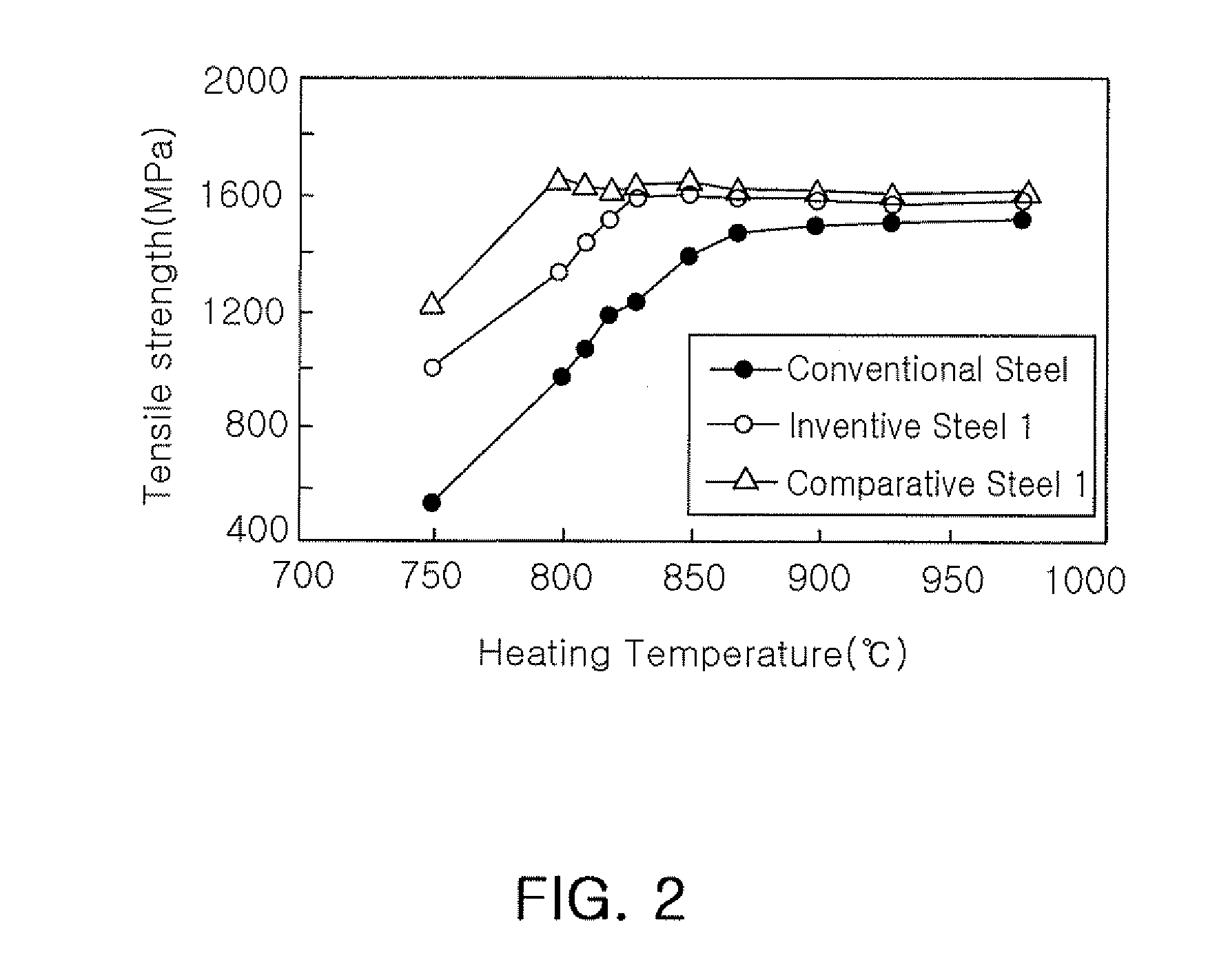

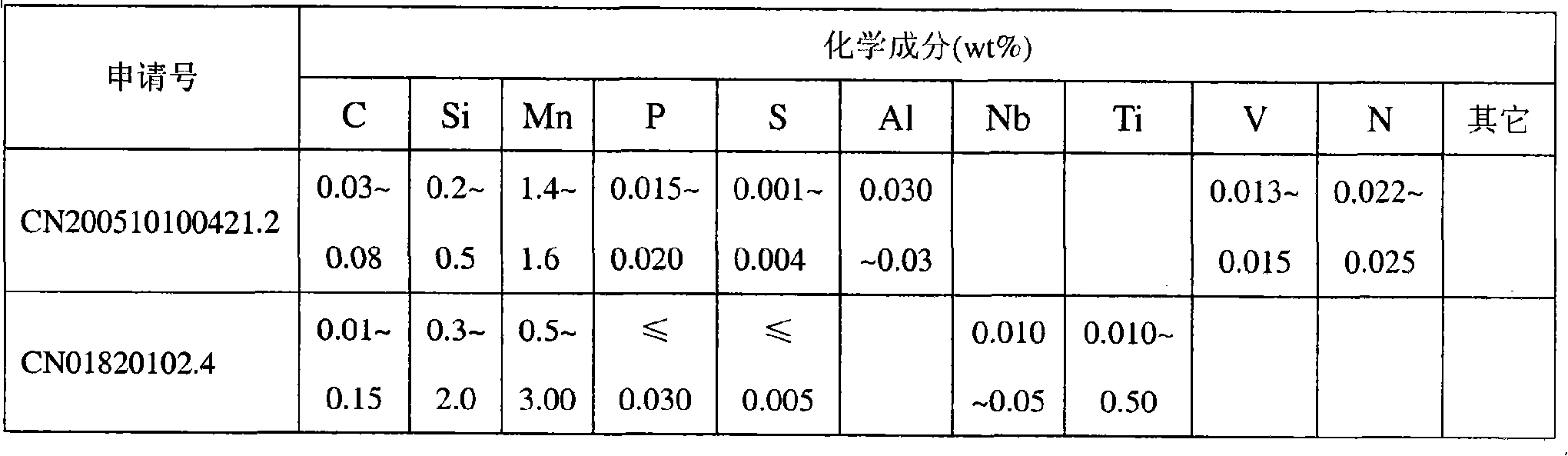

A steel sheet for forming having low-temperature heat treatment property, in which heat treatment is performed within a range of lower temperature than a conventional steel sheet in the event of hot press forming or post-heat treatment after cold forming, a method of manufacturing the same, and a method of manufacturing parts using the same. The steel sheet has a composition of, by weight, carbon (C): 0.15 to 0.35%, silicon (Si): 0.5% or less, manganese (Mn): 1.5 to 2.2%, phosphorus (P): 0.025% or less, sulfur (S): 0.01% or less, aluminum (Al): 0.01 to 0.05%, nitrogen (N): 50 to 200 ppm, titanium (Ti): 0.005 to 0.05%, tungsten (W): 0.005 to 0.1%, and boron (B): 1 to 50 ppm, wherein Ti / N: less than 3.4, where Ti / N is the atomic ratio of the corresponding elements, Ceq expressed by the following formula ranges from 0.48 to 0.58, and temperature Ar3 ranges from 670° C. to 725° C. Wherein Ceq=C+Si / 24+Mn / 6+Ni / 40+Cr / 5+V / 14 where C, Si, Mn, Ni, Cr and V indicate the contents (wt %) of the respective elements.

Owner:POHANG IRON & STEEL CO LTD

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

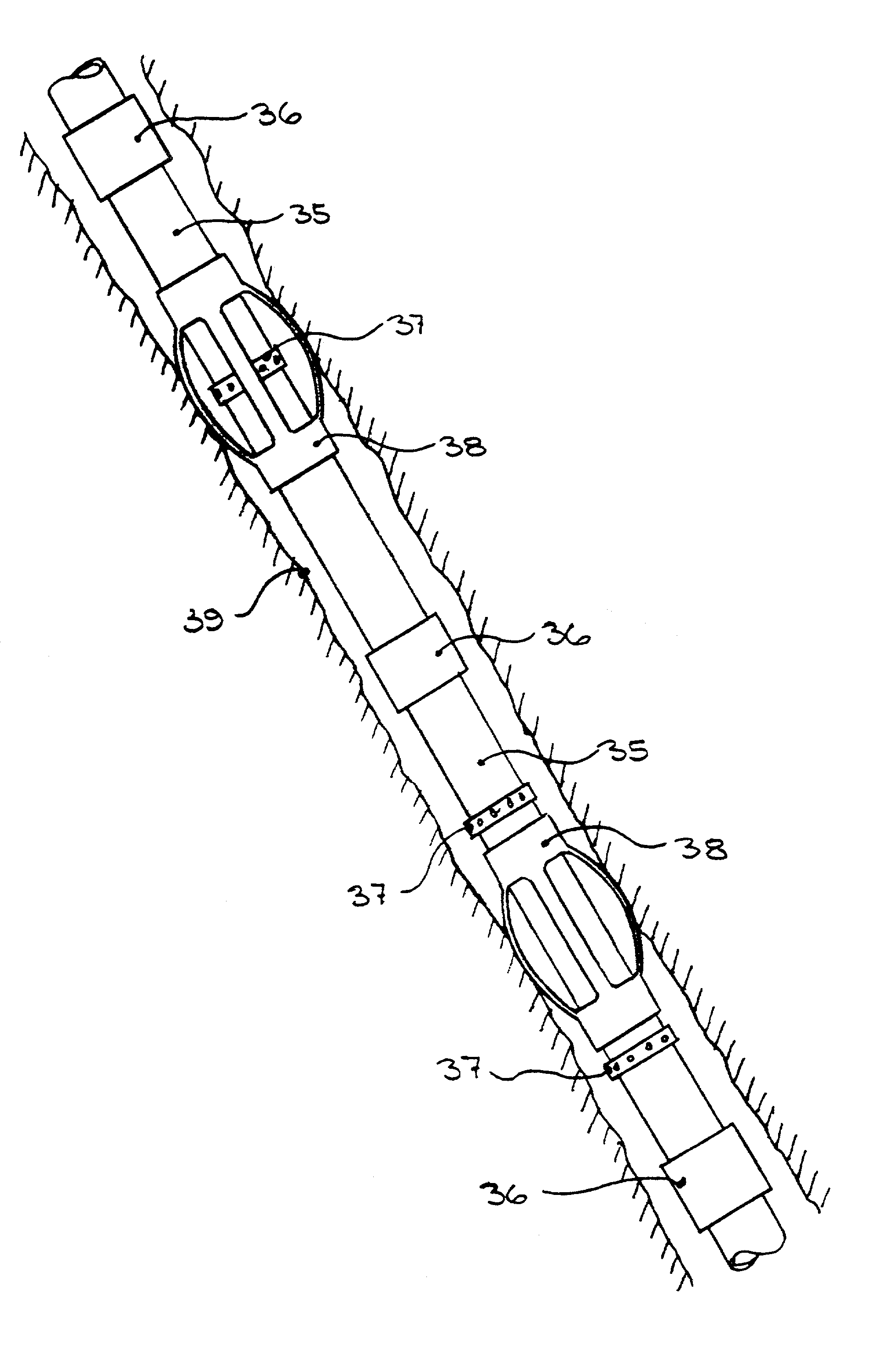

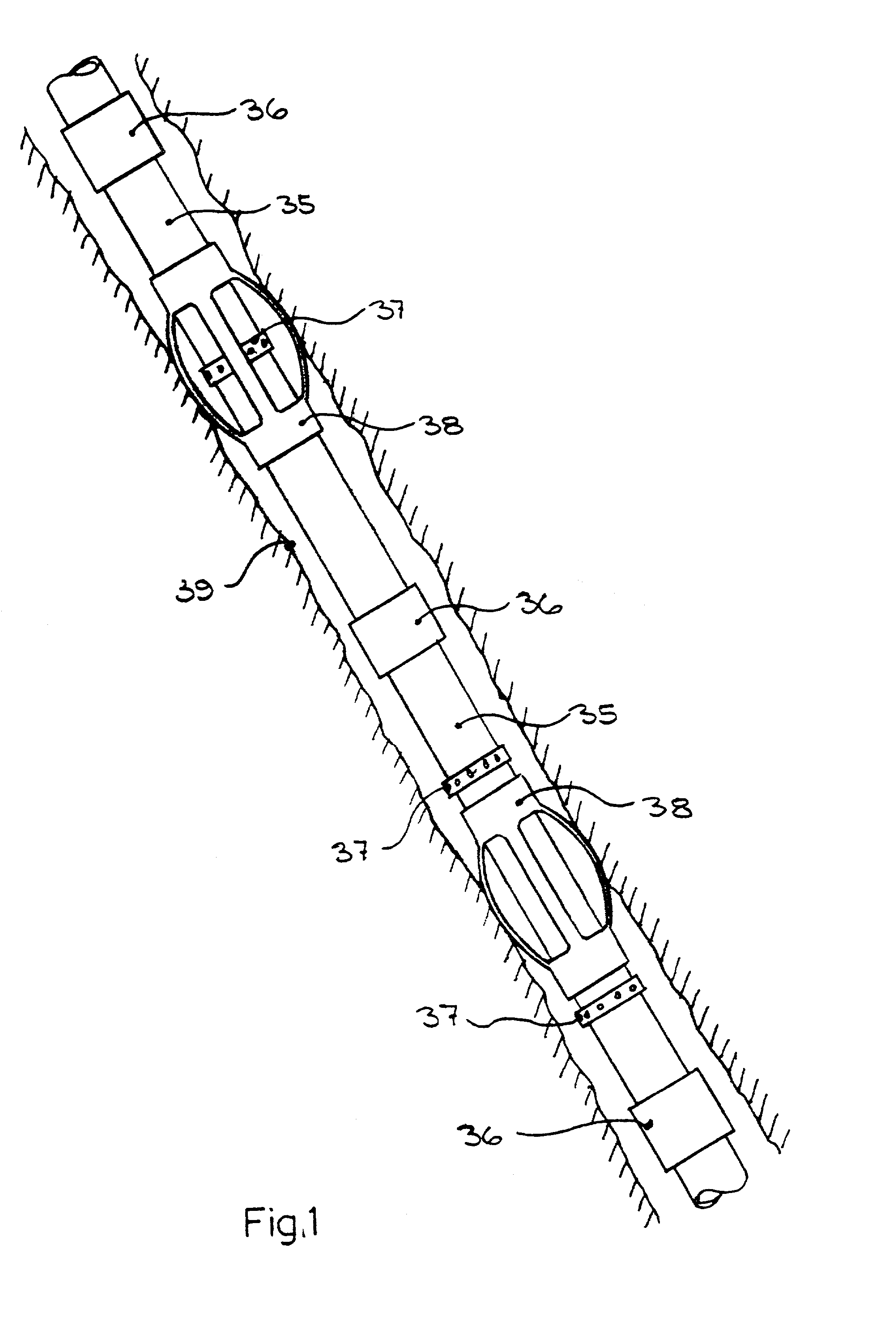

Method of making a centering device and centering device formed by that method

A spring centralizer device for supporting a tubular member spaced from the wall of a bore is made from a single piece of boron steel material. The spring centralizer device has first and second collars spaced apart along a longitudinal axis. Spring bow portions extend between the collars. As the device is made from a single piece of material, the material extends seamlessly from each collar portion through the bow portions so that there are no joins or points of weakness. Use of boron steel means that the device can be made by cold forming.

Owner:CENTEK

Automobile beam steel with tensile strength of 590MPa and manufacturing method thereof

ActiveCN101701316AHigh strengthImprove toughnessTemperature control deviceHeat treatment process controlChemical compositionLaminar cooling

The invention discloses automobile beam steel with tensile strength of 590MPa and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.07-0.13 C, 0.10-0.30 Si, 1.30-1.60 Mn, at most 0.025 P, at most 0.008 S, 0.015-0.070 Al, 0.025-0.050 Nb, 0.020-0.040 Ti, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the technical steps of molten iron desulfuration, bessemerizing, alloying, vacuum treatment, continuous casting, hot tandem rolling, Laminar cooling, reeling and finishing. Proved by practices, the automobile beam steel has stable chemical compositions and mechanical property as well as good cold forming performance and surface quality and completely meets the requirement for manufacturing novel frame structures of heavy-duty trucks and large vans.

Owner:武汉钢铁有限公司

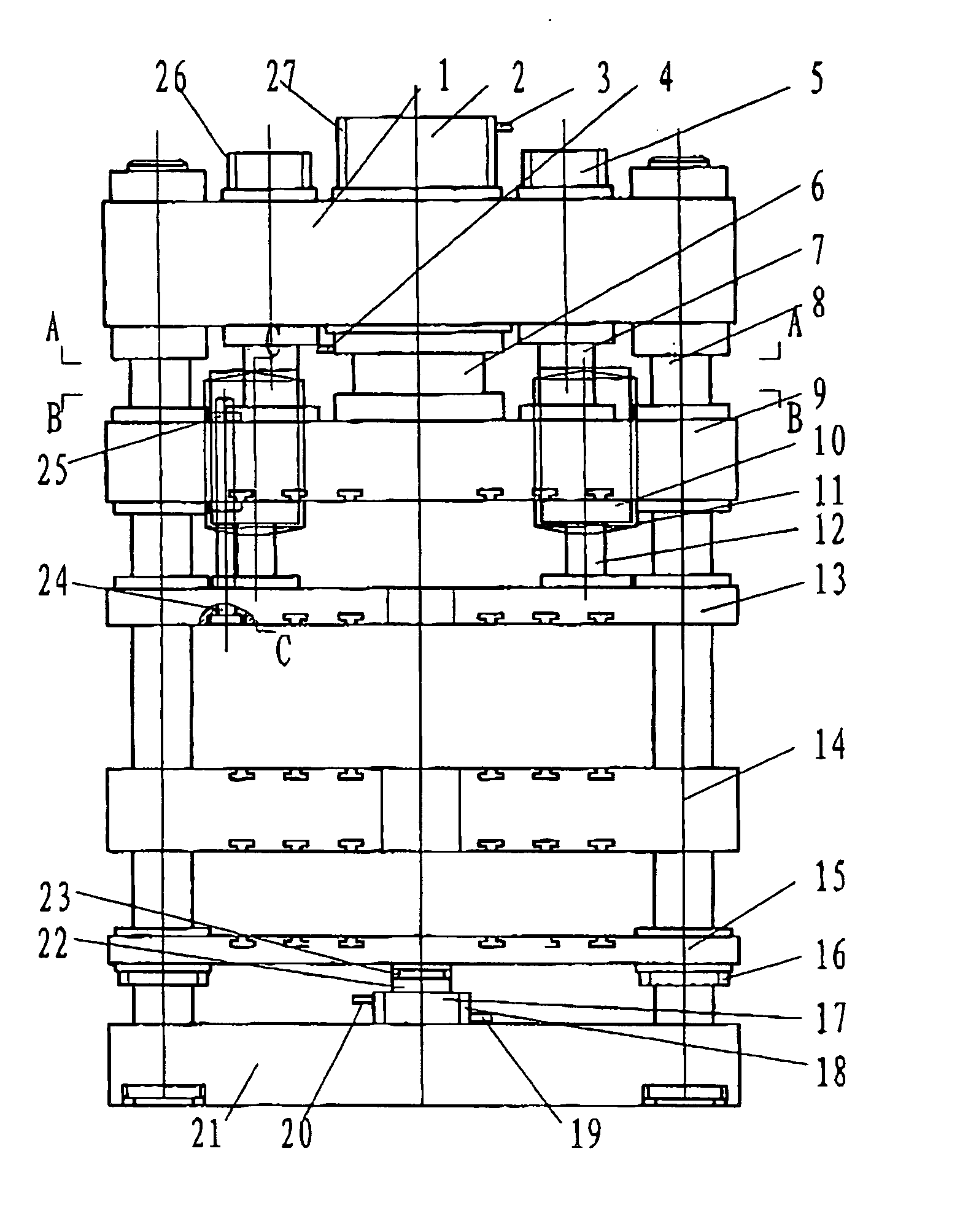

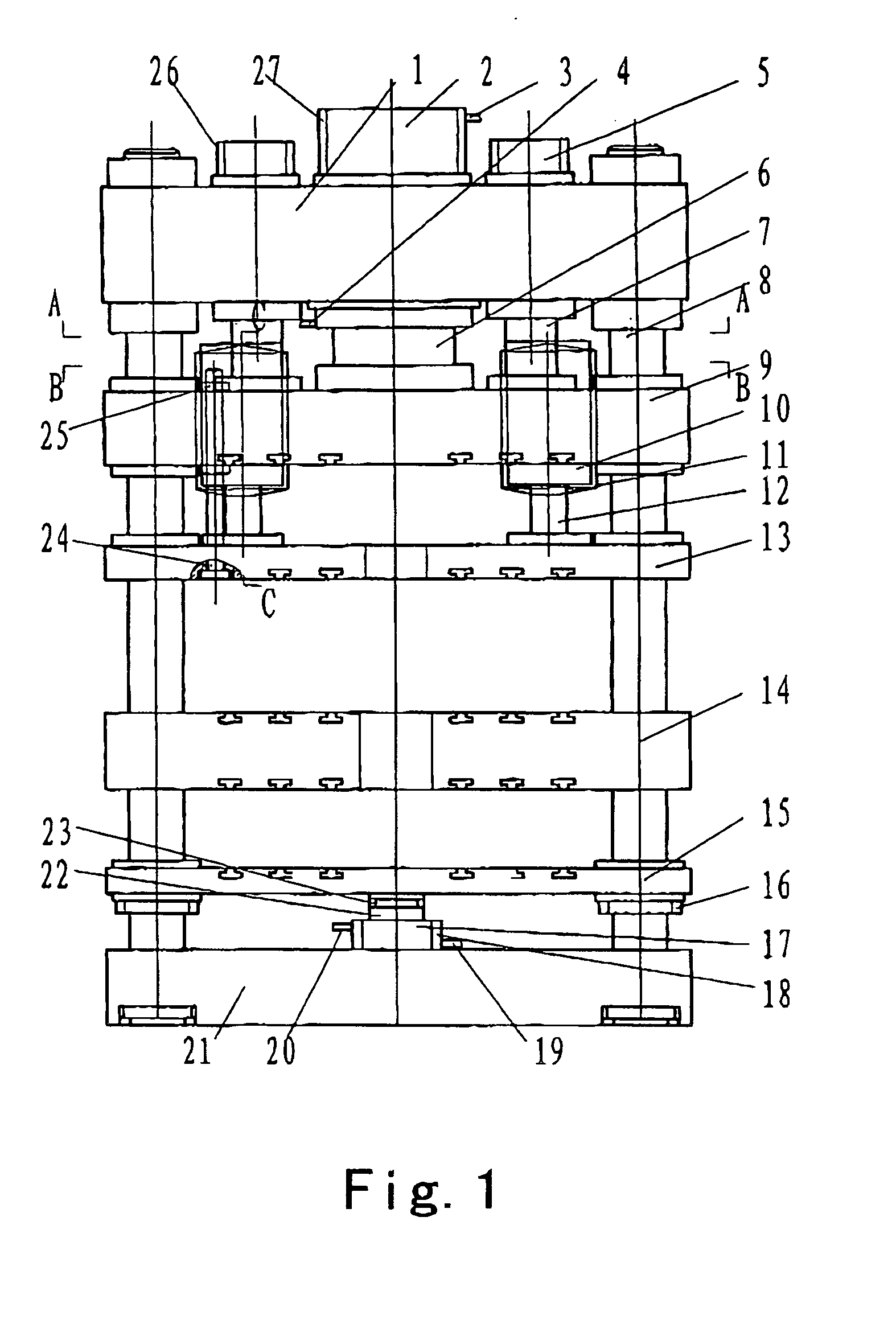

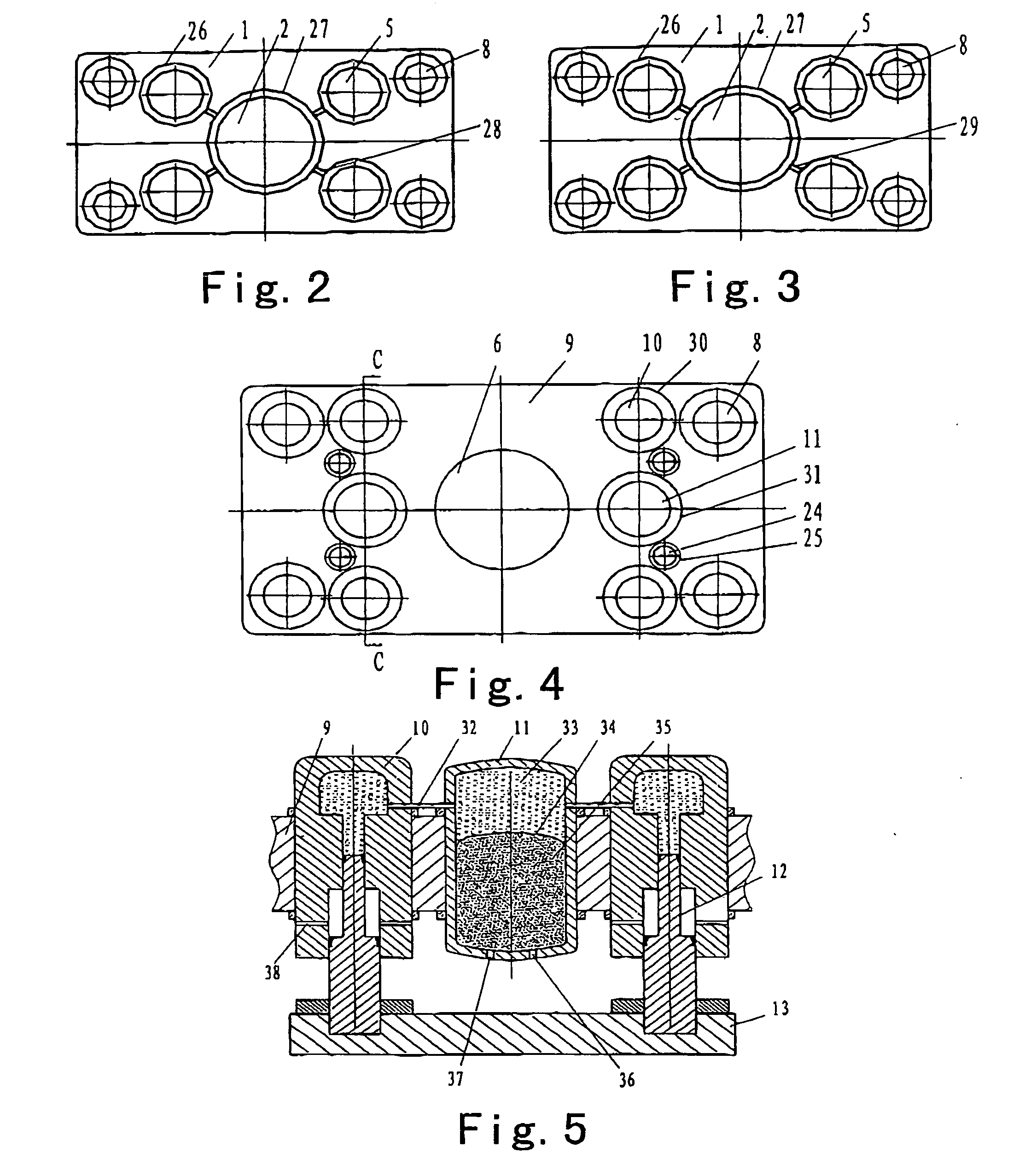

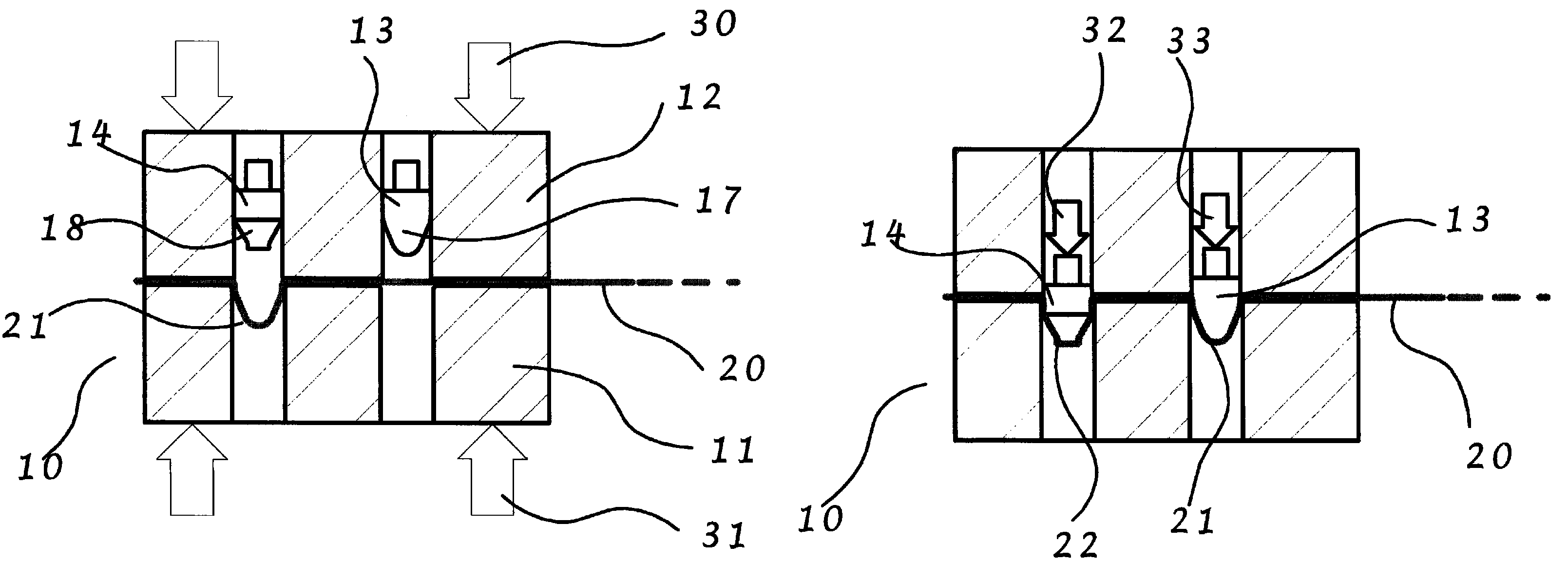

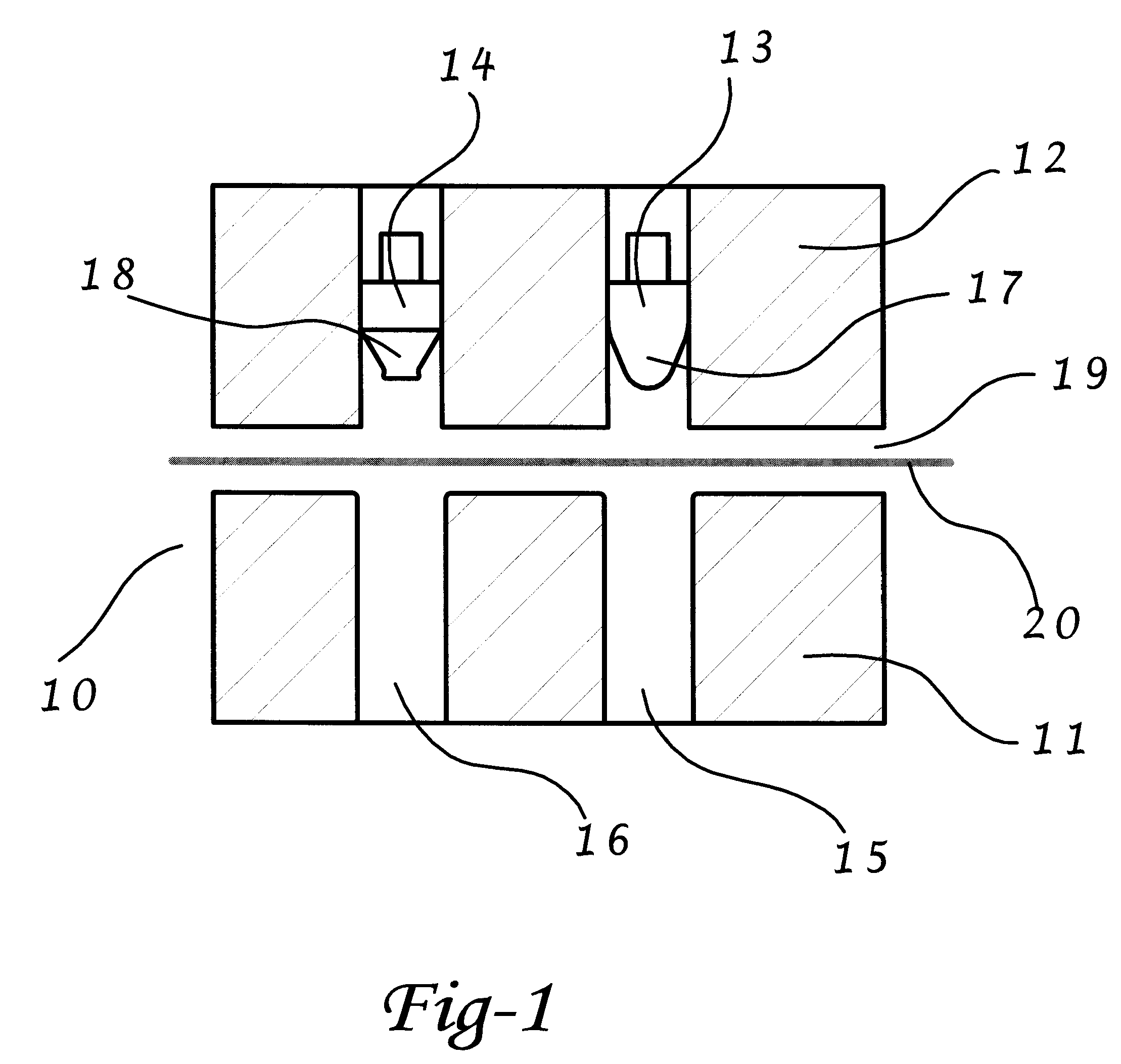

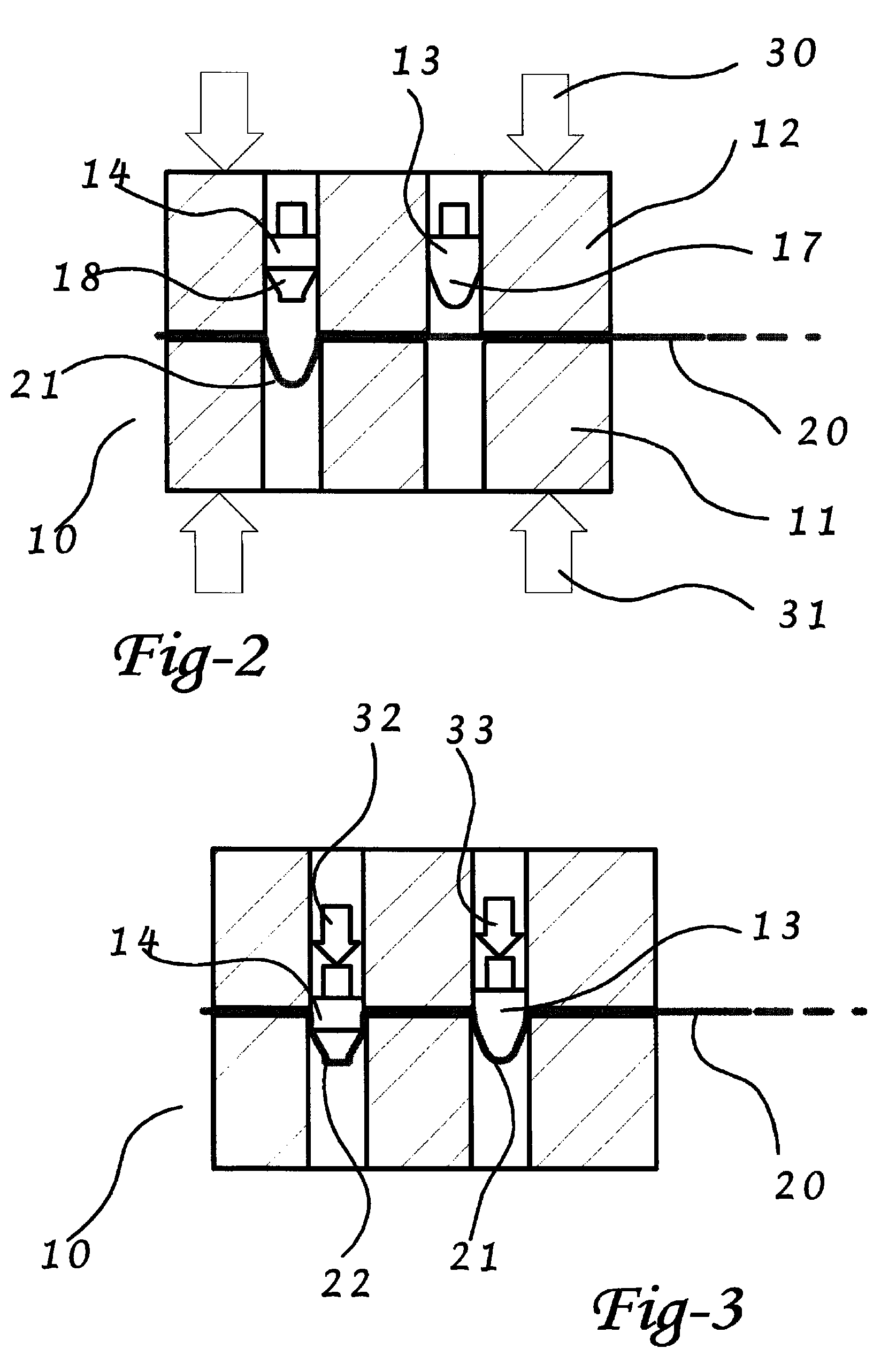

Adjustable Hydraulic Press With Both Upper And Lower Double Action

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

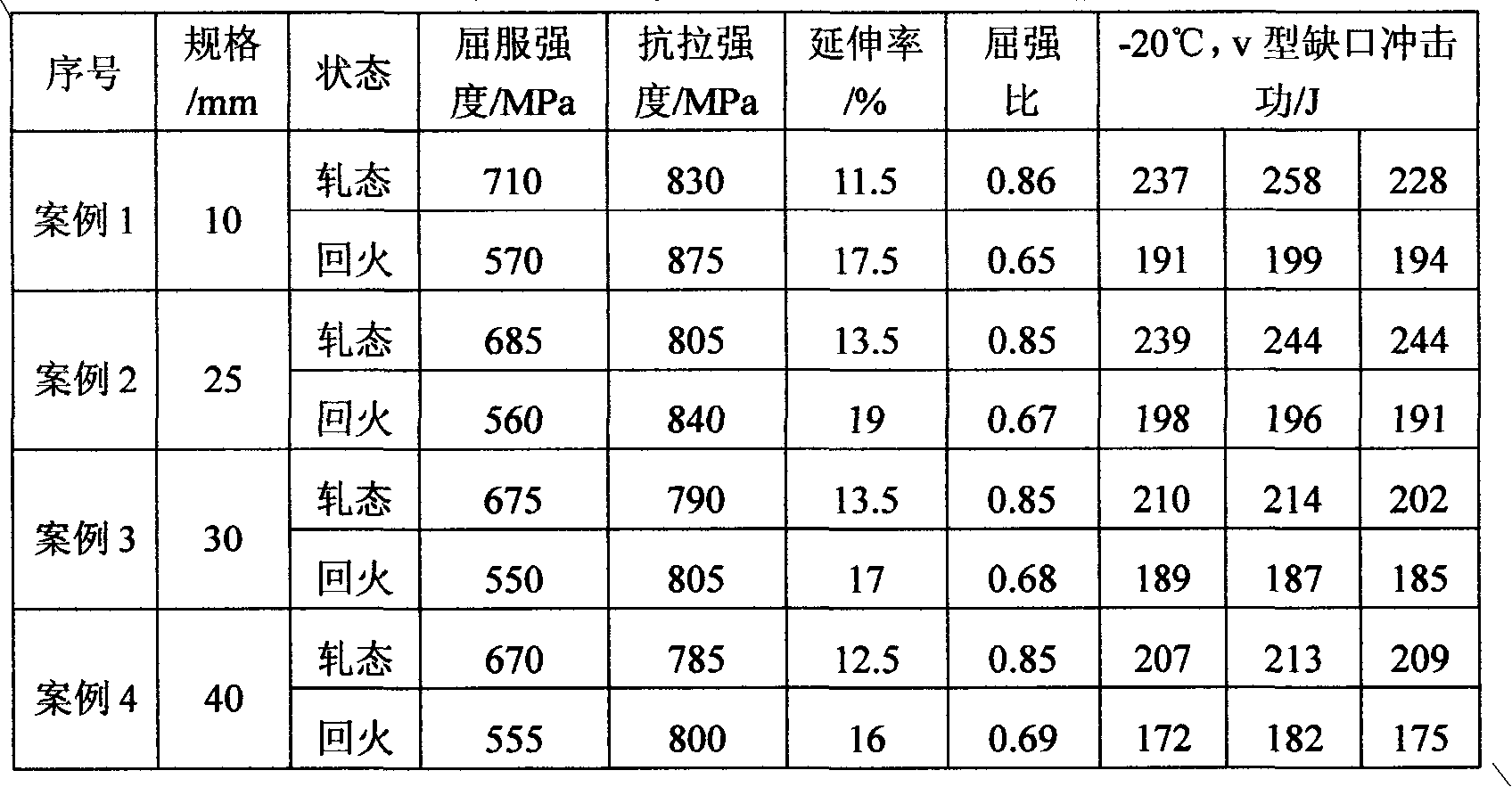

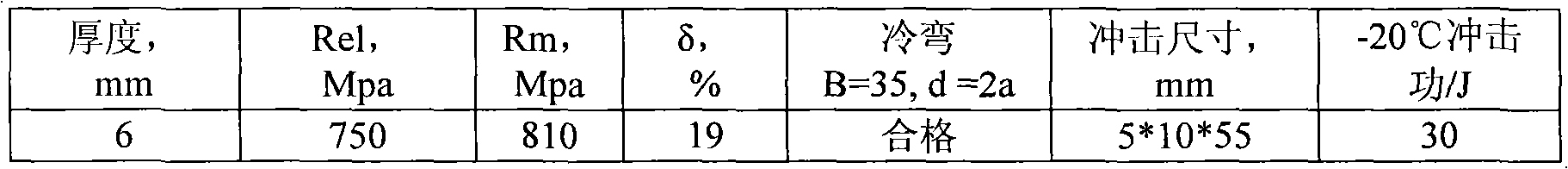

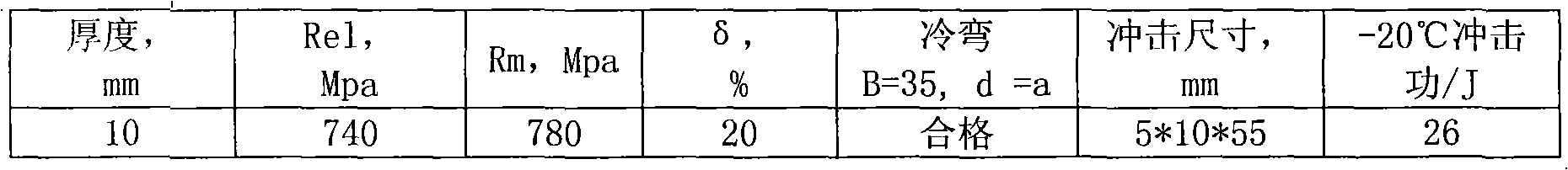

800 MPa-grade low-yield-ratio structural steel plate and production method thereof

ActiveCN102011068AGood welding performanceGood low temperature impact propertiesYield ratioHeat treated

The method relates to an 800 MPa-grade low-yield-ratio structural steel plate and a production method thereof. The steel comprises the chemical components in percentage by weight: 0.045 to 0.075 percent of C, 0.30 to 0.55 percent of Si, 1.55 to 1.95 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.0025 percent of S, 0.012 to 0.035 percent of Al, 0.15 to 0.25 percent of Cr, 0.15 to 0.3 percent of Mo, 0.2 to 0.4 percent of Cu, 0.2 to 0.4 percent of Ni, 0.008 to 0.04 percent of Nb, 0.008 to 0.04 percent of V, 0.008 to 0.03 percent of Ti, 0.0008 to 0.0015 percent of B, and the balance of Fe and inevitable impurities. The steel is subjected to RH vacuum treatment, ladle furnace (LF) external refining, full protection casting, a thermo mechanical control process (TMCP), and tempering heat treatment to form the steel plate with low yield ratio, high strength and high work hardening rate. The steel plate has the thickness specification of between 10 and 40 mm, the yield strength of more than or equal to 550MPa, the tensile strength of more than or equal to 800 MPa and the yield ratio of less than 0.70, and has excellent low temperature compact performance, cold forming performance and welding performance.

Owner:SHOUGANG CORPORATION

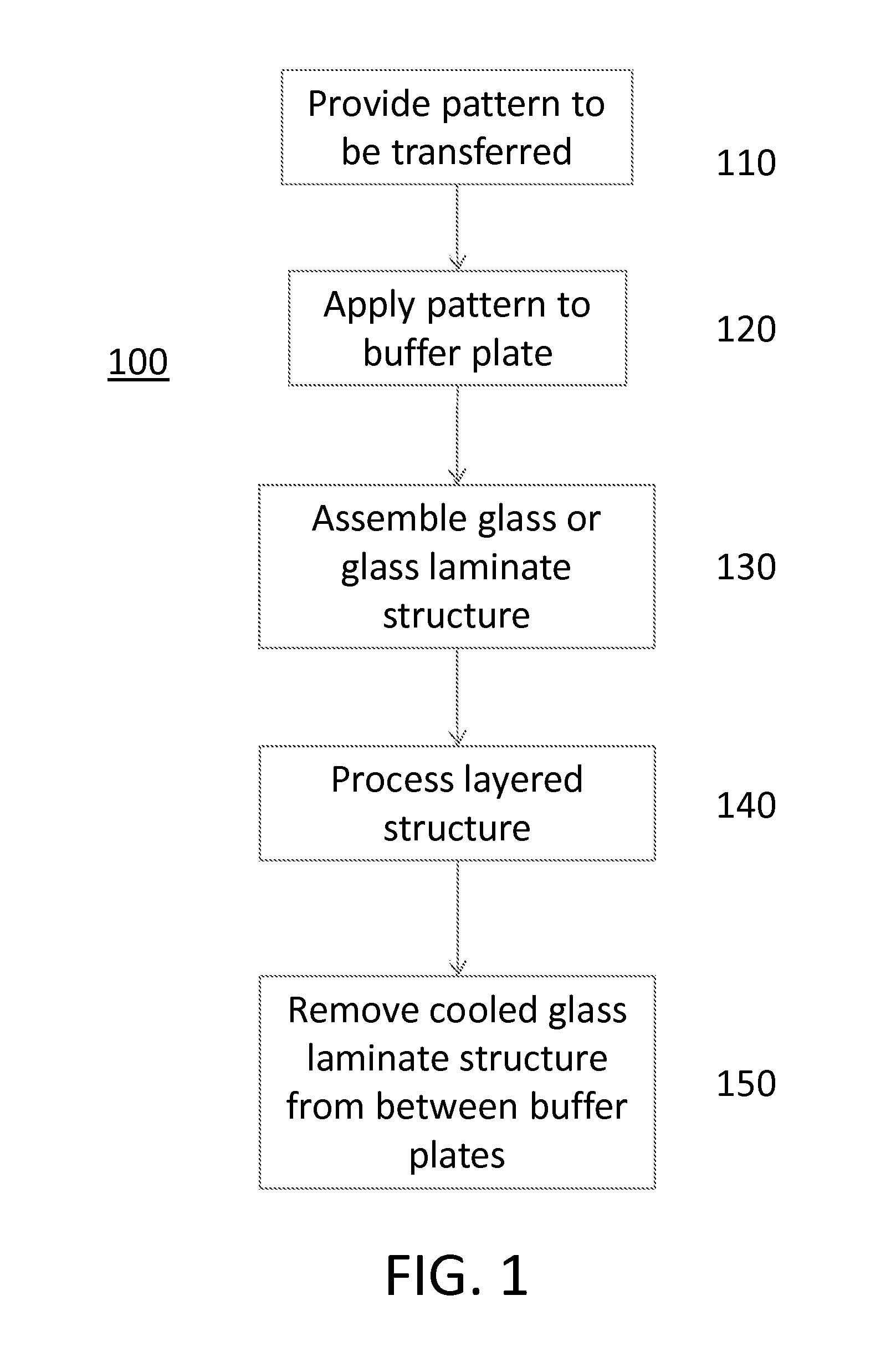

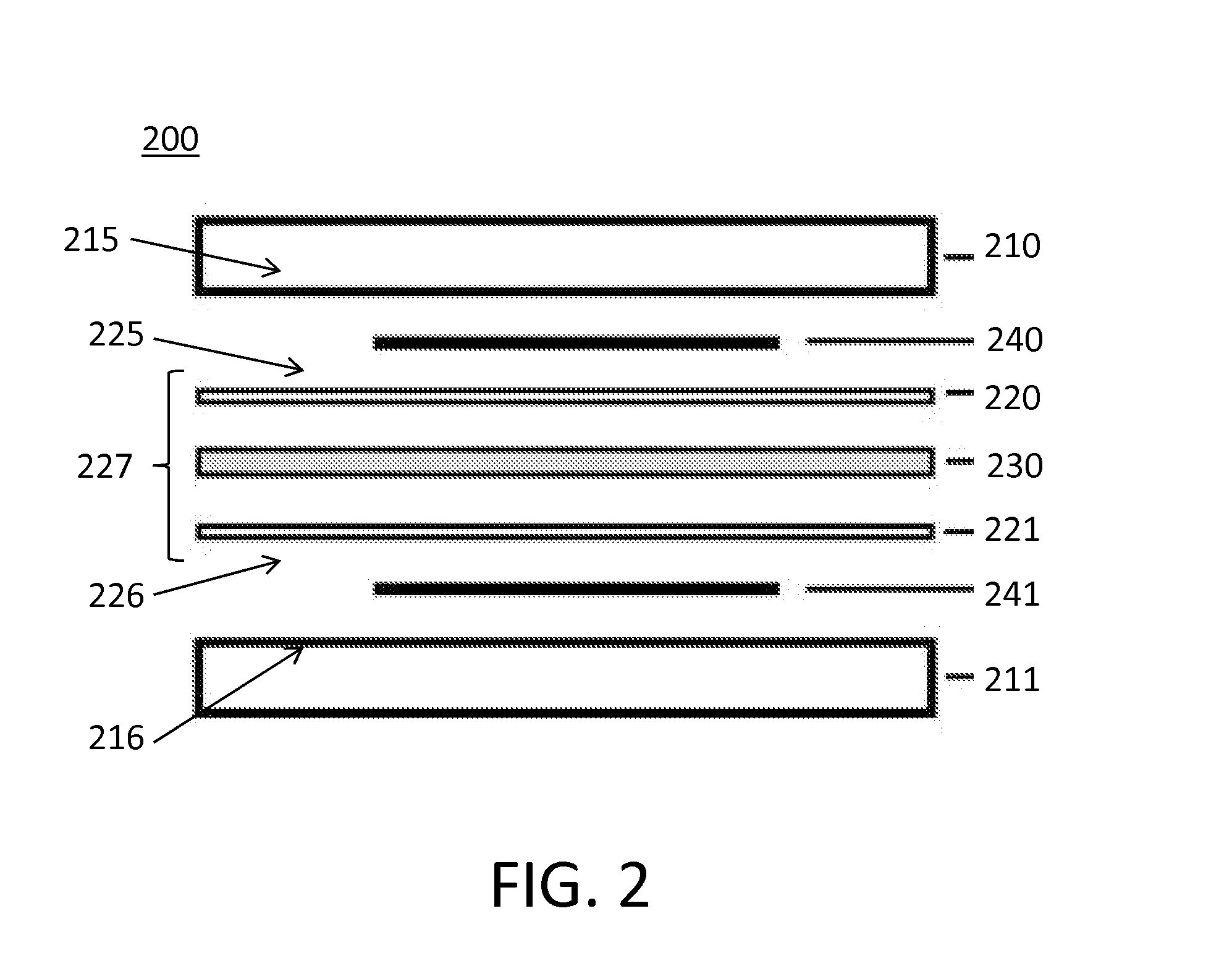

Methods for forming patterns in thin glass laminate structures

InactiveUS20160297176A1Tendency to deformSpecial ornamental structuresLaminationCold formedEngineering

A method of cold forming a glass laminate structure. The method includes assembling a multi-layer structure having two buffer plates and a glass laminate structure intermediate the two buffer plates, wherein one or both of the two buffer plates includes a pattern formed thereon or therein or the multi-layer structure includes non-deformable materials forming a pattern. The method further includes cold forming the glass laminate structure in the autoclave by heating the assembled structure to a temperature about 5 to 10 degrees above the softening point of the polymer interlayer for a predetermined period of time at a predetermined pressure. After processing the glass laminate structure can be removed from between the buffer plates wherein the pattern formed in or on the one or both buffer plates or non-deformable materials has been transferred to the glass laminate structure as a function of variances of thicknesses in the glass laminate structure.

Owner:CORNING INC

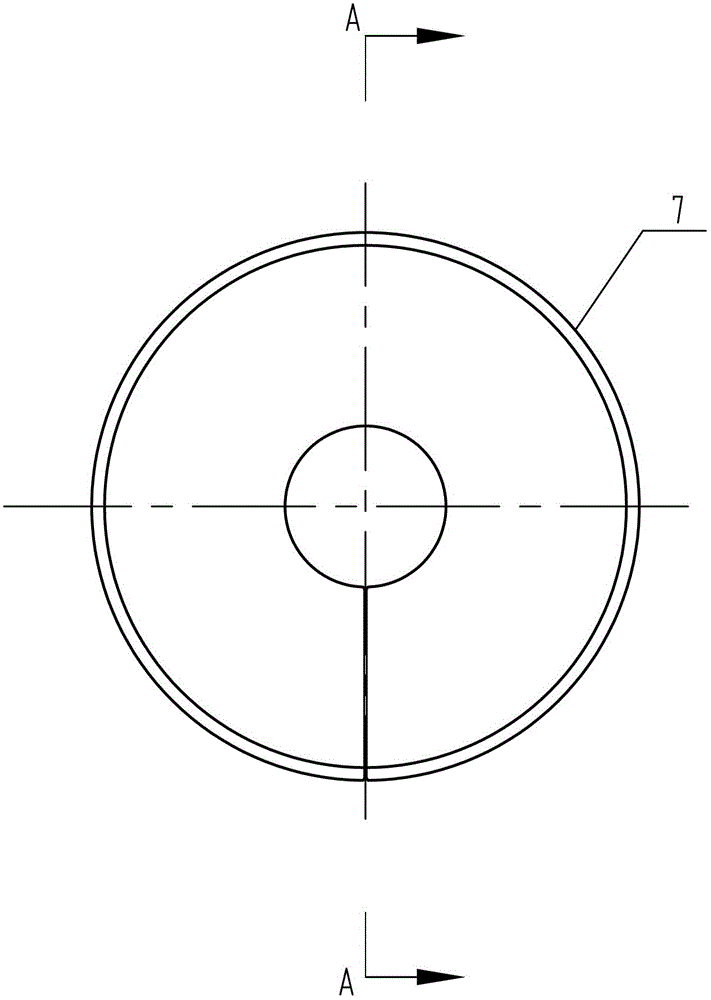

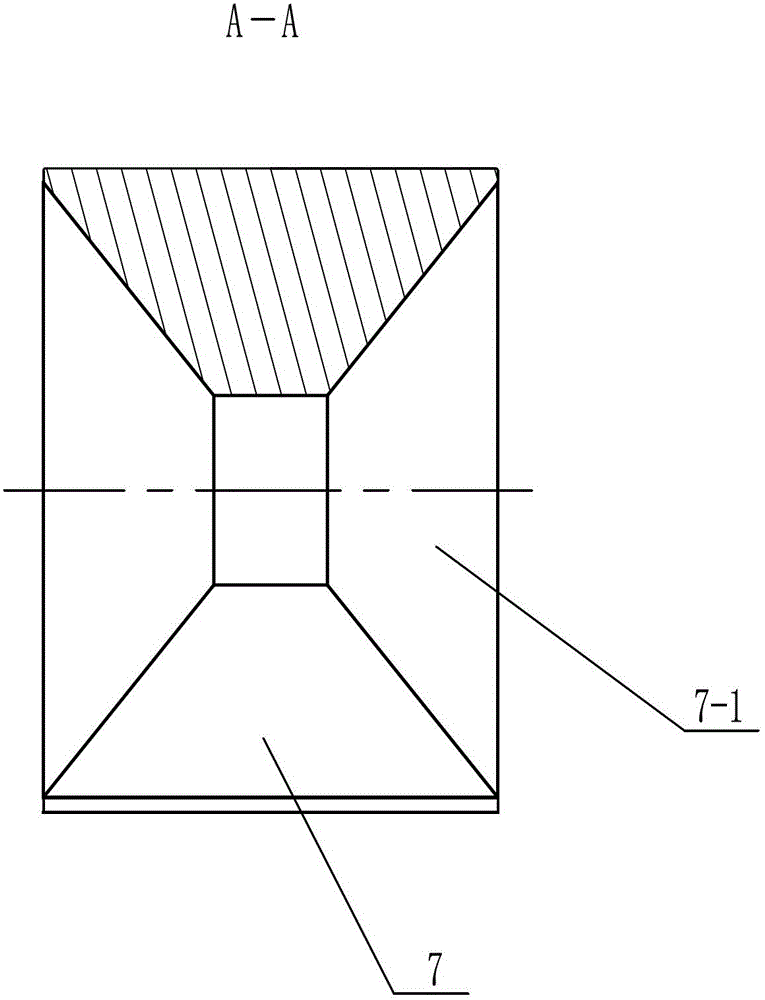

Cold-forming die steel collars anticentripetal composite casting technique for rail beam and section

The invention discloses a centrifugal composite casting technology for a cold working die steel roll collar used for a rail beam and section mill. The chemical compositions by weight percentage are as follows: outer layer compositions: 1.2 to 2.0 percent of C, less than 0.05 percent of P, less than 1.0 percent of Si, less than 0.05 percent of S, less than 1.0 percent of Mn, less than 1.0 percent of Ni, 10 to 15 percent of Cr, 0.1 to 1.0 percent of Mo, 0.1 to 1.5 percent of V, and the balance being Fe; core compositions: 1.2 to 3.0 percent of C, less than 0.05 percent of P, 1.0 to 3.0 percent of Si, less than 0.05 percent of S, 0.5 to 2.0 percent of Mn, less than 1.0 percent of Cr, less than 1.0 percent of Ni, less than 1.0 percent of Mo, and the balance being Fe. The centrifugal casting technology is adopted to manufacture the cold working die steel roll collar used for various rail beam and section mills; a core adopts high-toughness graphitic steel when the outer layer obtains high wearing resistance; and reasonable casting parameter matching is designed to guarantee the good combination of cold working die steel and the core. Compared with products produced by the prior forging method, the technology has equivalent application effect and low manufacturing cost, and the performance-price ratio is far higher than that of the forging production method. The technology realizes the casting which substitutes the forging, and satisfies the development direction of the industry.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

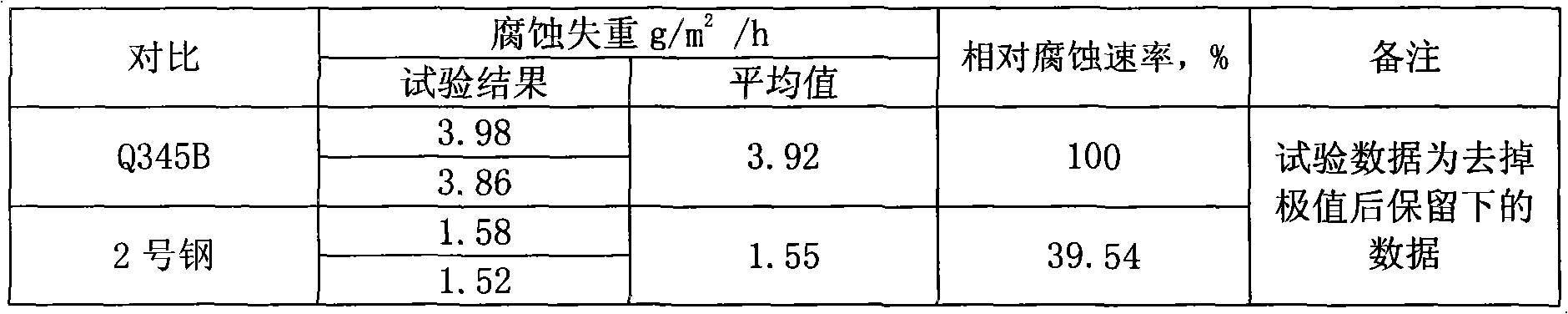

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

Deep draw container forming method

ActiveUS7963089B2Reduces the likelihood of thin spots, fracturesReduce layeringSmall article dispensingPharmaceutical containersContour formBlisters

The present disclosure is directed to processes for manufacturing shaped articles for unit-dose packaging with at least one formed recess (e.g., a blister), in particular for unit-dose packaging of pharmaceutical dosage forms. In certain embodiments, the first step of the process is directed to drawing the film material (e.g., metal-plastic foil) with one or more plungers to form a primary contour, the contour having a depth of at least 100% and up to 150% of the depth of the formed recess. The second stage involves shaping the primary contour with one or more plunger(s) to the desired formed recess, with a depth that is less than the depth of the primary contour, while substantially maintaining the surface area of the primary contour formed in the first stage. The formed recess may be formed using warm-forming or cold-forming techniques.

Owner:MYSTIC PHARMA INC

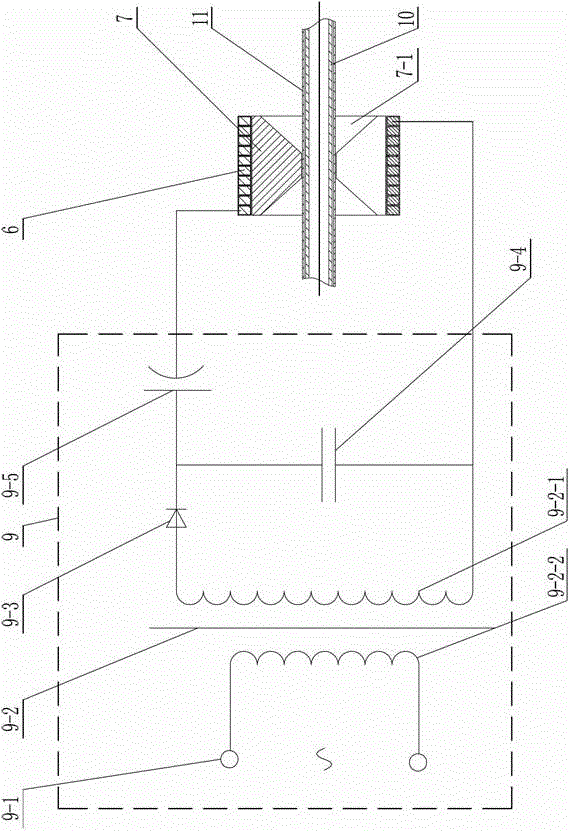

Magnetic pulse forming device and method of bimetal composite pipe

ActiveCN102744310AImprove bindingEconomic Forming Manufacturing TechnologyPulse controlMagnetic tension force

The invention relates to a magnetic pulse forming device and method of a bimetal composite pipe, relates to magnetic pulse forming devices and methods of composite pipes, and is is used for solving the problems of the composite bimetal pipe having the disadvantages of being low in combination intensity and limited in application occasions by adopting a cold forming method, as well as is high in investment and complex in production process by adopting a thermal processing method, and is high in dangerousness by adopting an explosion composite method. A pair of movable flat tongs is glidingly matched with a base fixing plate; a pair of fixed flat tongs is fixedly arranged on the base fixing plate; a pipe billet clamping block is fixedly arranged on the flat tongs; a screw rod is connected with the base fixing plate; the screw rod is installed on the movable flat tongs; a support frame is fixedly connected with the base fixing plate; a magnetic trap is supported through the support frame; a magnetic coil is wound on the outer annular surface of the magnetic trap; two output ends of a magnetic pulse control circuit are connected with two ends of the magnetic coil; and the method comprises the following steps of: cleaning the surface of a pipe billet to be composited; locating and clamping internal and external pipe billets; compositing and forming for first time; and subsequently and progressively compositing and forming till the bimetal composite pipe with required length is obtained. The magnetic pulse forming device and method of the bimetal composite pipe, disclosed by the invention, are used for magnetic pulse forming of the bimetal composite pipe.

Owner:HARBIN INST OF TECH

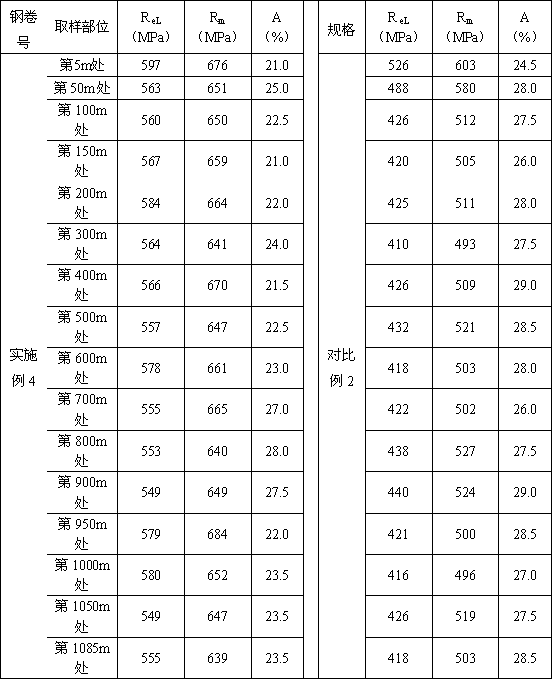

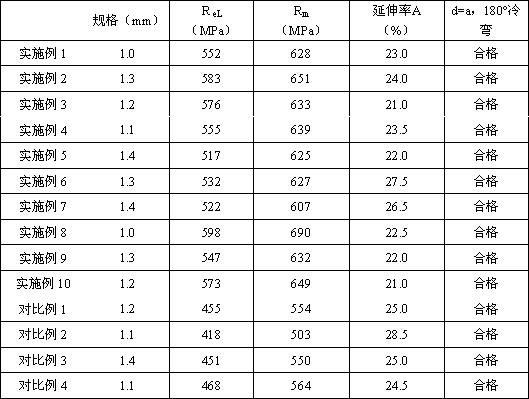

Ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level and manufacturing method thereof

ActiveCN102839321AIncrease the effective Ti contentImprove precipitation strengthening effectCold formedLaminar cooling

An ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level comprises the chemical components by weight: 0.02-007%of C, less than or equal to 0.50% of Si, 0.50-1.40% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.11% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O, or 0.17-0.20% of C, less than or equal to 0.50% of Si, 0.50-0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.08% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O. The process comprises melted iron desulfuration, converter blowing, argon blowing, LF furnace refining, continuous casting, rotary descaling, soaking pit soaking, descaling, seven-frame finish rolling, stream cooling and coiling. The ultrathin hot-rolled sheet strip has the advantages that the addition of the alloying element is low, the mechanical property is as follows: the yield strength is more than or equal to 500MPa, the product thickness is less than or equal to 1.4mm, the sheet shape is good, the production flow is short, and excellent cold forming and welding performances are achieved.

Owner:武汉钢铁有限公司

Method of producing an animal food product with a core and shell

ActiveUS20070020355A1Simple wayNot produce unpleasantMilk preservationAnimal feeding stuffFiberCold formed

The present invention relates to a method of producing an animal food product with a core and a shell at least partially covering the core, in which the core starting material includes meat and / or meat-like components, water, oil and / or fat, vitamins, minerals, salts, antioxidising agents, dyes and / or preservatives, vegetable fibres, and other ingredients. The shell starting material includes vegetable and / or animal protein, cereal, starch and / or dextrin, blood plasma, water, cereal derivative and / or sugar or sugar derivative, and vitamins, minerals, salts, antioxidising agents, dyes and / or preservatives. The method includes the steps of: either producing core particles by mixing the core materials, baking the mixture thus obtained, conditioning, cutting into small pieces and conditioning again, or producing core particles by mixing the core materials, cold forming the mixture thus obtained and cutting it into small pieces, and then mixing the core particles with the components of the shell in a coating pan, baking or deep-frying and finally conditioning.

Owner:MARS INC

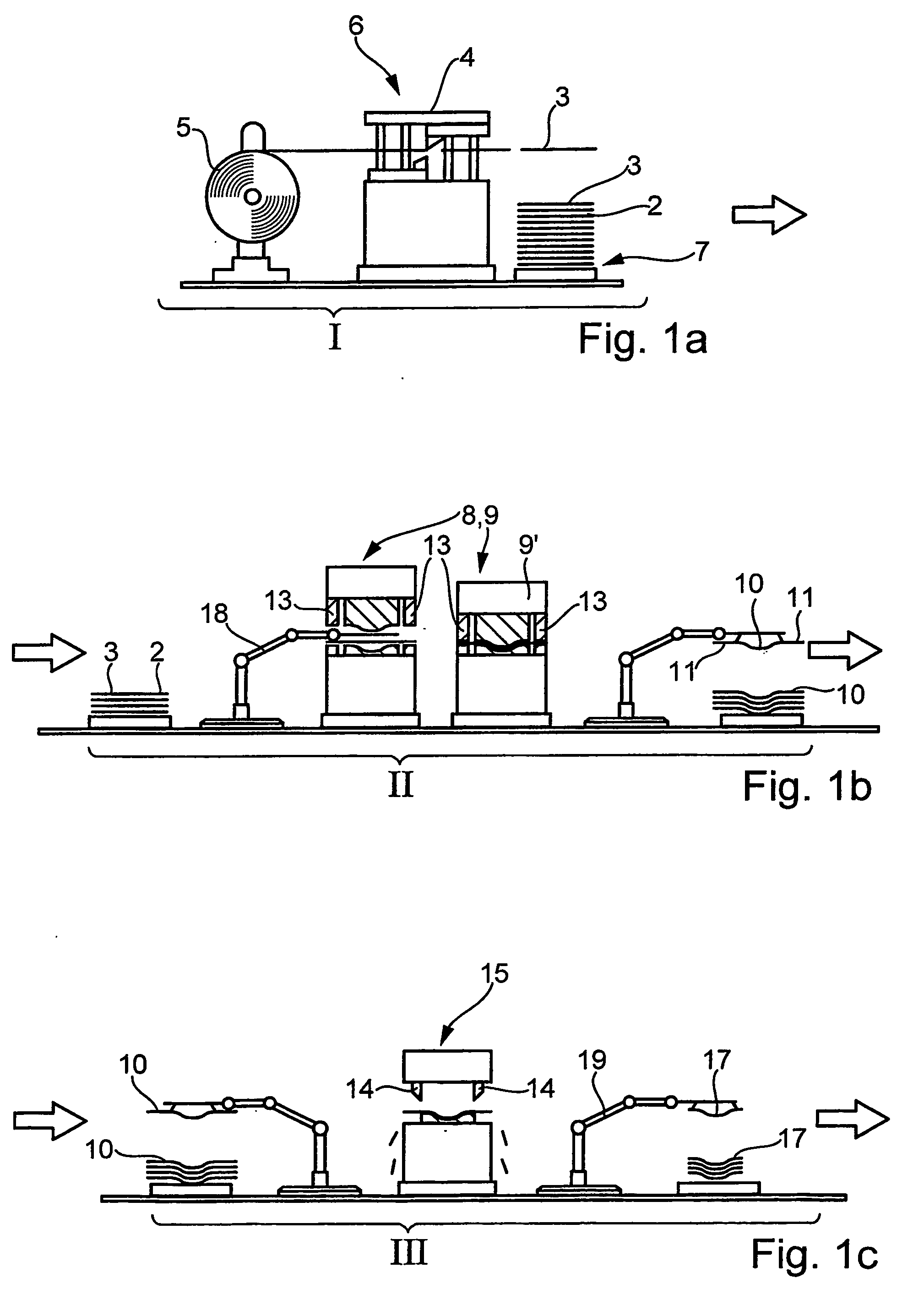

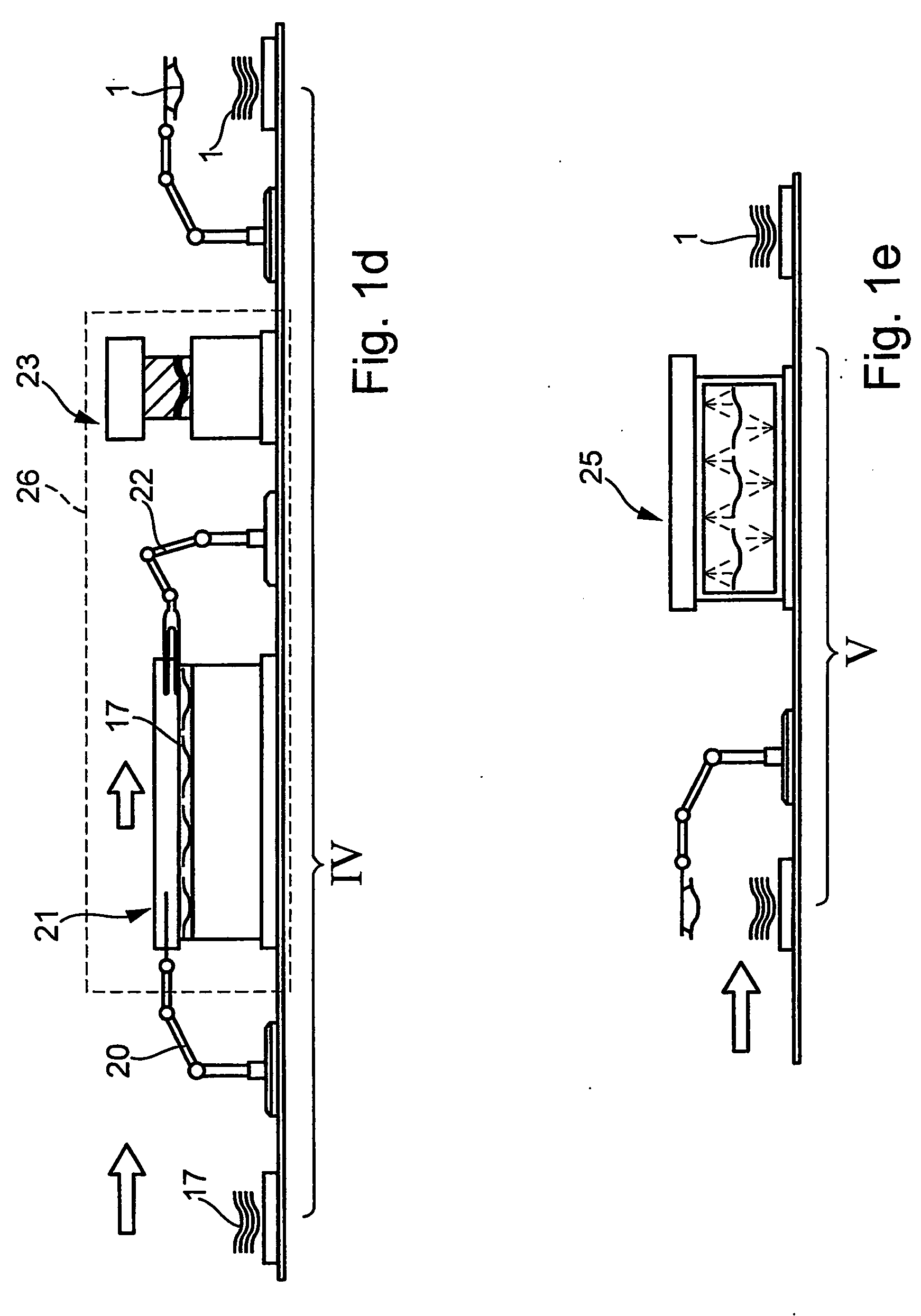

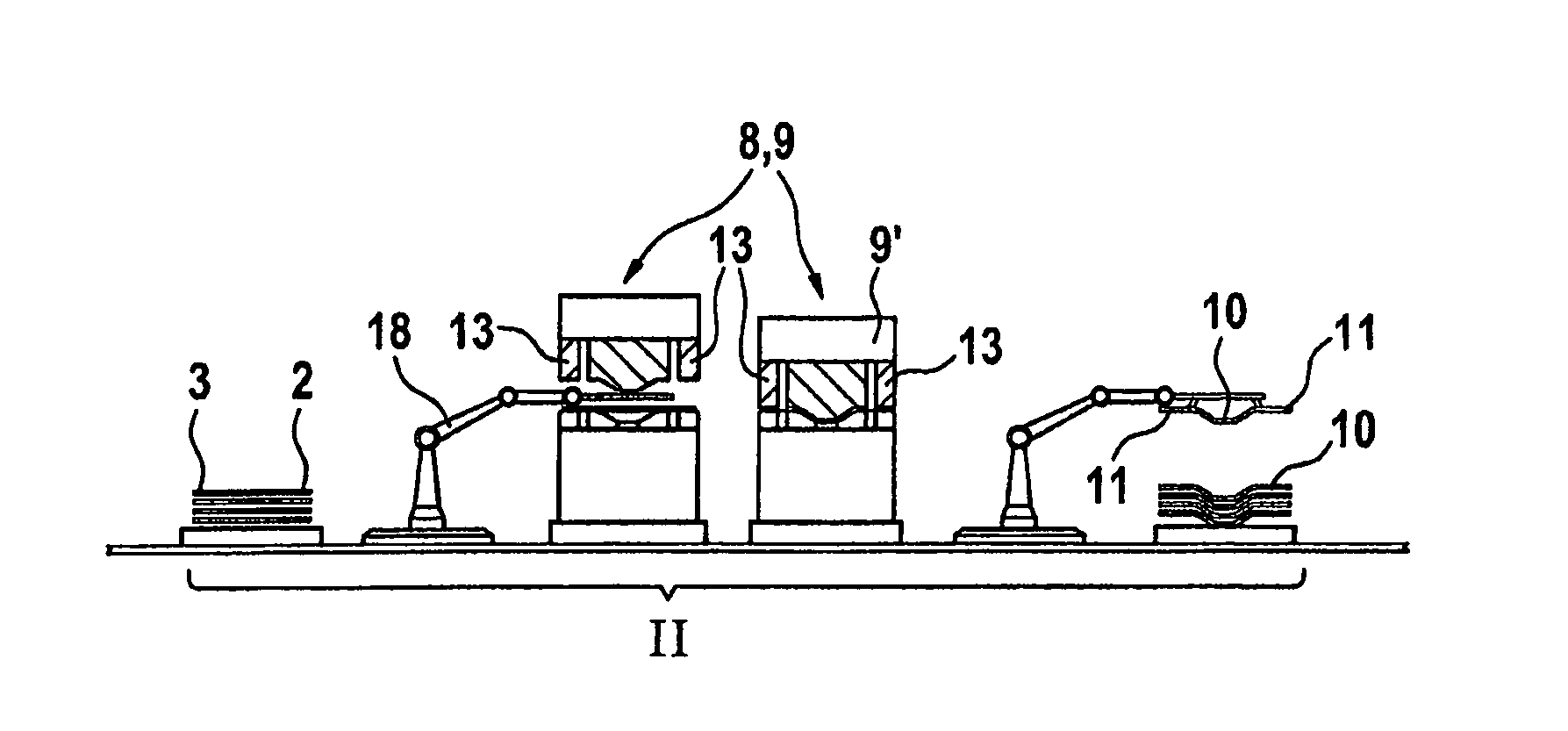

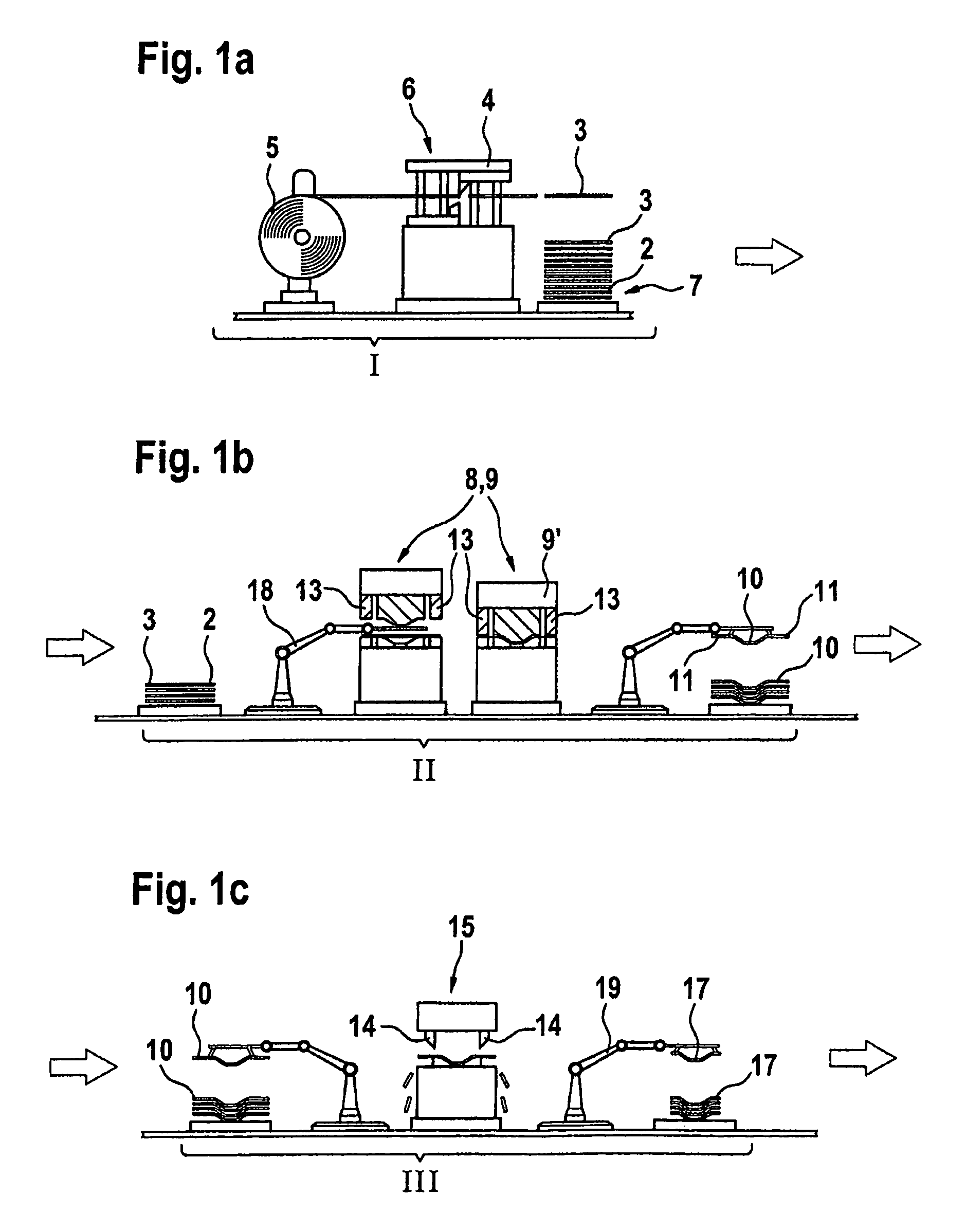

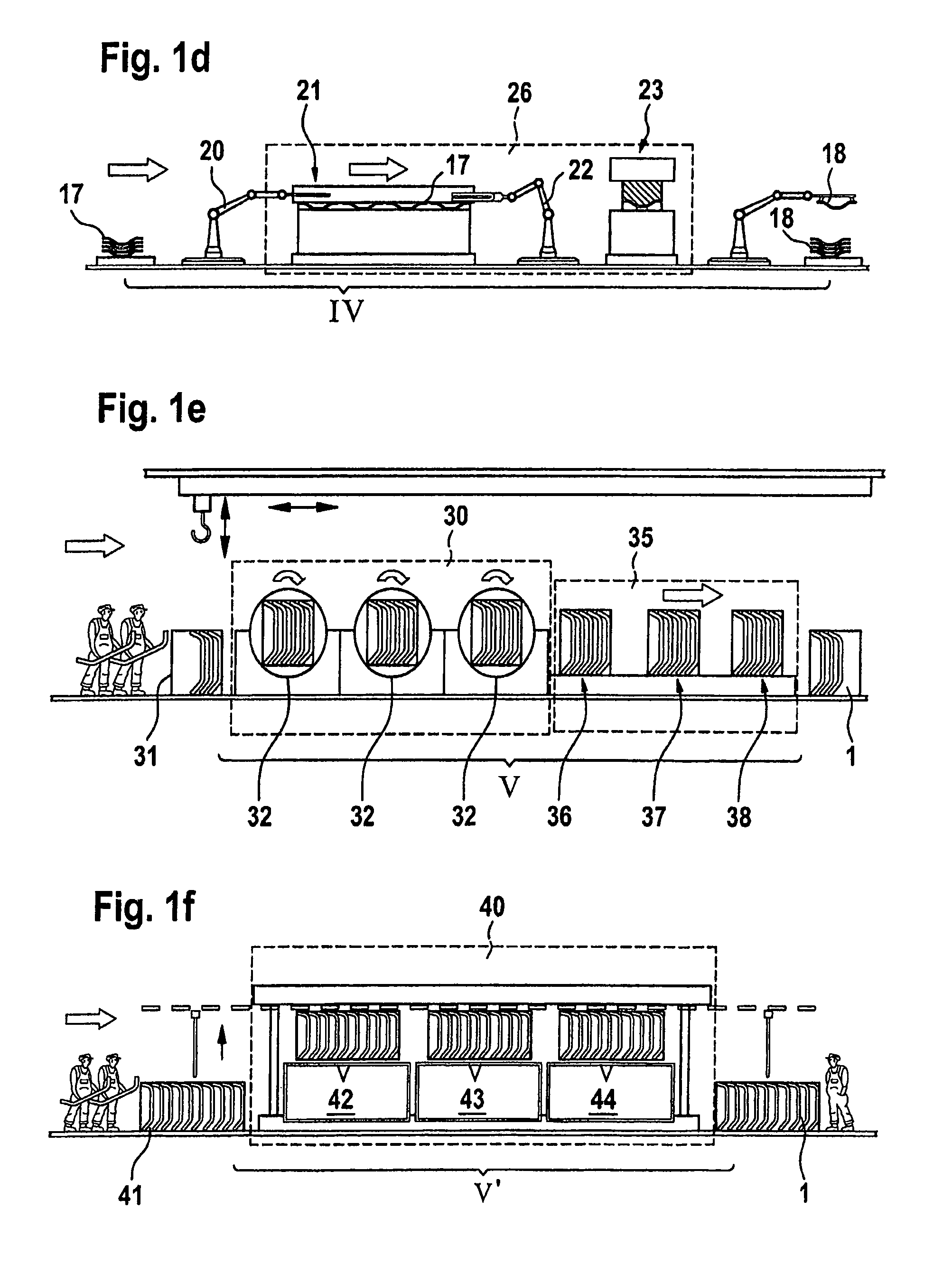

Press-hardened part and method for the production thereof

ActiveUS20060137779A1Optimization orderShorten the lengthFurnace typesVehicle componentsCycle timeMetal

Owner:DAIMLER AG

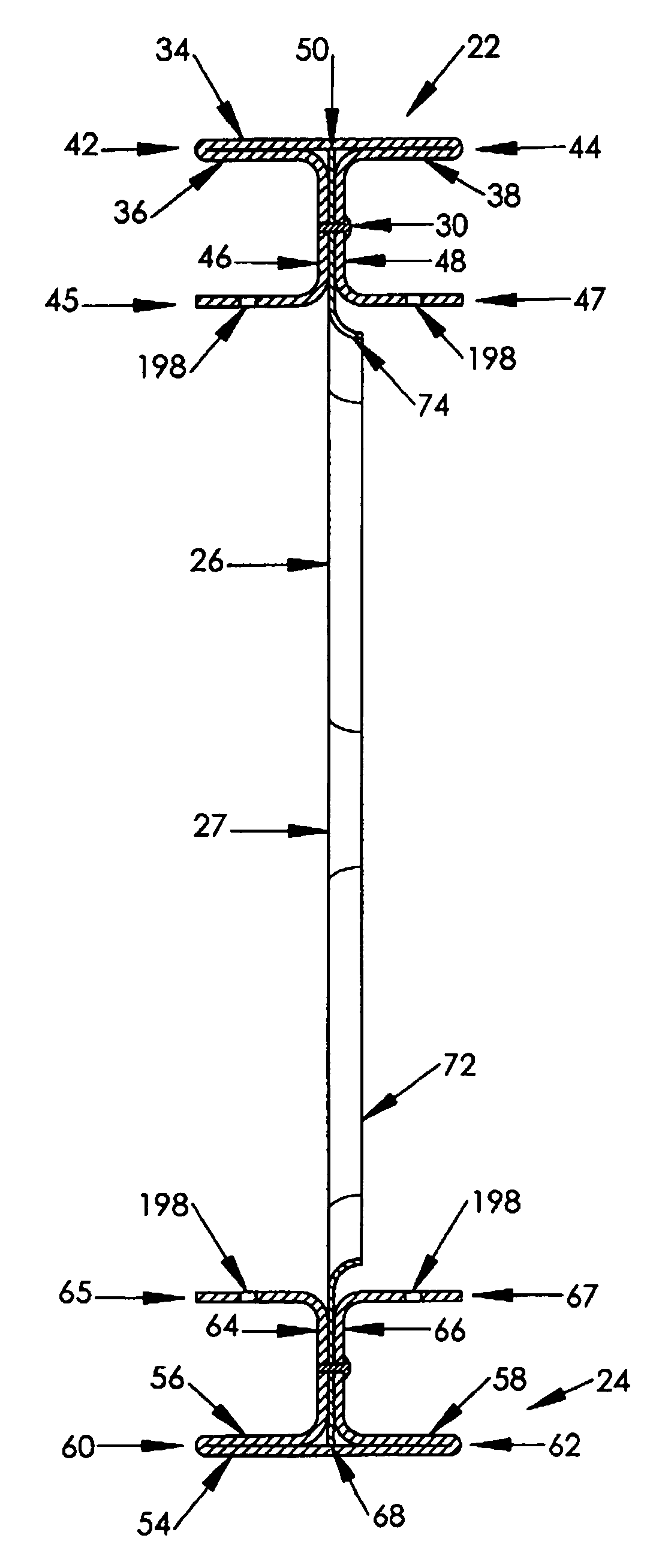

Interlocking closure device

InactiveUS6953542B2Improve leak-proof effectDesired audible and/or tactile effectsSnap fastenersMechanical working/deformationThermoplasticCold formed

A closure device for a thermoplastic bag which includes two opposing, longitudinally extending interlockable male and female fastening strips having respective male and female closure elements or profiles that are deformed to interdigitate and produce an audible clicking sound and or tactile effect that is perceptible to the touch as the closure device is opened and closed. Interdigitation of the two profiles is achieved by cold forming the profiles while interlocked. The shape of the cold form is a stepped deflection of both profiles so that their shapes are generally congruent. The stepped deflections provide a change in the occlusion and peel force of the interlocking closure device thereby resulting in an audible clicking or popping sound as the closure device is opened and closed and a tactile effect that is perceptible to the touch as the closure device is closed.

Owner:WATER KINETICS LTD

Lubricant for metal forming

Disclosed is a solid or aqueous lubricant concentrate used for the cold forming of metals, which, with reference to the solids content, including a) 20 to 50 parts by weight polyethylene with a softening point above 120 DEG C. and a particle size int he range between 0.1 and 50 mu m; b) 20 to 8 parts by weight polyacrylate with a molecular weight of 4,500 to 10,000 and c) 2 to 8 parts by weight styrene / acrylic acid copolymer with a molecular weight of 150,000 to 250,000 and a glass transition temperature of 45 to 55 DEG C., where, under the conditions of use, the acrylic acid component of the polymers in accordance with items b) and c) is predominantly present as salt of one or more inorganic cations, and the softening points of the individuals polymers are distributed over the temperature range defined by the limiting values of ambient temperature and 200 DEG C. The lubricant concentrate may contain homo-or copolymers or acrylic acid or the esters thereof with graded molecular weights as well as surfacant. Also disclosed is a method for facilitating the cold forming, where, by means of the lubricant concentrate, a lubricant film is applied on the workpiece from a dispersion having solids content of 5 to 25 wt-%.

Owner:MG TECH CO LTD

Process for producing a shaped foam article

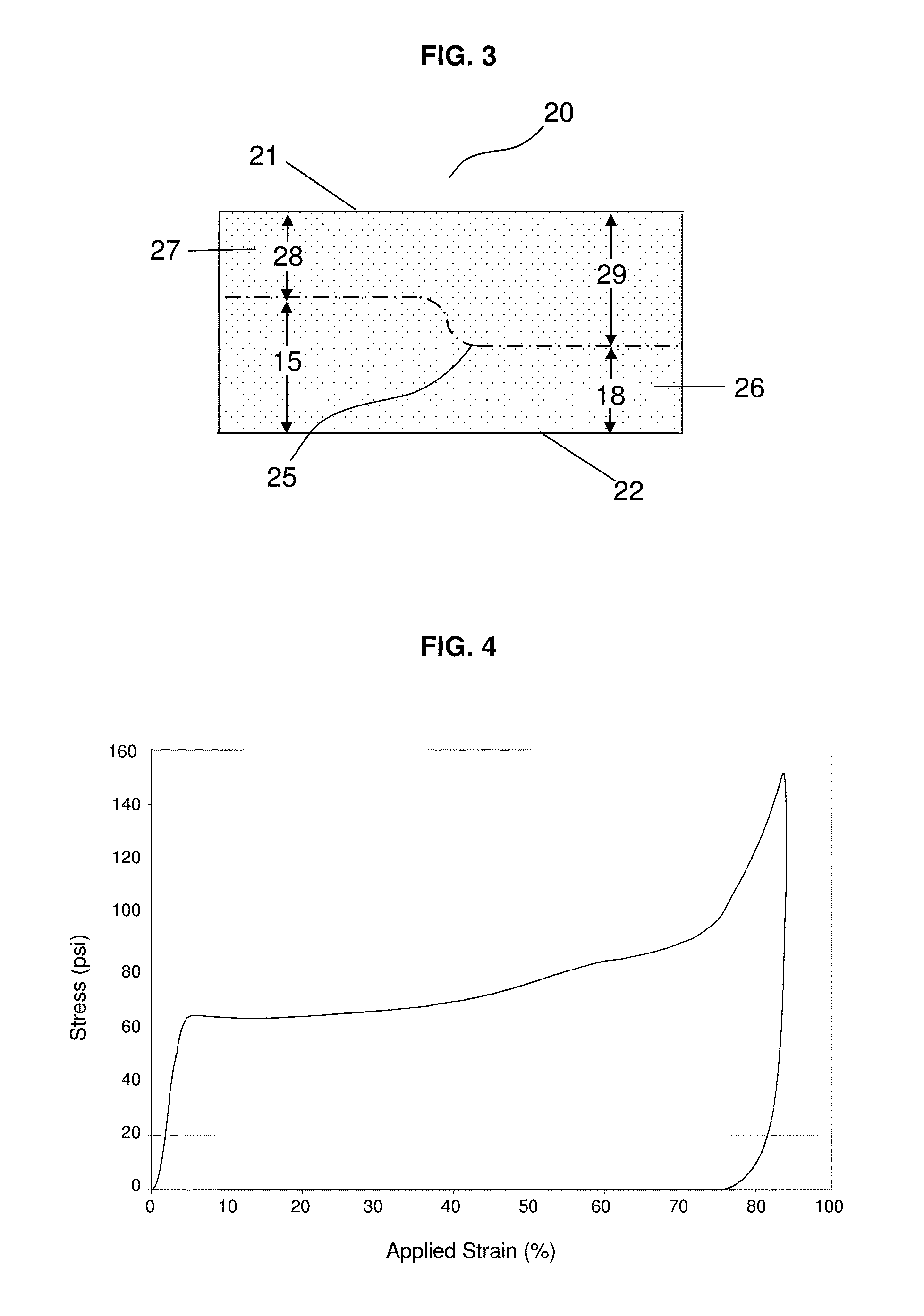

InactiveUS20110091688A1Reduce warpageReduce crackingLayered productsThin material handlingPolymer scienceCold formed

The invention relates to an improved method of cold forming a shaped foam article wherein the improvement is using a near net-shaped foam blank cut from a foam plank having a vertical compressive balance equal to or greater than 0.4 to produce the shaped foam article.

Owner:DOW GLOBAL TECH LLC

Spring steel and preparation method thereof

InactiveCN101671792AImprove fatigueOvercome the disadvantage of low fatigue strengthSpring steelQuenching

The invention discloses spring steel. Based on the total weigh of the spring steel, the spring steel comprises 0.56 to 0.64 weight percent of C, 1.6 to 2 weight percent of Si, 0.6 to 0.9 weight percent of Mn, 0 to 0.015 weight percent of Ti, 0.0055 to 0.03 weight percent of S, 0.01 to 0.02 weight percent of Als and the balance of Fe and inevitable impurities, wherein the weight ratio of the S to the Als is 0.55 to 3; and the Als is acid soluble aluminum. The invention also provides a preparation method of the spring steel, which comprises: subjecting the raw material of the spring steel to primarily smelting, refining, cold forming, rolling, quenching and tempering, wherein the composition of the raw material of the spring steel ensures the composition of the spring steel obtained is the same as the composition of the spring steel of the invention. The spring steel is high in fatigue resistance. The production method is simple and reduces cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

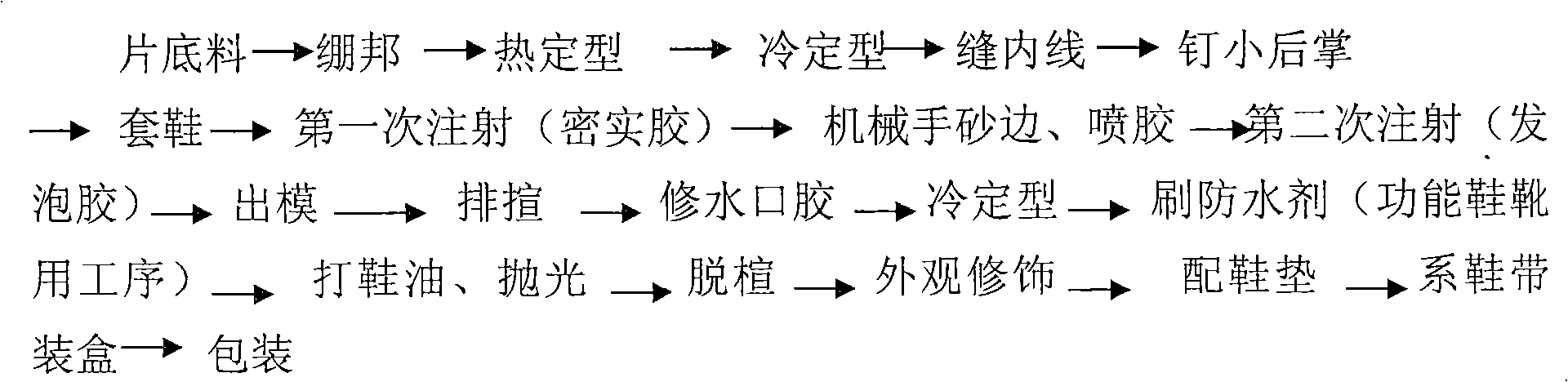

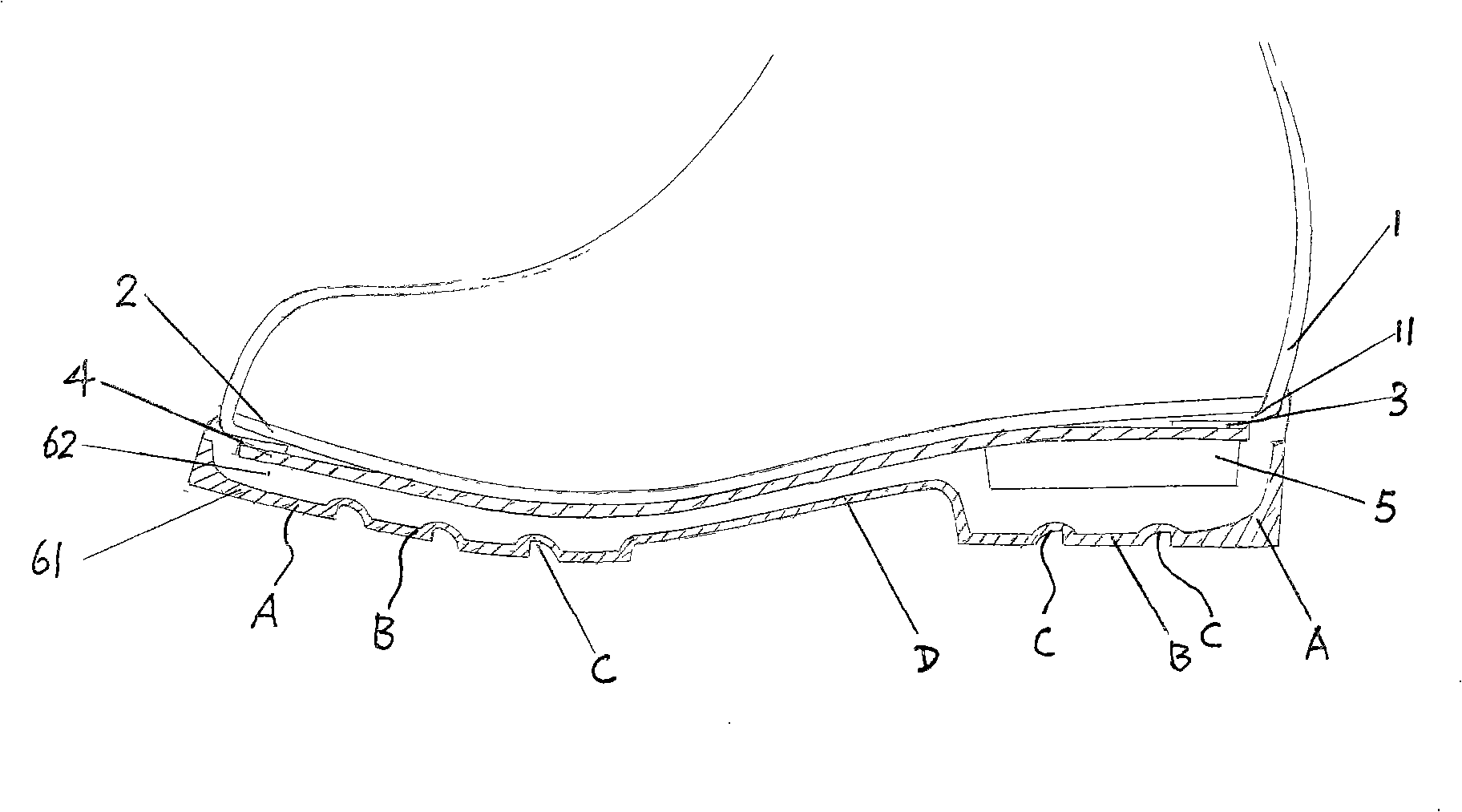

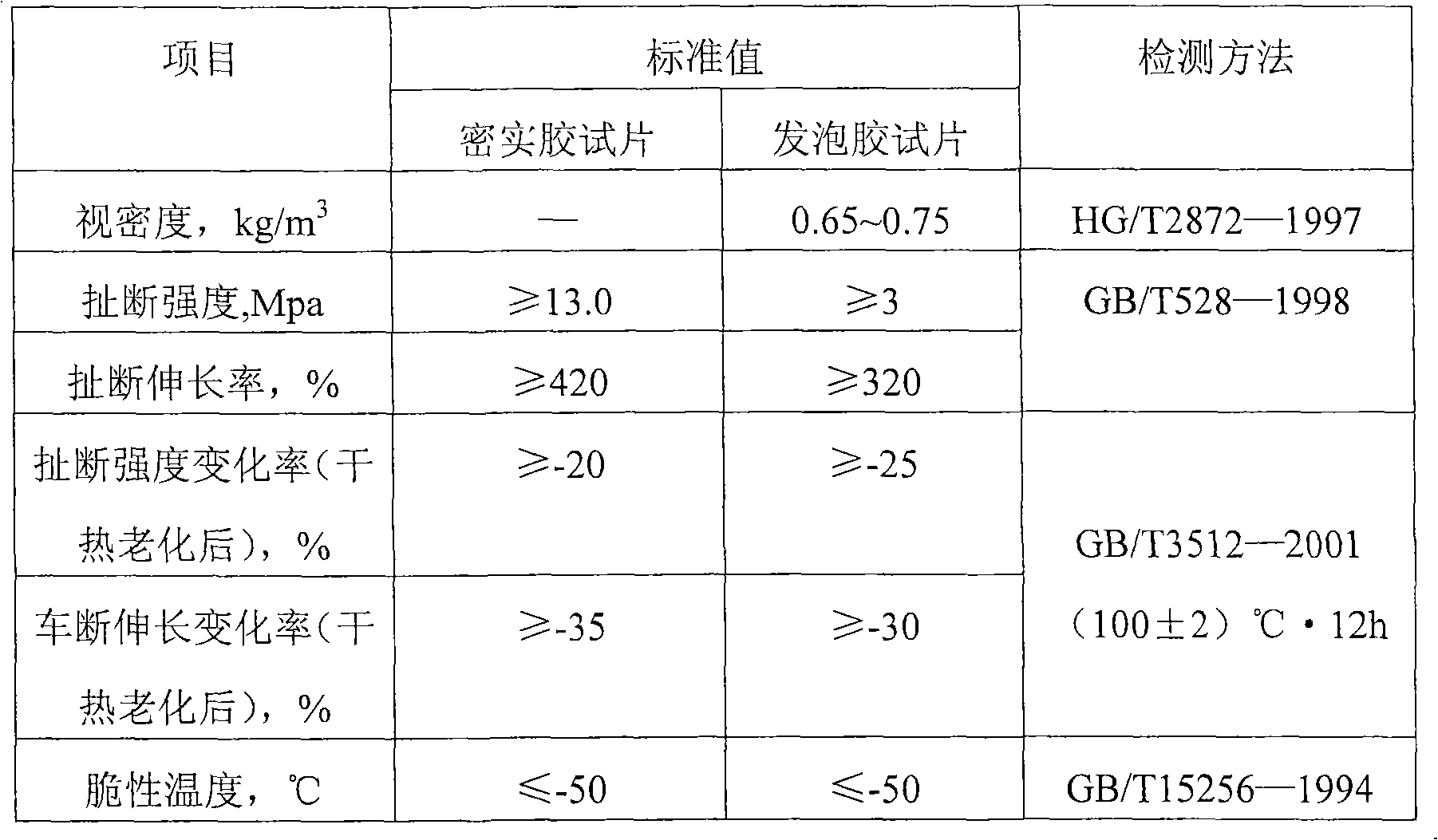

Duprene rubber double-density injection shoemaking method and functional shoes

The invention relates to a method for shoemaking by neoprene double-density injection. The method comprises the steps as follows: 1) after an upper, an inner sole and a middle sole are fixed in sequence, a small rear palm is nailed at the position of the heel of the middle sole to form a semifinished product of shoes; 2) dense glue is injected to a sole-centered die cavity for the first time, after a second last and a sole die are matched to be heated and pressed, the second last is removed to form a solid glue layer; then foaming adhesive is injected for the second time, an aluminium foot sheathed with the semifinished product of the shoe is put into the die cavity for matching moulds, heating and pressing, and a shoe blank is formed after mold stripping; 3) the shoe blank is processed for cold forming after being built with water gap glue, and the shoe is processed for subsequent treatment to obtain a finished product. A big sole of the invention comprises the solid glue layer and a foaming layer, thereby satisfying the wearing resistance and the strength requirement and also greatly reducing the weight of the sole simultaneously; the design of the grain of the big sole ensures that the thicknesses of the solid glue layer at different positions are changed to completely cater to the strength distribution characteristic when people walk; the heel of the shoe is added with the small rear palm, so the hardness at the heel is adjusted effectively. The finished product of the shoe manufactured by the invention has good forming performance and is substantial, firm, light and comfortable, and the method is suitable for manufacturing functional shoes.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

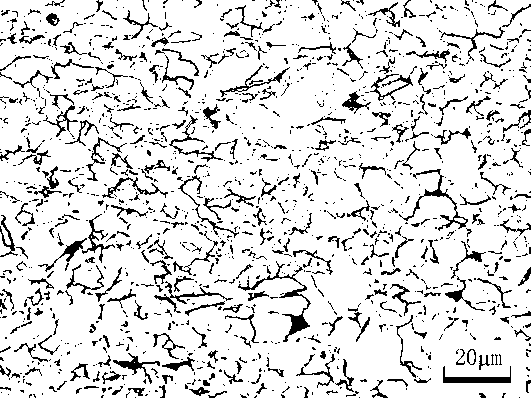

Method for producing annealing-free hot rolling S50C plate and strip

The invention relates to a method for producing an annealing-free hot rolling S50C plate and strip, belonging to the technical field of hot rolled plates and strips. The invention adopts the technical scheme that austenite rolling is adopted in rough rolling, a deformation-induced ferrite rolling and warm rolling combined process is adopted in finish rolling, temperature in a rough rolling region is controlled to be 960-1150 DEG C, accumulated screwdown rate is more than 50%, an intermediate blank obtained by the rough rolling is cooled by water and then enters into a finish rolling mill group, opening rolling temperature of a finish rolling mill is 760-850 DEG C, finished rolling temperature of the finish rolling mill is 650-750 DEG C, the accumulated screwdown rate is more than 50%, cooling rate after rolling is controlled to be 0.1-25 DEG C / s, and coiling temperature is controlled to be 550-700 DEG C. The austenite rolling during rough rolling is carried out, thus austenite crystals are refined; the deformation-induced ferrite rolling and warm rolling during finish rolling are carried out, thus ferrite is excessively separated out, carbide is modified in a deformation process, plasticity and toughness of steel are improved, the aim of direct moulding while annealing is eliminated is achieved, and a spheroidizing process before cold forming is eliminated.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-strength cold-formed hot continuous rolled steel plate and method of preparing the same

ActiveCN101153371AImprove mechanical propertiesReduce weightTemperature control deviceHeat treatment process controlCold formedQuenching

The invention relates to a high-strength cold-forming hot-continuous-rolling steel plate and the manufacture method thereof, wherein, the chemical composition of the steel plate is as follows: 0.05wt percent to 0.10wt percent of C, 0.10wt percent to 0.50wt percent of Si, 1.0wt percent to 2.0wt percent of Mn, less than or equal to 0.025wt percent of P, less than or equal to 0.010wt percent of S, 0.03wt percent to 0.08wt percent of Nb, 0.05wt percent to 0.15wt percent of Ti, 0.10wt percent to 0.50wt percent of Mo, 0.0010wt percent to 0.0050wt percent of Ca, 0.01wt percent to 0.05wt percent of Al and the rest, Fe and other inevitable impurities; the technical process of the steel plate includes hot metal deep desulfurization to converter top and bottom blowing to secondary refining to continuous casting (machine cleaning) to hot charging hot feeding soaking pit to plate blank reheating to controlled rolling to controlled cooling to coiling to finishing. With the yield strength reaching 700 MPa, the steel plate has excellent mechanical property and processing properties such as welding and roll forming; meanwhile, because less alloying element is added during the manufacture process of the steel plate, the invention has low production cost and convenient operation during big production without adopting heat treatment processes such as tempering and quenching and tempering. The invention can be used in fields such as engineering machinery and structural parts and container for special vehicle and strongbox, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

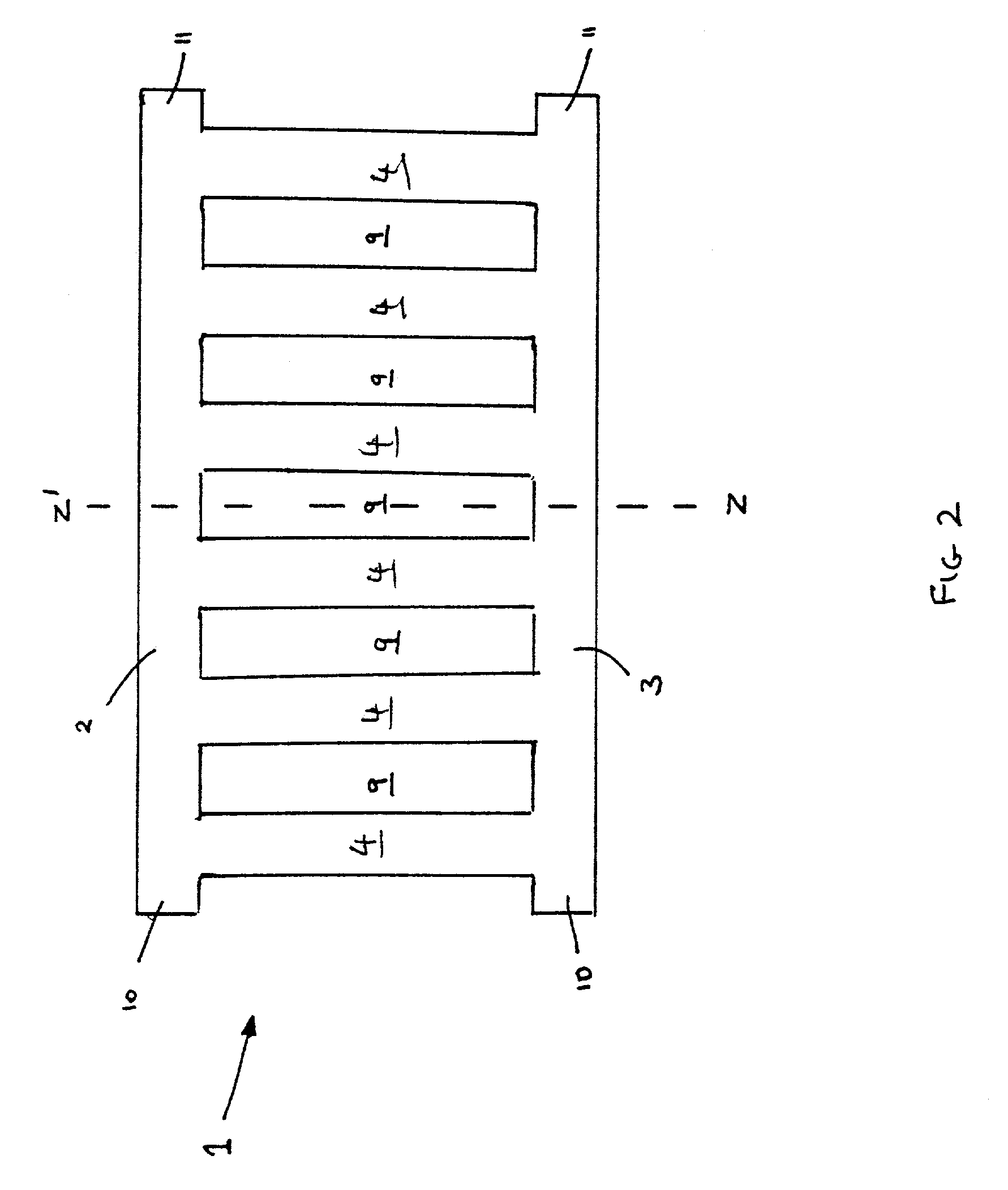

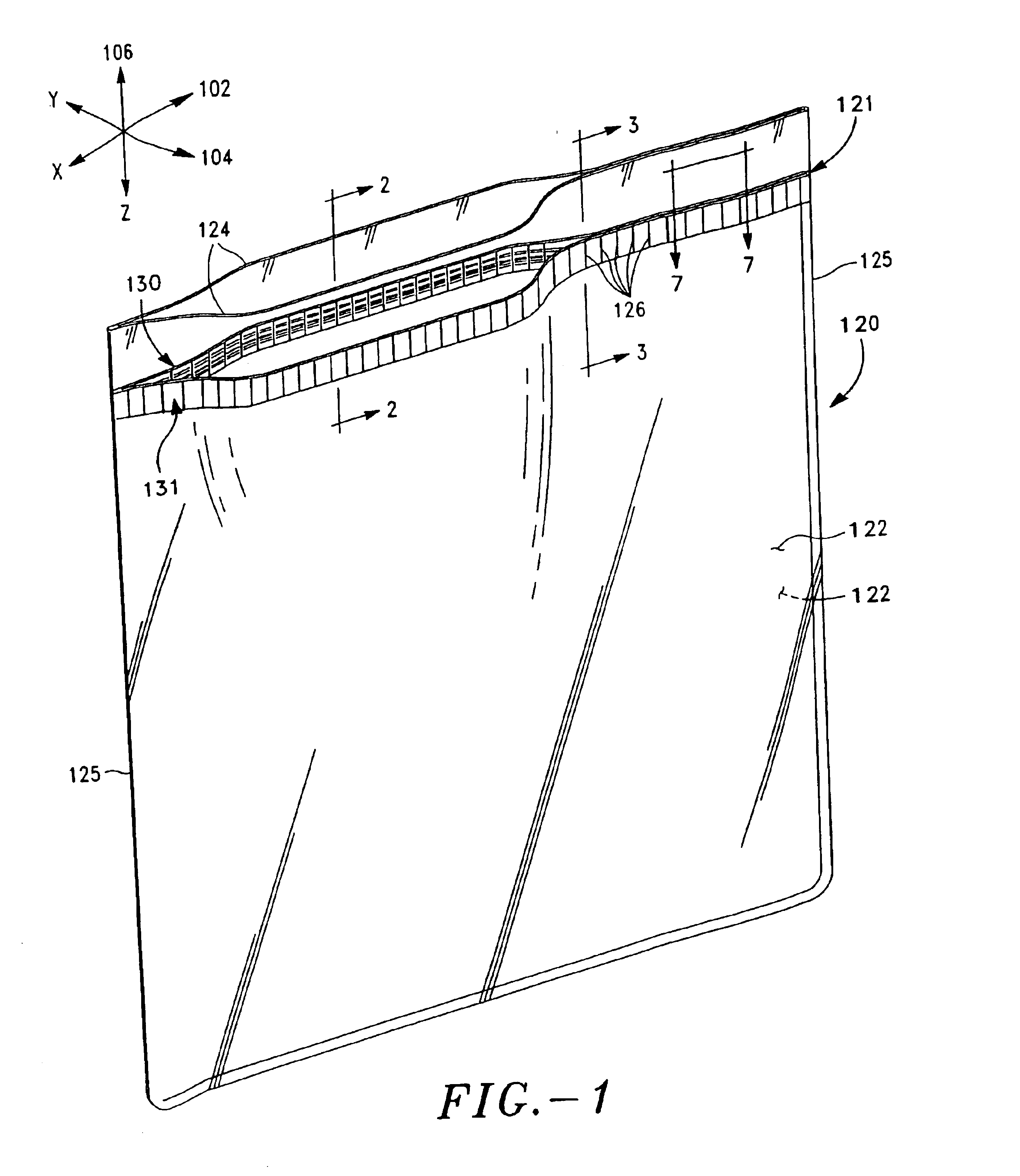

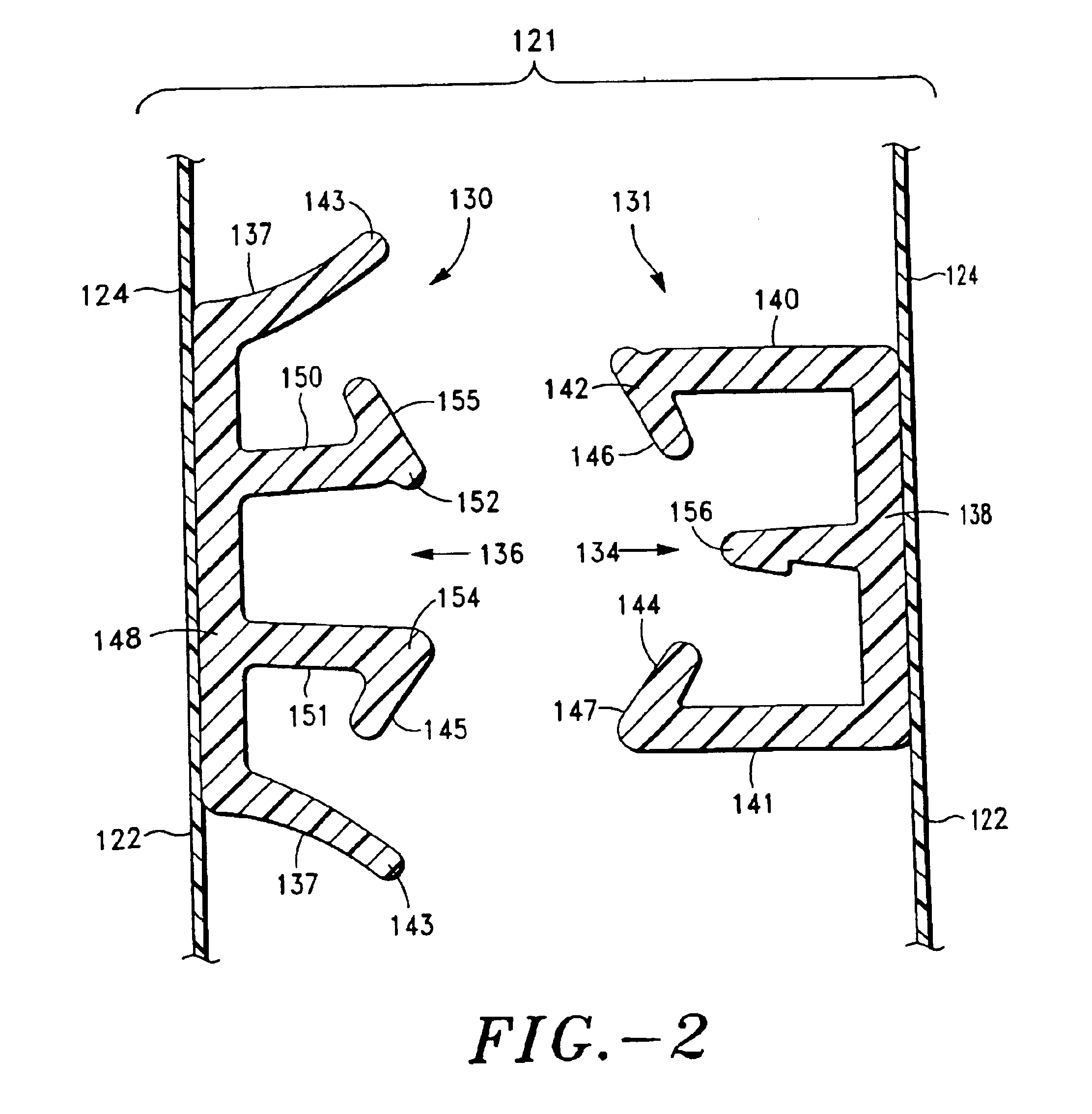

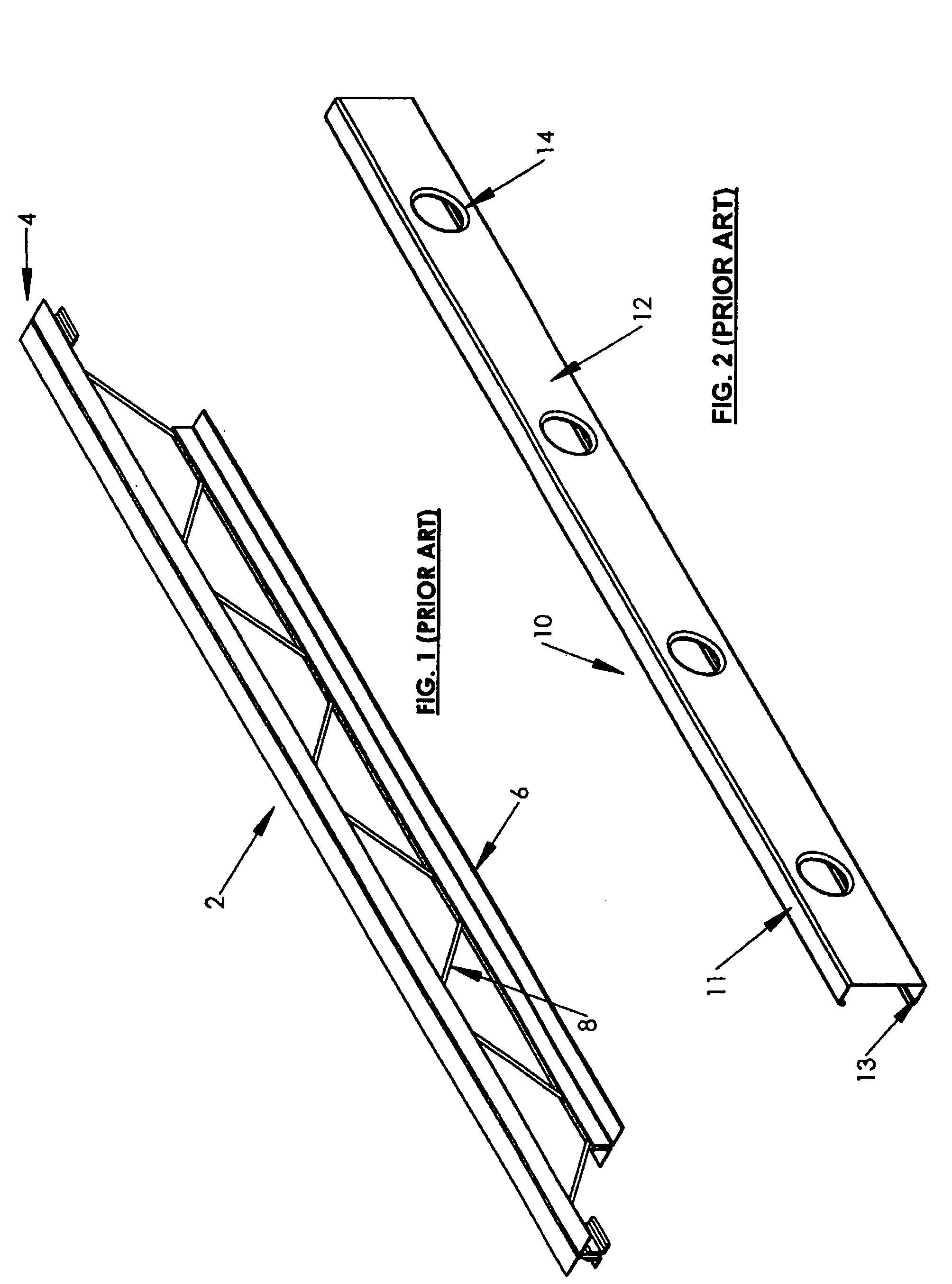

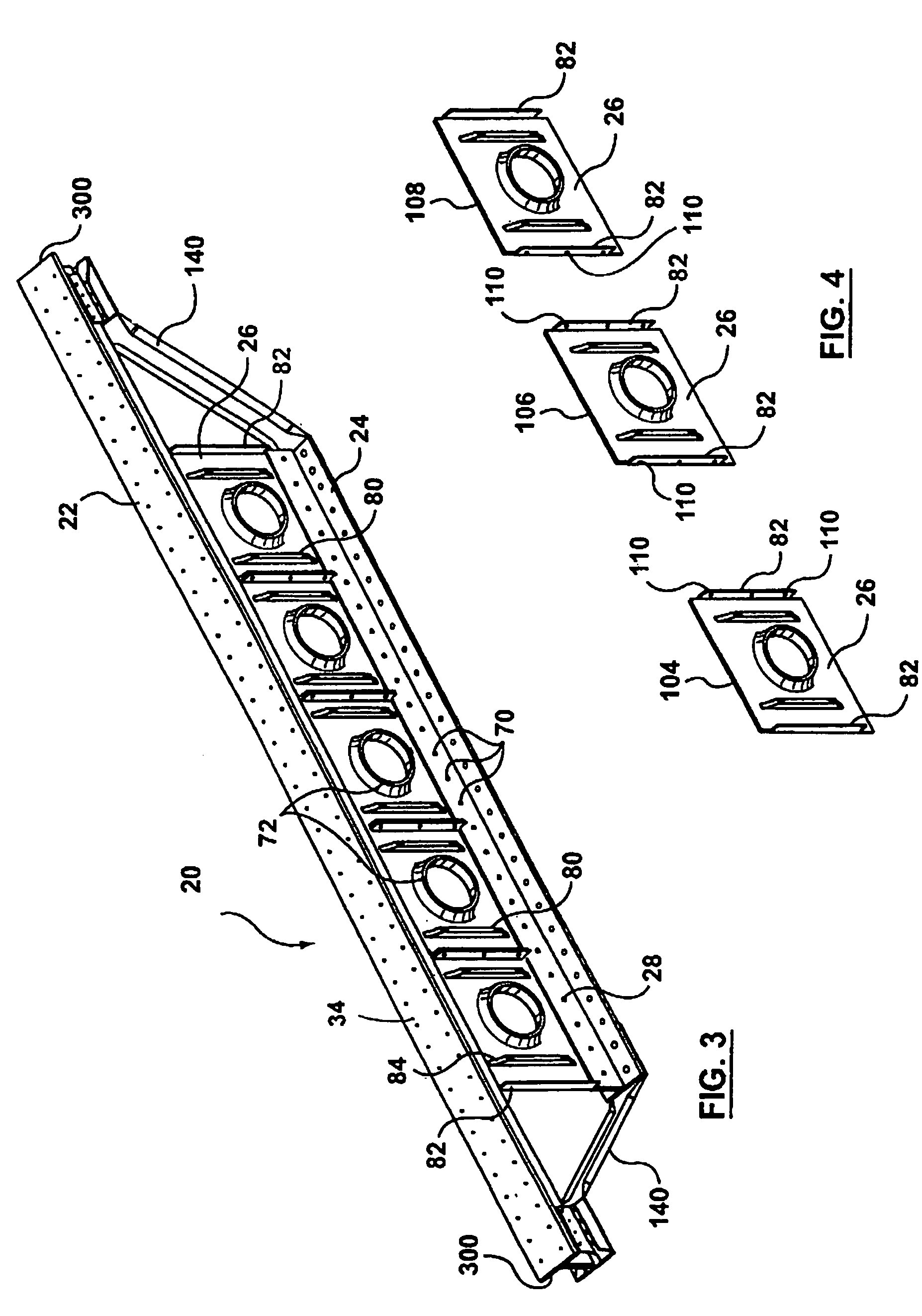

Cold-formed steel joists

A joist comprised of at least one cold-formed steel elongated chord member; a cold-formed steel web having a plurality of web members and means for securing said web to said chord member. A plurality of joists are generally for use in a support system for a platform or a deck in the construction of floors and roofs. The support system is of particular use in a composite floor and roof systems.

Owner:ISPAN SYST LP

High-strength thin band steel for cold forming and manufacturing method thereof

The invention relates to high-strength thin band steel for cold forming and a manufacturing method thereof. The method comprises the following steps: after discharging a cast band from a crystal roll, cooling the cast band forcibly and uniformly in a mode of spraying dry ice under high pressure; quickly cooling the cast band to be below 1,280 DEG C at the cooling speed of 200-300 DEG C / s; performing austenite on-line recrystallization rolling, wherein the rolling temperature is 1,050 to 1,200 DEG C and the rolling reduction is 20 to 50 percent; and quickly cooling the band steel subjected to hot rolling in an anti-oxidation mode, wherein the anti-oxidation quick cooling speed is 80 to 200 DEG C / s and the reeling temperature is 500 to 600 DEG C. By the method, the high-strength thin band steel for automobile cold forming and with low yield strength and excellent stamping performance can be obtained, can be directly used in a mode of substituting heat for cold, cancels the cold rolling procedure and greatly reduces the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

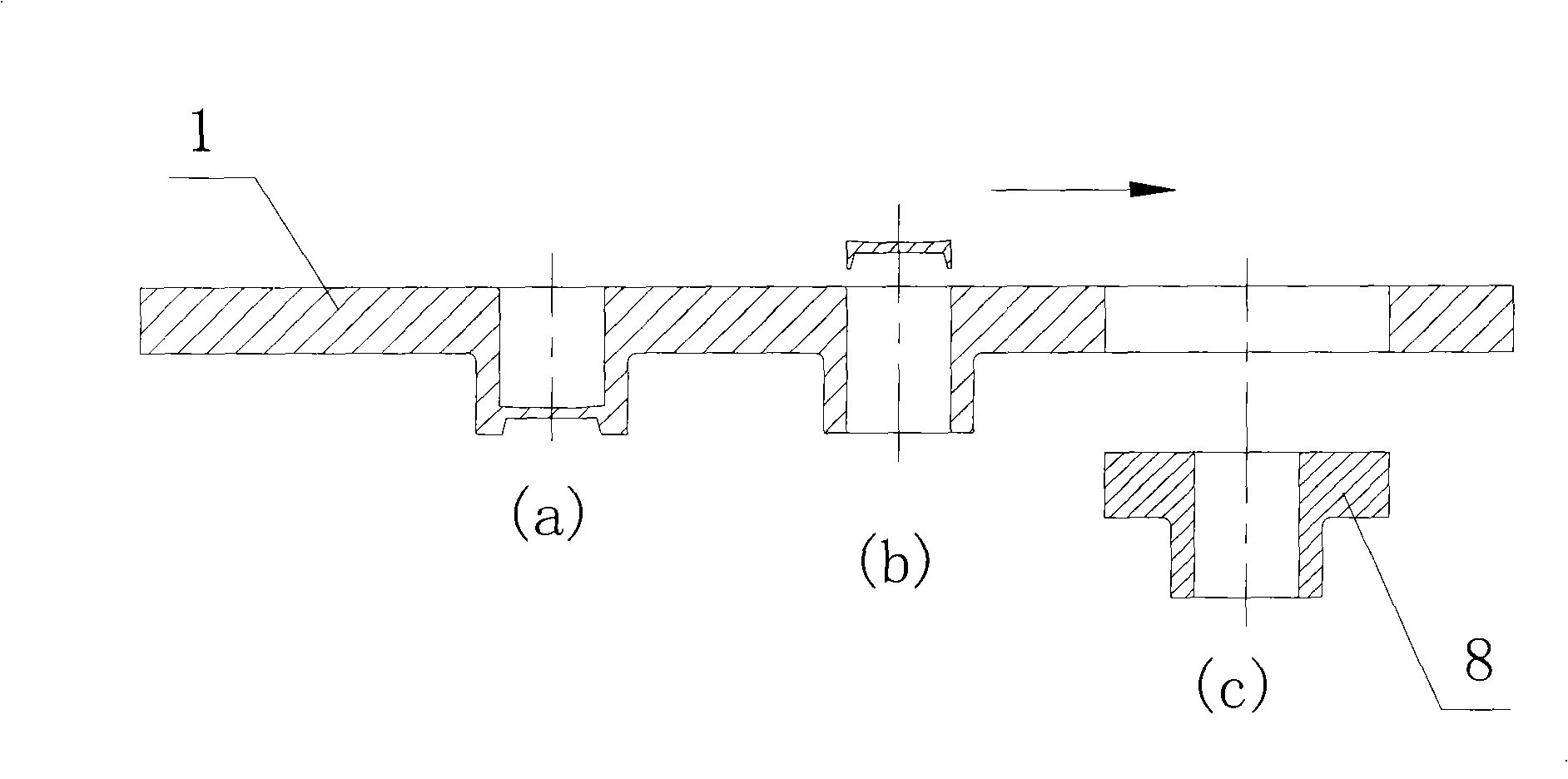

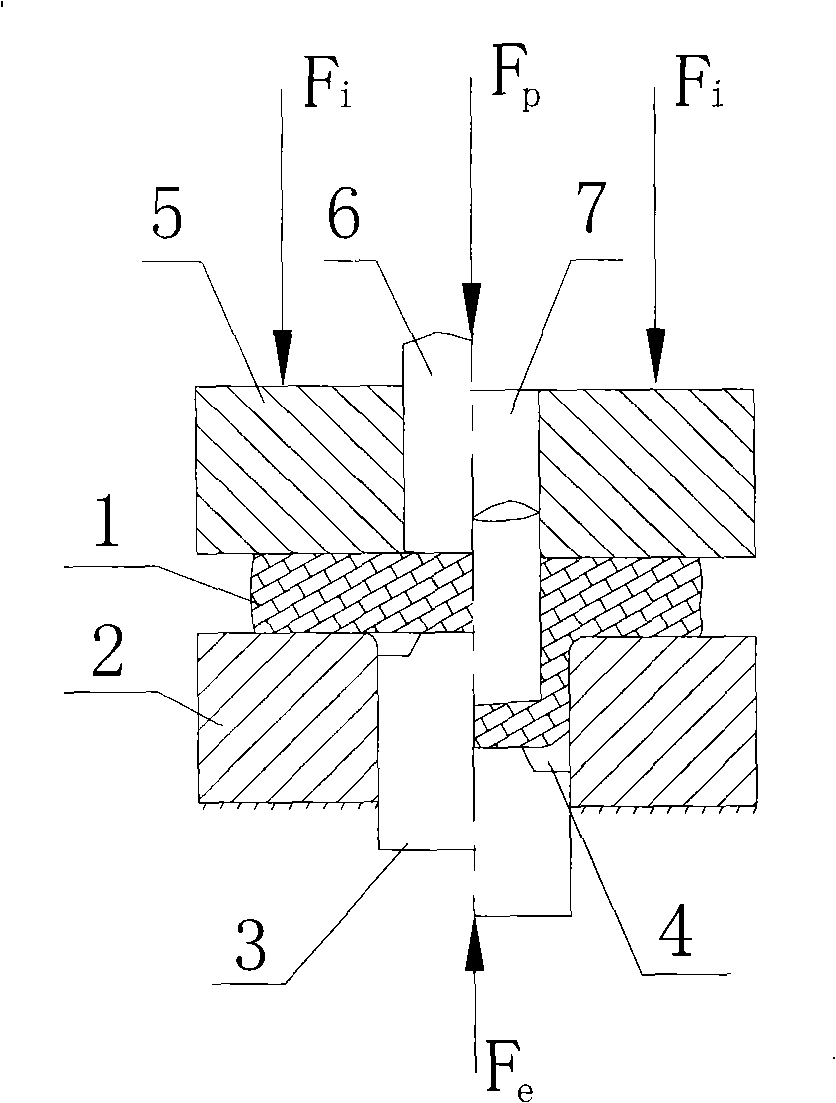

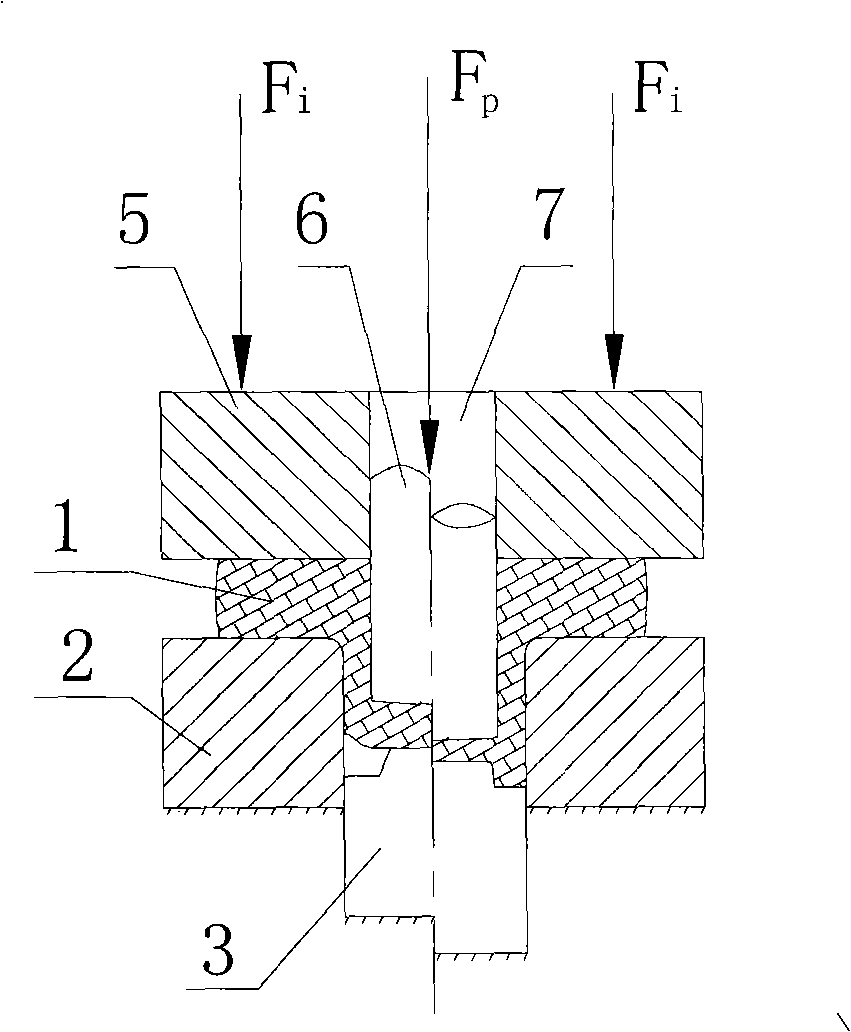

Forming technique for sheet metal stamping cold forging and fine blanking composite boss part

The invention relates to a forming process of a lug boss part. A shaping technique of a panel punching forge cold and fine punching compound lug boss part is characterized in including the following steps: 1) the lug boss is pre-shaped on the punching forge cold of the panel; a metal panel (1) is arranged on a cavity die (2) and pressed by using a holding pad (5); a punching force plug (6) drives a squeezing force plug (3) to move downwards under the action of punching pressure to lead the material of the metal panel (1) below the punching force plug (6) to flow into a die space; when the punching force plug (6) moves downwards to reach the lug boss shaping height of the lug boss part, the squeezing force plug is restrained to move; the punching force plug continuously moves downwards; the materials between the punching force plug (6) and the squeezing force plug (3) are squeezed so as to be filled with the die space and pre-shape the lug boss on the metal panel; 2) recoiling recess; 3) finely the profile of the lug boss part is punched to lead the lug boss part to be separated from the metal panel to obtain the lug boss part. The process can obtain the lug boss part with the high precision, the good quality and the low cost.

Owner:WUHAN UNIV OF TECH

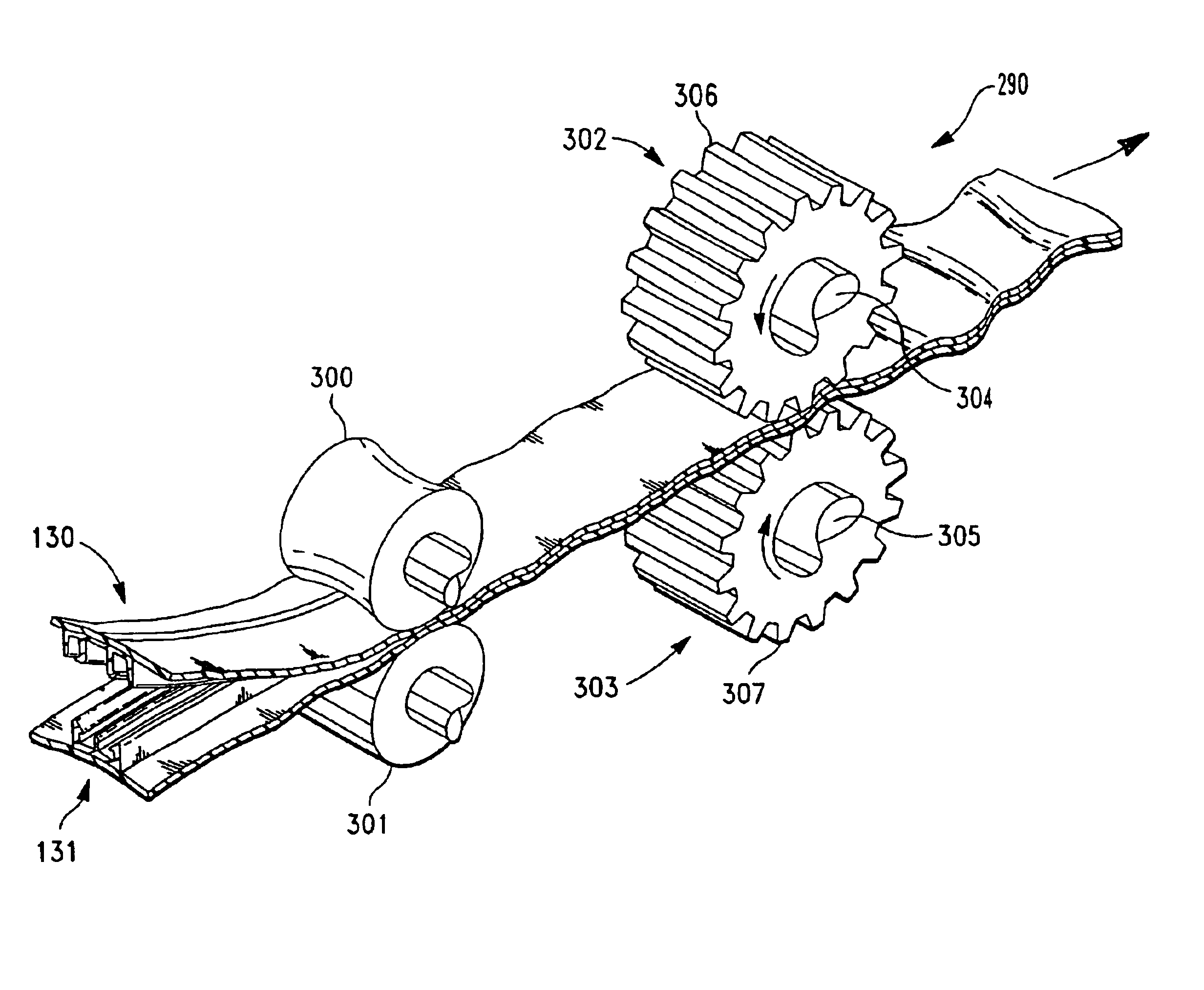

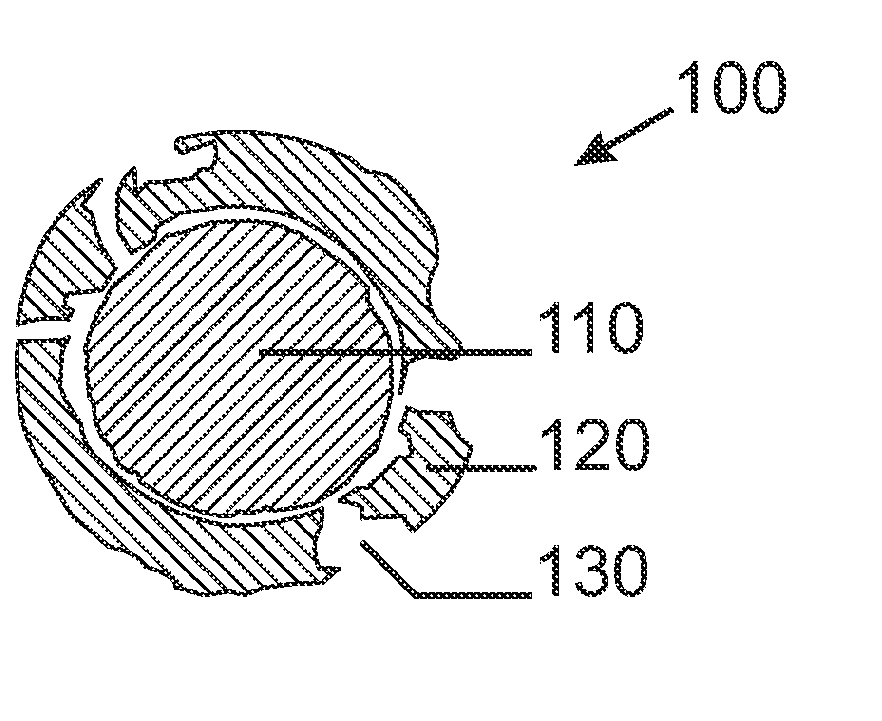

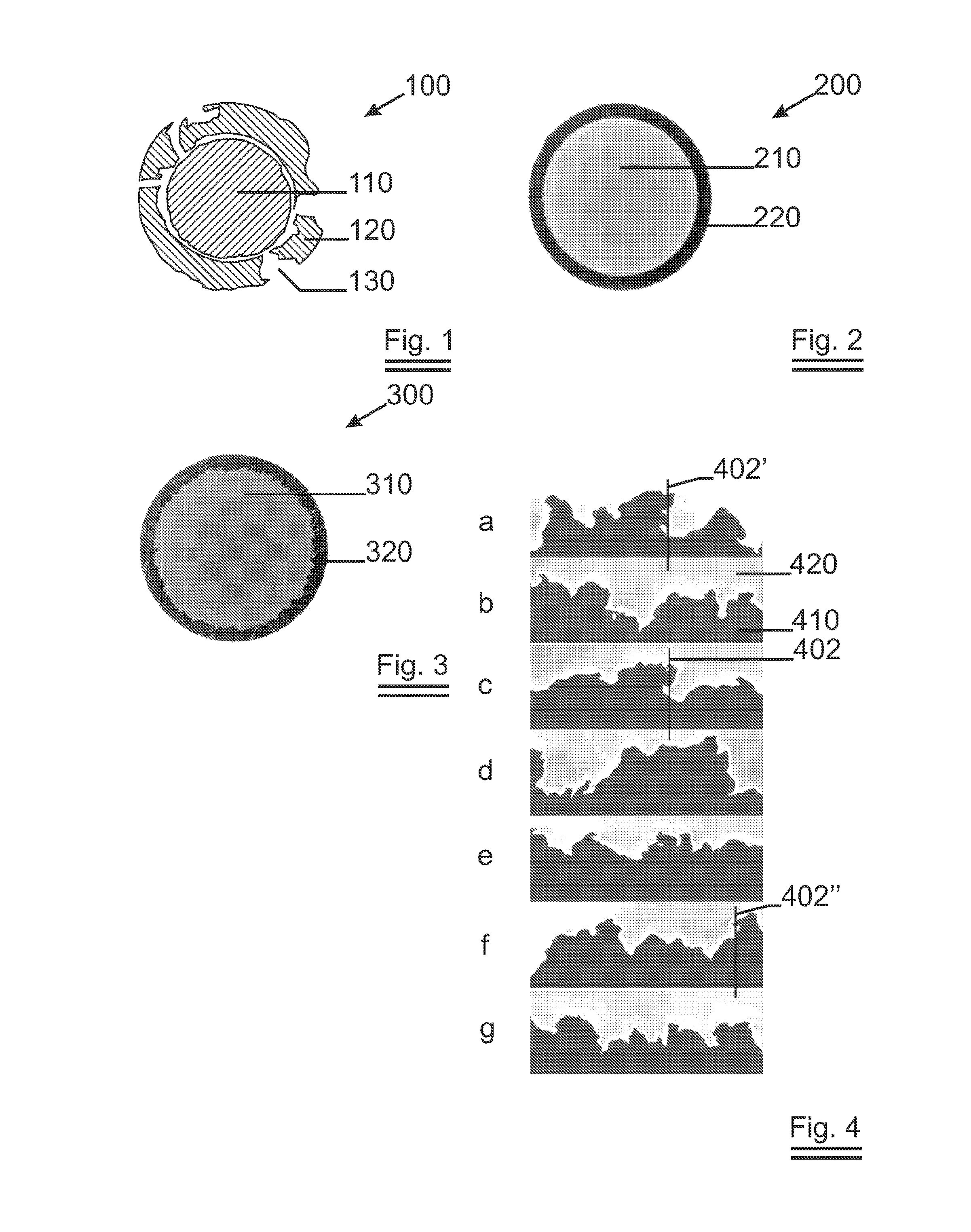

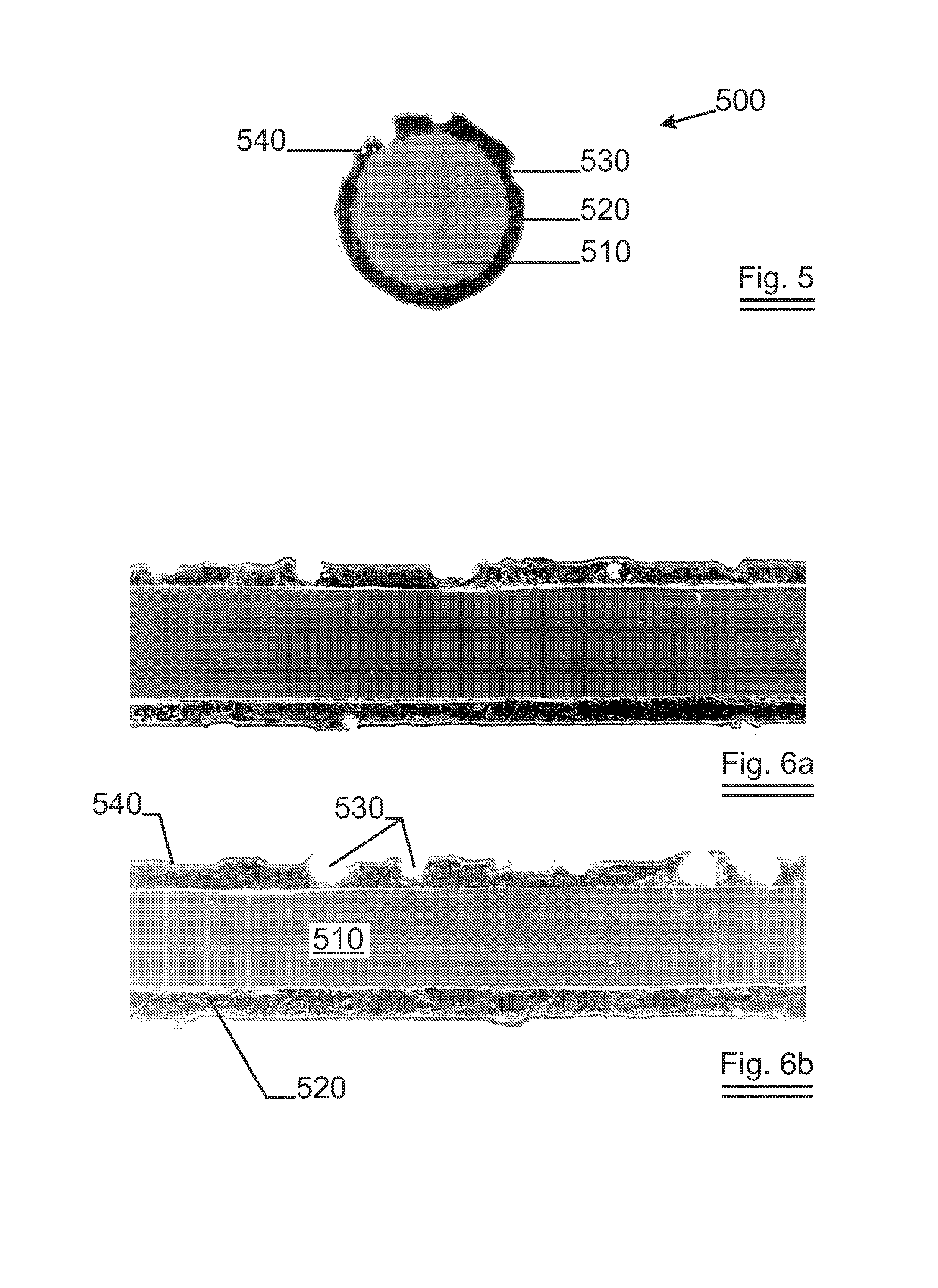

Fixed abrasive sawing wire with a rough interface between core and outer sheath

InactiveUS20120037140A1Extended service lifeMinimise kerf lossAbrasion apparatusMetal sawing toolsMetalMaterials science

A fixed abrasive sawing wire is presented that comprises a core (310) and an outer sheath layer (320) that is softer than the core. In the sheath abrasive particles are embedded that are held by a binding layer. The bond between core and sheath is enhanced by making it rough. The arithmetical mean deviating roughness must at least be higher than 0.50 micron. Particularly preferred is when interlocking between the core and the sheath is introduced. Such interface roughness can be obtained by subjecting the wire to sufficient cold forming by wire drawing. Interlocking will occur at even higher degrees of cold forming. The binding layer can be a metallic binding layer or an organic binding layer.

Owner:NV BEKAERT SA

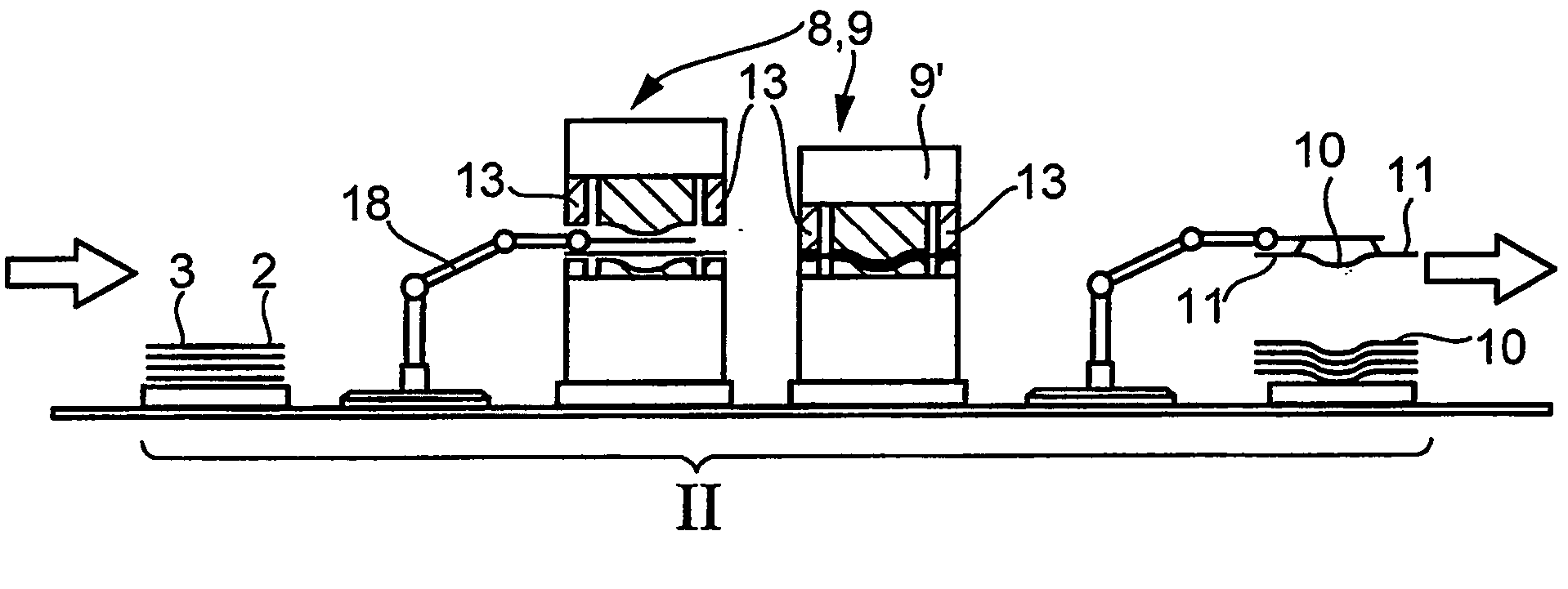

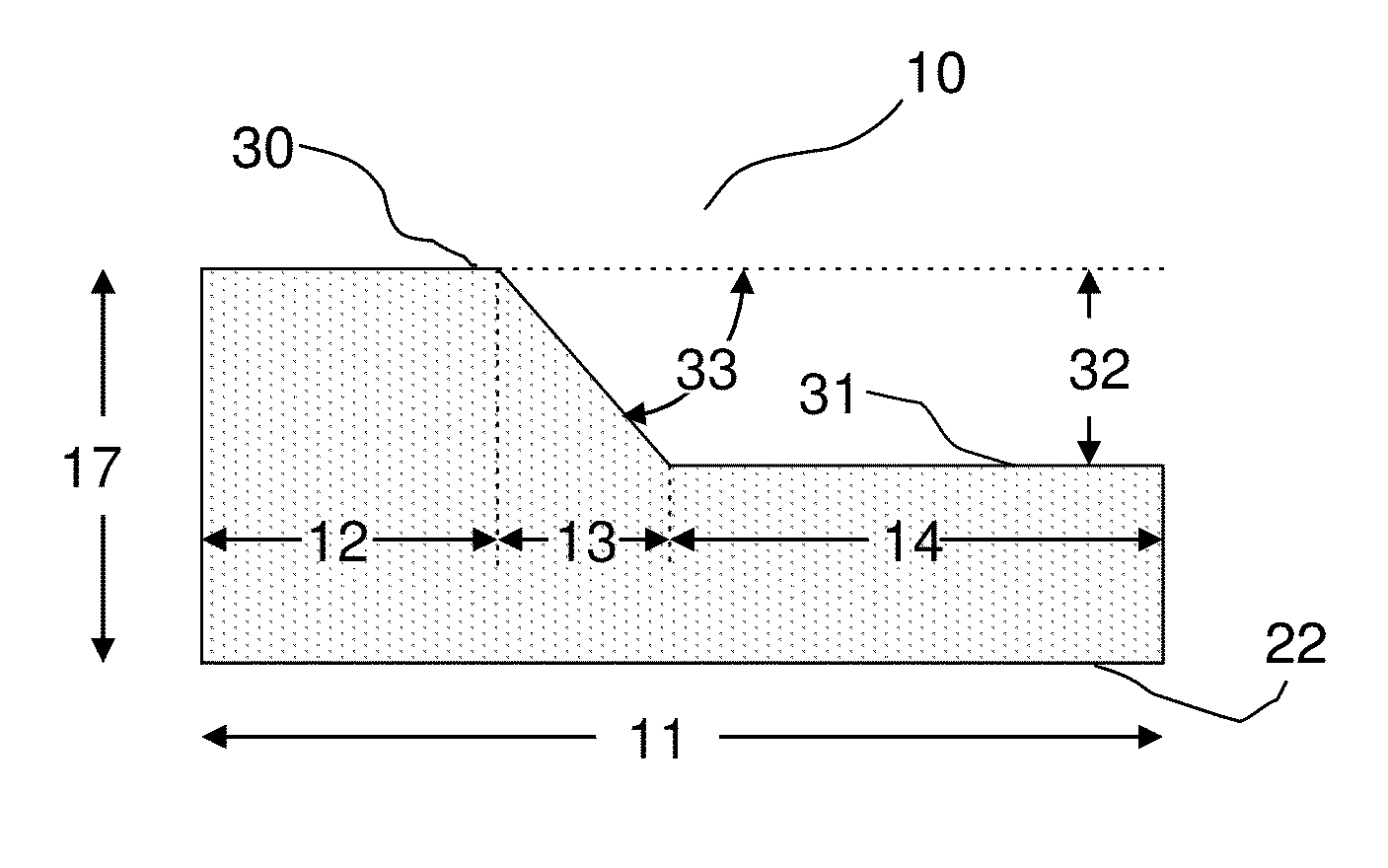

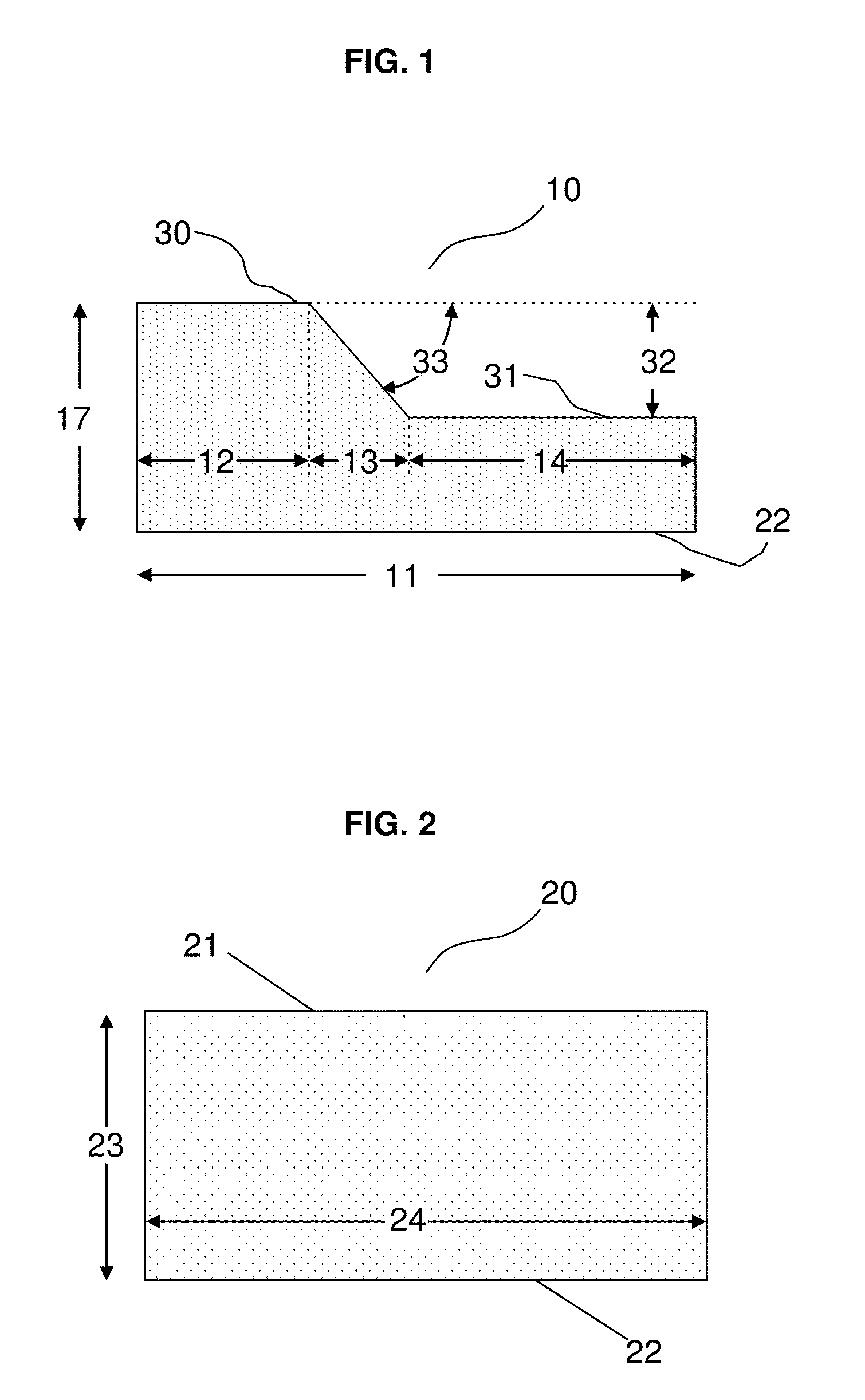

Press-hardened component and method for the production of a press-hardened component

ActiveUS8127449B2Reliable corrosion protectionHot-dipping/immersion processesLayered productsWork in processCold forming

A method for the production of press-hardened components, in particular a vehicle body component, from a semifinished product (2) made of unhardened, hot-workable steel sheet. A component blank (10) is formed from the semifinished product (2), pre-coated with a first coating (33), by a cold-forming method, in particular a drawing method. The component blank (10) is trimmed at the margins to a marginal contour (12′) approximately corresponding to the component (1) to be produced. The trimmed component blank (17) is heated and press-hardened in a hot-forming tool (23); then the press-hardened component blank (18) is covered with a second, anticorrosion coating (34) in a coating step.

Owner:THERMISSION

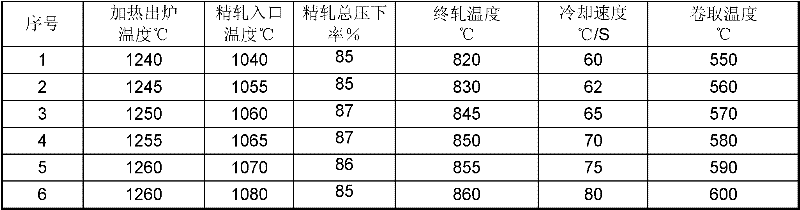

High-strength hot rolled steel plate with excellent cold forming property and preparation method thereof

InactiveCN102226249AHigh accuracy of shape and sizeHigh dimensional accuracyRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

The invention discloses a high-strength hot rolled steel plate with excellent cold forming property. The steel plate comprises the following chemical components by weight: 0.04-0.08% of C, 0.15-0.3% of Si, 1.20-1.90% of Mn, 0.020-0.060% of Al, not more than 0.015% of P, not more than 0.0009% of S, 0.06-0.08% of Nb, 0.09-0.12% of Ti, 0.05-0.1% of Mo, not more than 0.002% of O and not more than 0.004% of N. A preparation method is characterized in that the heating temperature is 1240-1260 DEG C; the rough rolling temperature is 1230-1100 DEG C; the finish rolling inlet temperature is 1080-1040 DEG C; the final rolling temperature is 820-860 DEG C; the total finish rolling reduction ratio is not less than 85%; the laminar flow is cooled at a speed being not less than 60 DEG C / s after finish rolling; and the coiling temperature is controlled between 550 DEG C and 600 DEG C.

Owner:MAANSHAN IRON & STEEL CO LTD

Manufacturing method of cold forming high intensity steel for welded structure

InactiveCN1563468AThe vertical and horizontal performance differences are narrowedImprove corrosion resistanceCold formedRare earth

This invention relates to a production method for cold forming high intensity welded construction steel taking low carben-Mn as the basis, added by Nb, Ti microalloy as the main composition and applying melted iron desulfurization technology, converter top and bottom combined blowing and vacuum process, among which, the melted steel is casted to slab after rare earth or Ca to be casted to slab process then to be rolled to cut deal or hot rolled plate by cut deal production technology or the hot tandem rolling technology.

Owner:武钢集团有限公司

Steel plate for automobile axle housing and production method thereof

Steel plates for automobile axle housings, the percentage by weight is C0.1~0.18%, Si≤0.5%, Mn1.2~1.6%, Ti0.01-0.06%, Nb0.01-0.04%, P:≤0.025%, S: ≤0.015% and the rest are Fe and impurities. The steel plate production method: casting molten steel smelted in a converter that meets the chemical composition requirements into a slab, according to the percentages of Ti, Fe and Nb, adding TiFe after LF refining treatment to create white slag, and adding NbFe in the converter process or LF refining; Put the slab into the furnace to heat and keep it warm; the starting temperature of rough rolling is 1080-1120°C, the starting temperature of finish rolling is 910-950°C, the temperature of finishing rolling is 830-870°C, three times of continuous rolling after finishing rolling, rolling The reduction rate of the last three passes is not less than 11%, 8%, and 6%; the shear temperature is 150-300°C. In order to improve the mechanical performance index and cold forming performance of the steel plate.

Owner:LIUZHOU IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com