Magnetic pulse forming device and method of bimetal composite pipe

A bimetallic composite tube and magnetic pulse forming technology, which is applied in the field of magnetic pulse forming devices, can solve the problems of low bonding strength of composite bimetallic tubes, high danger of explosion composite method, complicated production process, etc., and the applicable occasions are not limited. , the production process is simple, the device structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

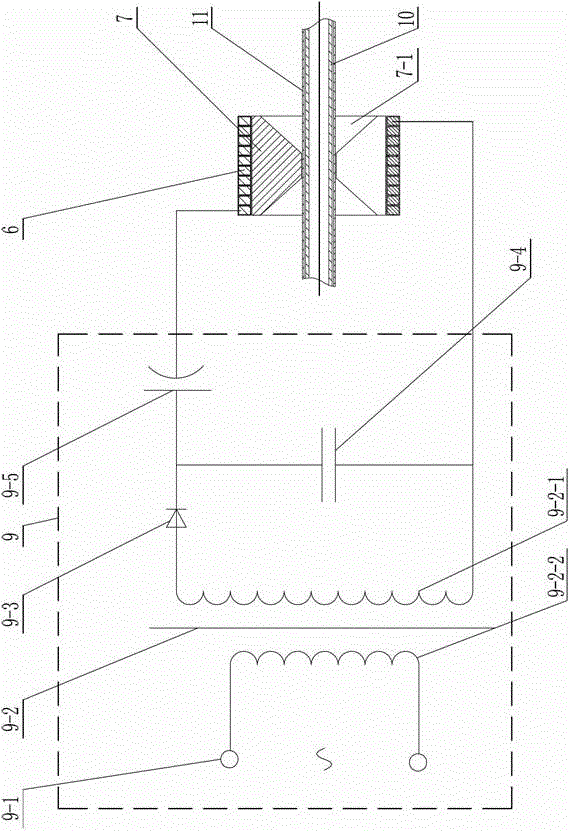

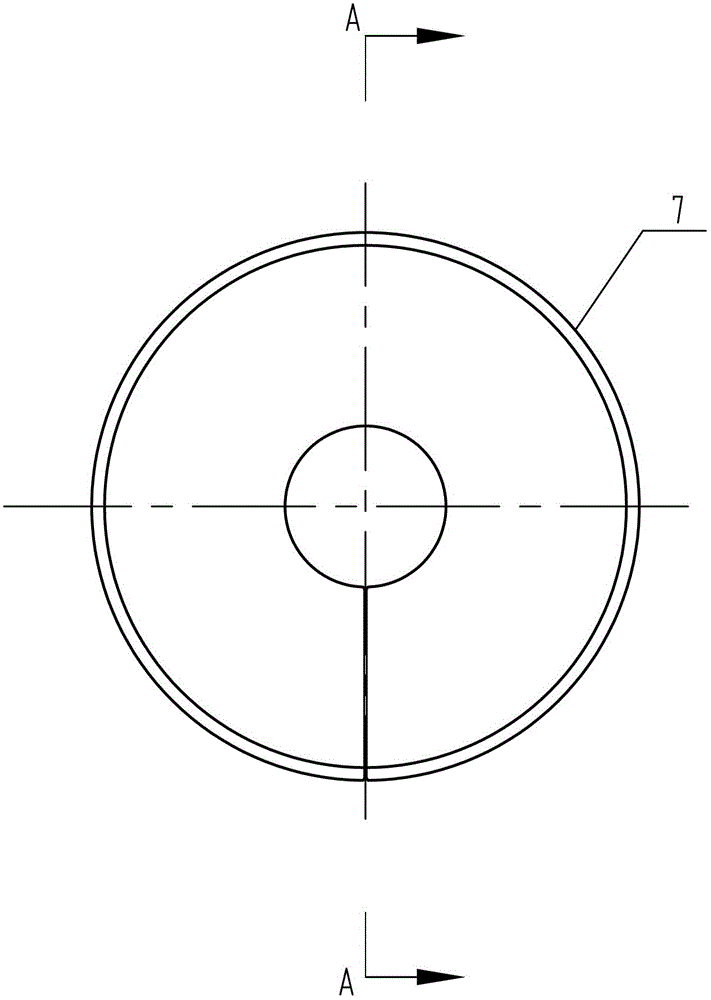

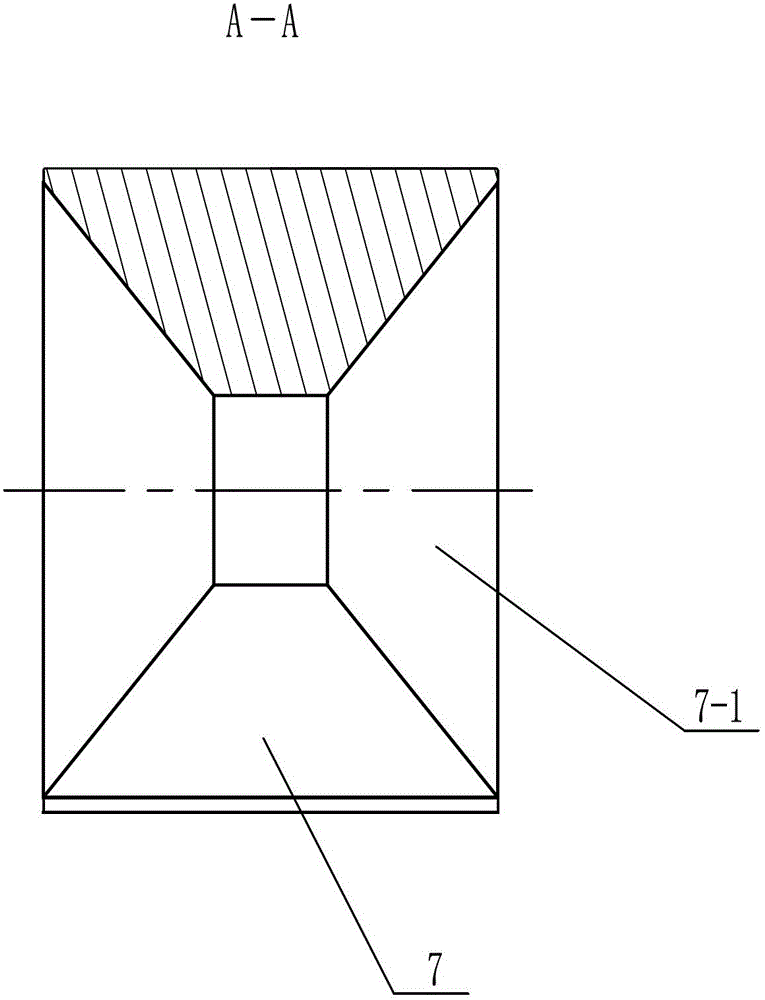

[0012] Specific implementation mode one: as Figure 1-Figure 5 As shown, the magnetic pulse forming device of the bimetallic composite pipe of the present embodiment includes a screw rod 1, a base fixing plate 2, a magnetic collector 7, a magnetic coil 6, a support frame 8, a magnetic pulse control circuit 9, two Tube blank clamping block 5 and two vise 4, the two vise 4 are respectively mobile vise 4-1 and fixed vise 4-2,

[0013] The upper end surface of the base fixed plate 2 is provided with a dovetail chute 2-1 along its length direction, and the lower end of the mobile vise 4-1 is provided with a dovetail slide that matches the dovetail chute 2-1 of the base fixed plate 2. Block 4-1-1, the dovetail slider 4-1-1 of the moving vise 4-1 slides with the dovetail chute 2-1 of the base fixing plate 2, and the fixed vise 4-2 is fixed on the base fixing plate 2, and the moving vise 4-1 and the fixed vise 4-2 are arranged oppositely, a tube blank clamping block 5 is fixed on eac...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Explain that the magnetic pulse control circuit 9 of this embodiment includes an AC power supply 9-1, a transformer 9-2, a rectifying element 9-3, a capacitor 9-4, and a high voltage switch 9-5; the secondary coil of the transformer 9-2 One end of 9-2-1 is connected with the anode of rectifier element 9-3, the cathode of rectifier element 9-3 is connected with the positive pole of high voltage switch 9-5 with one end of capacitor 9-4, and the negative pole of high voltage switch 9-5 is used as magnetic An output end of the pulse control circuit 9 is connected with one end of the magnetic force coil 6, and the other end of the secondary coil 9-2-1 of the transformer 9-2 is connected with the other end of the capacitor 9-4 and is used as the other end of the magnetic pulse control circuit 9. One output end is connected with the other end of the magnetic coil 6, and the two ends of the primary coil 9-2-2 of the transfo...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 and Figure 4 Note that the magnetic coil 6 of this embodiment is formed by winding 10 turns of a copper wire with a rectangular cross-section of 5 mm×7 mm. The copper wire of this specification and the corresponding number of turns are selected for winding the magnetic force coil, mainly because the electrical parameters of the magnetic force coil 6 are matched with the parameters of the electromagnetic forming machine, so as to obtain a relatively large value that is beneficial to the composite forming process. magnetic pressure. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com