Patents

Literature

308 results about "Electromagnetic forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

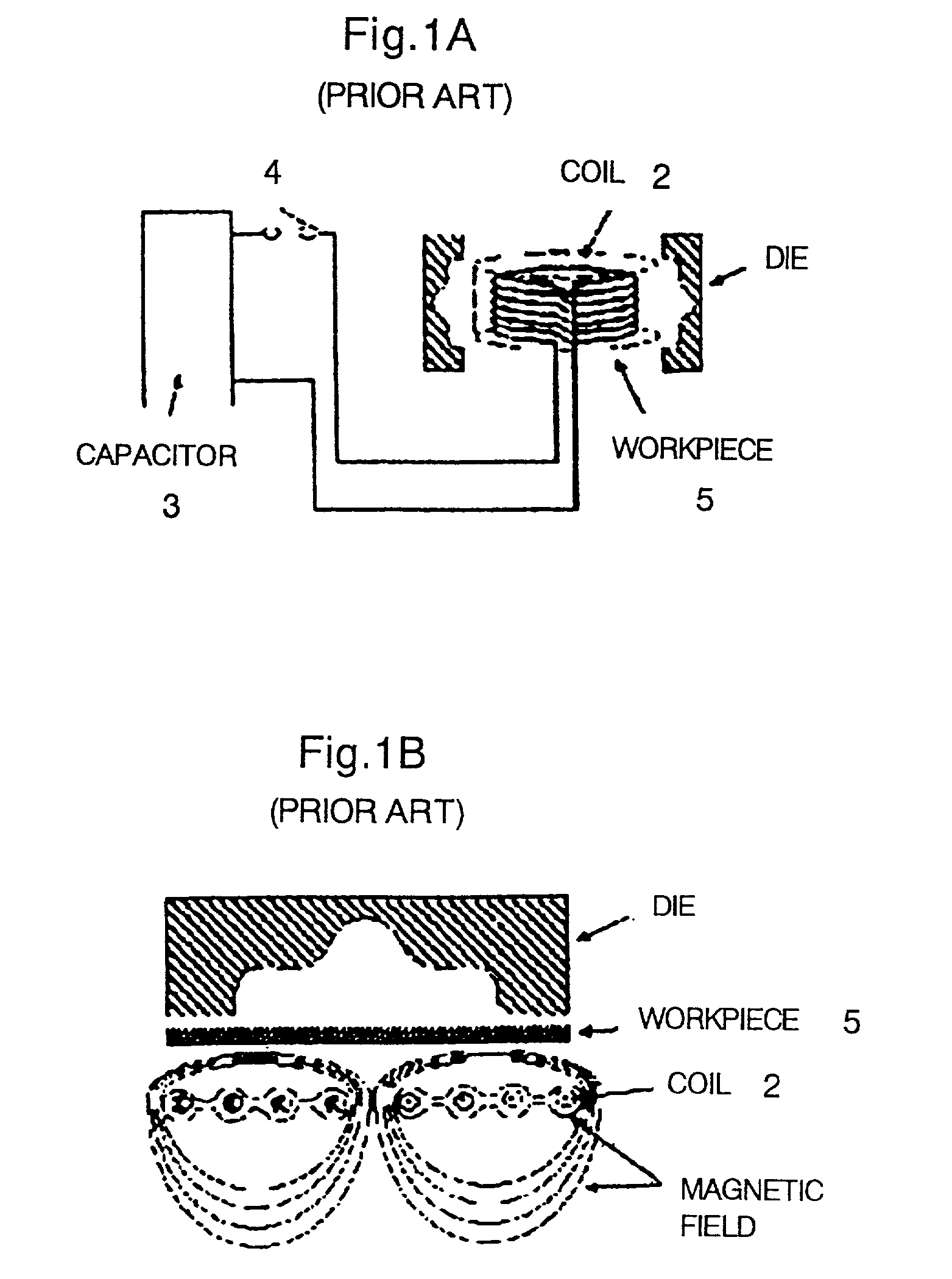

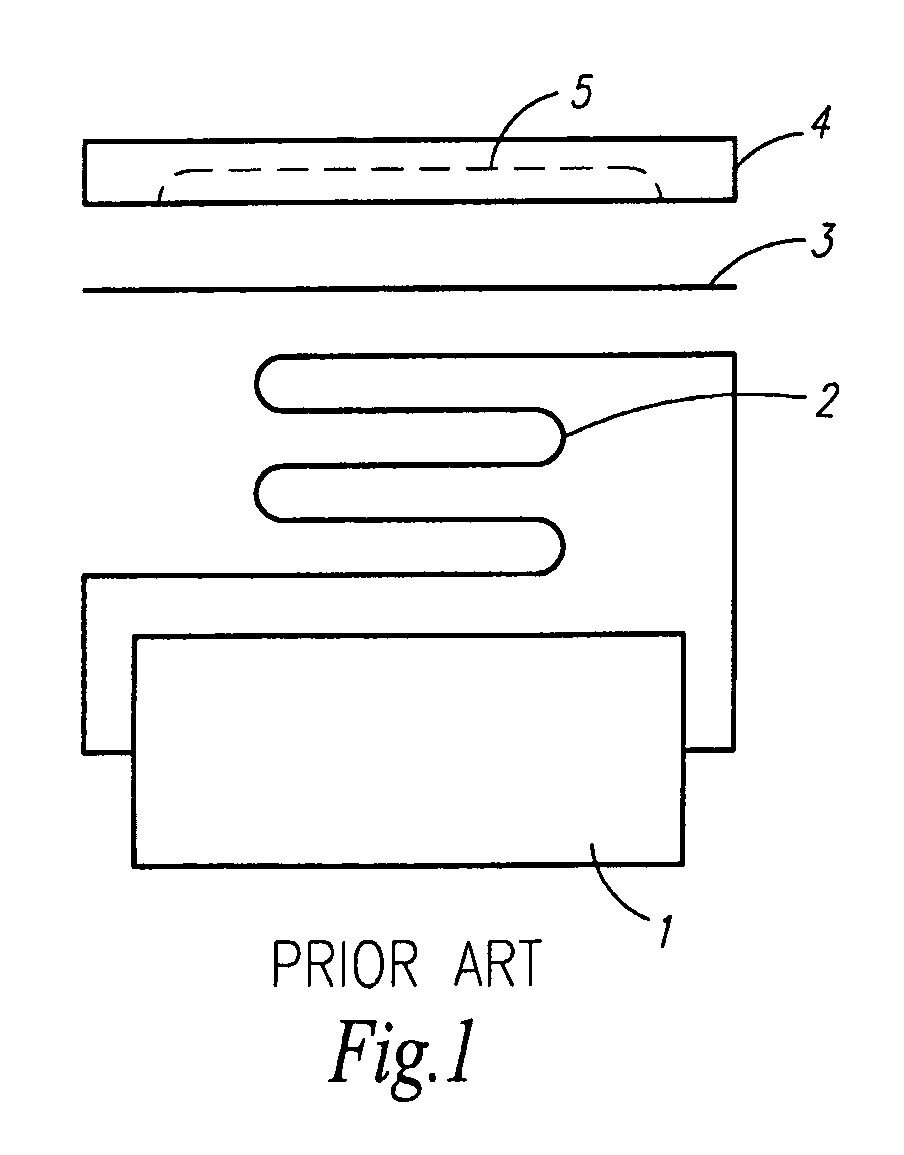

Electromagnetic forming (EM forming or magneforming) is a type of high velocity, cold forming process for electrically conductive metals, most commonly copper and aluminium. The workpiece is reshaped by high intensity pulsed magnetic fields that induce a current in the workpiece and a corresponding repulsive magnetic field, rapidly repelling portions of the workpiece. The workpiece can be reshaped without any contact from a tool, although in some instances the piece may be pressed against a die or former. The technique is sometimes called high velocity forming or electromagnetic pulse technology.

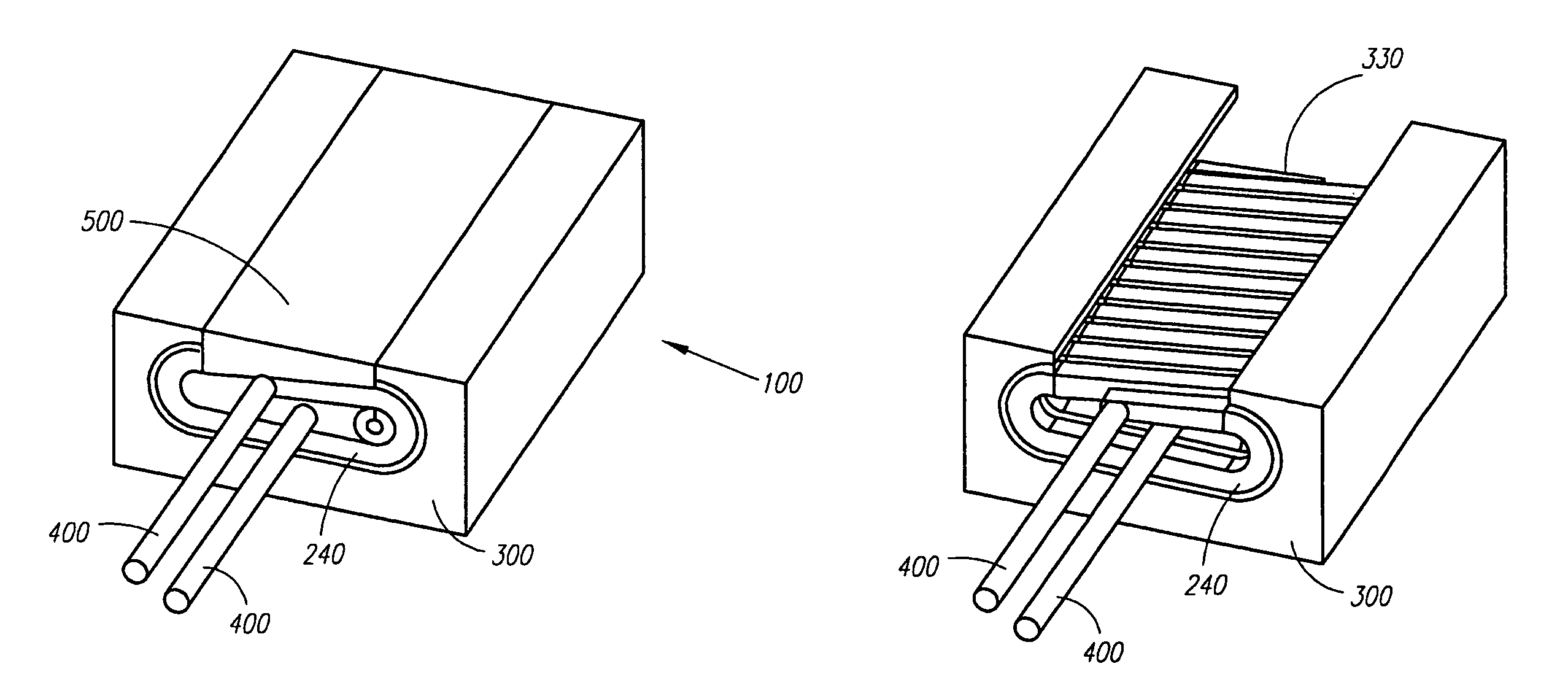

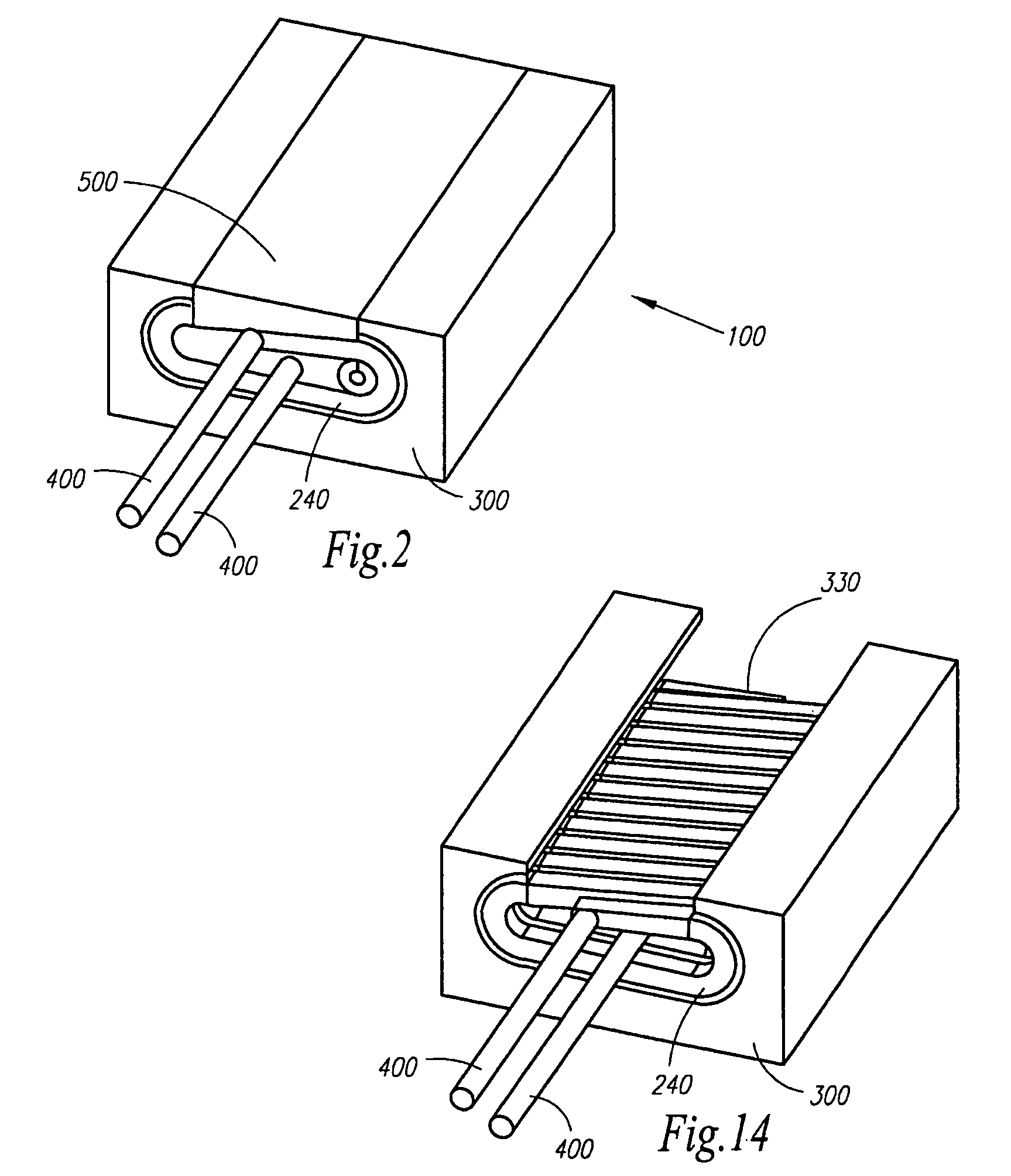

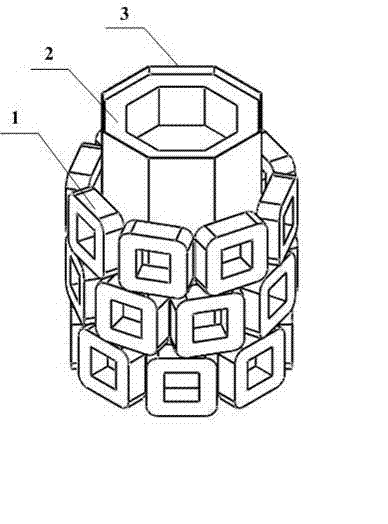

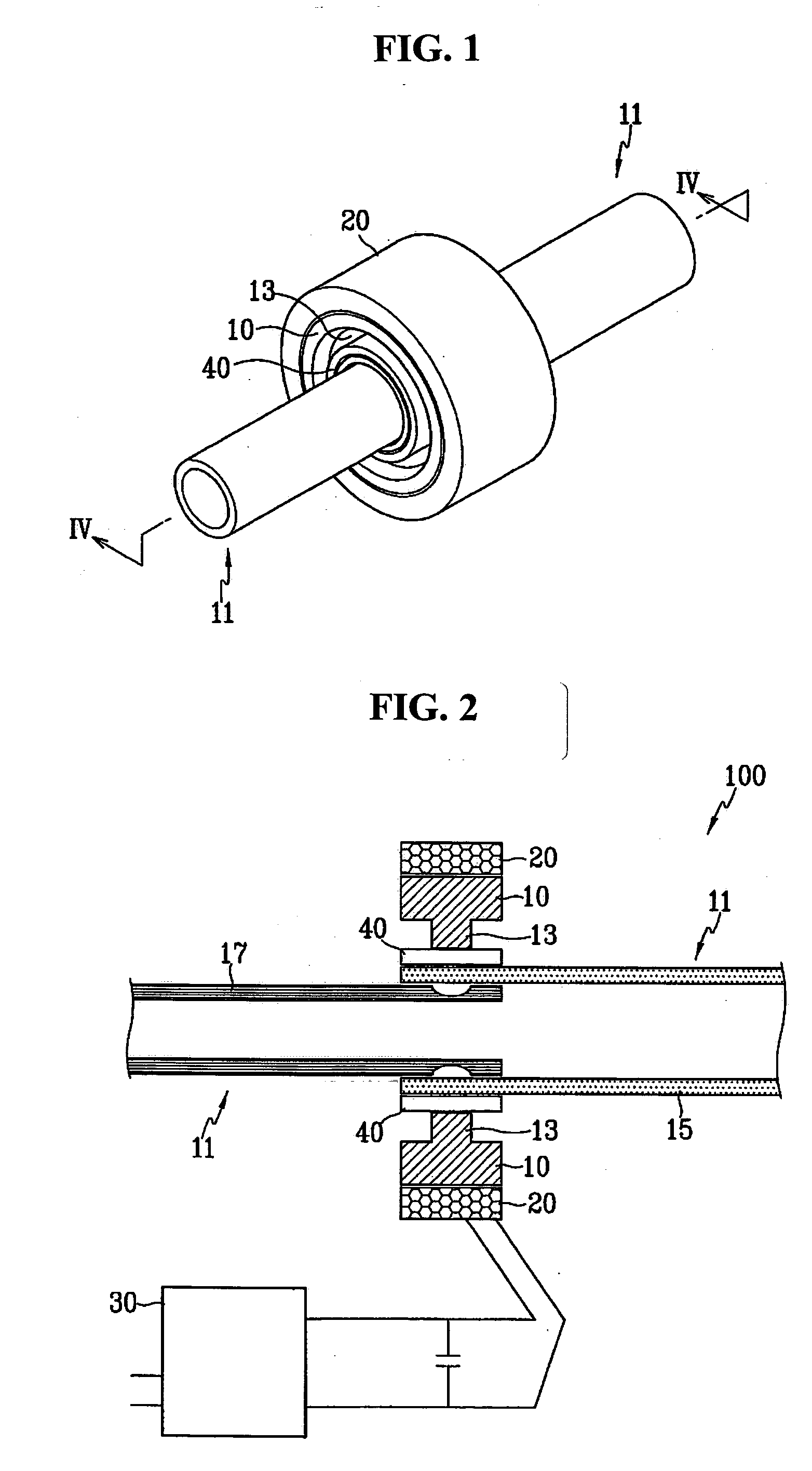

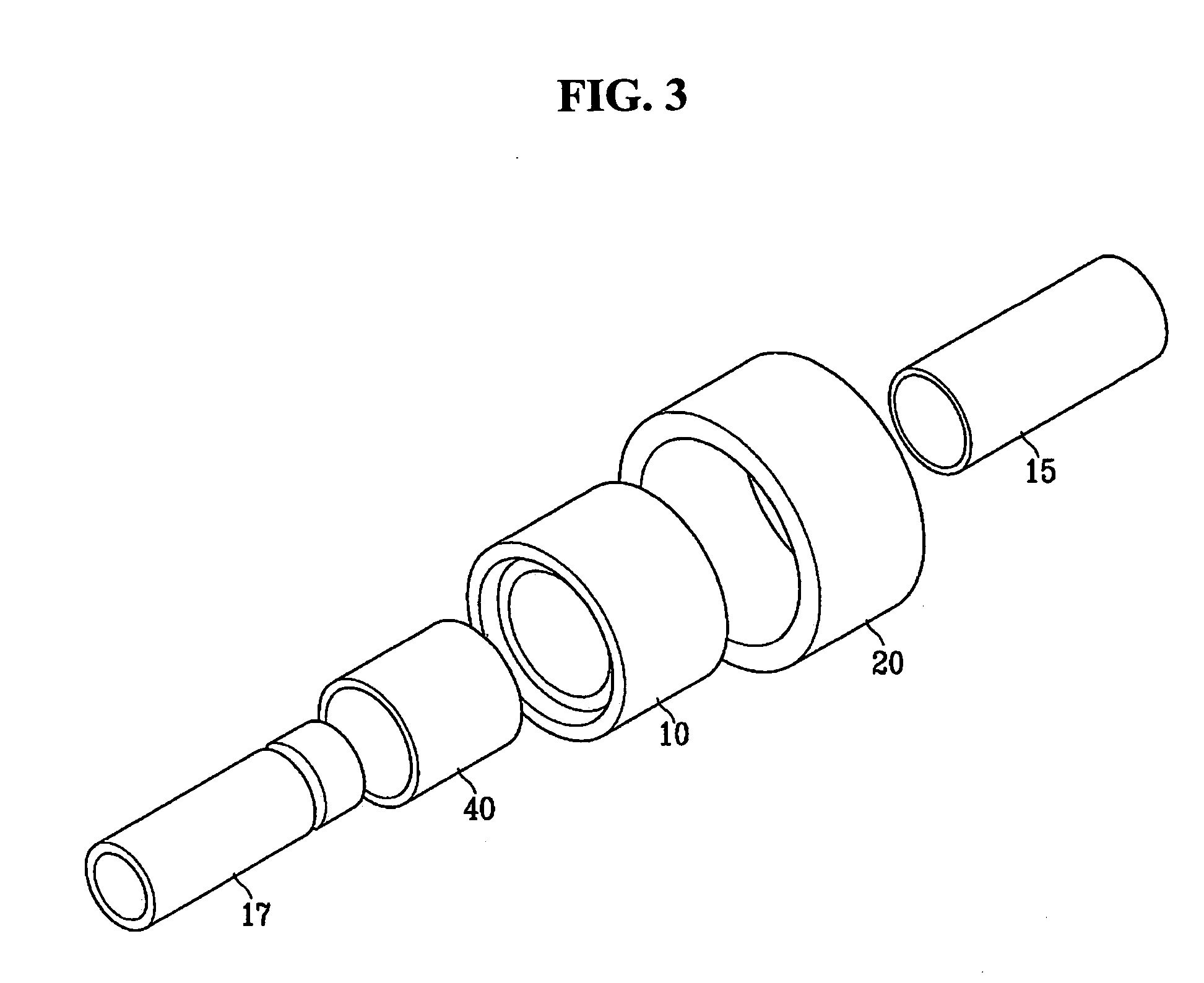

Magnetic field concentrator for electromagnetic forming

ActiveUS7513025B2Easily and quickly exchangedLow costJoints with sealing surfacesPipe elementsEngineeringElectromagnetic field

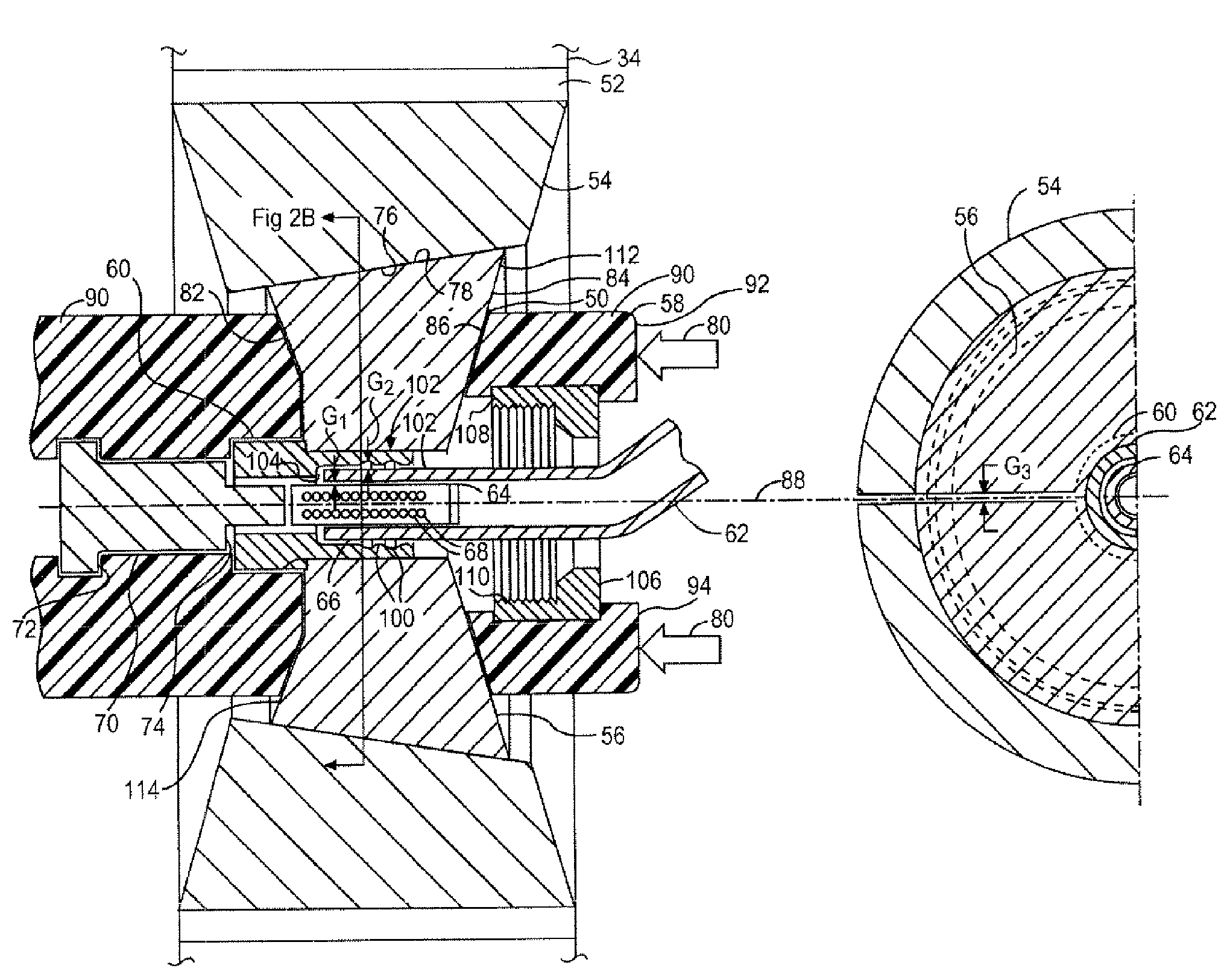

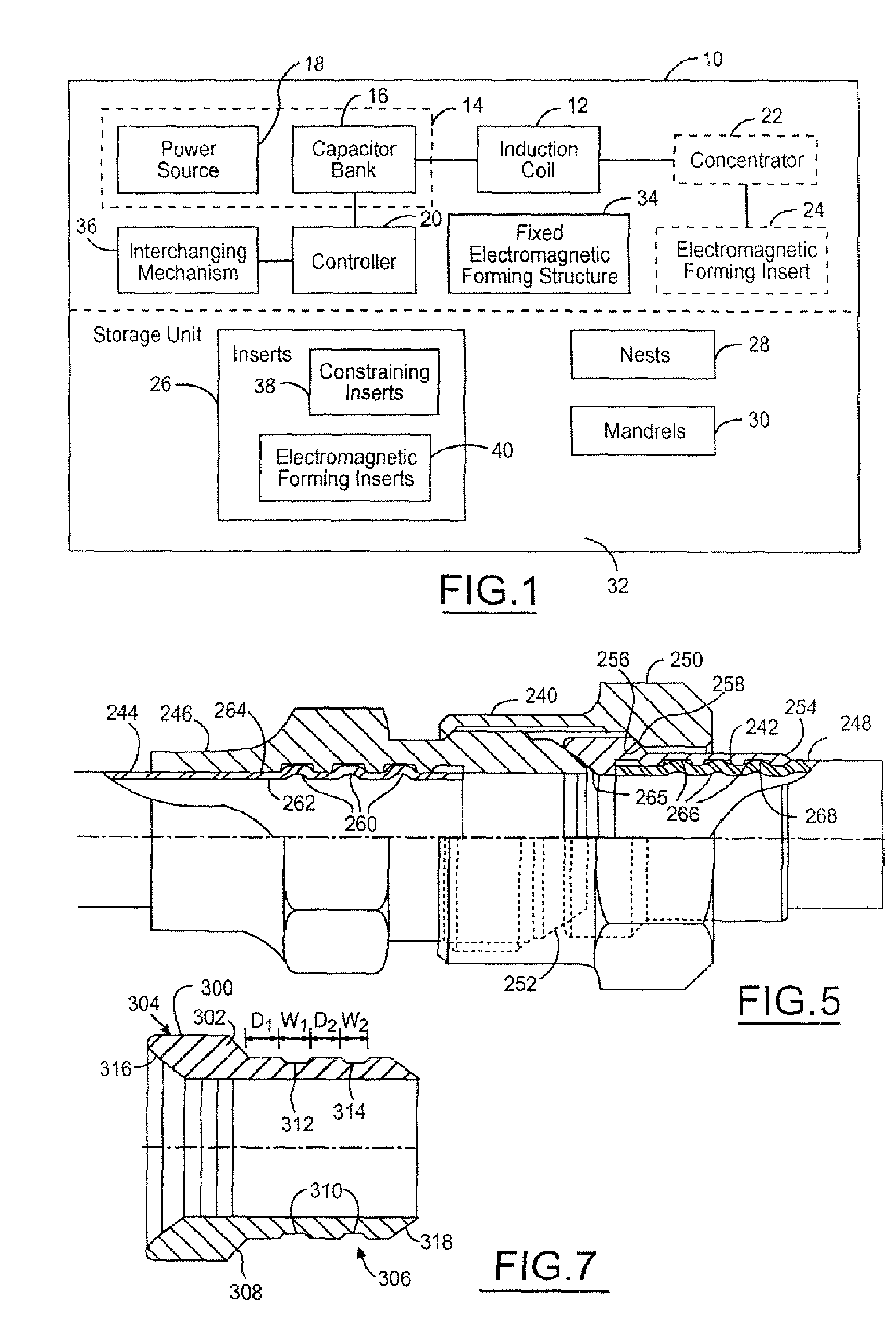

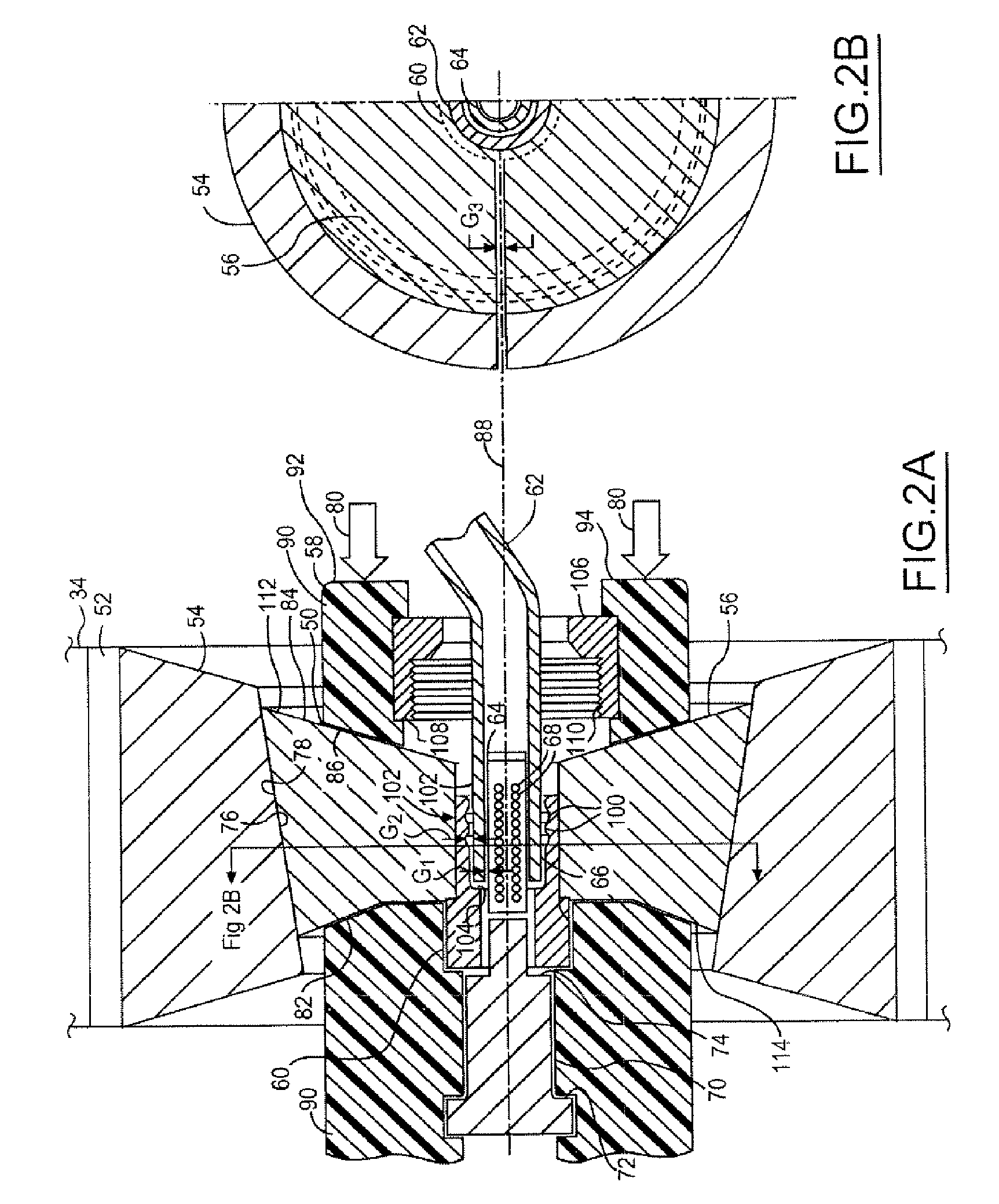

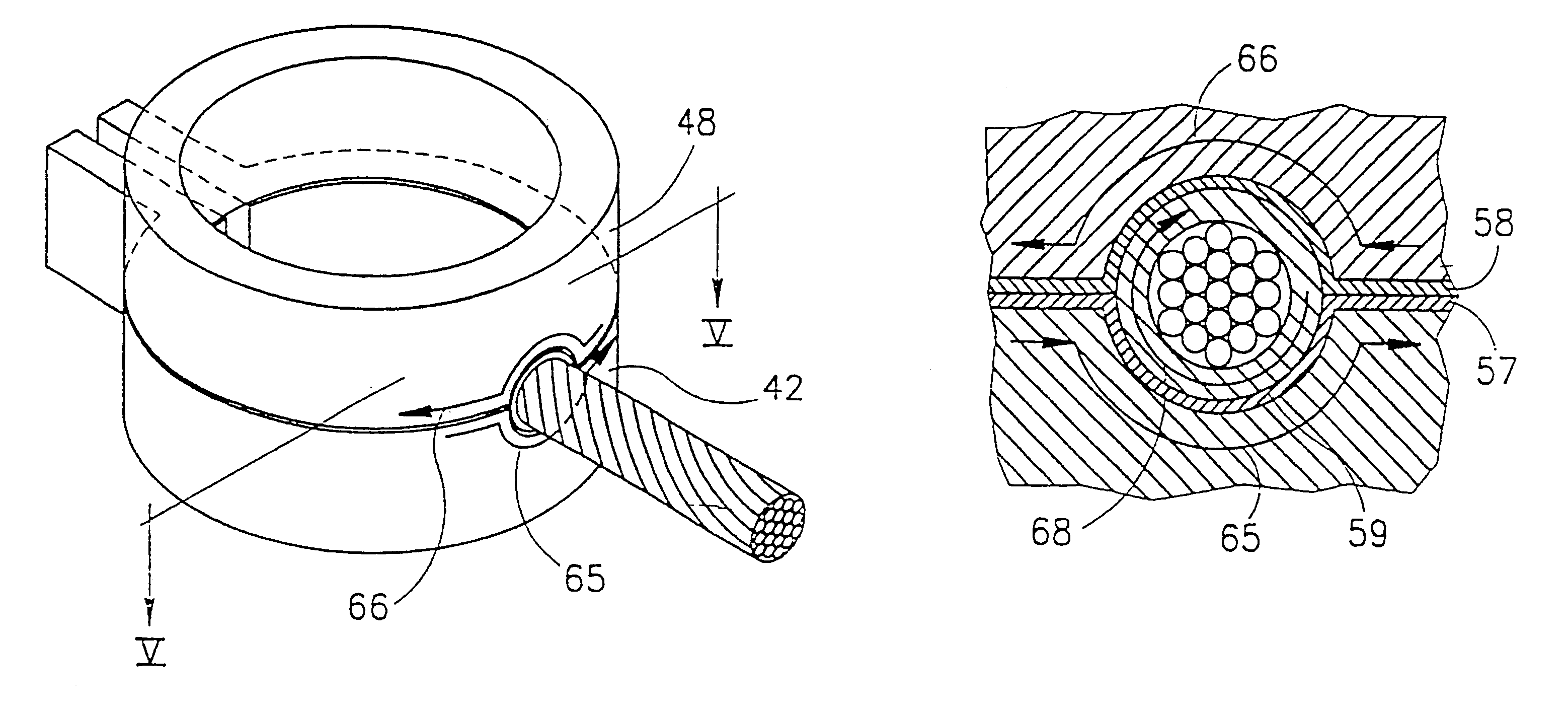

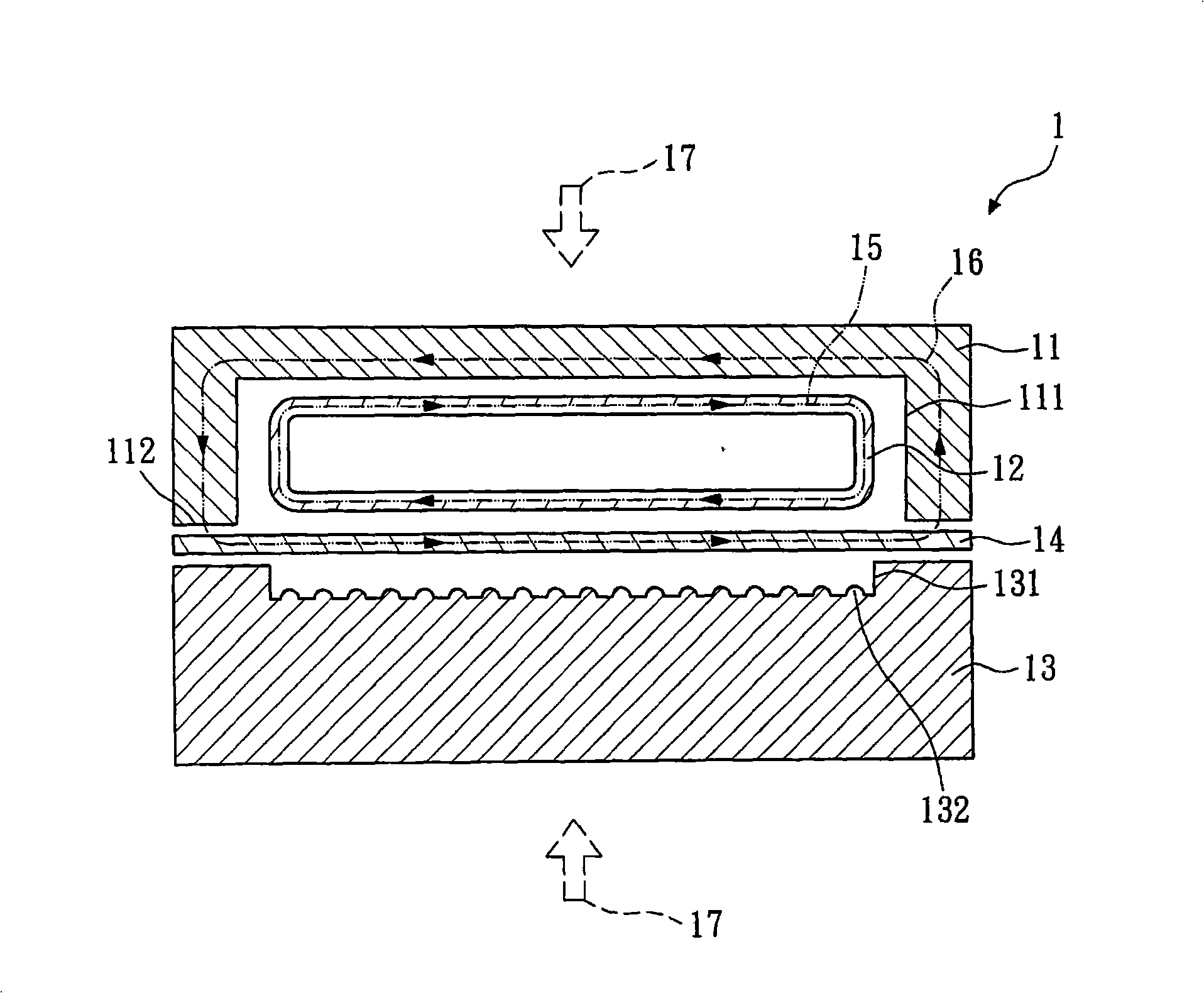

A magnetic forming system (10) for creating a fluid circuit joint between a tube and a fitting includes an induction coil (12). The induction coil (12) may form a first stage electromagnetic current. A field concentrator (132) may focus the first stage electromagnetic current to form a second stage electromagnetic current. An insert (136) may focus the second stage electromagnetic current to form an electromagnetic field. The electromagnetic field forms the fluid circuit joint. The induction coil (12) may be insertable within the tube, generate an electromagnetic field, and impose the electromagnetic field on and to expand a portion of the tube within the fitting to form the fluid circuit joint. The system (10) may include a receptacle (54) that is external to the tube and the fitting. An insert (56) may be mechanically coupled within the receptacle (54) and limit the outward expansion of the tube and the fitting.

Owner:THE BOEING CO

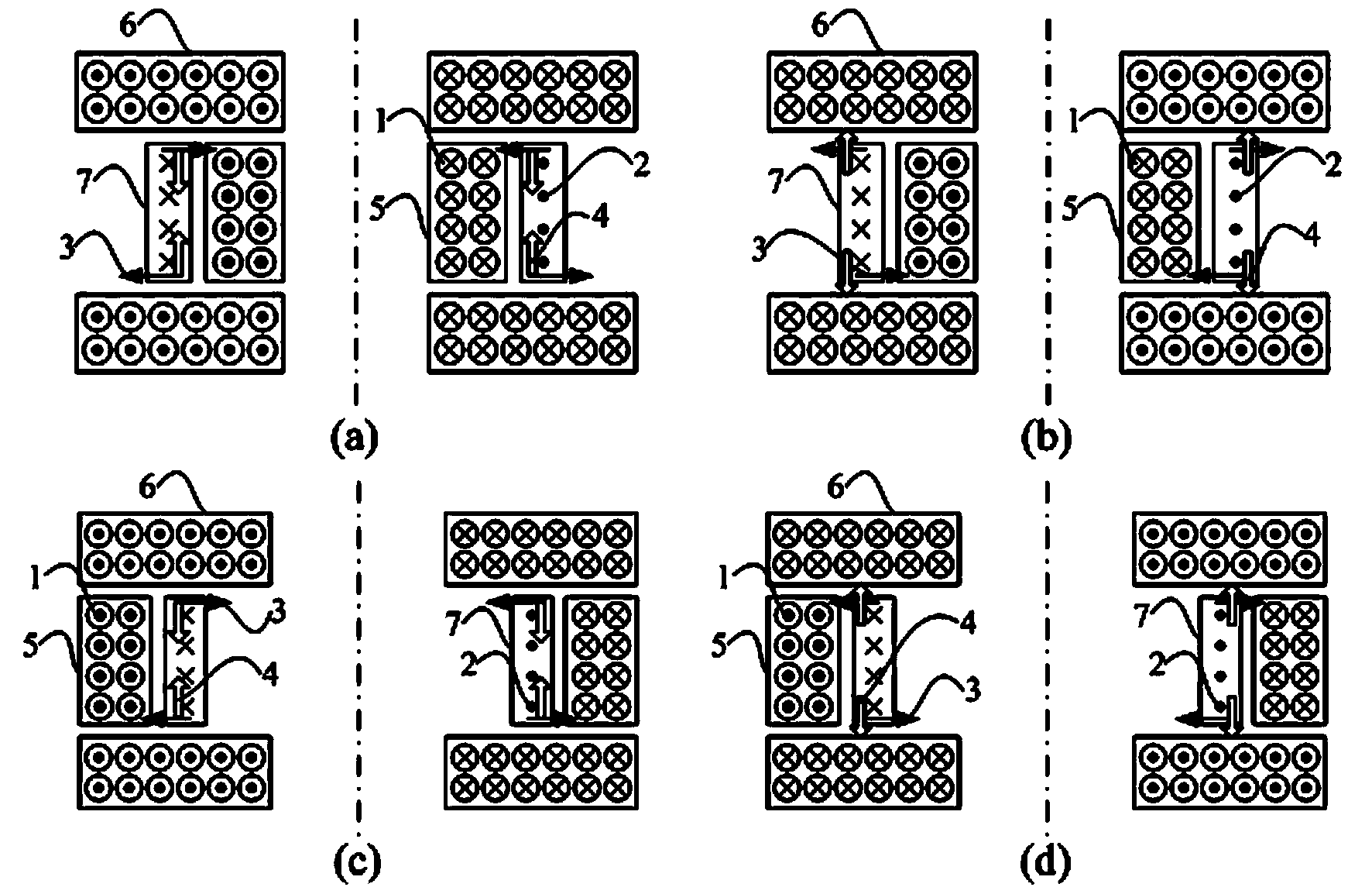

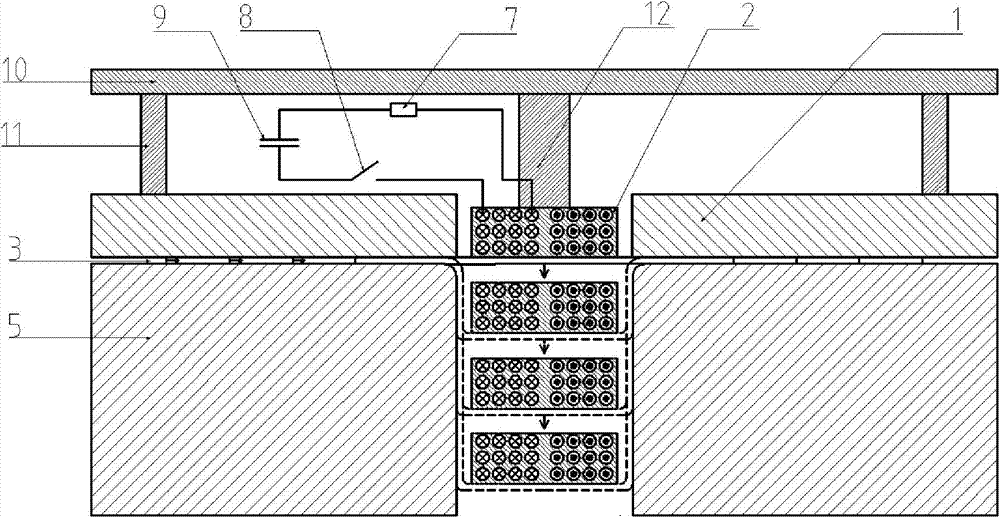

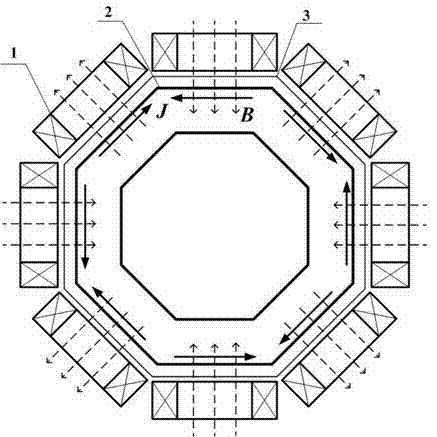

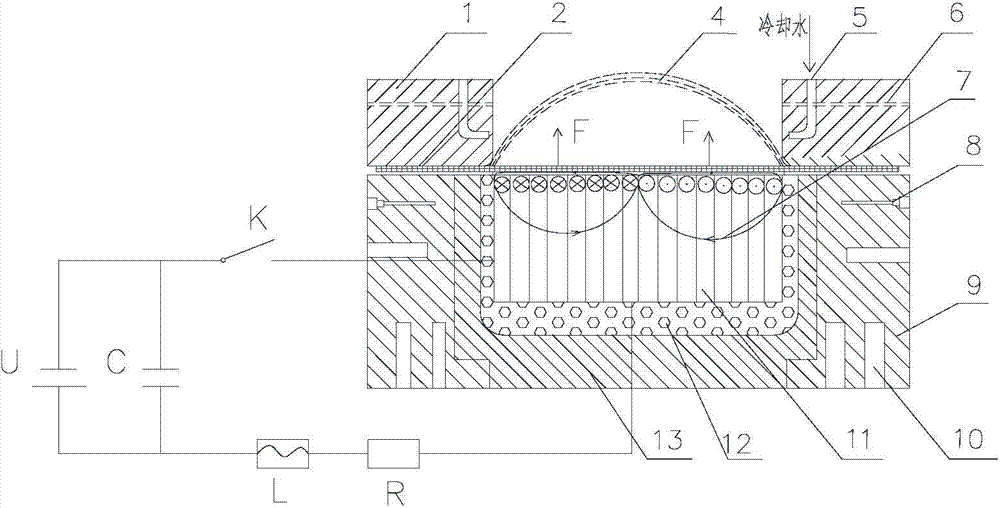

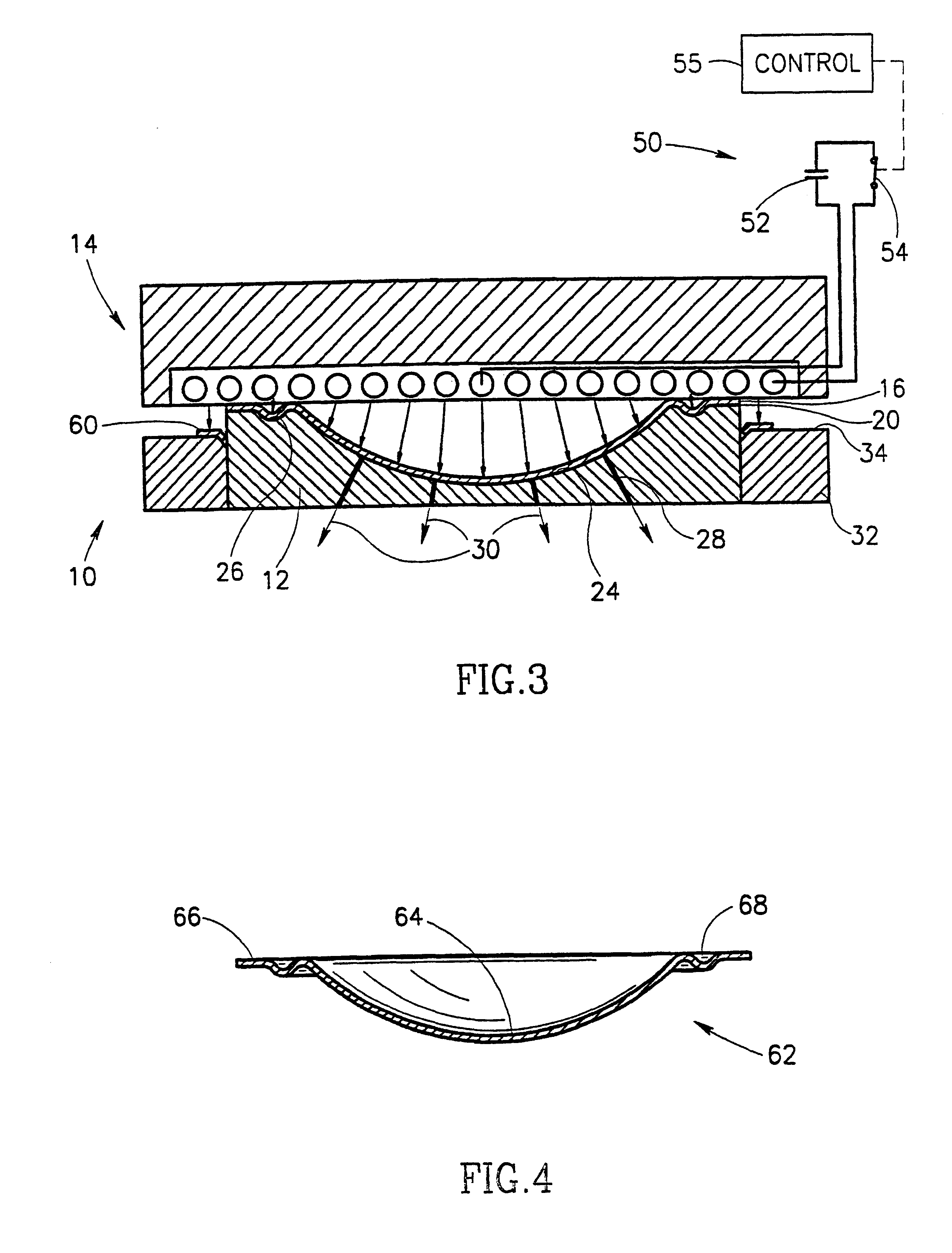

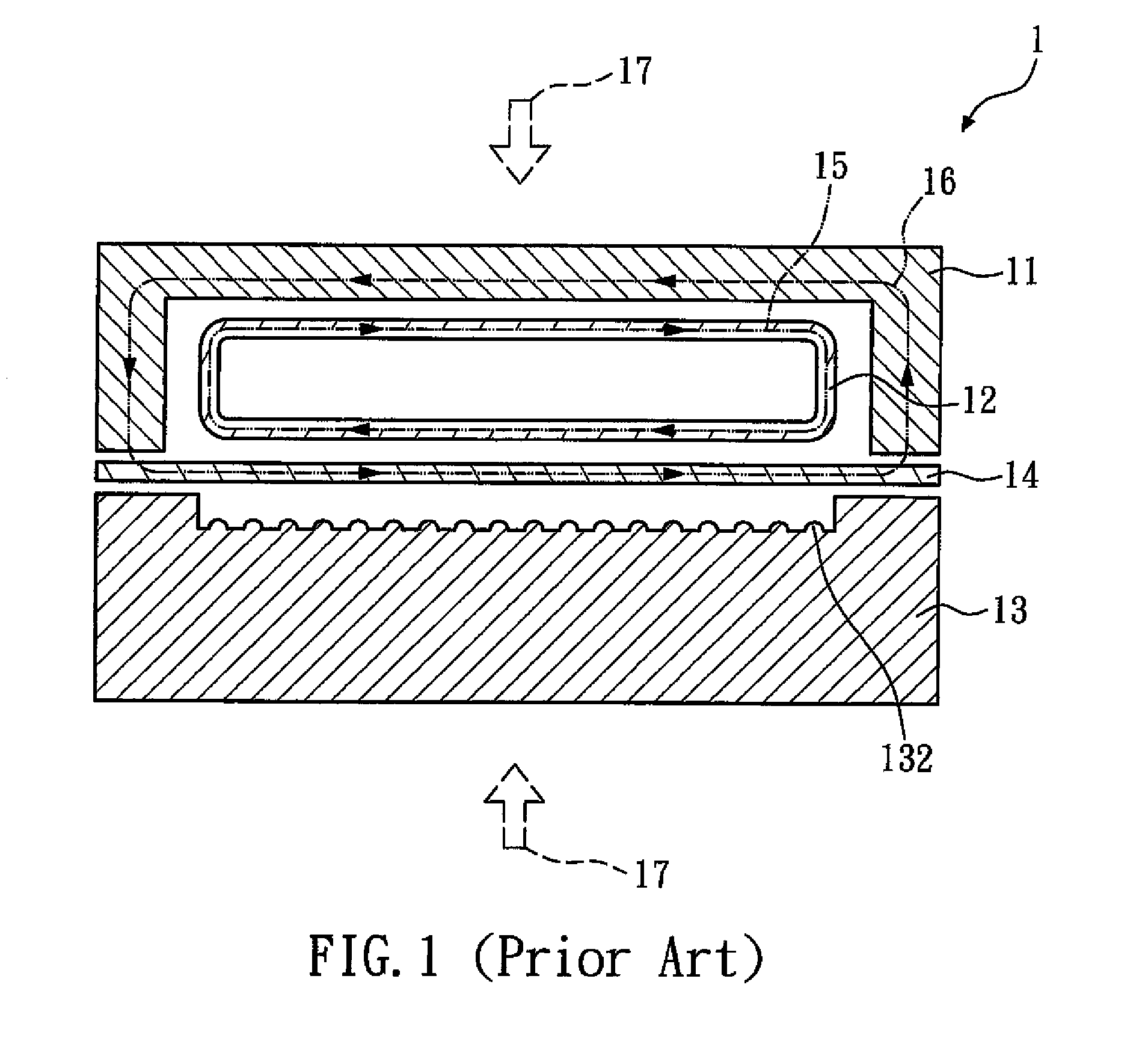

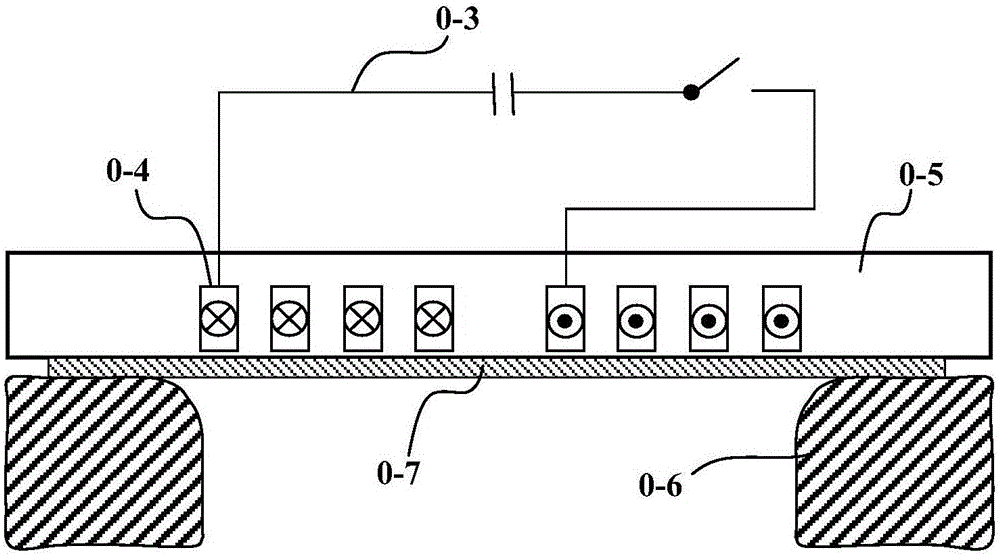

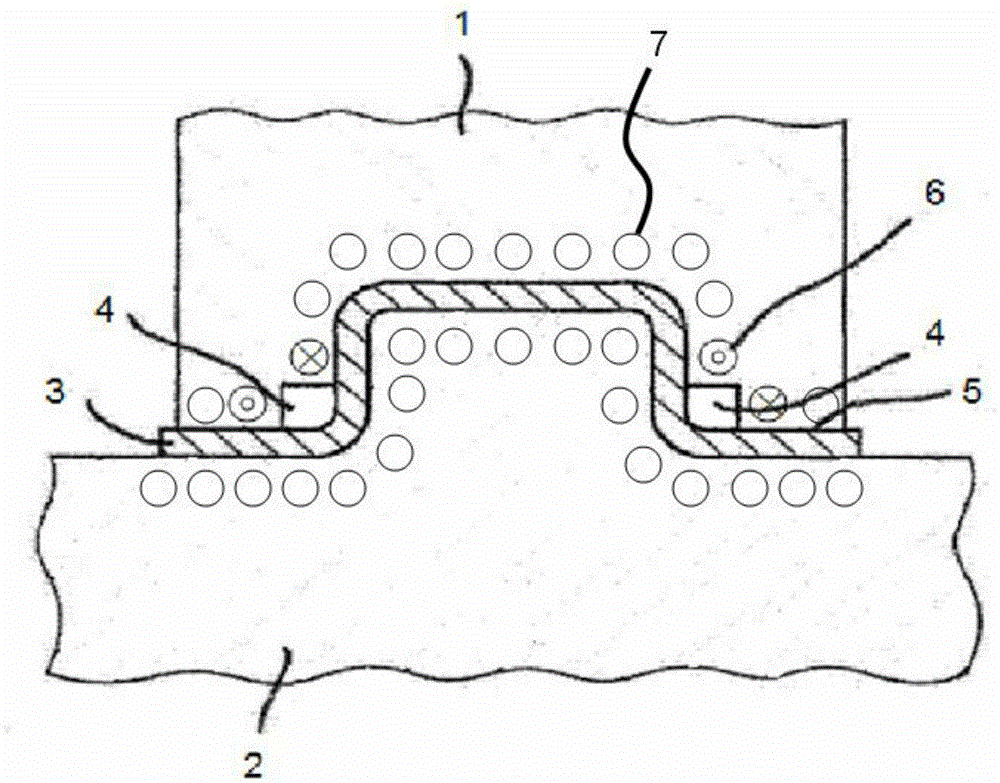

Multistage and multidirectional electromagnetic forming method and device

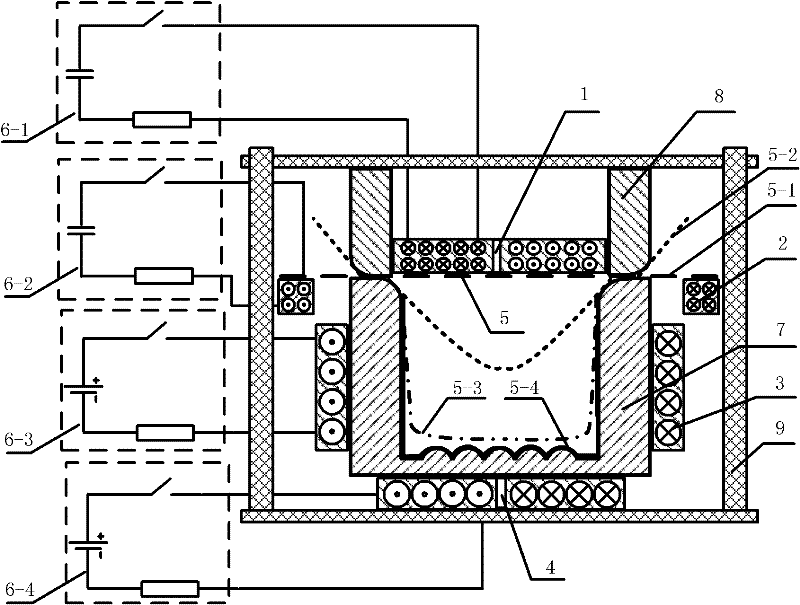

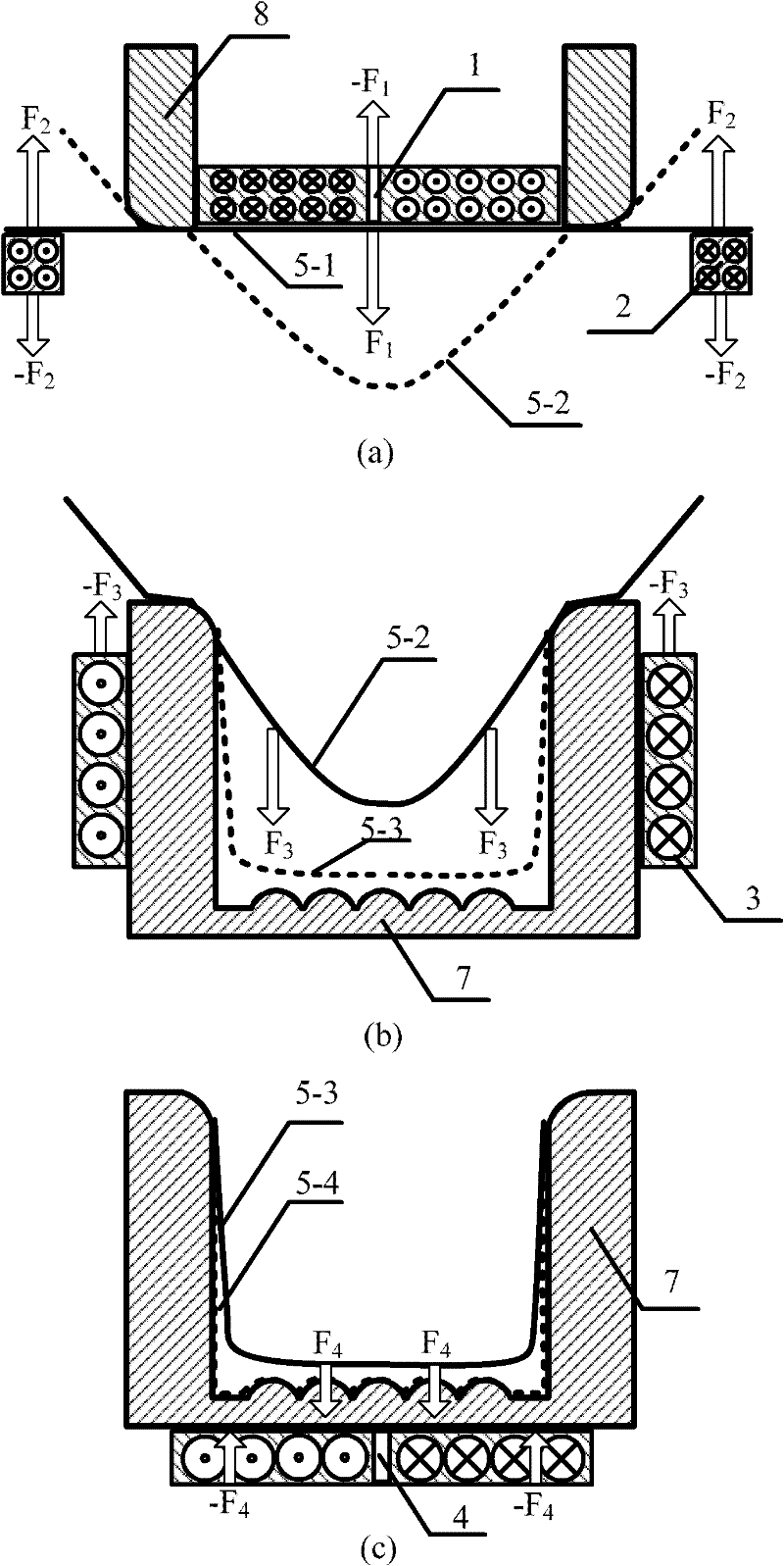

The invention provides a multistage and multidirectional electromagnetic forming method comprising the following steps of: establishing a stable magnetic field area by adopting quasi-steady state current; generating induced eddy current in a workpiece by using pulse current; driving the part of the workpiece, which is positioned outside a female die, to be deformed away from the direction of the female die by using an electromagnetic force between the induced eddy current and the pulse current and driving the part of the workpiece, which is positioned inside the female die, to be deformed towards the direction close to the female die; and when the part inside the female die is deformed to an area of a stable magnetic field area, driving the workpiece to do accelerated motion to be attached to the female die under the action of induced eddy current in the stable magnetic field and the woprkpiece to finish the forming. The invention also provides a device for realizing the method, mainly comprising an edge pressing ring and coils arranged at different positions of the female die. According to the method and device disclosed by the invention, the workpiece is accelerated in a multistage and multidirectional electromagnetic forming manner, the forming, the processing and the manufacturing in a longer time and larger space range are realized and the forming depth of the workpiece is effectively increased.

Owner:HUAZHONG UNIV OF SCI & TECH

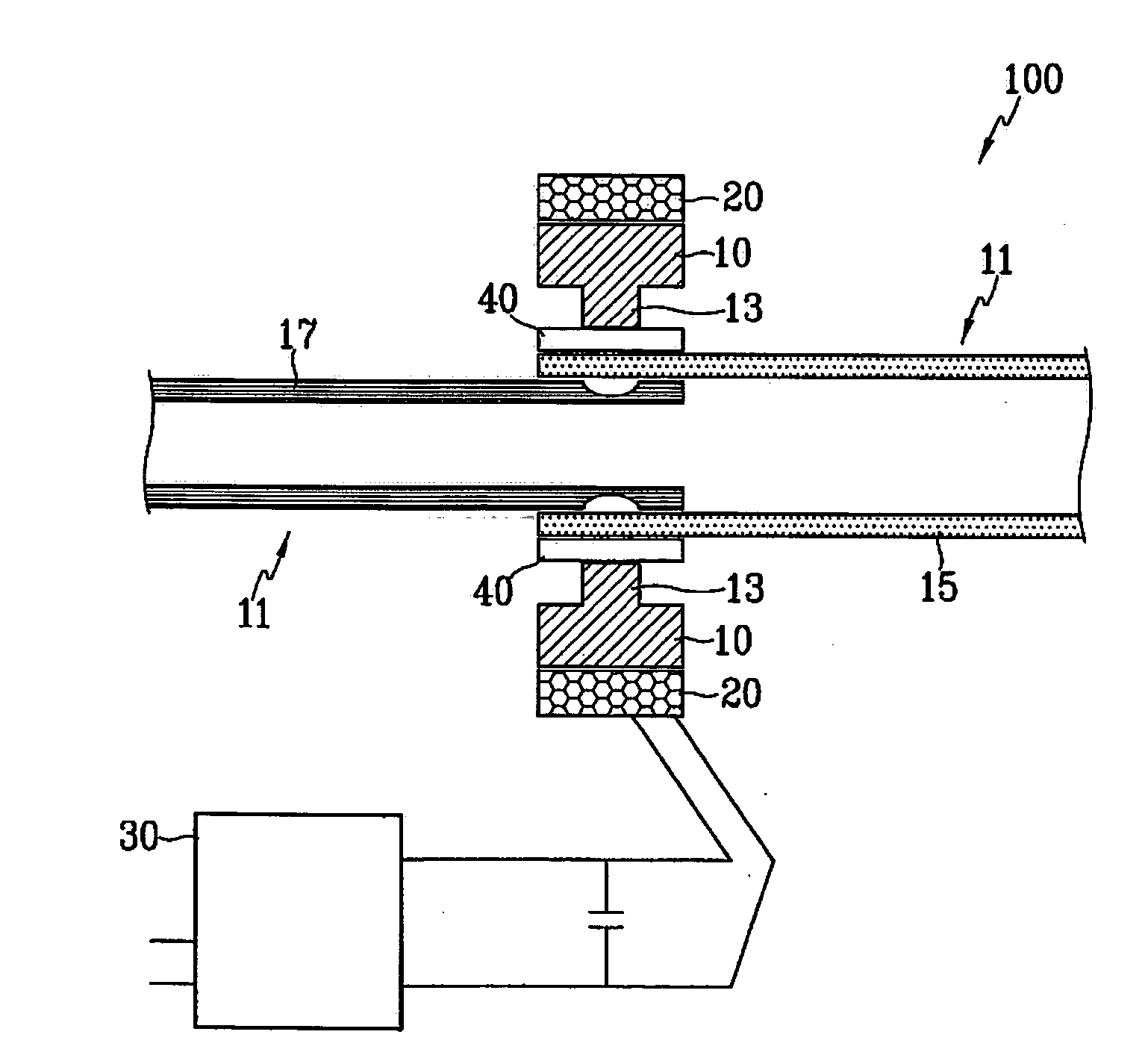

Electromagnetic forming apparatus

InactiveUS6229125B1Easy to placeElectric connection structural associationsHigh frequency current welding apparatusEngineeringElectromagnetic forming

A novel apparatus for pulse magnetic forming of a tubular workpiece is provided. The apparatus forms functionally a single wind coil and is particularly suitable for joining or welding of a tube onto another tube or a cylindrical object.

Owner:INFINITY IP COMMERCIALIZATION ISRAEL LTD

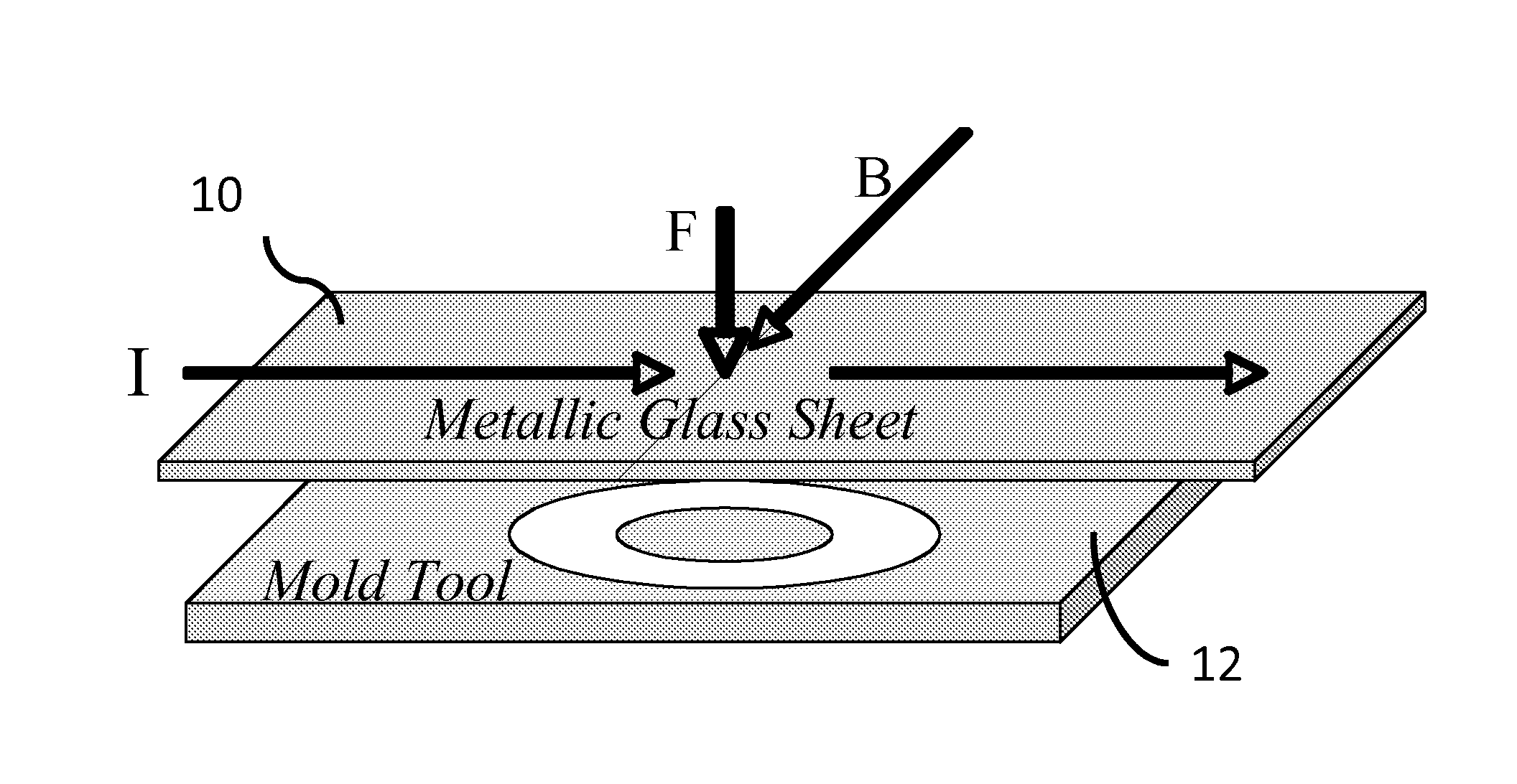

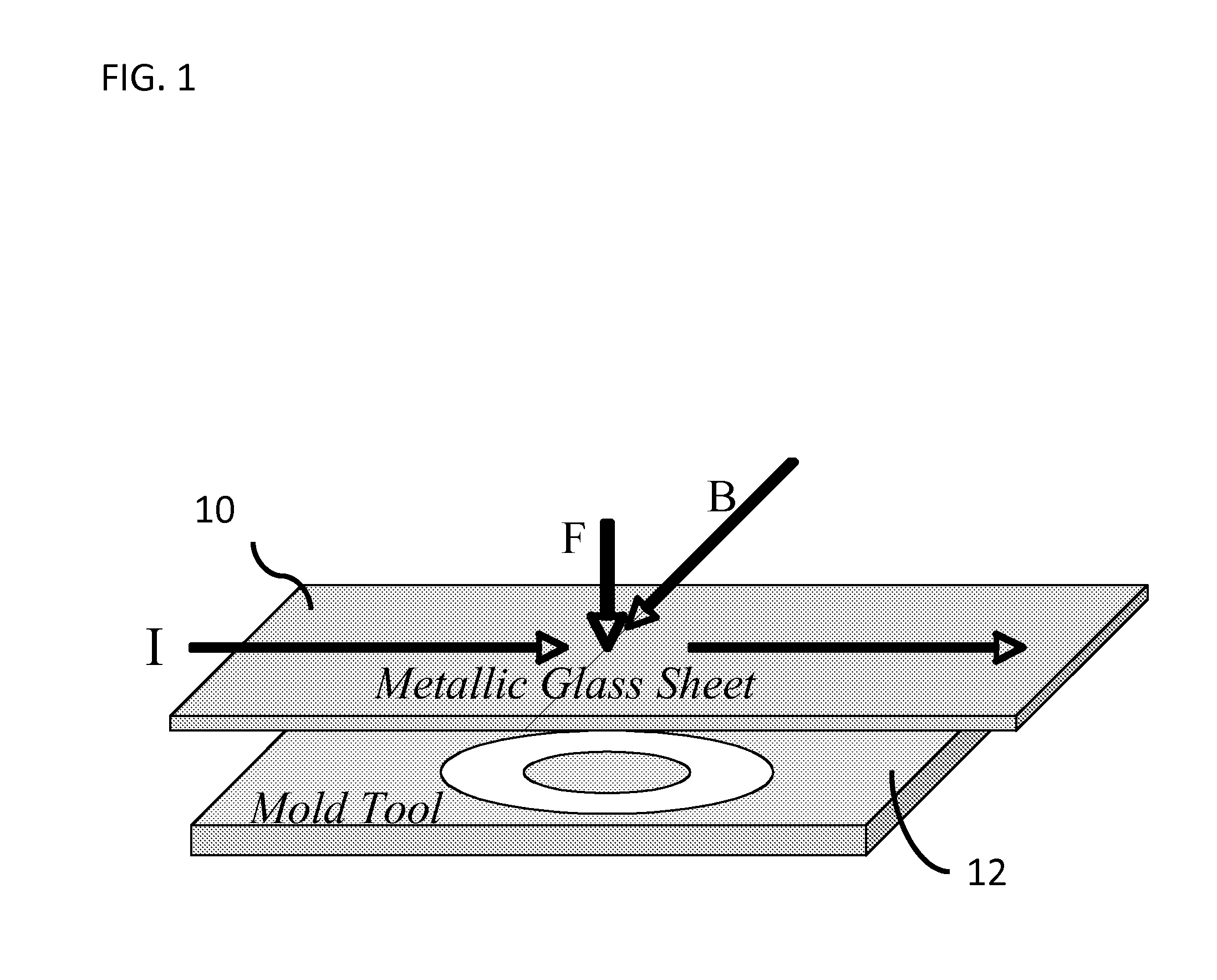

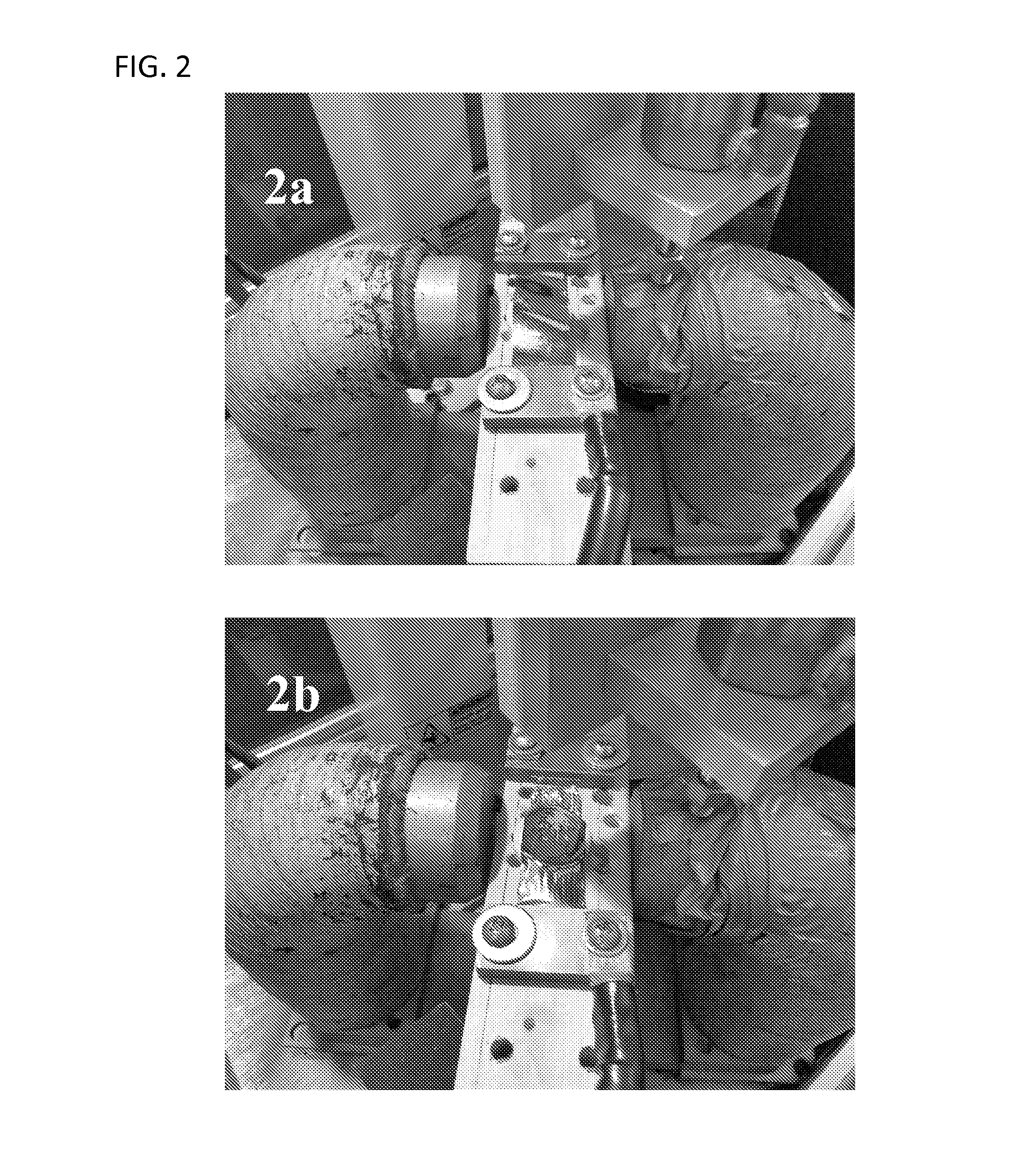

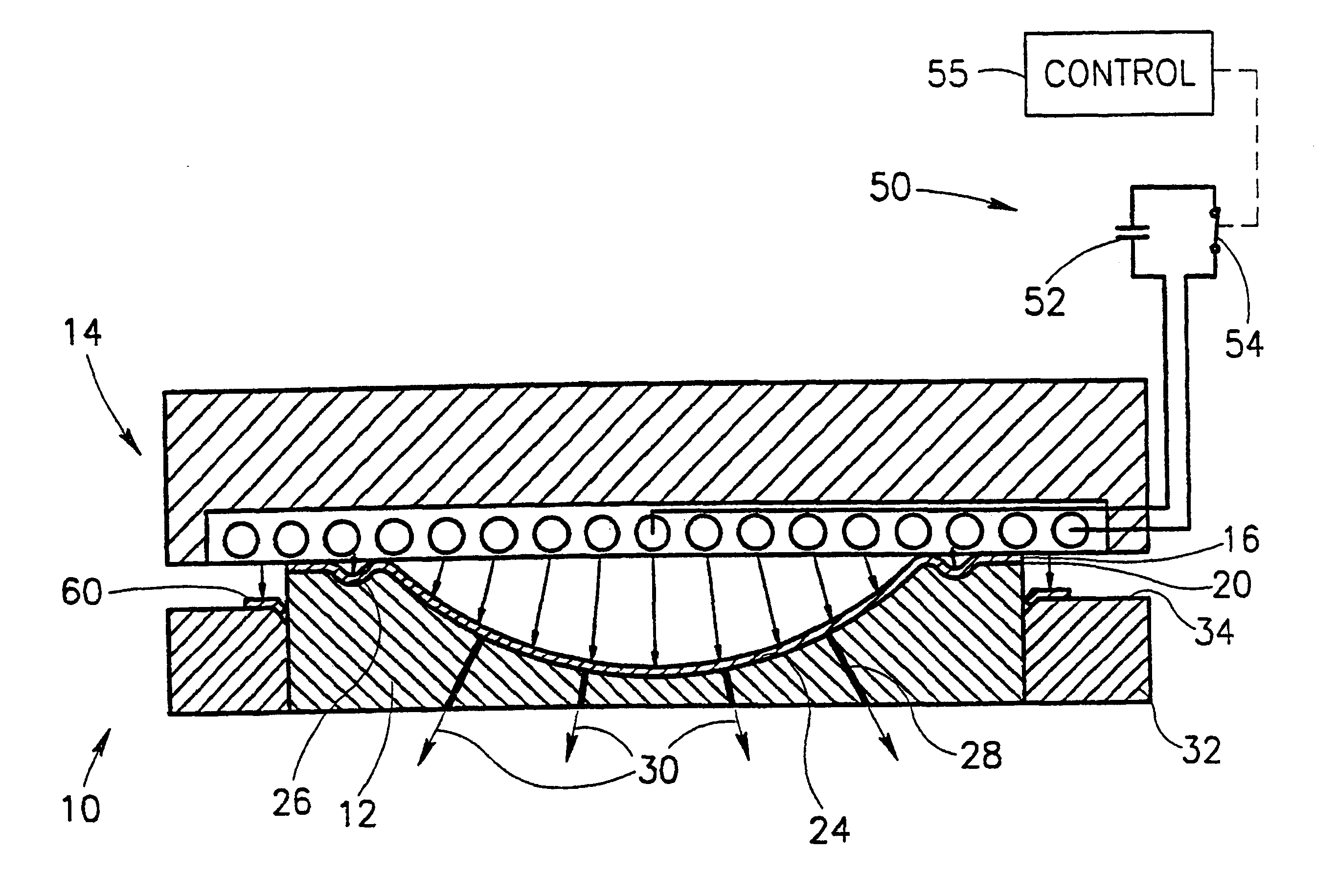

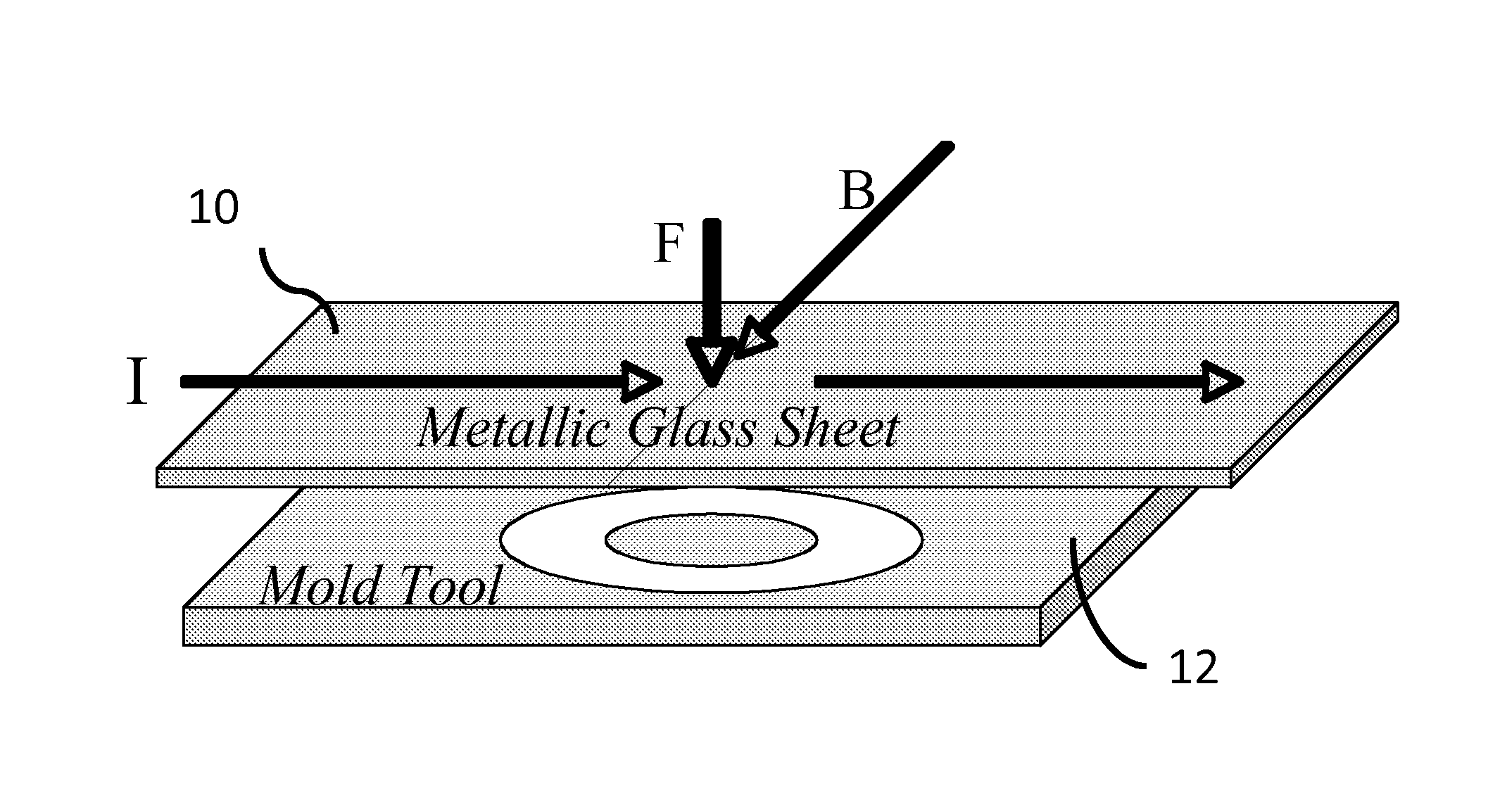

Electromagnetic forming of metallic glasses using a capacitive discharge and magnetic field

ActiveUS20120006085A1Welding/cutting media/materialsSoldering mediaCapacitanceTransverse magnetic field

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool in combination with an electromagnetic force generated by the interaction of the applied current with a transverse magnetic field. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous metal and the equilibrium melting point of the alloy in a time scale of several milliseconds or less, at which point the interaction between the electric field and the magnetic field generates a force capable of shaping the heated sample into a high quality amorphous bulk article via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time scale of less than one second.

Owner:CALIFORNIA INST OF TECH

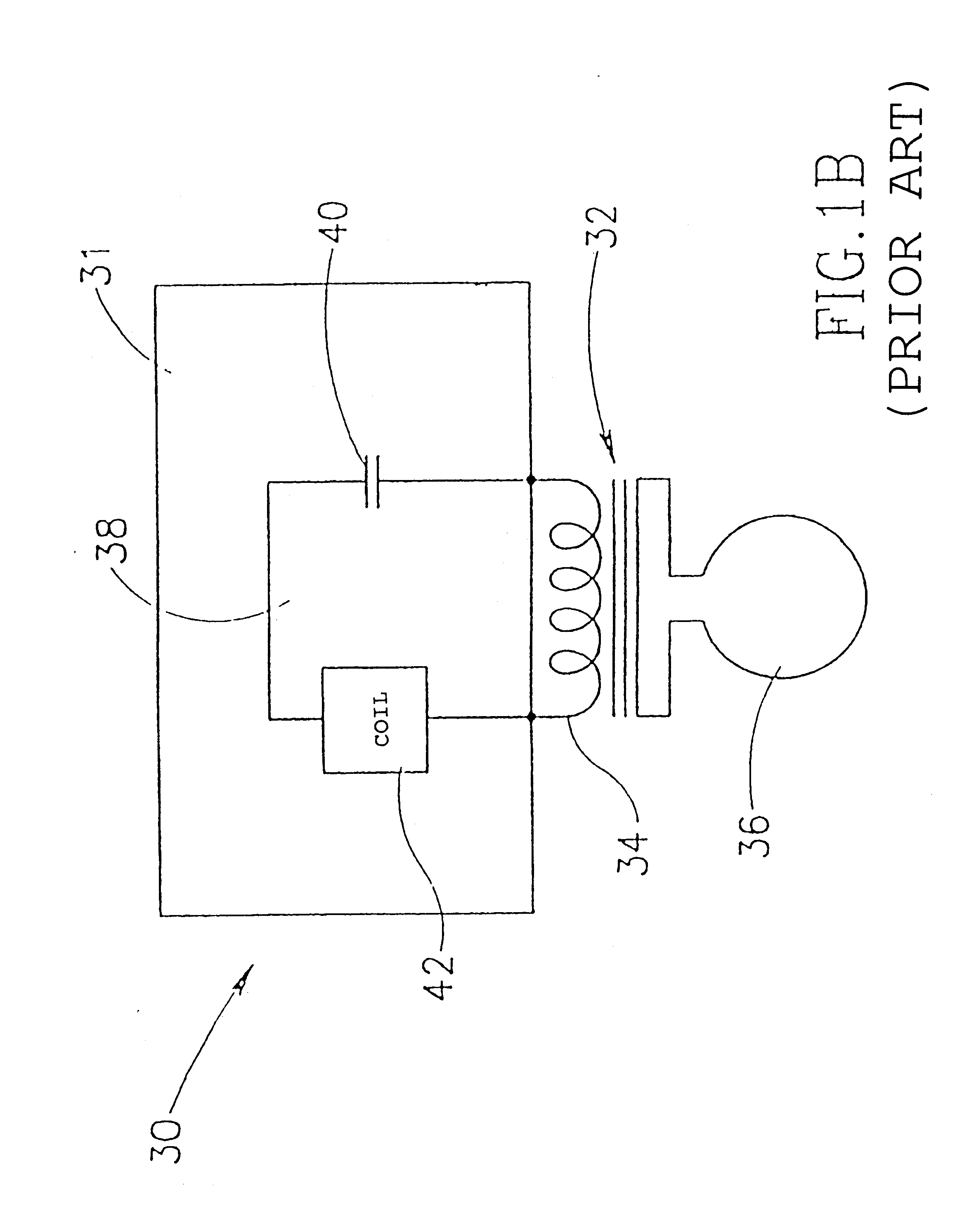

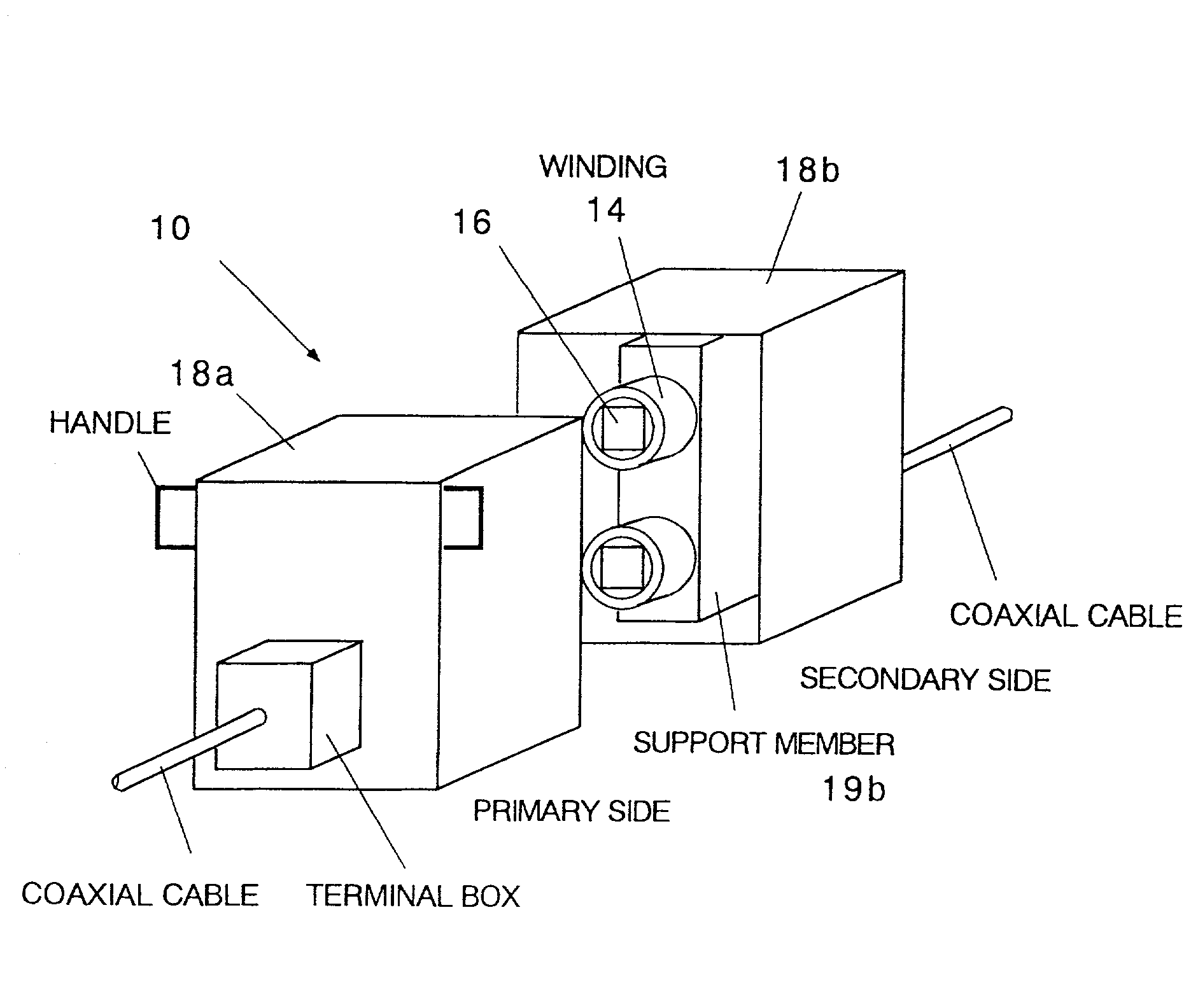

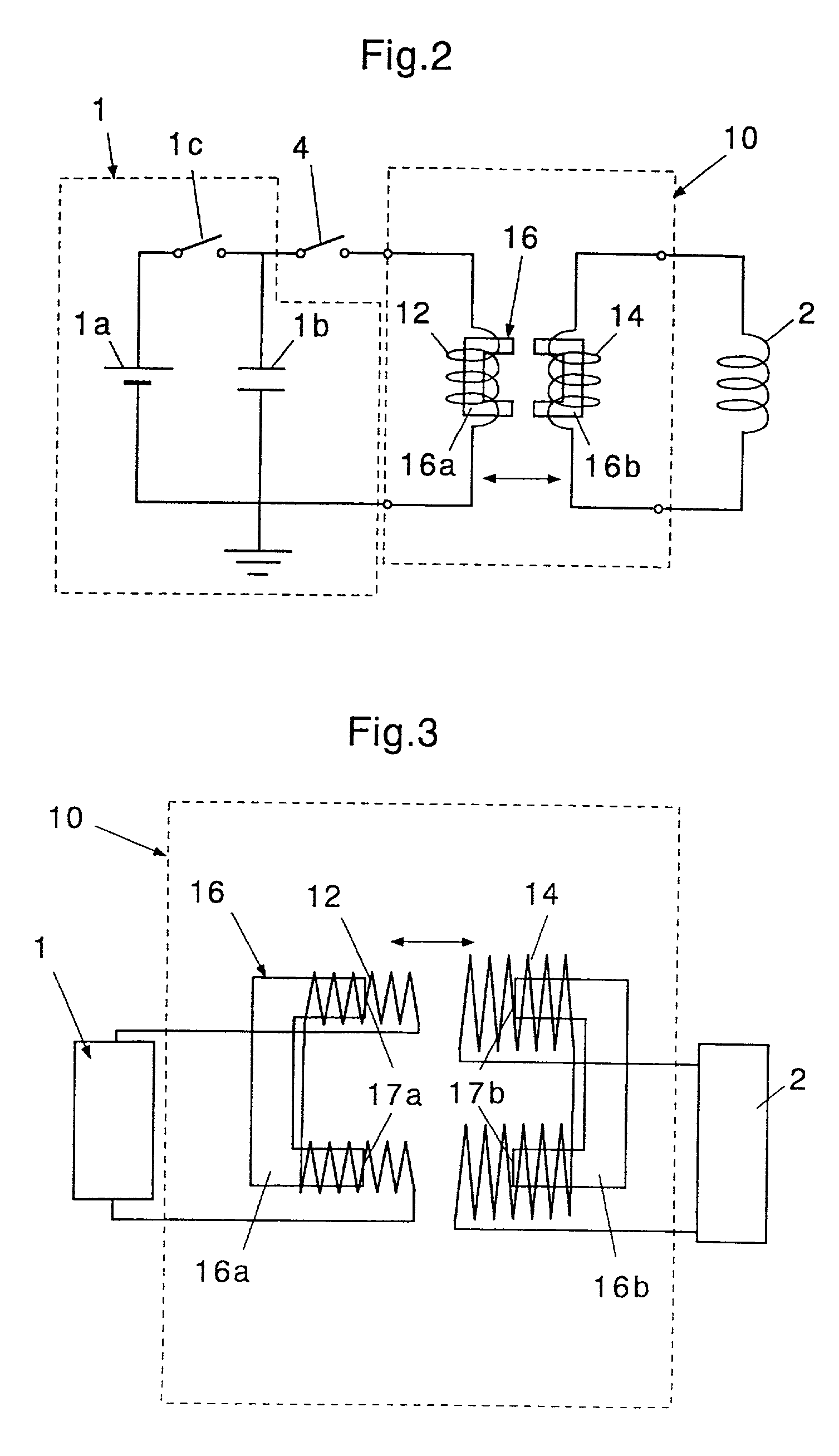

Electromagnetic connecting device for high voltage and large current

InactiveUS20020171525A1Guaranteed normal transmissionEasy to disconnectTransformersTransformers/inductances detailsElectromagnetic formingHigh pressure

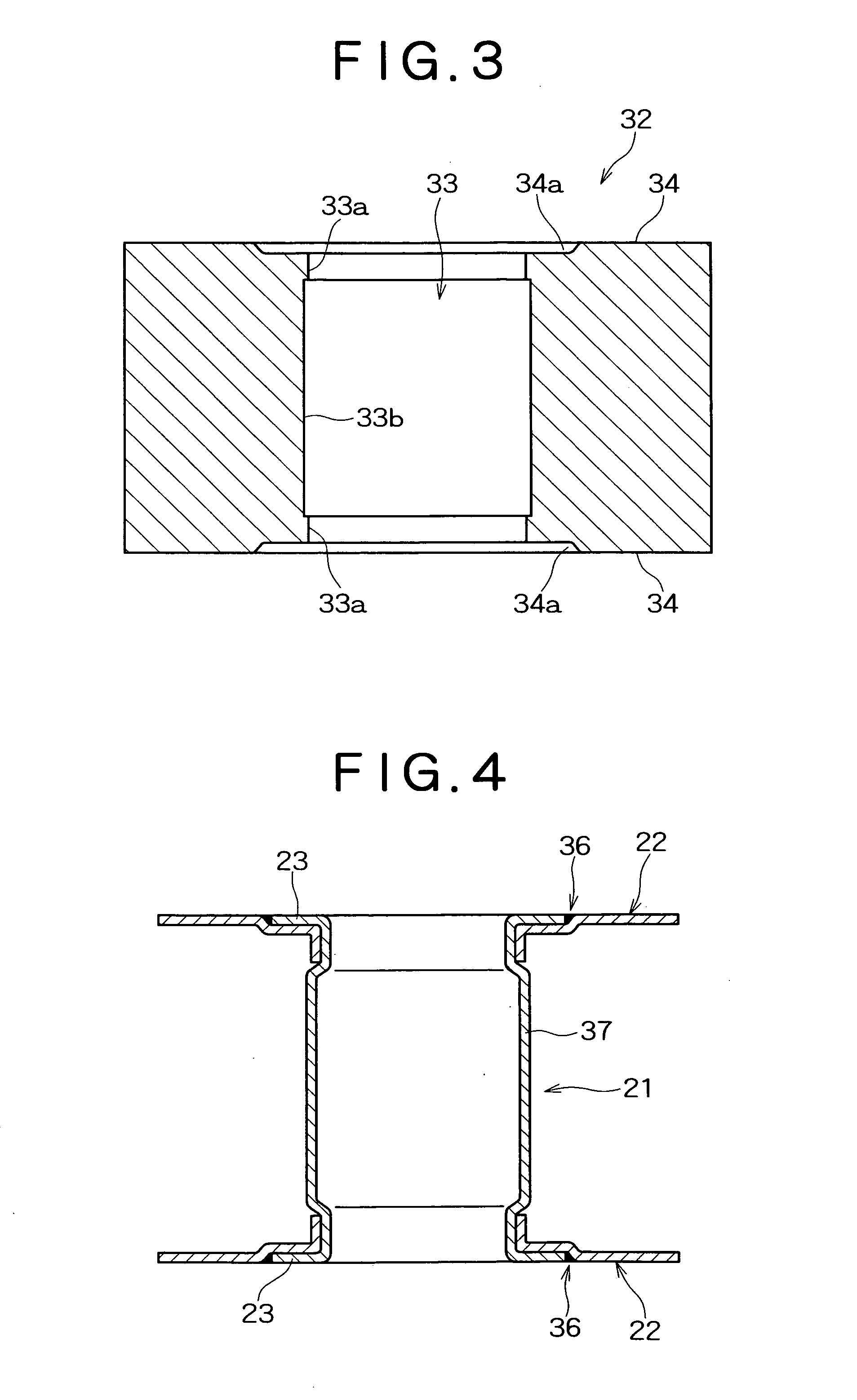

The major components are a primary winding 12 connected to a high-voltage, a large-current power supply 1, a secondary winding 14 connected to an electromagnetic forming coil 2, and a magnetic core 16 for guiding the magnetic flux produced by the primary winding. The magnetic core 16 is composed of a primary core 16a on which the primary winding is wound and a secondary core 16b on which the secondary winding is wound. The primary core and the secondary core are magnetically connected together by putting them in contact or in close proximity. And the primary core and the secondary core are separeated each other when the connector is disconnected. Thus, current pulses at a high voltage (for instance, 10 kV) with a large current (for example, 100 kA or more) and a narrow pulse width (e.g., 30 musec or less) can be efficiently transmitted, and the connector can be easily attached and removed.

Owner:IHI CORP

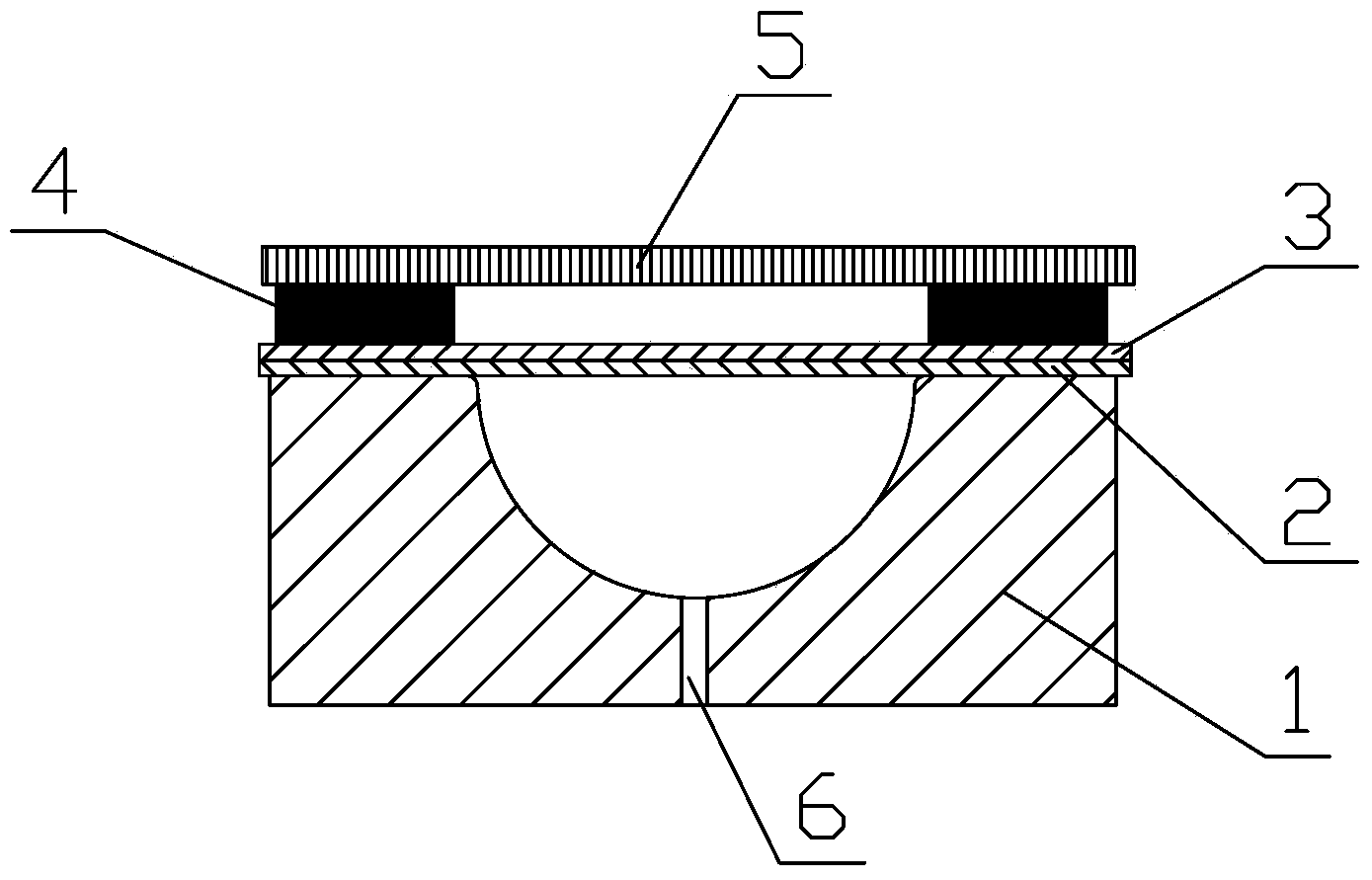

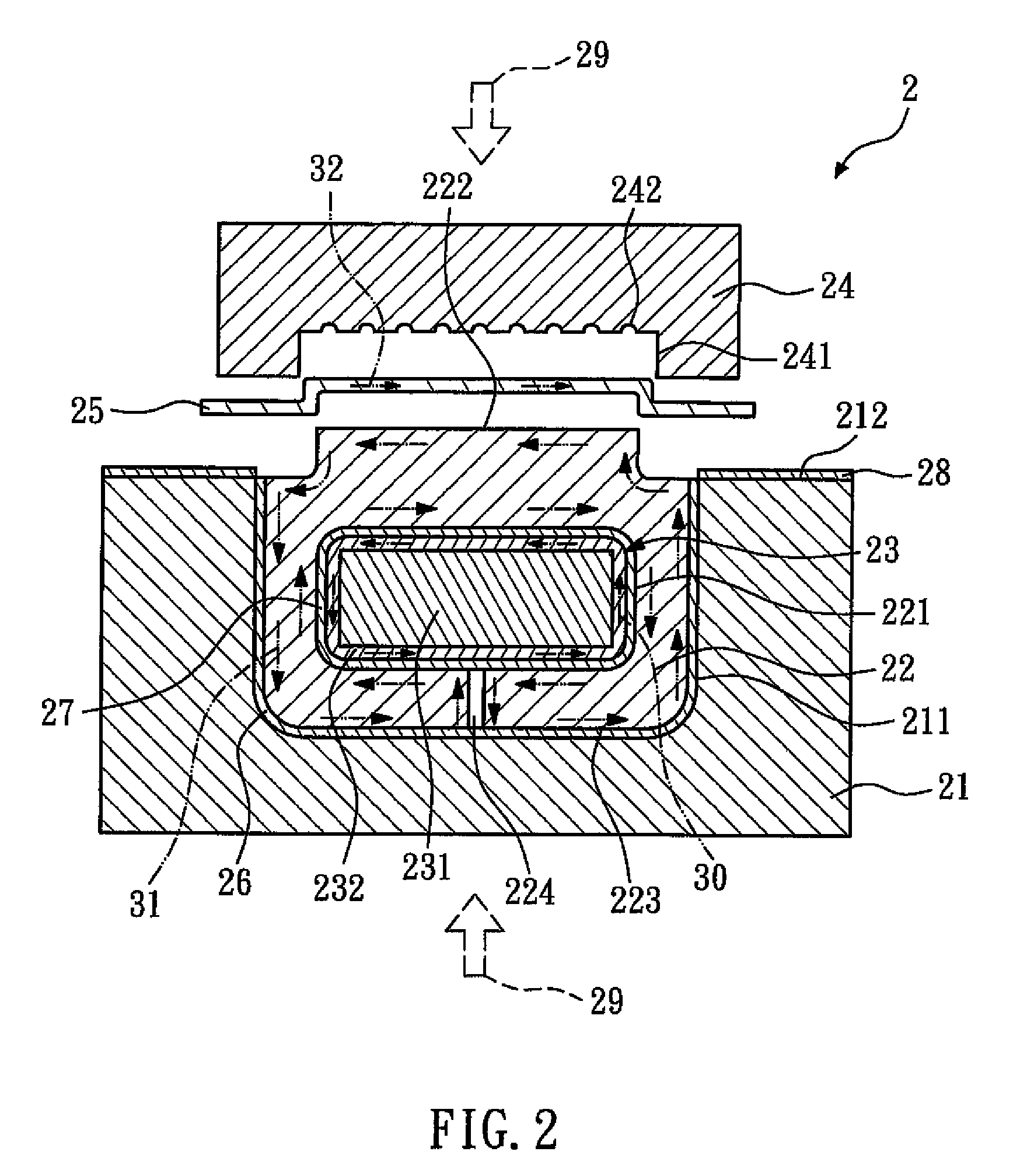

Electromagnetic forming device of sheet metal

The invention relates to an electromagnetic forming device of a metal sheet. The electromagnetic forming device comprises a permanent seat, a magnetic collection block, an electromagnetic generation device and a mould. The permanent seat is provided with an open groove; the magnetic collection block is positioned inside the open groove of the permanent seat; and the inside of the magnetic collection block is provided with a receiving space which is communicated with the surface of the magnetic collection block through clearance. The electromagnetic generation device is used for generating a magnetic field; and the electromagnetic generation device is positioned inside the receiving space of the magnetic collection block and is not contacted with the magnetic collection block. Clearance is arranged between the mould and the magnetic collection block; and the clearance is used for positioning the metal sheet. As the magnetic collection block is a block body, eddy current in the magnetic collection block is evenly distributed to cause the formed magnetic field in even distribution, thereby generating even forming power on the metal sheet.

Owner:METAL INDS RES & DEV CENT

Axial member with flange, connection member and production methods thereof

ActiveUS20060284432A1Reduce weightImprove energy absorptionSuperstructure connectionsMonocoque constructionsEngineeringAlloy

A target tubular member with flange, such as a bumper stay, has a flange having an outer diameter larger than the diameter of an axial section and is formed by electromagnetic forming without excessive expansion. The tubular member with flange includes an axial member made of a tubular aluminum alloy extrudate and a flange member joined to an end of the axial member. The axial member has an end flange being integrated at its end and having an area smaller than that of the flange member. The flange member has a hole, and a cylindrical hole flange at the edge of the hole. The axial member fits in the hole of the flange member, the end flange is in intimate contact with the flange member, and the outer periphery of a small-diameter portion of the axial member is in intimate contact with the inner periphery of the hole flange. The hole flange is held between the end flange and a protrusion. The tubular member with flange may be produced by inserting an untreated pipe into the hole of the flange member and expanding the untreated pipe by electromagnetic forming.

Owner:KOBE STEEL LTD

Driver plate for electromagnetic forming of sheet metal

ActiveUS20090090162A1Repeat usageRelieve pressureShaping safety devicesMetal working apparatusMetal formingEngineering

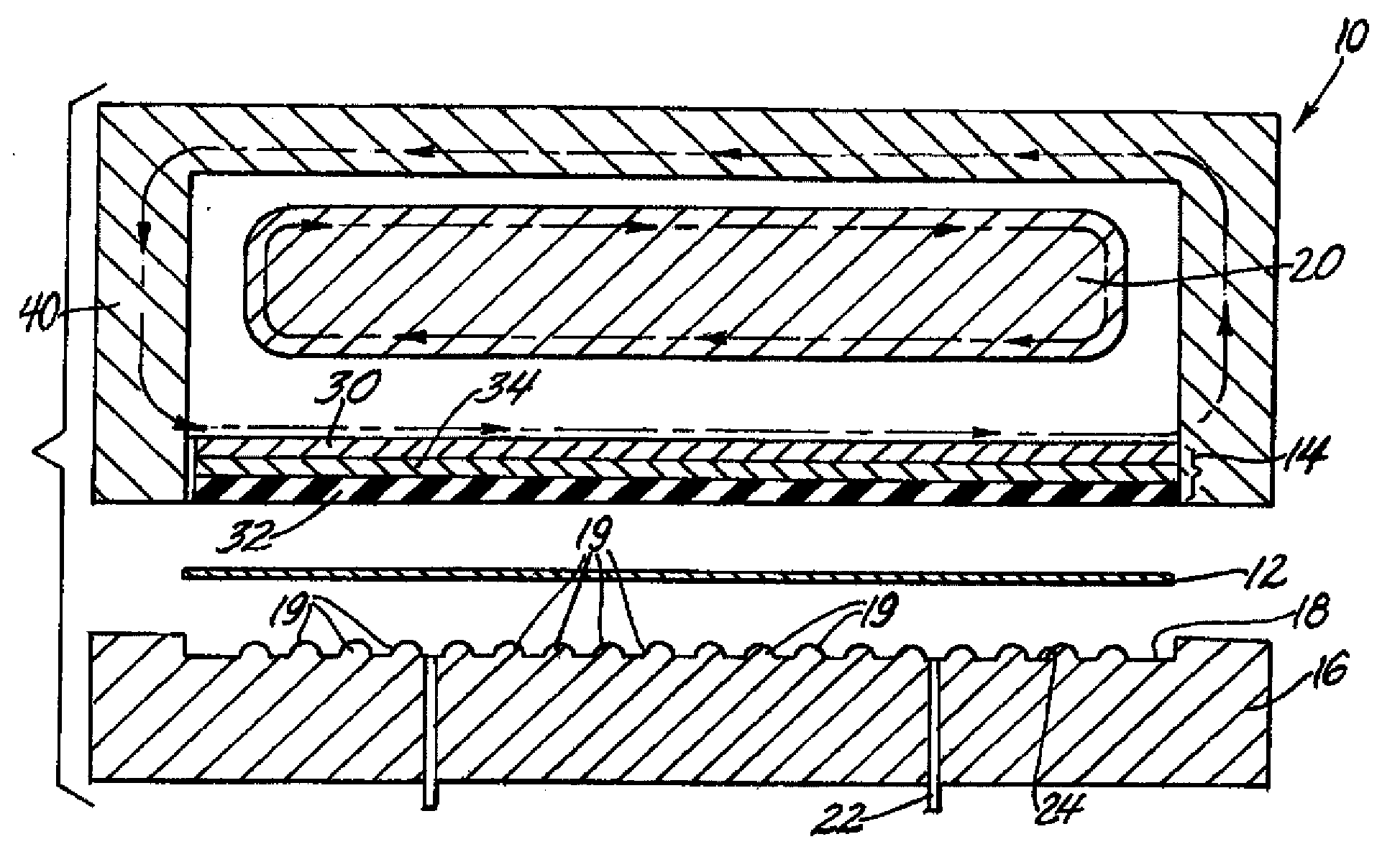

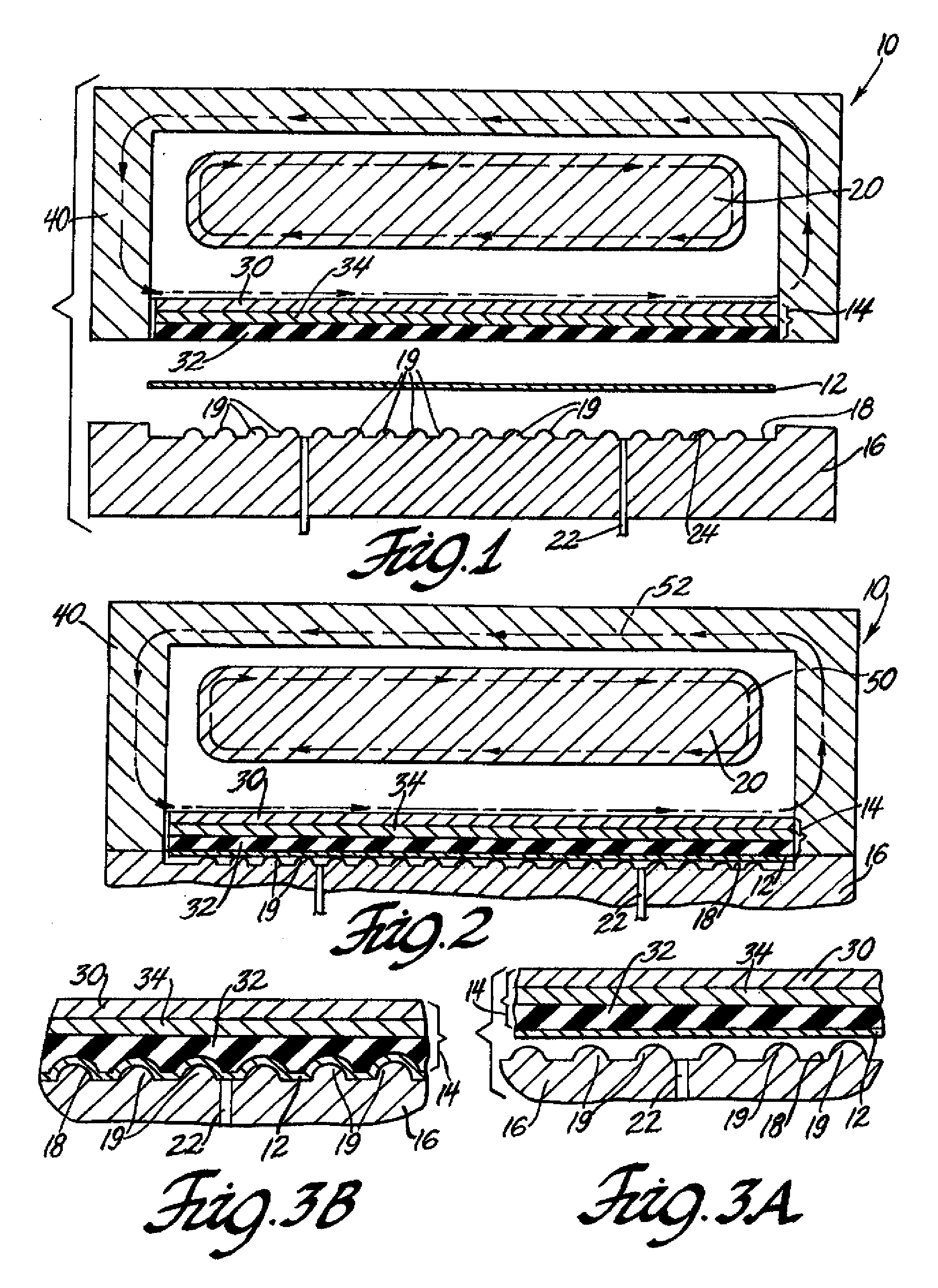

A multi-layer driver plate is disclosed for use in electromagnetic sheet metal forming operations. In one embodiment, the driver plate comprises a first layer characterized by low electrical resistivity and thickness for inducement and application of a suitable electromagnetic forming force, a second layer comprising an elastomeric material for compressing a sheet metal workpiece against a die surface and then regaining its original pre-forming structure, and a third layer interposed between the first layer and the second layer to protect the EMF force providing layer and to provide overall strength and durability to the EMF driver plate.

Owner:THE OHIO STATE UNIV RES FOUND +1

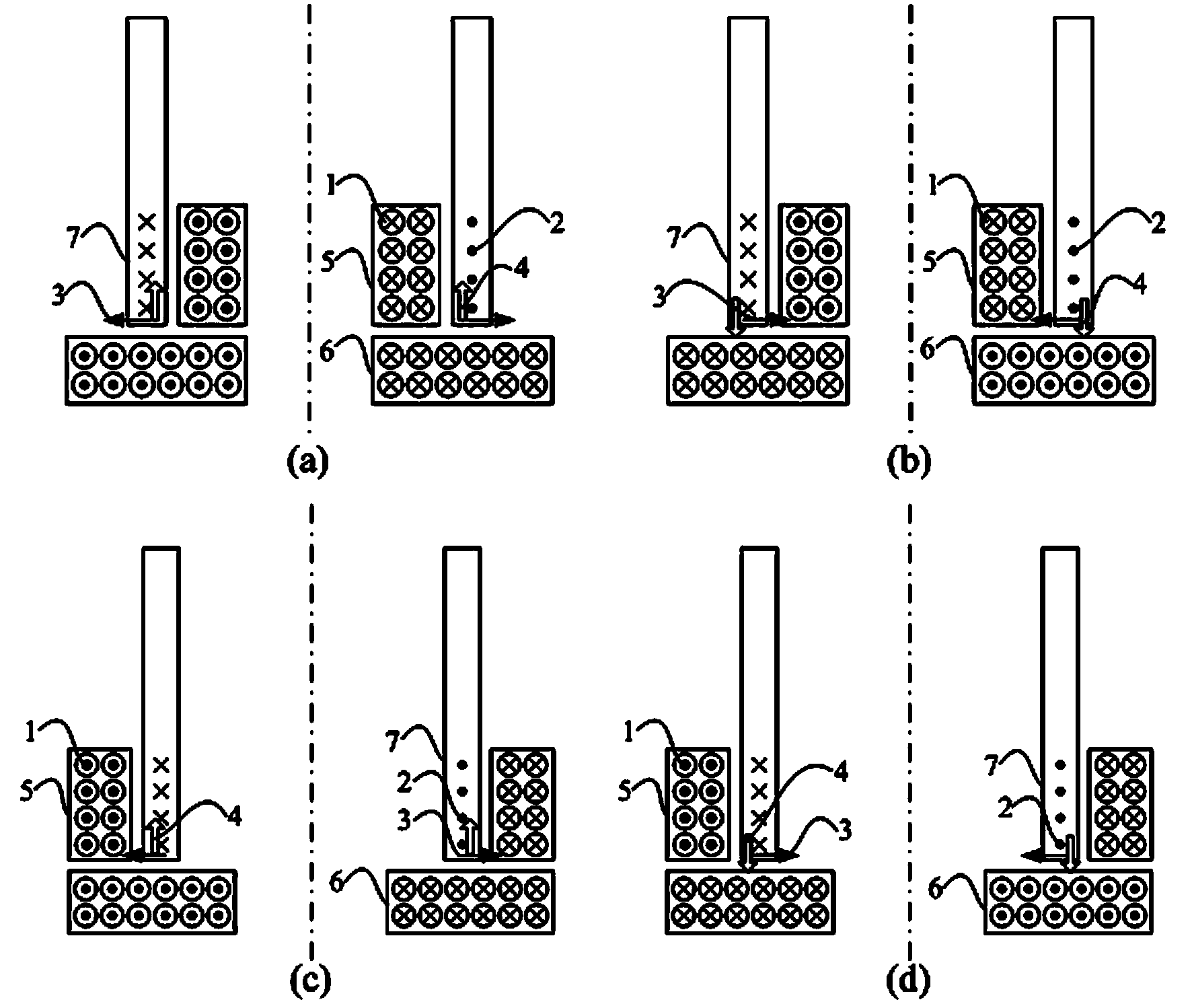

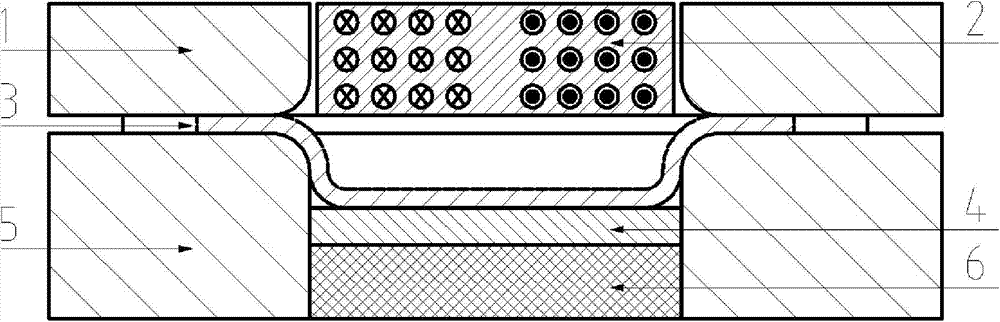

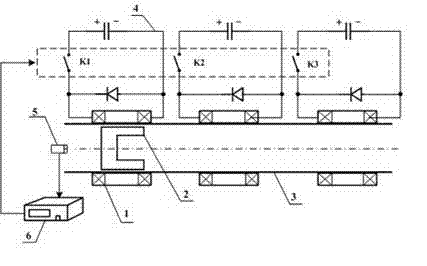

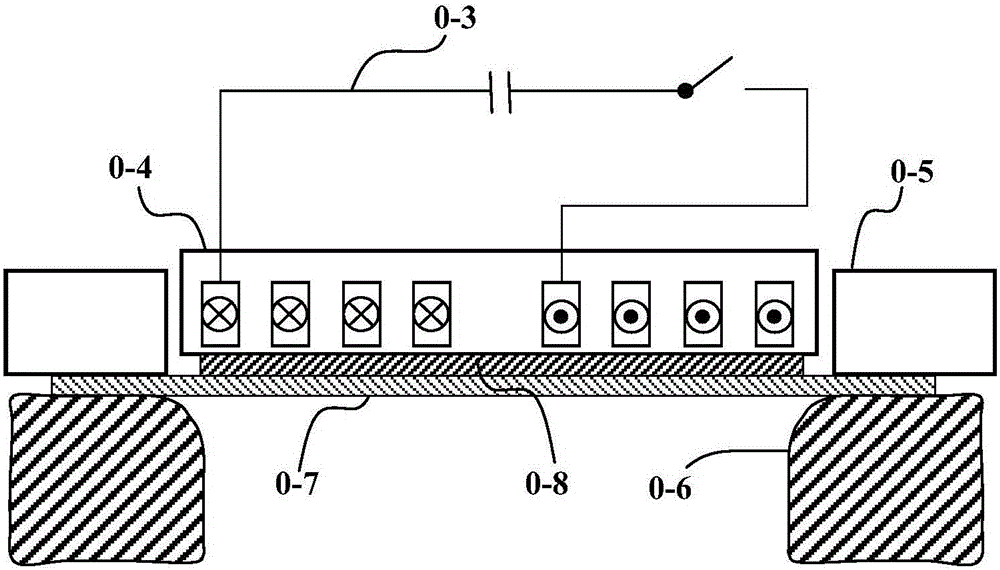

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418ASolve the single load of electromagnetic forming factorSolve the problem caused byAxial compressionPipe fitting

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

Method of forming metal

InactiveUS8015849B2Electromagnets without armaturesMetal-working apparatusEngineeringElectromagnetic forming

Electromagnetic forming can lead to better formability along with additional benefits. The spatial distribution of forming pressure in electromagnetic forming can be controlled by the configuration of the actuator. A type of actuator is discussed which gives a uniform pressure distribution in forming. It also provides a mechanically robust design and has a high efficiency for flat sheet forming.

Owner:AMERICAN TRIM

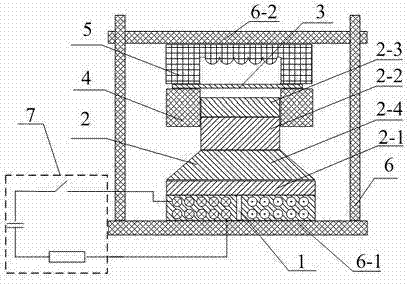

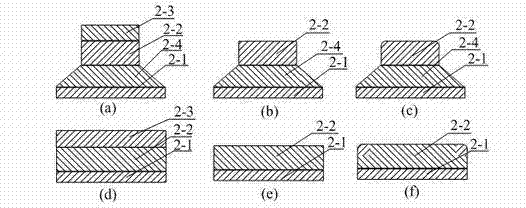

Electromagnetic force driven molded sheet forming method and equipment

InactiveCN102259132AImprove deformationUniform deformationShaping toolsHigh rateElectromagnetic interference

The invention discloses a method and equipment for forming a molded sheet material driven by electromagnetic force, which relates to the molding of a block plate-like ultra-fine grain material driven by electromagnetic force. Using electromagnetic force to drive the steel mold to achieve high-speed and severe deformation of the plate, thereby solving the problem that the effect of grain refinement is not obvious due to the limitation of material types and pressing passes when forming metal sheets based on conventional plastic deformation methods such as stamping forming. Its technology The feature is that the processed slab is put into the bending die for bending; the bent slab is leveled with the flattening die. Then, the slab is rotated 180° in the horizontal direction, so that the part of the sample that has not been sheared during the first two molding deformation processes enters the position of shear deformation, and then the bending is performed; Blanks are leveled. After 4 times of molding deformation, ultra-fine-grained slabs can be obtained without changing the dimensions of the slab. The invention effectively integrates the advantages of electromagnetic forming and molding deformation, and can prepare large-volume ultra-fine-grained plates of various metal materials.

Owner:HARBIN INST OF TECH

Apparatus for electromagnetic forming, joining and welding

InactiveUS6875964B2Decrease in electromagnetic forceReadily apparentHigh frequency current welding apparatusInduction heating apparatusLocking mechanismElectromagnetic forming

There is disclosed herein an apparatus for electromagnetic forming, joining or welding a workpiece, the apparatus including at least two multi-turn solenoid coils wound in a manner that cooperatively encircles the workpiece to be formed. The apparatus also includes an electrically insulative shell encasing each coil and an electromagnetic current source electrically connected to the coils that generates an electromagnetic field. A hinge mechanism connects the insulative shells and a locking mechanism secures the shells and coils around the workpiece during electromagnetic field generation. A conductive rod joins the solenoid coils and permits series current flow between the coils. The apparatus further includes a shaper that encircles the workpiece and which restricts movement of the workpiece during electromagnetic forming. The shaper concentrates the generated electromagnetic field on the workpiece.

Owner:FORD MOTOR CO

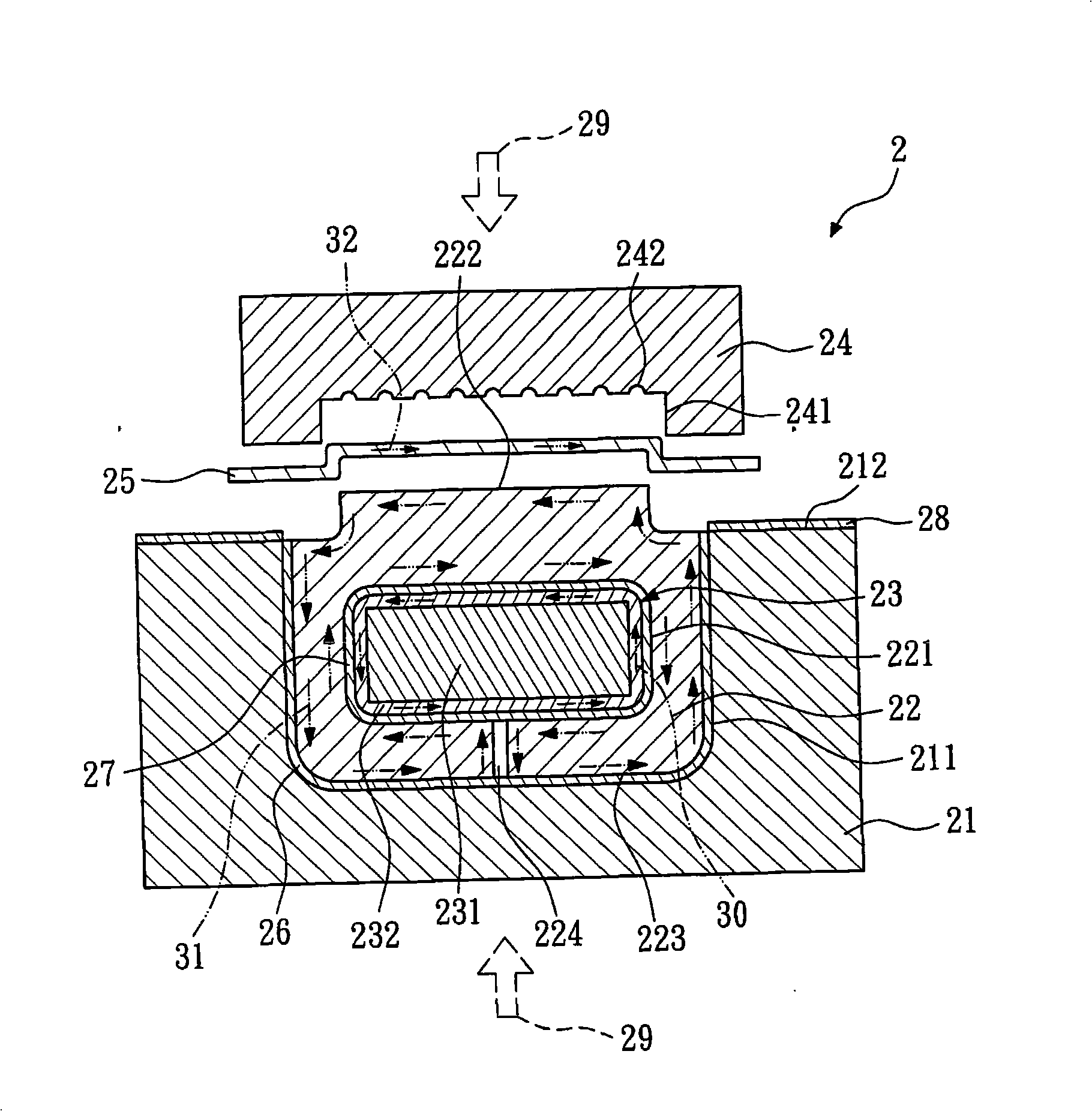

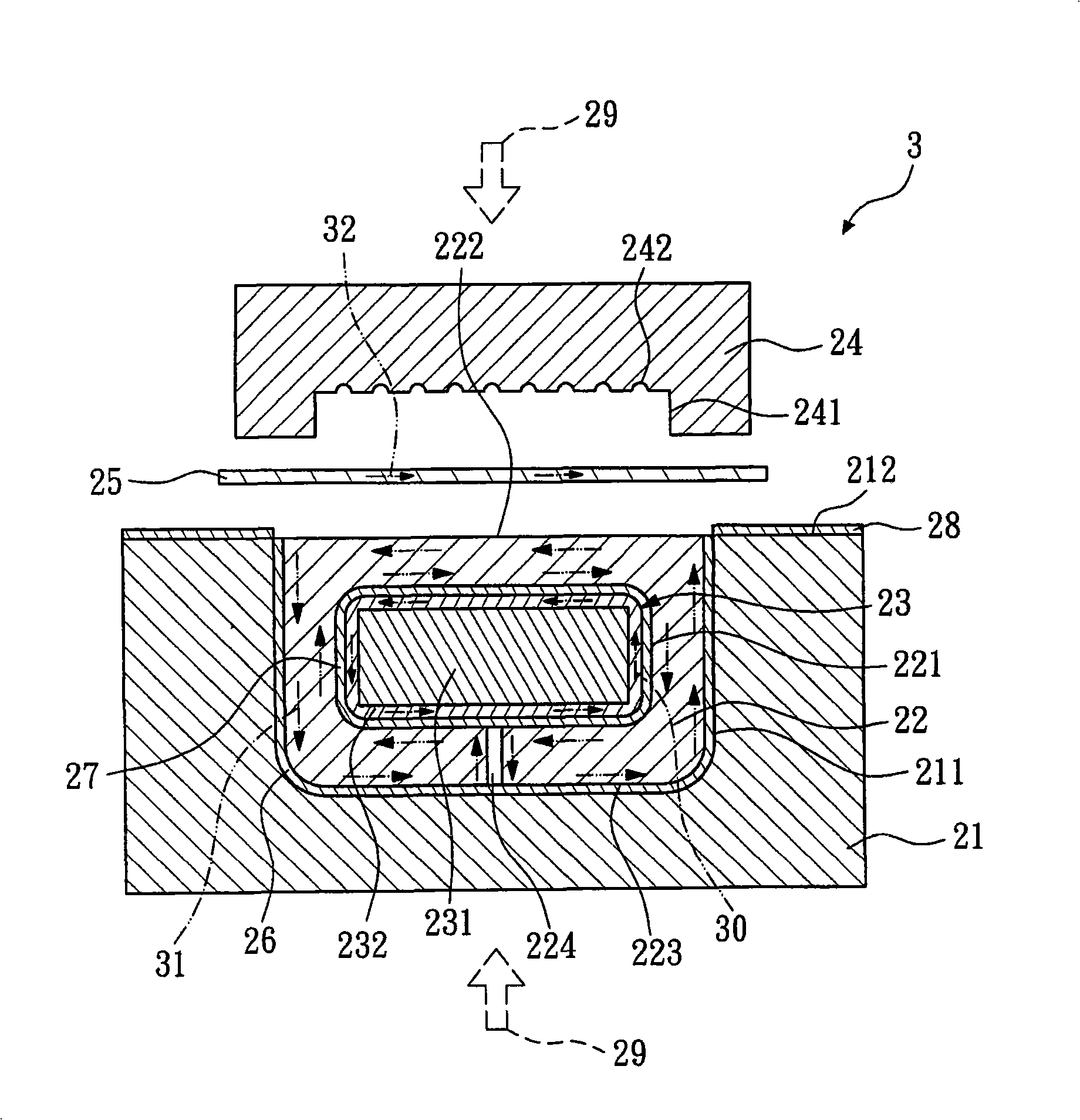

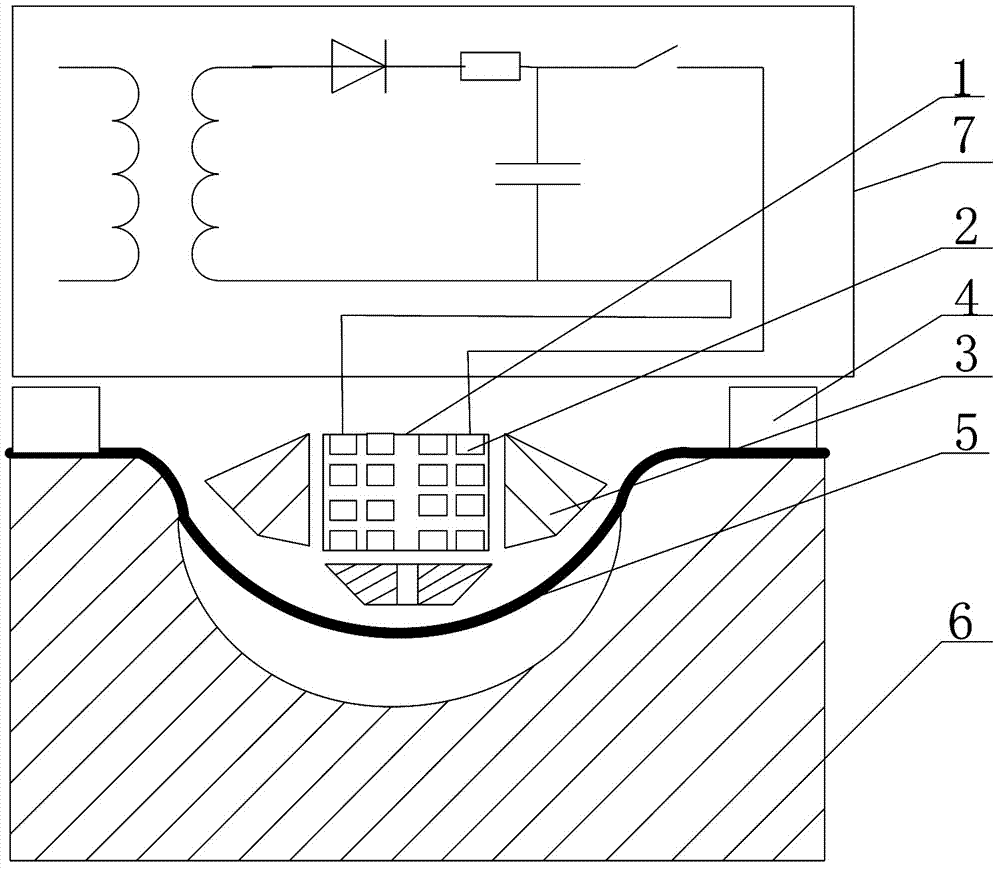

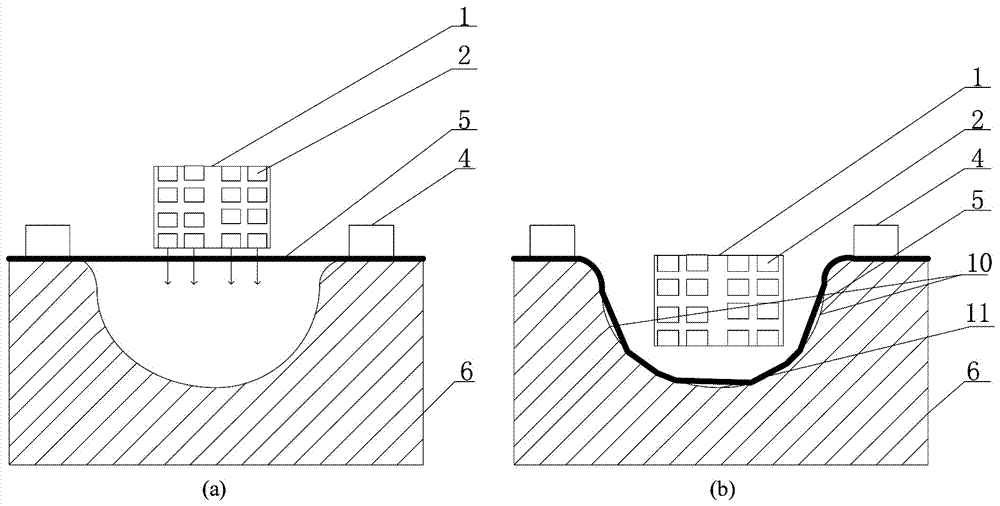

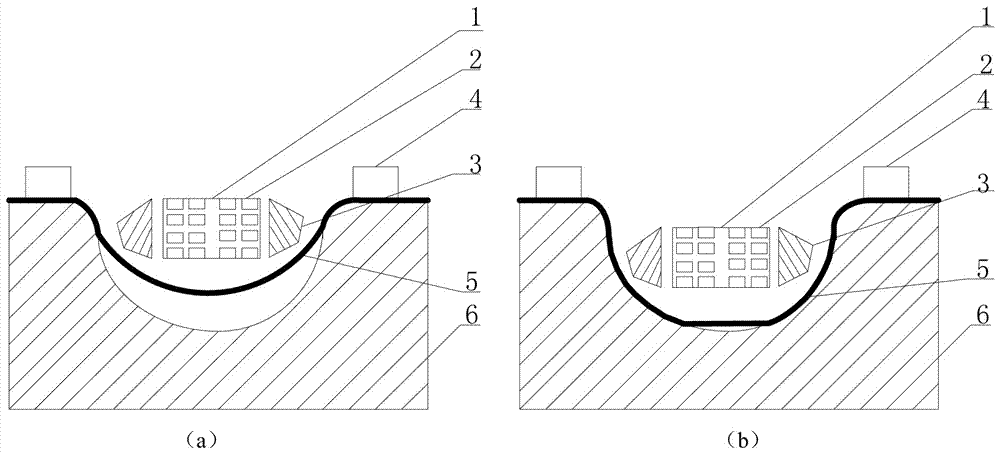

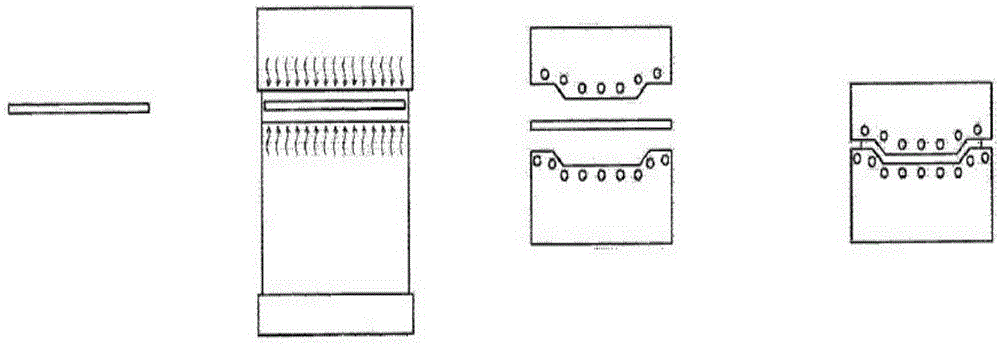

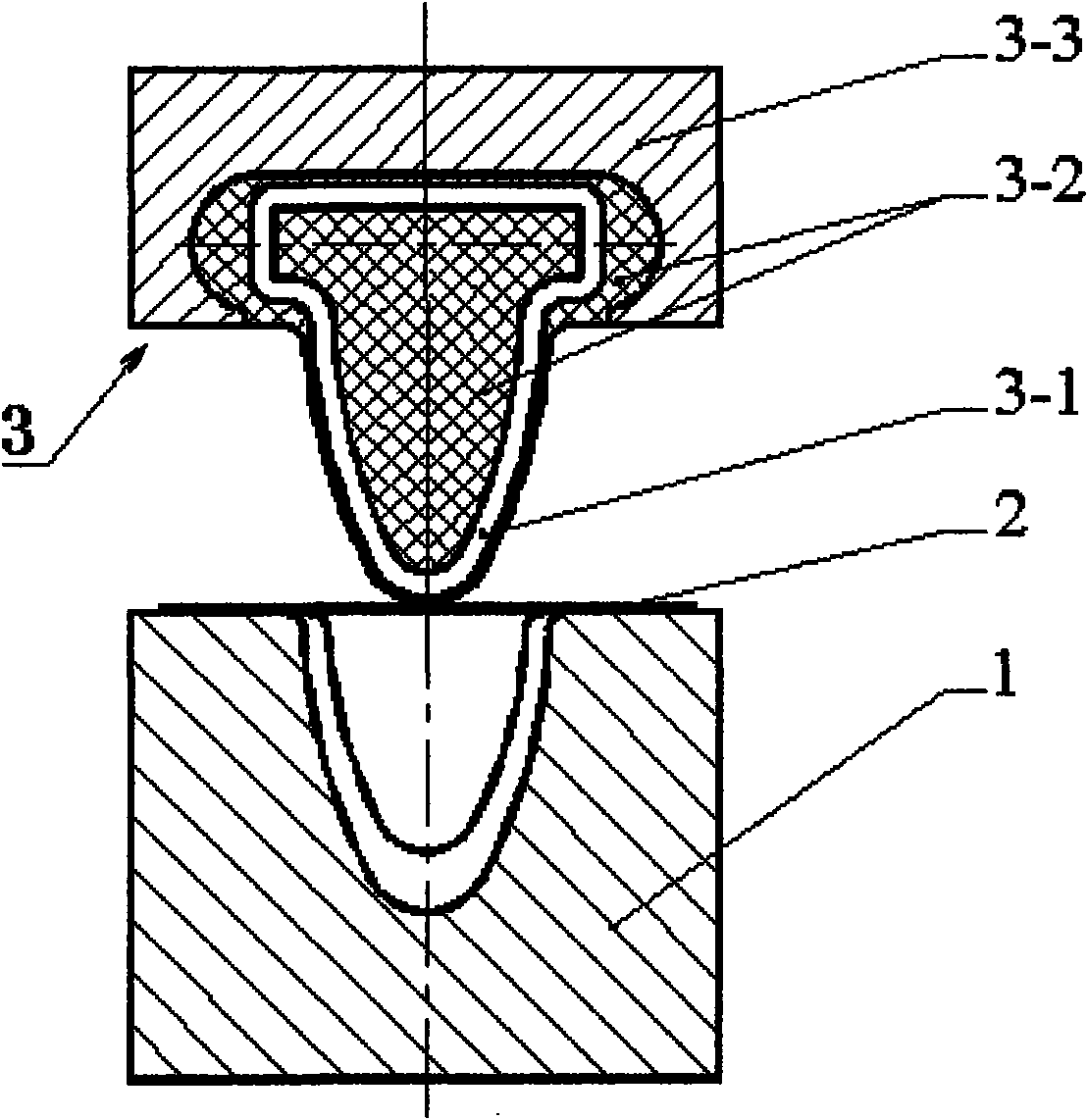

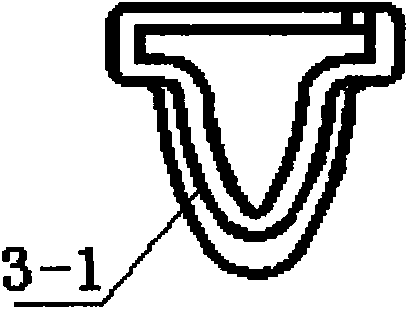

Electromagnetic forming method for deeply punched member

The invention provides an electromagnetic forming method for a deeply punched member. The method comprises the first step of placing a sheet to be formed in a female die, the second step of placing a coil on the sheet to be formed, the third step of allowing the sheet to be formed to be just in contact with a stop block of the female die, the fourth step of driving the coil to descend to the position where the coil is just in contact with the sheet to be formed, the fifth step of performing charging and discharging so as to generate pulse current in the coil to make the sheet to be formed be deformed at a high speed, the sixth step of performing heat treatment of annealing on the sheet to be formed, the seventh step of placing the sheet to be formed after the heat treatment of annealing back onto the female die and pressing the sheet to be formed tight through a drawing ring, and the eighth step of repeating from the second step to the seventh step until electromagnetic forming with a high depth-diameter ratio is completed. Deep drawing of the sheet to be formed (such as an aluminum alloy sheet) is achieved through the electromagnetic forming method of one-time discharging plus one-time annealing, and electromagnetic forming with the high depth-diameter (forming depth to the diameter of a final part) ratio larger than two to one is achieved; compared with common drawing at constant temperature, the extreme drawing ratio can be enhanced obviously.

Owner:HUAZHONG UNIV OF SCI & TECH

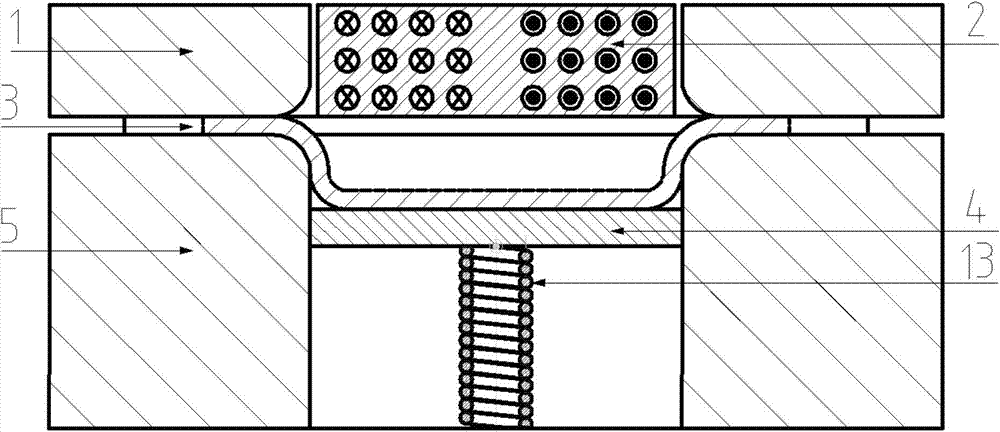

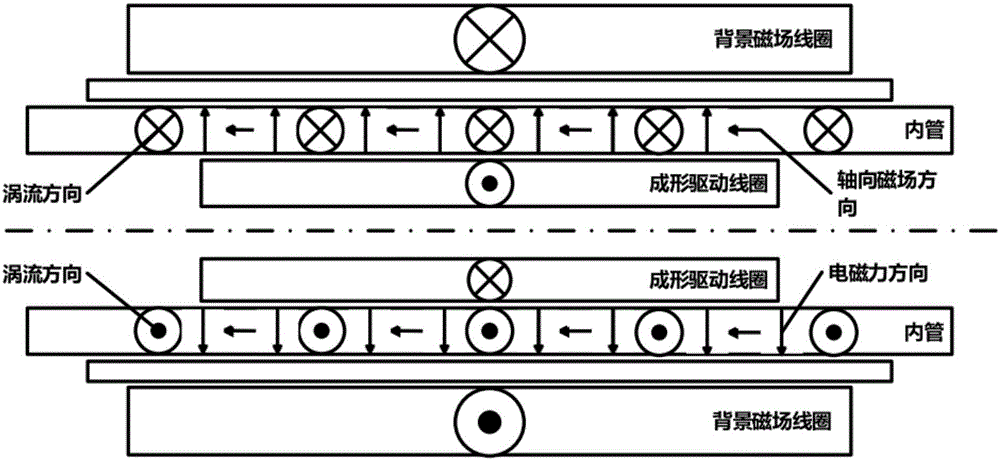

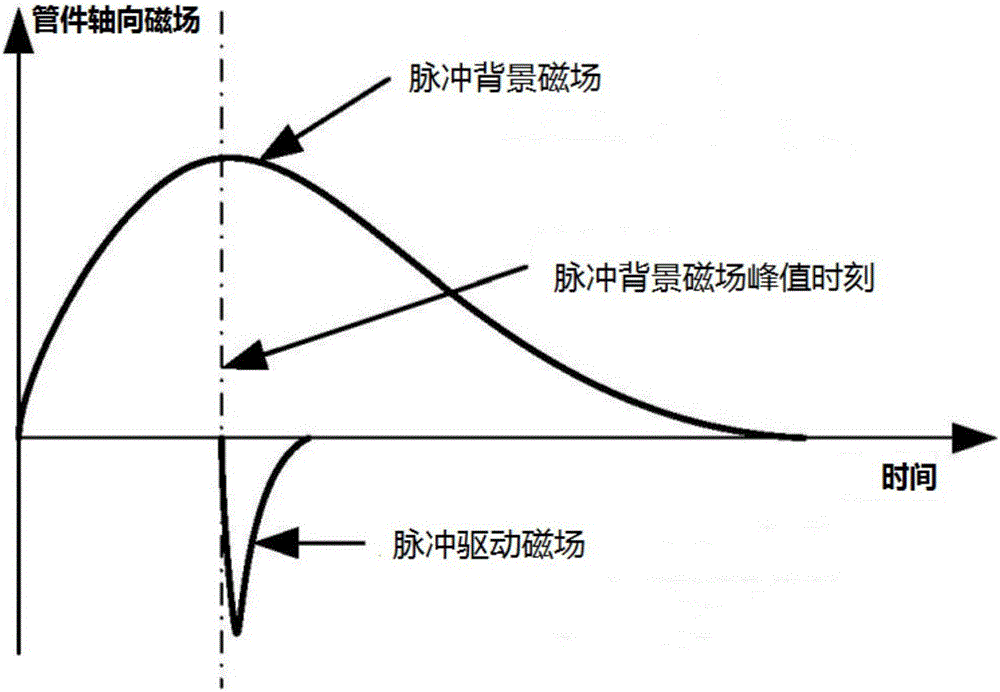

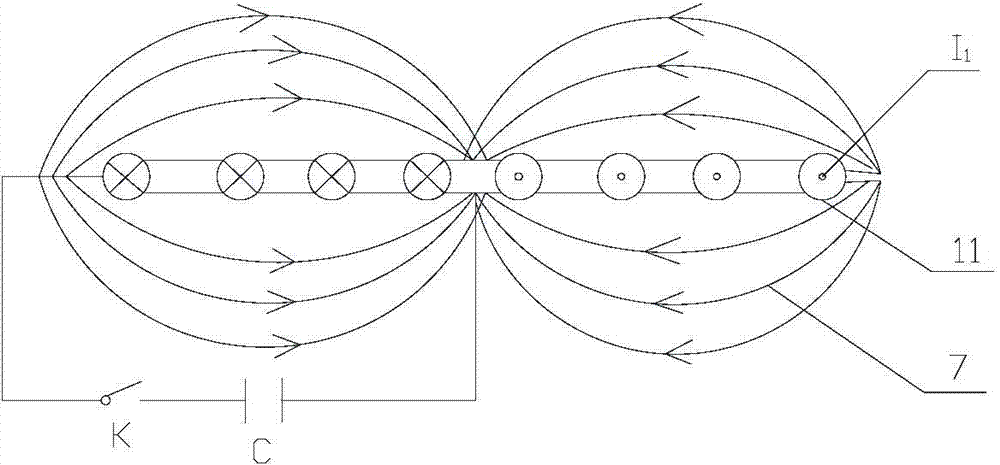

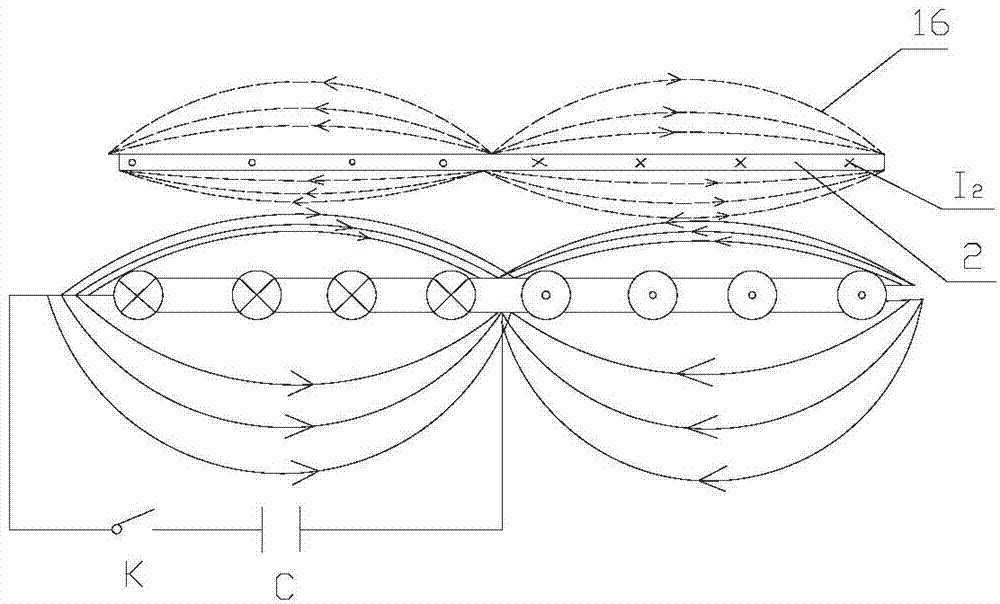

Electromagnetic forming device and method of metal pipe

ActiveCN106694681AHigh strengthSmall electromagnetic forceElectromagnetic formingUltimate tensile strength

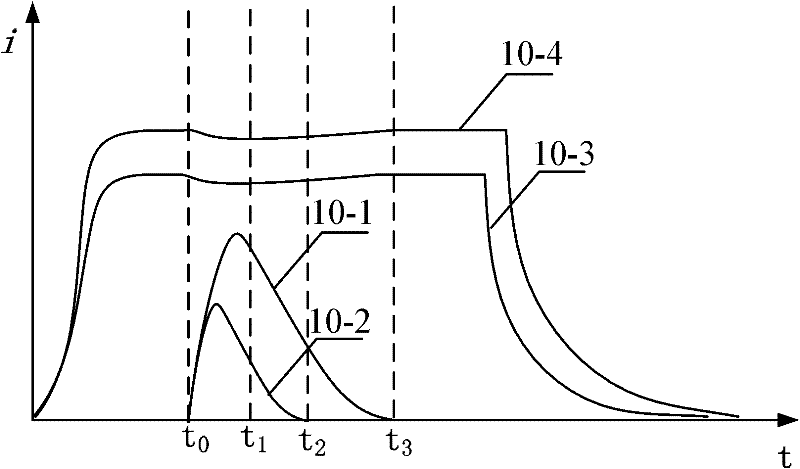

The invention discloses an electromagnetic forming device and method of a metal pipe. The device comprises a background magnetic field unit and a metal pipe forming driving coil, wherein the background magnetic field unit is used for generating a pulse background magnetic field on the metal pipe, and a pulse driving magnetic field can generate vortexes on the metal pipe; and the metal pipe forming driving coil is used for generating the pulse driving magnetic field on the metal pipe. Due to the fact that the pulse width of the pulse driving magnetic field is much smaller than that of the pulse background magnetic field, the vortexes generated by the pulse background magnetic field on the metal pipe can be ignored, meanwhile, the influences of the pulse driving magnetic field on a magnetic field on the metal pipe can be ignored, and thus, electromagnetic force is generated on the metal pipe through interaction of the pulse background magnetic field and the vortexes. By independently adjusting the pulse background magnetic field and the pulse driving magnetic field, the electromagnetic force can be improved, the metal pipe high in mechanical strength and low in conductivity can be formed, meanwhile, the design difficulty of the forming driving coil can be lowered, and the service life of the forming driving coil is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Rotary multi-pole moment field electromagnetic propeller

InactiveCN102192680ALarge electromagnetic acceleration forceLarge launch projectile massElectromagnetic launchersSingle motor speed/torque controlLocation detectionPropeller

The invention discloses a rotary multi-pole moment field electromagnetic propeller. The propeller mainly comprises a magnetic field coil, a projectile armature, a power supply circuit, a projectile location detection sensor and a synchronous accurate control chip, wherein the magnetic field coil adopts a multi-pole moment coil assembly, and the hierarchically arranged multi-pole moment coil assembly extends along the moving direction of the projectile armature; a flight duct is arranged between the multi-pole moment coil assembly and the projectile armature; and each coil in the multi-pole moment coil assembly is connected with the power supply circuit so as to acquire discharge pulse current. The rotary multi-pole moment field electromagnetic propeller can generate stronger axial electromagnetic accelerated thrust on the projectile armature, has the advantages of large electromagnetic accelerated force, large transmitted projectile mass, high outlet speed, balanced rotary motion, stable suspension and high efficiency and environmental friendliness, can be widely applied in the fields of locomotive thrust, rocket assist, electromagnetic forming, rotary excavation machinery and the like, and particularly in the technology of vacuum pipeline transporation.

Owner:SOUTHWEST JIAOTONG UNIV

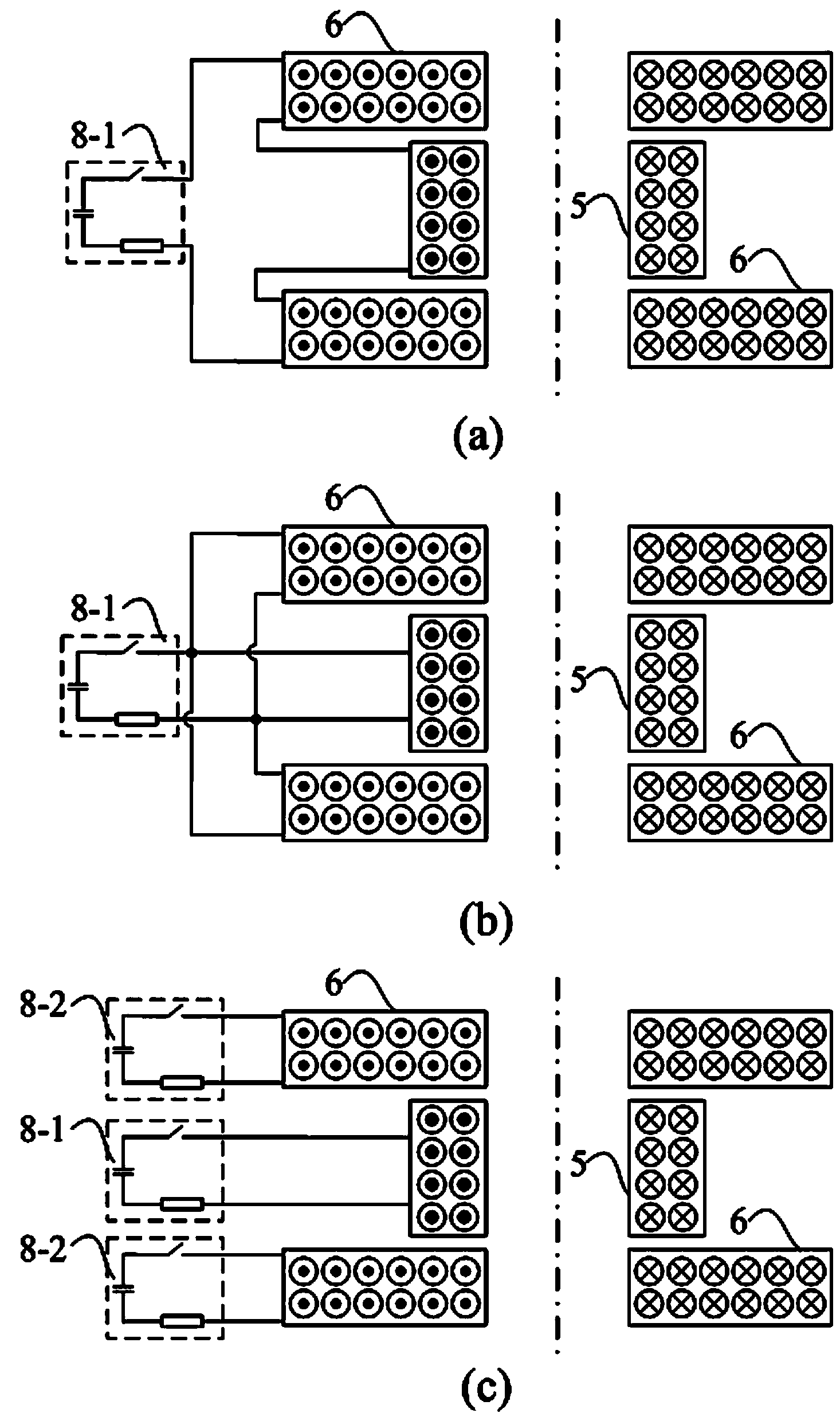

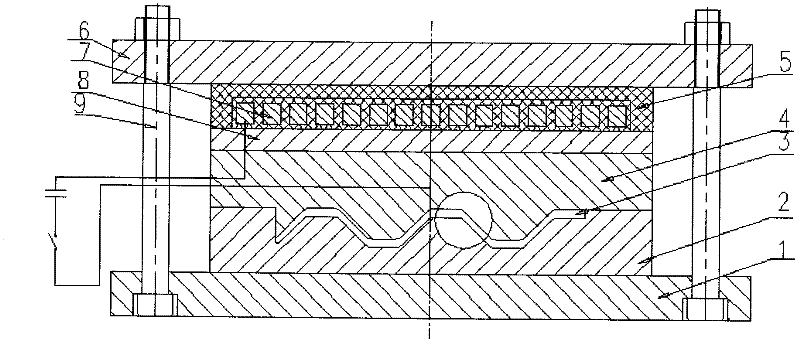

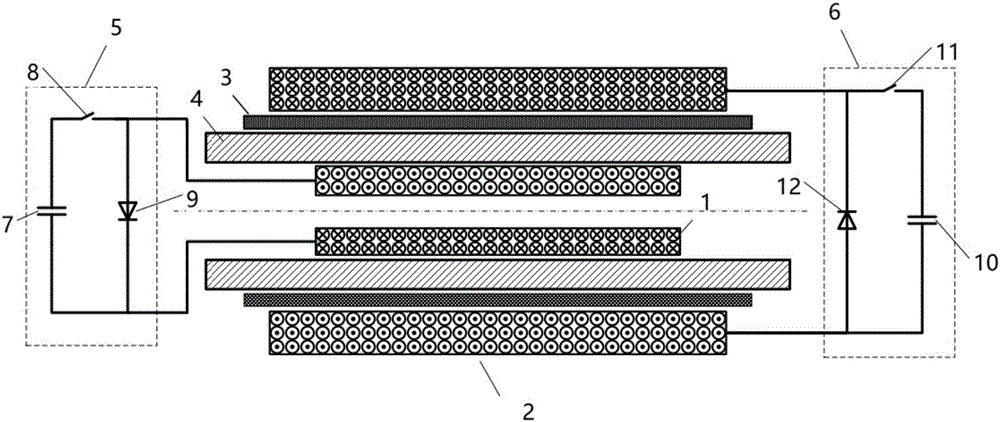

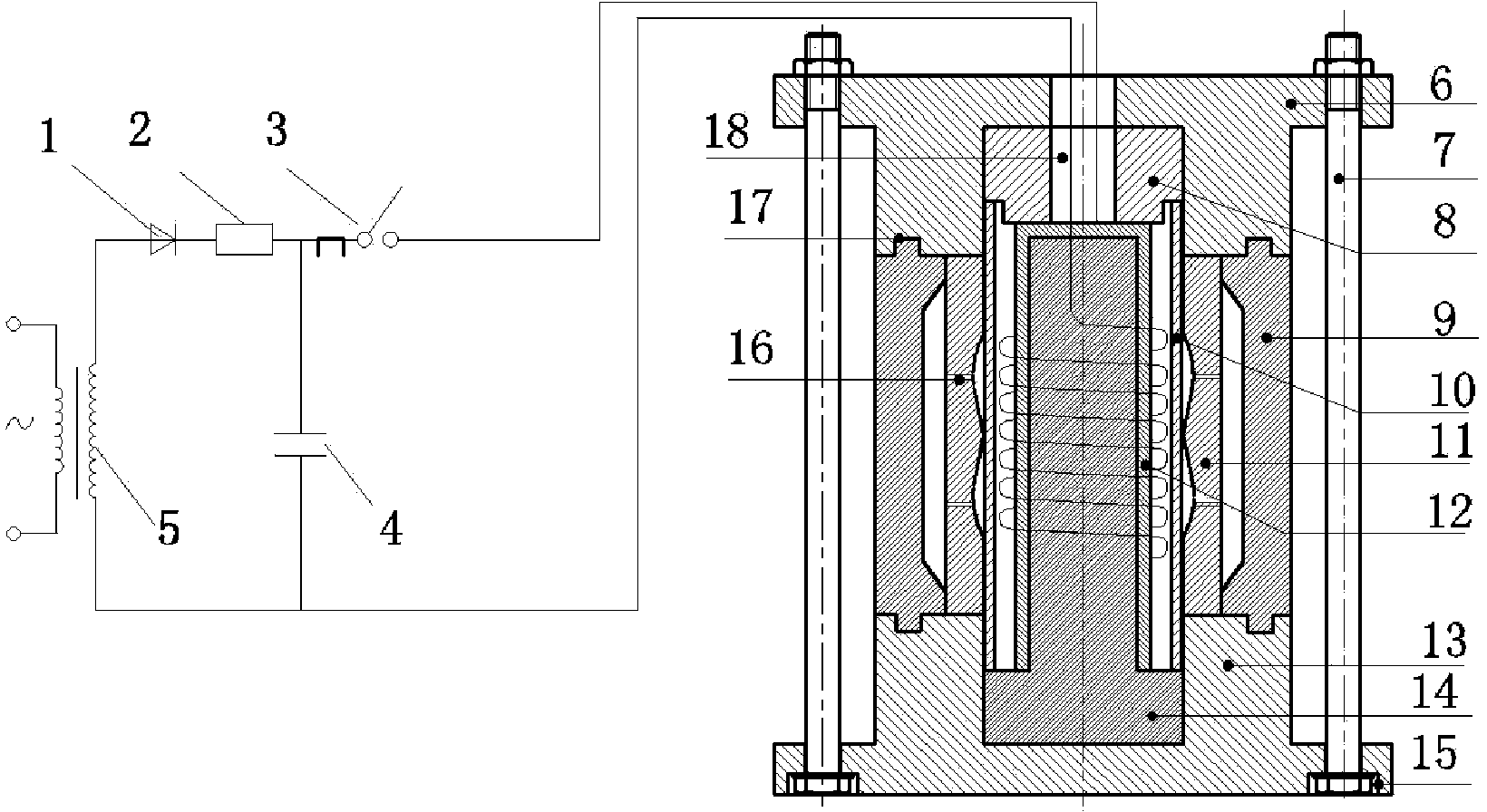

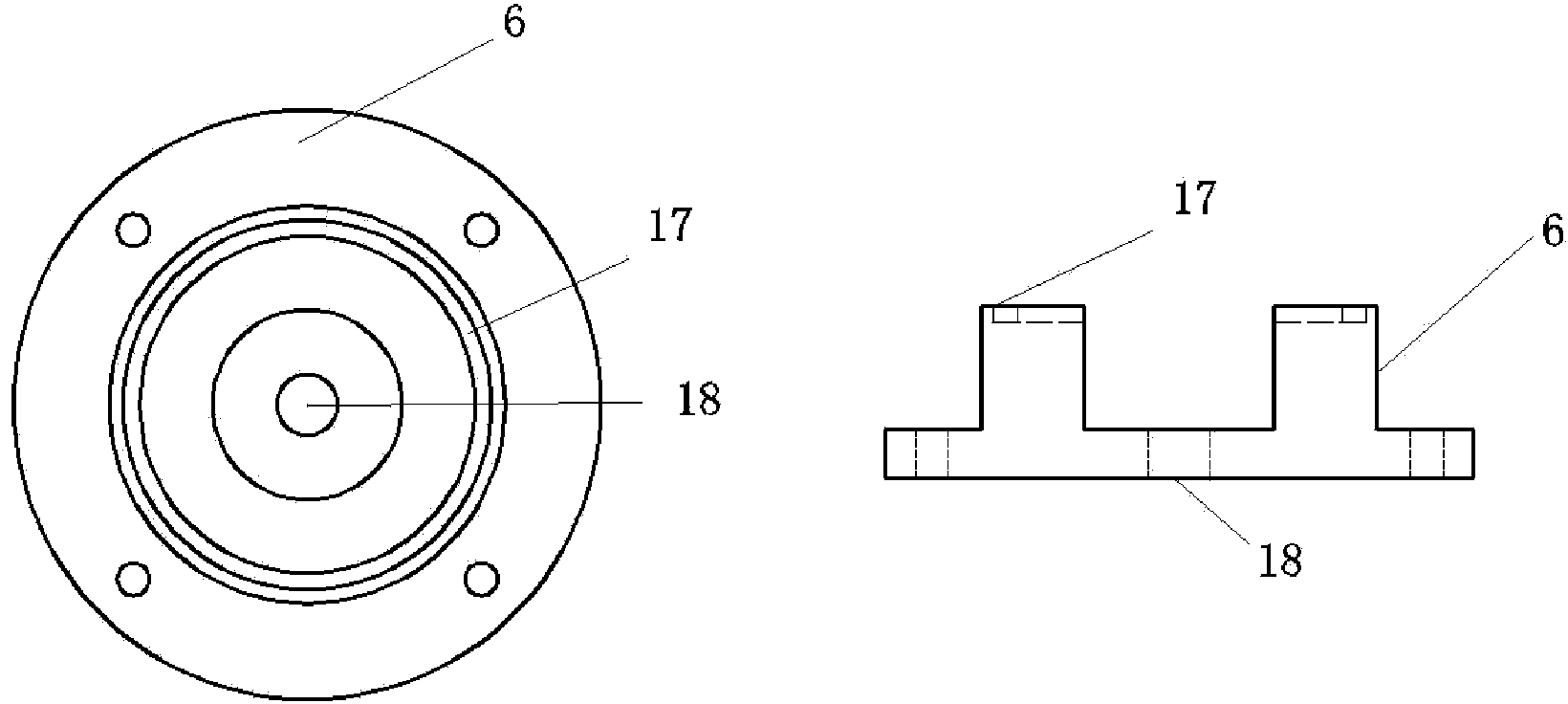

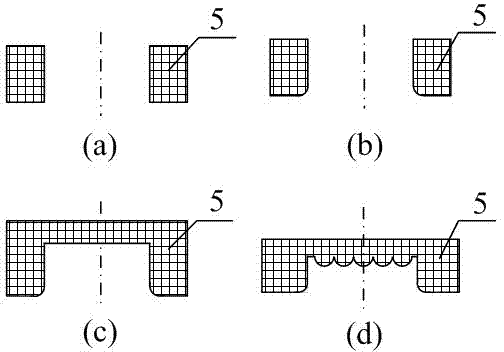

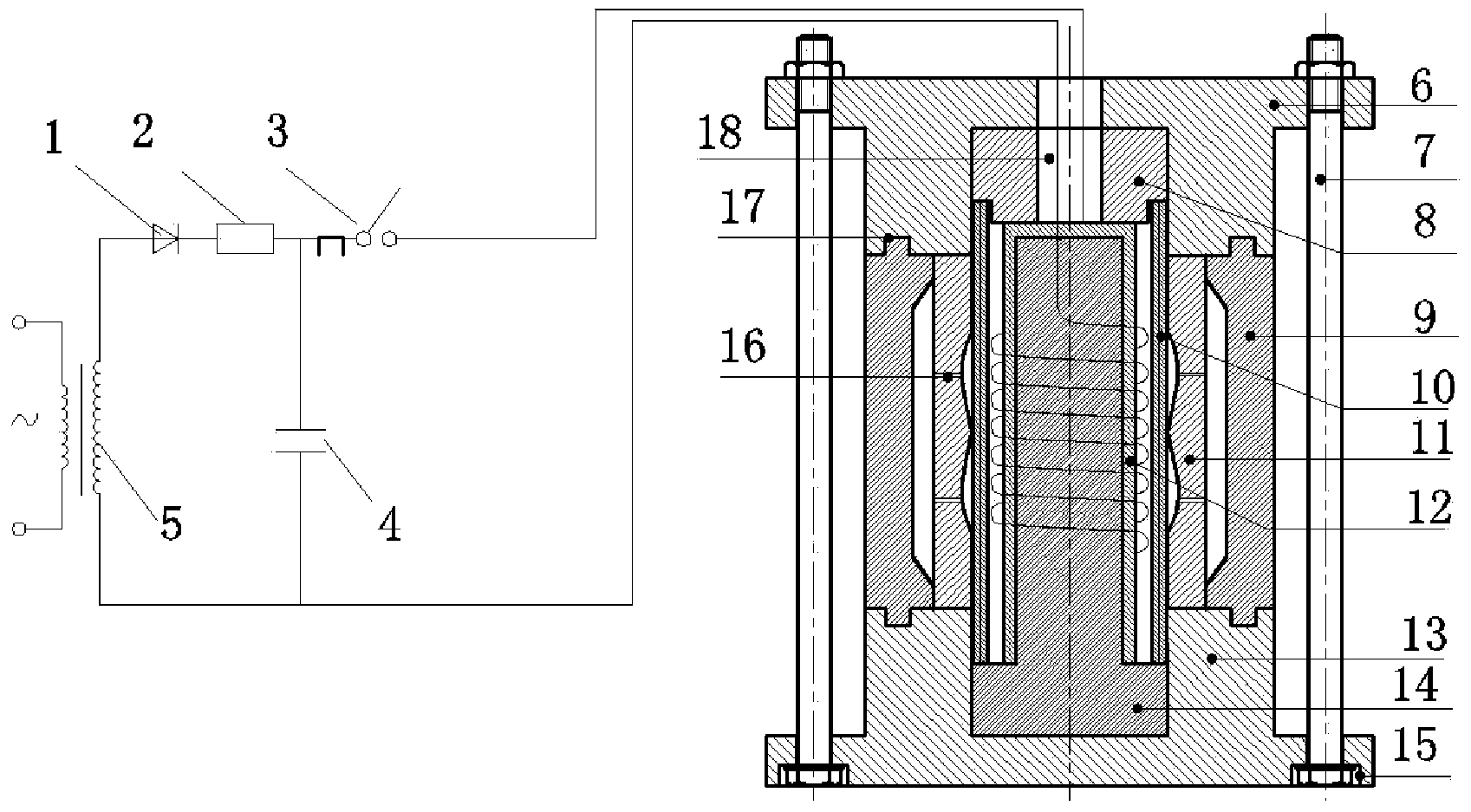

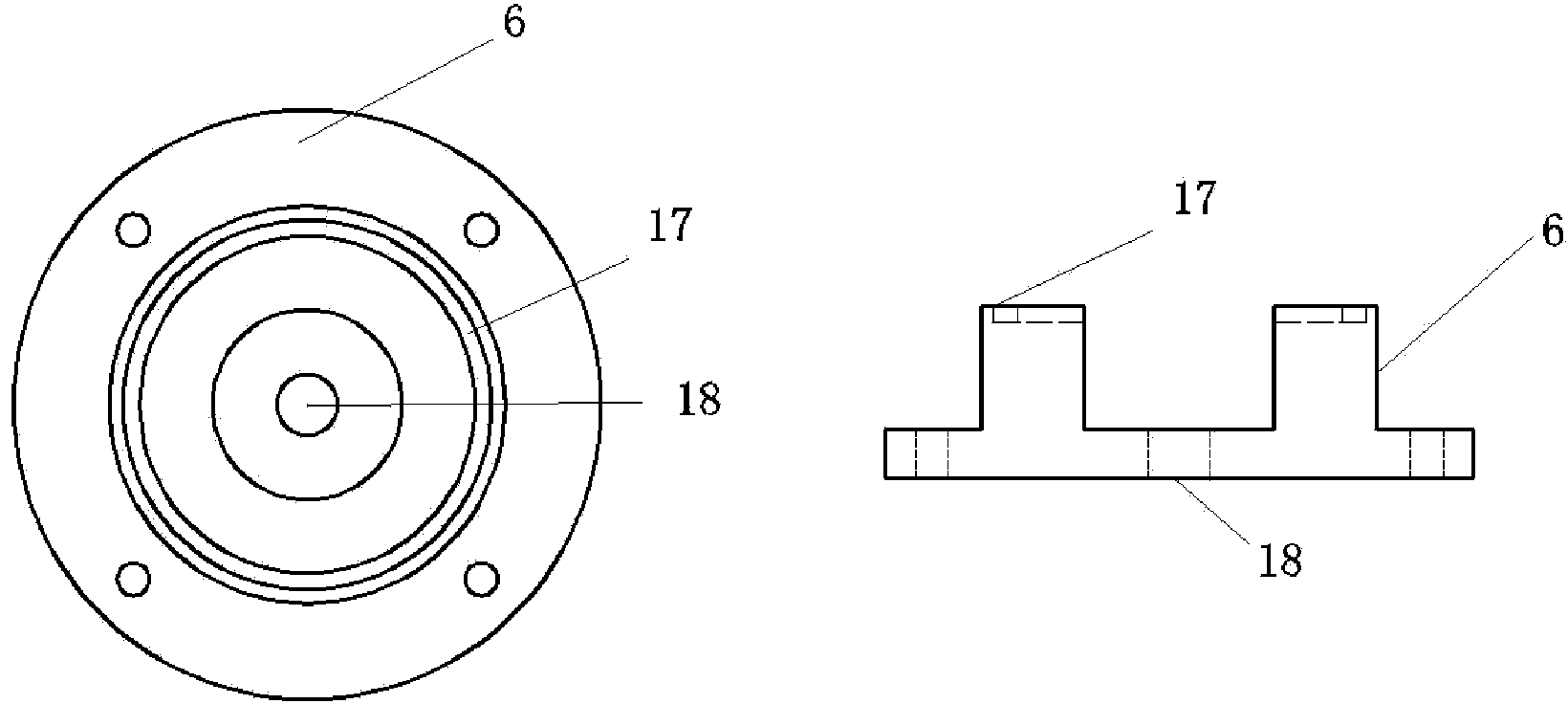

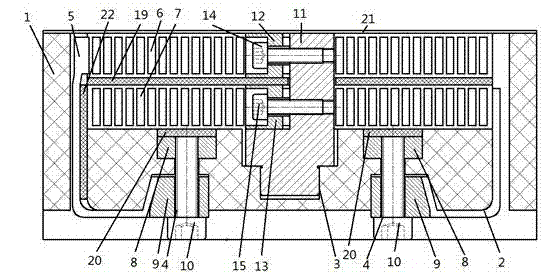

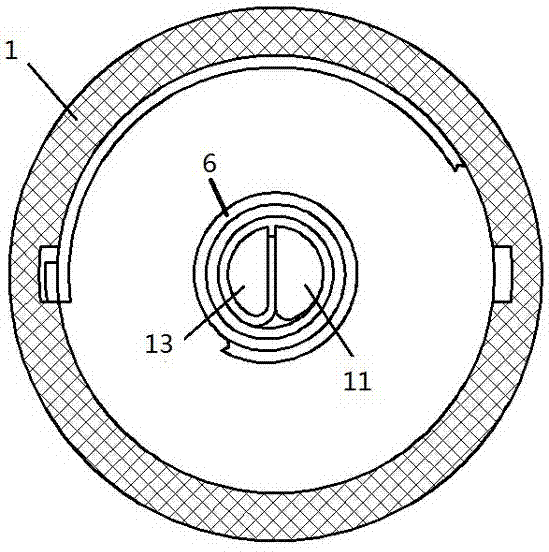

Corrugated pipe forming device and corrugated pipe machined through corrugated pipe forming device

The invention discloses a corrugated pipe forming device based on electromagnetic forming. The corrugated pipe forming device is characterized by comprising a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), fixing bolts (7), a pressing block (8), a mold base (9), a constraint mold (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), trapezoid holes (15), exhaust holes (16), fixing grooves (17) and a wire hole (18). In addition, a thin-wall energy-absorption corrugated pipe forming method based on the electromagnetic forming principle has the advantages that the number of machining processes is small, machining efficiency is high, forming accuracy is high, the pipe forming speed is high, a thin-wall metal pipe can be formed at a high strain rate, the plasticity of metal materials is improved greatly, and the yield strength of the materials is enhanced substantially. By changes of the shape of the constraint mold in the forming device, different wave shapes can be formed, and machining flexibility of the forming device is high.

Owner:HUNAN UNIV

Forming method of titanium alloy thin-walled casing

The invention discloses a forming method of a titanium alloy thin-walled casing. The forming method comprises the steps as follows: a concave mold is fixed on the workbench of a press; a titanium alloy plate 0.2-4 mm in thickness is placed on the concave mold, a lining plate is arranged above the titanium alloy plate, and an edge pressing ring is placed on the lining plate; an electromagnetic coil is fixed on the sliding block of the press, and the electromagnetic coil is contacted with the edge pressing ring since the sliding block on the press runs downwards; the electromagnetic coil is subjected to discharge by adopting an electromagnetic forming method, the lining pate deforms under the action of the electromagnetic force generated by the electromagnetic coil and further prompts the formation of a titanium alloy plate film, and a titanium alloy thin-walled casing 0.2-4 mm in wall thickness is obtained. The forming method has a simple method and a good formation effect. Resilience of the titanium alloy can be effectively avoided by adopting the method to form the titanium alloy thin-walled casing, and finally, the titanium alloy thin-walled casing with high size precision is formed.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Conjoining apparatus using electromagnetic forming

InactiveUS20050097934A1Simple processForging press detailsHigh frequency current welding apparatusElectricityElectromagnetic forming

A conjoining apparatus using electromagnetic forming includes a field shaper for concentrating a magnetic field to a conjoining working object, a coil for generating and applying the magnetic field to the field shaper such that the field shaper can form a reactive force, and a charging circuit for supplying electricity to the coil. An auxiliary ring having higher conductivity than steel is disposed between the field shaper and the working object for generating an induced magnetic field.

Owner:HYUNDAI MOTOR CO LTD

Magnetic impulse warm-hot dynamic drive forming device and forming method for titanium alloy plate

InactiveCN104772380AImprove ductilityReduce residual stressShaping toolsWater channelElectromagnetic forming

The invention discloses a magnetic impulse warm-hot dynamic drive forming device and a forming method for a titanium alloy plate. On the basis of a warm-hot electromagnetic forming method of the prior art, the problems of wrinkling and resilience in a forming process of a titanium alloy material are effectively solved for a purpose of carrying out plastic processing on a titanium alloy by means of simple technical means, such as additionally arranging aluminum driving pieces, respectively forming a plurality of ventilation holes in the front wall surface, the back wall surface, the left wall surface and the right wall surface of a concave die respectively and arranging a cooling water channel, which is communicated with the interior of the concave die, in the top of the concave die. The method for forming the aluminum alloy plate by adopting the magnetic impulse warm-hot dynamic drive forming device for the aluminum alloy plate is good in forming quality of parts, high in precision level, high in forming speed and short in workpiece forming period. The forming device and the forming method disclosed by the invention can be used for finishing forming of the titanium alloy plate through simple technical transformation on the basis of the prior art, the input-output benefit is very remarkable, and thus the forming device and the forming method have favorable market promotion application prospect.

Owner:SHANDONG UNIV OF SCI & TECH

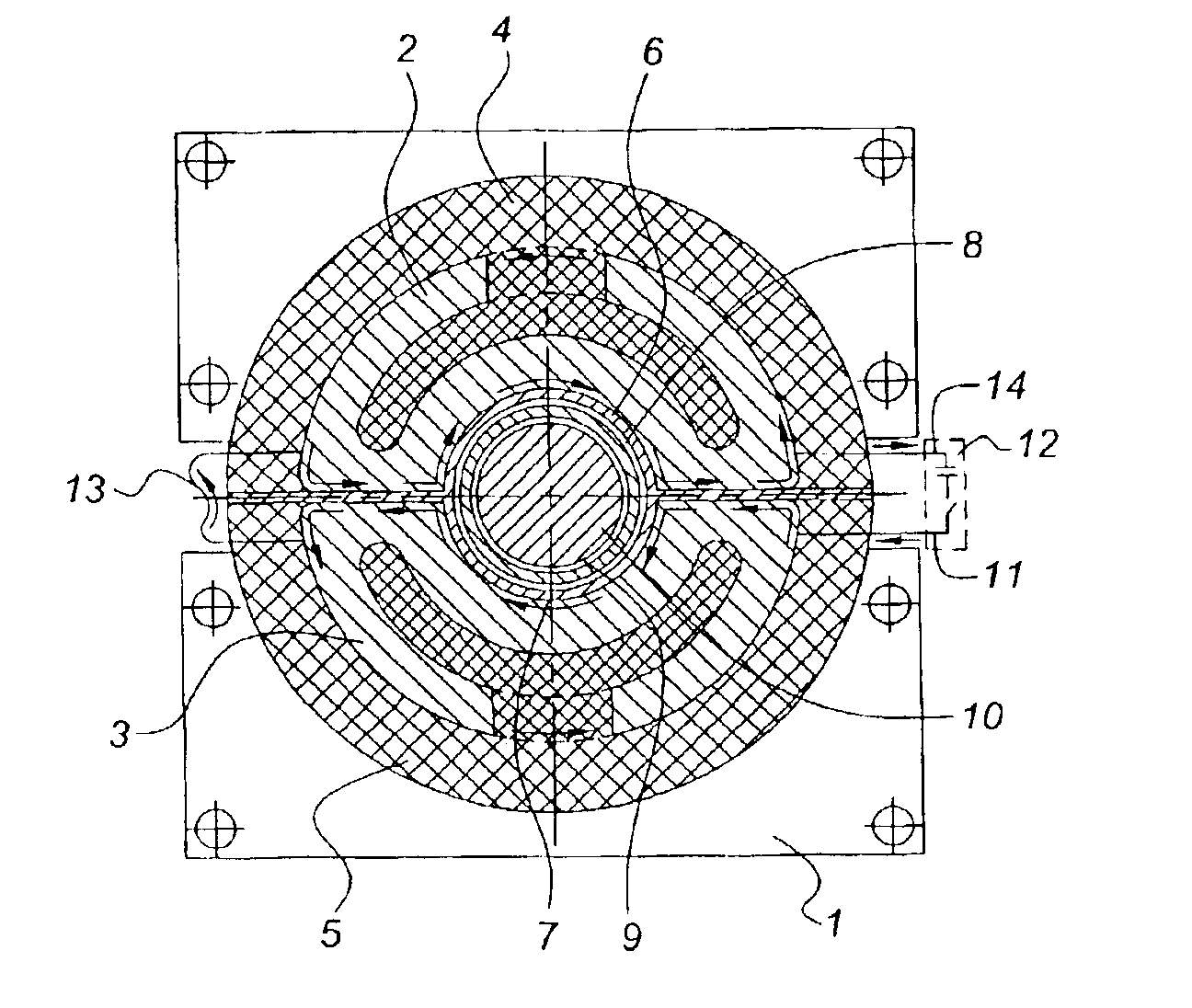

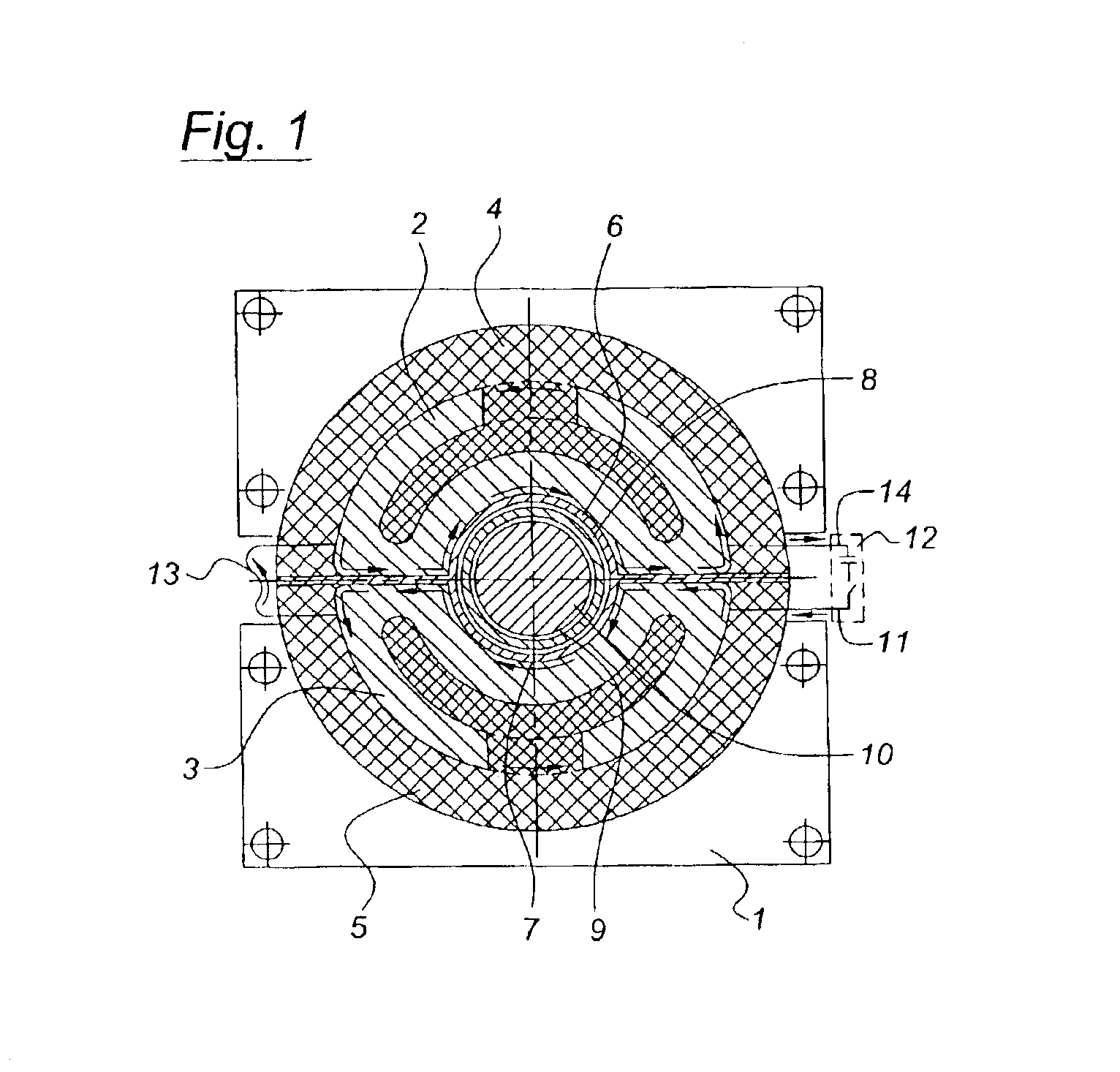

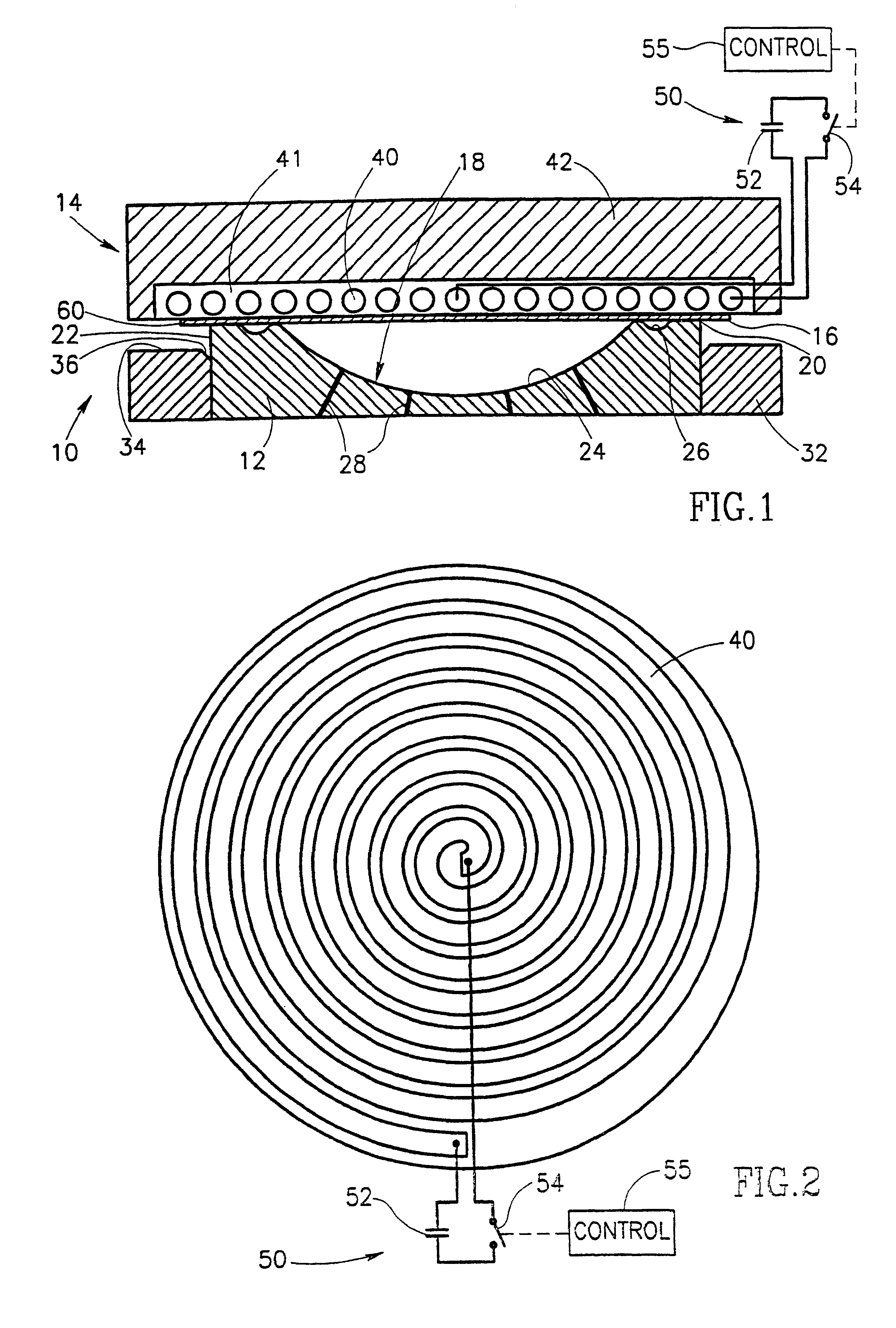

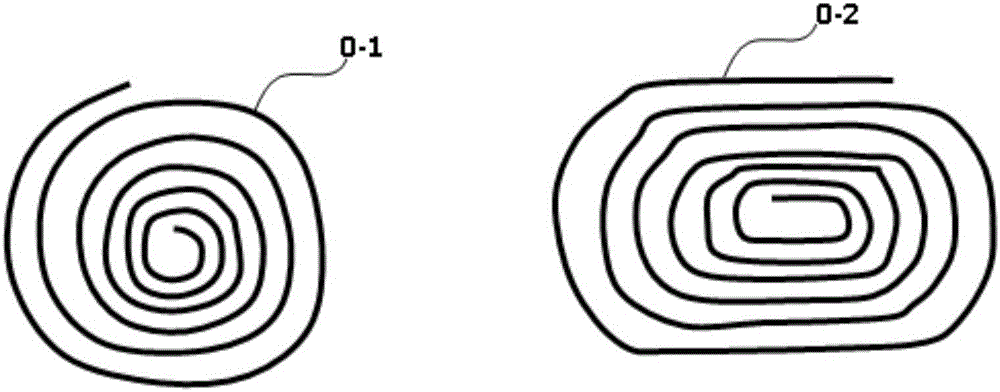

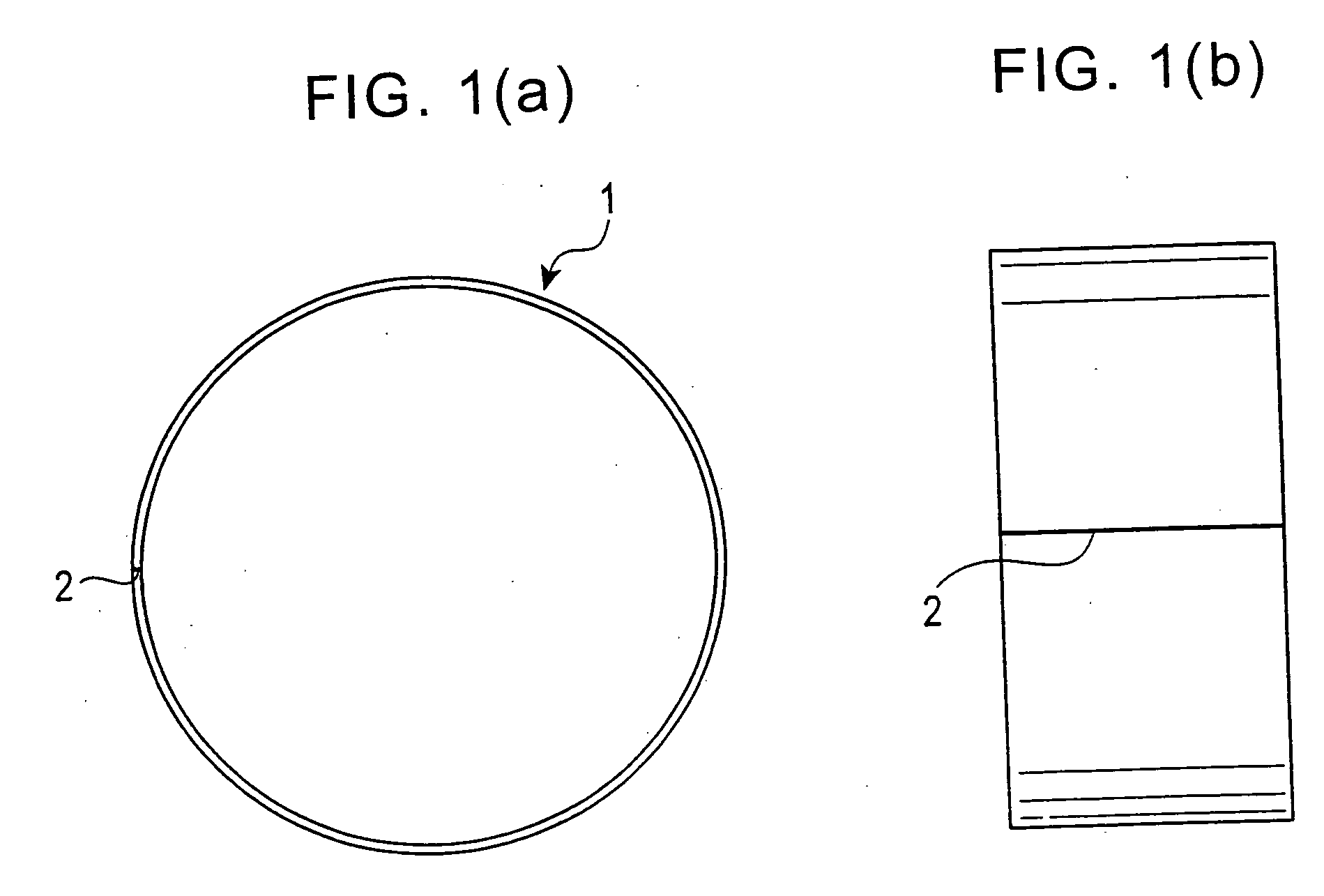

Apparatus and method for pulsed magnetic forming of a dish from a planar plate

An electromagnetic forming apparatus for forming an essentially planar metal plate into a dish having a three-dimensional pattern, is provided. The apparatus comprises a mould having a forming surface with a contour corresponding to said three-dimensional pattern; a forming coil device; and an electric discharge circuitry for discharging a short and intense electric current pulse through the forming coil device to yield a pulsed magnetic forming (PMF) force for deforming said plate.

Owner:INFINITY IP COMMERCIALIZATION ISRAEL LTD

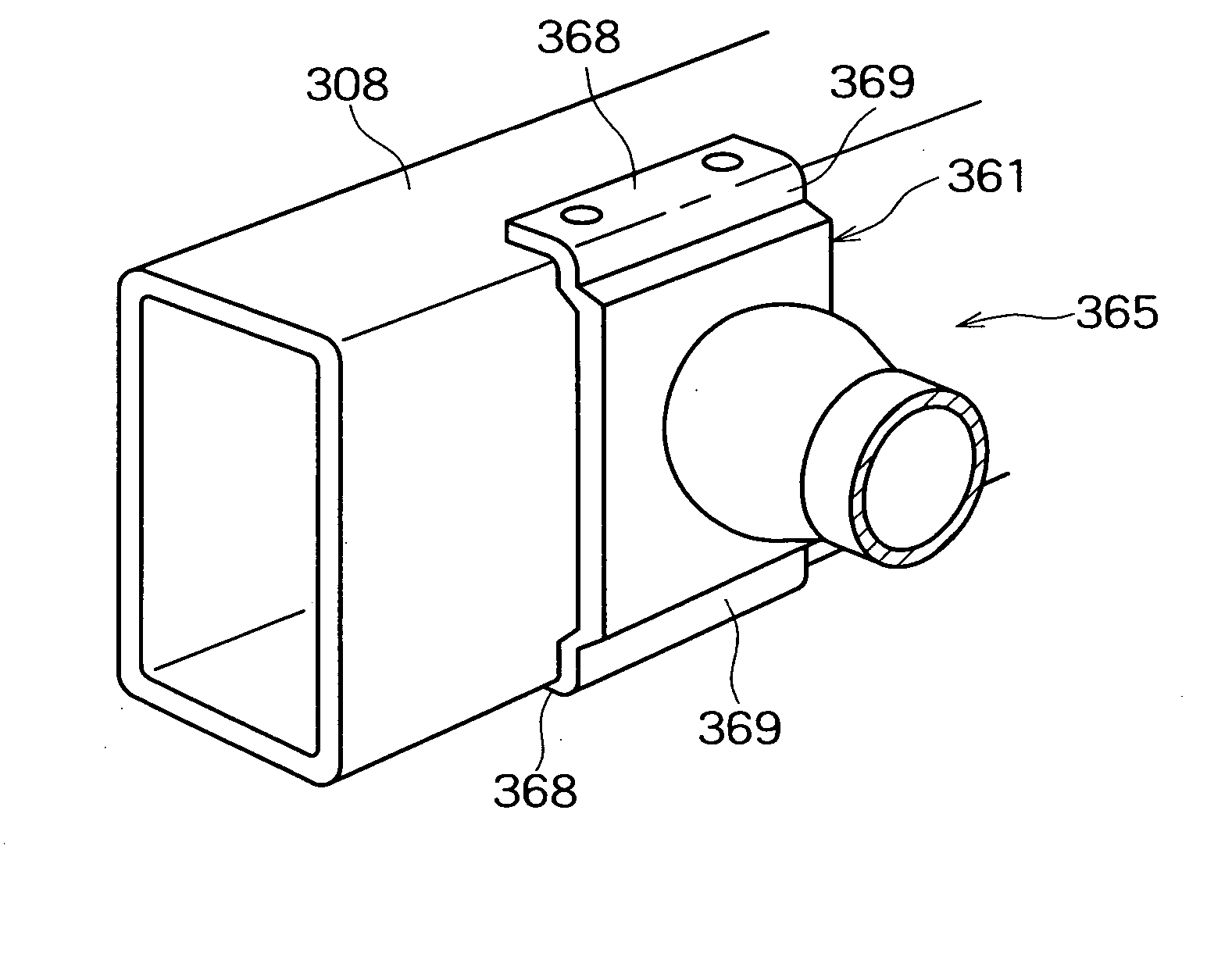

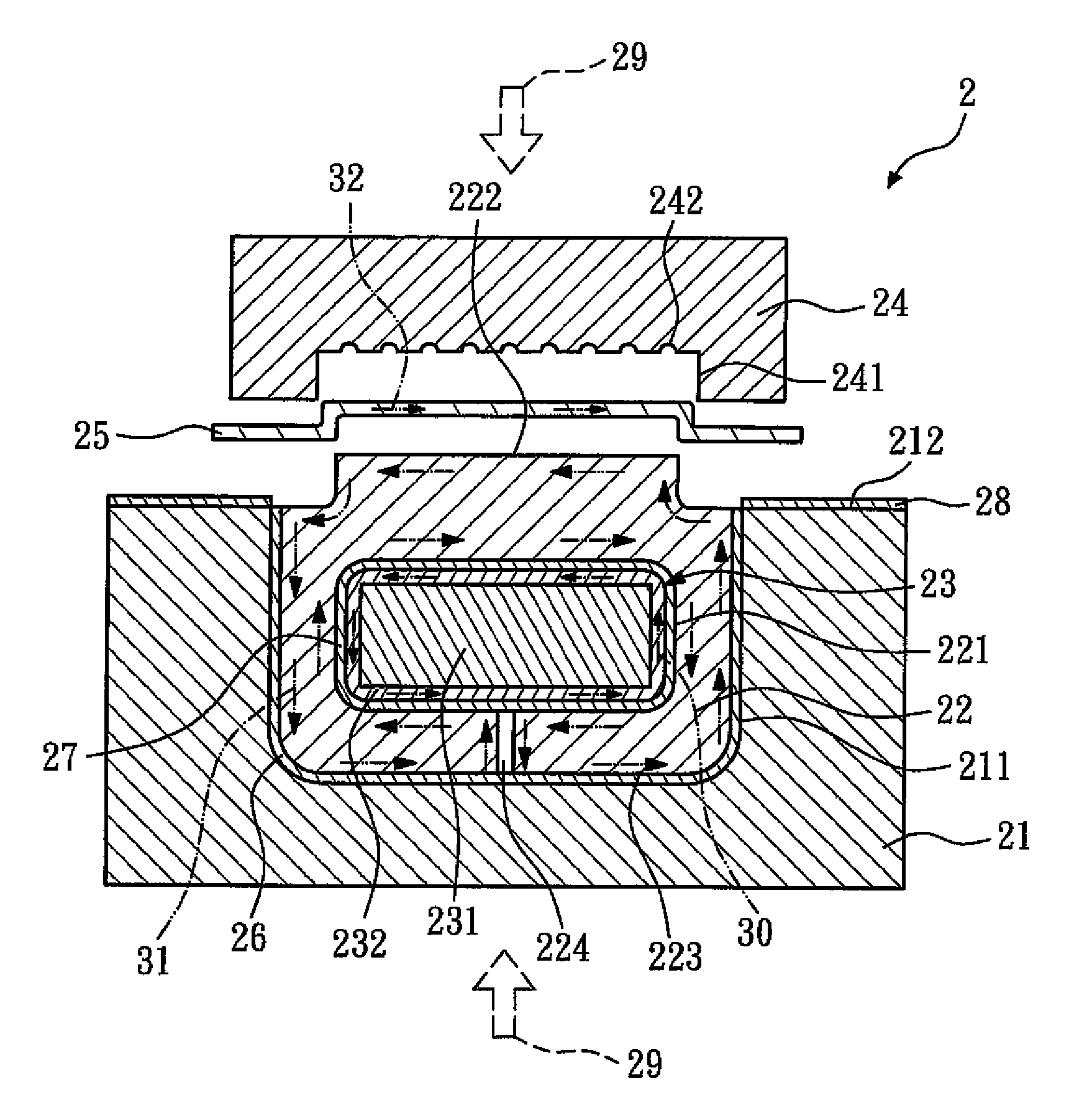

Electromagnetic forming device for sheet of material

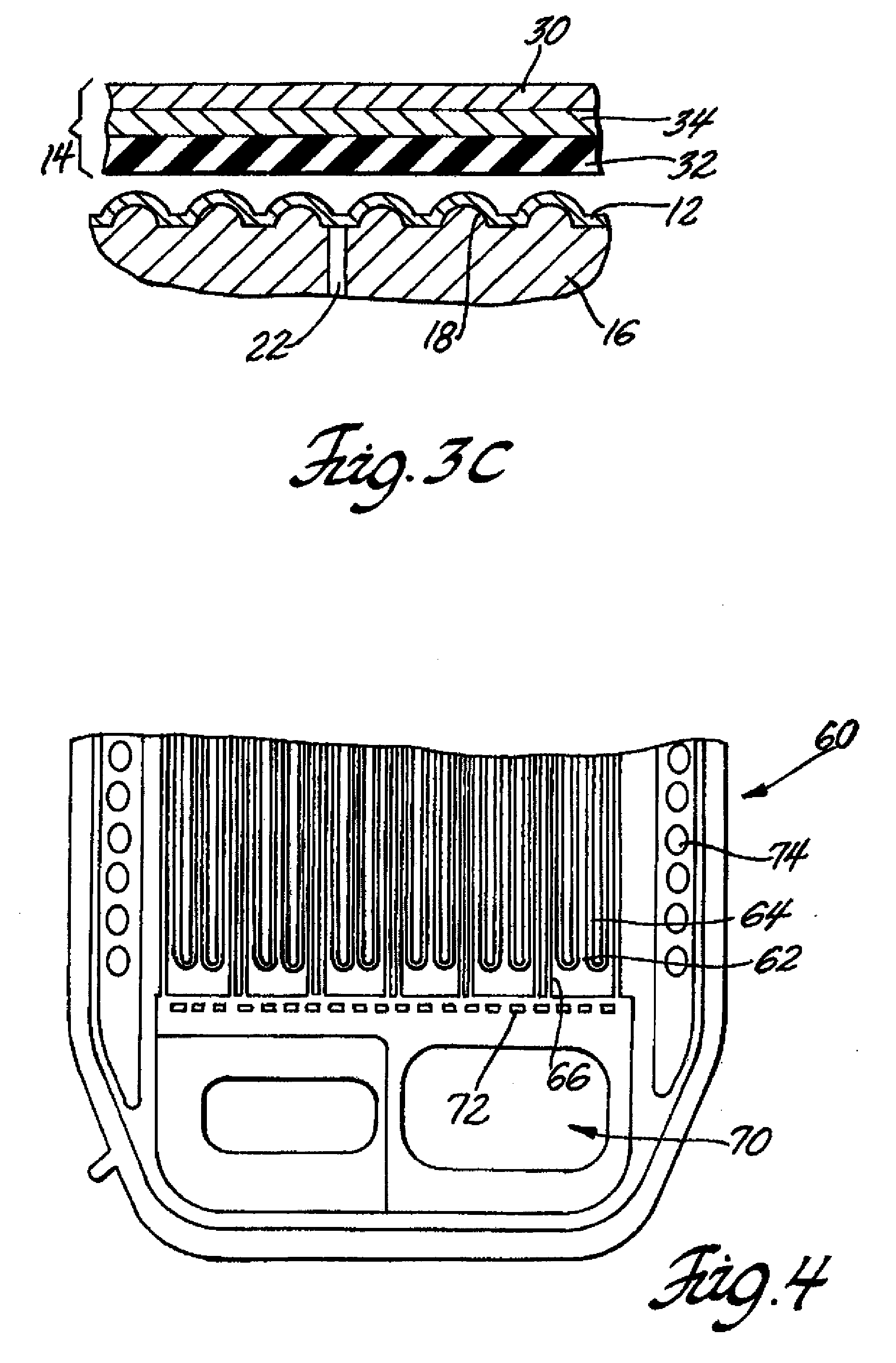

ActiveUS7389664B1Reduce manufacturing costMetal-working apparatusForming forceElectromagnetic forming

An electromagnetic forming device for a sheet of material is provided. The electromagnetic forming device includes a fixing base, a magnetic concentration block, an electromagnetic actuator, and a die. The fixing base has a groove. The magnetic concentration block is disposed in the groove of the fixing base, and has an accommodating space therein, which is in communication with a surface of the magnetic concentration block via a slit. The electromagnetic actuator, used to generate a magnetic field, is disposed in the accommodating space of the magnetic concentration block, but does not contact the magnetic concentration block. The die and the magnetic concentration block are separated by a gap, and a sheet of material can be disposed in the gap. As the magnetic concentration block is a block, eddy currents in the magnetic concentration block are distributed uniformly, so the generated magnetic field is also distributed uniformly, thus exerting a uniform forming force on the sheet of material.

Owner:METAL INDS RES & DEV CENT

Electromagnetic drive forming method and device

ActiveCN102248693AImprove the efficiency of conversion into kinetic energyDeep drawingShaping toolsPress ramControl systemPower control system

The invention provides an electromagnetic drive forming method and an electromagnetic drive forming device. In the method, pulse electromagnetic force is used for driving a composite punch to quickly impact a workpiece, so that the workpiece is attached to a female die to finish high-accuracy formation. The device comprises a drive coil, a power supply control system, the composite punch, a punch positioning mold and pressure equipment. By the method and the device, the problems of low film lamination performance and low efficiency during electromagnetic formation in the prior art are solved, and the efficiency of converting electromagnetic energy into kinetic energy is greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Electromagnetic forming of metallic glasses using a capacitive discharge and magnetic field

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool in combination with an electromagnetic force generated by the interaction of the applied current with a transverse magnetic field. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous metal and the equilibrium melting point of the alloy in a time scale of several milliseconds or less, at which point the interaction between the electric field and the magnetic field generates a force capable of shaping the heated sample into a high quality amorphous bulk article via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time scale of less than one second.

Owner:CALIFORNIA INST OF TECH

Coil-free electromagnetic-pulse forming device and method of metal plates

The invention provides a coil-free electromagnetic-pulse forming device and method of metal plates. The device comprises a female die, a sensing plate, a pressing plate and a power supply system. The method includes: placing a to-be-formed metal plate between the female die and a high-conductivity sensing plate; by the power supply system, directly applying pulse currents to the to-be-formed plate to generate an electromagnetic field, allowing the sensing plate close to the to-be-formed metal plate to generate reverse sensing currents to generate an electromagnetic field, and achieving plate formation by the pulse repulsion electromagnetic force effect, generated by the electromagnetic fields, on the to-be-formed plate. The coil-free electromagnetic-pulse forming device and method has the advantages that a winding type discharge coil structure required by traditional electromagnetic formation is not used, low-conductivity materials can be formed directly, a high-conductivity drive plate is not needed, and device cost can be lowered; the device is simple in structure, long in service life, capable of achieving cold formation of high-strength materials, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

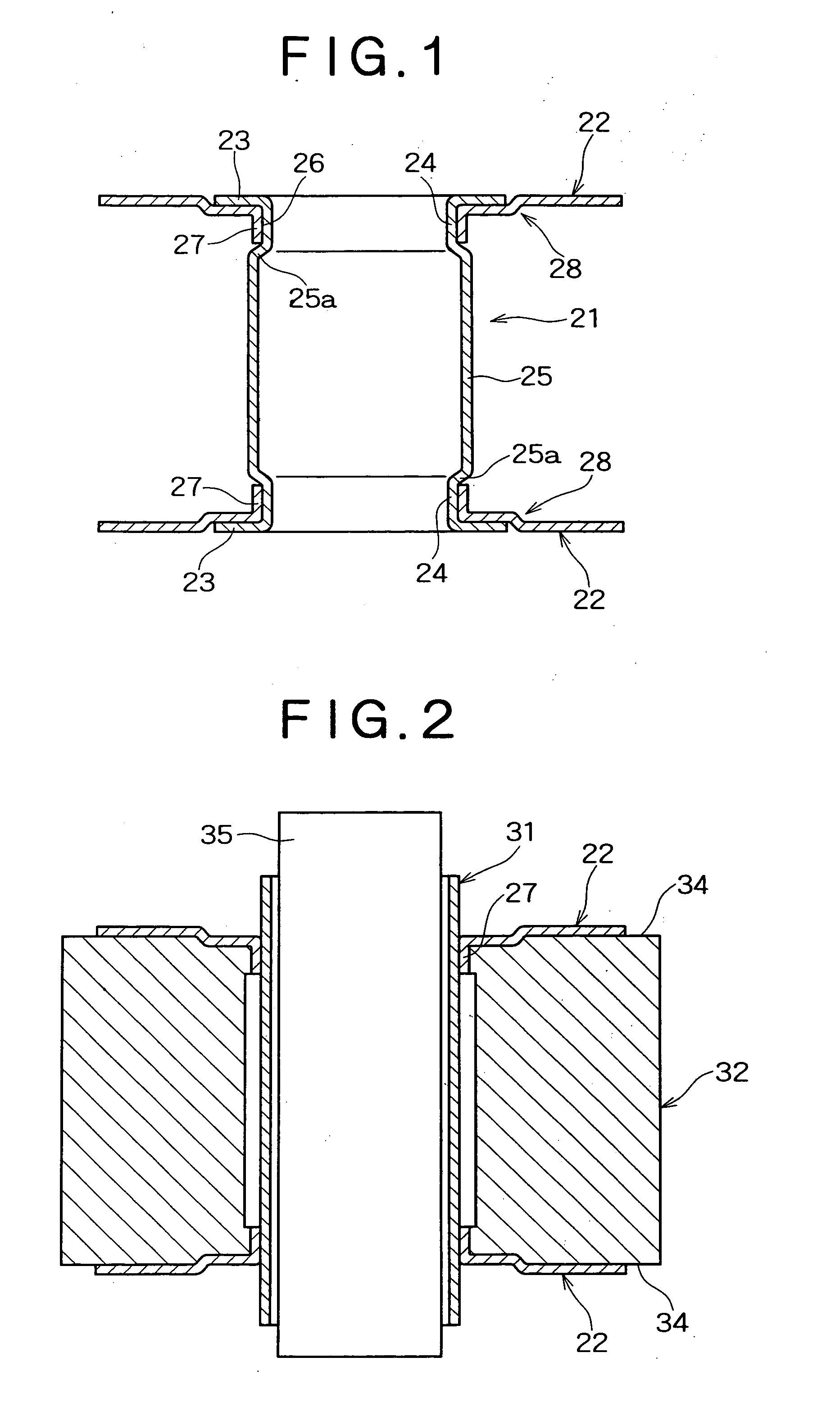

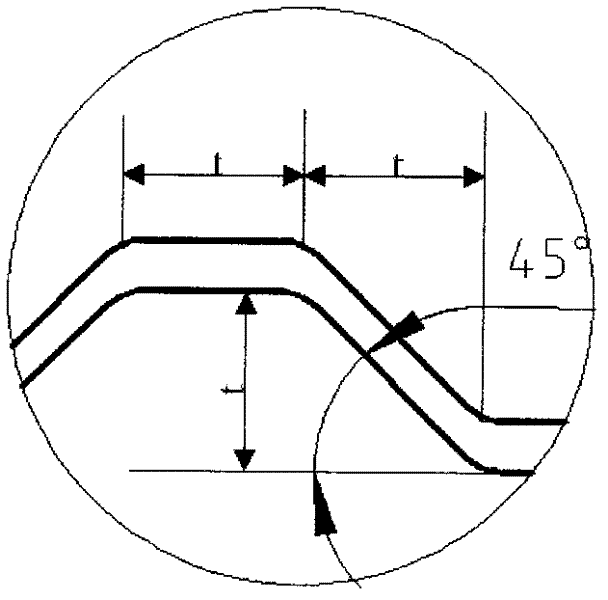

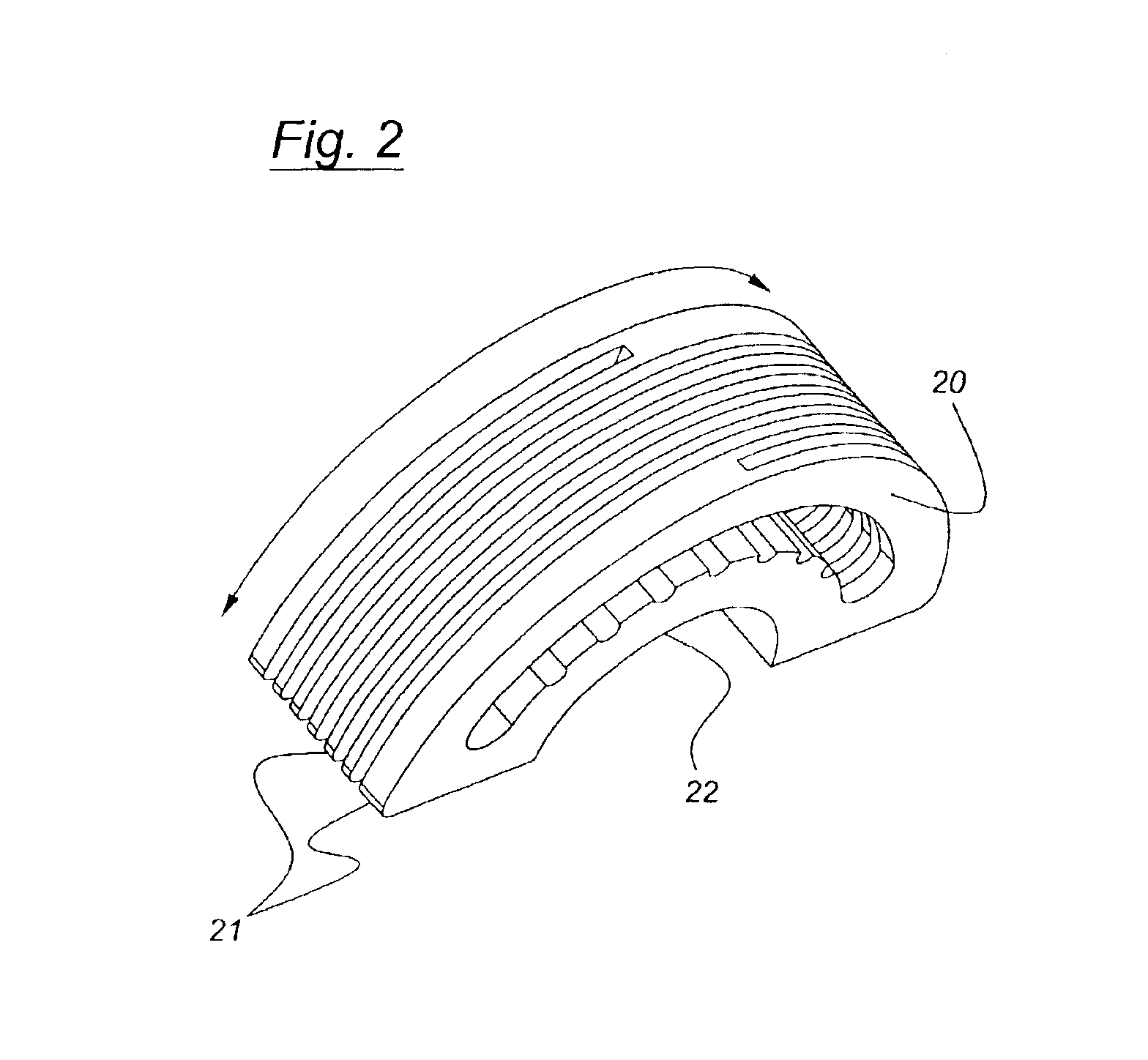

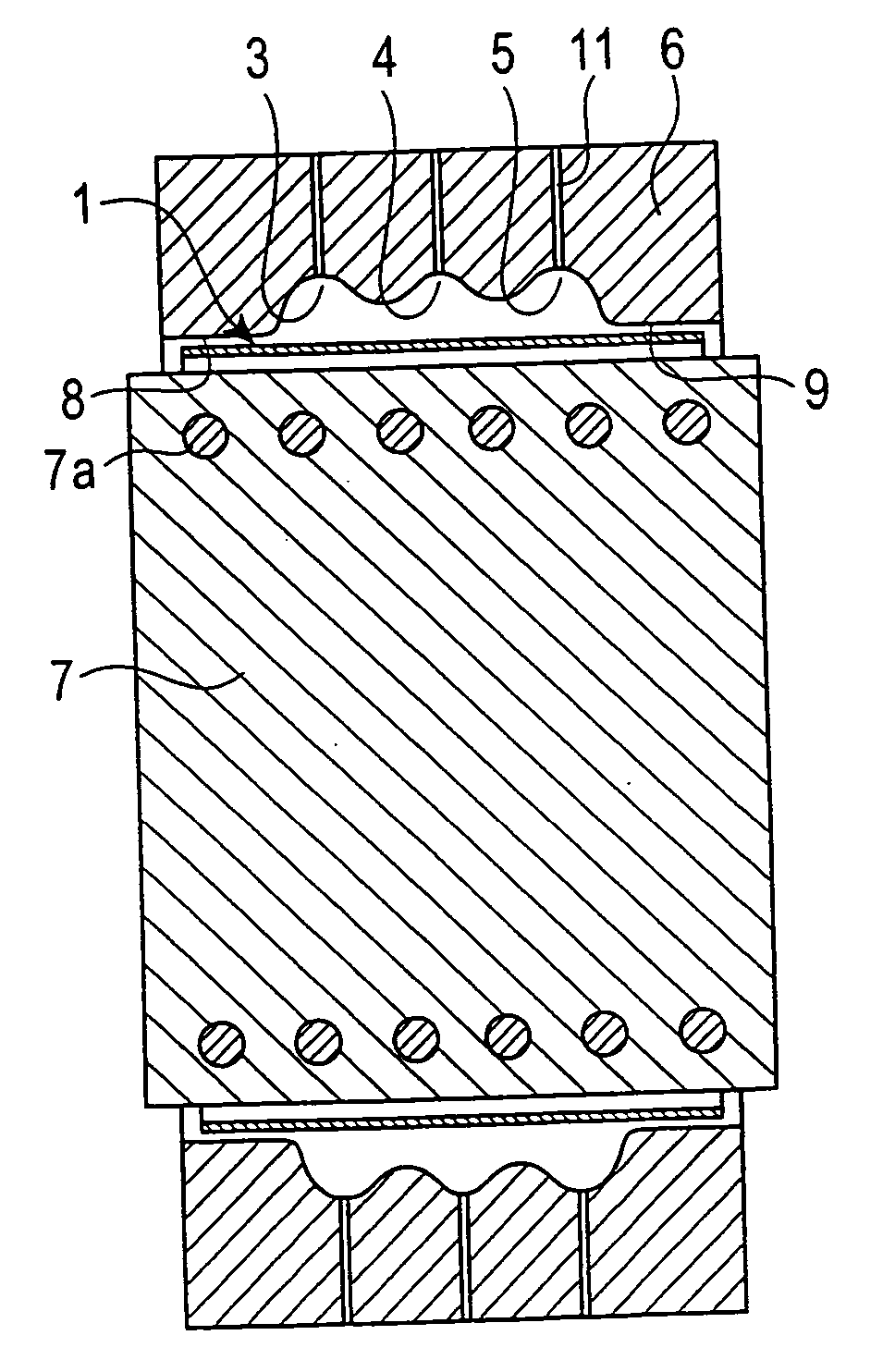

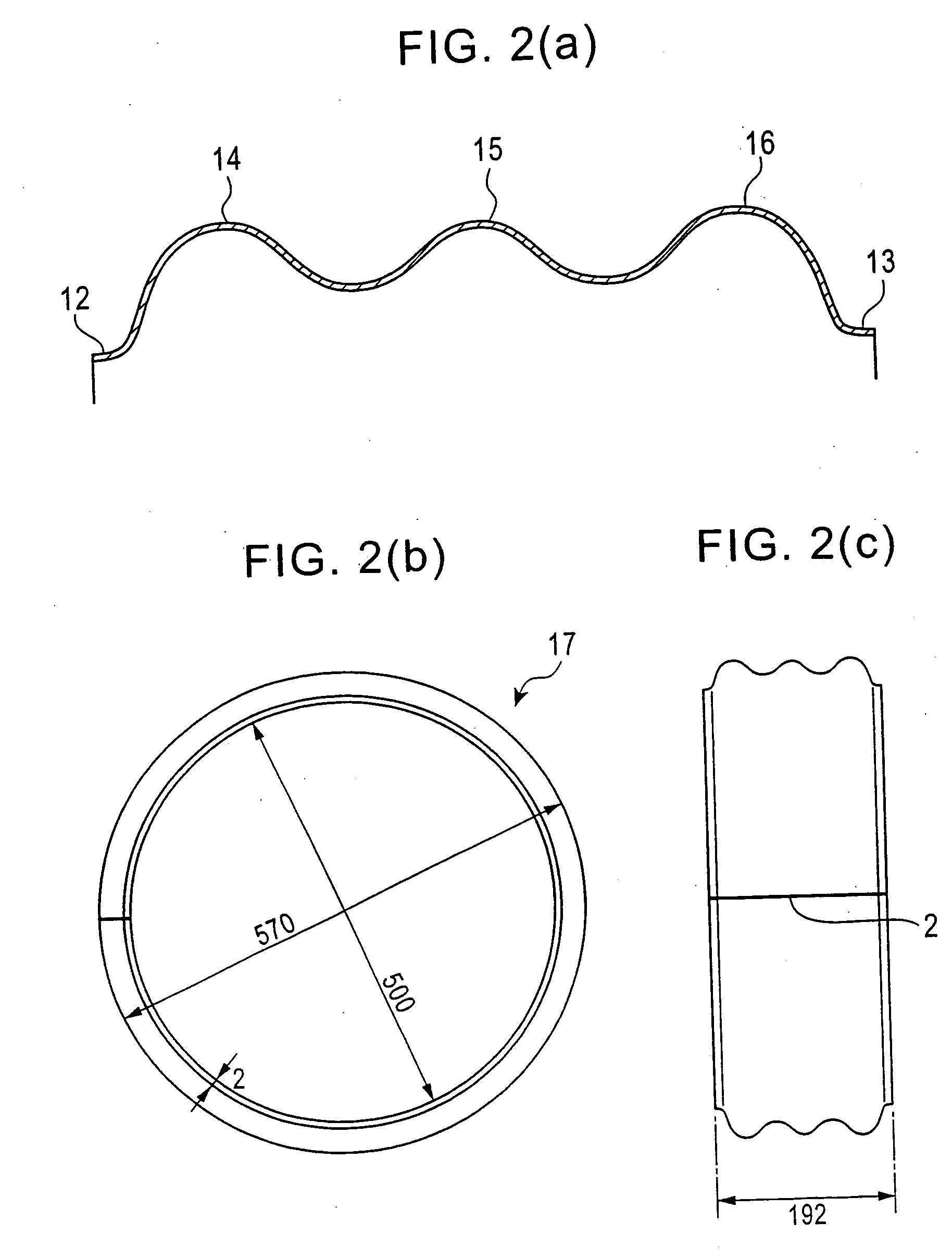

Process for producing tubular ring with beads and die for use therein

A metal mold is disposed adjacent to the outer circumference of a base ring, and has a molding face in the inner circumference and a plurality of grooves for forming beads on the molding face along the circumferential direction. A coil for electromagnetic forming is disposed adjacent to the inner circumference of the base ring. When a momentary large current is applied to the coil in this arrangement, the diameter of the base ring is expanded by pressing the base ring toward the molding face of the metal mold such that the base ring is molded into a shape corresponding to the molding face by electromagnetic forming. Improvements such as a metal mold capable of degassing, a separable metal mold, roll-correcting after electromagnetic forming, application of momentary large current over several times, a metal mold with a cutting blade, use of a base ring with a large number of holes, and a metal mold with positioning means are then added. With these improvements, a highly accurate cylindrical ring with beads can be produced at low cost and with high productivity.

Owner:BRIDTONE 50

Device and method for improving die attaching performance of electromagnetic formed workpiece

The invention relates to a device and method for improving die attaching performance of an electromagnetic formed workpiece. One or more magnetism collector devices are additionally arranged at the outer portion of a drive coil; and under the situation that a coil structure is not changed, magnetism collectors are used for transmitting coil energy to an area where approaching workpiece die attaching is difficult, distribution of electromagnetic force is changed, electromagnetic force in the area where die attaching is difficult is increased, seamless die attaching can be achieved for the metal workpiece, and the forming precision is improved. On the other hand, under the situation that the coil is not replaced, forming of different workpieces is achieved by replacing the different magnetism collector devices, and the flexibility of the device can be greatly improved. Due to the fact that the magnetism collectors are simple in structure, the machining period is short, the material is generally the most common copper, and the price is relatively low; and compared with coil replacement, magnetism collector replacement is more flexible, and cost is lower.

Owner:CHINA THREE GORGES UNIV

Composite corrugated pipe forming device based on electromagnetic forming

The invention discloses a composite corrugated pipe forming device based on electromagnetic forming. The composite corrugated pipe forming device is characterized by comprising a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), a fixing bolt (7), a pressing block (8), a die rack (9), a constraint die (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), a trapezoid hole (15), a vent hole (16), a fixing groove (17) and a wire hole (18). The composite corrugated pipe forming device has the advantages that the device is few in machining procedures, high in machining efficiency, high in forming precision, fast in pipe fitting forming, and capable of forming pipe fittings under high strain rate; due to high strain deformation, the device is applicable to forming of metal materials which are difficult to deform by conventional methods, plasticity of the metal materials is increased greatly, and yield strength of the materials is increased greatly; different corrugations can be formed by changing the shape of the constraint die, and high machining flexibility is achieved.

Owner:HUNAN UNIV

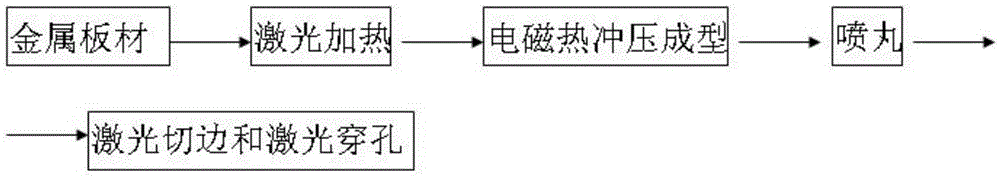

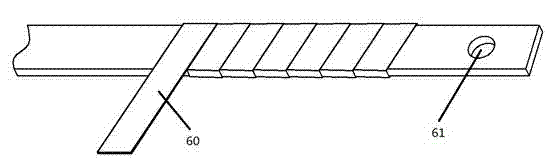

Steel plate electromagnetic hot stamping production line and hot stamping forming method thereof

InactiveCN105234264AReduce hardnessLow mechanical strengthShaping toolsHot stampingElectromagnetic forming

The invention discloses a steel plate electromagnetic hot stamping production line and a hot stamping forming method thereof. The steel plate electromagnetic hot stamping production line mainly comprises a blanking station, a laser heating station and a hot stamping and quenching station. The hot stamping and quenching station comprises a hot stamping press machine, a control system of the hot stamping press machine, and a hot stamping mould. The hot stamping mould comprises an upper mould and a lower mould which are provided with cooling channels. An electromagnetic forming component is arranged at the bent portion of one of the upper mould and the lower mould. The hot stamping forming method comprises the steps that blanking, heating, transfer, stamping and quenching and subsequent processing are conducted, after a formed part is taken out of the mould, oxide skin on the surface of the formed part is removed in an acid pickling or shot blasting mode, and the formed part is subjected to laser trimming and laser perforation.

Owner:JIANGSU JINYUAN FORGE

Aluminum alloy curved part electromagnetic compound forming method and device

InactiveCN101607286AUniform plastic deformationAvoid adverse effects on performanceShaping toolsCapacitancePunch press

The invention relates to an aluminum alloy curved part electromagnetic compound forming method and device. The method includes that an aluminum alloy plate blank is placed on a die; the energy-storage capacitor of an electromagnetic forming device is charged, and the charging loop is broken when charging voltage reaches forming voltage; under the action of a press machine, a coil punch presses the aluminium alloy plate blank into the die for performing, and the contact of the shell of a forming coil and the flange side of the aluminium alloy plate blank is ensured to be favourable; the electromagnetic forming discharging loop is closed, the energy-storage capacitor discharges to the forming coil by a cable, and the preformed aluminium alloy curved part contacts the die at high speed under the action of electromagnetic force, thus obtaining the required work piece. The forming device comprises a coil punch and a forming die; wherein the coil punch is formed by curing of electromagnetic forming coil and coil shell by high strength insulating resin. The method combines conventional punch forming and uniform pressure electromagnetic forming, solves the problems of large forming resilience, poor precision and difficult mould design, and also overcomes the defect that single electromagnetic forming can be only used in local forming.

Owner:WUHAN UNIV OF TECH

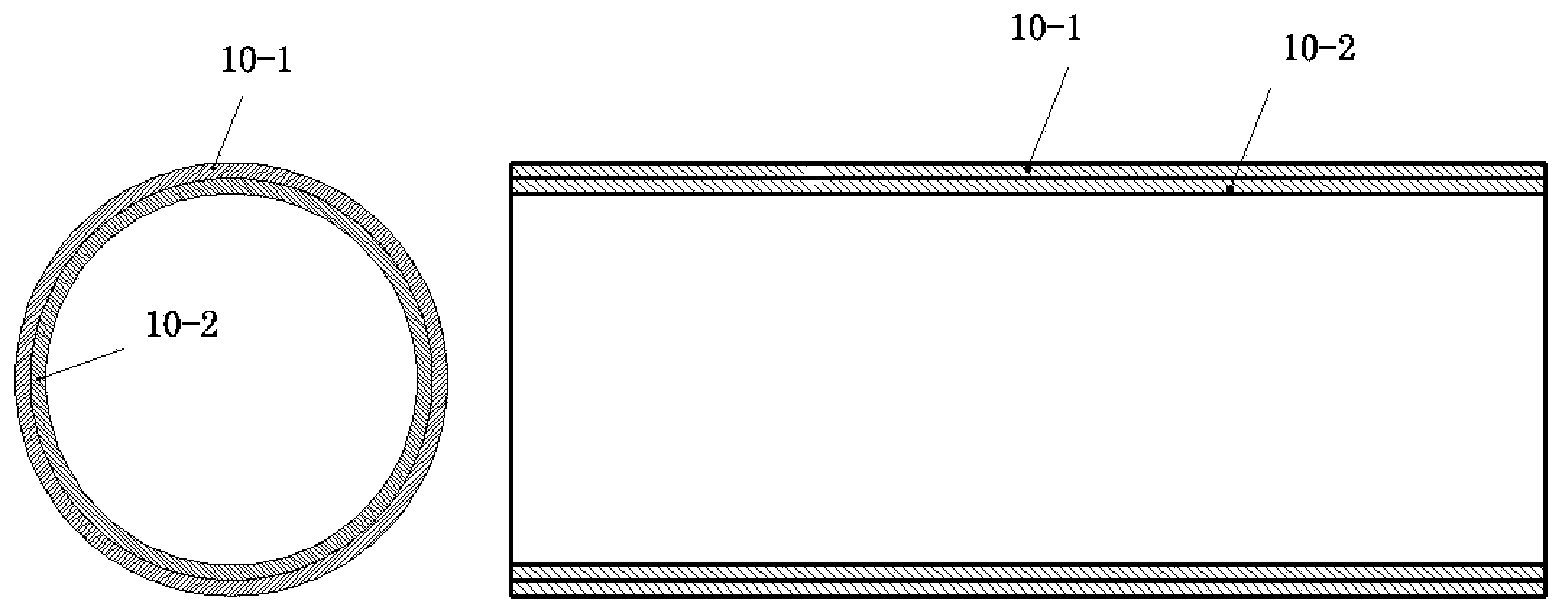

Double-layer coil for electromagnetic formation and manufacturing method of double-layer coil

InactiveCN104779029ASmall outer diameterIncrease the number of turnsCoils manufactureCoilsElectromagnetic formingBlind hole

The invention relates to a double-layer coil for electromagnetic formation and a manufacturing method of the double-layer coil. The double-layer coil comprises a casing; a circular groove where coils are arranged is formed in the front side of the casing; an upper layer coil body and a lower layer coil body are sequentially arranged in the groove from top to bottom; two rectangular through holes are respectively formed in two sides, close to the edge of the casing, in the groove; a step blind hole where a middle connector is arranged is formed in the middle of the groove; the middle connector is matched with the step blind hole; rectangular first blind holes are symmetrically formed in the two sides of the step blind hole; second blind holes corresponding to the first blind holes are formed in the back side of the casing; the first blind holes are communicated with the second blind holes; the beginning end of the upper layer coil body and the beginning end of the lower layer coil body are connected with the middle connector; the output end of the upper layer coil body and the output end of the lower layer coil body penetrate through the through holes and then are respectively connected with a power line in the second blind holes electrically. The double-layer coil has the advantage that the insulation and the mechanical strength of the coil are improved.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com