Forming method of titanium alloy thin-walled casing

A thin-walled shell and titanium alloy technology, which is applied in the field of forming titanium alloy thin-walled shells, can solve the problems of high resistivity and difficult forming of titanium alloy materials, and achieve good forming effects, simple methods, and avoid springback Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, forming a titanium alloy thin-walled shell with a wall thickness of 0.2mm is carried out by:

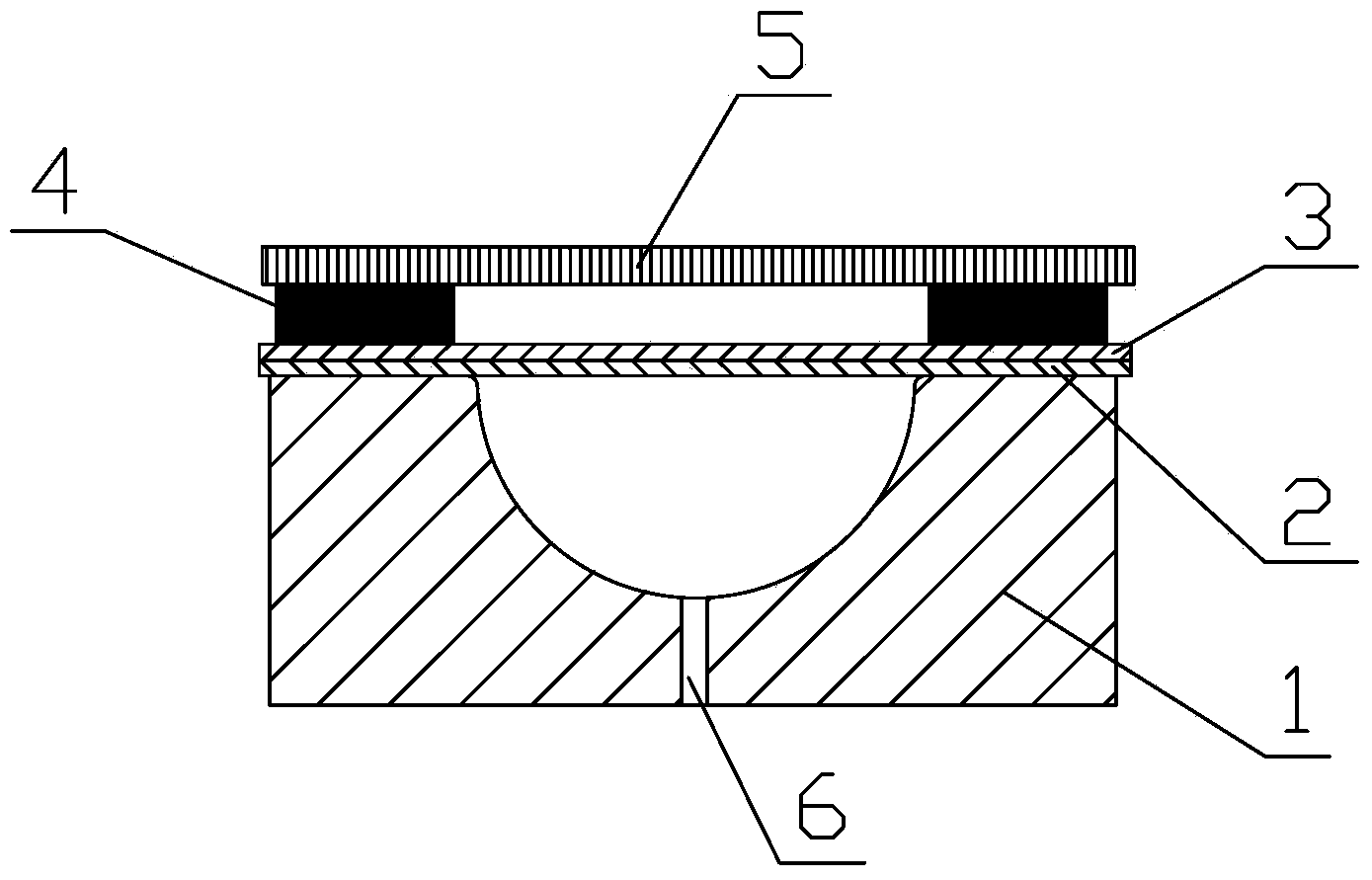

[0019] Such as figure 1 As shown, the die 1 (the inner height is 20mm, the ball radius SR is 30mm) is fixed on the working table of the press, and the bottom center of the die 1 is provided with a vent hole for releasing the air pressure in the cavity of the die 1 6. Place the titanium alloy plate 2 with a thickness of 0.2mm on the die 1, and set the lining plate 3 above the titanium alloy plate 2. The lining plate 3 is an aluminum plate with a thickness of 0.3mm, and place the blank holder 4 on the lining plate 3, the blank holder 4 is made of nylon 66; then the electromagnetic coil 5 is fixed on the upper slider of the press, and the upper slider of the press moves downward so that the electromagnetic coil 5 is in close contact with the blank holder 4; finally, the electromagnetic coil 5 is formed by electromagnetic forming. The electromagnetic coil 5 is...

Embodiment 2

[0022] In this embodiment, forming a titanium alloy thin-walled shell with a wall thickness of 1mm is carried out by:

[0023] Such as figure 1 As shown, the die 1 (with an inner height of 25 mm and a ball radius SR of 40 mm) is fixed on the working table of the press, and the center of the bottom of the die 1 is provided with a vent hole for releasing the air pressure in the cavity of the die 1 6. Place the titanium alloy plate 2 with a thickness of 1mm on the die 1, and set the lining plate 3 above the titanium alloy plate 2. The lining plate 3 is a copper plate with a thickness of 2mm, and place the blank holder 4 on the lining plate 3 , the blankholder 4 is made of common ABS; then the electromagnetic coil 5 is fixed on the upper slider of the press, and the upper slider of the press moves downward so that the electromagnetic coil 5 is in close contact with the blankholder 4; finally, the electromagnetic The coil 5 is discharged, and the discharge voltage is 13KV. The lin...

Embodiment 3

[0026] In this embodiment, forming a titanium alloy thin-walled shell with a wall thickness of 2mm is carried out by:

[0027] Such as figure 1 As shown, the die 1 (the inner height is 45mm, the ball radius SR is 50mm) is fixed on the working table of the press, and the bottom center of the die 1 is provided with a vent hole for releasing the air pressure in the cavity of the die 1 6. Place the titanium alloy plate 2 with a thickness of 2mm on the die 1, and set the lining plate 3 above the titanium alloy plate 2. The lining plate 3 is a copper plate with a thickness of 5mm, and place the blank holder 4 on the lining plate 3 , the blank holder 4 is made of high pressure resistant and heat-resistant polytetrafluoroethylene; then the electromagnetic coil 5 is fixed on the upper slider of the press, and the upper slider of the press moves downward so that the electromagnetic coil 5 is in close contact with the binder ring 4; Finally, the electromagnetic coil 5 is discharged by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com