Patents

Literature

590results about How to "Prevent springback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

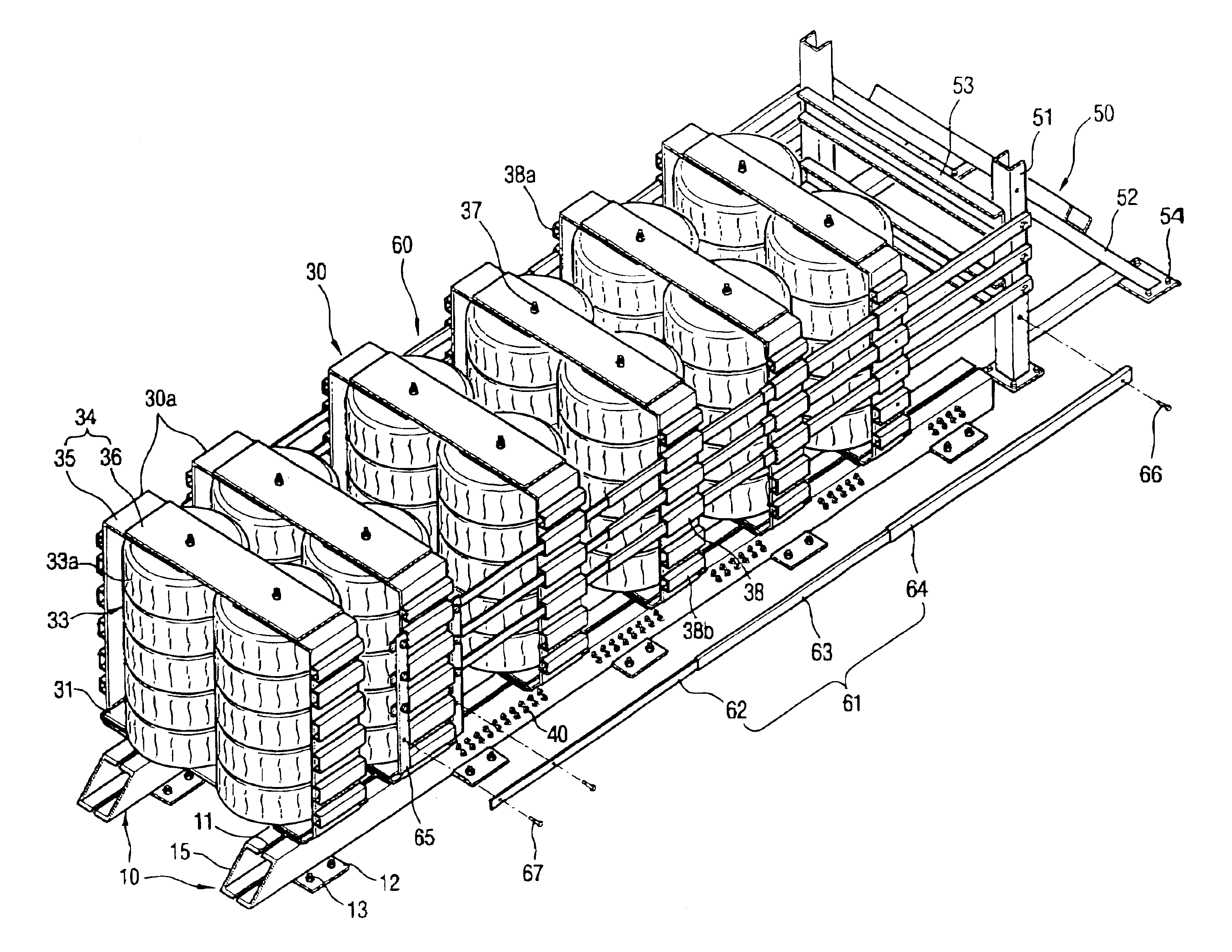

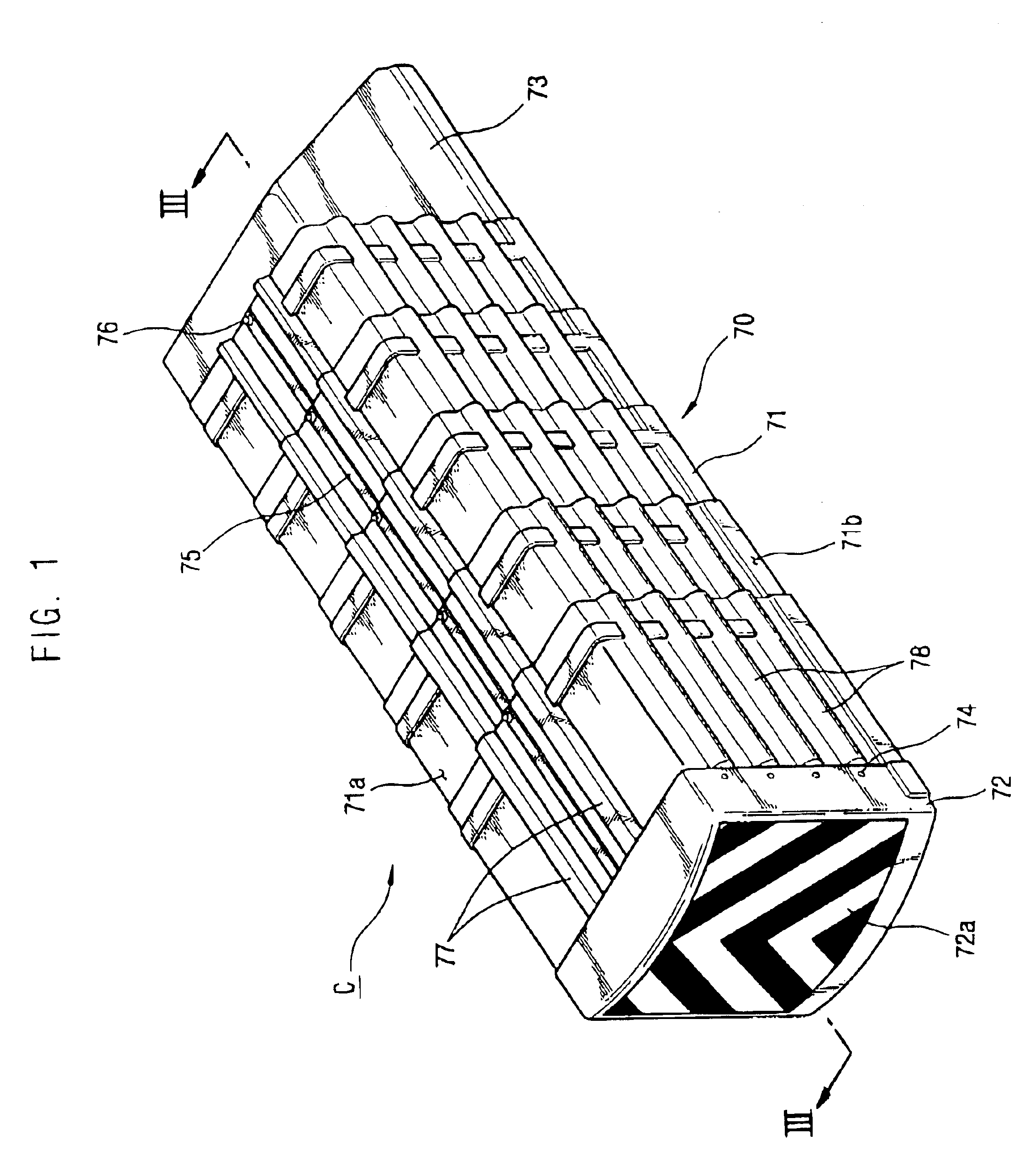

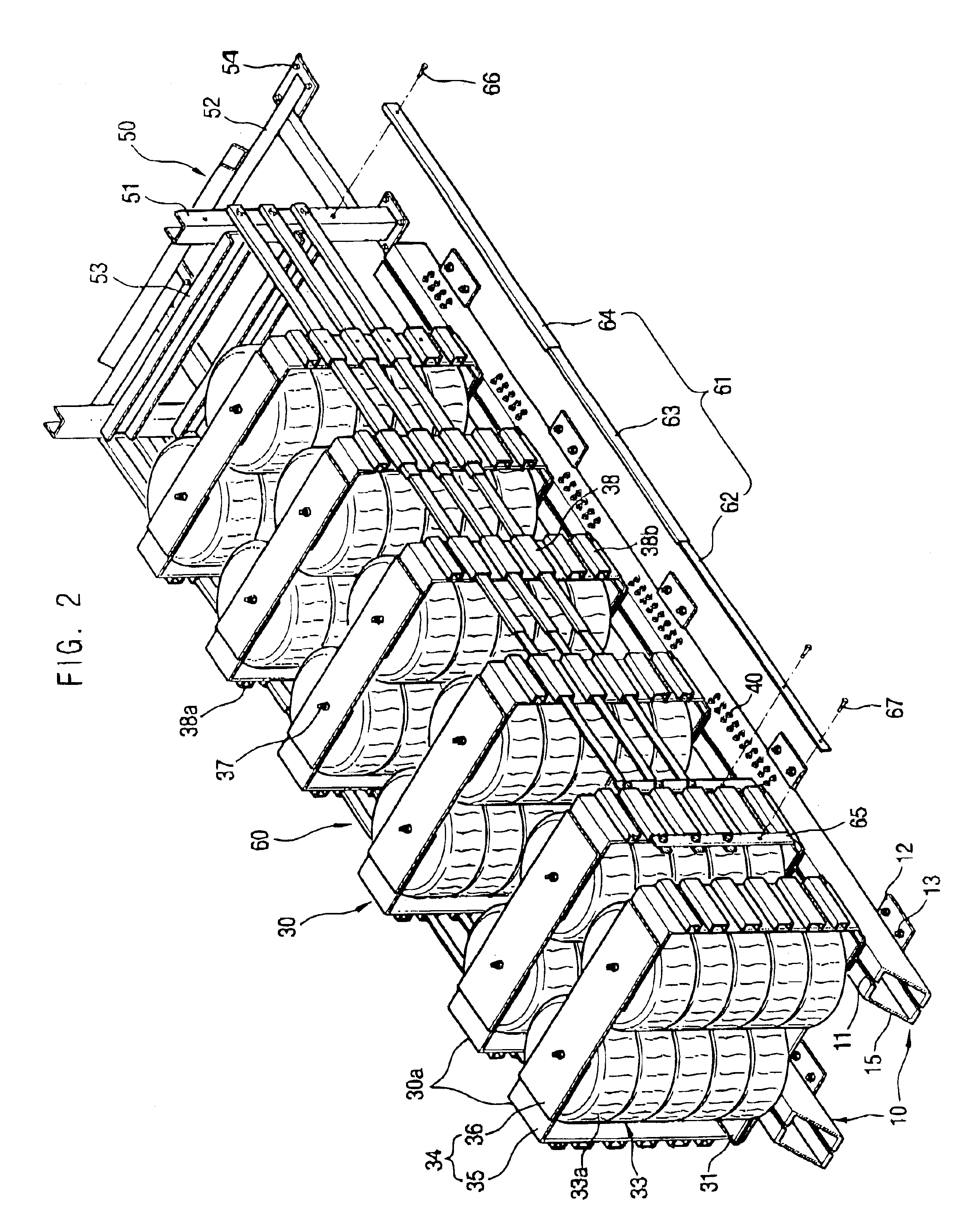

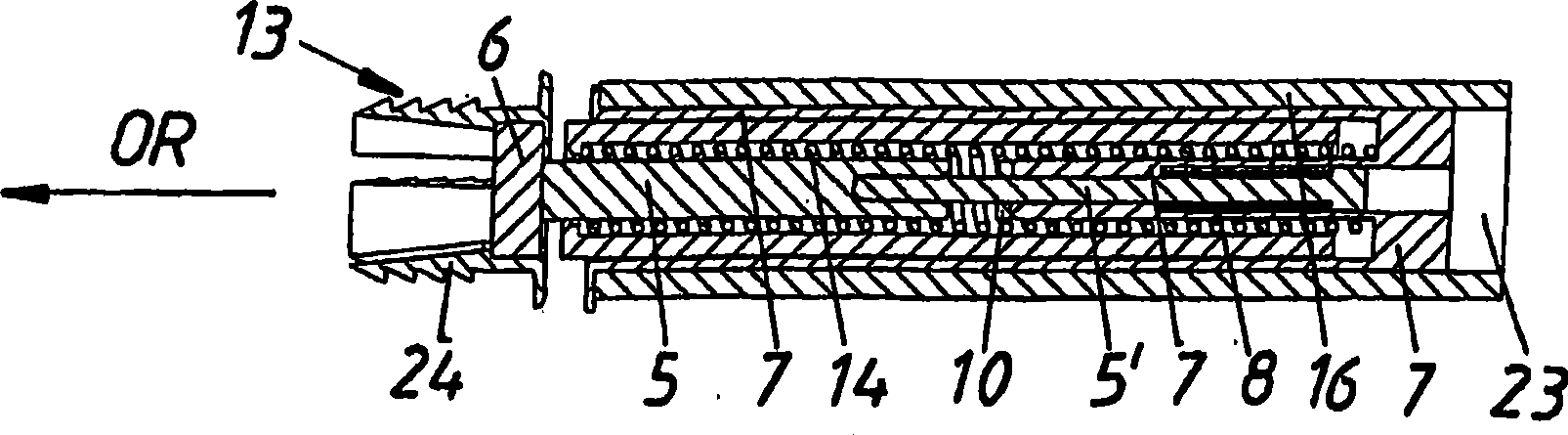

Vehicular impact absorbing apparatus having cushion pins

InactiveUS6905281B2Impact energy absorptionPrevent springbackRefuge islandsTraffic signalsEngineeringGuide tube

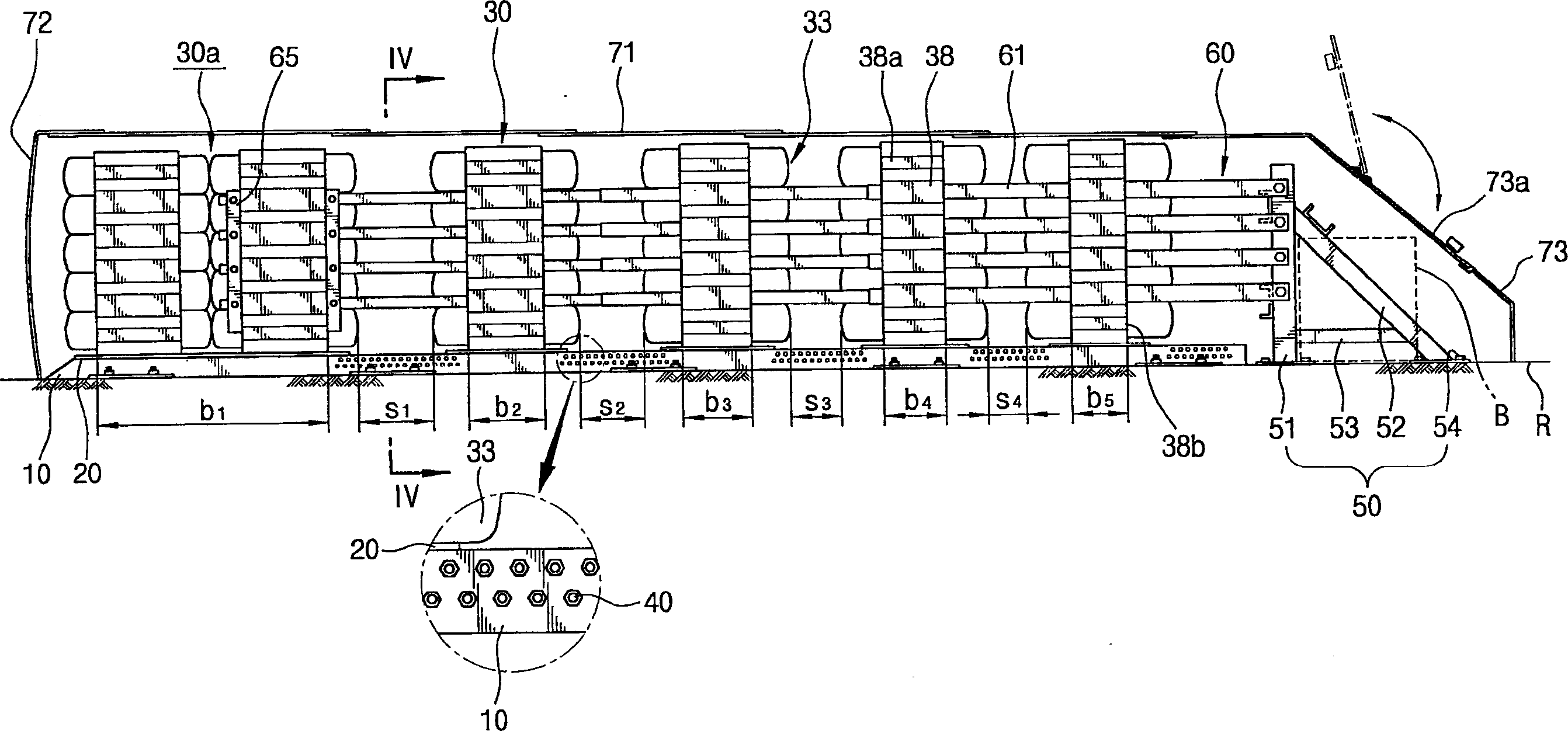

A vehicular impact absorbing apparatus includes a pair of tubular guide rails having a guide slit longitudinally formed at the upper part of each guide rail fixed to the ground. Sliders are movably mounted in the guide rail at predetermined intervals, the upper part of each slider is laid on the upper part of the guide rail through the guide slit. Cushion units are mounted on the upper part of each slider. Each cushion unit is elastically deformed by vehicular impact while retracting along the guide rail. Cushion pins are mounted across the guide rails at predetermined intervals between the sliders that also absorb the kinetic energy of an impact by being broken by the rearward retracting slider. A stopper is installed around the rear end of the guide rail for stopping the retracting cushion units. A successive cushion and deceleration of the impact is possible in this arrangement.

Owner:KANG SUNG KU

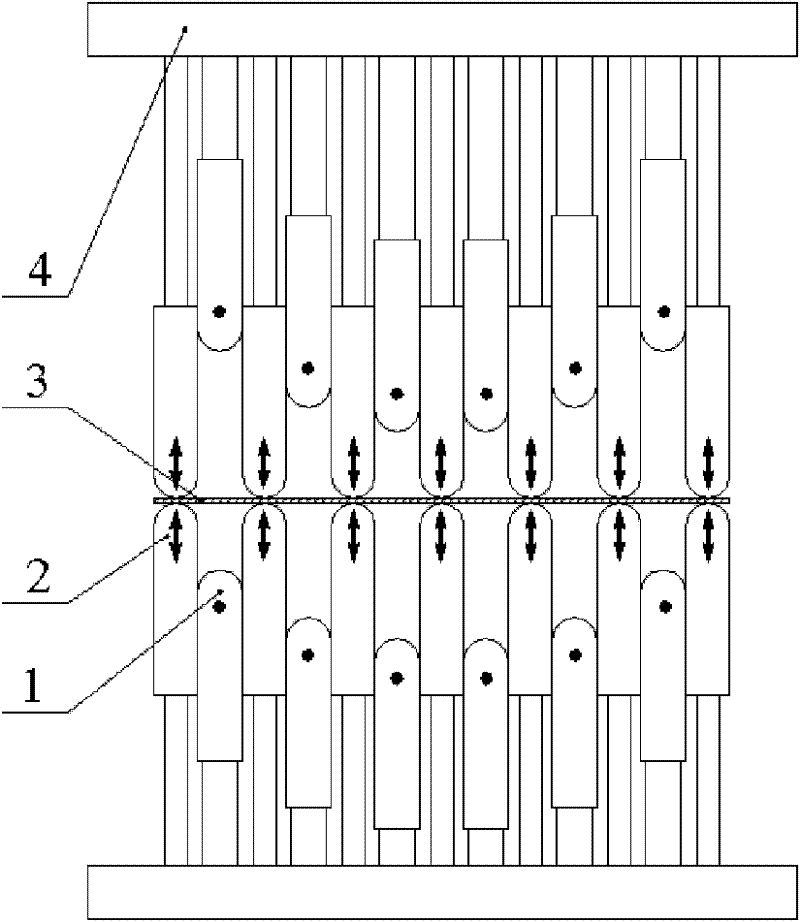

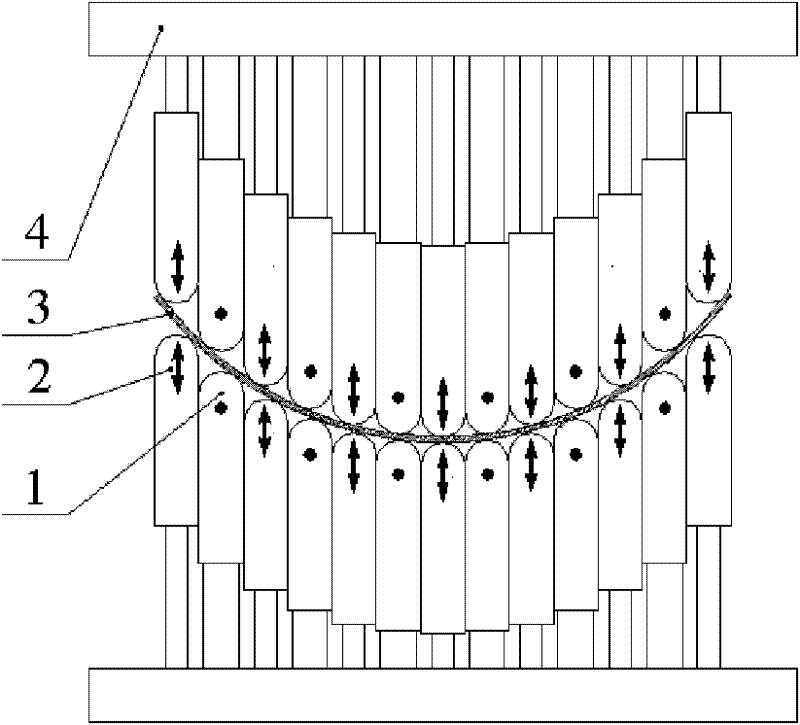

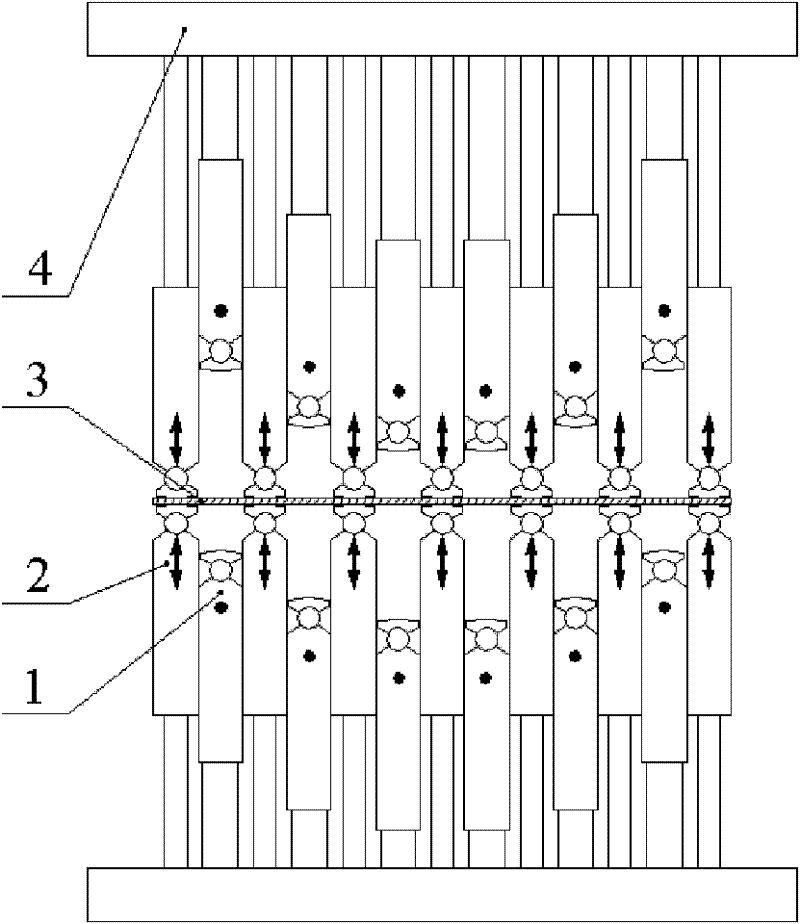

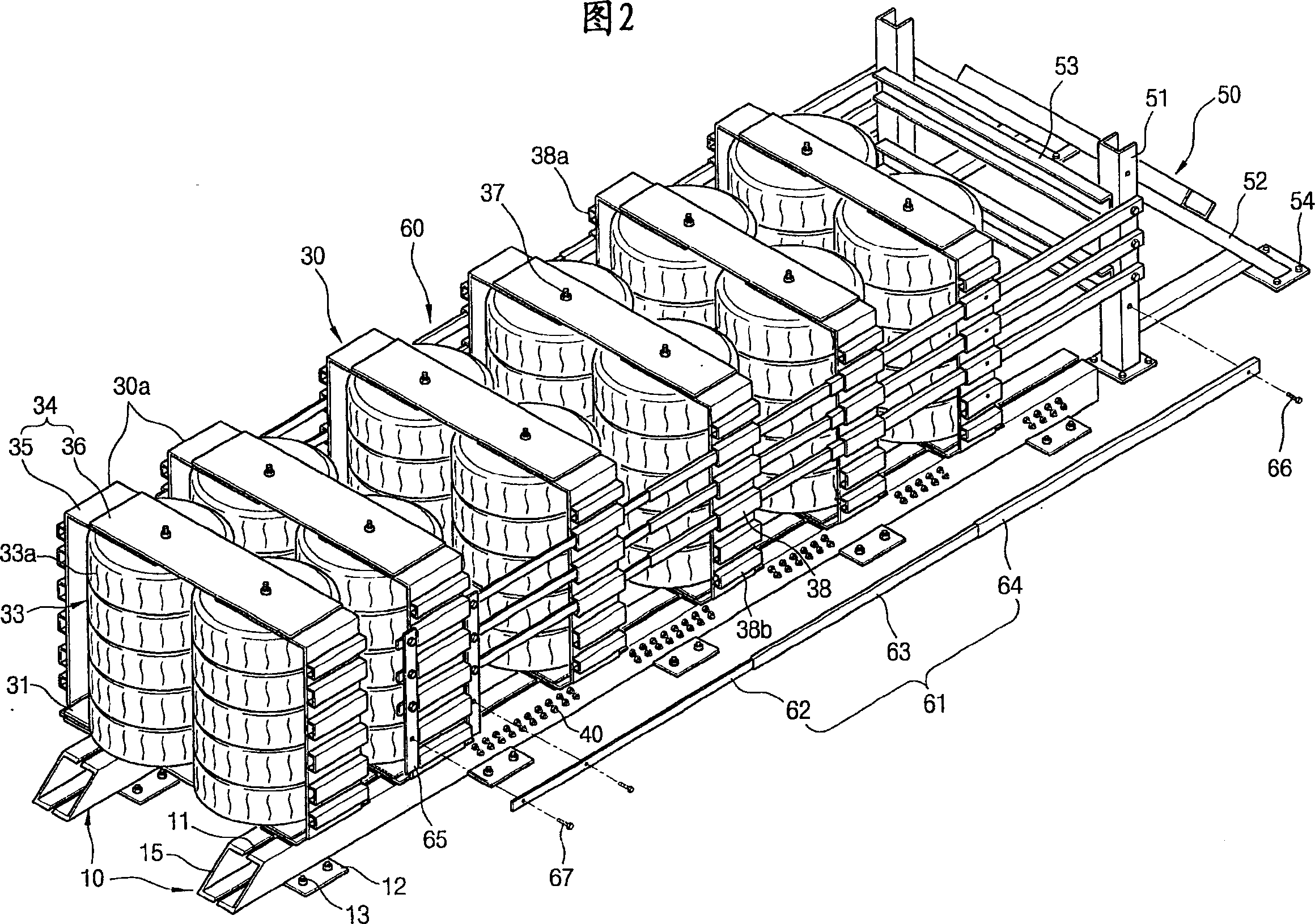

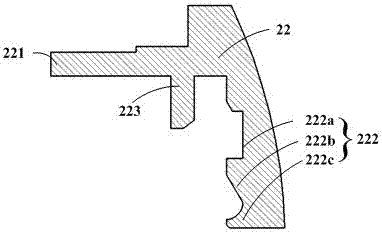

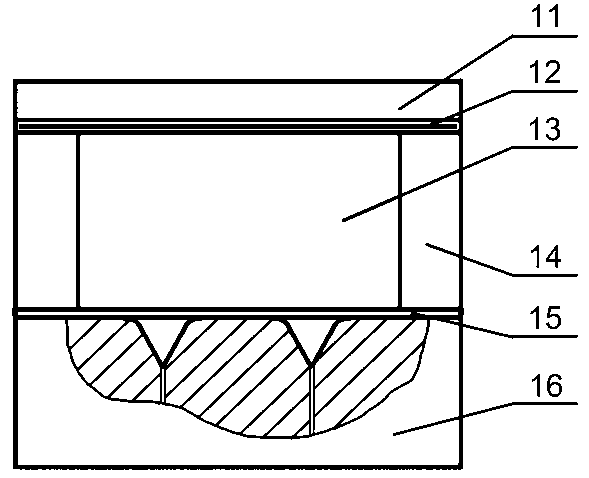

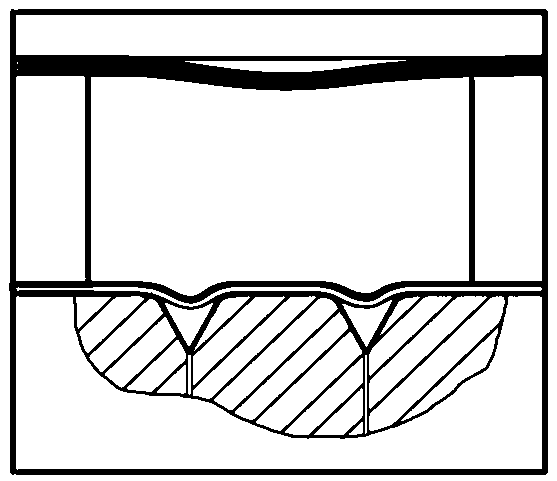

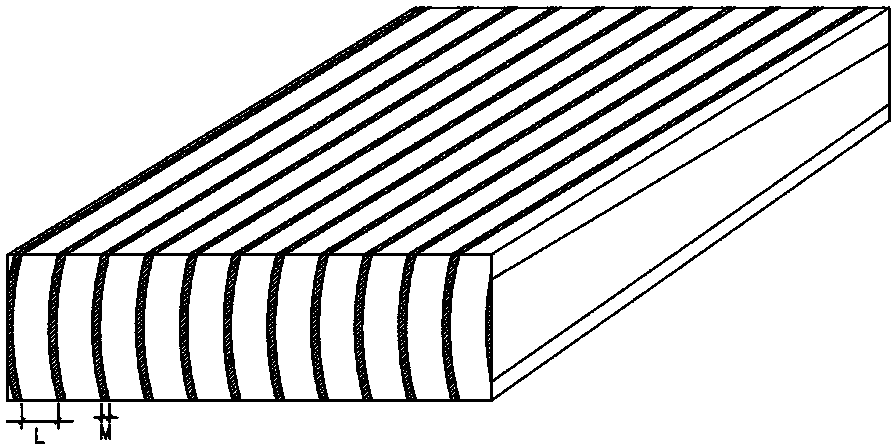

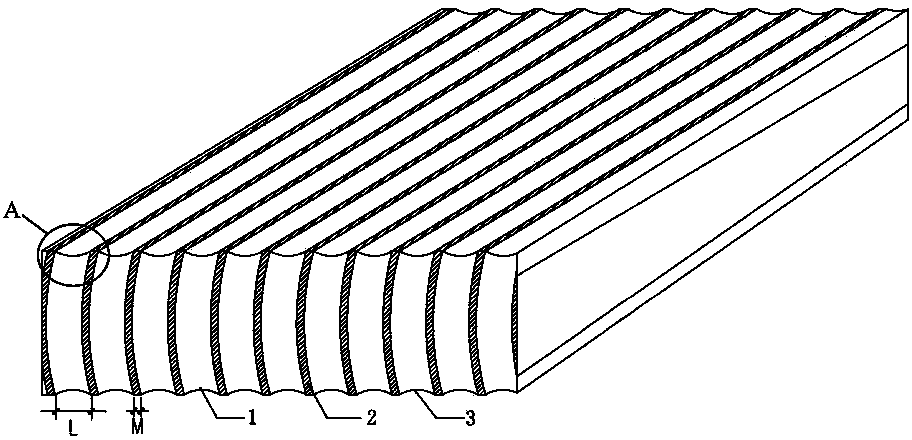

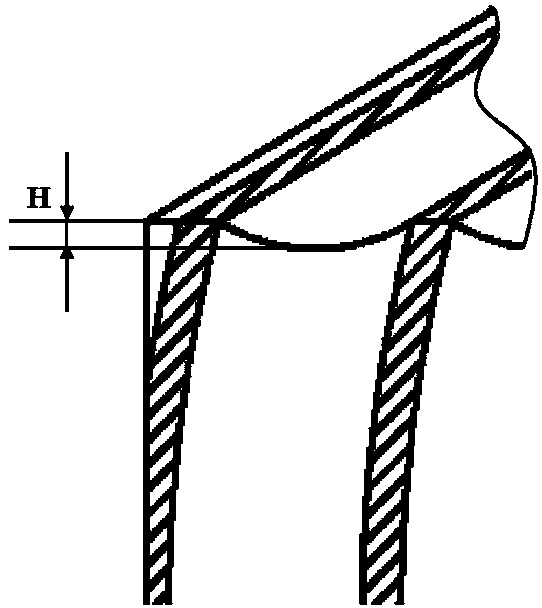

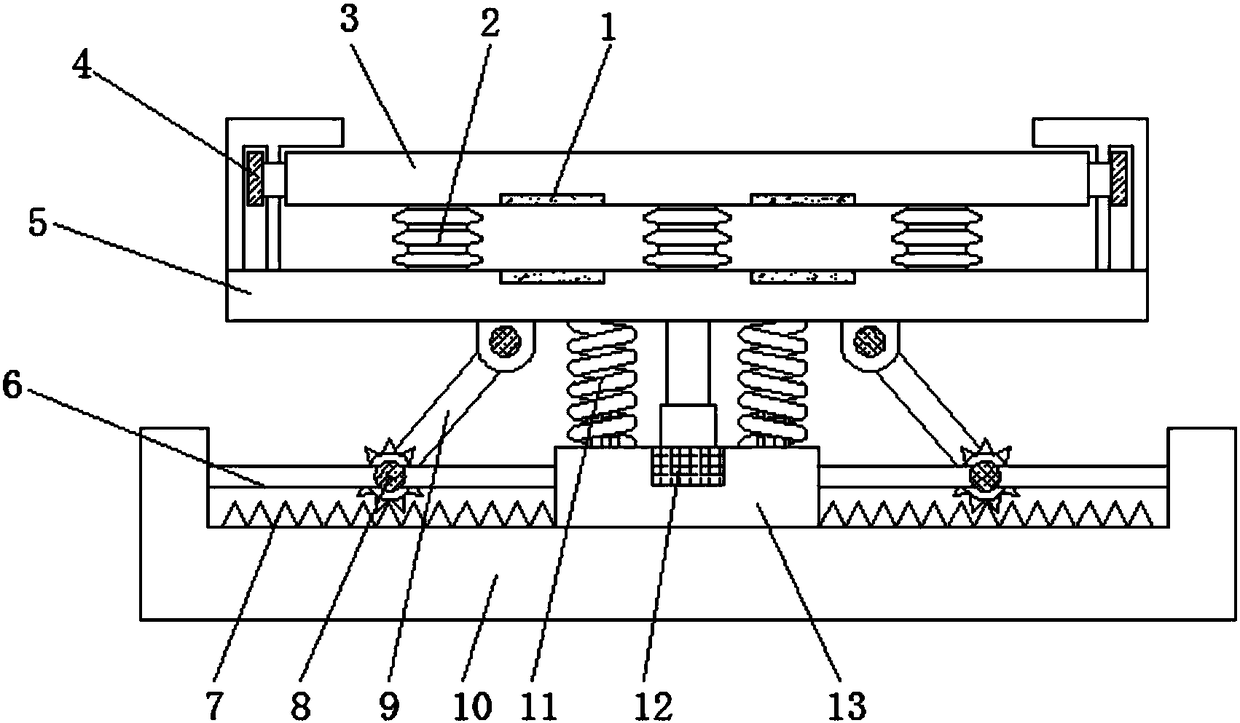

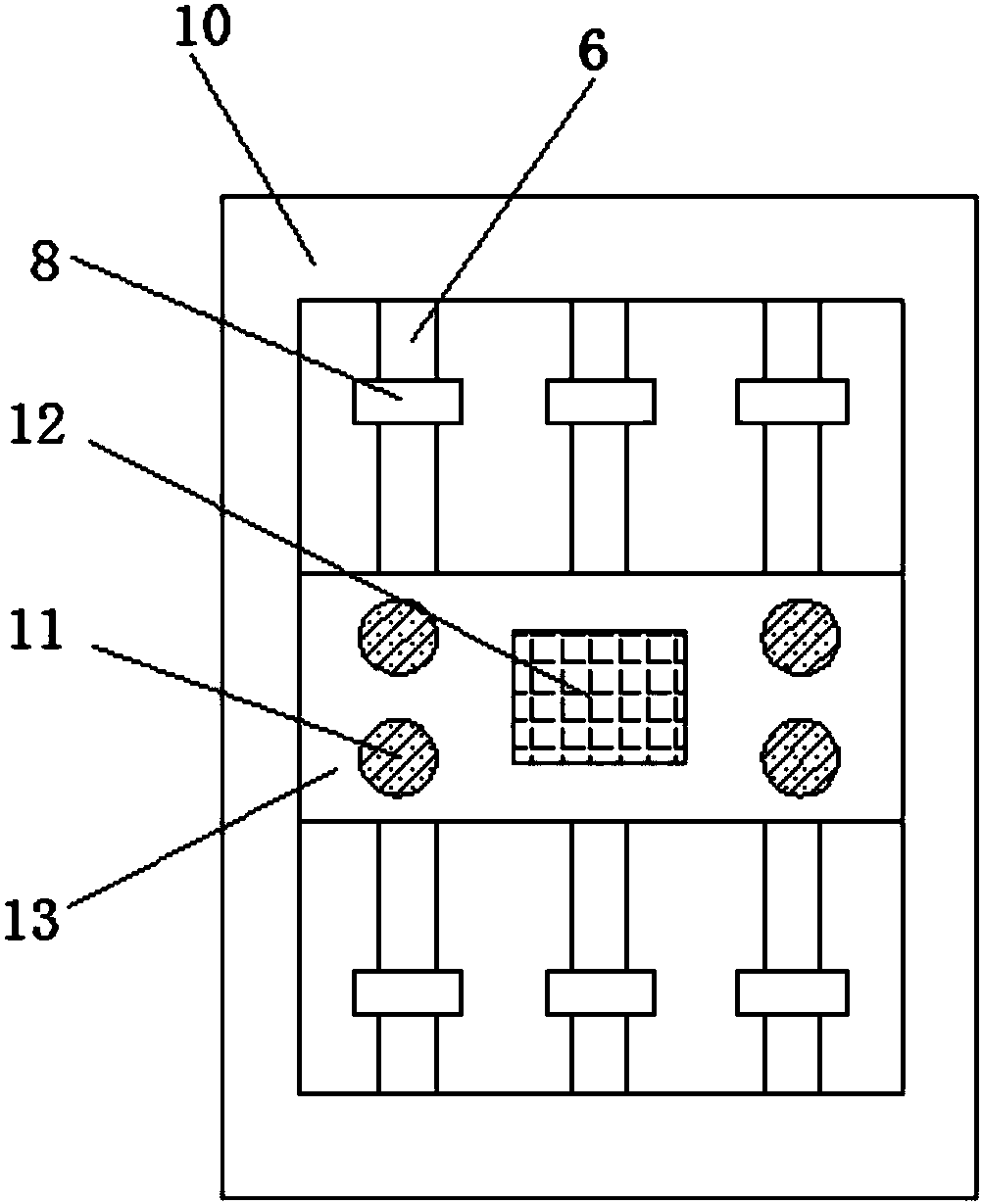

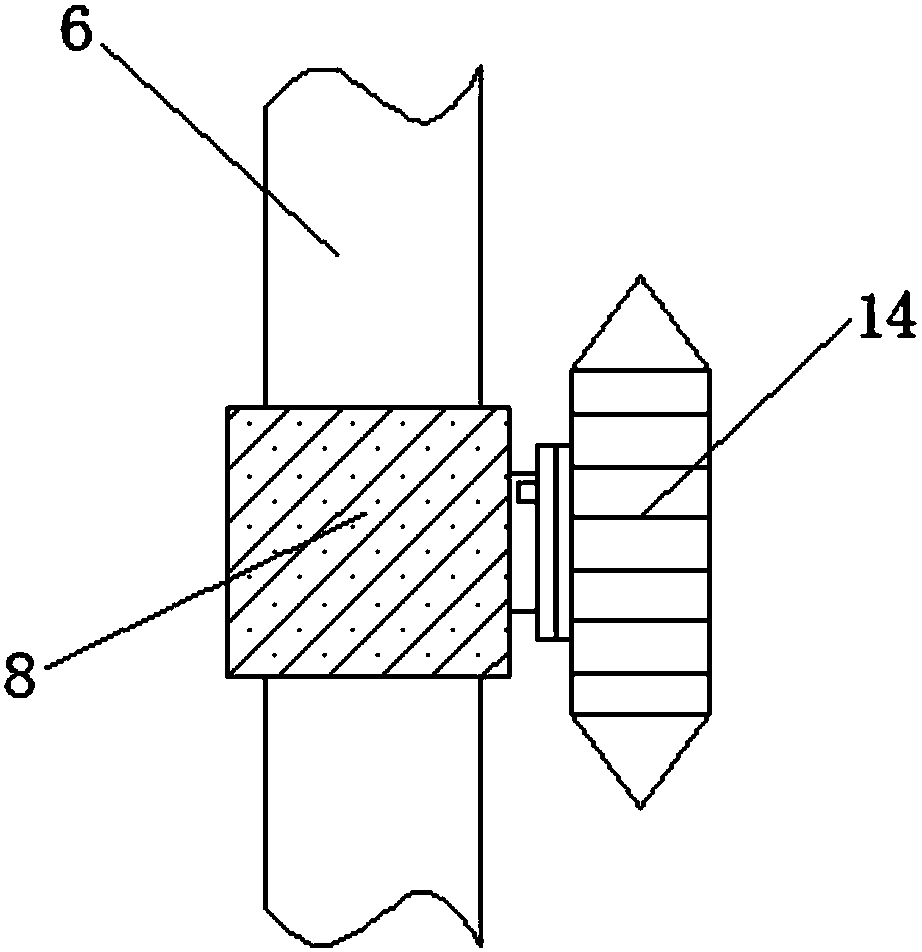

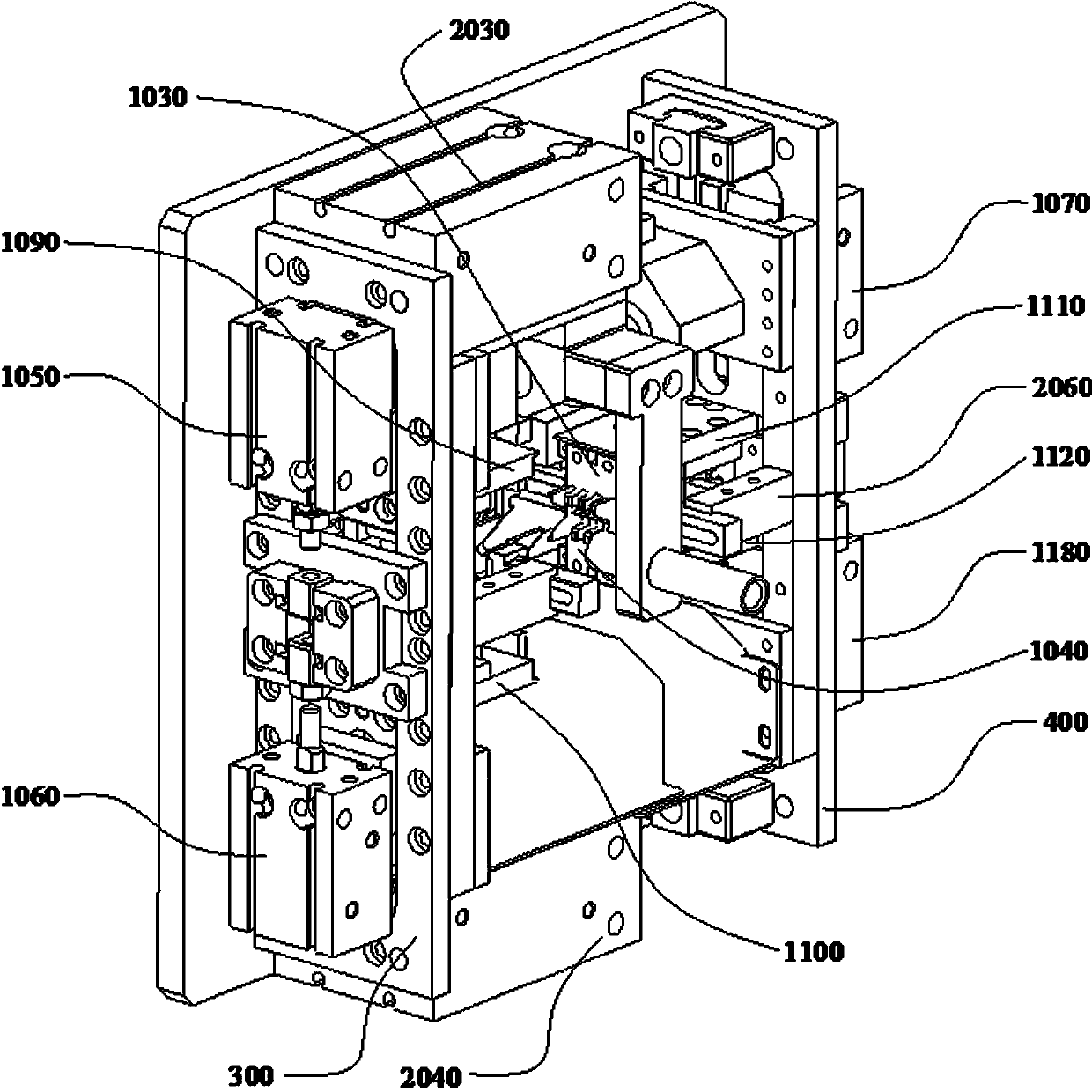

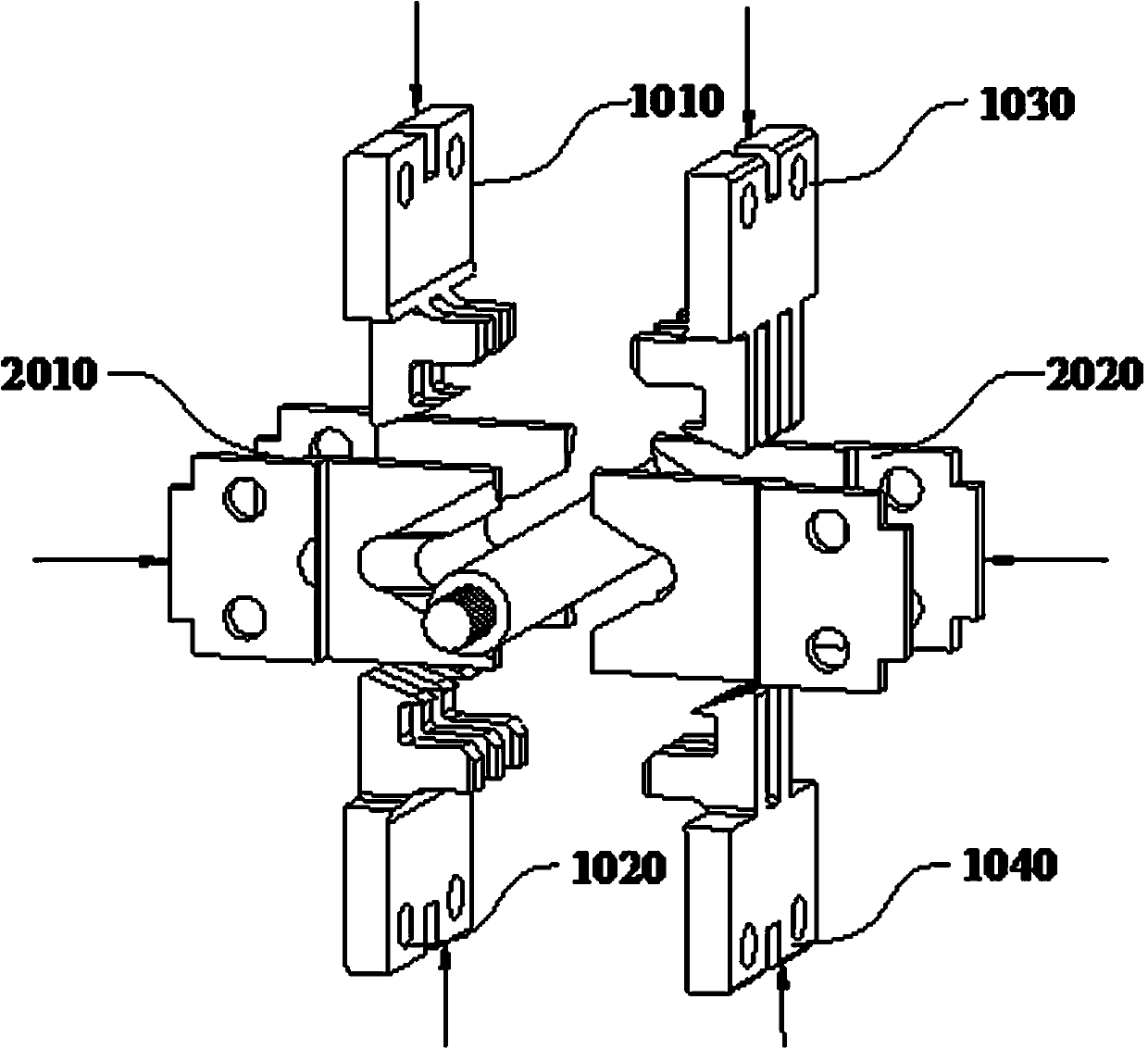

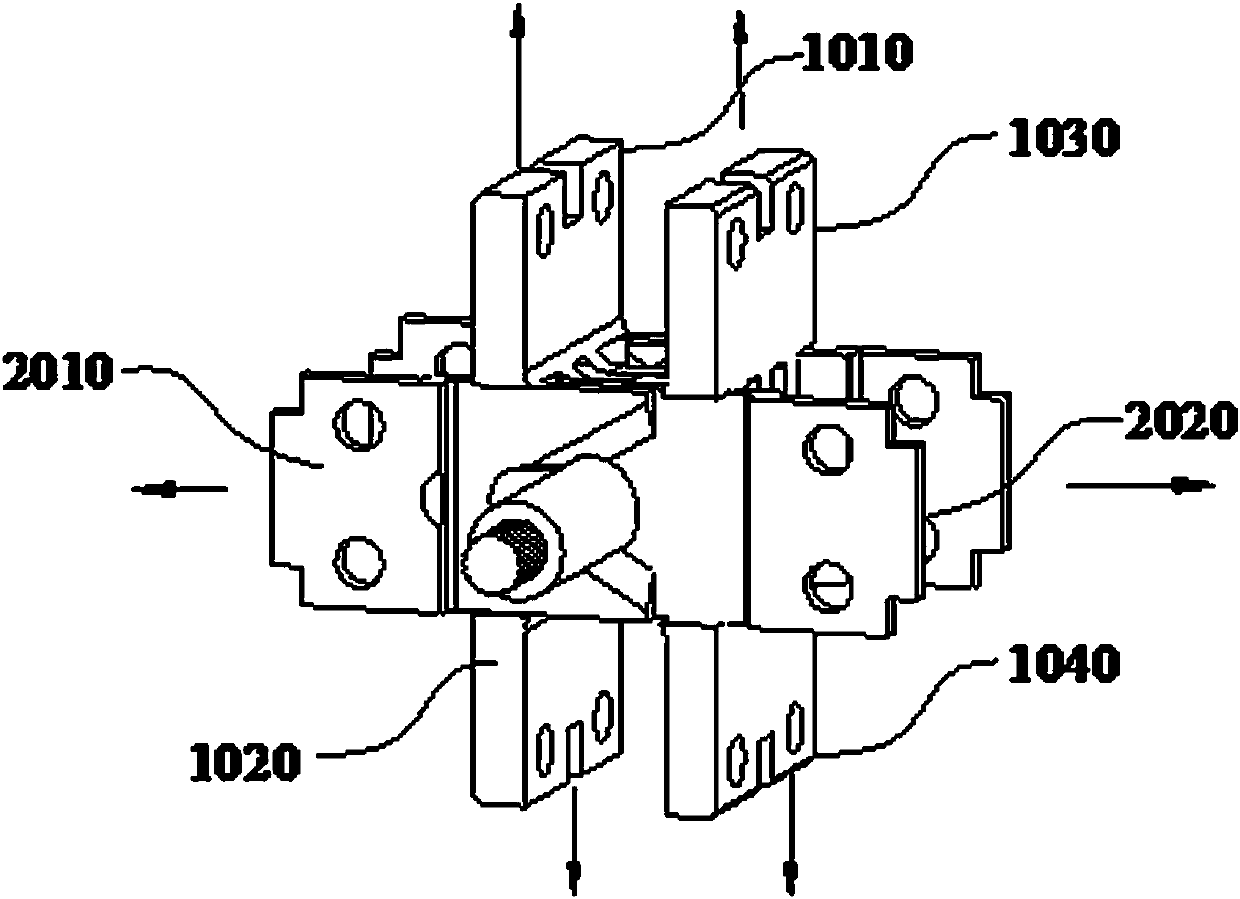

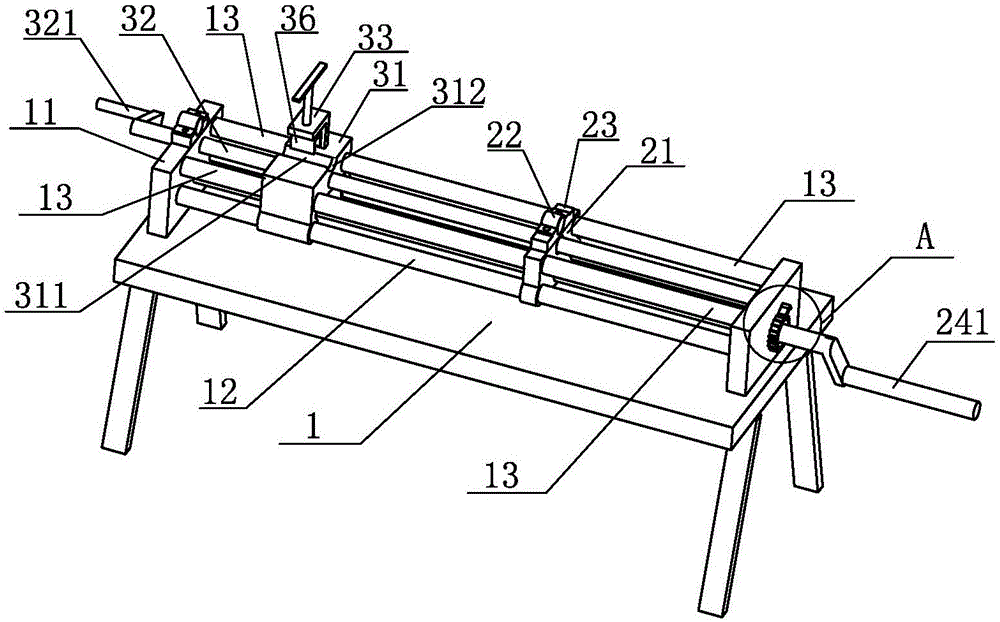

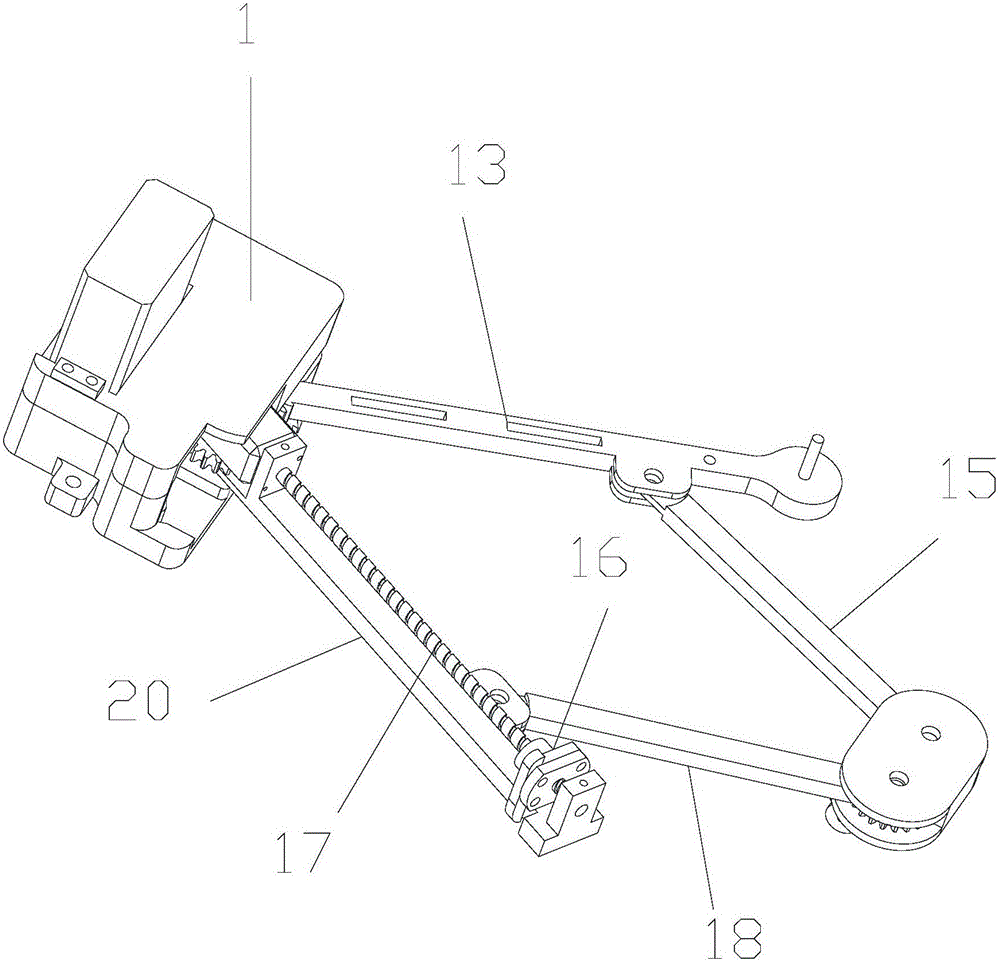

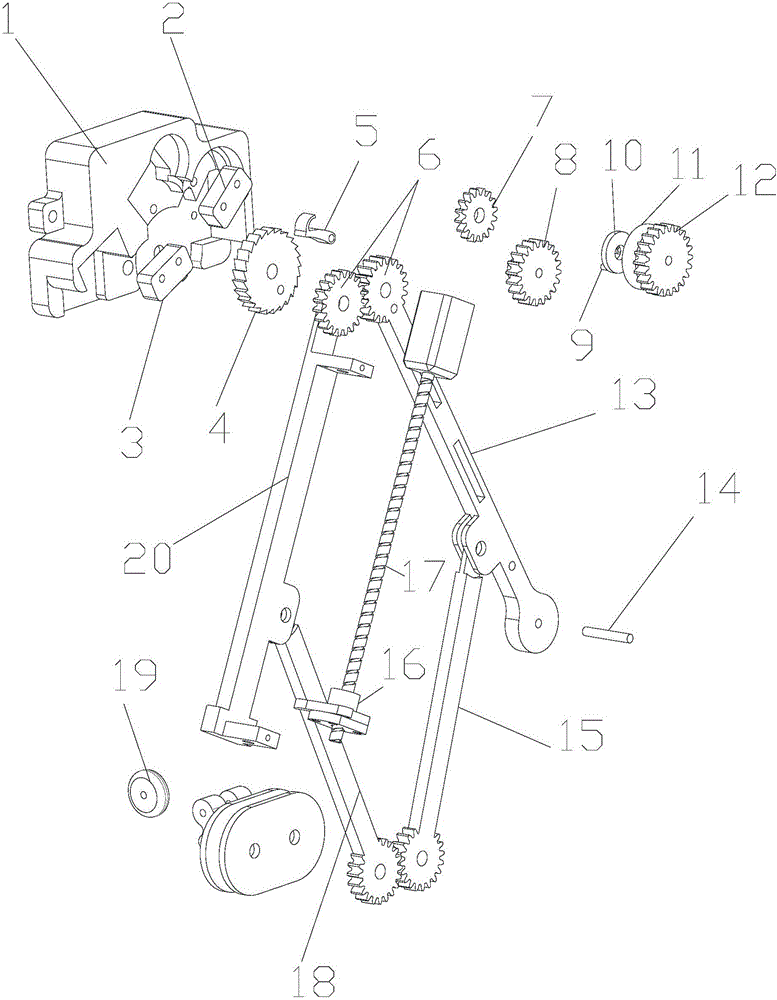

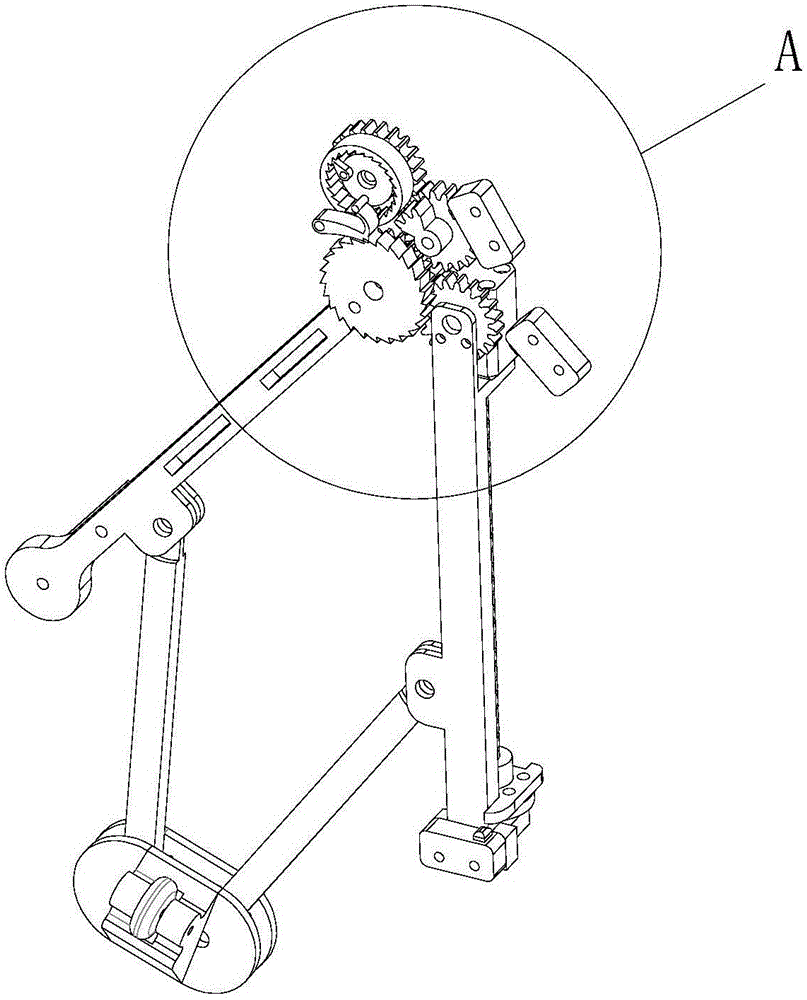

Plate multipoint forming device with crease resistant functions

ActiveCN102248053AReduce designAchieve moldless formingShaping toolsBiomedical engineeringEquipment use

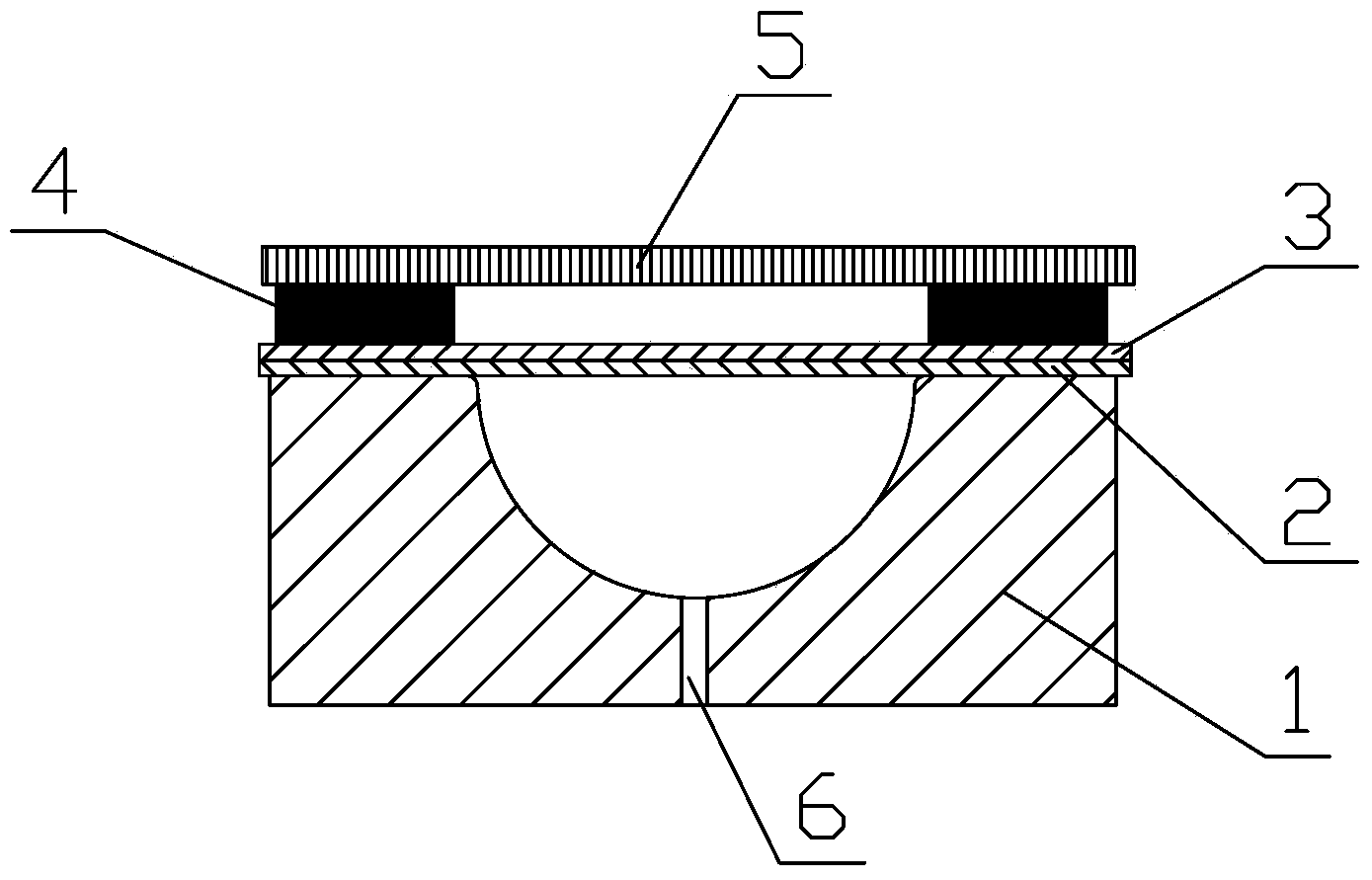

The invention discloses a plate multipoint forming device with crease resistant functions, relating to plastic processing equipment used for plate curved surface forming and belonging to the field of mechanical engineering. The device mainly comprises shape-adjusting units (1), clamping units (2), a unit fixing plate (4) and a loading mechanism and is characterized in that the shape-adjusting units (1) and the clamping units (2) are arranged in a staggering manner; enveloping surface shapes of the plurality of shape-adjusting units (1) with adjustable heights can be changed through a shape-adjusting mechanism; the traditional entity die is replaced; and the plurality of clamping units (2) which are shifted passively are used for clamping a plate through back pressure effects to replace a side-pressing mechanism. The device can be used for inhibiting creases and rebound when the plate is formed and used for forming complex outline curved surface members with different sizes, therefore, the step of cutting sides after forming is omitted, and the utilization rate of the plate is improved.

Owner:JILIN UNIV

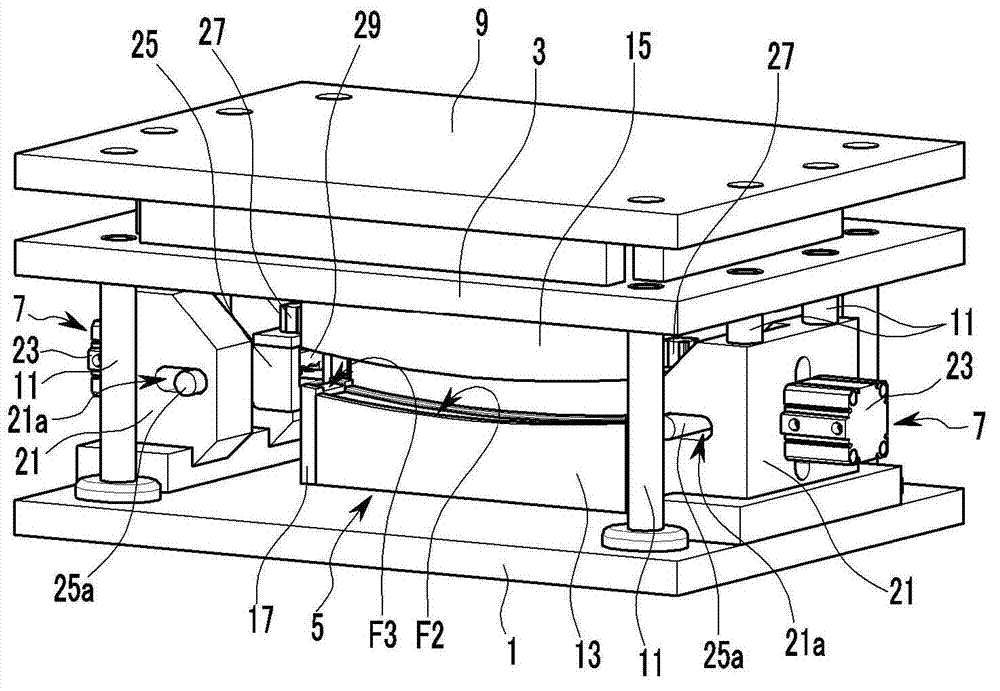

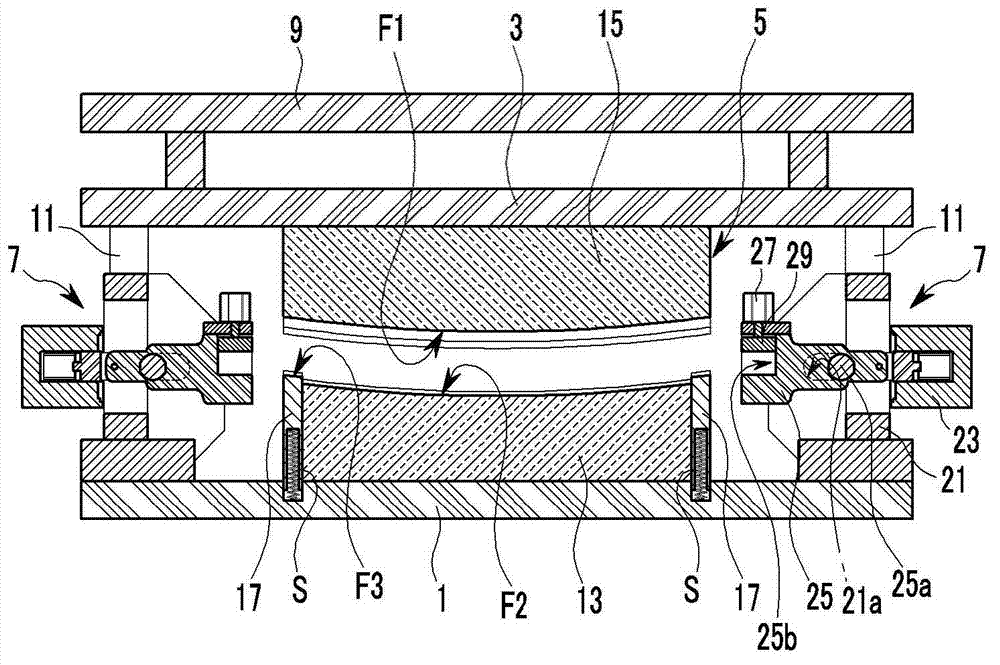

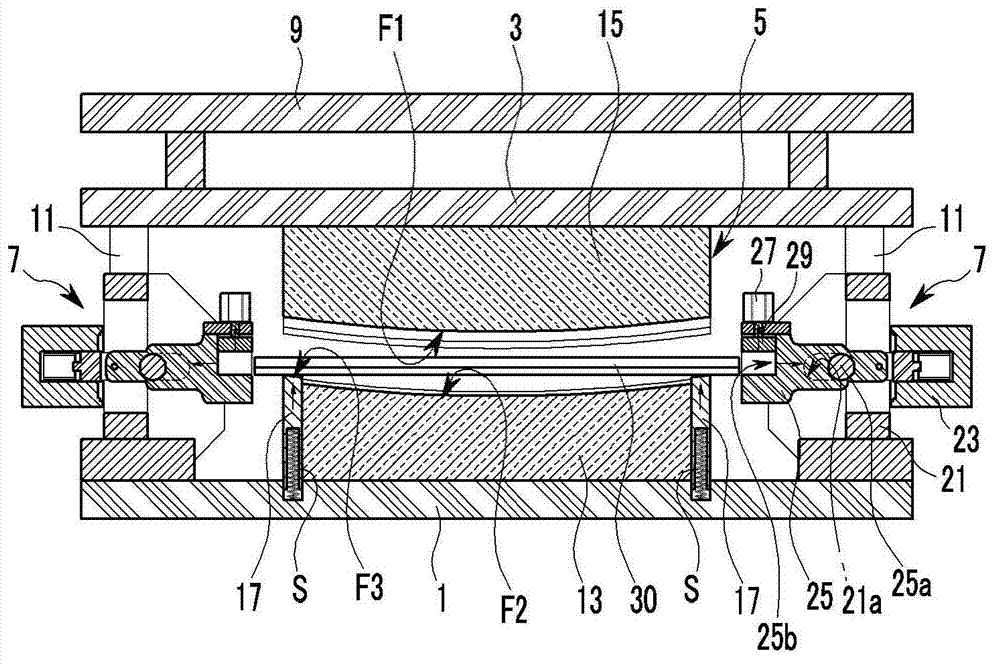

Bending press system

A bending press system is disclosed. The bending press system may include: at least one guide post; a slide plate mounted at a slider so as to be slidable upwardly or downwardly along the guide post; a bending die including a lower die having an upper surface and an upper die having a lower surface corresponding to the upper surface of the lower die and mounted on a lower surface of the slide plate, and adapted to bend an object supplied between the lower die and the upper die to have a predetermined curvature; and a pair of clamping means mounted respectively at both sides of the bending die corresponding to the bending die and adapted to clamp both end portions of the object.

Owner:SUNG WOO HITECH

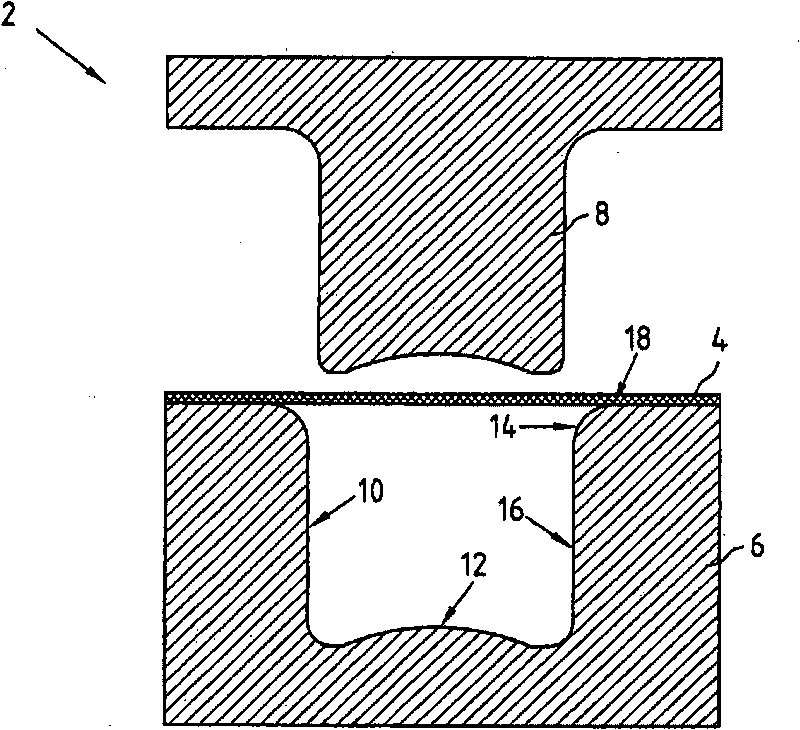

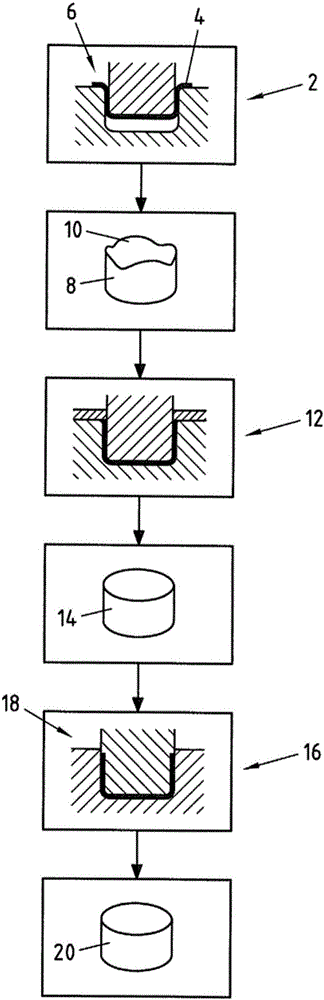

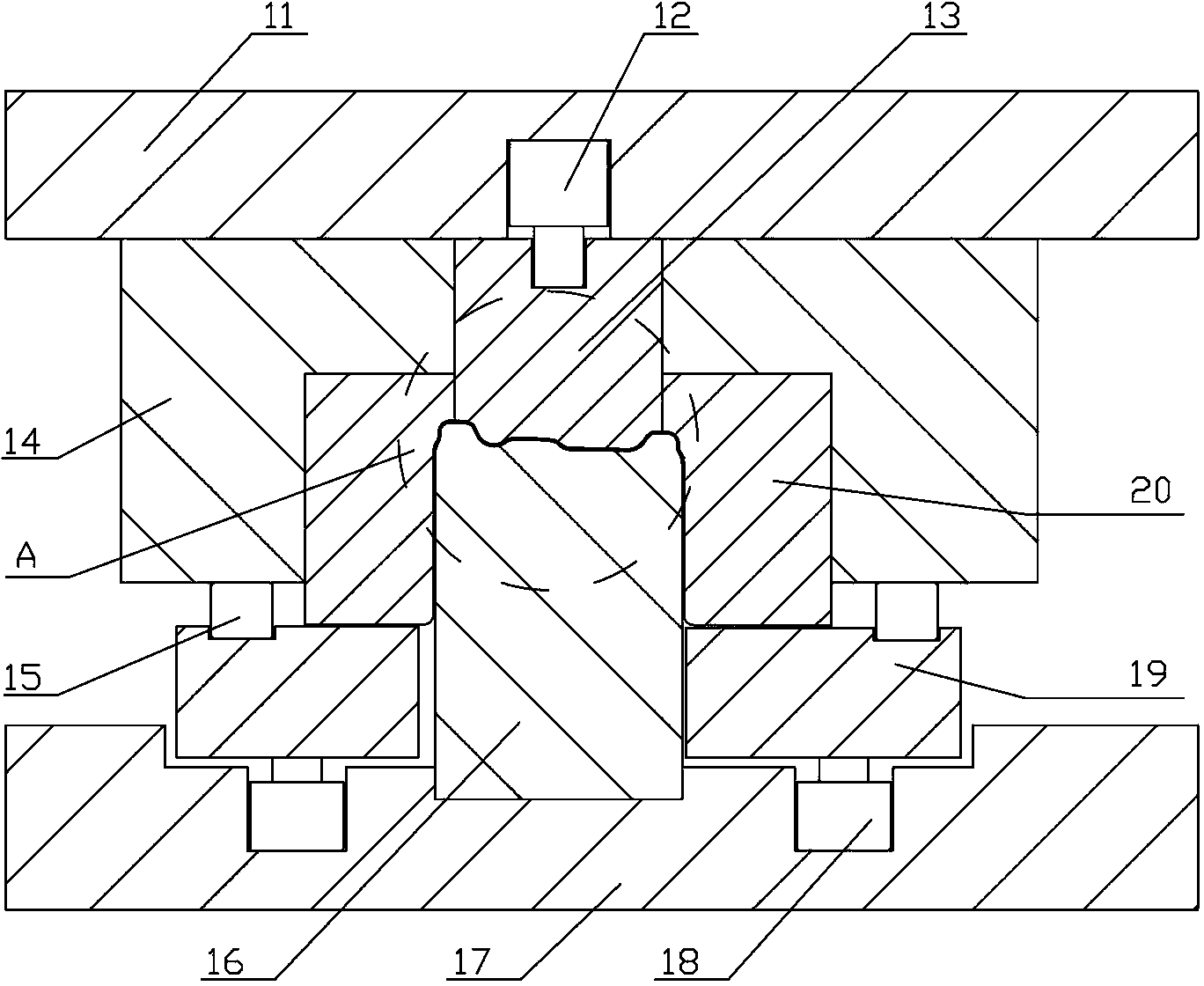

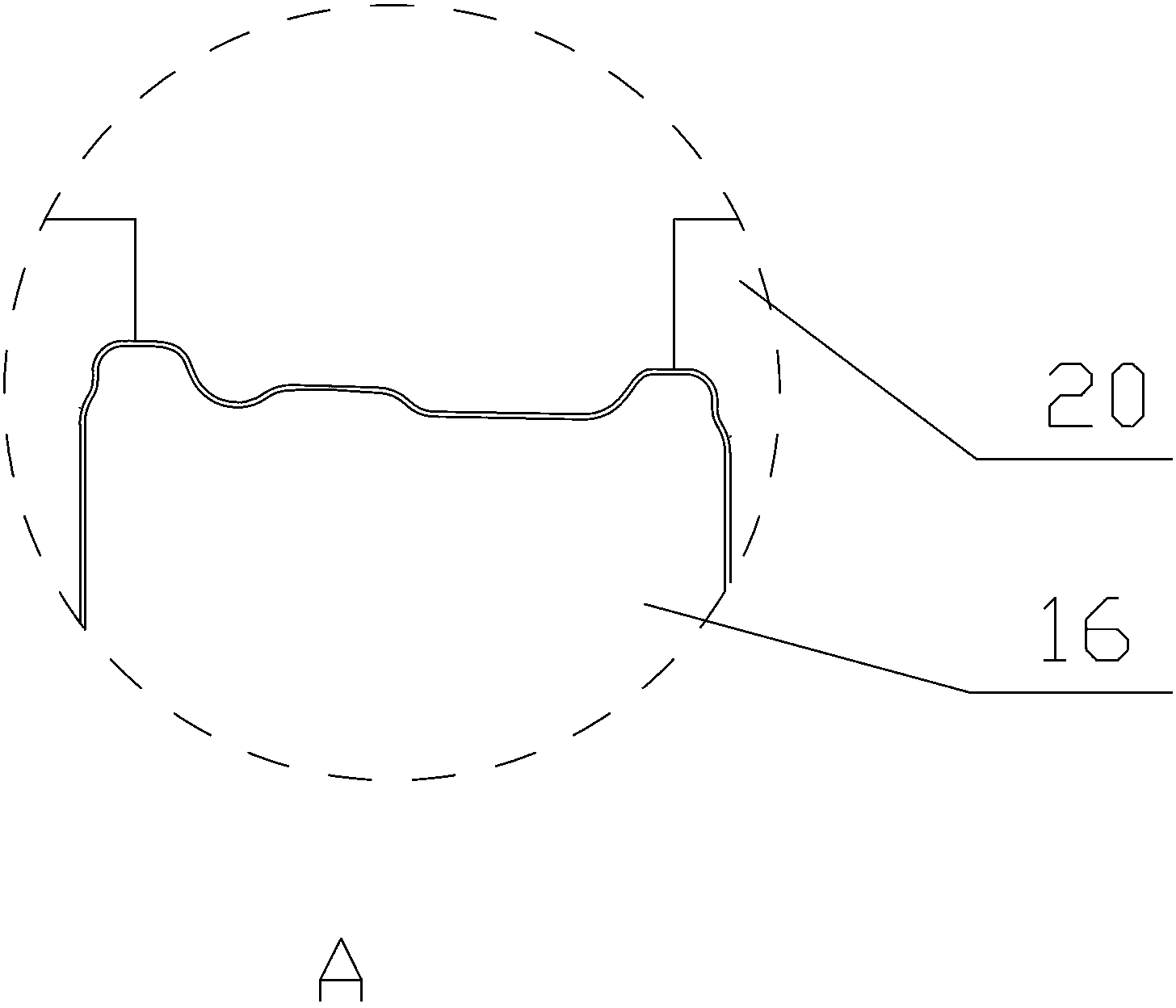

Method and device for producing highly dimensionally accurate flanged half shells

ActiveCN101758148AHigh dimensional accuracyPrevent springbackVehicle componentsBody regionDimensional precision

A method for producing highly dimensionally accurate, deep-drawn half shells with a base region (122), a body region (116) and a flange region (118), includes firstly forming a pre-formed half shell (24, 50, 72, 92) from a blank (4) and then shaping the pre-formed half shell (24, 50, 72, 92) into a finally formed half shell (112), wherein the pre-formed half shell has excess blank material due to its geometric shape and wherein, owing to the excess material during the shaping of the pre-formed half shell into its final shape the half shell is compressed into the finally formed half shell by at least one further pressing process. The method requires that the pre-formed half shell has excess blank material in a transition region between the body region and flange region.

Owner:THYSSENKRUPP STEEL EURO AG

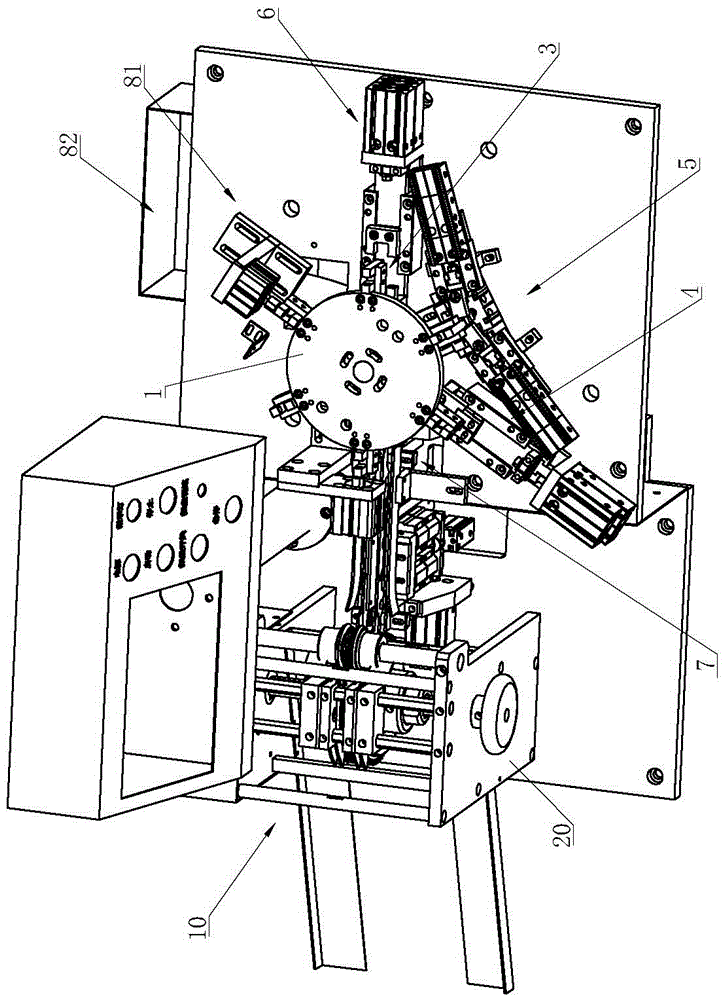

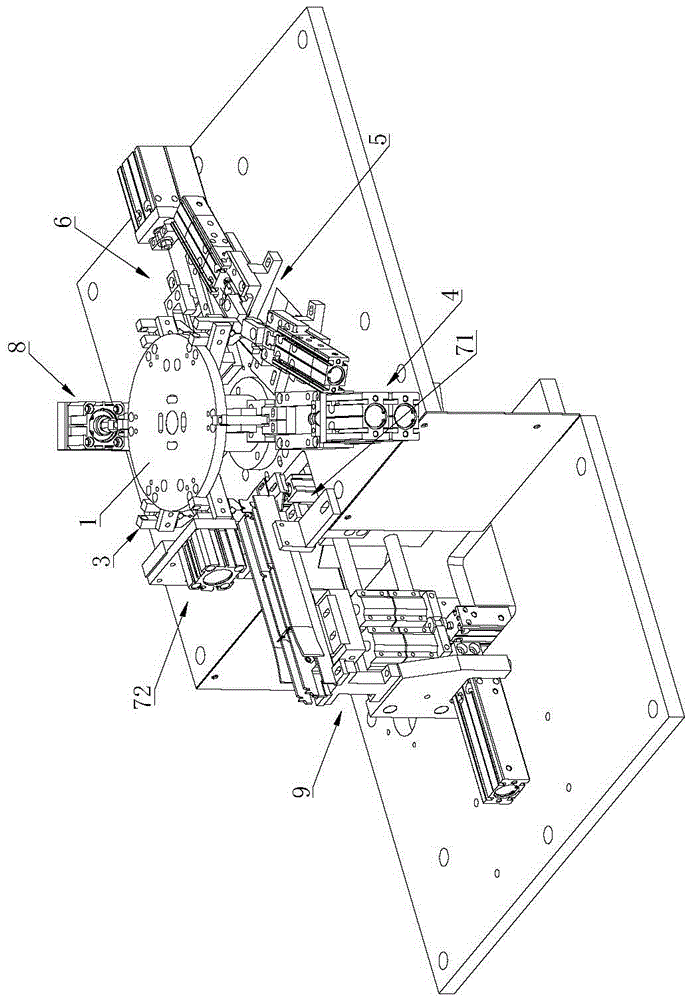

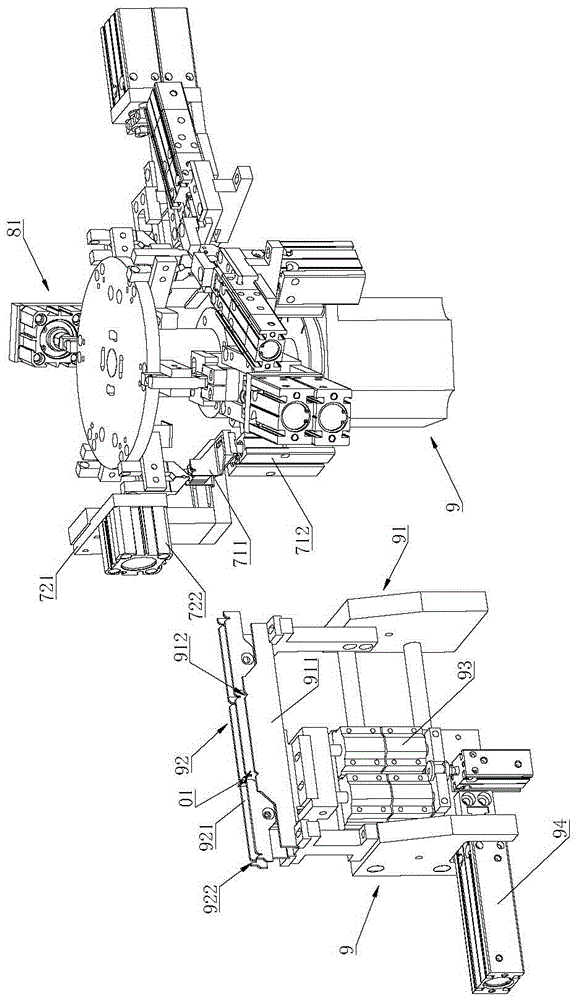

Electronic element pin forming machine

ActiveCN106391926AImprove continuityAvoid clamping errorsContact member manufacturingEngineeringElectronic component

The invention relates to the technical field of electronic element machining equipment, in particular to an electronic element pin forming machine. The electronic element pin forming machine comprises a turntable, a turntable driving mechanism, multiple clamps arranged on the turntable, a first bending device and a second bending device for bending pins of electronic elements in sequence, and a flattening device for flattening the bent pins. The electronic element pin forming machine is excellent in continuity of conveying and machining of the electronic elements, accelerates the production speed, meanwhile, prevents the clamping error generated by repeated clamping of the electronic elements, and guarantees the forming precision of the pins of the electronic elements. In addition, the electronic element pin forming machine adopts the structure of rotary feeding by the turntable, so that the equipment is compact in structure, less in occupied space and convenient for installation and transportation. After two times of bending are performed for the electronic elements, the flattening is performed, so that the forming is easier to operate, the damage and the resilience after forming of the pins caused by once forming are prevented, and the product yield is improved.

Owner:东莞市捷瑞自动化科技有限公司

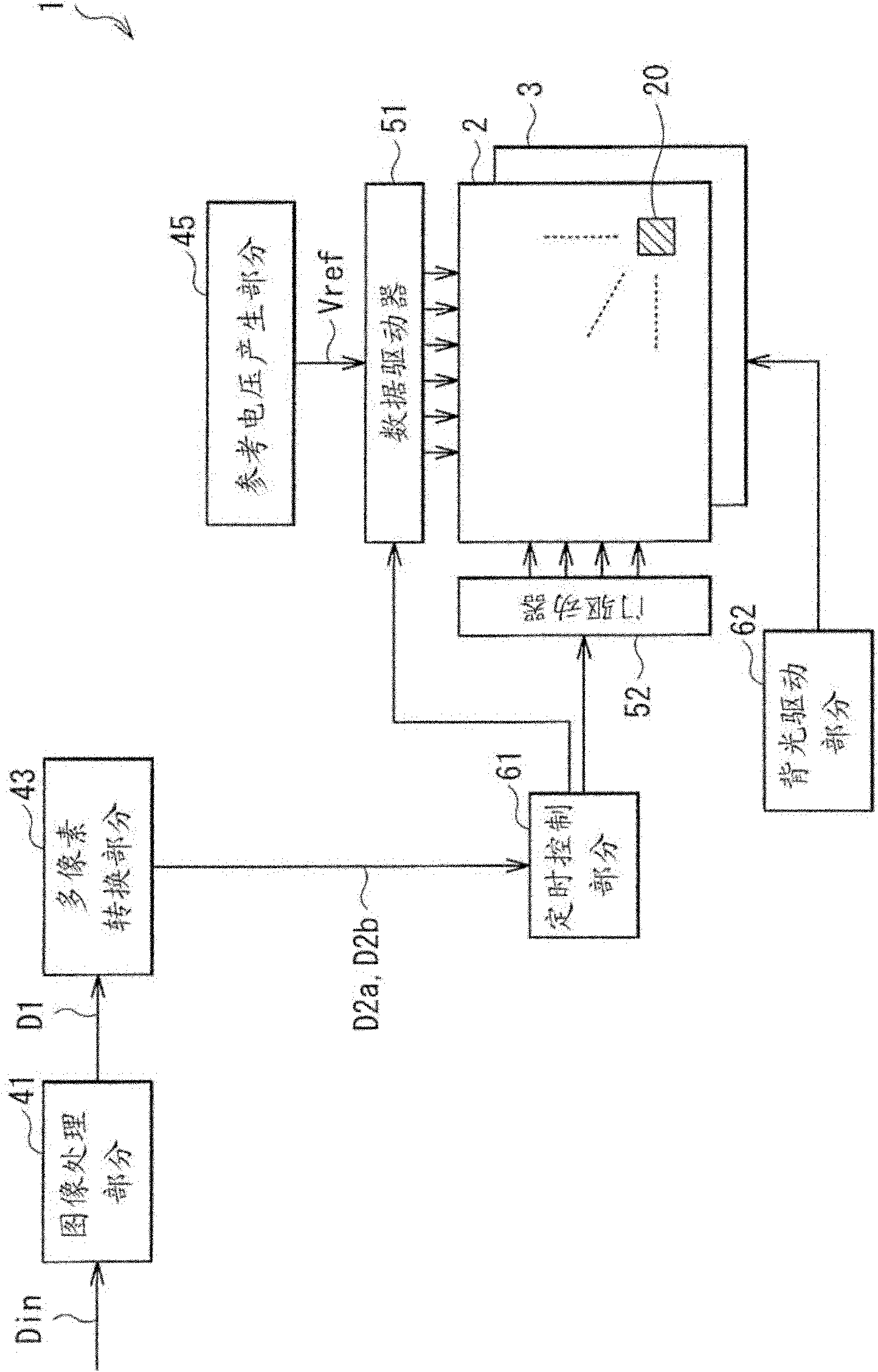

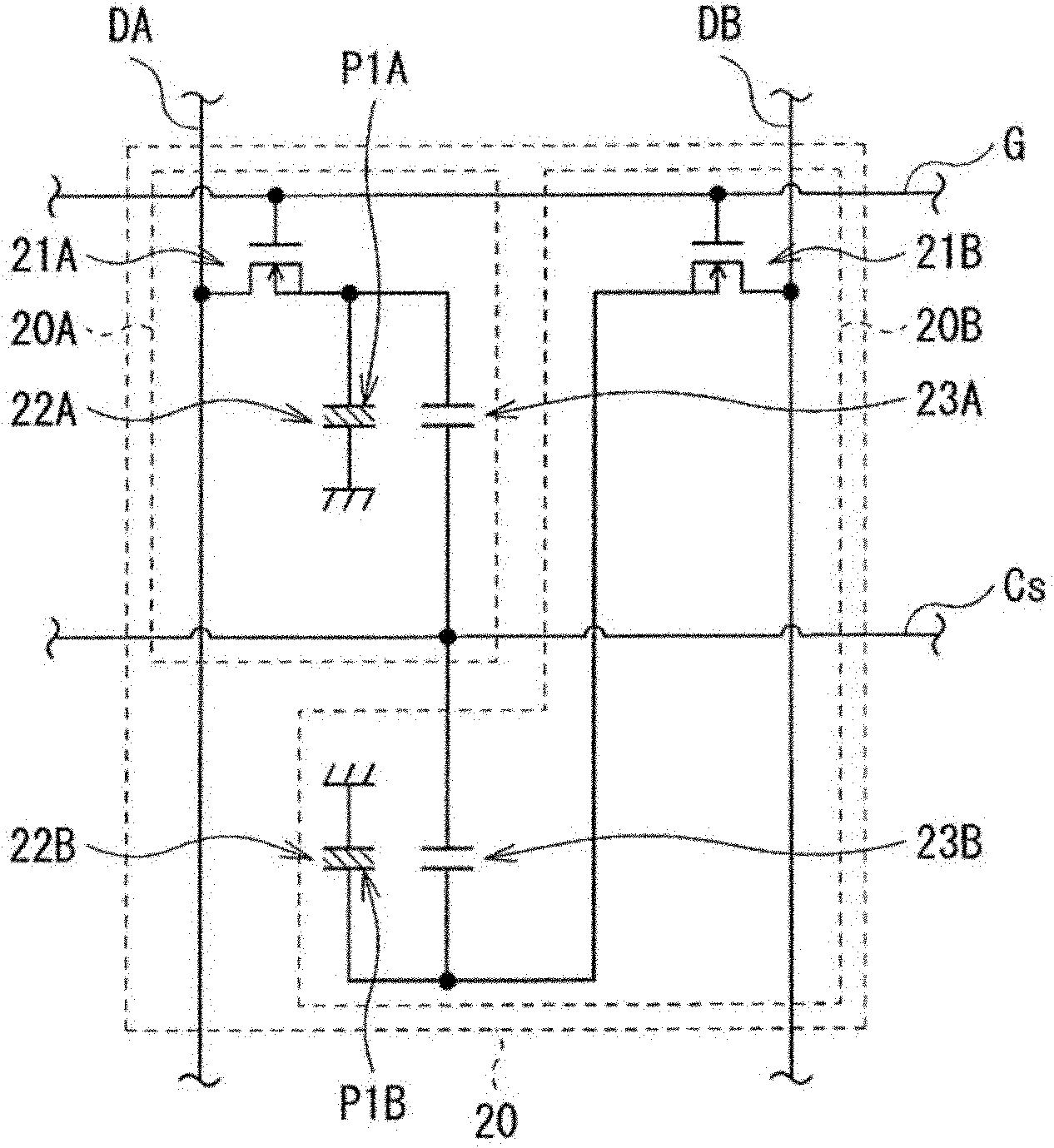

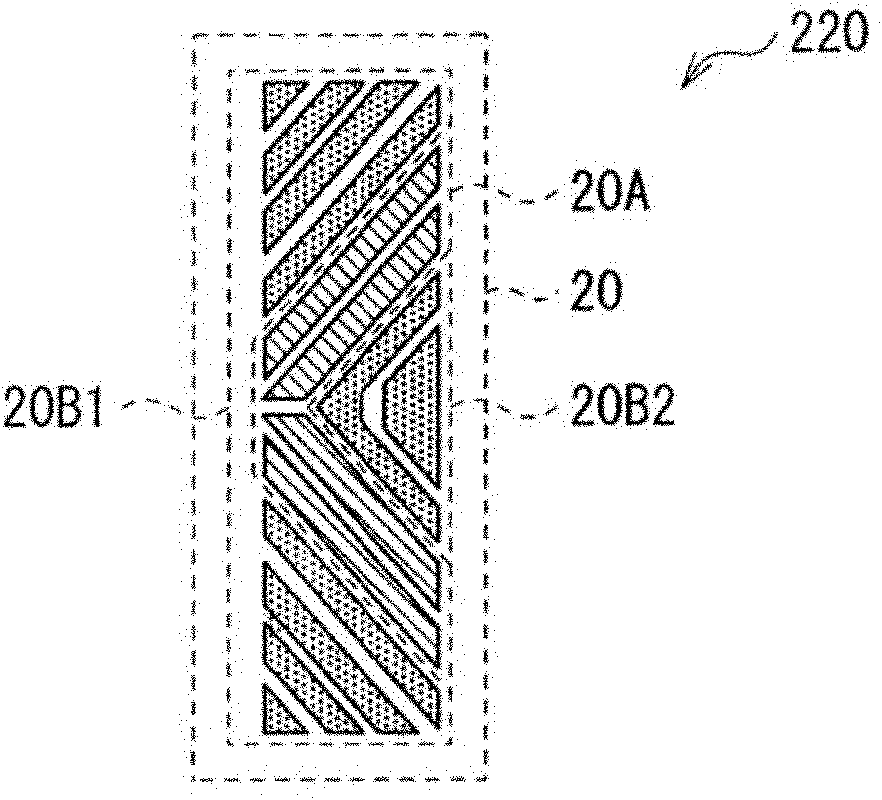

Liquid crystal display device

InactiveCN102138098APrevents the applied voltage from increasingImprove viewing angle characteristicsStatic indicating devicesNon-linear opticsLiquid-crystal displayLow voltage

Provided is a liquid crystal display device which uses a liquid crystal of a VA mode and which can improve a display picture quality better than the prior art while improving the field angle characteristics of luminance. At the time of divided drive actions on a sub pixel (20A), in a high luminance region, a liquid crystal applied voltage (D2a) to a liquid crystal element (22A) has a tendency to become lower than that in an intermediate luminance region while becoming a high voltage side at or higher than the input applied voltage for a picture signal (D1). As a result, the azimuthal angle deflection of the liquid crystal occurs less frequently than in the divided drive actions of the prior art. At the time of divided drive actions on a sub pixel (20B), in a low luminance region, on the other hand, a liquid crystal applied voltage (D2b) to a liquid crystal element (22B) has a tendency to become higher than that in the intermediate luminance region while becoming a low voltage side at or lower than the input applied voltage for the picture signal (D1). As a result, at the time of performing an overdrive, a rebounding phenomenon occurs less frequently than in the divided drive actions of the prior art.

Owner:SONY GRP CORP

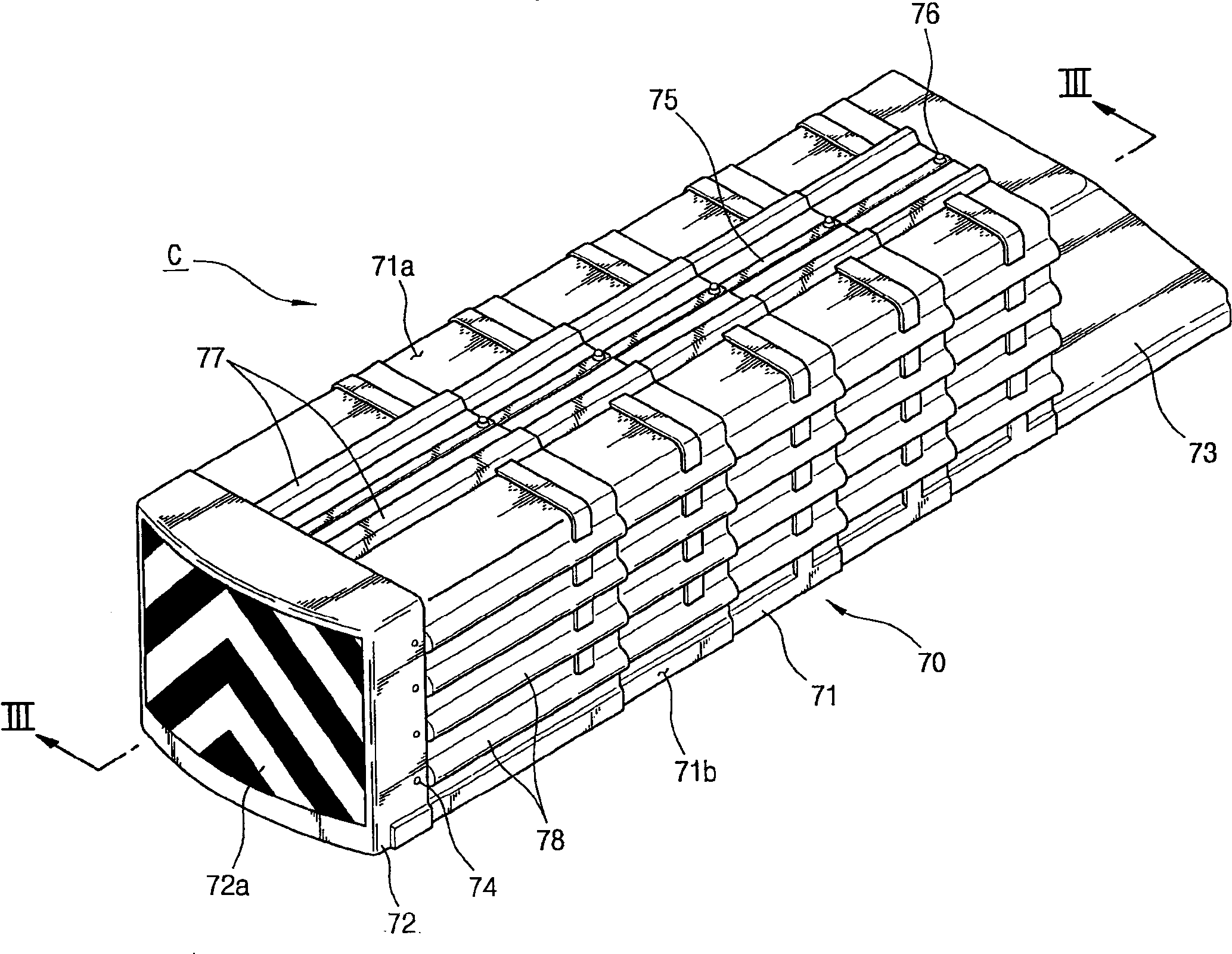

Vehicular impact absorbing apparatus having cushion pins

InactiveCN1653232AEffective absorptionPrevent springbackRefuge islandsRoadway safety arrangementsEngineeringCushion

A vehicular impact absorbing apparatus is disclosed. The apparatus includes a pair of tubular guide rails having a guide slit longitudinally formed at the upper part of each guide rail fixed to the ground. A plurality of sliders are movably mounted in the guide rail at a predetermined intervals, the upper part of each slider is laid on the upper part of the guide rail through the guide slit. A plurality of cushion units are mounted on the upper part of each slider. Each cushion unit is elastically deformed by vehicular impacts with retracting alongside the guide rail. A group of cushion pins are mounted across the guide rails at predetermined intervals between the sliders. The cushion pins also absorb the kinetic energy of an impact by being broken in turn by the slider that is retracting rearward. A stopper is installed around the rear end of the guide rail for stopping the retracting cushion units. A side fence is retractably mounted alongside the cushion units; the one end of the side fence is fixed to the stopper and the other to the front cushion unit. A successive cushion and deceleration of the impacts is possible in this arrangement.

Owner:姜胜求

Forming method of titanium alloy thin-walled casing

The invention discloses a forming method of a titanium alloy thin-walled casing. The forming method comprises the steps as follows: a concave mold is fixed on the workbench of a press; a titanium alloy plate 0.2-4 mm in thickness is placed on the concave mold, a lining plate is arranged above the titanium alloy plate, and an edge pressing ring is placed on the lining plate; an electromagnetic coil is fixed on the sliding block of the press, and the electromagnetic coil is contacted with the edge pressing ring since the sliding block on the press runs downwards; the electromagnetic coil is subjected to discharge by adopting an electromagnetic forming method, the lining pate deforms under the action of the electromagnetic force generated by the electromagnetic coil and further prompts the formation of a titanium alloy plate film, and a titanium alloy thin-walled casing 0.2-4 mm in wall thickness is obtained. The forming method has a simple method and a good formation effect. Resilience of the titanium alloy can be effectively avoided by adopting the method to form the titanium alloy thin-walled casing, and finally, the titanium alloy thin-walled casing with high size precision is formed.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

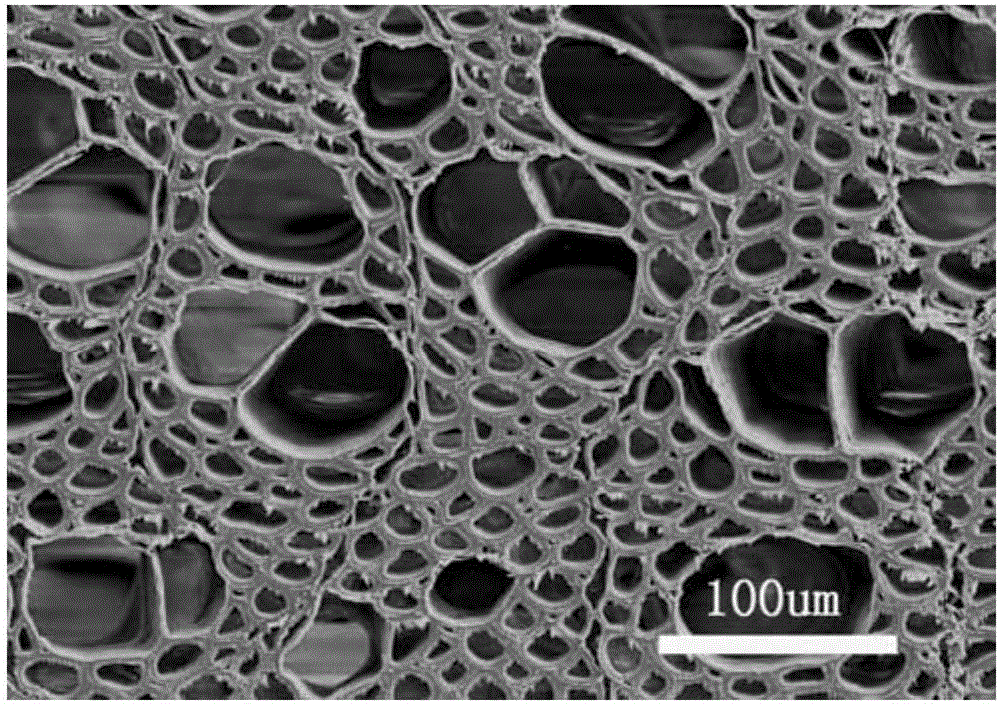

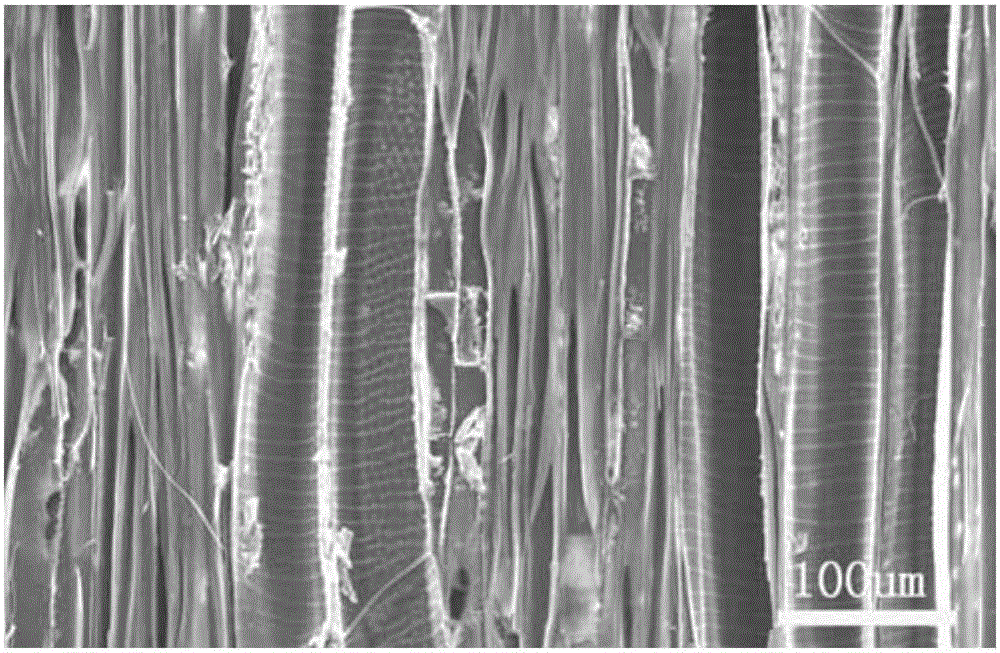

Method for manufacturing compressed carbonized poplar board

InactiveCN101733805AReduce stressGood dimensional stabilityWood compressionWood charring/burningCarbonizationHardness

The invention relates to a method for manufacturing fast-growing wood sheet, in particular to a manufacturing method for modifying a fast-growing poplar board, belonging to the technical field of sheet manufacture. The invention has the advantages of small internal stress of a compressed carbonized poplar board manufactured by the method and good stability of the size of the board, thereby ensuring the quality of a compressed carbonized wood. The invention overcomes the defects of a fast-growing poplar sheet, such as low density, low hardness, low strength, easy corrosion, difficult direct use and the like, improves the density of the sheet by carrying out compression and densification for the poplar sheet, carries out carbonization on the compressed poplar sheet on the condition of pressurization, and eliminates the compression stress inside the sheet so as to prevent springback of the sheet and improve the size stability, density and strength. The poplar board manufactured by the method can be directly used as a sheet. The compressed carbonized poplar board can be partially or entirely used to replace high-quality precious wood, thereby relieving the contradiction between continuously reduced precious wood resources and increasing demand for wood.

Owner:NANJING FORESTRY UNIV

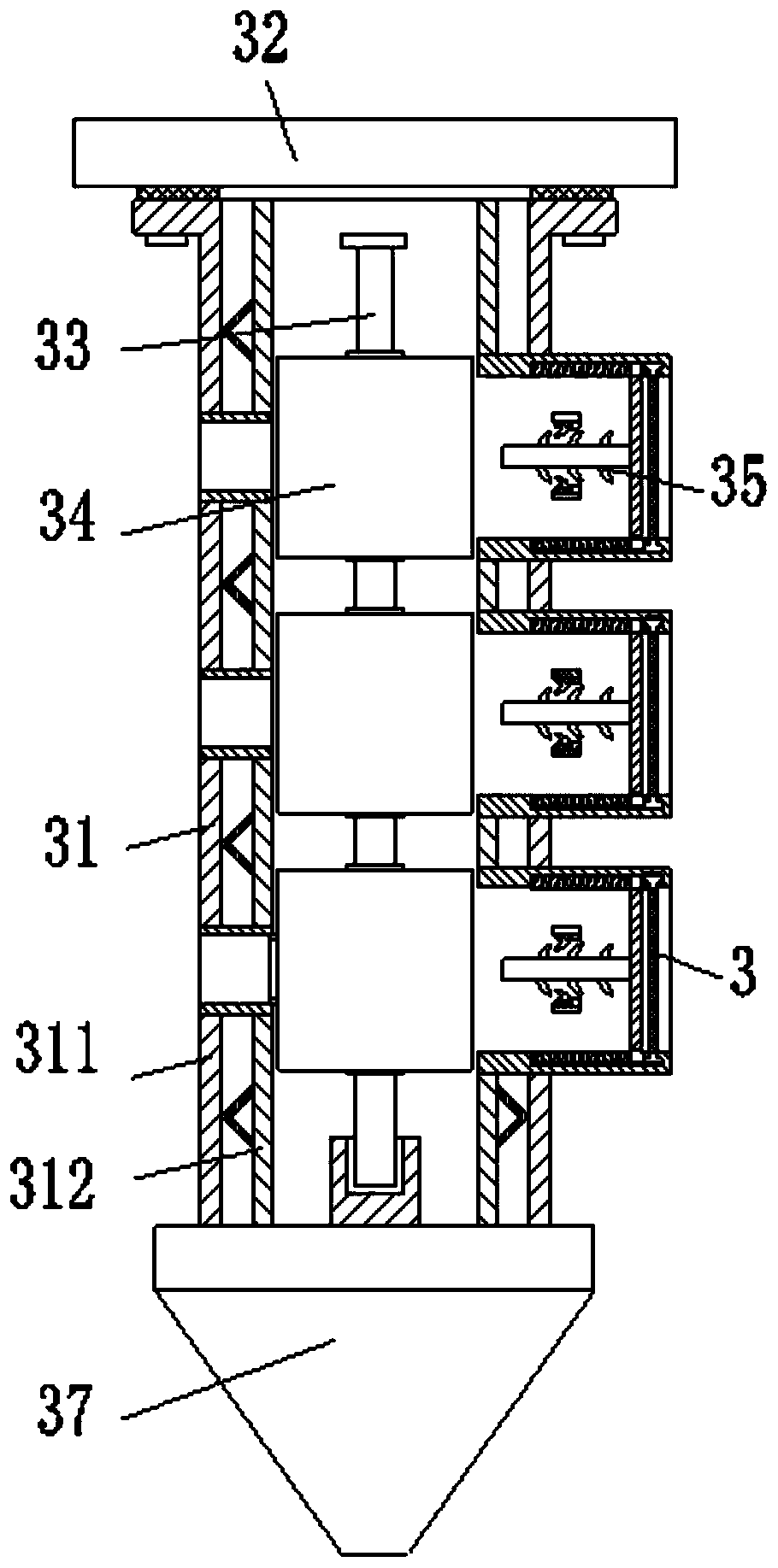

Multistage marine water quality stratified sampling equipment and sampling method thereof

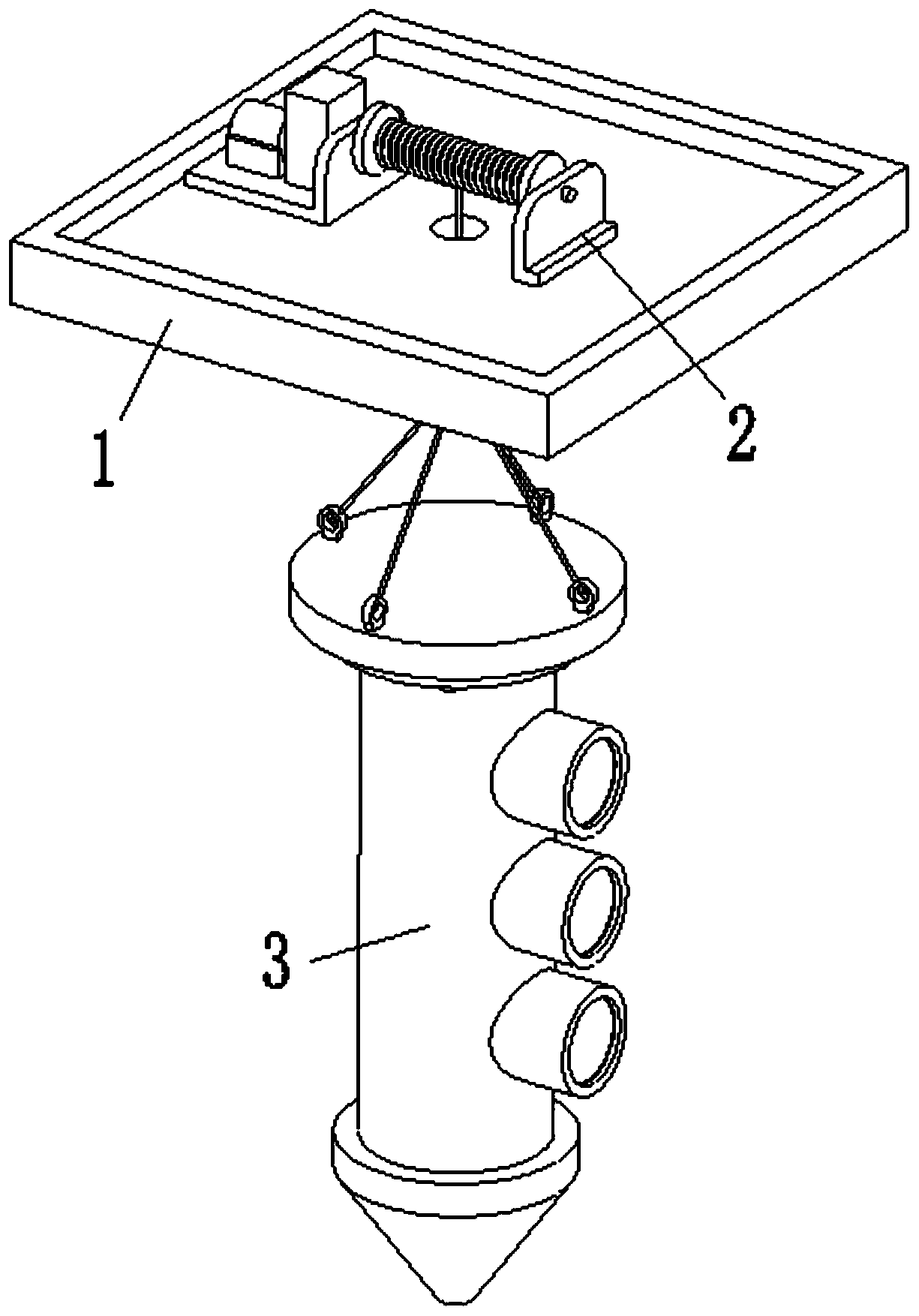

InactiveCN111024453APrevent springbackPrevent backflowWithdrawing sample devicesEnvironmental engineeringMarine water quality

The invention relates to multistage marine water quality stratified sampling equipment and a sampling method thereof. The multistage marine water quality stratified sampling equipment comprises a floating plate, a pay-off device and a sampling device, wherein the floating plate is of a rectangular structure, the pay-off device is installed at the upper end of the floating plate, the sampling device is arranged below the floating plate, and the sampling device is connected with the pay-off device through a steel wire rope. The problems as follows are solved: when the existing equipment is usedfor sampling the ocean water quality, the sampling effect is poor and the sampling is inaccurate, and stratified sampling cannot be effectively carried out on seawater with different depths, which isnot conducive to the study of ocean water quality; and the existing equipment cannot effectively seal the sampled seawater when sampling the ocean water quality, so that the sampled seawater is easilymixed with seawater in areas with different depths, the sample is inaccurate, and the accuracy of a water sample analysis result is influenced.

Owner:金宇龙

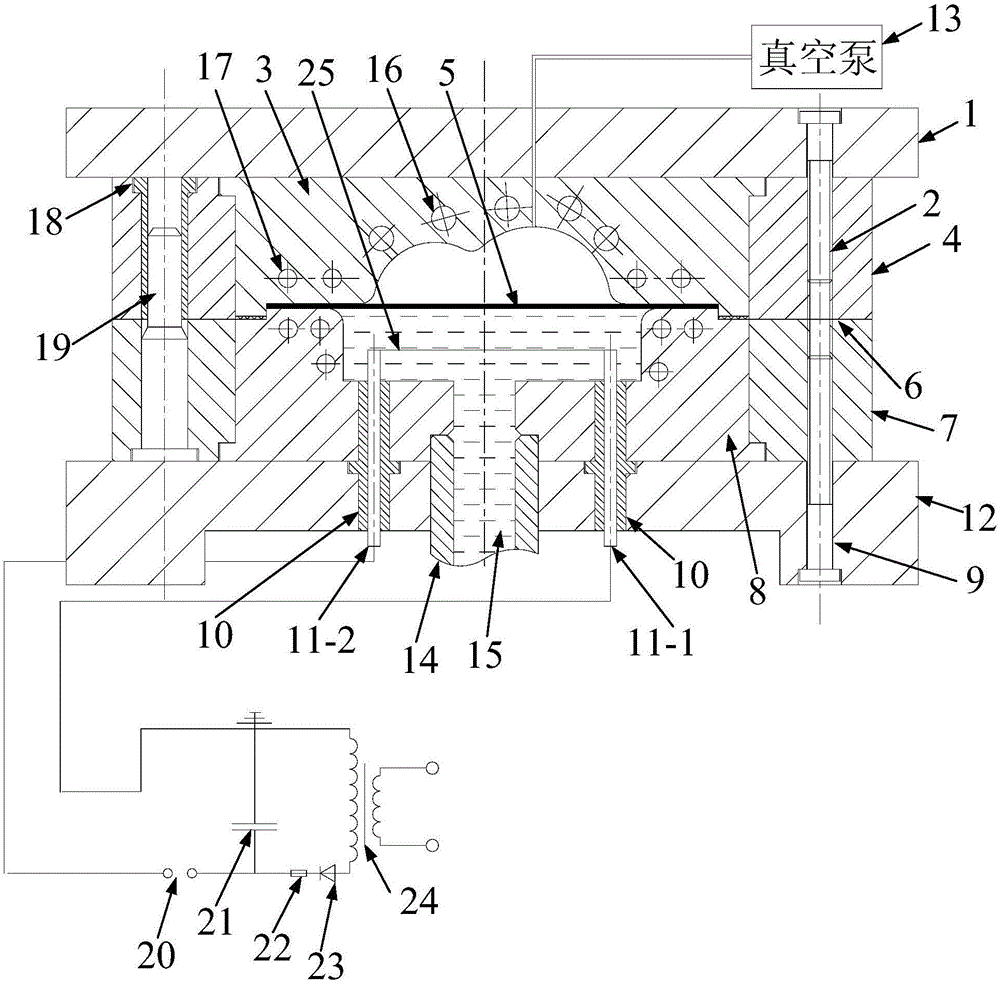

Plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and plate forming method achieved by adopting device

InactiveCN106734499AGuaranteed forming qualityAvoid crackingShaping toolsElectro hydraulicEngineering

The invention discloses a plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and a plate forming method achieved by adopting the device and relates to the field of metal material processing forming to solve the problems that forming of plates and complex parts is difficult, film attaching is poor, and deformation is not even. A vacuum pump is used for pumping out gas in a female die cavity; a fluid injection device is adopted for injecting high-temperature-resisting liquid to a liquid chamber; a heating device is used for heating the female die cavity, the high-temperature-resisting liquid in the liquid chamber is heated, preheating on a to-be-processed plate is completed, and heat preservation is conducted on the to-be-processed plate; an electromagnetic forming system is used for conducting discharging forming on the to-be-processed plate; high-pressure warm liquid is slowly injected into the liquid chamber under the quasi static condition, and quasi static hydraulic forming is conducted on the to-be-processed plate; and the high-pressure warm liquid in the liquid chamber is cooled to the room temperature within a period of time, waste liquid is recycled, an electro-hydraulic forming die is opened, and the to-be-processed plate is taken away. The device and the method are used for forming plates.

Owner:XIANGTAN UNIV

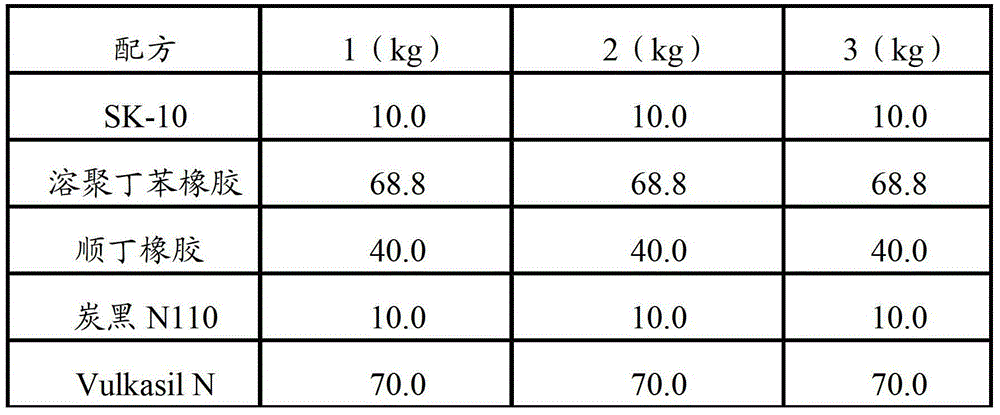

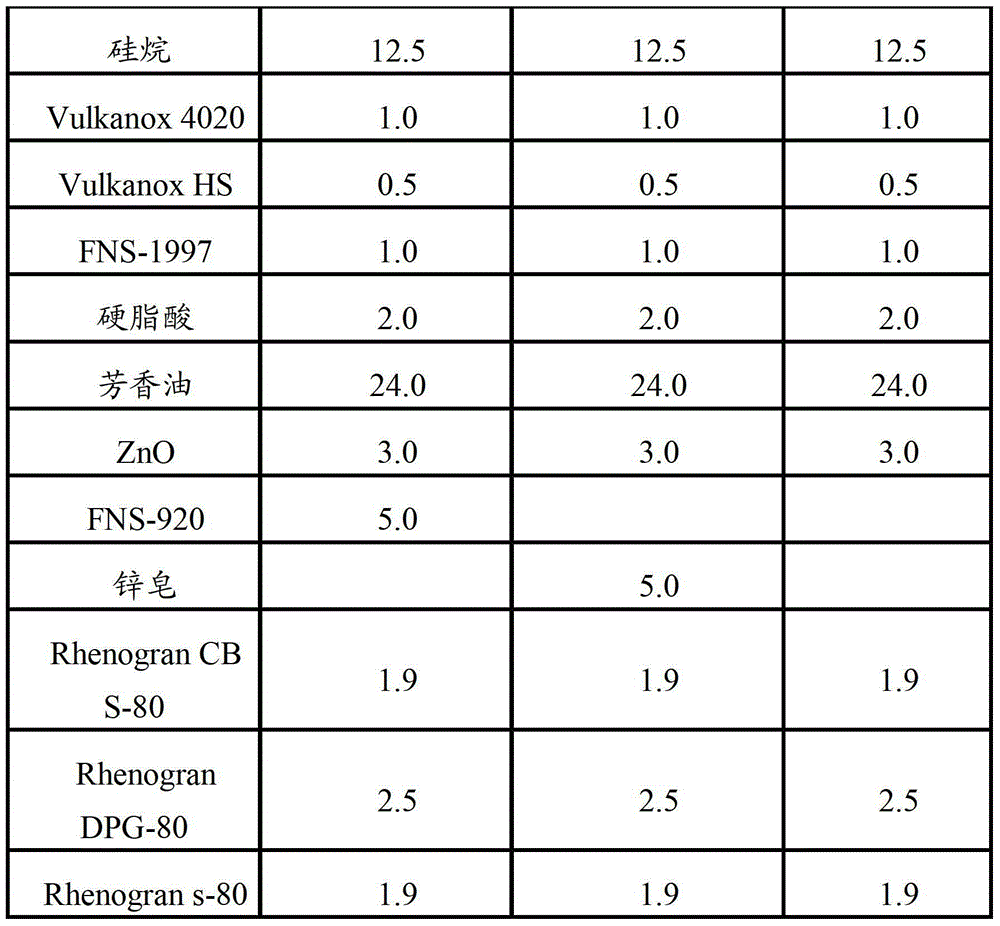

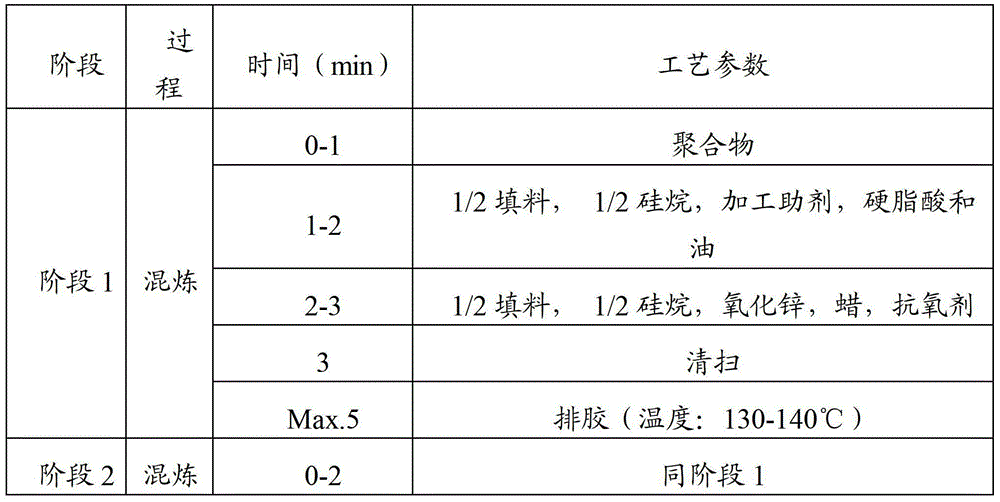

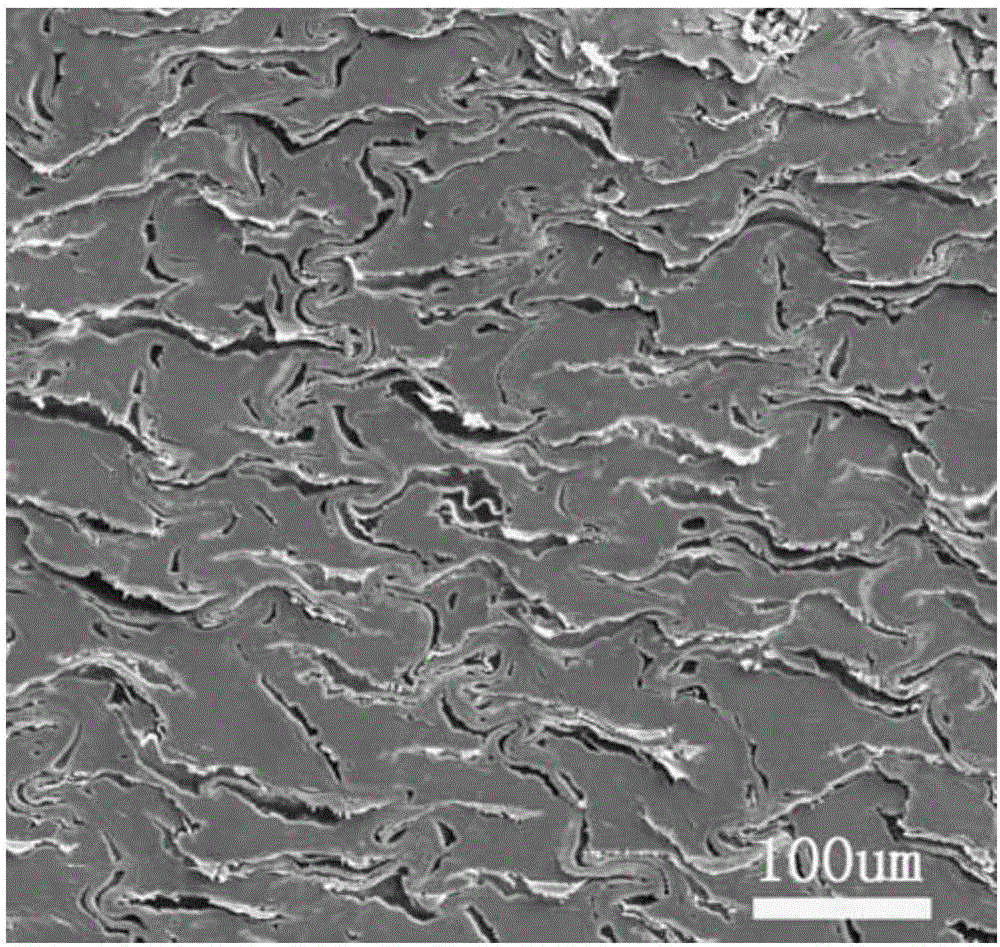

White carbon black dispersant and preparation method thereof

The invention discloses a white carbon black dispersant. The white carbon black dispersant comprises, by mass, 40 to 60% of C8-C22 fatty acid, 5 to 25% of protection wax, 10 to 28.8% of fatty acid ester, 6 to 10% of an inorganic filling material and 0.96 to 5% of an anti-oxidant. The invention also discloses a preparation of the white carbon black dispersant having a good white carbon black dispersion effect. The white carbon black dispersant is an environmentally-friendly high-dispersibility zinc-free white carbon black dispersant, can improve dispersibility of a filling material and rubber chemicals in rubber in rubber mixing, is suitable for improvement of dispersibility of rubber containing high-activity white carbon black, avoids re-condensation, improves wet-skid resistance of a tyre surface, and avoids the pollution produced heavy metal zinc on the environment.

Owner:青岛福凯橡塑新材料有限公司

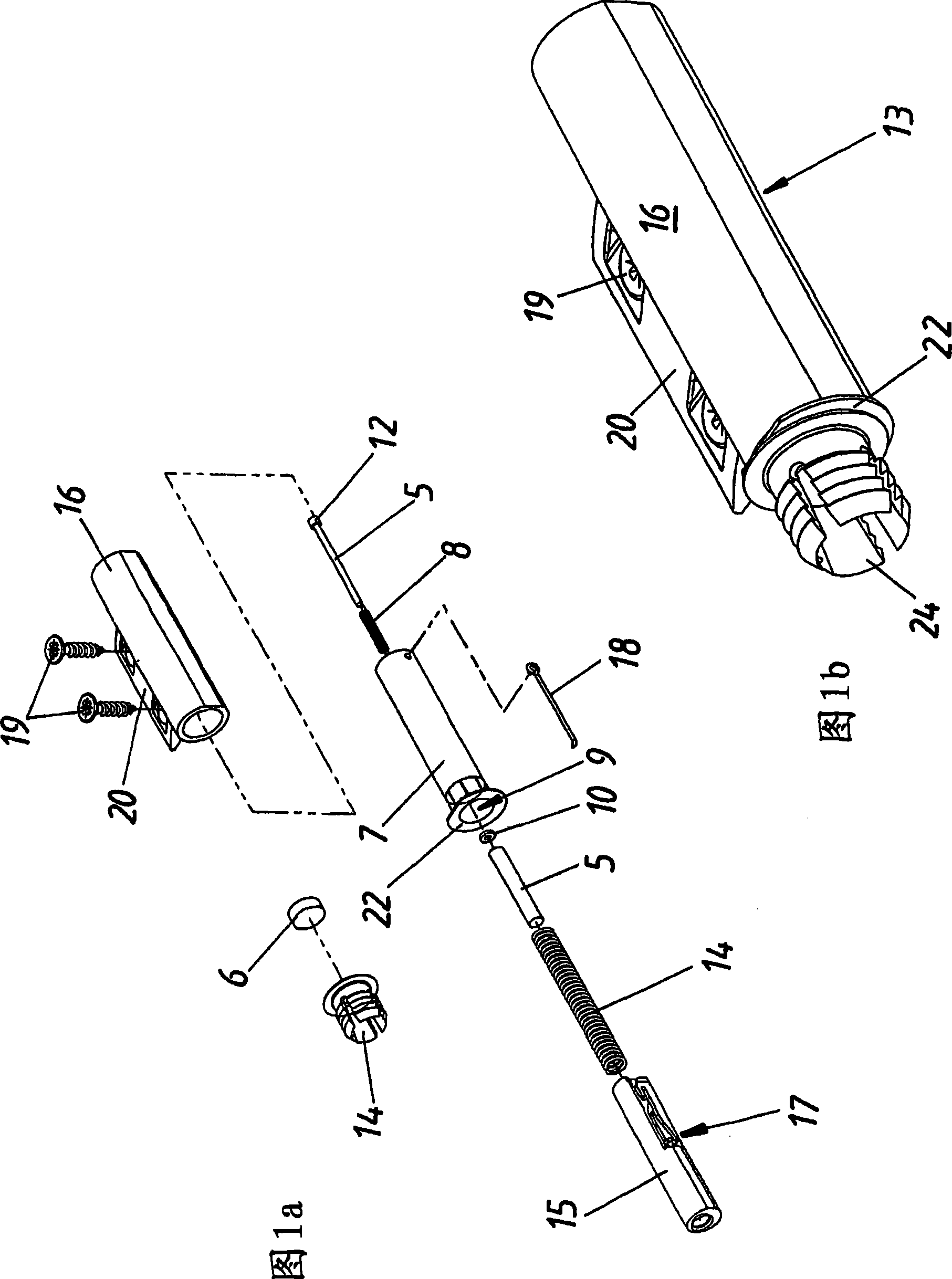

Magnetic locking device

ActiveCN101384788AReduce noiseRebound movement is reducedWing fastenersFastening meansEngineeringMechanical engineering

Owner:JULIUS BLUM GMBH

Production method of compressed compact carbonized wood

InactiveCN106493815AEasy to operateHigh strengthPressure wood treatmentWood compressionCelluloseCarbonization

A production method of compressed compact carbonized wood relates to wood modification methods and mainly solves the problem that existing wood modification methods cannot improve the mechanical strength and the waterproof dimensional stability of wood. The method comprises, I, wood softening pretreatment including immersing and heating wood in a pretreatment solution and then washing the wood to obtain softened wood, II, softened wood compression, and III, high-temperature wood carbonization. The production method of the compressed compact carbonized wood can solidify compressed deformation of wood, avoid resilience and reinforce cellulose framework structures to strengthen wood. Wood modified through the method obtains obvious enhancement in mechanical strength and dimensional stability. The production method of the compressed compact carbonized wood is applied to wood modification.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

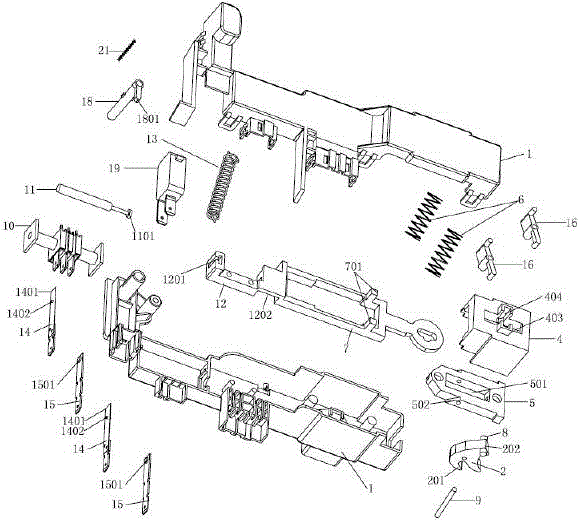

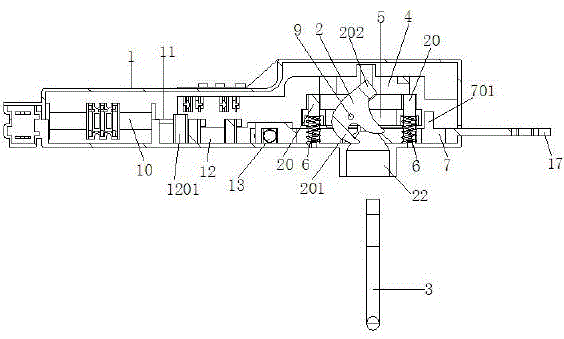

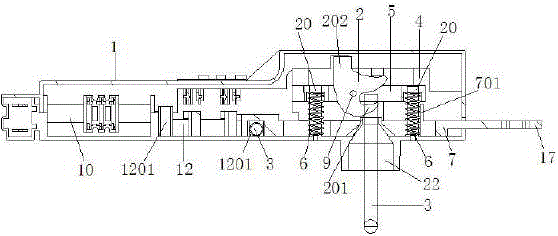

Washing machine door lock

ActiveCN104805644AEasy processing and assemblySimple cooperationOther washing machinesTextiles and paperLaundry washing machineControl theory

The invention discloses a washing machine door lock. The washing machine door lock comprises a lock case, a rotating part hooked up with a door hook and a locking device for locking or unlocking the rotating part combined with the door hook; the locking device comprises a first limiting part formed with a lug with a first inclined surface and capable of sliding left and right, a second limiting part formed with a second inclined surface matched with the first inclined surface and capable of sliding up and down, a limiting biasing part for applying bias pressure to the second limiting part towards the first limiting part, and a locking rod capable of locking or unlocking the second limiting part under the control of the first control device; the rotating part drives the first limiting part to move left and right by use of a first connecting structure; the limiting biasing element pushes the second limiting part to slide towards the first limiting part by virtue of the matching of the first inclined surface and the second inclined surface. According to the washing machine door lock, the rotating part is locked or unlocked by virtue of the sliding matching of the first limiting part, the second limiting part and the locking rod so that the washing machine door lock can be opened or closed; the washing machine door lock is easy to manufacture and assembly, and good in stability.

Owner:WENZHOU TIANJIAN ELECTRIC APPLIANCE

Method of using poplar or poplar and paulownia to manufacture imitated precious wood

InactiveCN103895070AWide variety of sourcesGuaranteed uniformityWood treatment detailsWood veneer joiningPaulownia coreanaPaulownia

The invention discloses a method of using a poplar or the poplar and paulownia to manufacture imitated precious wood. The method comprises the steps of force drying, dyeing, vacuum pressing and dipping, thermo-compression forming and the like. In the method, a paulownia single plate and a poplar bundle are dyed into a required color and then are assorted and combined, and alternatively different polar bundles dyed into different colors are assorted and combined according to the different colors; a traditional scientific method that when the wood is manufactured, large-warp wood is rotationally cut into specification single plates, then drying, dyeing, gluing and thermo-compression sizing are conducted, so that the imitated precious wood is manufactured is changed. The method makes good use of waste materials, and the use rate of the wood can reach more than 90%.

Owner:CHINA PAULOWNIA RES CENT

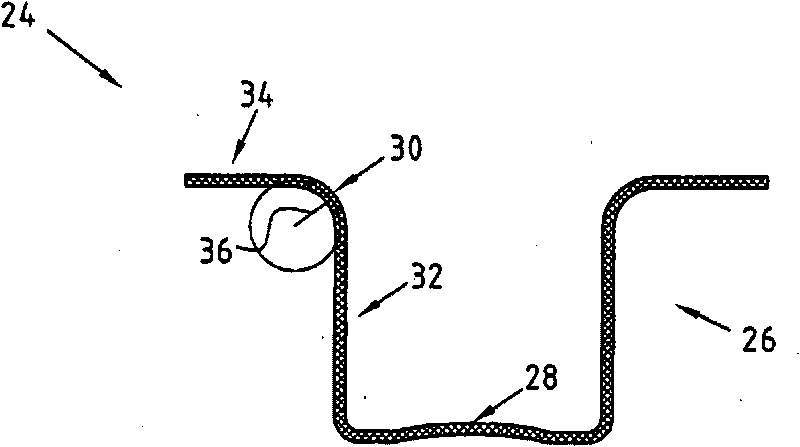

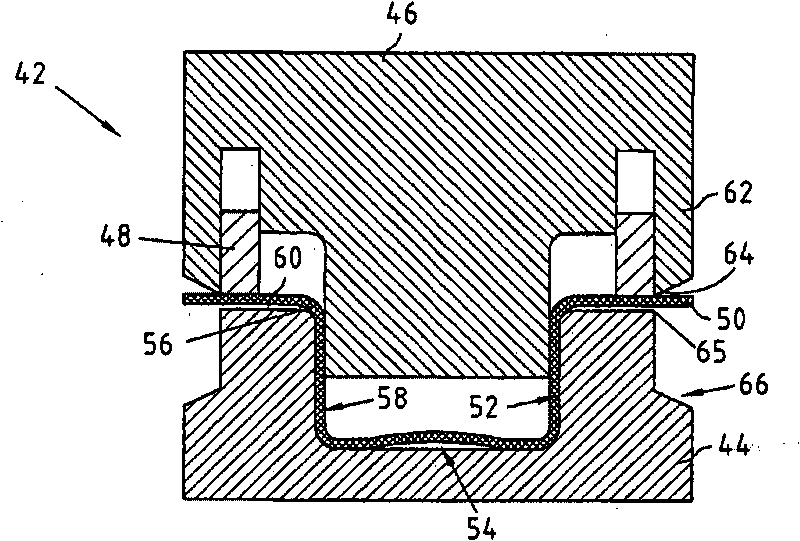

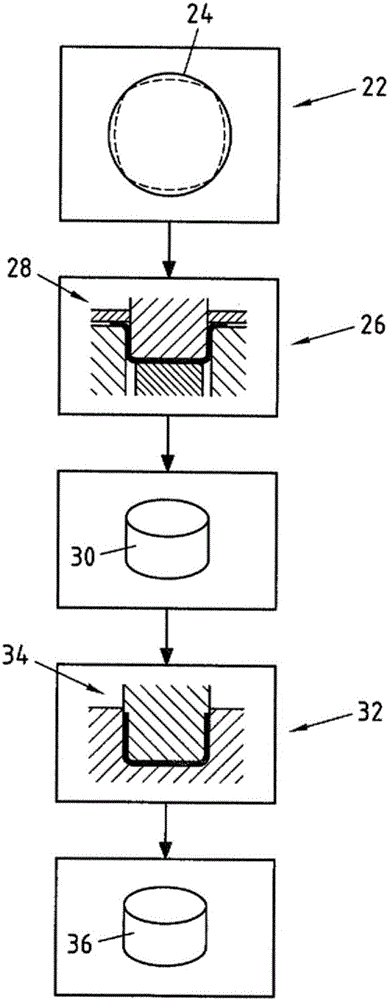

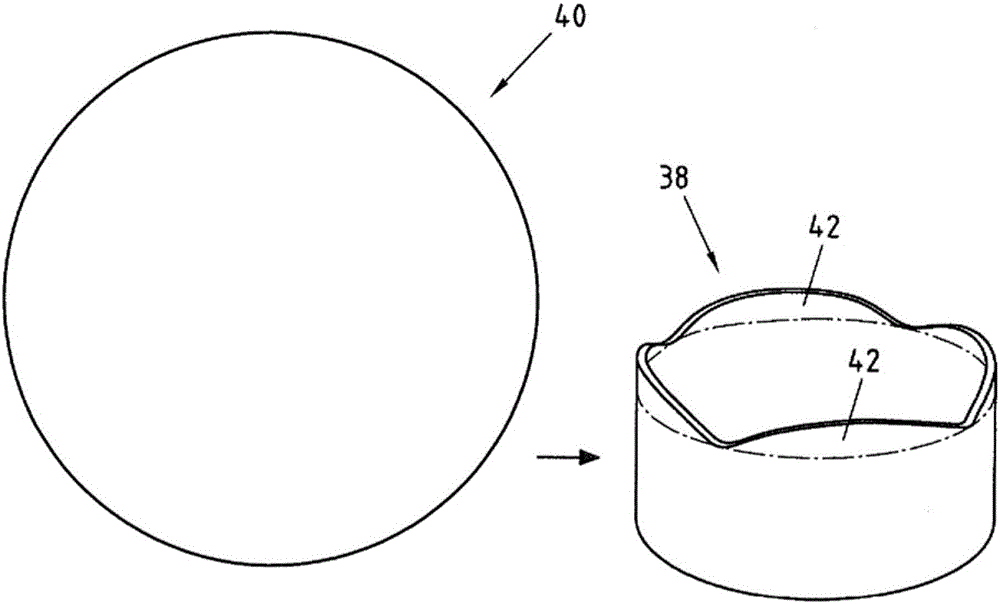

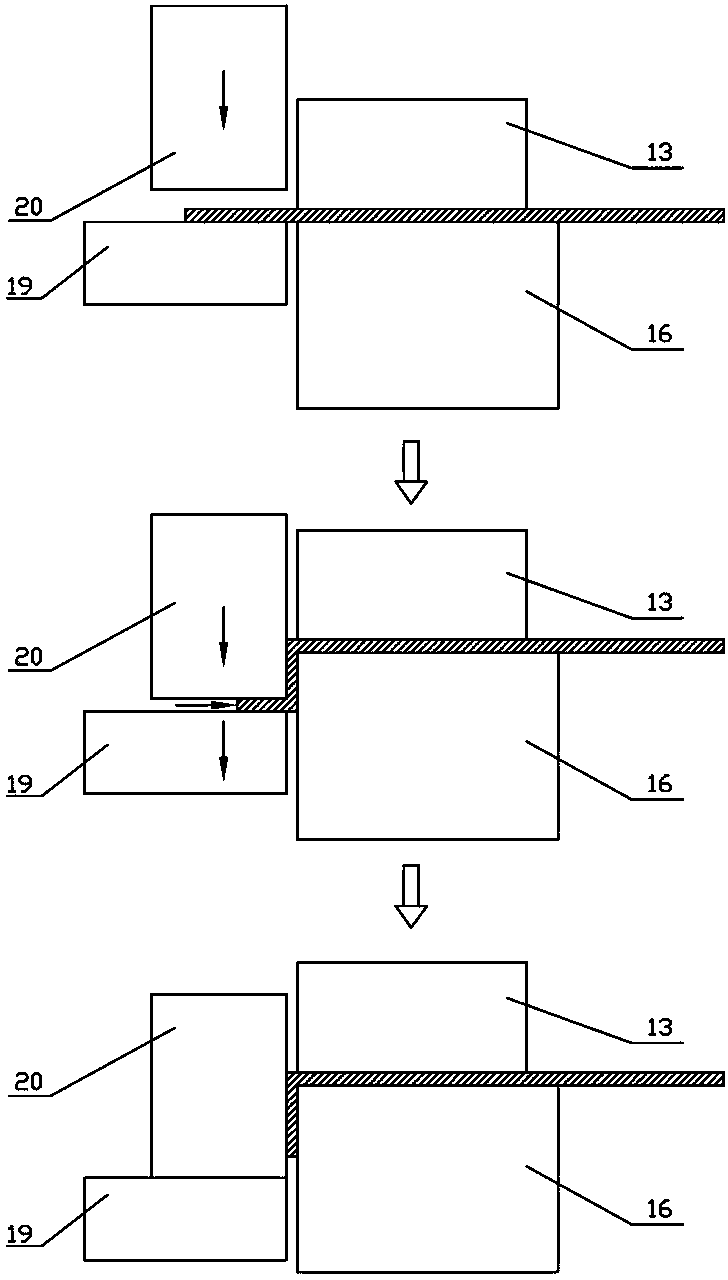

Method for producing highly dimensionally stable half shells and device for producing a half shell

The invention relates to a method for producing highly dimensionally stable half shells from a cut board, wherein the half shell is pre-formed by deep-drawing in a first die (28, 46), optionally using at least one hold-down (56), wherein the first die (28, 46) has at least one stamp (48), one die floor (50), one die supporting surface (52) and a frame region and wherein the pre-formed half shell (30, 60) is then finally formed in a second die (34, 62), particularly in a calibration tool. In addition, the invention relates to a device for producing a half shell. The problem of specifying a method which simplifies the production of highly dimensionally stable half shells is solved in that the board is cut having a positive dimensional deviation in the specified tolerance range, in consideration of the desired final form of the pre-formed and finally formed half shell, before deep-drawing, the die floor (50) of the first die (28, 46) is moved relative to the die supporting surface (52), the board is clamped between the die floor (50) and the stamp (48) of the first die (28, 46) and the board is guided in being deep-drawn.

Owner:THYSSENKRUPP STEEL EURO AG

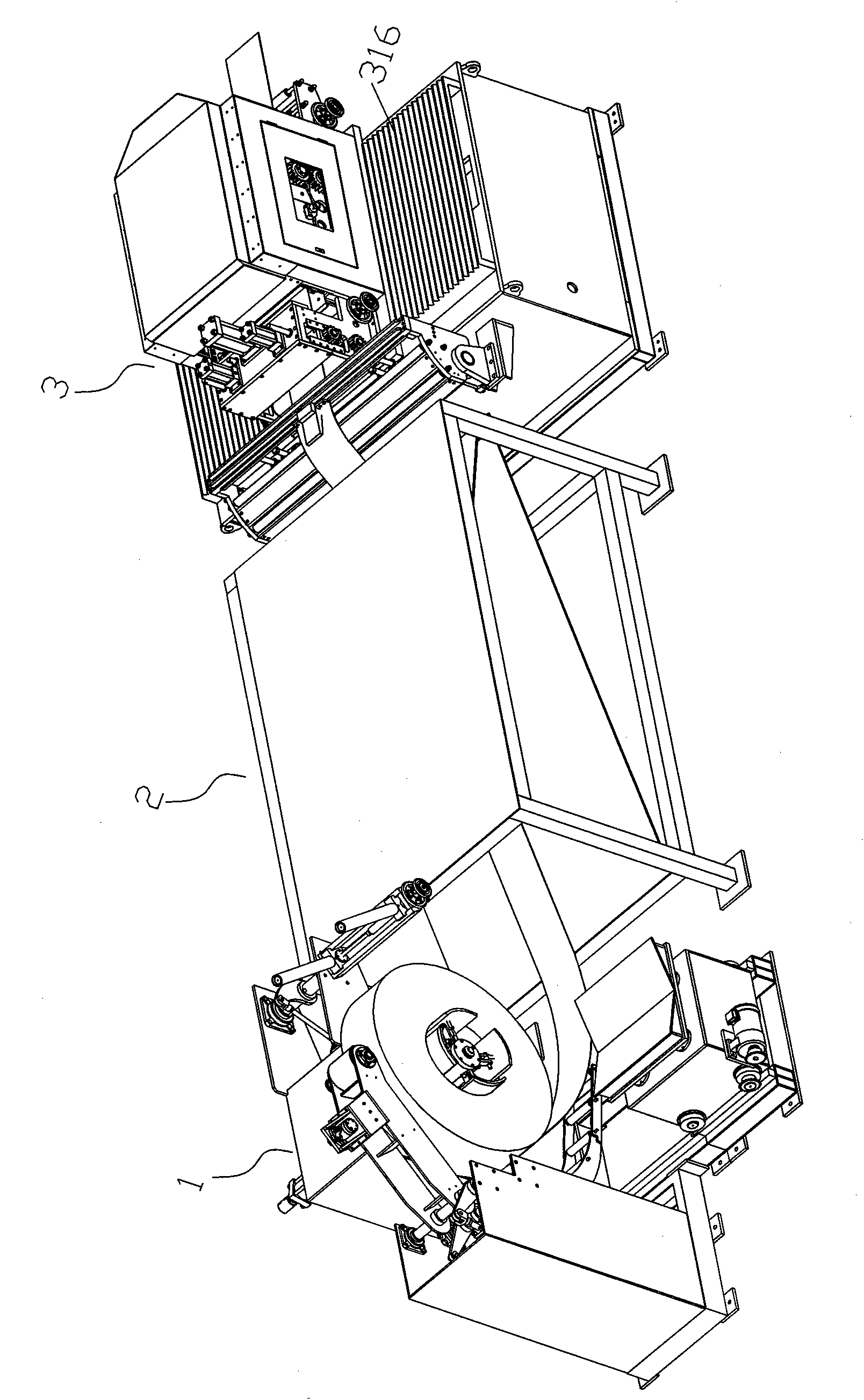

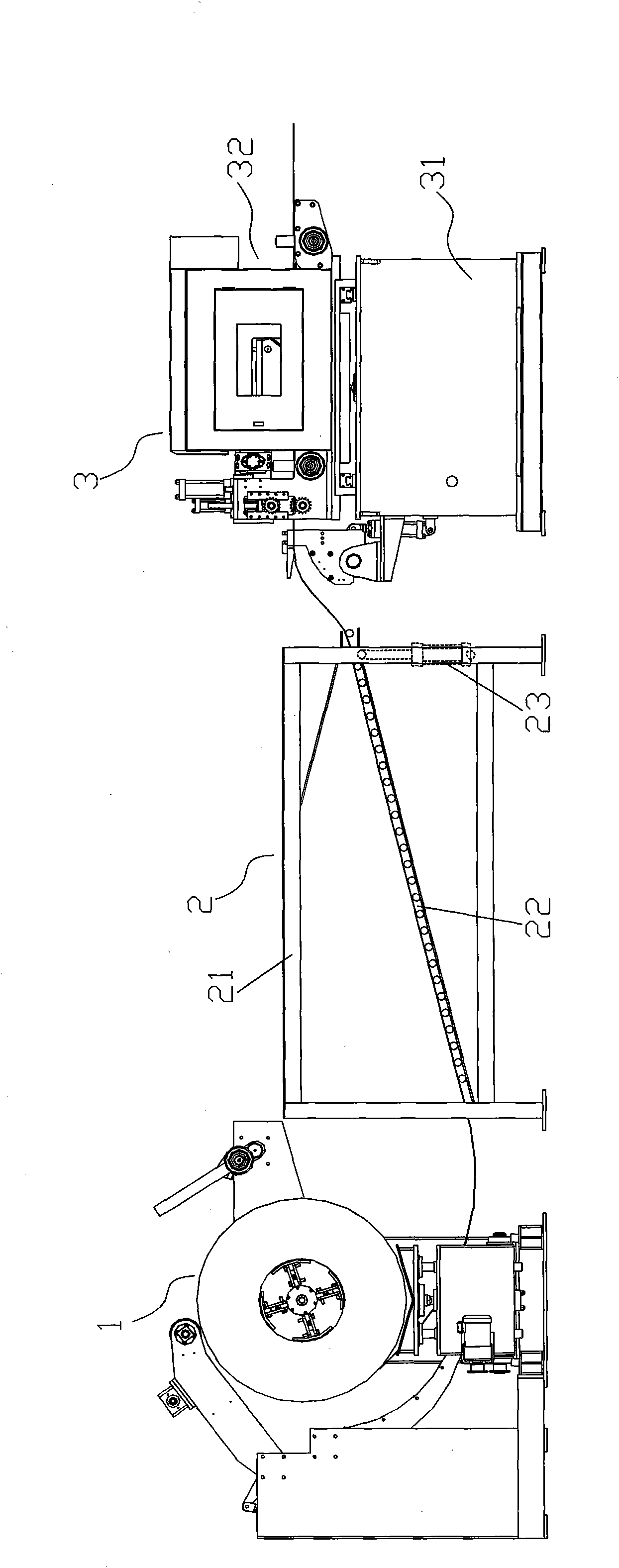

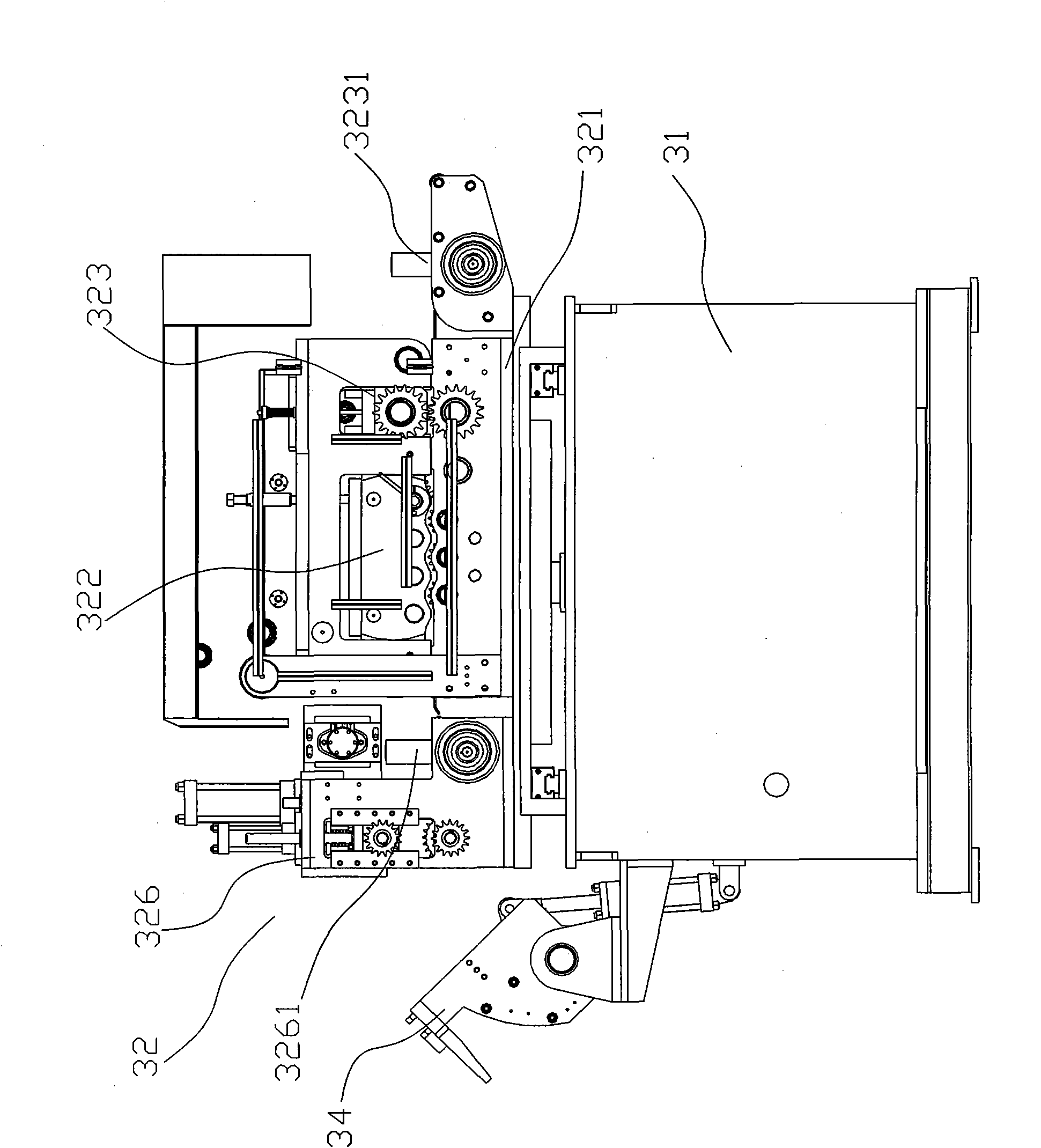

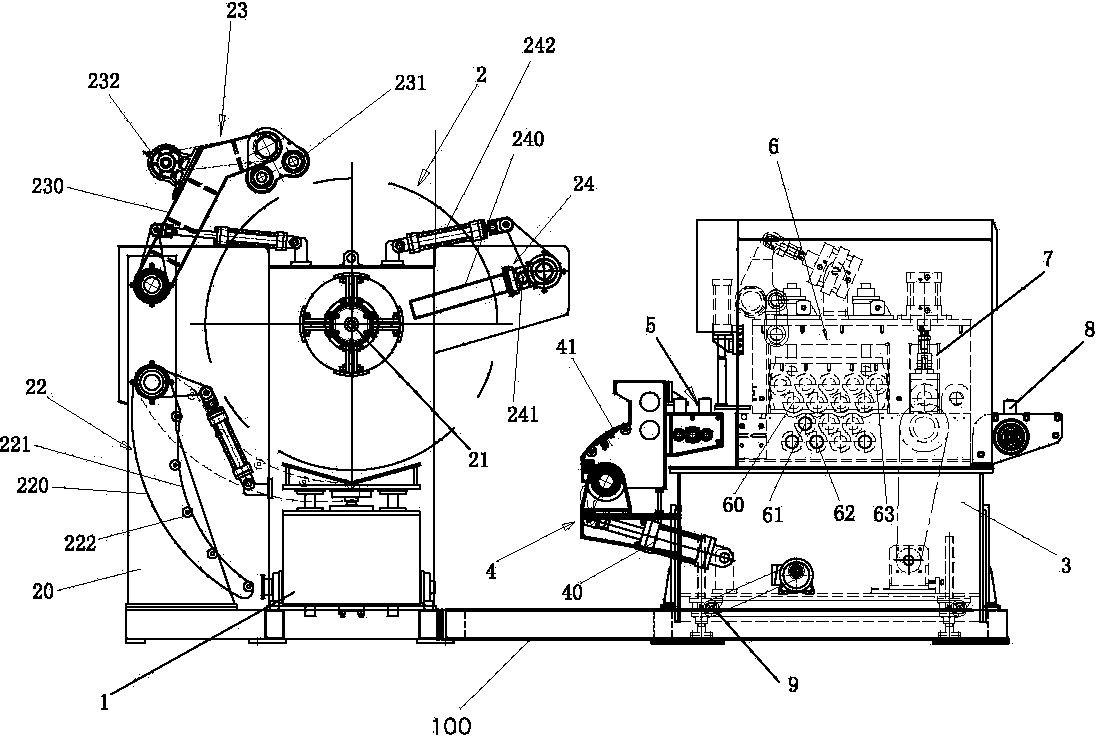

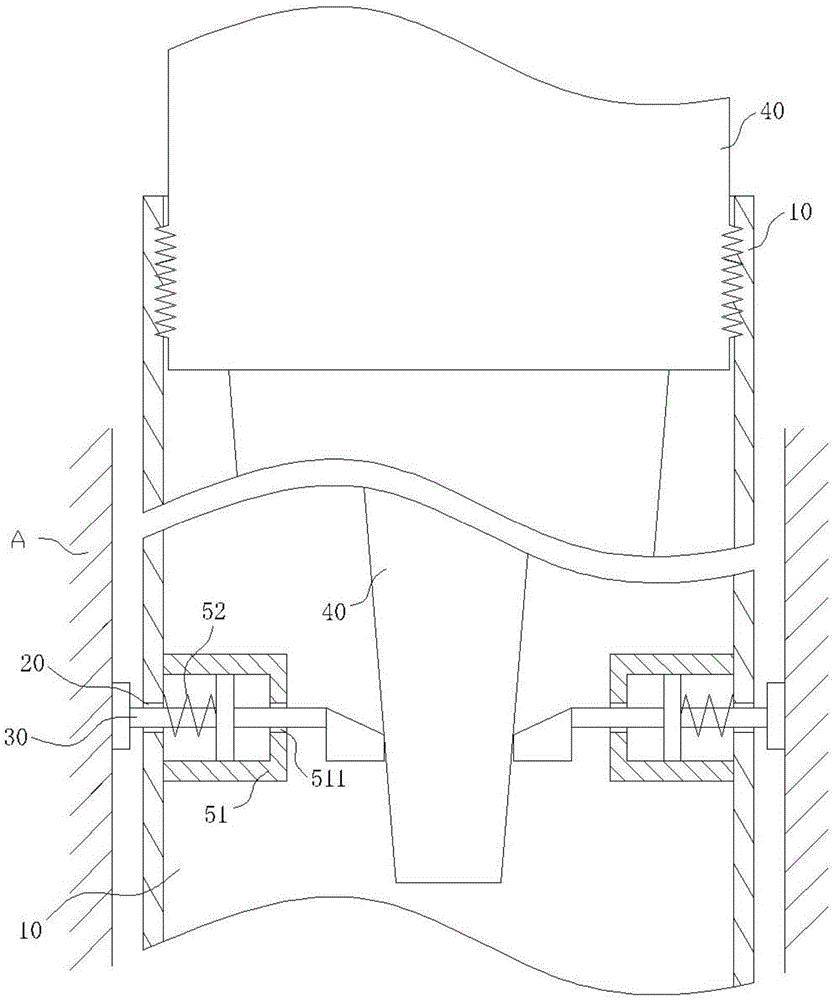

Deflection type servo feeding line

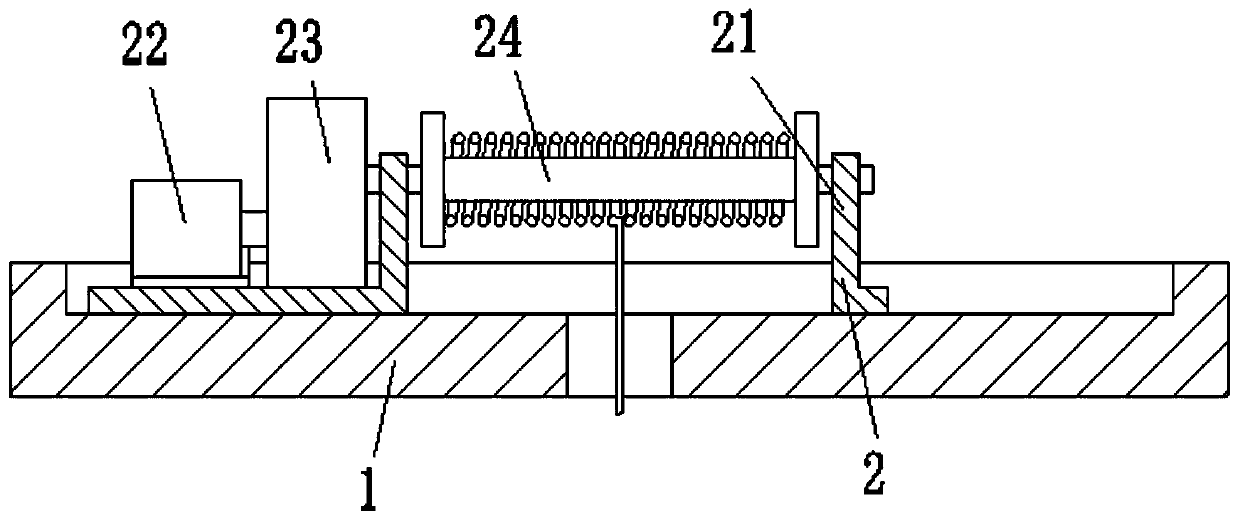

ActiveCN102069131AReduce wastePrevent springbackMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention relates to the technical field of peripheral equipment of a punch, in particular to a deflection type servo feeding line, which comprises an uncoiler, a transitional rack and a deflection type feeding host machine, wherein the deflection type feeding host machine comprises a main frame and an integral leveling and sizing host machine arranged on the main frame. A clamping feeding unit, a leveling unit and a sizing unit in the deflection type feeding host machine of the whole servo feeding line are integrated so as to reduce the occupied space, and the leveling and sizing operations of a plate are closely approached so as to improve the sizing accuracy and the acceptability of punched products. More significantly, the integral leveling and sizing host machine is integrally arranged on the deflectable deflection main frame, and the integral leveling and sizing host machine can be accurately controlled to deflect along the width direction of the plate according to the need so as to make the plate move in the width direction for a punch to stamp in the corresponding width direction, so the production efficiency is improved, the plate can be fully utilized, and plate waste is minimized.

Owner:东莞市金峥机械有限公司

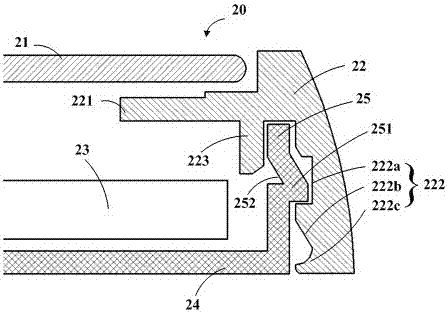

Liquid crystal module and liquid crystal display device

InactiveCN107219661AGuaranteed strength and rigidityEnsure that the middle frame has strength and rigidityNon-linear opticsLiquid-crystal displayLight guide

The invention provides a backlight module and a liquid crystal display device. A liquid crystal module comprises a light panel, a backplane and a middle frame, wherein the backplane is located below the light panel, and a first vertical plate is located on the edge of the backplane and extends towards the light panel; the middle frame comprises a second vertical plate and a third vertical plate which are arranged on two sides of the first vertical plate and a first support portion which is vertically connected with the second vertical plate and the third vertical plate; a plurality of buckle protrusions which are arranged at intervals are arranged on the side face of the first vertical plate, and buckle grooves which are matched with the buckle protrusions are formed in the second vertical plate; the second vertical plate further comprises a drop proof groove which is located on the end portion and a guide arm which is connected with the buckle grooves and the drop proof groove. The liquid crystal display device comprises a panel and the liquid crystal module. According to the backlight module and the liquid crystal display device, fixation with no screw of a front frame and the backplane can be achieved, the work efficiency of a complete machine assembling factory is improved, and the product appearance is optimized.

Owner:HISENSE VISUAL TECH CO LTD

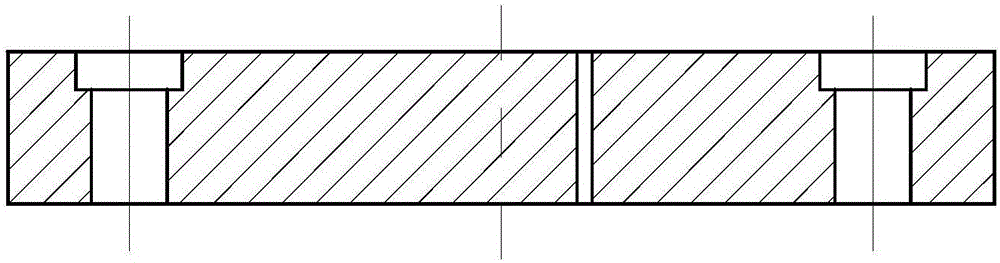

High-tension board forming device

The invention discloses a high-tension board forming device. The high-tension board forming device is characterized by comprising an upper die base, an upper die pressing plate, an upper die forming punch pin, a lower die forming punch pin, a lower die base and a lower die pressing plate, wherein the upper die pressing plate is connected with the upper die base, the upper die forming punch pin is arranged on the two sides of the upper die pressing plate, the lower die pressing plate is connected with the lower die base, the lower die forming punch pin is arranged in the middle of the lower die pressing plate, two outer side walls of the lower die forming punch pin are respectively provided with at least two convex hulls, and two inner side walls of the upper die forming punch pin are provided with grooves corresponding to the convex hulls. According to the high-tension board forming device, due to the convex hull structure, in the bending process, interior molecules of a plate flow along the outer walls of the convex hulls to have plastic deformation, the increased convex hulls can absorb materials accumulated in the bending process, the tension of the plate located at the bending position is dispersed, and springback of the plate is reduced; meanwhile, in the bending process, the bending pressure is increased due to the arrangement of the lower die pressing plate and a balance weight, and the situation that the plate wrinkles in the bending process is reduced.

Owner:RAINBOW METAL TECH

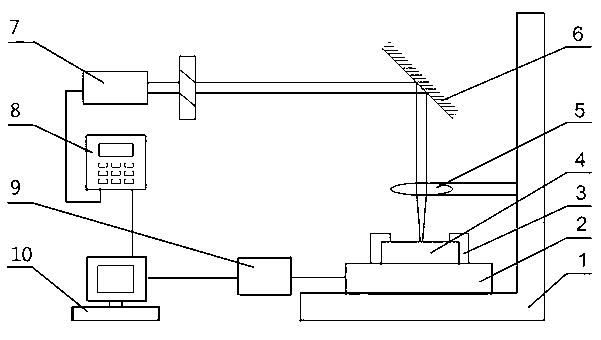

Precise micro-forming device and method thereof based on laser continuous stamping plasticine technology

InactiveCN103252588APrevent springbackEven by forceLaser beam welding apparatusComputer control systemNanosecond laser

The invention discloses a precise micro-forming device and a method thereof based on a laser continuous stamping plasticine technology. The device comprises a laser loading system, a plastic forming system and a computer control system. The laser loading system comprises a nanosecond laser, a reflection mirror and a focusing lens. The plastic forming system comprises a sample system, a clamp body, a three-dimensional moving platform and a base. The computer control system comprises a three-dimensional moving platform controller, a laser controller and a computer. According to the device and the method, plasticine is used for transmitting impact force, in a multi-time impact process, the plasticine and a workpiece are attached together gradually, stress on the workpiece is even, scratching cannot happen, surface quality of the workpiece is improved, and meanwhile according to the characteristic that the plasticine deforms in an plastic mode after being stressed, the workpiece and a micro mould can be attached with each other, rebounding of the workpiece is avoided, and forming precision of the workpiece is guaranteed.

Owner:JIANGSU UNIV

Surface strengthening ancient-Chinese-fir-imitation floor base material and manufacturing method thereof

InactiveCN103522384AGood dimensional stabilityHigh strengthWood treatment detailsPressure impregnationUltimate tensile strengthMachining

The invention discloses a surface strengthening ancient-Chinese-fir-imitation floor base material and a manufacturing method thereof. The surface strengthening ancient-Chinese-fir-imitation floor base material is mainly manufactured by using Chinese-fir converted timbers as raw materials, the surface layer density is 0.6g / cm<3>-0.8g / cm<3>, the hardness is improved by one time to be maximum and is larger than that of the Chinese-fir converted timbers, the wear loss is reduced by 50% to the maximum and is less than that of the Chinese-fir converted timbers, concave-convex grains are arranged on the surface of the base material, the depth of a groove is 1mm-3mm, and the manufacturing method comprises the steps of one-time drying, converted timber fine machining, immersion treatment, secondary drying and sizing treatment. The surface strengthening ancient-Chinese-fir-imitation floor base material is high in surface hardness and strength, has the three-dimensional relief and antiquing effects, and is good in size stability, green and environmentally-friendly. The manufacturing method is easy to operate, small in equipment investment, wide in raw material source, and low in cost.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

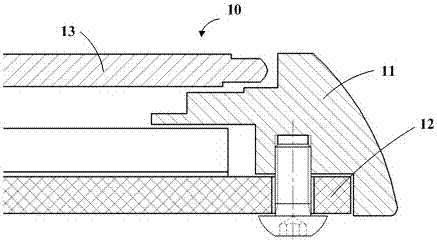

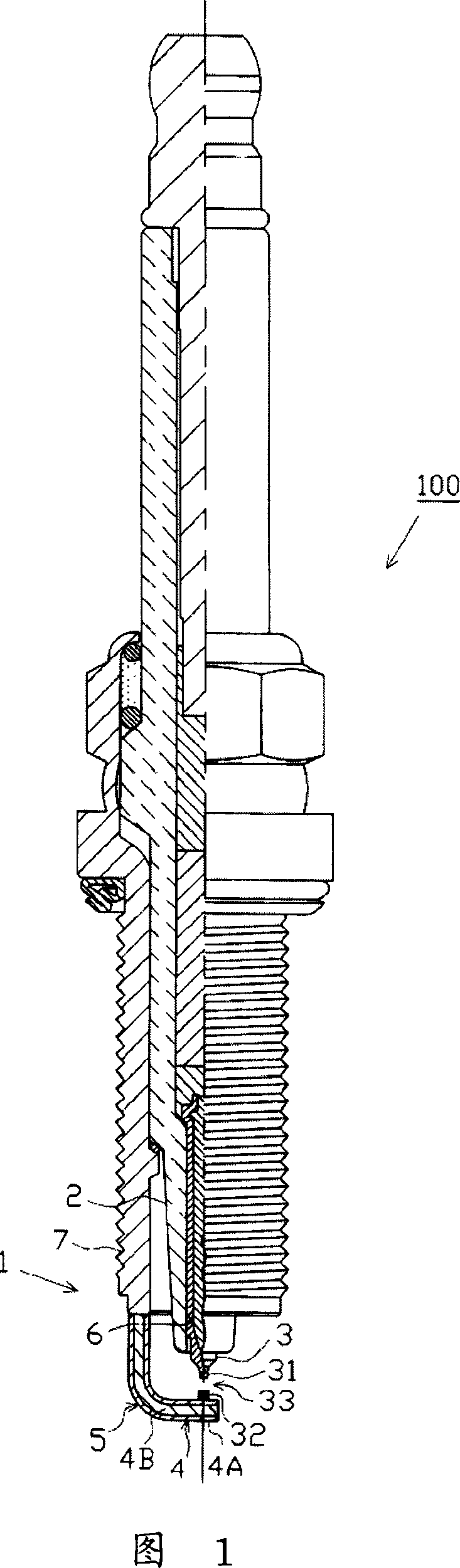

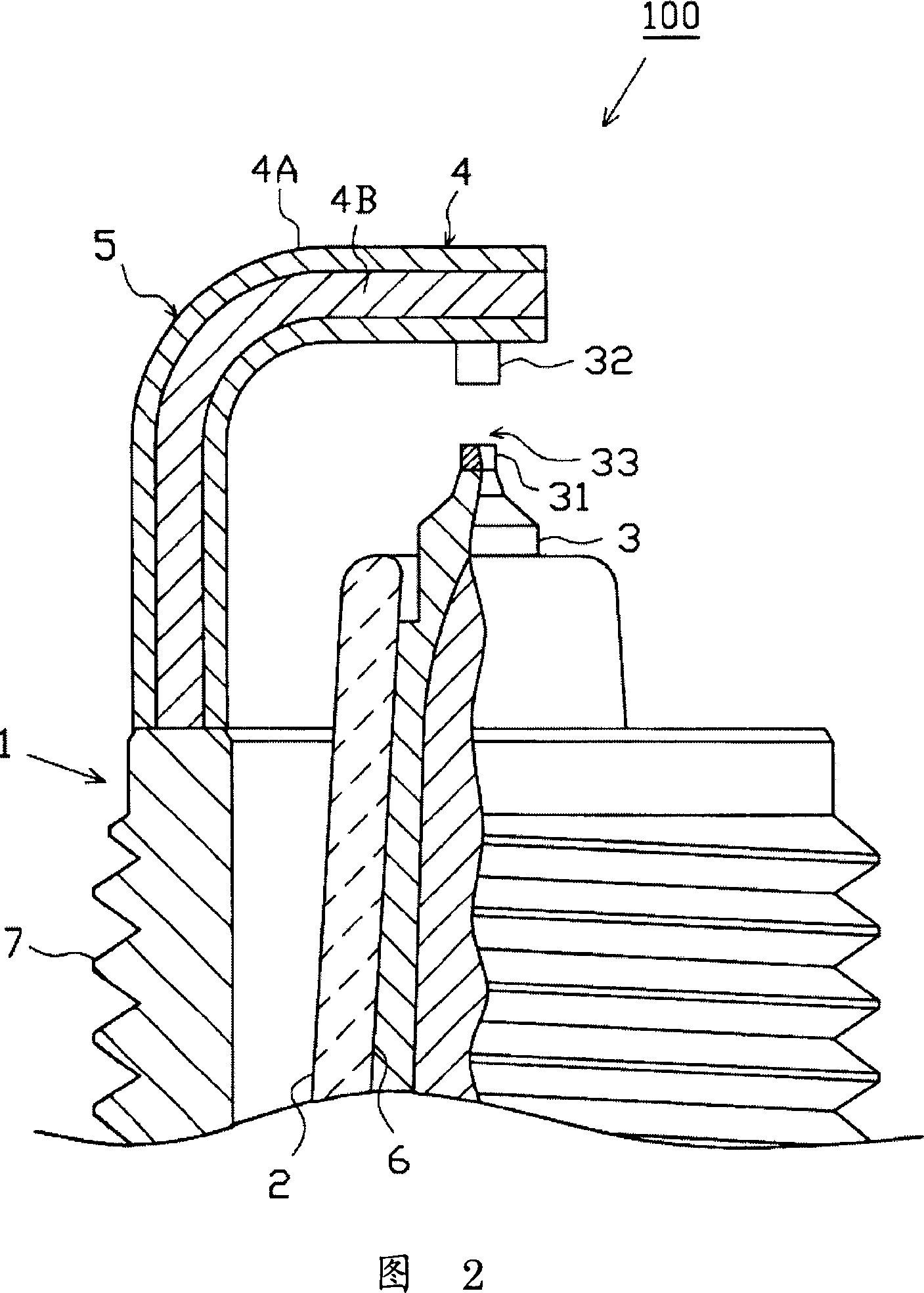

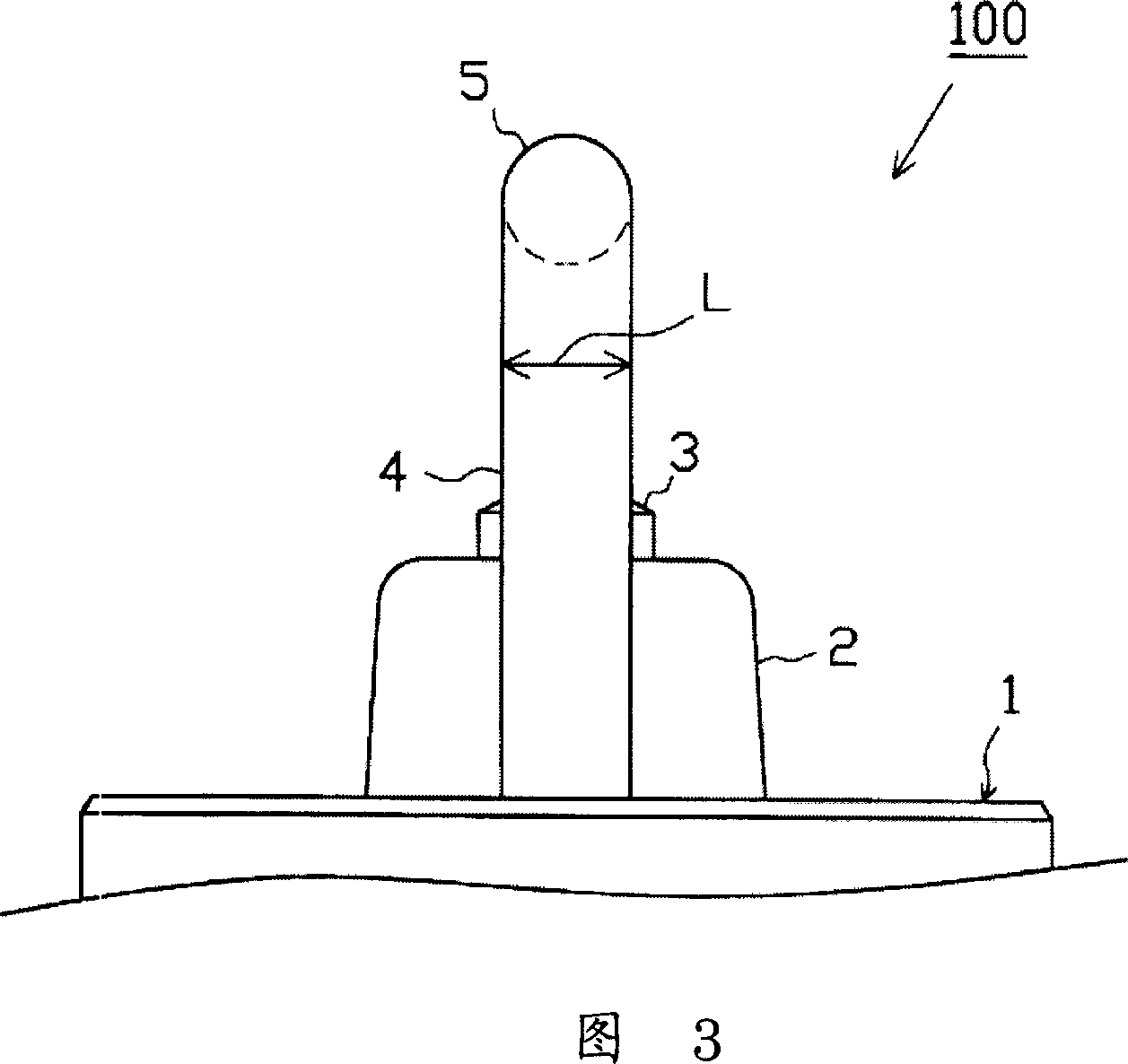

Spark plug for use in an internal-combustion engine

ActiveCN101043125APrevents deterioration of ignitabilityAvoid corrosionSparking plugsEngineeringNickel alloy

The present invention provides a spark plug 100 comprised of a metal shell 1, an insulator 2, a center electrode 3 and a ground electrode 4. A rear-end face of the ground electrode 4 is welded to a front-end face of the metal shell 1, and a bent portion 5 located at the intermediated position in the longitudinal direction is bent toward the center of the spark plug 100. The ground electrode 4 assumes a circular-shape with a diameter of 2 mm or less whereby an inflow of an air-fuel mixture is not disturbed even when the air-fuel mixture directly flows into a back face of the ground electrode 4. The ground electrode 4 is comprised of an outer layer 4 A made of a nickel alloy and an inner layer 4 B made of pure copper with an excellent thermal conductivity, in which a ratio of a cross-sectional area of the inner layer 4 B to the entire cross-sectional area of the ground electrode 4 is 10% or more to 35% or less. Thus, the spark plug 100 which is excellent in heat sinking ability and can prevent a spring back phenomenon due to a difference in a coefficient of thermal expansion.

Owner:NGK SPARK PLUG CO LTD

Efficient damping device for mechanical equipment

InactiveCN108343702APrevent springbackReduce vibration intensityNon-rotating vibration suppressionMagnetic springsAgricultural engineeringMagnetic poles

The invention discloses an efficient damping device for mechanical equipment. The efficient damping device comprises a fixing plate and a fixing base, a fixing block is welded to the middle position of the top of the fixing base, a hydraulic driver is arranged at the middle position of the top of the fixing block, the top of the hydraulic driver is connected with the fixing plate through a stretchable rod, the tops of the fixing block are located on the two sides of the hydraulic driver and are connected with the fixing plate through second damping springs, and three sets of connecting rods are welded to the outer side of the fixing block at equal intervals. According to the efficient damping device, the bottom of a containing plate is connected with the fixing plate through a first damping spring, magnet blocks are arranged at the bottom of the containing plate and the top of the fixing plate, magnetic poles of the magnet blocks are opposite, meanwhile, the bottom of the fixing plateis connected with the fixing plate through the second damping springs, the damping effect is better due to multiple damping, the object vibration strength is reduced, and damage to objects and loadersis prevented.

Owner:郑州宸通机械设备有限公司

Middle peeling device and peeling method for wire materials

ActiveCN103390852AAvoid rubber reboundImprove stabilityLine/current collector detailsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a middle peeling device and peeling method for wire materials. The middle peeling device for the wire materials comprises an axial cutter set which is used for enabling axial incisions to be formed on the middle portion rubber of the wire materials and a radial cutter set which is used for enabling radial incisions to be formed on the middle portion rubber of the wire materials; the radial cutter set is also used for peeling the middle portion rubber of the wire materials from the wire materials along the axial incisions. According to the middle peeling device and peeling method for the wire materials, the rubber with peeled openings on the middle portions of the wire materials is directly cut off, so that rubber springing back caused by only forming the incisions is avoided and stability of the peeled openings is improved.

Owner:XIAMEN HIPRECISE TECH CO LTD

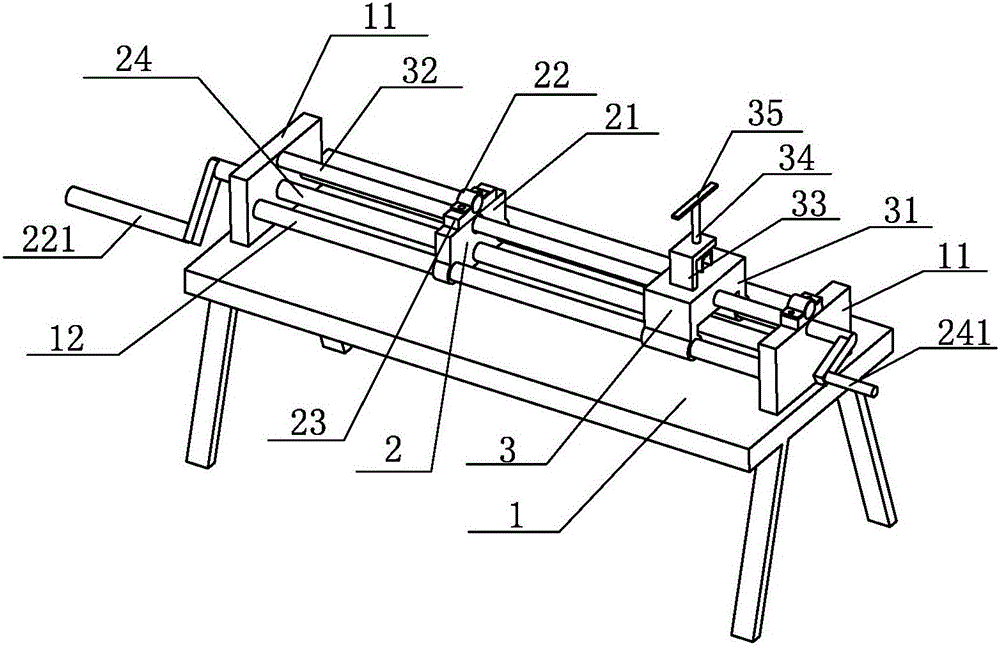

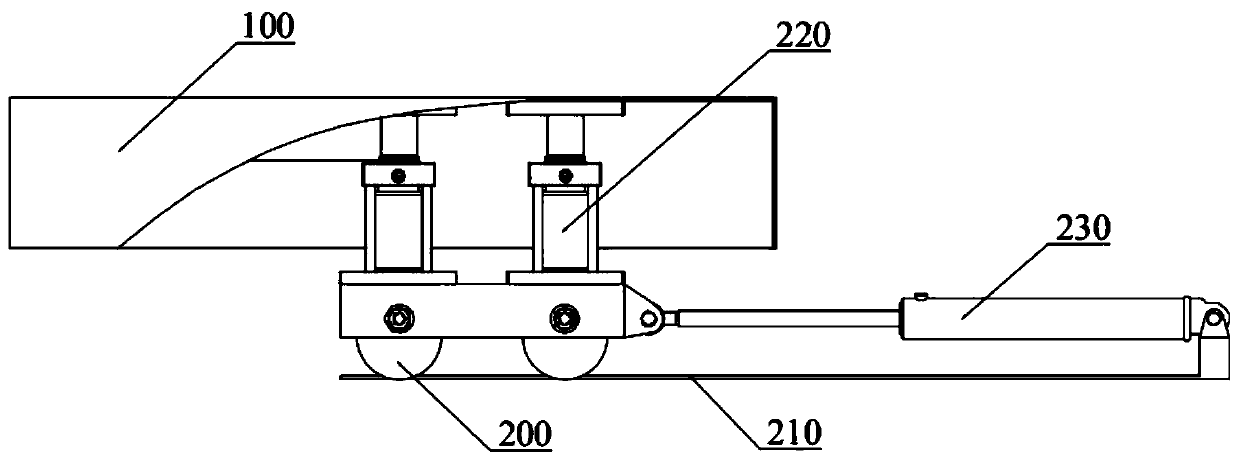

Power transmission wire tensioning and straightening device

InactiveCN106159802AImplementation orientationLarge transmission pullApparatus for overhead lines/cablesEngineeringElectric wire

The invention provides a power transmission wire tensioning and straightening device, which comprises a support frame, a tensioning mechanism and a straightening mechanism, wherein the support frame comprises a support platform; two opposite support vertical plates are arranged at the two ends of the support platform; two mutually parallel first guide rods are arranged between the support vertical plates; the tensioning mechanism comprises a tensioning slide block and a pulling lead screw; the tensioning lead screw is arranged between the two support vertical plates in a sleeving way; the tensioning slide block is arranged on the two first guide rods in a sleeving way; the straightening mechanism comprises a straightening slide block and a compression wheel. The power transmission wire tensioning and straightening device has the advantages that the structure is simple; the operation is convenient; the carrying is easy; during the power transmission line erection, the tensioning mechanism and the straightening mechanism in the power transmission wire tensioning and straightening device can be flexibly used for performing correction treatment on the bent position on a power transmission line, and the goal of fast and efficiently sorting the bent position on the power transmission line can be achieved.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

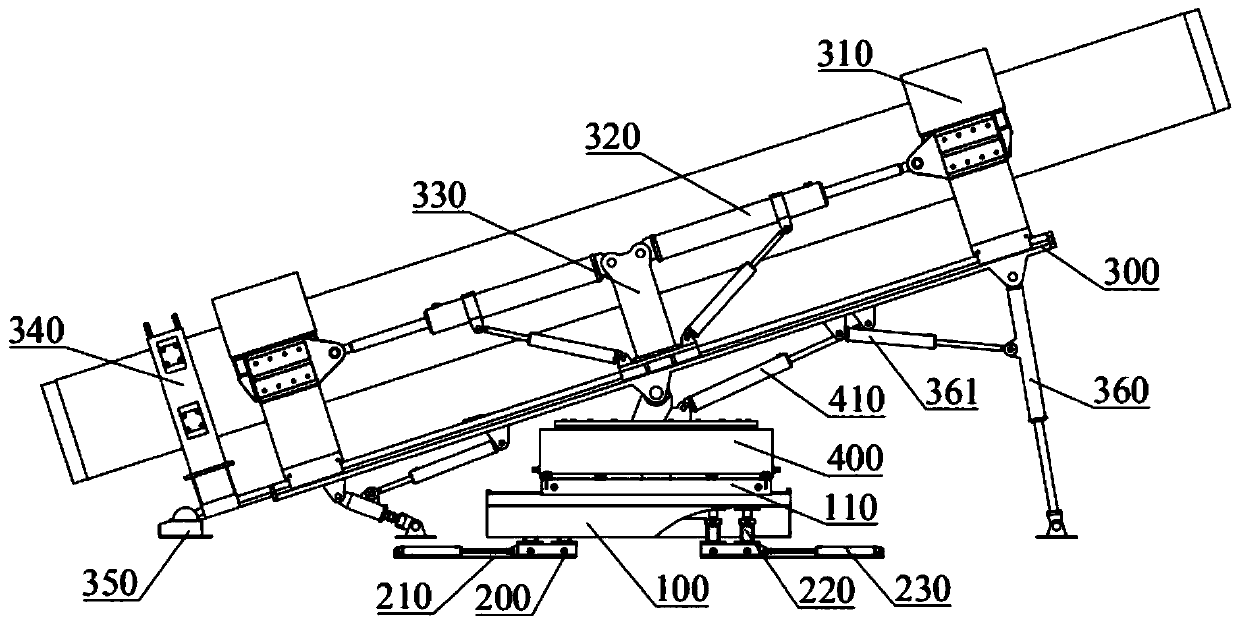

Novel pipe pushing and pulling device

PendingCN110792848ARealize multi-station pipe deliveryPrevent springbackPipe laying and repairHydraulic cylinderClassical mechanics

The invention provides a novel pipe pushing and pulling device. The device comprises a base, a pipe pushing and pulling mechanism and a walking mechanism are arranged on the base, the pipe pushing andpulling mechanism is rotatably mounted on the base, the walking mechanism comprises walking wheels and moving plates on the lower portions of the walking wheels, the walking wheels are connected withthe base through lifting hydraulic cylinders, and can completely shrink into the base, walking hydraulic cylinders arranged in the moving direction of the walking wheels are arranged on the moving plates, and two ends of the walking hydraulic cylinders are connected with the moving plates and the walking wheels. According to the technical scheme, through the lifting hydraulic cylinders, supporting stress of the walking wheels and the base can be switched, in cooperation with the walking hydraulic cylinders, stepping walking is achieved, the pipe pushing and pulling pipe mechanism is rotatablymounted on the base, a pushing and pulling mechanism is controlled to do 360-degree rotation in the horizontal direction, and multi-station pipe feeding of the pushing and pulling mechanism can be achieved.

Owner:ORIENT ENERGY & TECH CO LTD

Three-in-one straightening and feeding machine and straightening and feeding method thereof

InactiveCN103707068APrevent springbackAvoid deformationMetal-working feeding devicesOther manufacturing equipments/toolsTime lagEngineering

The invention relates to the technical field of production device of metal plates, and particularly to a three-in-one straightening and feeding machine and straightening and feeding method thereof. A decoilder machine, a feeding machine, a straighter machine and a shear gauge are integrated in the three-in-one precision-type material-frame straightening and feeding machine. Compared with independent devices, the three-in-one precision-type material-frame straightening and feeding machine has the advantages that the occupied space is small, the next procedure of straightening sheet metal is cutting length so that the design of foundations or pits are not needed. The three-in-one precision-type material-frame straightening and feeding machine can be easy to install and shift and the time lag is short, so that the rebound caused by internal stress of metal plates which are straightened can be prevented and the deformation of the metal plates can be avoided. Accordingly, the accuracy of cutting length can be improved and the enterprise operating cost can be reduced greatly.

Owner:东莞市金峥机械有限公司

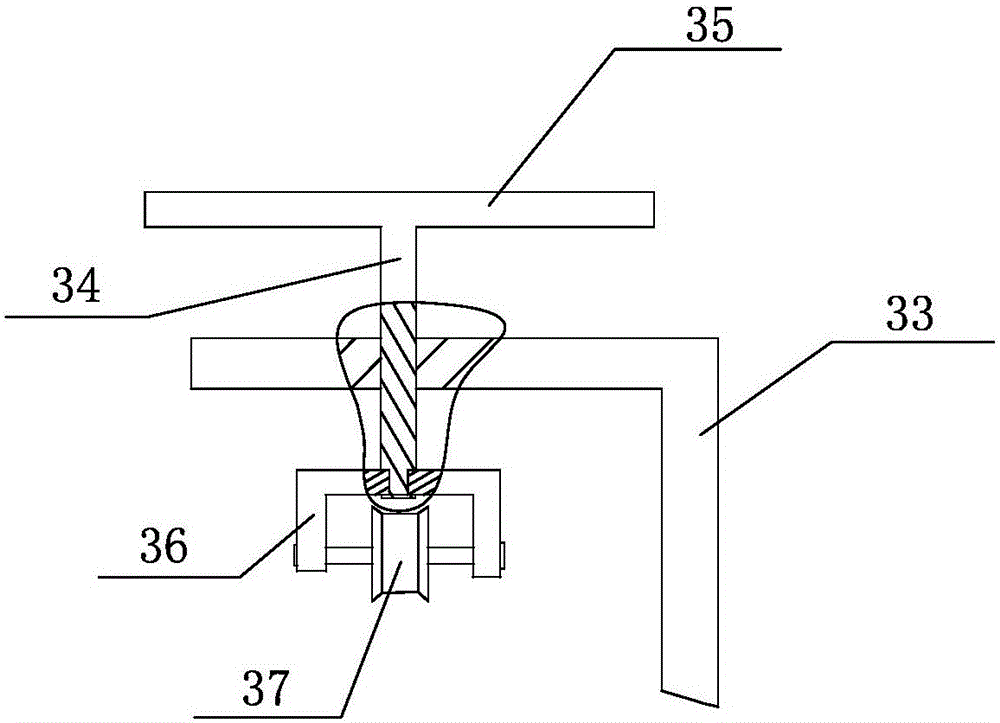

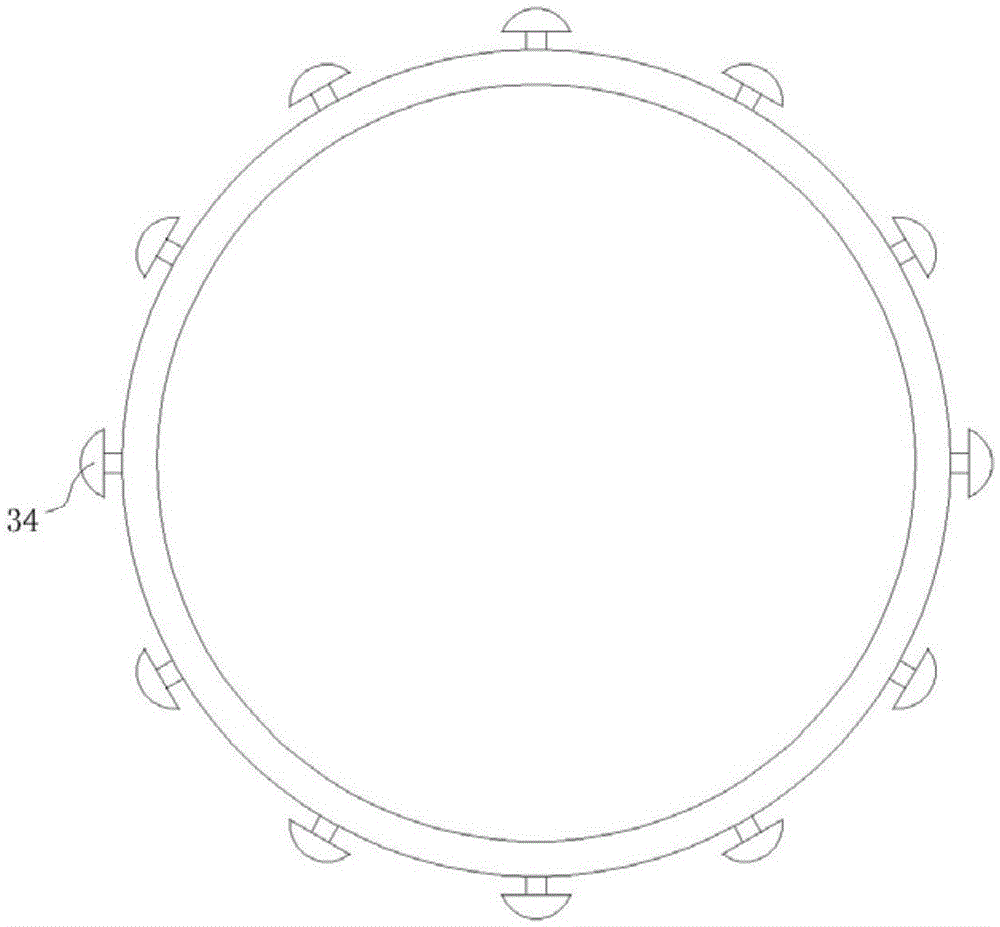

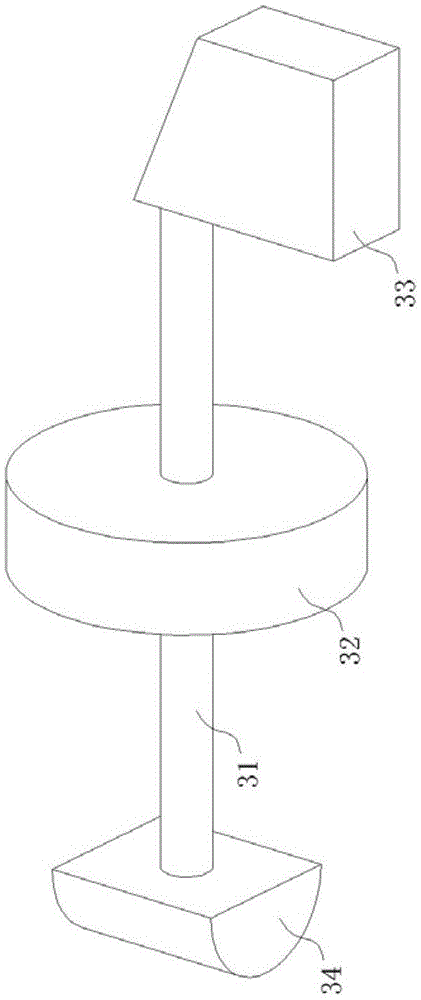

Ingot rod device for holding textile bobbins

The invention discloses an ingot rod device for holding textile bobbins. The ingot rod device comprises a hollow rod body, openings formed in the rod body, three of more stretching and contracting components capable of stretching and contracting in the openings and a matched mechanism allowing the stretching and contracting components to stretch and contract. The stretching and contracting components comprise rods and are evenly distributed along the circumference, the matched mechanism makes the stretching and contracting component have the tendency of moving towards the interior of the rod body, and the ingot rod device further comprises a conical rod capable of being inserted into the rod body. The conical rod is inserted into the rod body, each stretching and contracting component moves toward the exterior of the rod body and exerts pressure on the inner wall of the corresponding bobbin continuously, and thus the function of folding the corresponding bobbin is achieved. By means of the ingot rod device, the bobbins different in inner diameter can be reliably fixed to a spindle, and normal operation of textile work can be maintained.

Owner:浙江巨力宝纺织科技有限公司

Multi-connection-rod jumping mechanism

The invention discloses a multi-connection-rod jumping mechanism. The multi-connection-rod jumping mechanism comprises a rack, a multi-connection-rod mechanism, an elastic element, an energy storage assembly and a triggering device. The energy storage assembly is used for stretching the elastic element in a non-return mode. The triggering device can relieve the non-return function of the energy storage assembly to make the elastic element rebound. Resilience of the elastic element is used for driving the multi-connection-rod mechanism to be subjected to momentary deformation and pushing the multi-connection-rod mechanism to move upwards to achieve jumping through reactive force of connection rods and the ground during deformation. The multi-connection-rod jumping mechanism is simple in structure and capable of walking on a flat terrain and jumping when running into a barrier, ditches and other complex rugged terrains, and thus the passing performance of a robot is improved greatly.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com