Method and device for producing highly dimensionally accurate flanged half shells

A technology of dimensional accuracy and radius, which is applied in the field of manufacturing and equipment of half-shells with folded edges with high dimensional accuracy, and can solve problems such as high cost, difficulty, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

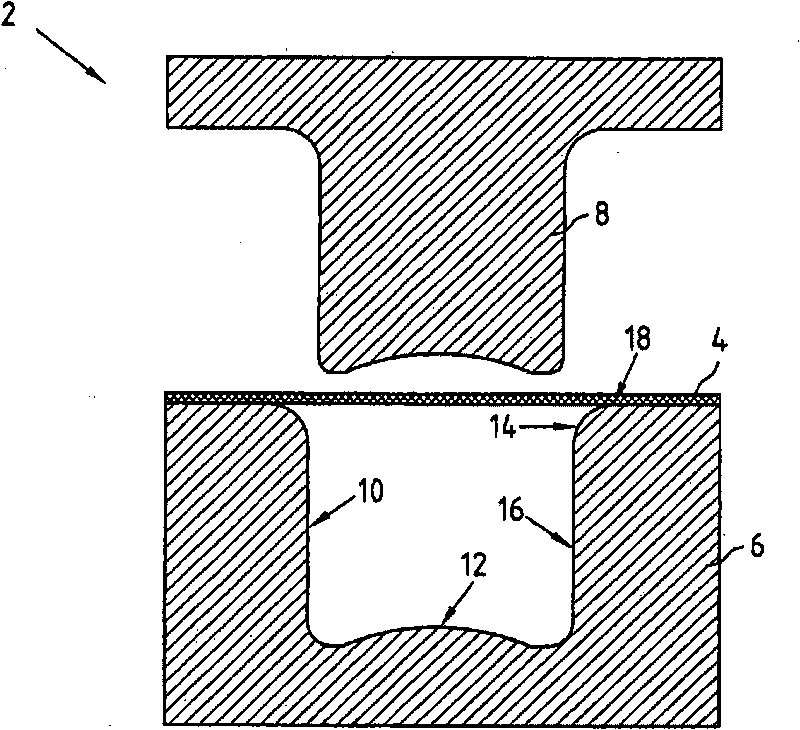

[0030] Such as figure 1 The first tool 2 of one embodiment of the kit according to the invention for producing a preformed half-shell from a blank 4 , shown in , comprises a first lower die 6 and an upper deep-drawn die 8 . The general shape of the inner side 10 of the lower mold 6 is similar to the shape of the outer side of the final shaped half-shell to be produced by the kit. However, in the transition region 14 between the body region 16 and the flange region 18 of the lower mold 6 and in the bottom region 12, the shape of the inner side 10 of the lower mold 6 is identical to that of the final shaped half-shell to be produced by the kit. The shape of the outer side is deviated. The inner side 10 of the lower mold 6 thus has an undulating shape in the bottom region 12 . Alternatively, simple concave or convex shapes or other shapes are also conceivable which deviate from the expected shape of the bottom region or of the final molded half-shell. Furthermore, the bead rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com