Patents

Literature

1756results about "Metal rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

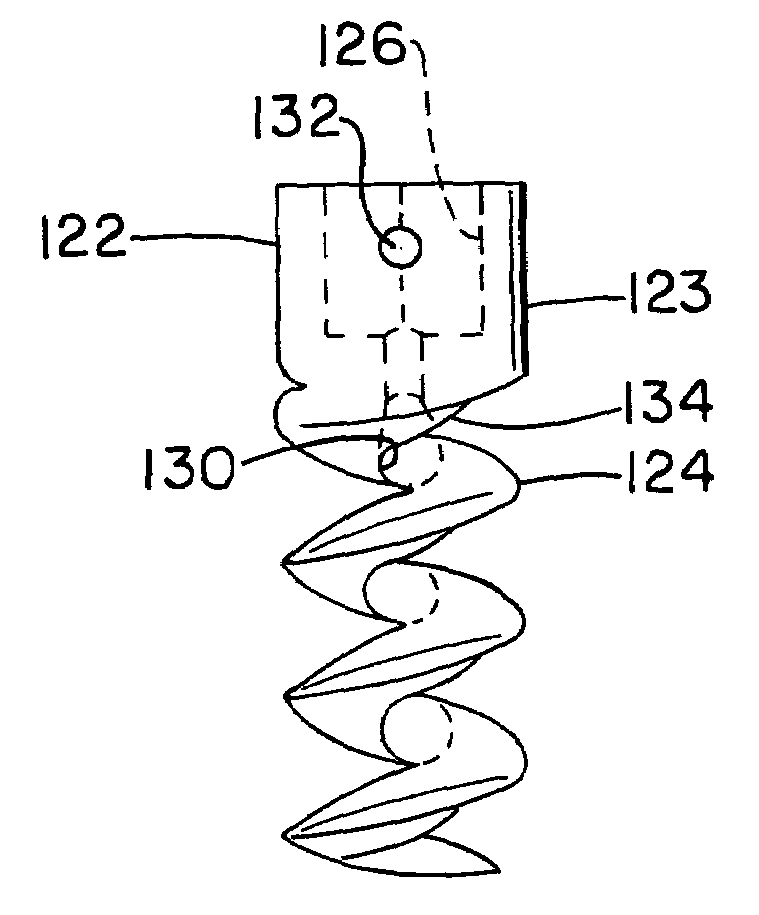

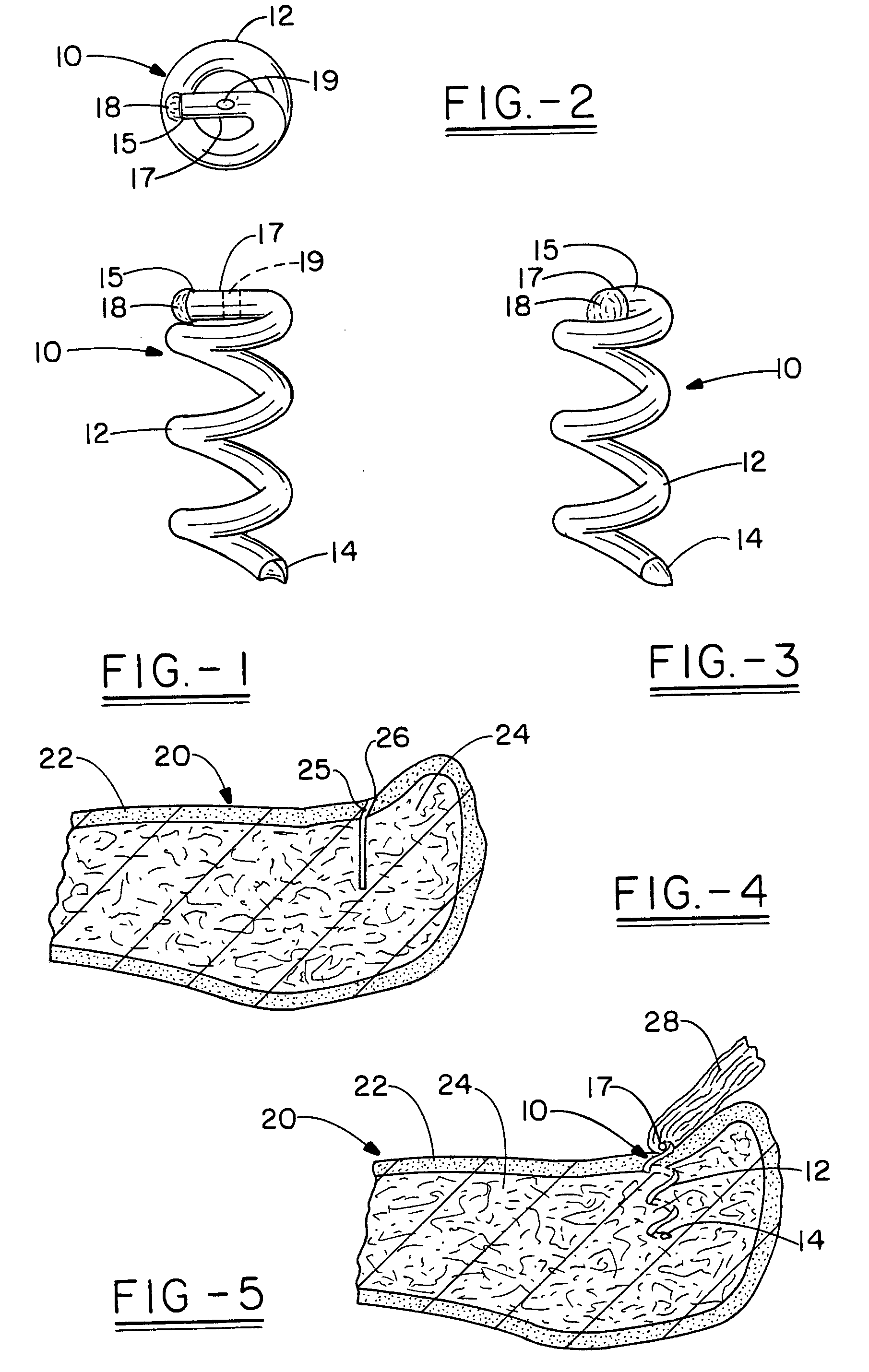

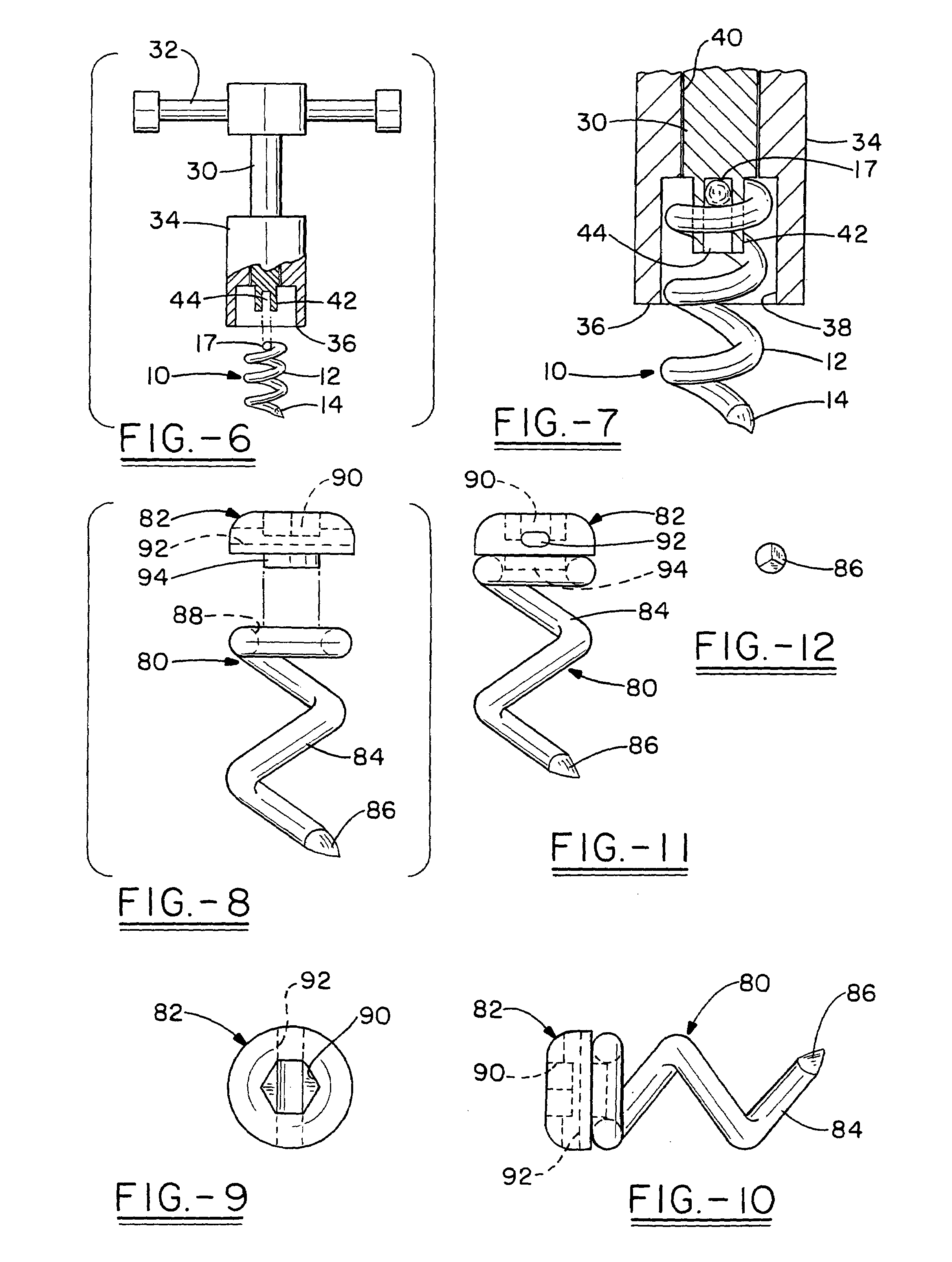

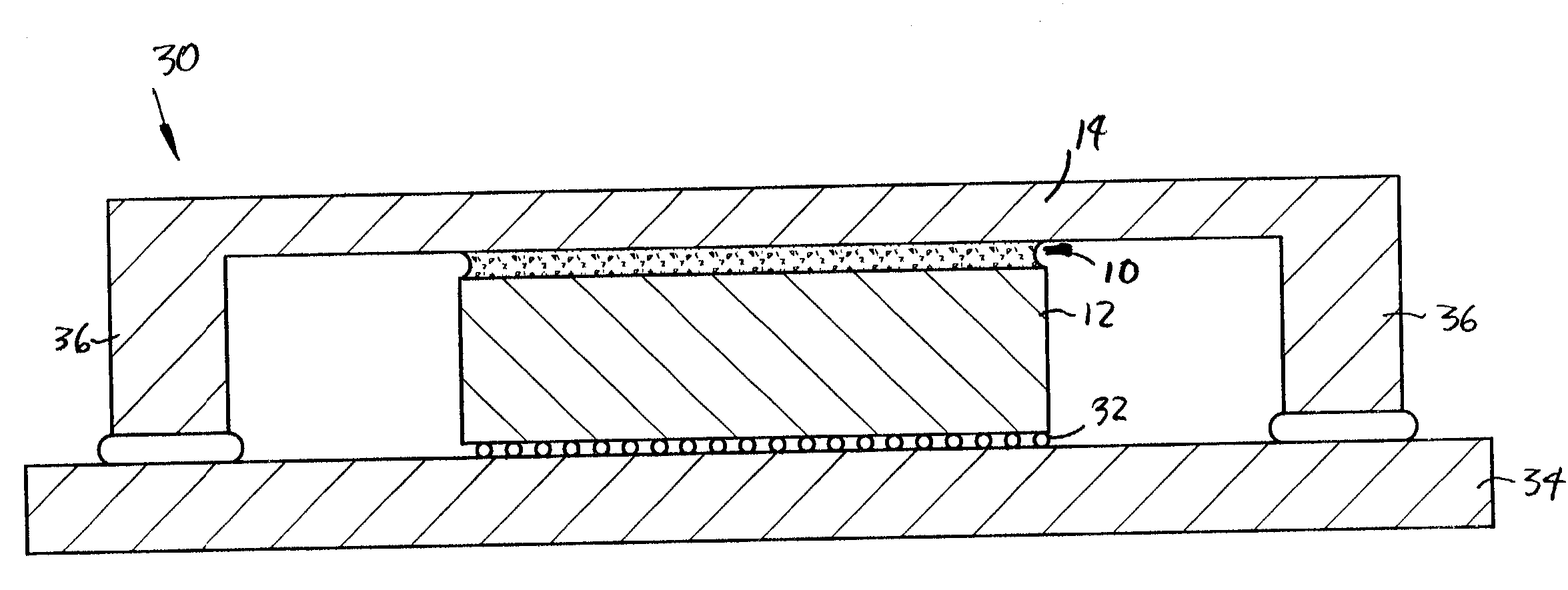

Open helical organic tissue anchor having recessible head and method of making the organic tissue anchor

InactiveUS7189251B2Easy to anchorStrengthens helixSuture equipmentsPinsSelf reinforcedLigament structure

The invention relates to a tissue anchor which is an open helix of biocompatible material having a slope of from 0.5 to 10 turns per centimeter, a length from 3 to 75 millimeters, a diameter of from 1.5 to 11 millimeters, and an aspect ratio of from about 3 to about 5 to 1. The anchor can have a head which is capable of securing or clamping tissue together, such as holding a suture to secure a ligament or tendon to bone. The anchor can also have a head which causes an inward, compressive loading for use in fastening bone to bone, orthopedic plates to bone, or cartilage to bone. The head may be an integral member and may include a self-reinforcing wedge which joins the helix to the head. Further, the elongate member, or filament that forms the helix may have a tapering diameter along its length.

Owner:ORTHOHELIX SURGICAL DESIGNS

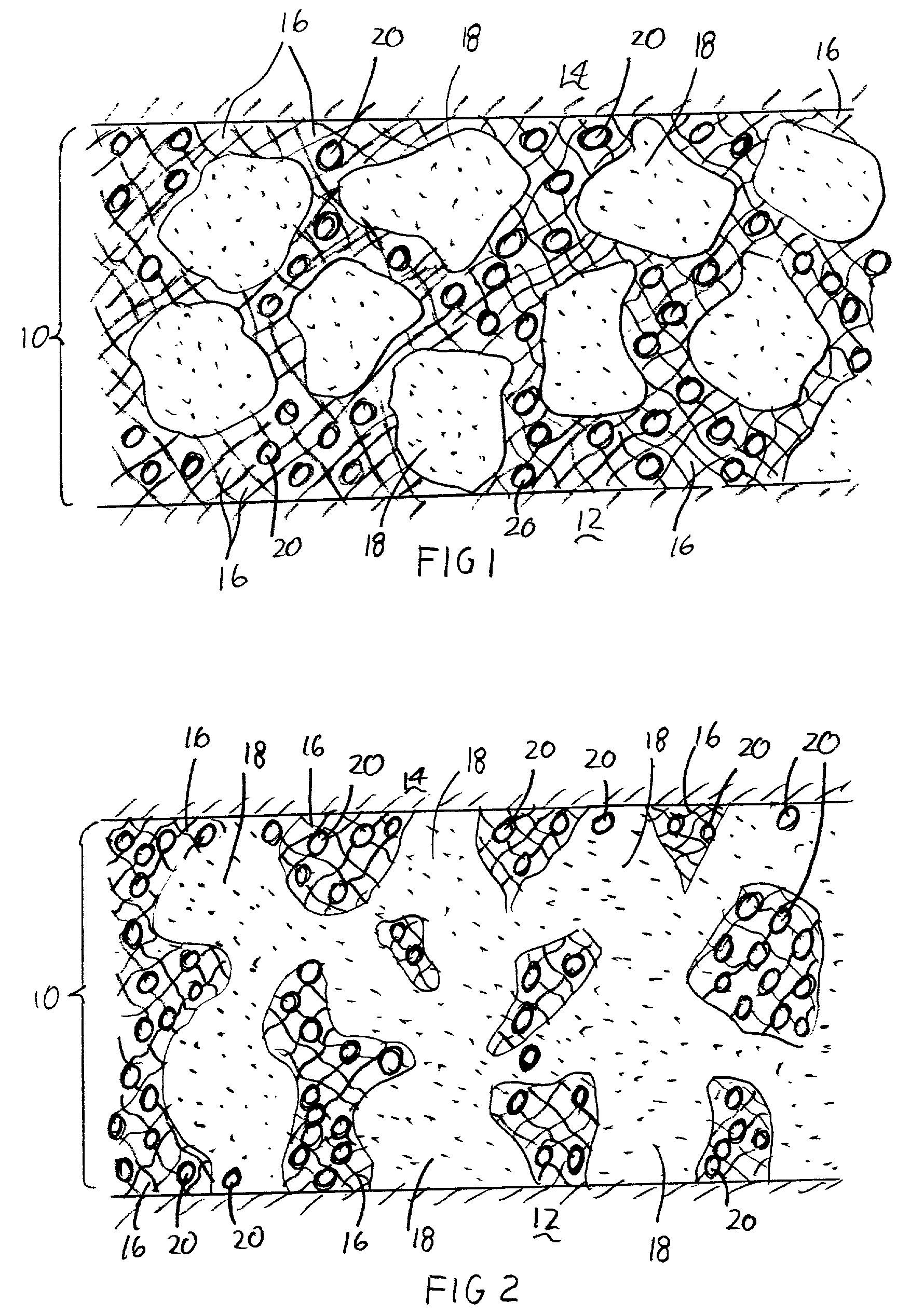

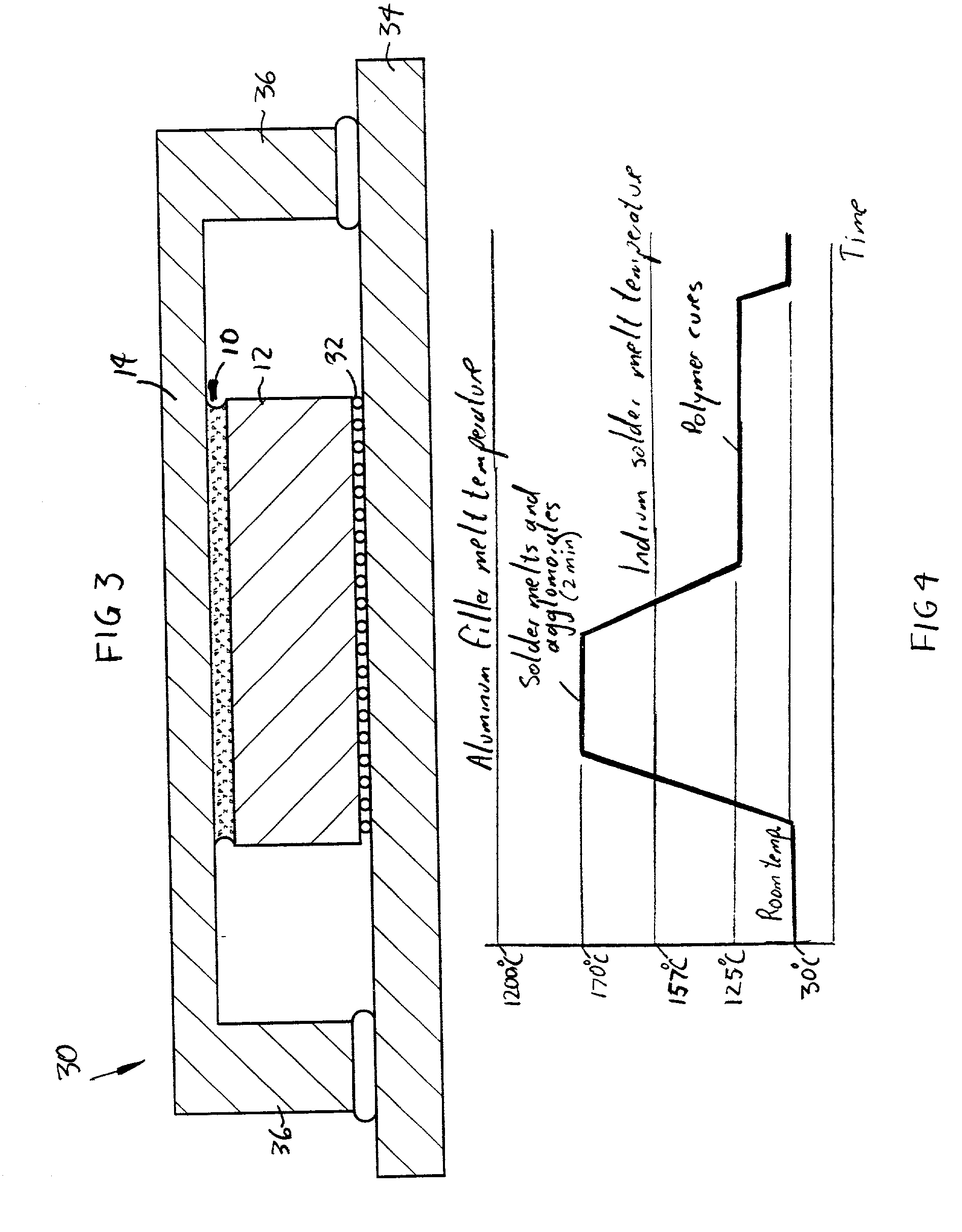

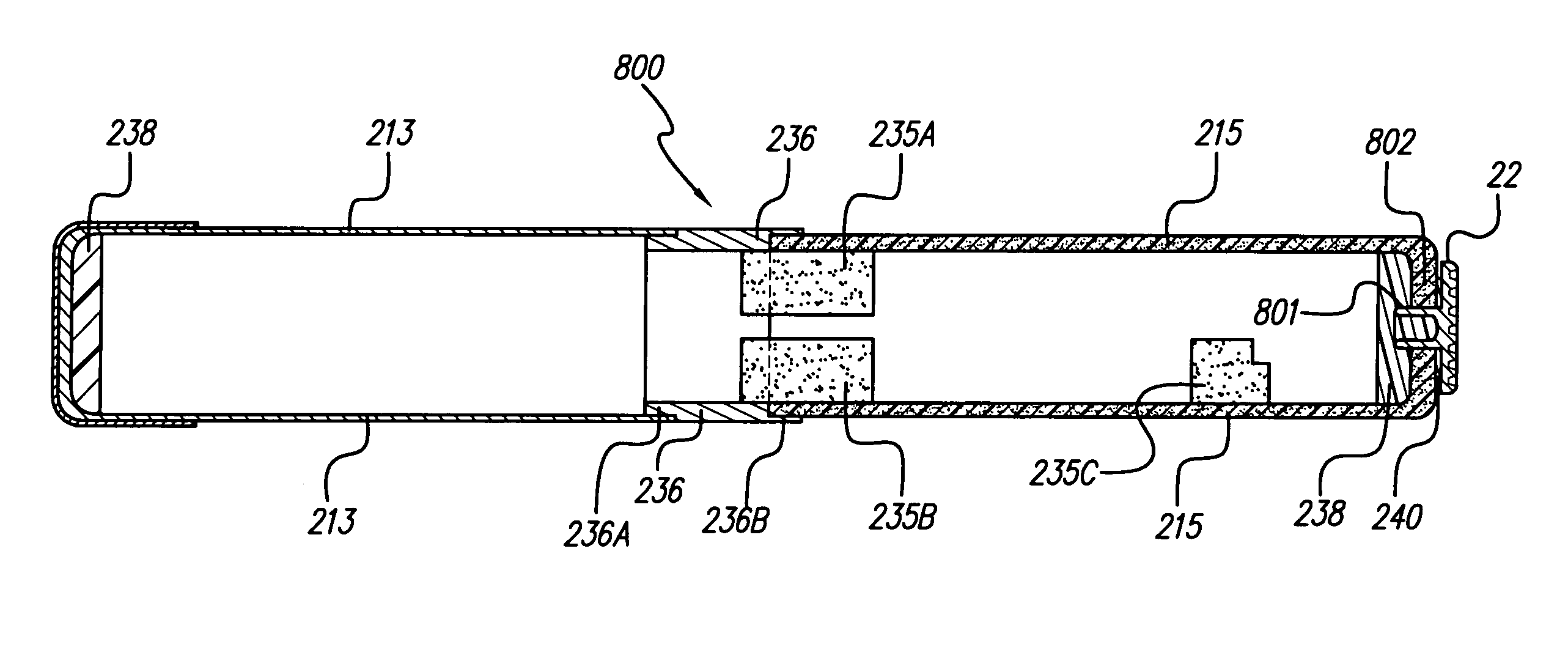

Thermal interface material and electronic assembly having such a thermal interface material

InactiveUS20030077478A1Artificial flowers and garlandsSemiconductor/solid-state device detailsStress conditionsIndium

A thermal interface material is described for thermal coupling of an electronic component to a thermally conductive member. The thermal interface material includes a viscoelastic polymer matrix material, fusible solder particles in the matrix material, and filler particles in the matrix material. The solder particles have a melting temperature below a selected temperature (e.g. 157° C. for indium) and the filler particles have a melting temperature substantially above the selected temperature (e.g. 961° C. for silver). The filler particles keep the thermal interface material intact under adverse thermal and stress conditions.

Owner:INTEL CORP

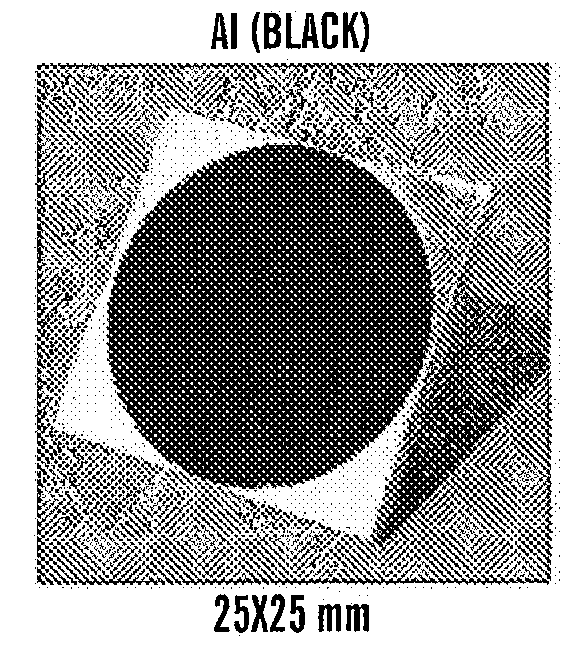

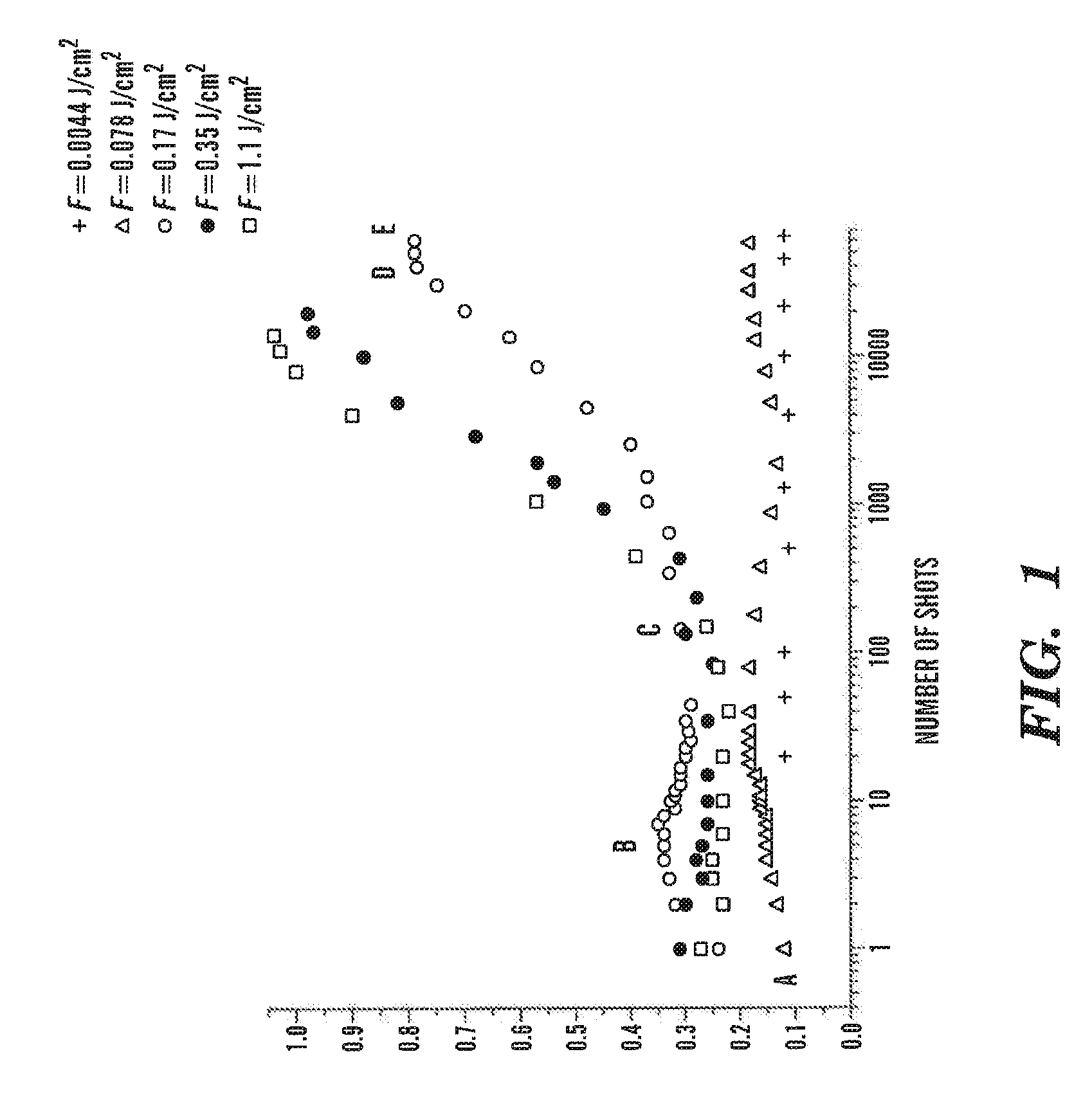

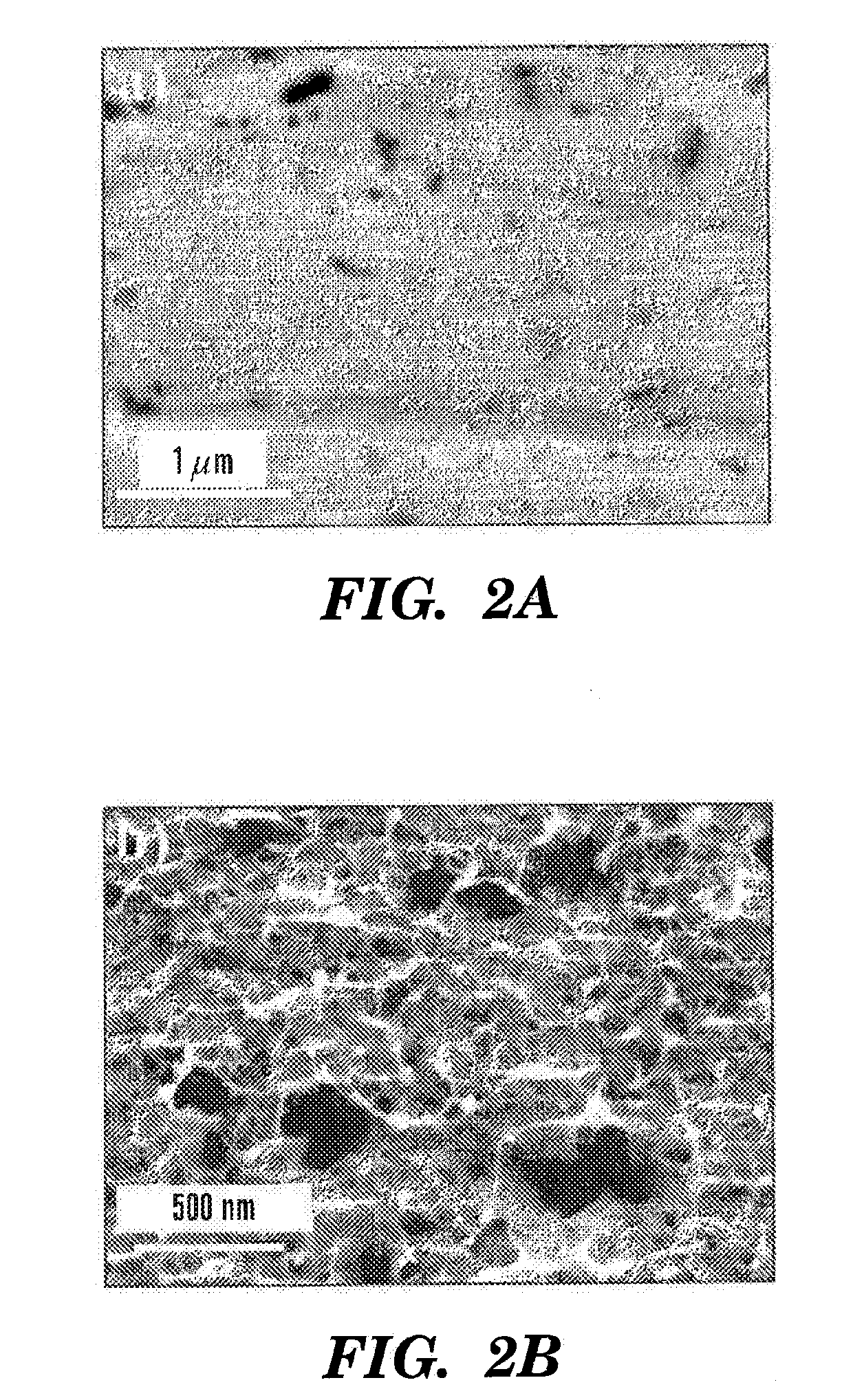

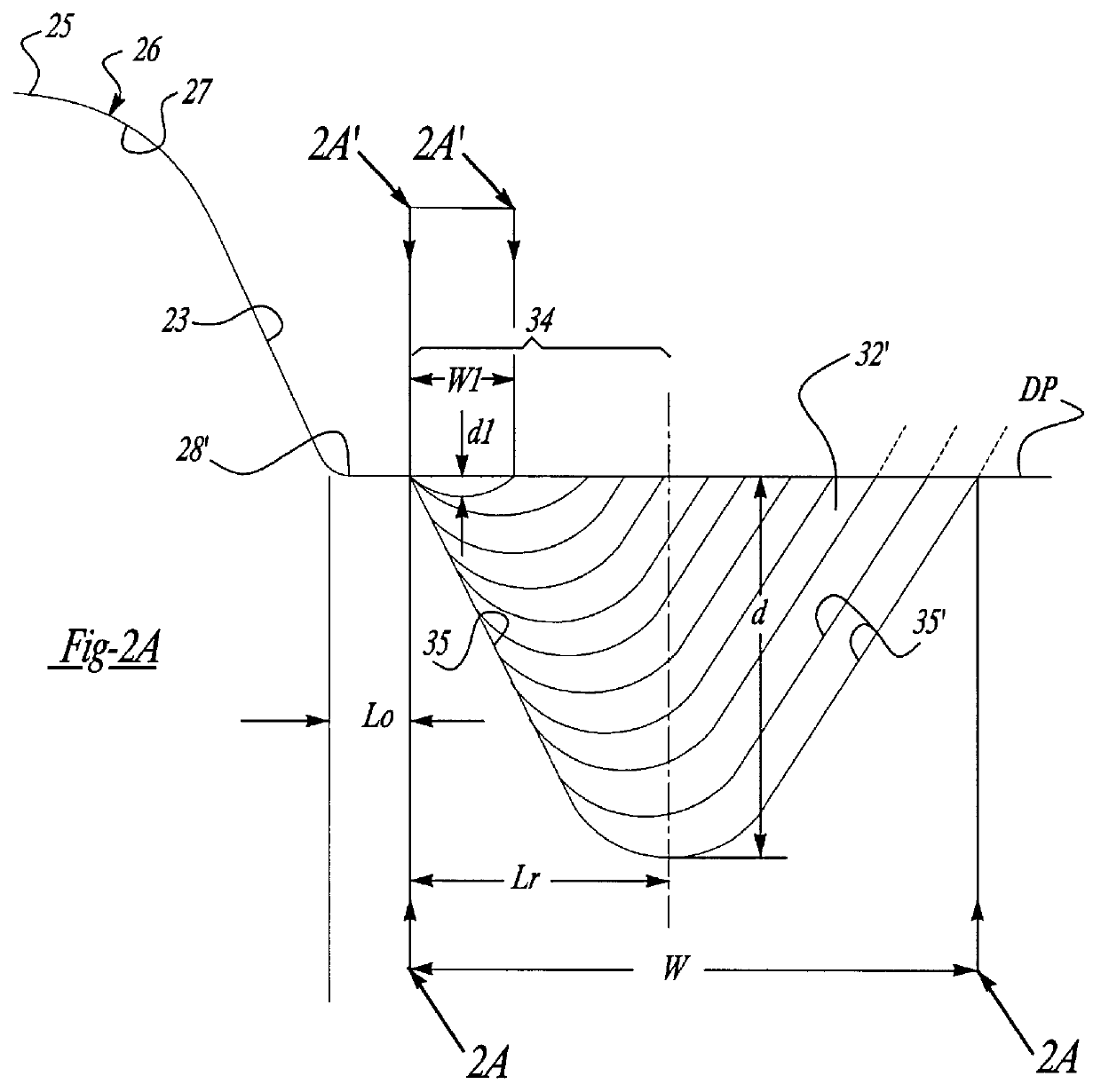

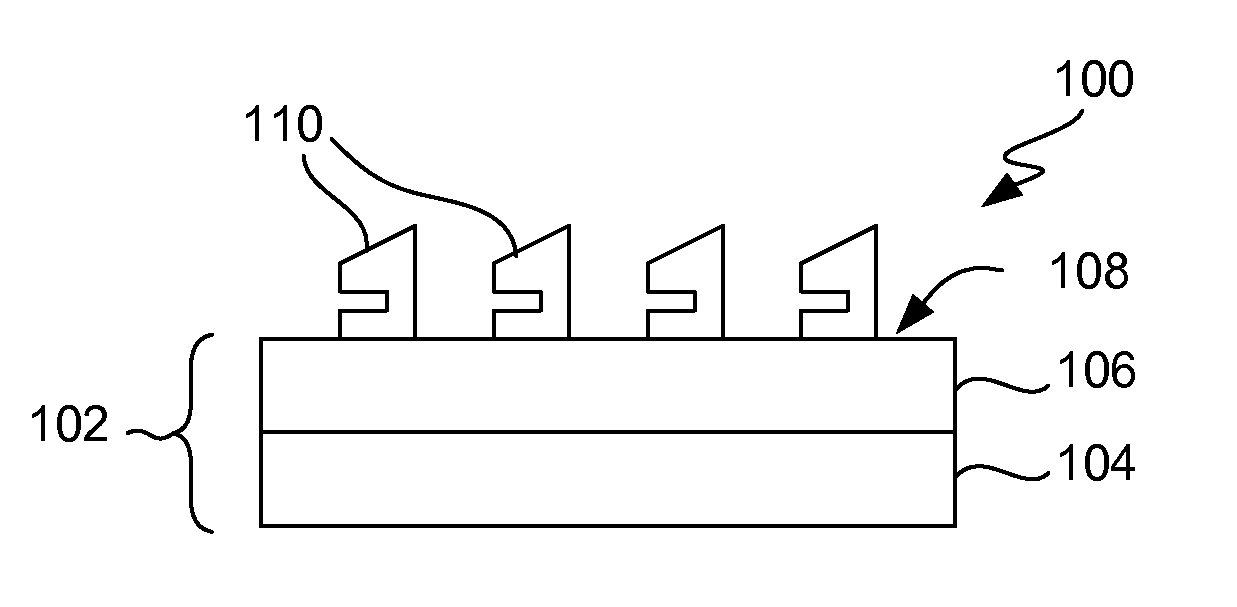

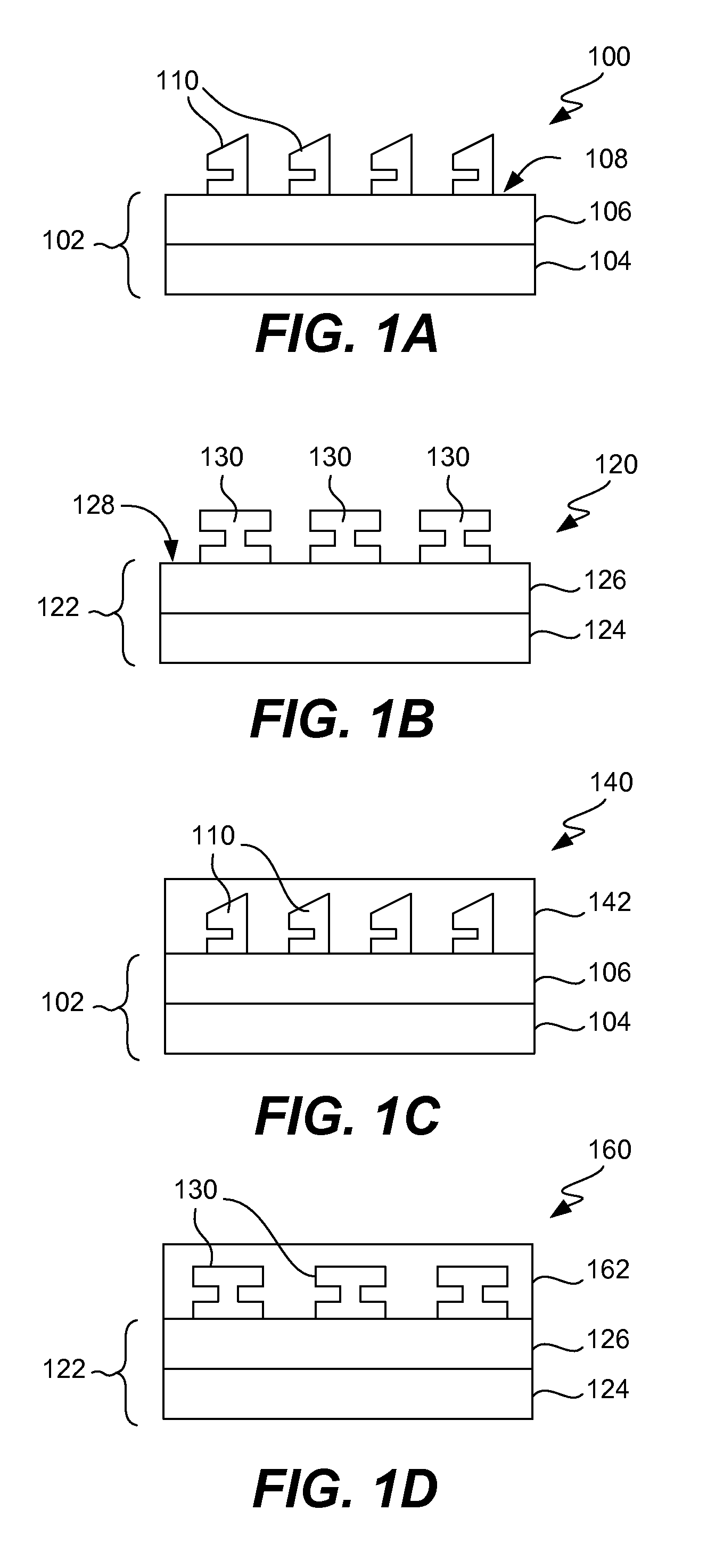

Femtosecond Laser Pulse Surface Structuring Methods and Materials Resulting Therefrom

InactiveUS20080299408A1Material nanotechnologyEngine sealsBiocompatibility TestingMaterials processing

Embodiments of the present invention are generally directed to materials processing methods using femtosecond duration laser pulses, and to the altered materials obtained by such methods. The resulting nanostructured (with or without macro- and micro-structuring) materials have a variety of applications, including, for example, aesthetic applications for jewelry or ornamentation; biomedical applications related to biocompatibility; catalysis applications; and modification of, for example, the optical and hydrophilic properties of materials including selective coloring.

Owner:UNIVERSITY OF ROCHESTER

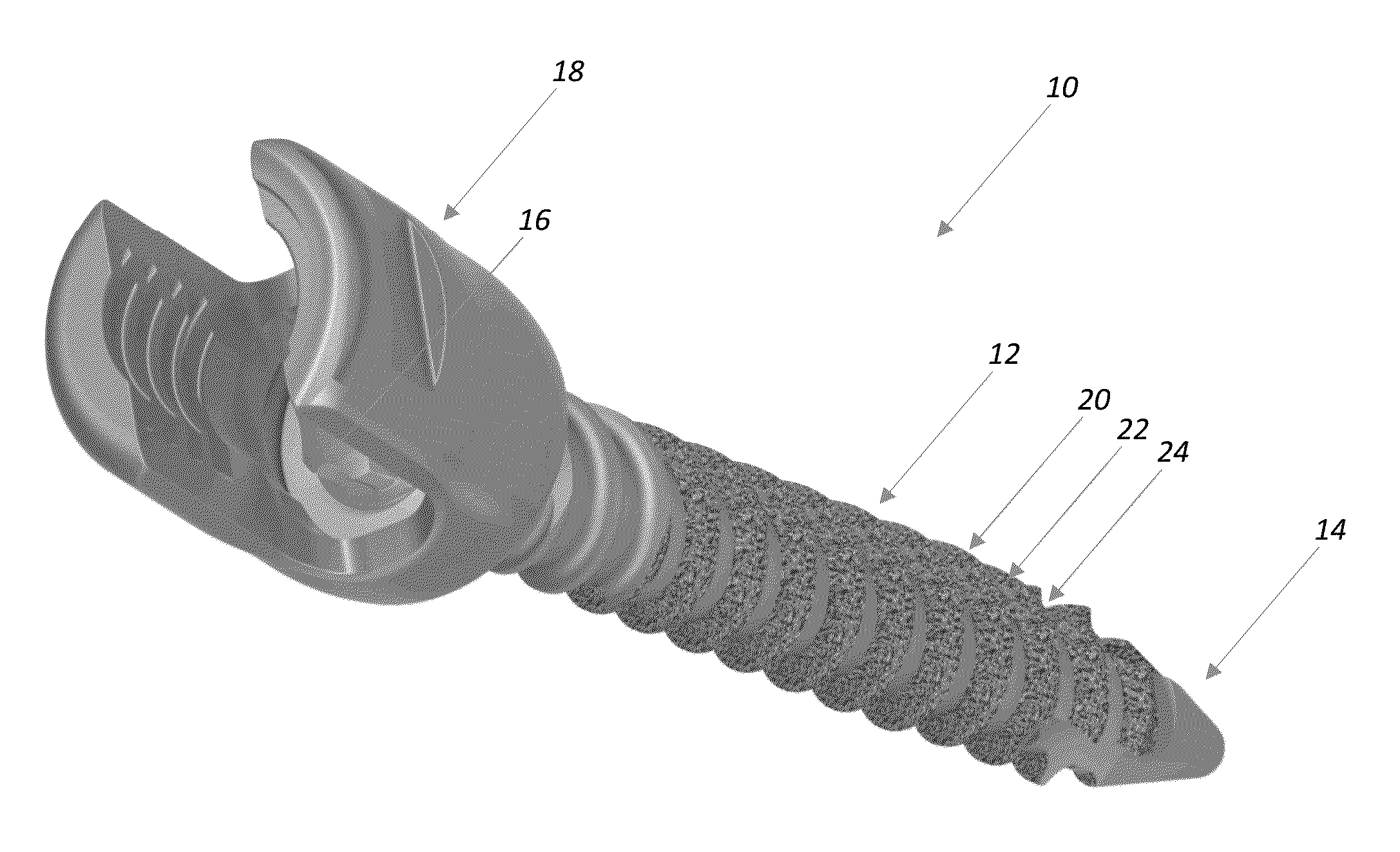

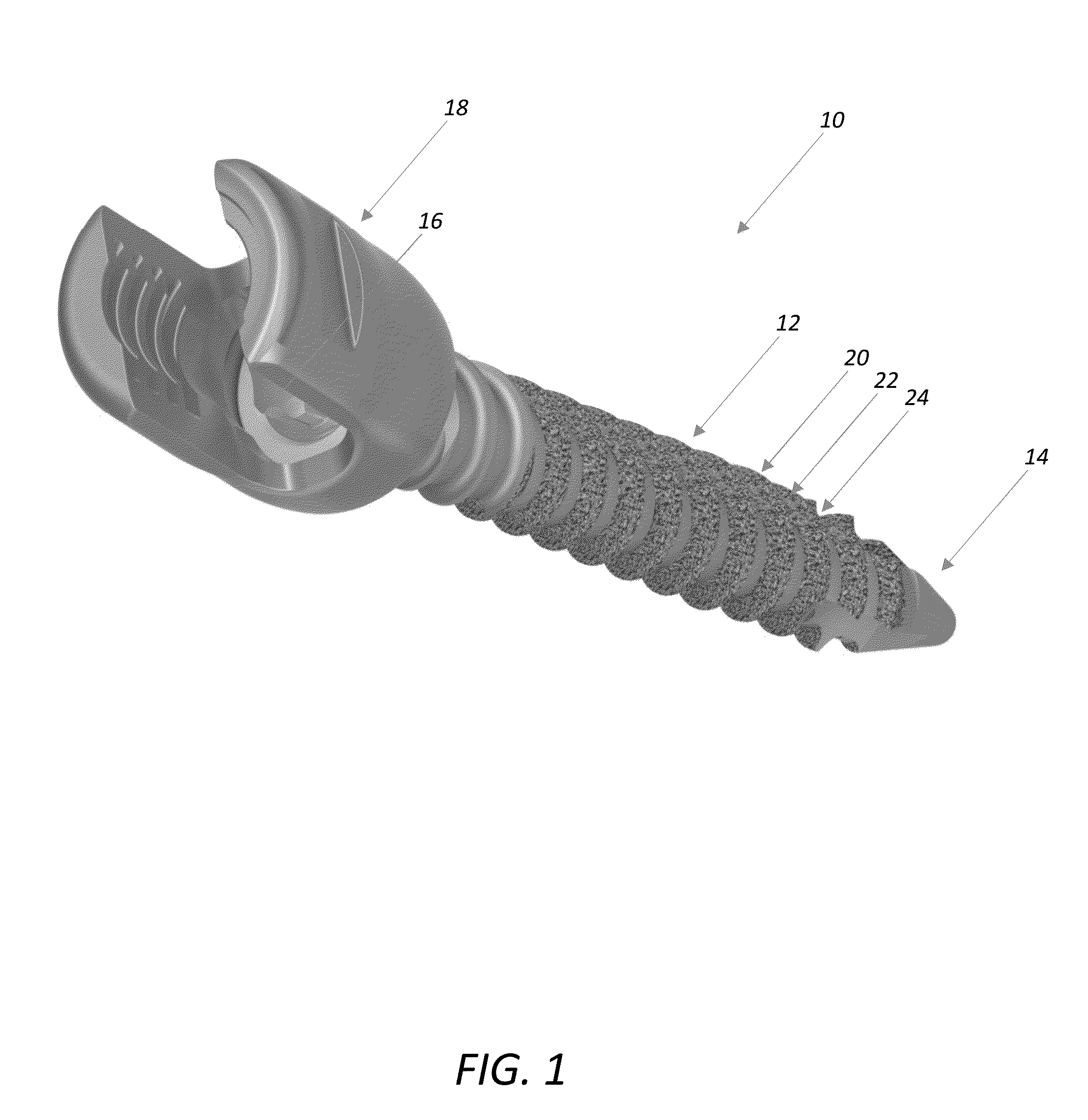

Bone screw incorporating a porous surface formed by an additive manufacturing process

ActiveUS20160157908A1Enhancing bony fixationEnhancing ingrowthSuture equipmentsAdditive manufacturing apparatusMachining processIliac screw

The present invention provides a bone screw or bone anchor, such as a threaded pedicle screw or the like, incorporating a porous surface for enhancing bony fixation, ingrowth, and purchase when implanted in bone. Preferably, this porous surface covers at least a portion of the threads of the bone screw or bone anchor. The porous surface is formed by a conventional or novel additive manufacturing process, such as three-dimensional (3D) printing or the like, optionally as well as a prior and / or subsequent machining process. The porous surface may include novel needle-like protrusions and / or lattice structures, and / or any other protruding / depressed features, whether regular or irregular.

Owner:KYOCERA MEDICAL TECH INC

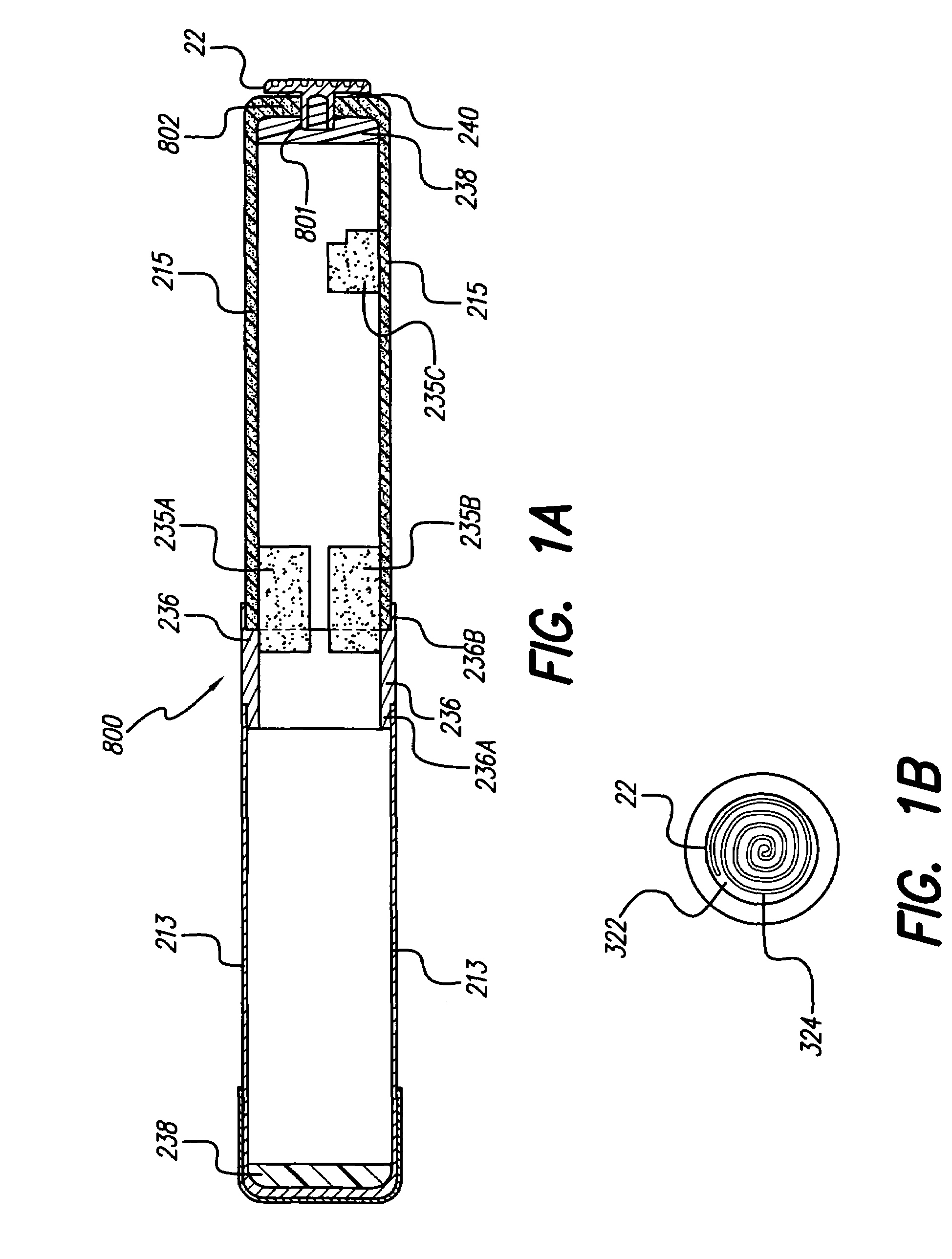

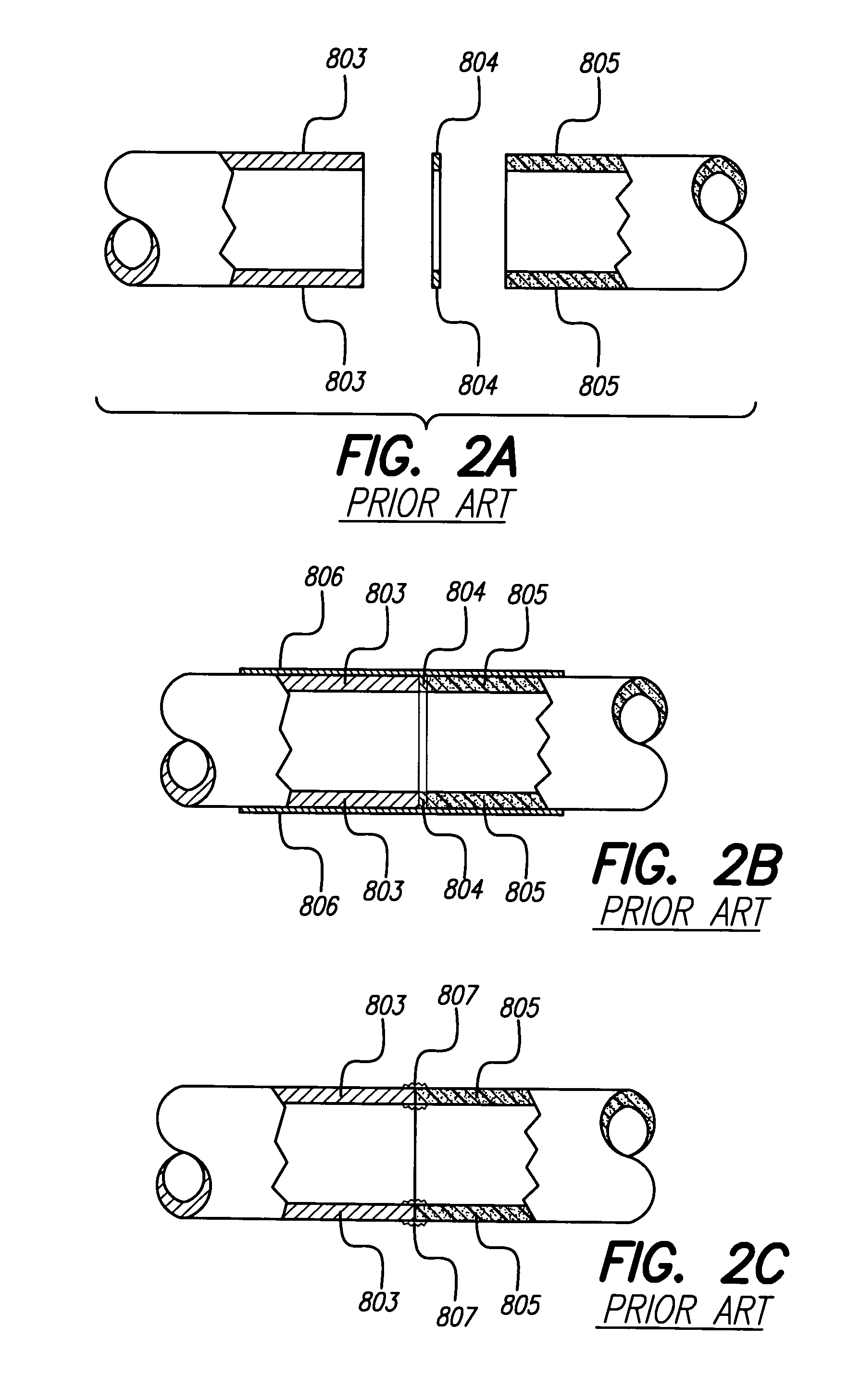

Self-centering braze assembly

ActiveUS7132173B2Increase surface areaPrevent materialNear-field transmissionBatteries circuit arrangementsConductive materialsMetal

Braze and electrode wire assemblies, e.g., used with an implantable microstimulator, include a wire welded in the through-hole of an electrode, which electrode is brazed to a ceramic case that is brazed to a metal ring that is welded to a metal can. The braze joints are step or similar joints that self-center the case, provide lateral support during braze assembly, and provide increased surface area that prevents braze material from exuding from the joints. The end of the ceramic case that is brazed to the metal ring need not be specially machined. The shell has a reference electrode on one end and an active electrode on the other, and is externally coated on selected areas with conductive and non-conductive materials.

Owner:BOSTON SCI NEUROMODULATION CORP

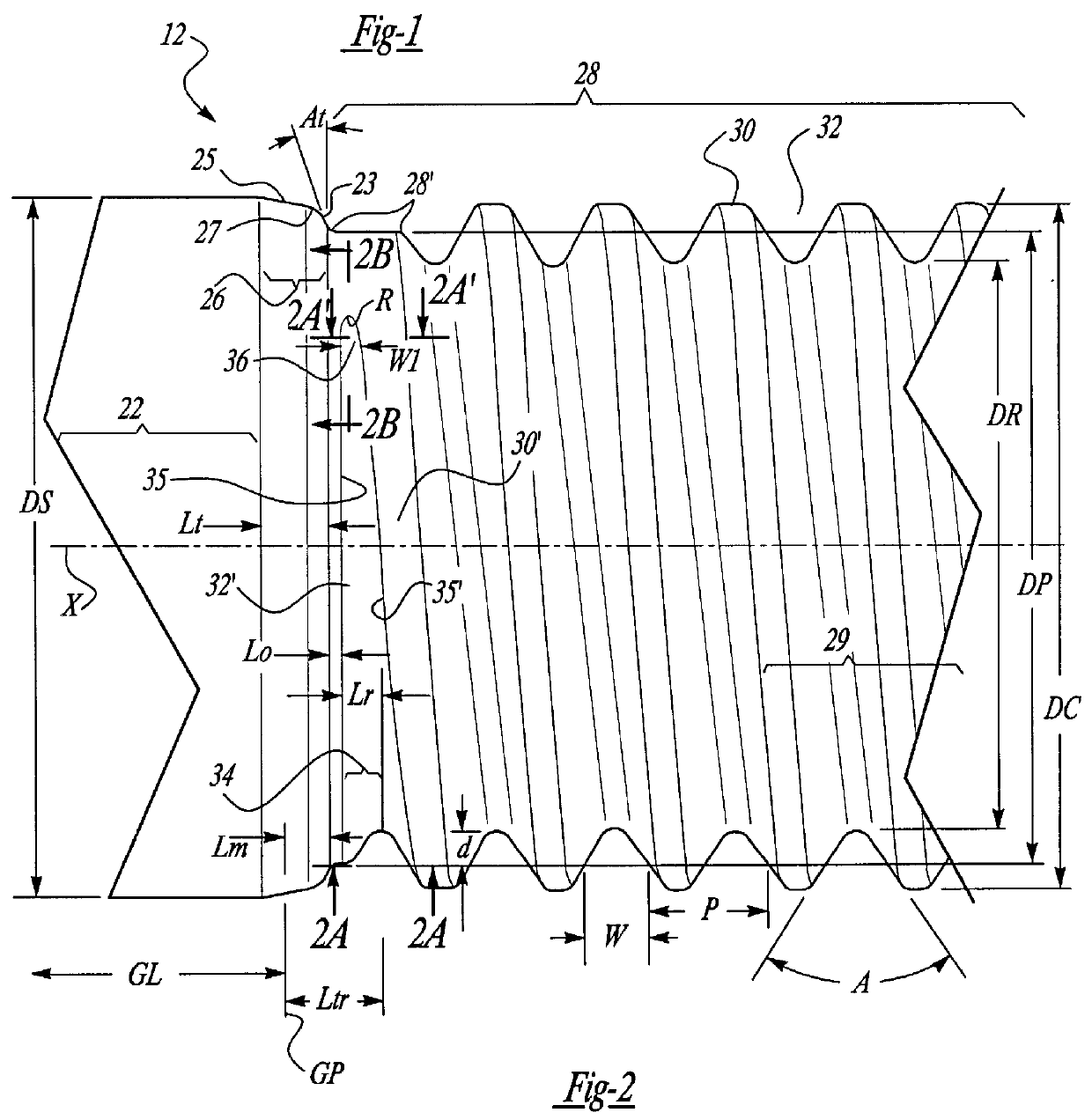

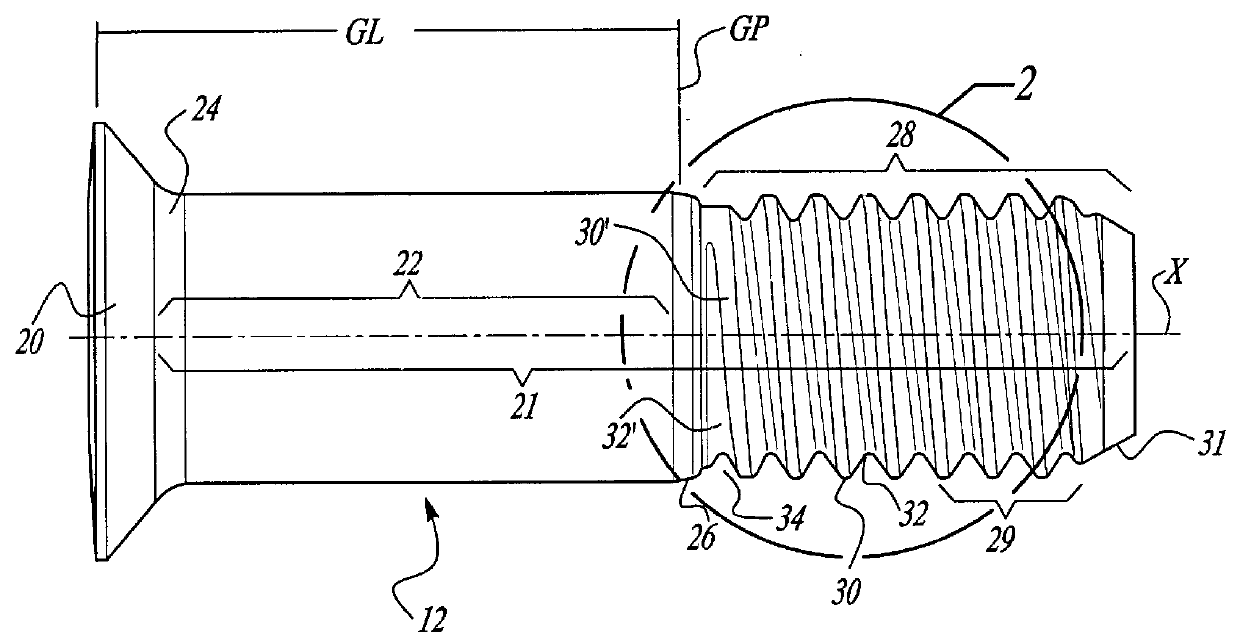

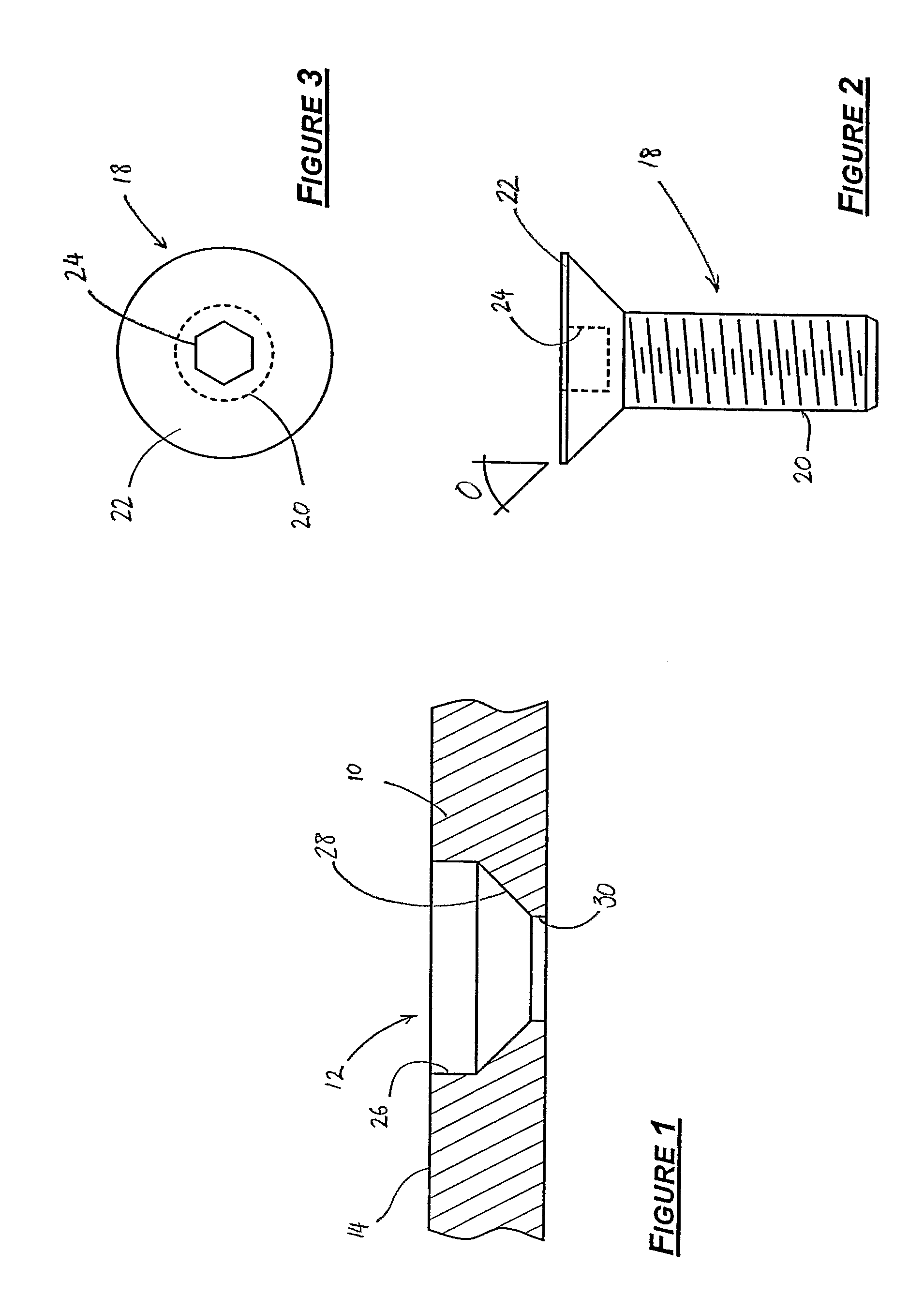

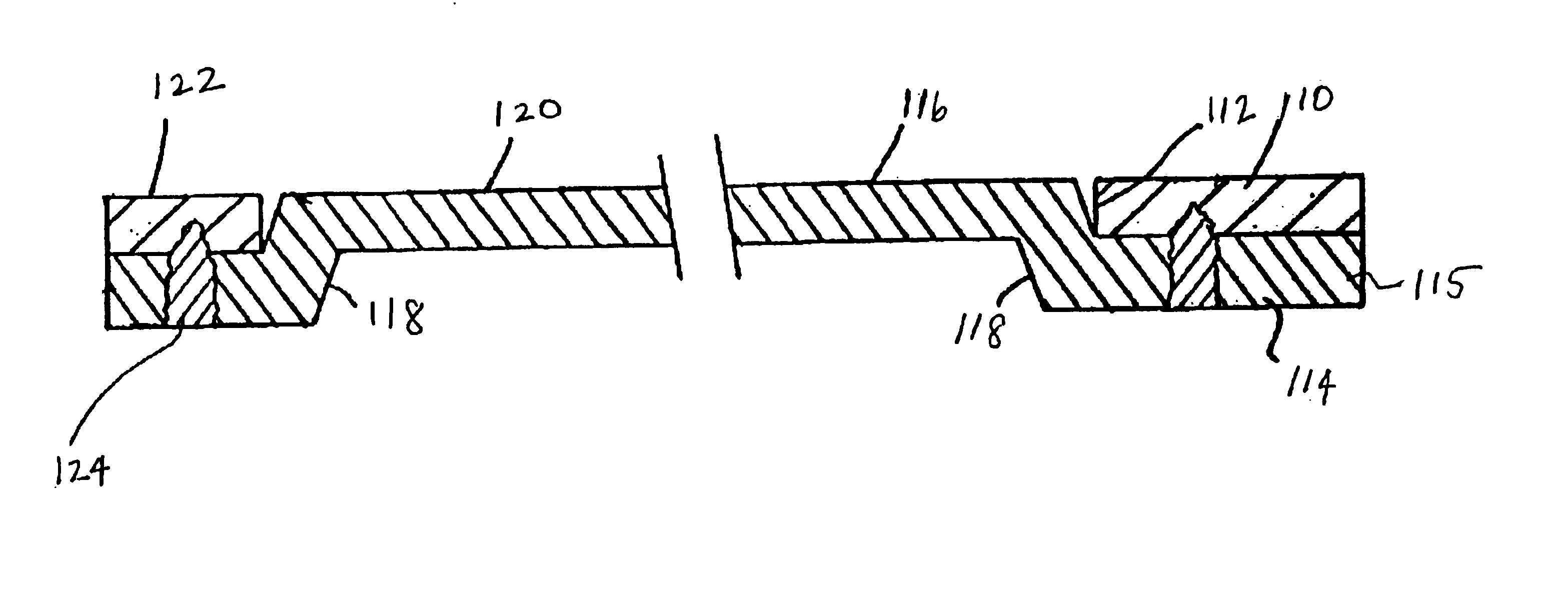

Lightweight threaded fastener and thread rolling die

InactiveUS6149363AImprove fatigue performanceImprove wear resistanceNutsBoltsEngineeringScrew thread

The present invention is to a lightweight threaded bolt type fastener having a shank with a large diameter portion and small diameter portion connected by a transition portion; a thread is roll formed on the small diameter portion and terminates in a run-out section where the thread gradually decreases in root depth and width and with the run-out section being of minimal axial length and being located closely adjacent the transition portion to produce a run-out zone of minimal axial length. A rolling die for forming the thread with minimal thread run-out having ridge segments with tapered end surfaces for providing the run-out thread with an end wall parallel to the transition portion and a method of making the bolt type fastener.

Owner:HUCK INT INC

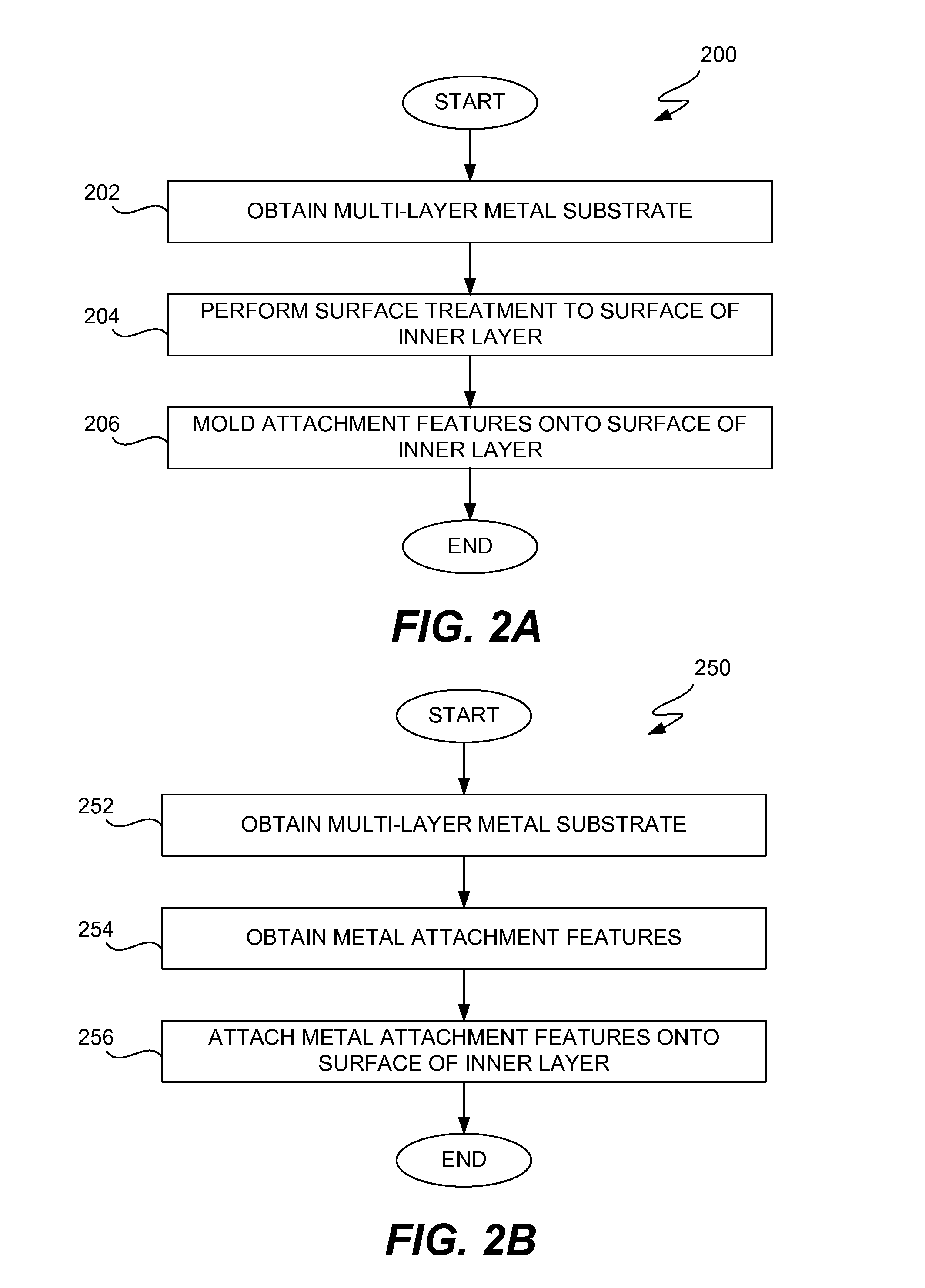

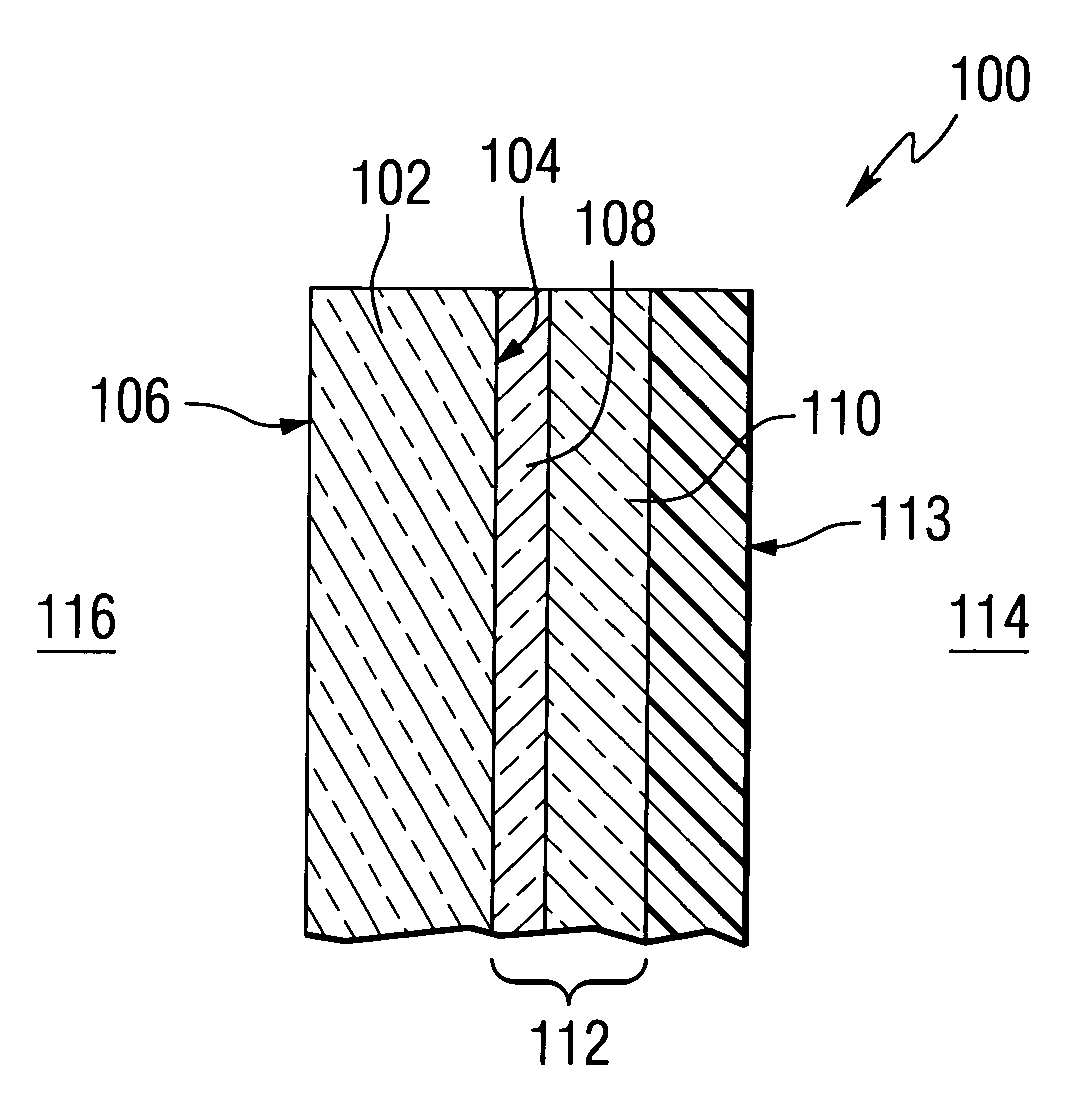

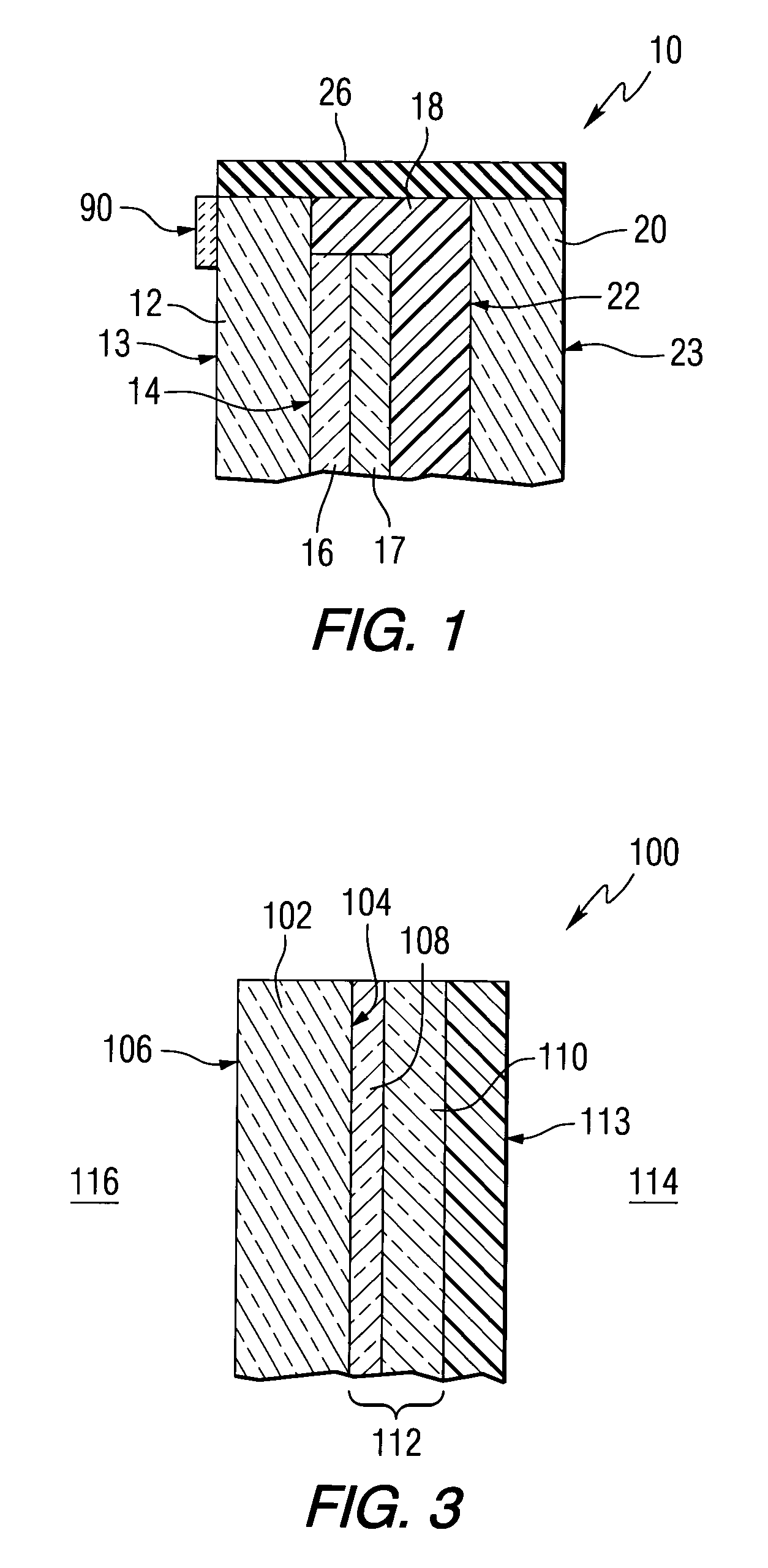

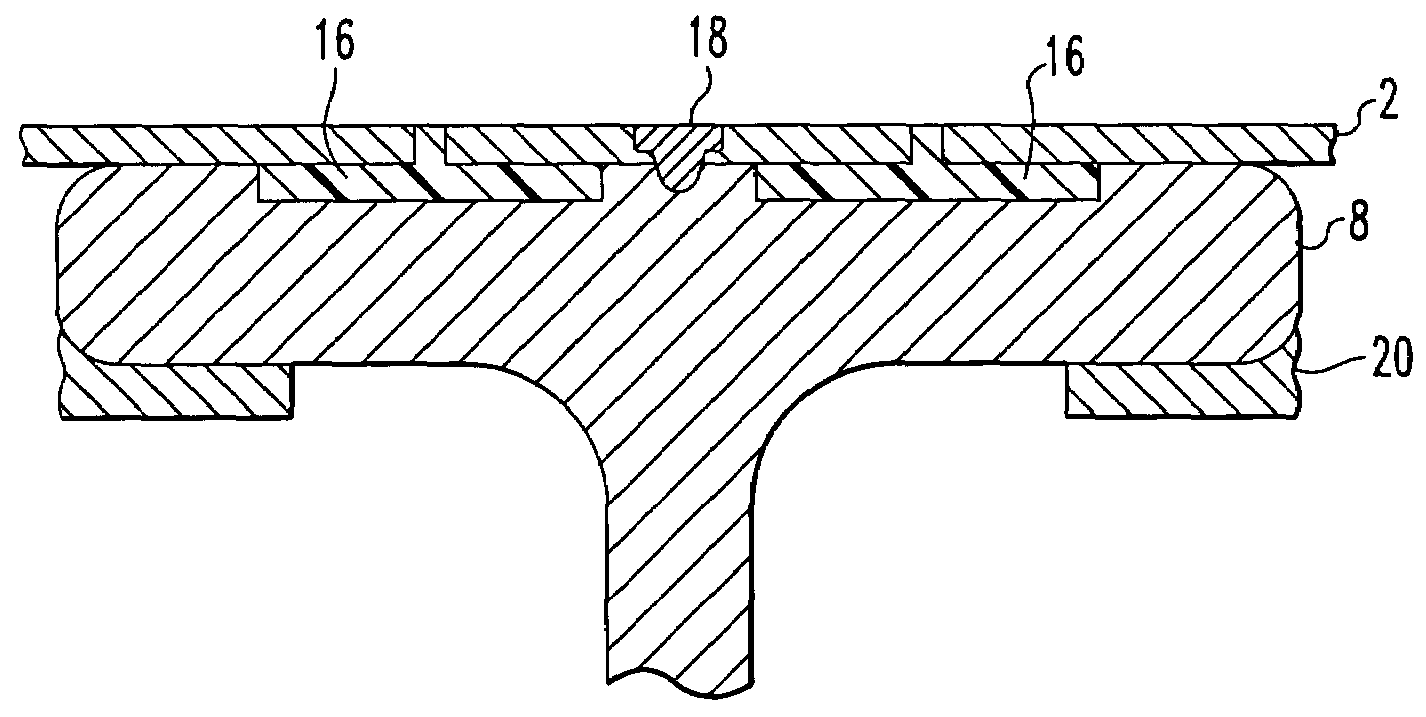

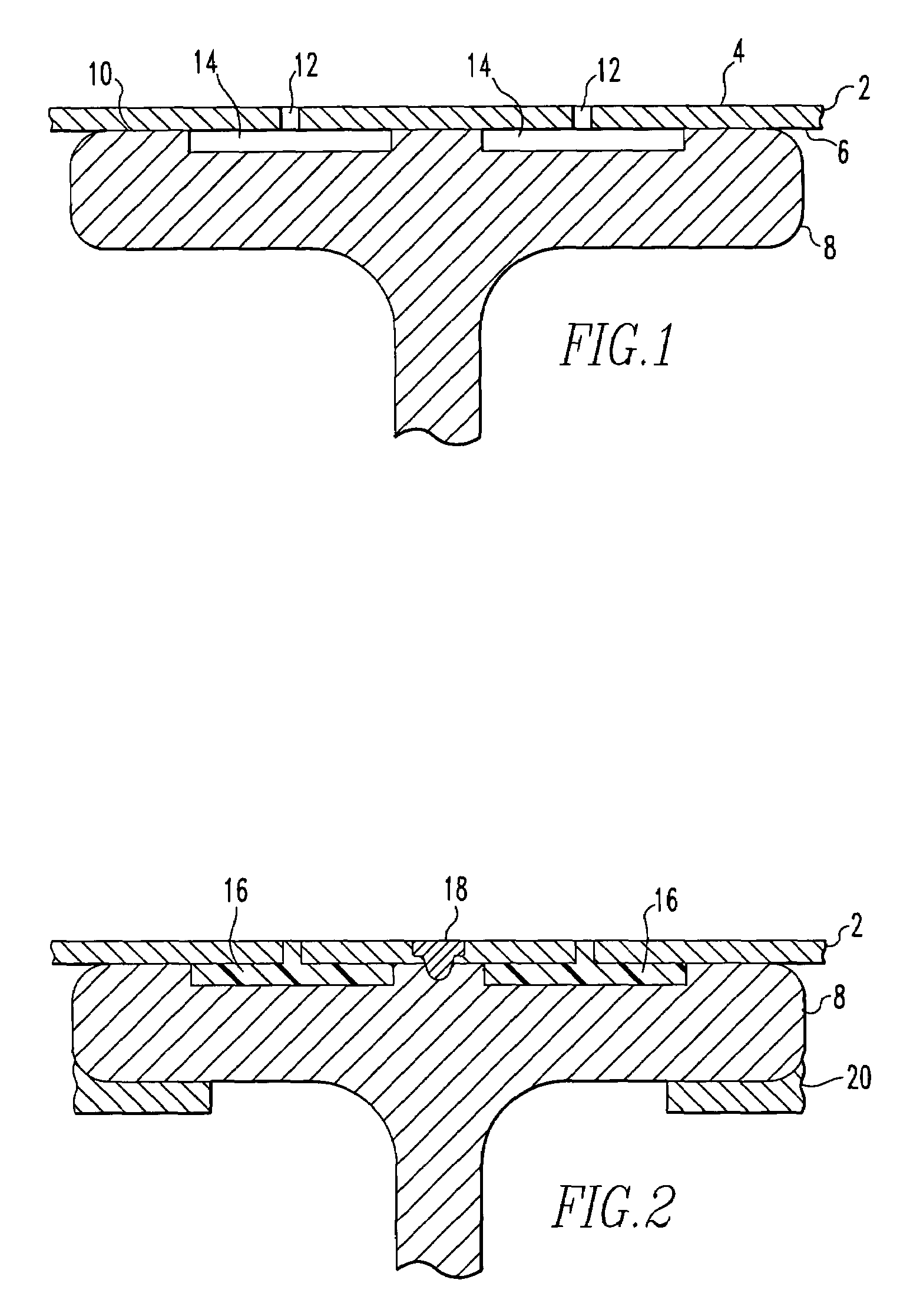

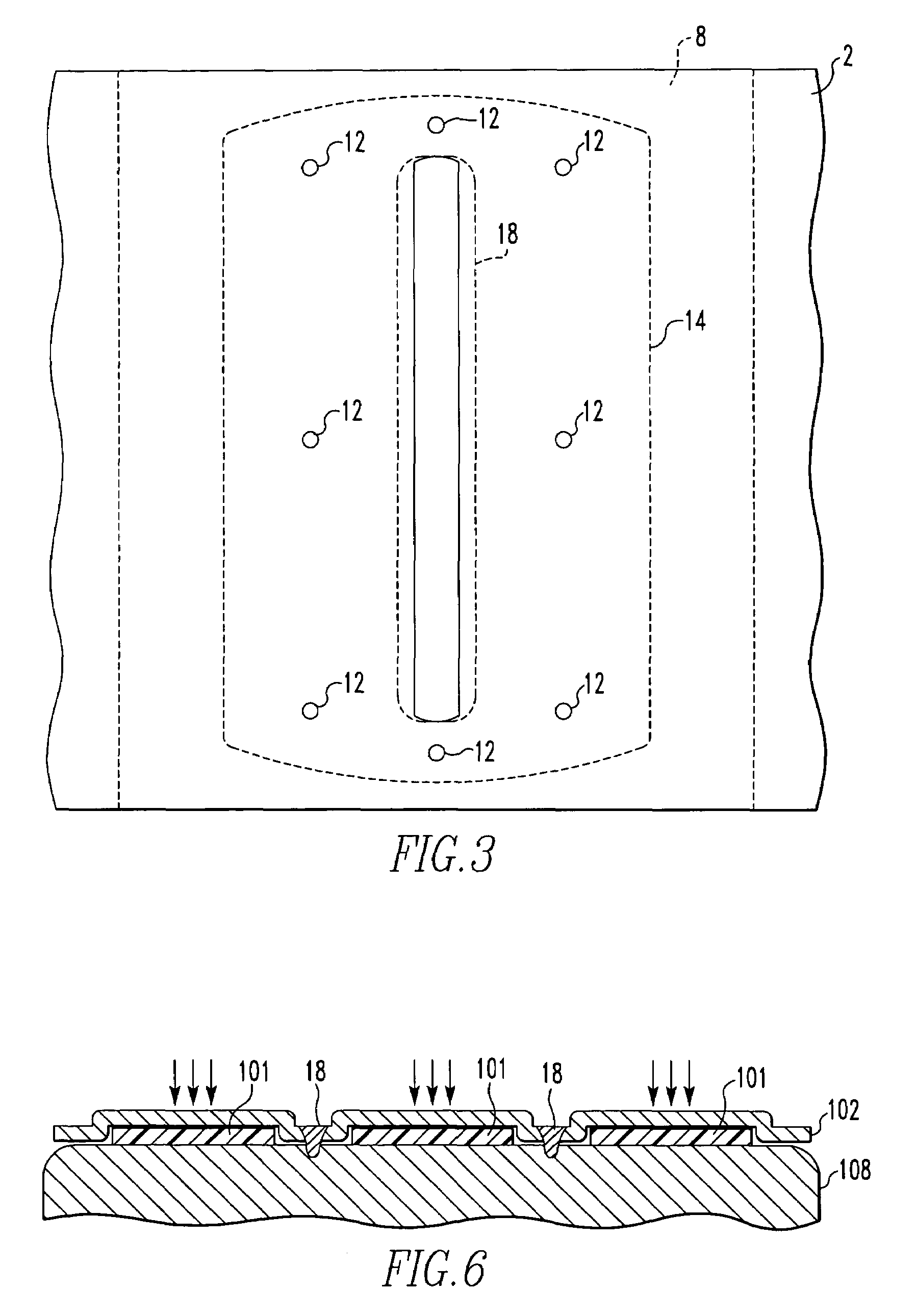

Methods and Systems for Forming Housings From Multi-Layer Materials

ActiveUS20090190290A1Easy to createFacilitate partDigital data processing detailsExtrusion containersElectronMetal

Methods and apparatus for forming a housing, such as for an electronic device, from multi-layer materials are disclosed. The multi-layer materials include at least two layers. Typically, one or more of the layers are metal. However, different layers of the multi-layer materials can be different metals. In one embodiment, an inner layer of the multi-layer materials can be provided with or form internal features that can be for attaching parts or components to the multi-layer materials. In another embodiment, processing of an inner layer of the multi-layer materials can facilitate part formation with increased curvature and / or internal part clearance. In another embodiment, the multi-layer materials can include an intermediate layer that facilitates creation of internal features that can be for attaching parts or components to the multi-layer materials. In still another embodiment, the multi-layer materials can provide a protective layer that serves to protect an outer surface of the housing during manufacturing and / or assembly.

Owner:APPLE INC

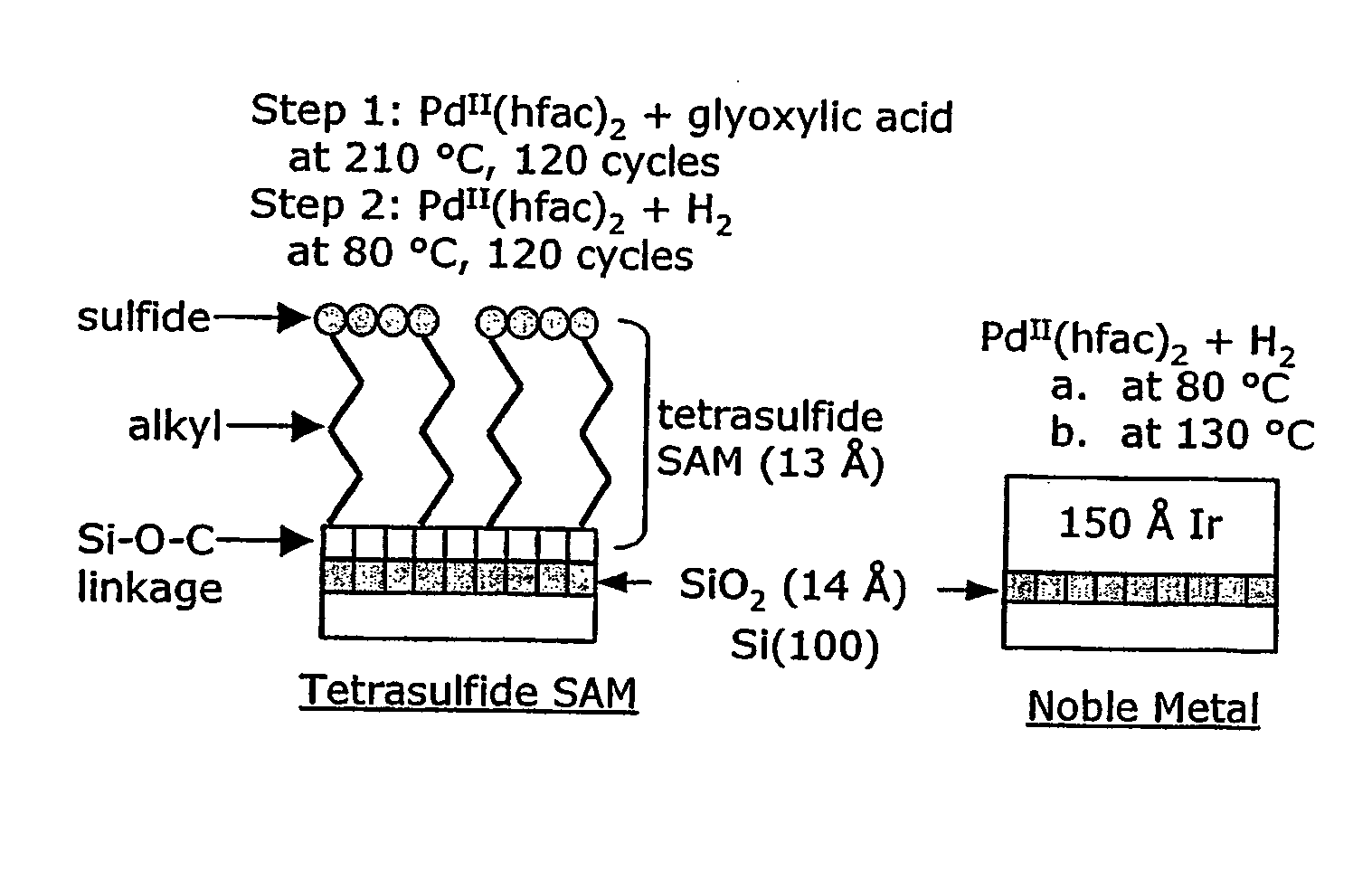

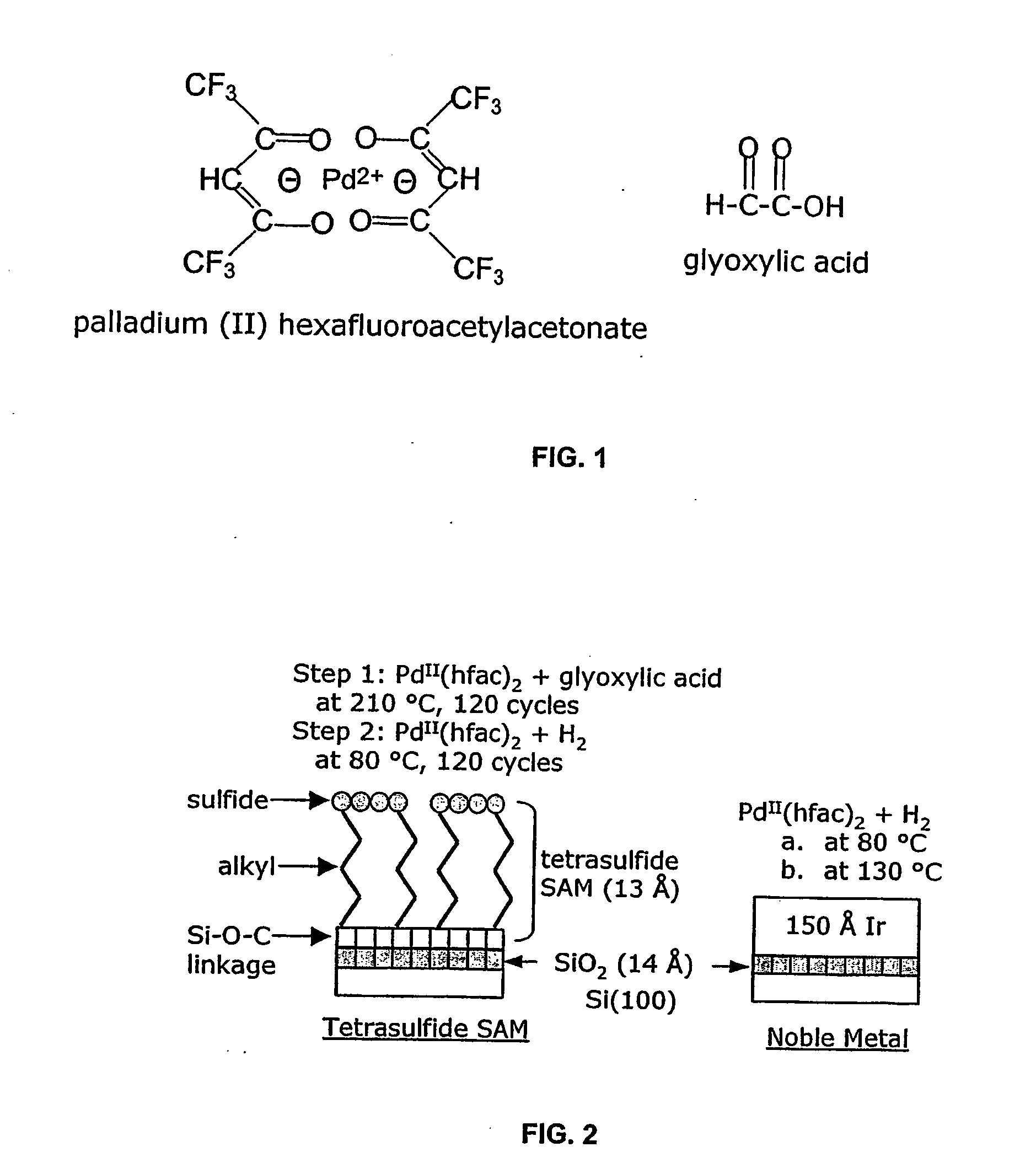

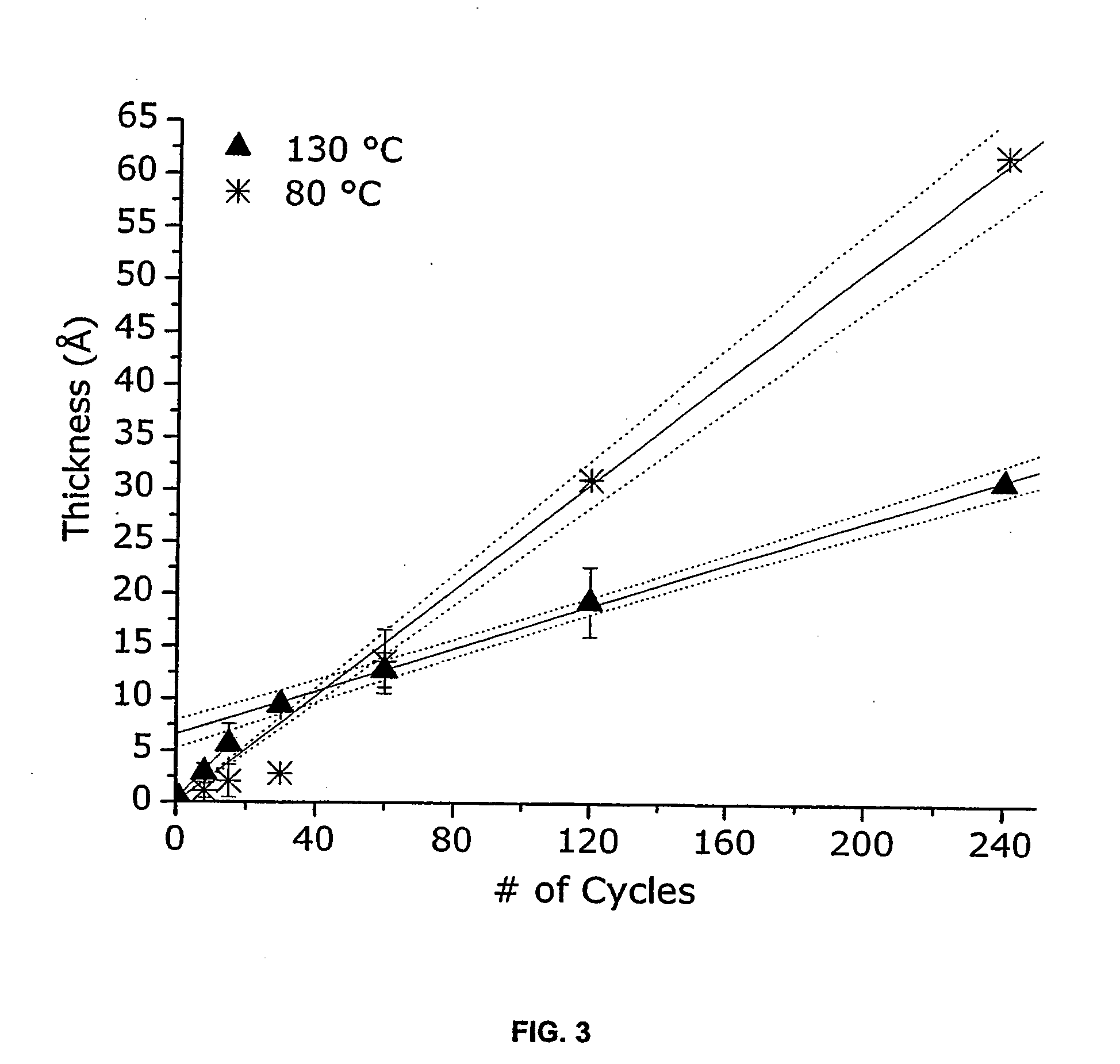

Atomic layer deposition of noble metals

The present invention relates to ALD processes for deposition of a metal selected from Pd, Rh, Ru, Pt and Ir wherein a layer including the metal is formed on a surface composed of a material selected from W, Ta, Cu, Ni, Co, Fe, Mn, Cr, V Nb, tungsten nitride, tantalum nitride, titanium nitride, dielectrics and activated dielectrics at a temperature ranging from >60° C. to <260° C. The layer is formed by sequentially pulsing into a chamber containing the surface a precursor for the metal and a reducing gas selected from hydrogen, glyoxylic acid, oxalic acid, formaldehyde, 2-propanol, imidazole and plasma-activated hydrogen.

Owner:SENKEVICH JOHN JOSEPH +1

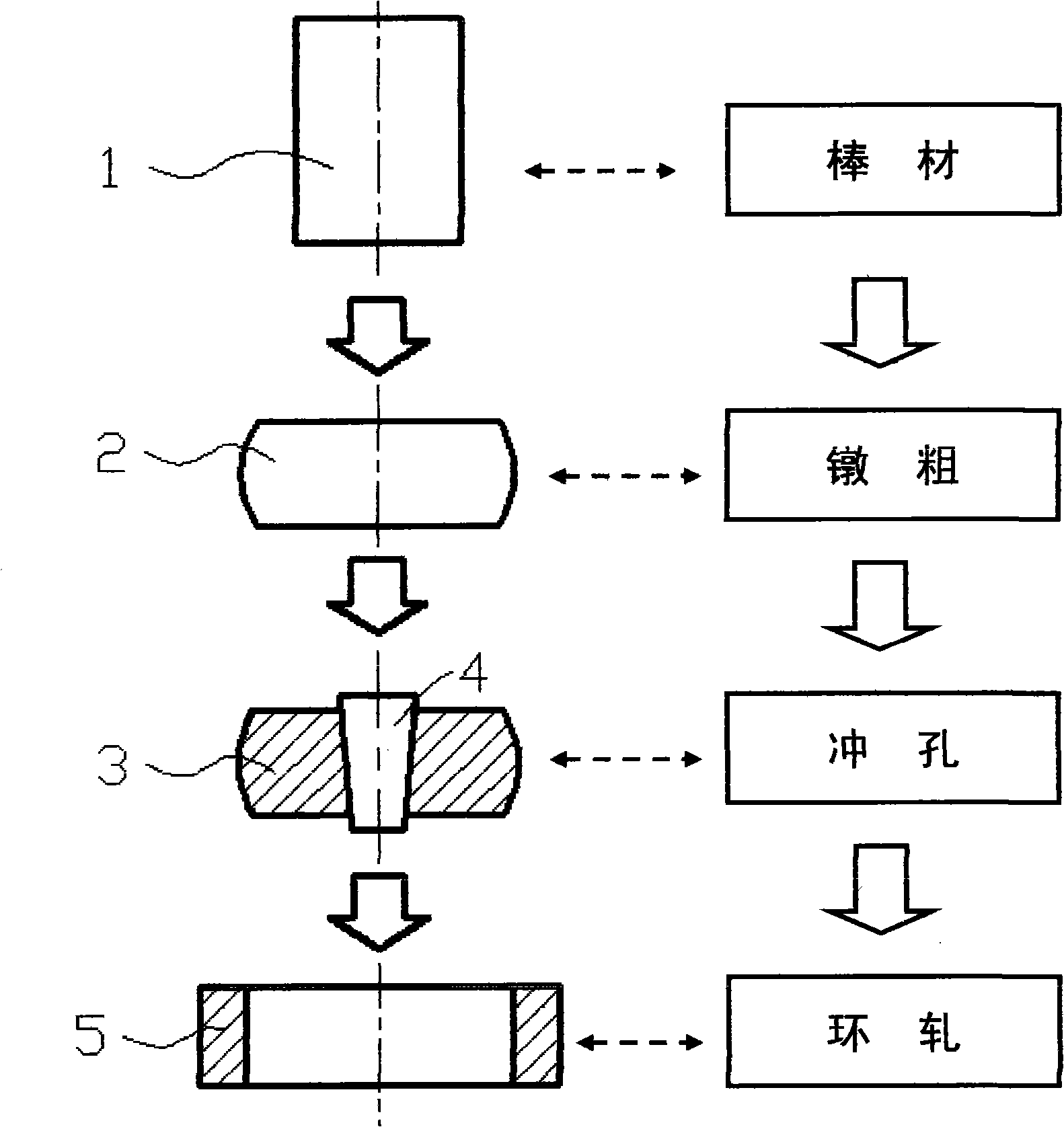

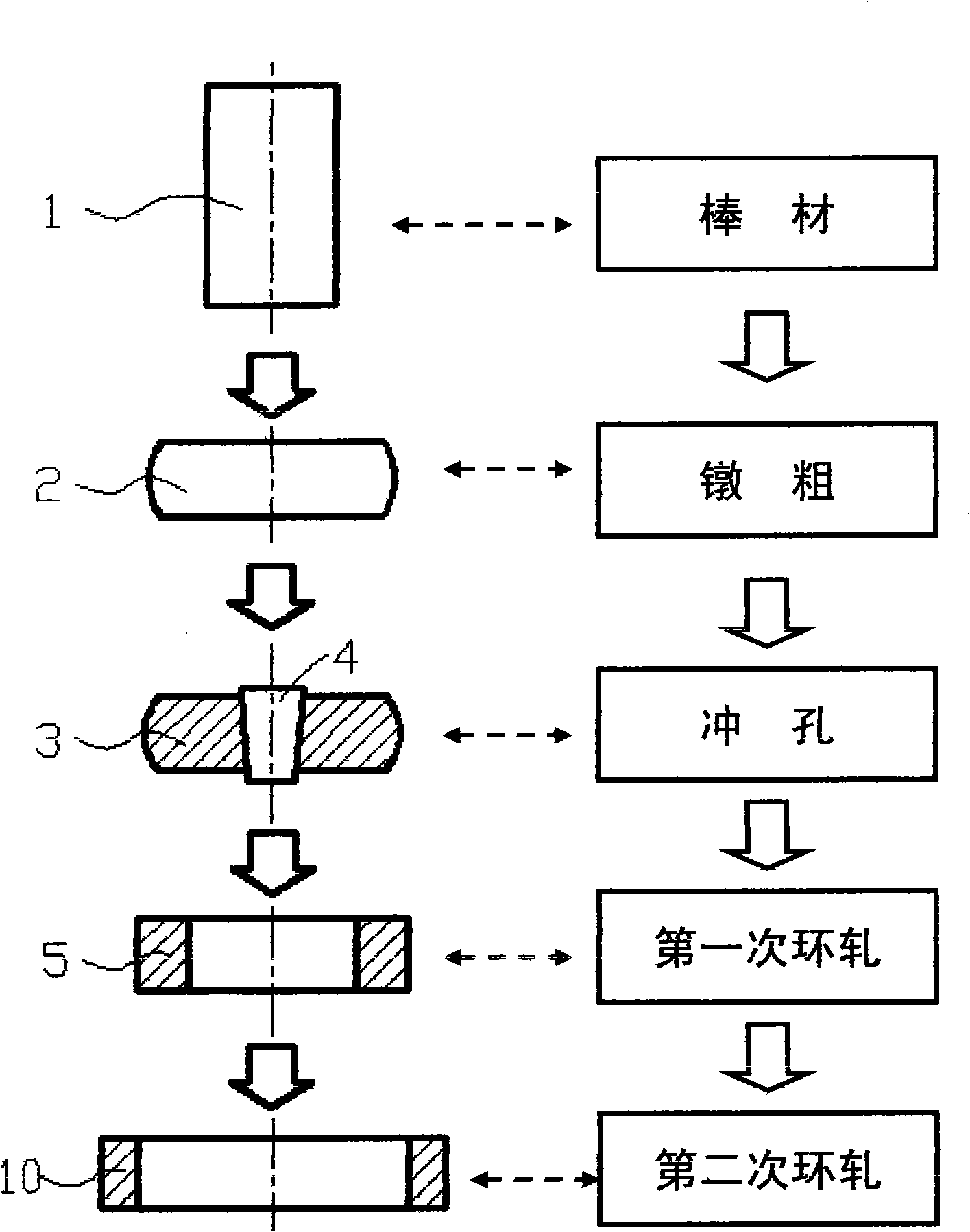

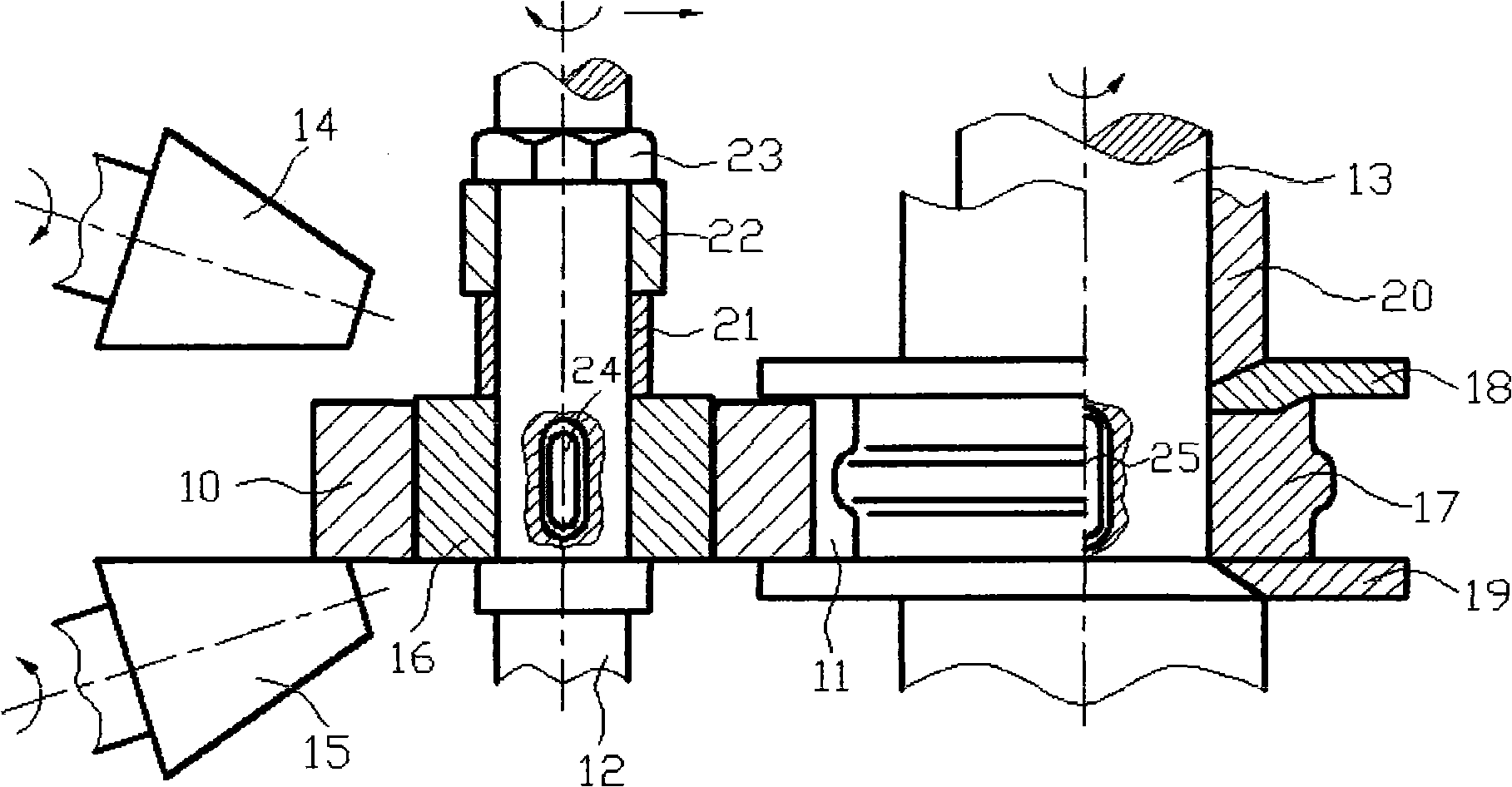

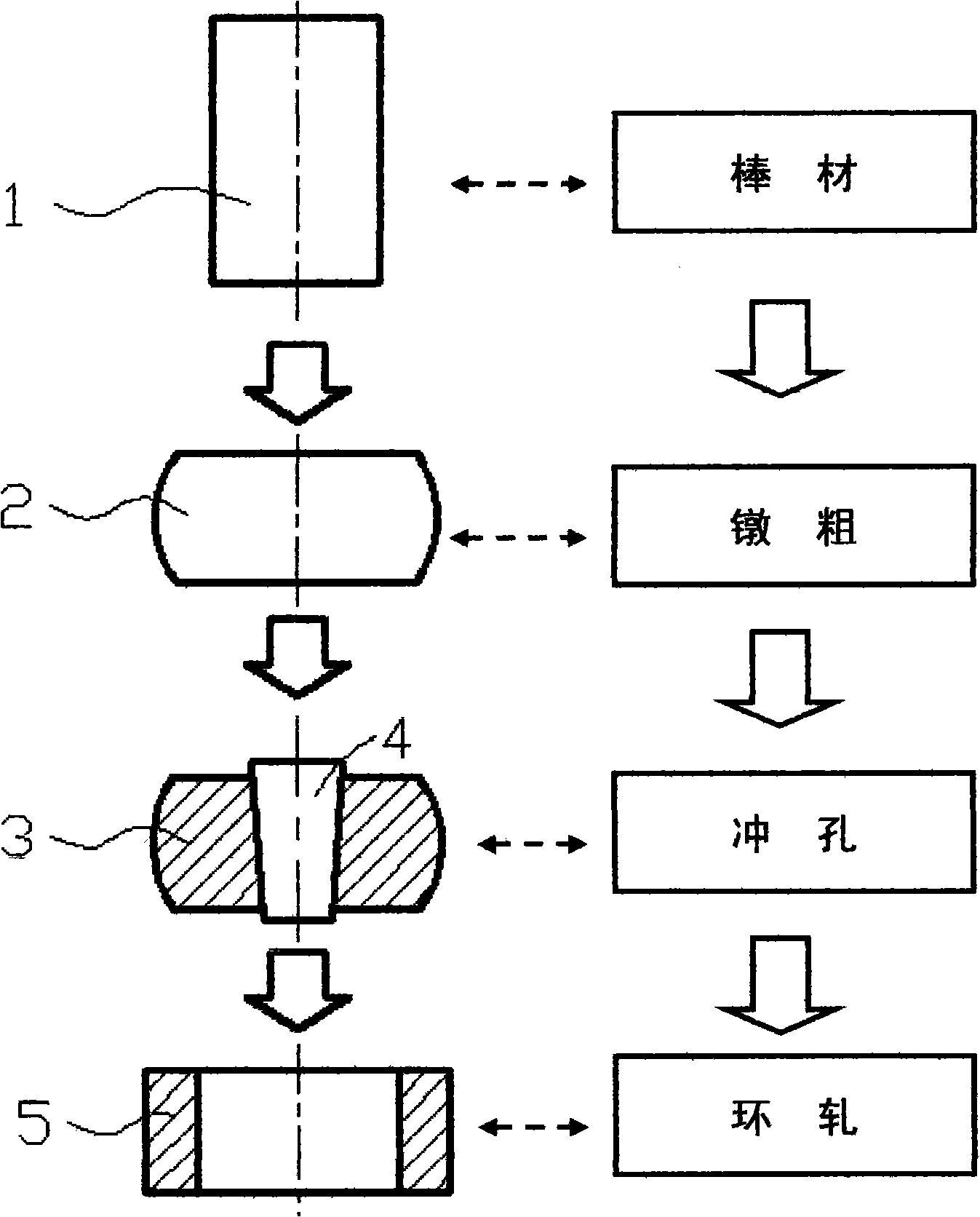

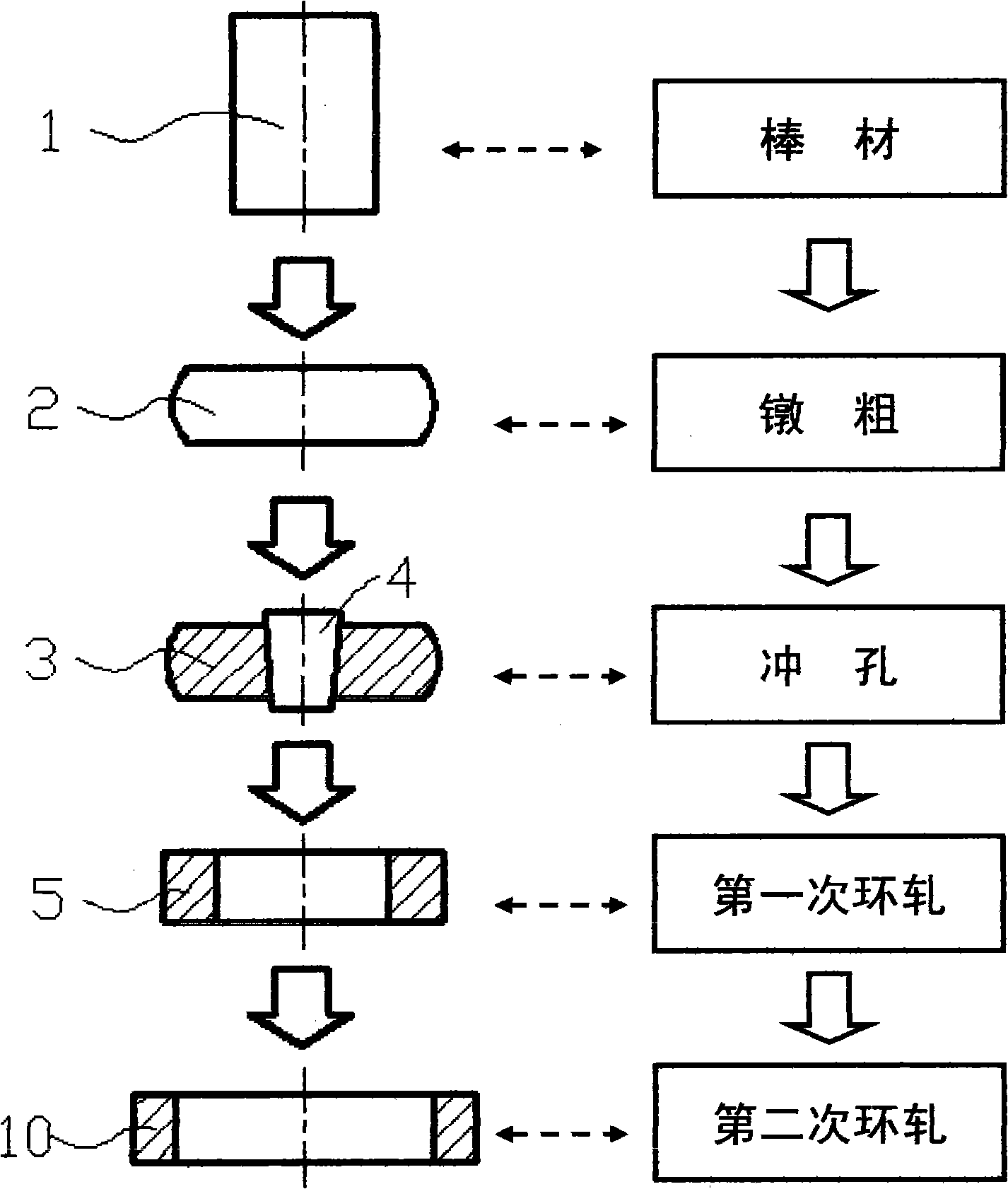

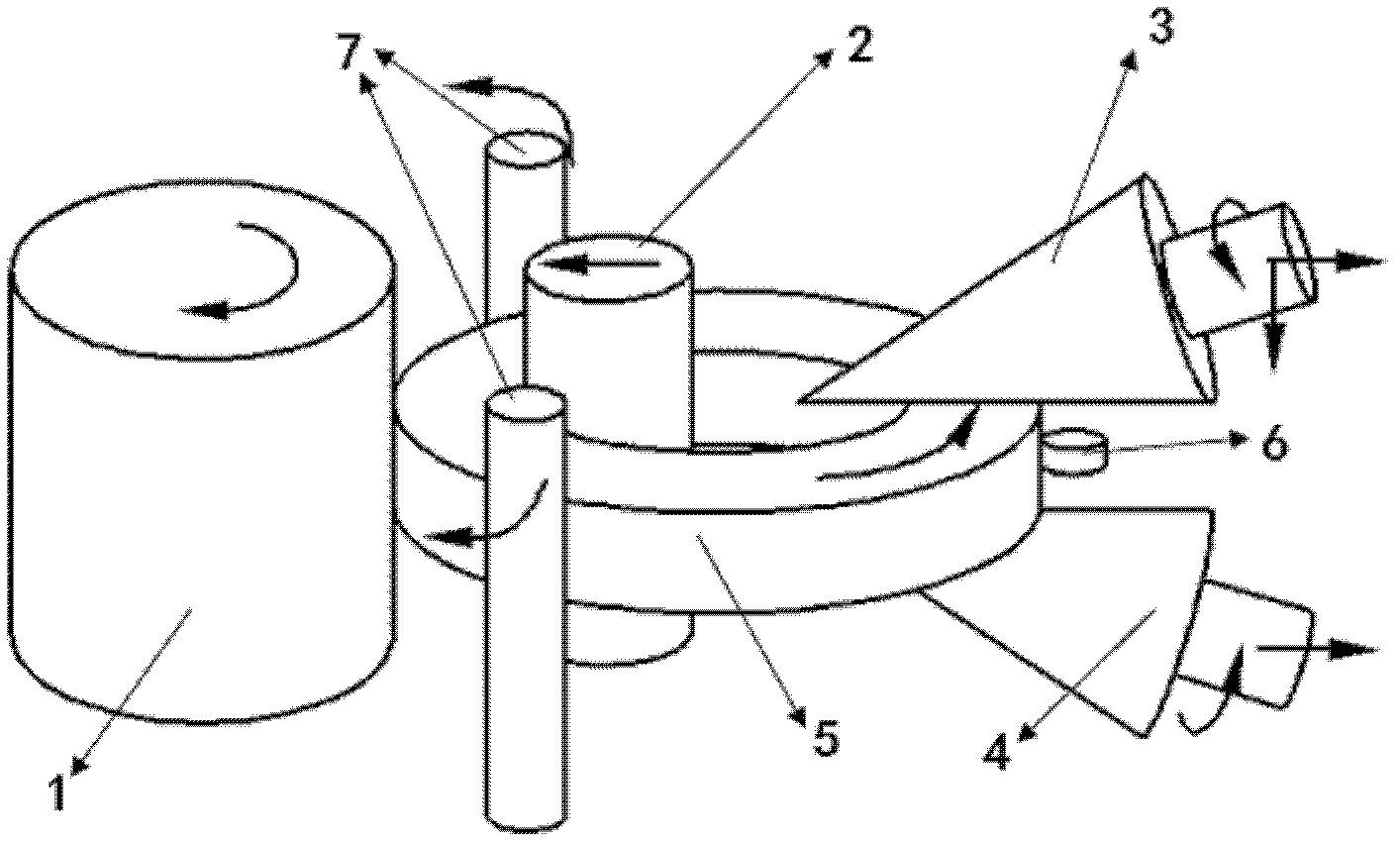

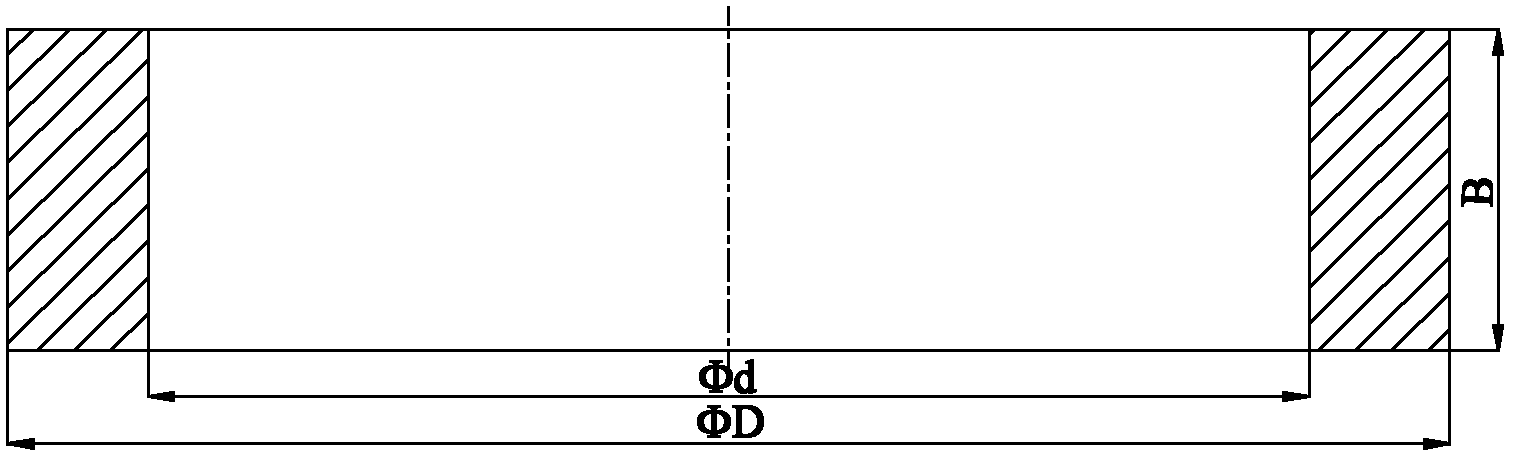

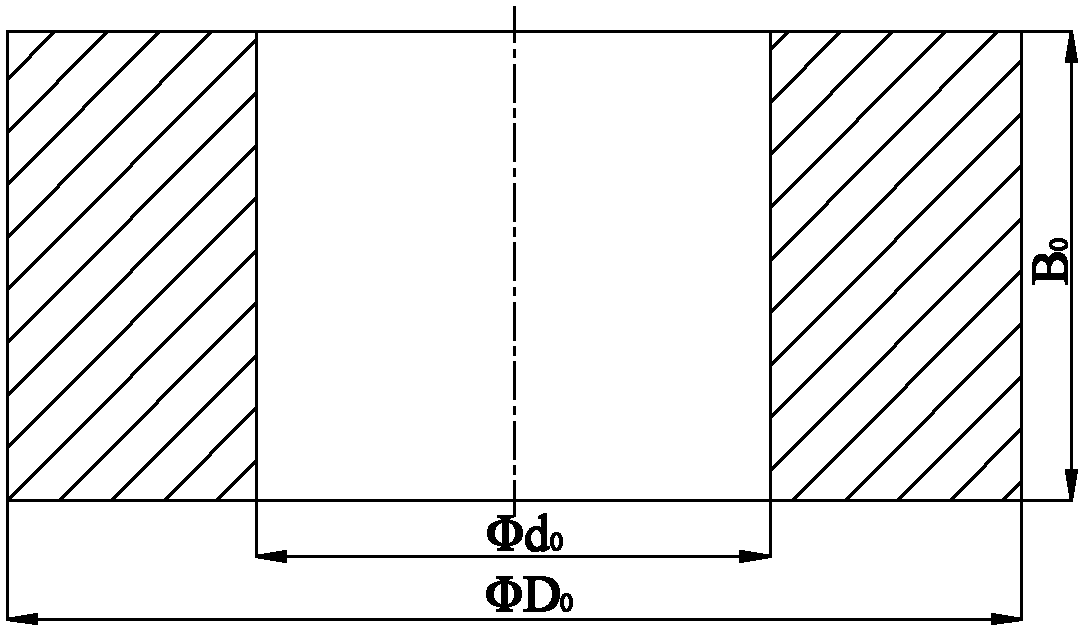

Method for rolling and shaping stainless steel special-shaped ring forging

The invention discloses a rolling and shaping method for a stainless steel heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

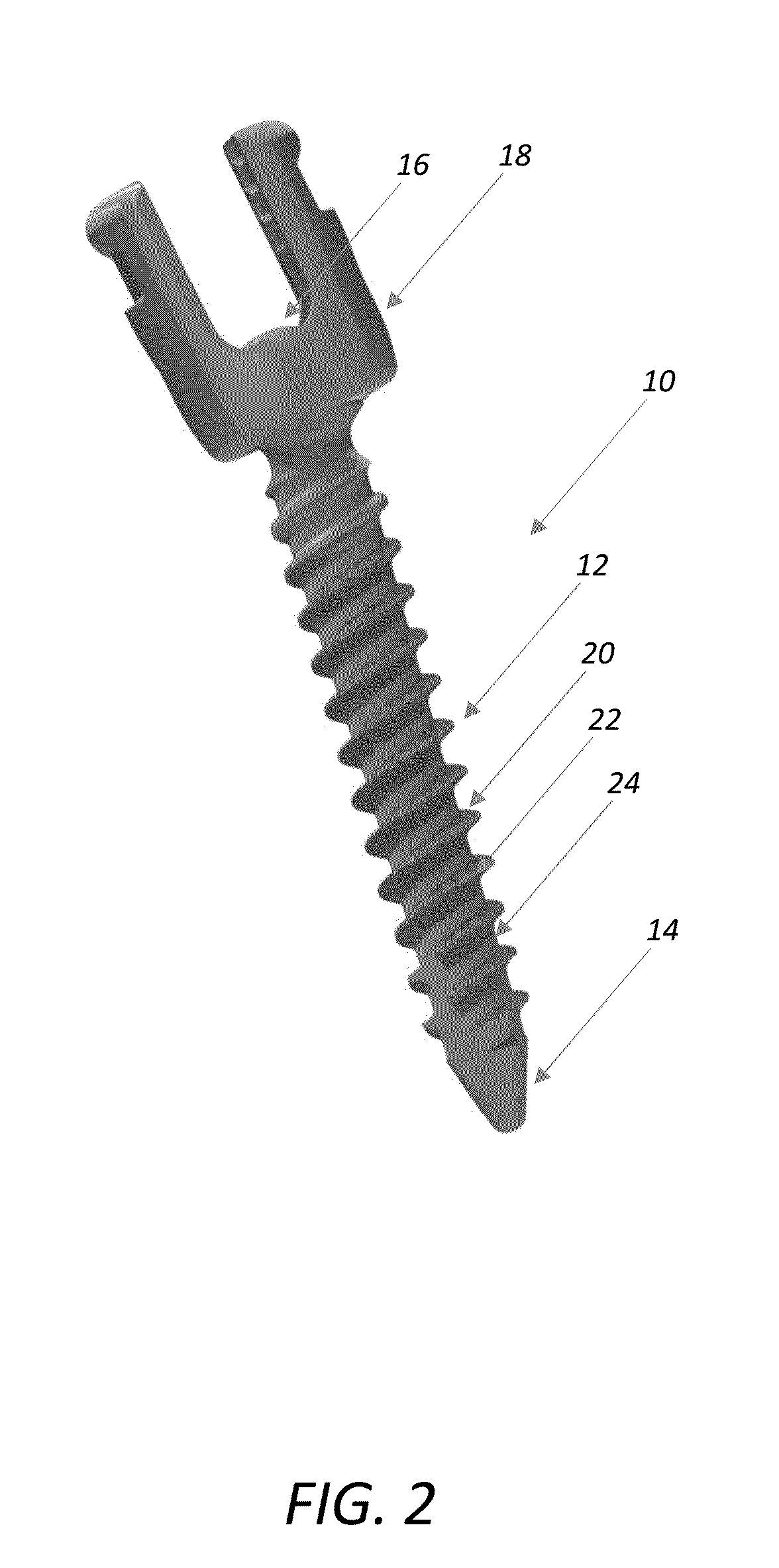

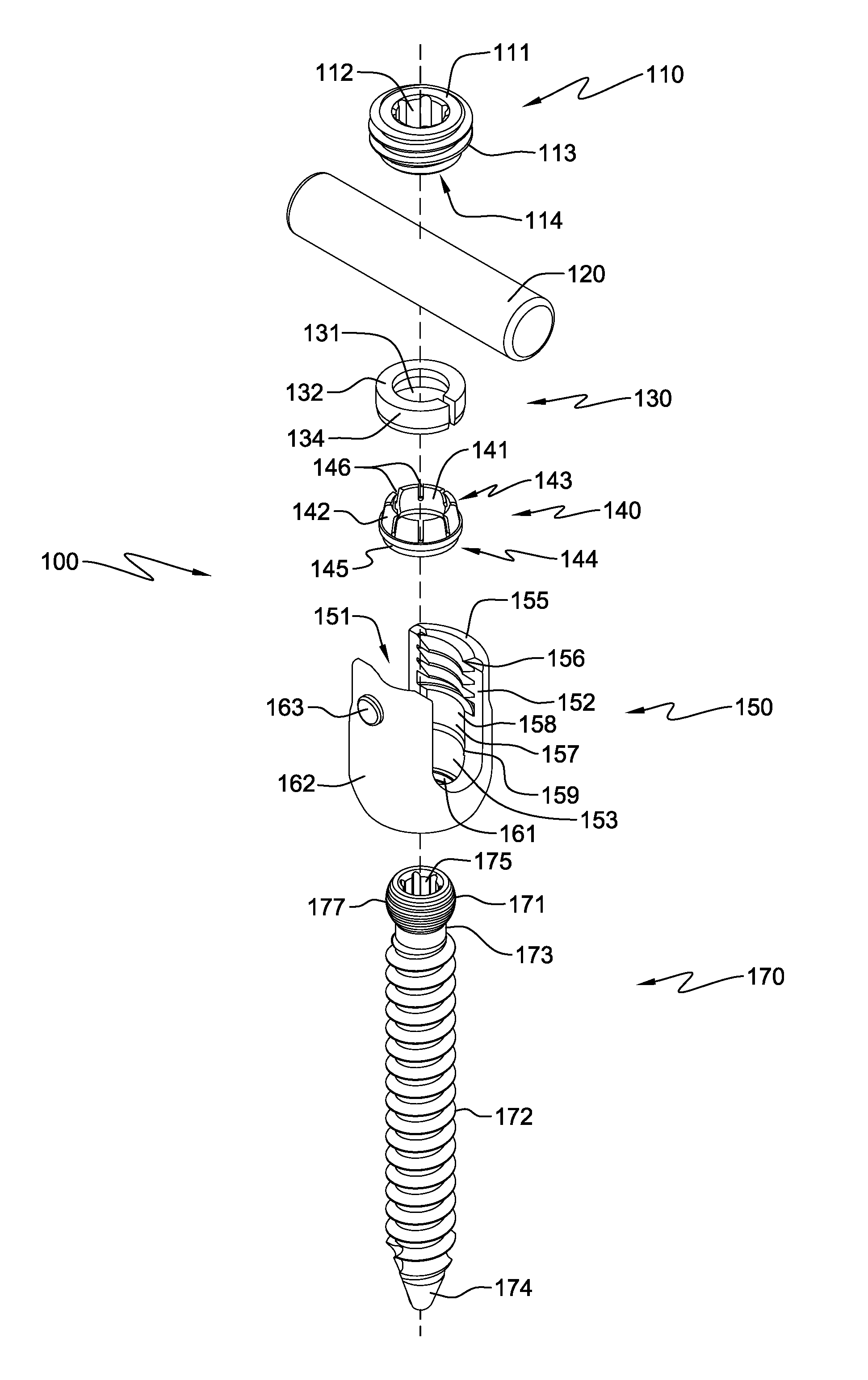

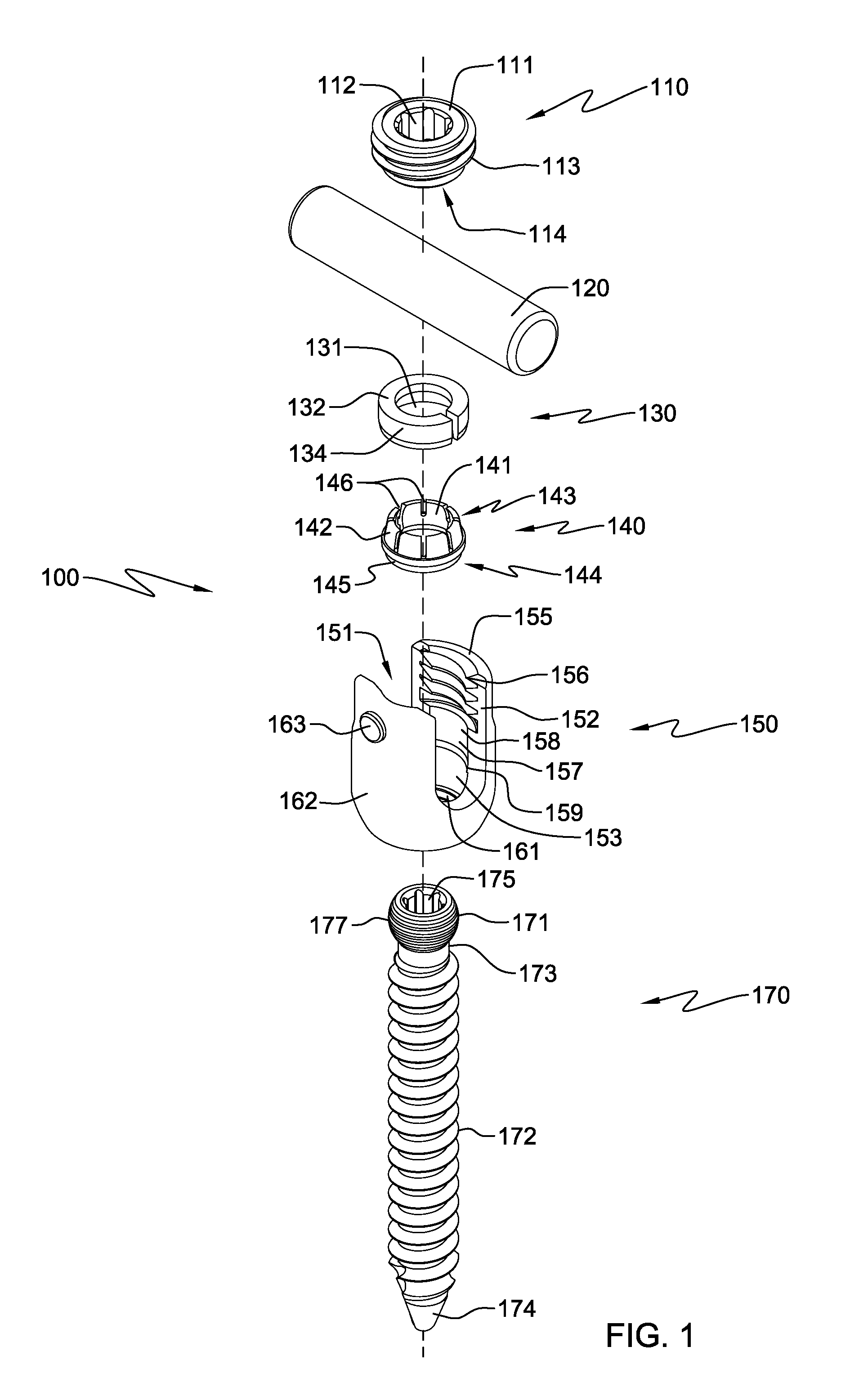

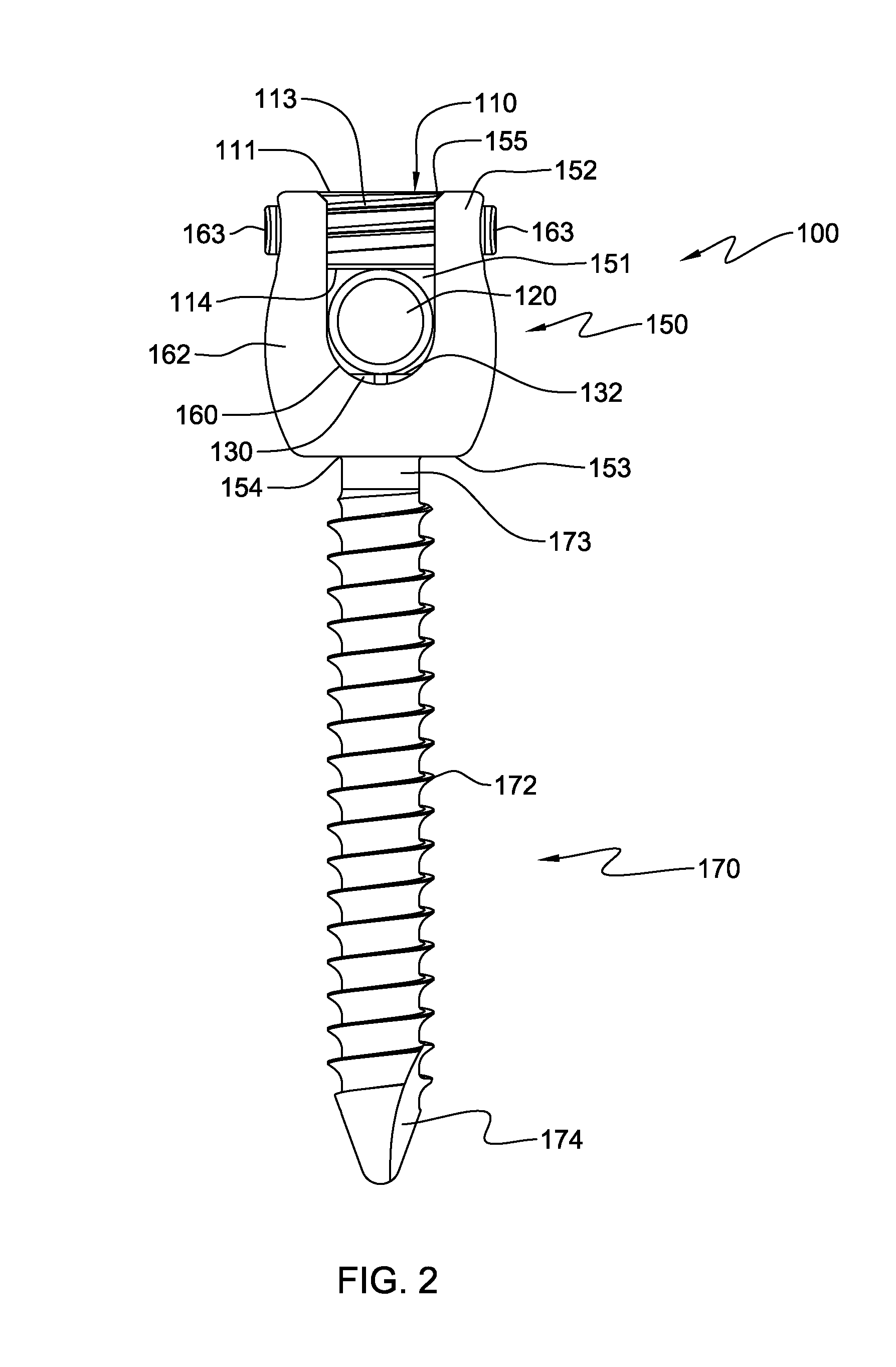

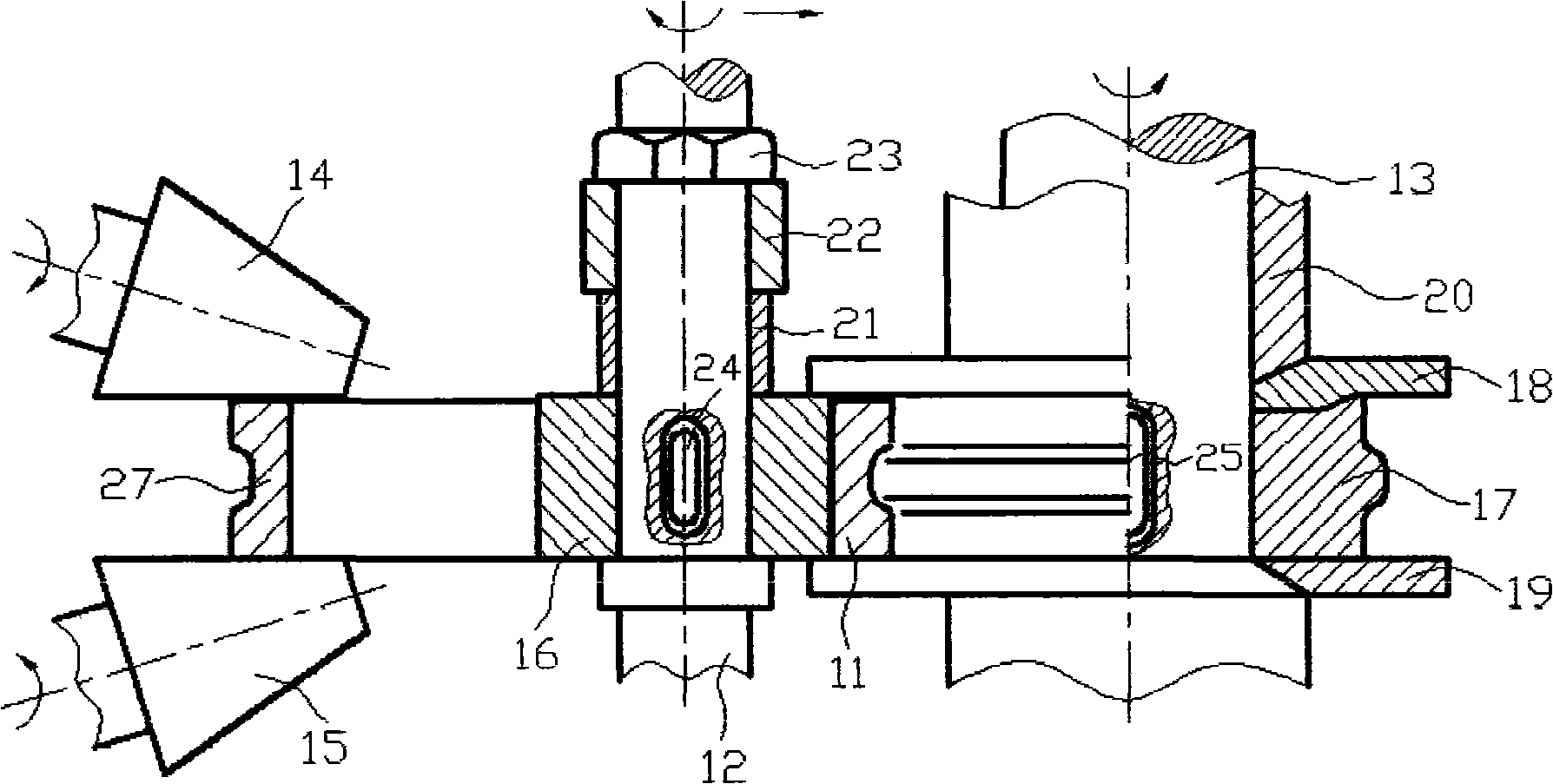

Pedicle screw assembly and method of assembly

ActiveUS20130211465A1Reduces splaying forceReduction in splaying forceSuture equipmentsInternal osteosythesisCompression memberPedicle screw

A pedicle screw assembly and method of assembly are disclosed. The pedicle screw assembly includes a bone fastener having a head at a proximal end and a threaded portion extending between the proximal end and a distal end. The assembly also includes a compression member having a conical inner surface and a locking member having an outer surface adapted to mate with the conical inner surface of the compression member. The assembly may also have an elongated member and a set screw that has a threaded portion. The assembly may also have a receiving housing having a central bore extending from a threaded proximal end to a distal end and a U-shaped cavity positioned perpendicular to the central bore and configured to receive the elongated member.

Owner:SKELETAL DESIGN PARTNERSHIP LLC

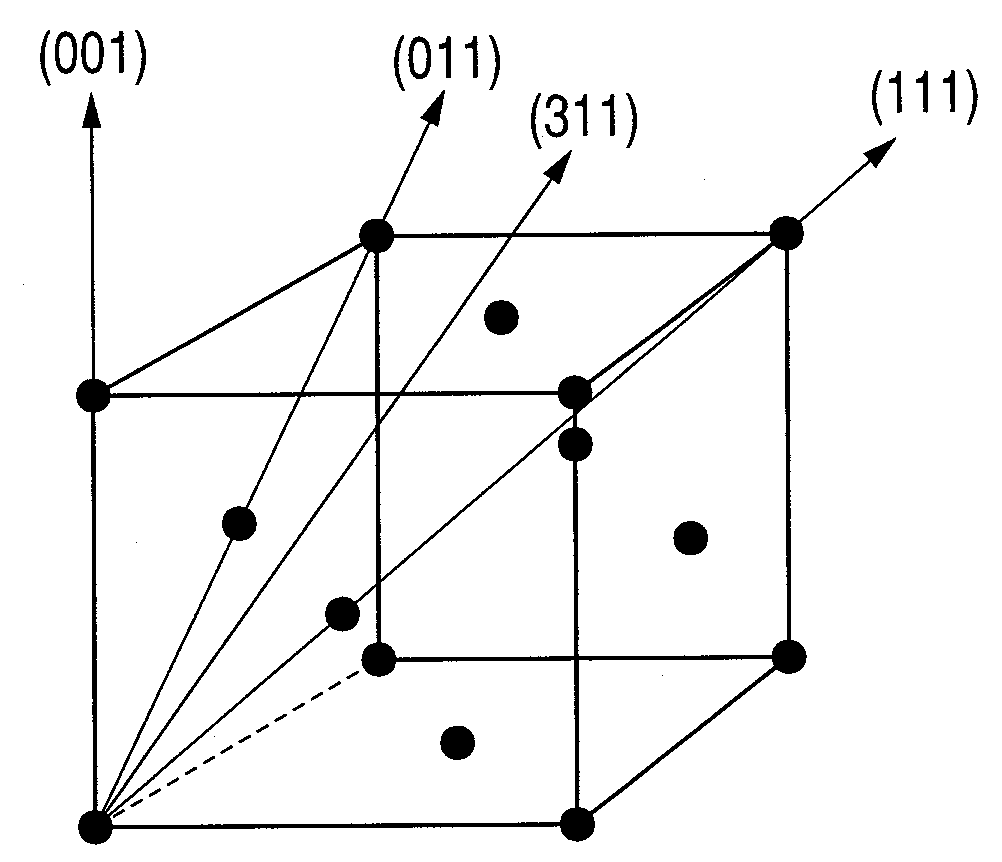

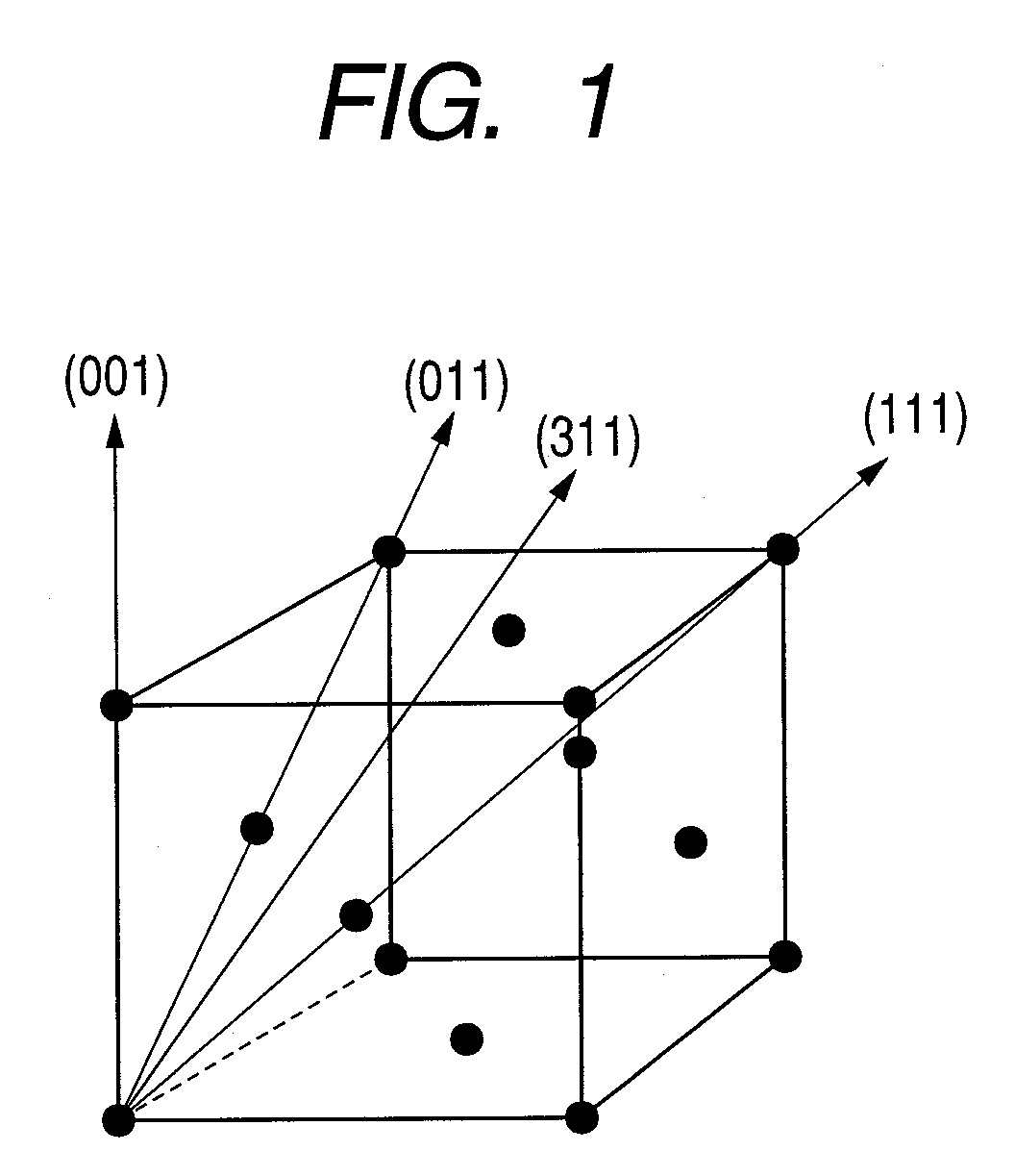

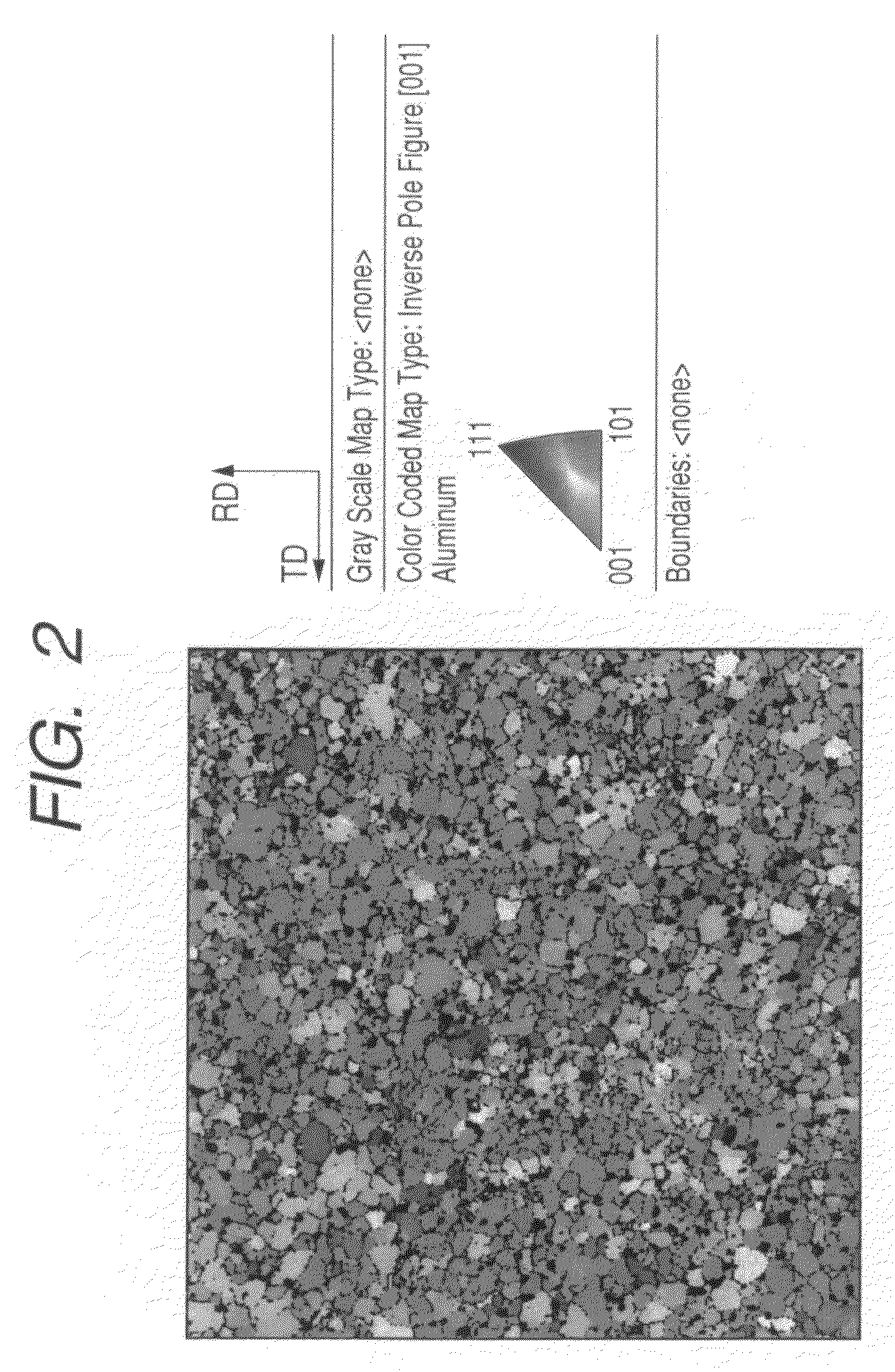

Ai-based alloy sputtering target and process for producing the same

InactiveUS20080223718A1Increase deposition rateSuppress the sputtering defectsCellsSemiconductor/solid-state device detailsSputteringAlloy

The present invention relates to an Al-based alloy sputtering target, comprising Ni in an amount of 0.05 to 10 atomic percent, wherein the Al-based alloy sputtering target satisfies: (1) that a ratio of a P value to a total area of a sputtering surface is 70% or more, wherein the P value indicates a total of area fractions of <001>±15°, <011>±15°, <111>±15° and <311>±15°; (2) that a ratio of the area fraction of <011>±15° to the P value is 30% or more; and (3) that a ratio of the area fraction of <111>±15° to the P value is 10% or less, when crystallographic orientations <001>, <011>, <111> and <311> in a normal line direction to a sputtering surface of the Al-based alloy sputtering target are observed in accordance with the electron backscatter diffraction pattern method.

Owner:KOBE STEEL LTD +1

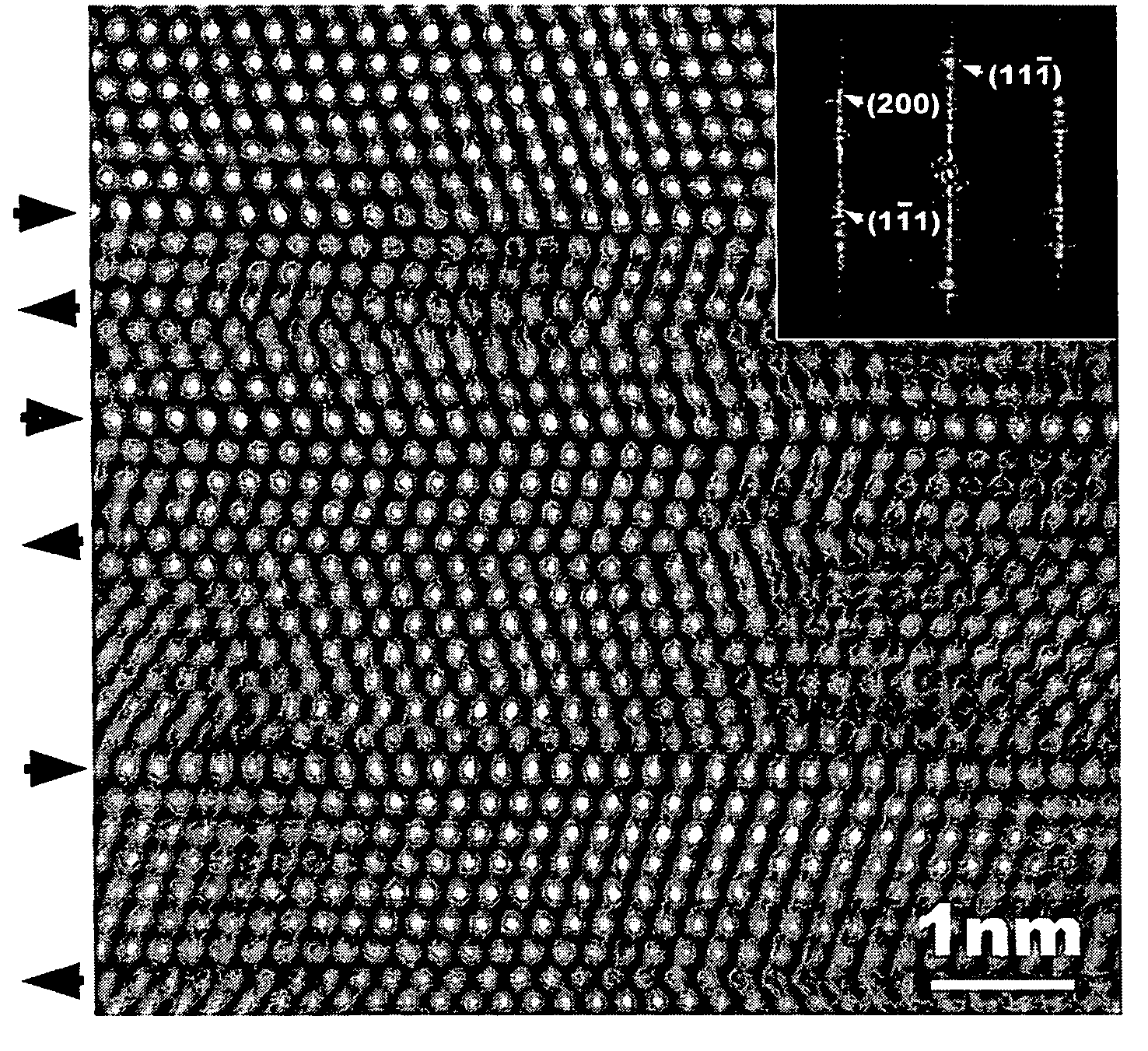

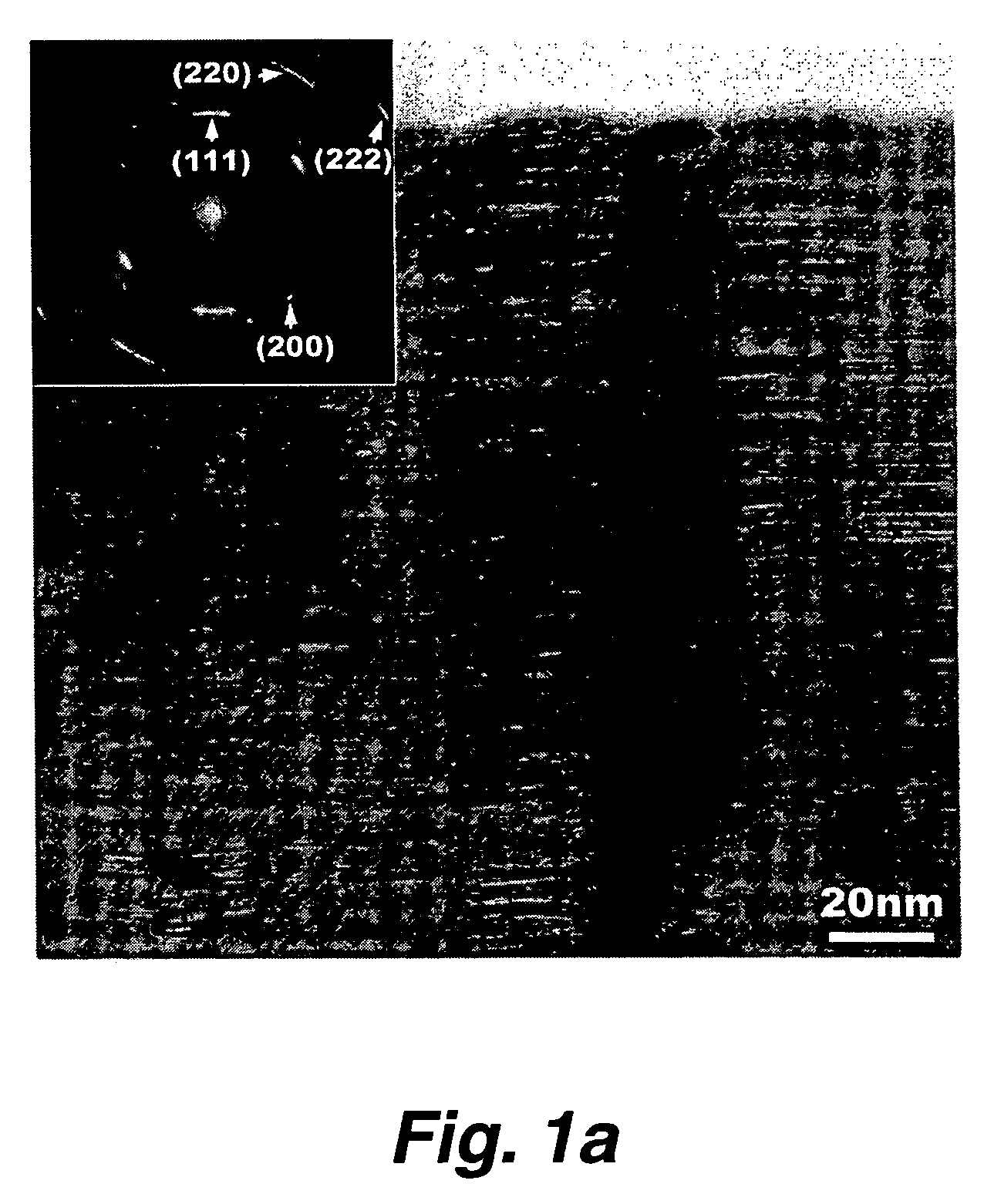

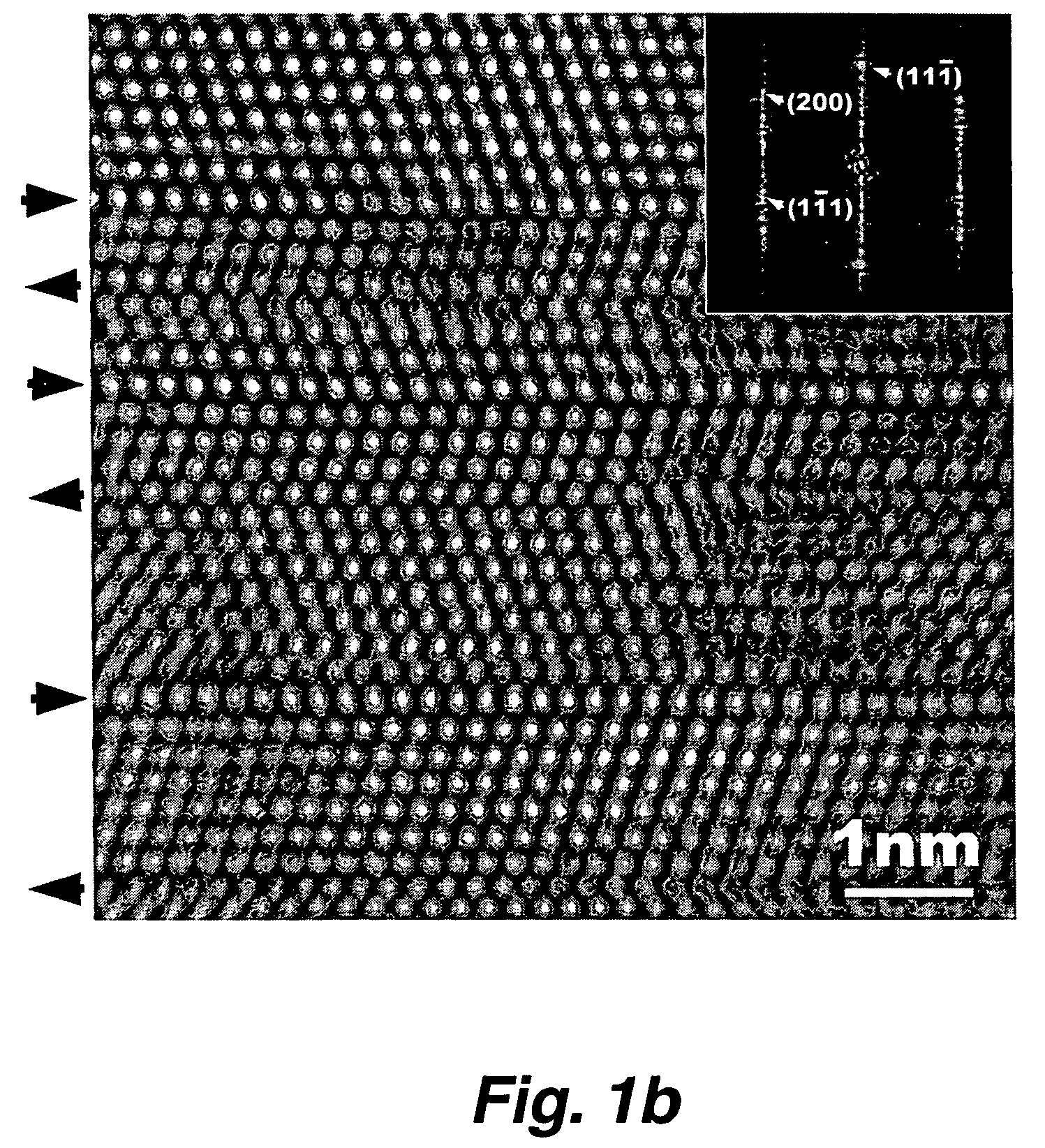

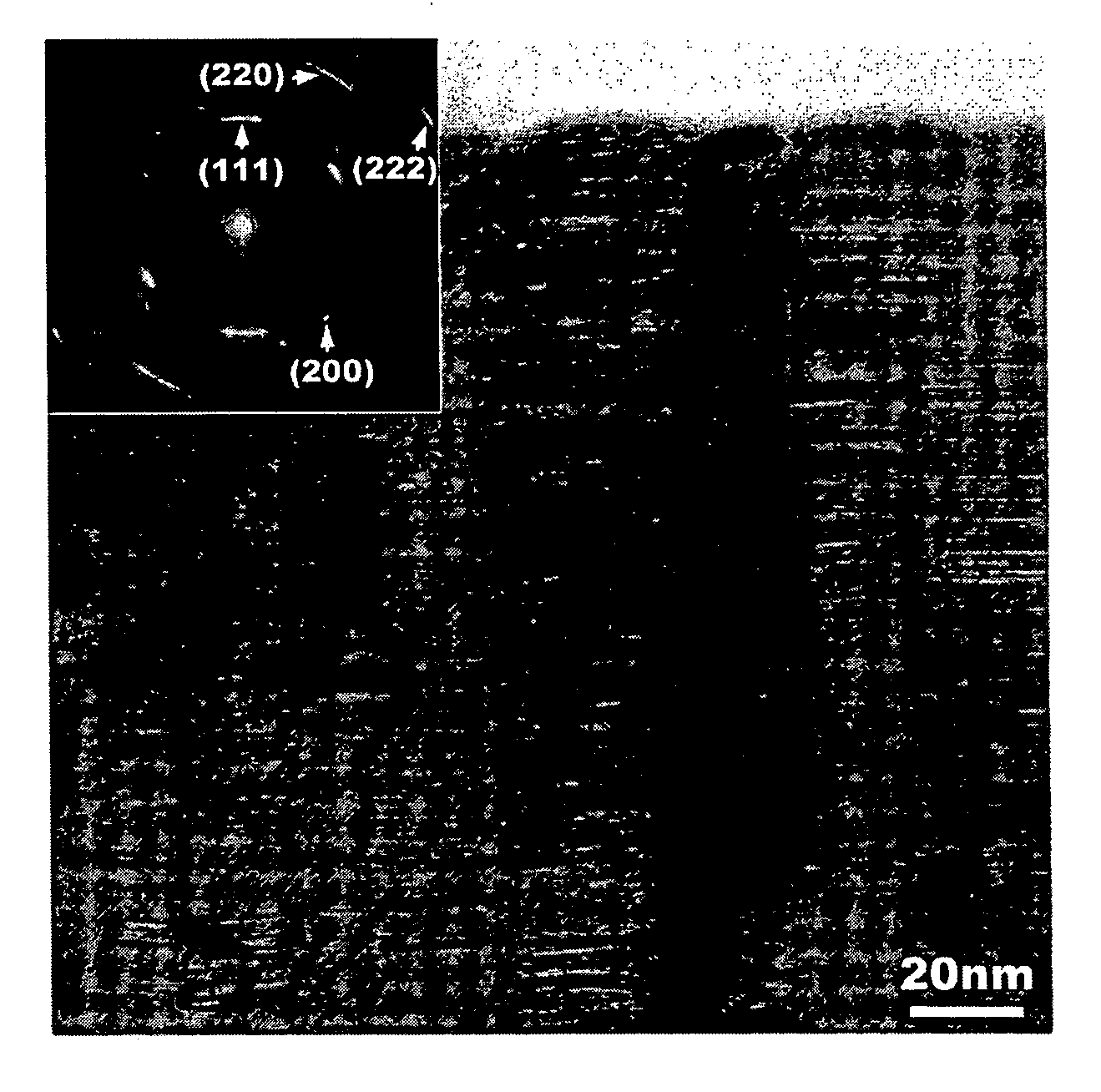

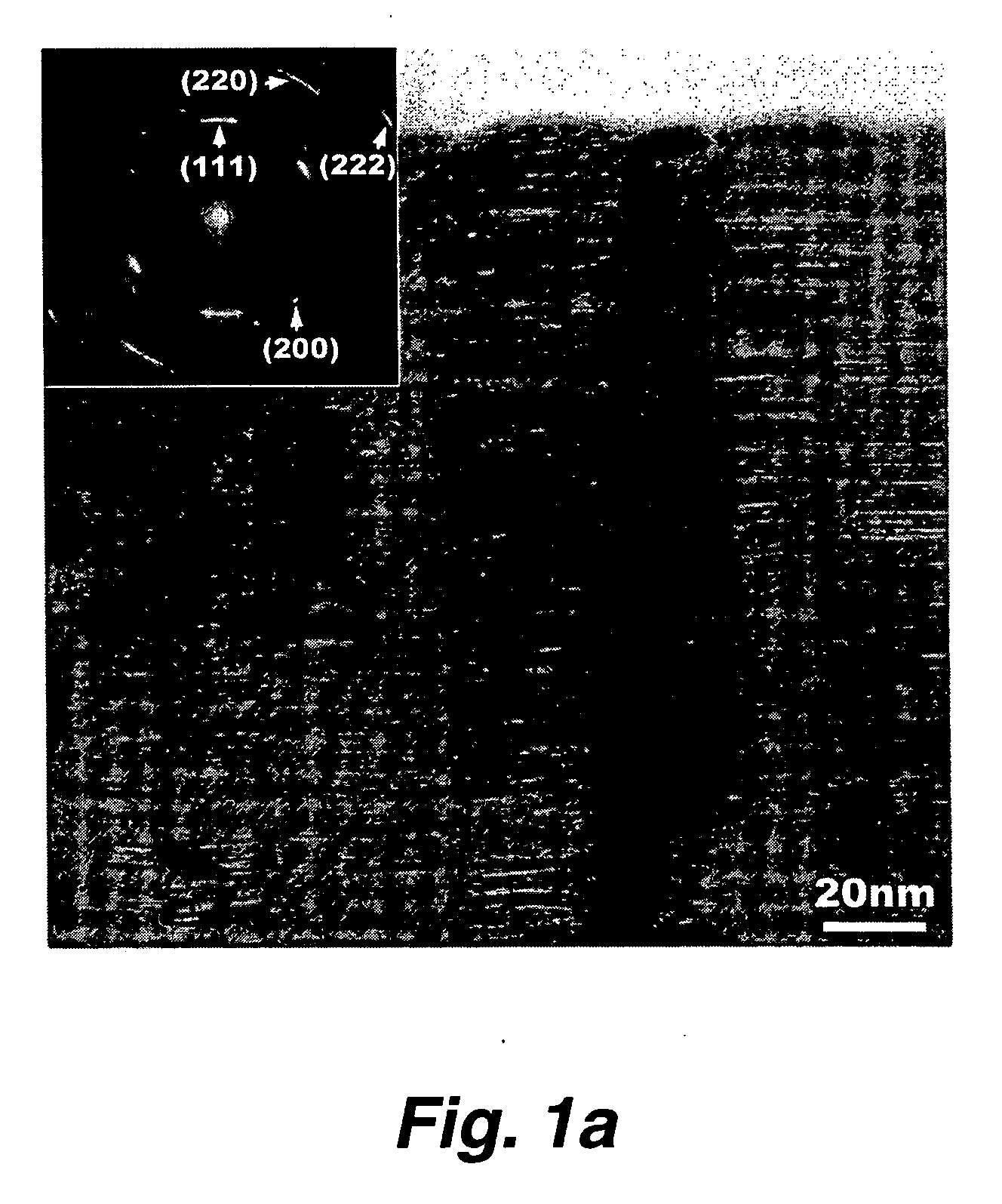

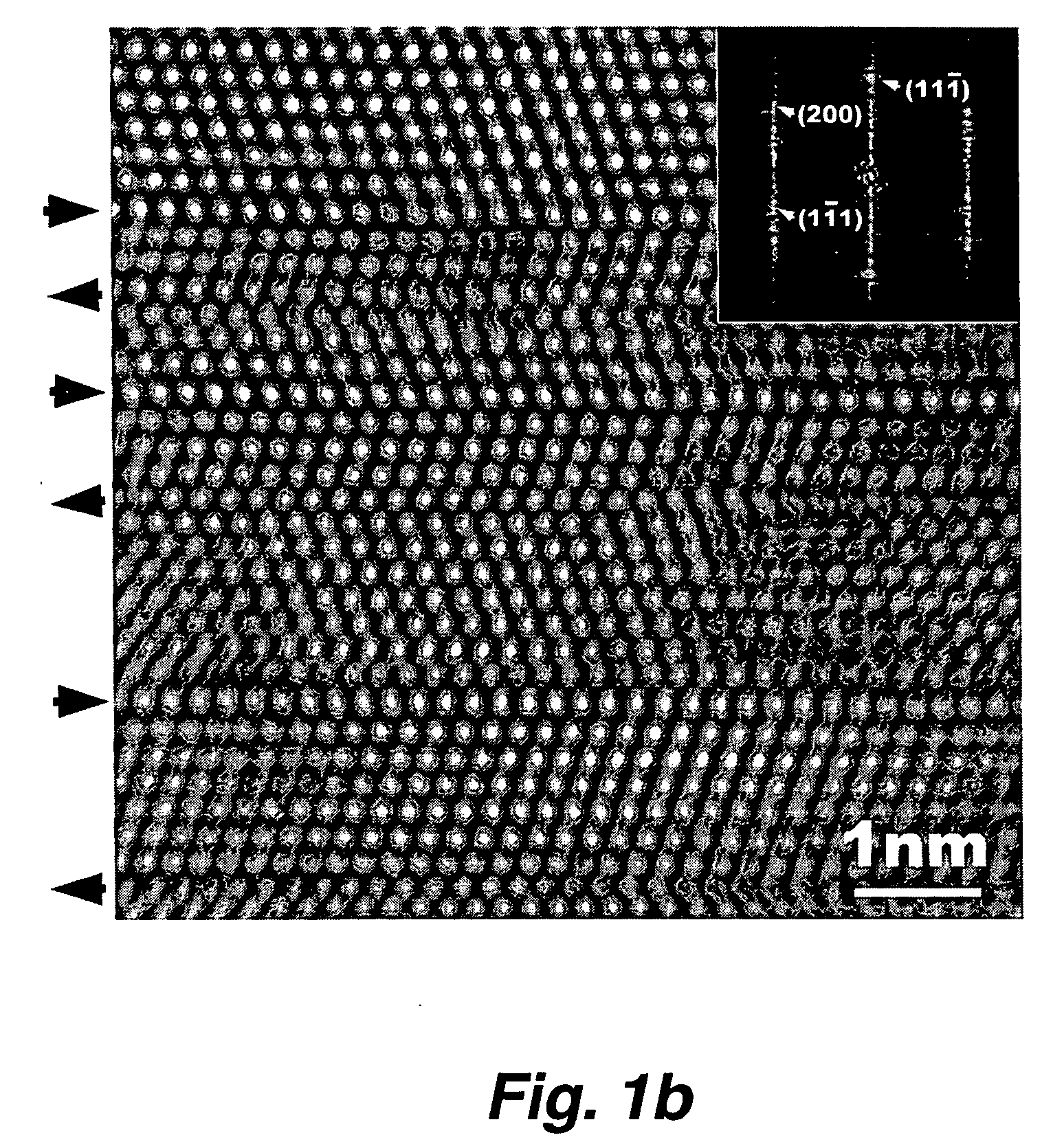

Preparation of high-strength nanometer scale twinned coating and foil

Very high strength single phase stainless steel coating has been prepared by magnetron sputtering onto a substrate. The coating has a unique microstructure of nanometer spaced twins that are parallel to each other and to the substrate surface. For cases where the coating and substrate do not bind strongly, the coating can be peeled off to provide foil.

Owner:LOS ALAMOS NATIONAL SECURITY

Method of making coated articles and coated articles made thereby

InactiveUS7311961B2Improve heat resistanceReducing and preventing oxidationLiquid surface applicatorsSemiconductor/solid-state device detailsRefractive indexPolymer

An article includes a first substrate, a functional coating deposited over at least a portion of the substrate, and a protective coating deposited over the functional coating. The functional coating and the protective coating define a coating stack. A polymeric material is deposited over at least a portion of the protective coating. The protective coating has a refractive index that is substantially the same as the refractive index of the polymeric material.

Owner:VITRO FLAT GLASS LLC

Preparation of high-strength nanometer scale twinned coating and foil

Very high strength single phase stainless steel coating has been prepared by magnetron sputtering onto a substrate. The coating has a unique microstructure of nanometer spaced twins that are parallel to each other and to the substrate surface. For cases where the coating and substrate do not bind strongly, the coating can be peeled off to provide foil.

Owner:LOS ALAMOS NATIONAL SECURITY

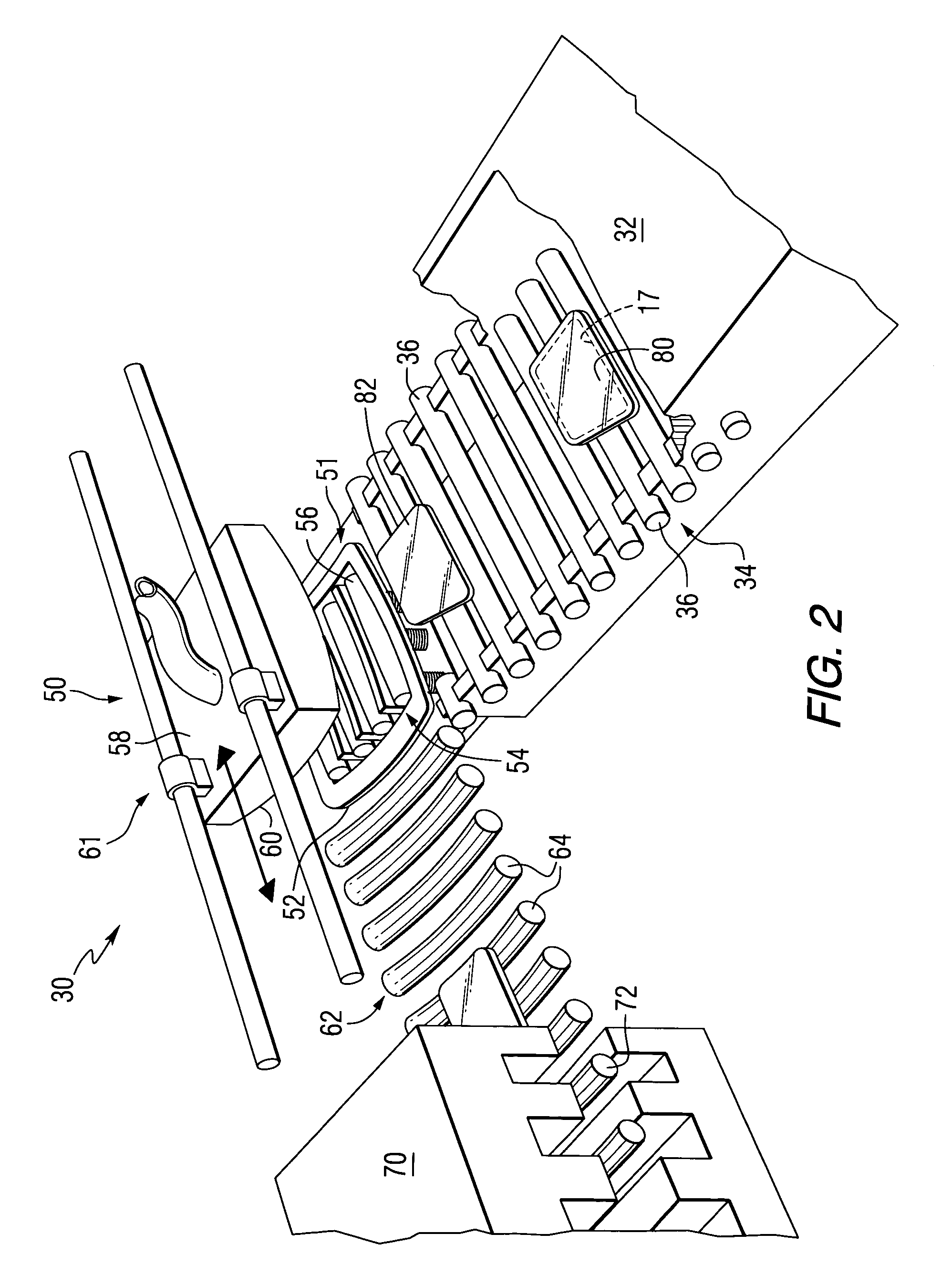

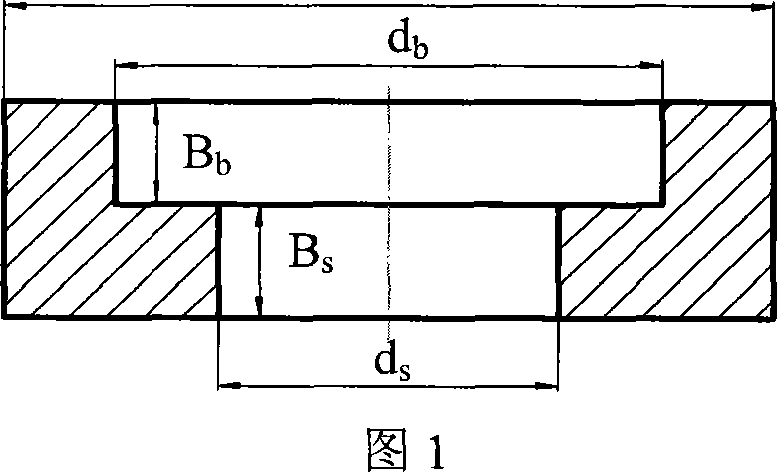

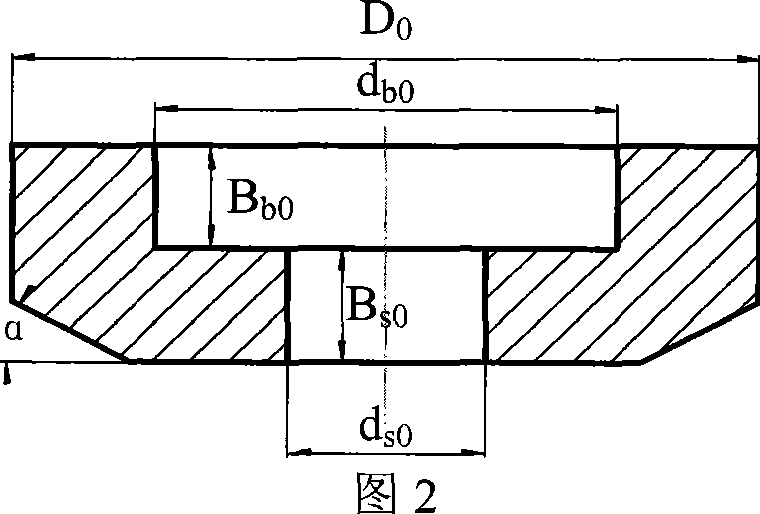

Method for rolling and shaping titanium alloy special-shaped ring forging

ActiveCN101279345AReduce manufacturing costHigh dimensional accuracyMetal rollingTitanium alloyAbnormal shaped

The invention discloses a rolling and shaping method for a titanium alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 65 to 70 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 25 to 30 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 25 to 30 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

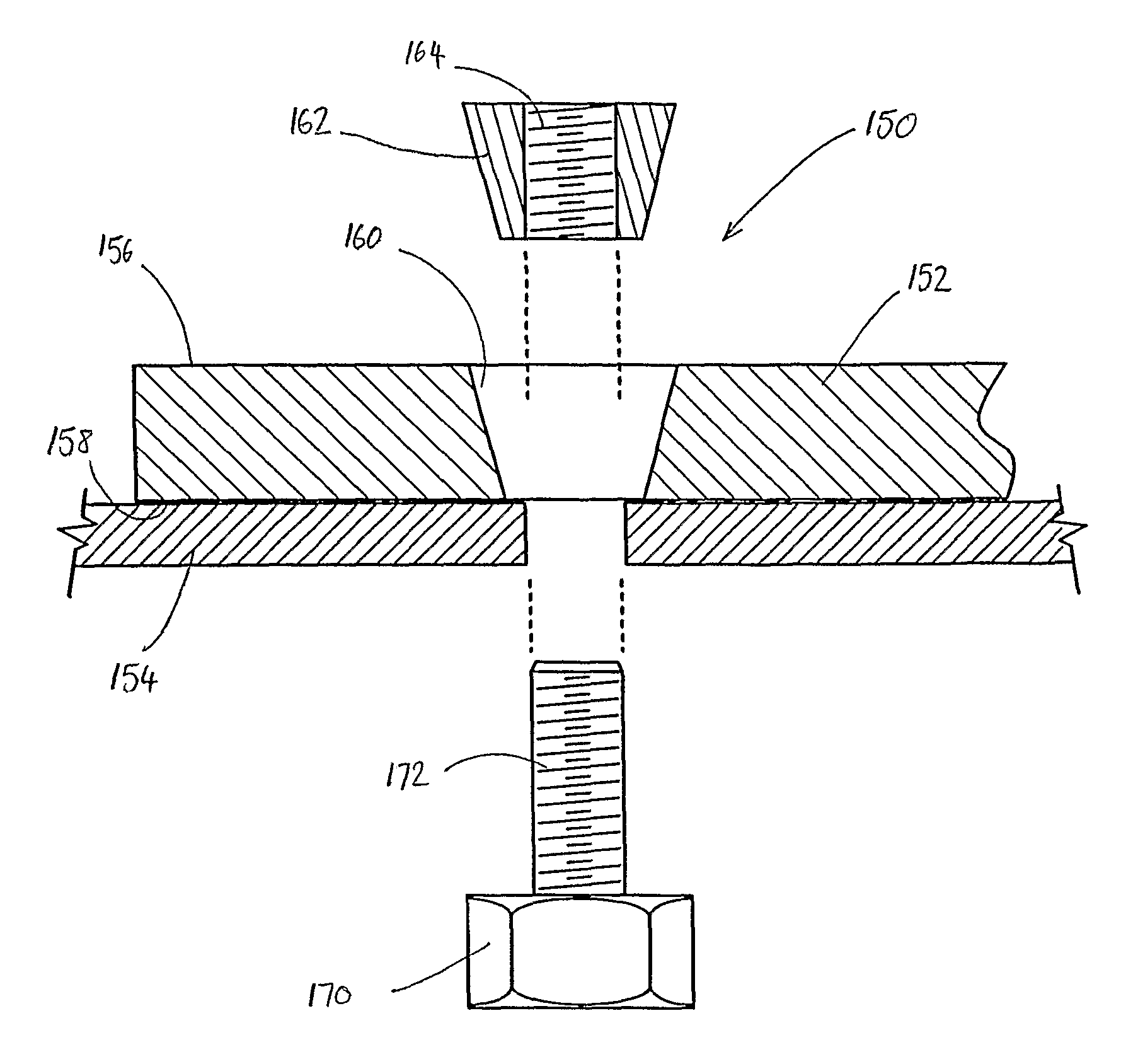

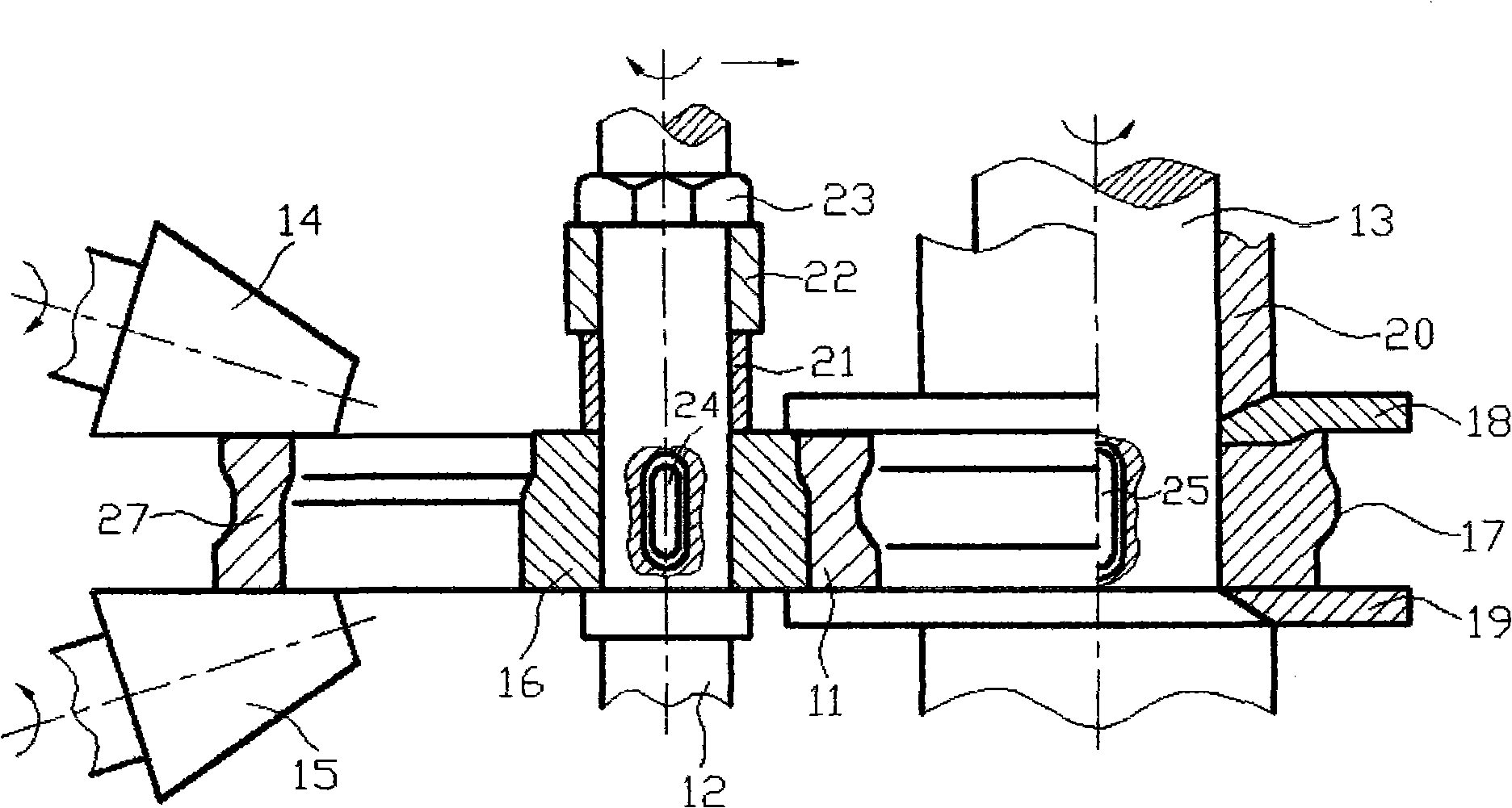

Fastener system for fixing hardened plates

A fastener system for fixing hardened plates includes a fastener element having a frusto-conical head and a threaded shaft portion, wherein a smallest outer diameter of the frusto-conical head is adjacent the threaded shaft, and a largest outer width of the shaft is smaller than a smallest diameter of the head.

Owner:METSO OUTOTEC (FINLAND) OY

Method for rolling and shaping aluminum alloy special-shaped ring forging

InactiveCN101279344AReduce manufacturing costHigh dimensional accuracyMetal rollingAbnormal shapedAero engine

The invention discloses a rolling and shaping method for an aluminum alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

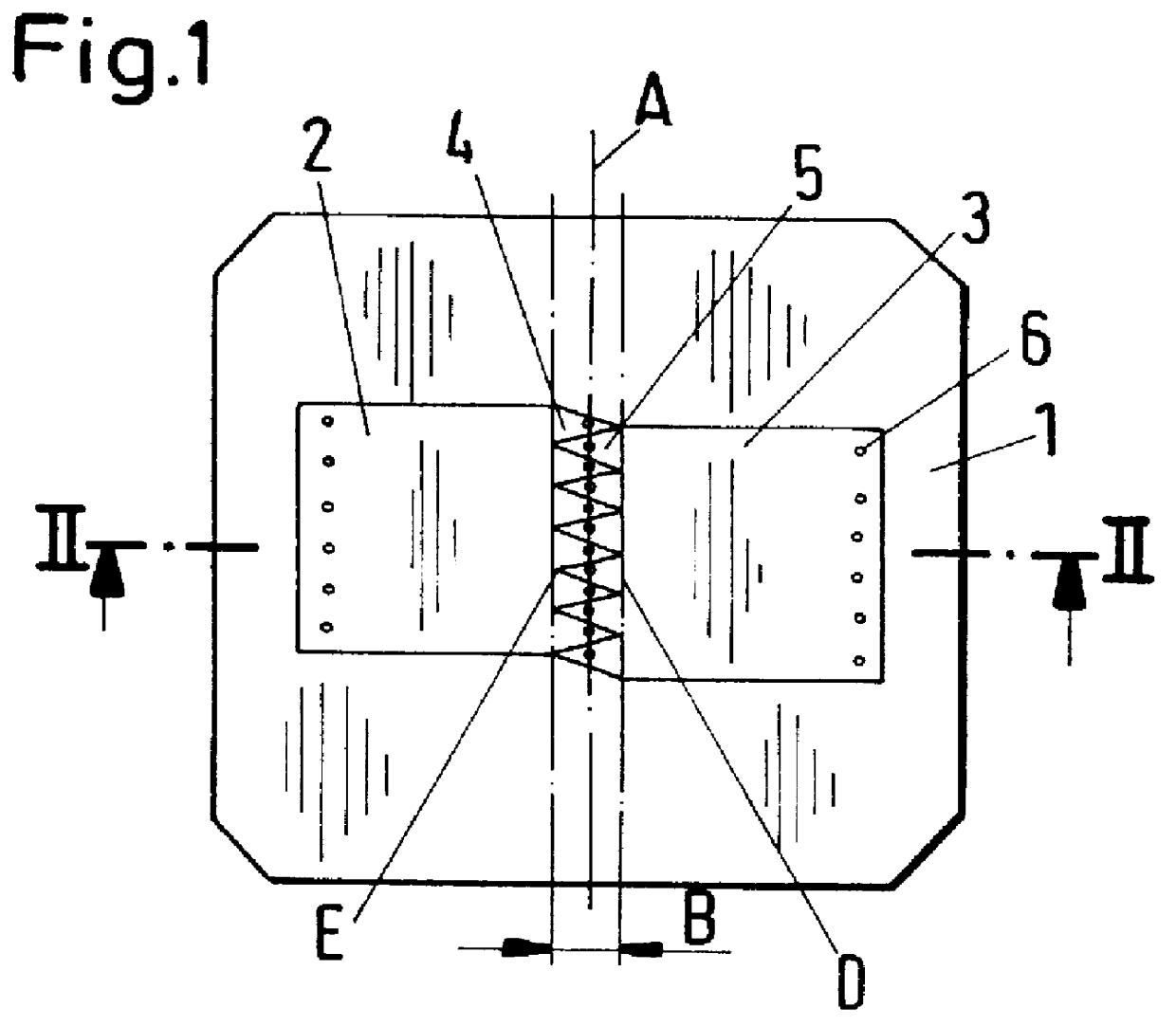

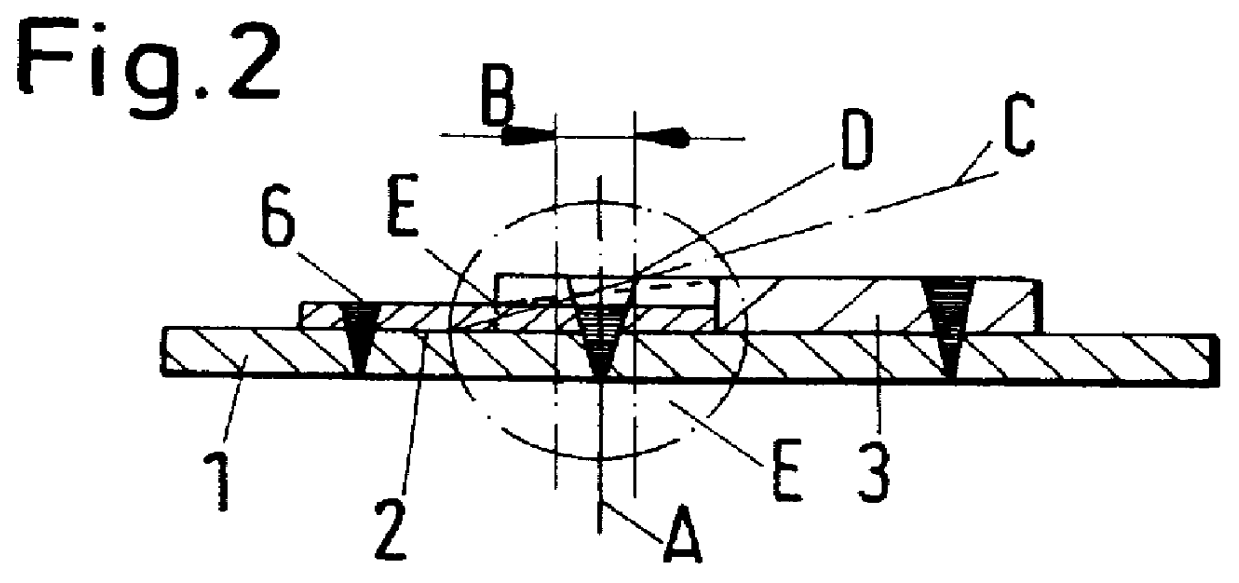

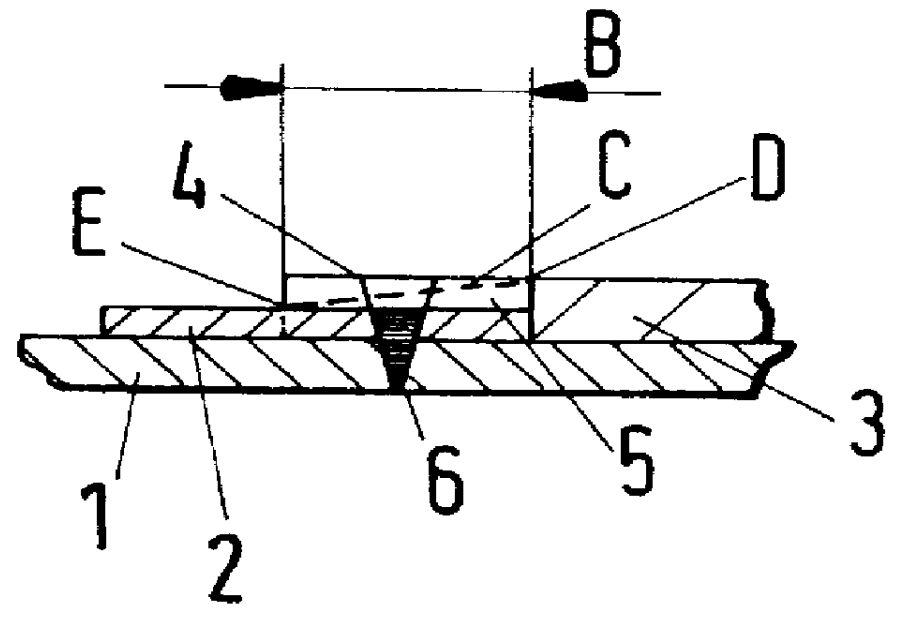

Multiple-plate structure of zonal design for a shaped part

InactiveUS6048628ALow production costLow costPig casting plantsExtrusion containersEngineeringLoad profile

A formed part having a multiple-plate structure of zonal design includes a base plate and a plurality of reinforcing plates fastened to the base plate. The multiple-plate structure is configured so that its strength is largely adapted to the load profile to be applied to the formed part and so that its cost of production is reduced. To this end, the thicknesses of the reinforcing plates vary as a function of the load structure to be applied to the formed part and the reinforcing plates engage each other in a positive locking manner so that the abutting edges are provided essentially with regularly arranged projections which are in mutual engagement.

Owner:VOLKSWAGEN AG

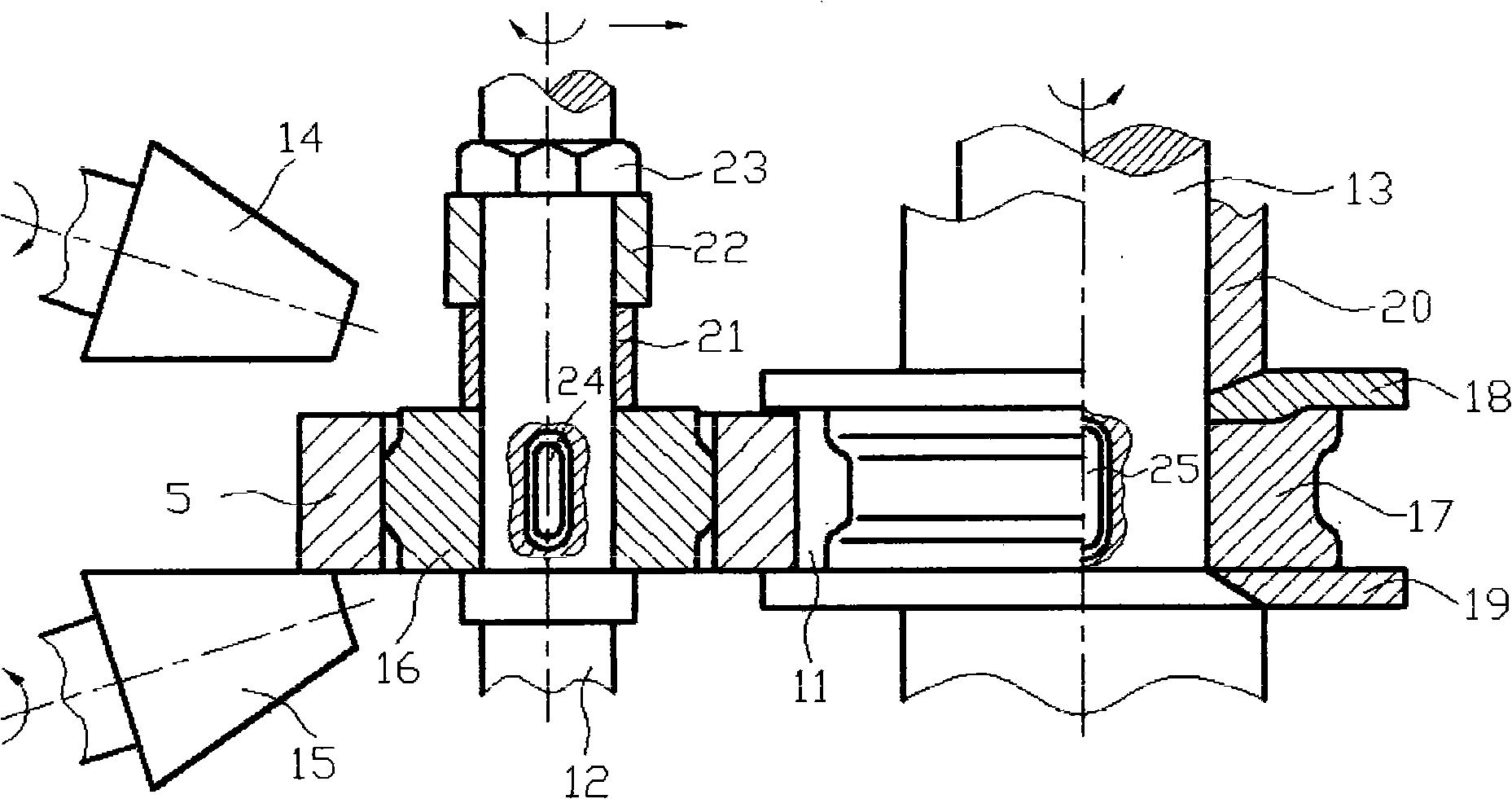

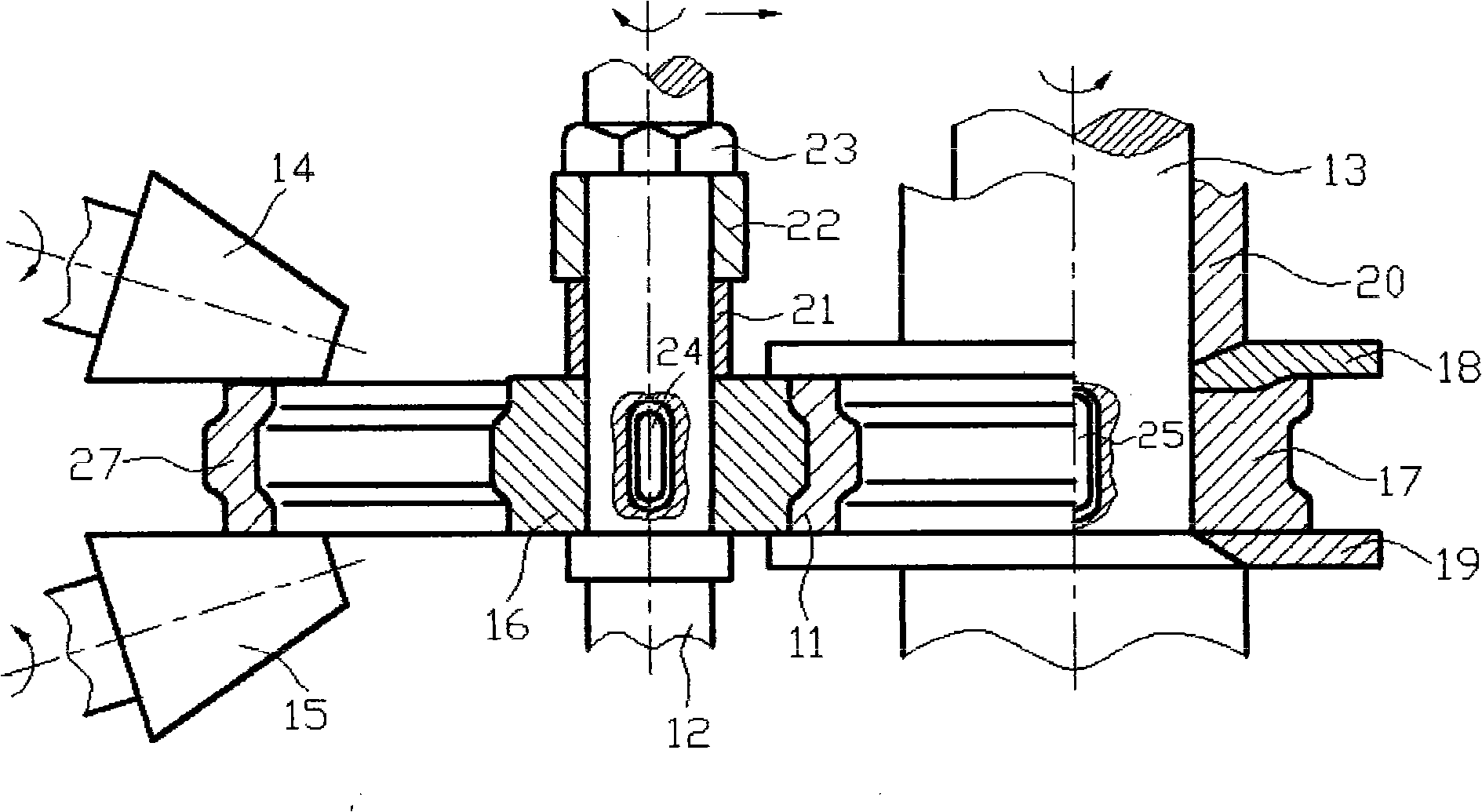

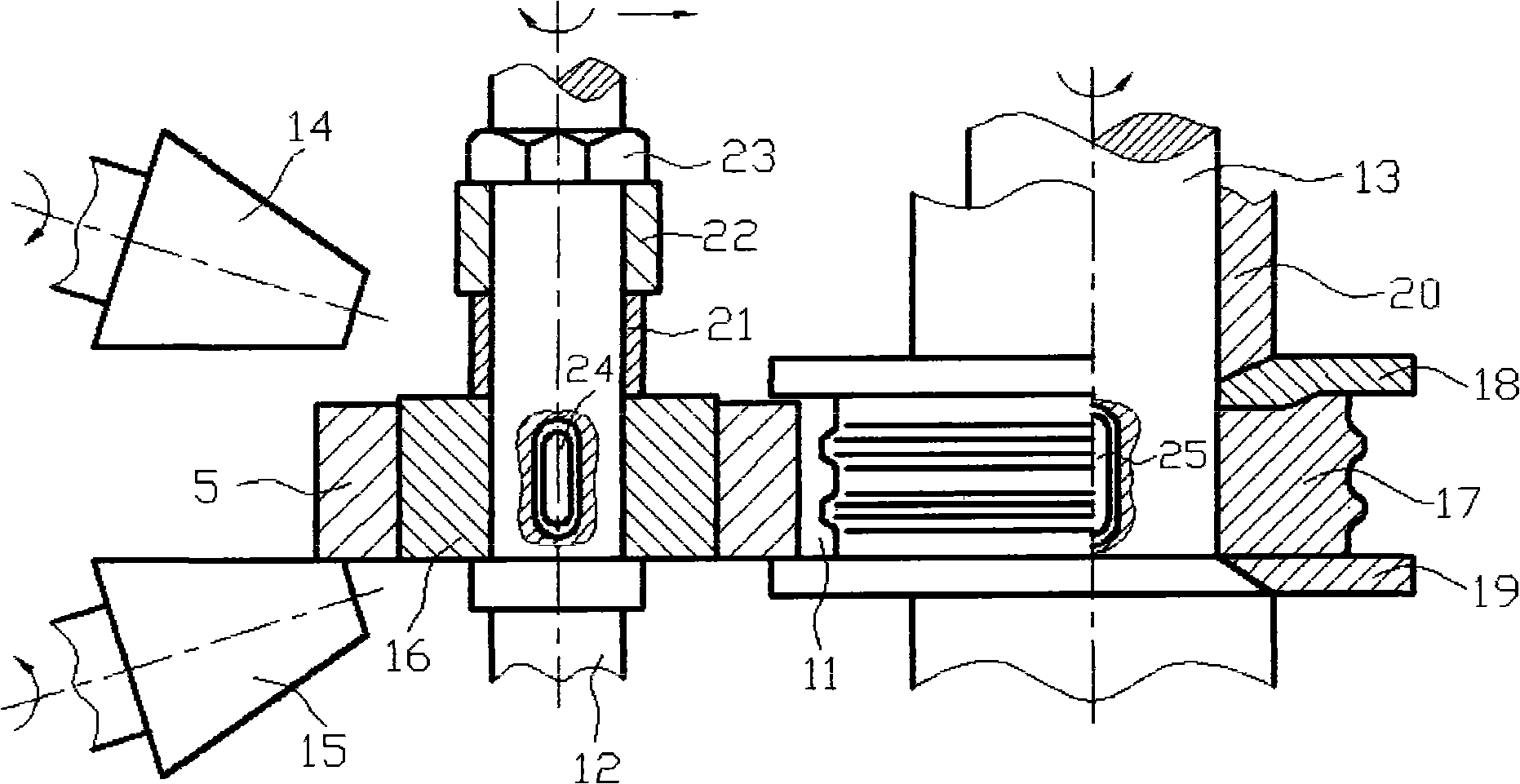

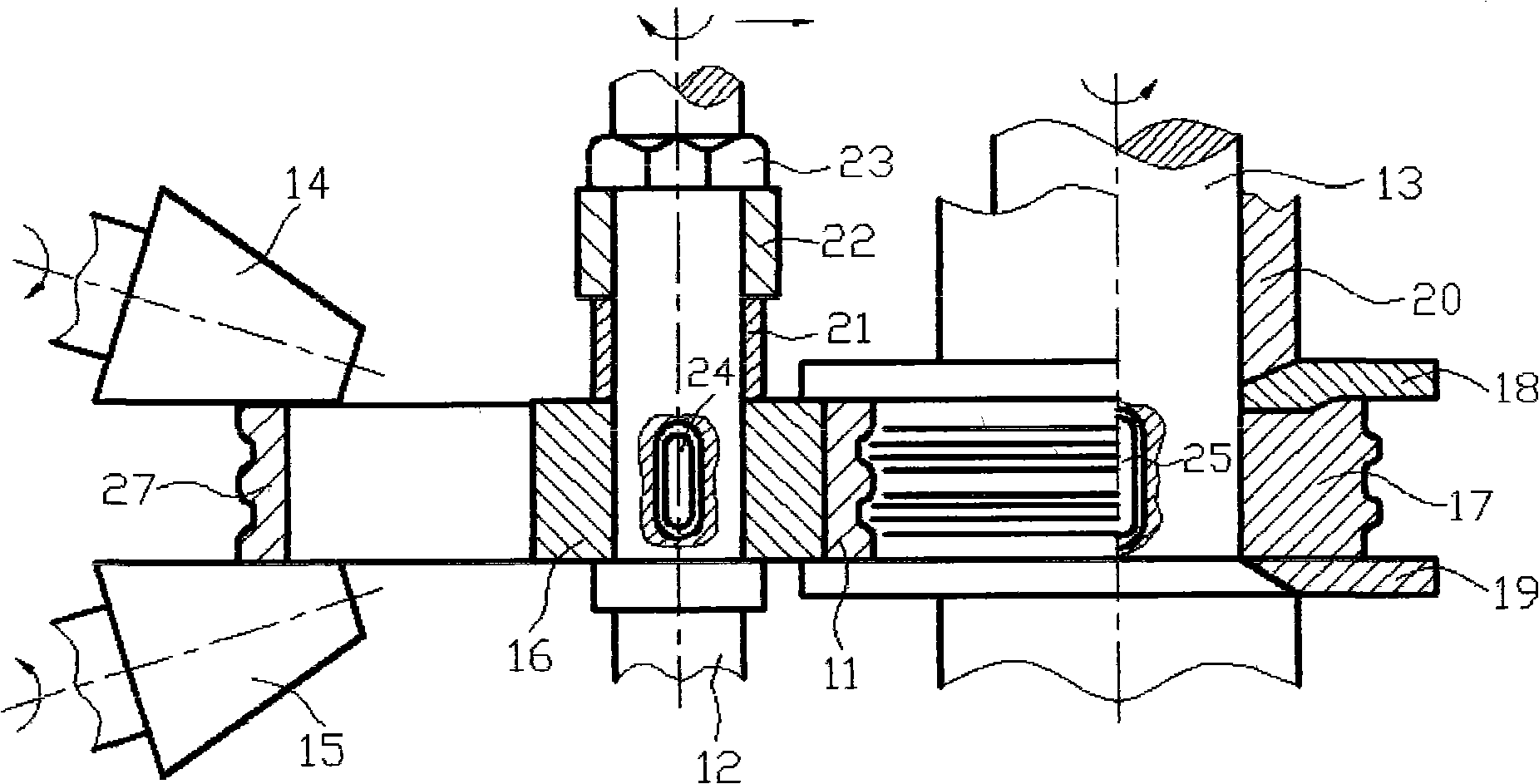

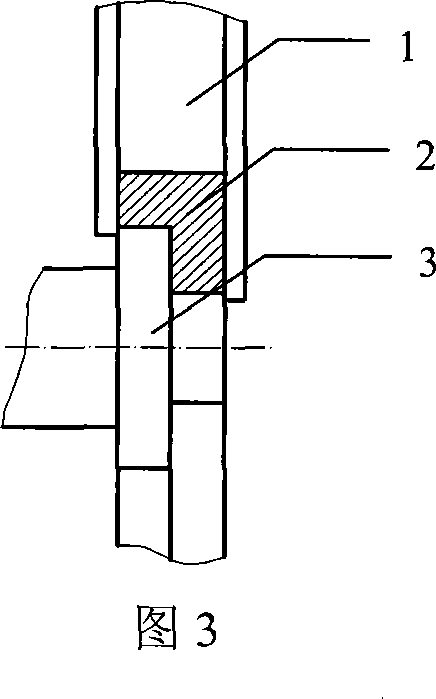

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

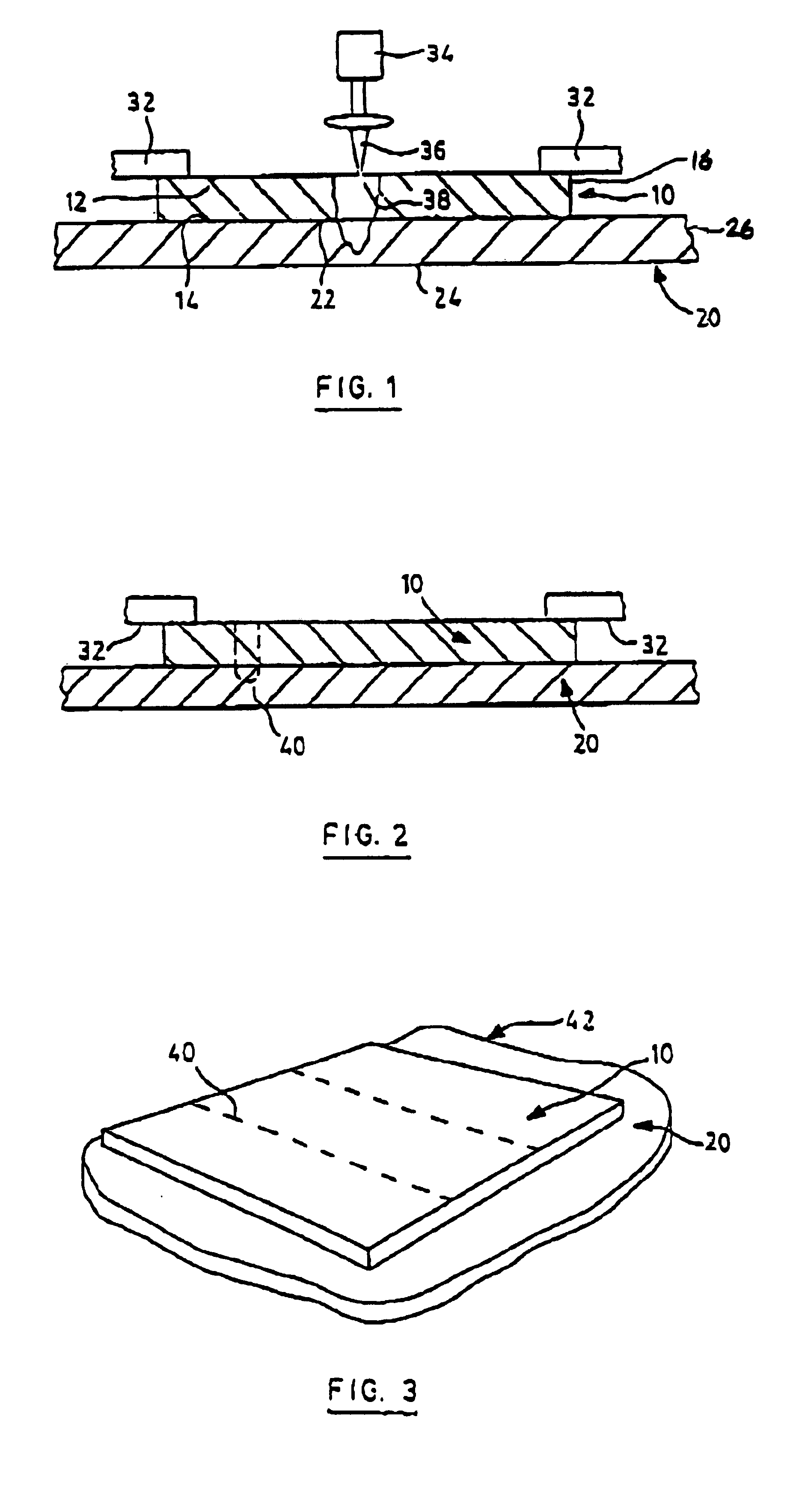

Method of combining welding and adhesive bonding for joining metal components

A method of joining metal components having the steps of depositing adhesive material between the components and welding the components together via solid-state or fusion welding. The welds are spaced apart from the adhesive material and are produced so as to prevent exposure of the adhesive material to the welding. The two types of bonds (adhesive and welding) are produced in the components separated by time and space.

Owner:ARCONIC INC

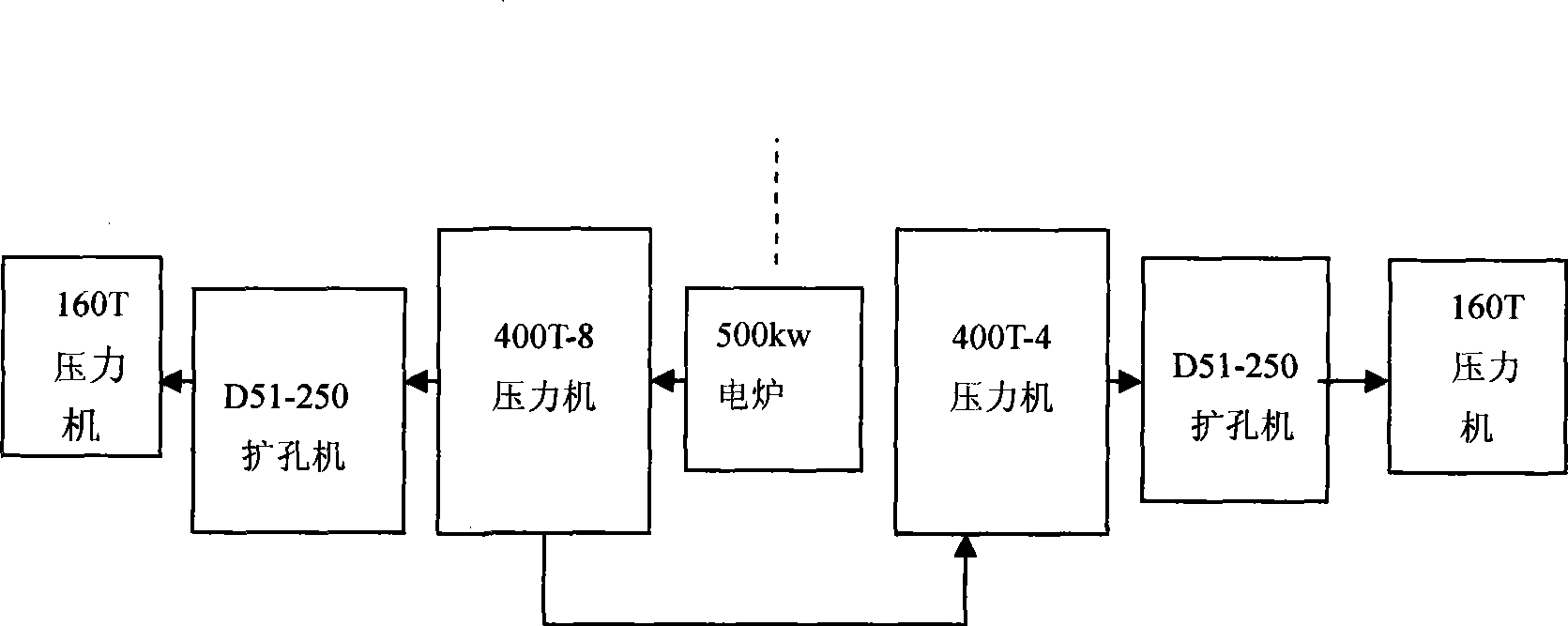

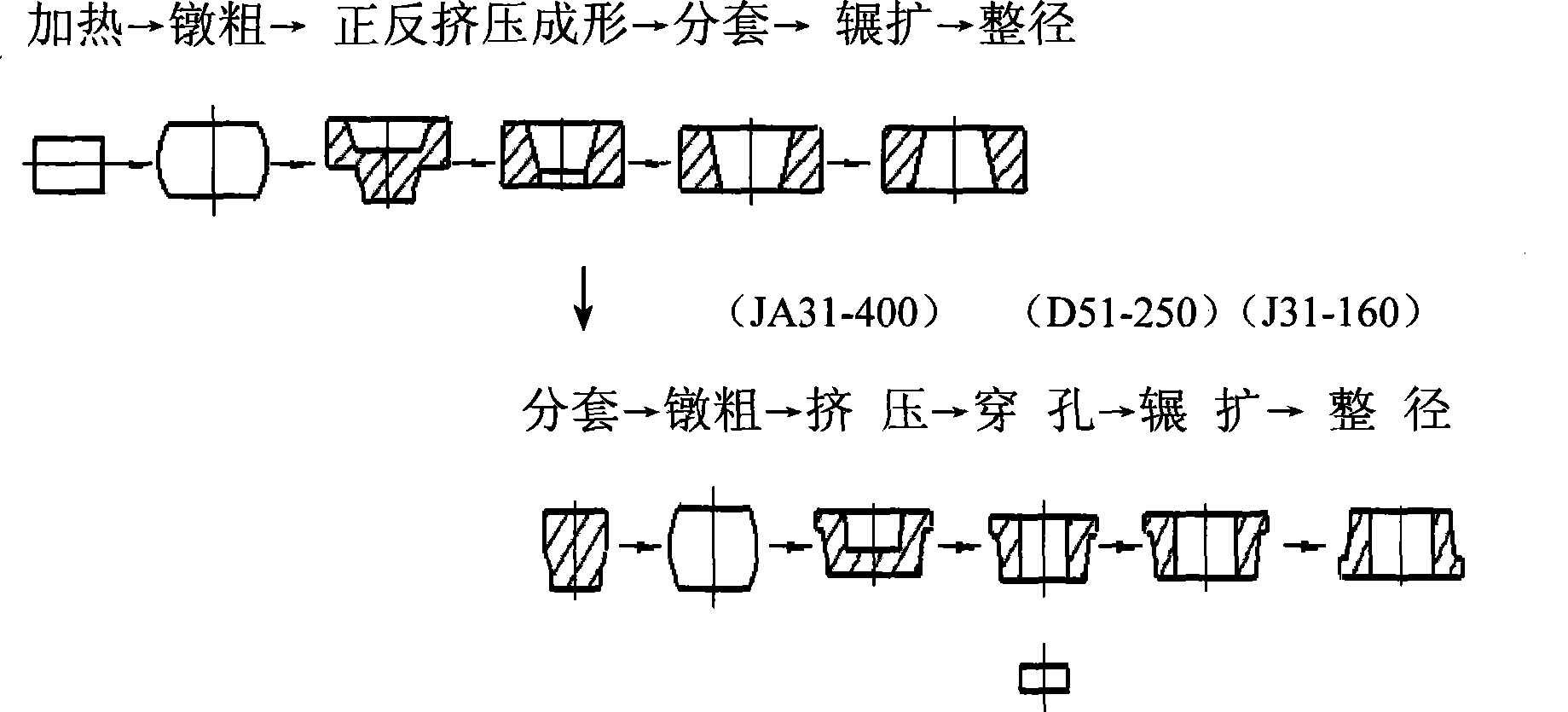

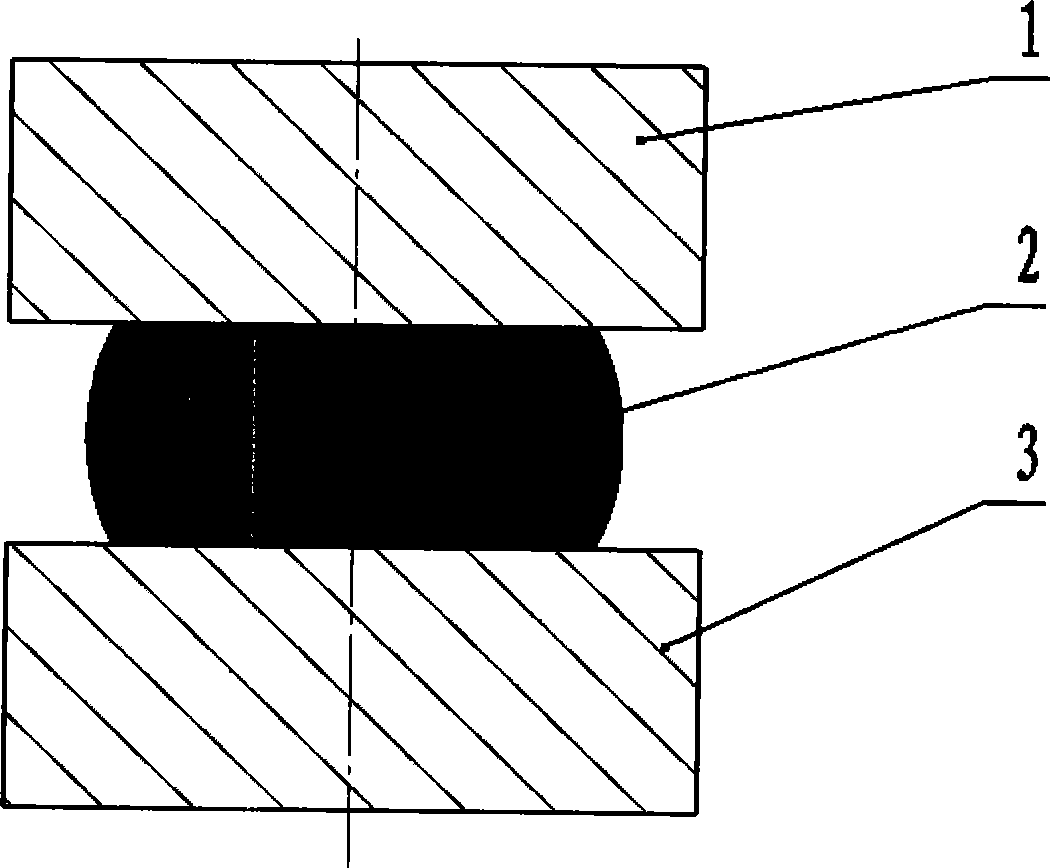

Tapered roller bearing ring double extension-sleeve forging technique

ActiveCN101417379AReduce labor intensityIncrease profitMetal rollingHigh volume manufacturingDouble diffusion

The invention relates to a double diffusion intussusception forge technique of a bearing ring of a tapered roller, belongs to the technical field of forging of the bearing ring of the tapered roller and mainly aims at solving the problems that the existing ring forging technique is not suitable for various bearing rings of the large and medium size tapered rollers. The technique is mainly characterized in that: (1) a GCr15 steel material section is heated to 1050 DEG C on a medium frequency induction furnace, then upset on a press, extruded backward and forward, formed, sheathed respectively and is separated into an outer sleeve and an inner sleeve or a small outer sleeve blank; (2) the outer sleeve blank is ring-rolled on a ring rolling machine, then reeled on the press and cooled into an outer sleeve forged parts of a bearing; and (3) the inner sleeve or the small outer sleeve blank is placed on the press, upset again, extruded and punched and then a ring part is obtained which is ring-rolled on the ring rolling machine, then an inner sleeve hot forged part after being ring-rolled is reeled on the press and then cooled to obtain the inner sleeve forged part of the bearing. The technique is mainly used for manufacturing the inner and outer ring forged parts of the bearing of the large and medium size tapered roller with various types, small batch or large batch.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

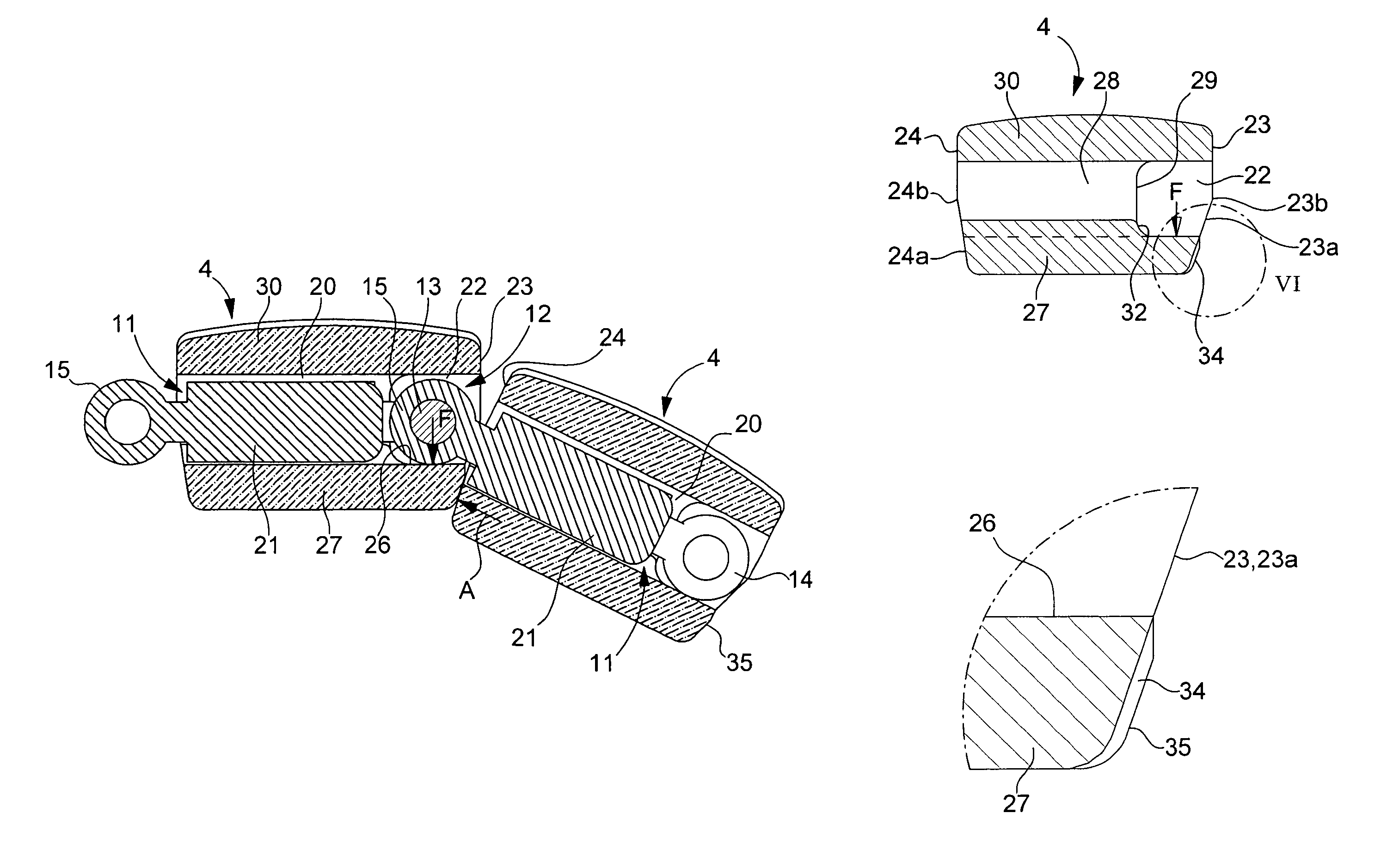

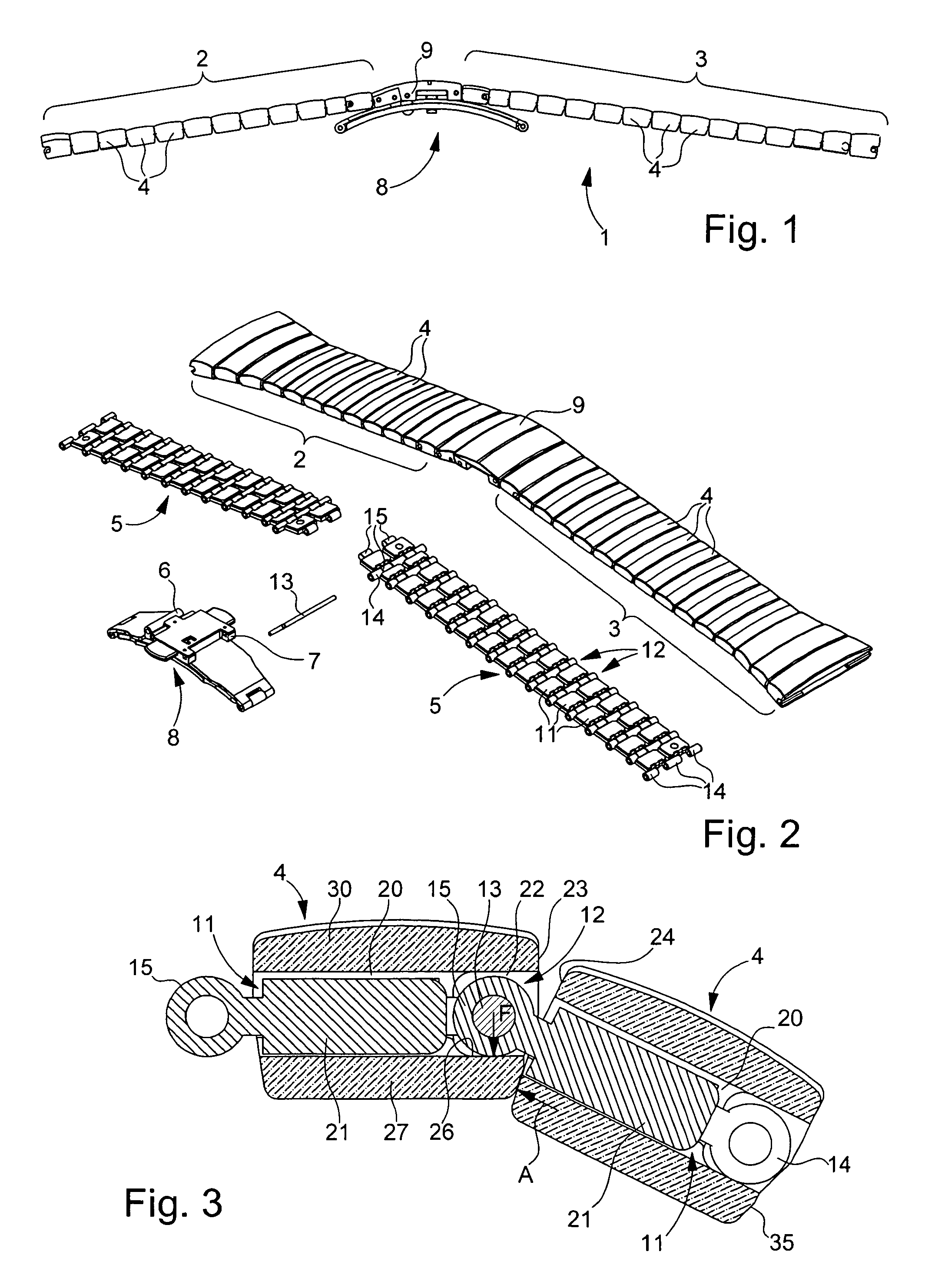

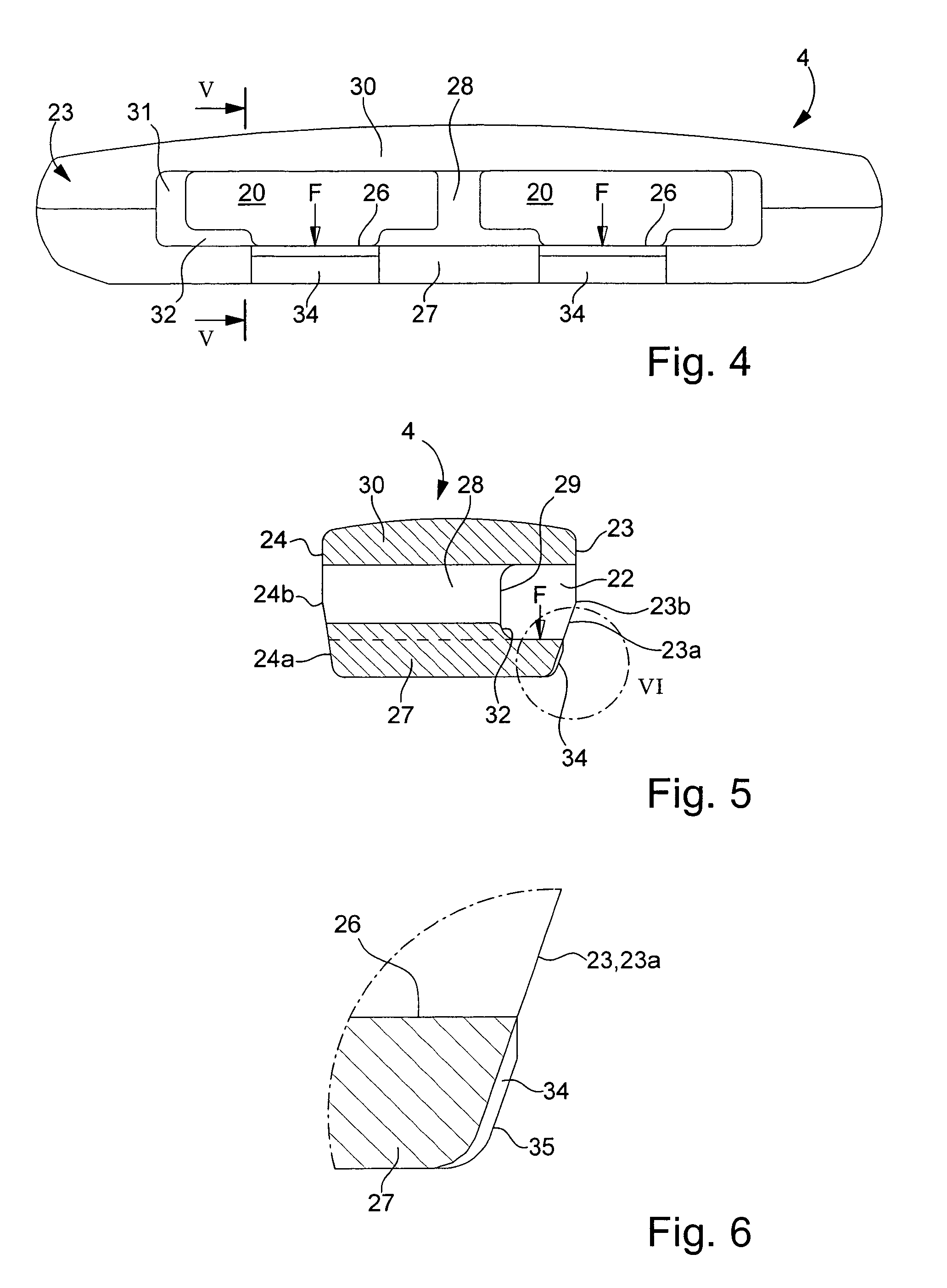

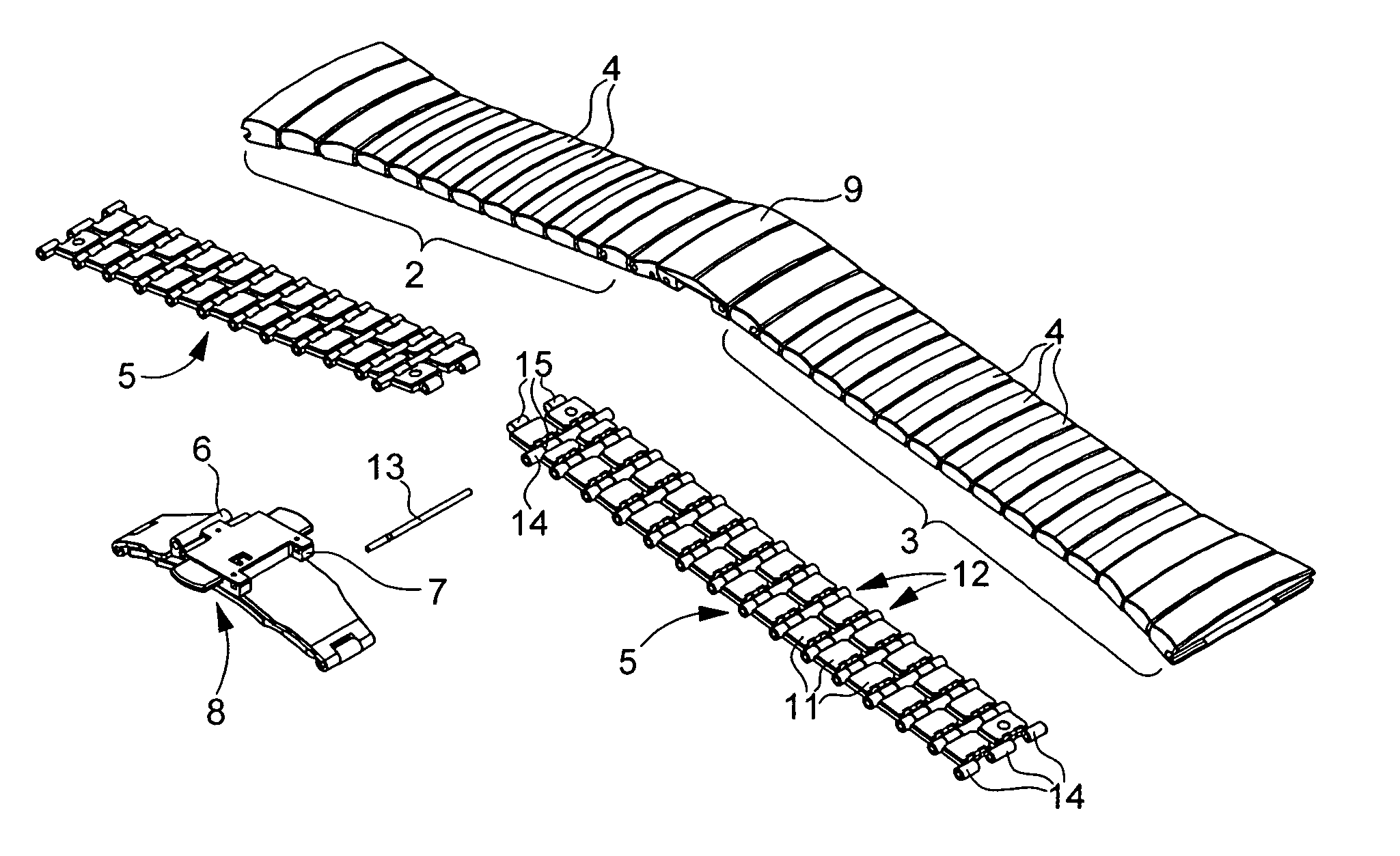

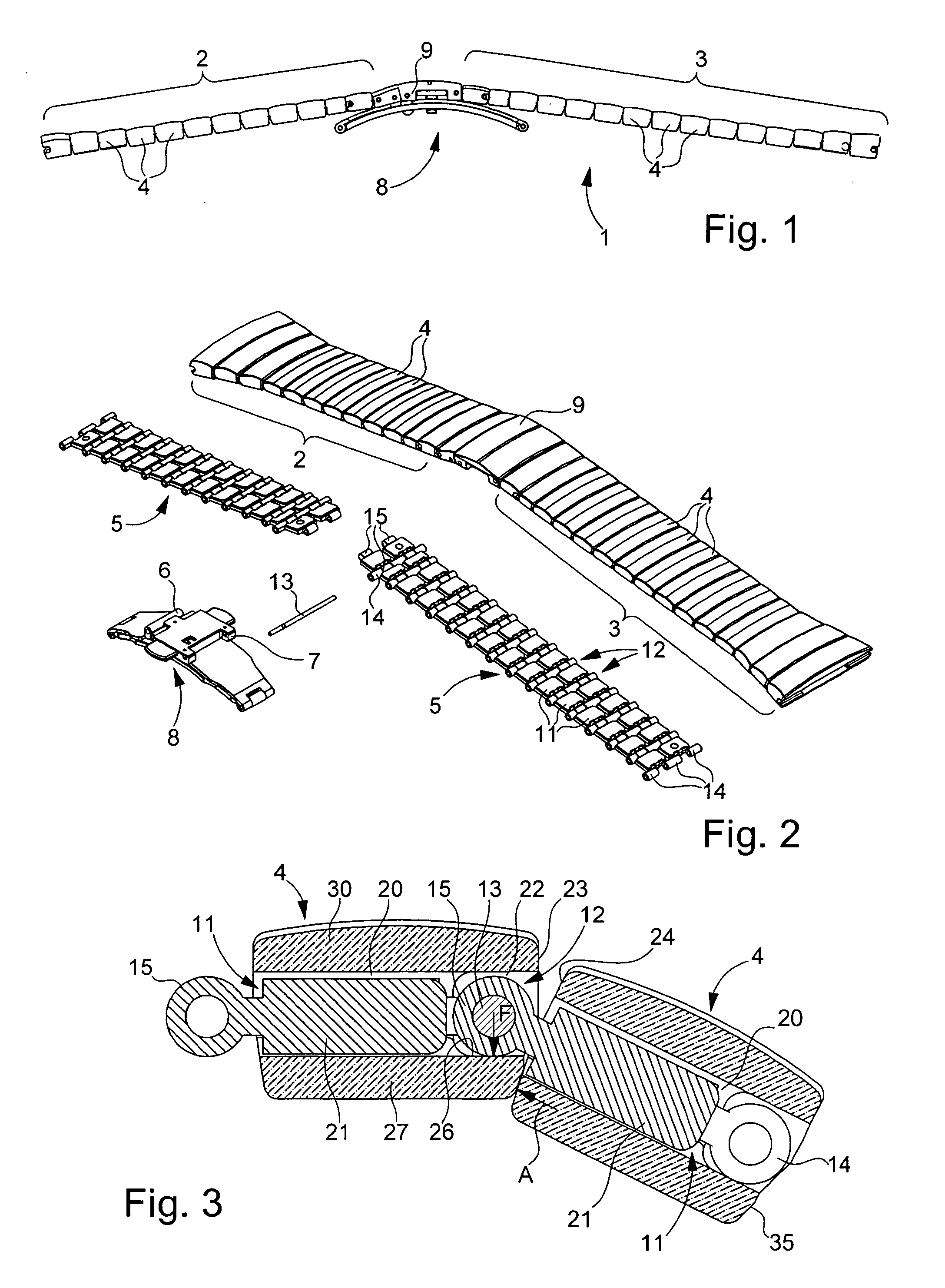

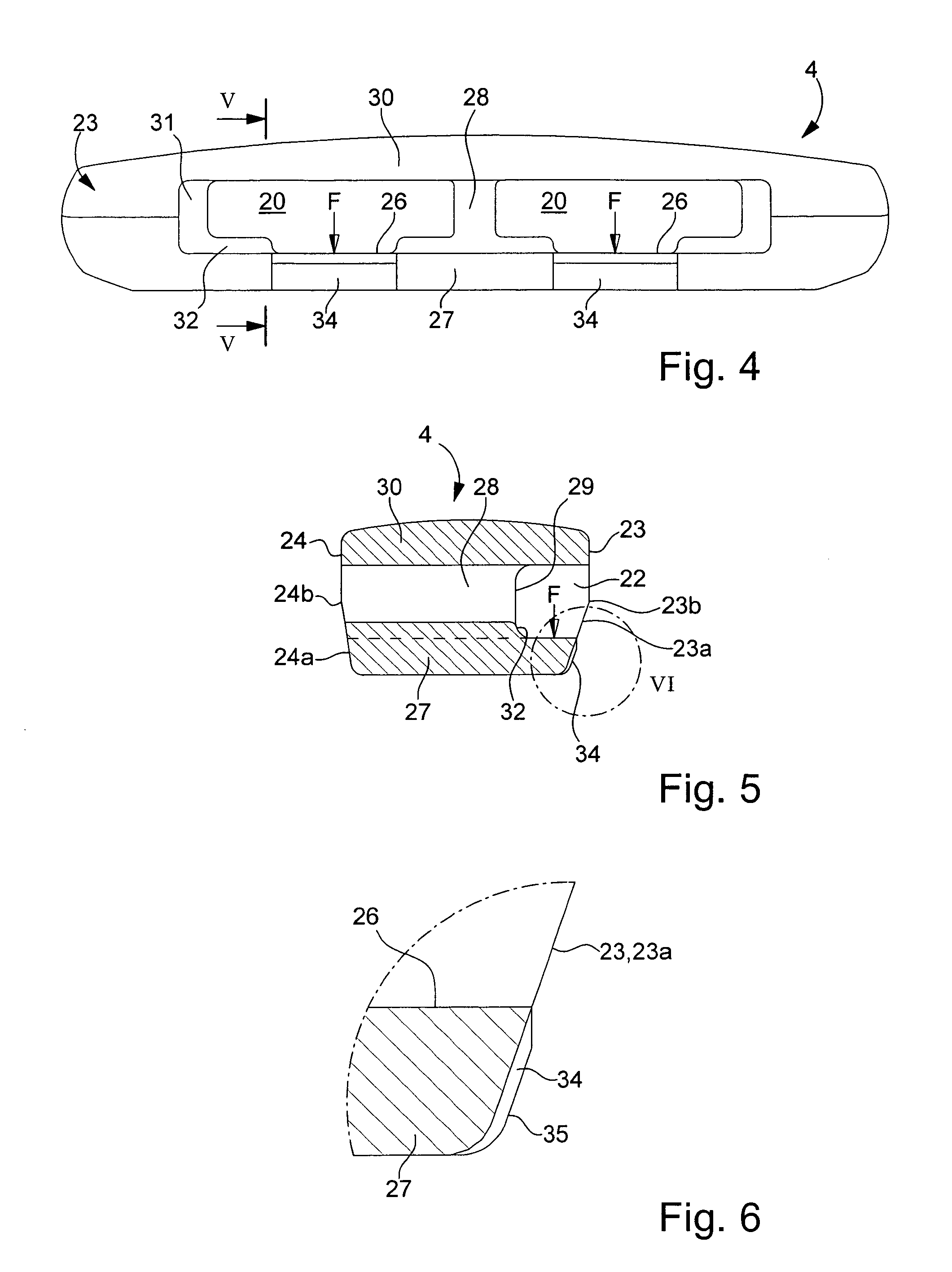

Articulated bracelet including decorative links threaded onto a chain

ActiveUS7013631B2Reduce stressSuppression reductionBraceletsHorseshoeEngineeringMechanical engineering

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

Method for rolling and shaping nickel-based high-temperature alloy special-shaped ring forging

The invention discloses a rolling and shaping method for a nickel-based high temperature alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 60 to 65 percent so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 20 to 25 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 20 to 25 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

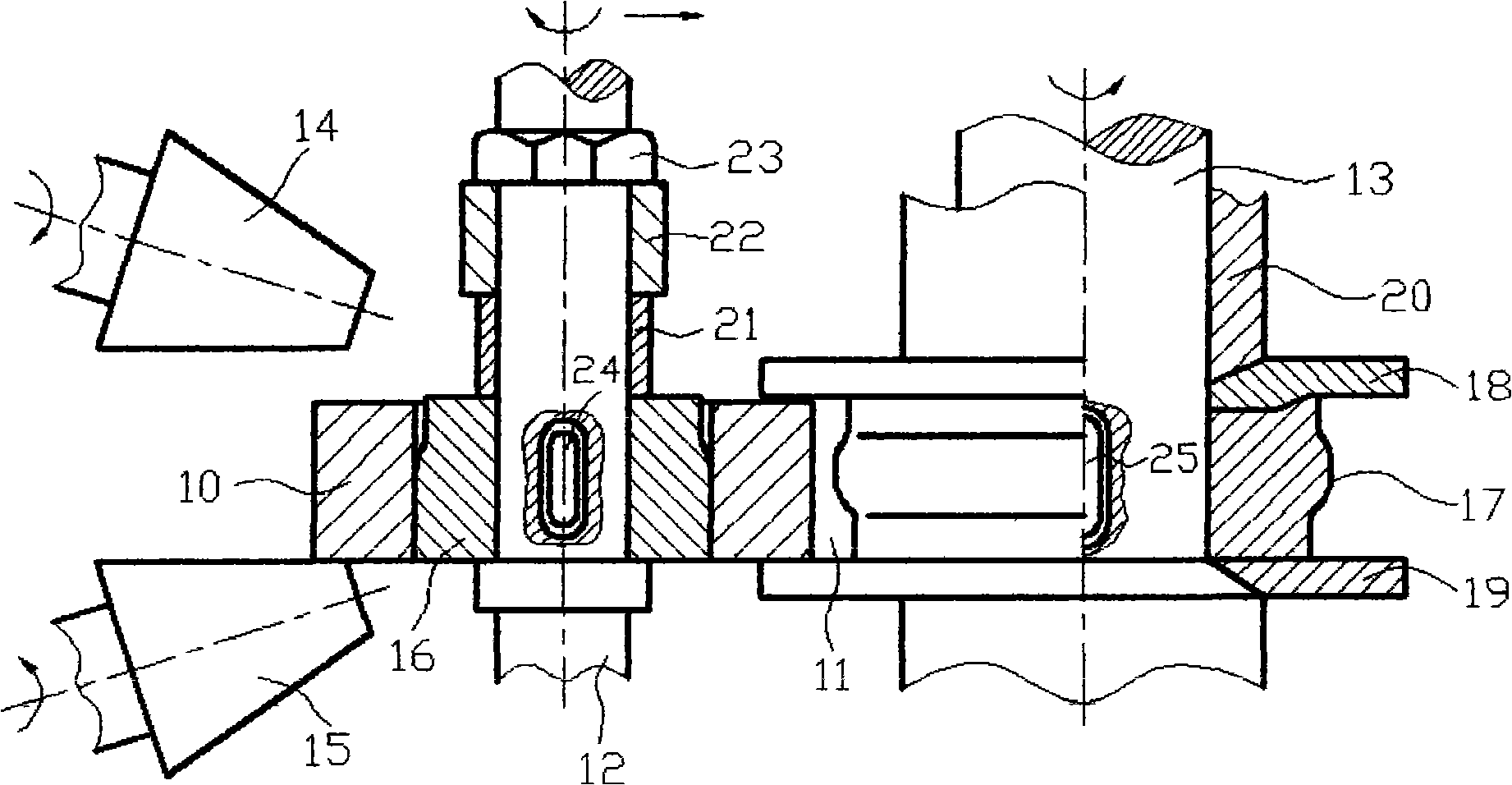

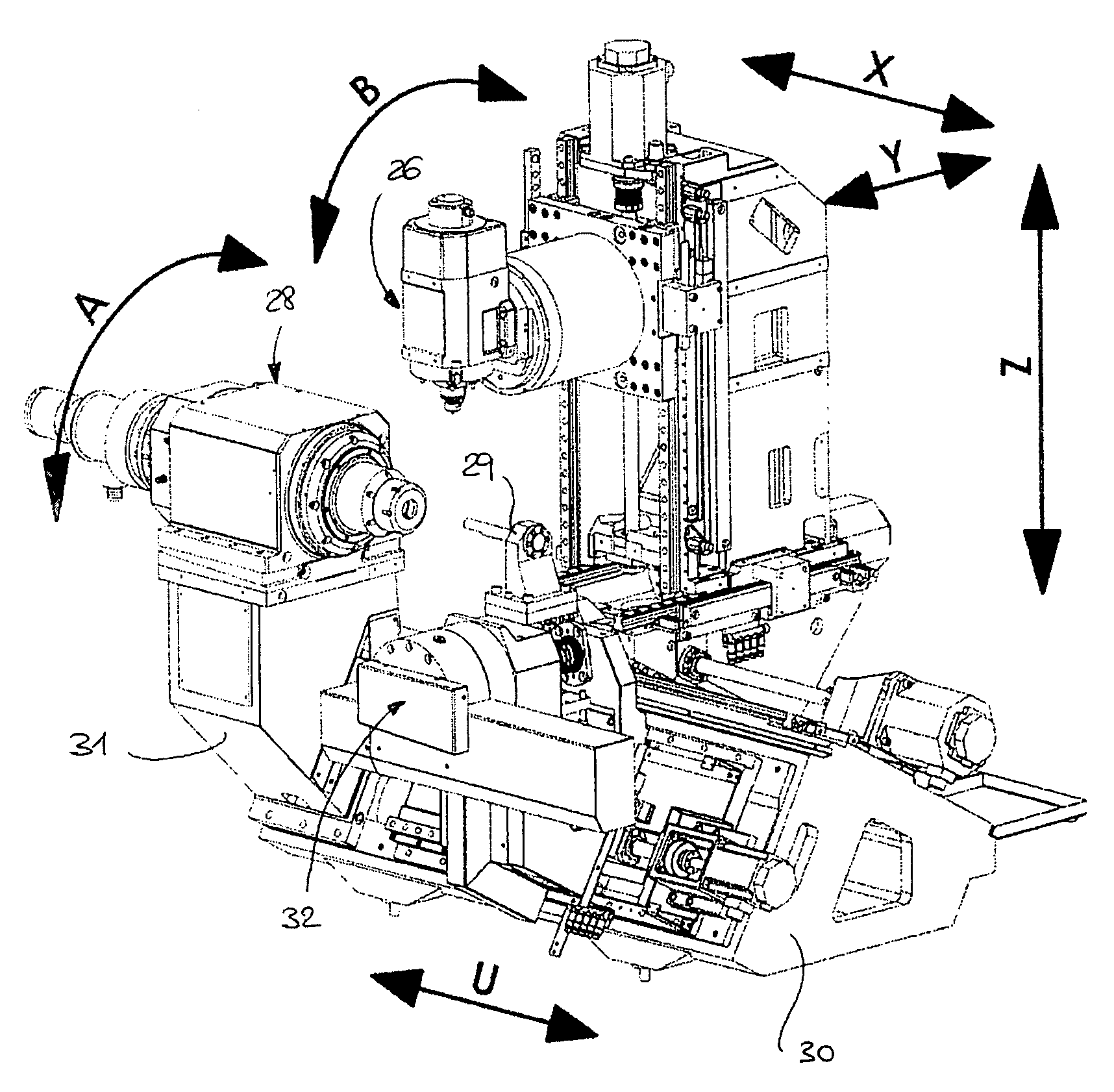

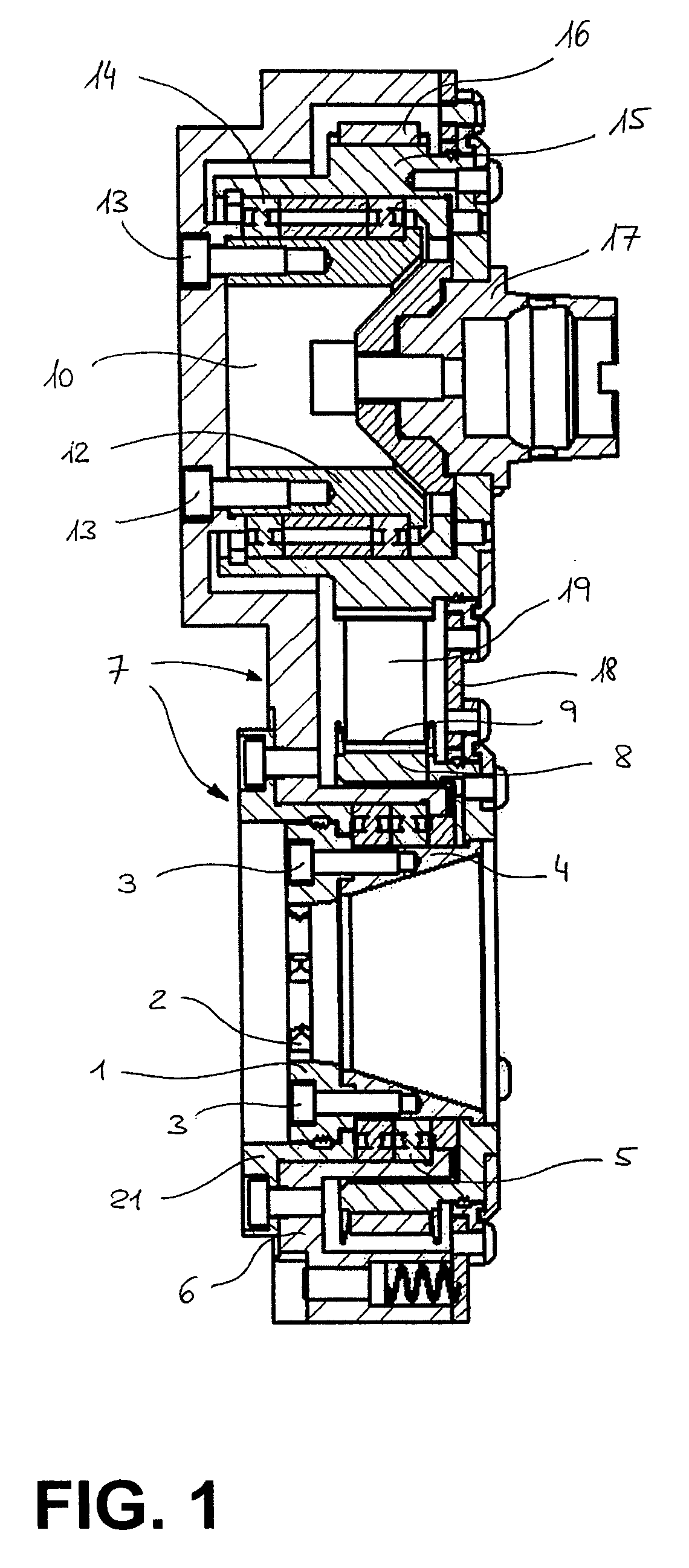

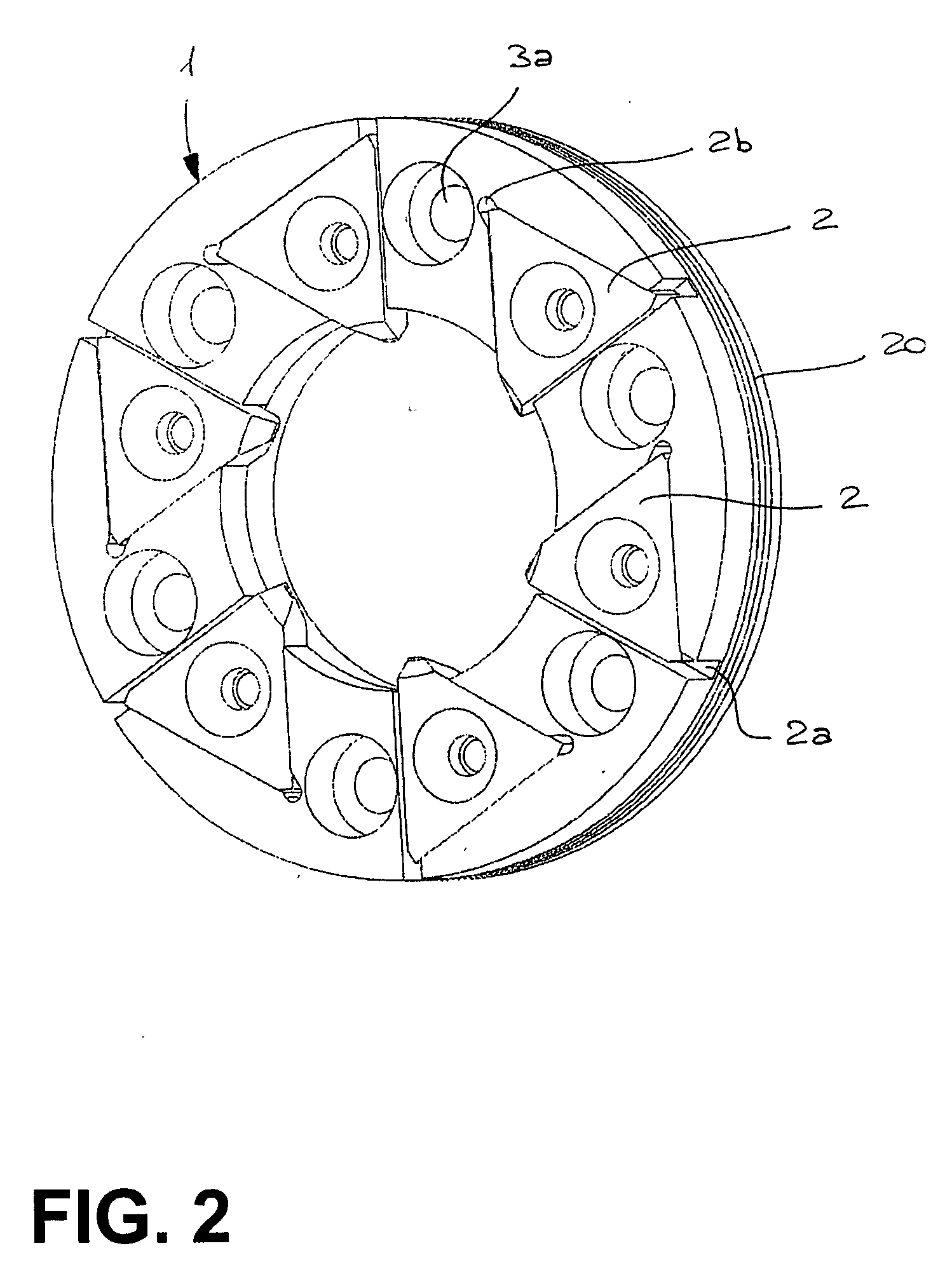

Whirling head and its use

The frame of the whirling head comprises the rigid casing (7), in which the part (10) contains the drive pulley (15) solidly attached to the coupling member (17) connected to the drive shaft of the spindle (26). By means of the belt (19), this pulley (15) drives the pulley (8) solidly attached to the connecting cone (4), which in turn comprises the internal milling cutter (1) which cuts the thread of the screw shaft (27) supported between the bar advance unit (28) and the tailstock centre (29). The latter is mounted as an exchangeable tool on the return unit (32).

Owner:WILLEMIN MACODEL

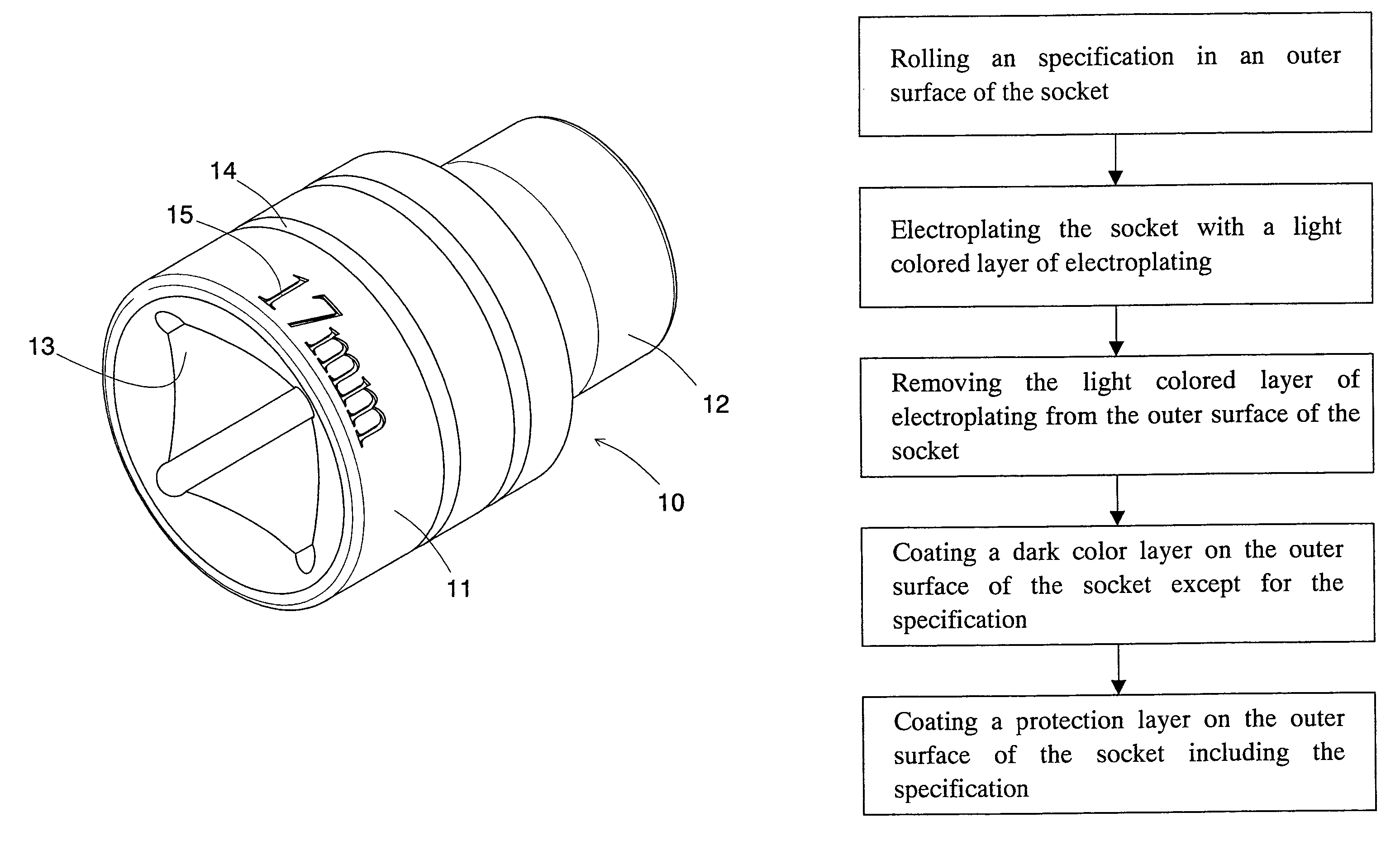

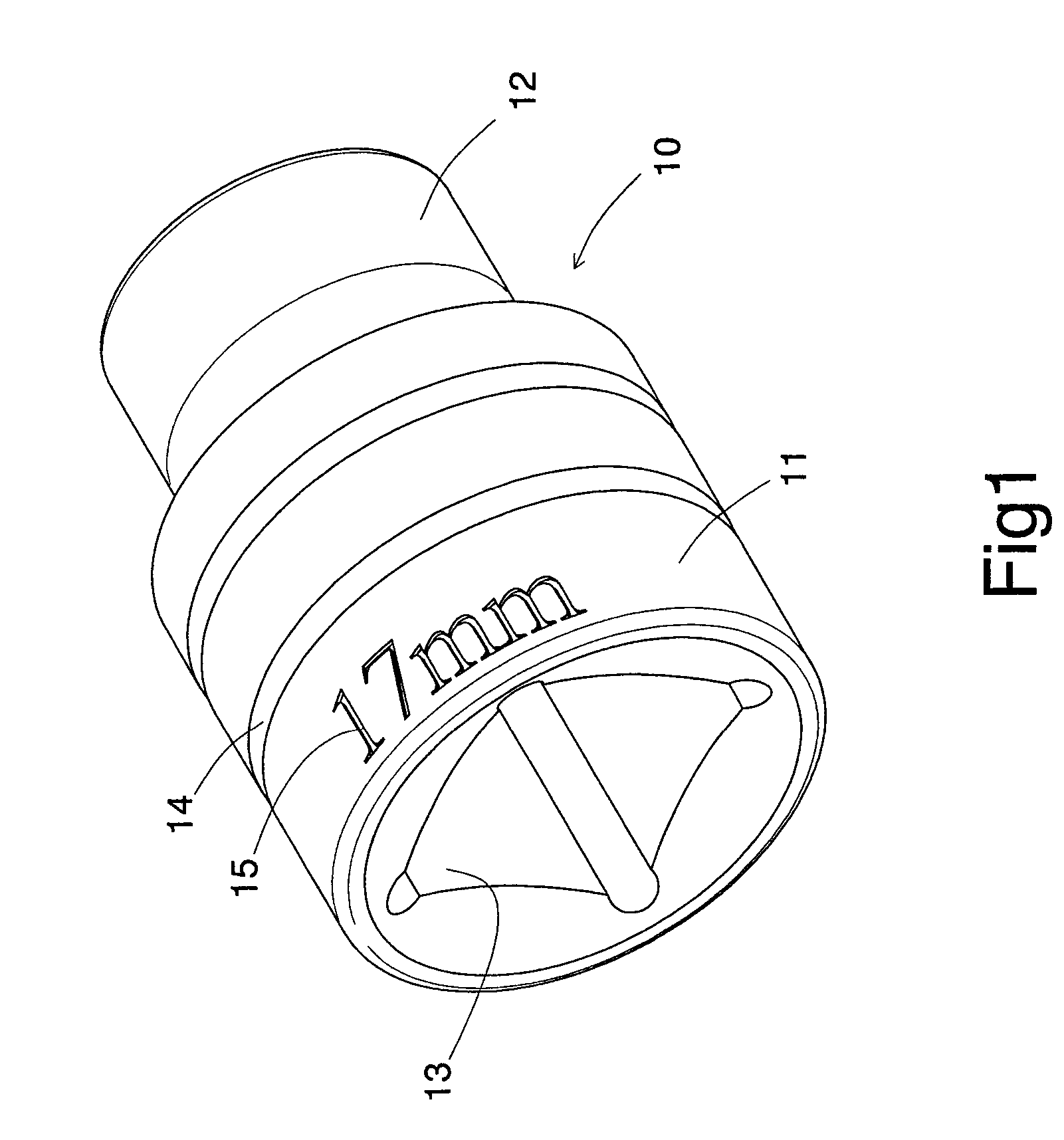

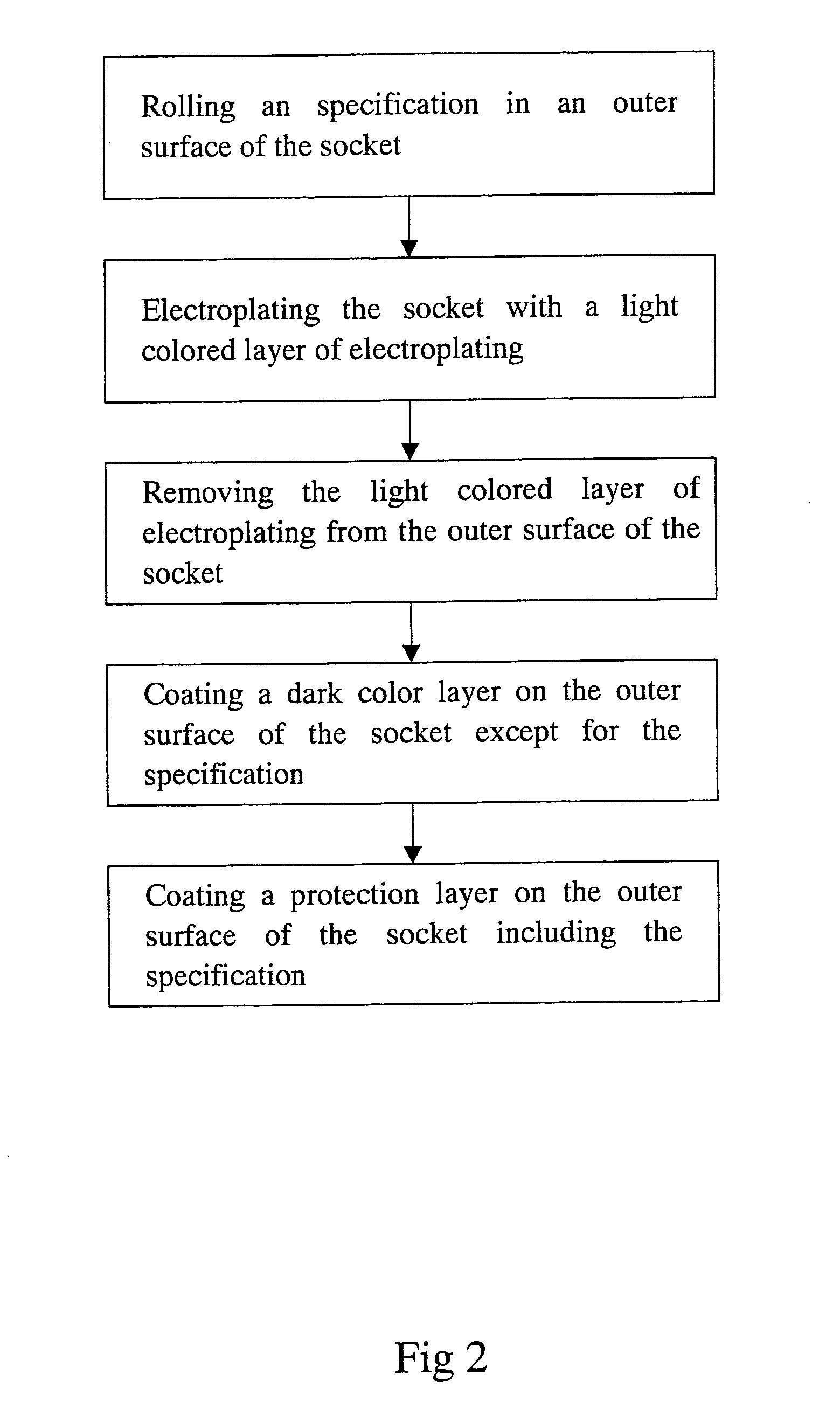

Sockets and method of surface treatment for sockets

A socket has a dark colored outer surface and a specification rolled in the outer surface of the socket and coated with a brighter colored electroplating. The method for the surface treatment of the socket includes rolling the specification in an outer surface of the socket; electroplating the socket with a light colored layer of electroplating; removing the light colored layer of electroplating from the outer surface of the socket except for the specification and coating a dark colored layer on the outer surface of the large section except for the specification. By the surface treatment, the specification is obvious from the dark colored outer surface of the socket.

Owner:YING HAO PENG

Articulated bracelet including decorative links threaded onto a chain

ActiveUS20050210857A1Reduce stressSuppression reductionBraceletsWrist-watch strapsEngineeringMechanical engineering

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

Fine-grain roll-forming method for large annular piece made of high alloy steel

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

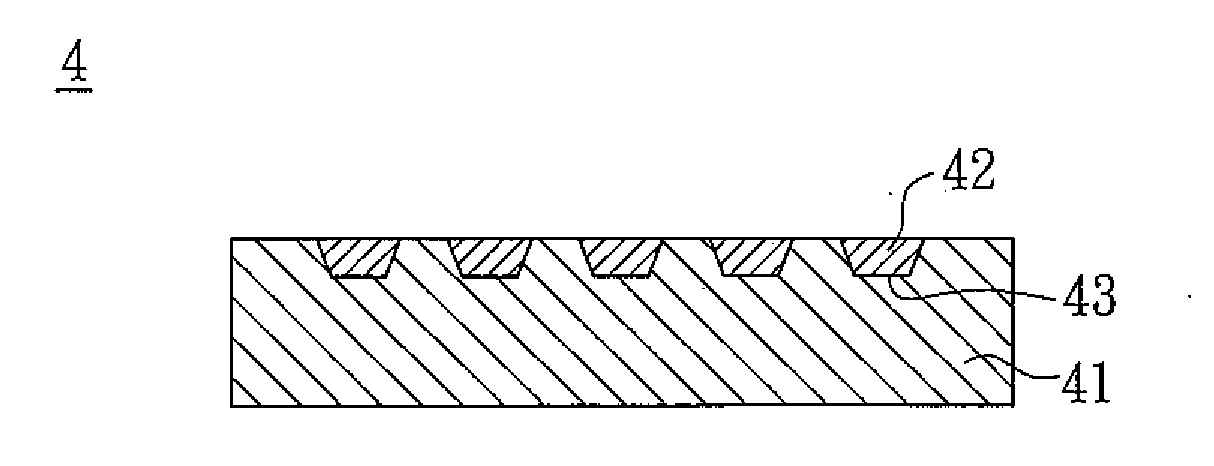

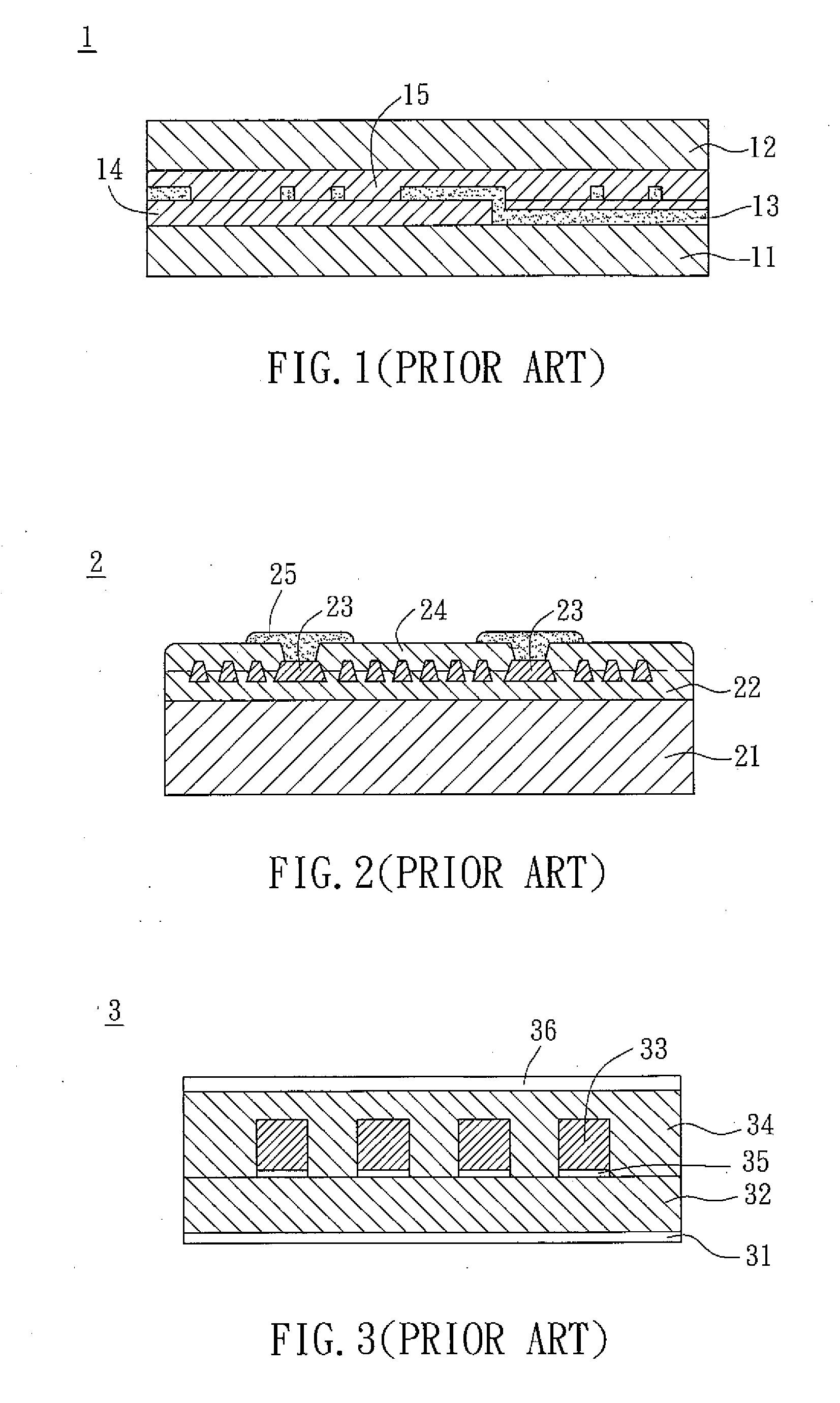

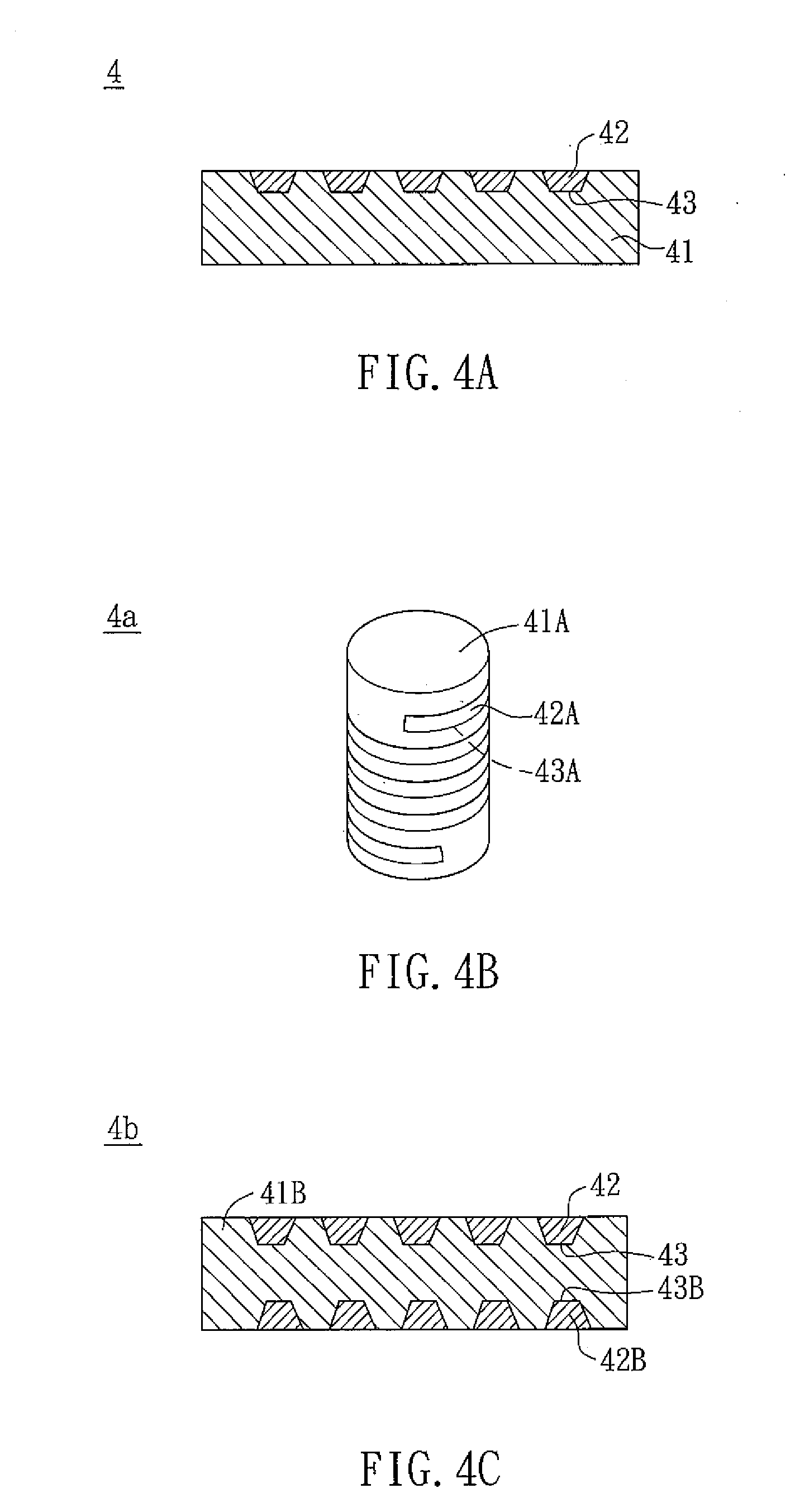

Magnetic device and manufacturing method thereof

InactiveUS20090029185A1Increase inductanceThin thicknessMouldsLayered productsElectrical and Electronics engineering

Owner:DELTA ELECTRONICS INC

Aircraft structure element made of an Al-Cu-Mg alloy

InactiveUS6569542B2Pig casting plantsSemiconductor/solid-state device detailsAlloyStructuring element

The purpose of the invention is a structure element, particularly an lower wing element of an aircraft, manufactured from a rolled, extruded or forged product made of an alloy with composition (% by weight):Cu=4.6-5.3, Mg=0.10-0.50, Mn=0.15-0.45, Si <0.10, Fe<0.15, Zn<0.20, Cr<0.10, other elements <0.05 each and <0.15 total, the remainder being Al treated by solution heat treating, quenching, controlled tension to more than 1.5% permanent deformation and aging.

Owner:RHENALU PECHINEY

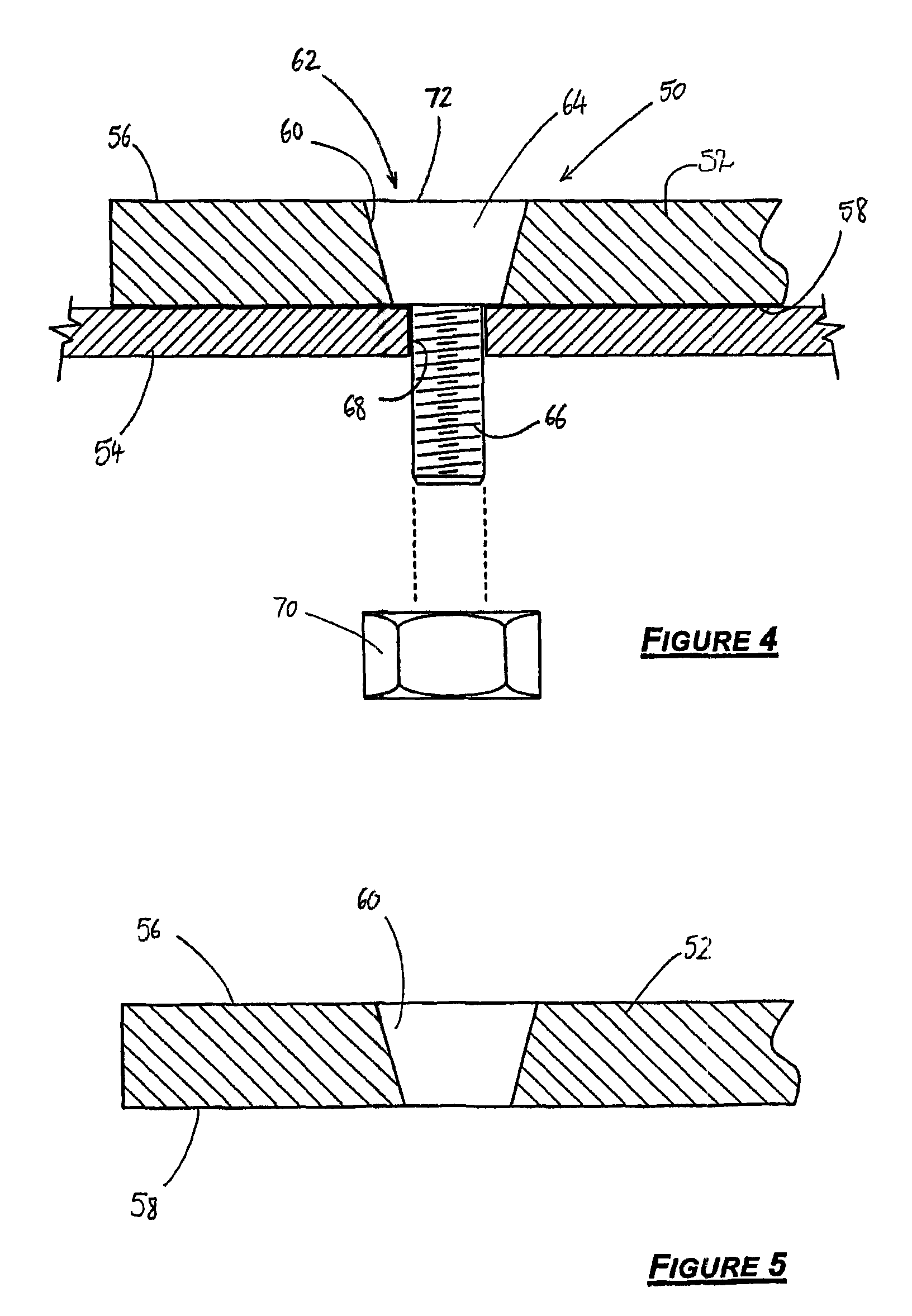

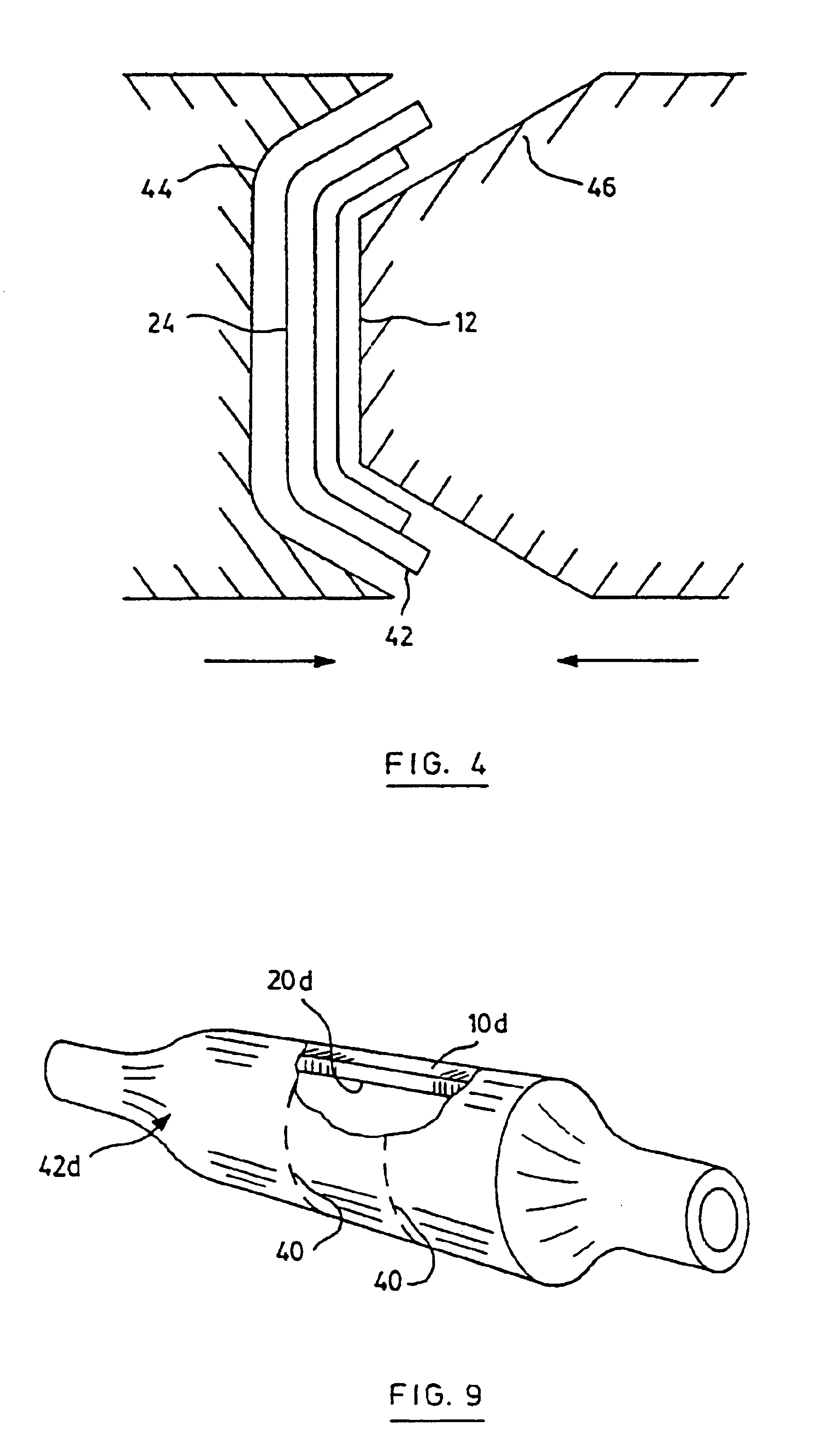

Tailored blank

The present invention provides a tailored blank having a pair of sheet metal constituent parts each having a pair of oppositely directed major surfaces. The first constituent part has an aperture while the second constituent part has an embossment to fit the aperture. The first and second constituent parts are then secured to one another to form the tailored blank. The blank may then be subsequently formed into a component of varying material characteristics.

Owner:DULEY WALTER +5

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com