Patents

Literature

962 results about "Thermal state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

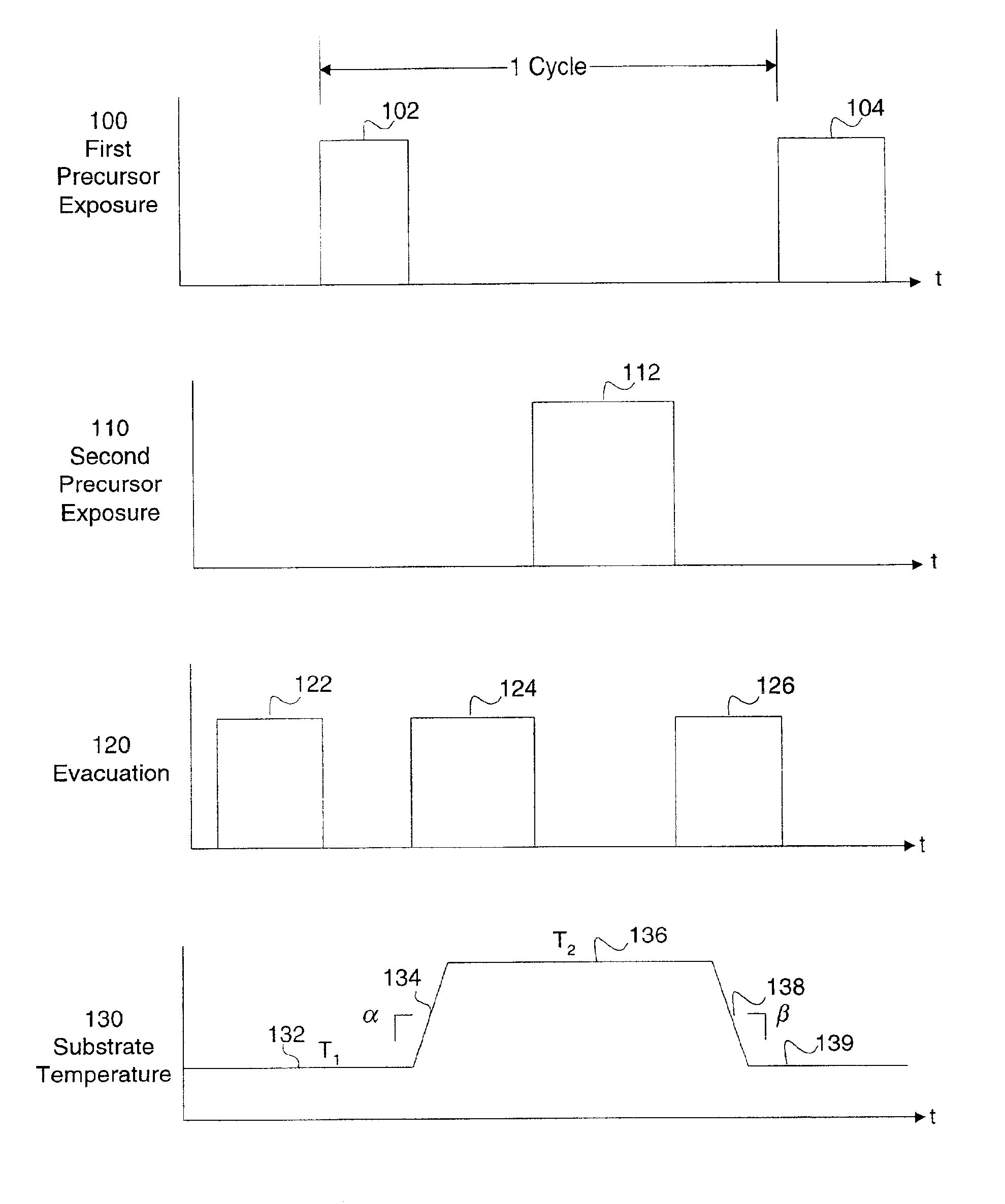

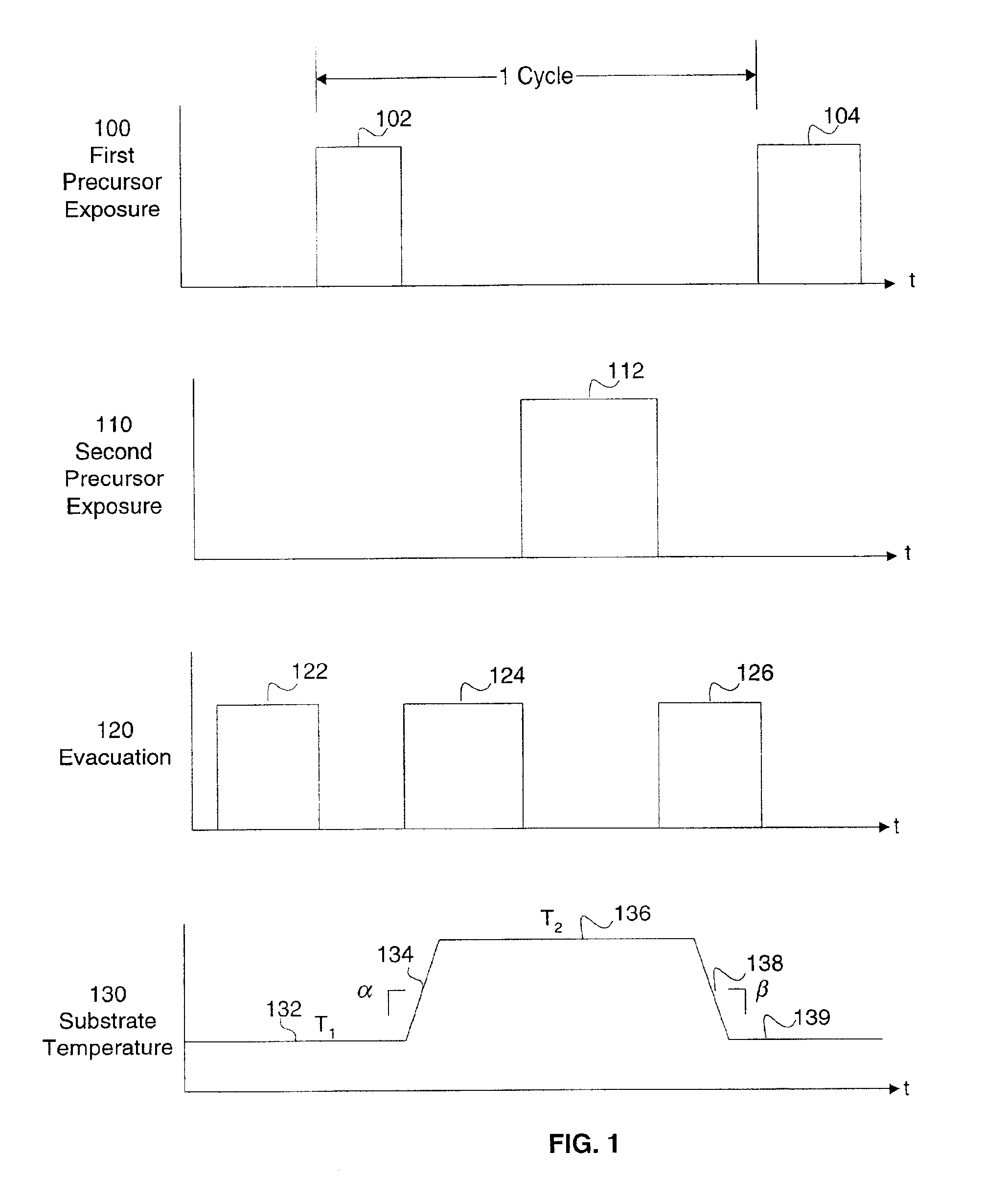

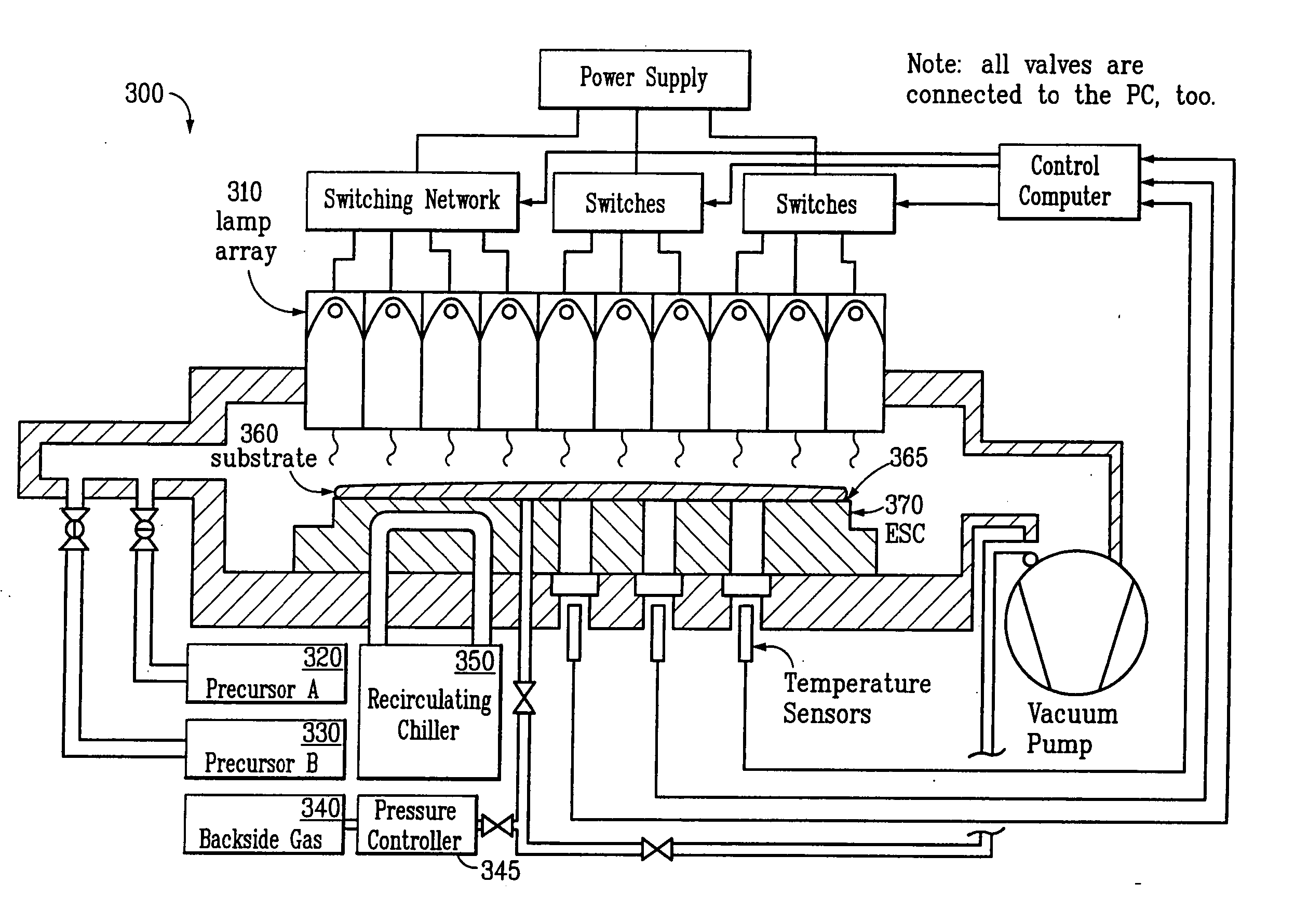

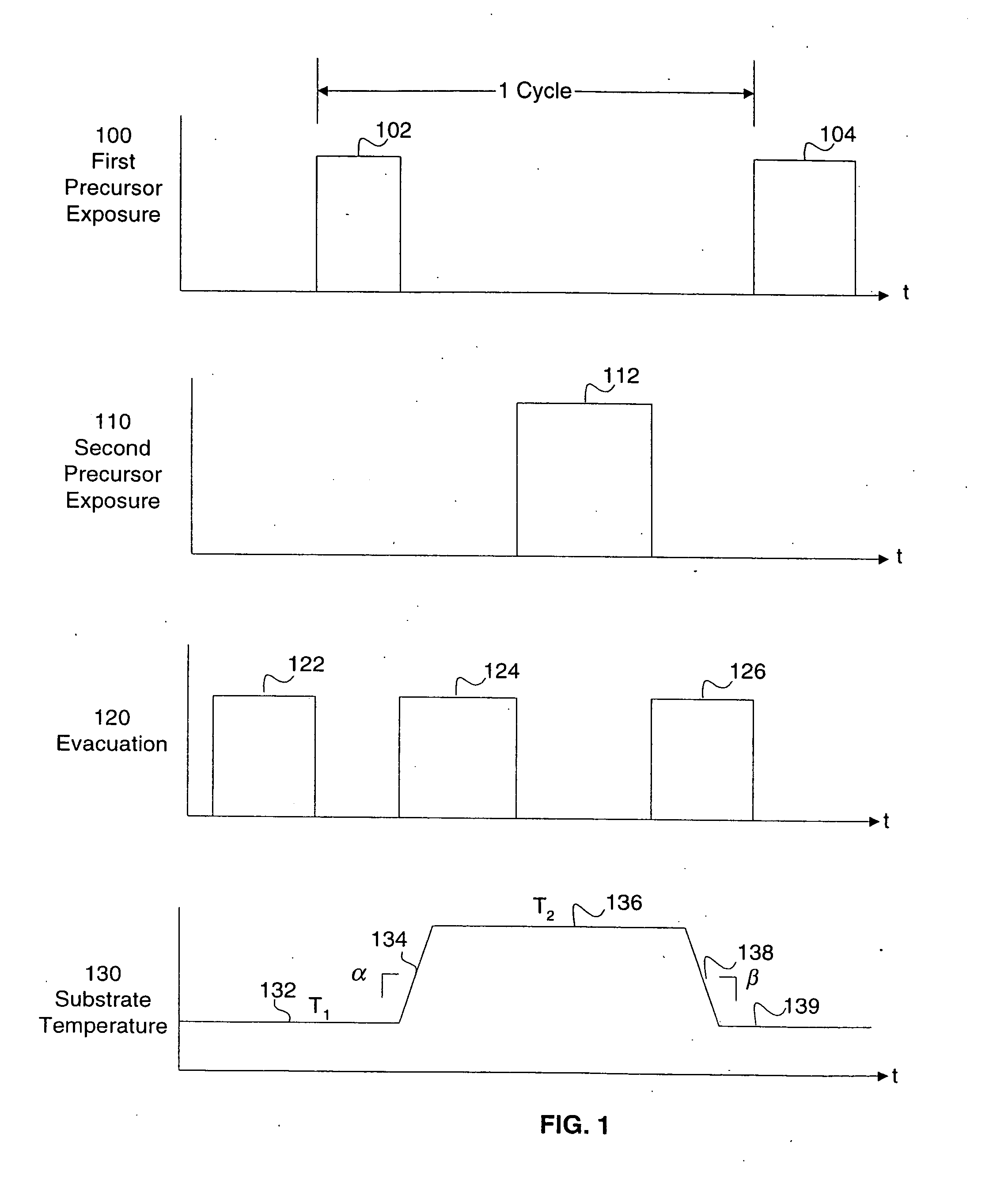

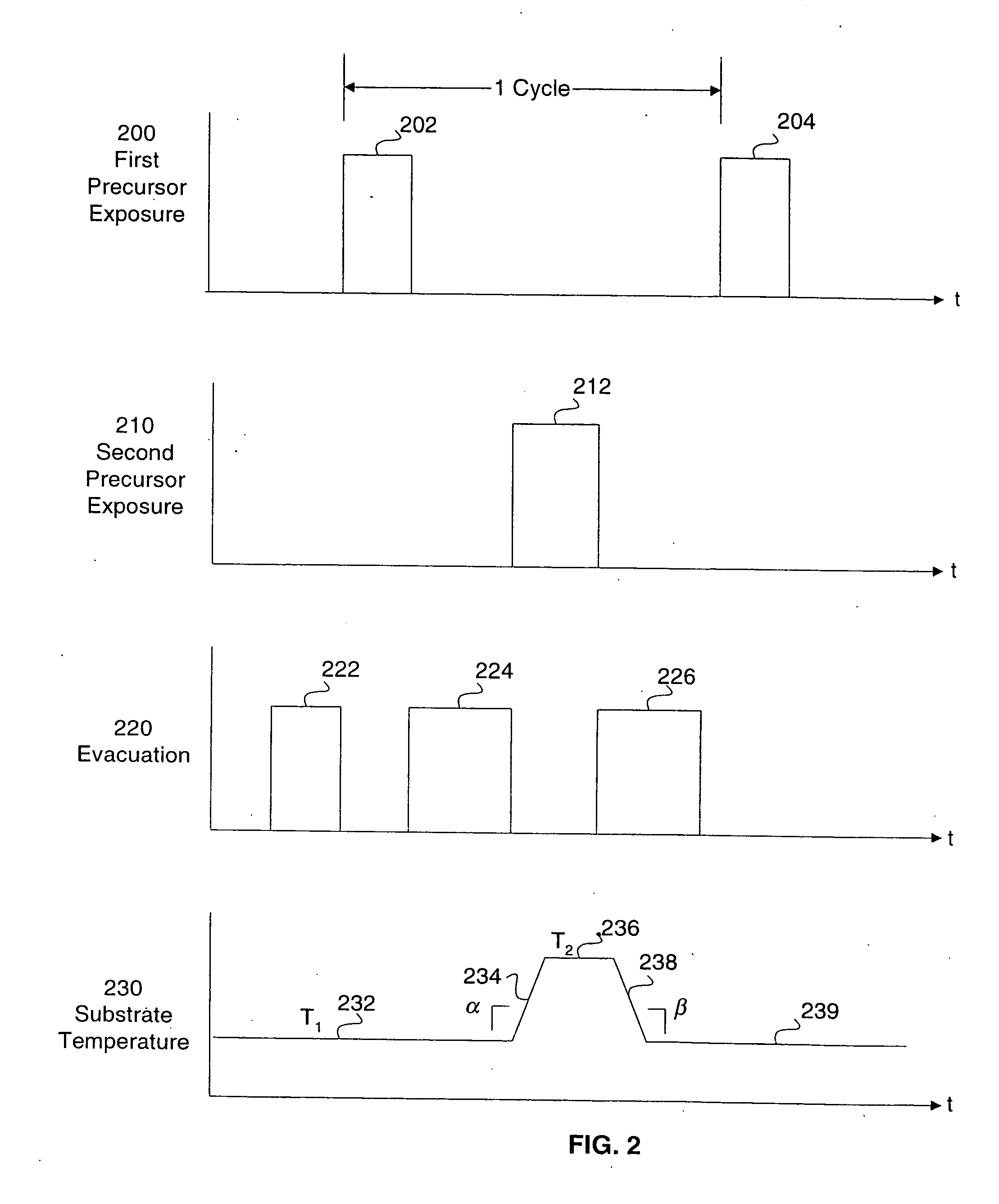

Method and apparatus for improved temperature control in atomic layer deposition

InactiveUS6878402B2Electric discharge heatingVacuum evaporation coatingTemperature controlThermal state

A system and method for that allows one part of an atomic layer deposition (ALD) process sequence to occur at a first temperature while allowing another part of the ALD process sequence to occur at a second temperature. In such a fashion, the first temperature can be chosen to be lower such that decomposition or desorption of the adsorbed first reactant does not occur, and the second temperature can be chosen to be higher such that comparably greater deposition rate and film purity can be achieved. Additionally, the invention relates to improved temperature control in ALD to switch between these two thermal states in rapid succession. It is emphasized that this abstract is provided to comply with rules requiring an abstract. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

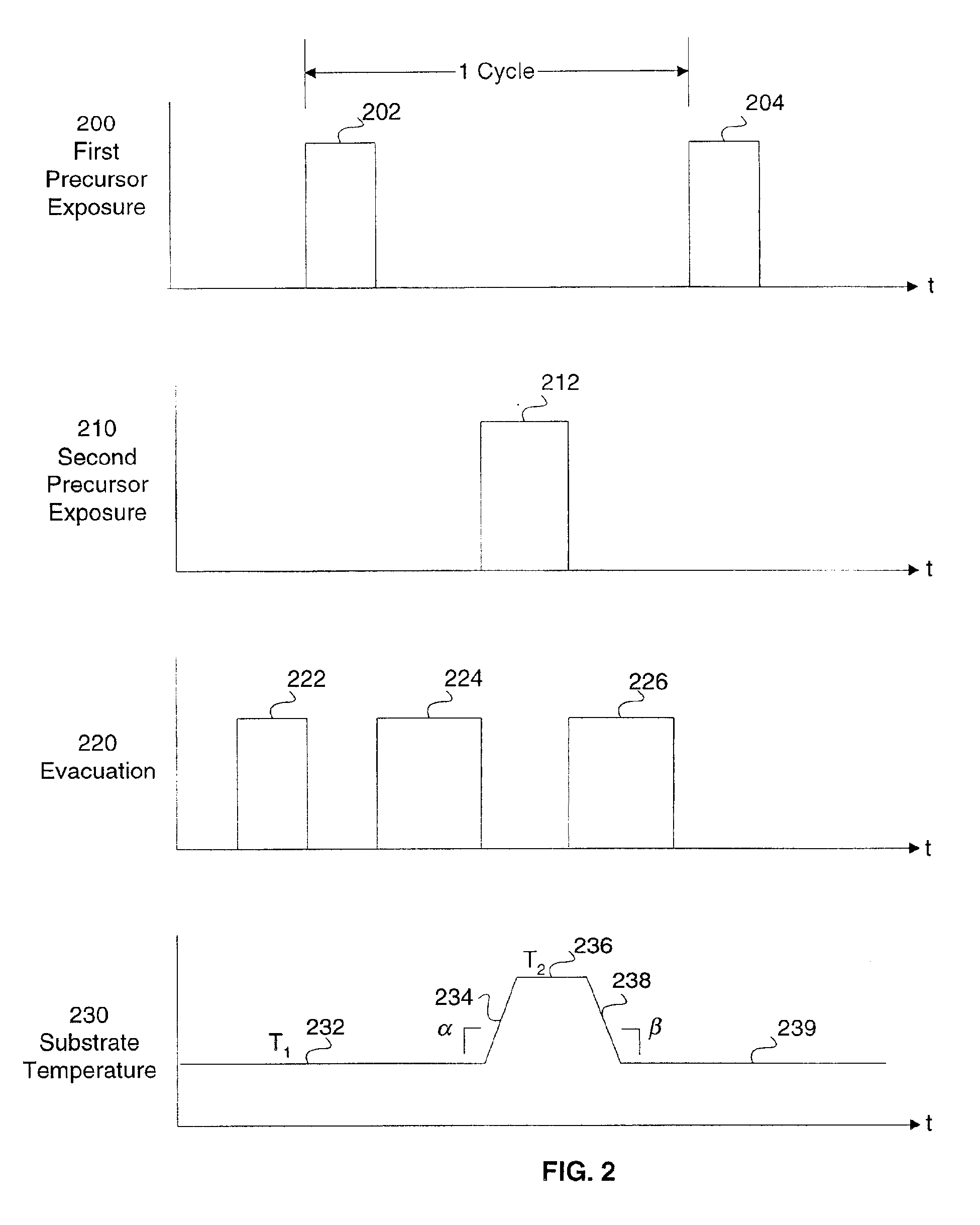

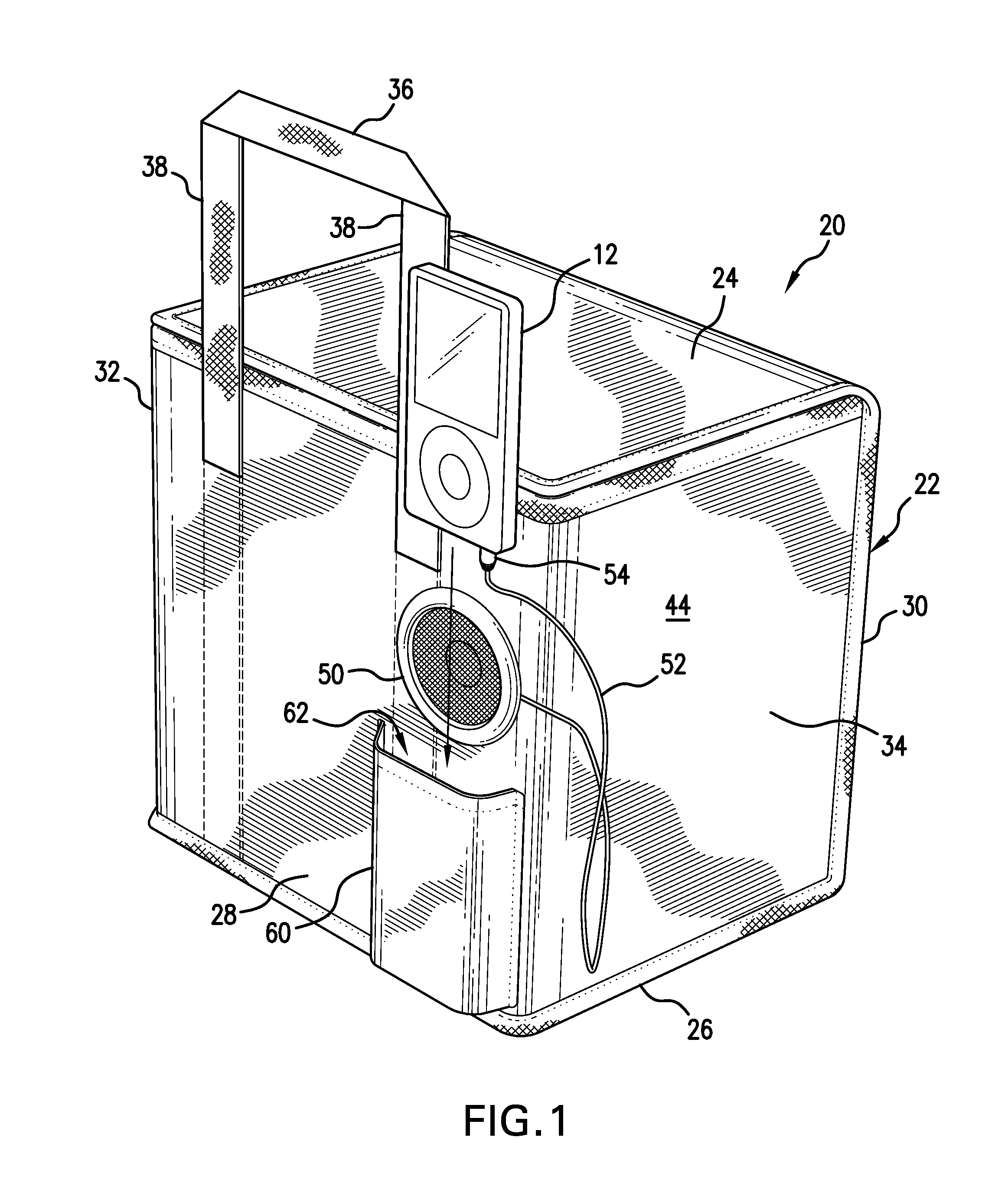

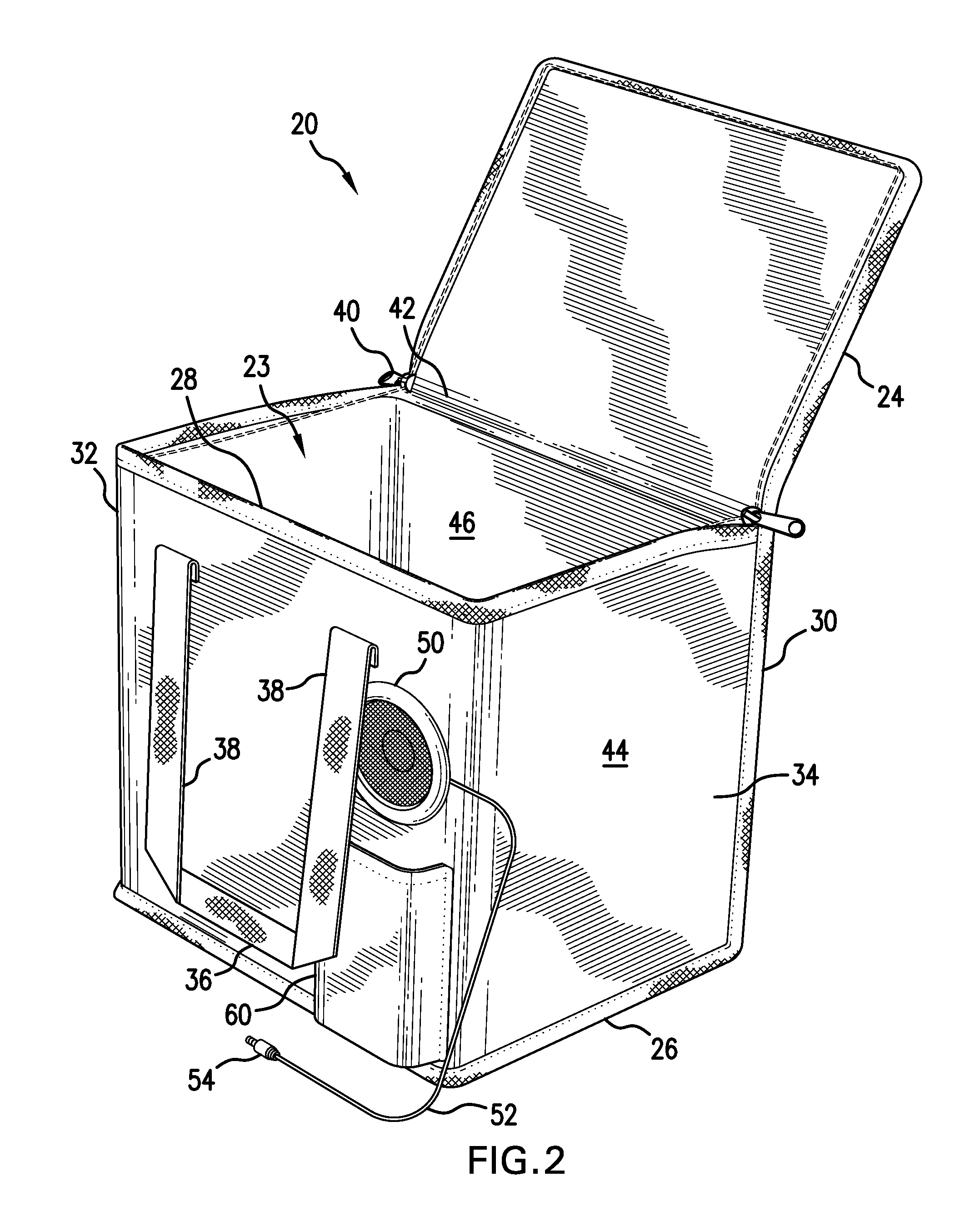

Non-woven cooler bag with speaker and mp3 hookup

A portable thermally insulated bag for maintaining contents thereof in a desired thermal state comprises an enclosure having a plurality of interconnected panels including a top, a bottom, front, back, and sides. The enclosure defines an interior volume for storing items to be kept in a desired thermal state and includes a flexible outer shell, an inner insulative layer, a zipper for at least partially separating one of the panels from the enclosure, and a handle. The bag also has a speaker for communicative connection to a personal playback device and a pocket external to one of the panels and proximate to the speaker. The pocket is sized to receive a personal playback device therein.

Owner:CONSUMER MOTIVATION GROUP

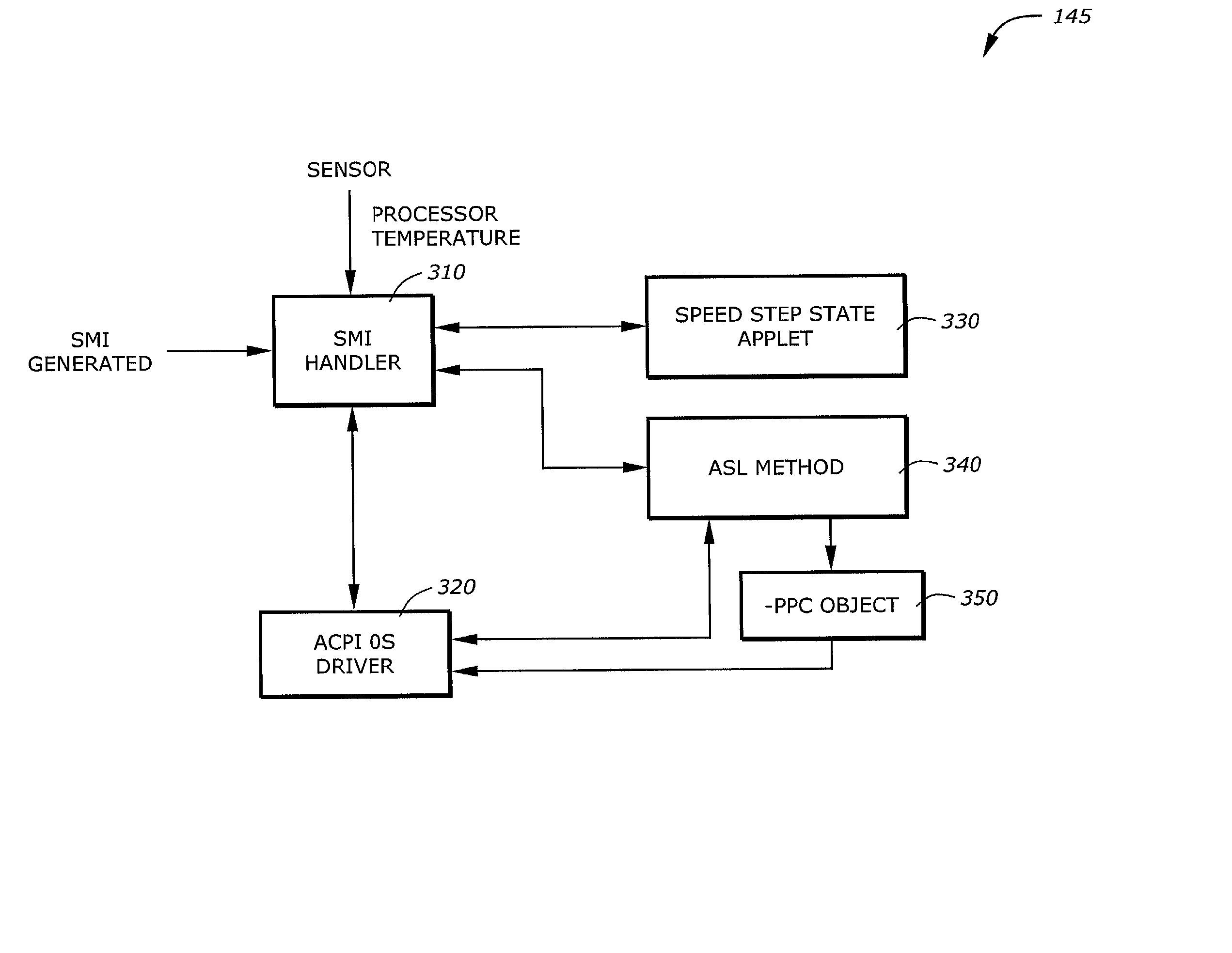

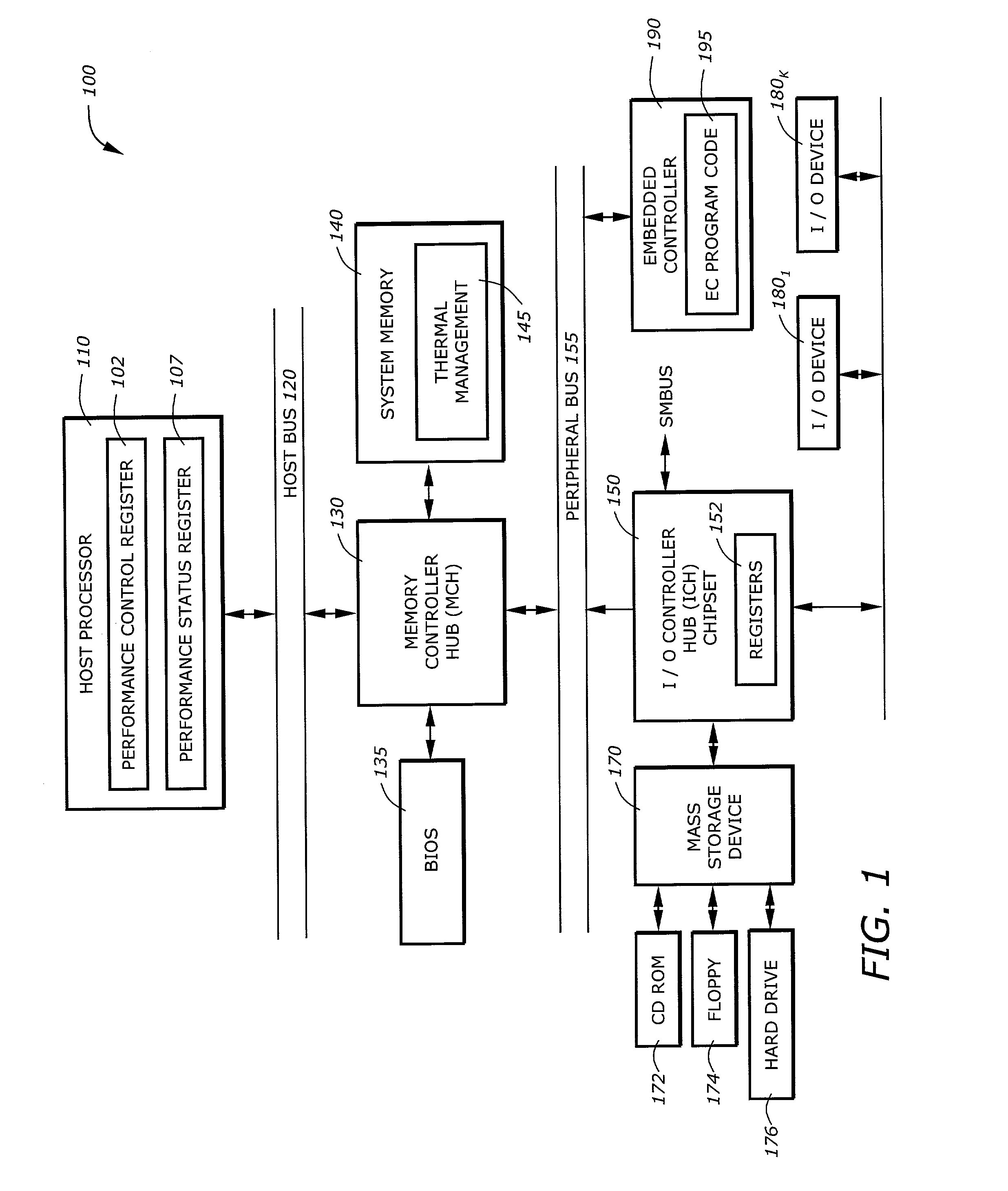

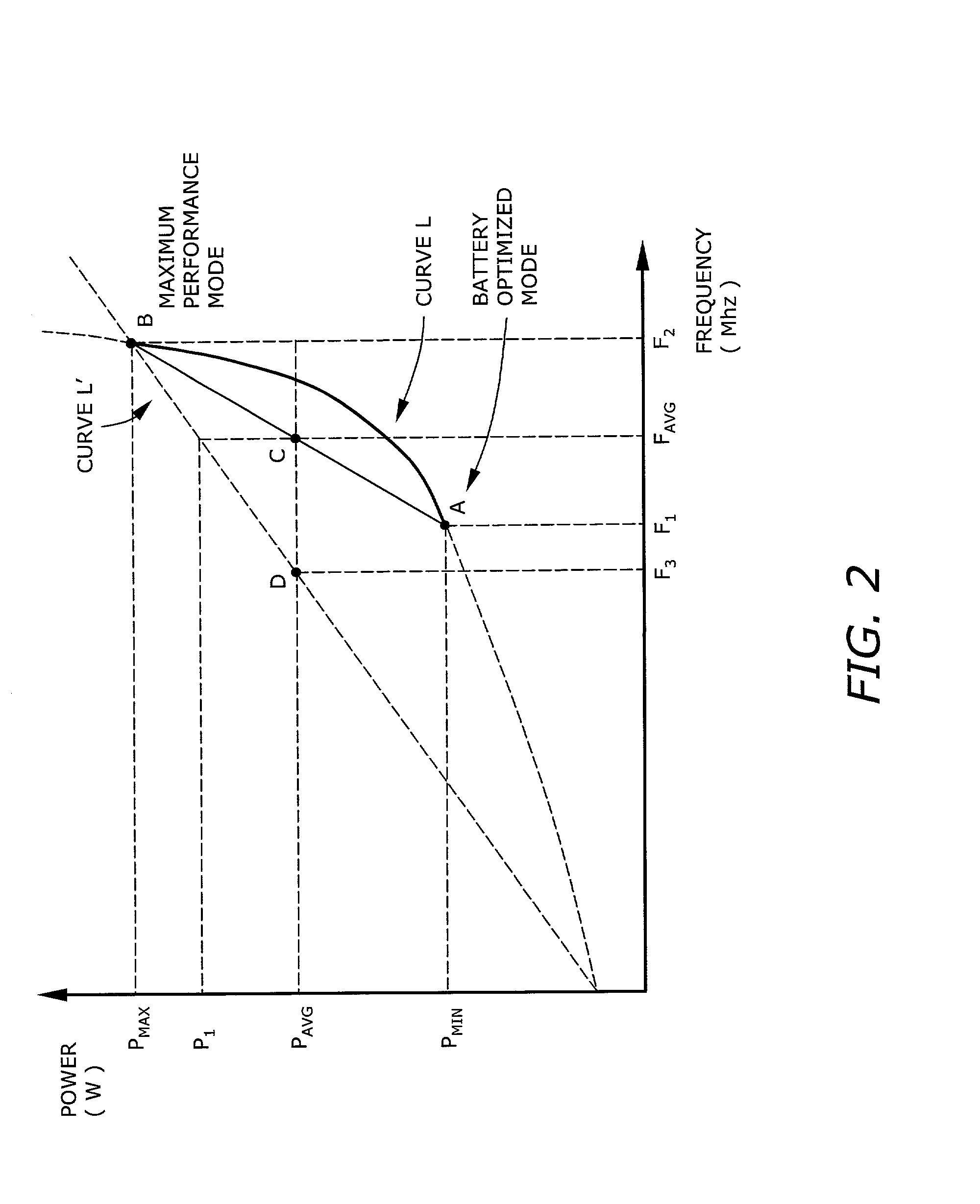

Universal thermal management by interacting with speed step technology applet and operating system having native performance control

InactiveUS20030117759A1Energy efficient ICTVolume/mass flow measurementThermal stateOperational system

In one embodiment of the invention, a system management interrupt (SMI) handler is invoked in response to an SMI. The SMI handler determines a thermal state of a processor. The SMI handler interacts with one of a speed step technology applet and a thermal driver in a thermal management operating system to transition the processor to one of a low power state and a high power state based on the thermal state according to a native performance control status.

Owner:INTEL CORP

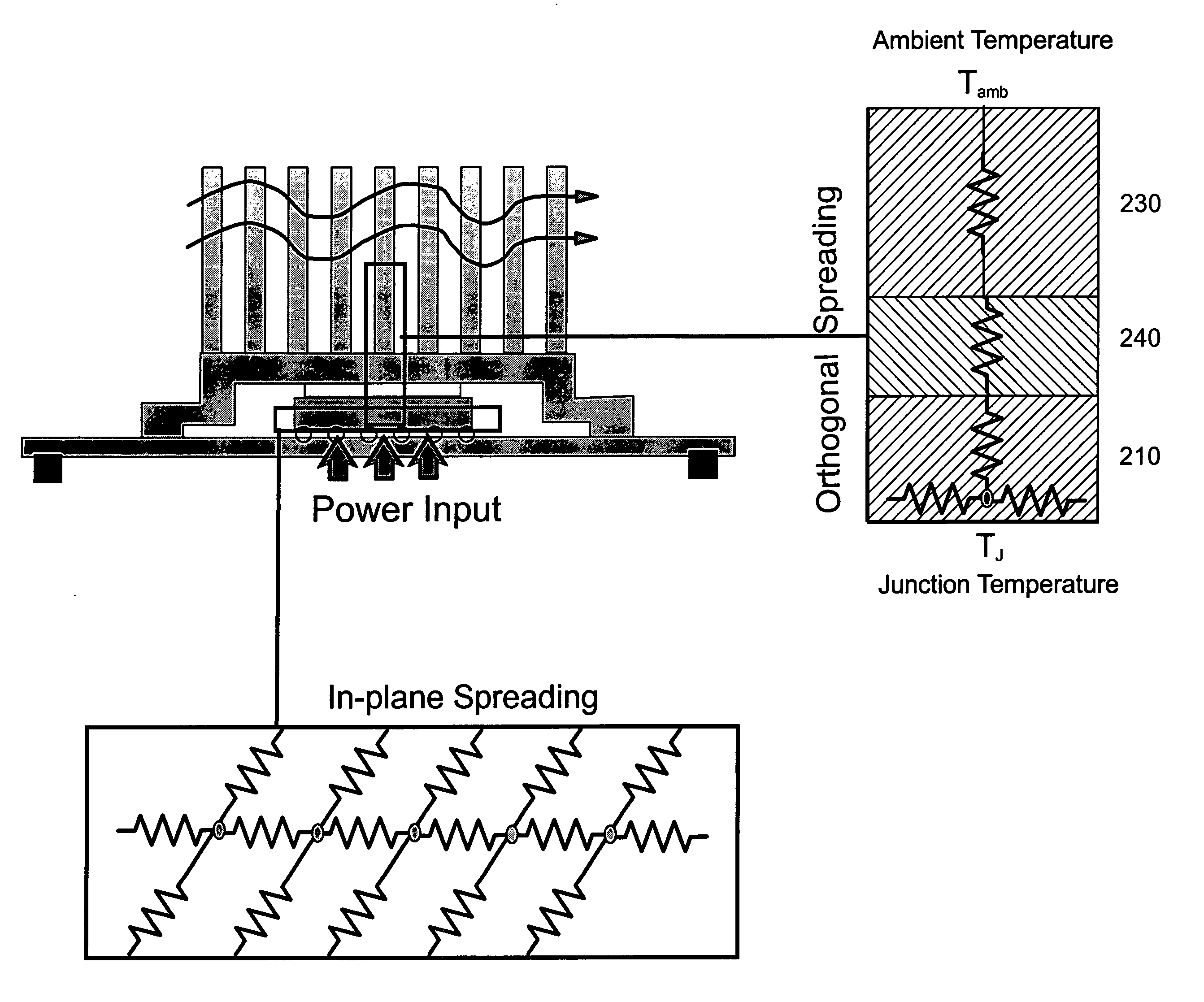

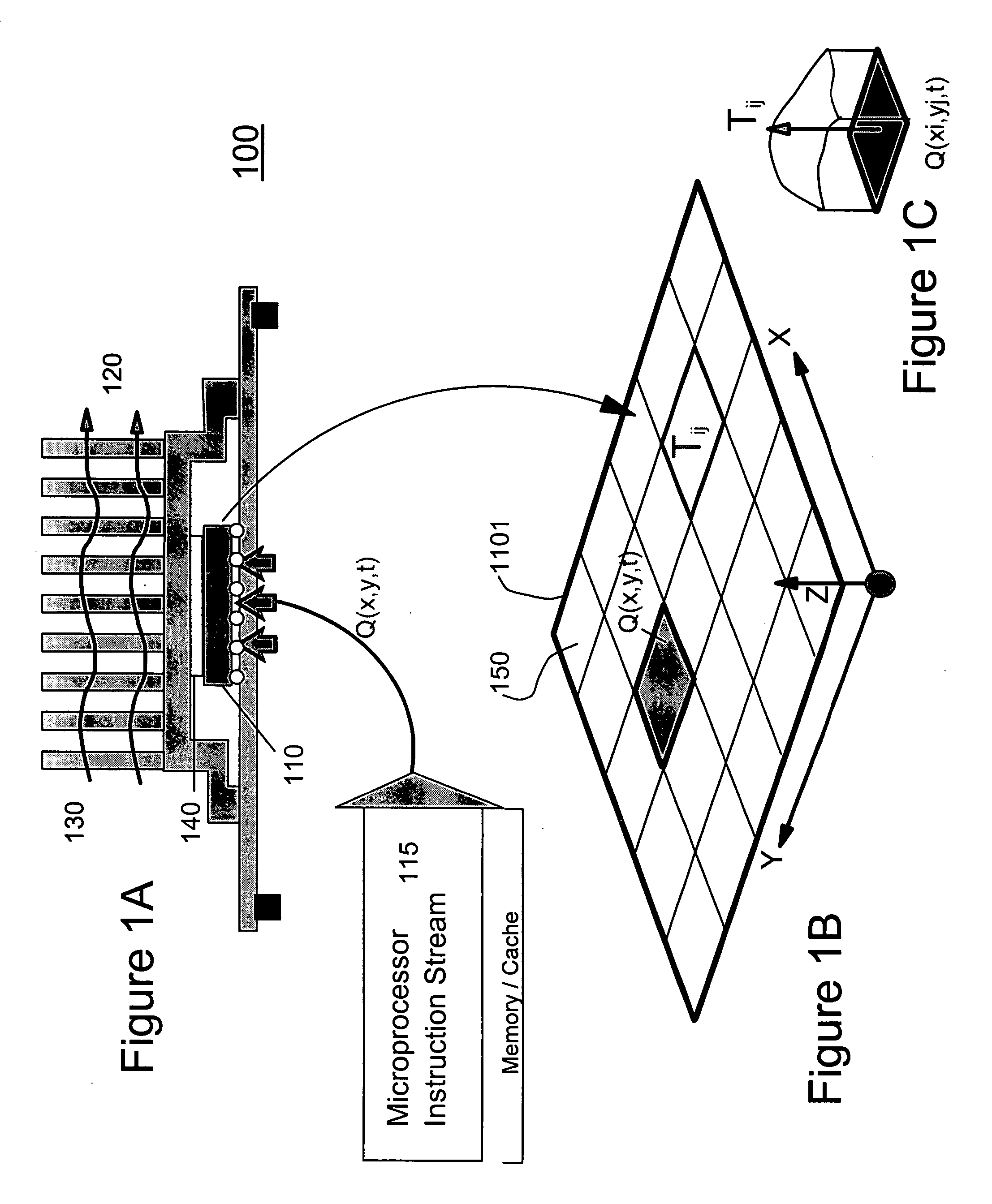

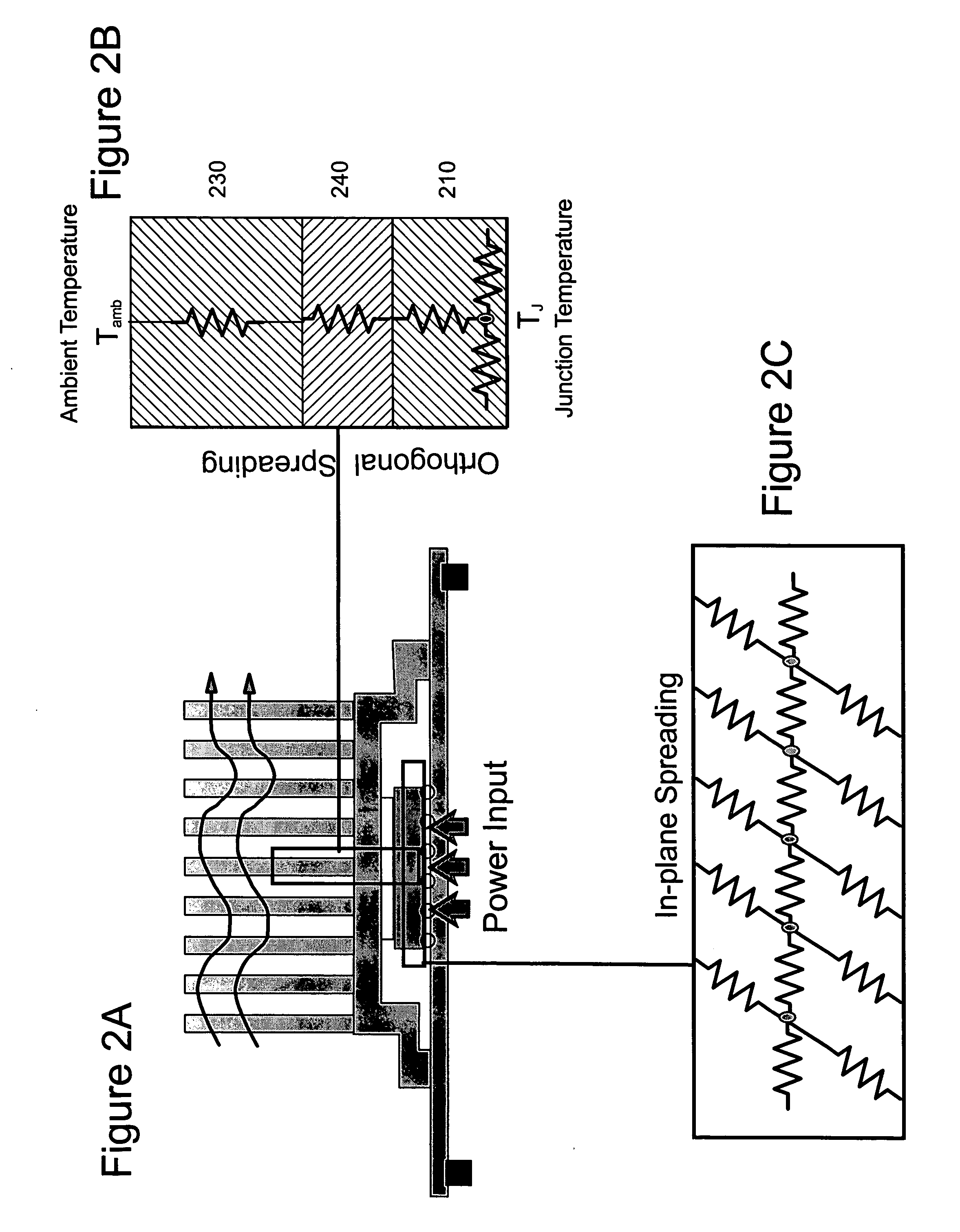

Method and system for real-time estimation and prediction of the thermal state of a microprocessor unit

ActiveUS20060013281A1Easy to calculateSimple methodDigital data processing detailsThermometers using electric/magnetic elementsThermal stateEngineering

A method (and system) of predicting a thermal state of a transient thermal system, includes combining sensor outputs and thermal parameters to construct a consistent set of estimates of internal temperature of a transient thermal system.

Owner:GLOBALFOUNDRIES US INC

Separate oil gallery for piston cooling with electronic oil flow control

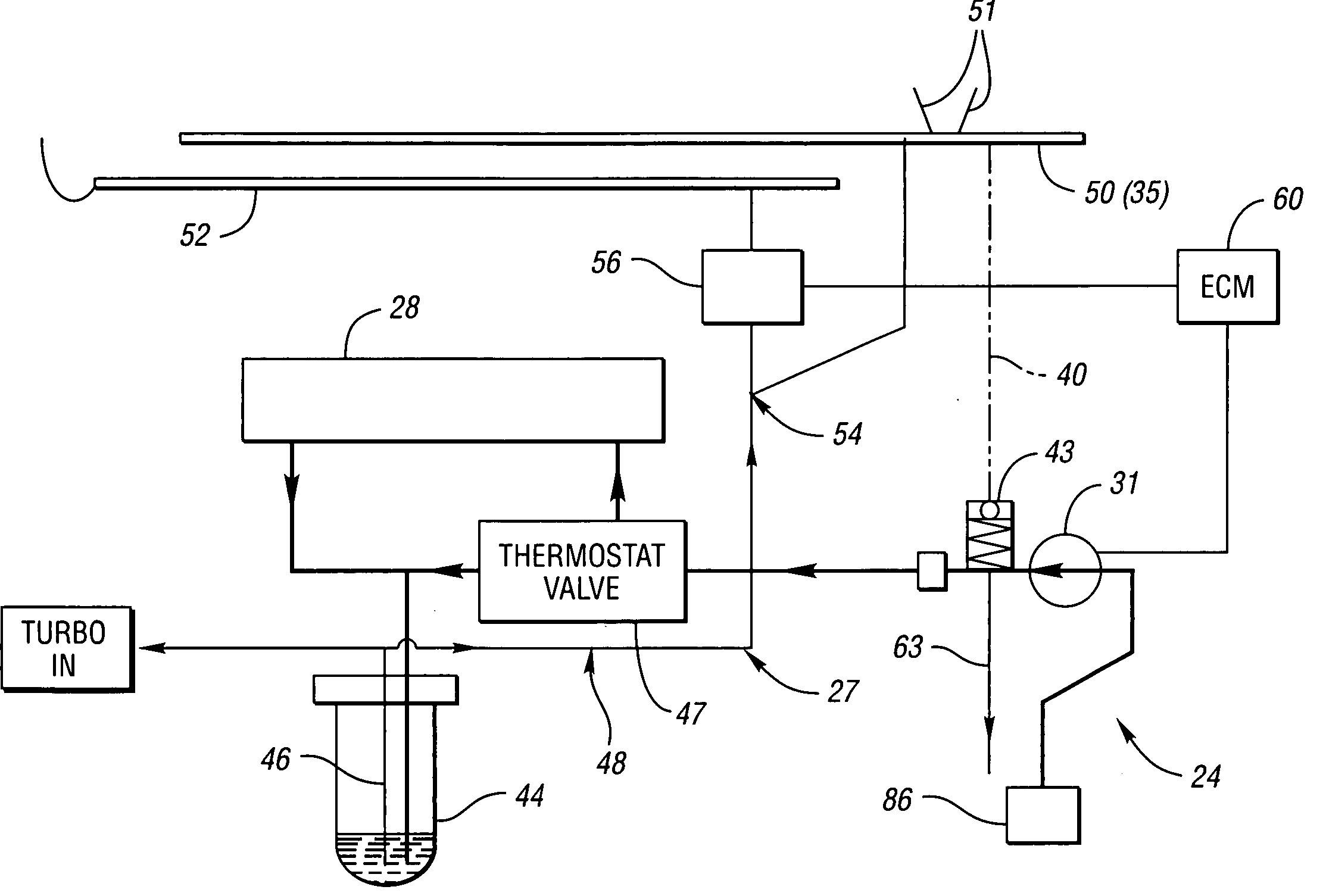

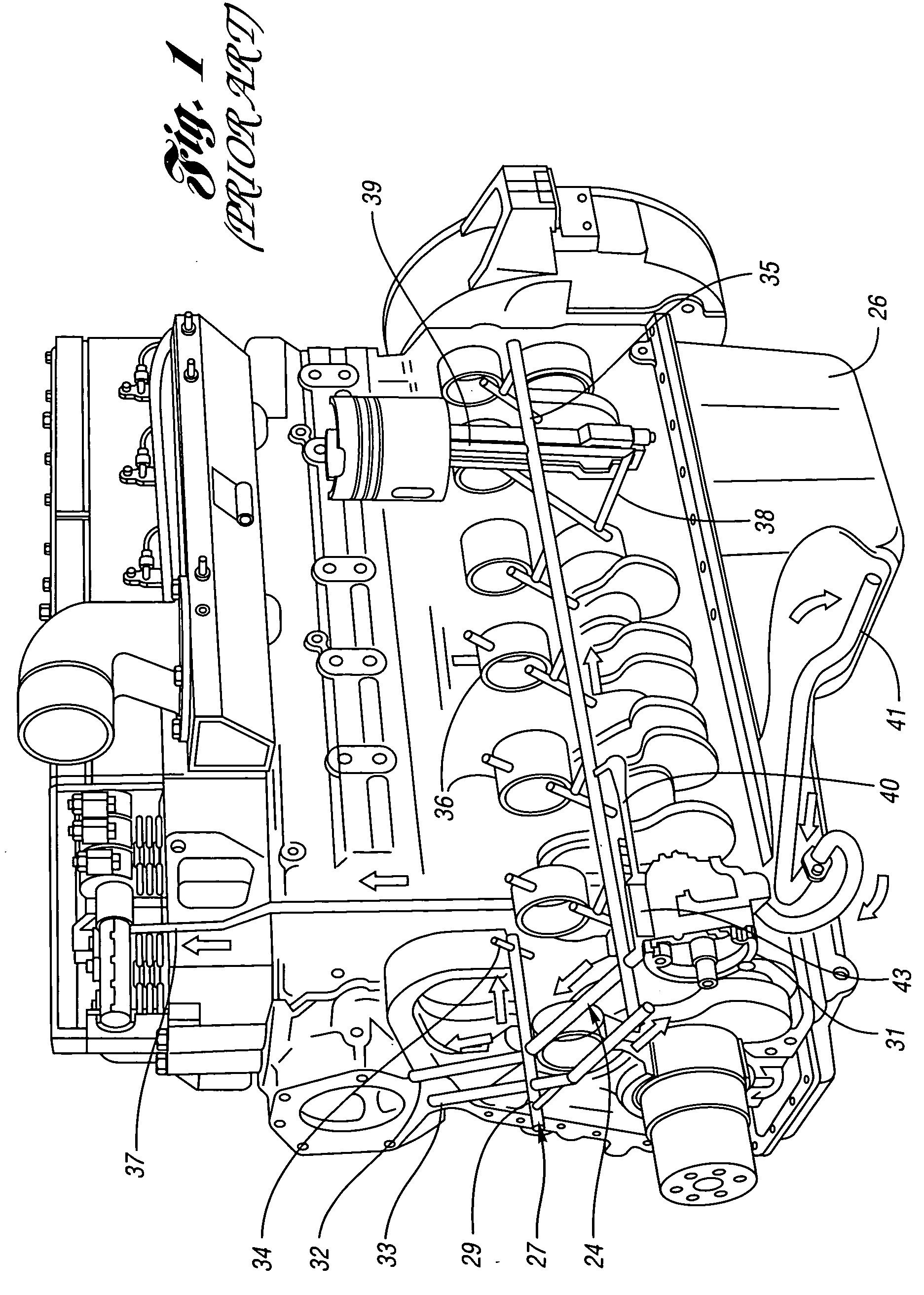

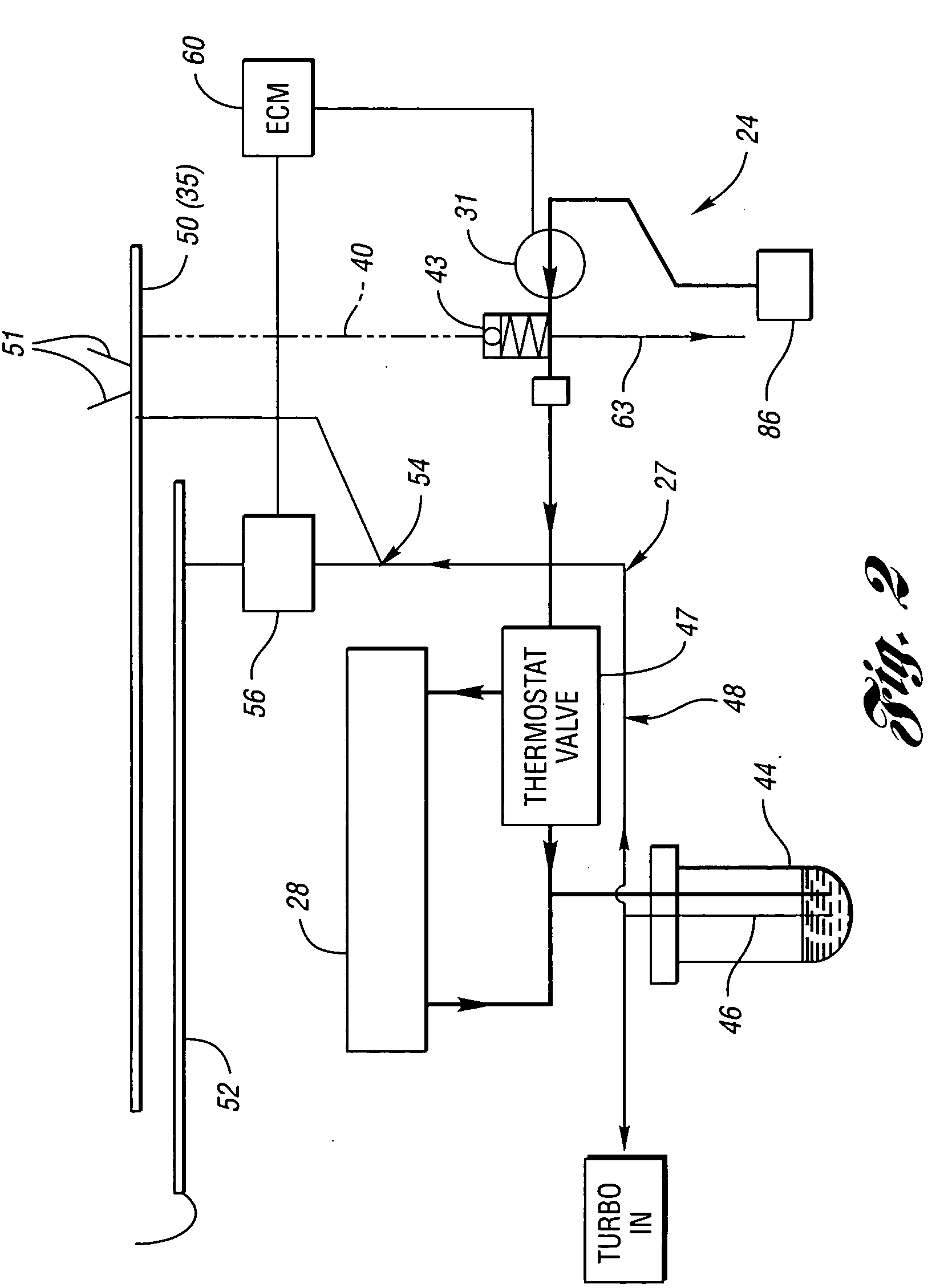

InactiveUS20050120982A1Reduce oil flowSaving in parasitic lossLiquid coolingCoolant flow controlThermal stateOil distribution

An engine oil distribution system for an internal combustion engine includes a main gallery and a separate oil gallery for piston cooling nozzles. The separate gallery may be controlled by a control valve that regulates the oil flow. The oil flow to the separate gallery may be controlled by an electronic control module in accordance with the piston cooling needs, for example, varied as a function of the load applied to the engine, or as a function of engine temperature. Preferably, engine temperature is sensed by coolant fluid temperature, or directly measured metal temperature, correlated to the thermal state of the piston.

Owner:DETROIT DIESEL CORP

Temperature control device and method

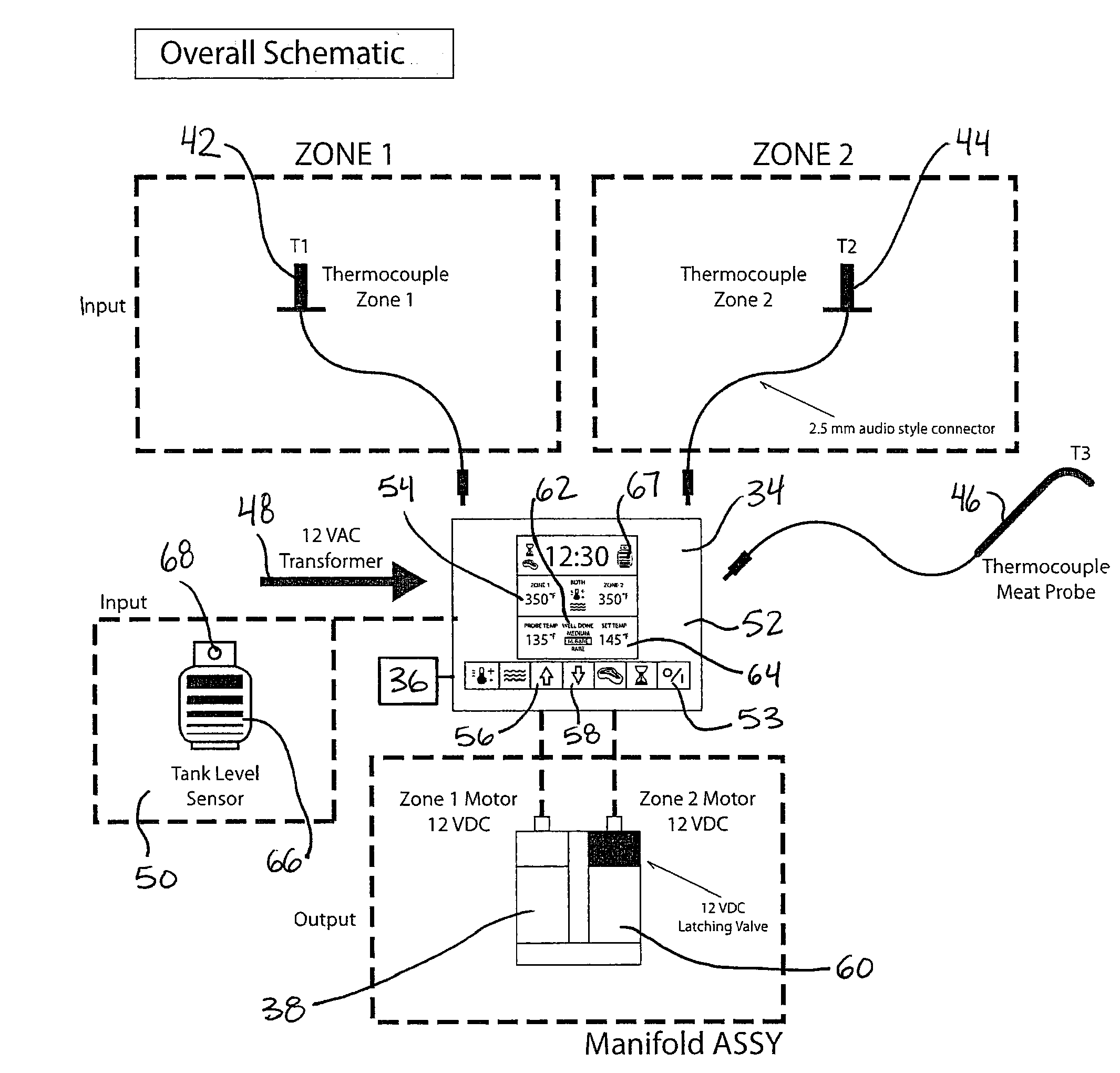

ActiveUS20090183729A1Control flowFuel supply regulationBoiling over preventionElectronic controllerThermal state

A temperature control system for safely controlling the rate of flow of a flammable fluid at generally constant pressure is disclosed. The system may include a flow control apparatus that is free of a regulator mechanism, for affecting the flow of the fluid. The flow control apparatus may be operable between at least a first flow rate and a second flow rate, and may have at least one upstream opening and at least one downstream opening. The system may also include a first burner in fluid communication with the downstream opening of the flow control apparatus and a conduit in fluid communication at one end thereof with the upstream opening of the flow control apparatus, and configured at the other end thereof for connection to a fuel supply. A thermocouple may be located in the vicinity of the burner or an appliance used in conjunction with the burner. The thermocouple converts a sensed thermal state into an electrical signal. An electronic controller, in communication with the flow control apparatus, for activating the flow control apparatus to one of said first and second flow rates, and being in communication with the thermocouple for receiving the electrical signal from the thermocouple is also provided. An interface connected to the controller for manually inputting a desired temperature may be included, wherein the controller is operable to automatically cycle the flow control apparatus between the first and second flow rates until the temperature sensed by the thermocouple is similar to the desired temperature.

Owner:WOLFEDALE ENG

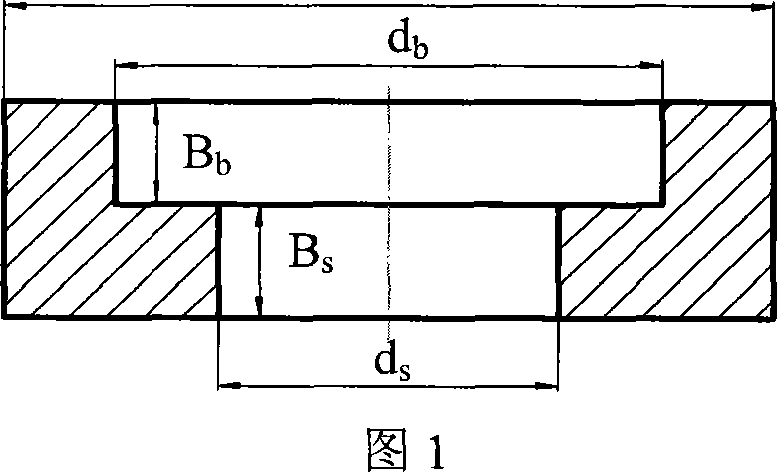

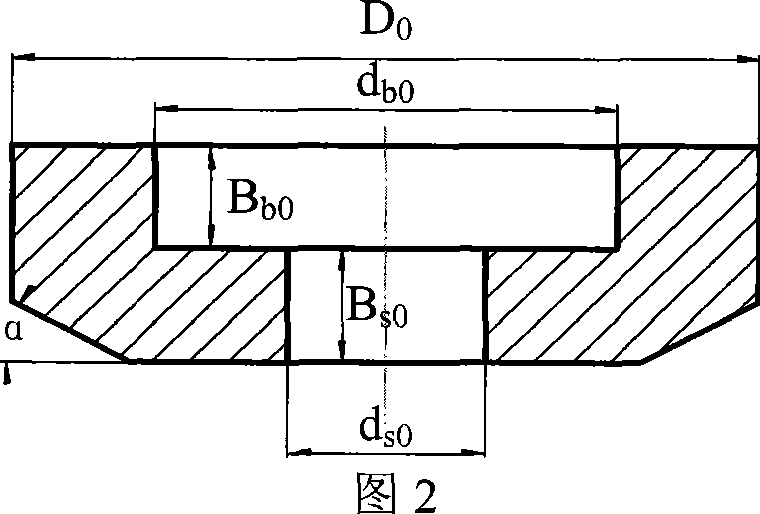

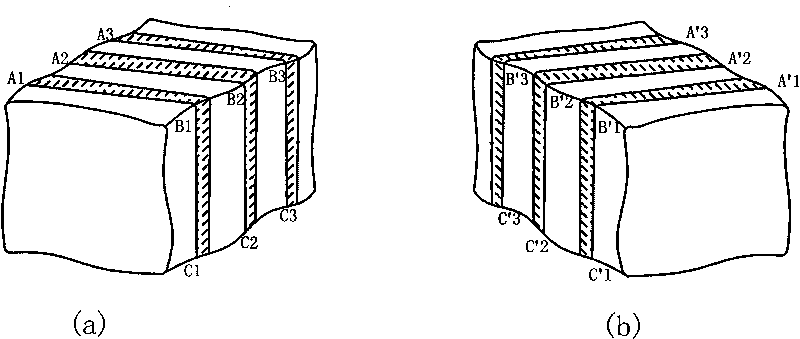

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

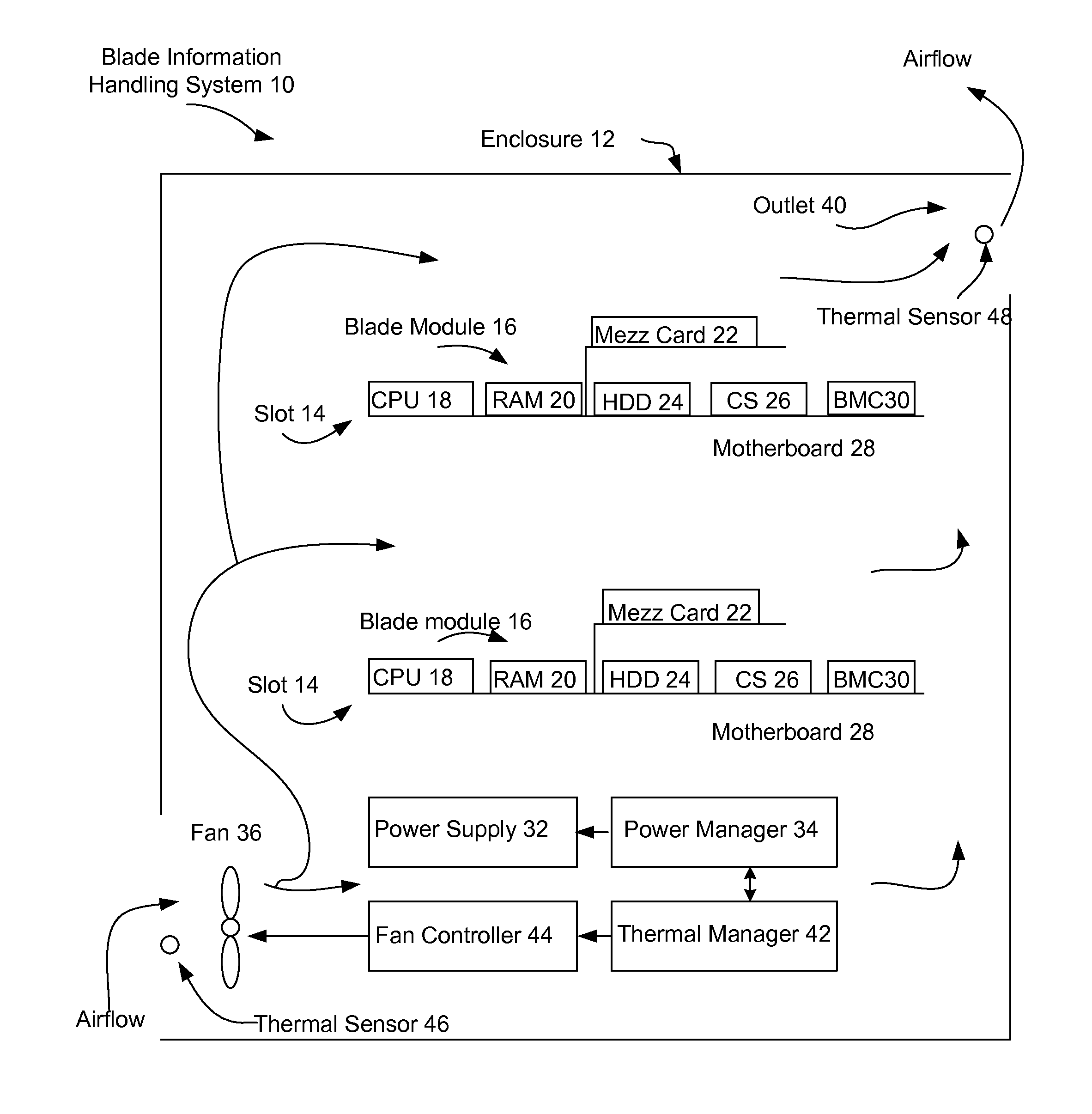

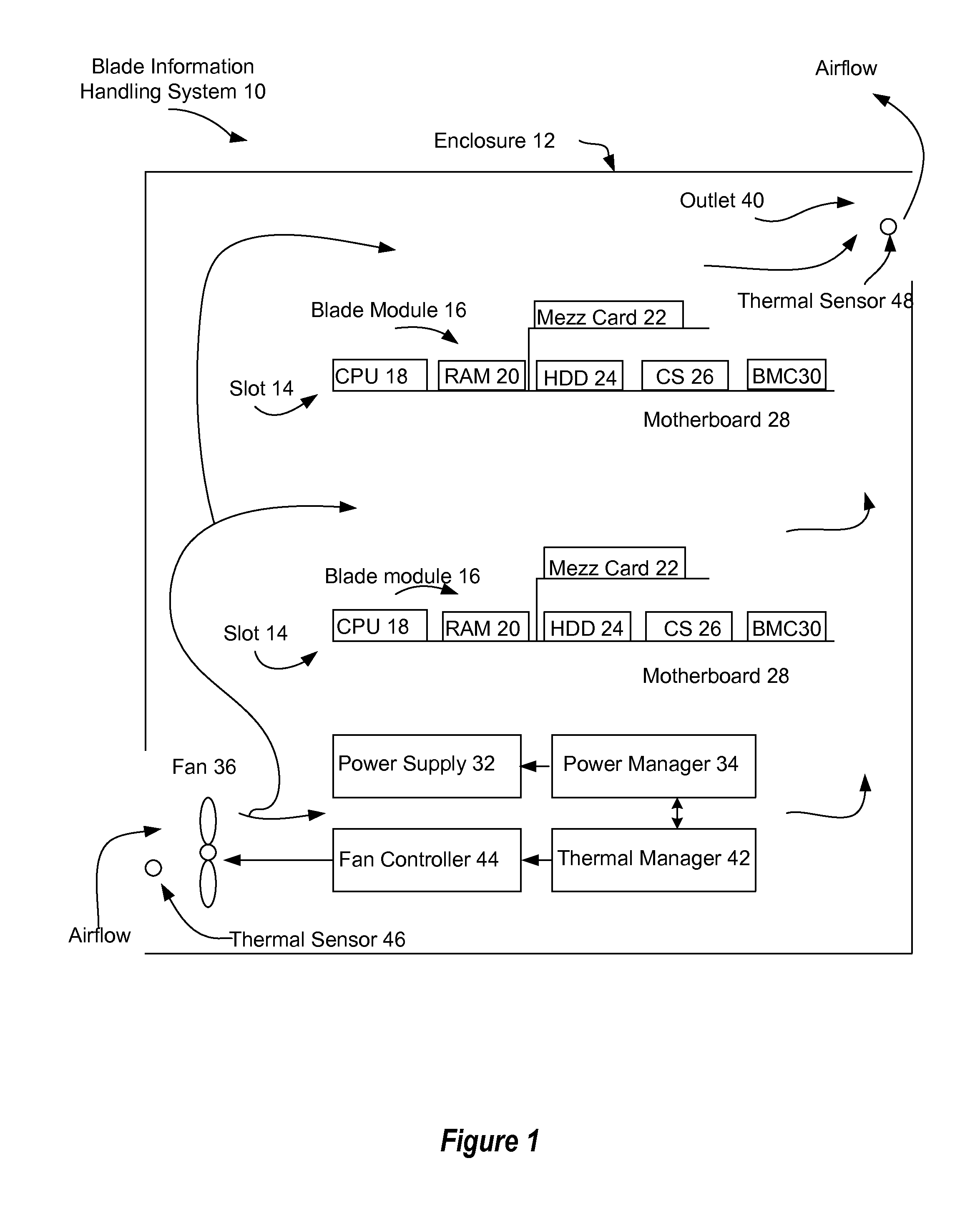

Information Handling System Thermal Control By Energy Conservation

ActiveUS20130258582A1Reduce disadvantagesReduce problemsEnergy efficient ICTTemperature control using plurality of sensorsThermal energyThermal state

A thermal state within an information handling system enclosure is managed within predetermined constraints by estimating thermal energy introduced to the enclosure by power dissipation to electronic components and thermal energy removed from the enclosure by a cooling airflow generated by a fan. A desired bulk temperature of a cooling airflow is attained at a predetermined position in an enclosure by selecting a fan speed and power allocation to the components that conserves energy within the enclosure at a predetermined thermal state.

Owner:DELL PROD LP

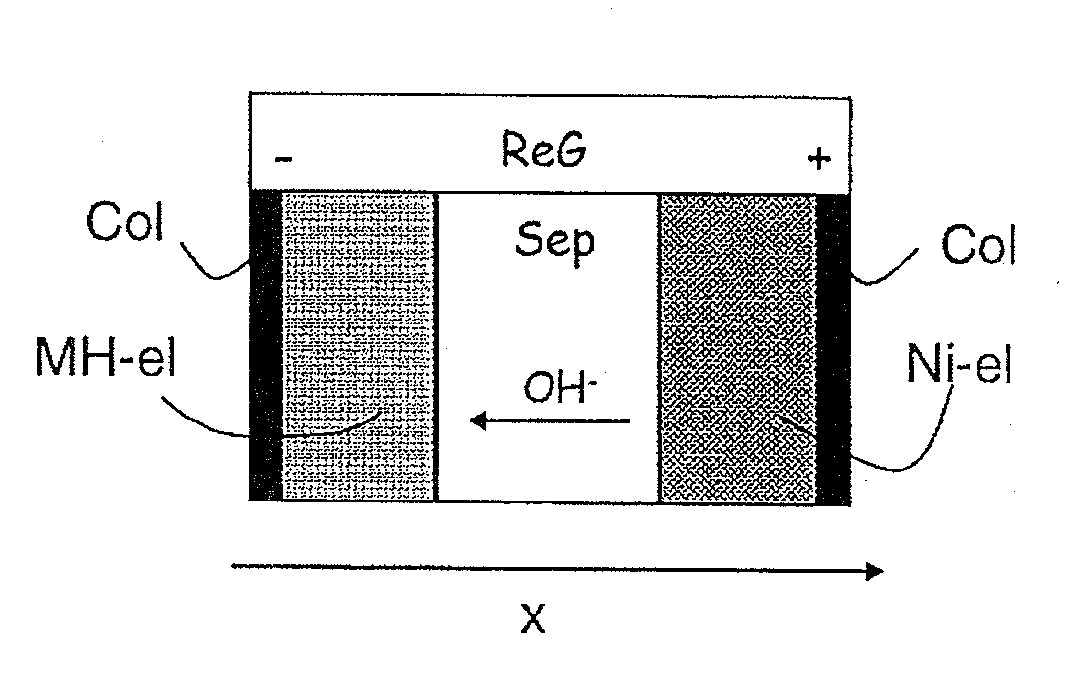

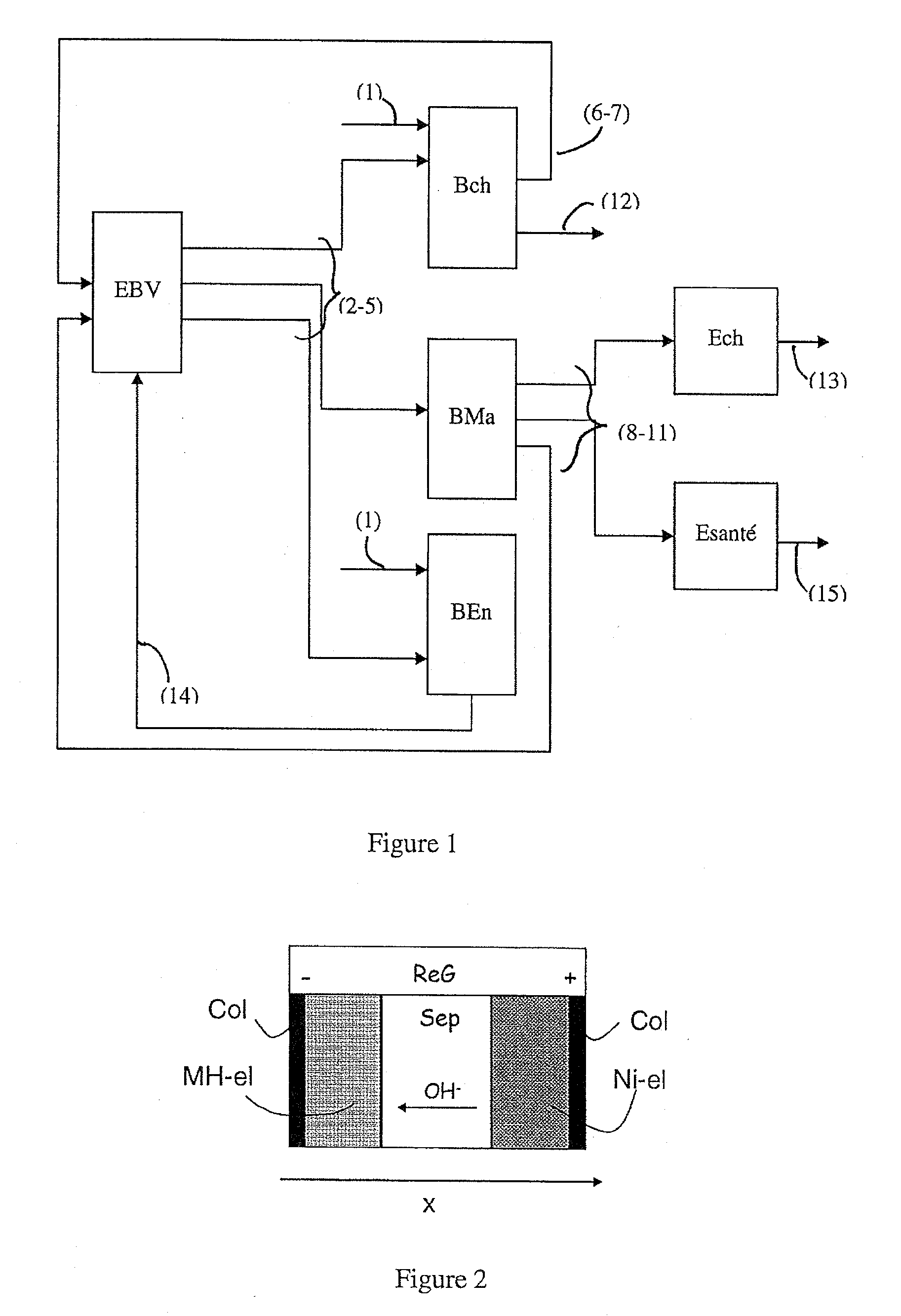

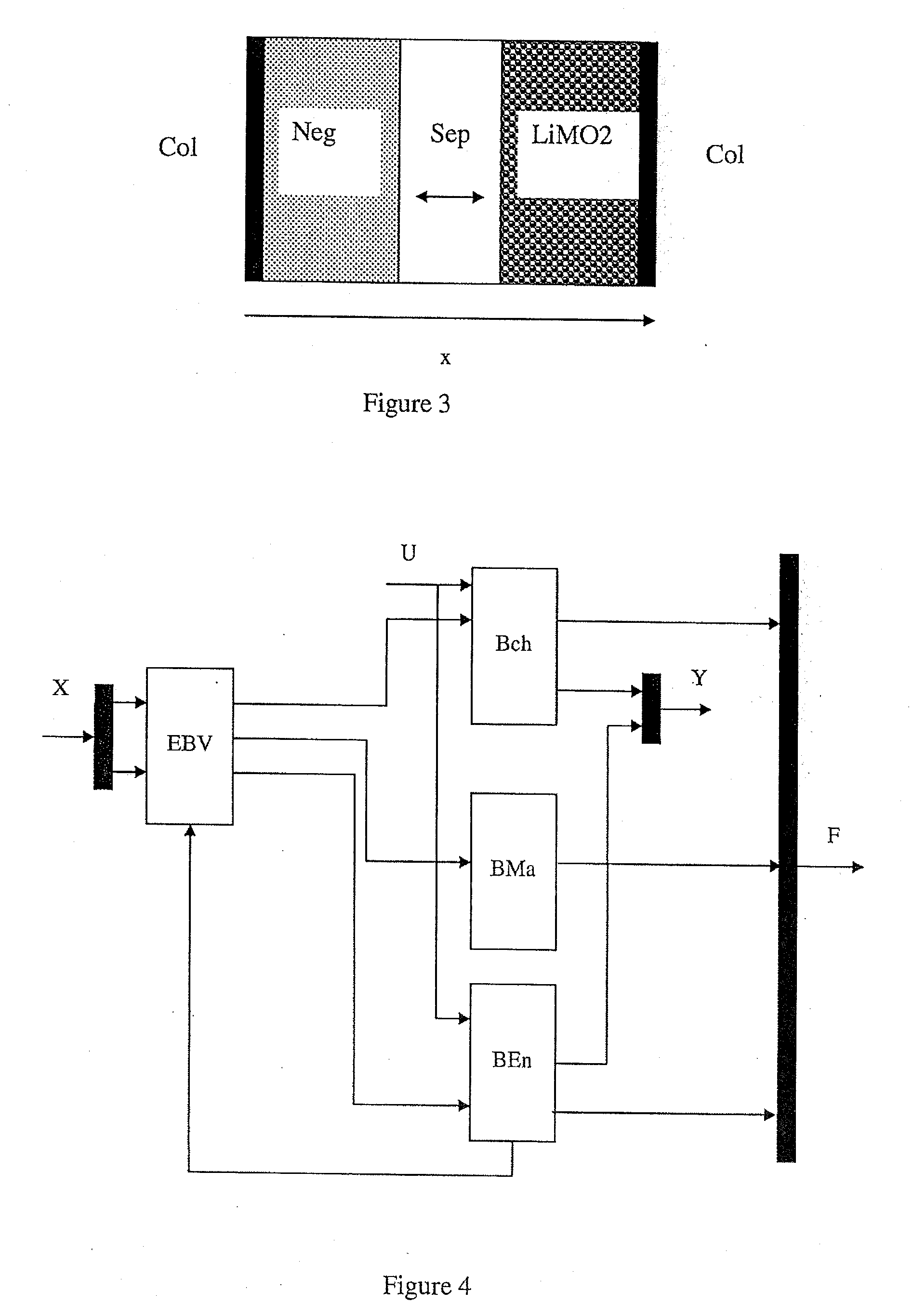

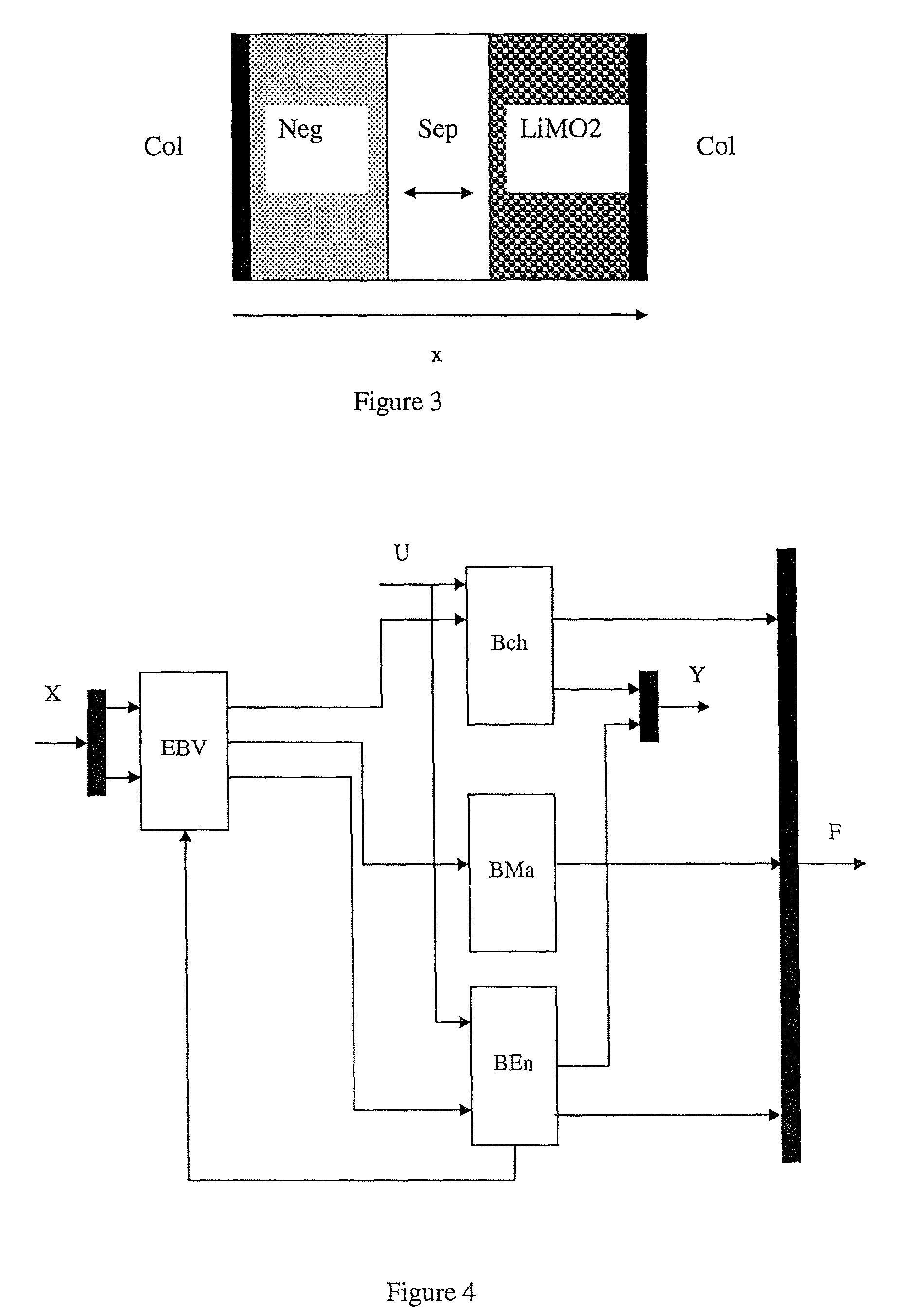

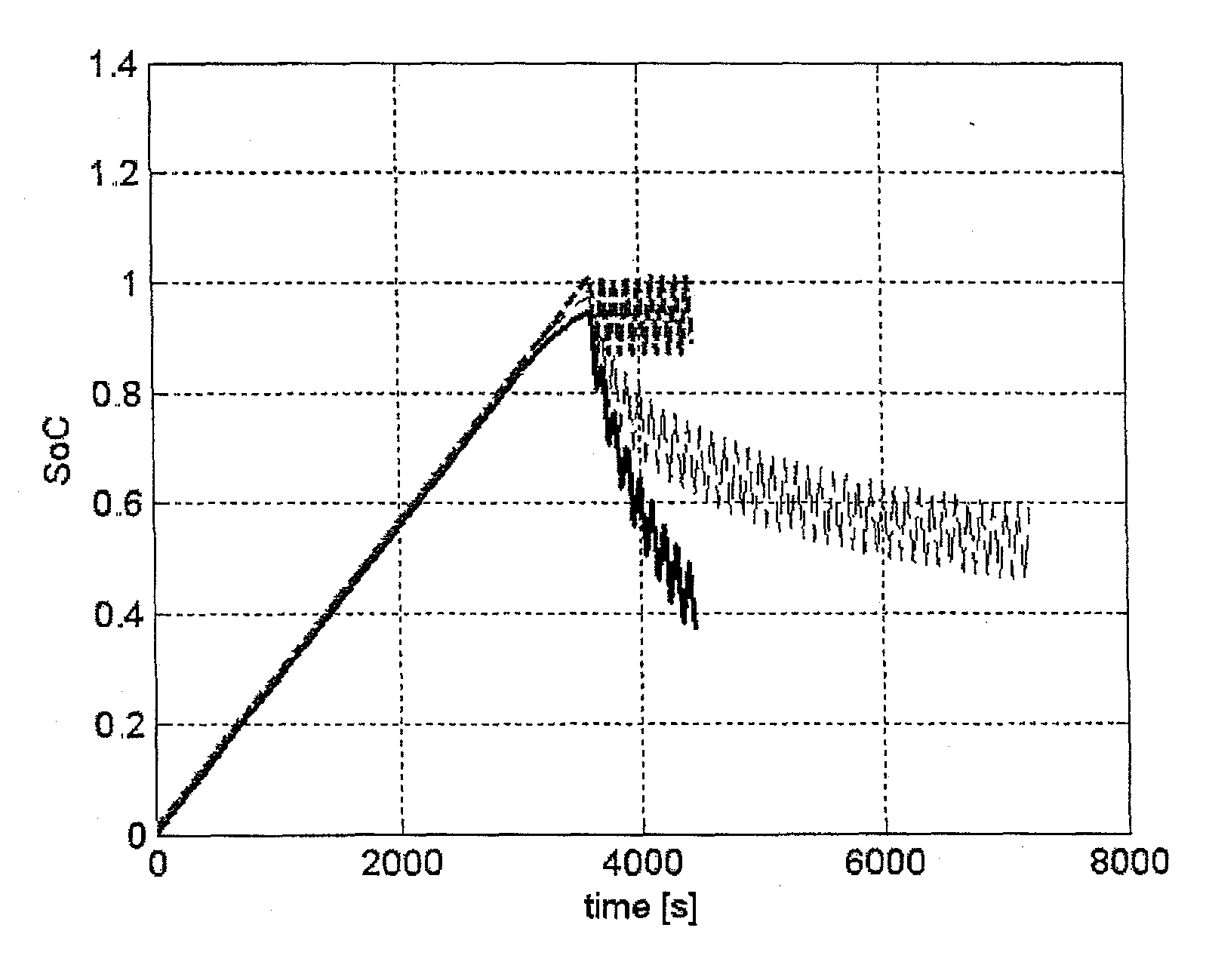

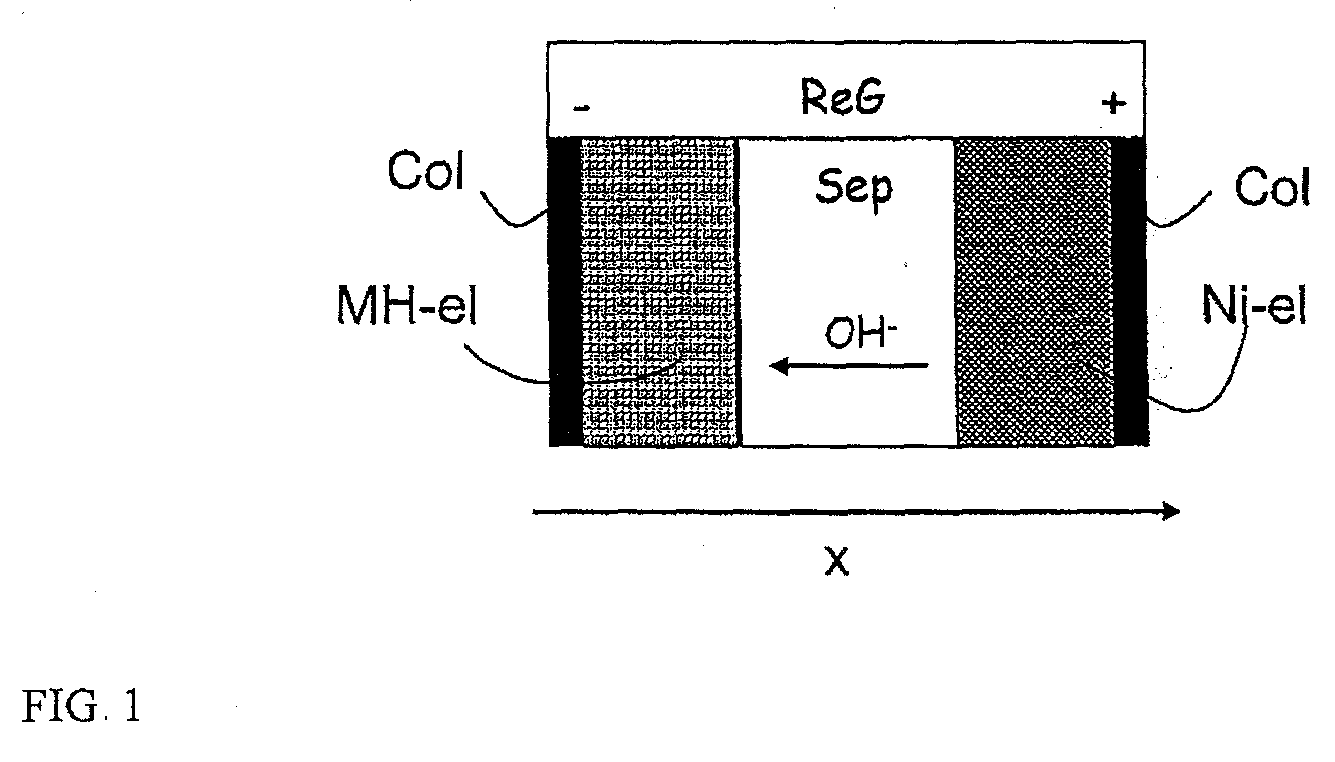

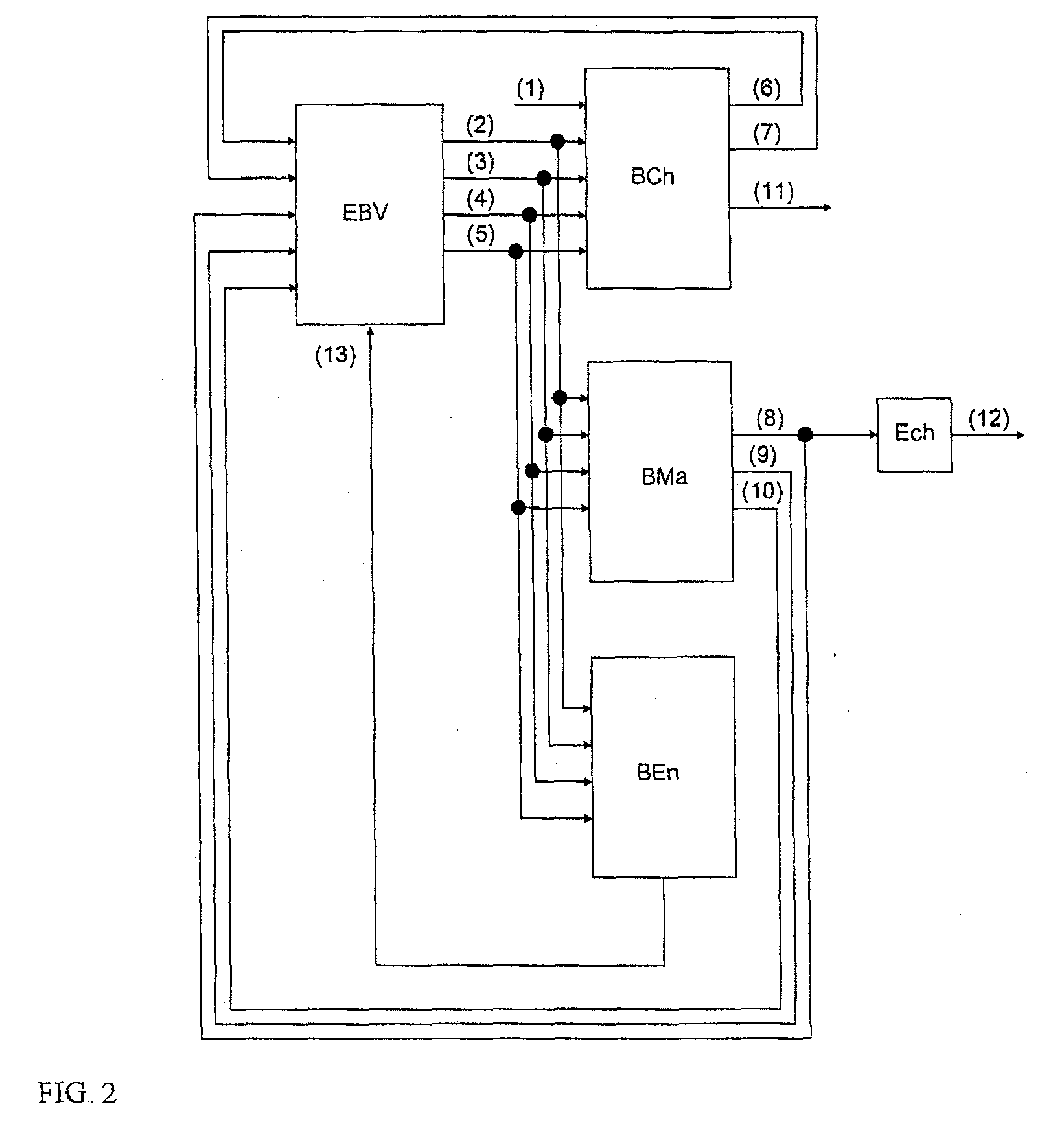

Method of estimating the non-measurable characteristics of an electrochemical system

InactiveUS20110054816A1Resistance/reactance/impedenceCurrent/voltage measurementThermal stateState of health

The present invention relates to a method of estimating the internal state of an electrochemical system by a zero-dimensional (0D) electrochemical mathematical model for estimating the characteristics of a battery that are not directly measurable during operation thereof. For applications relating to hybrid and electric vehicles, the most significant internal characteristics are the state of charge (SoC), the state of health (SoH) and the thermal state (T). Reconstruction of the internal characteristics is achieved using a mathematical model of the battery. The method can be used with the operation of the battery itself (real time) with a concentrated-parameter (0D) or off-line mathematical model, for calibration, an optimization or a validation of management and estimation strategies. The method allows simulation of the thermal and electrical behavior of a battery. The method according to the invention can also be useful for battery dimensioning and for optimization of the energy and thermal management strategies as a function of the desired application.

Owner:INST FR DU PETROLE

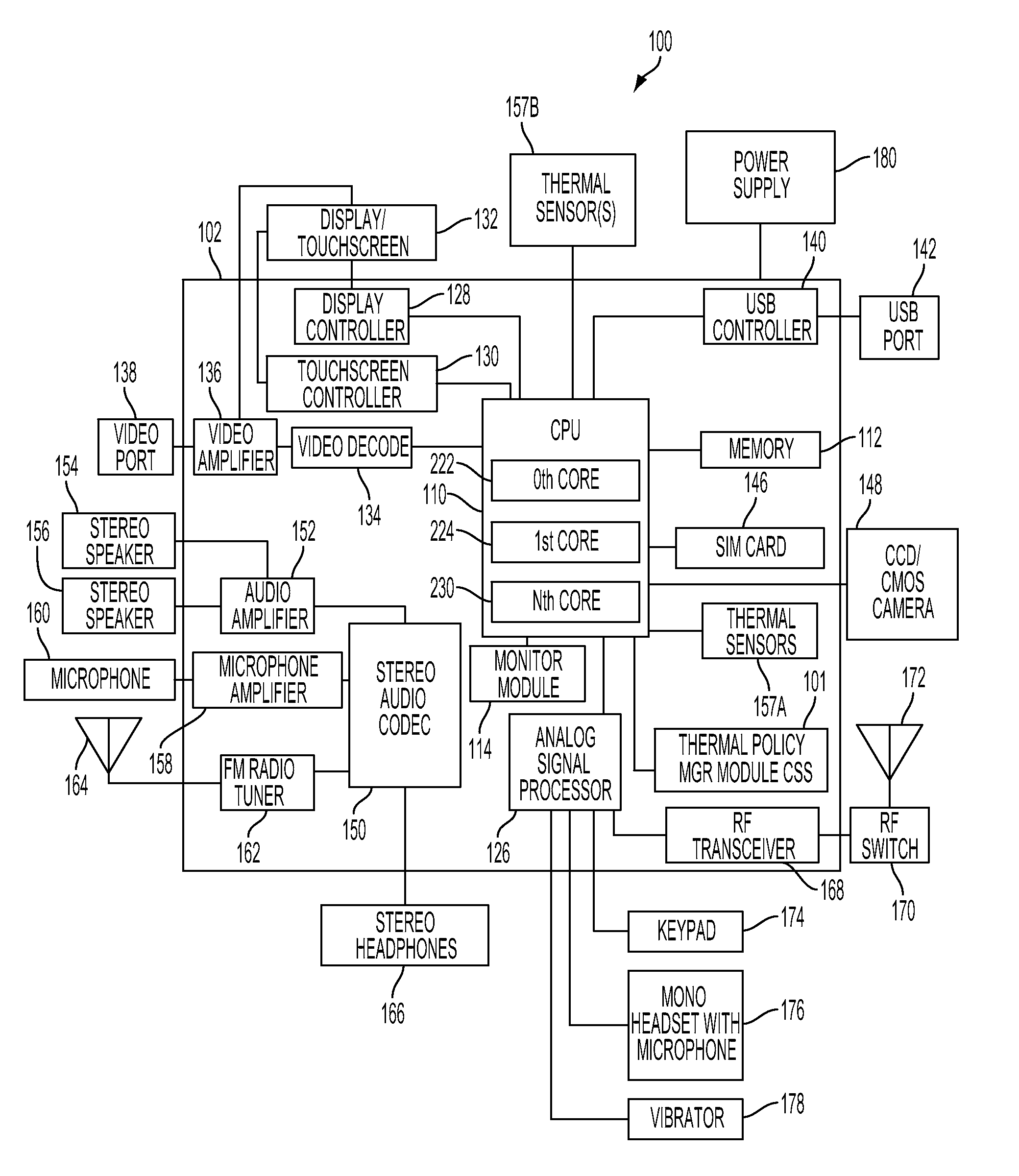

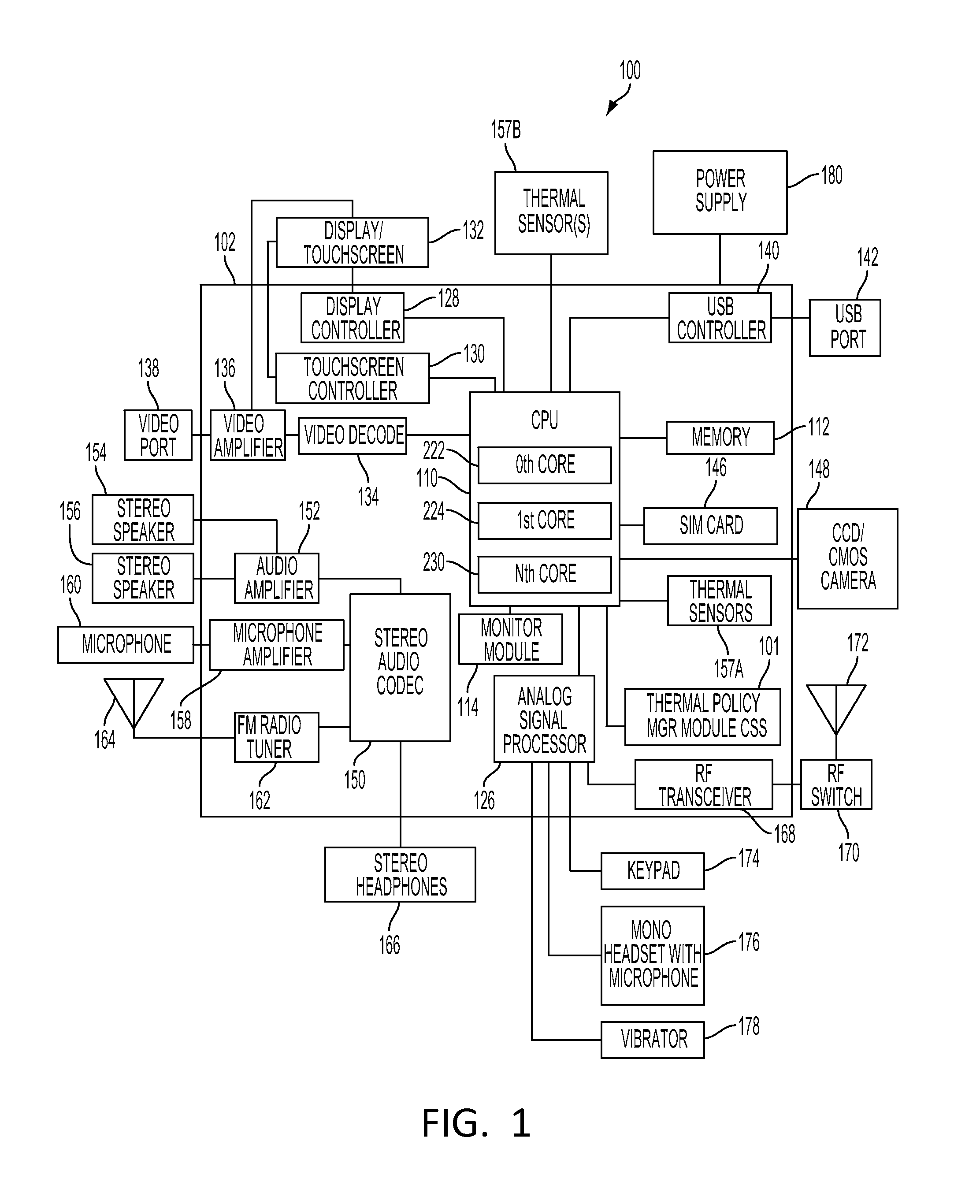

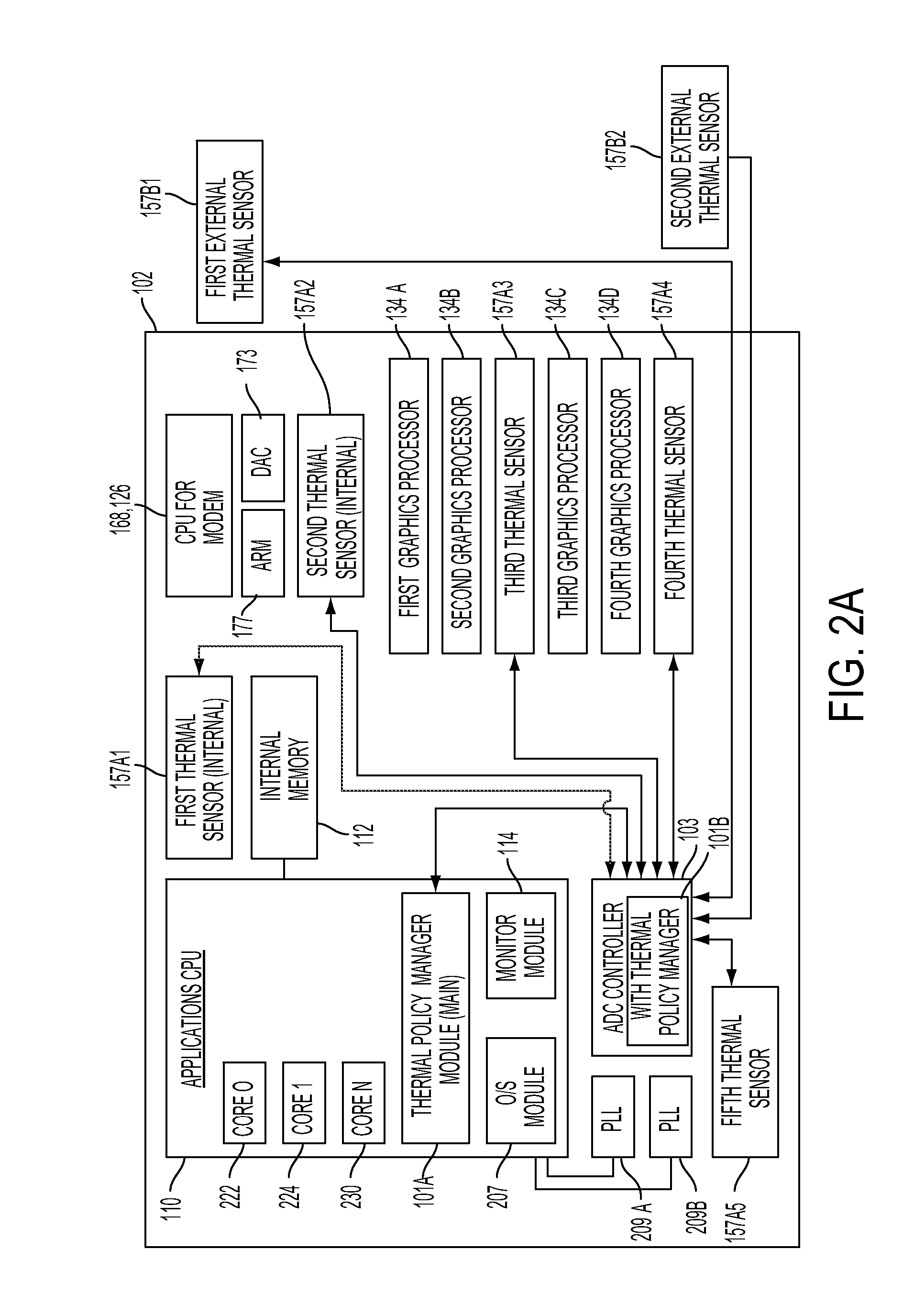

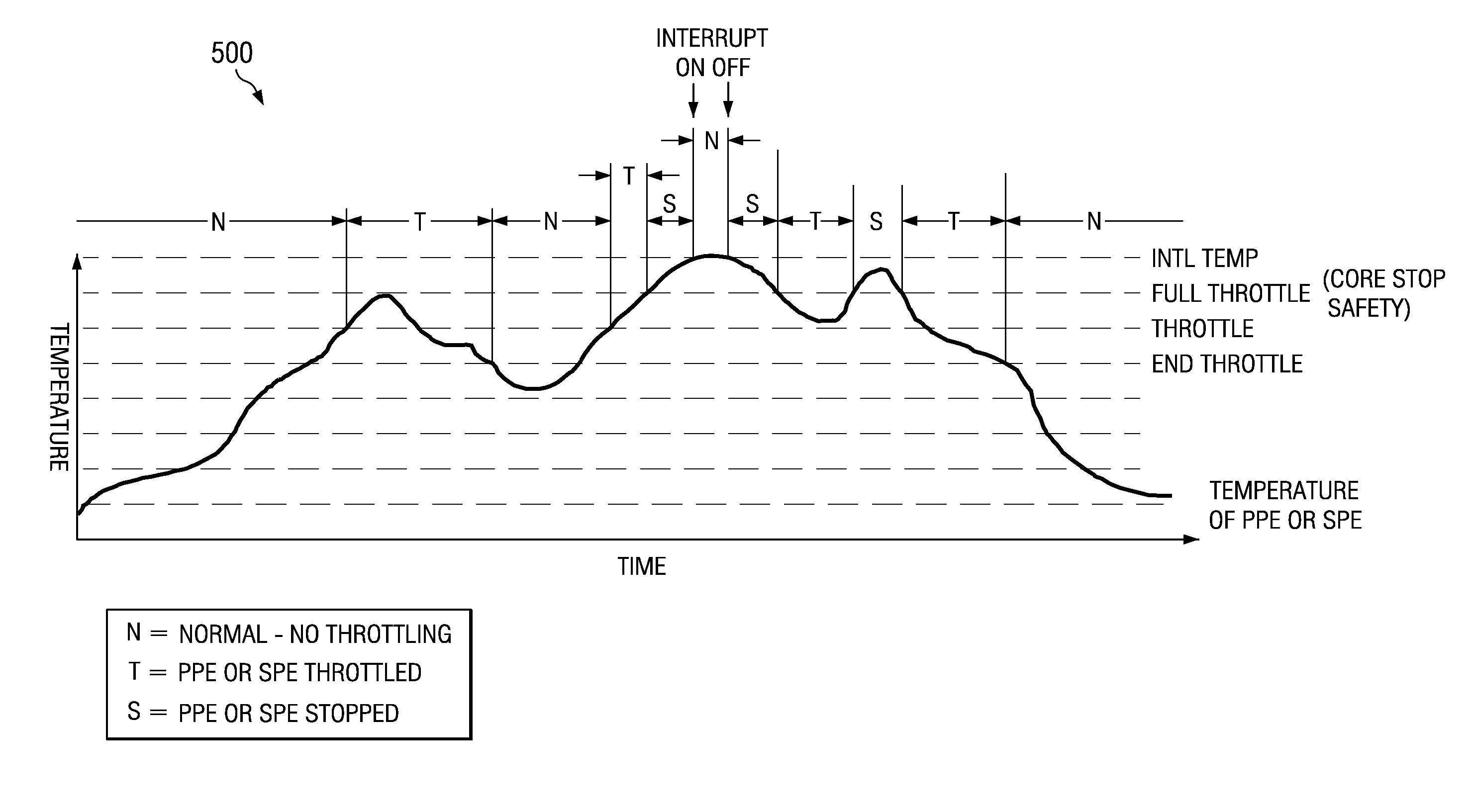

Method and system for managing thermal policies of a portable computing device

ActiveUS20120179303A1High frequencyEnergy efficient ICTTemperatue controlMonitoring temperatureThermal state

A method and system for managing one or more thermal policies of a portable computing device (PCD) includes monitoring temperature of the portable computing device with internal thermal sensors and external thermal sensors. If a change in temperature has been detected by at least one thermal sensor, then a thermal policy manager may increase a frequency in which temperature readings are detected by the thermal sensors. The thermal policy manager may also determine if a current temperature of the portable computing device as detected by one or more of the thermal sensors falls within one or more predetermined thermal states. Each thermal state may be assigned a unique set of thermal mitigation techniques. Each set of thermal mitigation techniques may be different from one another. The sets of thermal mitigation techniques may differ according to quantity of techniques and impacts on performance of the PCD.

Owner:QUALCOMM INC

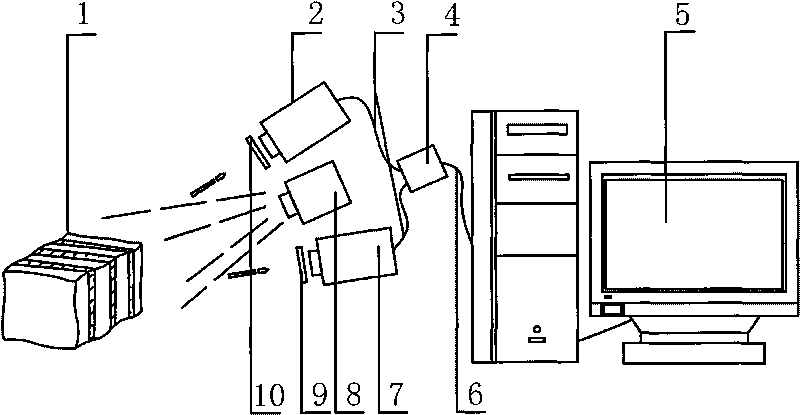

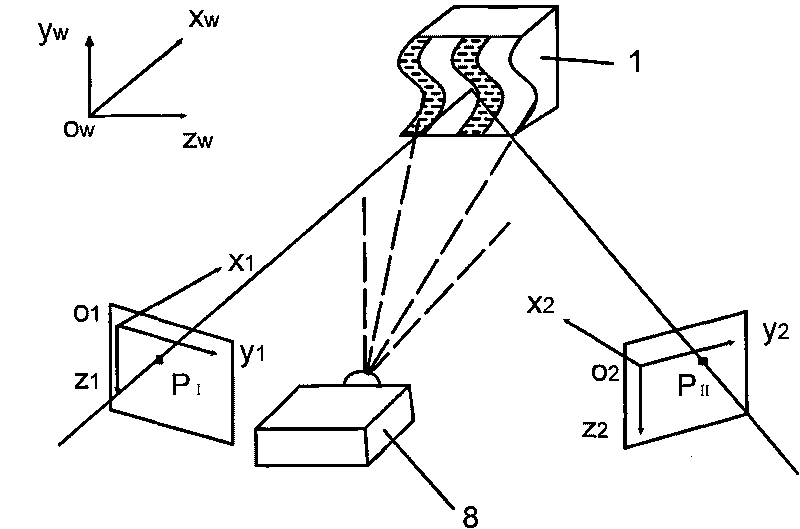

Non-contact measurement method for thermal state sizes of forgings

ActiveCN101713640ARealize real-time non-contact measurementGuaranteed real-time effectivenessImage analysisMetal-working apparatusThermal stateCalibration result

The invention relates to a non-contact measurement method for thermal state sizes of forgings, in particular to a method for measuring the sizes of the forgings by using strip structured light, and belongs to the field of high-temperature forging size measurement,. The method comprises the following steps of: dividing the forgings into a square class and a cylindrical class, then calibrating internal and external parameters of a first CCD camera and a second CCD camera, and building a coordinate relation of the cameras and an external viewing field; projecting the strip structured light to the high-temperature forgings; acquiring images of the high-temperature forgings projected by the strip structured light by an image acquisition system; processing the acquired images; quickly extracting feature points of the associated forging size by analyzing shape characteristics of the edge of the structured light on the cylindrical and the square forgings; combining calibration results of the first CCD camera and the second CCD camera to carry out three-dimensional modeling on the feature points of the forgings; and calculating the forging size and partial form and position errors of the forgings. The method adopts the binocular vision technology to shoot the images of the high-temperature forgings in real time, is quick and accurate in measurement, and can meet the requirements of industrial forging and stamping production.

Owner:DALIAN UNIV OF TECH

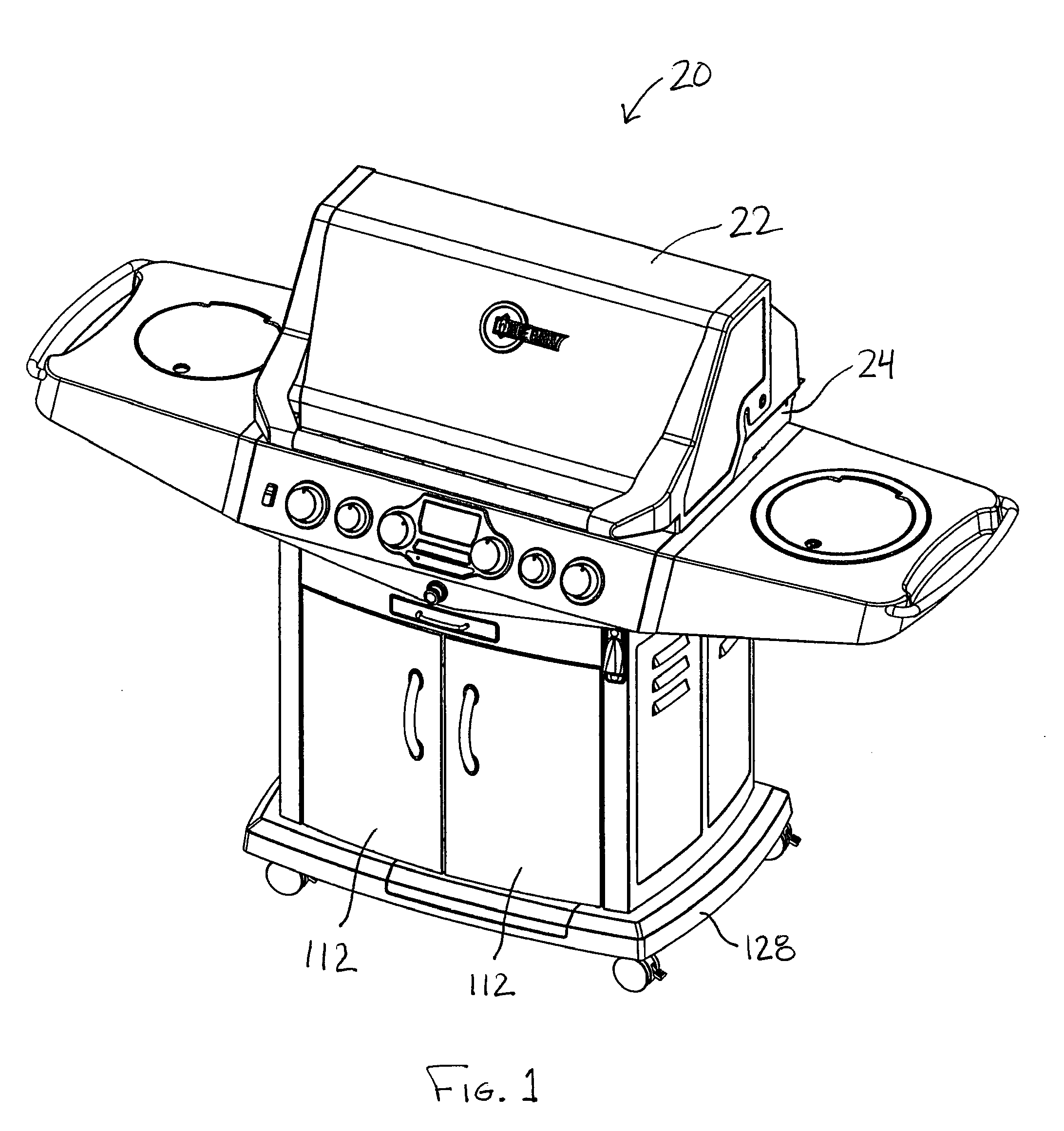

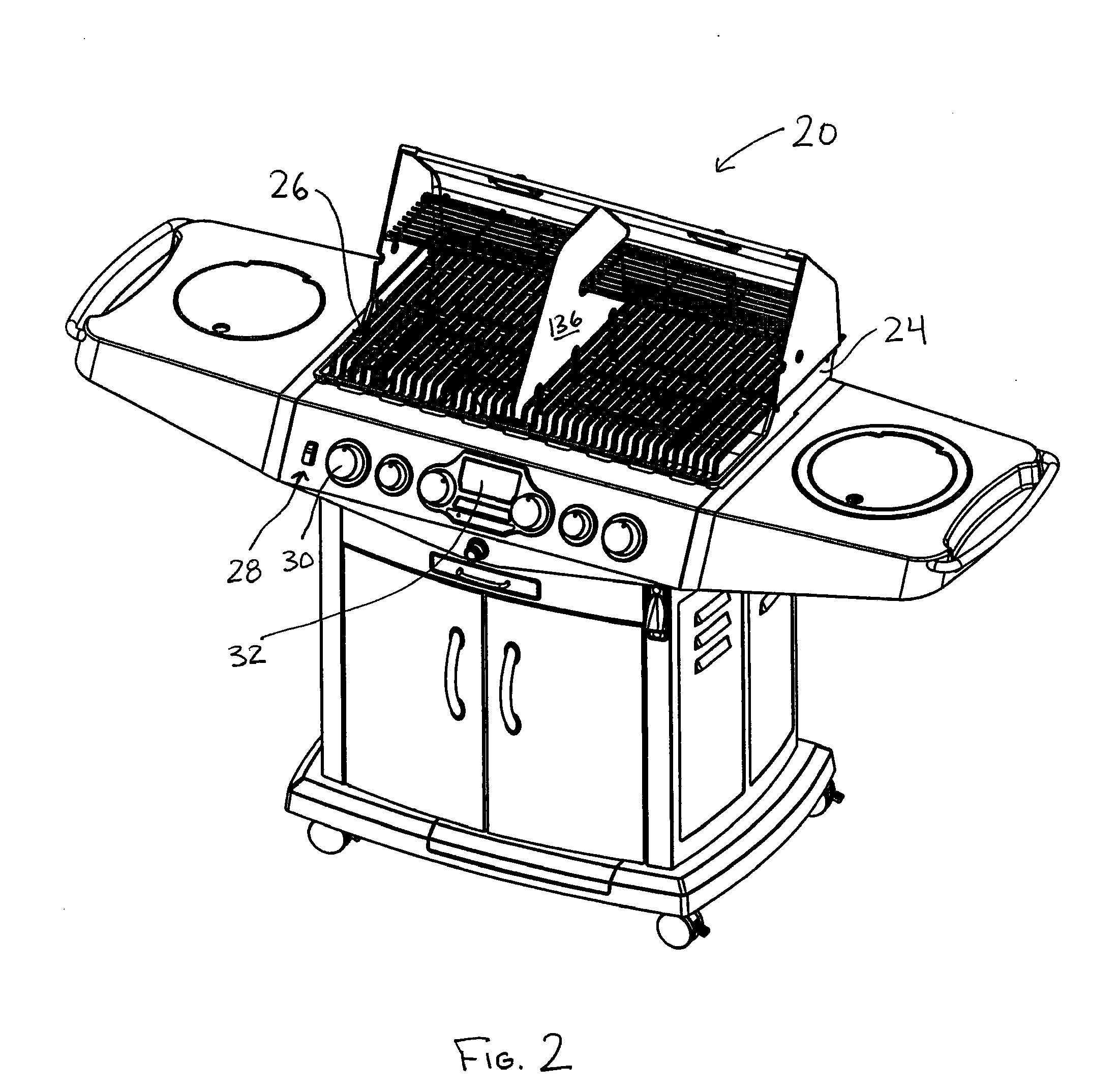

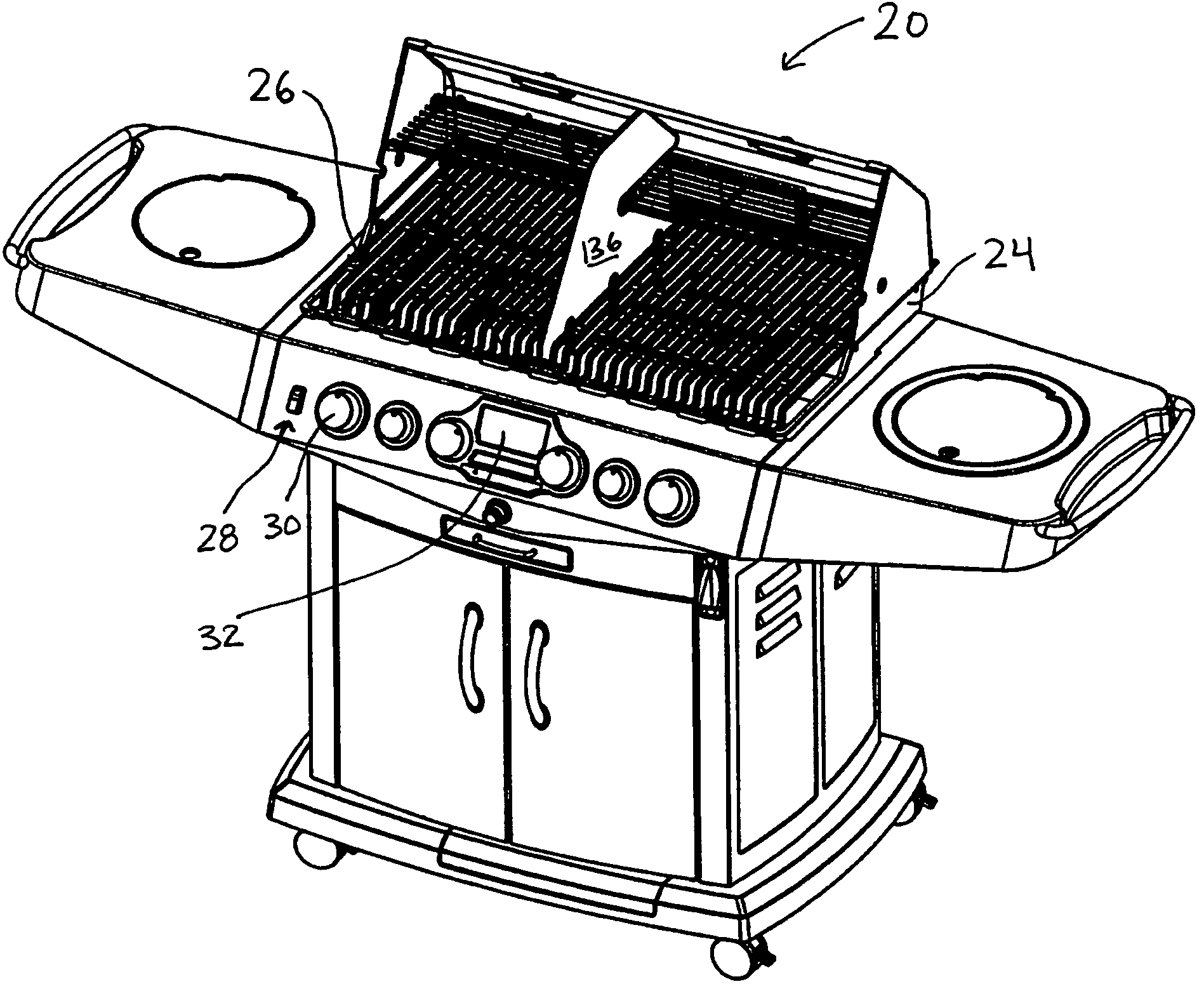

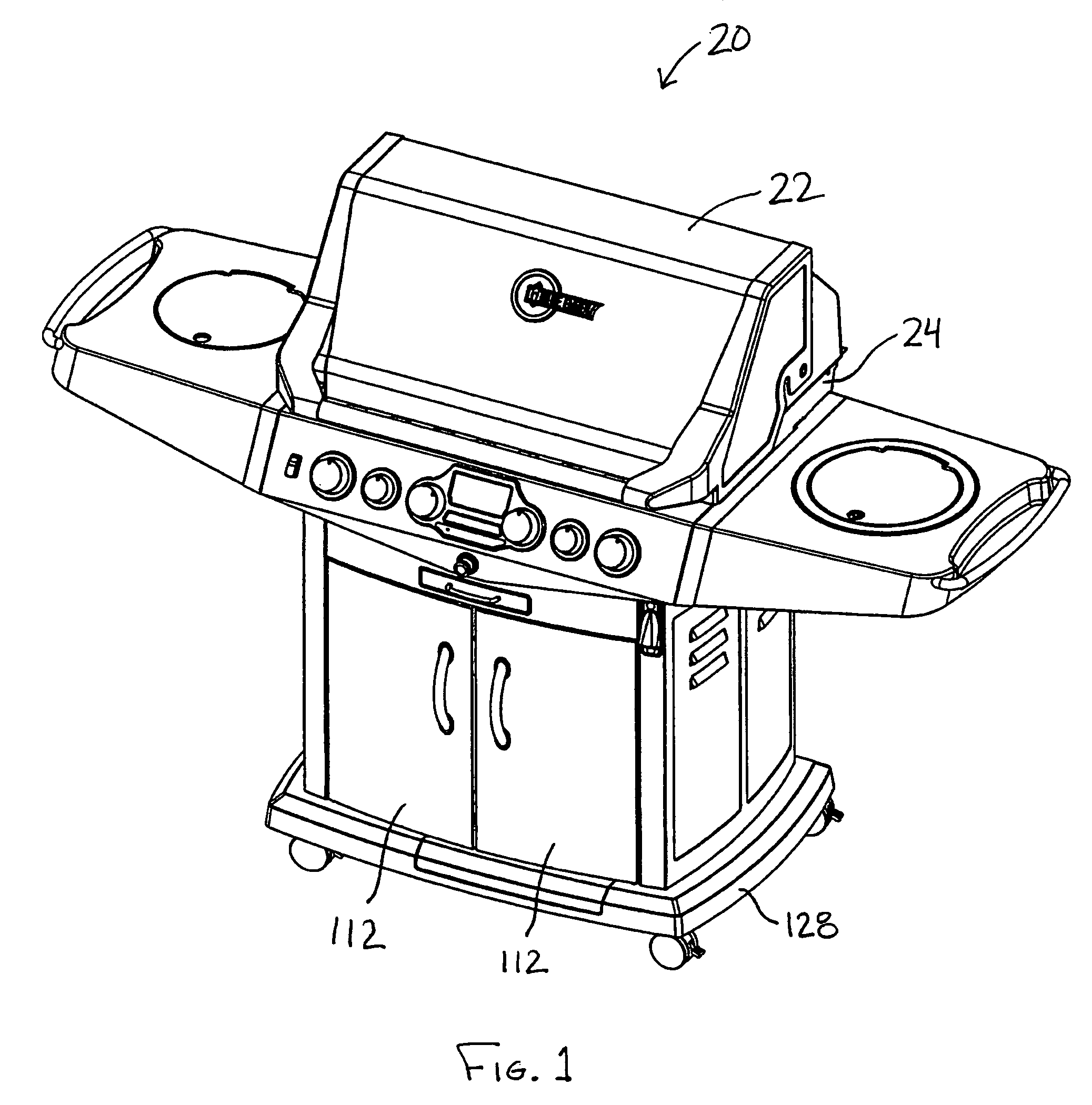

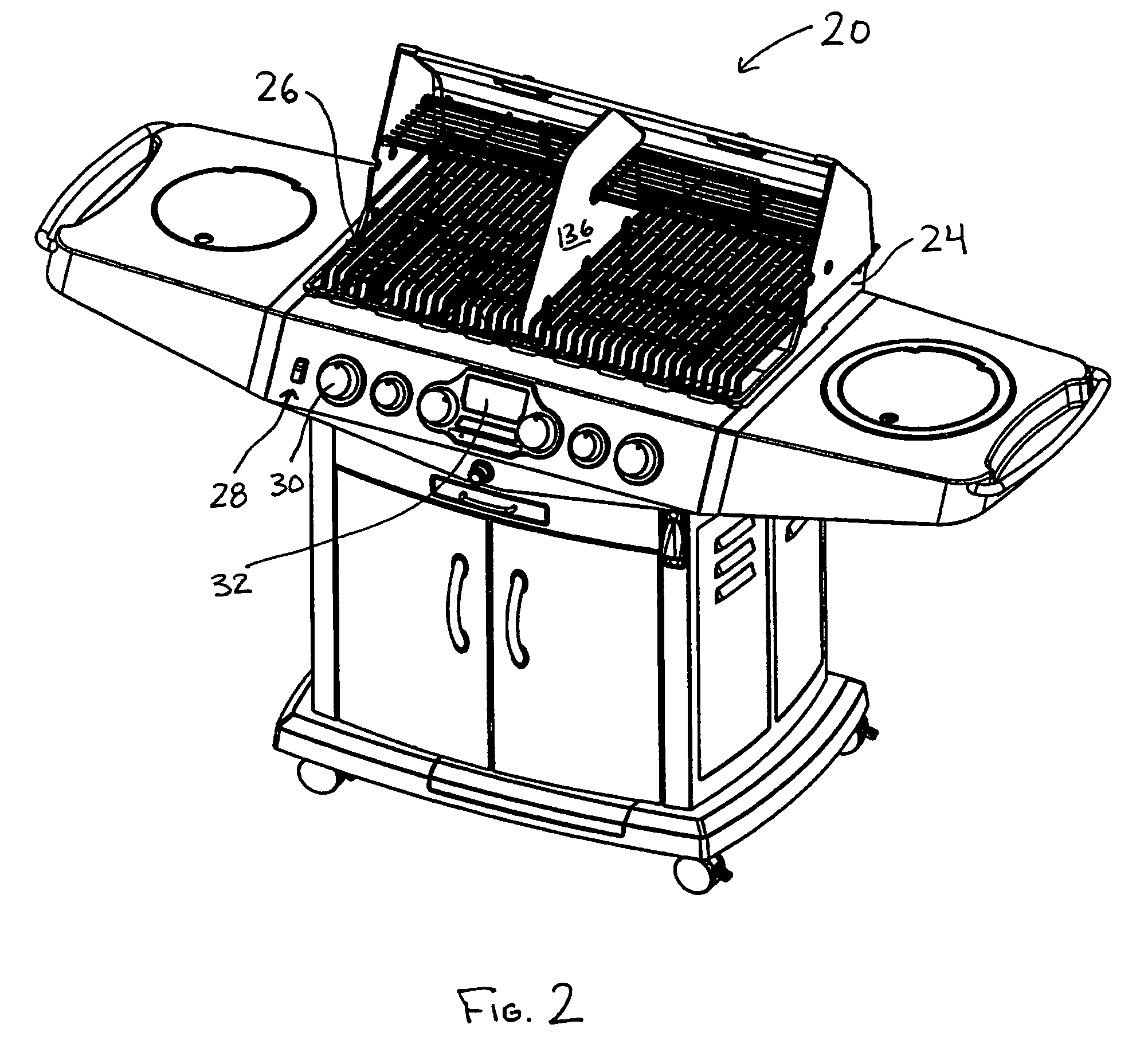

Temperature control apparatus and method for a barbeque grill

A temperature control system for controlling the rate of flow of a flammable fluid at generally constant pressure is disclosed. The system may include a flow control apparatus that is free of a regulator mechanism, for affecting the flow of the fluid. The flow control apparatus may be operable between at least a first flow rate and a second flow rate, and may have at least one upstream opening and at least one downstream opening. The system may also include a first burner in fluid communication with the downstream opening of the flow control apparatus and a conduit in fluid communication at one end thereof with the upstream opening of the flow control apparatus, and configured at the other end thereof for connection to a fuel supply. A thermocouple may be located in the vicinity of the burner, for converting a sensed thermal state into an electrical signal. An electronic controller, in communication with the flow control apparatus, for activating the flow control apparatus to one of said first and second flow rates, and being in communication with the thermocouple for receiving the electrical signal from the thermocouple is also provided. An interface connected to the controller for manually inputting a desired temperature may be included, wherein the controller is operable to automatically cycle the flow control apparatus between the first and second flow rates until the temperature sensed by the thermocouple is similar to the desired temperature.

Owner:WOLFEDALE ENG

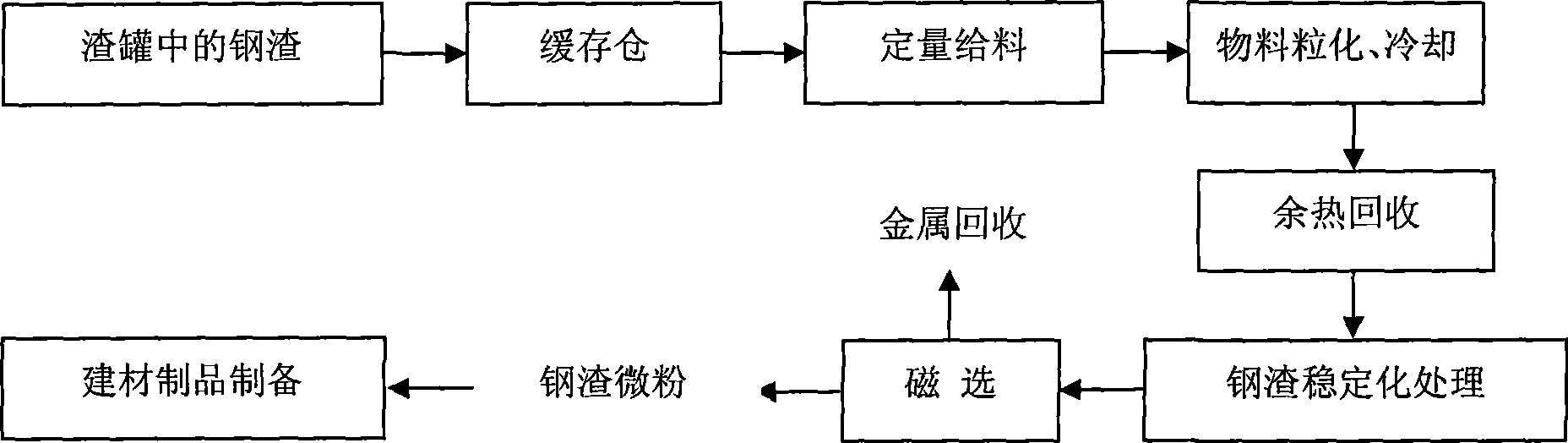

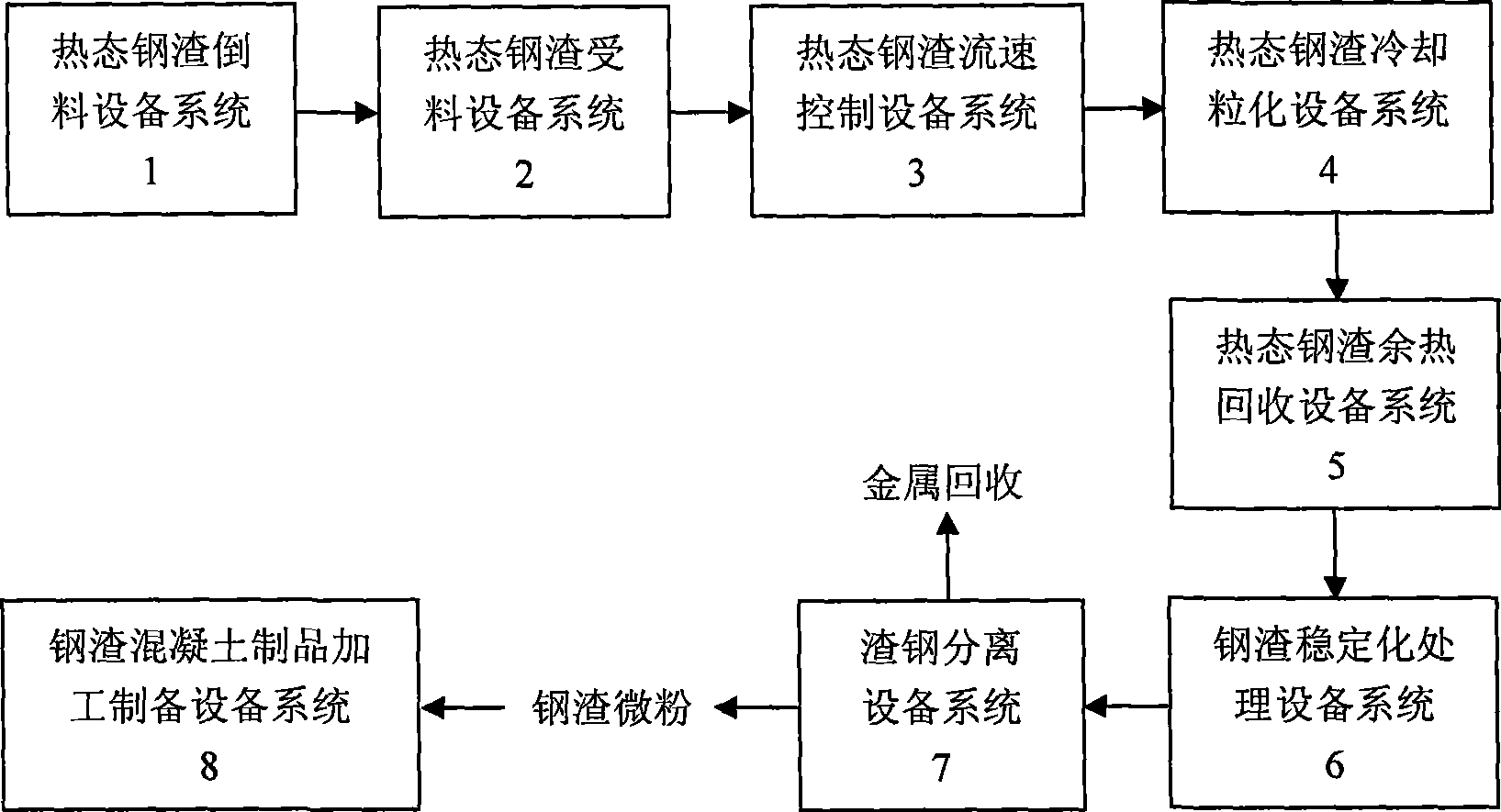

Method for recovery of waste heat of steel slag and comprehensively processing and utilizing steel slag

InactiveCN101413037AAvoid water explosionImprove energy efficiencyIncreasing energy efficiencyRecycling and recovery technologiesThermal stateSlag

The invention provides a mehtod for recovering waste heat of steel slag and comprehensively processing and using the steel slag, and belongs to the technical field of steel slag treatment. The method comprises the following steps: a thermal state steel slag material discharging system discharges steel slag into a thermal state steel slag material receiving system for primary crushing; the crushed steel slag is subjected to secondary crushing by a thermal state steel slag velocity control system and quantificationally fed into a thermal state steel slag cooling granulating system for re-crushing and cooling, high-temperaure hot air generatd in the cooling process is collected by a thermal state steel slag waste heat recovery system and enters a heat exchange system to form vapor for power generation or heat supply; the cooled steel slag enters a steel slag stabilizing treatment system, and the steel slag after the stabilizing treatment is treated by a steel slag separation system to obtain steel slag tailing micropowder and metal slag steel respectively; and, the steel slag micropowder is mixed with other materials and used to prepare concrete products by a steel slag concrete product processing preparation system. The method has the advantages of adaptability to various types of steel slag to be processed, good operational environment and no secondary pollution.

Owner:SHOUGANG CORPORATION

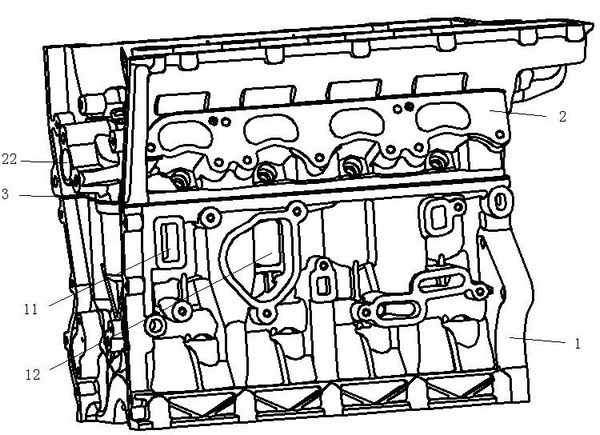

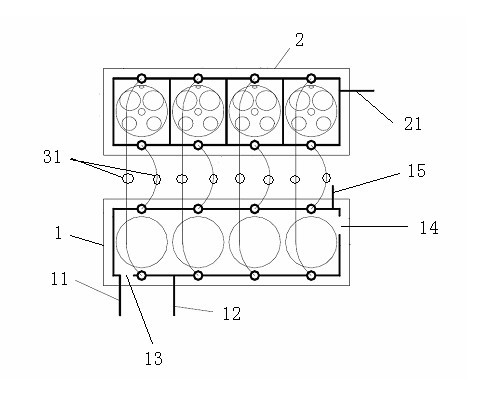

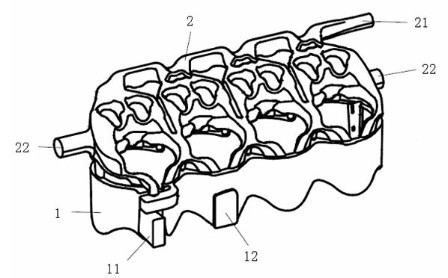

Engine cooling water jacket

InactiveCN102042116AImprove powerImprove performanceLiquid coolingCylinder headsThermal stateEngineering

The invention provides an engine cooling water jacket which has the advantages of simple structure, small volume, uniform flow rate and low pressure loss. The engine cooling water jacket comprises a cylinder body water jacket and a cylinder cover water jacket, wherein the cylinder body water jacket is separated by two baffle plates to form a first flow channel and a second flow channel, and the first flow channel and the second flow channel are communicated with the cylinder cover water jacket through water holes in a cylinder gasket; and coolant mainly flows into the first flow channel from a water inlet and flows through an air exhaust side, then flows into the cylinder cover water jacket through the water holes at one side of the cylinder gasket, subsequently flows into the second flow channel through the water holes at the other side of the cylinder gasket and flows through an air admission side, and finally flows out from a water outlet. Thus, the invention enables the flow rate of the coolant in the whole engine cooling water jacket to be more uniform, reduces the thermal-state deformation of the cylinder holes and improves the dynamic performance of the engine; and the water holes in the cylinder gasket can be arranged as required without being influenced by the design of traditional water jacket cylinder holes, thereby integrally increasing the flow areas of the water holes in the cylinder gasket, reducing the pressure loss of the whole water jacket and lowering the performance requirements for water pumps.

Owner:CHERY AUTOMOBILE CO LTD

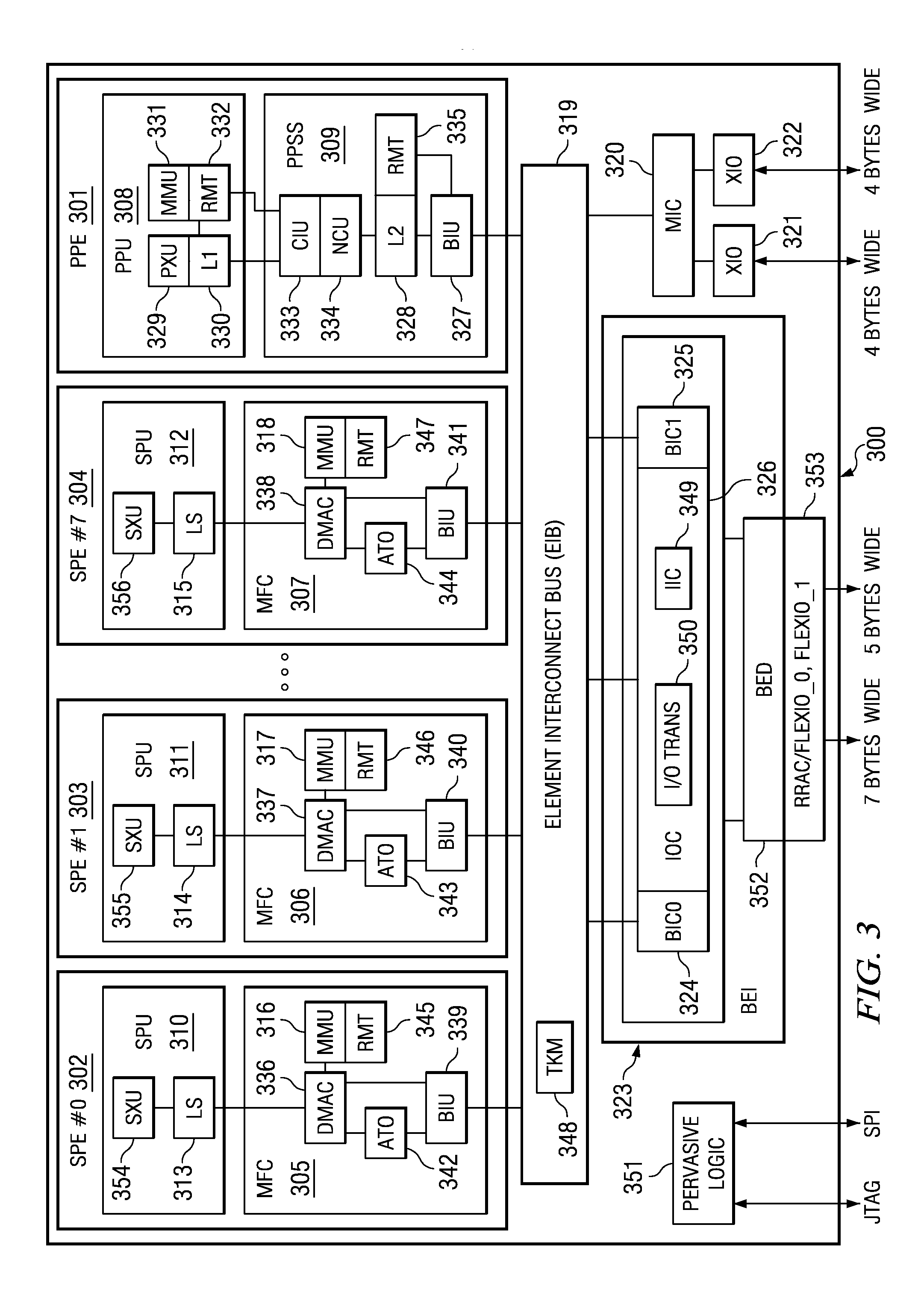

Dynamically adapting software for optimal thermal performance

InactiveUS20070260893A1Improve thermal performanceReduce resource utilizationEnergy efficient ICTSoftware engineeringData processing systemThermal state

A computer implemented method, data processing system, and computer usable code are provided for optimizing thermal performance of a computer system. Identification of a set of system resources associated with the computer system is performed and a thermal index is requested for each of the set of system resources to form a set of thermal indexes. An action from a set of actions is identified to reduce resource utilization. The action is implemented to reduce a thermal state of the computer system.

Owner:GLOBALFOUNDRIES INC

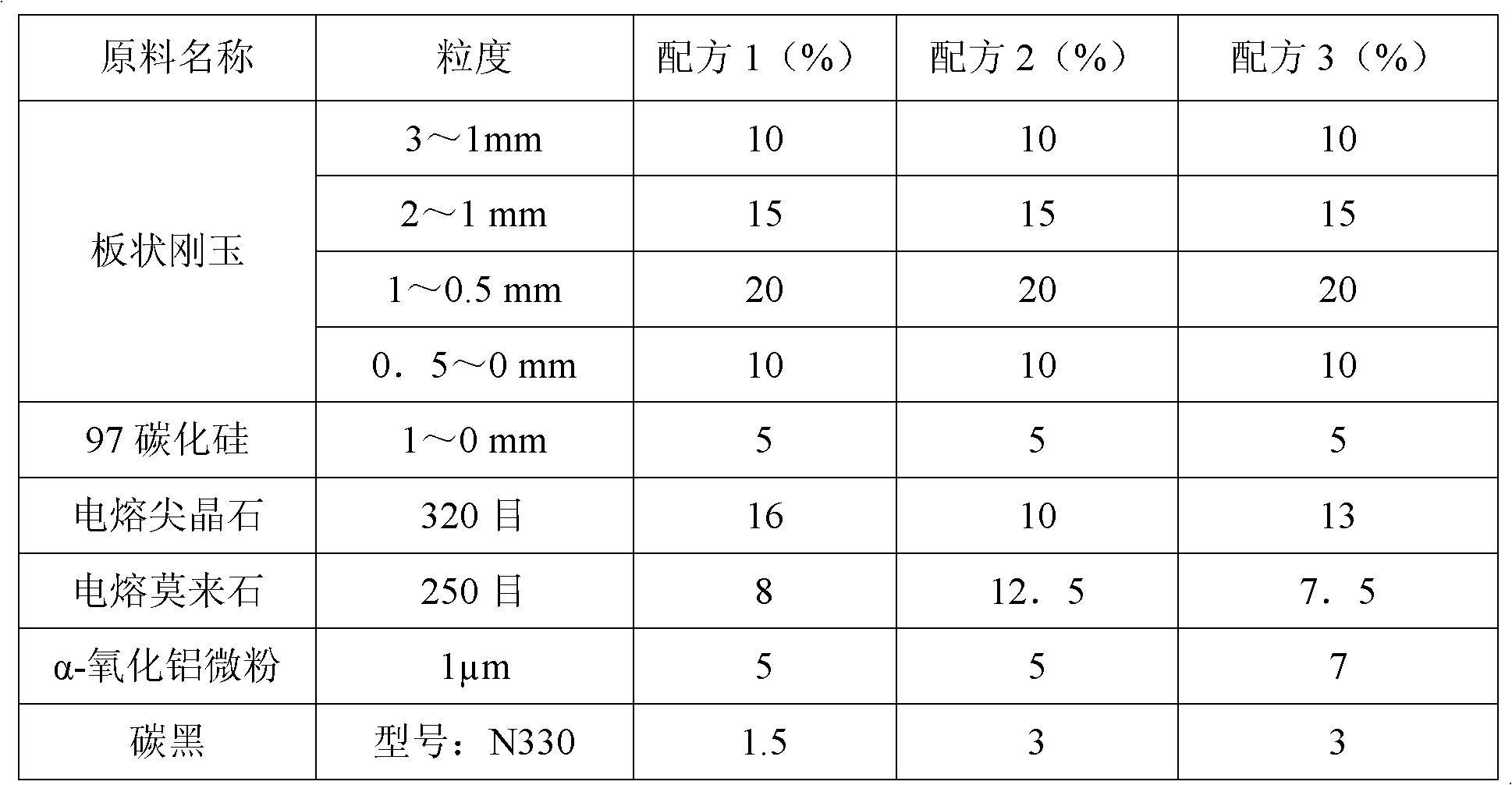

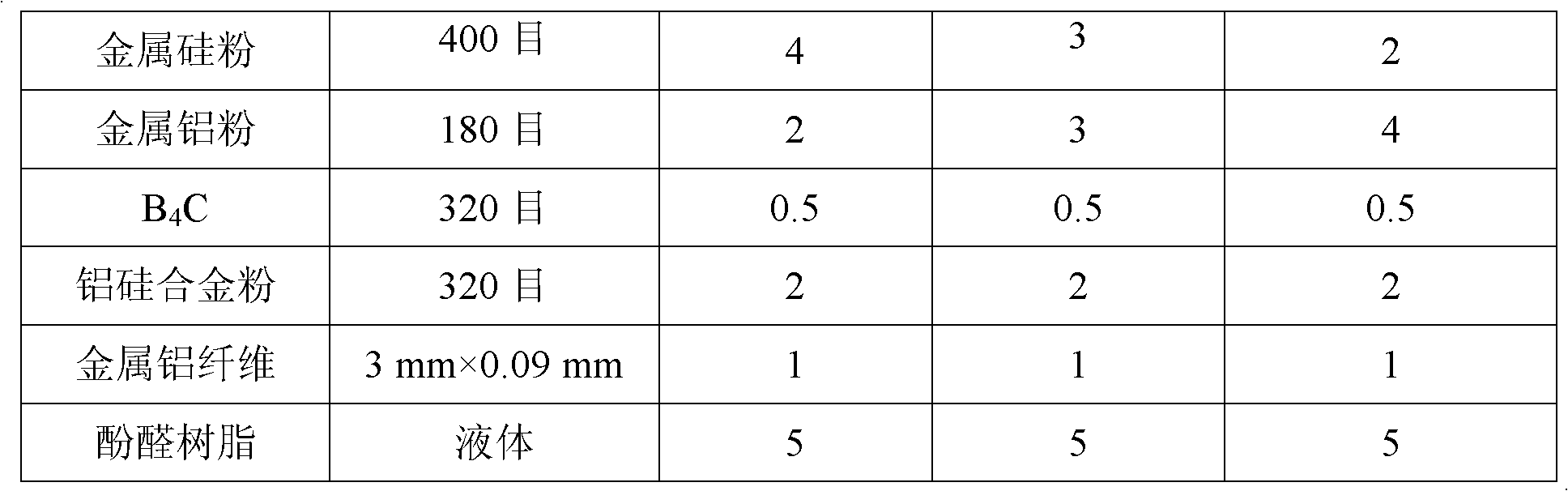

Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

The invention discloses a metal ceramic combination sintering free low carbon sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following components according to weight percentage: 50%-60% of sintered plate shape alundum, 10%-25% of electric melting akerite, 5%-15% of electric melting mullite, 1%-3% of soot carbon, 3%-8% of Alpha- aluminum oxide micropowder, 5%-10% of silicon carbide, 2%-5% of metallic silicon powder,1%-5% of metallic aluminium powder, 0.5%-1% of boron carbide, 1%-3% of aluminum-silicon alloy powder, and 0.5%-2% of metallic aluminium fiber. In the invention, the product has low carbon, high thermal state strength, thermal shock resistance and good oxidation resistance, hole reaming is uniform, galling is less and the crack is verysmall; the process of the invention is characterized in that drying is carried out at a low temperature, the production cycle is shortened from 30 days originally to 7 days, the natural gas consumption is reduced to 2.5% of original technology, and the sintering free low carbon sliding plate brick is indeed belongs to the environmental protective and energy-saving and environmental material resistance product.

Owner:无锡市南方耐材有限公司

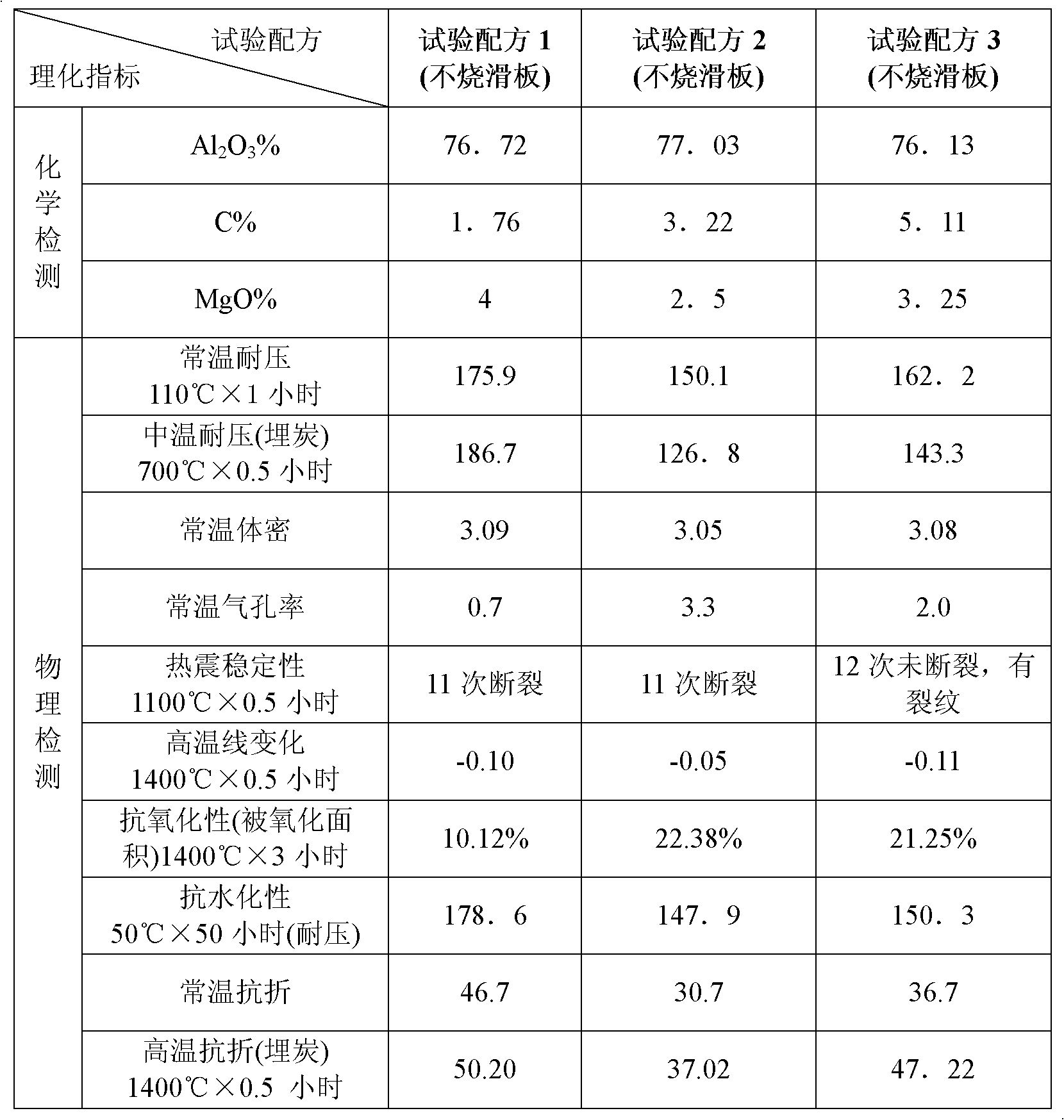

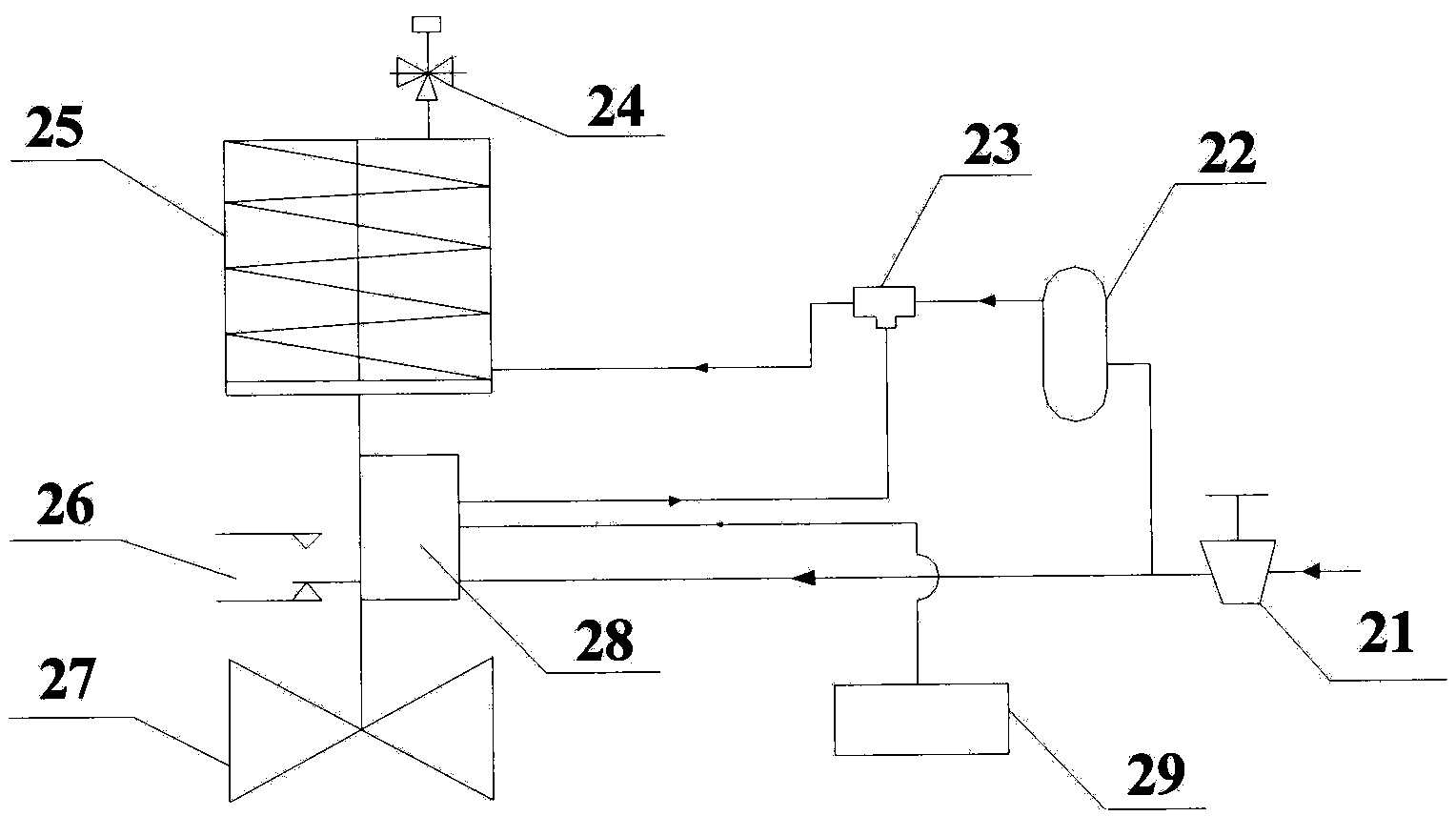

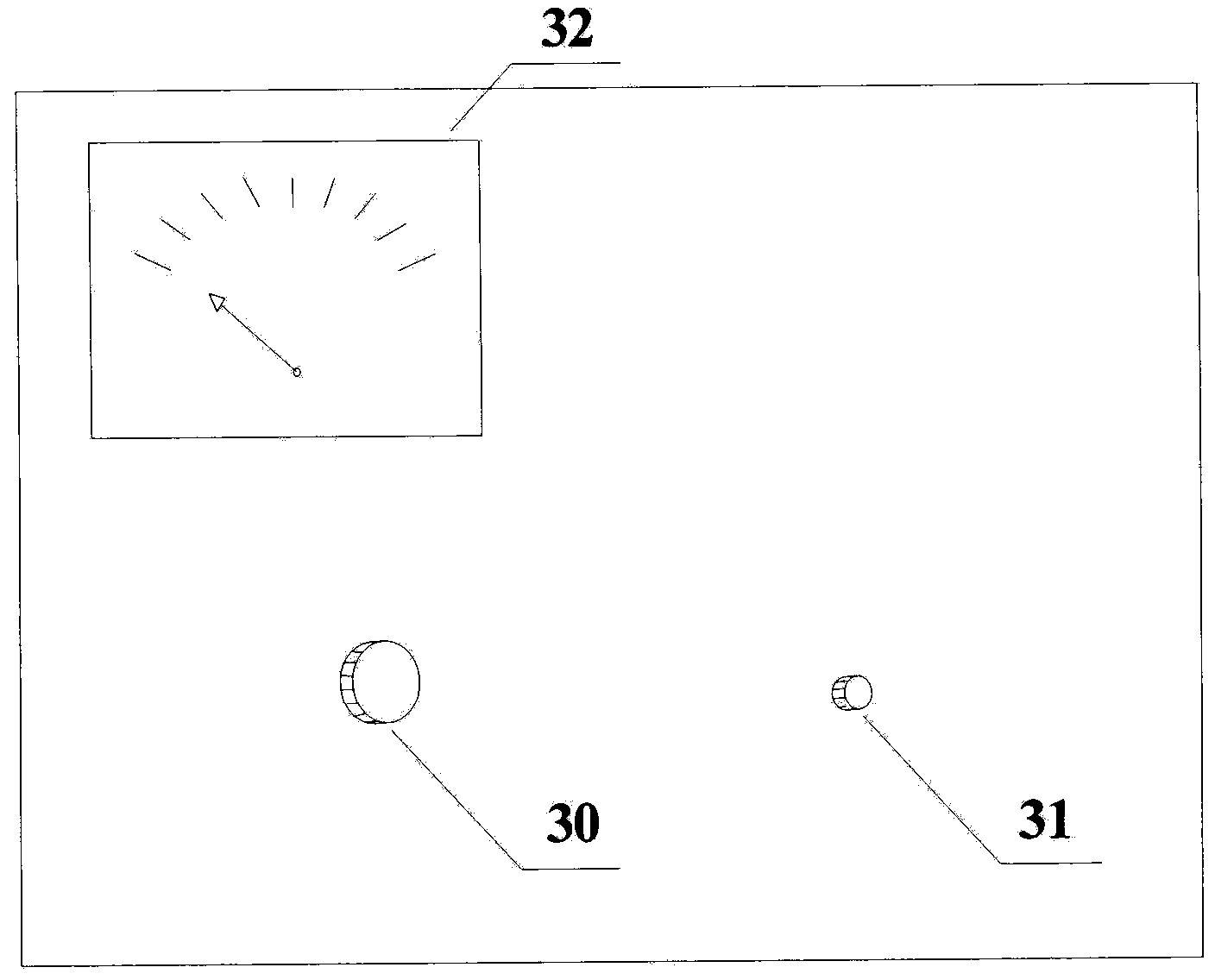

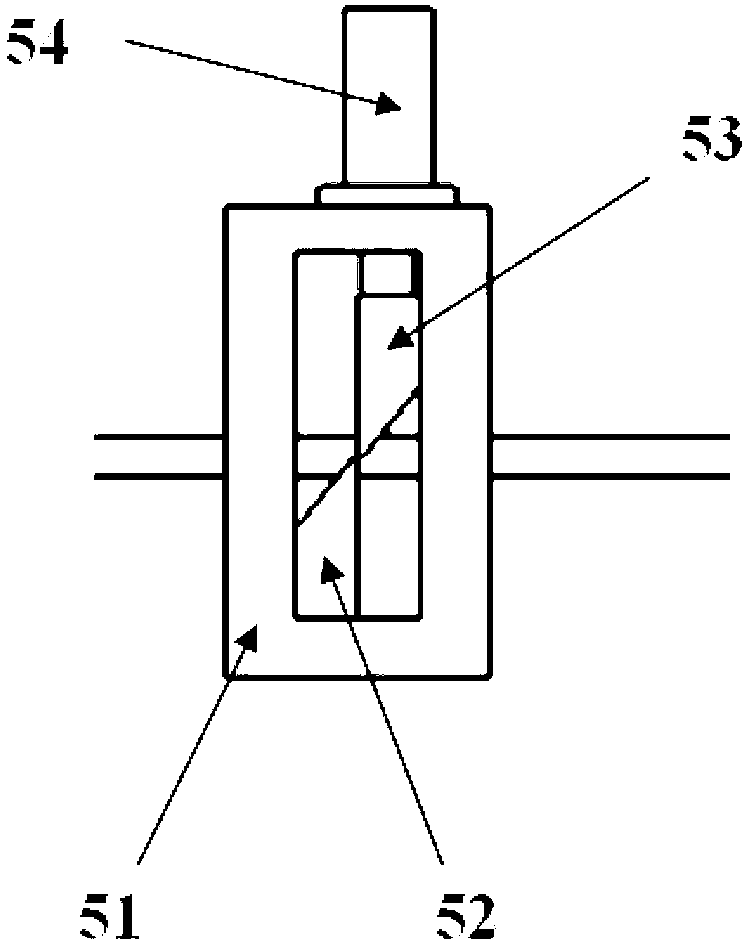

Test device and test method for testing heat-state mechanical performance of safety valve

ActiveCN103852245AAvoid the problem of frequency hoppingAccurate recording of mechanical propertiesMachine part testingSteam pressureThermal state

The invention relates to a test device and test method for measuring heat-state mechanical performance of a safety valve. A steam source is provided through a boiler, the pressure of an energy storage 3 is larger than that of an experimental container 4, rapid supplementing and cutting off of the steam of the experimental container of the safety valve can be achieved through a large-diameter adjusting valve, stable emission of the safety valve is kept, meanwhile, a rapid air release valve is controlled, and frequency hopping in the test process of the safety valve is avoided. According to a laser measuring device, the opening state test with the measuring precision of 10ms of the safety valve can be achieved, a non-contact type electromagnetic device measures the open high numerical value of the safety valve, and a high-pressure steam pressure measuring device measures pressure of the experimental container. Different scanning periods are set in the test state and the preparing state of the safety valve through the control system, mechanical performance relevant parameters of the safety valve are precisely measured, and the data handling capacity is also considered. The test device and test method of the heat state of the safety valve have the advantages of preventing frequency hopping of the safety valve, being high in measuring precision, high in safety, stable in system running and high in automation degree.

Owner:EAST CHINA UNIV OF SCI & TECH

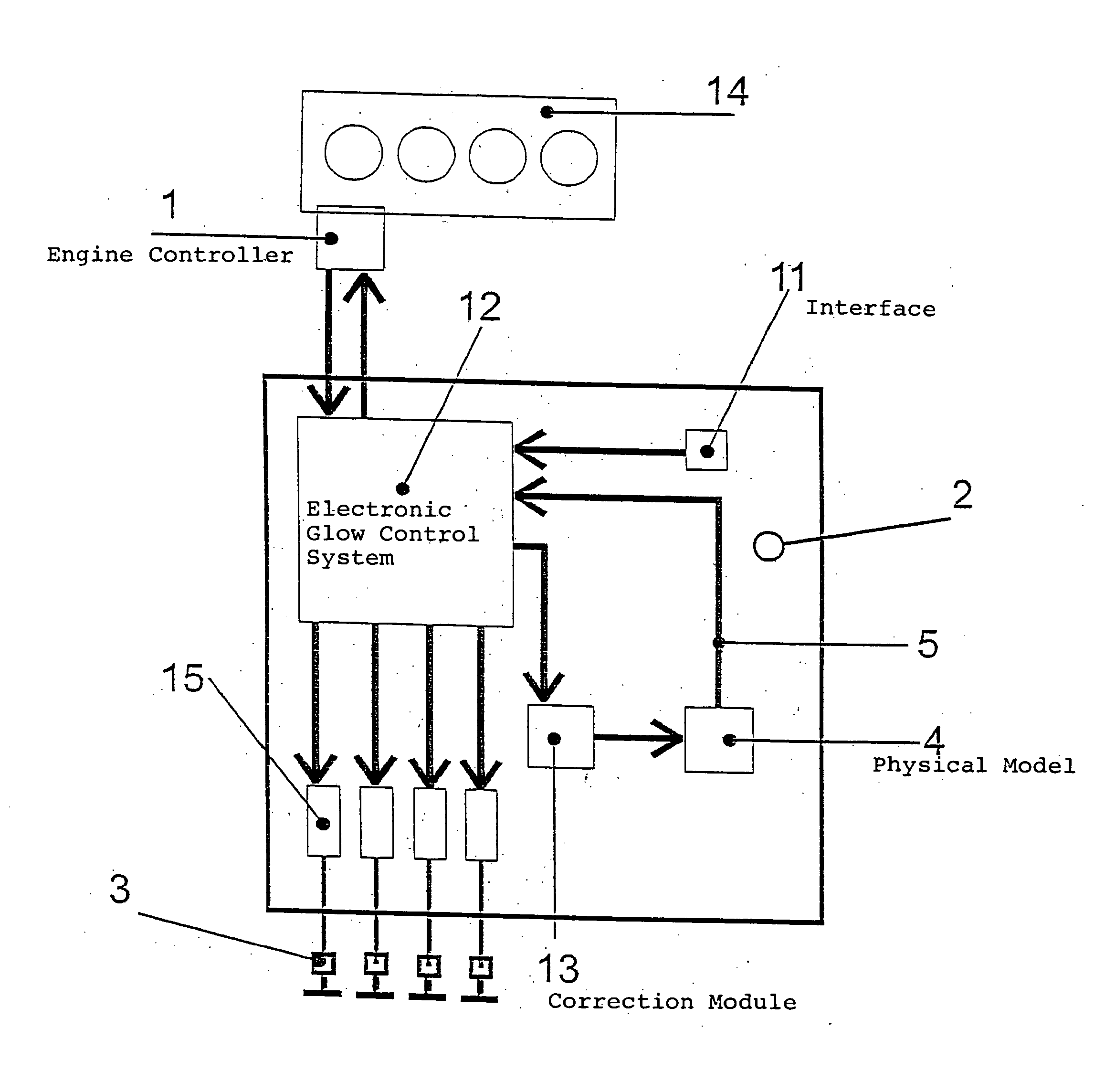

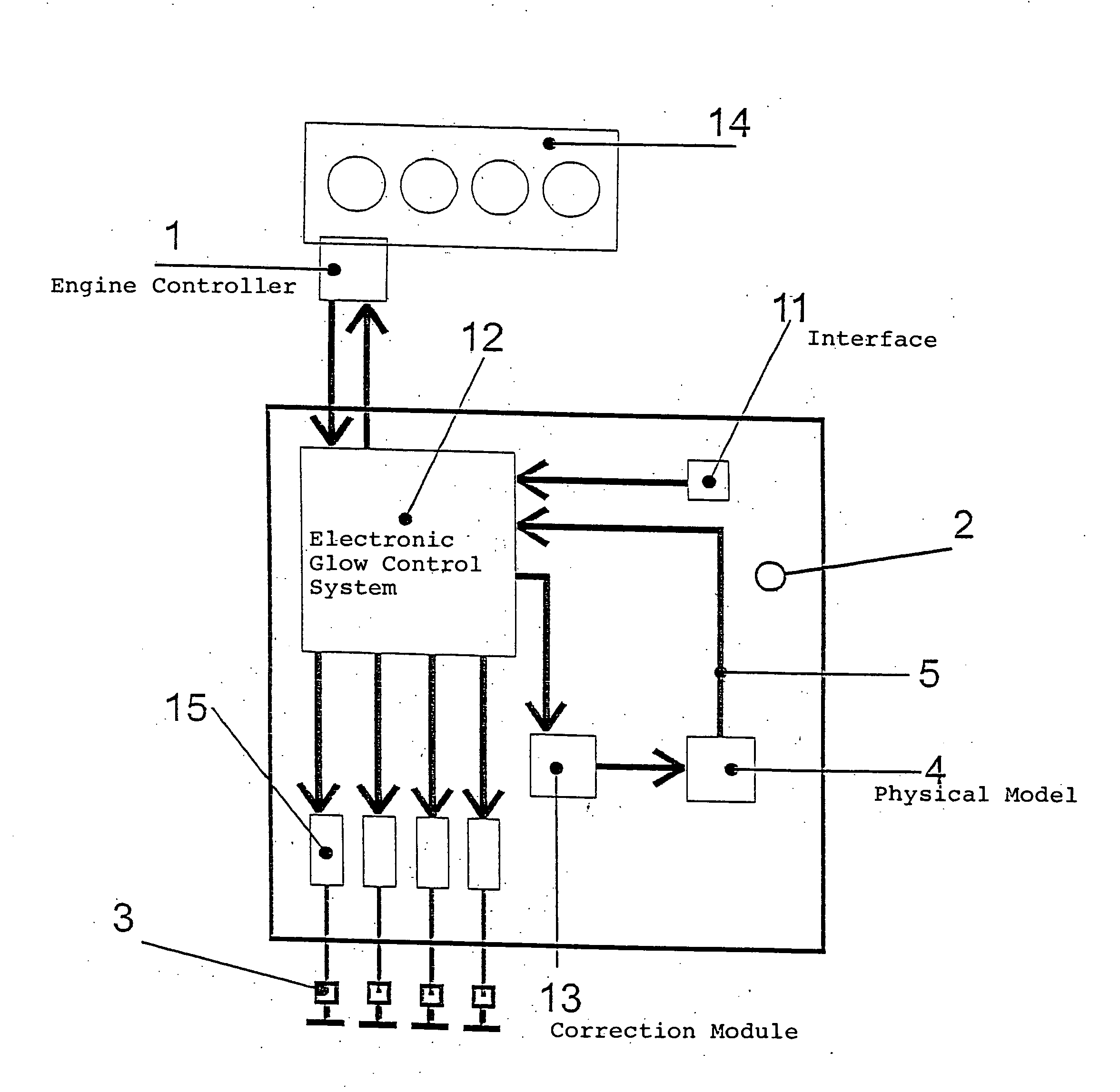

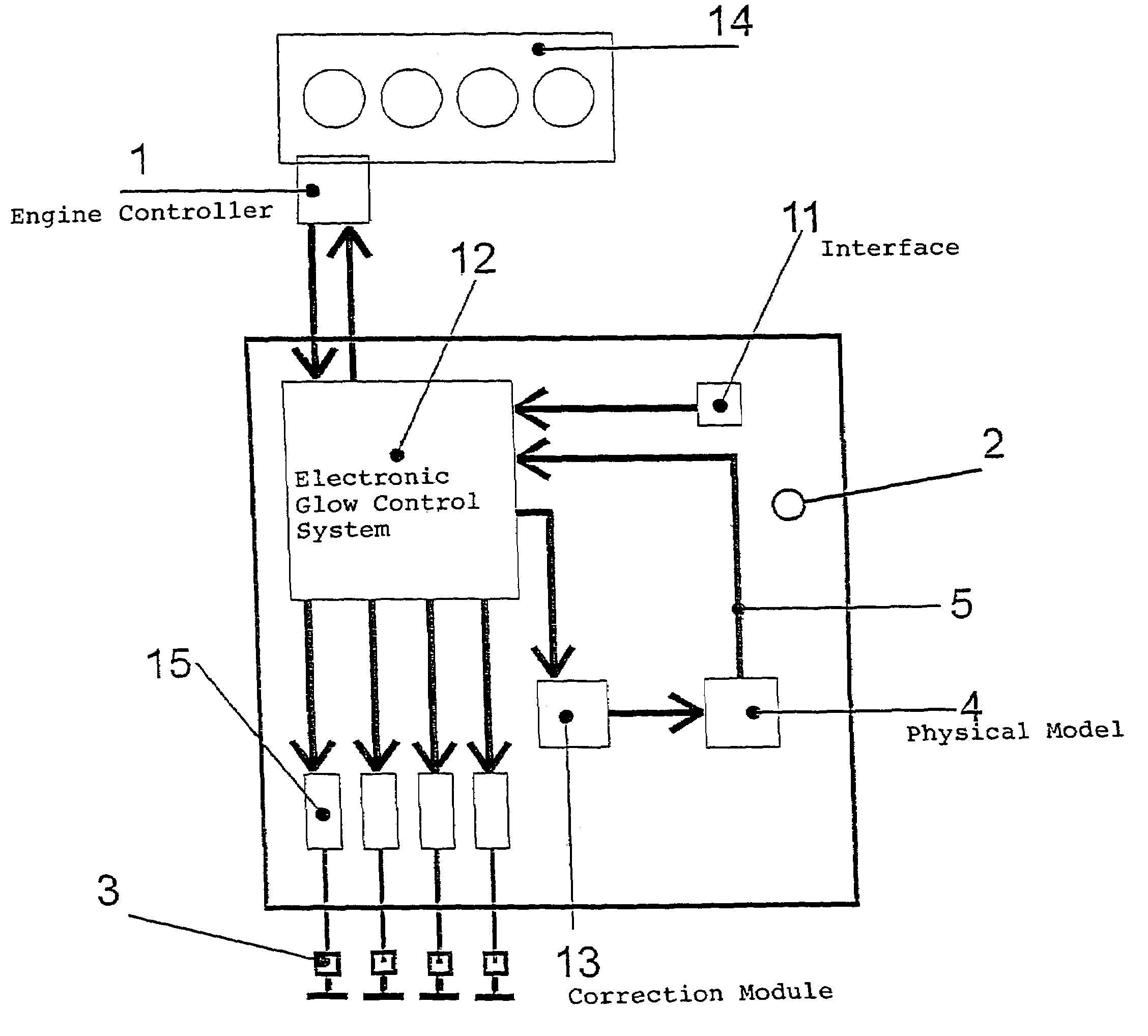

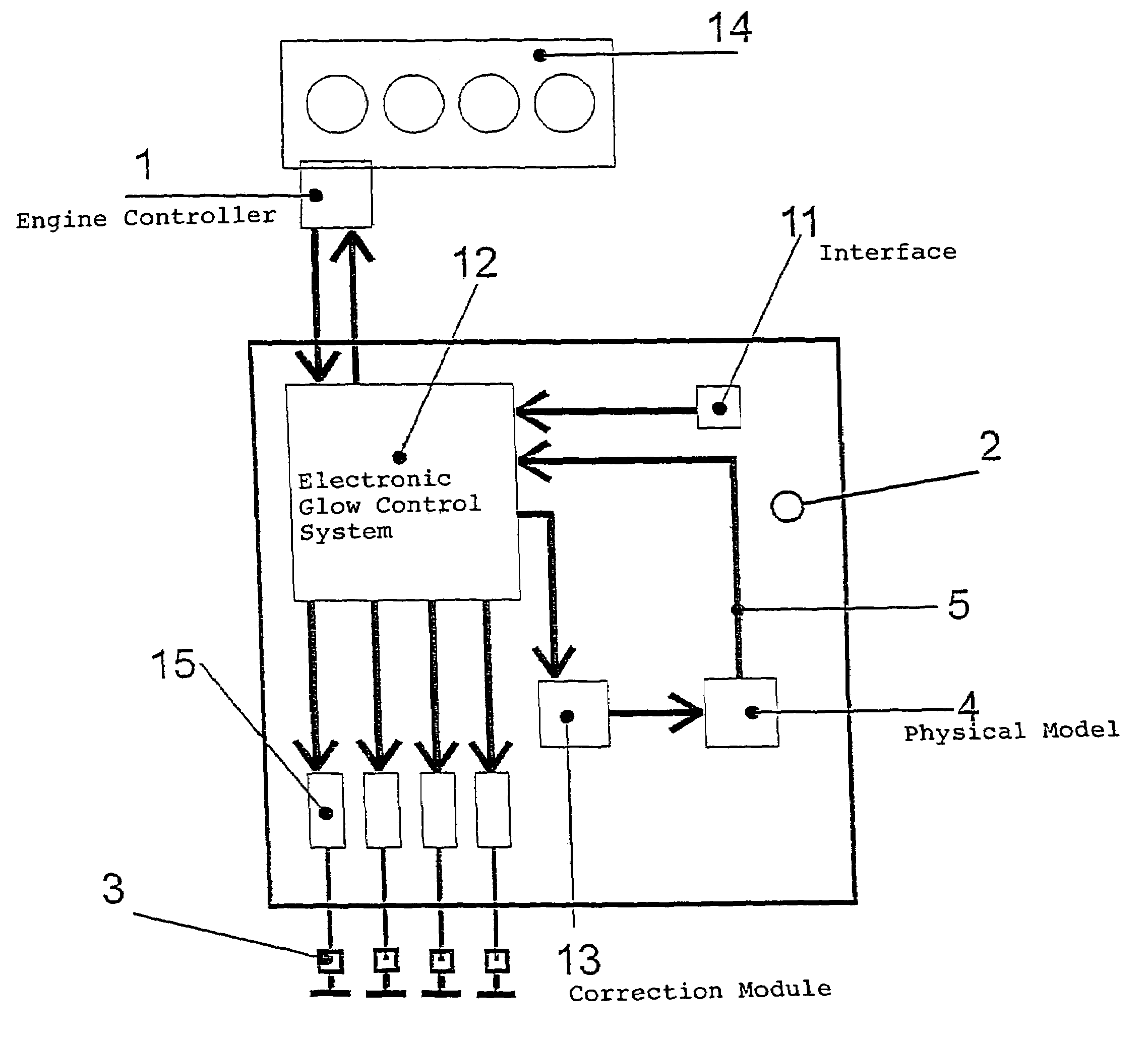

Method for heating a glow plug for a diesel engine

ActiveUS20050081812A1Avoid overall overheatingShort timeElectrical controlIncandescent ignitionThermal stateMathematical model

A method for heating a glow plug for a diesel engine to its desired temperature by supplying power to the glow plug in a controlled fashion. During a certain time interval after termination of a previous glow process, a mathematical model is used to determine the values for the supply of power to the glow plug, which includes the values of the actual thermal state of the glow plug, the time elapsed since the end of the previous glow process and the parameters of the diesel engine relevant for a glow process.

Owner:BERU AG DE

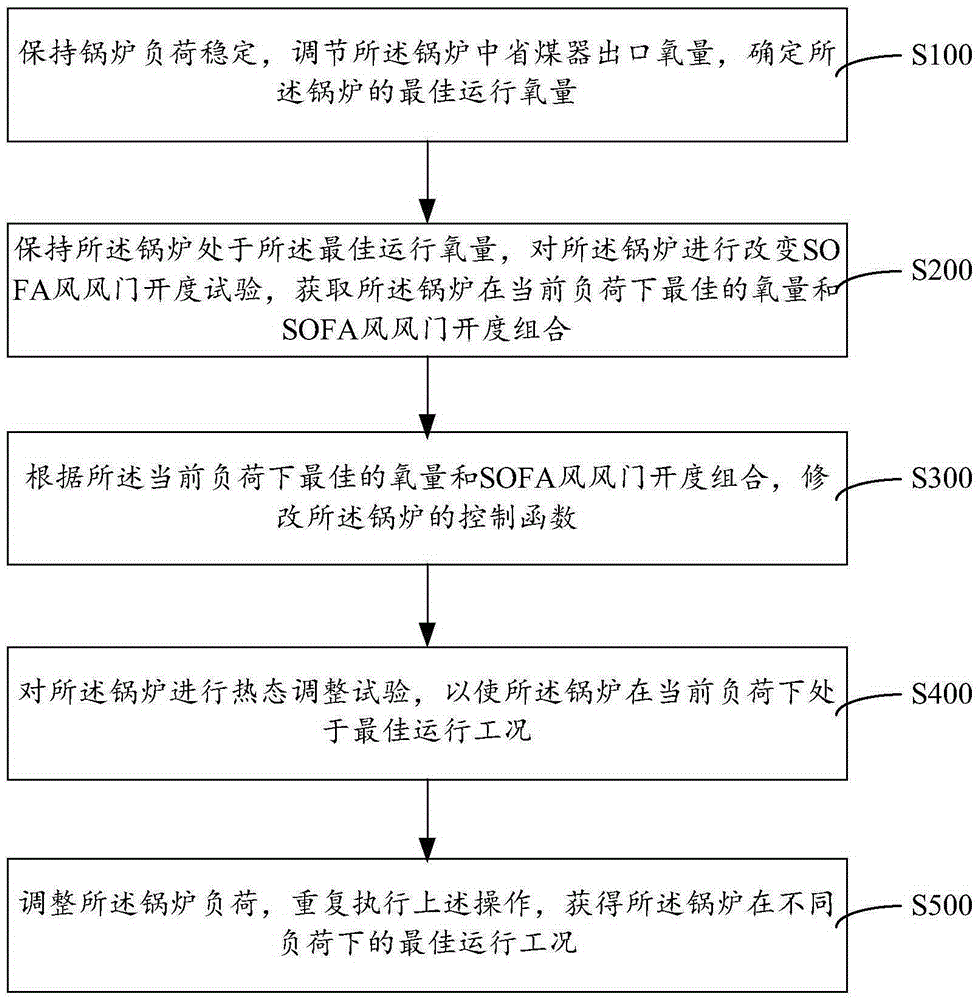

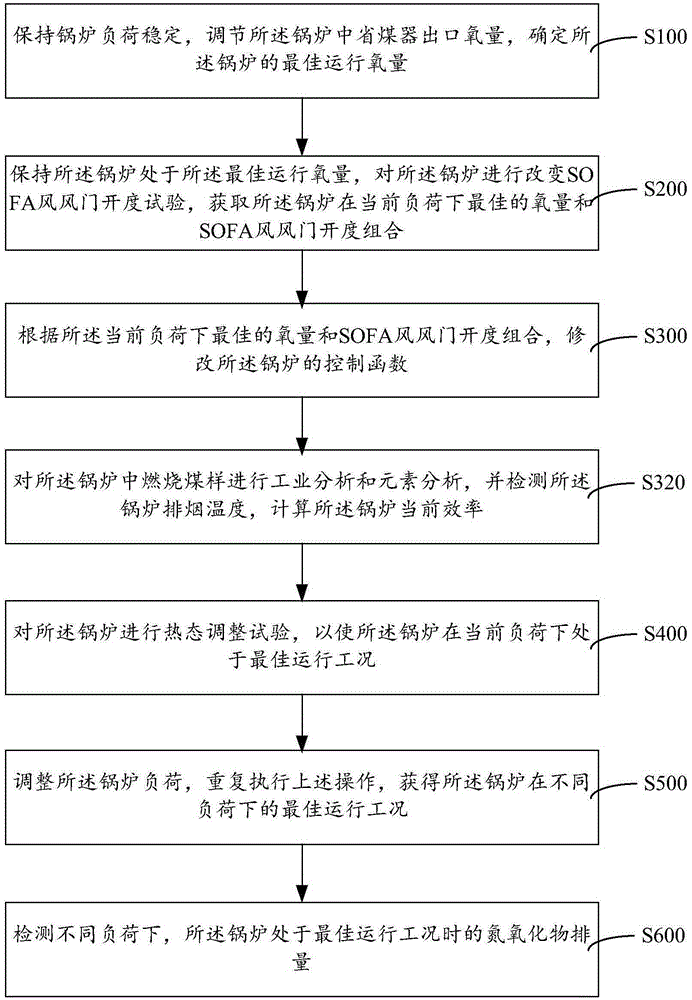

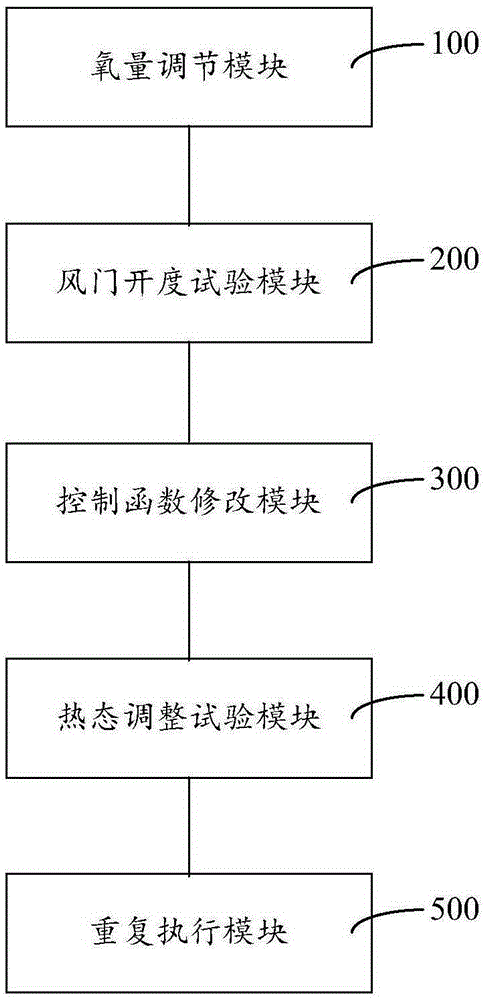

Adjustment and optimization method and system for combustion of power plant boiler

ActiveCN105276611AEvenly loadedOptimal operating oxygenCombustion regulationCurrent loadNitrogen oxides

The invention provides an adjustment and optimization method and system for combustion of a power plant boiler. The method comprises the steps that the load of the boiler is kept stable, the oxygen amount of an outlet of a coal economizer in the boiler is adjusted, and the optimal running oxygen amount of the boiler is determined; the boiler is kept in the optimal running oxygen amount, an SOFA valve opening degree changing test is carried out on the boiler, and the optimal oxygen amount of the boiler under the current load and an SOFA valve opening degree set are obtained; a control function of the boiler is modified according to the optimal oxygen amount under the current load and the SOFA valve opening degree set; a thermal state adjusting test is carried out on the boiler so that the boiler can be in the optimal running work condition under the current load; and the load of the boiler is adjusted, the operation is repeatedly executed, and the optimal running work condition of the boiler under different loads is obtained. In the whole process, based on the actual combustion condition of the combustion boiler, by means of the optimal running oxygen amount, the optimal oxygen amount, the SOFA valve opening degree set and the heat state adjustment, accurate adjustment and optimization on combustion of the power plant boiler are achieved, and nitrogen oxide emission is reduced.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

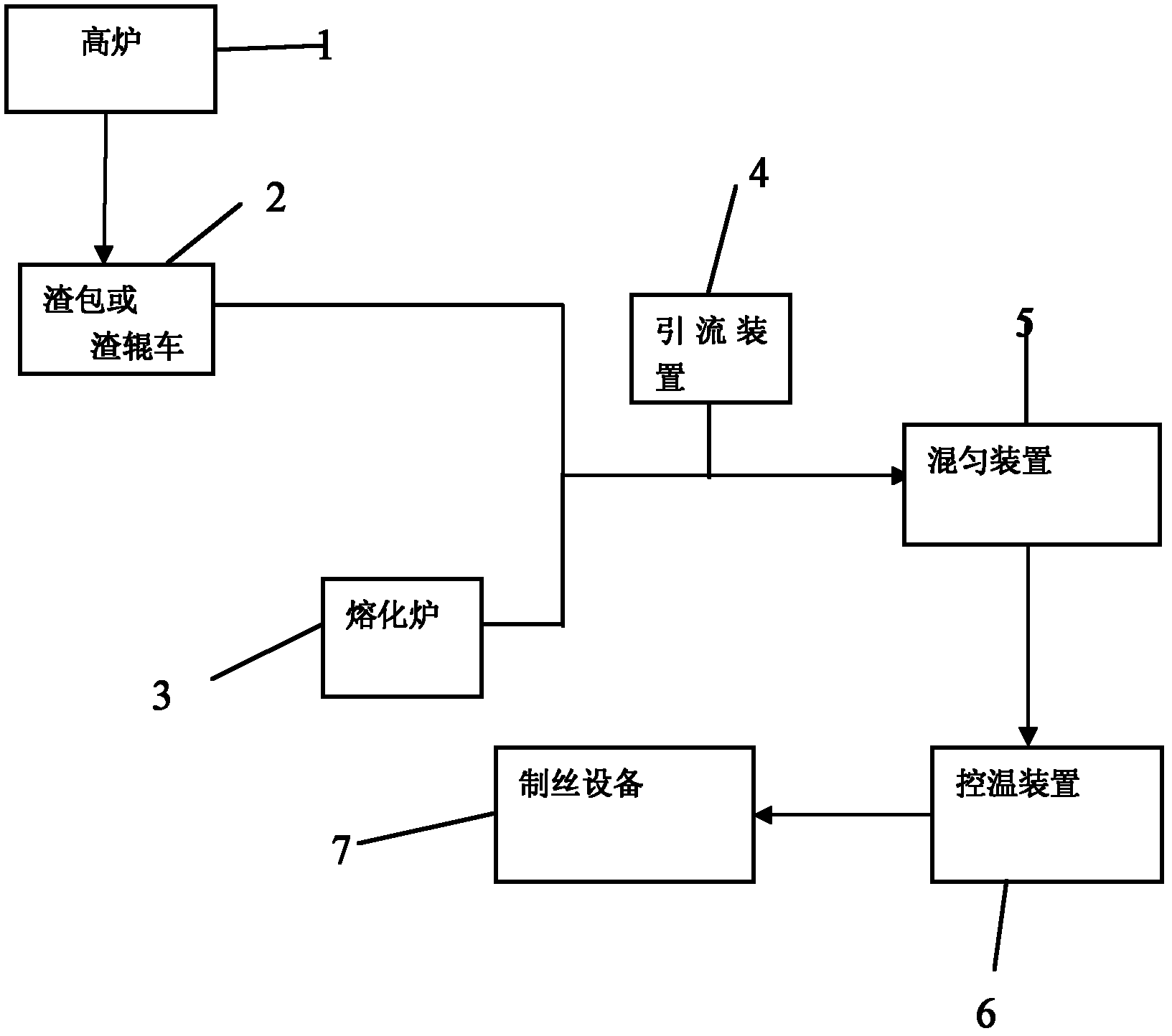

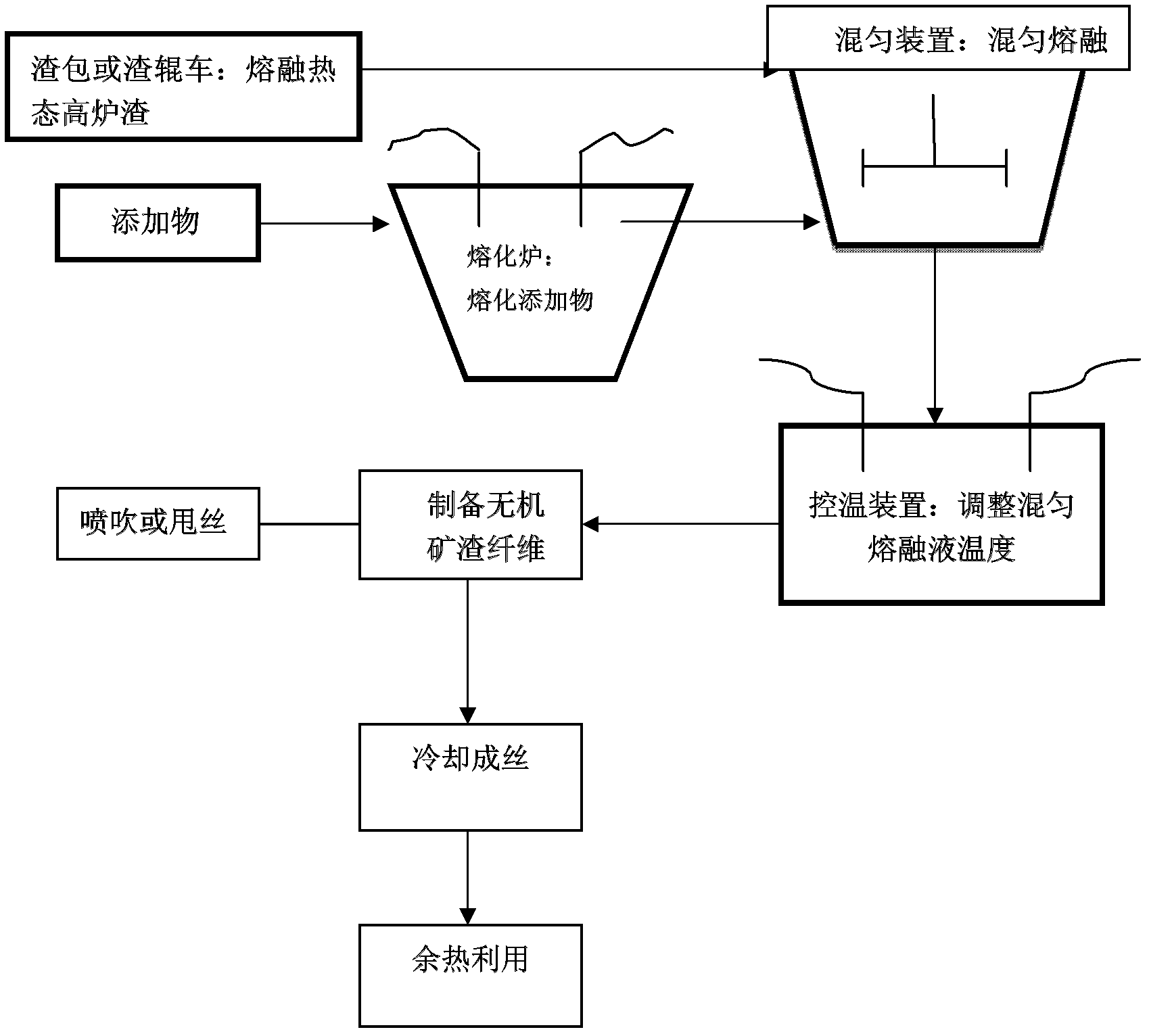

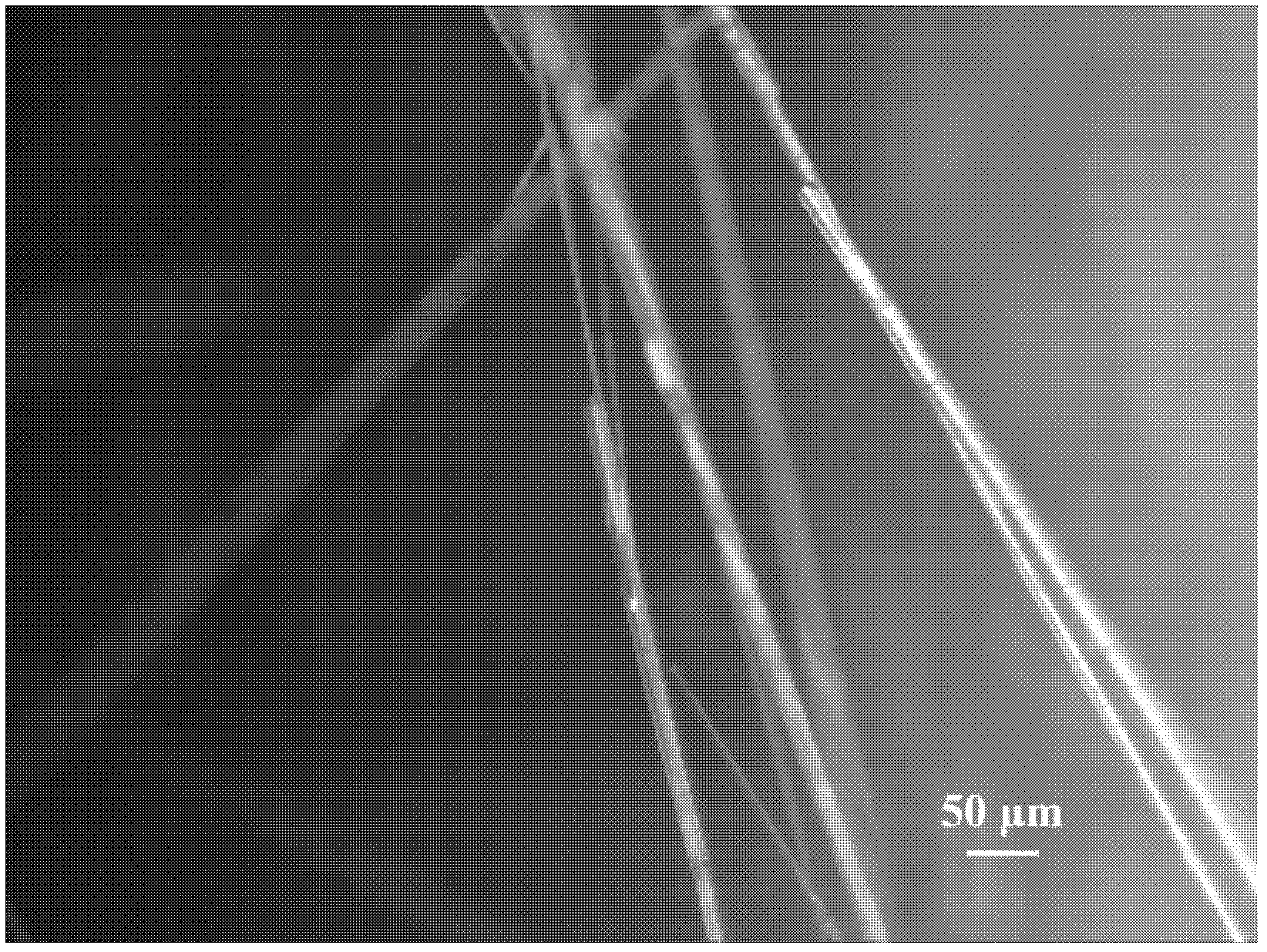

Equipment and method for preparing inorganic slag fiber from hot blast furnace slag

InactiveCN102276142ATake advantage ofRealize comprehensive utilizationGlass making apparatusFiberThermal state

The invention provides equipment and method for preparing inorganic ore slag fiber by utilizing thermal-state blast furnace slag. In the equipment, an additive melting furnace is designed. The method comprises the following steps: respectively melting the thermal-state blast furnace slag and the additive by utilizing the equipment and then evenly mixing so as to obtain a molten liquid which is evenly mixed; and making the molten liquid which is evenly mixed into silk so as to obtain the inorganic ore slag fiber. According to the invention, the method for preparing the inorganic ore slag by utilizing the novel equipment is simple and practicable and convenient for implementation, the sensible heat in a raw material is fully utilized, and the comprehensive utilization of different industrial waste materials such as thermal-state blast furnace slag and the like is realized, thereby overcoming the technical problems of fusing and evenly mixing; and the inorganic ore slag fiber having wide application and various good characteristics such as high temperature resistance, corrosion resistance, high strength, light specific gravity, good electric insulation property, low moisture absorption, small extension and the like can be prepared.

Owner:蓝天燕园科技有限公司

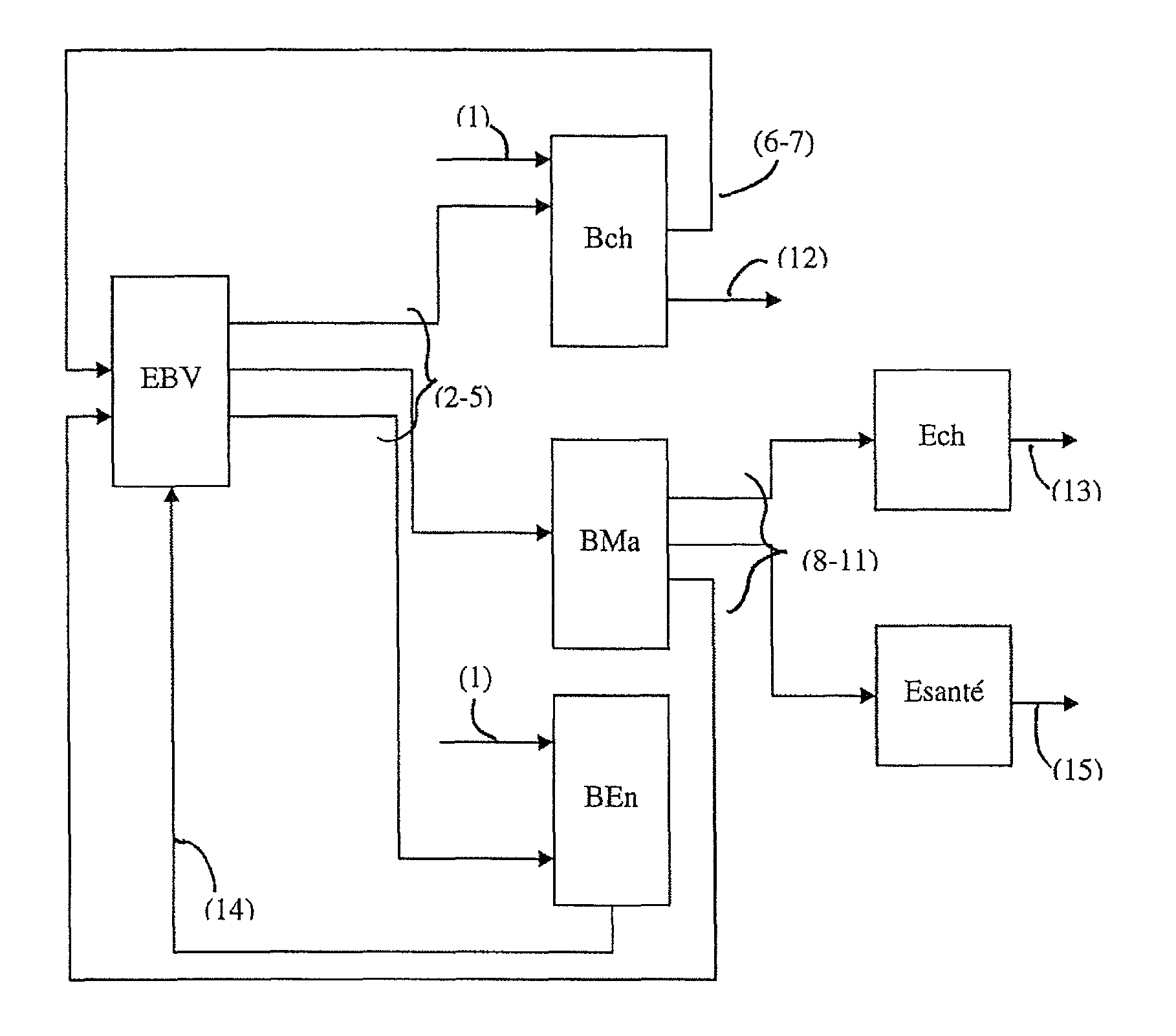

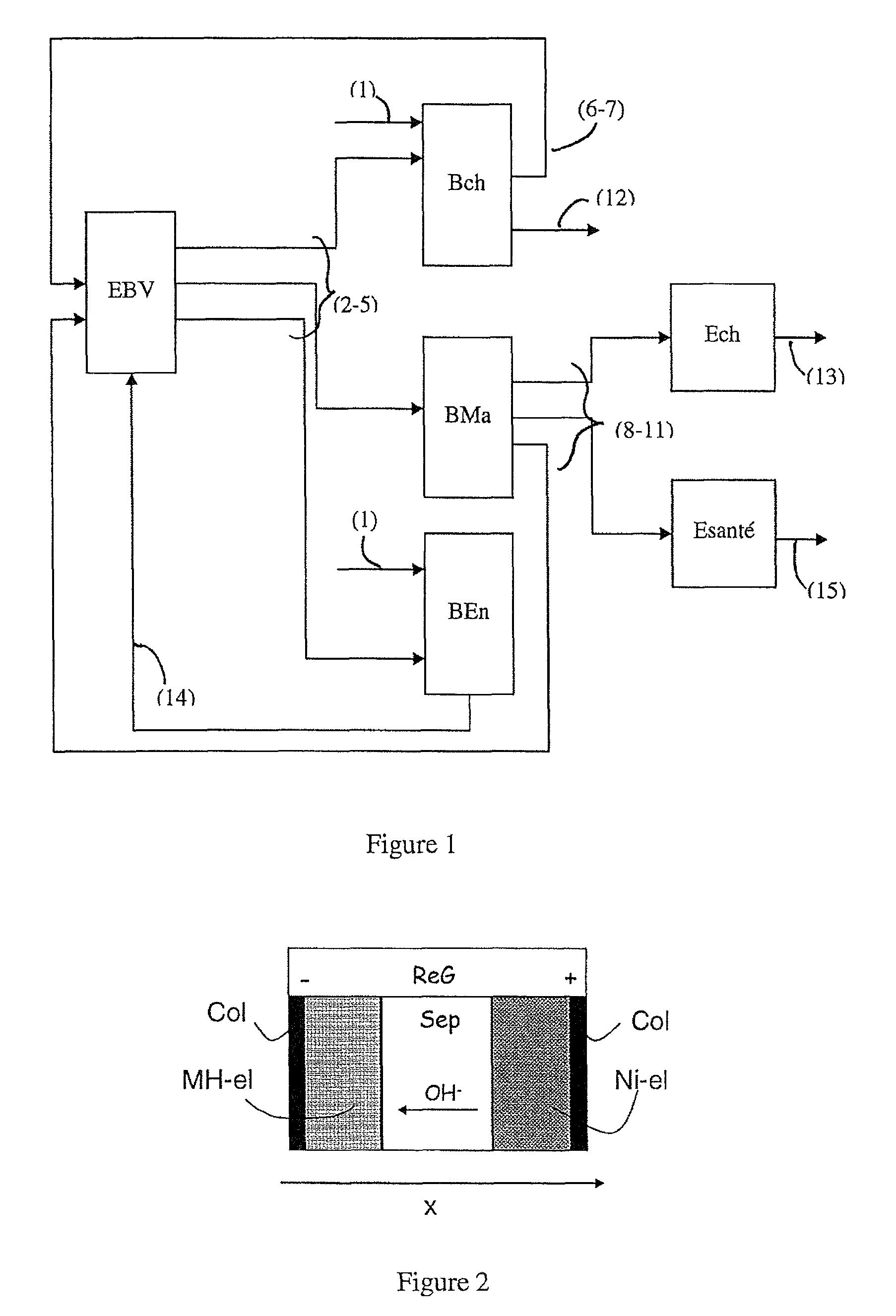

Method of estimating the non-measurable characteristics of an electrochemical system

InactiveUS8548762B2Current/voltage measurementResistance/reactance/impedenceThermal stateMathematical model

The present invention relates to a method of estimating the internal state of an electrochemical system by a zero-dimensional (0D) electrochemical mathematical model for estimating the characteristics of a battery that are not directly measurable during operation thereof. For applications relating to hybrid and electric vehicles, the most significant internal characteristics are the state of charge (SoC), the state of health (SoH) and the thermal state (T). Reconstruction of the internal characteristics is achieved using a mathematical model of the battery. The method can be used with the operation of the battery itself (real time) with a concentrated-parameter (0D) or off-line mathematical model, for calibration, an optimization or a validation of management and estimation strategies. The method allows simulation of the thermal and electrical behavior of a battery. The method according to the invention can also be useful for battery dimensioning and for optimization of the energy and thermal management strategies as a function of the desired application.

Owner:INST FR DU PETROLE

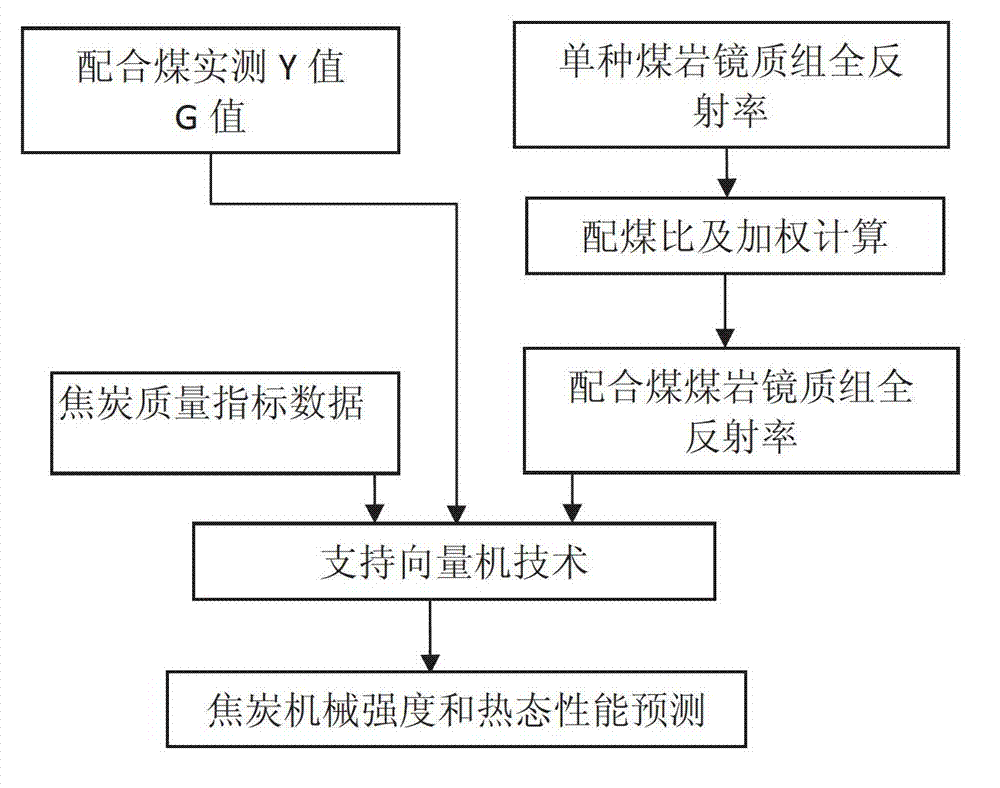

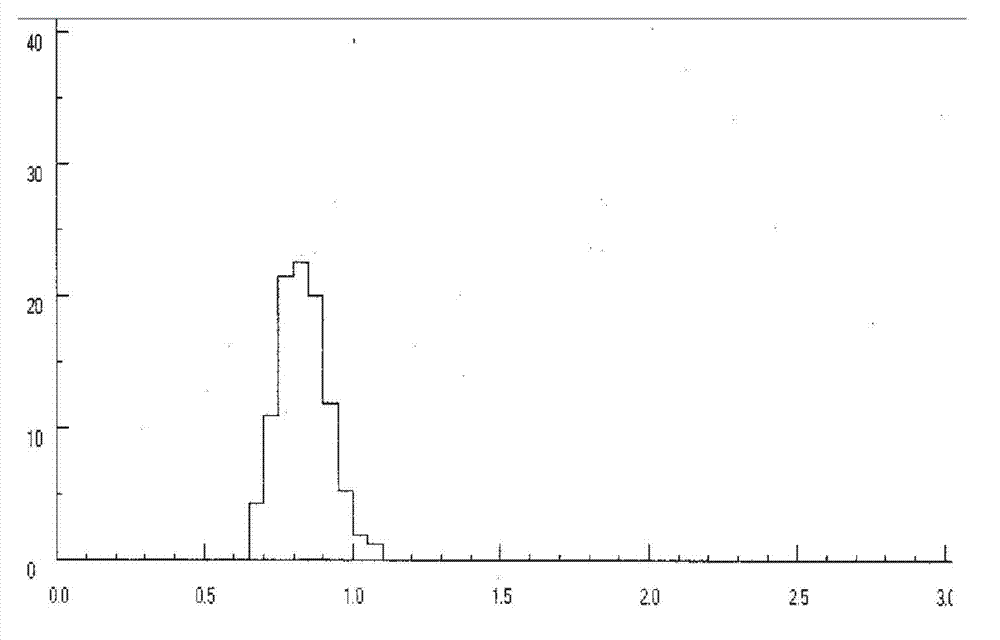

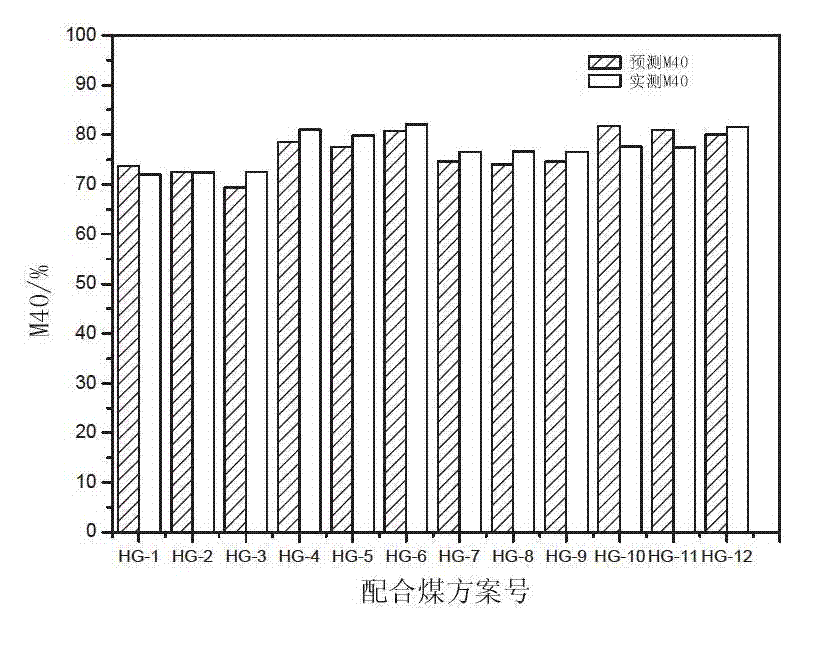

Method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance

ActiveCN102890144AMultiple Intrinsic Indicator ParametersThe prediction method is practicalFuel testingSupport vector machineThermal state

The invention discloses a method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance, thereby providing important technical assurance for the improvement of the stability and quality of coke produced by a coke making enterprise. The method provided by the invention comprises the following steps of: establishing a coking coal resource information database, and inputting the caking property index of coking blended coal and the coal rock index of single coking coal into the coking coal resource information database; and establishing a coke quality prediction model through a support vector machine, and then predicting the quality index of the coke according to the coal-quality caking property index level of the coking blended coal, wherein the coal-quality caking property index level comprises two factors, namely the maximum thickness value Y of a gelatinous layer and a caking index value G, and comprises coal rock vitrinite total-component reflectance and the liver-inert ratio of macerals. The method provided by the invention is capable of characterizing the maximum thickness value Y of the gelatinous layer indicating the quantity of metaplast in the softening process of the coking coal and indicating the caking property quality of the metaplast, thereby realizing the prediction process with the goal of predicting the mechanical strength and thermal state performance of the coke.

Owner:UNIV OF SCI & TECH LIAONING

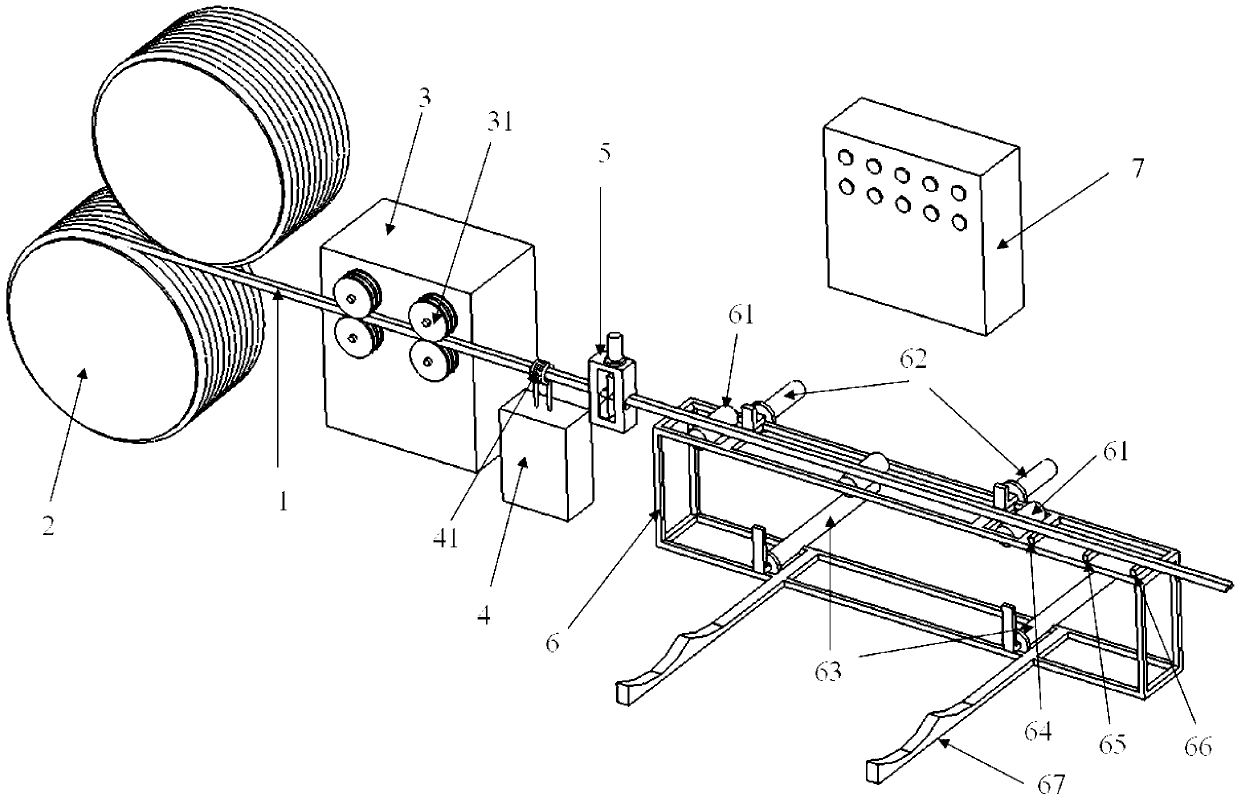

Full-automatic discharging method and equipment for steel strand anchor cable

The invention discloses a full-automatic discharging method and full-automatic discharging equipment for a steel strand anchor cable and relates to steel strand anchor cables for mine roadway support. The technical problems that the conventional steel strand anchor cable production method is low in efficiency and the environment is polluted are solved. The discharging method comprises the following steps of: (1) feeding a steel strand; (2) locally heating the steel strand 1; (3) rapidly cutting the steel strand in a local heat state through a hydraulic shearing device; (4) discharging the steel strand anchor cable, and finishing a full-automatic discharging process; and (5) packing a steel strand anchor cable group, and finishing production of a group of steel strand anchor cables. Because the steel strand anchor cable is produced by employing a dual-disc rack, a steel strand vortex local heating and hydraulic shearing, the full-automatic discharging method is used for discharging the steel strand anchor cables for mine roadway support and has the advantages of high production efficiency, safety, reliability and no pollution.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

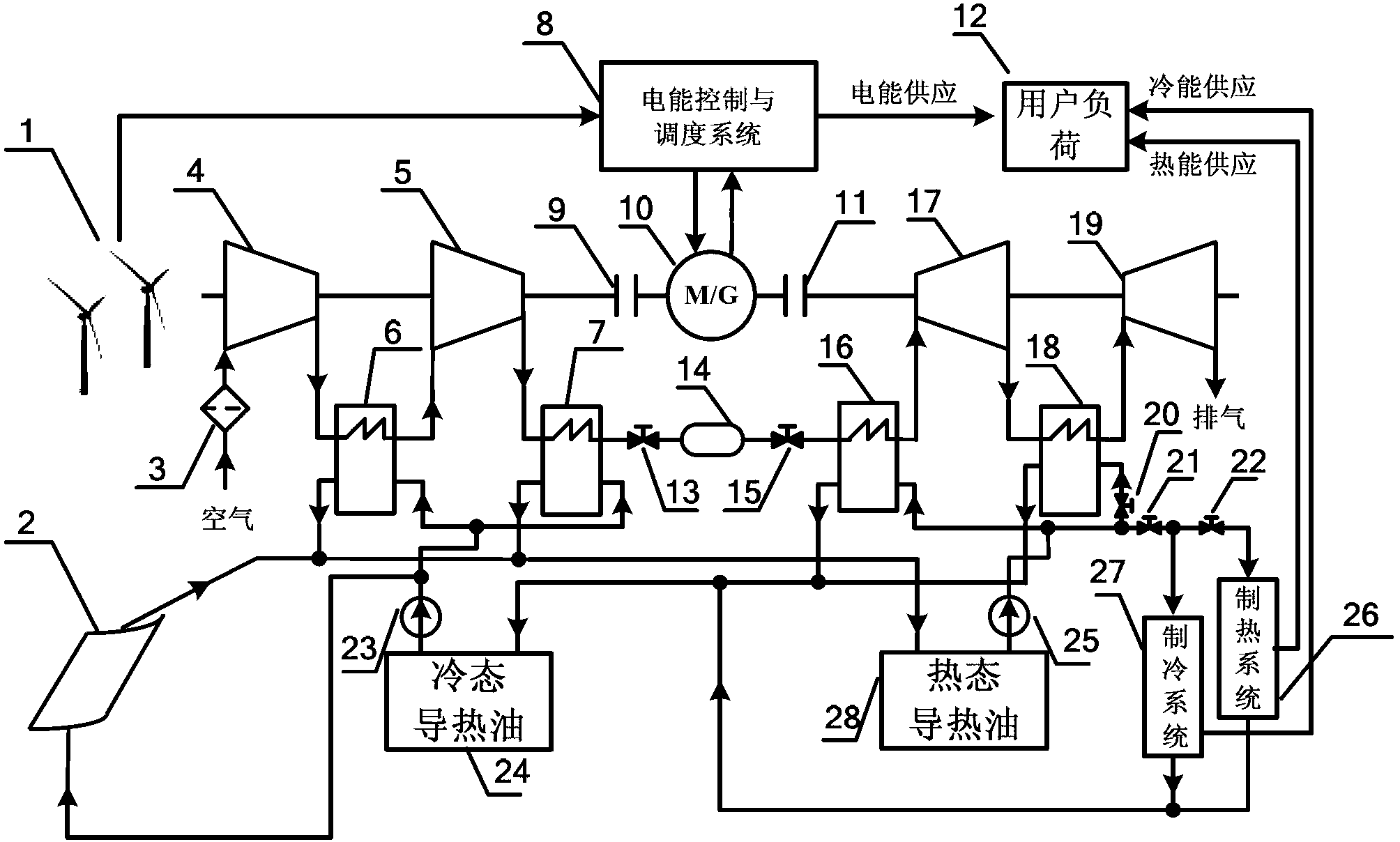

Wind-light-storage island-type combined cooling, heating and power system based on solar light-heat utilization

InactiveCN103291557AImprove consumption structureImprove utilization efficiencySolar heat devicesMachines/enginesThermal energyThermal state

The invention provides a wind-light-storage island-type combined cooling, heating and power system based on solar light-heat utilization. The system comprises a wind energy conversion system, a solar heat collecting system, a micro compressed air energy-storage system and a heat storage system. When wind speed is high, surplus electric energy drives a multistage compressor to compress air from a level of atmospheric pressure to a higher level of pressure to be stored into a compressed air storage pipeline, and heat in the process of compressing is recovered into the heat storage system, at the moment, supplying of cold energy and heat energy is realized after pumped thermal-state heat conducting oil is shunted and enters an absorption-type refrigerating system and a heating system. When the wind speed is low, after absorbing heat from the heat storage system, compressed air enters a turbine to expand for doing work so as to fill a demand gap of electric energy, so that demands of a user on cold energy and heat energy are met through the thermal-state heat conducting oil.

Owner:XI AN JIAOTONG UNIV

Method for heating a glow plug for a diesel engine

ActiveUS7234430B2Avoid overall overheatingShort timeElectrical controlIncandescent ignitionThermal stateMathematical model

A method for heating a glow plug for a diesel engine to its desired temperature by supplying power to the glow plug in a controlled fashion. During a certain time interval after termination of a previous glow process, a mathematical model is used to determine the values for the supply of power to the glow plug, which includes the values of the actual thermal state of the glow plug, the time elapsed since the end of the previous glow process and the parameters of the diesel engine relevant for a glow process.

Owner:BERU AG DE

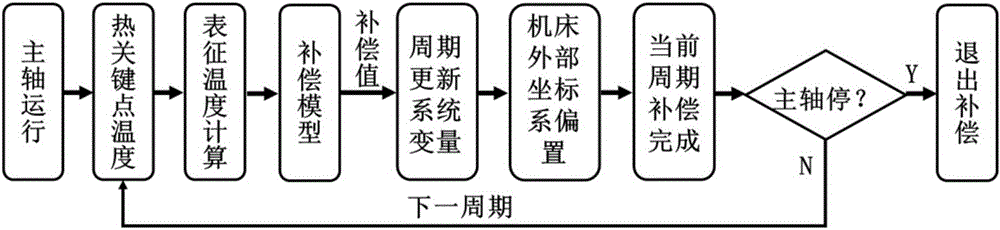

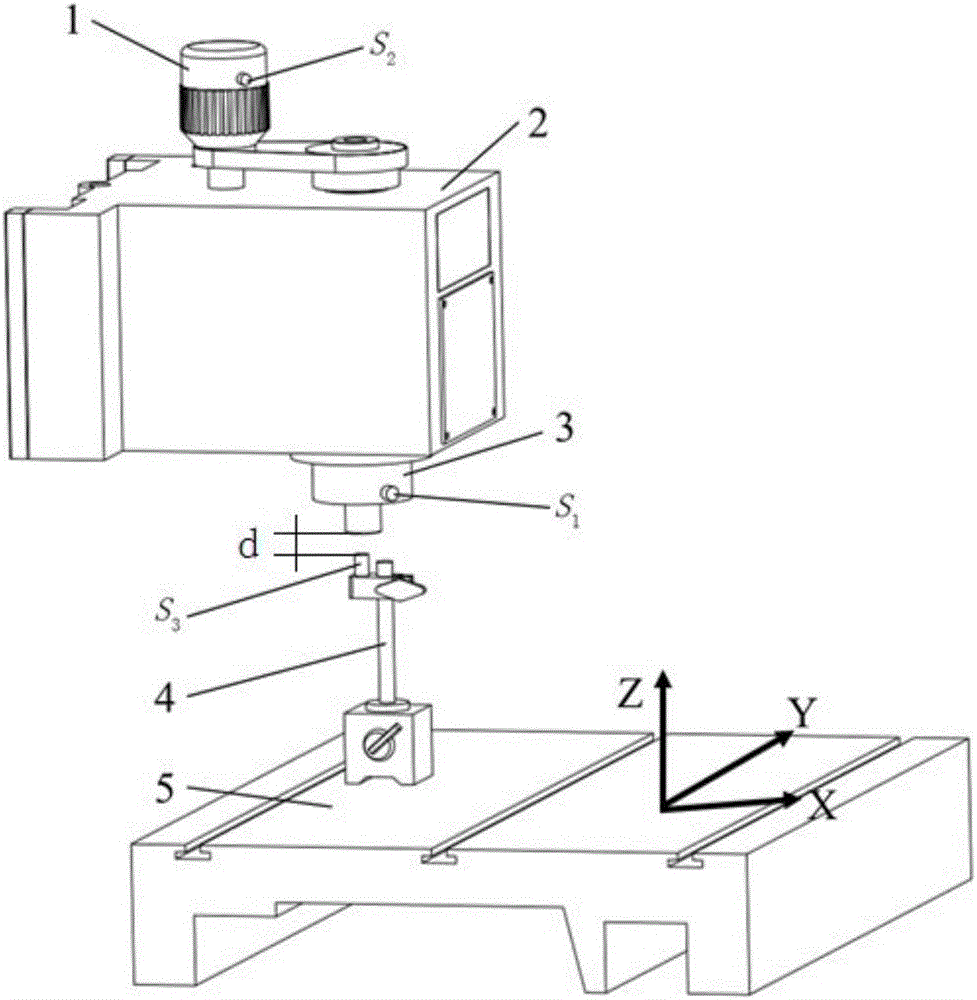

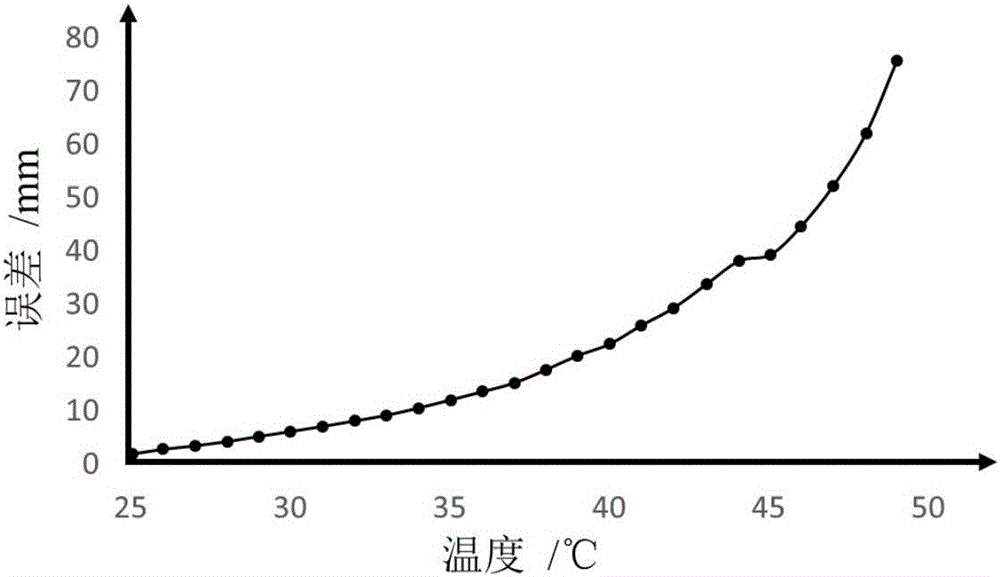

Numerically-controlled machine tool spindle thermal extension error real-time compensation method

ActiveCN106444628AImplement predictive compensationImprove working condition adaptabilityProgramme controlComputer controlNumerical controlThermal state

The invention relates to a numerically-controlled machine tool spindle thermal extension error real-time compensation method and belongs to the numerically-controlled machine tool machining field. According to the method, a temperature sensor is used to detect the temperature of a thermal critical point in real time under the current rotation speed of a spindle, and characterization temperature is calculated according to the degree of influence on the thermal extension error of the spindle caused by the temperature of the thermal critical point; spindle thermal extension error compensation amount under a current thermal state is calculated; system variables of the machine tool external coordinate system offset function of a linear shaft of which the axis is consistent with the axis of the spindle are updated according to a certain period; and the real-time compensation of the thermal expansion error of the spindle is completed. According to the numerically-controlled machine tool spindle thermal extension error real-time compensation method of the invention, a plurality of temperature variables are converted into one characterization temperature according to the degree of the influence on the thermal extension error of the spindle caused by the temperature of the thermal critical point, and therefore, temperature field information overlapping can be eliminated; and a method according to which a PLC is used as a compensation program carrier is adopted, so that the real-time performance of compensation can be ensured, and the complexity of a compensation process is decreased; and the compensation process is simple and fast and has high real-time performance.

Owner:DALIAN UNIV OF TECH

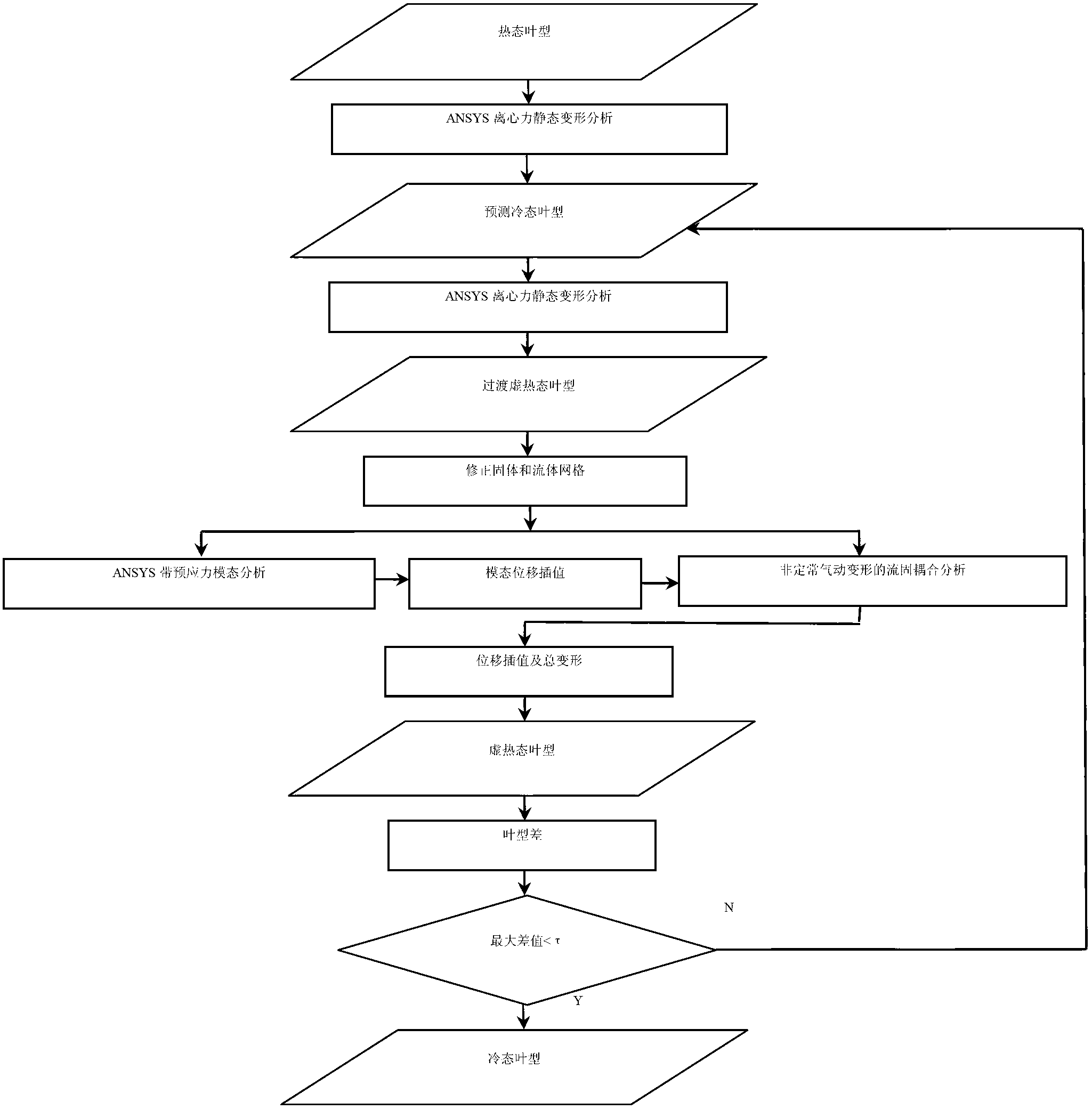

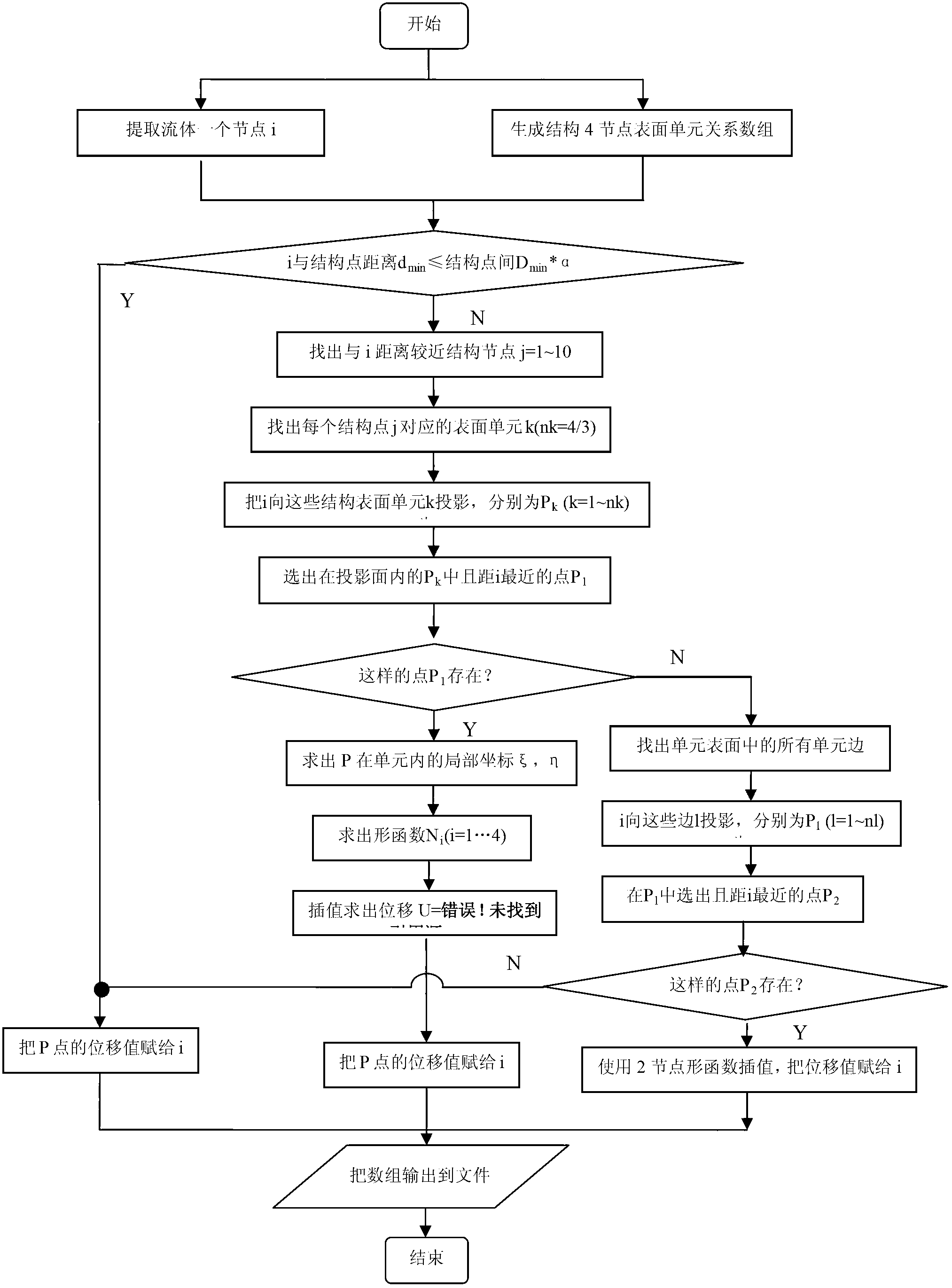

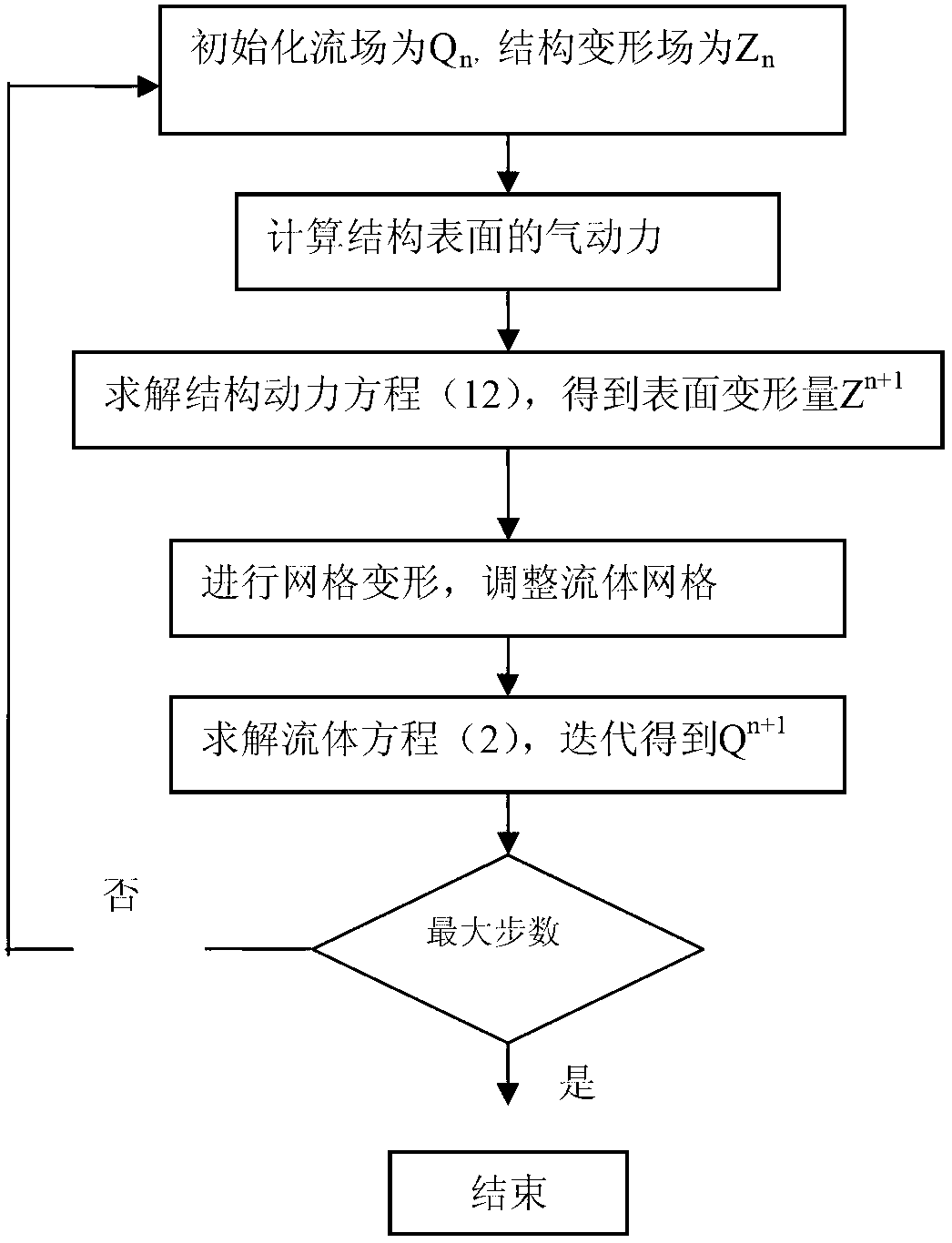

Method for estimating reverse twisting process of fan blade of gas turbine

InactiveCN102799730AImprove calculation accuracyOptimizing Manufacturing AirfoilsSpecial data processing applicationsThermal stateEngineering

The invention provides a method for estimating a reverse twisting process of a fan blade of a gas turbine, and aims to solve the problem that the conventional gas turbine fan blade reverse twisting design method is incomplete. According to the method, a cold state blade profile can be finally obtained by steps of performing analysis software (ANSYS) centrifugal force static deformation analysis on a thermal state blade profile, forecasting the cold state blade profile, then performing ANSYS centrifugal force static deformation analysis on the forecast cold state blade profile, transitioning a virtual thermal state blade profile, correcting a solid and liquid grid, performing aerodynamic force deformation fluid-solid coupling analysis and the like. The method has great significance for implementing consistency between the forecast thermal state blade profile and an actual working state blade profile of the blade under each pneumatic working condition and researching a method for precisely estimating the reverse twisting process of the fan blade of the gas turbine; and particularly, the method has important engineering application value in developing transonic speed fans with large bypass ratios.

Owner:BEIHANG UNIV

System for smart management of an electrochemical battery

InactiveUS20110060565A1Batteries circuit arrangementsMaterial analysis by electric/magnetic meansThermal stateElectrical battery

The present invention relates to a system for smart management of an electrochemical battery using a method of estimating the internal state of the battery, by use of mathematical models for management of an electrochemical battery during operation thereof, and notably for estimating the characteristics of the battery that are not directly measurable. For applications relative to hybrid and electric vehicles, the most interesting internal characteristics are the state of charge (SoC), the state of health (SoH) and the thermal state. Reconstruction of the internal characteristics is done using mathematical models of the batter.

Owner:INST FR DU PETROLE

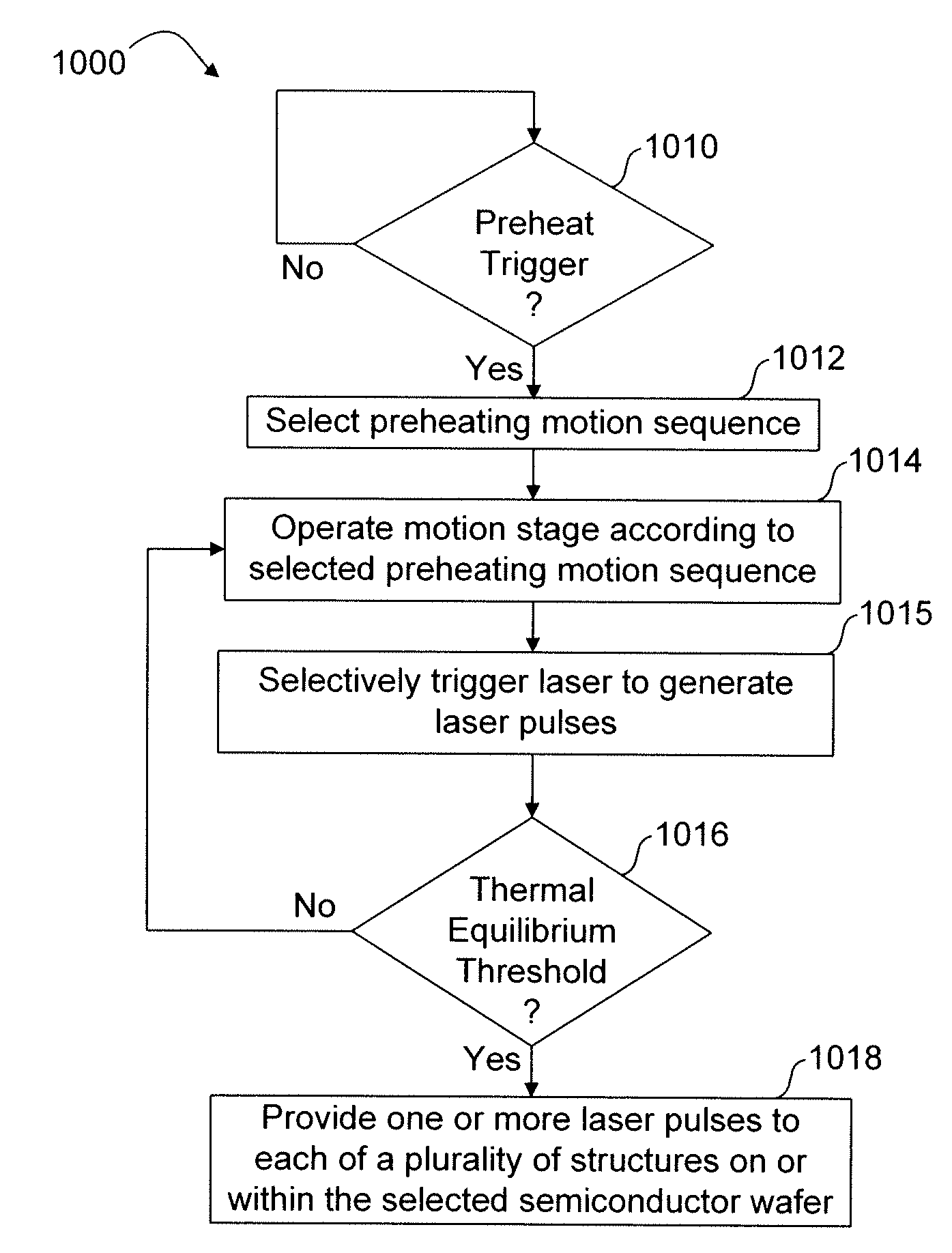

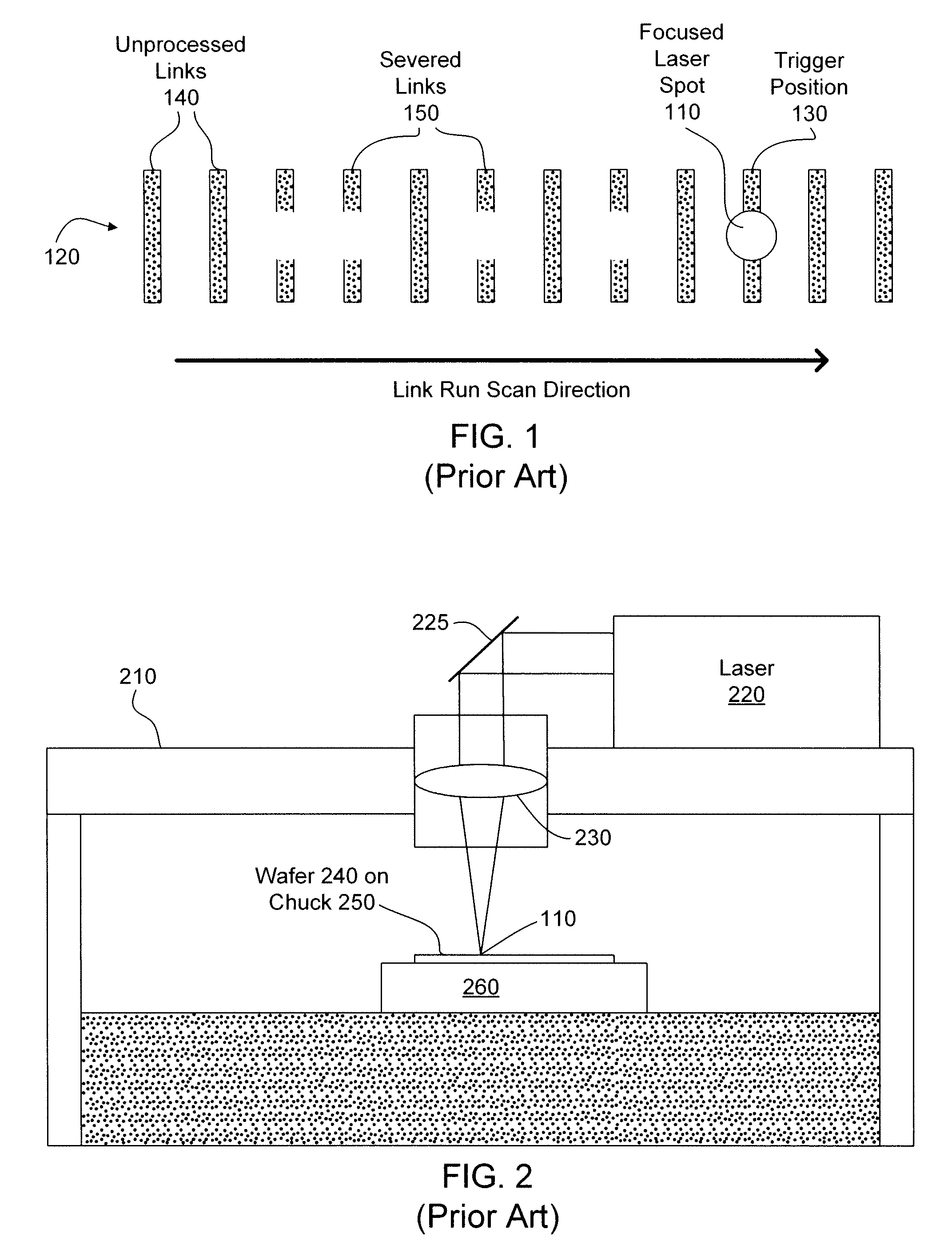

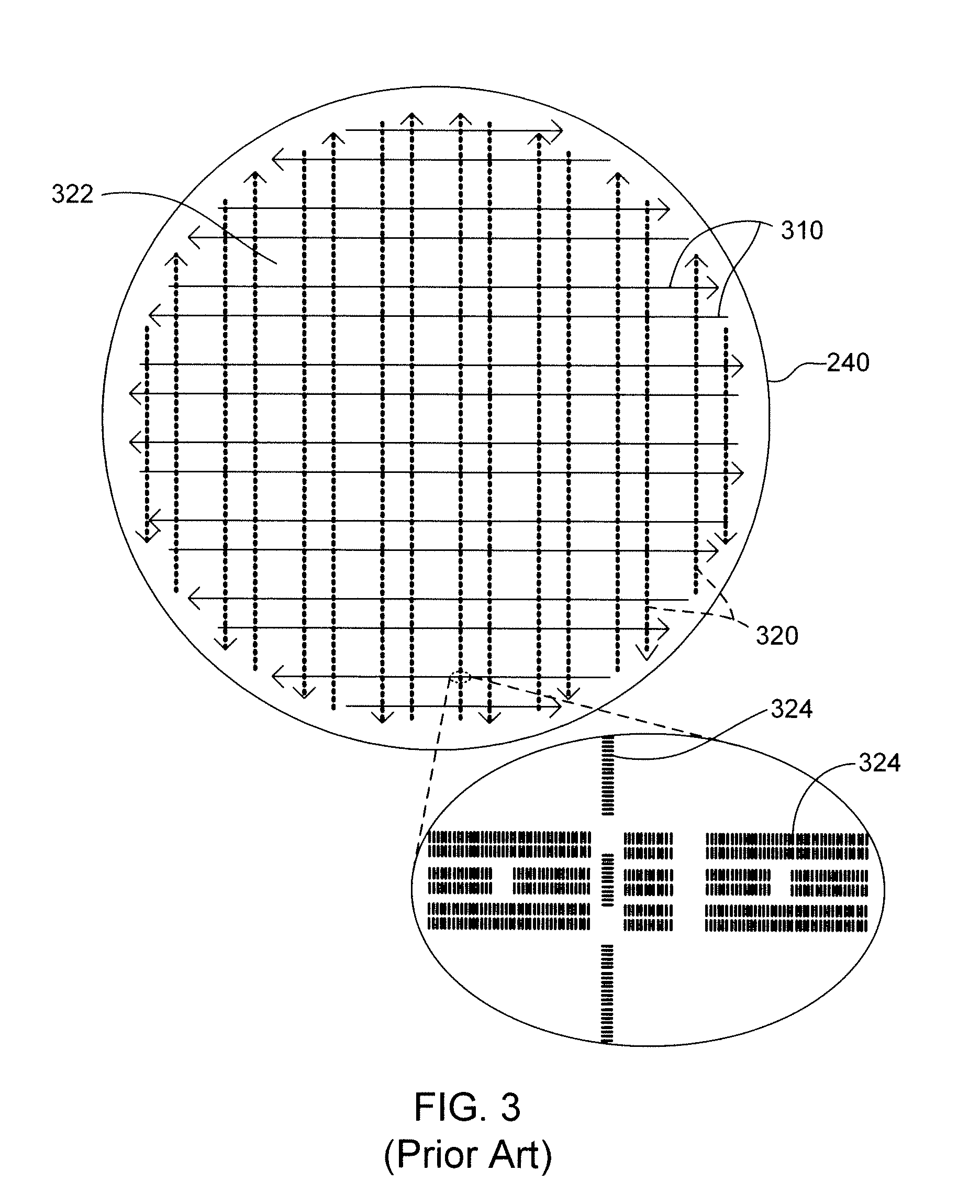

Systems and methods for adapting parameters to increase throughput during laser-based wafer processing

InactiveUS20080314879A1Reduce and eliminate damageRead-only memoriesSemiconductor/solid-state device manufacturingThermal stateEngineering

Systems and methods automatically modify a laser-based system for processing target specimens such as semiconductor wafers. In one embodiment, the laser-based system detects a trigger associated with a processing model. The processing model corresponds to a set of wafers. In response to the trigger, the system automatically adjusts one or more system parameters based on the processing model. The system then uses the modified system parameters to selectively irradiate structures on or within at least one wafer in the set of wafers. In one embodiment, the trigger includes variations in a thermal state related to a motion stage. In response to the variations in the thermal state, the system operates the motion stage in a series of movements until a thermal equilibrium threshold is reached. The sequence of movements may, for example, simulate movements used to process a particular wafer.

Owner:ELECTRO SCI IND INC

Controlling the temperature of a substrate in a film deposition apparatus

InactiveUS20050011457A1Electric discharge heatingVacuum evaporation coatingTemperature controlThermal state

A system and method for that allows one part of an atomic layer deposition (ALD) process sequence to occur at a first temperature while allowing another part of the ALD process sequence to occur at a second temperature. In such a fashion, the first temperature can be chosen to be lower such that decomposition or desorption of the adsorbed first reactant does not occur, and the second temperature can be chosen to be higher such that comparably greater deposition rate and film purity can be achieved. Additionally, the invention relates to improved temperature control in ALD to switch between these two thermal states in rapid succession. It is emphasized that this abstract is provided to comply with rules requiring an abstract. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:CHIANG TONY P +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com