Non-contact measurement method for thermal state sizes of forgings

A non-contact measurement and forging technology, applied in measurement devices, image data processing, instruments, etc., can solve the problems of slow data processing, large amount of information collection, and inability to meet real-time measurement of industrial forging production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The concrete implementation of the present invention is described in detail in conjunction with accompanying drawing and technical scheme:

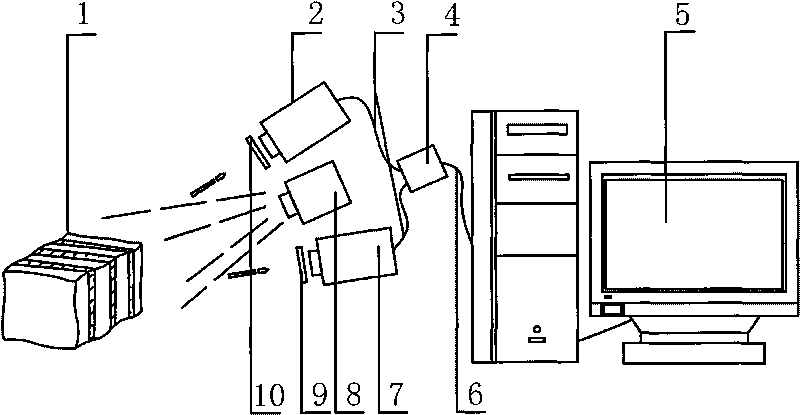

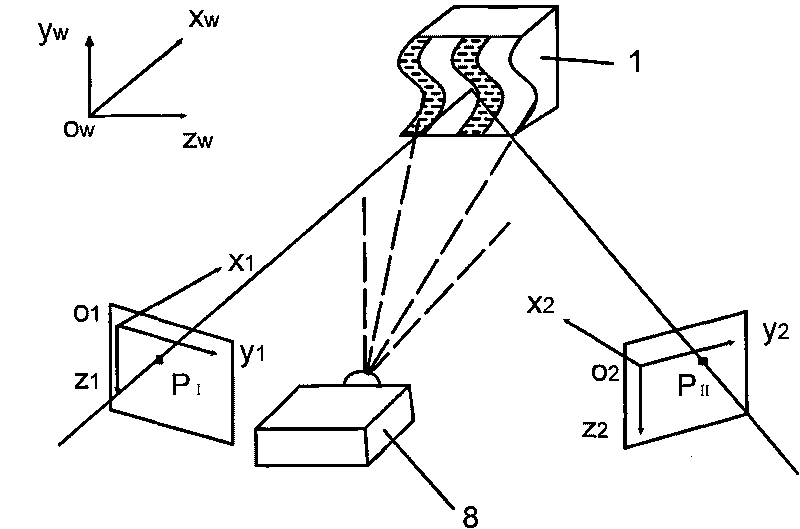

[0055] A schematic diagram of an image acquisition system of a non-contact measurement method for the hot state size of a forging is shown in figure 1 As shown, the DLP projector 8 is placed between the first and second CCD cameras 2 and 7 and is responsible for projecting strip-shaped structured light to the high-temperature forging 1. The first and second CCD cameras 2 and 7 are responsible for taking images of the high-temperature forging 1. The front end is connected to There are first and second low-pass filters 10 and 9 that can filter out the high-temperature radiation of the high-temperature forging 1, and the data line 3 connects the first and second CCD cameras 2 and 7 with the camera control box 4, and finally the data line 6 Connect the camera control box 4 and the computer 5 together.

[0056] (1) Determine the coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com