Reactor pressure vessel boron concentration measuring device based on modeling scaling method

The technology of a pressure vessel and a measuring device is applied in the field of a test device for simulating the mixing and diffusion process of a boric acid solution in a pressure vessel of a nuclear power plant. Cost of research, effect of improving the accuracy of predictive analytics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

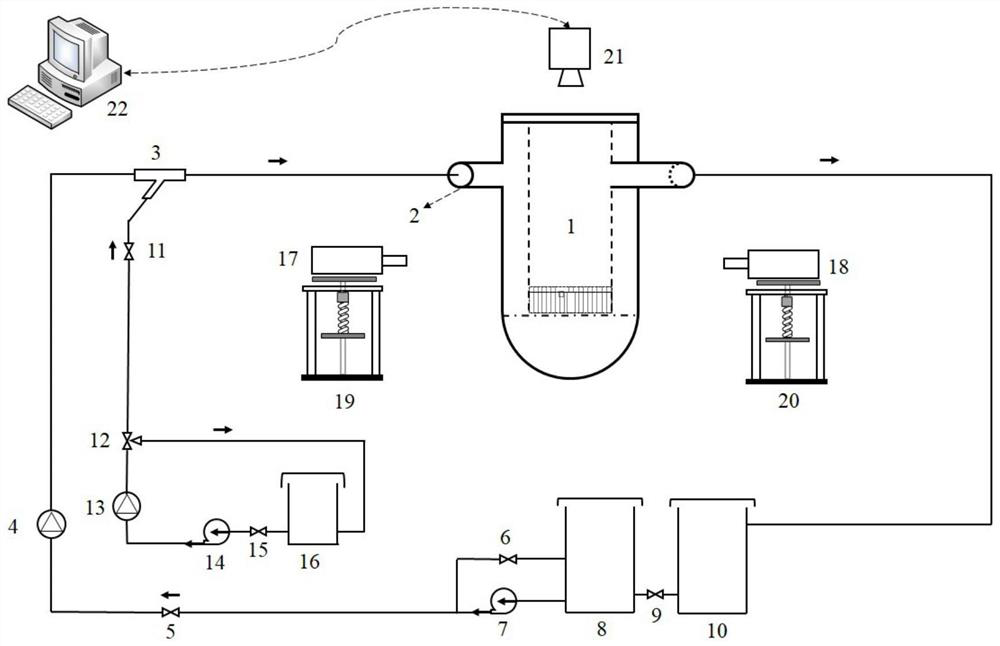

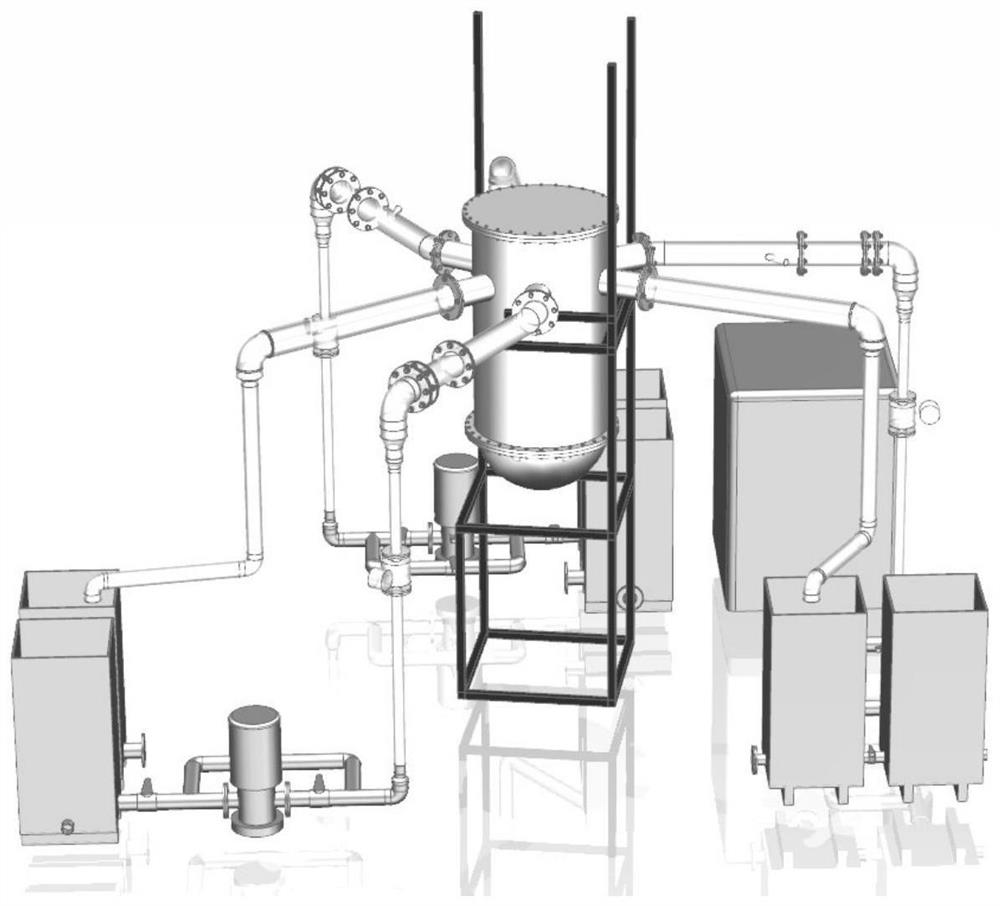

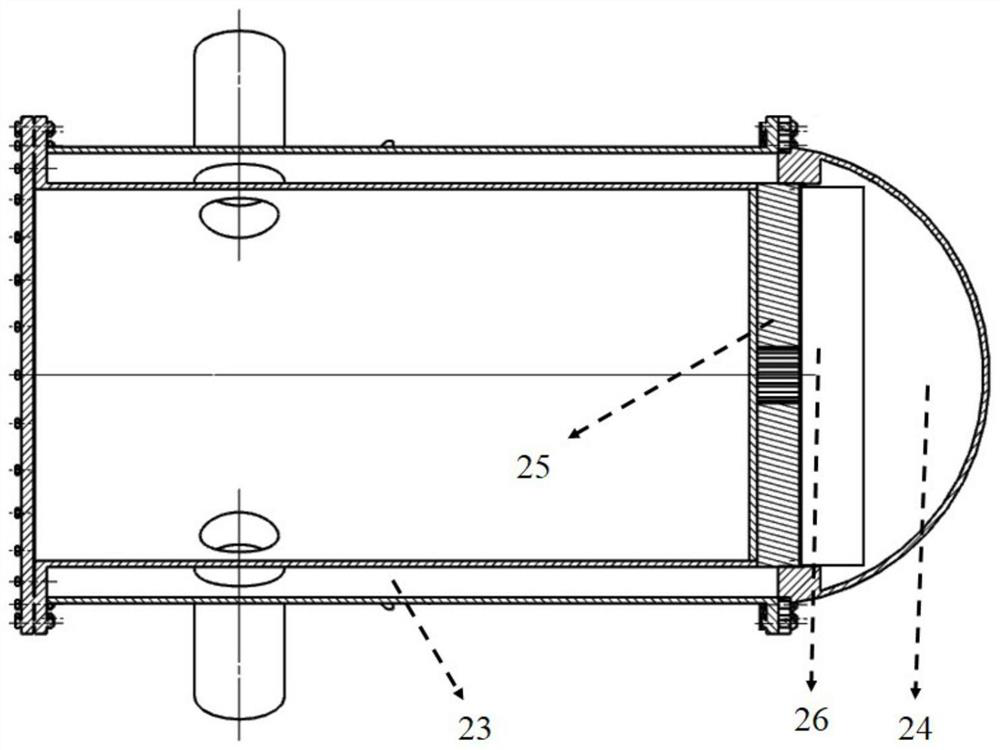

[0021] This experimental device is a two-dimensional visualization experimental device designed based on the similarity principle and laser-induced fluorescence technology. The key points of the technical plan are: based on the similarity principle, the boron transport and diffusion behavior in the reactor pressure vessel of the nuclear power plant is scaled and modeled. Obtain the similarity criterion of fluid flow in RPV and the transport and diffusion behavior of boric acid solution, and then design a visual test body that simulates the complex structure of RPV; based on laser-induced fluorescence technology, use a high-speed camera to shoot the flow process of the fluid in the complex structure of the pressure vessel , by recording the different degrees of fluorescence emitted by laser dyes in the fluid to measure the change of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com