Patents

Literature

246 results about "Boron concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concentrations of boron in surface water range widely, from 0.001 mg/litre to as much as 360 mg/litre. However, average boron concentrations are typically well below 0.6 mg/litre (see table below).

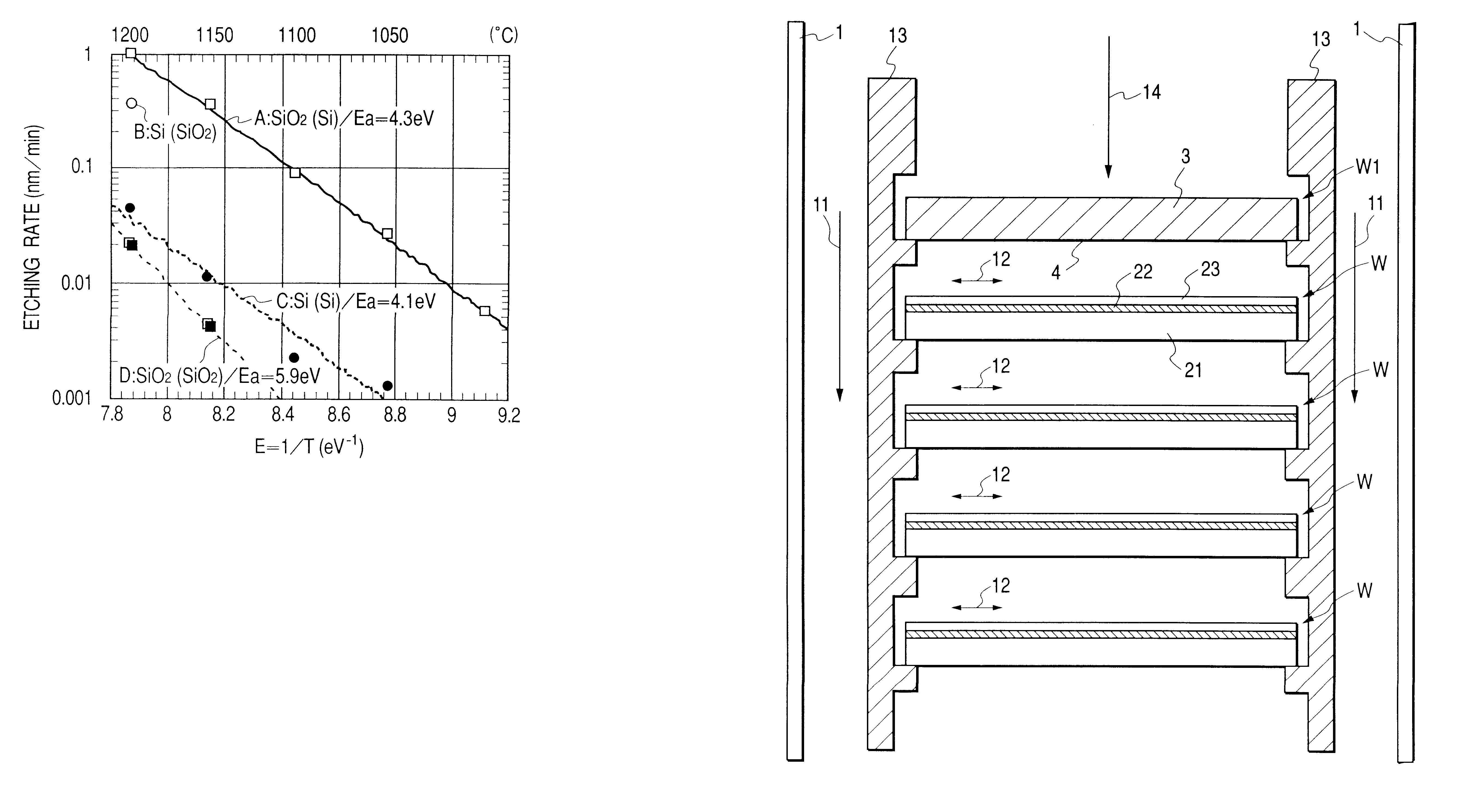

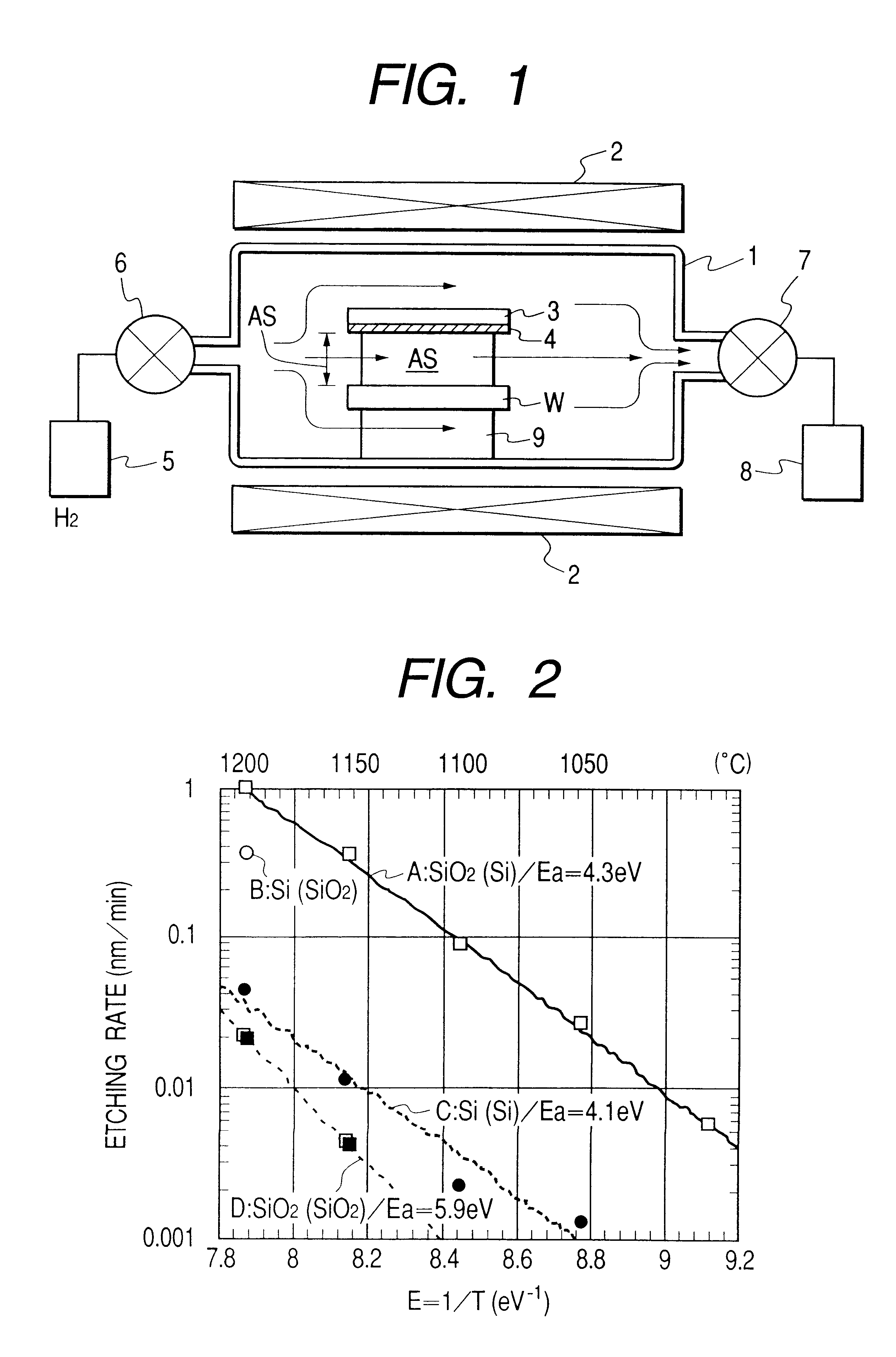

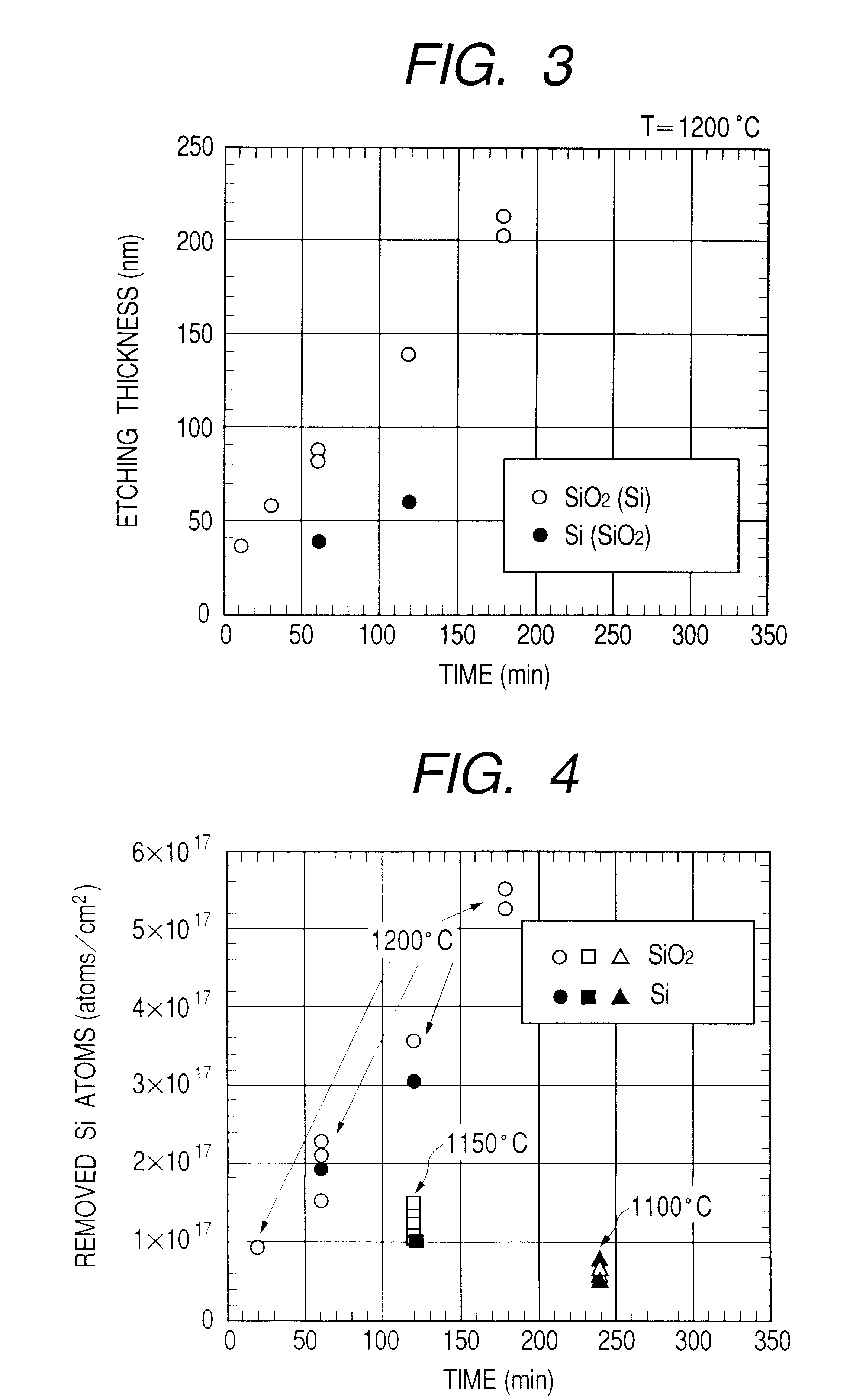

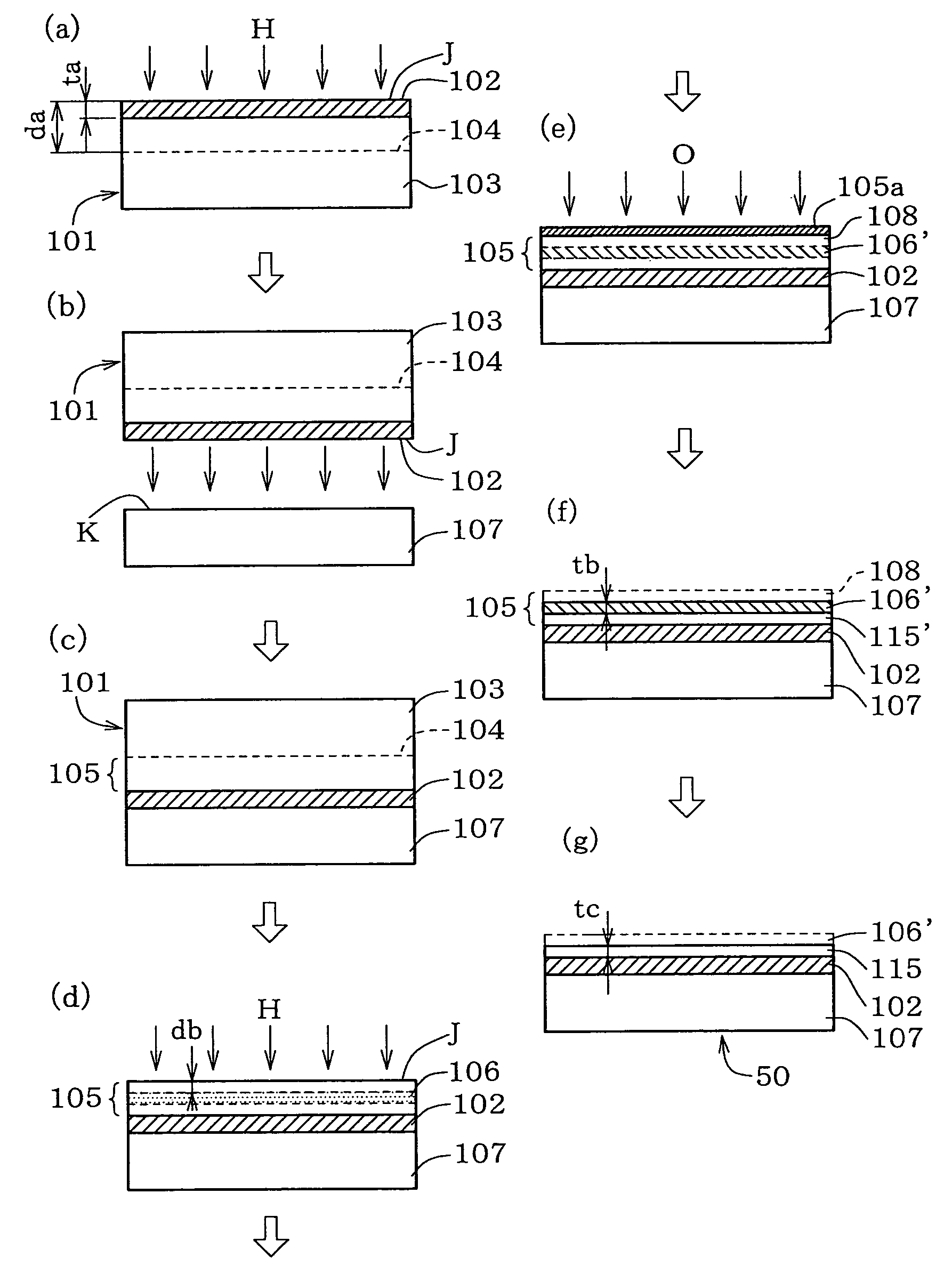

Method and apparatus for heat-treating an SOI substrate and method of preparing an SOI substrate by using the same

InactiveUS6171982B1Reduce the presence of impuritiesMaintain consistencyMuffle furnacesSolid-state devicesWaferingHydrogen

An SOI substrate having on the surface thereof a single crystal silicon film formed on an insulator is heat-treated in a hydrogen-containing reducing atmosphere in order to smooth the surface and reduce the boron concentration without damaging the film thickness uniformity in a single wafer and among different wafers. The method is characterized in that the single crystal silicon film is arranged opposite to a member of non-oxidized silicon for heat treatment.

Owner:CANON KK

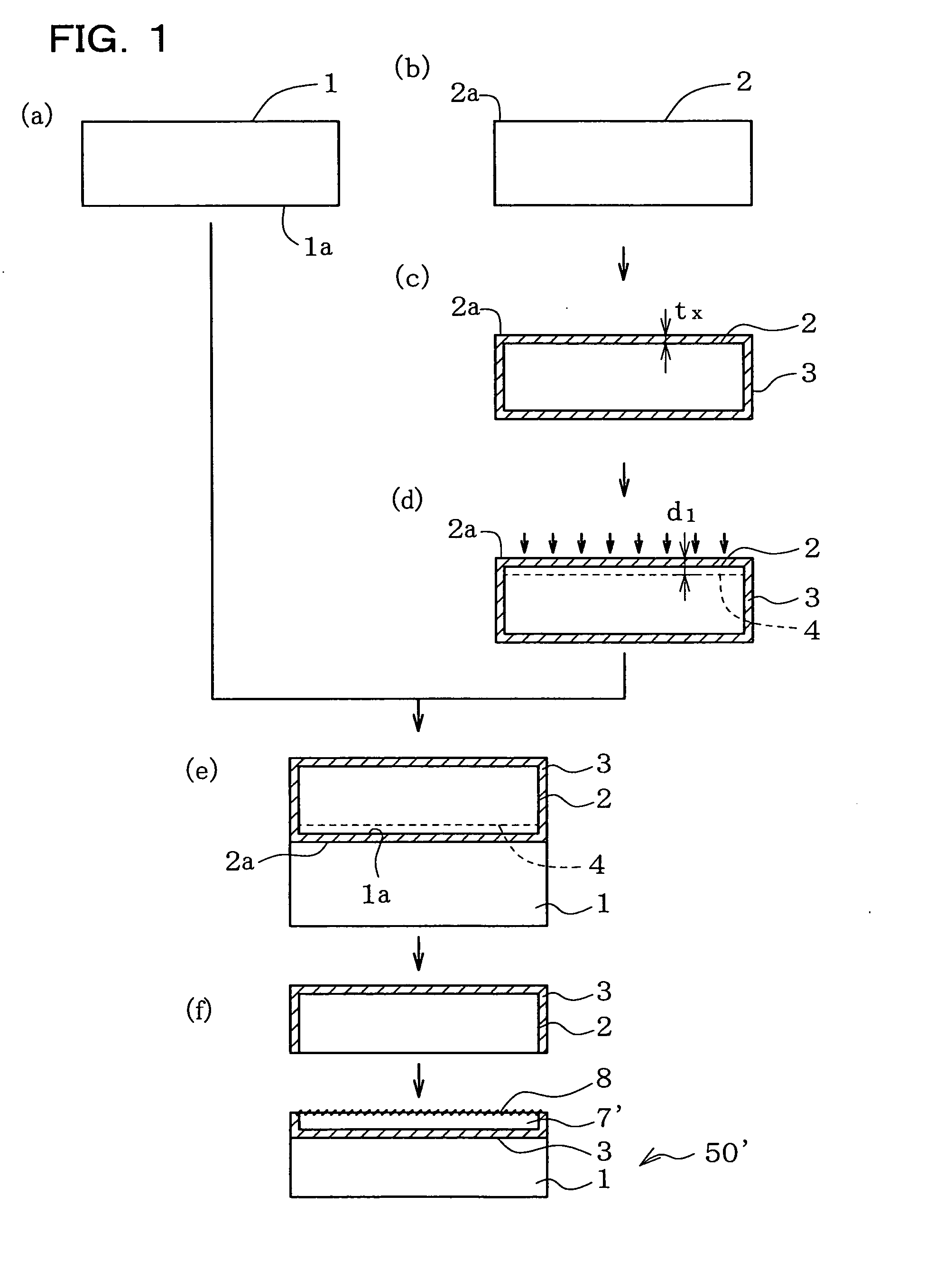

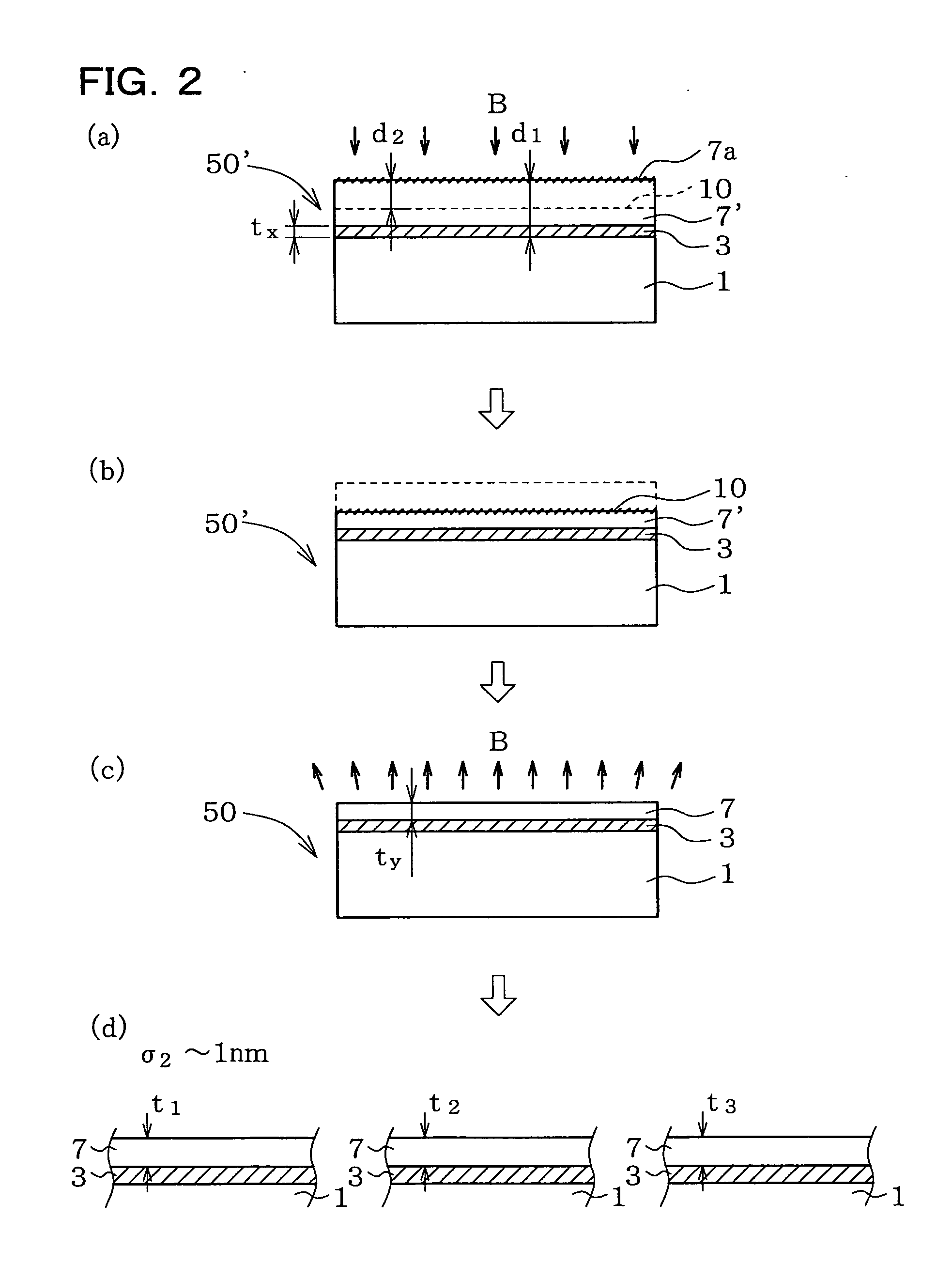

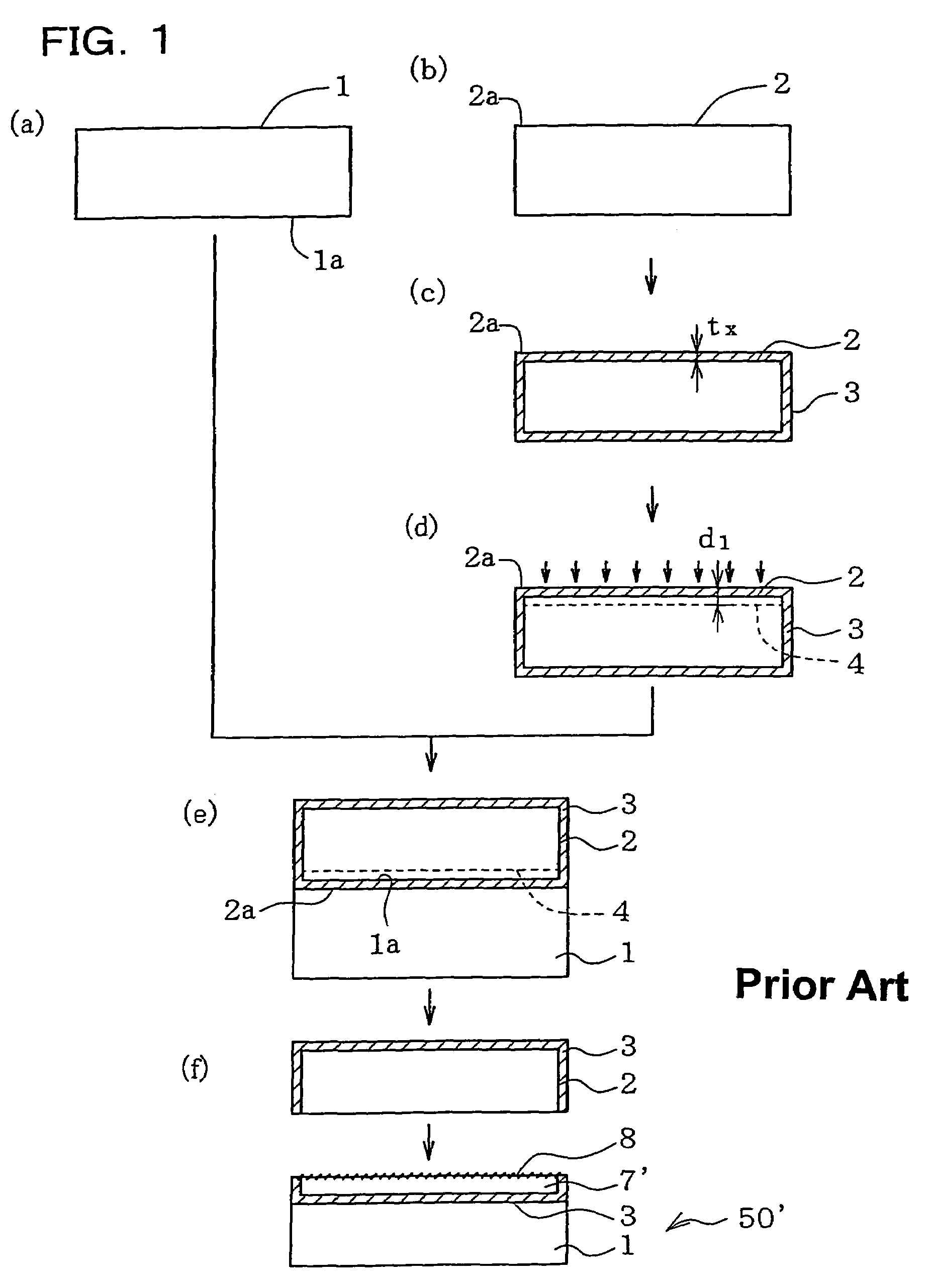

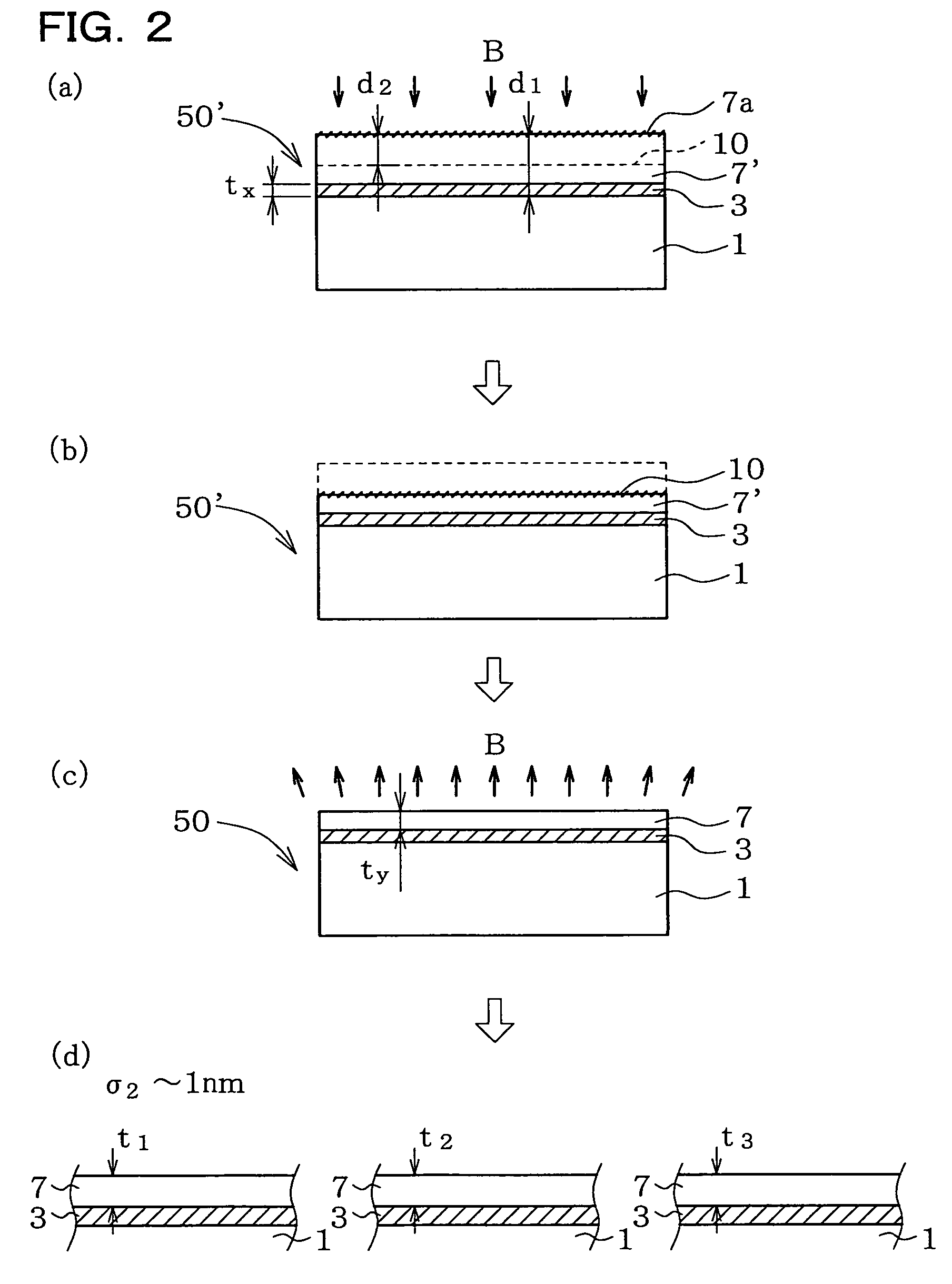

Production method for soi wafer

InactiveUS20050014346A1Improving film thickness distributionReduce surface defectsSolid-state devicesSemiconductor/solid-state device manufacturingEtchingThinning

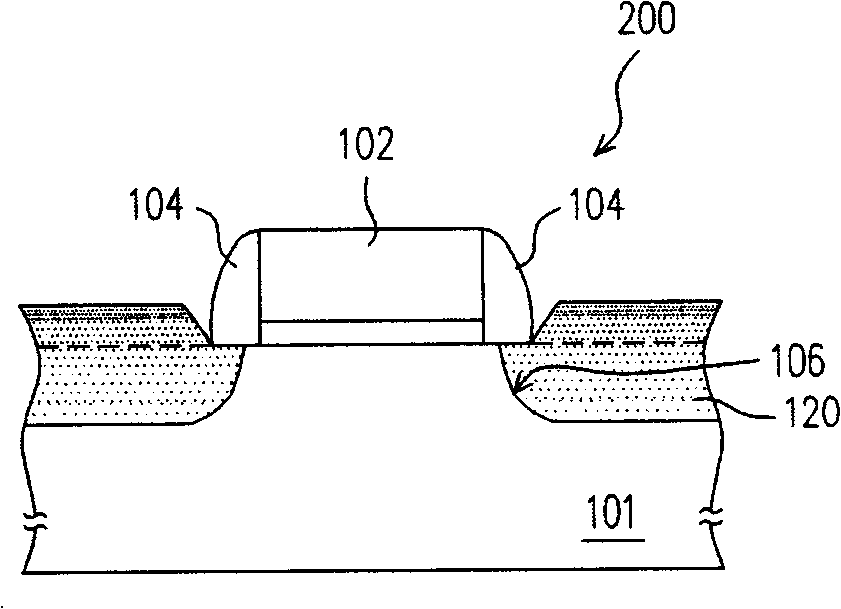

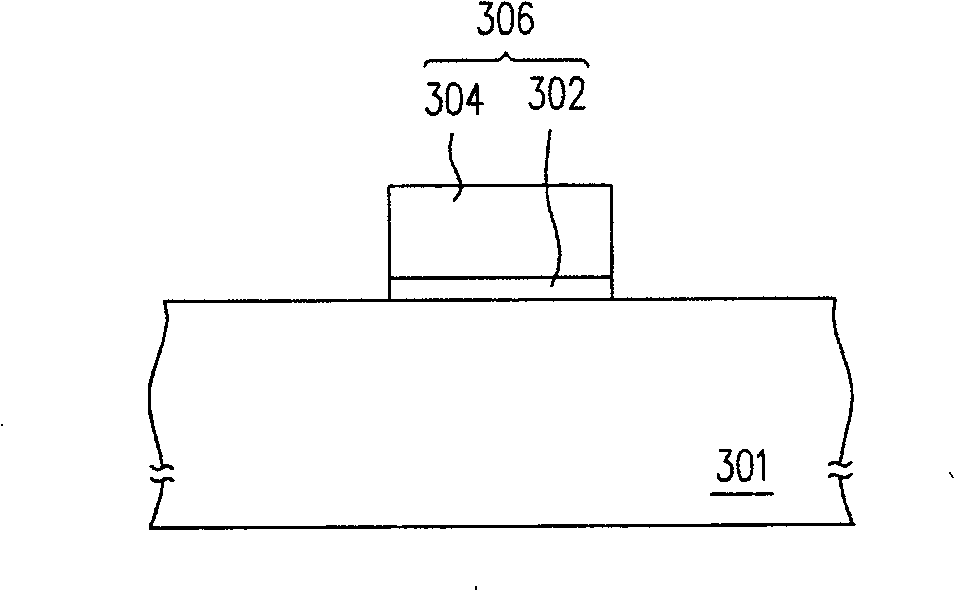

After completion of annealing for bonding of the base wafer 1 and bond wafer 2, the bond wafer 2 is thinned to a first thickness suitable for ion implantation, and boron is ion-implanted to thereby form a high-boron-concentration layer 10. A second thinning step based on selective etching is then carried out while using the high-boron-concentration layer 10 as an etch stop layer. This is successful in providing a method of fabricating an SOI wafer which is suppressed both in intra-wafer uniformity of the firm thickness and in inter-wafer uniformity of the film thickness even when a required level for the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

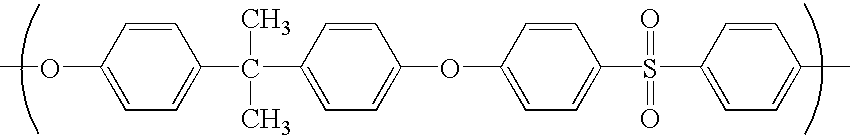

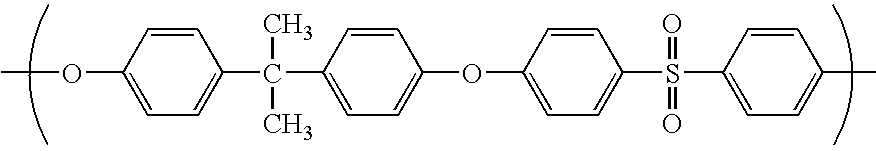

Reverse osmosis composite membranes for boron removal

InactiveUS20110049055A1Semi-permeable membranesGeneral water supply conservationSulfonyl halidePolyamide

Improved methods for reducing boron concentration in seawater or brackish water, while simultaneously maintaining or improving the salt rejection of membrane and flow performance of polyamide reverse osmosis (RO) membranes include contacting the water with a composite membrane comprising moieties derived from an aromatic sulfonyl halide, a heteroaromatic sulfonyl halide, a sulfinyl halide; a sulfenyl halide; a sulfuryl halide; a phosphoryl halide; a phosphonyl halide; a phosphinyl halide; a thiophosphoryl halide; a thiophosphonyl halide, an isocyanate, a urea, a cyanate, an aromatic carbonyl halide, an epoxide or a mixture thereof.

Owner:GENERAL ELECTRIC CO

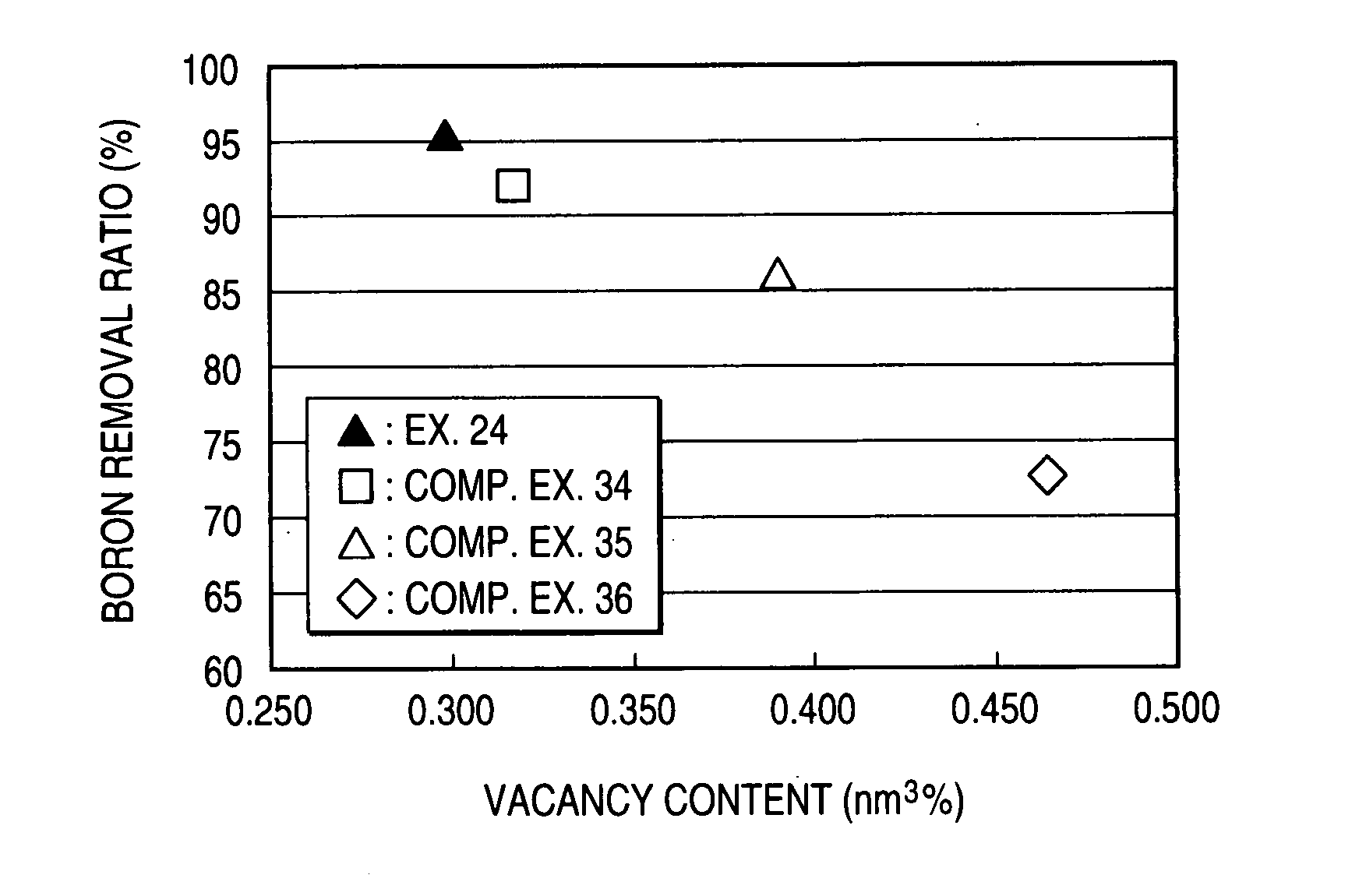

Composite semipermeable membrane, and production process thereof

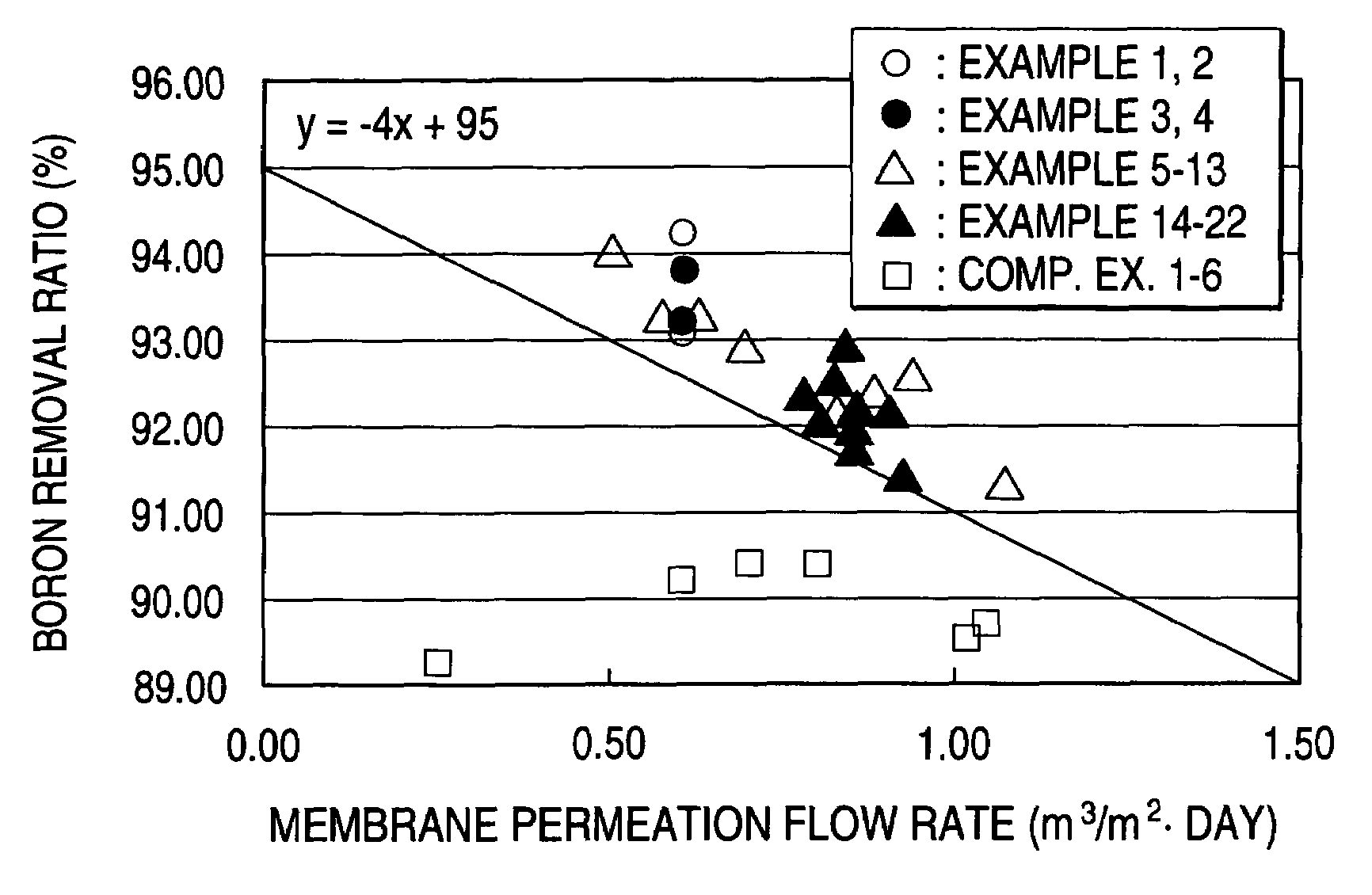

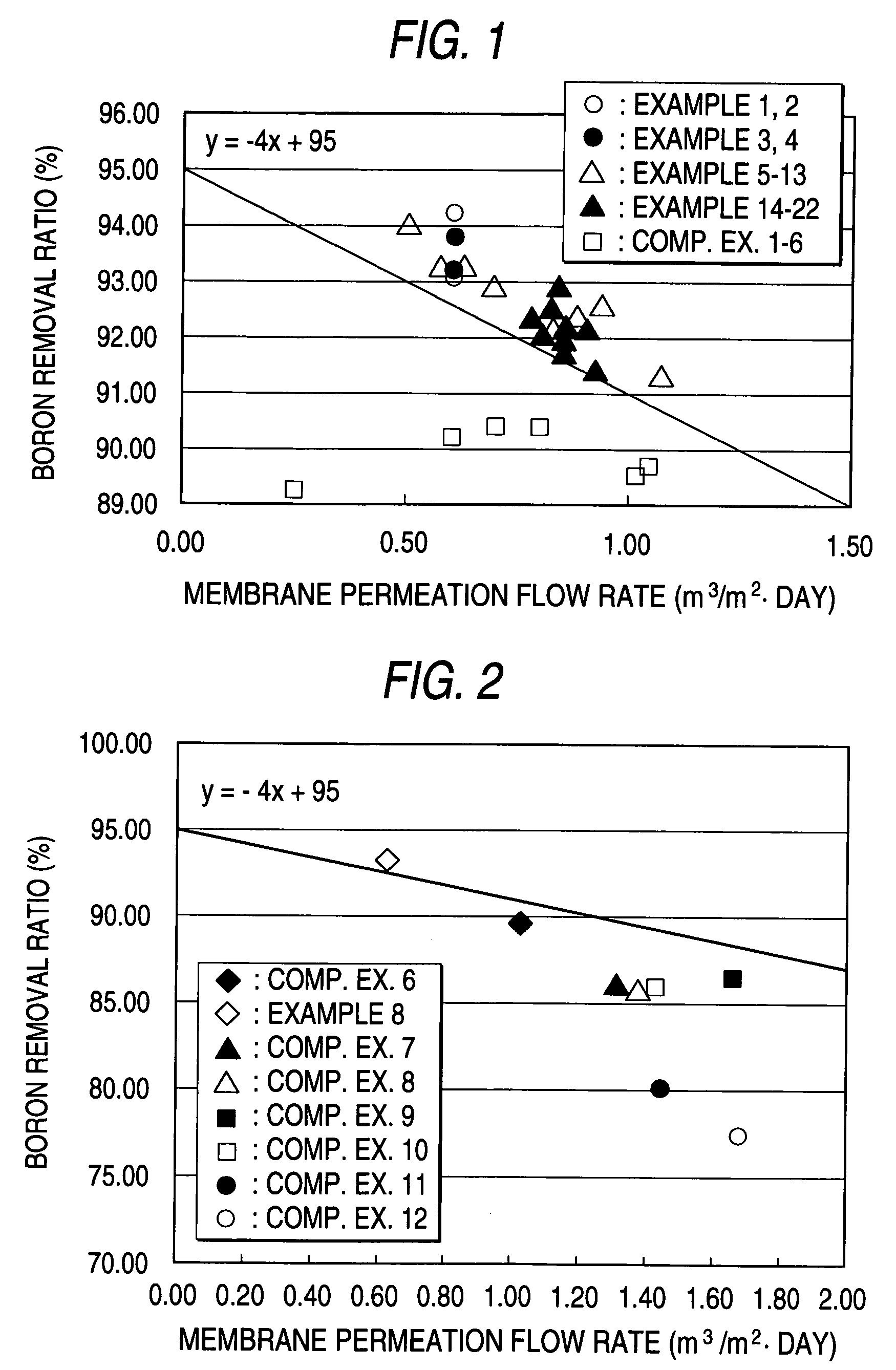

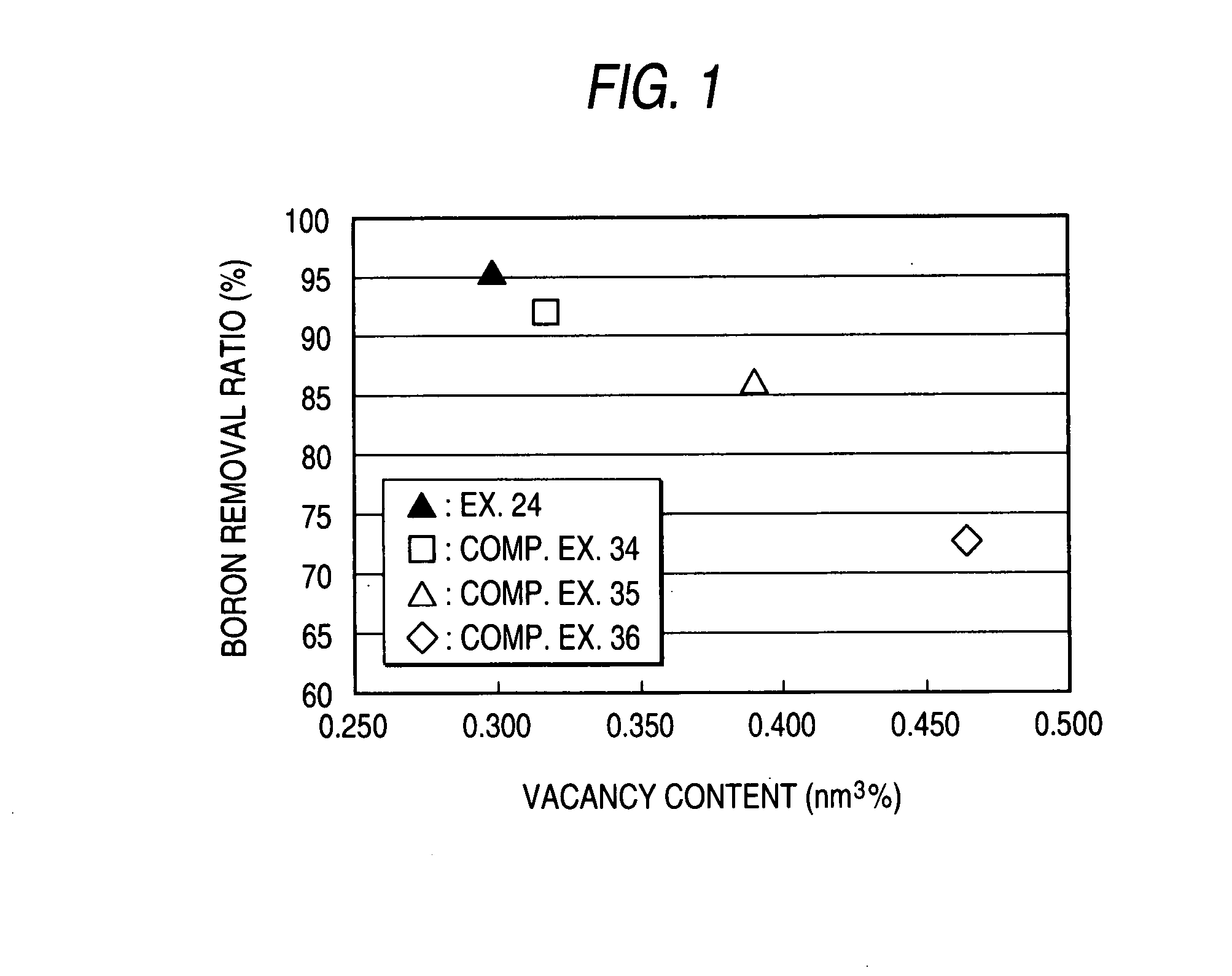

InactiveUS7279097B2High desalination rateImprove performanceMembranesGeneral water supply conservationSemipermeable membranePermeation

A composite semipermeable membrane which satisfies the following relationship when seawater at 25° C. having a pH of 6.5, a boron concentration of 5 ppm and a TDS concentration of 3.5% by weight is permeated under an operation pressure of 5.5 MPa: Boron removal ratio (%)≧95−4×membrane permeation flow rate (m3 / m2·day).

Owner:TORAY IND INC

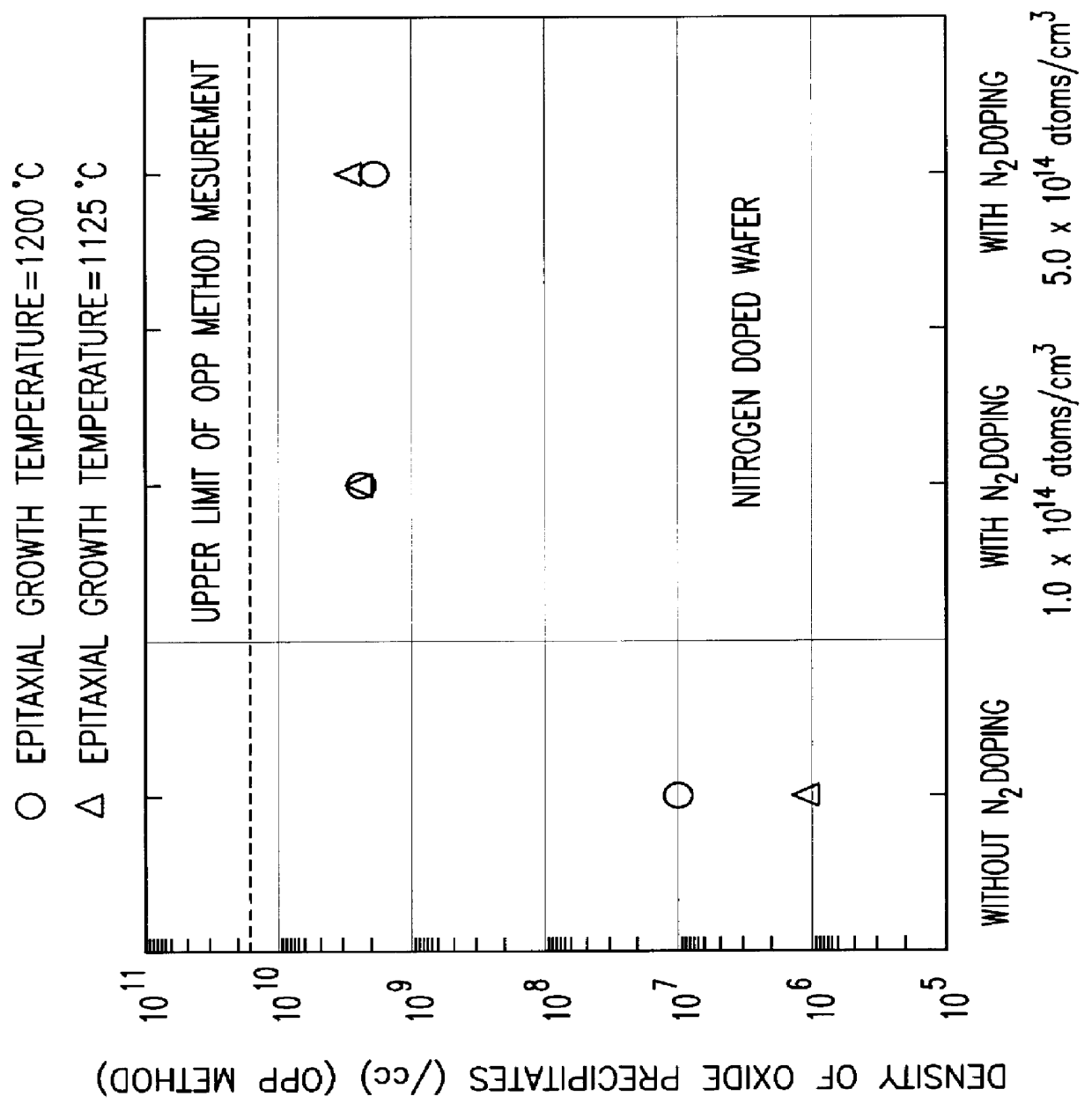

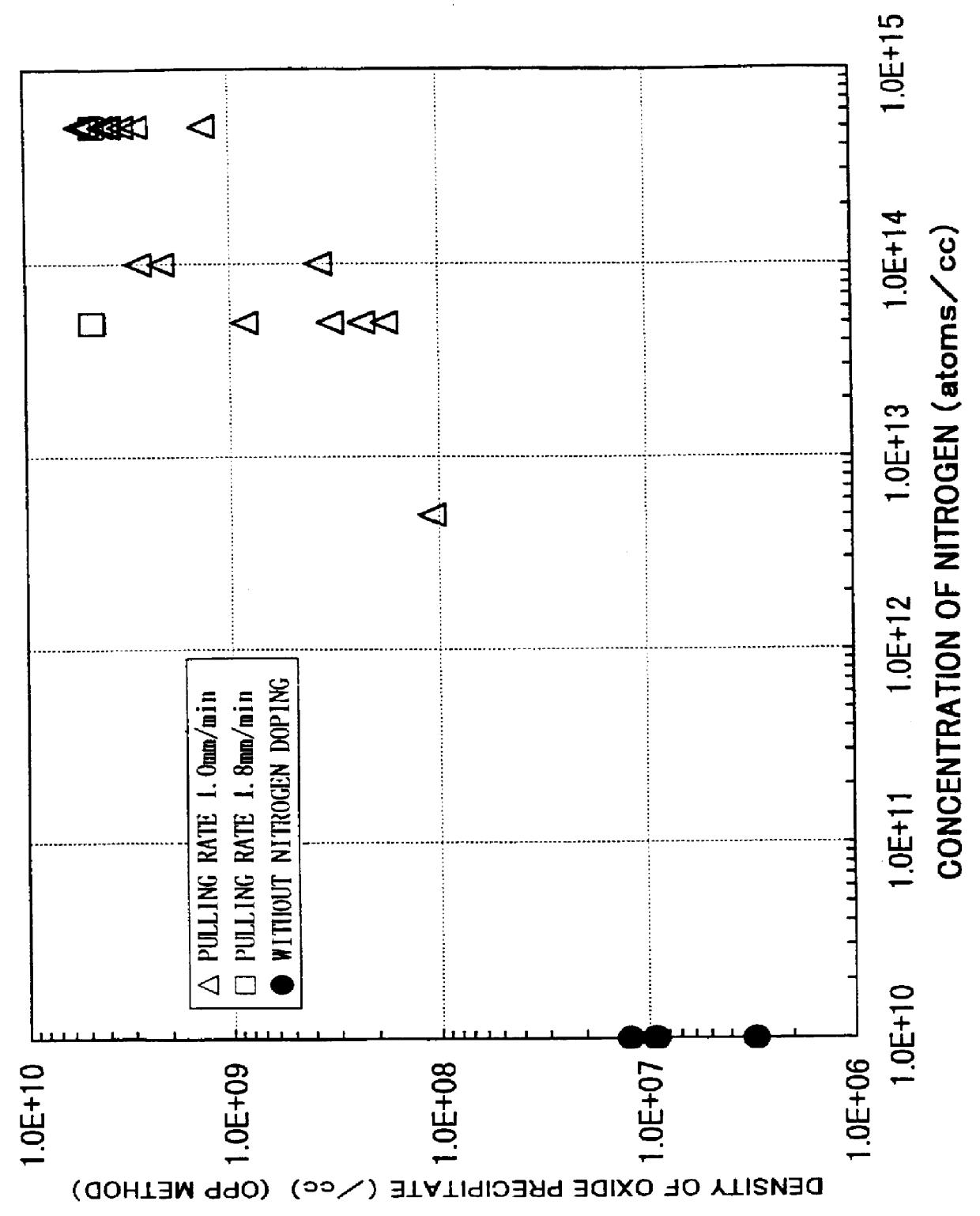

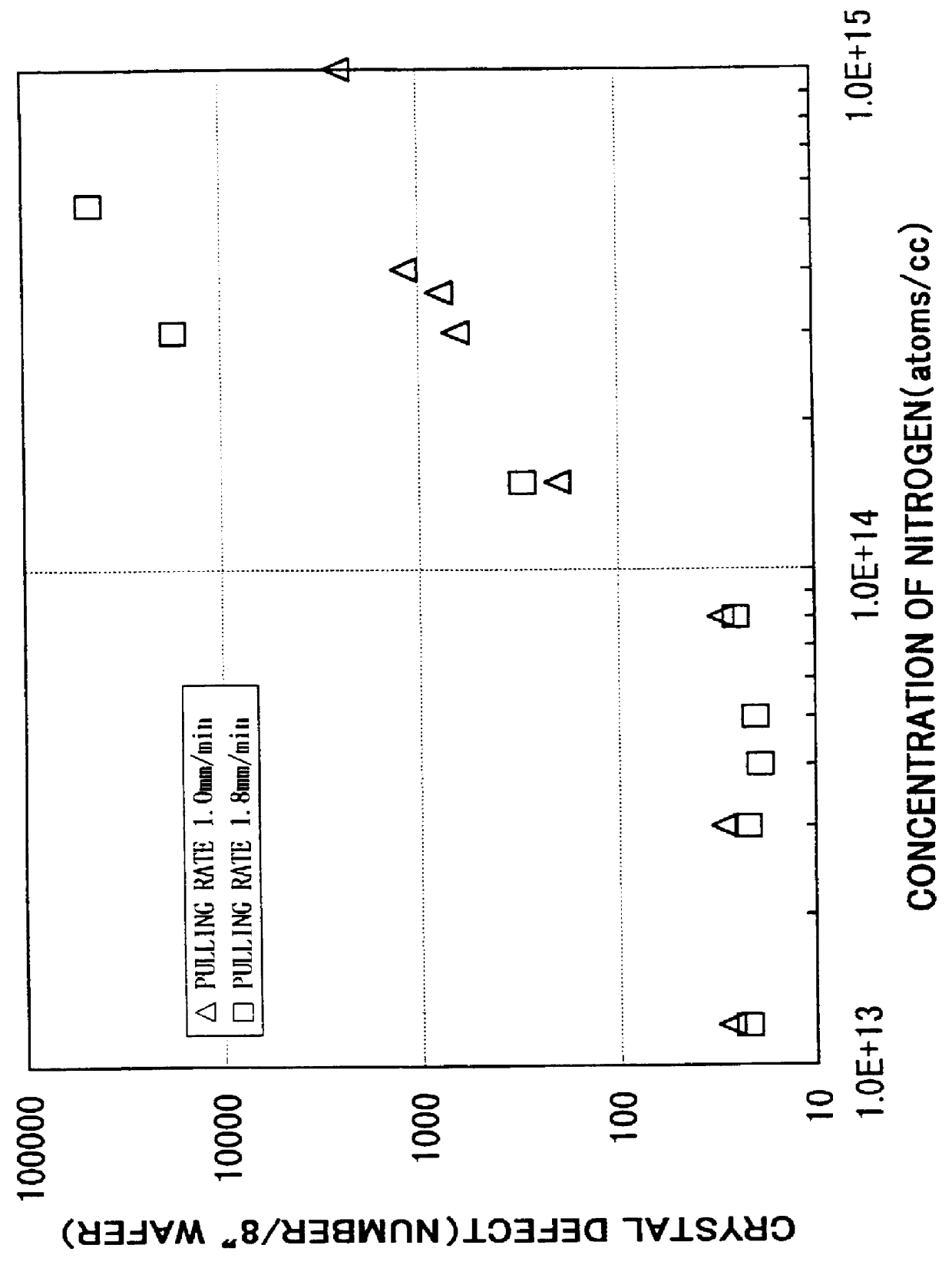

Method for producing an epitaxial silicon single crystal wafer and the epitaxial silicon single crystal wafer

InactiveUS6162708AReduce concentrationEasy to producePolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalCrystallinity

There is disclosed a method for producing an epitaxial silicon single crystal wafer comprising the steps of growing a silicon single crystal ingot wherein nitrogen is doped by Czochralski method, slicing the silicon single crystal ingot to provide a silicon single crystal wafer, and forming an epitaxial layer in the surface layer portion of the silicon single crystal wafer. There can be manufactured easily and in high productivity an epitaxial silicon monocrystal wafer which has high gettering capability when a substrate having a low boron concentration is used, a low concentration of heavy metal impurity, and an excellent crystallinity.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method of fabricating SOI wafer

InactiveUS7084046B2Sharp concentration profileImprove concentrationSolid-state devicesSemiconductor/solid-state device manufacturingEtchingThinning

After completion of annealing for bonding of the base wafer 1 and bond wafer 2, the bond wafer 2 is thinned to a first thickness suitable for ion implantation, and boron is ion-implanted to thereby form a high-boron-concentration layer 10. A second thinning step based on selective etching is then carried out while using the high-boron-concentration layer 10 as an etch stop layer. This is successful in providing a method of fabricating an SOI wafer which is suppressed both in intra-wafer uniformity of the firm thickness and in inter-wafer uniformity of the film thickness even when a required level for the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

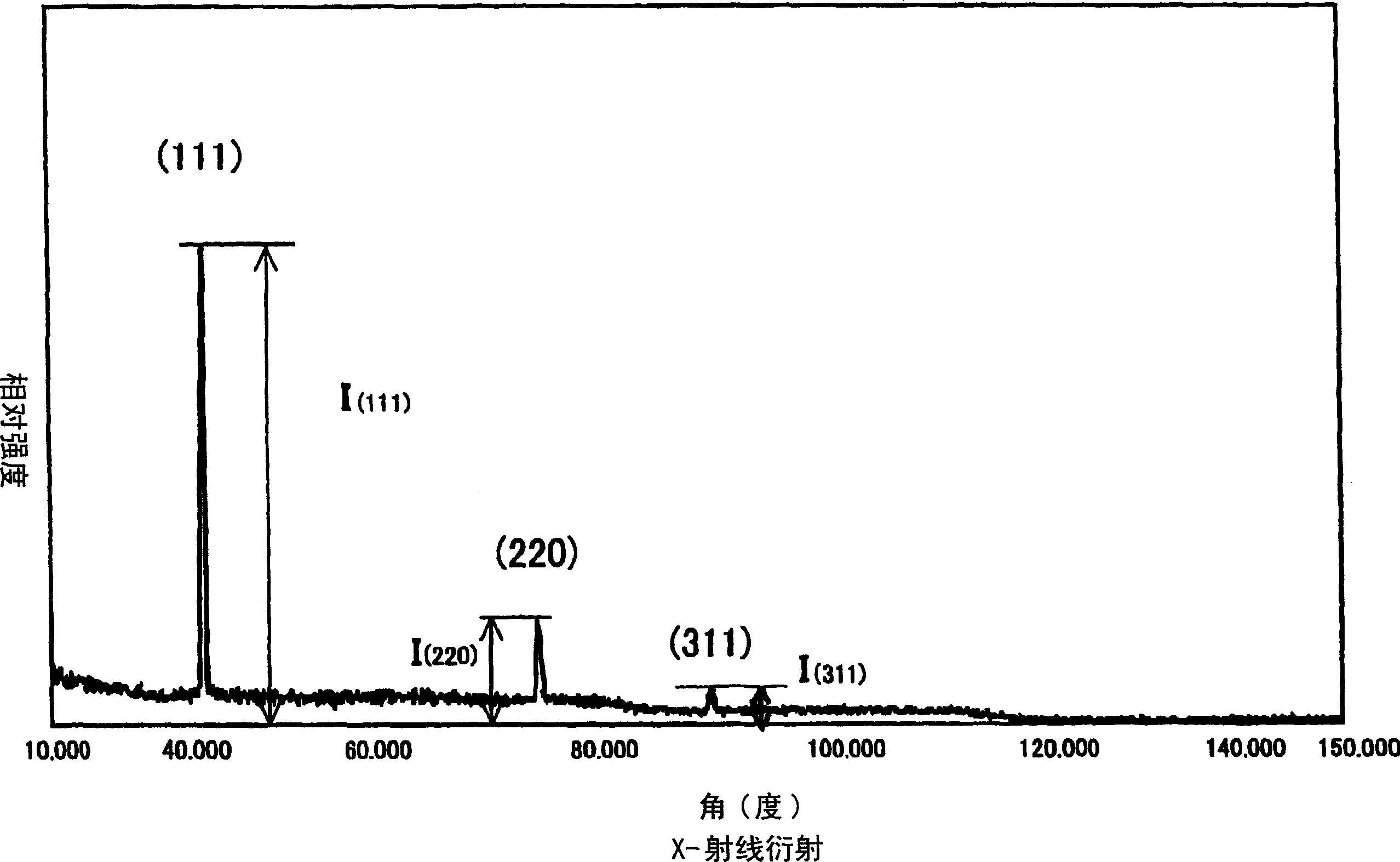

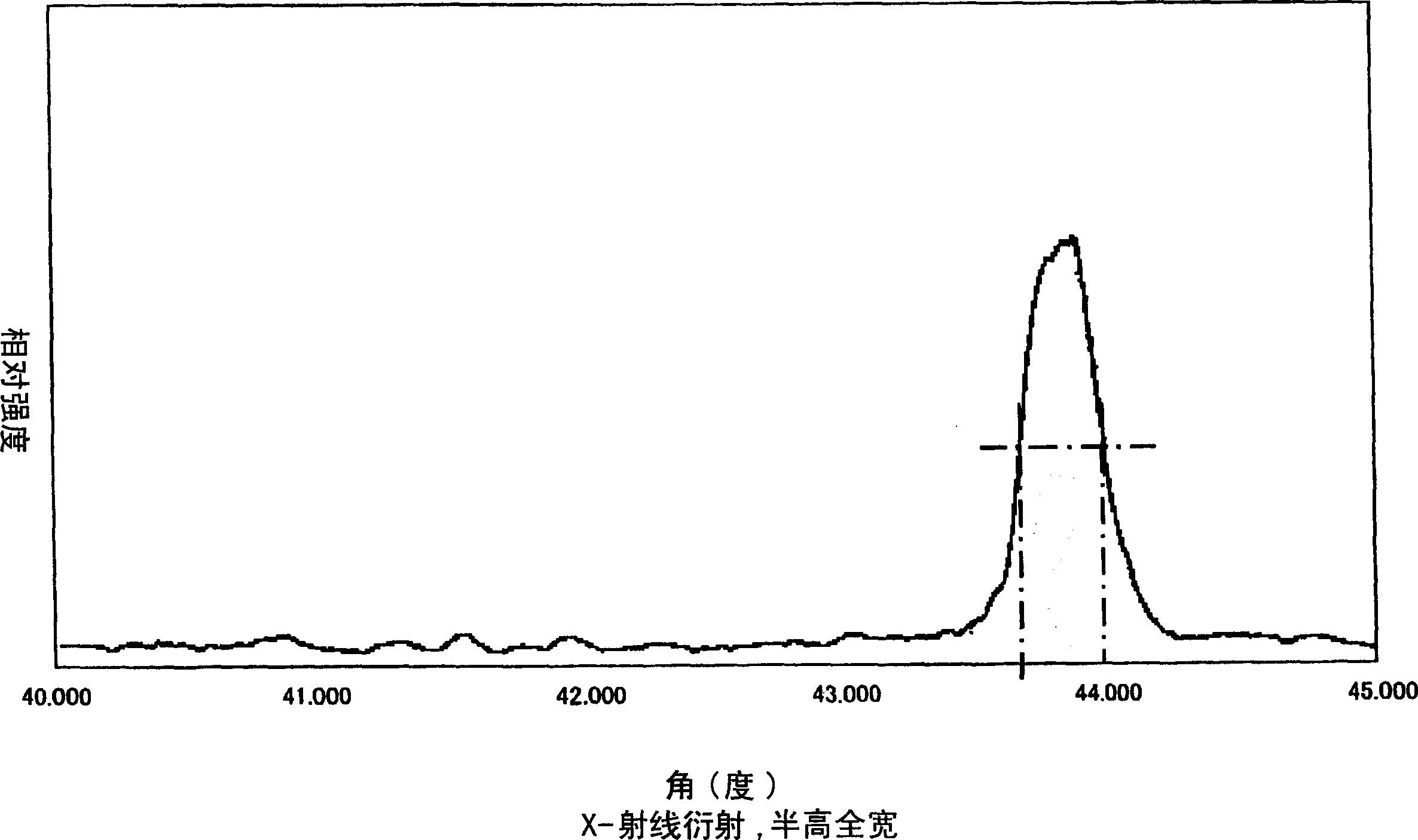

Boron doped diamond

InactiveUS7160617B2Increase in sizeSmall sizePolycrystalline material growthUltra-high pressure processesSingle crystalBoron

A layer of single crystal boron doped diamond produced by CVD and having a total boron concentration which is uniform. The layer is formed from a single growth sector, or has a thickness exceeding 100 μm, or has a volume exceeding 1 mm3, or a combination of such characteristics.

Owner:ELEMENT SIX TECH LTD

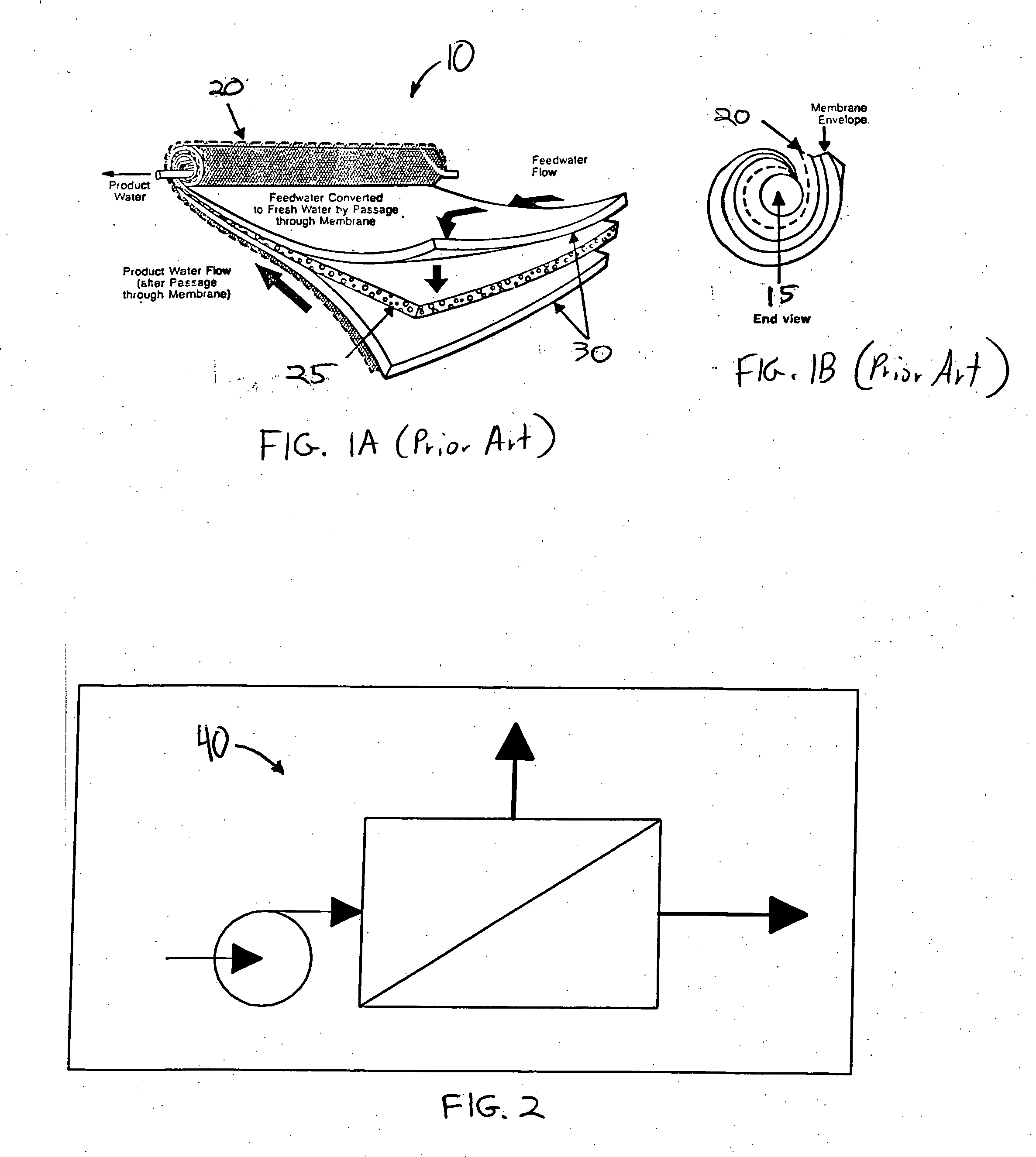

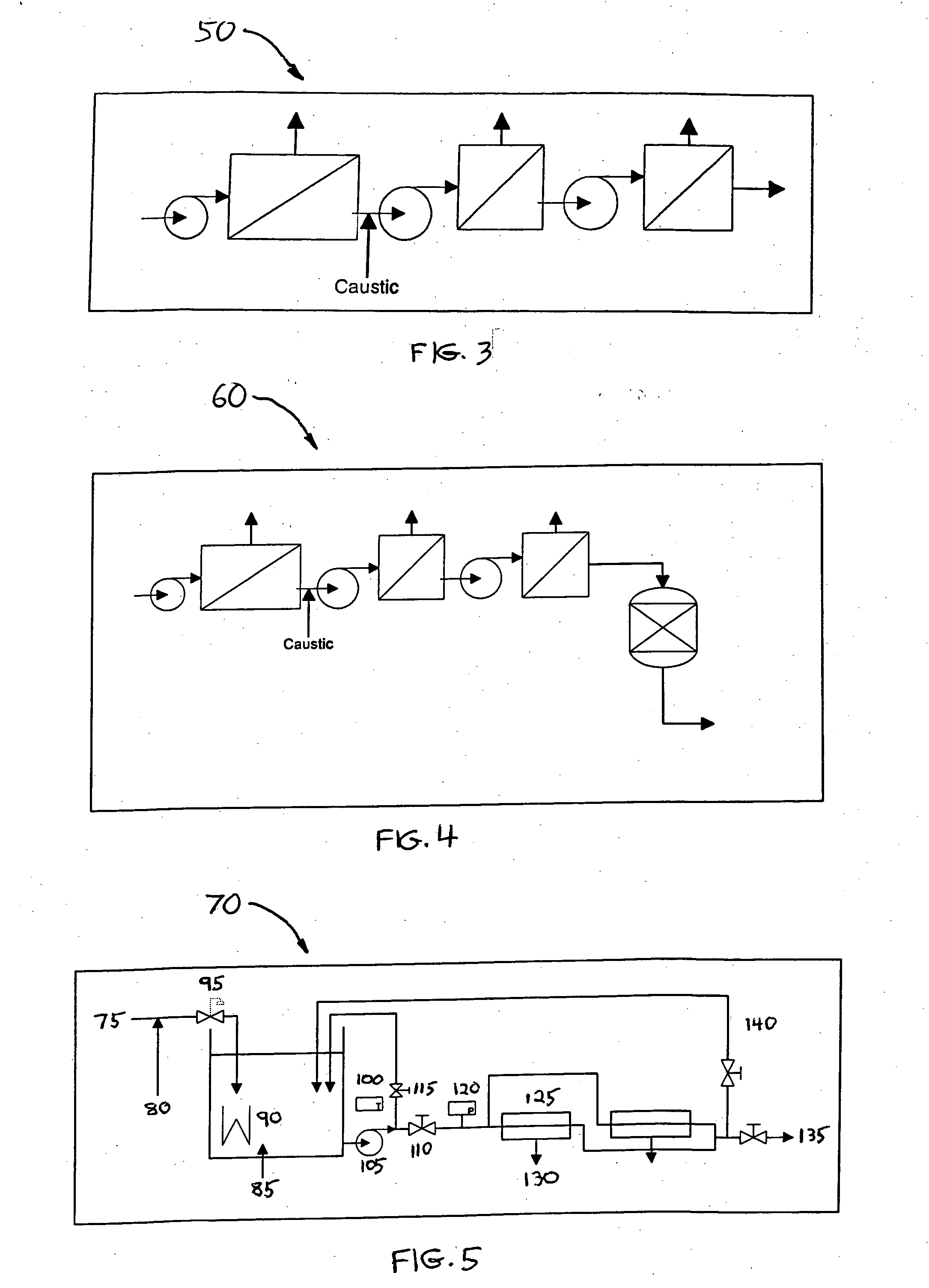

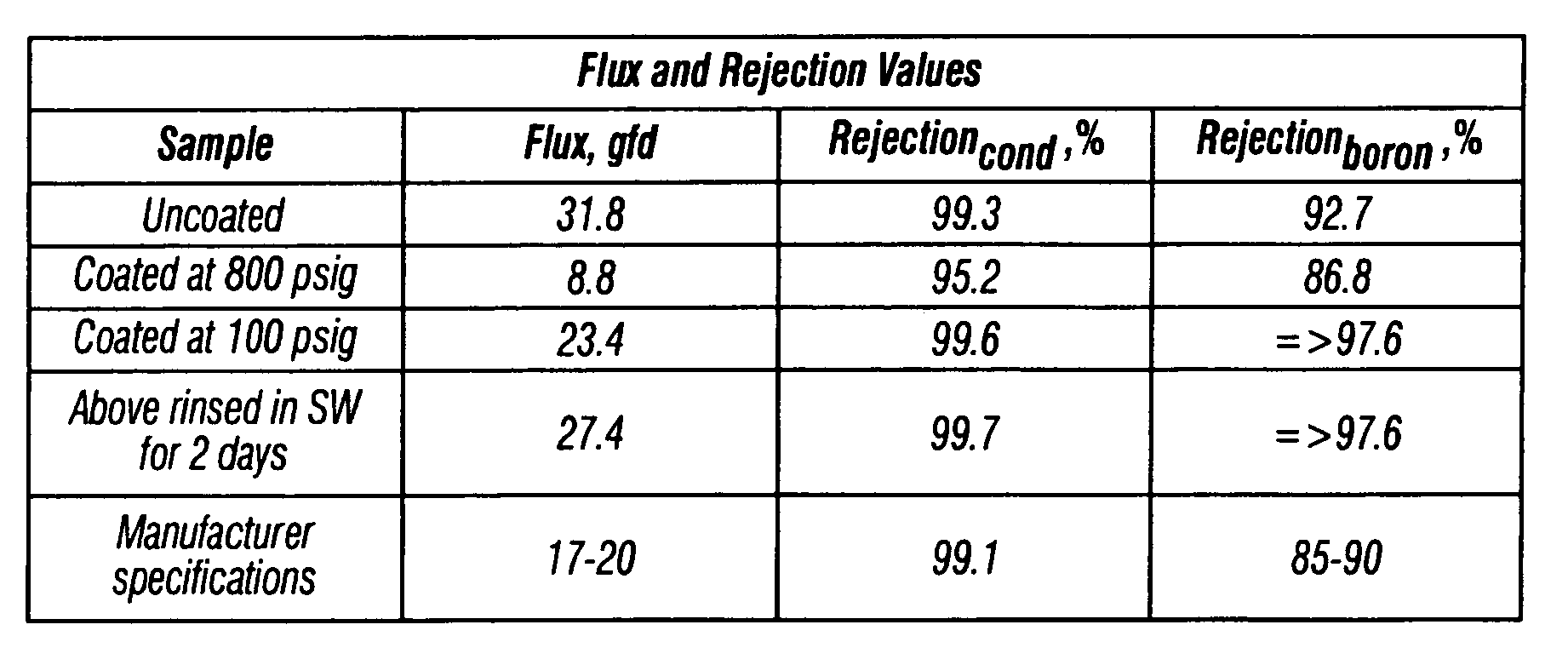

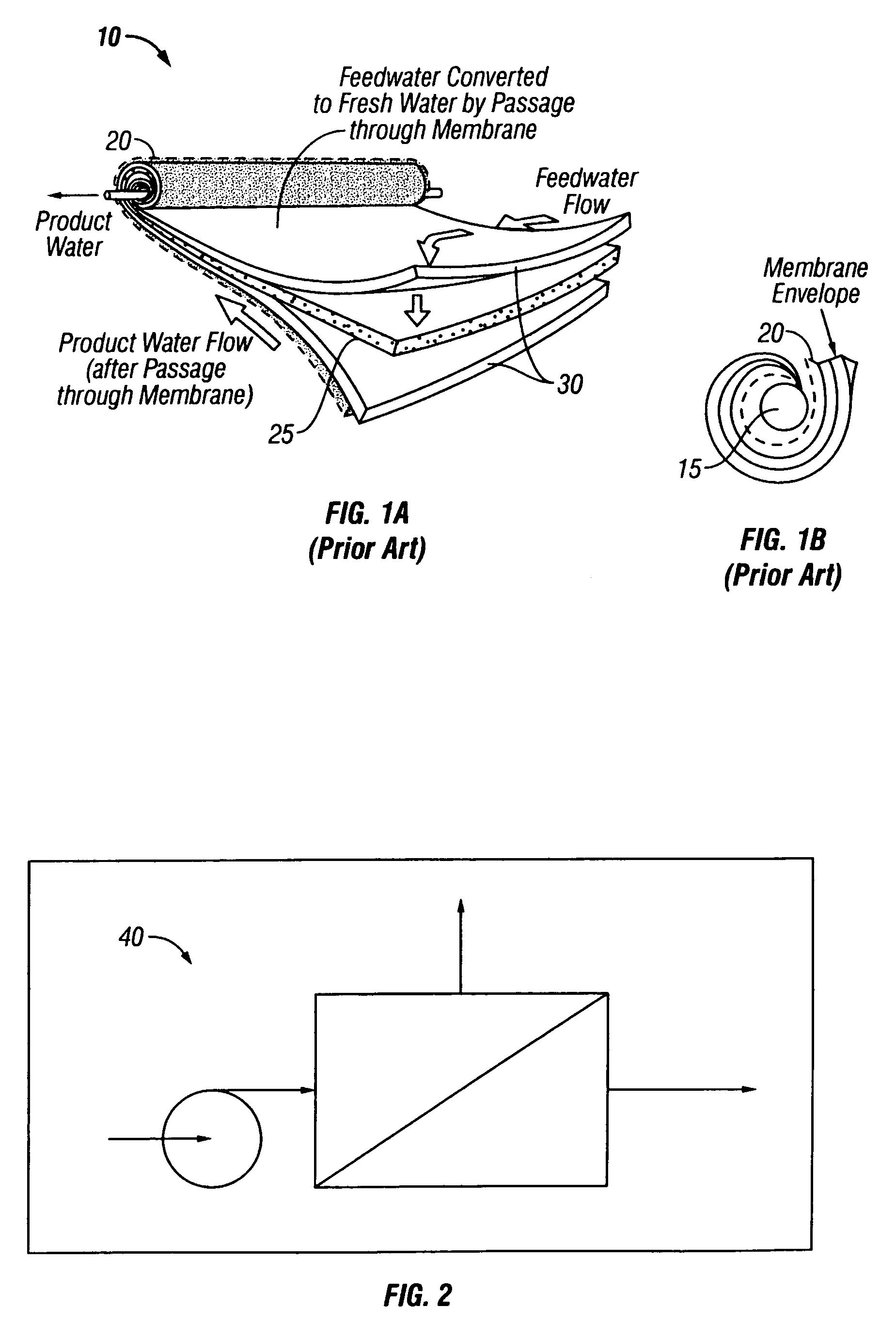

Method of treating reverse osmosis membranes for boron rejection enhancement

InactiveUS20060065598A1Reducing boron concentrationReduce concentrationLiquid separation auxillary apparatusMembranesBrackish waterReverse osmosis plant

The present invention provides a method of treating a reverse osmosis membrane for boron rejection enhancement, comprising contacting the reverse osmosis membrane with a chemical coating such as PHMB, wherein the reverse osmosis membrane is part of a single-pass reverse osmosis system is configured to reduce the boron concentration of normal seawater or brackish water to less than a predetermined amount.

Owner:KURITA WATER INDUSTRIES LTD

Method of treating reverse osmosis membranes for boron rejection enhancement

InactiveUS7491334B2Reduce concentrationImprove abilitiesMembranesWater/sewage treatment bu osmosis/dialysisBrackish waterReverse osmosis plant

The present invention provides a method of treating a reverse osmosis membrane for boron rejection enhancement, comprising contacting the reverse osmosis membrane with a chemical coating such as PHMB, wherein the reverse osmosis membrane is part of a single-pass reverse osmosis system is configured to reduce the boron concentration of normal seawater or brackish water to less than a predetermined amount.

Owner:KURITA WATER INDUSTRIES LTD

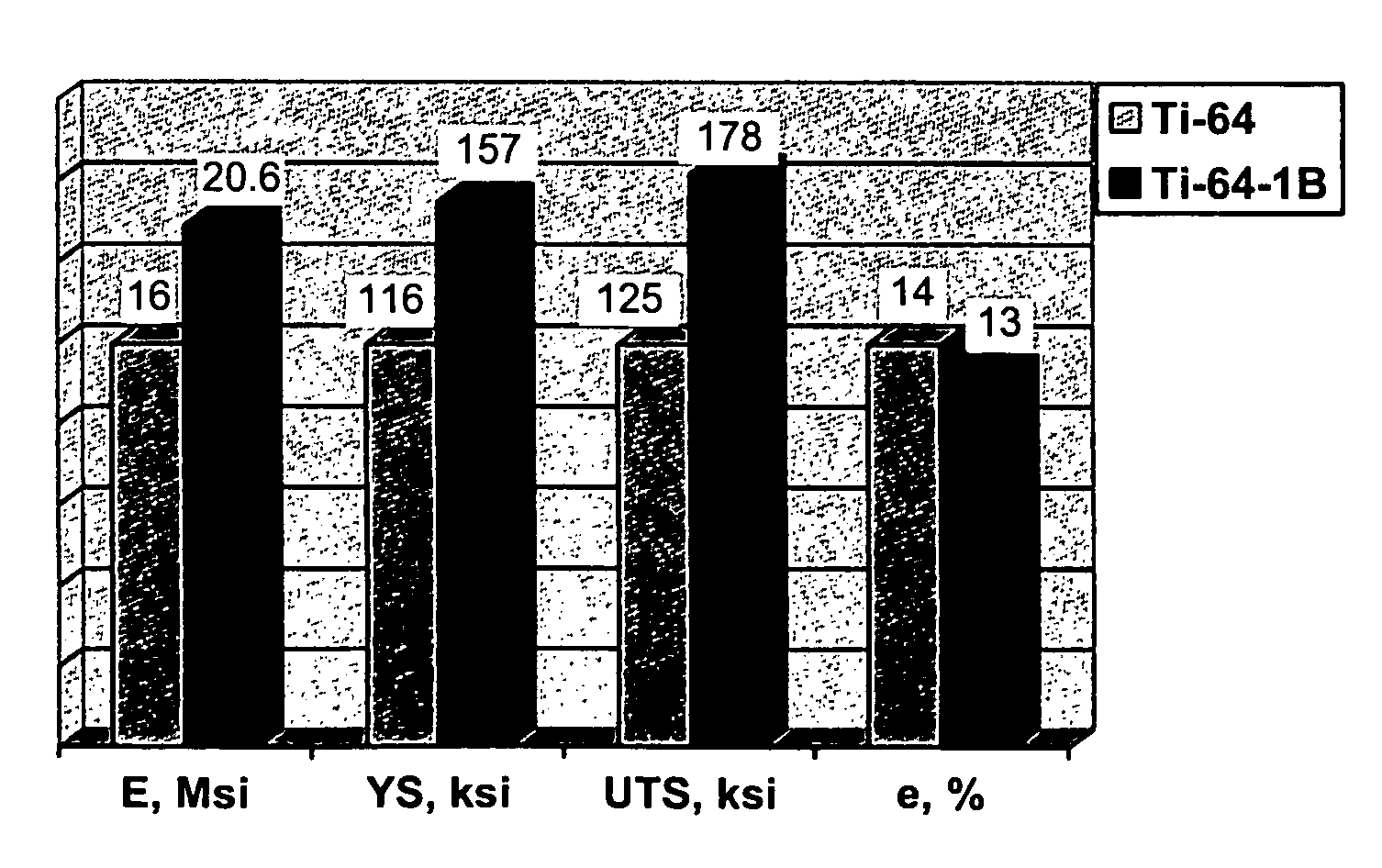

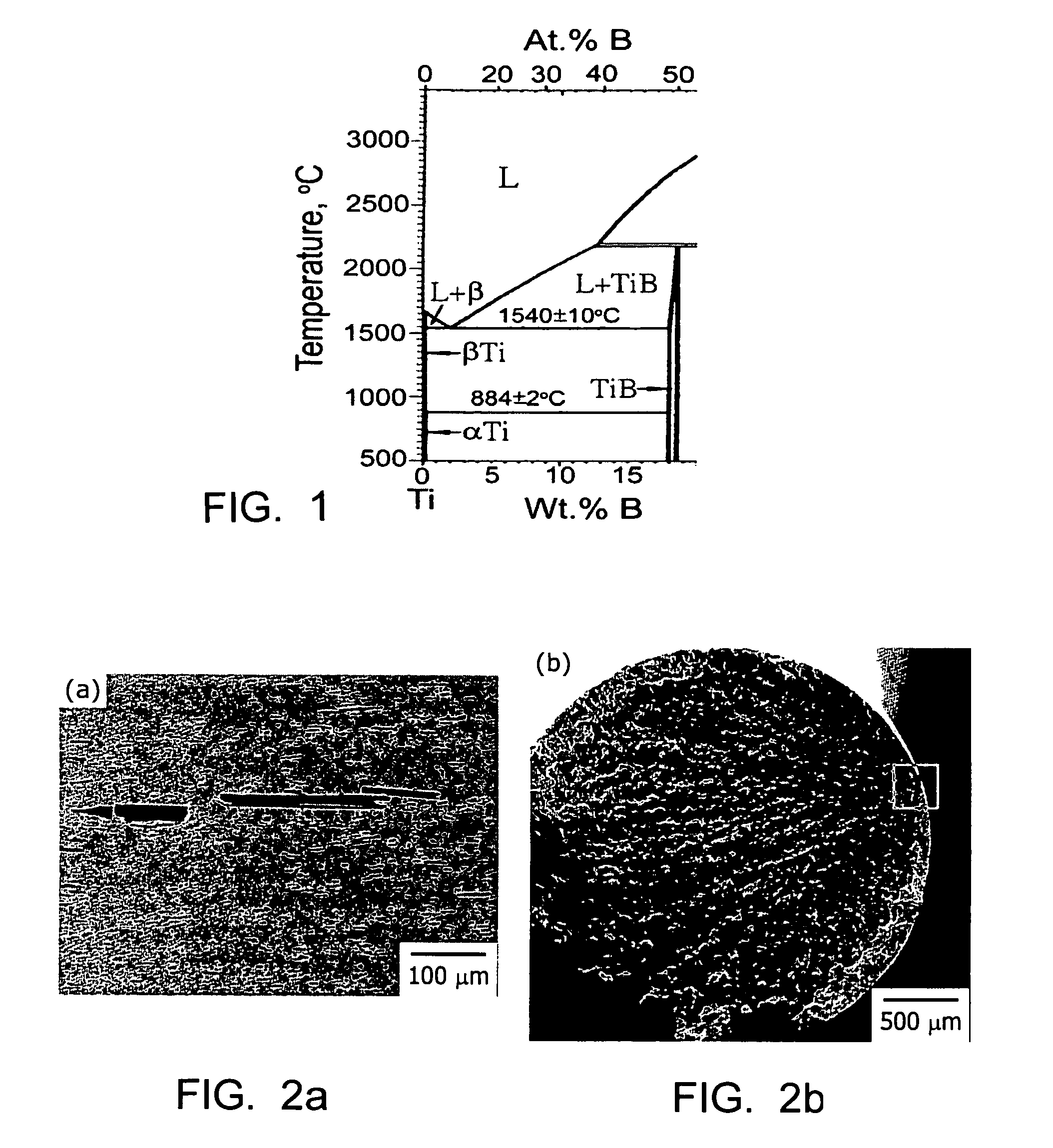

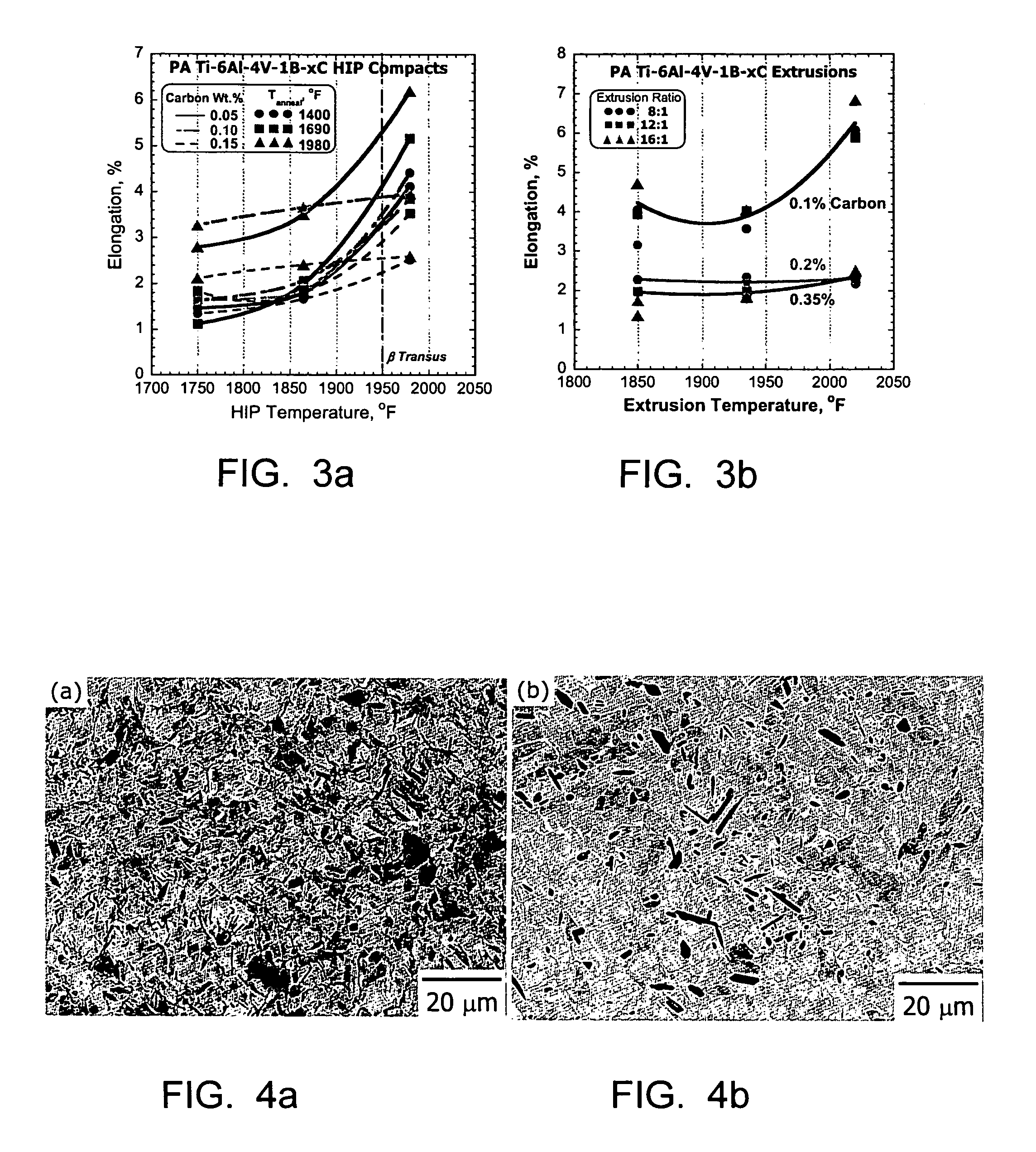

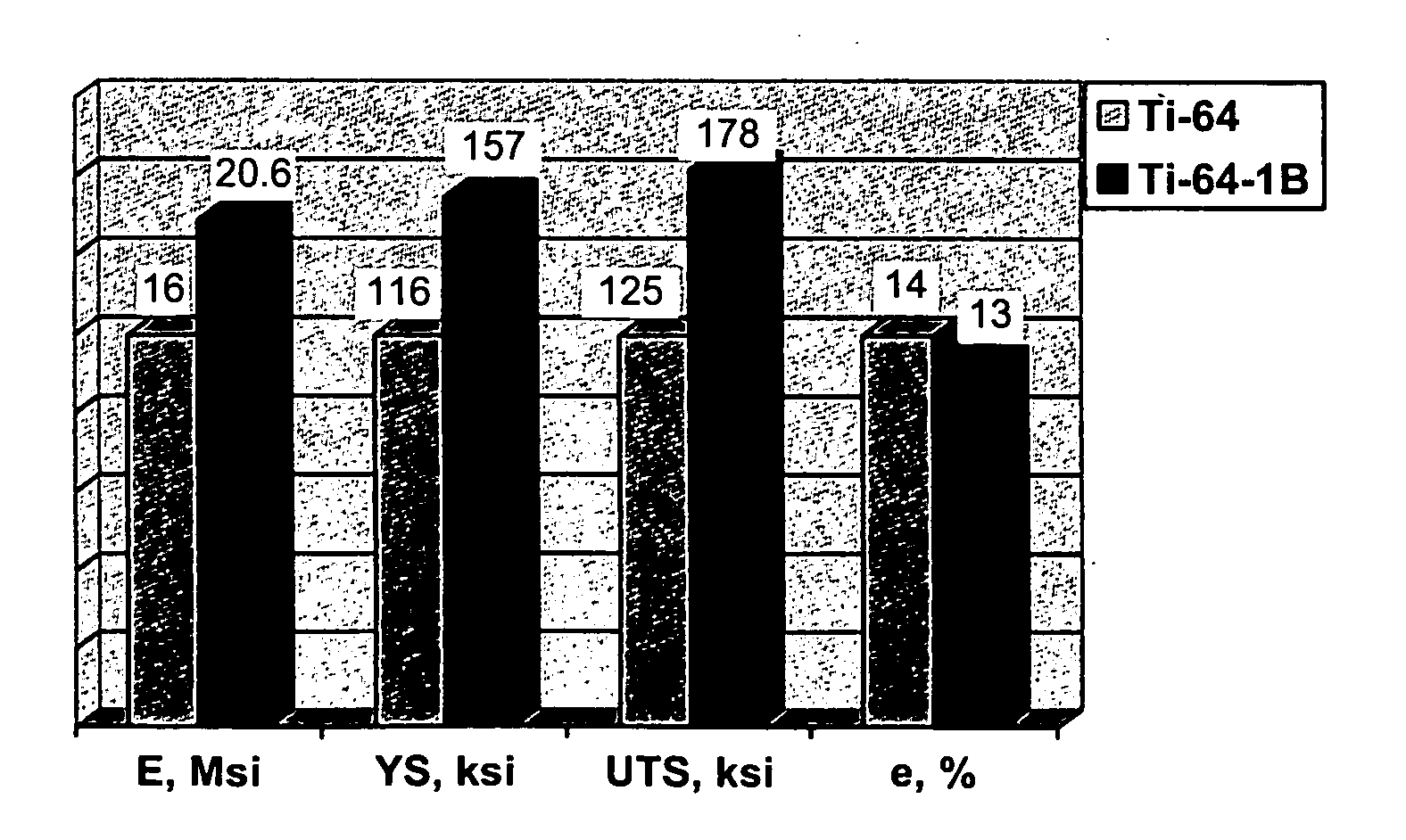

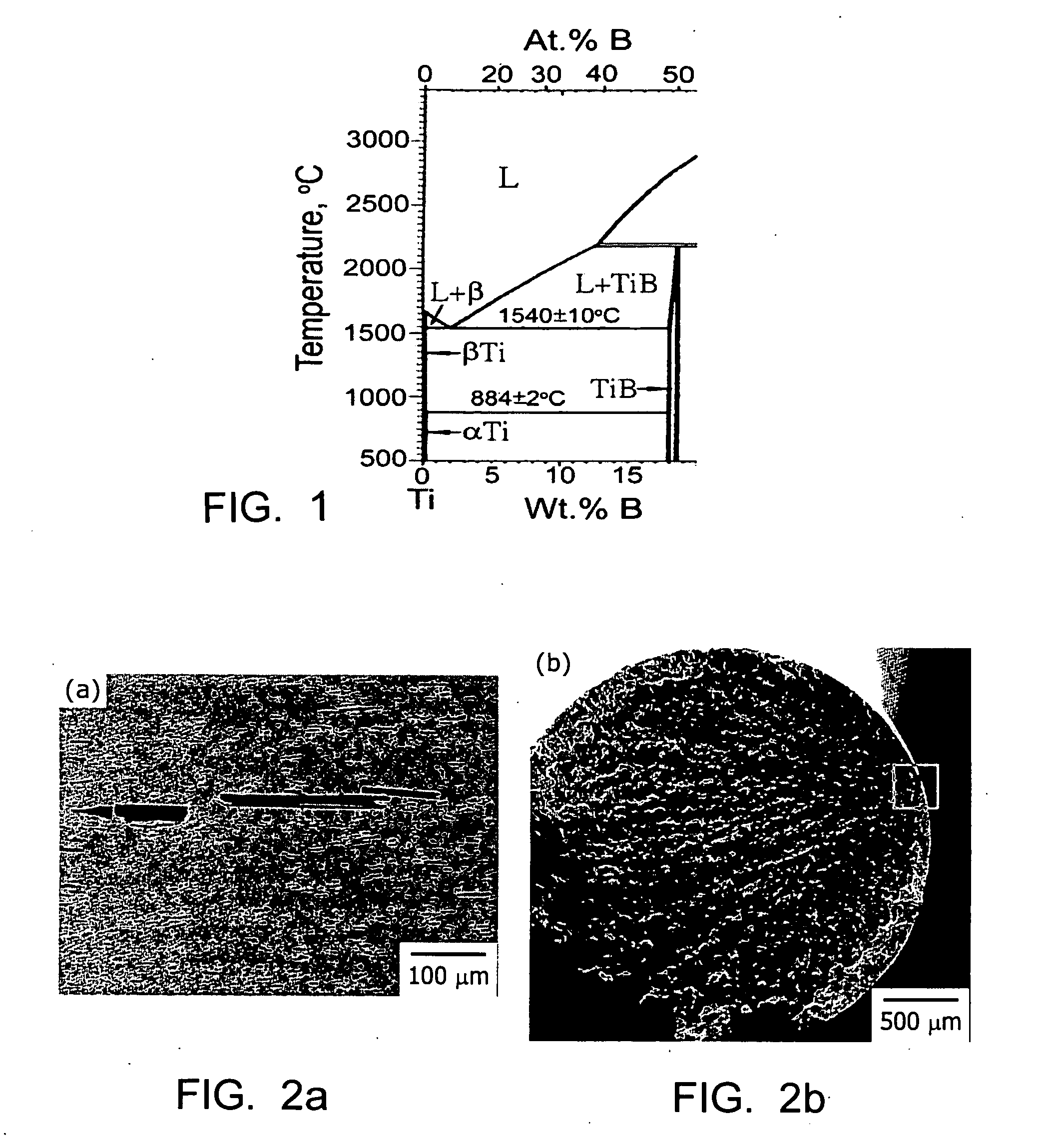

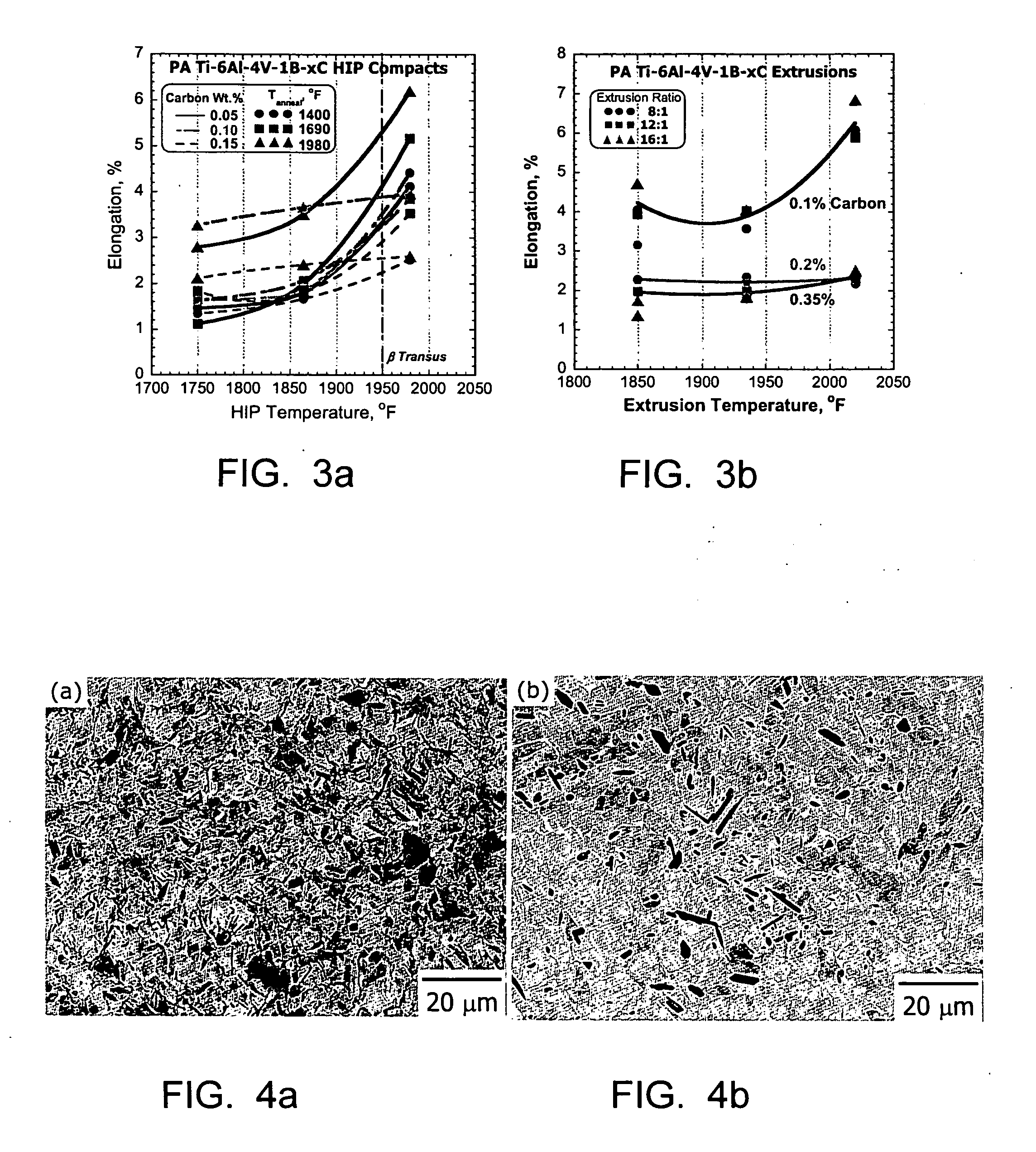

Method of producing high strength, high stiffness and high ductility titanium alloys

A method of producing a high strength, high stiffness and high ductility titanium alloy, comprising combining the titanium alloy with boron so that the boron concentration in the boron-modified titanium alloy does not exceed the eutectic limit. The carbon concentration of the boron-modified titanium alloy is maintained below a predetermined limit to avoid embrittlement. The boron-modified alloy is heated to a temperature above the beta transus temperature to eliminate any supersaturated excess boron. The boron-modified titanium alloy is deformed at a speed slow enough to prevent microstructural damage and reduced ductility.

Owner:ATI PROPERTIES +2

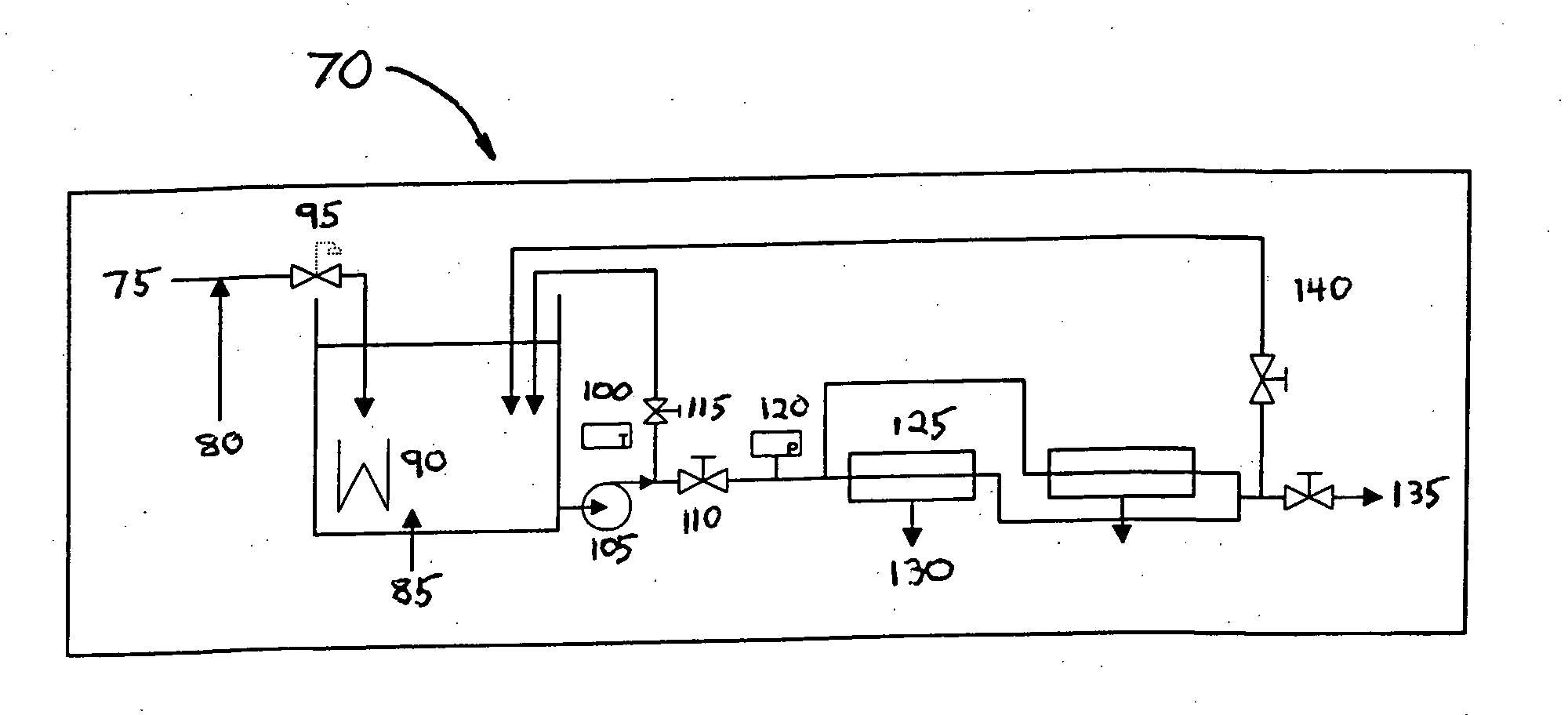

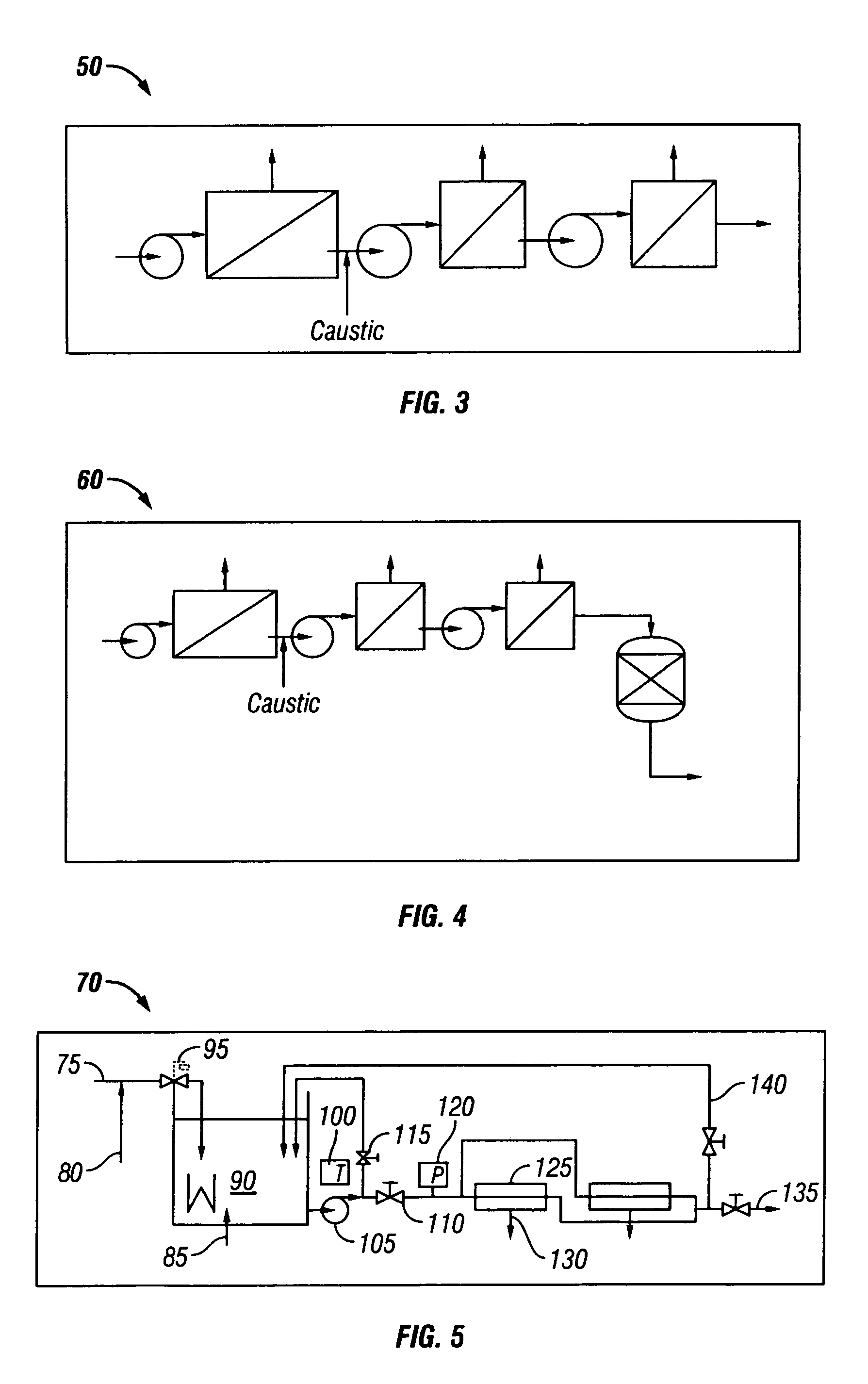

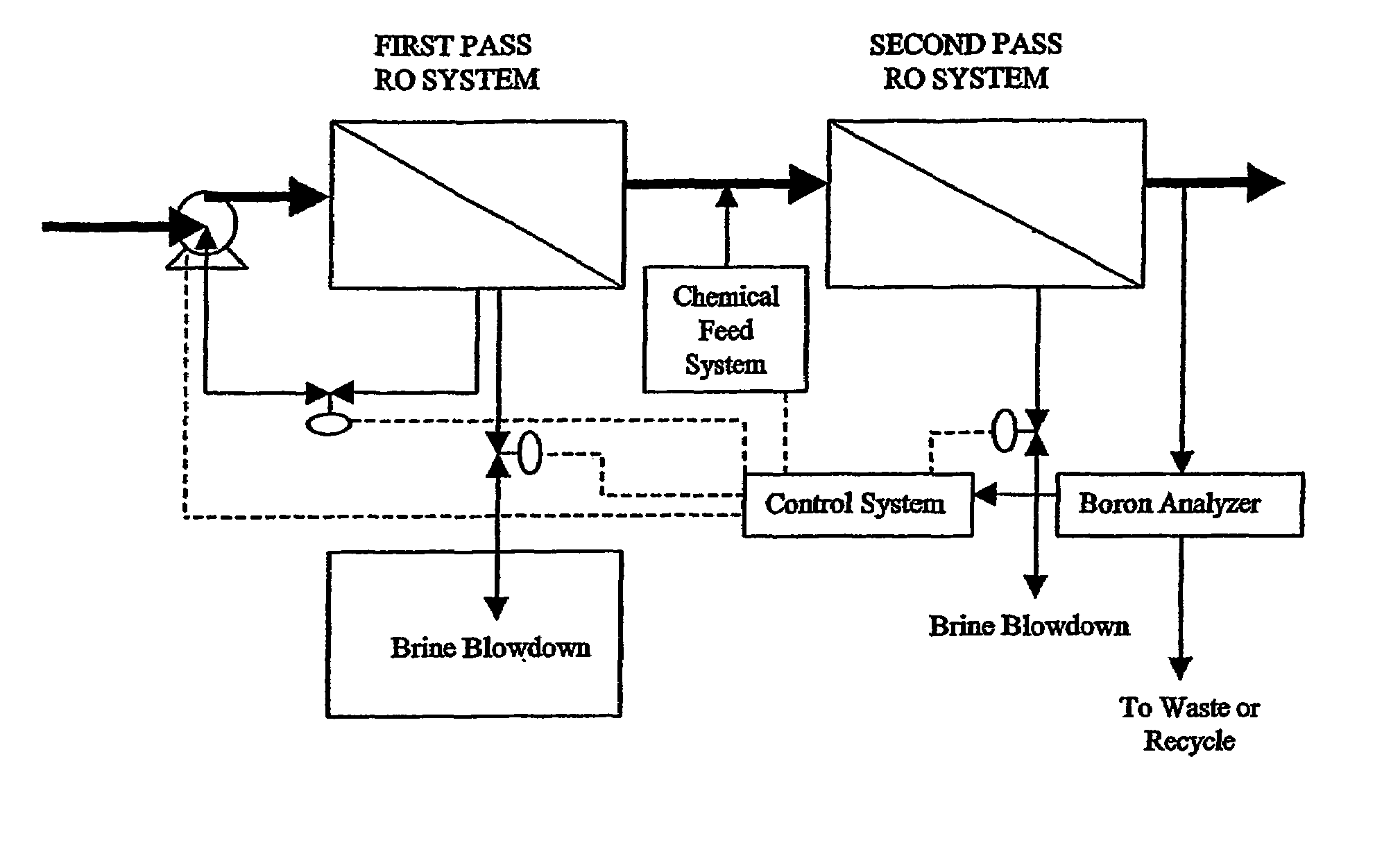

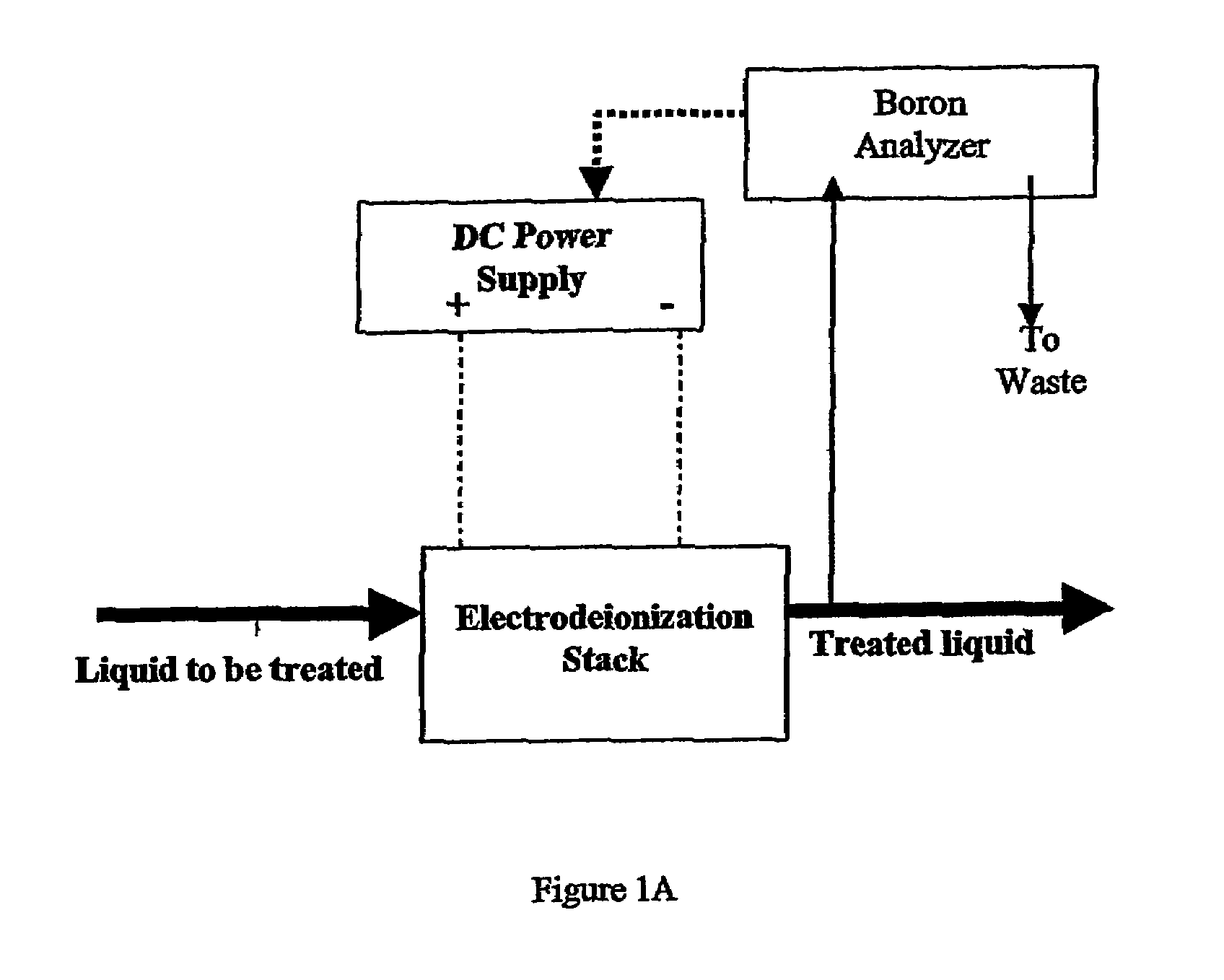

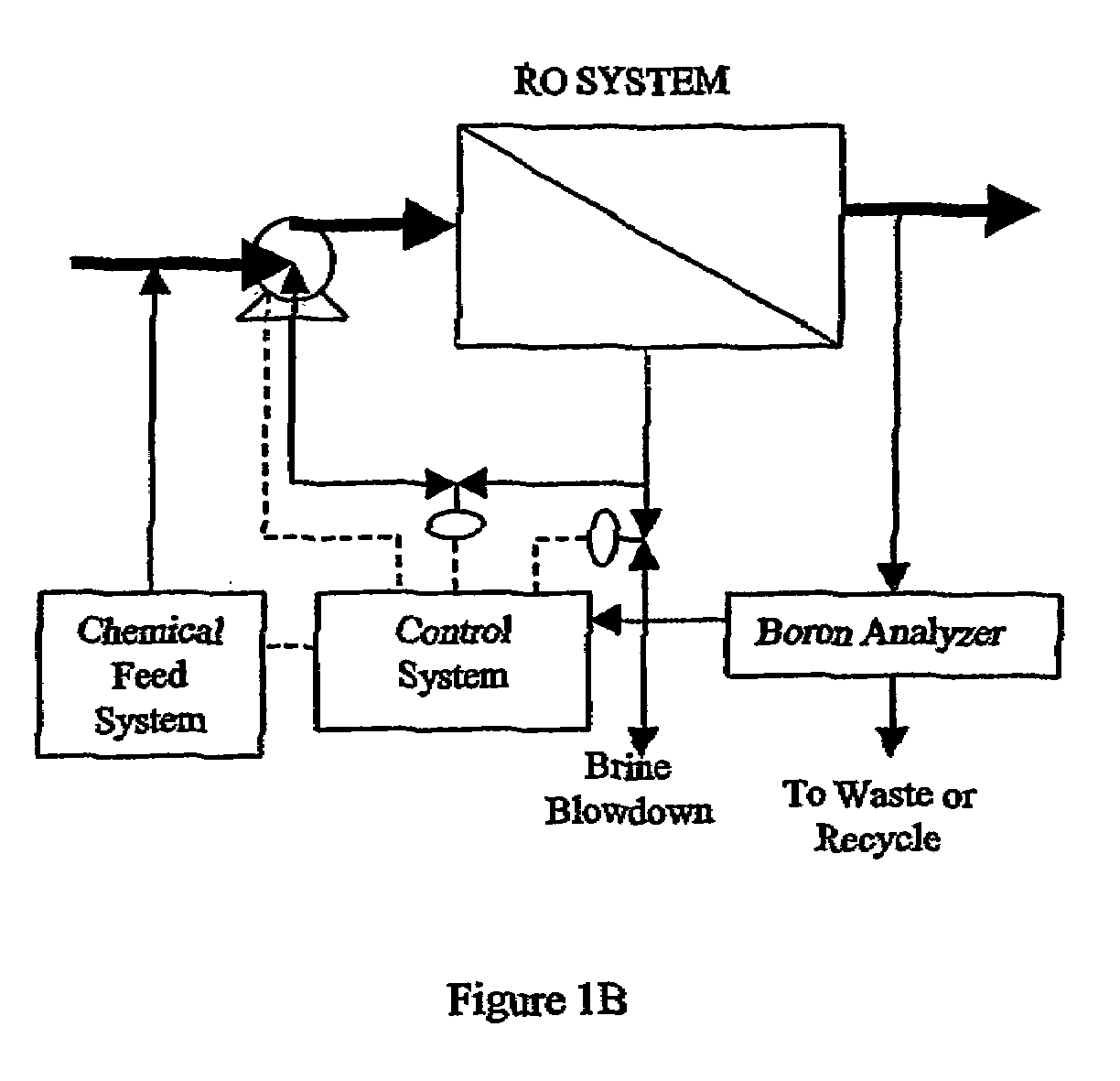

Control of water treatment system with low level boron detection

ActiveUS7264737B2Improve electricity efficiencyOptimize overall demineralizationSolvent extractionScale removal and water softeningWater treatment systemEngineering

A water treatment system and method including a membrane-based boron removal unit includes a boron analyzer for detecting the concentration of boron in a treatment stream. The boron removal unit can be a reverse osmosis (RO) or electrodeionization (EDI) treatment unit. A controller responds to the detected boron concentration to control an operation of the RO or EDI units. In an EDI system, the controller may adjust current or voltage supplied to match current to changes in ionic load and maintain a portion of the dilute cell in a substantially regenerated state. In an RO system, the controller may control the high pressure side flow rate, the brine blowdown rate, the product water permeation rate, pH, or feed rate of chemicals in response to the detected boron concentration value.

Owner:IONICS INC

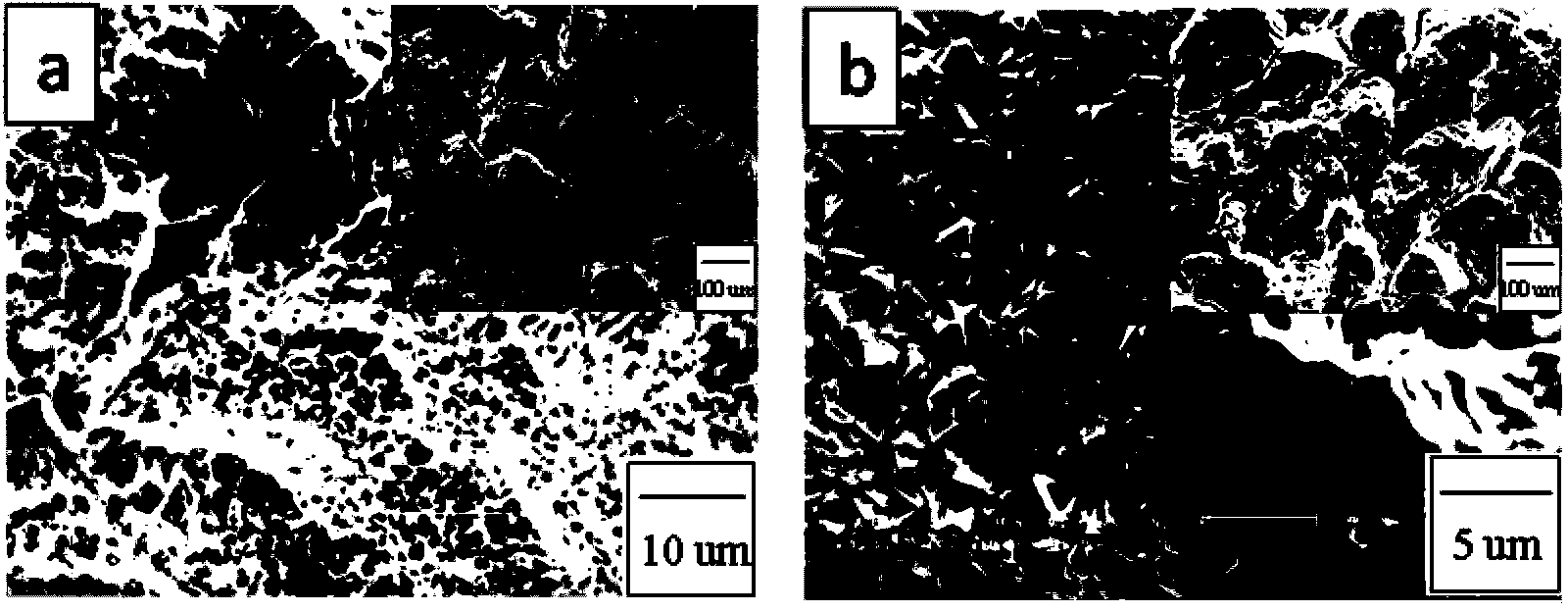

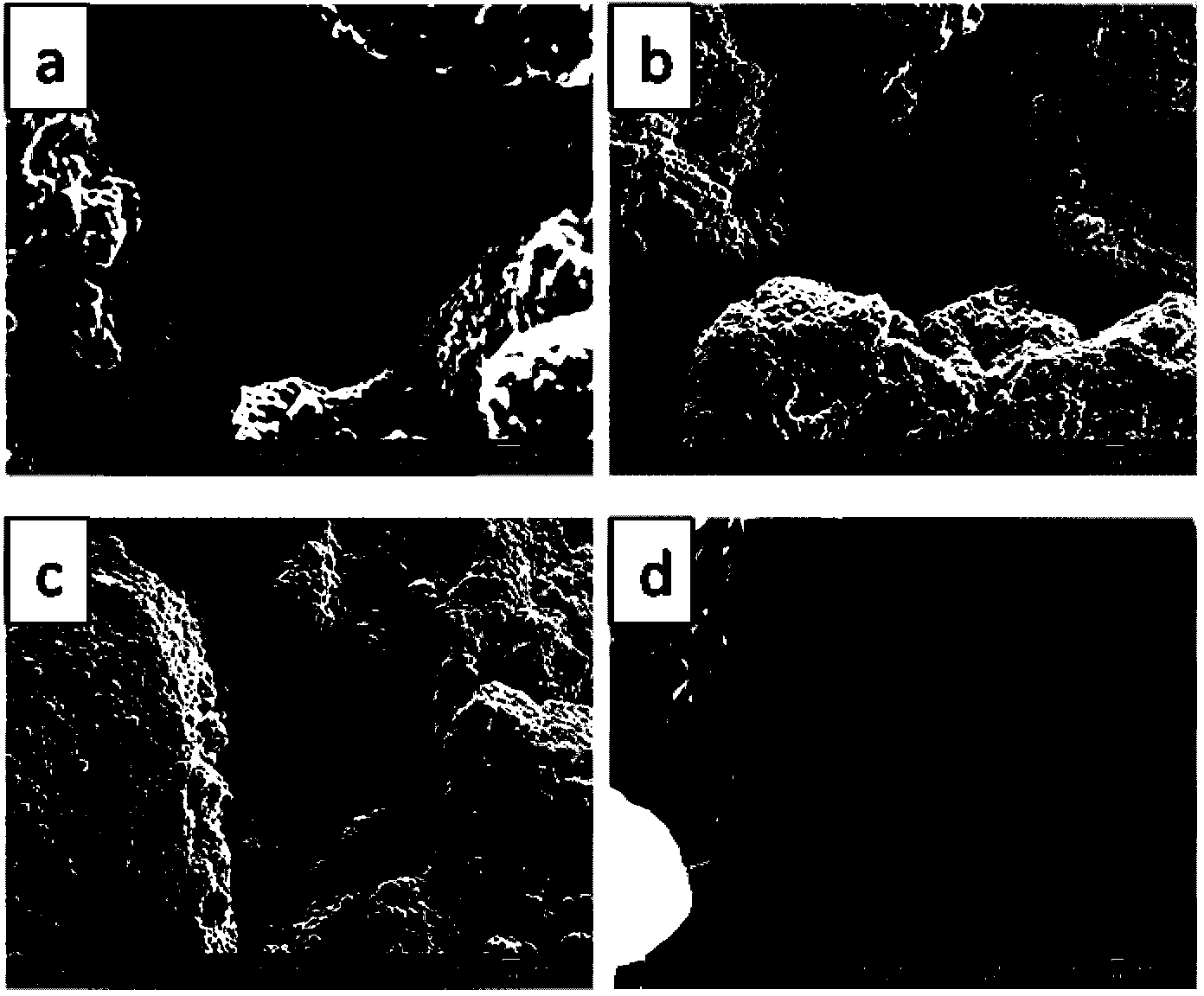

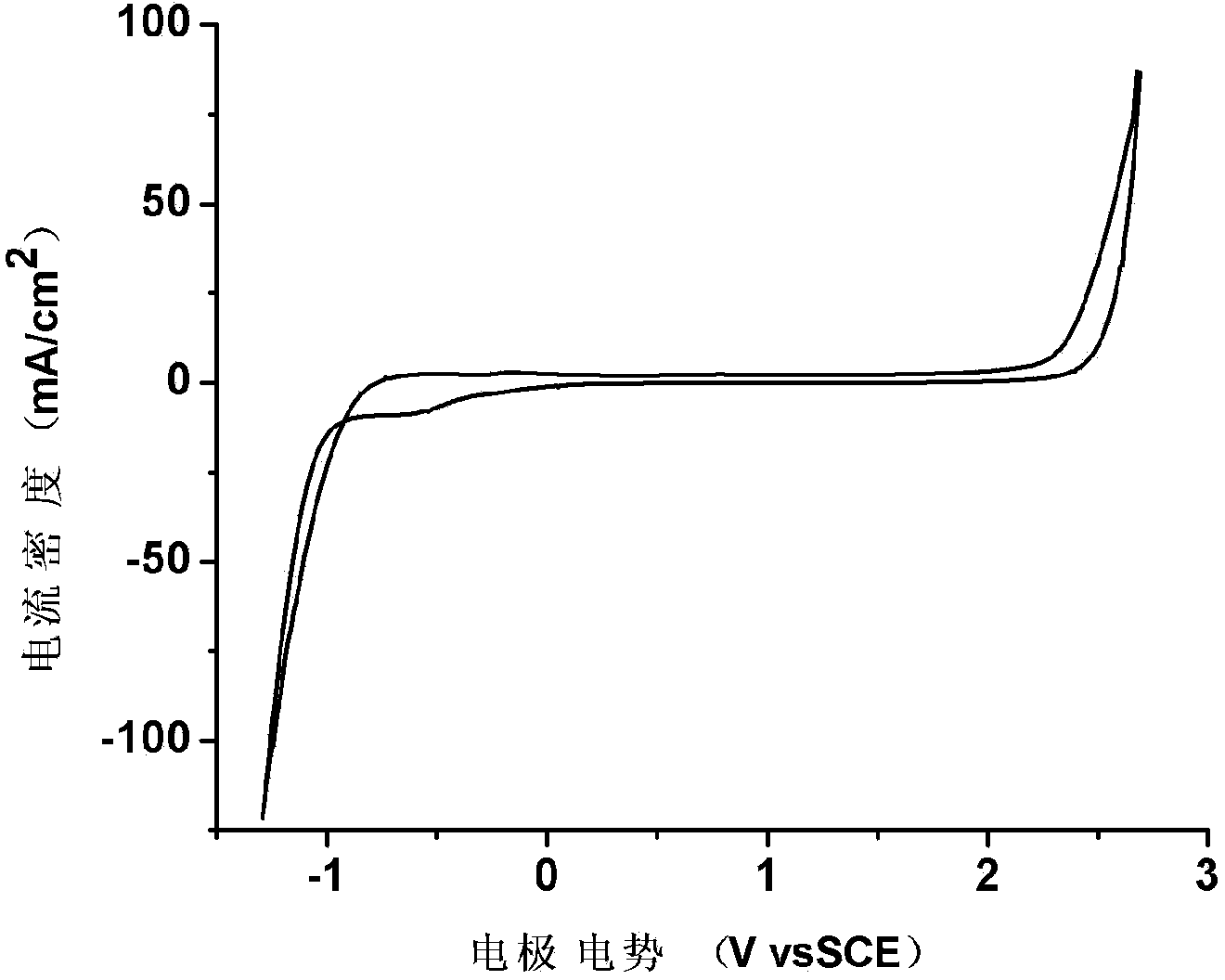

Preparation method of boron-doped diamond film electrode taking porous titanium as matrix

InactiveCN103643219AIncrease growth rateImprove stabilityChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention discloses a preparation method of a boron-doped diamond (BDD) film electrode taking porous titanium as a matrix. The preparation method is characterized in that the titanium matrix is a porous titanium material with the porosity of 20-50%, hot filament chemical vapor deposition equipment is adopted, and a porous titanium base BDD electrode is prepared through chemical vapor deposition by using a second-order boron concentration control mode. By adopting the method, the generation capacity of TiC is controlled by adjusting boron source concentrations of different stages during chemical vapor deposition, namely the formation of TiC is inhibited by using high boron doping at the initial stage to improve the bonding force between a base and a film, and the boron source concentration is reduced in the later period of reaction to perform low boron doping. The porous titanium base BDD electrode prepared by the method disclosed by the invention is uniform and compact in diamond grain, and the porous titanium matrix is completely covered by a diamond film, so that the electrode has good stability and a relatively wide potential window.

Owner:JILIN UNIV

Method of producing high strength, high stiffness and high ductility titanium alloys

A method of producing a high strength, high stiffness and high ductility titanium alloy, comprising combining the titanium alloy with boron so that the boron concentration in the boron-modified titanium alloy does not exceed the eutectic limit. The carbon concentration of the boron-modified titanium alloy is maintained below a predetermined limit to avoid embrittlement. The boron-modified alloy is heated to a temperature above the beta transus temperature to eliminate any supersaturated excess boron. The boron-modified titanium alloy is deformed at a speed slow enough to prevent microstructural damage and reduced ductility.

Owner:ATI PROPERTIES +2

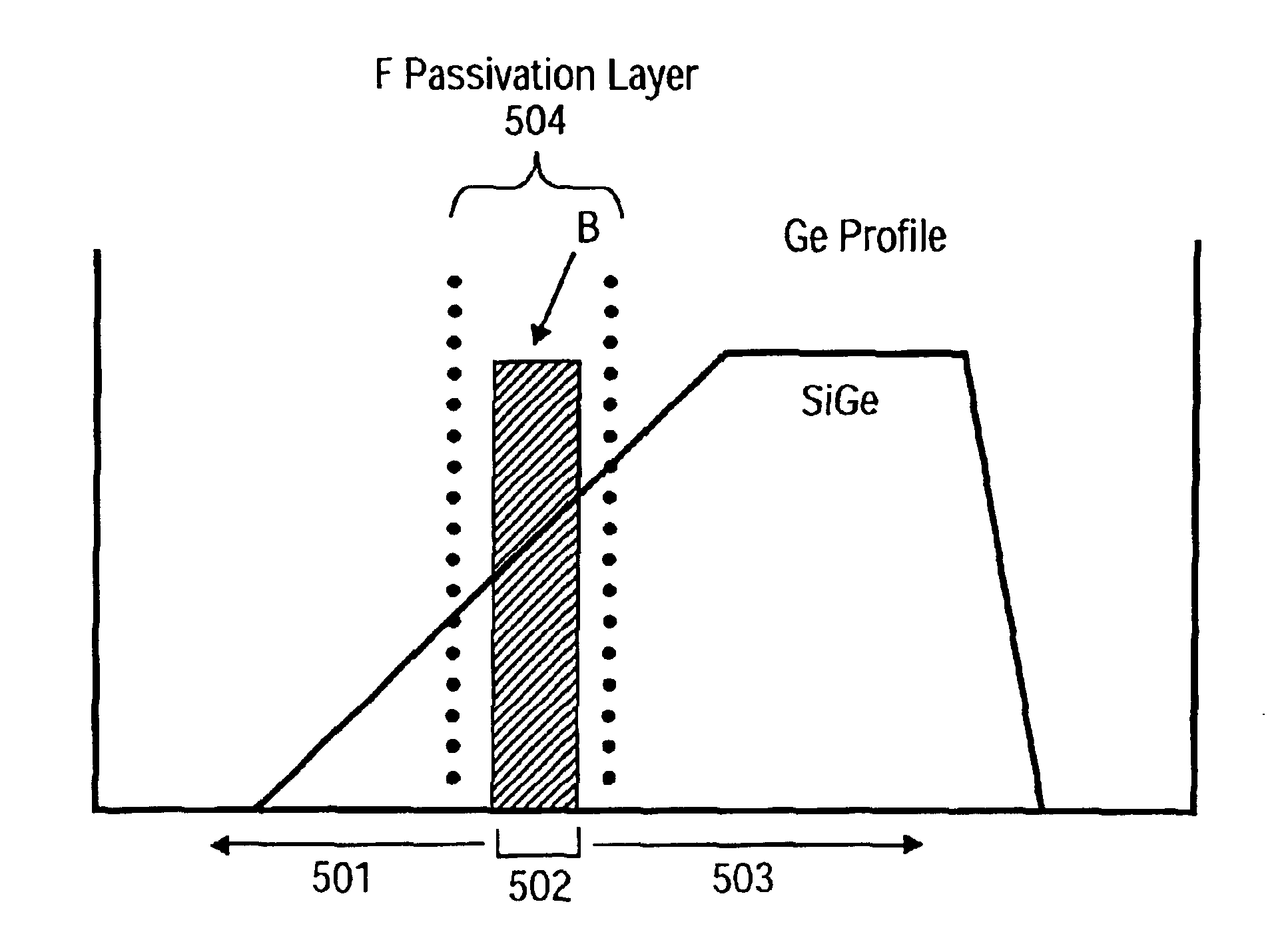

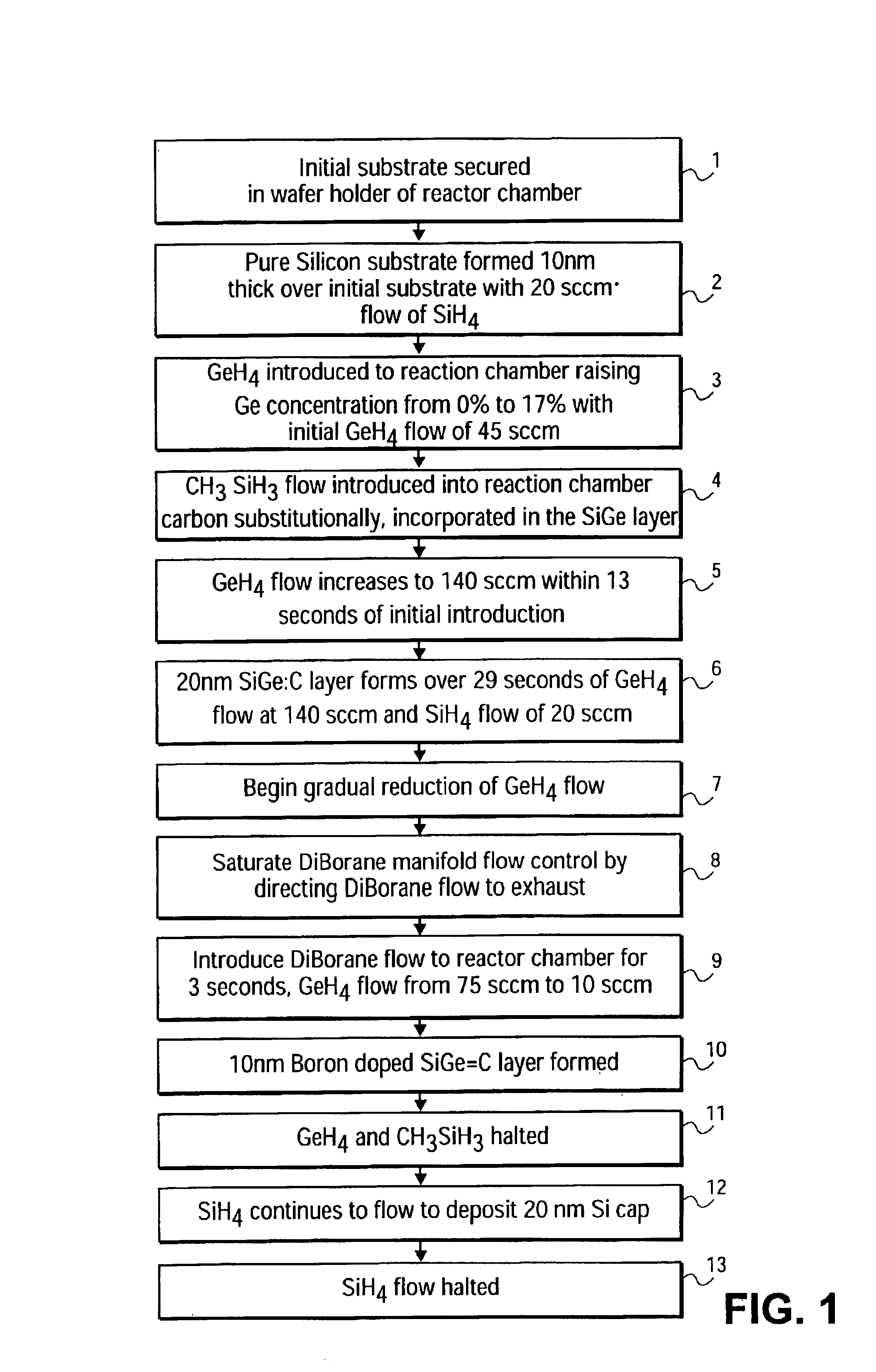

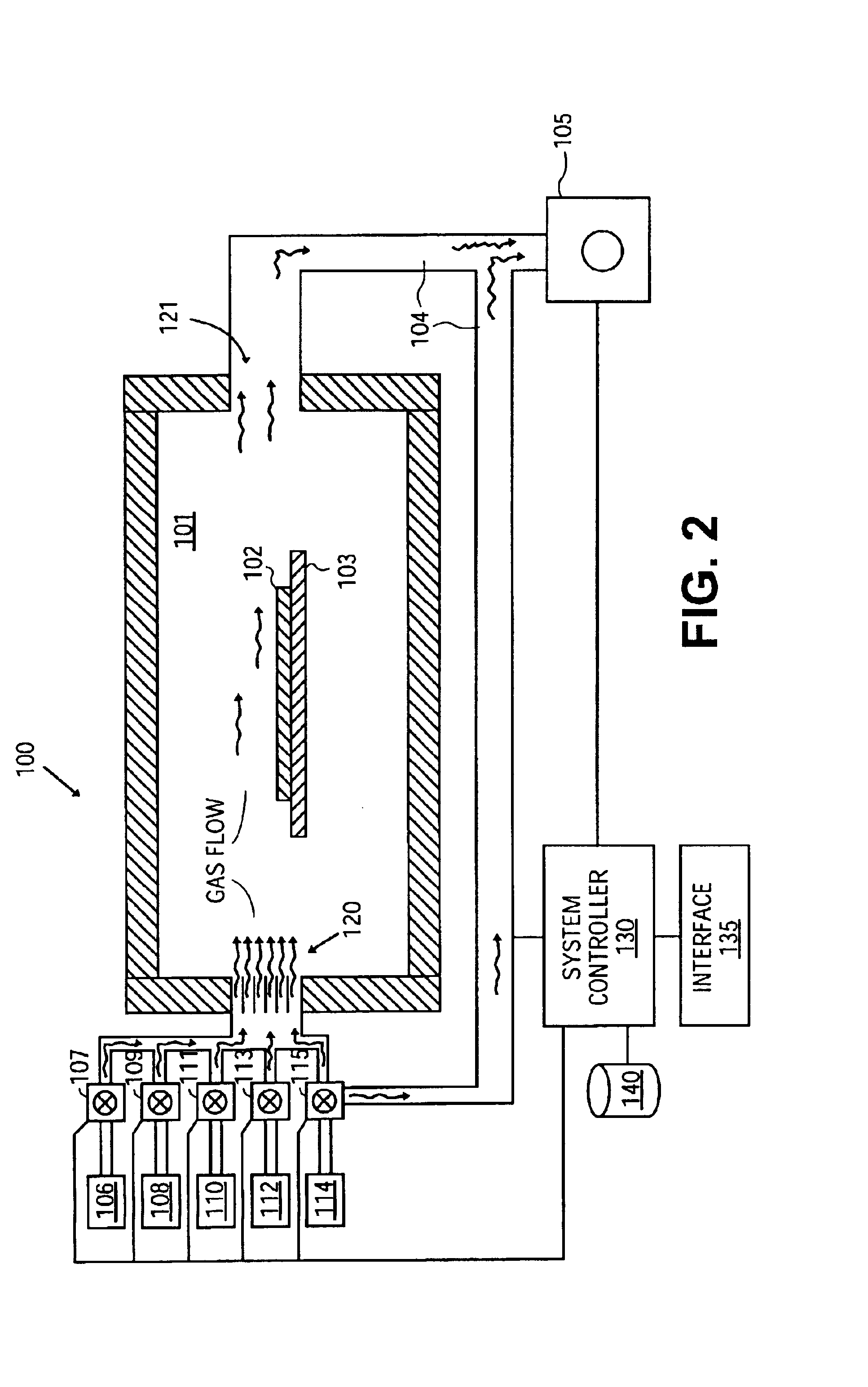

Method for fabricating a bipolar transistor base

InactiveUS6927140B2Semiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyTransistor

A method for forming a base of a bipolar transistor. A narrow base is formed using a flash of boron doping gas in a reaction chamber to create a narrow base with high boron concentration. This method allows for reliable formation of a base with high boron concentration while maintaining manageability in controlling deposition of other materials in a substrate.

Owner:INTEL CORP

Silicon wafer

ActiveUS20040089225A1Reduced strengthSufficient effectPolycrystalline material growthSiliconHigh concentrationDislocation

A silicon wafer is doped with boron and germanium in a range that satisfies a relational expression defined by: -0.8.times.10.sup.-3.ltoreq- .4.64.times.10.sup.-24.times.[Ge]-2.69.times.10.sup.-23.times.[B].ltoreq.1- .5.times.10.sup.-3. This can reduce the miss-fit dislocation which might be induced when an epitaxial layer is grown over the silicon wafer that has been added with boron in high concentration. It is to be noted that in the above relational expression, the [B] denotes a boron concentration, while the [Ge] denotes a germanium concentration and a concentration unit is indicated by atoms / cm.sup.3.

Owner:SUMITOMO MITSUBISHI SILICON CORP

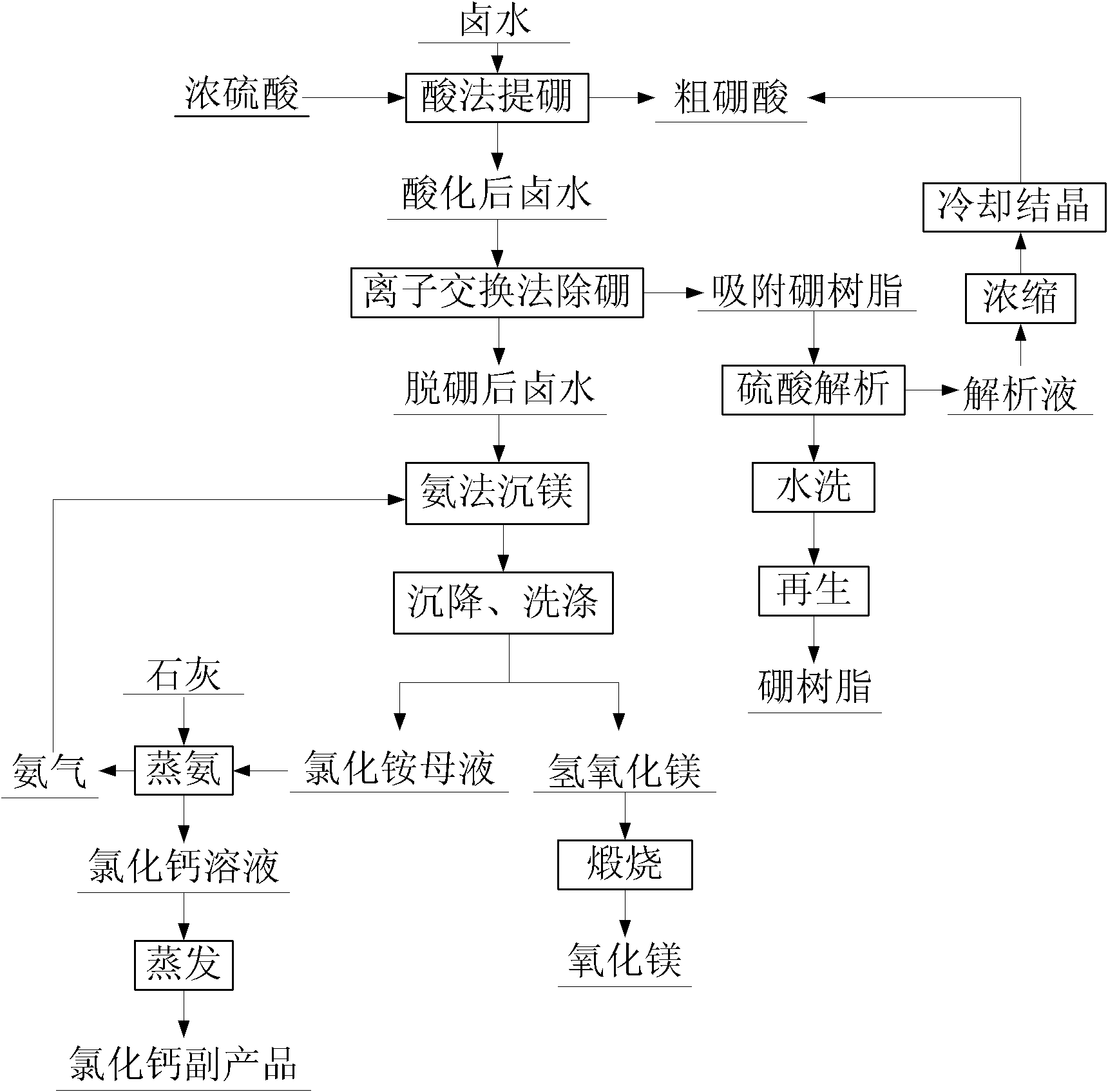

Method for preparing high-purity magnesium oxide with high boron salt lake brine

InactiveCN102491379ALarge particlesReduce extraction costsBoron-oxygen compoundsMagnesiaReaction temperatureIon-exchange resin

Provided is a method for preparing high-purity magnesium oxide with high boron salt lake brine. Salt lake brine is evaporated through a salt pan, concentrated to crystallize potassium sulfate, sodium chloride and potassium chloride and is drawn with lithium in adsorption mode so as to obtain master sauce brine containing magnesium and boron. Concentrated sulfuric acid is added into master sauce brine for reacting, and coarse boracic acid and acidized brine are obtained after cooling and filtering. Potential of hydrogen (pH) value of acidized brine is adjusted to be 5.5-6.5, and acidized brine passes through ion exchange resin adsorbing boron. When boron concentration in effluent liquid is higher than 5 mg / L, brine is not injected, boron-removed brine is obtained, then boron-removed brine and ammonium chloride solution are filled with ammonia for stirring and to produce magnesium sedimentation reaction, reaction temperature ranges from 60 DEG C to 80 DEG C, pH ranges from 7.5 to 8.0, the reaction is stopped when concentration of free ammonia reaches 1.8-2.2 mol / L, and magnesium hydroxide and magnesium sedimentation mother solution are obtained. Magnesium oxide is obtained by calcining magnesium hydroxide, content of magnesium oxide is larger than 99.8%, and magnesium extraction ratio is larger than 90%. Sedimentation mother solution adopts lime to steam ammonia, and generated ammonia circulates to magnesium sedimentation reaction. Mother solution after ammonia steaming is evaporated, concentrated and crystallized to obtain calcium chloride. Ion exchange resin adsorbing boron is washed, analyzed and regeneratively cycled for use. Boron-containing analysis solution is concentrated and cooled to pick up coarse boracic acid, and coarse boracic acid is recrystallized to obtain refined boracic acid with purity larger than 99%. High-purity magnesium oxide prepared by the method is high in purity, good in economic benefit, free of environment pollution, strong in operability and favorable for industrial production.

Owner:CENT SOUTH UNIV

Composite Semipermeable Membrane, Production Process Thereof, and Element, Fluid Separation Equipment and Treatment Method for Boron-Containing Water Using the Same

InactiveUS20080000843A1High desalination rateImprove performanceSemi-permeable membranesMembranesSemipermeable membraneBoron containing

A composite semipermeable membrane, which comprises a separating functional layer comprising a reactant of polyfunctional amine with polyfunctional acid halide, wherein a water-soluble organic material is in contact with the separating functional layer, and the separating functional layer has a boron removal ratio of 95% or more, when seawater at 25° C. having a pH of 6.5, a boron concentration of 5 ppm and a TDS concentration of 3.5% by weight is permeated under an operation pressure of 5.5 MPa.

Owner:TORAY IND INC

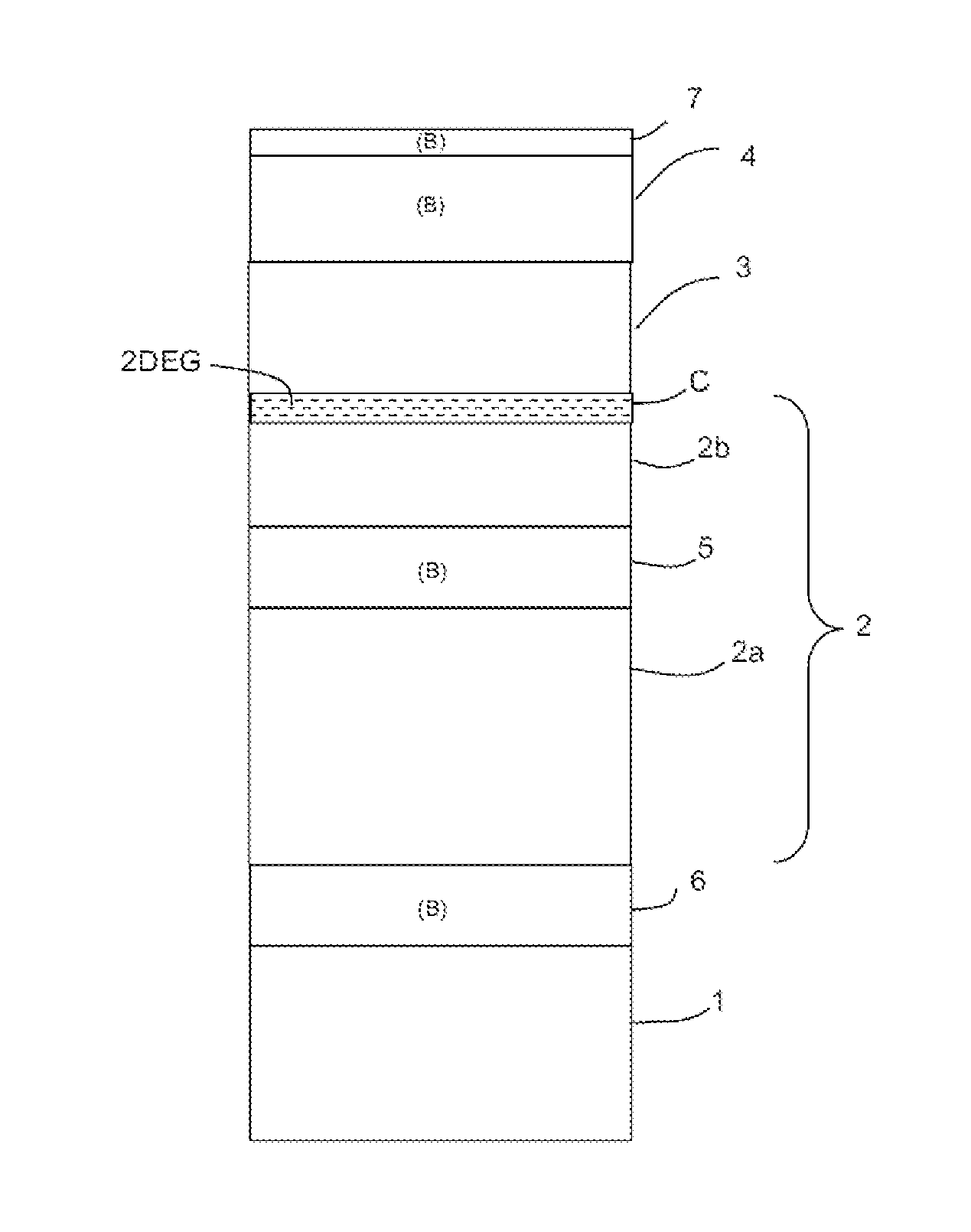

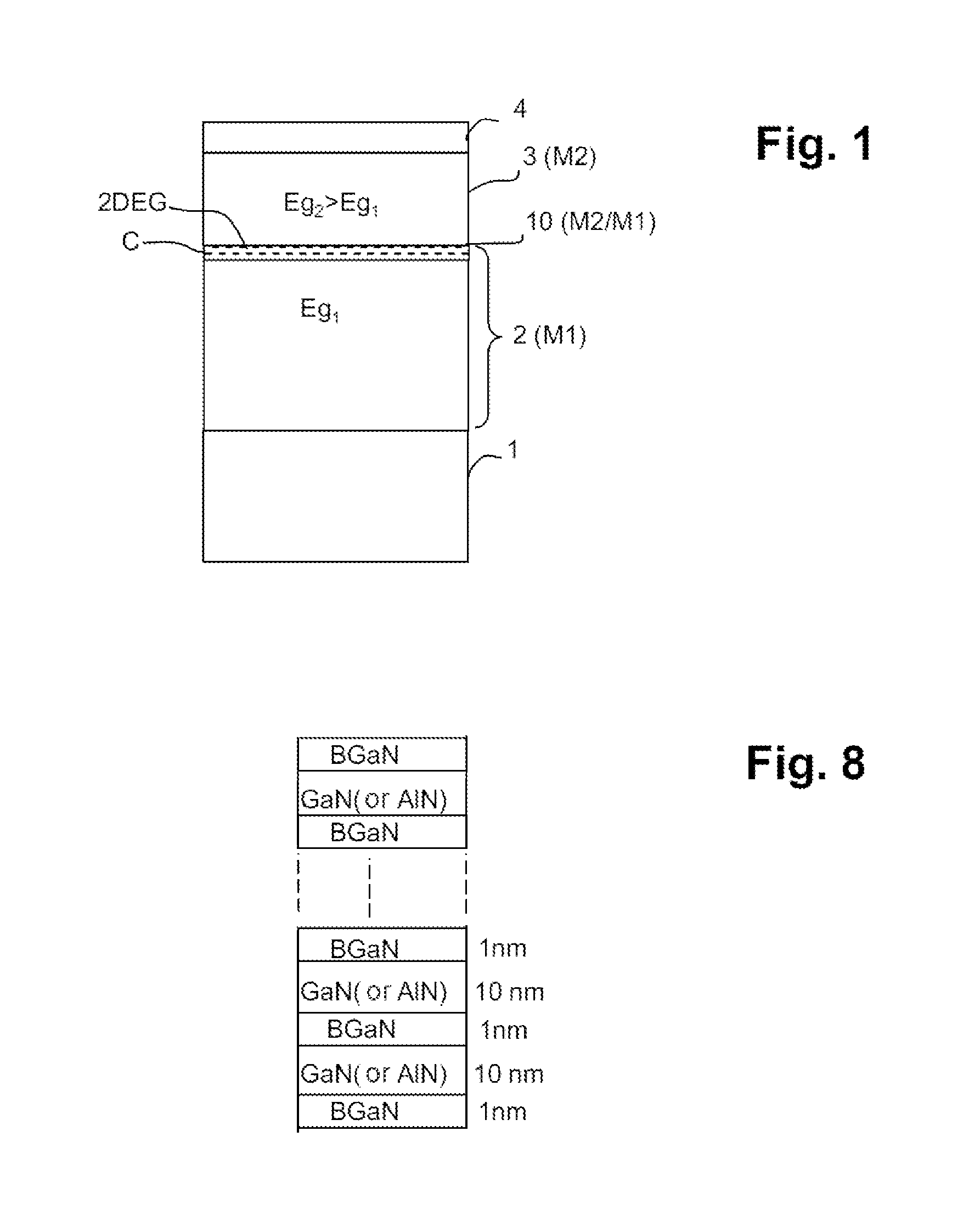

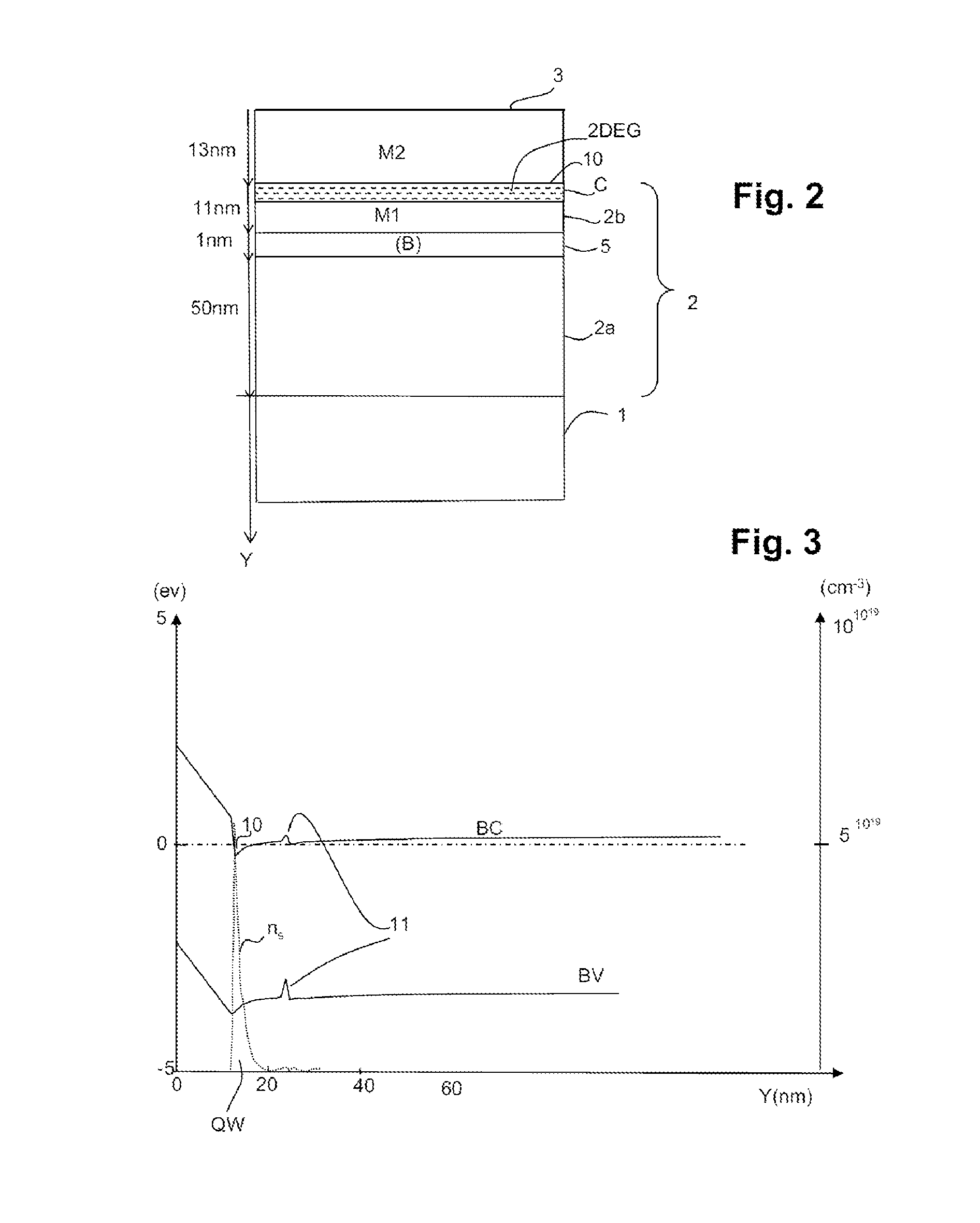

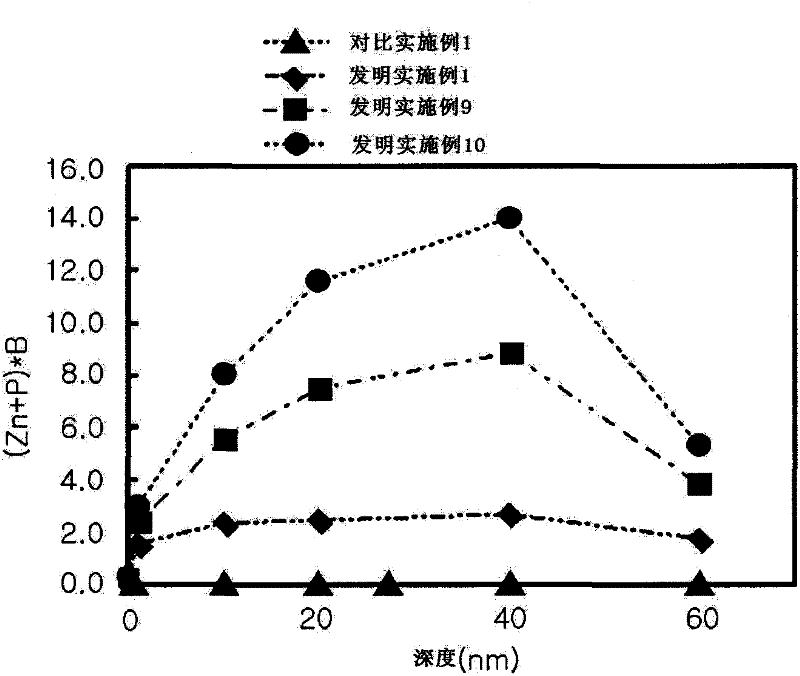

HEMT transistors consisting of (iii-b)-n wide bandgap semiconductors comprising boron

InactiveUS20140327012A1Promoting confinementHigh resistivityTransistorSemiconductor/solid-state device detailsHeterojunctionElectrical performance

An electronic HEMT transistor structure comprises a heterojunction formed from a first layer, called a buffer layer, of a first wide bandgap semiconductor material, and a second layer of a second wide bandgap semiconductor material, with a bandgap width EG.sub.2 larger than that Eg.sub.1 of the first material, and a two-dimensional electron gas flowing in a channel confined in the first layer under the interface of the heterojunction. The first layer furthermore comprises a layer of a BGaN material under the channel, with an average boron concentration of at least 0.1%, improving the electrical performance of the transistor. Application to microwave power components.

Owner:THALES SA +4

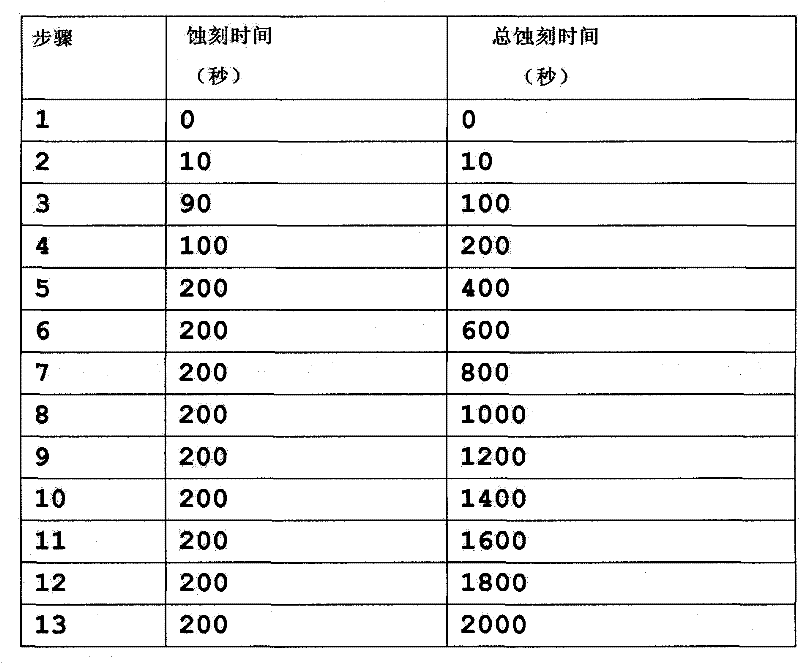

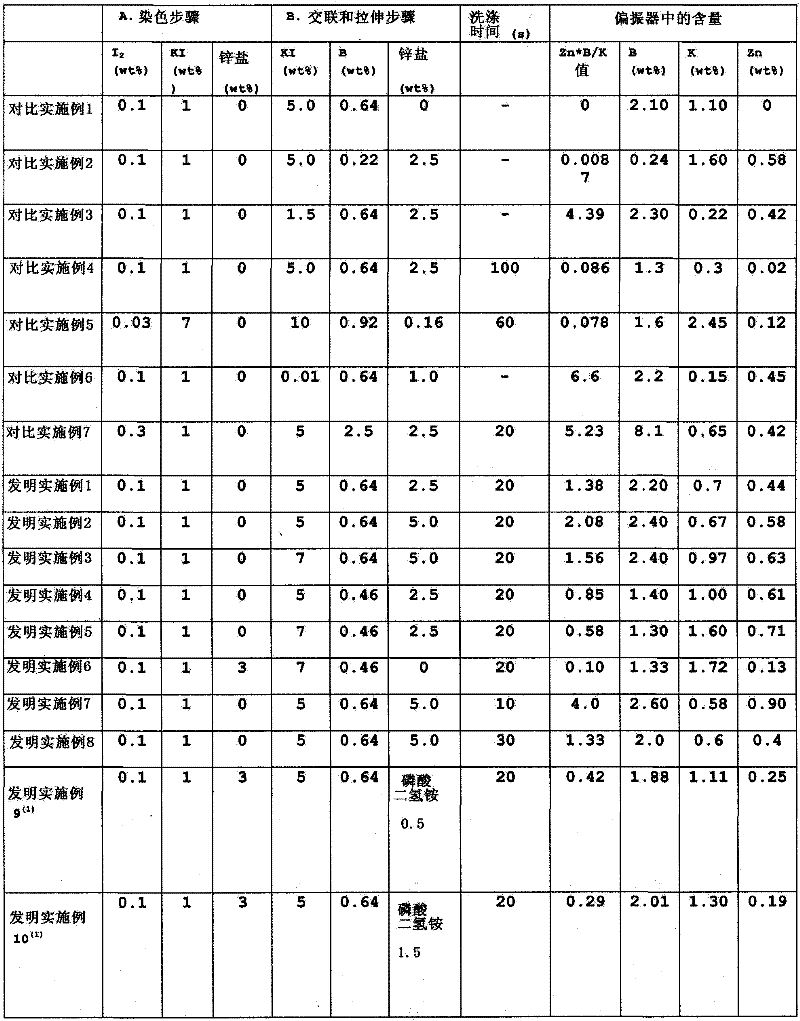

Polarizing element having excellent durability and heat resistance, polarizing plate and image display device, and method of manufacturing polarizing element

ActiveCN102301260AExcellent initial orthogonal transmittanceImprove transmittancePolarising elementsCold-cathode tubesDisplay devicePolarizer

Owner:LG CHEM LTD

Diamond-coated electrode and method for producing same

InactiveCN1735716AGood electrolyte peel strengthLower resistanceElectrodesElectrical resistance and conductanceDiamond electrodes

A diamond electrode having a sufficiently low resistance is disclosed which is realized by increasing the amount of boron added thereto. A method for producing a high-performance, high-durability electrode is also disclosed by which adhesiveness between a diamond coating and a substrate and separation resistance during electrolysis are sufficiently increased. An electrode composed of a substrate and a diamond layer coating the substrate is characterized in that the electrode is composed of a base coated with diamond and the diamond contains boron in such an amount that the boron concentration is not less than 10,000 ppm but not more than 100,000 ppm. The base is preferably made of an insulating material.

Owner:SUMITOMO ELECTRIC IND LTD

Boron doped diamond

InactiveUS20070092647A1Increase in sizeSmall sizePolycrystalline material growthFrom chemically reactive gasesSingle crystalChemical vapor deposition

A layer of single crystal boron doped diamond produced by CVD and having a total boron concentration which is uniform. The layer is formed from a single growth sector, or has a thickness exceeding 100 μm, or has a volume exceeding 1 mm3, or a combination of such characteristics.

Owner:ELEMENT SIX LTD

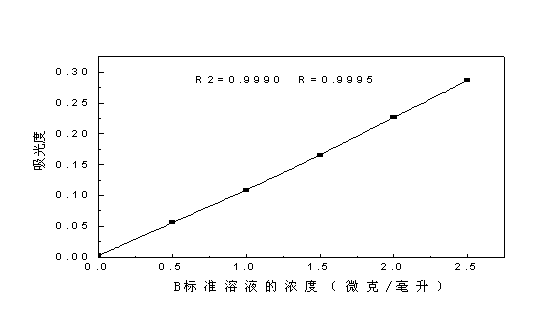

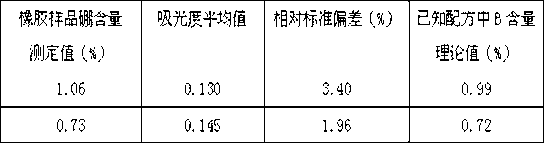

Method for determining boron content in rubber

ActiveCN102998275ARealize determinationImprove accuracyColor/spectral properties measurementsGraphiteMuffle furnace

The invention discloses a method for determining boron content in rubber. The method employs a graphite furnace atomic absorption spectrometry method for determination and calculation of boron content in rubber. The method comprises steps of: conducting pretreatment on a rubber sample; conducting high-temperature ashing by a muffle furnace; adding a mixed acid of hydrofluoric acid and concentrated sulfuric acid in the ash; digesting, drying and placing the ash in the muffle furnace; calcining at 800 DEG C; dissolving the ash with hydrochloric acid to gain a transparent sample solution, and conducting a blank test with the sample; preparing a boron standard work solution above 4 point by using a boron standard stock solution; adding a matrix modifier Ca (NO3) 2 with a same concentration into the sample solution, the blank solution and the standard work solution, and adding high purity water for constant volume; optimizing test conditions of the graphite furnace atomic absorption spectrometry, measuring boron absorbance of the sample solution, the blank solution and the standard solution, and drawing a standard working curve to obtain boron concentration in the sample solution; and calculating the content (in percentage) of boron in the rubber sample. The determination method has advantages of results with high precision and accuracy.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

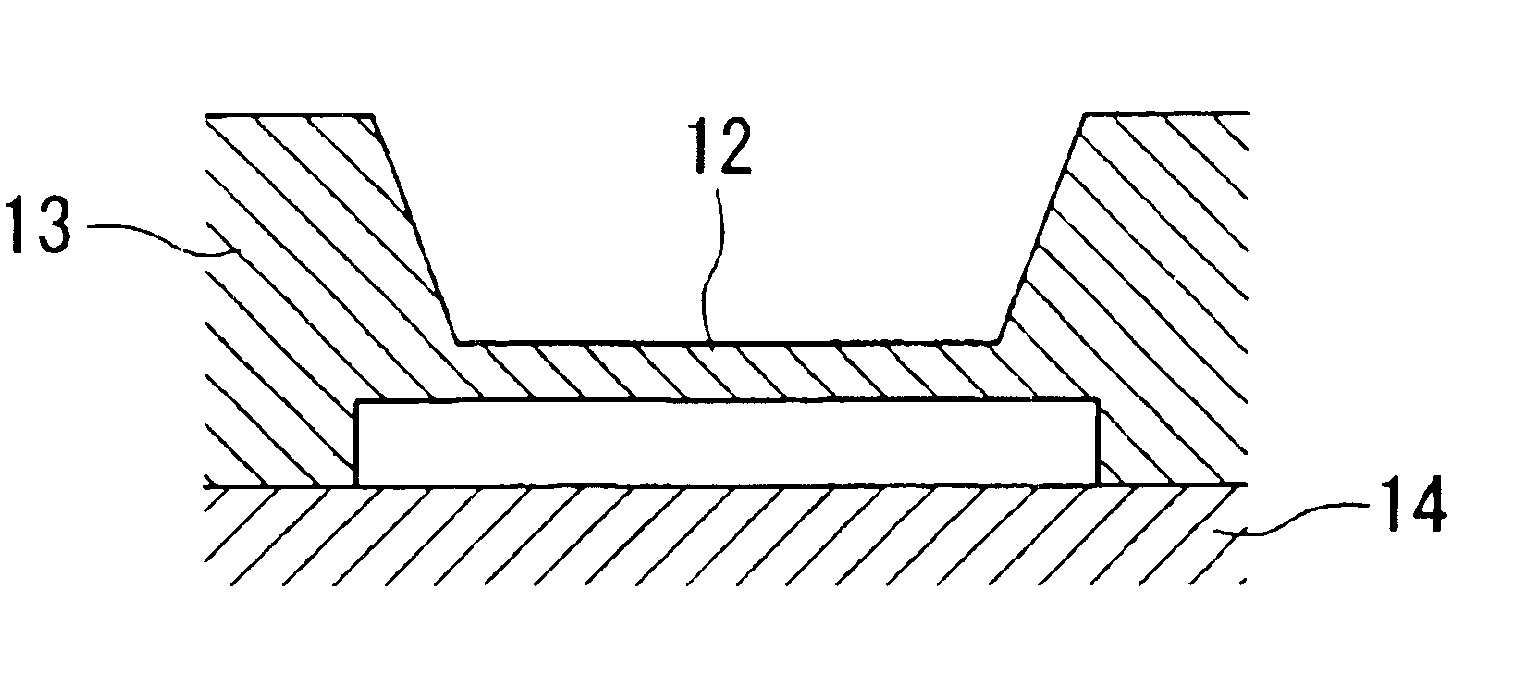

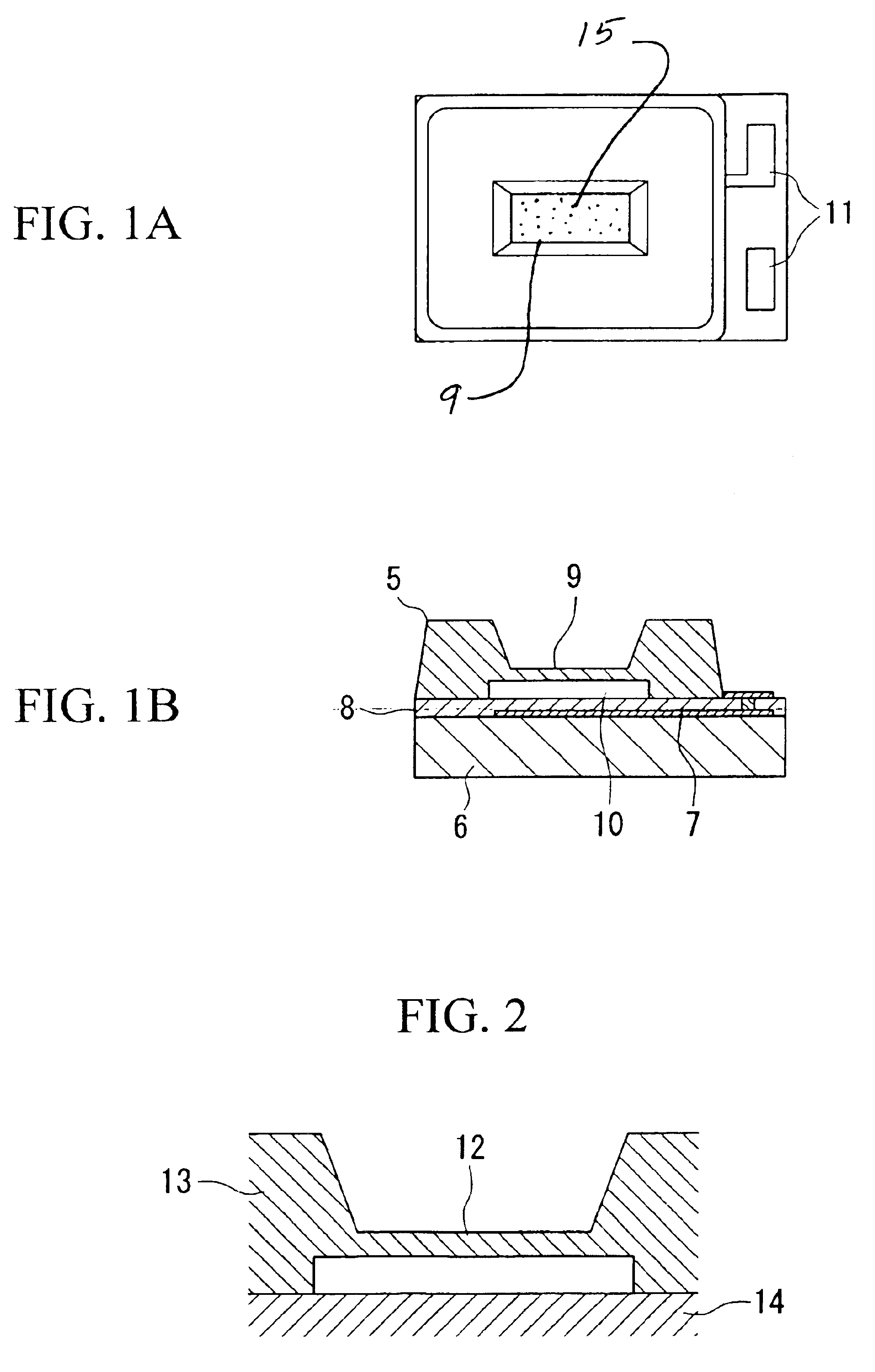

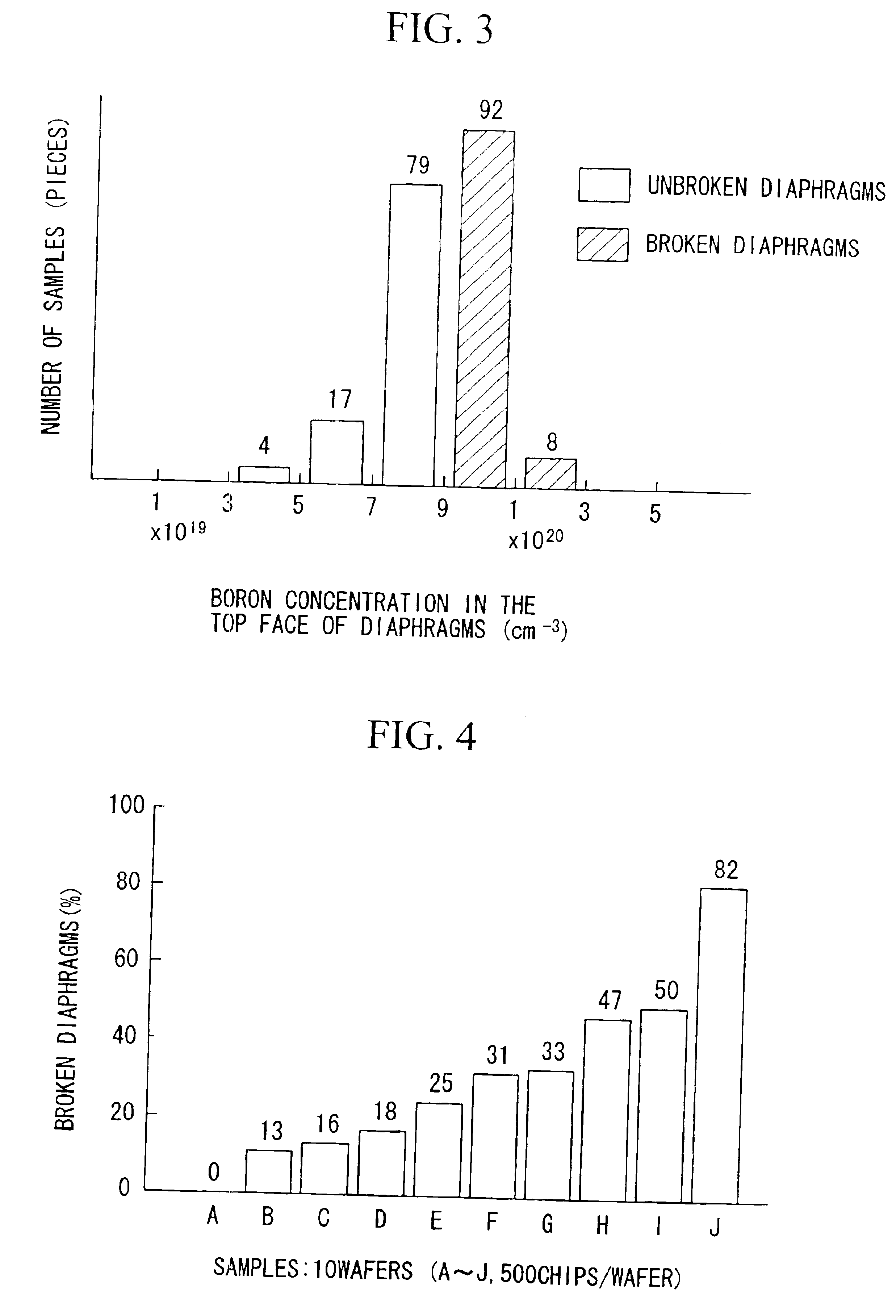

Pressure sensor and manufacturing method thereof

InactiveUS6860154B2High durability against overloadIncreased durabilityMaterial analysis by observing immersed bodiesFlow propertiesCapacitive pressure sensorEngineering

It is an object of the present invention to provide a touch mode capacitive pressure sensor having higher pressure durability than conventional sensors. In this invention, a touch mode capacitive pressure sensor has a diaphragm made from boron-doped silicon, and the boron concentration at the top face of the diaphragm is equal to or greater than 1×1019 cm−3 and less than 9×1019 cm−3. Further, in this invention, a touch mode capacitive pressure sensor has a conductive diaphragm made by doping of an impurity and anisotropic etching, and the etch pit density on the top face of the diaphragm is equal to or less than five per μm2, and preferably equal to or less than one per μm2. As a result, the pressure durability of the diaphragm is greatly improved.

Owner:THE FUJIKURA CABLE WORKS LTD

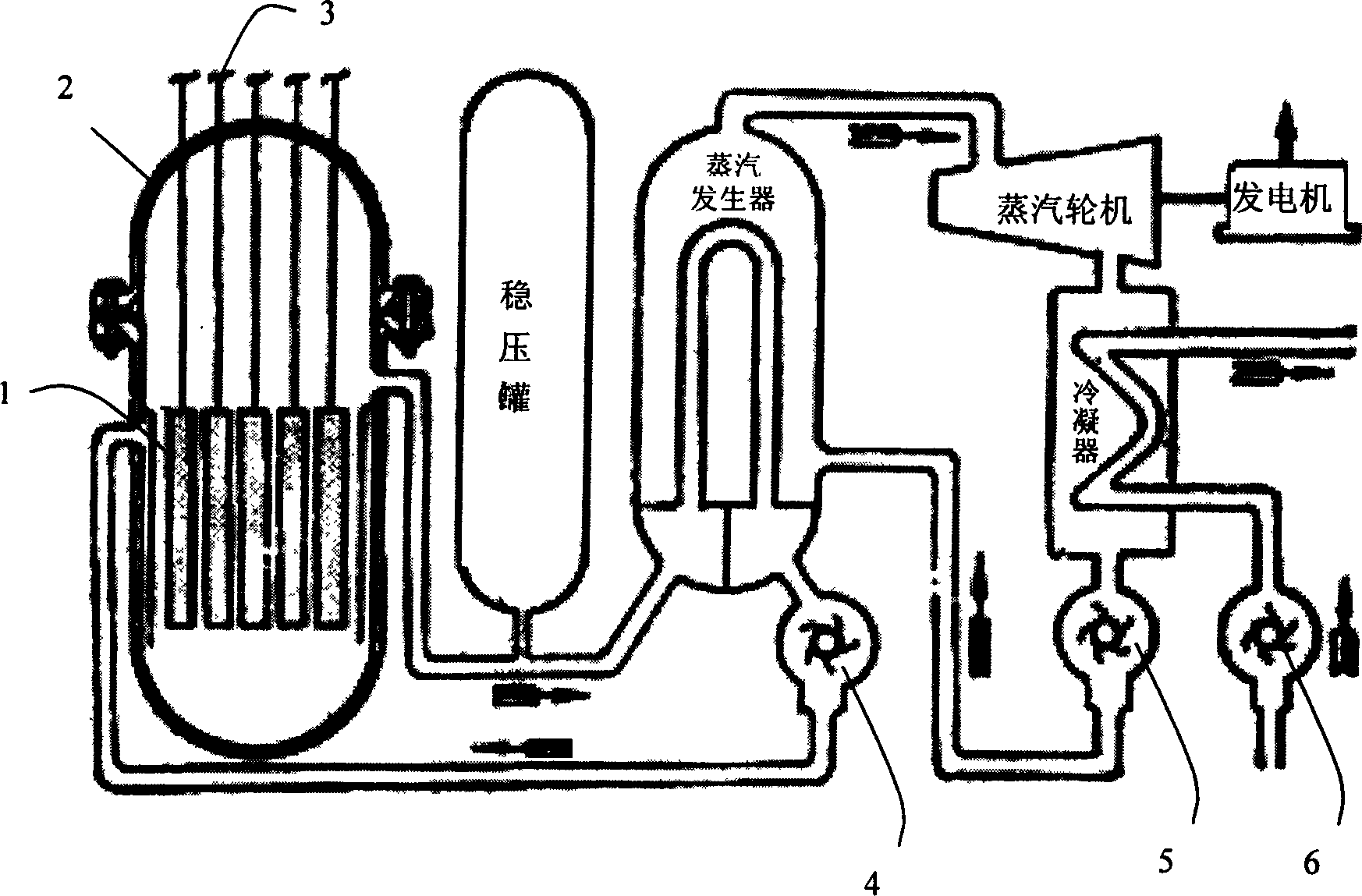

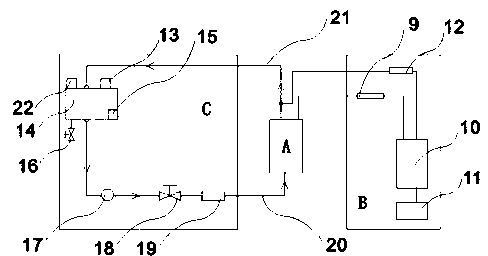

Method for improving integrated reliability of nuclear power station safety injection system

InactiveCN1783353ALower the low temperature alarm valueEliminate security concernsNuclear energy generationEmergency protection arrangementsNuclear powerPressurized water reactor

The present invention discloses a method of raising the integral reliability of safety injection system of pressurized water reactor in nuclear power station. The concentrated boron water tank is set in the connection pipeline of loop from the safety injection system to the pressurized water reactor. The method includes the following steps: mixing crystallized boron and deionized water, controlling the boron concentration inside the concentrated boron water tank in 7000-9000 ppm, and setting the low temperature warning value of the concentrated boron water tank as 35 deg.c. The present invention can eliminate pipeline jamming caused by boron crystal and raise the reliability of the safety system in pressurized water reactor nuclear power station.

Owner:DAYA BAY NUCLEAR POWER OPERATIONS & MANAGEMENT

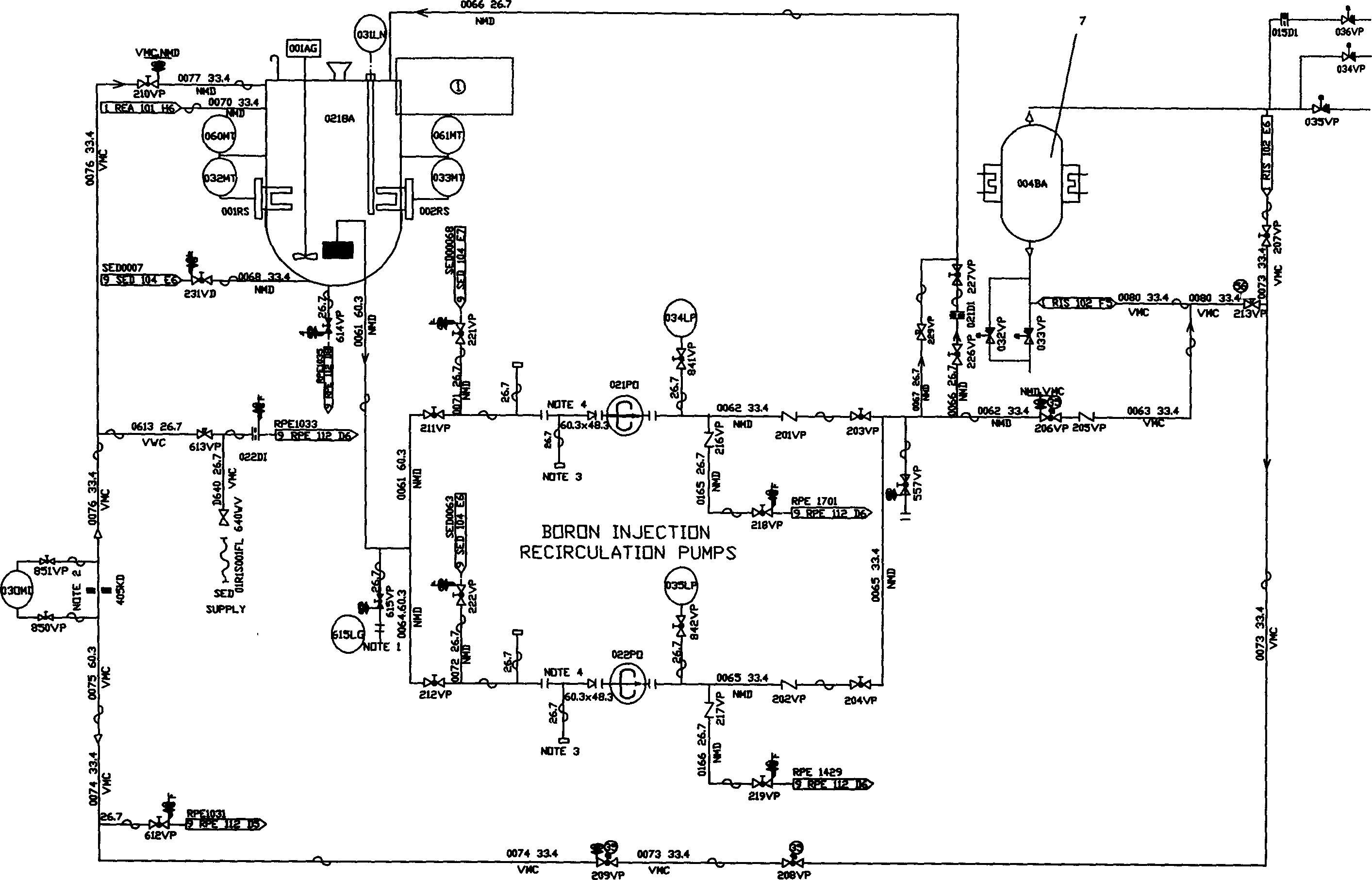

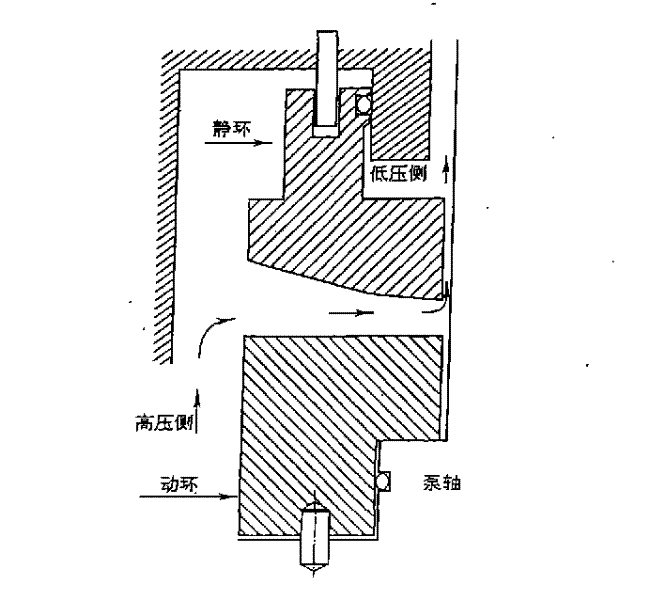

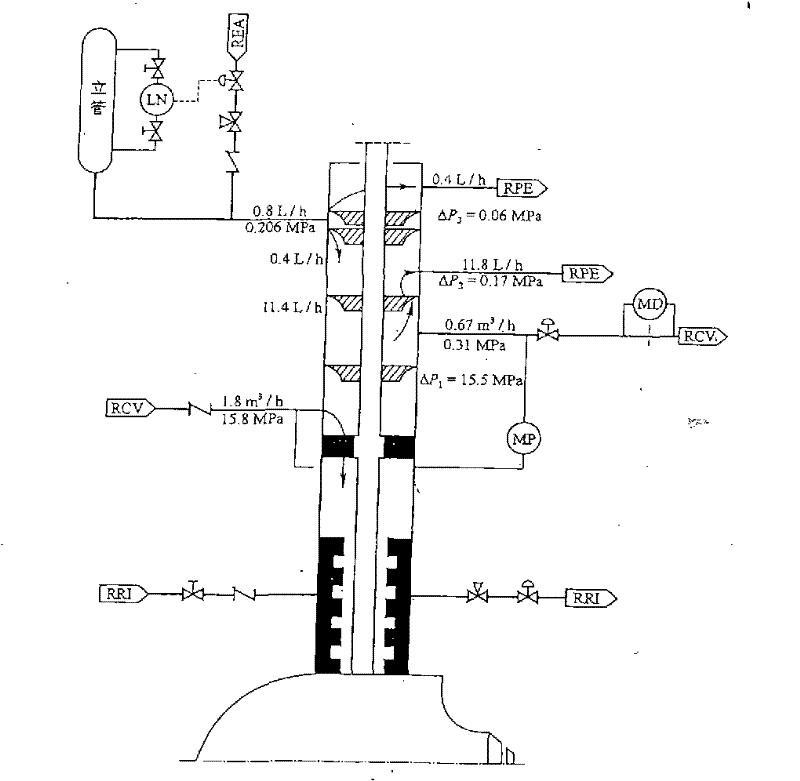

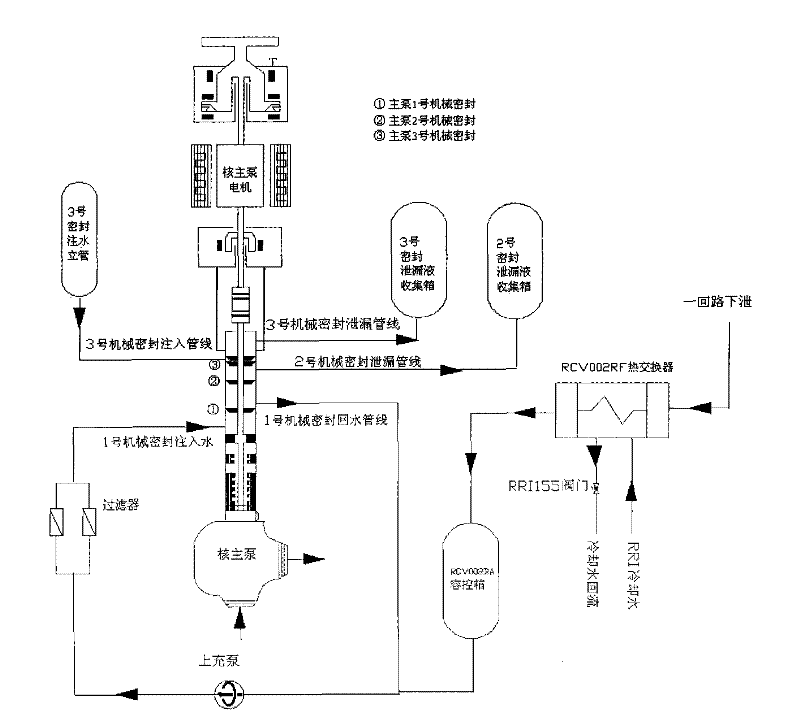

Method for preventing abnormity of mechanical seal leakage rate of nuclear reactor coolant pump

ActiveCN102456418AExtend your lifeImprove sealingNuclear energy generationNuclear monitoringEngineeringCoolant pump

The invention relates to a method for preventing abnormity of mechanical seal leakage rate of a nuclear reactor coolant pump. An injection water loop of a No. 1 shaft seal of a coolant pump is provided with two parallel columns of filters; one row of the filters are operating on the line, and the other column of filters are for standby. The preventive method comprises the following steps: S1. detecting a boron concentration of a loop; S2. comparing the boron concentration of the loop with that of the row of filters for standby; and S3. when a difference between the boron concentration of the standby row and that of the loop exceeds a preset value, switching the standby column of filters to on-line operation, and switching the on-line operating row of filters into a standby state. In the preventive method of the invention, when the difference between the boron concentration of the standby column and that of the loop exceeds the preset value, filter switching is carried out; and a sealing surface of the No. 1 shaft seal can be flushed timely by shaft seal injection water with a relative high boron concentration in the standby column of filters, so as to improve a seal status of the sealing surface of the No. 1 shaft seal timely and effectively.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +1

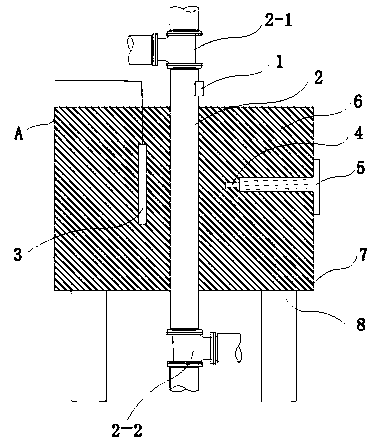

Boron concentration meter for nuclear power station and calibration method thereof

InactiveCN103680650ARealize online real-time monitoringSolve the problem of boron concentration measurement driftNuclear energy generationNuclear monitoringObservational errorMeasurement device

The invention discloses a boron concentration meter for a nuclear power station and a calibration method thereof. A detection device of the boron concentration meter is characterized in that a section of pipe on a drainage water monitoring branch is taken as a sampling pipe which serves as a sharing pipe section of a to-be-measured water monitoring branch and a calibration loop, and on-line communication of the sampling pipe and the calibration loop is realized through switching of tee branch control valves at two ends of the sharing pipe section; chemical titration as a standard, and the calibration for the boron concentration meter is finished ; and the operation is transferred to the monitoring branch after the calibration for real-time monitoring of boron concentration of primary loopwater . A measuring device adopts a linear mathematic model to establish a measurement relation in a piecewise fitting manner, so that the measurement precision is improved; and by means of an established on-line immediate calibration method, measurement drifting is eliminated, and measurement errors are corrected. The device is simple in structure, the measurement method is accurate and reliable, and the operation is easy; and by virtue of the calibration method, the insurmountable technical problem caused by enlargement of measurement errors of the boron concentration meter as time goes by is successfully solved, and accurate continuous on-line monitoring of the boron concentration of the primary loopwater is realized.

Owner:阴国玮

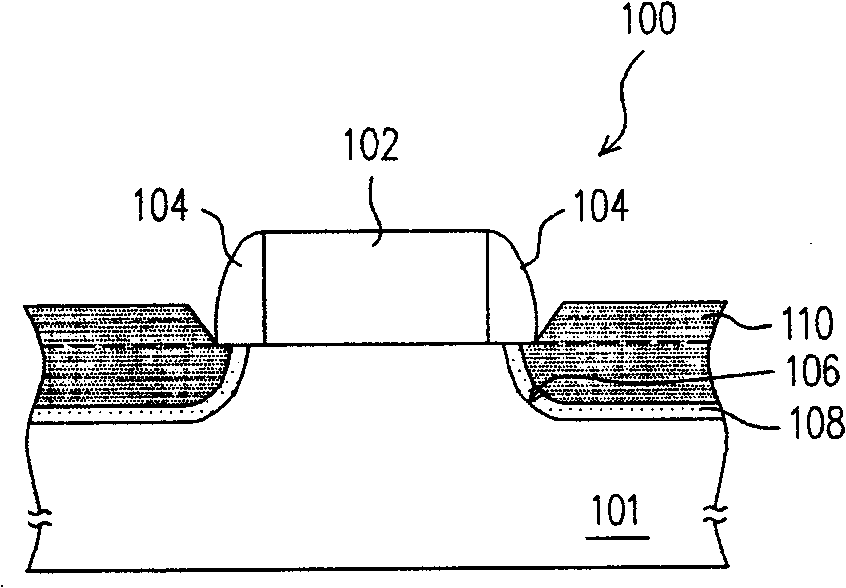

Semiconductor device and its manufacturing method

ActiveCN101257046AInhibition of outward diffusionImprove electrical breakdown effectSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor device

A semiconductor component includes a substrate, a grid structure, a gapping place wall, and a first polysilicon germanium layer with boron dope and a second polysilicon germanium layer. The substrate has two opening, and the grid structure are placed at the substrate between two openings. The gapping wall is configured at the lateral wall of the grid structure, and situated above the two openings. In addition, first polysilicon germanium layer is configured at the surface of the two opening of the substrate, moreover second polysilicon germanium layer is configured at first polysilicon germanium layer, and the top of second polysilicon germanium layer is higher than the surface of the substrate. Wherein, boron concentration of first polysilicon germanium layer is lower than that of second polysilicon germanium layer.

Owner:UNITED MICROELECTRONICS CORP

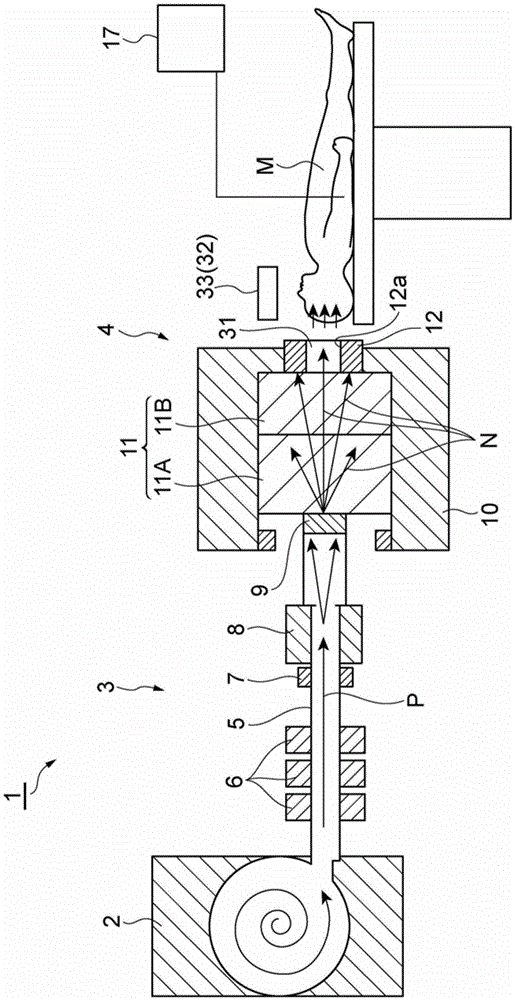

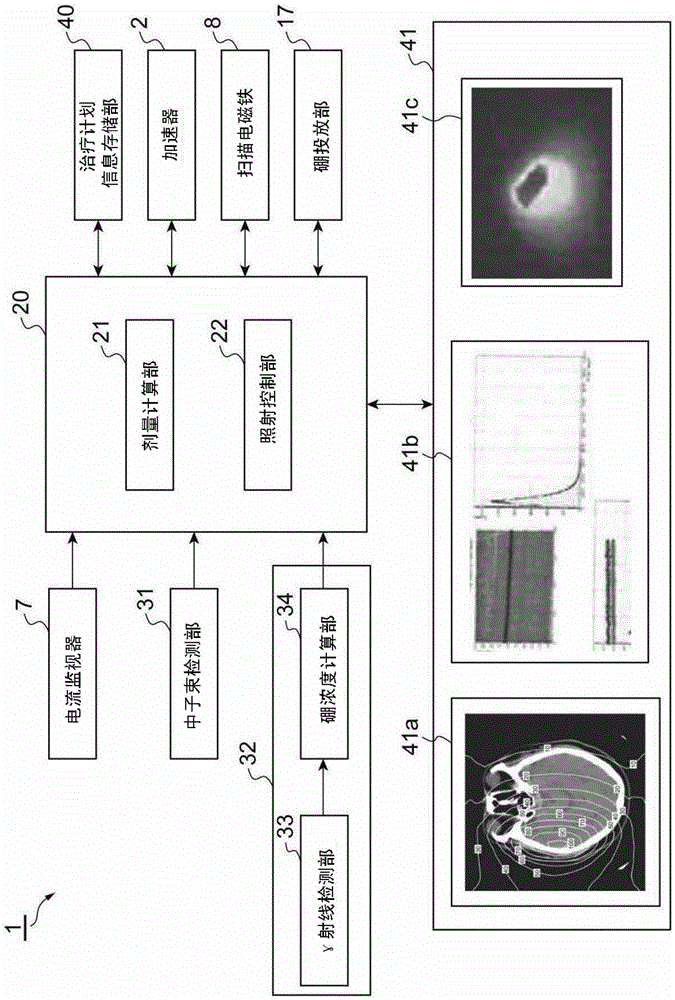

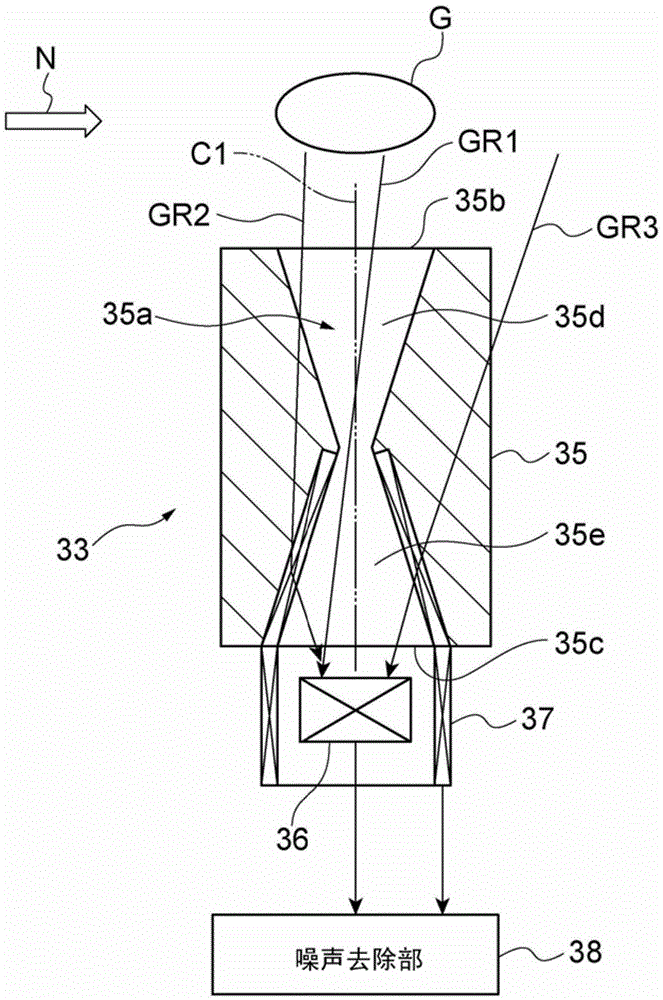

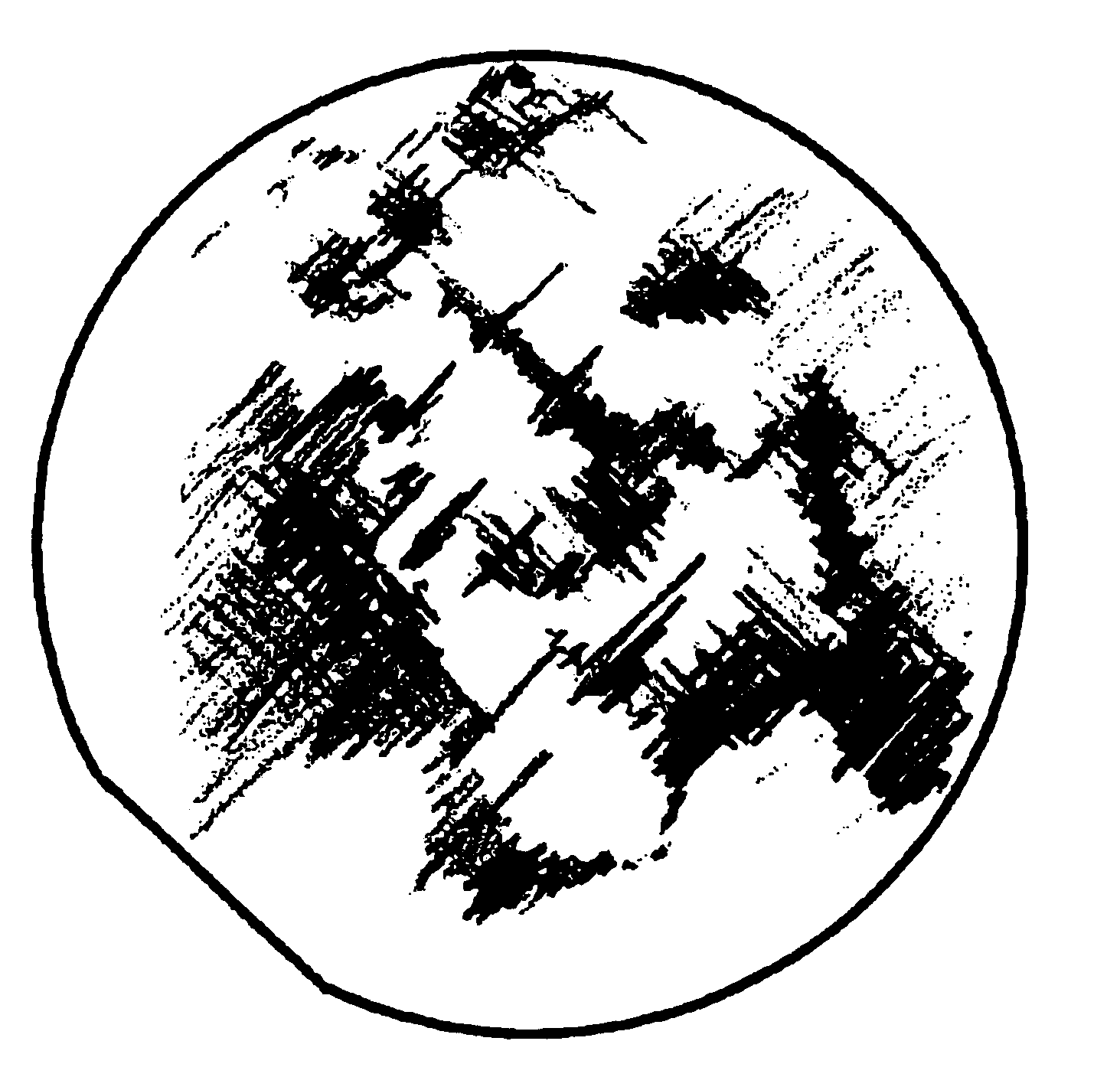

Neutron capture therapy device

ActiveCN105938731AImprove reliabilityDirect voltage acceleratorsIrradiation devicesNeutron captureBoron concentration

The invention provides a neutron capture therapy device which is capable of improving reliability of a boron neutron capture therapy. The neutron capture therapy device (1) in the invention is radiates neutron beams onto a object to be radiated (M), and boron in the radiated object (M) is enabled to react with the neutrons. The neutron capture therapy device (1) has a neutron beam radiating part (4) used for radiating the neutron beams (N) onto the object to be radiated (M) and a boron concentration measuring part (32) used for measuring in real time the concentration of boron in the object to be radiated (M) when the neutron beam radiating part (4) radiates the neutron beams (N).

Owner:SUMITOMO HEAVY IND LTD +1

Silicon wafer

InactiveUS6905771B2Reduce occurrencePolycrystalline material growthSiliconHigh concentrationWafering

Owner:SUMITOMO MITSUBISHI SILICON CORP

Boron diffusion method for N-type crystalline silica solar cell

ActiveCN102191562AIncrease surface boron concentrationEasy to manufactureDiffusion/dopingDiffusion methodsElectricity

The invention discloses a boron diffusion method for N-type crystalline silica solar cell. The method comprises the following steps: carrying out an etching wash treatment on a N-type silicon chip, carrying out a heat treatment on the N-type silicon chip in nitrogen which followed by heating up and access of a boron source to start boron diffusion; carrying out a cooling treatment on the silicon chip and introducing nitrogen gas to complete the diffusion process. According to the diffusion method in the invention, the boron concentration of the N-type silicon chip is substantially improved, the difficulty of subsequent metallization sintering is avoided, which facilitating the improvement of the electrical performance of the whole N-type crystalline silica solar cell.

Owner:CSI CELLS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com