Patents

Literature

681results about "Direct voltage accelerators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for treating the surface with neutral particle beams

InactiveUS6935269B2Wide effective cross sectionImprove throughputRadiation/particle handlingElectric discharge tubesTarget surfaceMetal

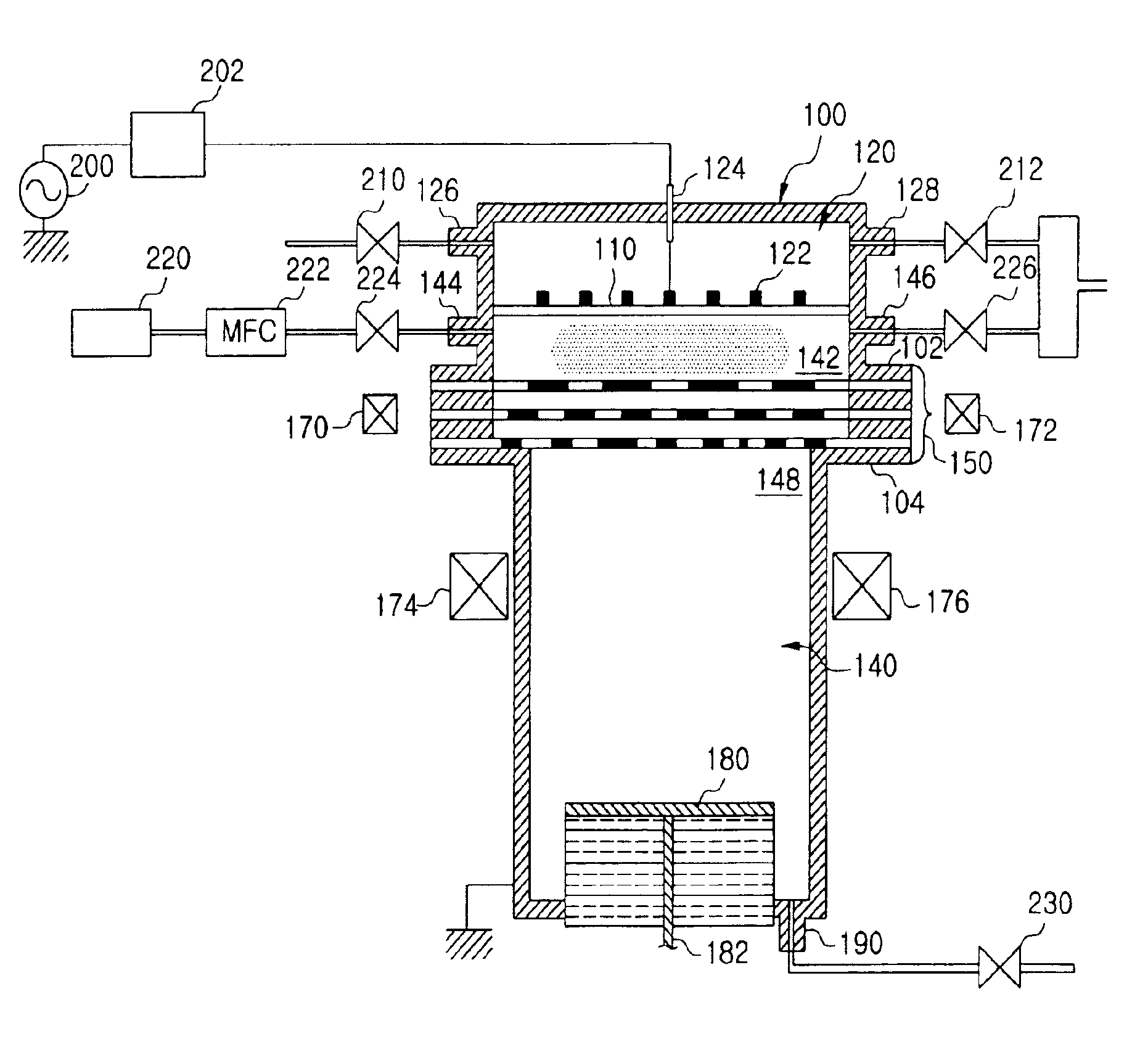

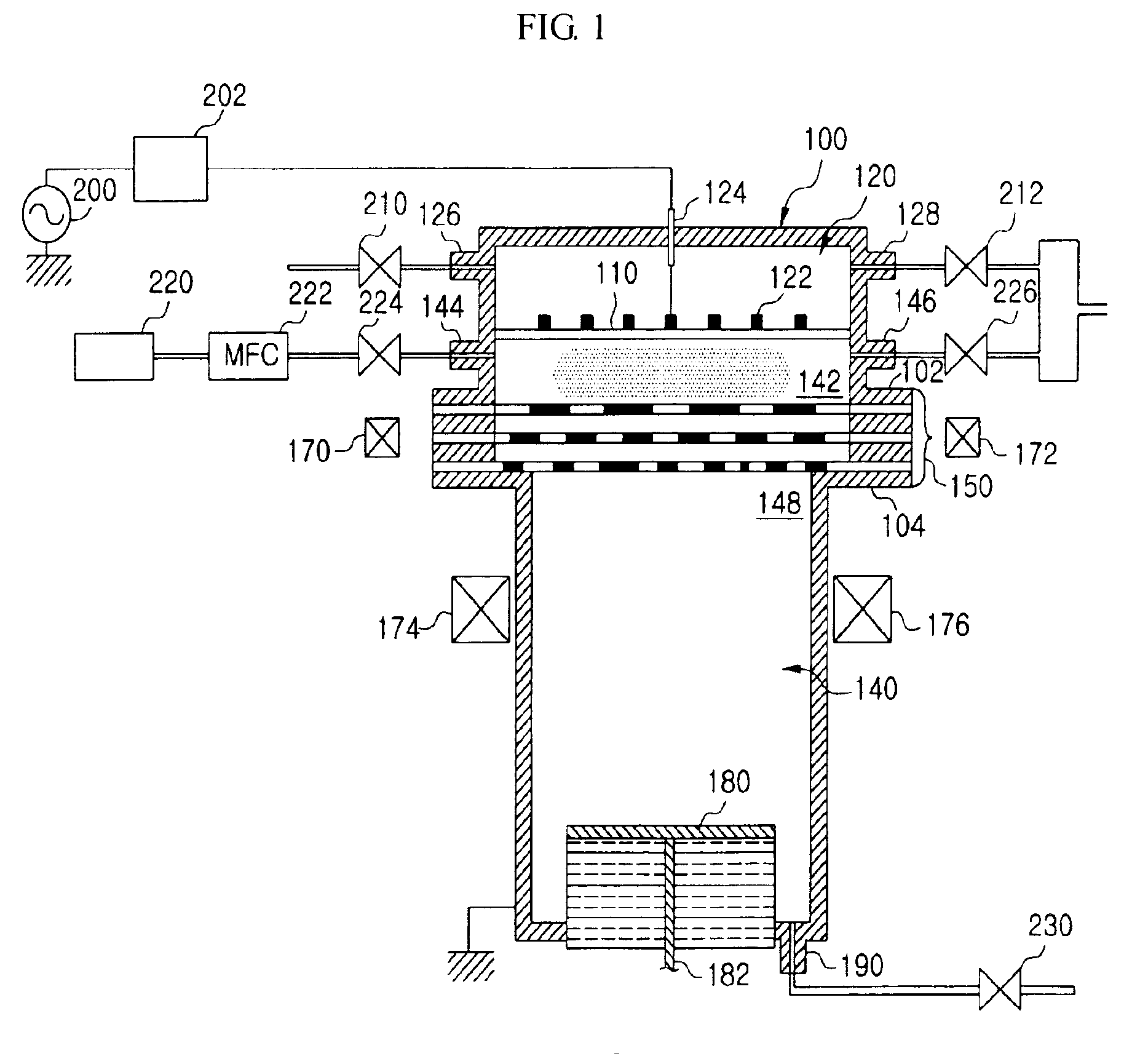

The present invention relates to an apparatus for treating the surface with neutral particle beams comprising an antenna container, a plasma generating part, a neutral particle beam generating part and a treating part, wherein the antenna container comprises antennas connected to high frequency electric power supply through which high frequency electric power supplies, the plasma generating part transfers gases from a gas injector into plasmas with the supplied power, the neutral particle beam generating part reverts the obtained plasmas to neutral particle beams via the collision thereof with metal plates, and the treating part treats the surface of a target with the neutral particle beams.

Owner:SEM TECH CO LTD +1

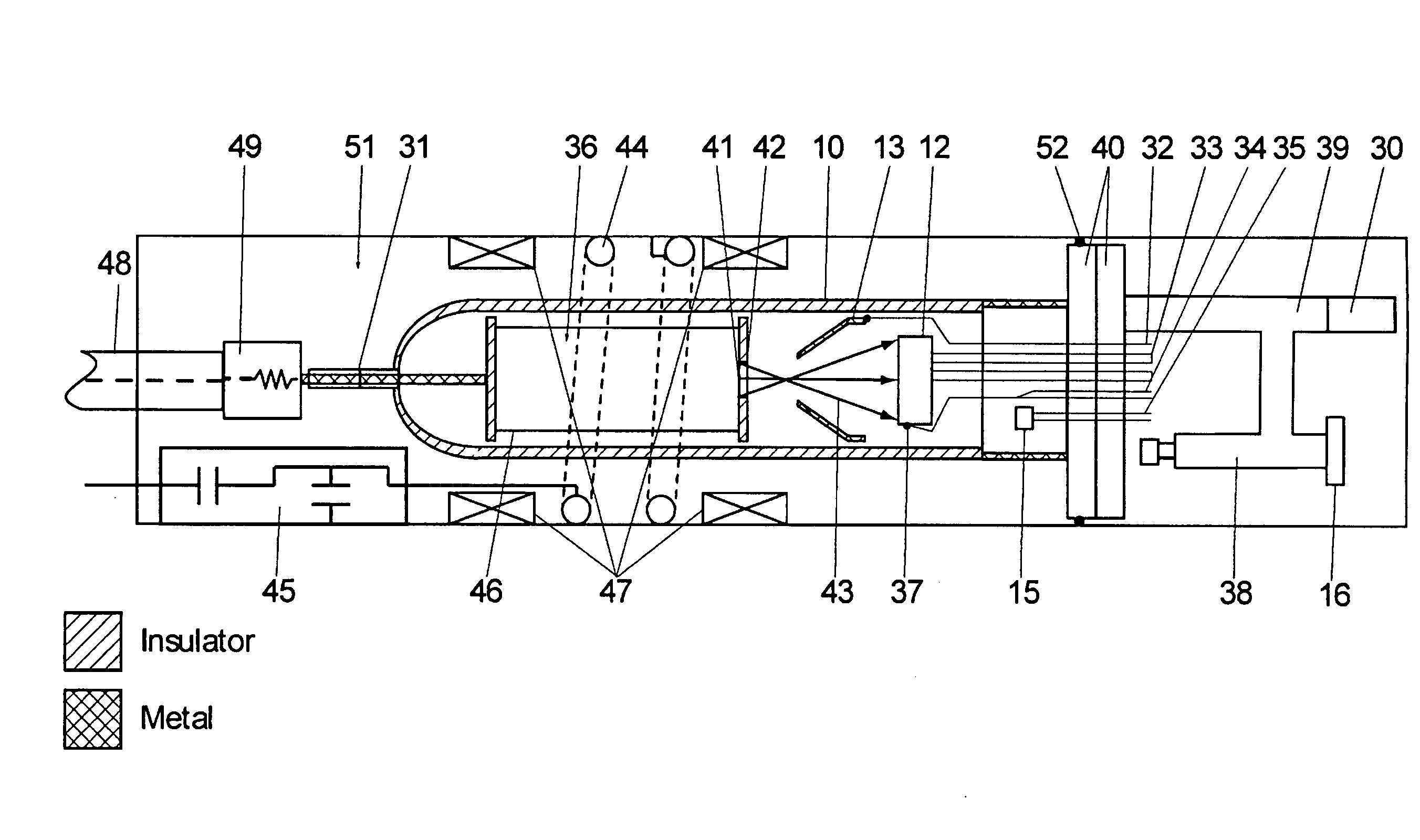

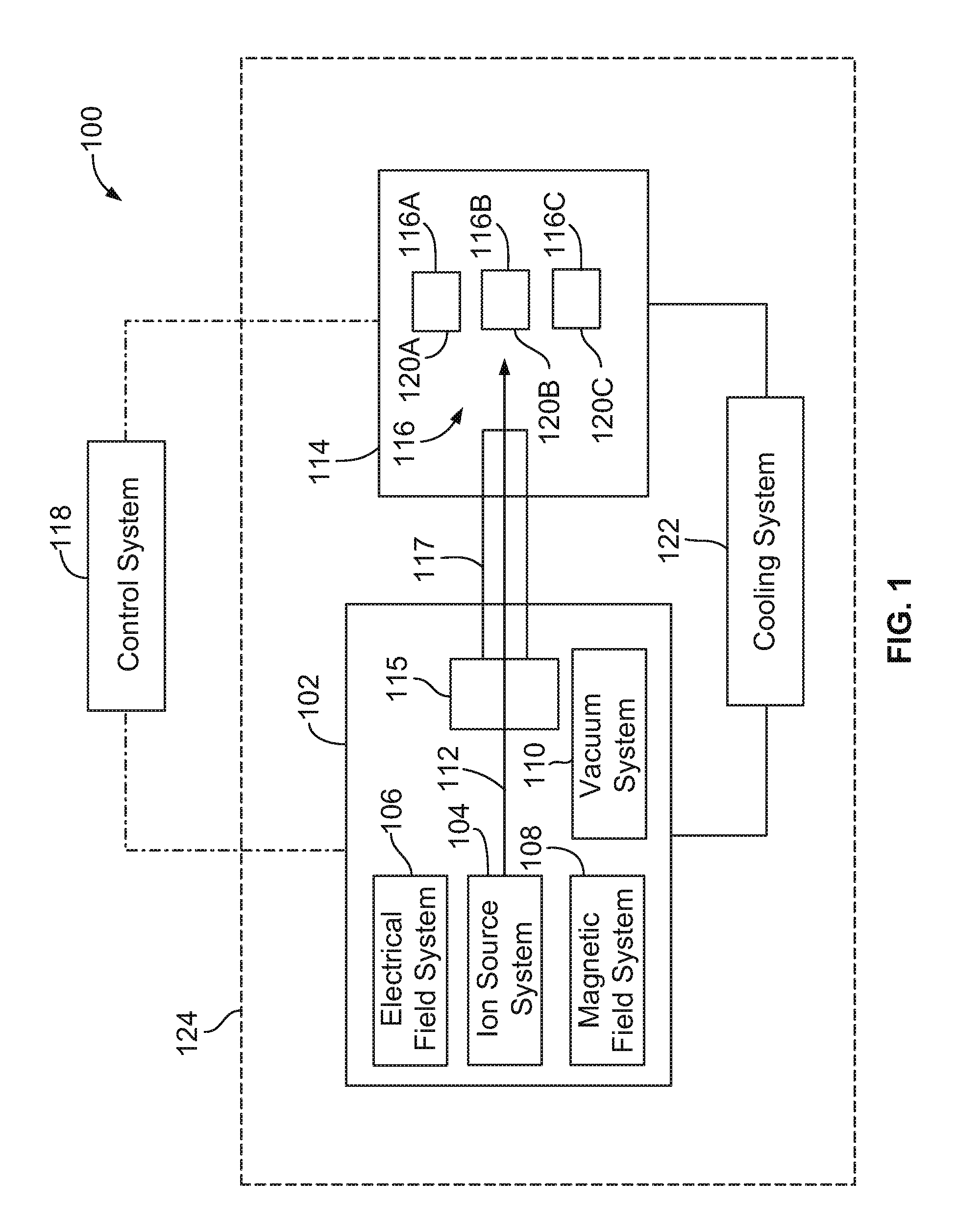

High-current DC proton accelerator

InactiveUS20100033115A1Reduce harmful effectsLimit divergence of beamTransit-time tubesDirect voltage acceleratorsHigh energyNeutron capture

A dc accelerator system able to accelerate high currents of proton beams at high energies is provided. The accelerator system includes a dc high-voltage, high-current power supply, an evacuated ion accelerating tube, a proton ion source, a dipole analyzing magnet and a vacuum pump located in the high-voltage terminal. The high-current, high-energy dc proton beam can be directed to a number of targets depending on the applications such as boron neutron capture therapy BNCT applications, NRA applications, and silicon cleaving.

Owner:ION BEAM APPL

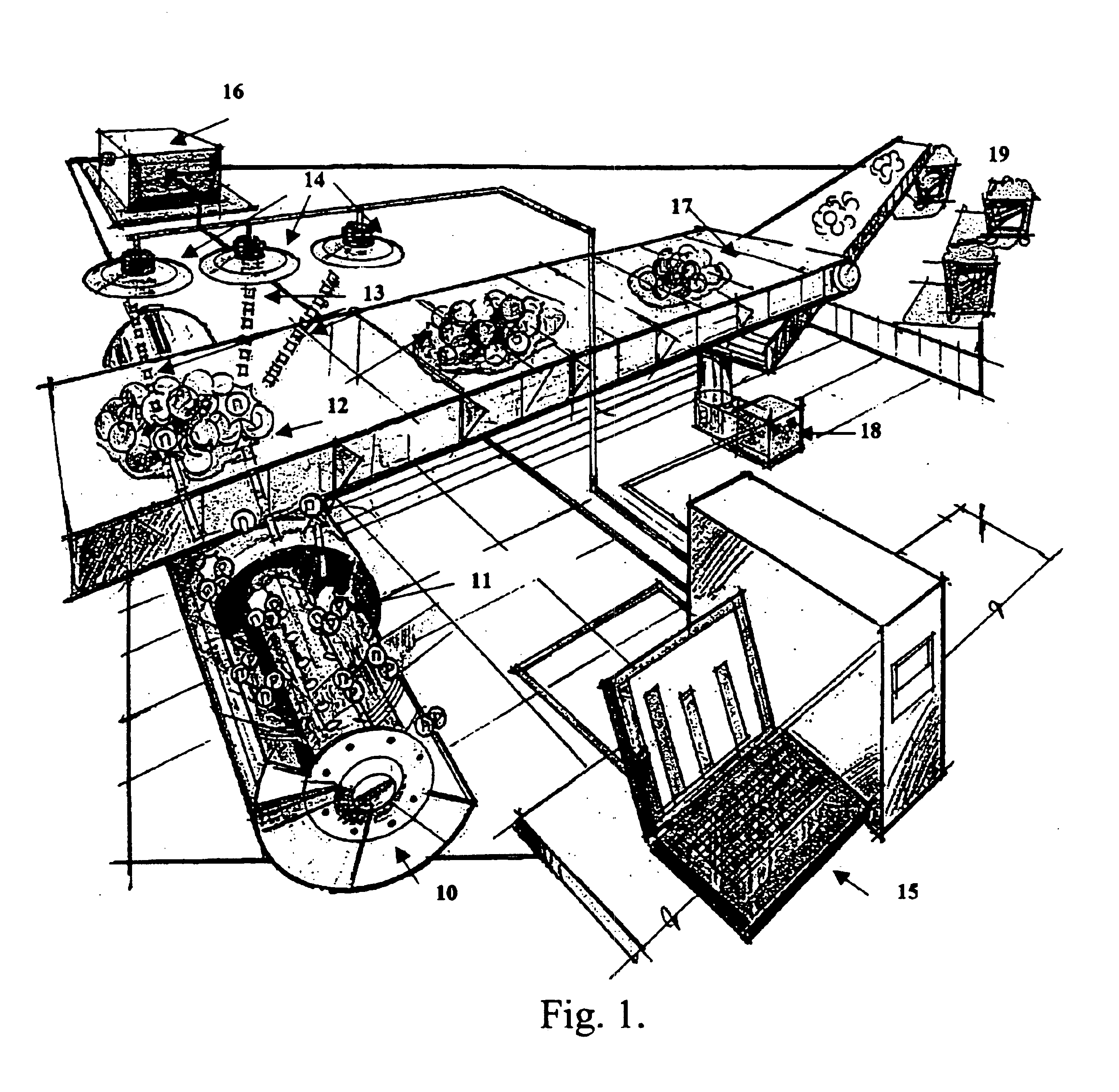

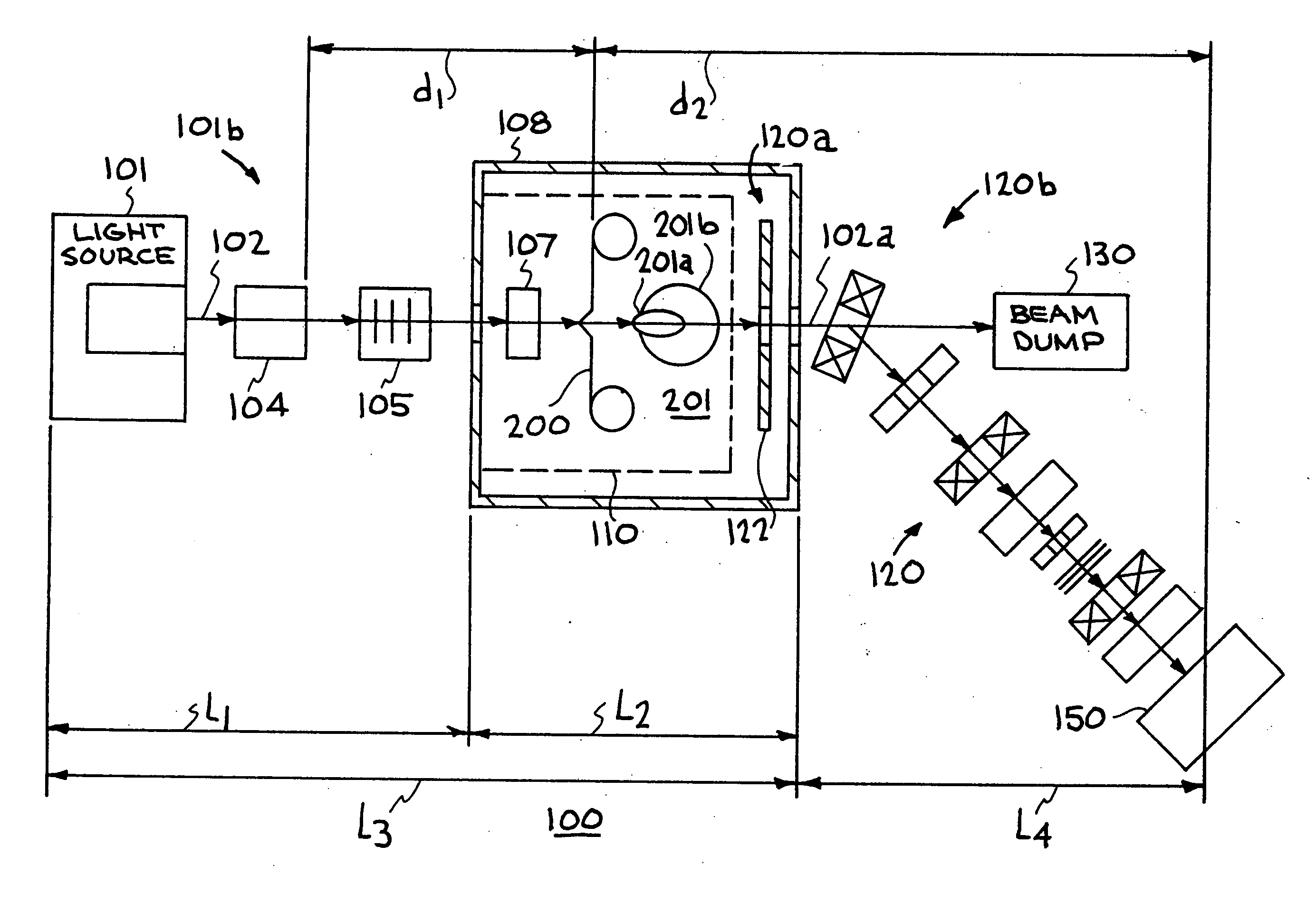

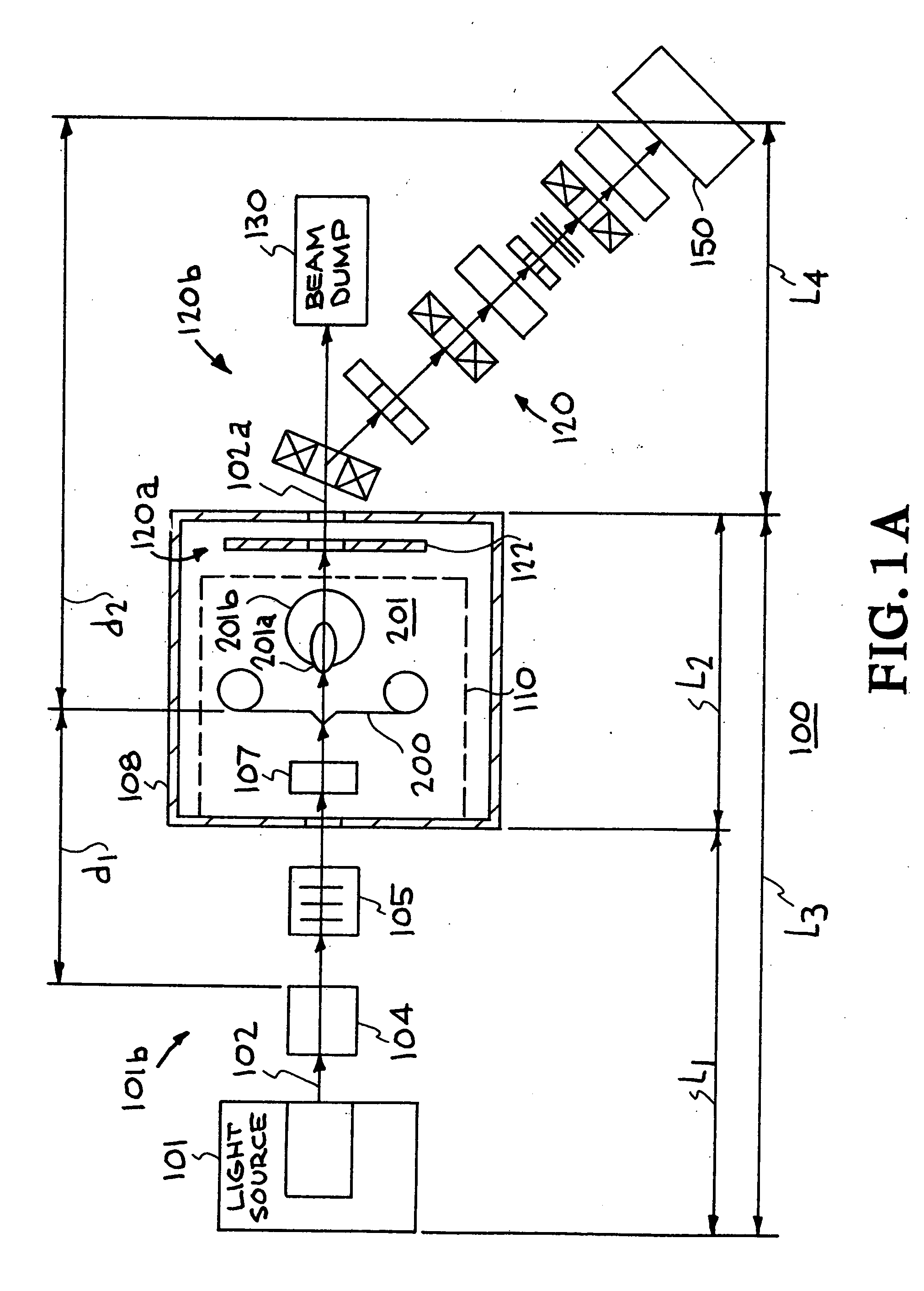

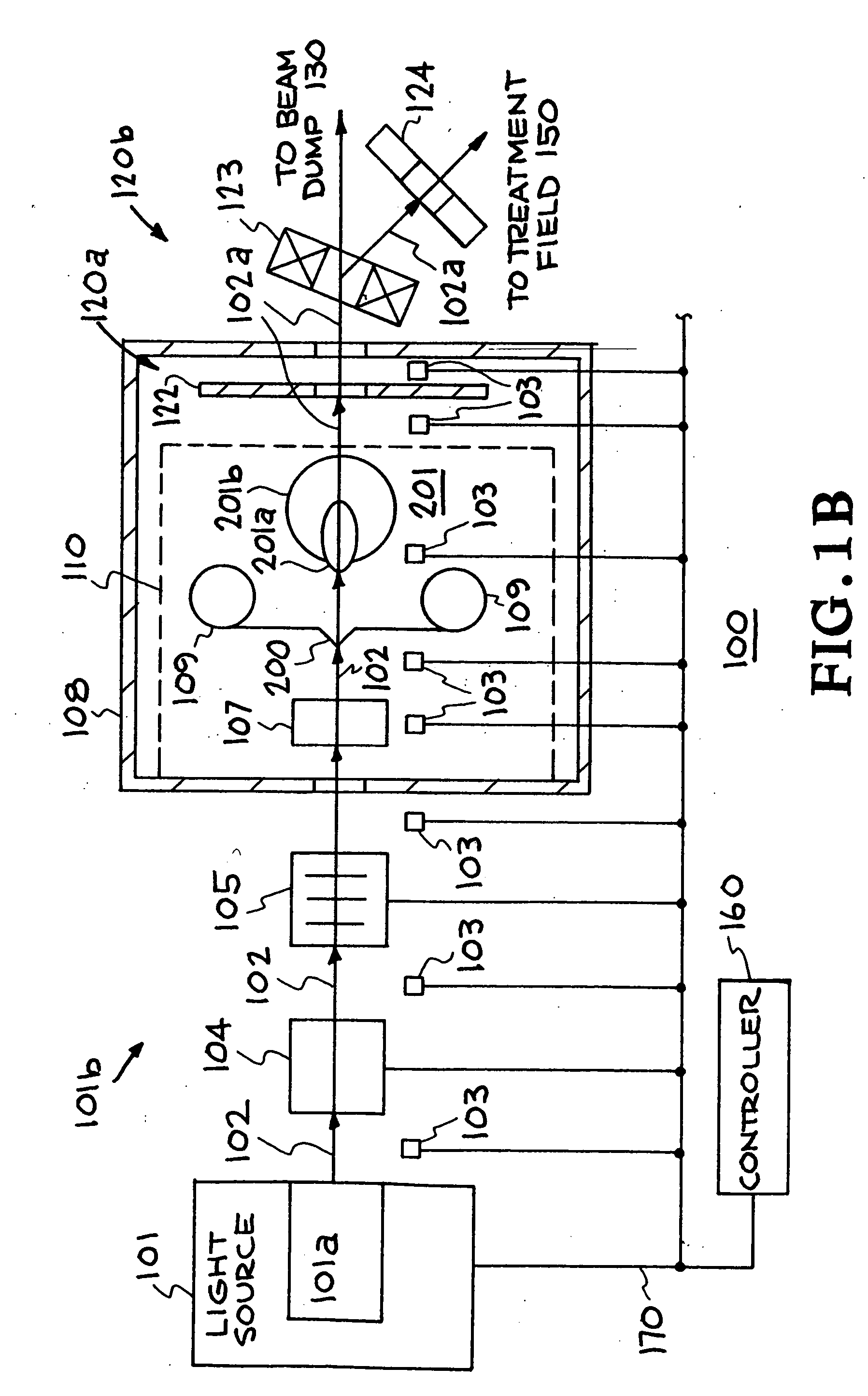

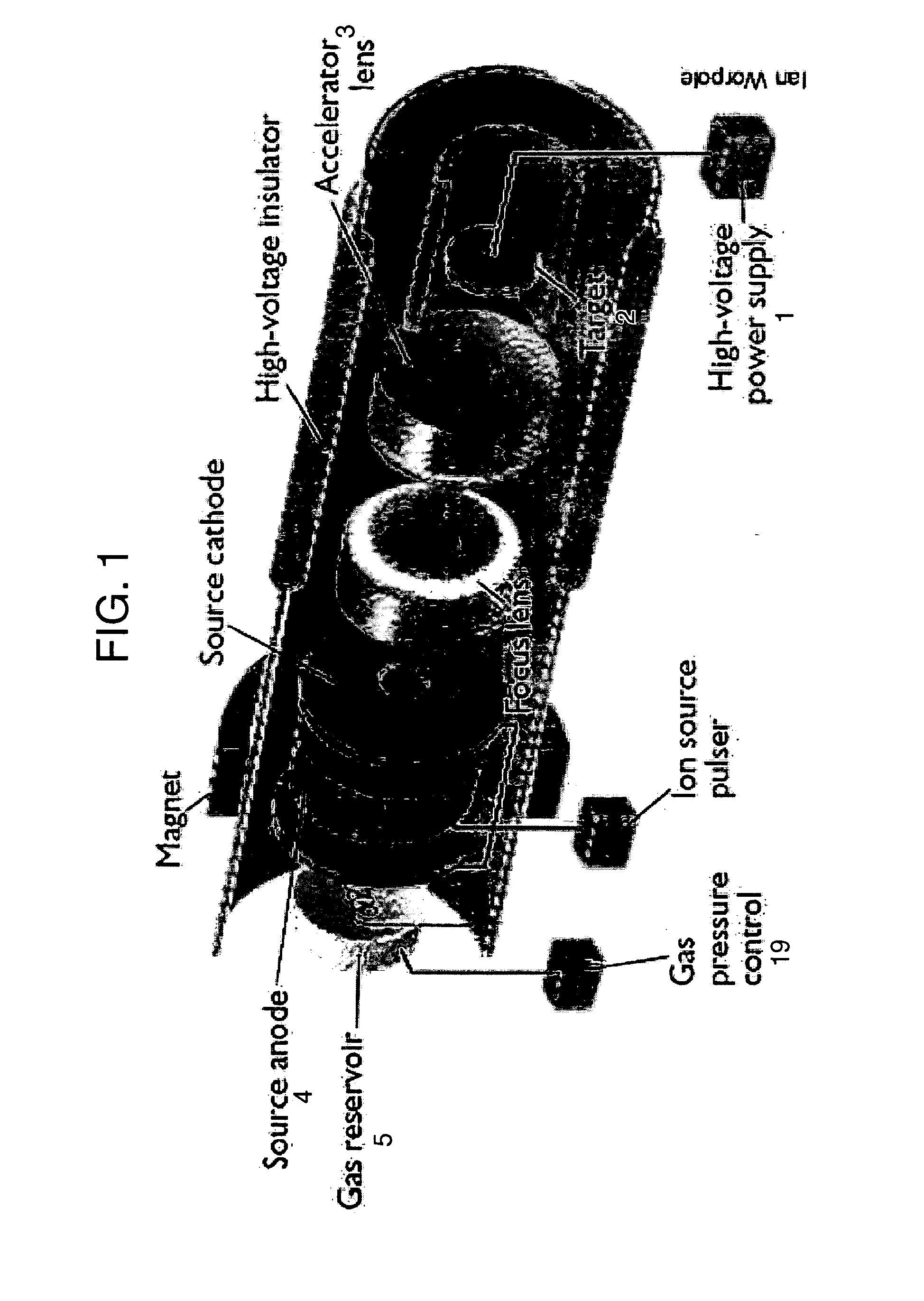

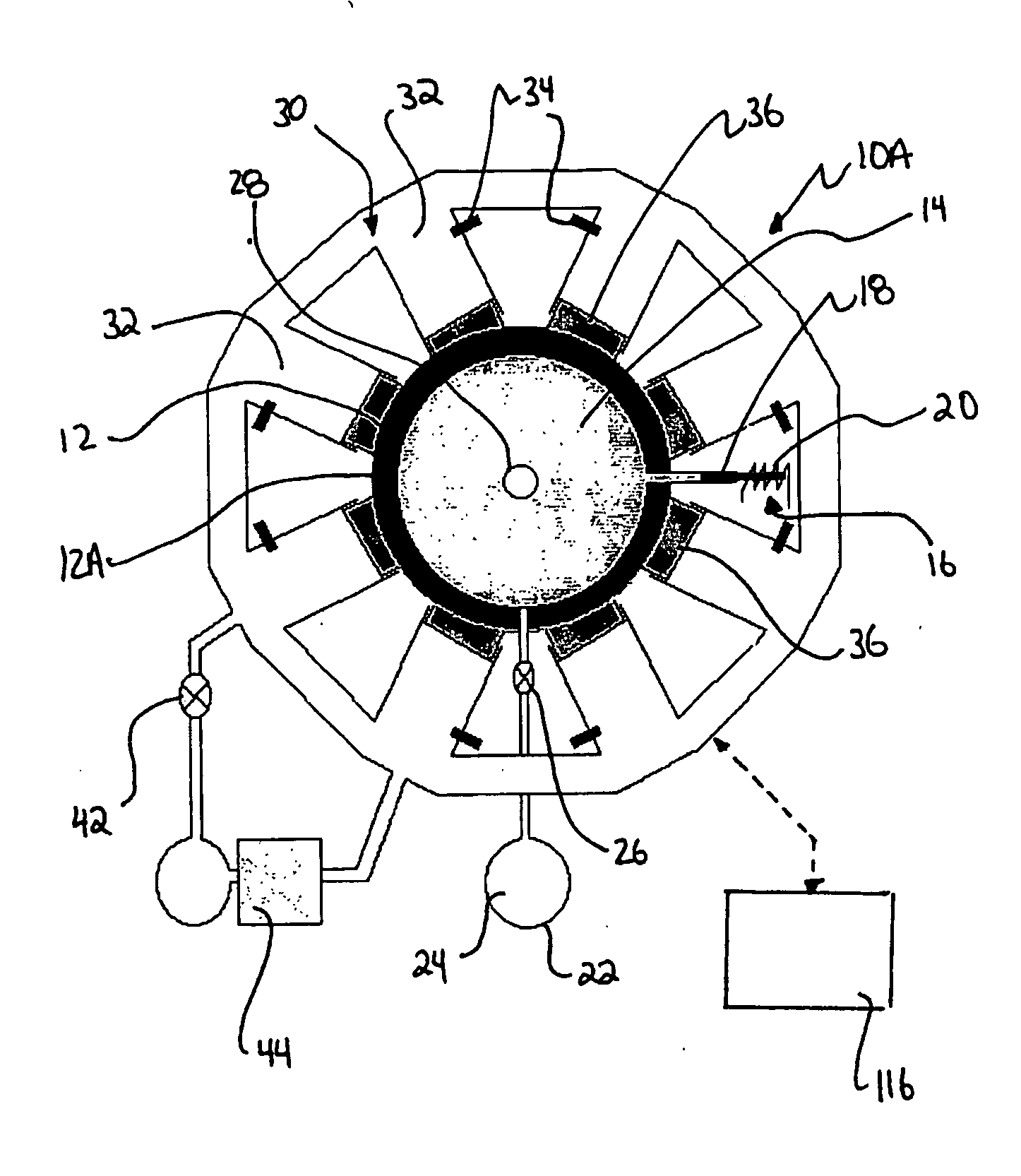

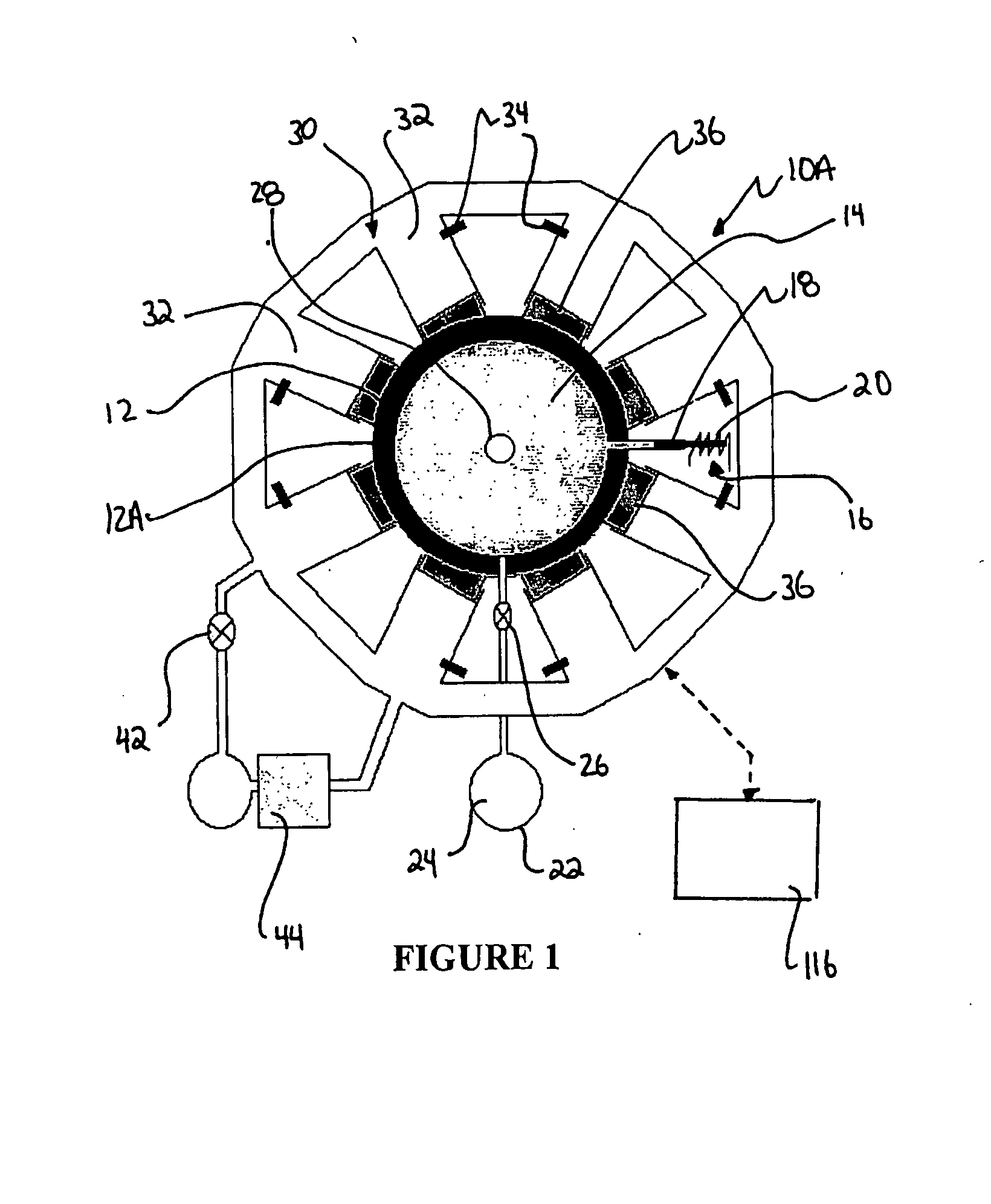

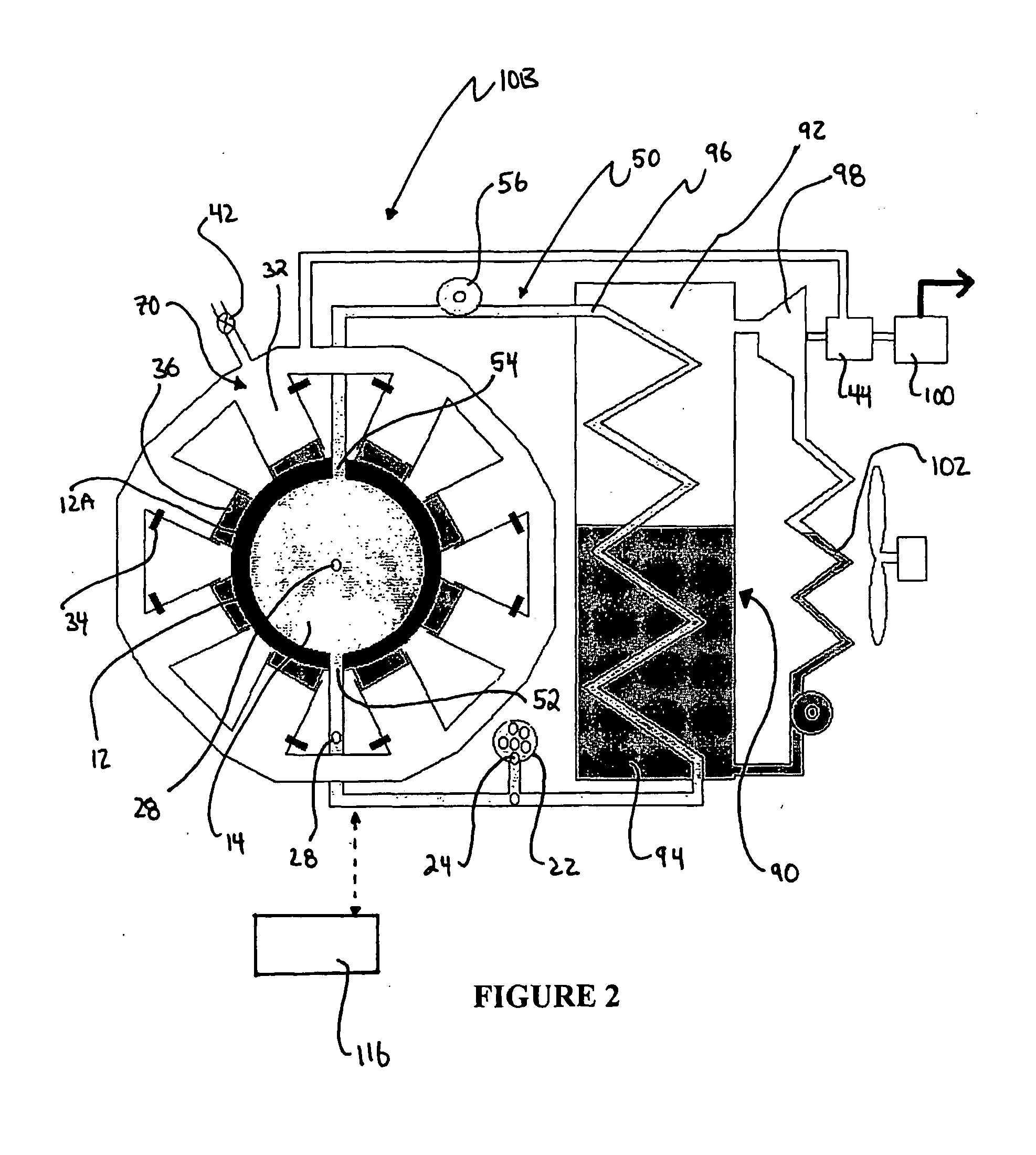

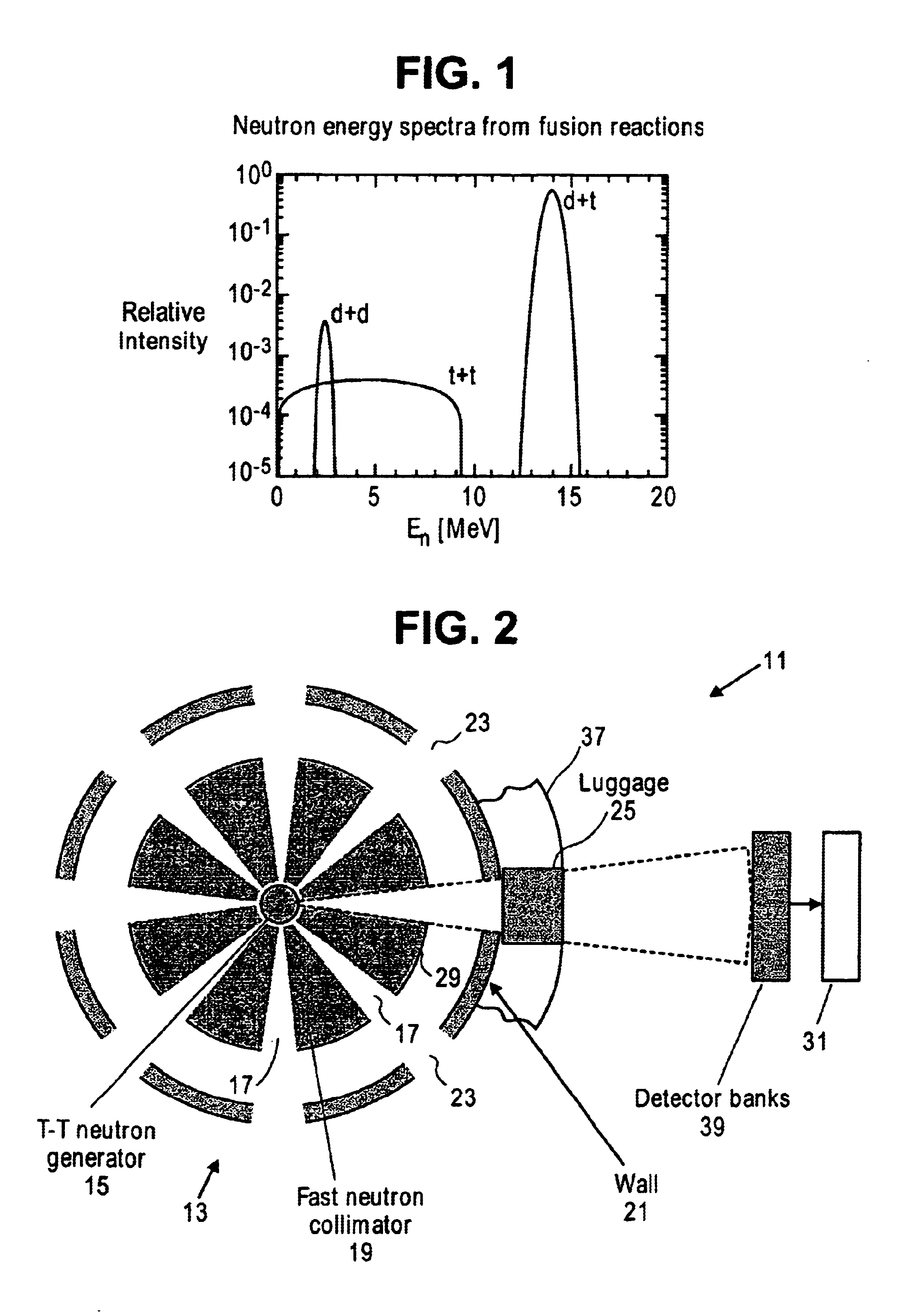

Gas-target neutron generation and applications

InactiveUS6922455B2Improve performanceMaximize productionNuclear energy generationX-ray tube electrodesHigh resistanceNeutron emission

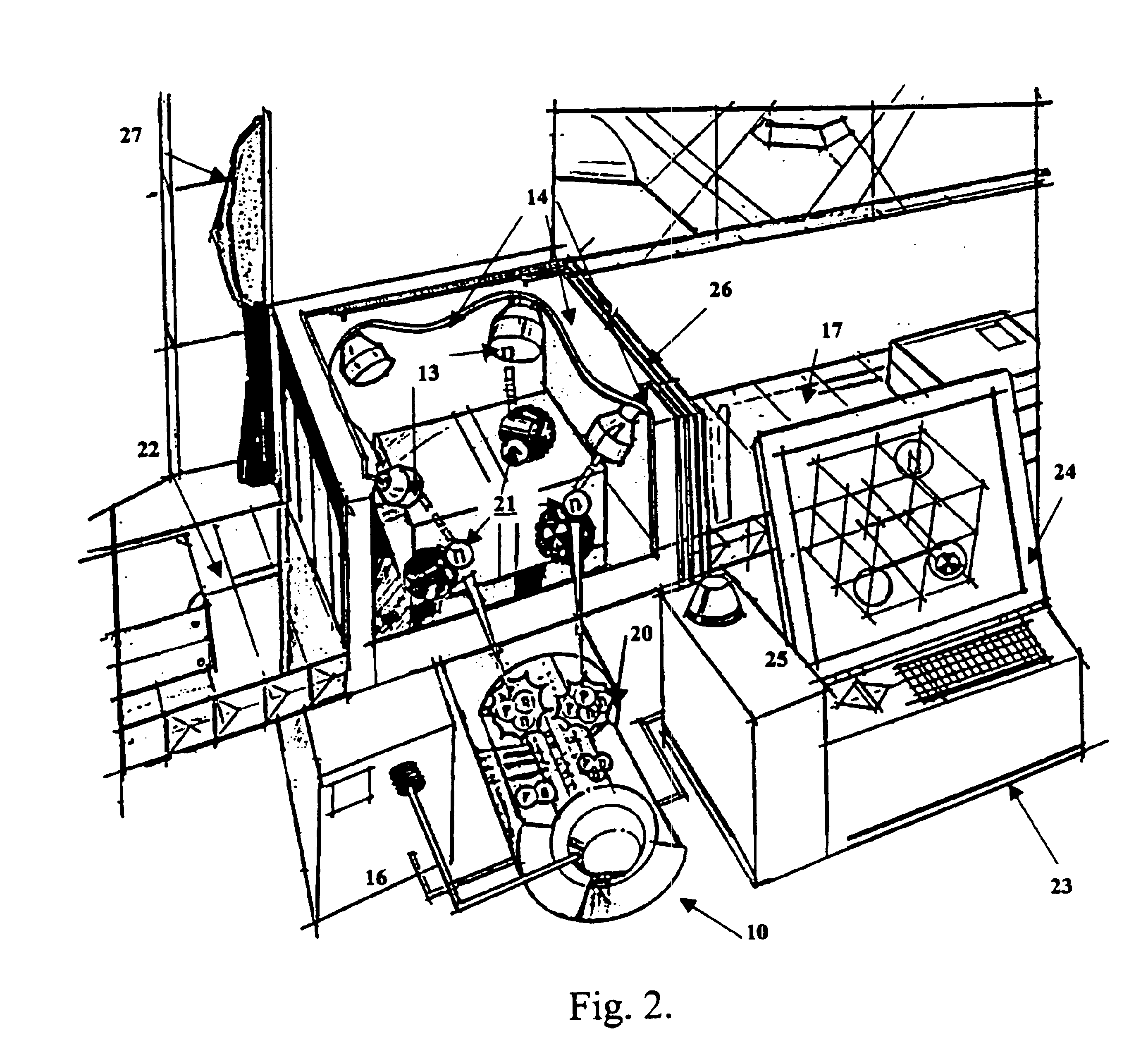

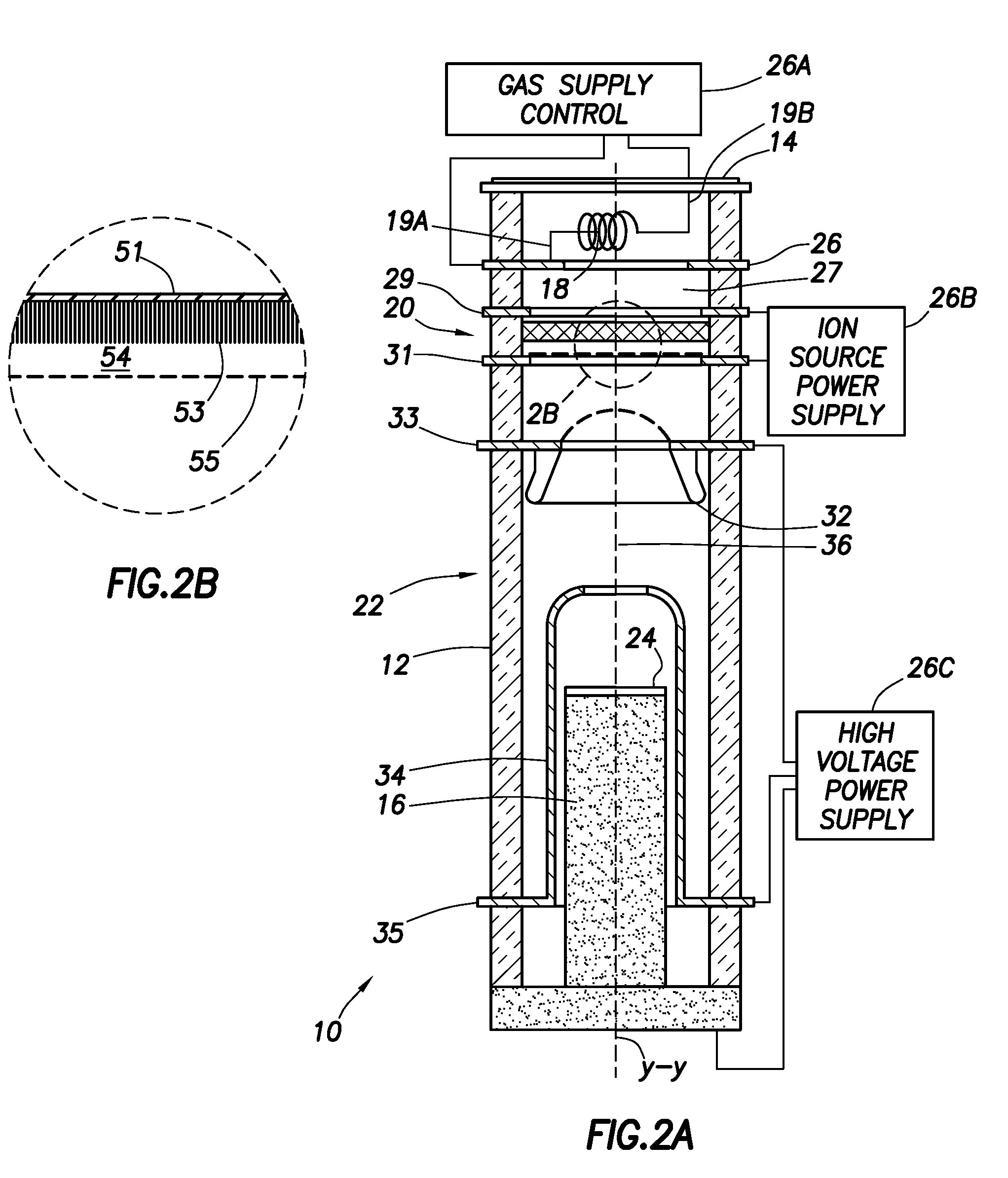

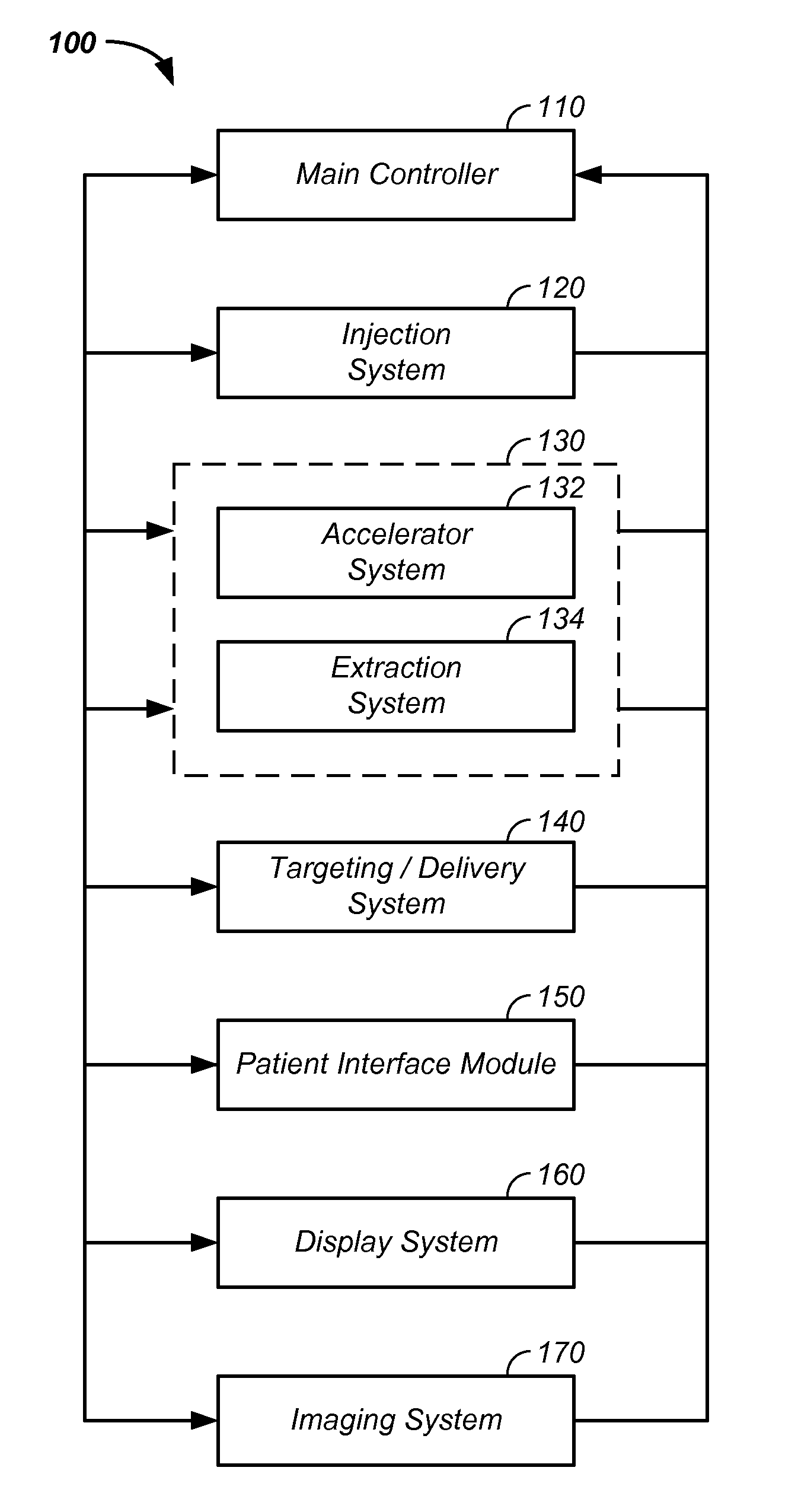

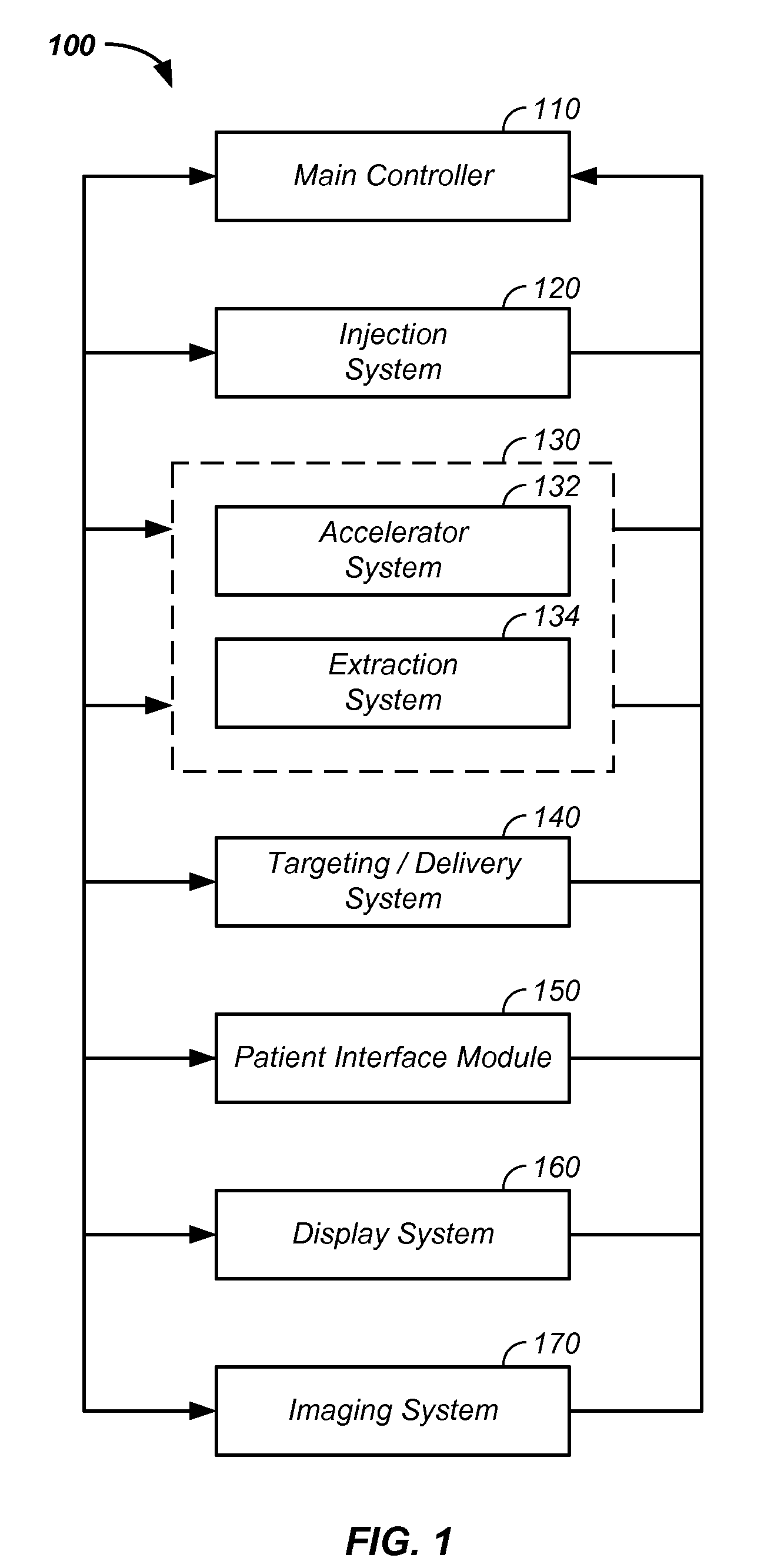

Described herein are integrated systems for generating neutrons to perform a variety of tasks including: on-line analysis of bulk material and industrial process control (as shown in FIG. 1), security interrogation (as shown in FIG. 2), soil and environmental analysis, and medical diagnostic treatment. These systems are based on novel gas-target neutron generation which embodies the beneficial characteristics of replenishable fusible gas targets for very long lifetime, stability and continuous operation, combined with the advantageous features common to conventional accelerator neutron tubes including: on / off operation, hermetically sealed operation, and safe storage and transport. Innovative electron management techniques provide gas-target neutron production efficiencies that are comparable or surpass existing sources. The high-pressure high-resistance gaseous discharge is presented as a favorable gas-target neutron generator embodiment, combining ion source regions, accelerator regions, gas-target regions and electron management components within a single simple cost-effective device that is adaptable to various geometric configurations that provide specific neutron emission profiles for greater analysis capacity.

Owner:STARFIRE INDS MANAGEMENT

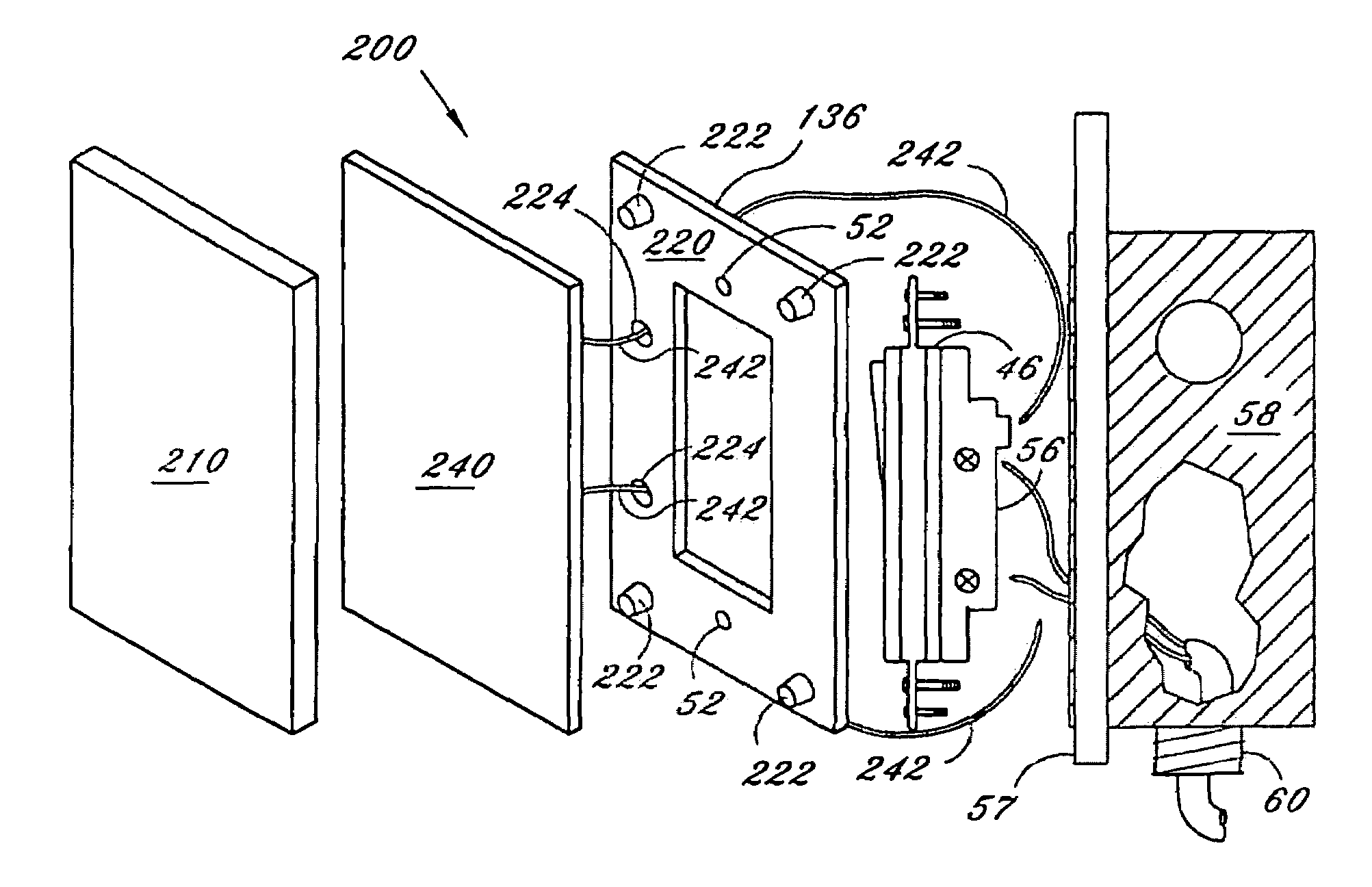

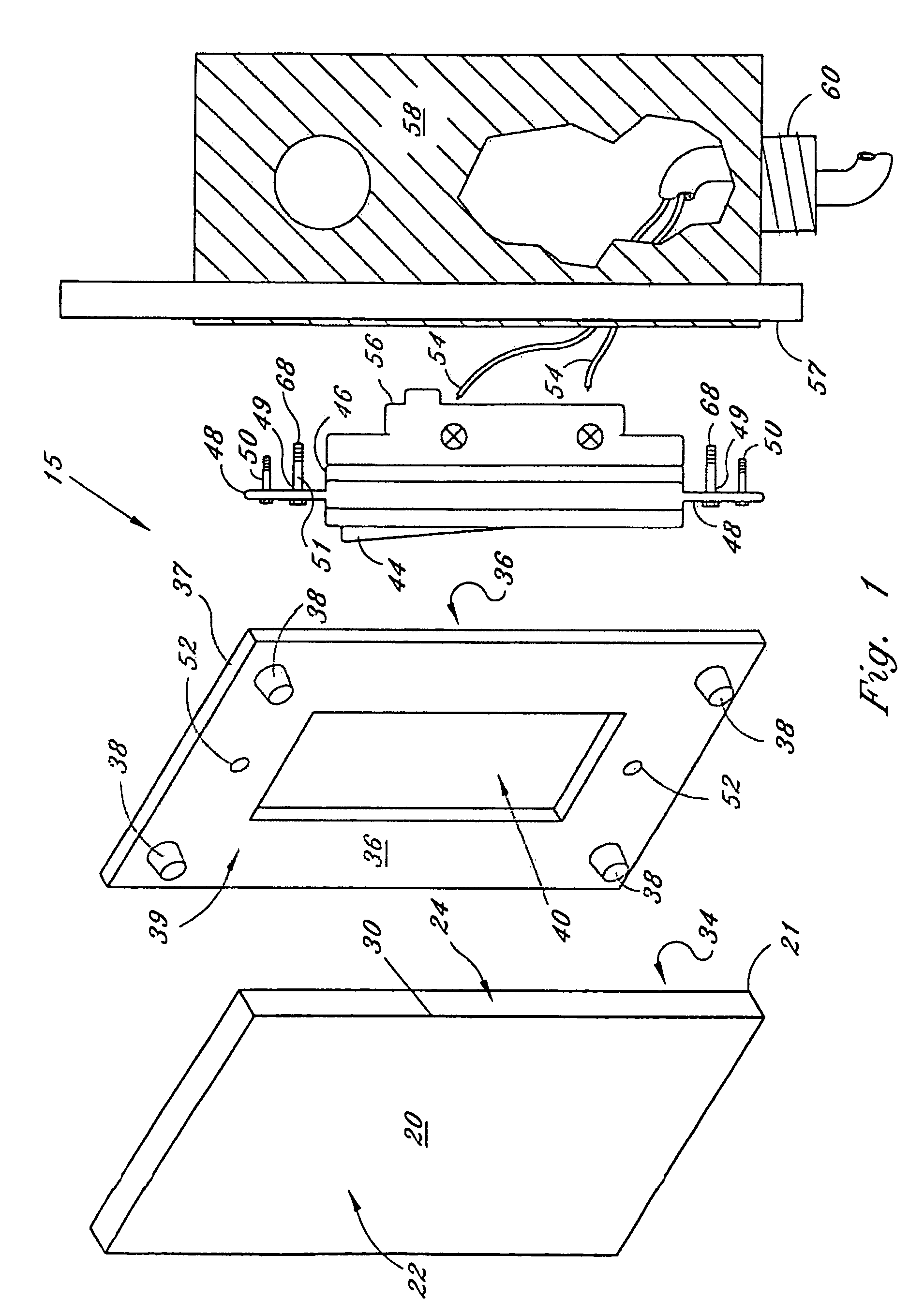

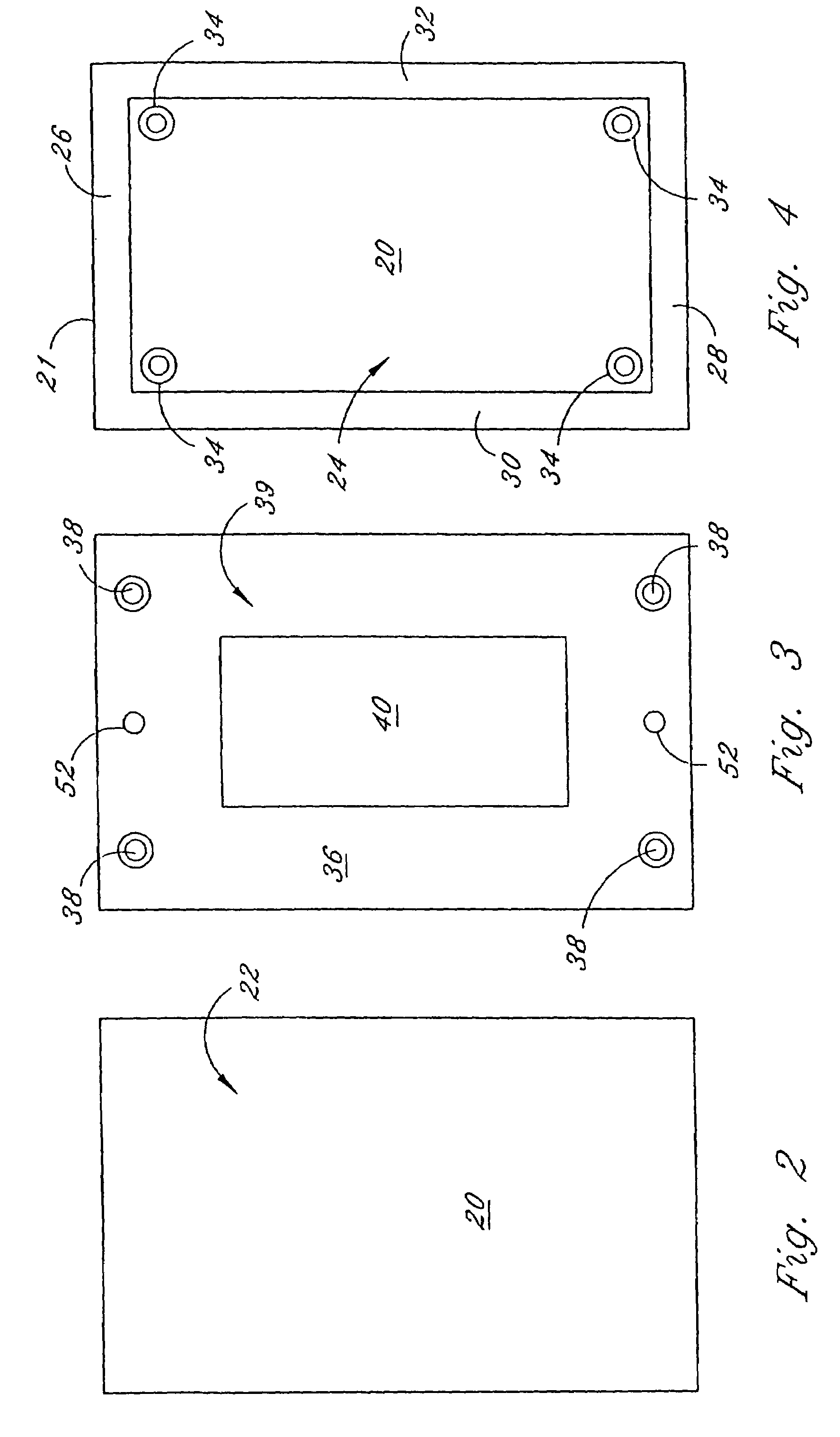

Light switch assembly

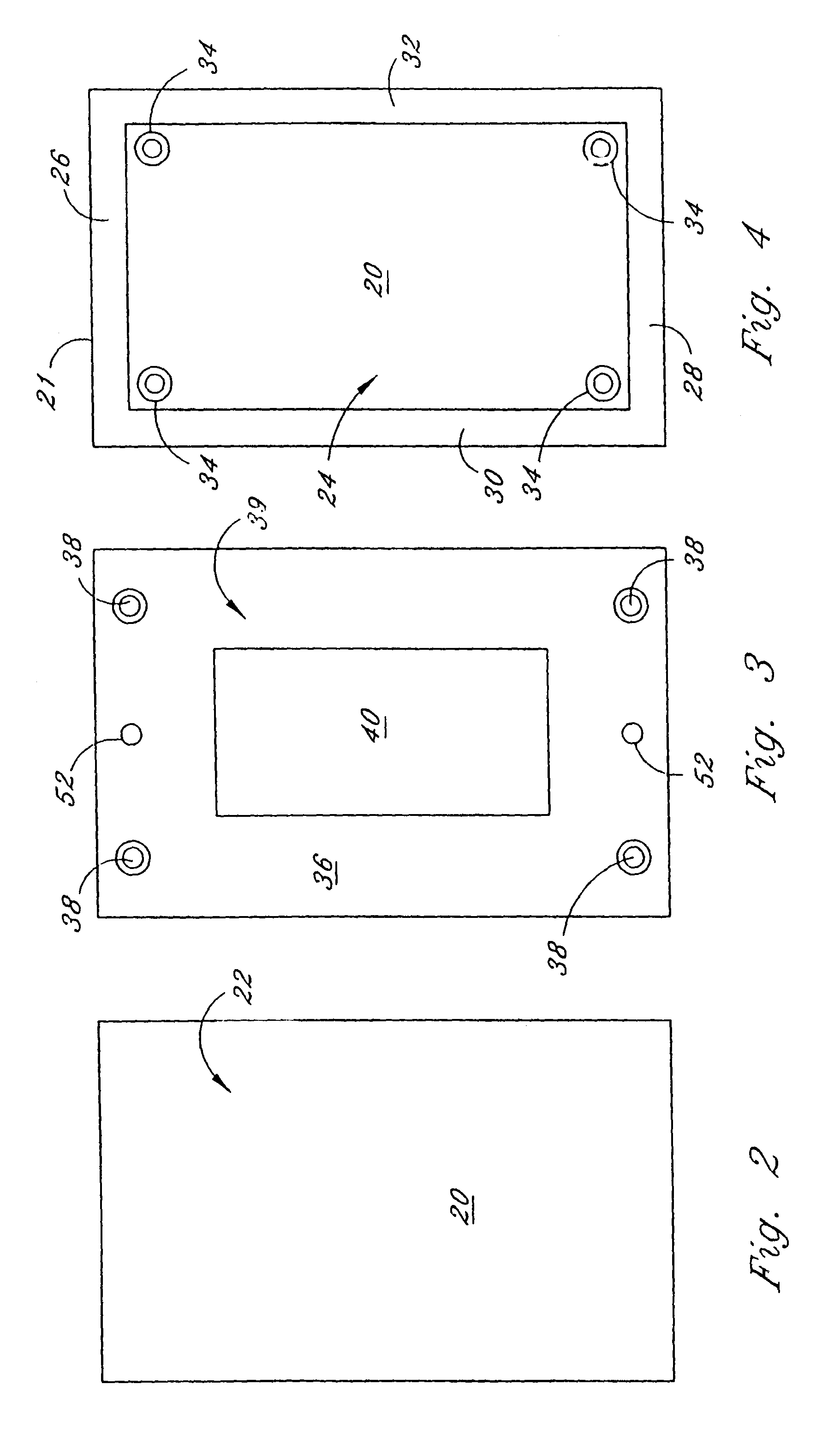

A light switch assembly to replace an existing light switch, which generally includes a mounting bracket attached to an electrical box. The assembly slides into the mounting bracket and is locked into place with the mounting bracket. A decorative light switch cover and custom artwork within the frame snaps and locks onto the outer perimeter of the mounting bracket to complete the assembly. The assembly provides for a battery hack-up system for power failure situations to illuminate the white, light emitting diodes in the event of a loss of power. The assembly senses the loss of power and unlocks the switch assembly from attachment to the mounting bracket. Unsnapping the decorative cover exposes the switch assembly so it can be removed from the mounting bracket. The switch assembly then becomes a mobile, hand-held emergency flashlight. The battery back-up system also allows for communication with first responders.

Owner:RINTZ WILLIAM J

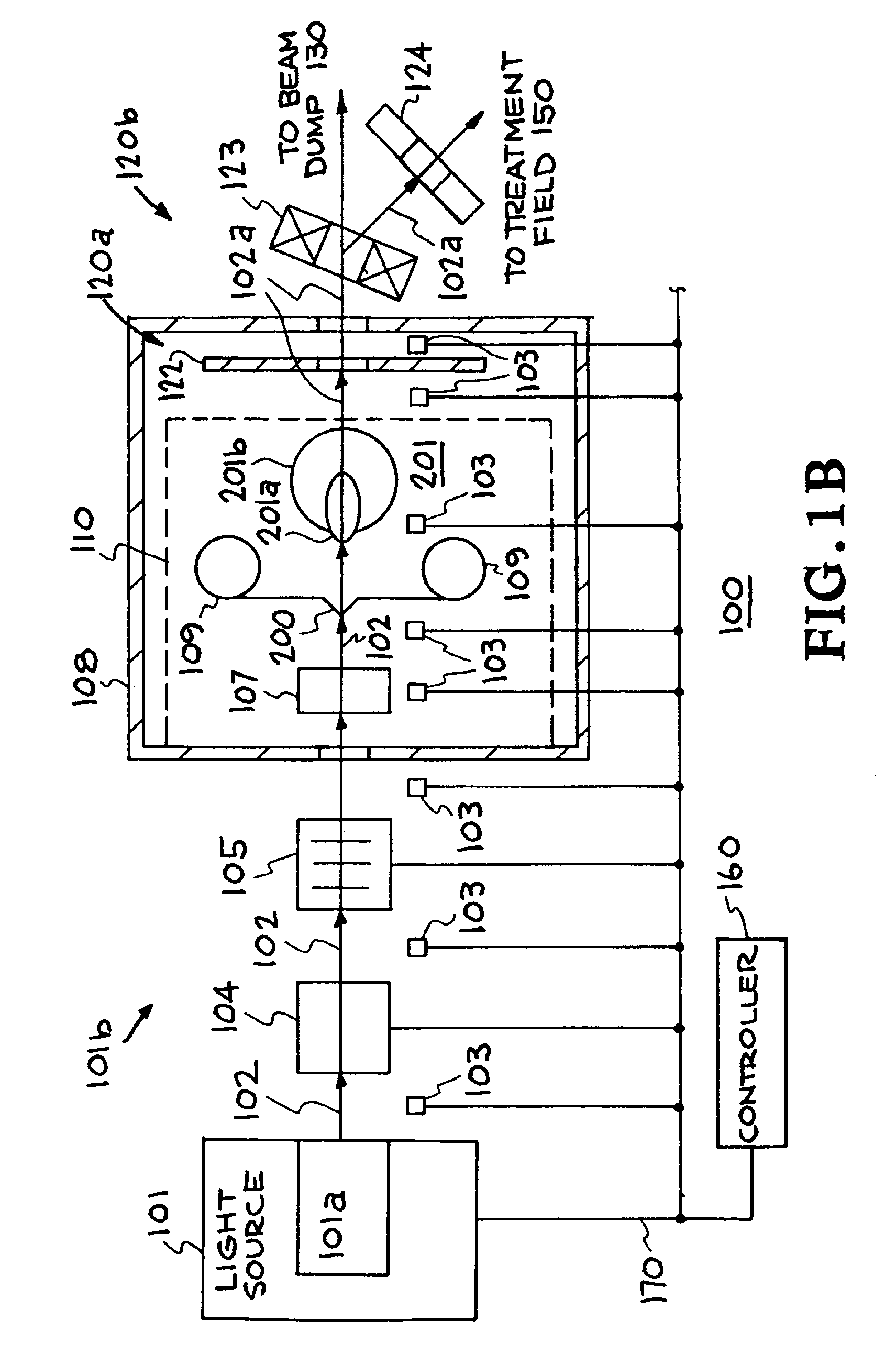

Laser driven ion accelerator

InactiveUS20050167610A1Thermometer detailsStability-of-path spectrometersIon accelerationIon accelerators

A system and method of accelerating ions in an accelerator to optimize the energy produced by a light source. Several parameters may be controlled in constructing a target used in the accelerator system to adjust performance of the accelerator system. These parameters include the material, thickness, geometry and surface of the target.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

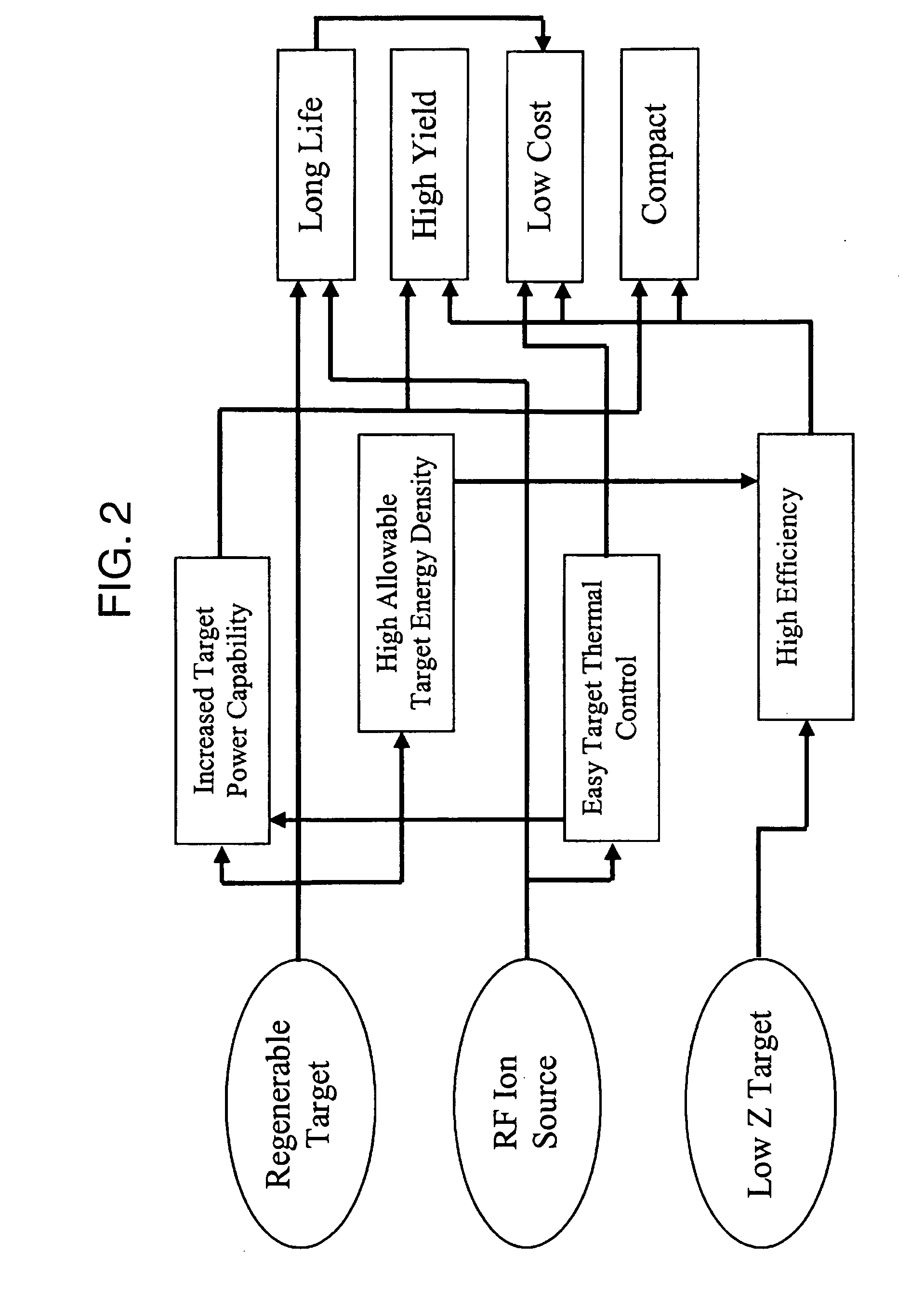

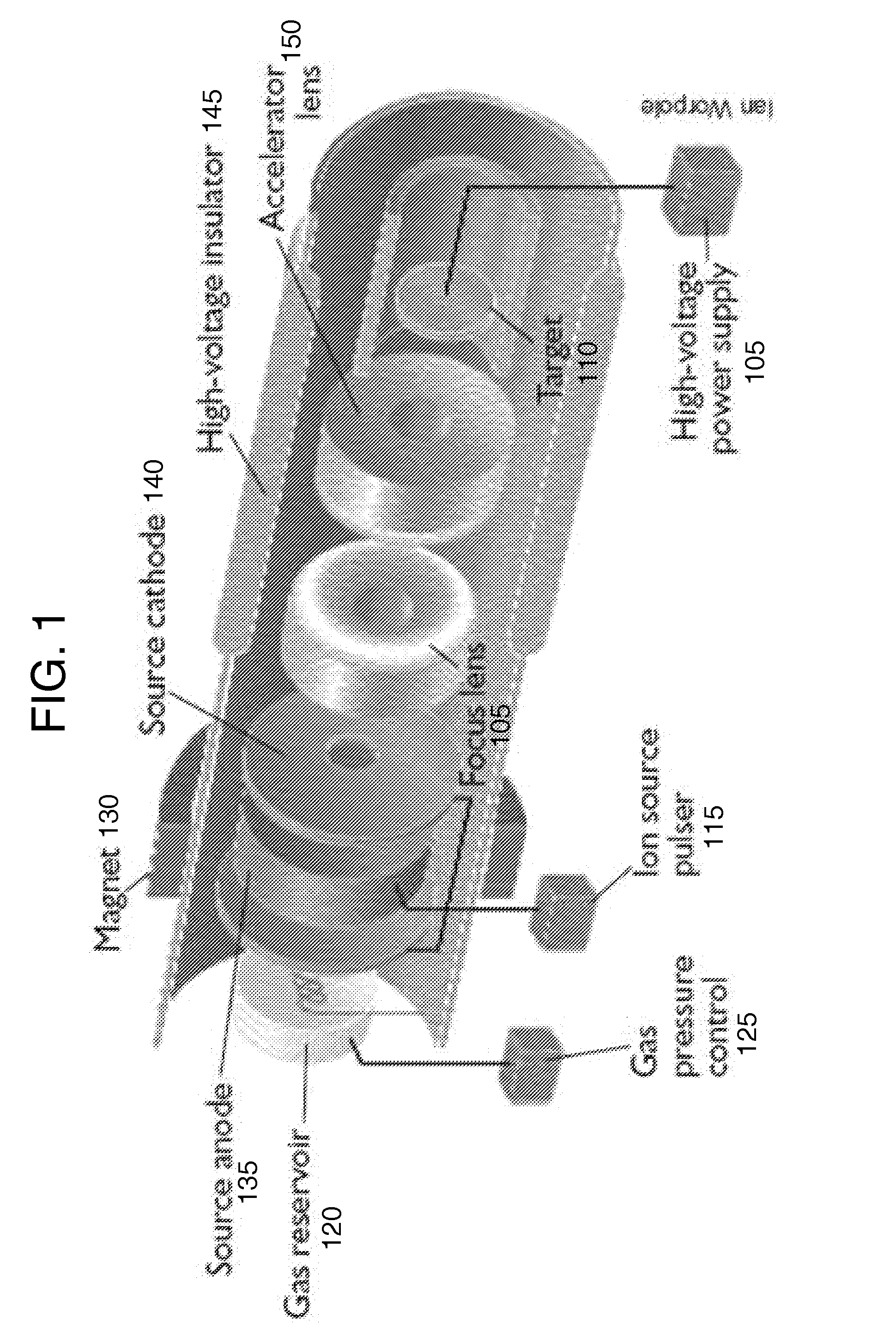

Long life high efficiency neutron generator

ActiveUS20110044418A1Small sizeLow efficiencyNuclear energy generationDirect voltage acceleratorsEngineeringEnergy spectrum

The design of a compact, high-efficiency, high-flux capable compact-accelerator fusion neutron generator (FNG) is discussed. FNG's can be used in a variety of industrial analysis applications to replace the use of radioisotopes which pose higher risks to both the end user and national security. High efficiency, long lifetime, and high power-handling capability are achieved though innovative target materials and ion source technology. The device can be scaled up for neutron radiography applications, or down for borehole analysis or other compact applications. Advanced technologies such as custom neutron output energy spectrum, pulsing, and associated particle imaging can be incorporated.

Owner:STARFIRE IND LLC

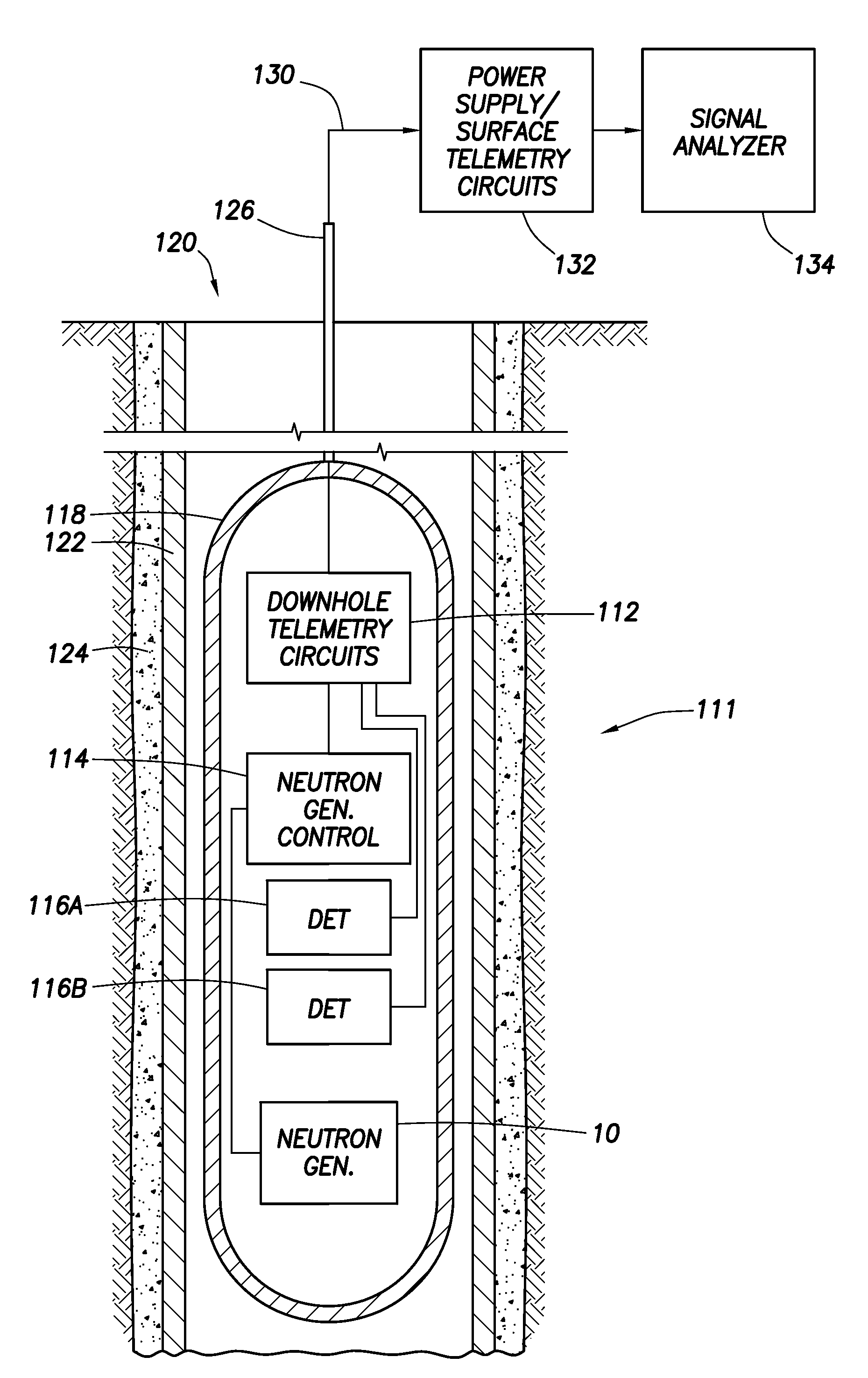

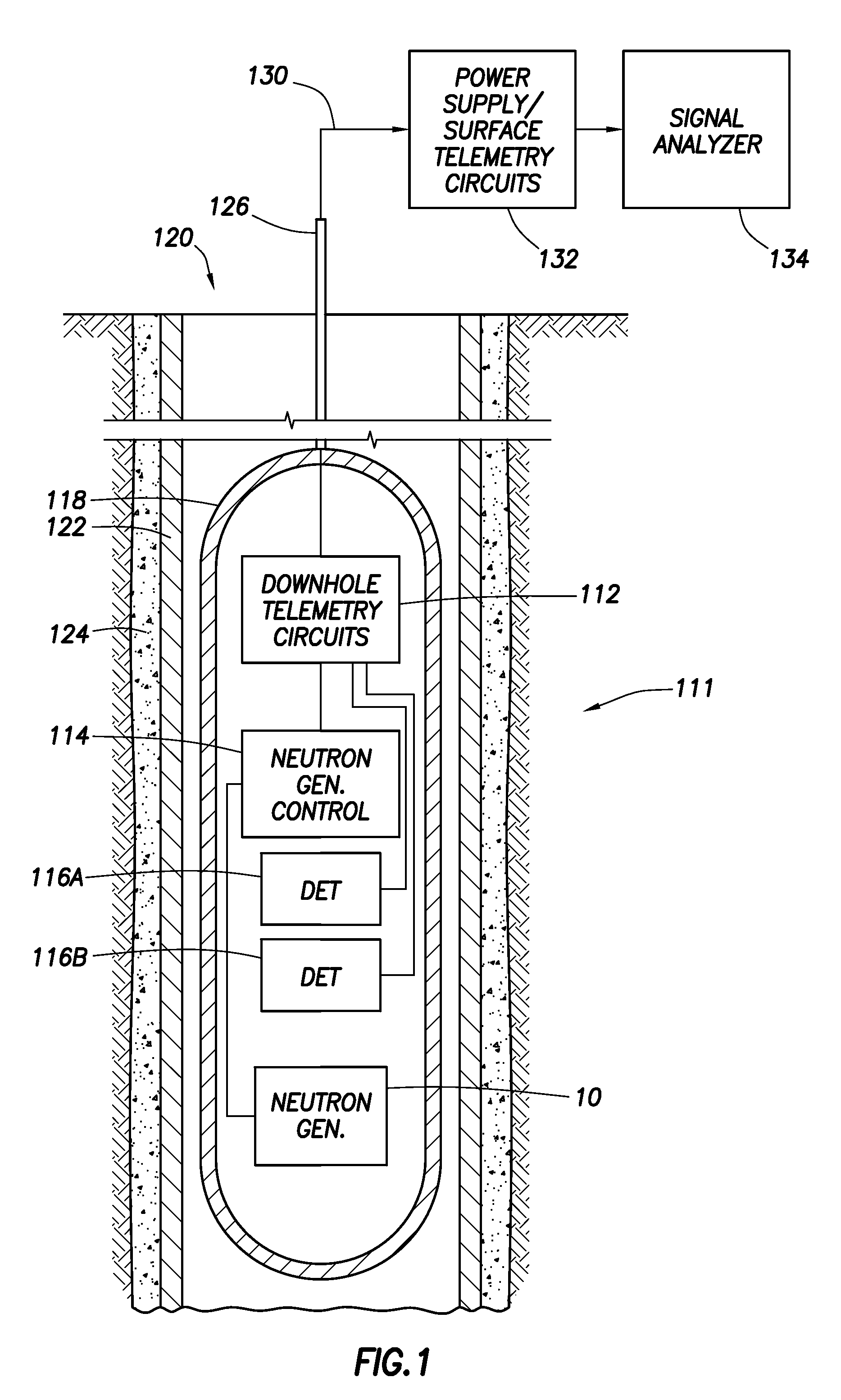

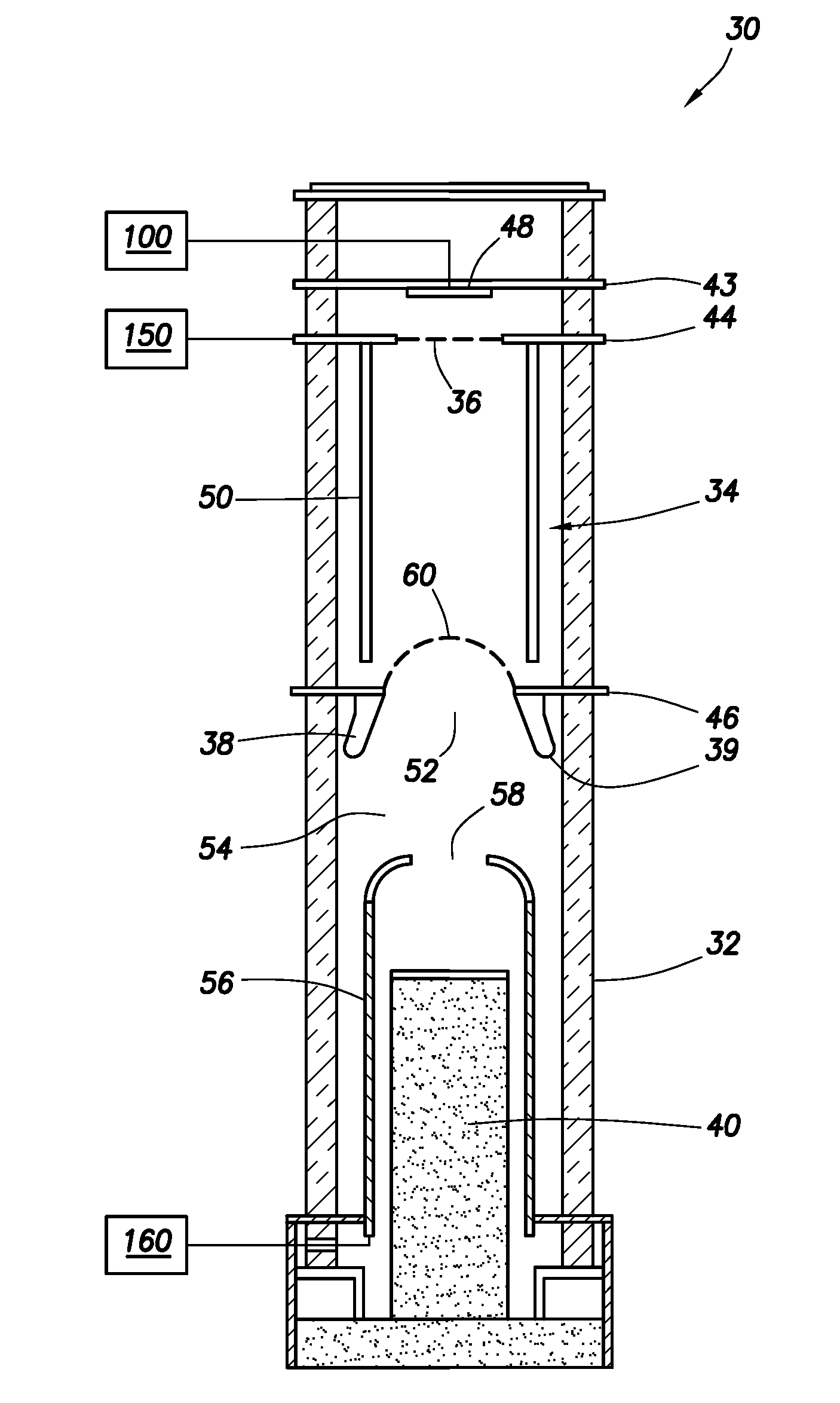

Neutron Generator

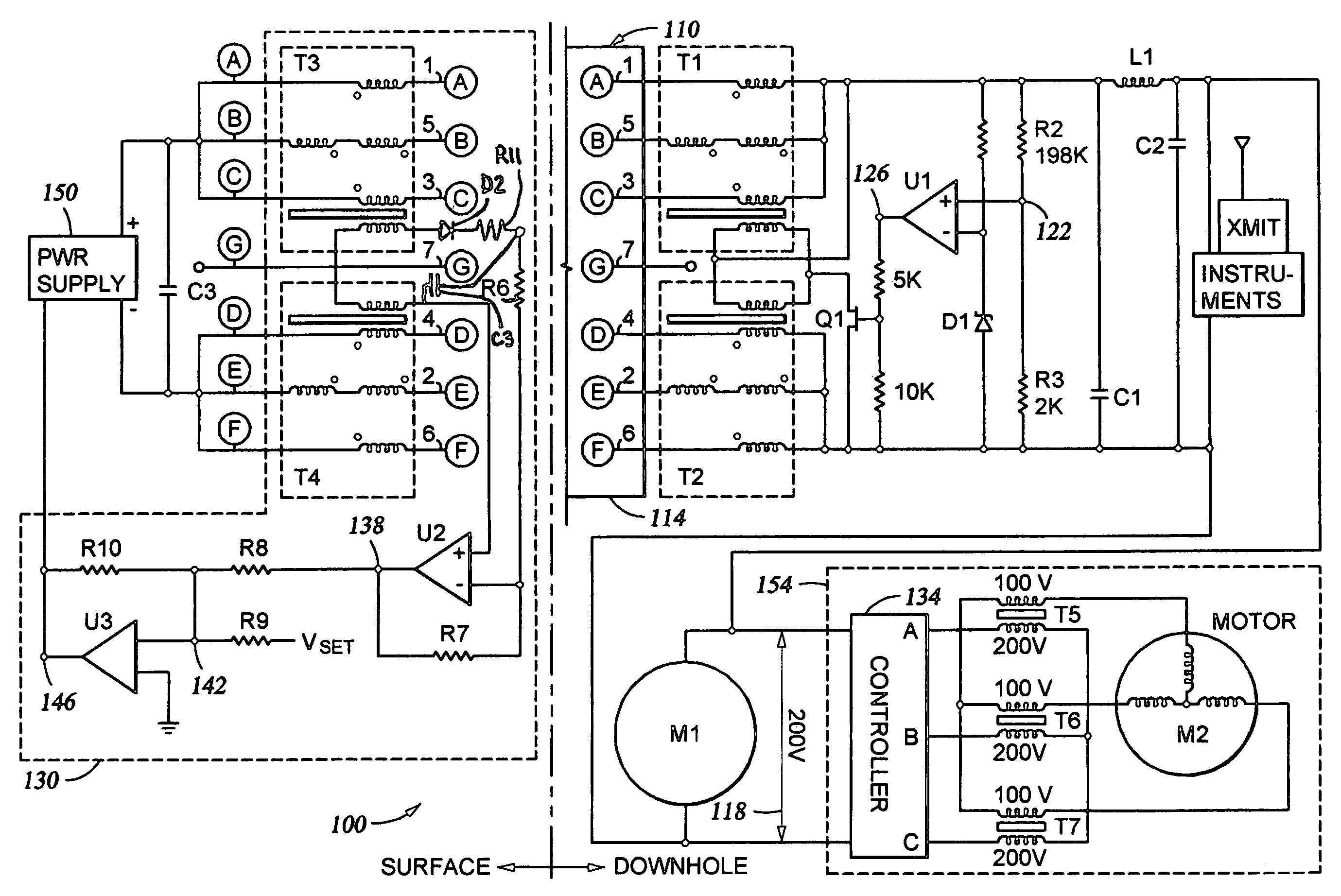

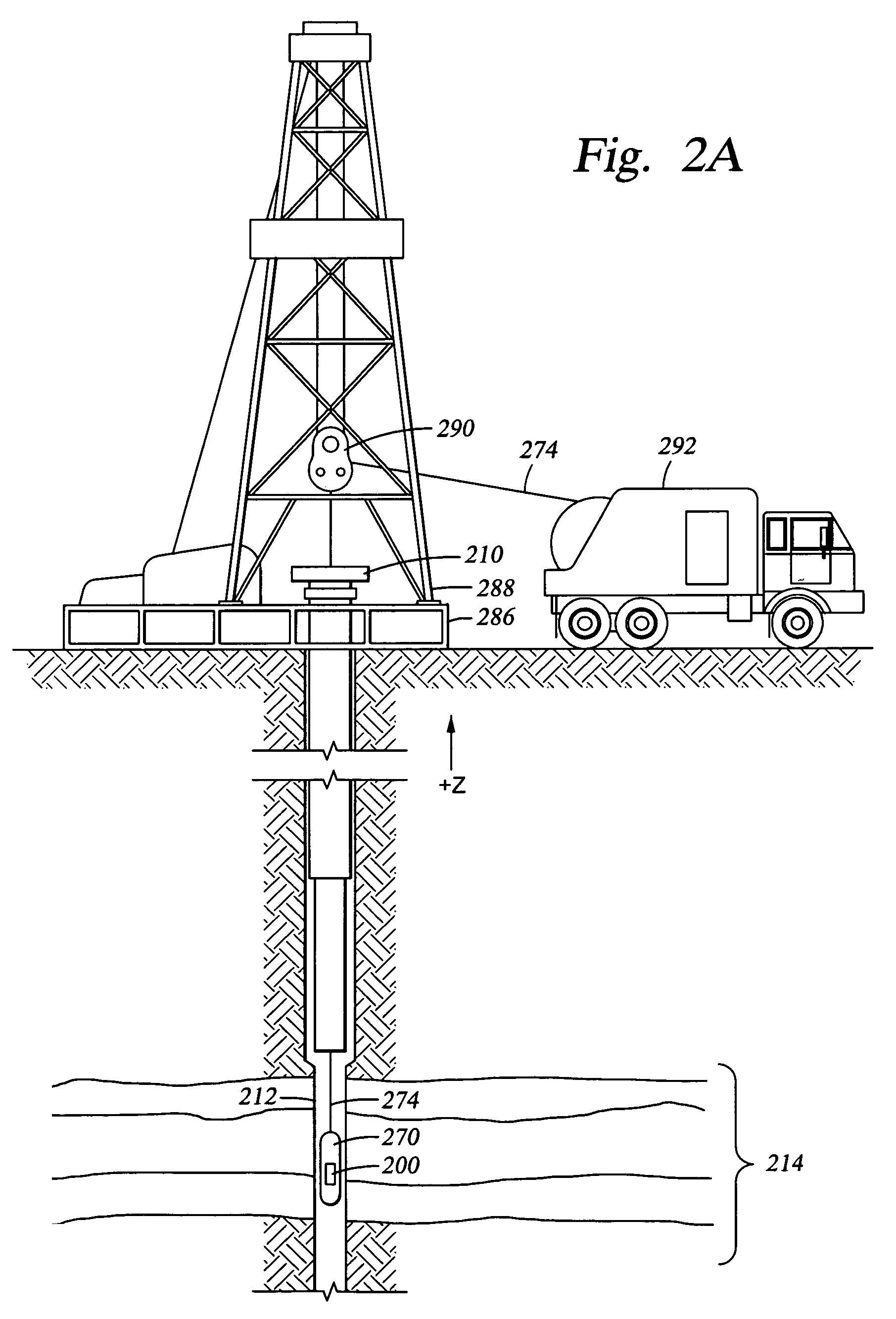

A neutron generator includes an ion source disposed in a pressurized environment containing an ionizable gas. The ion source includes a substrate with a bundle of carbon nanotubes extending therefrom. The ends of the nanotubes are spaced from a grid. Ion source voltage supply circuitry supplies a positive voltage potential between the substrate and the grid of the ion source to cause ionization of the ionizable gas and emission of ions through the grid. An ion accelerator section is disposed between the ion source and a target. The ion accelerator section accelerates ions that pass through the grid towards the target such that collisions of the ions with the target cause the target to generate and emit neutrons therefrom. The ion source, accelerator section and target are housed in a sealed tube and preferably the carbon nanotubes of the bundle are highly ordered with at least 106 carbon nanotubes per cm2 that extend in a direction substantially parallel to the central axis of the tube. The neutron generator provides gas ionization at much higher atomic to molecular ratio that the prior art, which allows for small compact size designs suitable for logging tools that are used in space-constrained downhole environments.

Owner:SCHLUMBERGER TECH CORP

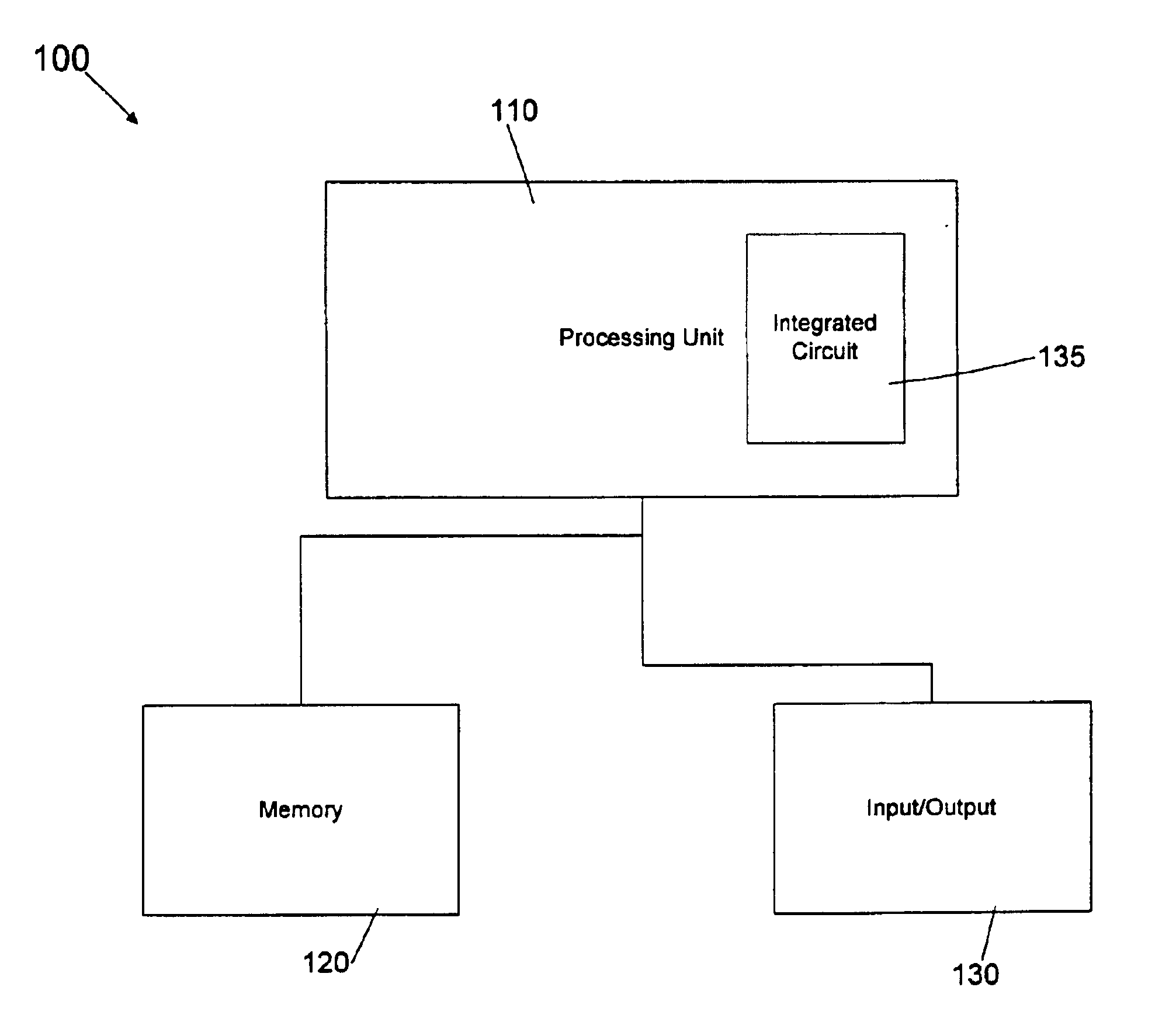

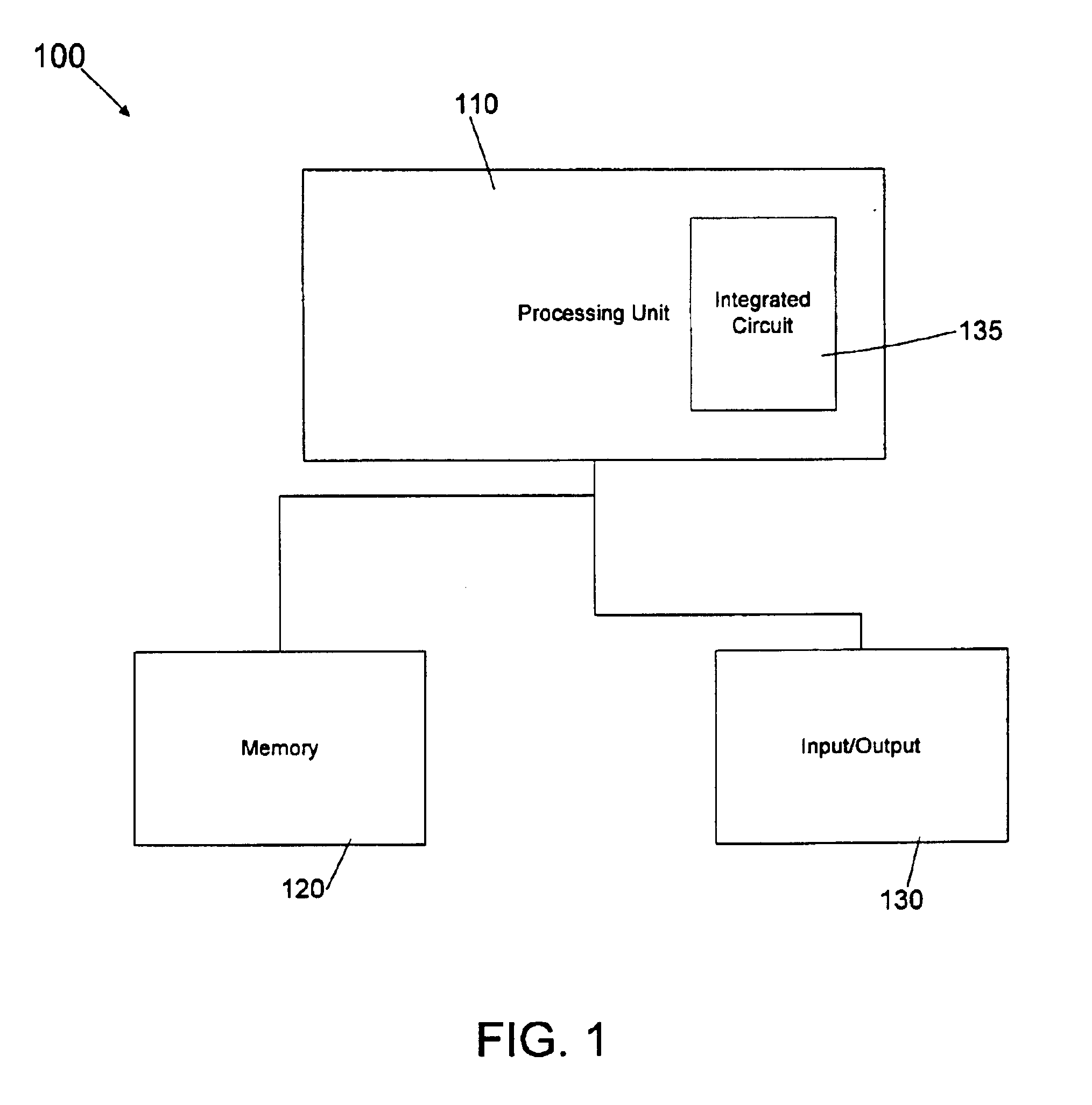

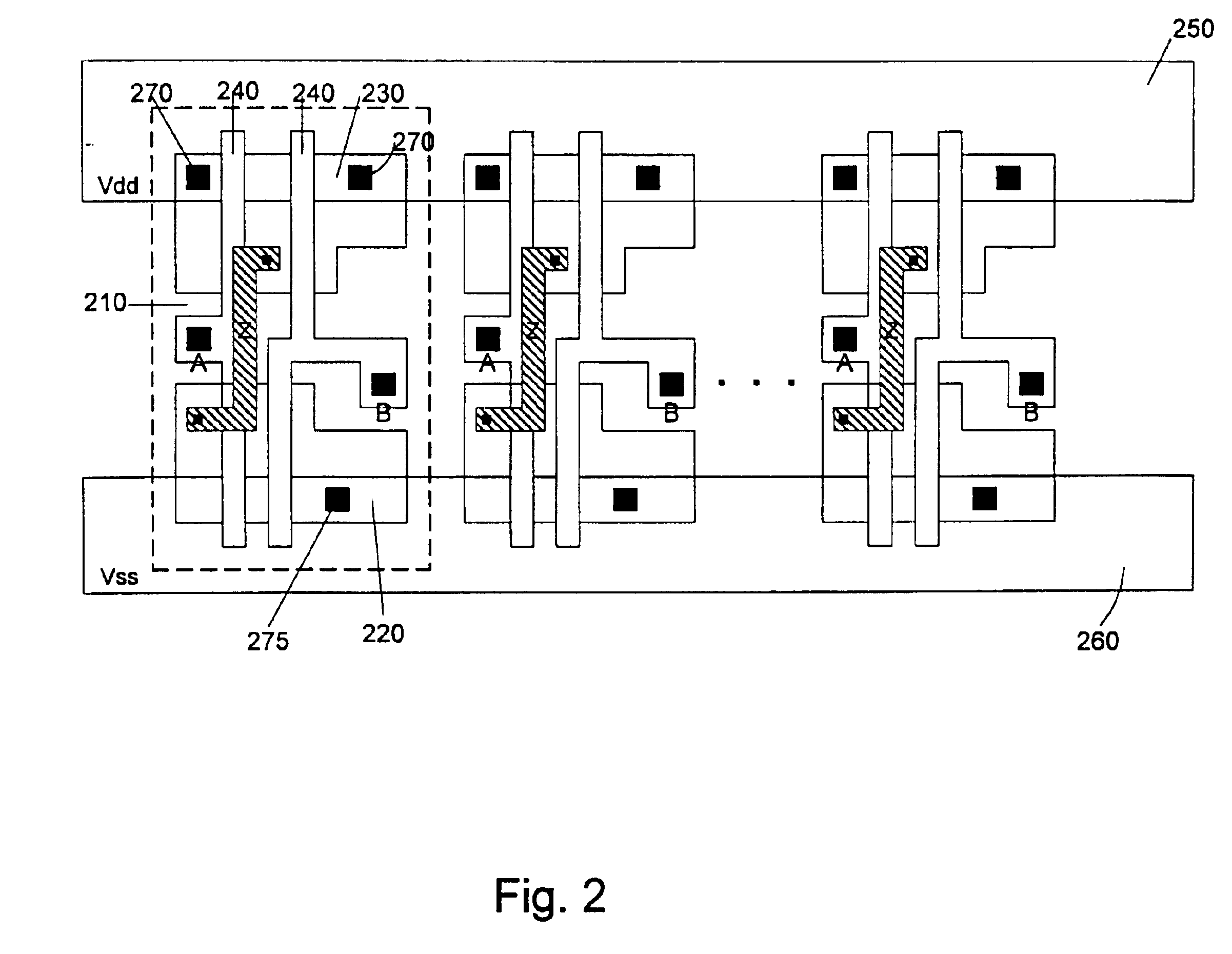

Dual-height cell with variable width power rail architecture

InactiveUS6838713B1TransistorSemiconductor/solid-state device detailsHigh densityElectrical conductor

A standard cell architecture with a basic cell that spans multiple rows of the standard cell. This multi-row basic cell may be a dual-height cell that spans two rows, or it may span more than two rows. The multi-row basic cell may be intermixed in a standard cell design with smaller, single-height cells for high-density applications. The single-height cells may be used where possible and higher-drive dual-height basic cells where larger transistors are desired. Other multiple height cells may also be included if even more current is desirable. The power rail may include conductors of varying width.

Owner:SYNOPSYS INC

Light switch assembly

A light switch assembly to replace an existing light switch, which generally includes a mounting bracket attached to an electrical box. The assembly slides into the mounting bracket and is locked into place with the mounting bracket. A decorative light switch cover and custom artwork within the frame snaps and locks onto the outer perimeter of the mounting bracket to complete the assembly. The assembly provides for a battery back-up system for power failure situations to illuminate the white, light emitting diodes in the event of a loss of power. The assembly senses the loss of power and unlocks the switch assembly from attachment to the mounting bracket. Unsnapping the decorative cover exposes the switch assembly so it can be removed from the mounting bracket. The switch assembly then becomes a mobile, hand-held emergency flashlight. The battery back-up system also allows for communication with first responders.

Owner:RINTZ WILLIAM J

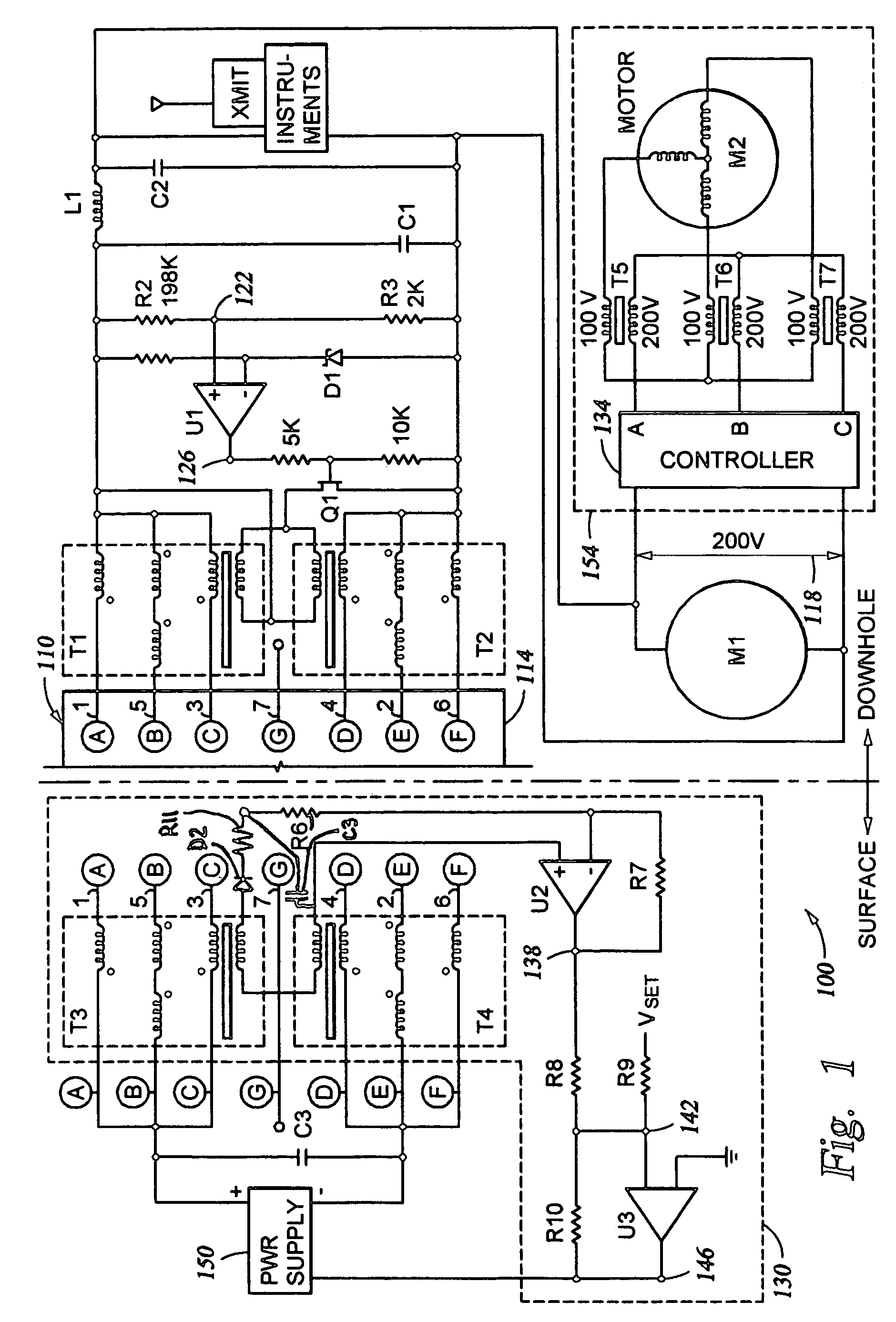

Shunt regulation apparatus, systems, and methods

Owner:HALLIBURTON ENERGY SERVICES INC

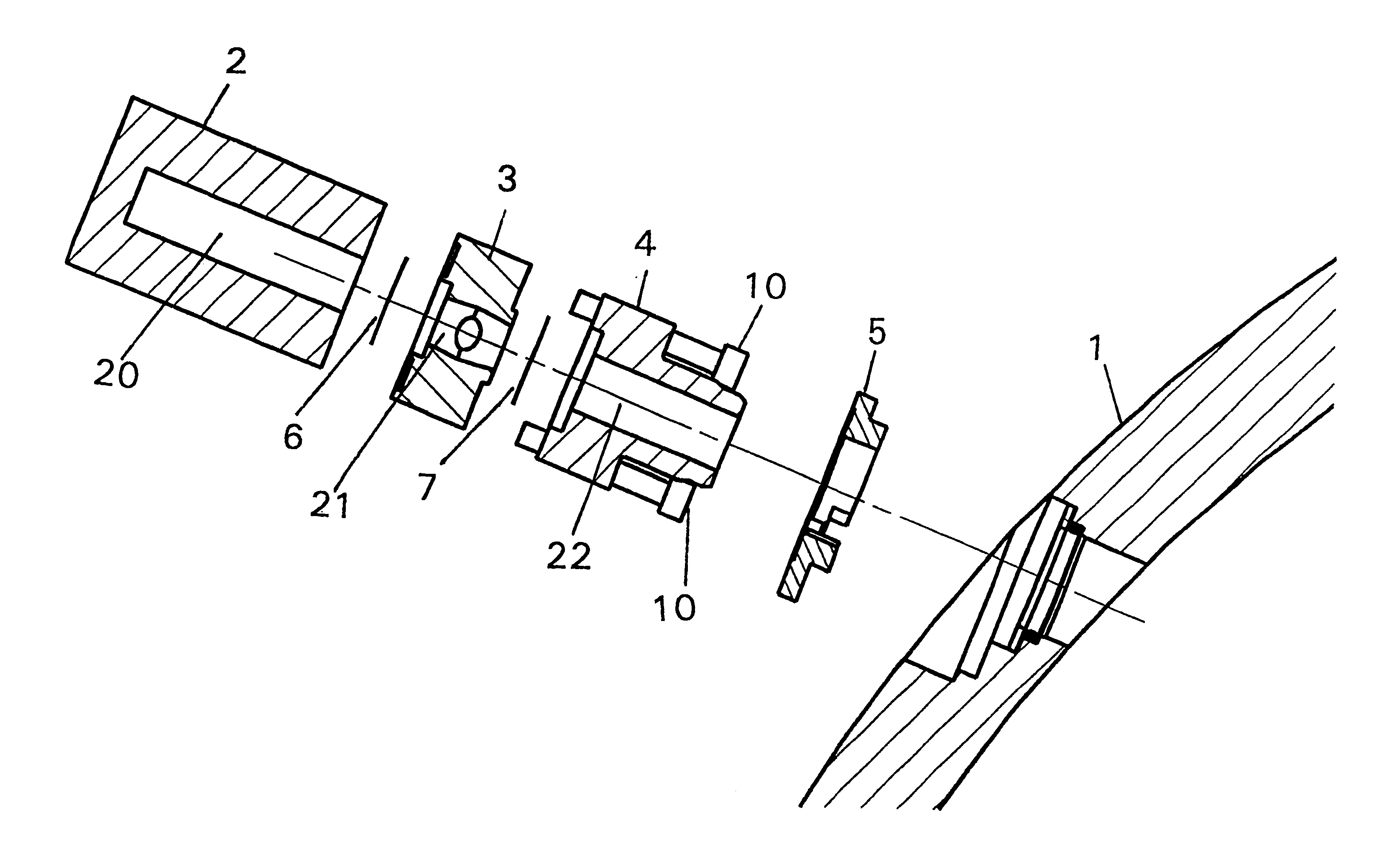

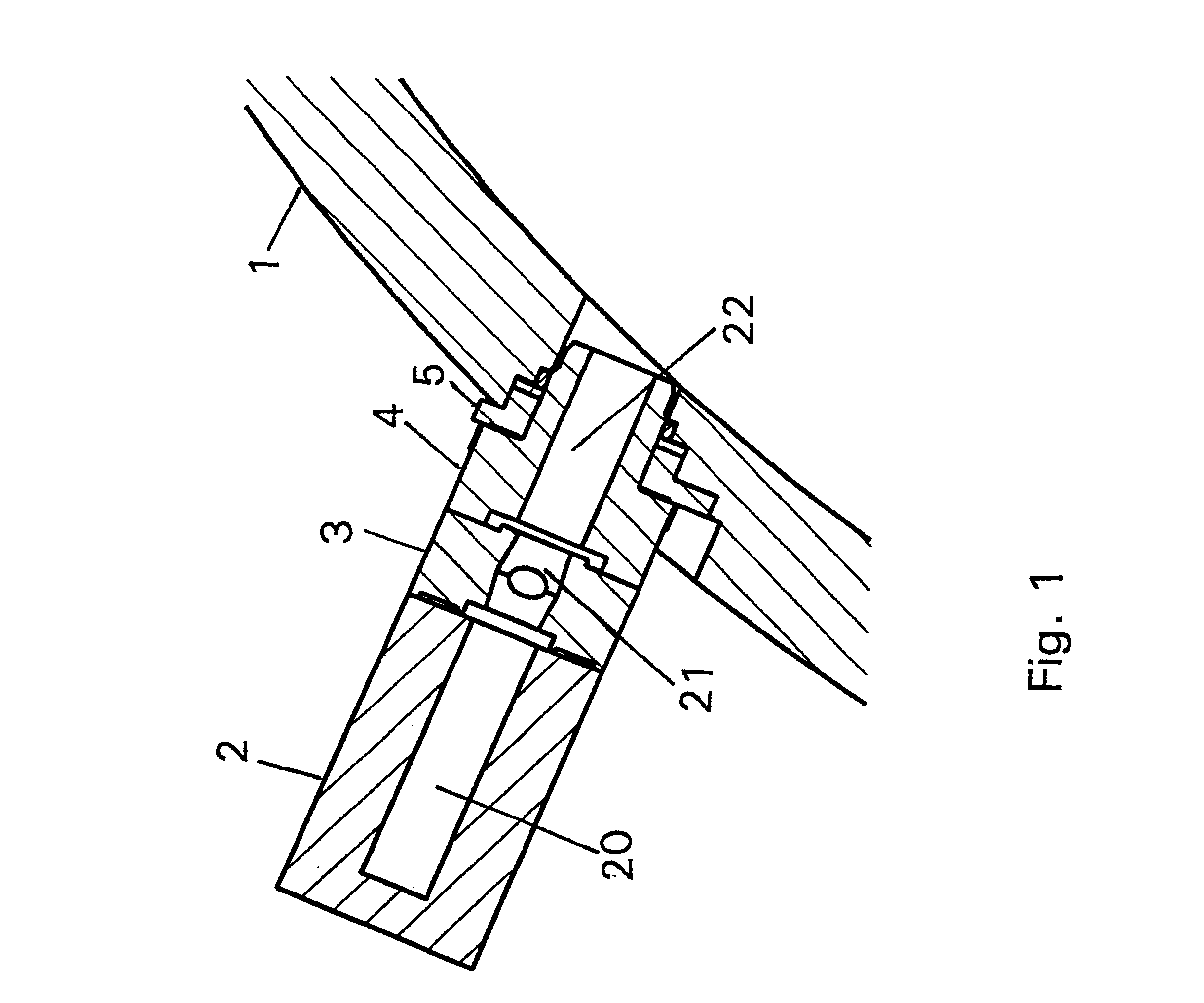

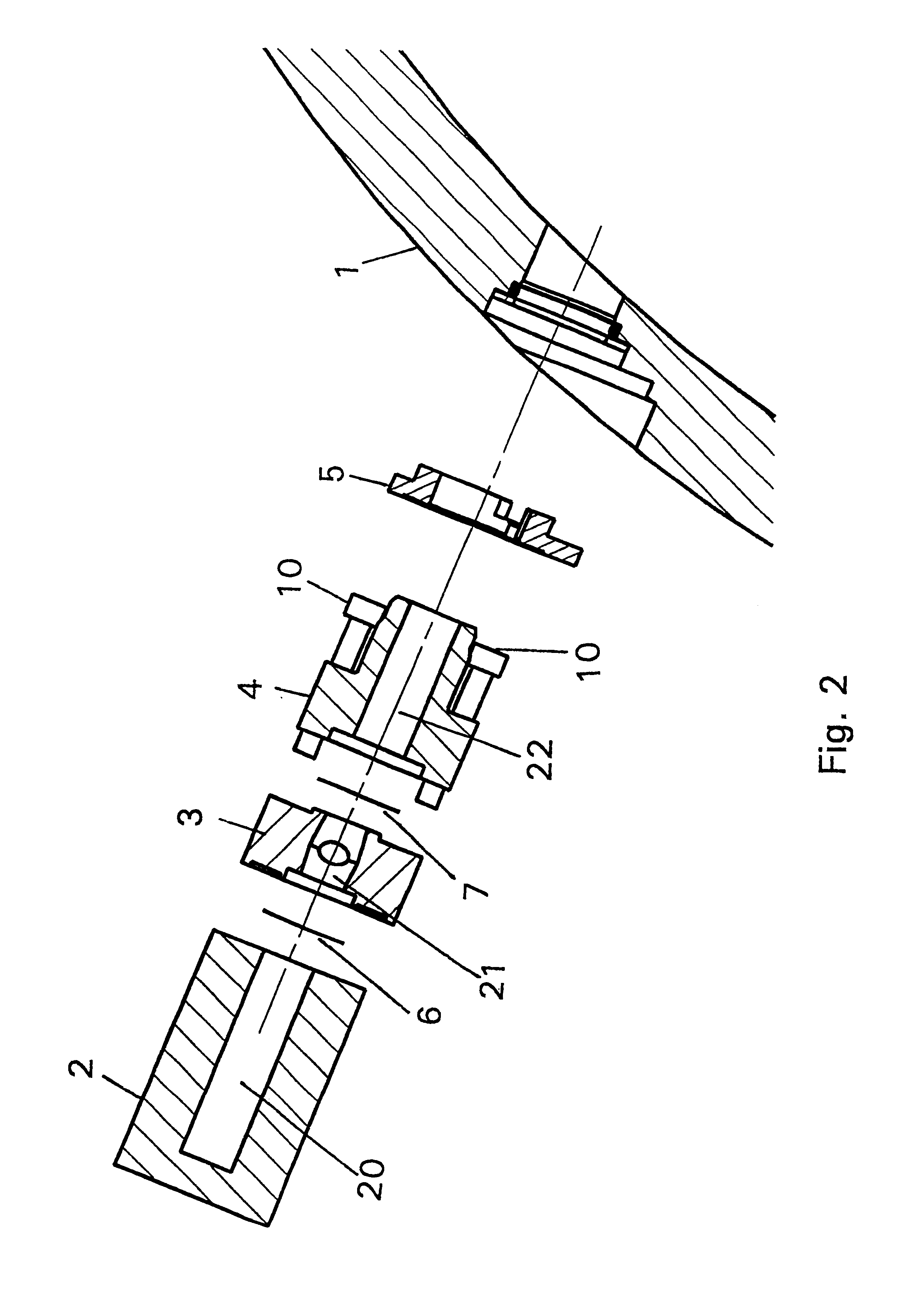

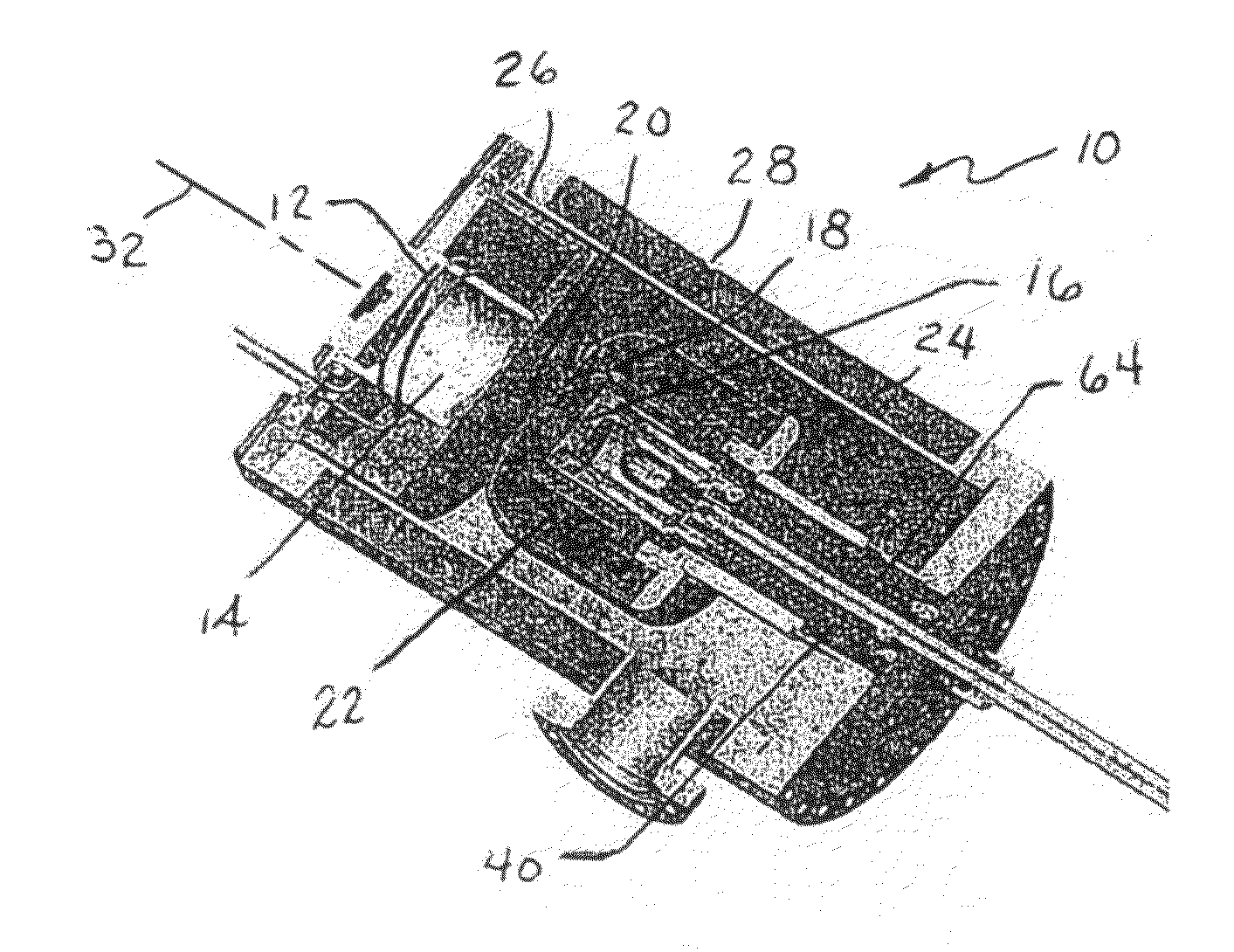

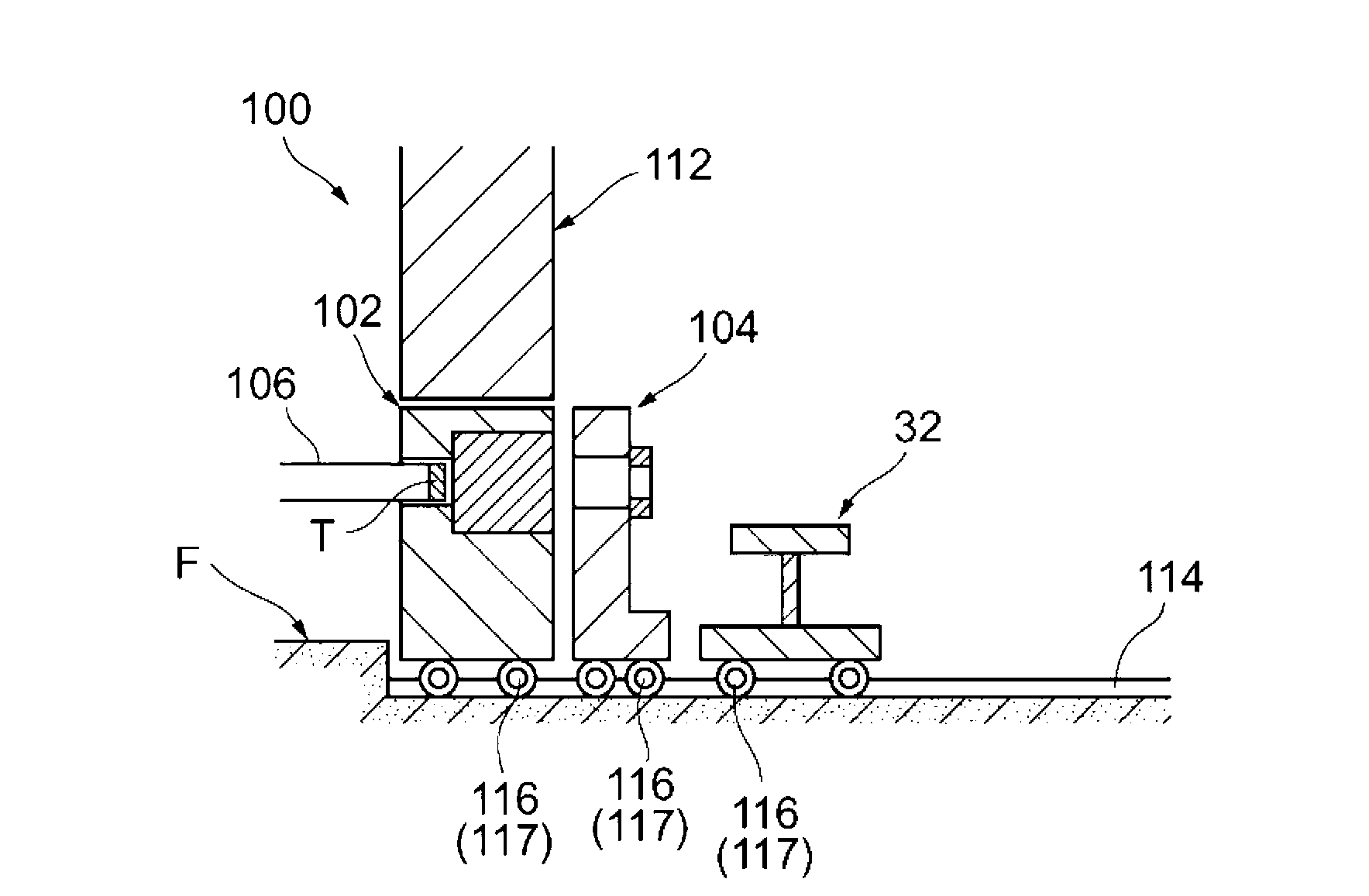

Device for fitting of a target in isotope production

InactiveUS6433495B1Minimize radiationFit fastThermometer detailsBeam/ray focussing/reflecting arrangementsInterior spaceIsotope

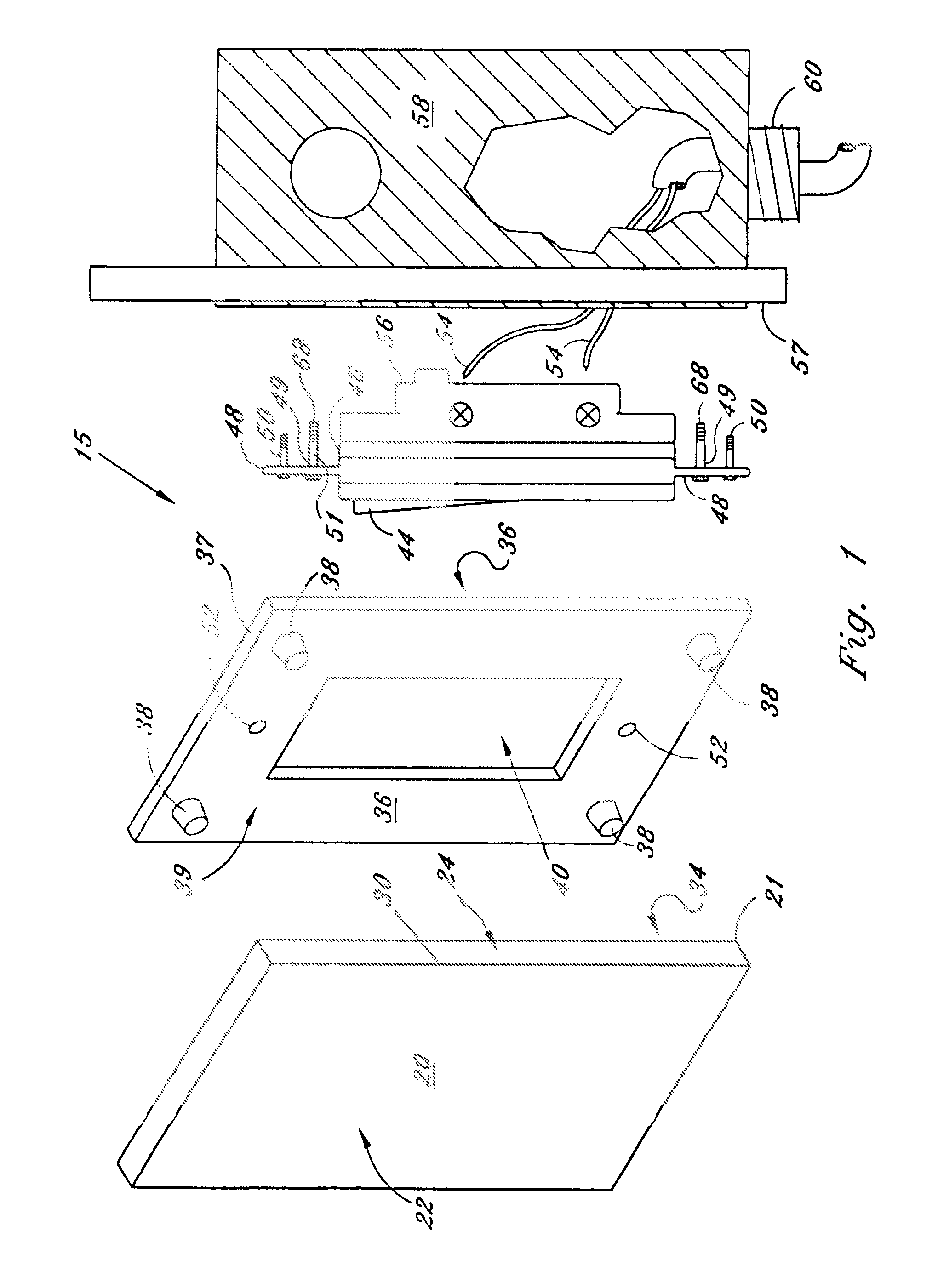

A device is disclosed for simple and quick disconnection of a target assembly at a cyclotron accelerator producing an ion beam irradiating the target assembly for PET radioisotope production. The device consists of a target body presenting a target space for introduction of target media to be irradiated by the ion beam from the cyclotron accelerator. The target body is separated into three portions by means of two separation window foils. The first separation window separates the internal space of a first body portion from a further internal space portion of a second target body portion and the second separation window separates a further internal space of the second target body portion from an internal space of a third target body portion being in communication with the vacuum space of the cyclotron. This third body portion forms a bayonet fitting to a corresponding bayonet fitting fixed to the cyclotron vacuum casing at a position where the ion beam is extracted, whereby the corresponding bayonet fitting also constitutes an insulating member. The device can by a small twisting be quickly released from the vacuum casing of the cyclotron after the vacuum has been removed for necessary maintenance and service.

Owner:GEMS PET SYST

Apparatus and method for fusion reactor

InactiveUS20050129161A1Nuclear energy generationDirect voltage acceleratorsNuclear fusionAtomic nucleus

A method for inducing nuclear fusion and a reactor for inducing nuclear fusion involve positioning a bubble containing fusionable nuclei at the center of a liquid filled spherical vessel and generating a spherically symmetric positive acoustic pulse in the liquid. The acoustic pulse surrounds and converges toward the center of the vessel to compress the bubble, thereby providing energy to and inducing nuclear fusion of the atomic nuclei.

Owner:GENERAL FUSION INC

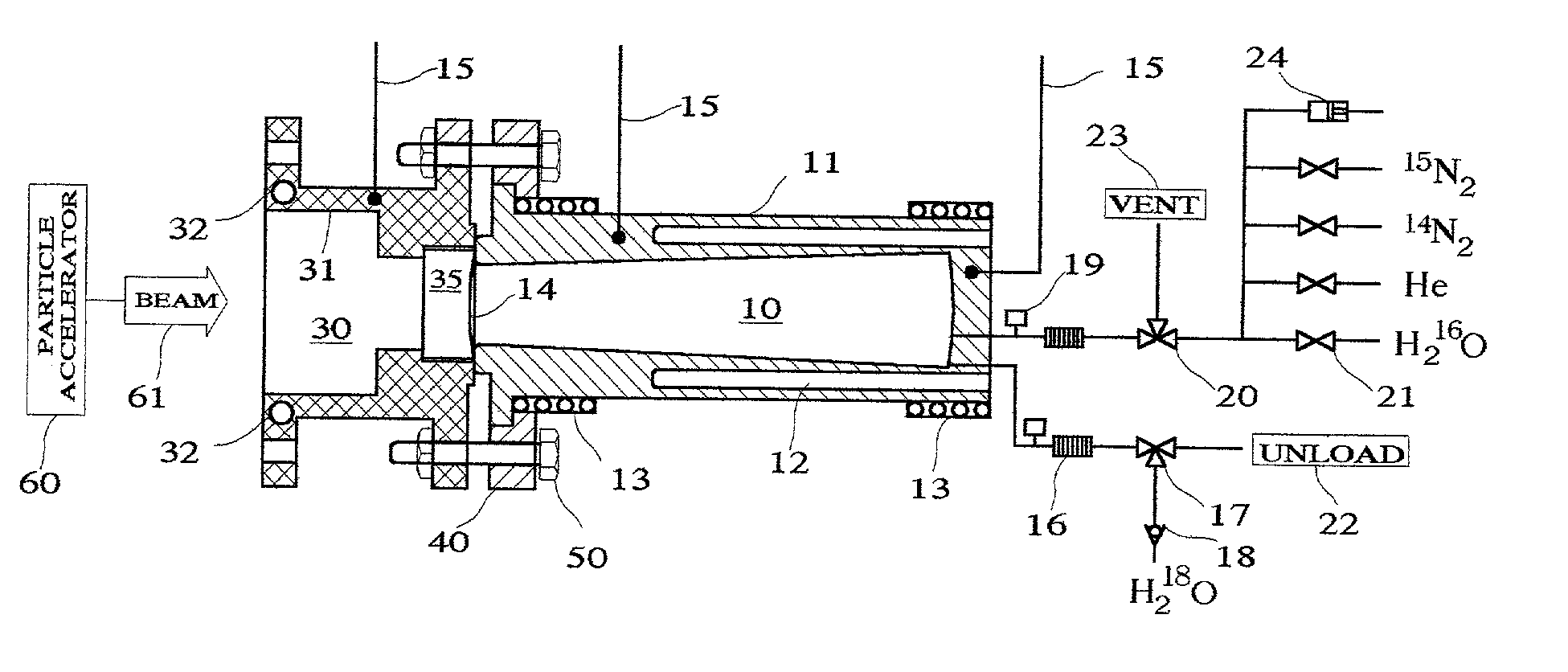

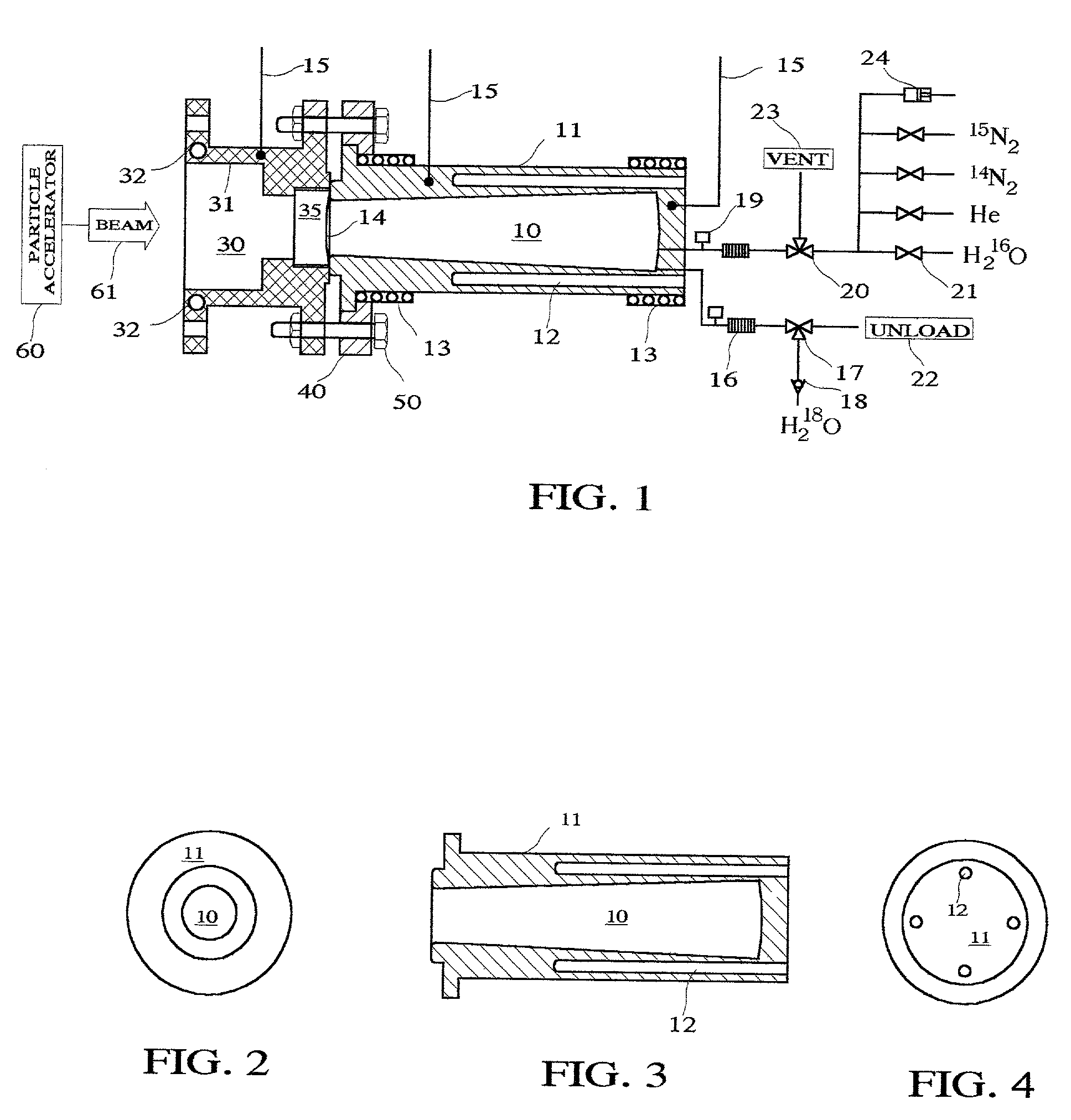

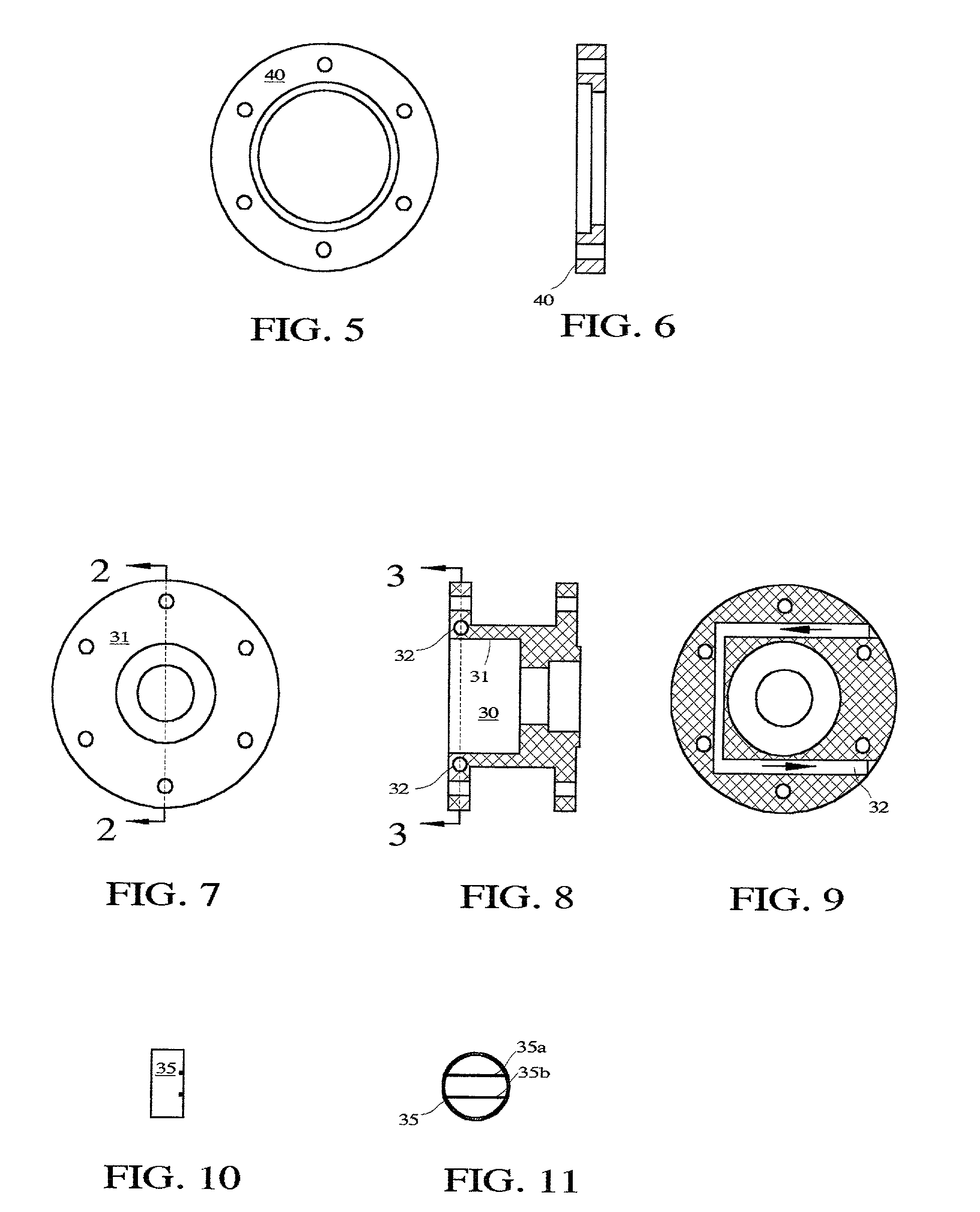

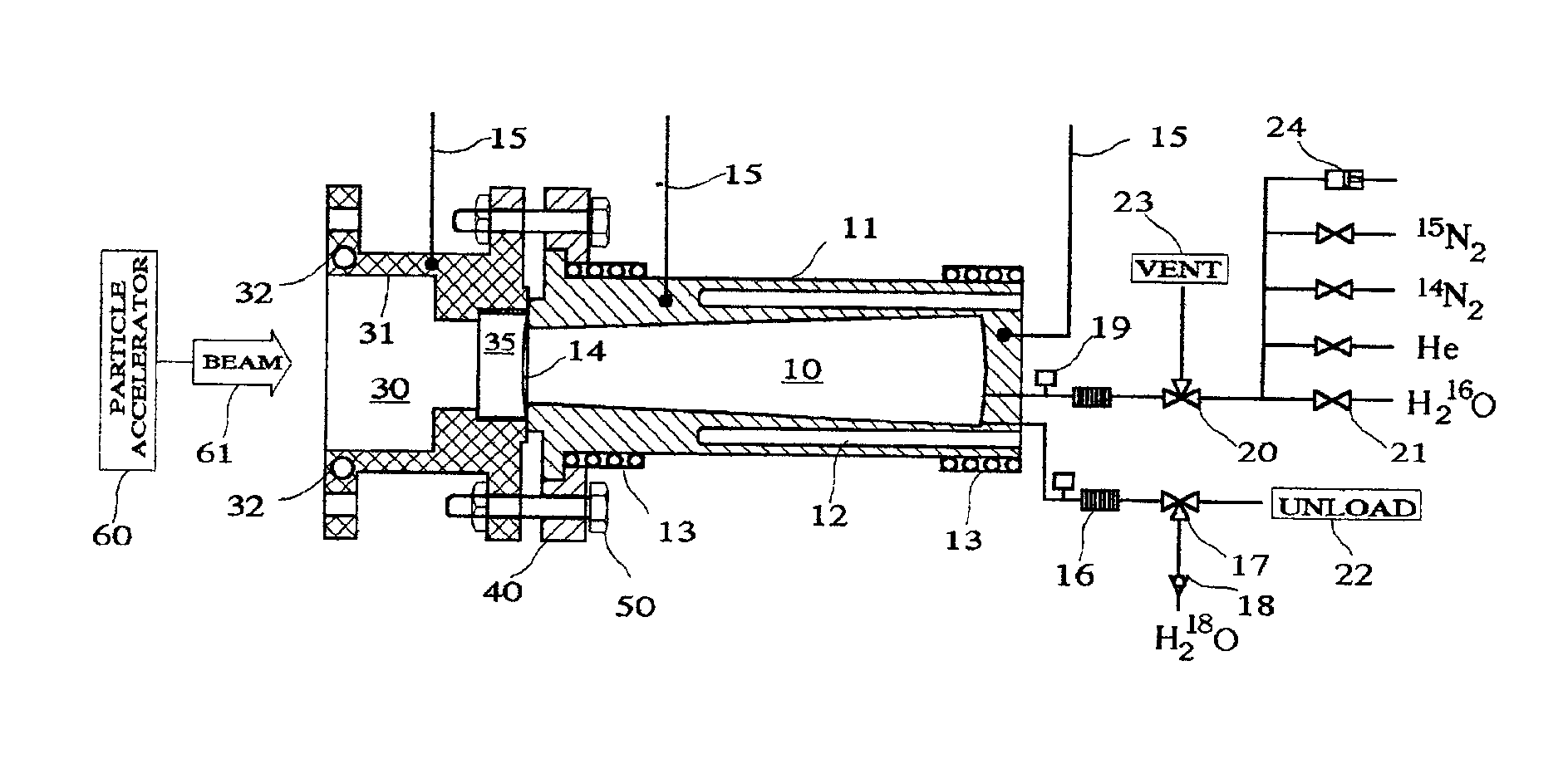

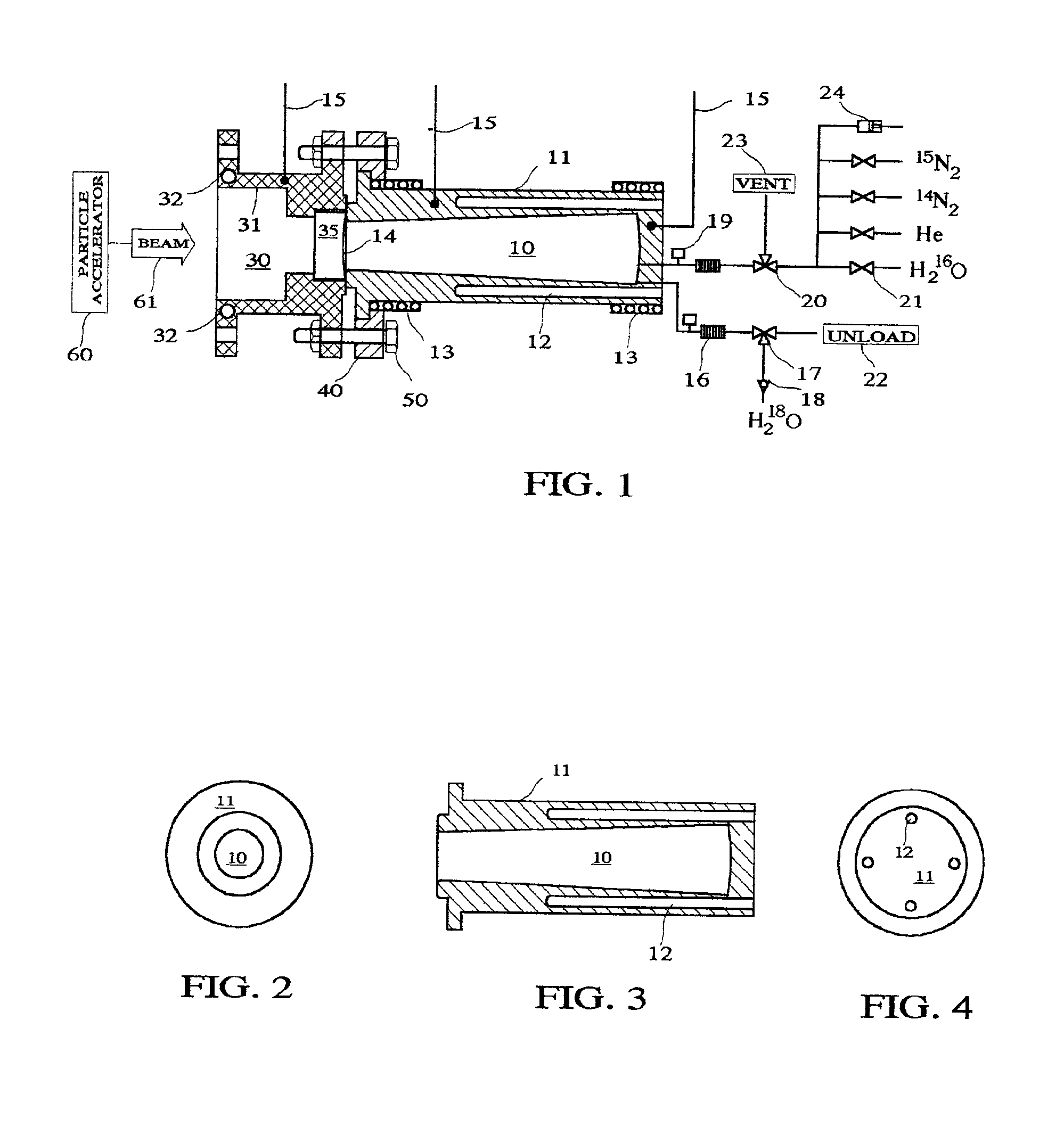

High power high yield target for production of all radioisotopes for positron emission tomography

InactiveUS20050061994A1Avoid low densitySuppress instabilityConversion outside reactor/acceleratorsNuclear monitoringCoolant flowInstability

A high power high yield target for the positron emission tomography applications is introduced. For production of Curie level of Fluorine-18 isotope from a beam of proton it uses about one tenth of Oxygen-18 water compared to a conventional water target. The target is also configured to be used for production of all other radioisotopes that are used for positron emission tomography. When the target functions as a water target the material sample being oxygen-18 water or oxygen-16 water is heated to steam prior to irradiation using heating elements that are housed in the target body. The material sample is kept in steam phase during the irradiation and cooled to liquid phase after irradiation. To keep the material sample in steam phase a microprocessor monitoring the target temperature manipulates the flow of coolant in the cooling section that is attached to the target and the status of the heaters and air blowers mounted adjacent to the target. When the target functions as a gas target the generated heat from the beam is removed from the target by air blowers and the cooling section. The rupture point of the target window is increased by a factor of two or higher by one thin wire or two parallel thin wires welded at the end of a small hollow tube which is held against the target window. One or two coils are used to produce a magnetic filed along the beam path for preventing the density depression along the beam path and suppression of other instabilities that can develop in a high power target.

Owner:AMINI BEHROUZ

Compact neutron source and moderator

InactiveUS20100061500A1Nuclear energy generationDirect voltage acceleratorsSecondary electronsIon source

A novel method and compact neutron source for generating thermal neutrons is described that uses an ion source to emit ions toward a target where neutrons are generated. Surrounding the target is a secondary electron shield, and surrounding the target is a first stage moderator to reduce the energy of generated fast neutrons. Enclosing the first stage moderator is a second stage moderator with a thermal neutron port.

Owner:RGT UNIV OF CALIFORNIA

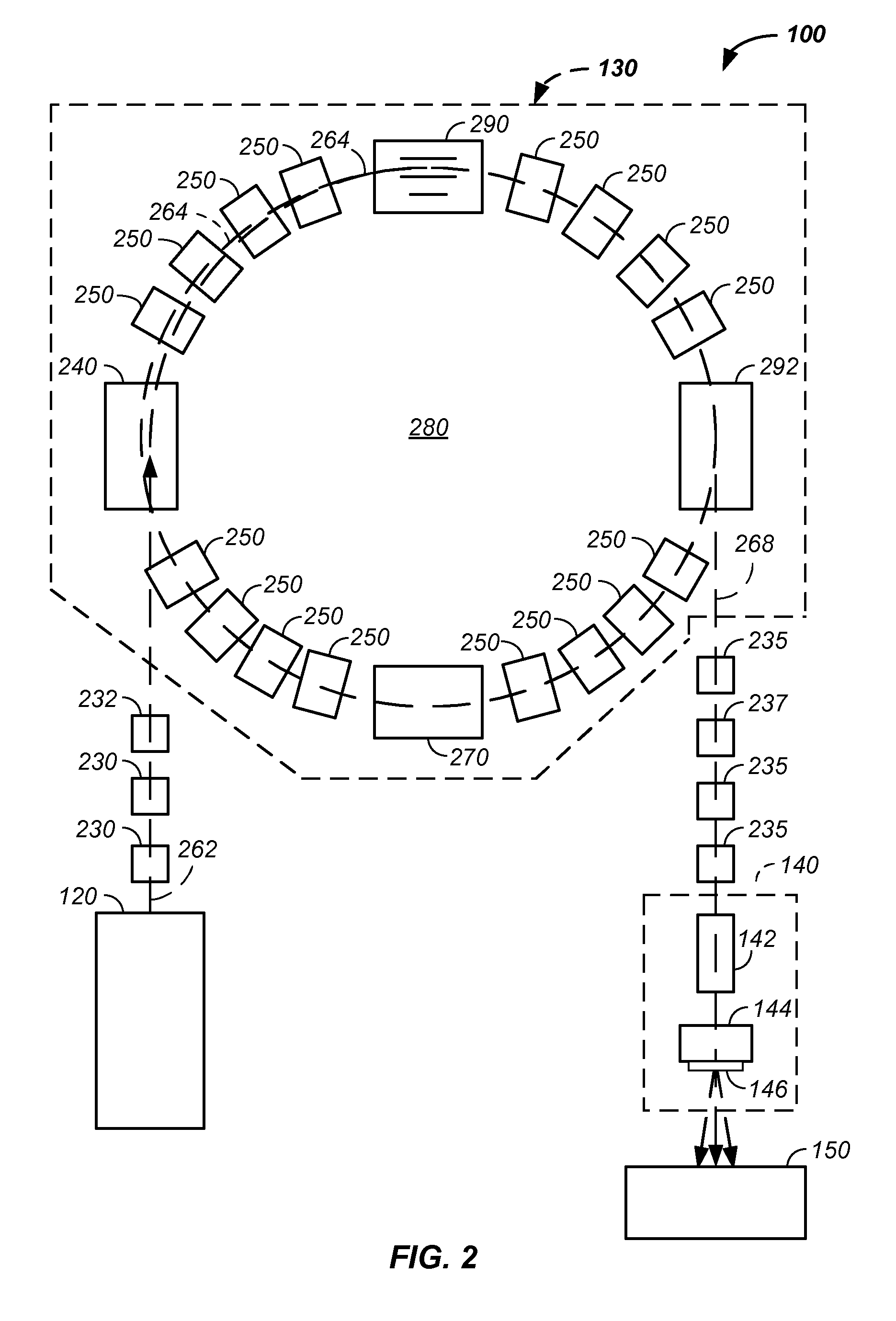

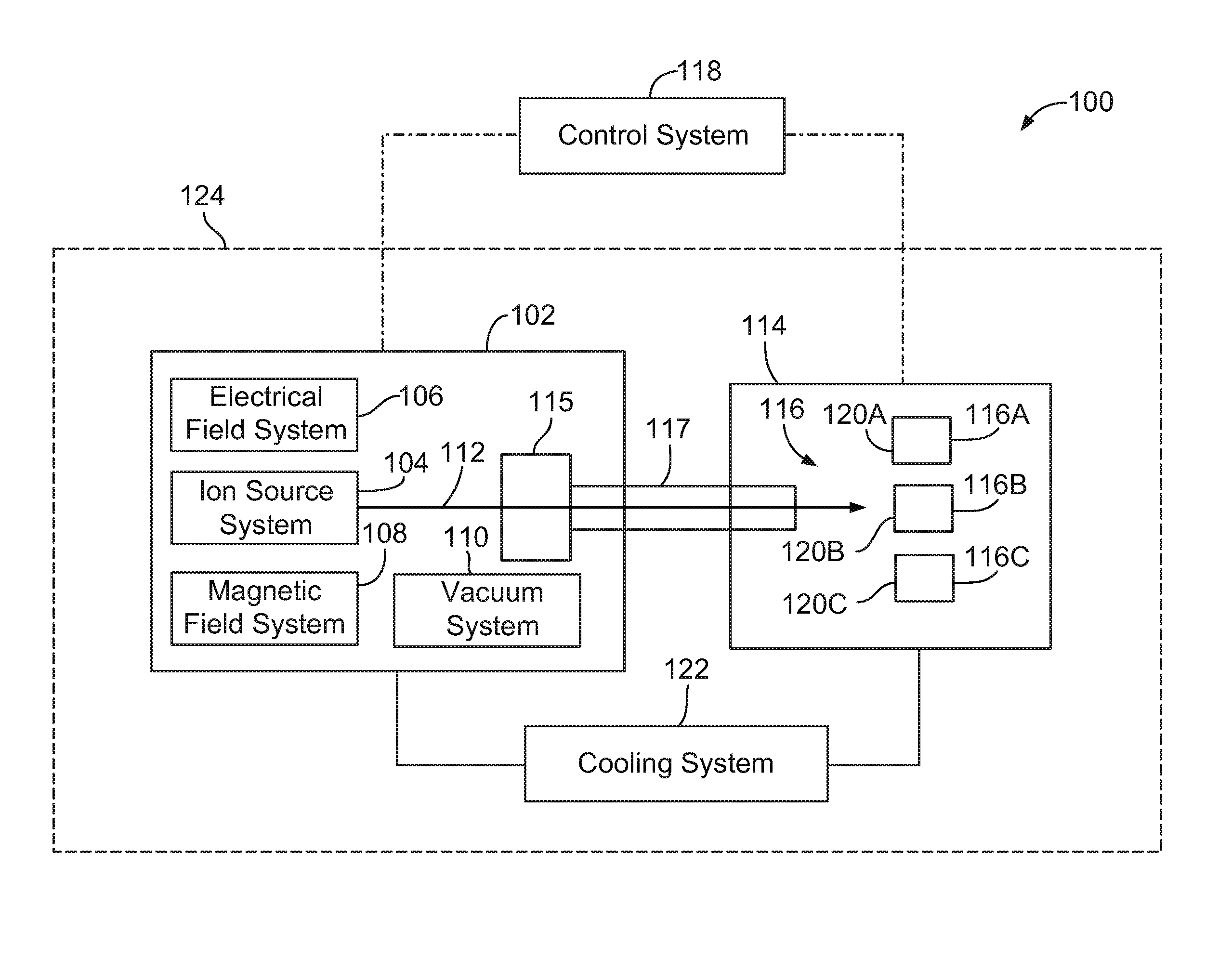

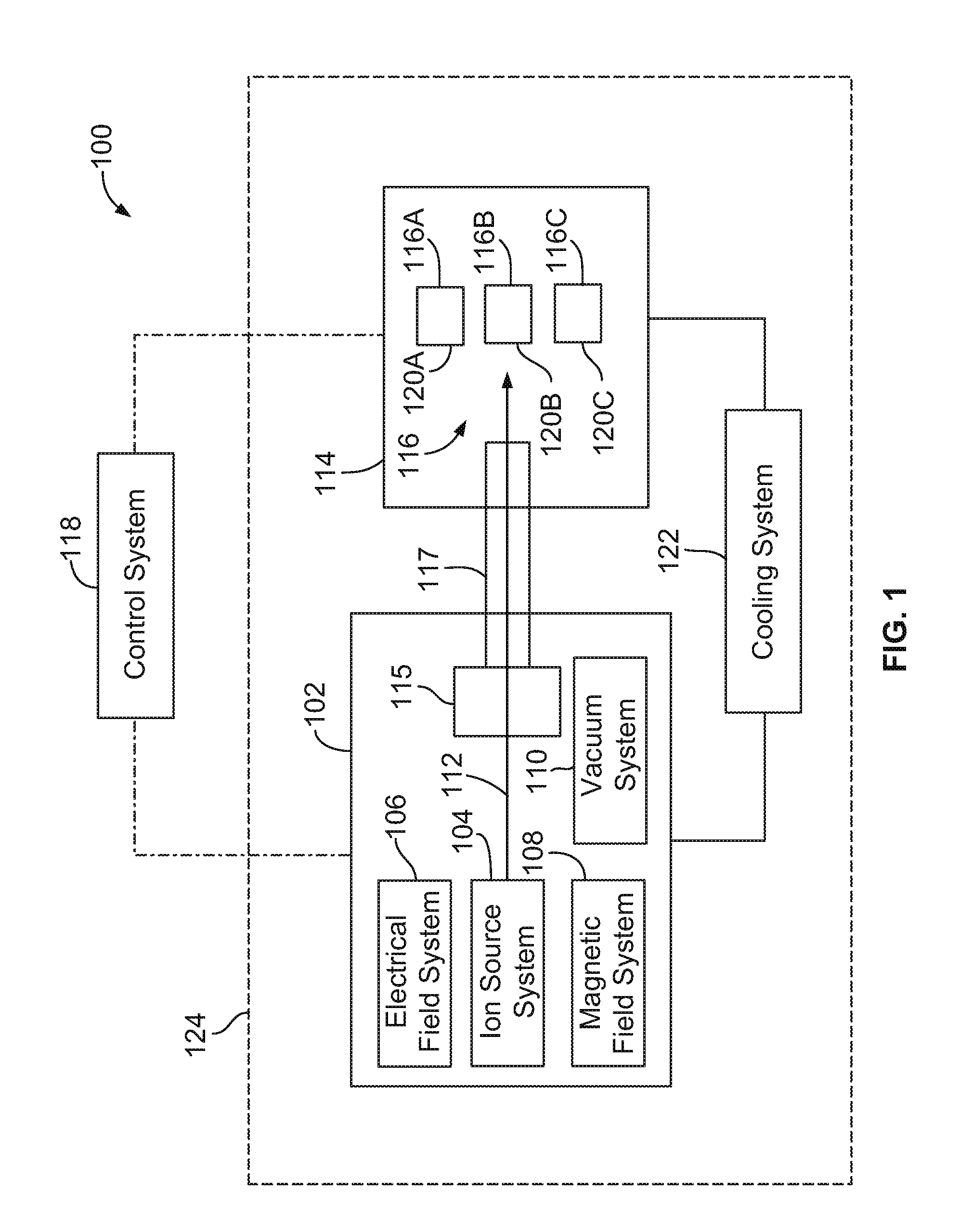

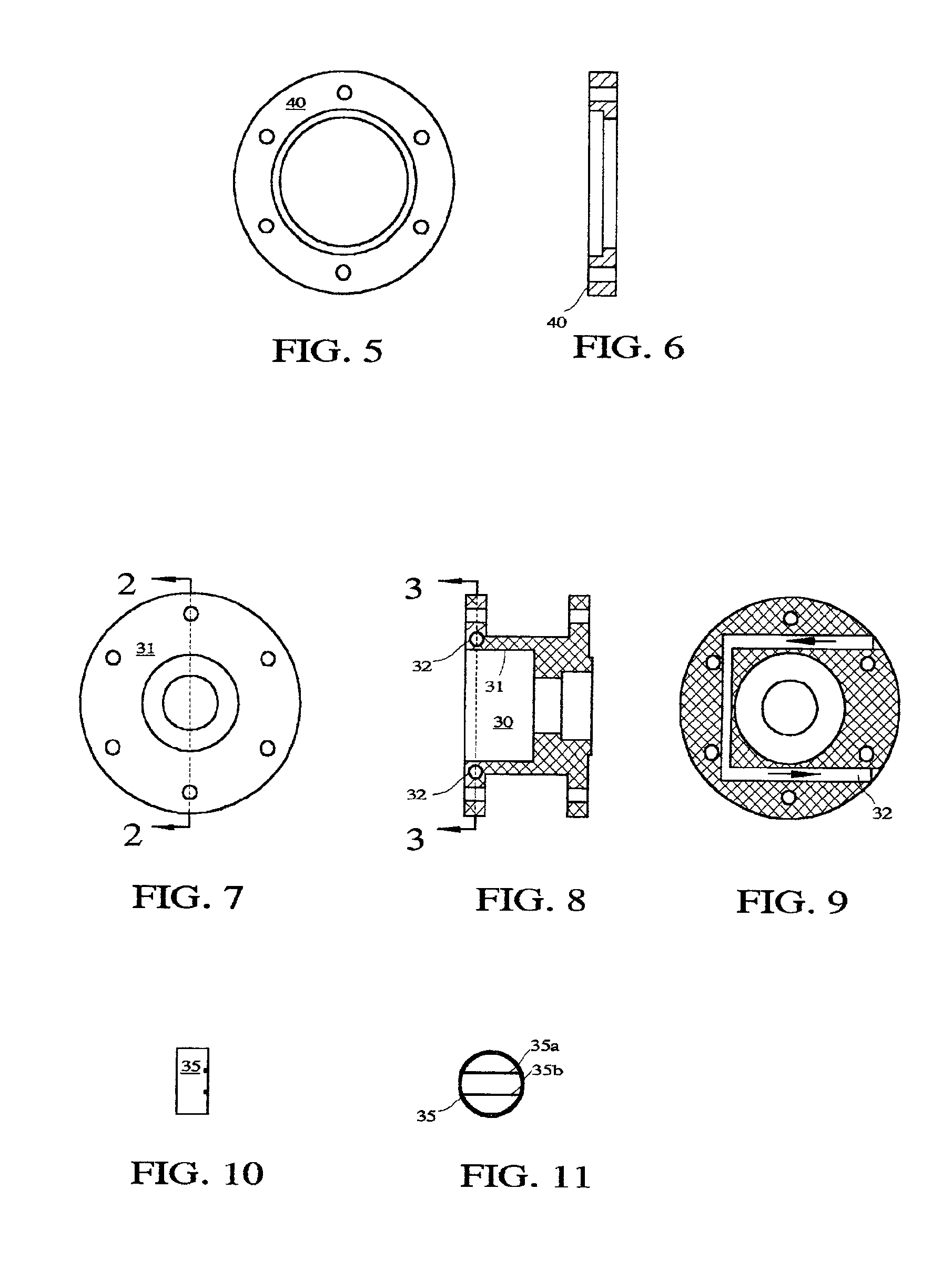

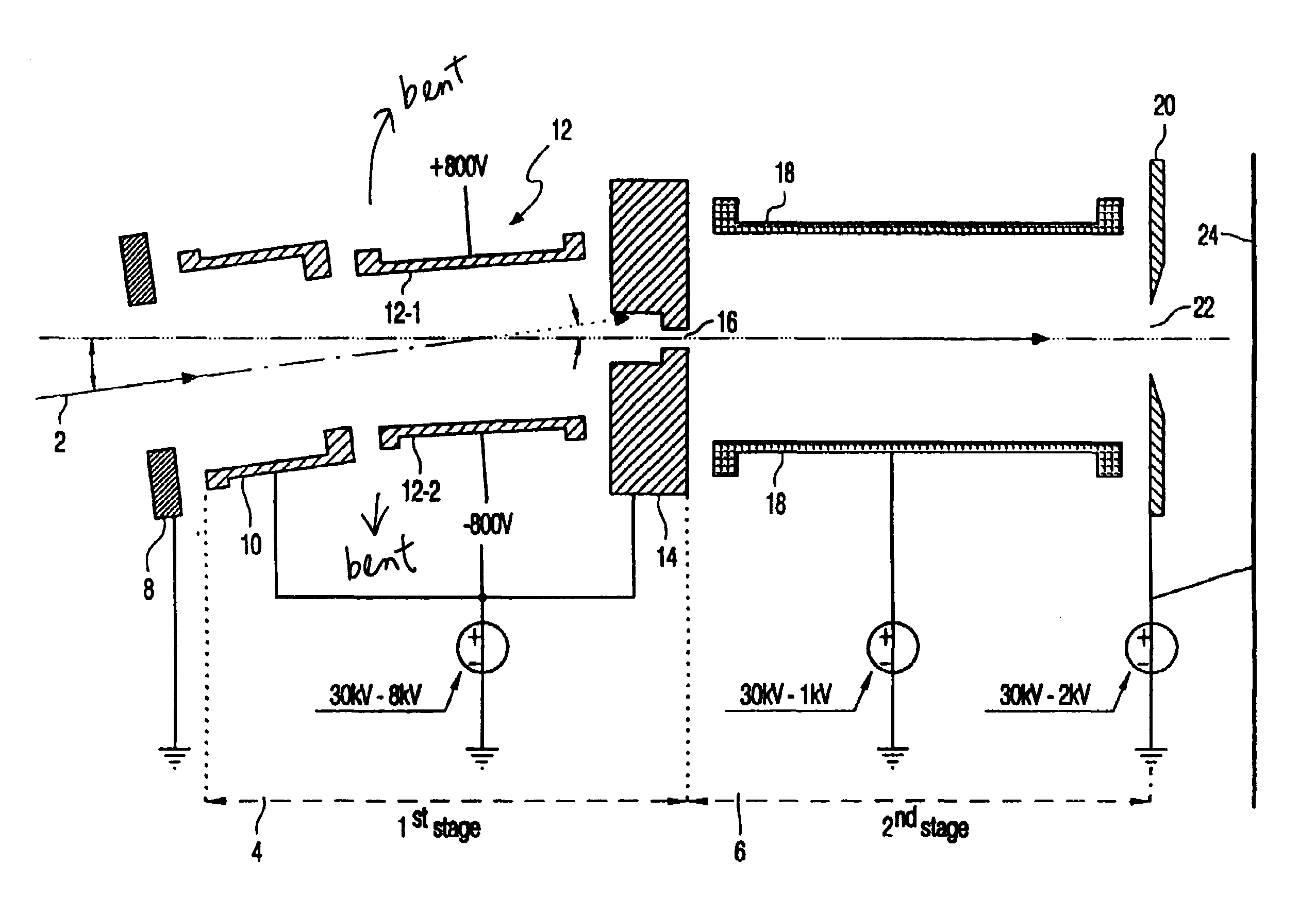

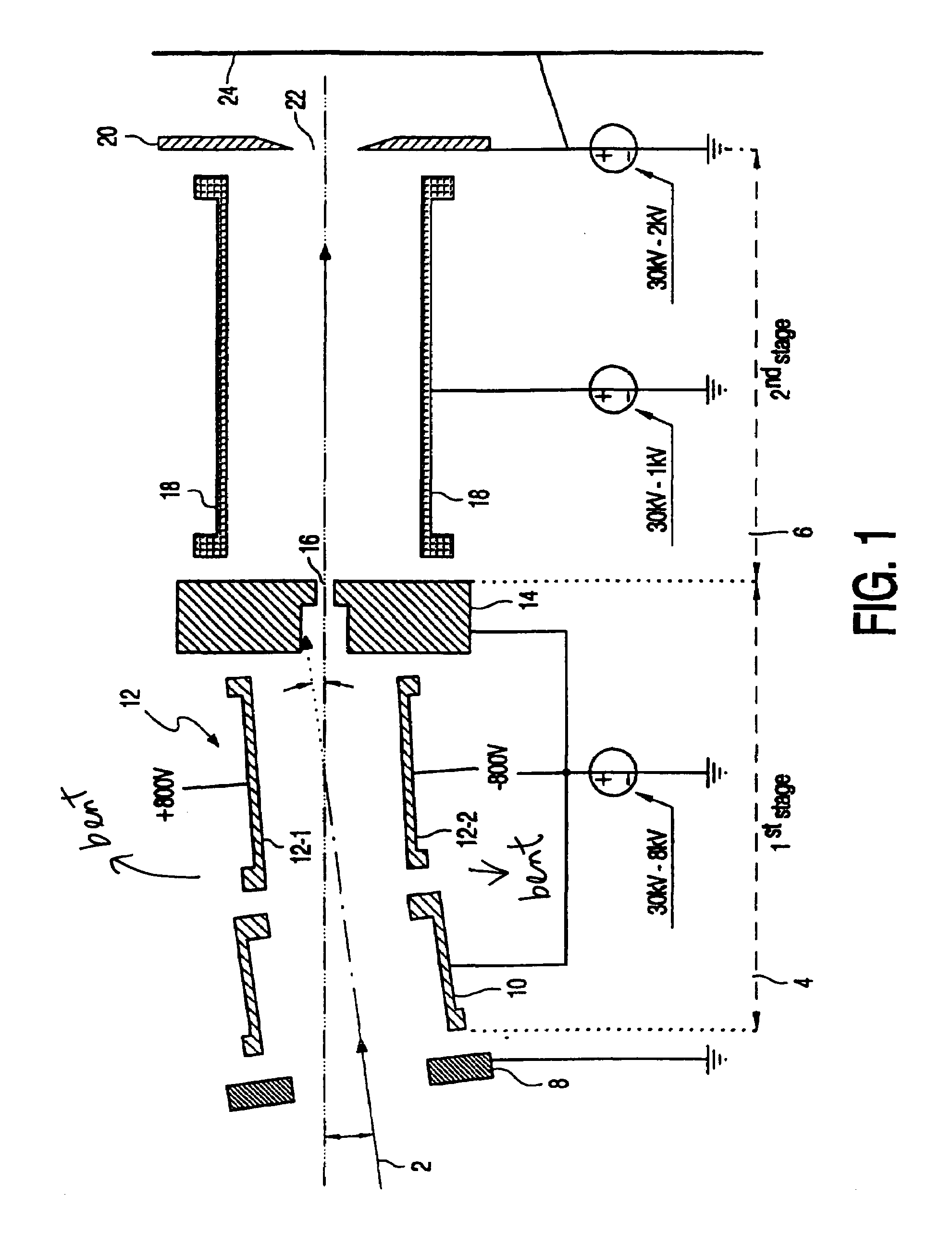

Tandem accelerator method and apparatus used in conjunction with a charged particle cancer therapy system

ActiveUS8198607B2Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsAbnormal tissue growthHydrogen

The invention comprises a tandem accelerator method and apparatus, which is part of an ion beam injection system used in conjunction with multi-axis charged particle radiation therapy of cancerous tumors. The negative ion beam source includes an injection system vacuum system and a synchrotron vacuum system separated by a foil, where negative ions are converted to positive ions. The foil is sealed to the edges of the vacuum tube providing for a higher partial pressure in the injection system vacuum chamber and a lower pressure in the synchrotron vacuum system. Having the foil physically separating the vacuum chamber into two pressure regions allows for fewer and / or smaller pumps to maintain the lower pressure system in the synchrotron as the inlet hydrogen gas is extracted in a separate contained and isolated space by the injection partial vacuum system.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

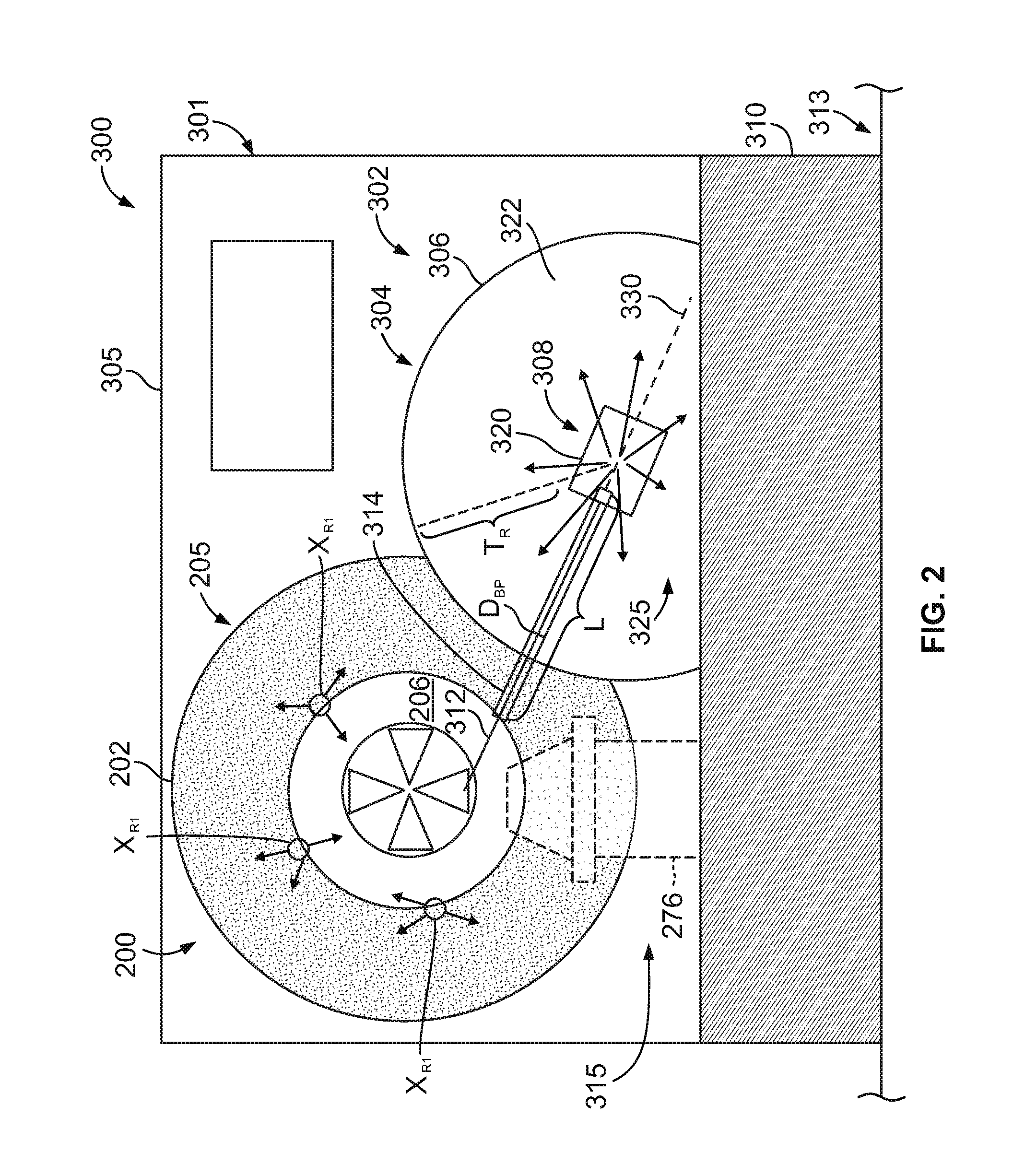

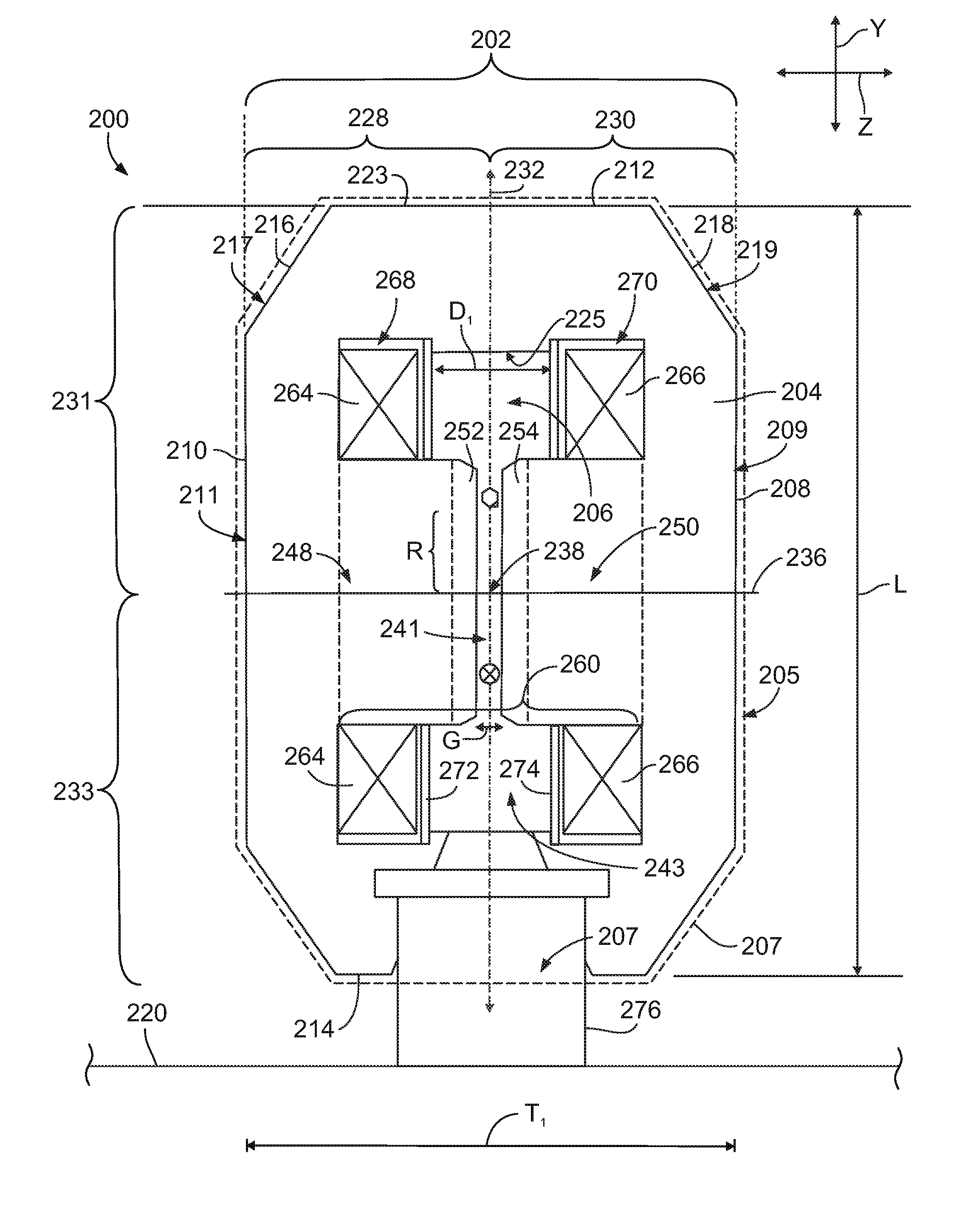

Isotope production system with separated shielding

ActiveUS20100329406A1Conversion outside reactor/acceleratorsNuclear energy generationParticle beamLight beam

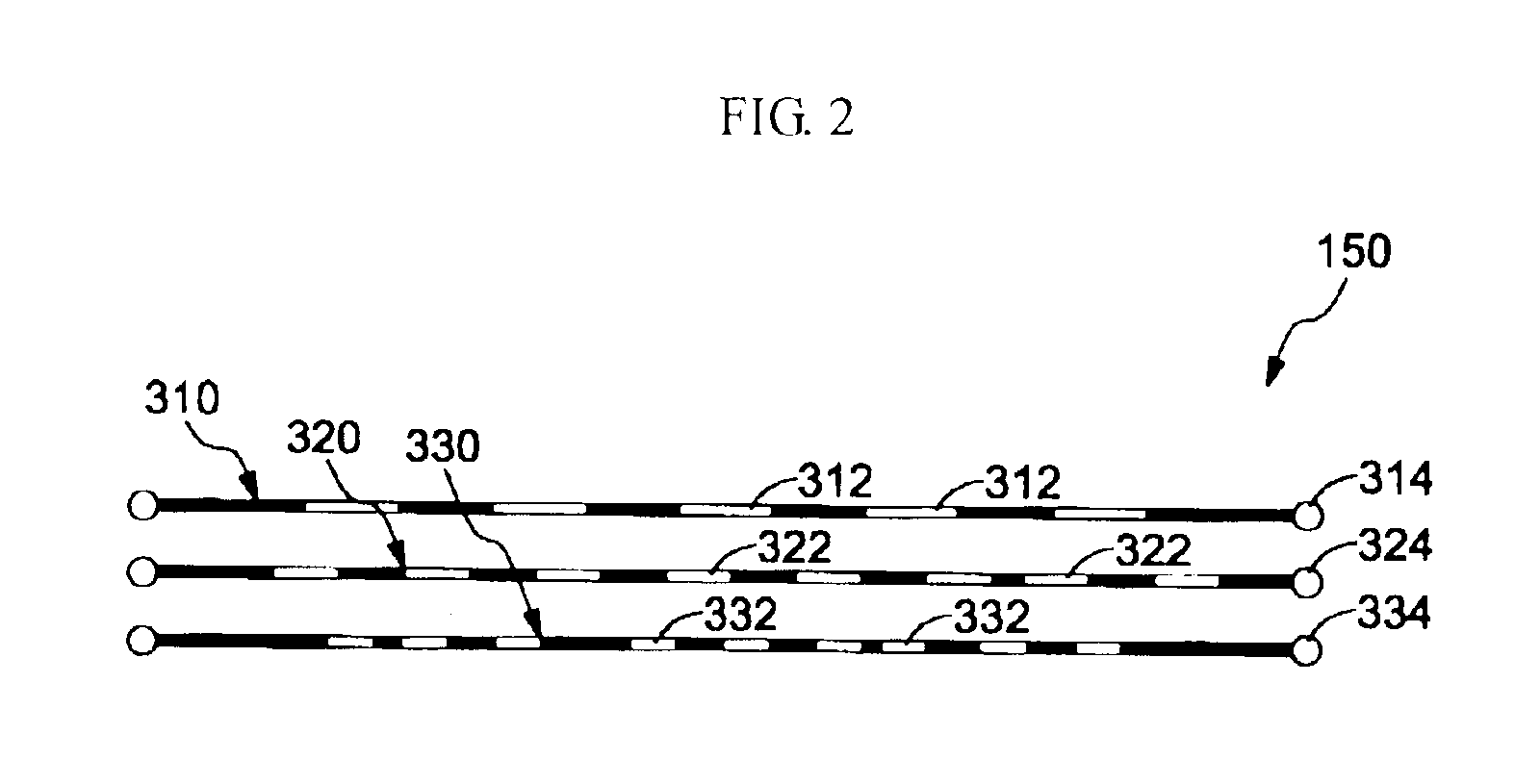

An isotope production system that includes a cyclotron having a magnet yoke that surrounds an acceleration chamber. The cyclotron is configured to direct a particle beam from the acceleration chamber through the magnet yoke. The isotope production system also includes a target system that is located proximate to the magnet yoke. The target system is configured to hold a target material and includes a radiation shield that extends between the magnet yoke and the target location. The radiation shield is sized and shaped to attenuate gamma rays emitted from the target material toward the magnet yoke. The isotope production system also includes a beam passage that extends from the acceleration chamber to the target location. The beam passage is at least partially formed by the magnet yoke and the radiation shield of the target system.

Owner:GENERAL ELECTRIC CO

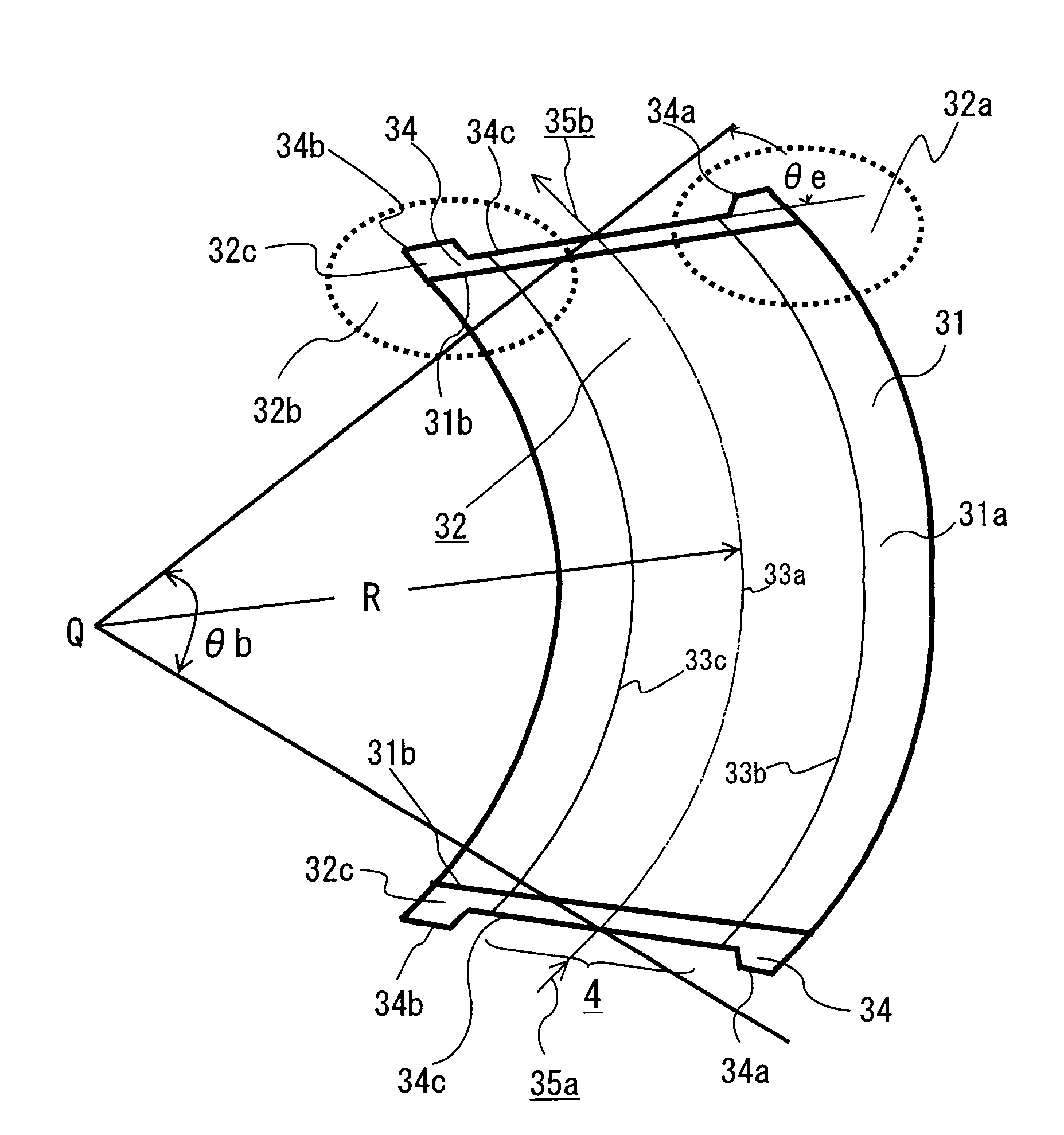

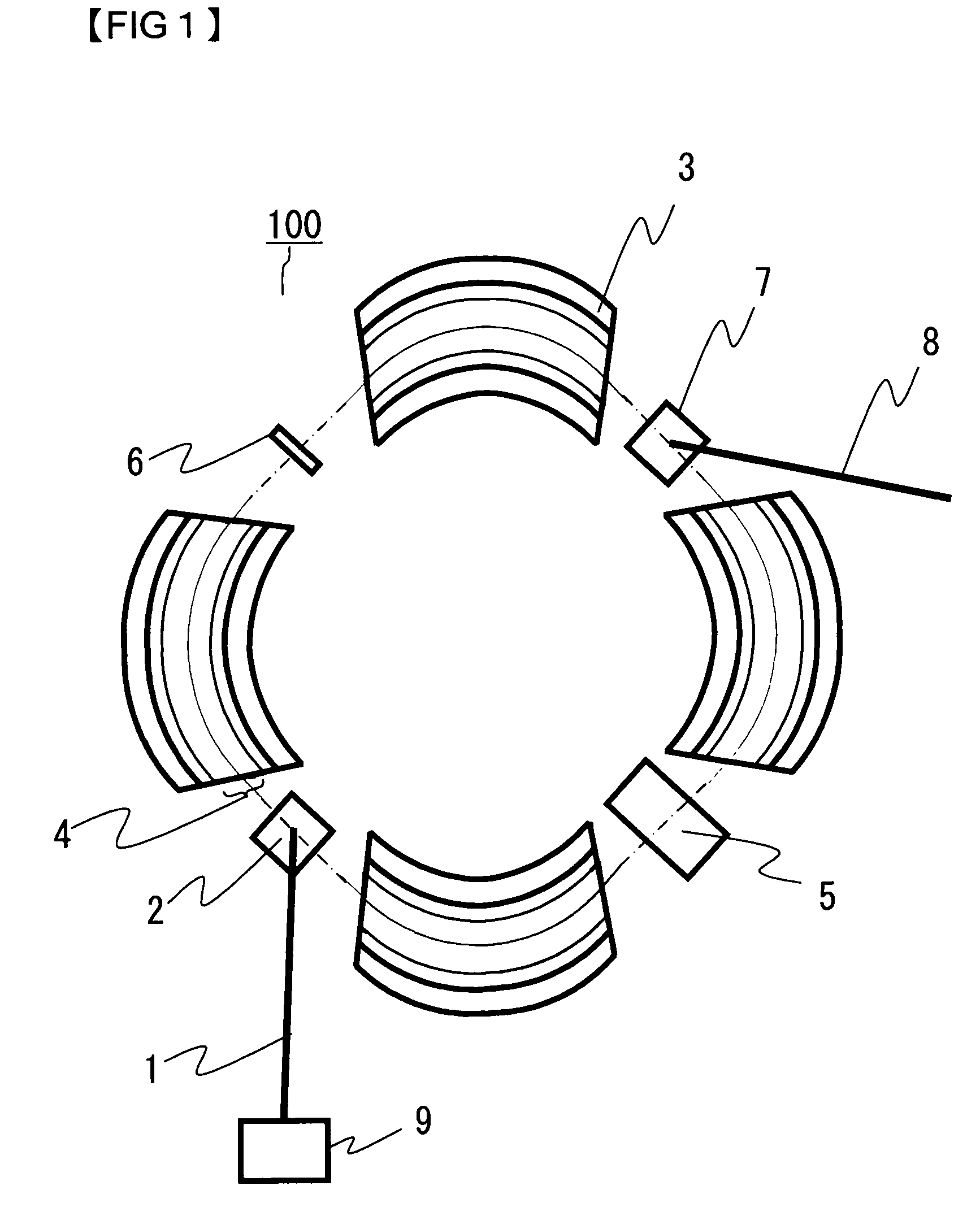

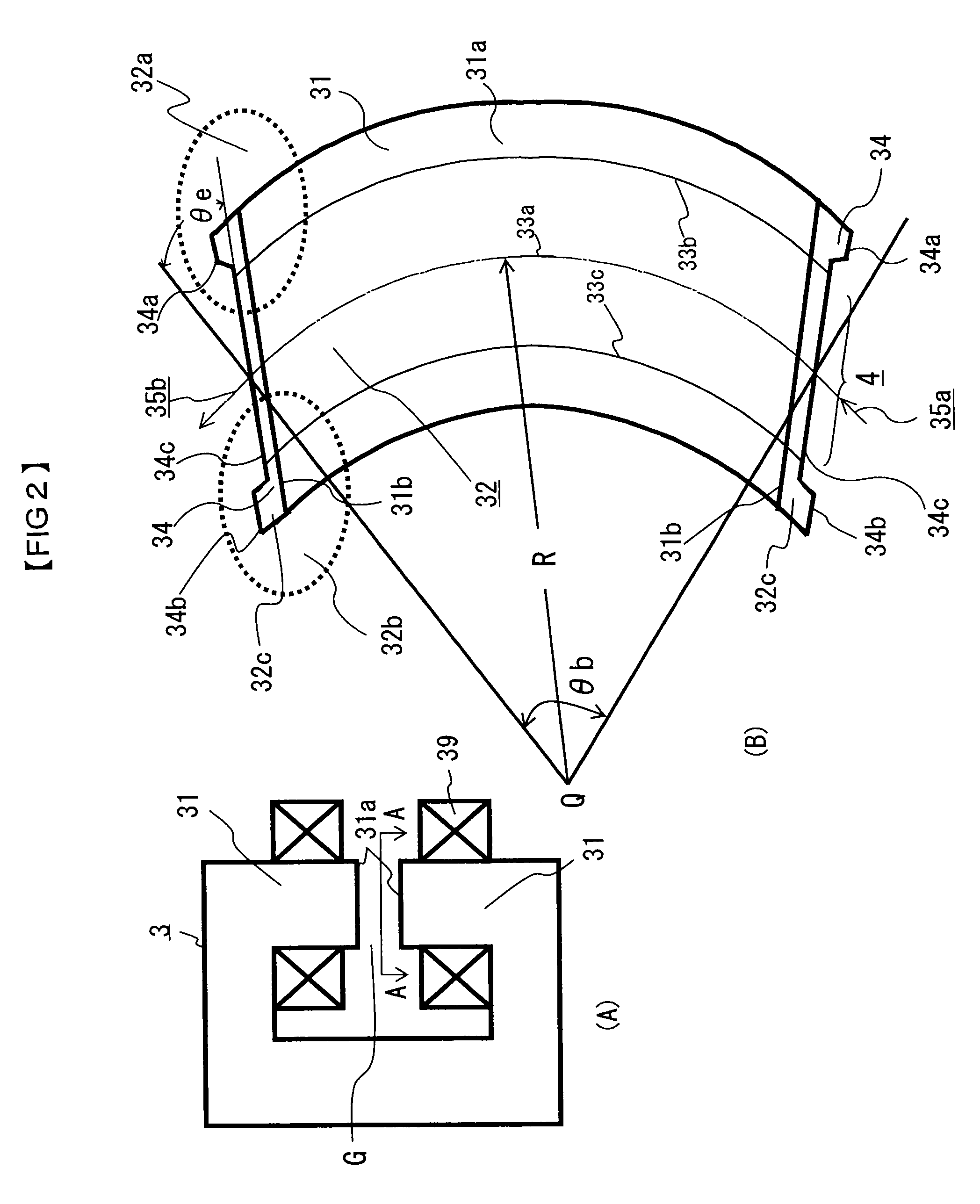

Circular accelerator

InactiveUS7982416B2Easy to controlShorten adjustment timeMagnetic induction acceleratorsTransit-time tubesMagnetic polesLight beam

In a circular accelerator, a magnetic pole edge portion of a bending electromagnet into and from which a charged particle beam enters and exits is provided with endpacks. A first protrusion is provided at that part of each end pack which is radially outside the equilibrium orbit of a center energy beam, while a second protrusion is provided at that part of each end pack which is radially inside the equilibrium orbit of the center energy beam. The shapes of the first and second protrusions are set so that the betatron oscillation numbers of beams of different acceleration energies may be held constant or become linear to the energies. In case of emitting the charged particle beam out of the circular accelerator, the change of a tune attributed to the change of the beam orbit can be statically corrected, the tune is linearly changed, and an adjustment of the emission of the beam becomes easy.

Owner:MITSUBISHI ELECTRIC CORP

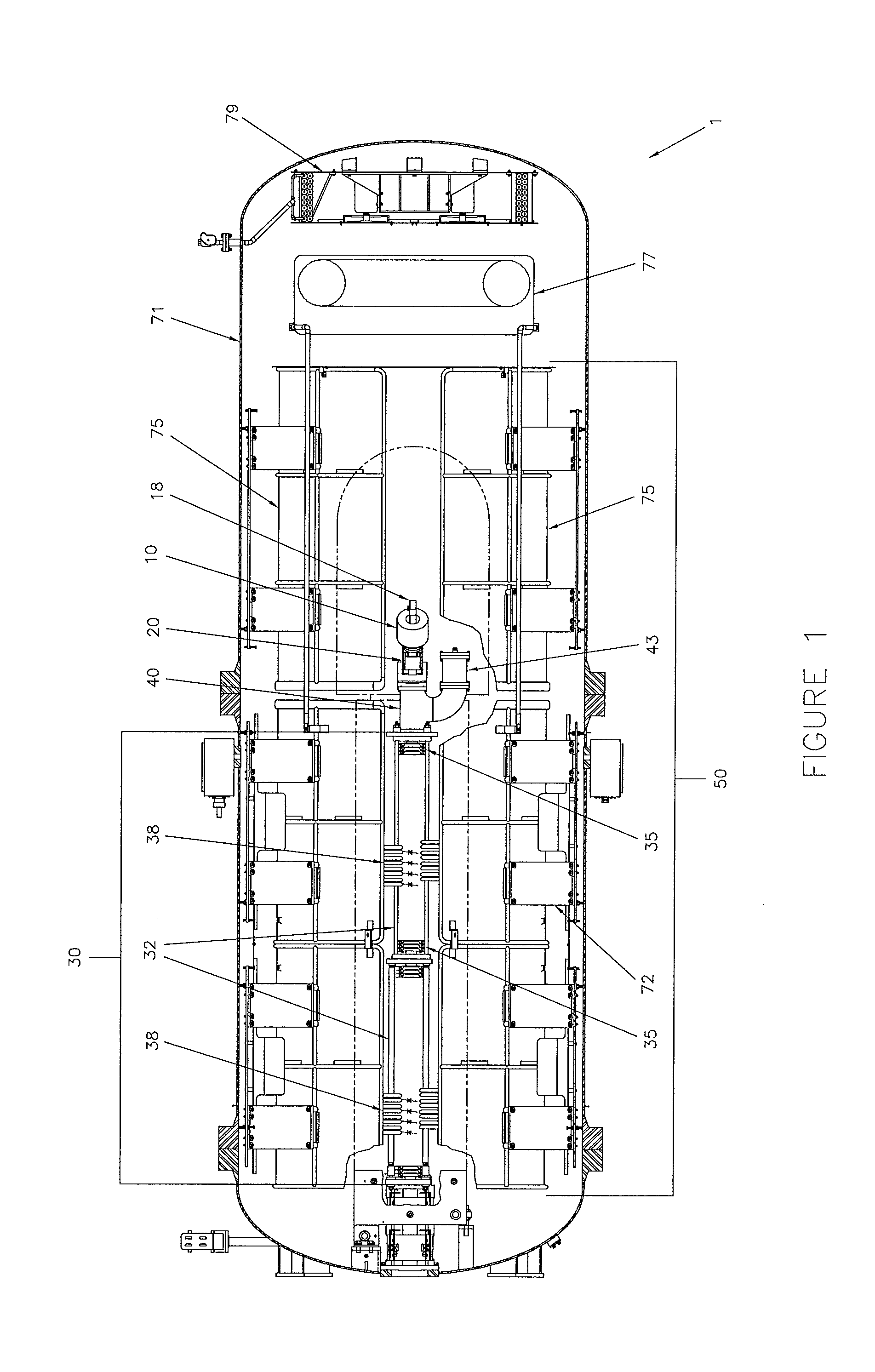

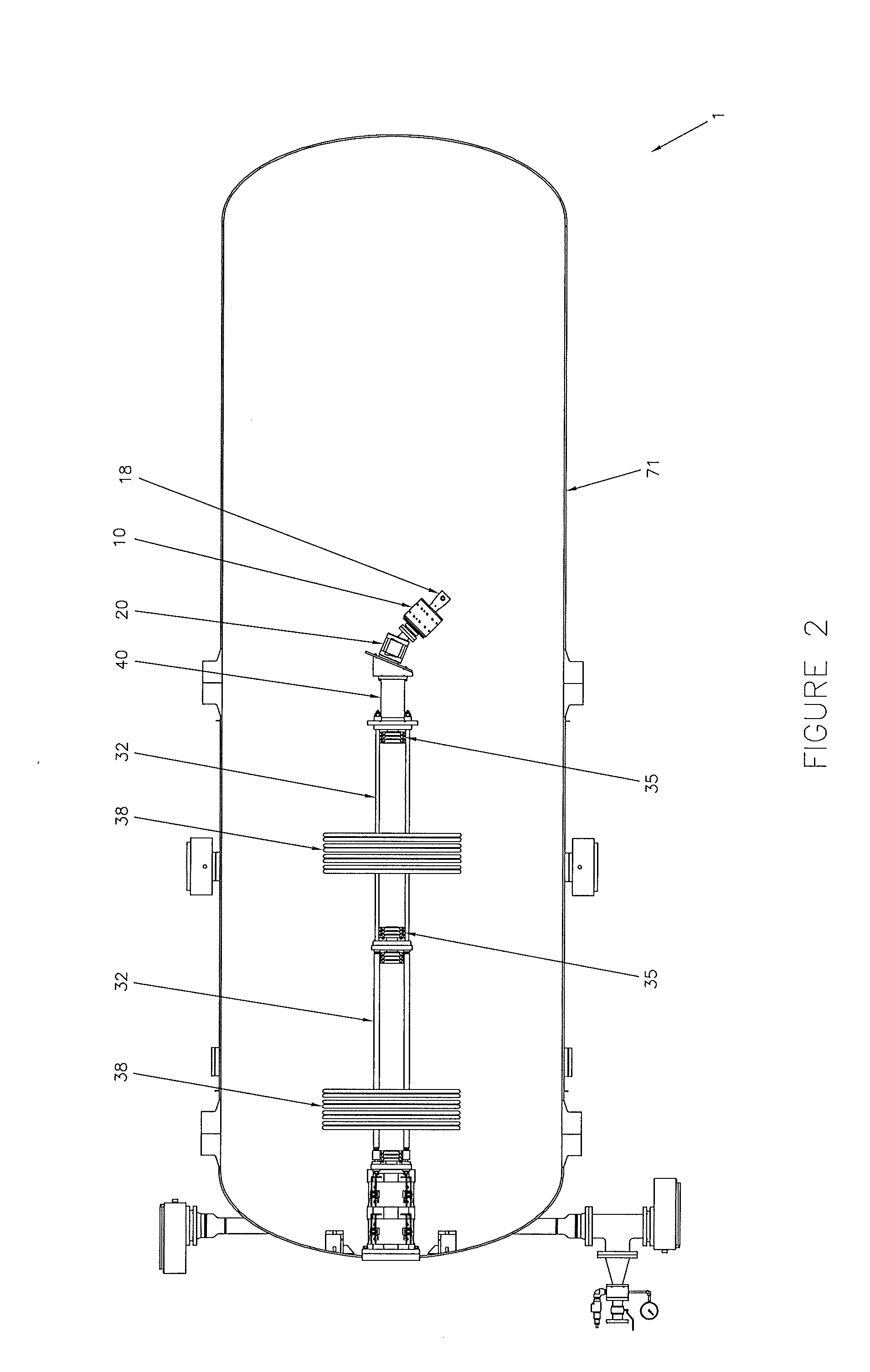

Isotope production system and cyclotron having reduced magnetic stray fields

A cyclotron that includes a magnet yoke that has a yoke body that surrounds an acceleration chamber and a magnet assembly. The magnet assembly is configured to produce magnetic fields to direct charged particles along a desired path. The magnet assembly is located in the acceleration chamber. The magnetic fields propagate through the acceleration chamber and within the magnet yoke. A portion of the magnetic fields escape outside of the magnet yoke as stray fields. The magnet yoke is dimensioned such that the stray fields do not exceed 5 Gauss at a distance of 1 meter from an exterior boundary.

Owner:GENERAL ELECTRIC CO

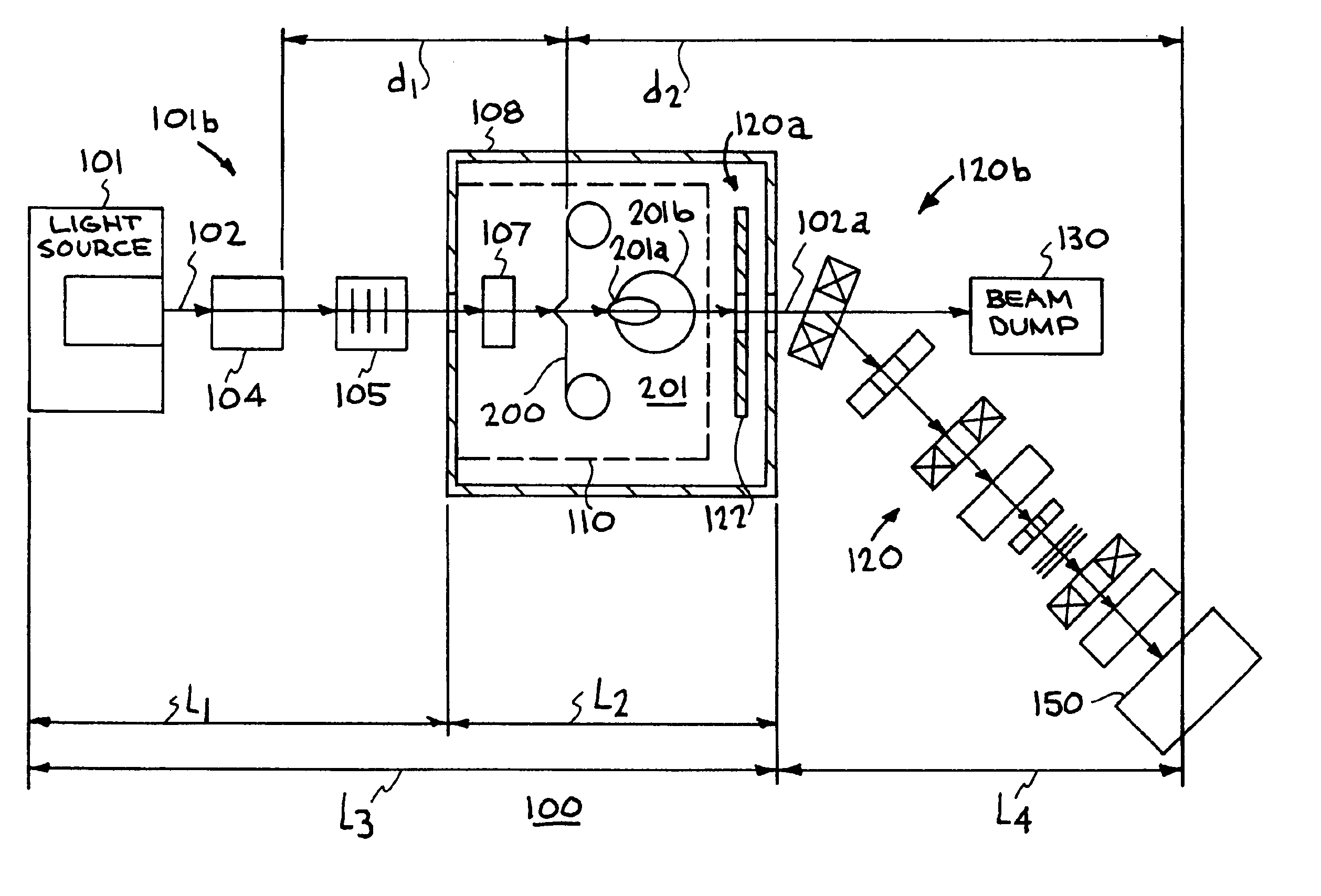

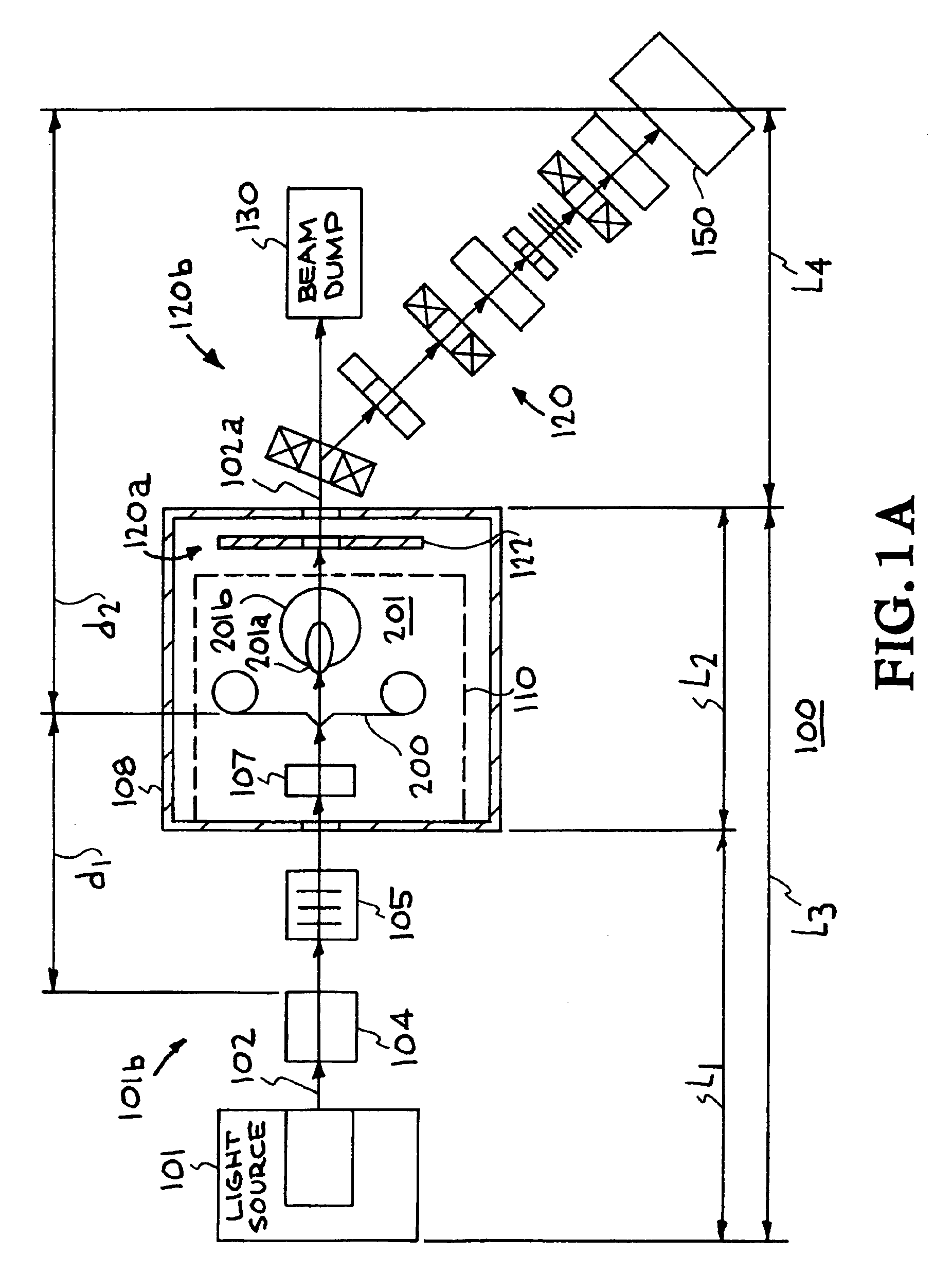

Laser driven ion accelerator

InactiveUS6906338B2Thermometer detailsStability-of-path spectrometersIon accelerationIon accelerators

A system and method of accelerating ions in an accelerator to optimize the energy produced by a light source. Several parameters may be controlled in constructing a target used in the accelerator system to adjust performance of the accelerator system. These parameters include the material, thickness, geometry and surface of the target.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

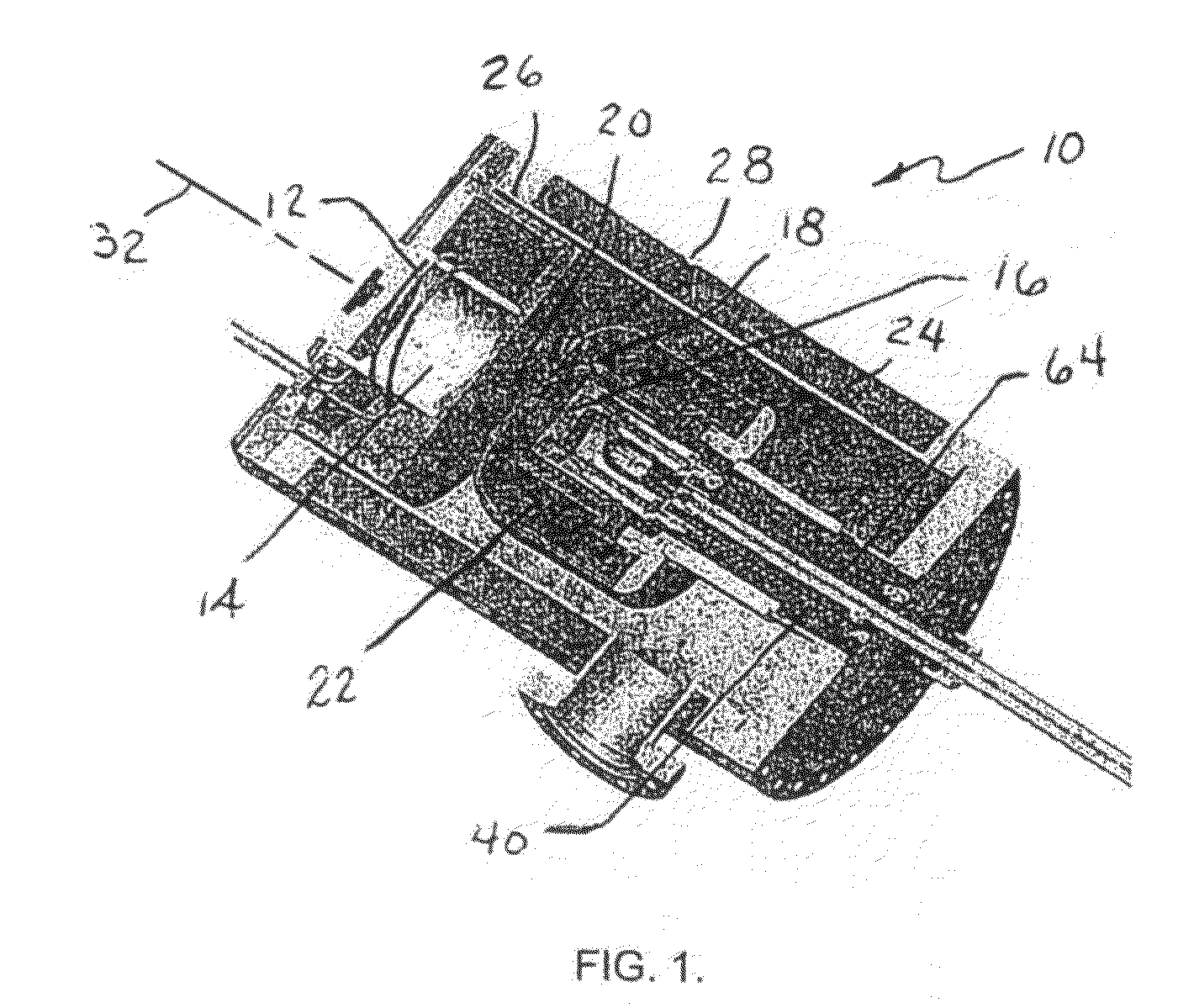

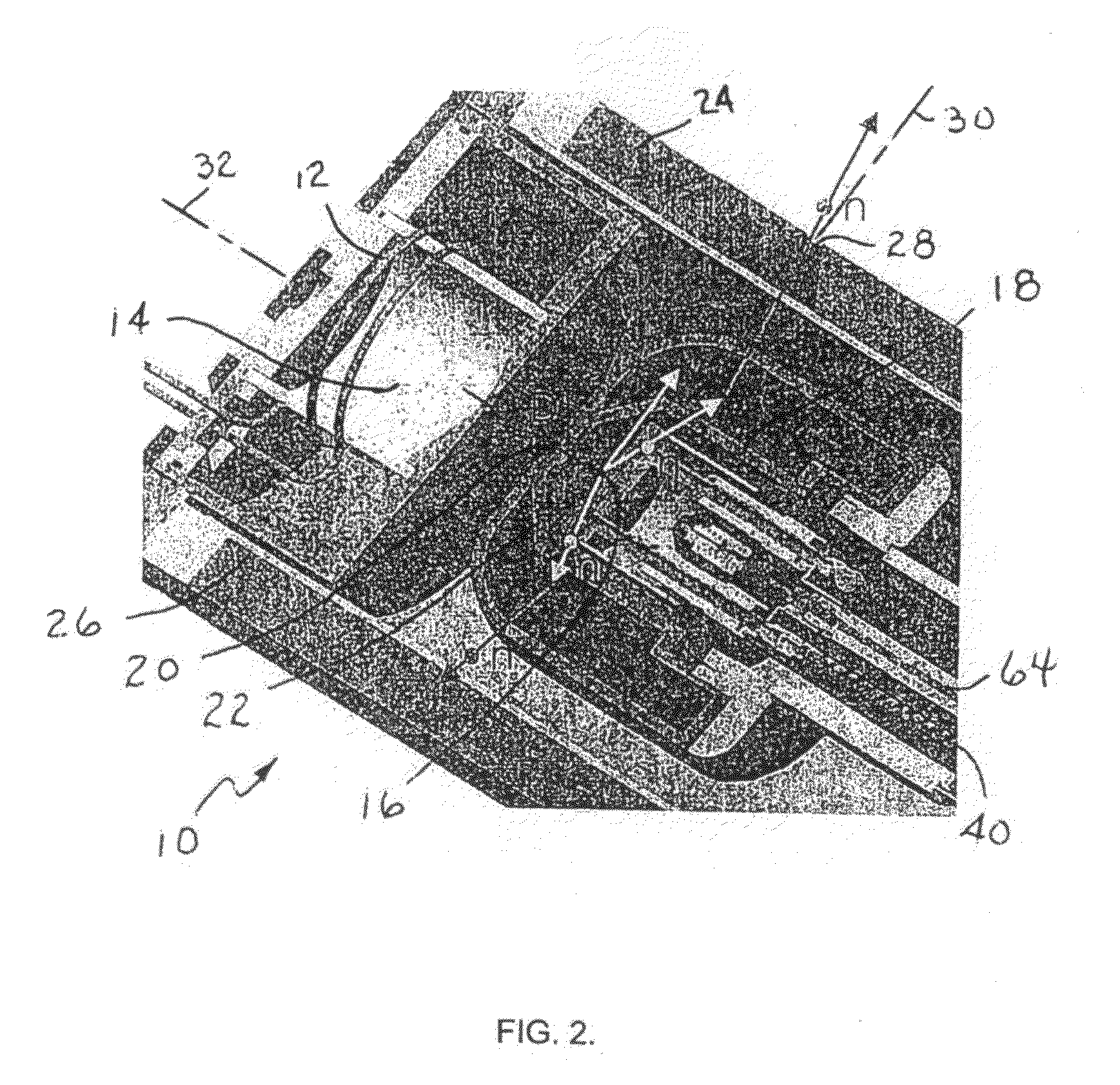

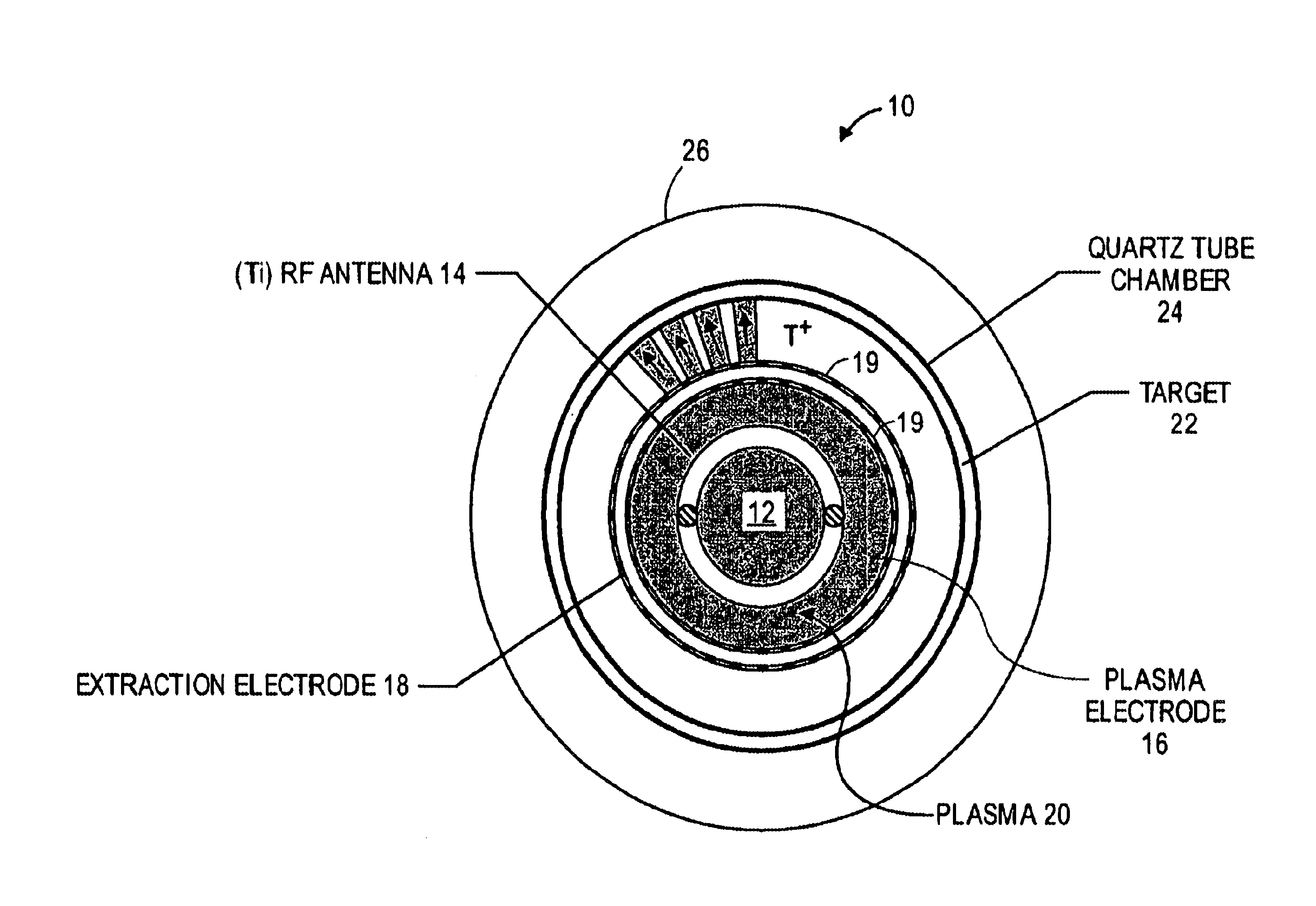

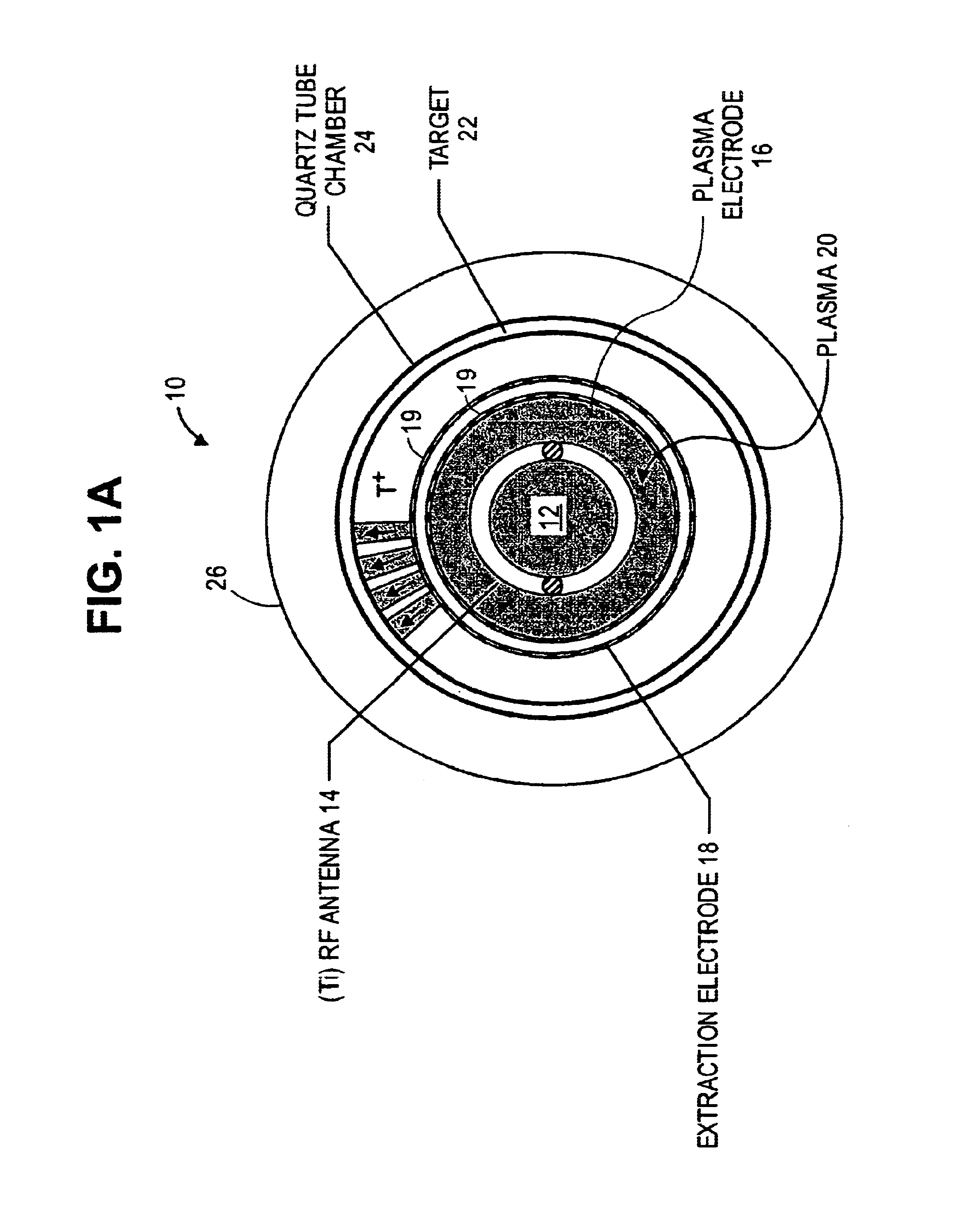

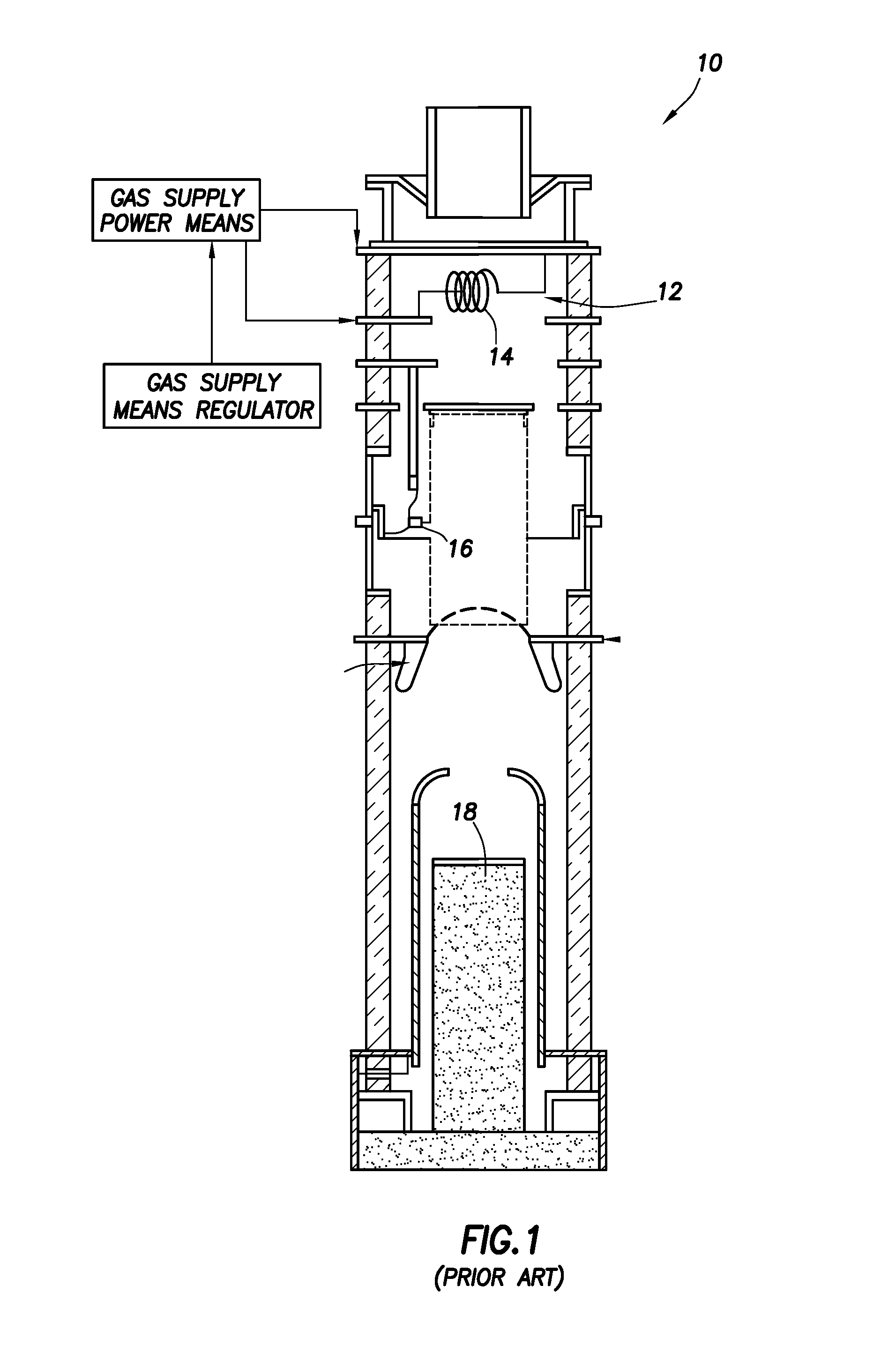

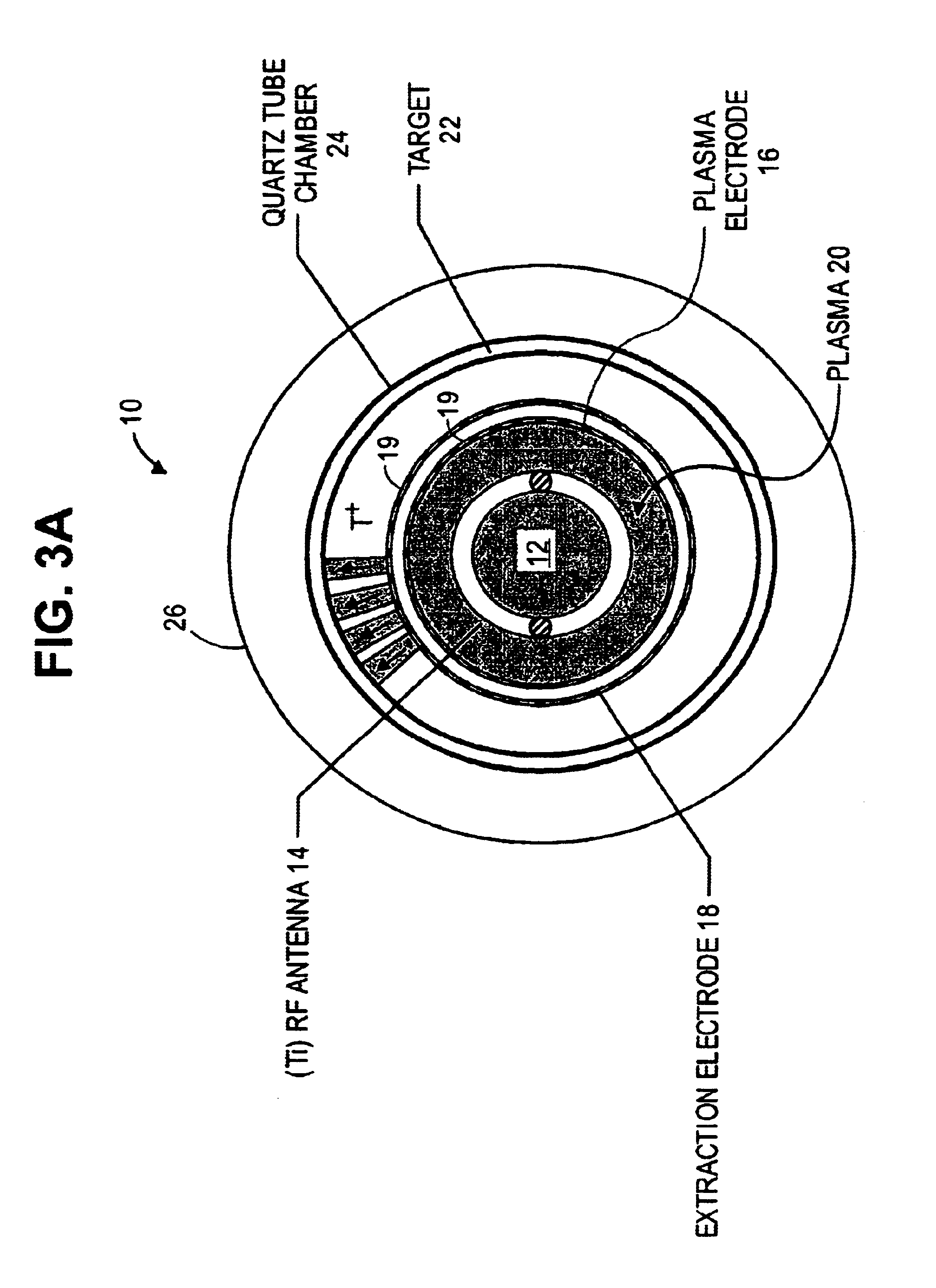

Cylindrical neutron generator

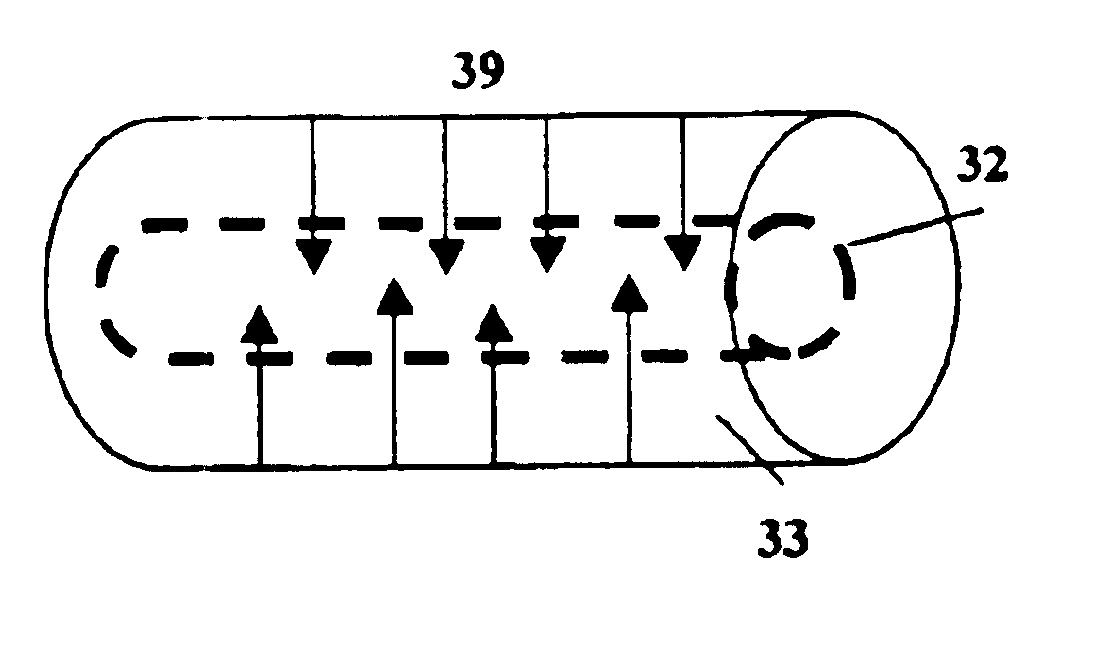

InactiveUS6907097B2Increase neutron fluxHigh densityConversion outside reactor/acceleratorsNuclear energy generationPlasma generatorNeutron flux

A cylindrical neutron generator is formed with a coaxial RF-driven plasma ion source and target. A deuterium (or deuterium and tritium) plasma is produced by RF excitation in a cylindrical plasma ion generator using an RF antenna. A cylindrical neutron generating target is coaxial with the ion generator, separated by plasma and extraction electrodes which contain many slots. The plasma generator emanates ions radially over 360° and the cylindrical target is thus irradiated by ions over its entire circumference. The plasma generator and target may be as long as desired. The plasma generator may be in the center and the neutron target on the outside, or the plasma generator may be on the outside and the target on the inside. In a nested configuration, several concentric targets and plasma generating regions are nested to increase the neutron flux.

Owner:RGT UNIV OF CALIFORNIA

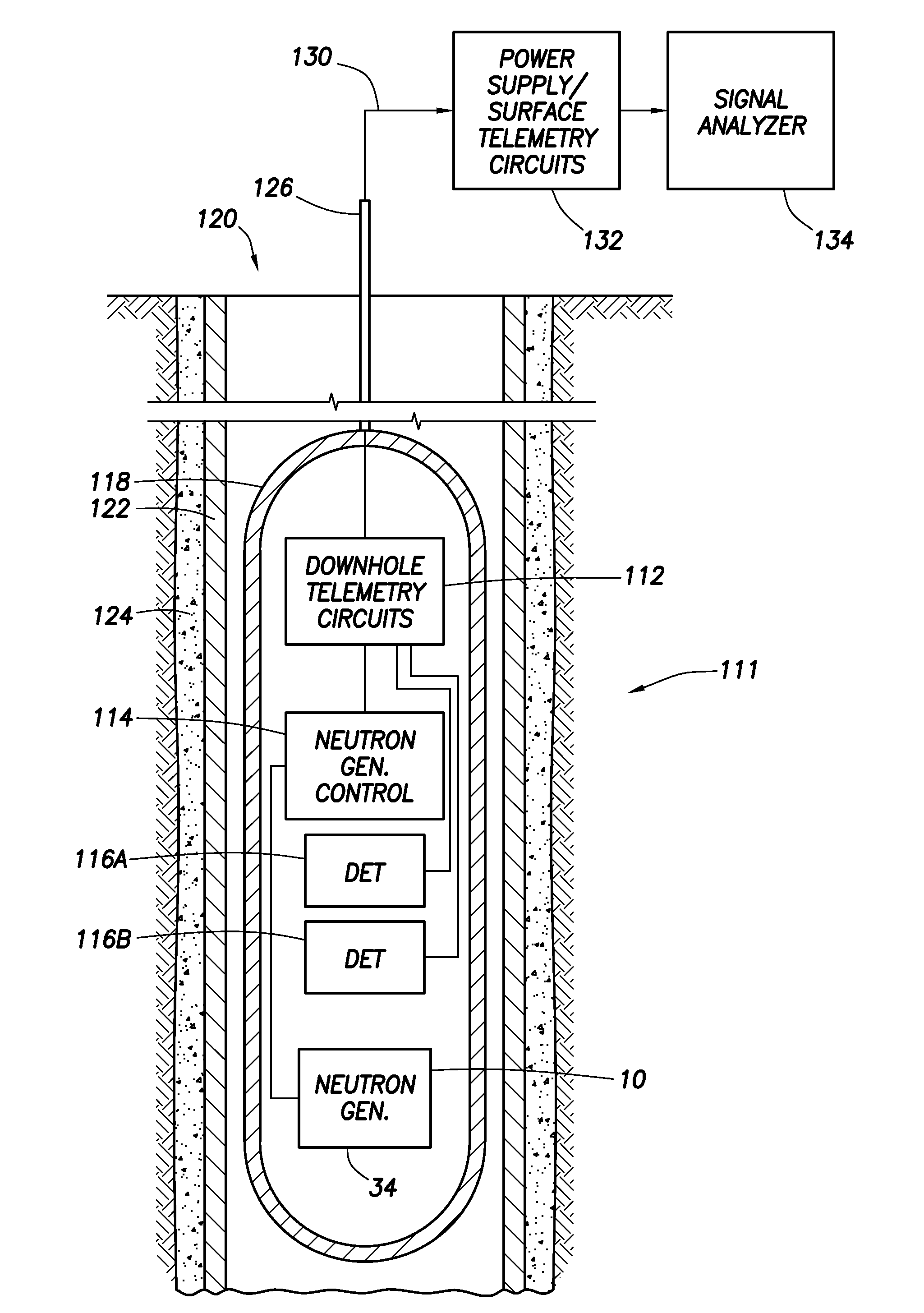

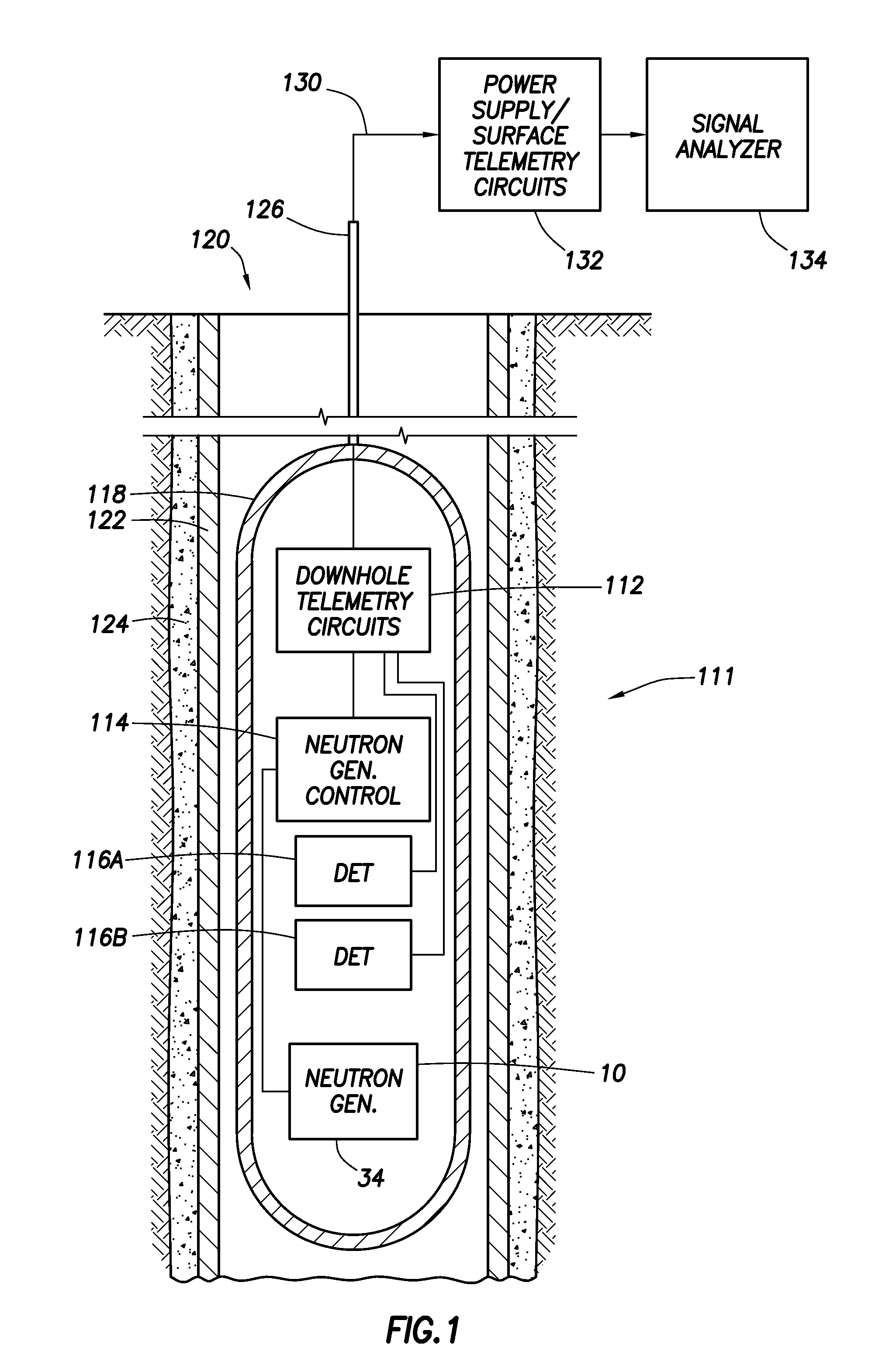

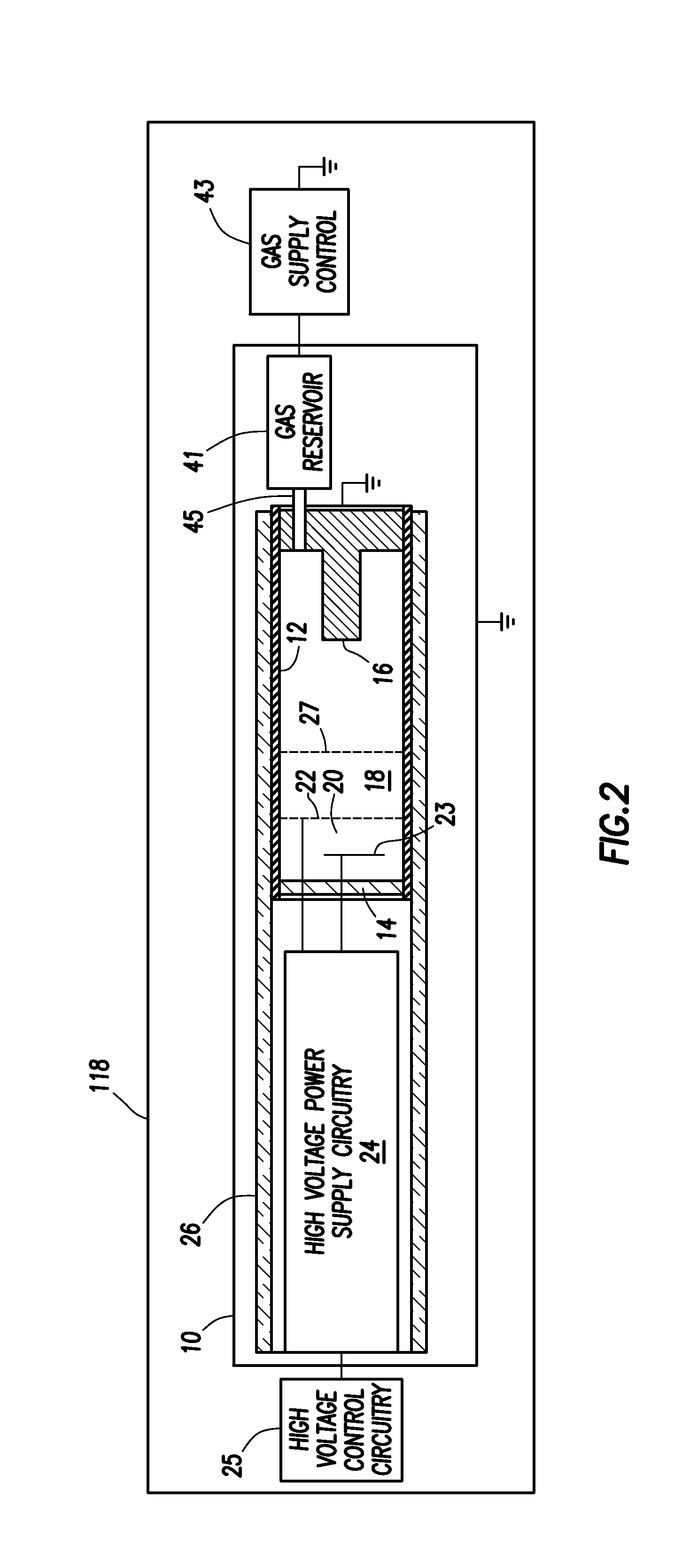

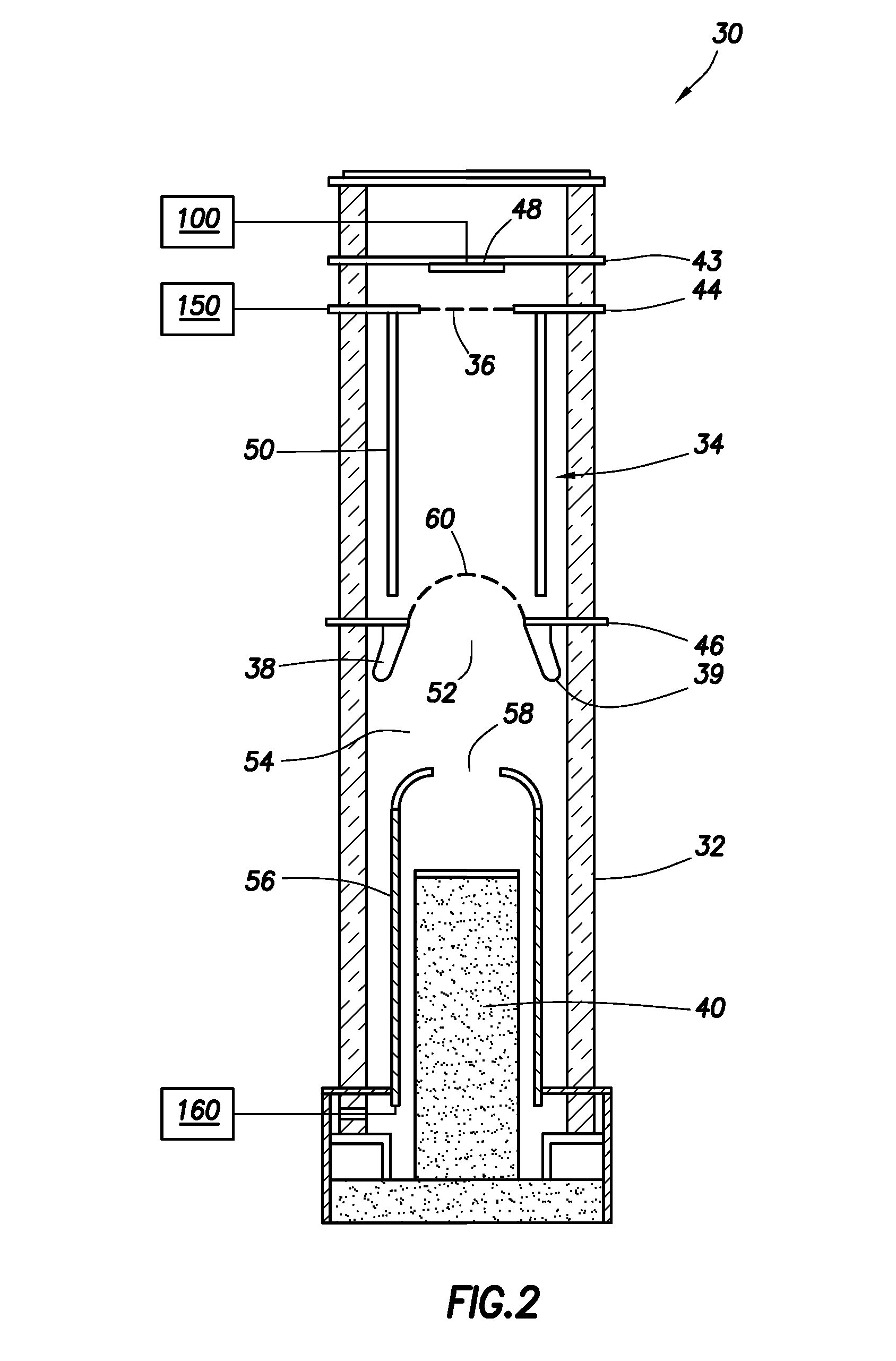

Neutron generator

ActiveUS20110180698A1Poor thermal conductionImprove cooling effectNuclear energy generationDirect voltage acceleratorsLow voltageHigh pressure

A neutron generator includes a sealed envelope providing a low pressure environment for a gas. One end of the envelope defines an ion source chamber. A target electrode is disposed at the other end of the envelope. An extracting electrode is spaced apart from the target electrode by an accelerating gap. The extracting electrode bounds the ion source chamber. A dispenser cathode electrode and grid electrode are disposed in the ion source chamber for inducing ionization in the ion source chamber. The dispenser cathode electrode, the grid electrode and the extracting electrode operate at a positive high voltage potential and the target electrode operates at or near ground potential. This configuration provides an electric field gradient that accelerates ions towards the target electrode to induce collisions of ions with target material, thereby causing fusion reactions that generate neutrons. High voltage power supply circuit means supplies a positive high voltage signal to the electrodes of the ion source. The positive high voltage signal has a low voltage signal component floating on a positive high voltage signal component. For the dispensing cathode electrode, the low voltage signal component can be a DC or AC signal suitable for emitting electrons from the dispensing cathode electrode. For the grid electrode, the low voltage signal component can be a positive pulsed-mode signal (preferably with magnitude in the range between 100 to 300 volts). High voltage insulation surrounds and electrically insulates the high voltage power supply circuit means. Other ion source electrode configurations, such as cold cathode (Penning) ion source and RF-driven ion source, can also be used.

Owner:SCHLUMBERGER TECH CORP

Low Power Neutron Generators

A neutron generator and method of constructing the same. The generator includes a grid configured to produce an ionizable gas when heated by electrons impinging thereon. A cathode emits electrons to heat the grid and to collide with produced ionizable gas atoms to generate ions. Neutrons are generated from a collision of ions impinging on a target in the generator. A tool for subsurface use incorporating the neutron generator.

Owner:SCHLUMBERGER TECH CORP

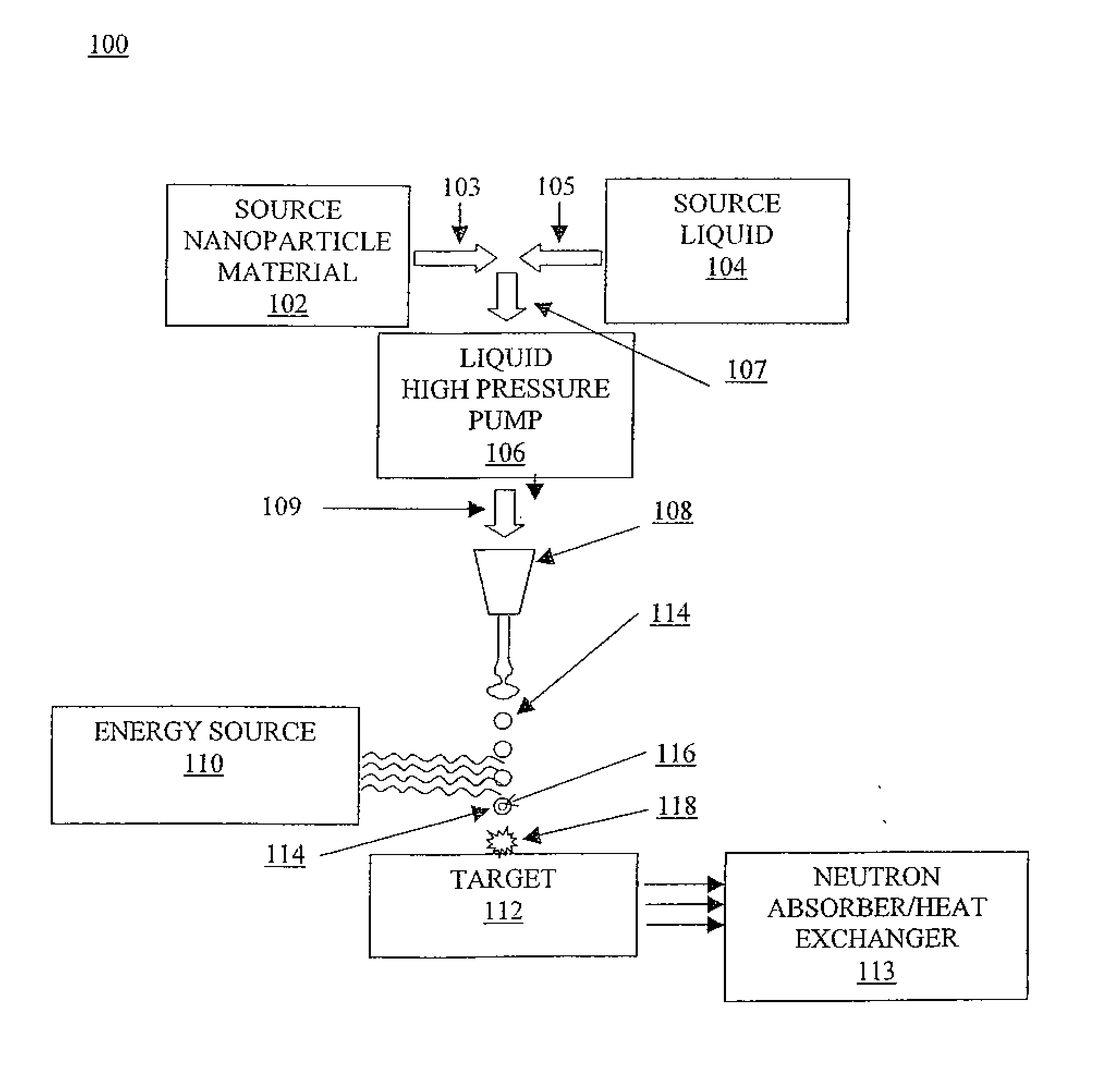

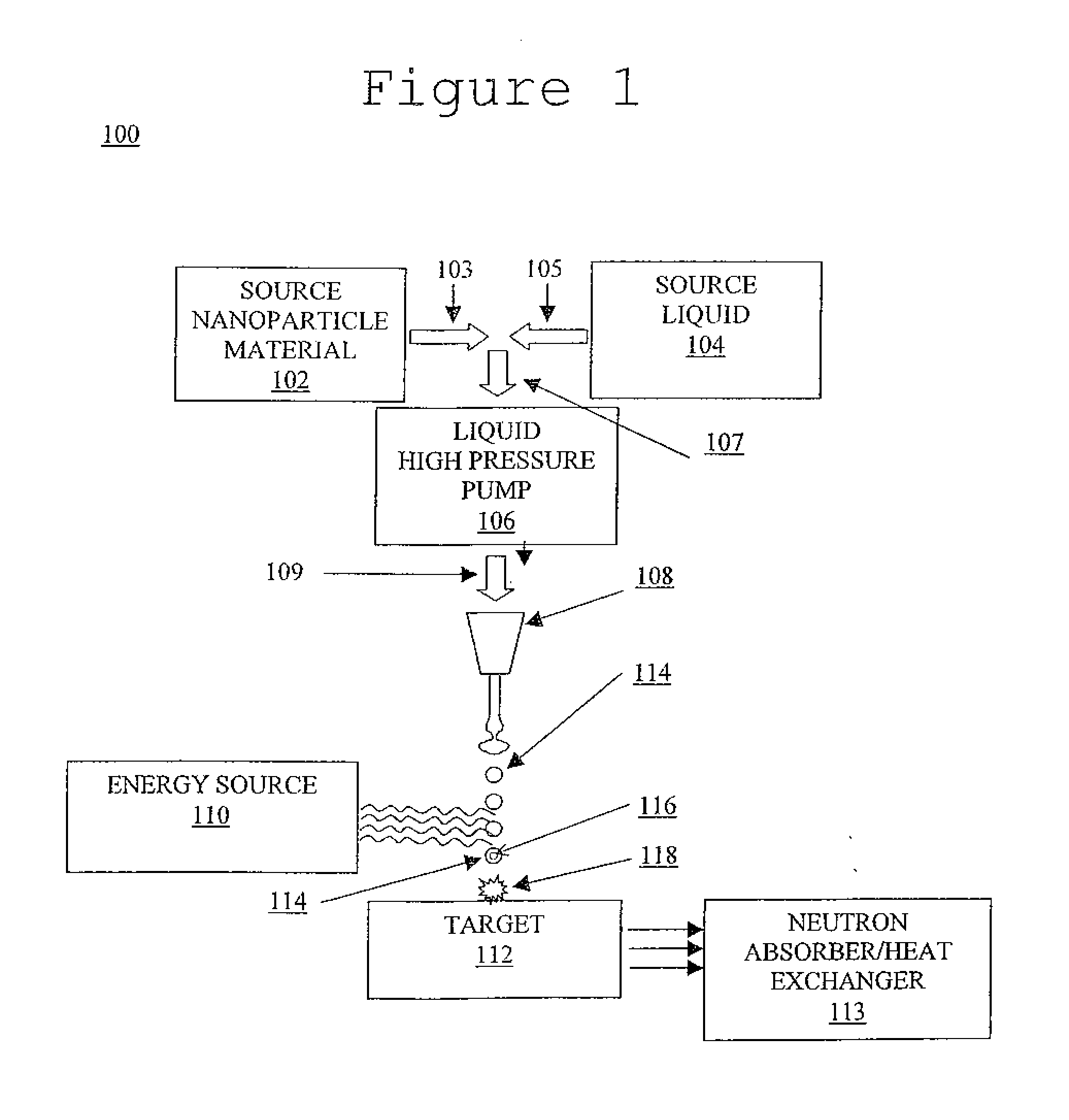

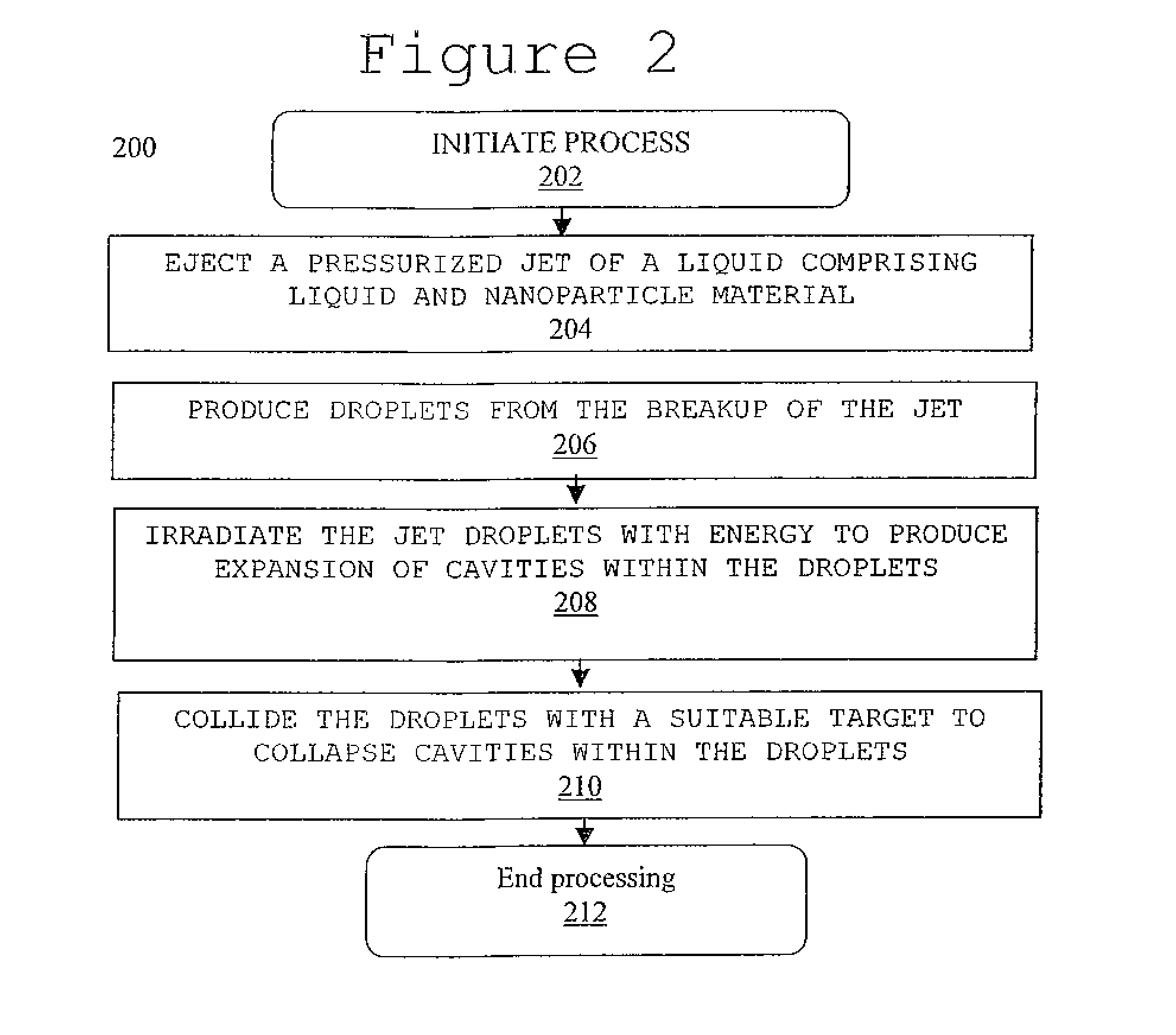

System and method for creating liquid droplet impact forced collapse of laser nanoparticle nucleated cavities

InactiveUS20110228890A1Promote crashEnhance implosion energyNuclear energy generationDirect voltage acceleratorsNanoparticleBreakup

A device, method and system for causing a controlled collapse of cavities formed within liquid droplets wherein a pressurized jet comprising a liquid and nanoparticle material produces droplets from the breakup of the jet stream. The liquid droplets may be irradiated with energy to produce and expand cavities formed within the droplets by irradiation of the nanoparticles contained within the droplets or alternatively, a volatile fluid with or without a metal nanoparticle may form the cavity. The droplets are collided with a target to collapse the cavities within the droplets. The irradiating (if provided) and colliding are timed to enhance implosion energy resulting from the cavities' collapse. The implosion energy and the fuel in the cavity may be used to activate and sustain a fusion reaction or from any other purposes.

Owner:SYNERGY INNOVATIONS INC

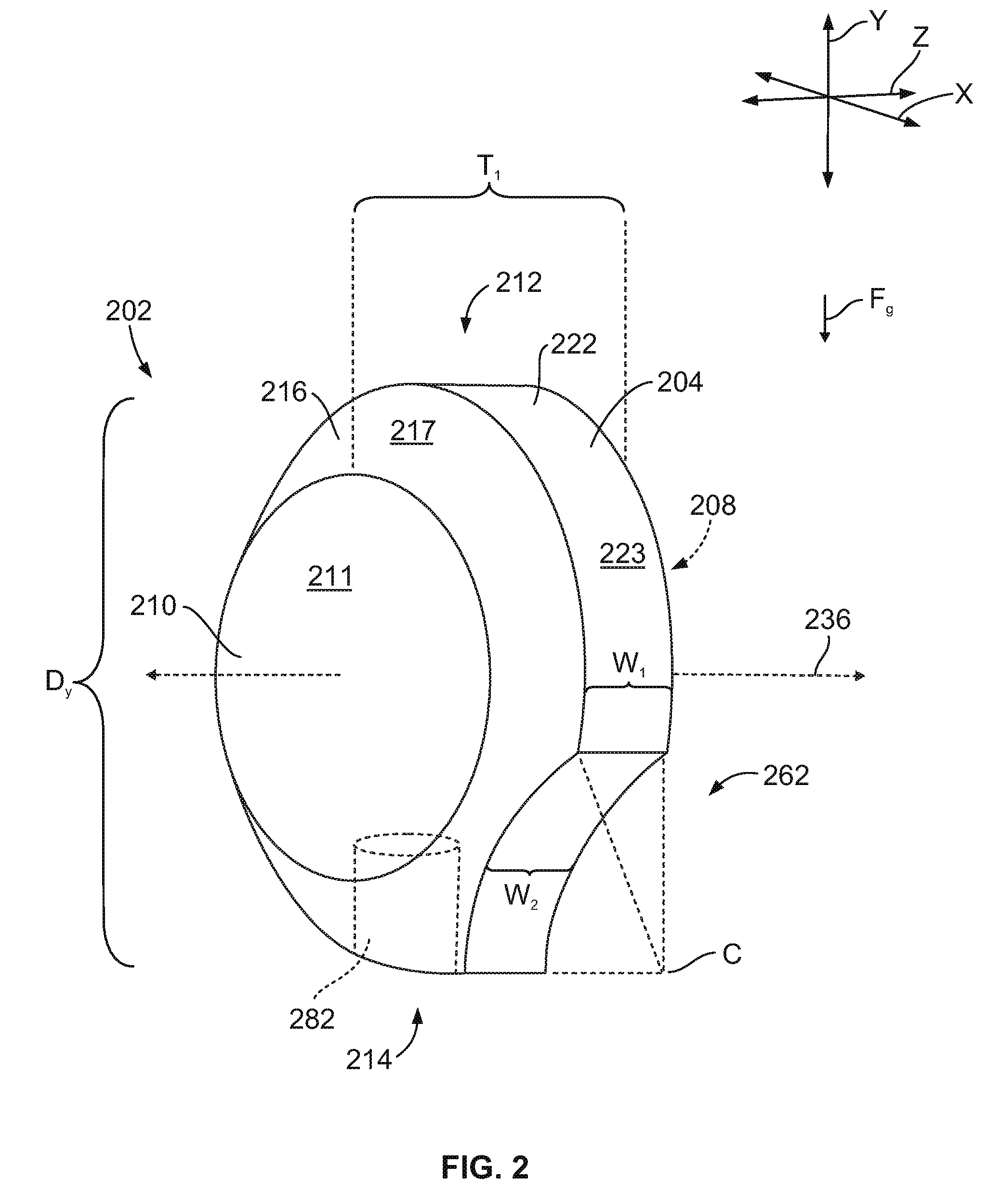

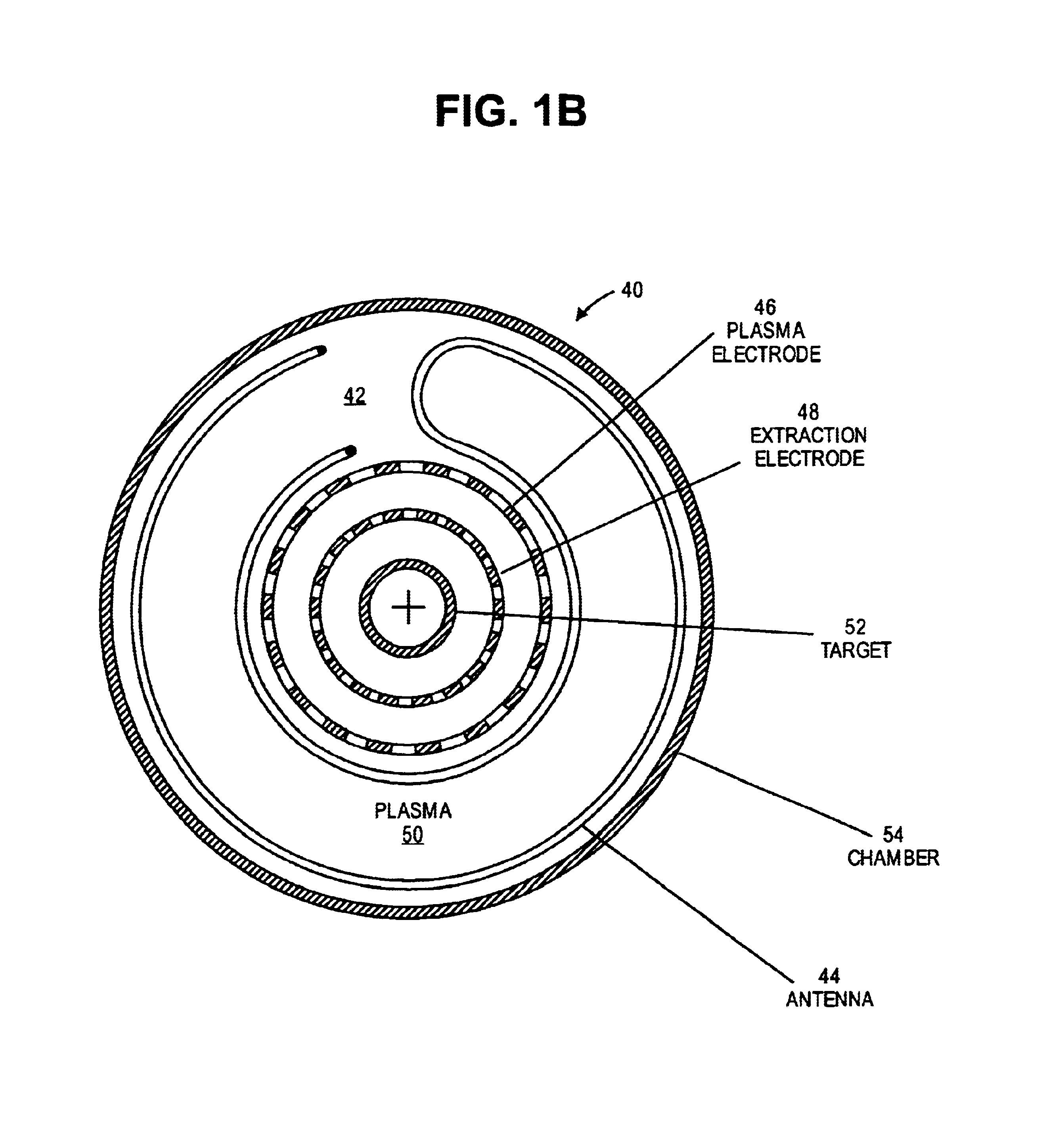

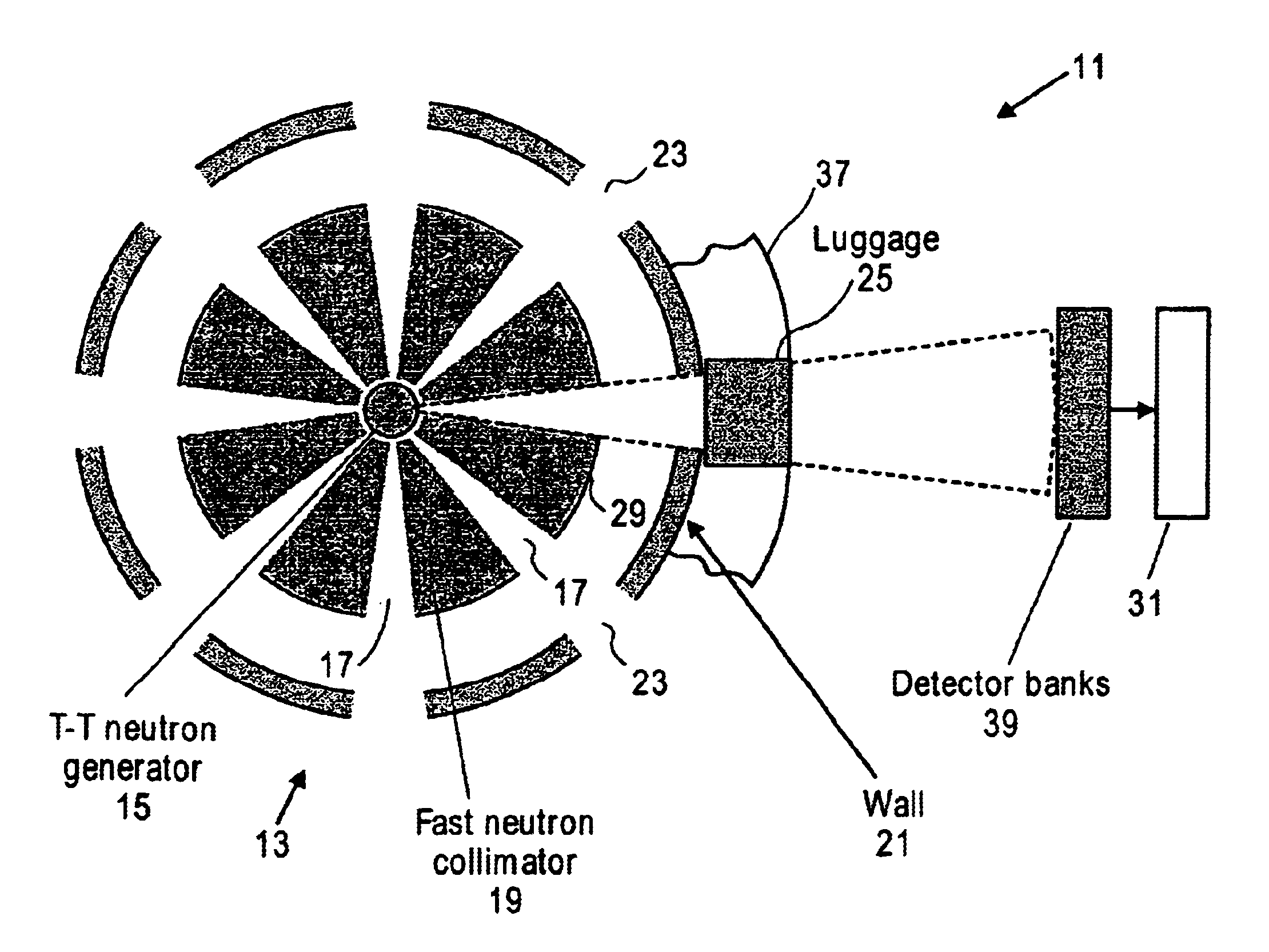

Compact neutron generator

InactiveUS6870894B2Reasonable levelMaterial analysis using wave/particle radiationConversion outside reactor/acceleratorsTarget surfaceTitanium

A compact neutron generator has at its outer circumference a toroidal shaped plasma chamber in which a tritium (or other) plasma is generated. A RF antenna is wrapped around the plasma chamber. A plurality of tritium ion beamlets are extracted through spaced extraction apertures of a plasma electrode on the inner surface of the toroidal plasma chamber and directed inwardly toward the center of neutron generator. The beamlets pass through spaced acceleration and focusing electrodes to a neutron generating target at the center of neutron generator. The target is typically made of titanium tubing. Water is flowed through the tubing for cooling. The beam can be pulsed rapidly to achieve ultrashort neutron bursts. The target may be moved rapidly up and down so that the average power deposited on the surface of the target may be kept at a reasonable level. The neutron generator can produce fast neutrons from a T-T reaction which can be used for luggage and cargo interrogation applications. A luggage or cargo inspection system has a pulsed T-T neutron generator or source at the center, surrounded by associated gamma detectors and other components for identifying explosives or other contraband.

Owner:RGT UNIV OF CALIFORNIA

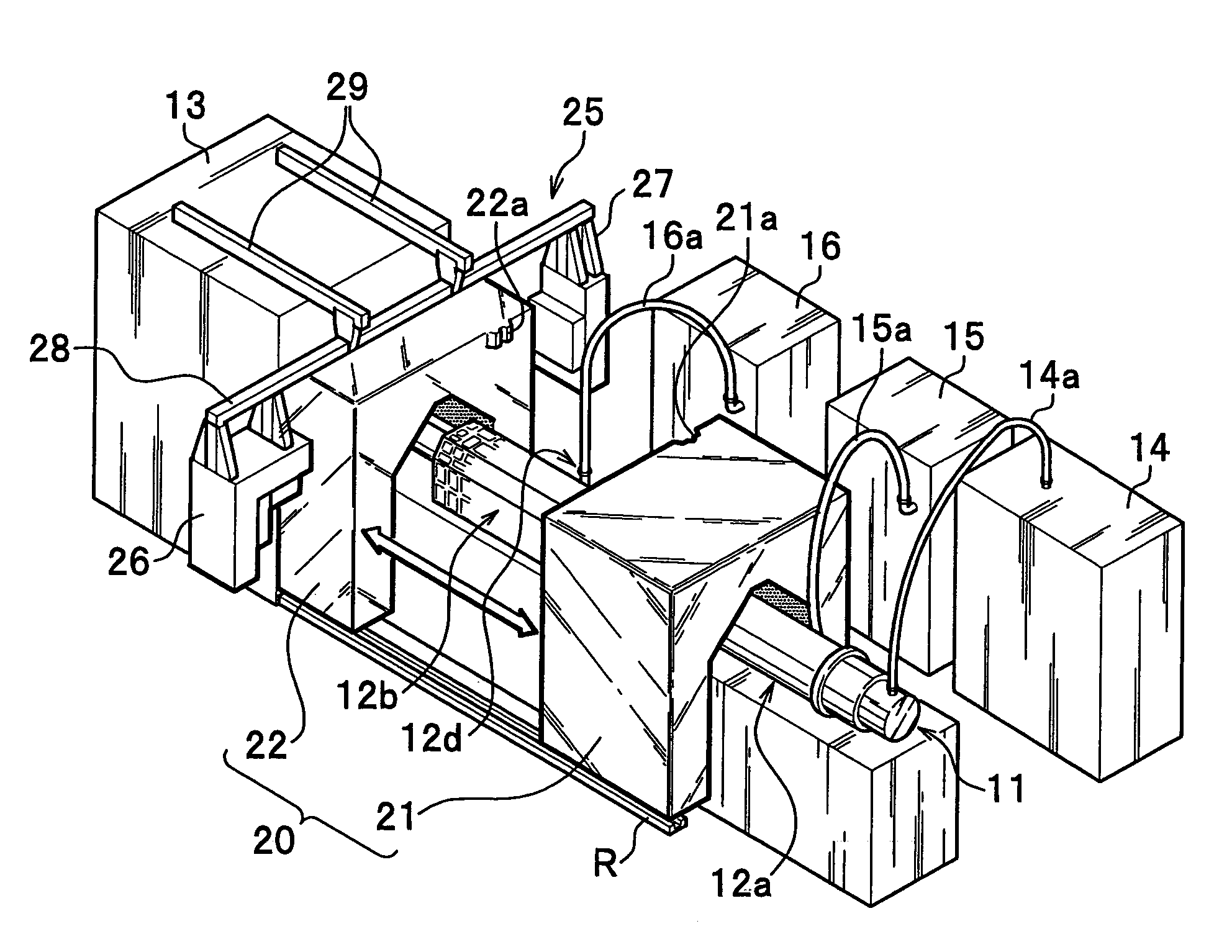

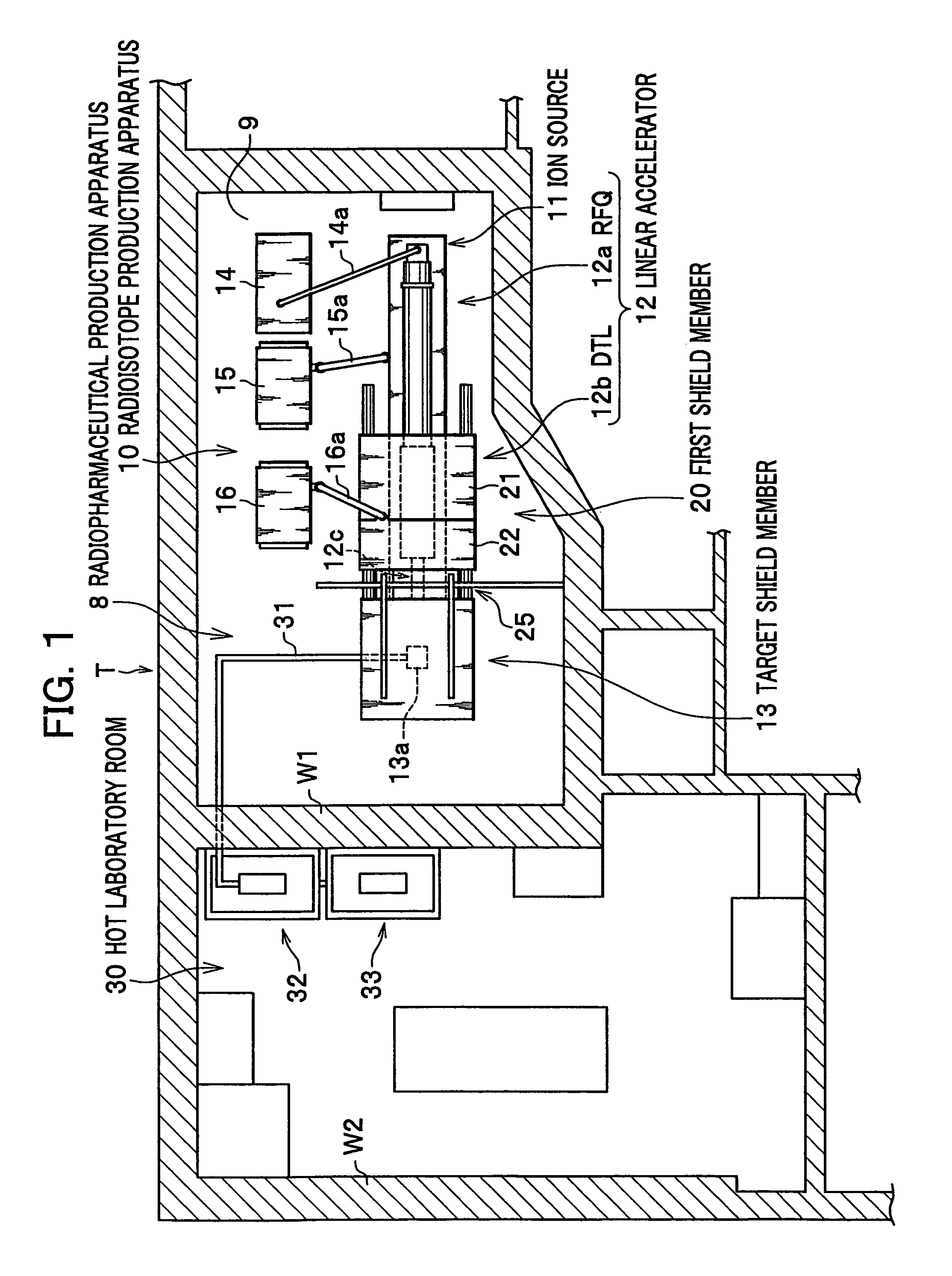

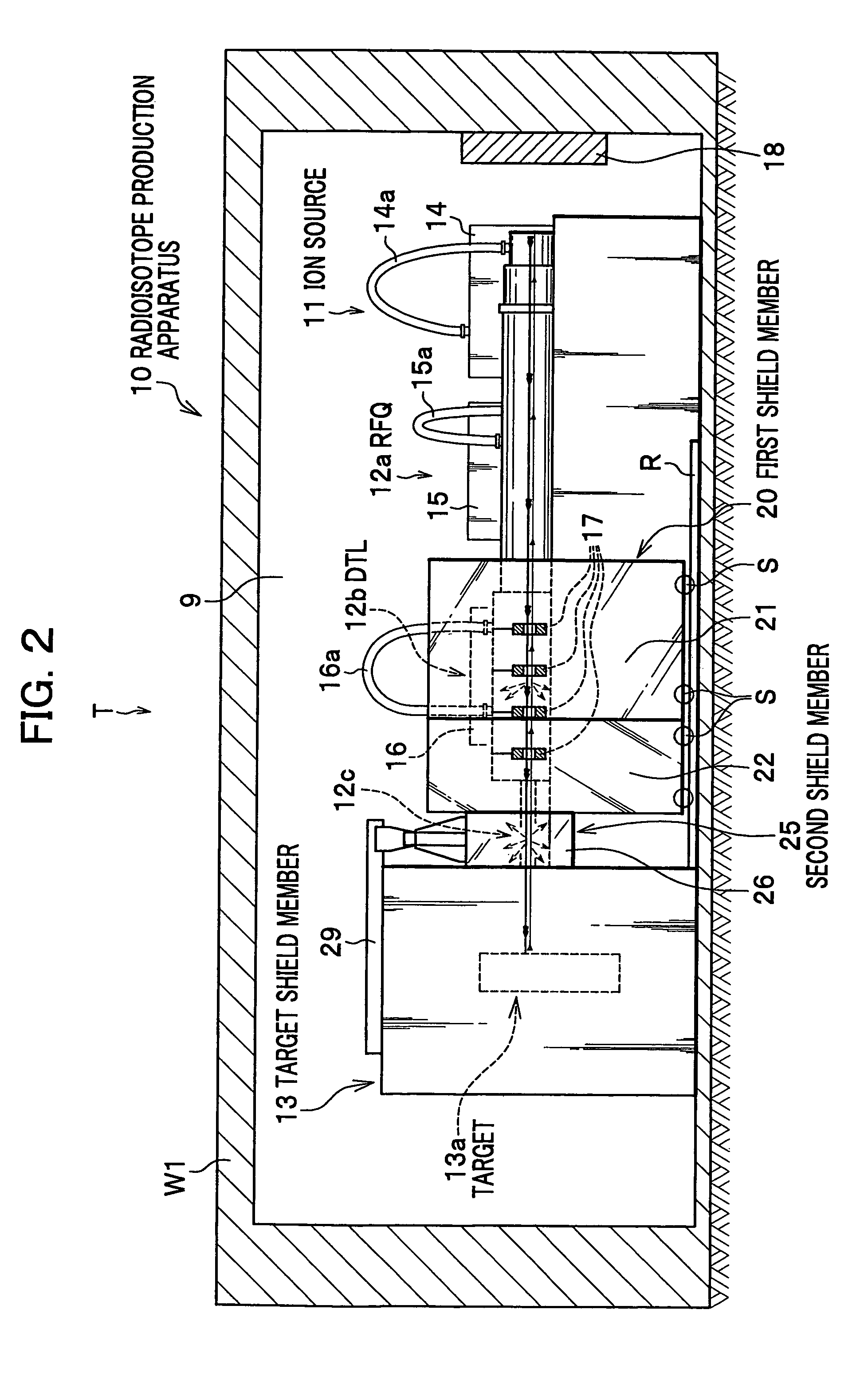

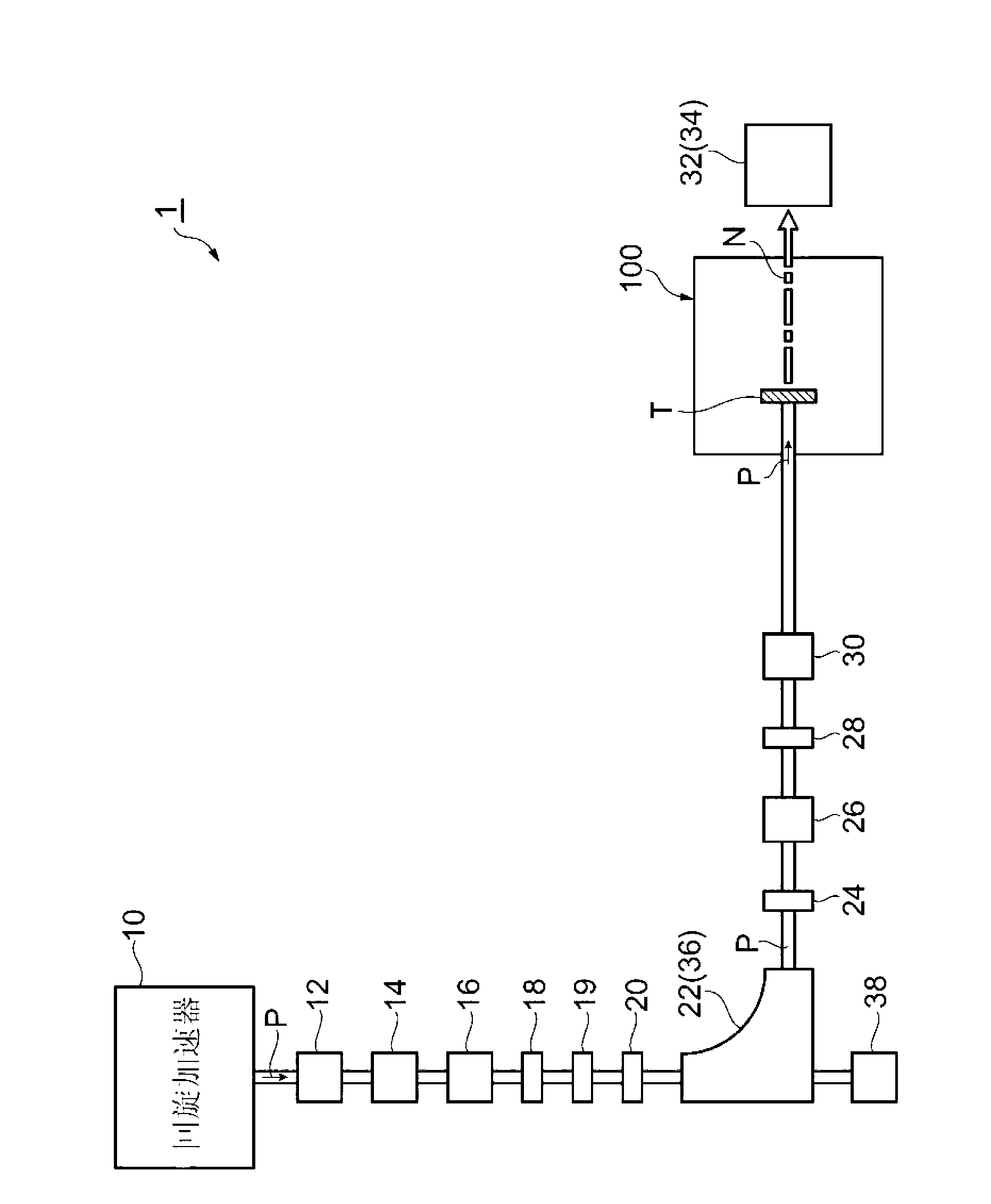

Radioisotope production apparatus and radiopharmaceutical production apparatus

InactiveUS7394081B2Reduce construction costsImprove abilitiesLaser detailsConversion outside reactor/acceleratorsEngineeringRadio frequency

A radioisotope production apparatus includes: a linear accelerator for accelerating an ion beam and irradiating a target with the ion beam, radio frequency power supplies for supplying radio frequency waves through coaxial tubes and the linear accelerator, a target shield member containing the target, a first radiation shield member covering the linear accelerator, and a movable second radiation shield member covering the side of target shield member of the linear accelerator between the first radiation shield member and the target shield member. The first radiation shield member is movably divided in opposite directions, respectively, of the axial direction of the linear accelerator from the base point of the connection point of the coaxial tube connected to the linear accelerator.

Owner:HITACHI LTD

High power high yield target for production of all radioisotopes for positron emission tomography

InactiveUS6917044B2Avoid low densityConversion outside reactor/acceleratorsNuclear monitoringInstabilityAir blower

A high power high yield target for the positron emission tomography applications is introduced. For production of Curie level of Fluorine-18 isotope from a beam of proton it uses about one tenth of Oxygen-18 water compared to a conventional water target. The target is also configured to be used for production of all other radioisotopes that are used for positron emission tomography. When the target functions as a water target the material sample being oxygen-18 or oxygen-16 water is heated to steam prior to irradiation using heating elements that are housed in the target body. The material sample is kept in steam phase during the irradiation and cooled to liquid phase after irradiation. To keep the material sample in steam phase a microprocessor monitoring the target temperature manipulates the flow of coolant in the cooling section that is attached to the target and the status of the heaters and air blowers mounted adjacent to the target. When the target functions as a gas target the generated heat from the beam is removed from the target by air blowers and the cooling section. The rupture point of the target window is increased by a factor of two or higher by one thin wire or two parallel thin wires welded at the end of a small hollow tube which is held against the target window. One or two coils are used to produce a magnetic filed along the beam path for preventing the density depression along the beam path and suppression of other instabilities that can develop in a high power target.

Owner:AMINI BEHROUZ

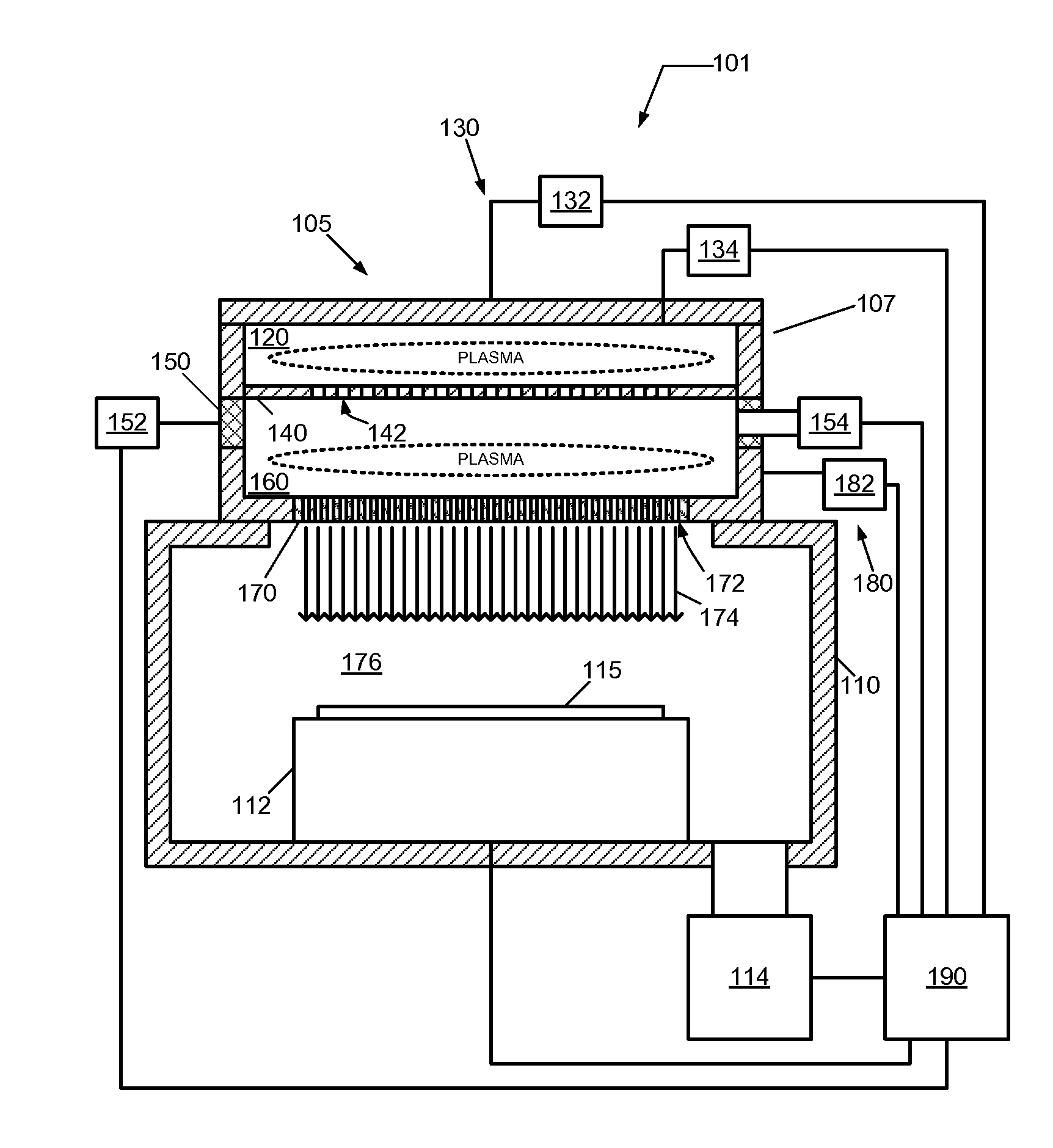

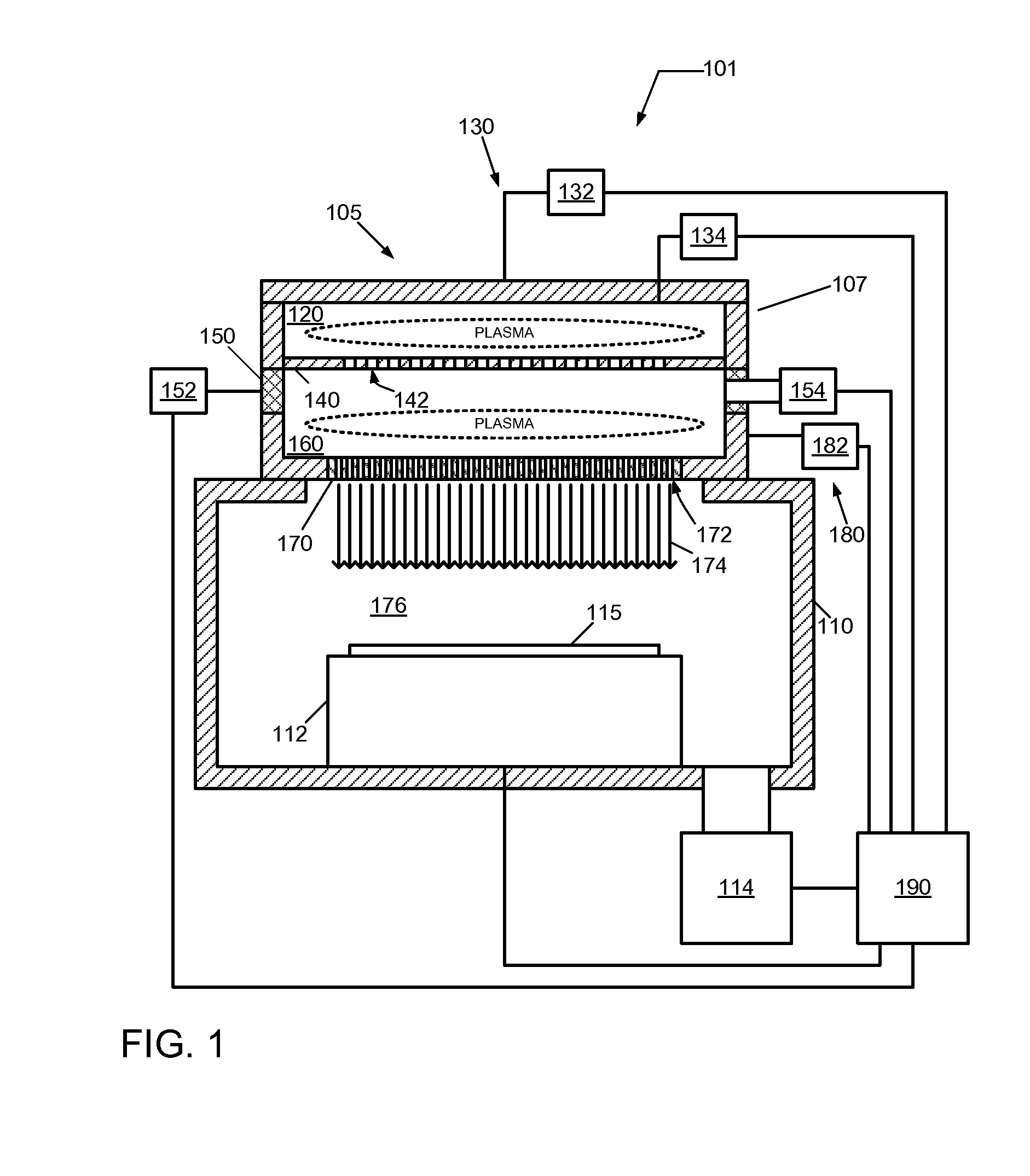

Neutron beam irradiation system

InactiveCN103052425AImprove work efficiencyRadiation/particle handlingMedical devicesNeutron irradiationCharged particle beam

A neutron beam irradiation system that irradiates an irradiation object with a neutron beam includes: a neutron beam generating section that generates a neutron beam by being irradiated with a charged particle beam; a housing section that includes at least a moderator and that houses the neutron beam generating section; a neutron beam converging section that converges the neutron beam with which the irradiation object is irradiated; a mounting stage on which the irradiation object is mounted; and a relative movement means that relatively moves the mounting stage closer to and away from the neutron beam generating section, the housing section, and the neutron beam converging section.

Owner:SUMITOMO HEAVY IND LTD

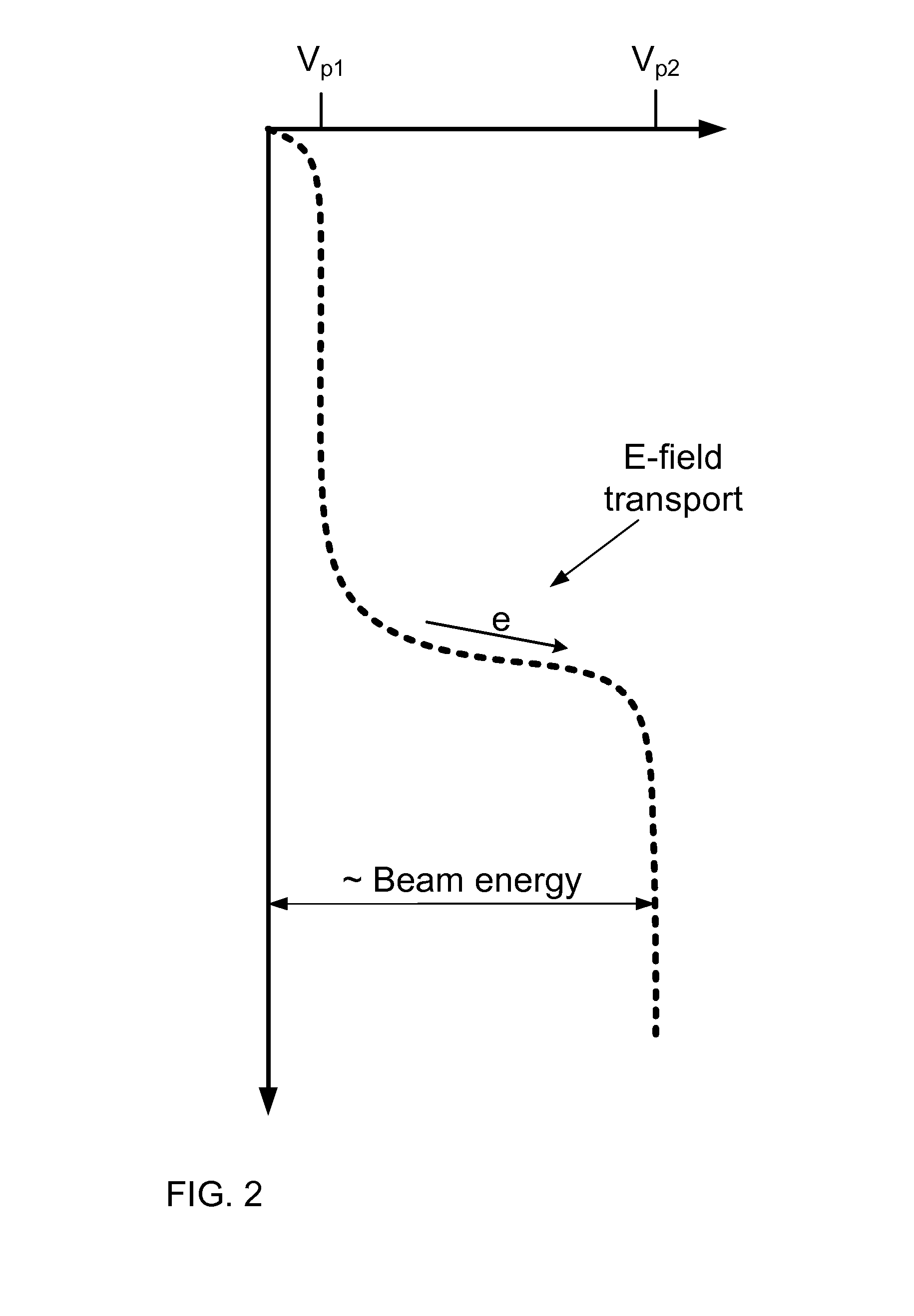

Multi-plasma neutral beam source and method of operating

Method and system for producing a neutral beam source is described. The neutral beam source comprises a plasma generation system for forming a first plasma in a first plasma region, a plasma heating system for heating electrons from the first plasma region in a second plasma region to form a second plasma, and a neutralizer grid for neutralizing ion species from the second plasma in the second plasma region. Furthermore, the neutral beam source comprises an electron acceleration member configured to accelerate the electrons from the first plasma region into the second plasma region. Further yet, the neutral beam source comprises a pumping system that enables use of the neutral beam source for semiconductor processing applications, such as etching processes.

Owner:TOKYO ELECTRON LTD

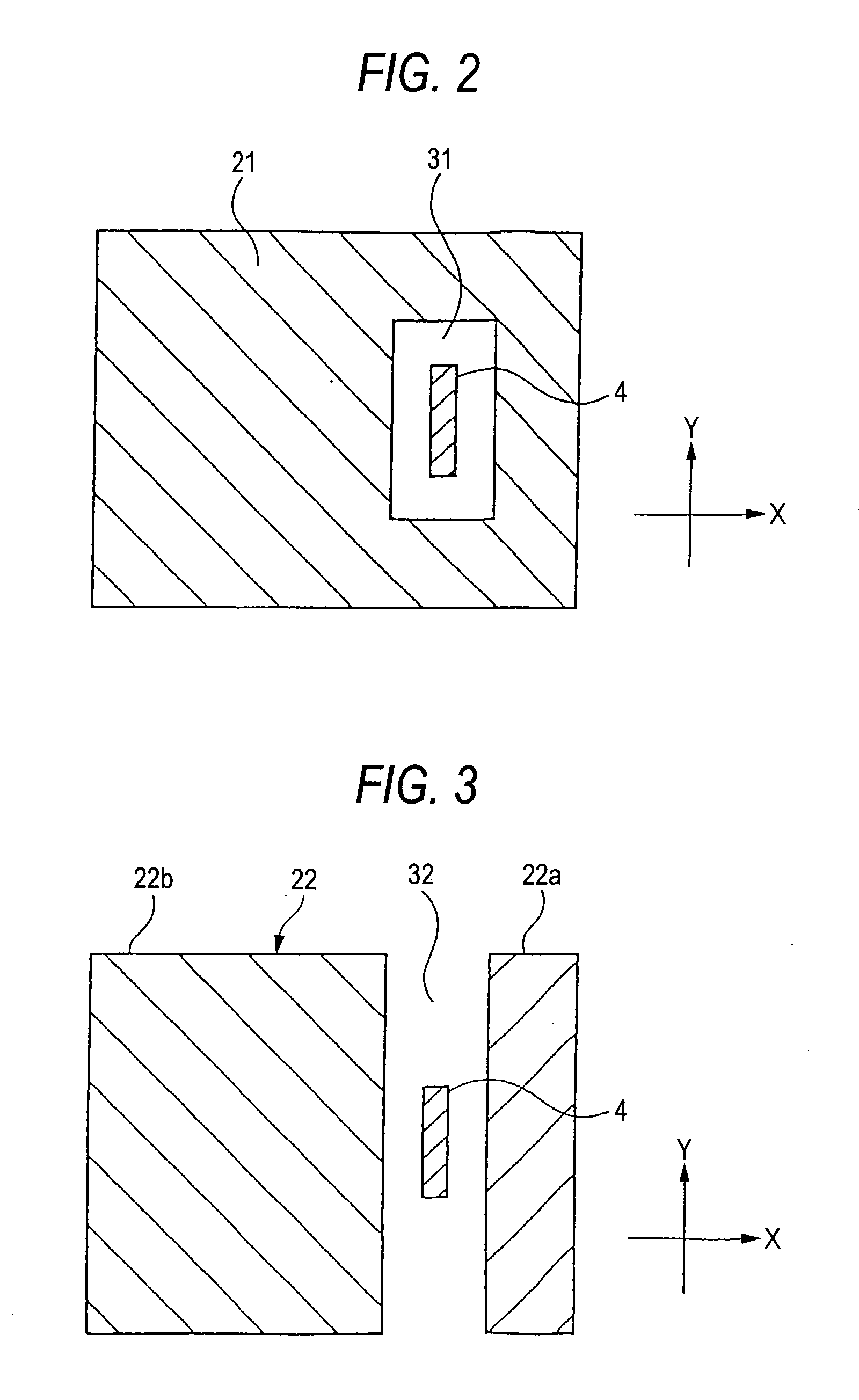

Electrostatic accelerator and ion implanting apparatus with the same

InactiveUS7098614B2Shorten the transportation distanceTransit-time tubesDirect voltage acceleratorsOrbitIon implantation

Owner:NISSIN ION EQUIP CO LTD

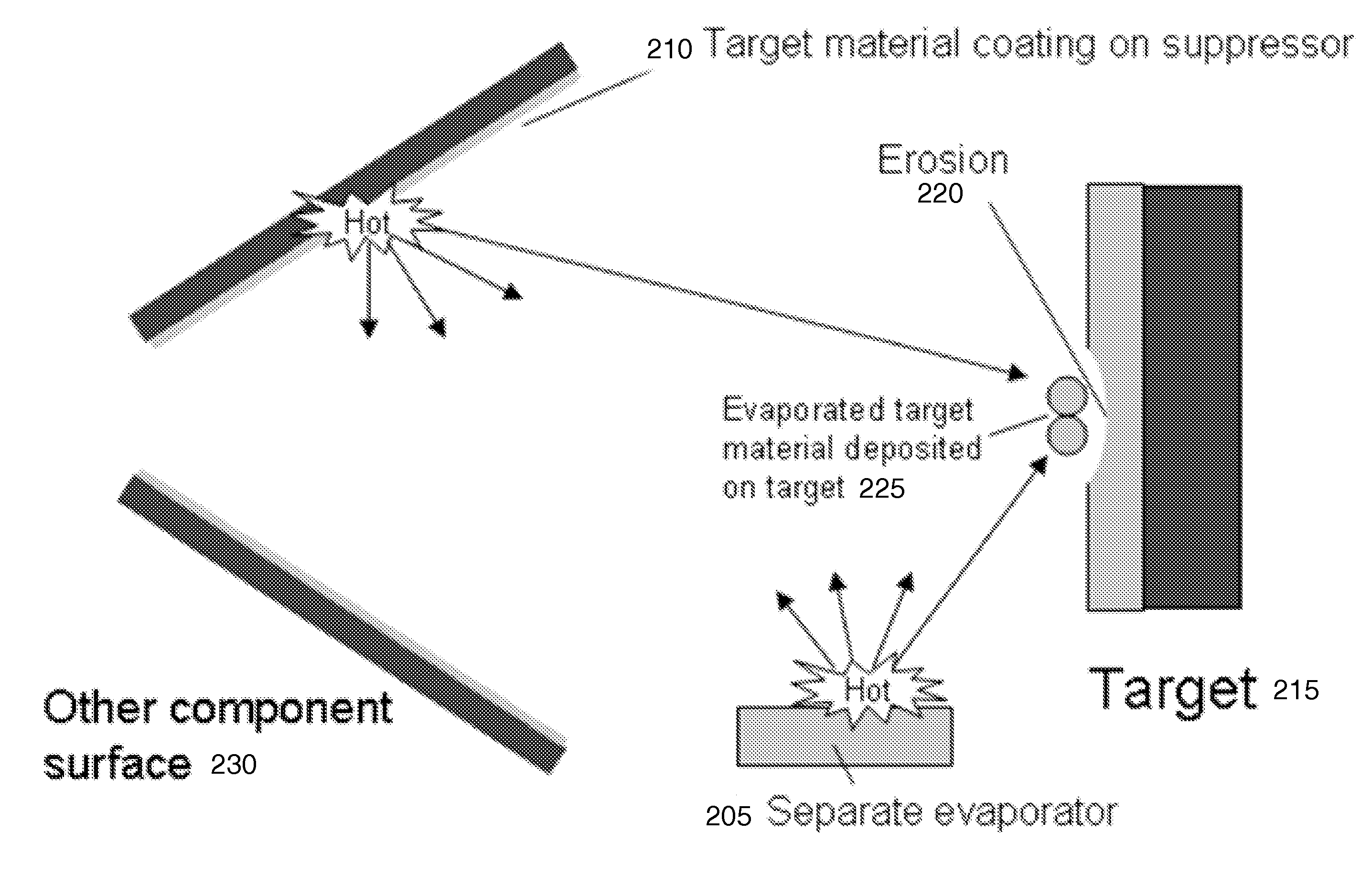

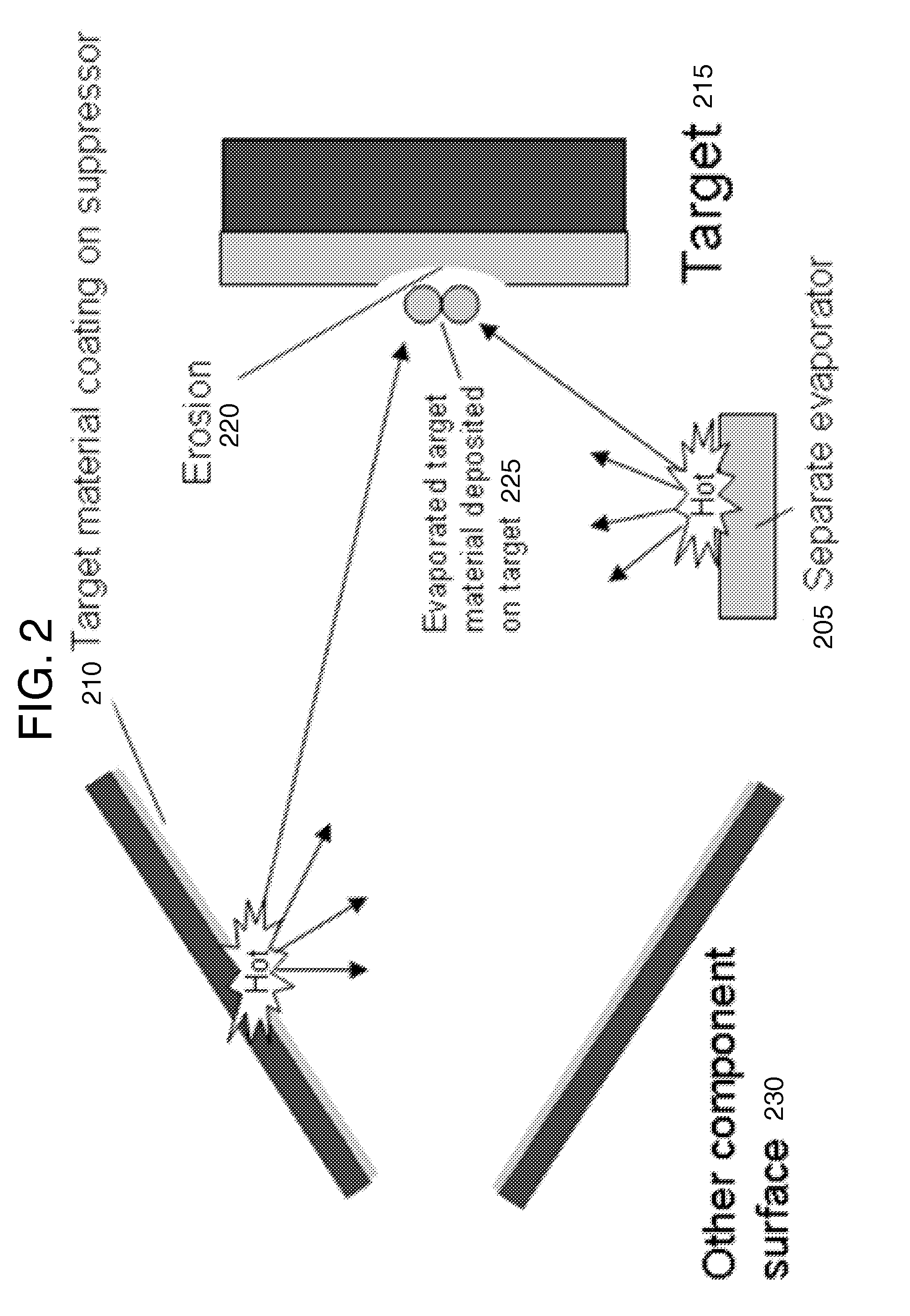

Method and system for in situ depositon and regeneration of high efficiency target materials for long life nuclear reaction devices

ActiveUS20110091000A1Maintain purityMinimize the numberNuclear energy generationDirect voltage acceleratorsNeutron energy spectrumNuclear reaction

Aspects of the invention relate to several methods to deposit and regenerate target materials in neutron generators and similar nuclear reaction devices. In situ deposition and regeneration of a target material reduces tube degradation of the nuclear reaction device and covers impurities on the surface of the target material at the target location. Further aspects of the invention include a method of designing a target to generate neutrons at a high efficiency rate and at a selected neutron energy from a neutron energy spectrum.

Owner:STARFIRE IND LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com