Patents

Literature

533 results about "Nuclear fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear fusion is a reaction in which two or more atomic nuclei are combined to form one or more different atomic nuclei and subatomic particles (neutrons or protons). The difference in mass between the reactants and products is manifested as either the release or absorption of energy. This difference in mass arises due to the difference in atomic "binding energy" between the atomic nuclei before and after the reaction. Fusion is the process that powers active or "main sequence" stars, or other high magnitude stars.

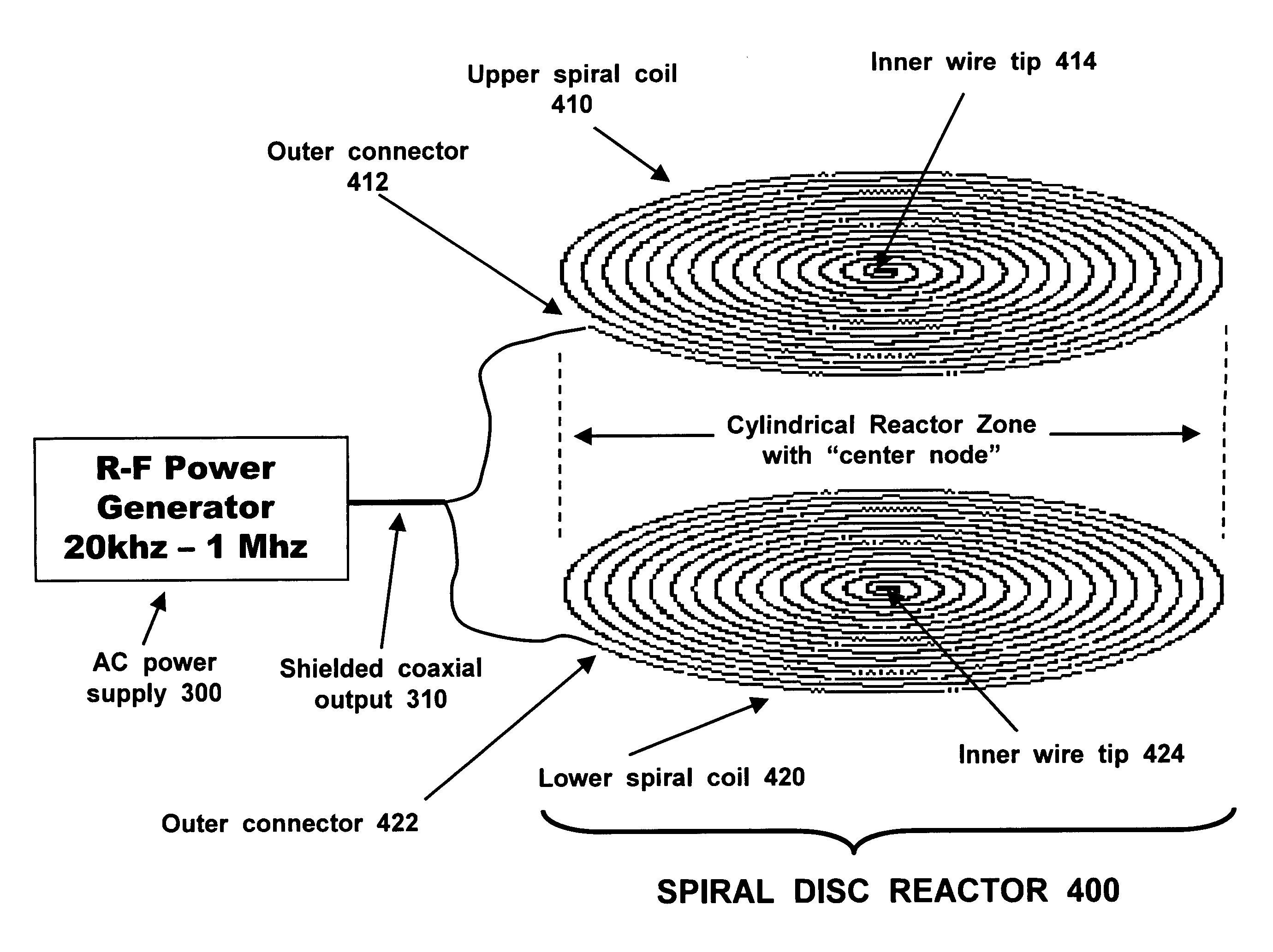

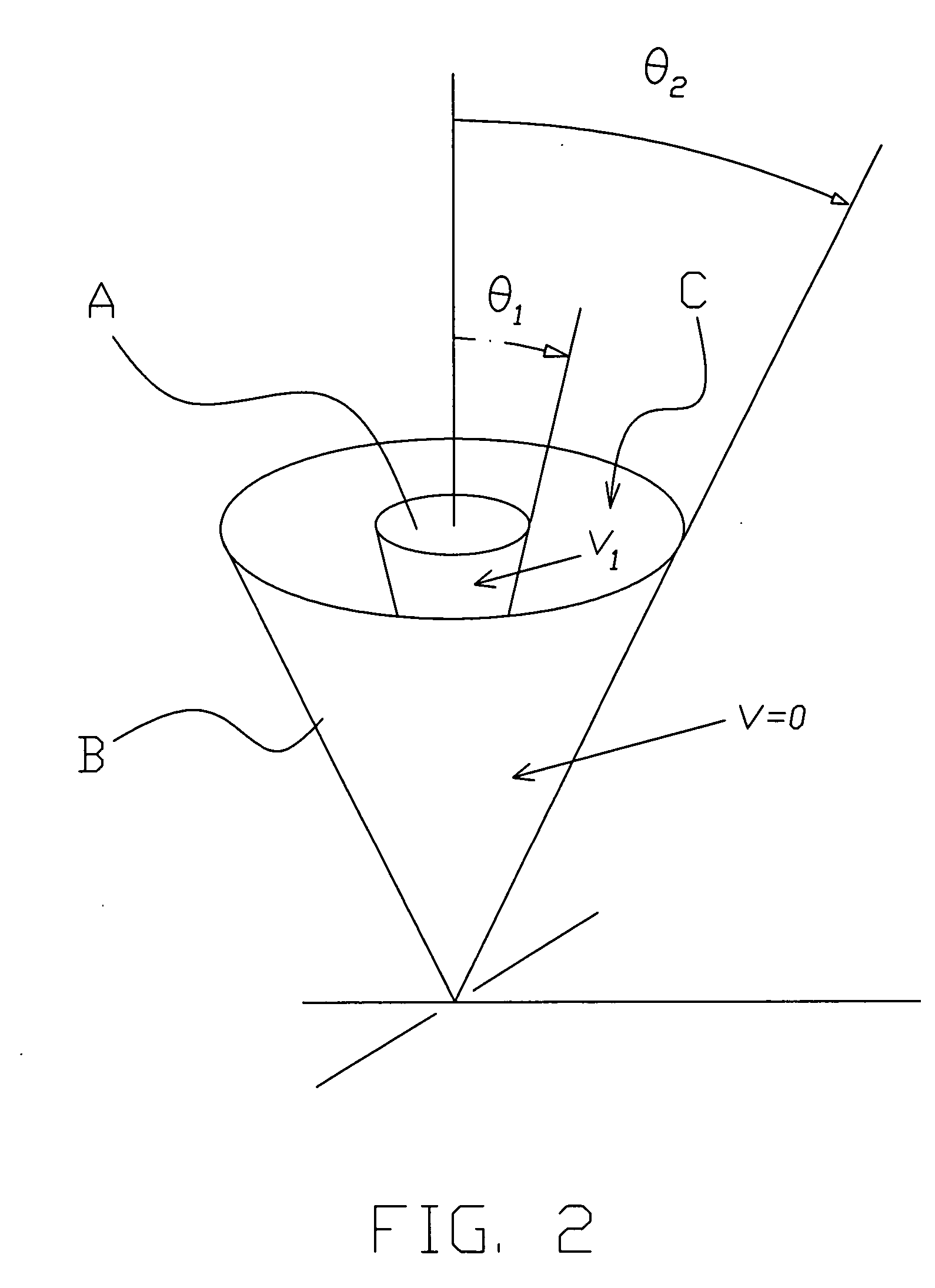

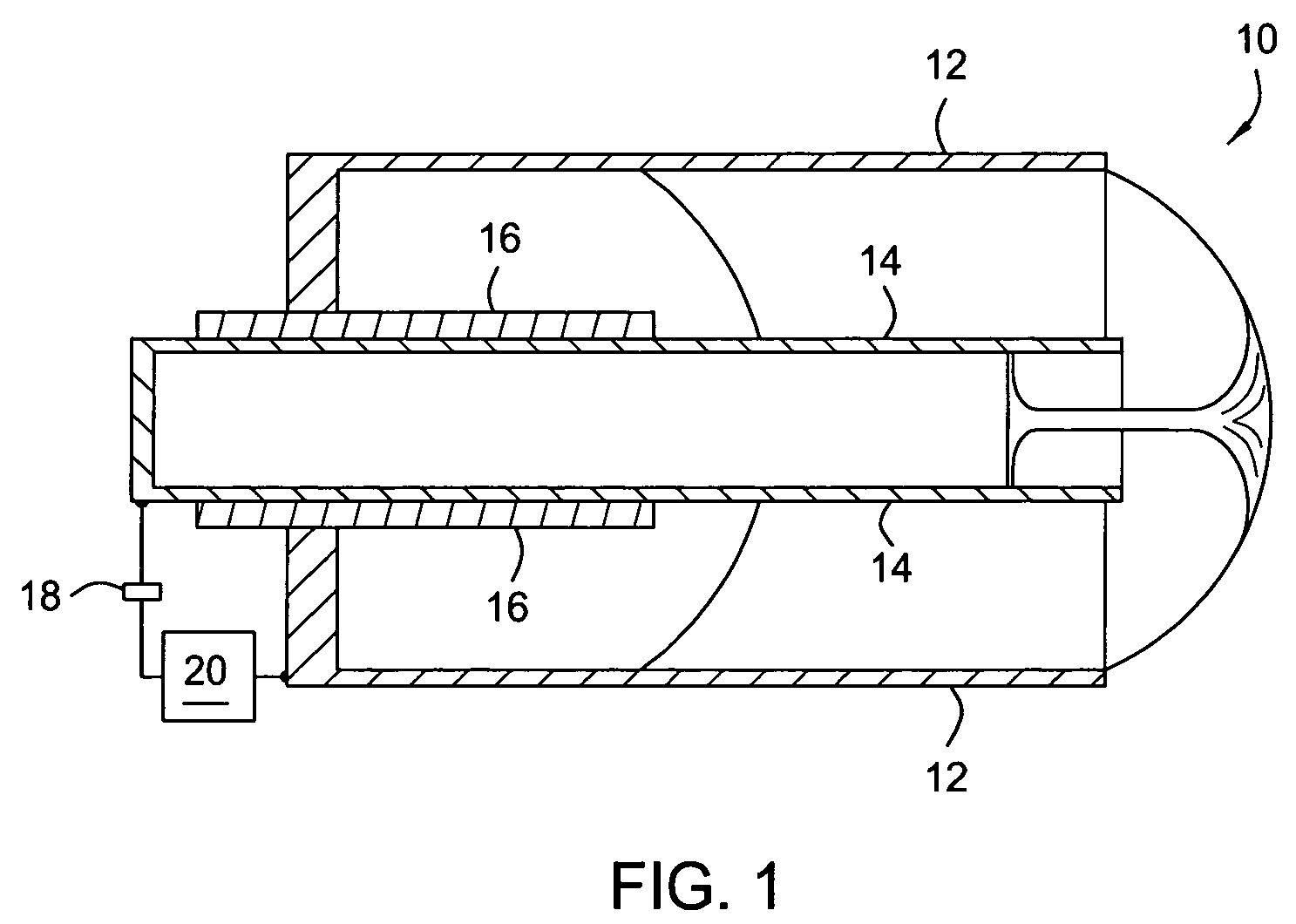

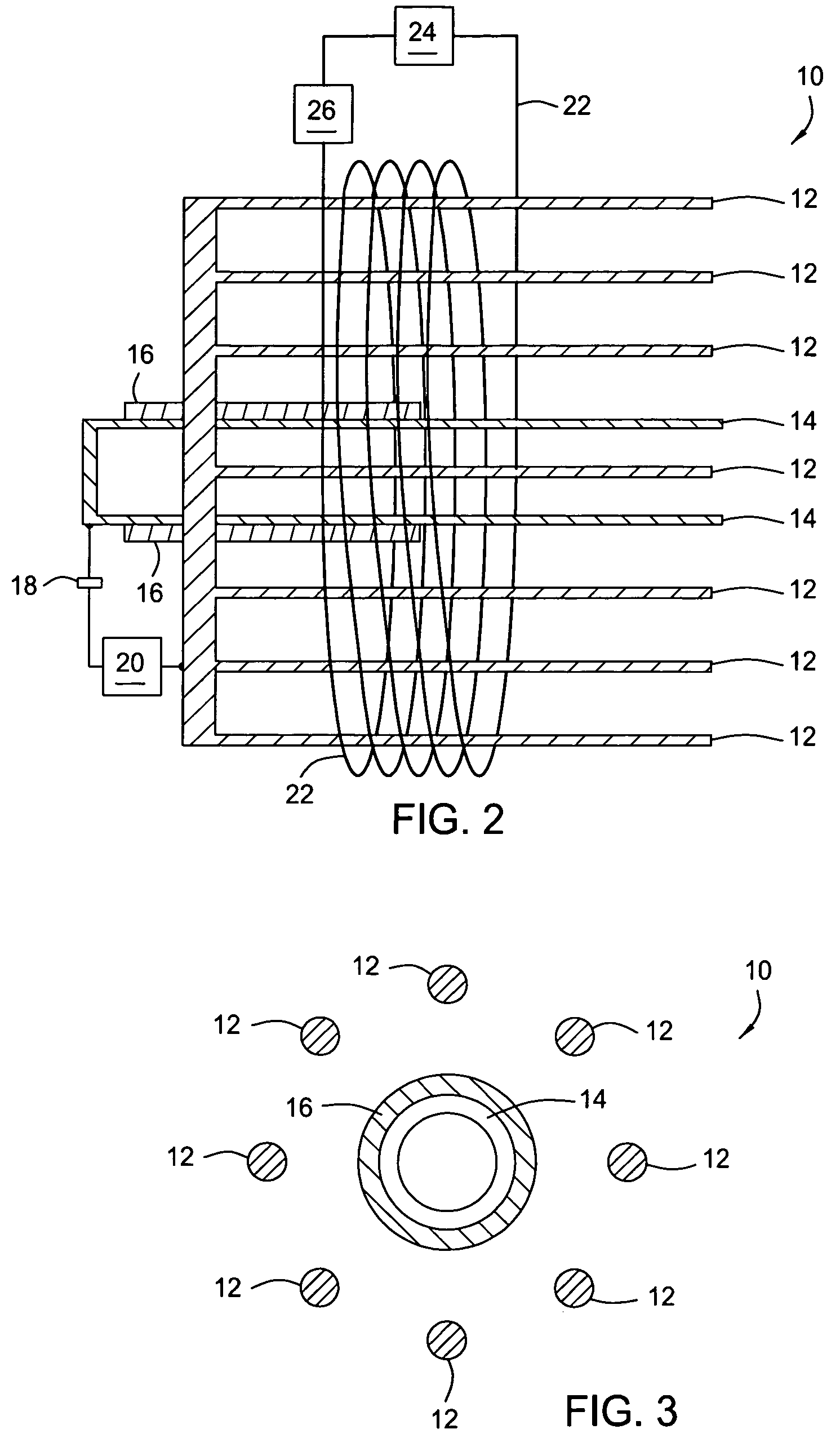

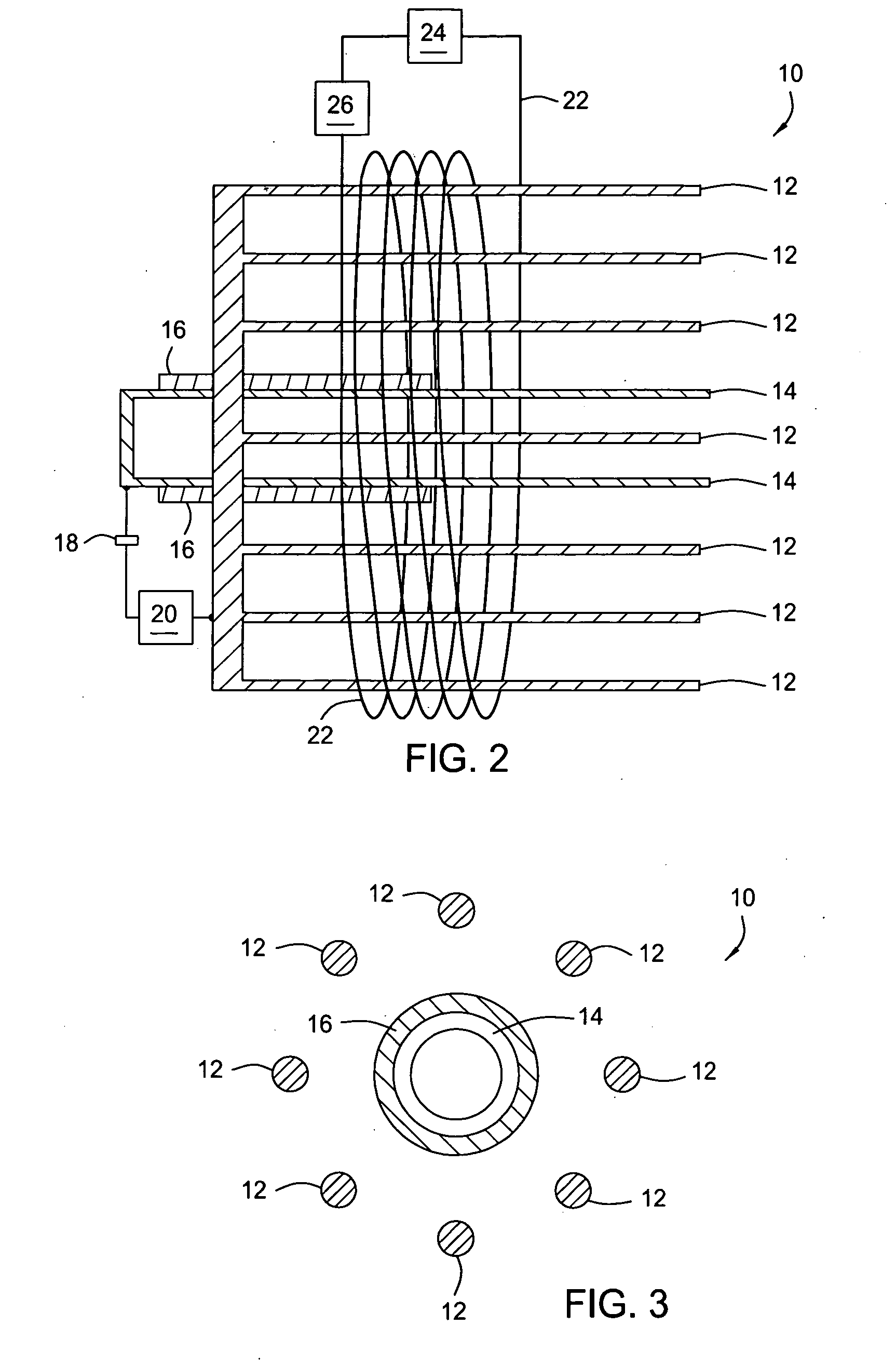

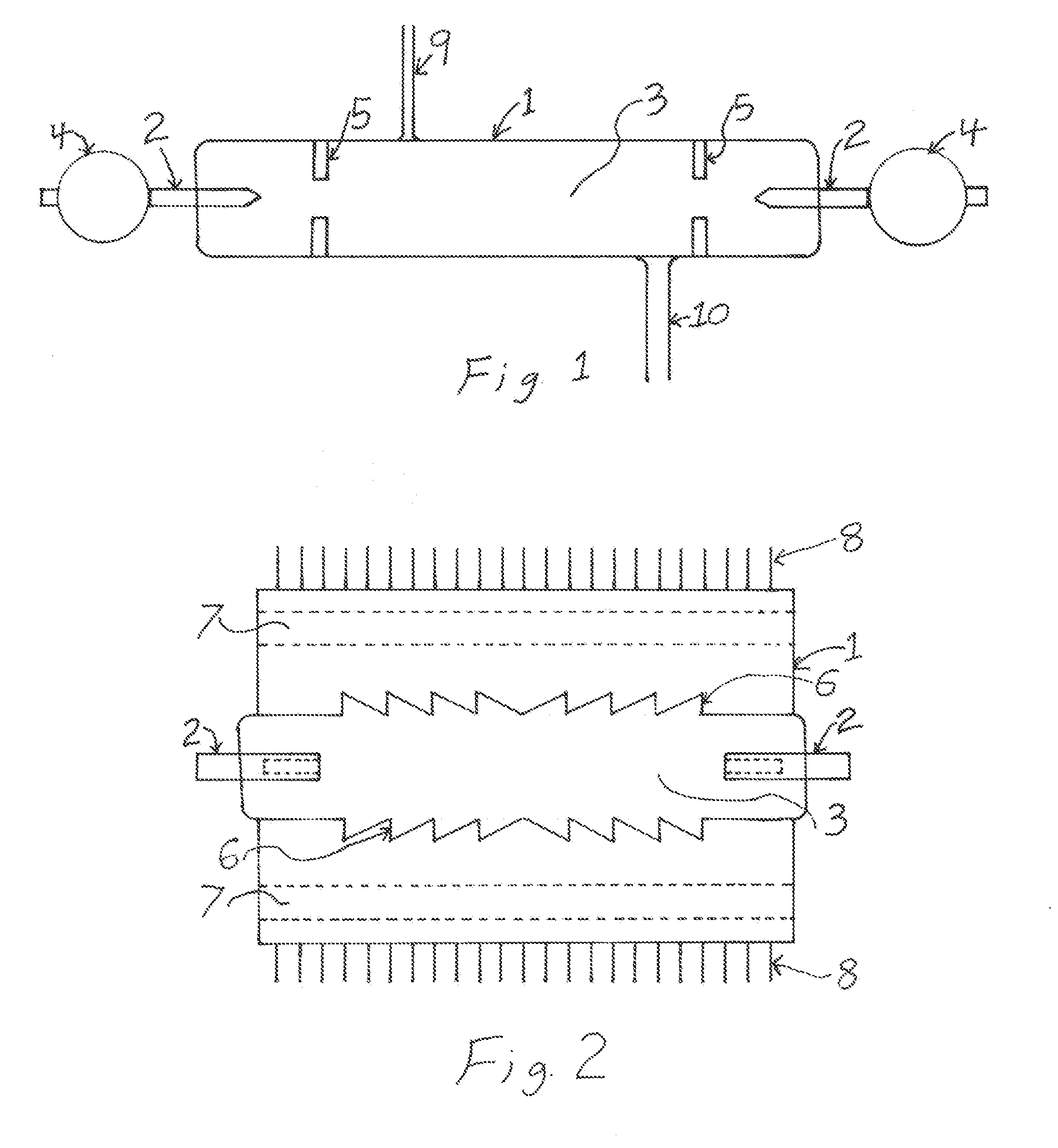

Electromagnetic systems with double-resonant spiral coil components

InactiveUS7973296B2Easy to operateHigh outputNuclear energy generationSemiconductor/solid-state device manufacturingCapacitanceElectrical conductor

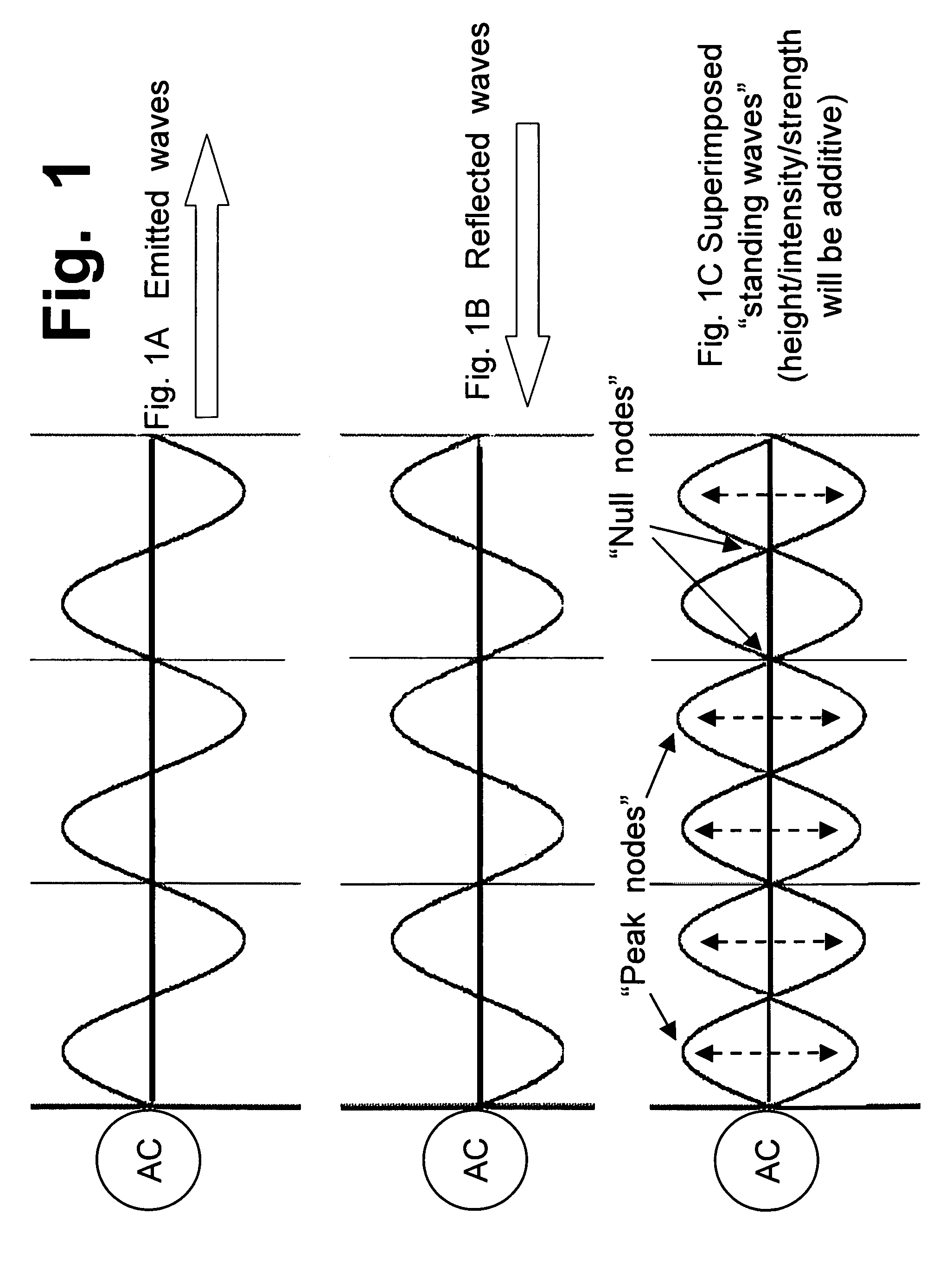

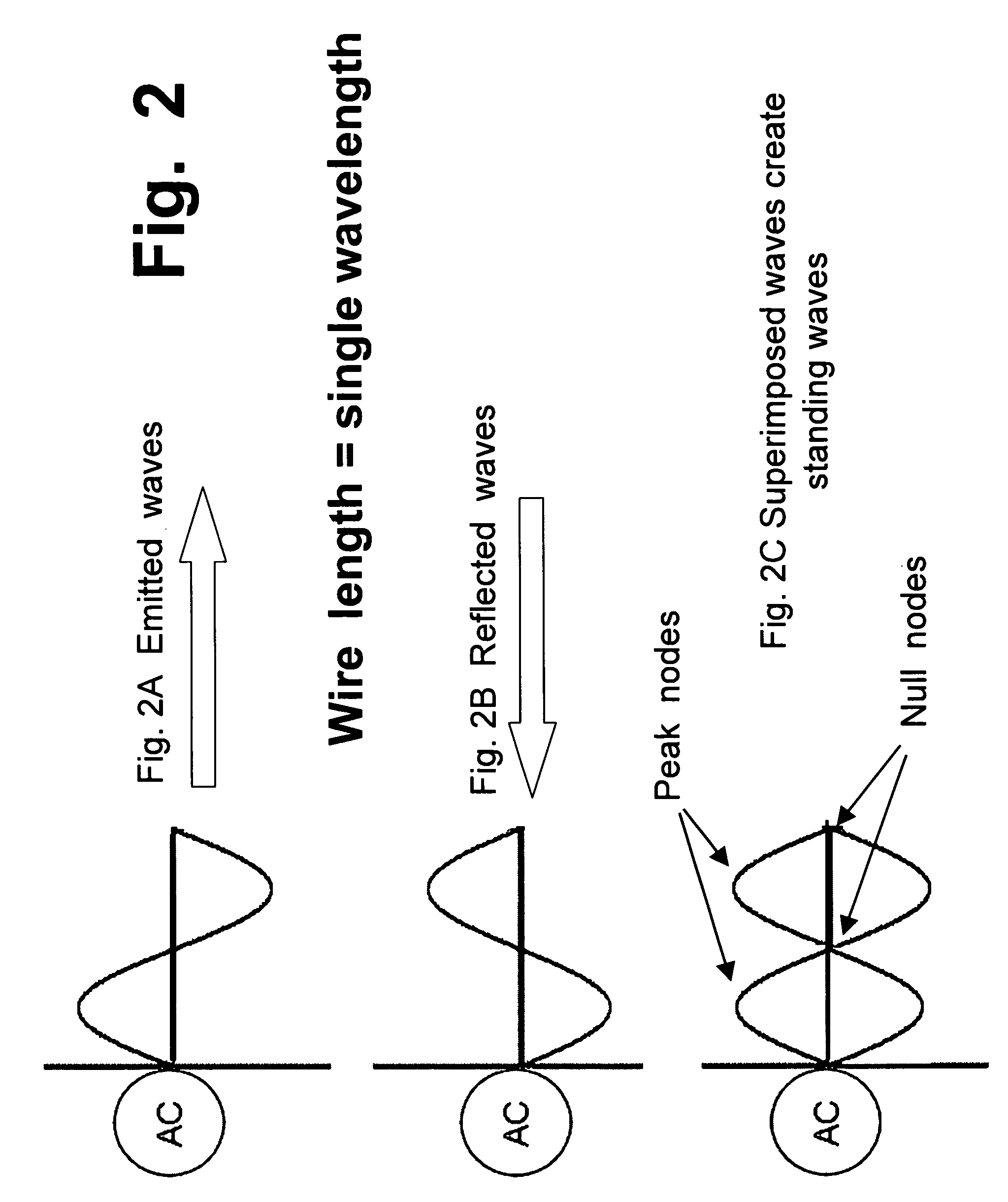

Spiral coils generate very powerful electromagnetic fields by operating with two different but simultaneous resonant behaviors. Quarter-wave resonance is established by adjusting the frequency (and wavelength) of a radiofrequency (RF) voltage source until the length of the spiral conductor is equal to ¼ of the wavelength of the alternating voltage. This generates an electromagnetic standing wave with at least one peak node and at least one null node. Inductive-capacitive (L / C) resonance is established by optimizing the thickness and width of the wire ribbon used to make the spiral coil. When inductance and capacitance are balanced, the current response will synchronize with the voltage input, creating in-phase behavior, minimal total impedance, and maximal power output. If two such coils are placed near each other, they will create an extremely powerful electromagnetic field between them, which can promote chemical and plasma reactions involving charged particles such as ions or plasma particles, possibly including nuclear fusion reactions.

Owner:TETRAHEED

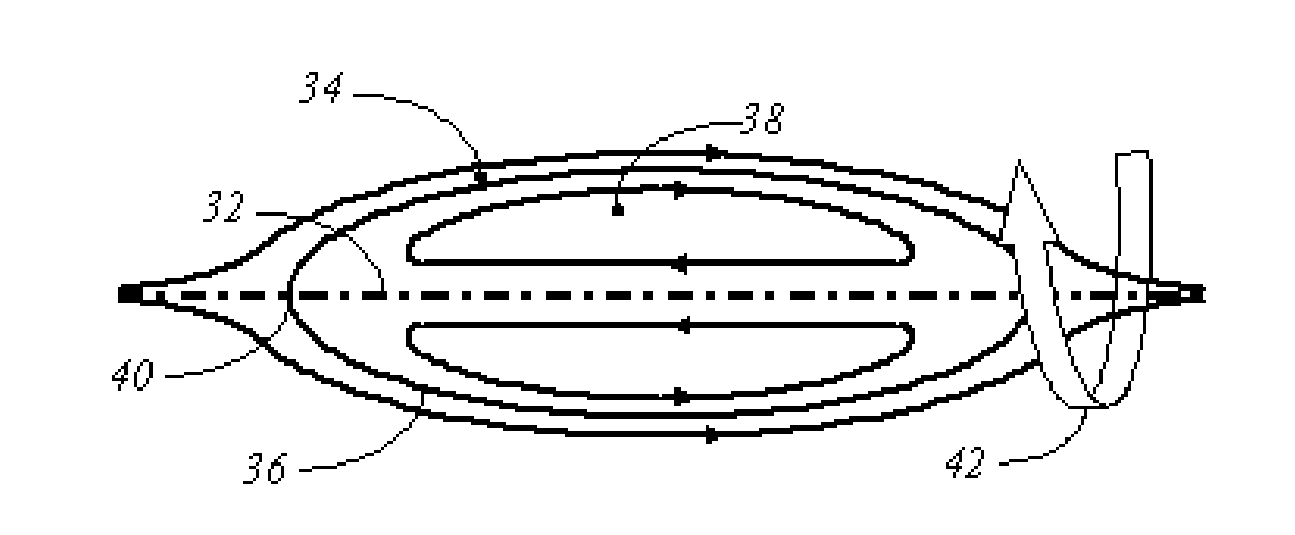

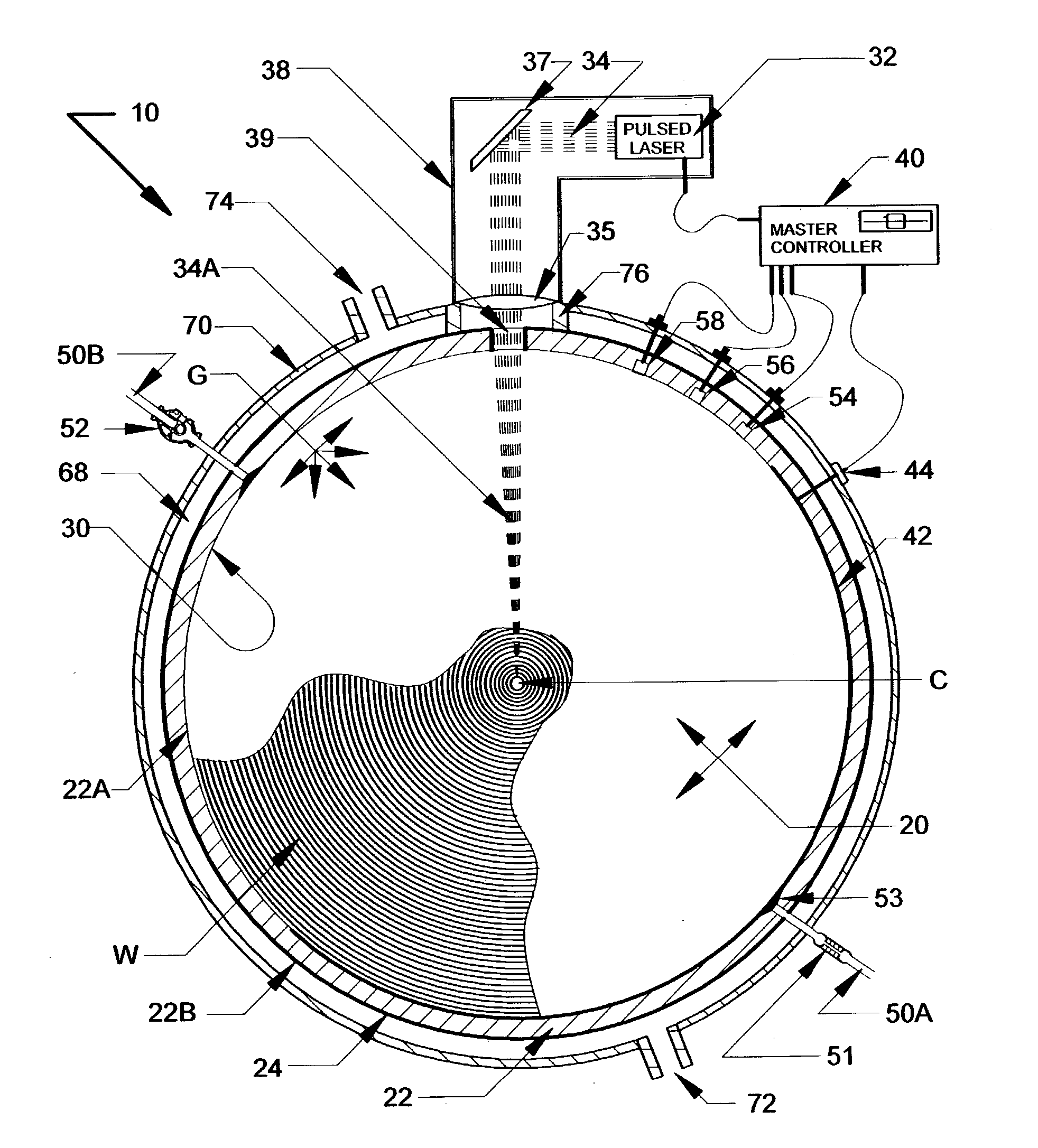

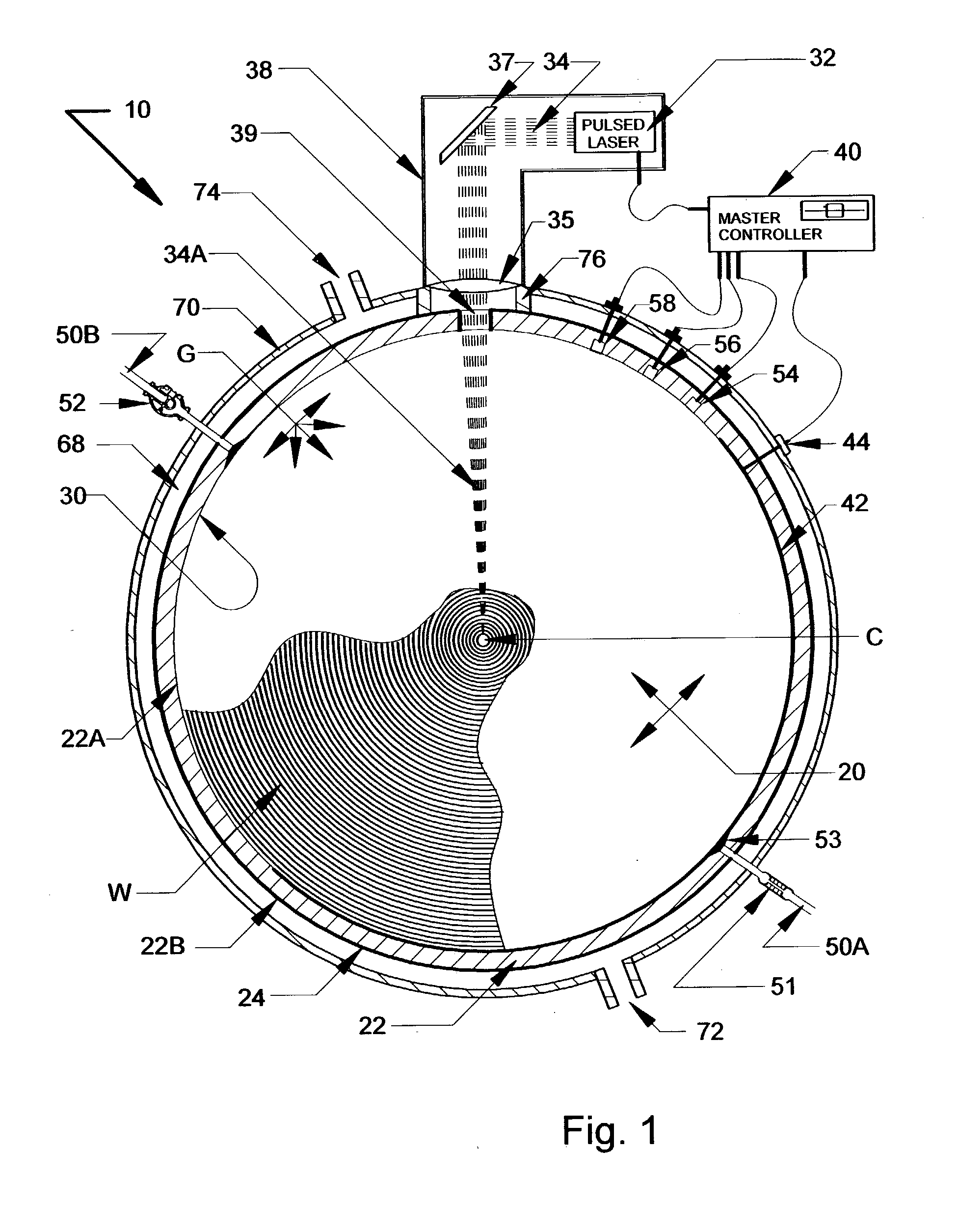

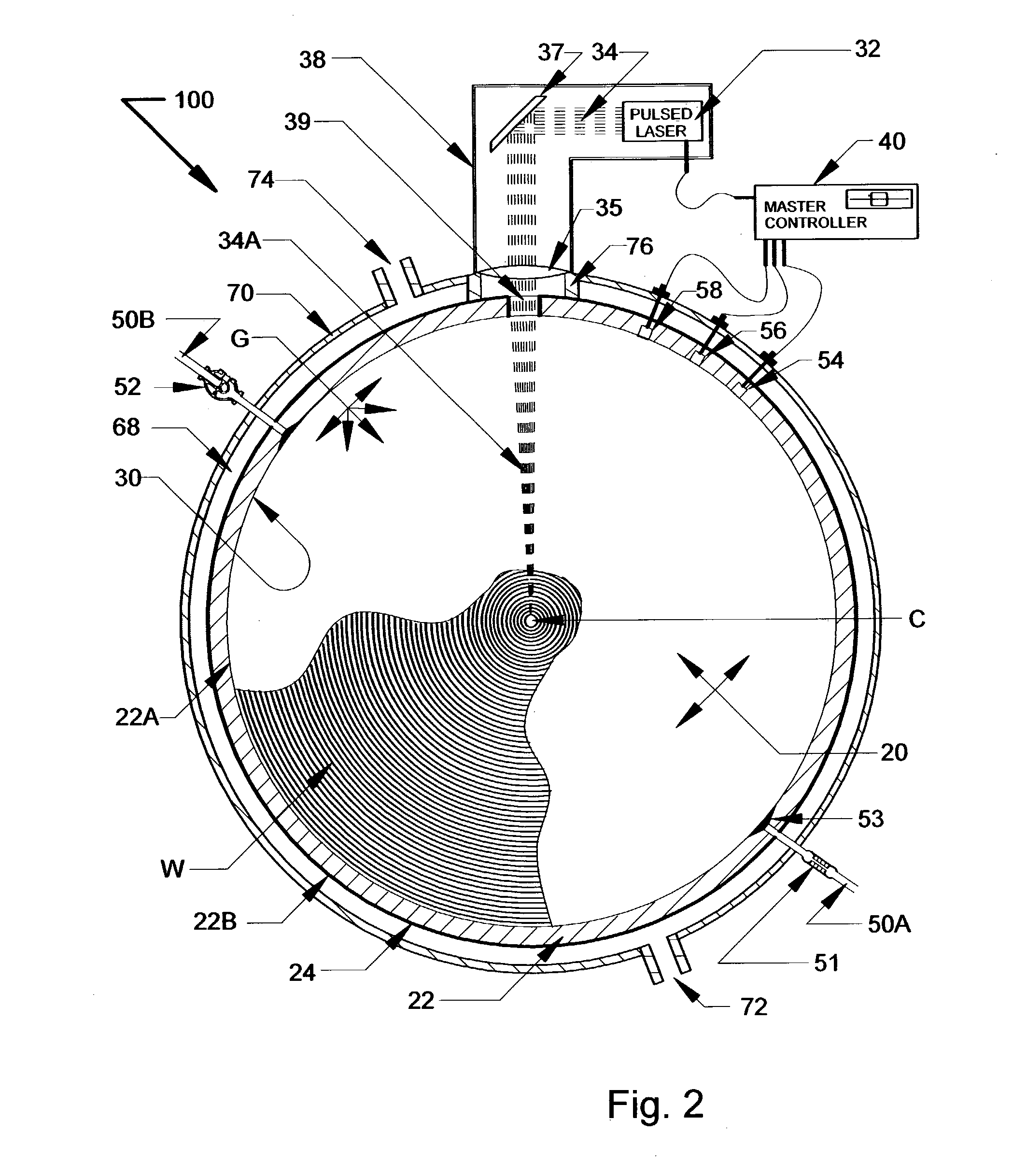

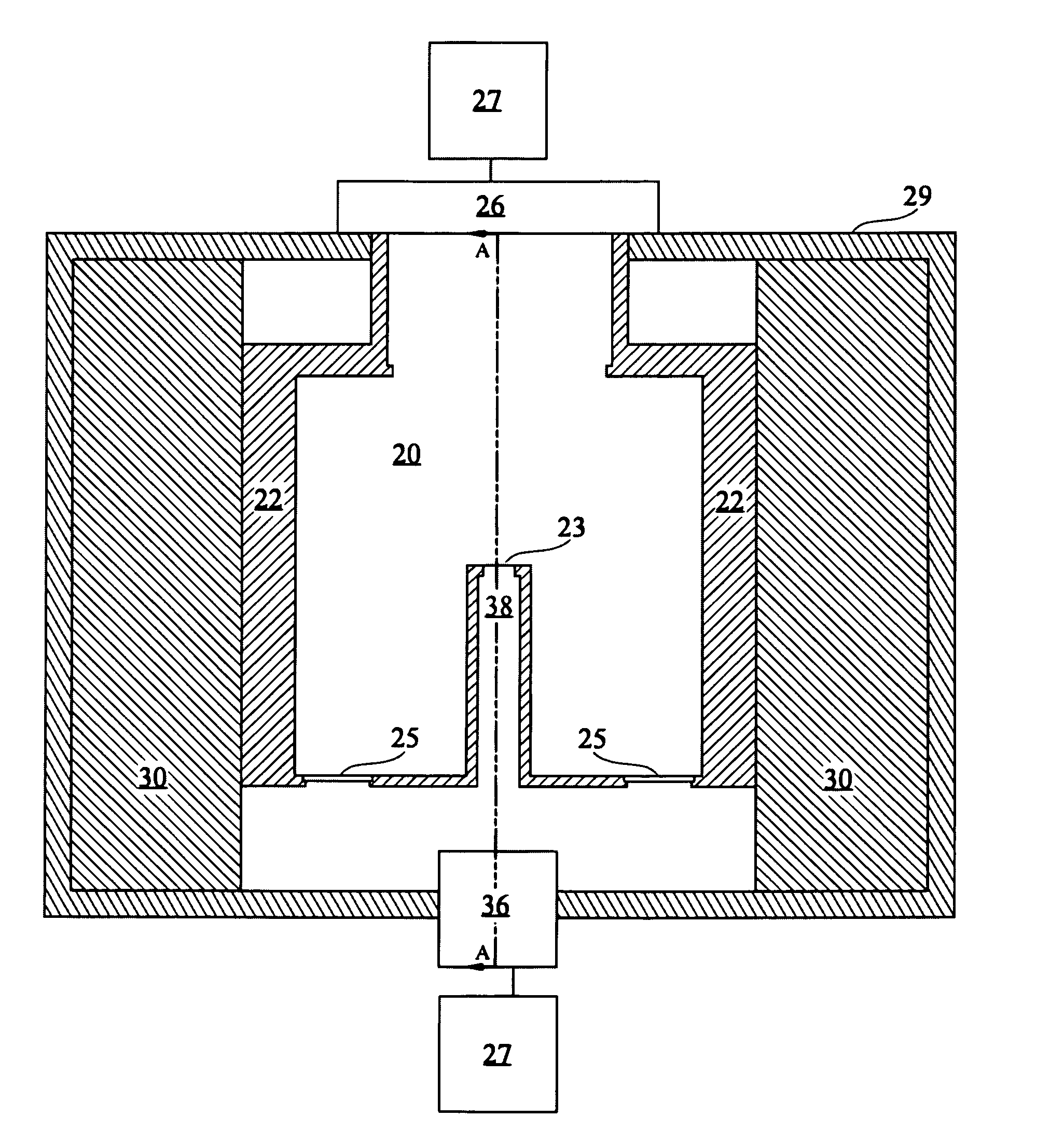

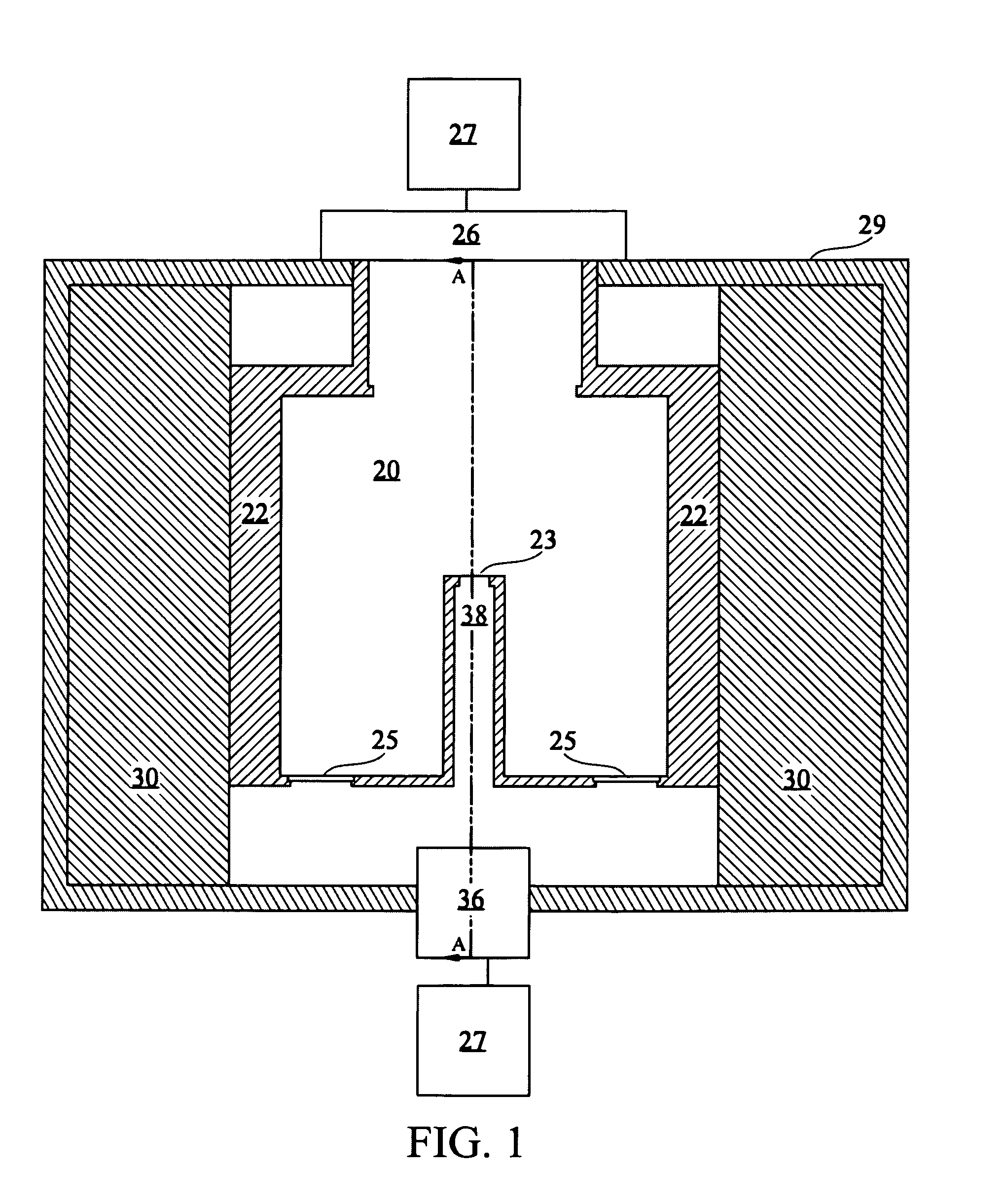

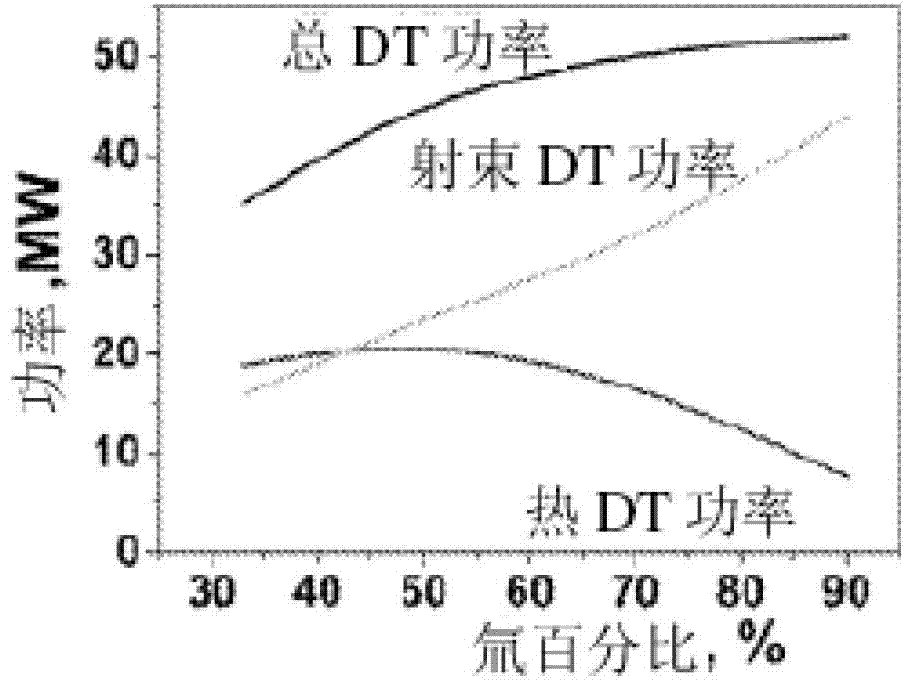

Plasma Centrifuge Heat Engine Beam Fusion Reactor

InactiveUS20080226011A1Improve responseReduce the temperatureNuclear energy generationPlasma techniqueField lineNuclear fusion

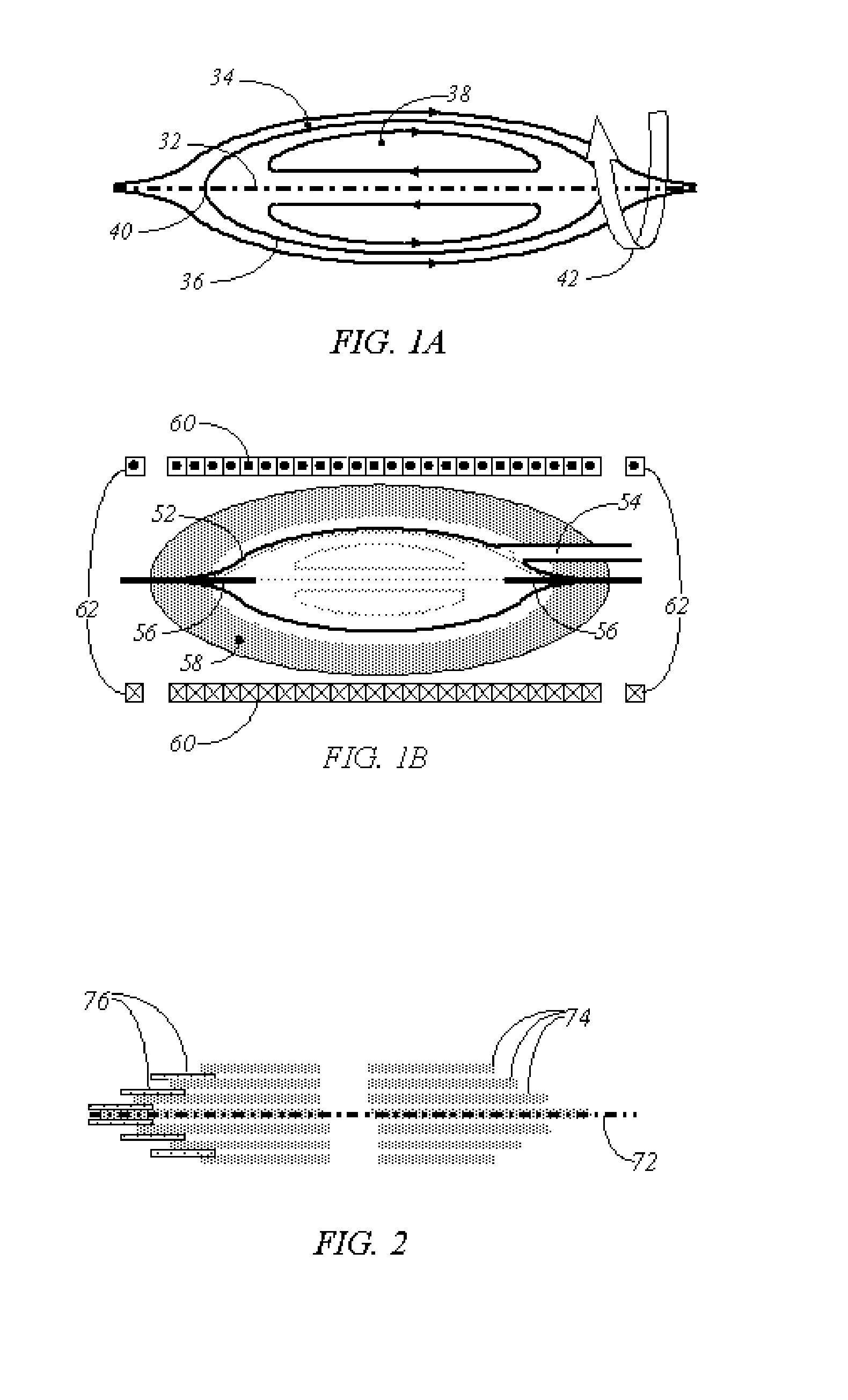

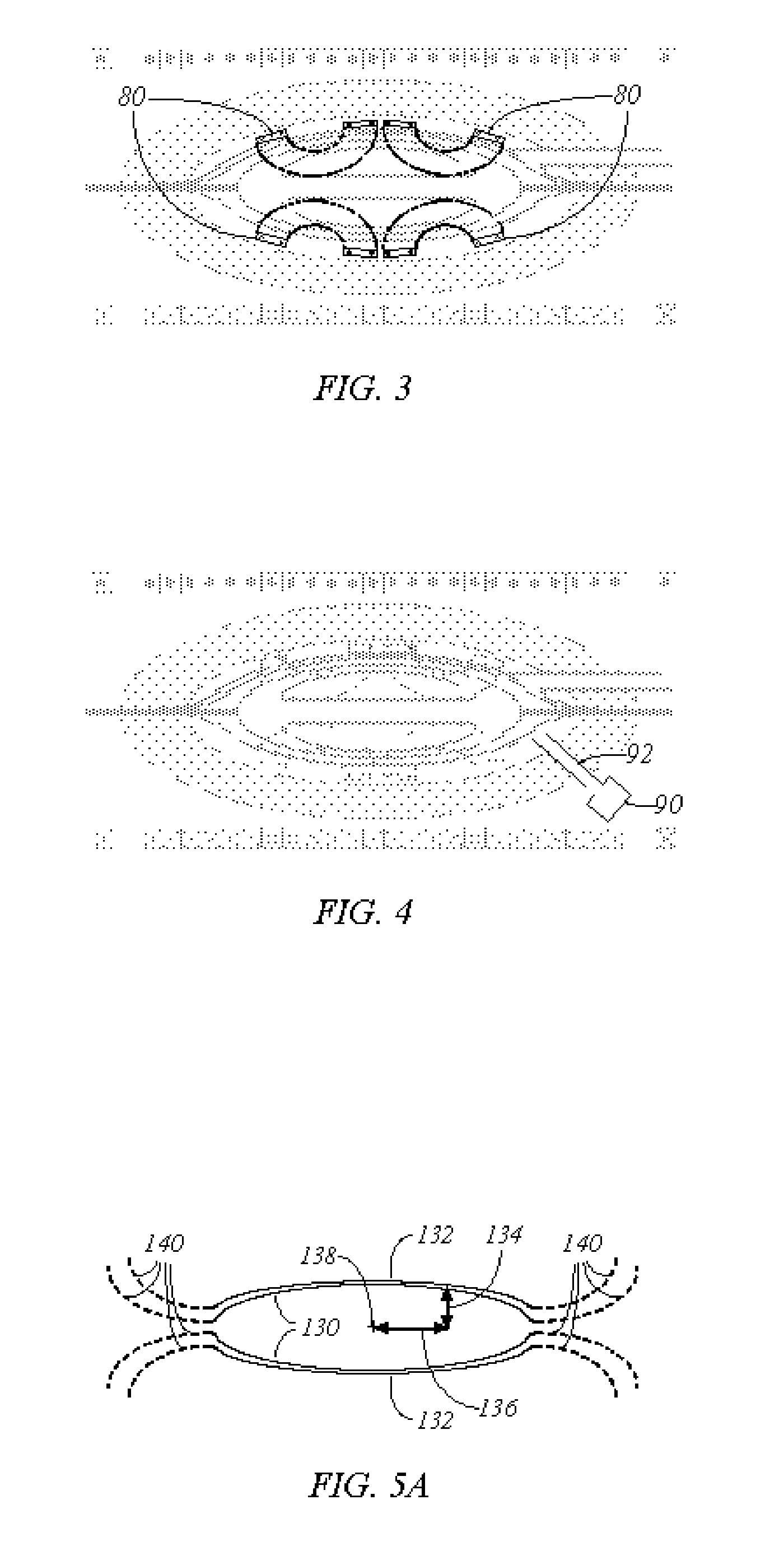

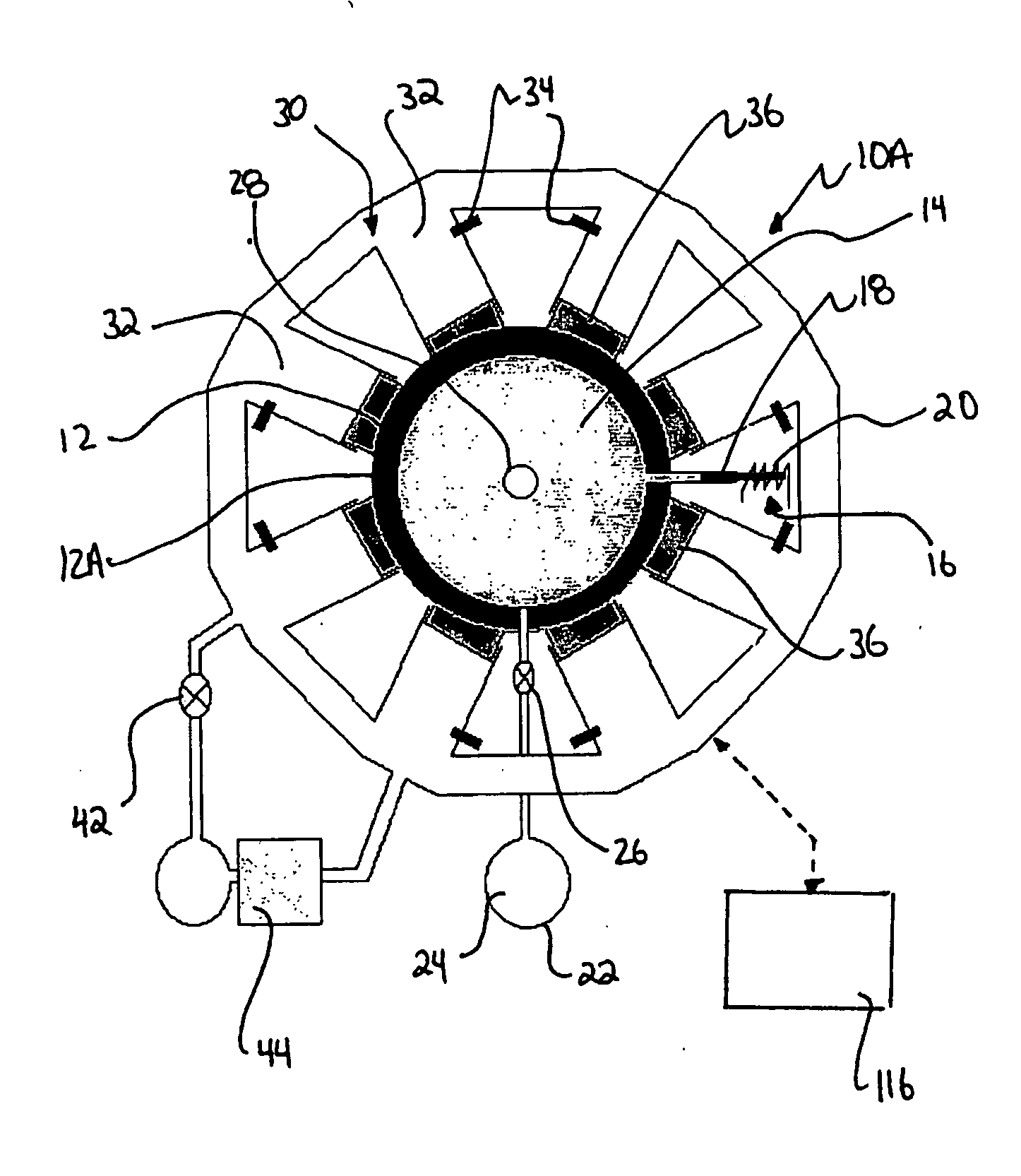

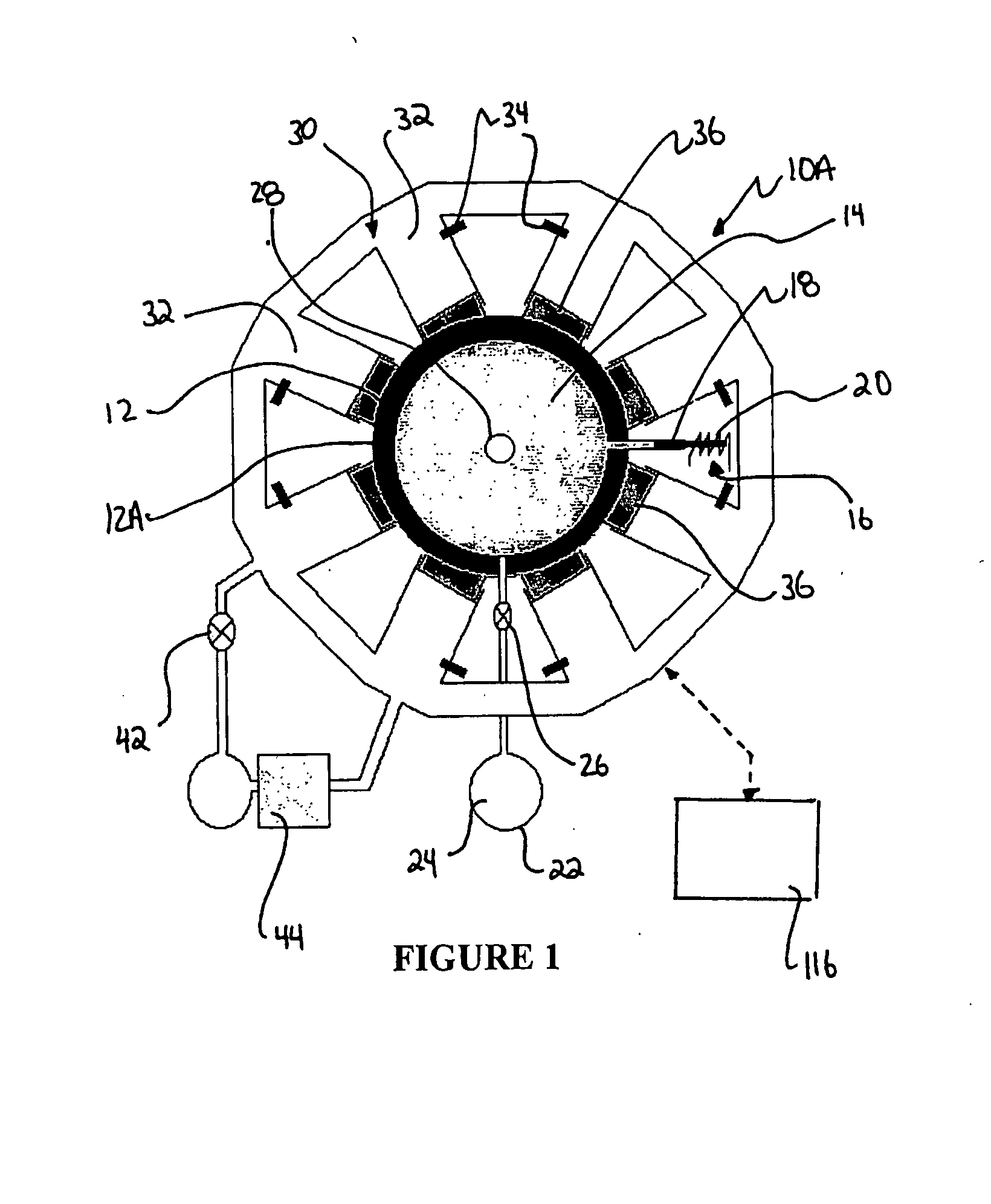

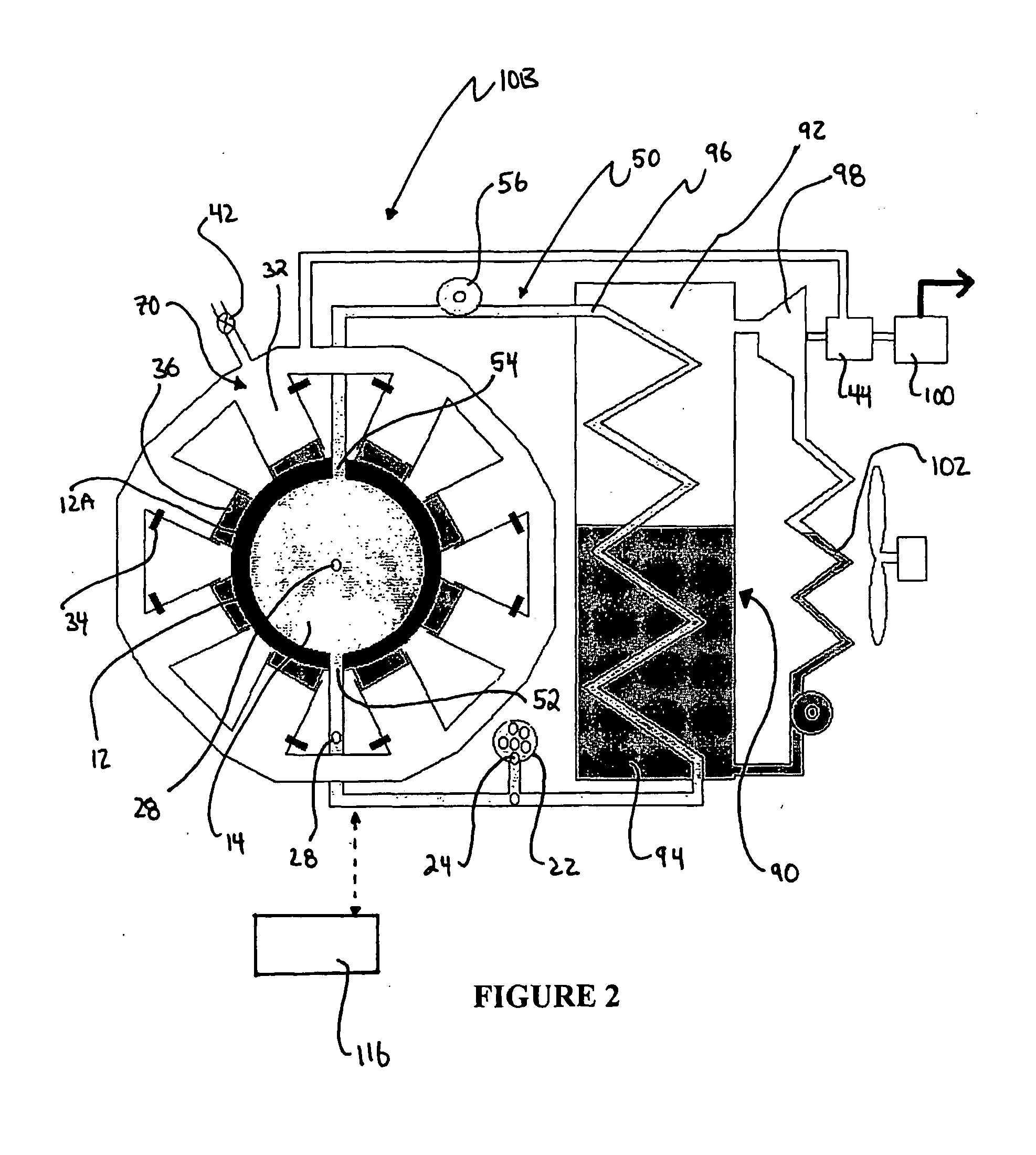

A system and apparatus for a magnetized plasma nuclear fusion reactor, incorporating special design features which induce a plasma heat engine cycle in a rapidly rotating plasma. The heat engine operates either continuously or by oscillations. A continuous heat engine is formed in the open field outside a field reversed configuration. The oscillatory system operates in synchronism with cyclic acceleration, collision, and deceleration of plasma masses to produce nuclear fusion reactions at an economically useful rate with a relatively small driving power required. A special magnetic field design is combined with applied electrical voltages at the end of the field lines to produce required conditions. Design features allow recovery of large fraction of collision heat which would otherwise be dissipated as a parasitic loss.

Owner:BARNES DANIEL C

Methods and apparatus to induce D-D and D-T reactions

InactiveUS20050135532A1Sufficient energyNuclear energy generationNuclear explosivesStored energyCavitation

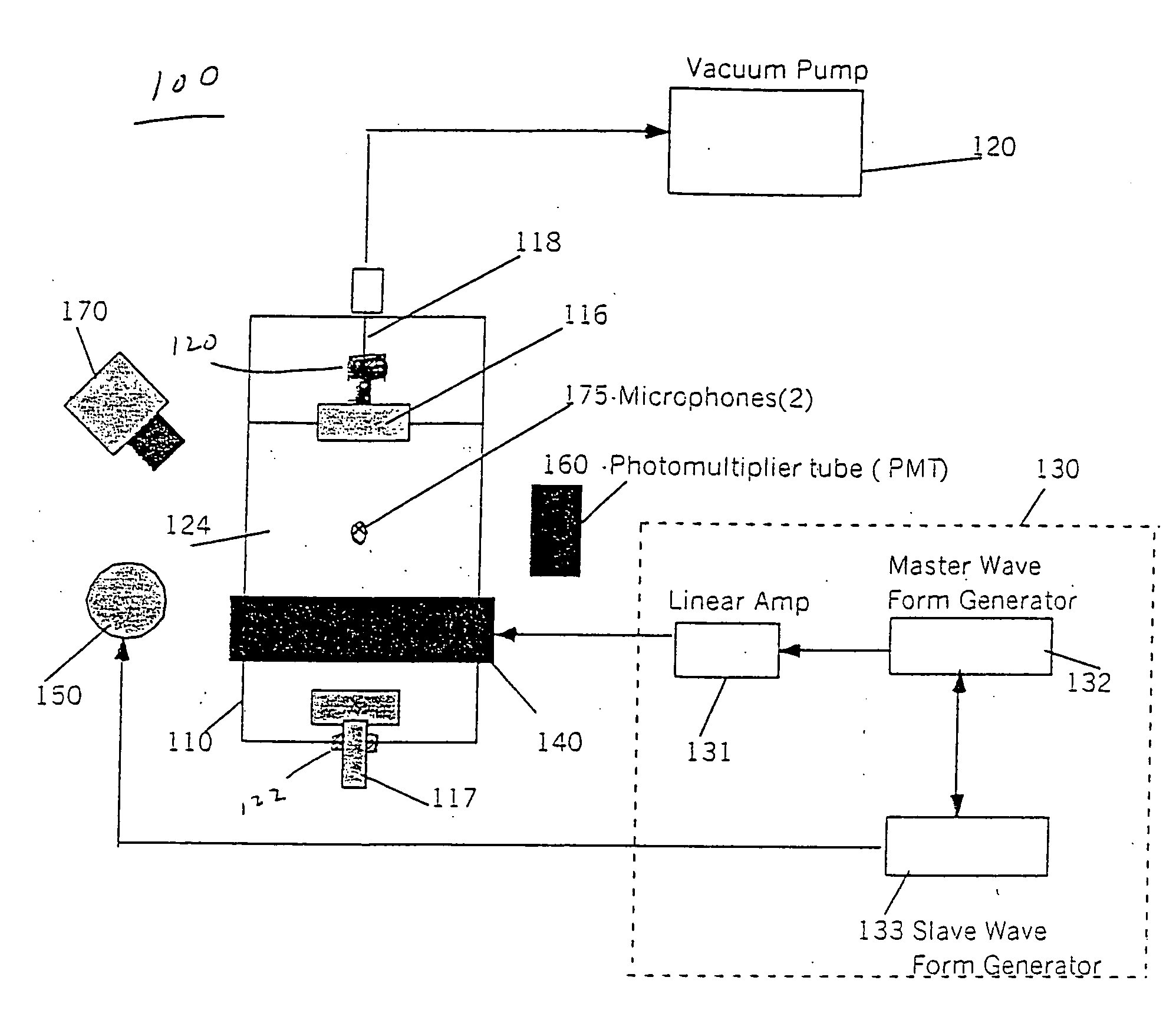

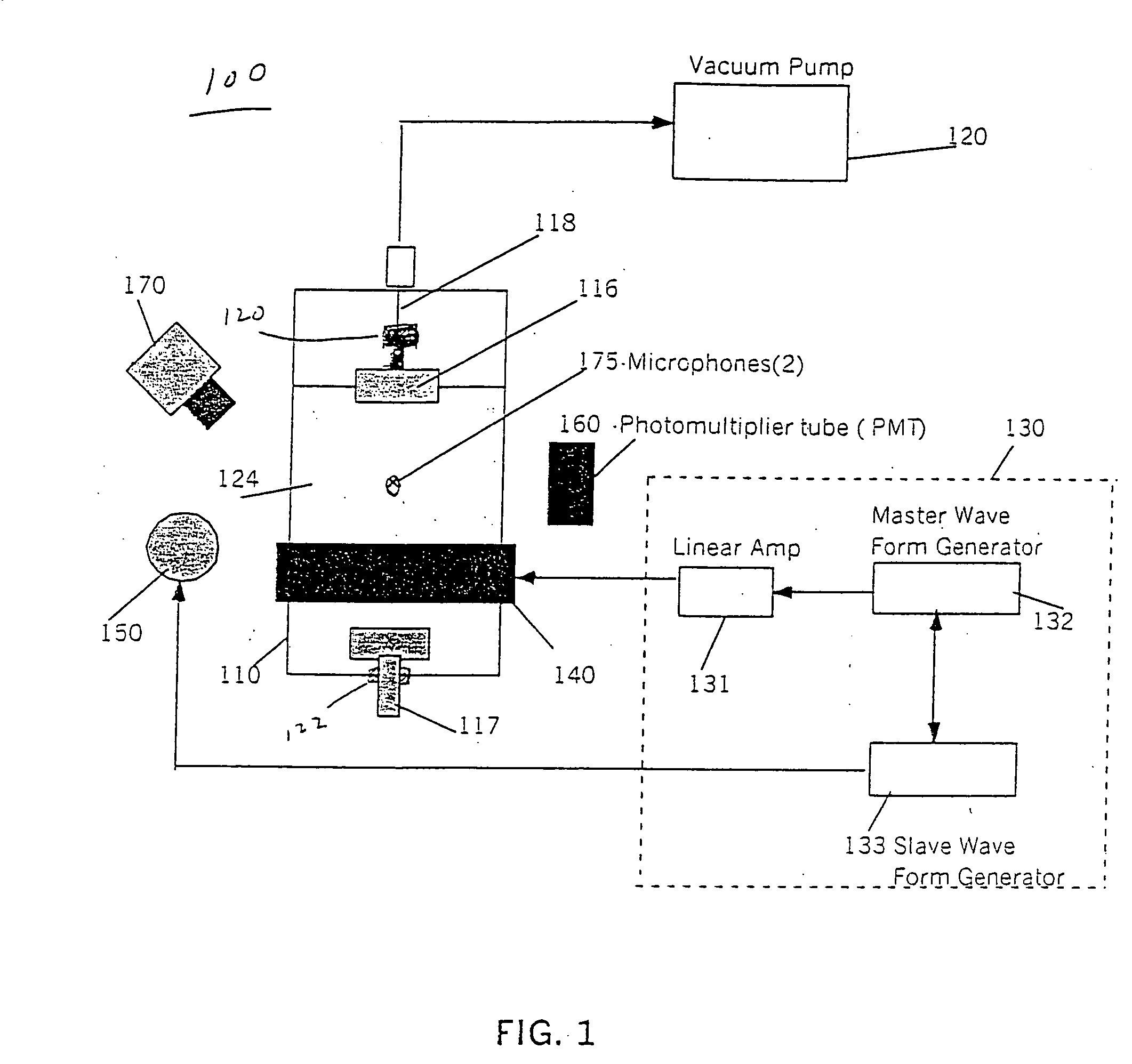

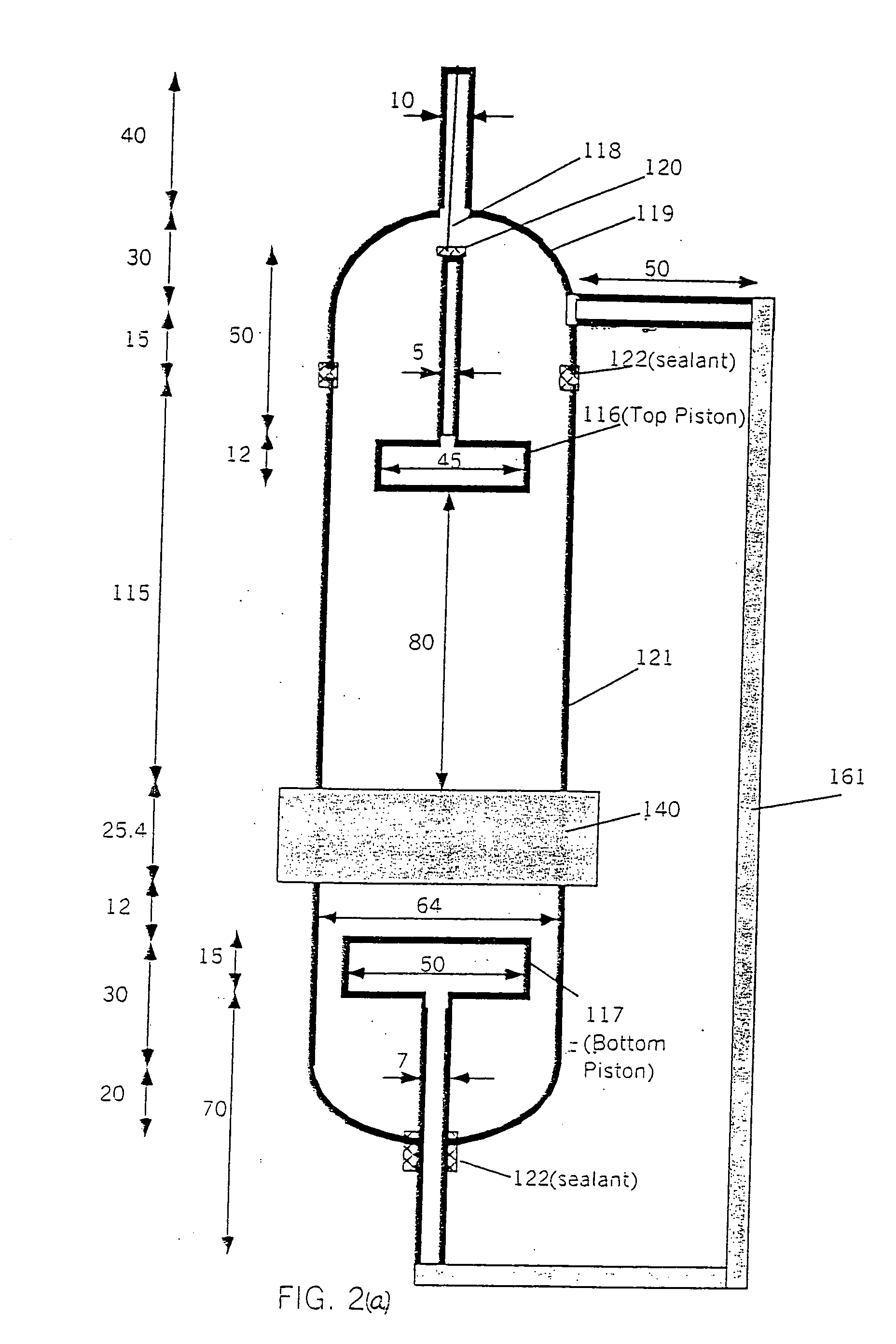

A nuclear fusion reactor including a structure for placing at least a portion of a liquid into a tension state, the tension state being below a cavitation threshold of the liquid. The tension state imparts stored energy into the liquid portion. A cavitation initiation source provides energy to the liquid portion sufficient to nucleate at least one bubble having a bubble radius greater than a critical bubble radius of the liquid. A structure for imploding the bubbles produces imploded cavities. The temperature generated by the implosion process can be sufficient to induce a nuclear fusion reaction involving the liquid. A method of providing nuclear fusion tensions a liquid, cavitates the tensioned to form at least one bubble, then implodes the bubble, wherein a resulting temperature is generated that is sufficient to induce a nuclear fusion reaction involving the liquid.

Owner:TALEYARKHAN RUSI DR +1

Apparatus and method for fusion reactor

InactiveUS20050129161A1Nuclear energy generationDirect voltage acceleratorsNuclear fusionAtomic nucleus

A method for inducing nuclear fusion and a reactor for inducing nuclear fusion involve positioning a bubble containing fusionable nuclei at the center of a liquid filled spherical vessel and generating a spherically symmetric positive acoustic pulse in the liquid. The acoustic pulse surrounds and converges toward the center of the vessel to compress the bubble, thereby providing energy to and inducing nuclear fusion of the atomic nuclei.

Owner:GENERAL FUSION INC

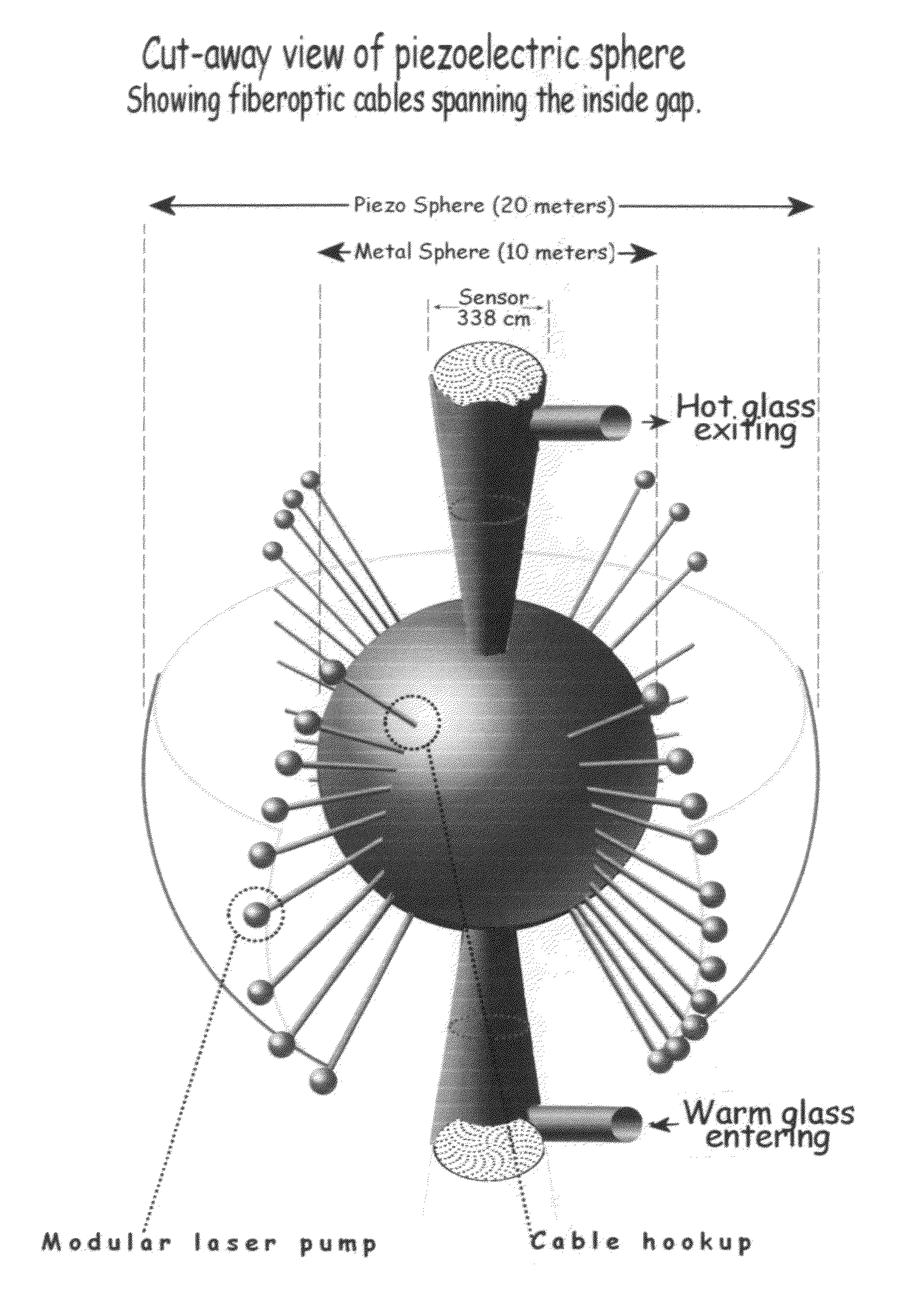

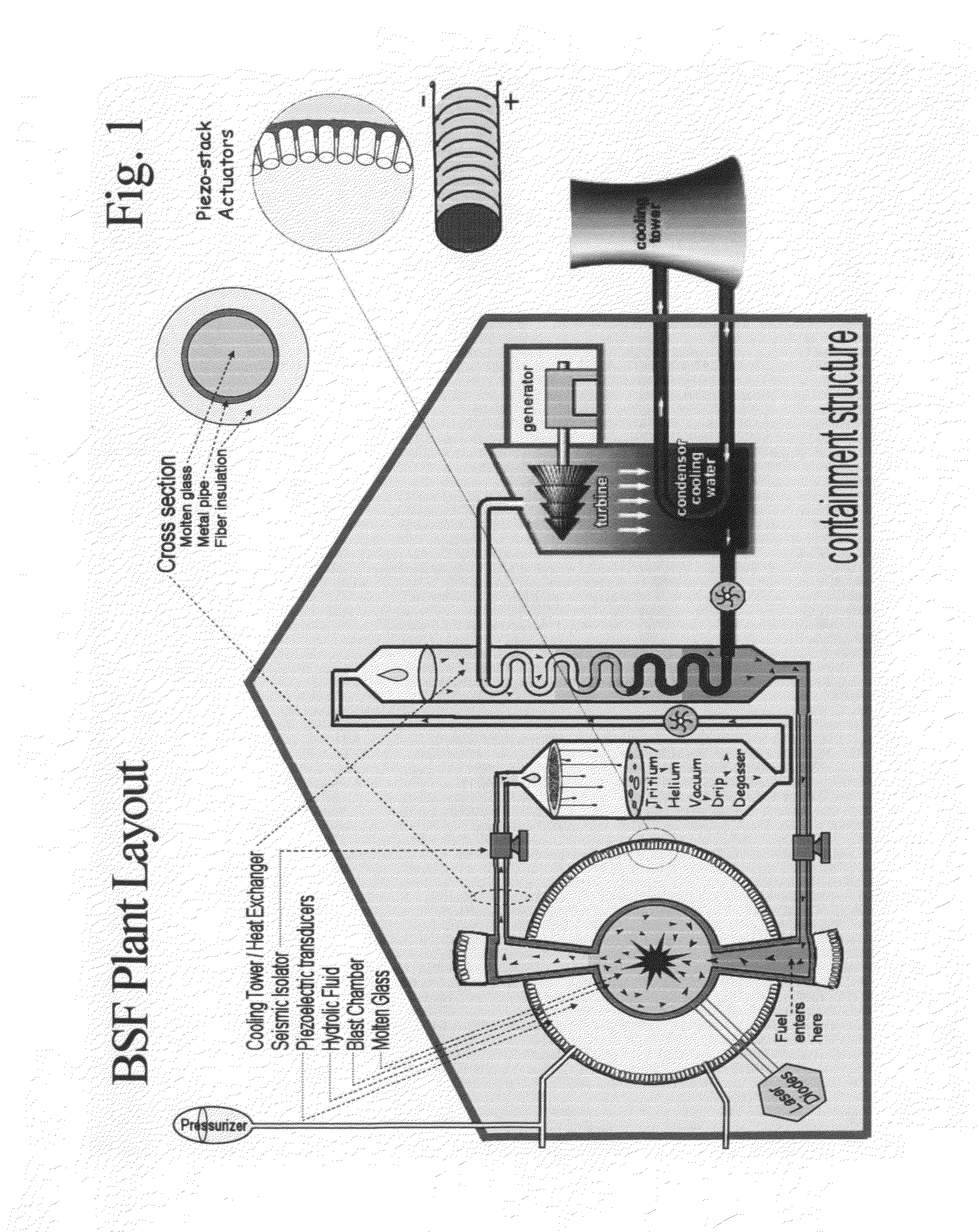

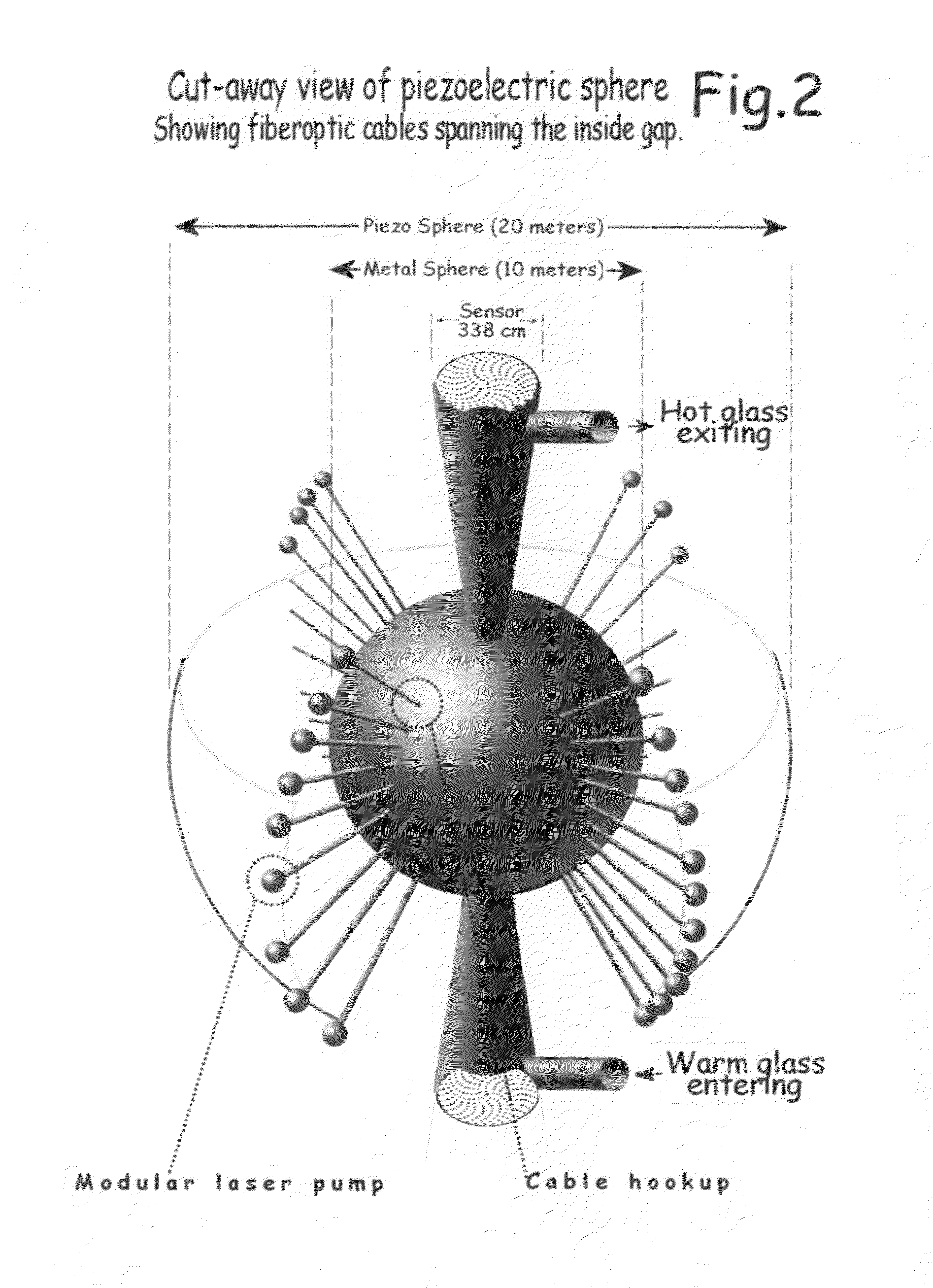

Nuclear fusion power plant having a liquid reactor core of molten glass that is made laseractive and functions as a tritium breeding blanket which is capable of acousticly compressing/confining fuel so that it radiates and triggers outgoing laser cascades that will reflect from the blast chamber's spherical inside wall and return like photonic Tsunamis, crushing, heating, and causing thermonuclear ignition of the fuel so that heat engines and piezoelectric harvesters can convert the released energy into electricity

InactiveUS20120014491A1Highly compressibleProne to feverNuclear energy generationLow temperature fusion reactorNuclear fusionNuclear engineering

A nuclear fusion power plant having a spherical blast-chamber filled with a liquid coolant that breeds tritium, absorbs neutrons, and functions as both an acoustical and laser medium. Fuel bubbles up through the sphere's base and is positioned using computer guided piezoelectric transducers that are located outside the blast-chamber. These generate phase-shifted standing-waves that tractor the bubble to the center. Once there, powerful acoustic compression waves are launched. Shortly before these reach the fuel, an intense burst of light is pumped into the sphere, making the liquid laser-active. When the shockwaves arrive, the fuel temperature skyrockets and it radiates brightly. This, photon-burst, seeds outgoing laser cascades that return, greatly amplified, from the sphere's polished innards. Trapped within a reflecting sphere, squeezed on all sides by high-density matter, the fuel cannot cool or disassemble before thorough combustion. The blast's kinetic energy is absorbed piezoelectrically.

Owner:DEETH MIKE

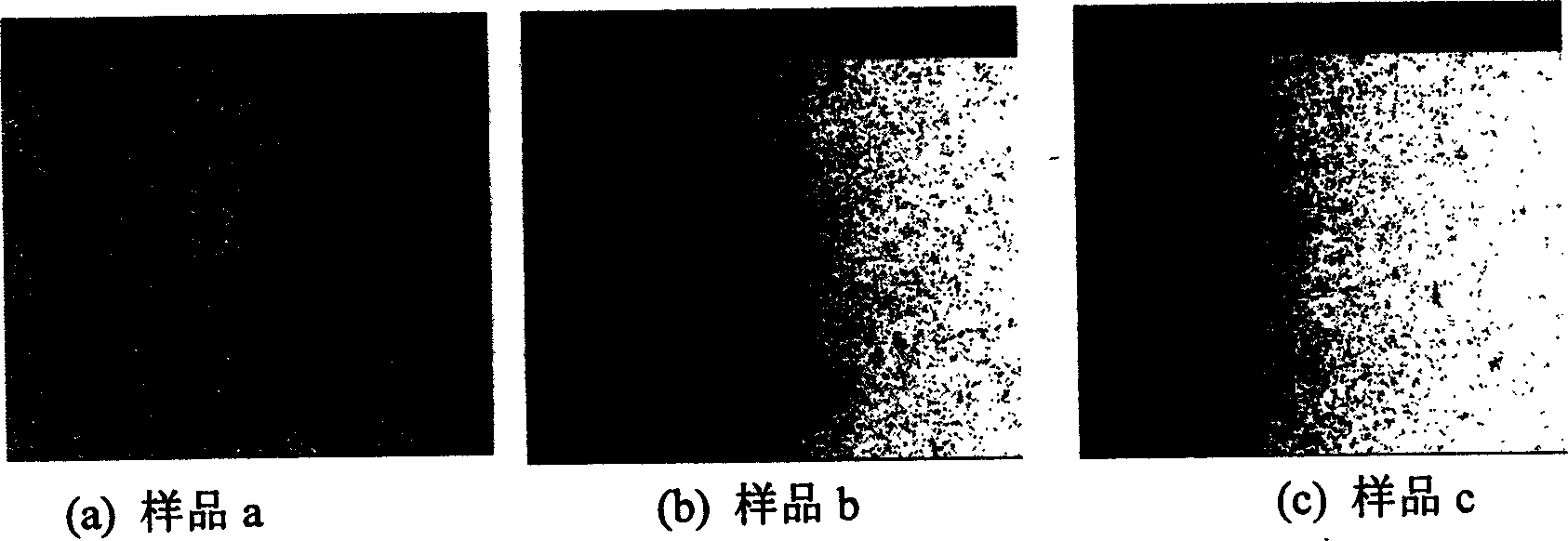

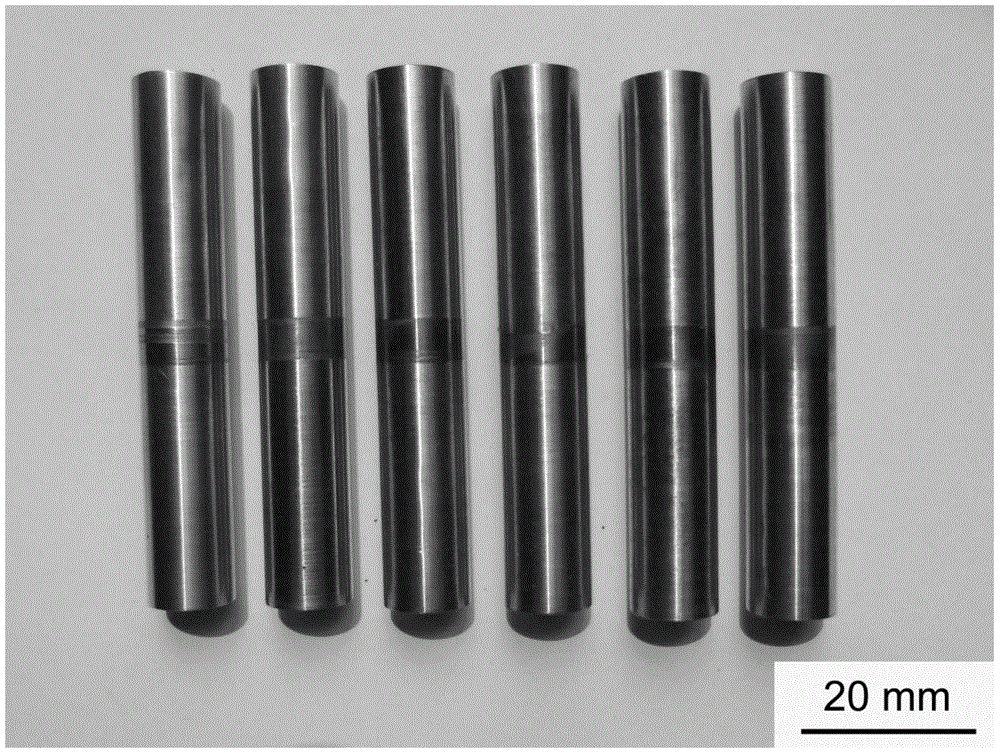

Method for preparing tungsten/copper functional gradient material by infiltration - weld method

InactiveCN1593818AEasy to prepare and effectiveSolve thermal stressMetal layered productsFritGradient material

The invention relates to a new method of making tungsten-copper functional gradient material, which consists of pure tungsten layer and tungsten-copper gradient transit layer. First, make the gradient hole-framework with boring fluid of percent 5~80 volume ratio and tungsten powder of 1~20 micron. Infiltrate copper fluid to make the tungsten-copper gradient transit layer. Weld the W / Cu gradient layer and the pure tungsten by hot pressure. The process is following: mix the material and mould them, then frit framework, Infiltrate copper, weld and check. The method has both the advantage of melt-casting technique and jointing technique. The tungsten-copper functional gradient material made by this method is better heatproof and suited to electric sealing material, heat sinking material, and anti-high temperature plasma scouring unit such as the first layer material in nuclear fusion.

Owner:UNIV OF SCI & TECH BEIJING

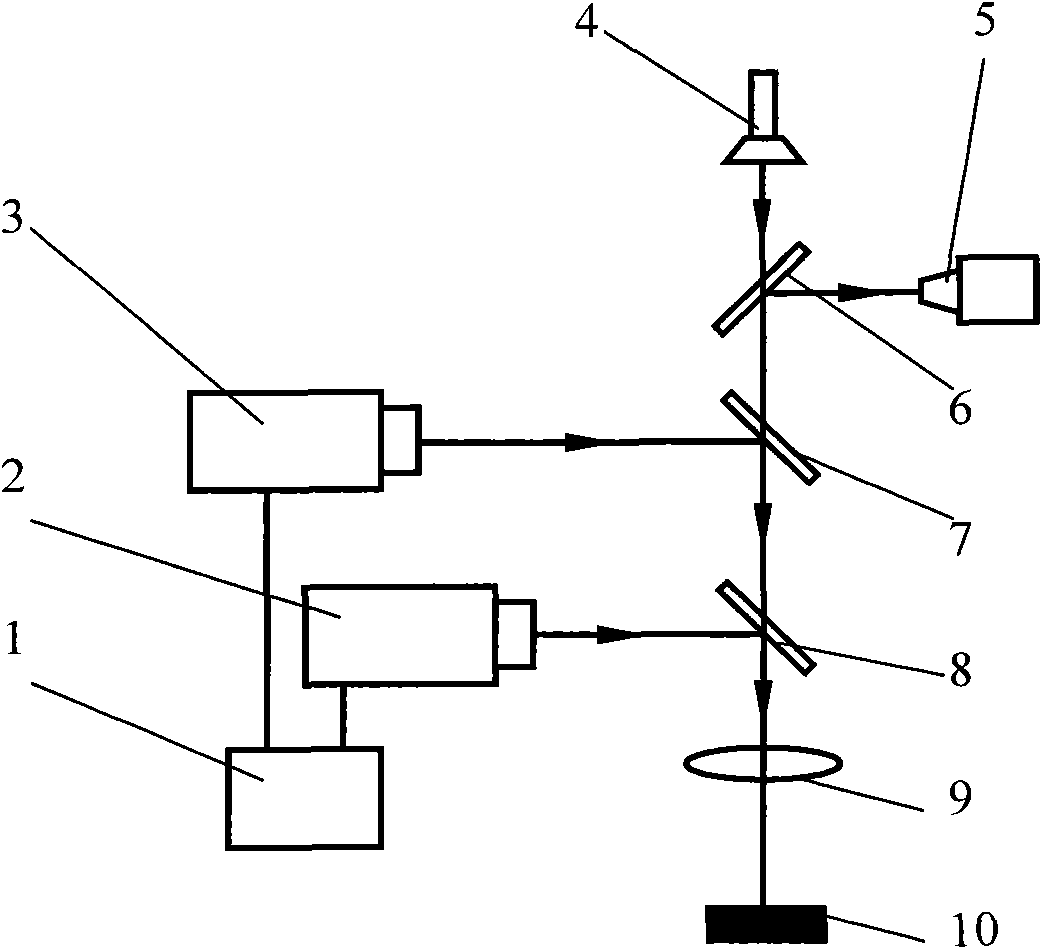

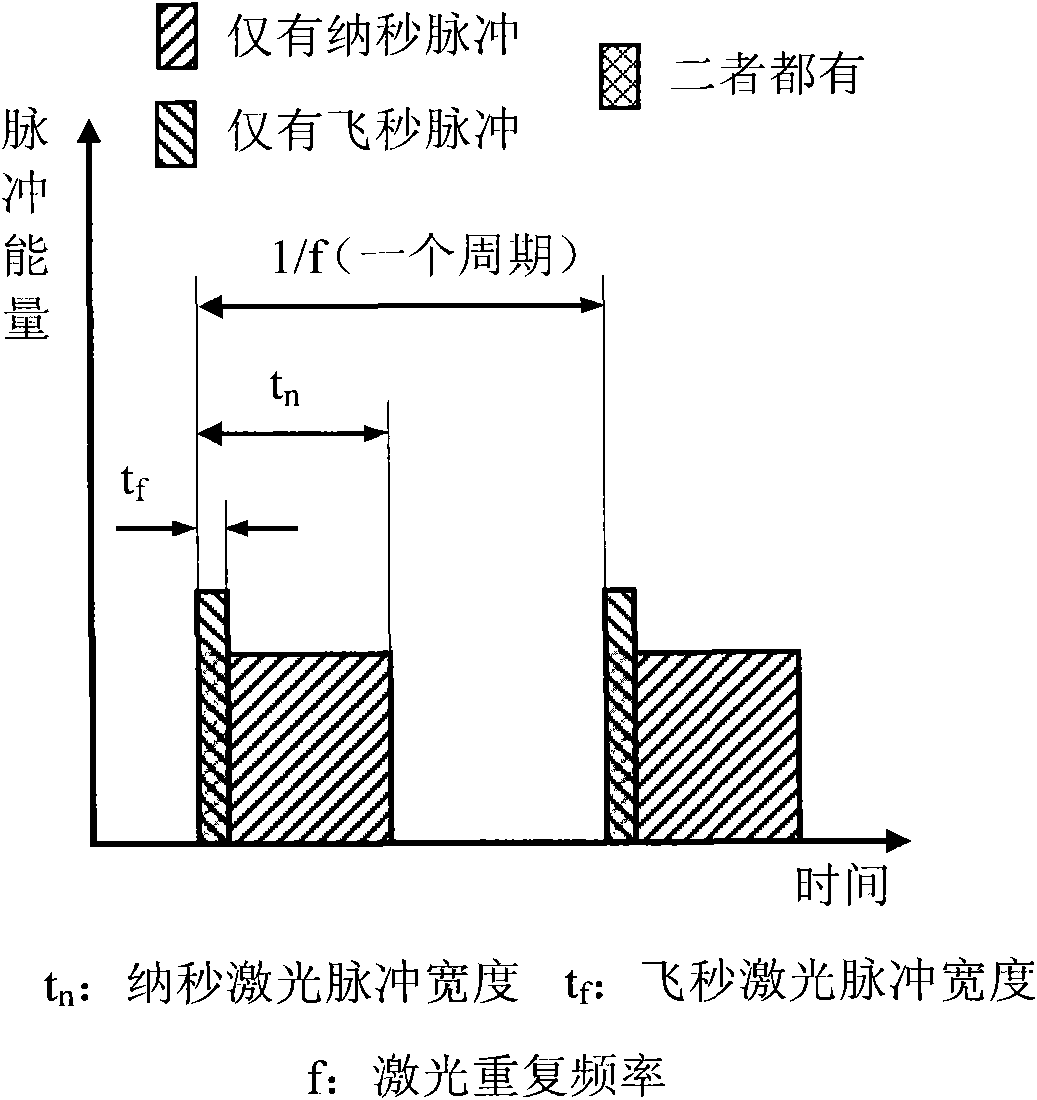

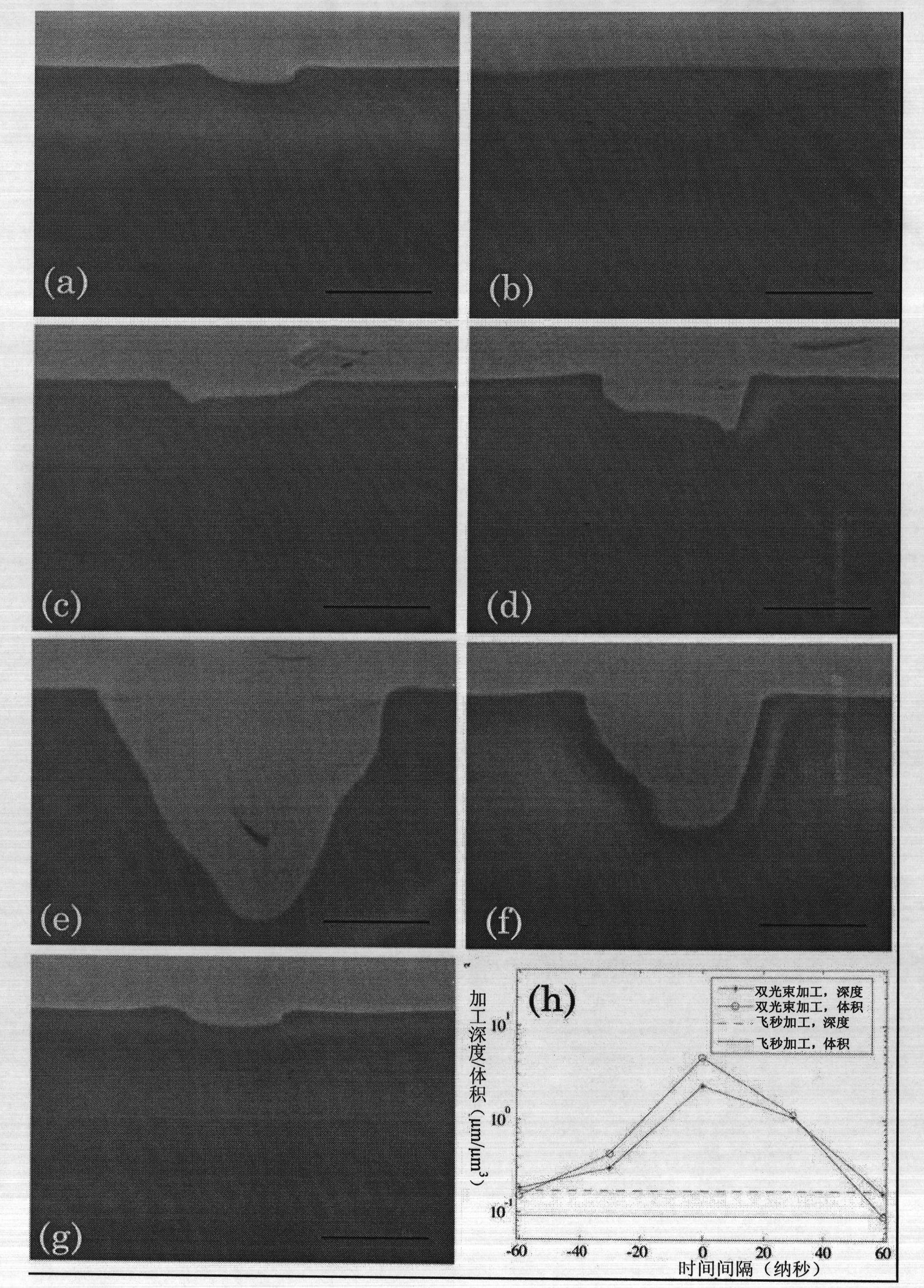

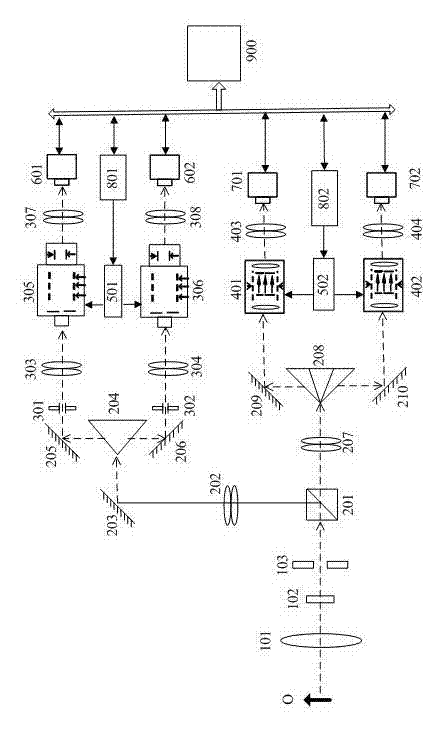

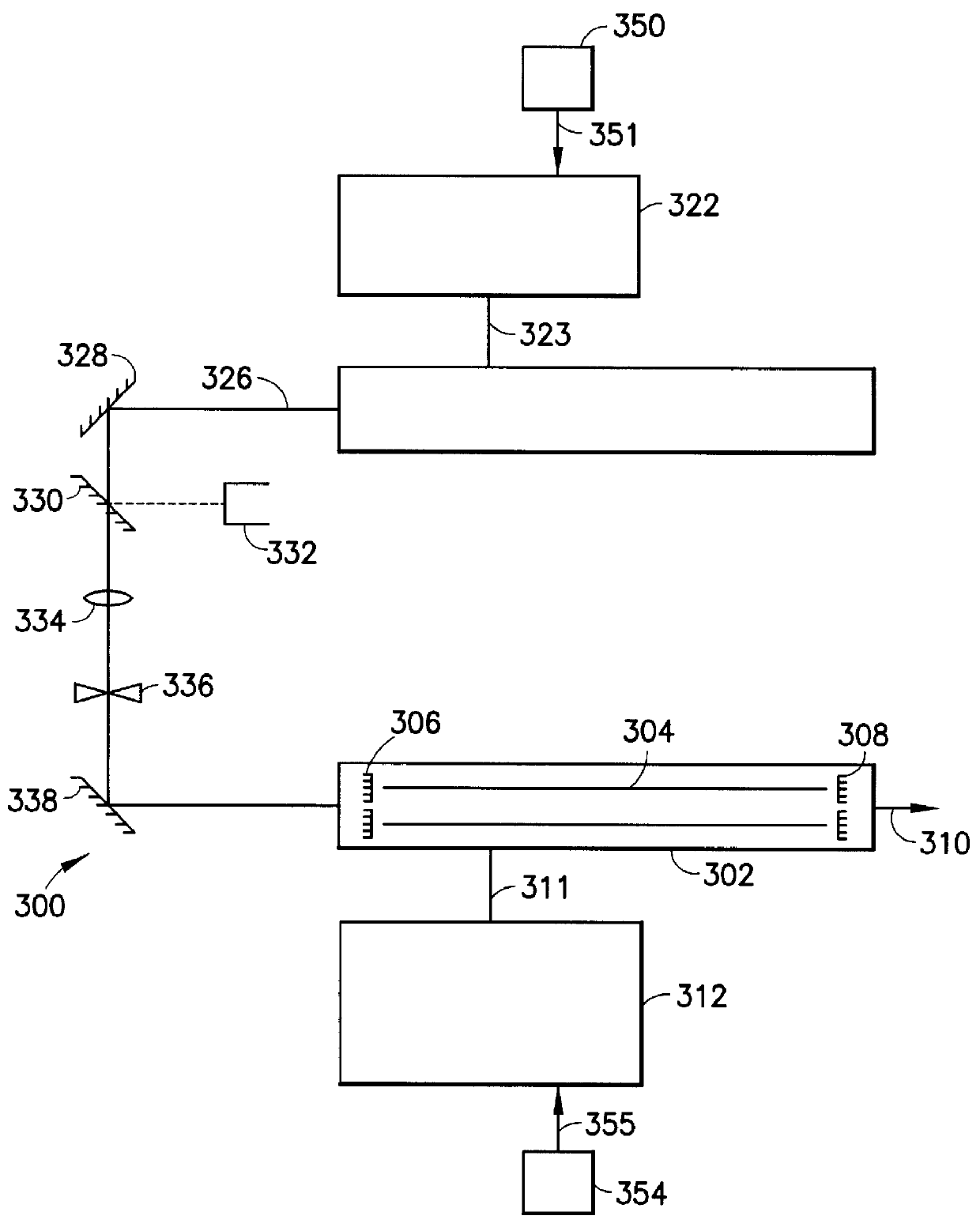

Nano-femtosecond dual-laser composite machining system

InactiveCN102059451AHigh precisionHigh nanosecond laser processing efficiencyLaser beam welding apparatusOptical elementsMicro nanoNuclear fusion

The invention relates to a nano-femtosecond dual-laser composite machining system. The system comprises a femtosecond laser, a nanosecond laser, a synchronous control circuit, an illuminating light source, a semi-transparent semi-reflecting mirror, a first dichroscope, a second dichroscope, a focusing lens and a charge coupled device (CCD) image detector, wherein the synchronous control circuit controls laser pulse output of the femtosecond laser and the nanosecond laser, and accurately adjusts relative time of nanosecond pulse and femtosecond pulse in the aspect of time to synchronize leading edges of the two pulses; the illuminating light source is positioned on one side of the semi-transparent semi-reflecting mirror, and the second dichroscope, the first dichroscope and the focusing lens are coaxially arranged on the other side of the semi-transparent semi-reflecting mirror in turn and are positioned on a straight line together with the illuminating light source; and the CCD image detector is positioned at the tail end of a reflecting light path of the semi-transparent semi-reflecting mirror. Through the system, the advantages of high femtosecond laser machining accuracy and high nanosecond laser machining efficiency are simultaneously integrated, and high-accuracy and high-efficiency micro-nano machining is realized; and the system can be widely applied to the fields such as high-accuracy machining of aviation and aerospace key parts, microstructure machining of a laser fusion ignition target, microstructure machining of a microsensor and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nuclear fusion reactor and method

A nuclear fusion reactor comprising a spherical reaction chamber with a mirrored interior surface filled with a nuclear fusible and laser active gaseous medium such as deuterium. Using rapid gaseous expansion caused by a focused pulsed laser source and / or timed oscillations from piezoelectric transducer, a harmonic spherical acoustic wave pattern centered within the reaction chamber is created. This wave pattern is created near a desired frequency and centered in the sphere. The wave pattern contains a central gaseous ball of high-density, pressure, and temperature that causes ionization and radiation to occur. This radiation causes the mirrored chamber to activate a spherical laser effect focused on the high pressure plasma at the center of the reaction chamber. This spherical laser pulse acting on high pressure high-density of the central standing wave produces ignition of the gas and fusion. The tremendous energy from fusion drives the acoustic process which ideally allows for a self sustaining ignition temperature plasma requiring the addition of fuel only.

Owner:ENFINGER ARTHUR L

High density storage of excited positronium using photonic bandgap traps

A device is provided that can capture and store electrically neutral excited species of antimatter or exotic matter (a mixture of antimatter and ordinary matter), in particular, excited positronium (Ps*). The antimatter trap comprises a three-dimensional or two-dimensional photonic bandgap (PBG) structure containing at least one cavity therein. The species are stored in the cavity or in an array of cavities. The PBG structure blocks premature annihilation of the excited species by preventing decays to the ground state and by blocking the pickoff process. A Bose-Einstein Condensate form of Ps* can be used to increase the storage density. The long lifetime and high storage density achievable in this device offer utility in several fields, including medicine, materials testing, rocket motors, high power / high energy density storage, gamma-ray lasers, and as an ignition device for initiating nuclear fusion reactions in power plant reactors or hybrid rocket propulsion systems.

Owner:RAYTHEON CO

Dual-plasma fusion and fission fuel cells

InactiveUS20060045228A1More powerMore electricityNuclear energy generationMachines/enginesThermal energyElectric force

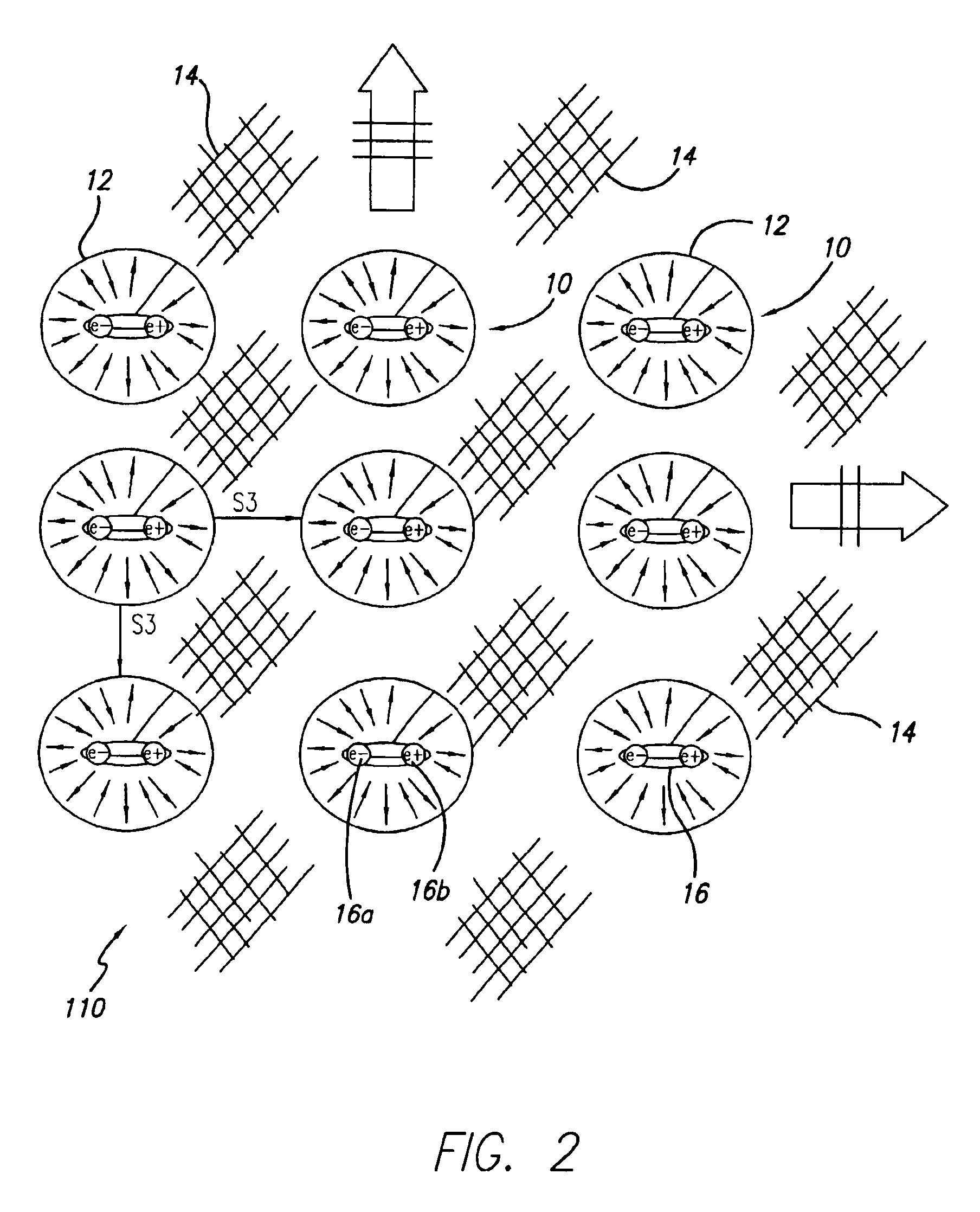

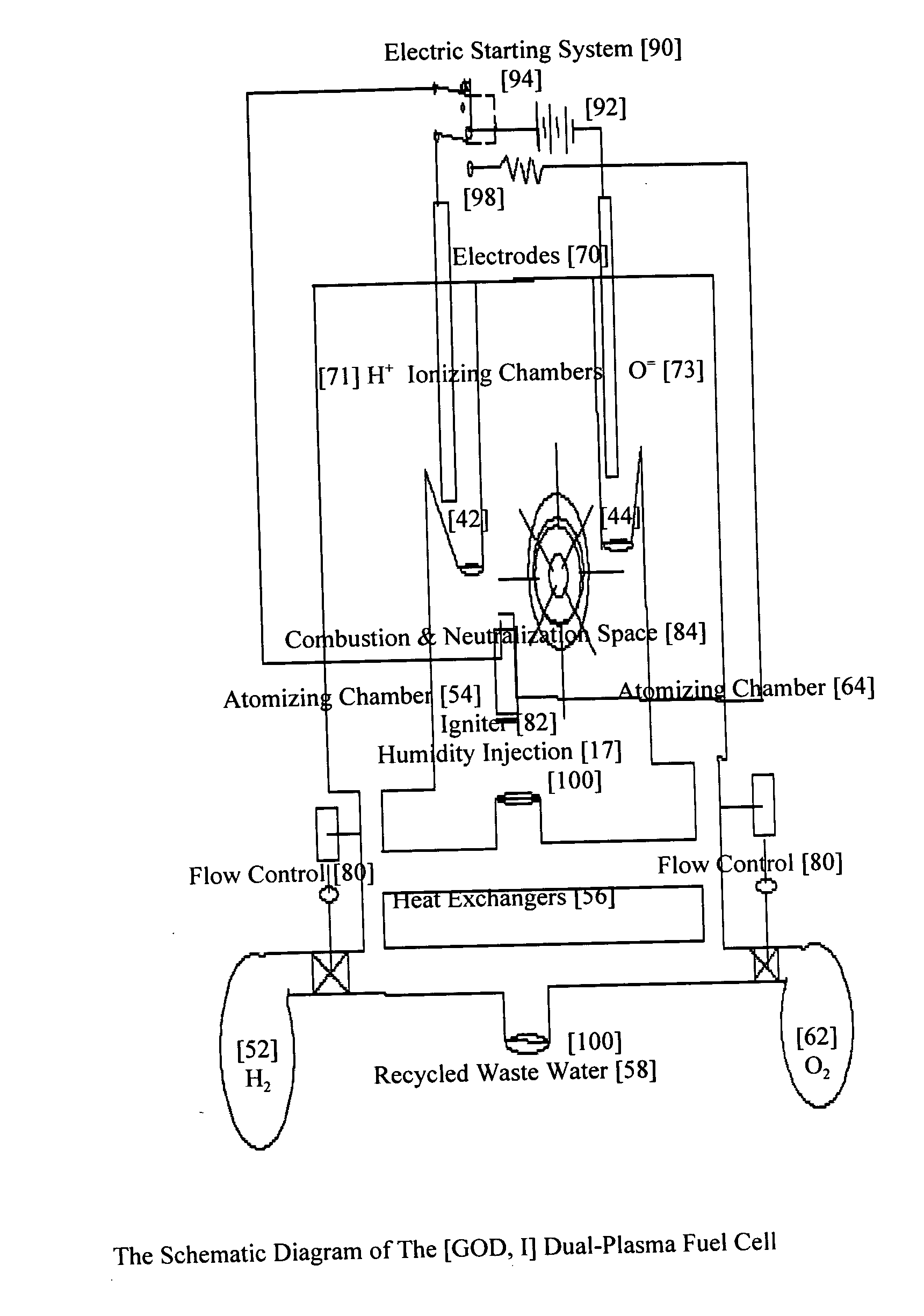

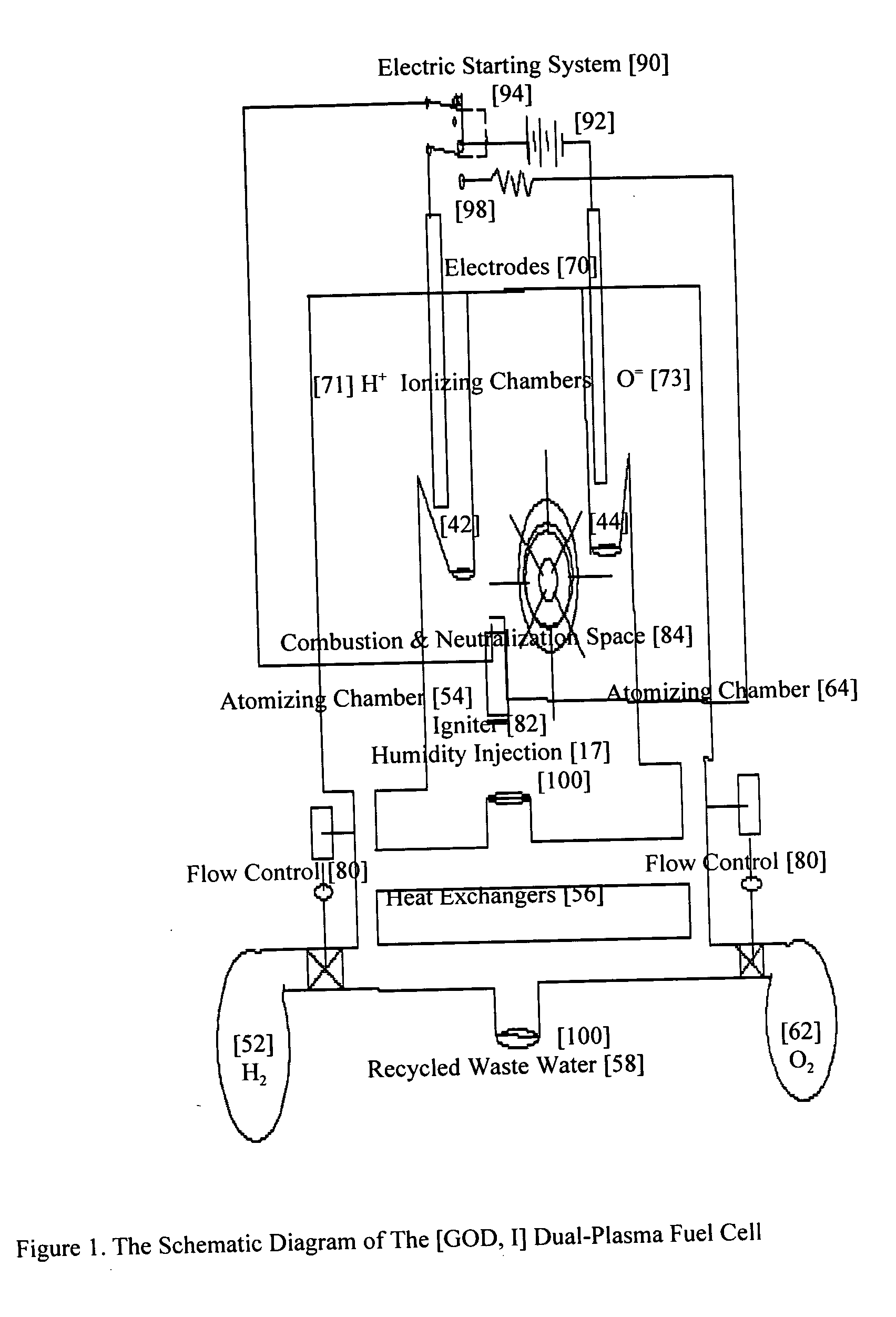

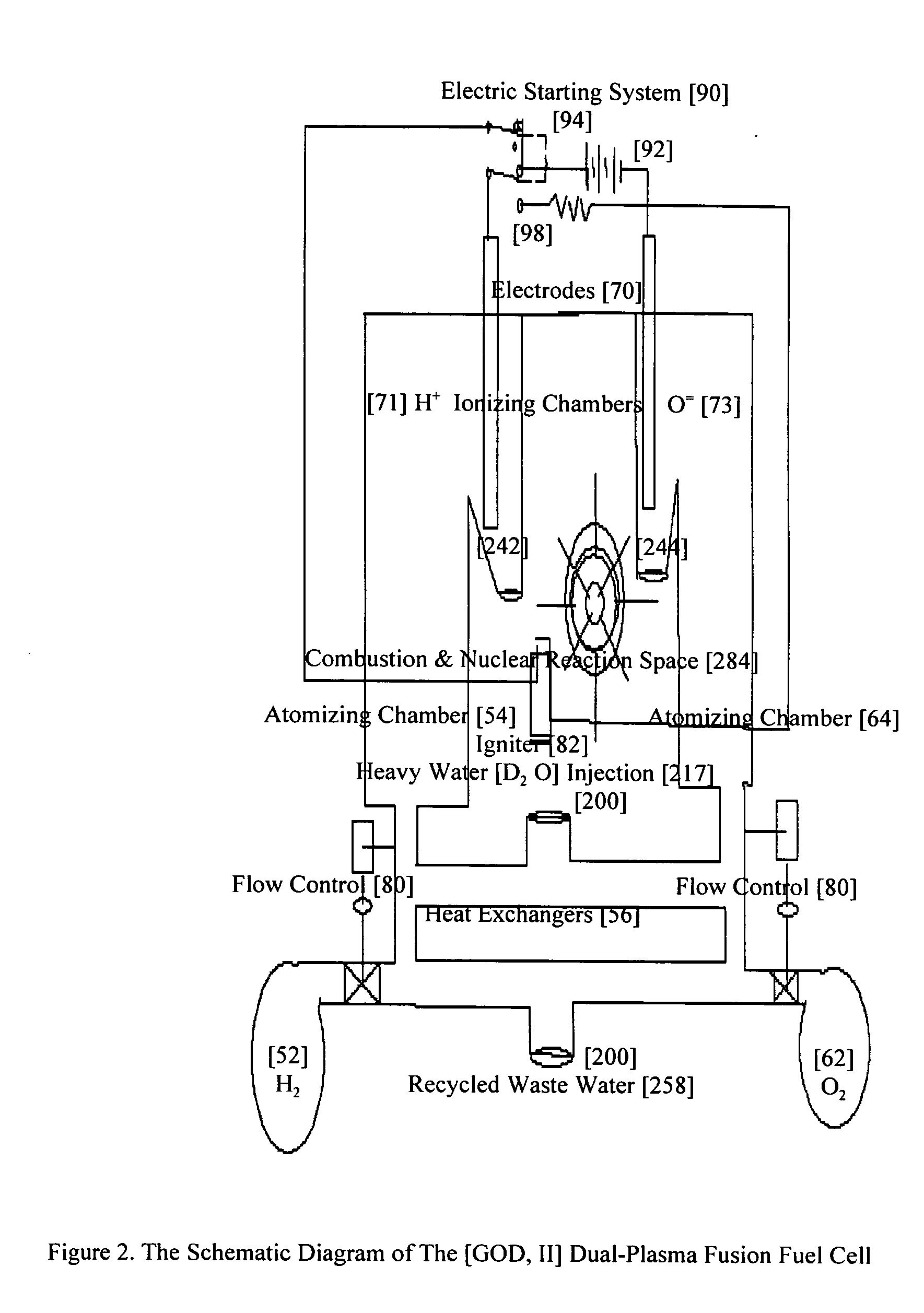

New [GOD, I], [GOD, II], & [GOD, III] dual-plasma fuel cells provide the electric start systems to start their warm-up processes, automatically. After their warm-up processes done and the operation temperatures reached, the dual-plasma fuel cells will run independently by continuously supplying fuels and moisture into the units. In dual-plasma nuclear [fusion and / or fission] fuel cells' configuration, electrical power will be generated from the nuclear-thermal-plasmas reaction by exothermal heating from combustion & nuclear reactions. With conducting high-electrons' current, the cable, loads, and electrodes are connected among one another between two plasmas' ionizing chambers for civil utility purposes. In the [GOD, II] dual-plasma fusion fuel cell, heavy water [D2O] injection into the atomizing chambers increases the plasmas heating and electrical conductivities. And the un-like charges of the heavy water's [D2O+], & [D2O−] react with plasmas' [2H+& O=] combustion heating which will induce the fusion reaction and release much more nuclear heating power for initiation of the next plasmas-generation cycle much easily. For the [GOD, III] dual-plasma fission fuel cell, fission fuels located in the combustion & nuclear reaction space through robotic movements provide additional nuclear-thermal energy that allows for initiation of the plasmas-generation process for the next cycle. For [GerTh. I] dual-plasma jet thruster, the dual plasmas are ejected to an opening end of a ‘C’ shaped magnet, and linear thrust is generated, according to the right-hand rule as in a jet thruster of propulsion for space traveling.

Owner:DAW SHIEN SCI RES & DEV

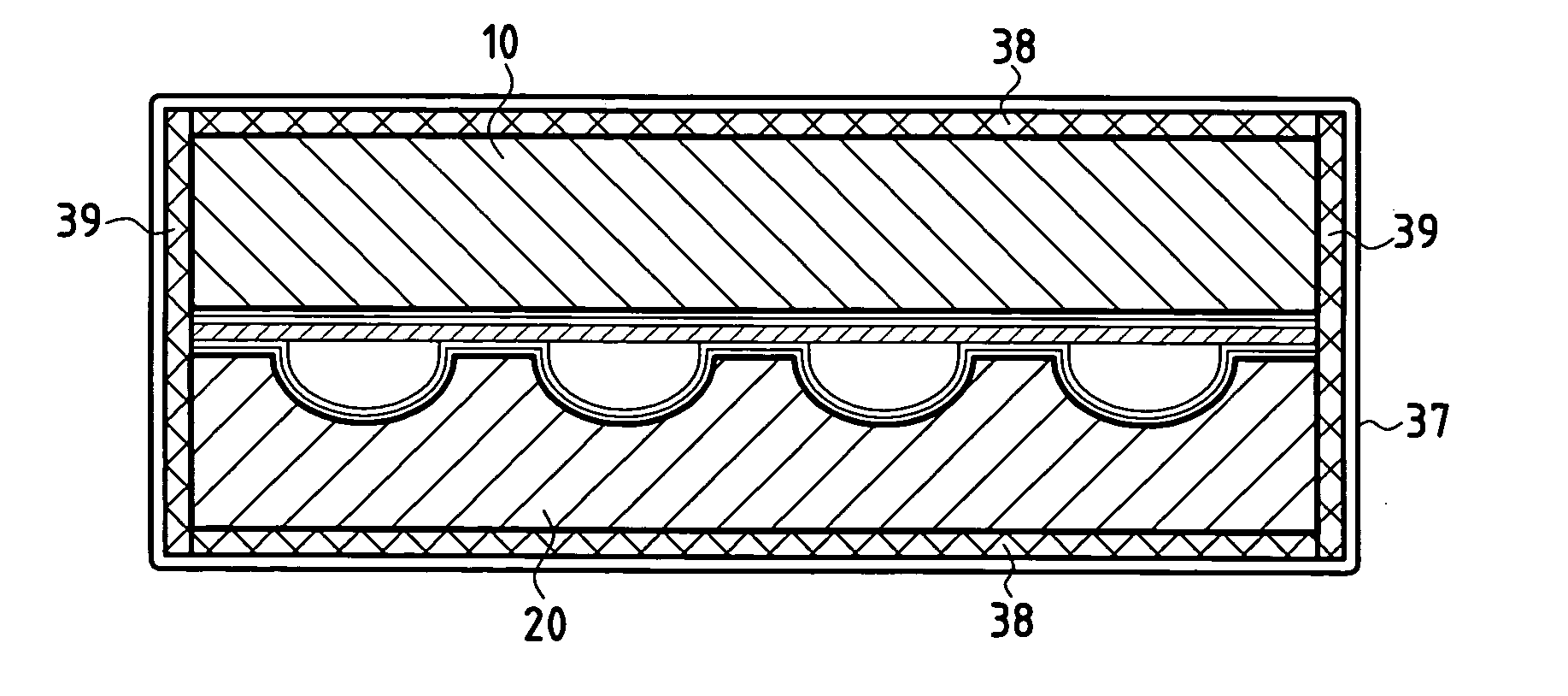

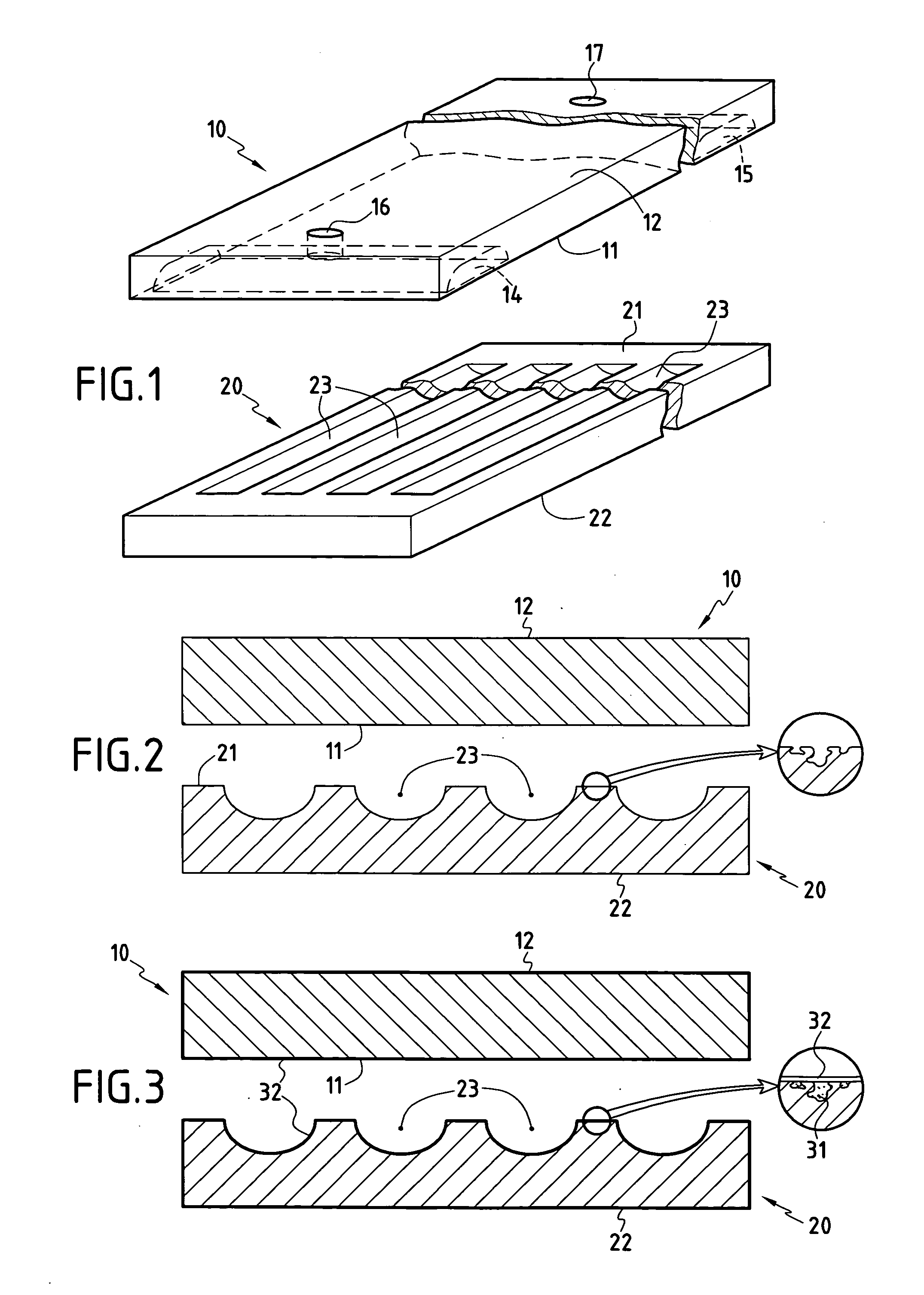

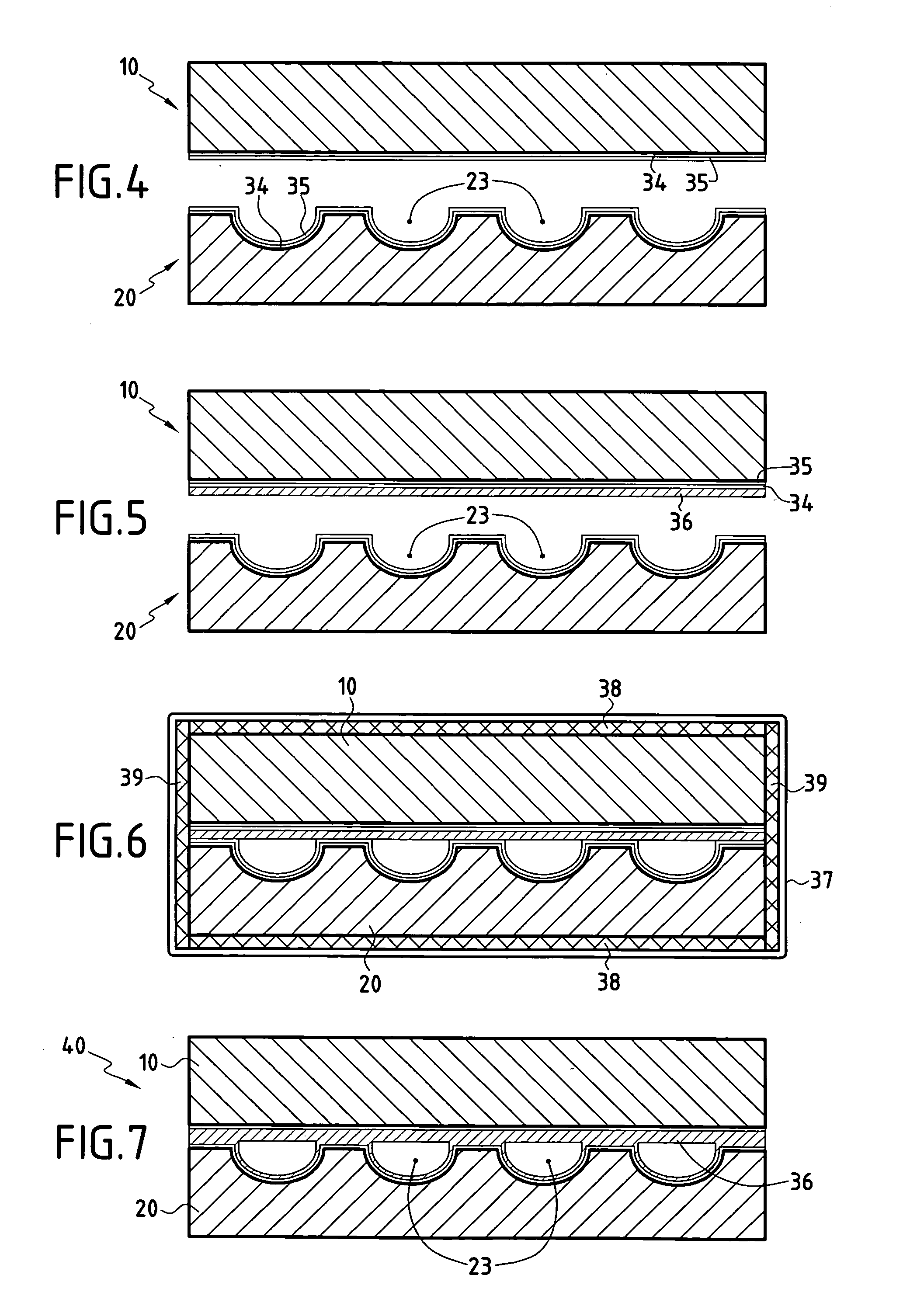

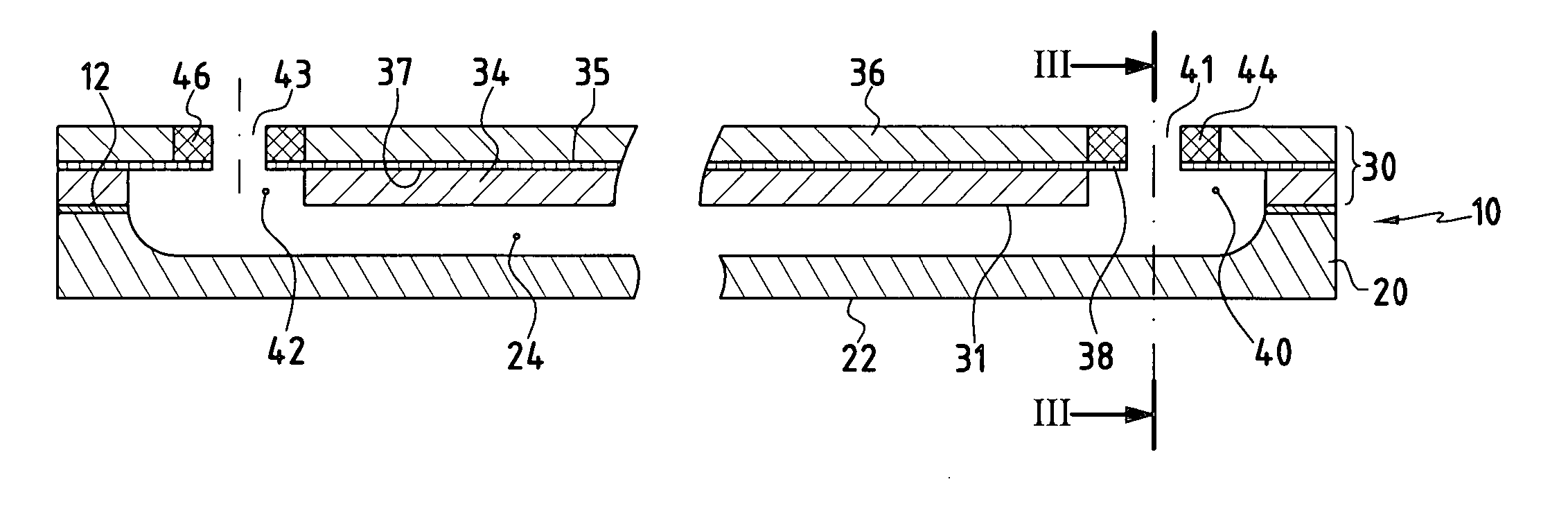

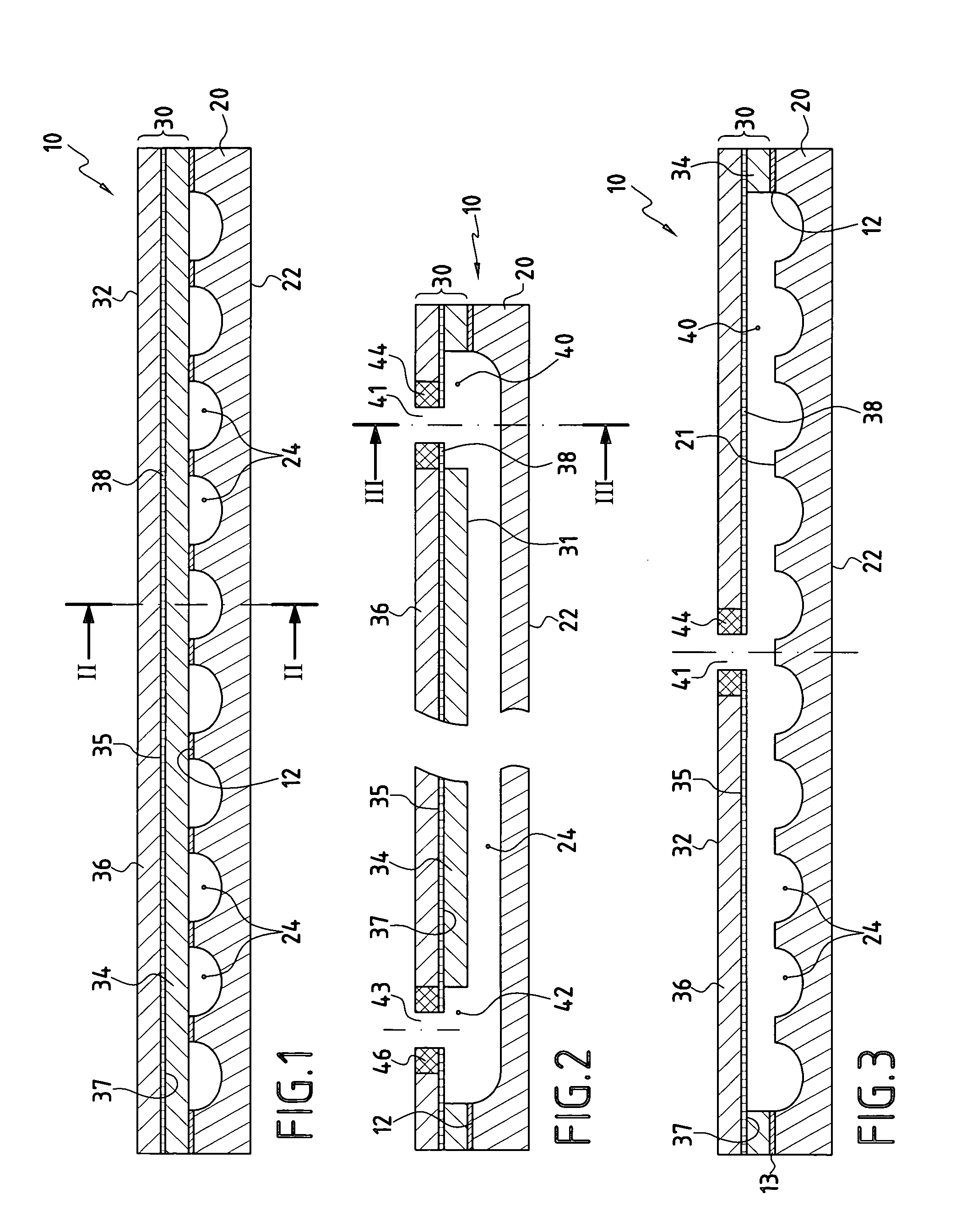

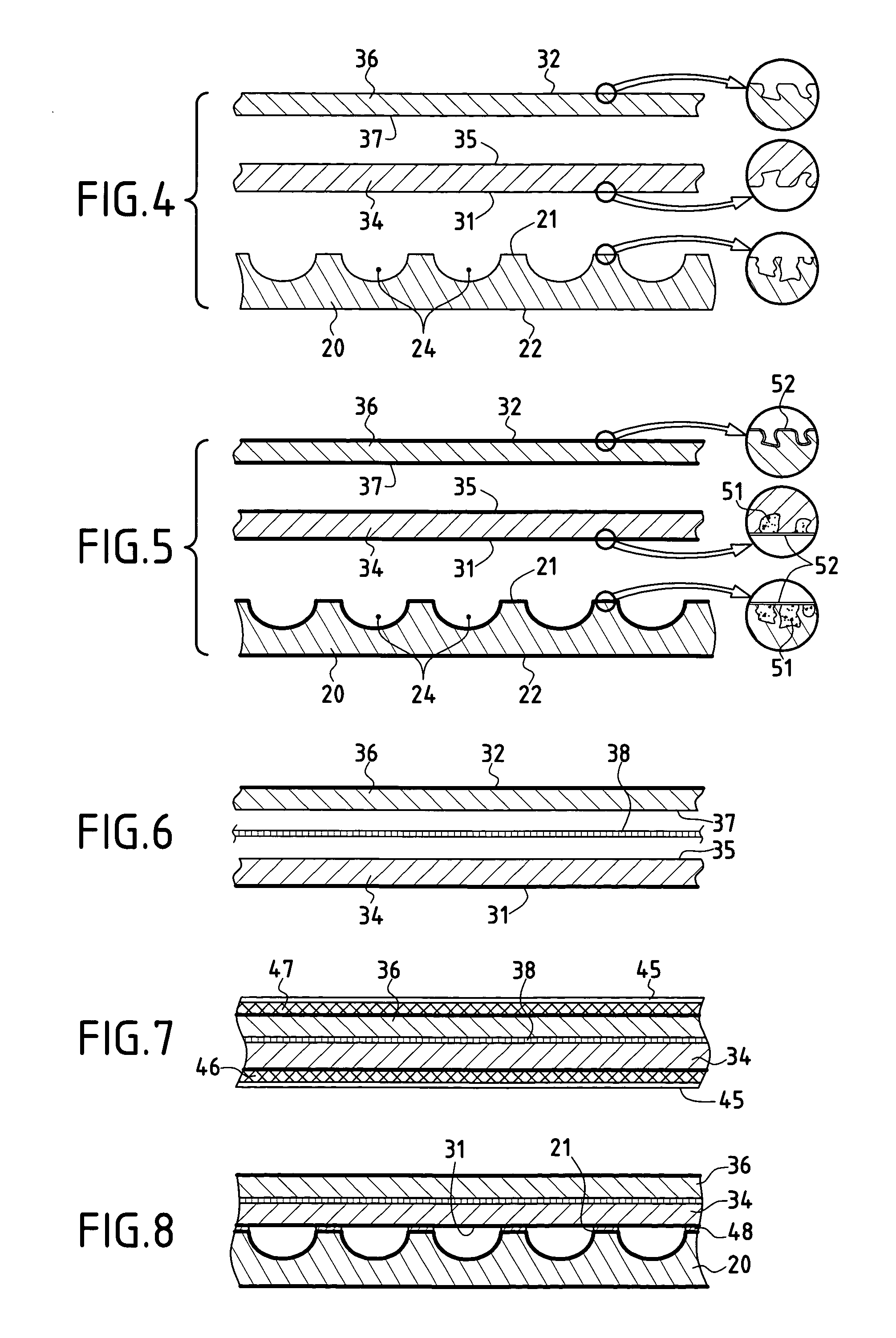

Method of manufacturing an active cooling panel out of thermostructural composite material

InactiveUS20050077341A1Effective and durableReduce usageContinuous combustion chamberNuclear energy generationMetal coatingCombustion chamber

A metal coating is formed on the inside face of a first thermostructural composite material part presenting indentations forming channels, and also on the inside face of a second thermostructural composite material part for being applied against the inside face of the first part, and the first and second parts are assembled together by bonding said inside faces together by hot compression, in particular by hot isostatic pressing, thereby obtaining a thermostructural composite material cooling panel having integrated fluid flow channels. The invention is applicable to making heat exchanger walls such as the walls of combustion chambers in aircraft engines, or the diverging portions of rocket engines, or plasma confinement chambers in nuclear fusion reactors.

Owner:SNECMA PROPULSION SOLIDE

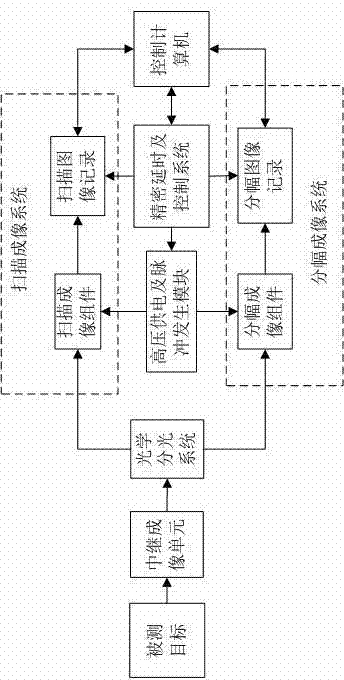

Simultaneously framing and scanning ultra-high-speed photoelectricity shooting system

InactiveCN103197499AGuarantee the same time baseGuaranteed Space BasePhotogrammetry/videogrammetryHigh-speed photographyNuclear fusionInstability

The invention discloses a simultaneously framing and scanning ultra-high-speed photoelectricity shooting system. The system comprises a relaying imaging unit, an optical beam splitting system, a scanning imaging system, a framing imaging system, a precise delay and control system, a high-voltage power supply and pulse generating module and a control computer. An object to be measured is synchronously imaged to the scanning imaging system and the framing imaging system through the relay imaging unit and the optical beam splitting system, and synchronous imaging is controlled by the precise delay and control system and the high-voltage power supply and pulse generating module. The simultaneously framing and scanning high-speed photoelectricity shooting system is wide in application prospect in the field of ultra-high-speed process testing, can absolutely provide high-quality digital images for researches with ultra-fast processes of electromagnetic implosion plasma discharging, controlled nuclear fusion, interaction of lasers and substances, high-voltage spark discharging, material micro jet and interface instability within nanosecond-to-10<-8> second .

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Method for preparing ceramic tritium proliferation agent in fusion stack cladding

InactiveCN101510450AImprove bindingHigh strengthNuclear energy generationThermonuclear fusion reactorNuclear fusionSlurry

The invention relates to a method for preparing a ceramic tritium breeding agent in a fusion reactor blanket, pertaining to the nuclear fusion field, in particular to a technique for preparing the ceramic tritium breeding agent pellets in the fusion reactor blanket. The method is characterized in that: organic monomers that can generate free radical polymerization and a crosslinking agent are mixed and dissolved with water or an organic solvent to prepare a pre-mixed solution, then ceramic tritium breeding agent powder is added and an initiator and a catalyst are added after defoaming treatment so as to prepare a slurry; the slurry is dripped into a medium by using a dripping device and the medium is in the state of being heating and is exclusive to the solvent used in the slurry. After entering the medium, the dripping liquid takes the form of pellet, solidifies and maintains the shape during the dropping process; the pellet is collected, cleaned, dried and sintered into the tritium breeding agent ceramic pellet material. The formed blanket has high strength and toughness; the formed pellet has high degree of sphericity, smooth surface and good evenness; the shrinkage after drying and sintering are slight, the size of the pellet is easy to be controlled and the strength is high; additionally, the cost is relatively low and the technique is flexible.

Owner:UNIV OF SCI & TECH BEIJING

Active cooling panel of thermostructural composite material and method for its manufacture

InactiveUS20040194941A1Reduce thermomechanical stressReduce surface porosityContinuous combustion chamberNuclear energy generationCombustion chamberActive cooling

Owner:SNECMA PROPULSION SOLIDE

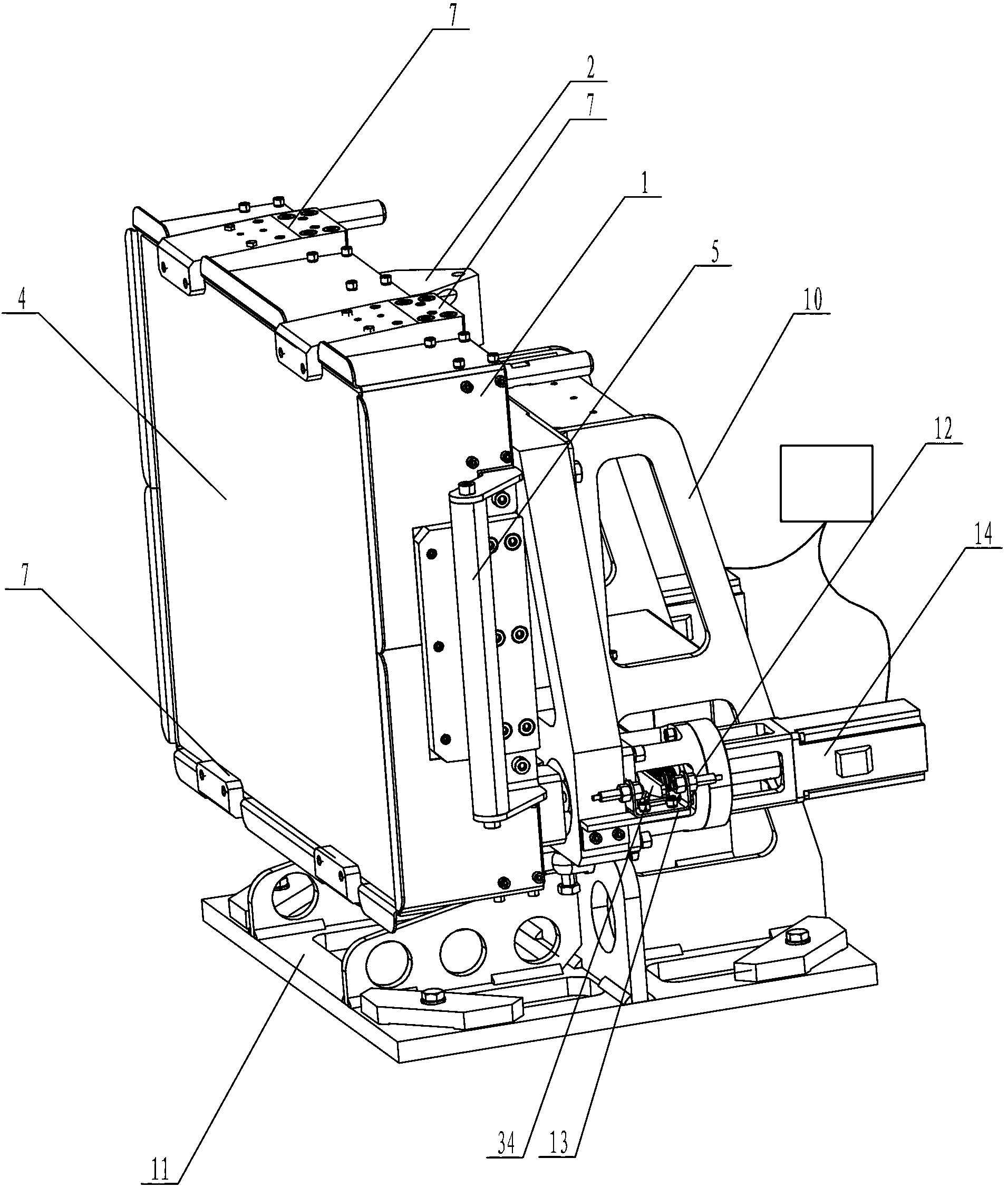

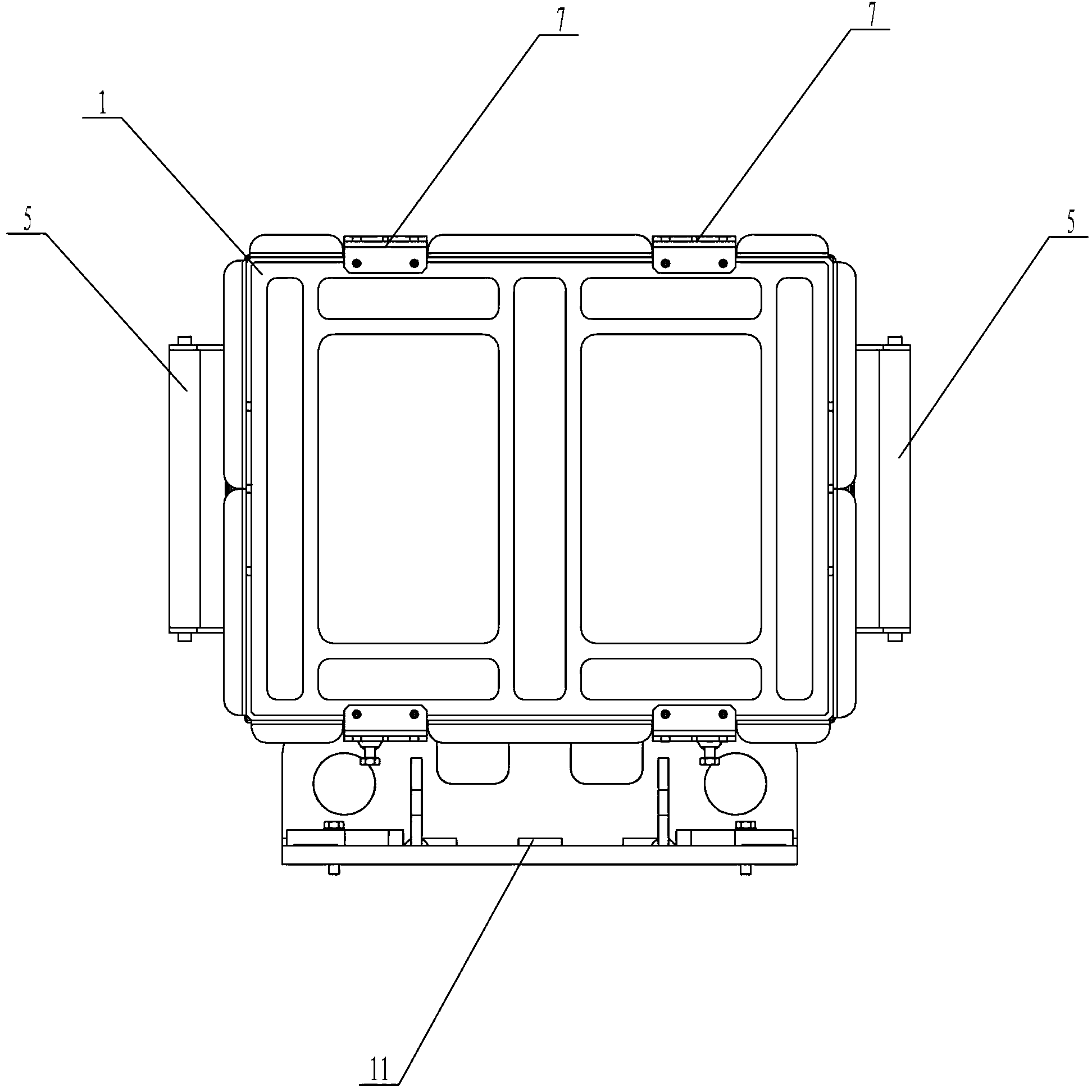

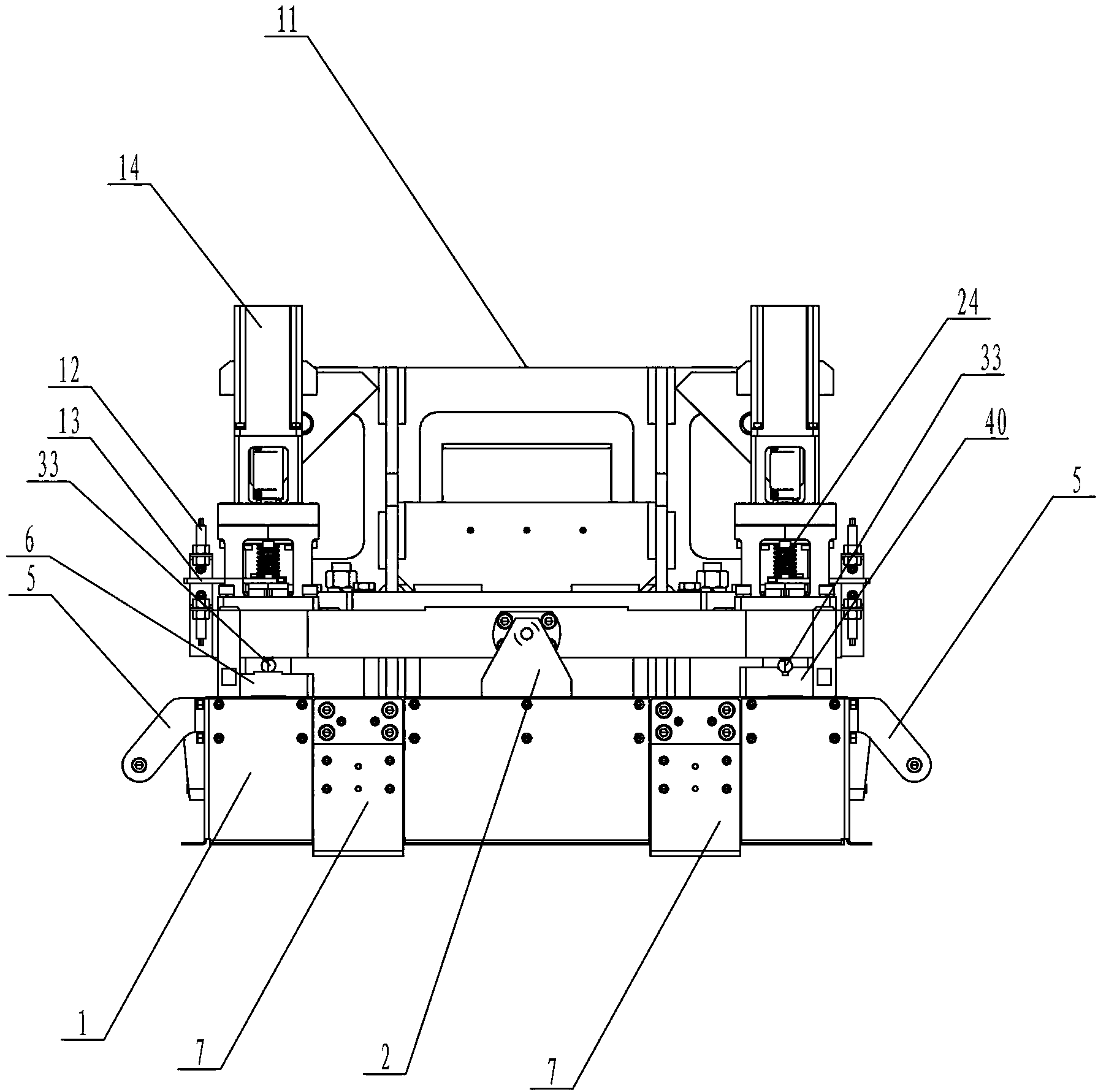

Three-point high-precision large-aperture electric reflector frame

The invention provides a three-point high-precision large-aperture electric reflector frame, relating to an electric reflector frame. According to the three-point high-precision large-aperture electric reflector frame, the transmission direction of large-aperture laser beams is precisely guided and controlled, and the problems of the alignment and guidance of the laser beams in an inertial confinement laser nuclear fusion device and the near-field adjustment of light beams are solved. The reflector frame component is arranged at the front end of a machine frame component; the reflector frame component is connected with the machine frame component in a rotating manner; two micro driver components pass through the reflector frame component and the machine frame component sequentially from front to back; a drive control system is connected with the two micro driver components through conducting wires and is used for controlling the two micro driver components; the reflector frame component is suspended on a machine frame through a spherical support; and the left spherical tip is contacted with a plane support block, and the right spherical tip is contacted with a V-shaped support block. The three-point high-precision large-aperture electric reflector frame is applicable to inertial confinement laser nuclear fusion equipment.

Owner:HARBIN INST OF TECH

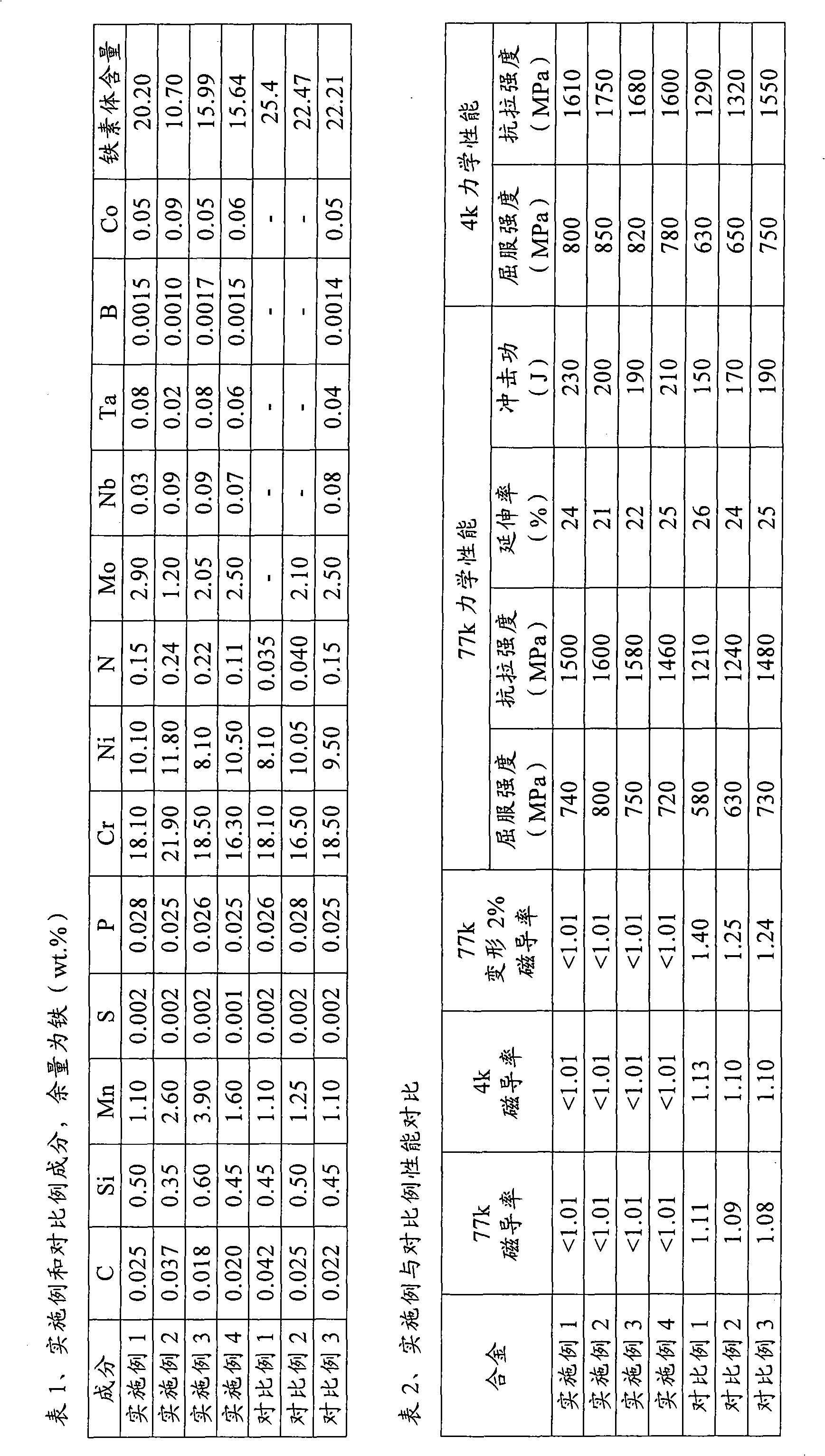

Austenitic stainless steel

ActiveCN102041457AHigh low temperature strengthHigh strengthTemperature control deviceProcess efficiency improvementNuclear fusionMetallurgy

The invention relates to austenitic stainless steel which is high in low temperature strength, low temperature toughness and low temperature non-magnetism as well as better in neutron irradiation resistance, can be used in a magnet support structure of a nuclear fusion reactor, and comprises the components by mass percent: 16.00-22.0% of Cr, 8.00-12.00% of Ni, 1.00-3.00% of Mo, 0.06-0.25% of N, 0.010-0.040% of C, 1.00-4.00% of Mn, less than or equal to 1.00% of Si, 0.01-0.10% of Nb, 0.01-0.10% of Ta, 0.030-0.10% of Co, less than or equal to 0.03% of P, less than or equal to 0.005% of S, 0.0005-0.0018% of B, and the balance of Fe and unavoidable impurities; and furthermore, the value of Val (Cr-Ni) is less than 20.5, and Val (Cr-Ni)= 3* (Cr+Mo)+4.5*Si-2.8*Ni-1.4*Mn-84*(C+N).

Owner:BAOSTEEL DESHENG STAINLESS STEEL

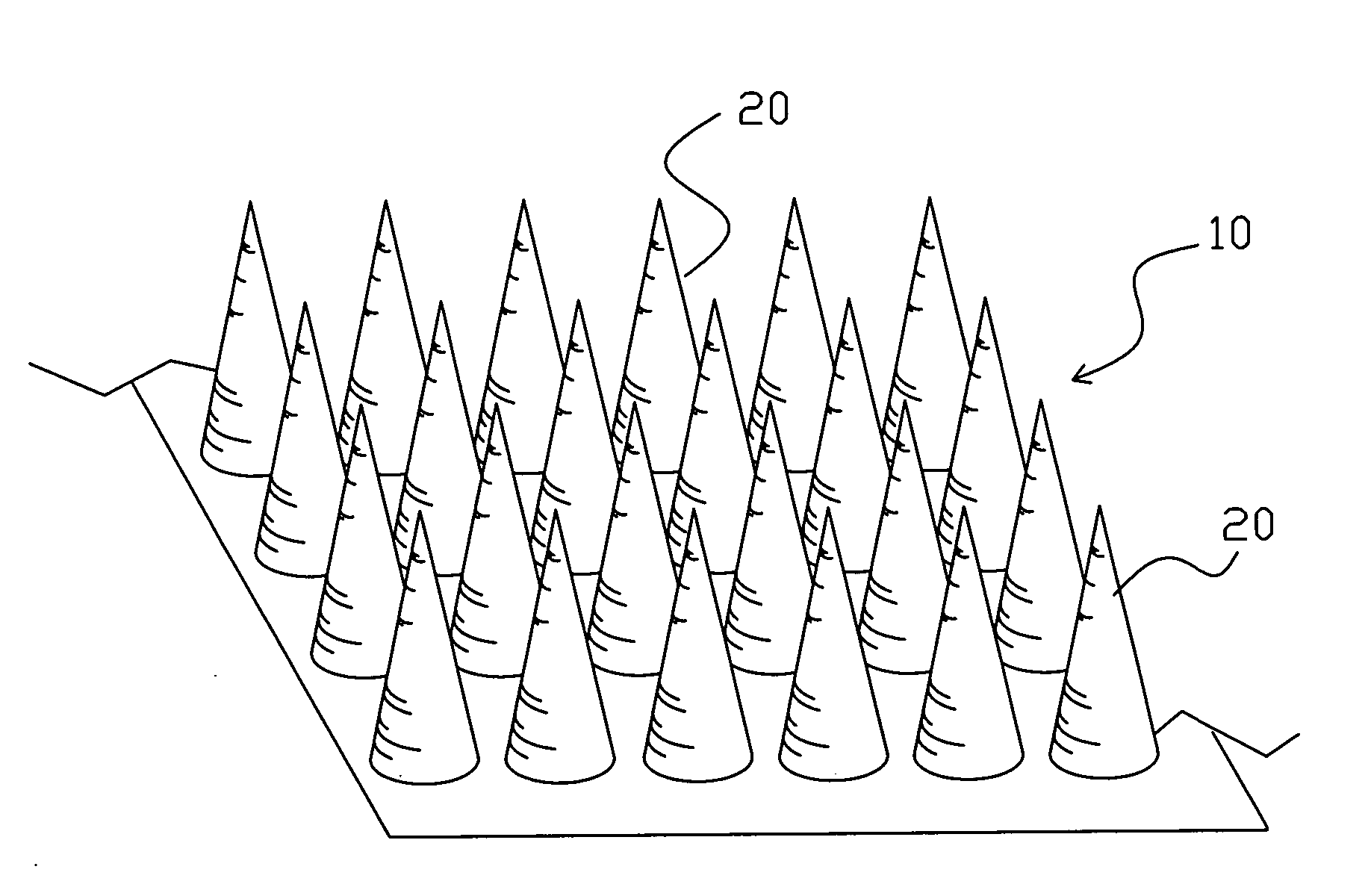

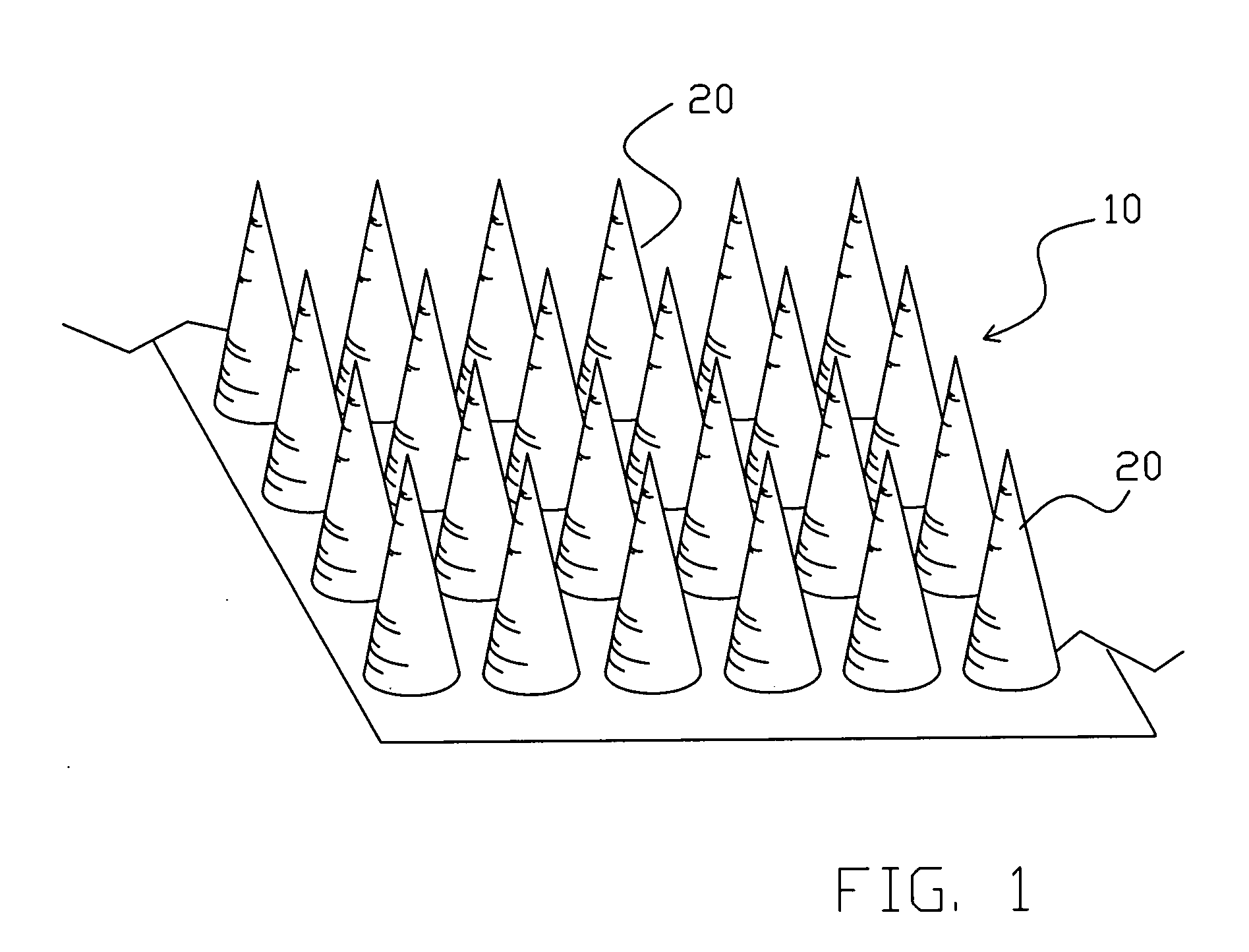

Apparatus and method for facilitating nuclear fusion

InactiveUS20050129160A1Improve responseNuclear energy generationLow temperature fusion reactorHydrogenNuclear fusion

An apparatus and method for facilitating nuclear fusion, wherein micro-scale, controlled hydrogen nuclear fusion is effectuated without the introduction of extreme temperatures and pressures, and wherein the utilization of a geometrically-enhanced reacting surface induces and / or facilities multiple room temperature fusion reactions thereon.

Owner:INDECH ROBERT

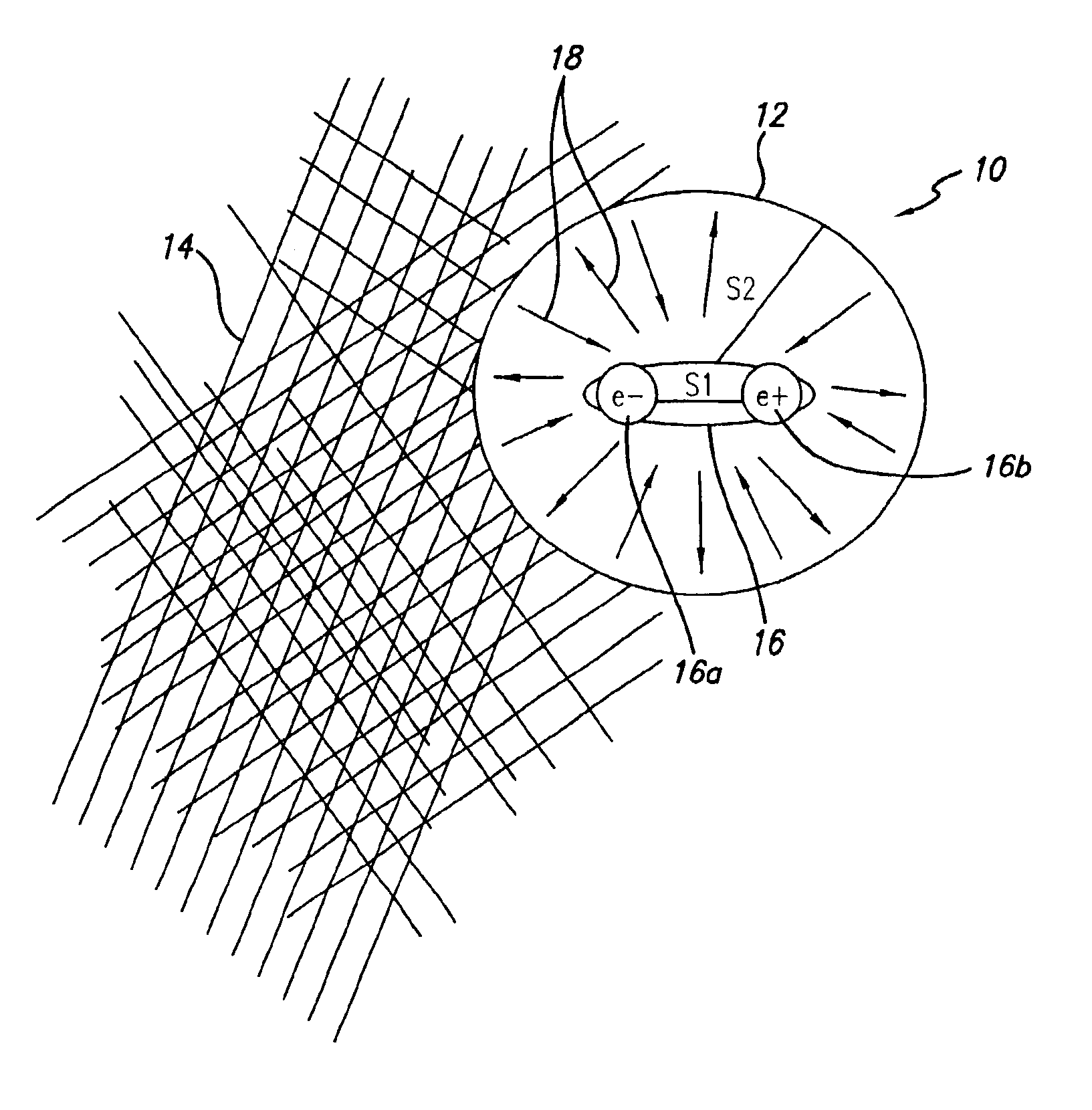

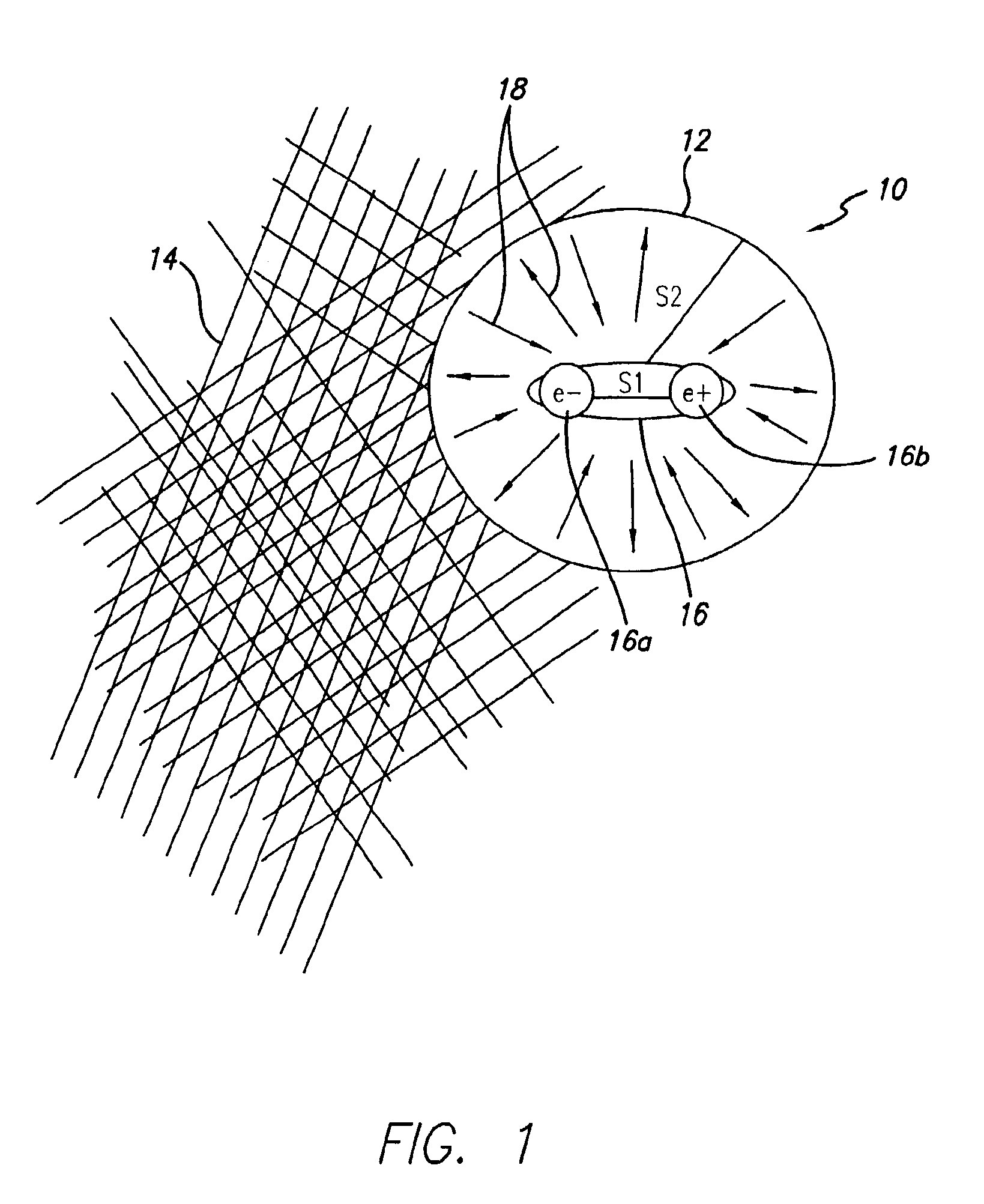

Method and apparatus for producing x-rays, ion beams and nuclear fusion energy

ActiveUS7482607B2Cheap, and effectively an unlimited energy sourceEliminate needRadiation pyrometryParticle separator tubesNuclear fusionFusion power

Owner:LAWRENCEVILLE PLASMA PHYSICS

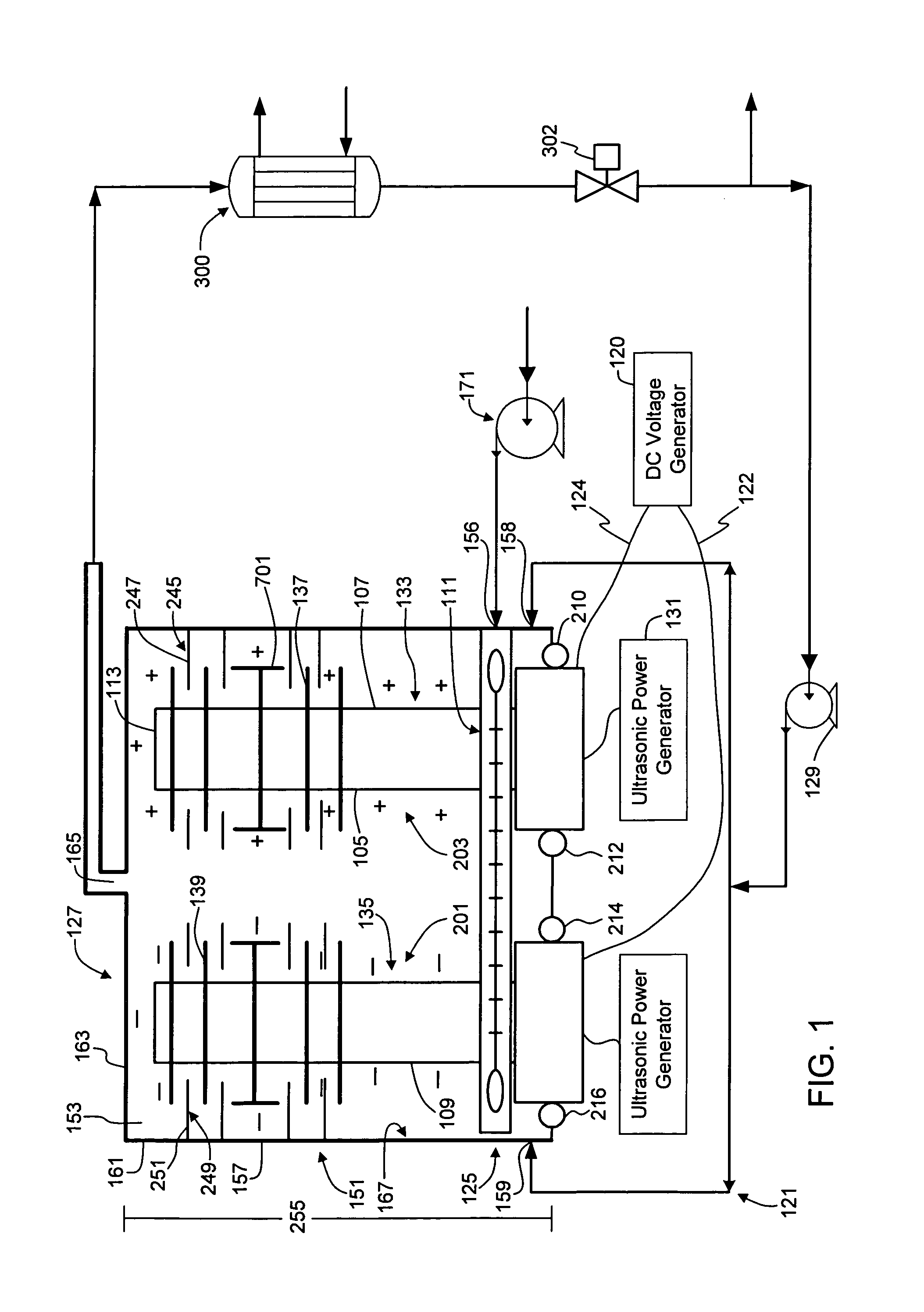

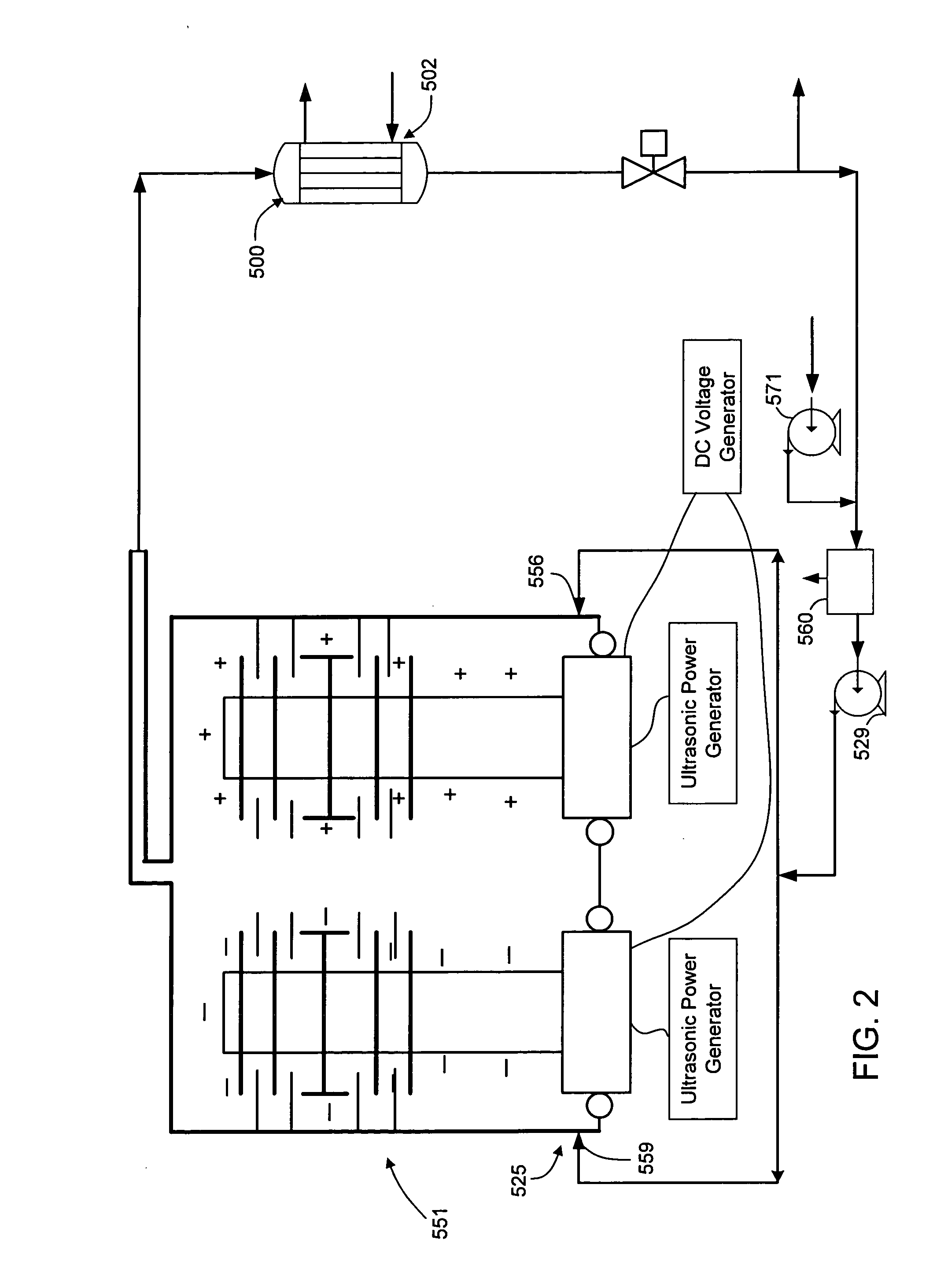

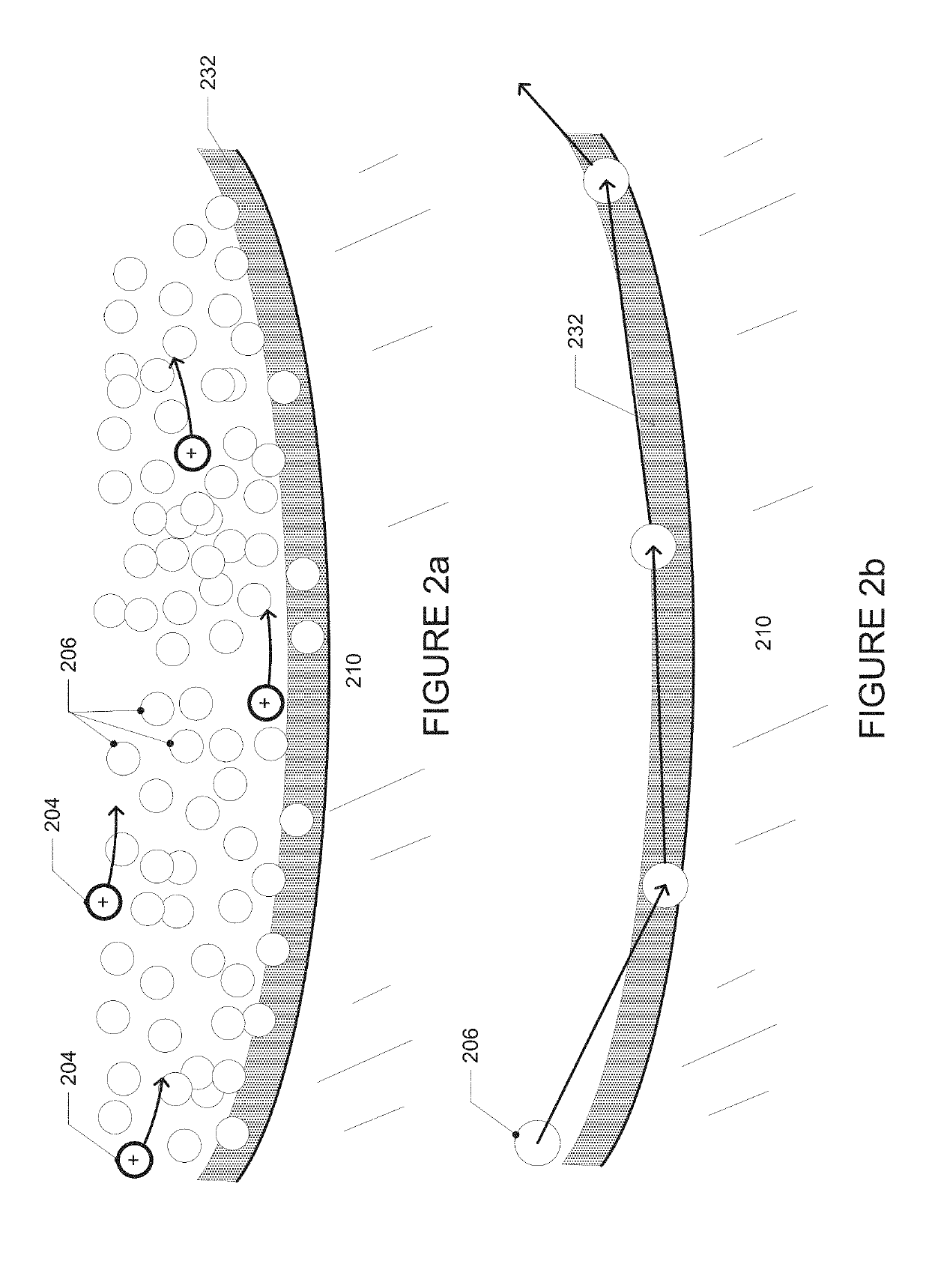

Method and apparatus for the production of nuclear fusion

InactiveUS20110216866A1Improve fusion efficiencyIncrease the number ofNuclear energy generationDirect voltage acceleratorsNuclear fusionThin sheet

By firing ionized reactant particles into a solid block of reactant, fusion reactions occur. As these particles are fired longitudinally into a thin sheet of reactant, fusion products are ejected laterally into a series of charged collectors. Unfused reactant ions that prematurely exit the solid reactant are recirculated by electric fields within the invention, boosting efficiency. Through the use of several collectors, charged particles of many energies are efficiently collected and converted to electric potential. The use of a solid sheet of reactant greatly increases the probability of fusion events taking place. The shape of the sheet acts to isolate the incoming reactant ions from the outgoing fusion products. Fusion products are not generally converted to heat by virtue of the small amount of material present in a typical product trajectory. Singly and together, these improvements act to greatly increase the efficiency of the reactor over prior art.

Owner:PEARSON TIMOTHY RAYMOND

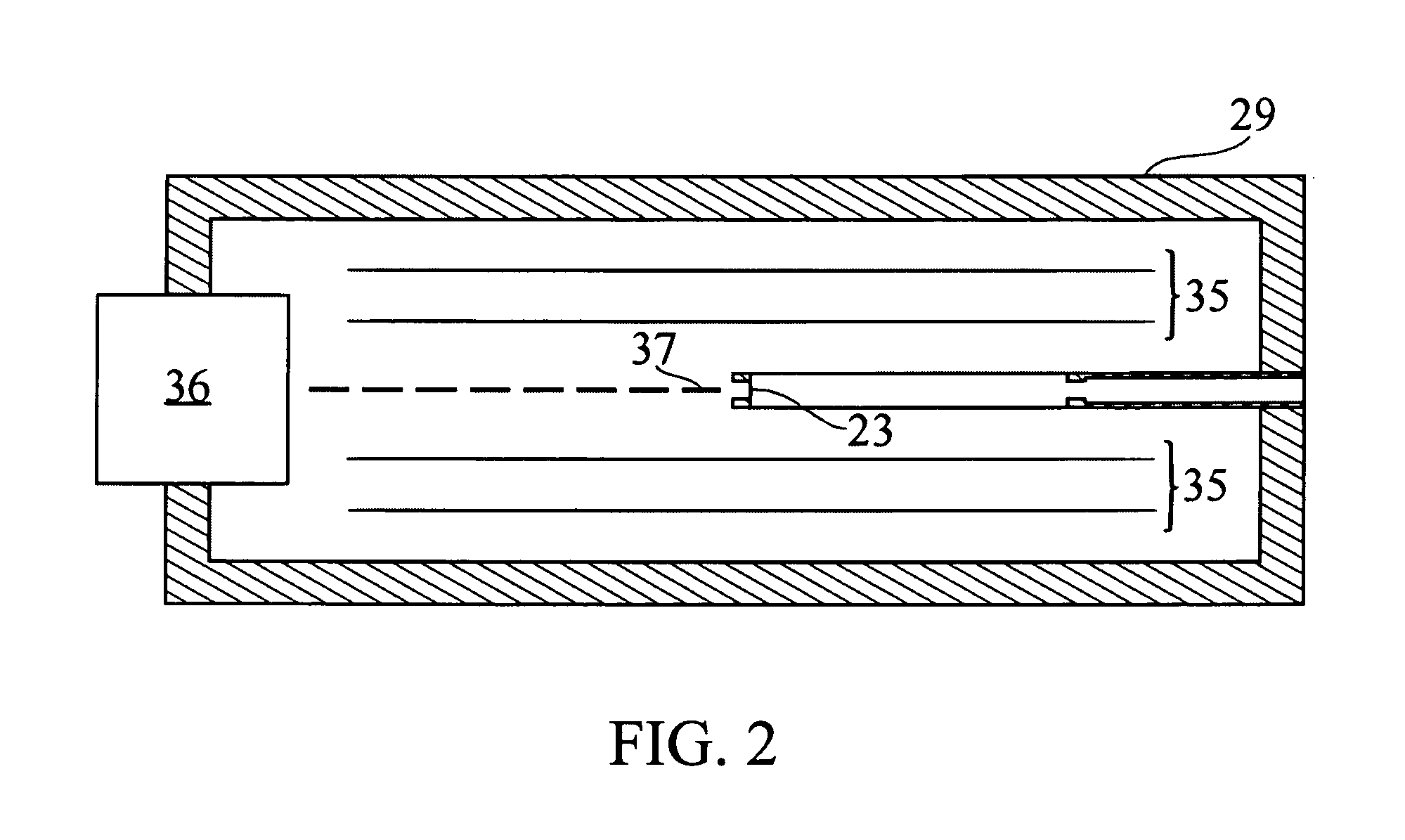

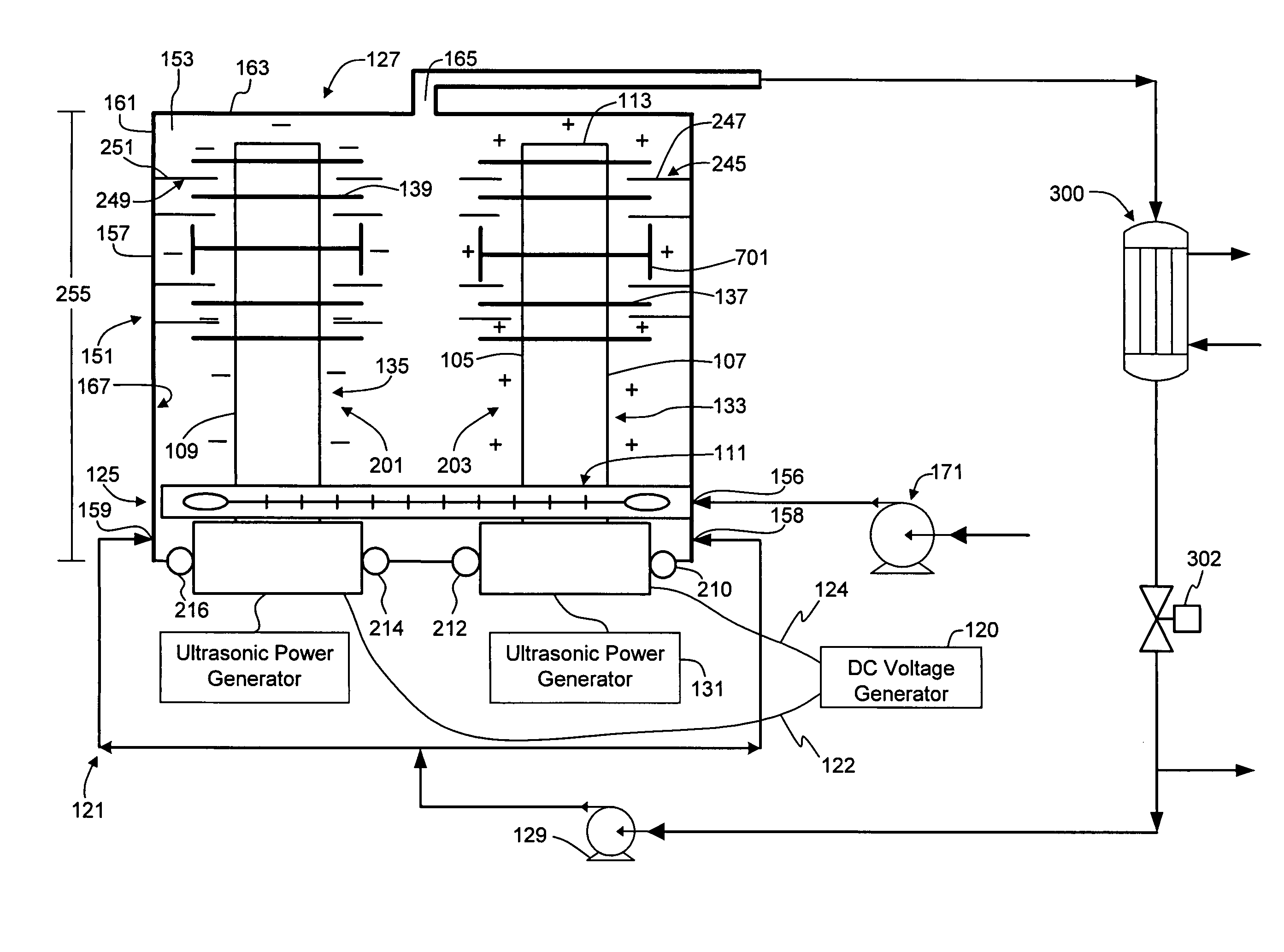

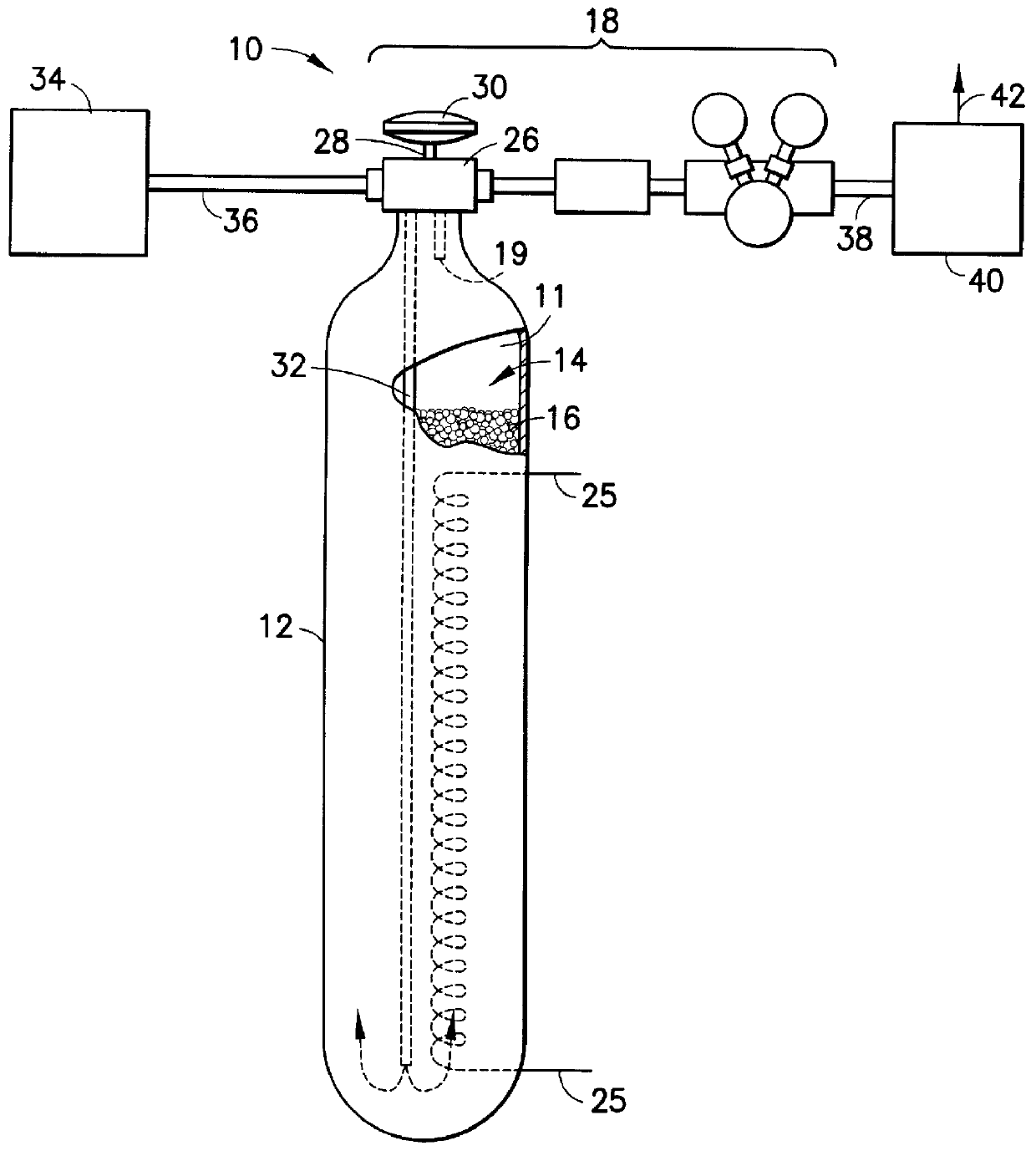

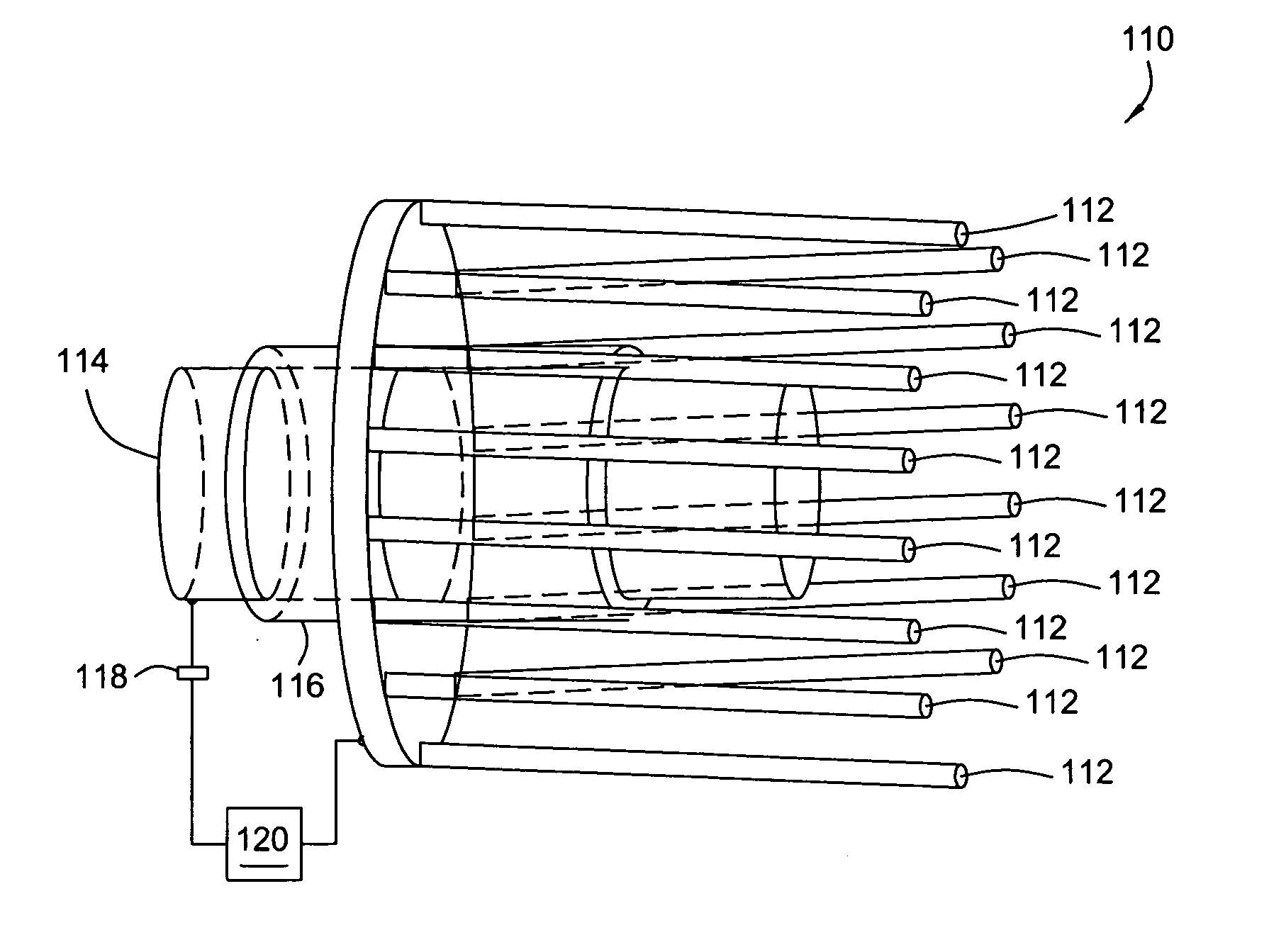

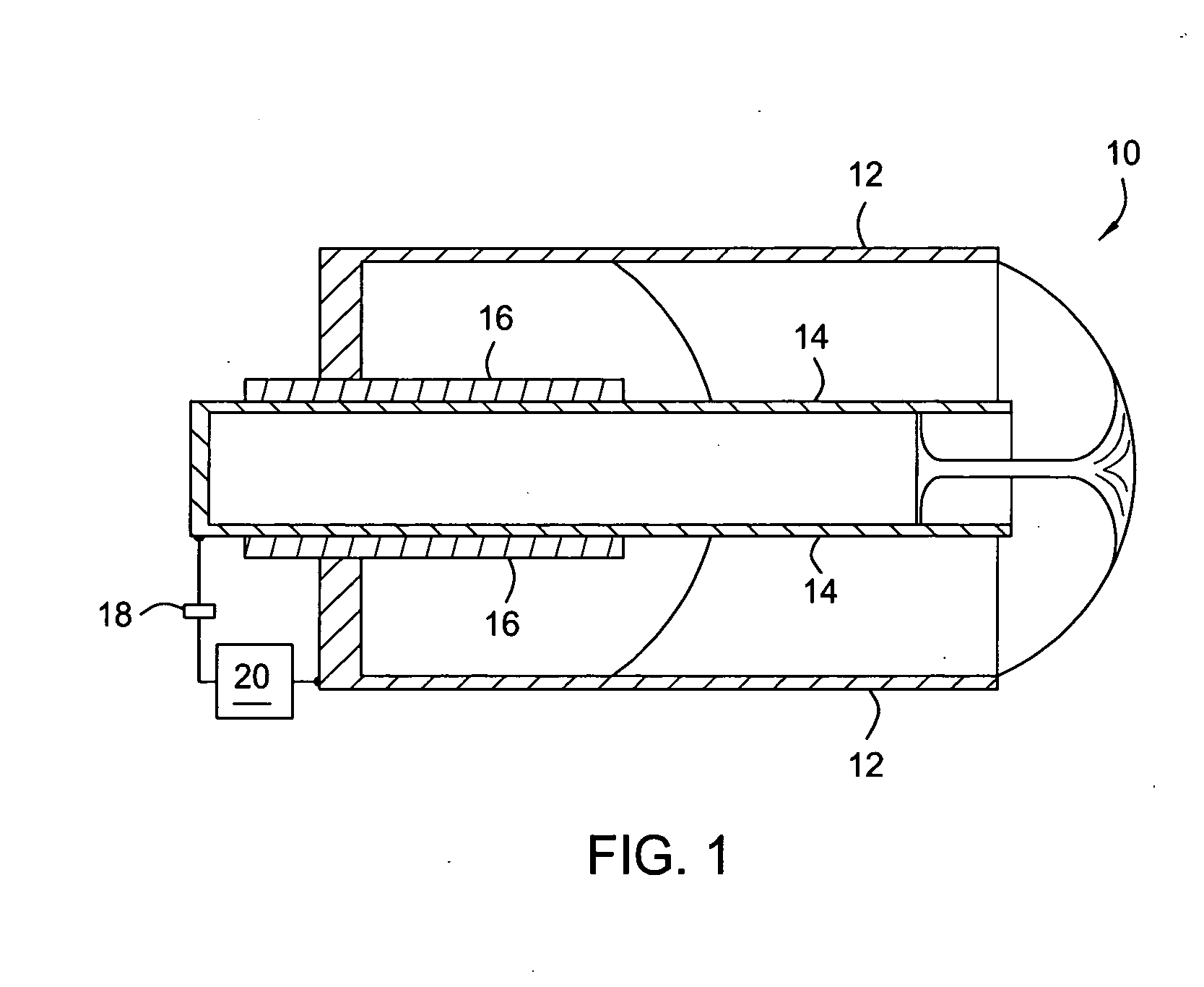

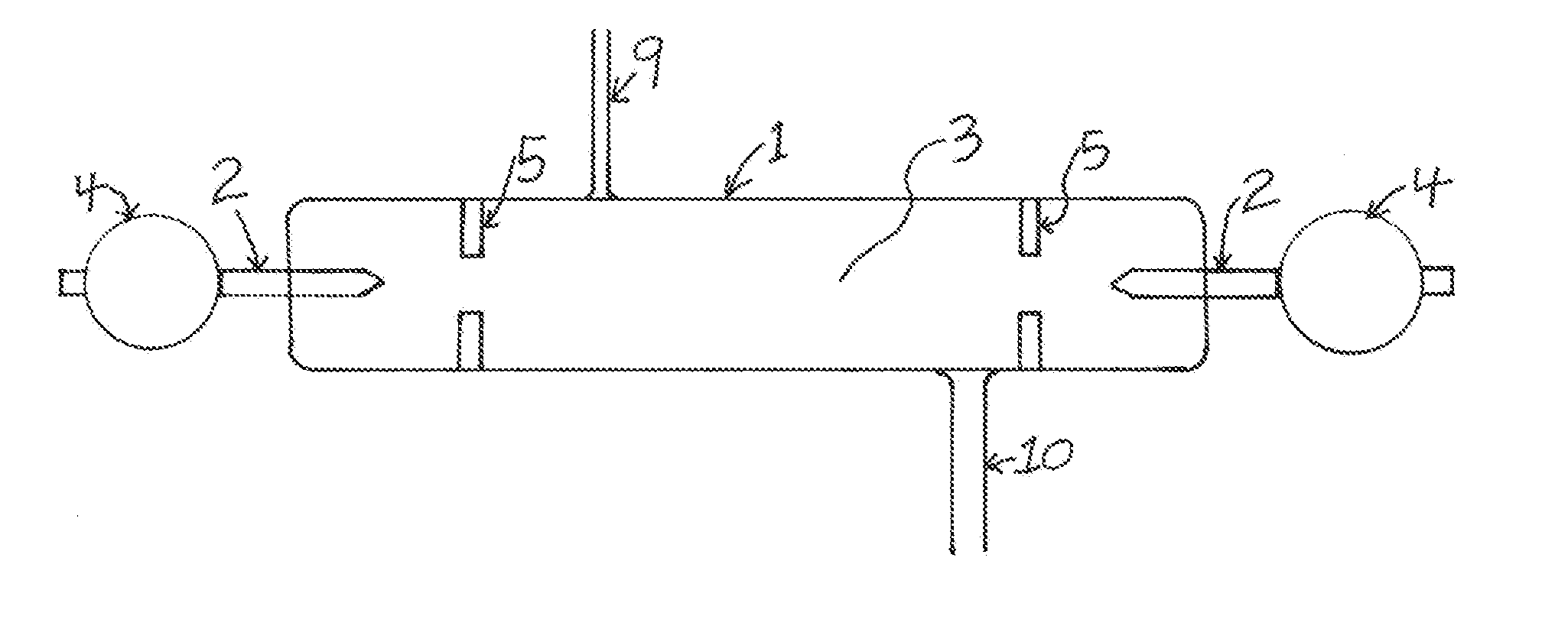

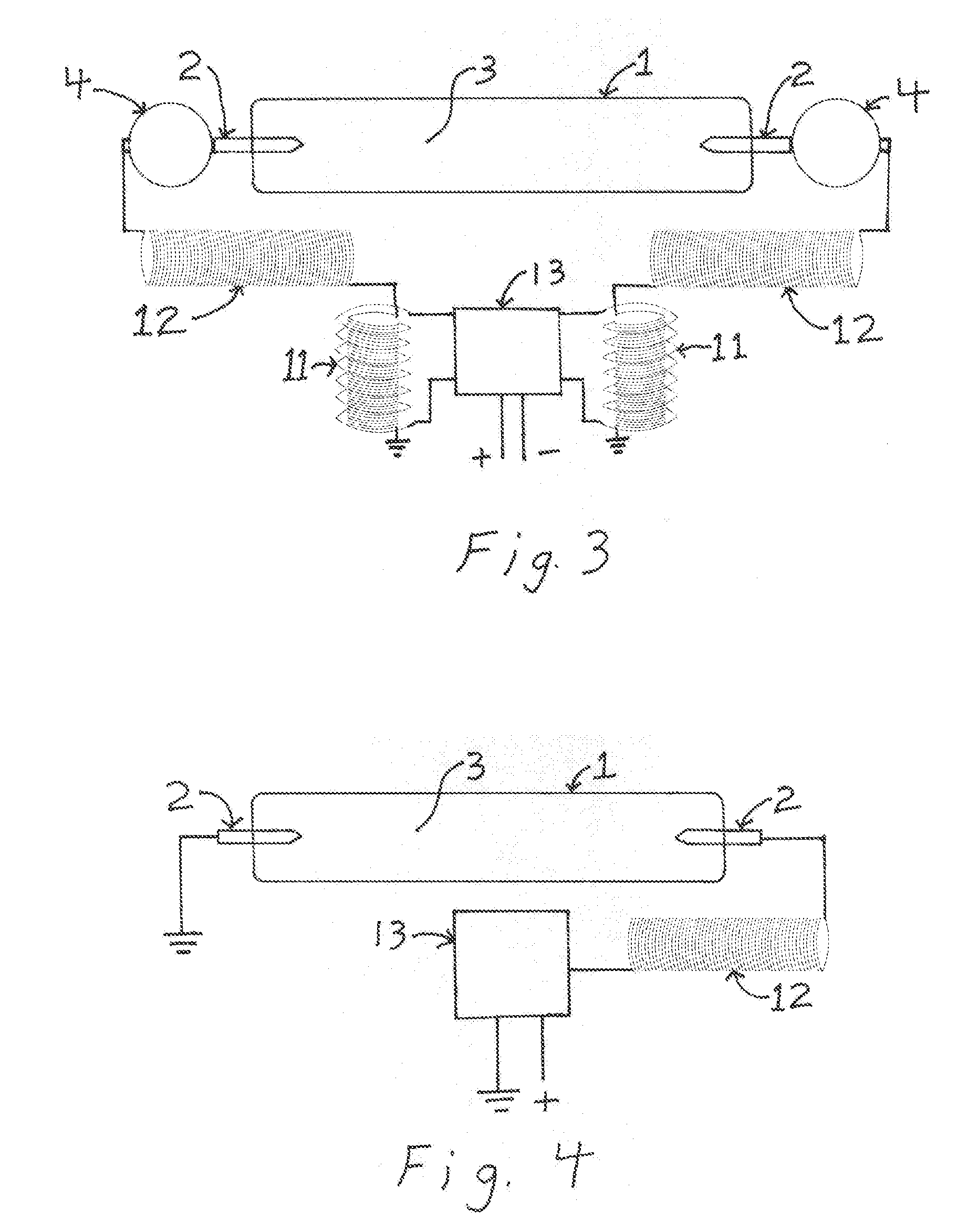

Ultrasonic treatment chamber for initiating thermonuclear fusion

InactiveUS20090147905A1Nuclear energy generationLow temperature fusion reactorElectrode potentialUltrasonic cavitation

A thermonuclear fusion system having a treatment chamber in which gas isotopes are fused to initiate a thermonuclear fusion reaction is disclosed. Specifically, the treatment chamber has an elongate housing through which liquid and gas isotopes flow longitudinally from an inlet port to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency and a predetermined electrode potential to ultrasonically enhance the concentration of dissolved hydrogen gas isotopes within the housing or energize and electrolyze the liquid and gas isotopes within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the liquid and gas isotopes being treated in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

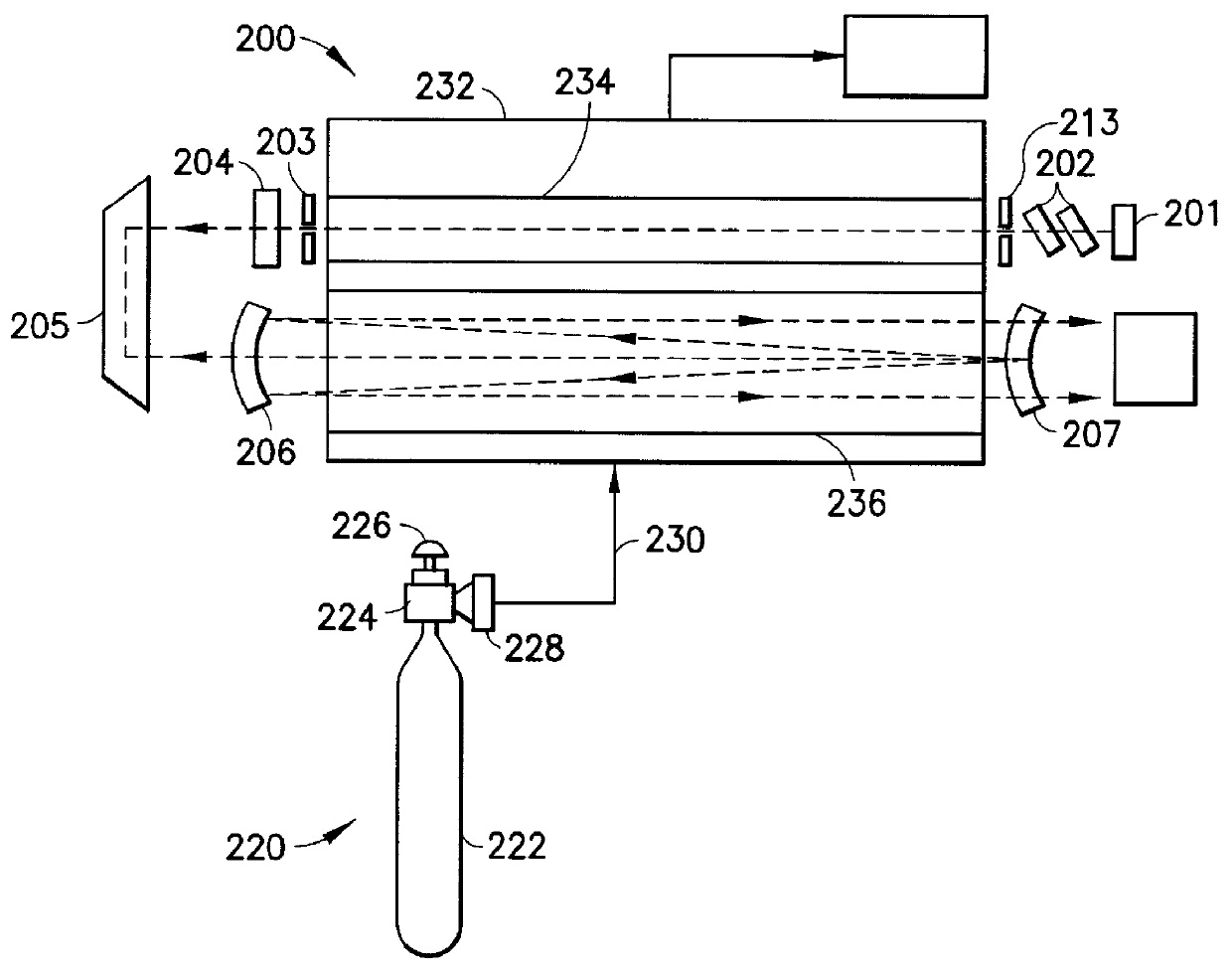

Laser system utilizing sorbent-based gas storage and delivery system

A laser system utilizing a fluid as the excitatory medium for stimulated light emission, wherein the fluid is supplied from a sorbent-based fluid storage and dispensing system coupled in fluid-supplying relationship with the laser apparatus. The laser may be an excimer laser utilizing as the laser working fluid a rare gas halide compound such as fluorides and / or chlorides of krypton, xenon and argon, as well as fluorine and / or chlorine per se. The laser system may alternatively be a far infrared gas laser utilizing a gas such as CO2, N2O, CD3OD, CH3OD, CH3OH, CH3NH2, C2H2F2, HCOOH, CD3I, CH3F, and C13H3F. Laser systems of the present invention may be utilized in applications such as materials processing, measurement and inspection, reading, writing, and recording of information, holography, communications, displays, spectroscopy and analytical chemistry, remote sensing, surveying, marking, and alignment, surgical and medical applications, plasma diagnostics, laser weaponry, laser-induced nuclear fusion, isotope enrichment and atomic physics.

Owner:ENTEGRIS INC

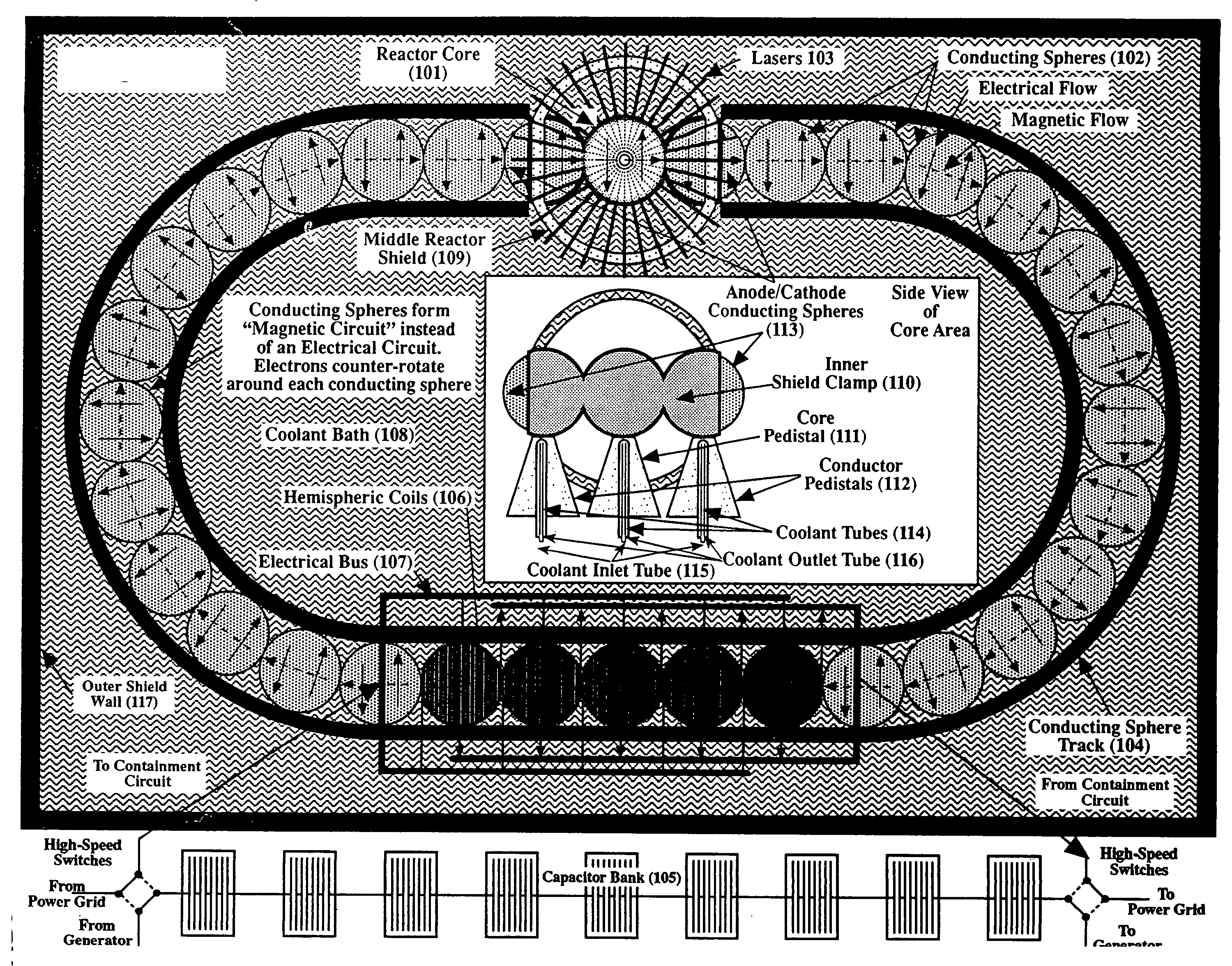

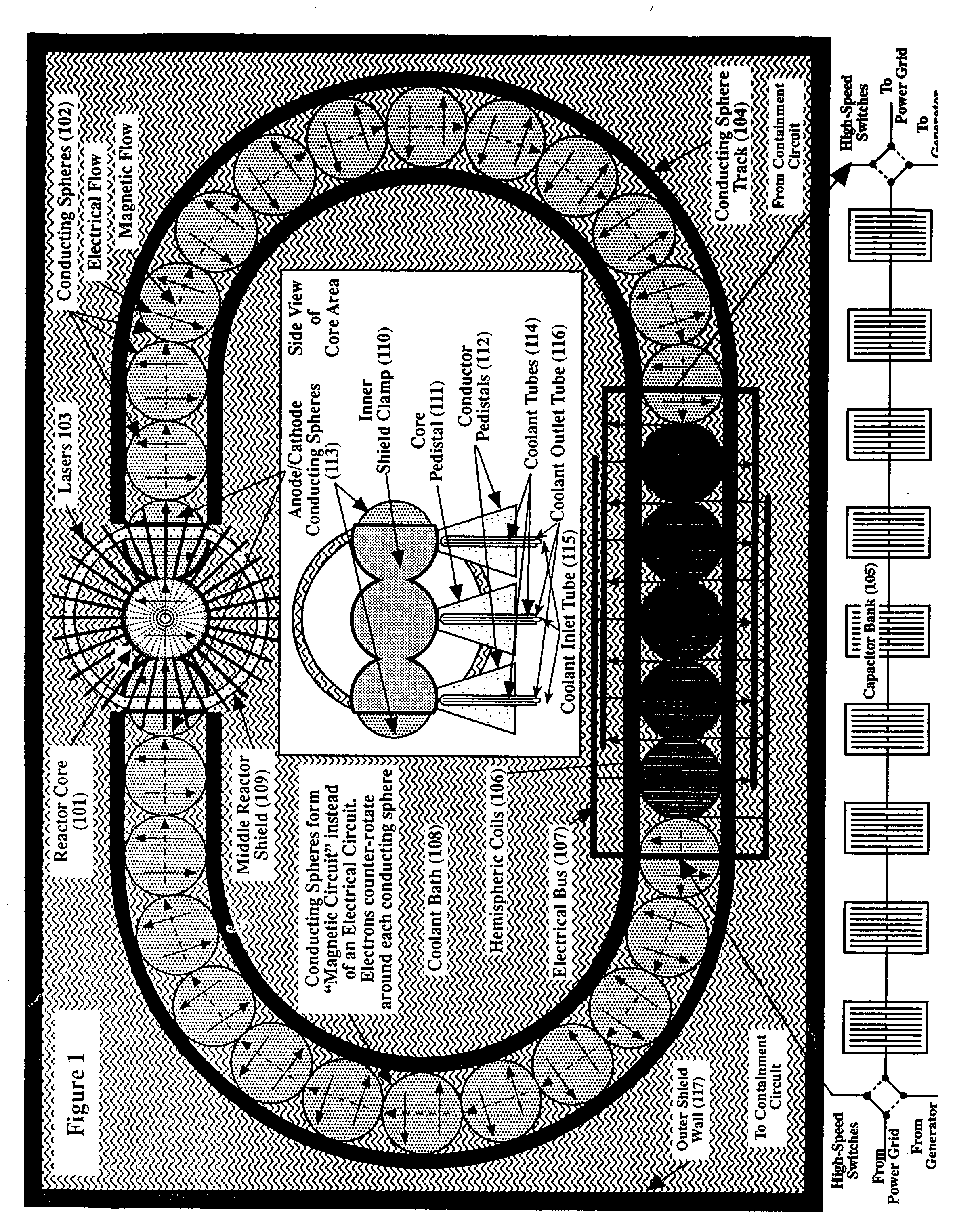

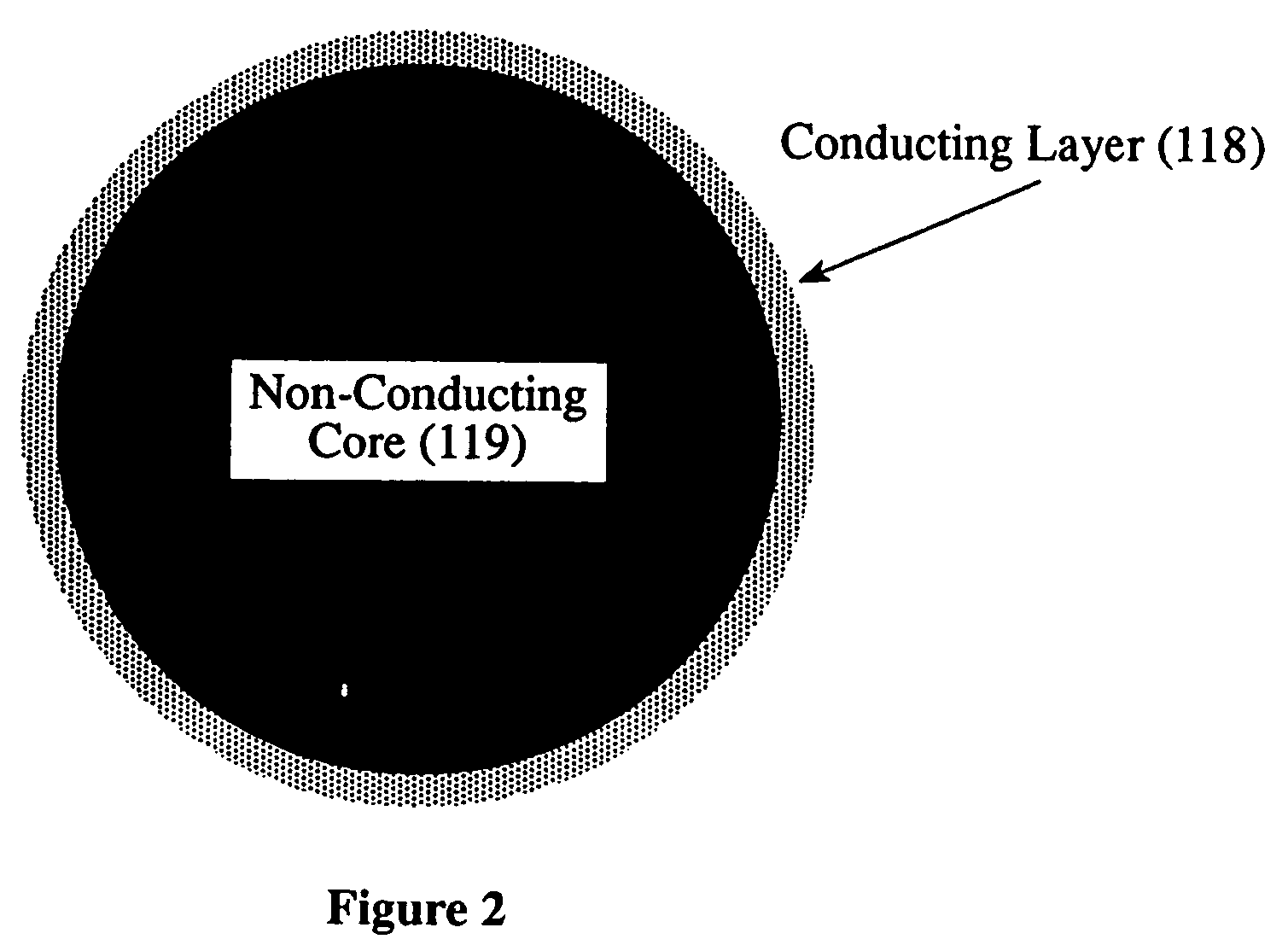

Nuclear fusion reactor incorporating spherical electromagnetic fields to contain and extract energy

InactiveUS20050157832A1Clean harmonicLow costNuclear energy generationTransformers/inductances coils/windings/connectionsReactor systemNuclear fusion

A nuclear fusion reactor system includes a reactor core containing nuclear fusionable material and a plurality of conducting spheres arranged adjacent each other with at least two of said conducting spheres adjacent the reactor core. The reactor core and the conducting spheres form a electro / magnetic circuit such that fusion of fusionable material in the reactor core establishes an electro / magnetic flow around the electro / magnetic circuit. Preferably, a spherical electromagnetic confinement field is initiated around the reactor core such that fusion of the nuclear fusionable material generates a plasma which interacts with the spherical electromagnetic confinement field in a magnethydrodynamic manner. Preferably, electrical energy is inductively extracted in response to the electro / magnetic flow through a coil arrangement located around at least one of the conducting spheres.

Owner:NORDBERG JOHN T

Method and apparatus for producing X-rays, ion beams and nuclear fusion energy

ActiveUS20070201598A1Eliminate needCheap, and effectively an unlimited energy sourceNuclear energy generationX-ray apparatusNuclear fusionX-ray

The present invention includes an apparatus and method for producing x-rays, and / or ion beams and for enabling the generation of fusion energy and the conversion of the energy into electrical energy including an anode and a cathode positioned coaxially and at least partially within a reaction chamber that imparts an angular momentum to a plasmoid. The angular momentum may be imparted through the cathode having a helical twist; a helical coil about the cathode or a combination thereof. The anode has an anode radius and the cathode has a cathode radius that imparts a high magnetic field. The reaction chamber contains a gas and an electronic discharge source in electrical communication with the anode and the cathode. As a result of an electronic discharge a dense, magnetically confined, plasmoid is created about the anode and emits of one or more particles.

Owner:LAWRENCEVILLE PLASMA PHYSICS

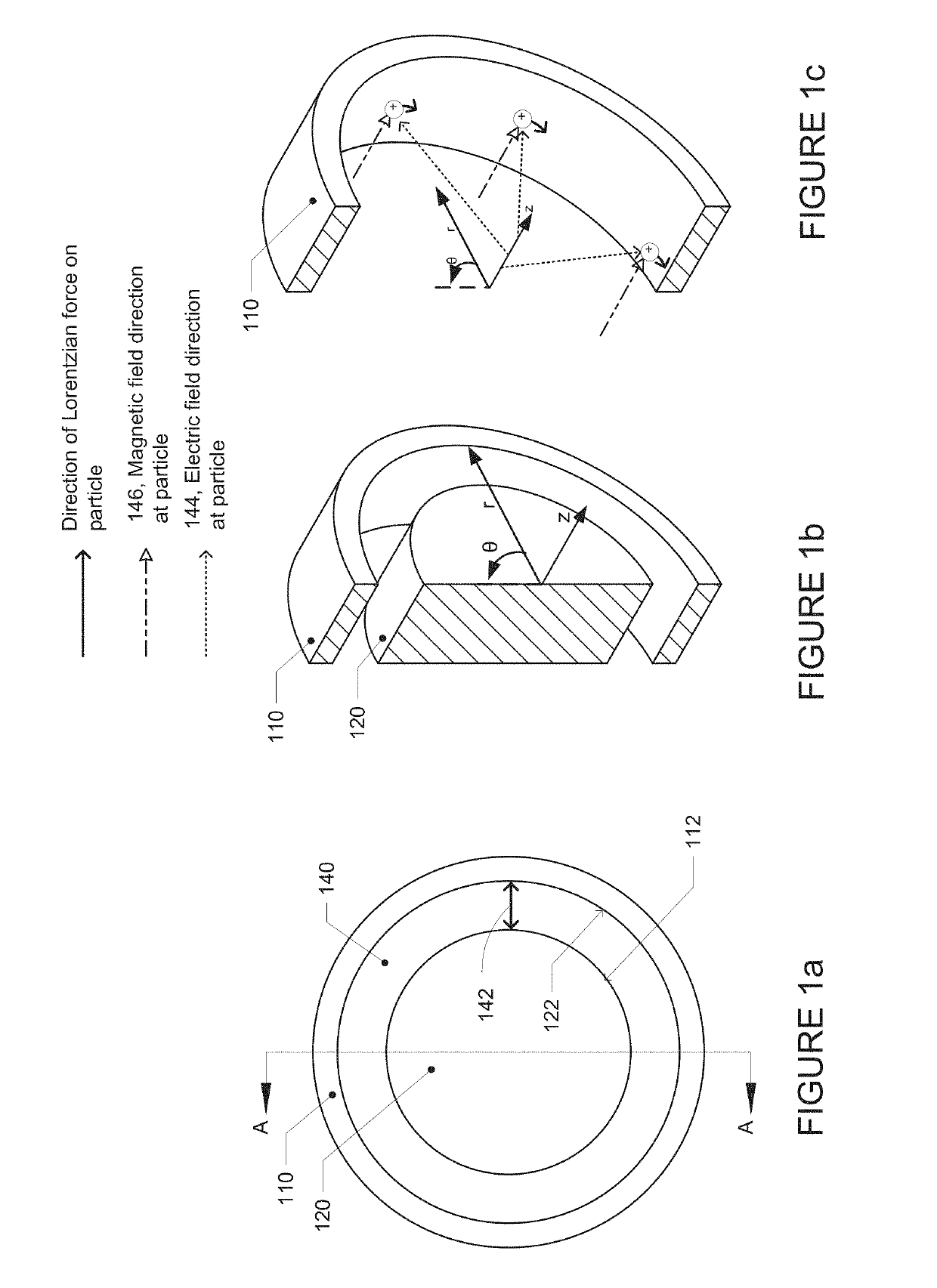

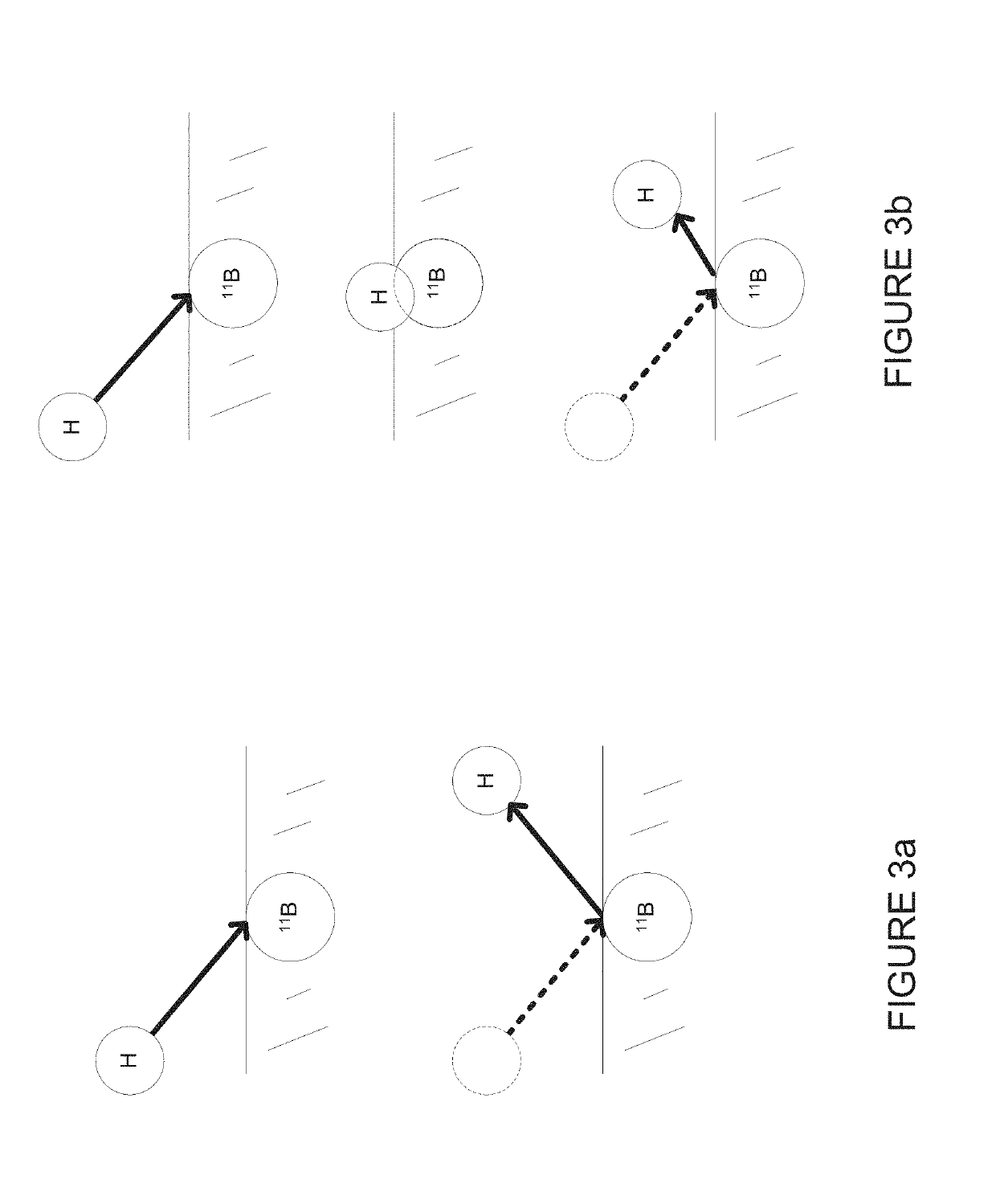

Reactor using electrical and magnetic fields

Methods, apparatuses, devices, and systems for producing and controlling and fusion activities of nuclei. Hydrogen atoms or other neutral species (neutrals) are induced to rotational motion in a confinement region as a result of ion-neutral coupling, in which ions are driven by electric and magnetic fields. The controlled fusion activities cover a spectrum of reactions including aneutronic reactions such as proton-boron-11 fusion reactions.

Owner:ALPHA RING INT LTD

Method for preparing fine-grained tungsten and molybdenum coatings by atmospheric plasma spraying method

InactiveCN101818318AReduce porosityImprove mechanical propertiesMolten spray coatingPorosityWear resistant

The invention discloses a method for preparing fine-grained tungsten and molybdenum coatings by an atmospheric plasma spraying method. The fine-grained tungsten and molybdenum coatings are prepared by performing granulation treatment on ultrafine tungsten powder and molybdenum powder, arranging a protective gas curtain during a spraying process, and adopting atmospheric plasma spraying technology. The process comprises the following steps of: drying the tungsten powder and molybdenum powder with the grain size of 30nm to 30mu m or carbonyl tungsten powder with the average grain size of 15 to 30mu m for later use, wherein a spraying substrate adopts an oxygen-free copper, copper alloy or stainless steel plate; and performing spraying by using atmospheric plasma spraying equipment, wherein the equipment has a power of between 27kW and 40kW, and argon serves as primary spraying gas and hydrogen serves as secondary spraying gas. The method has the advantages that: the fine-grained tungsten and molybdenum coatings prepared by the method of the invention have lower porosity and better mechanical property and thermal-shock resistance, and are suitable for a wear-resistant surface protective layer of a mechanical component, a high-temperature resistant plasma scouring component, such as a first wall material in a nuclear fusion device and the like.

Owner:UNIV OF SCI & TECH BEIJING

First wall part or low activation steel heat sink material coated with thick tungsten coating and making method thereof

InactiveCN1755840AInhibit growthImprove performanceNuclear energy generationVacuum evaporation coatingTemperature controlThermal deposition

The invention discloses first wall part with thick wolfram coating or low-activation steel thermal deposition material and opposite manufacture method. Wherein, selecting base plate as low-activation martensitic / ferritic steel to clear with transferred arc; using 70% stainless steel powder and 30% wolfram powder as interlayer of 0.5mm; spraying plasma arc has center temperature as 15000K speed as 500m / s, average particle size of wolfram powder is 10~15 microns, the coating has thickness as 2mm, density as 78~88% of body material and oxygen content is 0.06~0.15%; during whole spraying process, using active water cooling to control base plate temperature under 500Deg. As low-activation steel both as structure support material and thermal deposition material, this invention solves large area linkage key-problem and can bear stably long-time action of 1MW / m2 thermal load given active cooling condition.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

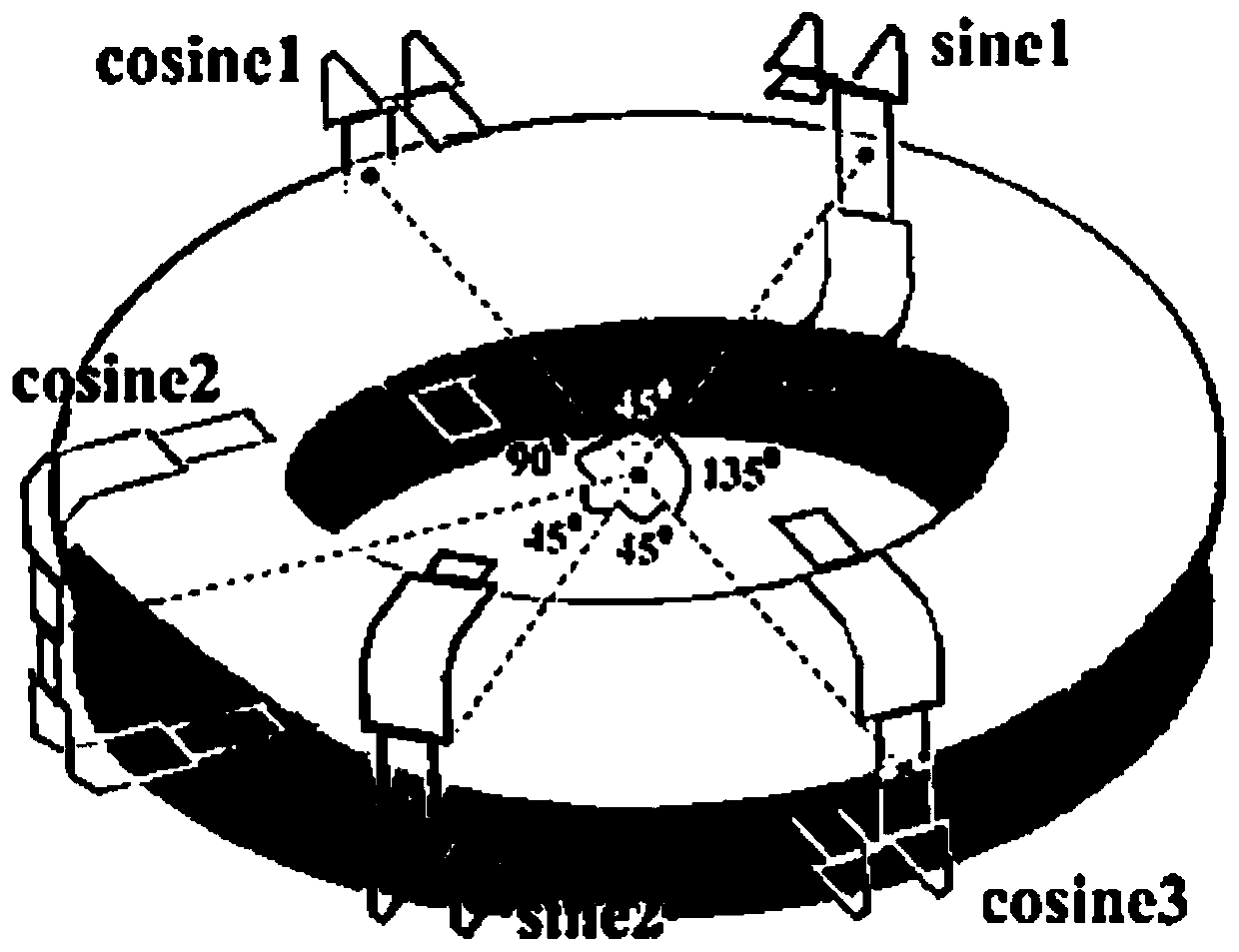

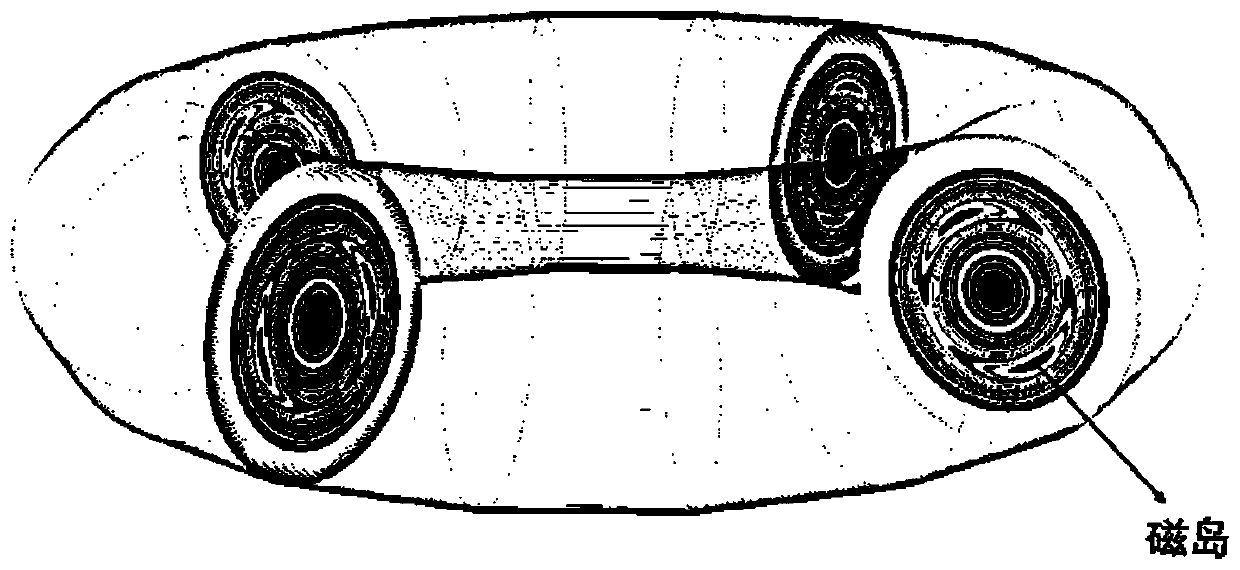

Simulation method for controlling novel classic tearing mode through resonance magnetic disturbance in tokamak

ActiveCN110232205AGood combination experimentImprove computing efficiencyDesign optimisation/simulationSpecial data processing applicationsNumerical stabilityMagnetic disturbance

Owner:DALIAN UNIV OF TECH

Resonant Vacuum Arc Discharge Apparatus for Nuclear Fusion

InactiveUS20120008728A1Improve efficiencyImprove fusion efficiencyNuclear energy generationDirect voltage acceleratorsWell loggingNuclear fusion

The present invention relates to a resonant vacuum arc discharge apparatus for producing nuclear fusion. A resonant high-frequency high-voltage alternating current (AC) power supply is used to efficiently power a fusion tube normally containing deuterium, tritium and / or helium-3 vapor. Metals that can hold large amounts of hydrogen isotopes such as palladium and titanium can be used to increase the target density. The nuclear fusion device can be used for energy production, well logging, uranium mining, neutron activation analysis, isotope production or other applications that require a neutron source.

Owner:FLEMING RAY R

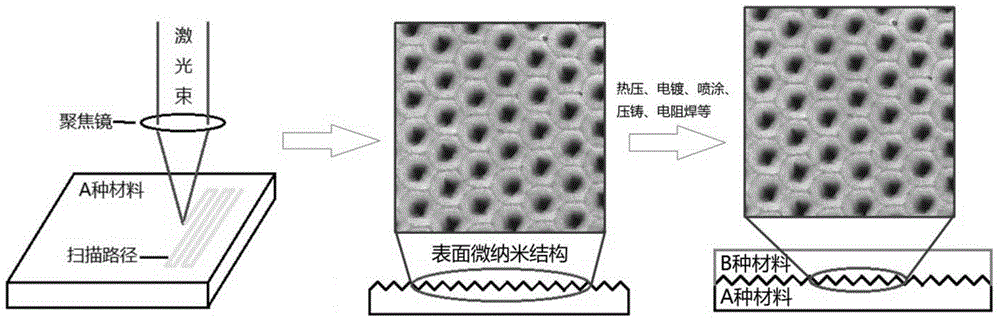

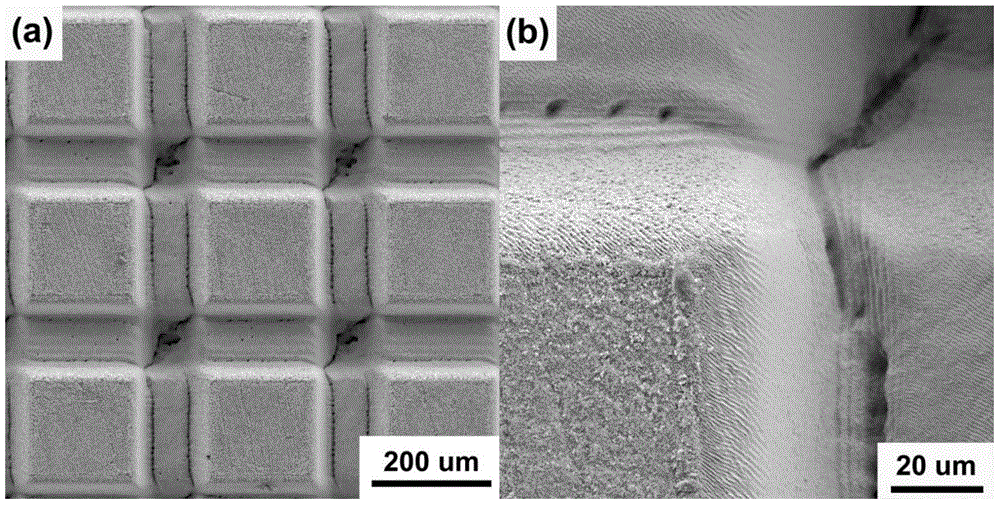

Method for connecting materials difficult to connect through ultrafast lasers

ActiveCN104439956AImprove power densityReduce meltingLaser beam welding apparatusNuclear fusionAdvanced composite materials

The invention discloses a method for connecting materials difficult to connect through ultrafast lasers. The method includes the following steps that firstly, a material A is ablated through ultrashort pulse lasers, removing is achieved through laser ablation, and a nano-micro-meter structure is obtained on the surface of the material A; secondly, impurities on the surface, with the nano-micro-meter structure, of the material A are removed through corrosive liquid; thirdly, in an inert gas or vacuum environment, a material B is deformed and flows to fill the nano-micro-meter structure of the material A, the material A and the material B are combined in a mechanical combination mode, and therefore the material A and the material B are connected, wherein the melting point and the hardness of the material A are higher than the melting point and the hardness of the material B. The method for connecting the materials difficult to connect through the ultrafast lasers is a new method which is flexible, high in efficiency and wide in application range and is used for improving the connecting strength of the materials, and the application of the method includes but is not limited to the development of a nuclear fusion reactor oriented to plasma materials, electric contact materials, heat sink materials, electronic packaging and advanced composite materials.

Owner:TSINGHUA UNIV

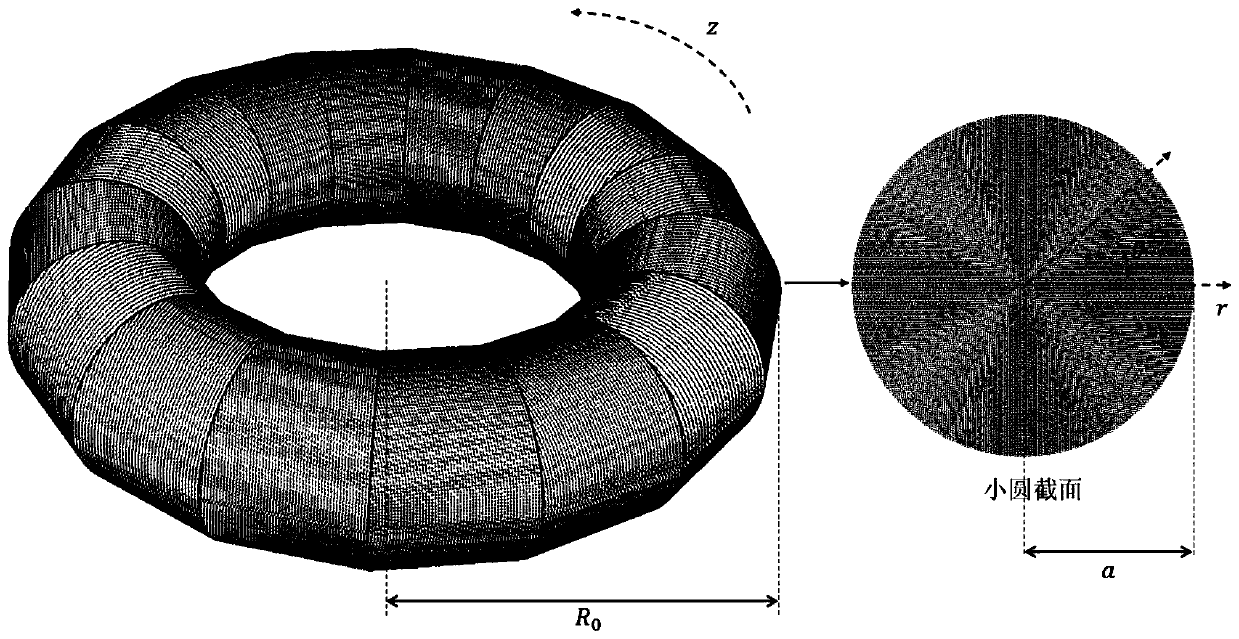

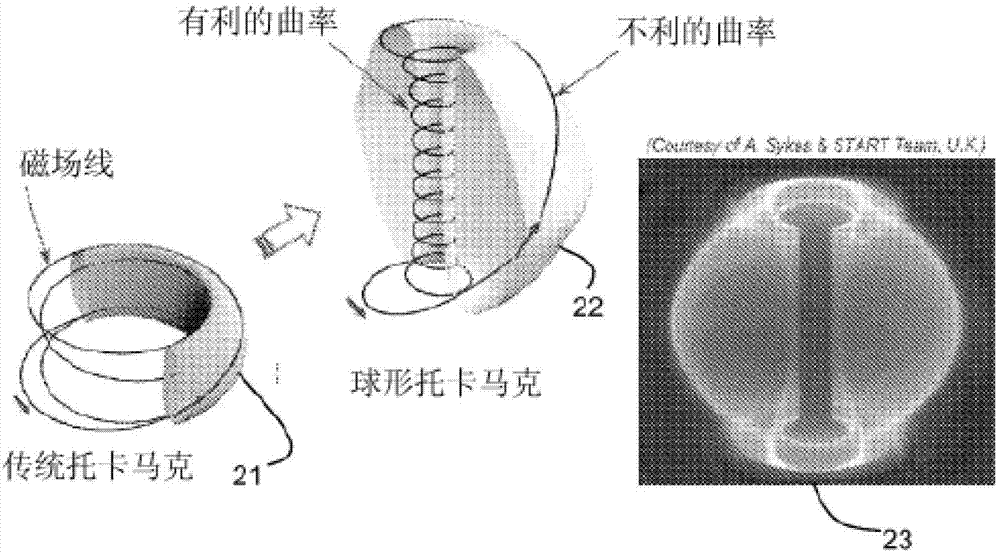

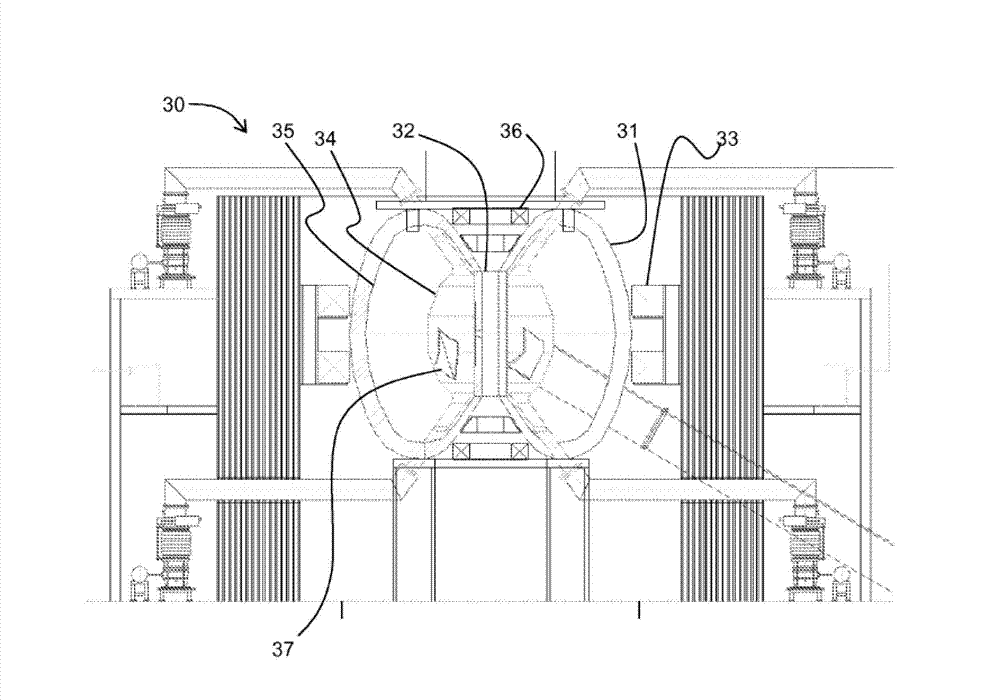

Compact fusion reactor

InactiveCN103081021ANuclear energy generationDirect voltage acceleratorsNuclear fusionPlasma confinement

A compact nuclear fusion reactor for use as a neutron source is described. The reactor comprises a toroidal plasma chamber (34) and a plasma confinement system (31) arranged to generate a magnetic field for confining a plasma in the plasma chamber (34). The plasma confinement system (31) is configured so that a major radius of the confined plasma is 0.75 m or less. The reactor is configure to operate with a plasma current of 2 MA or less. The magnetic field includes a toroidal component of 5 T or less. Despite these low values, the reactor can generate a neutron output of 1 MW or more.

Owner:TOKAMAK ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com