Patents

Literature

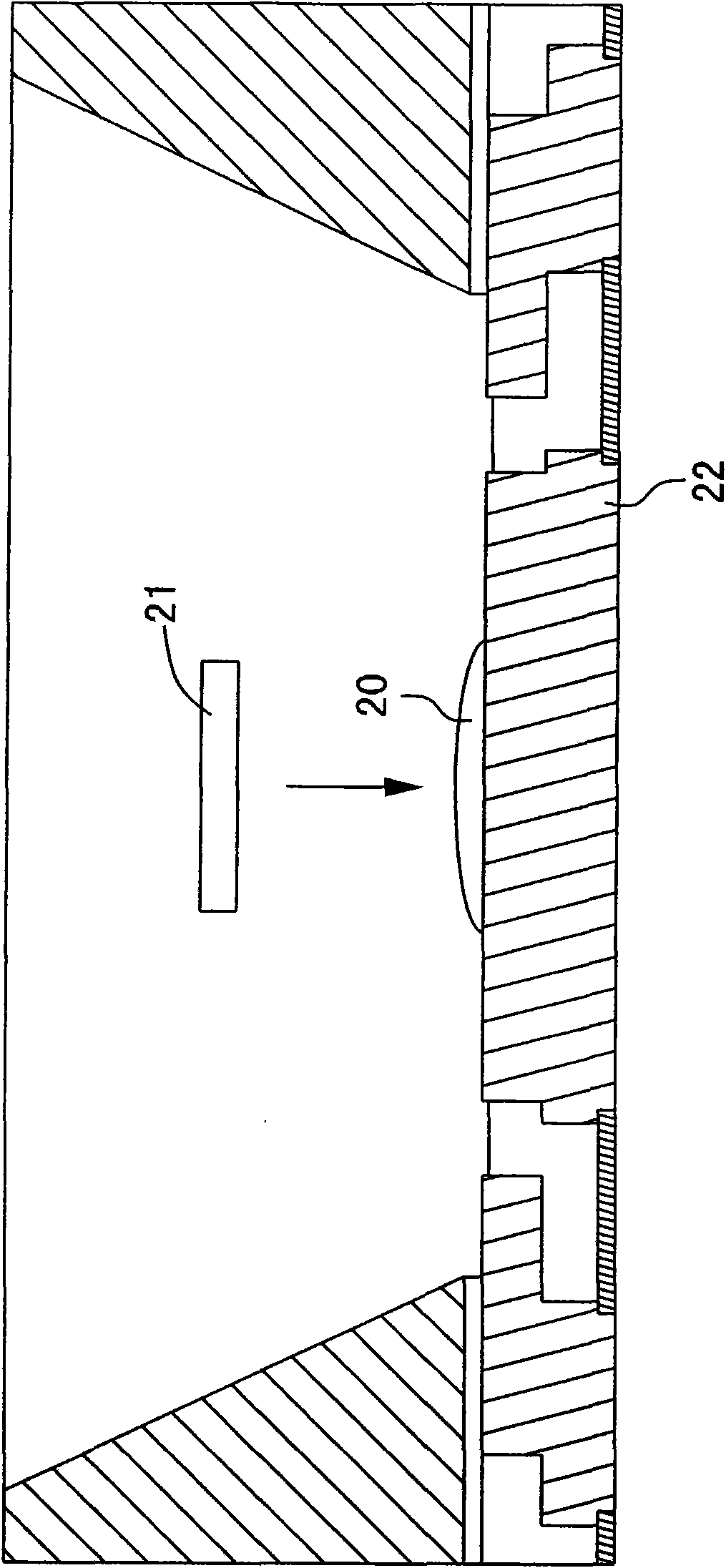

60results about How to "Solve thermal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tungsten/copper functional gradient material by infiltration - weld method

InactiveCN1593818AEasy to prepare and effectiveSolve thermal stressMetal layered productsFritGradient material

The invention relates to a new method of making tungsten-copper functional gradient material, which consists of pure tungsten layer and tungsten-copper gradient transit layer. First, make the gradient hole-framework with boring fluid of percent 5~80 volume ratio and tungsten powder of 1~20 micron. Infiltrate copper fluid to make the tungsten-copper gradient transit layer. Weld the W / Cu gradient layer and the pure tungsten by hot pressure. The process is following: mix the material and mould them, then frit framework, Infiltrate copper, weld and check. The method has both the advantage of melt-casting technique and jointing technique. The tungsten-copper functional gradient material made by this method is better heatproof and suited to electric sealing material, heat sinking material, and anti-high temperature plasma scouring unit such as the first layer material in nuclear fusion.

Owner:UNIV OF SCI & TECH BEIJING

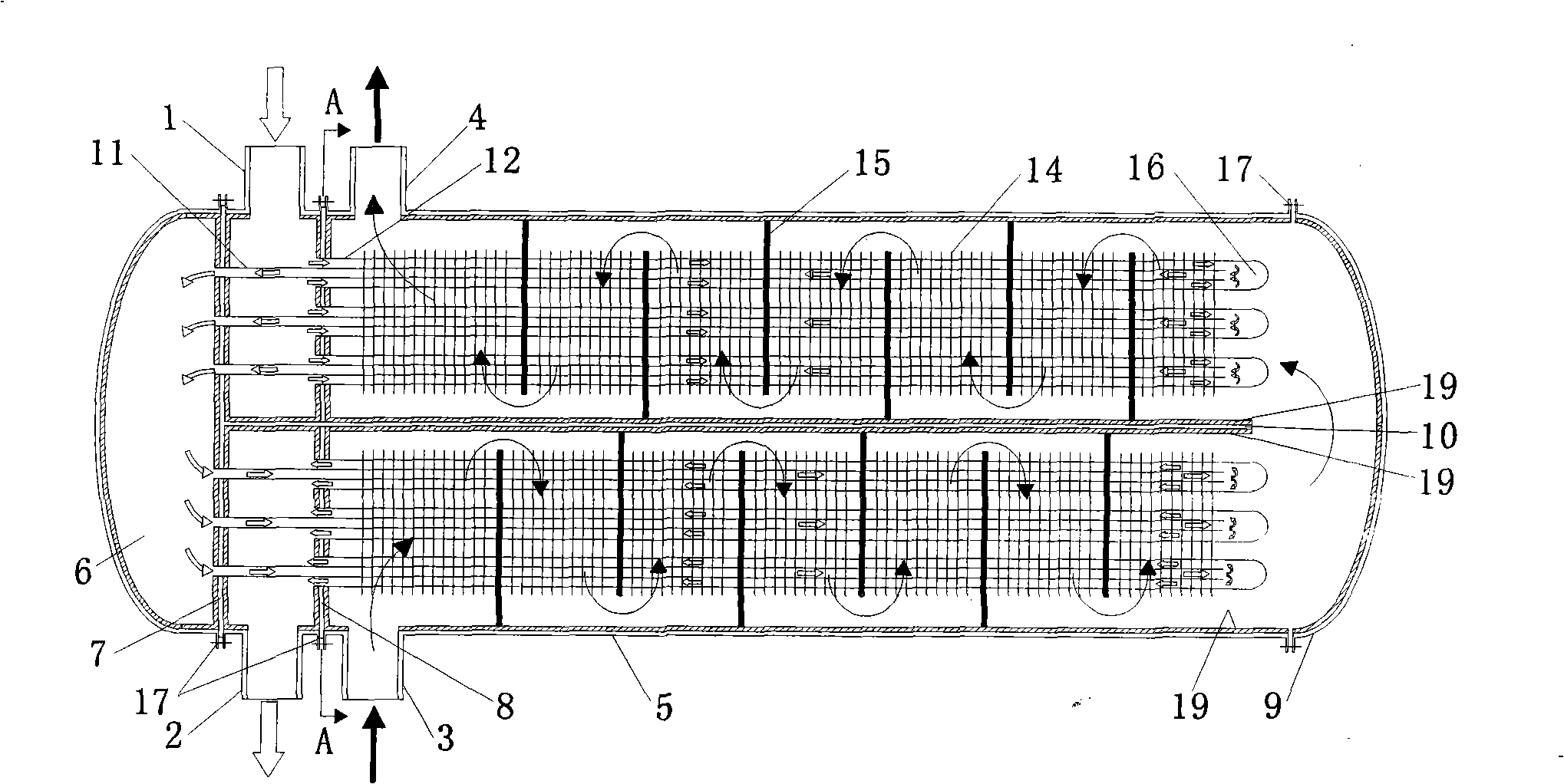

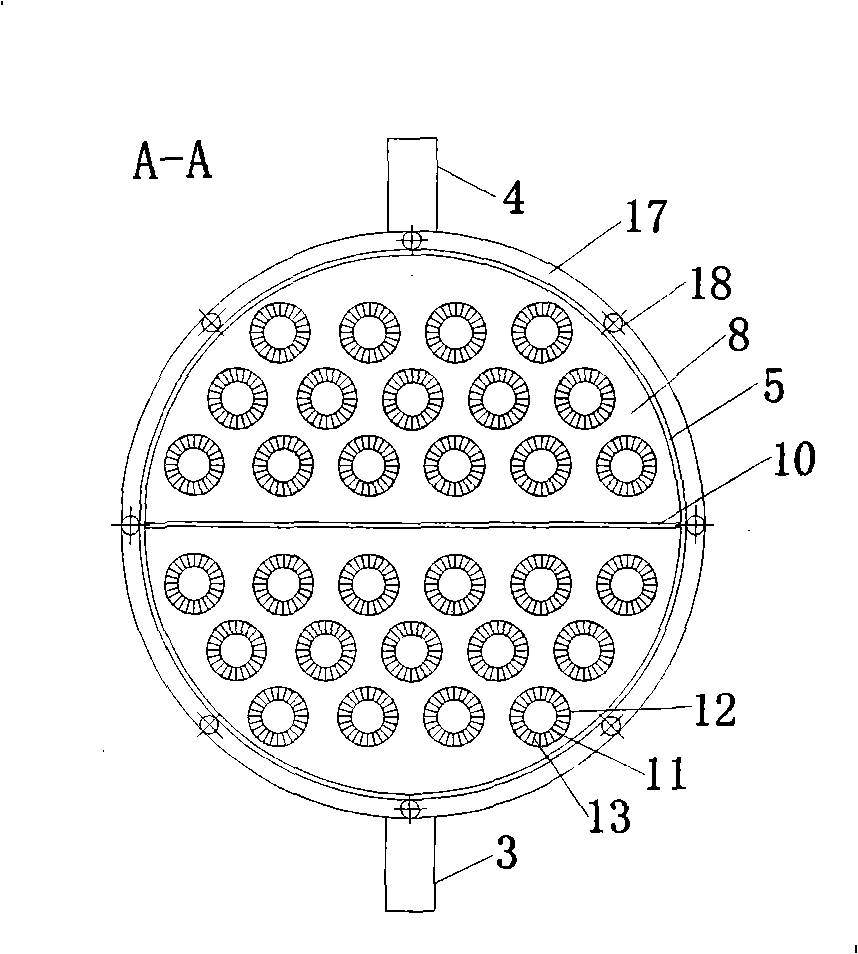

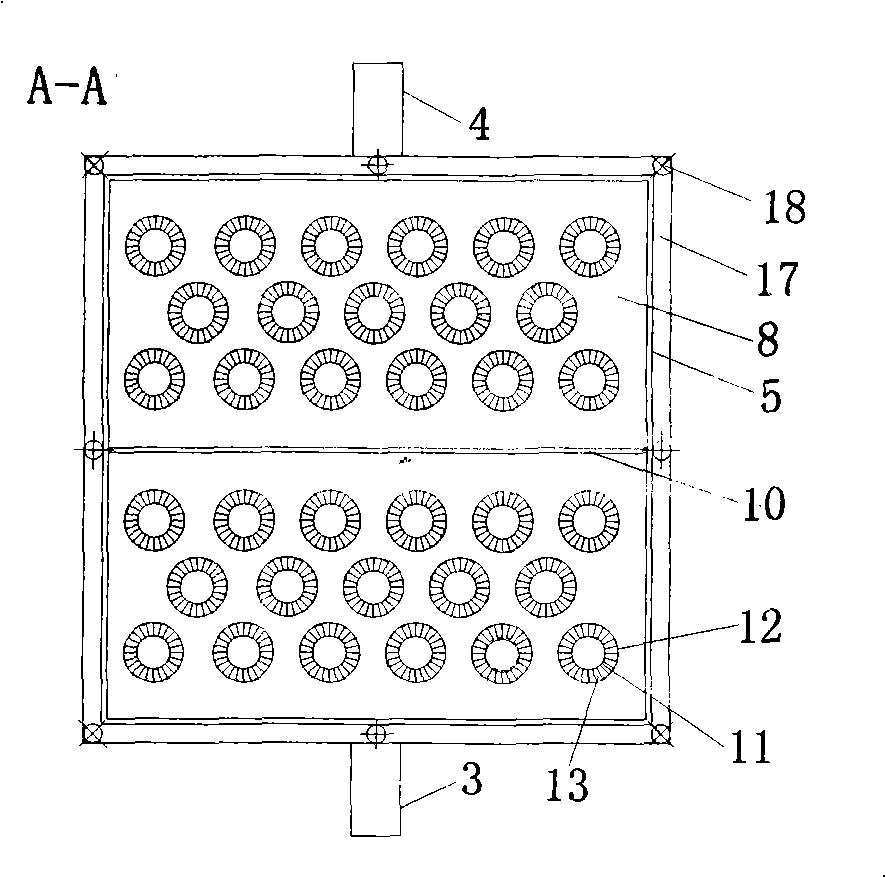

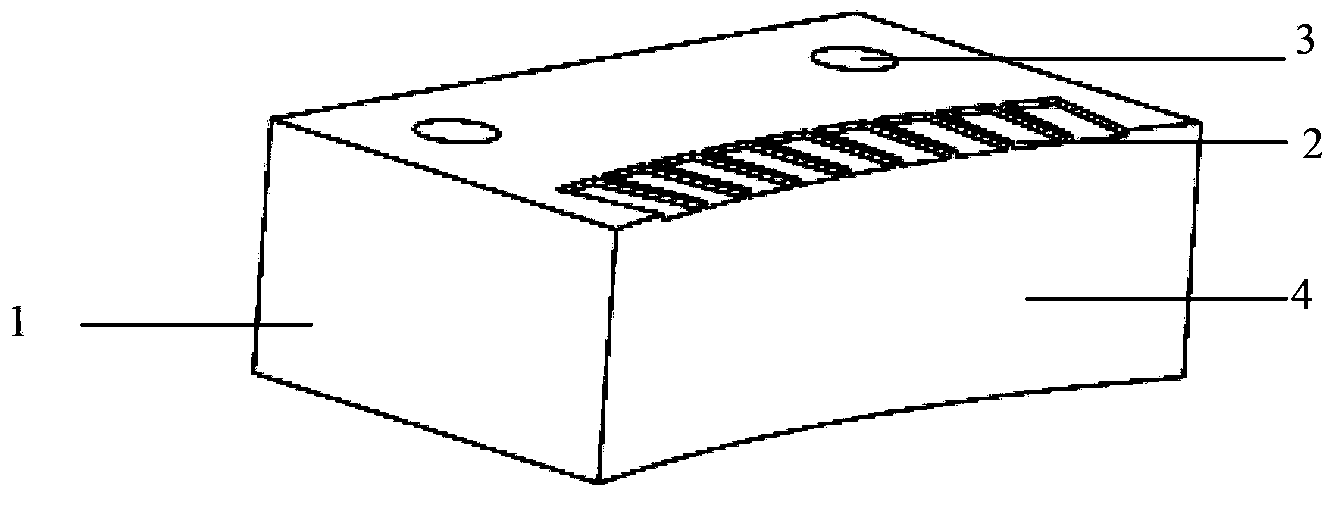

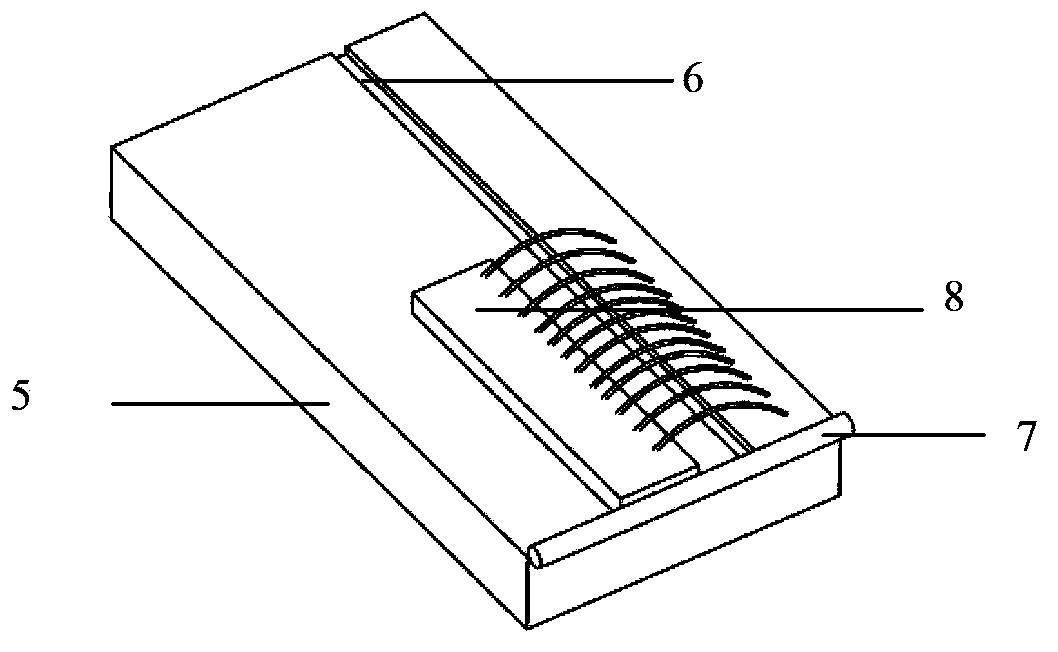

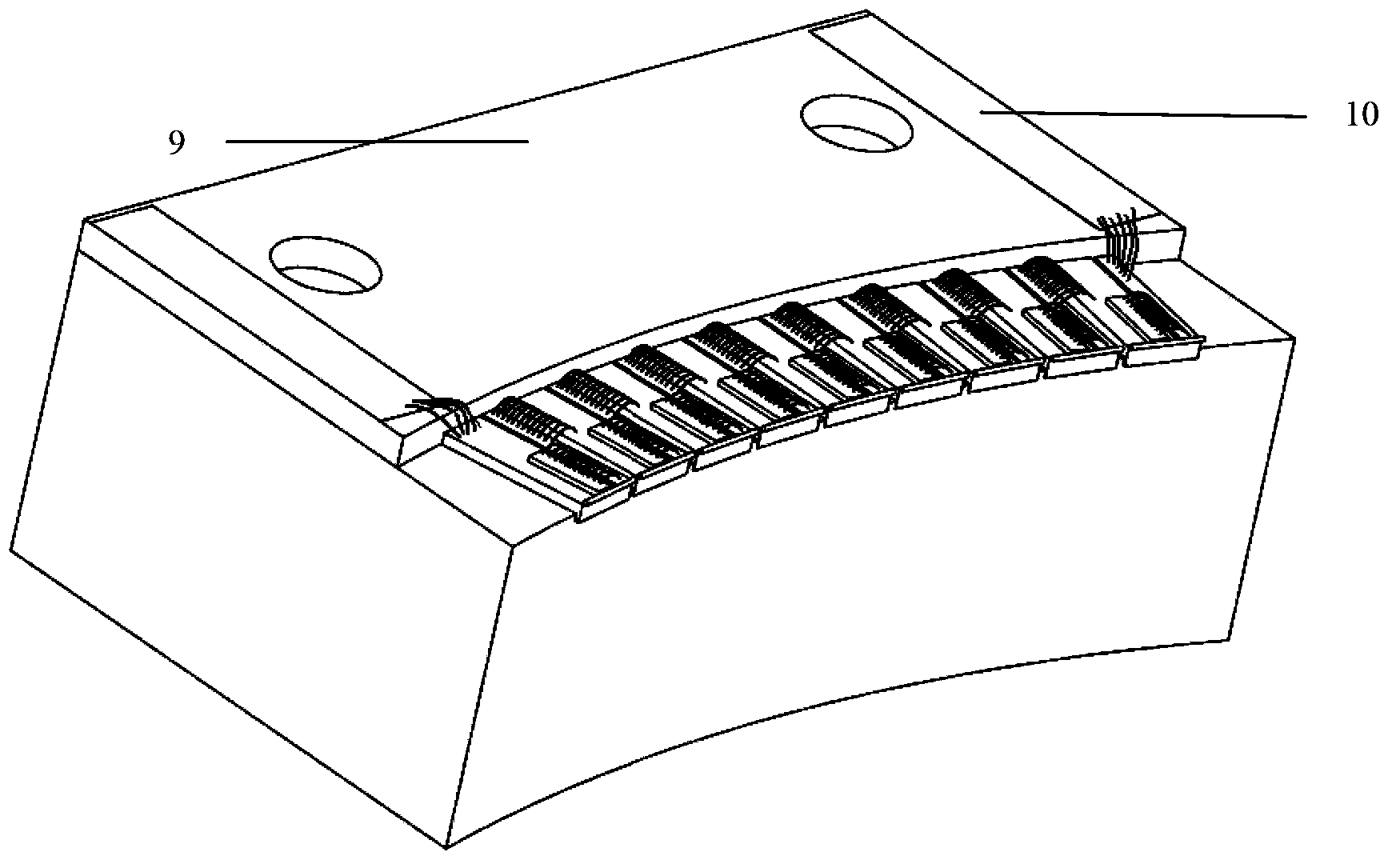

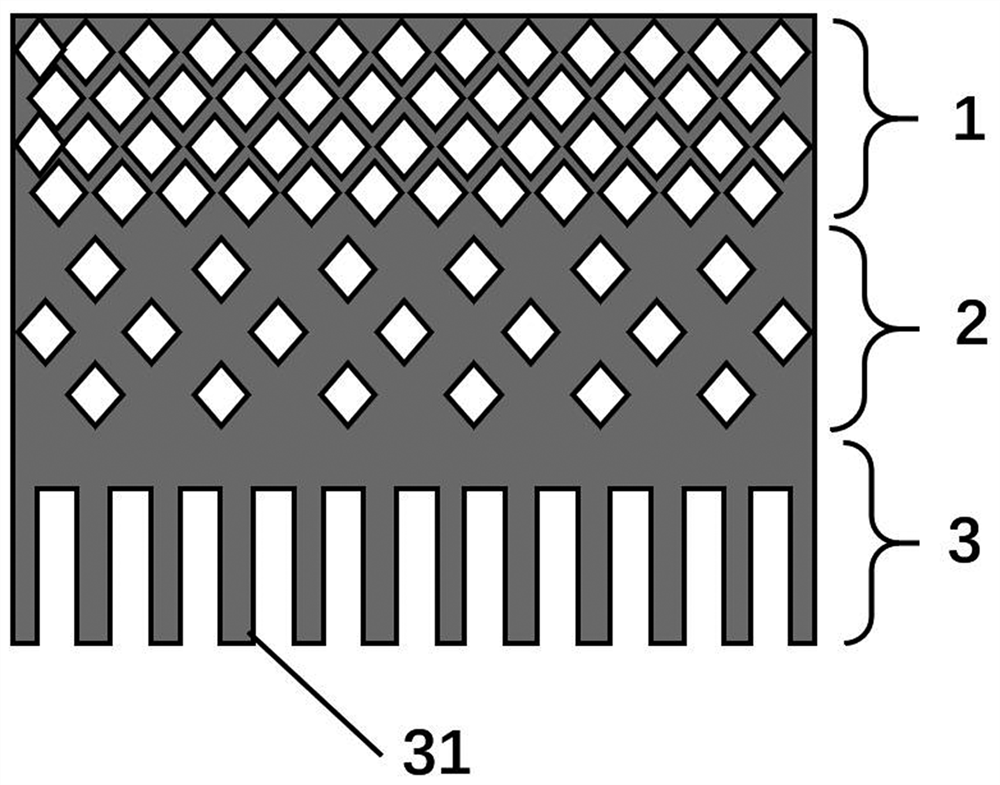

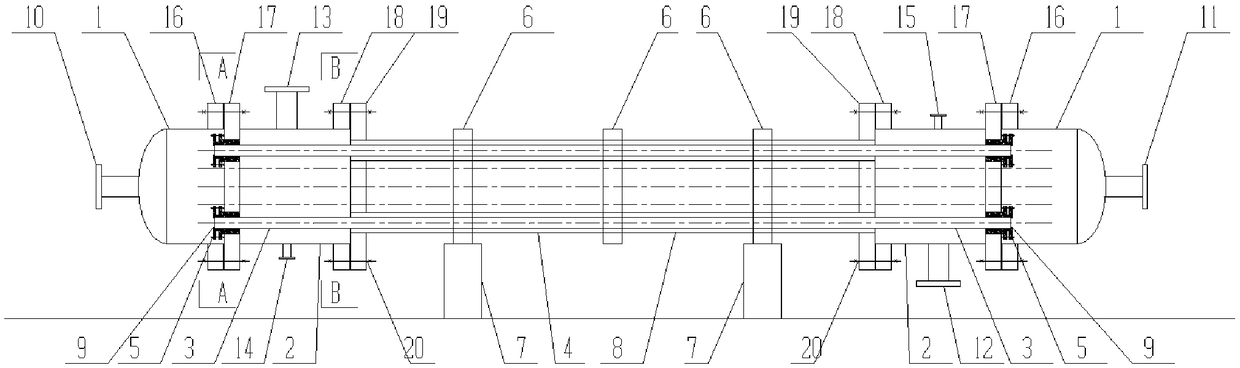

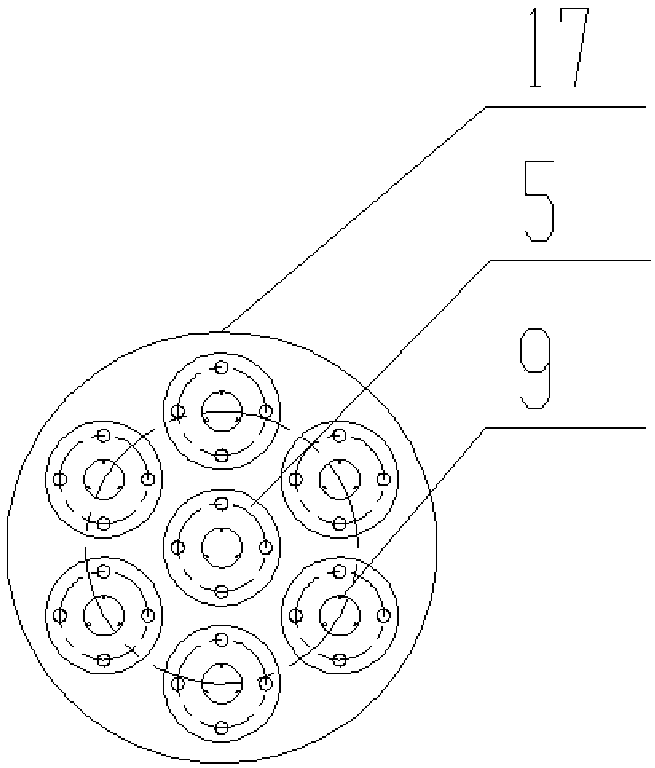

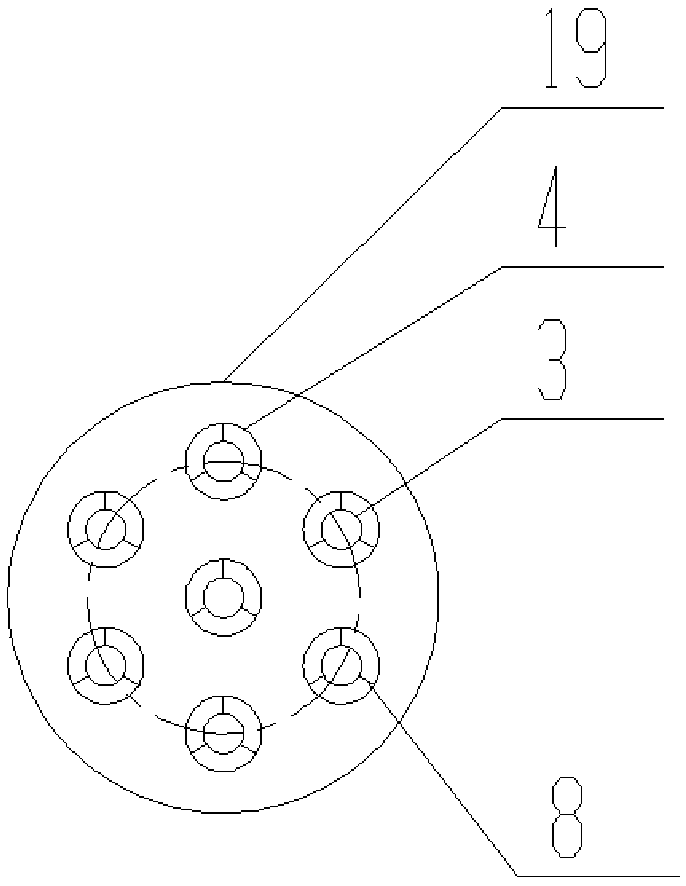

Internal and external fins intubatton type high temperature heat exchanger

InactiveCN101349514ASolve thermal stressImprove stabilityStationary tubular conduit assembliesManufacturing cost reductionHoneycomb

The invention relates to an internal and external fin bayonet-tube type high temperature exchanger, which comprises a casing, a tube box which is connected on the casing, a closed head, a longitudinal baffle, a baffle plate, tube plates of an internal tube and an external tube, a tube side inlet and outlet pipe, a casing side inlet and outlet pipe, wherein one ends of the internal tube and the external tube are respectively fixed on the tube plates of the internal tube and the external tube, and the other ends are both free ends, the internal tube is a honeycomb duct whose two ends are open, and the external tube is a heat exchange tube whose one end is open, and the other end is closed, the internal and external walls of the external tube are respectively provided with an internal fin and an external fin to form an internal and external fin bayonet-tube heat exchanging unit, and the internal fin can relatively move to the internal tube. The exchanger is divided into a high temperature shell pass and a low temperature shell pass, the components of the two shell passes are respectively produced by high temperature-resistant material and common material, also can be produced by the same material. The internal walls of the casing, the longitudinal baffle and the tube plates of the internal tube and the external tube are provided with ceramic insulating layers, and fluid on two sides of a shell is crossly flow in reverse directions. The invention can increase the heat exchange efficiency and compactness of the exchanger, reduces production cost, and can overcome the thermal stress problem, and can be applied in high temperature condition.

Owner:XI AN JIAOTONG UNIV

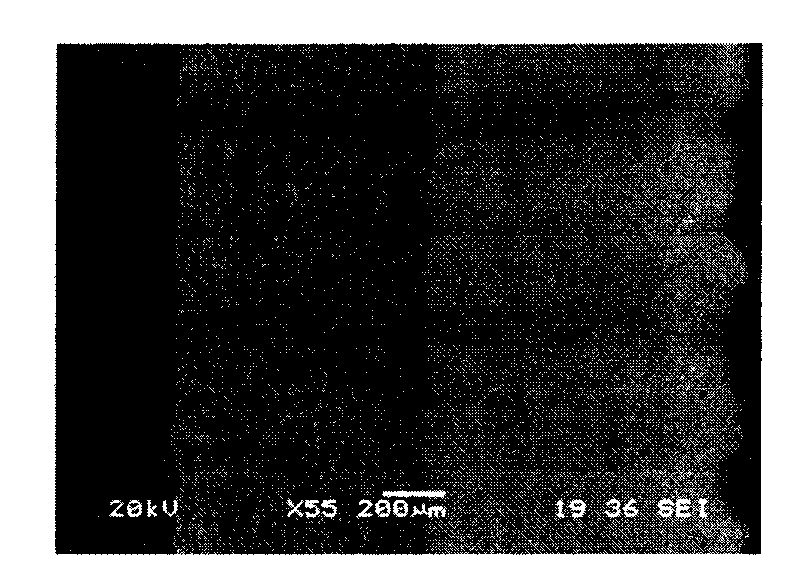

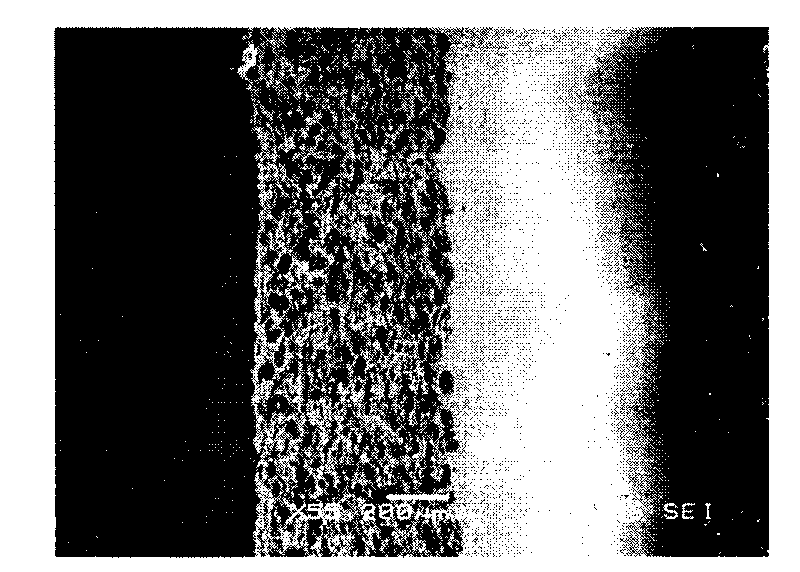

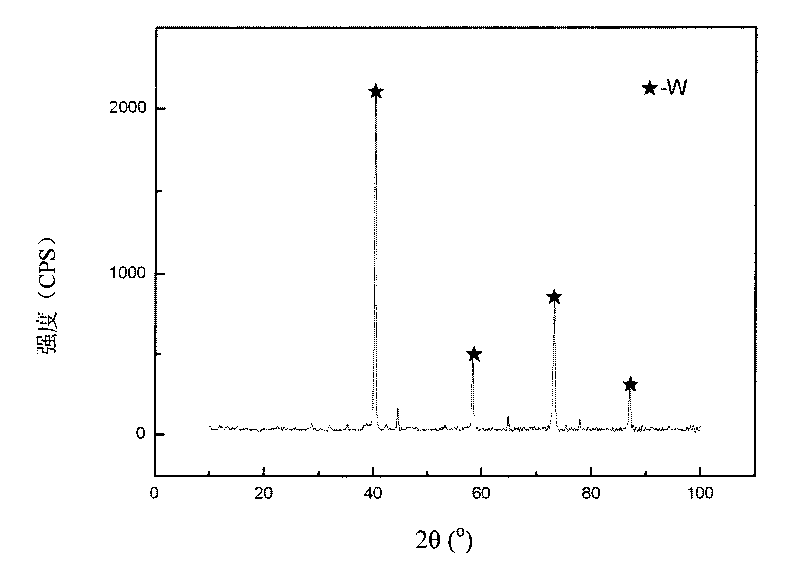

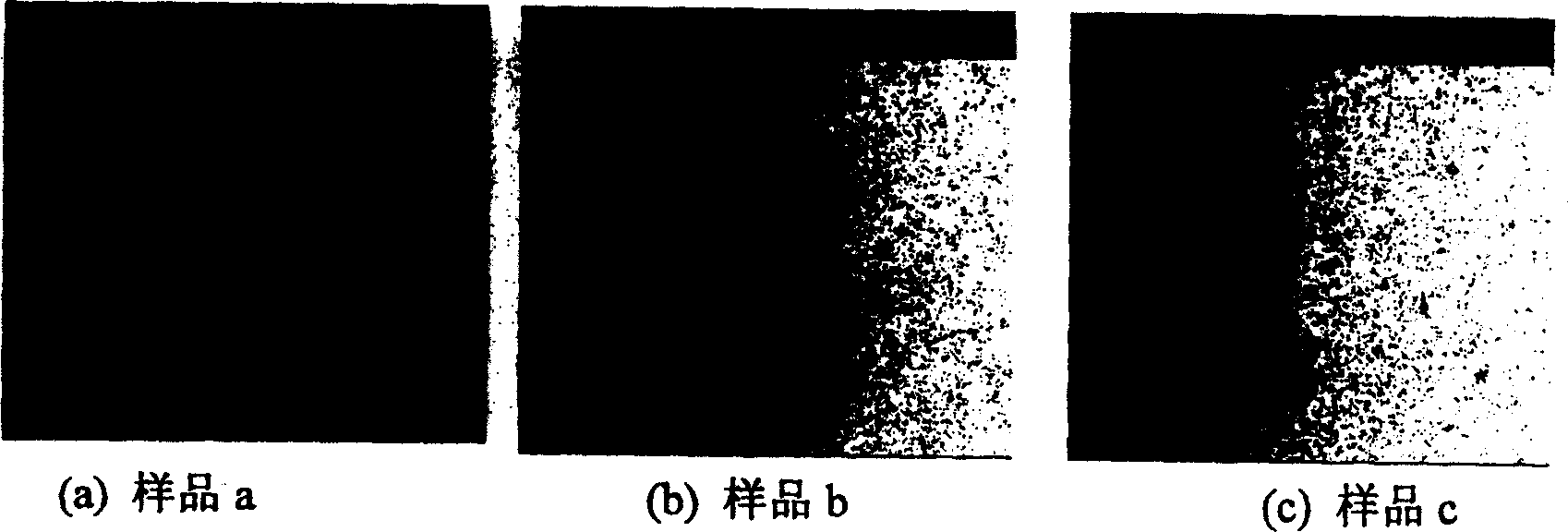

Method for preparing copper-base tungsten coating through compounded process of laser and thermal spraying

ActiveCN101717910AImprove heat resistanceImprove thermal shock resistanceMolten spray coatingThermal sprayingCoating system

The invention relates to a method for preparing a copper-base tungsten coating through a compounded process of laser and thermal spraying. The method is characterized by comprising the following steps of: preparing a nickel base alloy transition bottom layer on the surface of a copper matrix by using a low pressure plasma coating system, and remelting the transition bottom layer with laser beams; and then preparing an intermediate transmission layer and the tungsten coating of a Ni-W alloy by using the low pressure plasma coating system, and then remelting with the laser beams to obtain the tungsten coating. By using a gradient coating structure, the method effectively solves the problem of thermal stress caused by mismatching of the coefficient of thermal expansion of the copper and the tungsten, and improves the cohesion strength of the tungsten coating and the matrix, the tungsten coating and the tungsten coating. The coating and the matrix can achieve metallurgical bonding by using the laser beam remelting, bonding property is also improved and the tungsten coating with compact surface is obtained. The tungsten coating prepared by the method has excellent anti-heat radiation and anti-thermal shock properties and is suitable to be used as heated end component materials in equipment, such as first wall material in a ray target, a rocket nozzle, an airplane nozzle throat and a nuclear fusion device.

Owner:GUANGDONG INST OF NEW MATERIALS

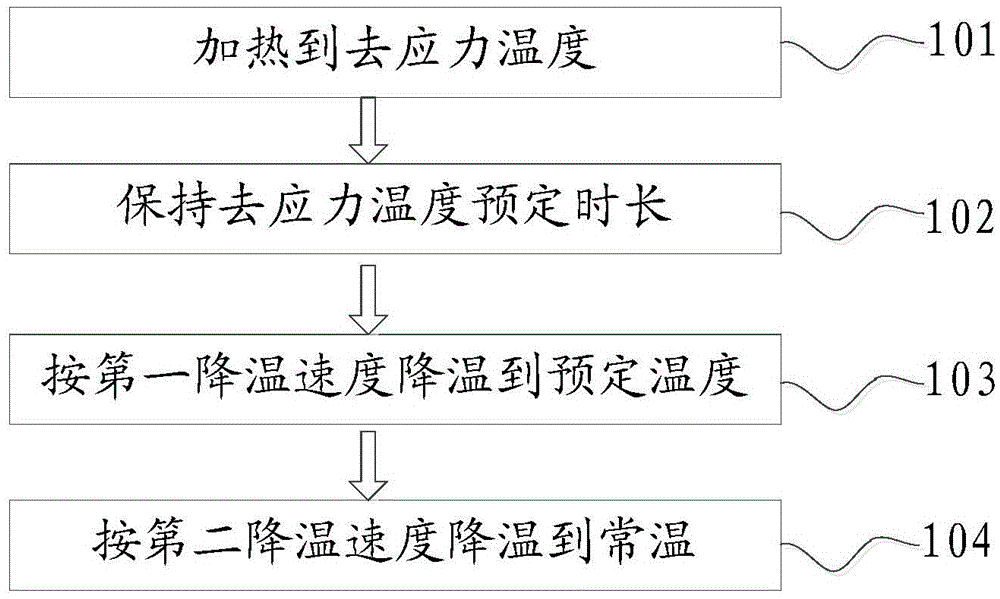

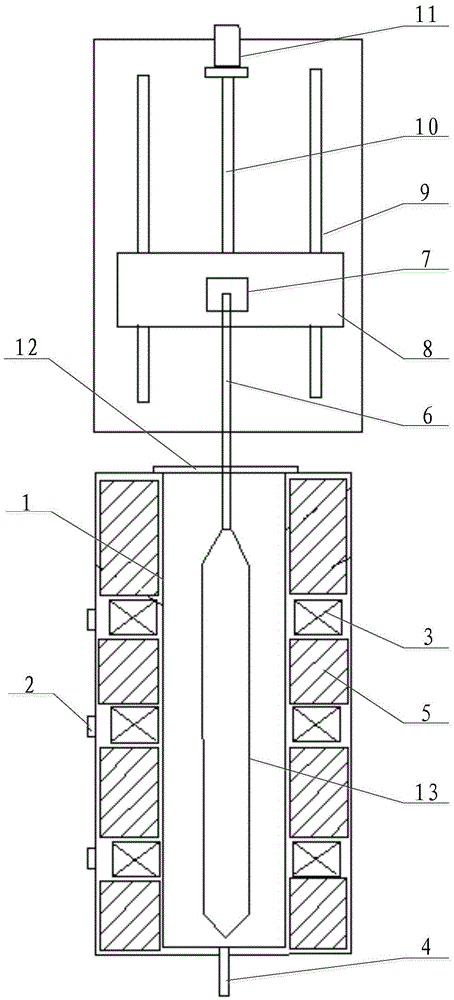

Thermal stress relief process of prefabricated rod and thermal stress relief equipment thereof

InactiveCN105541102AAddressing new thermal stress issuesSolve thermal stressGlass making apparatusEngineeringStress relief

The invention discloses a thermal stress relief process of a prefabricated rod. The process includes: heating the prefabricated rod to a stress relief temperature; maintaining the prefabricated rod for a predetermined period of time at the stress relief temperature; cooling the prefabricated rod from the stress relief temperature to a predetermined temperature by a first predetermined cooling rate; cooling the prefabricated rod from the predetermined temperature to room temperature according to a second predetermined cooling rate, with the first predetermined cooling rate being smaller than the second predetermined cooling rate. Phased cooling is implemented at the cooling stage of the prefabricated rod to ensure that the internal heat of the prefabricated rod can be diffused slowly and evenly, thereby effectively avoiding generating new thermal stress in the thermal stress relief process of the prefabricated rod. The thermal stress relief process can effectively solve the problem of new thermal stress generated after prefabricated rod reheating for thermal stress relief. The invention also discloses prefabricated rod thermal stress relief equipment utilizing the process.

Owner:FUTONG GROUP CO LTD

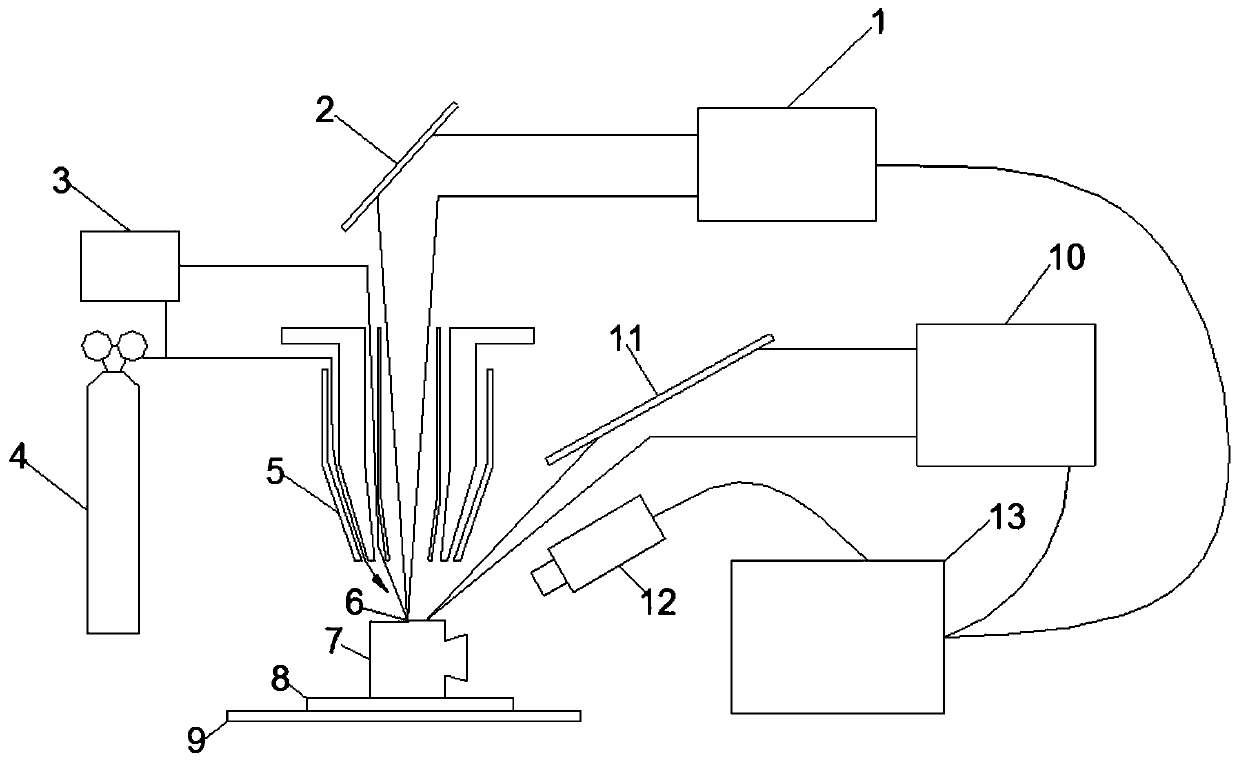

Laser melting deposition and laser shock strengthening combined manufacturing device and method

PendingCN110802226AIncrease stressImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyControl systemMonitoring system

The invention provides a laser melting deposition and laser shock strengthening combined manufacturing device. The device comprises a melting deposition system, a shock strengthening system and an online monitoring system which are connected by leads; the melting deposition system includes a melting laser device, a laser path assembly, a powder feeder, a melting deposition head and a three-dimensional processing platform; after being guided by the laser path assembly, a laser beam emitted from the melting laser device passes through the melting deposition head and reaches the three-dimensionalprocessing platform to form a laser spot; the shock strengthening system includes a shock strengthening laser device and a laser guide assembly; and the online monitoring system includes an online monitoring sensor and an information collection control system which are connected by leads. The combined manufacturing device can further overcome the problem of combined manufacturing of complex curved surface parts while solving the thermal stress problem in the process of laser melting deposition, and in addition, laser shock control is employed, the combined manufacturing device has the advantages of fast response, no contact, high controllability and the like.

Owner:西安空天机电智能制造有限公司

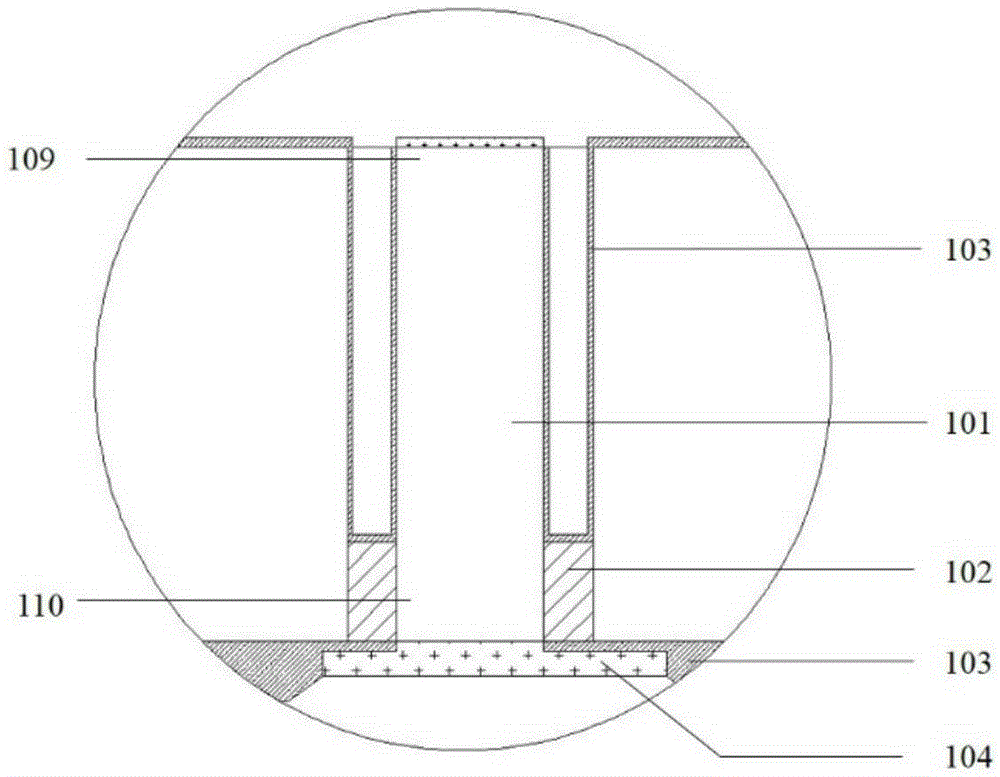

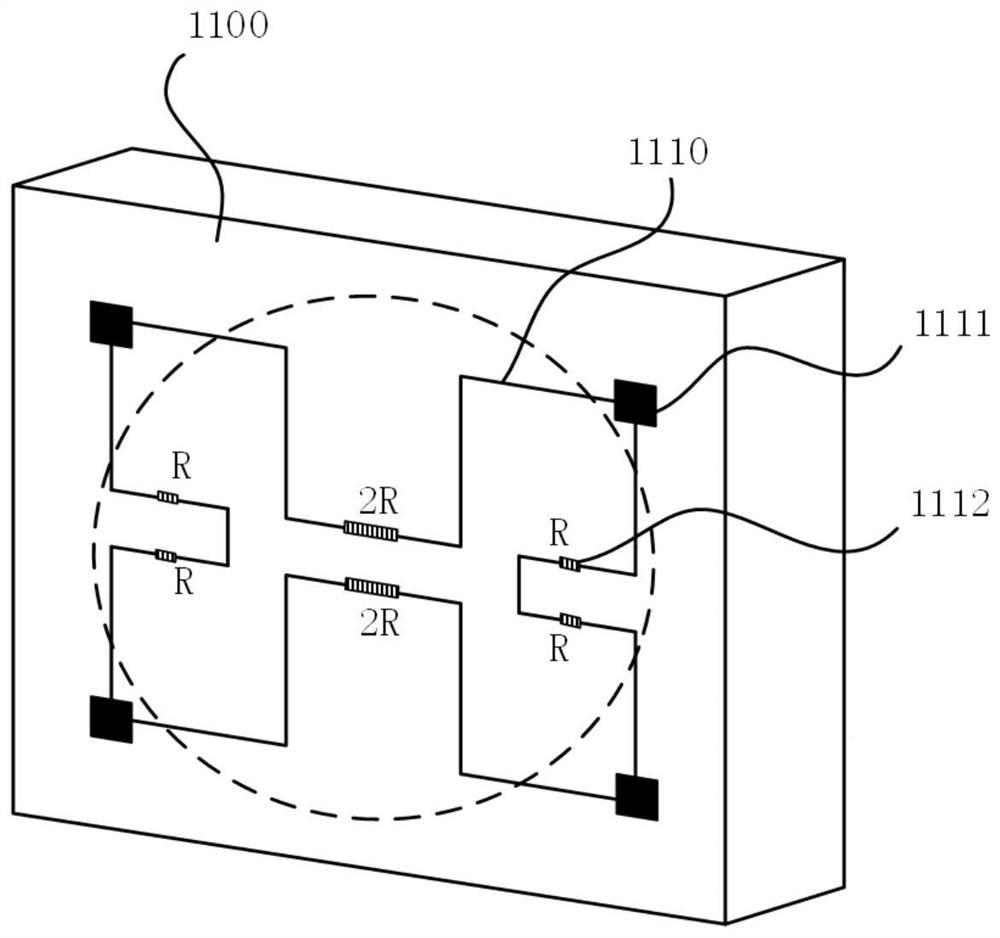

Novel TSV switch board and manufacturing method

InactiveCN105405838ASolve thermal stressReduce parasitic capacitanceSemiconductor/solid-state device detailsSolid-state devicesIndirect contactOhm

The invention relates to a novel TSV switch board and a manufacturing method. The switch board comprises a substrate, the substrate is provided with a plurality of free columns, one ends of the free columns are separated from the substrate via gaps, the other ends of the free columns and the substrate are fixed in an insulation manner via insulating materials, the upper surface and the lower surface of the substrate and sidewalls of the free columns are covered by insulating layers, free end surfaces and fixed end surfaces of the free columns are all provided with ohmic contact formed by metal layers, the substrate is made of a low-resistance silicon material (<=0.1 ohm*cm), the insulating materials employed by indirect contact of the free columns and the substrate refer to one of silicon dioxide, glass frit, and resin, and the metal layers for forming ohmic contact with the free ends and the fixed ends of the free columns refer to one of copper, aluminum, gold, and tin. According to the switch board, the problem of thermal stress caused by mismatch of thermal expansion coefficient between Cu, Au, and W and the silicon substrate is fundamentally avoided, and the TSV switch board with low thermal stress is realized.

Owner:苏州含光微纳科技有限公司 +1

High-entropy alloy connection silicon carbide ceramic connecting part as well as preparation method and application thereof

The invention belongs to the technical field of non-oxide ceramic connection and discloses a high-entropy alloy connection silicon carbide ceramic connecting part as well as a preparation method and application thereof. The high-entropy alloy connection silicon carbide ceramic connecting part is prepared by mixing high-entropy alloy AlCoCrFeNi powder with SiC powder, performing stirring and ultrasonic treatment by using absolute ethyl alcohol as a solvent so as to obtain a uniform brazing filler metal, uniformly smearing the brazing filler metal to a SiC surface after polishing, and performingthermal treatment through SPS (spark plasma sintering) sintering at 1000-1400 DEG C at connection pressure of 5-30MPa, wherein the structure of the connecting part is SiC / AlCoCrFeNi-SiC / SiC. When thehigh-entropy alloy is used as a connecting layer, not only is low-temperature connection of a silicon carbide ceramic achieved, but also the internal stress of the ceramic connector can be reduced, and the connecting part can be applied to harsh working environments at high temperatures and high pressure, and particularly can be widely applied to the nuclear industry.

Owner:GUANGDONG UNIV OF TECH

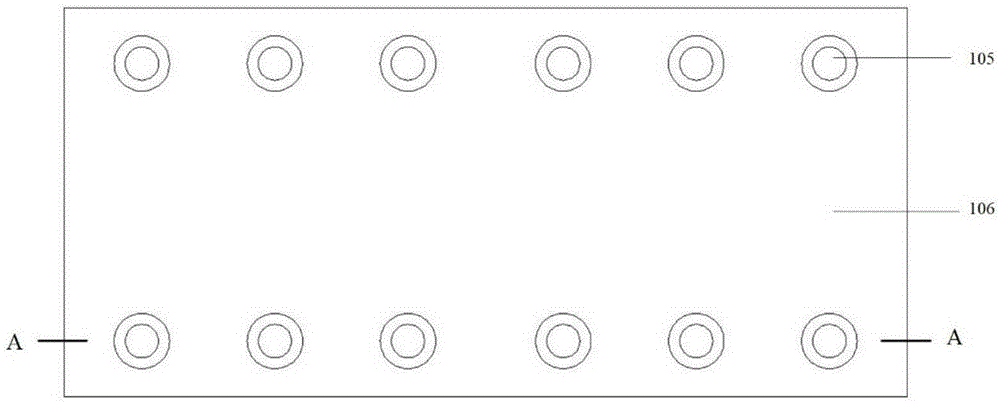

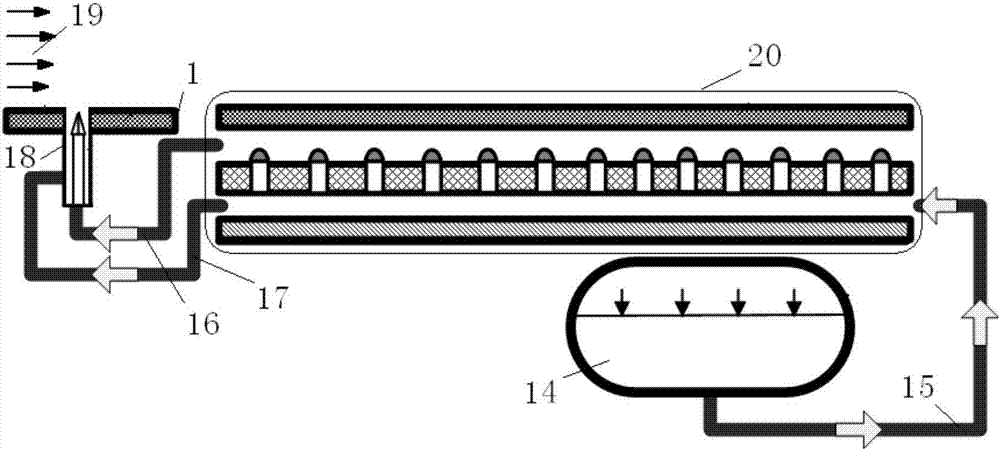

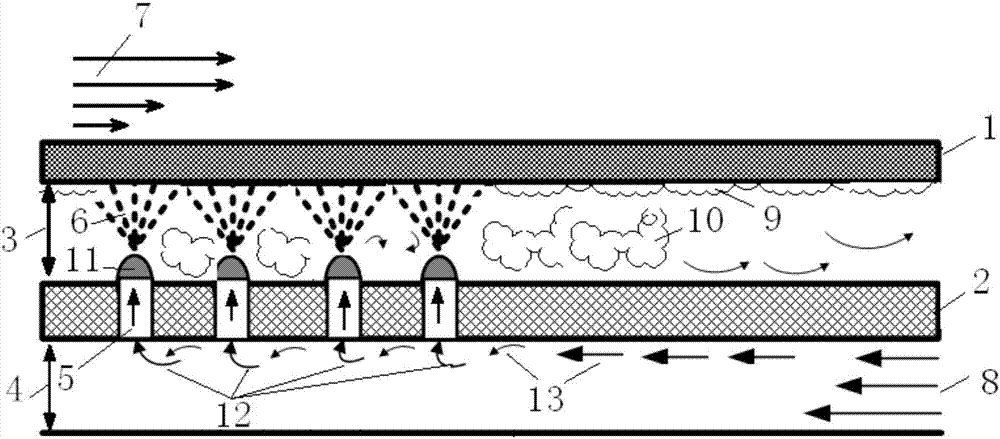

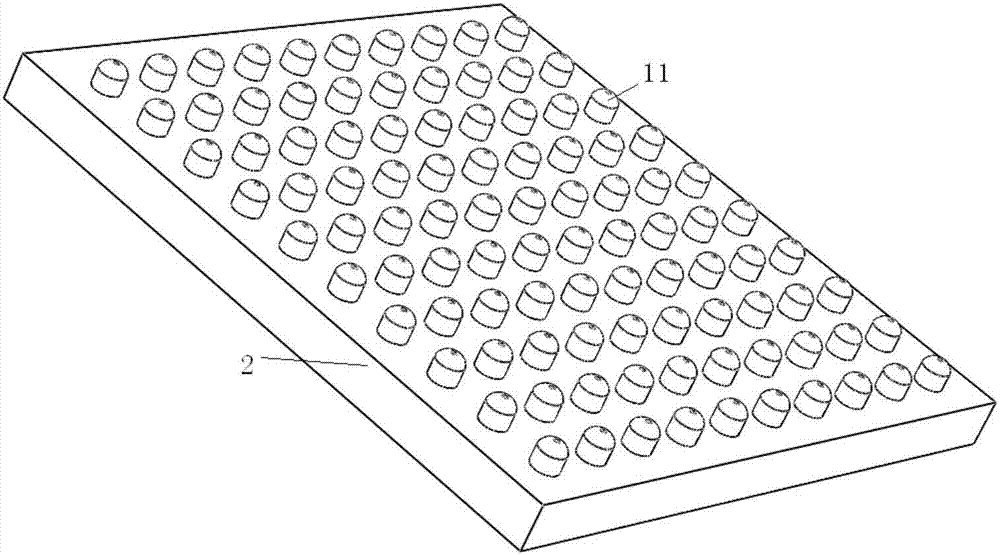

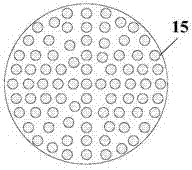

Regenerative cooling double flow channel scheme strengthening heat exchange through spray wall impingement

ActiveCN106949497AImprove heat transfer efficiencyGood choiceContinuous combustion chamberCombustion systemHeat flow

The invention provides a heat exchange strengthening structure used for regenerative cooling of a supersonic combustion chamber through a spraying / convection composite type heat exchange mode. A double flow channel design is adopted, and the characteristic of the large heat flux of a spraying cooling mode is fully utilized to conduct heat exchange strengthening on the wall face of the combustion chamber. A scheme is composed of a double layer heat exchange scheme of the outer layer wall and the inner layer wall. A flow channel formed by partitioning of the outer layer wall and the inner layer wall is used for spray wall impingement strengthening heat exchange. Spraying nozzles are arranged on the inner layer wall. The number and distribution density of the spraying nozzles are determined according to the heat exchange strength and the heat exchange area. Part of heated liquid fuel and gaseous fuel formed by spray heat absorption are supplied to a nozzle of an engine combustion system in different phase states, and the liquid fuel is atomized in a mode of pneumatic atomization assisting. By adopting the design that a gas heat exchange flow channel and a liquid heat exchange flow channel are partitioned, the problem of flow supplying fluctuation caused by nonuniform gas and liquid distribution in the conveying process of the two phase flows of fuel after heat absorption to the combustion system is avoided.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

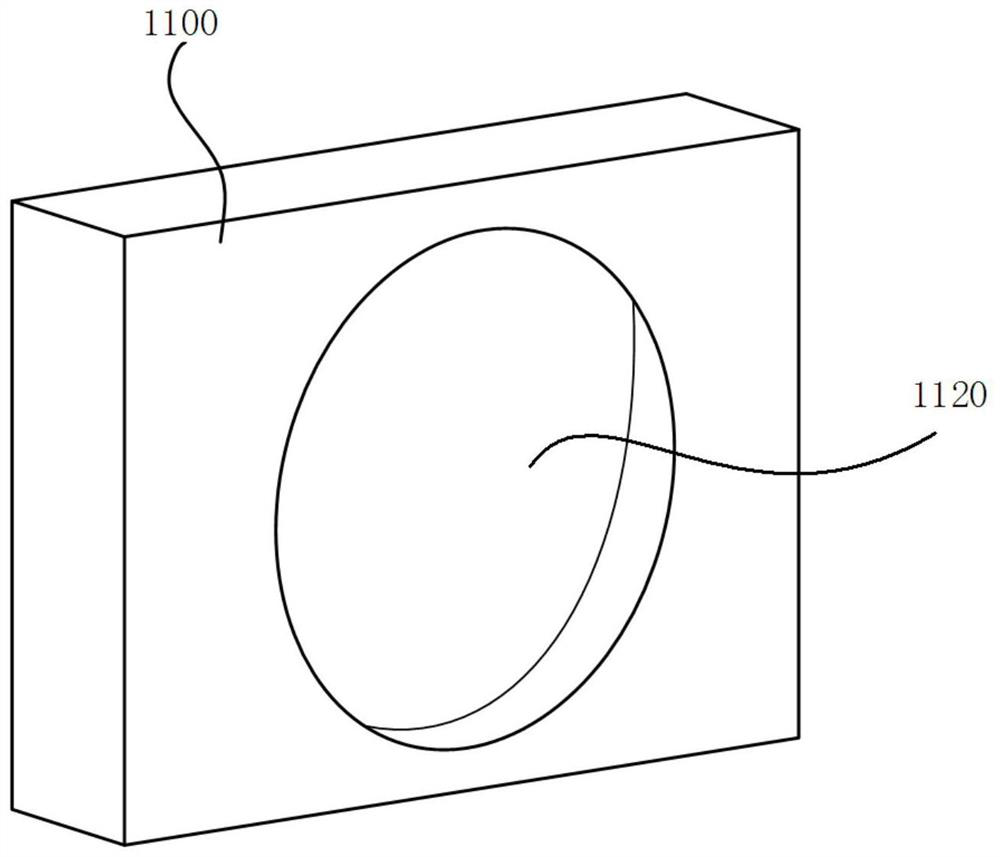

High-power laser module and packaging method thereof

InactiveCN104283108AAvoid thermal buildupImplement alternative operationsLaser detailsSemiconductor lasersHigh power lasersOptoelectronics

The invention relates to a high-power laser module which comprises a heat sink. A plurality of laser single-tube chip units connected in series are arranged on the surface of the heat sink and one side of the light emitting end. The laser single-tube chip units connected in series are arranged on one side of the light emitting end of the heat sink in a circular arc or circular arc internally-tangent polyline mode. Due to the fact that high-power laser single tubes are connected in series, the high-power module is replaceable, and the heat effect caused by dense bars is avoided; the arc face design replaces a slow-axis compression lens, and therefore the laser power consumption is reduced.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

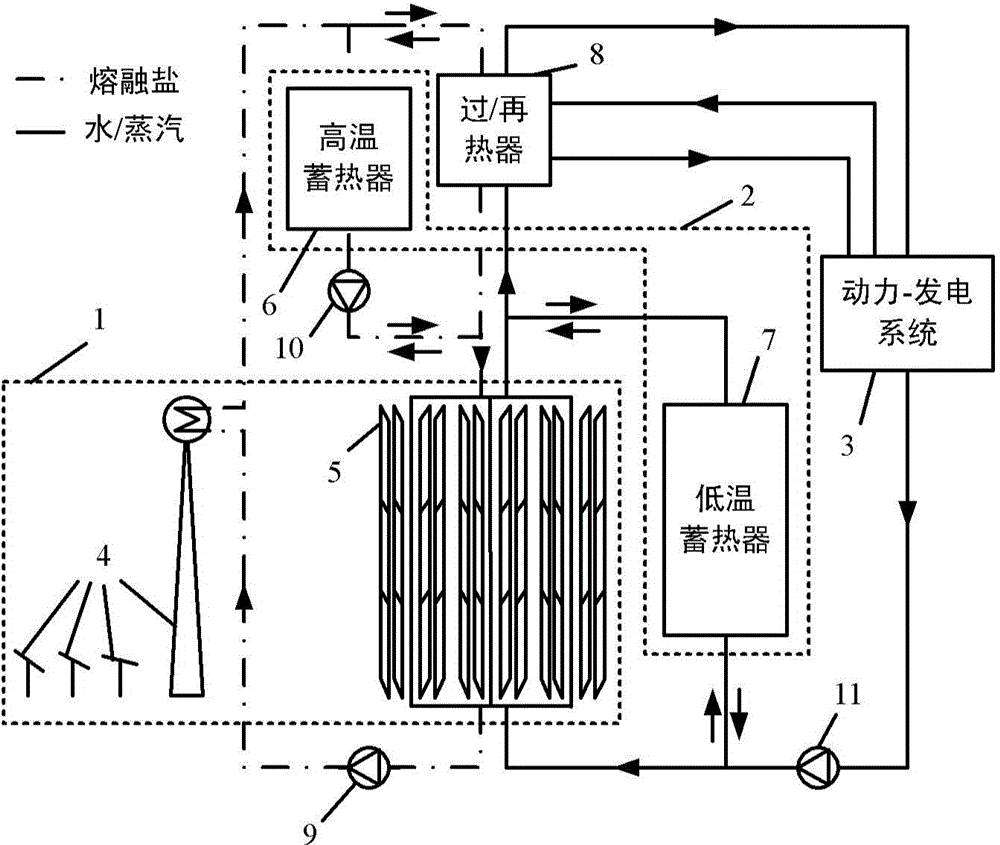

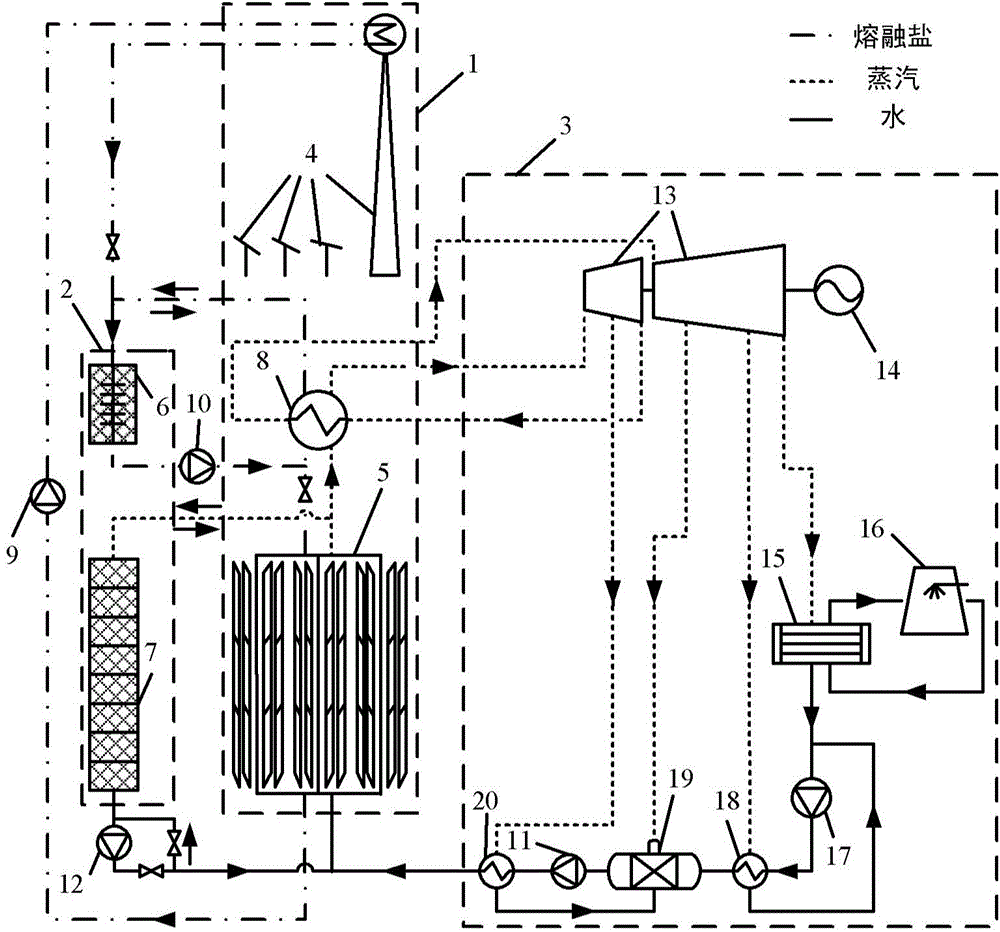

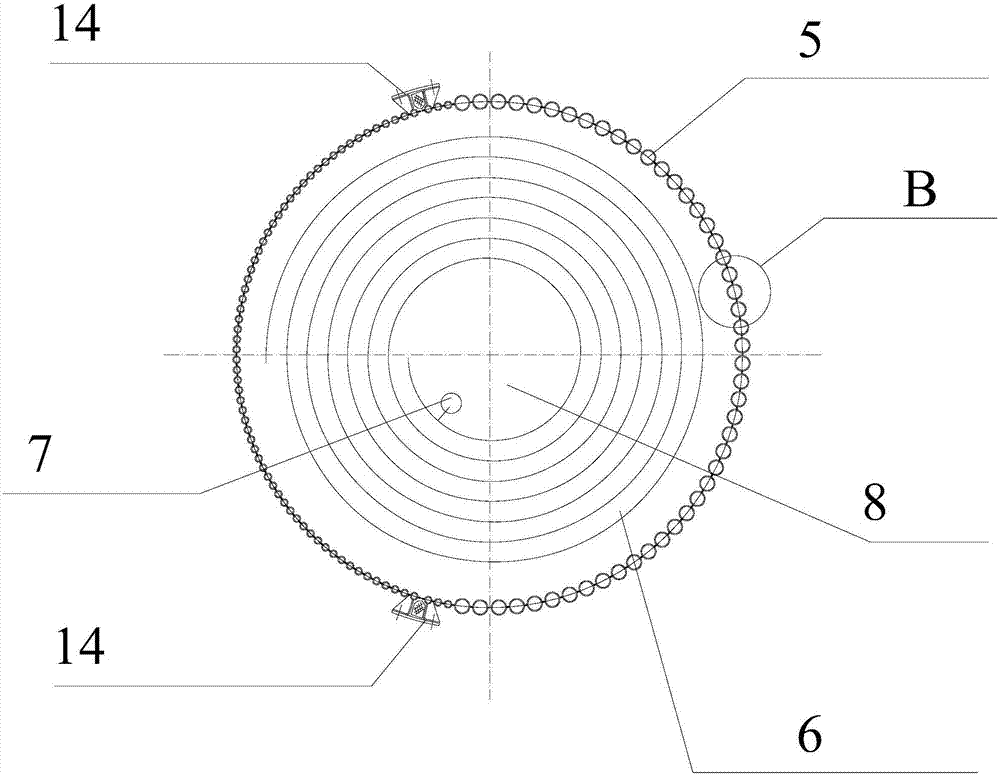

A solar thermal power generation system of a dot-line focusing coupling heat collecting field

InactiveCN104533737ARealize rational utilization of cascadeImprove superheated steam parametersSolar heating energyFrom solar energyEngineeringHeat energy

The invention discloses a solar thermal power generation system of a dot-line focusing coupling heat collecting field. The solar thermal power generation system includes a dot-line focusing coupling heat collecting subsystem, a heat storage subsystem, and a power-electricity generating subsystem. Wherein, the dot-line focusing coupling heat collecting subsystem includes a tower-typed heat collecting field, a linear Fresnel-typed or parabolic trough-typed heat collecting field and auxiliary equipment, and is used for focusing the solar energy so that water is heated to create steam; the heat storage subsystem includes a high-temperature heat accumulator, a low- temperature heat accumulator and auxiliary equipment, and is used for storing heat in the case of good irradiating condition and releasing heat in the case of unfavorable irradiating condition so that the system can continuously run; the power-electricity generating subsystem includes a steam turbine, a generator unit and auxiliary equipment, and is used for converting heat energy to electric energy and outputting the electric energy. The solar thermal power generation system of a dot-line focusing coupling heat collecting field increases a steam parameter. Thus, the electricity generating efficiency is evidently enhanced and the comprehensive heat collecting efficiency is enhanced so that heat loss during the heat collecting course is reduced, and reasonable gradient usage of high-quality energy is realized. Therefore, the energy usage ratio is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

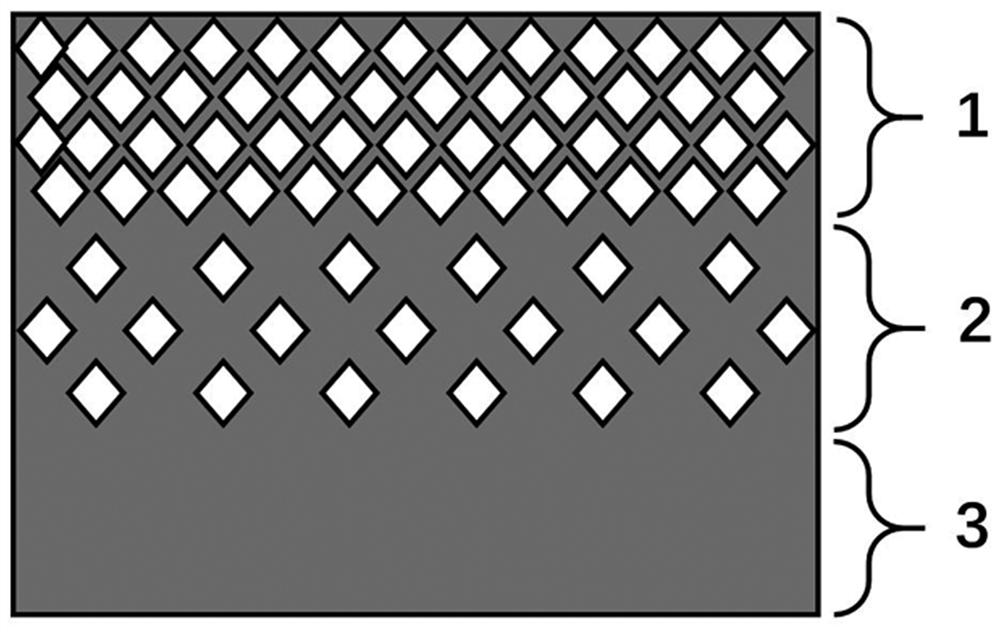

Composite heat sink material with thermal expansion coefficients in gradient distribution and preparation method thereof

PendingCN112222381ASolve thermal stressEliminate interfacial thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceThermal dilatation

The invention discloses a composite heat sink material with thermal expansion coefficients in gradient distribution and a preparation method thereof, and belongs to the technical field of electronic packaging materials. By adopting a method for preparing diamond preforms with different volume content, and carrying out infiltrating, cooling and demolding, the composite heat sink material with the thermal expansion coefficients in gradient distribution, which consists of three parts, namely a first diamond / metal composite layer, a second diamond / metal composite layer and a metal heat dissipationlayer with different diamond volume content is prepared, and the three parts are connected through metal and are integrally formed. According to the composite heat sink material and the preparation method thereof, gradient distribution of the thermal expansion coefficients in the heat dissipation path direction is achieved, the packaging structure and process are simplified, the problem of thermal stress between a heat sink and a radiator is avoided, therefore, the heat dissipation capacity, reliability and quality stability of a power semiconductor device are improved.

Owner:成都本征新材料技术有限公司

Optical glass having high refractive index

The invention relates to a precise molded optical glass having a high refractive index and a low dispersion and an optical element, an optical parts or an optical assembly containing the optical glass. The refractive index nd of the optical glass is more than or equal to 1.74 but less than or equal to 1.82, an Abbe coefficient ud is more than or equal to 40.0 but less than or equal to 47 and a transformation temperature Tg is less than or equal to 600 DEG C. The optical glass contains the following oxide based weights: SiO2 of 1 to 5 wt. %, B2O3 of 14 to 30 wt. %, La203 of 18 to 28 wt. %, Gd2O3 of 5 to 20 wt. %, Ta2O5 of 2 to 13 wt. %, Li2O of 1to 5 wt. %, ZnO of 14 to 25 wt. %, ZrO2 of 2 to 6 wt. %, WO3 of 5 to 12 wt. %, Nb2O5 of 1 to 7 wt. %, Na2O of 0 to 1 wt. % and Yb2O3 of 0 to 1 wt. %. For favorable application, the optical component can be produced without finishing, such as lens for digital camera. The precise molded optical component can be applied to the fields of imaging, projecting, remote communication, photo-communication engineering and laser technique.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

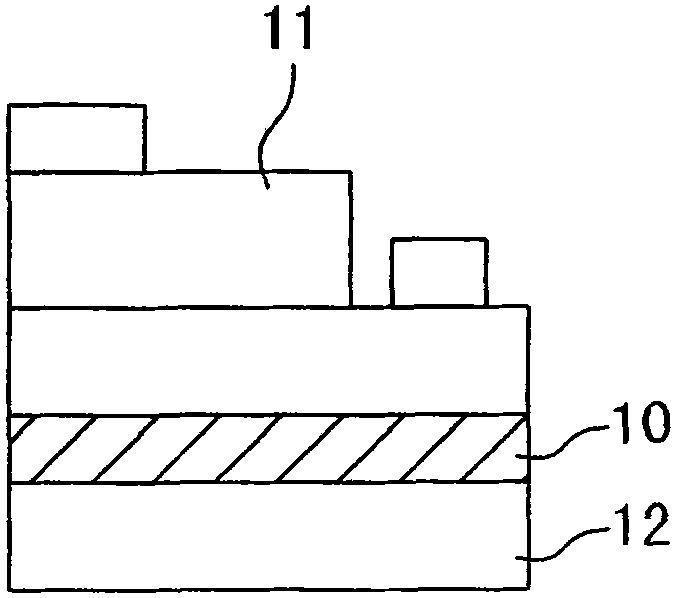

Method for forming die bonding connection structure of reflective LED at low temperature

The invention discloses a method for forming a die bonding connection structure of a reflective LED at low temperature, which comprises the following steps of: forming a first metal layer on a first surface of a base plate, and providing an LED epitaxial structure on a second surface of the base plate; forming a second metal layer on a base body, wherein the material of the second metal layer is different from that of the first metal layer; applying a force to the base plate and the base body so that the first metal layer and the second metal layer produce plastic deformation and are primarily bonded together; and heating the base plate and the base body in a high temperature furnace, wherein the first metal layer and the second metal layer are subjected to solid state diffusion in an interface to form a diffusion alloy layer.

Owner:IND TECH RES INST

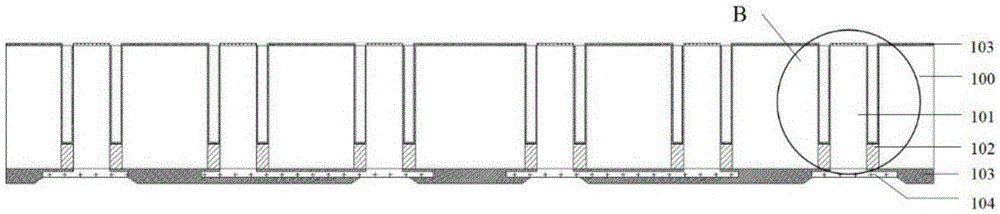

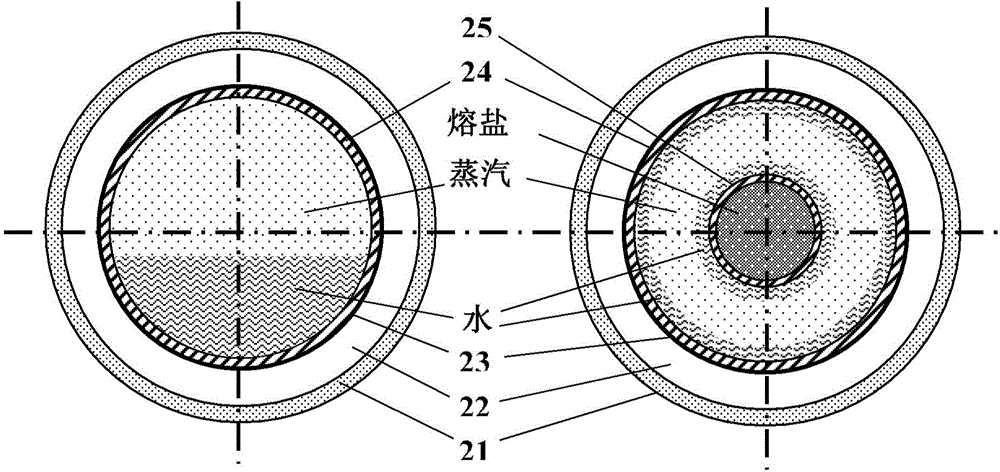

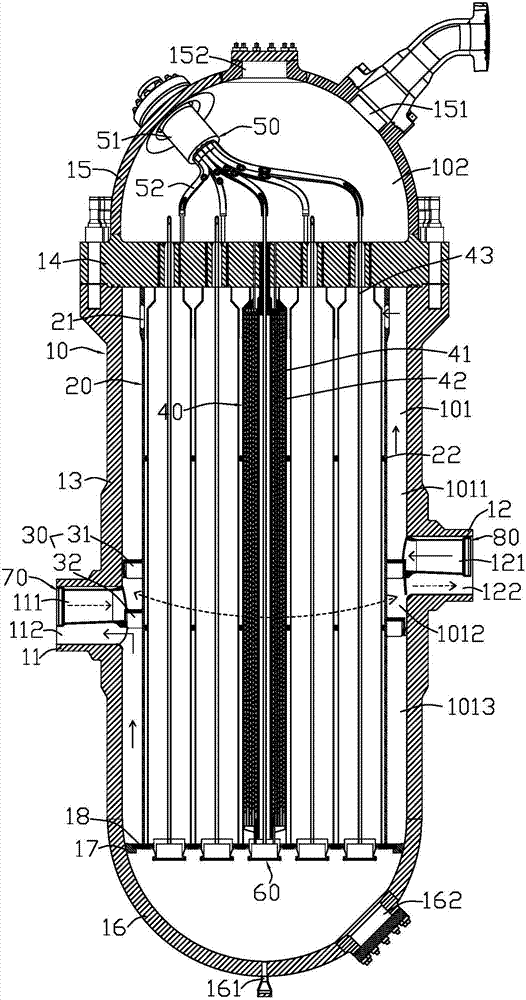

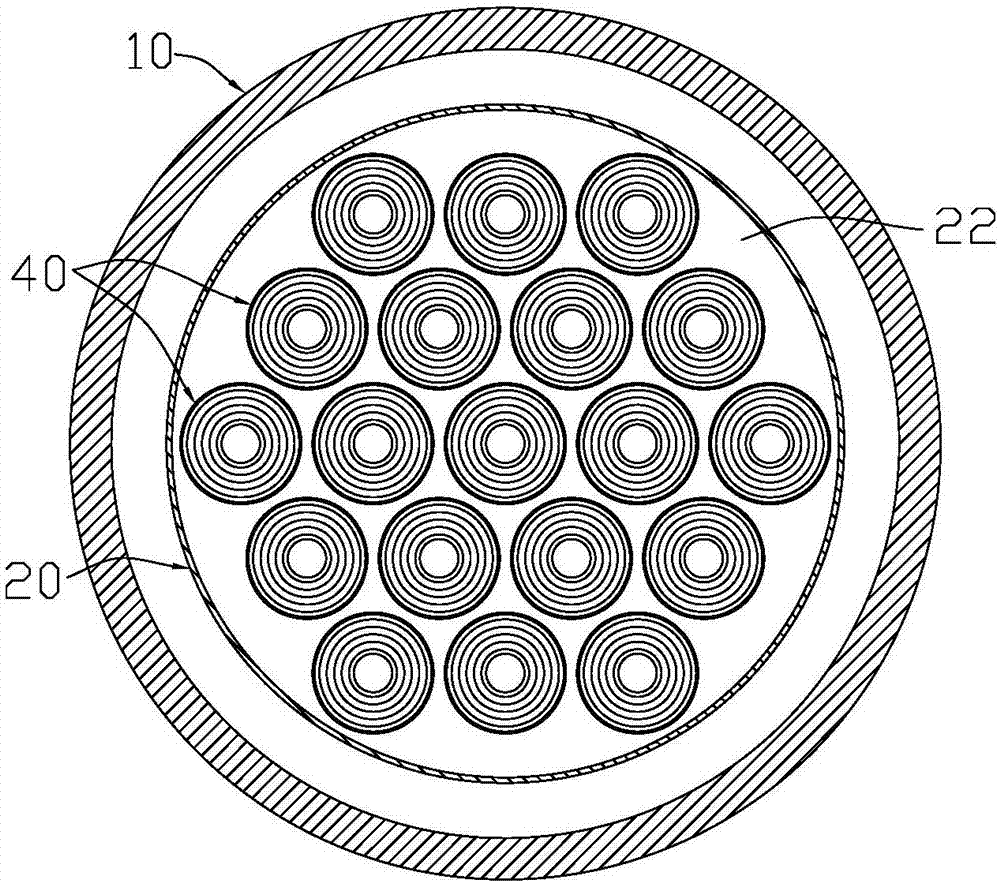

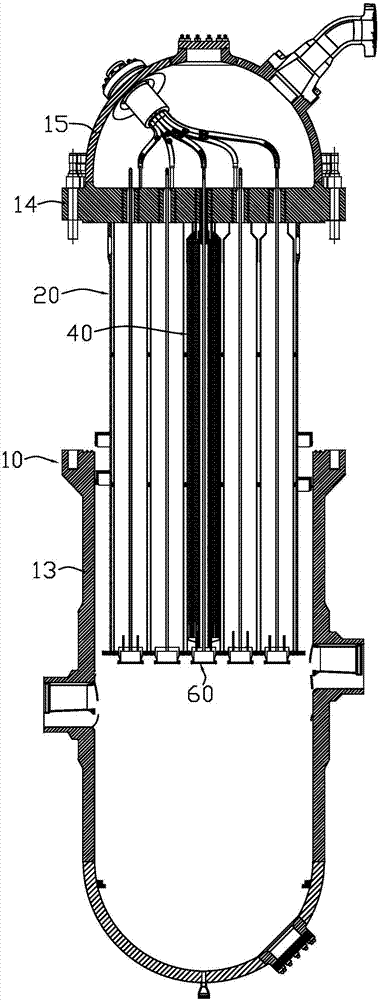

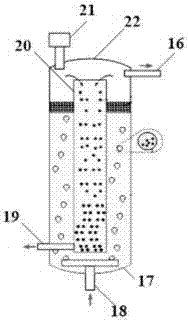

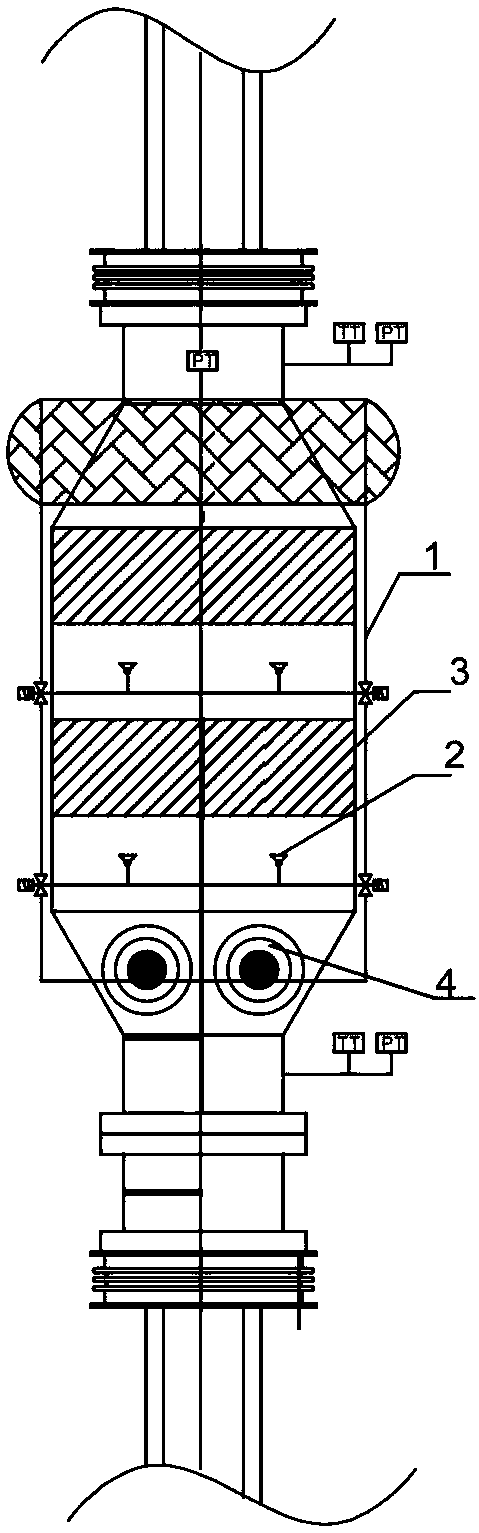

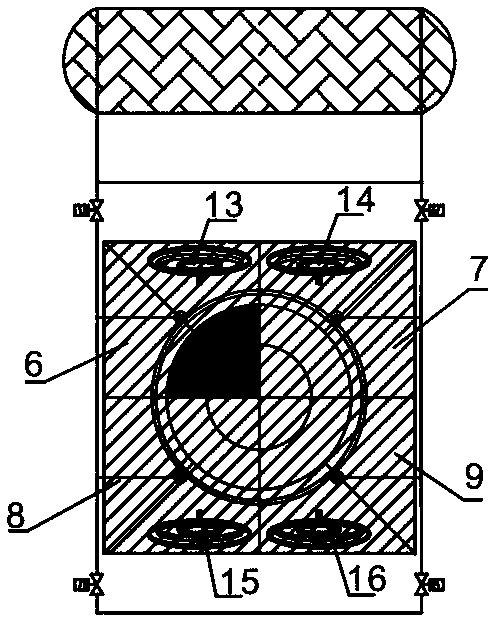

Multi-unit pipe type direct-current steam generator

ActiveCN107143833ACompact layoutImprove applicabilitySteam generation heating methodsSteam boilersReturn channelWater supply

The invention discloses a multi-unit pipe type direct-current steam generator. The steam generator comprises a container body, a sleeve, a partition plate assembly and heat exchange units; a cavity is formed between the sleeve and the inner wall of the container body; the partition plate assembly divides the cavity into an upper cavity body, a middle cavity body and a lower cavity body; a first filler neck and a second filler neck are arranged on the container body; a water inlet channel of the second filler neck, the upper cavity body, the interior of the sleeve, the interiors of the heat exchange units, the lower cavity body and a water outlet channel of the first filler neck communicate with one another in sequence to form a primary side medium channel; the water inlet channel of the first filler neck, the middle cavity body and the water outlet channel of the second filler neck communicate with one another in sequence to form a water return channel; the top of the container body is provided with a steam chamber and a water supply assembly; the heat exchange units are provided with water supply pipelines; and the water supply assembly, the water supply pipelines, an inner flow passage of a heat exchange pipe and the steam chamber communicate with one another in sequence to form a secondary side medium channel. The steam generator has the advantage that the compact arrangement can be realized.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

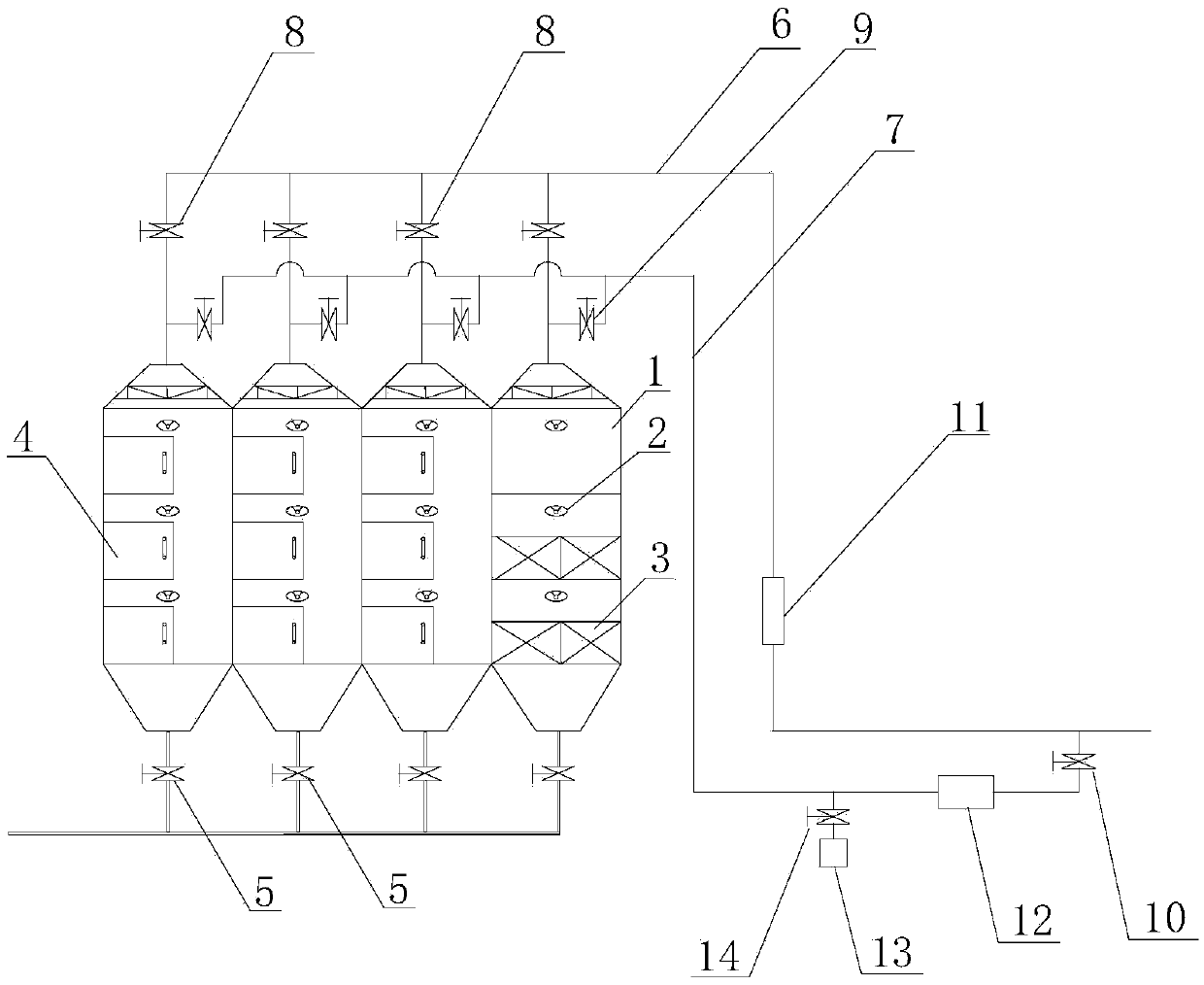

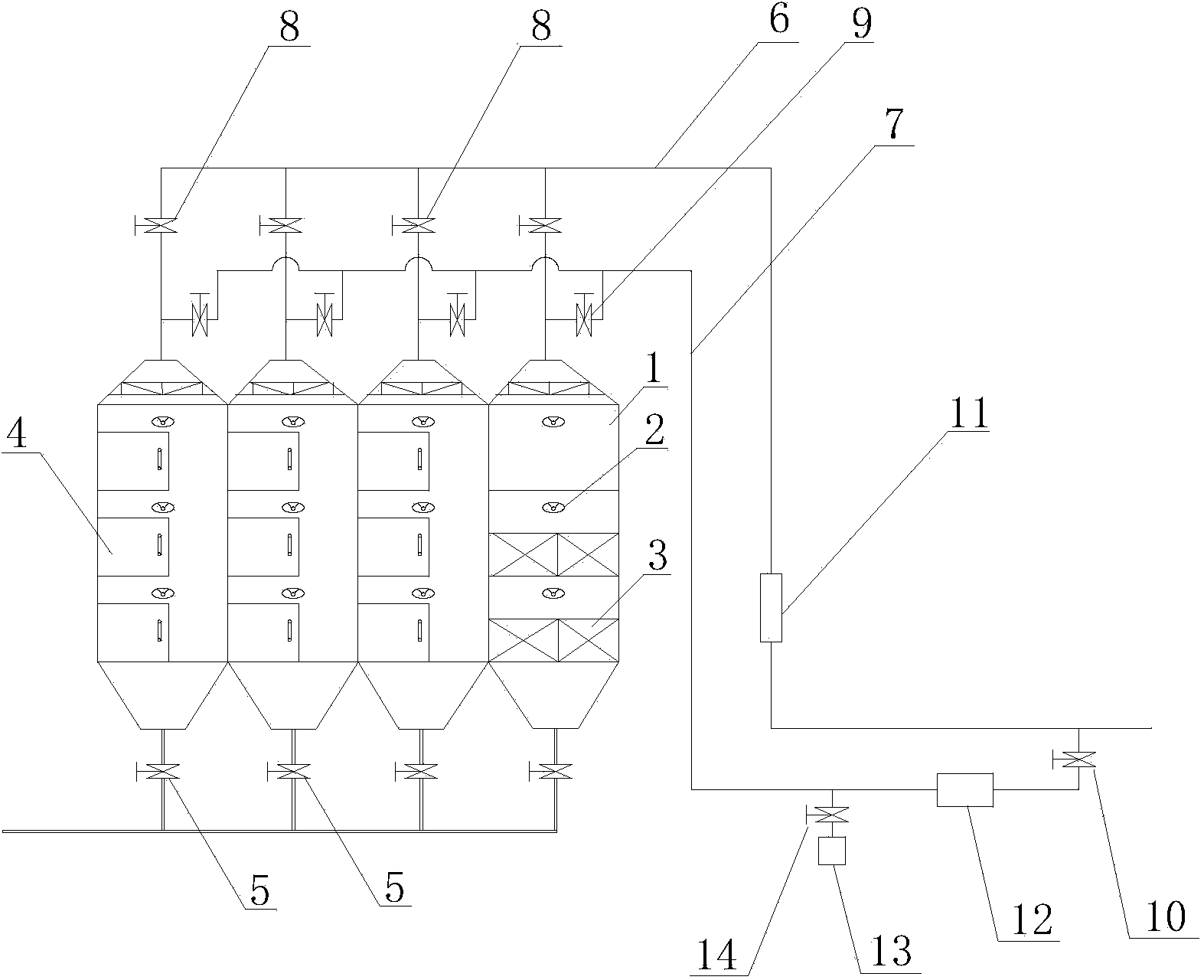

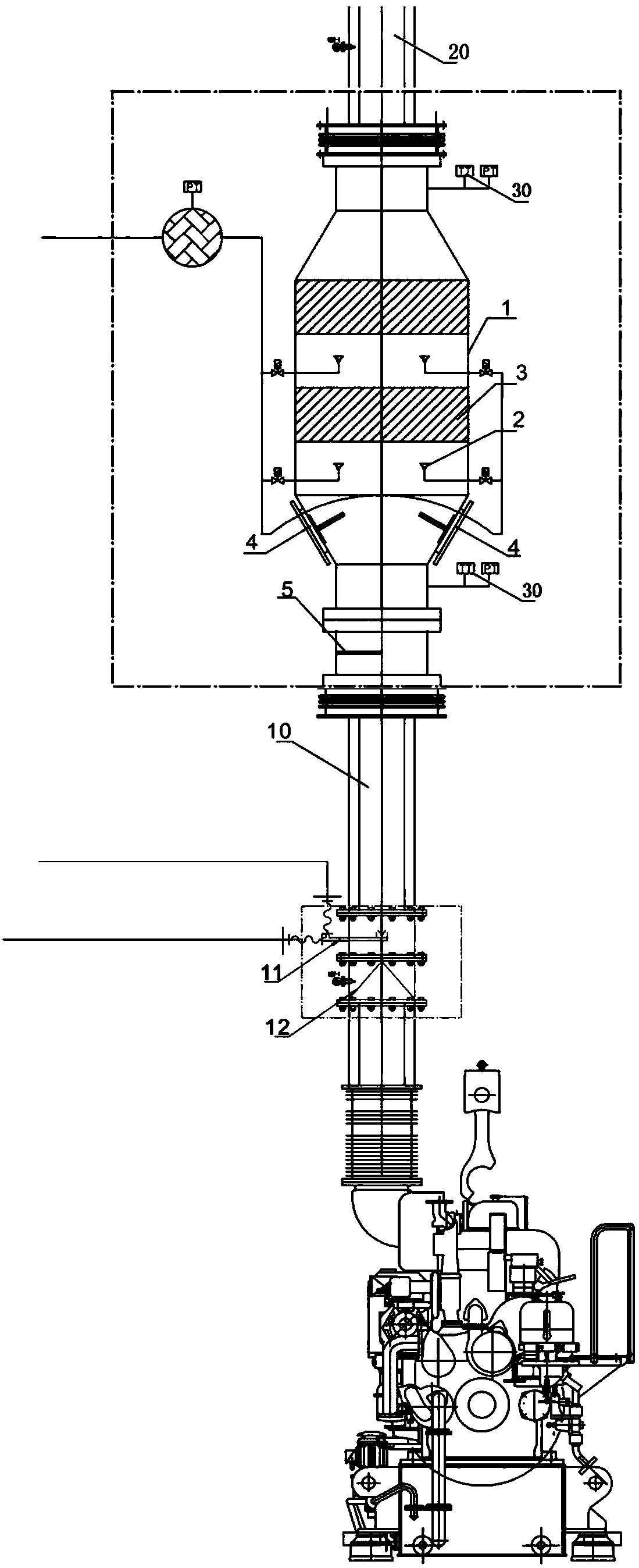

Denitration method using single bin heating regeneration denitration system special for low-temperature flue gas

ActiveCN105363346ASolve thermal stressEasy to operateGas treatmentDispersed particle separationNitrogen oxidesFlue gas

The invention discloses a denitration method using a single bin heating regeneration denitration system special for low-temperature flue gas. The system is mainly composed of a low-temperature denitration system, a reheating system, and an online ash cleaning system. The denitration catalyst has high low-temperature denitration ability; the reheating system separately heat each bin to recover catalyst activity; and the online ash cleaning system has the advantages of simple structure, less investment and easy operation. After passing through the system, the nitrogen oxide in the low temperature flue gas is reduced to nitrogen and water. The method provided by the invention has the advantages of simple operation, small land occupation, high efficiency and low cost.

Owner:ANHUI TONGXING ENVIRONMENTAL PROTECTION ENG

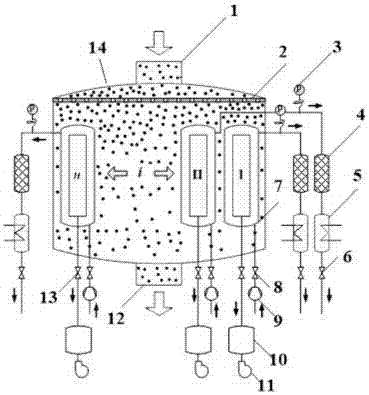

Bubbling type methane decomposition reaction device for high-temperature particle heating

ActiveCN107986231ASolve thermal stressReduce entryHydrogenHydrogen/synthetic gas productionHydrogenReactive gas

The invention discloses a bubbling type methane decomposition reaction device for high-temperature particle heating. The device is mainly applied to an ultra-high temperature condensation solar system. A plurality of special bubbling type direct methane decomposition reactor units are arranged in a main body part (a heat-carrying particle heat release tank) of the device; high-temperature heat-carrying particles downwards flow through the reactor units from the top of the heat release tank and transfer heat to heat-carrying fluid in the reactor units; methane bubbles are decomposed to producehydrogen and carbon nano-particles in the heat-carrying fluid; the carbon nano-particles and reactive gases are separated in the reactor units and extracted by an induced draft fan; and after discharged from the reactor units, the reacted mixed gases (the hydrogen and unreacted methane gas) are cooled to be fed into the next-stage reactor units to be continuously reacted or fed out of the device to enter a hydrogen separation system. According to the device disclosed by the invention, the heat-carrying fluid does not need to be fed out of the device to be heated, and safe and stable operationsof the system are ensured; and due to the modular design of the reactor units, the zoom design of the device is conveniently realized.

Owner:CHINA UNIV OF MINING & TECH

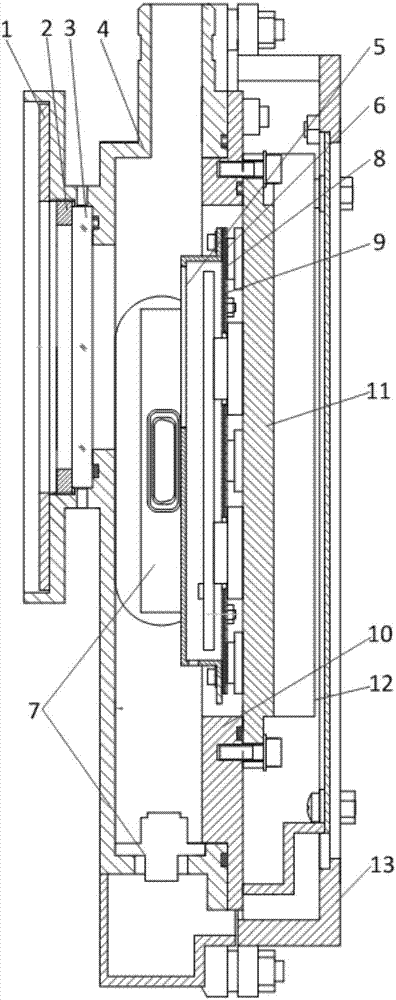

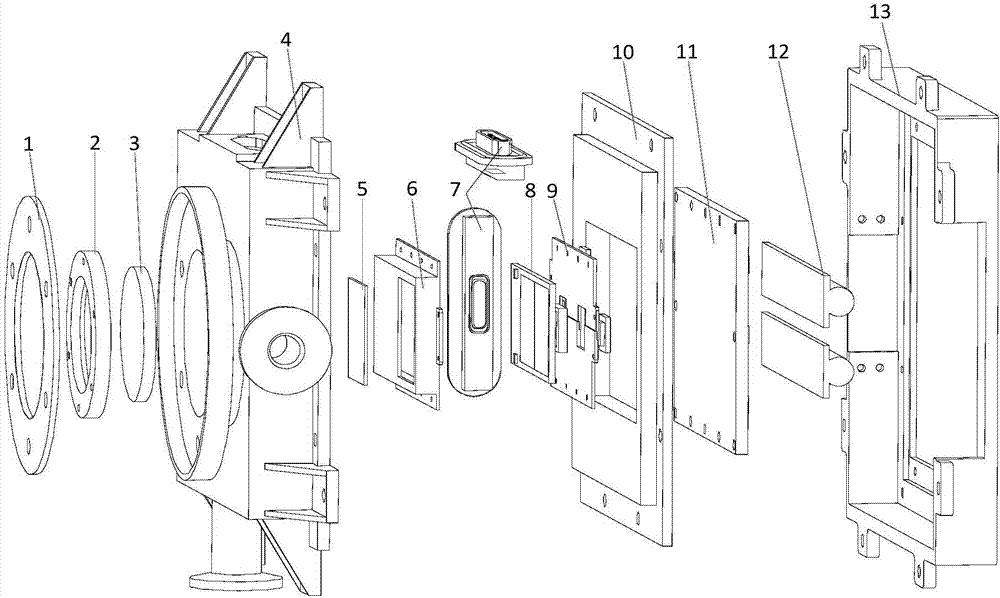

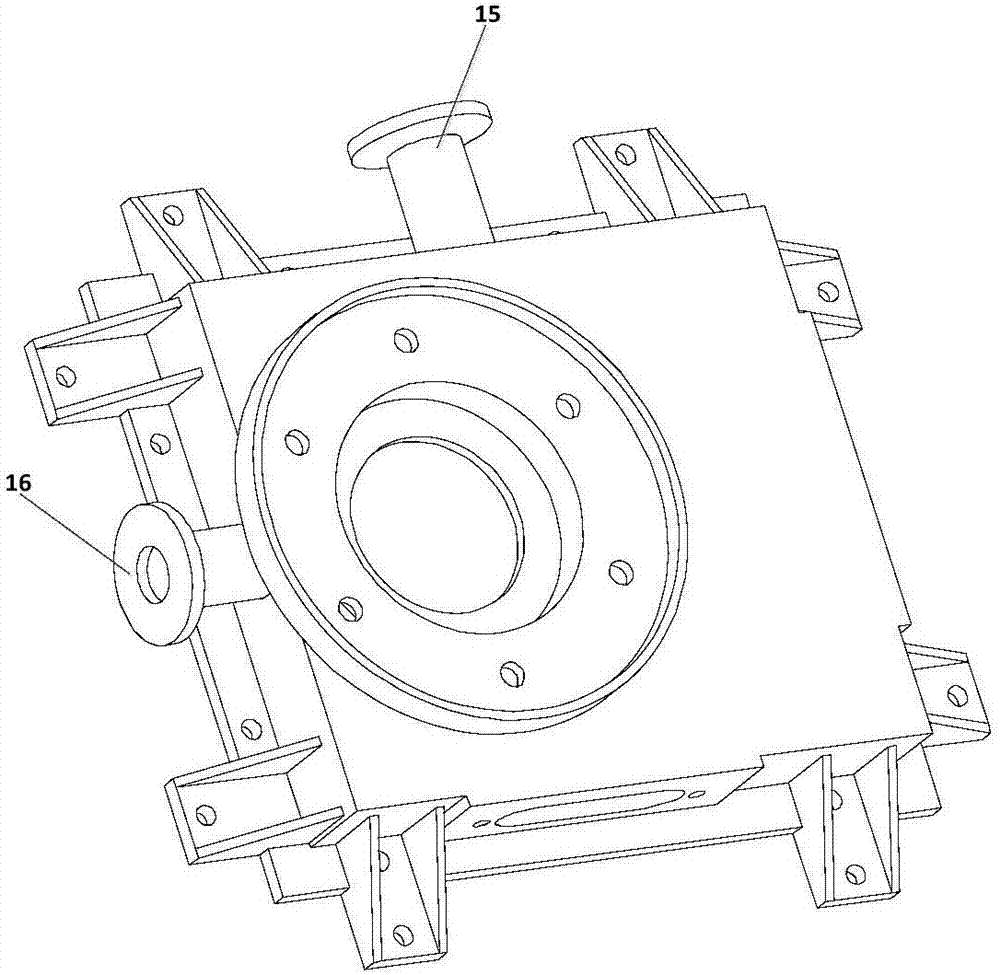

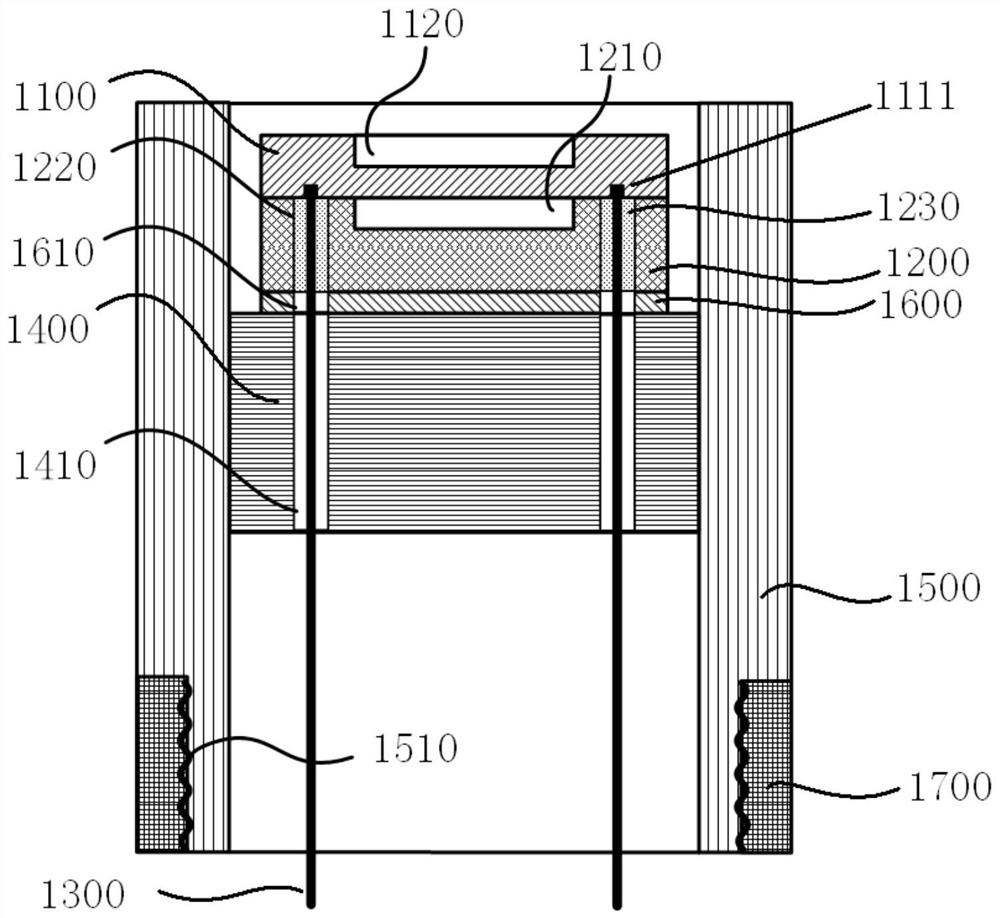

Active-cooling vacuum-sealing focal plane assembly of space camera

ActiveCN107045251ASolve pollutionSolve thermal stressCamera body detailsActive coolingHeat sensitive

The invention provides an active-cooling vacuum-sealing focal plane assembly of a space camera. Via the assembly, a detector can be cooled below -60 DEG C, and the problem that a traditional focal plane detector of the camera causes steam pollution during cooling is solved. The assembly comprises a focal plane case trimming pad, a clamping ring, a vacuum glass window, a vacuum focal plane case, a vacuum sealing connector, a cooling assembly, a focal plane case pedestal, a focal plane case base plate, heat tubes, a relay box, thermistors and thermoelectric coolers, the vacuum glass window seals and compresses a light inlet via the clamping ring, and the focal plane case trimming pad is arranged in the front end of the clamping ring; the cooling assembly comprises a cold screen window, a cold screen, an active cooling CCD assembly and a cold screen base plate; the cold screen window is installed in a gap of the cold screen; the back side of the cold screen base plate is provided with the thermistors and thermoelectric coolers; and the cooling assembly, the focal plane case pedestal, the focal plane case base plate and the heat tubes are all arranged in a cavity formed by the vacuum focal plane case and the relay box, and the heat tubes are arranged in the back side of the focal plane case base plate.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Special single-bin heating regeneration denitration system for low-temperature flue gas, and denitration method

ActiveCN104324612ASimple and flexible installationEasy to operateGas treatmentDispersed particle separationNitrogen oxidesHeating system

The invention discloses a special single-bin heating regeneration denitration system for low-temperature flue gas. The system comprises a low-temperature denitration system, a reheating system and an online ash removal system. In the system, a denitration catalyst has very high low-temperature denitration capacity; the reheating system is capable of heating every independent bin separately alone so as to enable the catalyst to recover activity; the online ash removal system has the advantages of being simple in structure, less in investment, convenient to operate, etc. After the low-temperature flue gas passes through the system, nitrogen oxides are reduced into nitrogen and water. The system is simple to operate, small in floor space, high in efficiency and low in cost.

Owner:ANHUI TONGXING ENVIRONMENTAL PROTECTION ENG

Method for preparing tungsten/copper functional gradient material by infiltration - weld method

InactiveCN1290653CEasy to prepare and effectiveSolve thermal stressMetal layered productsFritGradient material

The invention relates to a new method of making tungsten-copper functional gradient material, which consists of pure tungsten layer and tungsten-copper gradient transit layer. First, make the gradient hole-framework with boring fluid of percent 5~80 volume ratio and tungsten powder of 1~20 micron. Infiltrate copper fluid to make the tungsten-copper gradient transit layer. Weld the W / Cu gradient layer and the pure tungsten by hot pressure. The process is following: mix the material and mould them, then frit framework, Infiltrate copper, weld and check. The method has both the advantage of melt-casting technique and jointing technique. The tungsten-copper functional gradient material made by this method is better heatproof and suited to electric sealing material, heat sinking material, and anti-high temperature plasma scouring unit such as the first layer material in nuclear fusion.

Owner:UNIV OF SCI & TECH BEIJING

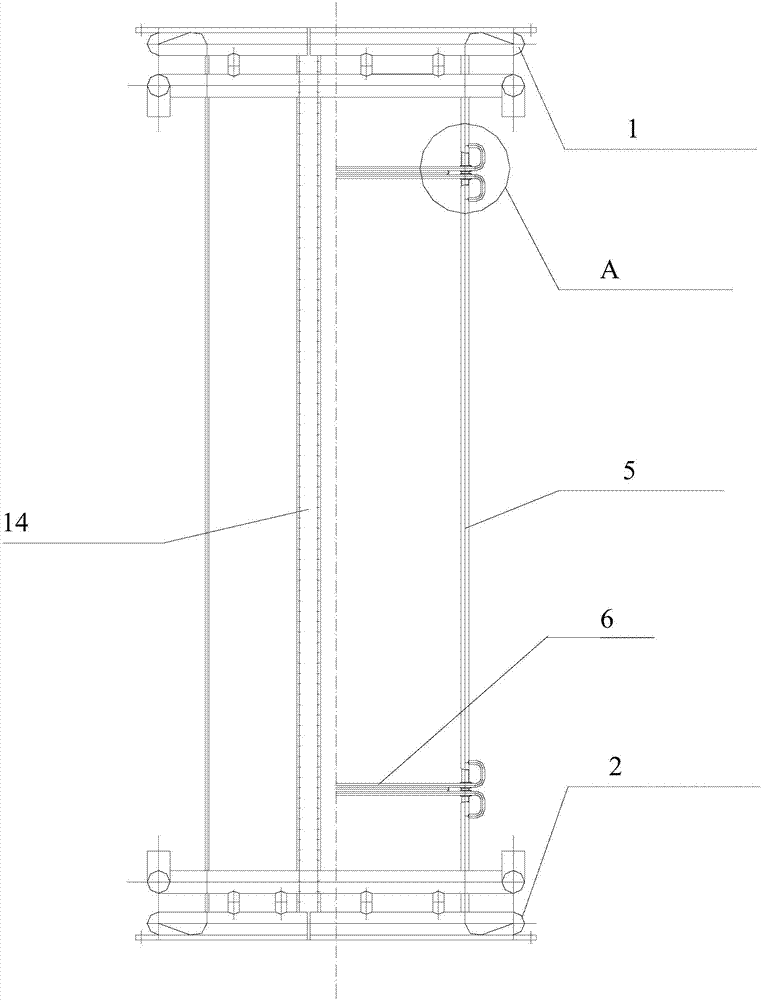

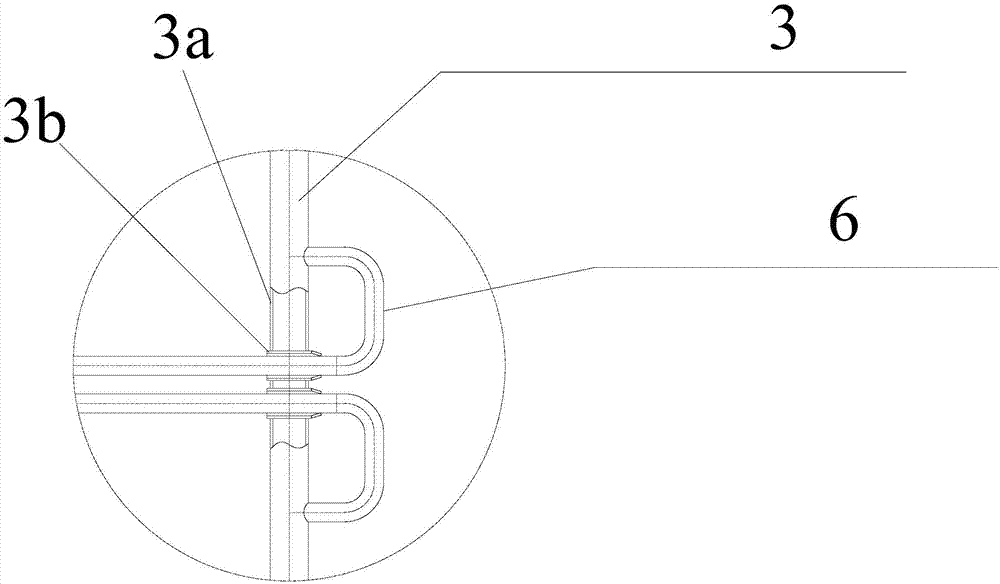

Novel multi-sleeve integrated rapid demounting and mounting heat exchanger

InactiveCN109029023AQuick disassemblyQuick changeHeat exhanger sealing arrangementHeat exchanger casingsPlate heat exchangerEngineering

The invention discloses a novel multi-sleeve integrated rapid demounting and mounting heat exchanger. The novel multi-sleeve integrated rapid demounting and mounting heat exchanger is mainly composedof inner tube passes, outer tube passes, inner tube boxes, outer tube boxes, packing box sealing structures, outer tube positioning plates and supporting seats. Fins are arranged on the outer walls ofthe inner tube passes to serve as movable supports. The outer tube passes and outer tube box tube plates are fixed in a welded mode. The inner tube boxes and inner tube plates are connected through flanges. The outer tube boxes and the inner tube boxes are connected through flanges. The inner tube passes are sealed on the inner tube plates through the packing box structures. Packing boxes and thetube plates are fixed in a welded mode, and packing seals are compressed by glands. The inner tube passes can move, and the glands are provided with positioning stop blocks to limit the moving rangeof the inner tubes. In this way, the novel multi-tube-pass rapid demounting and mounting sleeve heat exchanger which is compact in structure and convenient to demount and mount is formed. The problemsthat blockage is prone to occurring during heat transferring of a solid-containing fluid; direct heat exchanging of a medium is difficult, and the heat exchange efficiency is low; leakage is prone tooccurring; demounting, mounting and overhauling are difficult, and the maintenance cost is high; and cleaning is difficult are solved while the novel multi-sleeve integrated rapid demounting and mounting heat exchanger has the high heat transferring coefficient.

Owner:深圳龙澄高科技环保股份有限公司

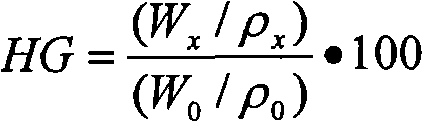

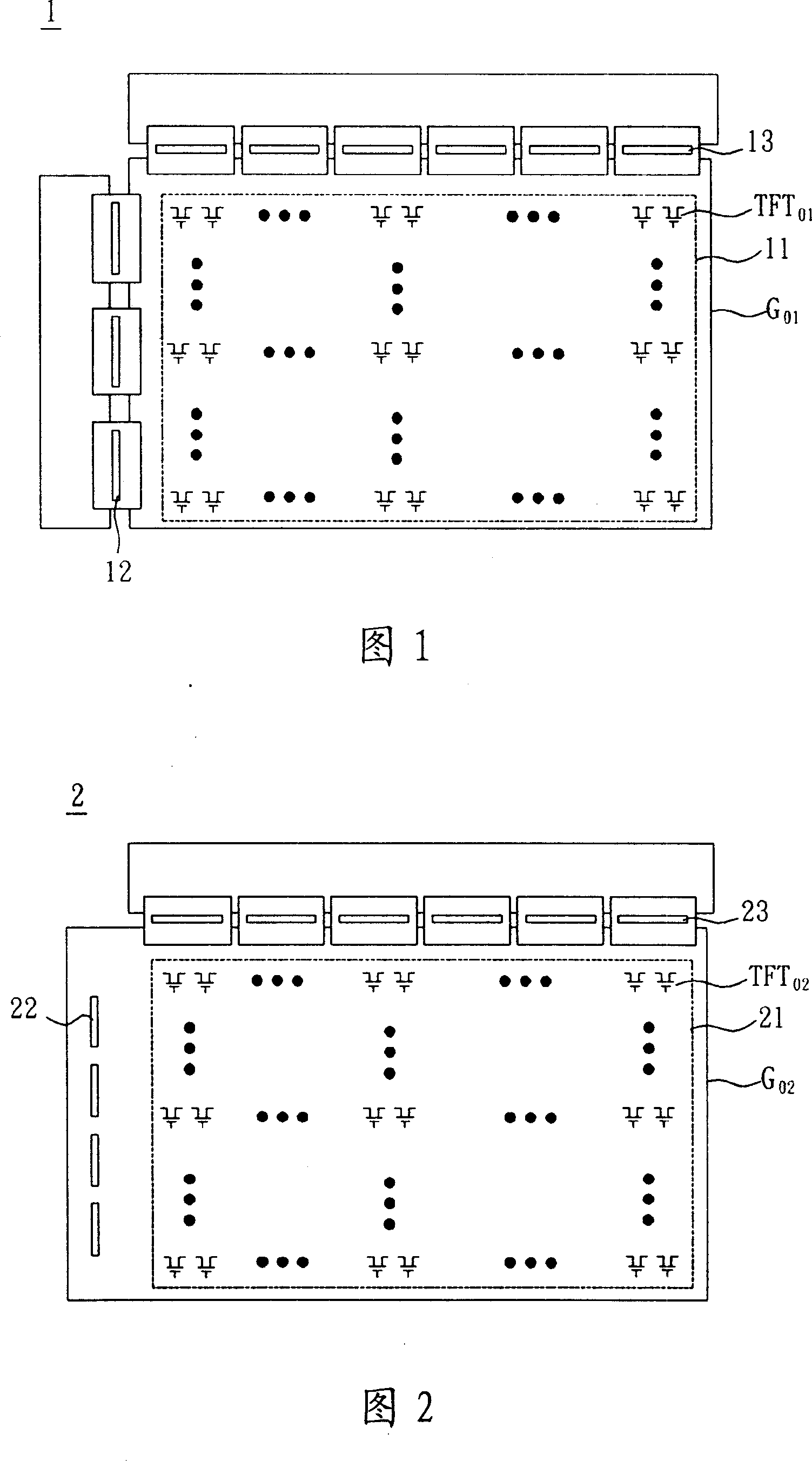

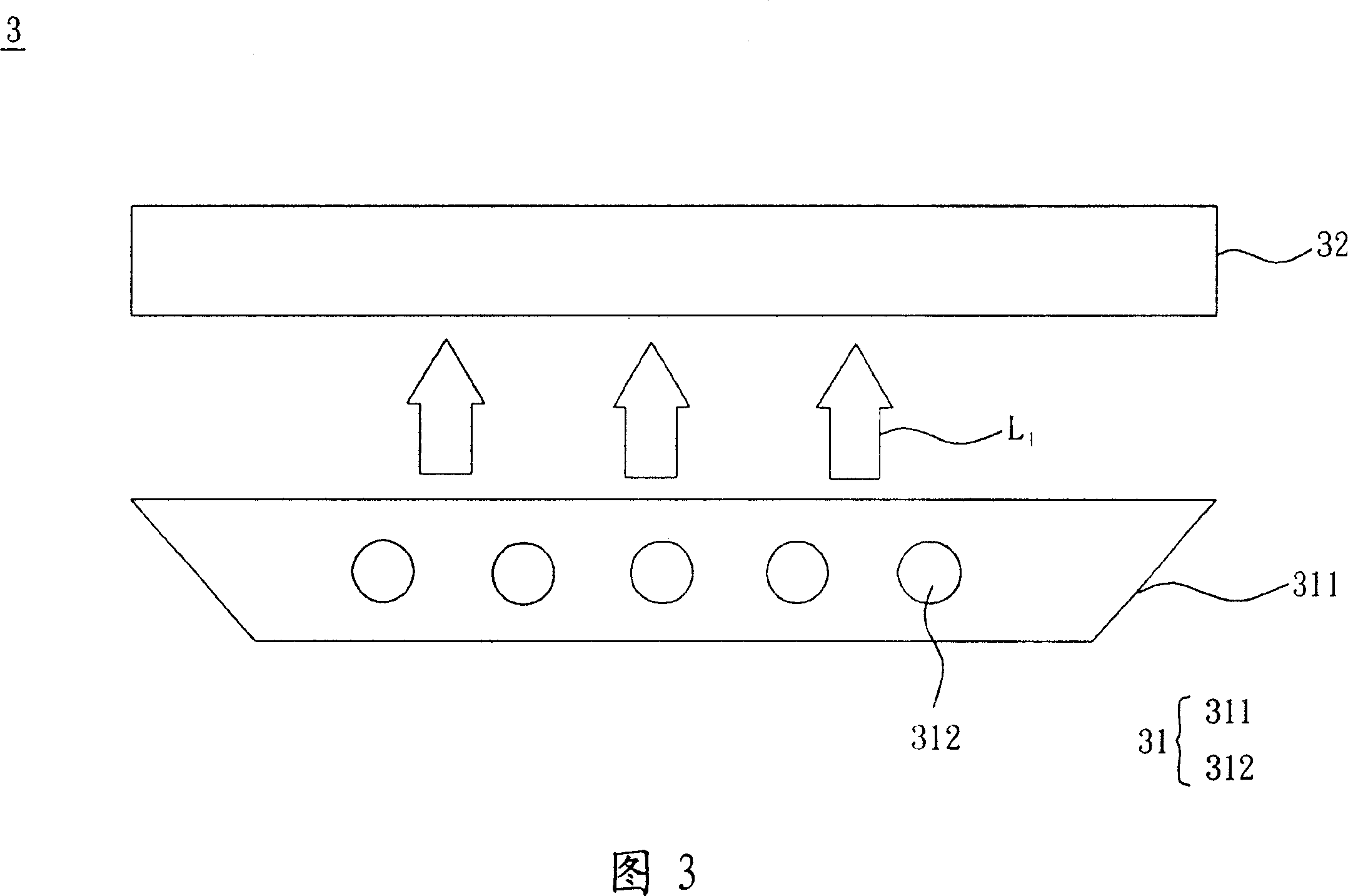

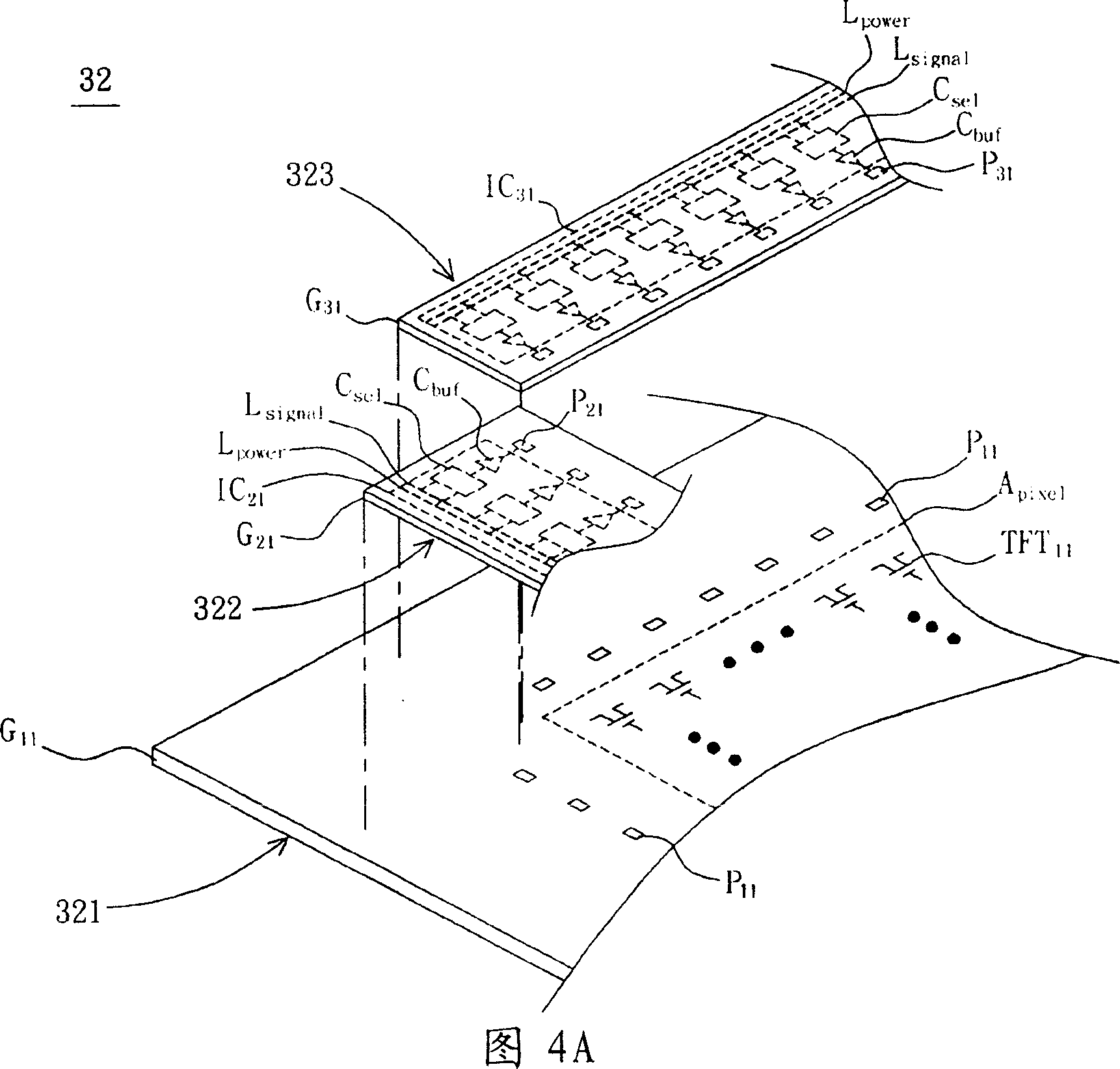

Planar display panel and planar display device

InactiveCN101122693AAvoid heat stress problemsSolve thermal stressStatic indicating devicesNon-linear opticsStress ProblemElectrical connection

The invention relates to a plane display panel and a plane display device. The plane display device is provided with a backlight module and a plane display panel; wherein, the plane display panel includes a pixel array circuit board and a first glass circuit board. The pixel array circuit board is provided with a pixel array; the first glass circuit board is provided with a first collective drive loop; wherein, the first collective drive loop is electrically connected with the pixel array. The invention makes use of the mutual electrical connection between the glass circuit board with collective drive loop and the pixel array circuit board and the collective drive loop is directly arranged on the glass circuit board, thus avoiding the thermal stress problem because of different thermal expansion coefficient.

Owner:GIGNO TECH CO LTD

Integrated single-cabin heating regeneration denitration system special for waste gas of internal combustion engine and denitration method

InactiveCN108926992AEasy to operateSmall footprintGas treatmentDispersed particle separationExternal combustion engineProcess engineering

The invention discloses an integrated single-cabin heating regeneration denitration system special for waste gas of an internal combustion engine. The integrated single-cabin heating regeneration denitration system is characterized by comprising a denitration reactor, an air inlet main pipeline connected with the internal combustion engine and an air outlet main pipeline connected with the denitration reactor, wherein the denitration reactor is divided into four reactor cabins, the denitration reactor is internally provided with a soot blower and a denitration catalyst, the denitration reactoris further provided with four maintenance doors, pressure transmitters are arranged at the joints of the denitration reactor with the air inlet main pipeline and the air outlet main pipeline; and a fan-shaped electric butterfly valve is arranged between the air inlet main pipeline and the denitration reactor, an ammonia spraying device is arranged in the middle of the air inlet main pipeline anda spoiler is positioned below the ammonia spraying device. The system is simple and flexible, can be used for conducting on-line heating regeneration and overhauling, and is simple to operate, small in occupied area and high in efficiency.

Owner:NANJING SOUTHEAST IND EQUIP CORP

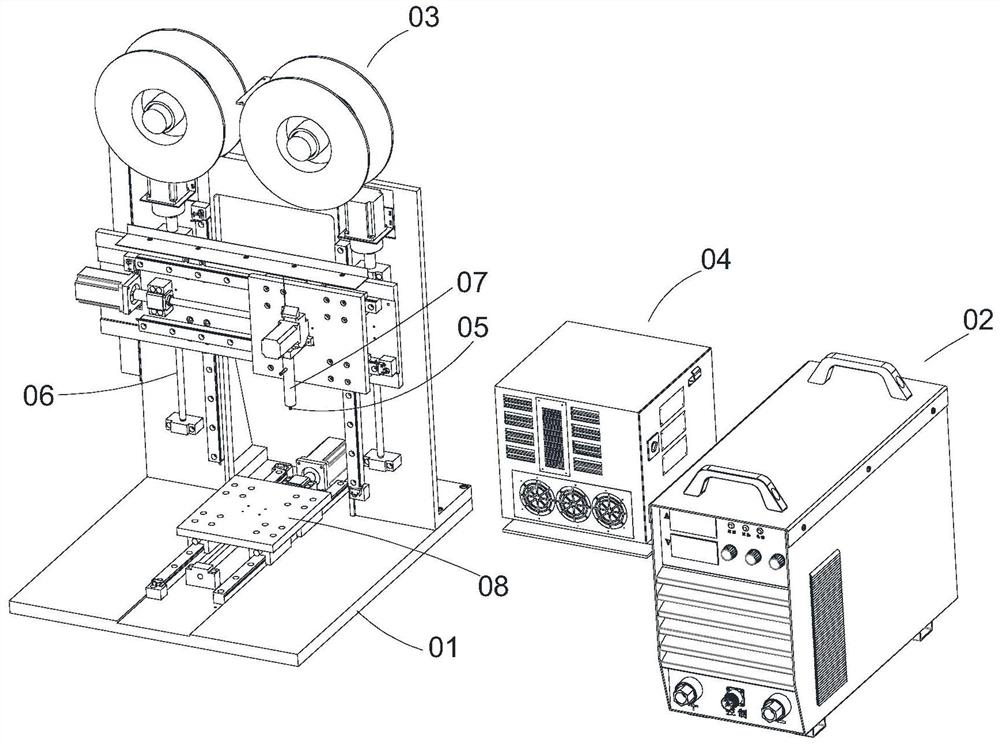

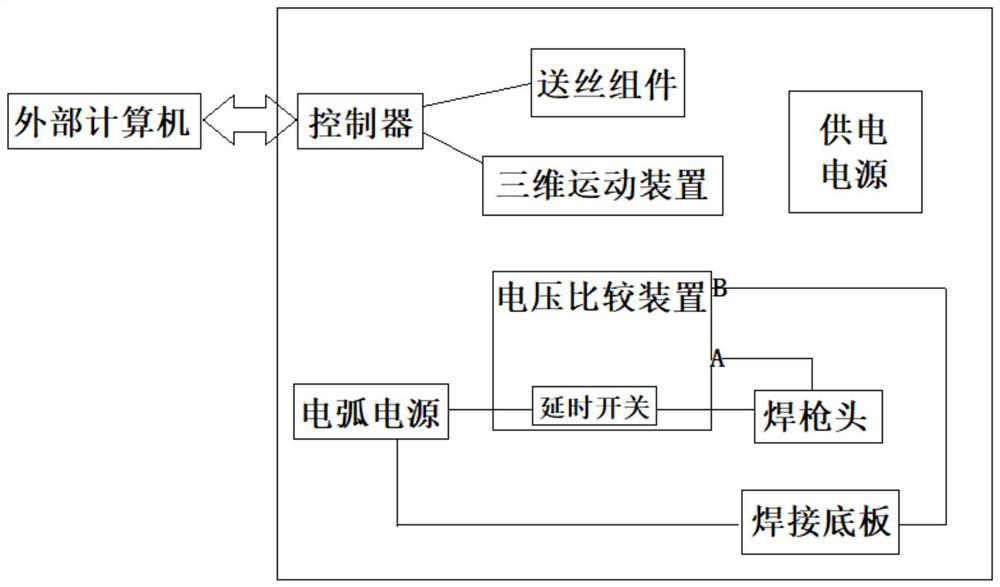

Special welding machine system for rapid metal forming through electric arc method and control method of special welding machine system

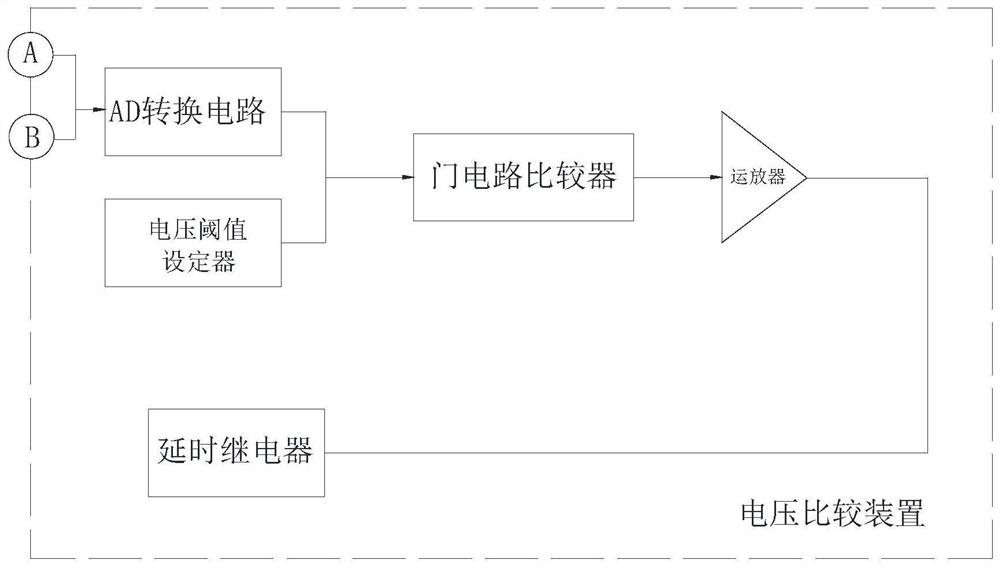

PendingCN111805058AImprove efficiencyReduce accumulationWelding accessoriesIncreasing energy efficiencyMetal formingElectrical connection

The invention relates to a special welding machine system for rapid metal forming through an electric arc method and a control method of the special welding machine system. The system comprises a controller, a rack, an electric arc power source, a wire feeding assembly and a voltage comparison device. A metal wire is arranged in the wire feeding assembly. A three-dimensional movement device is arranged on the rack. A welding gun head and a welding bottom plate which are connected with the wire feeding assembly are respectively arranged on the three-dimensional movement device. The metal wire penetrates into the welding gun head. The welding gun head and the welding bottom plate are electrically connected with the electric arc power source. The voltage comparison device is provided with a first voltage detection end, a second voltage detection end and a delay switch. The first voltage detection end is electrically connected with the welding gun head. The second voltage detection end iselectrically connected with the welding bottom plate. The delay switch is connected into a connecting line of the welding gun head and the electric arc power source in series or connected into a connecting line of the welding bottom plate and the electric arc power source in series. The system is adopted in the control method. According to the special welding machine system for rapid metal formingthrough the electric arc method and the control method of the special welding machine system, transient short-circuit time is controlled through the voltage comparison device, heat accumulation is reduced, and the problem of thermal stress is avoided.

Owner:江苏军智增材航空科技有限公司

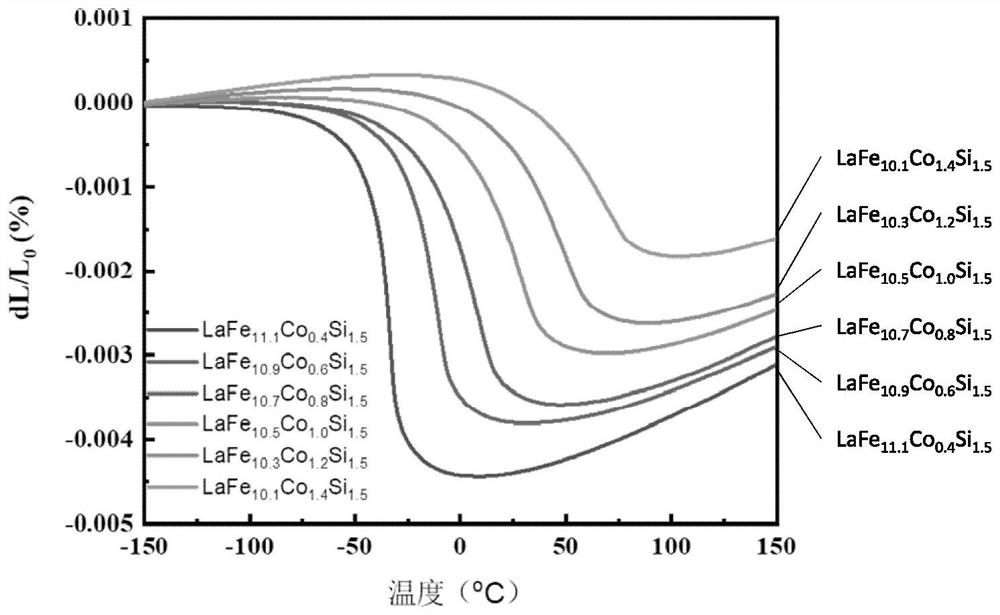

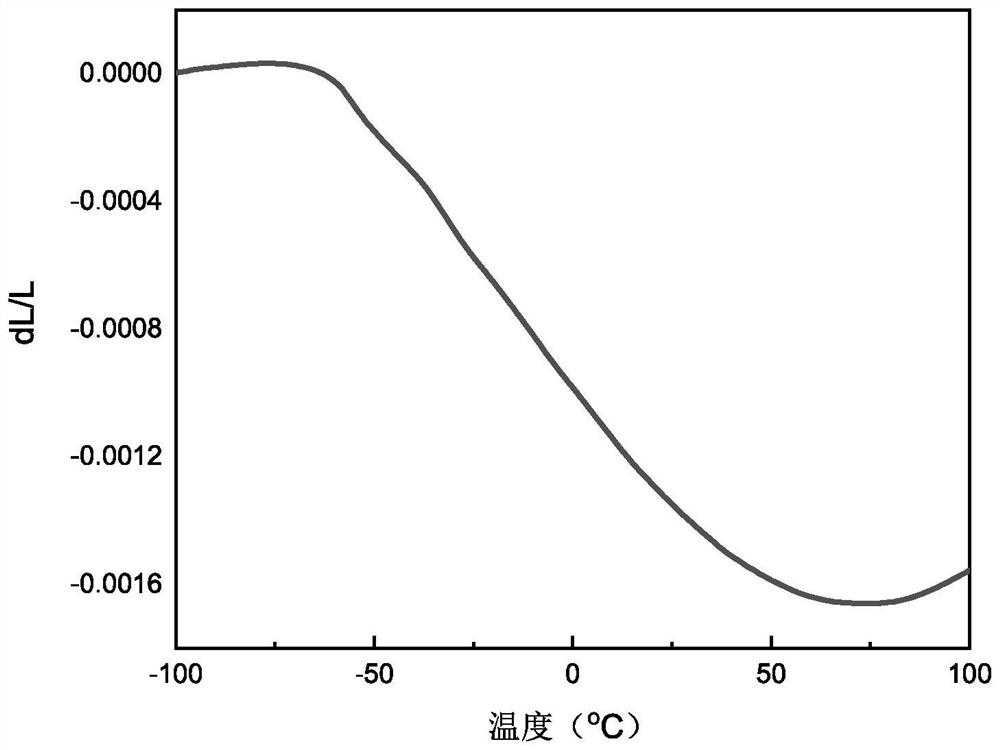

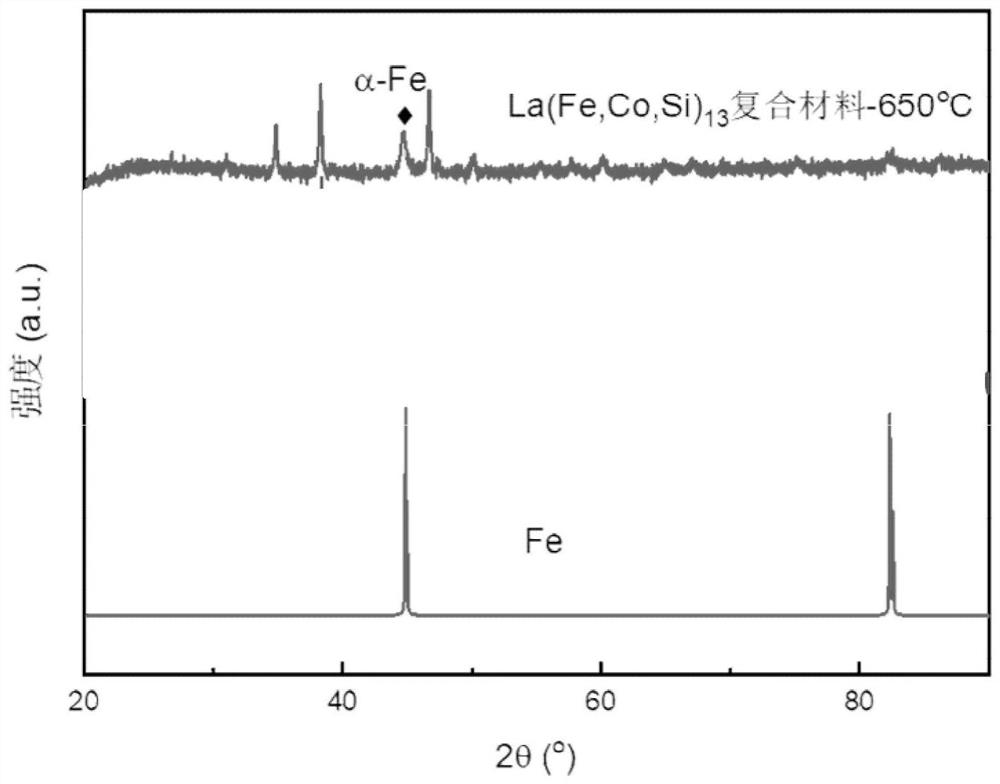

Wide-temperature-range huge negative thermal expansion metal-based composite material and preparation method thereof

The invention provides a wide-temperature-range huge negative thermal expansion metal-based composite material and a preparation method thereof, and belongs to the field of metal-based composite materials and preparation thereof. The raw material is La (Fe, Si) 13-based isotropic negative thermal expansion alloy; the preparation method comprises the following steps: weighing metal elementary substances in a stoichiometric ratio, smelting the metal elementary substances in an electric arc furnace, annealing to obtain La (Fe, Si) 13 alloys with different negative thermal expansion coefficients and temperature zones, grinding and mixing the La (Fe, Si) 13 alloys, and sintering the La (Fe, Si) 13 alloys through discharge plasma to obtain a target product. Alpha-Fe phases are generated among the components of the La (Fe, Si) 13 alloy, so that the mechanical property is improved, and the La (Fe, Si) 13 alloy can better adapt to extreme use environments. The La (Fe, Si) 13-based series alloy has huge negative thermal expansion in different temperature zones between-150 DEG C and 150 DEG C. The material obtained by compounding the La (Fe, Si) 13 alloy with different components has the characteristics of wide temperature range and isotropic negative thermal expansion.

Owner:UNIV OF SCI & TECH BEIJING

A thermal treatment method for a solar battery encapsulating adhesive film

ActiveCN108749044ASolving Shrinkage ProblemsSolve thermal stressPhotovoltaic energy generationSemiconductor devicesVitrificationProduction line

The invention relates to a thermal treatment method, particularly a thermal treatment method for a solar battery encapsulating adhesive film. The adhesive film includes a polyolefin adhesive film, anEVA adhesive film or PVB. Constant-temperature and cooling shaping workshop sections are adopted. The objective is to allow the temperature to be higher than the melting point, the softening temperature or glass transition temperature of a material so that a thermal stress problem of an extruded film material is solved at a high temperature, the shrinkage problem of the material is thoroughly solved, and an option for increasing the speed of a production line is provided.

Owner:ZHEJIANG SINOPONT TECH +2

Method for preparing tungsten-copper gradient composite material

PendingCN113084166ASynergistic improvement in anti-ablation performanceGood thermal conductivity and ablation resistanceAdditive manufacturing apparatusIncreasing energy efficiencyElectro conductivityThermal conductivity

The invention discloses a method for preparing a tungsten-copper gradient composite material, which comprises the following steps of: preparing a porous tungsten framework of which the porosity is in gradient distribution by using a selective laser melting technology based on a single-component multi-copper and less-tungsten composite material, pressurizing and infiltrating copper under the protection of hydrogen, and finally, carrying out a two-pass rolling process, and carrying out annealing treatment, the tungsten-copper gradient composite material with synergistically improved heat conductivity, conductivity, strength and ablation resistance can be obtained. According to the method for preparing the tungsten-copper gradient composite material provided by the invention, the problem that in the prior art, the heat conductivity and the ablation resistance of a tungsten-copper composite material used for an electromagnetic railgun guide rail cannot be considered at the same time is solved.

Owner:XIAN UNIV OF TECH

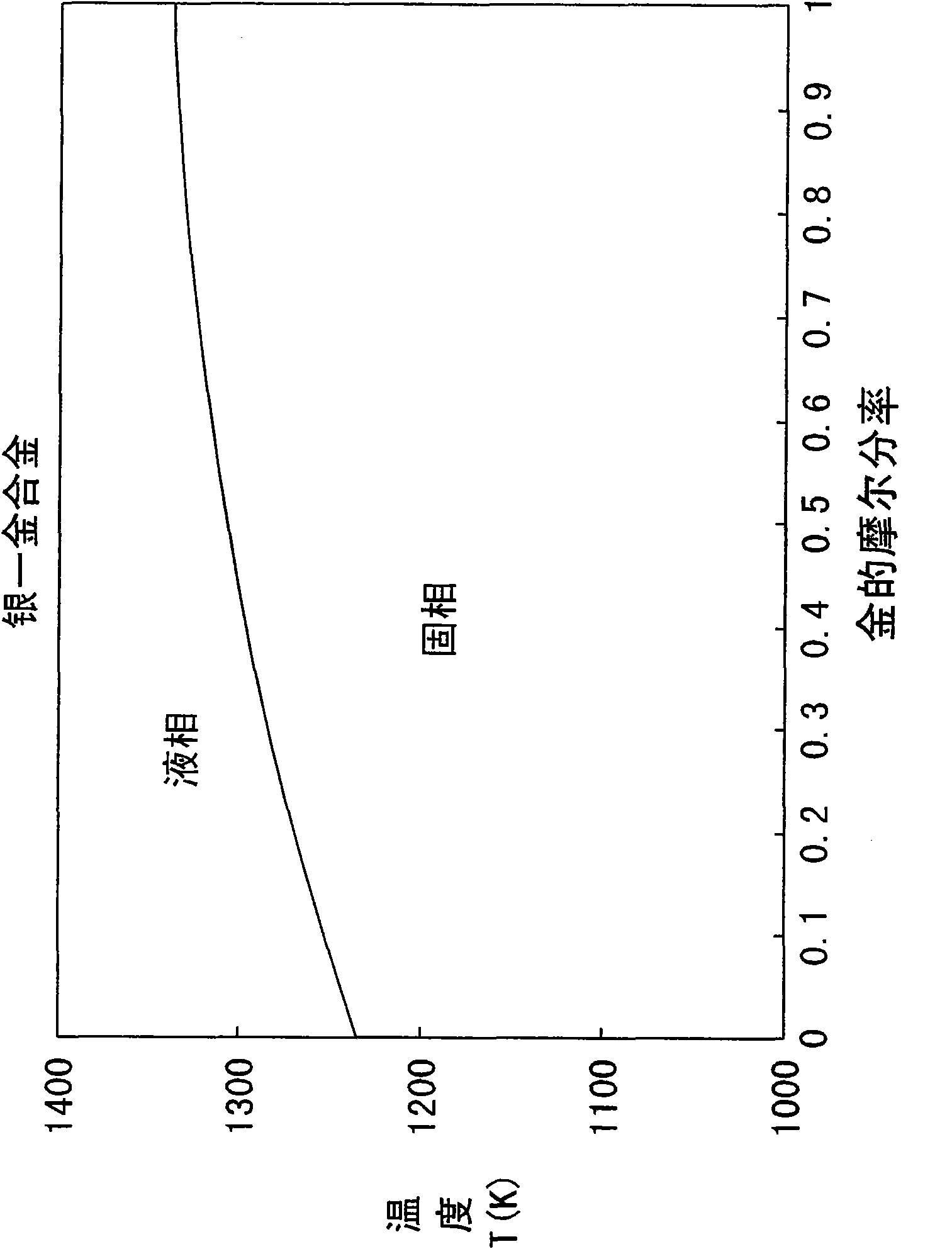

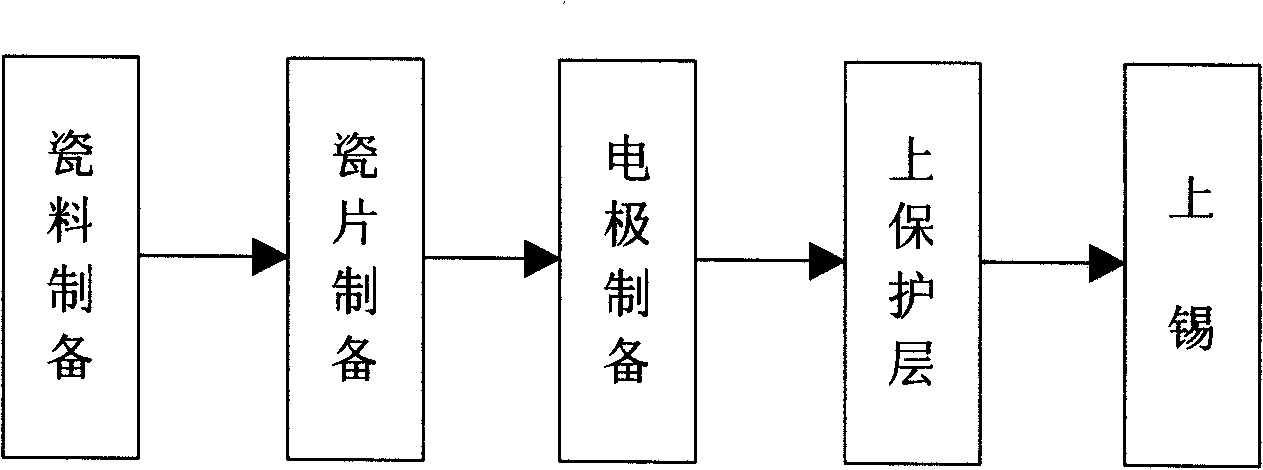

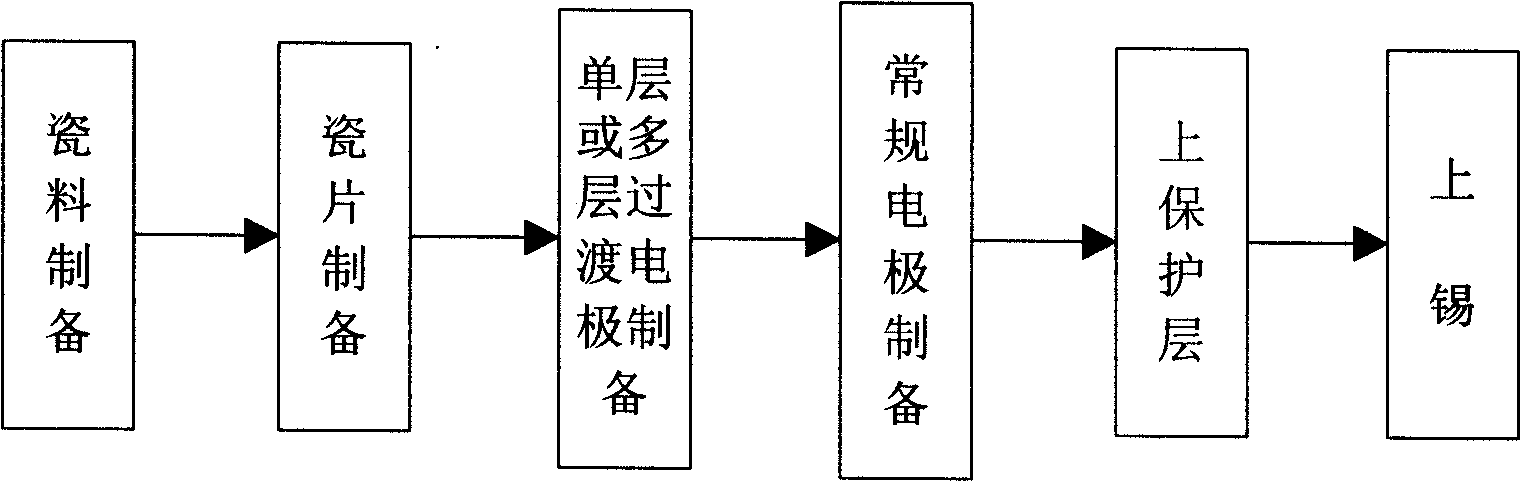

Method for preparing heat impact resisting ceramic capacitor

ActiveCN101494116AImproved thermal shock resistanceSolve thermal stressFixed capacitor electrodesThermal conductivityMetallurgy

The invention discloses a preparation method of a heat shock-resistant ceramic capacitor and pertains to the field of electric elements and material technology, in particular to a preparation method of a ceramic capacitor; the preparation method comprises the steps: the preparation of transition electrodes is added into the conventional ceramic-capacitor preparation engineering; single-layer or multi-layer transition electrodes with different silver contents are prepared at two sides of a ceramic chip; due to the different silver contents in the transition electrodes and electrode materials, the thermal conductivities of the transition electrodes and electrode materials are different; therefore, thermal gradient exists between the transition electrodes, which can relieve the thermal stress produced by the synergy of the ceramic capacitor in an environment in which the temperature changes dramatically. On the basis of ensuring electrical characteristics of the ceramic capacitor, the preparation method significantly improves the heat shock resistance of the ceramic capacitor so that the ceramic capacitor can adapt to the environment in which the temperature changes between minus 55 DEG C to 125 DEG C and particularly meets the performance requirements of a special ceramic capacitor in automotive electronics.

Owner:CHENGDU HONGMING & UESTC NEW MATERIALS

Converter deep waste heat recovery boiler

ActiveCN107975781ASmooth circulationAvoid explosionExhaust gas handlingManufacturing convertersEngineeringRecovery boiler

The invention discloses a converter deep waste heat recovery boiler. The boiler comprises an upper collecting box, a lower collecting box, a boiler outer wall and a boiler flue, wherein the boiler outer wall is isolated and connected with the upper collecting box and the lower collecting box; the boiler flue with a smoke inlet and a smoke outlet is formed among the upper collecting box, the lowercollecting box and the boiler outer wall; the boiler outer wall is of a cylindrical structure, and is composed of a plurality of outer wall pipes which are vertically arranged and a plurality of flatsteel bars, and the outer wall pipes are vertically communicated between the upper collecting box and the lower collecting box, and are evenly distributed at intervals along a circle, and a flat steelbar is hemetically welded between every two adjacent outer wall pipes; the boiler flue is internally provided with convection heating surface tubes, and the end parts of the convection heating surface tubes hemetically penetrate out of the boiler outer wall, and is hemetically communicated with the outer wall pipes. The converter deep waste heat recovery boiler has strong anti-explosion performance and good sealing performance.

Owner:江苏道和环保科技有限公司

A leadless packaging structure and packaging method for a piezoresistive sensor

ActiveCN109781334BImprove high temperature stabilityHigh precisionFluid pressure measurement using ohmic-resistance variationCarbide siliconHemt circuits

The invention discloses a leadless packaging structure and packaging method of a piezoresistive sensor. The packaging structure comprises a silicon carbide chip, a silicon carbide cup, a kovar pin, abase, a metal shell and a first transition layer. A chip circuit is arranged on the front surface of the silicon carbide chip, and a first groove is formed in the back surface of the silicon carbide chip; a second groove is formed in the back surface of the silicon carbide cup; the front surface of the silicon carbide chip and the back surface of the silicon carbide cup are bonded together to forma bonding object; the kovar pin is inserted into the through hole in the silicon carbide cup sequentially through the base and the through hole in the first transition layer and is connected with themetal bonding pad; the bonding object, the base and the kovar pin are combined together through sintering and are fixed in an inner cavity of the metal shell; and the metal shell is fixed on the fixing piece through a thread structure. The high-temperature stability and reliability of the sensor are improved in a leadless packaging mode.

Owner:XI AN JIAOTONG UNIV

A high-entropy alloy connected silicon carbide ceramic connector and its preparation method and application

ActiveCN110452010BSmall coefficient of thermal expansionSolve thermal stressNon oxide ceramicsCarbide silicon

The invention belongs to the technical field of non-oxide ceramic connection, and discloses a high-entropy alloy connection silicon carbide ceramic connection piece, a preparation method and application thereof. The high-entropy alloy connecting silicon carbide ceramic connector is to mix the high-entropy alloy AlCoCrFeNi powder and SiC powder, use absolute ethanol as a solvent, stir and ultrasonically form a uniform brazing material, and apply the brazing material evenly on the polished SiC The surface is made by SPS sintering and heat treatment at 1000-1400°C, and the connection pressure is 5-30MPa; the structure of the connecting piece is SiC / AlCoCrFeNi-SiC / SiC. When the high-entropy alloy of the present invention is used as the connecting layer, it can not only realize the low-temperature connection of silicon carbide ceramics, but also reduce the internal stress of the ceramic connecting body. The connecting piece can be applied to harsh working environments such as high temperature and high pressure, especially in the nuclear industry. Applications.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com