Novel TSV switch board and manufacturing method

An adapter board, a new type of technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of thermal expansion coefficient mismatch, high cost, high process technology requirements, etc., and achieve low thermal stress and small parasitic capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

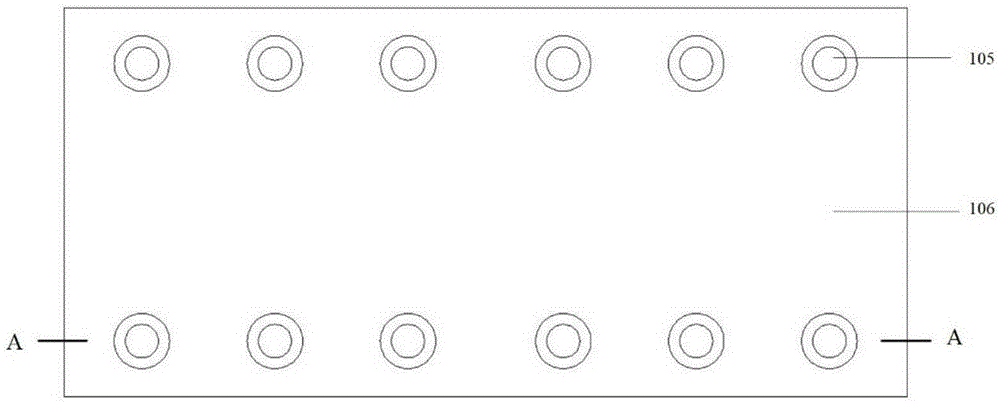

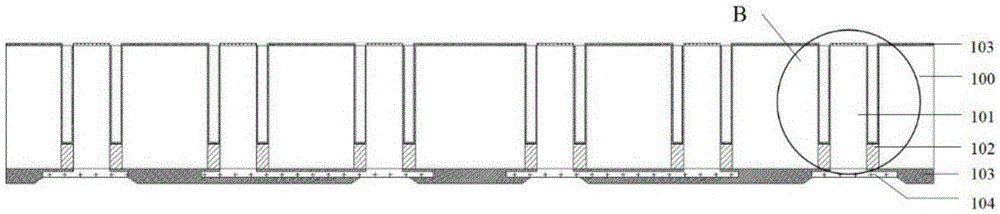

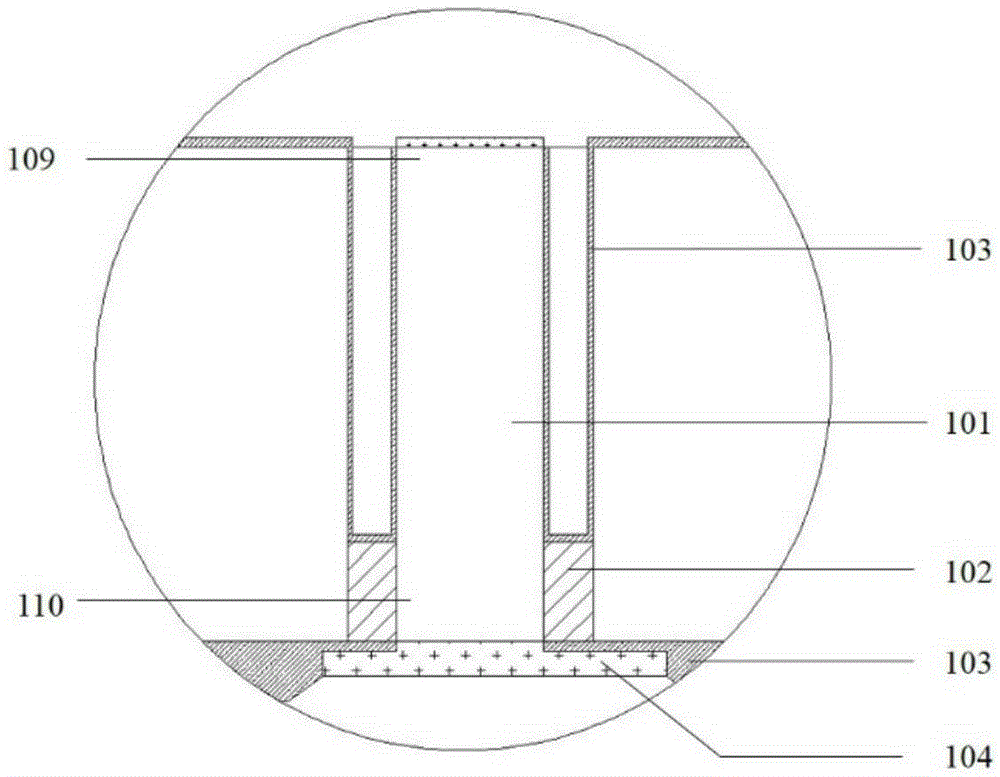

[0041] A new type of TSV adapter plate structure such as figure 2 Shown:

[0042] Substrate 100, there are several free pillars 101 on the said substrate, it is characterized in that one end is separated from the substrate through the gap, the other end is fixed with the substrate through the insulating material 102, and is insulated from the substrate, the upper and lower sides of the substrate 106, 108 ( See figure 1 , Figure 4 ) and the side wall of the free post is covered with a layer of insulating layer 103, and the free end face 105 and the fixed end face 107 of the free post all have ohmic contacts 300 made of metal layers (300 see Figure 11 );

[0043] Preferably, the materials of the substrate and the free column are both low-resistance silicon materials (≤0.1Ω·cm);

[0044] Preferably, the insulating material 102 used for the indirect contact between the free column 101 and the substrate 100 is one of silicon dioxide, glass paste and resin;

[0045] Preferab...

Embodiment 2

[0047] A new type of TSV adapter plate structure such as figure 2 Shown:

[0048] Substrate 100, there are several free pillars 101 on the substrate, it is characterized in that one end is separated from the substrate through a gap, the other end is fixed to the substrate through an insulating material 102, and is insulated from the substrate, the upper and lower sides of the substrate 106, 108 and The side wall of the free post is covered with a layer of insulating layer 103, and the free end face 105 and the fixed end face 107 of the free post all have an ohmic contact 300 made of a metal layer (300 see Figure 11 ).

[0049] Preferably, the materials of the substrate and the free column are both low-resistance silicon materials (≤0.1Ω·cm),

[0050] Preferably, the insulating material 102 used for the indirect contact between the free column 101 and the substrate 100 is one of silicon dioxide, glass paste and resin.

[0051] Preferably, the front and back sides of the su...

Embodiment 3

[0055] A new type of TSV adapter plate structure such as figure 2 Shown:

[0056] Substrate 100, there are several free pillars 101 on the substrate, it is characterized in that one end is separated from the substrate through a gap, the other end is fixed to the substrate through an insulating material 102, and is insulated from the substrate, the upper and lower sides of the substrate 106, 108 and The side wall of the free post is covered with an insulating layer 103, and both the free end face 105 and the fixed end face 107 of the free post have an ohmic contact 300 formed with the metal layer.

[0057] Preferably, the materials of the substrate and the free column are both low-resistance silicon materials (≤0.1Ω·cm),

[0058] Preferably, the insulating material 102 used for the indirect contact between the free column 101 and the substrate 100 is one of silicon dioxide, glass paste and resin.

[0059] Preferably, the front and back sides of the substrate 100 and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com