Converter deep waste heat recovery boiler

A waste heat recovery boiler, deep technology, applied in the field of boilers, can solve the problems of lower calorific value of converter gas, waste of high-quality waste heat resources, increase of water content of converter gas, etc., to achieve good effect, improve heat recovery efficiency and smooth circulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

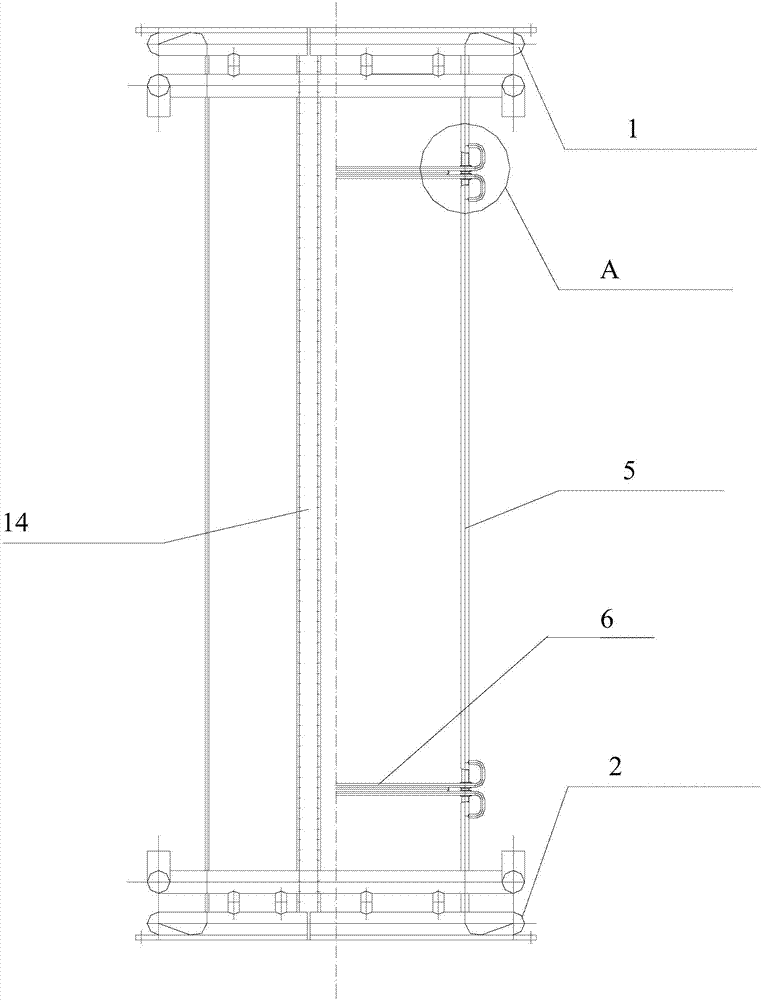

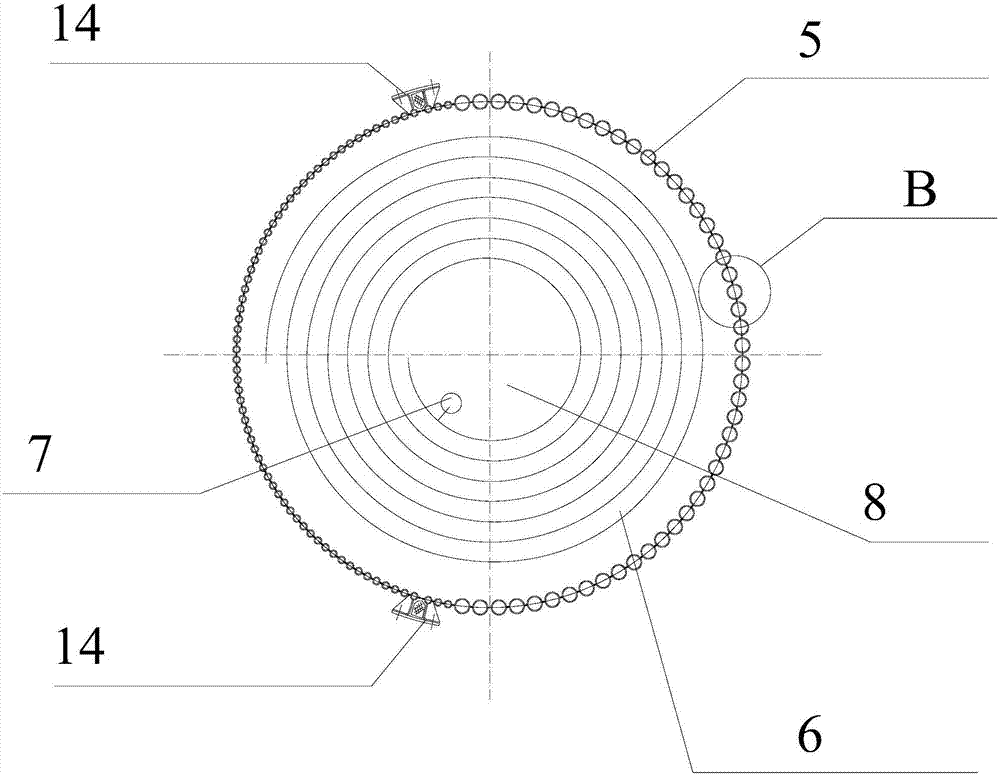

[0049] Figure 1 to Figure 6 It shows a specific embodiment of the converter deep waste heat recovery boiler of the present invention. Like the traditional waste heat boiler, this boiler also includes: an upper header 1; a lower header 2; a sealing connection between the upper header and The boiler outer wall 5 between the lower headers; and the boiler flue 9 formed between the upper header, the lower header and the boiler outer wall and having a smoke inlet and a smoke outlet.

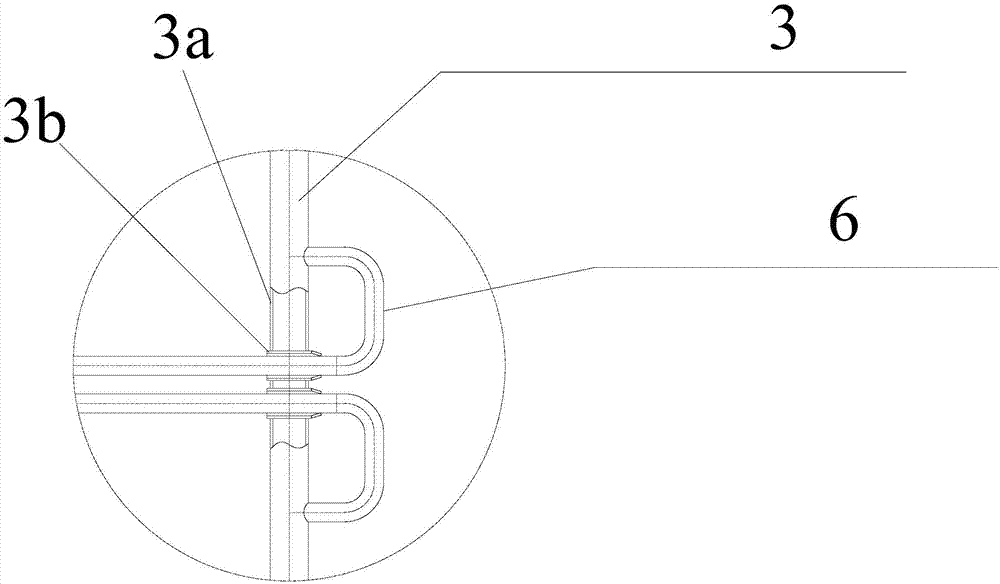

[0050]The key improvement of this embodiment is that the outer wall 5 of the boiler is a cylindrical structure, which is composed of many outer wall tubes 3 and many flat steel bars 4, and these outer wall tubes 3 are vertically connected between the upper header and the lower header. Between the headers, and these outer wall tubes 3 are distributed along a circular interval, and a flat steel bar 4 is sealed and welded between any two adjacent outer wall tubes 3, that is, the outer wall of the boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com