Patents

Literature

564 results about "Roller screw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A roller screw, also known as a planetary roller screw or satellite roller screw, is a low-friction precision screw-type actuator, a mechanical device for converting rotational motion to linear motion, or vice versa. Planetary roller screws are used as the actuating mechanism in many electro-mechanical linear actuators. Due to its complexity the roller screw is a relatively expensive actuator (as much as an order of magnitude more expensive than ball screws), but may be suitable for high-precision, high-speed, heavy-load, long-life and heavy-use applications.

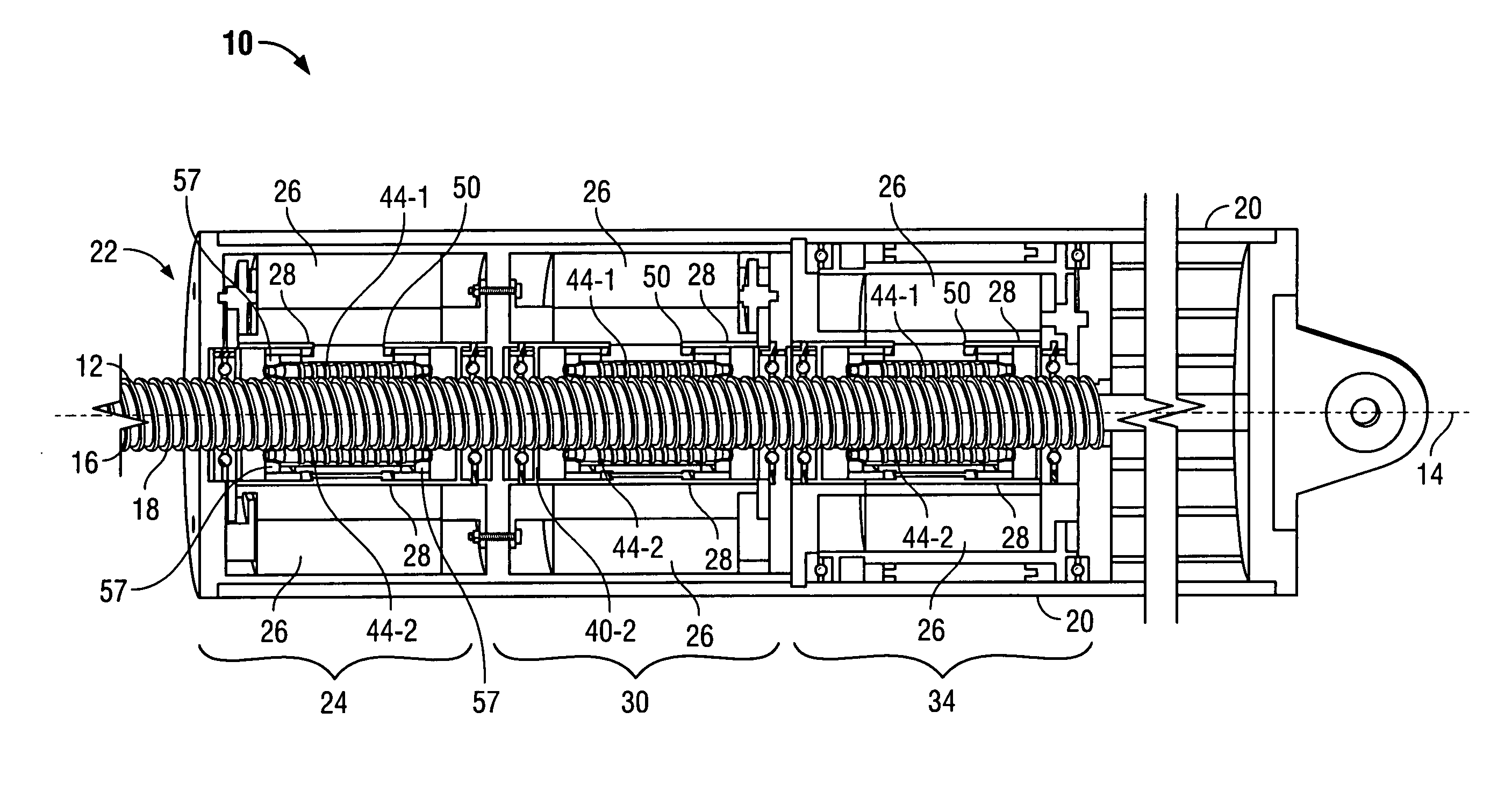

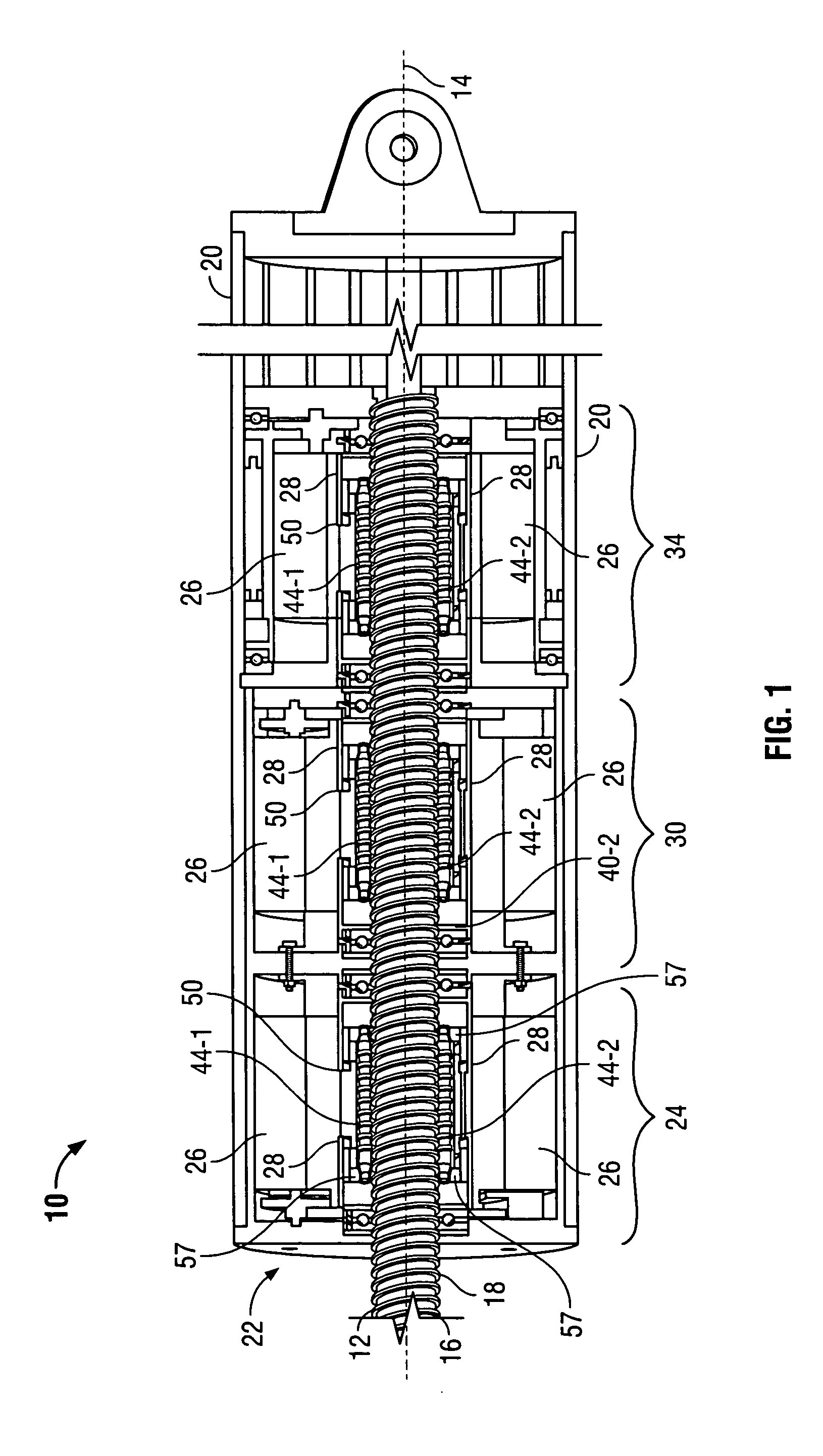

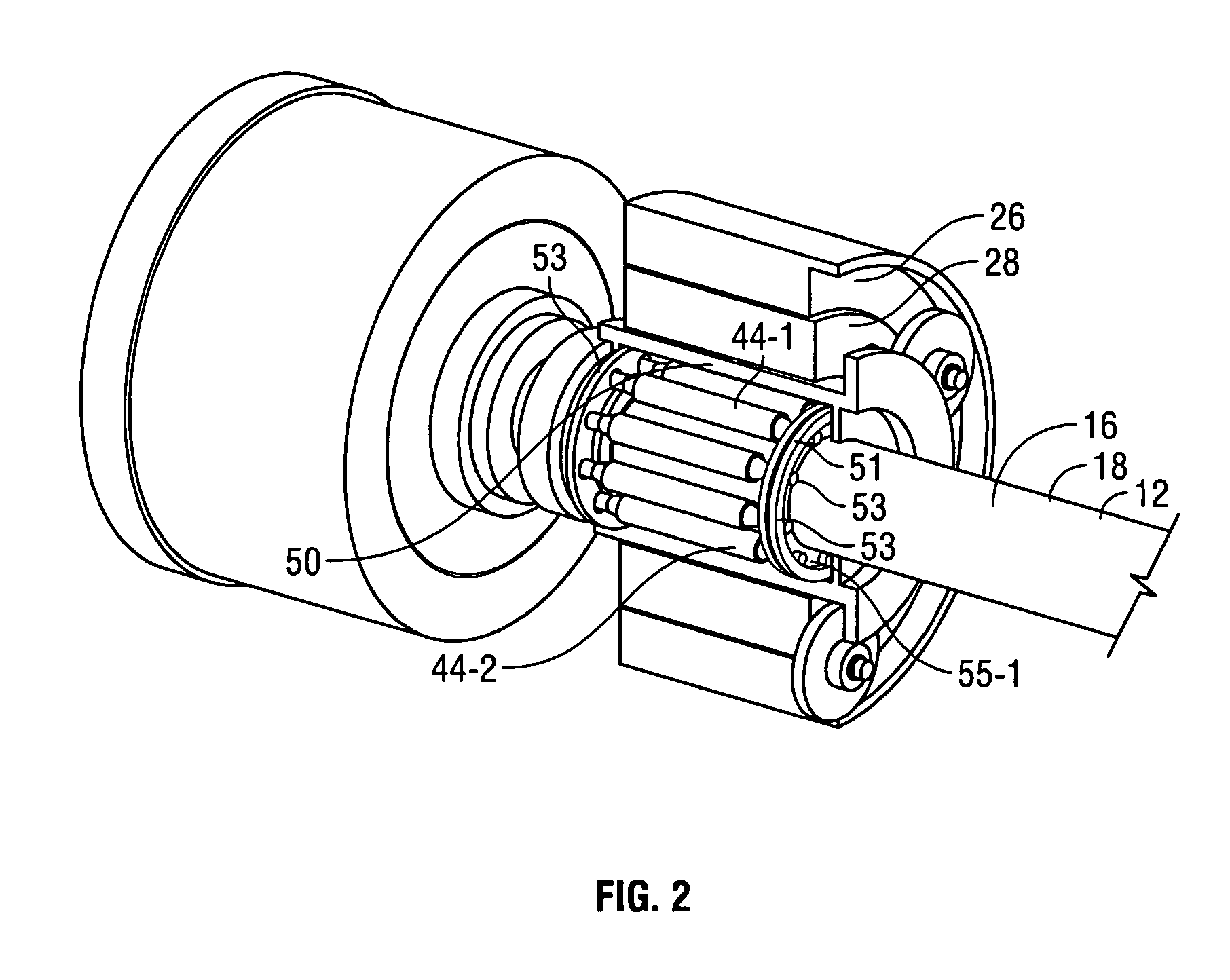

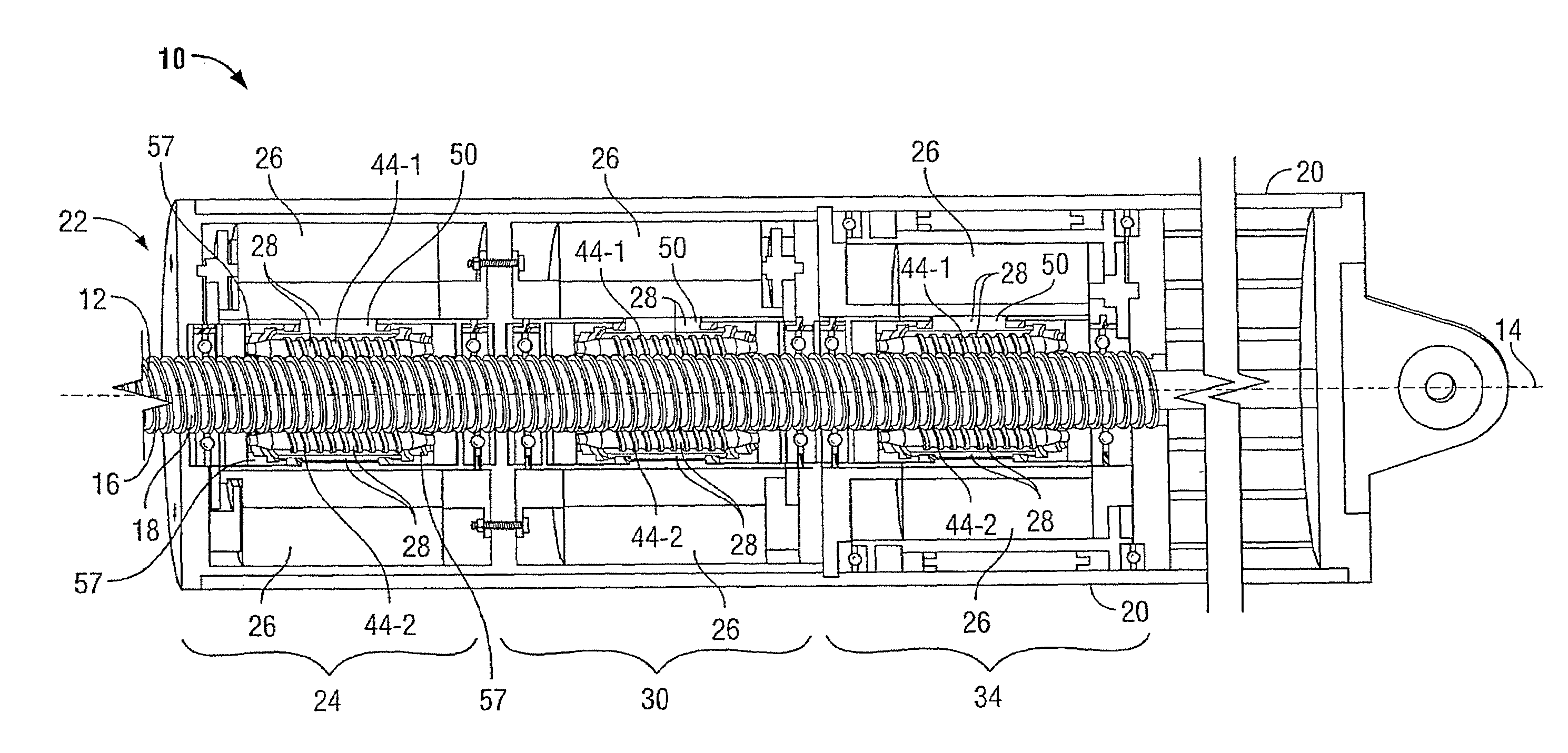

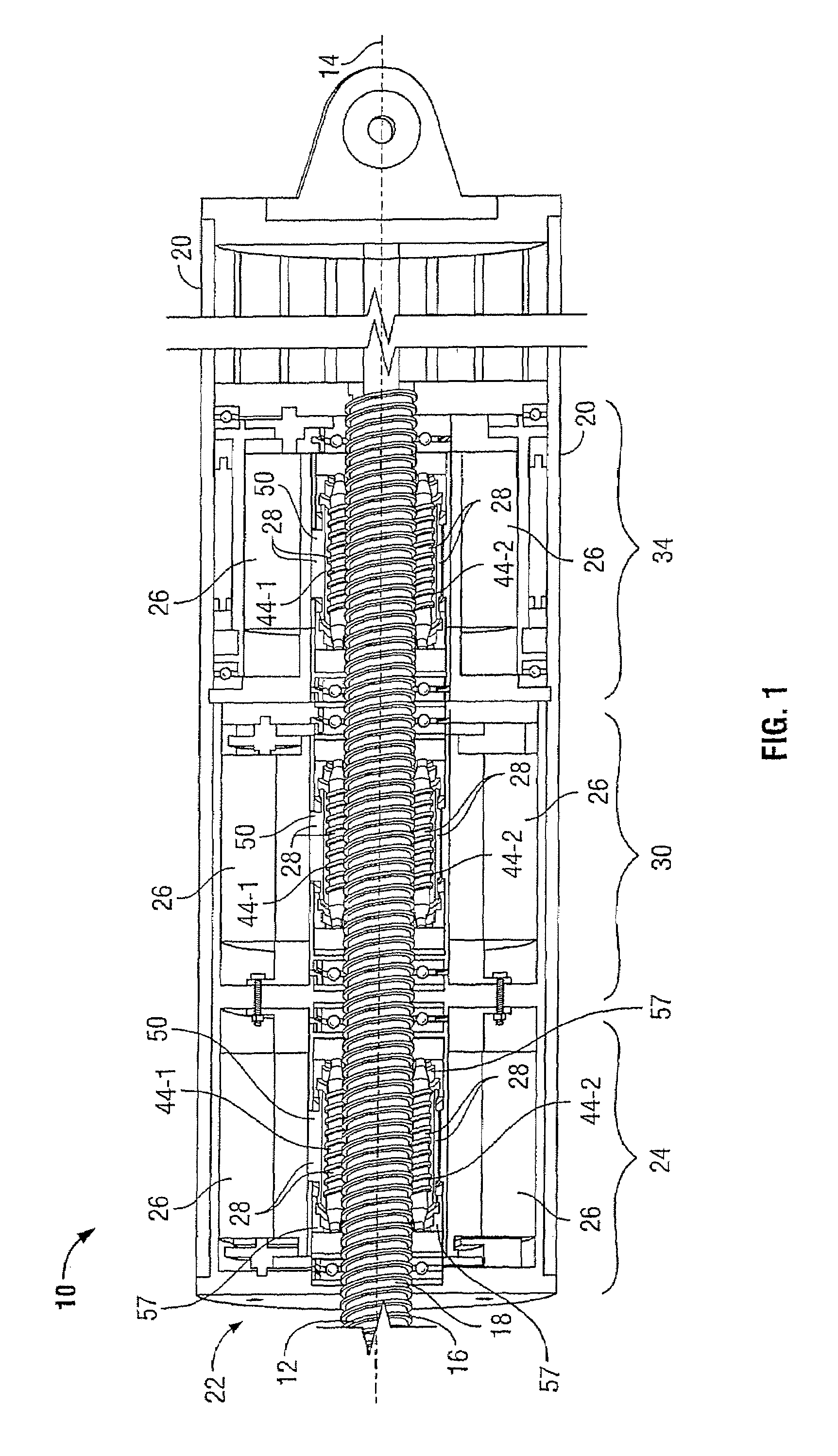

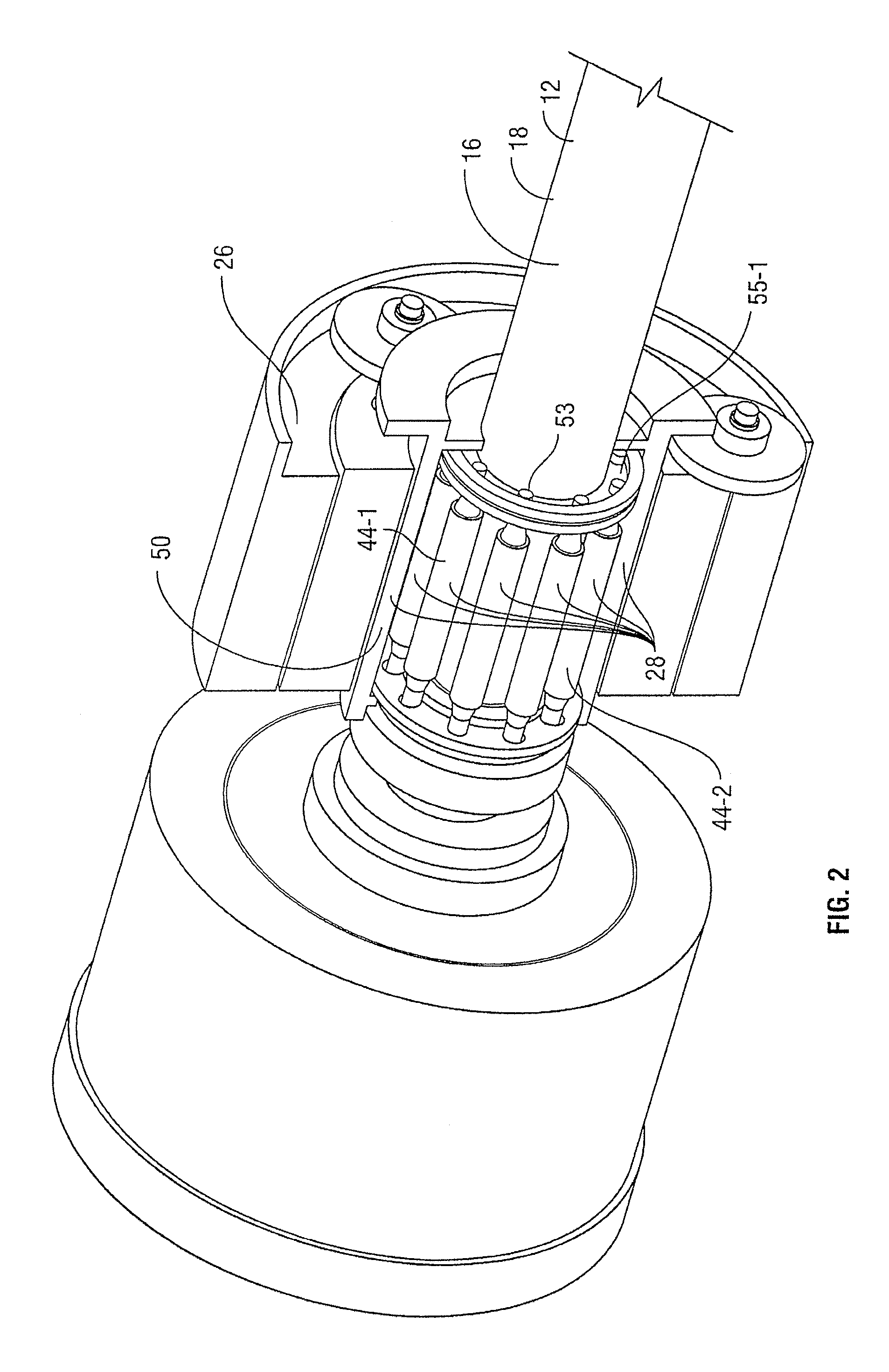

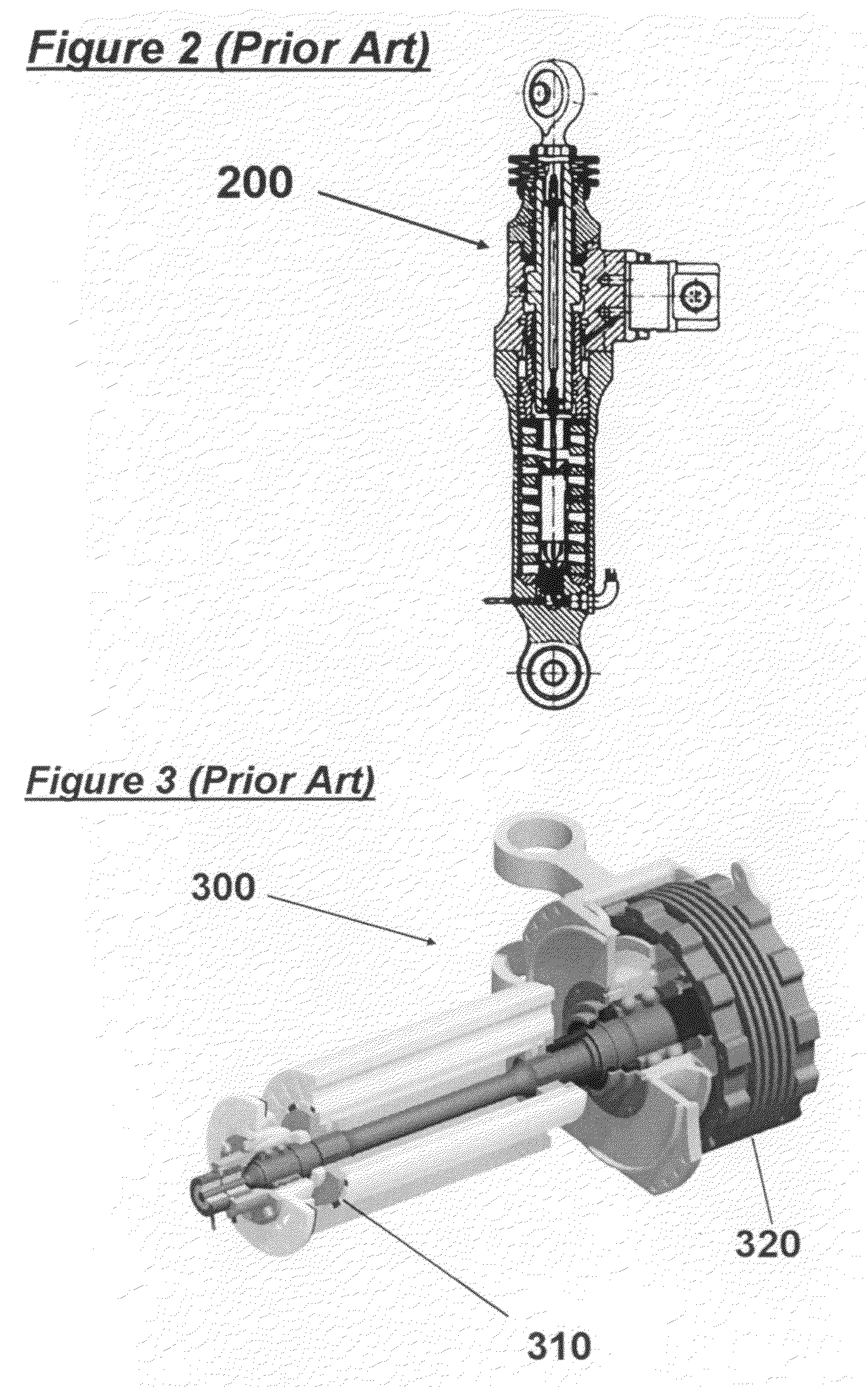

High-reliability electro-mechanical actuator

An electrical actuator comprises two or more electrical motors to drive a threaded screw ram. Each motor has an armature that drives a threaded roller screw that is engaged to the threaded screw ram. Each armature of each motor is independently engageable and / or dis-engageable with the ram. The motor armatures are engageable and disengageable by way of threaded roller screws, the ends of which are tapered to enable them to be lifted away from or lowered into engagement with the threaded ram.

Owner:THE BOEING CO

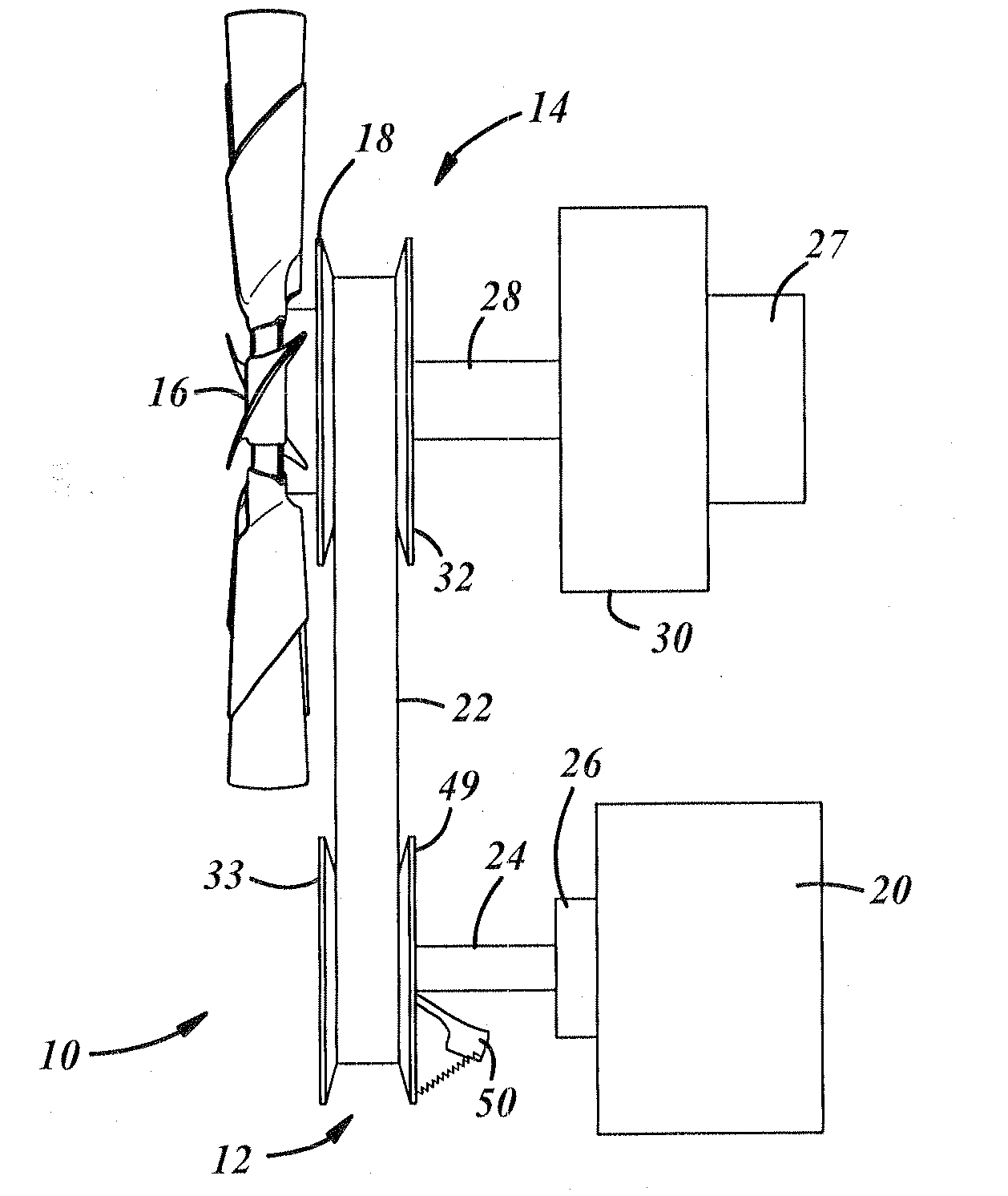

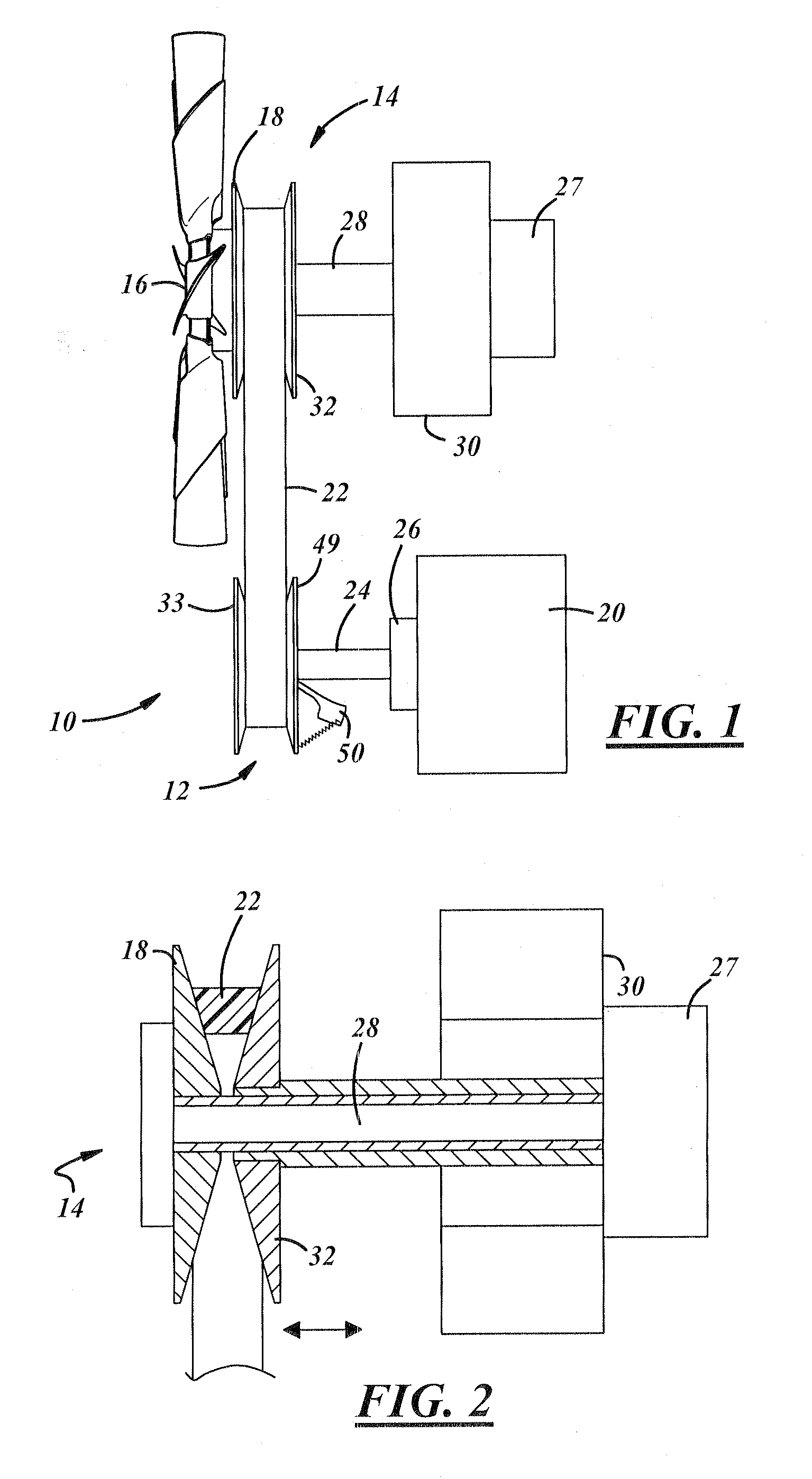

Fault-tolerant electro-mechanical actuator having motor armatures to drive a ram and having an armature release mechanism

An electrical actuator comprises two or more electrical motors to drive a threaded screw ram. Each motor has an armature that drives a threaded roller screw that is engaged to the threaded screw ram. Each armature of each motor is independently engageable and / or dis-engageable with the ram. The motor armatures are engageable and disengageable by way of threaded roller screws, the ends of which are tapered to enable them to be lifted away from or lowered into engagement with the threaded ram.

Owner:THE BOEING CO

Automated linear displacement sensor calibration device

ActiveCN103630099AEasy structure settingReduce work intensityMeasurement devicesDual frequencyGrating

Owner:CHANGZHOU INST OF MEASUREMENT & TESTING TECH

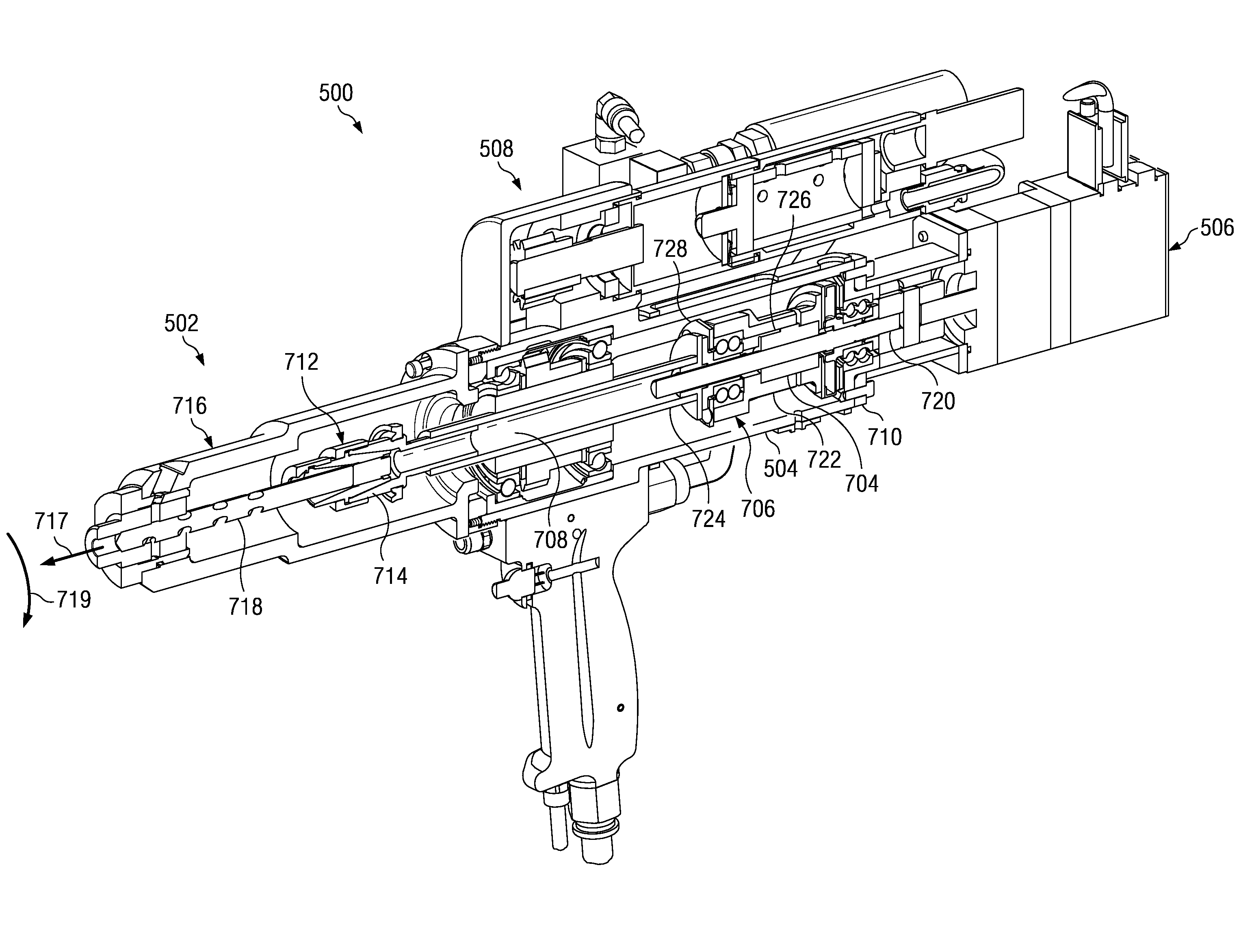

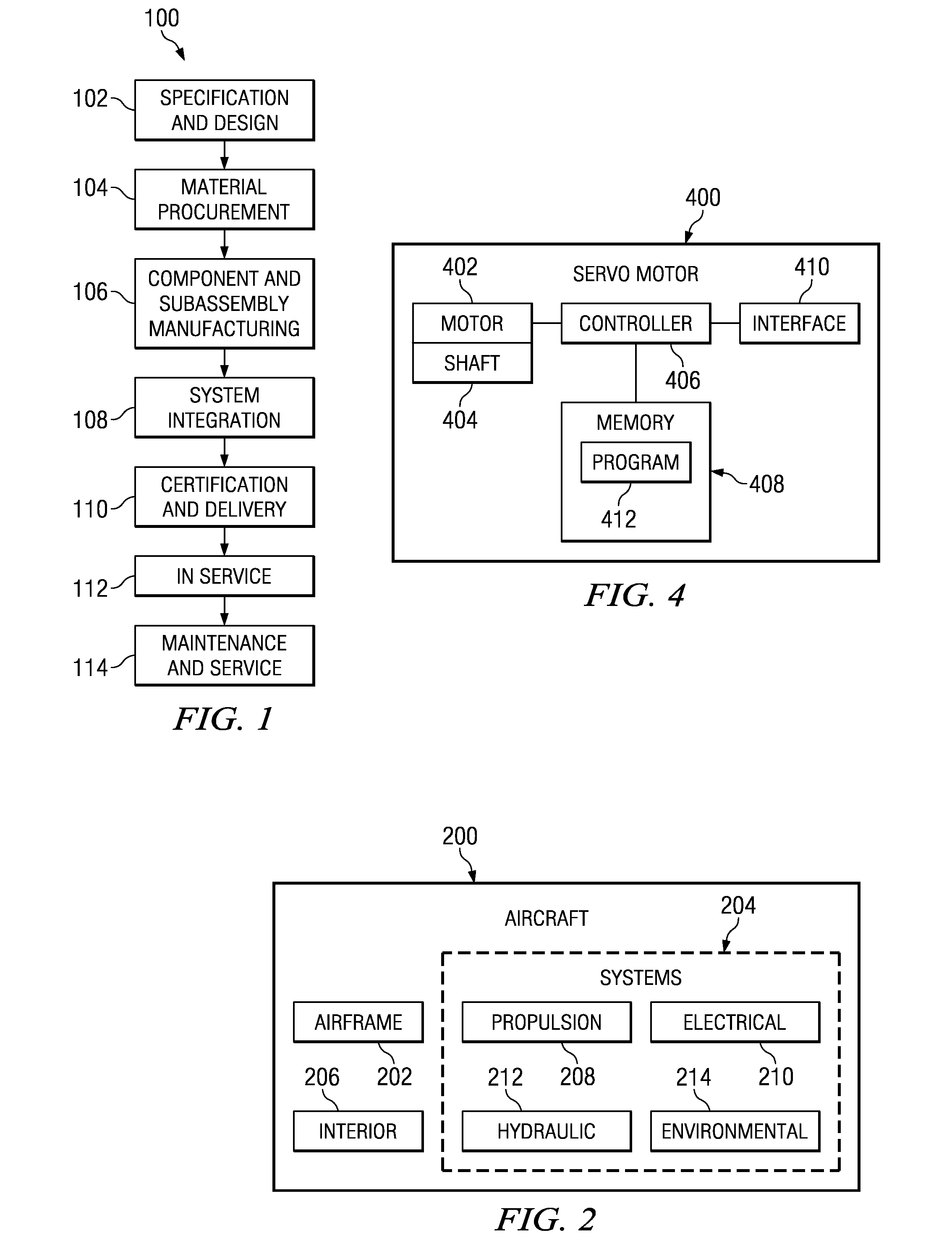

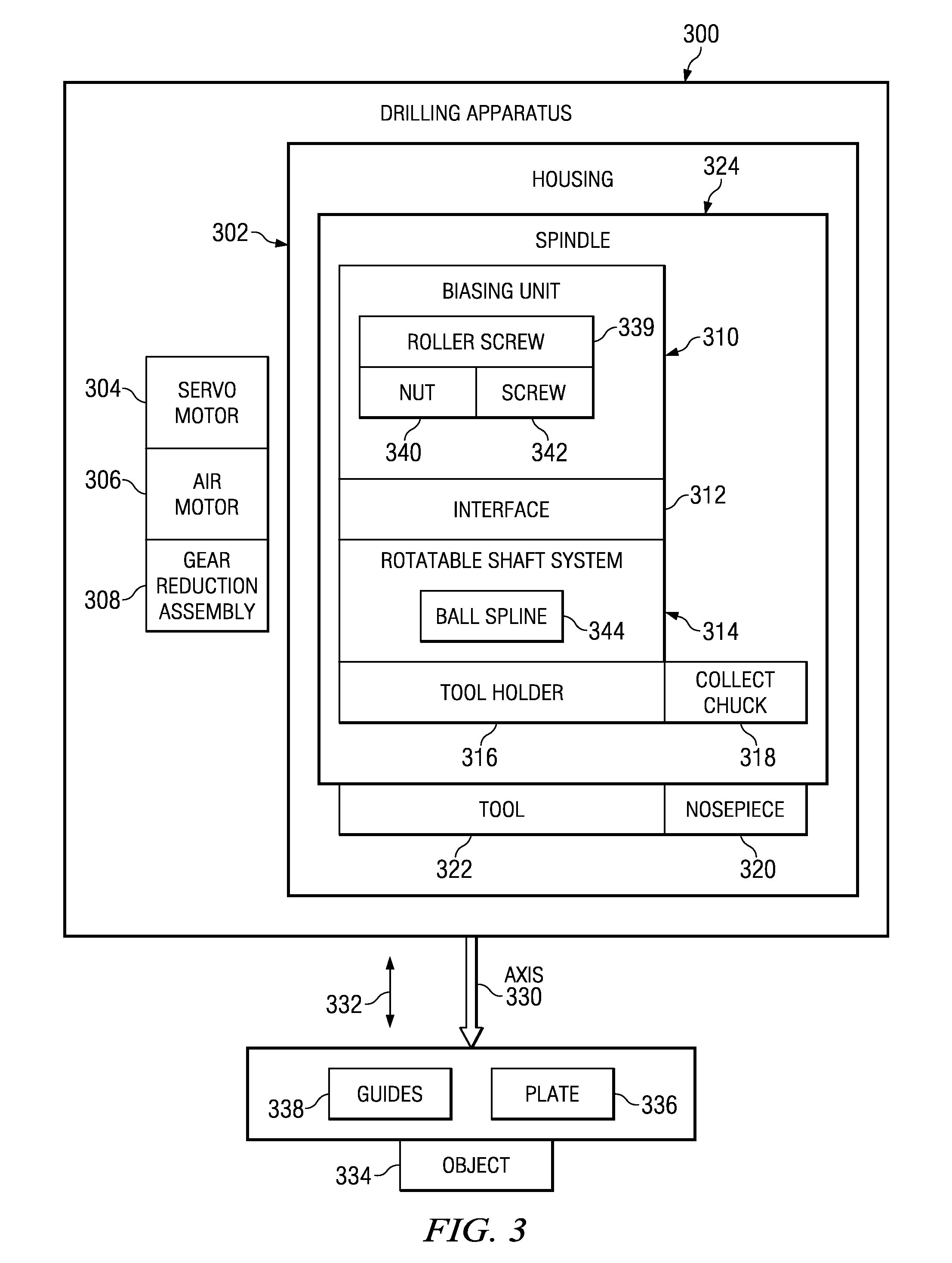

Method and apparatus for a spindle with servo feed control

A method and apparatus for a power feed drill. The power feed drill comprises a servo motor, a roller screw, a ball spline shaft, an air motor, and a collet chuck. The roller screw is rotatably mounted to the servo motor. The ball spline shaft has a first end connected to the roller screw, wherein rotation of the roller screw in a first direction moves the ball spline shaft in the first direction and wherein rotation of the roller screw in a second direction moves the ball spline shaft in an opposite direction to the first direction along an axis. The air motor is capable of transmitting rotation motion to the ball spline shaft to rotate around the axis. The collet chuck is fixably attached to a second end of the ball spline shaft, wherein the collet chuck is adapted to receive a tool.

Owner:THE BOEING CO

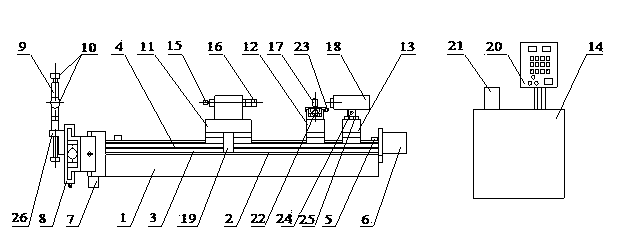

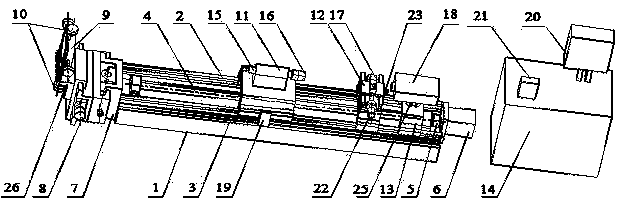

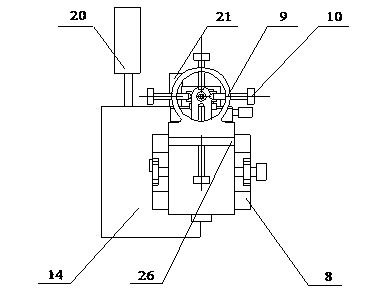

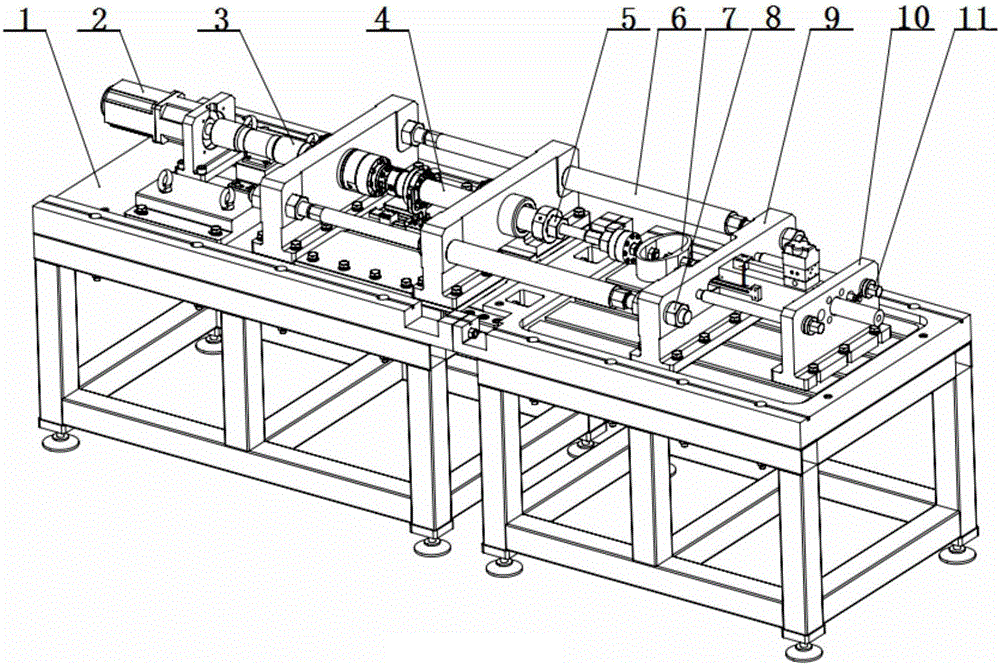

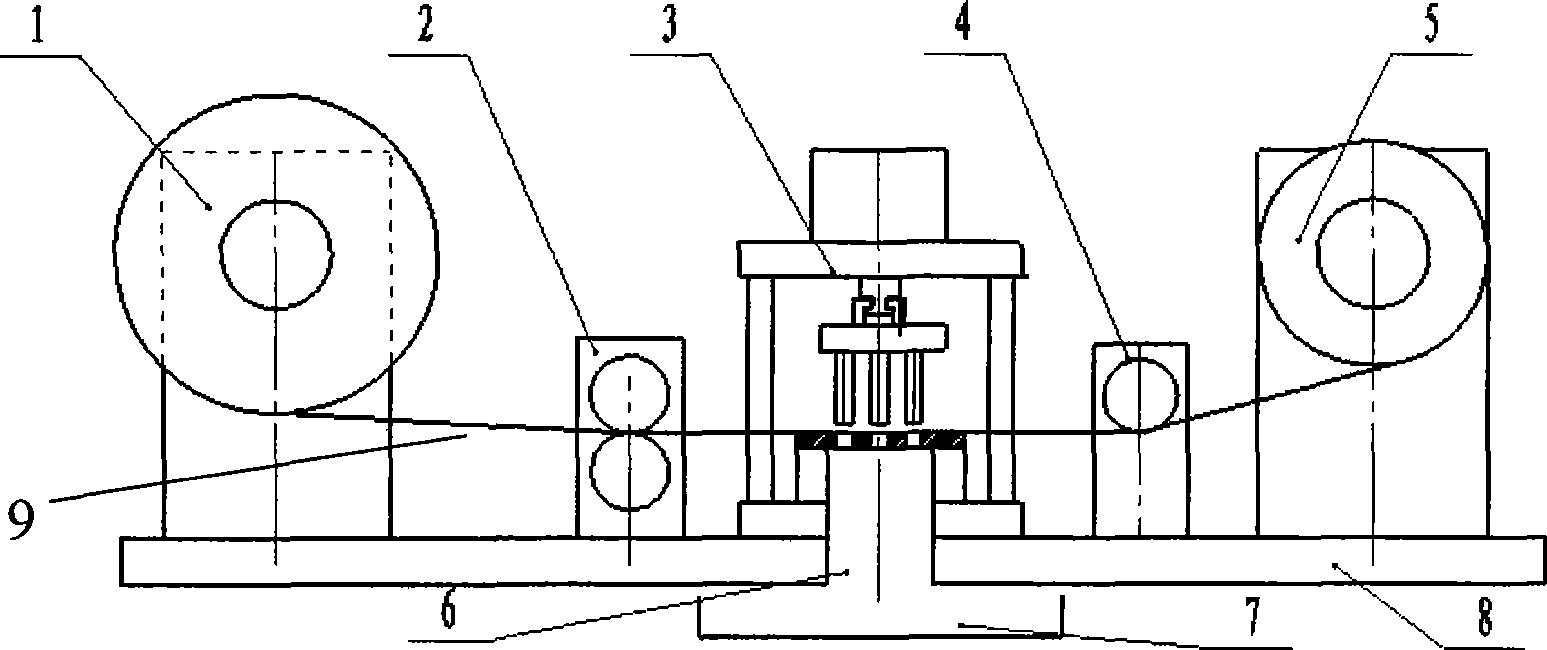

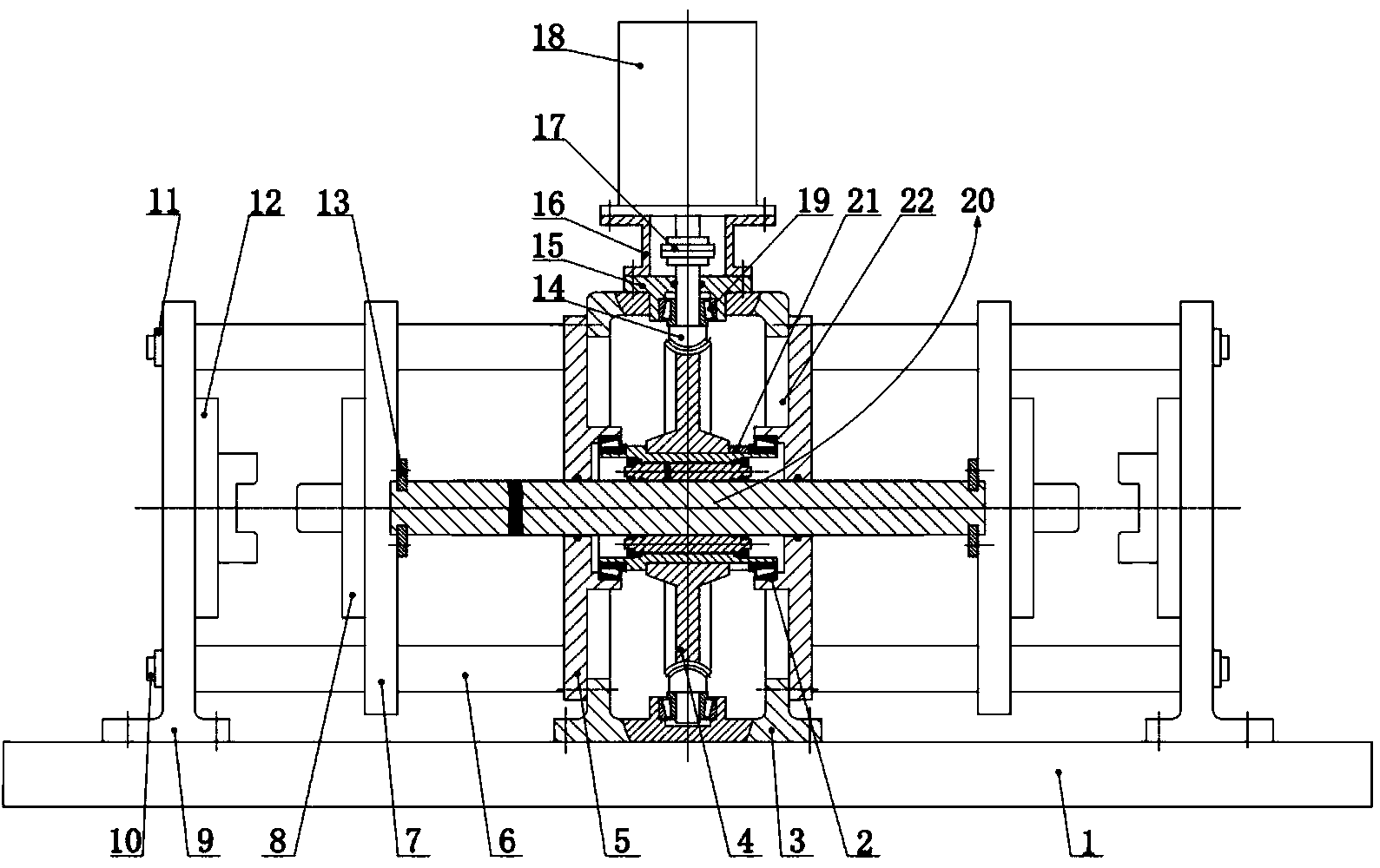

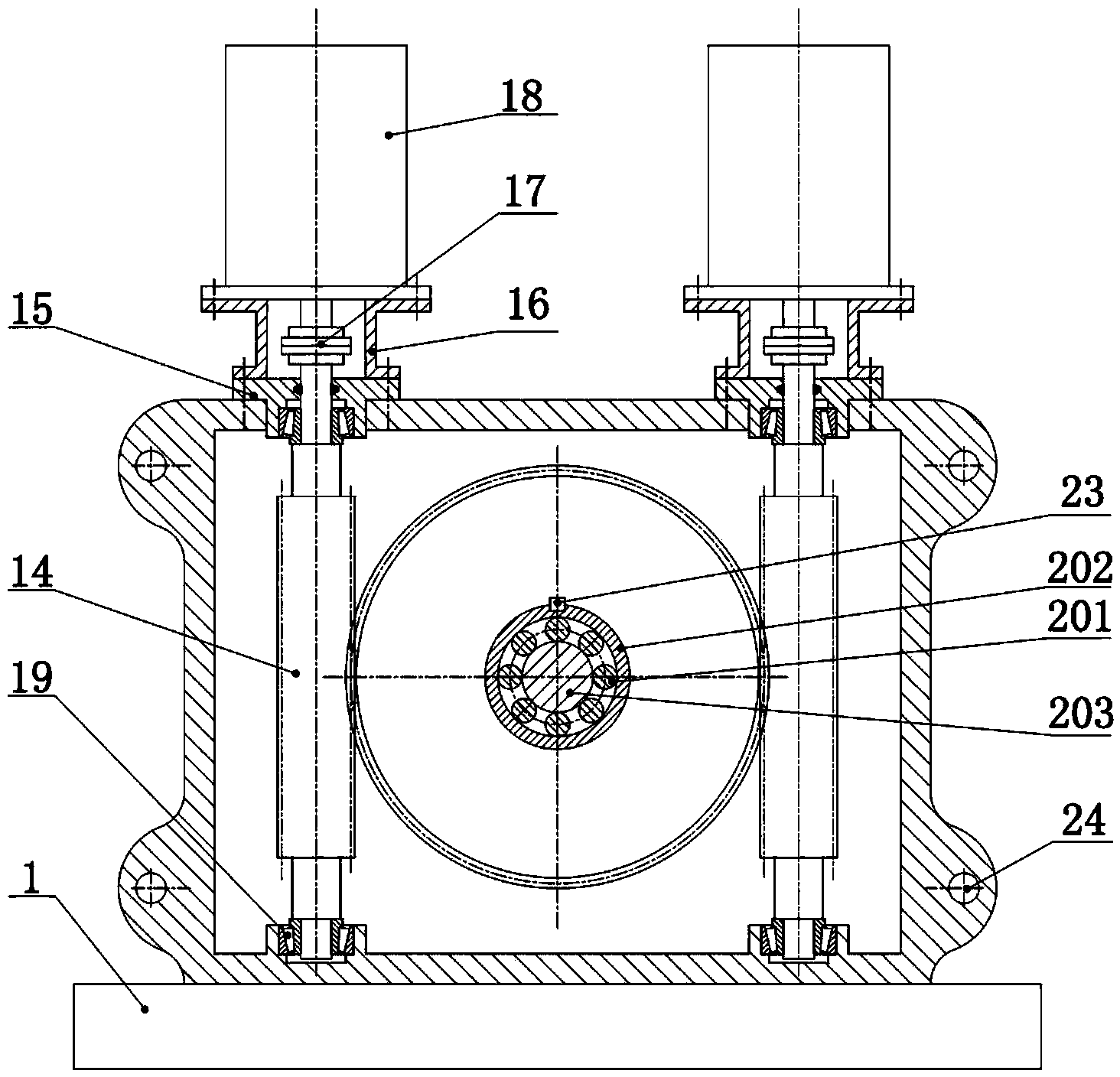

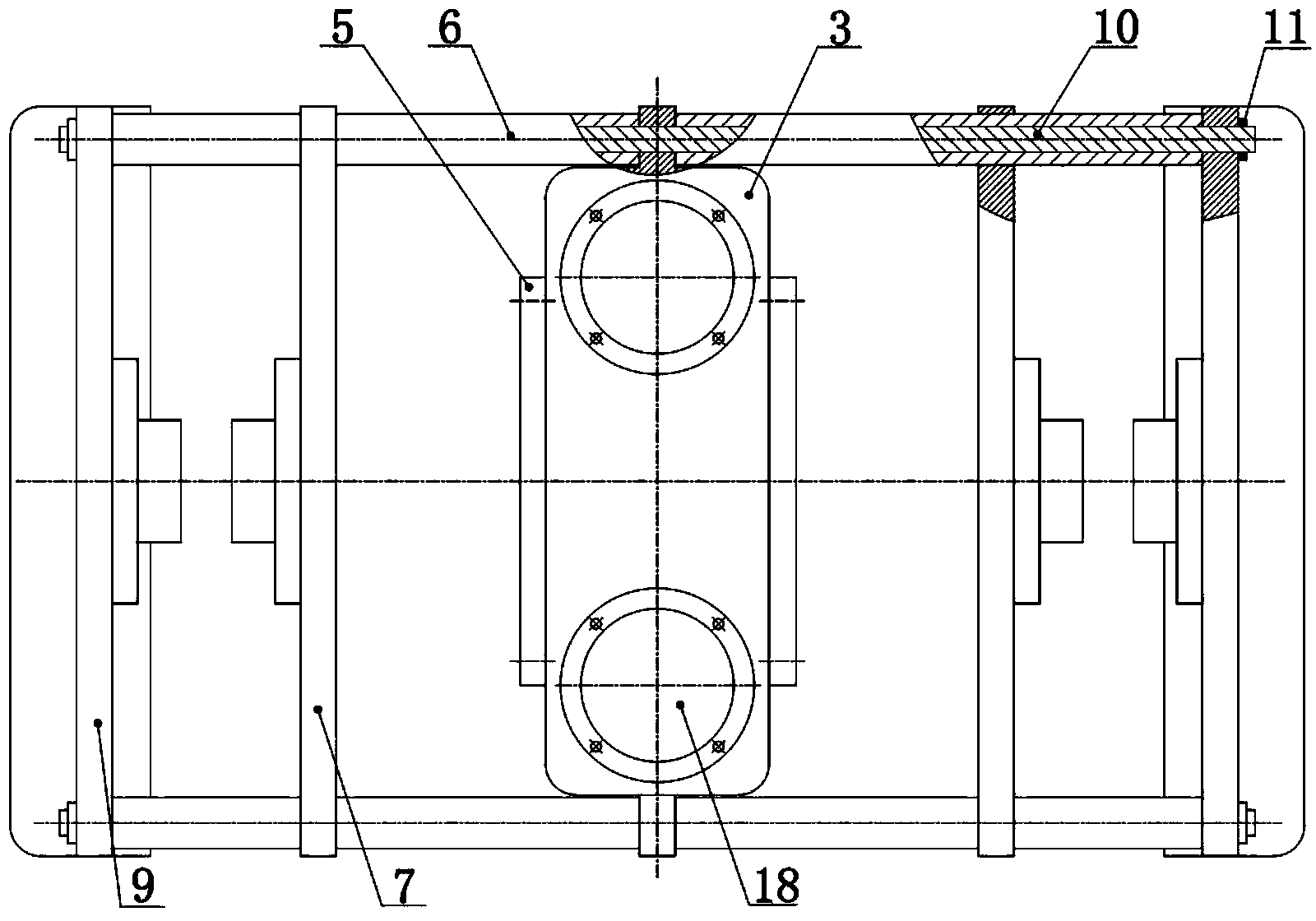

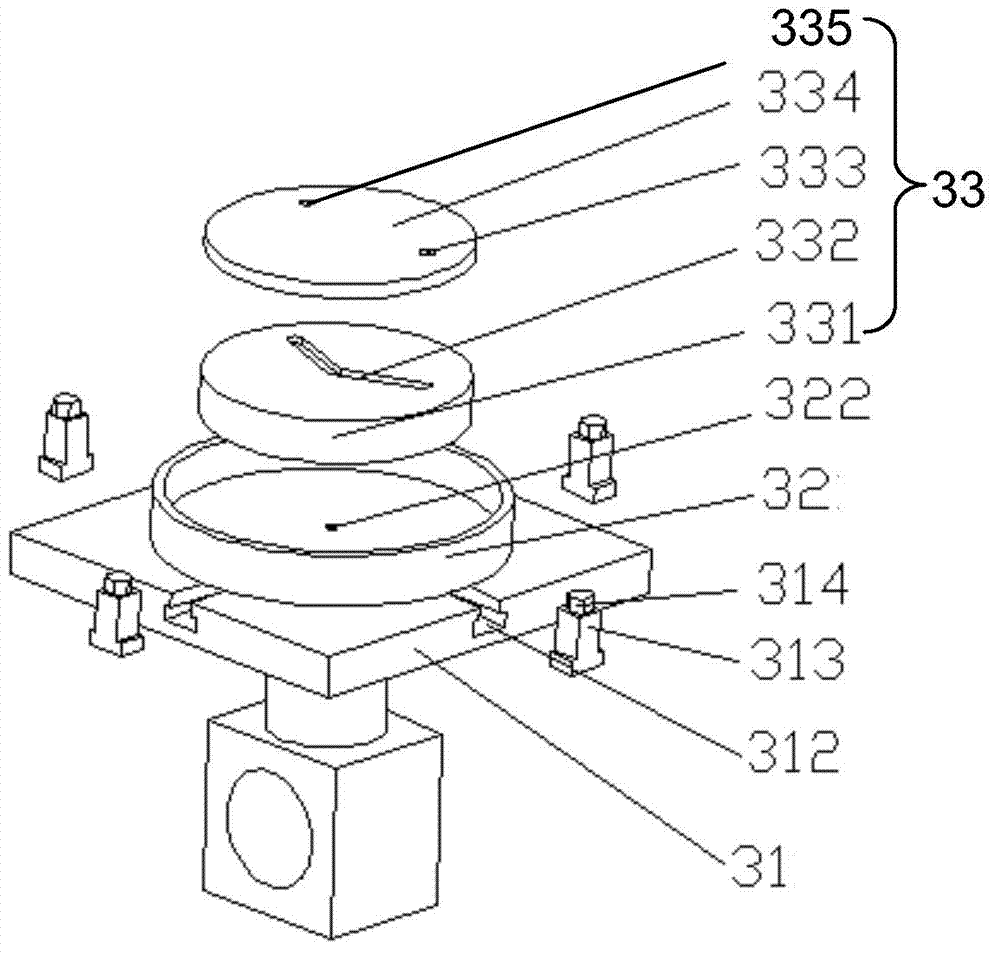

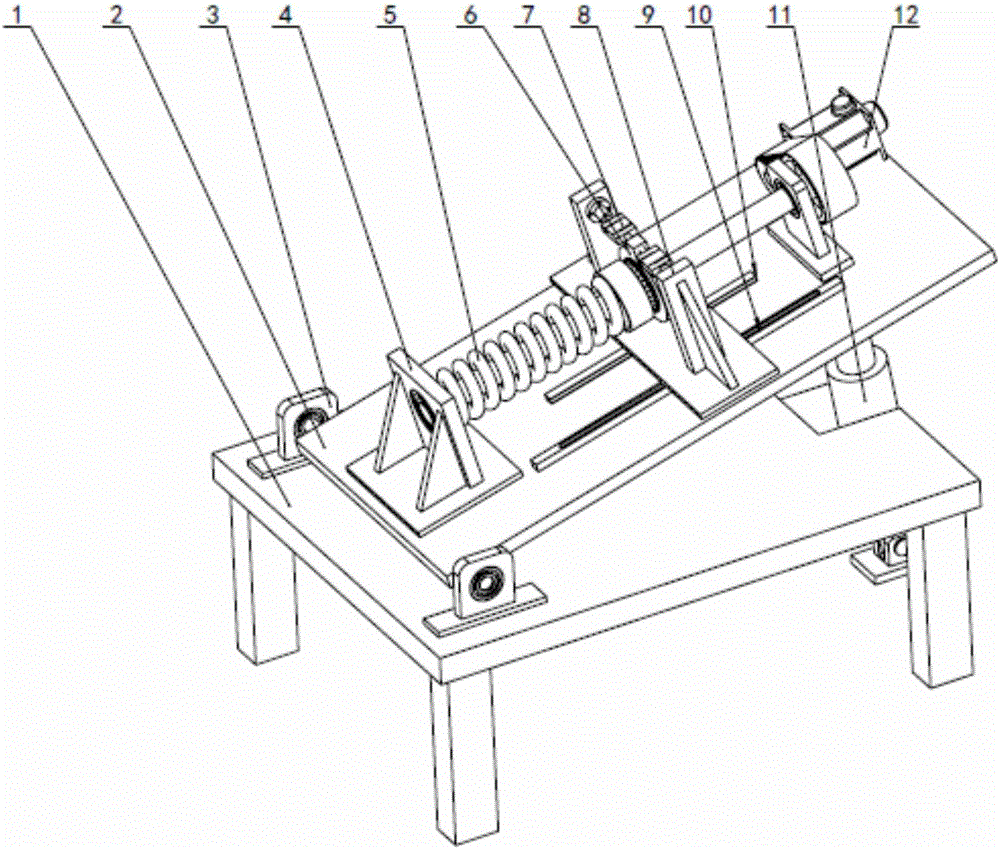

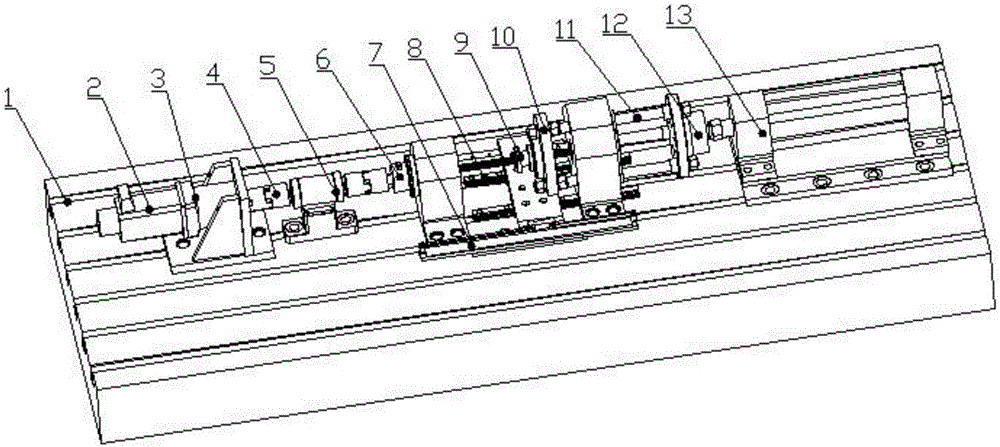

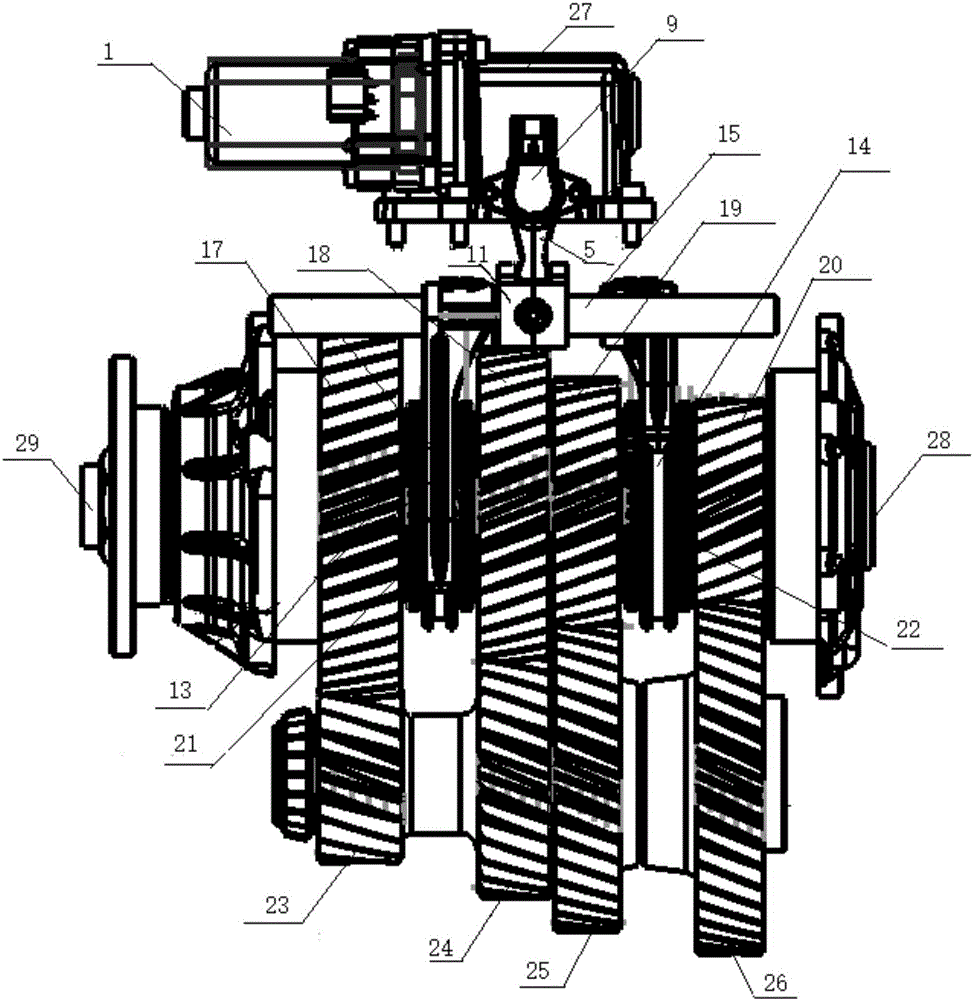

Comprehensive performance test bench for planetary roller screw

InactiveCN105890895AReal-time detection of rotation angleReal-time detection timesMachine gearing/transmission testingTest performanceGrating

The invention discloses a comprehensive performance test bench for a planetary roller screw. A driving assembly provides power for the planetary roller screw; a test assembly is used for mounting a planetary roller screw of a different model; a hydraulic loading assembly is adopted to carry out dynamic and static loading on a planetary roller screw nut, load borne by the planetary roller screw during actual work is simulated, and a force closed loop is adopted to ensure accuracy of the loading force. The test bench is provided with a torque sensor, an angle encoder, a circular magnetic grating, a grating ruler, a LVDT, and a force sensor. Measurement on torque, an angle, displacement and force is realized through the sensor. Through analyzing the test data, test on performance of the position precision, the speed, the acceleration, the transmission efficiency, the transmission clearance and the axial stiffness of the planetary roller screw of the different model in the load state can be completed. The test bench has the advantages of simple and flexible structure, thorough and accurate test performance parameters, high loading precision and strong test scalability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

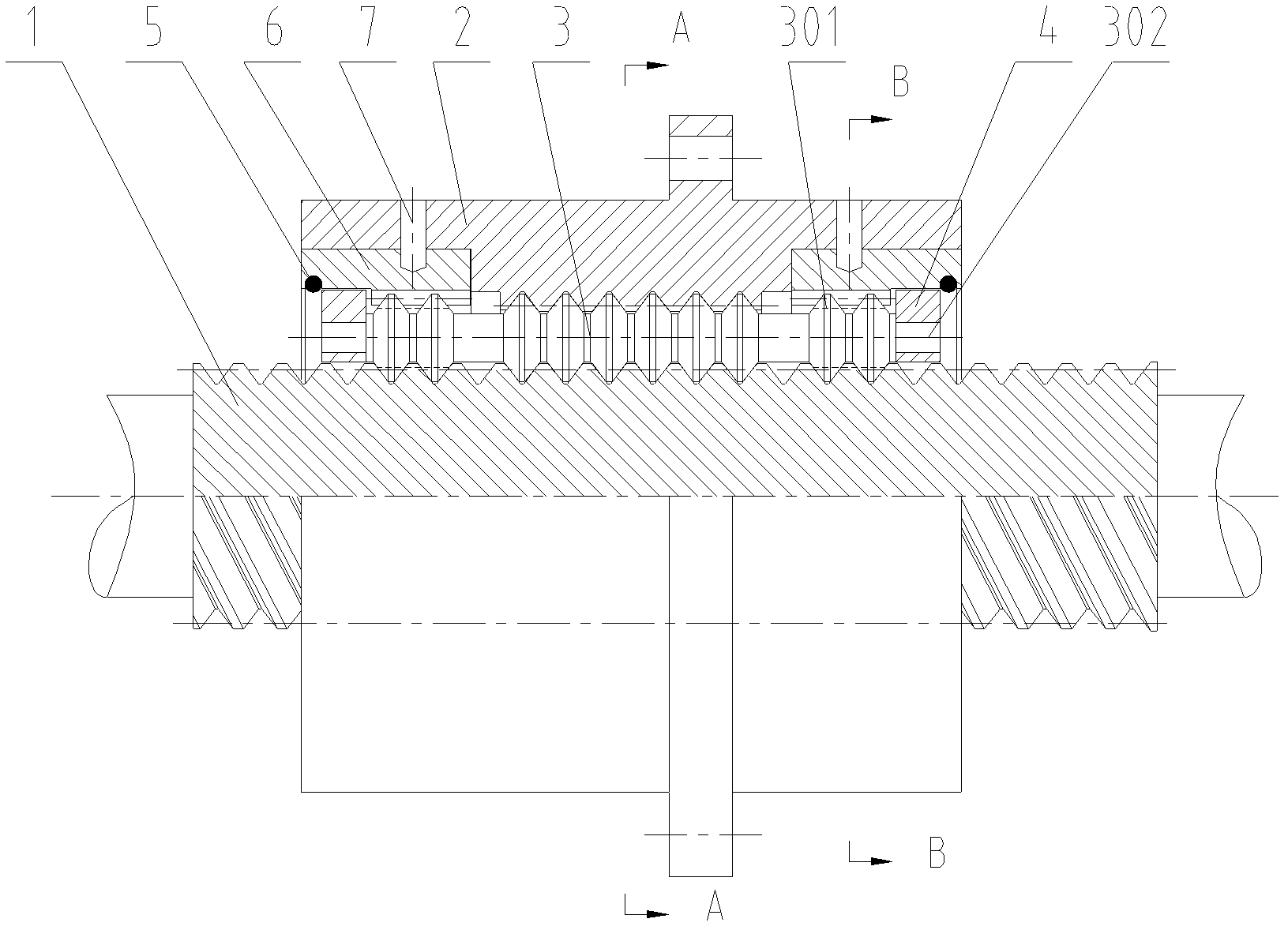

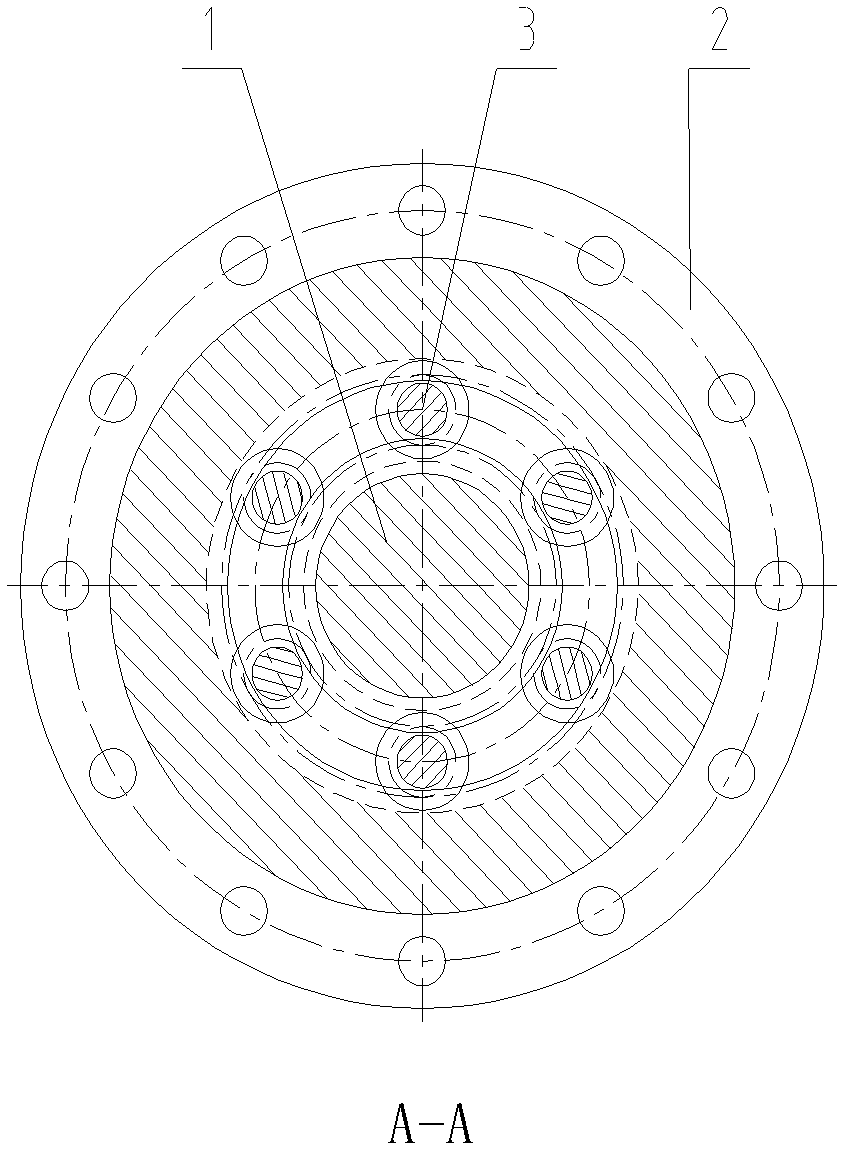

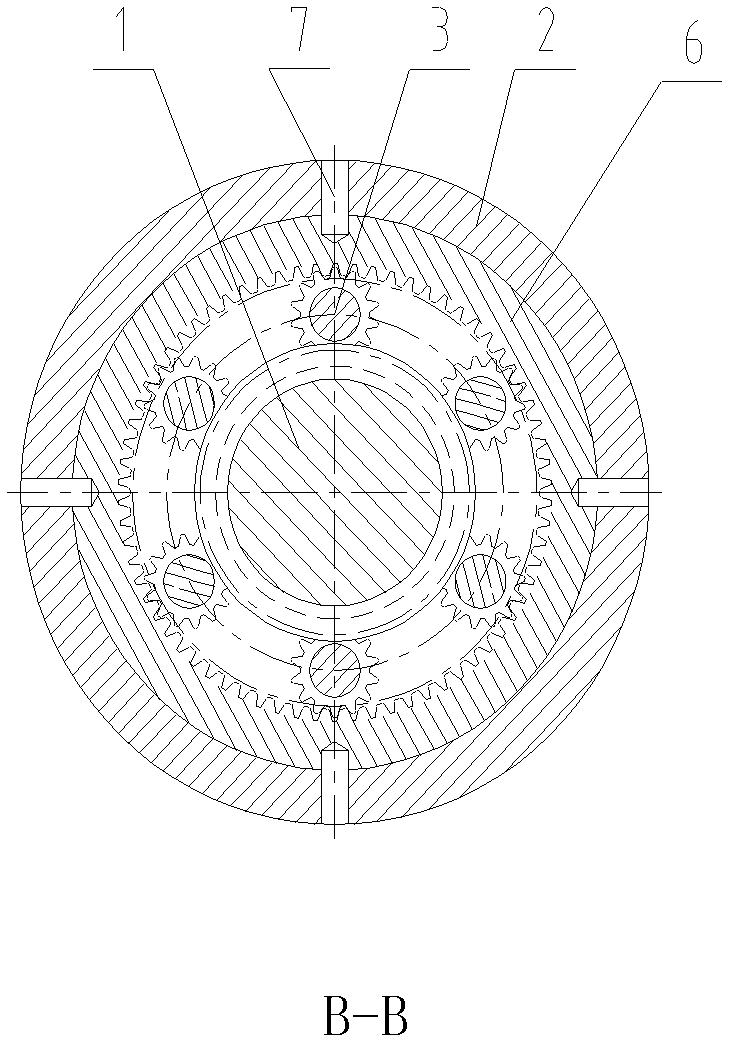

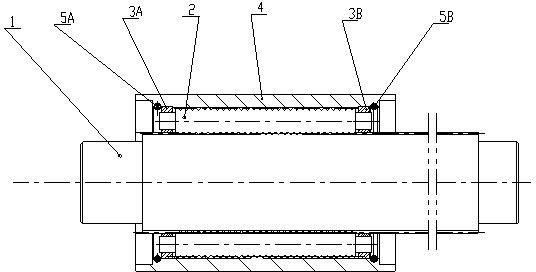

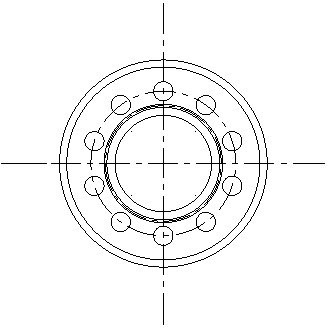

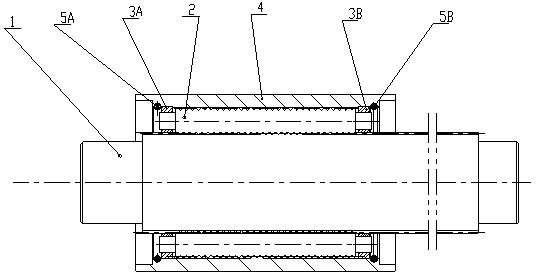

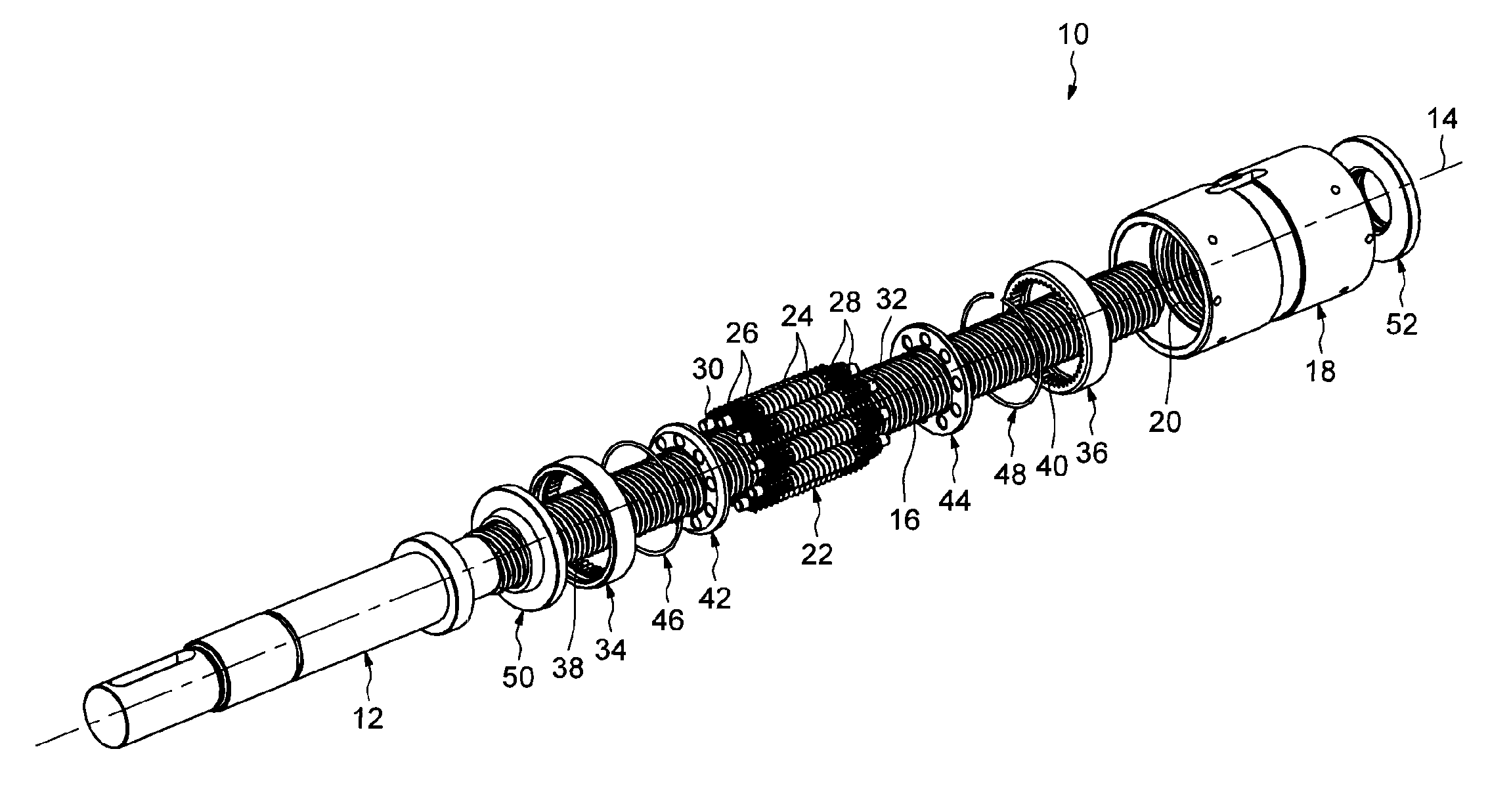

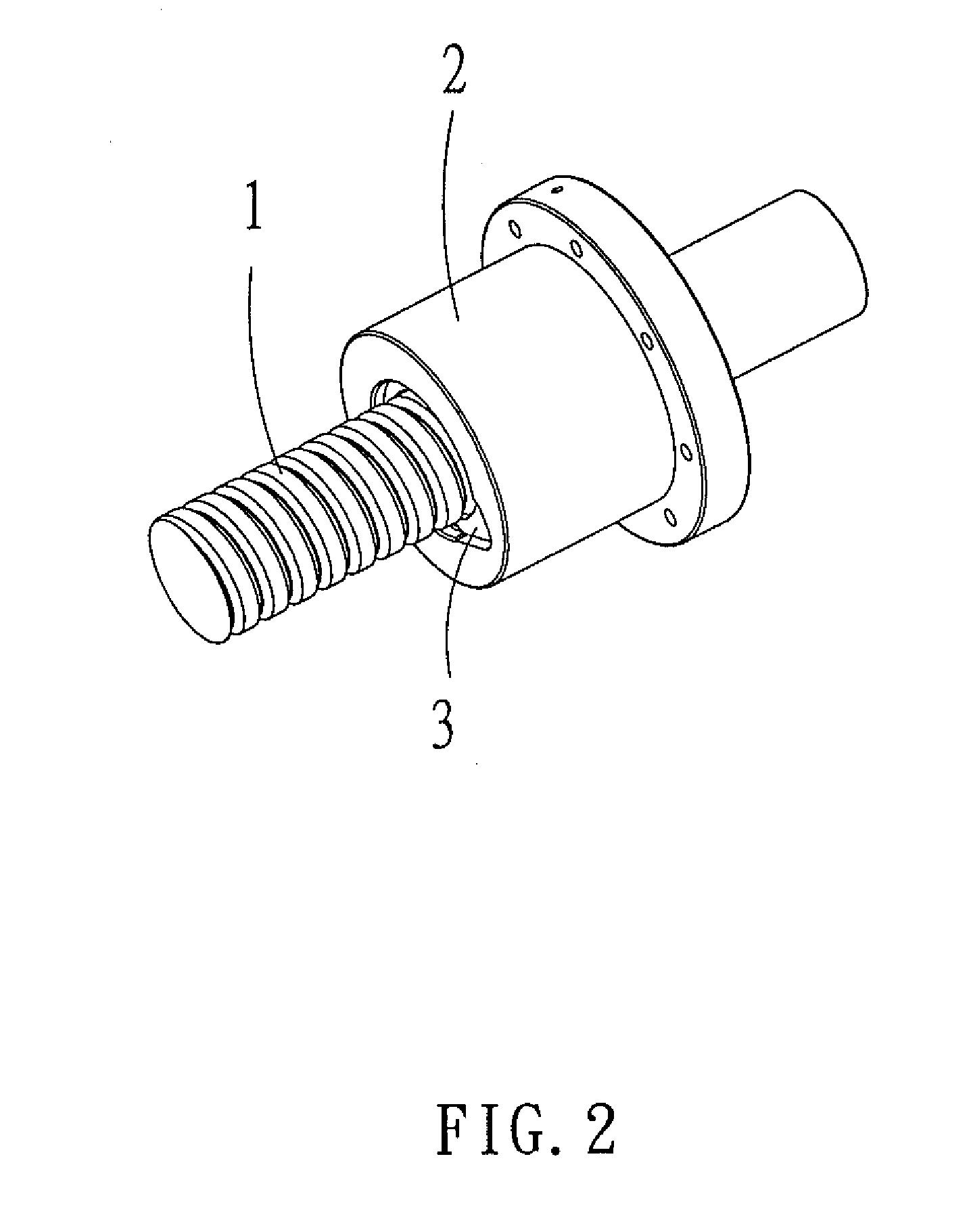

Planetary roller screw

InactiveCN102562986AImprove carrying capacityHigh movement precisionGearingNumerical controlOptical axis

The invention discloses a planetary roller screw which comprises a lead screw, a nut, two roller retainers, two elastic inner check rings, two inner gear rings and a plurality of rollers arranged between the lead screw and the nut; the two inner gear rings are respectively fixed at the two end parts of an inner hole of the nut, parallel annular tooth sockets are arranged at the middle part of the inner hole of the nut, the two roller retainers are respectively sleeved in the inner holes of the two inner gear rings and are respectively blocked and located by the two elastic inner check rings embedded in the inner gear rings, retaining holes, whose number is consistent with that of the rollers, are arranged on the roller retainers, parallel teeth embedded with the threads of the lead screw and the annular tooth sockets of the nut are arranged at the middle parts of the rollers, the two end parts of the rollers are plain spindle heads, and the plain spindle heads are respectively inserted in the retaining holes of the two roller retainers. The planetary roller screw has a reasonable structure, convenience for manufacture, high transmission efficiency, large bearing capacity, high movement precision and low manufacturing cost, so that the planetary roller screw can be extensively applied on such apparatuses as numerical control machine frames and harbor machinery, etc.

Owner:上海久能机电制造有限公司

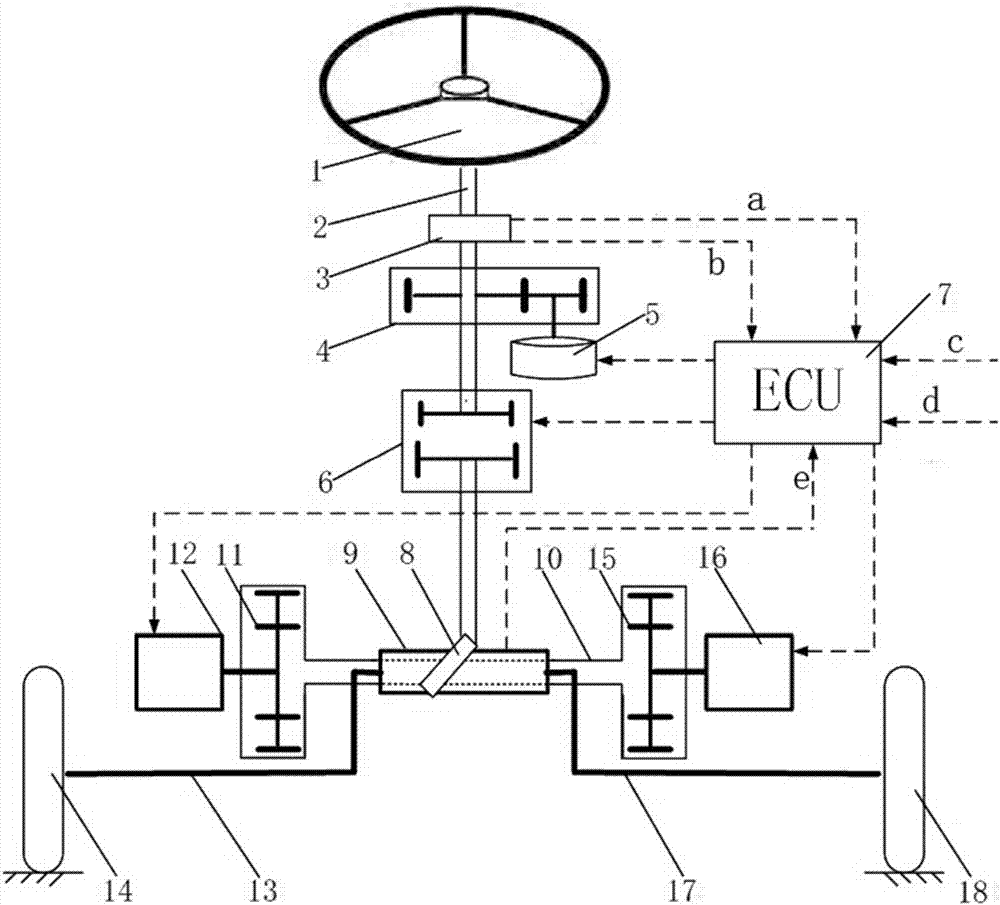

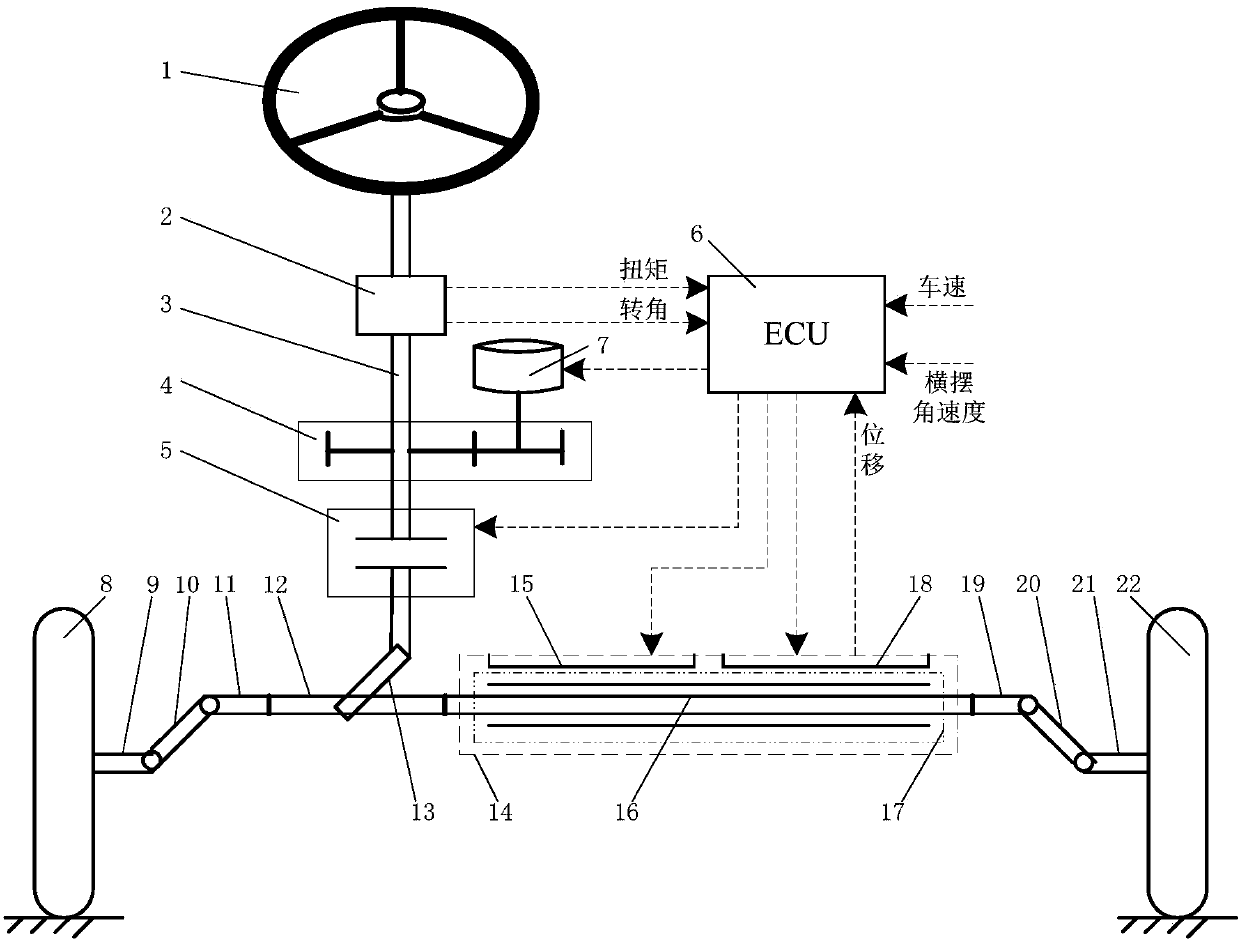

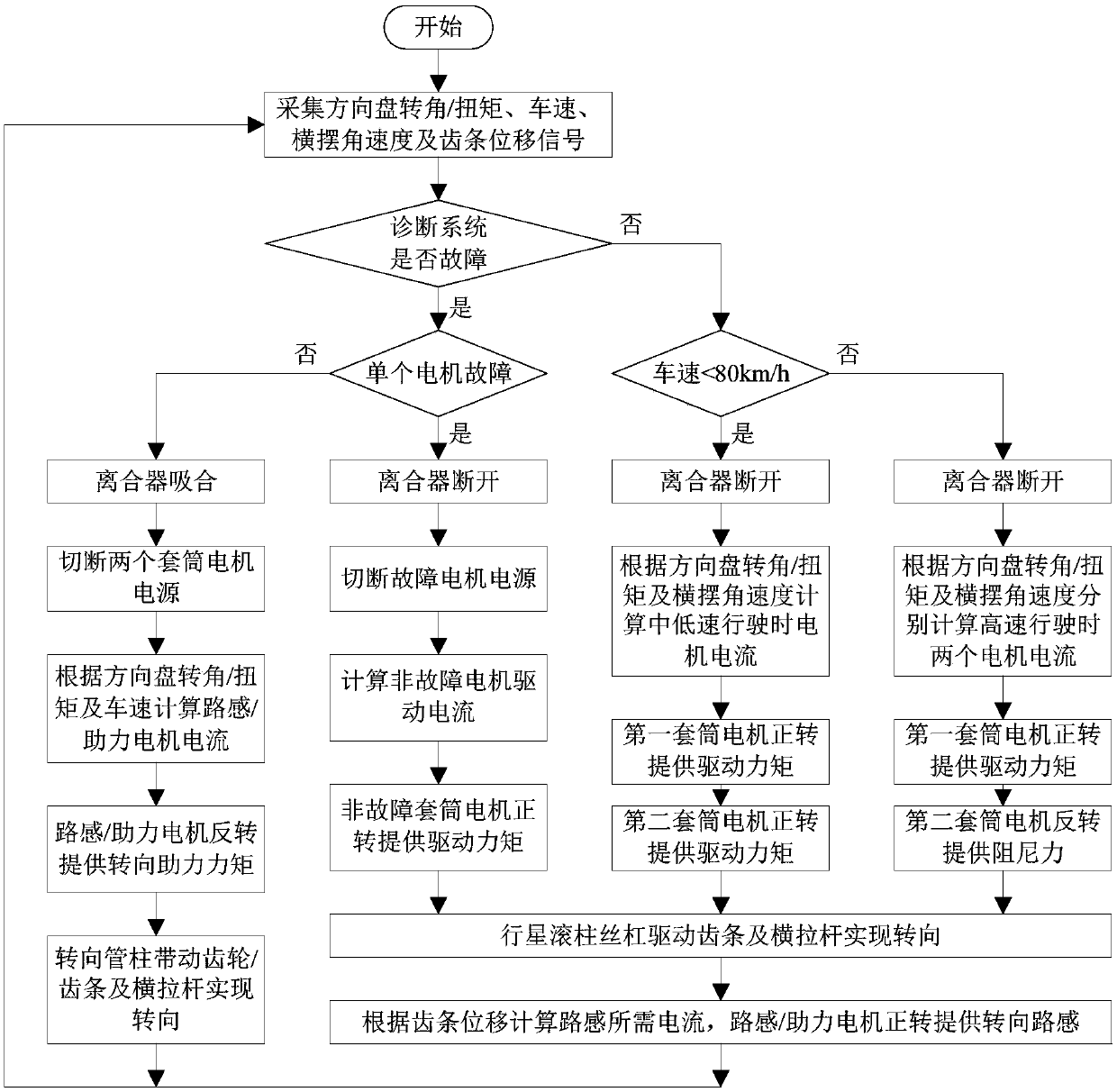

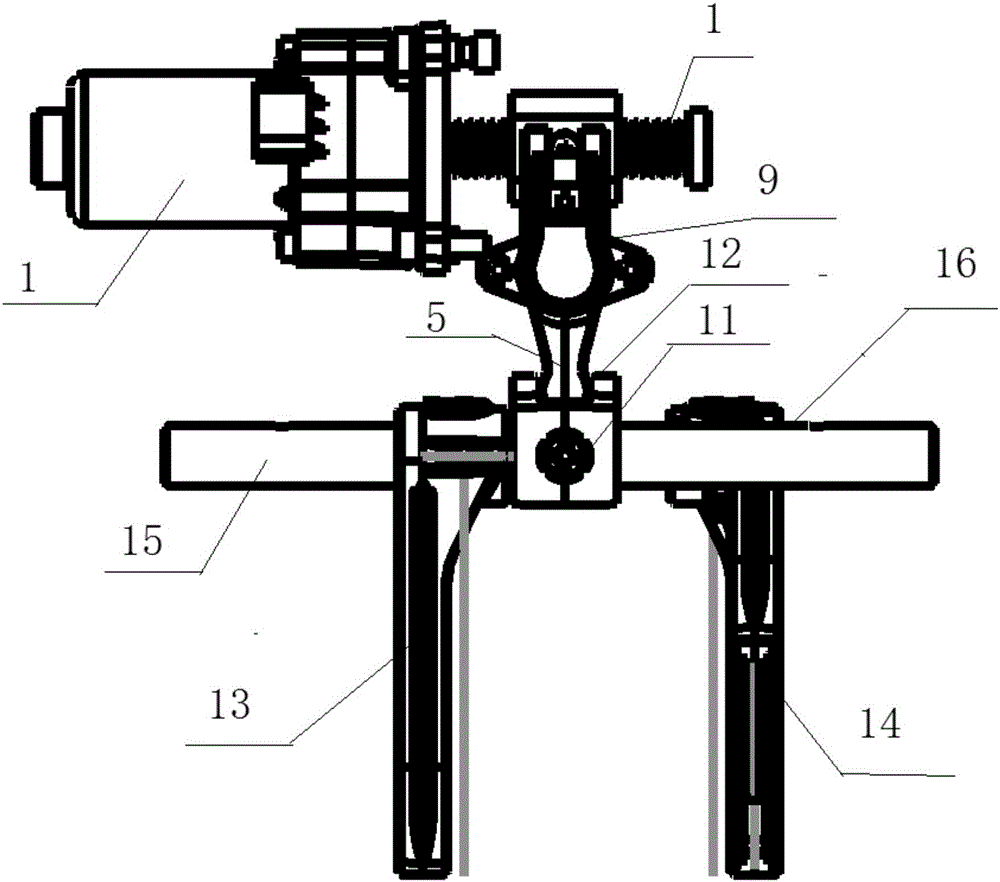

Dual-motor redundant steer-by-wire device and control method thereof

PendingCN107953928AImprove stabilityImprove driving stabilityElectrical steeringDriver/operatorSteering wheel

The invention discloses a dual-motor redundant steer-by-wire device and a control method thereof. The device comprises an electric control unit (ECU), a torque sensor, a motor, a steering gear rack, asteering gear pinion and a steer-by-wire mechanism. The electric control unit (ECU) of the device judges the steering intention of a driver by collecting steering wheel turning angle signals; when the steer-by-wire mechanism works normally, an electromagnetic clutch is disengaged, the motor plays a part in providing road feel, and a roller screw steering mechanism completes a steering instruction; when the steer-by-wire mechanism breaks down, the electromagnetic clutch is engaged, the motor rotates reversely, and the steering gear pinion and the steering gear rack complete the steering instruction and play a part in providing steering assistance. The device is simple in structure, high in precision and reliable in work, by means of the roller screw steering mechanism, steering displacement can be precisely controlled, and meanwhile, the device can automatically return to a mechanical steering state when the steer-by-wire mechanism fails to complete the steering instruction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

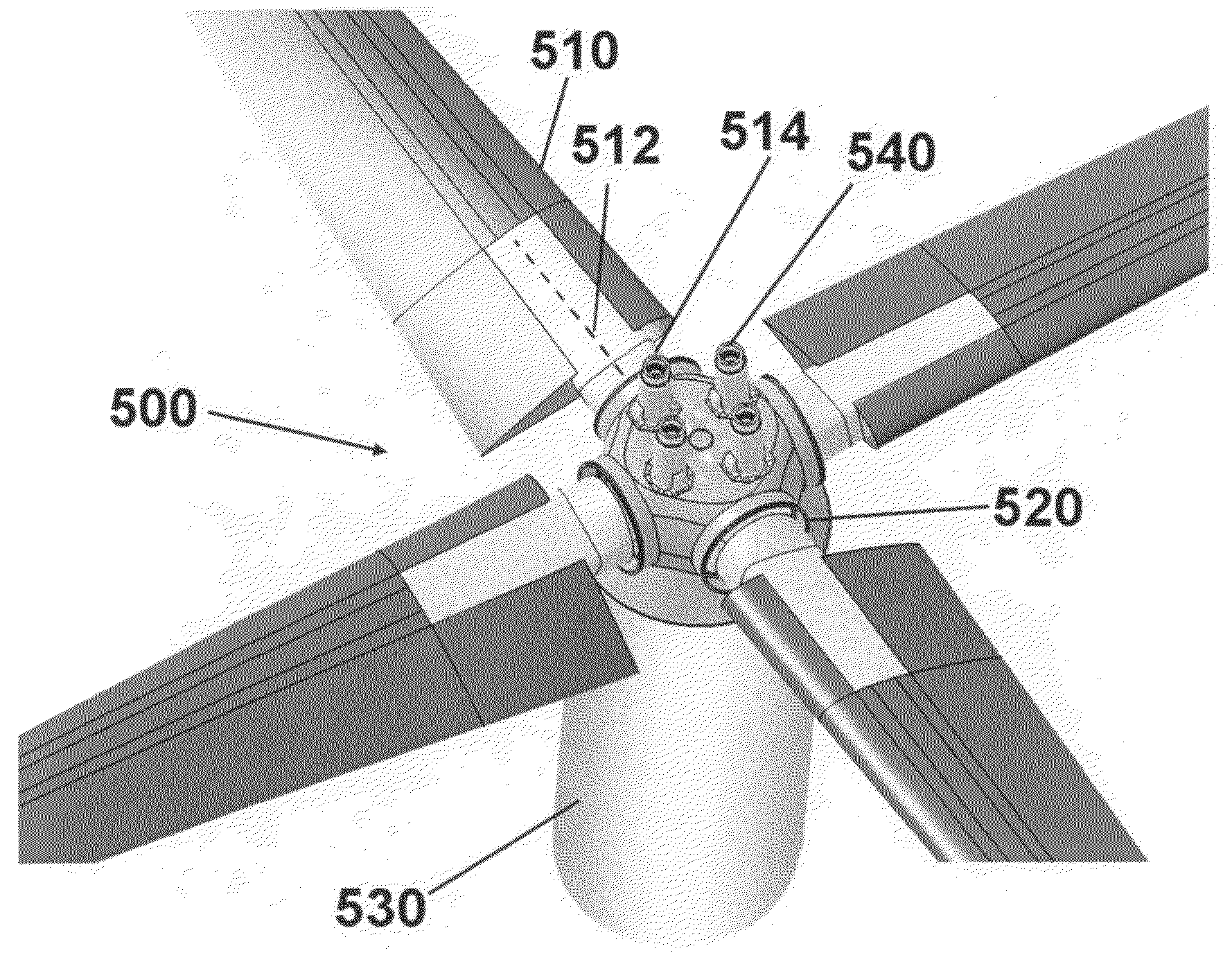

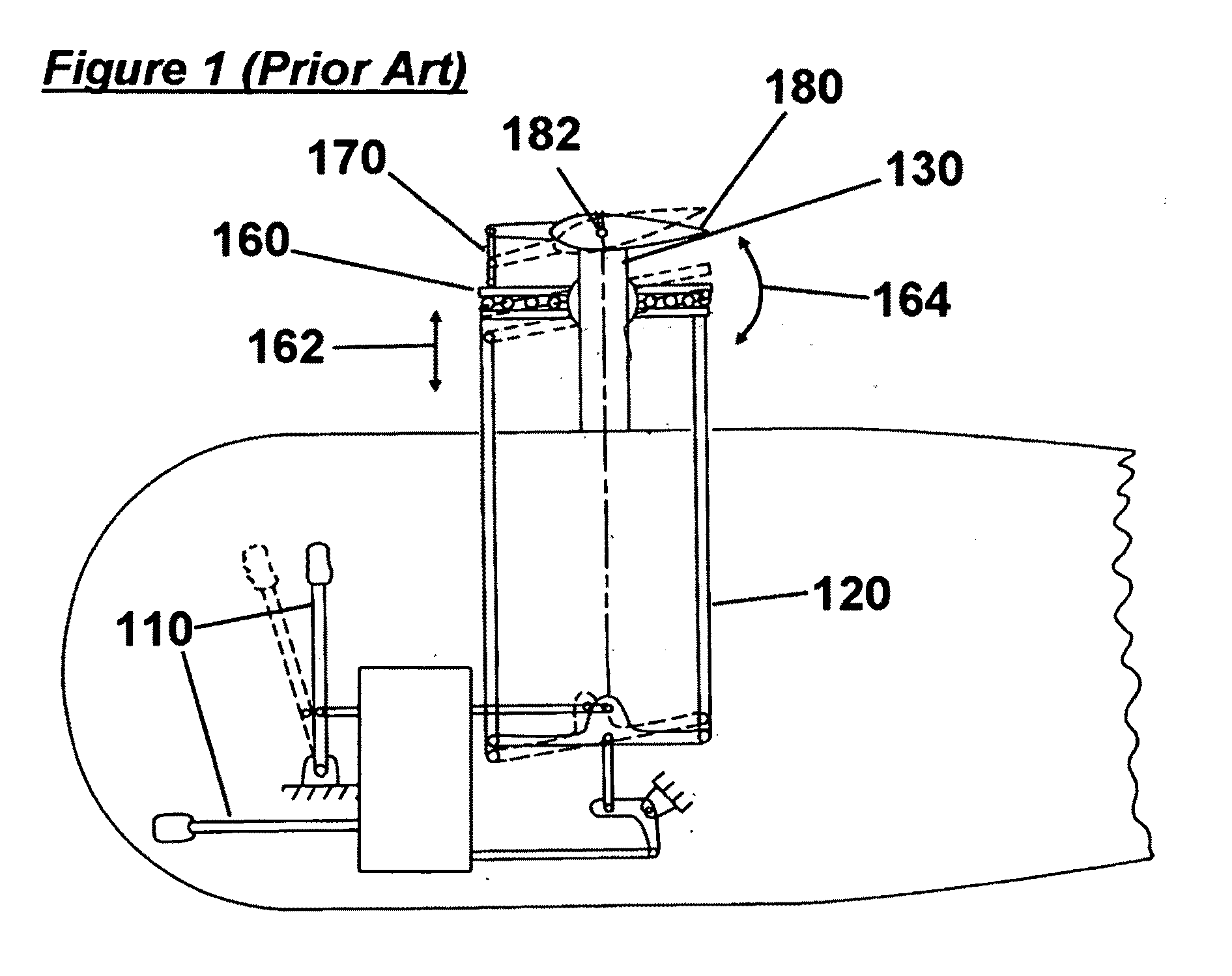

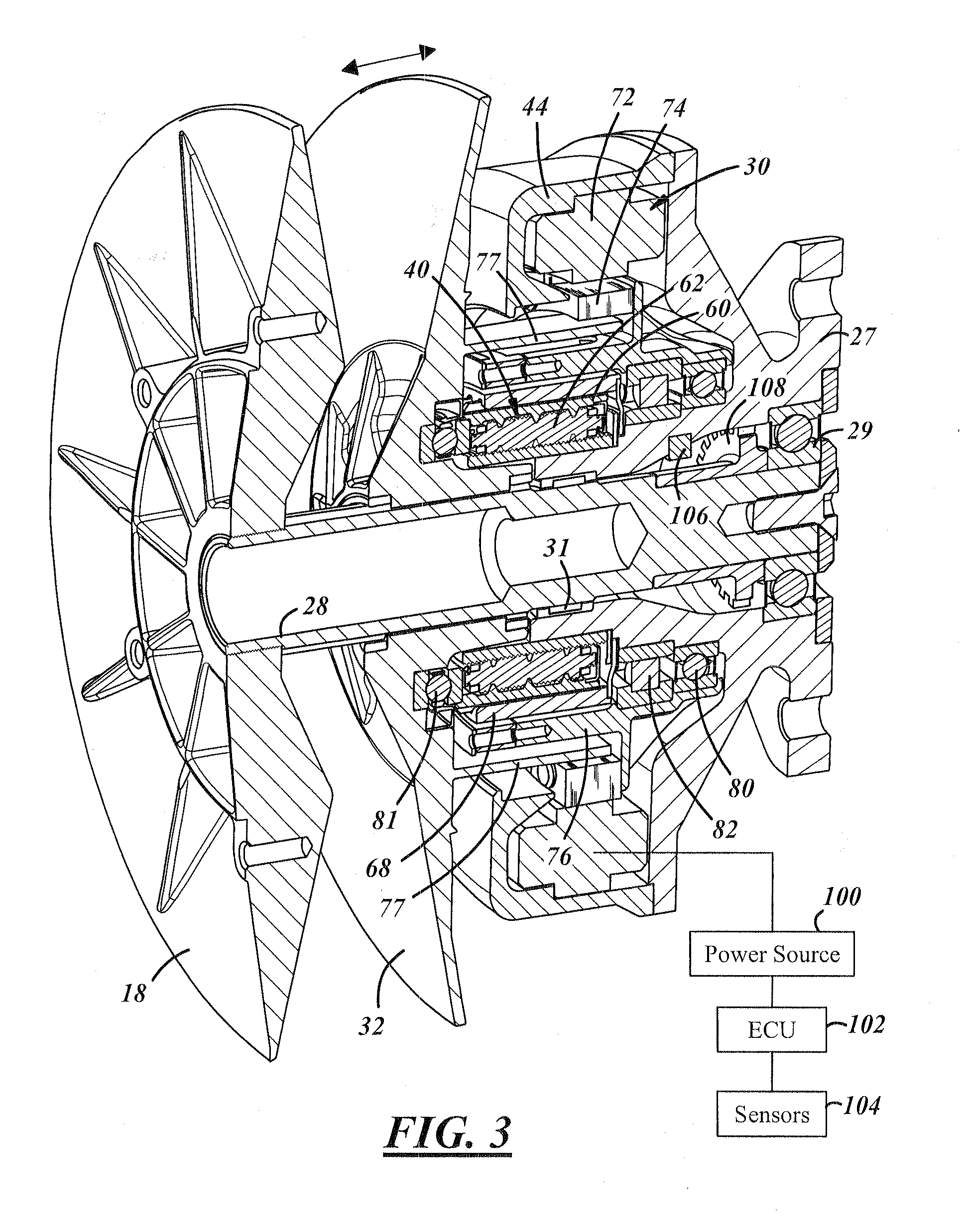

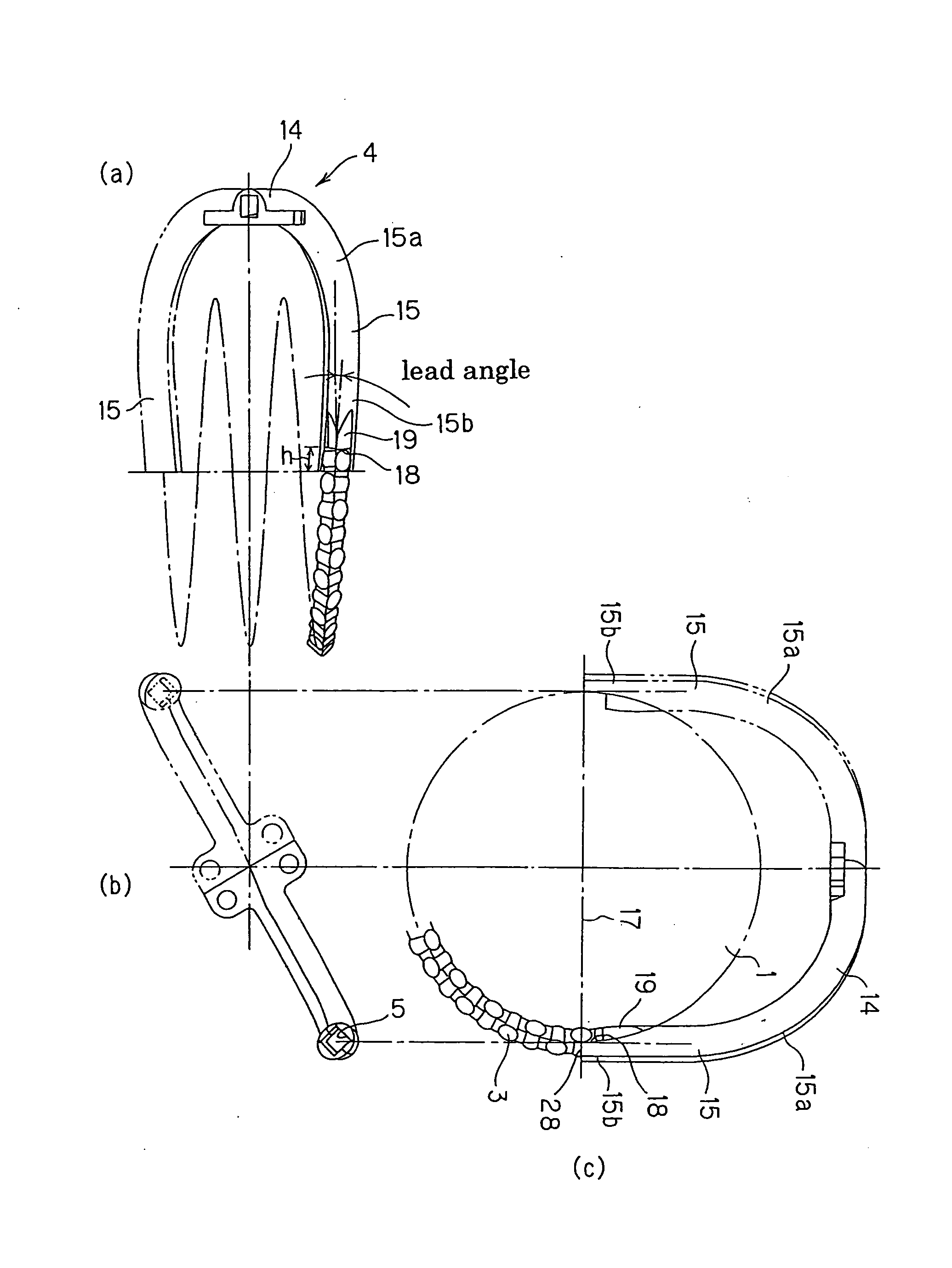

Swashplateless rotorcraft with fault tolerant linear electric actuator

An electric linear actuator is disposed to pitch a blade of a hingeless, swashplateless rotor in rotary motion. This actuator can be equipped with an electric motor advantageously made fault tolerant by winding the motor for at least 4, 5, 6, 8, or even 12 phases. Rotational motion of the electric motor is preferably converted to a translatory linear actuator output motion using a planetary roller screw coupling the rotation of the motor with pitch of the blade. The output link of the actuator can be advantageously coupled to the planetary roller screw using an internal spherical joint providing an isolated load path through the actuator. It is contemplated that a preferred rotorcraft having an electric blade pitch actuator might also be equipped with a controller that could provide the vehicle with individual blade control, in which the pitch of any rotor blade can be controlled independently of the others.

Owner:KAREM AIRCRAFT INC

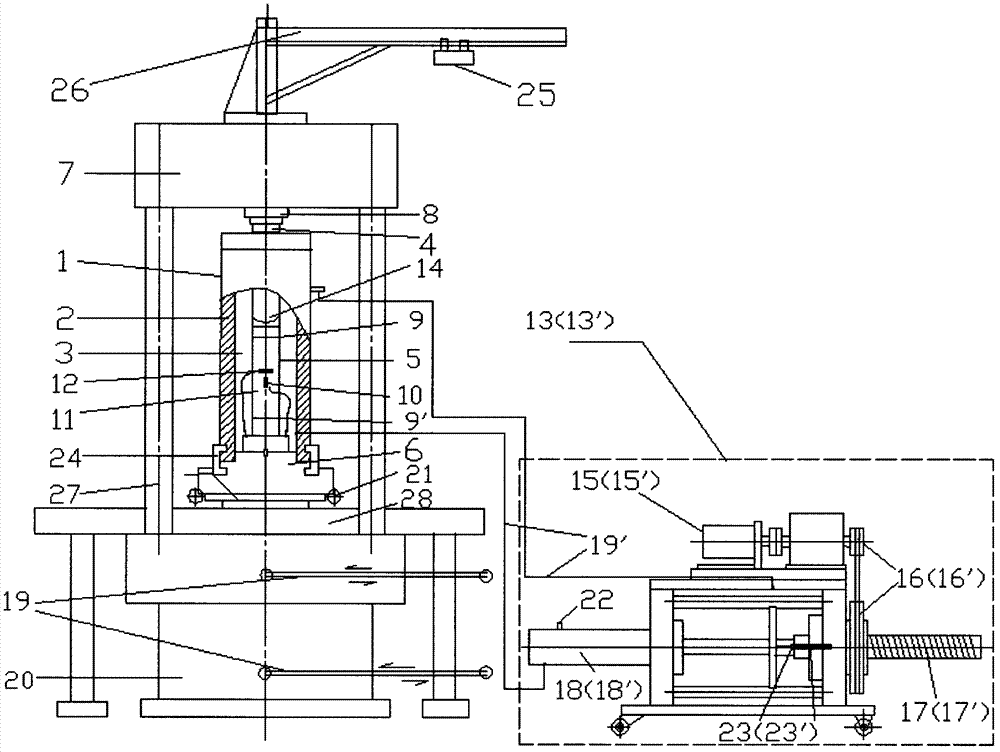

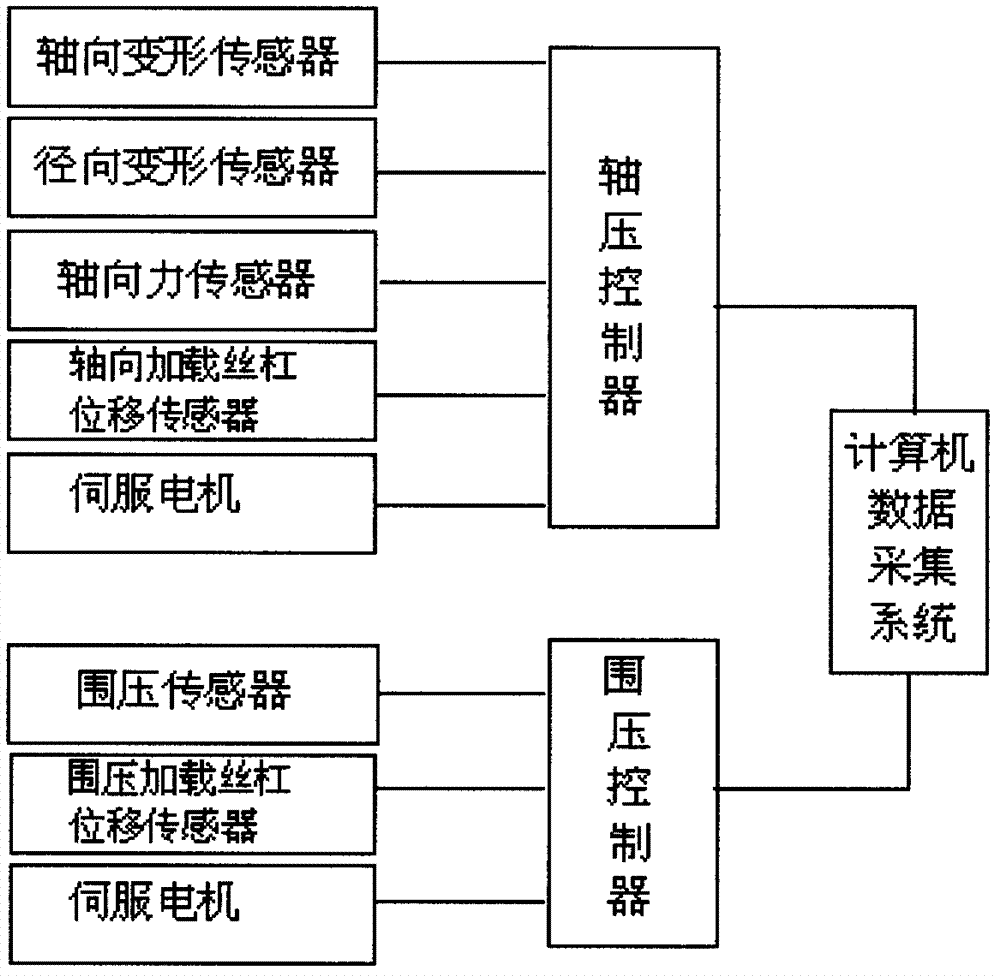

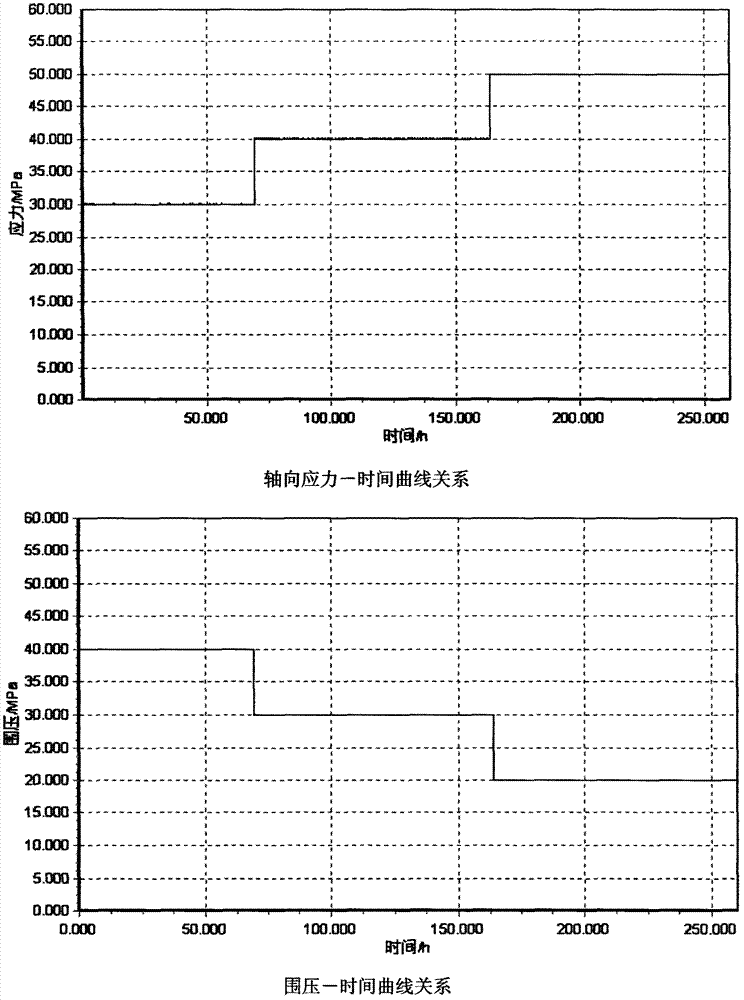

Triaxial rheological testing apparatus and testing method of electro-hydraulic servo rock

InactiveCN102890033AEasy to disassembleQuick and easy disassemblyMaterial strength using tensile/compressive forcesControl systemAxial pressure

The invention discloses a triaxial rheological testing apparatus and a testing method of an electro-hydraulic servo rock; an axial loading system is used for pressurizing an under cylinder; a cylinder piston component is used for pushing a test piece in a pressure chamber device to move upwards; a balance piston component is used for bearing an axial force, and transmitting a signal to an axial pressure controlling system by an axial force sensor; a confining pressure loading system is used for pressurizing a cylinder which is arranged in the pressure chamber device; a confining pressure sensor is used for transmitting a signal to a confining pressure controlling system; the axial pressure controlling system and the confining pressure controlling system are used for controlling axial pressure and confining pressure to be constant for a long time in a process of a rheological test; in the process, creep deformation occurs on the test piece, so that instant fluctuations of the axial pressure and the confining pressure can be caused; the axial force sensor and the confining pressure sensor can transmit signals to the axial pressure controlling system and the confining pressure controlling system at any time, and systems can respectively send instructions to start a servo motor depending on fluctuations of feedback signals, so as to control a roller screw rod to move forwards or backwards by a servo means; a pressurizing cylinder piston rod is moved, and the axial pressure and the confining pressure which are outputted by the pressurizing cylinder are respectively regulated; the testing apparatus is high in controlling pressure stabilizing precision and is capable of automatically stabilizing pressure for a long time.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

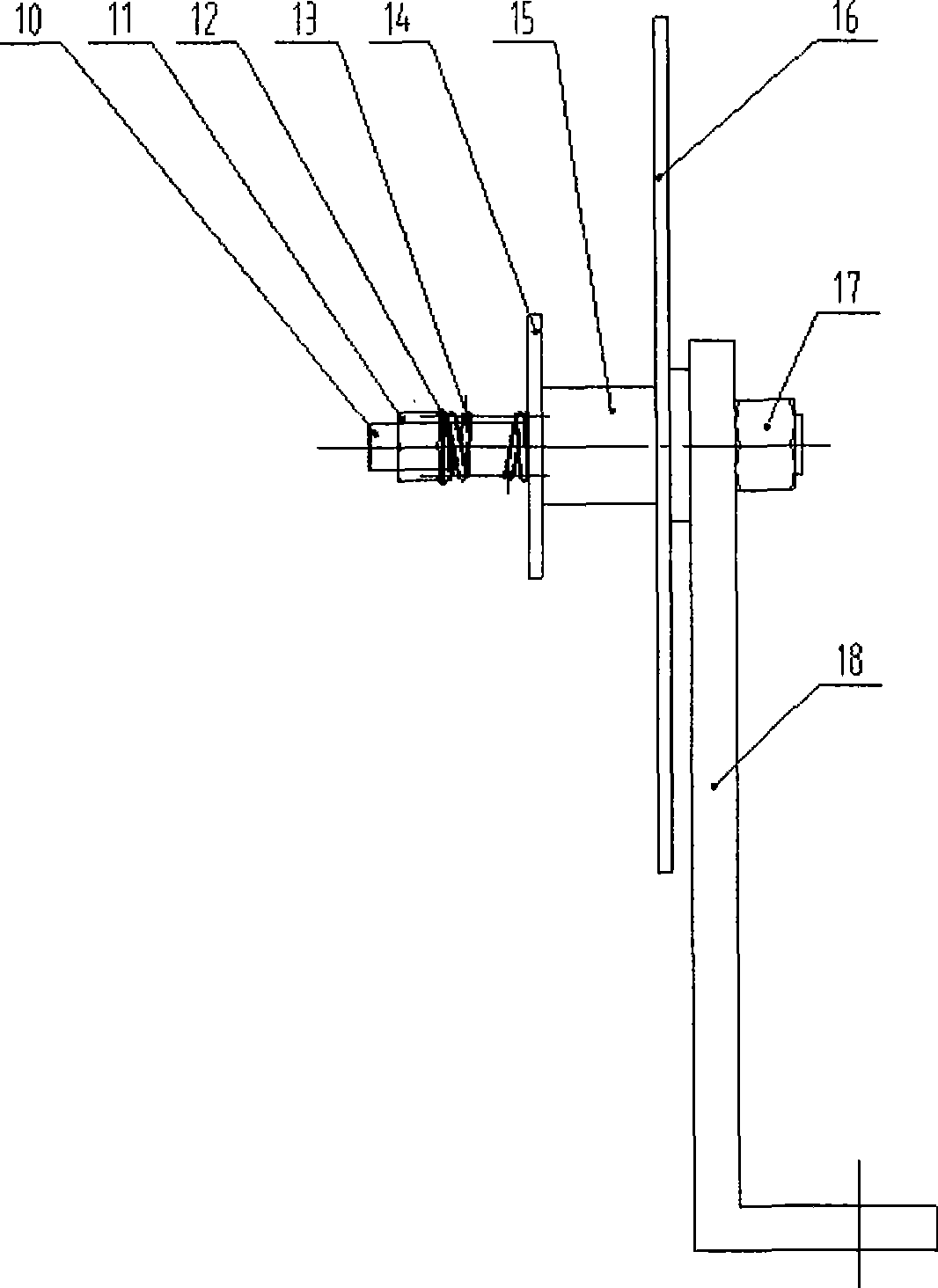

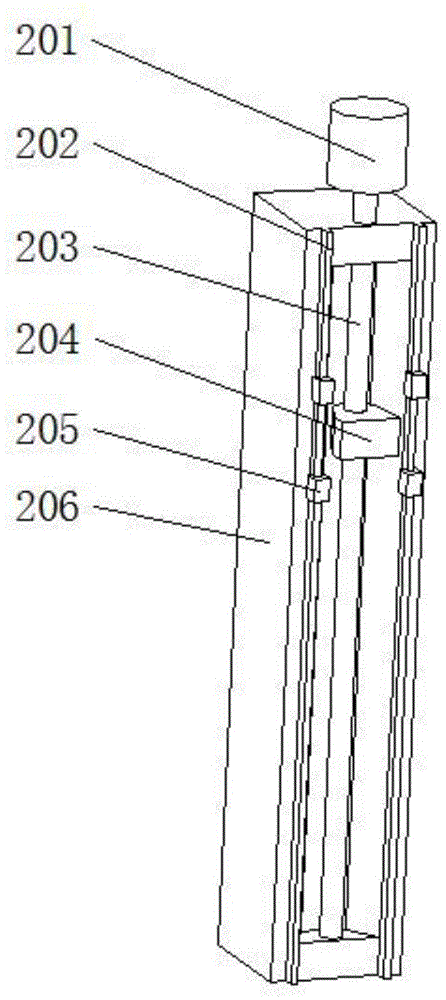

Eight-arm mechanical pusher

The invention discloses a mechanical eccentering arm with eight arms including a motor, a clutch, a roller threaded spindle, drive parts and an eccentering arm; the motor is connected to the roller threaded spindle by the clutch and is transferred to the drive parts by the roller threaded spindle after the circumference direction rotating displacement changes to the axial direction moving displacement, an elasticity thrust mechanism is arranged on the drive parts, the eccentering arm stretches out or folds up under the action of the elasticity thrust mechanism. The invention has advantages of simple and reasonable structure, convenient maintenance and high reliability and so on.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Planetary roller screw

The invention provides a planetary roller screw which is simple and compact in structure, large in bearing ability, difficult to wear, wide in screw pitch range, capable of realizing high-speed operation and high in reliability. The structure of the planetary roller screw comprises a screw, one or more rollers, two roller planetary retainers, a nut and two limiting spacer rings. The planetary roller screw is small in axial gap, high in transmission efficiency and capable of realizing high-speed transmission from a small screw pitch to an extra large helical pitch, not only can realize conversion of rotary motion and linear motion, but also can realize high-speed rotation of the screw and the rotary motion of the nut in a corresponding speed ratio.

Owner:扬州众孚传动科技有限公司

Automatic clicker of cell diaphragm

The invention relates to an automatic gouging machine for a battery diaphragm, which is characterized by comprising an unreeling mechanism, a paper feeding mechanism, a punching mechanism, a guide mechanism, a reeling mechanism and a PLC control system which are sequentially fastened on a large base plate according to the process order; the unreeling mechanism comprises an unreeling shaft and an unreeling bracket; the paper feeding mechanism comprises a suspended sliding type adjusting mechanism and a roller screw-in structure; the punching mechanism comprises a gas cylinder bracket mechanism and a die bracket mechanism which adopt the modular design; the guide mechanism mainly comprises a guide roller bracket and a guide roller; and the reeling mechanism mainly comprises a friction adjusting mechanism, a winding core, a speed reducing motor, a reeling bracket and a reeling shaft. The gouging machine can adapt to the production requirements of button battery diaphragm with a plurality of specifications, and has the characteristics of simple structure, high efficiency and low cost.

Owner:HEBEI UNIV OF TECH

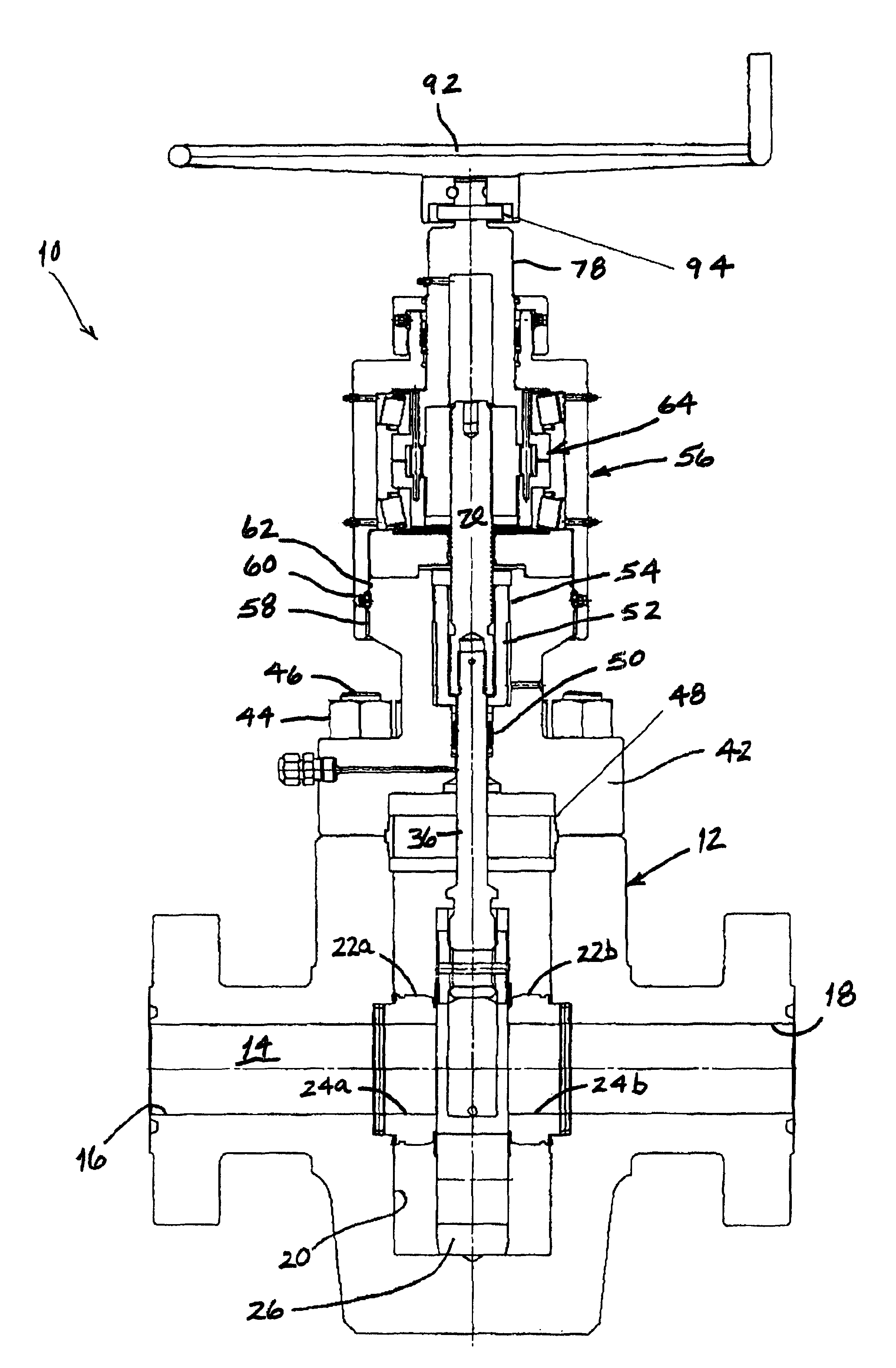

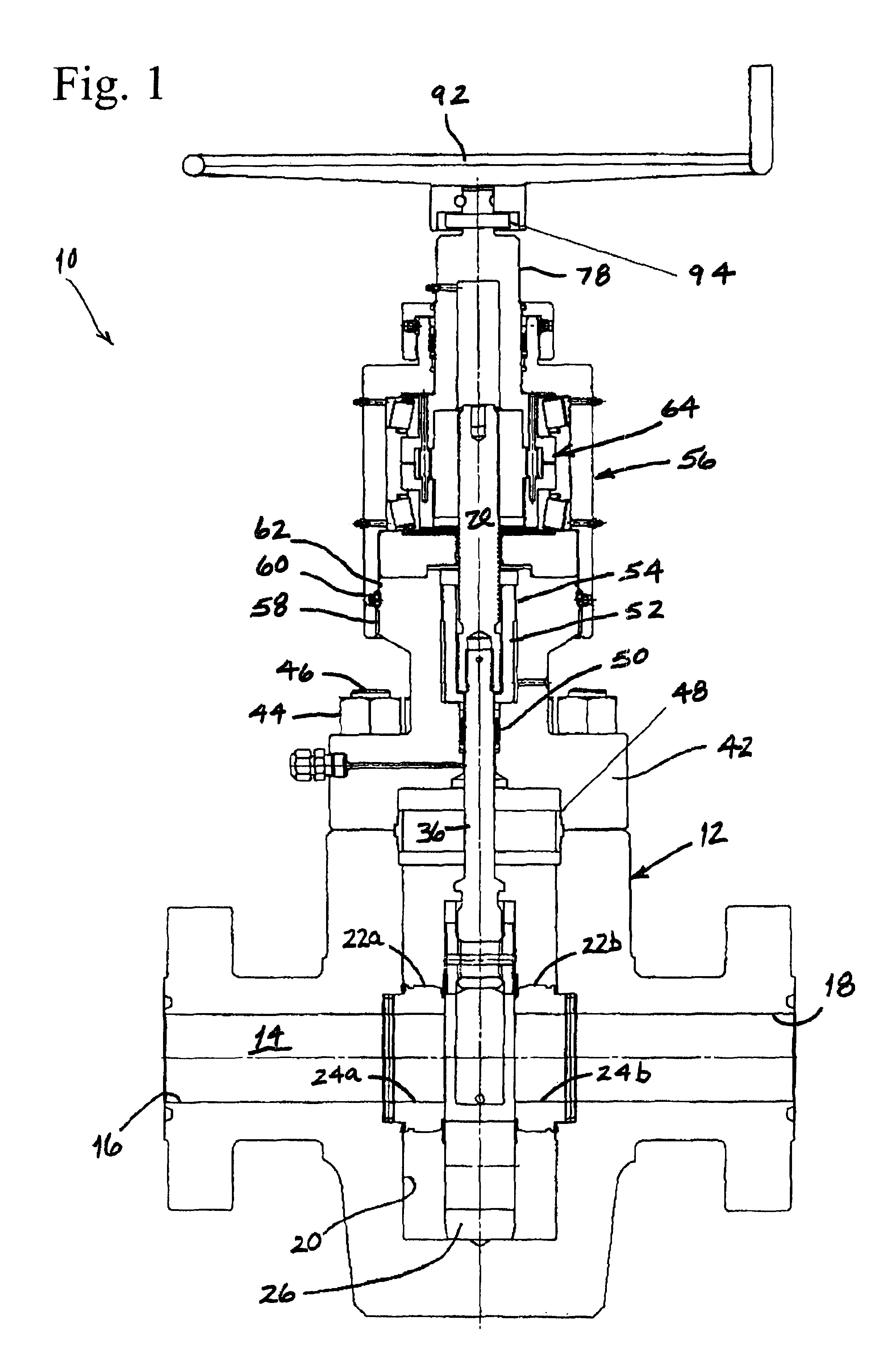

Reduced torque gate valve with roller screw

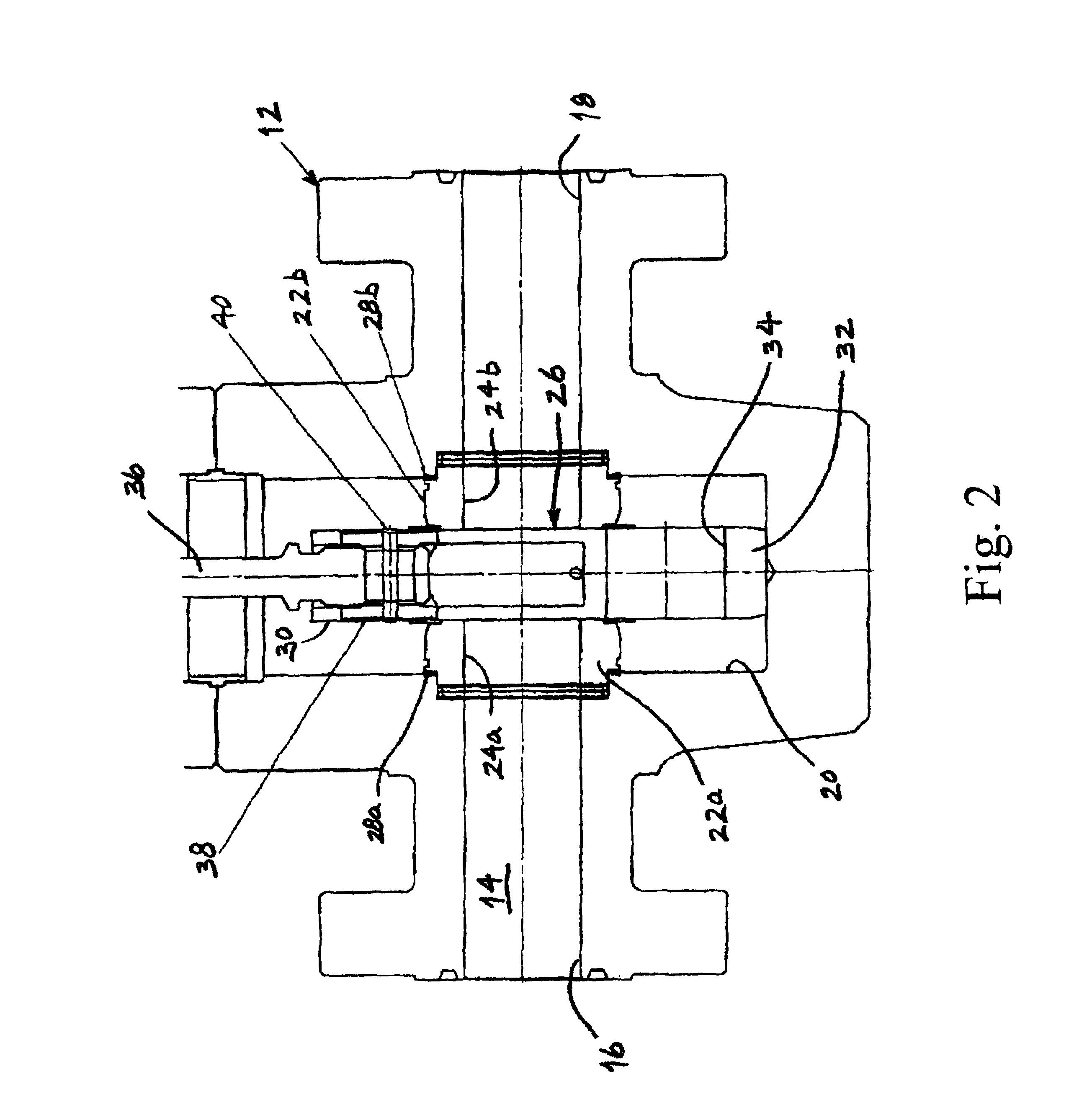

InactiveUS6918574B2Low gateGrow fastOperating means/releasing devices for valvesSlide valveRoller screwValve stem

A gate valve is disclosed which comprises a valve body which includes a flow bore that extends completely therethrough and a gate cavity that extends partially therethrough and intersects the flow bore, a bonnet which is connected to the valve body over the gate cavity, a gate which is disposed in the gate cavity across the flow bore and includes a transverse opening that extends completely therethrough, a valve stem which includes a first portion that is connected to the gate and a second portion that extends through the gate cavity, a handwheel, and a roller screw assembly which is connected between the handwheel and the second portion of the valve stem and which converts rotation of the handwheel into translation of the valve stem. In this manner, translation of the valve stem raises or lowers the gate to bring the opening into or out of alignment with the flow bore to either open or close the gate valve, respectively.

Owner:FMC TECH INC

Portable electromechanical tool

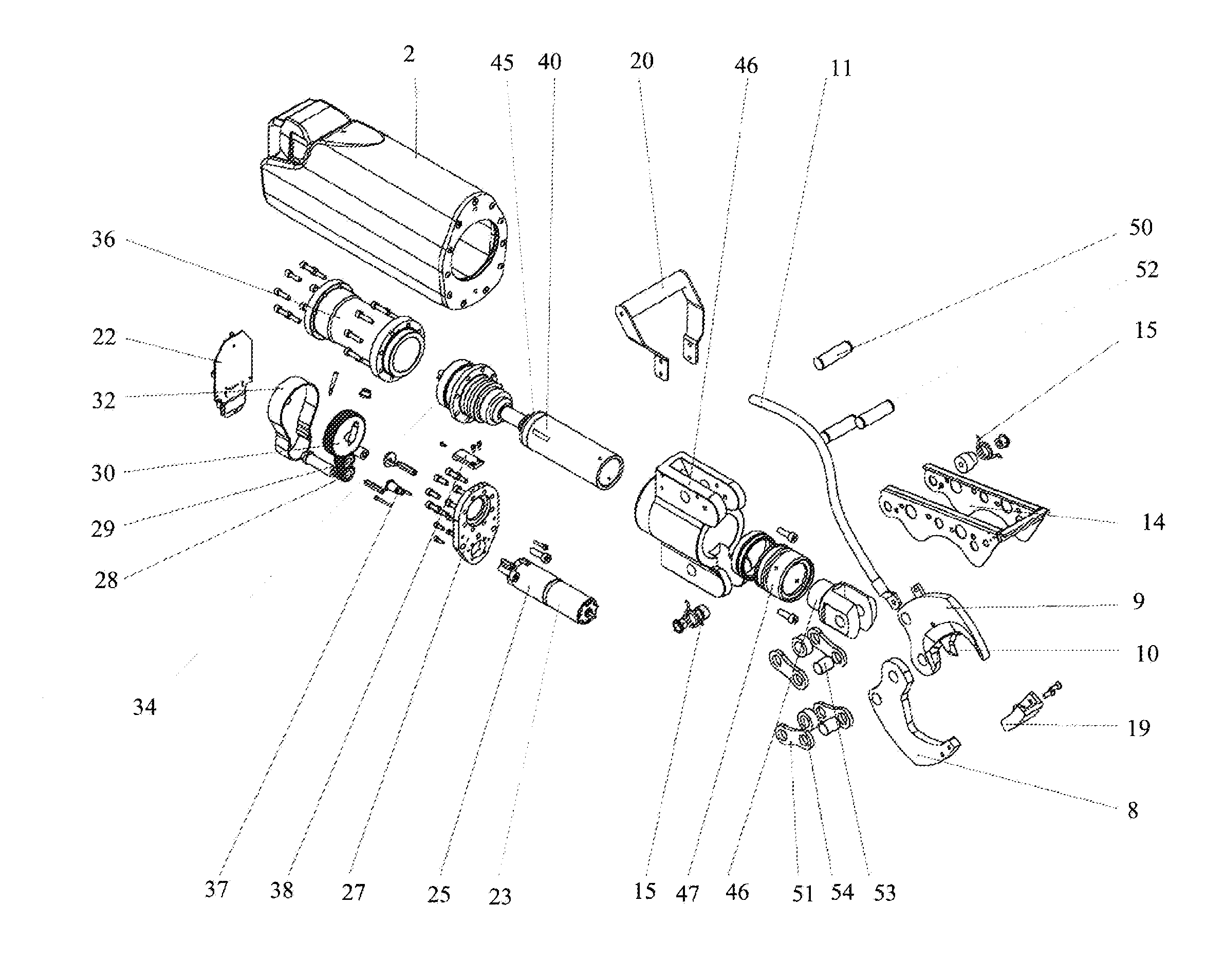

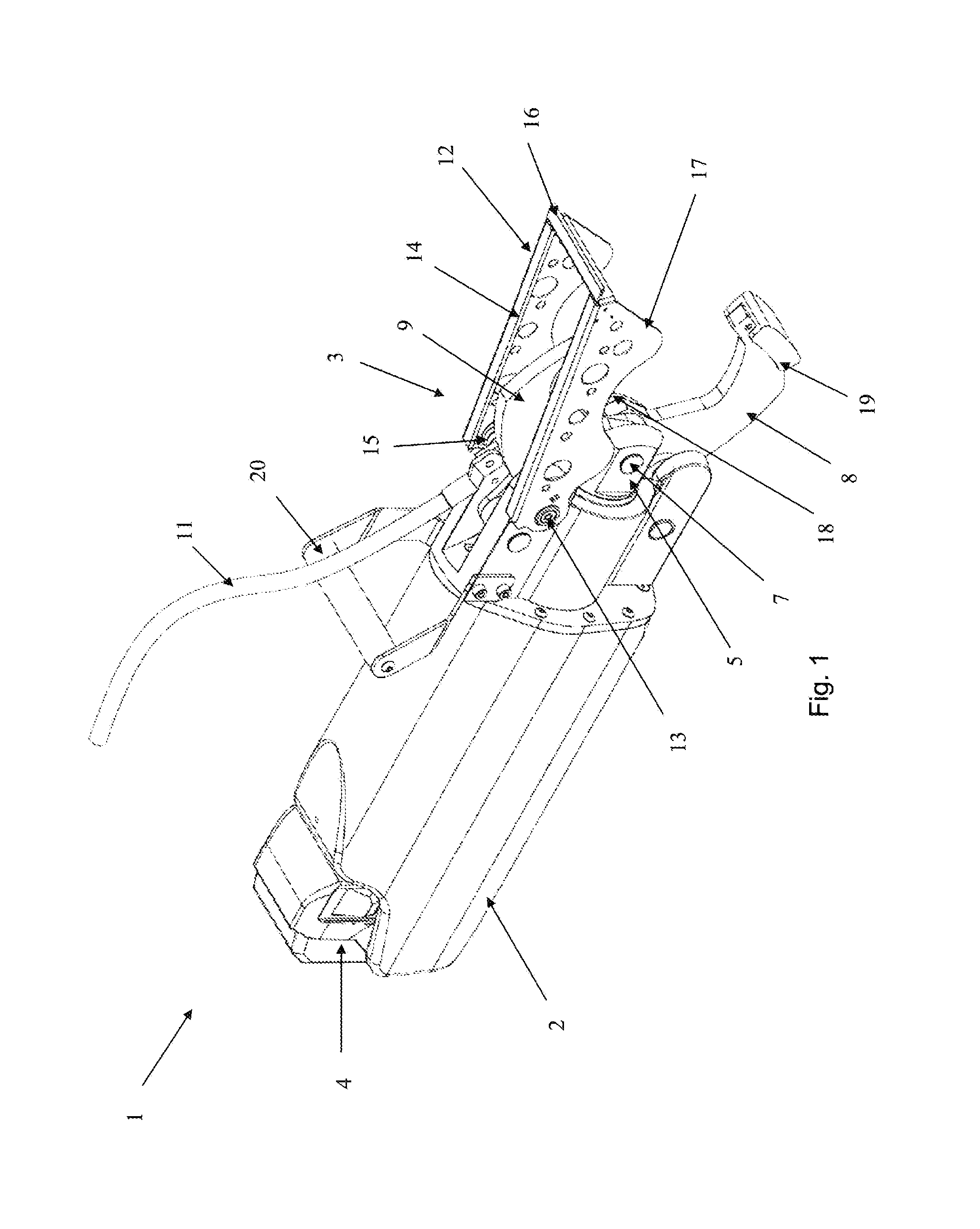

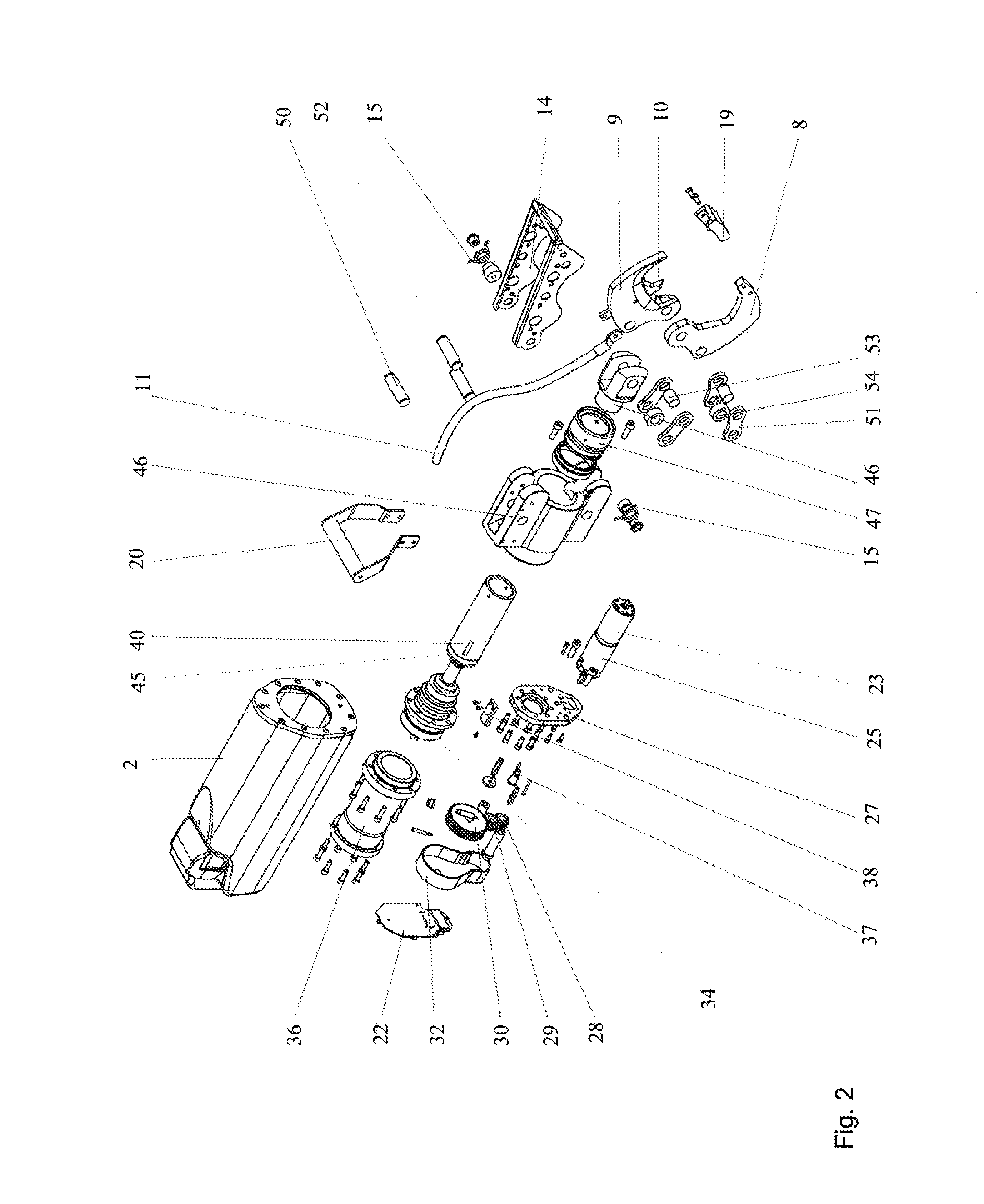

InactiveUS20140157522A1Small sizeImprove tool lifeApparatus for cutting/splicing cablesDrilling rodsRoller screwEngineering

Portable electromechanical tool comprising a unit (2) enclosing a continuous current electric motor (23) powered by a storage battery (4), a mechanical reduction gear (25) driven by the output shaft of said motor, which activates a working head (3) by means of a device (40) for converting the rotary motion of the motor (23) into a longitudinal translation movement, which is transmitted to said working head (3). According to the invention, said converting device (40) comprises a planetary roller screw, said screw comprising a threaded part (41), which is driven in rotation by said reduction gear to transmit motion via planetary rollers (43) to a threaded nut (42) that drives a mobile part (5) of said working head (3) in translation.

Owner:MAGE APPL

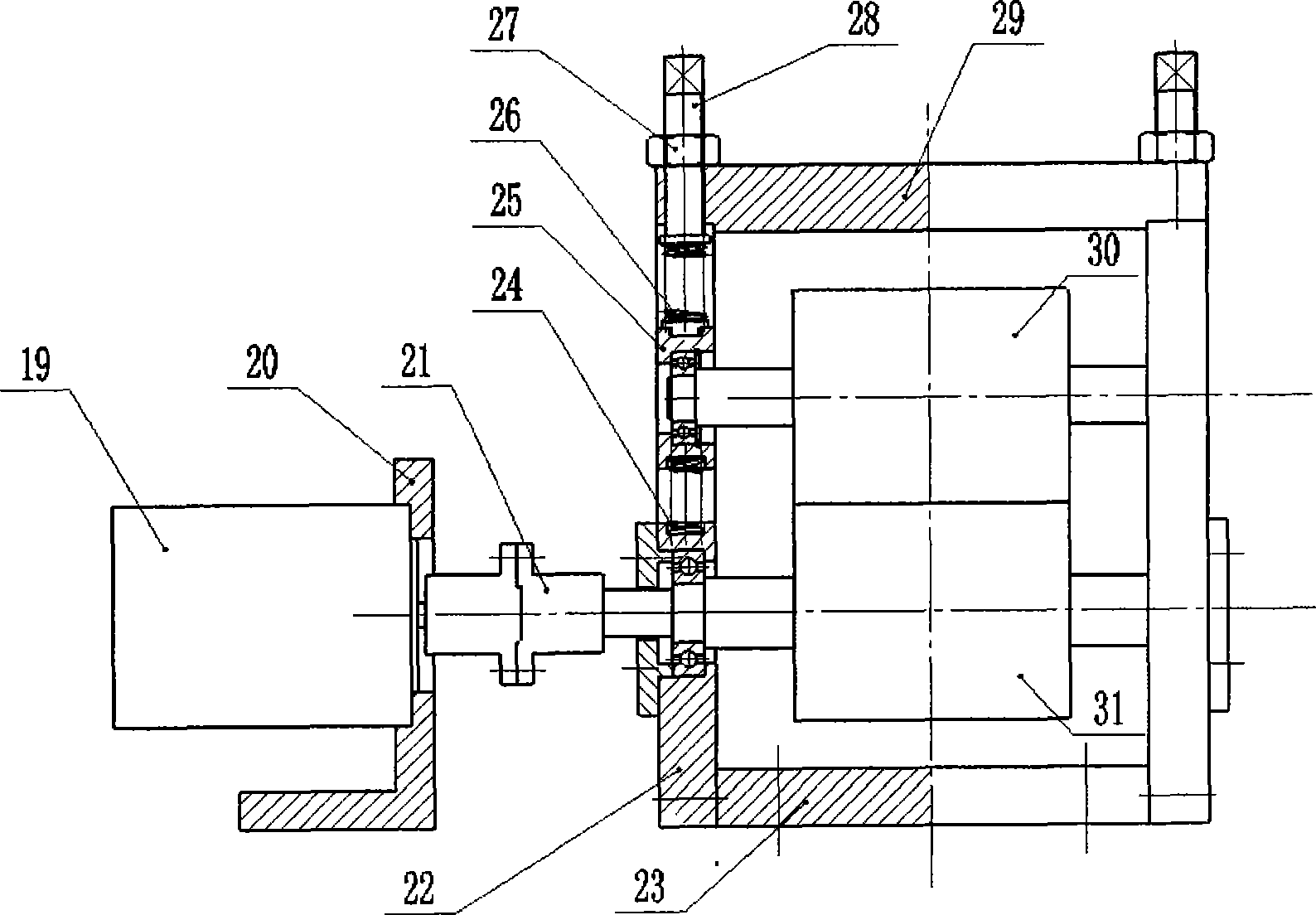

Two-way horizontal servo pressure machine for transmission of planet roller lead screw

ActiveCN103802343AReduced commutation frequencyExtend your lifeGearingPortable liftingLinear motionGear drive

The invention discloses a two-way horizontal servo pressure machine for transmission of a planet roller lead screw. Two servo motors simultaneously drive one worm gear through two worms, a planet roller lead screw device is embedded into the worm gear, the worm gear drives a planet roller lead screw nut to rotate, the nut converts rotation into linear motion of the lead screw through a roller, dies at the two ends are driven to perform two-way stamping, the horizontal type arrangement form is adopted, a driving device is installed in a machine body, the machine body is installed in the middle of the pressure machine, the dies are symmetrically arranged on the two sides of the machine body, the structure is greatly simplified, and the structure of the whole machine is compact; the stamping efficiency is improved, energy consumption is reduced, and the service life of the motors is prolonged; loads of each worm are reduced, power of each motor is reduced, and cost is reduced.

Owner:XI AN JIAOTONG UNIV

Steel pipe lifting and taking device

The invention discloses a steel pipe lifting and taking device. The steel pipe lifting and taking device comprises a base. A vertical arm is arranged on the base. A supporting plate is arranged at the upper end of the vertical arm. A sliding rail is arranged on the lower surface of the supporting plate. A rotary motor is arranged at the upper end of the vertical arm, and a roller screw is arranged at the rotation end of the rotary motor. The roller screw is sleeved with a movable box which can move in the length direction, and the upper end of the movable box is embedded in the sliding rail. A linear motor is arranged on the lower surface of the movable box. A supporting seat is arranged at the telescopic end of the linear motor and provided with a bi-directional air cylinder. A pair of piston rods of the bi-directional air cylinder are provided with vertical rods respectively, and the pair of vertical rods are provided with supporting claws. The vertical arm is provided with a control panel. The control panel is electrically connected with the rotary motor, the linear motor and the bi-directional air cylinder. The steel pipe lifting and taking device has the beneficial effects of being simple in structure and high in practicability.

Owner:刘洋

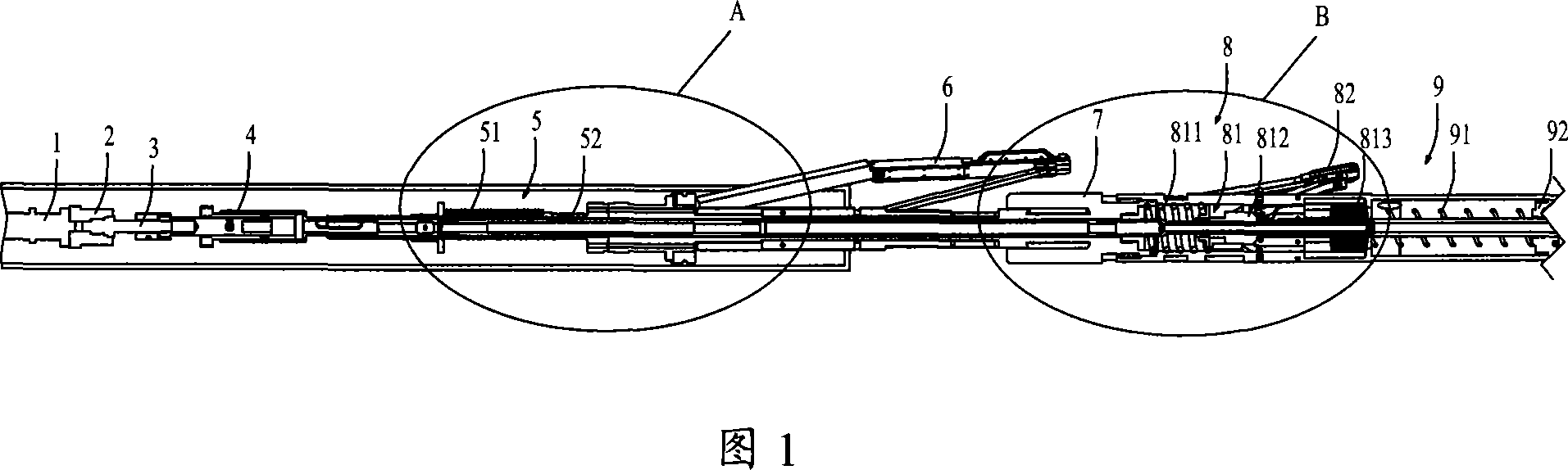

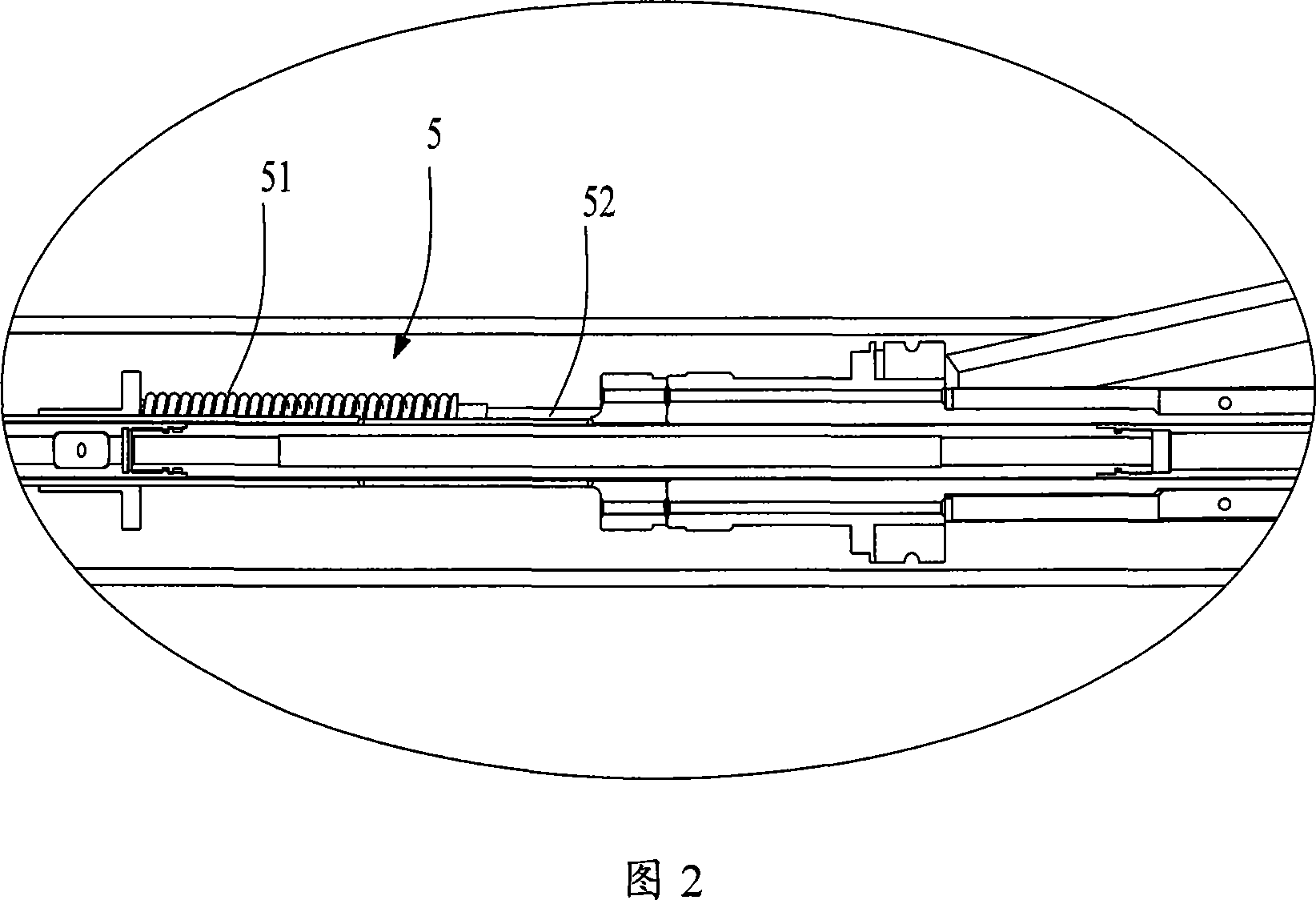

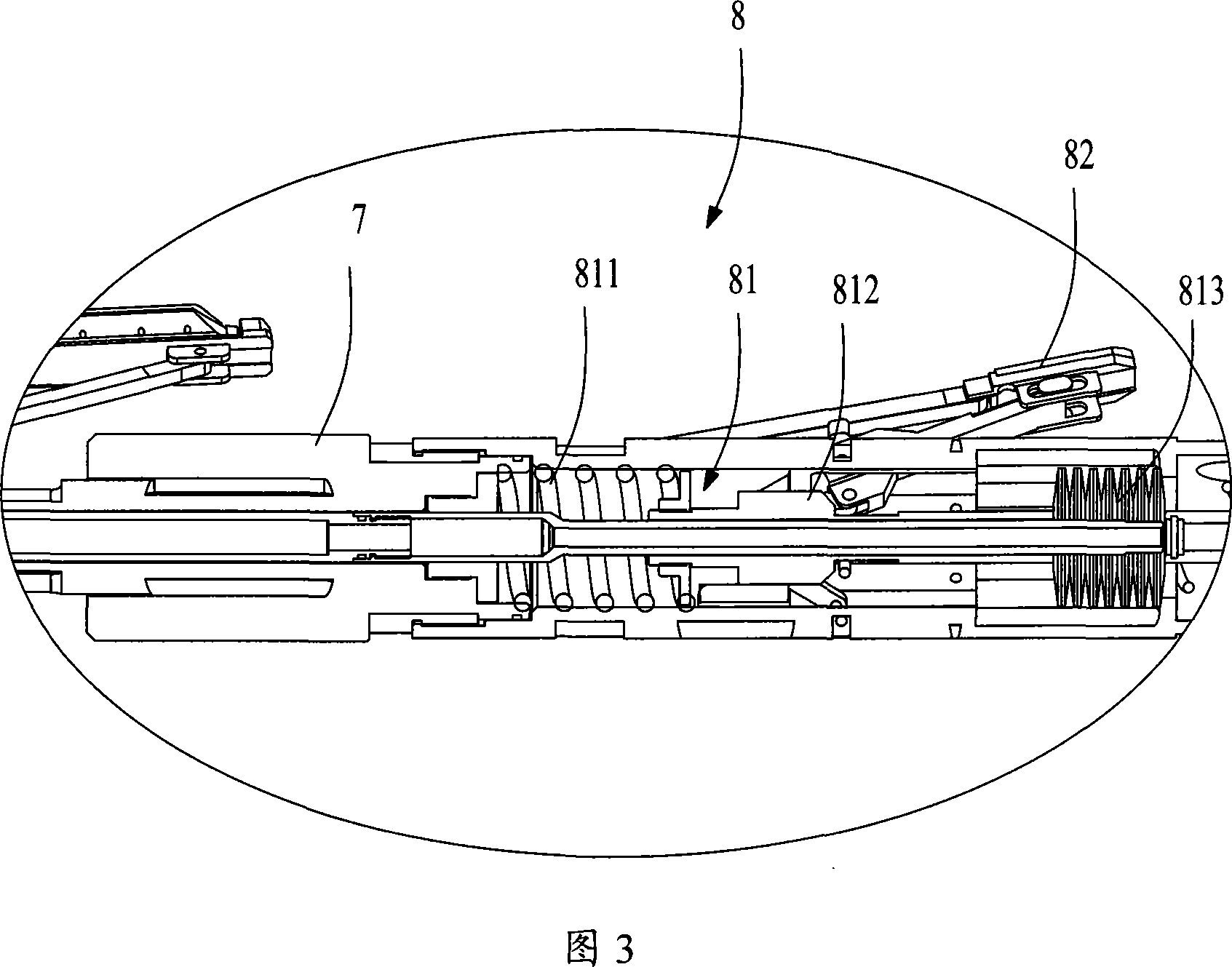

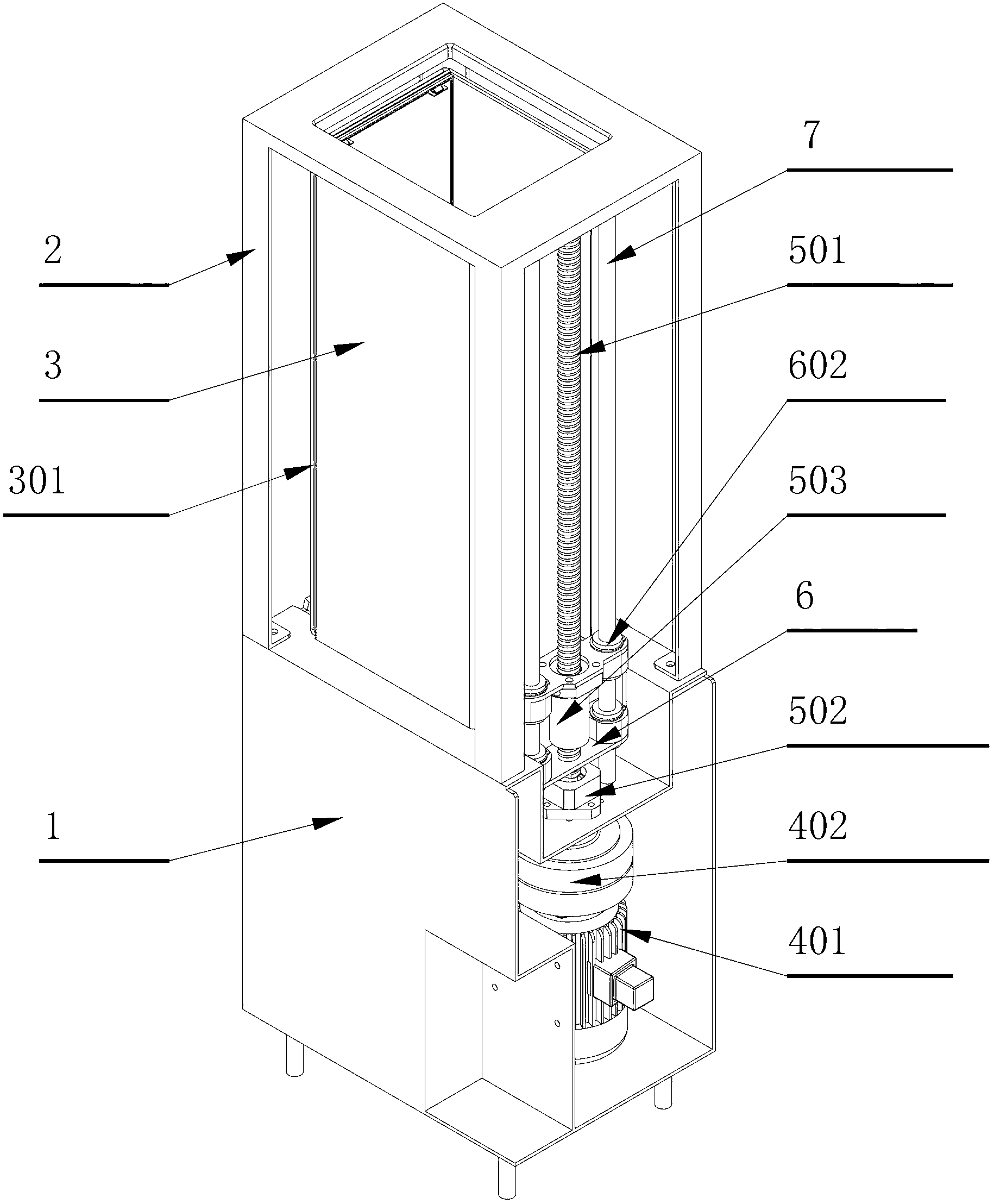

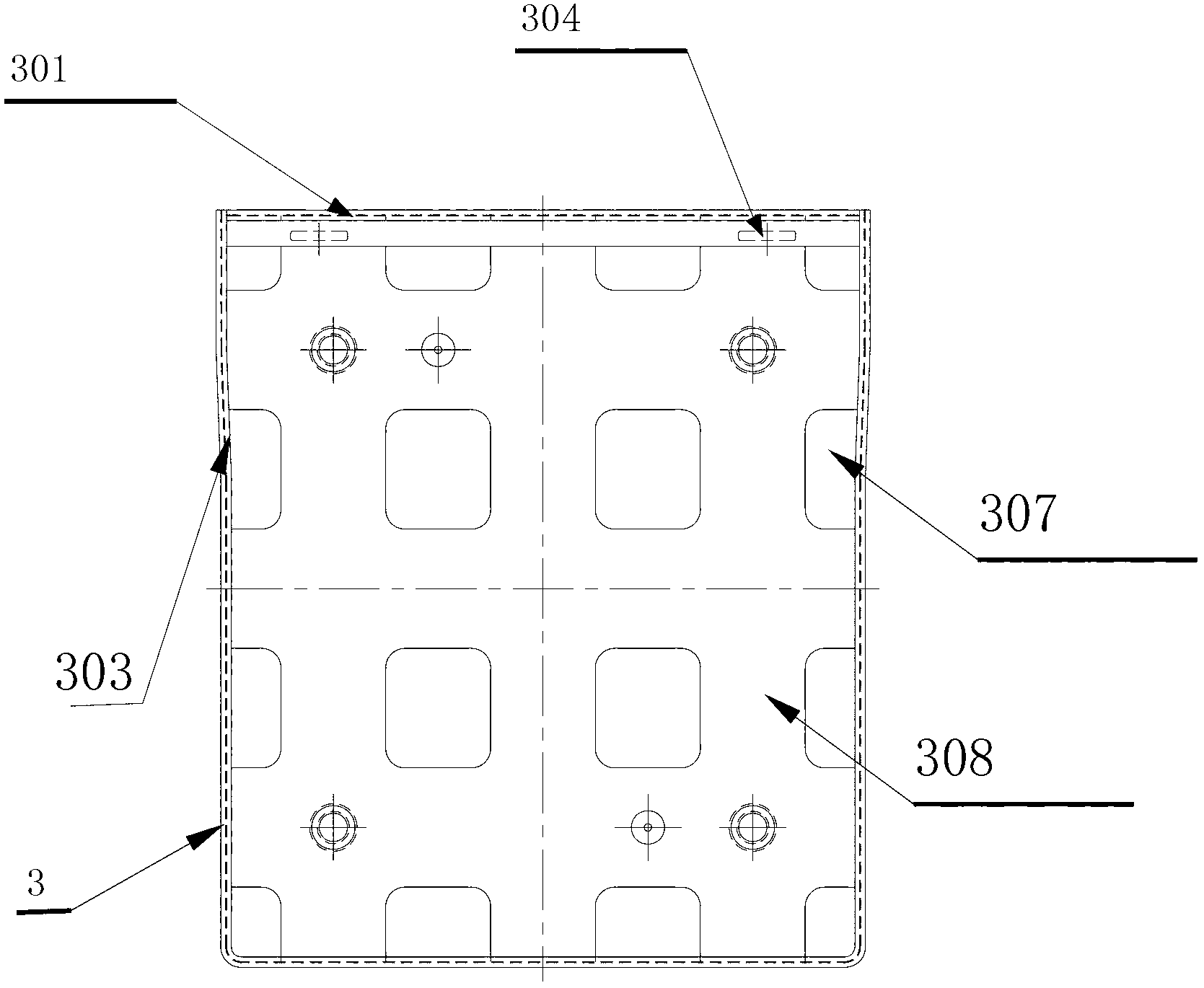

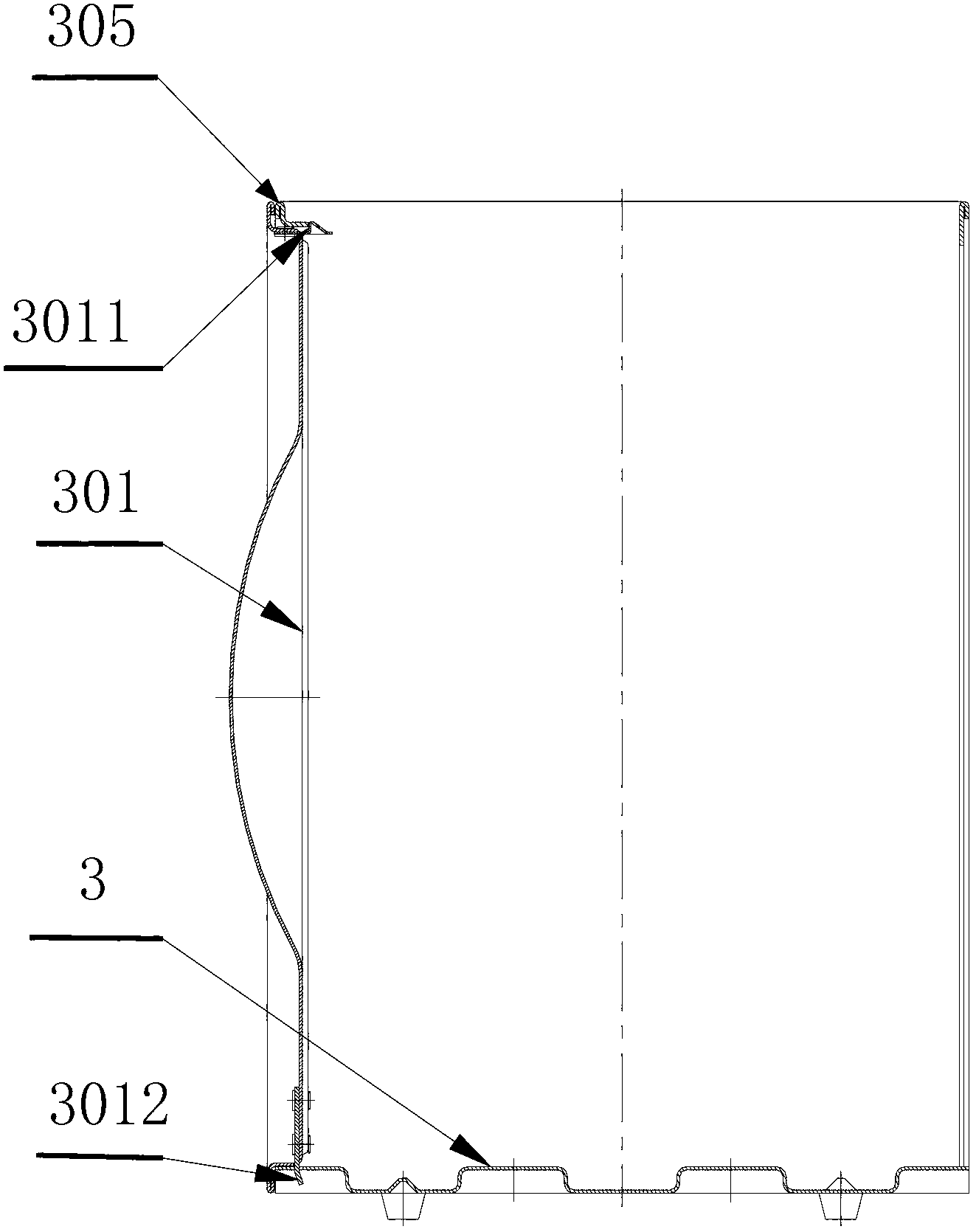

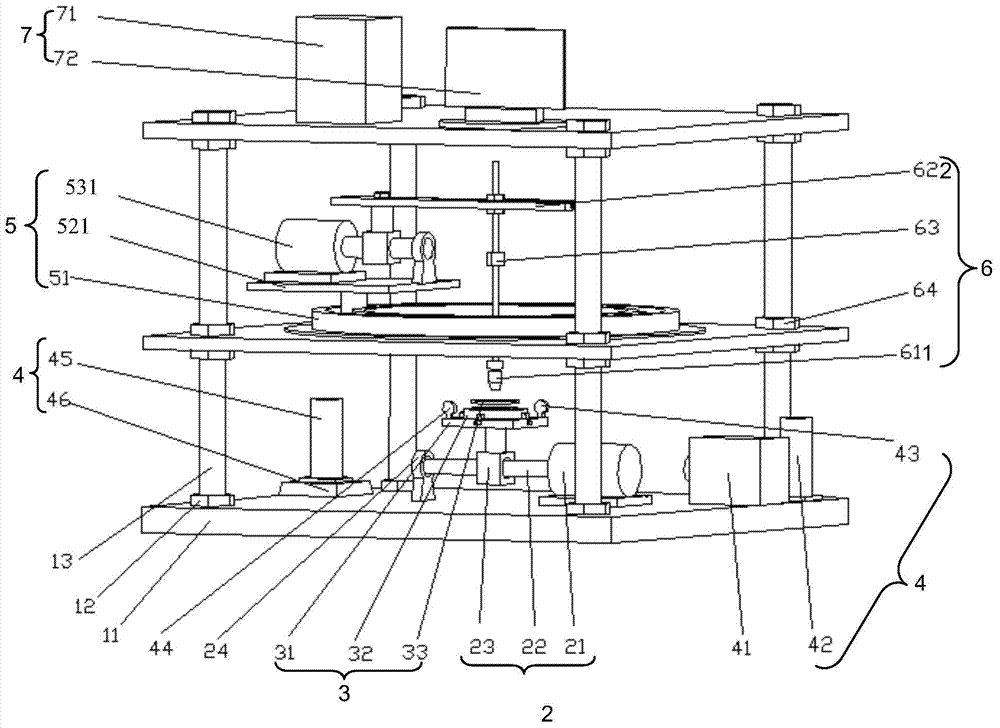

Automatic cartridge clip type feeding device

ActiveCN103010741AIncrease productivityLabor savingMetal working apparatusConveyor partsRoller screwCoupling

The invention discloses an automatic cartridge clip type feeding device, and relates to an automatic feeding device. The automatic cartridge clip type feeding device comprises a machine seat (1), a rack (2), a storage tank (3), a servo motor (401), a coulter (402), a roller screw rod (501), a screw rod sliding block (503), a screw rod support seat (502), a sliding support (6) and a guide shaft (7), wherein the rack (2) is fixed on the machine seat (1); the servo motor (401) is installed inside the machine seat (1); the servo motor (401) is connected with the screw rod (501) through the coupler (402); the other end of the rod (501) is fixed on the top part of the rack (2) through the screw rod support seat (502); the sliding support (6) is fixedly connected with the screw rod sliding block (503); one end of the guide shaft (7) is fixed on the top part of the rack (2); the other end of the guide shaft (7) is fixed on the machine seat (1); and a guide mechanism (602) and support bars (601) which are matched with the guide shaft (7) are fixedly assembled on the sliding support (6). The automatic cartridge clip type feeding device can be used in match with various automatic assembling machines, automatic silk-screen machines and part machining machines, and compared with manual feeding, the automatic cartridge clip type feeding device increases the production efficiency for more than two times and reduces more than half of the manual operation.

Owner:深圳市北鼎晶辉科技有限公司

In-situ observation testing device for simulating micro oil displacing interface

The invention discloses an in-situ observation testing device for simulating a micro oil displacing interface. The in-situ observation testing device comprises a base, a runner test sample movement component, a runner test sample component, an oil displacing component, a microscope movement component, a microscope component and a control acquisition component, wherein the runner test sample movement component comprises a servo motor, a first roller screw rod and a first screw rod screw nut; the runner test sample component comprises a support platform, a temperature control device and a test sample group; the oil displacing component comprises a peristaltic pump, a displacement liquid reagent bottle, inlet pressure acquisition equipment, outlet pressure acquisition equipment, volume measuring equipment and a weighing balance; the microscope component comprises a microscope lens, a microscope support component and an image acquisition device; the control acquisition component is used for acquiring image data and for acquiring and analyzing pressure, volume and mass data, and for controlling the movement of the servo motor and the flow of the peristaltic pump. By adopting the in-situ observation testing device, the interaction of micro surfaces and interfaces among different displacement liquids, crude oil and runners in the crude oil exploration process can be simulated, and study on oil-displacement mechanisms can be promoted.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hybrid fan drive with CVT and electric motor

InactiveUS20120328454A1Improve fuel economyReduce undesirable vehicle emissionCoolant flow controlGearingRoller screwAccessory drive

A hybrid accessory drive system having two operational modes, a mechanical mode and an electric mode. The accessory is typically a cooling fan. A continuously variable mechanical belt drive mechanism drives the accessory as one mode of operation. An electric motor along with a planetary roller screw mechanism which converts rotary motion to axial motion is used to change the sheave position and thus the drive ratio. Upon disengagement of the mechanical drive mode, the electric motor can be used to drive the accessory in a second mode.

Owner:BORGWARNER INC

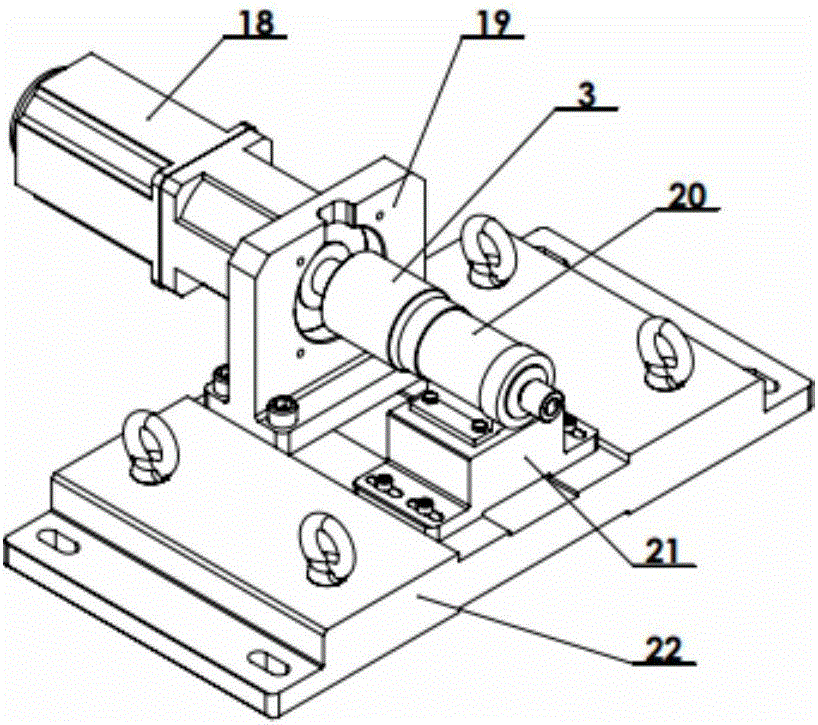

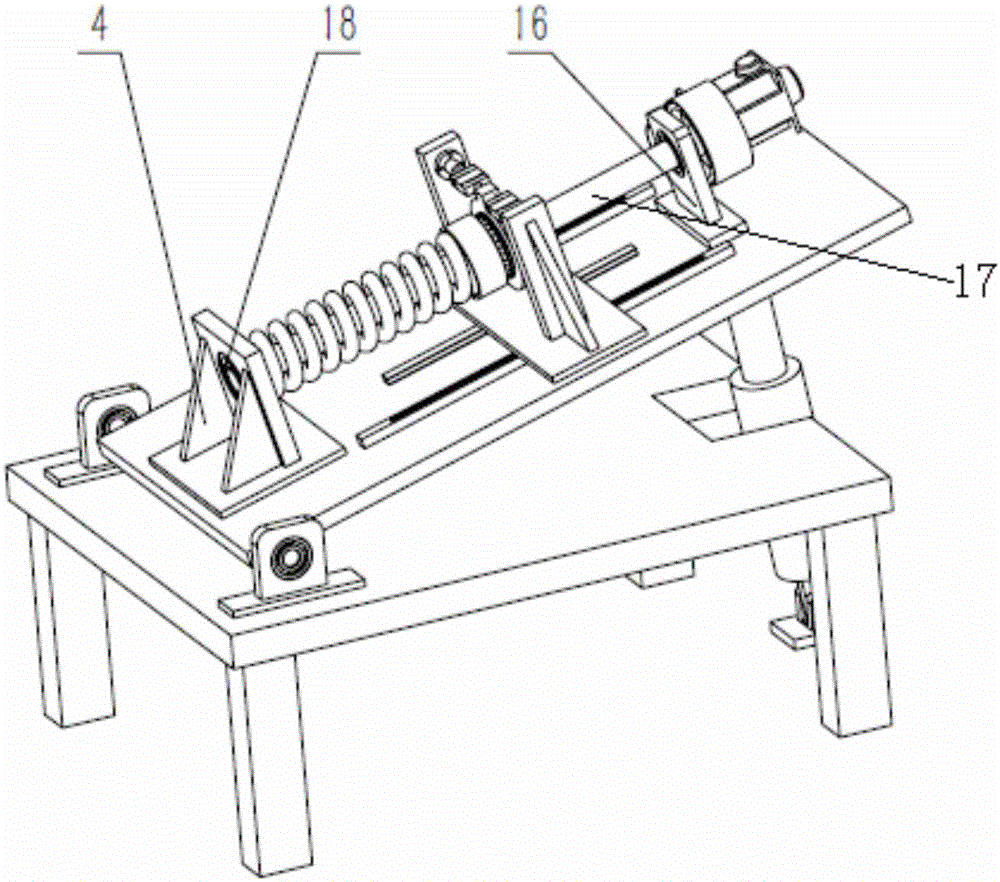

Planetary roller screw pair friction torque measurement device

InactiveCN105954017ARealize measurementSimple structureMachine part testingLinear motionTension compression

The invention discloses a planetary roller screw pair friction torque measurement device. Friction torque measurement is realized by a base plate, a jack and a tension-compression sensor together. A planetary roller screw pair is loaded by a spring. The tilt angle of the base plate is adjusted by the jack to realize friction torque measurement. A support base is disposed on a guide rail, and slides front and back along the guide rail. The tension-compression sensor is installed between a nut and the support base, one end of the tension-compression sensor is connected with the support base, the other end is connected with the nut, and the tension-compression sensor is used to measure and calculate the comprehensive friction. When a screw rotates, the screw drives the nut to do linear motion, and the tension-compression sensor is connected with the nut and limits the rotation of the nut, and measures the size of friction. The spring is embedded into a retainer cup, and a thrust ball bearing is installed between the retainer cup and the nut, which can avoid the situation in which the spring and the nut directly contact each other to generate fiction to affect the final measurement result. The measurement device is simple in structure, highly universal, and safe and reliable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Reciprocating compressor

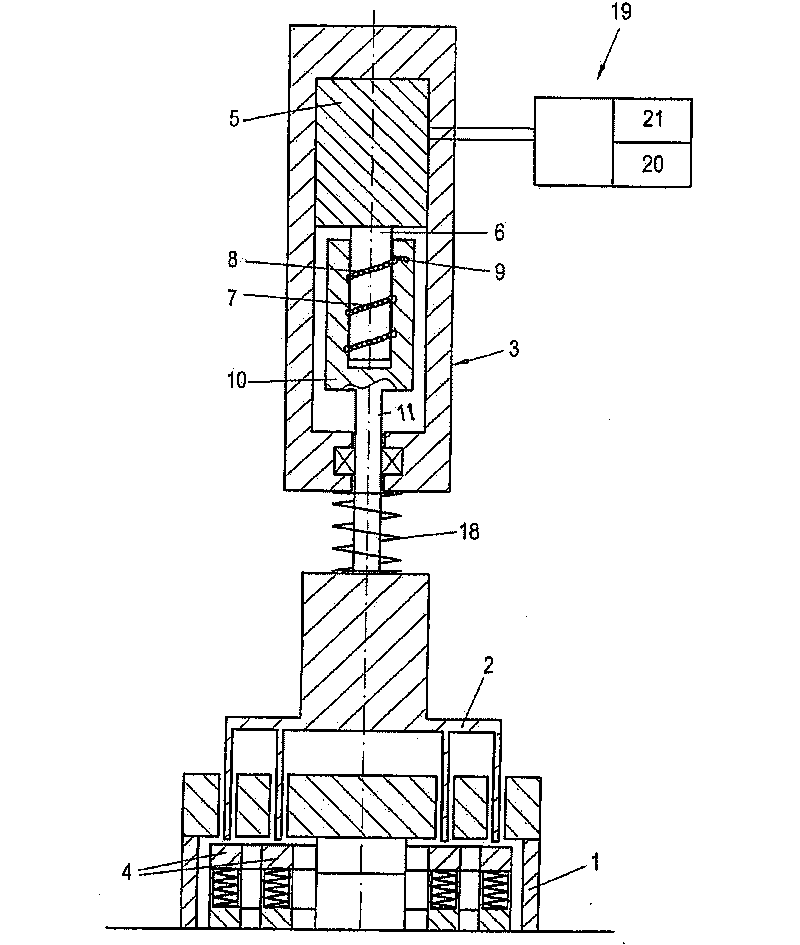

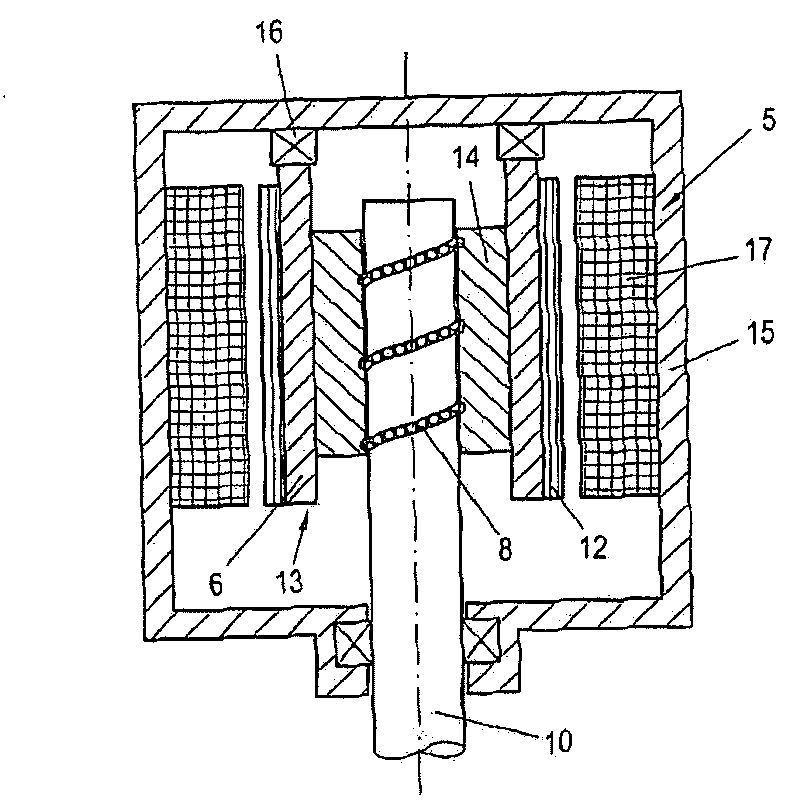

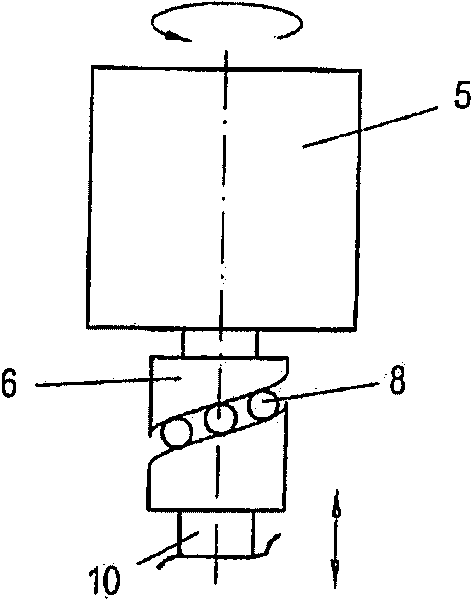

InactiveCN101725505AHigh actuation forceHigh dynamic performancePositive displacement pump componentsPump controlRoller screwElectric machine

The present invention discloses a reciprocating compressor which is provided with an output speed controller, wherein, an actuator (3) which is used for causing a valve unloader (2) on a suction valve (1) to keep open comprises an electric motor (5) used as a driving device. A driven component (6) of the electric motor (5), a nonrotatable lifting component (10) of the valve unloader (2) and a rolling component (8) provided therebetween are combined to a roller screw driver. Thus the actuator (3) which has the advantages of smaller dimension, capacity for precisely adjusting, higher actuating force and higher dynamic moving performance is realized.

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

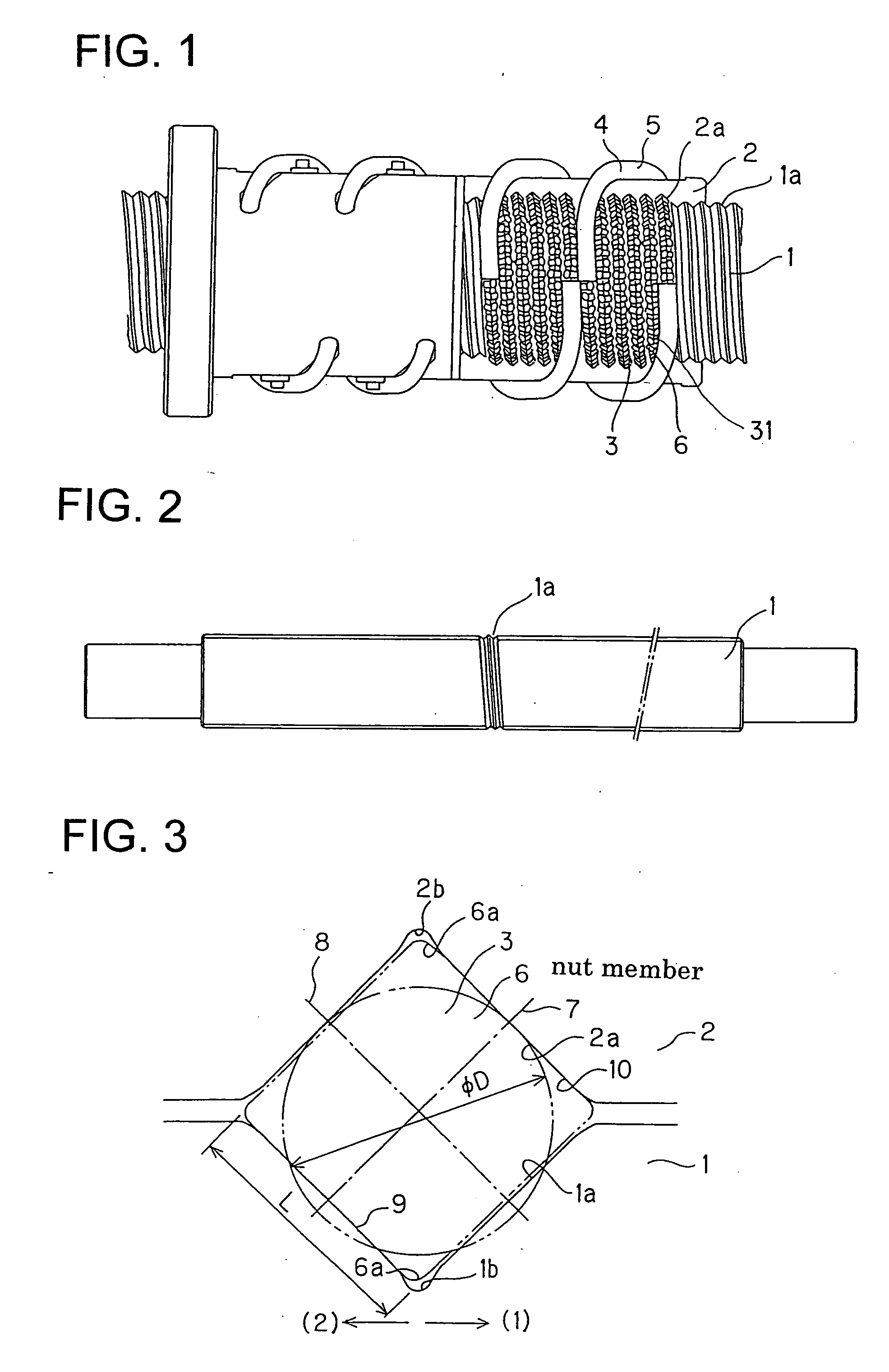

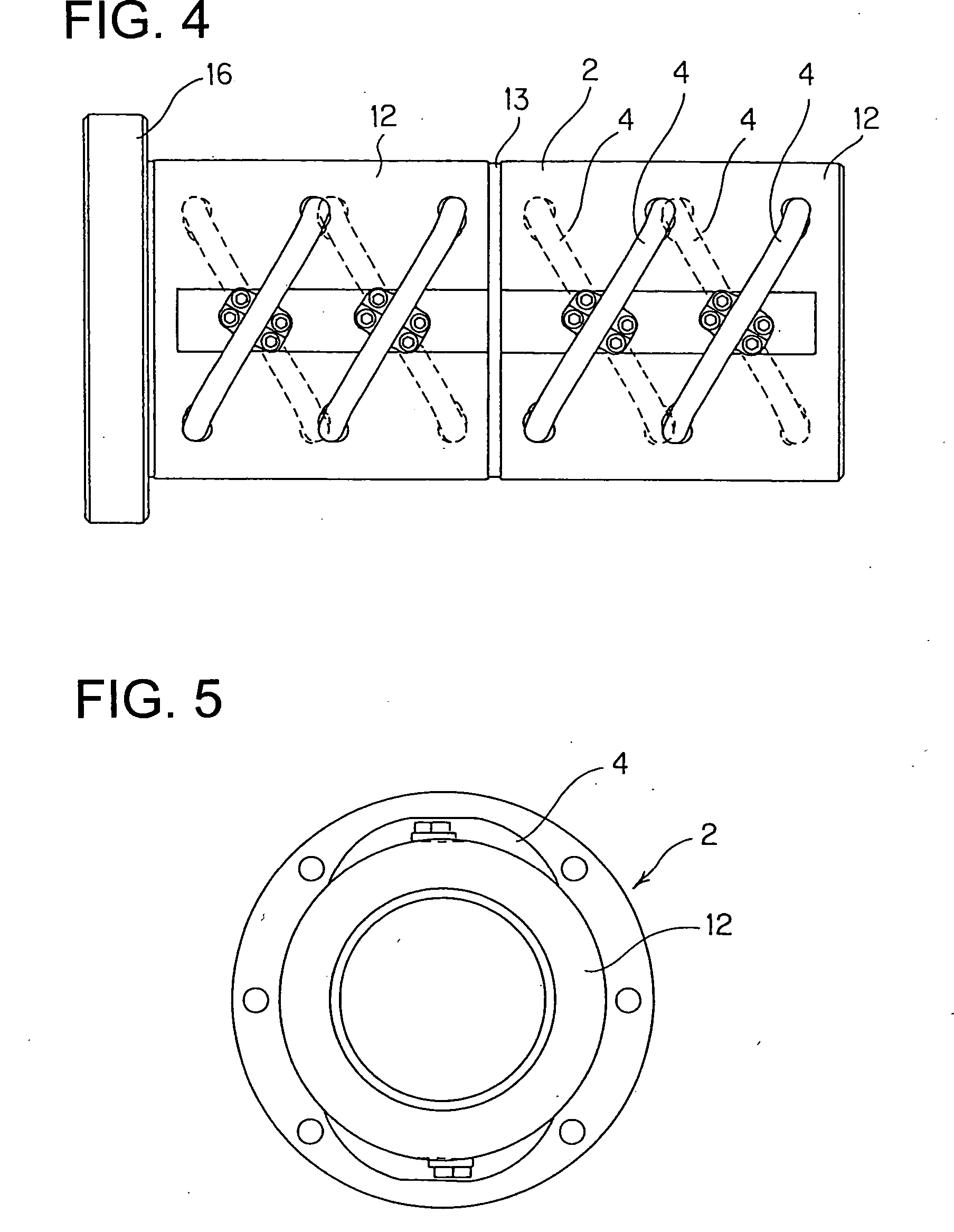

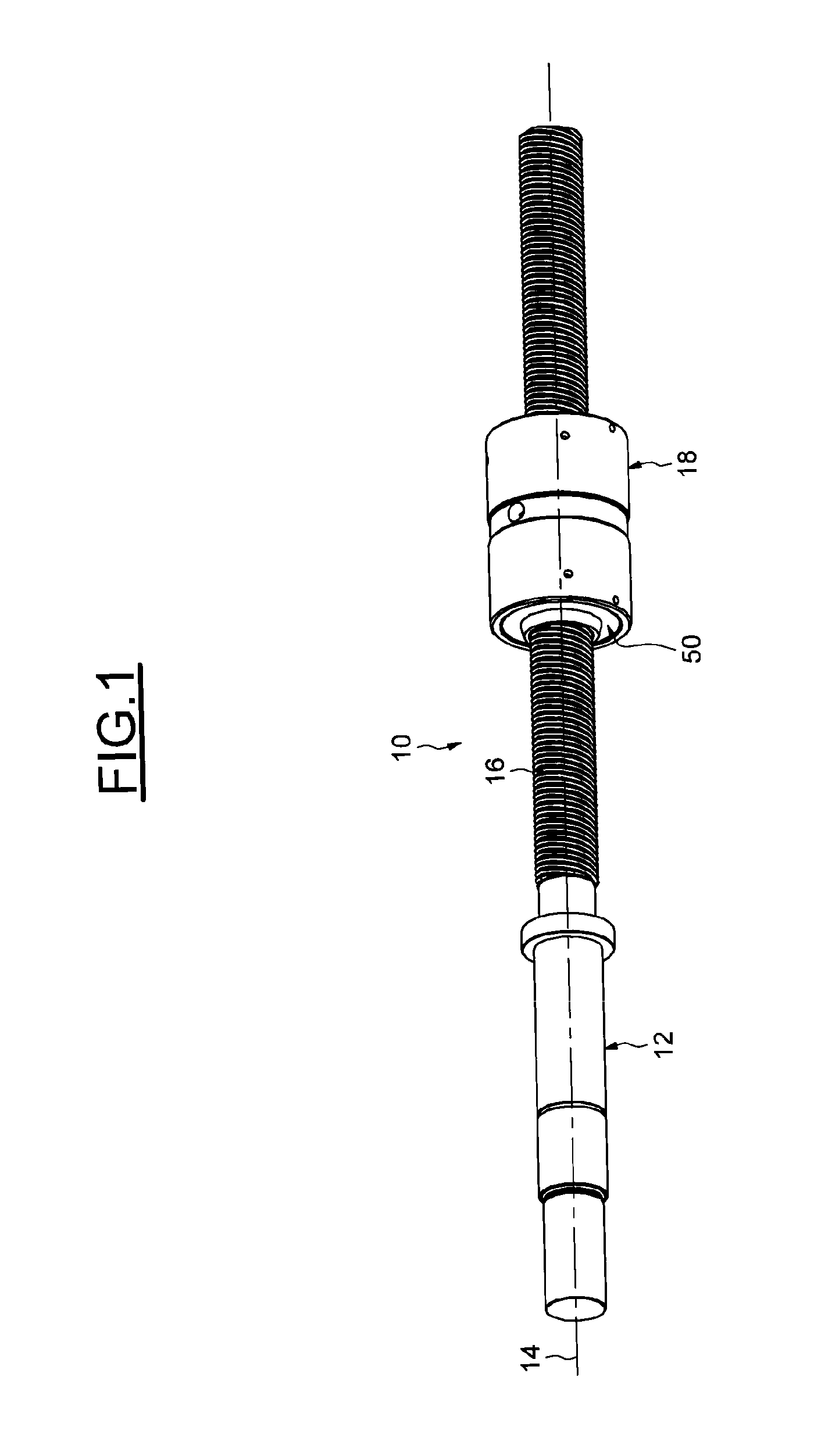

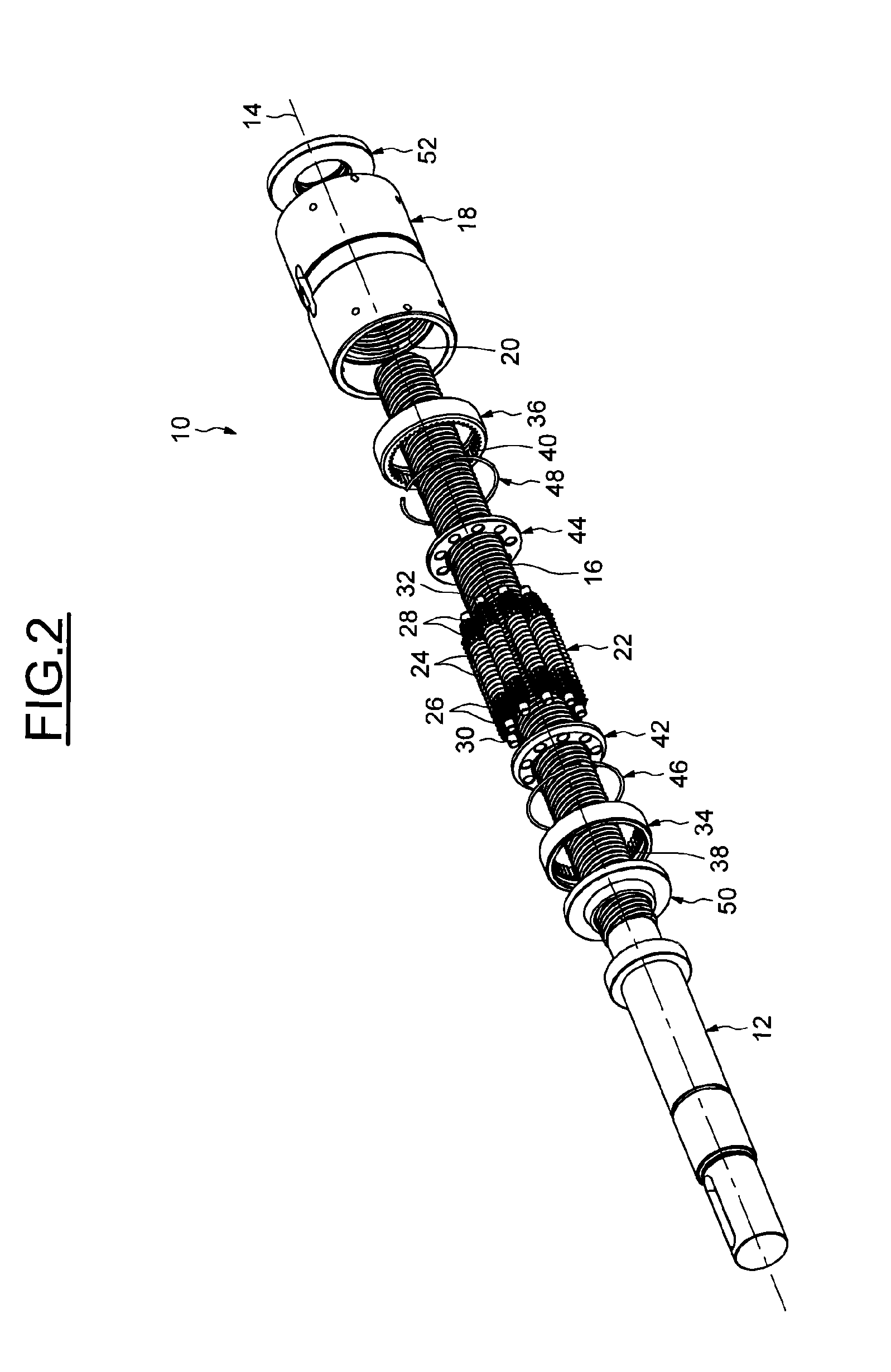

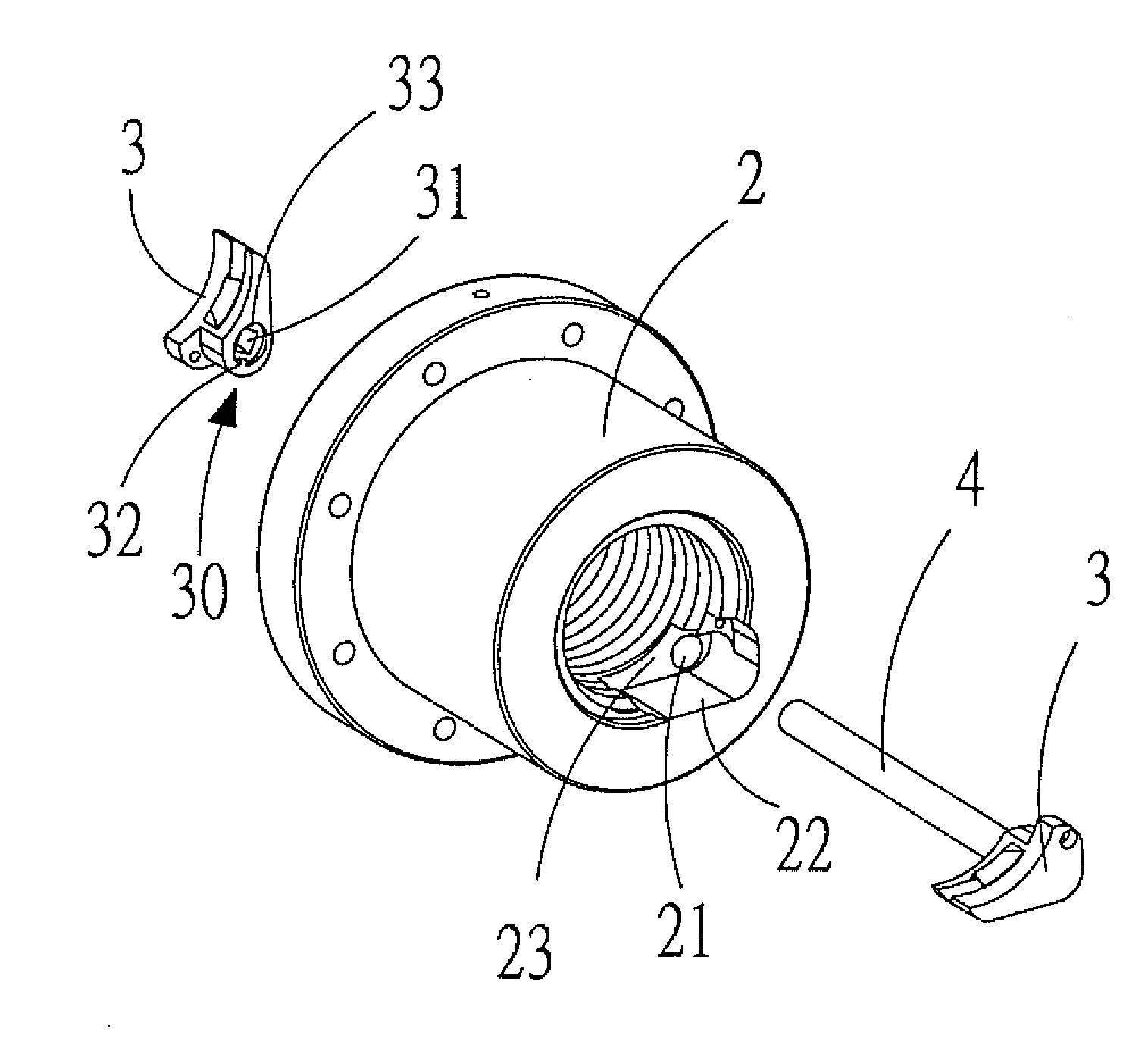

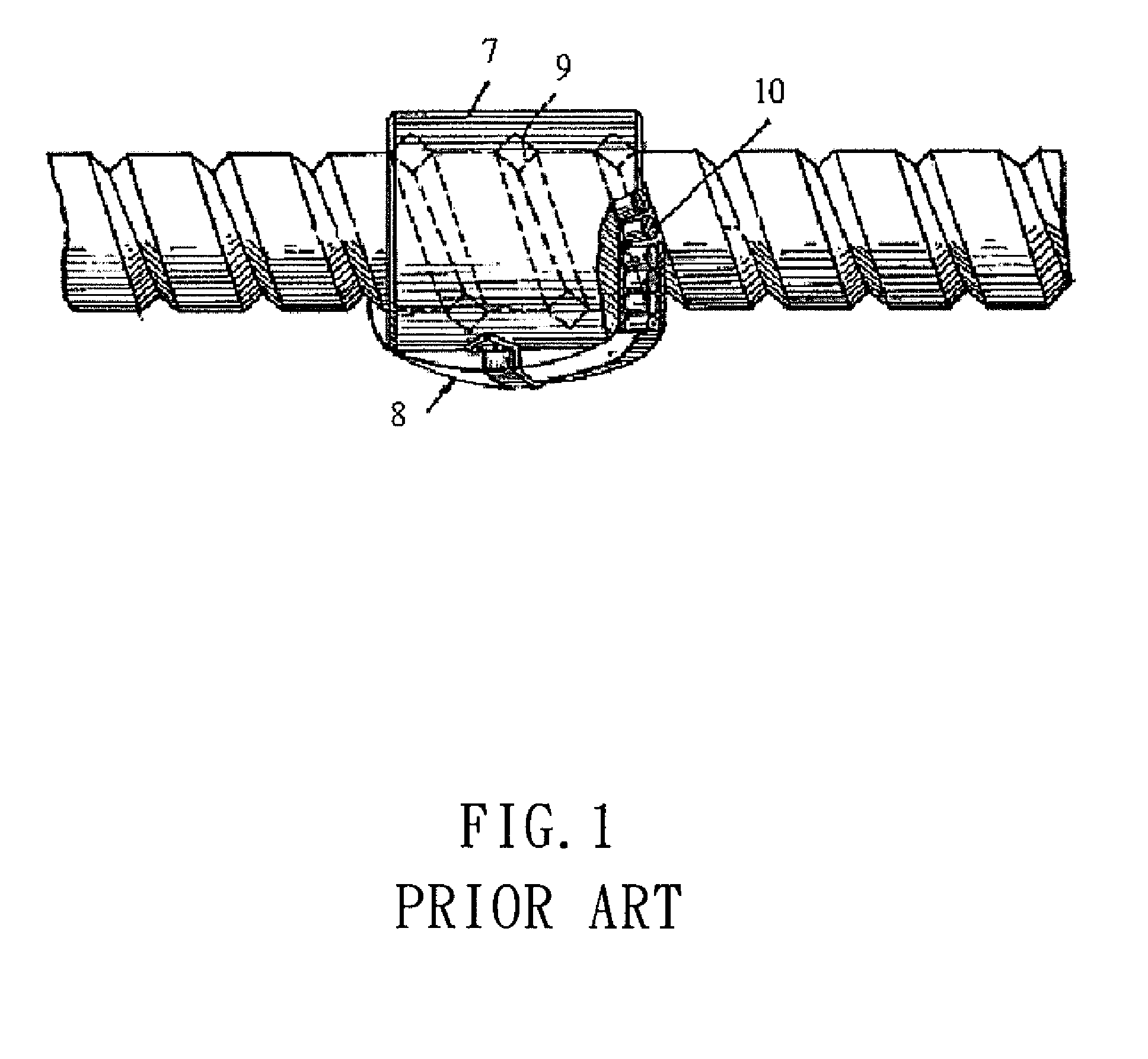

Roller screw

InactiveUS20070028712A1Smooth circulationAvoid skewToothed gearingsPortable liftingRoller screwEngineering

A roller screw includes: a screw shaft 1 having an outer peripheral surface in which a spiral roller rolling groove 1a is formed; a nut member 2 having an inner peripheral surface in which a spiral loaded roller rolling groove 2a is formed so as to oppose to the roller rolling groove 1a; a return pipe 4 connecting one and another ends of a loaded roller rolling groove 2a of the nut member 2; and a plurality of rollers 6 disposed in the loaded roller rolling passage 3 and the return pipe 4. A spacer 31 is disposed between a pair of adjacent rollers 6, 6 so as to prevent the paired rollers 6, 6 from contacting each other. According to such roller screw, the rollers can be smoothly circulated without causing any skew.

Owner:THK CO LTD

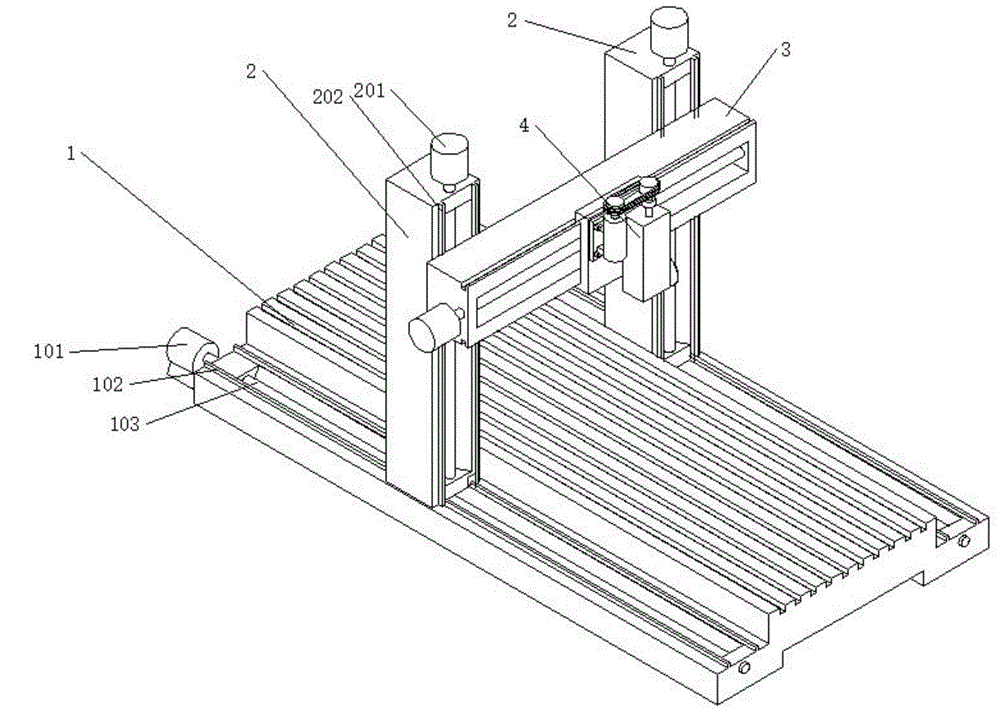

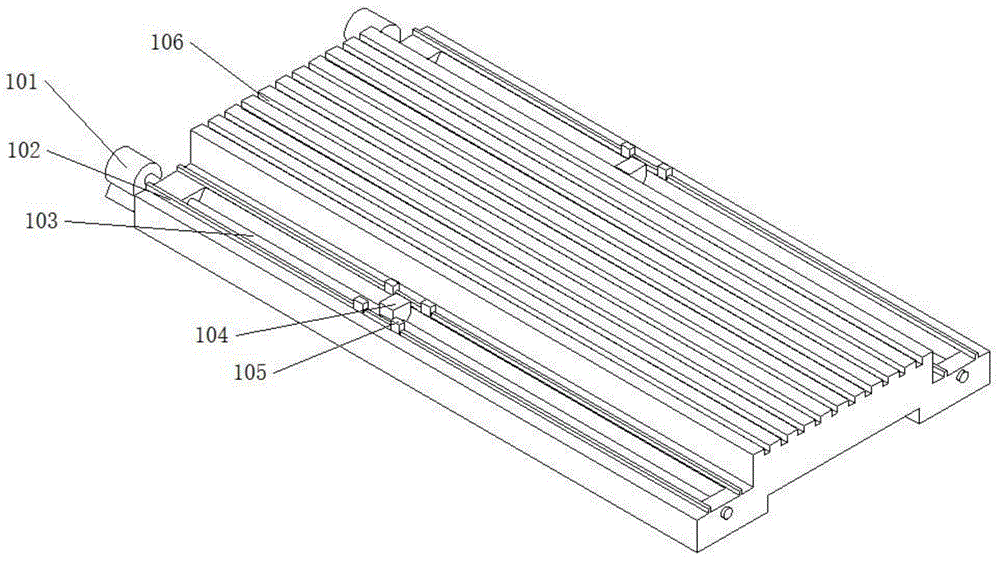

Large efficient cutting machine

InactiveCN104959898ARealize multi-station simultaneous processingImprove efficiencyGrinding carriagesGrinding drivesRoller screwEngineering

The invention discloses a large efficient cutting machine. The machine comprises a worktable, upright columns, a cross beam and a cutting device. The upright columns are installed on the two sides of the worktable, the two ends of the cross beam are connected with the upright columns, and the cutting device is connected with the cross beam. A gantry support structure is adopted in the machine, the support can move in the X-axis direction, the cross beam can move in the Z-axis direction, and the cutting device can move in the Y-axis direction. Roller screw transmission is adopted, and the cutting machine has the advantages of being high in efficiency and high in precision. Meanwhile, the machine is a combined machine tool, the number of gantry supports can be increased or the number of the cutting device on the single gantry support can be increased, so that workpieces are machined at multiple stations at the same time, and machining efficiency is improved easily.

Owner:孟如苗

Roller screw

The roller screw mechanism is provided with a screw including an external thread, with a nut arranged about and coaxial with said screw, the nut including an internal thread, and with a plurality of rollers inserted between the screw and the nut and each including an external thread engaging the external and internal threads of said screw and of said nut. The screw is axially moveable in relation to the rollers. The flanks of the thread of the screw have a concave profile in cross section.

Owner:AB SKF

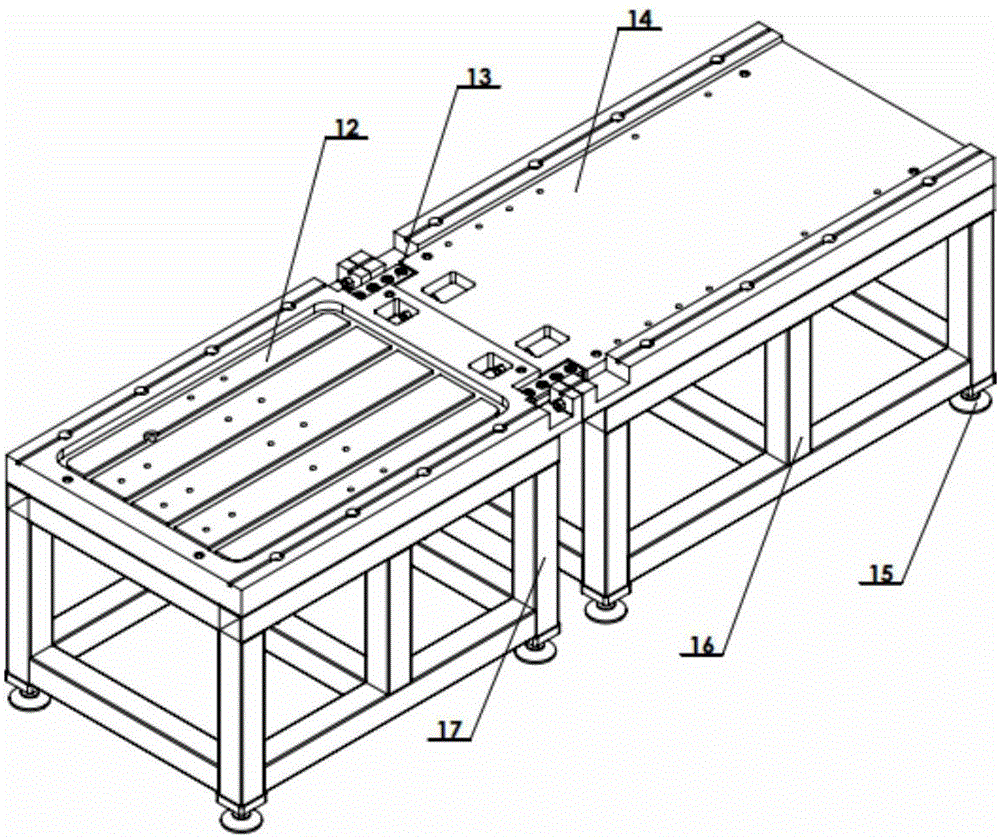

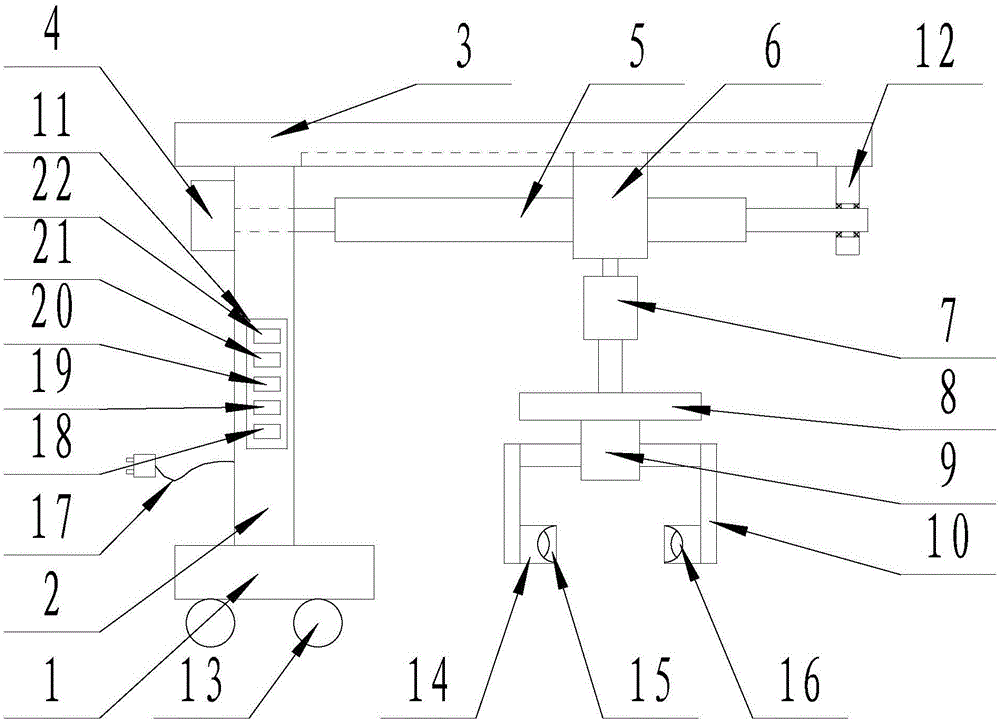

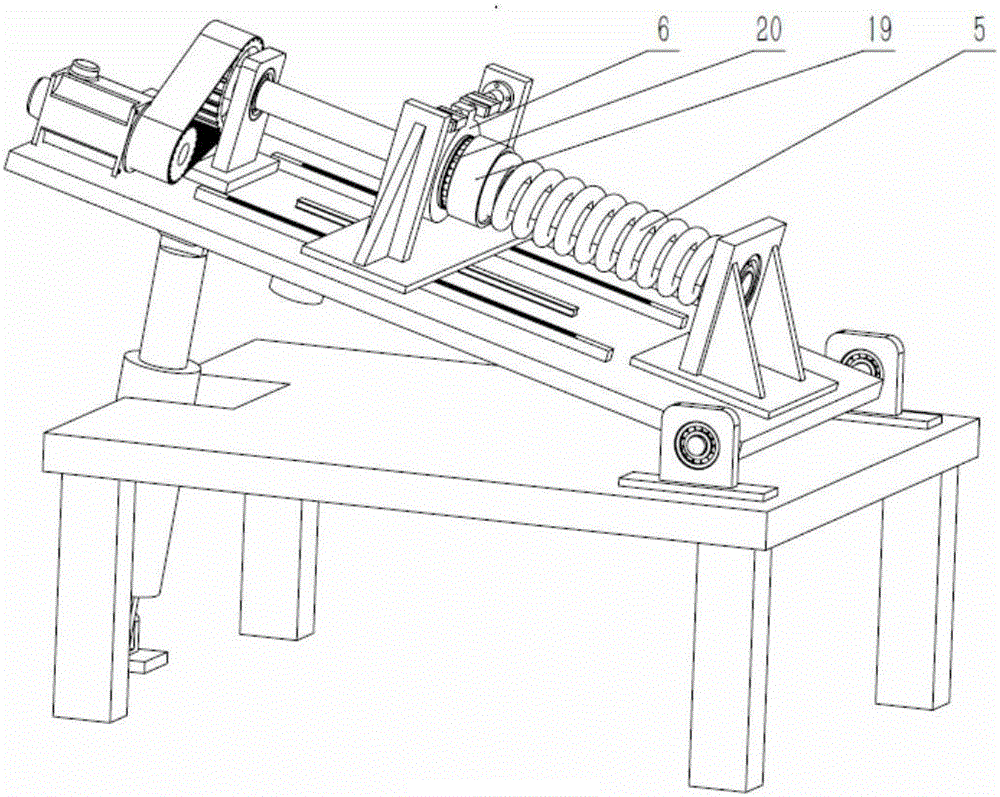

Comprehensive performance testing platform for planetary roller screw

InactiveCN106679958AWith automated measurementWith feverMachine part testingUsing optical meansHydraulic cylinderRoller screw

The invention relates to testing platforms, in particular to a comprehensive performance testing platform for a planetary roller screw, and aims to solve the problem that currently a comprehensive performance testing platforms for the planetary roller screw does not exist in China. The comprehensive performance testing platform comprises a cast iron platform, an alternating-current servo motor, a planetary reducer, an elastic coupler, a torque sensor, a rotation encoder, a linear guide rail, a movable platform, three bearing columns, a pull pressure sensor and a hydraulic cylinder, wherein the alternating-current servo motor, the planetary reducer, the elastic coupler, the torque sensor, the rotation encoder, the movable platform, the pull pressure sensor and the hydraulic cylinder are sequentially arranged on the upper surface of the cast iron platform from left to right, the alternating-current servo motor is connected with the planetary reducer, and the planetary reducer is connected with the torque sensor through the elastic coupler. The comprehensive performance testing platform belongs to the field of mechanical performance testing.

Owner:HARBIN INST OF TECH

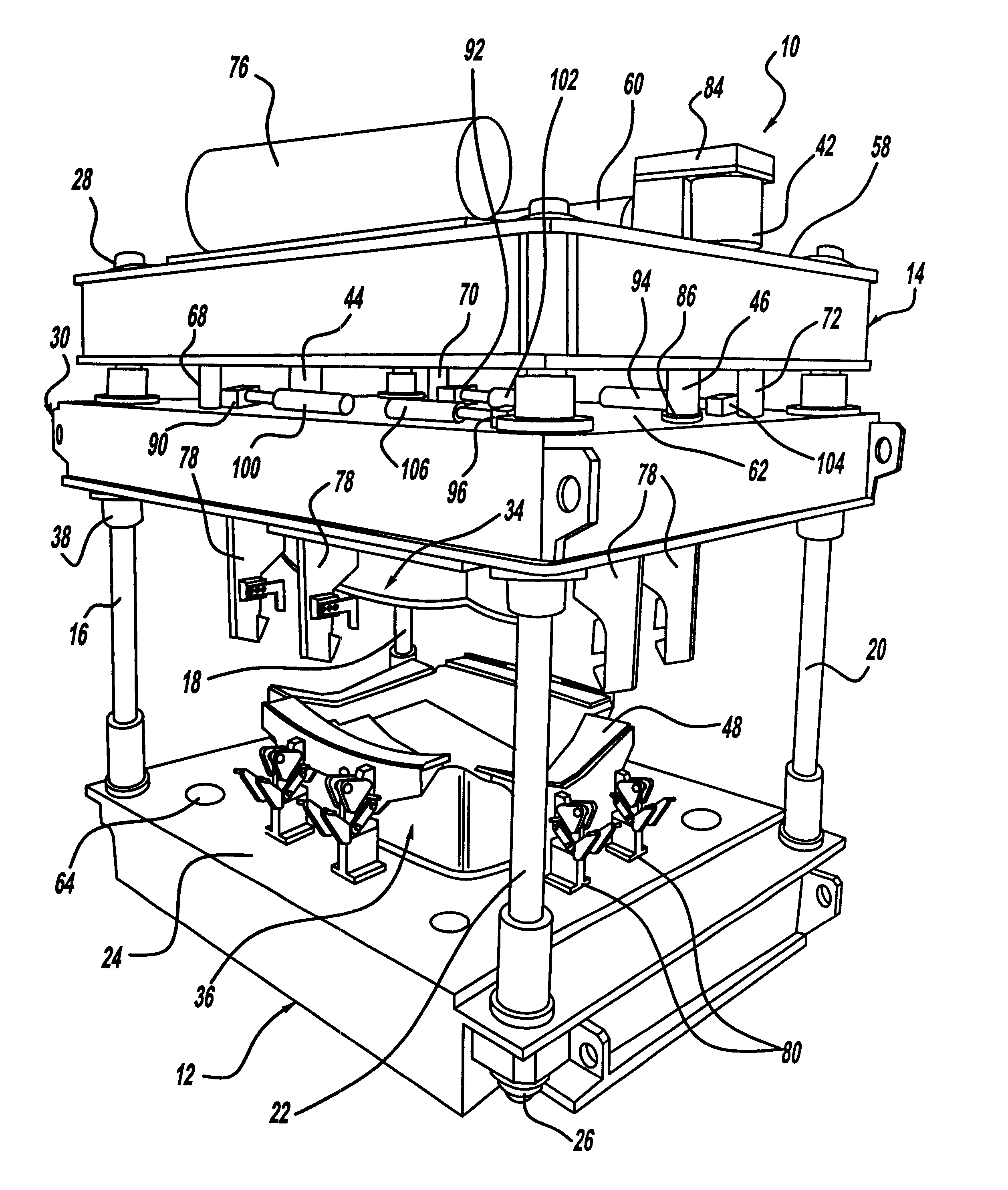

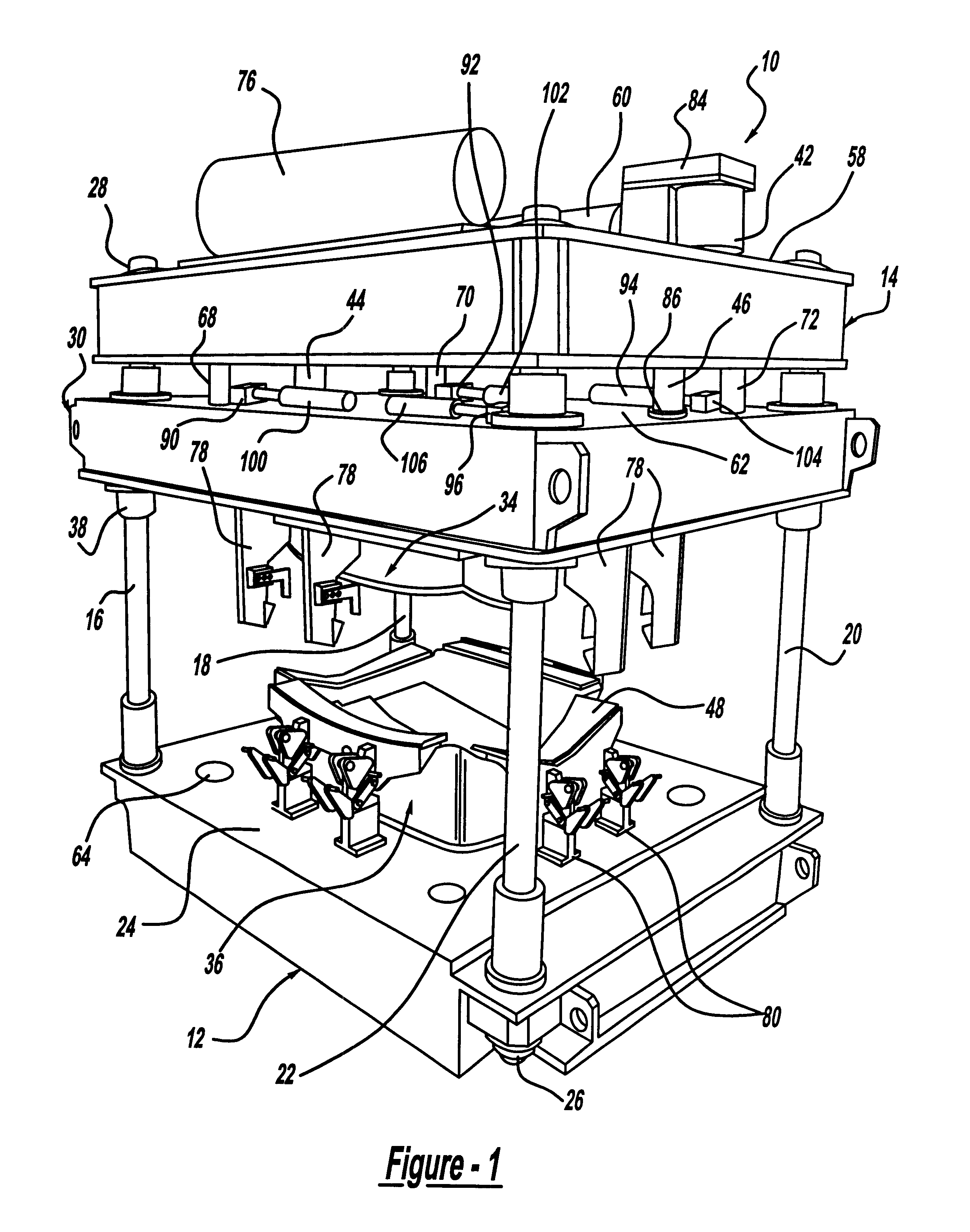

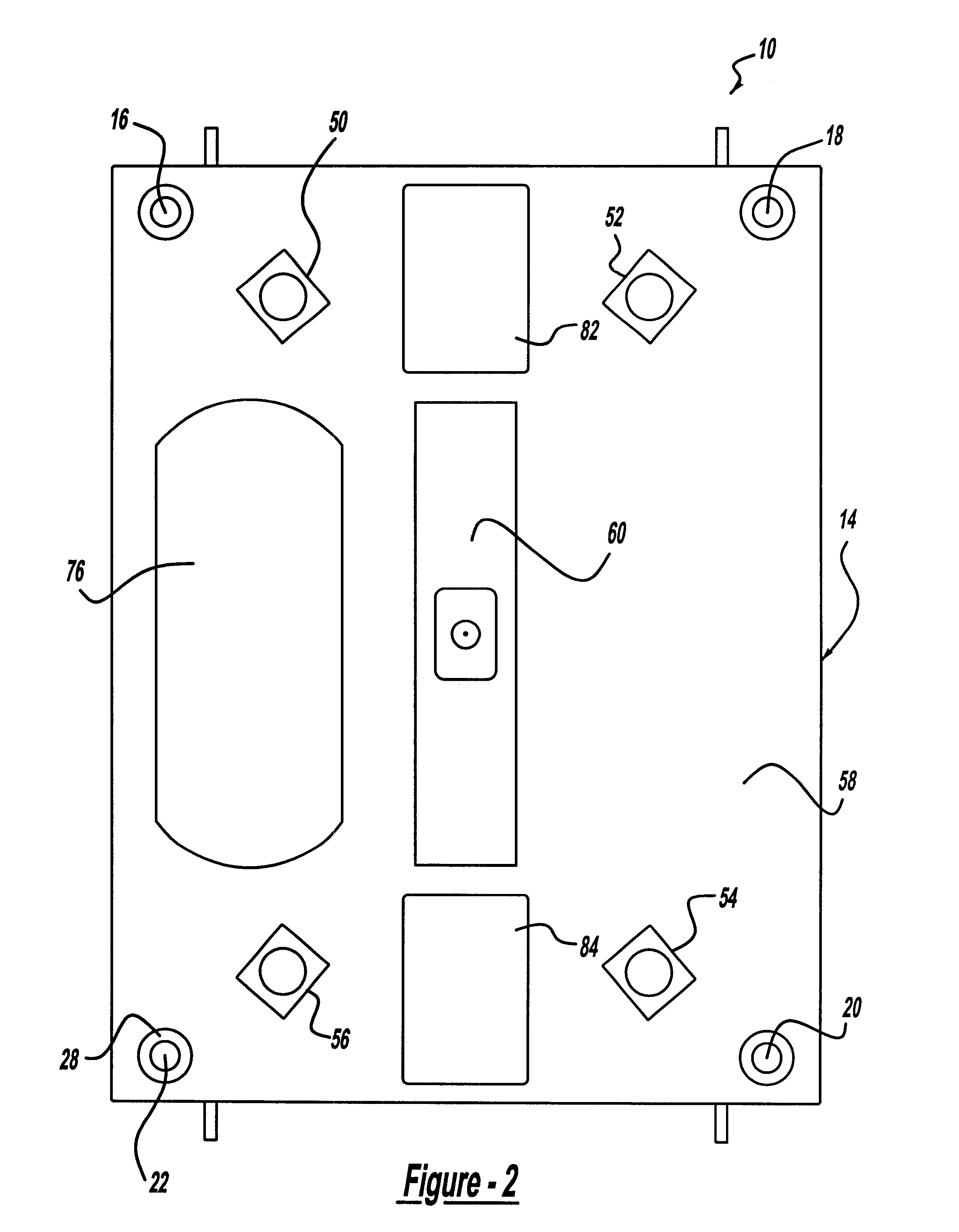

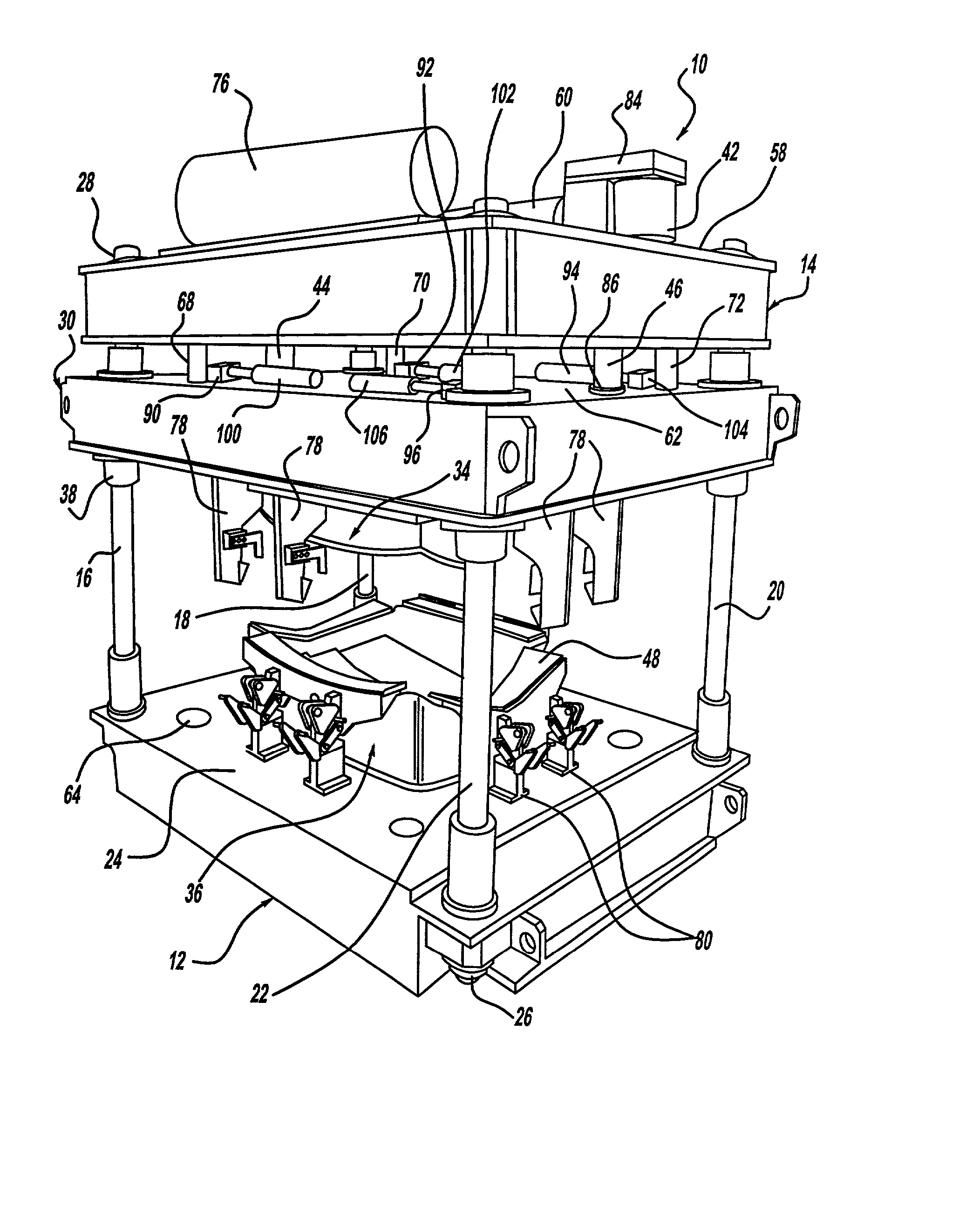

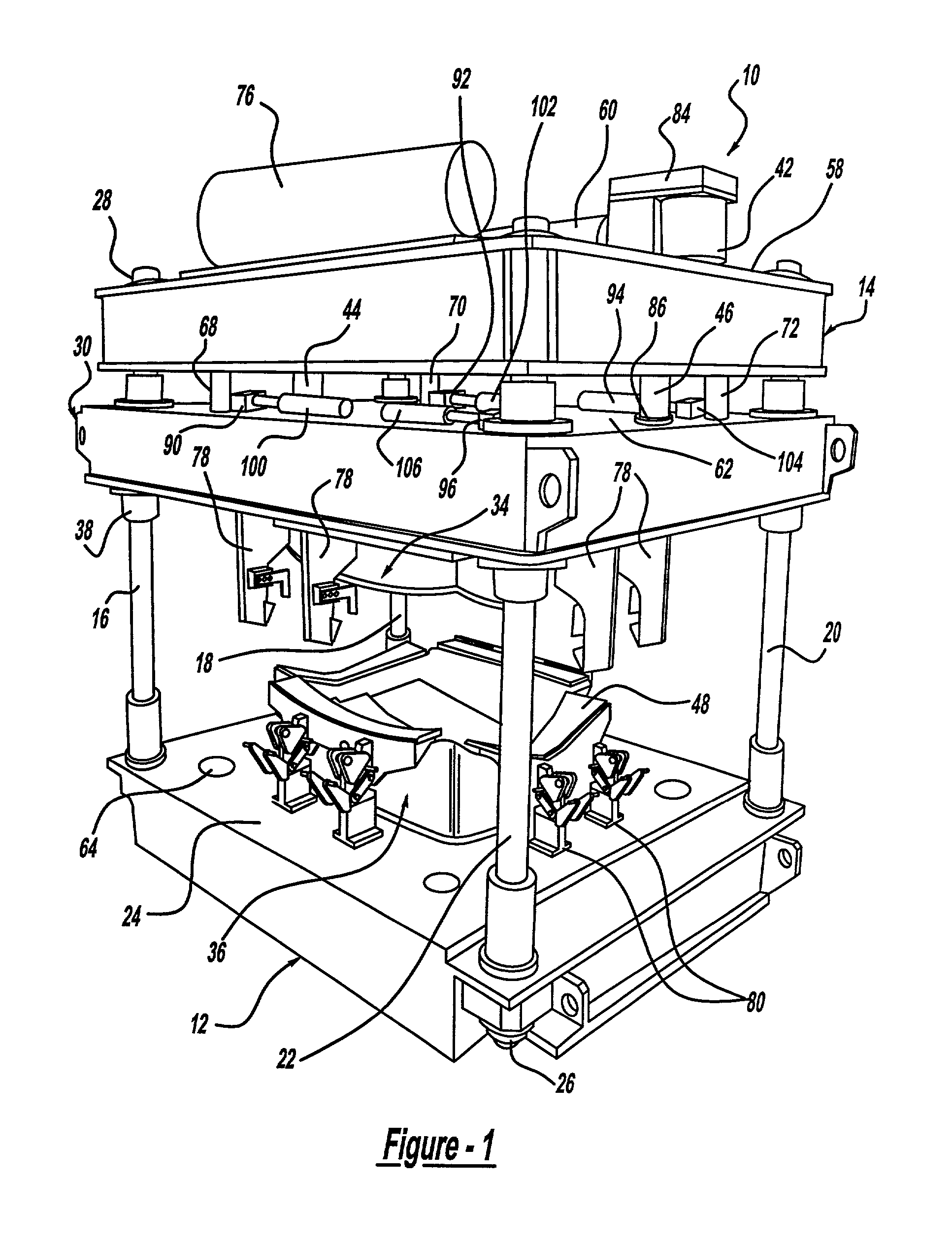

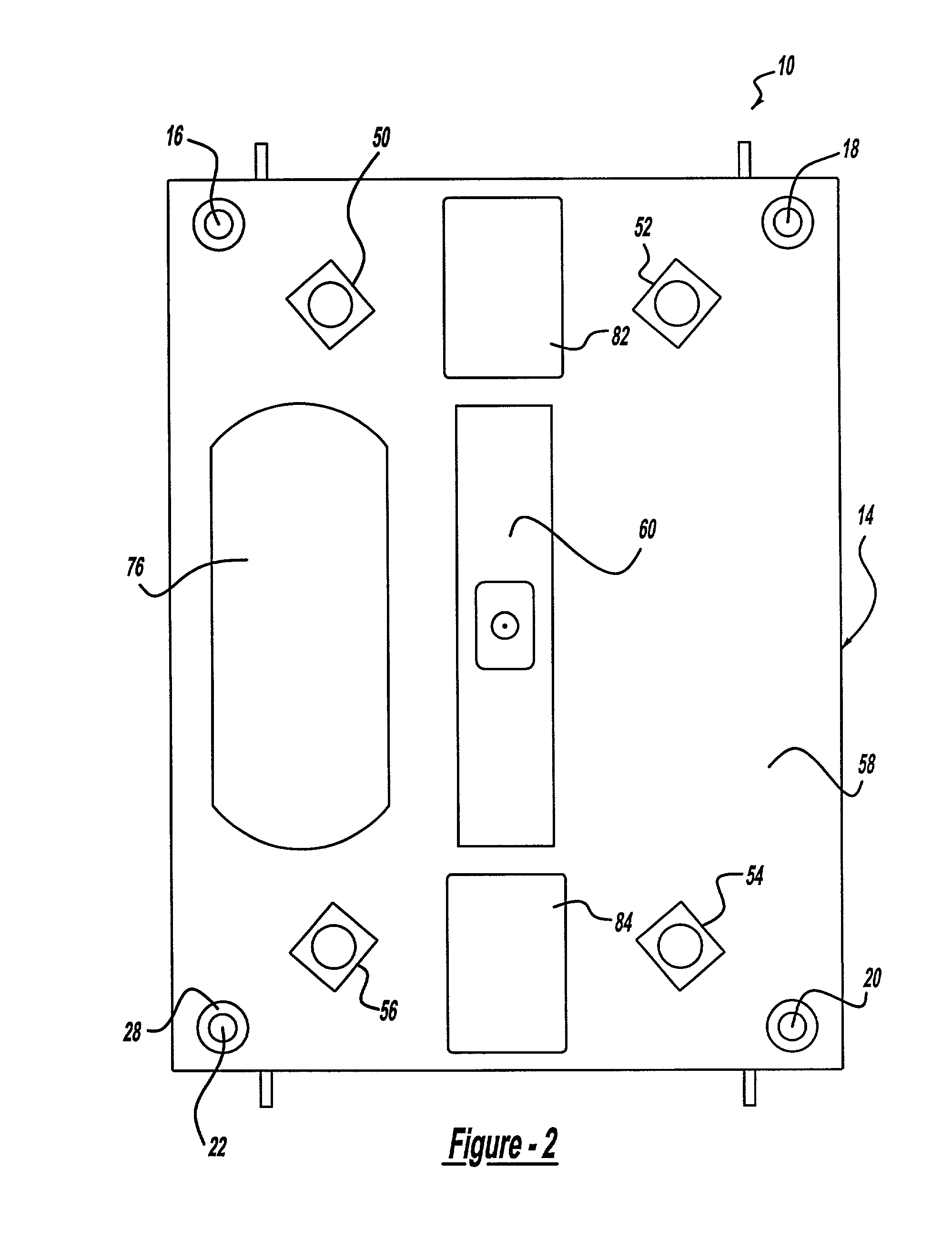

Electric hemming press

A hemming press that includes a crown and a base plate separated by four corner posts. A press ram is slidably mounted on the posts between the crown and base plate. A first die is mounted to a lower surface of the press ram and a second die is mounted to an upper surface of the base plate. Workpieces to be hemmed are placed in the second die, and the press ram is moved from an upper home position to a lower hem position to perform the hemming process. Pre-hemming and final hemming steps are performed by one continuous stroke of the press ram. A pre-hem pressure is provided to the press ram by at least one electric servomotor and roller screw assembly, and a final hem pressure is provided to the press ram by at least one hydraulic actuator.

Owner:SANYO MACHINE AMERICA

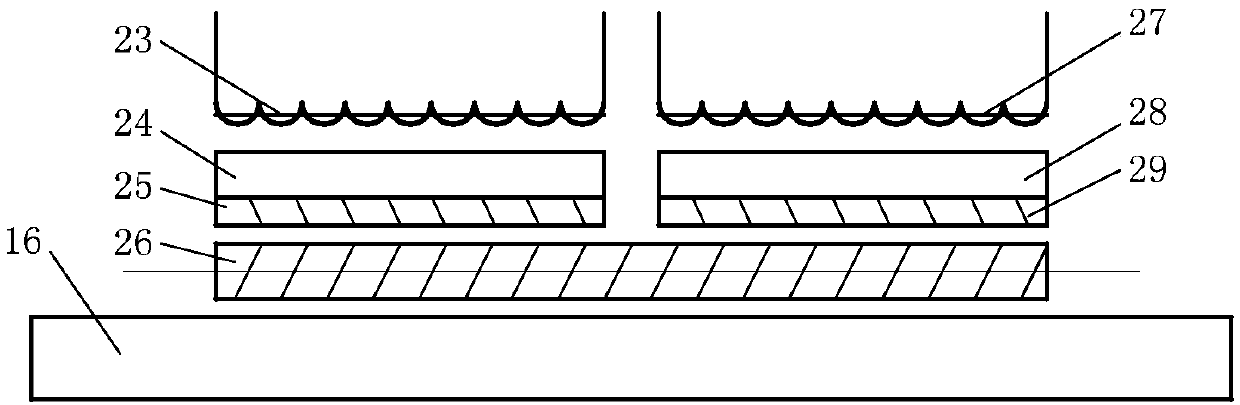

Sleeve motor steer-by-wire device and control method

PendingCN107792168AReduce radial sizeCompact structureMechanical steering gearsElectrical steeringRoller screwReduction drive

The invention discloses a sleeve motor steer-by-wire device and a control method. The steer-by-wire device comprises a steering wheel, a steering pipe column connected with the steering wheel, a leftside wheel steering transmission mechanism connected with a left side wheel, a right side wheel steering transmission mechanism connected with a right side wheel and a mechanical steering transmissionmechanism connected with the steering pipe column through an electromagnetic clutch. The steering pipe column is connected with a road sensing / assistant power motor through a reducer, the steeringdevice further comprises a steer-by-wire execution mechanism, the steer-by-wire execution mechanism comprises a first sleeve motor, a second sleeve motor and a planetary roller screw mechanism drivenby the first sleeve motor and / or the second sleeve motor. The sleeve motor steer-by-wire device adopts the double sleeve motors and the planetary roller screw mechanism, and sufficiently utilizes the axial spaces of a rack and a tie rod protective sleeve to reduce the radial sizes of the motors, is high in transmission efficiency, and liable to improve the driving consistency of the double sleeve motors when working with a heavy load.

Owner:ZHEJIANG WANDA AUTOMOBILE DIRECTION MACHINE CO LTD +1

Electric hemming press

A hemming press that includes a crown and a base plate separated by four corner posts. A press ram is slidably mounted on the posts between the crown and base plate. A first die is mounted to a lower surface of the press ram and a second die is mounted to an upper surface of the base plate. Workpieces to be hemmed are placed in the second die, and the press ram is moved from an upper home position to a lower hem position to perform the hemming process. Pre-hemming and final hemming steps are performed by one continuous stroke of the press ram. A pre-hem pressure is provided to the press ram by at least one electric servomotor and roller screw assembly, and a final hem pressure is provided to the press ram by at least one hydraulic actuator.

Owner:SANYO MACHINE AMERICA

Roller Screw System

InactiveUS20080110285A1Small sizeSmooth circulationPortable liftingToothed gearingsRoller screwScrew system

A roller screw system comprises a screw shaft, a nut, a pair of return members, a return pipe and a plurality of rollers. The nut is interiorly defined with a receiving recess for accommodation of the return members, and an abutting surface. The roller screw system is characterized in that a through hole is defined in the nut and is in communication with the return hole. The return pipe is disposed in the through hole of the nut. The return members are disposed in the receiving groove of the nut, forming a return system. And the return system is to be connected to the helical groove of the screw shaft and the nut, thus forming a roller screw system. By such arrangements, the rollers can circulate more smoothly and the size of the nut will not be increased.

Owner:HIWIN TECH

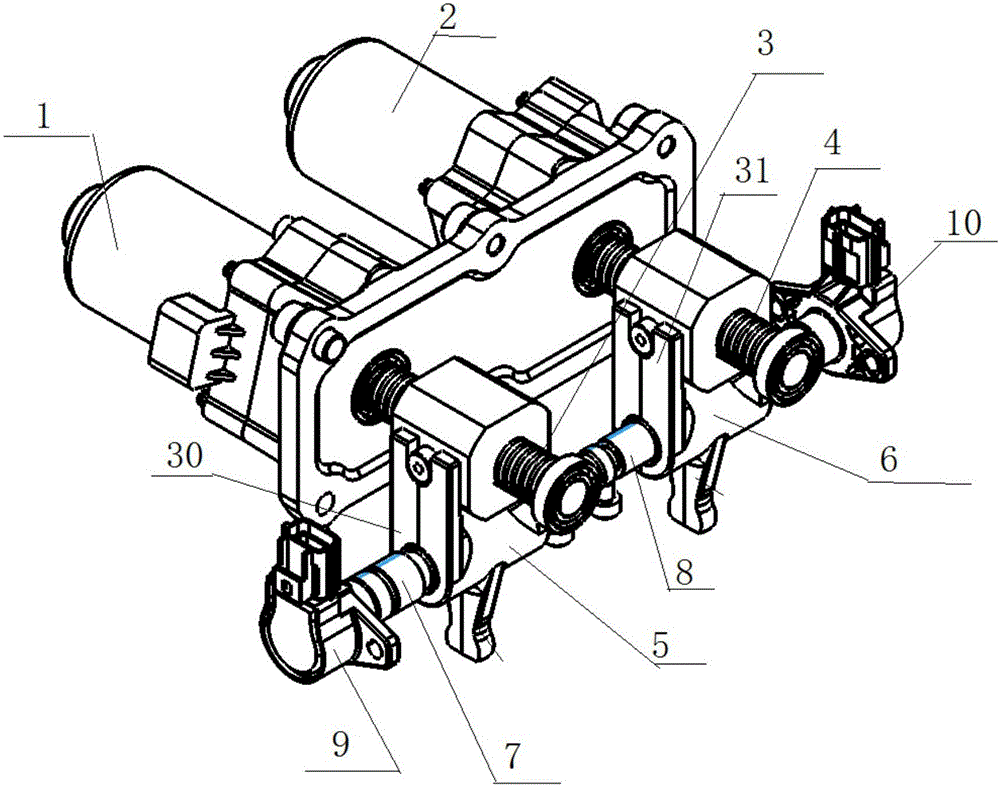

Multi-gear gearbox and control method thereof

InactiveCN106051137AImprove efficiencyConvenience power performance requirementsControlled membersGearing controlRoller screwEngineering

The invention belongs to the field of electric automobile gearboxes and relates to a multi-gear gearbox and a control method thereof. The gearbox comprises a shifting mechanism and an executing mechanism, wherein the shifting mechanism comprises a first shifting motor, a first roller screw rod, a first shifting block, a first shifting shaft, a first sensor, a first guide shoe, a first and second gear shifting yoke, a first shifting yoke shaft, a second shifting motor, a second roller screw rod, a second shifting block, a second shifting shaft, a second sensor, a second guide shoe, a third and fourth gear shifting yoke, and a second shifting yoke shaft. The electric shifting mechanism and the executing mechanism are adopted, and two sets of independent motors and roller screw rod mechanisms are respectively used for shifting executing action of first gear and second gear as well as third gear and fourth gear, and shift selecting operation in a conventional AMT gearbox is cancelled; the multi-gear gearbox disclosed by the invention has the advantages of being simple in structure, high in control accuracy, high in response speed, and convenient to disassemble, assemble and maintain. According to the method disclosed by the invention, shift selection and shifting are automatic shifting controlled by a TCU automatic gearbox control unit without being controlled manually.

Owner:泰州市海博汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com