Patents

Literature

302 results about "Ball spline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

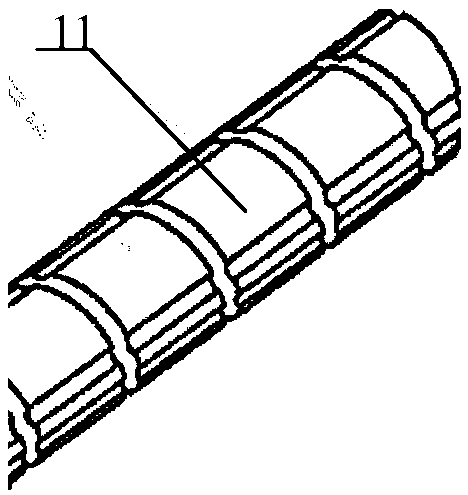

Ball splines (Ball Spline bearings) are a special type of linear motion bearing that are used to provide nearly frictionless linear motion while allowing the member to transmit torque simultaneously. There are grooves ground along the length of the shaft (thus forming splines) for the recirculating ground balls to run inside. The outer shell that houses the balls is called a nut rather than a bushing, but is not a nut in the traditional sense—it is not free to rotate about the shaft, but is free to travel up and down the shaft.

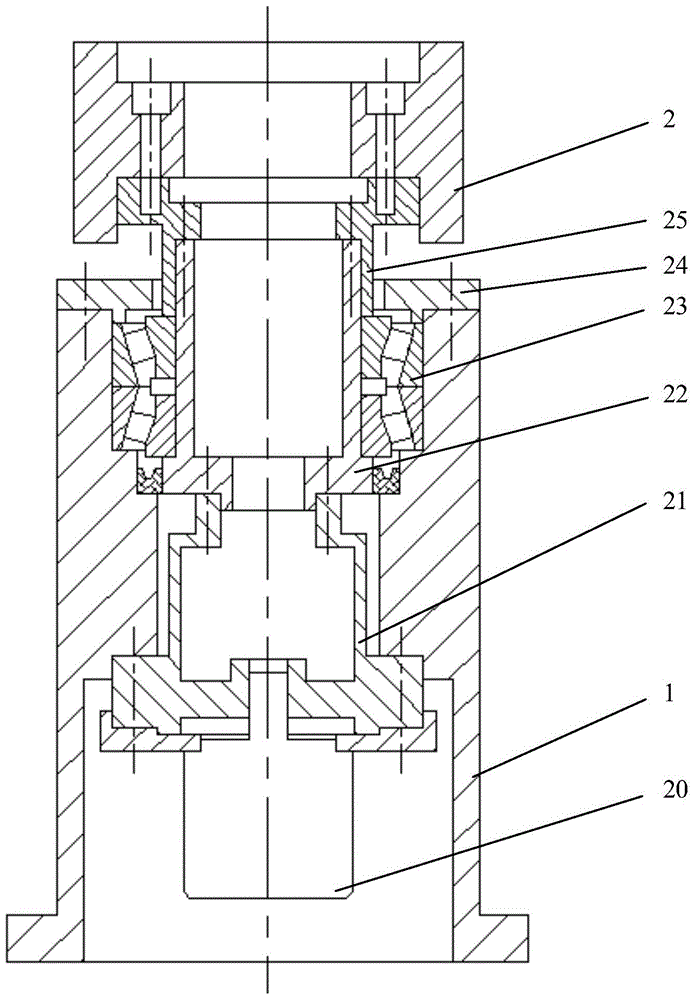

Toroidal type continuously variable transmission

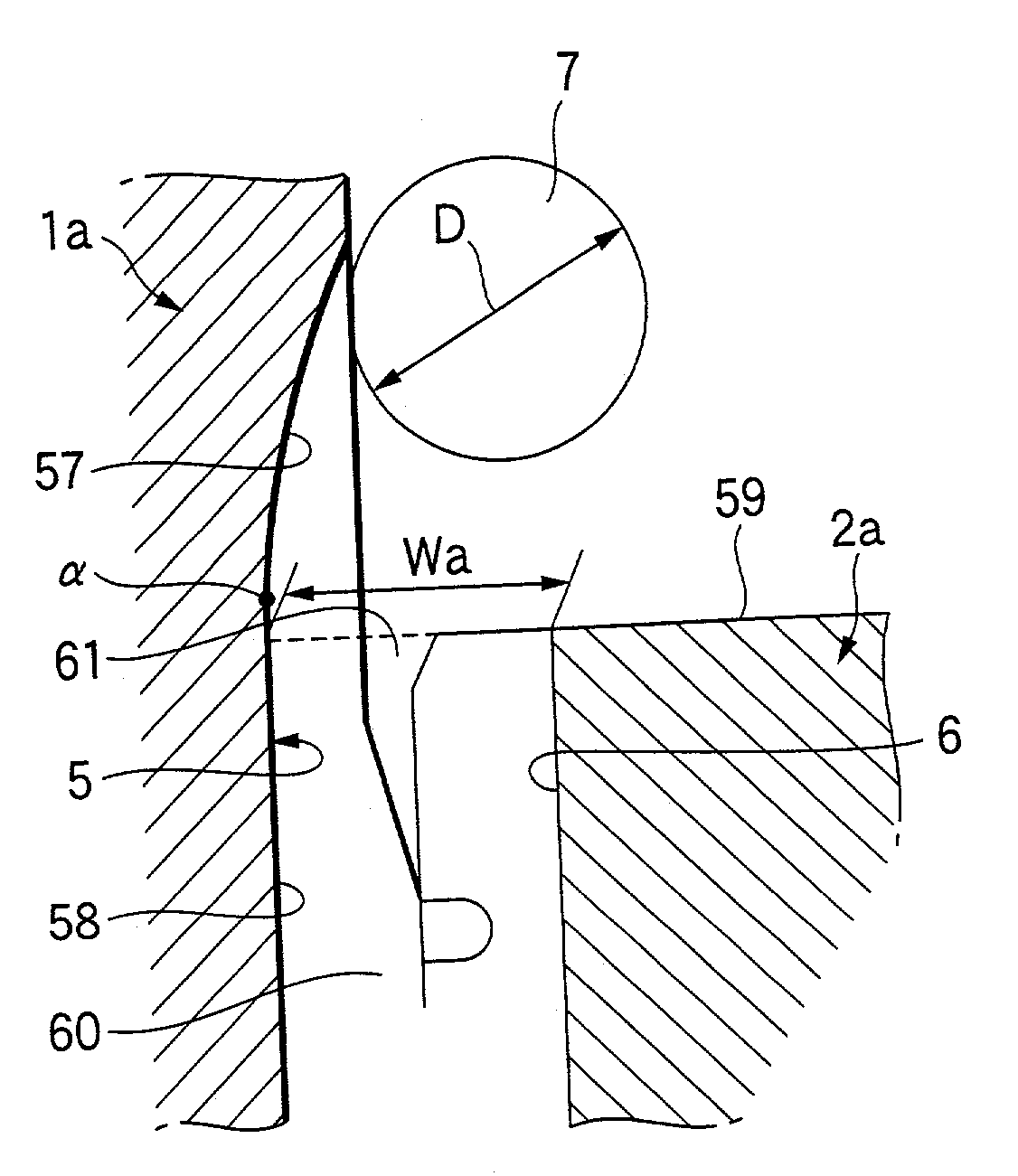

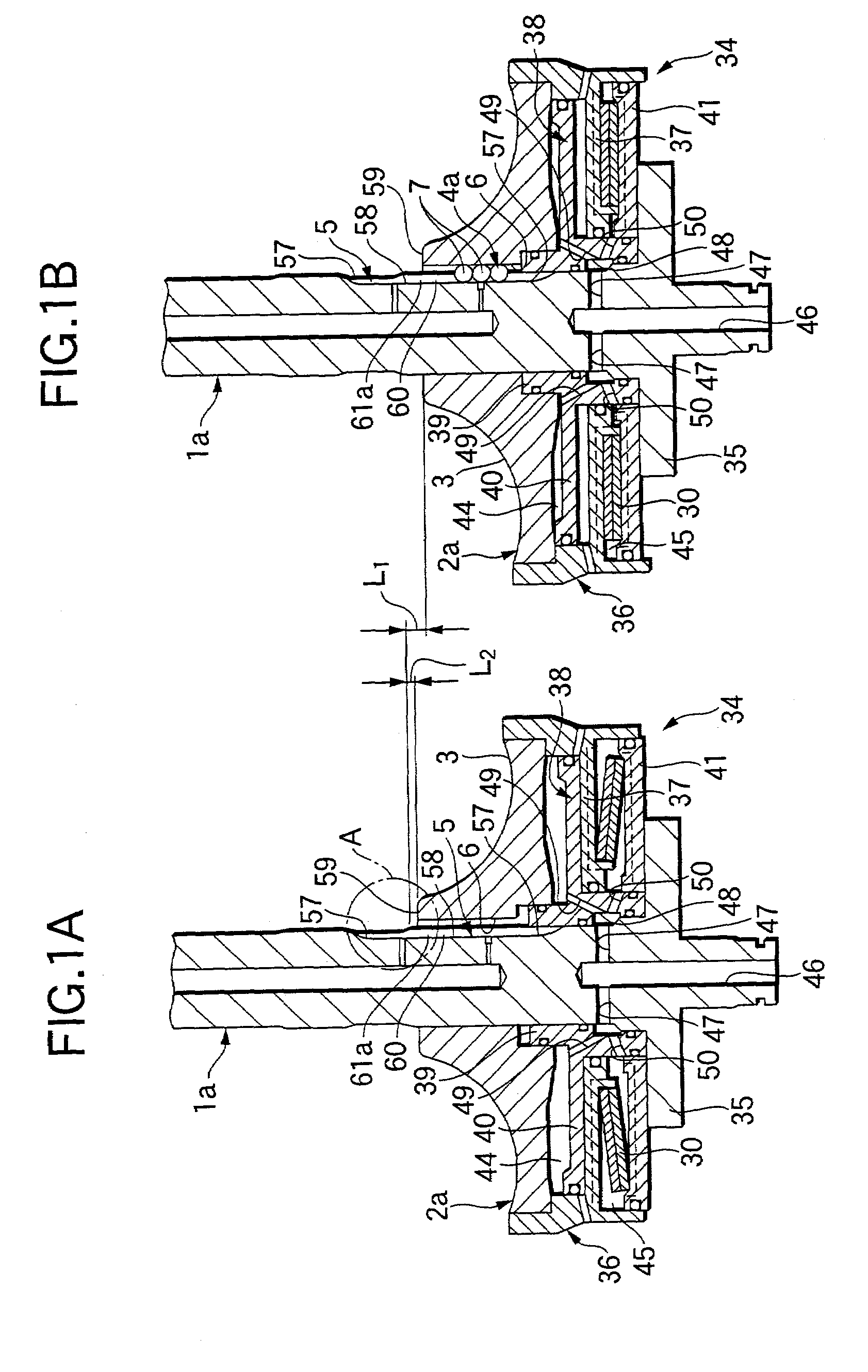

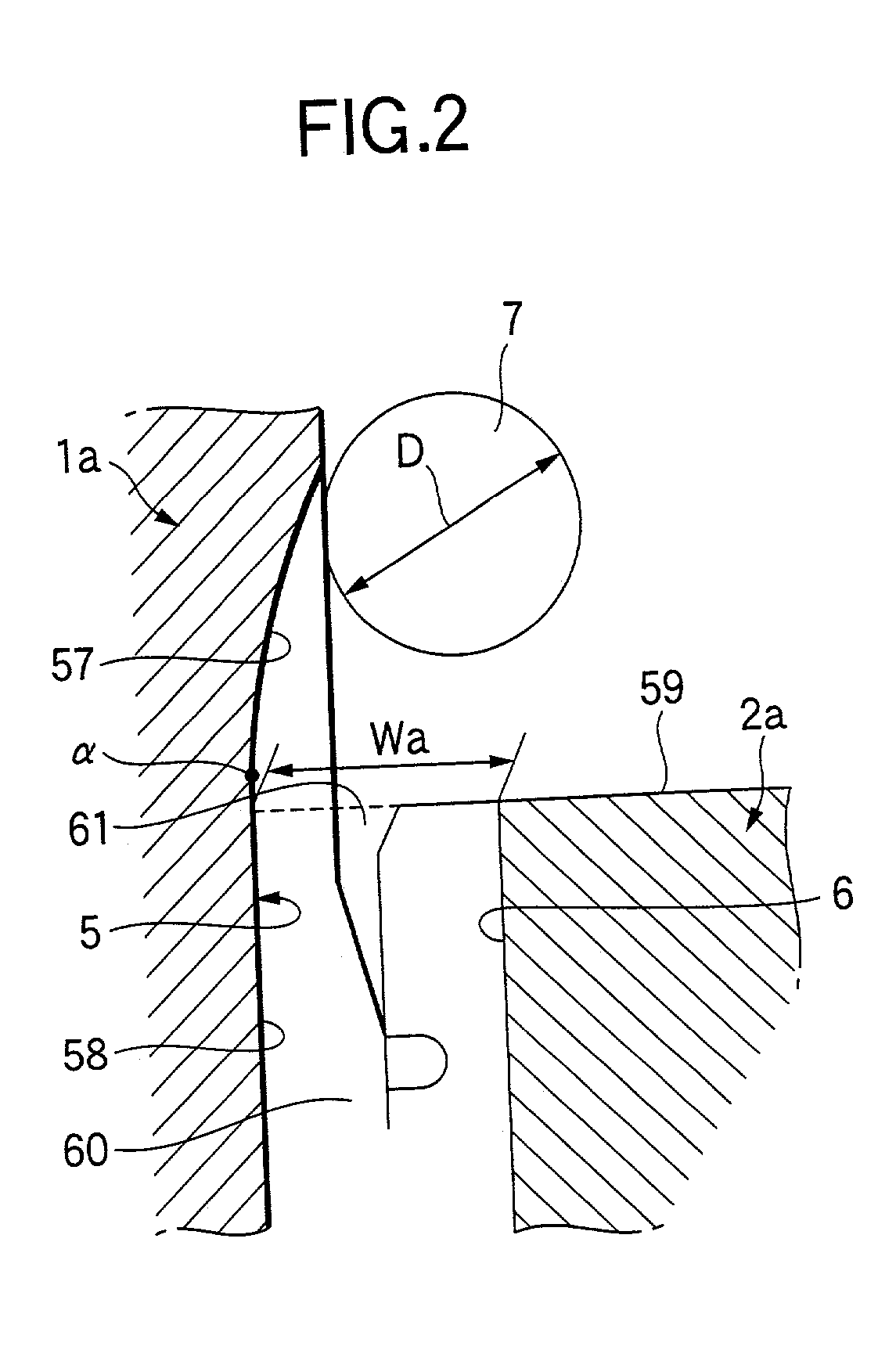

A toroidal type continuously variable transmission having first and second discs supported around a rotating shaft and receiving power rollers therebetween includes a ball spline having a first spline groove formed in an outer circumferential surface of the rotating shaft, a second spline groove formed in an inner circumferential surface of the first disc, and balls provided between the first spline groove and the second spline groove rollably. An axial position of an end portion of an effective groove portion of the first spline groove is located to correspond to an axial position of an inner end portion of the second spline groove or more closely to the second disc than the axial position thereof when a pressing unit, a preload spring and the first disc are installed around the rotating shaft, pressure oil is not fed to the pressing unit, and the preload spring is not elastically deformed.

Owner:NSK LTD

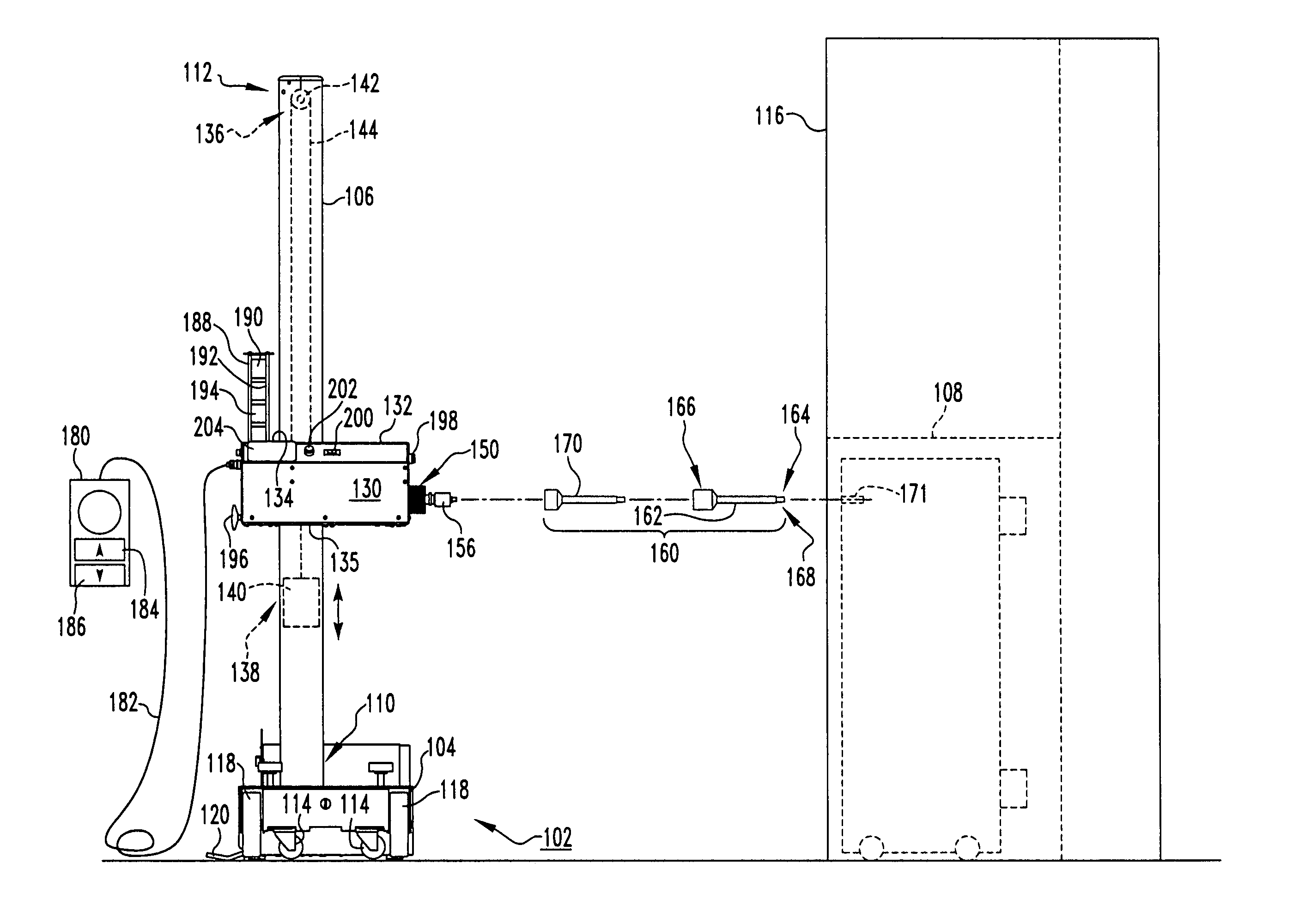

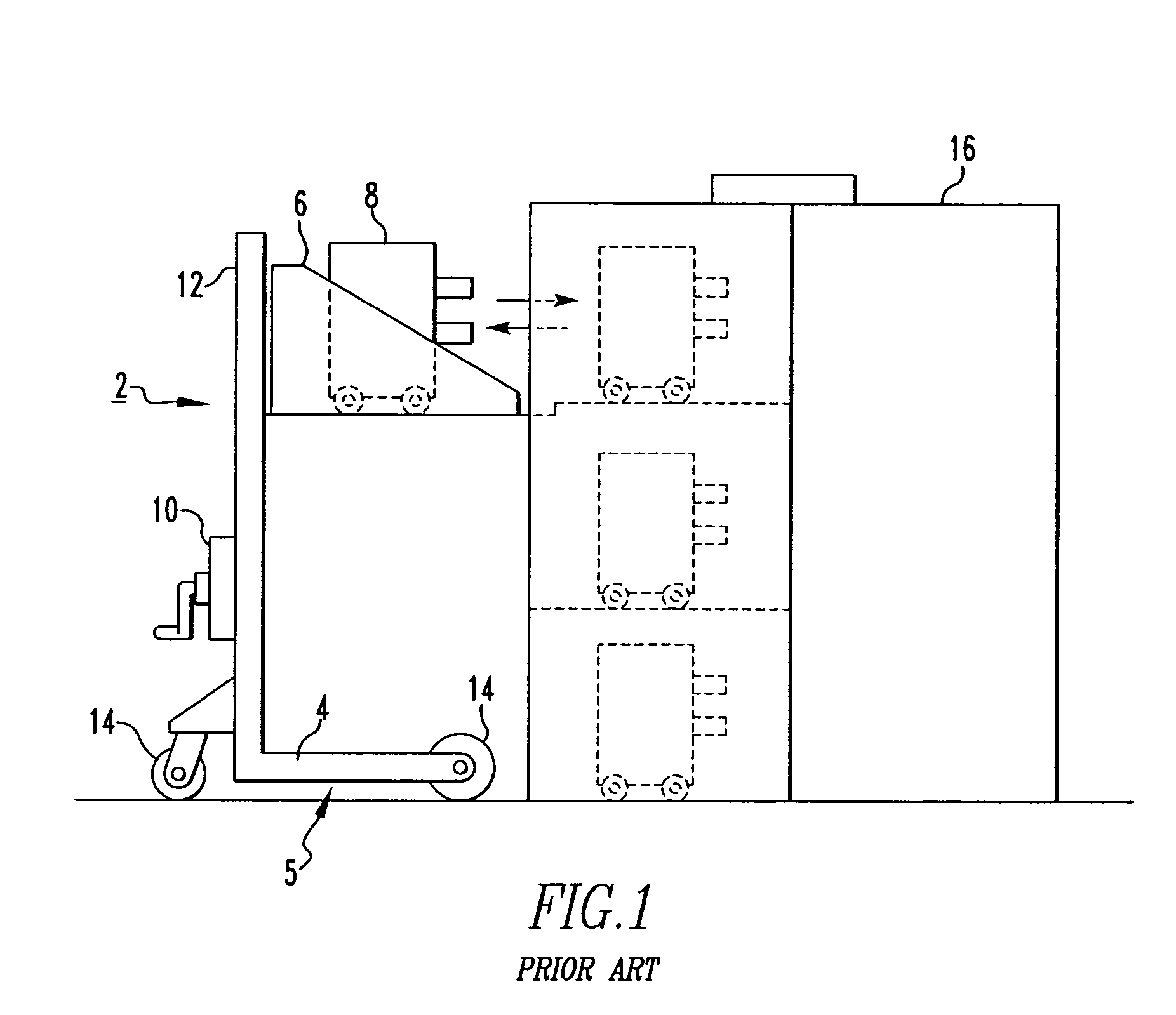

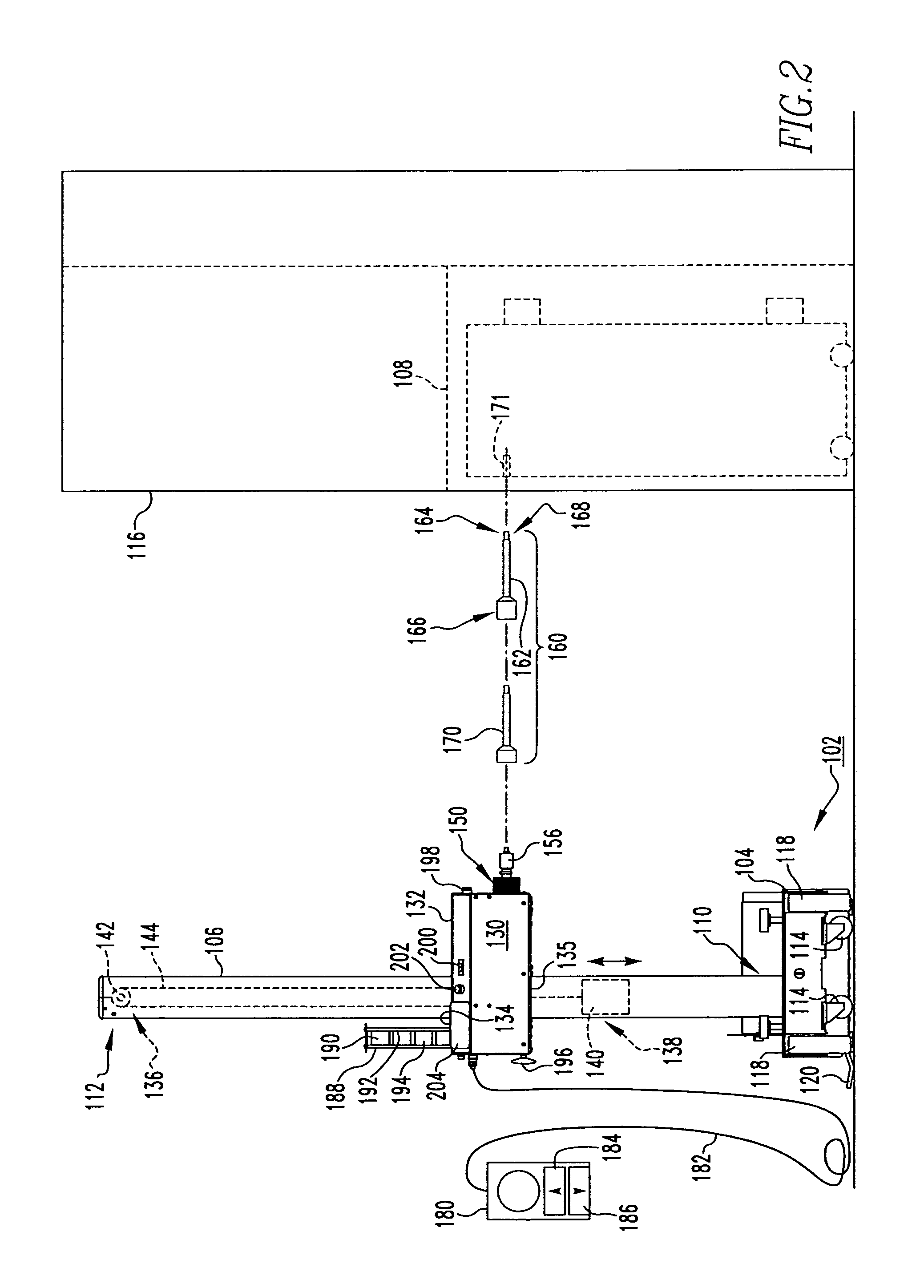

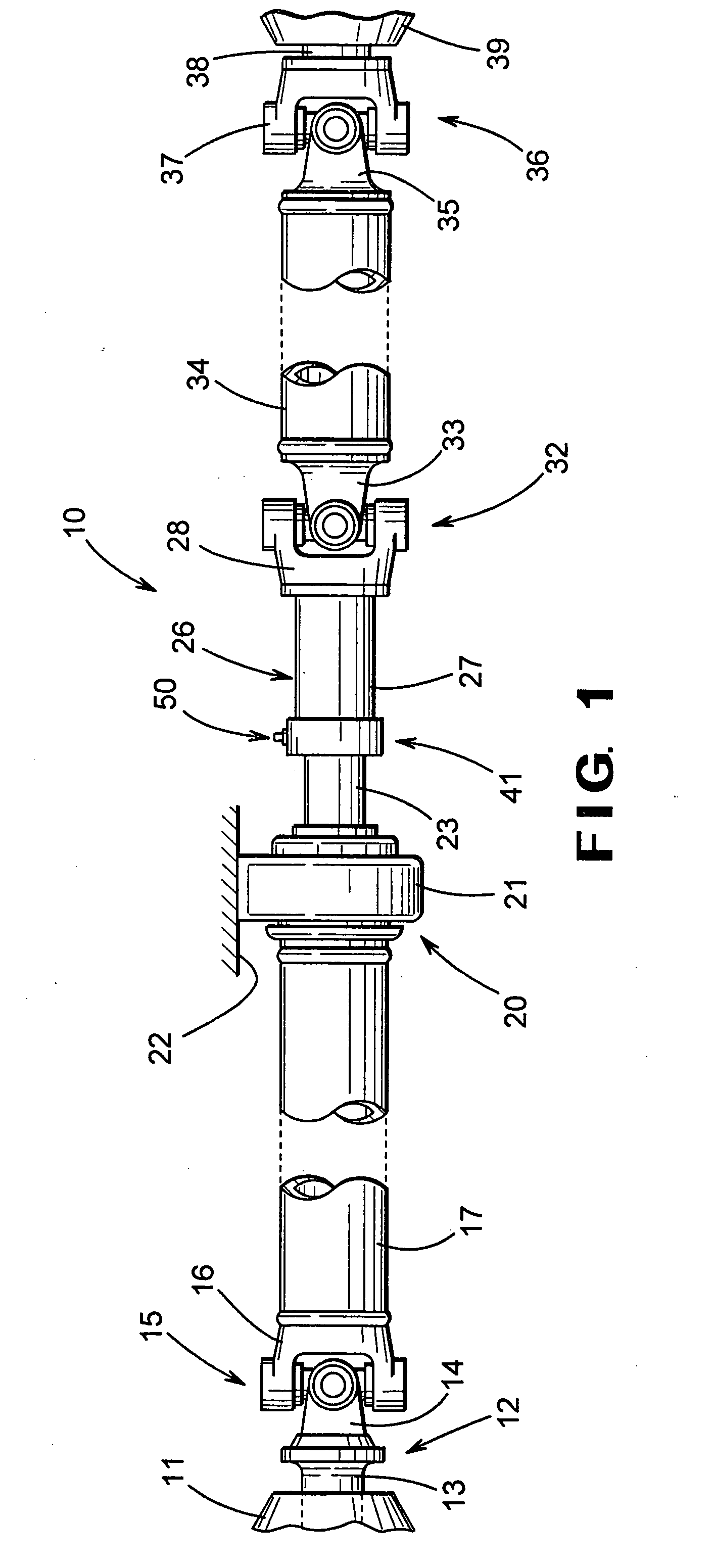

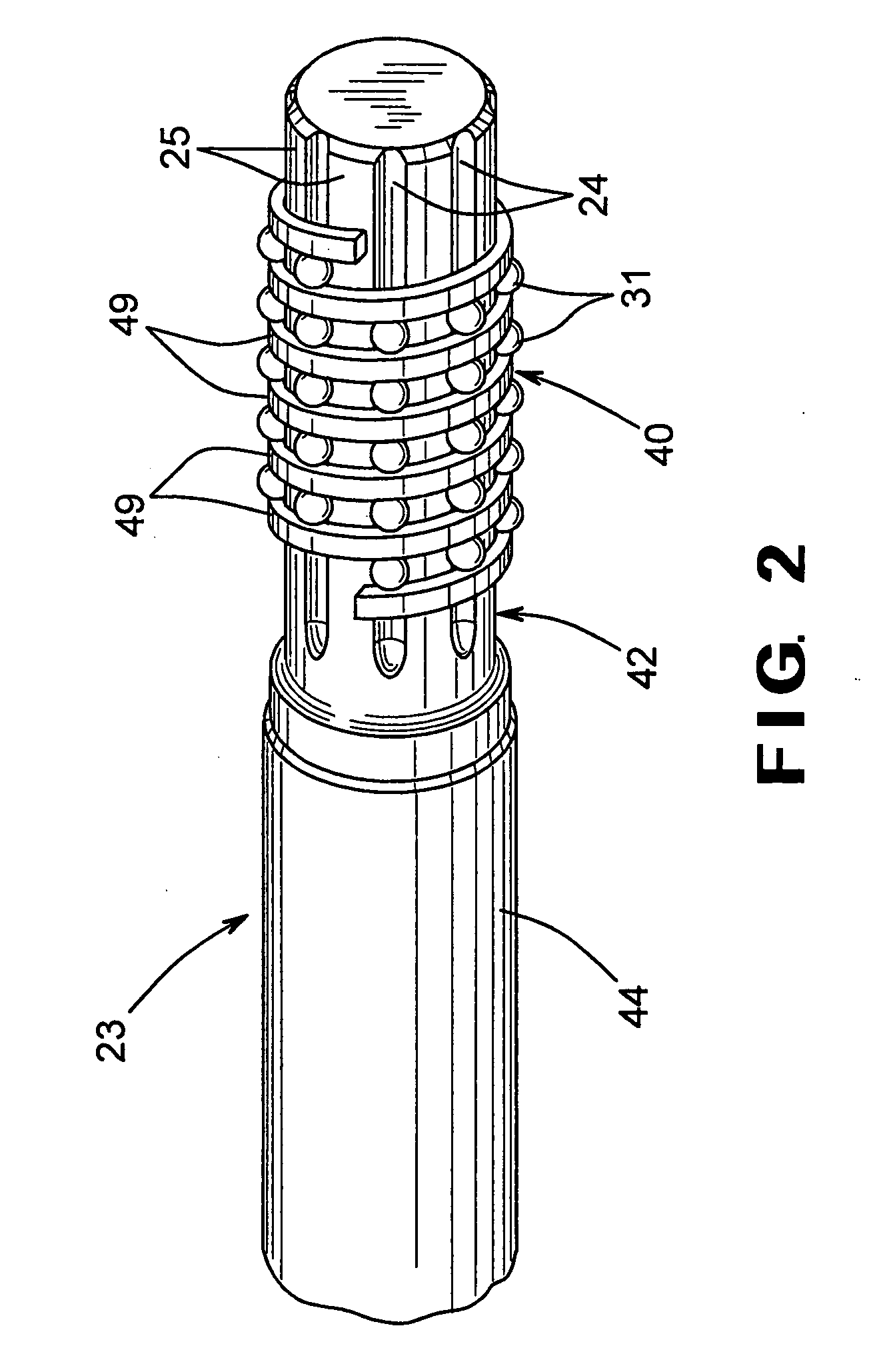

Racking device and power module therefor

ActiveUS7019230B1Quick and easy manipulationSimple designSwitchgear with withdrawable carriageHigh-tension/heavy-dress switchesEngineeringSwitchgear

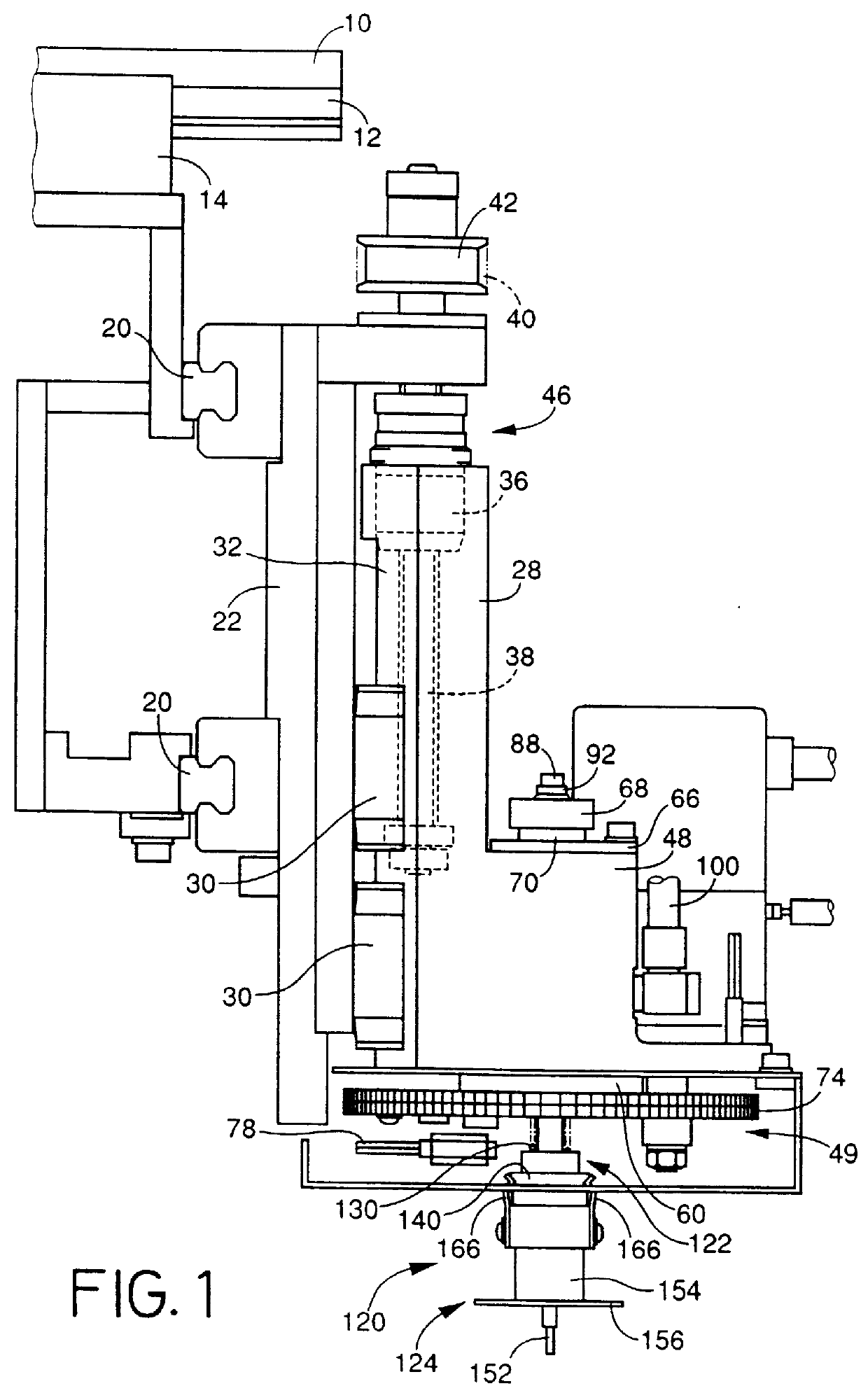

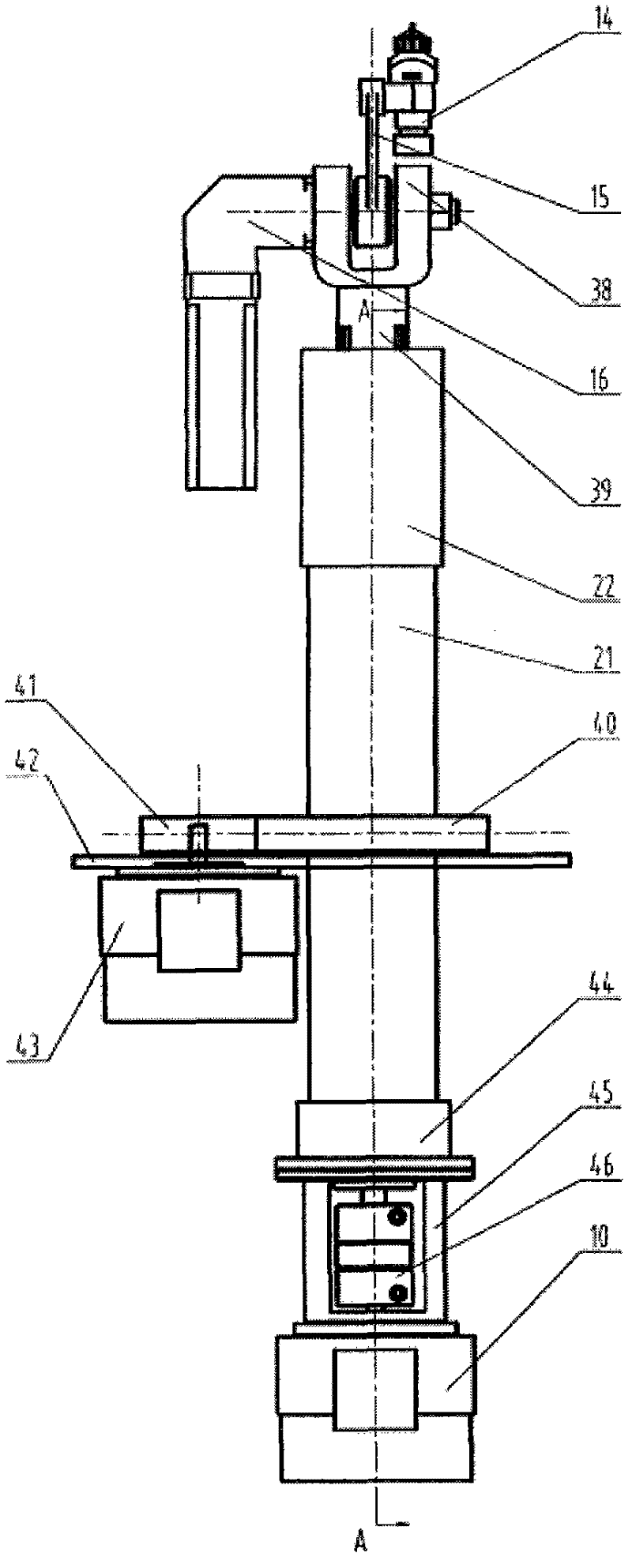

A racking device performs a circuit breaker racking operation. The racking device includes a base with wheels and a brake to facilitate moving the racking device and positioning it with respect to a switchgear cabinet. An elongated tubular member extends substantially vertically from the base. A self-contained counter-balanced power module includes an enclosure having a pair of opposing openings for receiving the elongated tubular member, and a counterweight system for counter-balancing the power module. An actuator including a motor, a ball spline and a torque member moves a linkage assembly having an end effector with a negator spring that positively engages the circuit breaker. A switch module actuates the actuator from a remote location in order to move the linkage assembly and thus the circuit breaker to perform the racking operation from the remote location. Complicated field programming of the power module is not required.

Owner:EATON INTELLIGENT POWER LIMITED

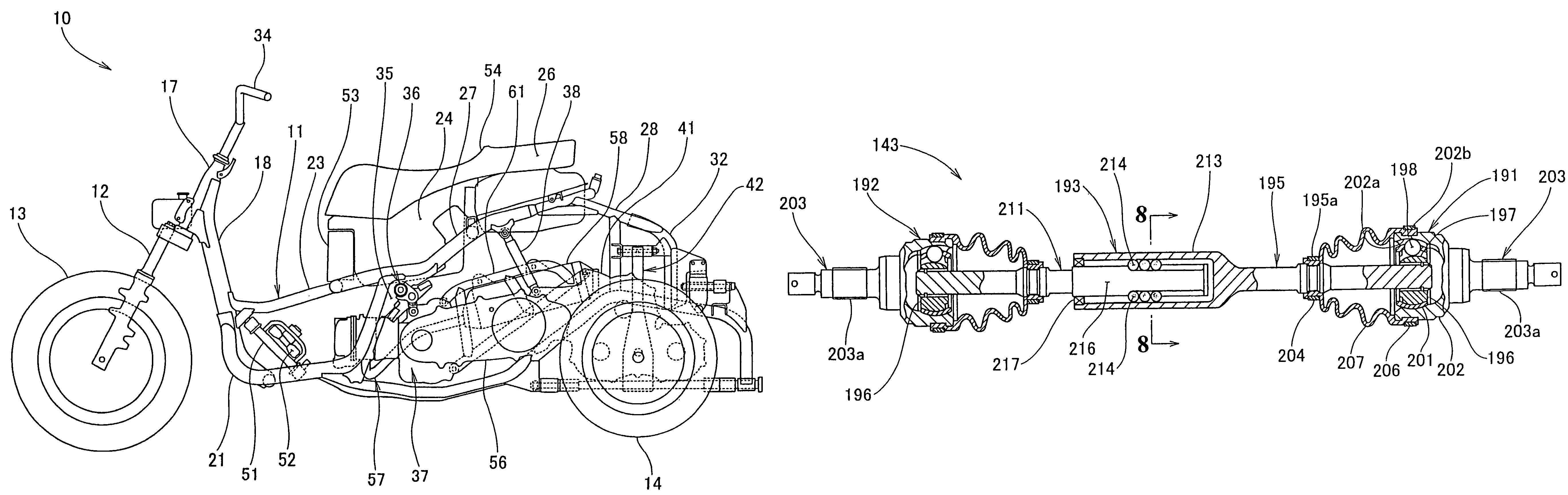

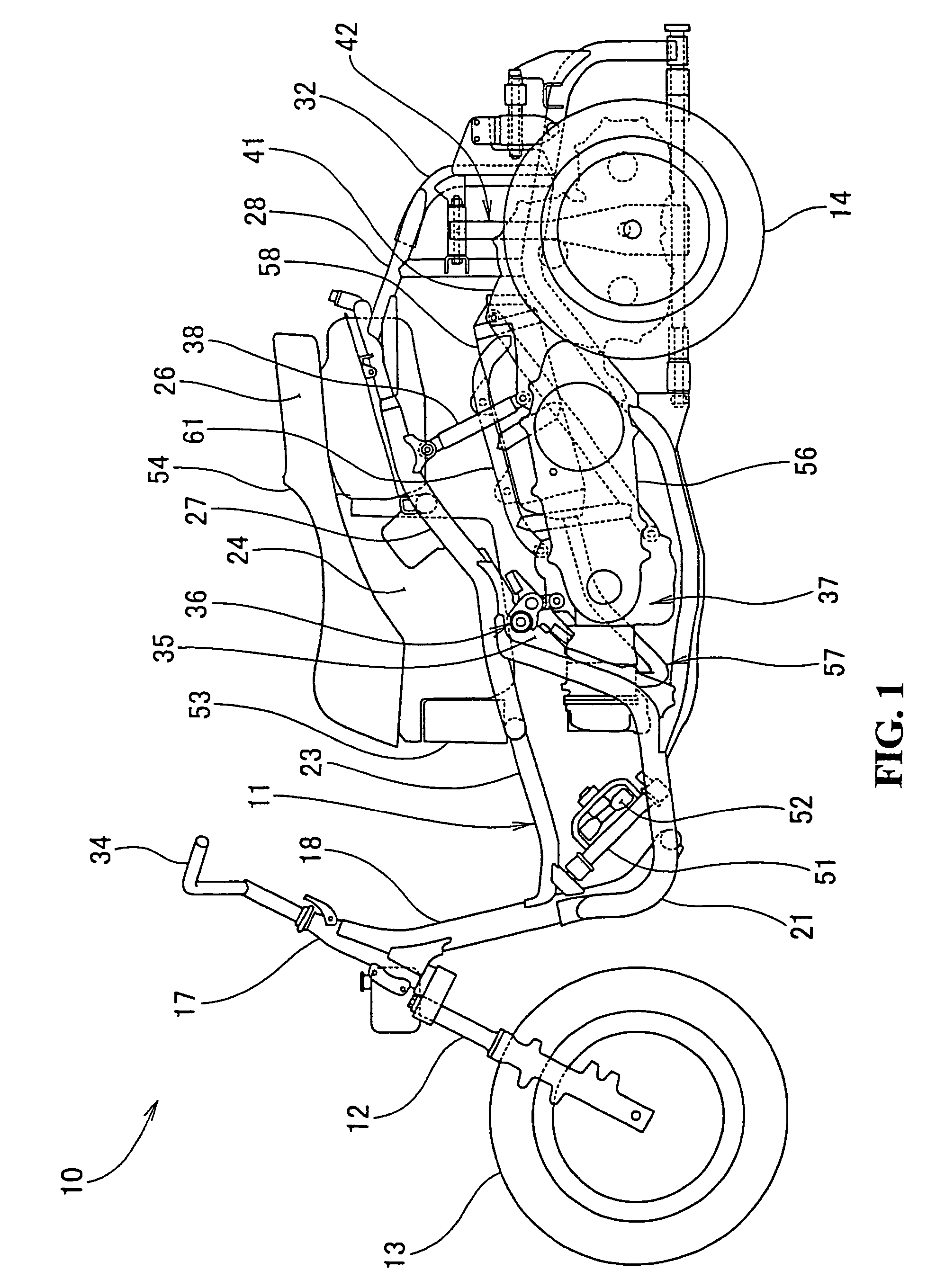

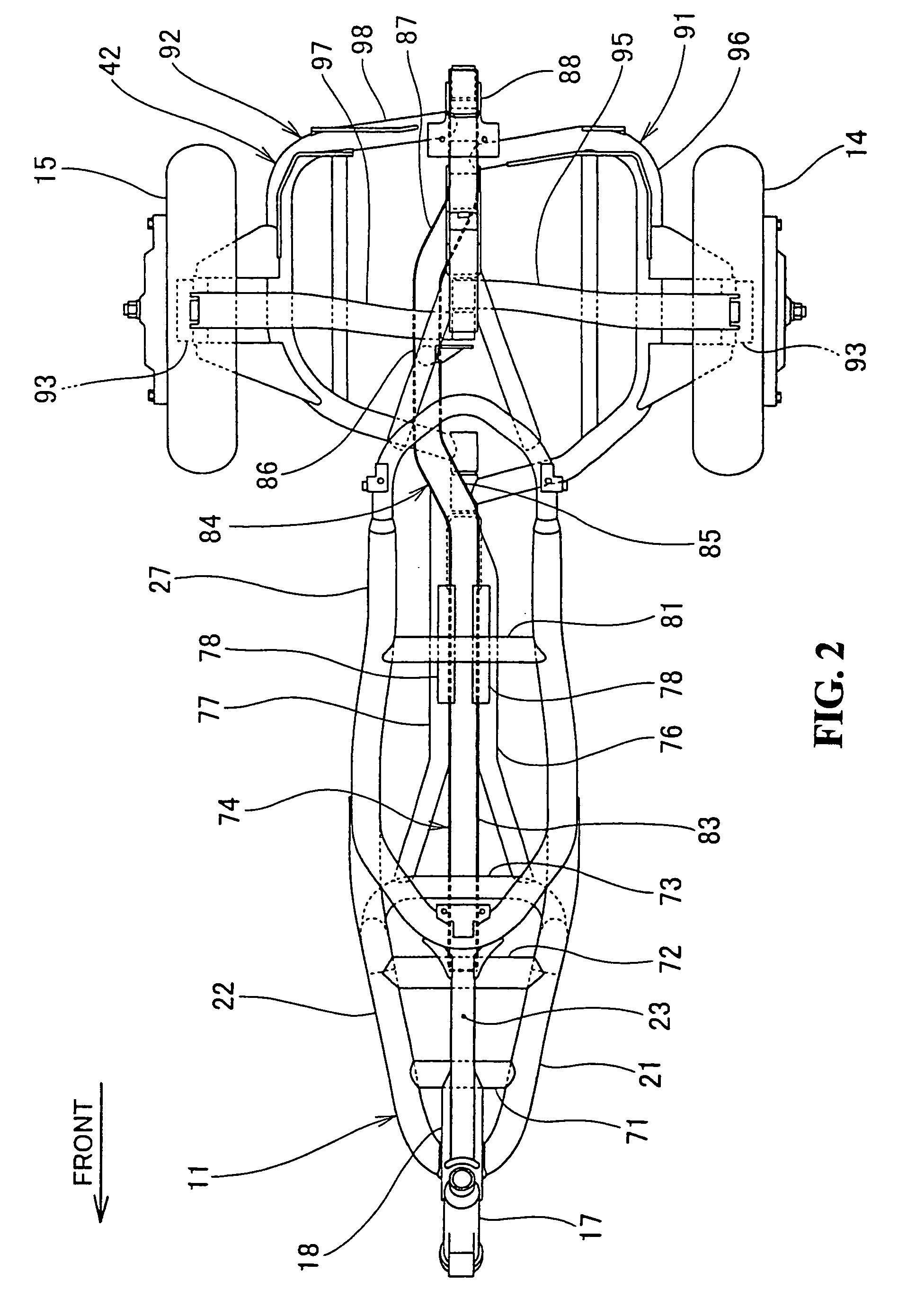

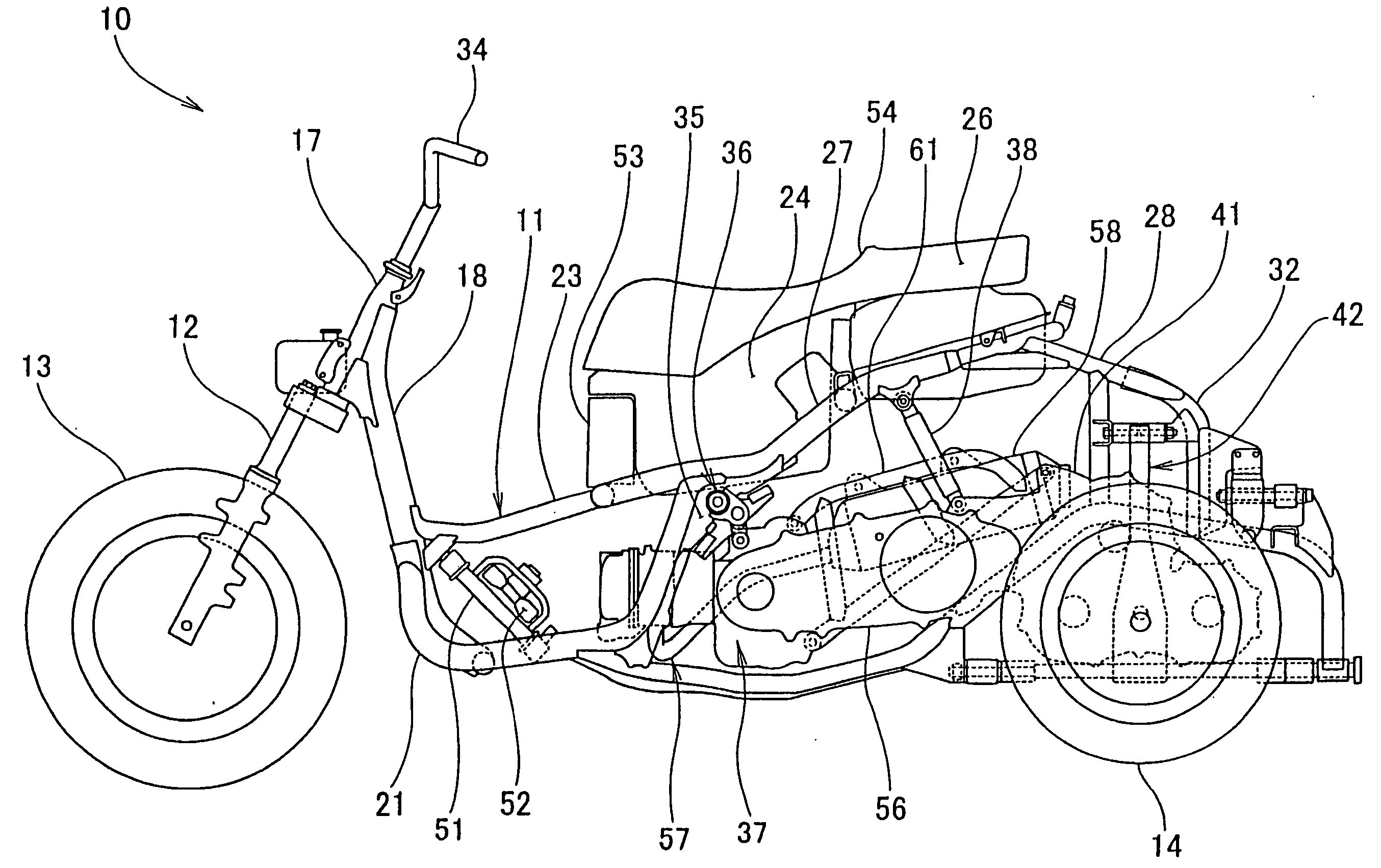

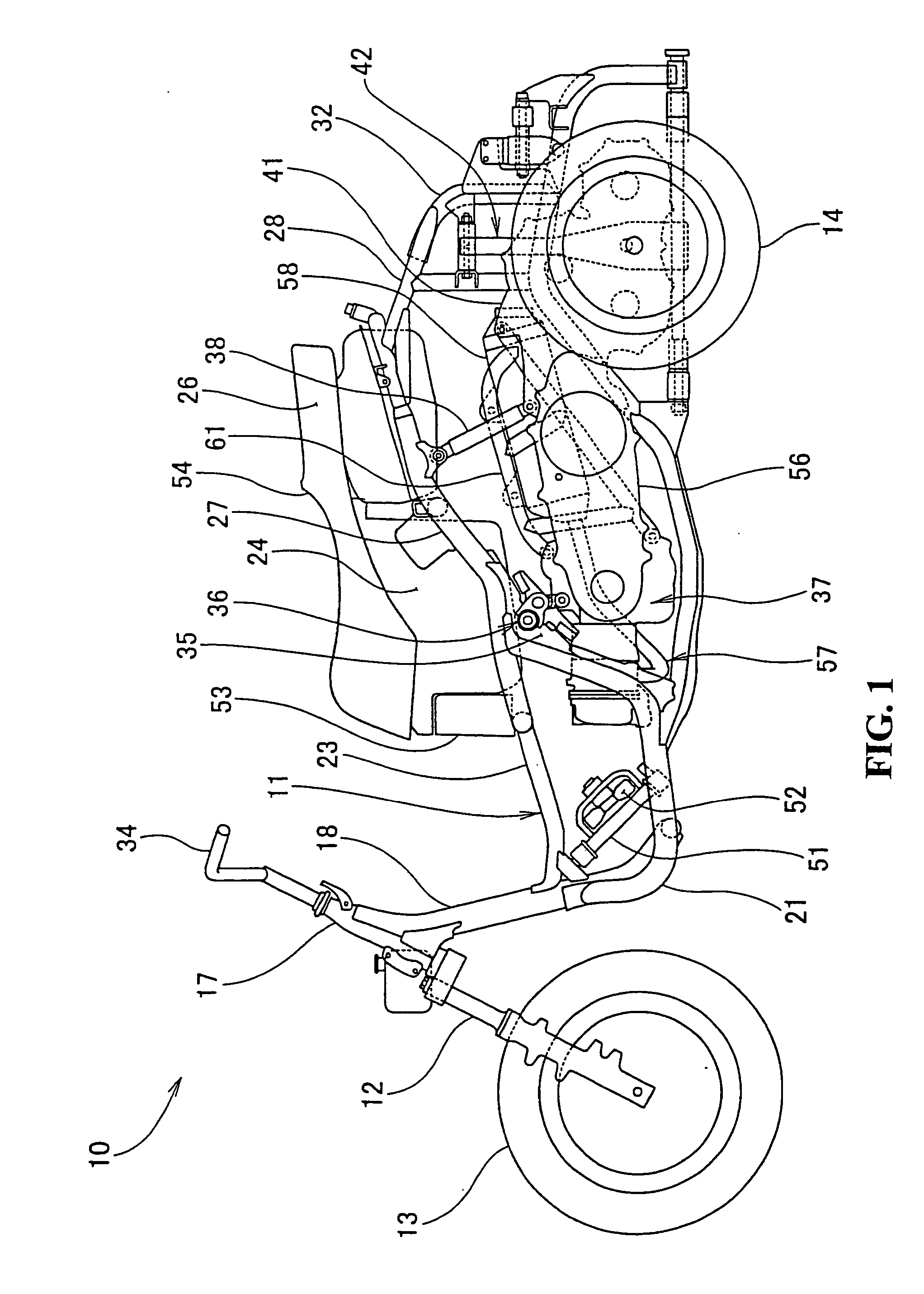

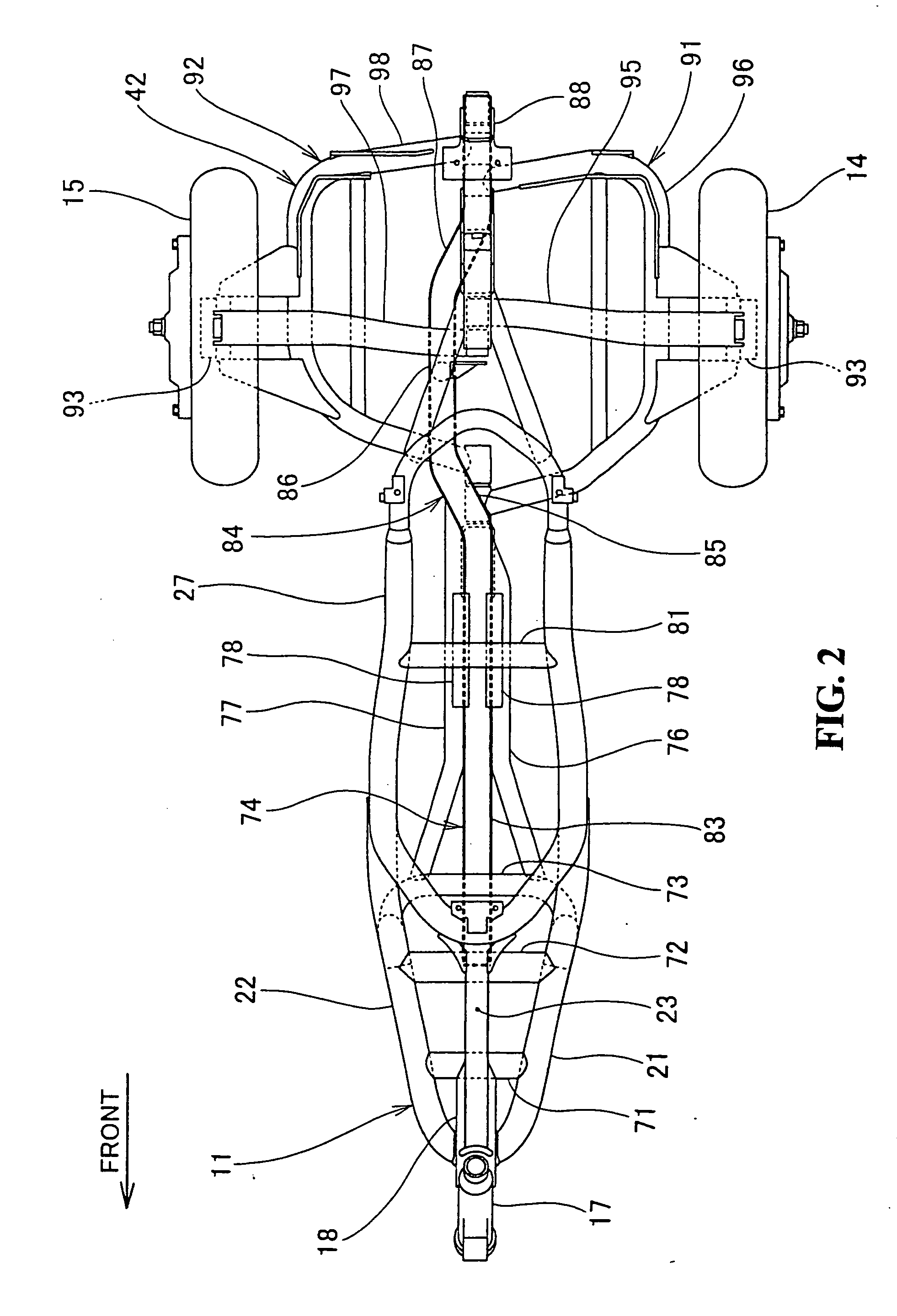

Swingable vehicle

InactiveUS7311167B2Increase freedomEnlarge the bend anglesCyclesVehicle body-frame connectionsDrive shaftEngineering

A left drive shaft and a right drive shaft each include an inside constant velocity joint and an outside constant velocity joint with a ball spline mechanism provided between the inside constant velocity joint and the outside constant velocity joint for enabling the distance between the inside constant velocity joint and the outside constant velocity joint to be contracted and extended. The ball spline mechanism includes a spline shaft having an outer circumferential surface provided with a plurality of axial grooves extending in the axial direction, a tubular portion surrounding the periphery of the spline shaft and having an inner circumferential surface provided with a plurality of axial grooves extending in the axial direction and a plurality of balls capable of rolling while being fitted in the axial grooves and in the axial grooves. In addition, a left lower arm and a right lower arm are formed into an A-shape and are supported by a lower part of a rising portion and a lower end of the downwardly extending portion via a lower supporting shaft.

Owner:HONDA MOTOR CO LTD

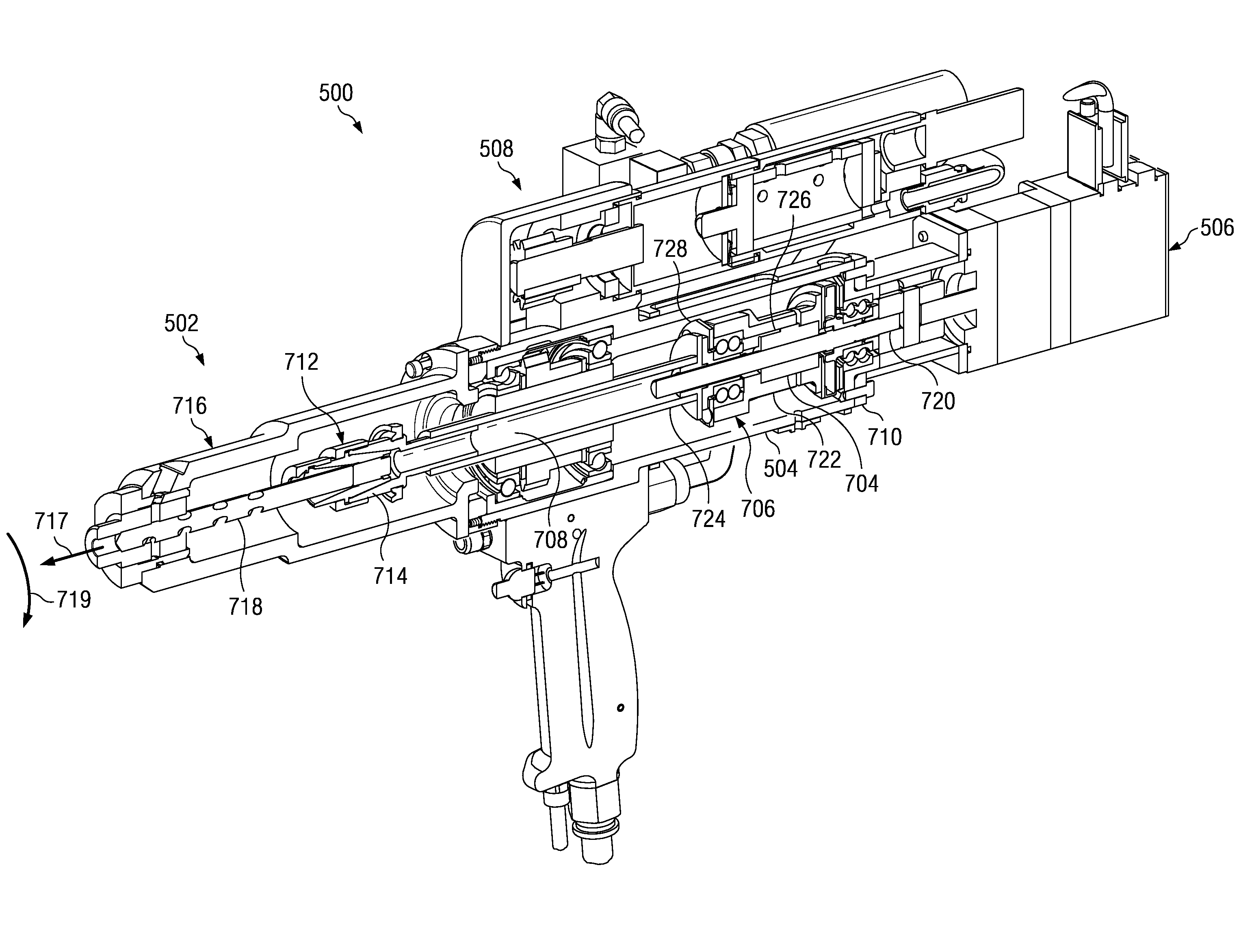

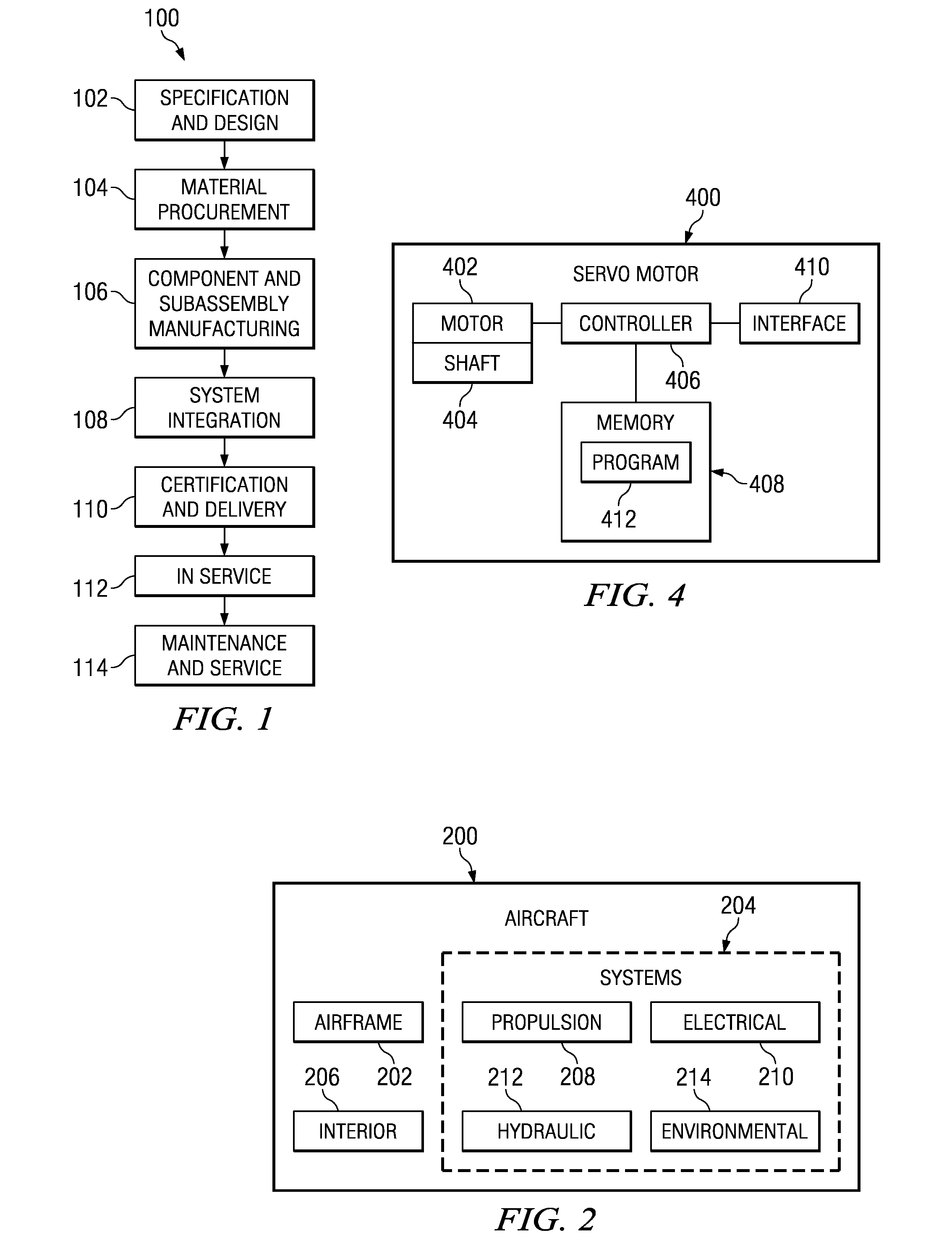

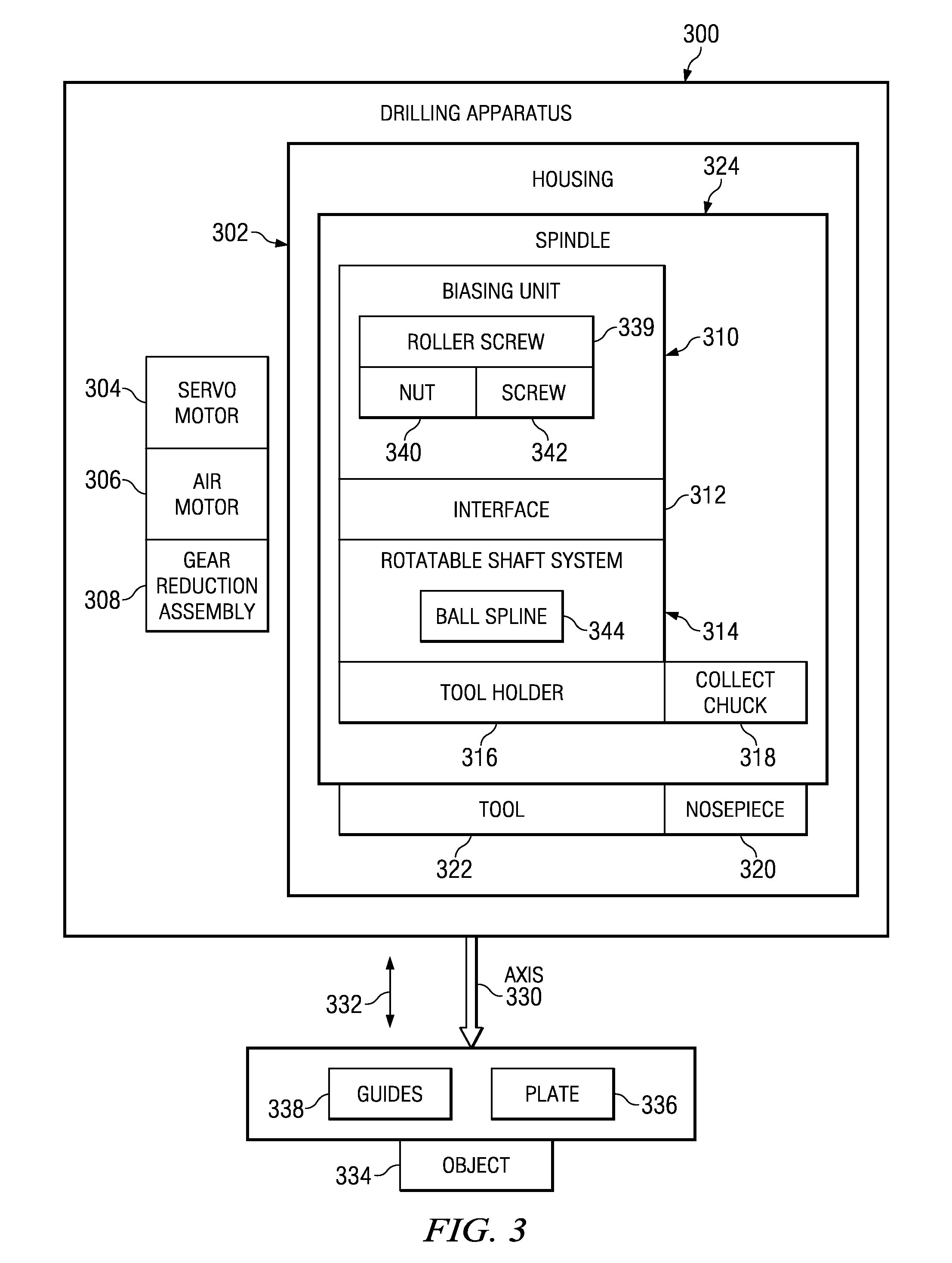

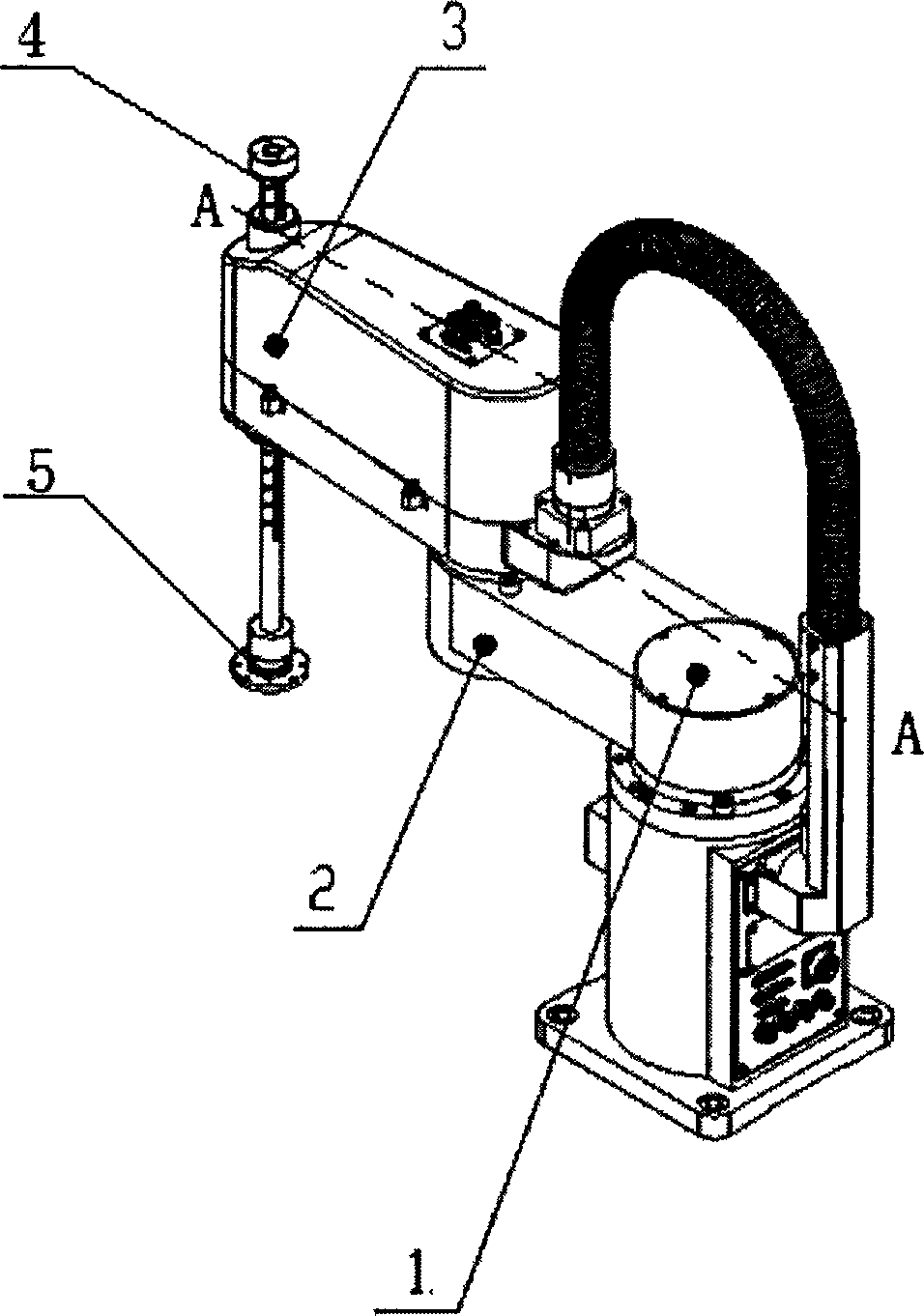

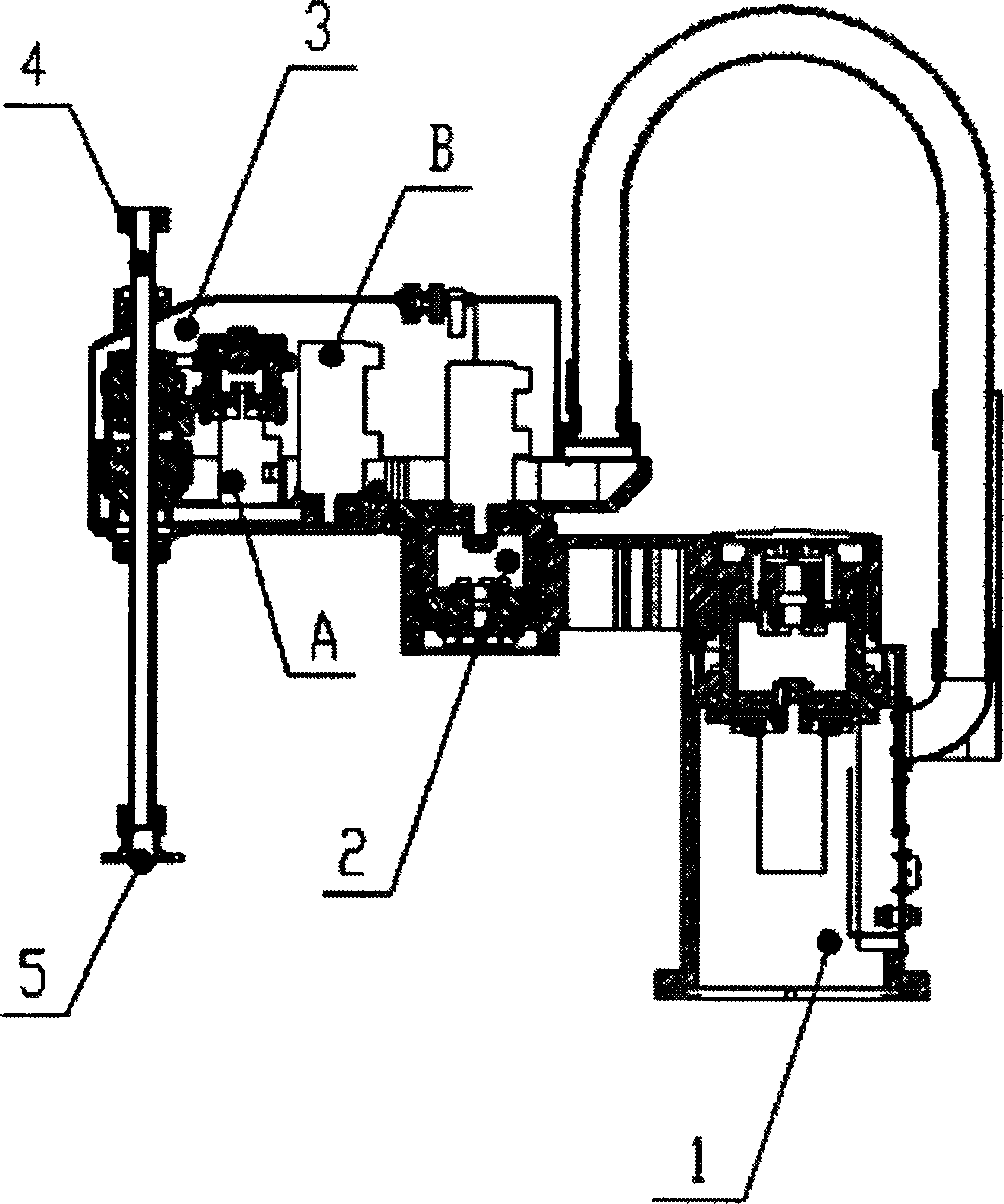

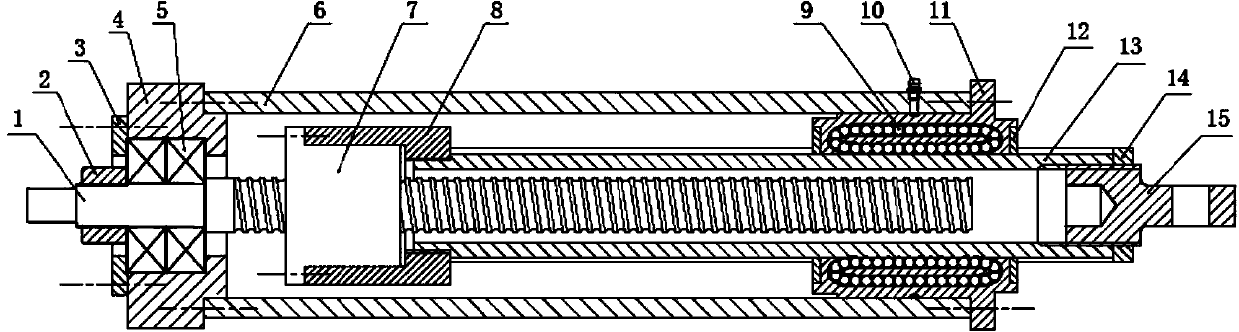

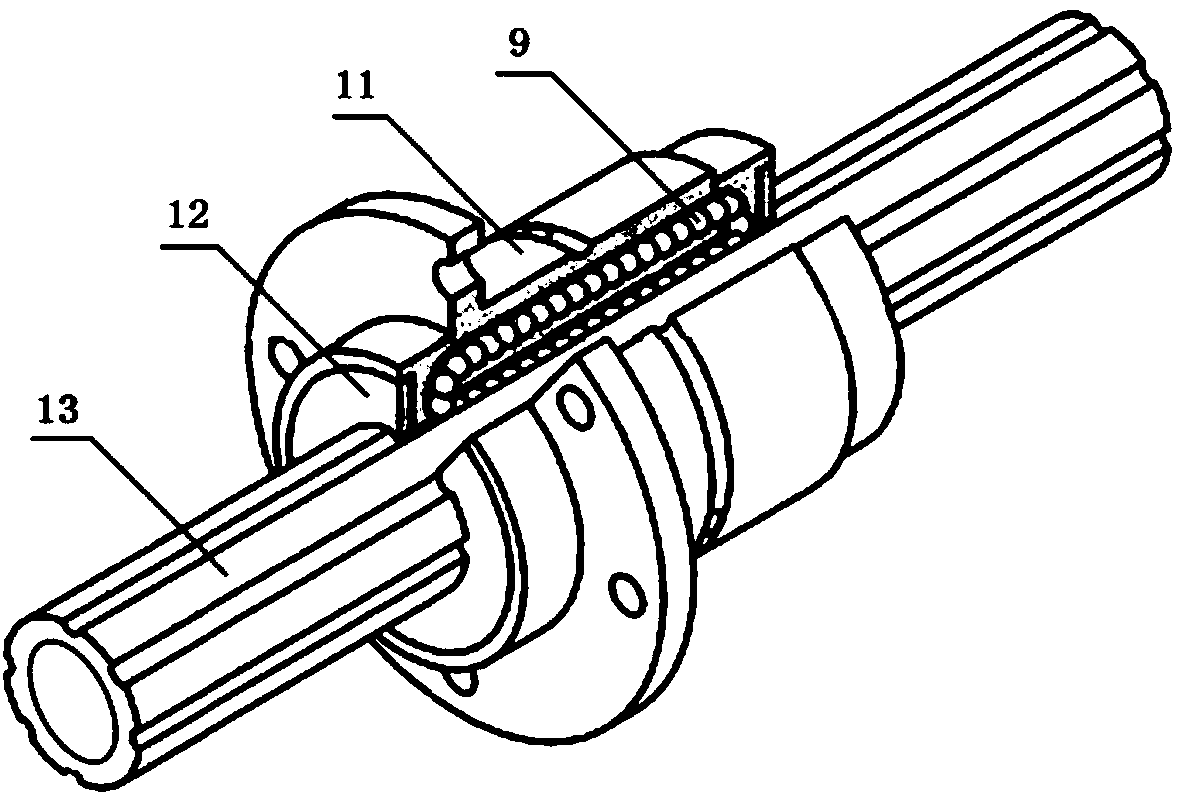

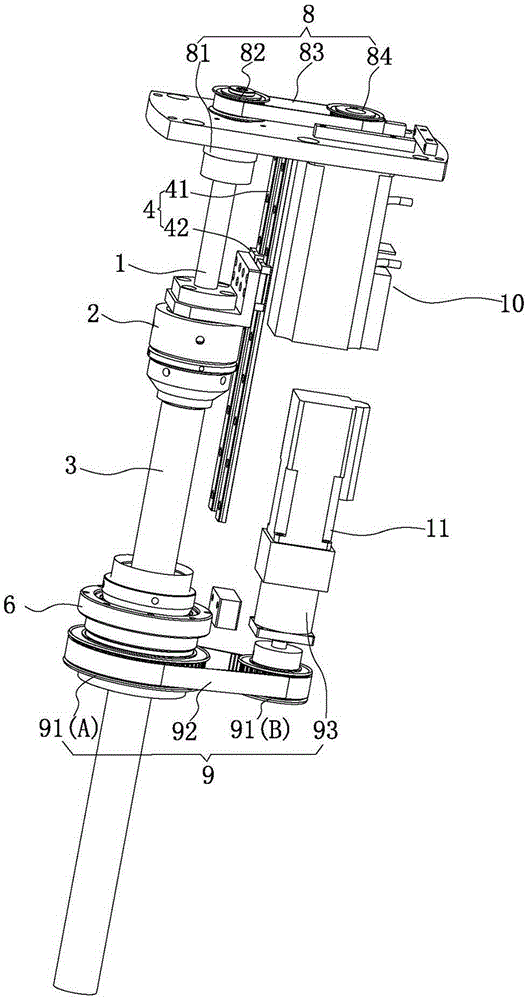

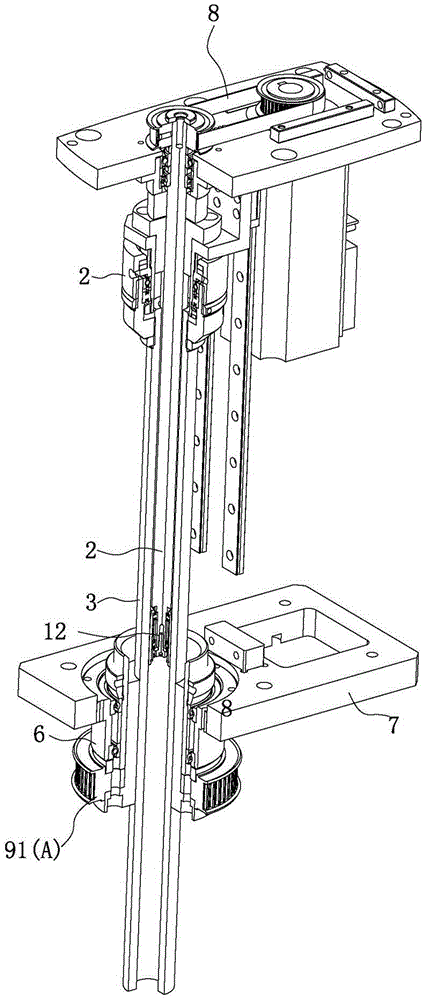

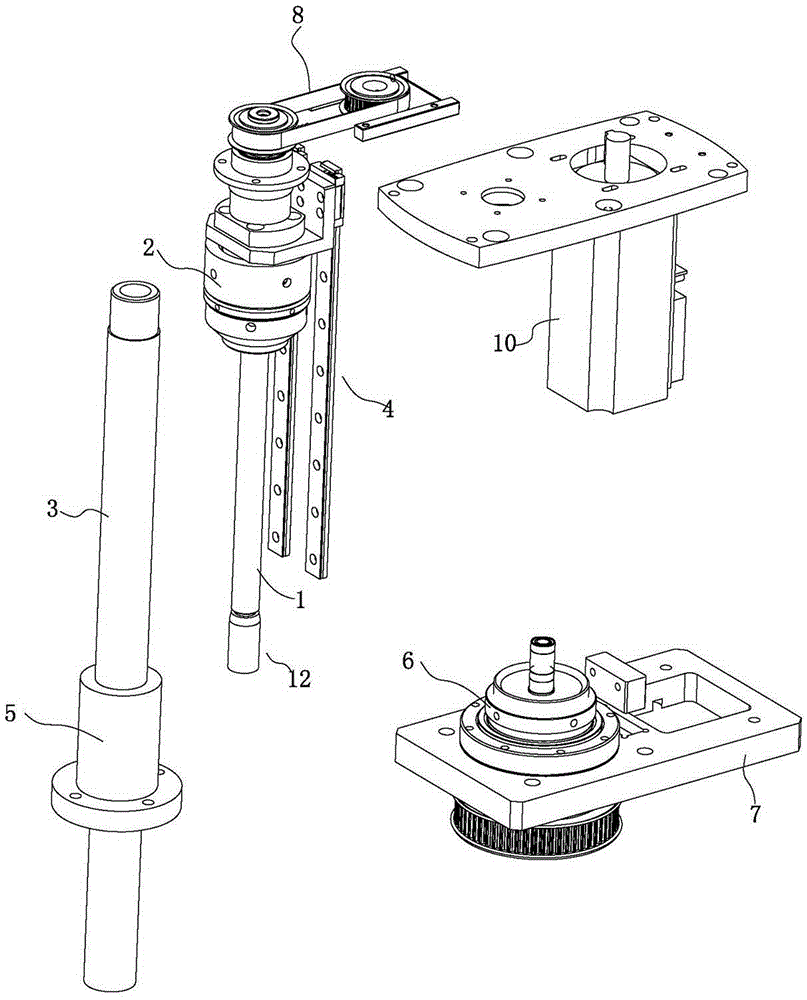

Method and apparatus for a spindle with servo feed control

A method and apparatus for a power feed drill. The power feed drill comprises a servo motor, a roller screw, a ball spline shaft, an air motor, and a collet chuck. The roller screw is rotatably mounted to the servo motor. The ball spline shaft has a first end connected to the roller screw, wherein rotation of the roller screw in a first direction moves the ball spline shaft in the first direction and wherein rotation of the roller screw in a second direction moves the ball spline shaft in an opposite direction to the first direction along an axis. The air motor is capable of transmitting rotation motion to the ball spline shaft to rotate around the axis. The collet chuck is fixably attached to a second end of the ball spline shaft, wherein the collet chuck is adapted to receive a tool.

Owner:THE BOEING CO

Swingable vehicle

InactiveUS20050077098A1Reduce length of driveIncrease freedomCyclesVehicle body-frame connectionsDrive shaftEngineering

A left drive shaft and a right drive shaft each include an inside constant velocity joint and an outside constant velocity joint with a ball spline mechanism provided between the inside constant velocity joint and the outside constant velocity joint for enabling the distance between the inside constant velocity joint and the outside constant velocity joint to be contracted and extended. The ball spline mechanism includes a spline shaft having an outer circumferential surface provided with a plurality of axial grooves extending in the axial direction, a tubular portion surrounding the periphery of the spline shaft and having an inner circumferential surface provided with a plurality of axial grooves extending in the axial direction and a plurality of balls capable of rolling while being fitted in the axial grooves and in the axial grooves. In addition, a left lower arm and a right lower arm are formed into an A-shape and are supported by a lower part of a rising portion and a lower end of the downwardly extending portion via a lower supporting shaft.

Owner:HONDA MOTOR CO LTD

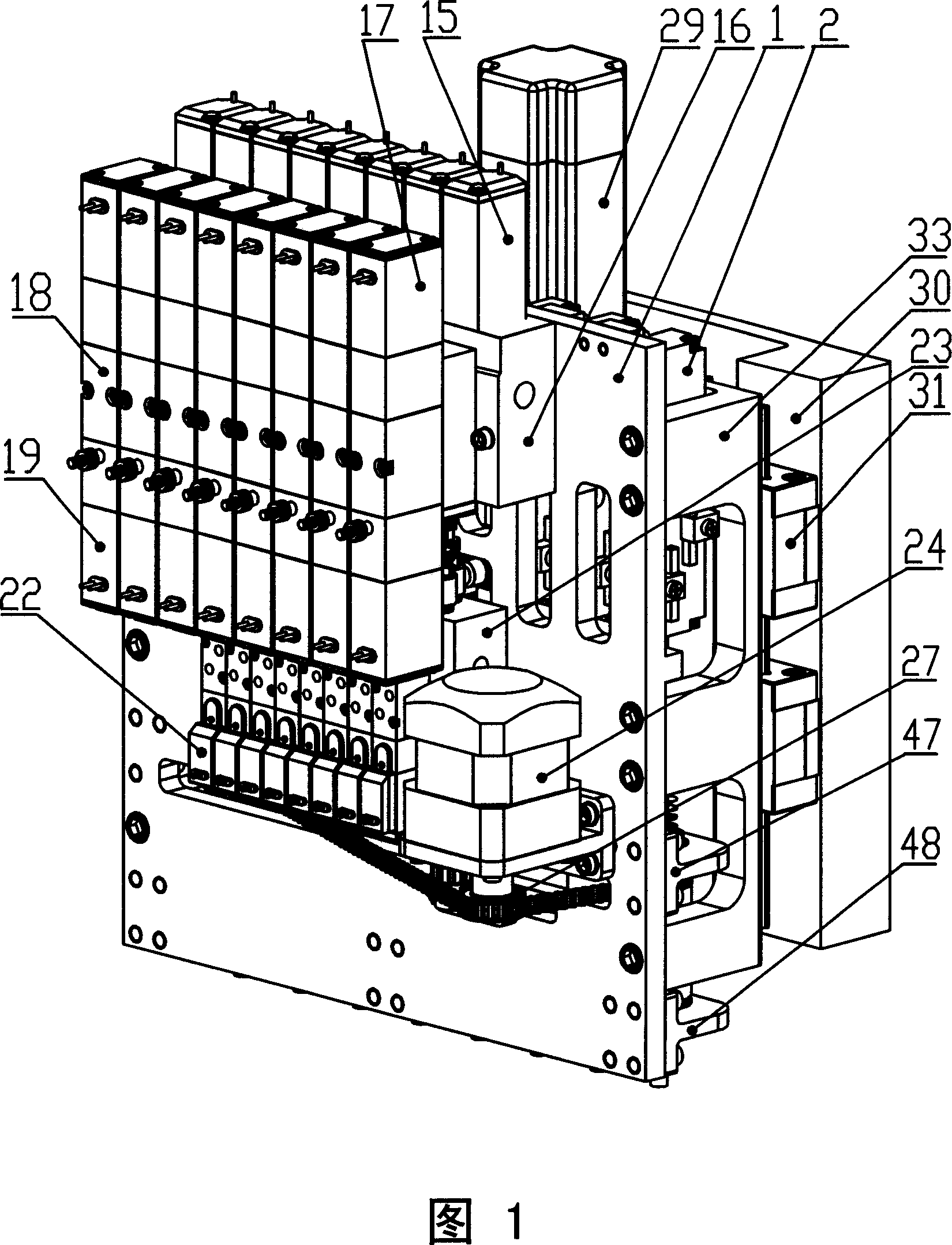

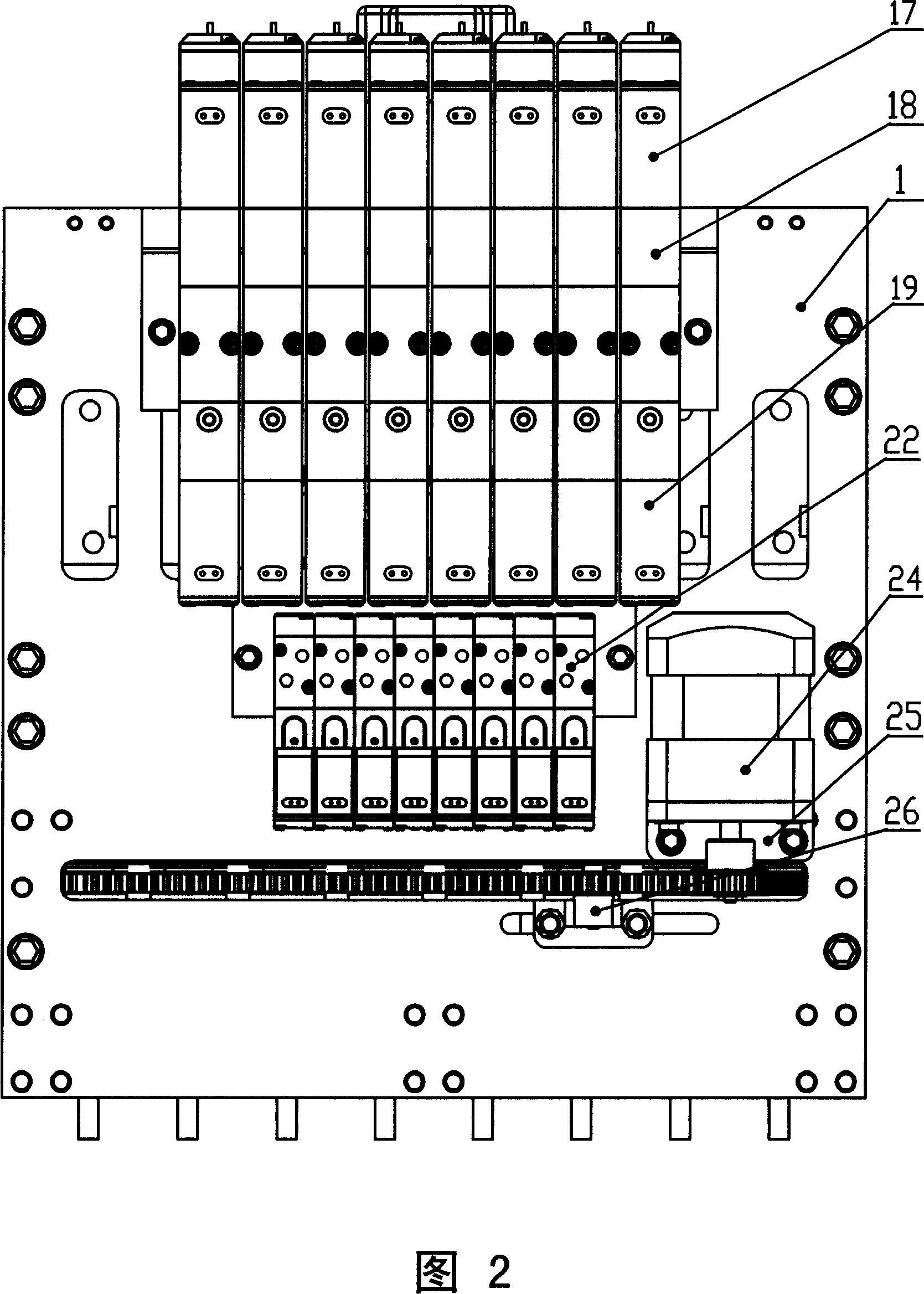

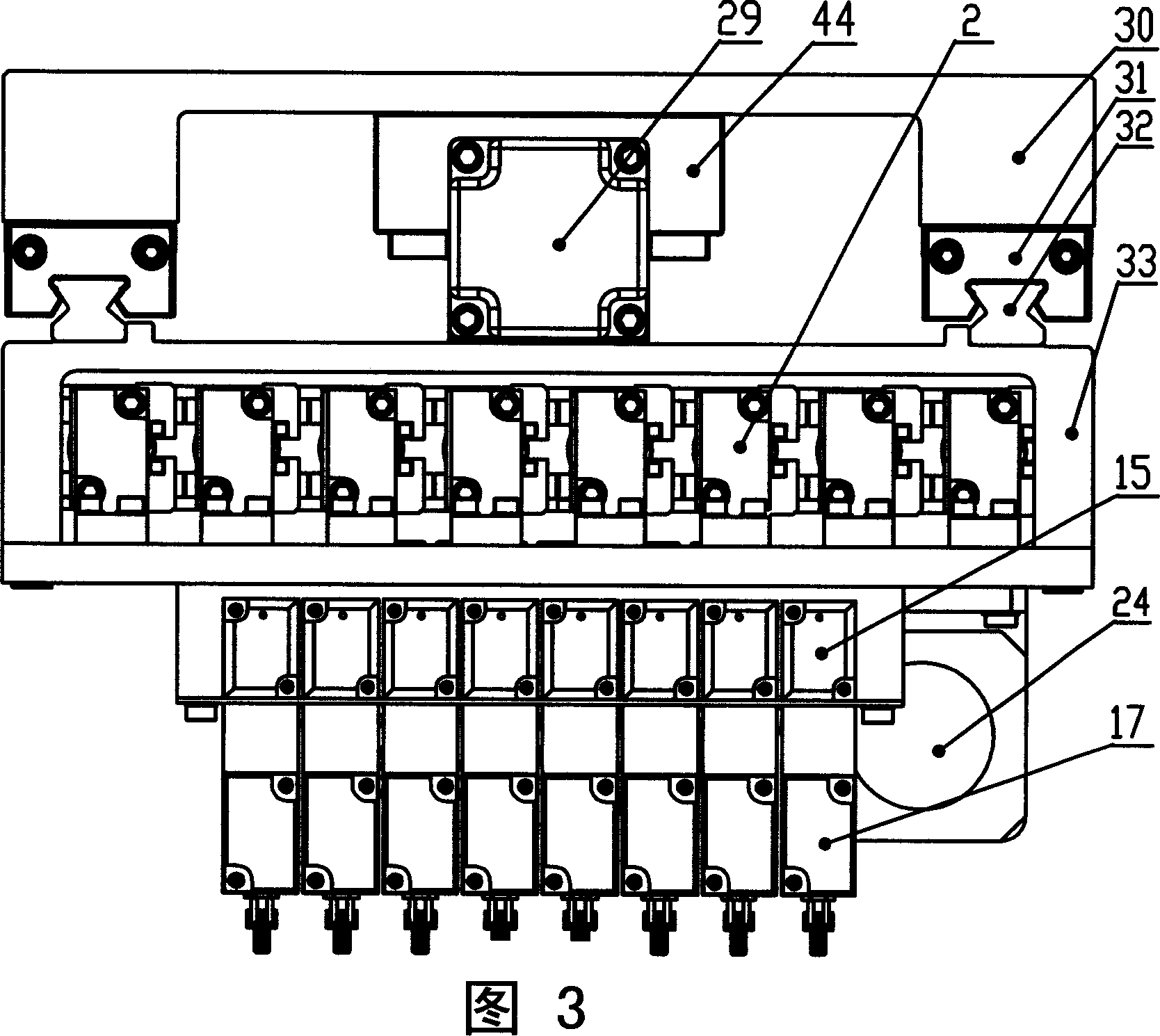

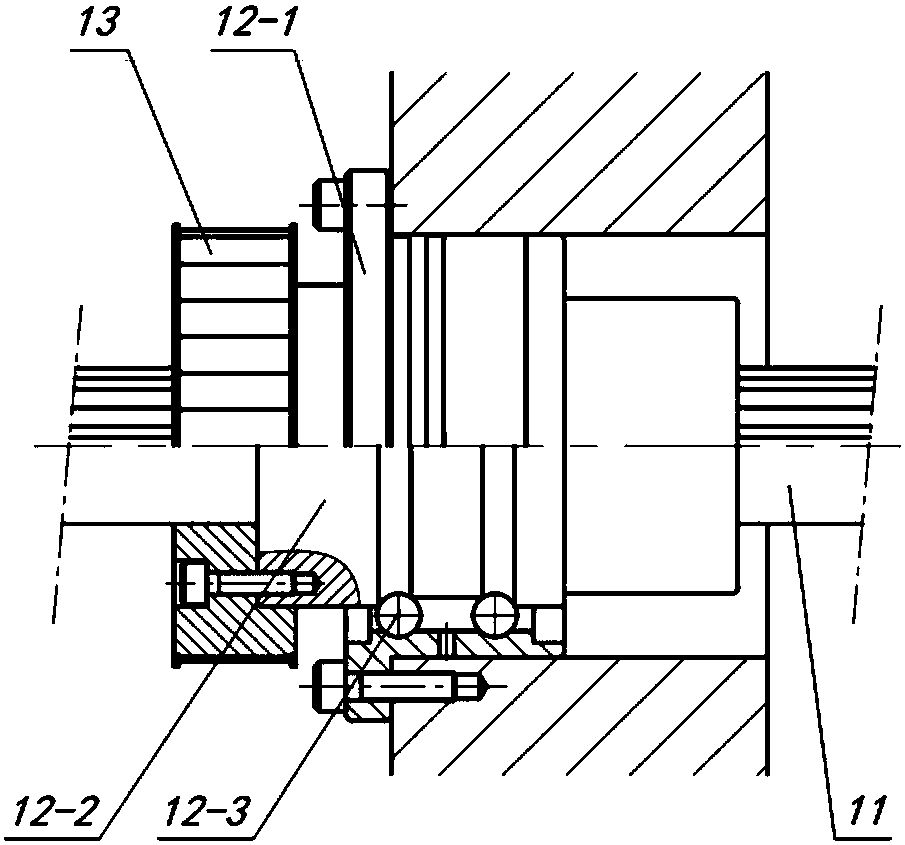

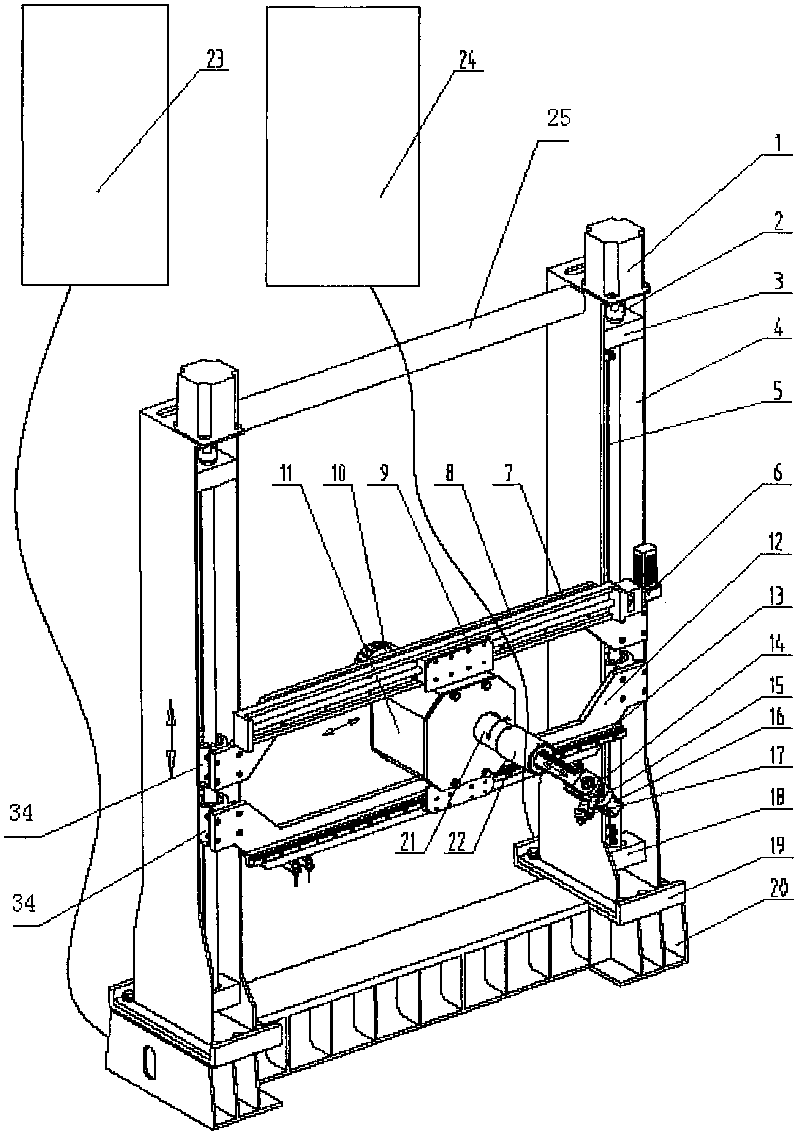

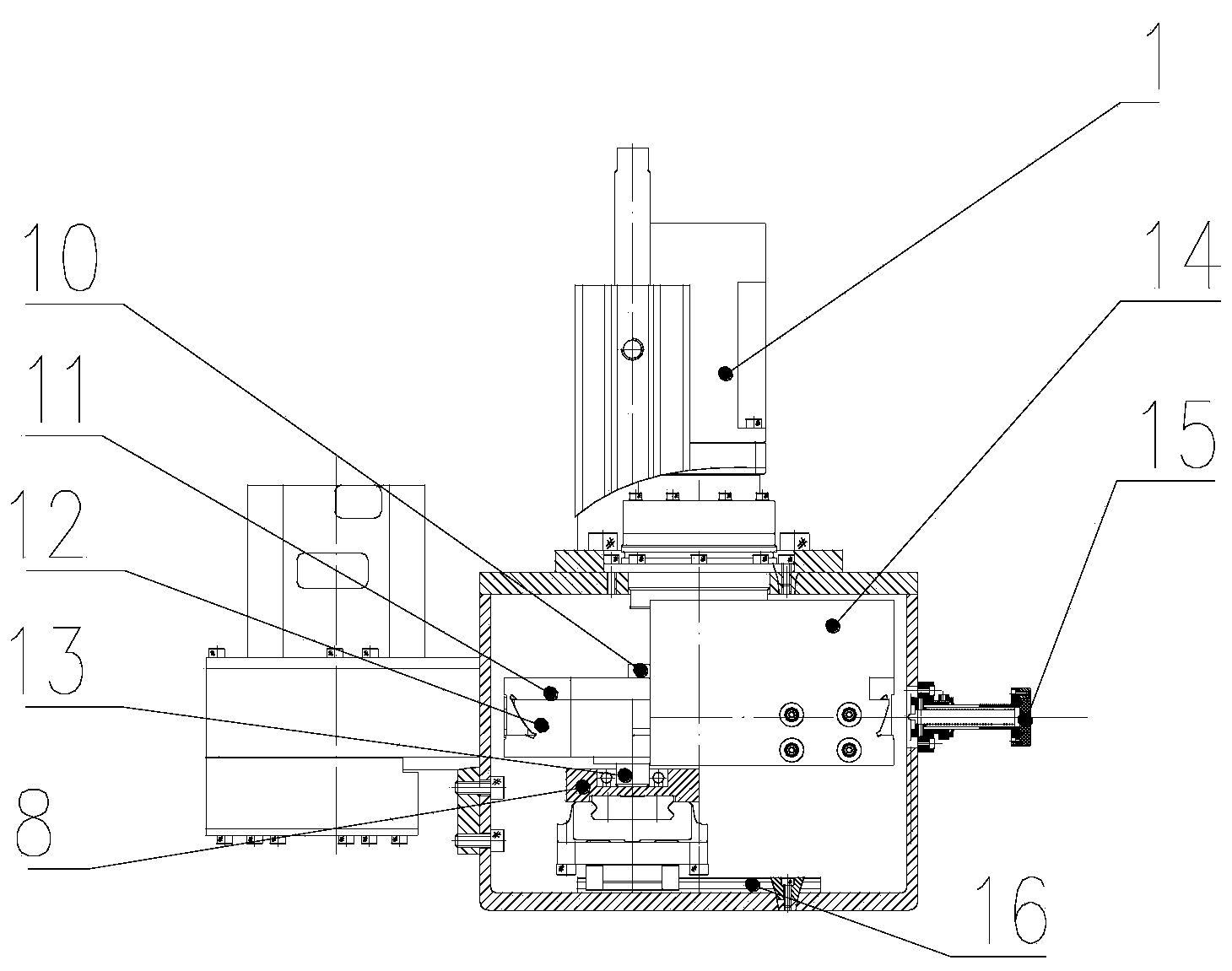

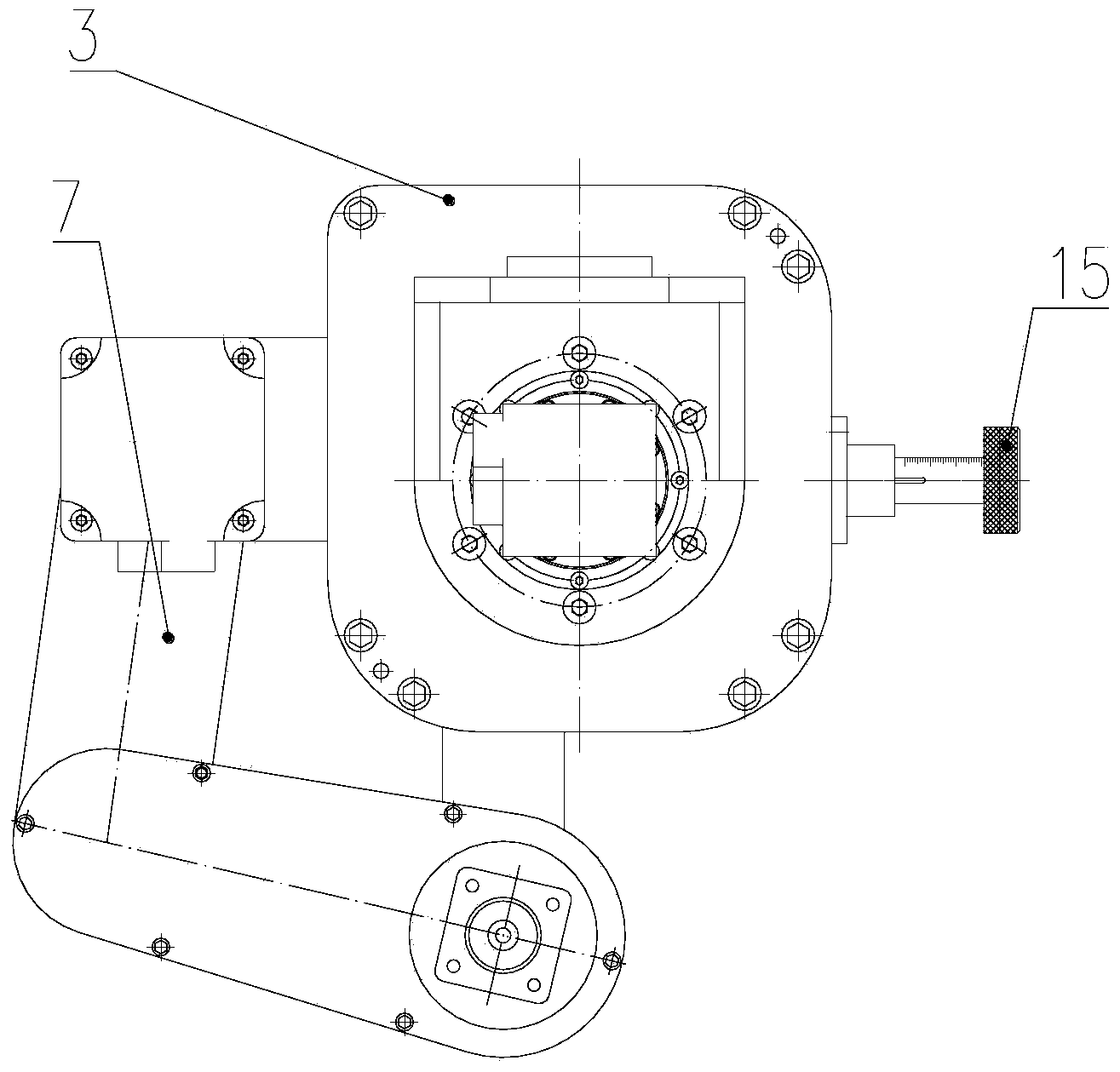

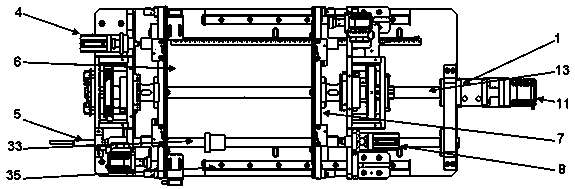

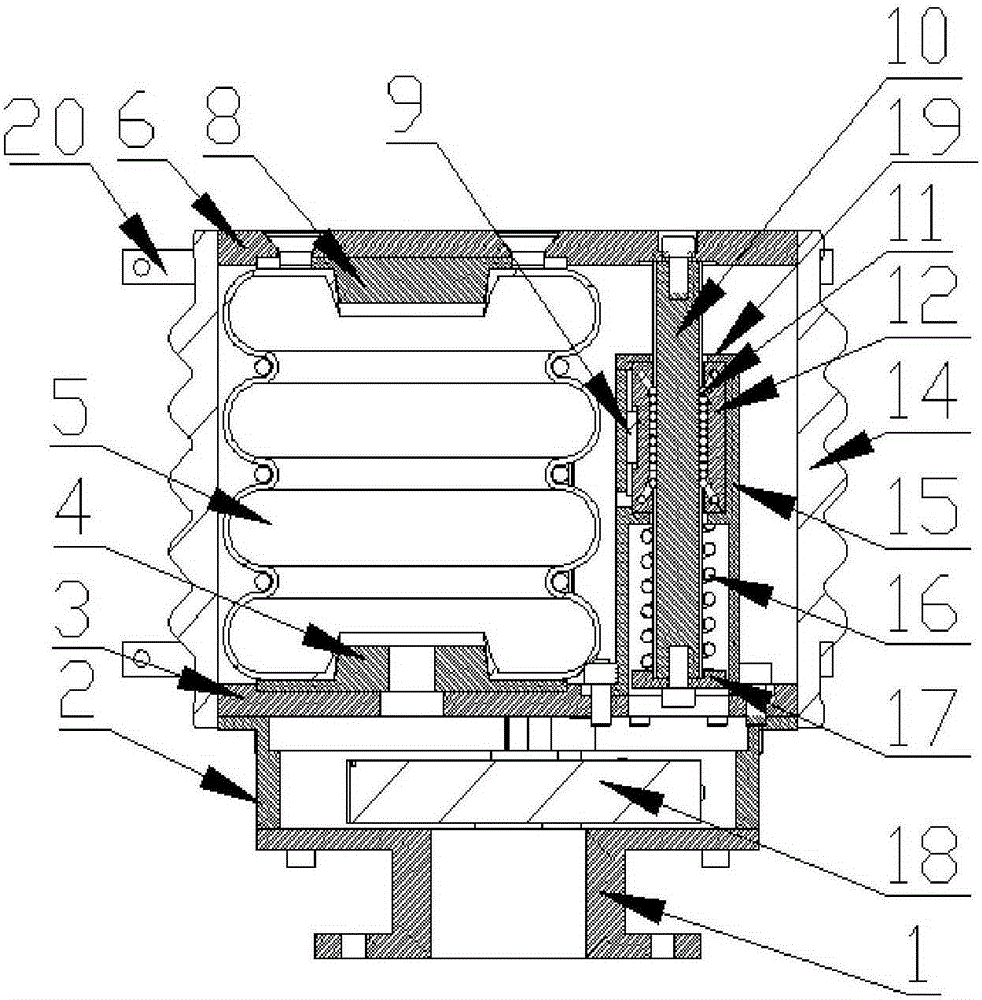

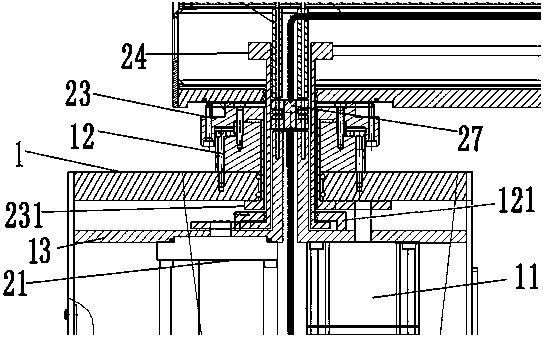

High speed full-automatic paster machine array type mounting head

InactiveCN101098618AReduce the center axis distanceConvenient sourcePrinted circuit assemblingElectrical componentsControl signalControl system

The invention provides a high-speed full-automatic paste machine array paste head, which uses a main frame as core, while other systems and modules are assembly on the main frame. A cylinder module, a cylinder control module, and a Z-axis motion system form the Z-axis motion of the paste head. When in use, the cylinders of the cylinder module execute paste missions in turn, while only one cylinder works at one time. A ball spline module and a theta control system process the bias correction of chop. When moves at theta angle, all splines of the ball spline module work together, while the bias parameter of each spline is realized by a control-software. A vacuum system generates the control signals for the blow and adsorption of a vacuum resource and a chip, while the vacuum resource via a vacuum inlet of a micro cylinder in the cylinder module, a hollow piston rod, and a hollow spline shaft of the ball spline module, transmits vacuum to the end of the paste head to absorb and paste the chip.

Owner:BEIHANG UNIV

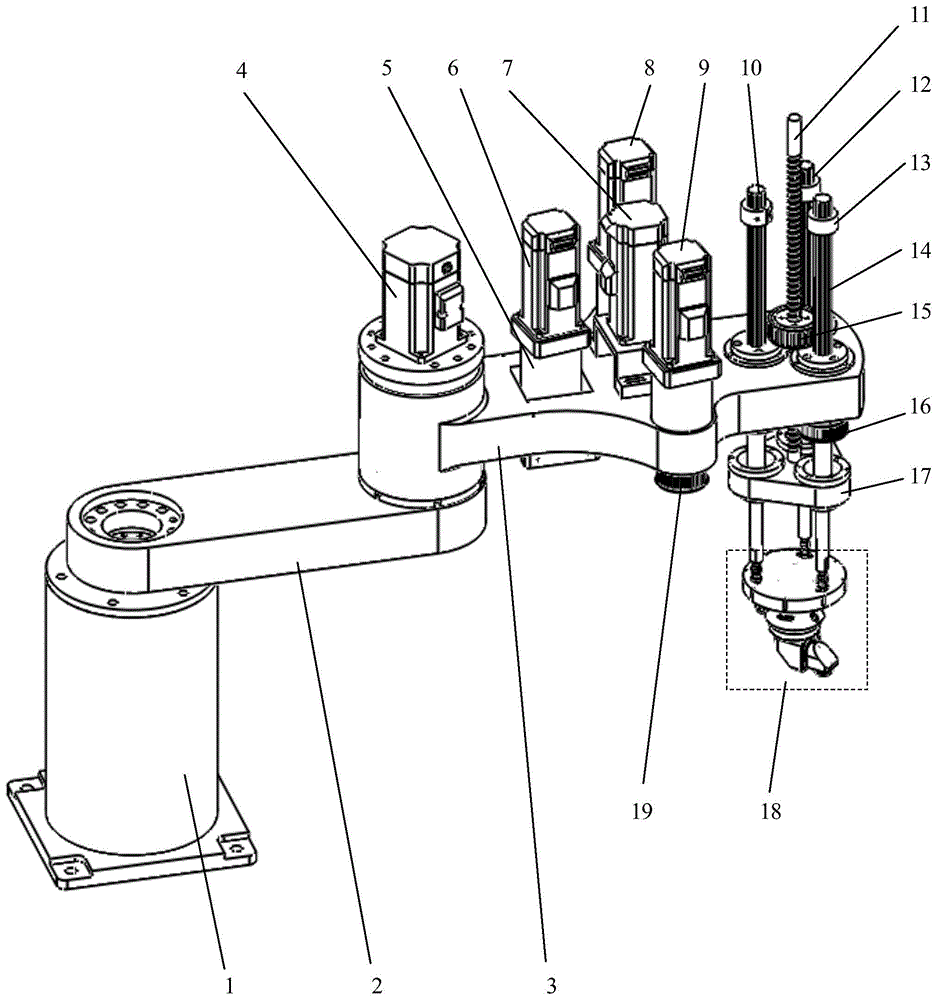

Scara robot

InactiveCN103624794AImprove running stiffnessFulfil requirementsProgramme-controlled manipulatorJointsBall bearingThird harmonic

The invention discloses a Scara robot which comprises a first rotation joint, a second rotation joint, a rotation and movement compound motion joint and a spline lead screw. The first rotation joint is connected with the second rotation joint, the other end of the second rotation joint is connected with the rotation and movement compound motion joint, the rotation and movement compound motion joint comprises a rotation joint and a movement joint, the rotation joint is output through a third servo motor, decelerated through a third harmonic reducer and driven to a ball spline inner ring through a synchronous belt, and a deep groove ball bearing is added in the third harmonic reducer to be used as an auxiliary support. According to the Scara robot, the deep groove ball bearing is added in the third harmonic reducer in the rotation and movement compound motion joint, therefore, the operation rigidity of the robot is effectively improved, the structure is compact, and the accuracy is high.

Owner:ZHANGJIAGANG NUOXIN AUTOMATION EQUIP

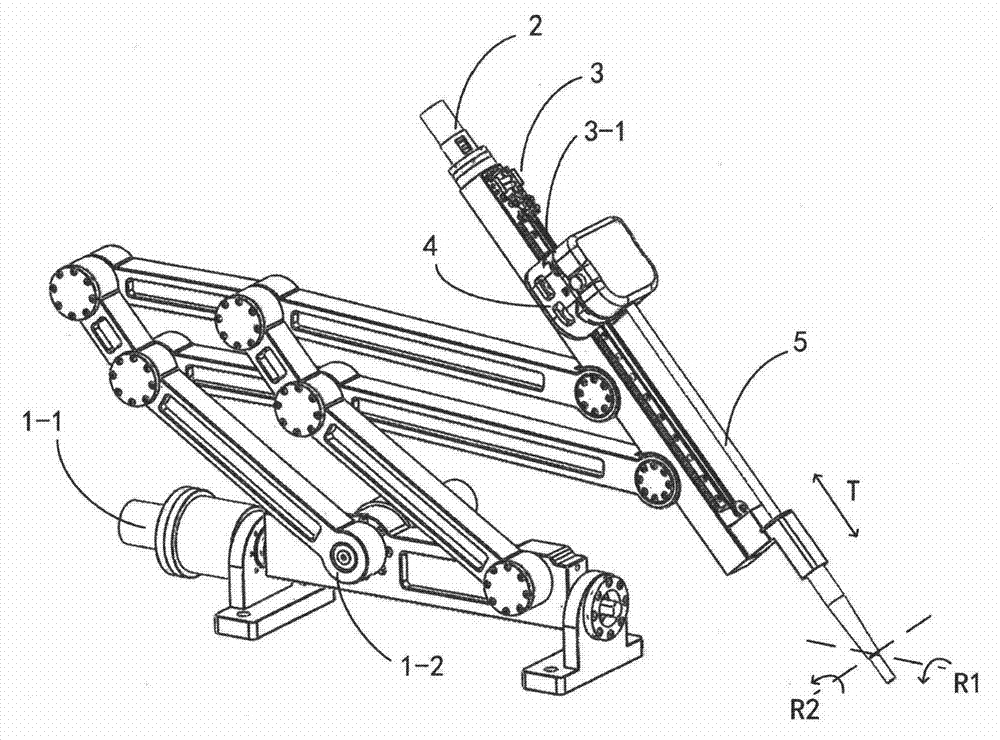

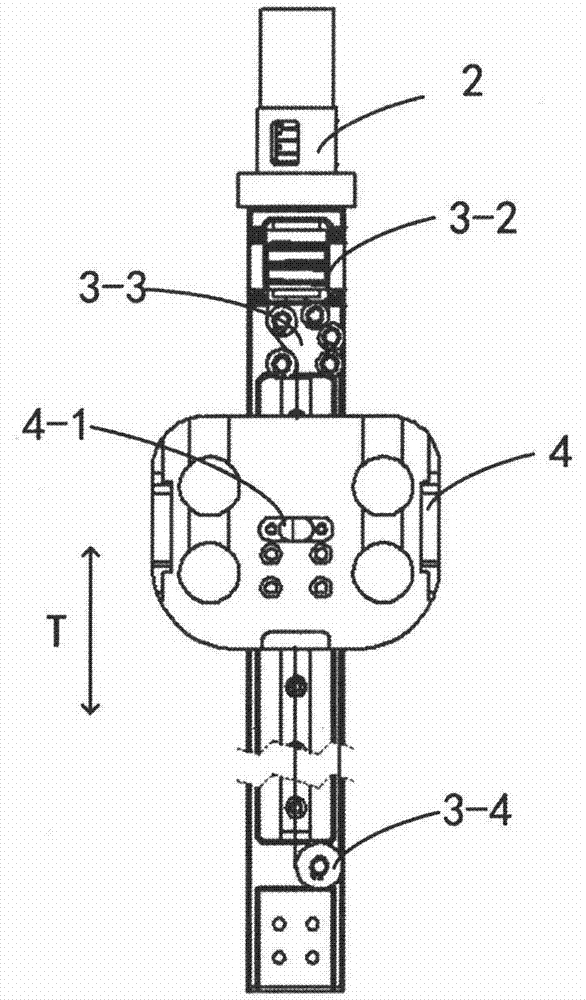

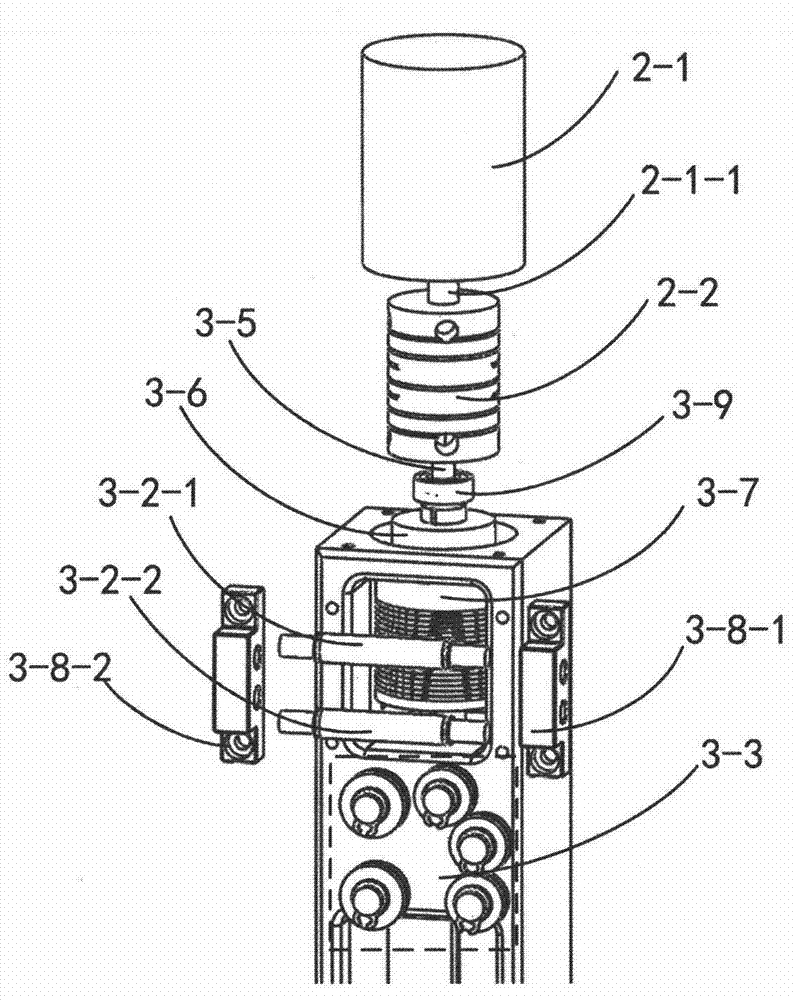

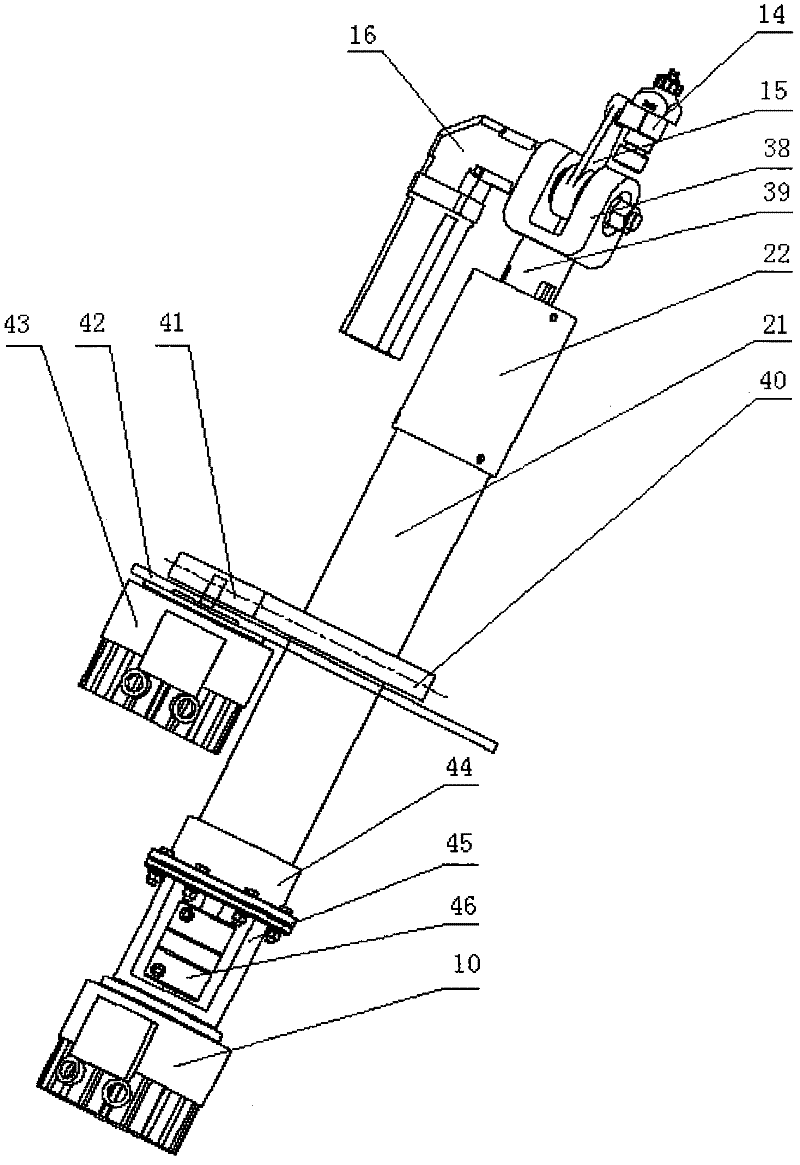

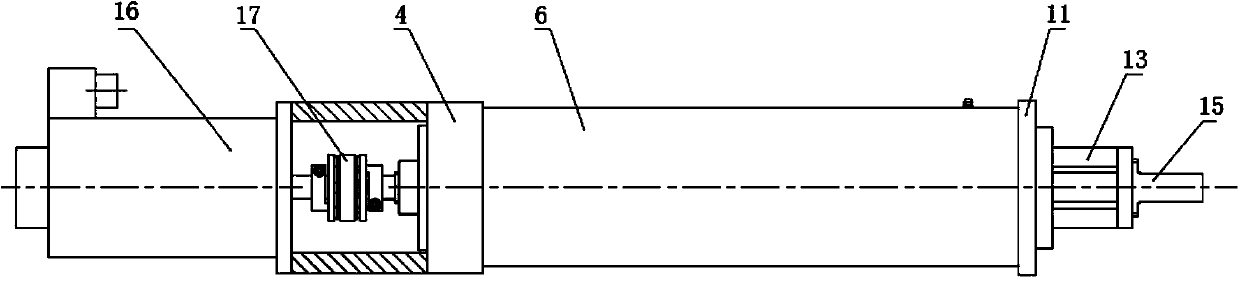

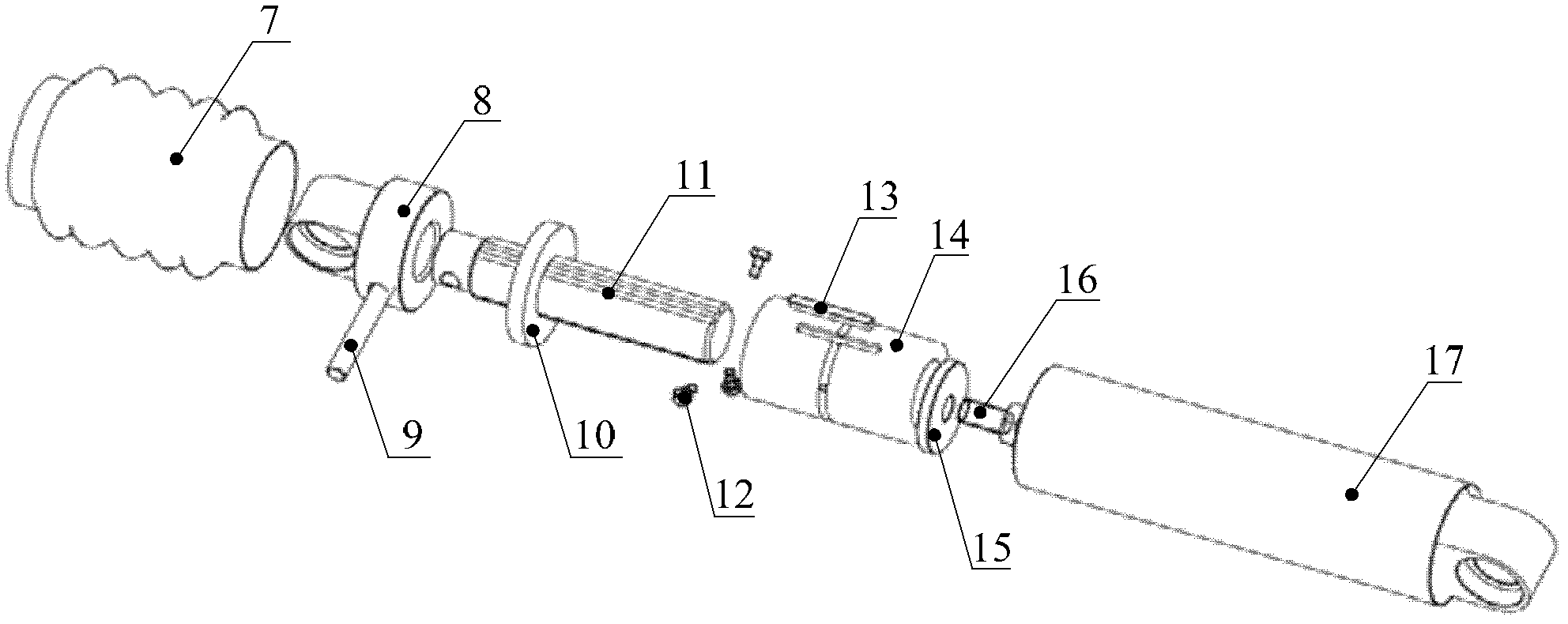

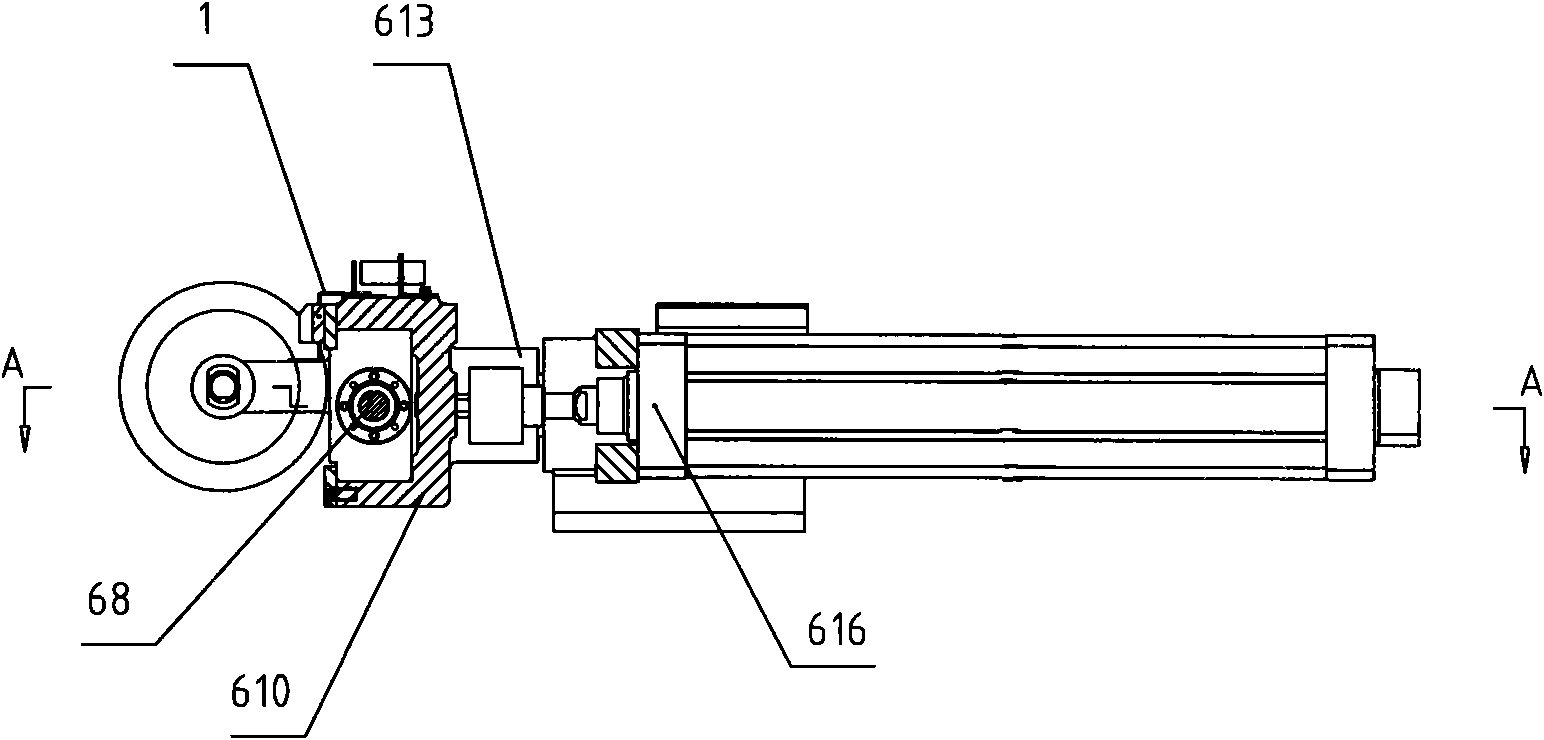

Steel wire rope transmitting linear telescopic mechanism for minimally-invasive surgery robot

The invention discloses a steel wire rope transmitting linear telescopic mechanism for a minimally-invasive surgery robot. The steel wire rope transmitting linear telescopic mechanism mainly comprises a driving system, a steel wire rope transmitting device and a tail end actuating mechanism. The driving system is composed of a rear servo motor, a speed reducer and a coupler, wherein the output shaft of the speed reducer is connected with a ball spline shaft through the coupler to transmit movement to the steel wire rope transmitting system. The steel wire rope transmitting system is composed of a steel wire rope, a ball spline, a spline screw barrel, a guide shaft and a guide wheel. The mutual conversion between the circumferential motion and the linear motion of the steel wire rope is achieved, and the self linear motion direction change of the steel wire rope is obtained. The tail end actuating mechanism is fixed to a telescopic supporting rod, a linear guide rail is arranged on the telescopic supporting rod, the tail end actuating mechanism is connected with the steel wire rope through a fixing screw device, and the linear motion of the steel wire rope can be transmitted to the tail end actuating mechanism. The steel wire rope is arranged in a closed loop mode. The linear telescopic mechanism has the advantages of being small in occupancy, simple in structure, accurate in control, free of hysteresis error and high in transmitting efficiency.

Owner:TIANJIN POLYTECHNIC UNIV

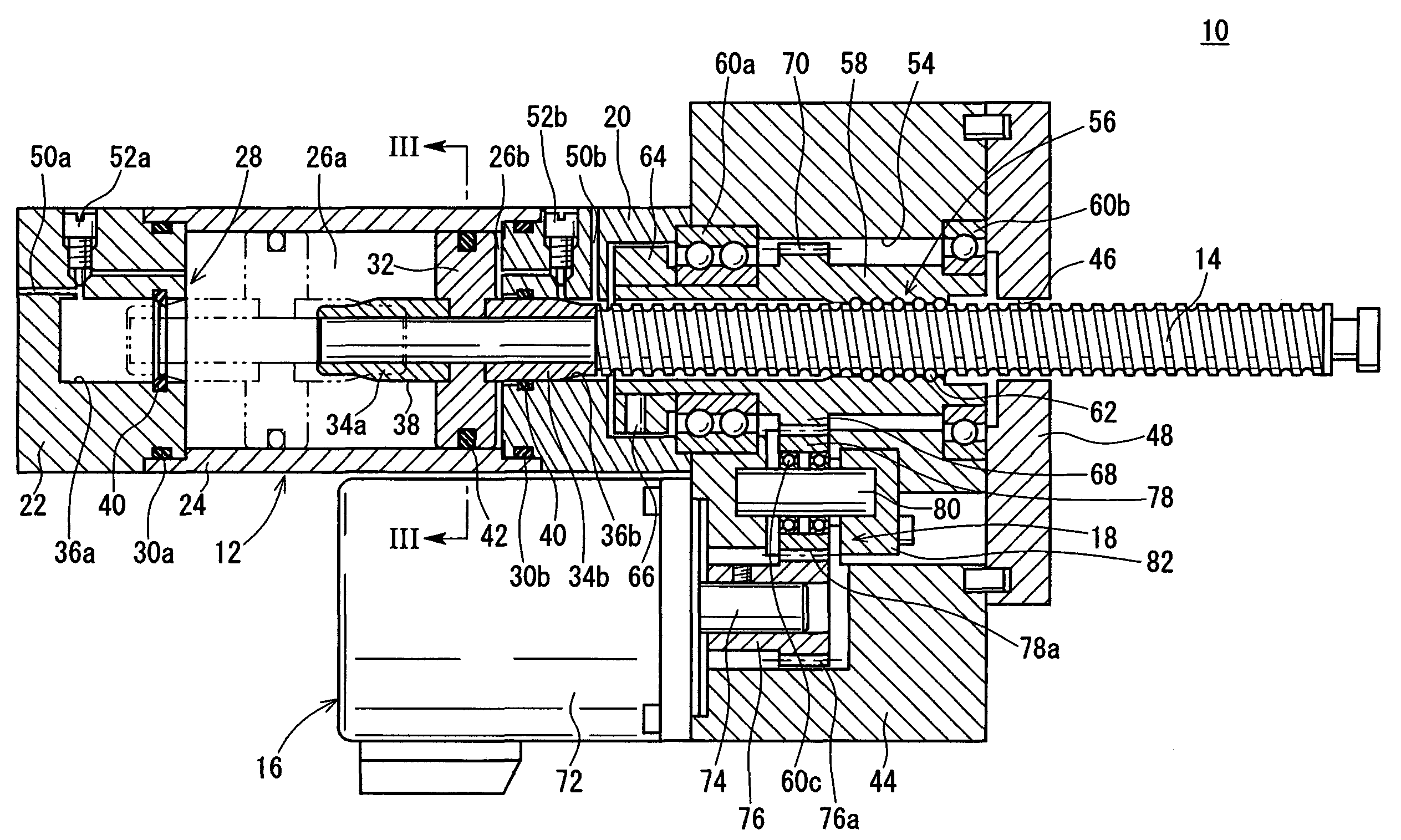

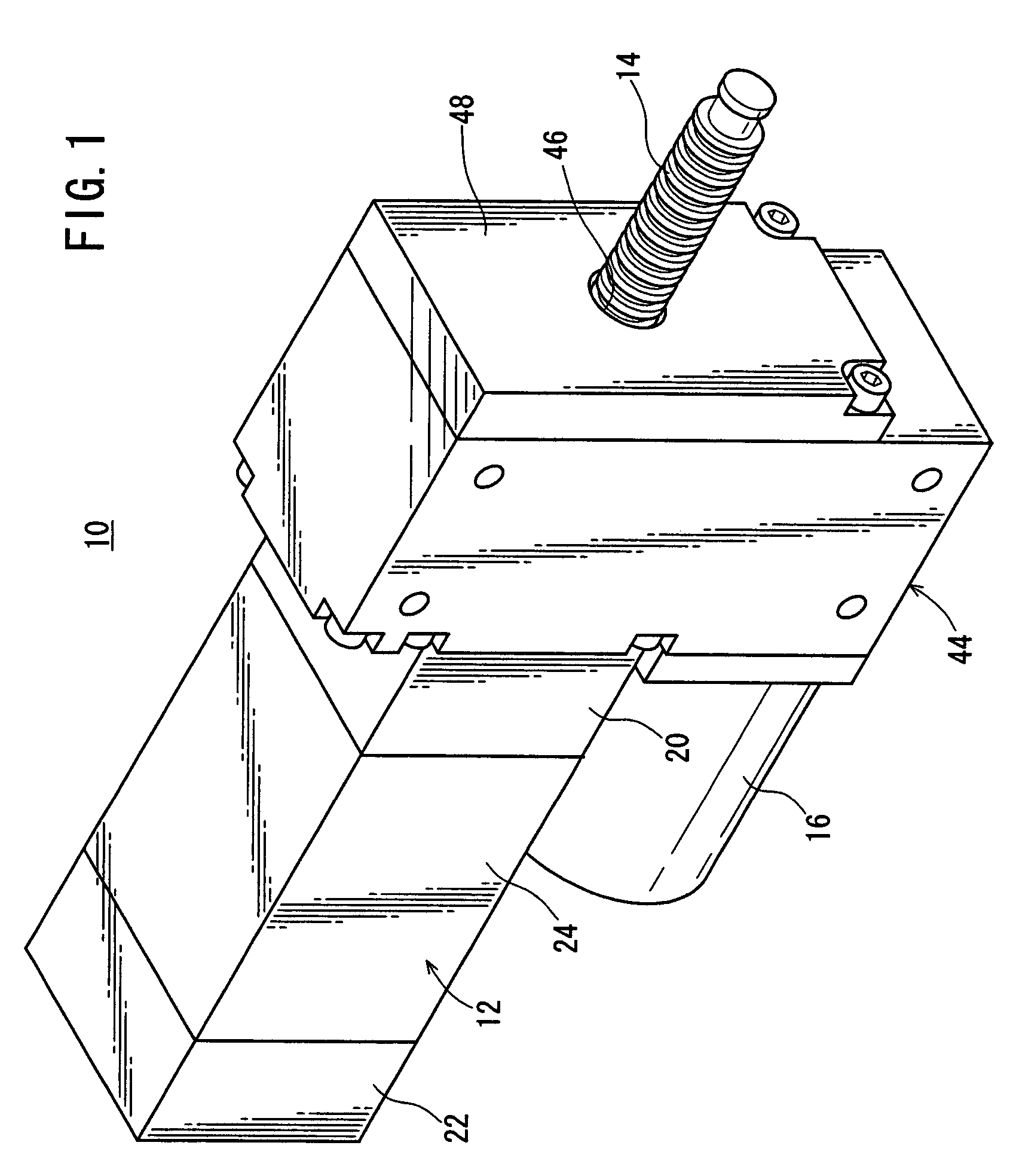

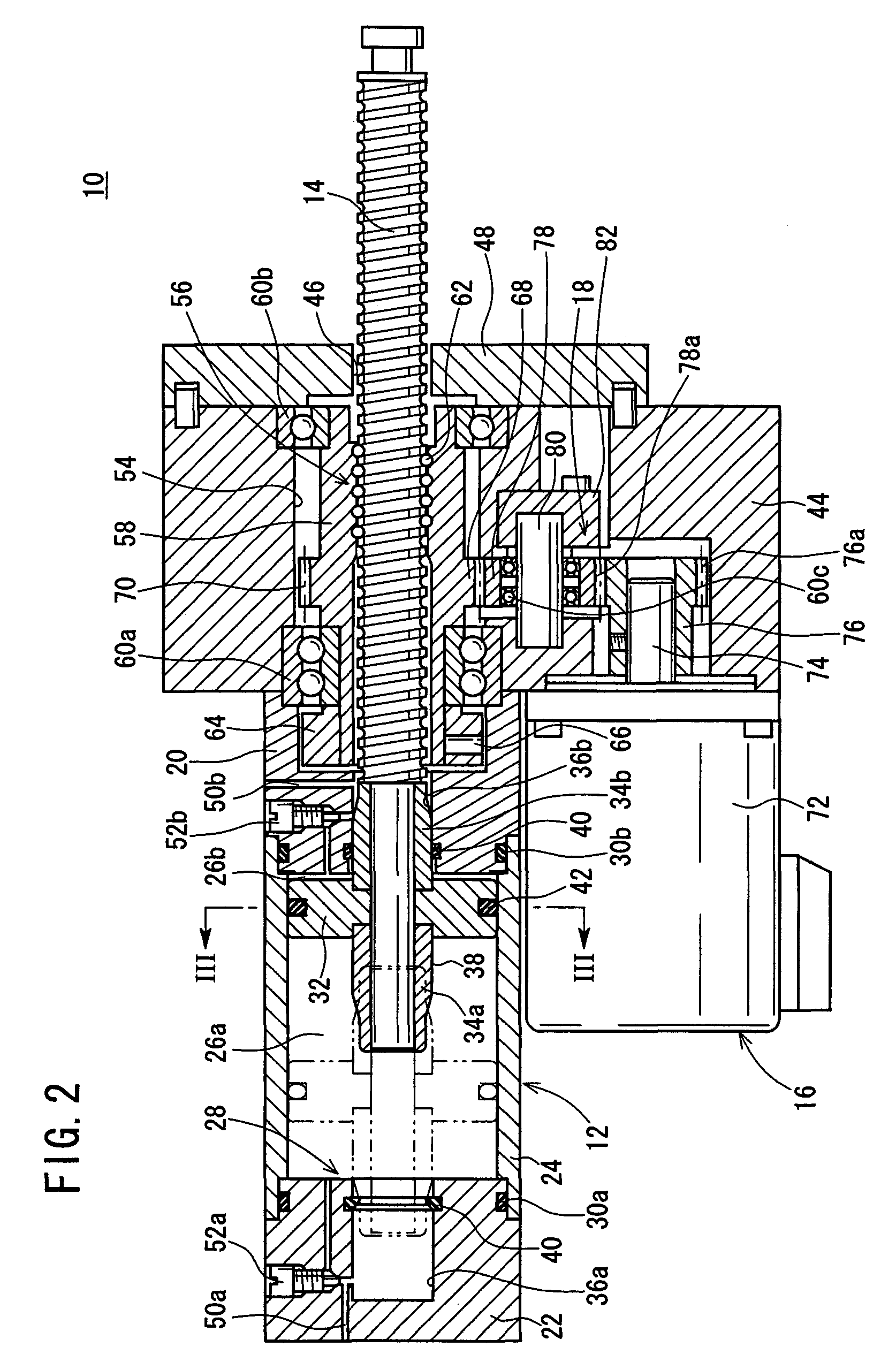

Electronic-component mounting head, electronic-component mounting apparatus, and electronic-component mounting method

InactiveUS6012222APrinted circuit assemblingAutomatic control devicesEngineeringElectronic component

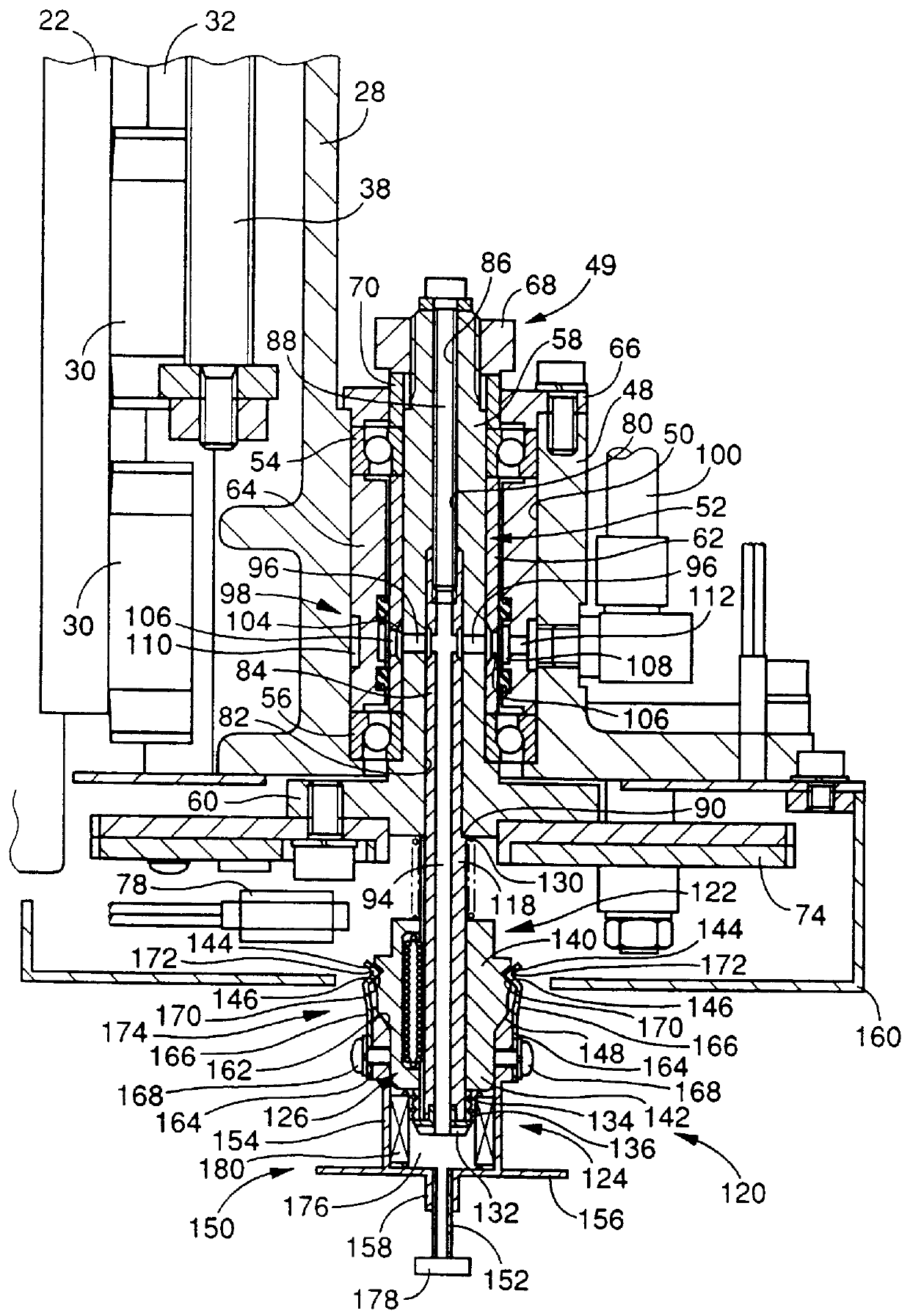

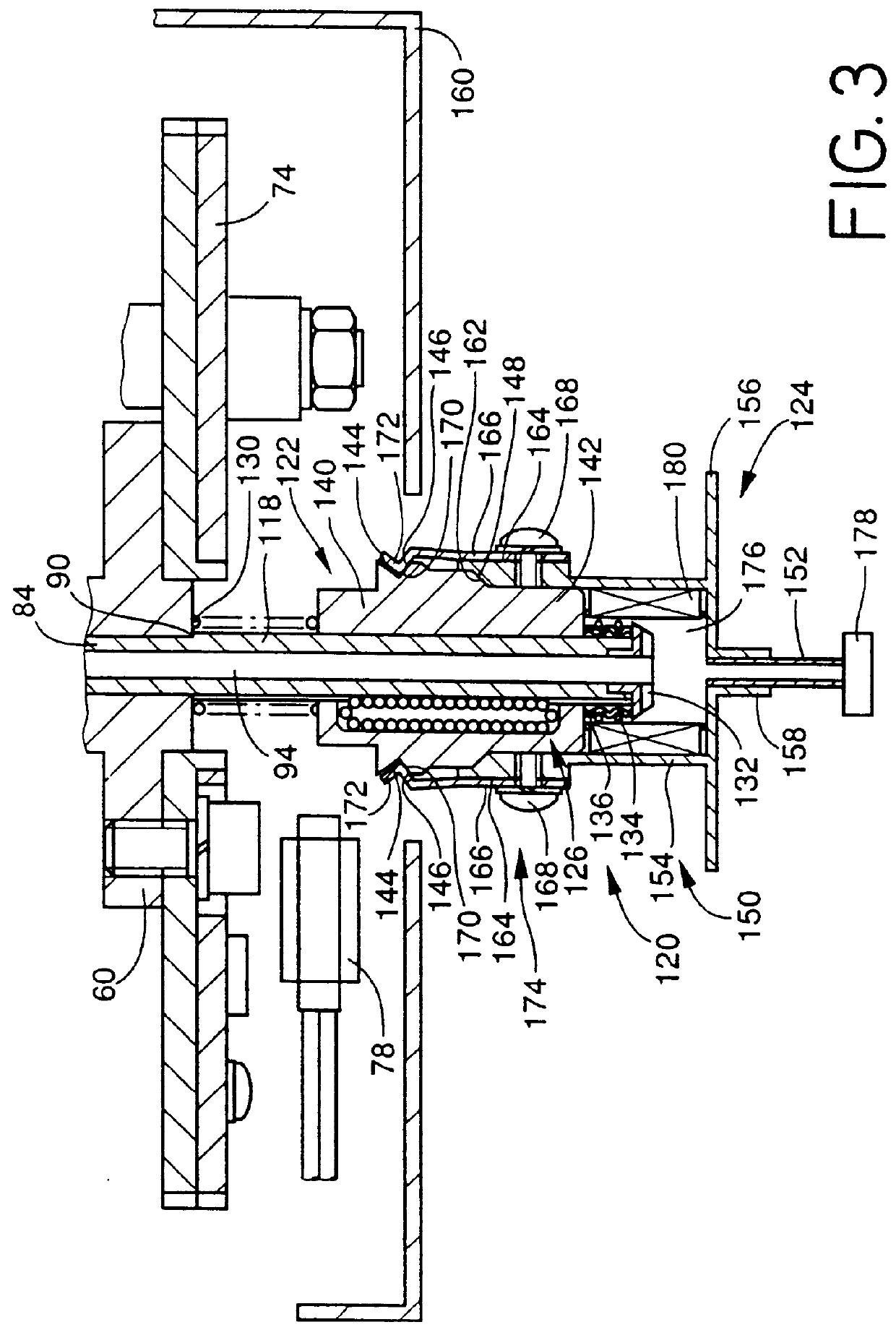

A mounting head, a mounting apparatus, and a mounting method which are capable of contacting an electronic component with a substrate with a small contact load and mounting the component on the substrate, are provided. A suction device 120 is fit on a splined axis portion 118 of a support shaft 84 via a ball spline 126, is biased downward by a first spring 130, and is biased upward by a second spring 134. A suction nozzle 124 is attached to a nozzle holder 122 by engaging engagement ridges 172 of sheet springs 166 fixed to the suction nozzle 124 with engagement grooves 144 of the nozzle holder 122, respectively. Prior to the mounting of electronic components 178, a relationship between contact load and position of lift 28 is obtained, and a position to which the lift 28 is moved downward for mounting each electronic component 178 is pre-determined. Thus, each component 178 is contacted with a printed circuit board with an appropriate load. Each component 178 is contacted with the circuit board with a small load, by removing the self weight of the suction device 120 owing to the biasing action of the second spring 134 and reducing the frictional resistance produced between the suction device 120 and the axis member 84 owing to the provision of the ball spline 126.

Owner:FUJI MASCH MFG CO LTD

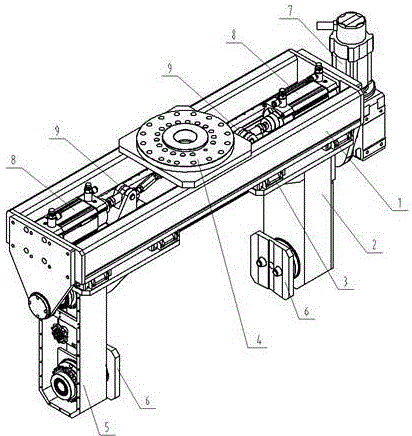

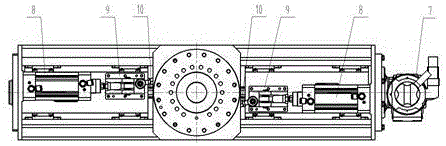

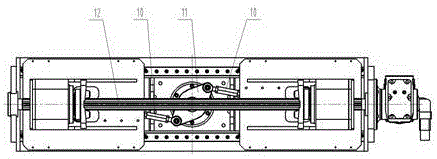

Automatic single-drive double-movement bolt tightening device and bolt tightening method thereof

InactiveCN107584274AReduce friction and wearImprove efficiencyMetal working apparatusProduction lineElectromagnetic clutch

The invention discloses an automatic single-drive double-movement bolt tightening device. The device comprises a motor, a speed reducer, a torque sensor, a drive tooth-shaped belt wheel A, a transmission shaft, an electromagnetic clutch, a drive tooth-shaped belt wheel B, an electromagnetic brake, a frame, a tooth-shaped belt A, a ball screw rod spline shaft, a rotation type ball nut component, adriven tooth-shaped belt wheel A, a tooth-shaped belt B, a driven tooth-shaped belt wheel B, a rotation type ball spline sleeve component, a non-contact displacement sensor, a reflection plate, a flange-type ball spline sleeve, a limit ring, a connection component, a compression spring and a spanner component. The automatic single-drive double-movement bolt tightening device is single-drive, full-automatic, high in efficiency, compact in structure, and suitable for being used on an automatic production line. The automatic single-drive double-movement bolt tightening device has the coupling ability, has wide application range, and can be used for tightening bolts with different screw pitches. The invention further provides a bolt tightening method of the automatic single-drive double-movement bolt tightening device.

Owner:赵阳

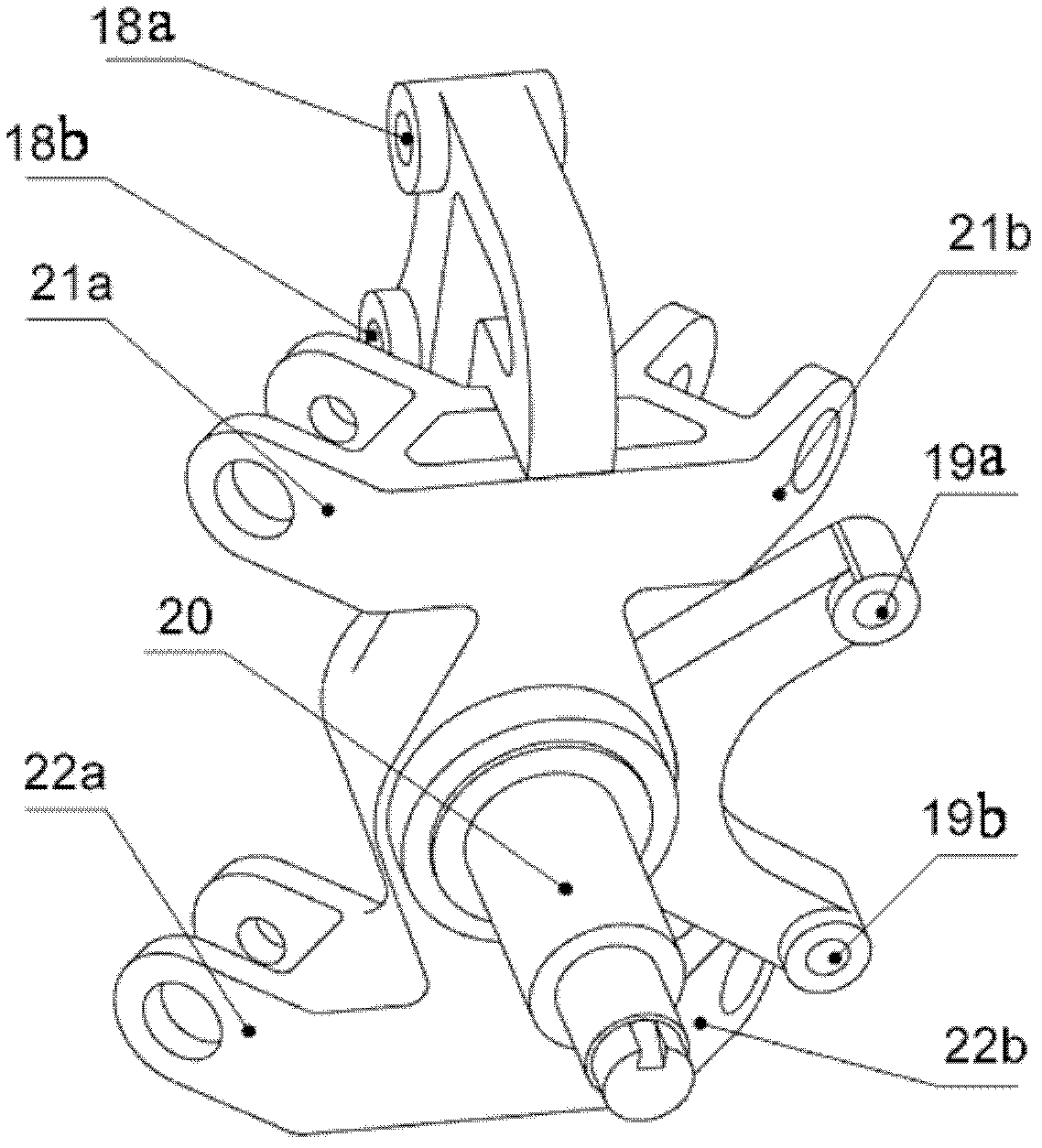

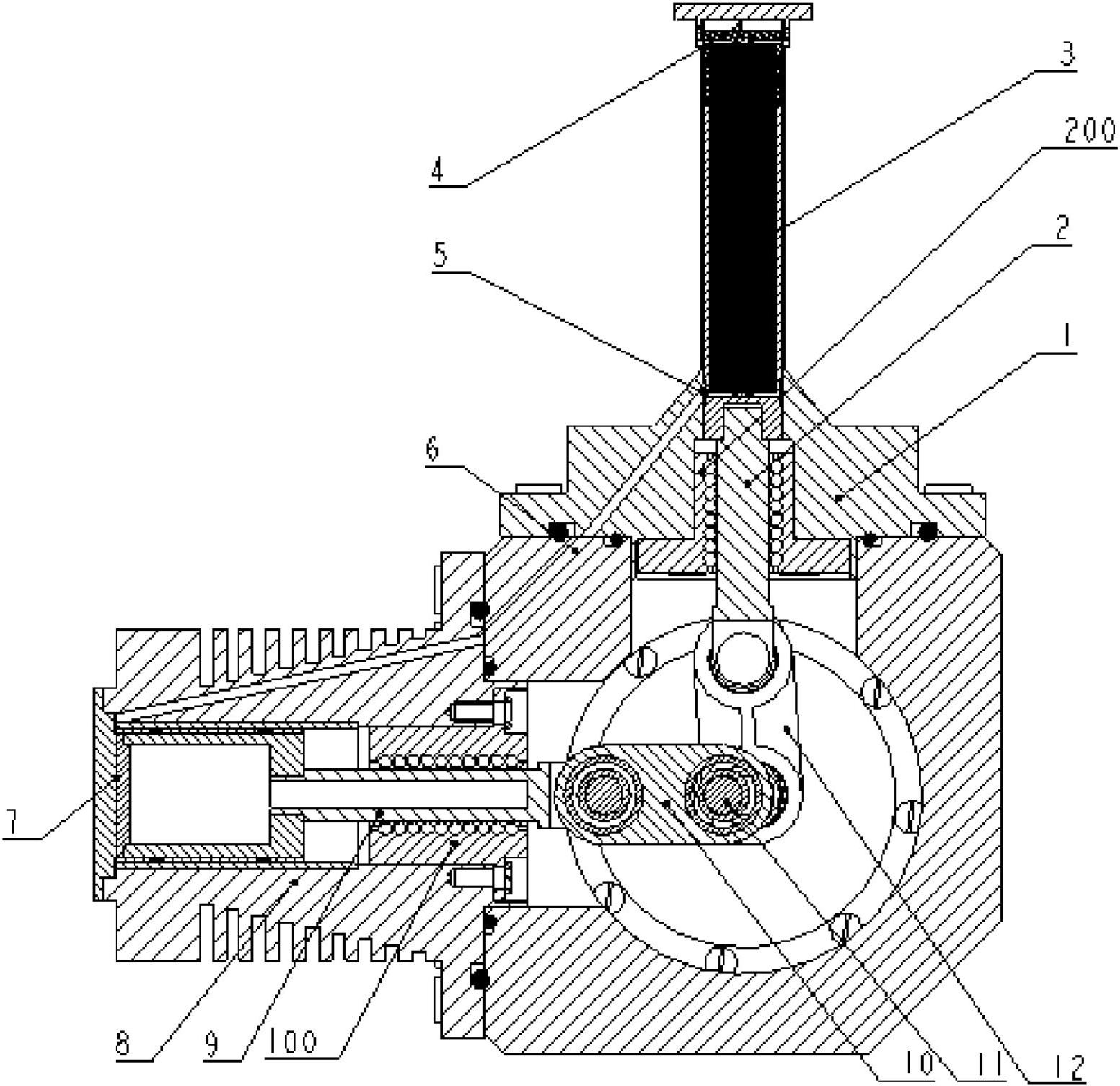

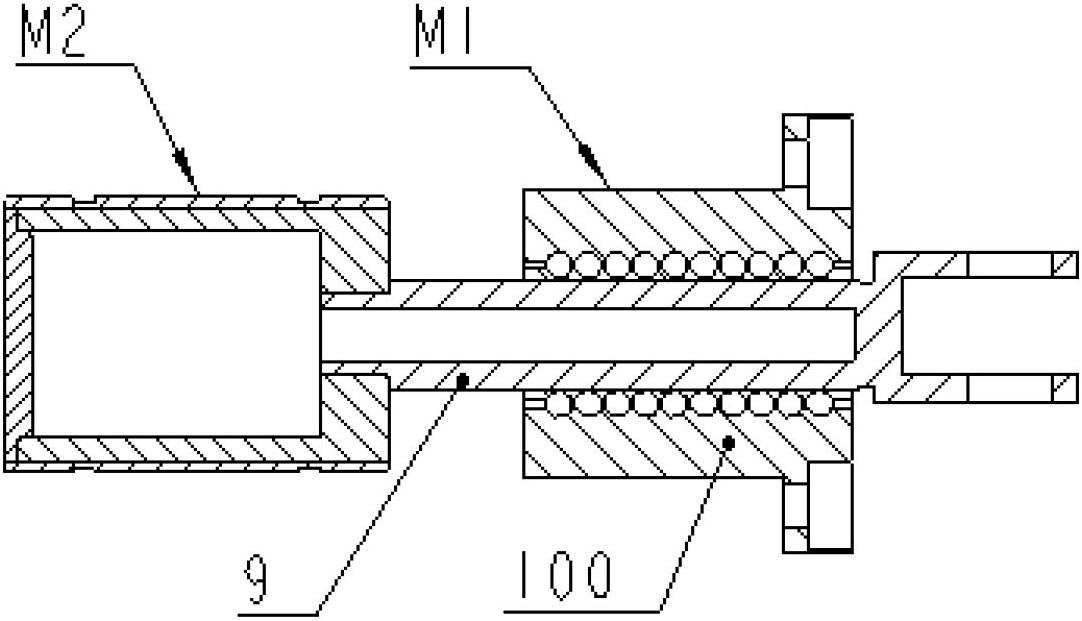

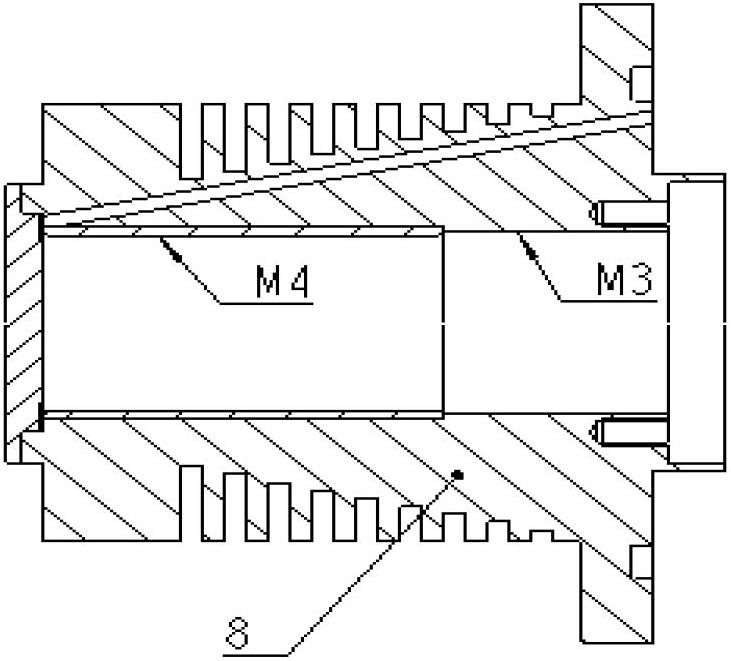

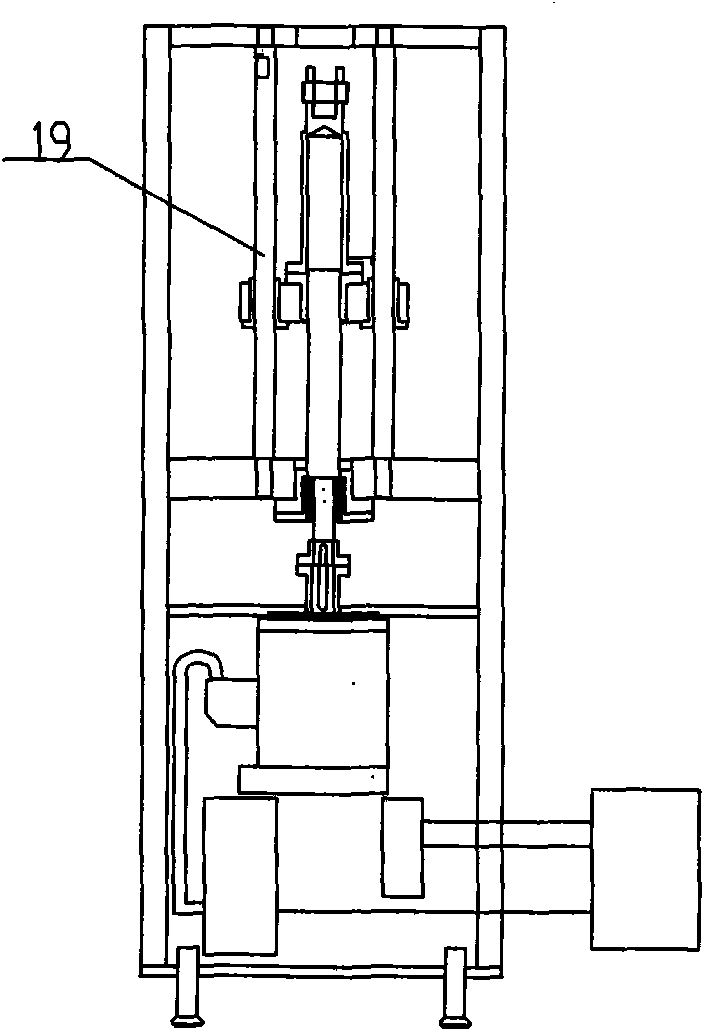

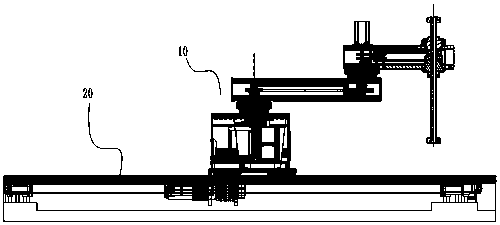

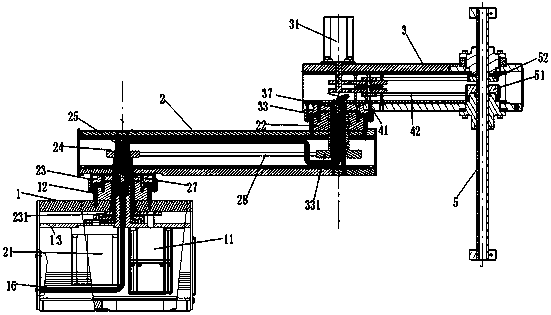

Spraying robot mechanical arm driving device

The invention relates to a spraying robot mechanical arm driving device, comprising an intermediate rotating driving mechanism, a telescopic driving mechanism and a swinging driving mechanism at the front end, wherein the rotating driving mechanism drives a mechanical arm to rotate by virtue of a servo motor; the telescopic driving mechanism drives a lead screw to rotate by virtue of the servo motor, a ball spline shaft converts rotation motion of a ball lead screw nut into telescopic motion of the mechanical arm; and the swinging driving mechanism at the front end is connected with the front end of a telescopic shaft of the telescopic driving mechanism by virtue of a tensioning sleeve, and the swinging driving mechanism at the front end drives a swinging and rotating shaft to rotate by virtue of the servo motor and a reducer, thus a spray gun is driven to swing.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD

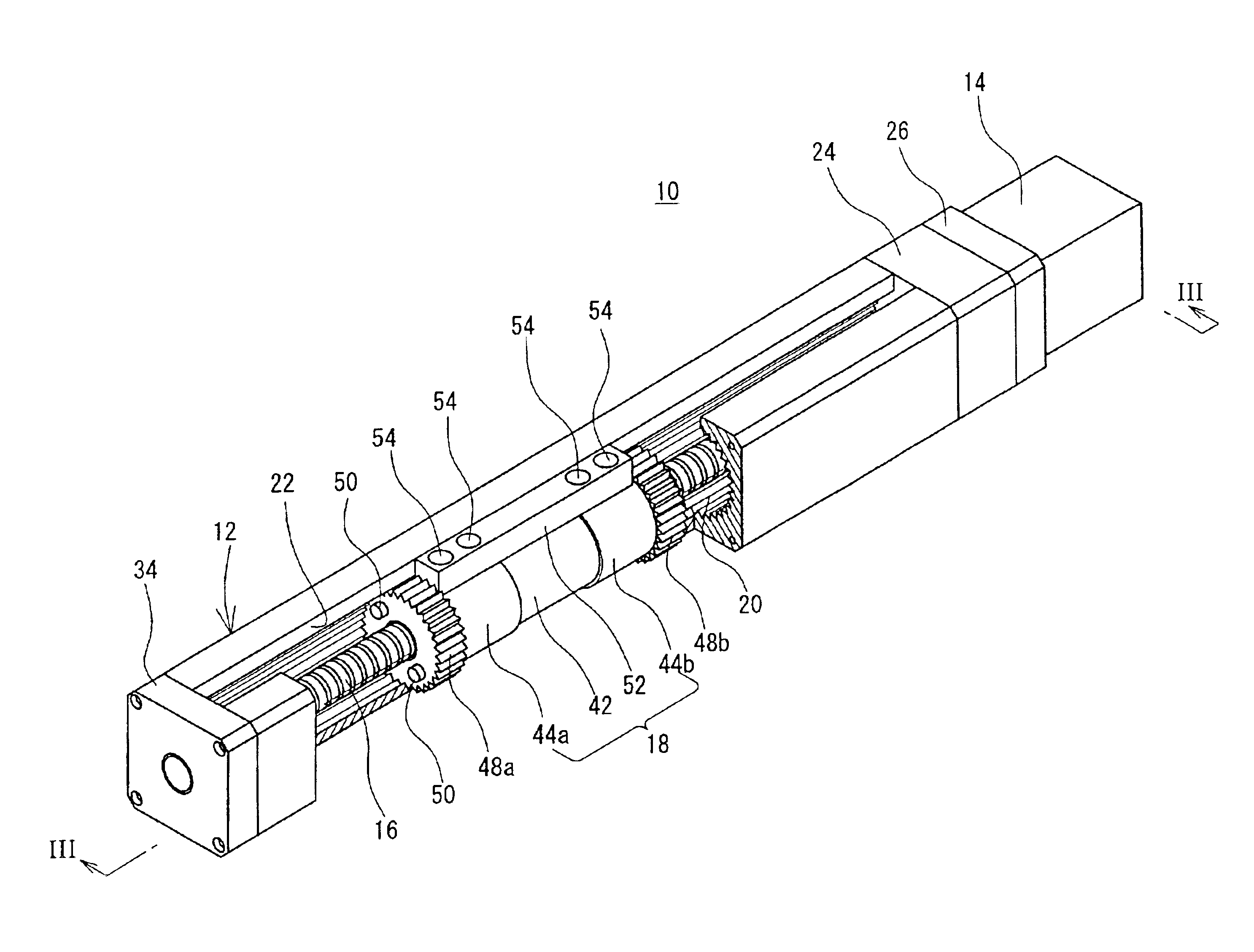

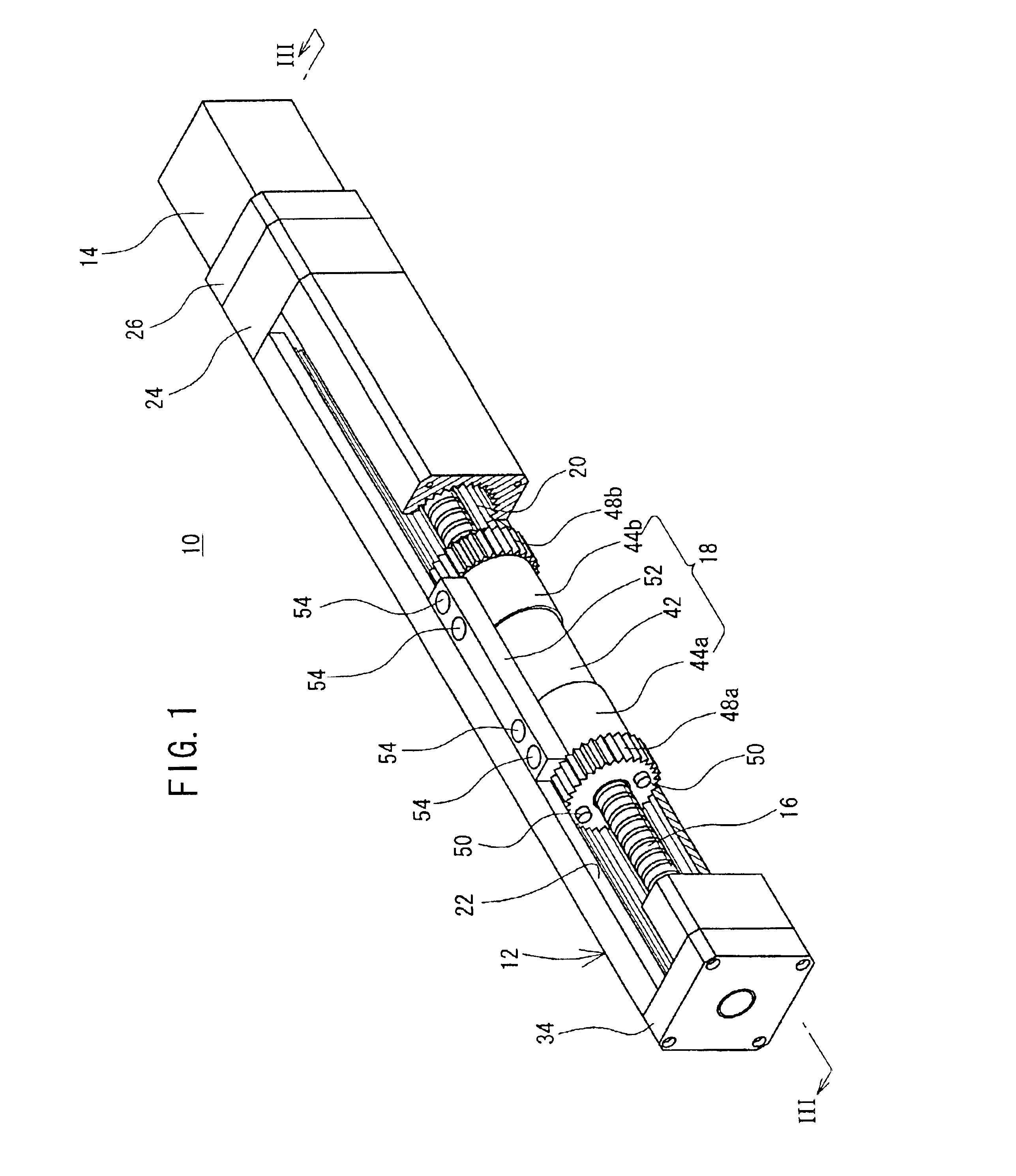

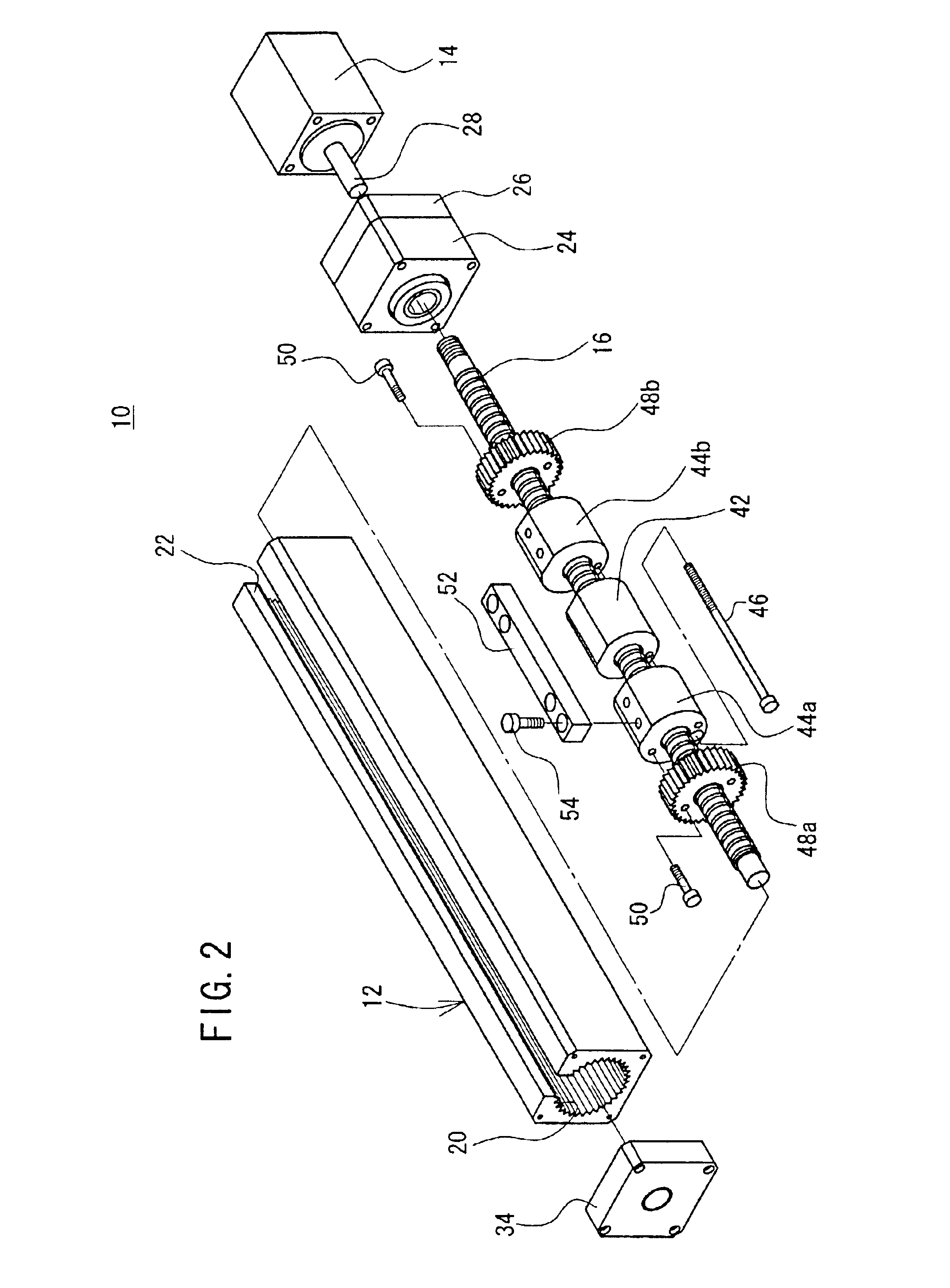

Electric actuator

The rotary motion of a ball screw shaft is converted into the rectilinear motion by a ball spline nut provided integrally with displacement members by the aid of an attachment section. Involute splines are engraved on outer circumferential surfaces of spline pistons connected to the displacement members. The spline pistons are slidably meshed with a splined bore of the involute splines formed on an inner wall surface of a frame. The attachment section is displaceable in a longitudinal direction of the frame by the aid of the splined bore and the spline pistons.

Owner:SMC CORP

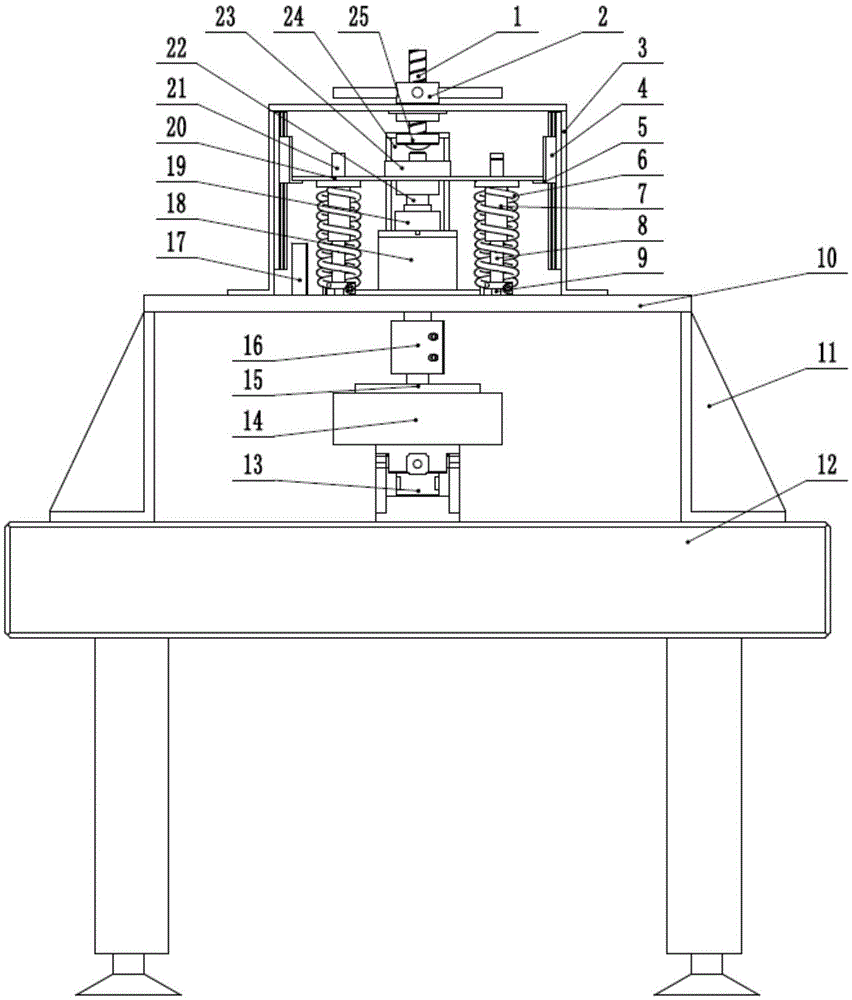

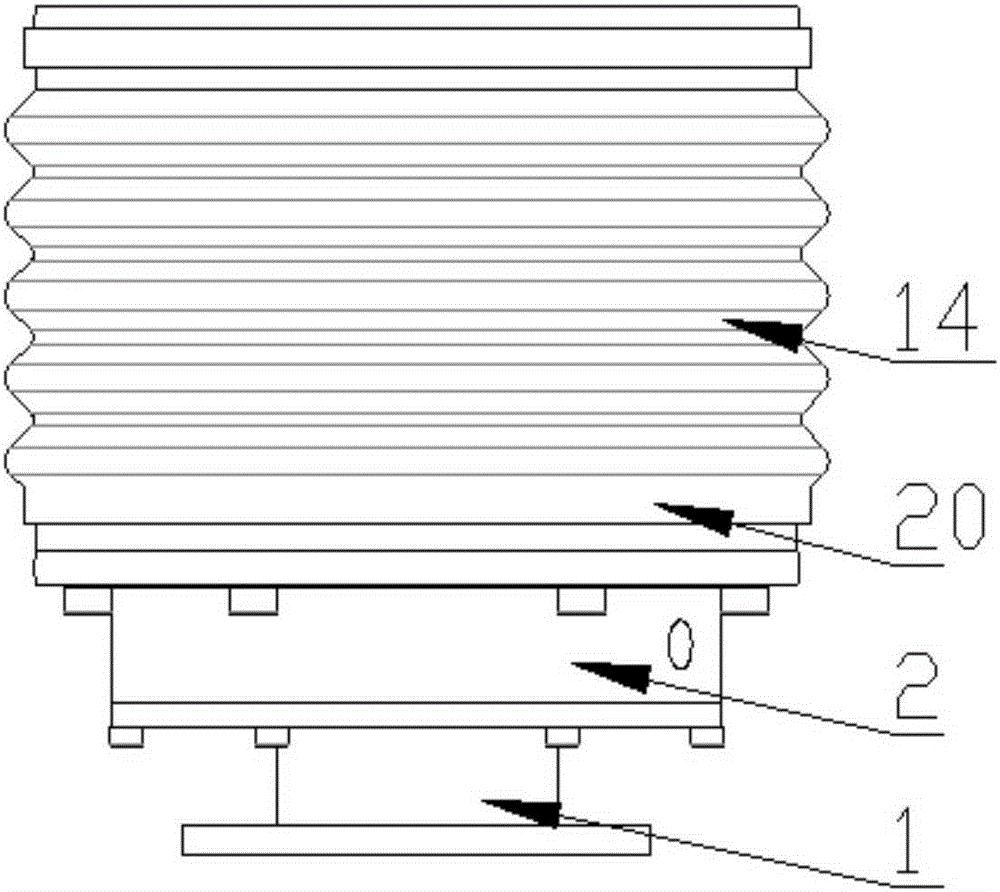

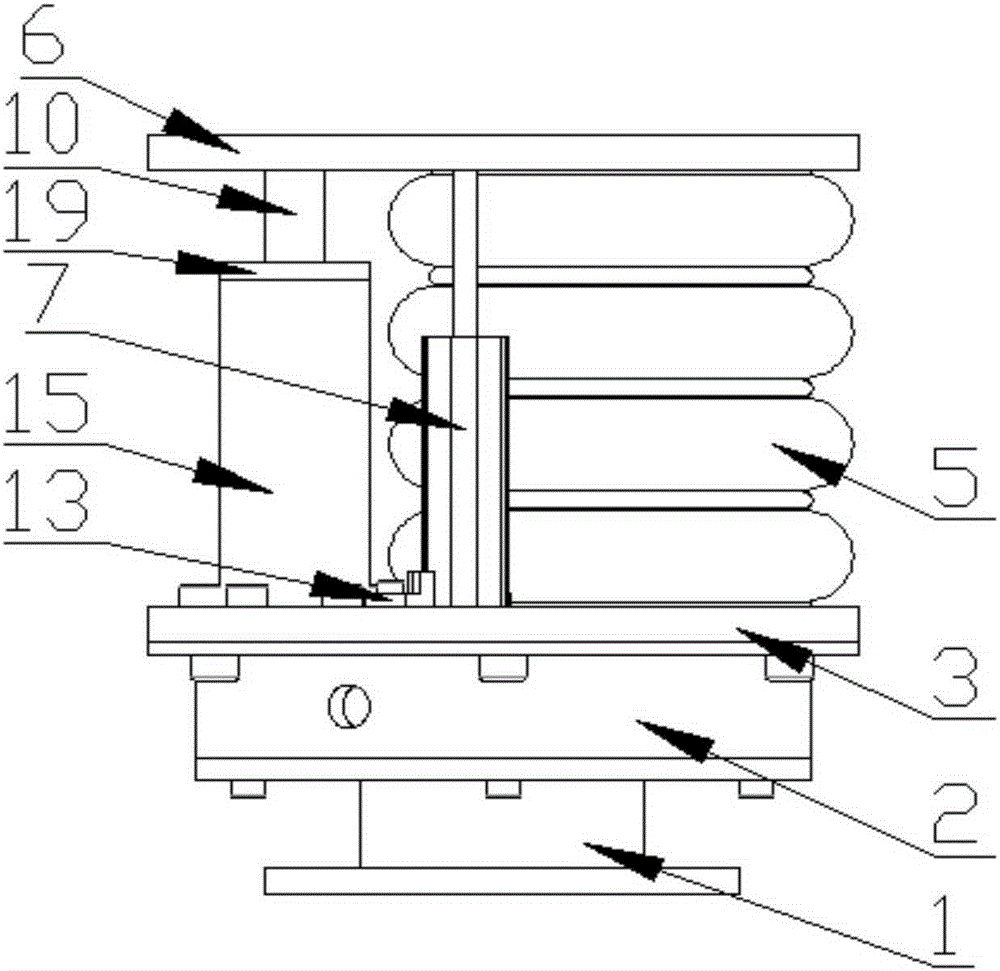

Hydraulic pressure suspension polishing method and device thereof

ActiveCN105538046AImprove stabilityReduce vibration effectsGrinding drivesGrinding feed controlEngineeringForce sensor

The invention discloses a hydraulic pressure suspension polishing method and a device thereof. A servo motor and a synchronous pulley drive a shaft sleeve and a ball spline shaft so as to directly drive a polishing disk to rotate at high speed, and the processing efficiency is improved. A wedge groove is formed in the polishing disk pasted with a workpiece, and a wedging effect is formed at high speed and in small gap, so that the polishing disk drives the ball spline shaft to float upwards along the shaft sleeve, and uniform non-contact polishing is realized. A bottom container is lifted through an electric lifting platform to realize initial positioning. A force measuring sensor is mounted at the top and is used for positioning a cutter between the polishing disk and the container to ensure the reliability of positioning. The spline shaft is connected with a balance plate together through a supporting seat, and four groups of springs are arranged between the balance plate and a bottom plate and are used for overcoming the gravity of a polishing component. A laser displacement sensor mounted on the bottom plate is used for measuring the distance of floating up or down of the balance plate in the polishing process. An electrical vortex sensor and a pressure sensor are mounted at bottom container and are used for detecting the size of a polishing gap and hydraulic pressure.

Owner:ZHEJIANG UNIV OF TECH

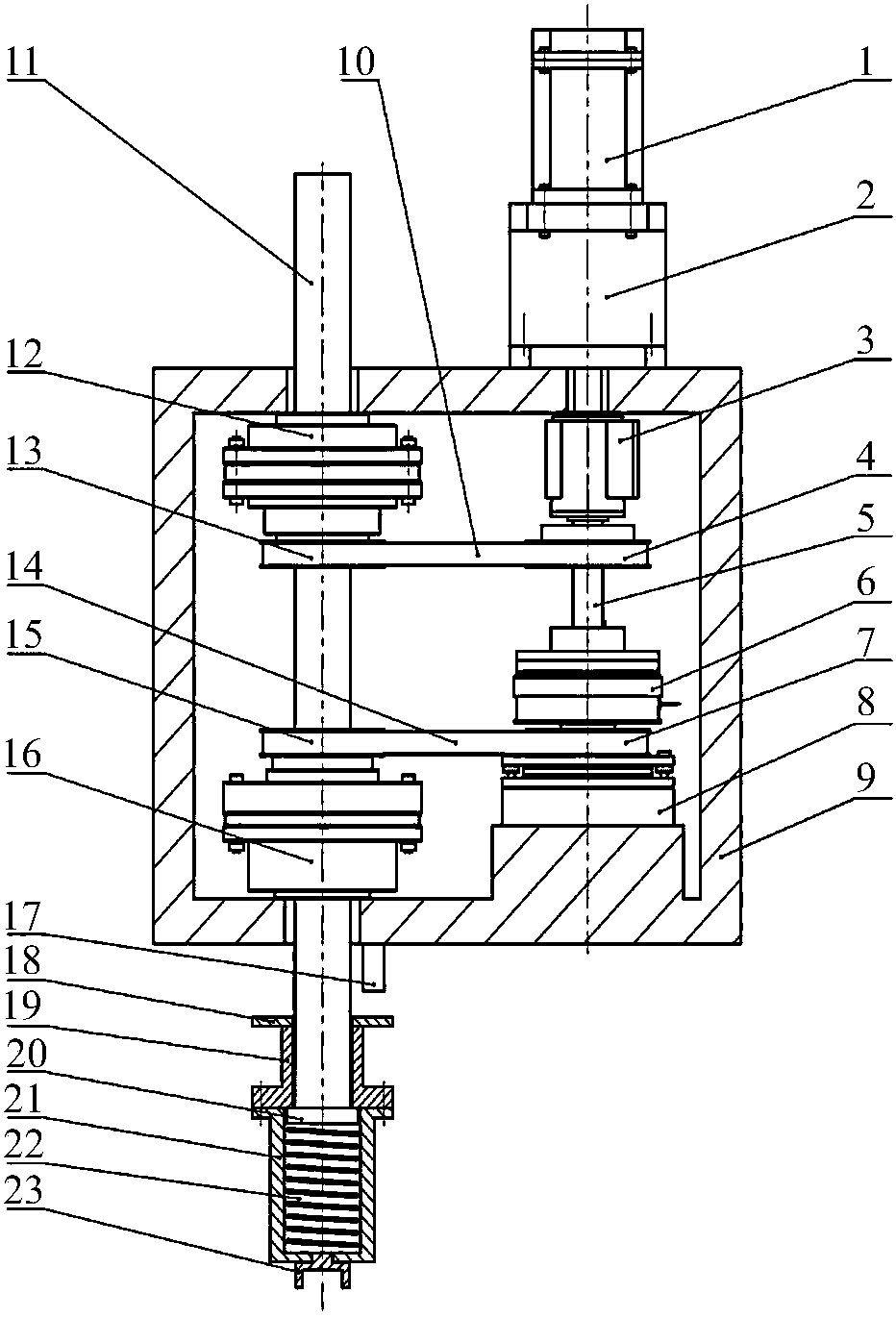

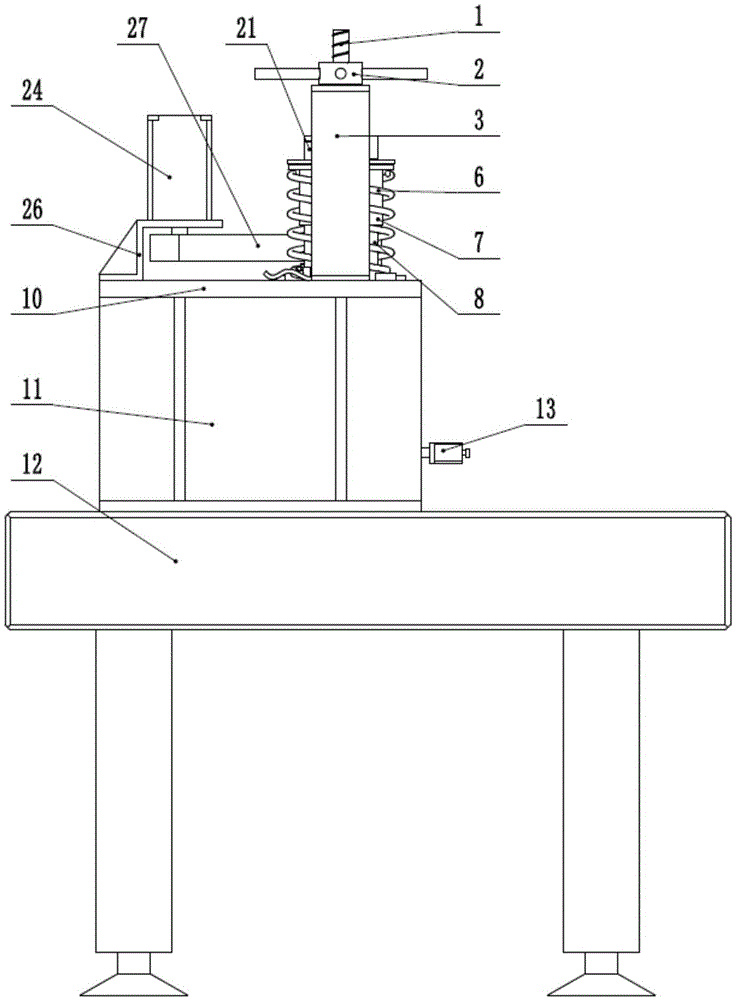

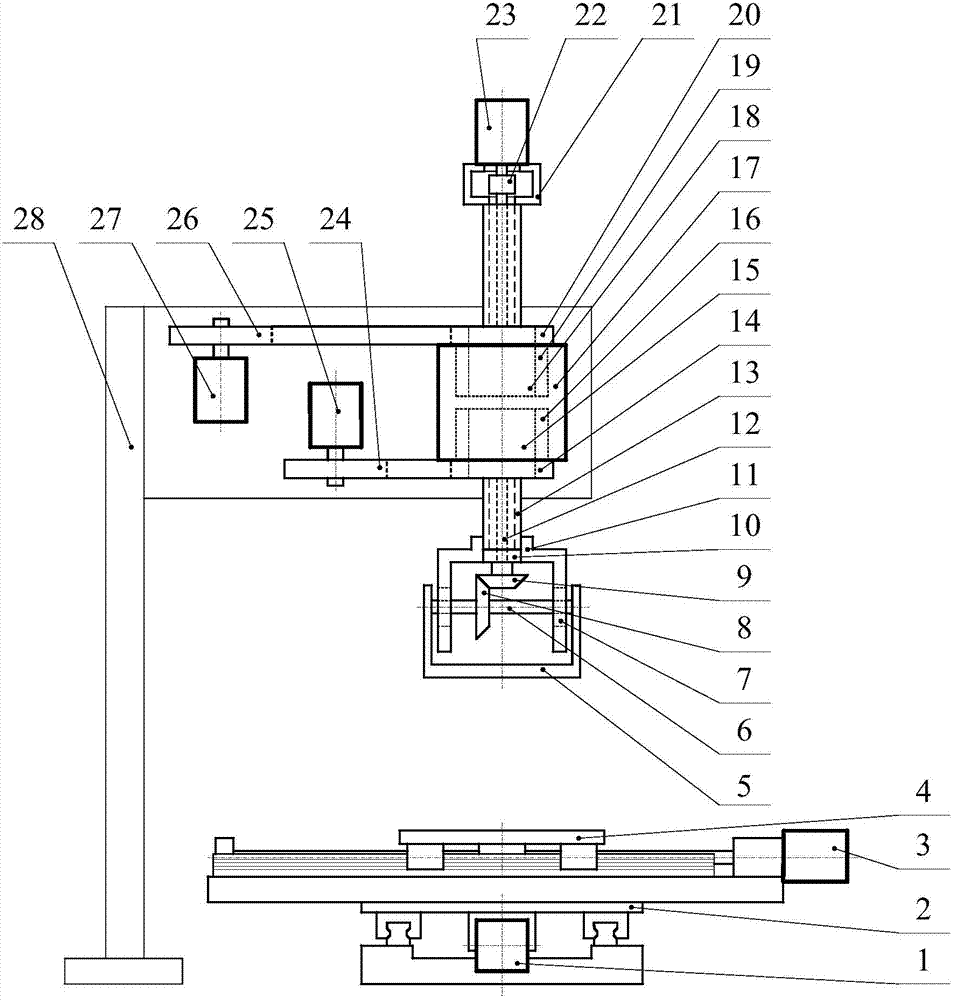

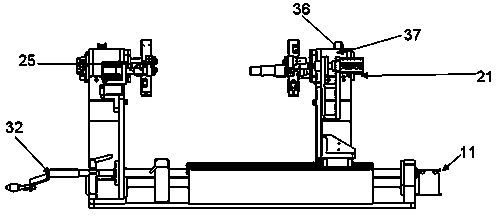

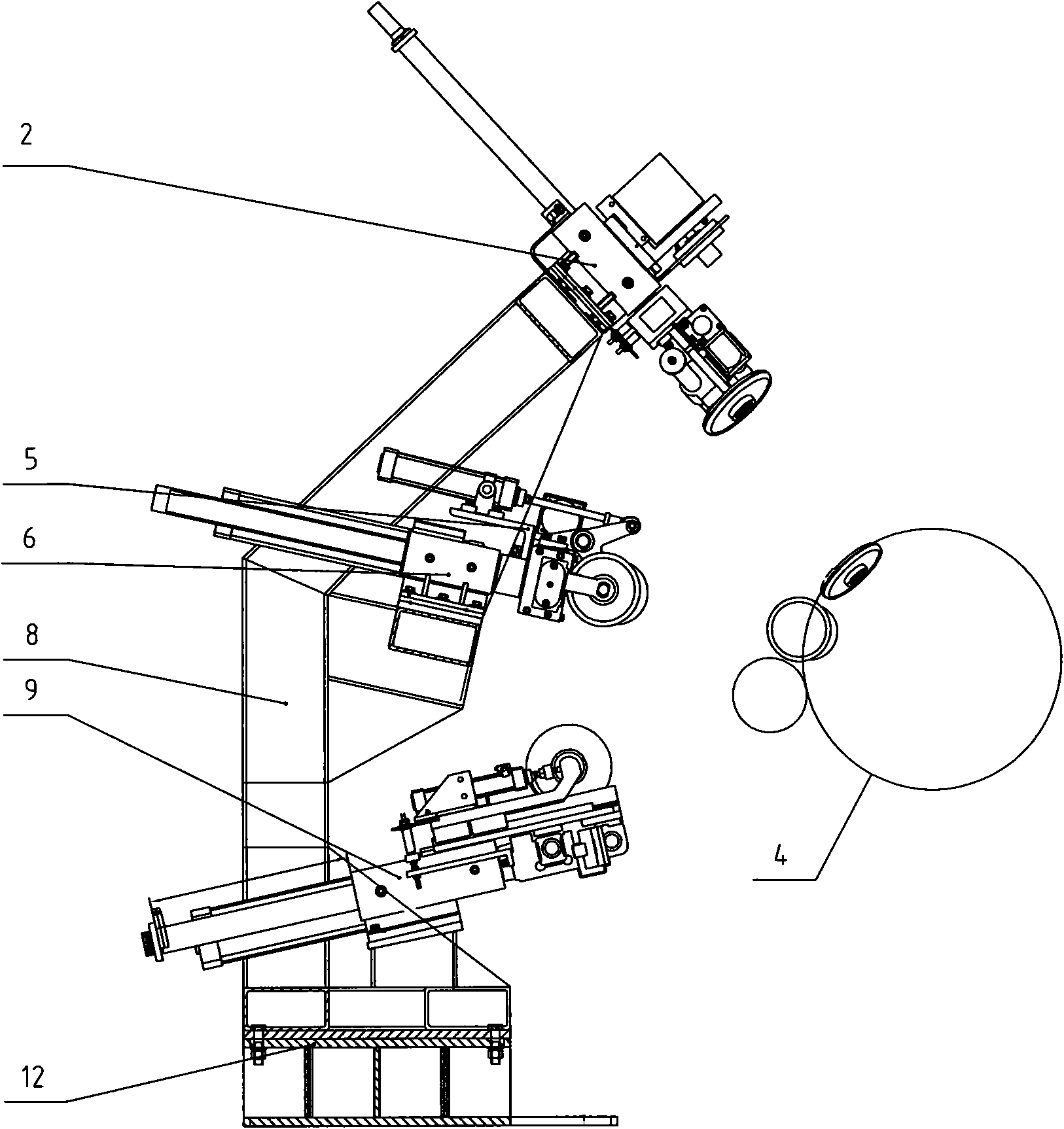

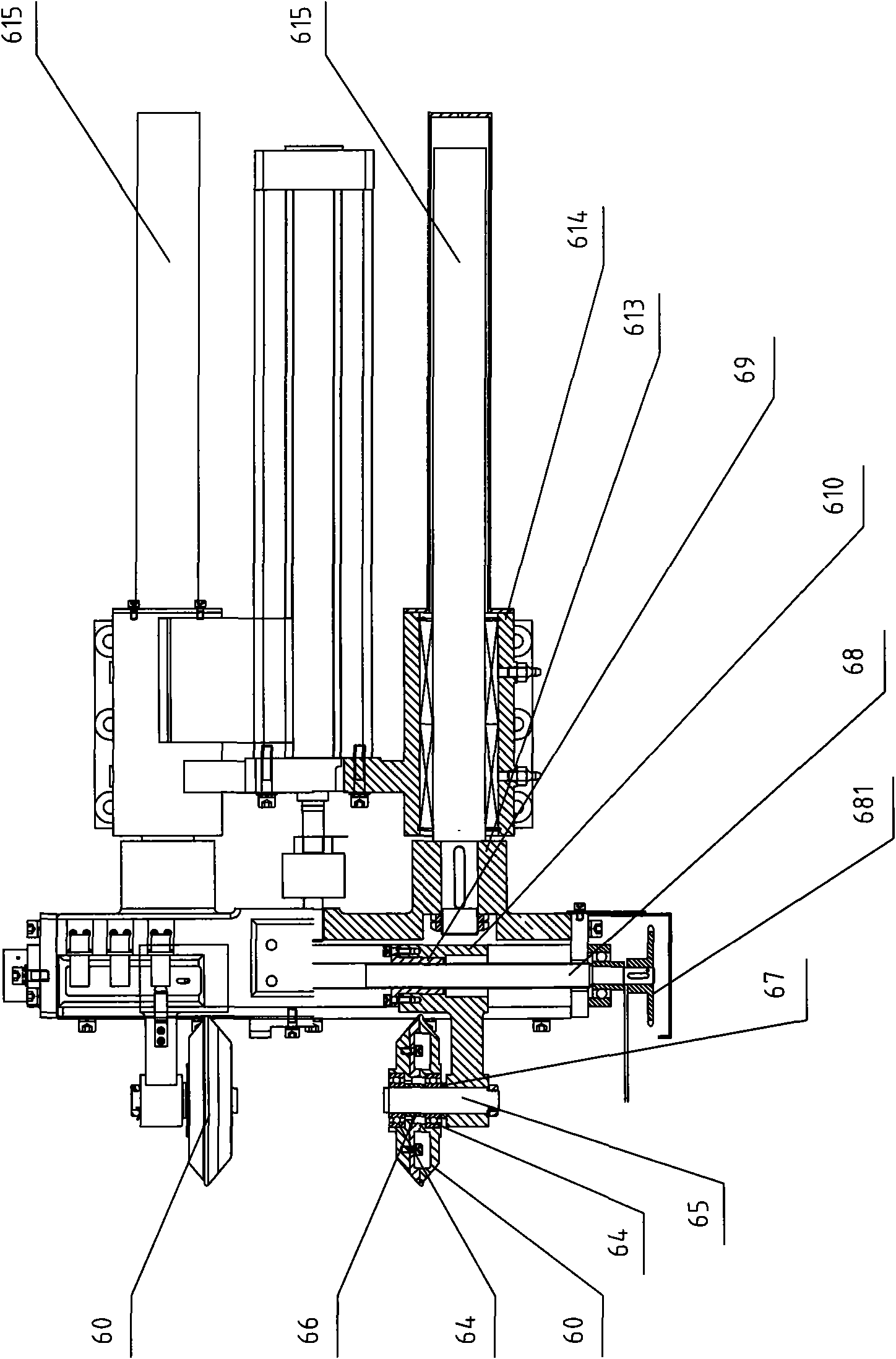

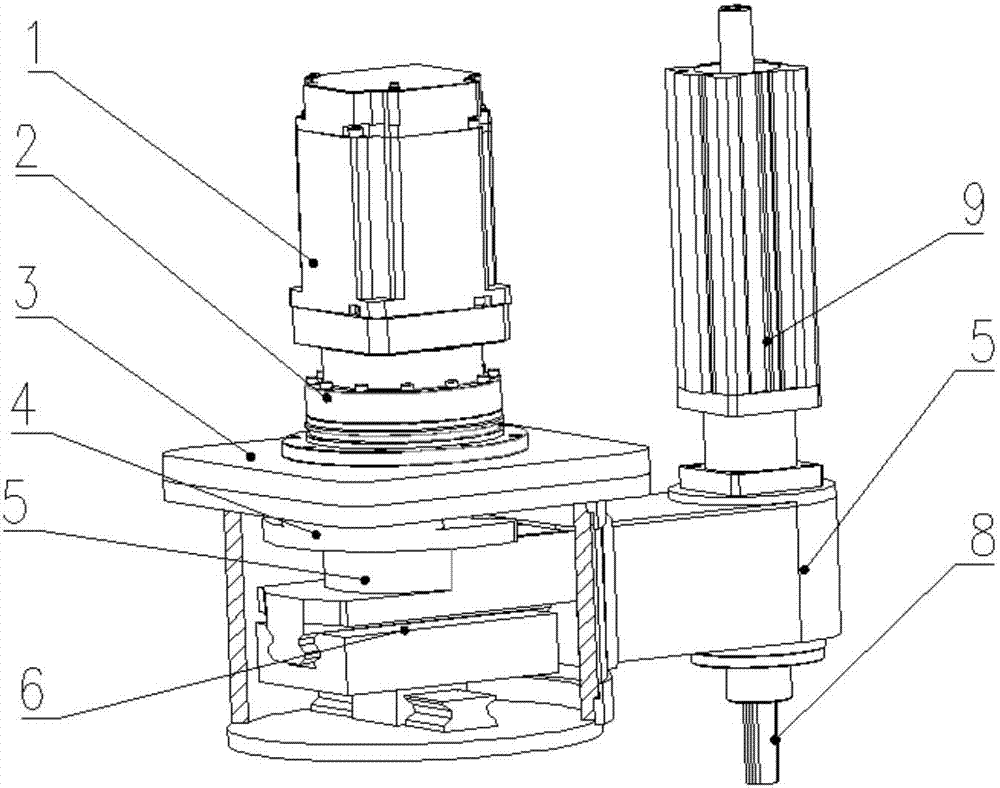

Robotic planetary polishing unit for polishing of large-diameter aspheric surfaces

InactiveCN104290004AReduce the impactEasy to controlOptical surface grinding machinesMotor driveEngineering

The invention discloses a robotic planetary polishing unit for polishing of large-diameter aspheric surfaces. The robotic planetary polishing unit comprises a revolution drive mechanism, an autorotation drive mechanism, a polishing shaft component and a counterweight eccentric regulator. Two servo motors drive the robotic planetary polishing unit to autorotate and revolve respectively. The revolution drive mechanism allows horizontal revolution of planetary motion. The counterweight eccentric regulator is an eccentric regulation and synchronous center-of-mass balancing mechanism, allowing a counterweight to reversely synchronously change with an eccentric distance. The autorotation drive mechanism employs two-stage belt drive, allows an auto-rotating motor to be fixed and allows transmission of autorotation motion at the premise of not performing horizontal rotation. The polishing shaft component is in a hollow combination of a low-friction cylinder and a female rotary ball-and-spline shaft, allowing the cylinder and a piston not to perform autorotation motion. The hollow structure allows a dynamic and static polishing process. The pressure of a polishing disc is precisely controlled by a proportional valve through reduction in the friction.

Owner:TIANJIN UNIV

Five degree-of-freedom combined robot platform

ActiveCN103495971AReduce couplingReasonable mechanical designProgramme-controlled manipulatorThree degrees of freedomBall screw

Owner:HEFEI UNIV OF TECH

Six-DOF (Degree Of Freedom) planar joint robot

ActiveCN104802164AAccurately doneMeet certain requirements in industrial productionProgramme-controlled manipulatorBall screwDegrees of freedom

The invention discloses a six-DOF (Degree Of Freedom) planar joint robot, and belongs to the technical field of industrial robots. The six-DOF planar joint robot comprises a base, a first arm, a driving device of the first arm, a second arm, a driving device of the second arm, a three-DOF wrist and a driving device of the three-DOF wrist; the first arm is arranged on the base; the second arm is arranged at the tail end of the first arm; the three-DOF wrist is connected with three ball splines and is driven by the driving device which is arranged on the second arm through a synchronous belt wheel and the ball splines; the motion of the three-DOF wrist in the vertical direction is supplied by a ball screw. According to the six-DOF planar joint robot provided by the invention, the three-DOF wrist is additionally arranged on the basis of a three-DOF SCARA (Selective Compliance Assembly Robot Arm) robot, and three transverse moving DOFs along an X axis, a Y axis and a Z axis and three rotation DOFs along the X axis, the Y axis and the Z axis are obtained; the six-DOF planar joint robot is suitable for realizing complicated motion, and six-DOF motion of an operated target can be realized.

Owner:ANHUI TIANYI HEAVY IND

Precise electric cylinder

InactiveCN104052188AImprove work performanceSmooth runningMechanical energy handlingReciprocating motionElectric machine

A precise electric cylinder comprises a driving motor, a cylinder barrel, a lead screw pair, a thrust bearing, a hollow barrel-shaped piston rod and a ball spline sleeve, wherein the lead screw pair is composed of a lead screw shaft and a lead screw nut. The lead screw shaft is arranged along the central axis of the cylinder barrel, the power input end of the lead screw shaft is in transmission connection with an output shaft of the driving motor, the lead screw shaft is axially positioned through the thrust bearing, an outer ring of the thrust bearing and the cylinder barrel are fixed coaxially, the lead screw nut and the barrel-shaped piston rod are coaxially and fixedly connected, and the other end, opposite to the power input end, of the lead screw shaft stretches into the hollow barrel-shaped piston rod. When the driving motor drives the lead screw shaft to rotate and the piston rod is driven to conduct reciprocating motion, rolling of balls replaces original sliding friction between the piston rod and a supporting component and between the piston rod and a guiding component, so that abrasion is reduce, and efficiency, control accuracy and reliability are improved.

Owner:SHANGHAI AORUI CONTROL SYST

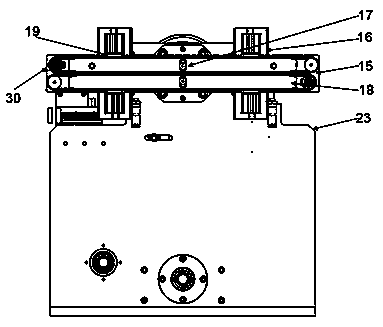

Full-automatic overturn plate positioning mechanism

ActiveCN104386463ACompact structureSolve processing problemsControl devices for conveyorsEngravingBall screwElectric machinery

The invention relates to a full-automatic overturn plate positioning mechanism which comprises an overturn power transmission mechanism, an overturn clamping mechanism, an overturn positioning mechanism, a belt power mechanism, a track width regulating mechanism and an overturn bottom plate, wherein the overturn power transmission mechanism comprises a motor, a ball spline, a synchronous belt and two synchronizing wheels; the overturn clamping mechanism comprises two overturn conveying positioning strips; the overturn positioning mechanism comprises an overturn limit sensor, an overturn positioning cylinder and an L-shaped positioning block; the belt power mechanism comprises a stepping motor, a double-shaft cylinder, a power wheel, a dynamical friction wheel and a belt idler; the track width regulating mechanism is provided with two linear sliding tracks and two ball screws. The full-automatic overturn plate positioning mechanism solves the difficulty in single-station double-faced plate processing by virtue of the structure, is small and compact in structure, and is accurate in overturn operation positioning and rapid in speed, the size of integrated equipment is greatly reduced and the production efficiency is improved.

Owner:苏州华工自动化技术有限公司

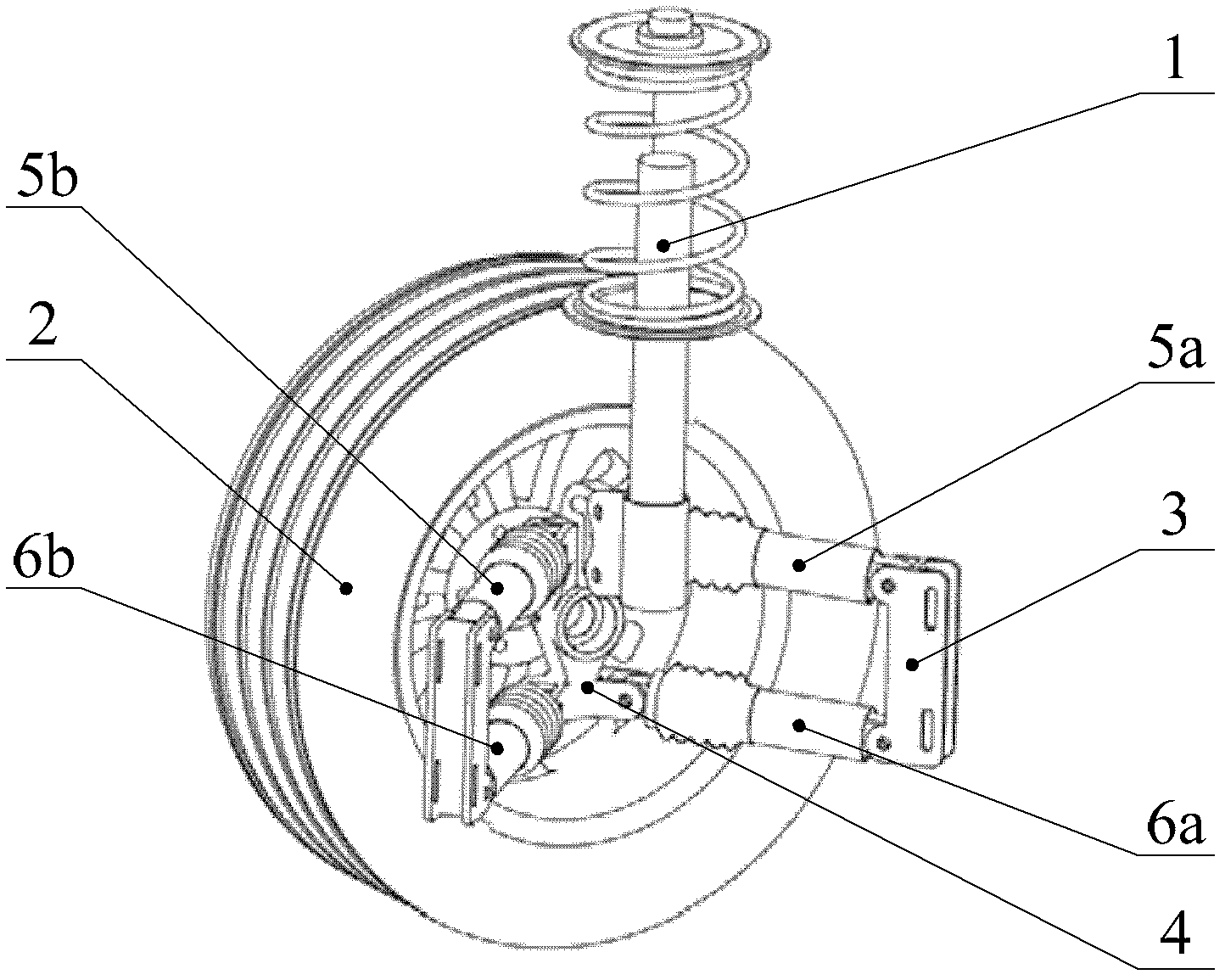

Multi-connecting-rod rectilinear movement hanger bracket adopting ball spline pair

ActiveCN102627061AReduce wearImprove handling stabilityResilient suspensionsCamber angleCaster angle

The invention relates to a multi-connecting-rod rectilinear movement hanger bracket adopting a ball spline pair. The multi-connecting-rod rectilinear movement hanger bracket comprises a spring shock absorber, wheels, a vehicle body, a steering knuckle, an upper-side first hanger bracket branched chain, an upper-sided second hanger bracket branched chain, a lower-side first hanger bracket branched chain and a lower-side second hanger bracket branched chain, wherein the spring shock absorber is hinged with the steering knuckle and the vehicle body respectively, the steering knuckle is matched with the wheels by wheel hub units, and the two ends of each hanger bracket branched chain are respectively hinged with the steering knuckle and the vehicle body. The multi-connecting-rod rectilinear movement hanger bracket has the advantages that the positional parameters such as the camber angle, the kingpin inclination angle and the caster angle of the wheels, the toe-in (toe-out) of the front wheel, the distance between the left wheel and the right wheel, and the distance between a front shaft and a rear shaft can be kept constant during the process that the wheels jump up and down, so that the abrasion of the tires is lowered greatly, and the operation stability, the driving smoothness and the riding comfort of the vehicle can be improved effectively; the hanger bracket branched chains are simple in structure, the ball spline pair can be changed after being abraded, and the service lives of the hanger bracket branched chains are prolonged.

Owner:WANXIANGQIANCHAO CO LTD +1

Tyre building machine combined roller and method thereof

The invention relates to a tyre building machine combined roller and a method thereof, aiming to solve the fitting problem caused in the process of rolling a tyre shoulder externally circular conical surface by adopting a movable finned roller and improve the flexibility in the process of automatically adjusting the press roll initial interval in an on-line manner. The combined roller is provided with a rack installed on a base; a first roller device, a second roller device, a third roller device and a fourth roller device are respectively connected on the rack by a respective bracket; the second roller device has two groups of rollers 2 and roller cylinders 2, and two groups of roller ball splines 2 and driving devices for driving the roller 2 to do transversely horizontal displacement which are all arranged at the front end of the roller device 2; the roller 2 comprises at least two rollers which are in fastened connected with each other and are sheathed on an intermediate shaft via bearing sleeves; adjacent rollers are made of different materials and are in gapless section contact; and the intermediate shaft is connected with the robber bracket arranged on the driving device.

Owner:MESNAC

Force-controlled flange for polishing operation of industrial robot and polishing method

InactiveCN105234807ALow positioning accuracy requirementsReduced precision requirementsGrinding machine componentsSpringsProduction lineBall bearing

The invention discloses a force-controlled flange for the polishing operation of an industrial robot and a polishing method. The force-controlled flange comprises an upper base, a lower base, an air spring and a proportional valve. The upper base and the lower base are arranged in a spaced mode up and down. The air spring is arranged between the upper base and the lower base. The proportional valve can adjust the pressure in the air spring. A displacement sensor is arranged between the upper base and the lower base. The proportional valve comprises a pressure sensor for monitoring the pressure in the air spring. According to the force-controlled flange for the polishing operation of the industrial robot and the polishing method, the adjustment of the contact force can be achieved; the requirement for position precision of the industrial robot in the polishing process is lowered; the production cost is reduced, and the quality of products can be improved. The force-controlled flange is simple in structure, convenient to control and easy to popularize in a grinding production line. A ball spline is selected for replacing a guiding rail and a rectilinear motion ball bearing, and the rotational degree of freedom is restrained, accordingly, the influence of the radial force (relative to the guiding rail) can be better eliminated.

Owner:SUZHOU UNIV

Electric actuator

An electric actuator comprises a gear mechanism which transmits the rotary driving force of a rotary driving source, and a ball spline mechanism which includes a ball spline shaft provided movably back and forth from a connecting block to the outside and which converts a rotary motion transmitted by the gear mechanism into a rectilinear motion. The electric actuator has a ball spline nut which is externally fitted to the ball spline shaft to be meshed with the gear mechanism and which is integrally formed with a gear section having a plurality of teeth arranged circumferentially about the gear section.

Owner:SMC CORP

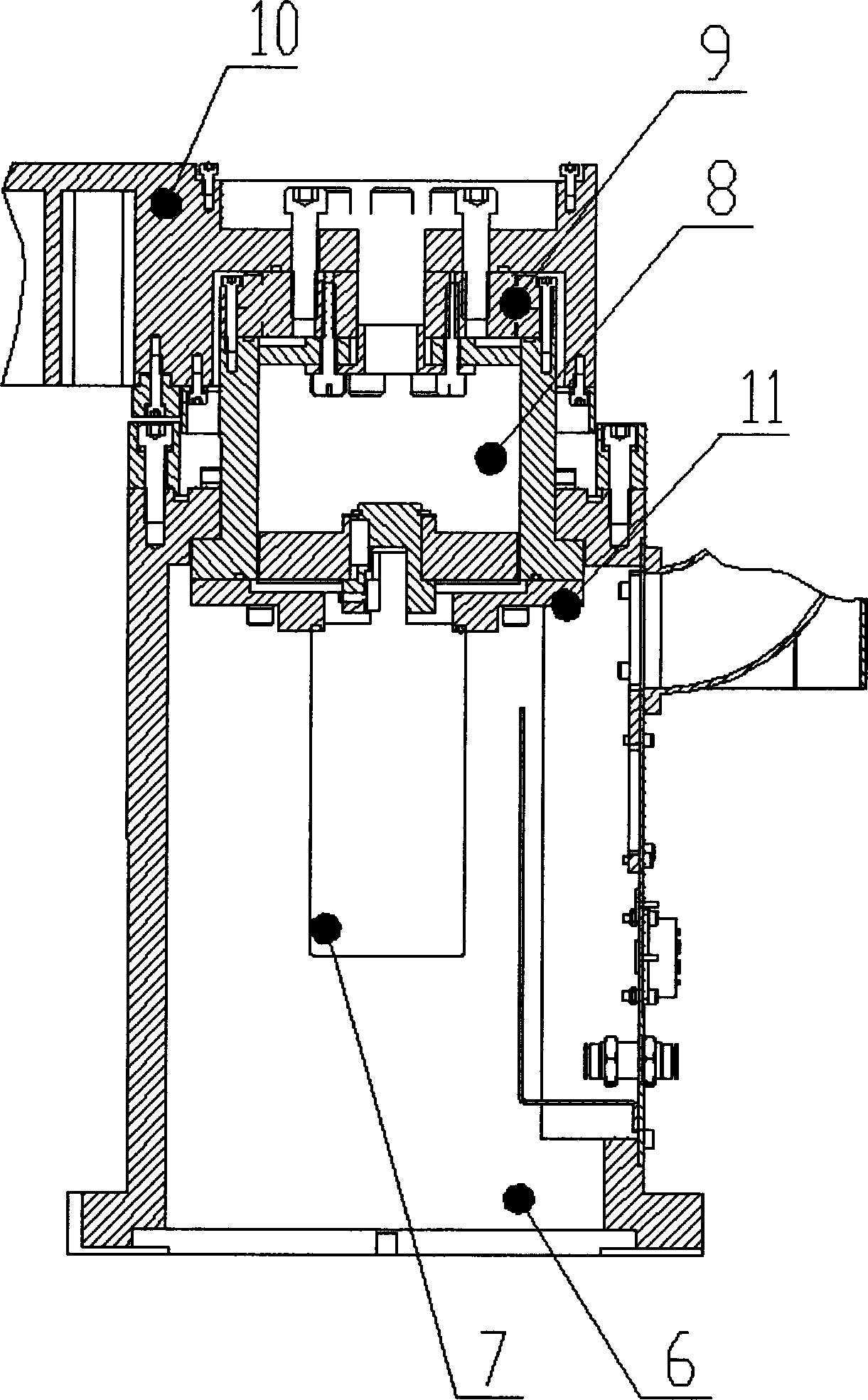

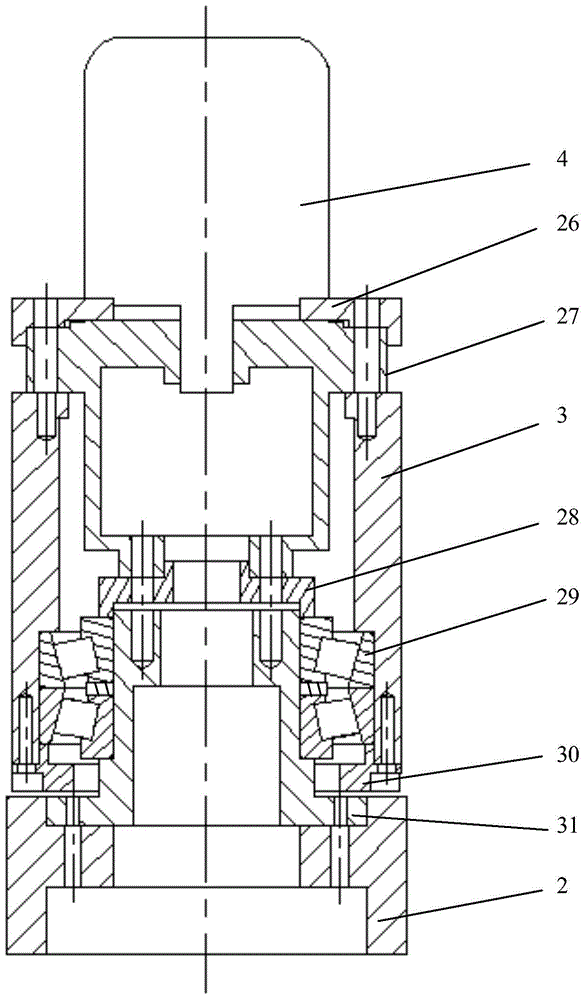

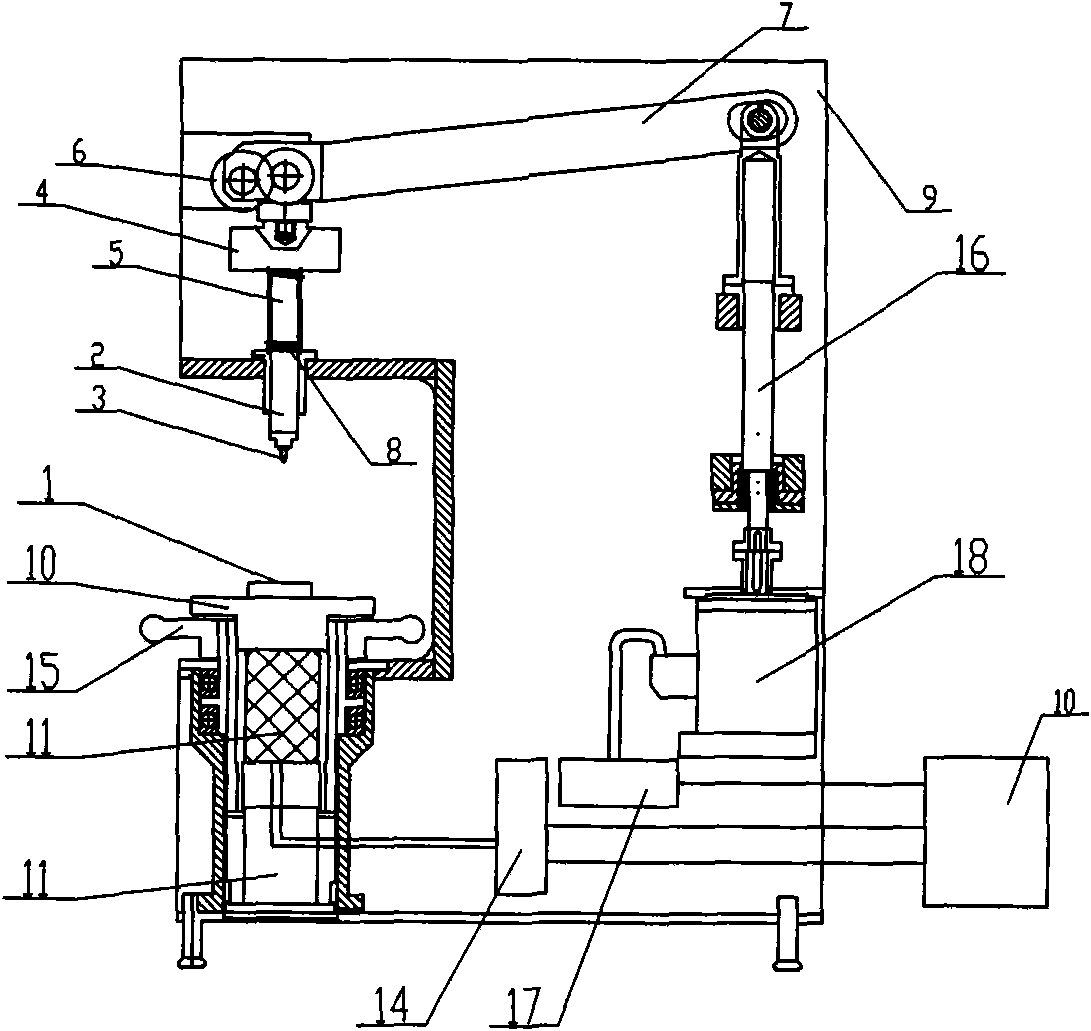

Ball spline supporting Stirling refrigerator

InactiveCN102654325ASimple structureImprove thermal performanceCompression machinesElectric machineryEngineering

The invention discloses a ball spline supporting Stirling refrigerator, which comprises a compressor system, a cold head system and a motor crankshaft driving system, wherein the compressor system is composed of a cylinder and a piston assembly; the piston assembly is composed of a piston and a piston ball spline; the cold head system is composed of a cooling cylinder, an ejector, a regenerator and an ejector ball spline; the regenerator is positioned in the ejector; the motor crank driving system is composed of a motor, a piston connecting rod, a crankshaft and an ejector connecting rod; and the cylinder, the cooling cylinder and the motor are installed on a crankcase. The ball spline supporting Stirling refrigerator has the advantages of stable thermal performance and high reliability, and the service life of the refrigerator is prolonged.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

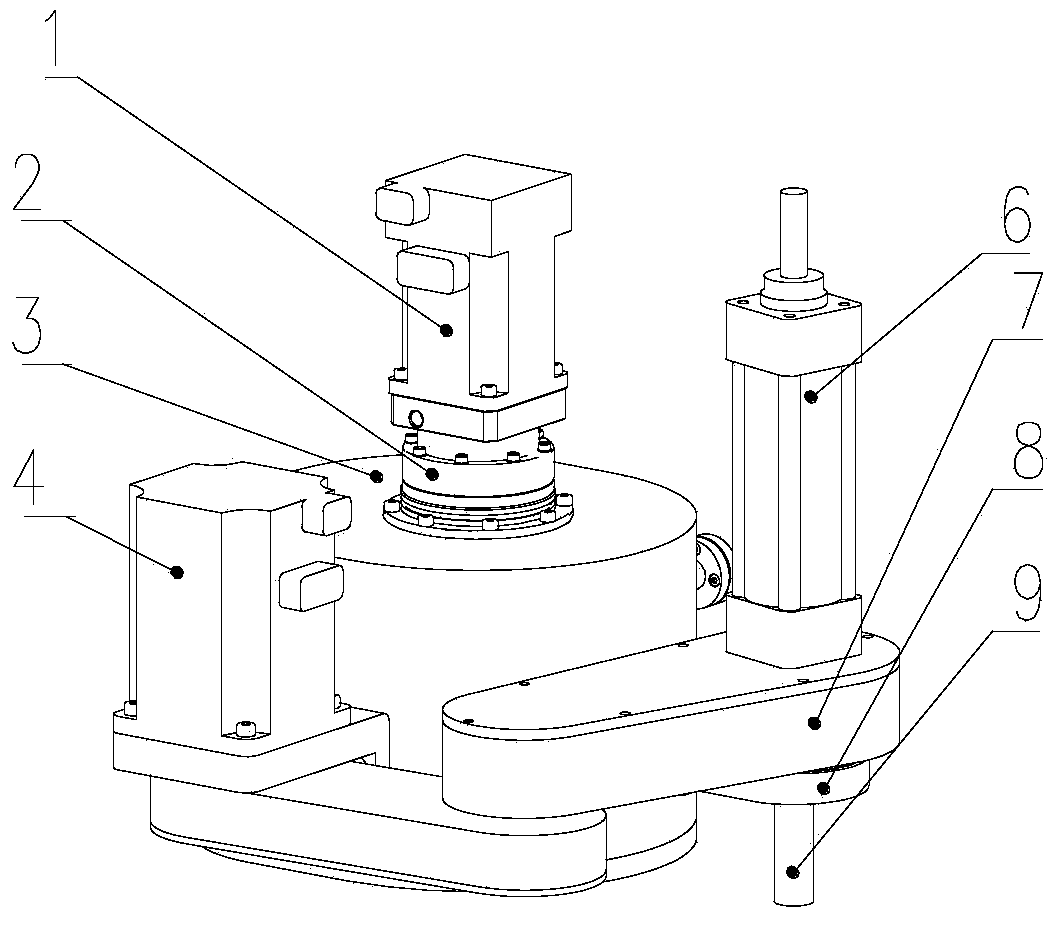

Novel high-precision electrical electronic Brinell hardness tester

The invention provides a novel high-precision electrical electronic Brinell hardness tester, comprising a body, a test platform and a pressure head; wherein the test platform drives the tester to lift up and down through hand wheel and screw rod; the pressure head seat is connected with ball spline; the upper portion of the ball spline is connected with a pressure sensor; the upper portion of the pressure senor is orderly connected with a high hardness platform, a high rigidity lever driving the ball spline to do vertical linear motion; the other end of the lever is provided with a precision ball screw pair having an exact guiding device; the ball screw pair is driven by the servo-actuator; the invention is characterized in that: the ball spline is precise; precision of the ball screw pair is higher that 3 class; the lower portion of the test platform is mounted with a piezoelectric ceramic force value loading block composed by overlapping multiple piece of piezoelectric ceramics; the piezoelectric ceramic force value loading block is connecting with the driver. The invention is featured with electric closed-loop controlling the loading, fast, stable and reliable loading, high loading force value precision achieving to + / -0.1%.

Owner:BEIJING CHANGCHENG METERING TEST TECH INST NO 1 GRP CO CHINA AVIATION IND

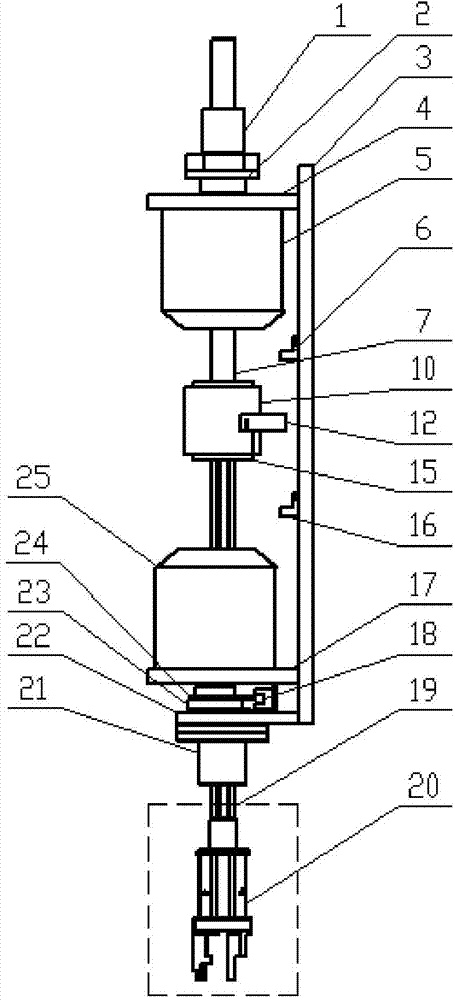

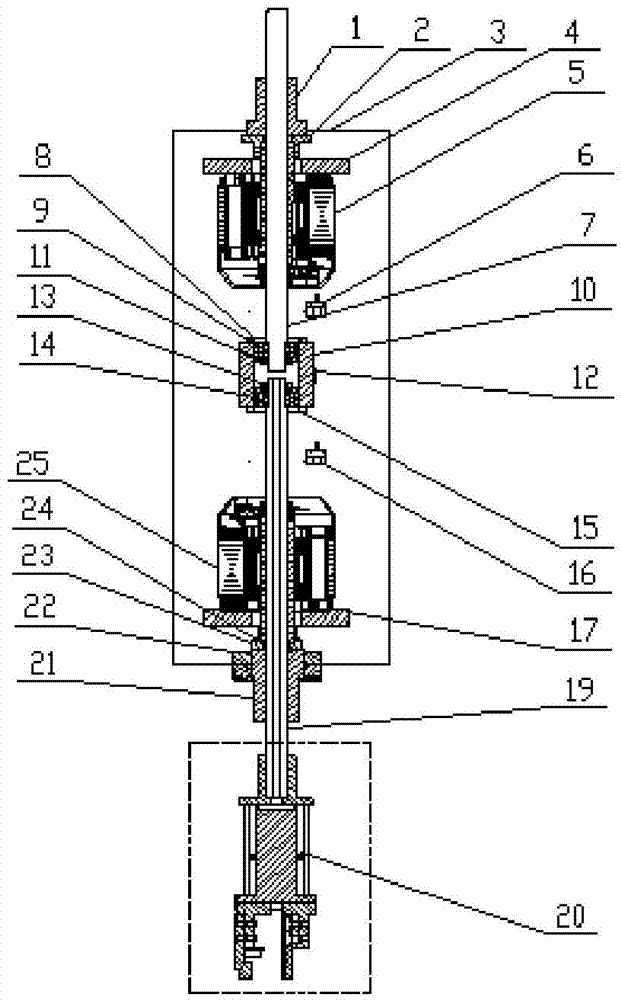

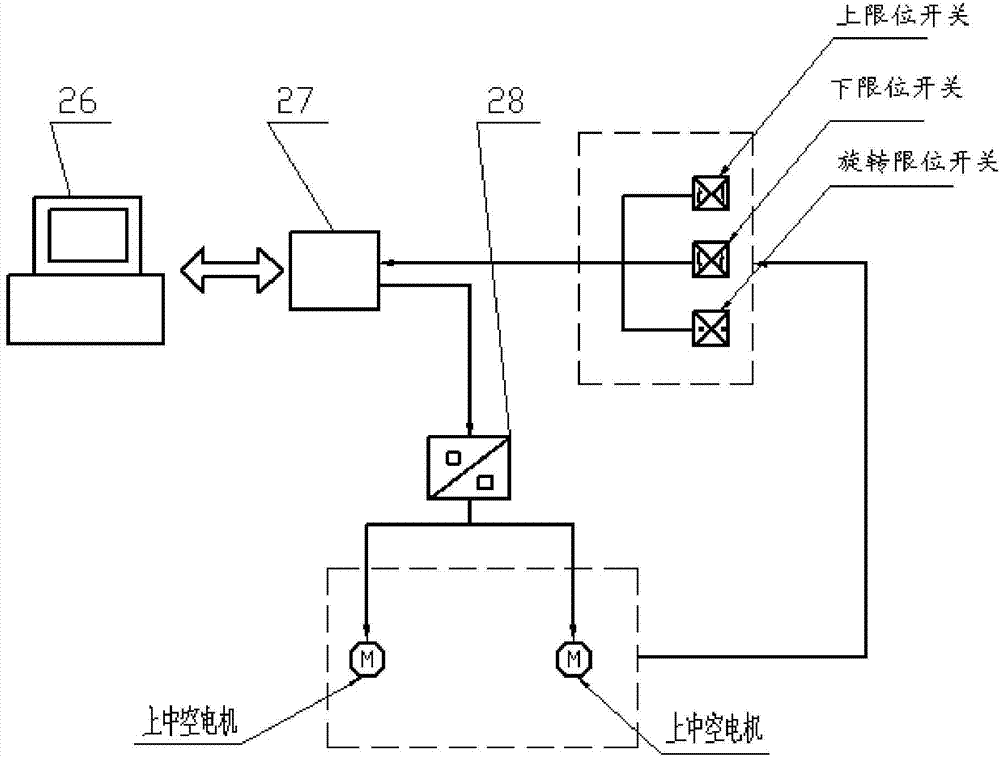

Integrated type two-degree-freedom mechanical arm and control system thereof

ActiveCN104723333AImprove response speedHigh transmission precisionProgramme-controlled manipulatorControl systemBall screw

The invention discloses an integrated type two-degree-freedom mechanical arm and a control system thereof. The mechanical arm comprises a ball screw, an outer cylinder rotation type ball spline, an upper hollow motor, a lower hollow motor, a screw-spline connecting piece and a fixing plate, wherein the ball screw is located in the Z-axis direction, the outer cylinder rotation type ball spline is capable of conducting rectilinear motion and rotational motion simultaneously, the upper hollow motor is arranged on the ball screw, the lower hollow motor is arranged on the ball spline, the screw-spline connecting piece connects the ball screw with the ball spline, and the upper hollow motor and the lower hollow motor are fixed on the fixing plate. According to the mechanism arm, through the two hollow motors, the ball screw and the ball spline are connected with a motor shaft directly without a synchronous belt, the cumulative errors are reduced, and the response speed and transmission accuracy of the mechanical arm are improved; the two motors, the ball screw and the ball spline are located on the same axis, the decoupling of rectilinear motion and rotational motion is achieved, the structure is simple, the size of the mechanism is further shrunk, and meanwhile the machining cost is lowered.

Owner:SUZHOU UNIV

Novel ZR shaft assembly of horizontal multi-joint manipulator

InactiveCN105269560AReduce the numberLight in massProgramme-controlled manipulatorBall screwEngineering

The invention discloses a novel ZR shaft assembly of a horizontal multi-joint manipulator. The novel ZR shaft assembly comprises a ball screw, wherein the upper end of the ball screw is connected with a first driving device through a first transmission assembly; a ball screw nut penetrates through the ball screw, the lower end of the ball screw nut is connected with a ball spline shaft, a hollow inner hole allowing the ball screw to sleeve in is formed in the ball spline shaft, and the ball screw and the ball spline shaft are always coaxially arranged; the ball screw nut is further connected with a linear guide rail; the first driving device drives the ball screw to revolve and rotate, the ball screw nut follows the ball screw to revolve and rotate, and the ball spline shaft is carried to move in a vertical direction; and a spline is arranged on the ball spline shaft in a sleeving manner, the ball spline shaft is further connected with a second driving device through a second transmission assembly, the second driving device drives the ball spline shaft to horizontally revolve, and the spline supports the movement and the revolving of the ball spline shaft. The ZR shaft assembly is simple in structure, is small in assembly size, is flexible, is convenient to assemble, and is low in manufacture cost.

Owner:FUJISAN IND TECH CO LTD OF SHENZHEN CITY

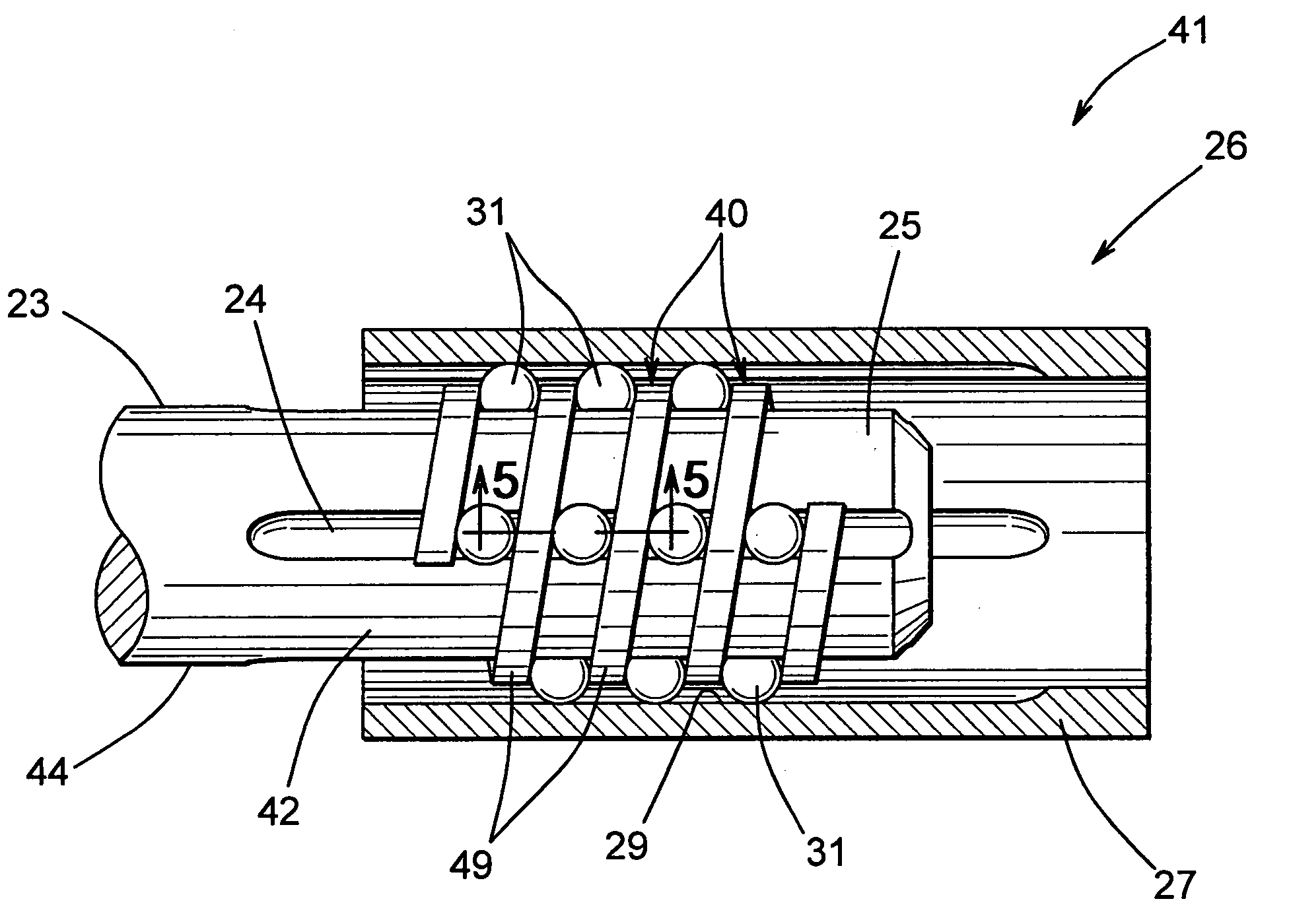

Rolling ball spline slip joint with helically shaped cage

InactiveUS7018299B2Simple structureReduce manufacturing costYielding couplingLinear bearingsEngineeringSlip joint

A slip joint includes a slip shaft having a plurality of axially extending grooves, and a slip yoke having a plurality of axially extending grooves. The slip yoke is in telescoping engagement with the slip shaft, and the grooves formed in the slip shaft are circumferentially aligned with the grooves formed in the slip yoke. A plurality of torque transmitting balls is disposed in the grooves. A helically shaped cage is positioned radially between the slip shaft and the slip yoke. The cage secures the balls to maintain the balls spaced apart from one another and within the grooves.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Multi-station SCARA industrial robot

PendingCN107639631ALower acquisition costsReduce weightProgramme-controlled manipulatorWire rodControl engineering

The invention discloses a multi-station SCARA industrial robot. The industrial robot includes a SCARA robot mechanism and a displacement drive mechanism, and the SCARA robot mechanism comprises a base, a first arm, a first arm drive device, a second arm, a second arm drive device, a ball spline wire rod and a power supply cable; a first motor and a second motor on the first and second arm drive devices are arranged inside the base, the rotation and lifting of the ball spline screw rod are driven by a third motor through a third drive component, and the SCARA robot mechanism can move under thedrive of the displacement drive mechanism. When the multi-station SCARA industrial robot is produced, multiple workstations require sharing only one SCARA robot mechanism, and thus the occupied spaceand the acquisition costs of equipment are reduced. Additionally, in the SCARA robot mechanism, the first and second motors are arranged inside the base, only the third motor is arranged on the secondarm, the weight of the load on the second arm can be reduced, the cost of spare parts is reduced, and the motion accuracy is improved.

Owner:GUANGDONG INST OF INTELLIGENT MFG

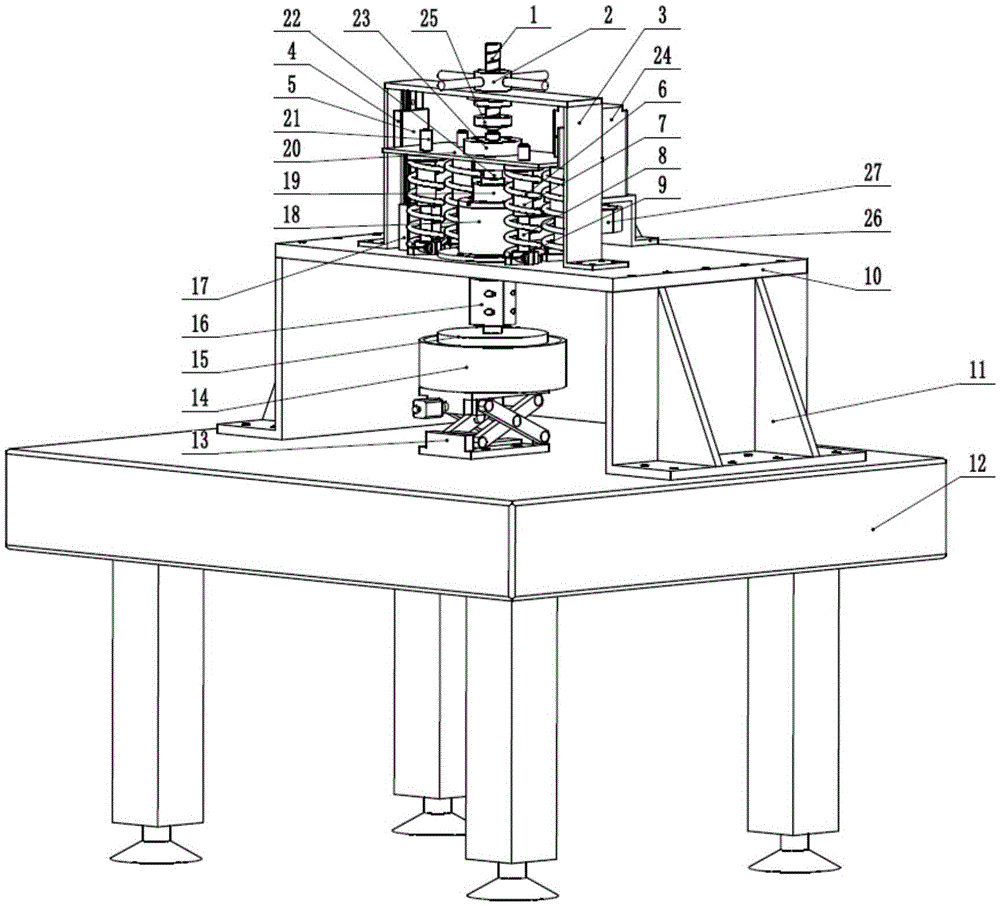

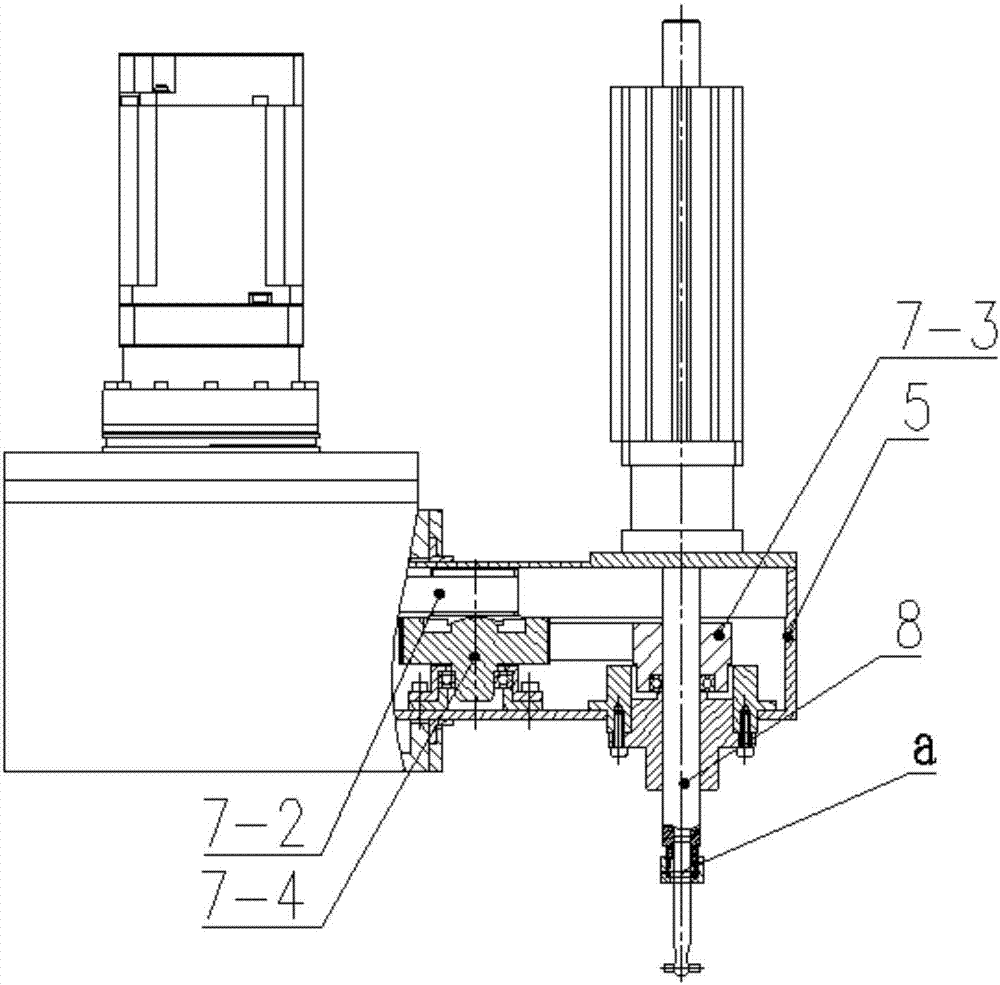

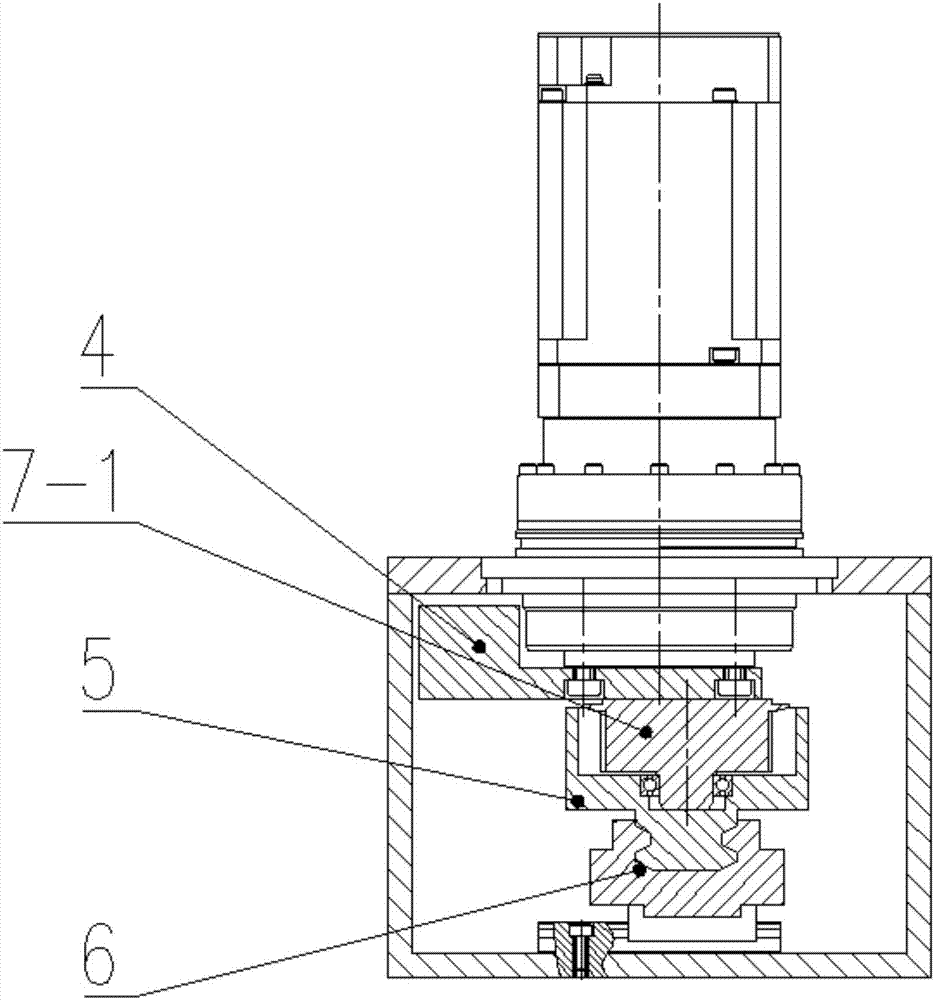

Eccentric planetary polishing device of large-caliber aspheric robot

InactiveCN107414631ASmall sizeReduce weightOptical surface grinding machinesGrinding drivesDynamic balanceFriction force

The invention discloses an eccentric planetary polishing device of a large-caliber aspheric robot. The main structure of the eccentric planetary polishing device is composed of an eccentric planetary transmission mechanism and a polishing shaft assembly. The eccentric planetary transmission mechanism achieves revolution motion and rotation motion of end execution of the polishing device at the same time through the same motor and comprises a planetary transmission mechanism body and a mass center balance mechanism, and dynamic balance stability during mechanism operating can be achieved. The polishing shaft assembly is composed of a low-friction air cylinder, a rotary ball spline and a polishing hollow shaft. The polishing hollow shaft can inject a polishing solution to a polishing disc during polishing, and therefore dynamic-pressure and static-pressure polishing is achieved. The influence of friction force on the polishing shaft of a pure rolling connection manner under pressure control is low, and therefore high control precision is achieved.

Owner:TIANJIN UNIV

Rotary assembly robot gripper

InactiveCN106426254AImprove operation accuracyCompact structureProgramme-controlled manipulatorGripping headsEngineeringCylinder block

A rotary assembly robot gripper comprises a frame, a left gripper arm, linear guide rails, a connecting plate, a right gripper arm, gripper bodies, a servo motor, cylinders, hinge pedestals, connecting rods, a synchronous rotation mechanism and a ball spline. The connecting plate is mounted on the frame. A pair of parallel linear guide rails is fixed on the frame. The left gripper arm and the right gripper arm are symmetrically mounted on the left and the right of the linear guide rails. Cylinder block ends of the two cylinders are fixed at the left end and the right end of the frame. Ends of the two connecting rods with the same length are respectively hinged to the hinge pedestals mounted on the left gripper arm and the right gripper arm. The other ends of the connecting rods are hinged to the synchronous rotation mechanism mounted on the frame. The rotary assembly robot gripper is compact in structure and integrates multiple functions, the operation precision is remarkably superior to the manual operation precision, the production cost is reduced, the production efficiency can be remarkably improved, and the labor intensity is reduced.

Owner:YTO LUOYANG WIT TOOLS & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com