Multi-connecting-rod rectilinear movement hanger bracket adopting ball spline pair

A ball spline, multi-link technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of large sliding friction at the moving pair, many hinge moving pairs, poor stiffness, etc., to improve the control stability. performance, improve working life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

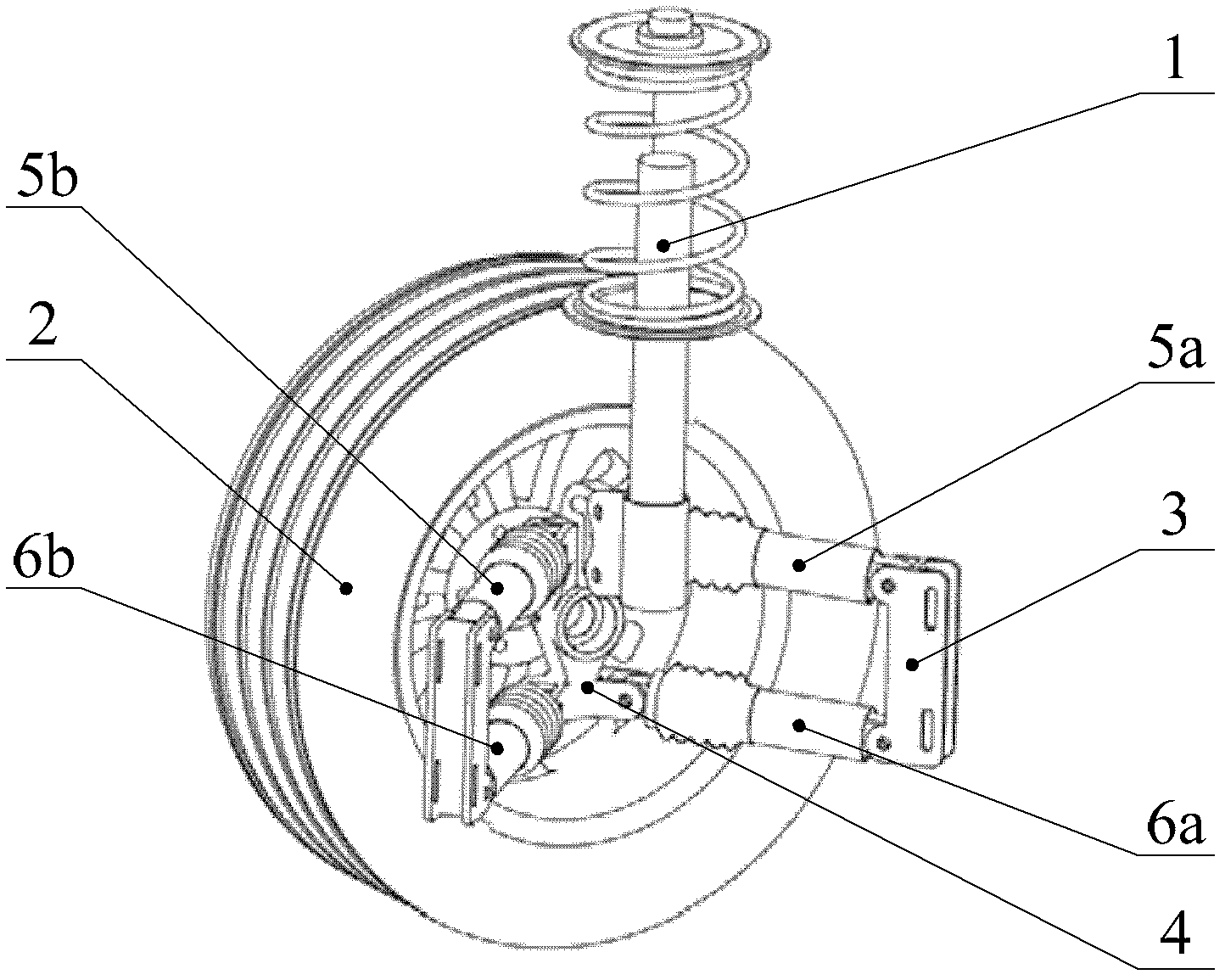

[0022] Example: such as figure 1 , the multi-link linear translation suspension includes a wheel 2 , a body 3 , a spring damper system 1 and a steering knuckle 4 . The steering knuckle 4 is connected to the wheel 2 through the hub unit, and the spring damper system 1 is hinged to the steering knuckle 4 and the vehicle body 3 respectively. The system also includes four suspension branch chains, which are the first suspension branch chain 5a on the upper side, the second suspension branch chain 5b on the upper side, the first suspension branch chain 6a on the lower side, and the second suspension branch chain on the lower side. The two ends of the suspension branch chain 6b are respectively hinged with the steering knuckle 4 and the vehicle body 3 .

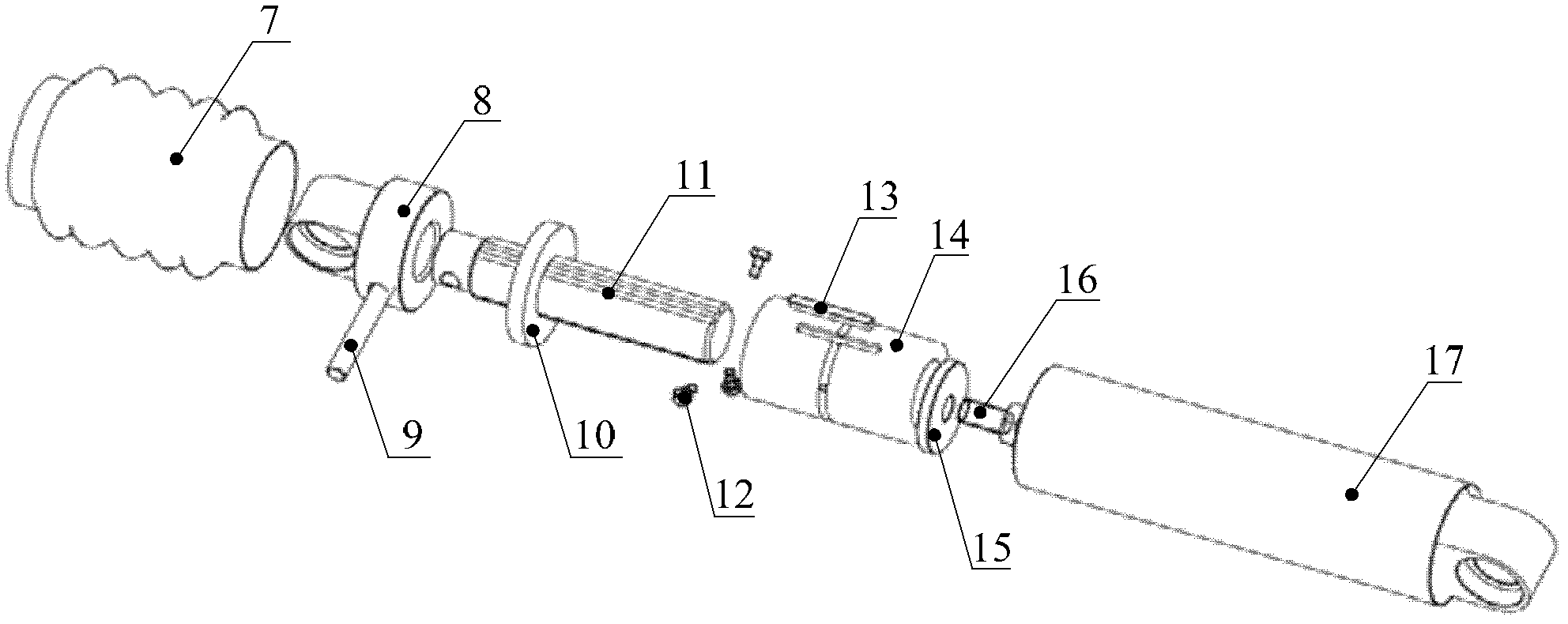

[0023] figure 2The suspension branch chains shown include a dust cover 7, a short connecting rod 8, a fixed pin 9, a buffer washer 10, a spline shaft 11, an oil hole screw 12, a flat key 13, a spline sleeve 14, and a retaining r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com