Patents

Literature

1050 results about "Axle track" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The axle track in automobiles and other wheeled vehicles which have two or more wheels on an axle, is the distance between the centerline of two roadwheels on the same axle. In a case of the axle with dual wheels, the centerline in the middle of the dual wheel is used for the axle track specification.

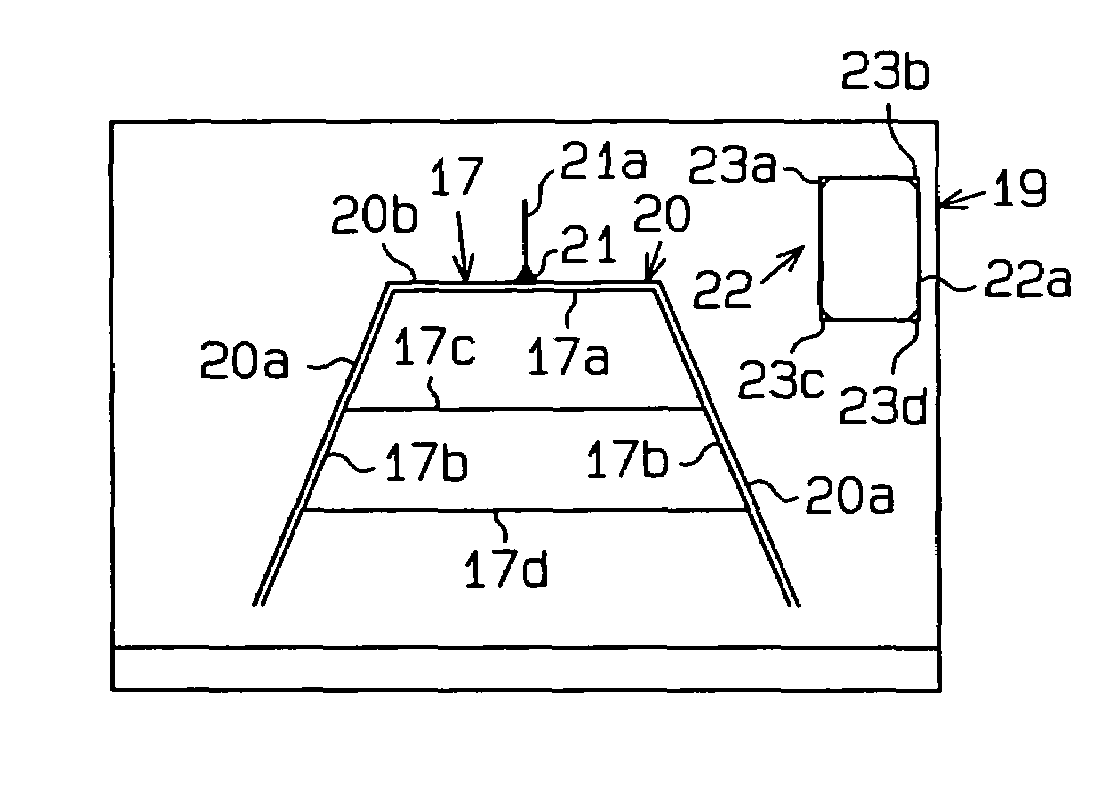

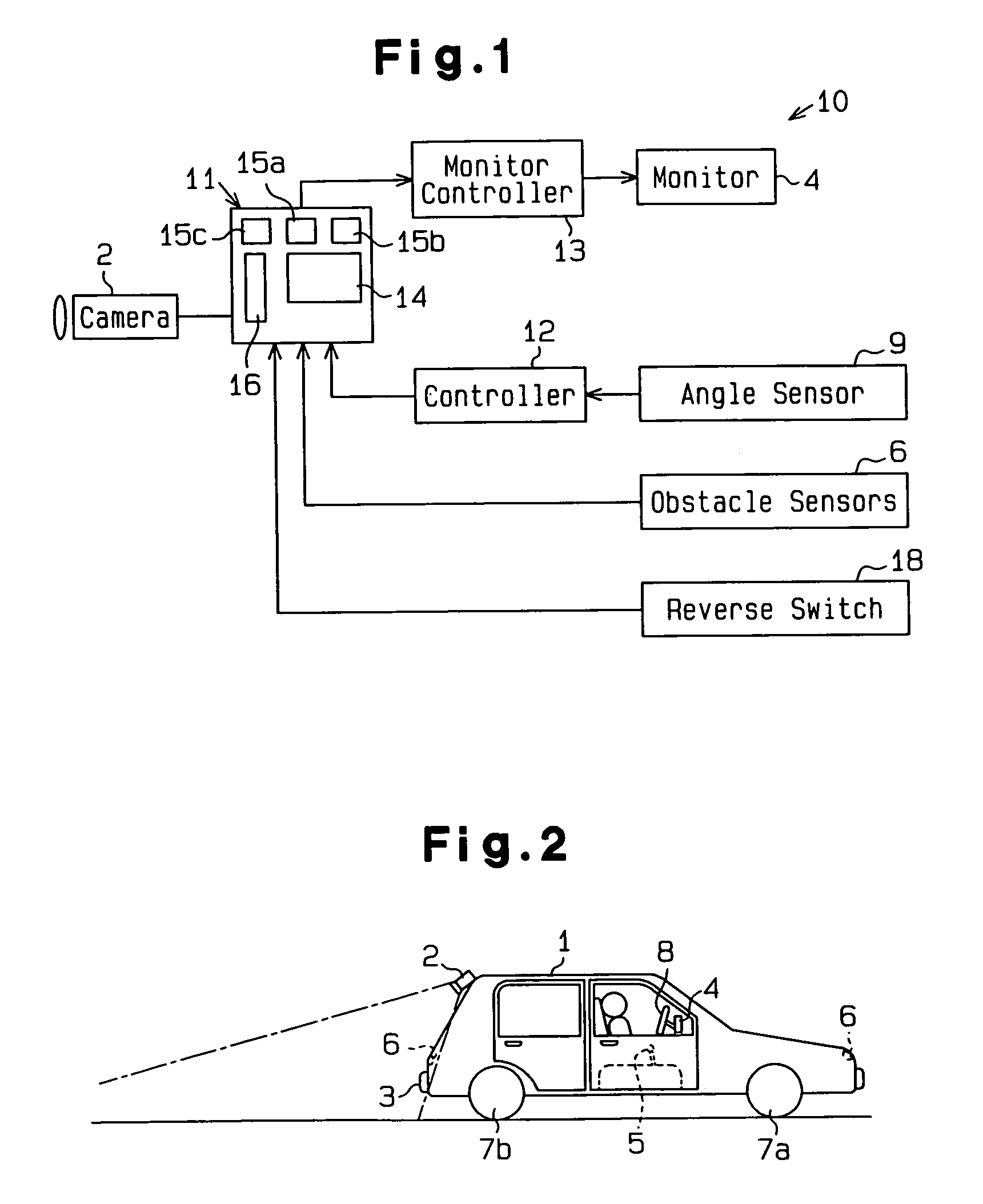

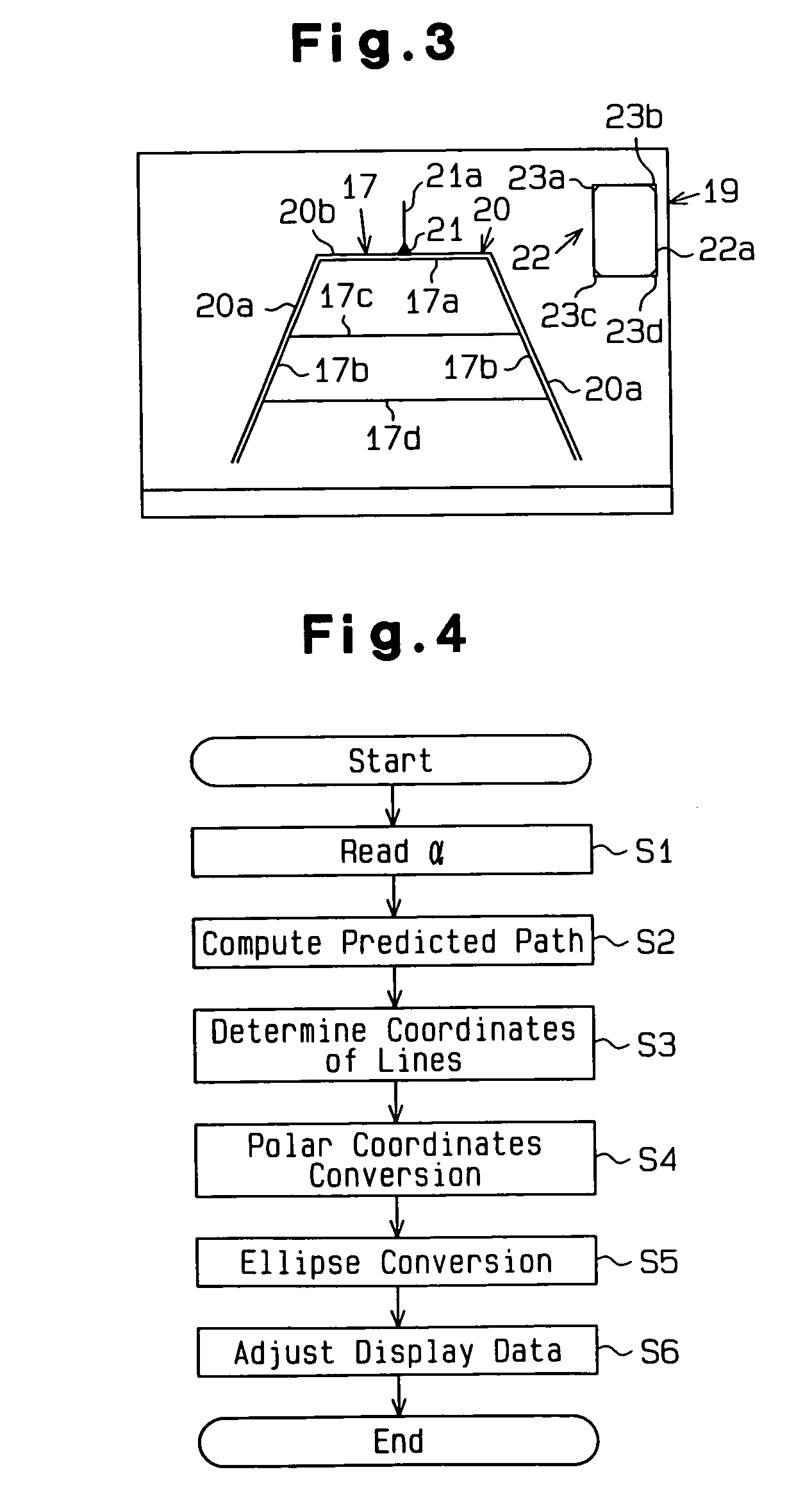

Apparatus for assisting steering of vehicle when backing

InactiveUS7295227B1Easy to moveDigital data processing detailsAnti-collision systemsDriver/operatorImaging processing

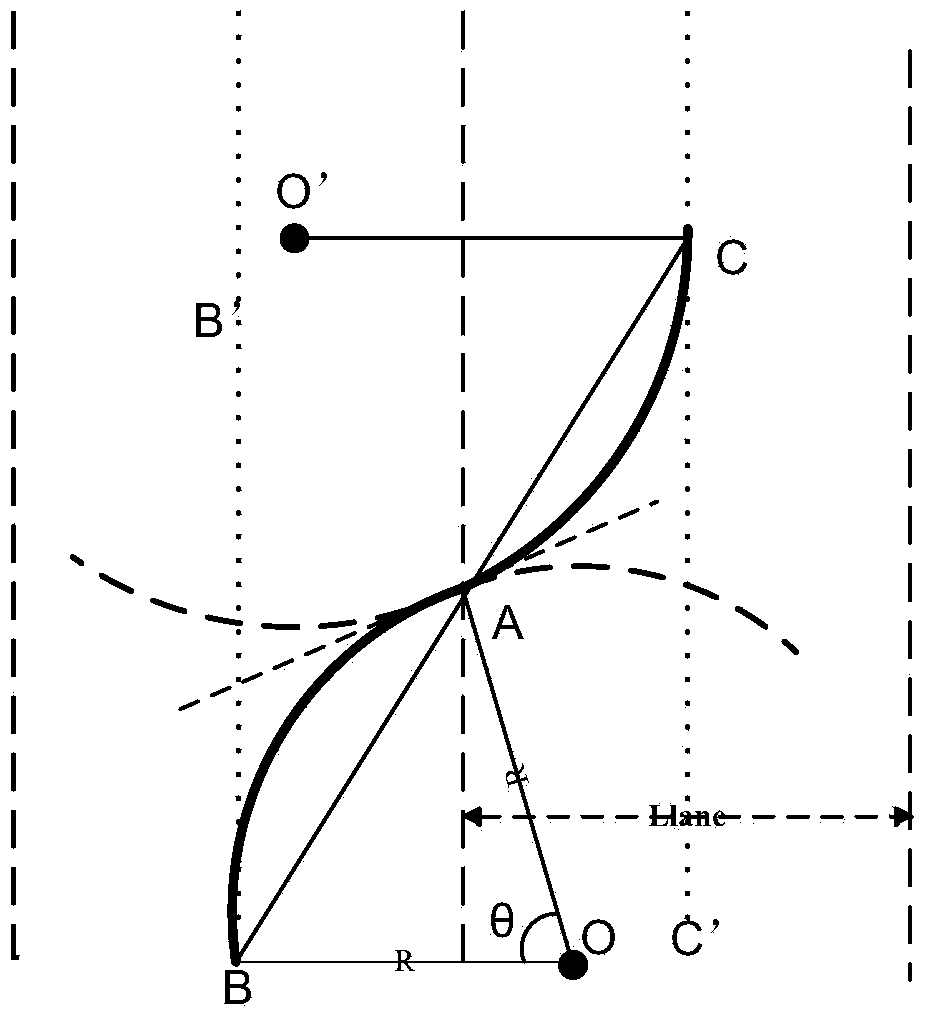

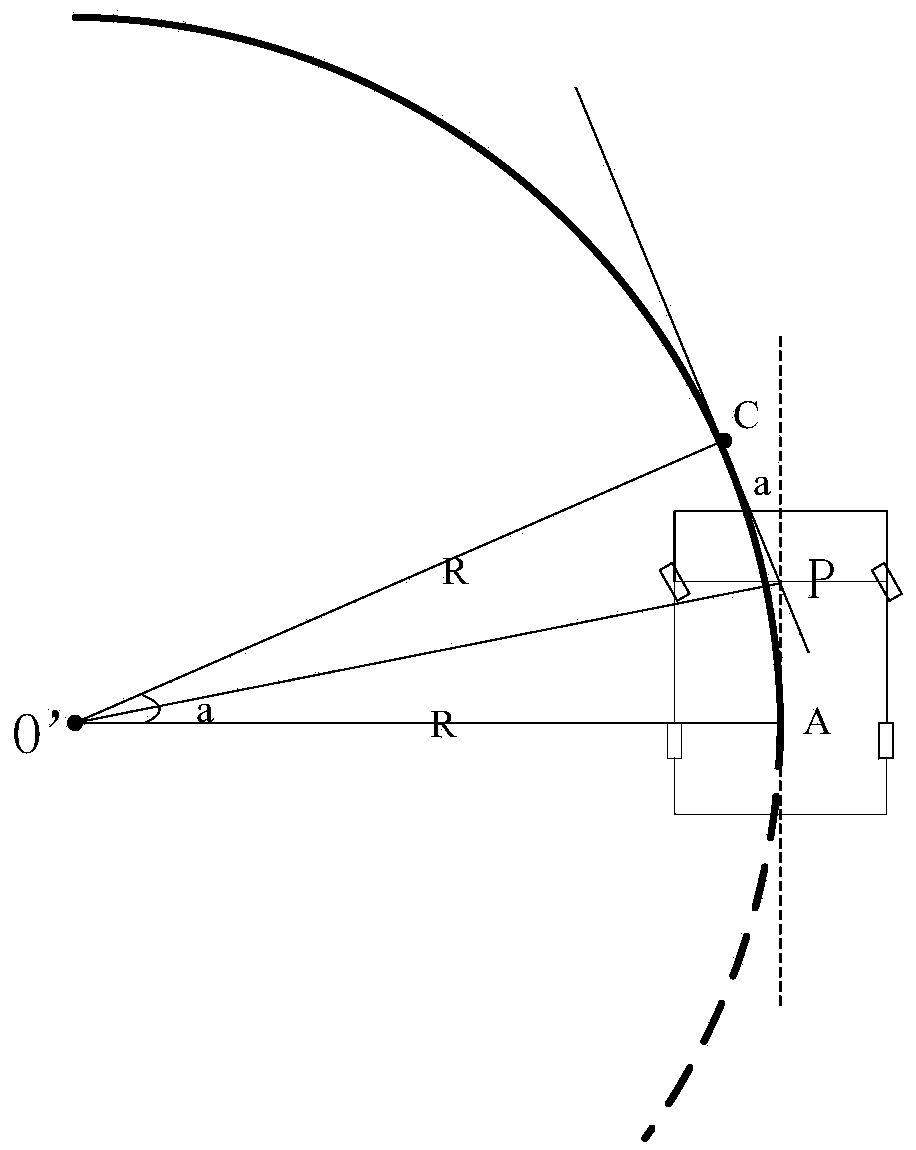

A steering assist apparatus that assists a driver when backing a vehicle in an S-shaped path or parallel parking. The apparatus displays guidance marking on a monitor screen and the driver refers to the guidance marking, which permits the driver to easily back the vehicle to a desired position. The apparatus includes a camera, a monitor, an angle sensor, obstacle sensors, an image processing unit, a controller and a monitor controller. The image processing unit computes the predicted path of the vehicle at the current wheel angle. The monitor shows an image captured by the camera. The image processing unit generates data representing a guidance marking based on the predicted path and superimposes the marking on the monitor screen. The location of the marking on the screen is determined based on the current wheel angle. The marking represents part of the predicted path. Specifically, the marking matches the width of the vehicle. In the monitor screen, a marking is separated from the rear bumper of the vehicle by a distance corresponding to the wheelbase of the vehicle.

Owner:TOYOTA IND CORP

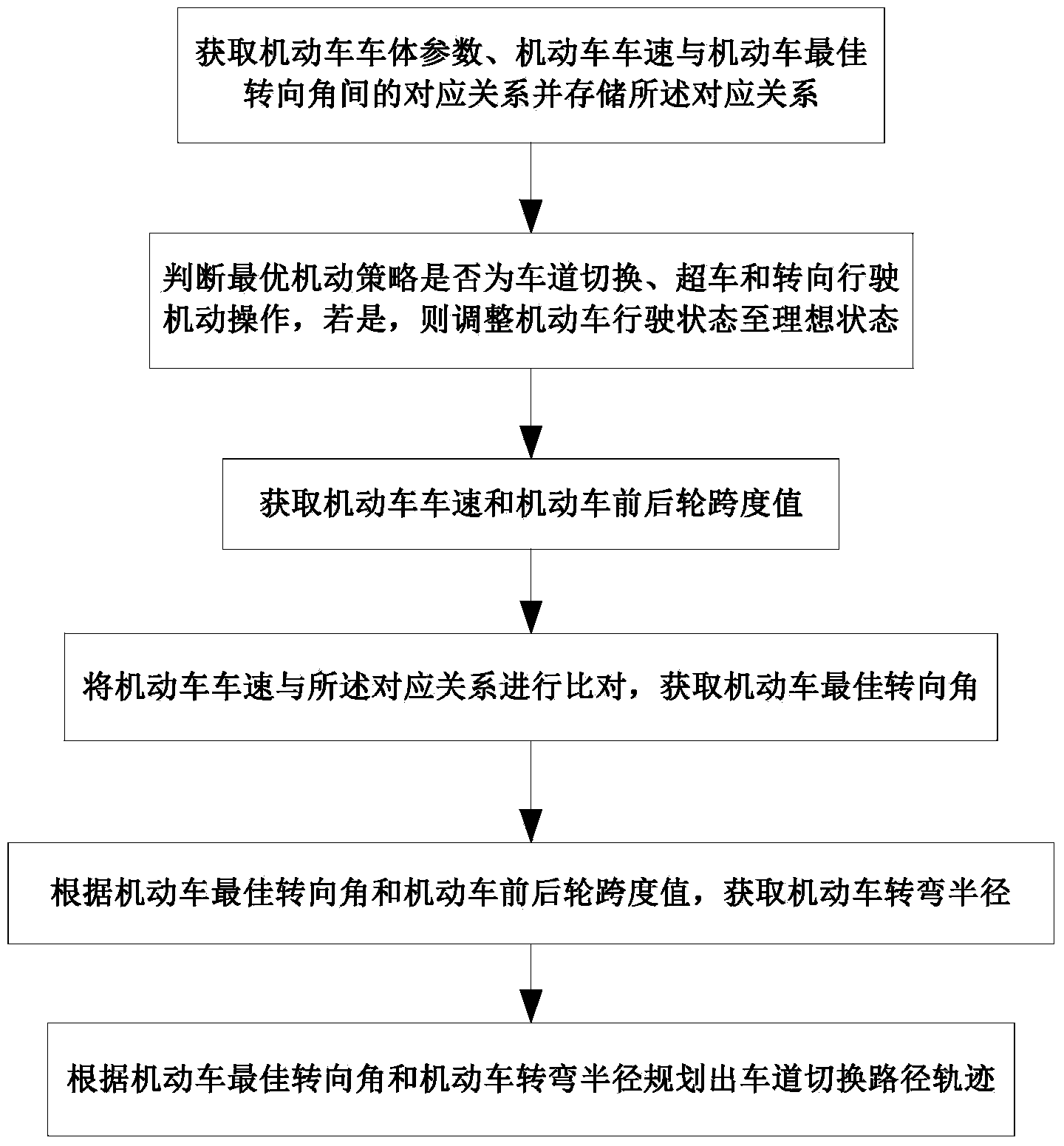

Automatic driving method and automatic driving system

ActiveCN103646298AEnsure driving safetyAvoid accidentsForecastingPosition/course control in two dimensionsAutomotive engineeringAxle track

The invention provides an automatic driving method and an automatic driving system. A corresponding relation among vehicle body parameters of the motor vehicle, a vehicle speed and an optimum turning angle of the motor vehicle are acquired firstly; a driving state of the motor vehicle is adjusted to be an ideal state when optimum maneuvering strategies are lane switching, overtaking and turning driving maneuvering operation; the speed of the motor vehicle and a distance of front and back wheel shafts are acquired; contrast between the speed of the motor vehicle and the corresponding relation is carried out to acquire an optimum turning angle of the motor vehicle; a turning radius of the motor vehicle is acquired according to the optimum turning angle of the motor vehicle and the distance of the front and back wheel shafts; and a lane switching path locus of the motor vehicle can be planned according to the optimum turning angle and the turning radius of the motor vehicle. Through the method and the system, the lane switching path locus of the motor vehicle under an automatic driving state can be planned according to the optimum maneuvering strategies, and most accurate reference basis is provided for automatic driving of the motor vehicle.

Owner:SHANDONG INST OF ADVANCED TECH CHINESE ACAD OF SCI CO LTD

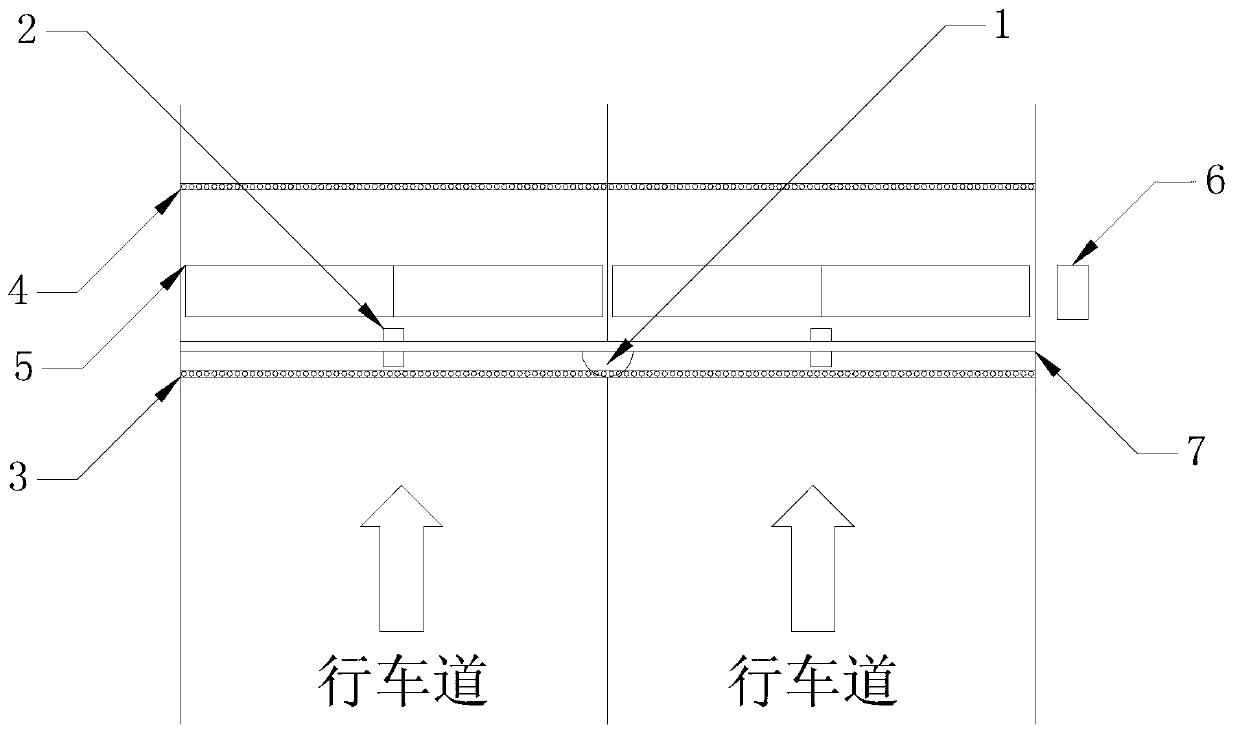

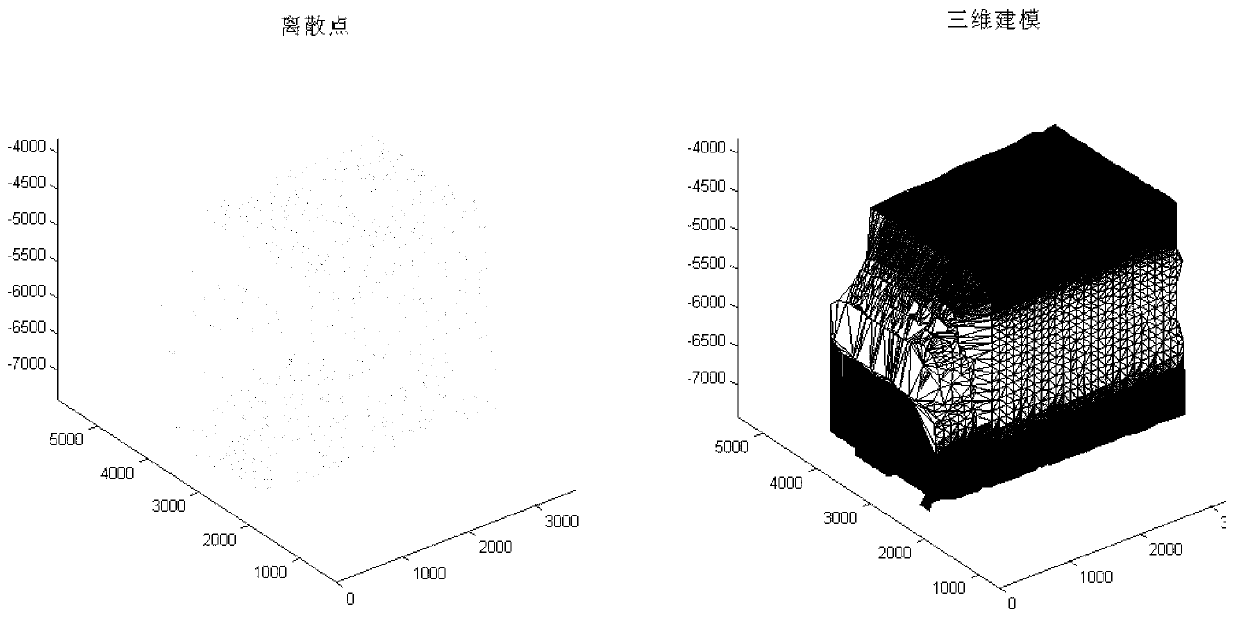

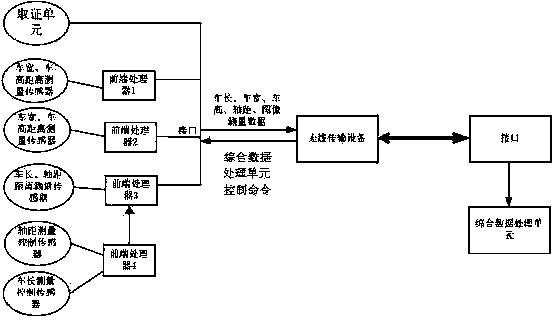

Vehicle information detecting and recognizing system under multilane condition

ActiveCN103279996AImprove detection accuracyEasy to identifyTicket-issuing apparatusRoad vehicles traffic controlDot matrixLaser scanning

The invention discloses a vehicle information detecting and recognizing system under the multilane condition. The vehicle information detecting and recognizing system comprises a computer system and a portal frame stretching over lanes, wherein a laser scanner and a high-definition license plate recognition device are arranged on the portal frame, a first dot matrix type wheel shaft sensor, a shaft weight sensor and a second dot matrix type wheel shaft sensor are sequentially arranged on the lane under the portal frame, and the laser scanner, the high-definition license plate recognition device, the first dot matrix type wheel shaft sensor, the shaft weight sensor and the second dot matrix type wheel shaft sensor are respectively connected with the computer system. The vehicle information detecting and recognizing system has the advantages that the two-dimension cross section size and the running position of a vehicle are detected through the laser scanner, and the vehicle three-dimension reconstitution and the vehicle separation are realized; the license plate information and the human face information are precisely collected through the license plate recognition device; the vehicle information such as the shaft distance, the shaft length, the shaft number, the shaft type, the wheel distance, the wheel width and the wheel number are measured according to signals output after a vehicle tyre presses the wheel shaft sensor; and the shaft weight and the total weight are measured through the shaft weight sensor.

Owner:广州顺如电子科技有限公司

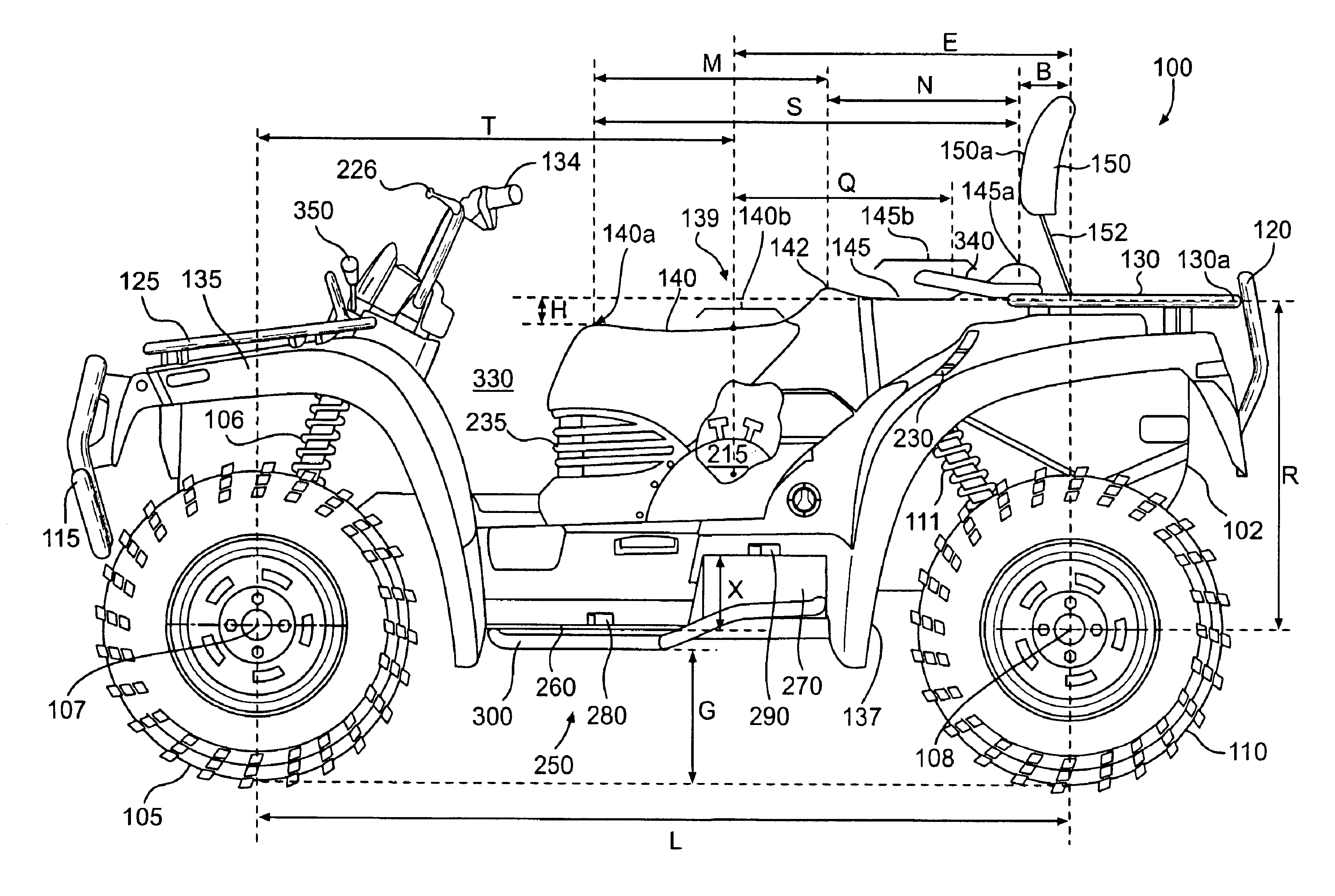

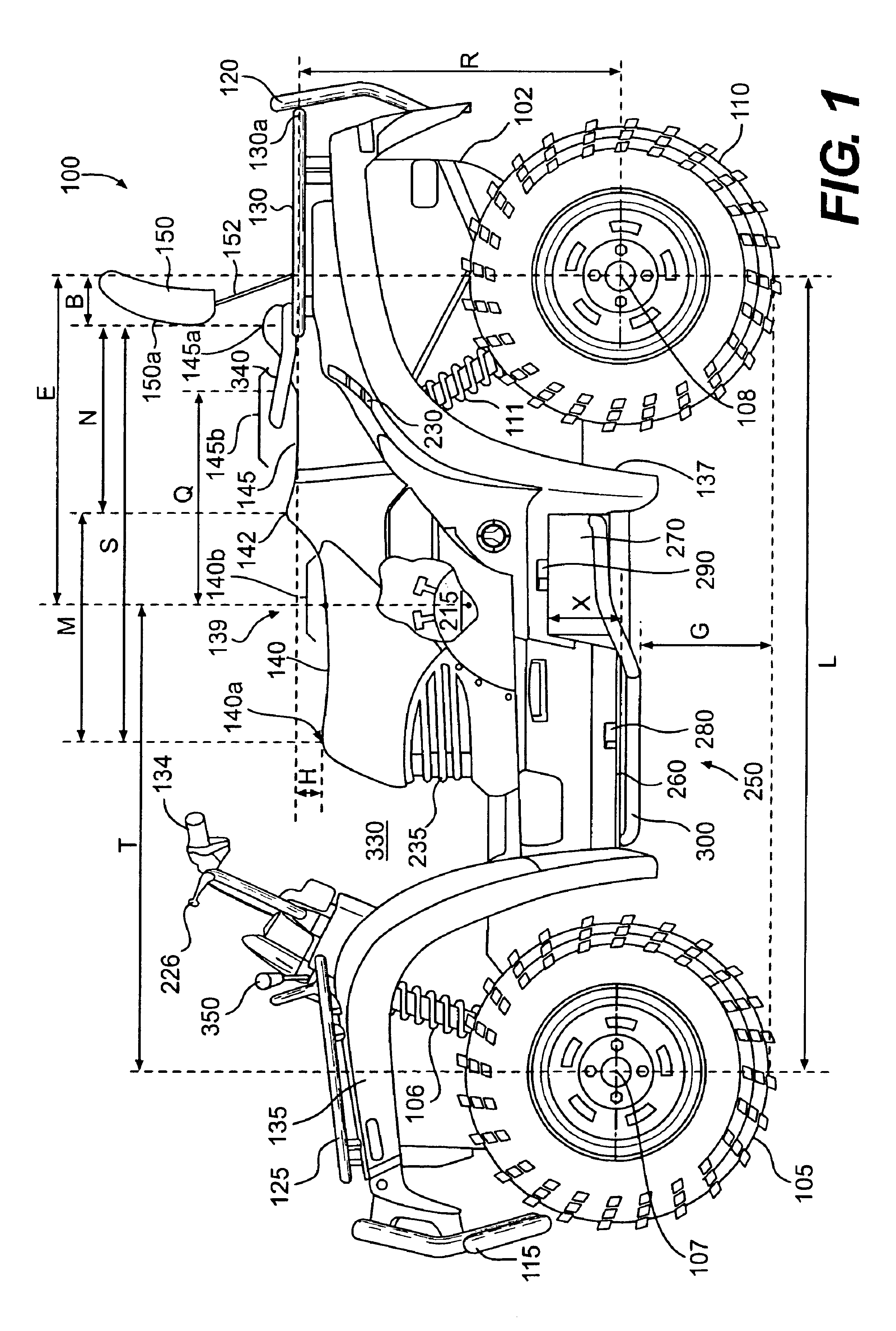

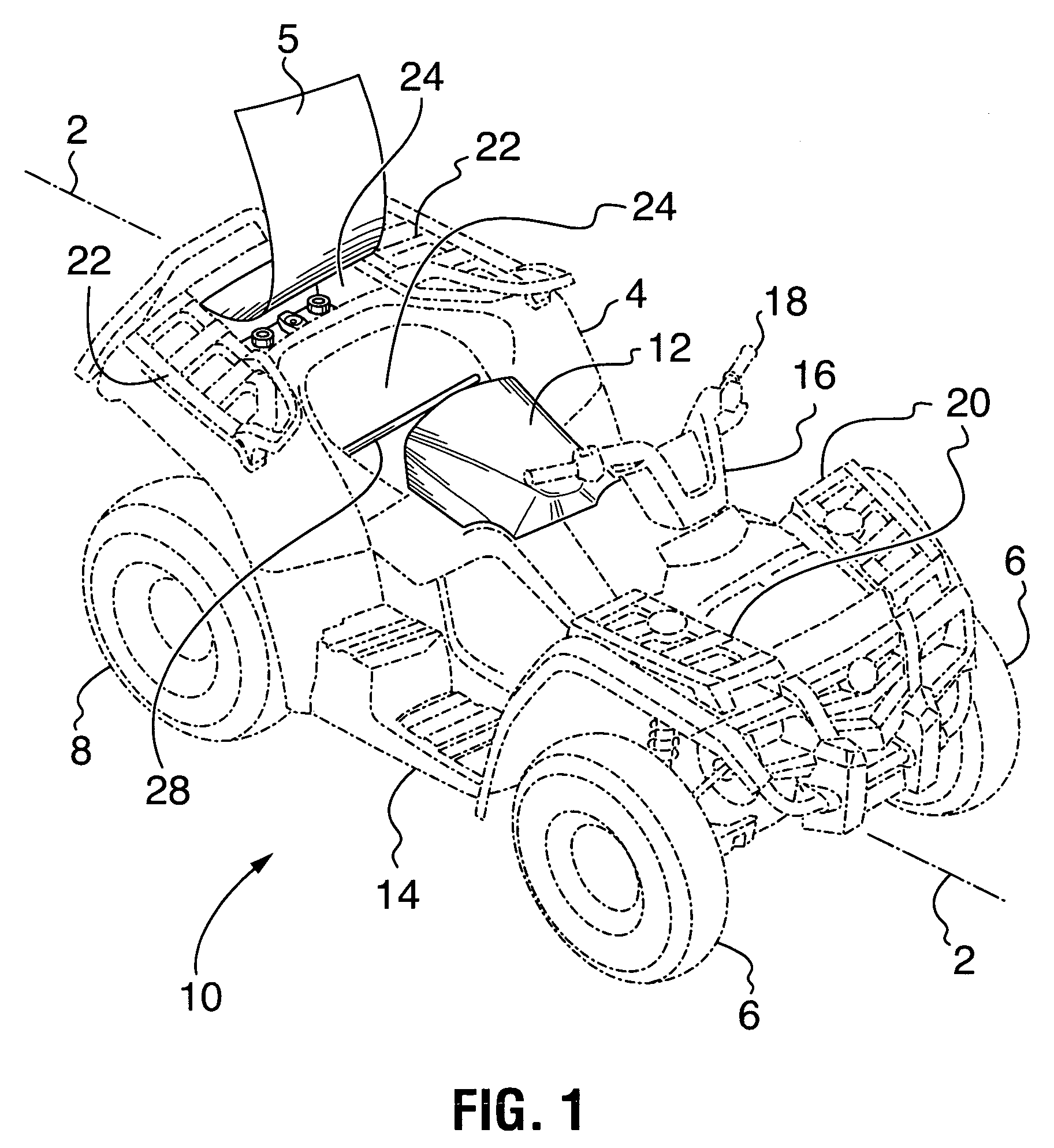

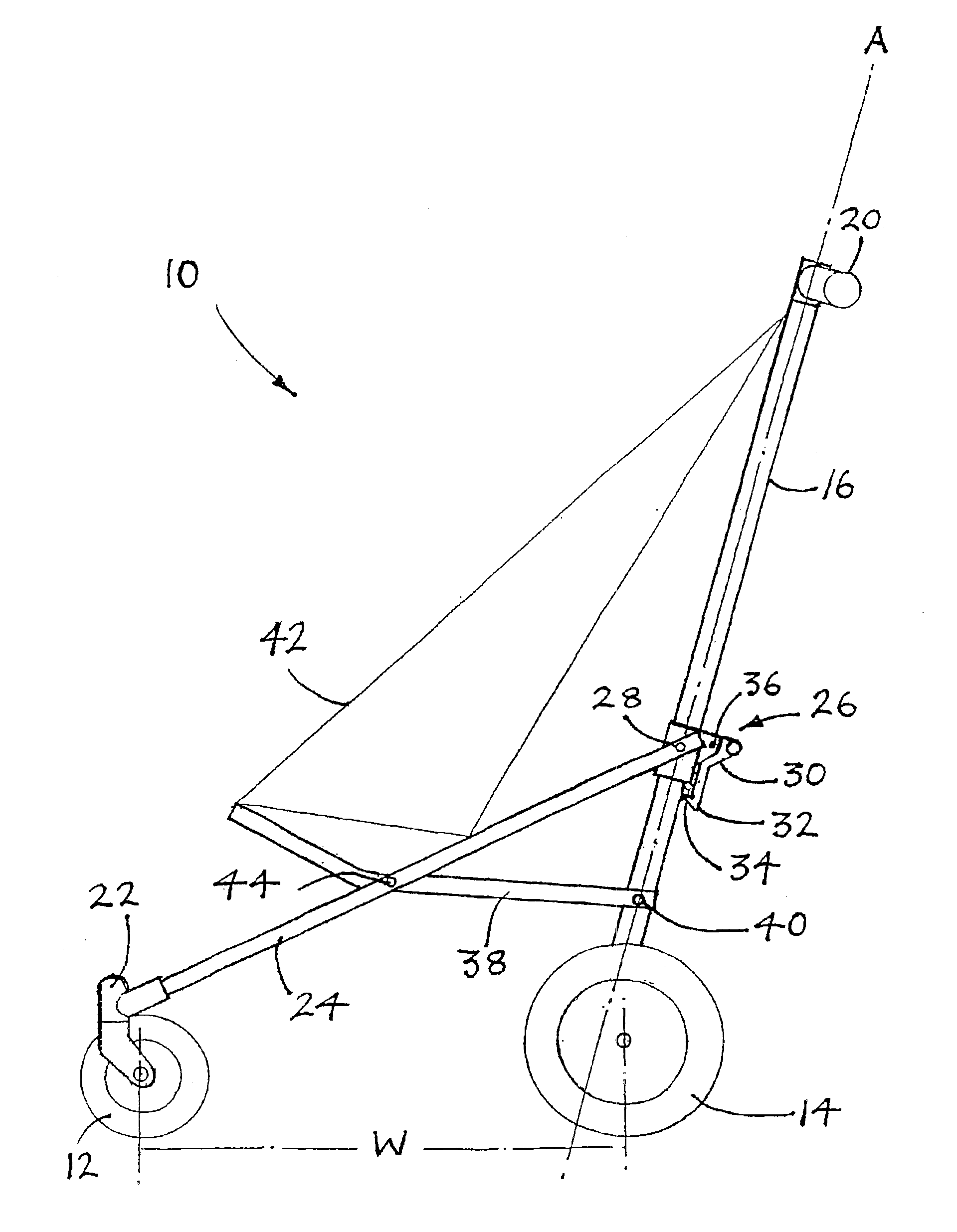

ATV with improved driver positioning and/or multi passenger capacity

InactiveUS6968917B2Safely accommodatedIncrease the wheelbaseCyclesLuggage carriersDriver/operatorEngineering

An all-terrain vehicle (ATV) includes a frame and a pair of front and rear wheels suspended from the frame. A straddle-type seat has a main portion and a secondary portion to accommodate a driver and a passenger. The wheelbase of the ATV is increased in length (compared to conventional ATVs) so as to increase stability and comfort for the driver, and / or to accommodate a passenger behind the driver. The passenger and secondary seat portion are disposed in front of the rear wheel axis and moved closer to the center of the wheelbase. Moreover, the combined center or gravity of the ATV, rider, and passenger is moved closer to the center of the wheelbase to improve stability, comfort and / or safety. The driver and passenger each have sufficient space to actively position themselves without significantly interfering with each other.

Owner:BOMBARDIER RECREATIONAL PROD INC

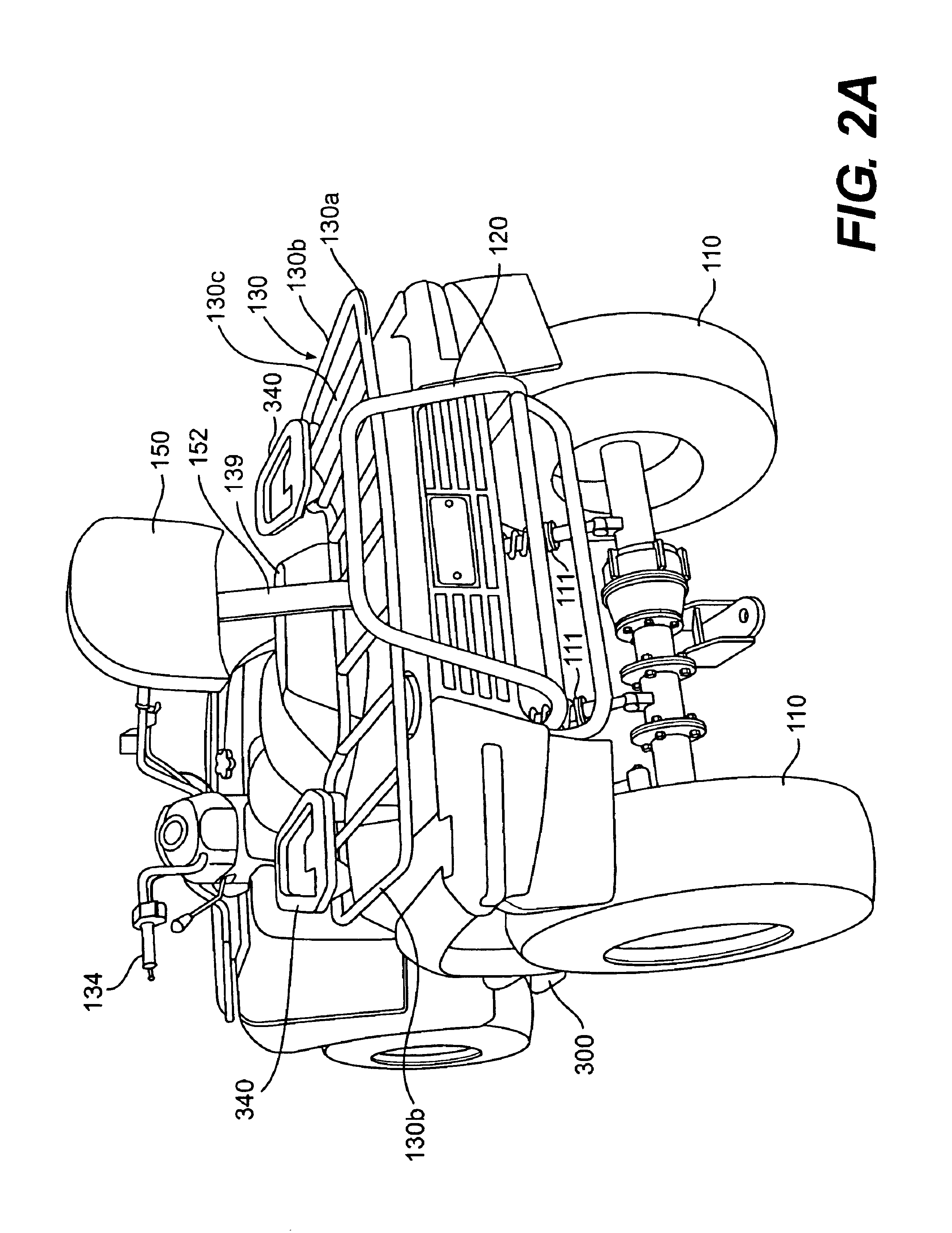

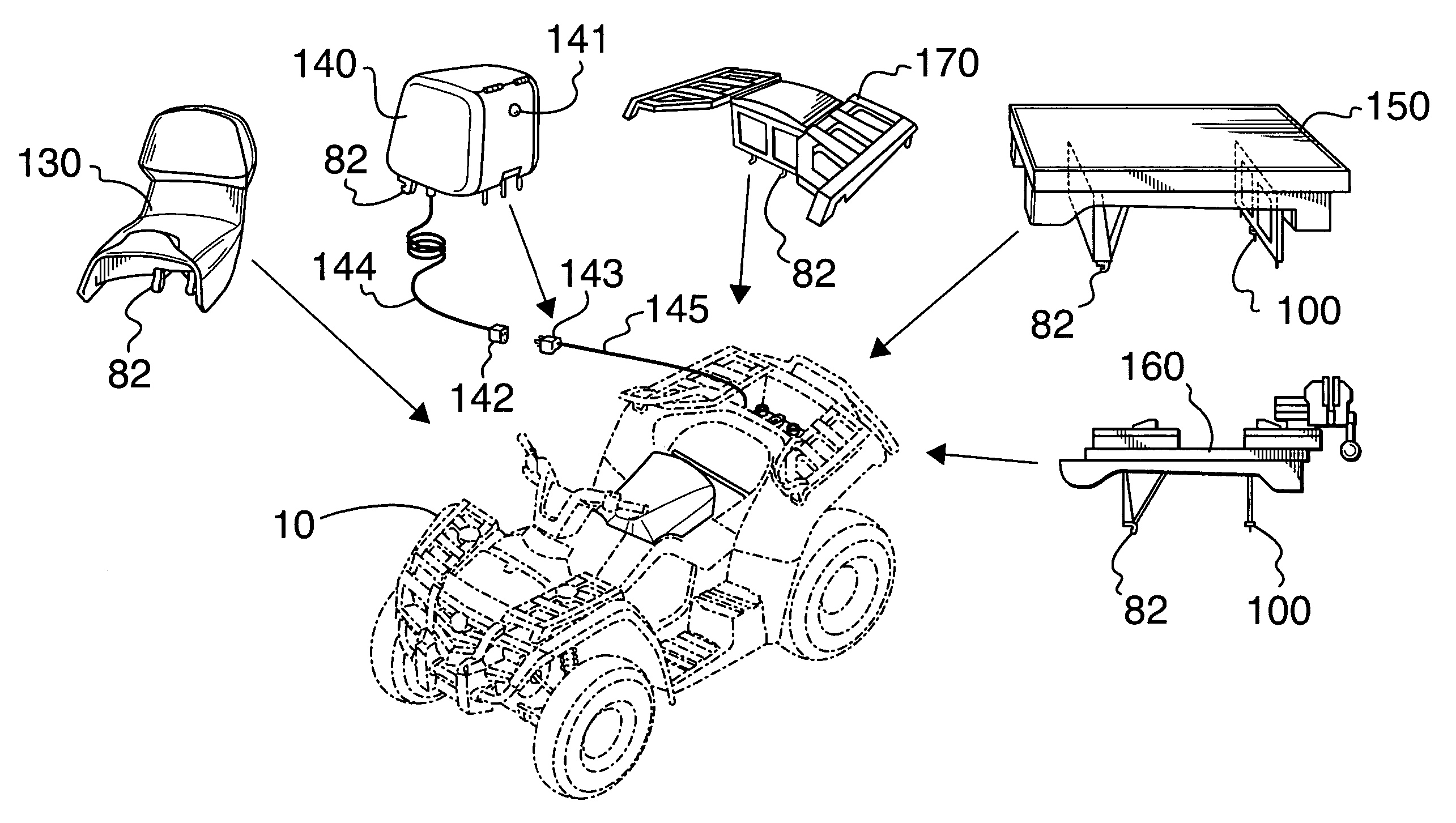

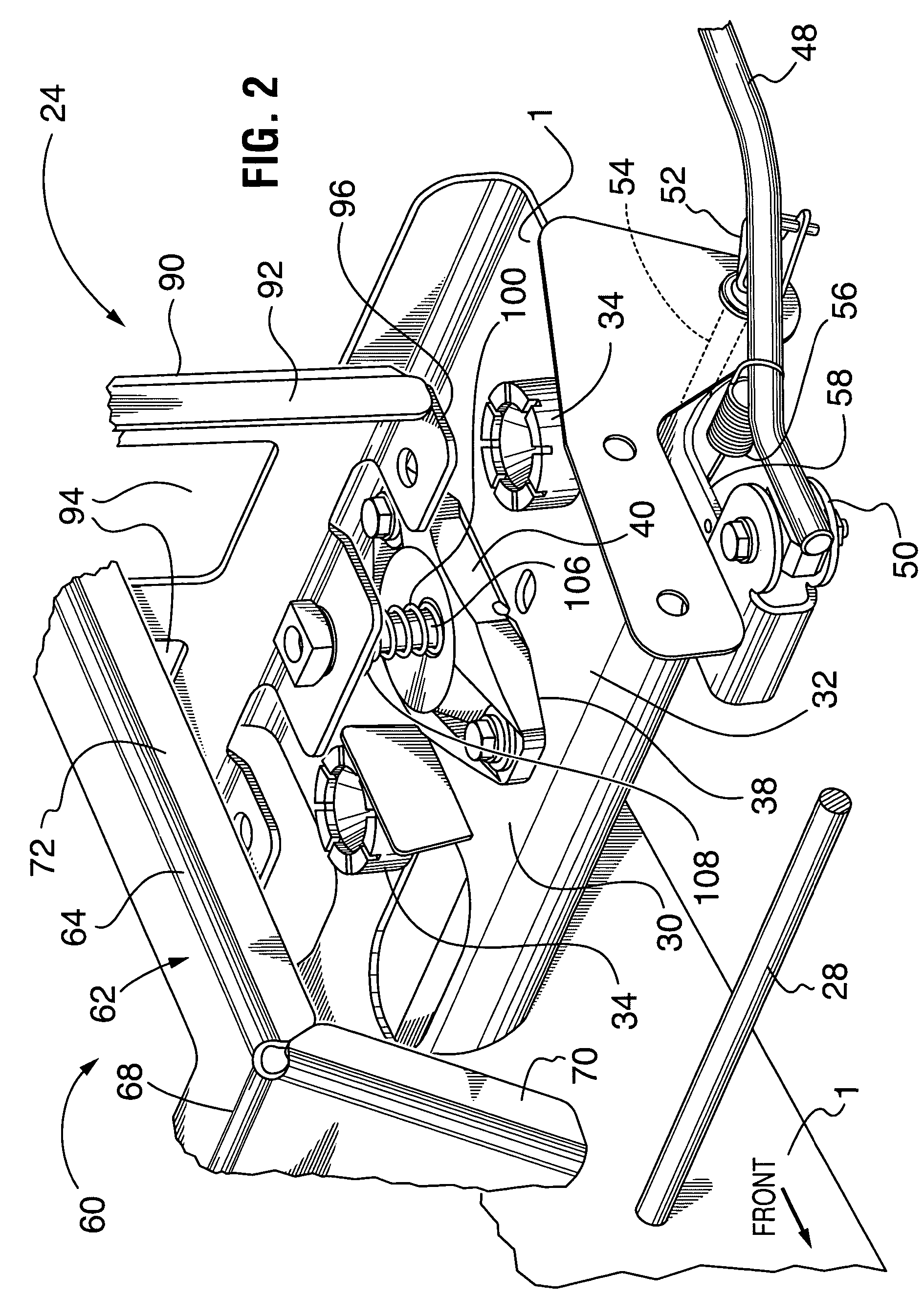

Modular components for an all-terrain vehicle

InactiveUS7377570B2Easy to replaceEasy interchangeCyclesSuperstructure subunitsModularityElectrical connection

An all-terrain vehicle (ATV) with an elongated wheelbase has a rear-mounted receptacle for receiving one of a plurality of interchangeable modular components, such as a passenger seat, a cargo container, a cargo rack, a flatbed or a workbench. The modular component has an electrical connection and a mechanical connector on an underside thereof which has hooks and posts for engaging, respectively, a transverse rod and sockets. A latching mechanism locks the modular component to the rear of the vehicle. Accordingly, the modular component is selectively releasable to easily and quickly interchange one modular component with another.

Owner:BOMBARDIER RECREATIONAL PROD INC

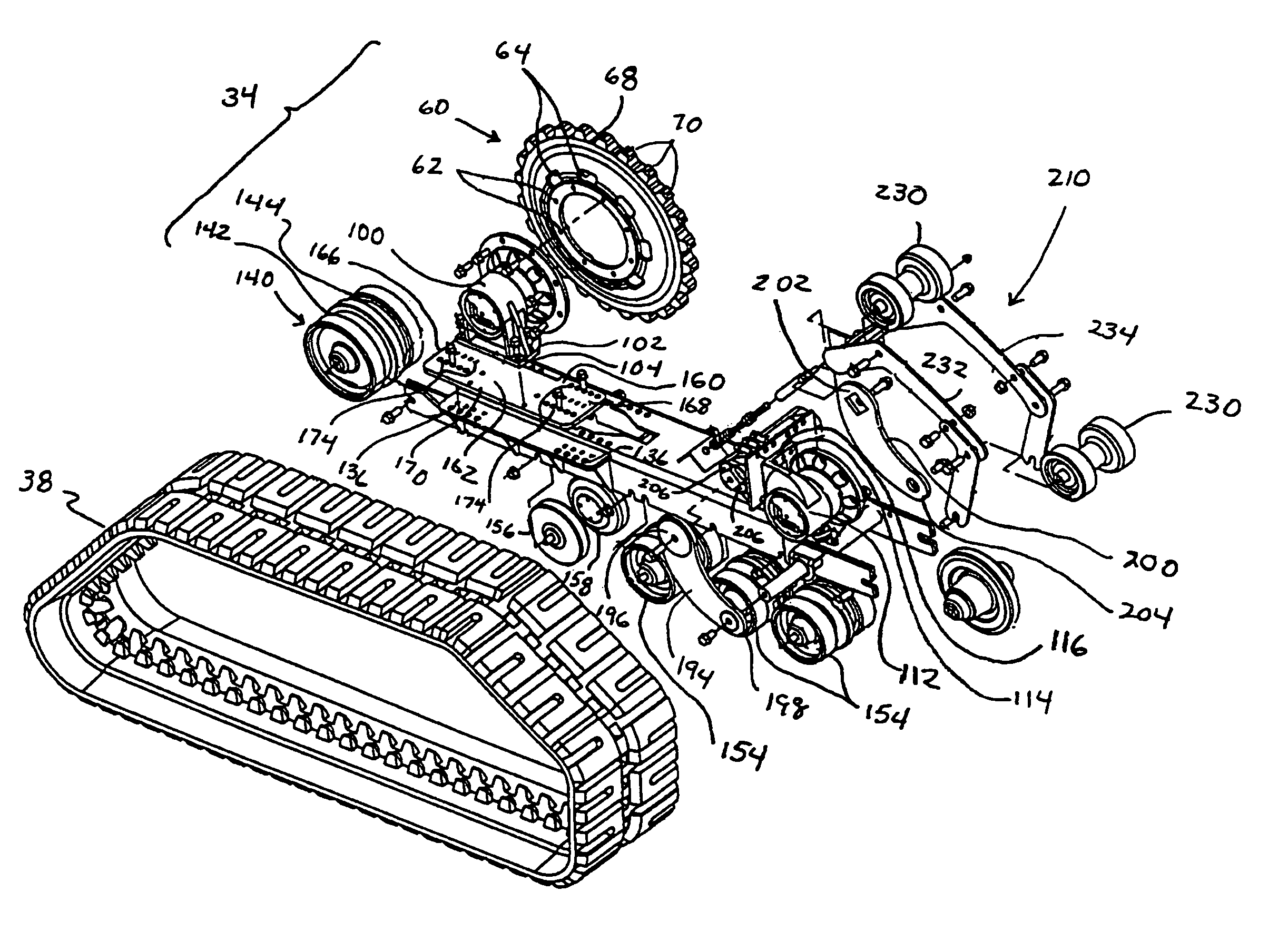

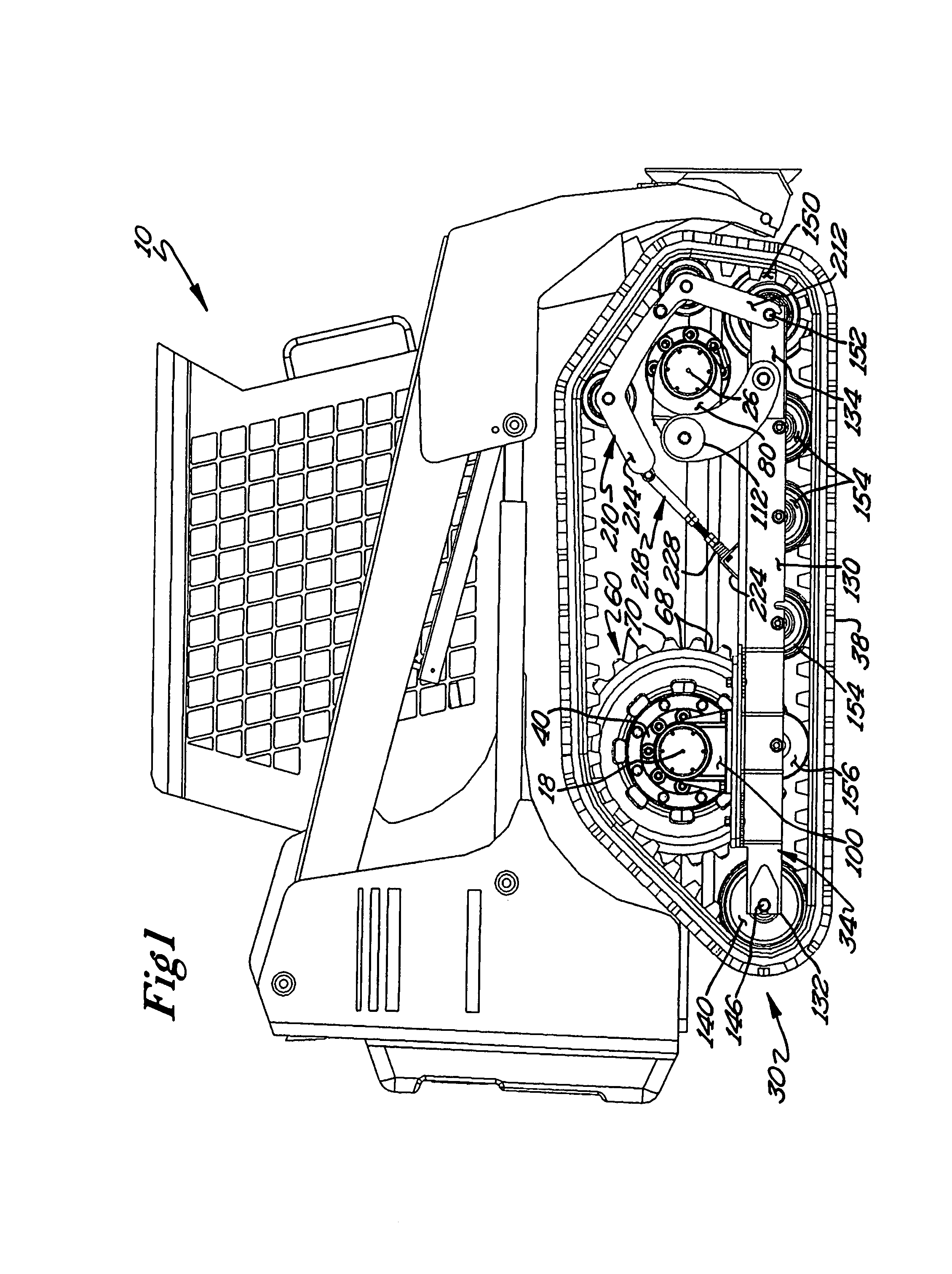

Track assembly

ActiveUS7255184B2Improve stabilityGreat tractionGearingEndless track vehiclesBraced frameEngineering

Owner:ASV HLDG INC

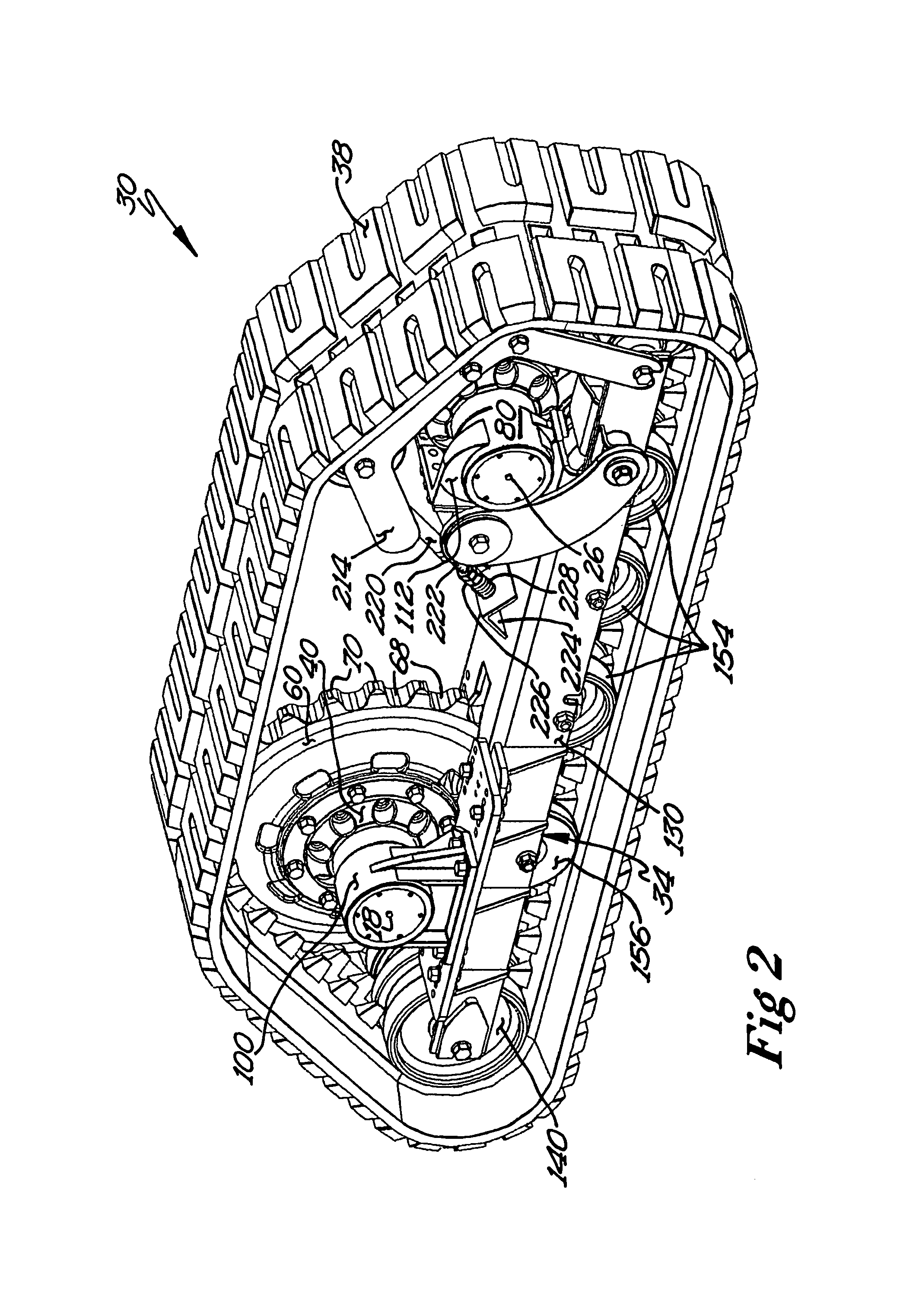

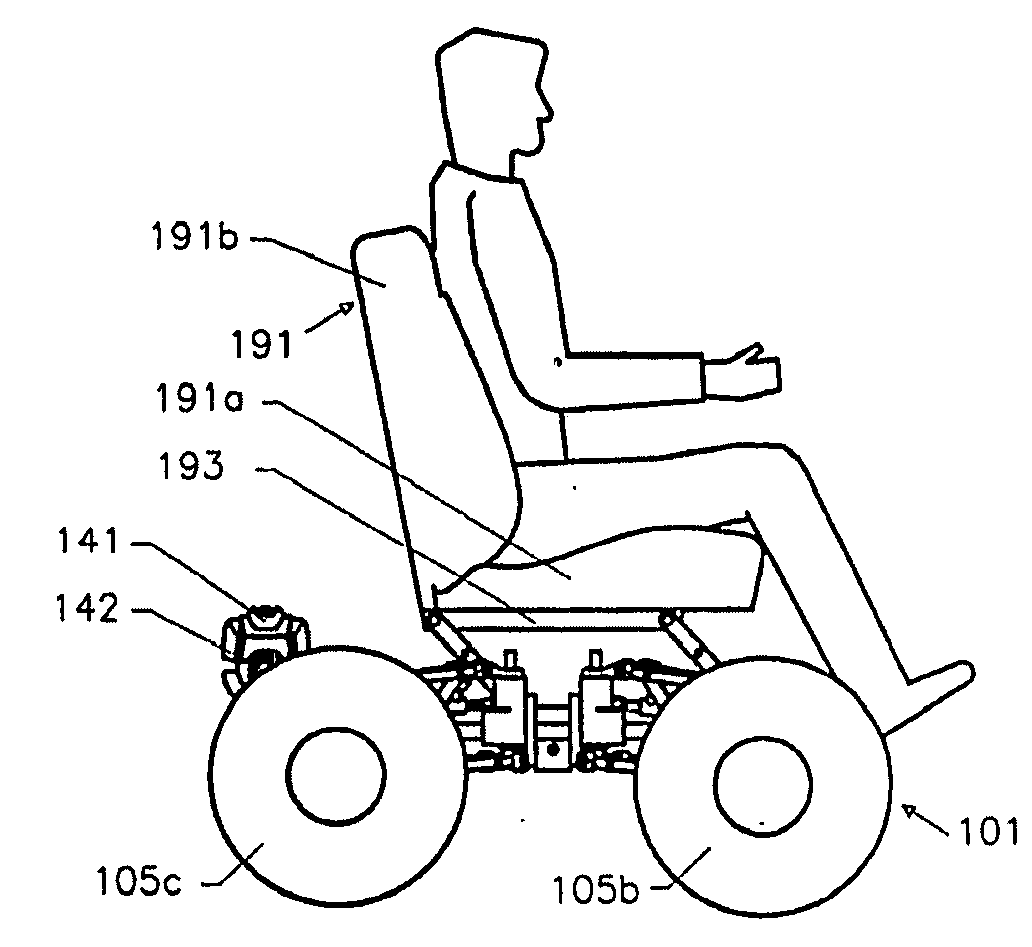

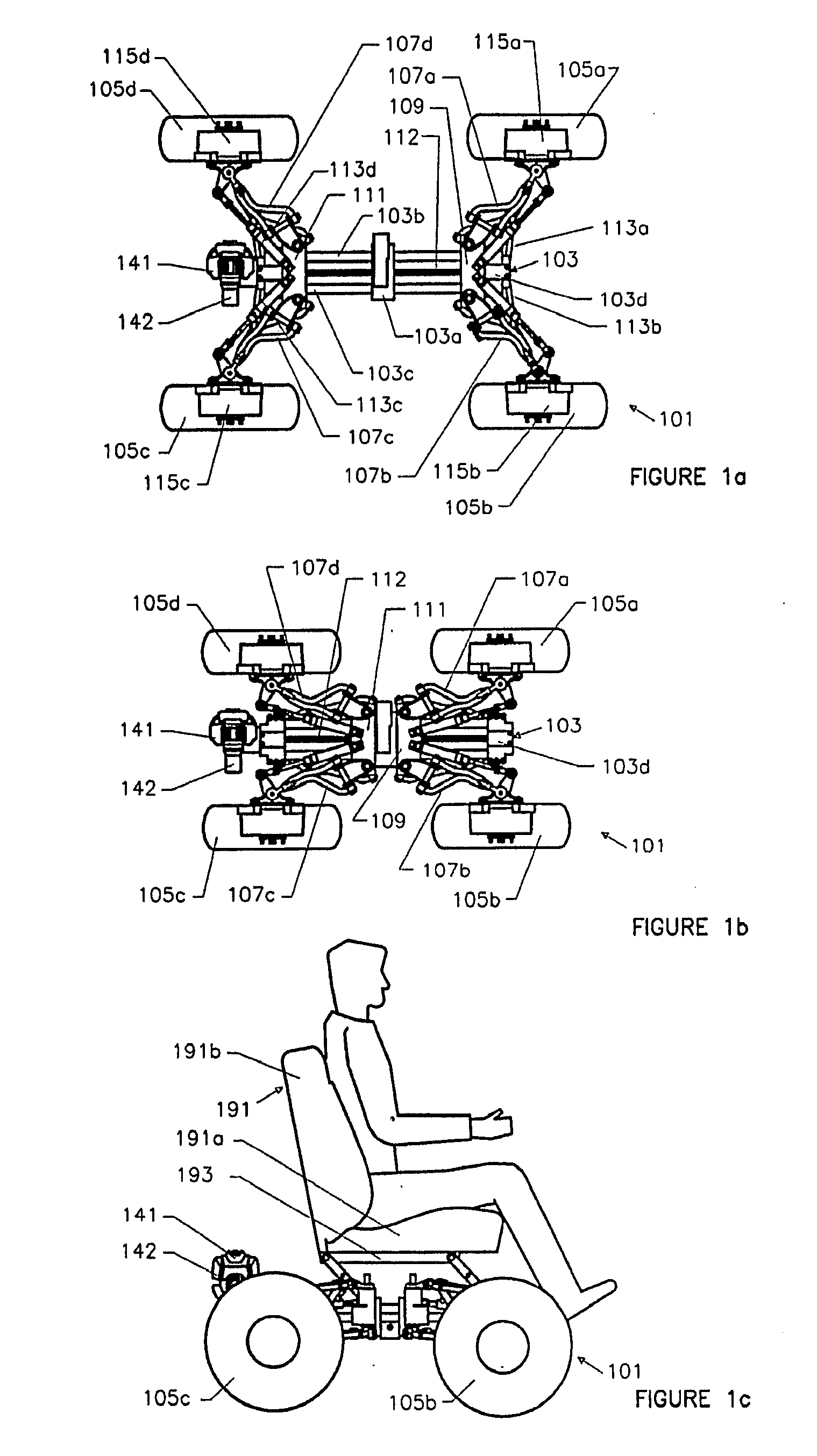

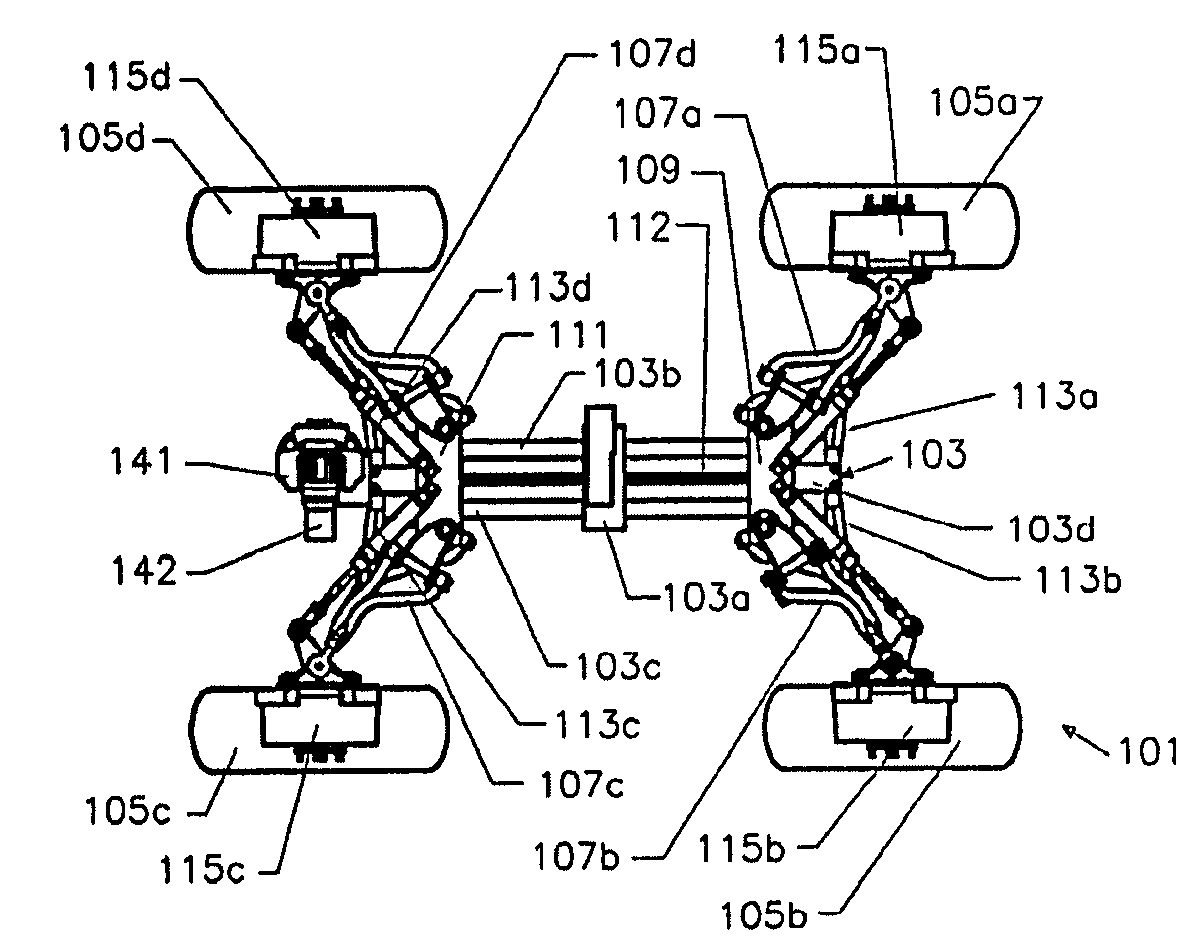

Vehicle

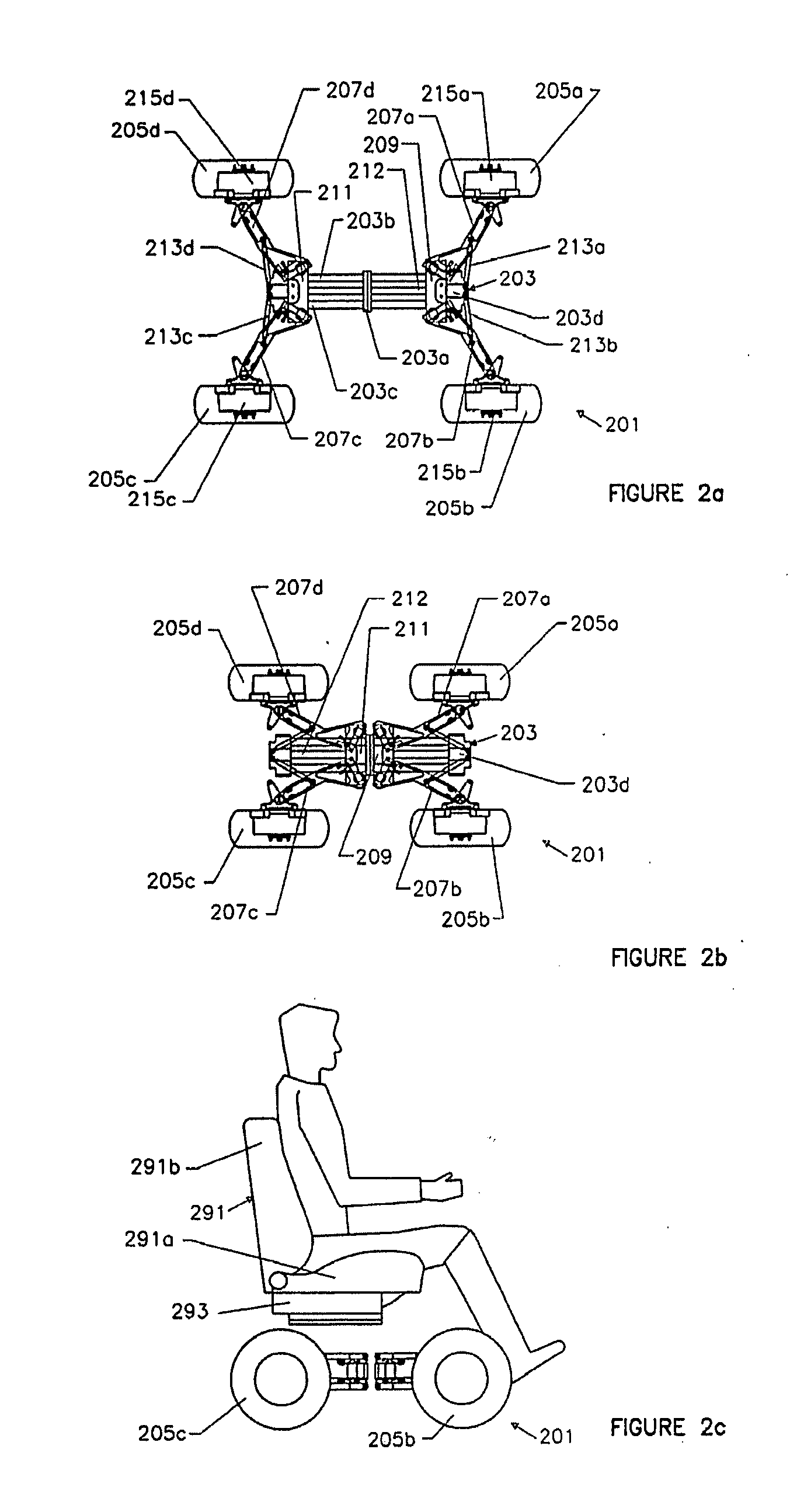

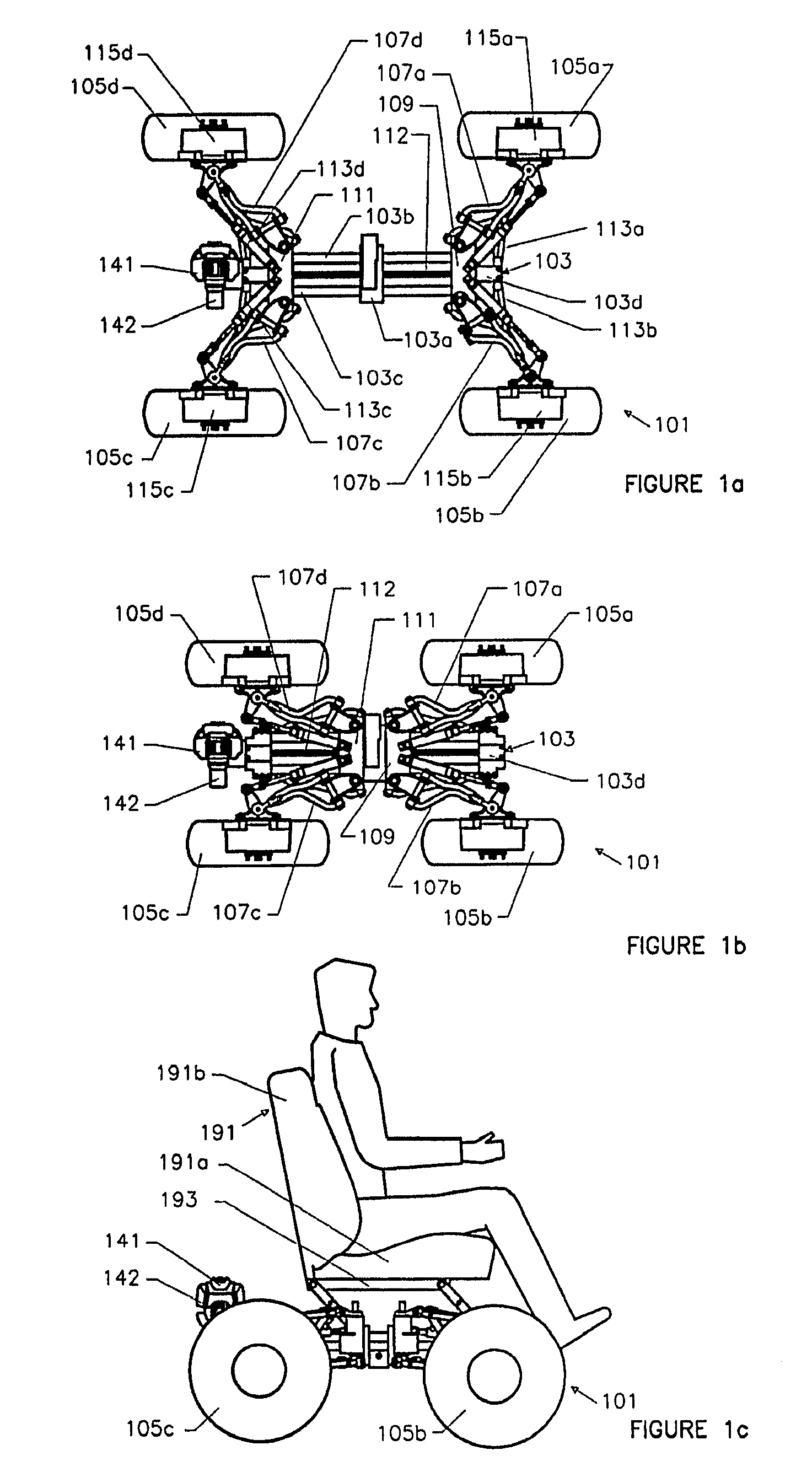

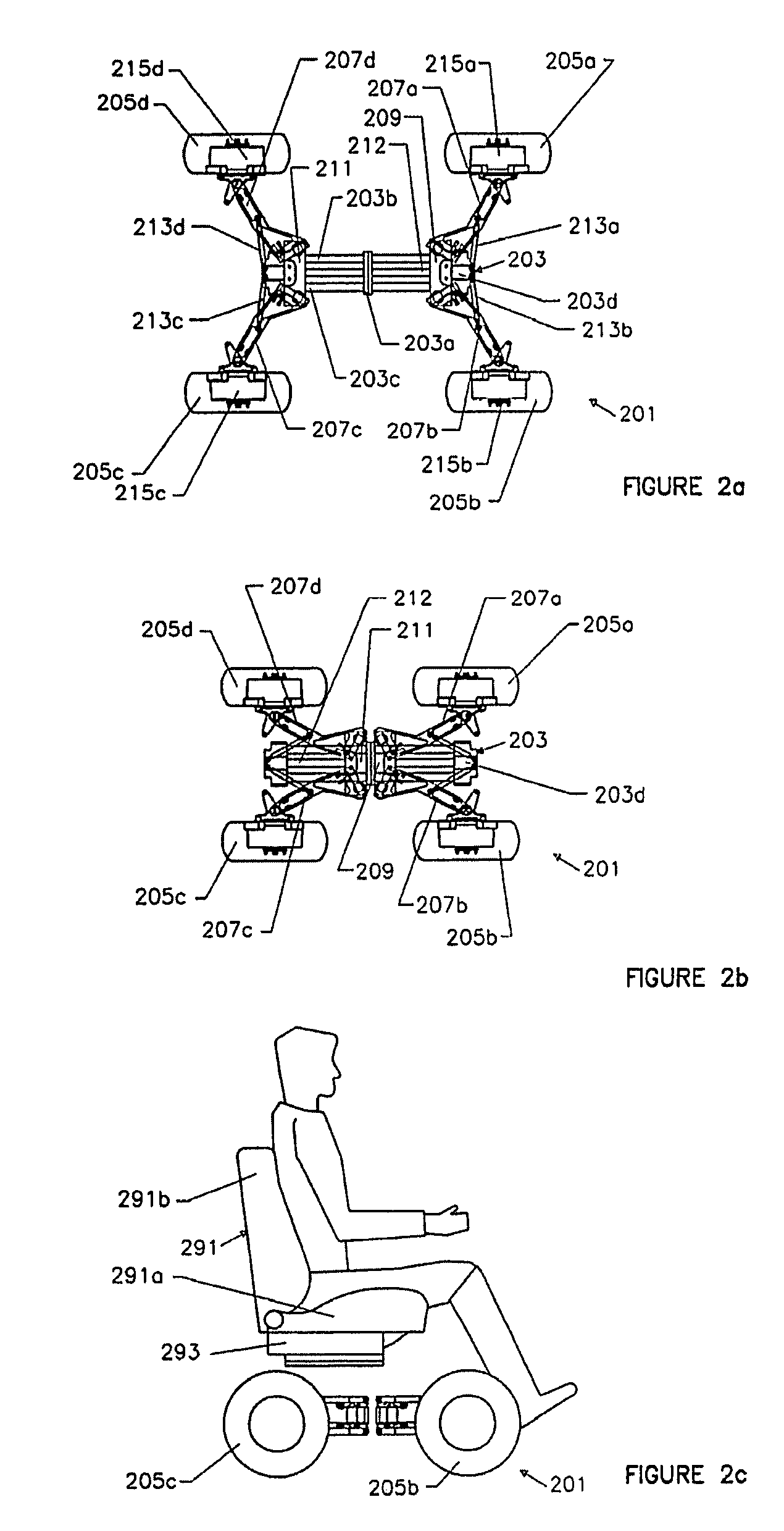

InactiveUS20080190682A1Minimize damageElectric propulsion mountingWheelchairs/patient conveyanceWheelbaseAxle track

A vehicle for transporting a person has a chassis (103) and four wheels (105a, 105b, 150c, 105d) supporting the chassis above a ground surface. The wheels enable the vehicle to move along the ground surface. Each of the four wheels is adjustable in position to enable the wheelbase length and track width of the vehicle to be changed. Each of the wheels is steerable to enable the changes in the wheelbase length and the track width to be effected whether the vehicle is substantially stationary or in motion.

Owner:MAHY GRAHAM JOHN +2

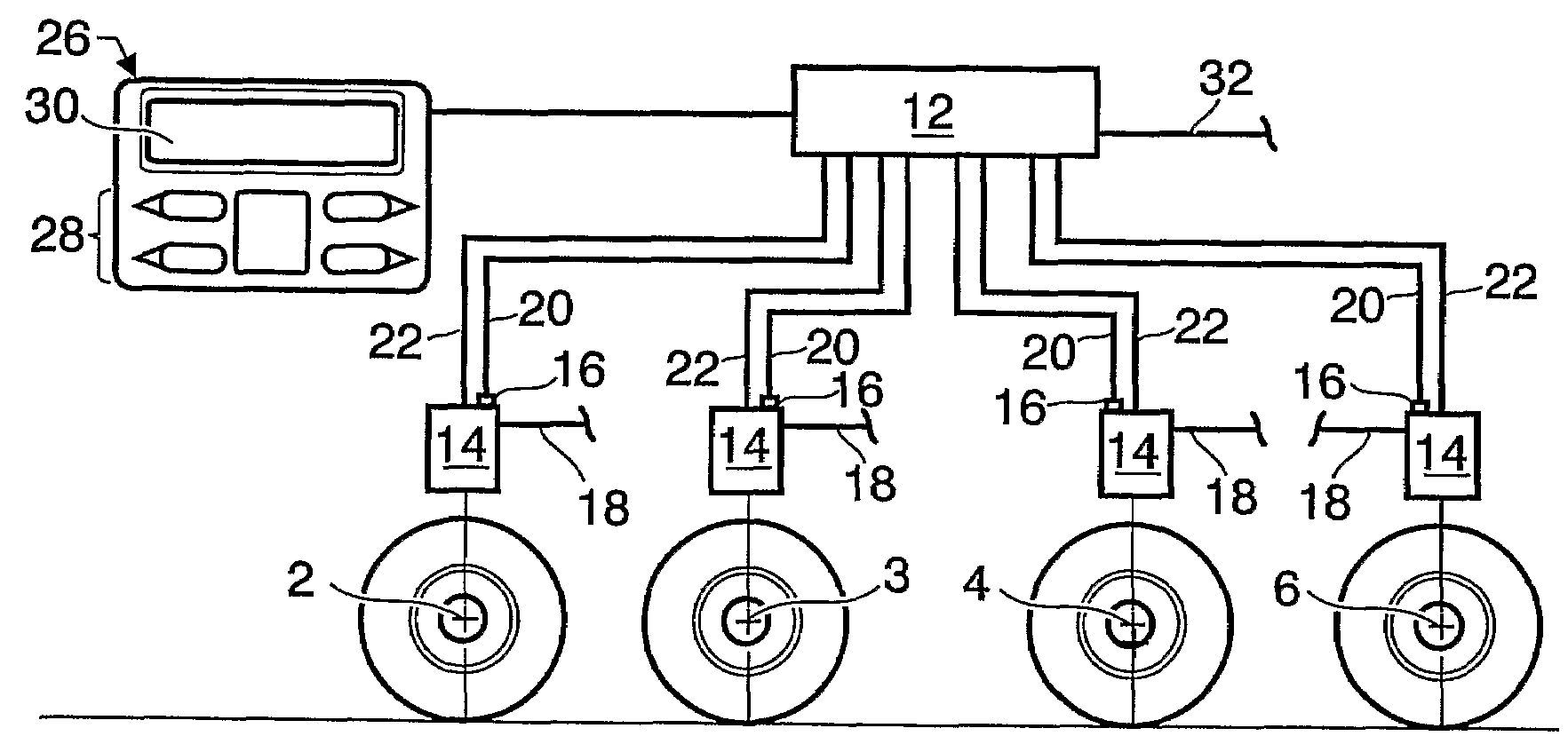

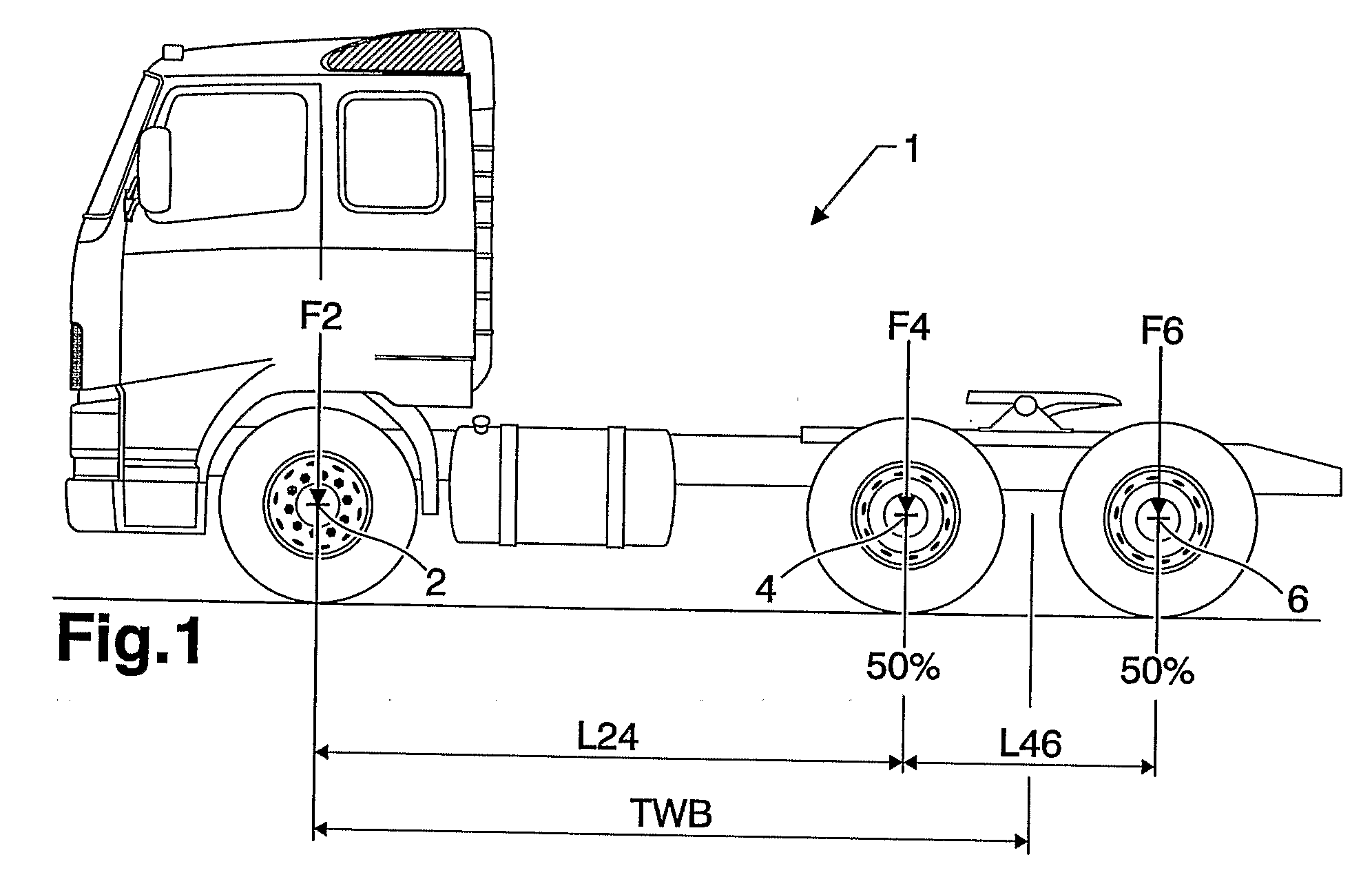

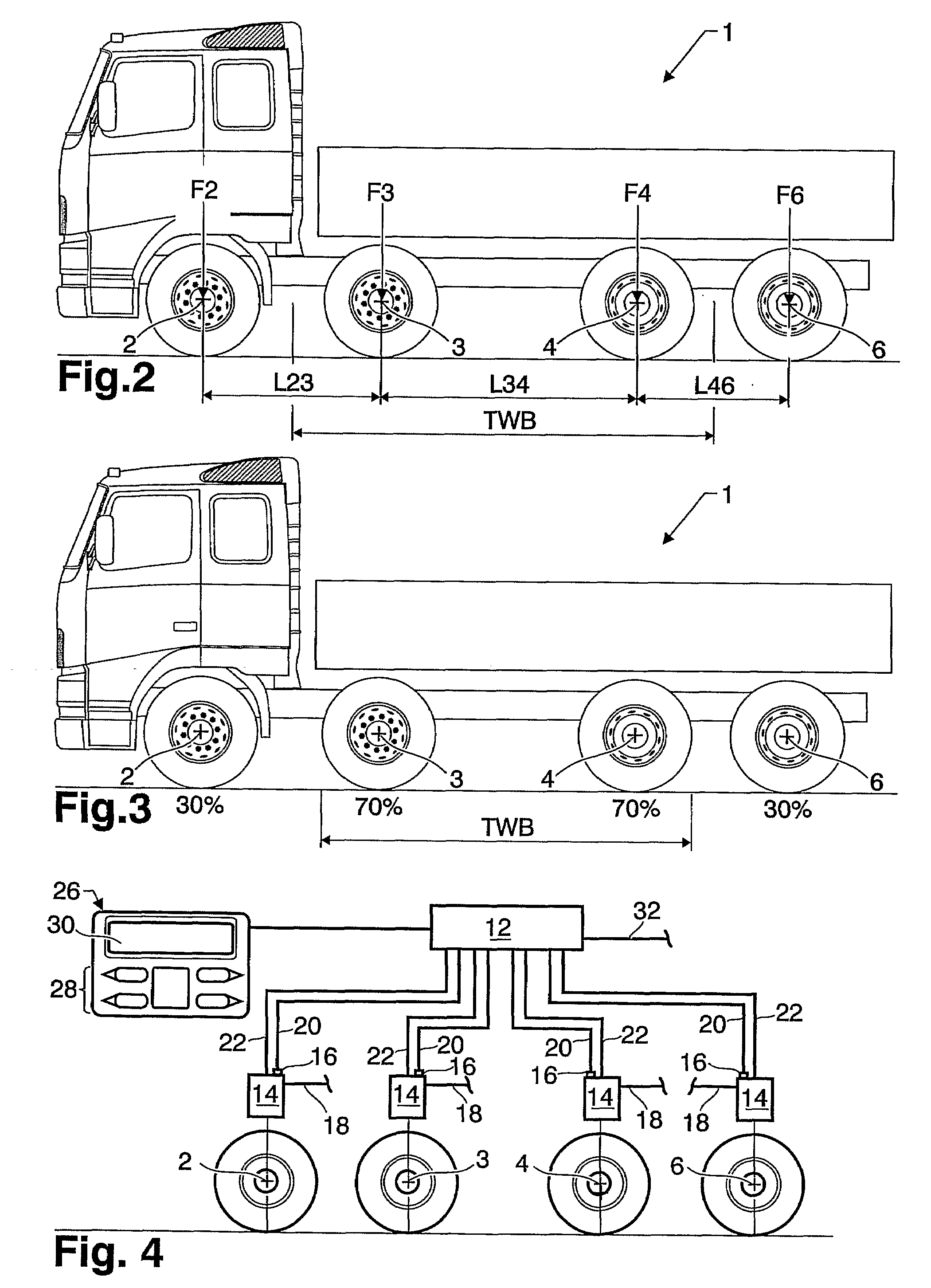

System and Method for Controlling the Axle Load Split Ratio on a Vehicle With Two Front Axles

InactiveUS20080269986A1Risk minimizationImprove vehicle handlingDigital data processing detailsAnimal undercarriagesMobile vehicleAdjustable stiffness

A system is provided for controlling the load split between the axles and thereby the theoretical wheelbase of a vehicle having two front axles being suspended in suspension units at least some of which have springs with adjustable stiffness. A method for controlling the load split between the axles and to a motor vehicle including such a system and / or by use of such a method is also disclosed.

Owner:VOLVO LASTVAGNAR AB

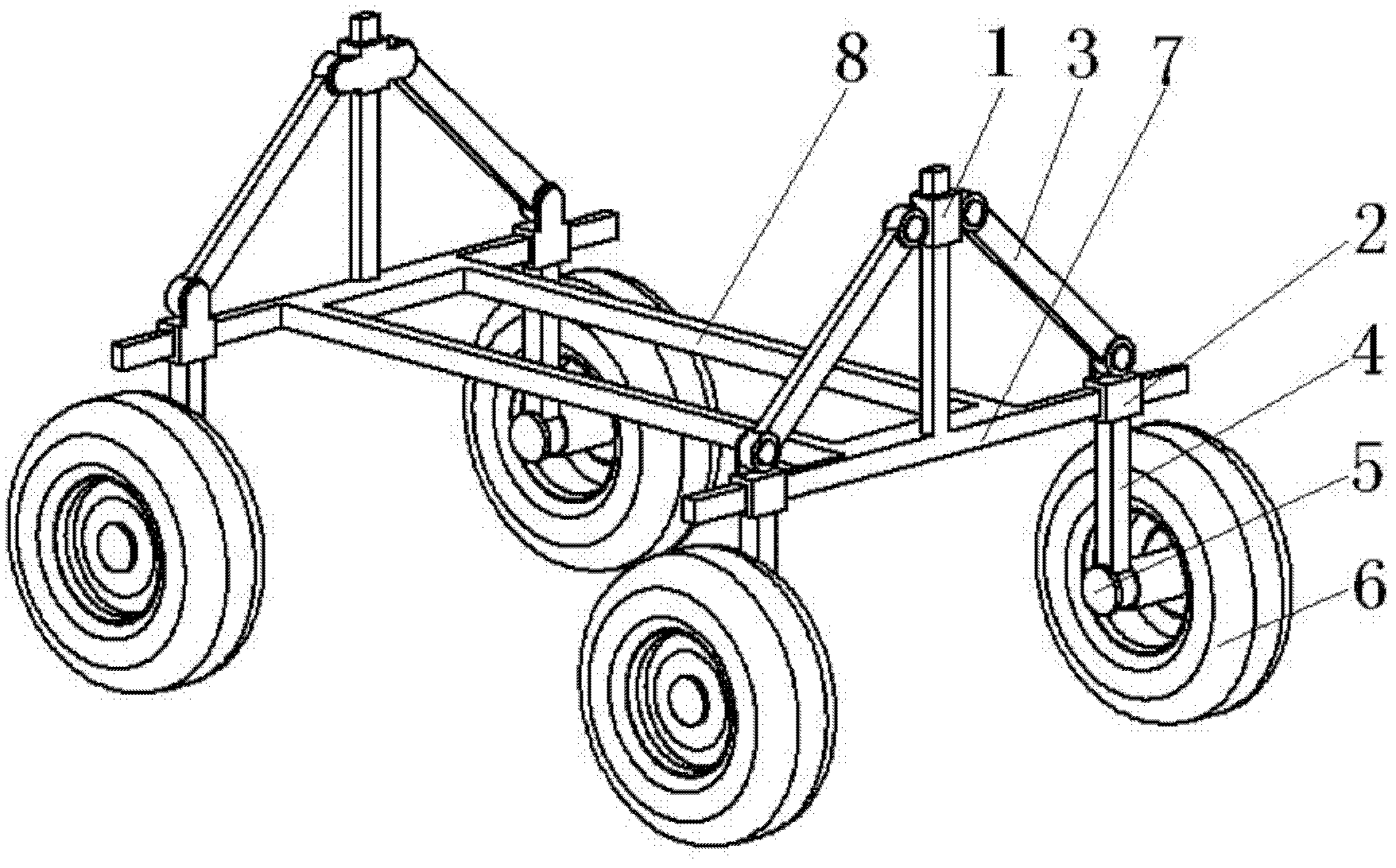

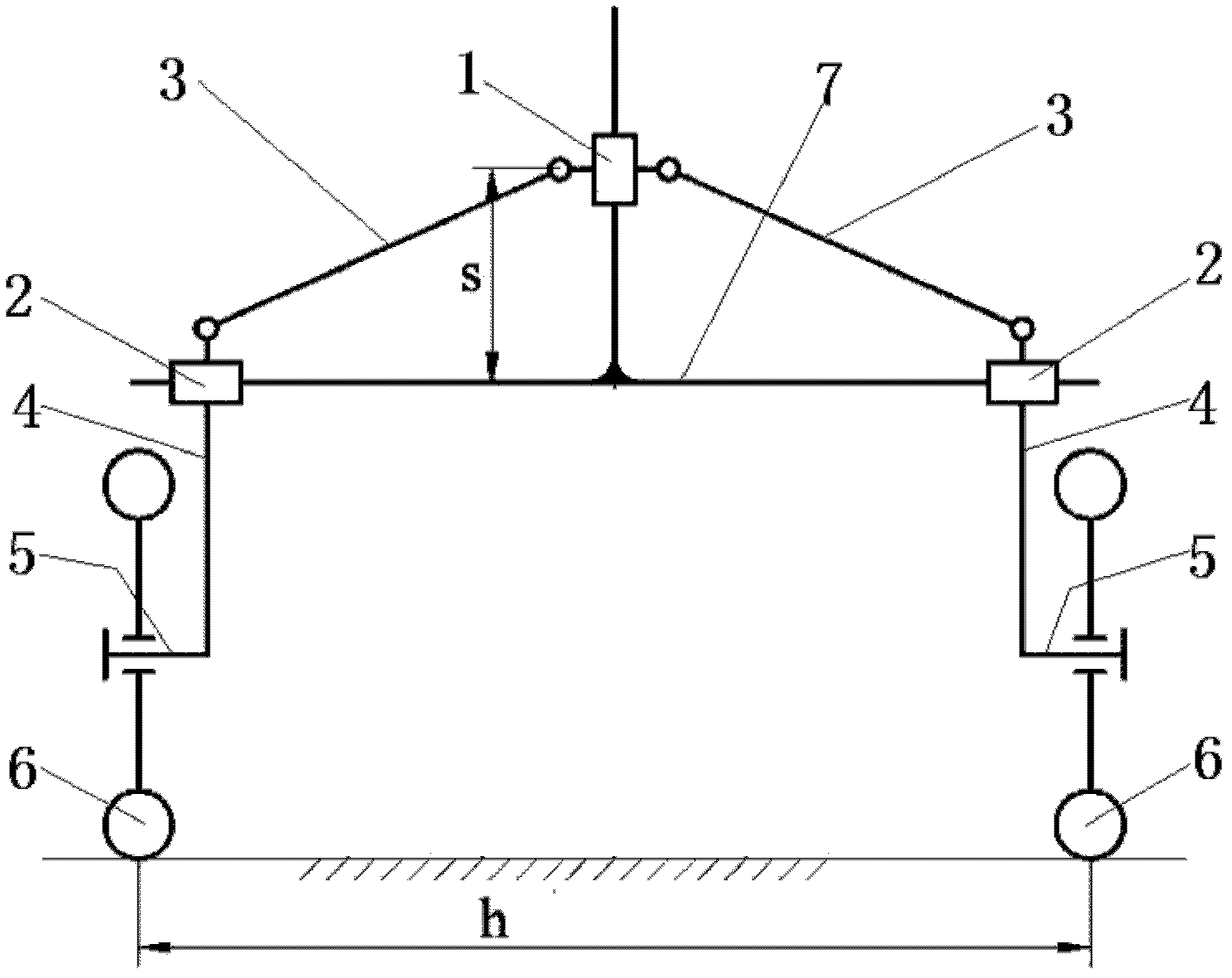

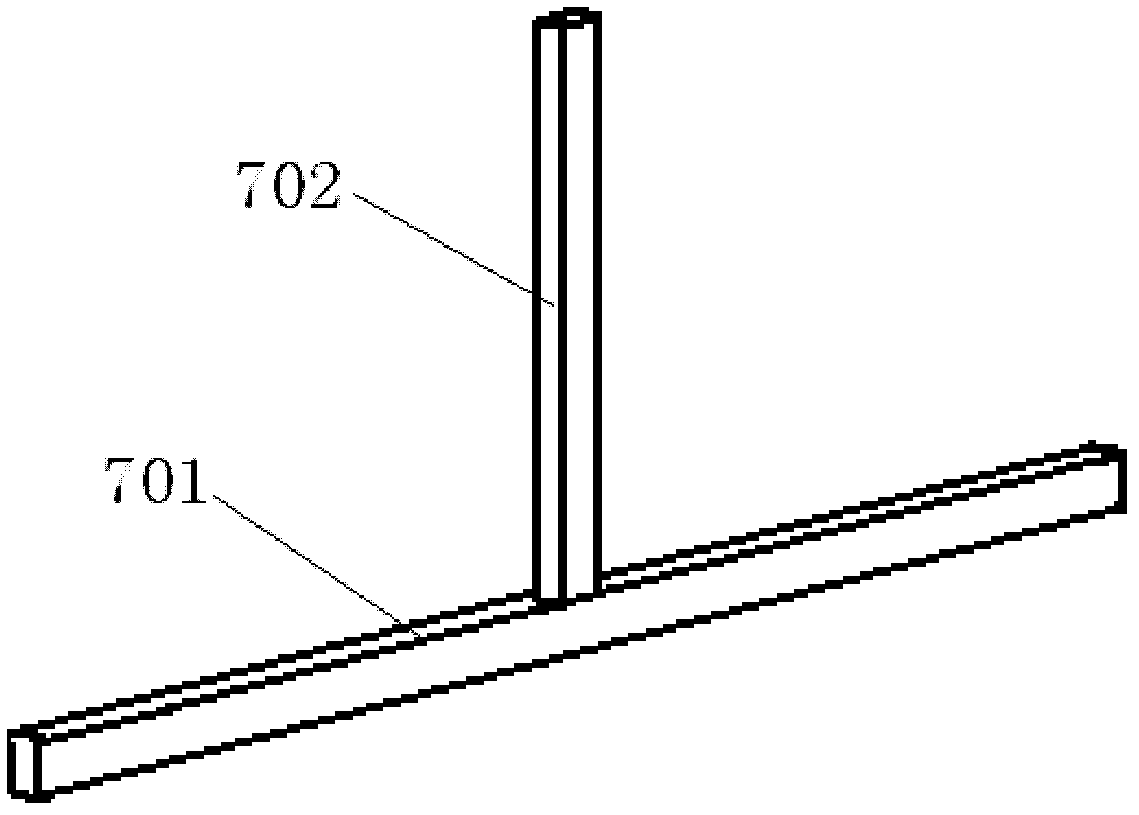

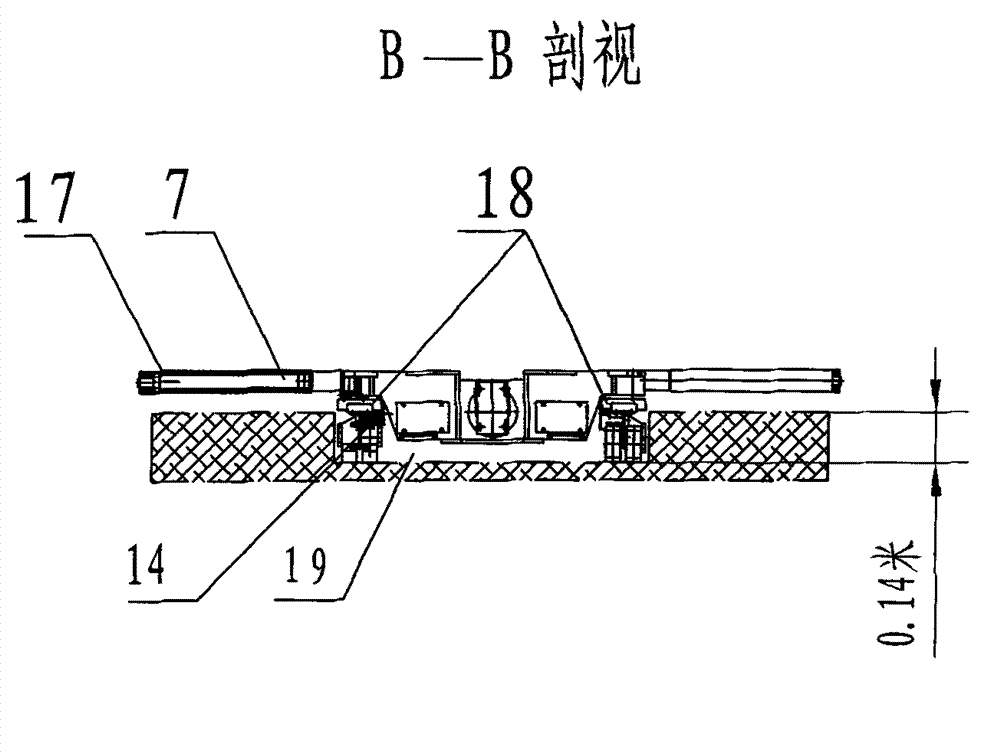

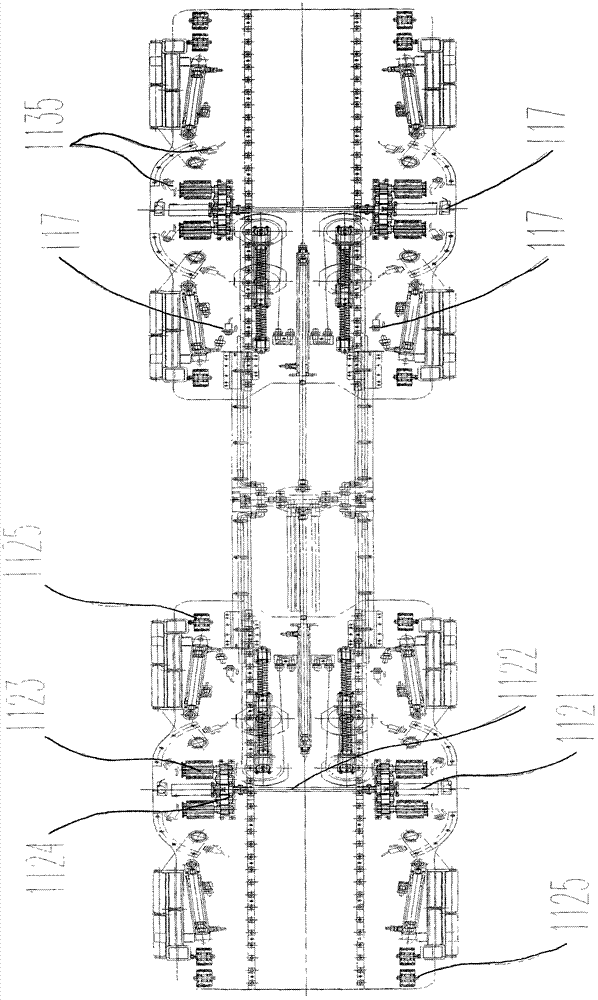

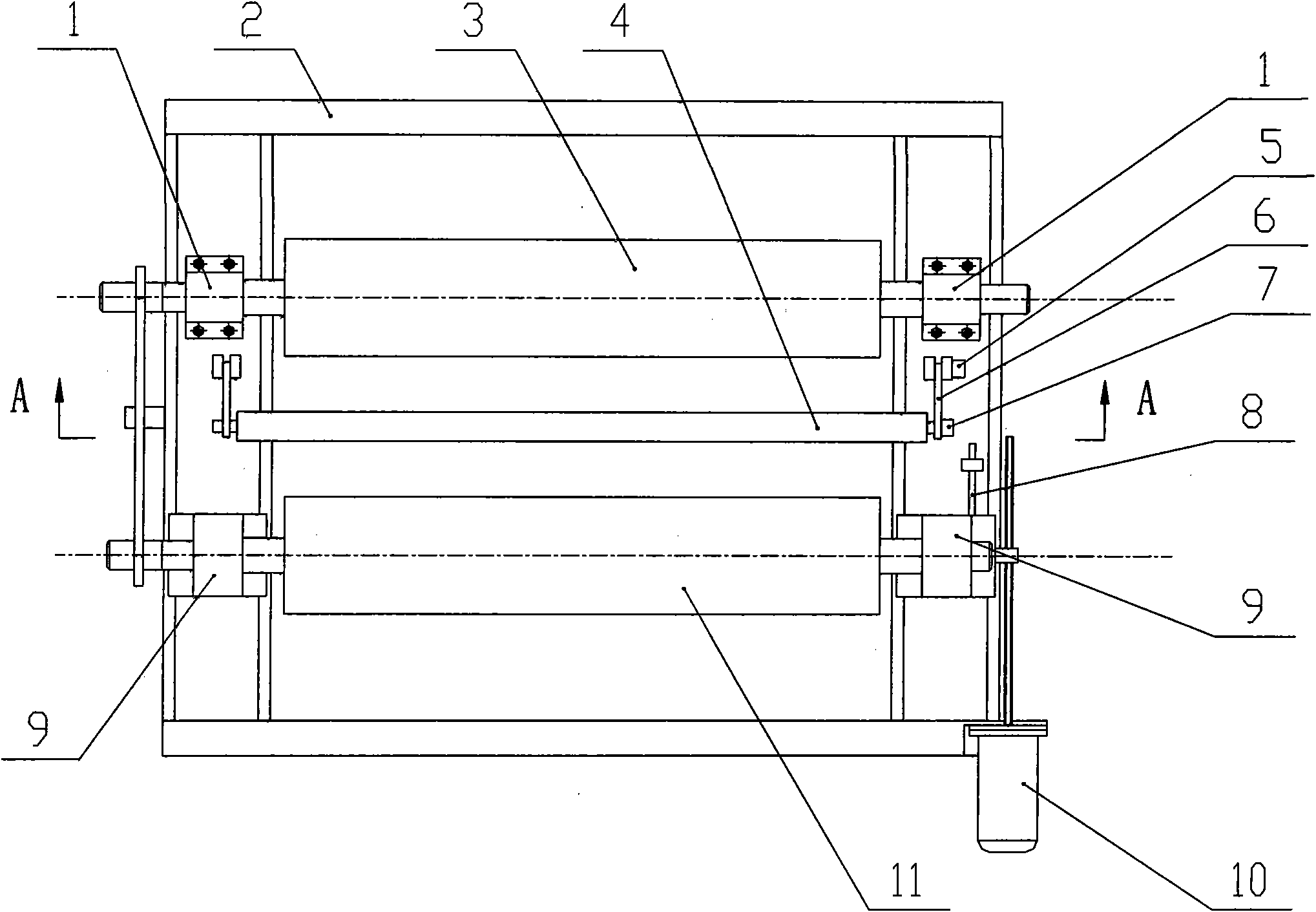

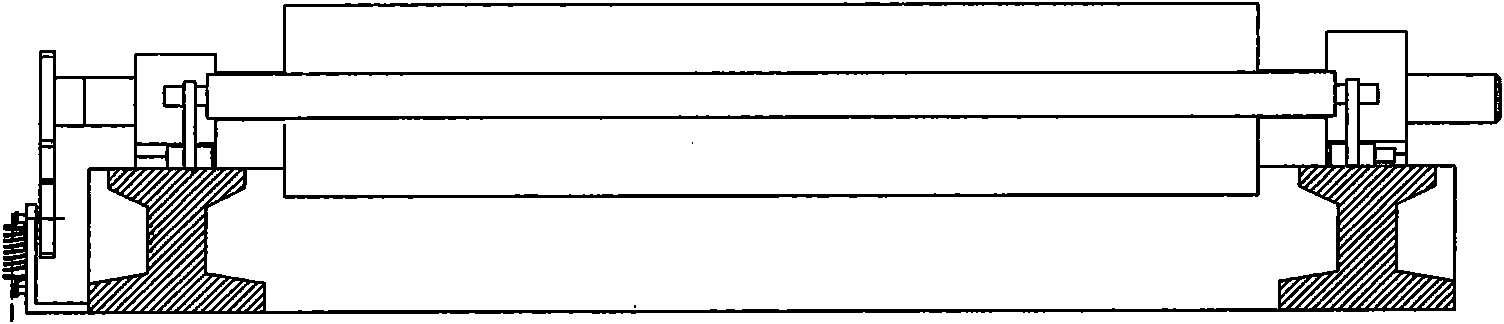

Wheel track adjustable agricultural vehicle chassis

InactiveCN102514626AAdapt to the requirements of mechanized operationsRealize centralized controlUnderstructuresVehicle frameAgricultural engineering

The invention belongs to the technical field of vehicle chassis, and relates to a wheel track adjustable agricultural vehicle chassis. Two groups of agricultural vehicle wheel track adjusting devices share a longitudinal center plane of a vehicle and are arranged in a front-and-back mode on a frame according to a wheel base of wheels; and the two groups of wheel track adjusting devices are respectively fixedly connected with front and back ends of the frame through a horizontal rail of a support to form the wheel track adjustable agricultural vehicle chassis. Each group of agricultural vehicle wheel track adjusting device consists of a driving slider, driven sliders, connecting rods, supporting rods, wheel axles, wheels and a frame; distances between driving sliders and horizontal rails in the front and back agricultural vehicle wheel track adjusting devices are synchronously changed and kept equal by external driving power, and distances of wheels and the longitudinal center plane ofthe vehicle are symmetrically changed, so that the stepless adjustment of the wheel track of the agricultural vehicle chassis is realized and requirements on mechanical operation for crops in different row spacing are met. The wheel track adjustable agricultural vehicle chassis is suitable for field management mechanical operation in a growth period of crops.

Owner:CHINA AGRI UNIV

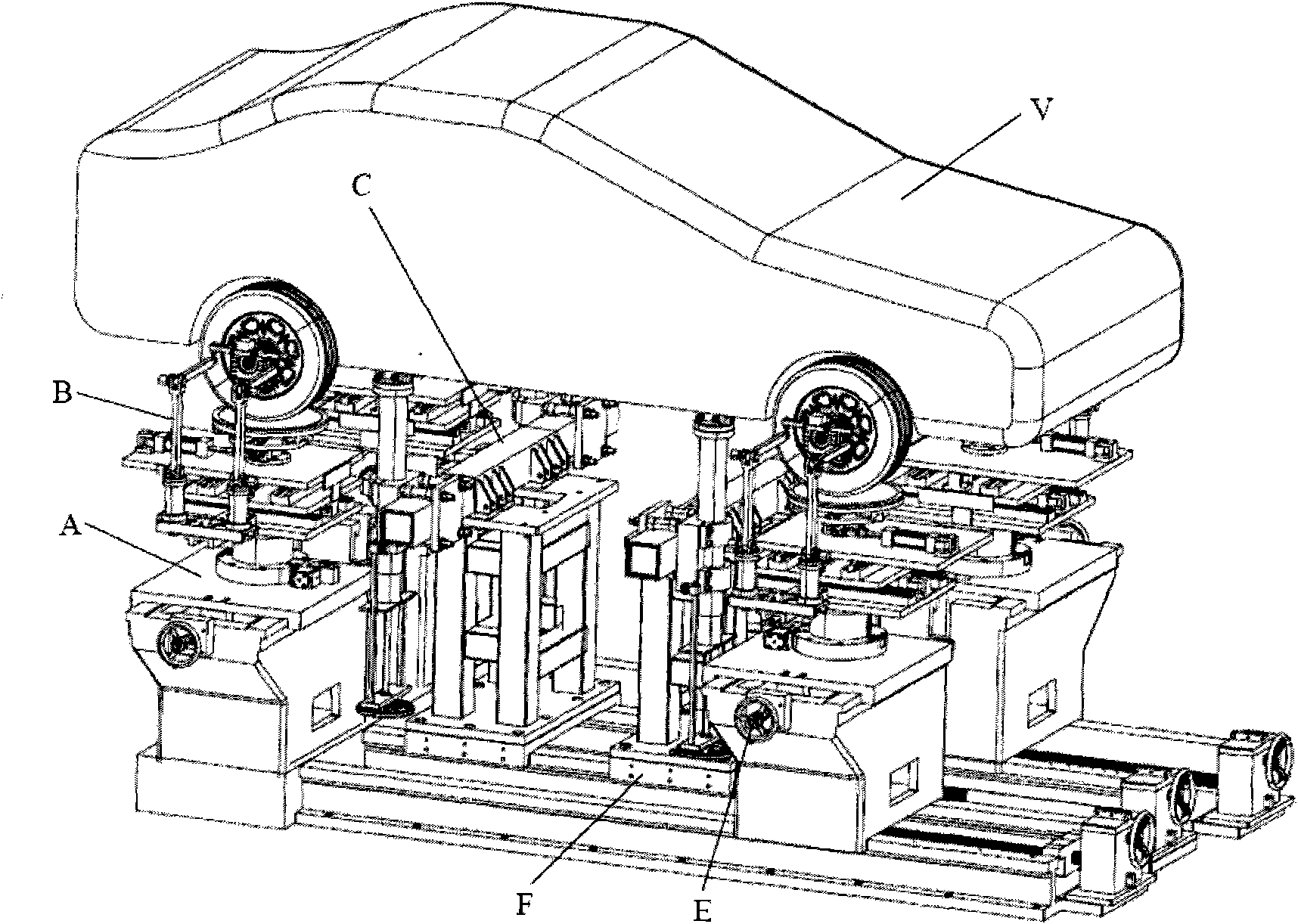

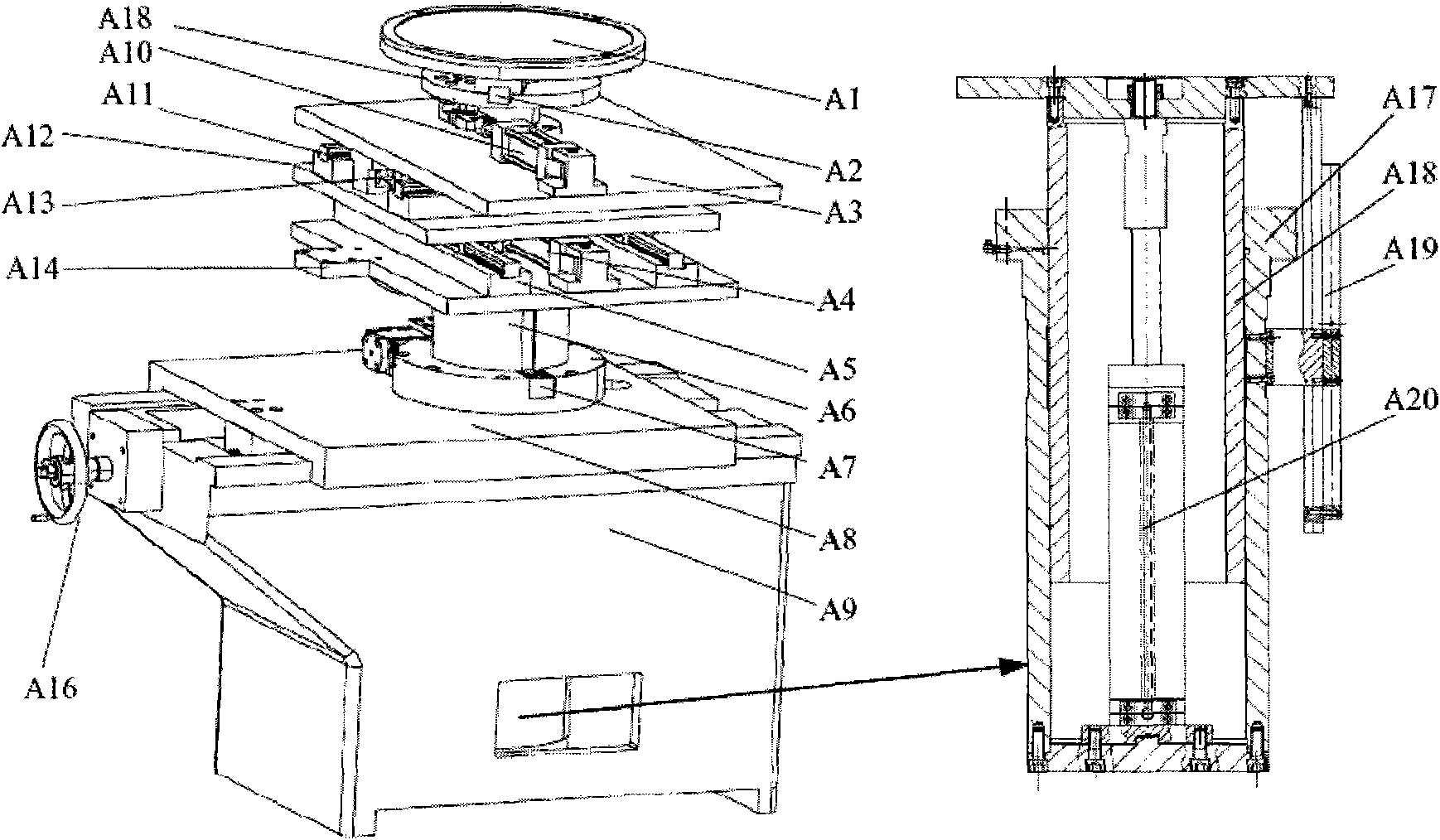

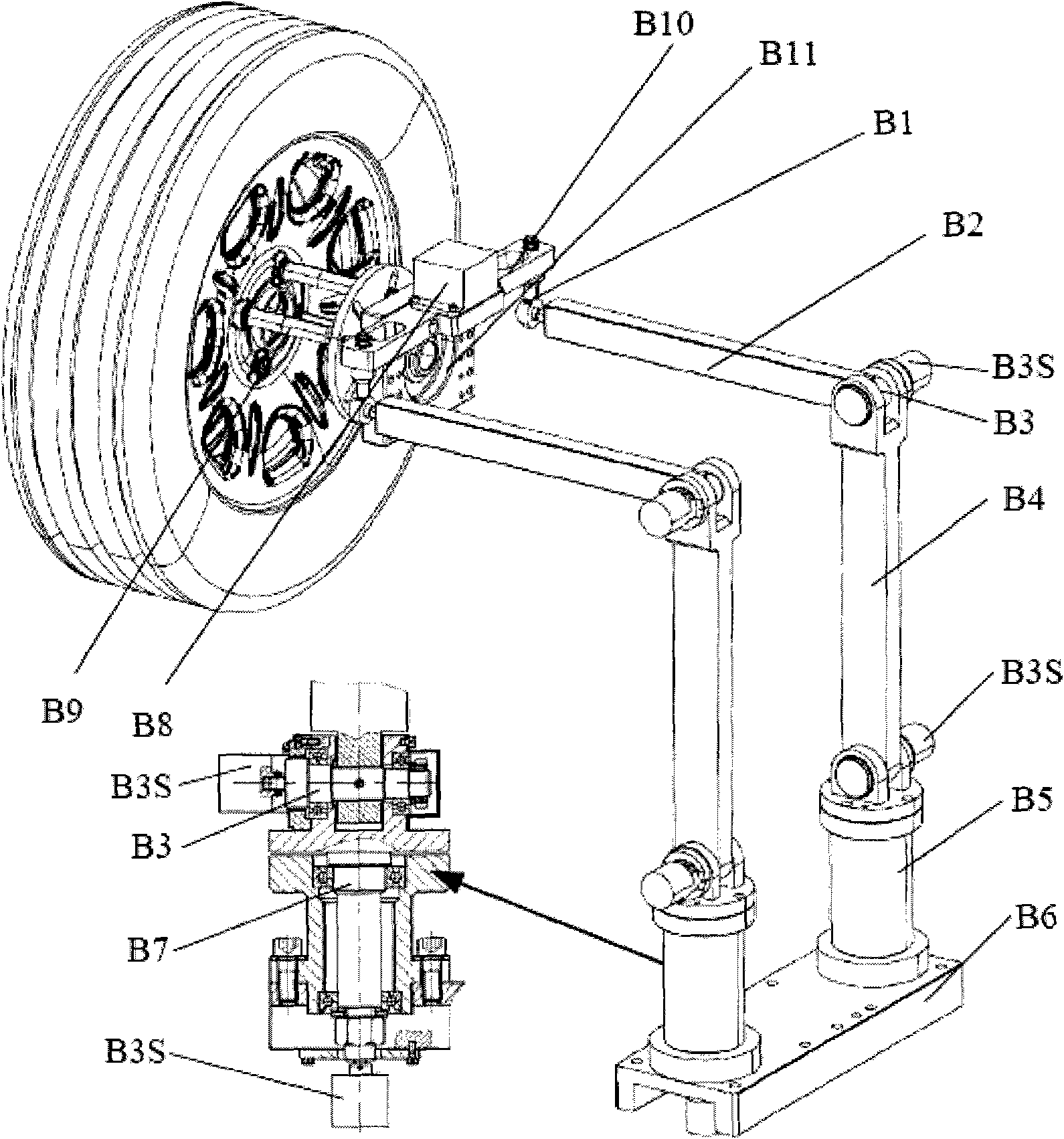

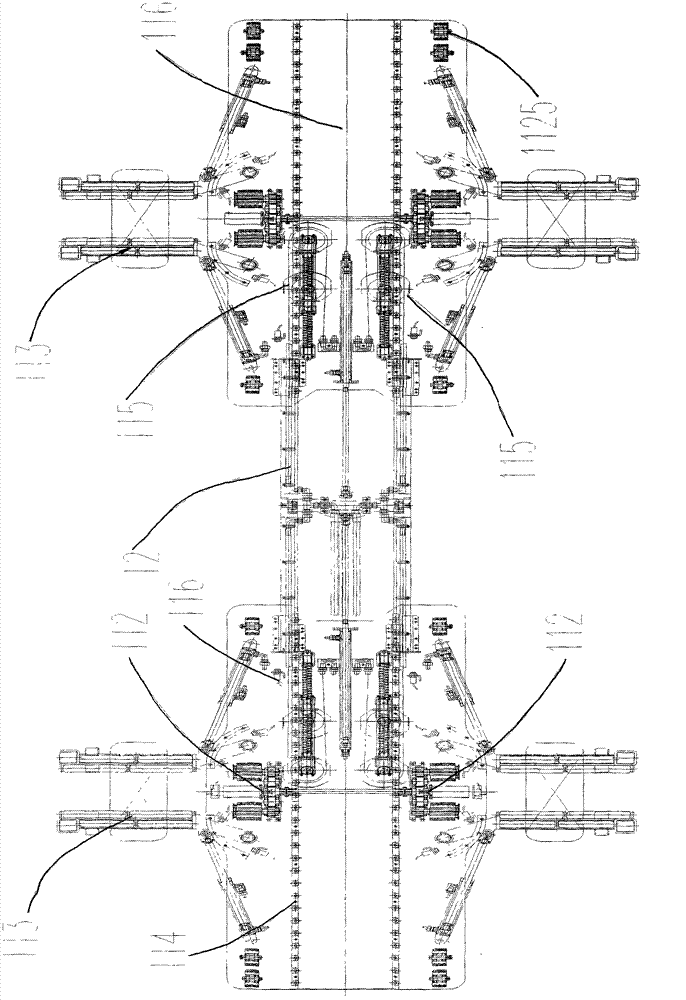

Kinematics and total working condition elastic tester of suspension bracket

A kinematics and total working condition elastic tester of a suspension bracket comprises a loading platform (A) capable of testing six component forces, a six-degree-of-freedom movement measuring mechanism (B) of a wheel, a vehicle body clamping system (C), a wheel distance adjusting system (E) and a data collecting and processing system, further comprising an axle distance adjusting system (F). A tester for a whole vehicle and a tester for a separated suspension bracket system can be assembled according to different user requirements and different clamping manners so as to satisfy different requirements on the test of the all-directional kinematics characteristic and the total working condition deformation characteristic.

Owner:KH AUTOMOTIVE TECH CHANGCHUN

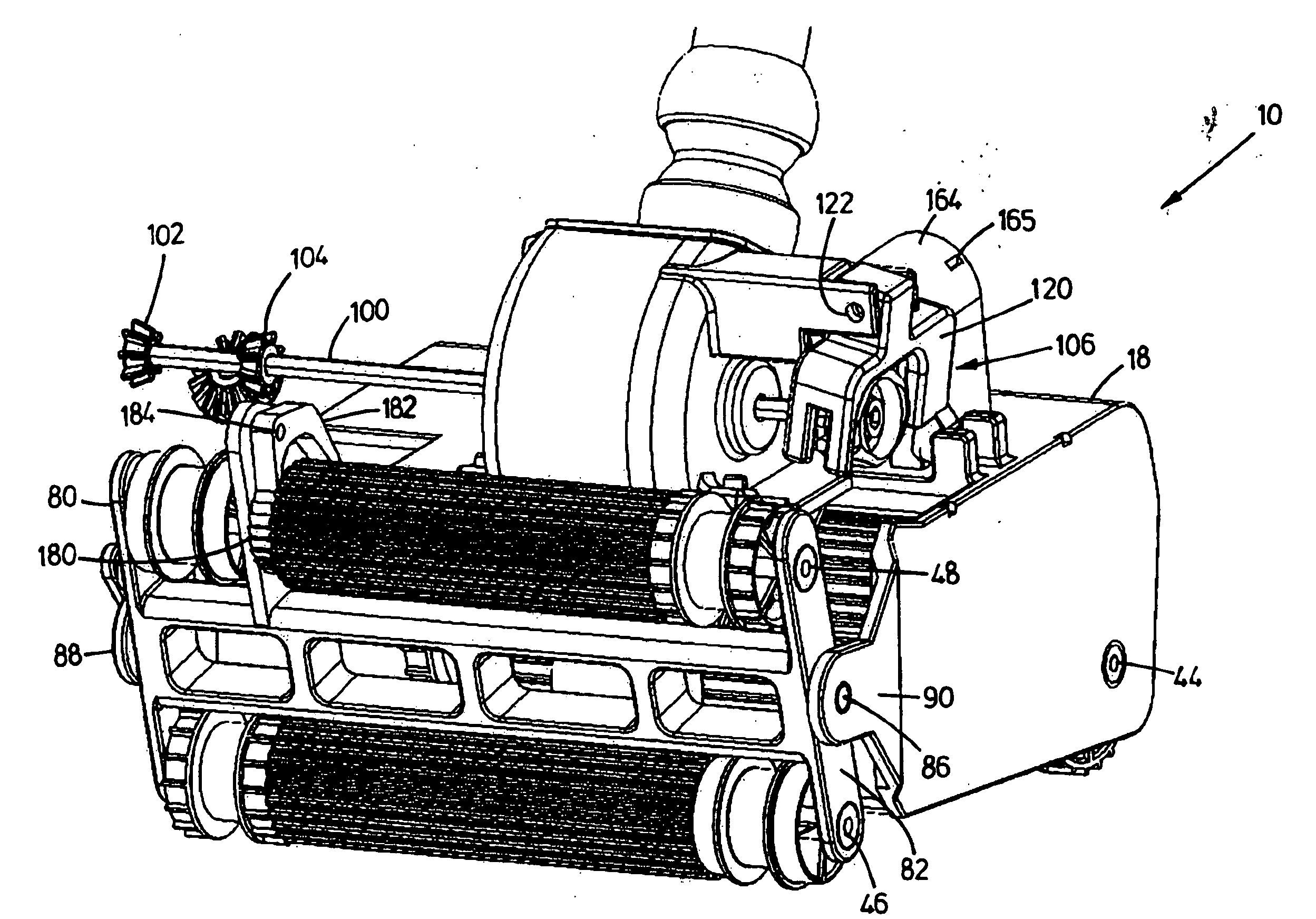

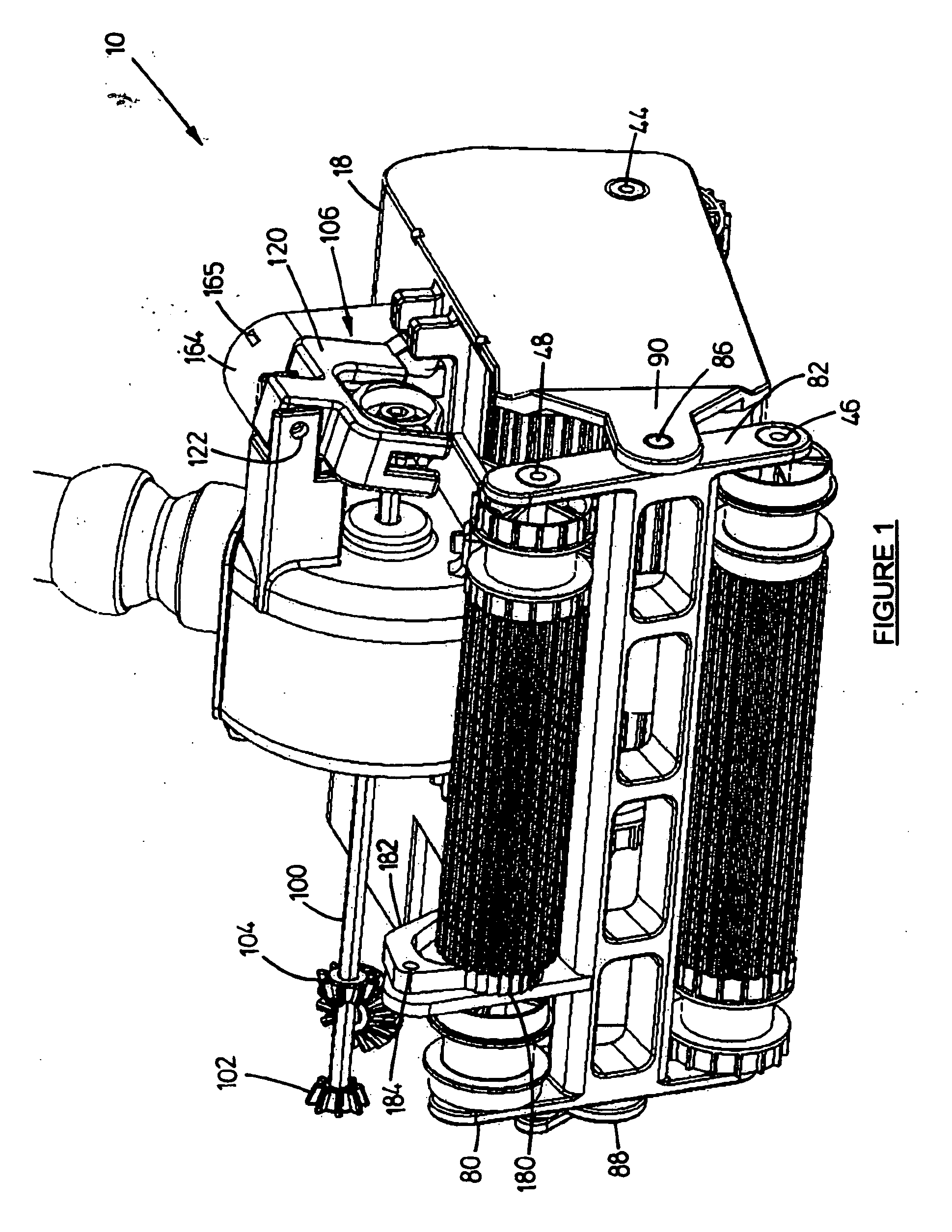

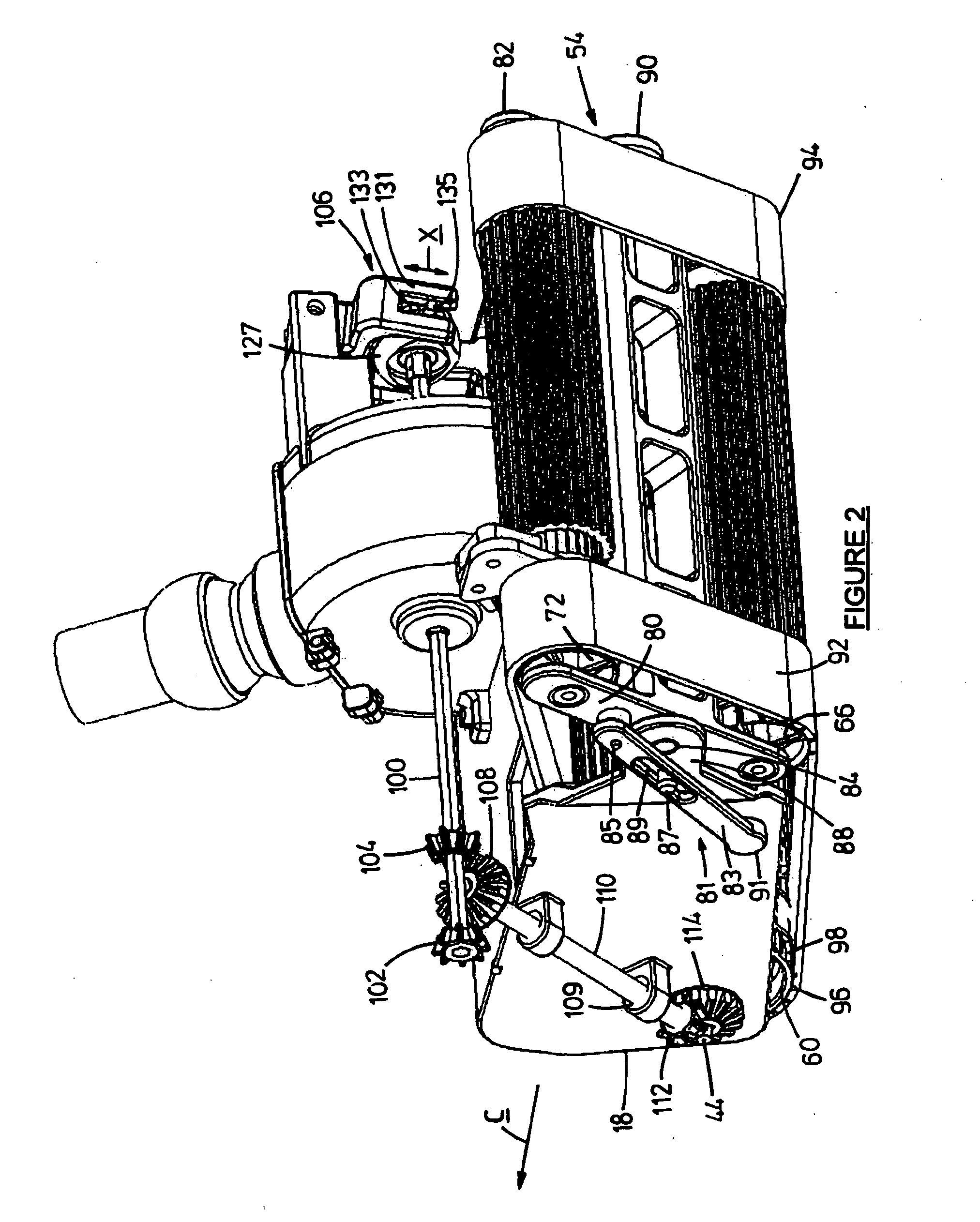

Undercarraige for automatic pool cleaner

An automatic swimming pool cleaner includes a body (18) and a wheeled undercarriage (42) for the body. The undercarriage comprises a first submerged surface (14) engaging section (50) and a normally leading second section (52). The second section is pivotable in elevation () relative to the first section. The pivotable second section enables the cleaner to negotiate sharp corners between a floor (14) and a wall (16) of the pool and further lengths a wheelbase provided by the first section during reverse motion of the cleaner. A surface engaging brake (81) on the second section facilitates change of direction during reverse motion of the cleaner.

Owner:PENTAIR POOL PROD INC

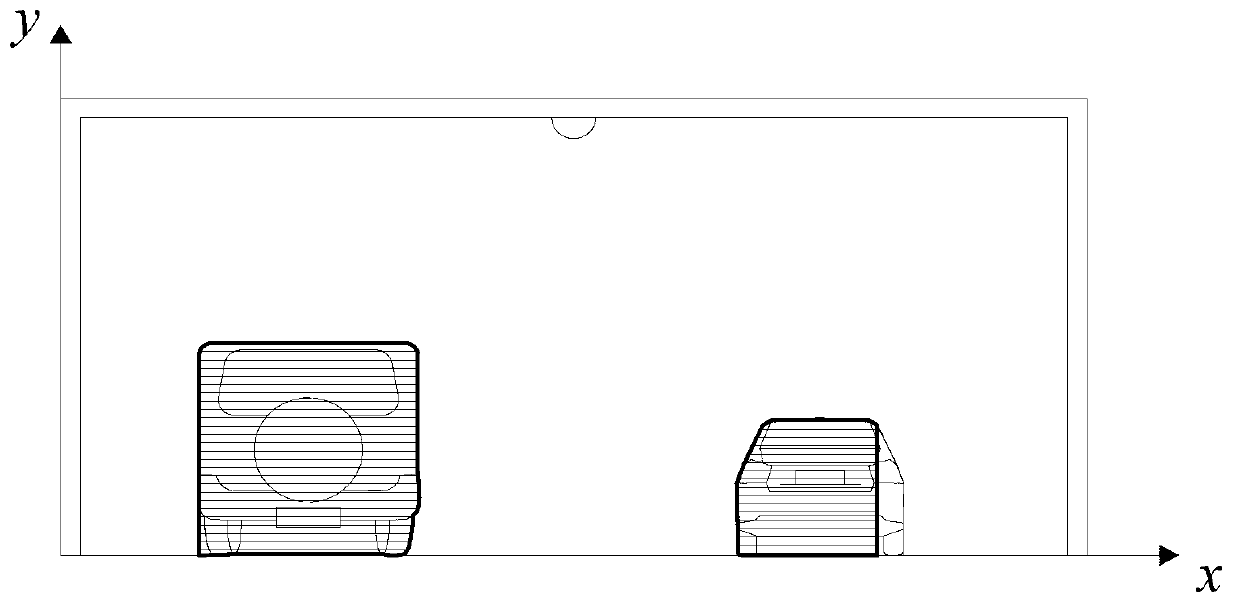

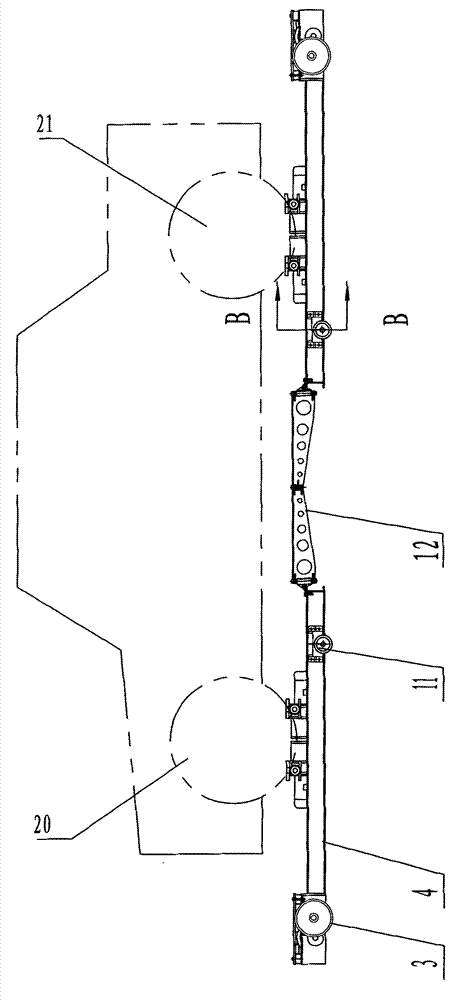

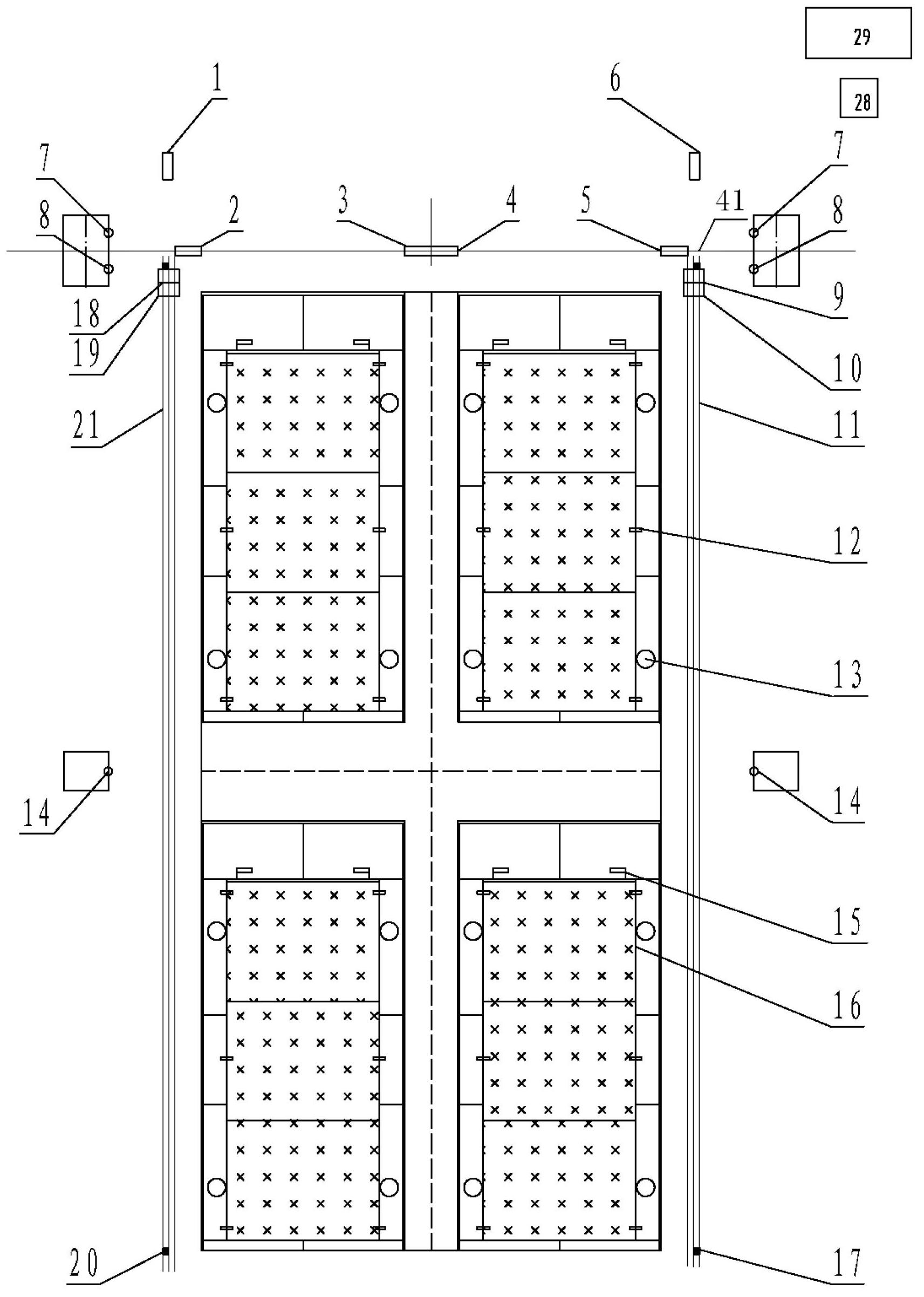

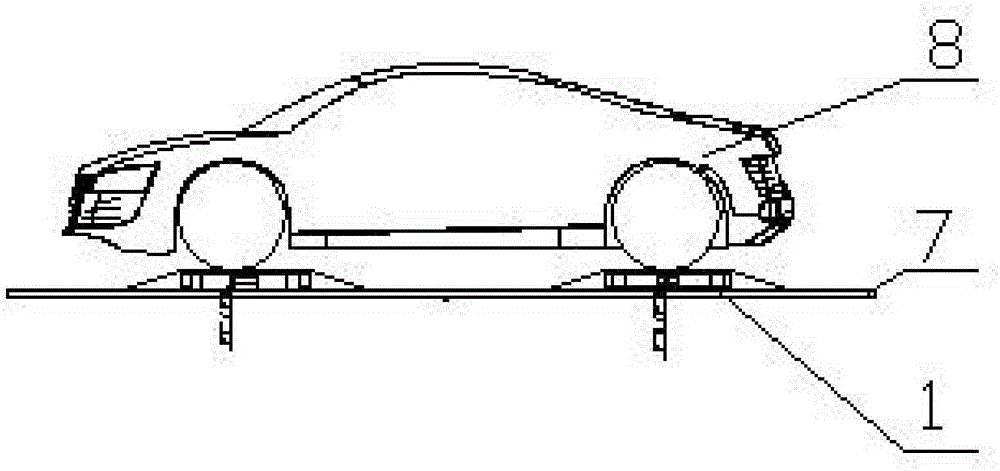

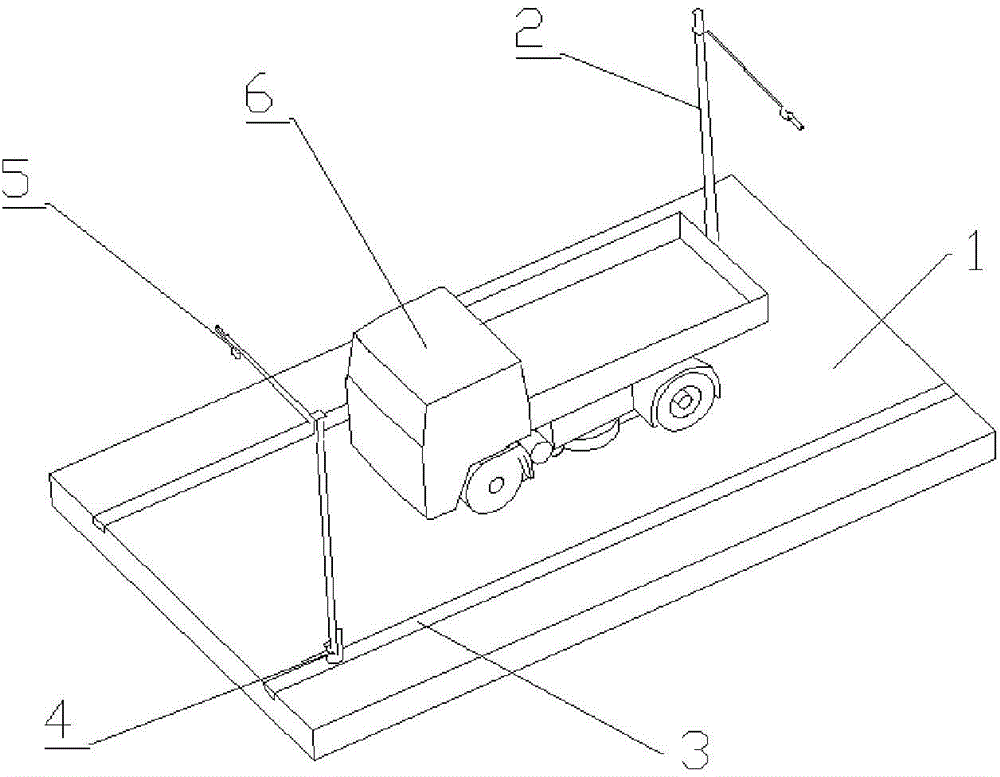

Longitudinal shifting carrier for cars

The invention relates to a longitudinal shifting carrier for cars and relates to the technical field of parking and carrying equipment for garages. The longitudinal shifting carrier for cars comprises a front trolley and a rear trolley. The two rear trolleys are integrally connected through moving chains. A travel mechanism of each trolley comprises two drive wheels, two driven wheels, a motor and a reducer of the motor. Two left pairs of wheel clamping arm mechanisms and two right pairs of wheel clamping arm mechanisms are further disposed on each trolley and are used for clamping four tiers of a car placed on track grooves. Each trolley is also provided with a synchronous wheel-clamping lifting mechanism. The defects in the prior art are overcome. The longitudinal shifting carrier for cars has the advantages of simple structure, stability in car shifting, high reliability, small occupied area, convenience and flexibility in operation, durability, low manufacturing cost and the like. The longitudinal shifting carrier for cars is adaptable to various cars different in type, axle distance and wheel thread. The longitudinal shifting carrier for cars is used for carrying, storing and parking cars, and is especially applicable to intersection systems of large mechanical stereo garages.

Owner:北京宏地车港科技有限公司

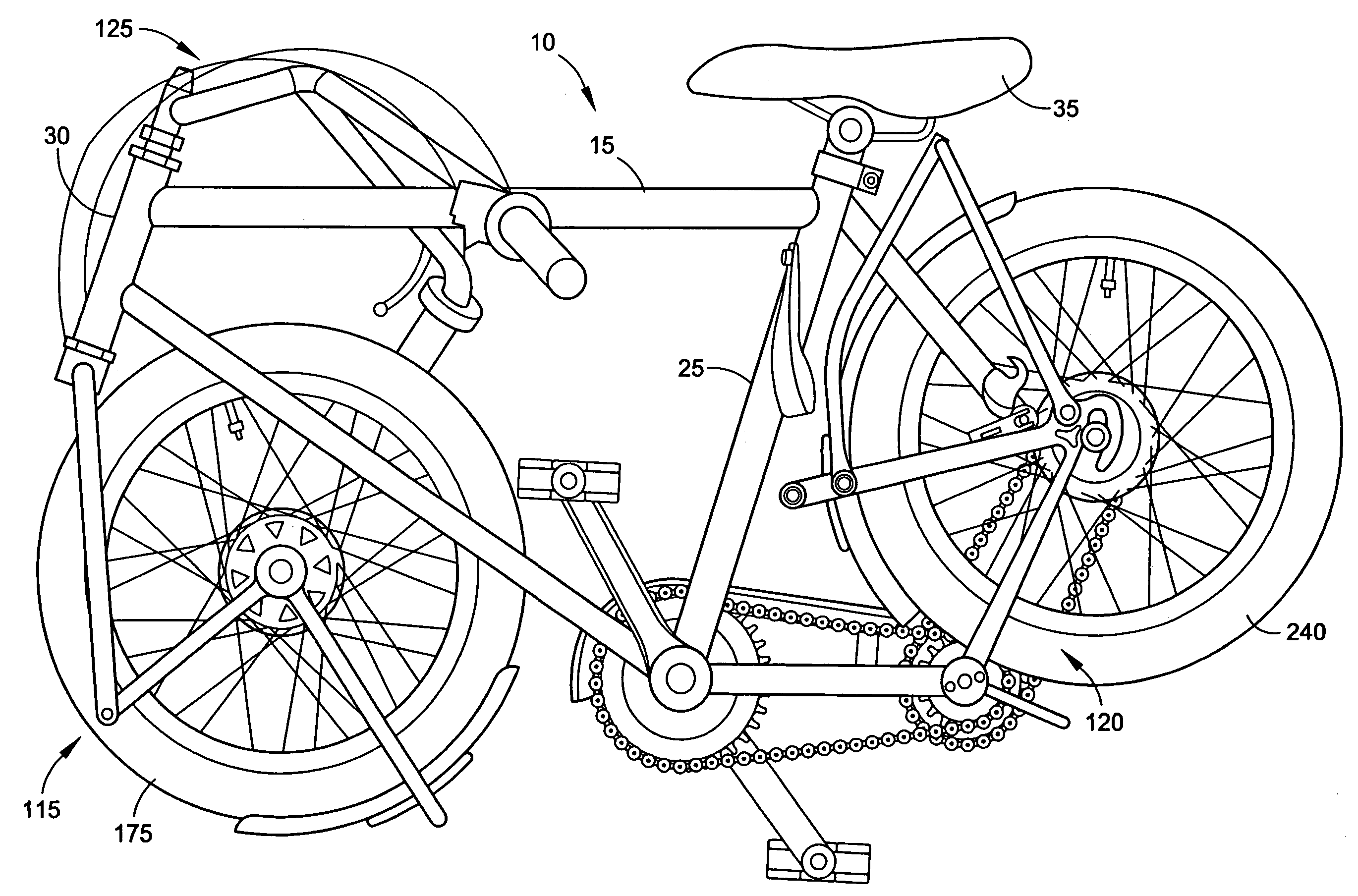

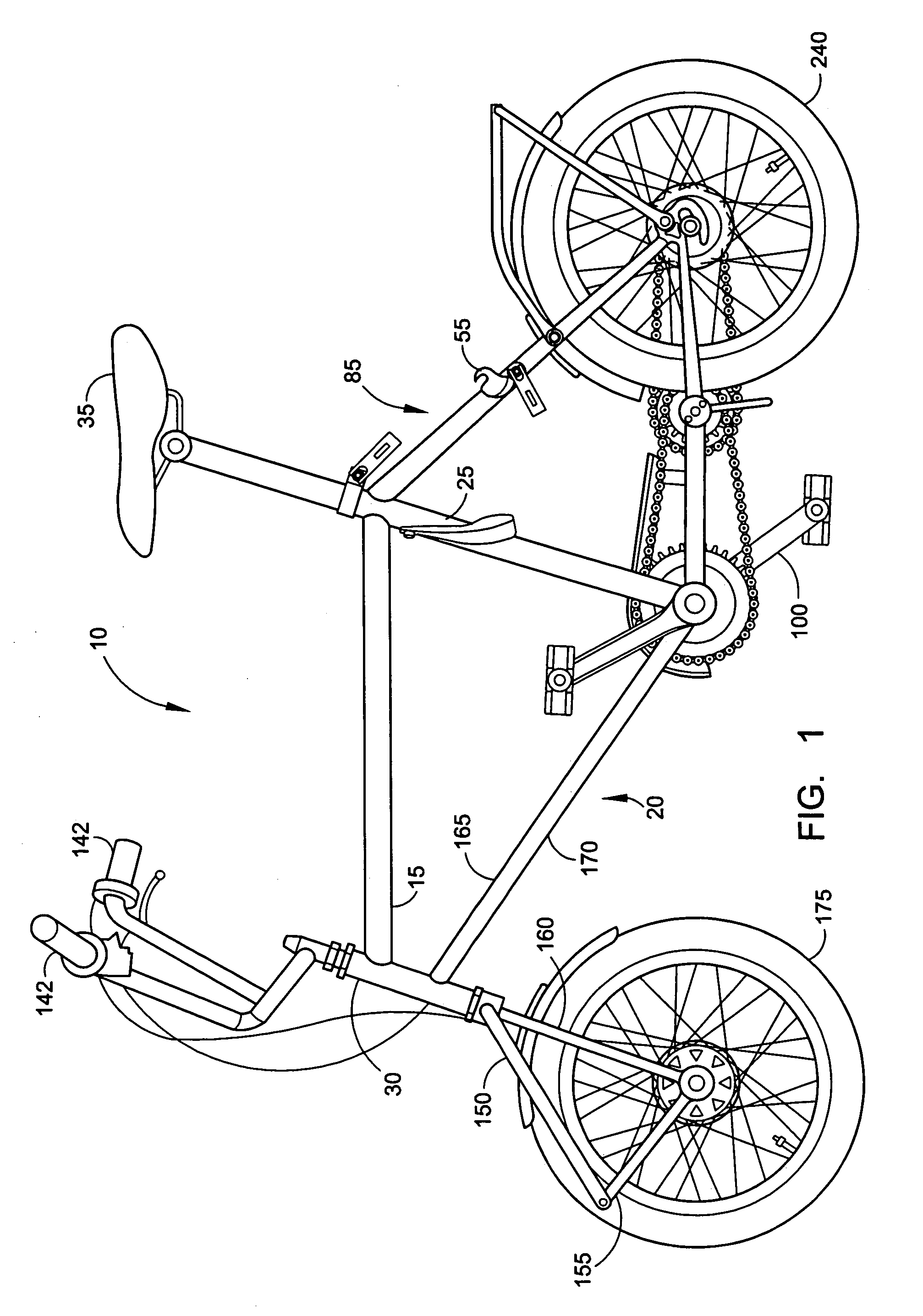

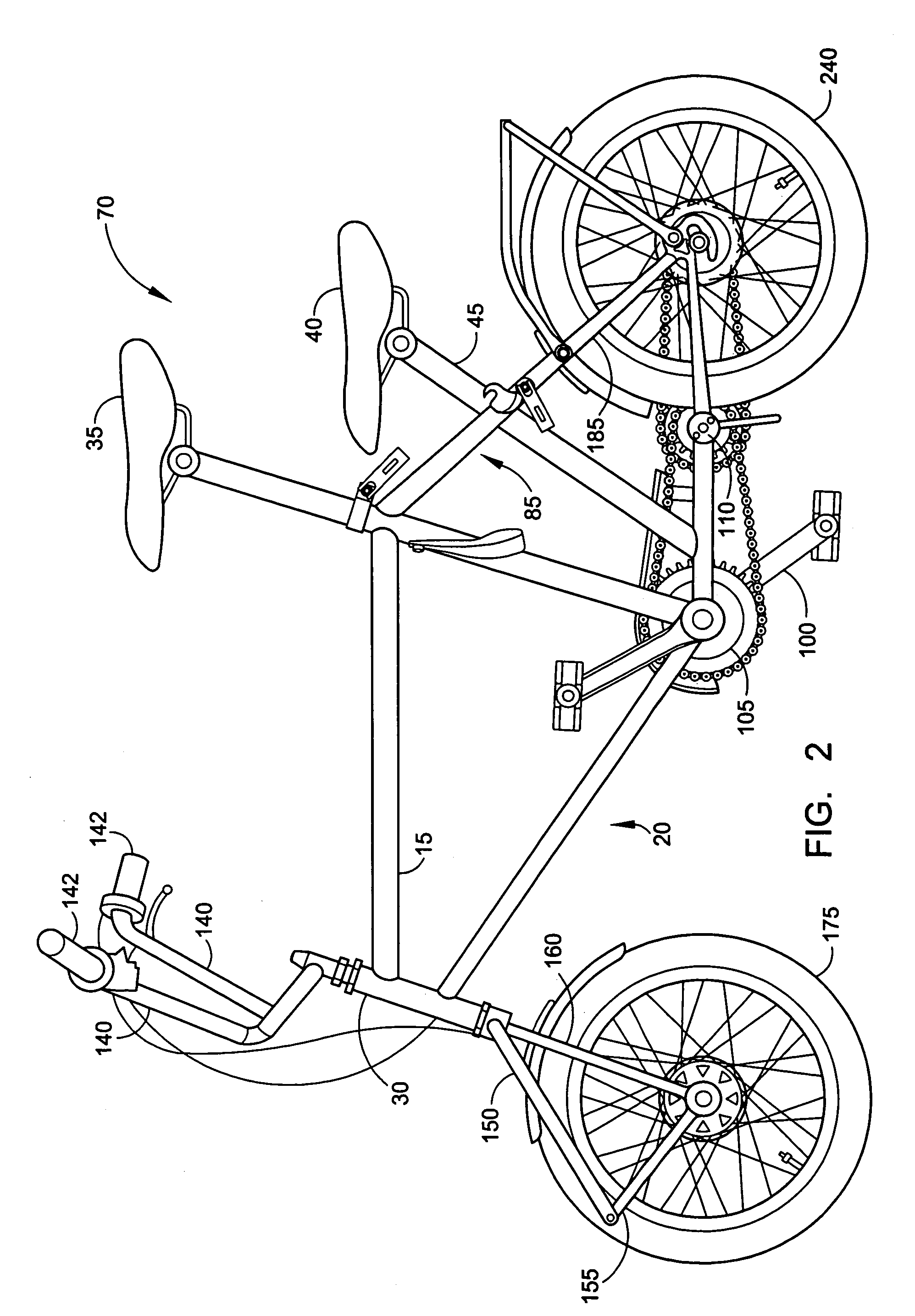

Folding bicycle

InactiveUS7229089B2Small sizePromote ergonomic riding characteristics of a non-folding bicyclePassenger cyclesWheel based transmissionSubject matterEngineering

Owner:STUDIO MODERNA SA

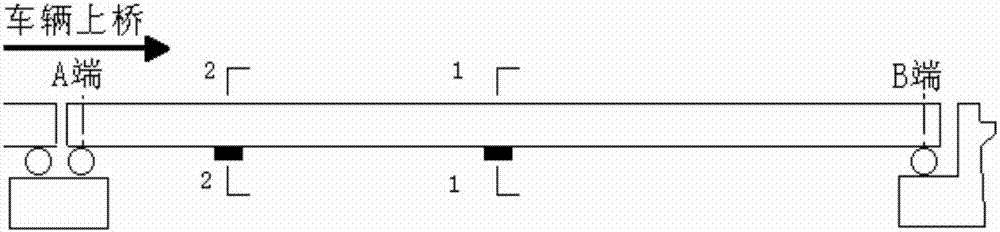

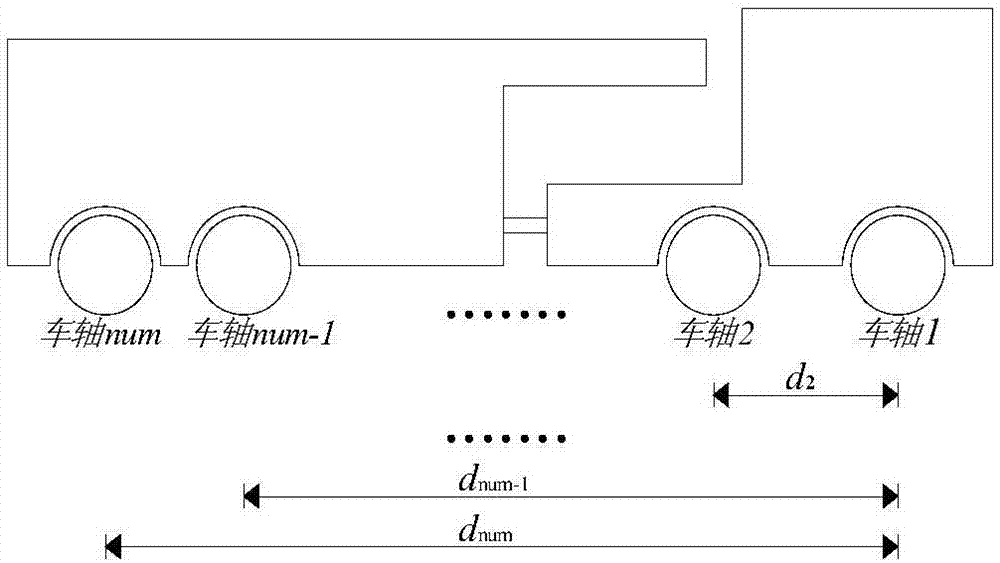

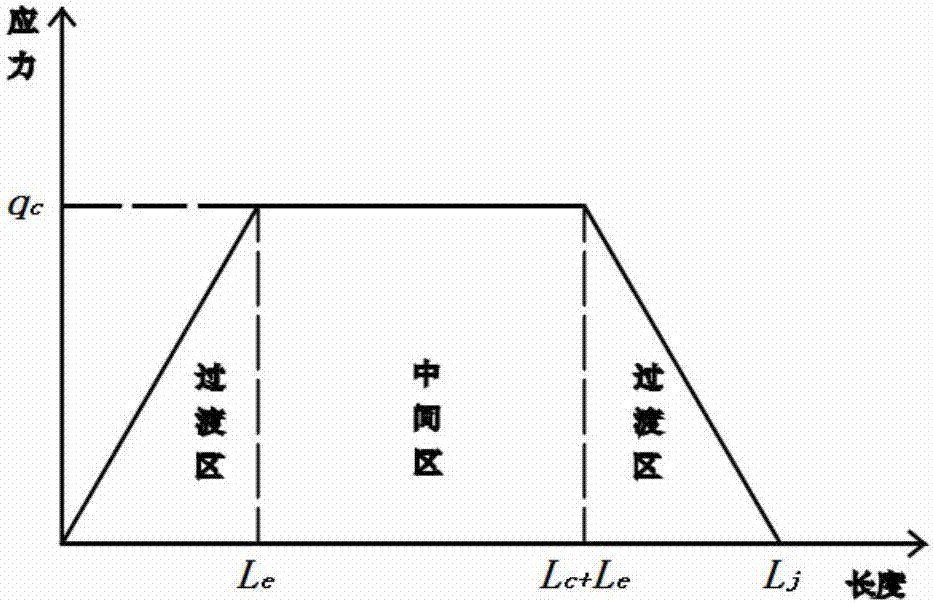

Rapid bridge detection method based on influence lines

ActiveCN107132011AImprove measurement and calculation accuracyQuick checkInformaticsSpecial data processing applicationsInfluence lineSpecific function

The invention relates to a rapid bridge detection method, which belongs to the technical field of civil engineering application. Firstly, a loading test vehicle with known axle load and wheelbase is adopted for loading to measure response of a test point; then, a method of adopting a specific function (piecewise polynomial and sine wave stacking) to fit the dynamic response of the test point is adopted to extract influence line information of the bridge; a tire-pavement stress distribution emprical formula is introduced to build a tire-pavement contact force trapezoid distribution model; in combination of the actual influence line information and the vehicle tire-pavement contact force distribution model, a linear superposition method is adopted to reconstruct bridge test point response information under different vehicle load combination effects, and thus, rapid bridge detection based on the influence lines is realized. Based on few driving tests on a single vehicle, the actual influence line information can be acquired rapidly and accurately, the bridge response information under different static load combination working conditions is reconstructed, rapid bridge detection is achieved, and the defects that the existing bridge detection method is long in consumed time, high in economic cost and long in traffic block time can be solved.

Owner:CENT SOUTH UNIV

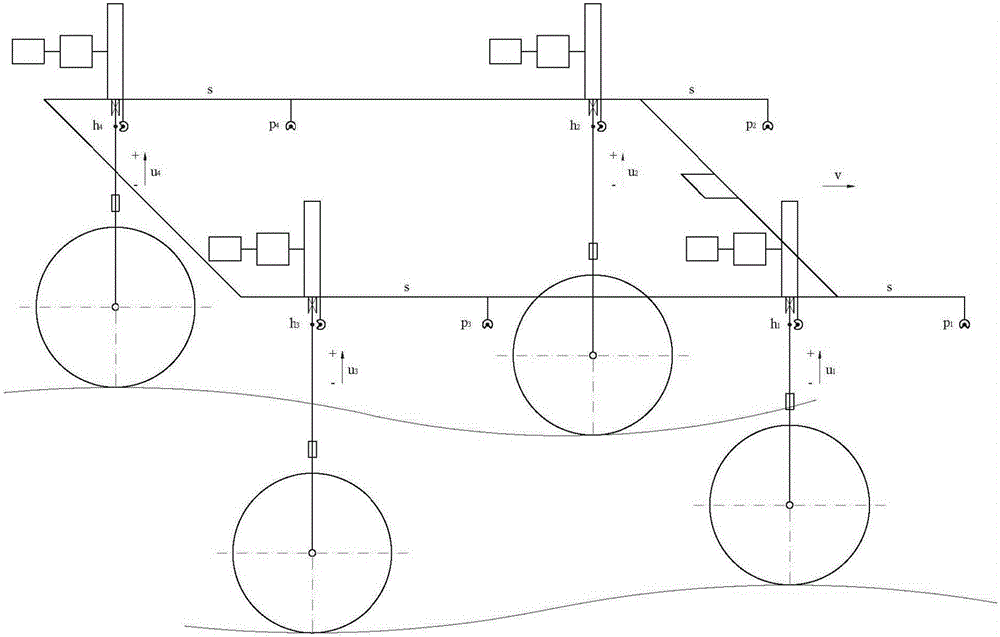

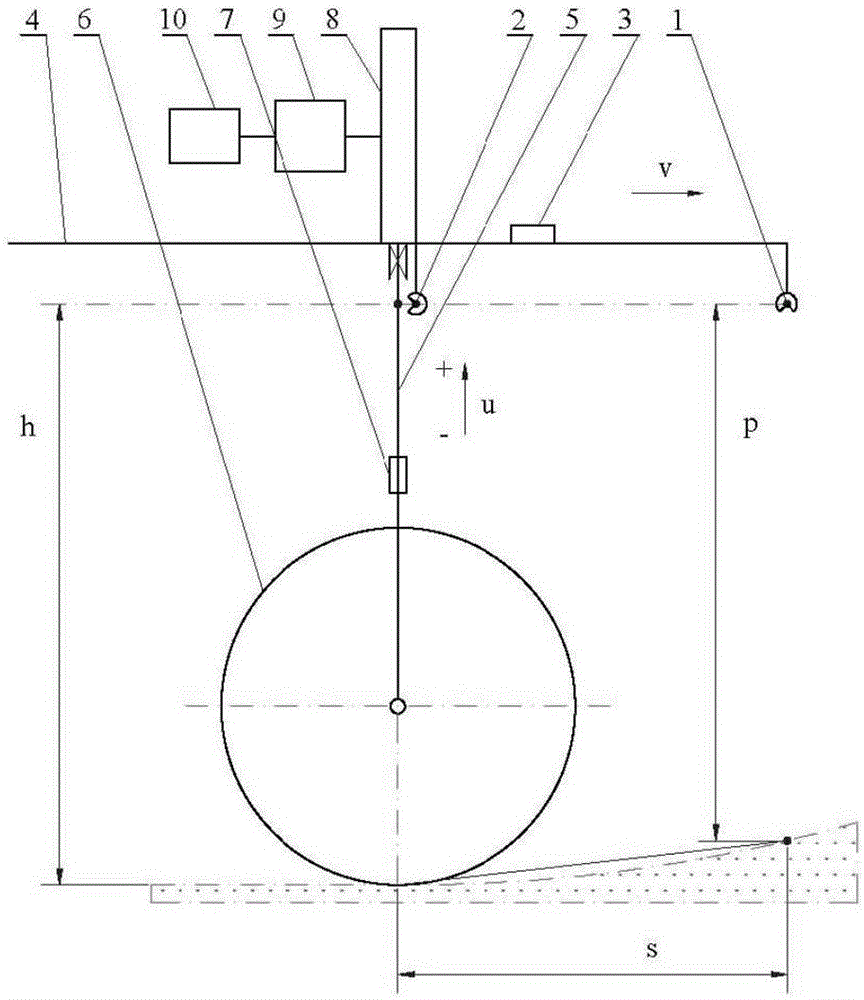

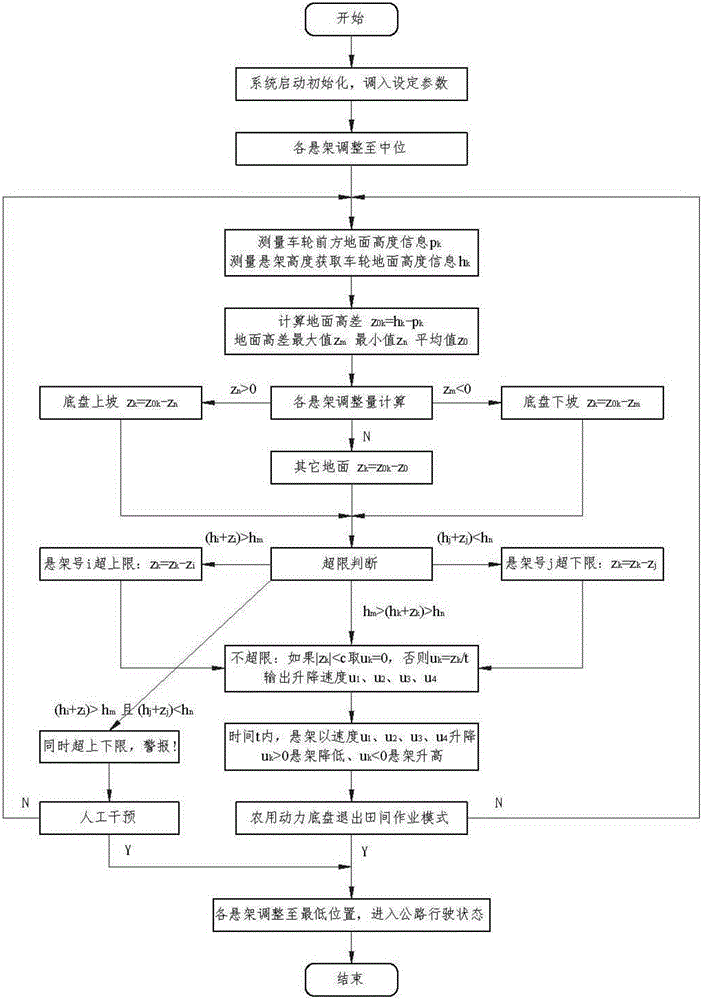

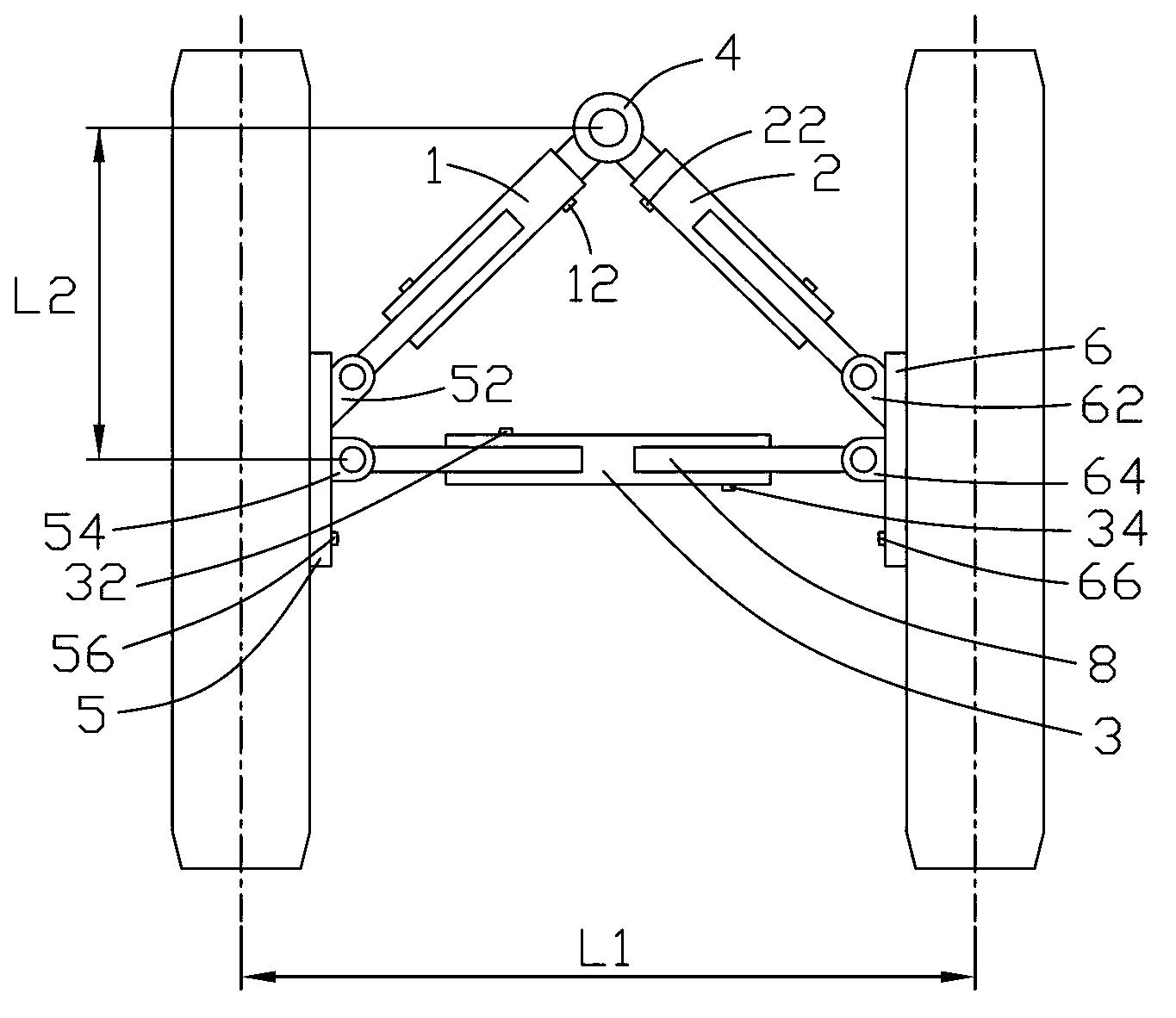

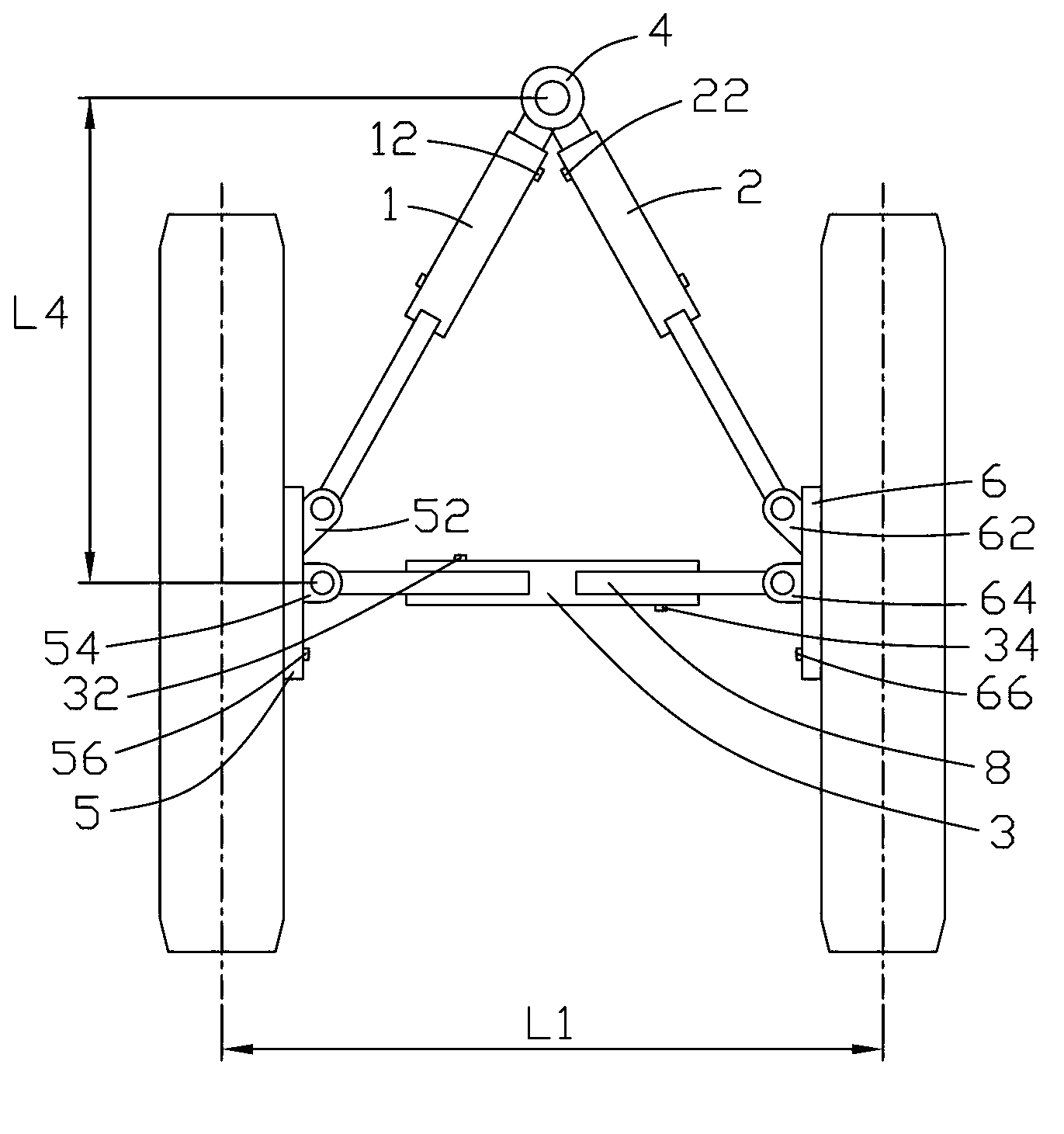

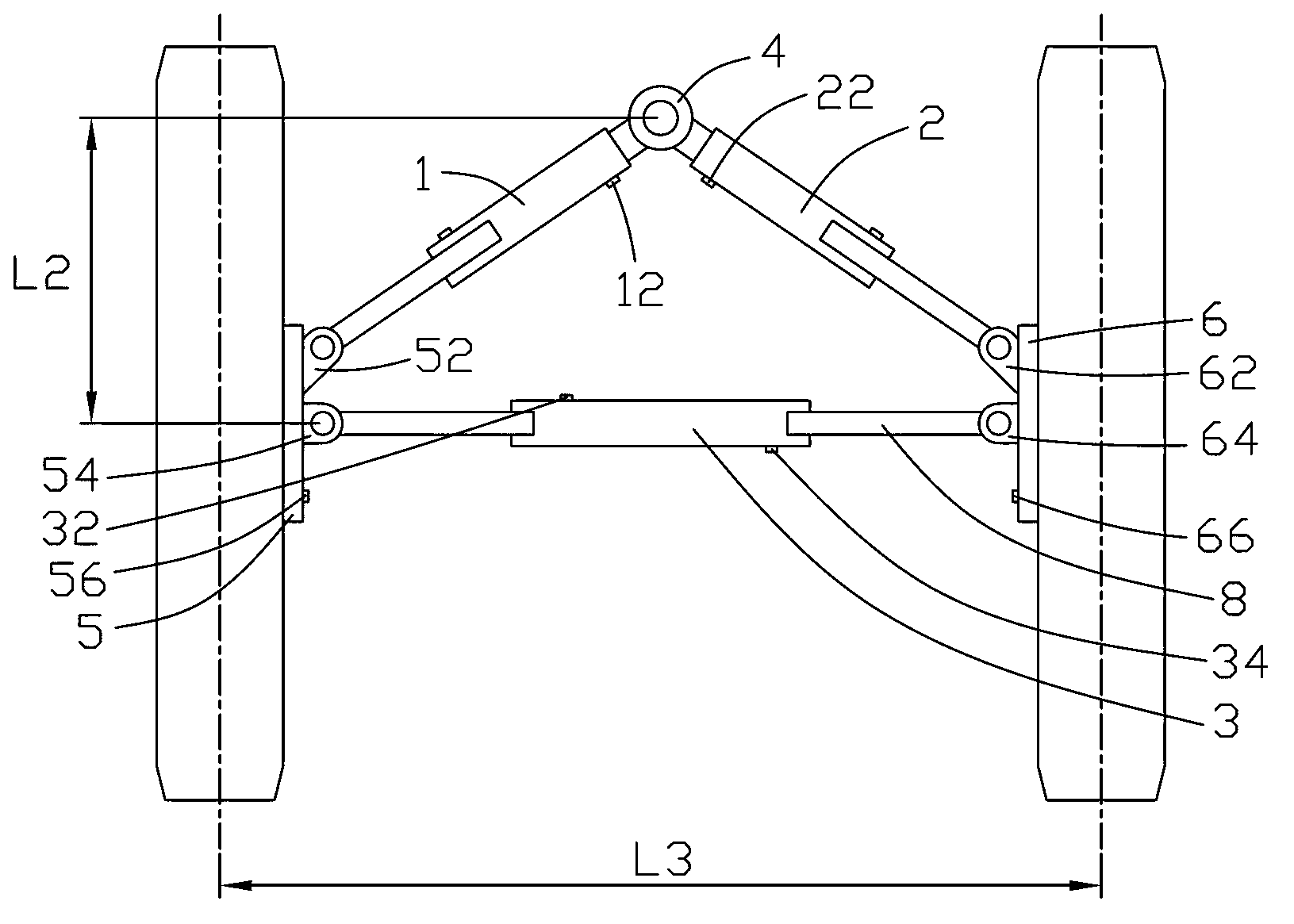

Leveling system and leveling method for agricultural power chassis

ActiveCN106427451ASatisfy plant protectionMeet the harvestAgricultural vehiclesResilient suspensionsTerrainVehicle frame

The invention discloses a leveling system and a leveling method for an agricultural power chassis, and belongs to the technical field of vehicle chassis. The leveling system for an agricultural power chassis comprises a distance measuring sensor, a position sensor, a central processor, a vehicle frame, suspensions and wheels; four groups of the suspensions are mounted on the vehicle frame in bilateral symmetry according to the given wheelbase and wheel track, and the lower ends of the suspensions are connected with the wheels; the information of terrain height in front of the wheels is measured by the distance measuring sensor; the heights of the suspensions are measured by the position sensor to obtain the wheel-terrain height information; calculation and analysis are carried out by the central processor; the suspensions are driven by a servo motor and the heights of the suspensions are adjusted in real time; and the wheels actively contour the ground, so that dynamic leveling of the vehicle body during traveling and operation of the agricultural power chassis is achieved.

Owner:CHINA AGRI UNIV

Telescopic device and vehicle provided with same

ActiveCN103231625AExpanded ability to adapt to road conditionsImprove driving stabilityAxle unitsEngineeringMechanical engineering

The invention provides a telescopic device which comprises a first telescoping mechanism, a second telescoping mechanism, a horizontal telescoping mechanism, a mounting seat, a first mounting board and a second mounting board, wherein a first end of the first telescoping mechanism and a first end of the second telescoping mechanism are hinged with the mounting seat respectively; a second end of the first telescoping mechanism and a second end of the second telescoping mechanism are hinged with the first mounting board and the second mounting board respectively; and a first end and a second end of the horizontal telescoping mechanism are hinged with the first mounting board and the second mounting board respectively. The invention further provides a vehicle provided with the telescopic device. With the adoption of the telescopic device and the vehicle, the wheelbase and the tread of the vehicle can be adjusted respectively or simultaneously.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

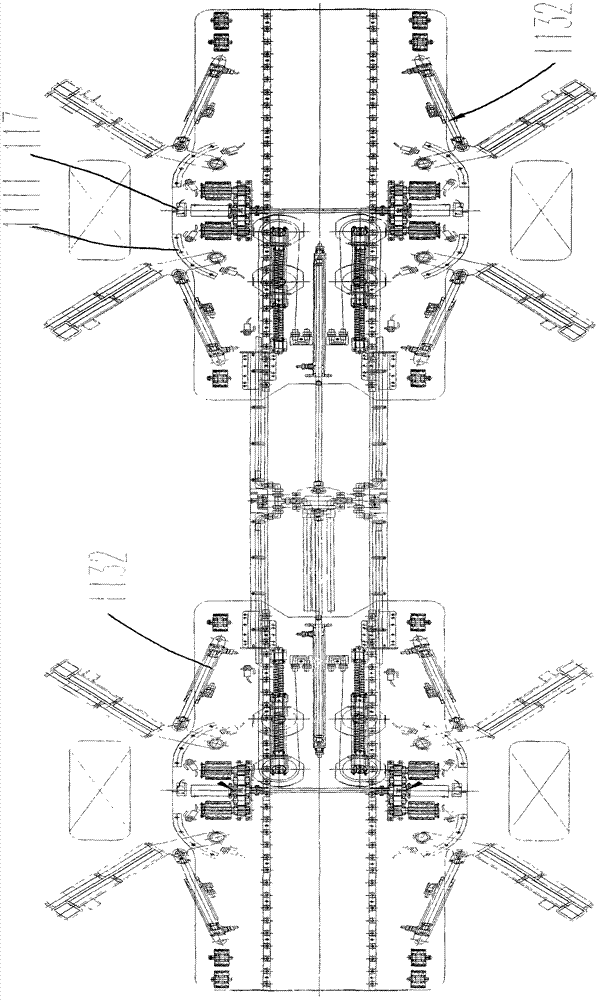

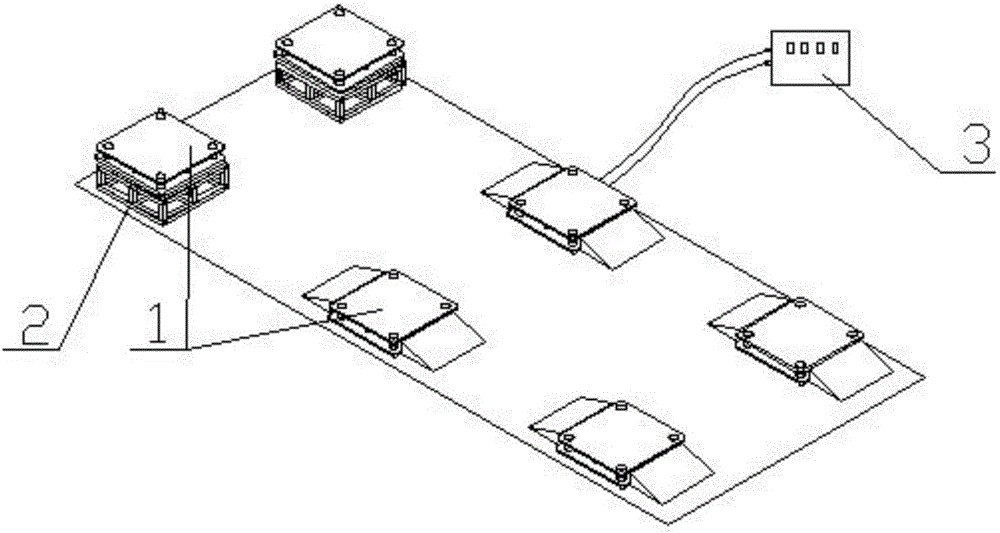

Handling robot and mechanical three-dimensional garage using the handling robot

The invention relates to a handling robot, in particular to an intelligent mechanical three-dimensional garage using clamping tires of the handling robot to lift cars (or similar goods) and carry out front-back bi-directional carrying-depositing actions. The mechanical three-dimensional garage consists of a handling robot, a car storage place, a carrier, a loading platform, and a platform rail. The handling robot includes two moving trolleys in front and back sides, a retractable device is arranged between trolleys. The moving trolley comprises a trolley rack, a moving mechanism, clamping arms, a steering wheel assembly and an oil-way circuit slewing mechanism. According to the handling robot and a mechanical three-dimensional garage using the handling robot, problems of depositing cars in limited space are solved, automatic positioning of tires of cars with different wheelbases is flexibly realized, and the front-back bi-directional carrying-depositing actions are achieved. Besides, a moving drive mechanism can be independently installed on the loading platform to suitable for a flat mobile type parking system, and a lifting mechanism can be installed on the loading platform with the moving mechanism to suitable for an aisle-stacking parking garage, so as to realize three-dimensional movement of objects.

Owner:SHENZHEN YEEFUNG AUTOMATION TECH CO LTD

Vehicle

InactiveUS7717210B2Minimize damageElectric propulsion mountingWheelchairs/patient conveyanceEngineeringWheelbase

A vehicle for transporting a person has a chassis (103) and four wheels (105a, 105b, 150c, 105d) supporting the chassis above a ground surface. The wheels enable the vehicle to move along the ground surface. Each of the four wheels is adjustable in position to enable the wheelbase length and track width of the vehicle to be changed. Each of the wheels is steerable to enable the changes in the wheelbase length and the track width to be effected whether the vehicle is substantially stationary or in motion.

Owner:MAHY GRAHAM JOHN +2

Braking process-based dynamic automobile gravity position detector and method

InactiveCN102692297AQuick measurementAccurate measurementStatic/dynamic balance measurementTraffic accidentData acquisition

The invention relates to braking process-based dynamic automobile gravity position detector and a method. The device consists of an axle weight, a braking force detector, an axle base measuring device, a wheel base measuring device and a data collection processing system; dynamic gravity detection algorithm is obtained by derivation on the basis of braking process, the device is applied to collect axle weight and braking force signals, axle base signals and wheel base signals, thus being capable of calculating the position of the automotive gravity. Based on the automotive gravity position calculation method, sideslip and rolling-over of vehicles can be analyzed to calculate limiting values of sideslip and rolling-over of vehicles under different road conditions and give out early-warning information to avoid occurrence of traffic accidents. The invention can be widely applied in safety driving control process of various vehicles.

Owner:JILIN UNIV

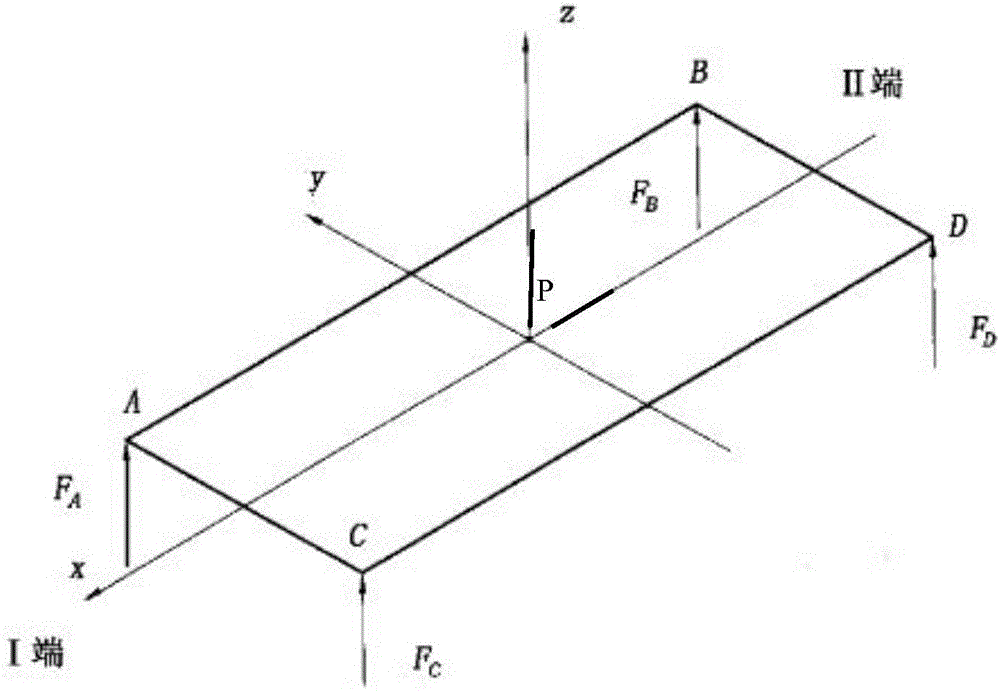

Vehicle centroid position measuring device and method

The invention relates to a vehicle centroid position measuring device and a vehicle centroid position measuring method. The vehicle centroid position measuring device includes measurement modules and height brackets; the height brackets are arranged below one group of parallel measurement modules; the other group of measurement modules are arranged on the ground or a horizontal table; the measurement modules are used for measuring the weight of the front wheel and rear wheels of a braked vehicle; based brackets in the measurement modules are adjusted, so that the four wheels of the vehicle can be in the same plane; and the height brackets are used for supporting the wheels by a certain height. With the vehicle centroid position measuring device and method of the invention adopted, complex mechanical structures are not required, and other measurement modules are not required to be adopted additionally, and vehicles with different wheel treads and wheelbases can be measured.

Owner:DALIAN ROILAND SCI & TECH CO LTD

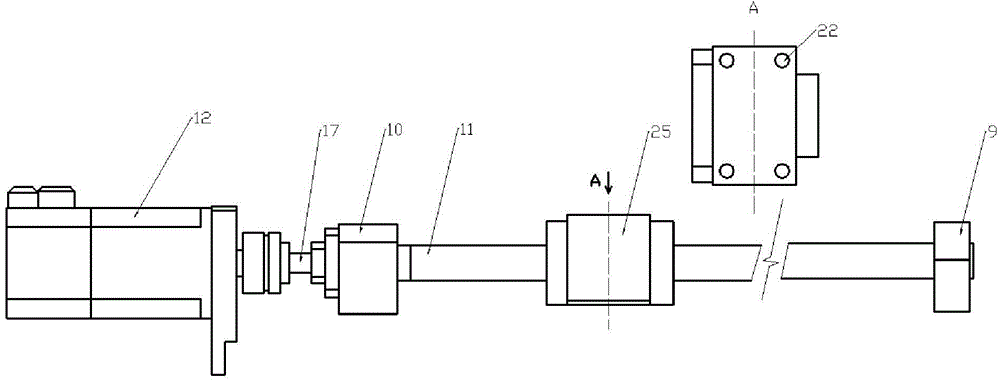

Measuring device for automobile basic parameters and measuring method of measuring device

The invention provides a measuring device for automobile basic parameters and a measuring method of the measuring device. A laser distance measuring sensor which serves as a direct measuring tool is installed on a bracket provided with a lifting mechanism and a rotary mechanism, and the bracket is driven by a linear driving device to move along the length direction of a base, so that the laser distance measuring sensor is moved to a needed position to be measured. The measuring device provided by the invention further comprises a wheel center positioning device for positioning the center of a found wheel, a wheel track measuring assistant device for measuring the distance between left and right wheels in an assistant manner, and an angle measuring assistant device for measuring the approach angle and departure angle of the automobile in an assistant manner. The measuring device provided by the invention can be used for solving the problems that the conventional manual measuring method is relatively great in measuring error, inconvenient to operate and the like and can be used for precisely measuring length, width, height, distance between front and back wheels, a wheel base, the approach angle and the departure angle.

Owner:JILIN UNIV

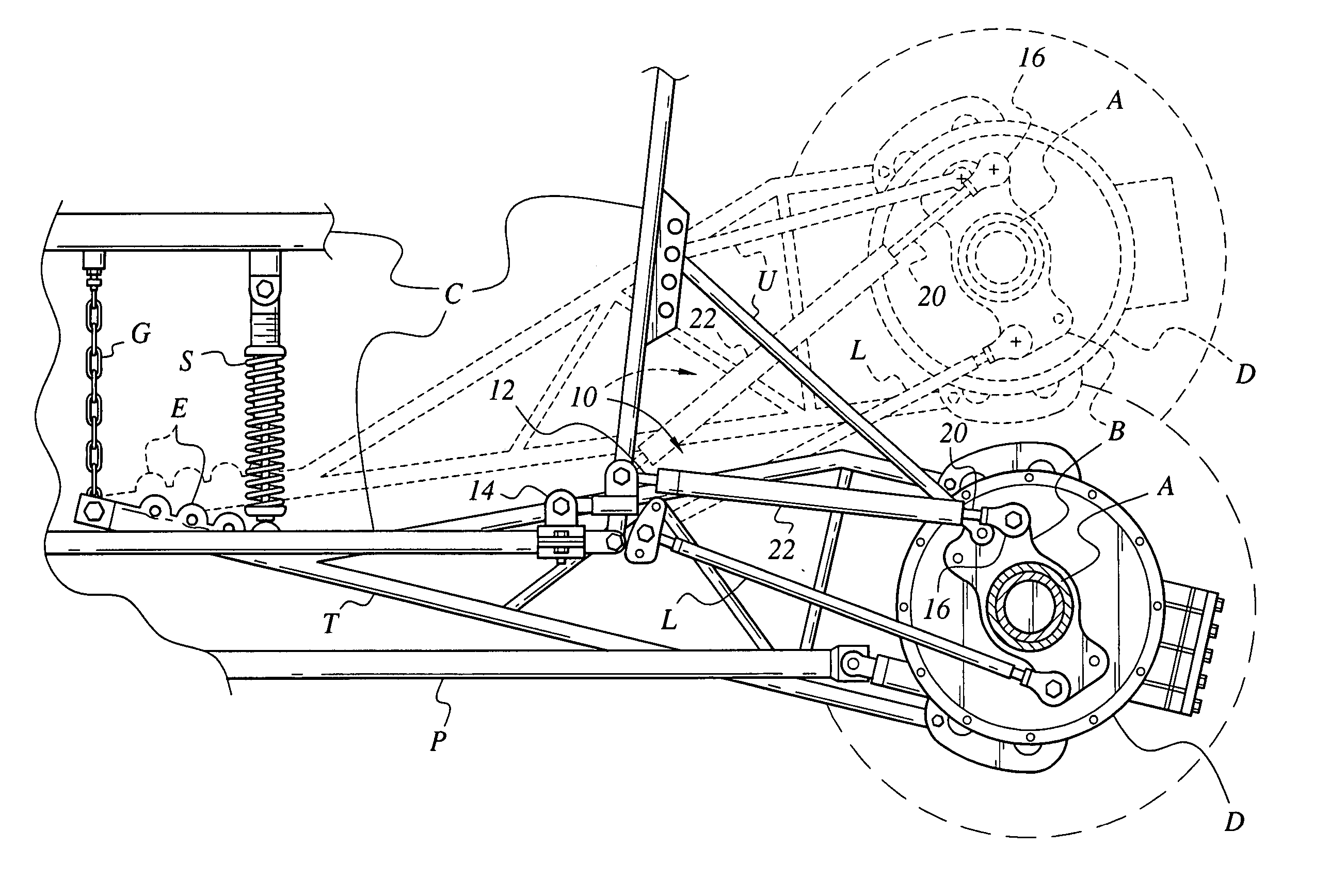

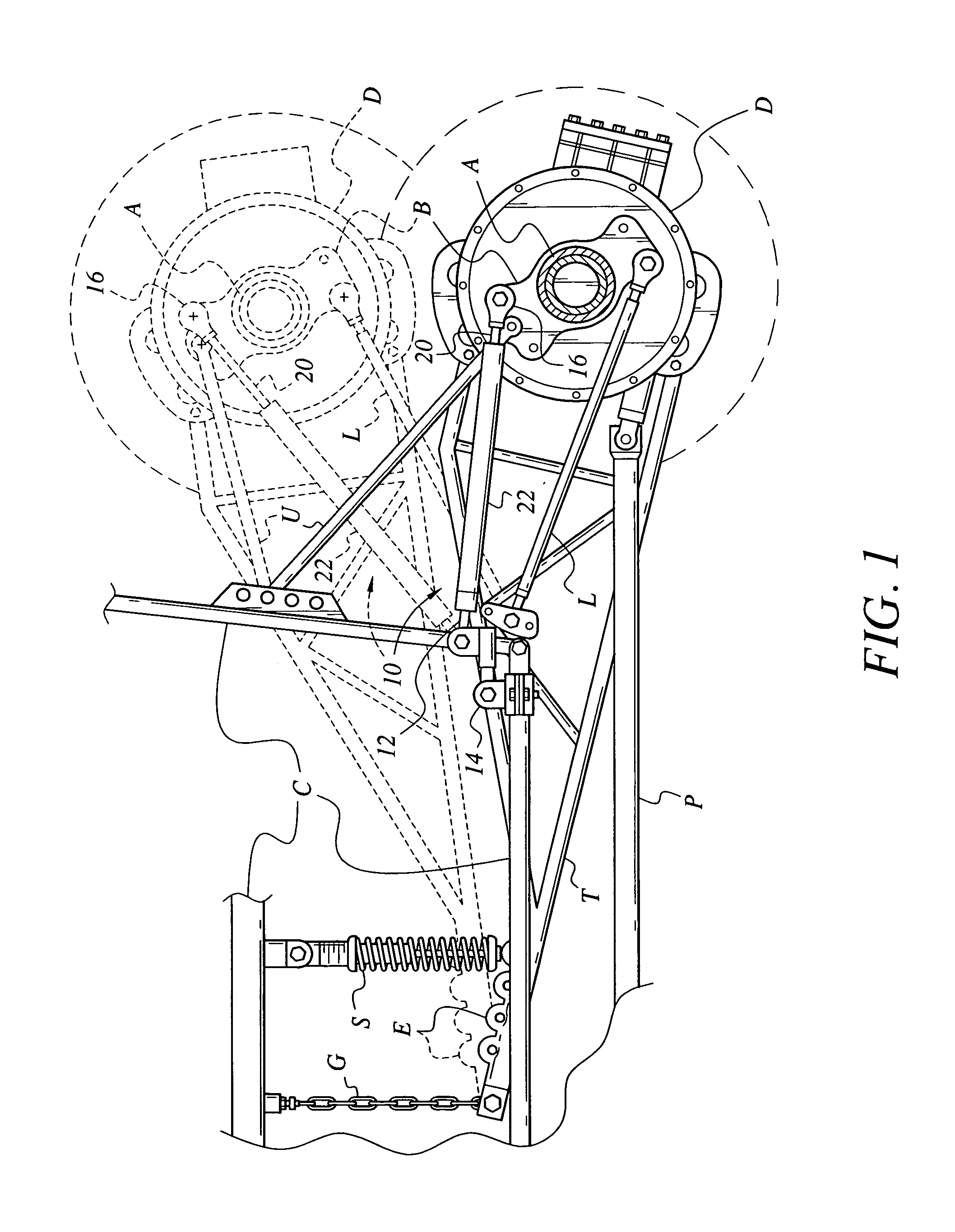

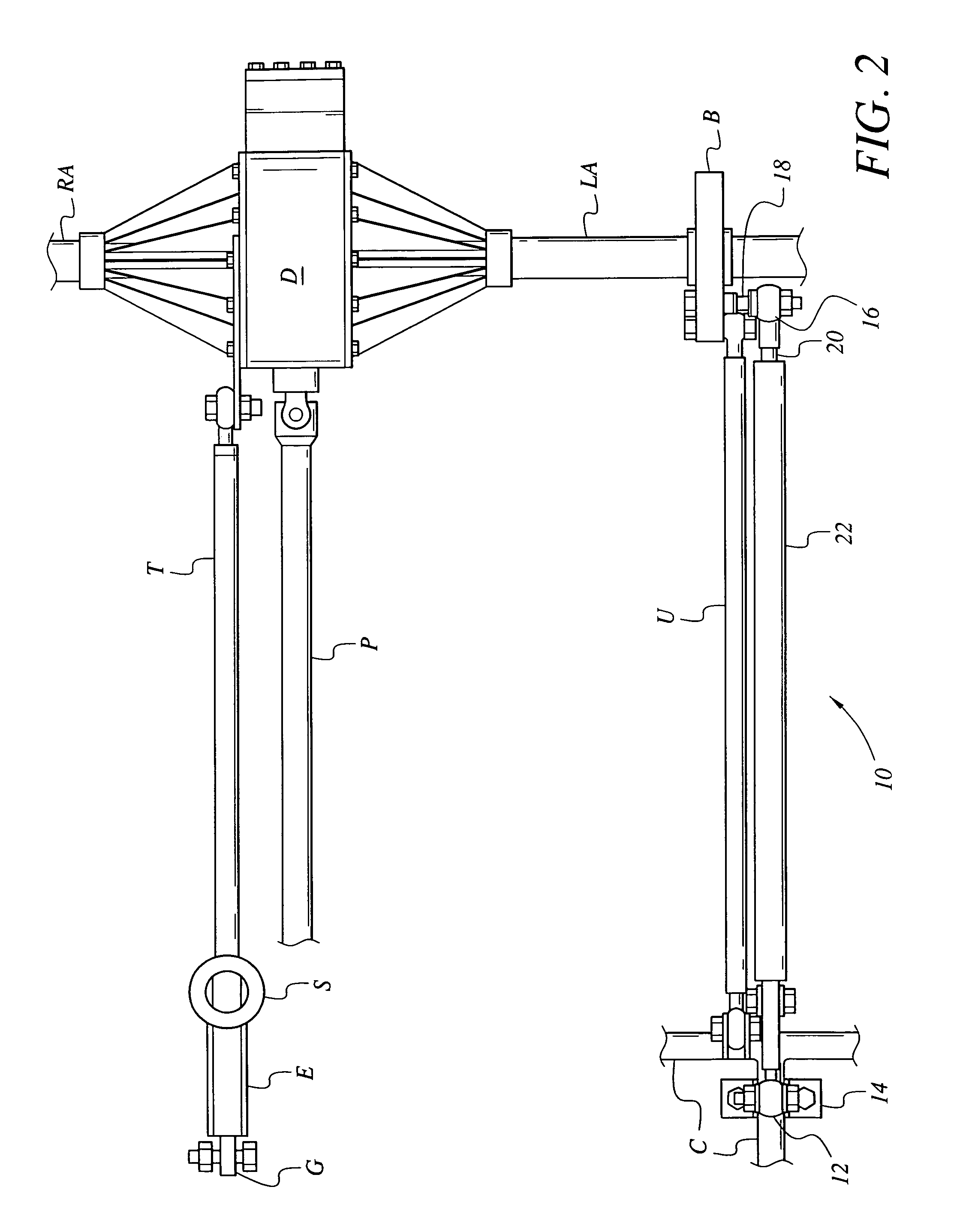

Torque reaction damper for a drive axle

The present torque reaction damper for a drive axle is a series of embodiments of installations and attachment bracketry for use in dirt track late model (DTLM) racing vehicles. Such cars are set up to provide relatively large vertical deflections of the solid rear drive axle, to drive the inboard wheel downwardly against the track surface for better traction and to shift the axle angularly to promote oversteer through the turns when the throttle is applied. The present torque reaction damper solves the problem of sudden “chassis drop” and its destabilizing effect, when the throttle is suddenly closed at the end of a straight before entering a turn. The present damper comprises a shock absorber installed either forwardly or rearwardly between the “bird cage” axle bracket and the chassis and serves to cushion the movement of the chassis when the throttle is closed, thereby facilitating car stability and control.

Owner:HUPPERICH HERBERT L JR

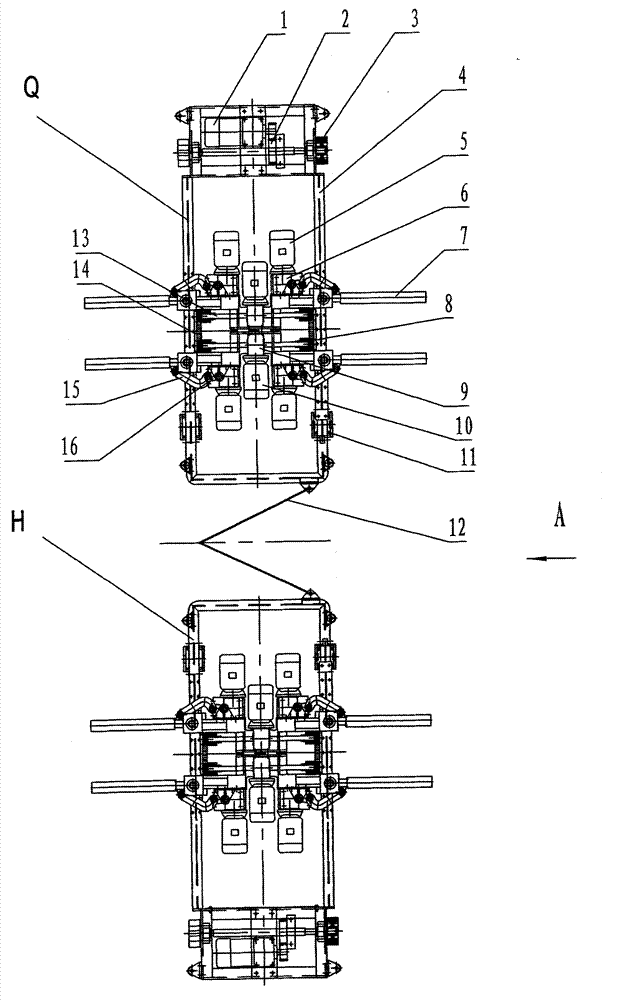

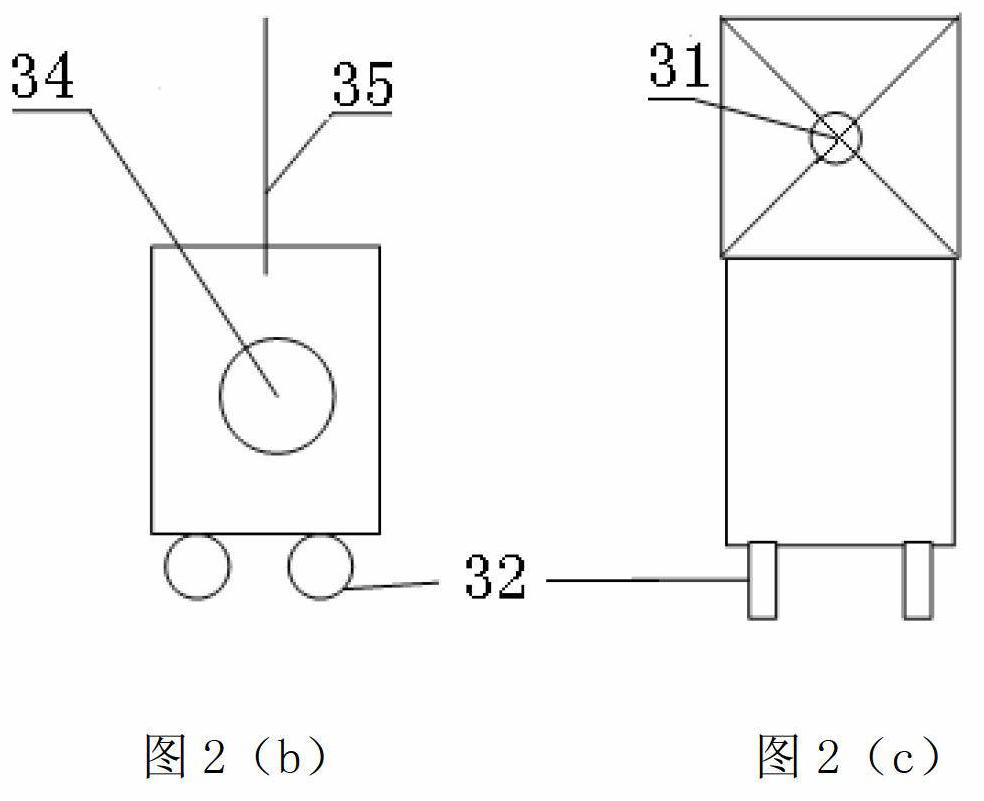

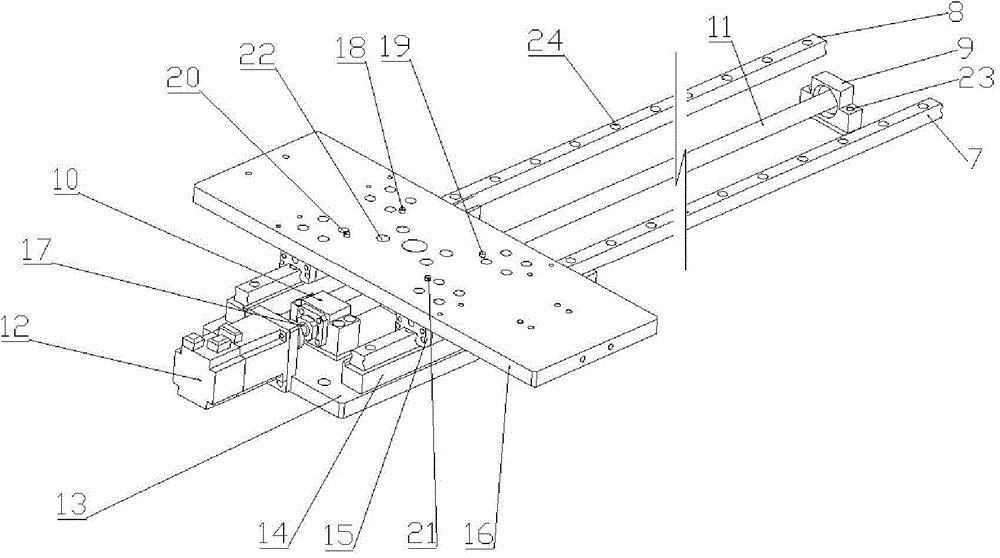

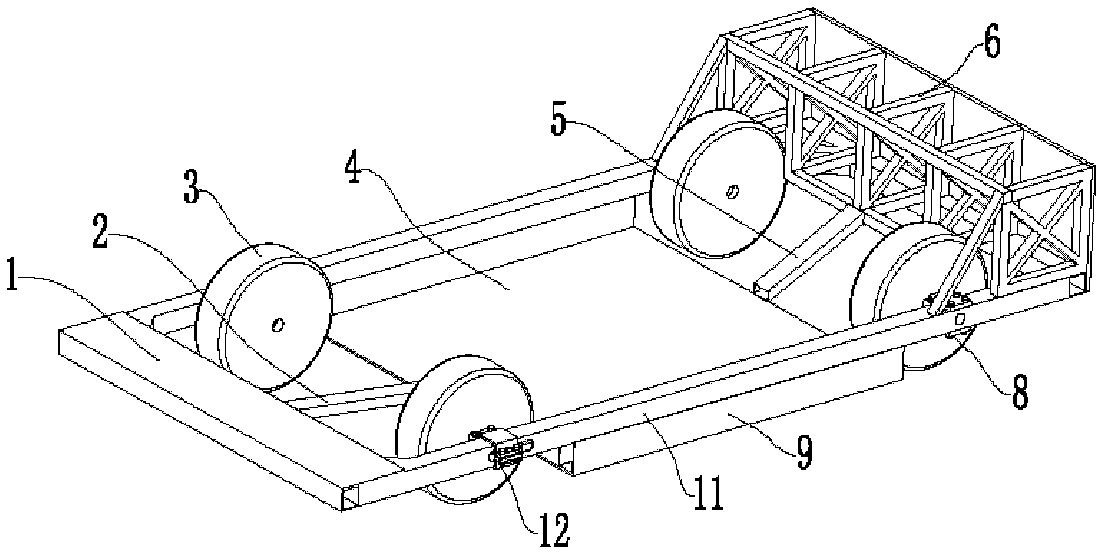

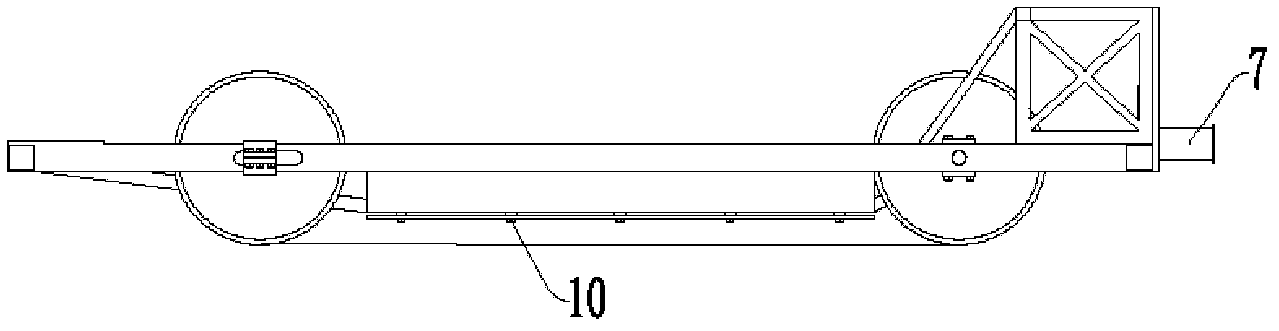

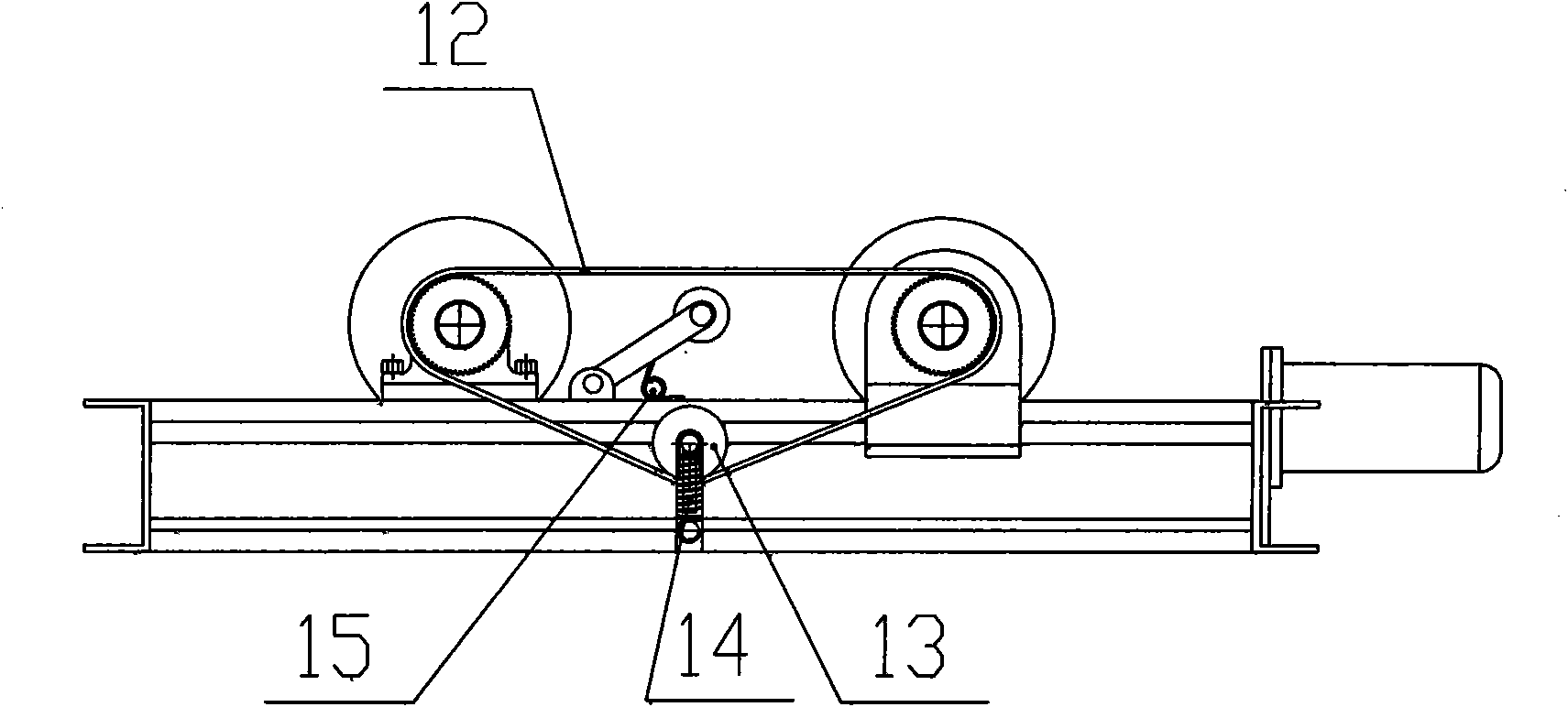

Adjustable-type trolley for impact test

InactiveCN102607793ASave on crash test costsSimple structureVehicle testingShock testingEngineeringMechanical engineering

An adjustable-type trolley for an impact test comprises a trolley frame (1) and wheels (3), and further comprises a front wheel track adjusting mechanism (8), a rear wheel track adjusting mechanism, a trolley axle track adjusting mechanism (12) and a bottom plate height adjusting mechanism (10), wherein the rear wheel track adjusting mechanism is integrated with the trolley axle track adjusting mechanism (12). The adjustable-type trolley for the impact test disclosed by the invention can adjust the wheel track of the wheels and an axle track, and correspondingly adjust the height of a trolley bottom plate, so as to realize good combination with varisized trolley bodies. Moreover, the adjustable-type trolley for the impact test is simple in structure, convenient in adjustment, and low in cost.

Owner:HUNAN UNIV

Third axle assembly for log hauling trailers

InactiveUS20070126196A1Increased payload capacityImprove mobilityVehicle to carry long loadsTractor-trailer combinationsBogieEngineering

Improved third, tag, axle for a standard two-axle log-carrying trailer to permit carrying additional load. The inventive third axle assembly is pivotally linked directly to the bunk of a standard log trailer bogie by two, laterally-spaced hitch assemblies that permit vertical motion of the third axle, but not lateral movement. The inventive third axle assembly increases the payload capacity of the trailer with better maneuverability. A pivoting cone support and centering assembly is used to insure proper alignment of the tag axle during transport and when first unloaded. By following the bunk, the inventive axle more closely follows the tractor front wheel path during turns, rather than worsening the cut-across effect of ordinary turn geometry. That is, the inventive tag axle tracks more nearly in the proper lane, tending significantly less to cut across inside the tractor turn in both left and right turns, and thus is a safer rig.

Owner:KLAHN KENNETH FRITZ

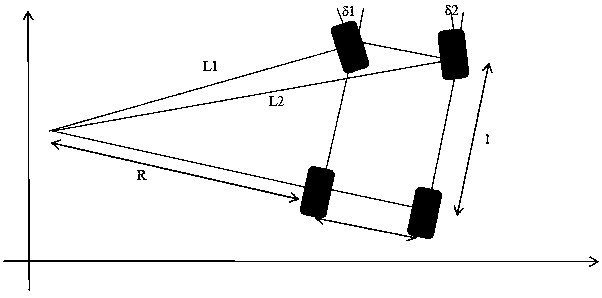

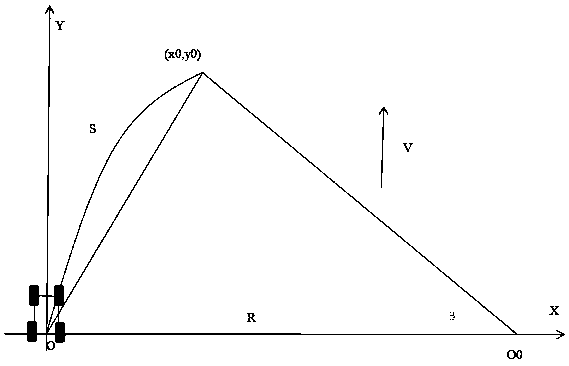

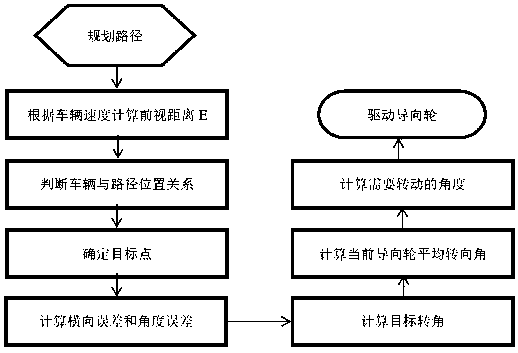

Control method for automatic driving of four-wheel vehicle

ActiveCN107544520AReduce complexityShorten operation timePosition/course control in two dimensionsTime errorEngineering

The invention discloses a control method for automatic driving of a four-wheel vehicle. The control method mainly comprises the following steps that (1) an initial state of the system is set, whereina traveling path is planned in advance, and vehicle parameters including guide wheel tread and vehicle body wheel base are measured; (2) the real-time position of the vehicle and the real-time angle of a guide wheel on either side are measured; (3) real-time errors, including a position error and an angle error, of the vehicle and the planned path are calculated; (4) a target angle is calculated;(5) the angle by which tires need to be rotated is calculated; (6) the tires are controlled to rotate by a delta-theta angle. According to the control method, the foresight distance is associated withthe speed, the foresight distance is determined based on the real-time vehicle speed, and meanwhile the target point corresponding to the path is calculated based on the foresight distance, so that the path tracking stability at a complicated traveling speed is met; meanwhile, the complexity of the algorithm is low, so that the operation time of the program is greatly reduced, and good real-timeperformance is provided for the system.

Owner:SHANGHAI ALLYNAV TECH CO LTD

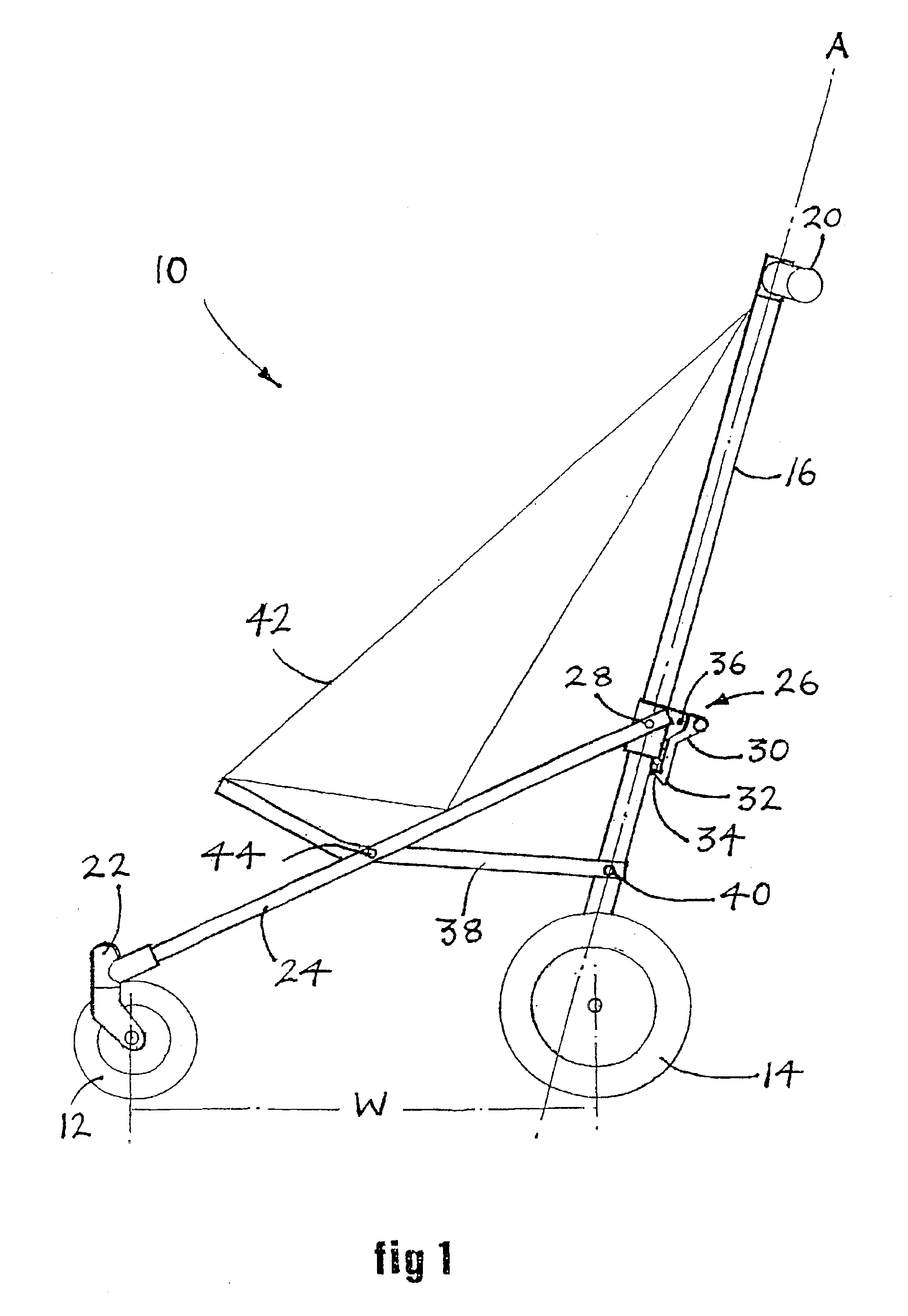

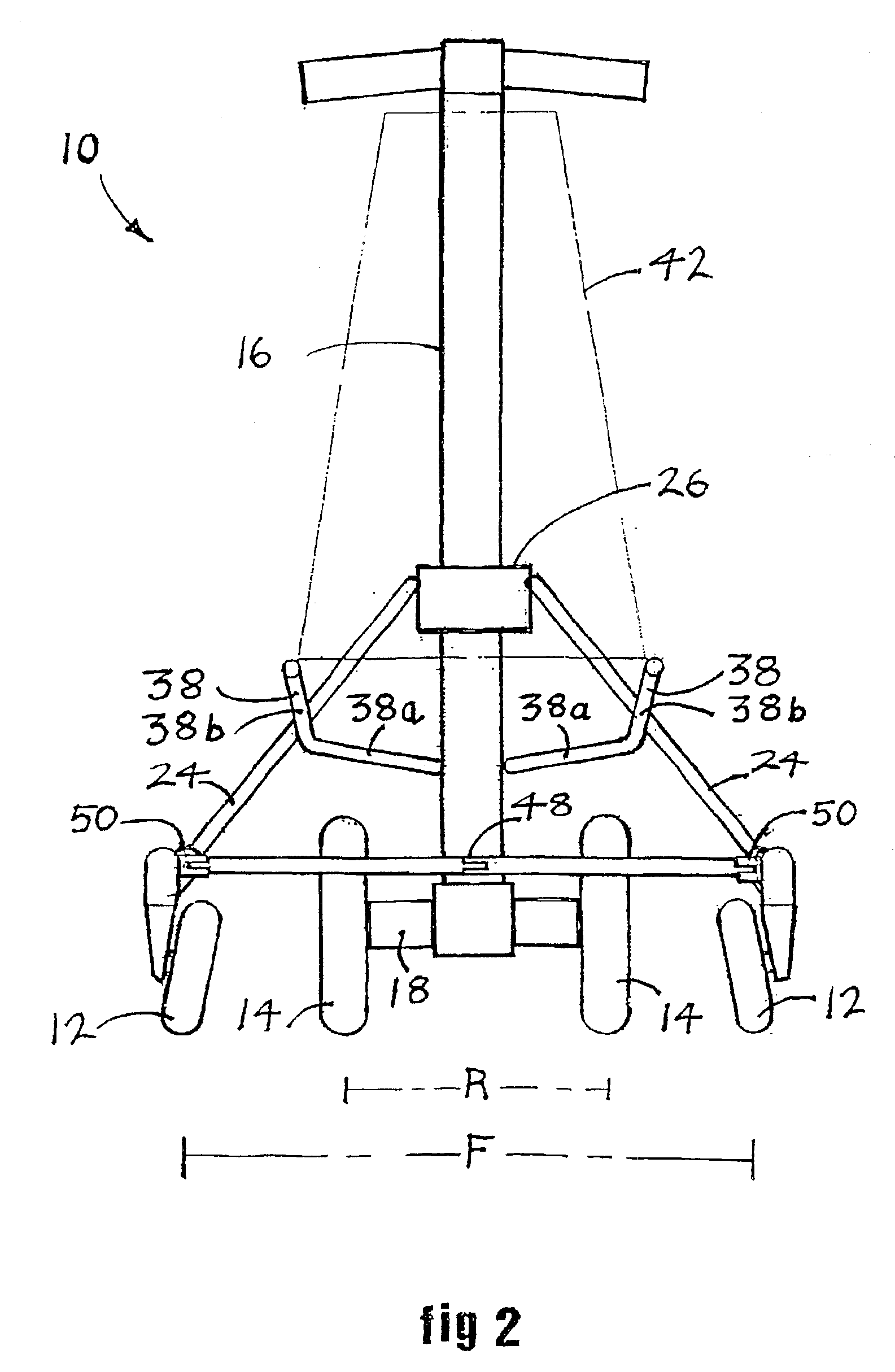

Collapsible pushchair/carrier

A collapsible pushchair / carrier has wheels at the front and back. An upstanding spine extends between the rear wheels and handles. A lockable slider assembly can be moved up and down the spine. The front wheels are supported by wheel assemblies connected by pivotable support legs to the slider assembly. Beneath the slider assembly there are pivot joints linked to cranked support arms pivotably connected to the support legs. A foldable transverse strut extends between the front wheel assemblies. A seat is mounted to the ends of the arms remote from the pivot joints to the legs and the spine. The slider assembly can be moved between two operating positions. In one position, the pushchair is operative with the wheels defining a wheelbase between the front and rear wheels and front and rear wheel tracks between the front and rear wheels respectively. In the other position the pushchair is stowed and collapsed with the legs and arms alongside the spine and the front wheels within the rear wheel track. The now folded strut rests on a floor surface to support the stowed pushchair in an upstanding position. In moving between the stowed and operative positions the front wheel assemblies splay outwardly.

Owner:MICRALITE IP LTD

Adjustable-axle distance roller device

InactiveCN101886981AEasy to drive outRealize automatic adjustmentWork measurementTesting/calibration of speed/acceleration/shock measurement devicesAdhesion coefficientDistance detection

The invention discloses an adjustable-axle distance roller device, which comprises a machine frame, a primary roller, a secondary roller, a tire diameter detection device, a roller axle-distance detection and regulation device, a transmission device and a tensioning mechanism. When the device is used, vehicle detection equipment, such as braking detection platforms, chassis dynamometers and speedometer calibration consoles, can realize the automatic adjustment of the axle distance of rollers, the requirements for the longitudinal positioning of tires of different diameters and the adjustment of an adhesive force in a detection process are met, the detection accuracy and efficiency are improved, and the range of vehicles detected is enlarged; a wheel lifting mechanism is not required to be arranged between the primary and secondary rollers; and the adhesive force can be regulated by changing the sum of the supporting forces applied by the rollers onto the wheels in a normal direction so as to realize the simulation of different adhesion coefficients.

Owner:SHANDONG JIAOTONG UNIV

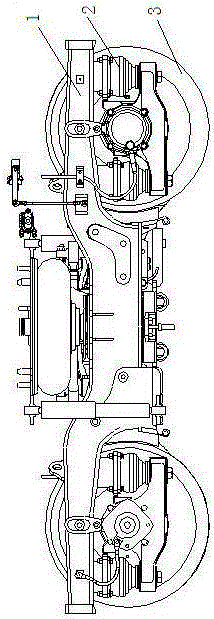

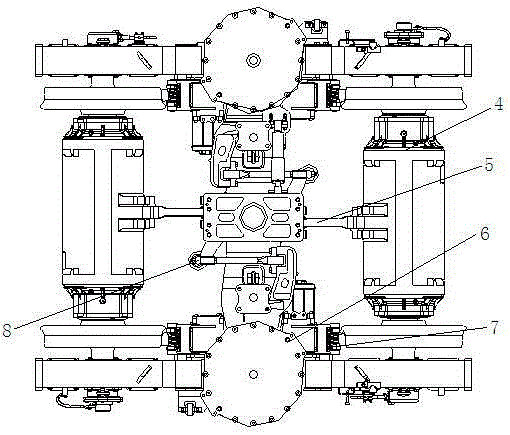

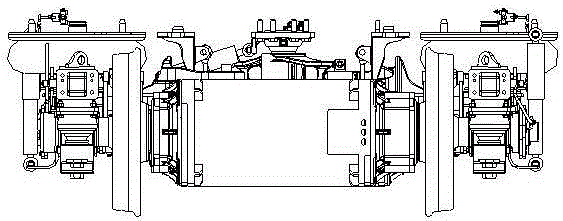

Motor hold shaft installation type permanent-magnetic direct-drive bogie

InactiveCN105197021AImprove efficiencyReduce volumeElectric motor propulsion transmissionAxle-boxes mountingBogieElectric machine

A motor hold shaft installation type permanent-magnetic direct-drive bogie comprises two frame devices, two permanent-magnetic synchronous traction motors, two triangular elastic supporting devices and four wheel pair box devices, wherein two adjacent front and rear wheel pair box devices are connected through the frame devices, two wheels on the left and right symmetric sides are connected through an axel, the permanent-magnetic synchronous traction motors and the axle are integrated through rotors, and driving is realized by rotating the axel; the two frame devices are symmetrically located on the left side and the right side of the advancing direction of a railway vehicle and are connected by double traction rod devices, and the triangular elastic supporting devices are connected with the permanent-magnetic synchronous traction motors and the double traction rod devices. According to the motor hold shaft installation type permanent-magnetic direct-drive bogie, the permanent-magnetic synchronous traction motors are adopted, rotor excitation power is saved, the motor efficiency is improved, the transmission efficiency is improved further after a gear box device is saved, the wheel base of the bogie is shortened, and the motor hold shaft installation type permanent-magnetic direct-drive bogie has the advantages that energy is saved, environment is protected and the small curve through capacity is high, and can be widely applied to various urban railway traffic vehicles.

Owner:CRRC NANJING PUZHEN CO LTD

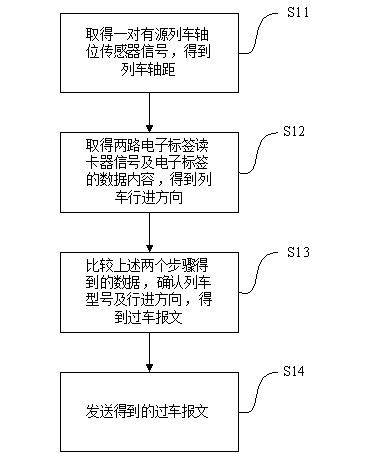

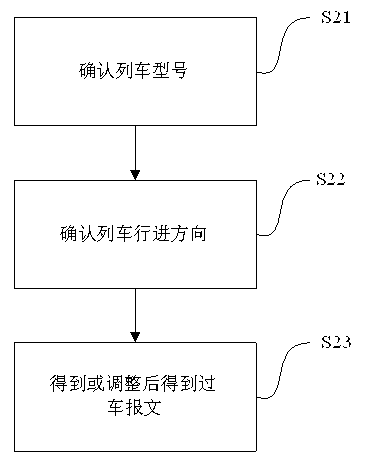

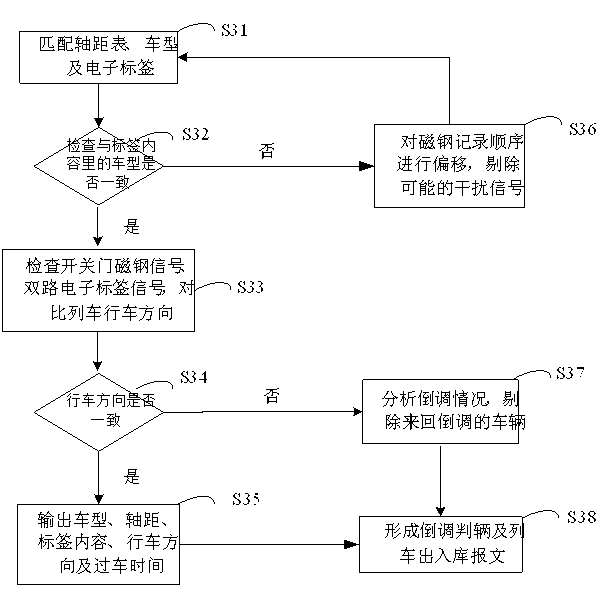

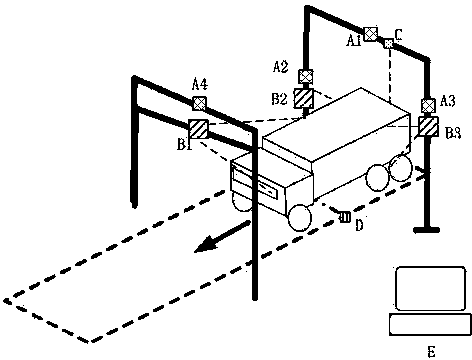

Method and device for identifying and judging train advancing direction and shunting situation by train number

ActiveCN102837717AThe result is accurateLow costIndication/recording movementSensing record carriersMassageEngineering

The invention relates to a method for identifying and judging a train advancing direction and a shunting situation by a train number. The method comprises the following steps of: acquiring output signals generated by a pair of active train wheel sensors installed in set positions when a train passes by, and acquiring a train axle distance according to the signals; acquiring signals which are read by two paths of radio frequency antennas installed in set positions and working in time division and are emitted by electronic tags installed on the train, and receiving data transmitted by the signals; acquiring the advancing direction of the train according to the time for receiving the two paths of signals; processing the data acquired through the steps, determining the model, the advancing direction and the shunting situation of the train, and acquiring train passing massages; and outputting the massages. The invention also relates to a device for implementing the method. The method and the device for judging the train passing model and the advancing direction have the beneficial effects that under the condition of frequent shunting of a factory section, the train advancing direction can be judged accurately, and the cost is low.

Owner:INVENGO INFORMATION TECH

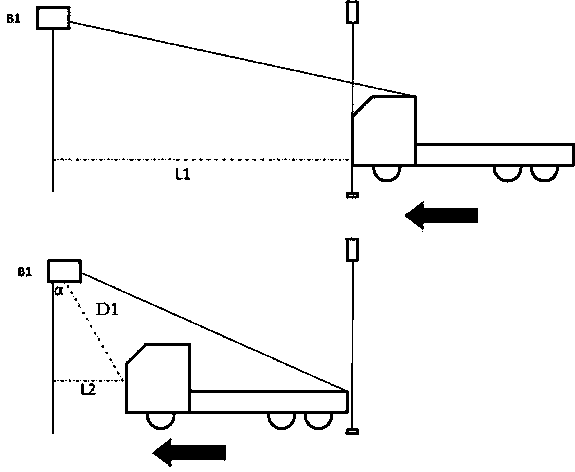

Vehicle outline and wheel base automatic measuring system and measuring algorithm

InactiveCN103954222ASimple structureOptimize the installation positionUsing optical meansTime conditionSynthetic data

The invention discloses a vehicle outline and wheel base automatic measuring system and a measuring algorithm. The vehicle outline and wheel base automatic measuring system comprises three distance measuring units, an outline measurement control unit, a wheel base measurement control unit, an evidence collection unit, a comprehensive data processing unit and a measurement channel. The distance measuring units, the outline measurement control unit, the wheel base measurement control unit and the evidence collection unit are arranged on the measurement channel. The three distance measuring units are the first distance measuring unit B1, the second distance measuring unit B2 and the third distance measuring unit B3 respectively. The outline measurement control unit is connected with the three distance measuring units respectively. The wheel base measurement control unit is connected with the first distance measuring unit B1. The distance measuring units are connected with the comprehensive data processing unit. The evidence collection unit is used for monitoring and recording the real-time condition of running of a detected vehicle. The vehicle outline and wheel base automatic measuring system can automatically measure vehicle outline data including the length, width and height of the vehicle and wheel base data of the vehicle, ensure the measuring accuracy and improve the measuring efficiency.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com