Motor hold shaft installation type permanent-magnetic direct-drive bogie

A technology of permanent magnet direct drive and shaft installation, which is applied in the field of rail vehicle bogies, and can solve problems such as the difficulty in significantly improving bogie performance indicators such as energy saving, low transmission efficiency of gearbox couplings, and large wheelbases of bogie wheels. problem, to achieve the effect of ensuring the passing performance of small curves, improving the passing performance of small curves, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

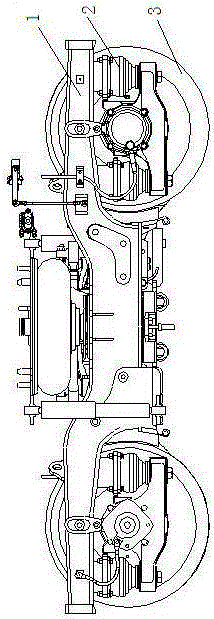

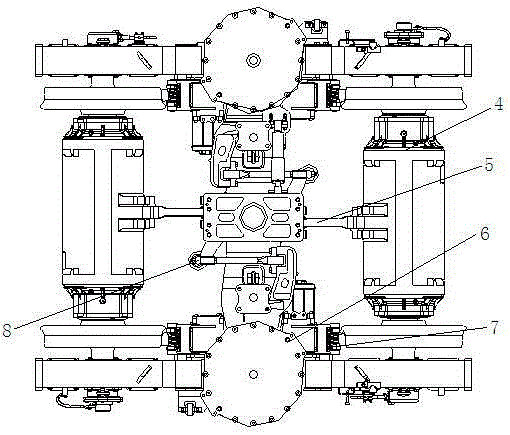

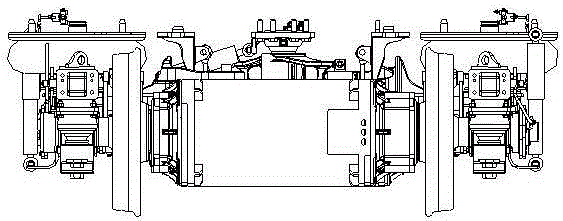

[0038]It can be seen from the accompanying drawings that the motor shaft-mounted permanent magnet direct drive bogie is used to be installed under the rail vehicle and used for steering during the running of the rail vehicle. Each bogie includes a frame device 1, two A permanent magnet synchronous traction motor 4, two triangular elastic support devices 5, and two wheel-to-axle box devices 3, the two wheel-to-axle box devices 3 are arranged in a rectangular array below the rail vehicle, located at the front of the rail vehicle in the forward direction The two adjacent wheel-to-axlebox devices 3 are connected by the frame device 1, and the two wheel-to-axlebox devices 3 located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com