Patents

Literature

934results about "Axle-boxes mounting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

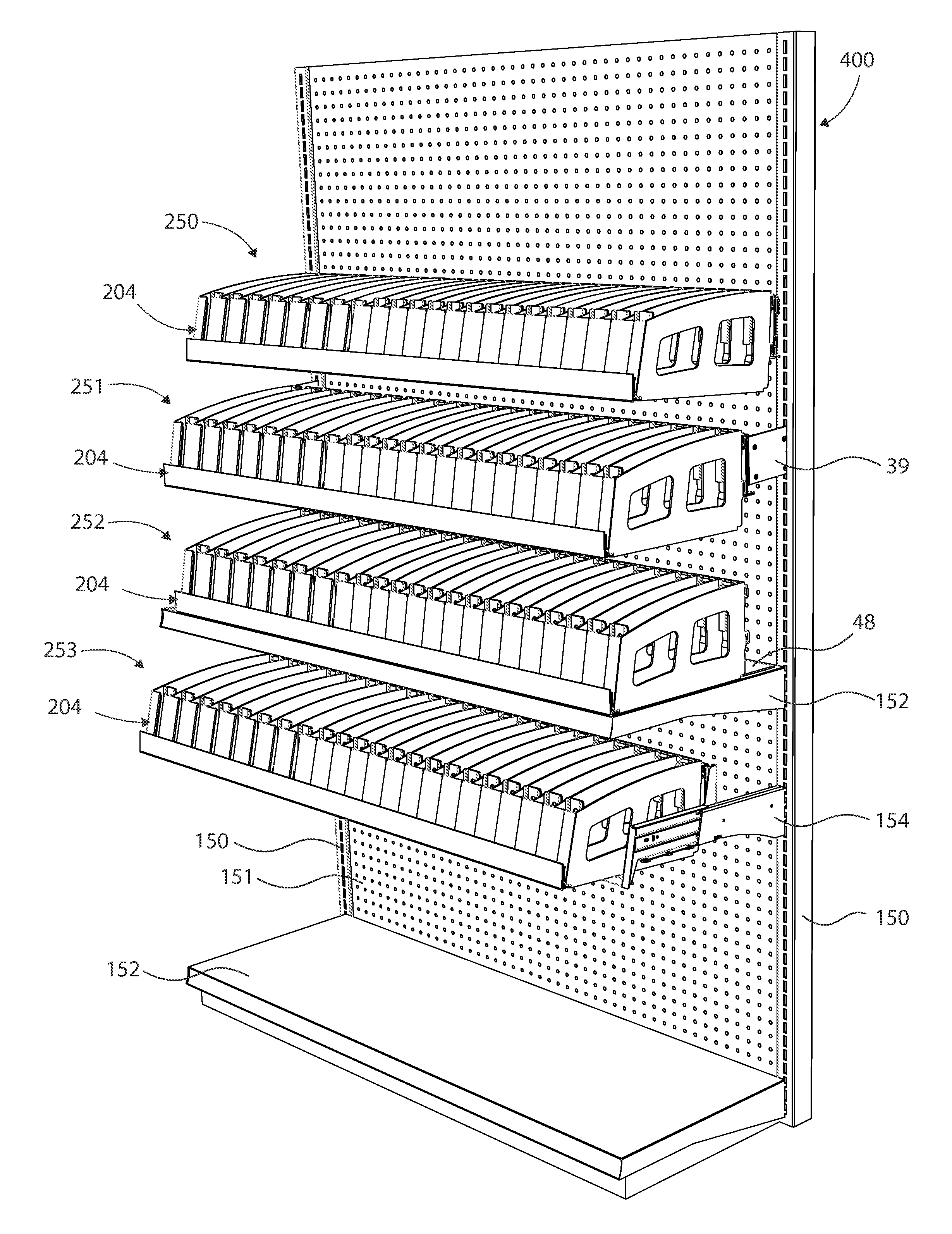

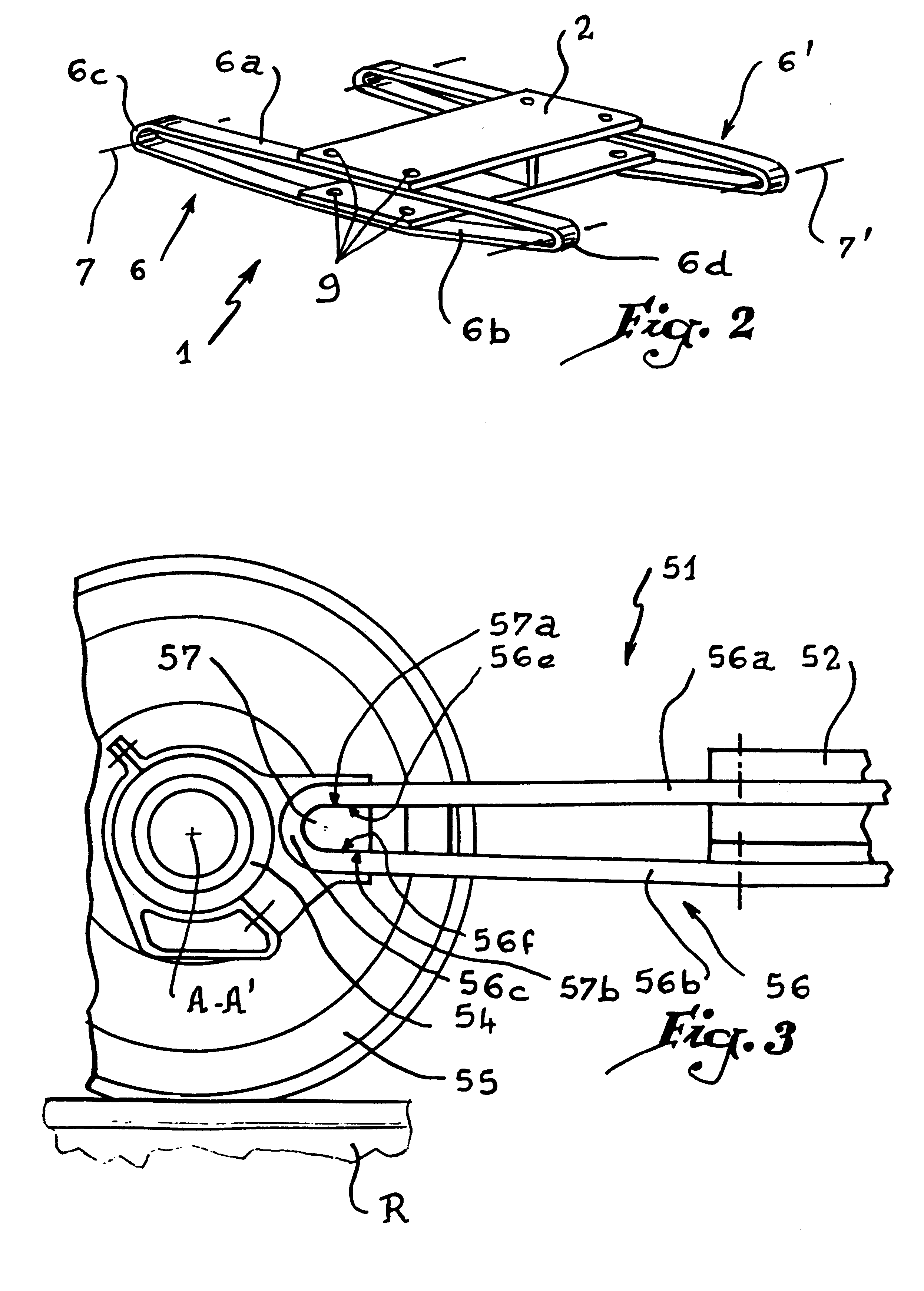

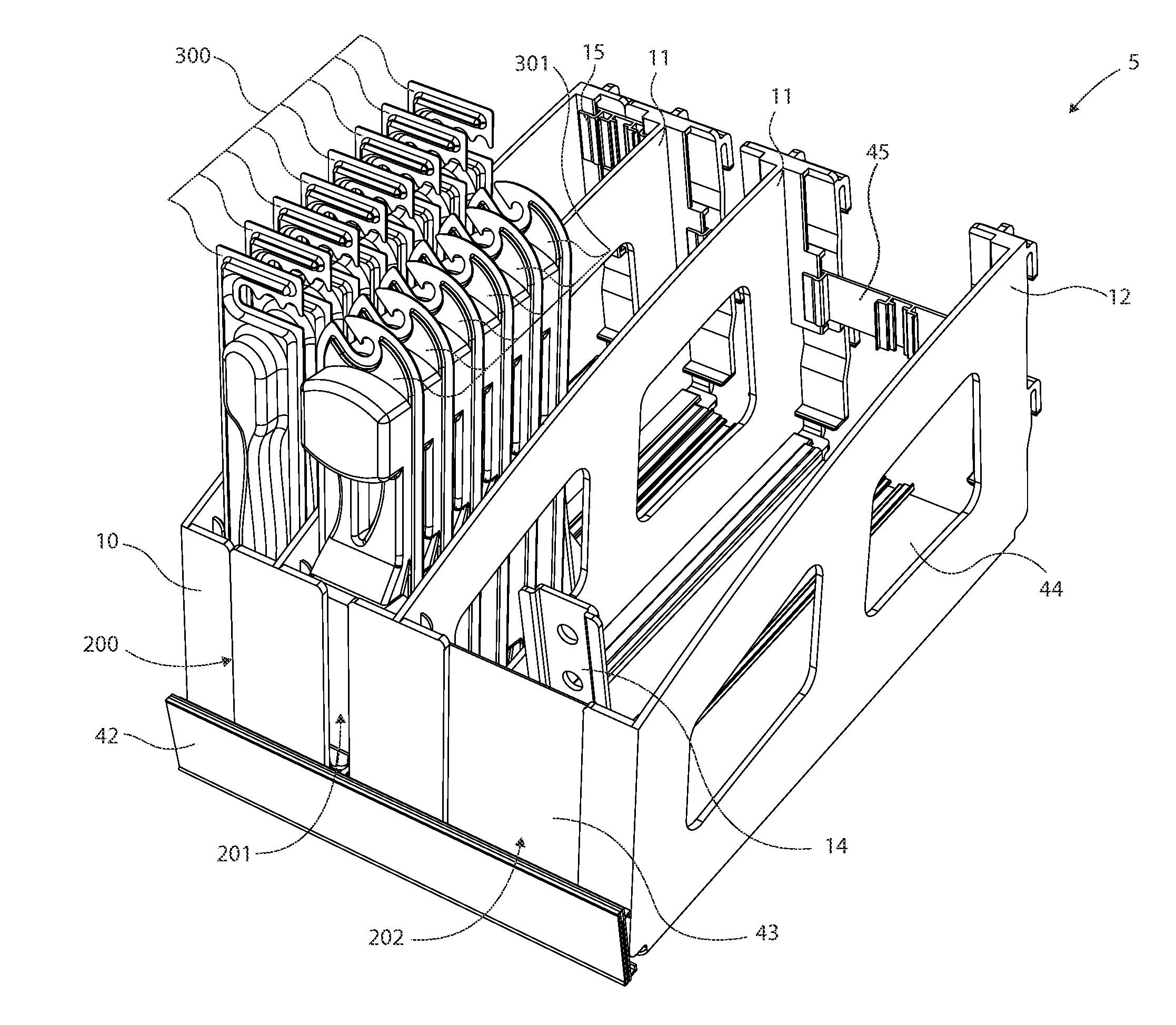

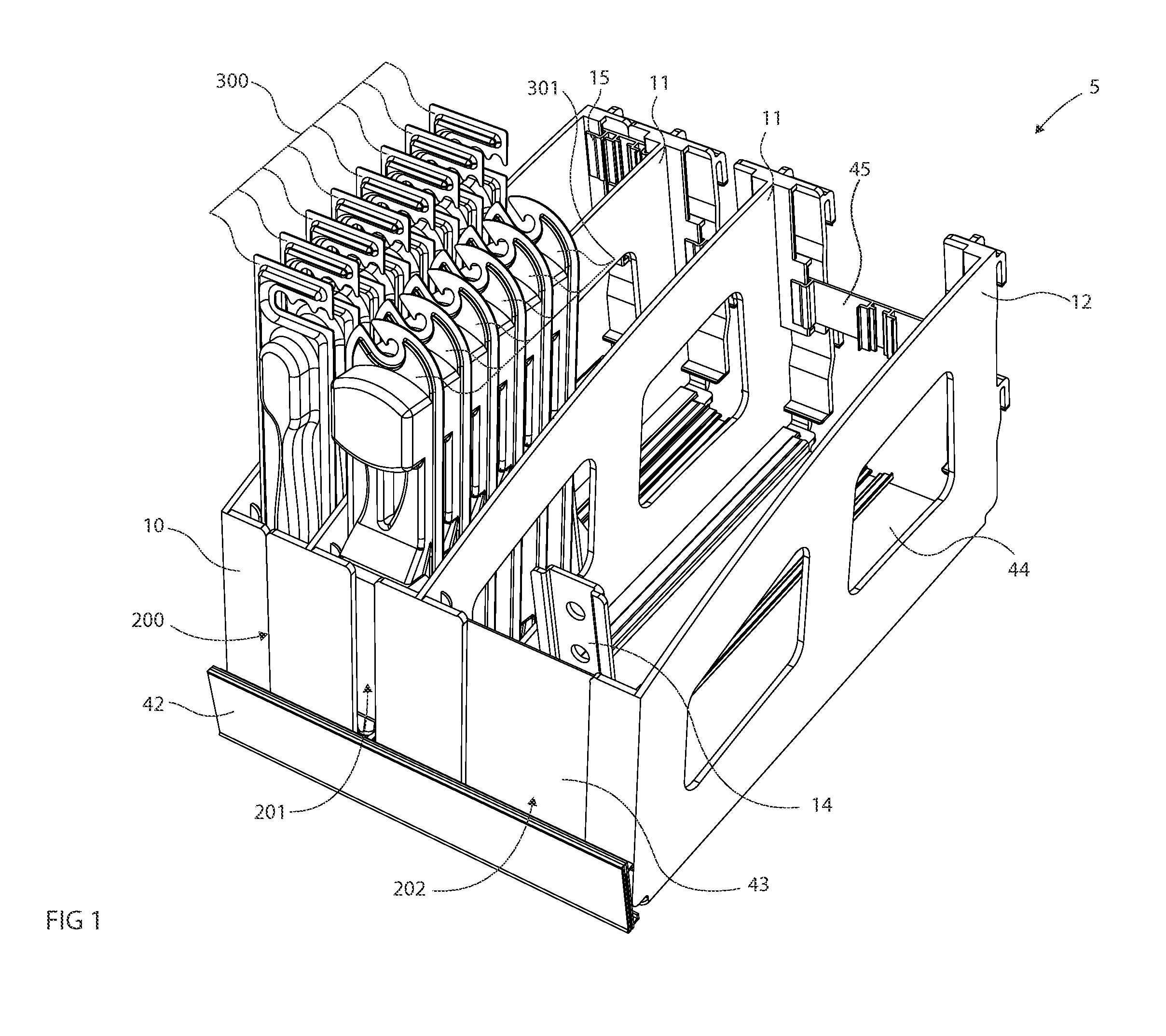

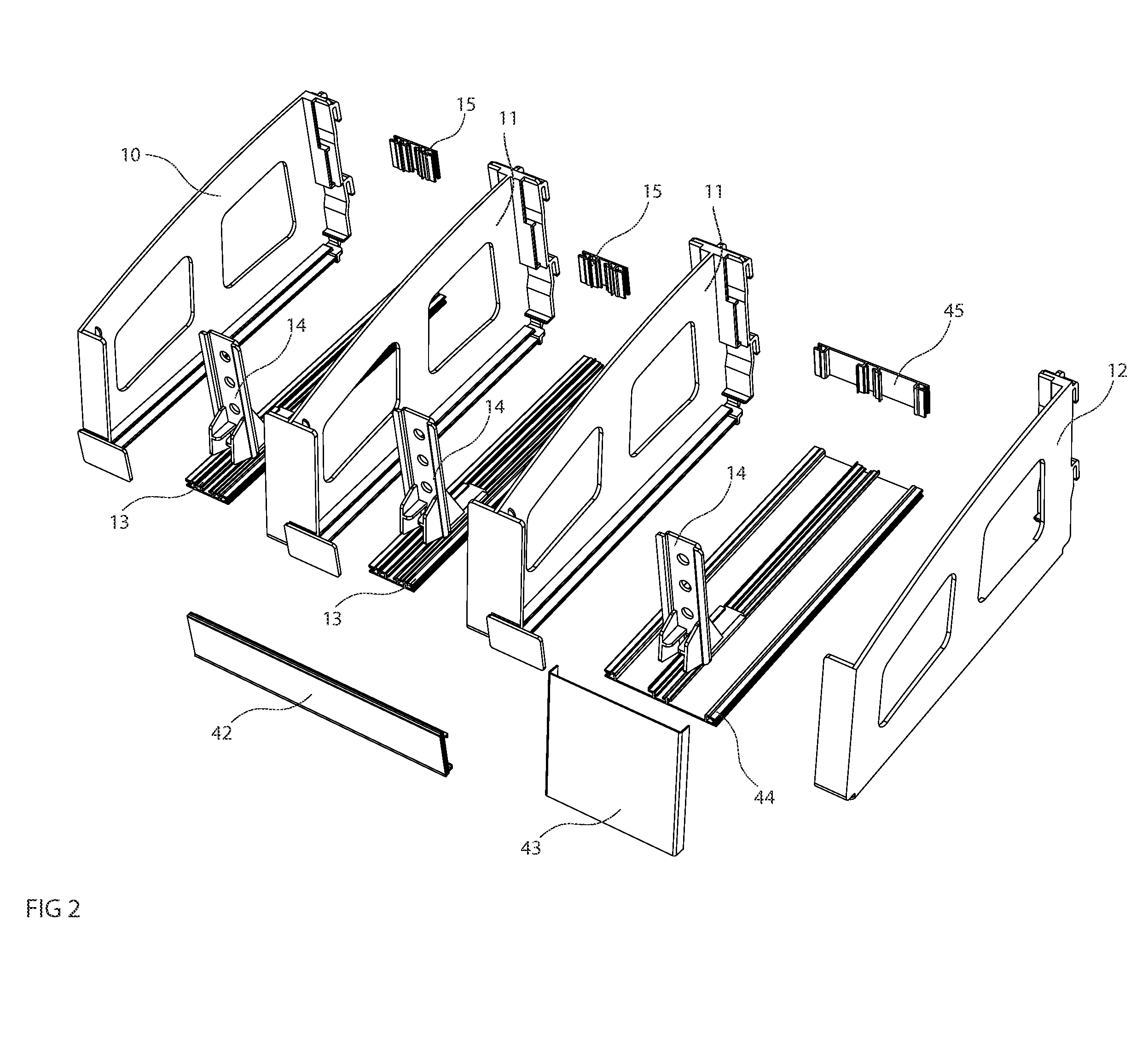

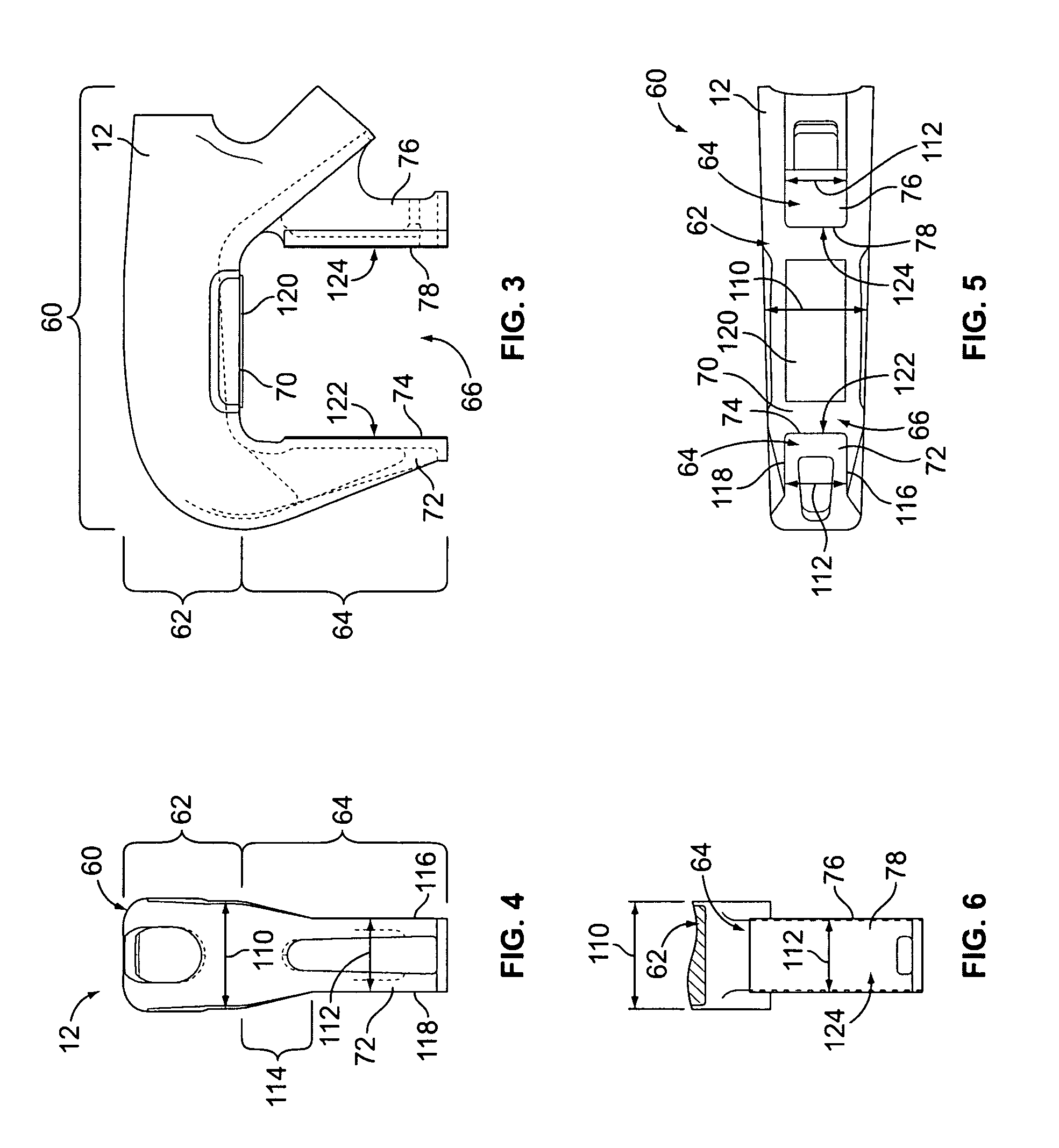

Adjustable depth merchandising crossbar systems and methods for dividing, pushing and/or dispensing one or more retail products

Adjustable depth merchandising crossbar systems and methods dispense retail products, the crossbar systems and methods having a fixed portion comprising a first outer mounting assembly, a second outer mounting assembly movably connected to the first outer mounting assembly, and upright mounting hooks provided at rear sides of the first outer mounting assembly and the second outer mounting assembly, wherein the upright mounting hooks are configured to be mountable to retail aisle uprights and a sliding portion comprising a first inner sliding assembly and a second inner sliding assembly movably connected to the first inner sliding assembly. The crossbar systems and methods also have an expandable attachment bar connected to the first and second inner sliding assemblies of the sliding portion of the crossbar, wherein the expandable attachment bar is configured to receive at least one retail product merchandising pusher system for dispensing retail products and a plurality of sliding assemblies connected the fixed portion to the sliding portion of the crossbar. The sliding portion of the crossbar is movable to a closed position or to an at least partially extended position via the plurality of sliding assemblies.

Owner:MARKETING IMPACT

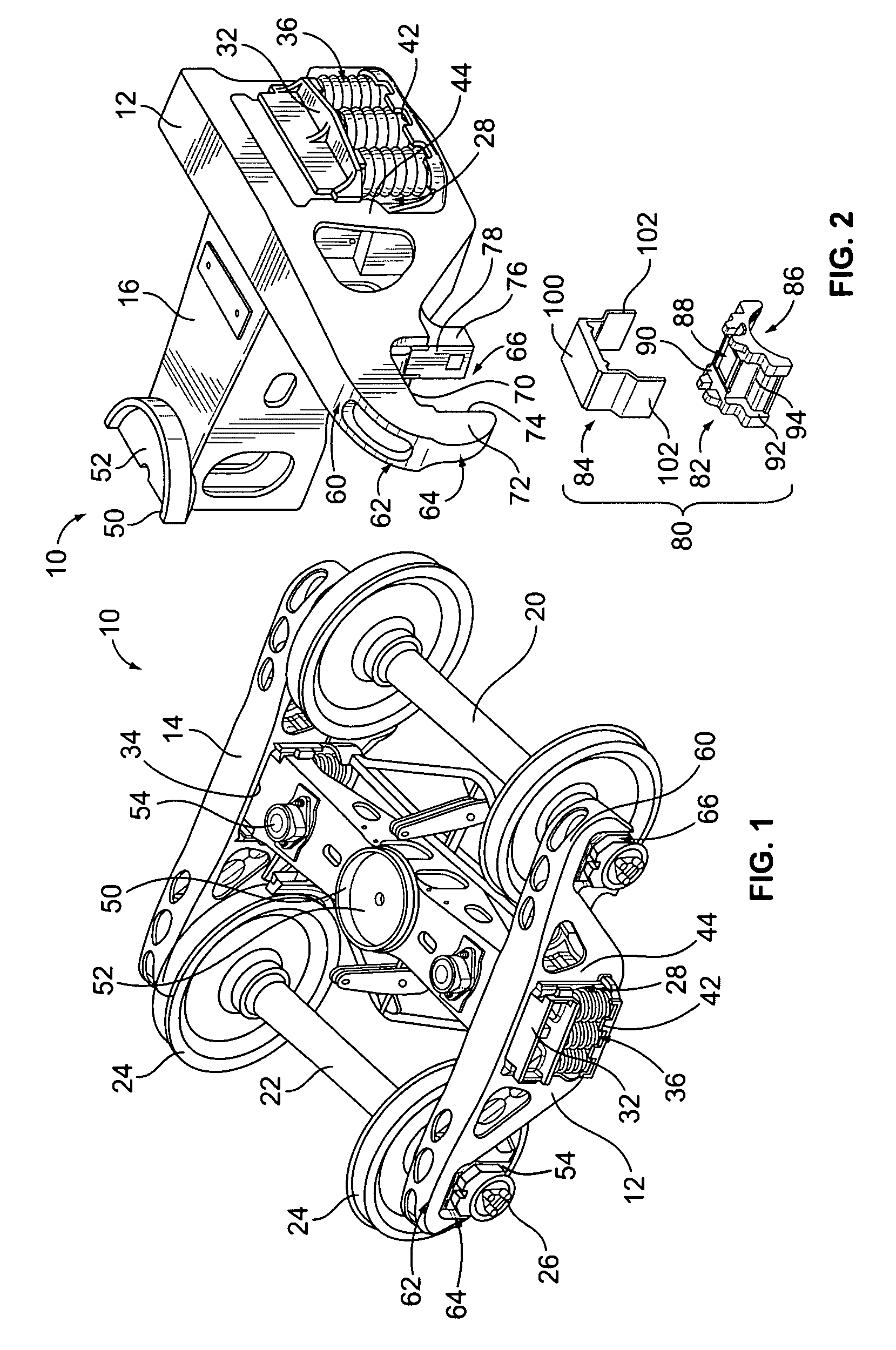

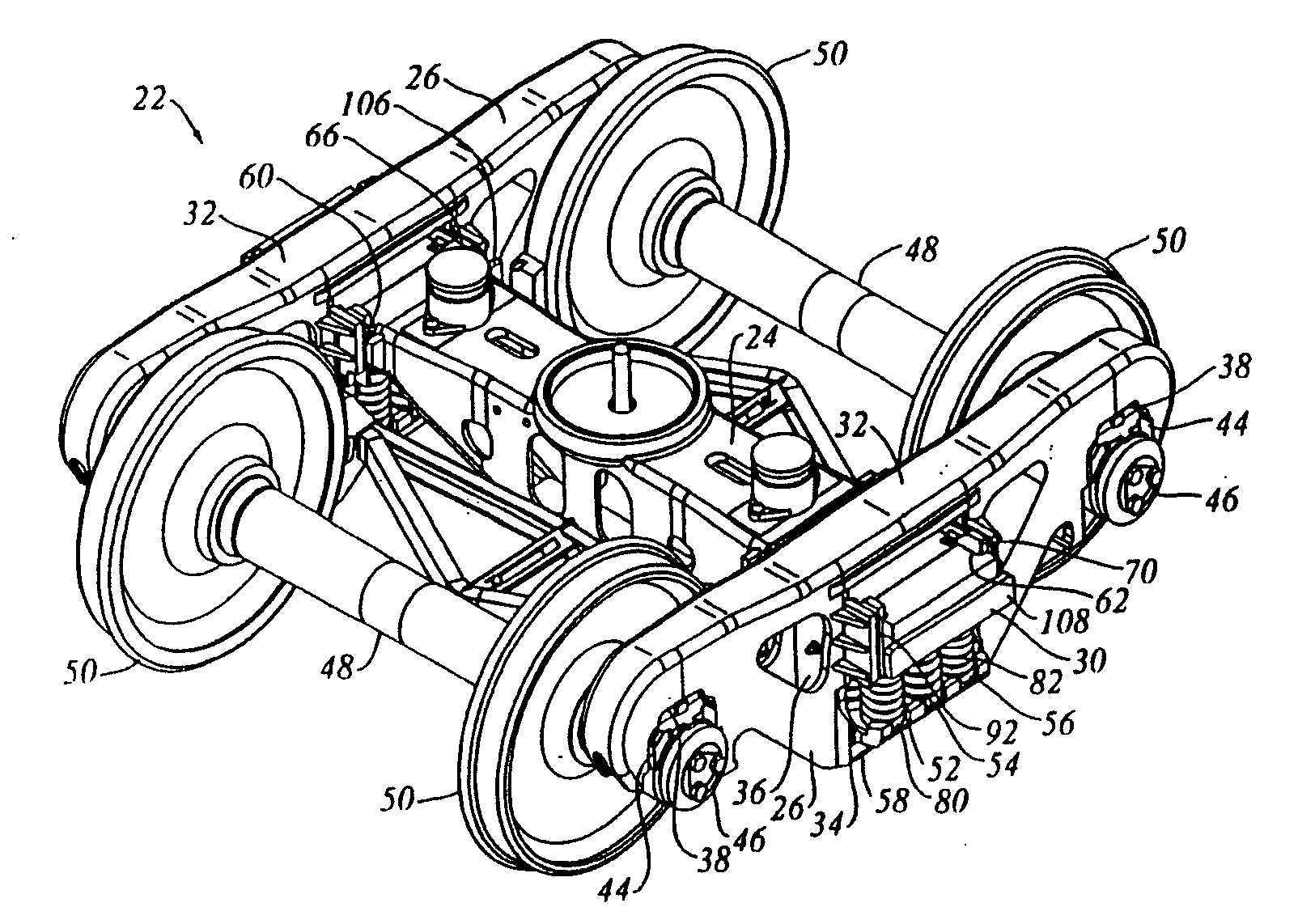

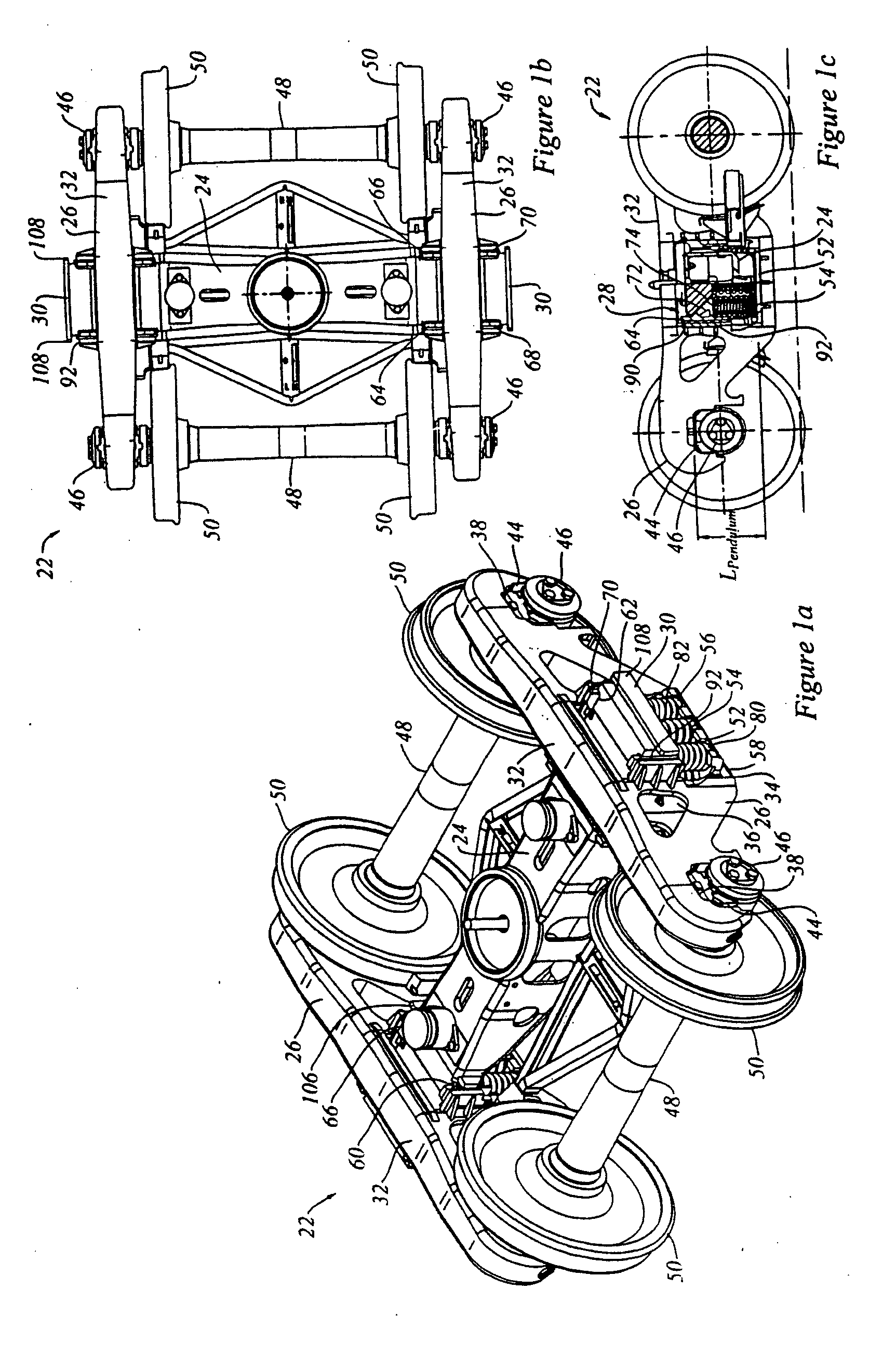

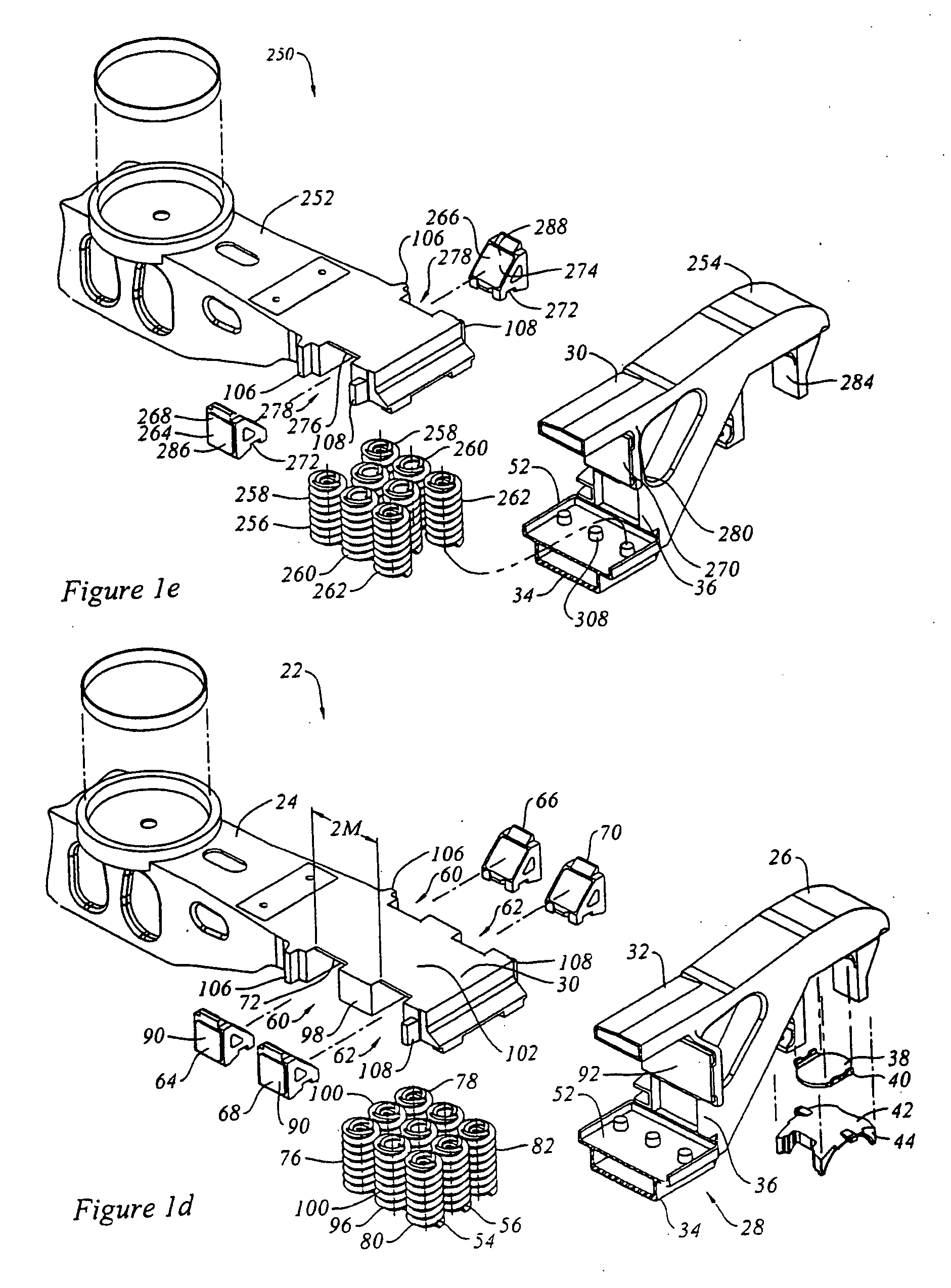

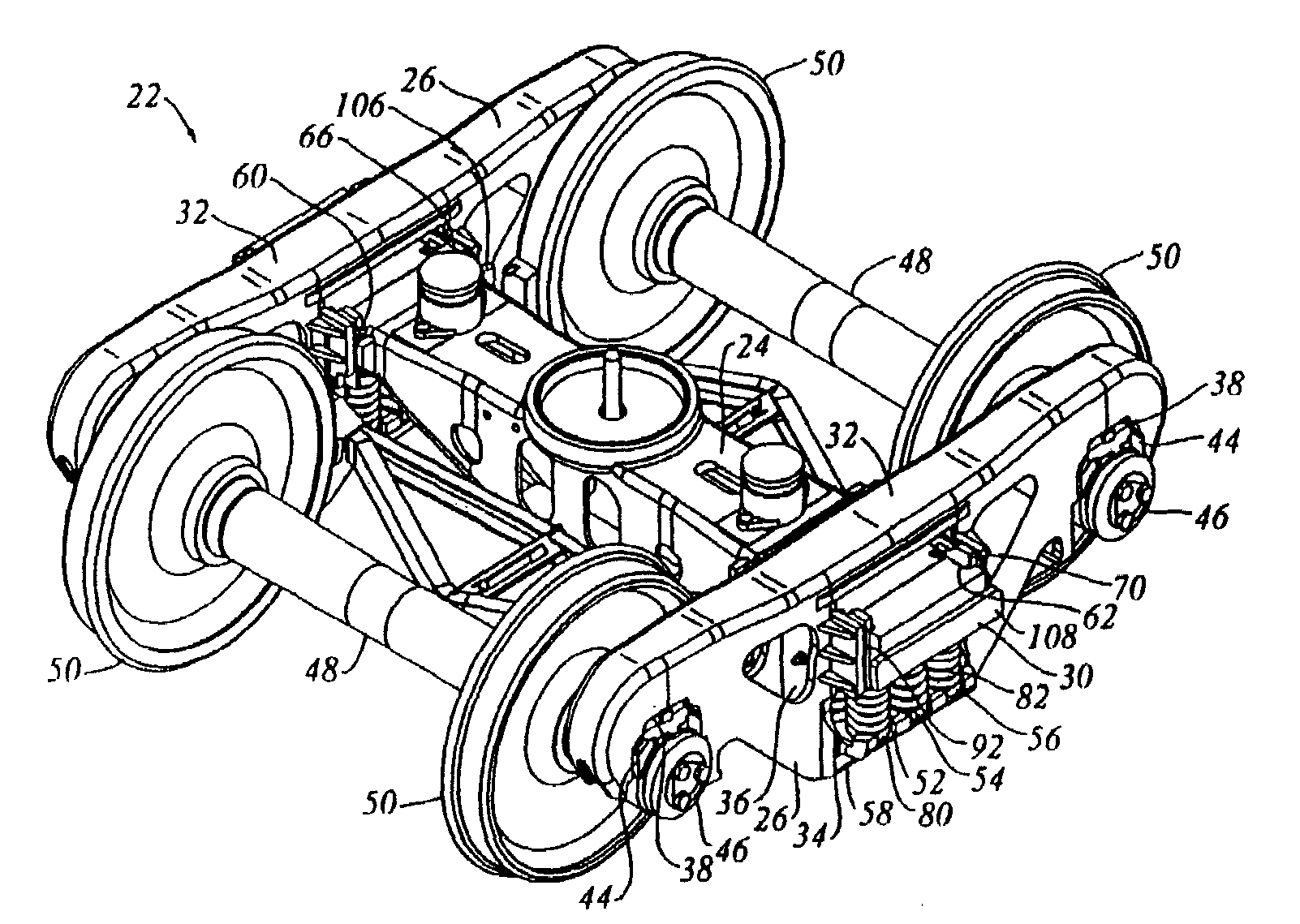

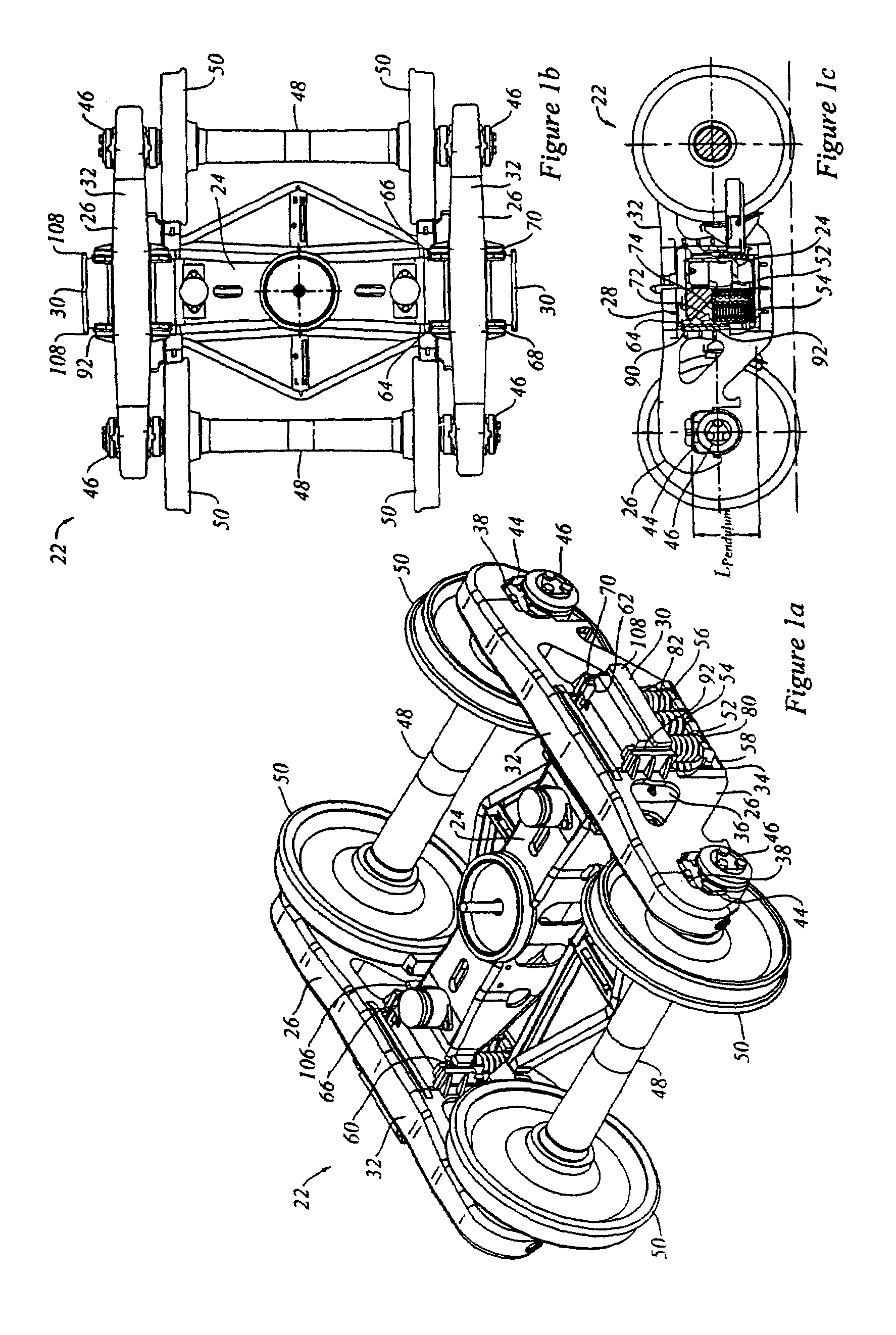

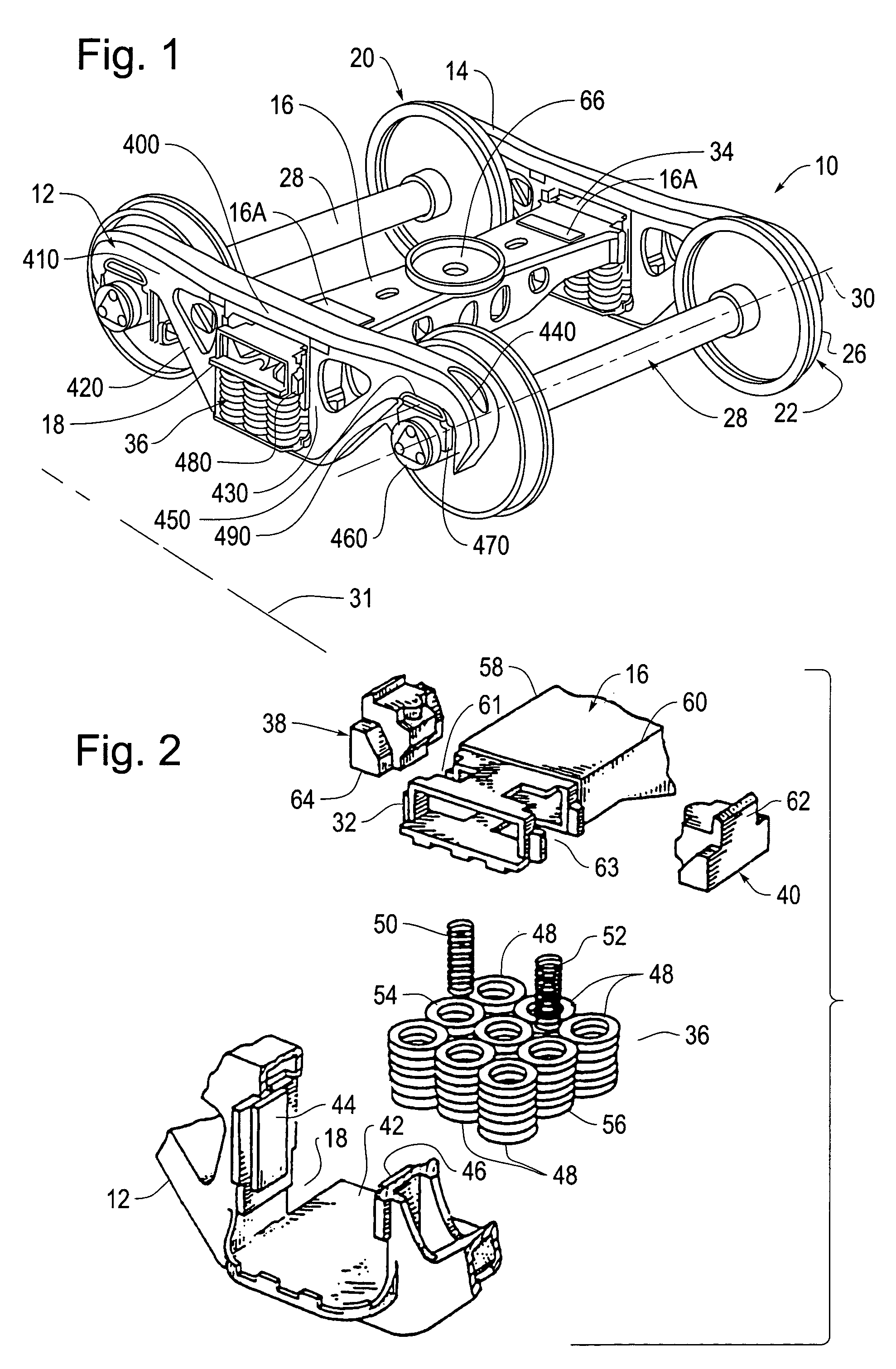

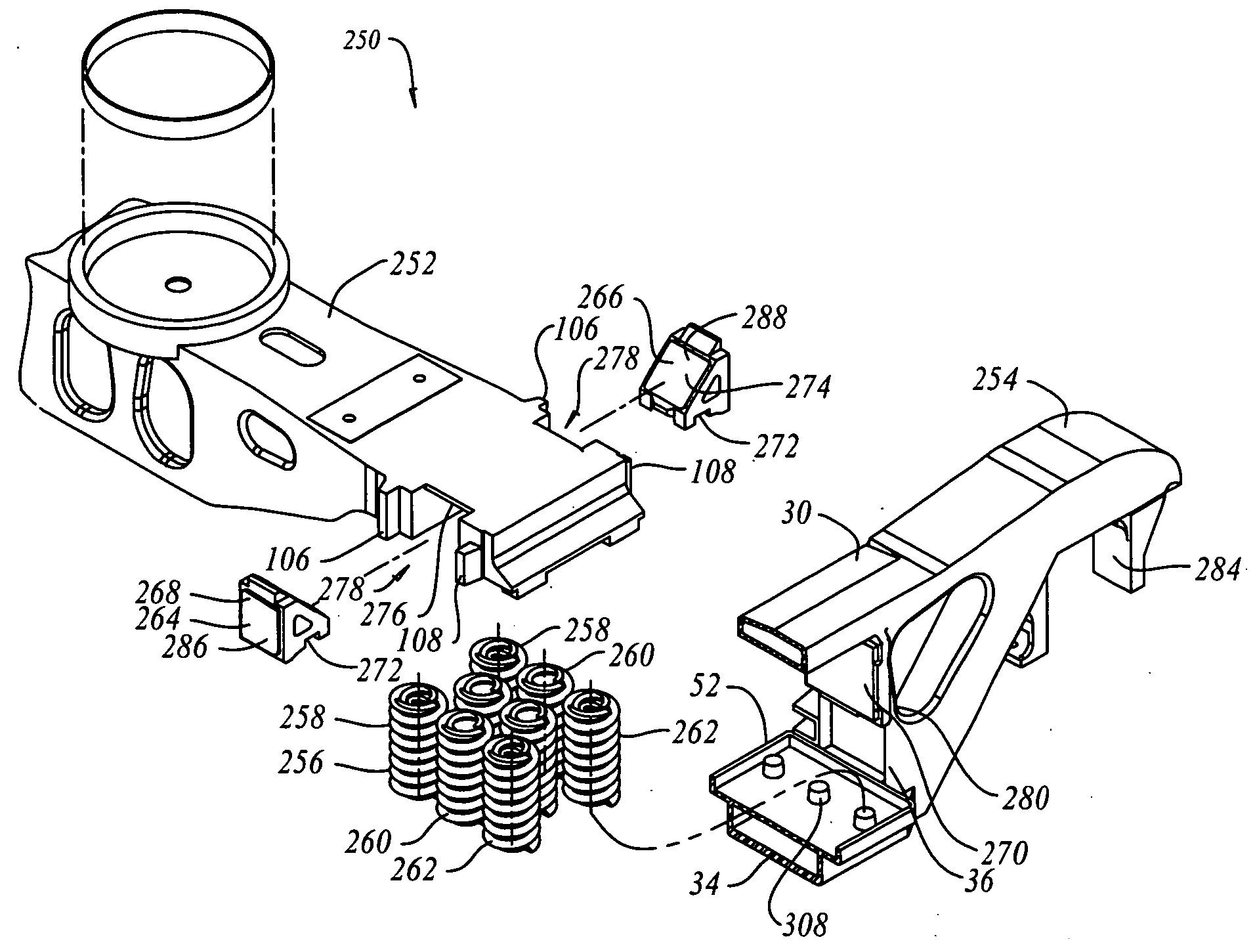

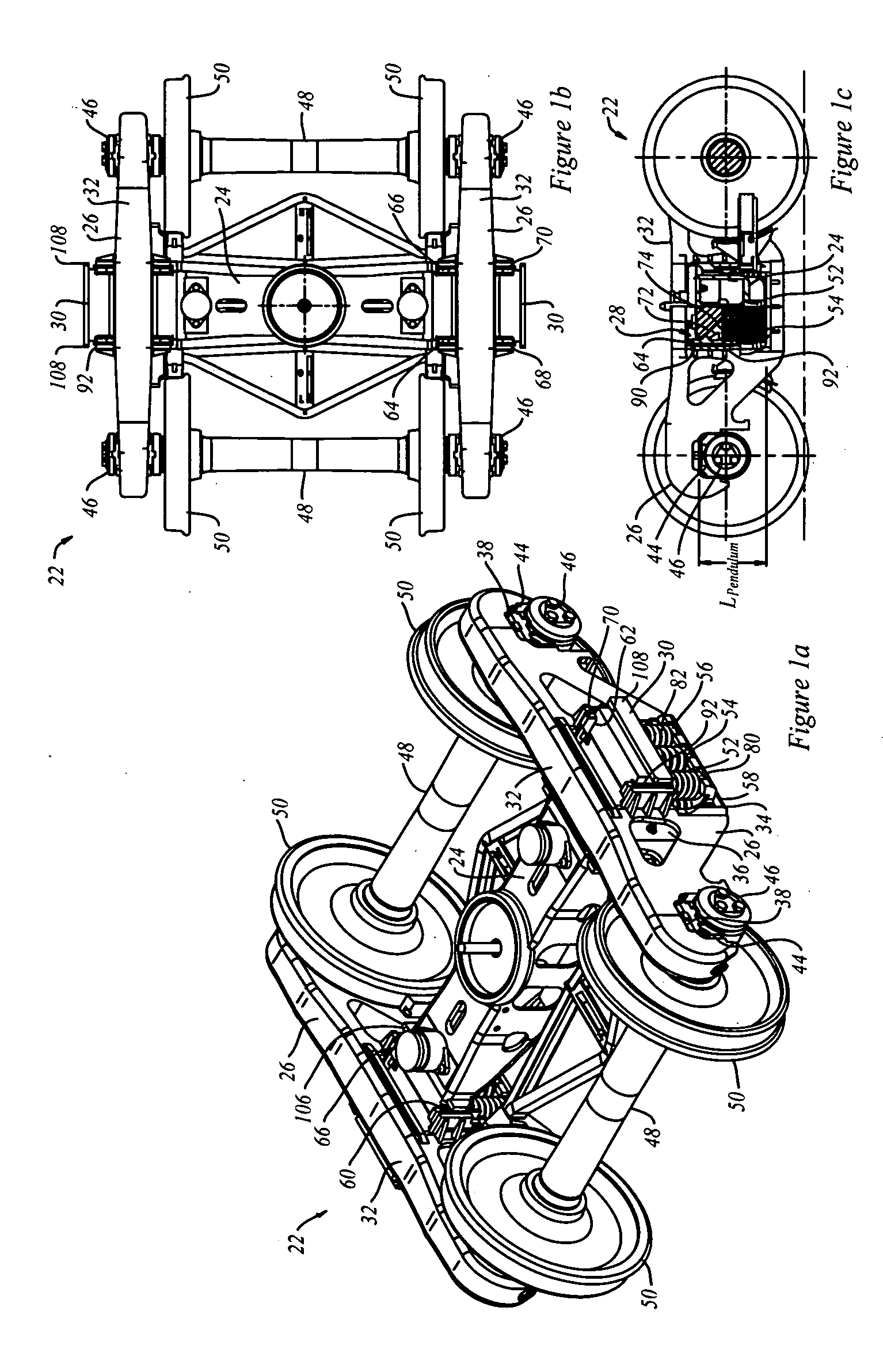

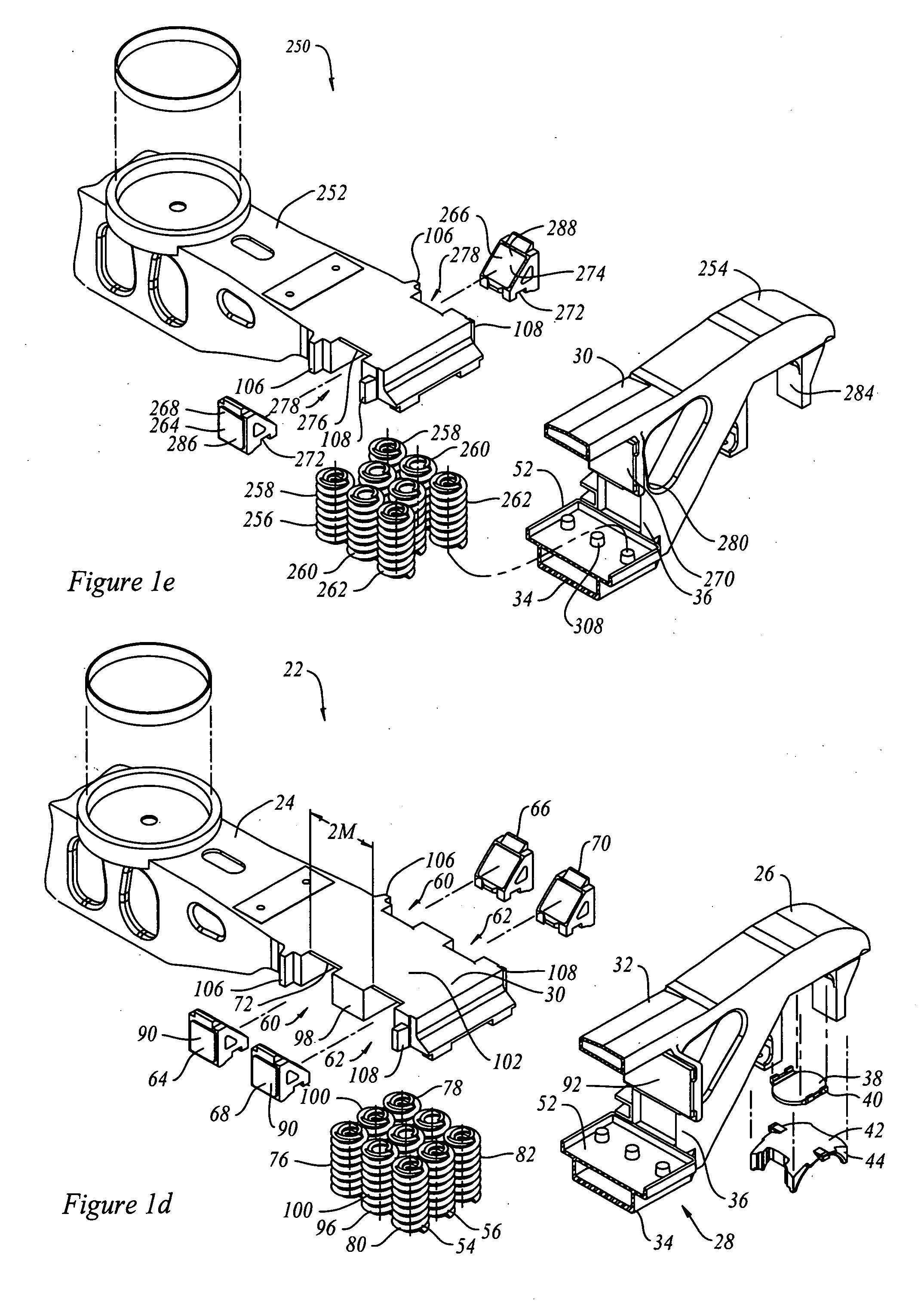

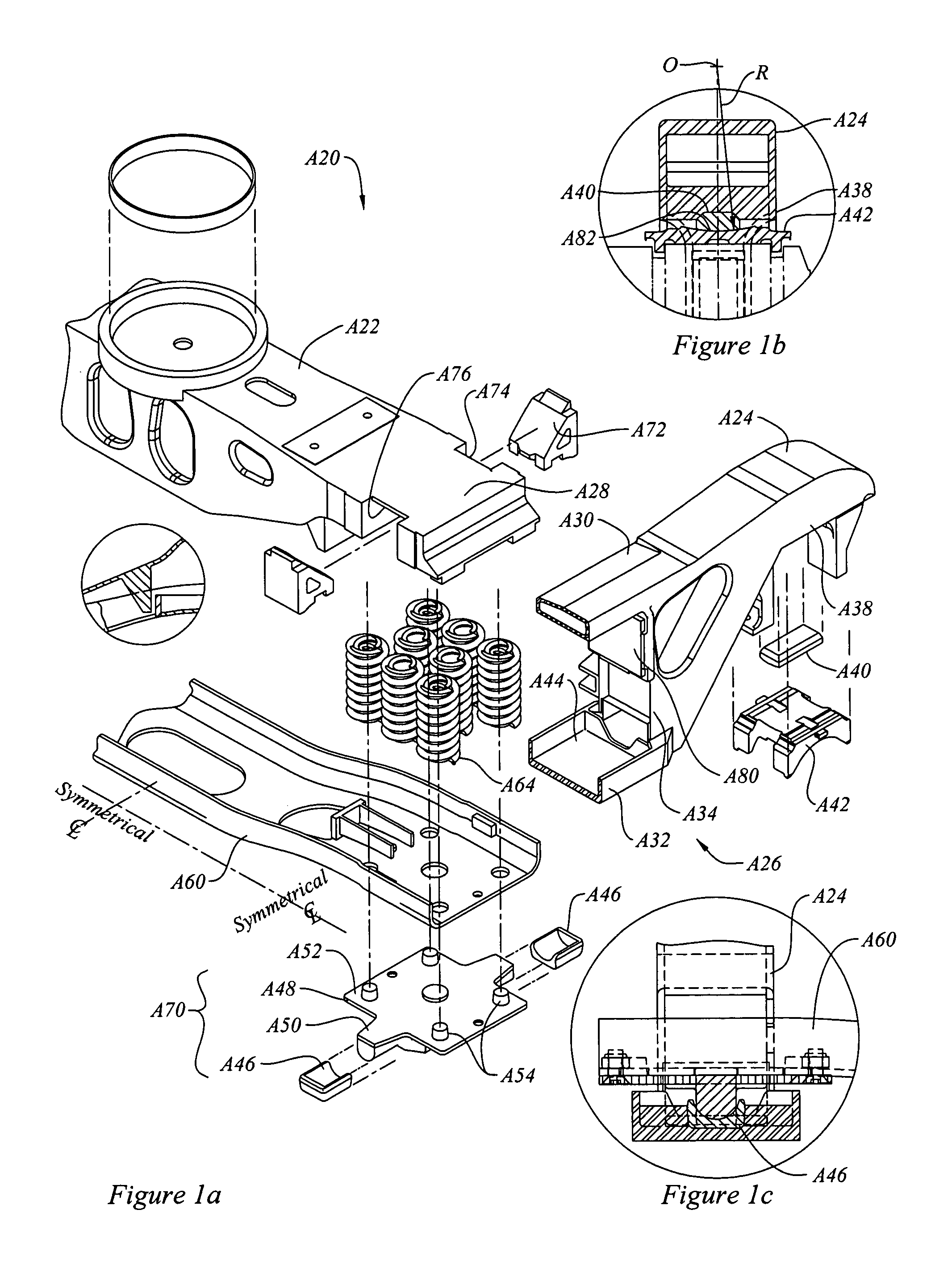

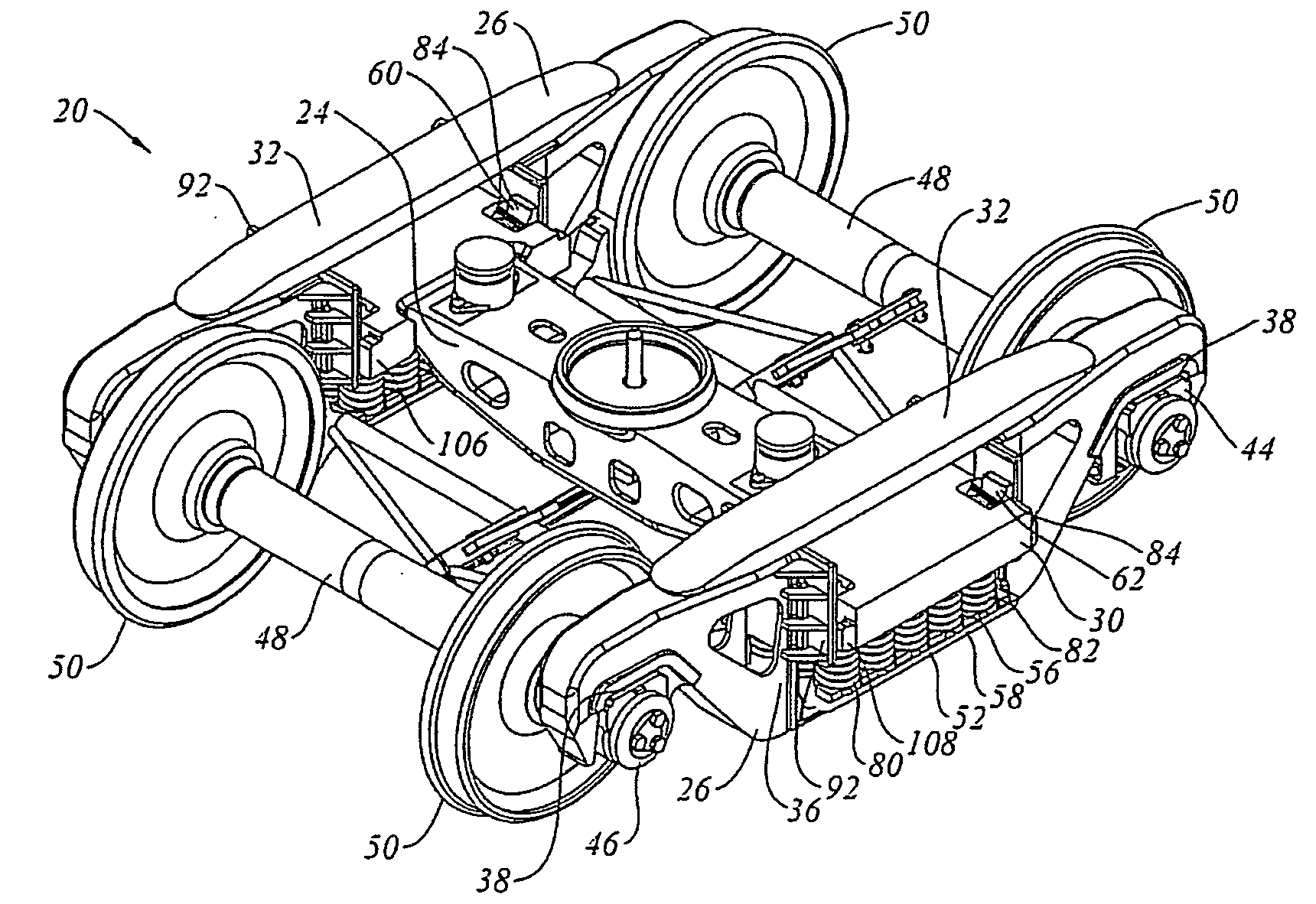

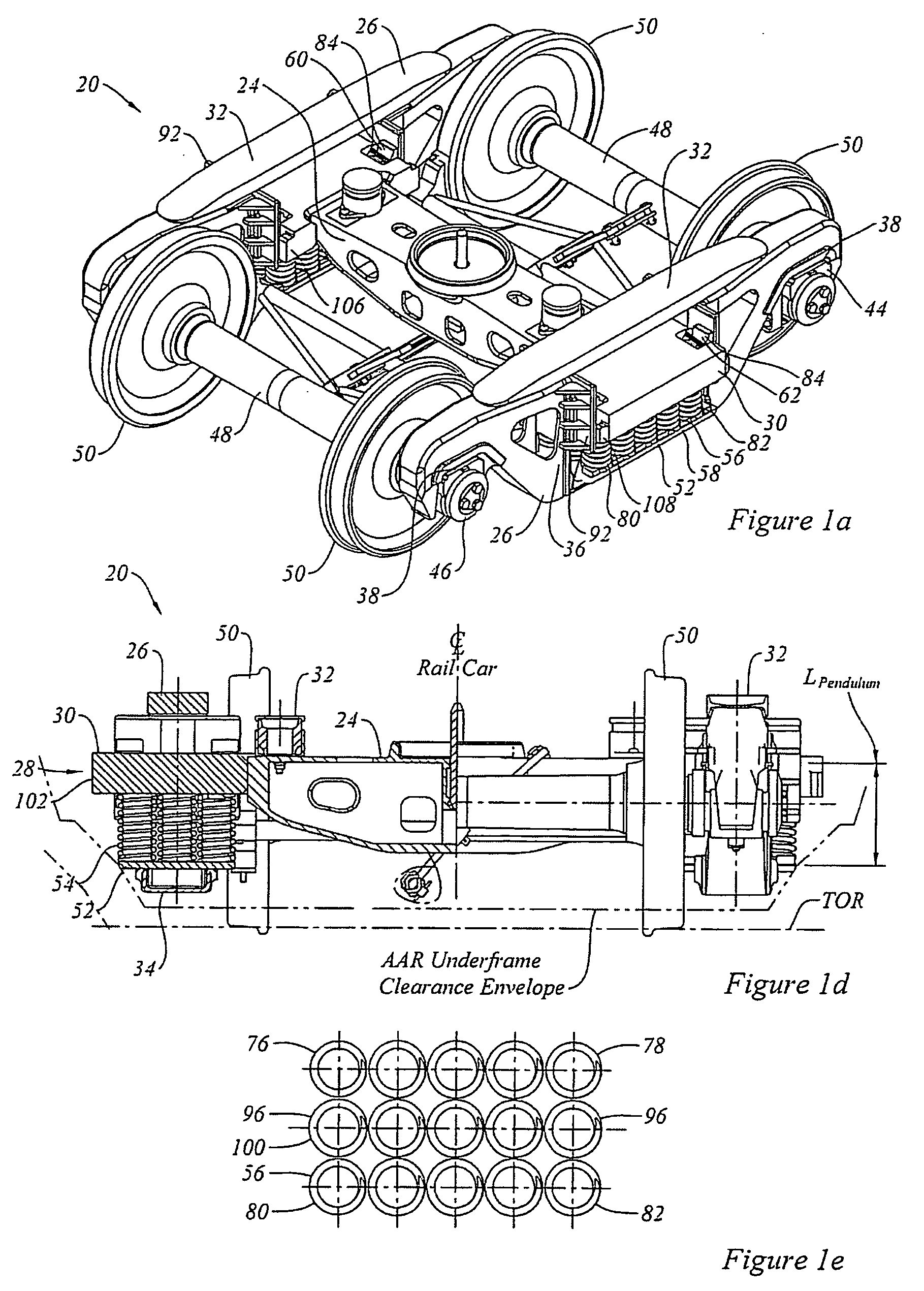

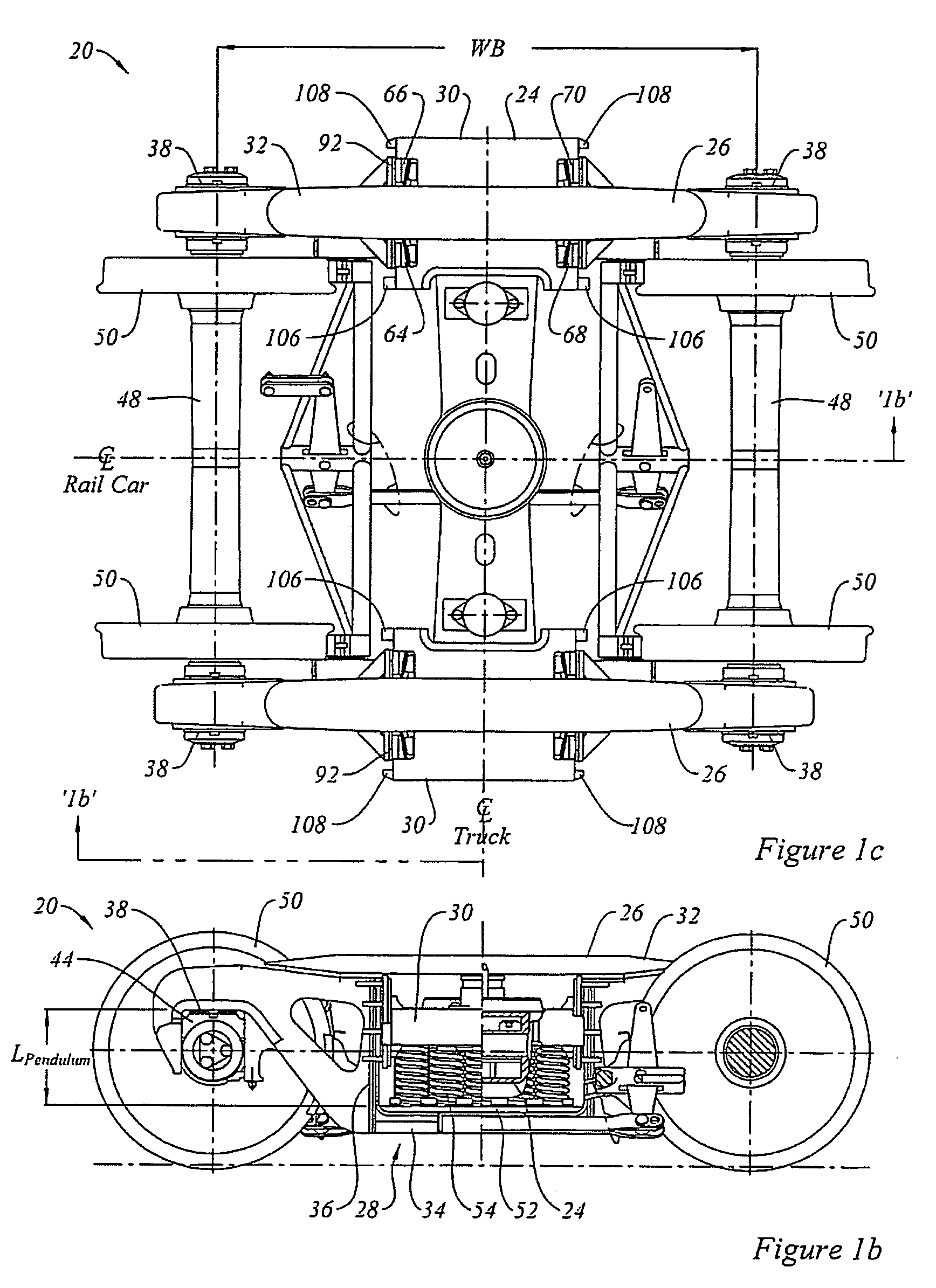

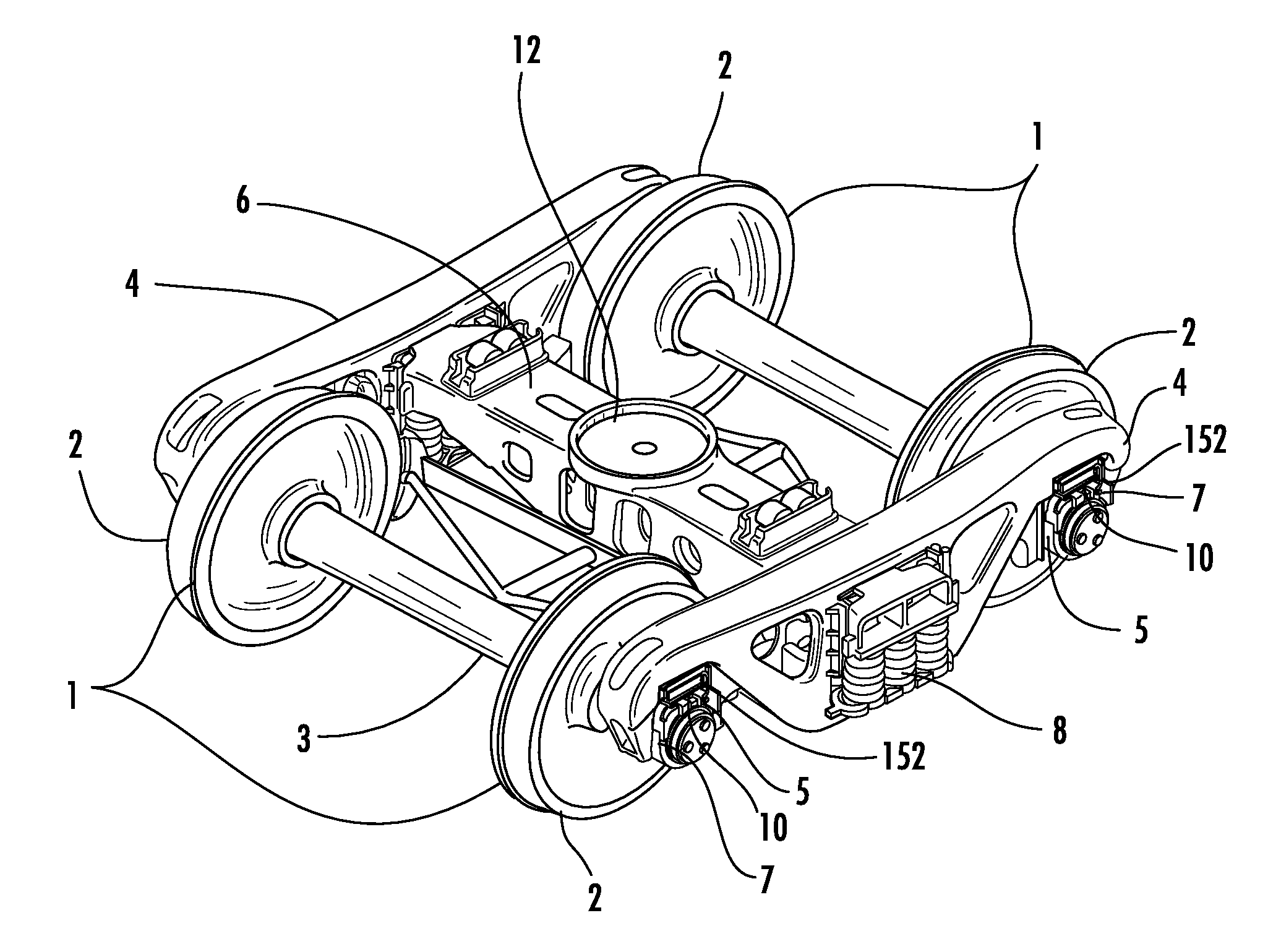

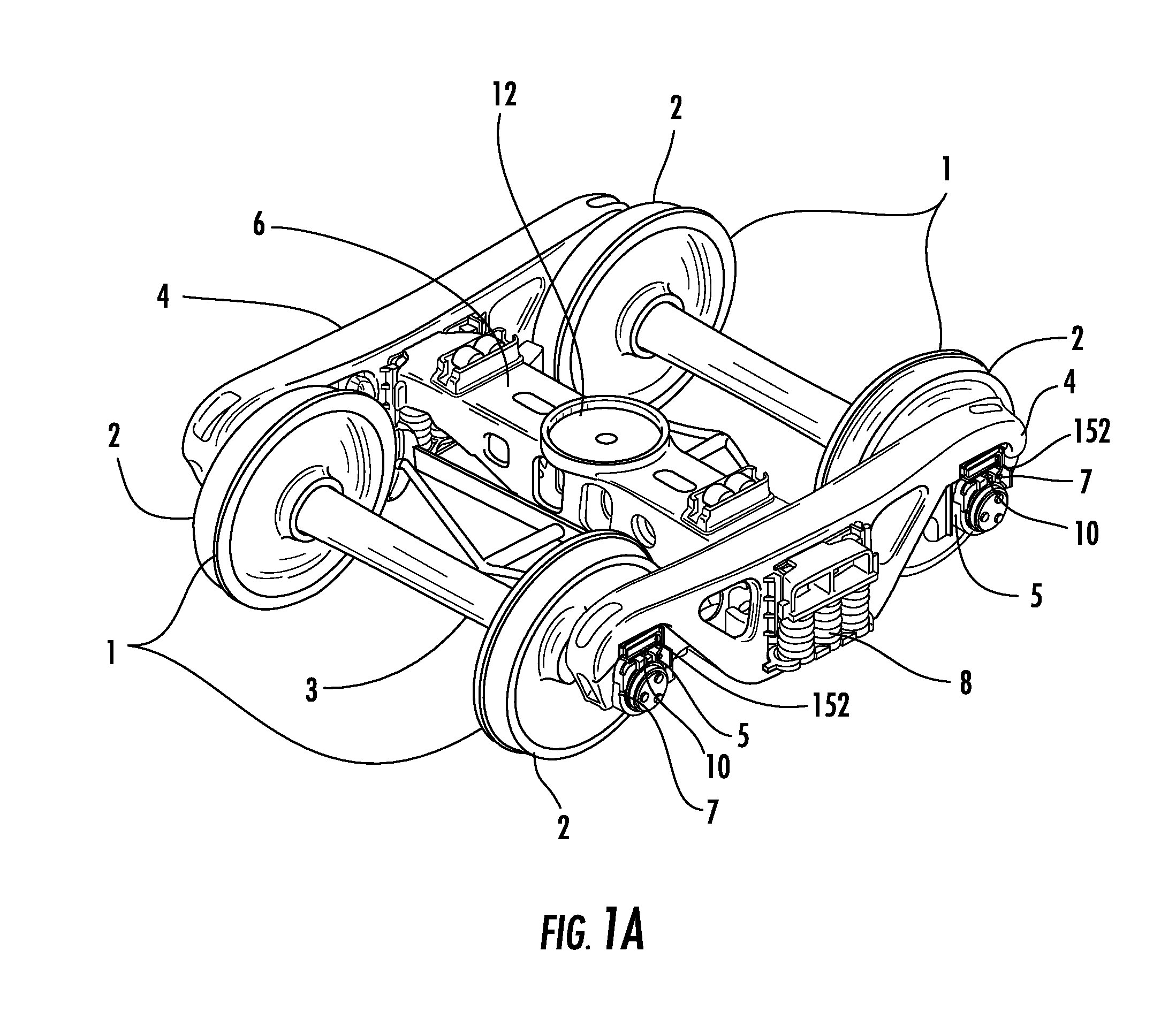

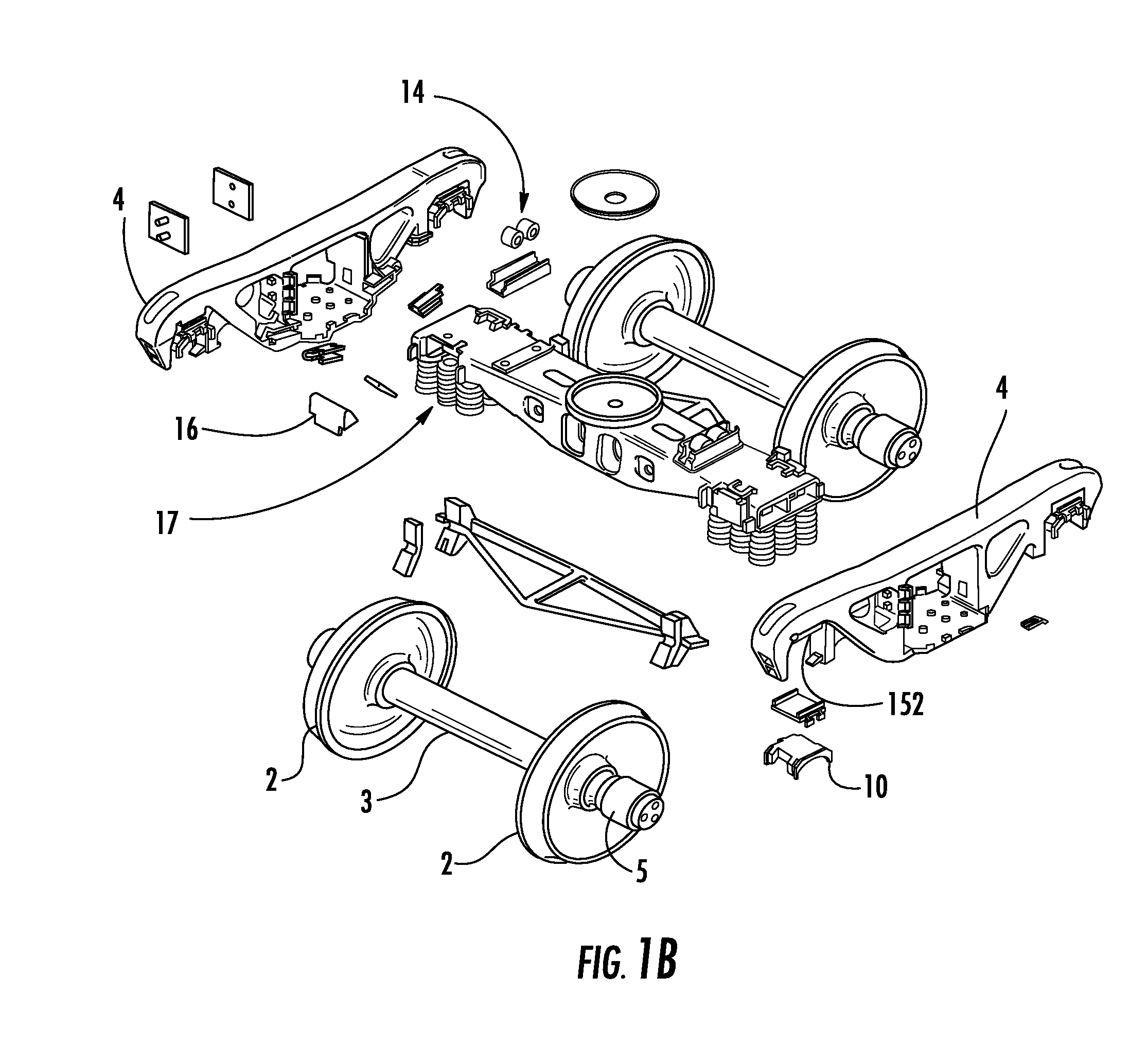

Rail road car truck and fittings therefor

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to deflection that is proportional to the weight carried across the interface. The truck may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both. The friction dampers may operate to yield upward and downward friction forces that are not overly unequal. The friction dampers may be mounted in a four-cornered arrangement at each end of the truck bolster. The spring groups may include sub-groups of springs of different heights.

Owner:NATIONAL STEEL CAR

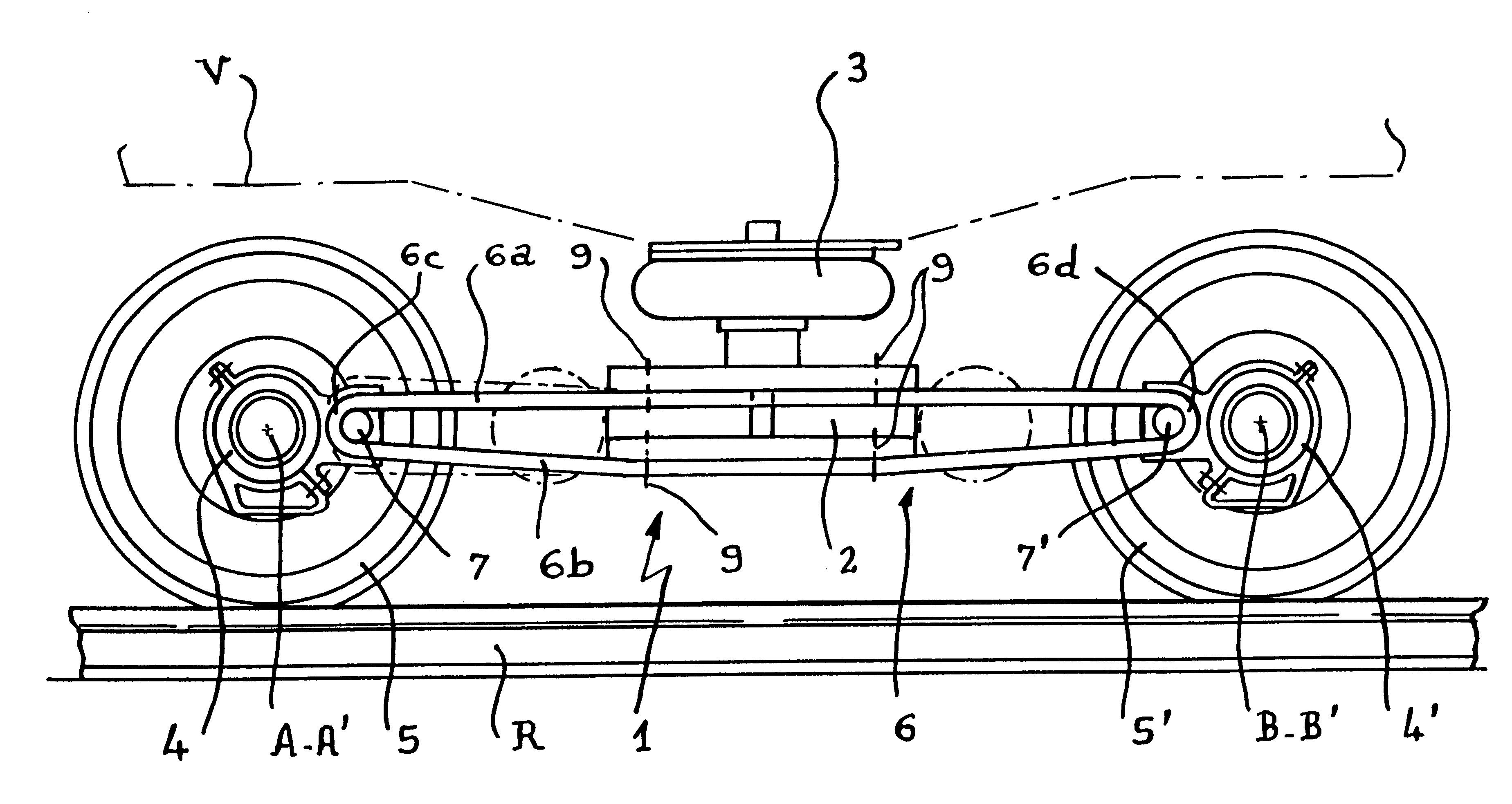

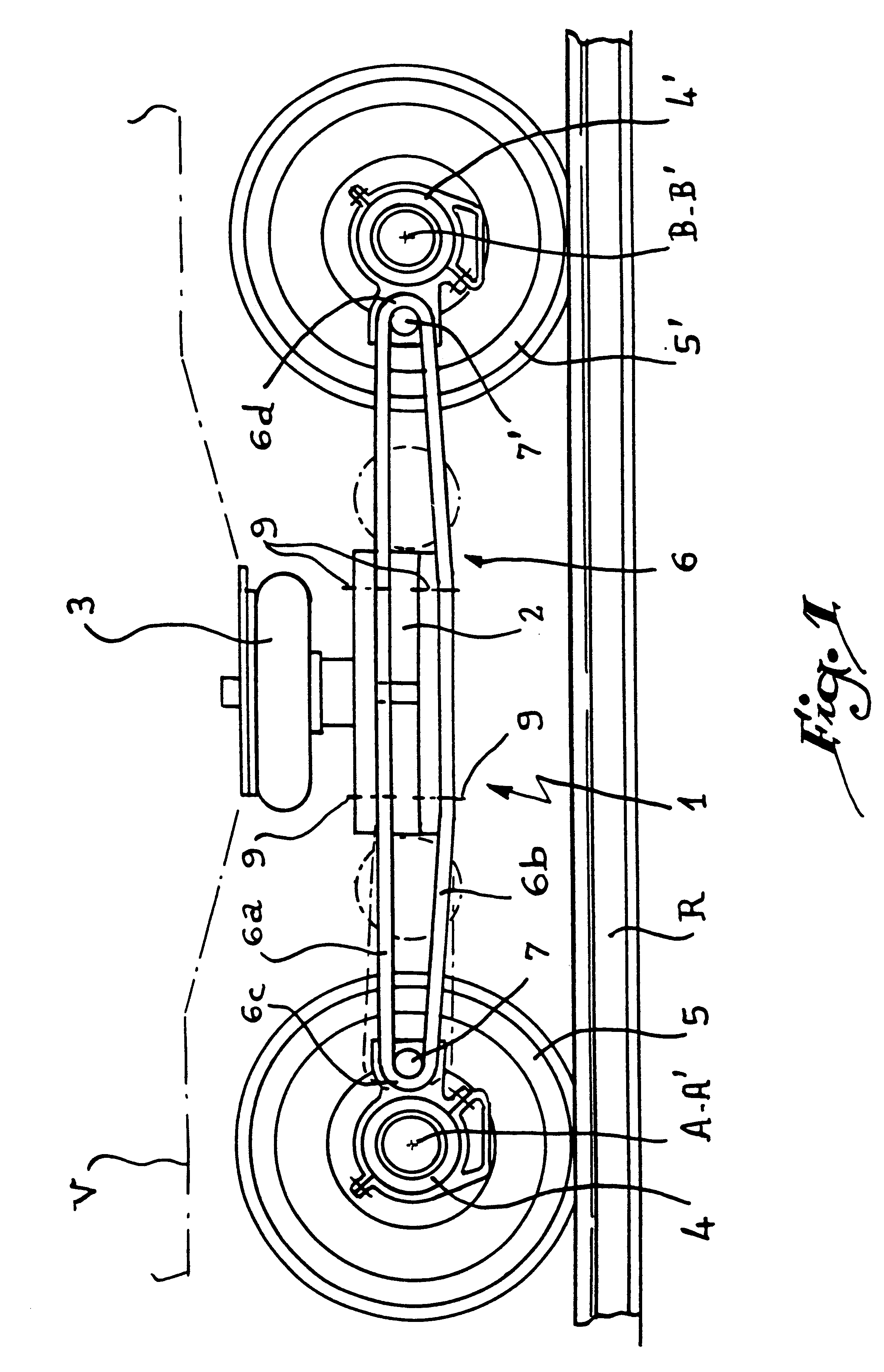

Railway vehicle bogie and process for manufacturing a side member of such a bogie

A railway vehicle bogie, including at least two axles, at least one side member being provided to connect the axles to a central part of the bogie. The side member is formed by an elastic blade shaped as a vertically oriented continuous flattened loop which may be made of composite material or of metal. A process for manufacturing a side member of composite material consists in winding a continuous lap of reinforcing fibers over at least one turn around two studs so as to form a loop, and polymerizing a resin-based matrix around the fibers.

Owner:ALSTOM TRANSPORT TECH SAS

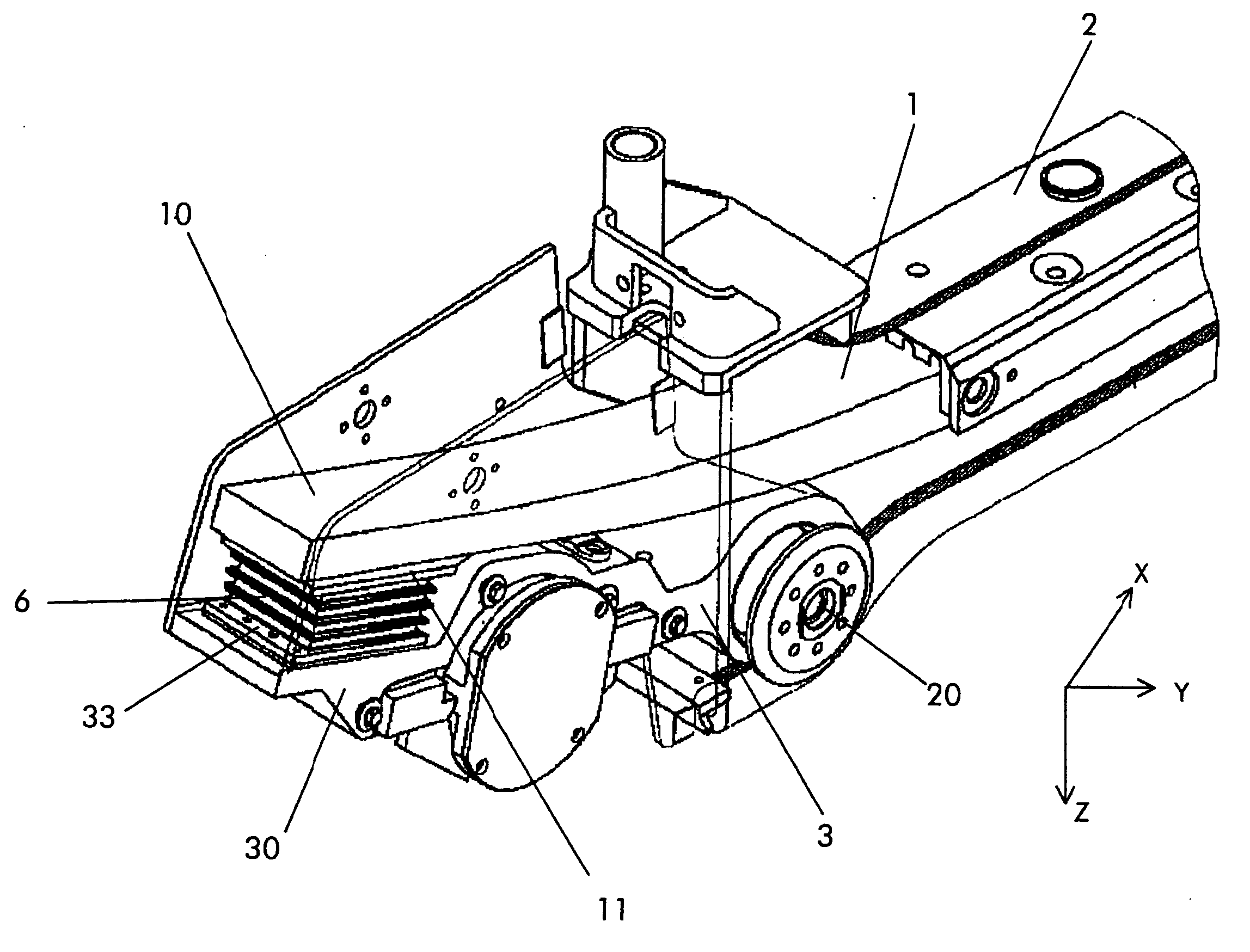

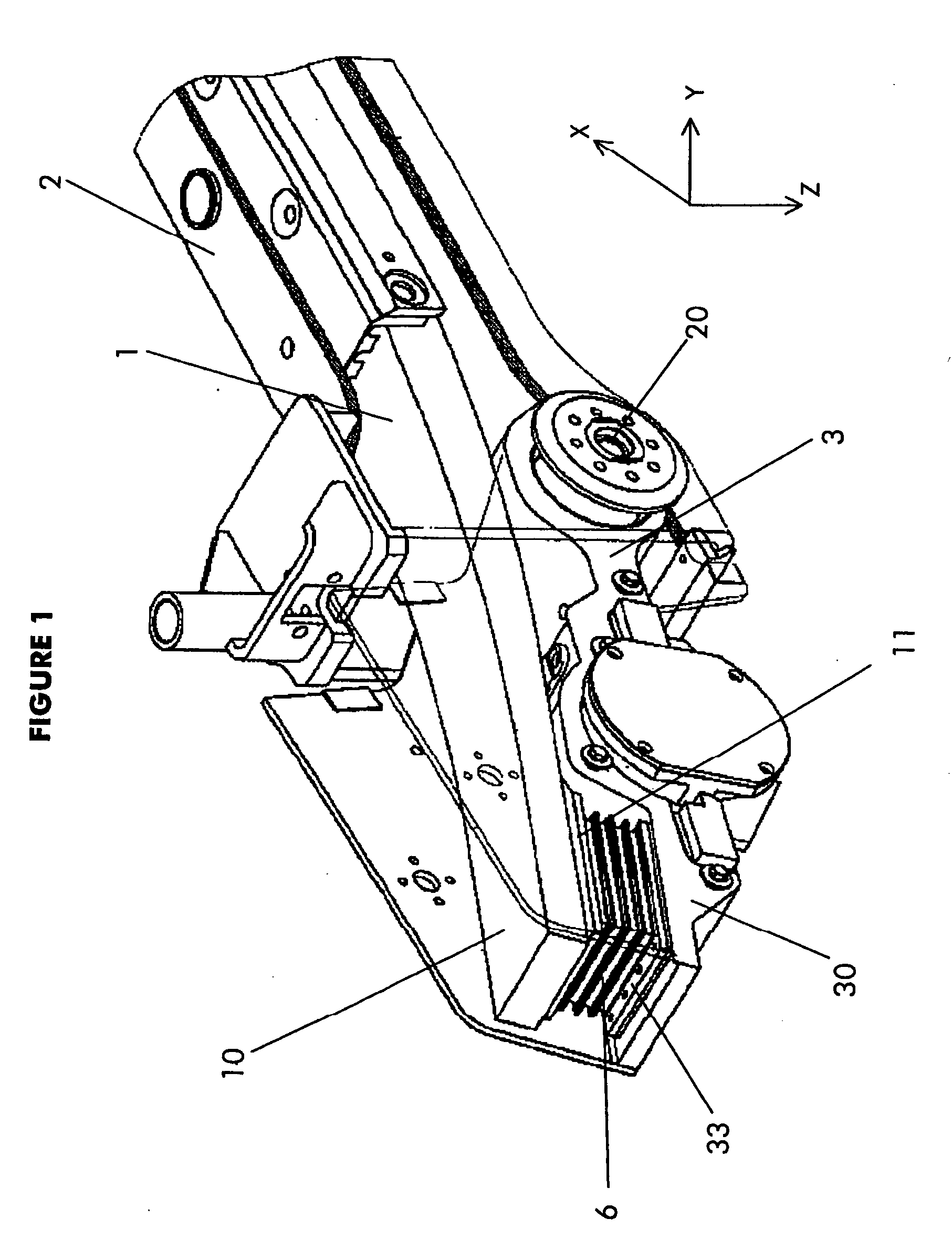

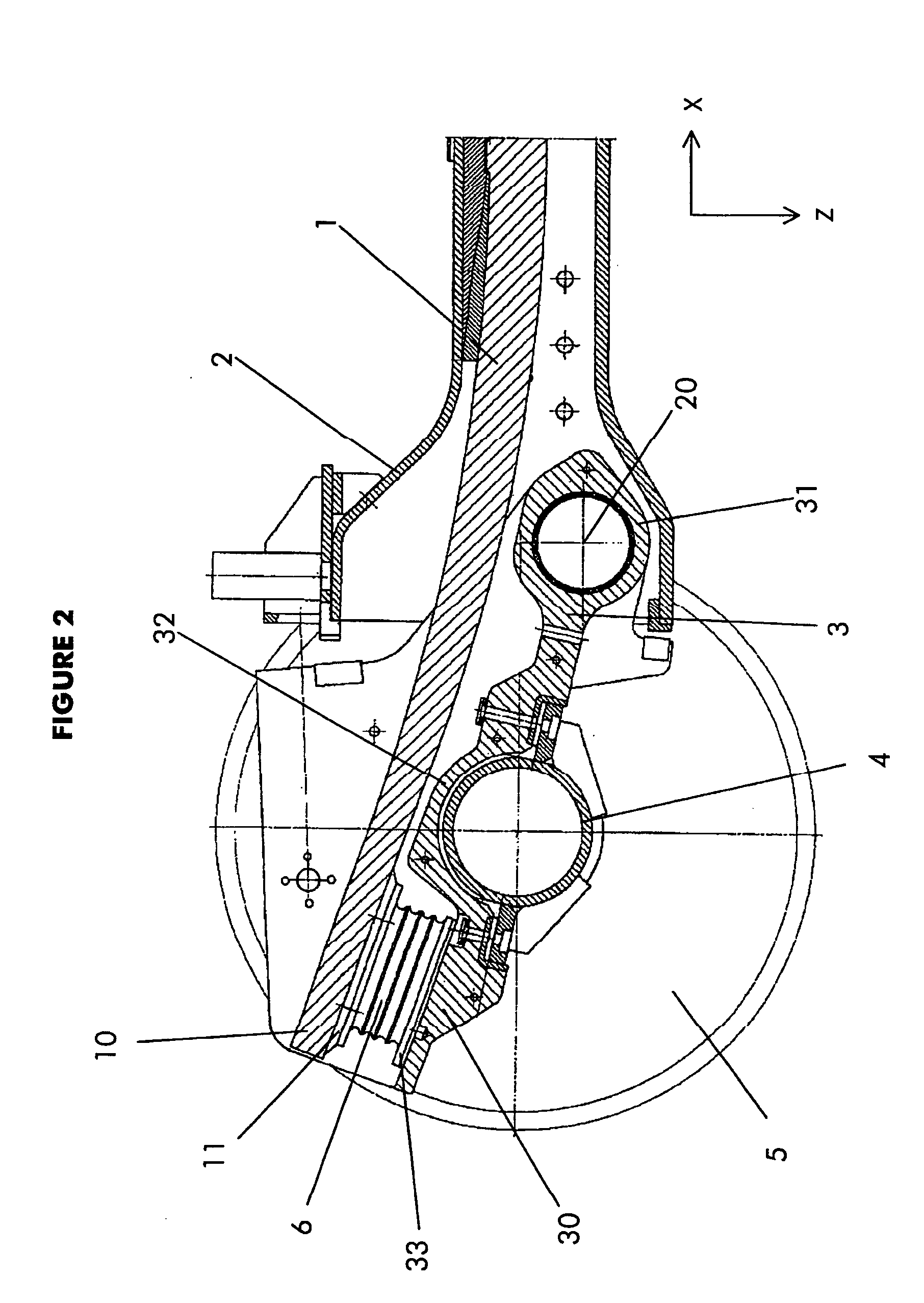

Flexible connection device between a bogey side beam and an axle-box

ActiveUS20050116436A1Reduce noise transmissionStop solid noiseUnderstructuresRailway transportRelative displacementEngineering

The flexible connection device of the invention is disposed between a flexible side beam of a bogey frame and an arm of an axle-box, and wherein the stiffness of the connection is greater in the vertical direction (Z) than in the two horizontal directions (X, Y). This enables the side beam to be decoupled from the axle-box, thereby reducing the stresses at the interfaces between these parts when the bogey frame moves transversely and vertically relative to the axles. This also presents the advantage of allowing relative displacements between the side beam and the axle-box.

Owner:ALSTOM TRANSPORT TECH SAS

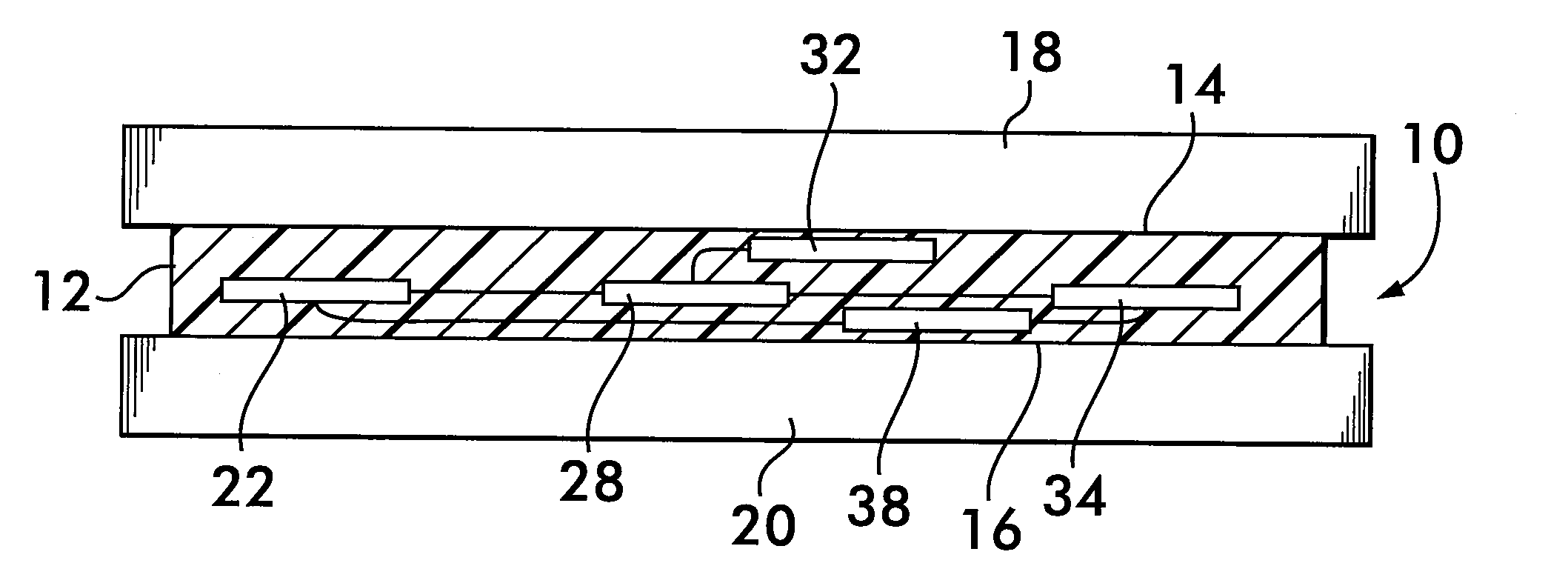

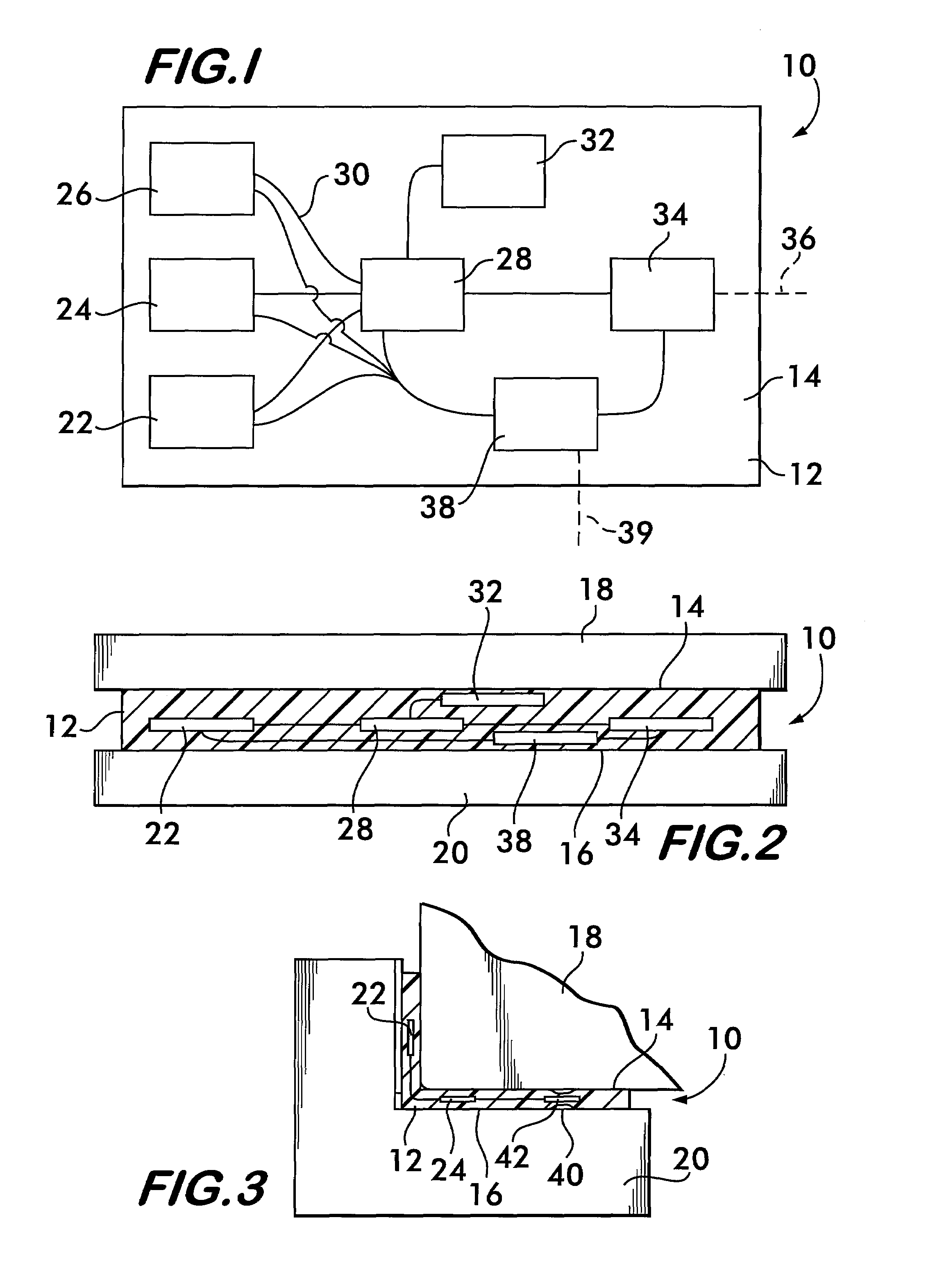

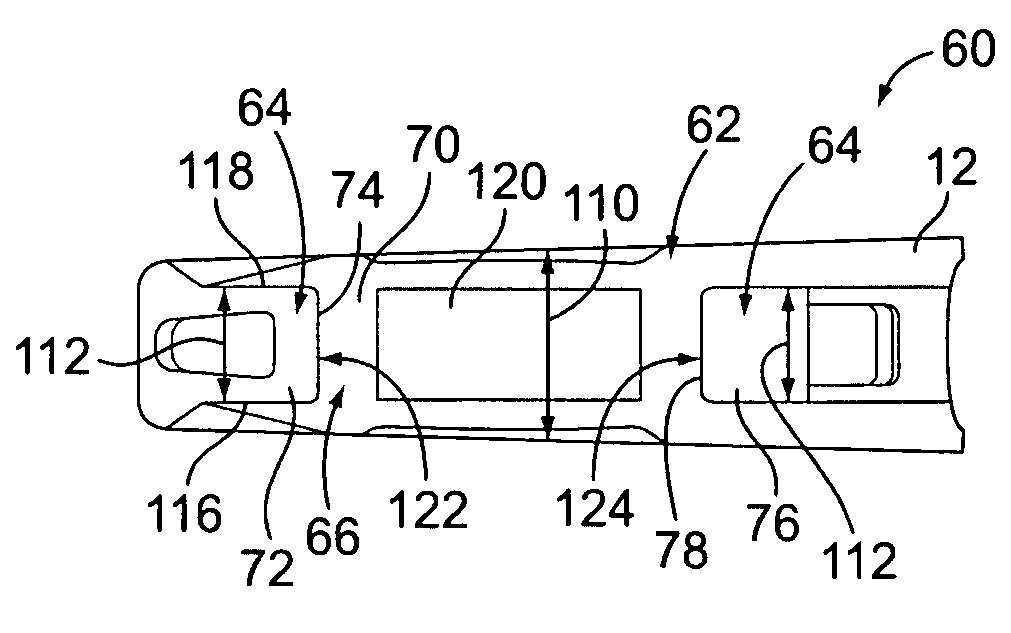

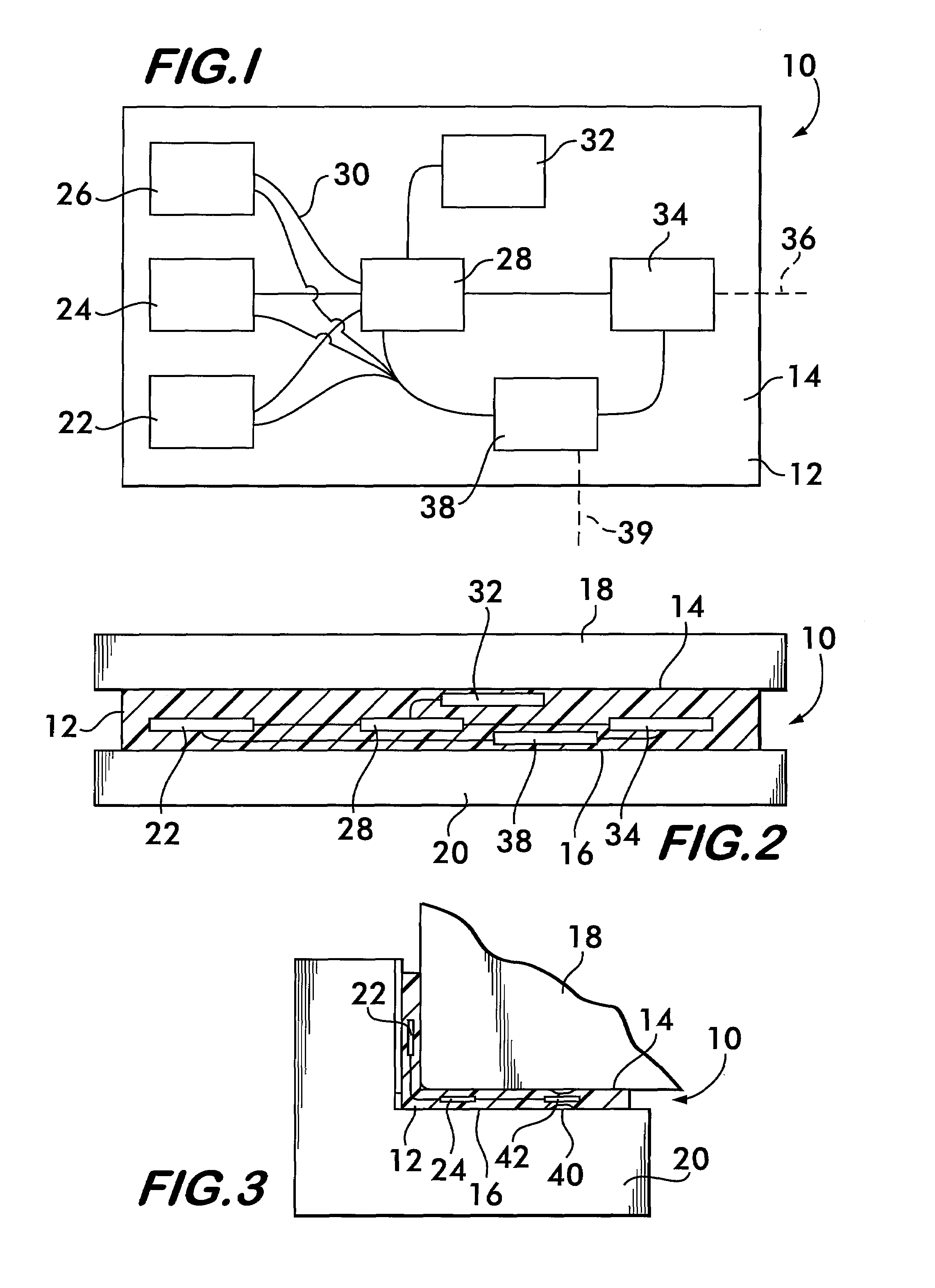

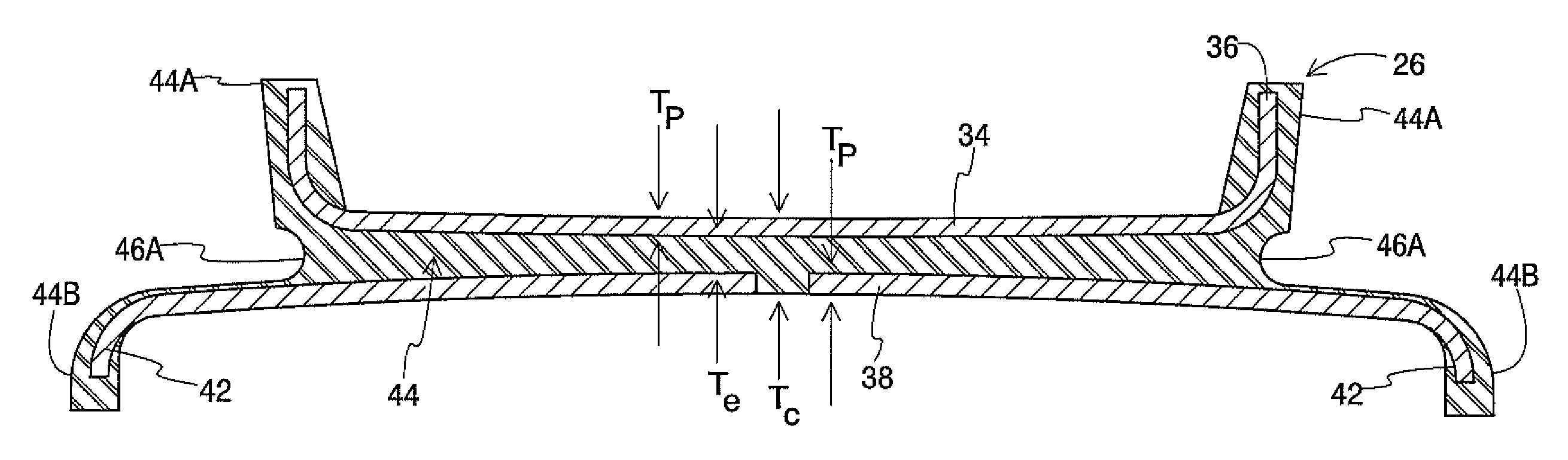

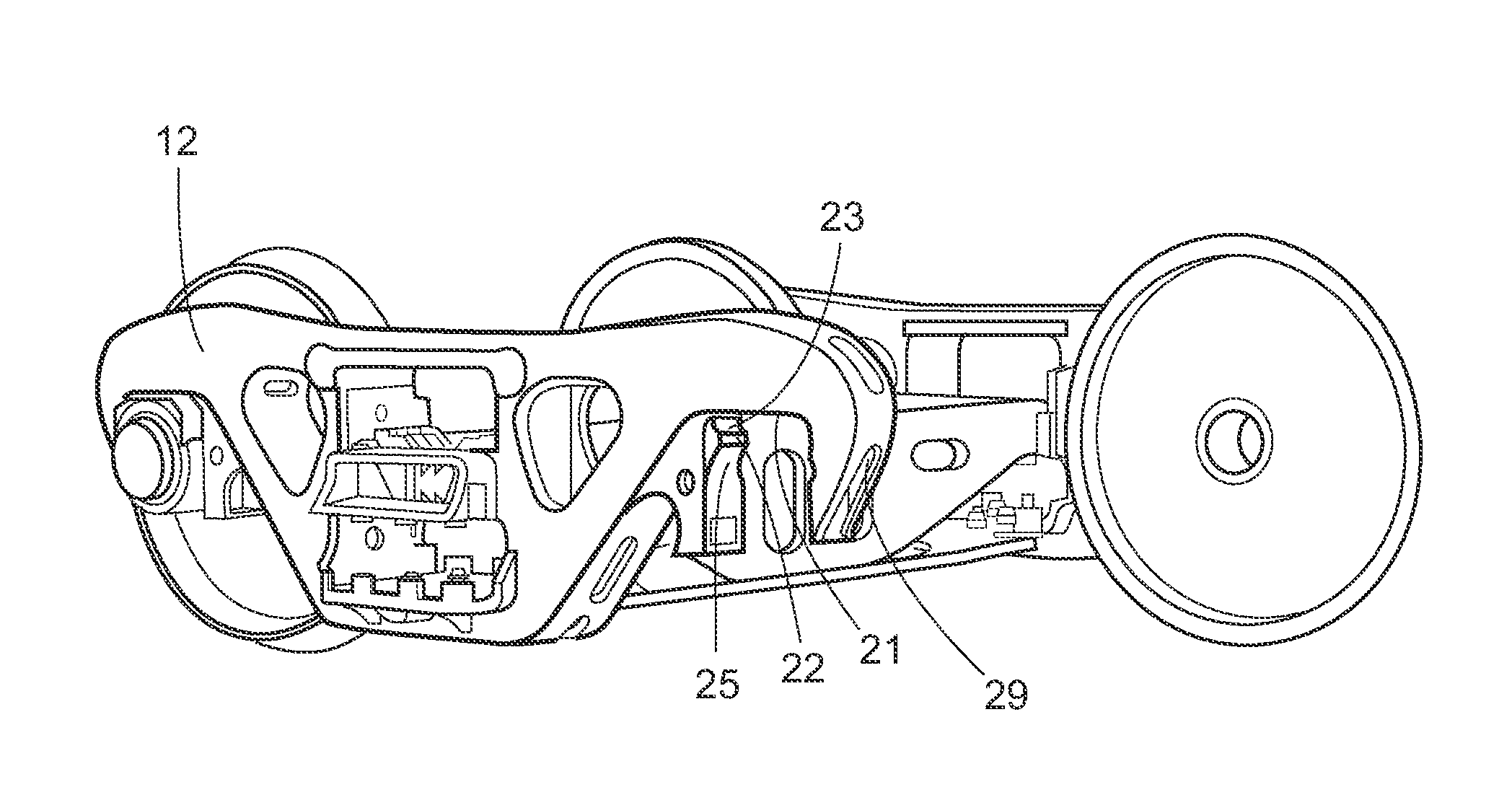

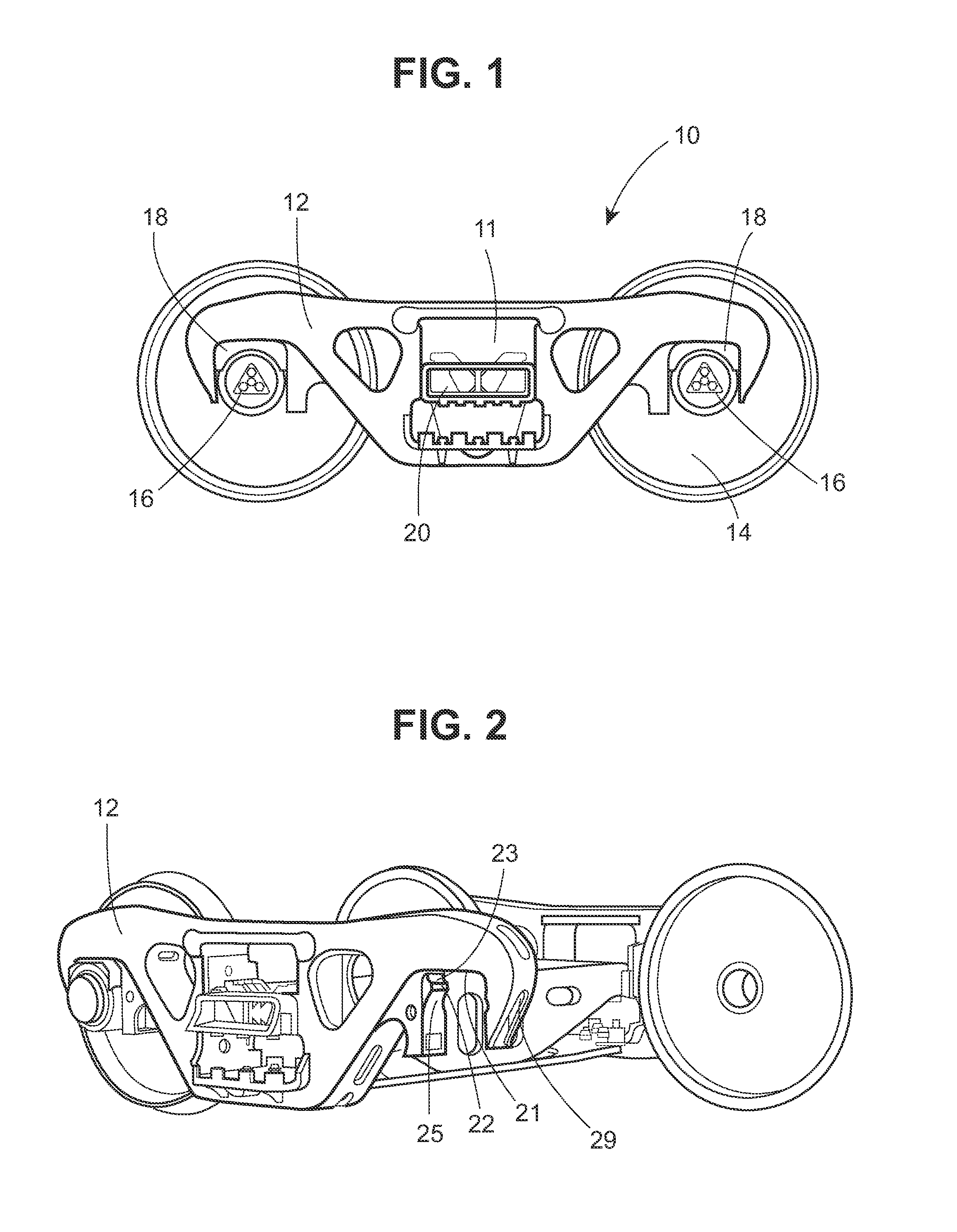

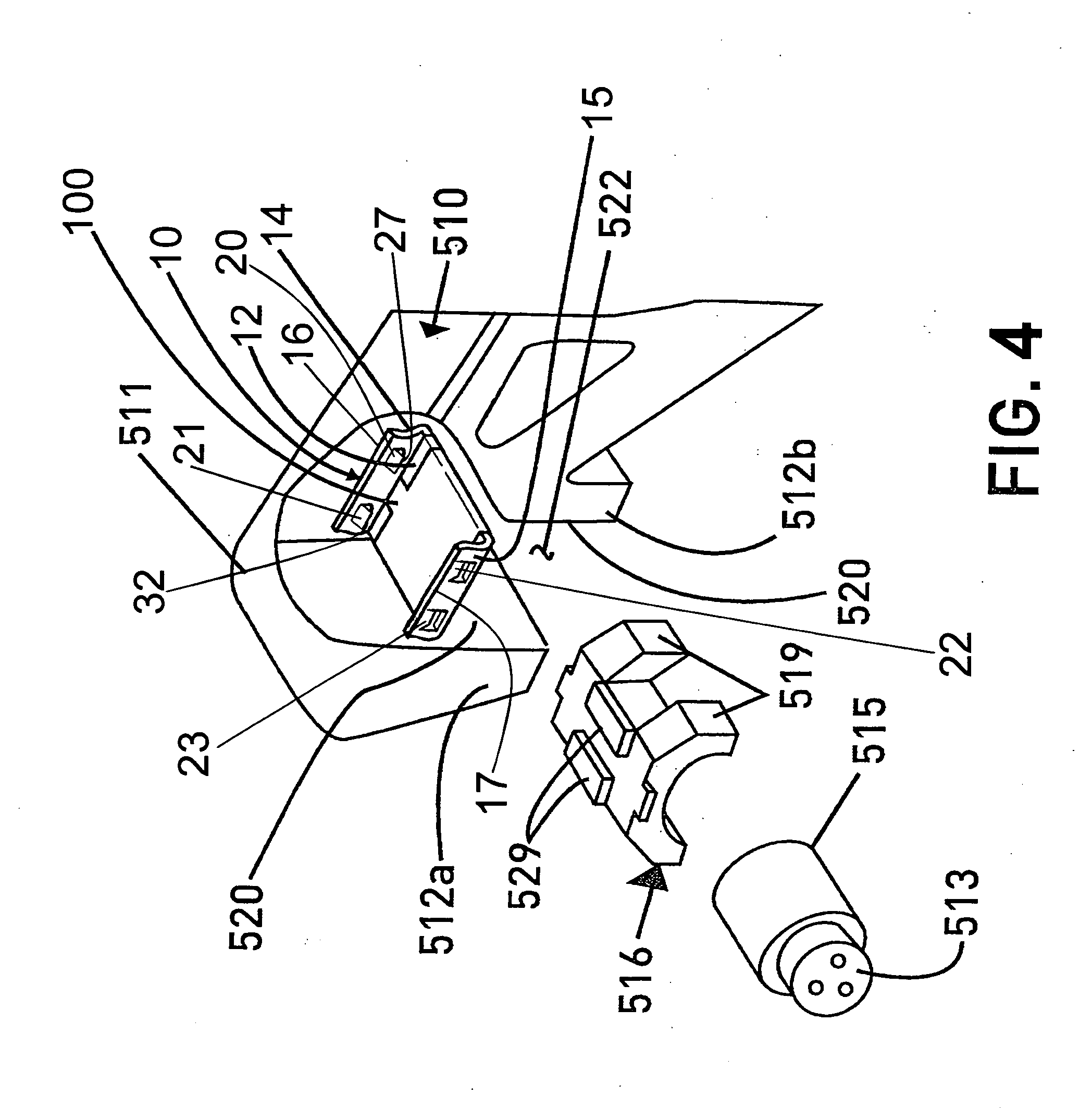

Sensor interface

ActiveUS20070255509A1Bearing assemblyMeasurement apparatus componentsMain processing unitElectronic component

A sensor interface is disclosed including a flexible substrate in which are embedded sensors for measuring physical parameters such as temperature, displacement, velocity, acceleration, stress, strain, pressure and force present between objects such as a railcar bearing and a truck side frame. The substrate is positioned between the objects of interest Electronic components such as a data processing unit, a data storage device, a communication device and a power source may also be embedded within the substrate. The electronic devices communicate with one another and the sensors to process signals generated by the sensors indicative of the parameters being measured.

Owner:AMSTED RAIL CO INC

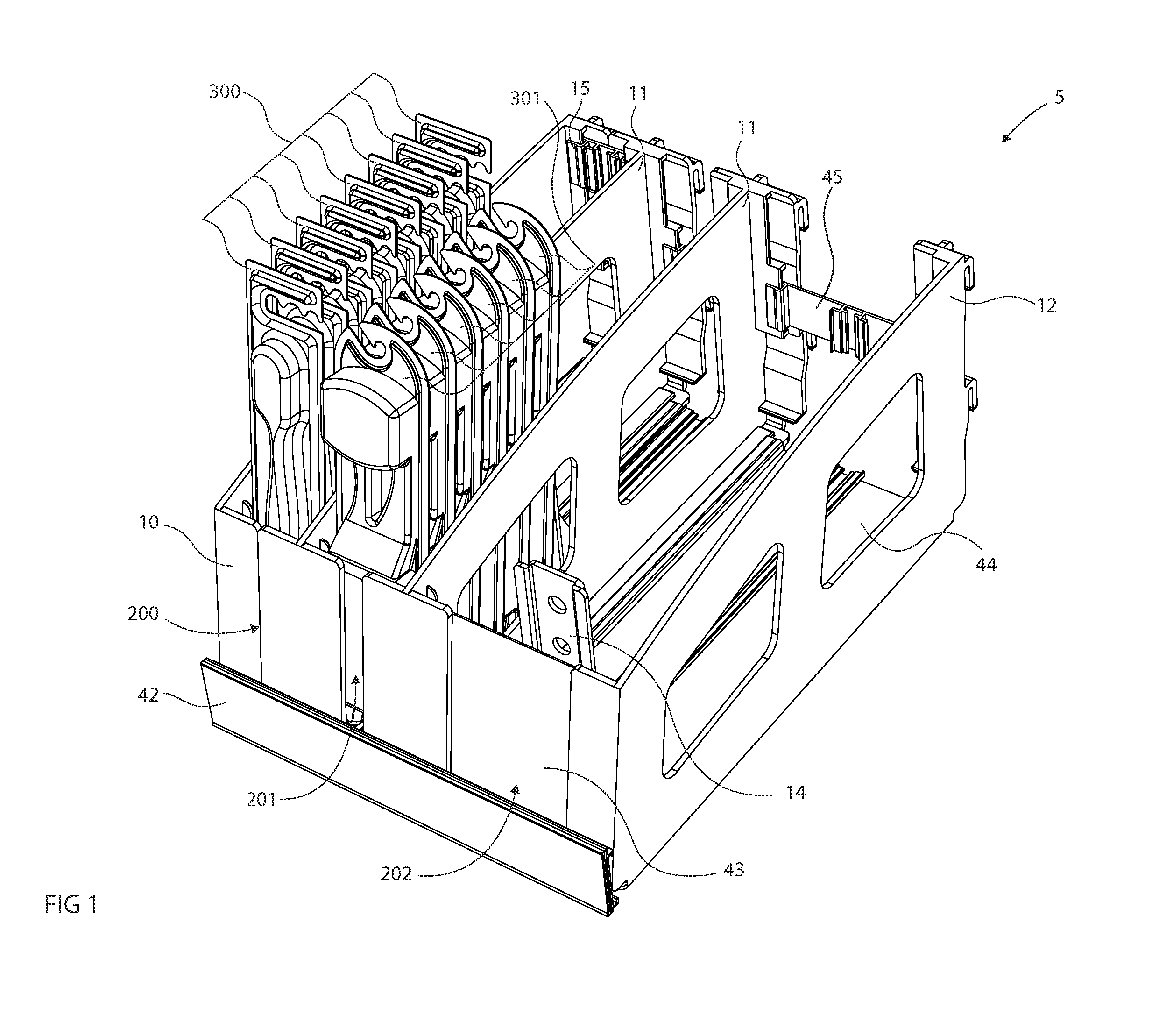

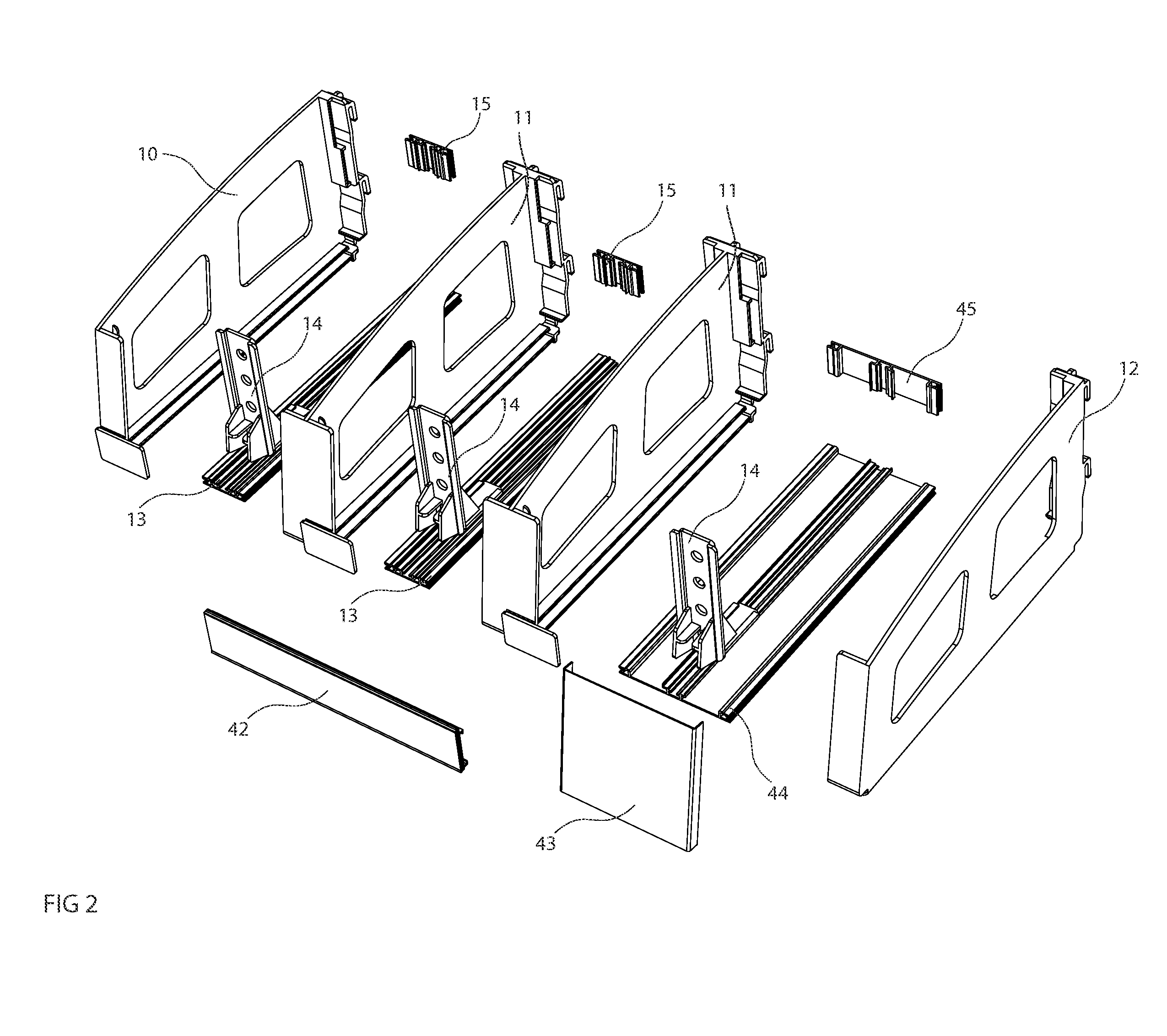

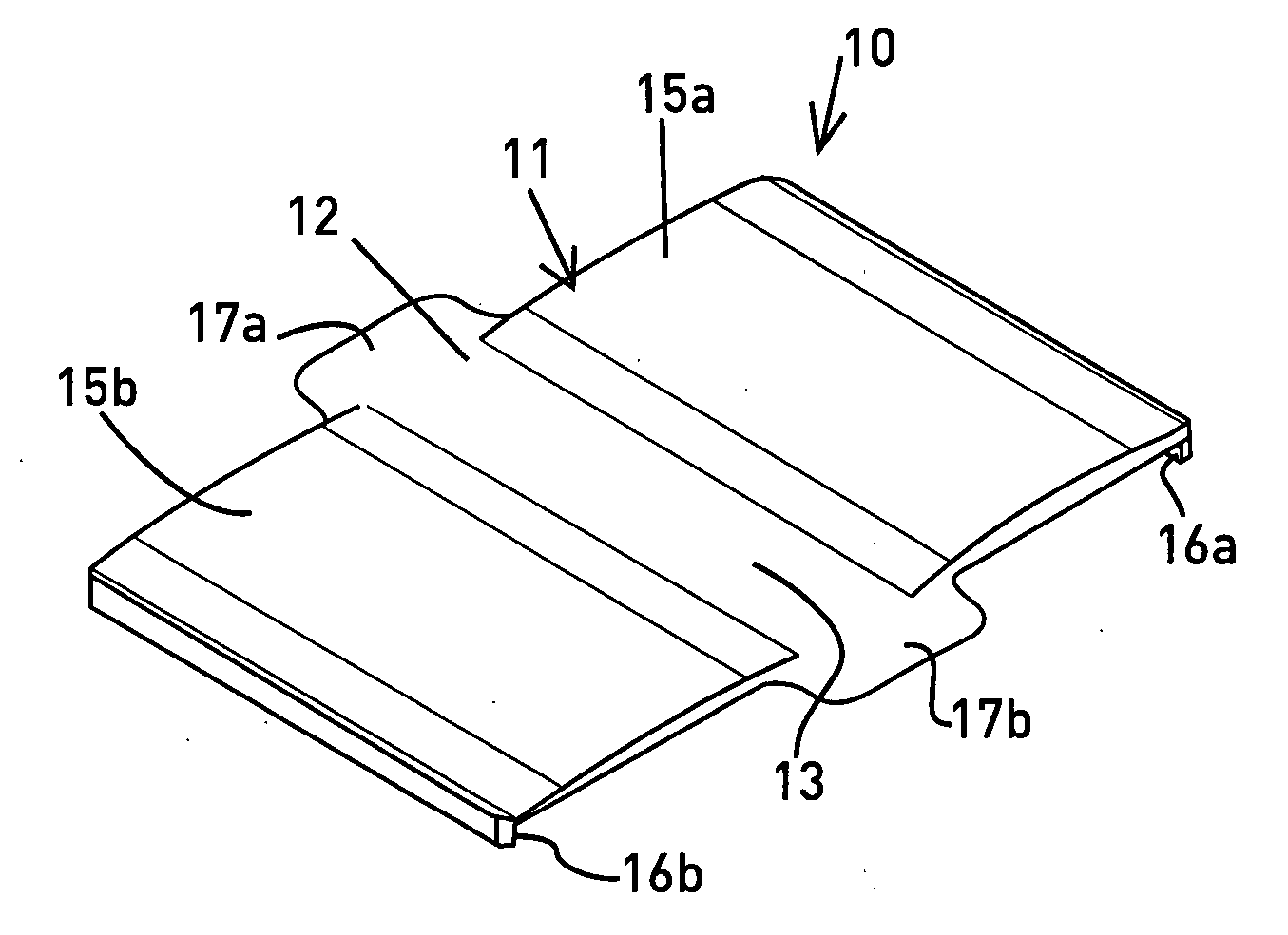

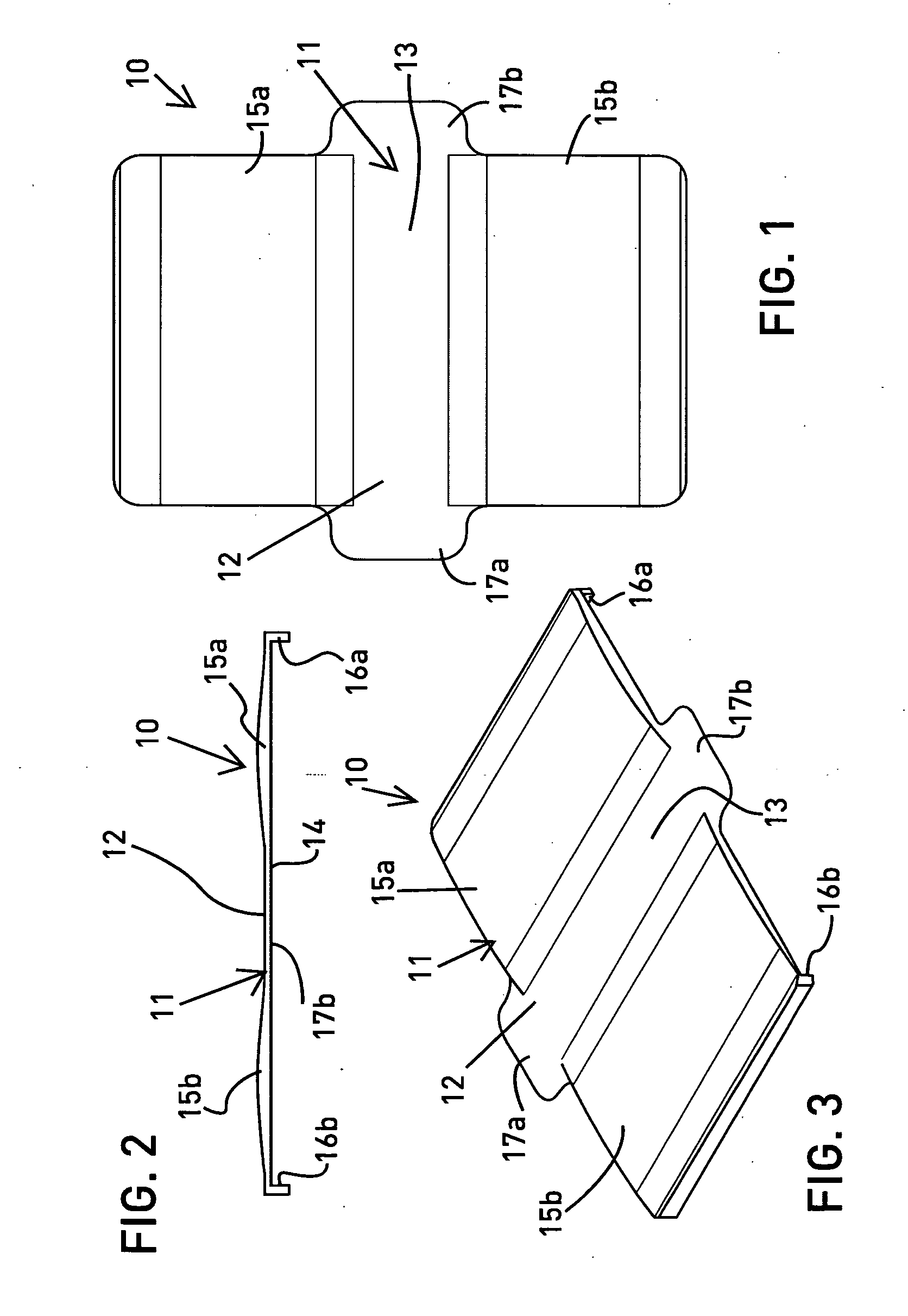

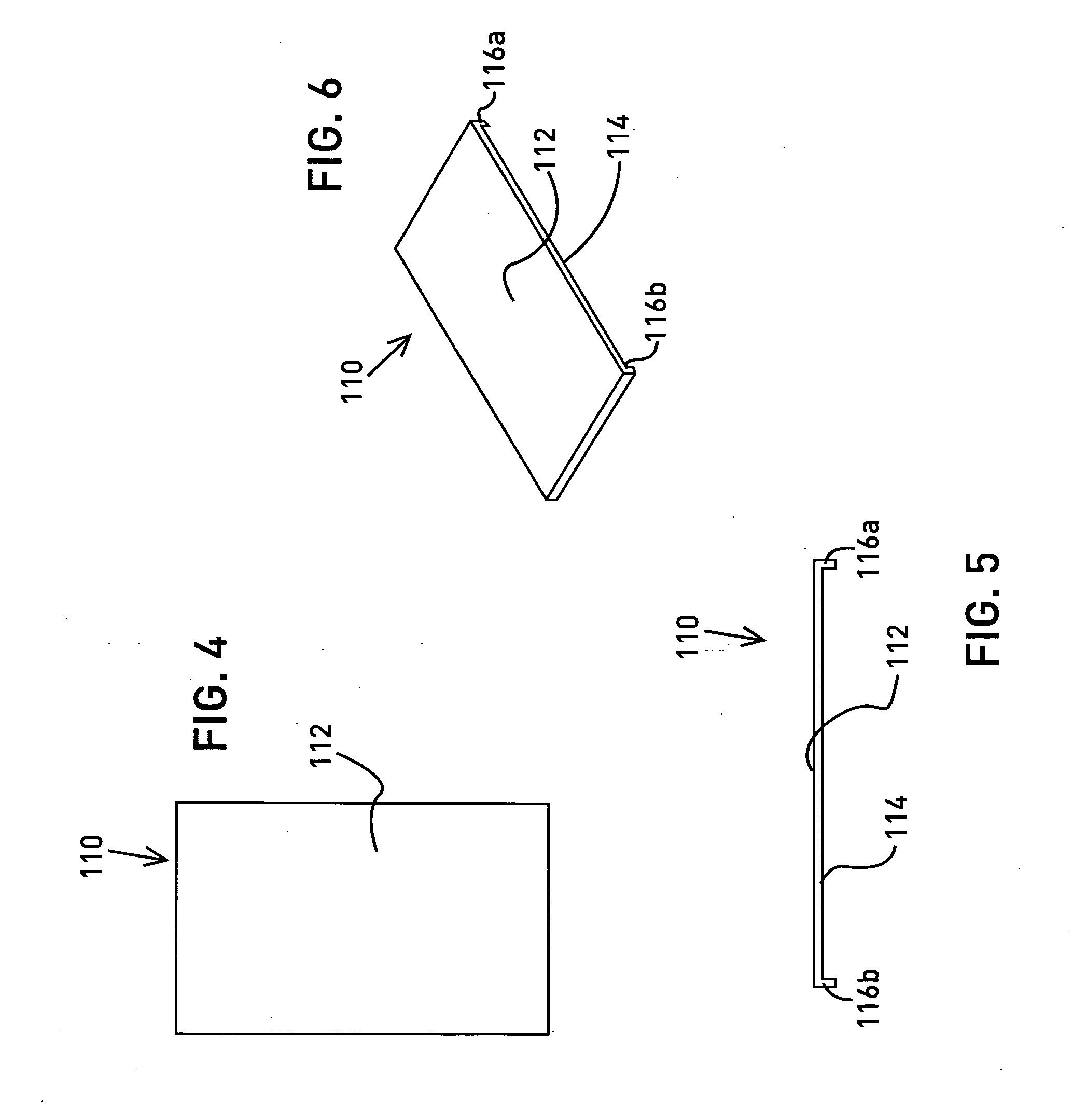

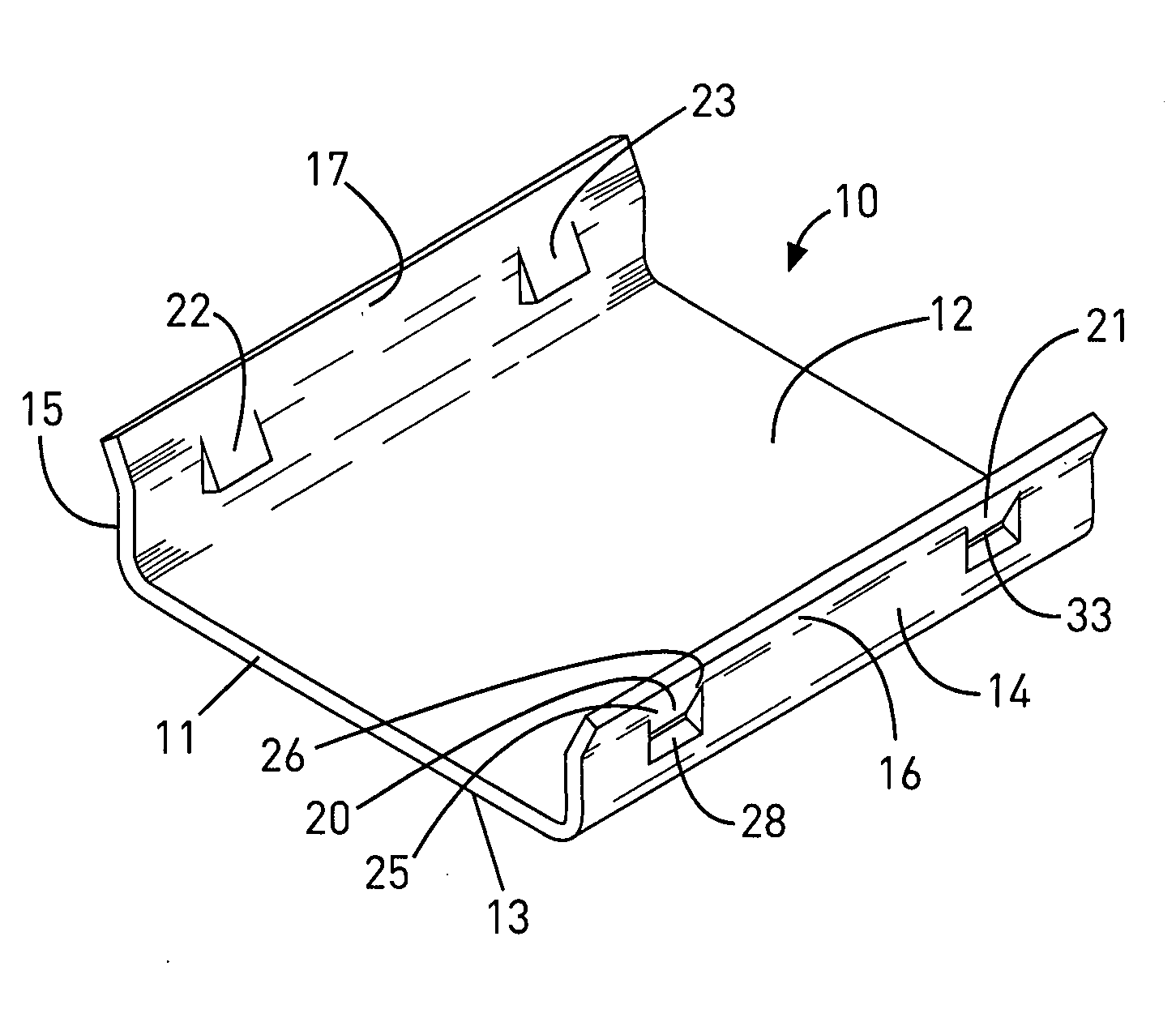

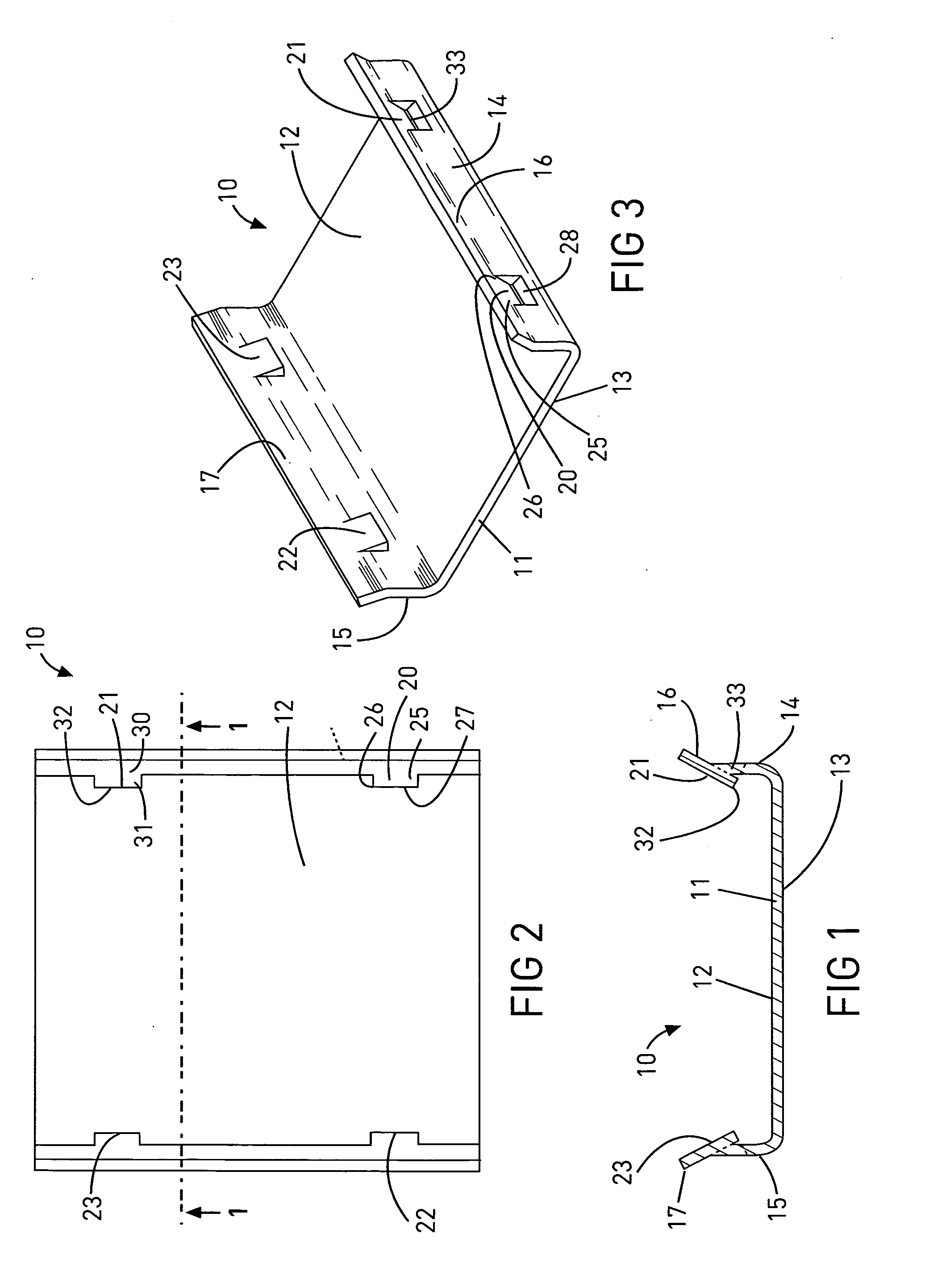

Hanging product divider and pusher systems and methods for dividing, pushing and/or dispensing one or more retail products

ActiveUS20140305889A1Avoid damageMaintaining organizationRacksElectric locomotivesEngineeringFront and back ends

A hanging merchandising product divider and pusher system and method dispense retail products. The system and method have a first divider having a length defined between a front end and a rear end and a height defined between a top end and a bottom end, at least one second divider having a length defined between a front end and a rear end and a height defined between a top end and a bottom end, and at least one connection plate connecting at least a portion of bottom end of the first divider to at least a portion of the bottom end of the second divider. The system and method also have at least one rear support connector connecting at least a portion of the rear end of the first divider to at least a portion of the rear end of the second divider and a first pocket defined by the first and second dividers, the connection plate, the rear support connector and the front ends of the first and second dividers, wherein the first pocket is sized or configured to receive one or more first retail products. Further, the system and method have a pusher paddle movably connected to the connection plate between the first and second dividers, wherein the pusher paddle is urged towards a front-side of the hanging system such that the pusher paddle moves the one or more products towards the front-side of the hanging system when the one or more first retail products are positioned within the first pocket of the hanging system, and rear mounting hangers located at a back-side of the hanging system.

Owner:MARKETING IMPACT

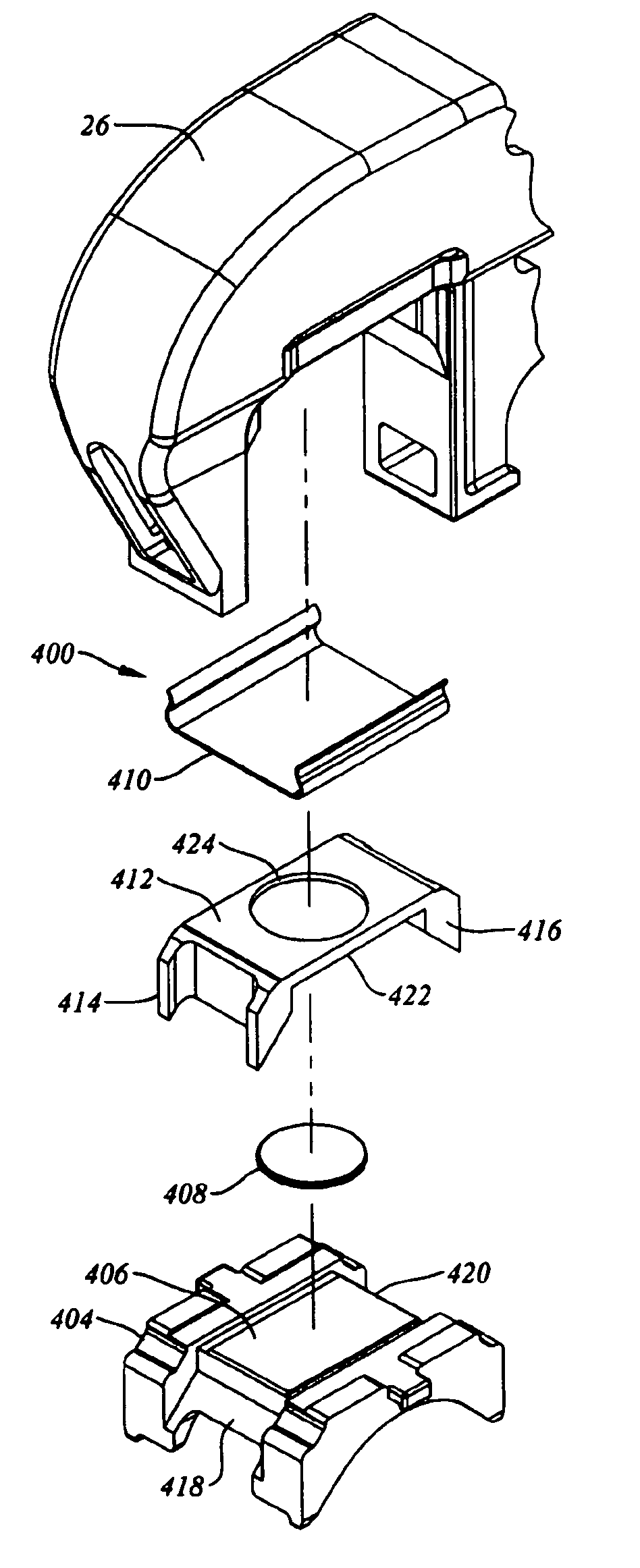

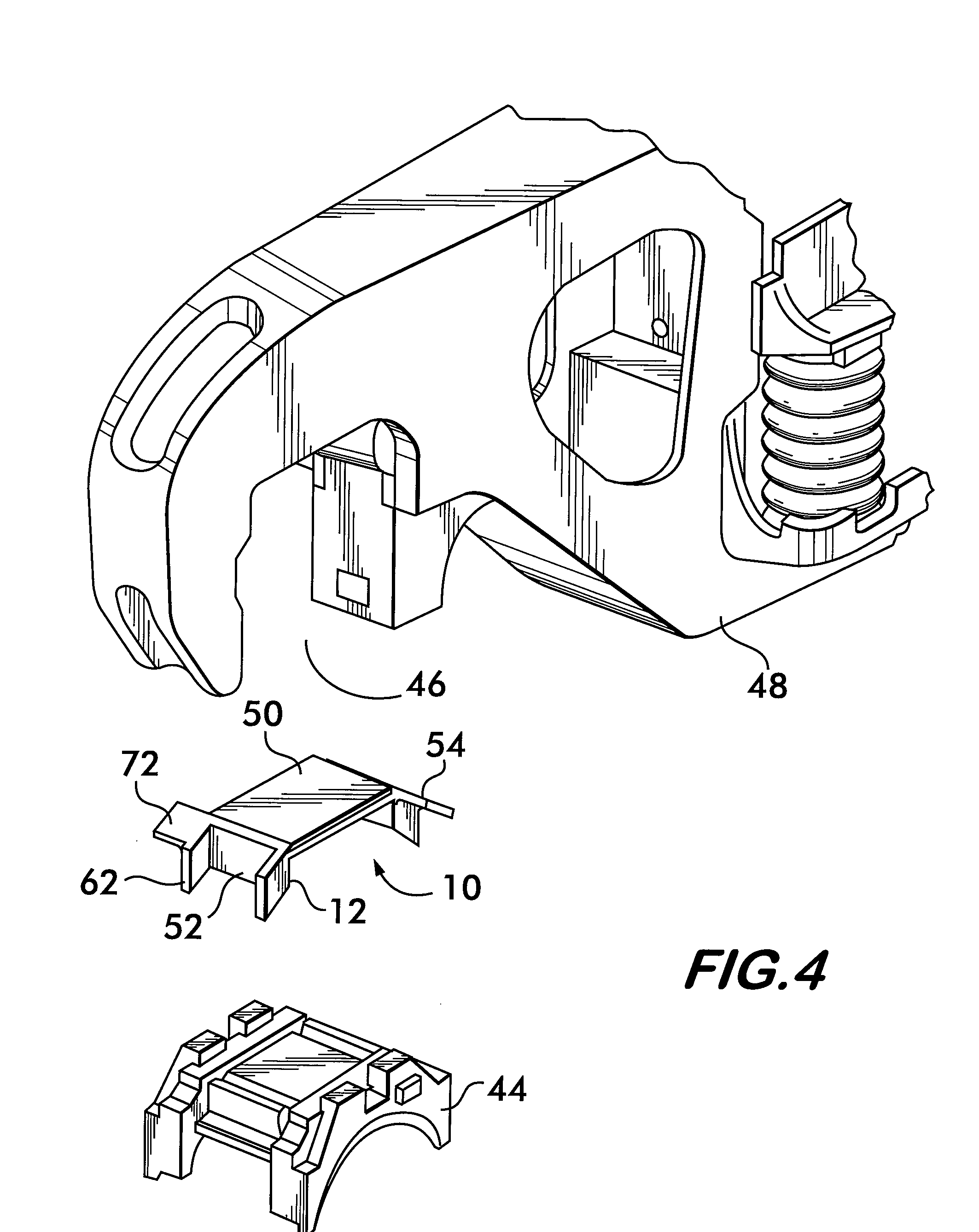

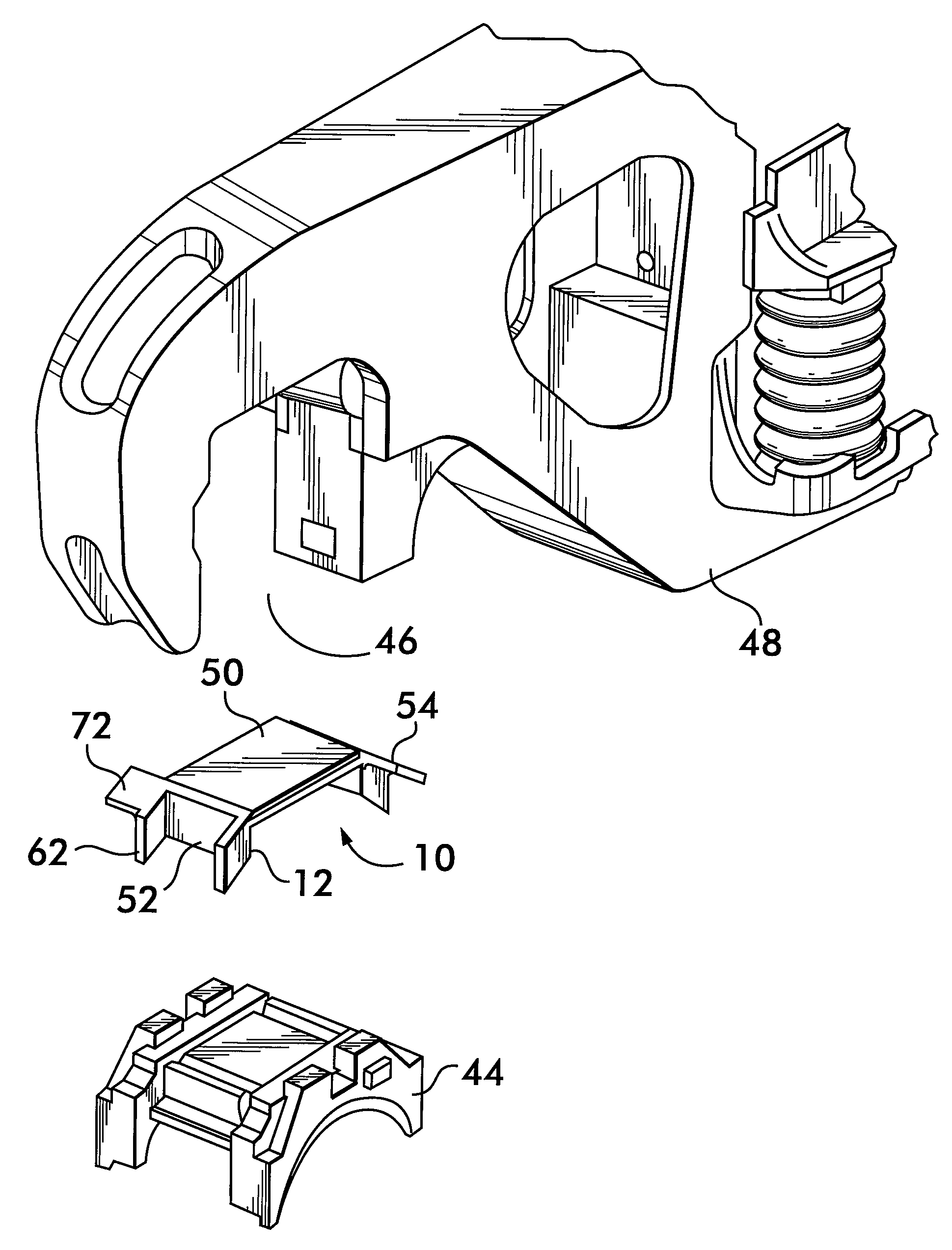

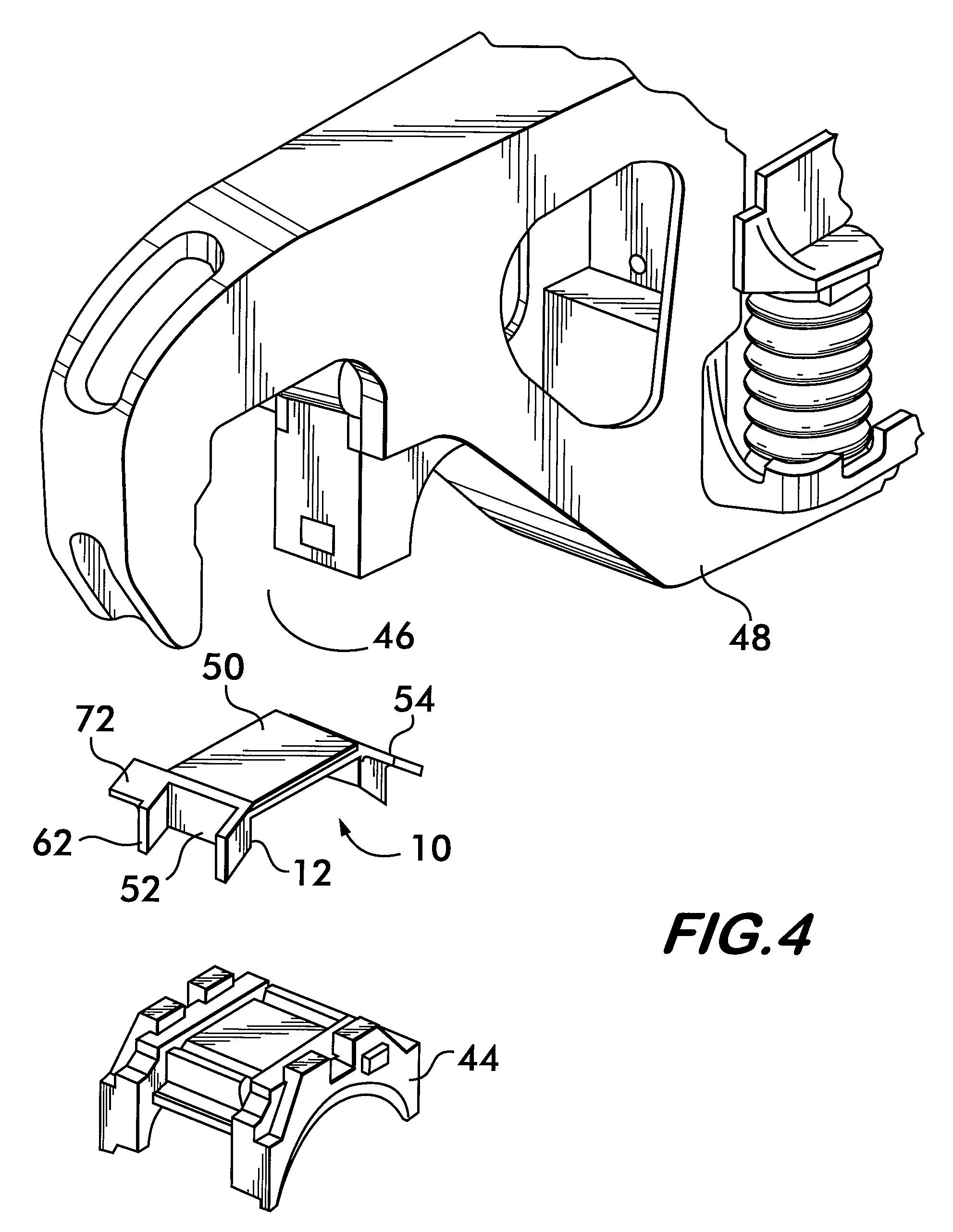

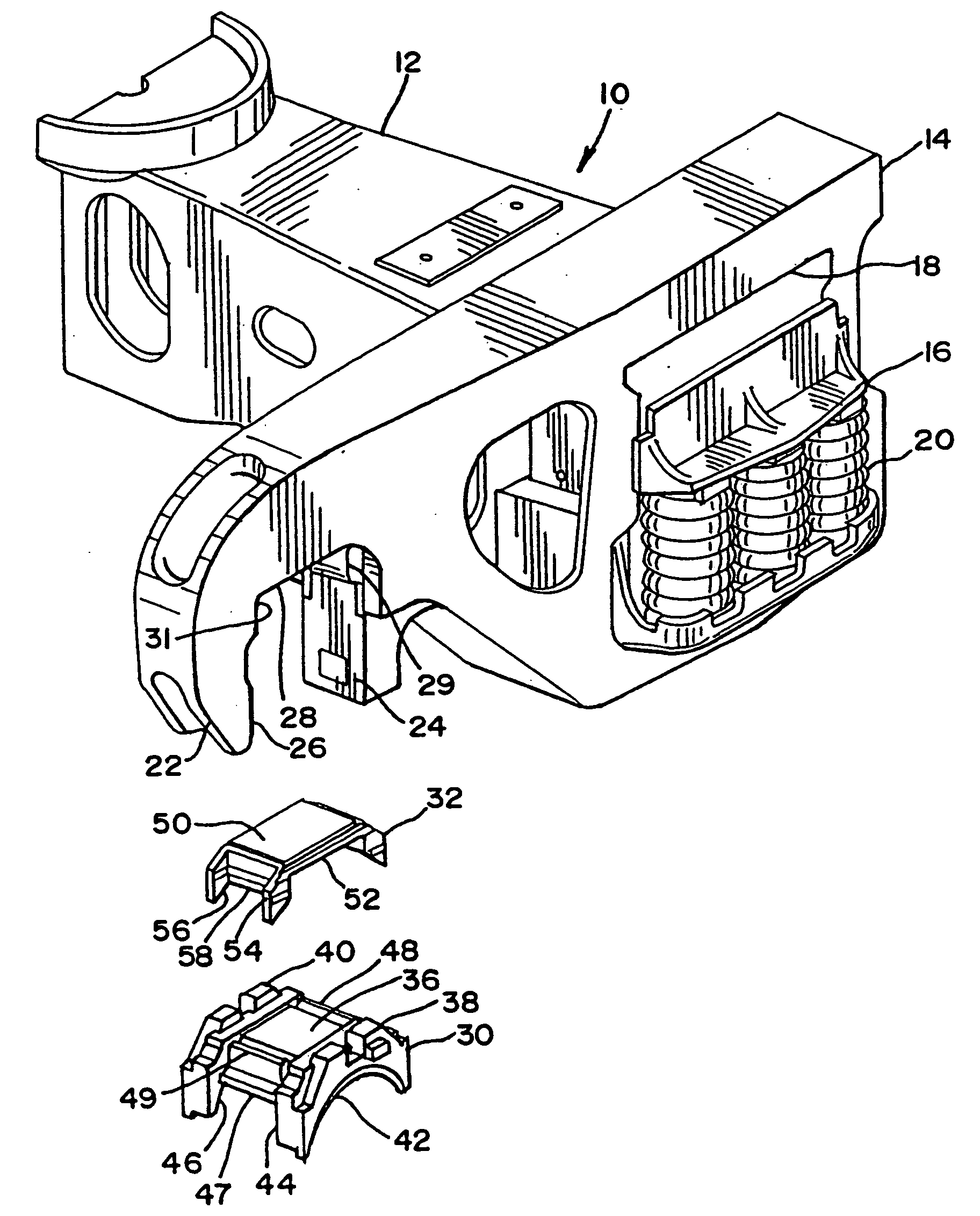

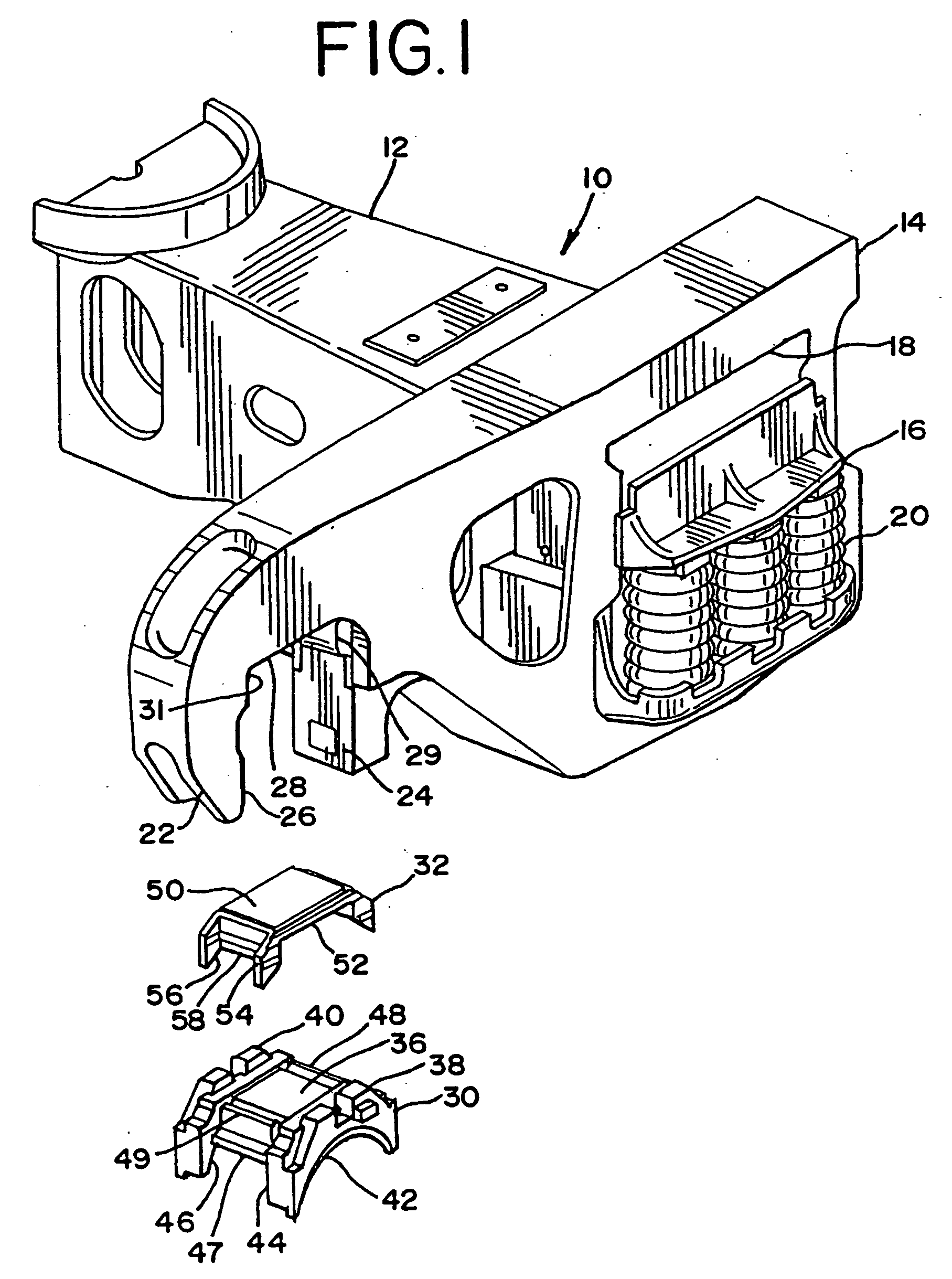

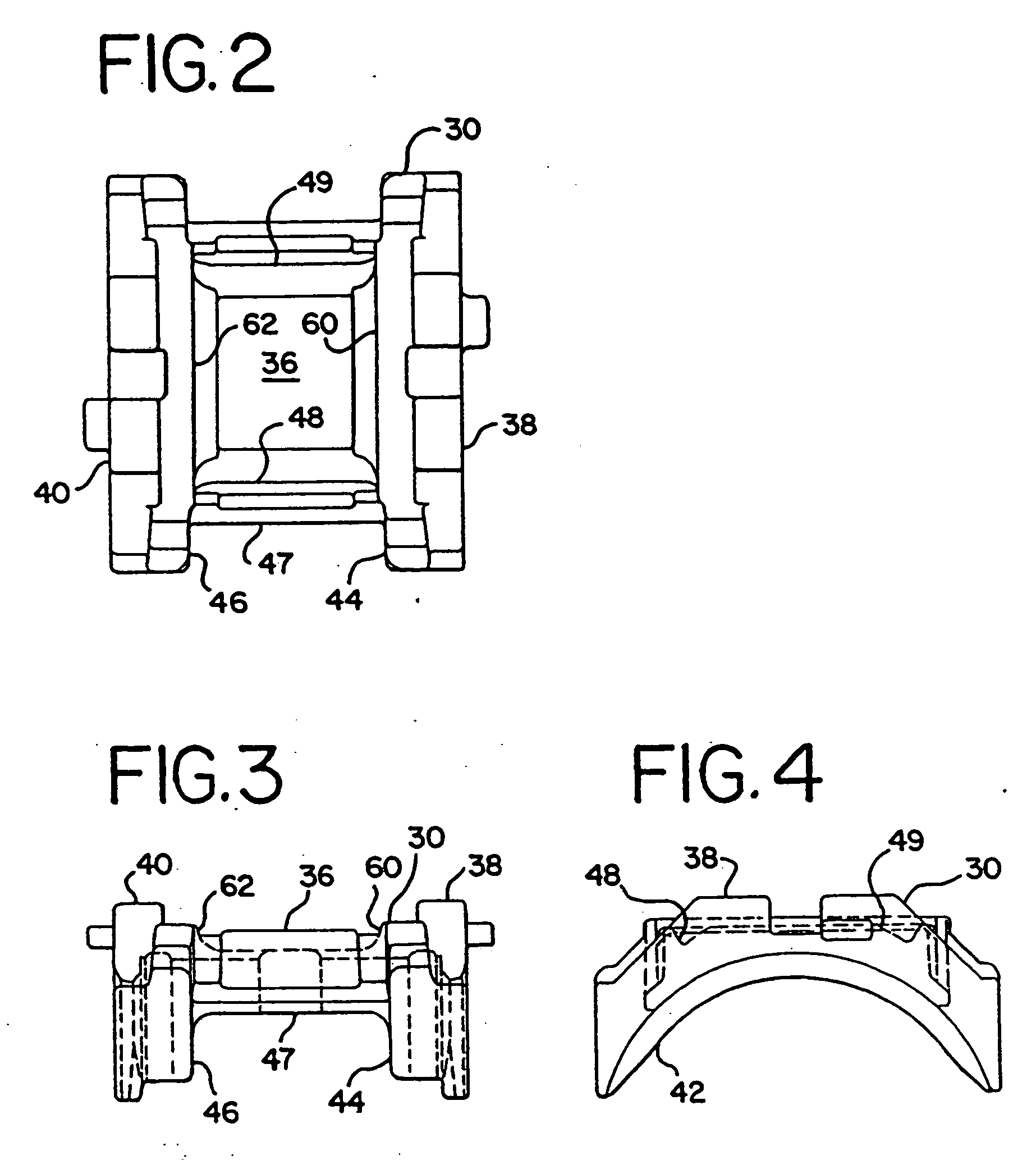

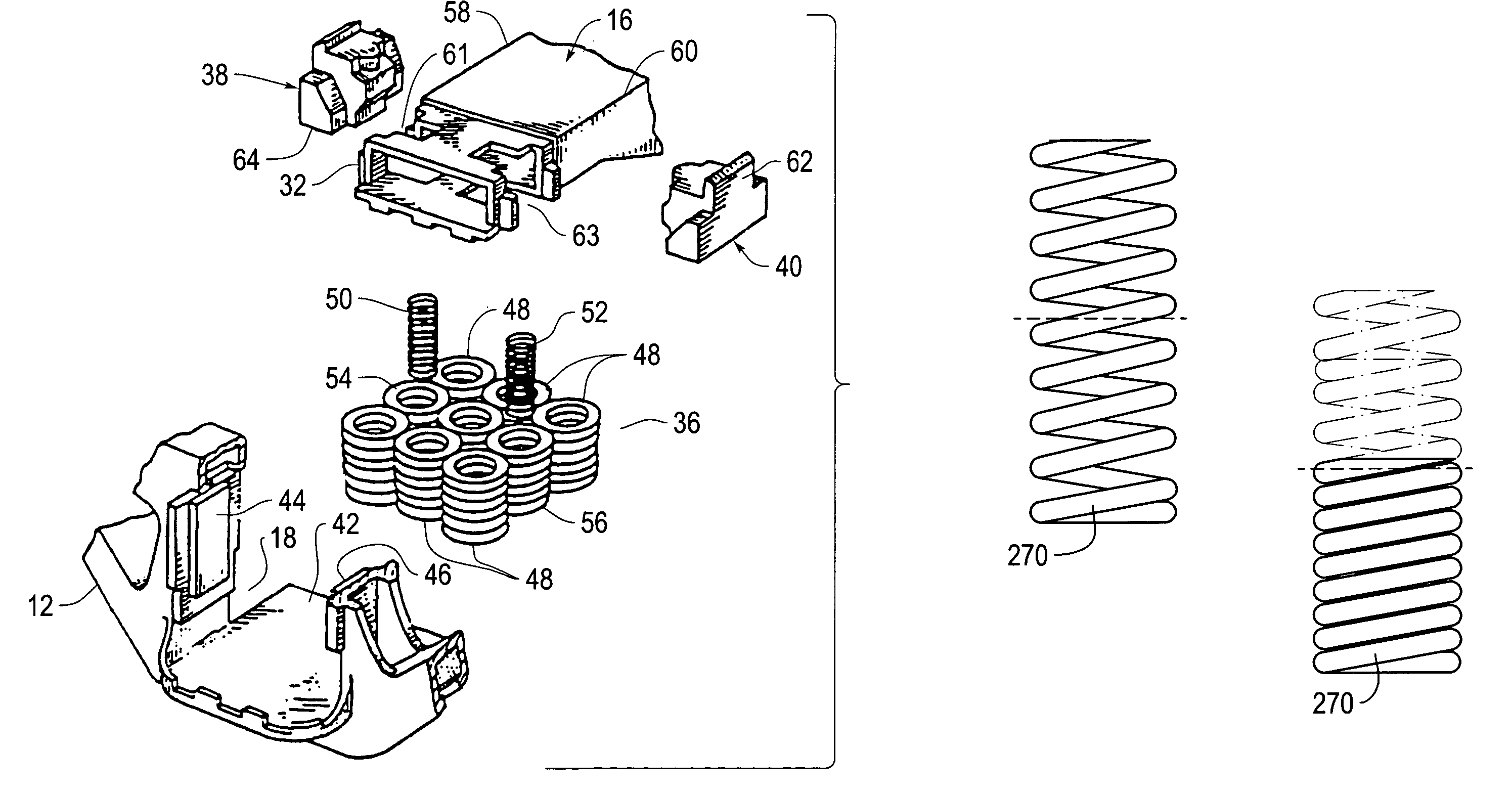

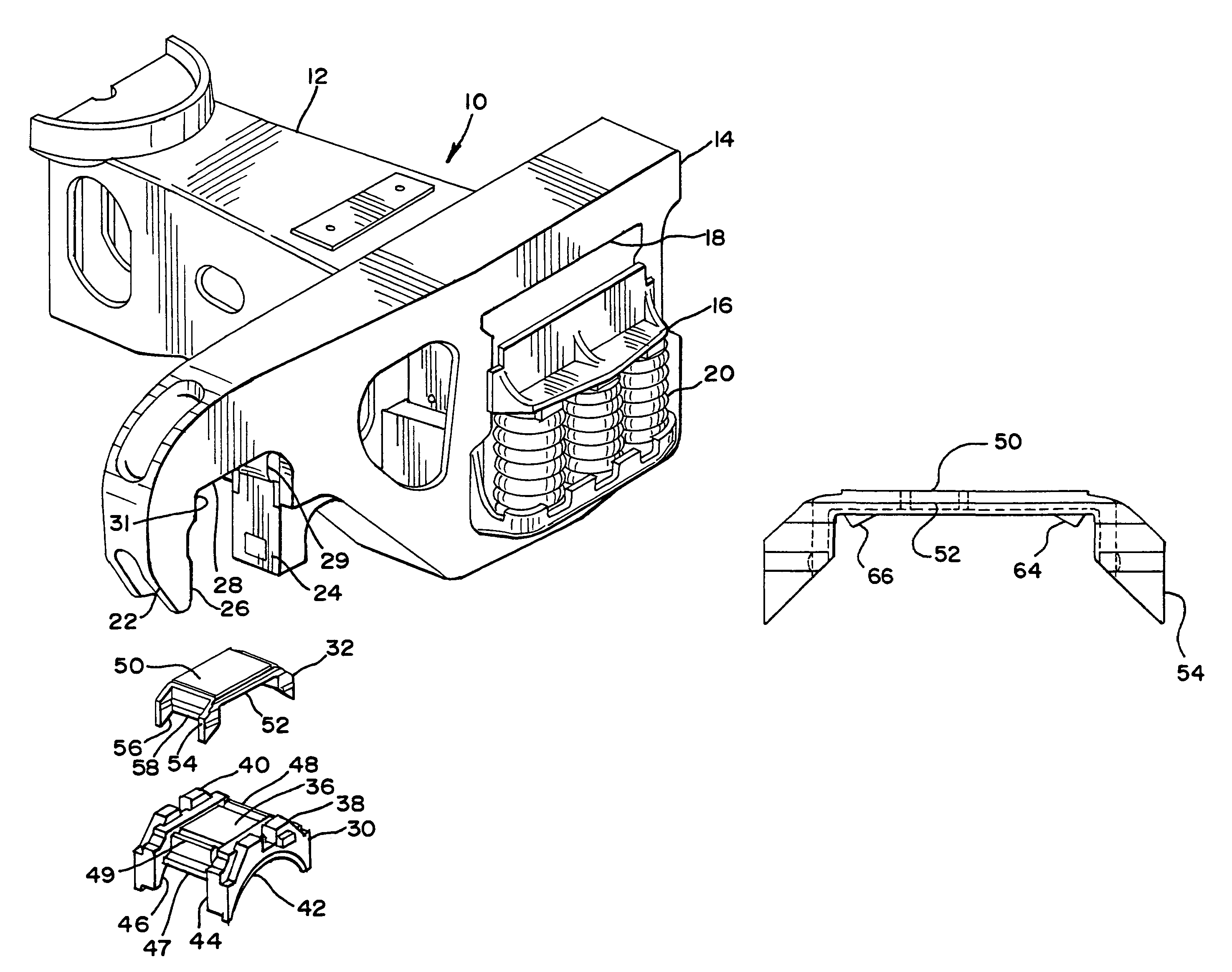

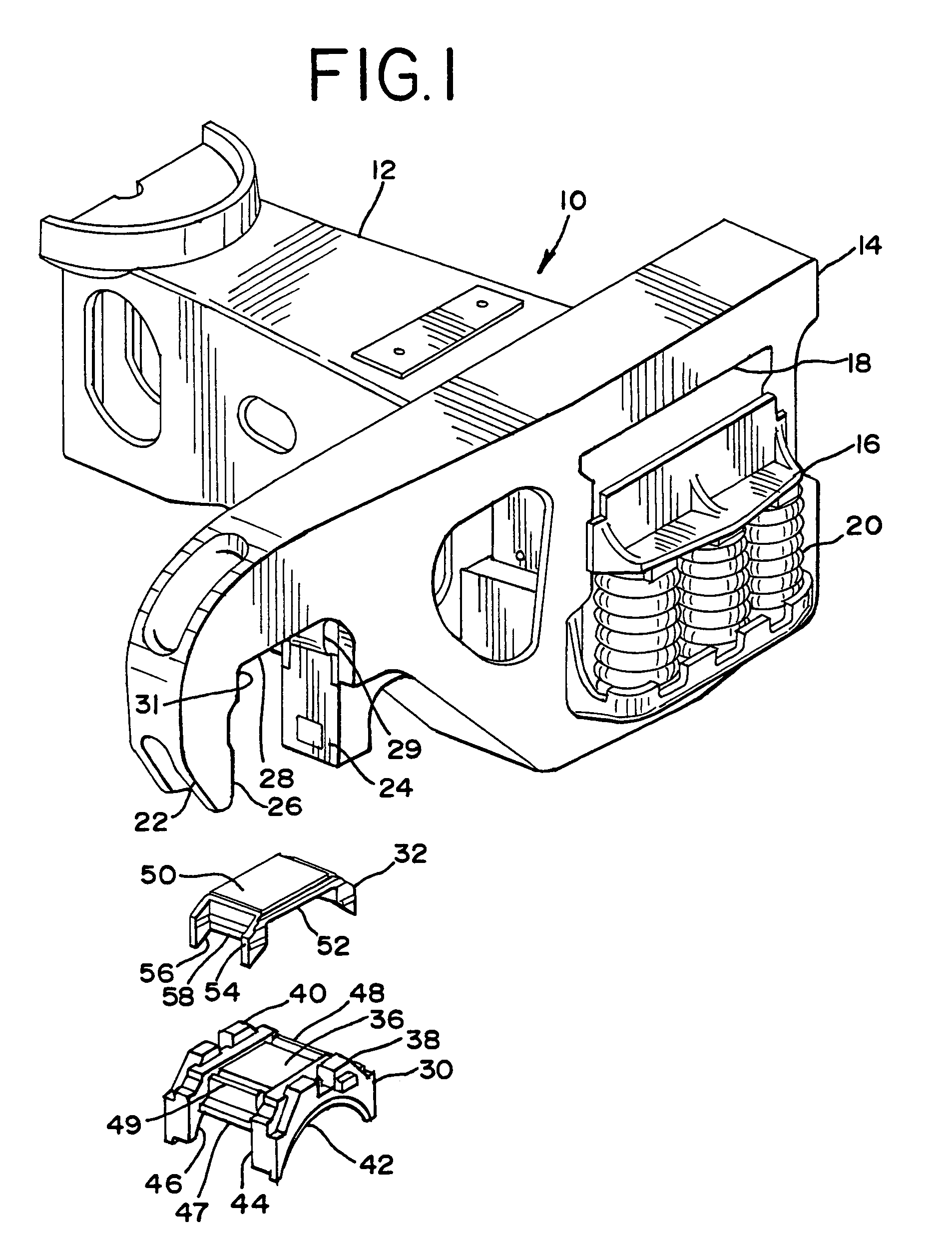

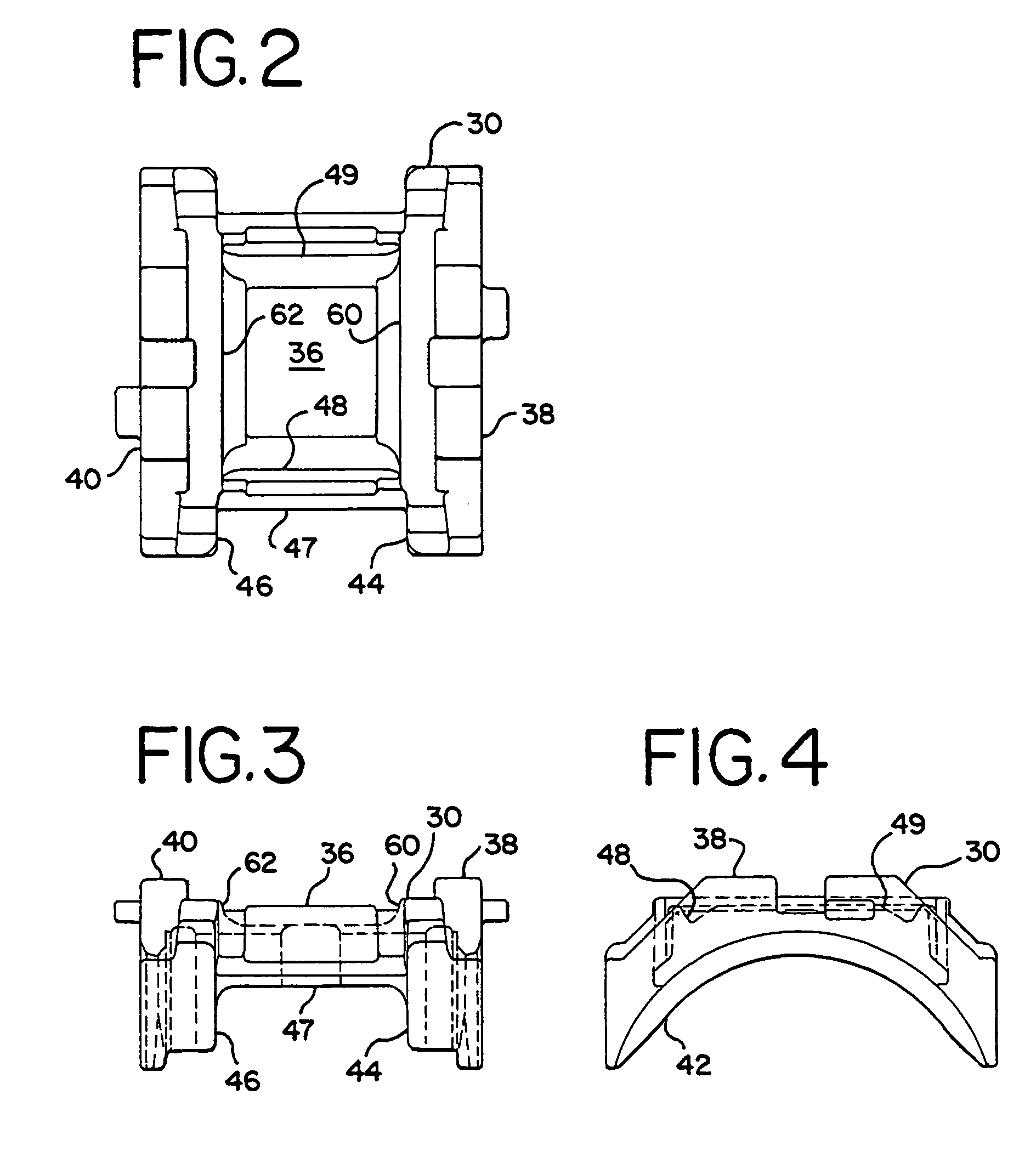

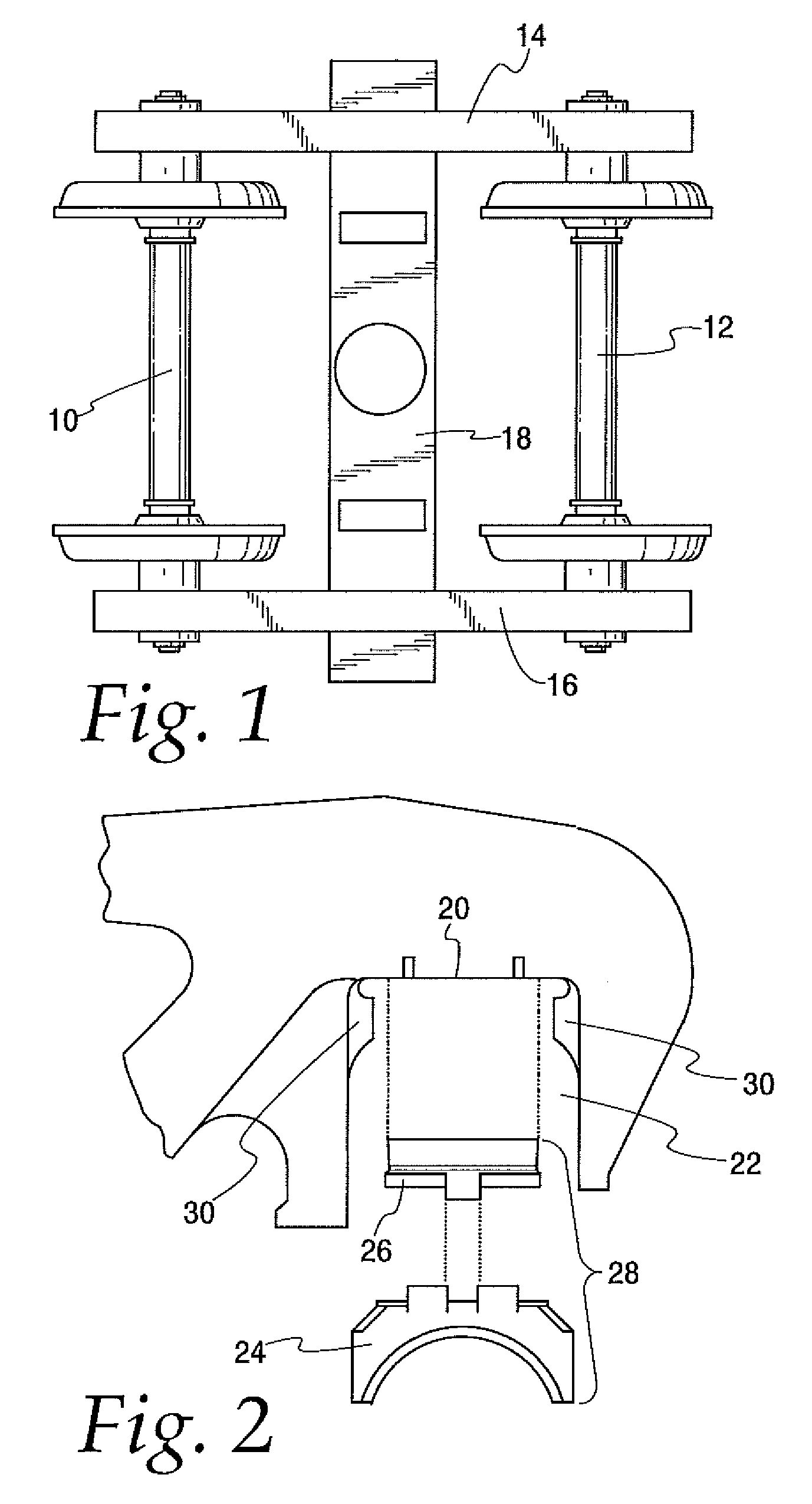

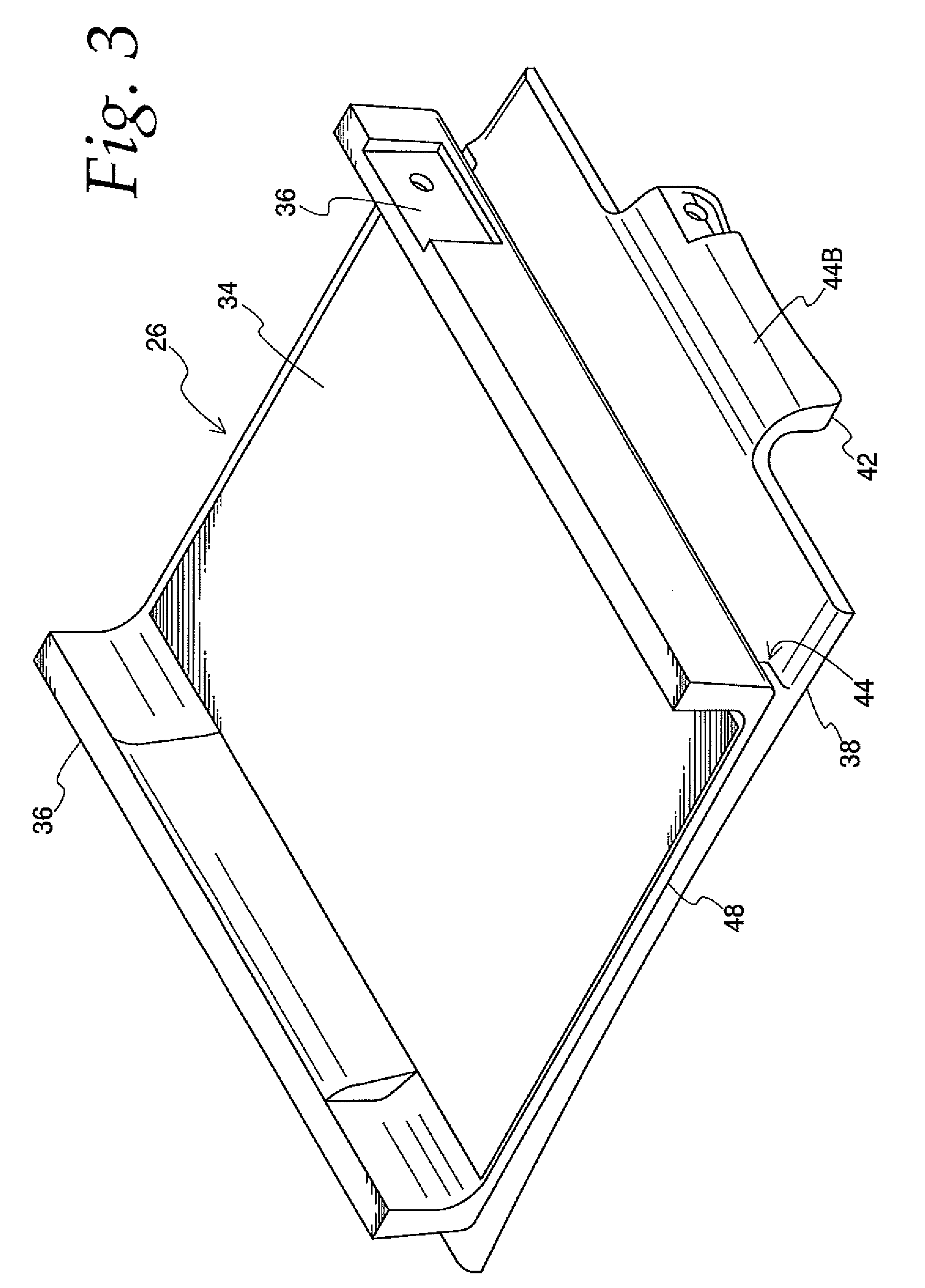

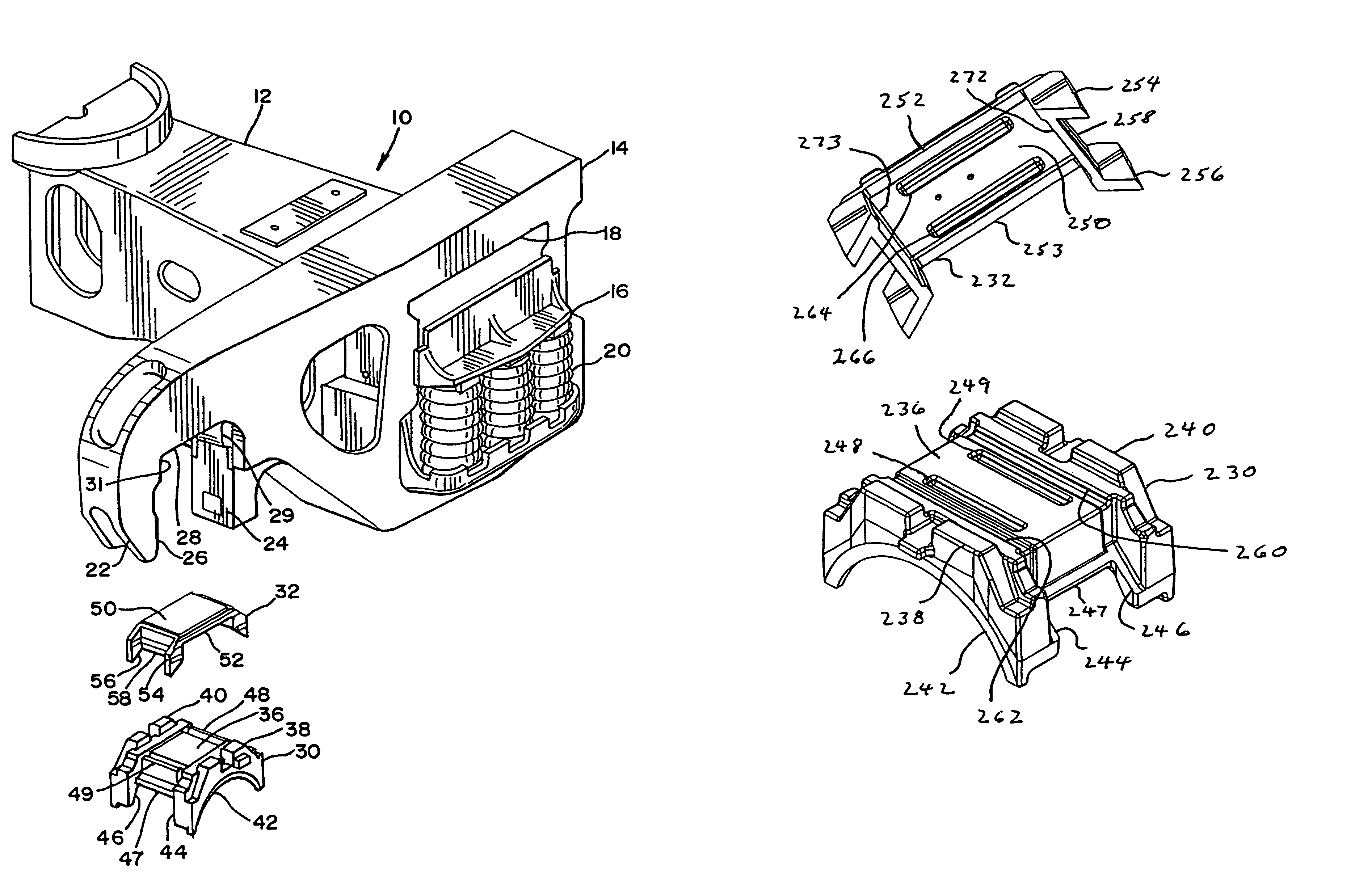

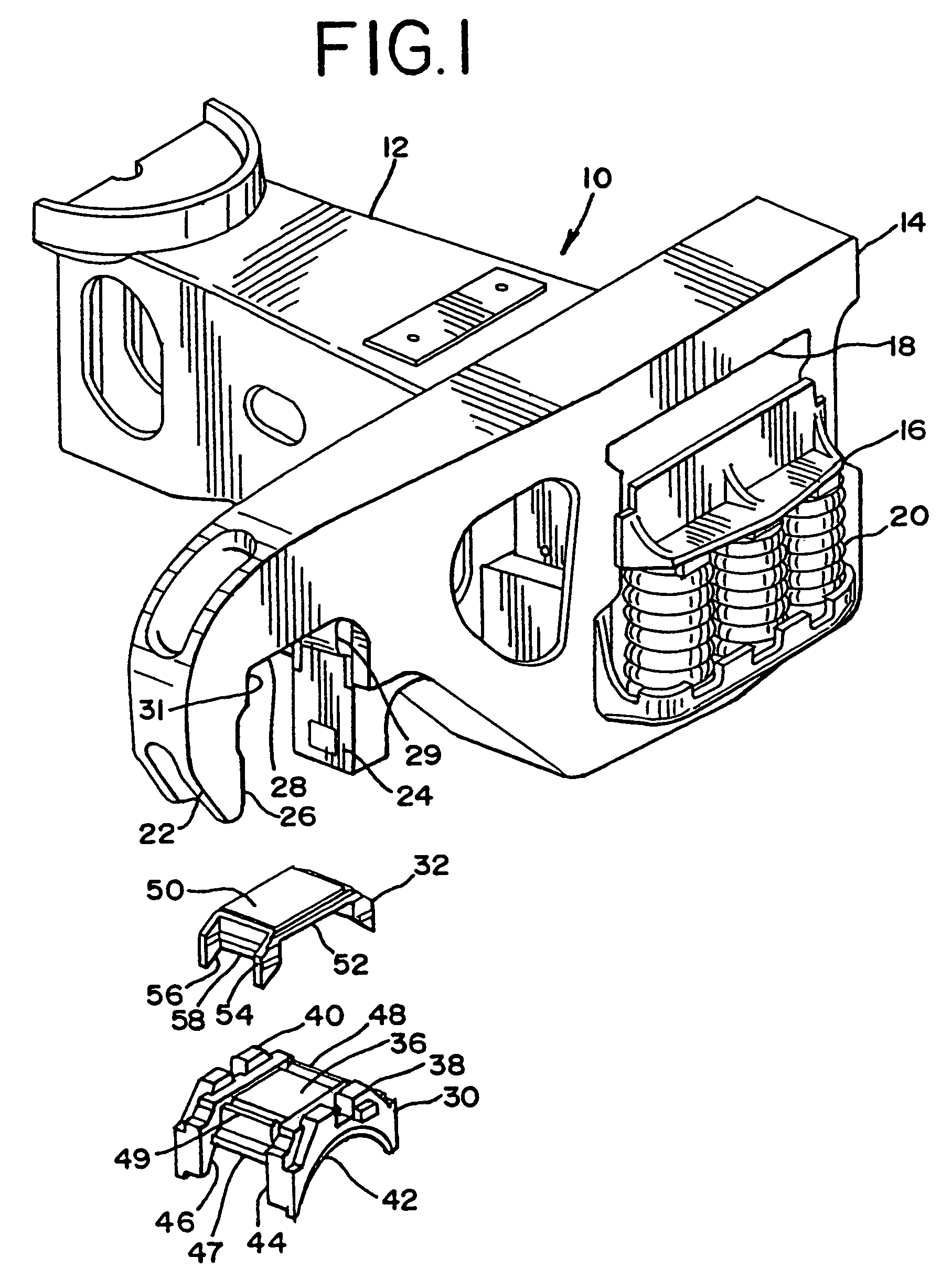

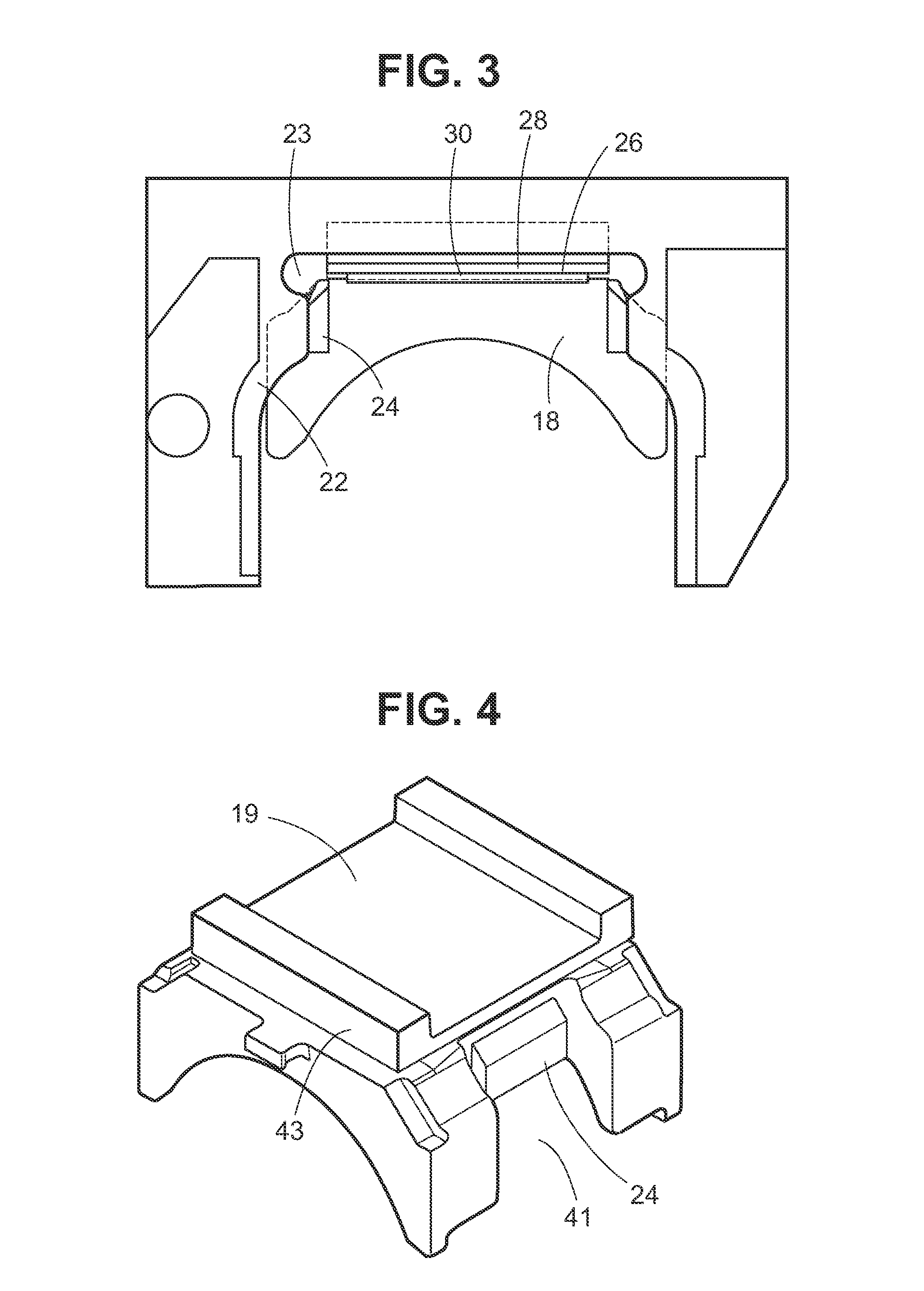

Railway truck pedestal bearing adapter

A railway car truck includes side frames each having a pedestal formed on longitudinally opposite ends thereof. Each pedestal has an upper jaw and a lower jaw surrounding a pedestal opening. The upper jaw has a roof section above the pedestal opening and the lower jaw has an inner wall and an outer wall on opposite sides of the pedestal opening. The inner and outer walls are spaced apart from one another to define a wide pedestal opening. A bearing adapter is received in each pedestal opening. Each bearing adapter includes a concave opening to receive a bearing and a generally rectangular center section having a top surface generally opposite the concave opening. The bearing adapter has steps extending outward from sides thereof that have outer surfaces separated by a distance corresponding to the width of the pedestal opening. The railway car truck also includes an elastomeric adapter pad mounted on top of the bearing adapter that has a generally flat, generally rectangular top section and depending legs that extend along the outer surfaces of the steps. The top section defines a pad for engaging the roof section. The depending legs define pads for engaging the inner and outer walls.

Owner:AMSTED RAIL CO INC

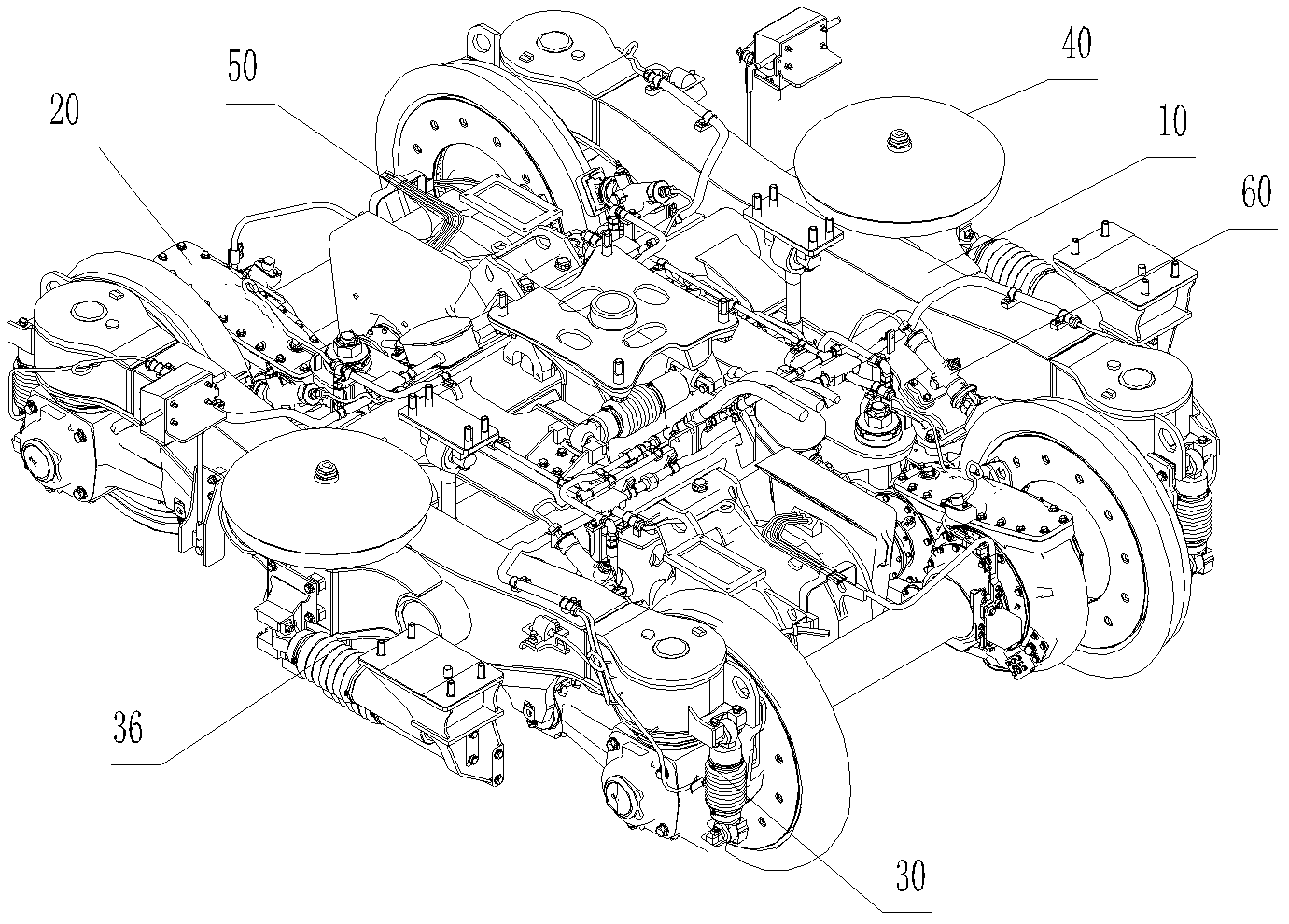

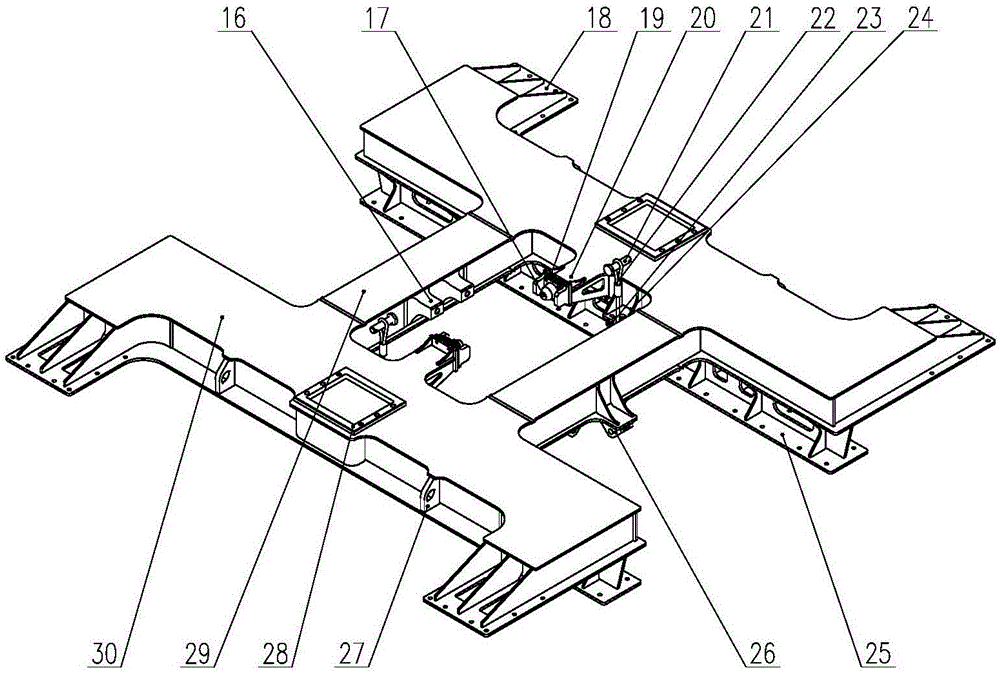

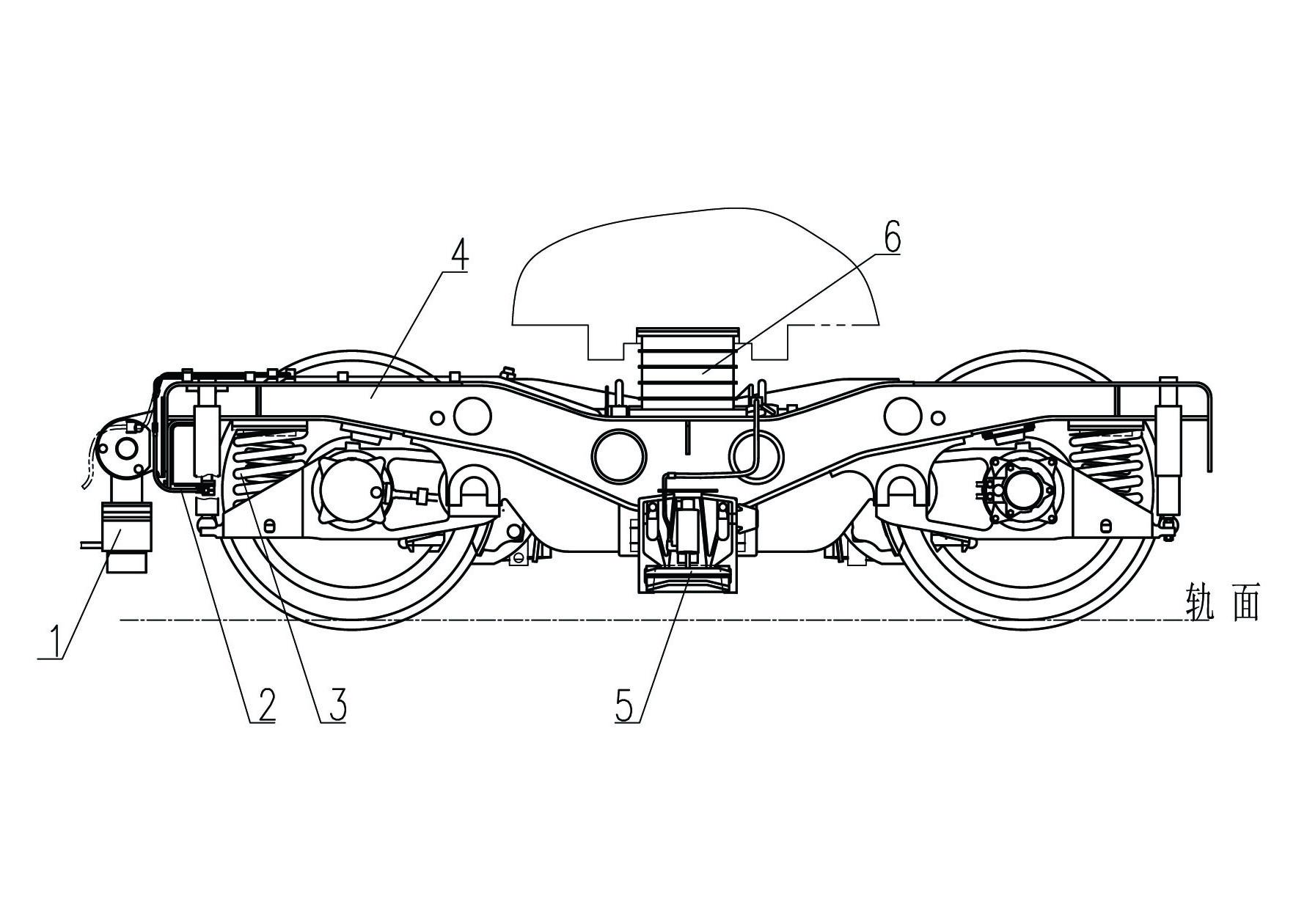

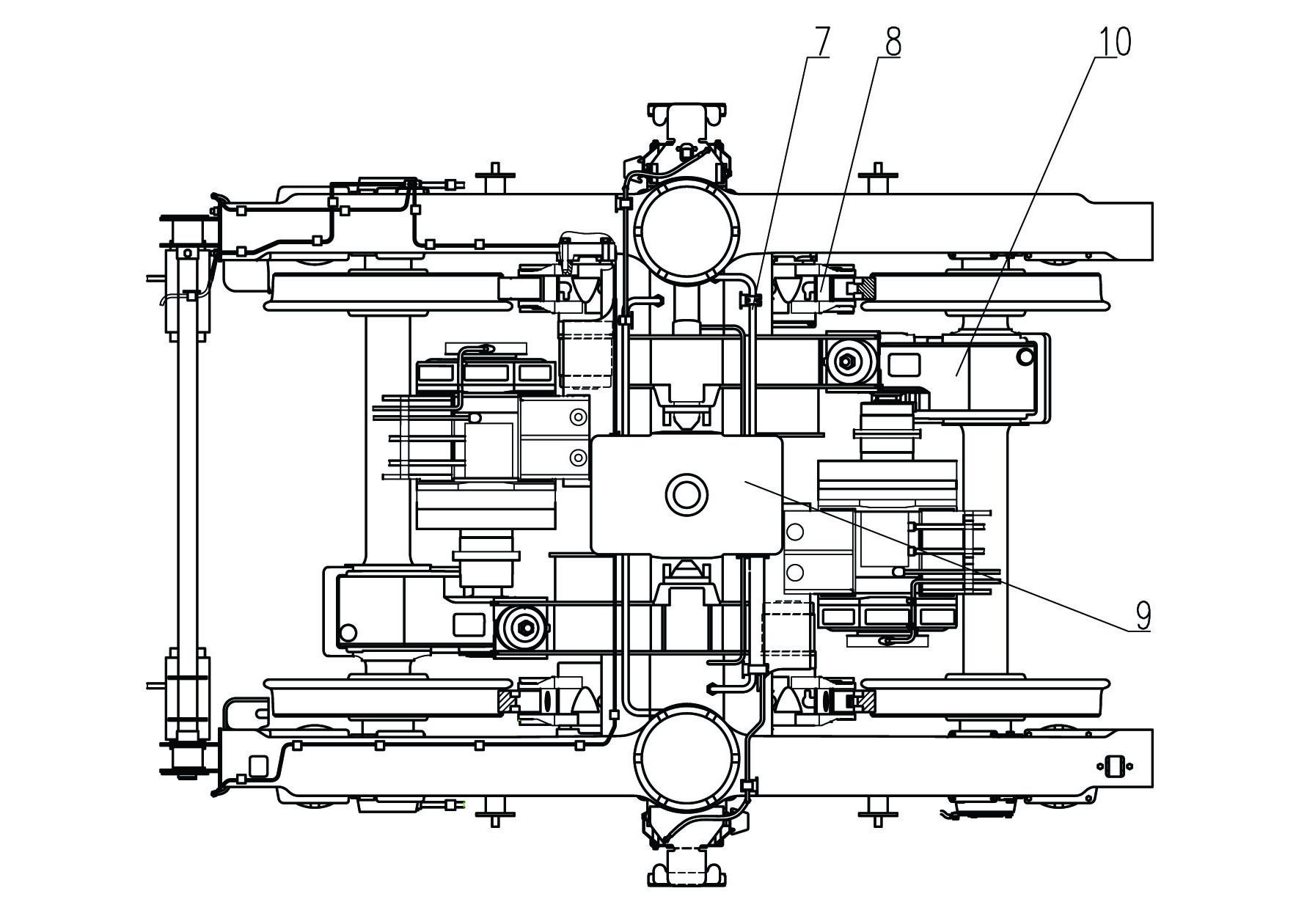

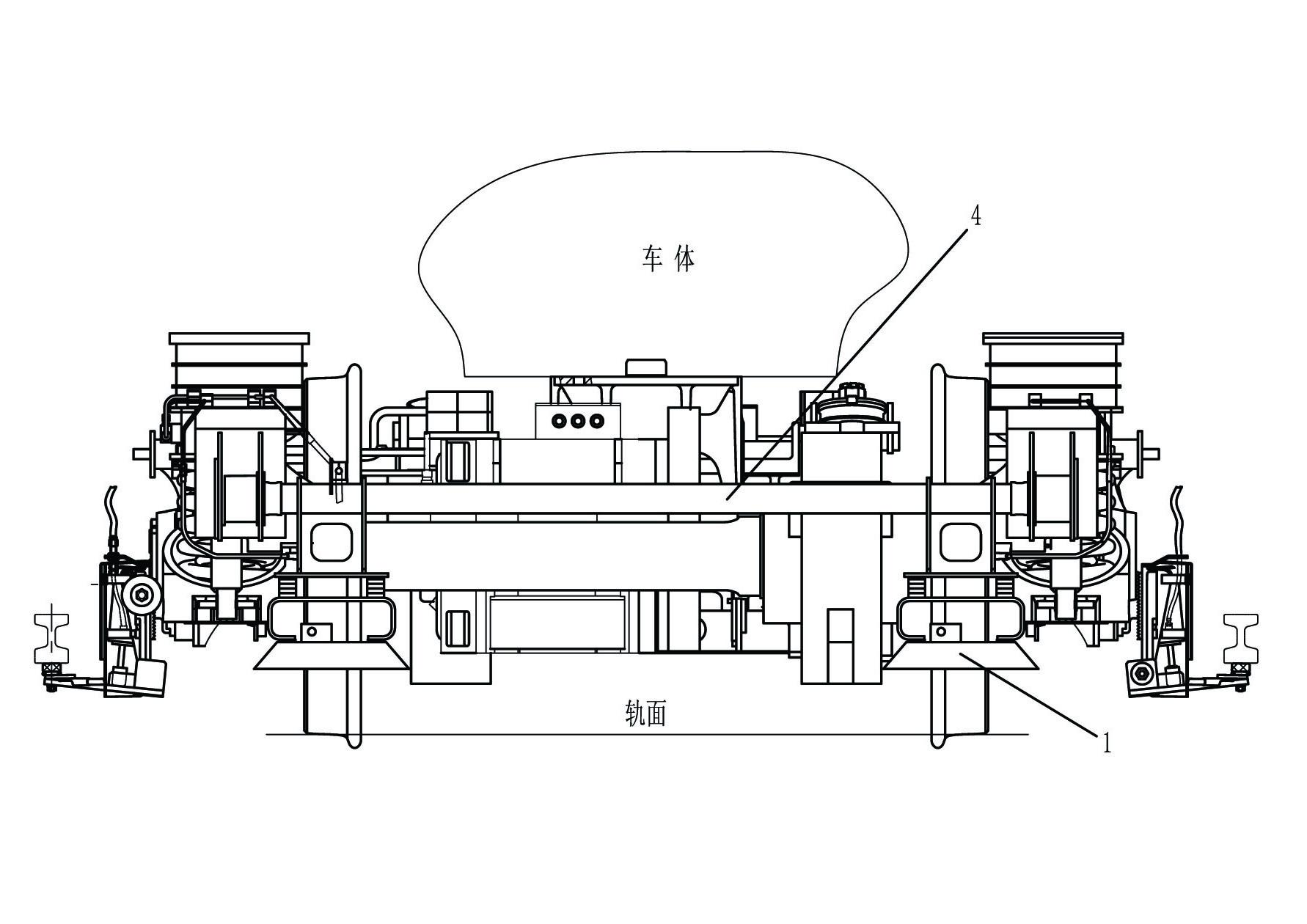

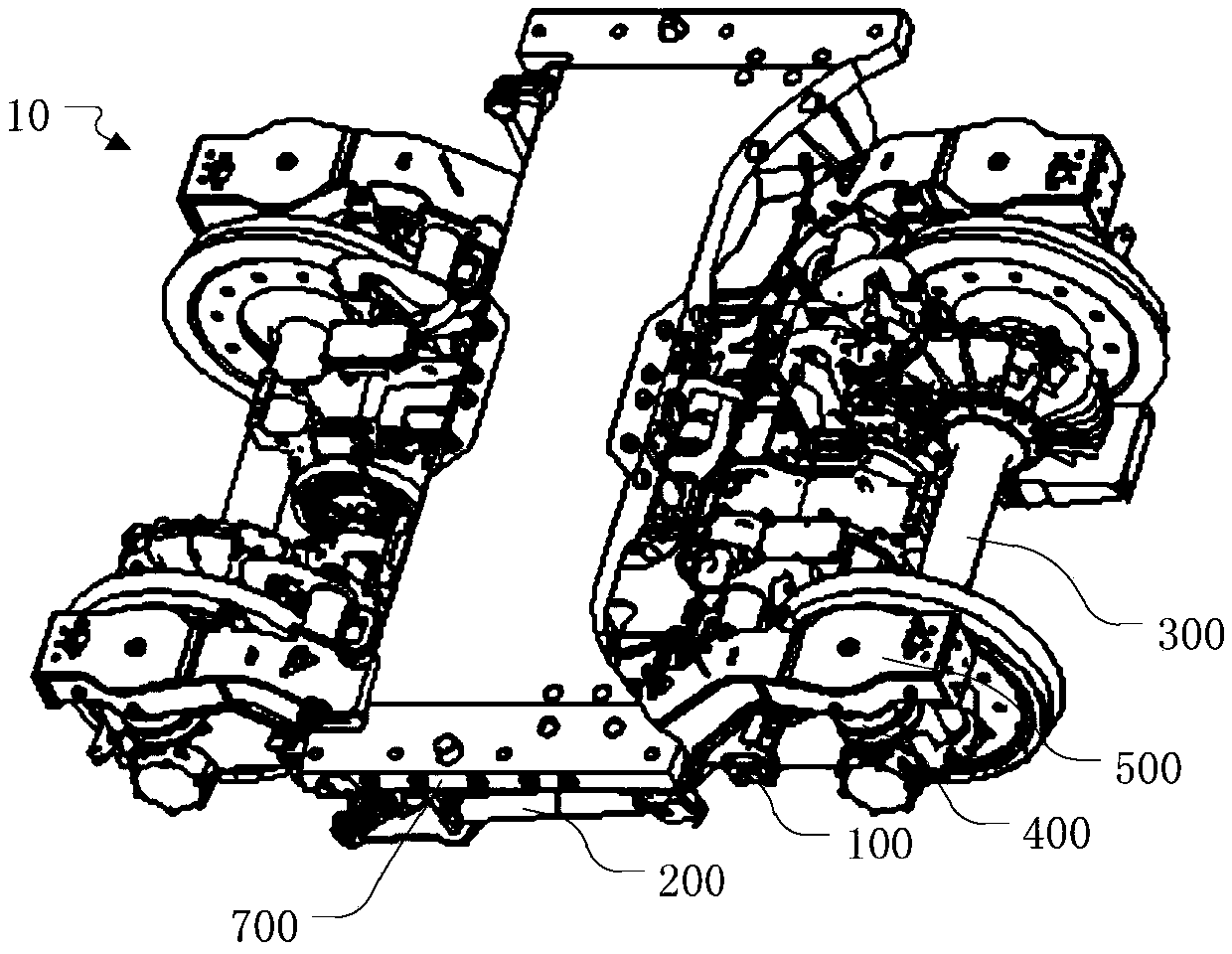

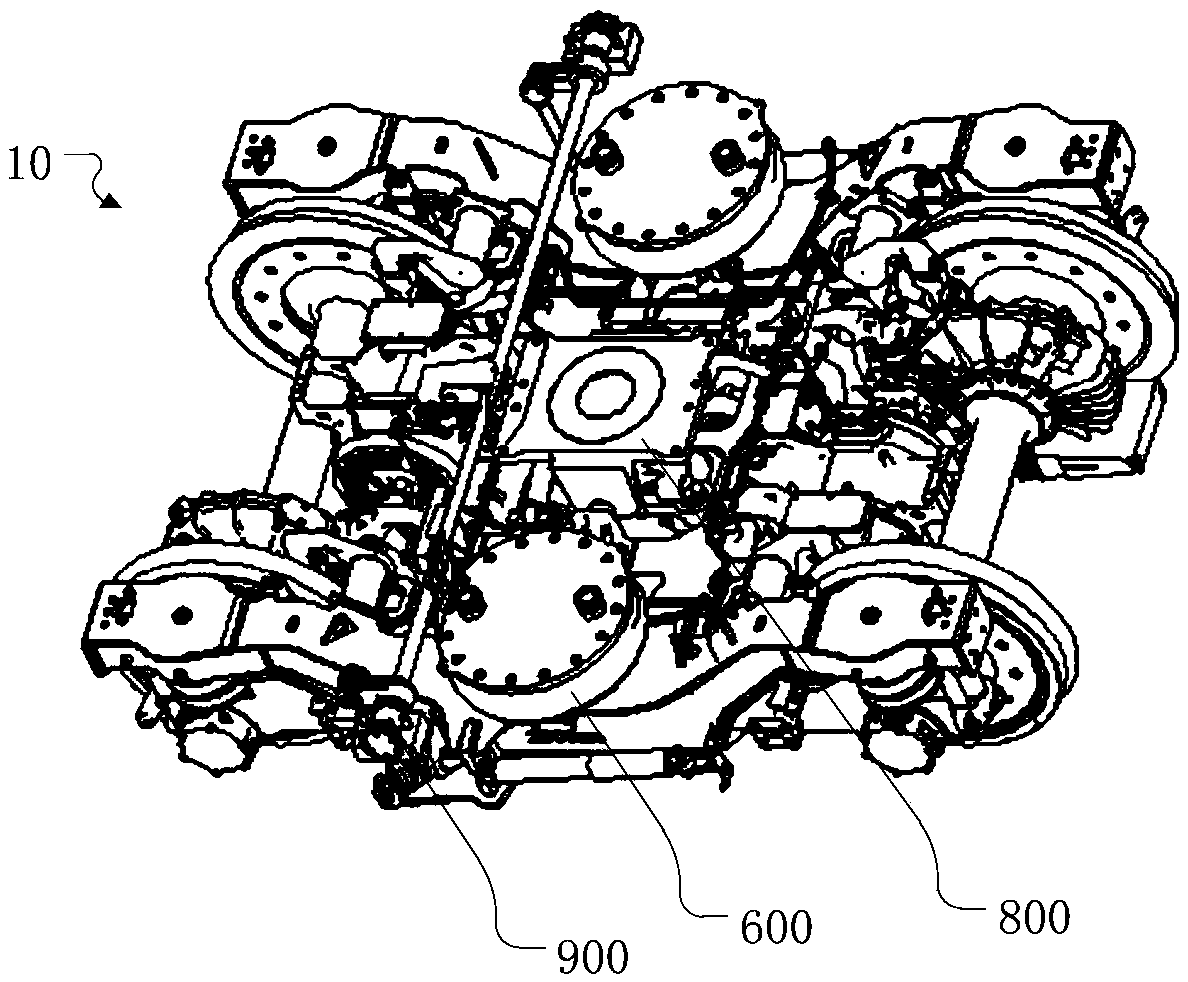

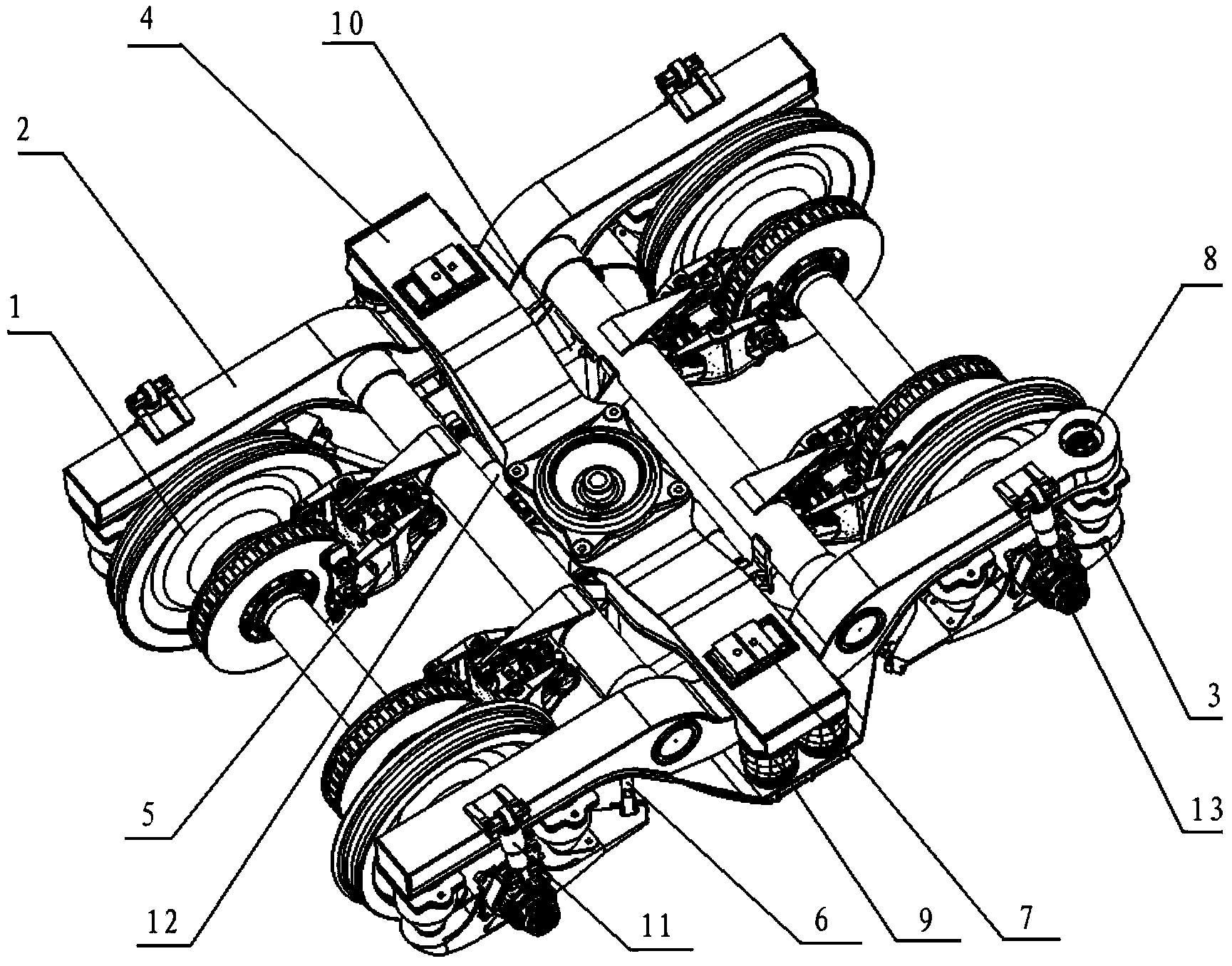

Bogie of high-speed motor train unit

InactiveCN102923153AAchieve lightweight designGuaranteed stabilityBogiesWheel-axle combinationsBogieAir spring

The invention discloses a bogie of a high-speed motor train unit. By adopting a brand-new bogie structure and a hanging connection and traction mode, overall lightweight design is realized, the unsprung weight of the bogie is reduced, and the hanging parameter between the bogie and a body is optimized. On the basis that the high-speed running speed is met, stability when the bogie passes through a big corner and good traction and braking performance are expected. The bogie comprises a framework, two groups of wheel set travelling devices, a linear motor, a first hanging device, a second hanging device, a traction device and a foundation brake device. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure, and comprises a pair of upper and lower cover plates and a pair of lateral web plates which are welded; each cross beam assembly comprises a pair of hollow steel pipes penetrating the lateral web plates and welded with the lateral web plates; and a pair of air spring supporting beams is welded at two ends of a steel pipe and outside the lateral web plates.

Owner:CRRC QINGDAO SIFANG CO LTD

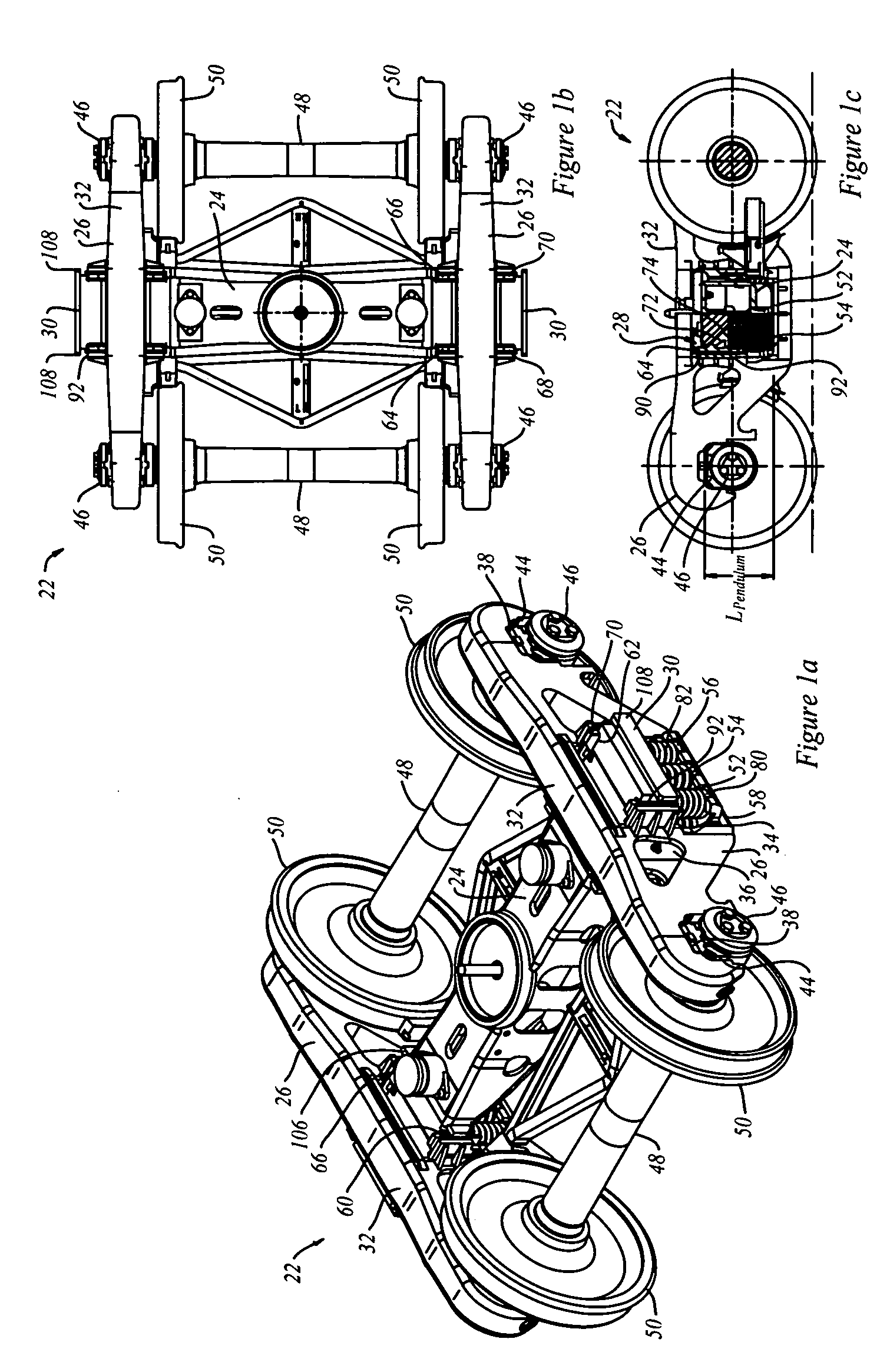

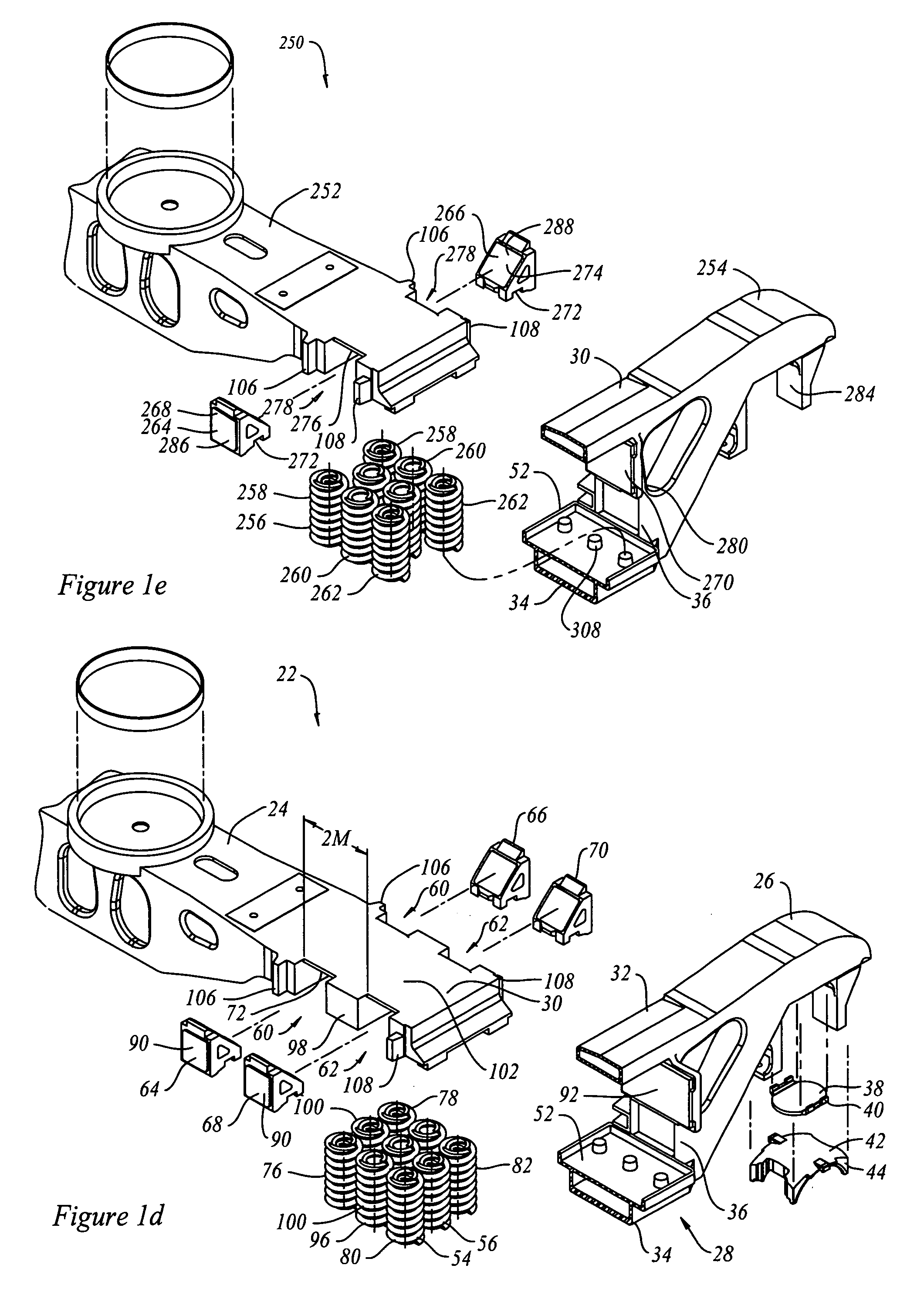

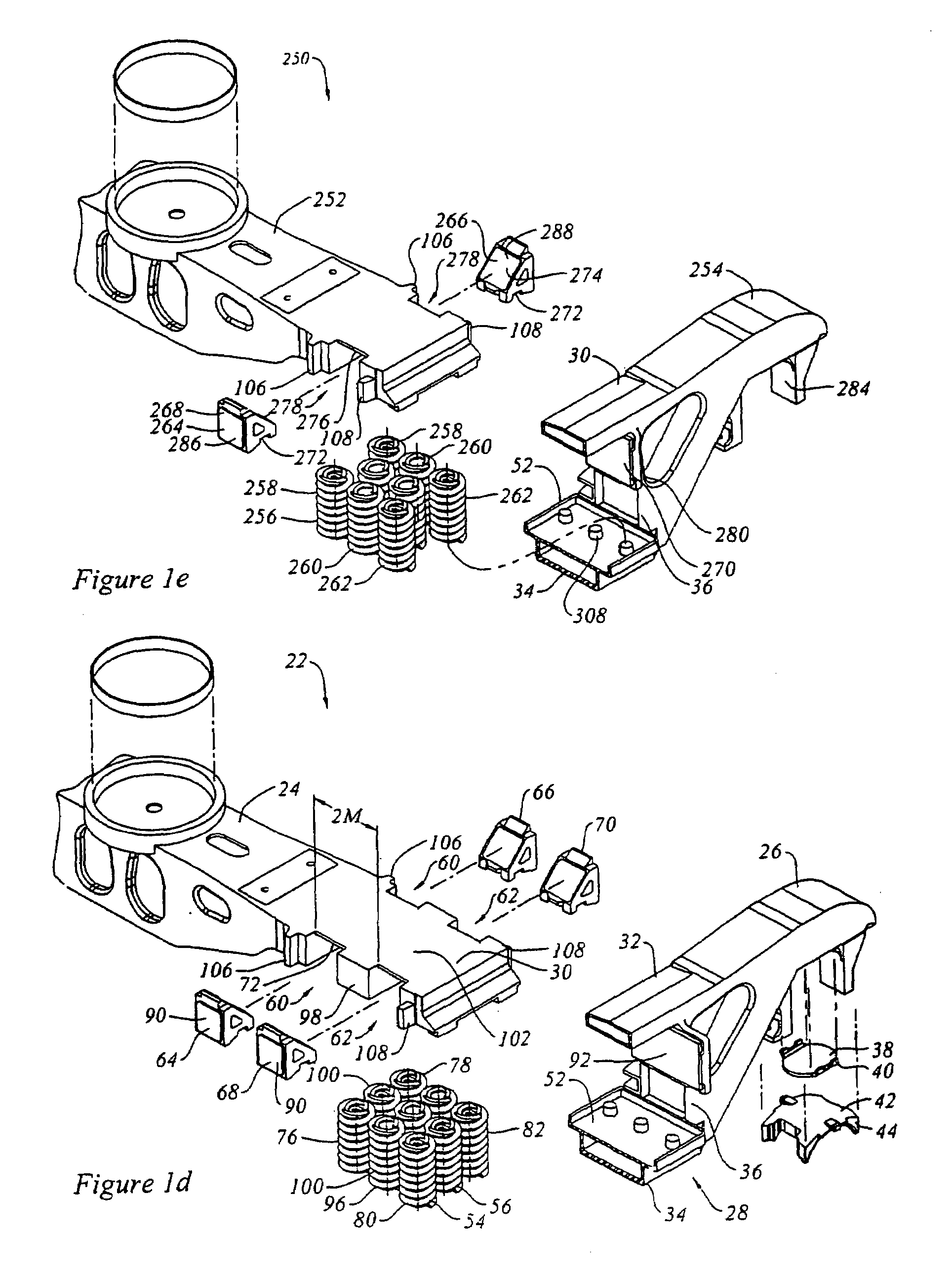

Rail road car truck and bolster therefor

ActiveUS20060117985A1Precise positioningAvoid misdirectionUnderframesPassenger carriagesBogieEngineering

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to deflection that is proportional to the weight carried across the interface. The truck may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both. The friction dampers may operate to yield upward and downward friction forces that are not overly unequal. The friction dampers may be mounted in a four-cornered arrangement at each end of the truck bolster. The spring groups may include sub-groups of springs of different heights.

Owner:NATIONAL STEEL CAR

Flexible sensor interface for a railcar truck

A sensor interface is disclosed including a flexible substrate in which are embedded sensors for measuring physical parameters such as temperature, displacement, velocity, acceleration, stress, strain, pressure and force present between objects such as a railcar bearing and a truck side frame. The substrate is positioned between the objects of interest Electronic components such as a data processing unit, a data storage device, a communication device and a power source may also be embedded within the substrate. The electronic devices communicate with one another and the sensors to process signals generated by the sensors indicative of the parameters being measured.

Owner:AMSTED RAIL CO INC

Rail road car truck and bolster therefor

ActiveUS7631603B2Precise positioningAvoid misdirectionUnderframesPassenger carriagesEngineeringRotational degrees of freedom

Owner:NATIONAL STEEL CAR

Railway truck pedestal bearing adapter

A railway car truck is provided that includes two sideframes and a bolster. Each sideframe has a pedestal opening at each end to receive a bearing adapter assembly. The bearing adapter assembly includes a cast steel bearing adapter that is formed to fit on top of a bearing assembly. An adapter pad, comprised of a selected hardness elastomer, is fit on top of the bearing adapter. Protrusions extend from the adapter pad and are received in depressions in the bearing adapter to provide longitudinal stability for the adapter pad on the bearing adapter itself. Each adapter pad includes at least two wear tabs extending laterally outwardly from a top section of the adapter pad.

Owner:AMSTED RAIL CO INC

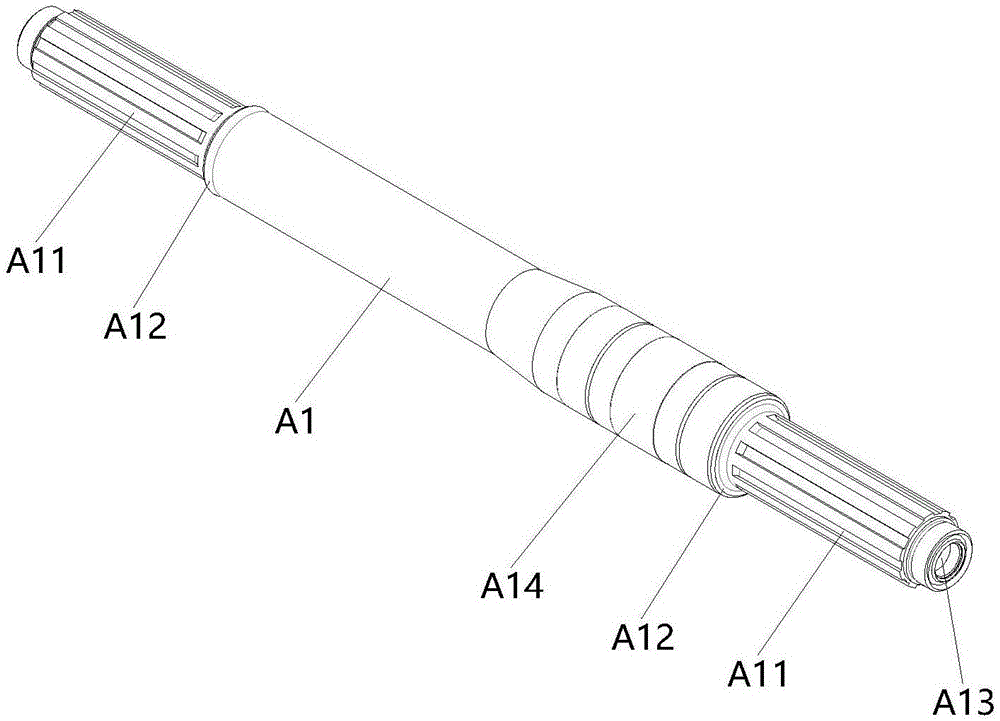

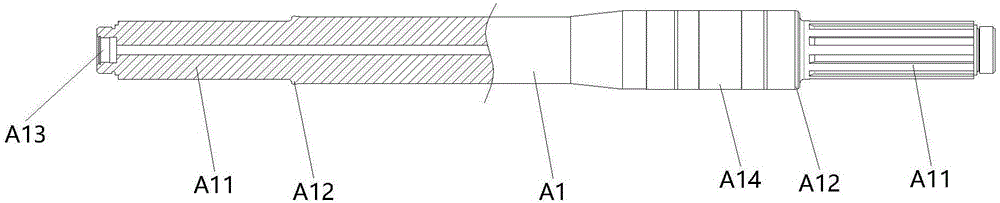

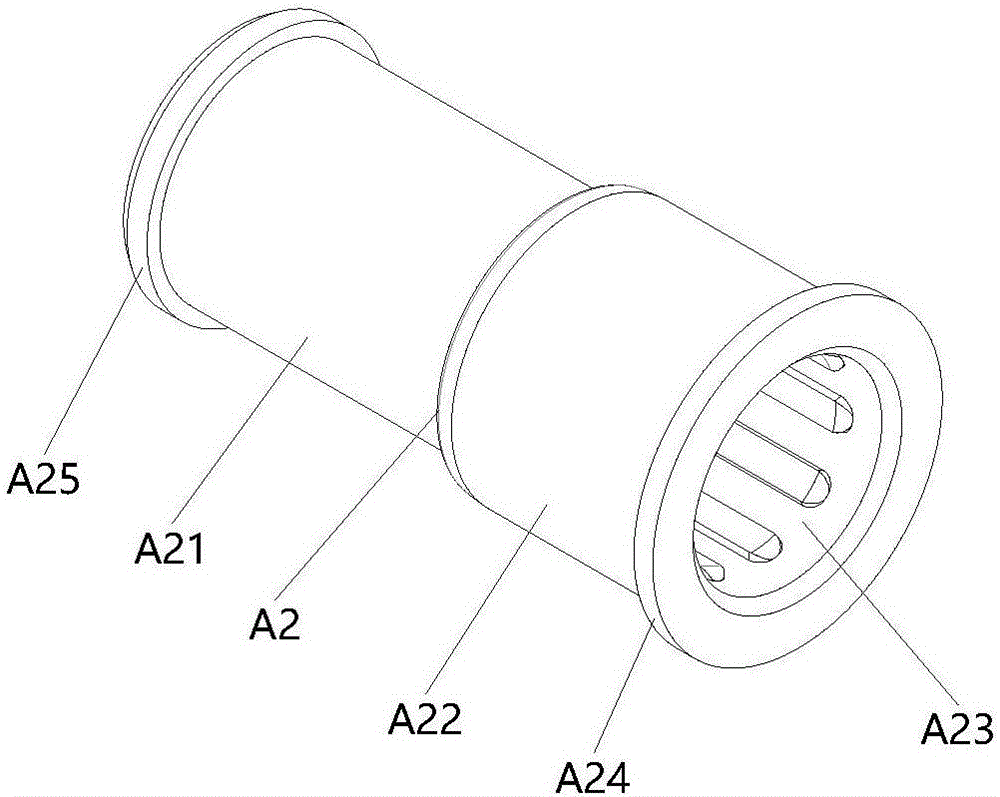

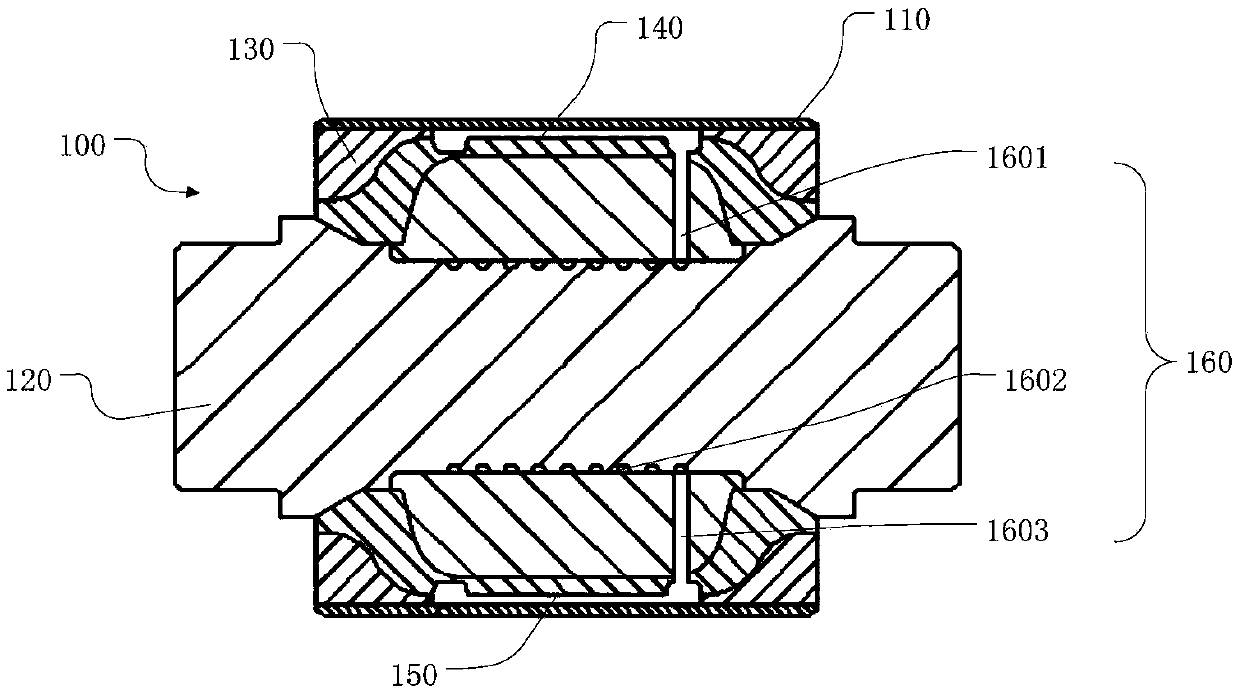

Variable gauge bogie

The invention belongs to the technical field of bogie systems, and particularly relates to a variable gauge bogie. The variable gauge bogie comprises an axle assembly, a sliding key assembly and an axle box assembly. The axle assembly comprises an axle and a bearing and wheel integrated mounting seat. The sliding key assembly comprises a sliding part. The axle box assembly comprises an axle box and a bearing. The position from a wheel seat to the end part of the axle is provided with a moving pair connecting part. The bearing and wheel integrated mounting seat comprises a bearing mounting seat and a wheel mounting seat which are mutually connected and further comprises a moving pair junction part. The moving pair junction part and the moving pair connecting part form an axial moving pair. The sliding part is of a cylindrical body. The outer side wall of the cylindrical body is in axial slidable connection with the axle box. The inner side wall of the cylindrical body is in axial fixed connection with the bearing mounting seat through the bearing. The wheel axial direction of the variable gauge bogie is adjustable to be adapted to different gauges, railway transportation of ''Silk Road Economic Belt'' is developed, and the problem that railway gauges are not uniform must be solved, therefore, it is very important and far-reaching to carry out design of the variable gauge bogie.

Owner:SOUTHWEST JIAOTONG UNIV +1

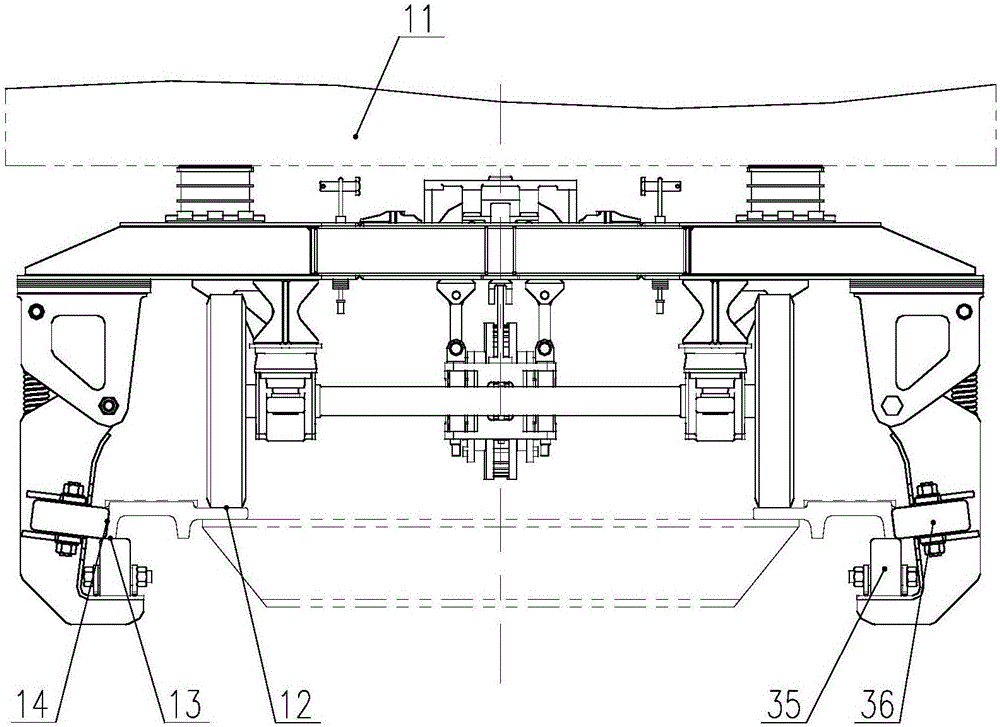

Magnetic levitation railway vehicle and bogie thereof

The invention discloses a magnetic levitation railway vehicle and a bogie thereof. The bogie comprises a frame composed of a lateral beam and a transverse beam, a plurality wheelset shaft box device below the frame, a plurality of guide devices installed on the outer side of the lateral beam of the frame, a first-stage suspension device, a second-stage suspension device, a traction device used for being installed between the inner side of the transverse beam of the frame and a vehicle body, and a transverse stop dog. An anti-disengaging and hoisting device is installed between the inner side of the lateral beam of the frame and the vehicle body. A foundation braking device is installed between the bottom of the transverse beam of the frame and an axle of the wheelset shaft box device. The bogie can adapt to running of medium-speed and low-speed magnetic levitation railway vehicles, and the moving problem of the medium-speed and low-speed magnetic levitation railway vehicles on tracks is solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

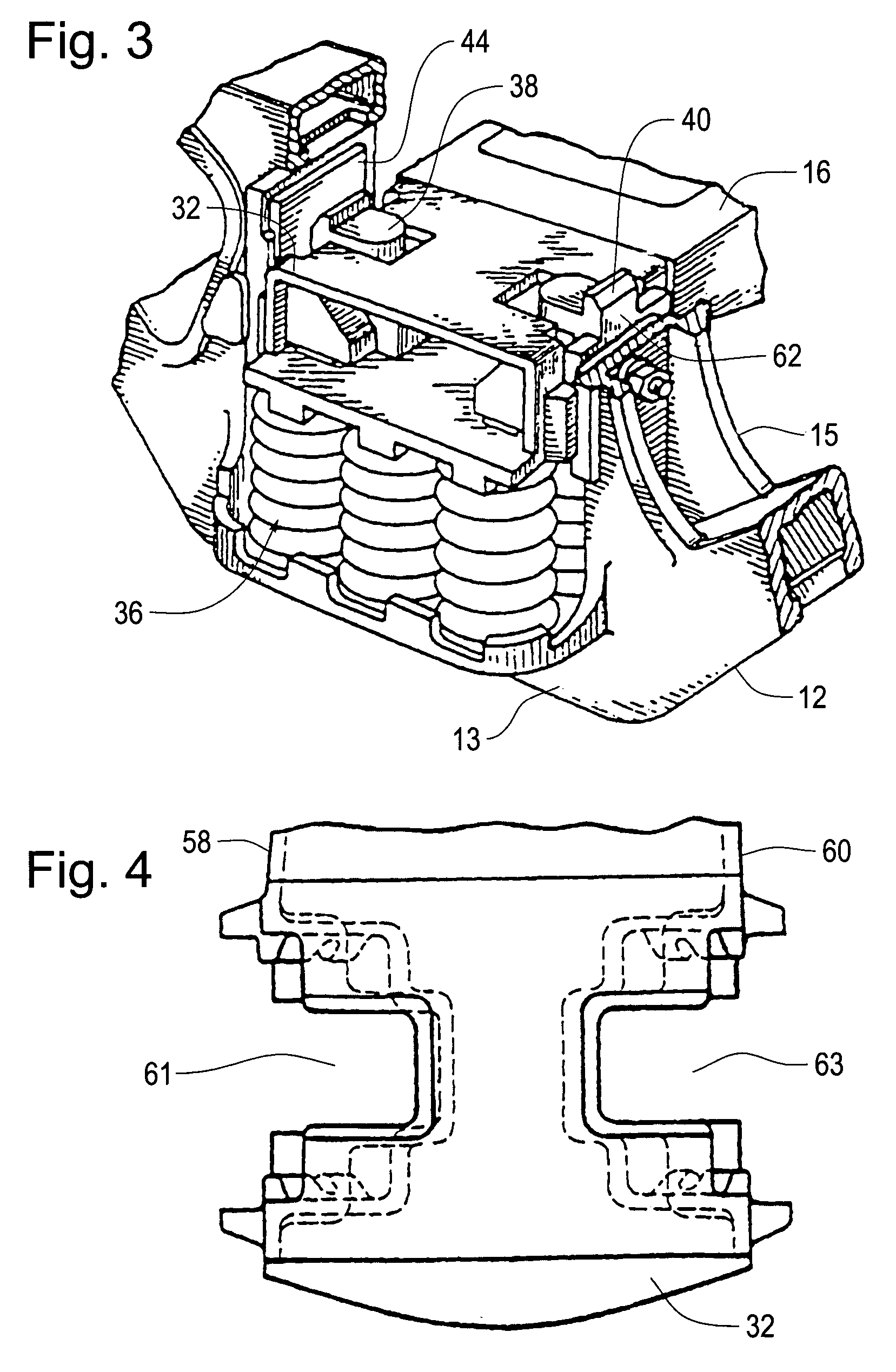

Three-piece motion control truck system

An improved three-piece truck system for railroad cars provides long travel side bearings for improved stability, a “wide” friction shoe design or equivalent to improve sideframe and bolster squareness, a resilient pedestal pad for improved curving performance and enhanced wear resistance, and a suspension system tuned and optimized for rail cars to have a minimum reserve capacity of less than 1.5 to improve motion control and ride quality, increase resistance to suspension bottoming, and increase hunting threshold speed. Such a motion control truck system is able to meet recent, more stringent American Association of Railroads standards, such as M-976, for railcars having a 286,000 lb. gross rail load rating.

Owner:AMSTED RAIL CO INC

Resilient pad for railroad vehicle

ActiveUS20120186486A1Prevents and minimizes problemIncreased installation effortAxle-boxesBogiesEngineeringMechanical engineering

A resilient pad having a base with two side arms and two side lips for resiliently holding the base on a pedestal wear plate, the pad being configured with dome shaped portions disposed substantially perpendicular to the direction of the pad and being spaced apart from each other, where the pad, when installed with a pedestal wear plate serves to improve the force load handling and preferably re-distributes the load bearing surface from the edges and center of the adapter to the flat load bearing surface of the adapter, thus eliminating load on areas that have no support. Because the spring arms do not depend on bending of the base for their resiliency, the pad of the invention provides improved service stress capabilities and allows for longer life of the wear plate.

Owner:PENNSY CORP

Railway truck pedestal bearing adapter

A railway car truck is provided that includes two sideframes and a bolster. Each sideframe has a pedestal opening at each end to receive a bearing adapter assembly. The bearing adapter assembly includes a cast steel bearing adapter that is formed to fit on top of a bearing assembly. An adapter pad, comprised of a selected hardness elastomer, is fit on top of the bearing adapter. Protrusions extend from the adapter pad and are received in depressions in the bearing adapter to provide longitudinal stability for the adapter pad on the bearing adapter itself.

Owner:AMSTED RAIL CO INC

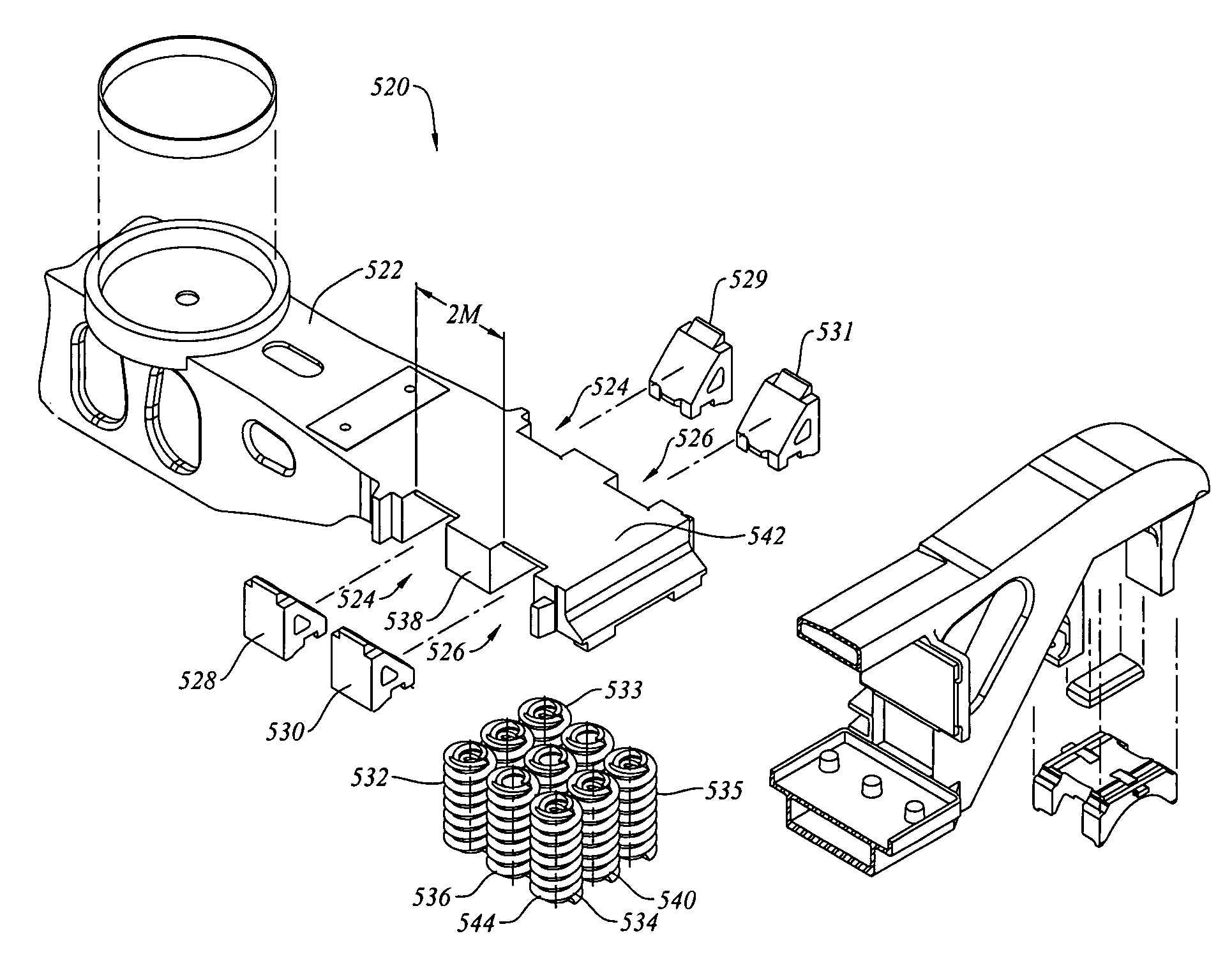

Rail road car truck and fittings therefor

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to deflection that is proportional to the weight carried across the interface. The truck may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both. The friction dampers may operate to yield upward and downward friction forces that are not overly unequal. The friction dampers may be mounted in a four-cornered arrangement at each end of the truck bolster. The spring groups may include sub-groups of springs of different heights.

Owner:NATIONAL STEEL CAR

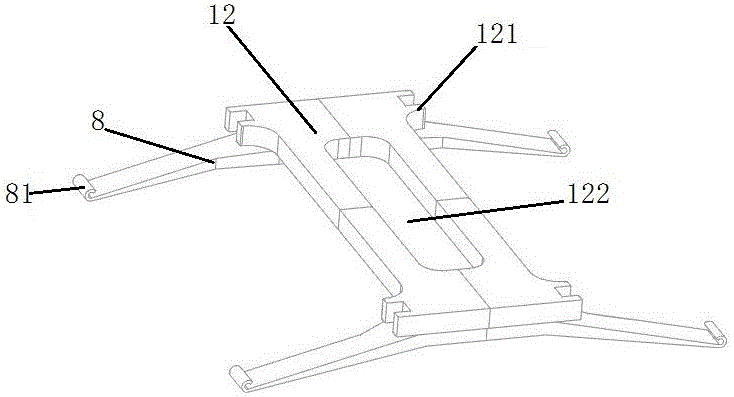

Rail engineering truck steering frame

ActiveCN102114851AEasy to disassembleEasy maintenanceBogiesBogie-underframe connectionsLower limitBogie

The invention discloses a rail engineering truck steering frame belonging to the field of rail vehicle steering frames. Aiming at the defects of large turning radius and incapability of meeting the low-speed operation working conditions of the traditional rail engineering truck, the steering frame comprises an H-type frame, ATP (Array Transform Processor) induction coil devices arranged at end parts of two lateral beams of the frame, rim lubricating devices arranged at two ends of a locomotive, a primary suspension device, a secondary suspension device, a third rail current collector arranged at the middles of the lateral beams of the frame, a basic brake device transversely arranged on the lateral beams of the frame, and a traction device connected with the frame by adopting a full-suspension manner; and a gear box is hung on a cross beam of the frame and is internally provided with two stages of gear transmissions with total transmission ratio of (7.63-10.03):1. The rail engineering truck steering frame has the highest operation speed of 90km / h, the continuous speed of about 18km / h and the lowest operation speed of below 5km / h and has the advantages of small turning radius, high low limit, simpler structure, convenience for maintenance and high reliability.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

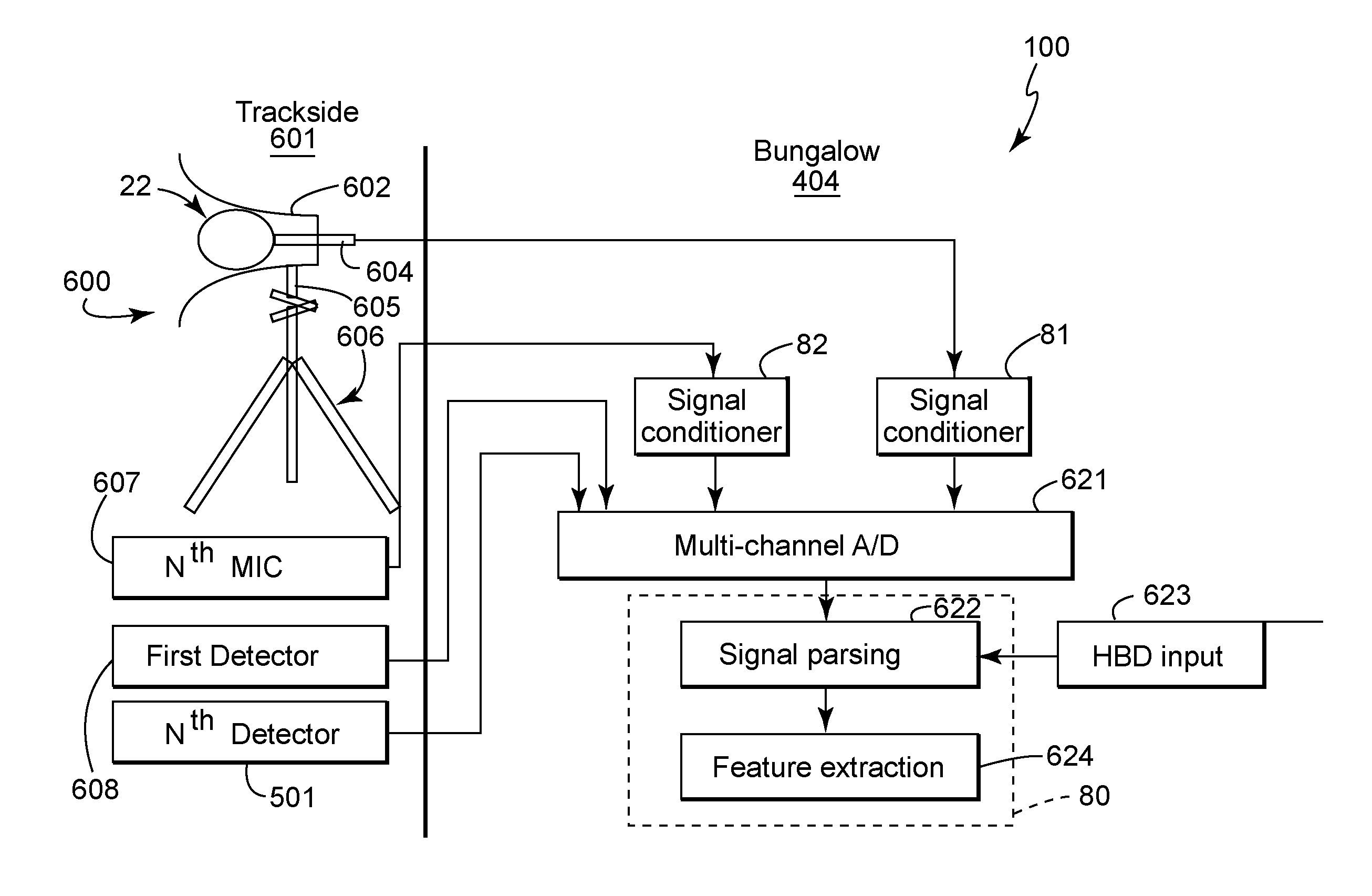

Low profile shear pad and adapter

A low profile mounting assembly for use between a rail car side frame pedestal and the rail car roller bearing includes a shear pad and a bearing adapter. In one embodiment, the shear pad has relatively thin plates joined by an elastomeric layer. In another embodiment, the shear pad includes a projection extending downwardly from a plate to be received and retained by a recess defined in a top surface of the adapter. In another embodiment, a central cavity formed in a lower plate of the shear pad cooperates with the adapter top surface to distribute forces on the roller bearing. In another embodiment, an elastomeric projection of a shear pad plate bears against ridges on the adapter top surface to prevent disengagement.

Owner:IDEAL IND INC +1

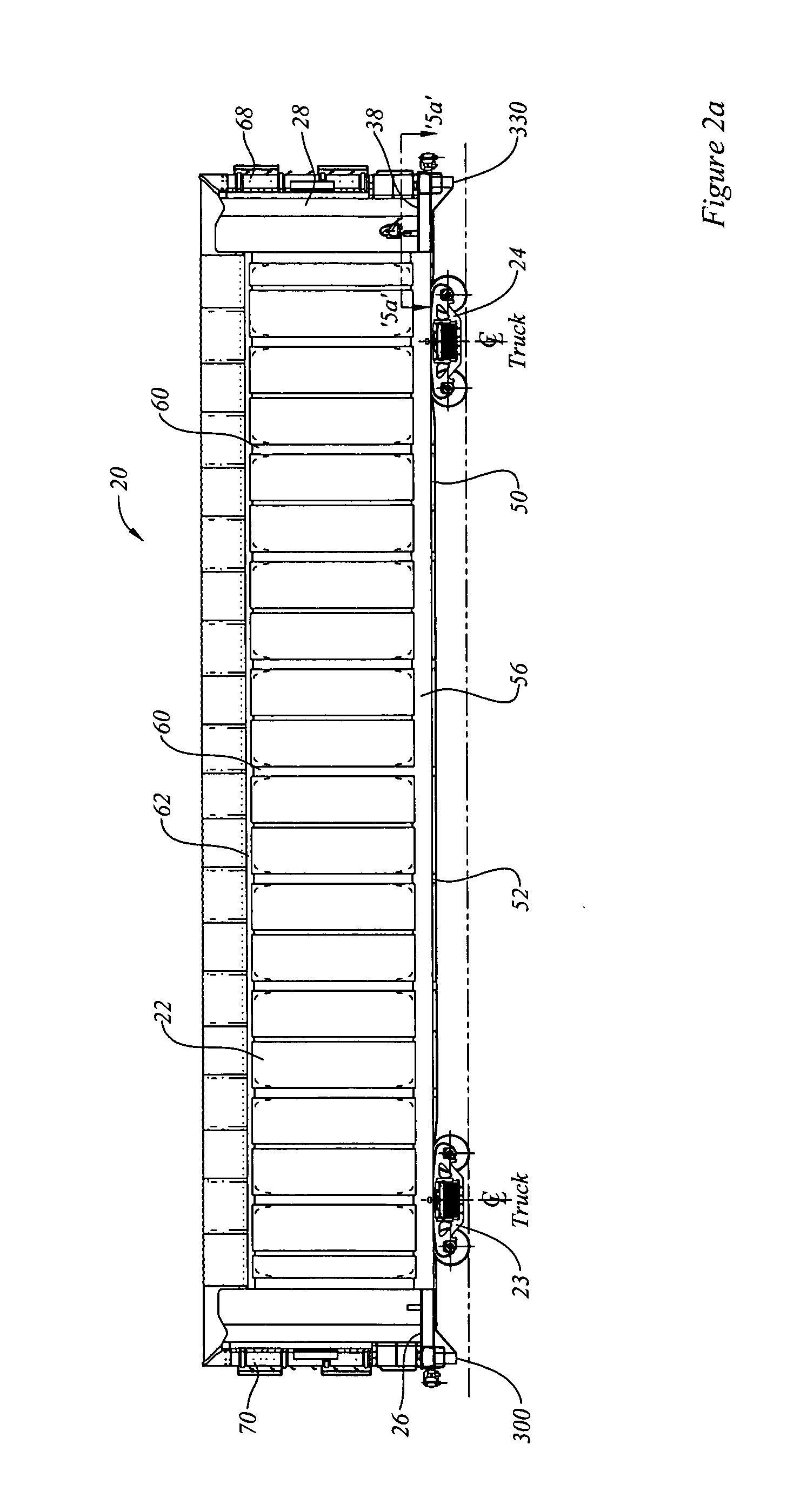

Rail road car and truck therefor

An autorack rail road car is provided with a truck that includes a pair of sideframes supported on wheel sets with bearing adapters positioned therebetween. The bearing adapters and the sideframes have associated parts or surfaces with curvatures configured to permit lateral swinging of the sideframes. A bolster is supported by the sideframes, and sets of laterally arranged dampers are provided therebetween to control the relationship between the sideframes and the bolster.

Owner:NATIONAL STEEL CAR

Railway truck pedestal bearing adapter

A railway car truck is provided that includes two sideframes and a bolster. Each sideframe has a pedestal opening at each end to receive a bearing adapter assembly. The bearing adapter assembly includes a cast steel bearing adapter that is formed to fit on top of a bearing assembly. An adapter pad, comprised of a selected hardness elastomer, is fit on top of the bearing adapter. Protrusions extend from the adapter pad and are received in depressions in the bearing adapter to provide longitudinal stability for the adapter pad on the bearing adapter itself. Each adapter pad includes at least two wear tabs extending laterally outwardly from a top section of the adapter pad.

Owner:AMSTED RAIL CO INC

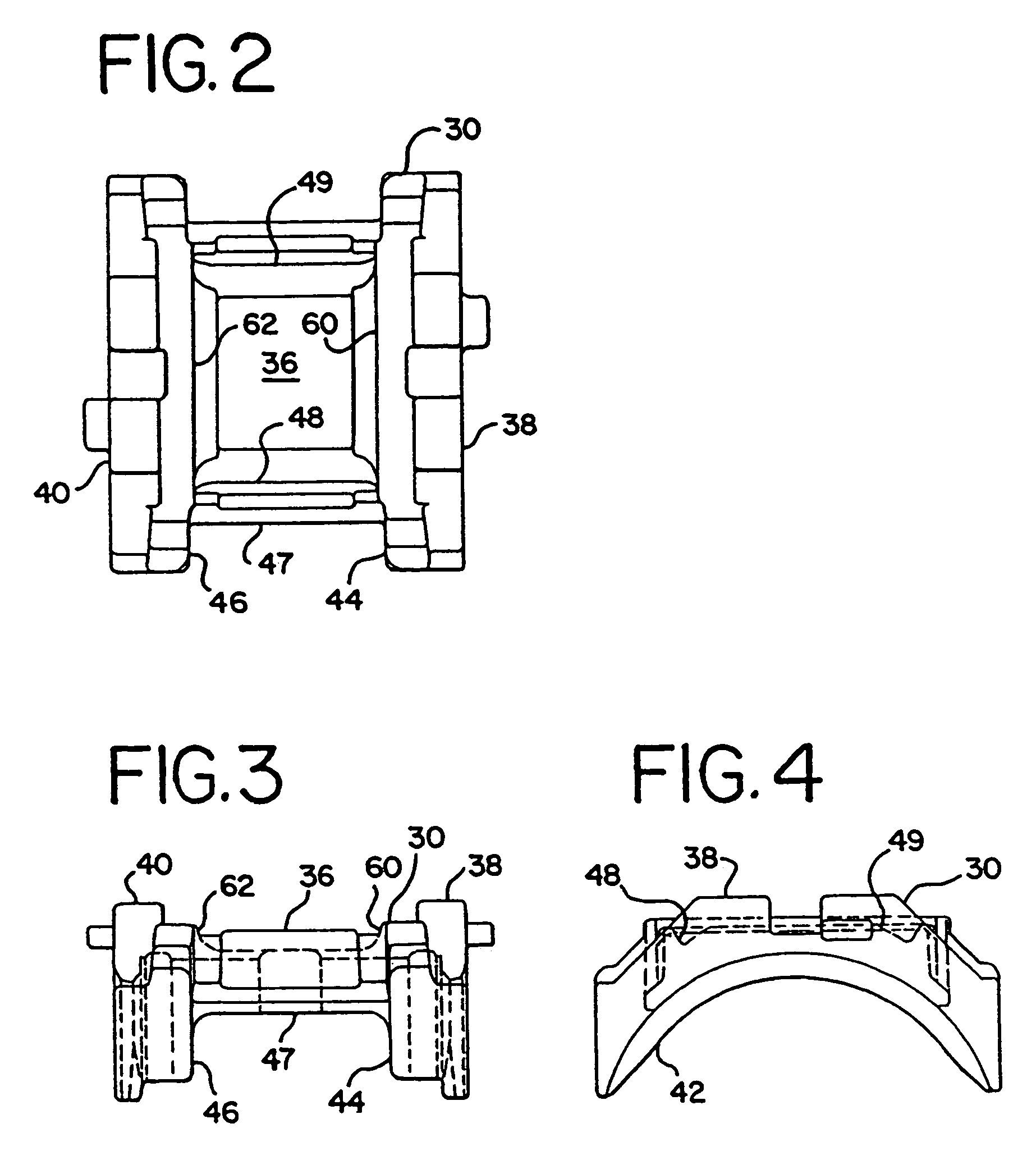

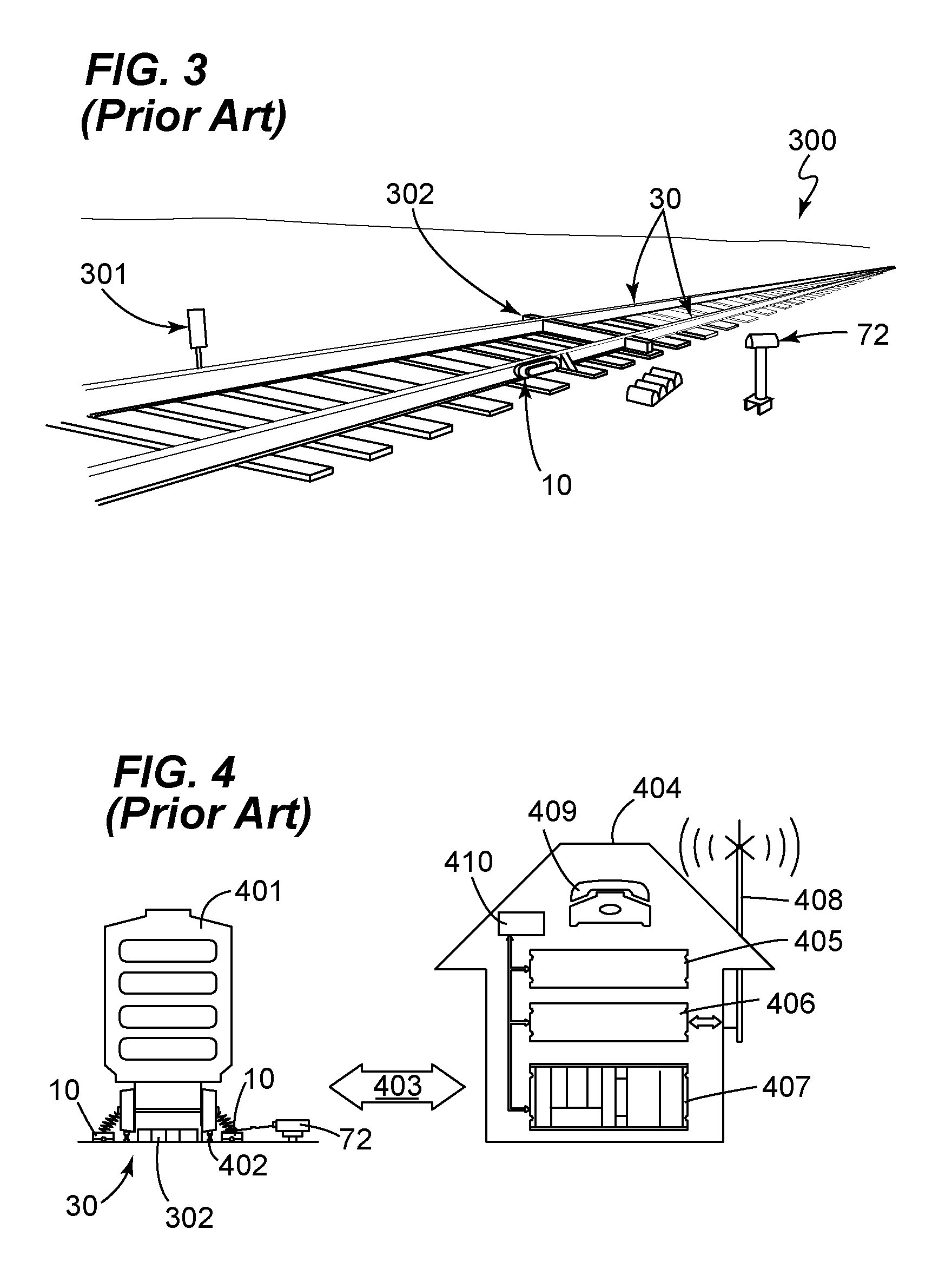

Apparatus and method for identifying a defect and/or operating characteristic of a system

ActiveUS20080306705A1Reduce probabilityImprove accuracyTemperature measurement of moving solidsThermometers using physical/chemical changesMonitoring systemComputer science

An apparatus and methods for identifying a defect and / or an operating characteristic of a system being monitored (and / or one or more of the system's components) are described. In an embodiment, orthogonally related data monitored by two or more detectors may be fused to determine whether a component of a system is defective and / or malfunctioning. Additionally or alternatively, data from a first detector may be determined to be accurate using non-orthogonally related data outputted by a second detector. Both types of determinations may be made with minimal or no false indications, which lowers the cost of operating the system being monitored. Embodiments of the invention may also be configured to forecast and / or prevent accidents and / or damage to the system being monitored by predicting whether a defect and / or a malfunction will occur

Owner:PROGRESS RAIL SERVICES

Rail road car truck

A rail road freight car truck has a truck bolster and a pair of side frames, the truck bolster being mounted transversely relative to the side frames. The mounting interface between the ends of the axles and the sideframe pedestals allows lateral rocking motion of the sideframes in the manner of a swing motion truck. The lateral swinging motion is combined with a longitudinal self steering capability. The self steering capability may be obtained by use of a longitudinally oriented rocker that may tend to permit resistance to self steering that is proportional to the weight carried across the interface. The trucks may have auxiliary centering elements mounted in the pedestal seats, and those auxiliary centering elements may be made of resilient elastomeric material. The truck may also have friction dampers that have a disinclination to stick-slip behaviour. The friction dampers may be provided with brake linings, or similar features, on the face engaging the sideframe columns, on the slope face, or both.

Owner:NATIONAL STEEL CAR

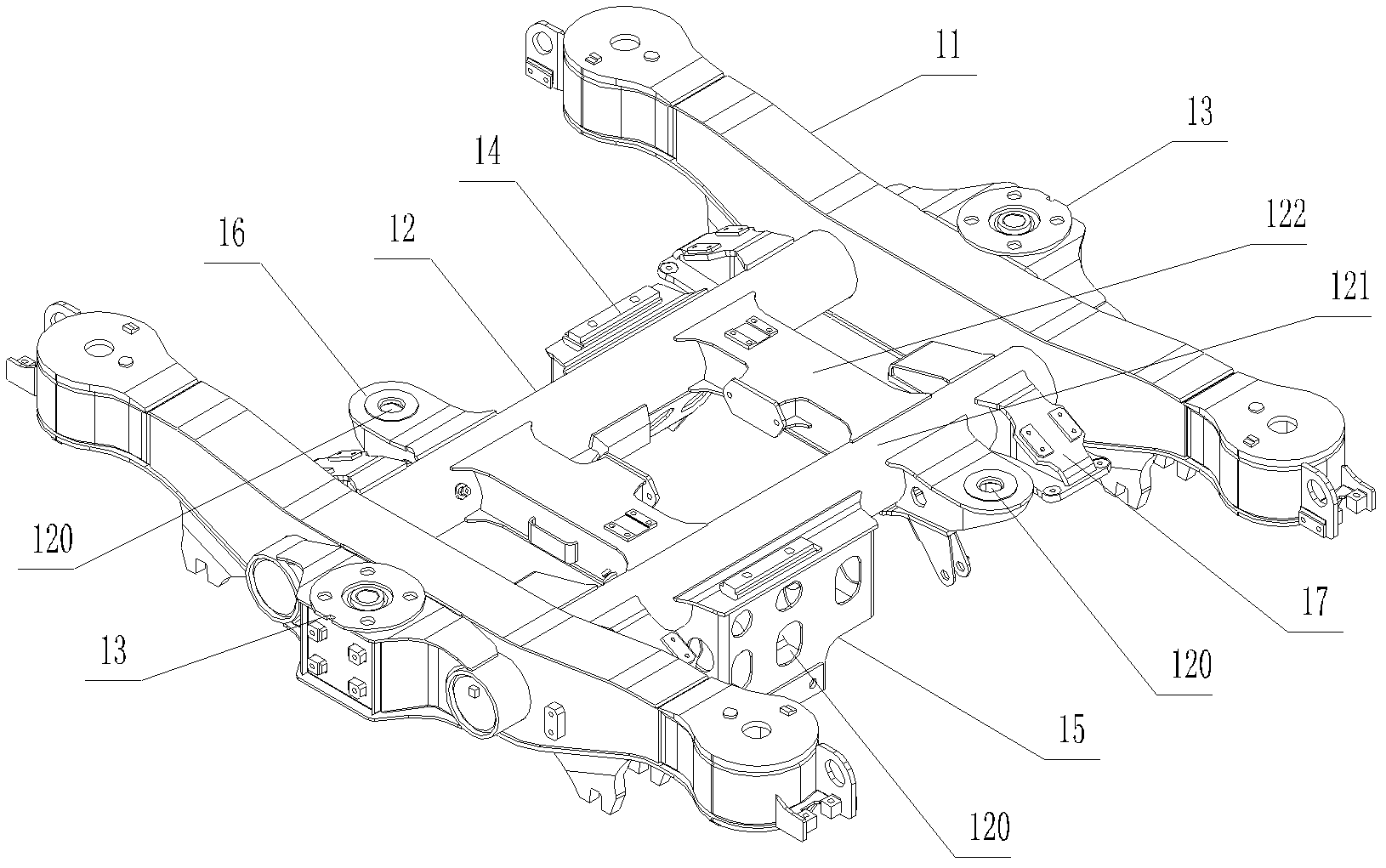

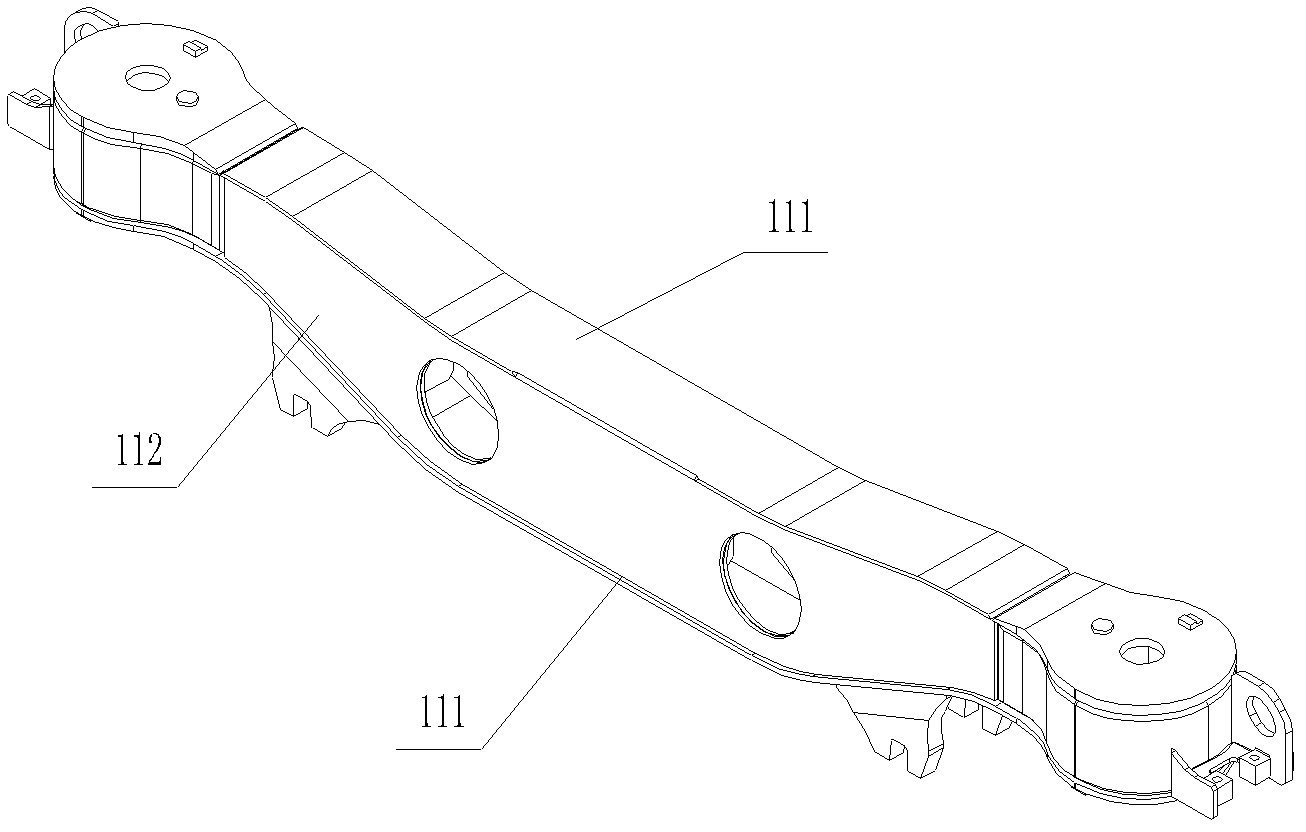

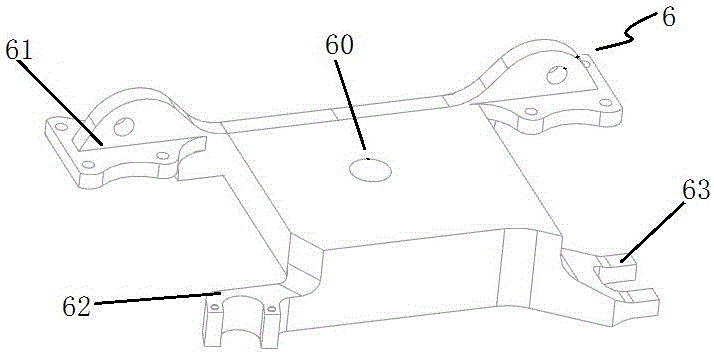

Framework and bogie comprising same

ActiveCN105905126AGood weldabilityAchieve decouplingRailway braking systemsRailway transportBogieEngineering

The invention discloses a framework. The framework comprises a cross beam and a side beam, wherein the side beam is of a sheet structure and hunches up in the center in the longitudinal direction; and the cross beam is connected to the hunching-up top of the side beam and detachably connected with the side beam. The invention further provides a bogie at the same time. The bogie comprises the framework; integration mounting bases are installed on the upper surfaces of the transverse two ends of the cross beam correspondingly; each integration mounting base comprises a foundation seat, a pair of brake mounting seats, a vertical absorber seat and an antiroll device mounting seat, wherein the brake mounting seats are arranged on one side of the foundation seat in the same straight line in a back-to-back mode, the vertical absorber seat is arranged at one end of the other lateral side of the foundation seat, and the antiroll device mounting seat is arranged on the other end of the other lateral side of the foundation seat; and the side beam, the cross beam and the integration mounting bases are in series connection sequentially through fasteners. The problem that a framework made from carbon fiber composite materials is poor in welding property is solved. The longitudinal, transverse and vertical rigidity decoupling of the side beam and the cross beam is achieved. The framework and the bogie have the advantages that the structure and assembling process of the bogie are simplified, and the loading burden of the framework is relieved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

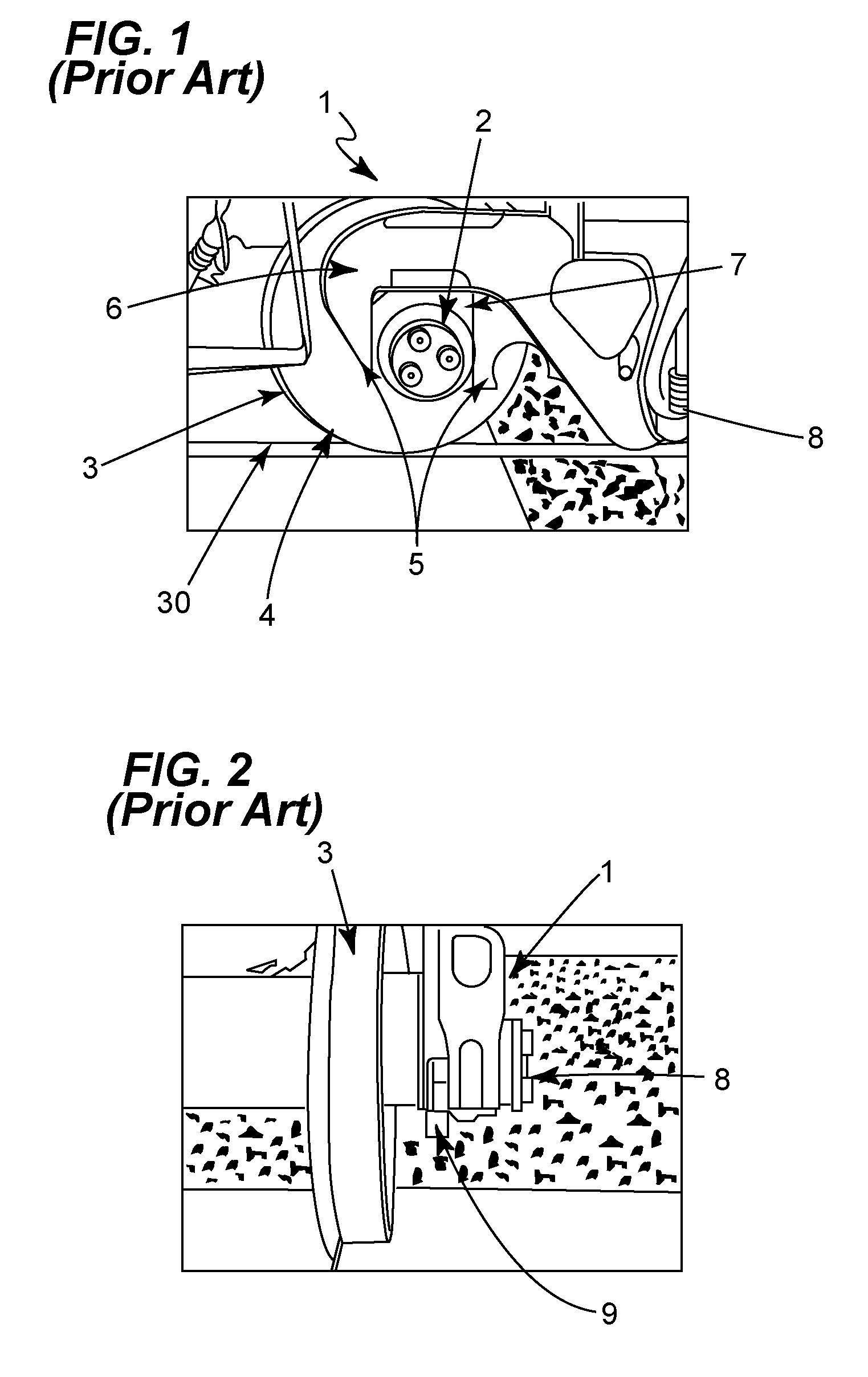

Railcar truck roller bearing adapter pad systems

A railcar truck and adapter pad system for placement between a roller bearing and side frame pedestal roof of a three-piece railcar truck. Many different features of the pad and / or the adapter-pad interface are configured to improve stiffness characteristics to satisfy both curving and high speed performance of the railcar truck.

Owner:NEVIS IND

Wheelset to side frame interconnection for a railway car truck

InactiveUS20140060380A1Increase the spring rateReduce the spring rateAxle-boxesBogiesHysteresisEngineering

The invention relates to a railway car truck incorporating a novel interconnection between the side frame and bearing adapter characterized by a low lateral spring constant relative to the longitudinal spring constant. The interconnection provides a proportional restoring force with minimal internal friction and hysteresis. In embodiments, the interconnection comprises compressed elastomeric members positioned between the thrust lug of the side frame and the bearing adapter in the longitudinal direction and a low friction interface between the roof of the pedestal jaw and the top of the bearing adapter.

Owner:STRATO AG

Rubber node, power bogie and rail vehicle

The invention provides a rubber node, a power bogie, and a rail vehicle; the rubber node comprises a mandrel, a sheath, and a rubber layer filled between the mandrel and the sheath; a first cavity and a second cavity are symmetrically arranged on two sides of the rubber layer around the mandrel, and connected through a first connecting channel; the first and second cavities are filled with liquid, yet not fully filled; the rubber node is connected between an axle box and a truss of the power bogie; the rail vehicle comprises the rubber node; the first and second cavities are symmetrically arranged on two side of the rubber layer round the mandrel, connected through the first connecting channel, and filled with liquid, so the rigidity of the rubber node can change with liquid flow resistances, thus adapting to rail vehicle vibration frequency.

Owner:CRRC TANGSHAN CO LTD

Malleable resilient pedestal wear plate

ActiveUS20120234202A1Improve the immunityEasy constructionAxle-boxesBogiesTruckMechanical engineering

Owner:PENNSY CORP

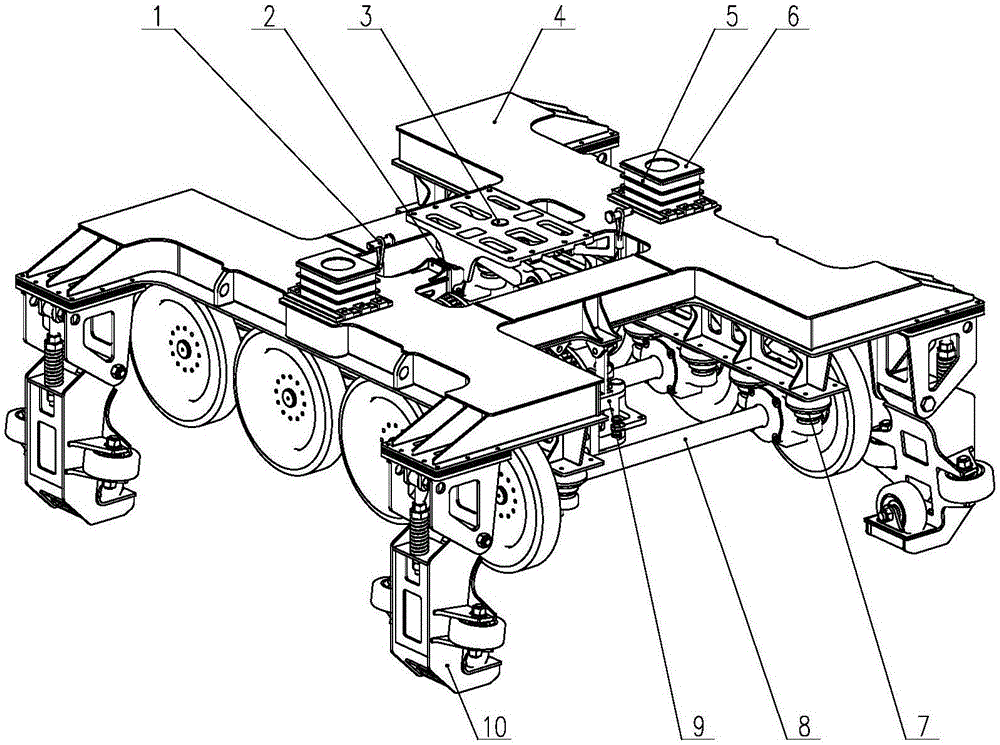

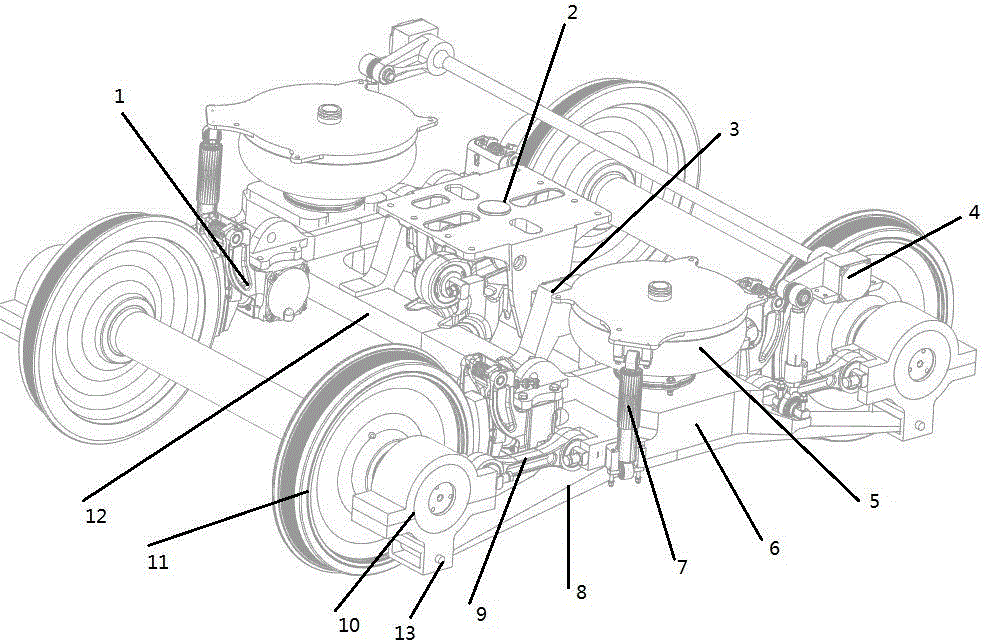

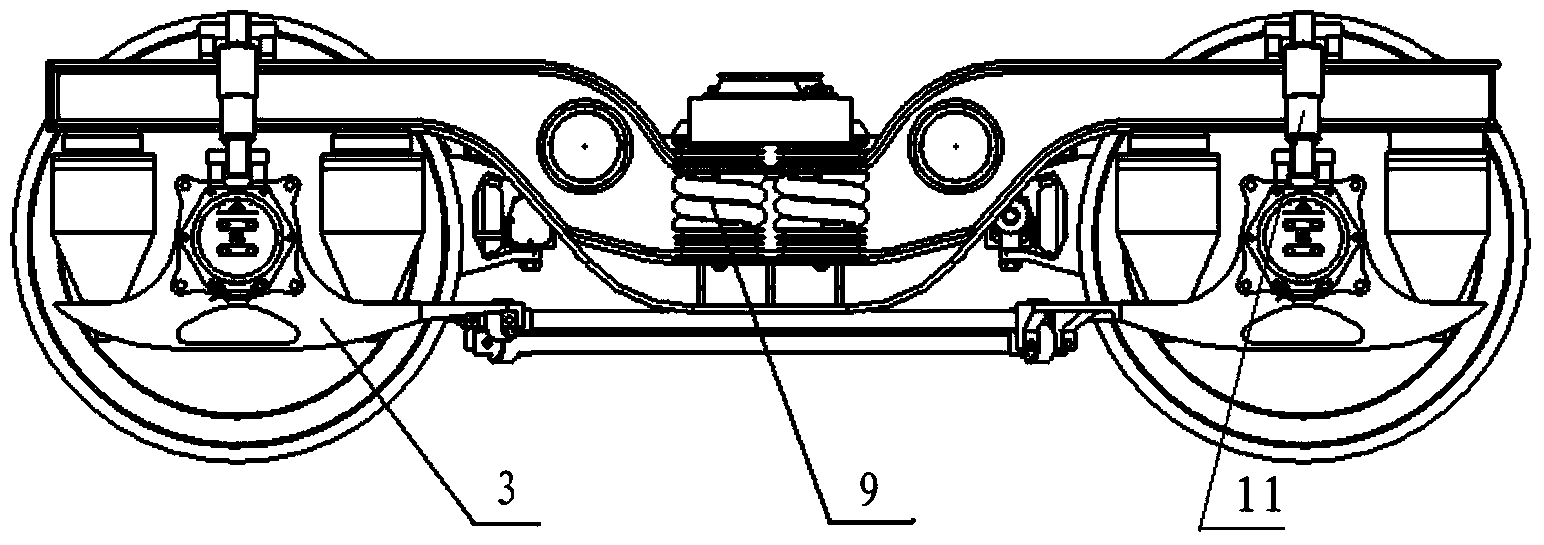

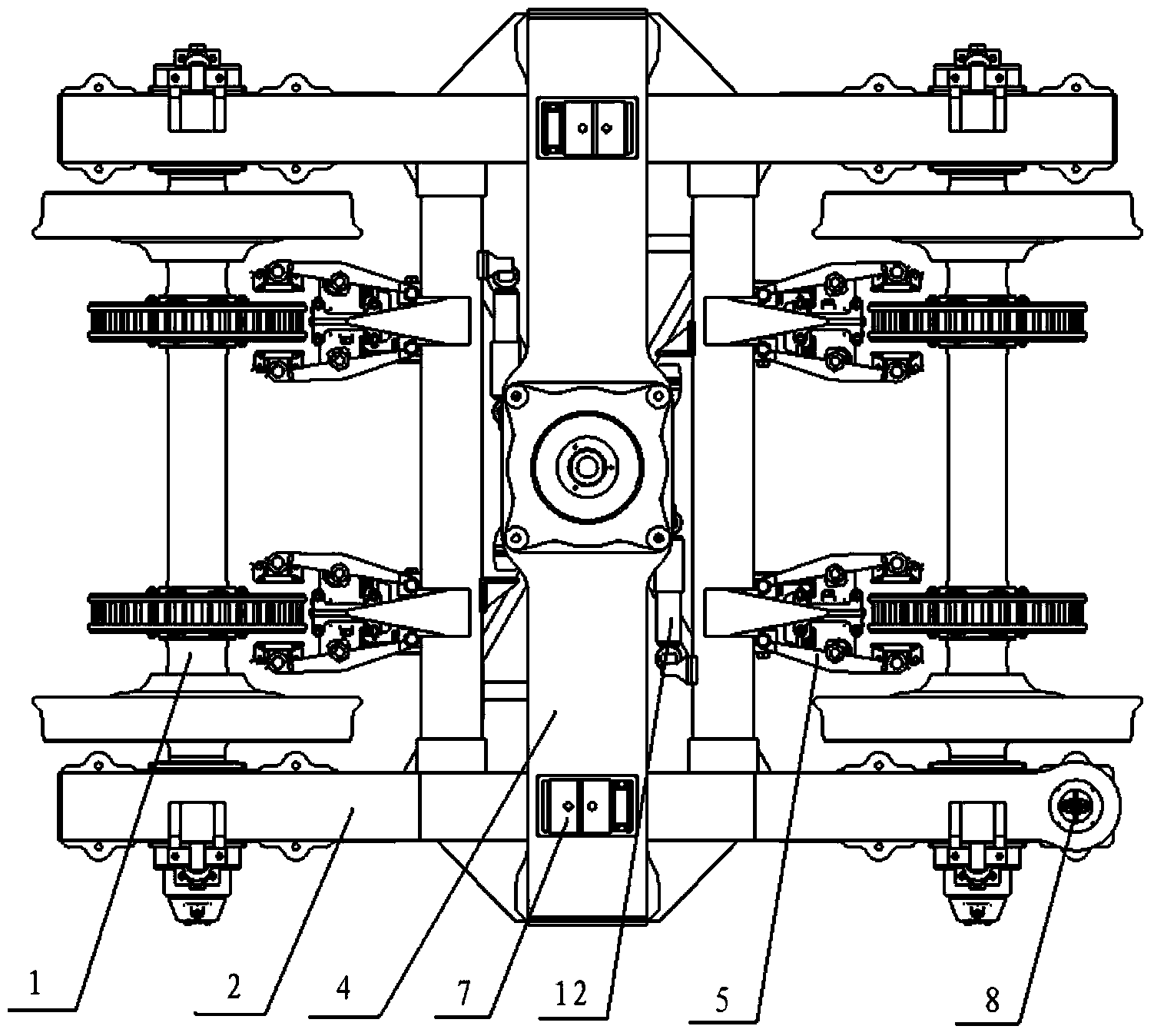

Rapid freight car radial bogie

InactiveCN103661464AReduce forceReduce lateral vibration accelerationBogie-underframe connectionsAxle-boxes mountingBogieTruck

The invention discloses a rapid freight car radial bogie. The rapid freight car radial bogie comprises an axle assembly, a frame, a swing bolster, a braking device, central suspension devices, a radial device, a side bearing device arranged on the swing bolster and an axle box suspension device, wherein the frame is installed on the axle assembly through the axle box suspension device, the two ends of the swing bolster are fixedly installed in the middle of the frame respectively through the central suspension devices, the frame is composed of two side beams and parallel cross beams connected with the side beams, and bearing platforms where the central suspension devices are installed are arranged outside the middle portions of the side beams. The rapid freight car radial bogie structure obviously reduces wheel-rail wear and wheel-rail noise, reduces wheel-rail acting force, reduces vehicle transverse vibration acceleration and improves vehicle operation lateral stability, straight line stability and curve line negotiating capacity. The unsprung mass of the bogie is reduced, the speed of the bogie is high, vehicle braking performance is improved, wheel-rail wear and wheel-rail noise are small, vehicle operation stability is good, and stability and safety are high.

Owner:CRRC MEISHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com