Patents

Literature

77results about How to "Reduce the spring rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

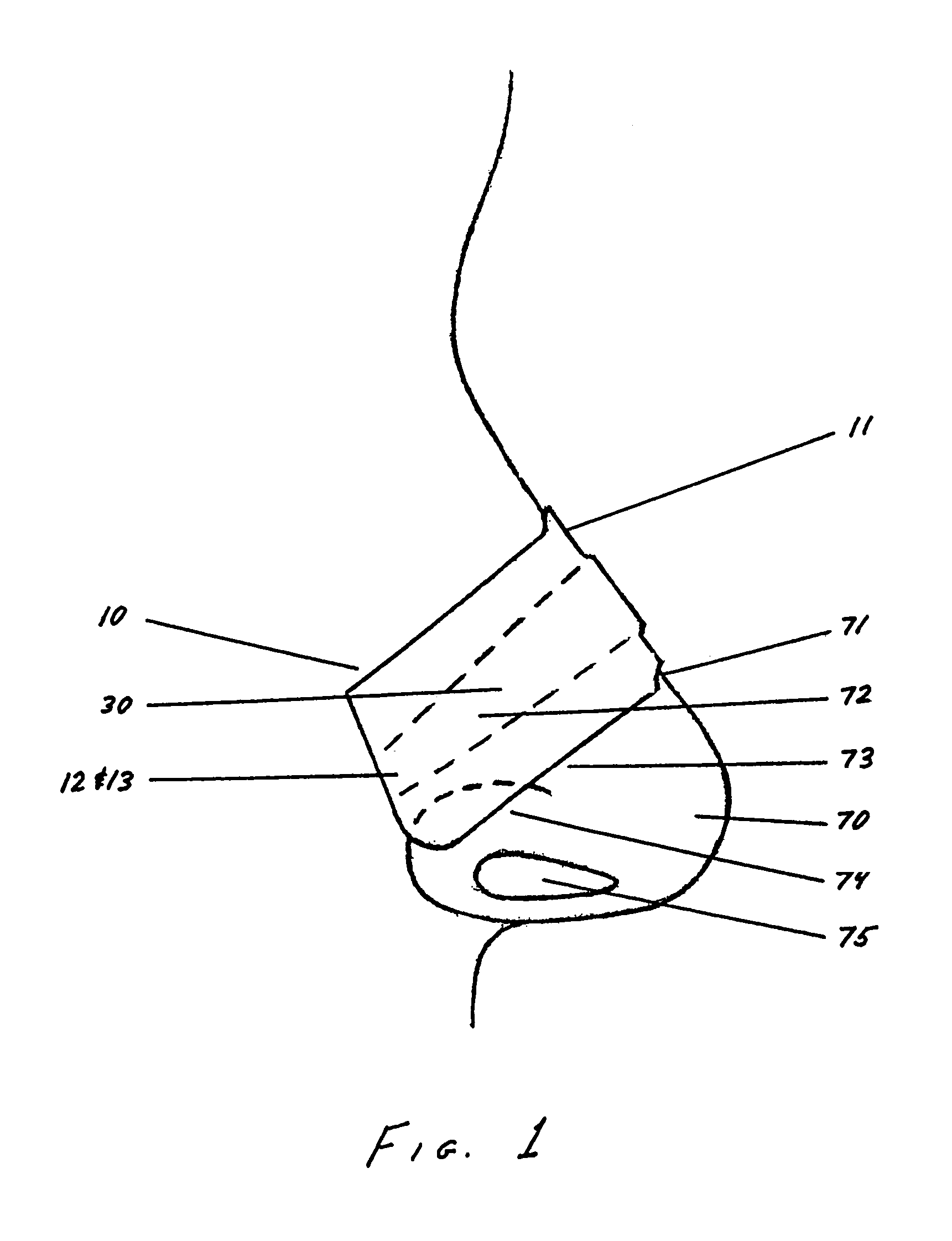

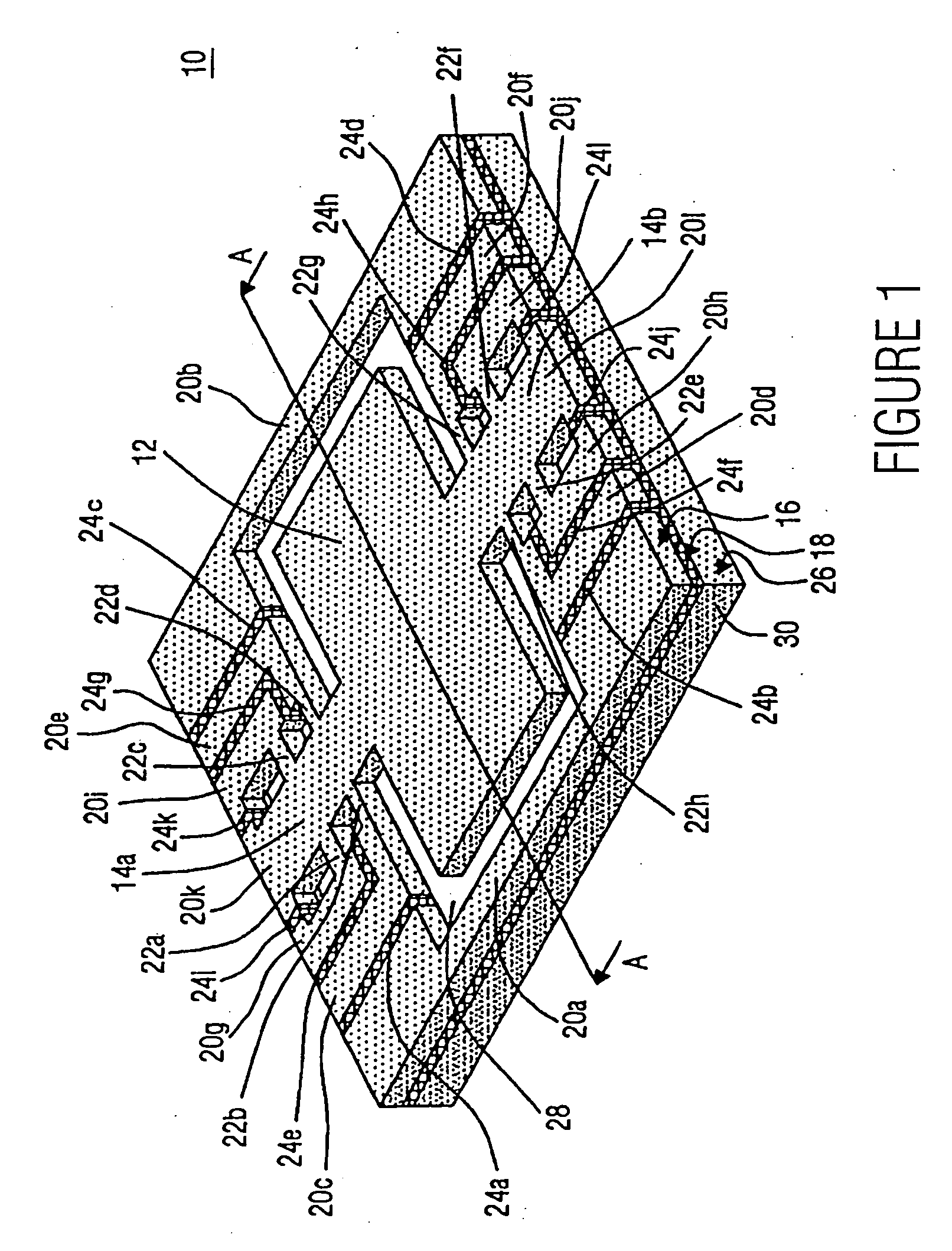

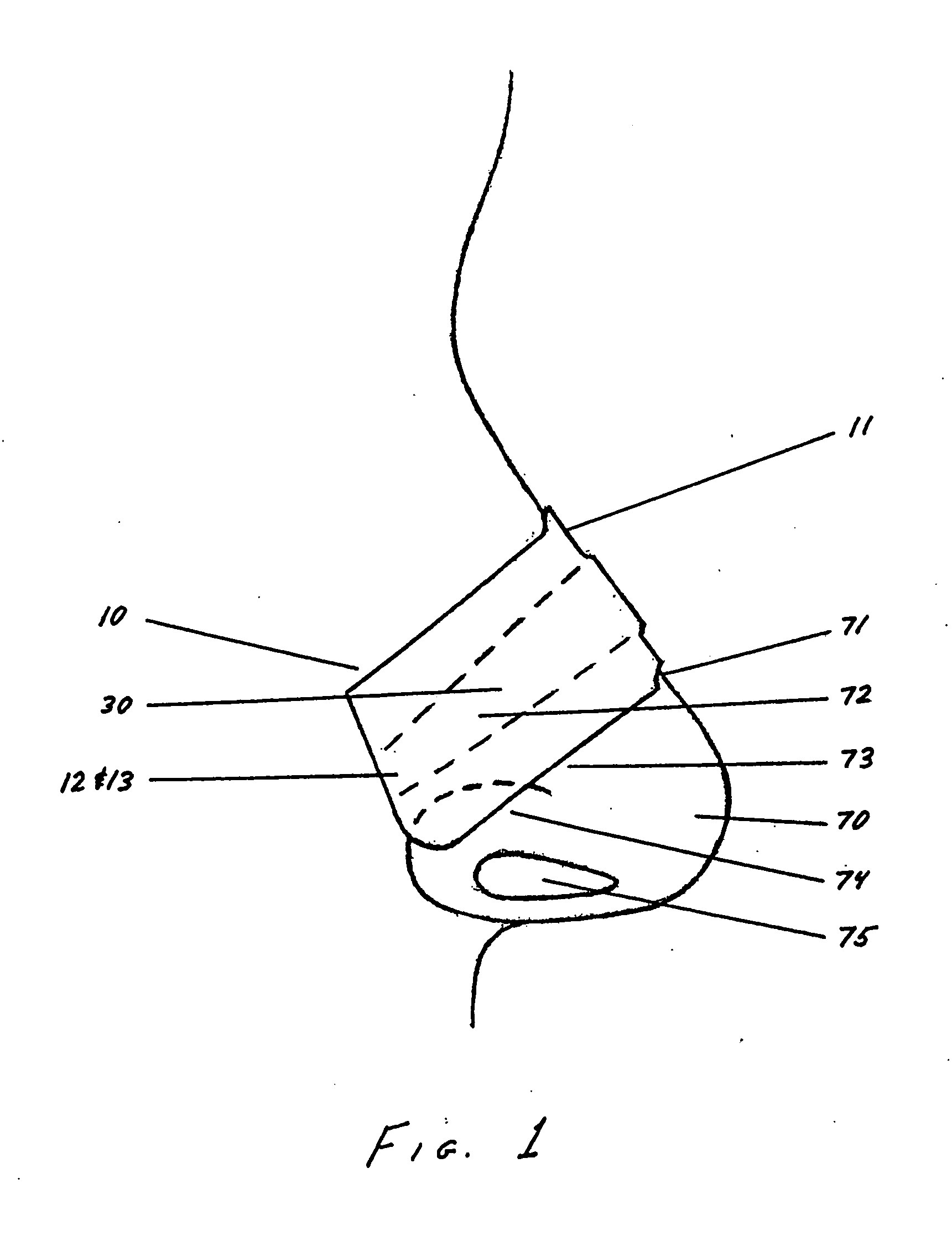

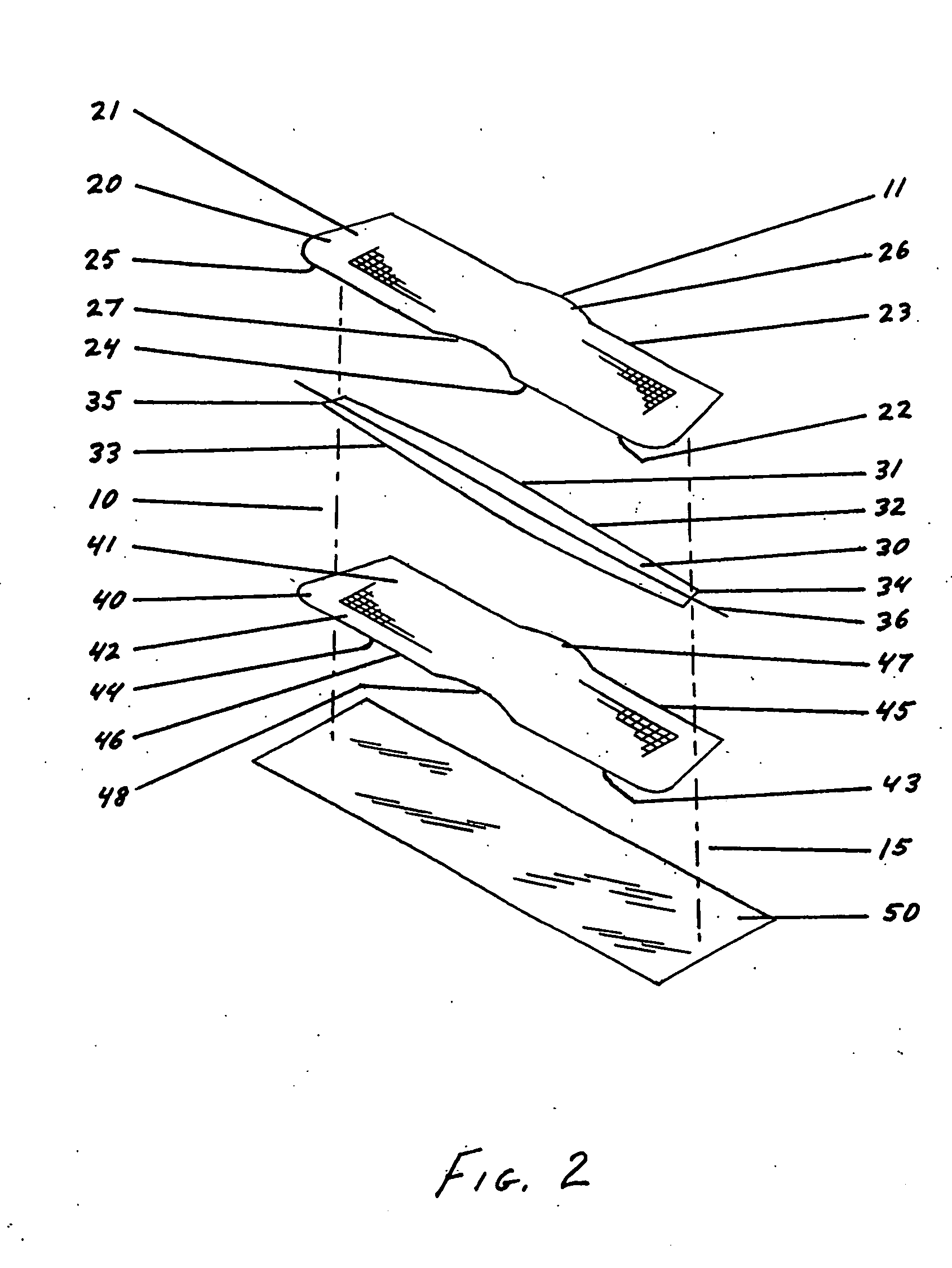

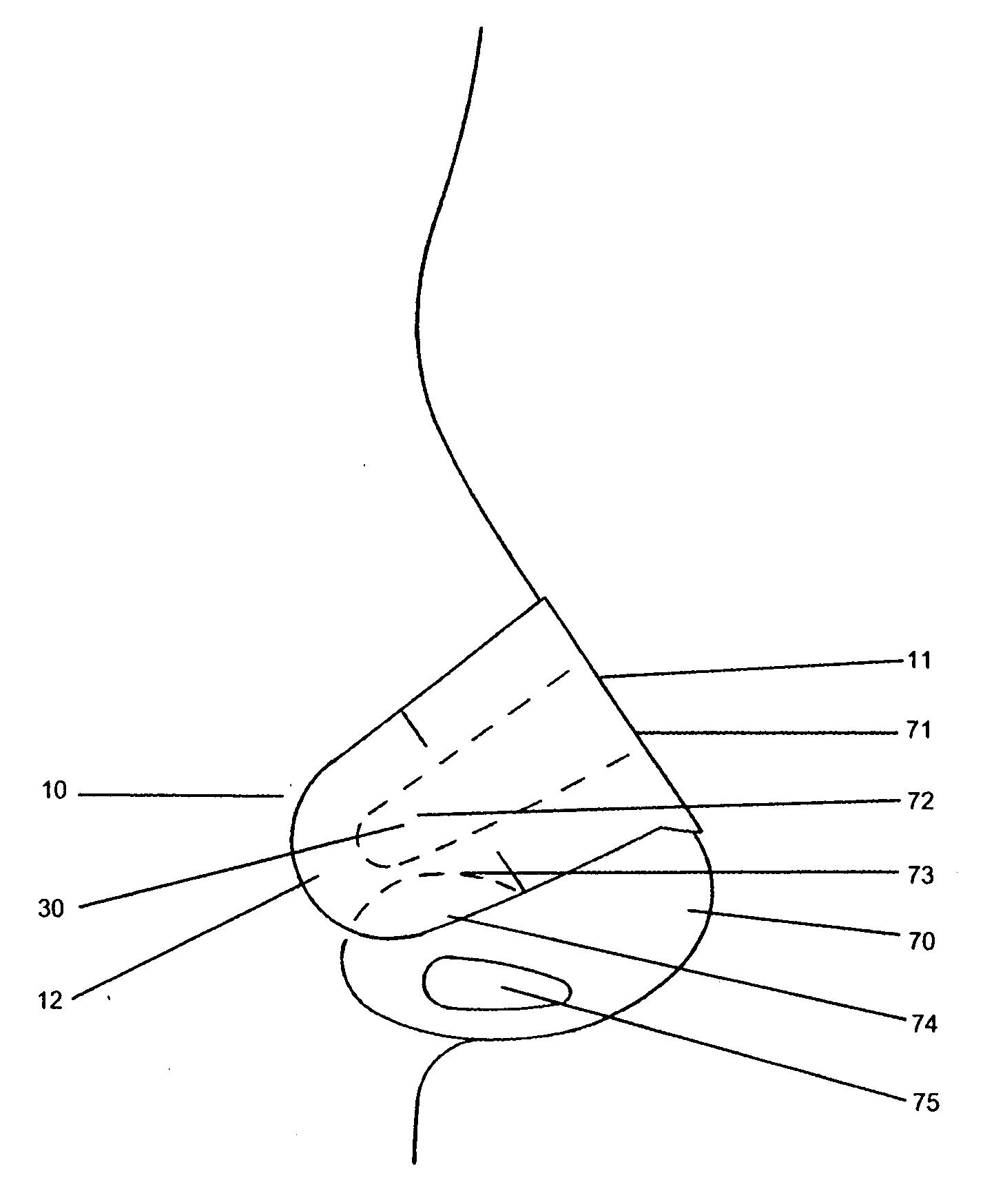

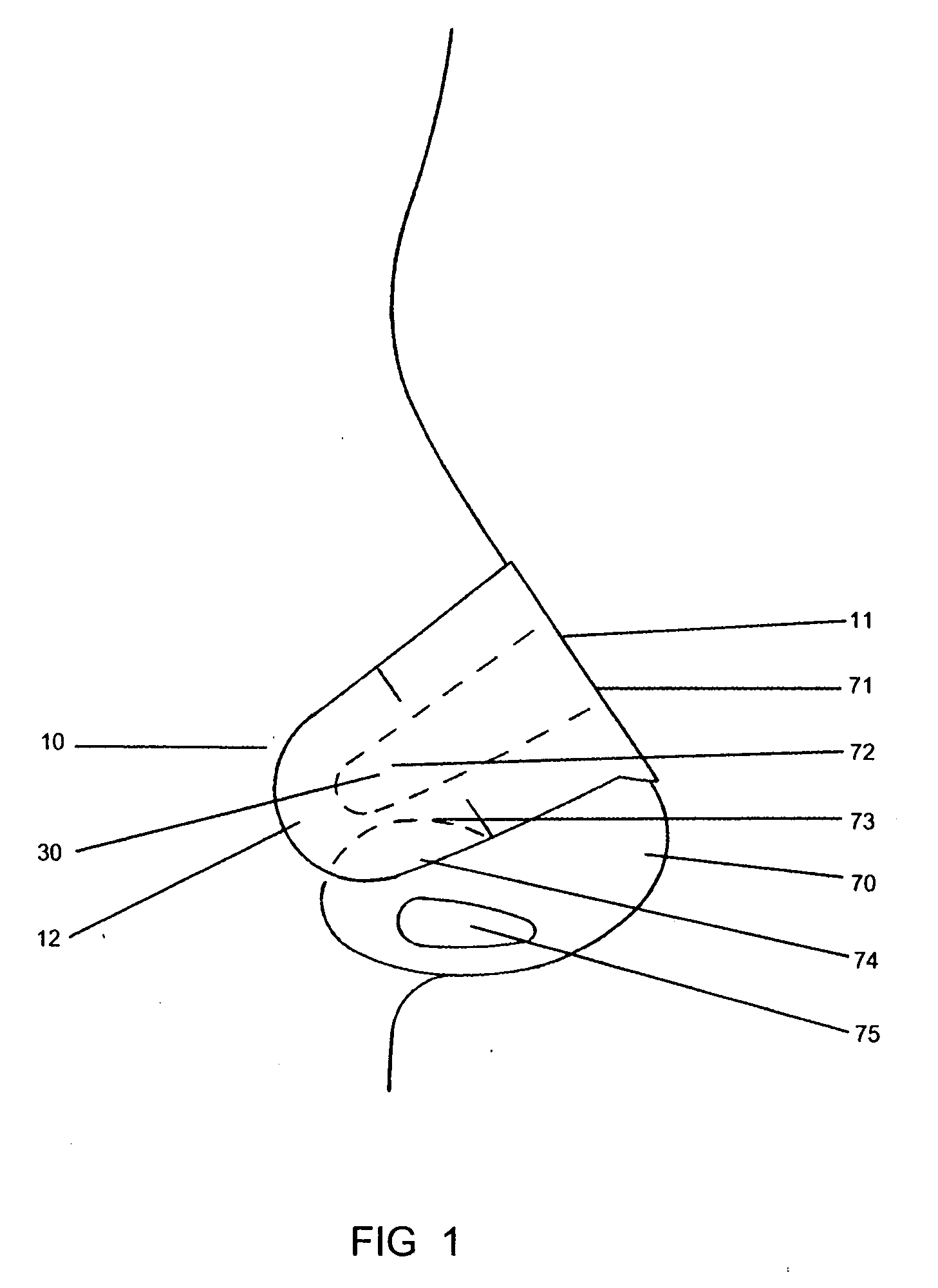

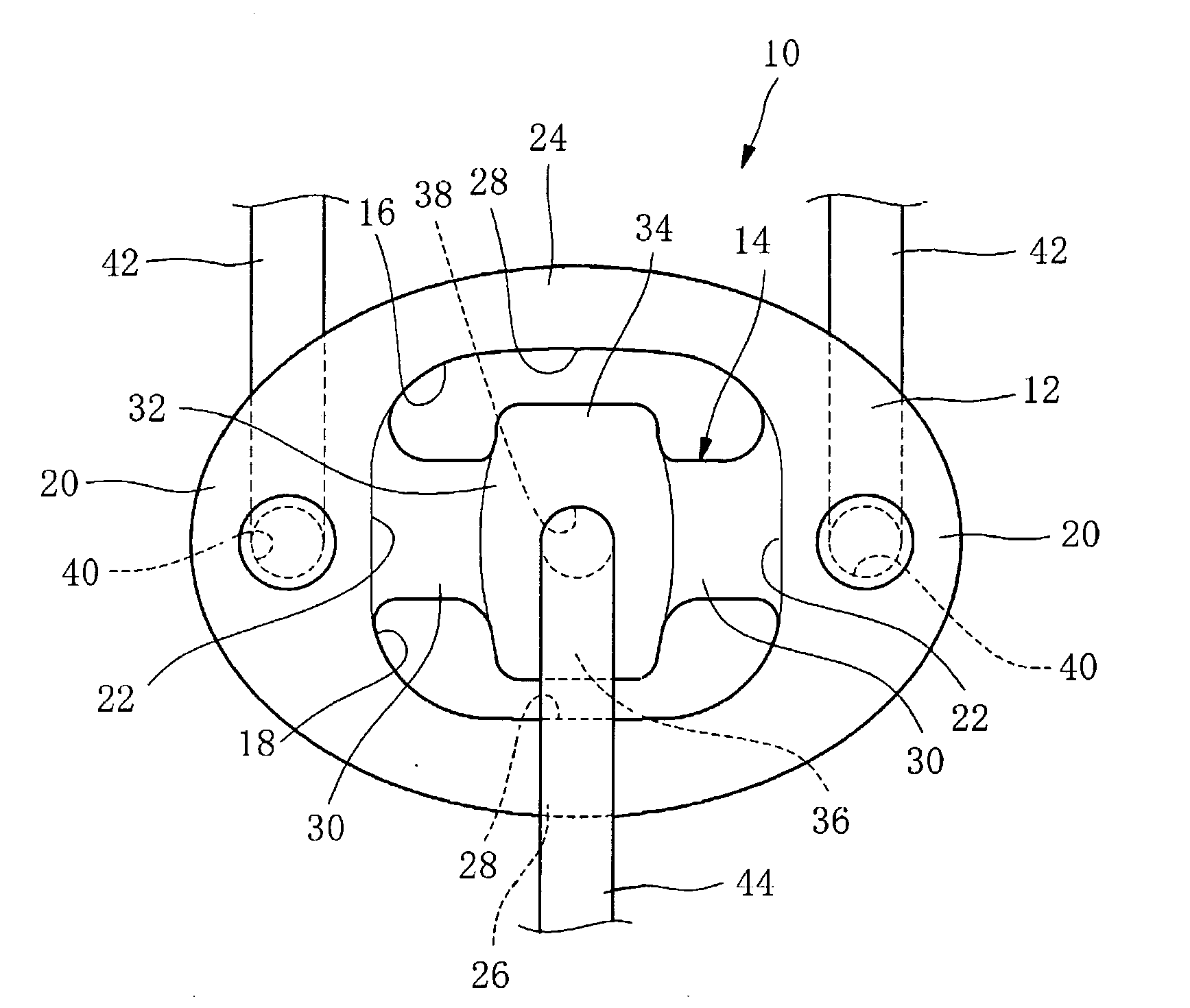

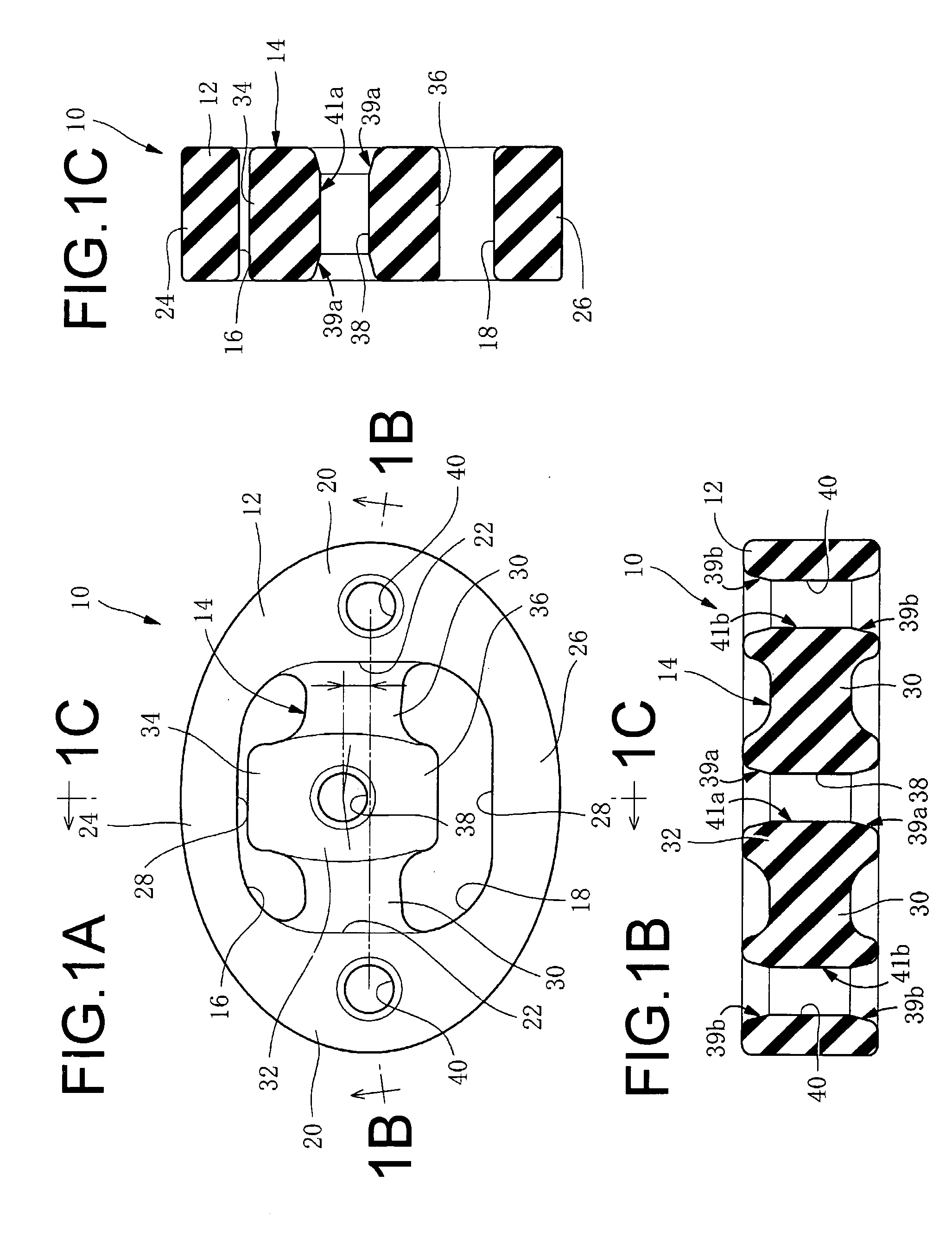

Nasal strip with variable spring rate

A nasal dilator capable of introducing separating stresses in nasal outer wall tissues has a truss of a single body with a resilient member secured therein and a pair of spaced-apart end surfaces which, when forced toward one another from initial positions to substantially reduce direct spacing therebetween by a spacing reducing force external to said truss, results in restoring forces in the truss tending to return to the original direct spacing between the end surfaces. A resilient member, which is symmetrical with respect to a centerline of the truss that is perpendicular to the long axis of the truss, has a spring rate which continuously diminishes from the centerline to the end surfaces. An adhesive on the end surfaces adhesively engages exposed surfaces of nasal outer wall tissues sufficiently to keep the truss attached to the nasal wall surfaces while subjecting them to the restoring forces.

Owner:INFINITE FINANCIAL SOLUTIONS

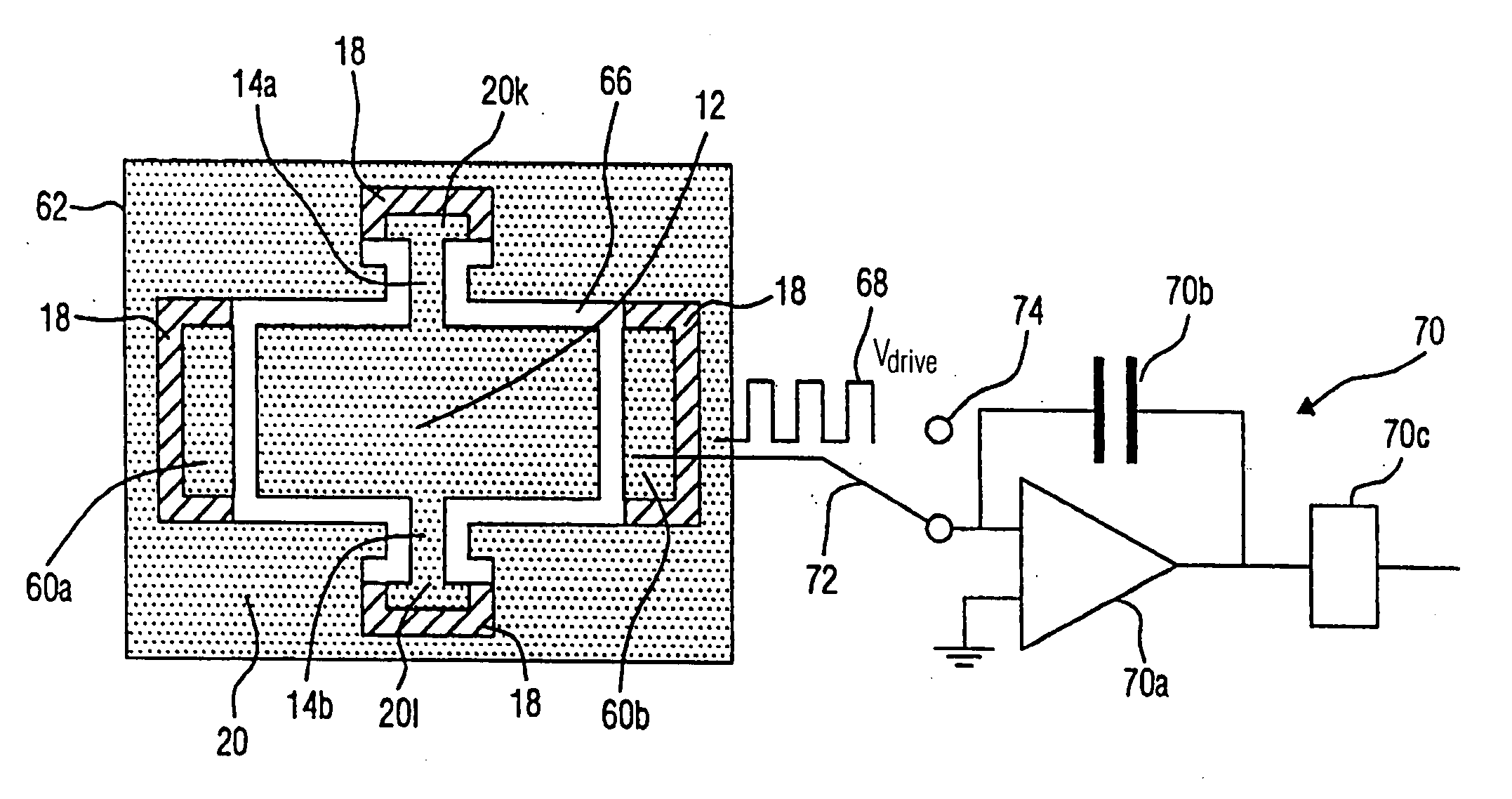

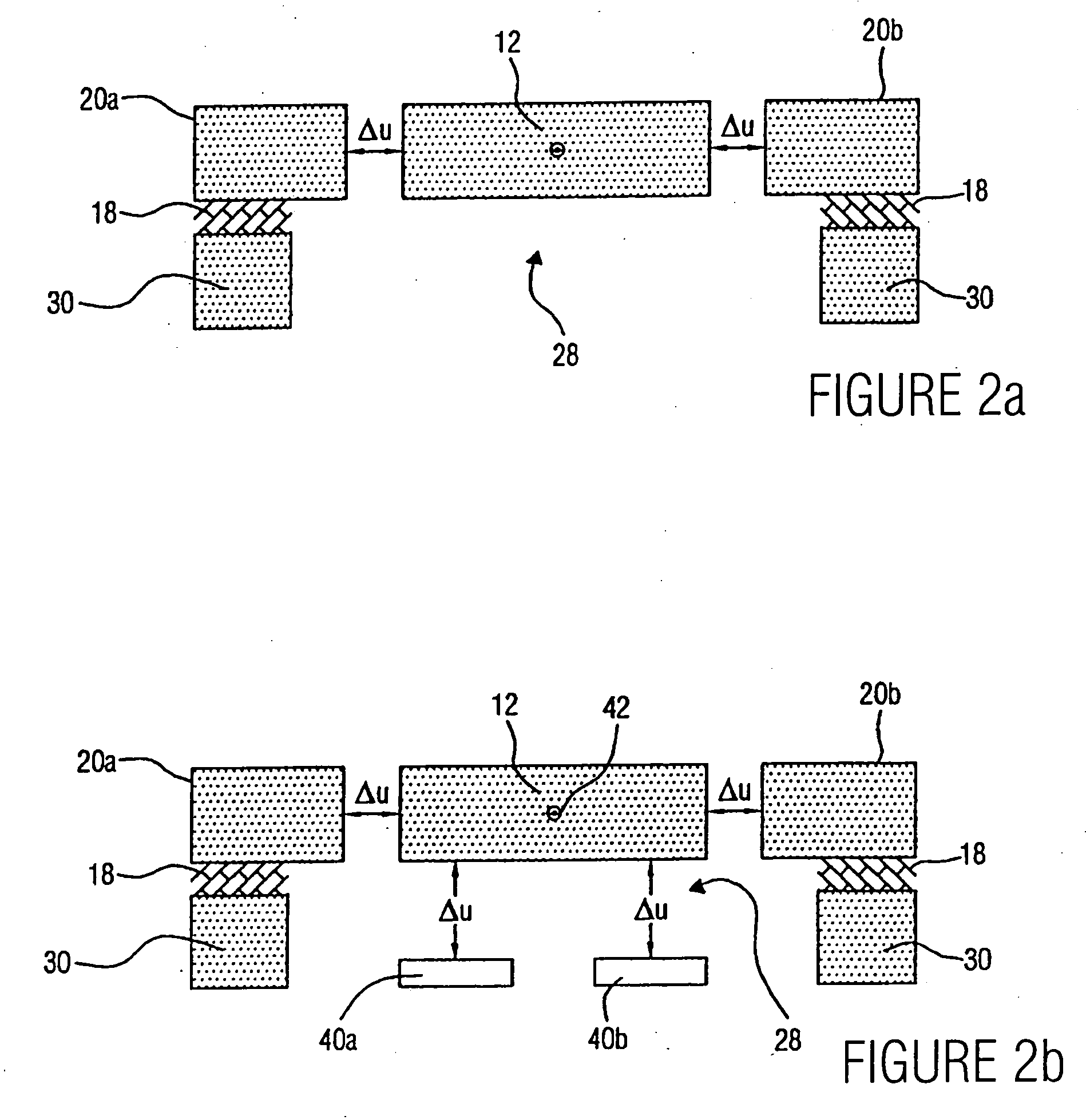

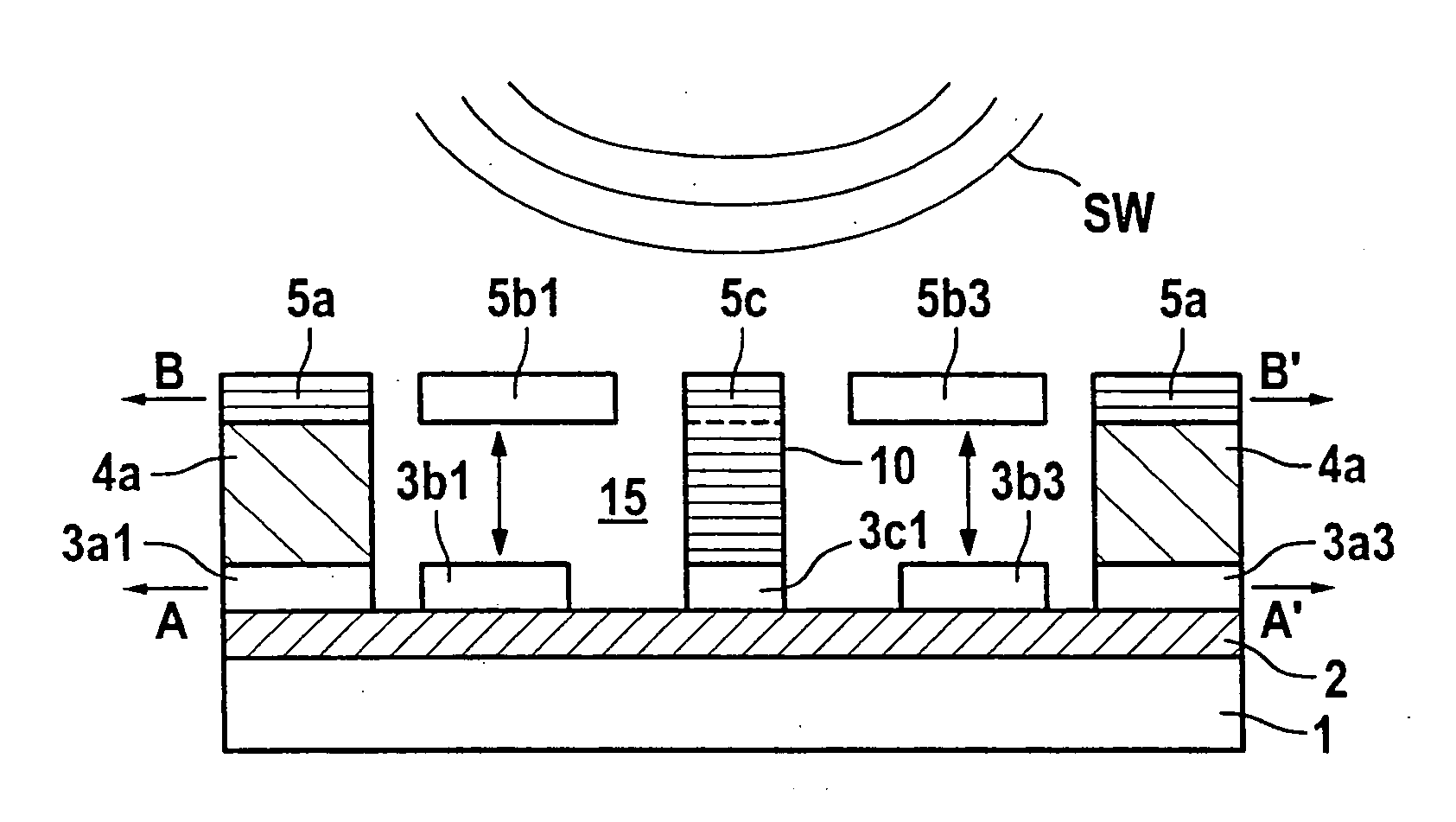

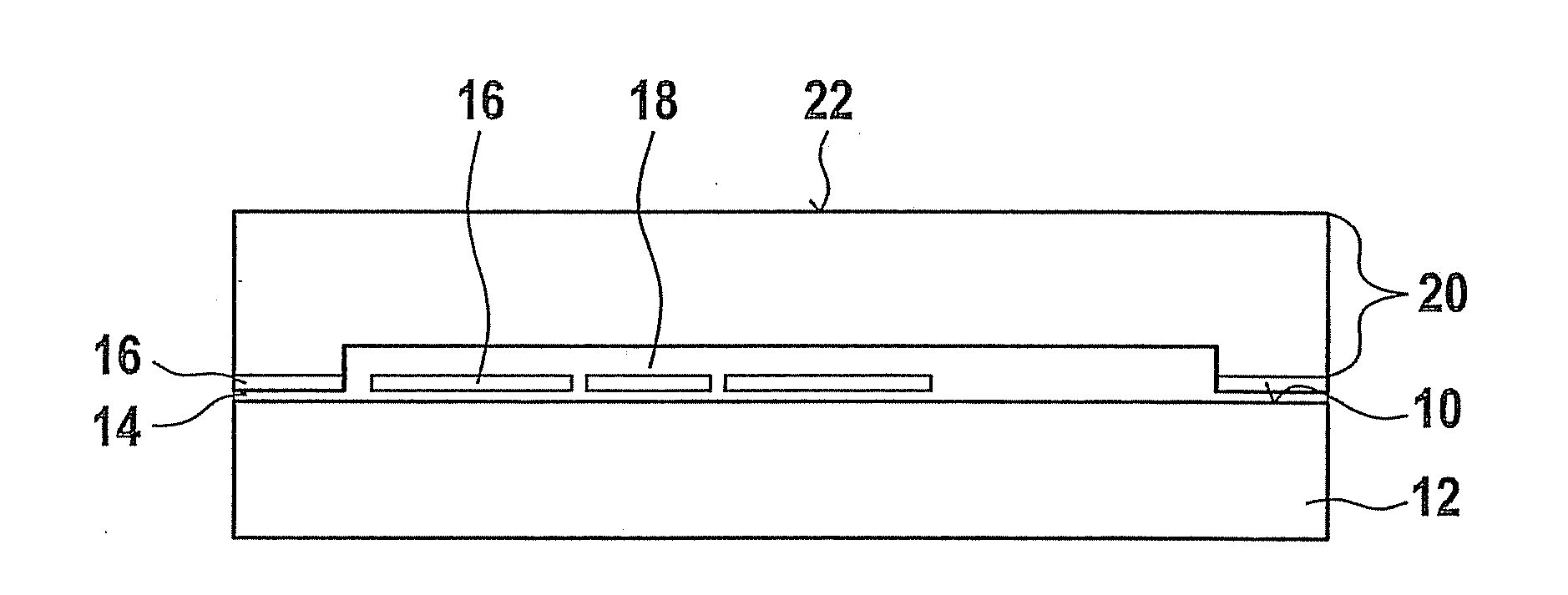

Micromechanical element having adjustable resonant frequency

InactiveUS20060071578A1Less complicatedHigh yieldImpedence networksSpeed measurement using gyroscopic effectsAcousticsVoltage

A micromechanical element described includes a vibrating system having a vibrating body and an elastic suspension by means of which the vibrating body is suspended to be able to vibrate, and an adjuster for adjusting a resonant frequency of the vibrating system by applying a voltage difference between at least one part of the vibrating body and at least one stationary electrode.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

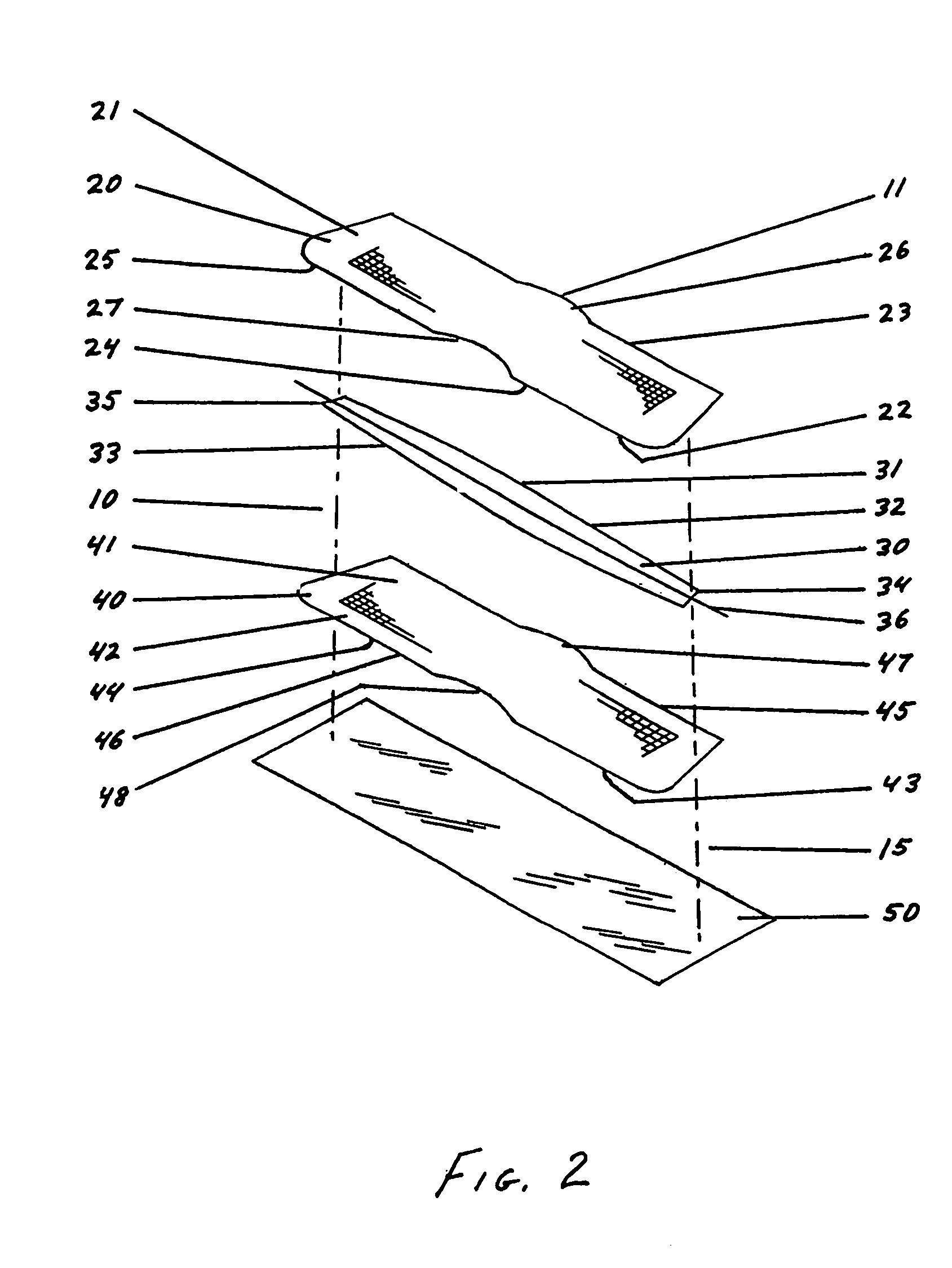

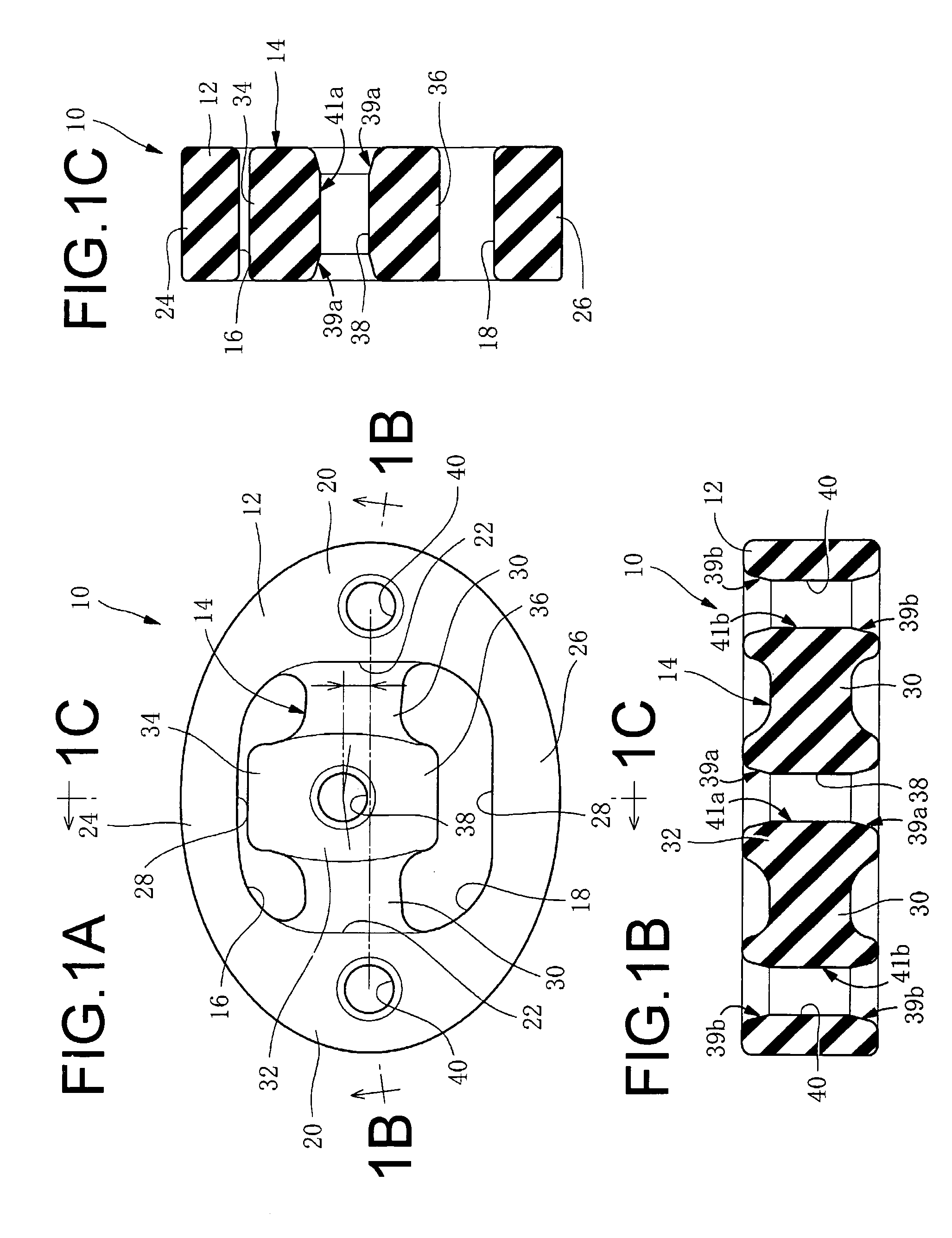

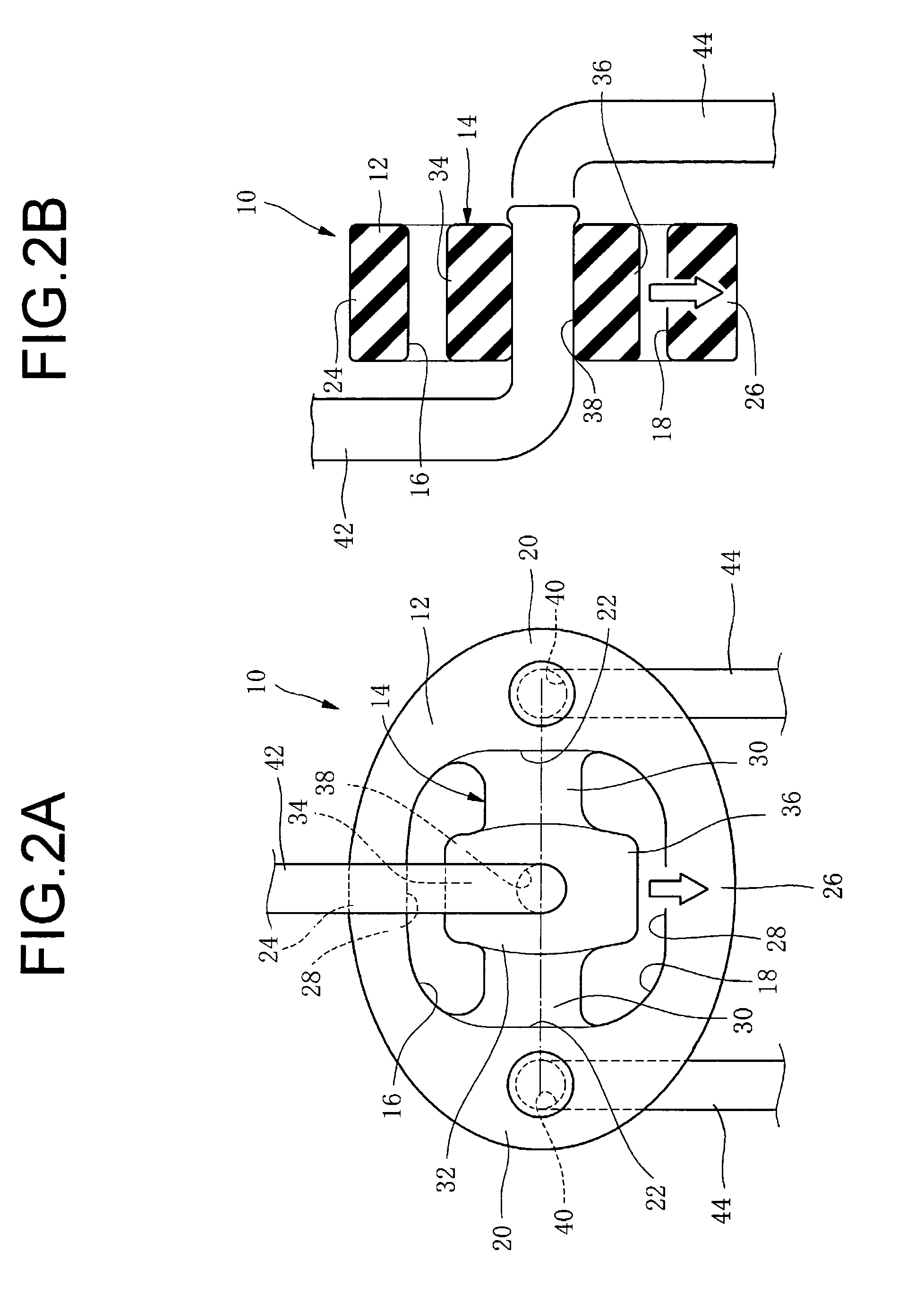

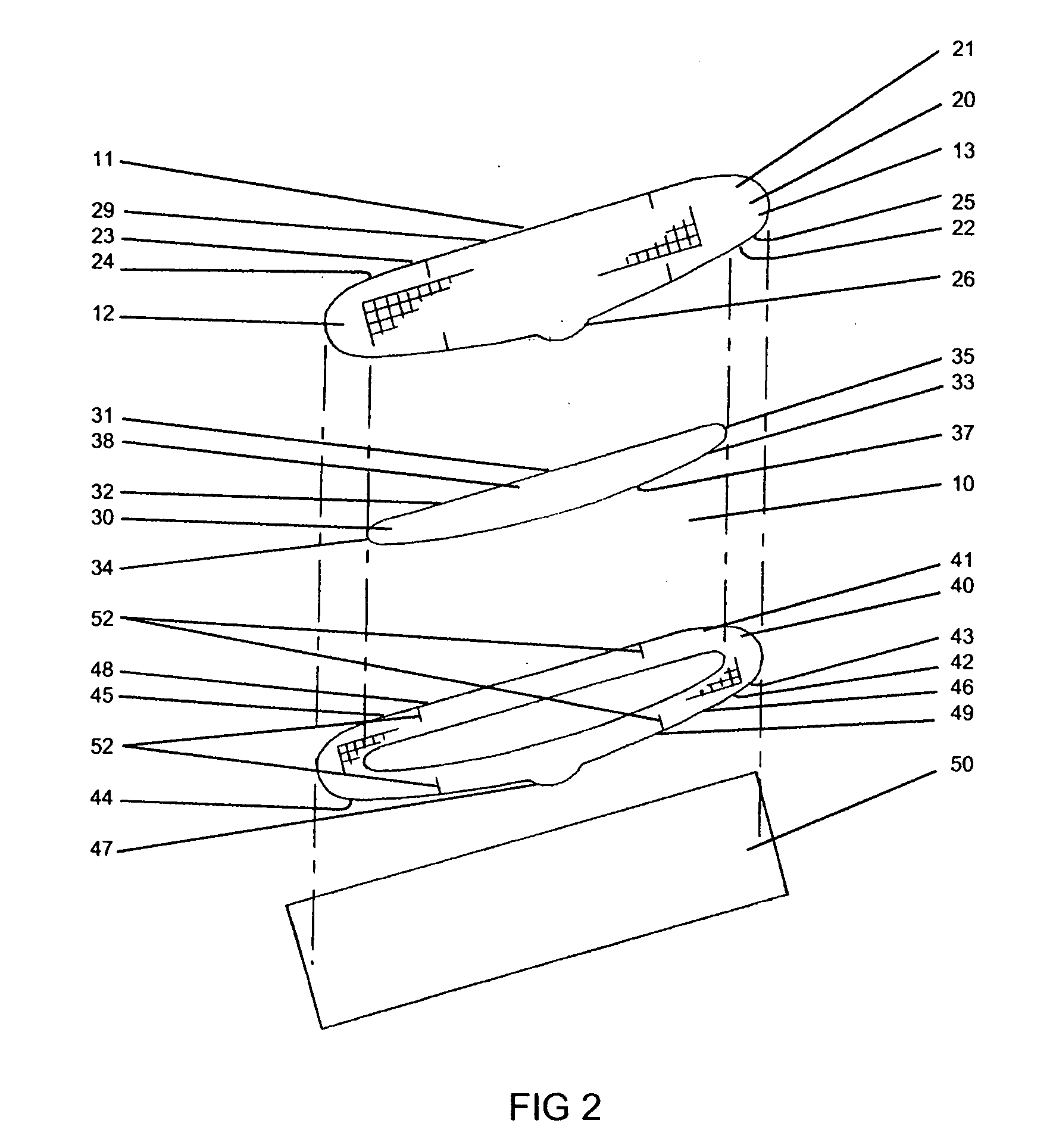

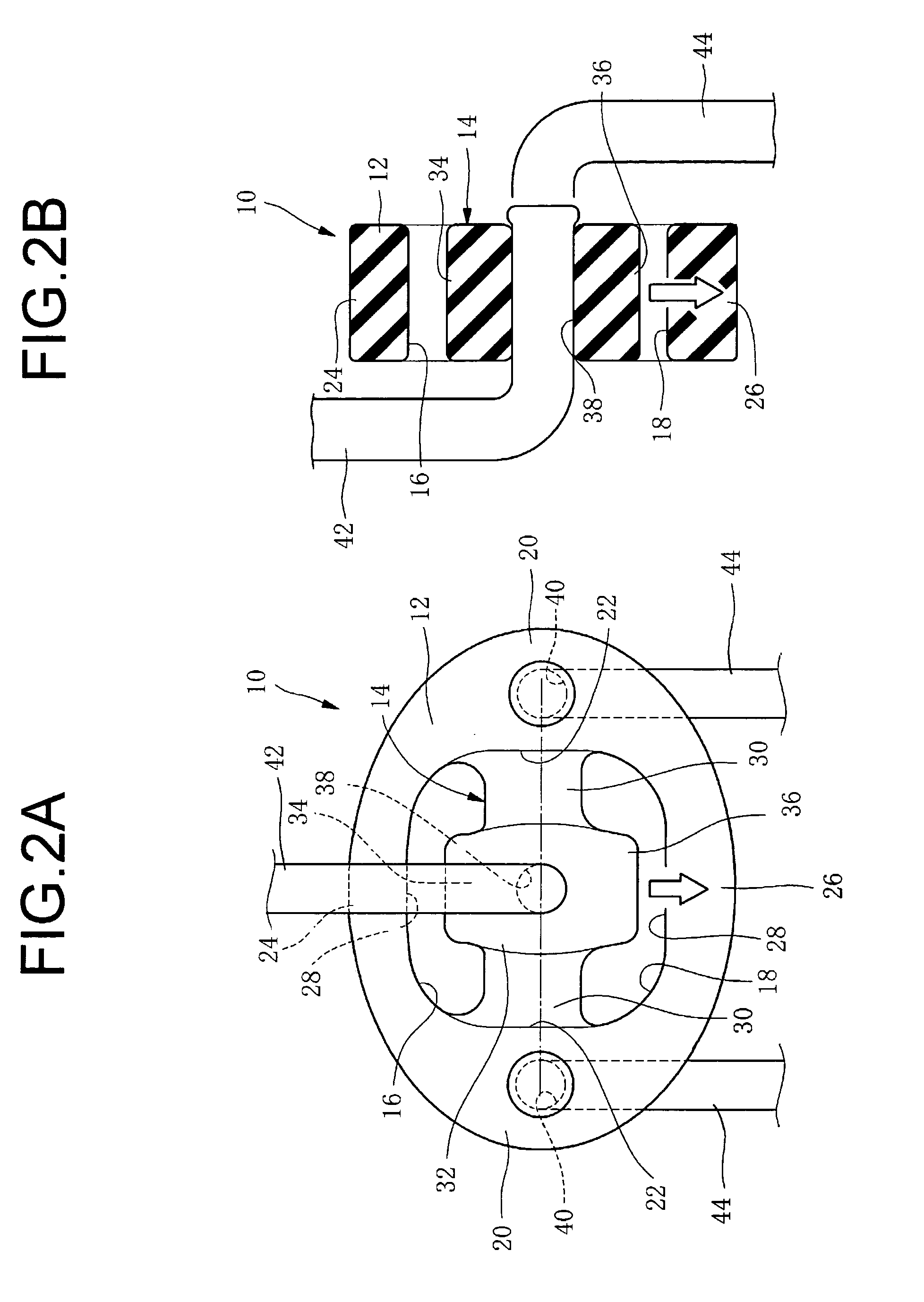

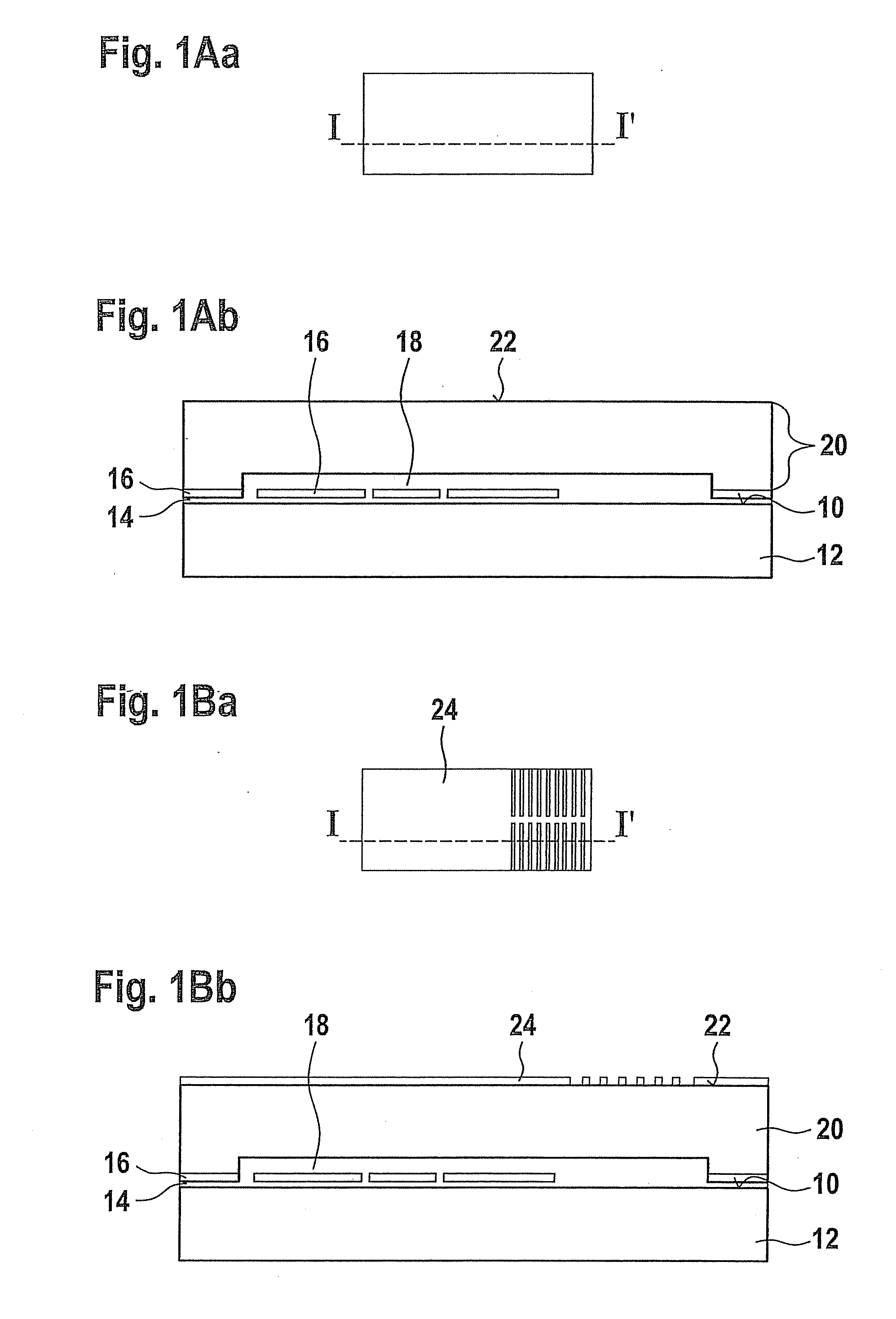

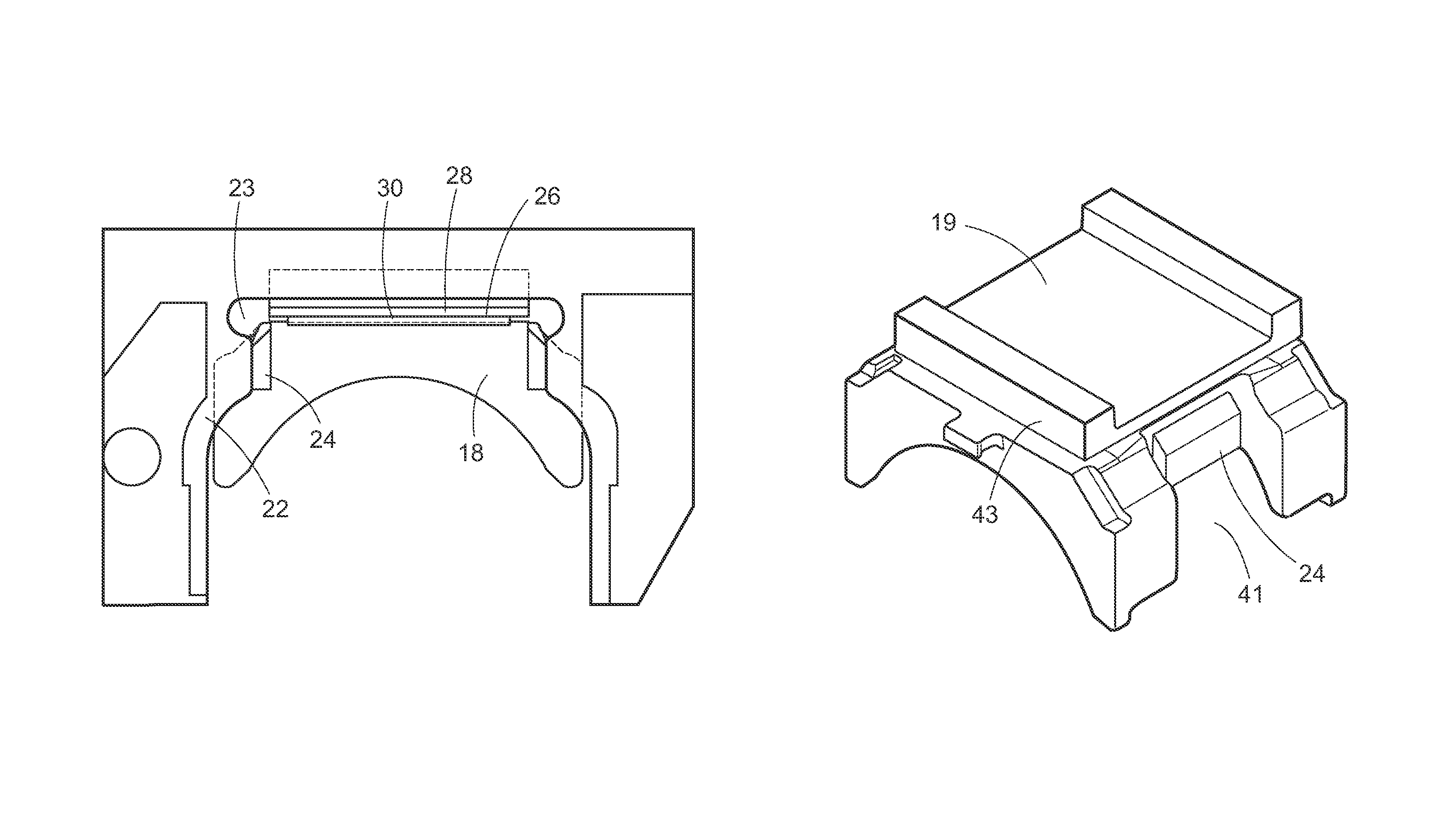

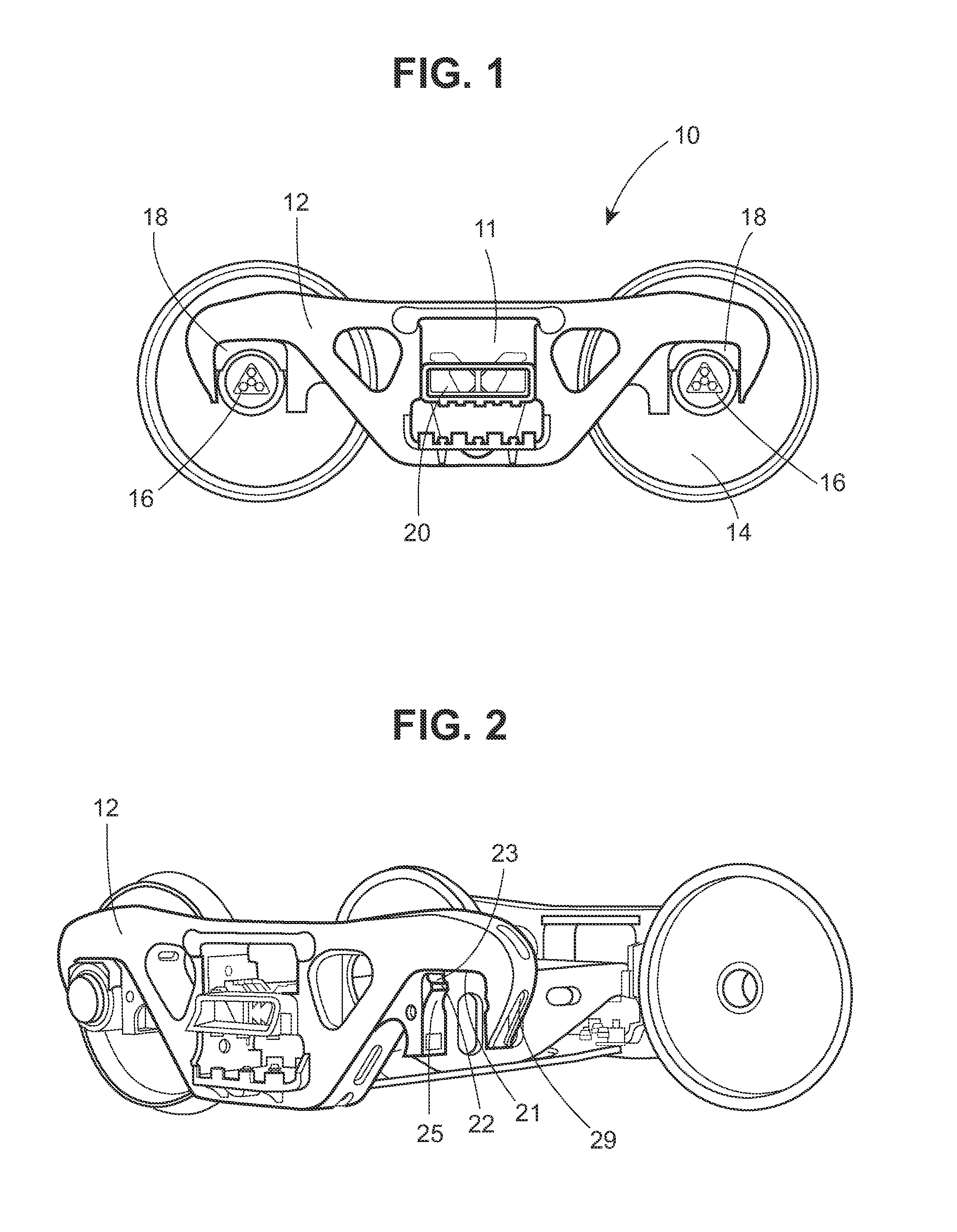

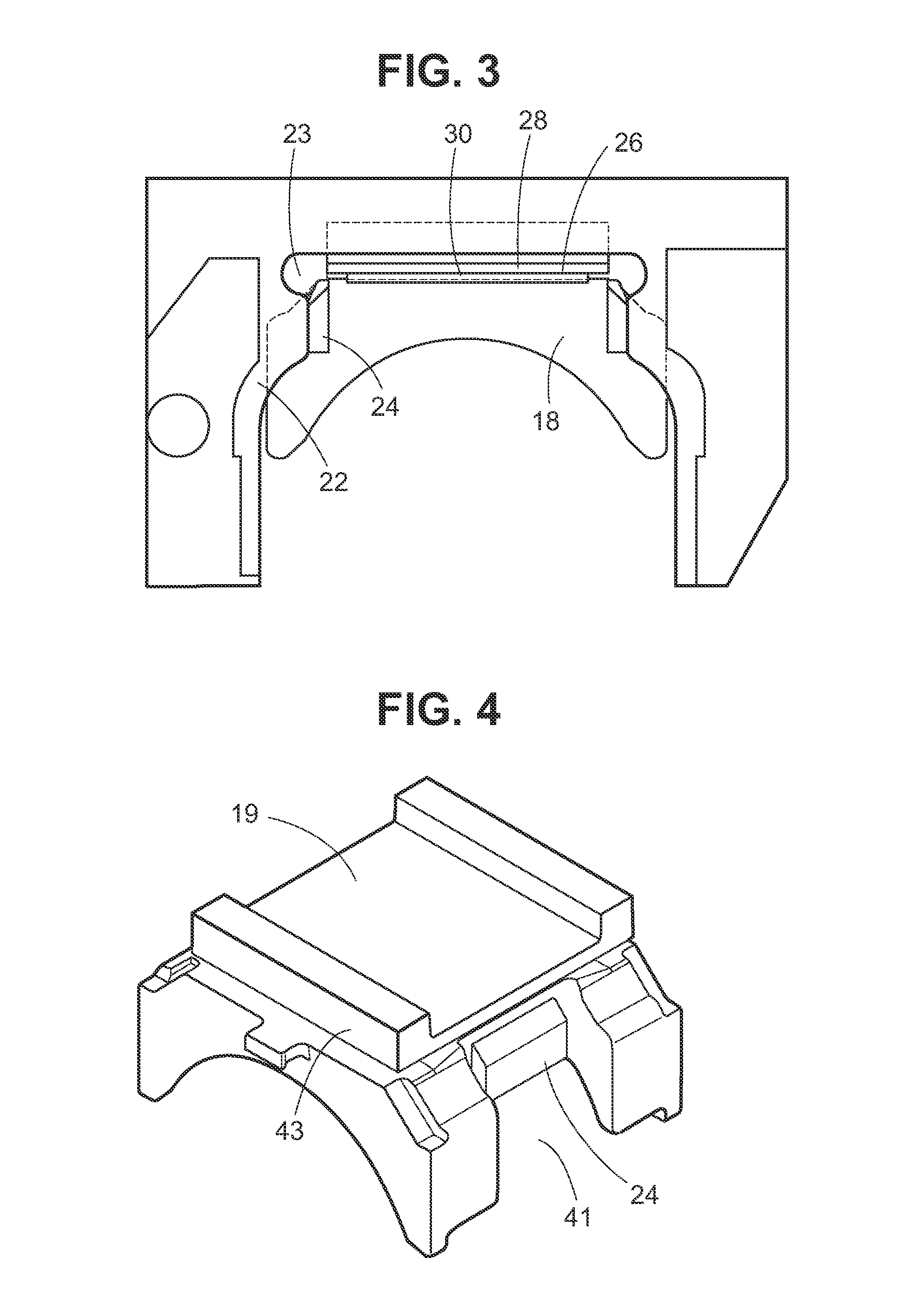

Nasal dilator with variable spring rate

InactiveUS20110224717A1Reduce the spring rateReduce widthNon-surgical orthopedic devicesAdhesiveMedicine

A nasal dilator strip and methods, the strip including a first layer including a cover having adhesive on a surface thereof, the cover having a first edge with a convex locating feature and a second edge opposite the first edge, the second edge being an uninterrupted edge, and a second layer having opposite surfaces, one opposite surface of the second layer being secured to the first layer, at least a portion of the other opposite surface of the second layer having adhesive to hold the two-layer nasal dilator strip in place on a user's nose, the second layer including a substantially planar resilient member, the resilient member having a constant thickness and longitudinal sides which converge from a center of the resilient member to a pair of spaced apart ends.

Owner:LOCKWOOD JR HANFORD N

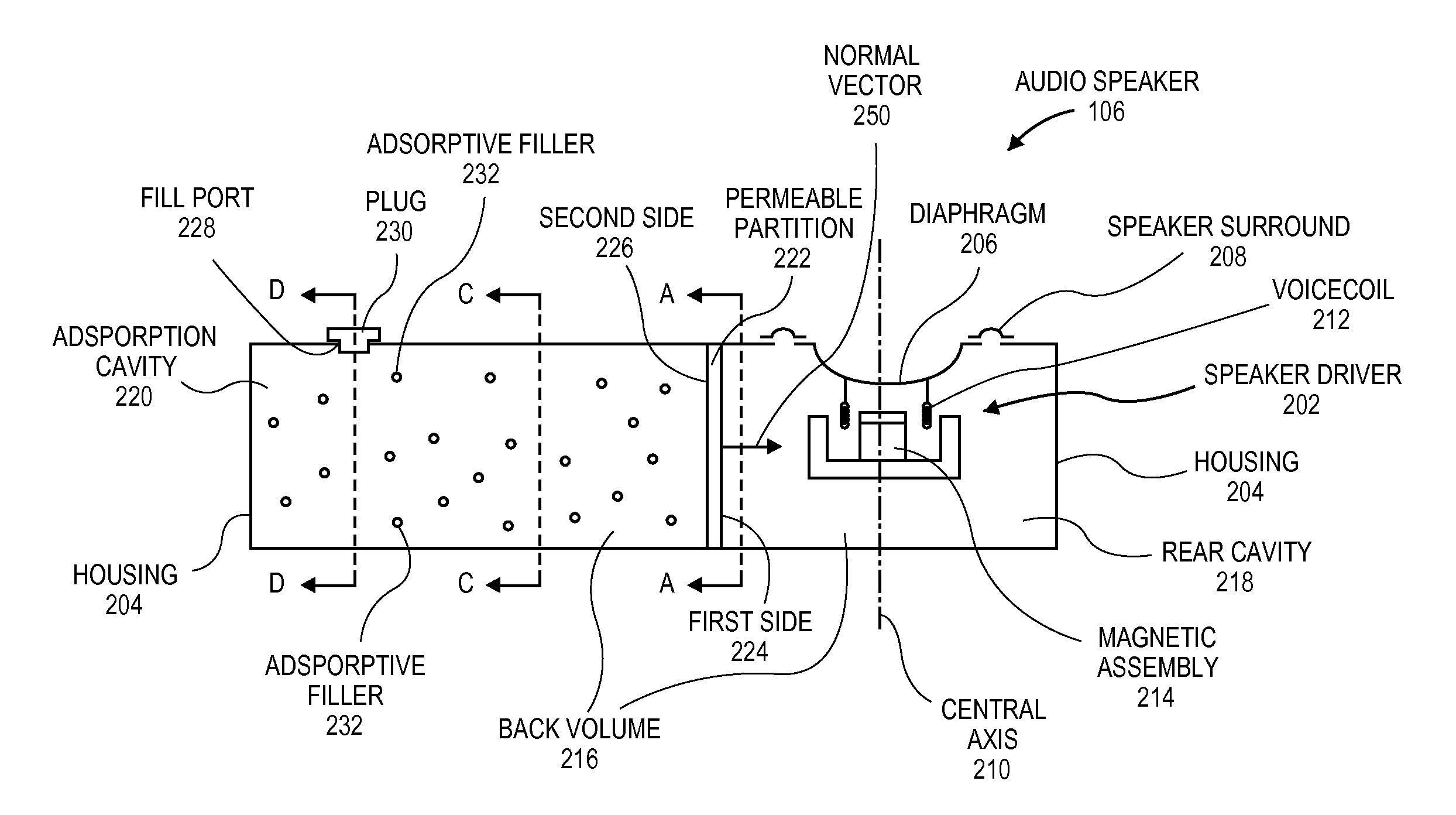

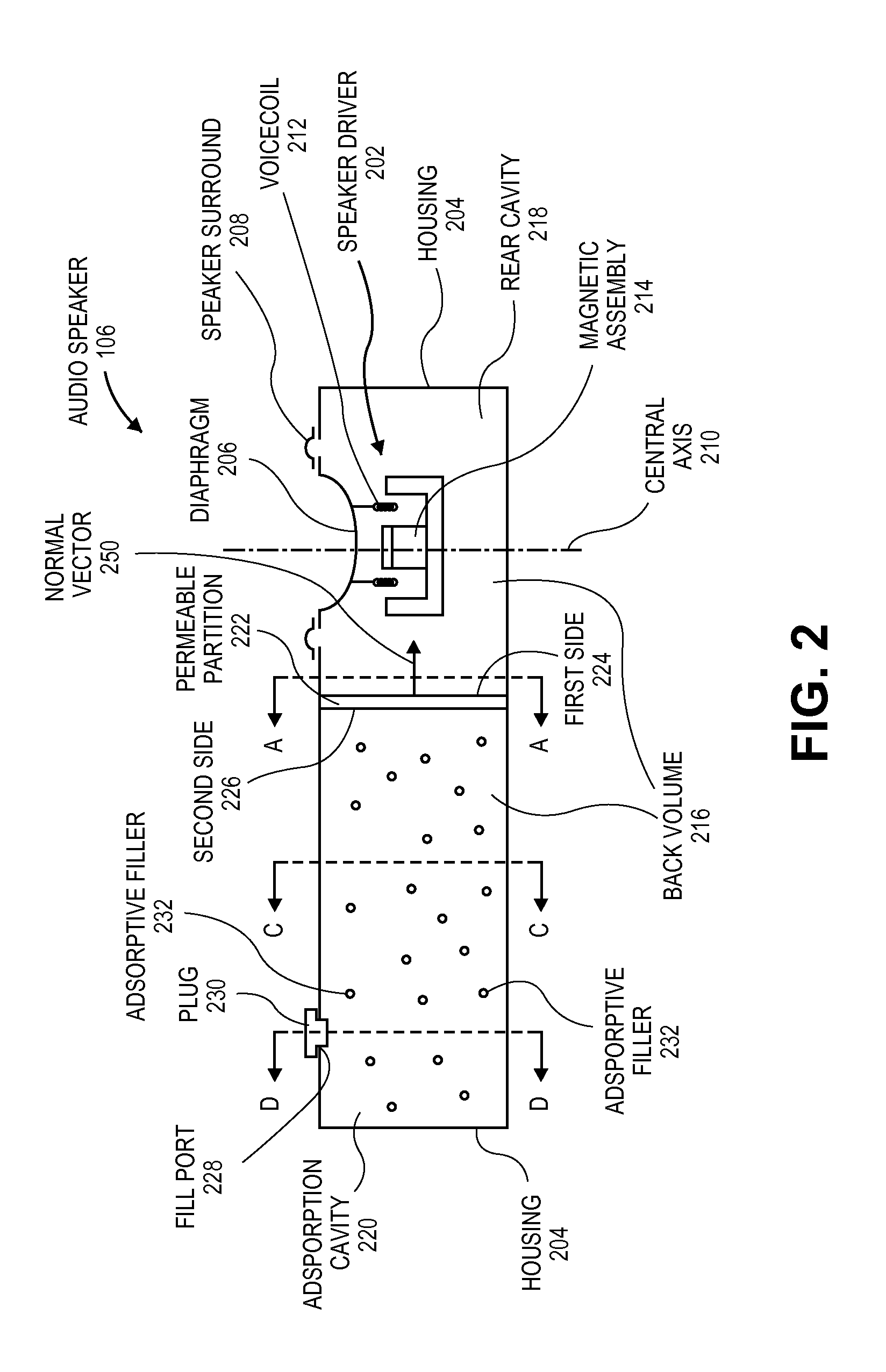

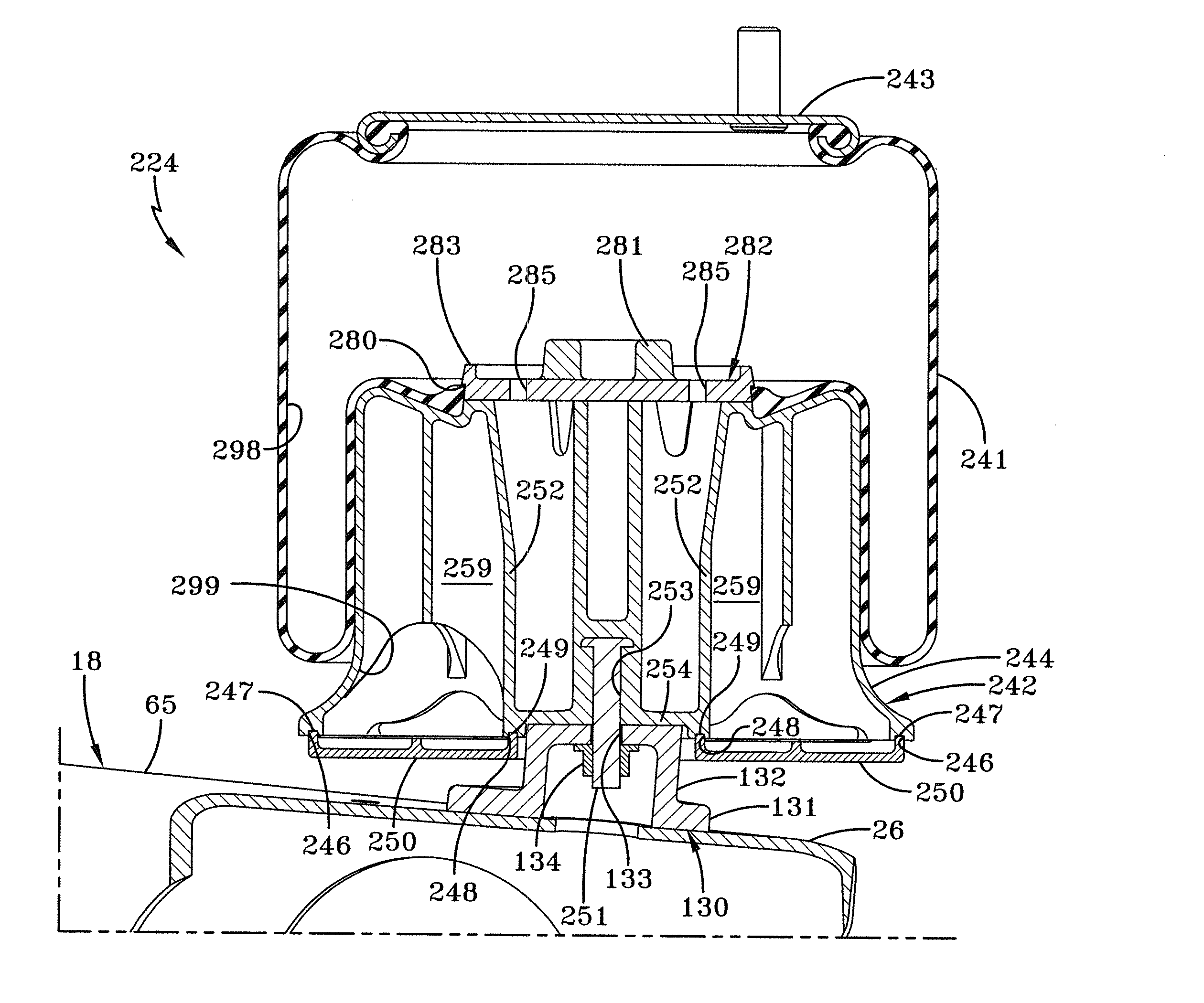

Audio speaker with back volume containing adsorptive material

ActiveUS20160345090A1Reduce spacingEffective back volume can be increasedGas treatmentDispersed particle separationEngineeringSound production

An audio speaker having a speaker housing surrounding a back volume that is divided into a rear cavity behind a speaker driver and an adsorption cavity separated from the rear cavity by a permeable partition, is disclosed. More particularly, the adsorption cavity may be defined between the speaker housing and the permeable partition, and may be directly filled with adsorptive particles to adsorb gas during sound generation. The permeable partition may allow the gas to flow between the rear cavity and the adsorption cavity, and may retain the adsorptive particles within the adsorption cavity. Other embodiments are also described and claimed.

Owner:APPLE INC

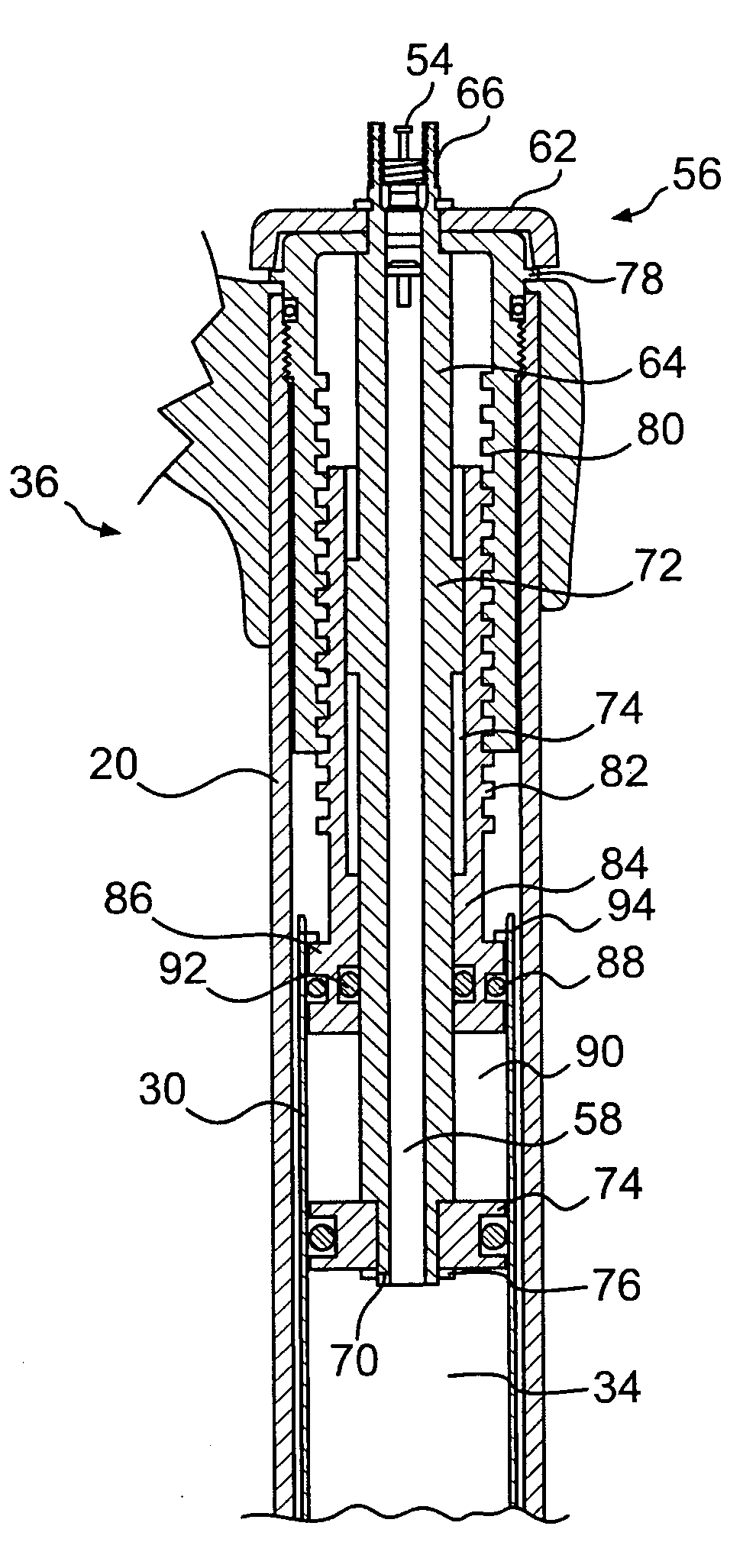

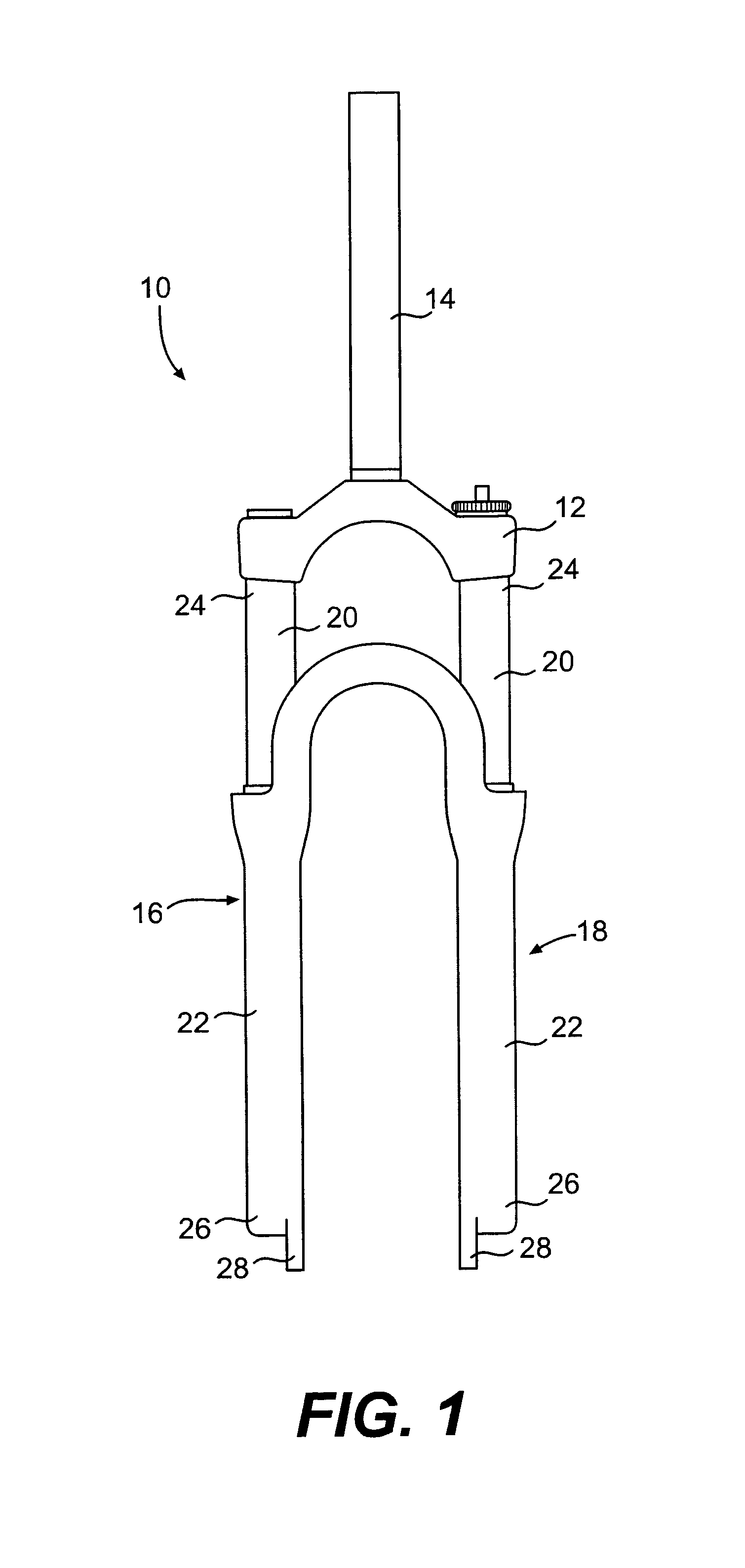

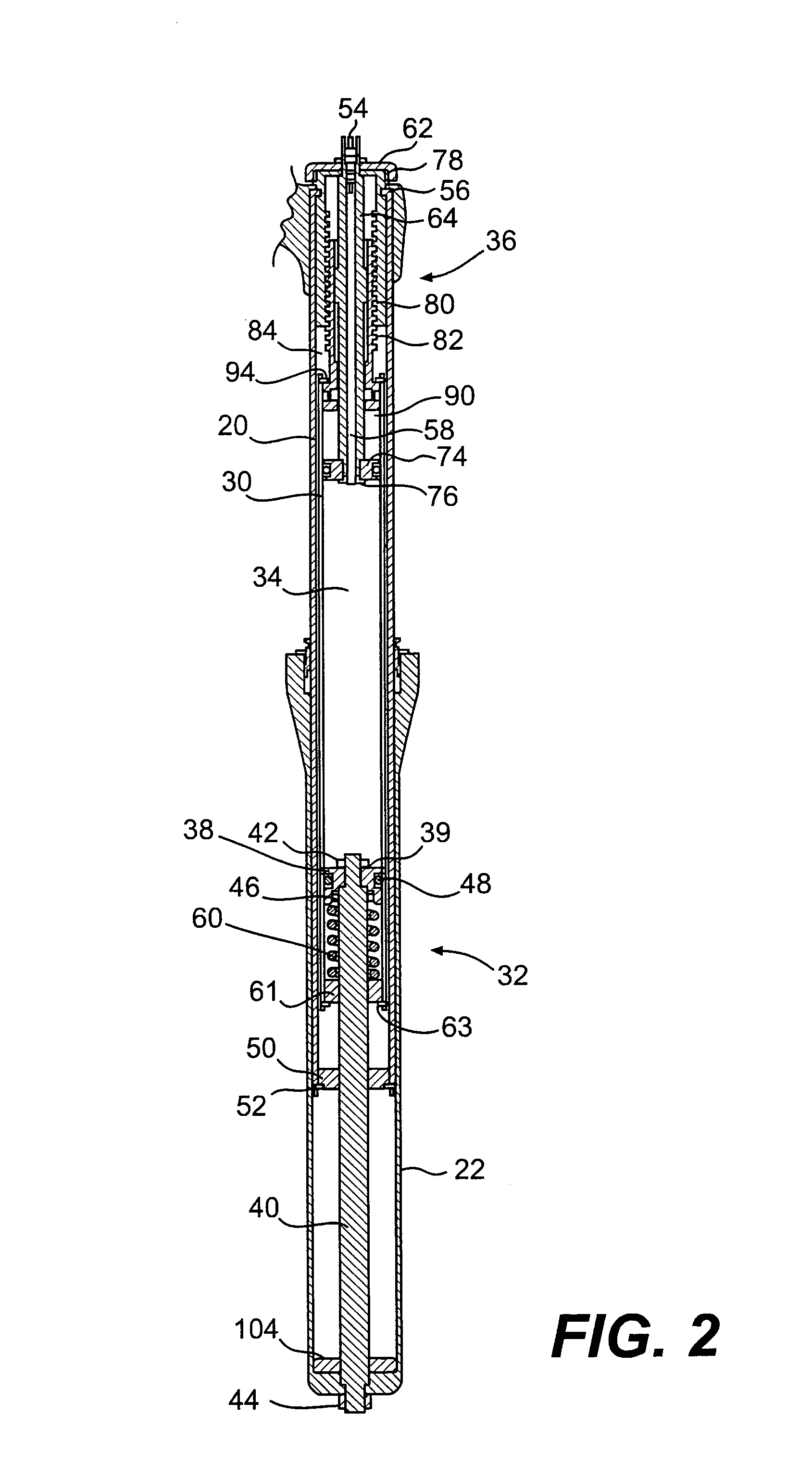

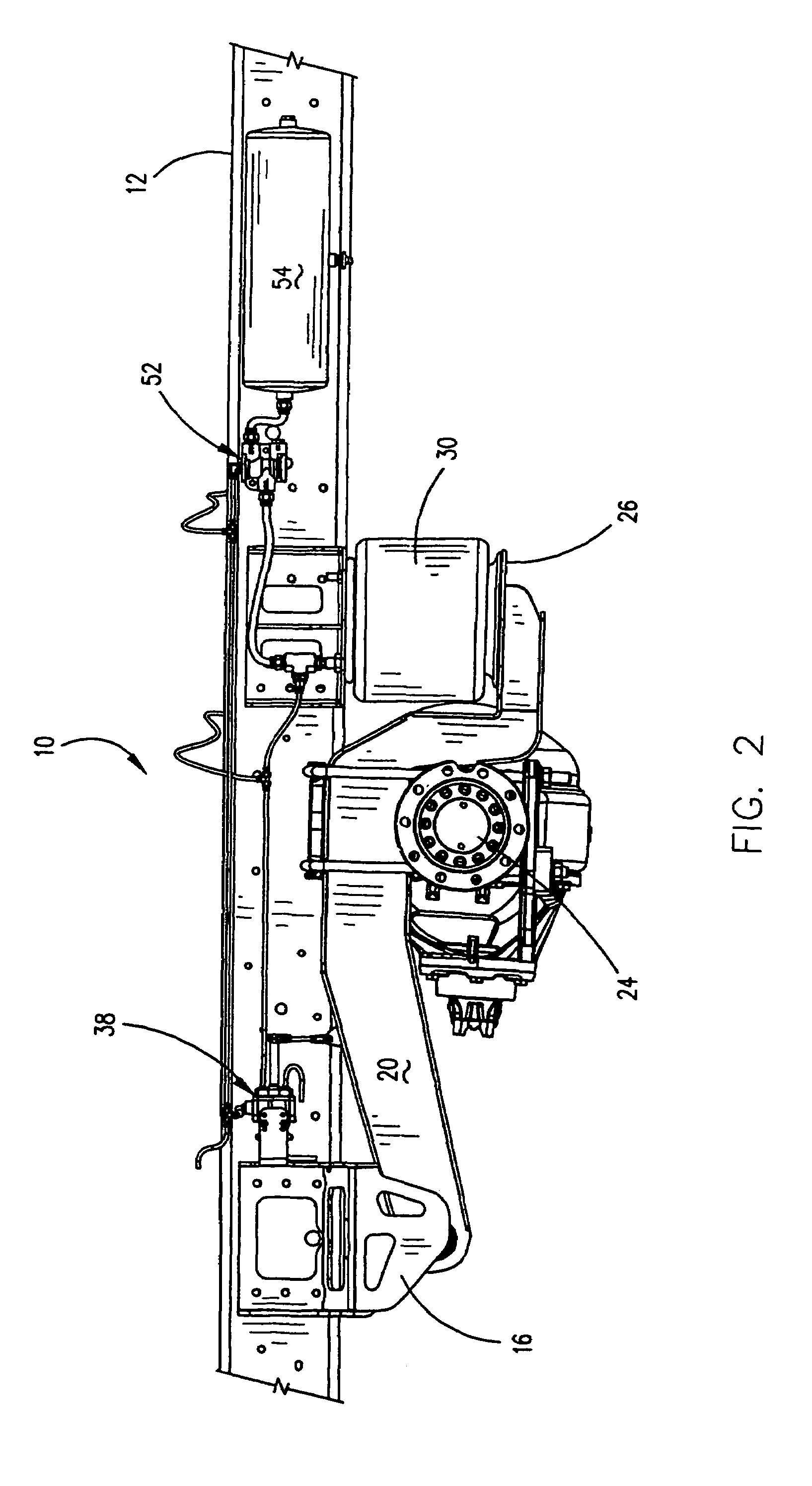

Adjustable gas spring suspension system

ActiveUS7195234B2High rebound rateSoft spring ratePassenger cyclesWheel based transmissionAxial displacementGas spring

Owner:SRAM CORPORATION

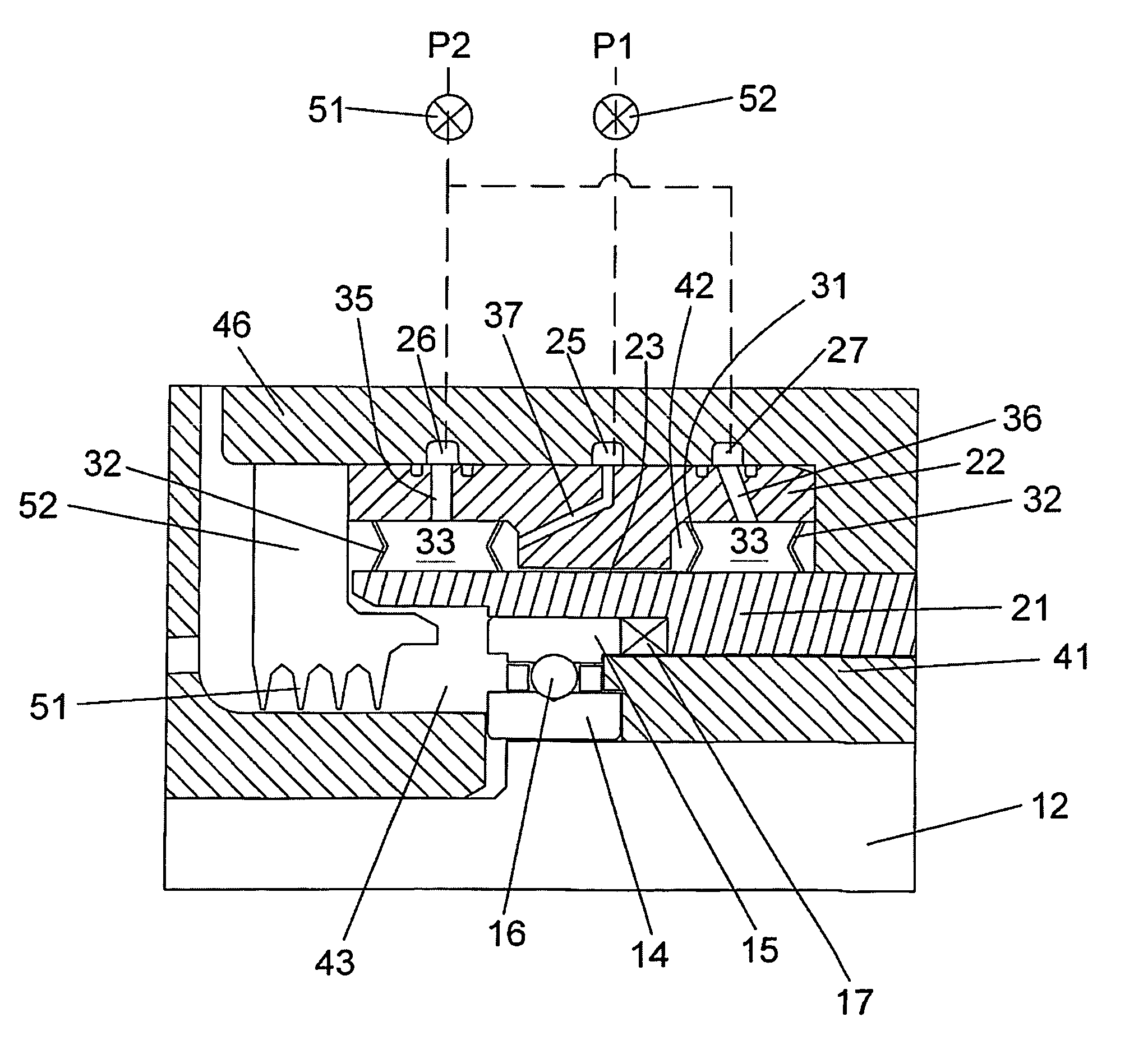

Squeeze film damper with highly variable support stiffness

InactiveUS7798720B1Reduce weight and sizeEasy to controlPump componentsShaftsVariable stiffnessEngineering

A squeeze film damper assembly having a variable stiffness and damping control. The squeeze film damper includes a damper chamber formed by two flexible bellows chambers of the sides. A first pressure source is applied to the damper chamber to regulate the damping. A second pressure source is applied to the flexible bellows chambers to vary the stiffness of the damper. The flexible bellows chambers are secured between an outer member and an inner member of the damper assembly and form the sealed damper chamber. A pressure ratio between the bellows chambers and the damper chamber can vary to control the stiffness of the squeeze film damper.

Owner:FLORIDA TURBINE TECH

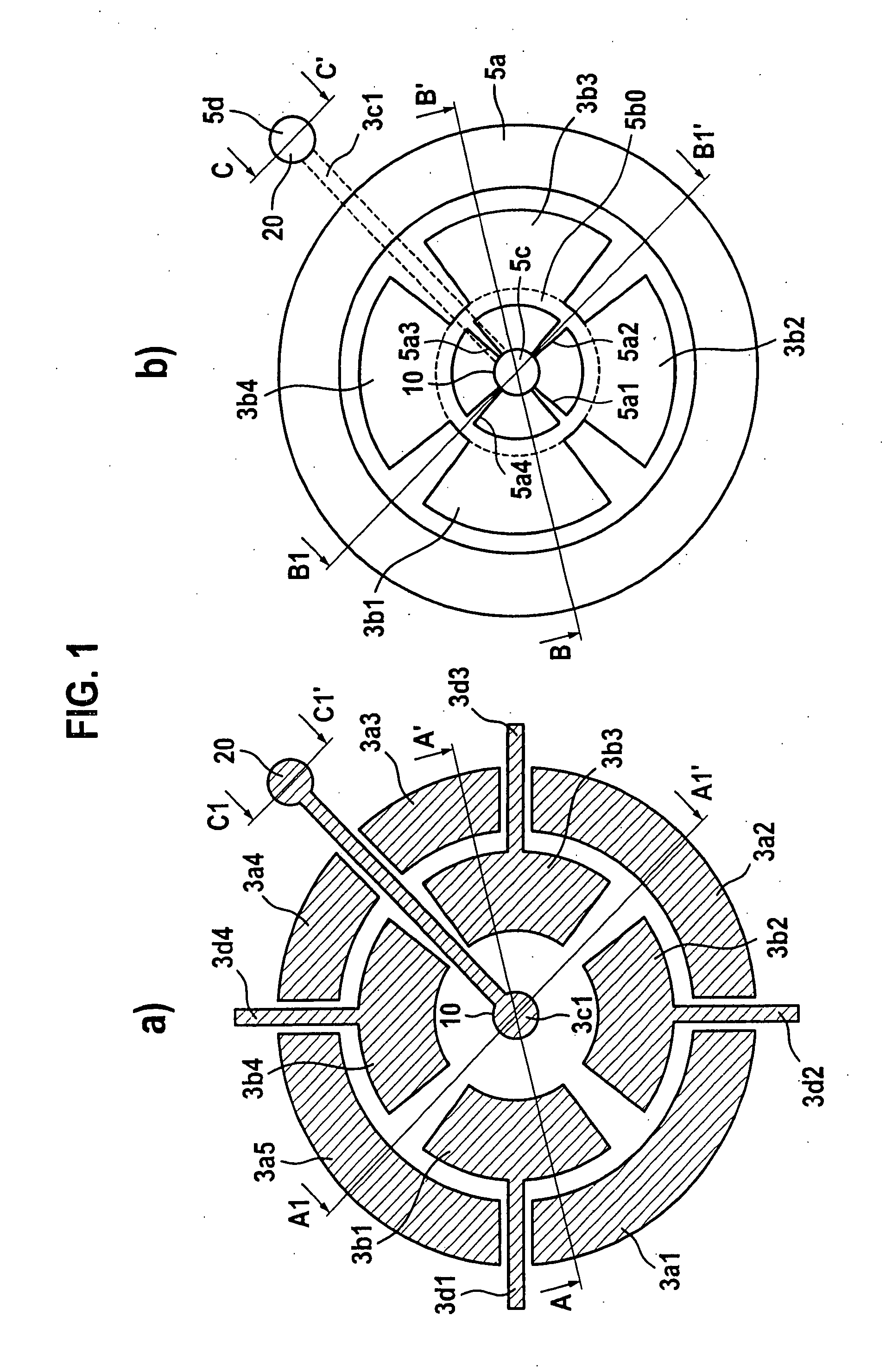

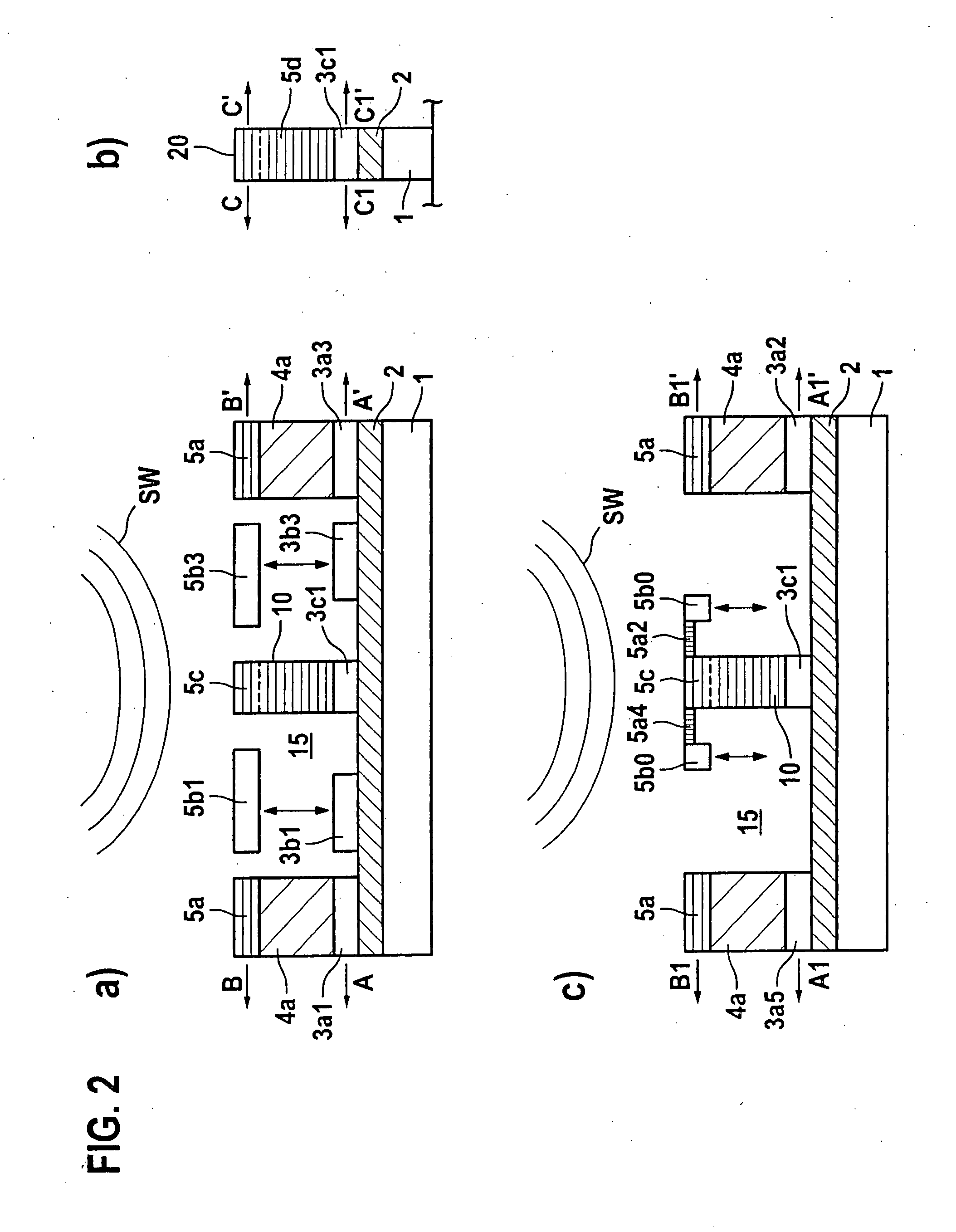

Micromechanical component and corresponding manufacturing method

InactiveUS20070222006A1Efficient conductionAccurate detectionSolid-state devicesElectrostatic transducersCapacitanceEngineering

A micromechanical component which includes a substrate; a first rigid electrode system situated on or in the substrate; a second electrode system suspended on the substrate; an intermediate space provided between the first electrode system and the second electrode system; the second electrode system being mounted on the suspension post in an elastically deflectable manner with respect to the first electrode system such that the capacitance of a capacitor formed by the first electrode system, the second electrode system, and the intermediate space may be modified.

Owner:ROBERT BOSCH GMBH

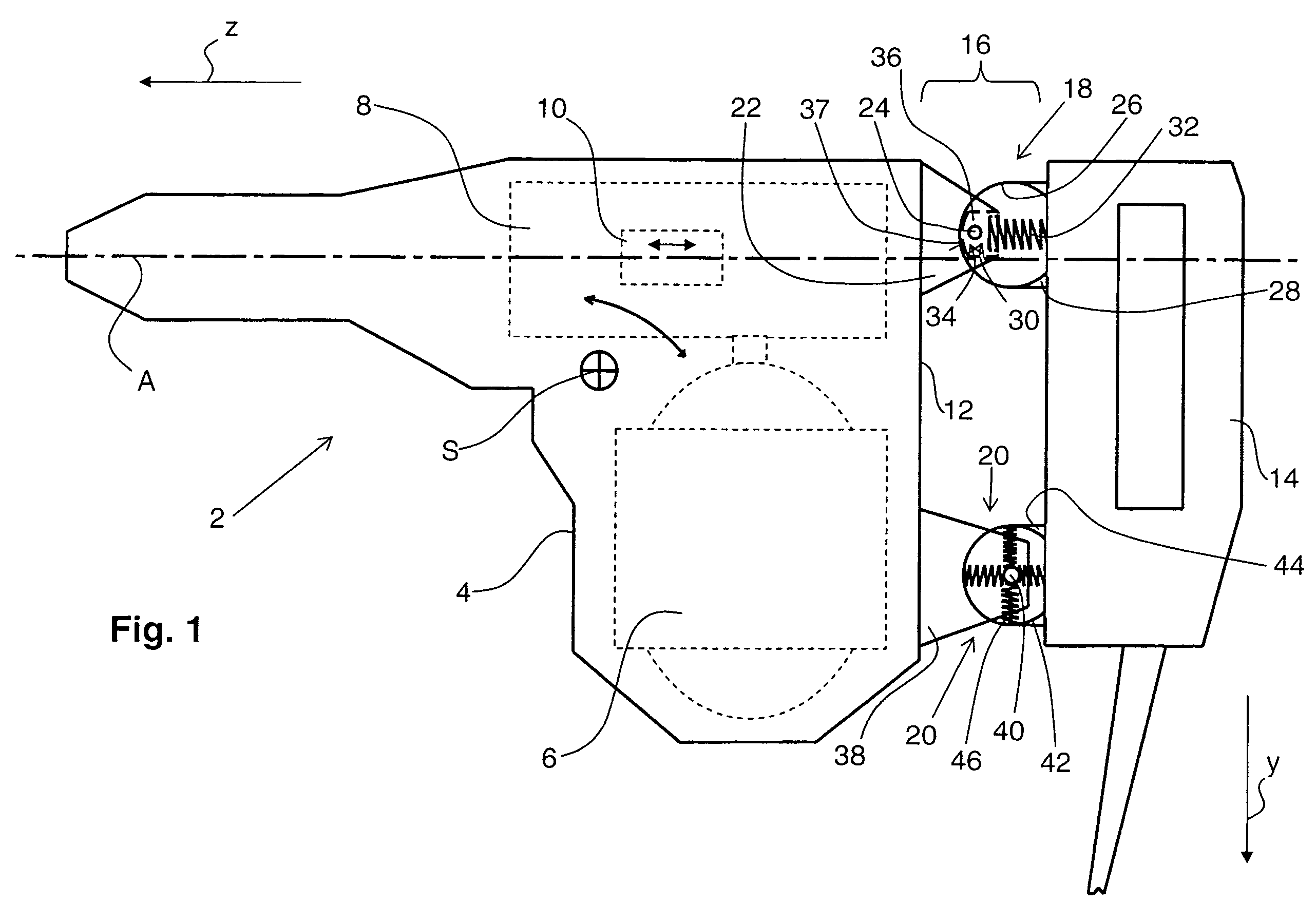

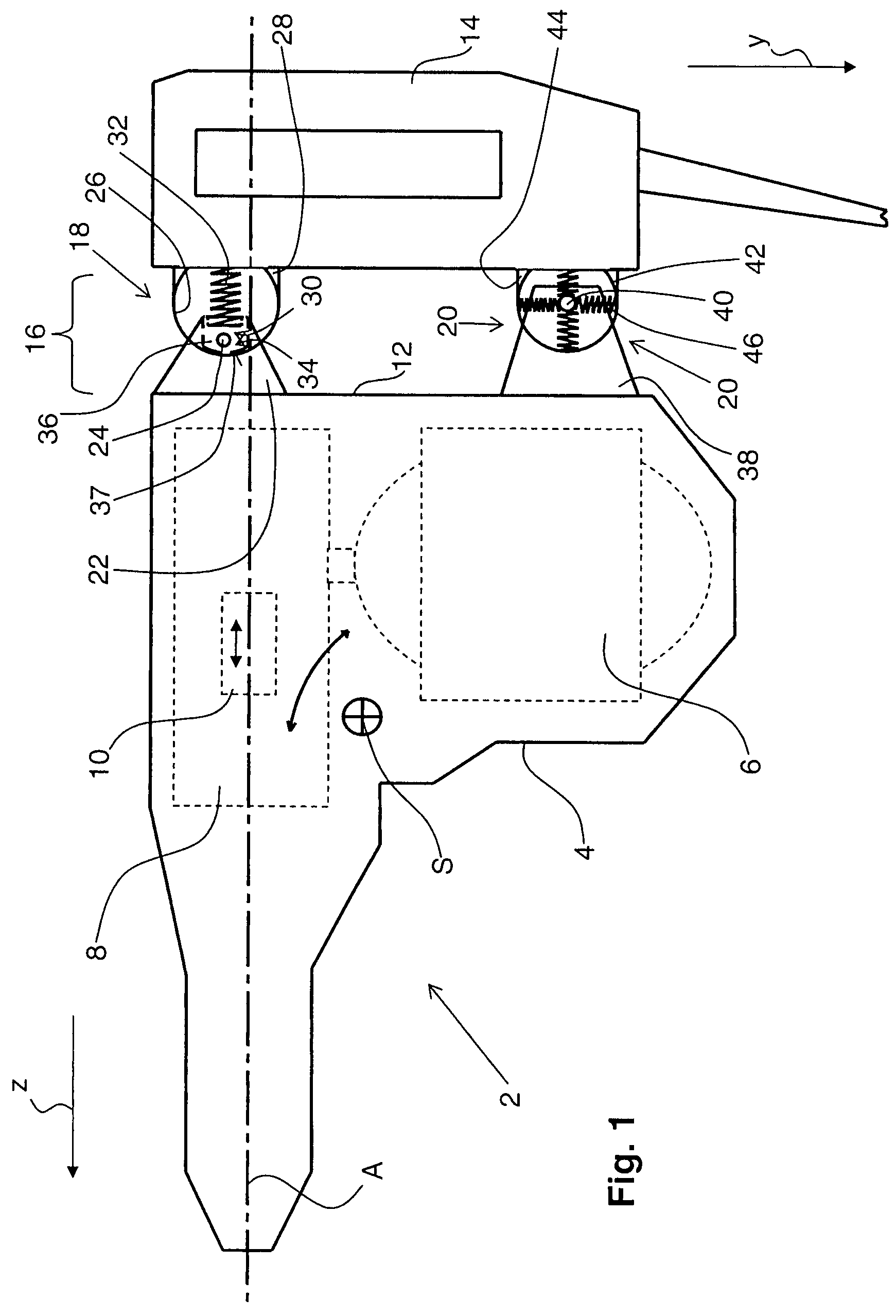

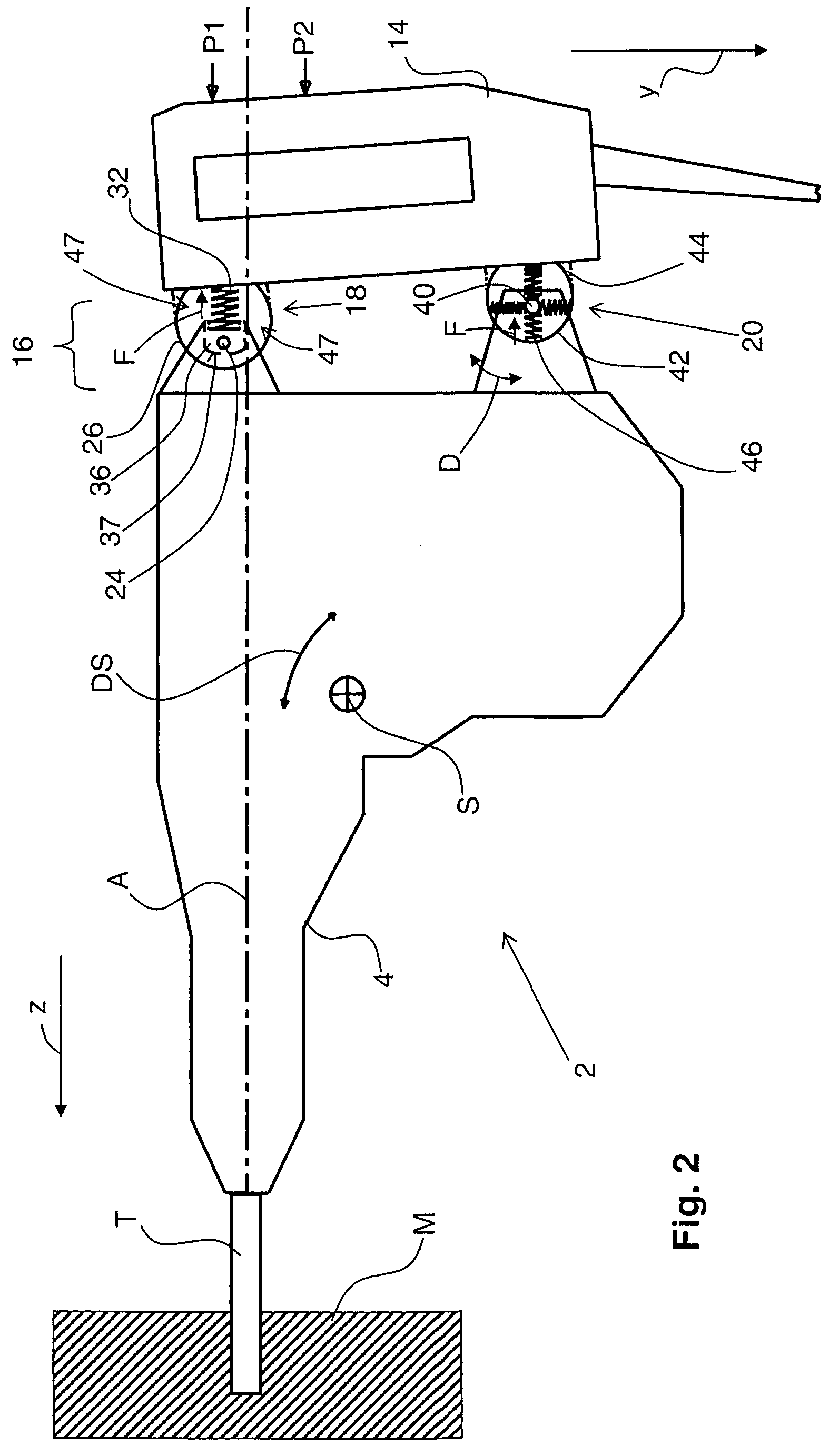

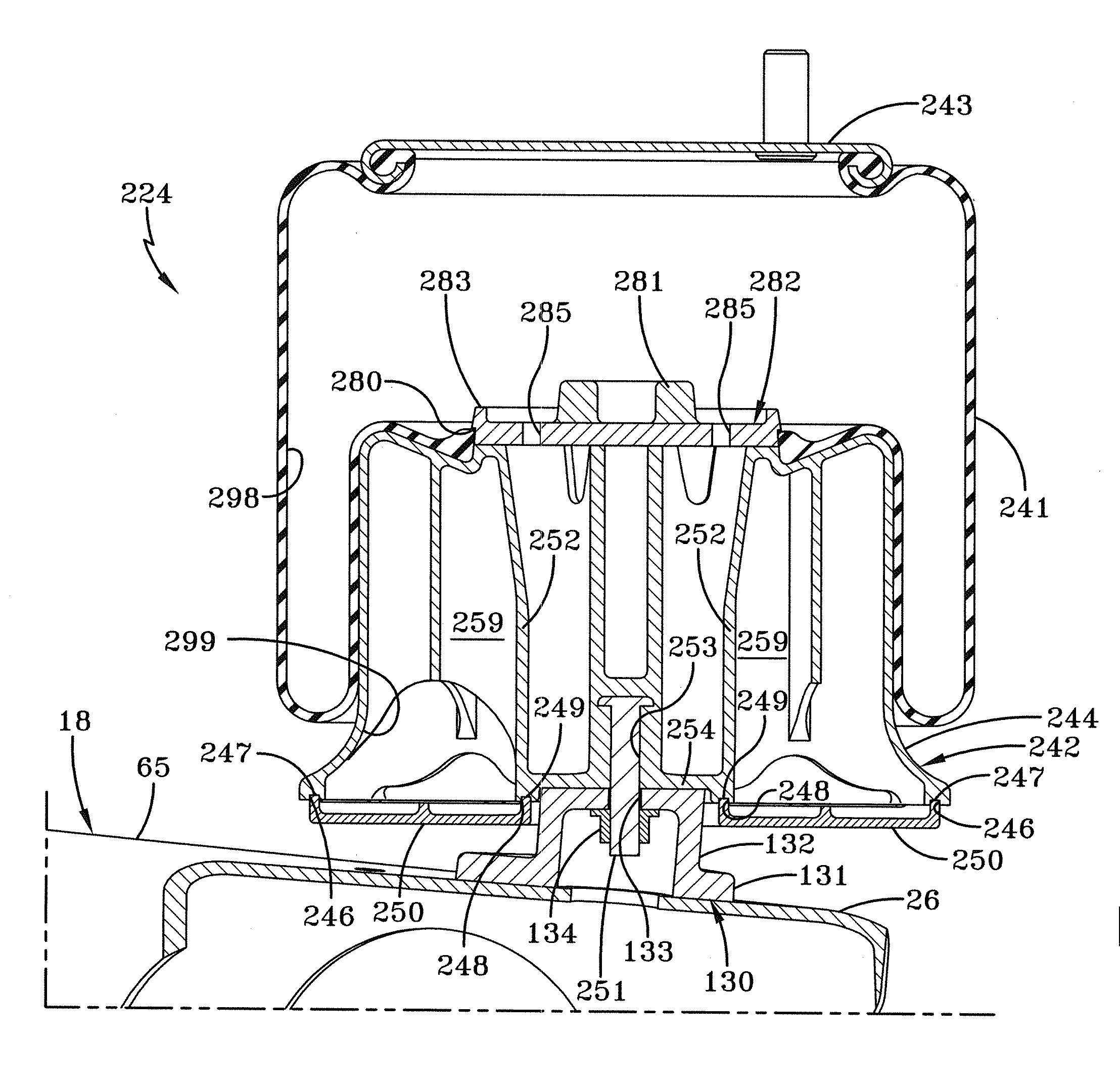

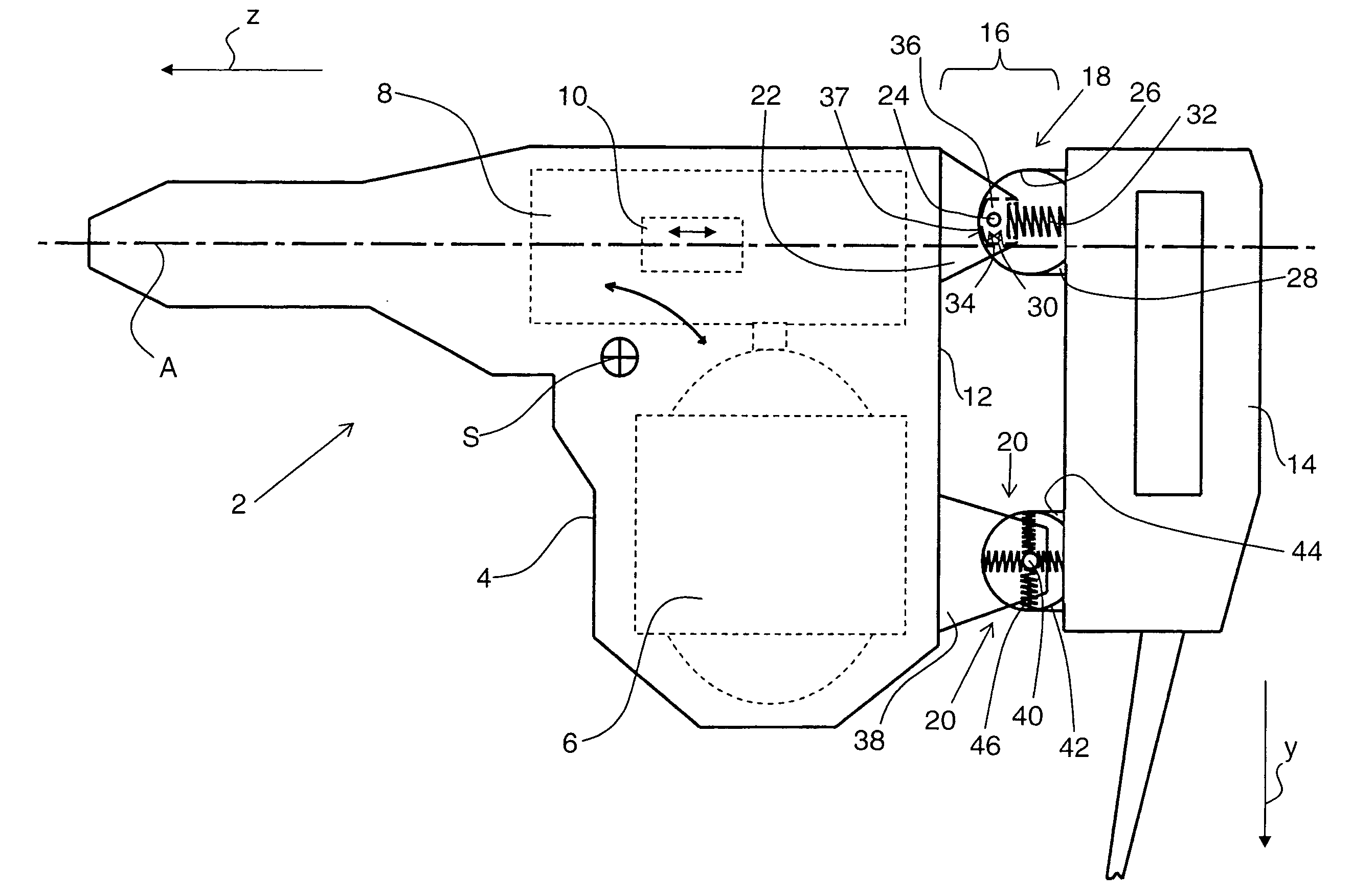

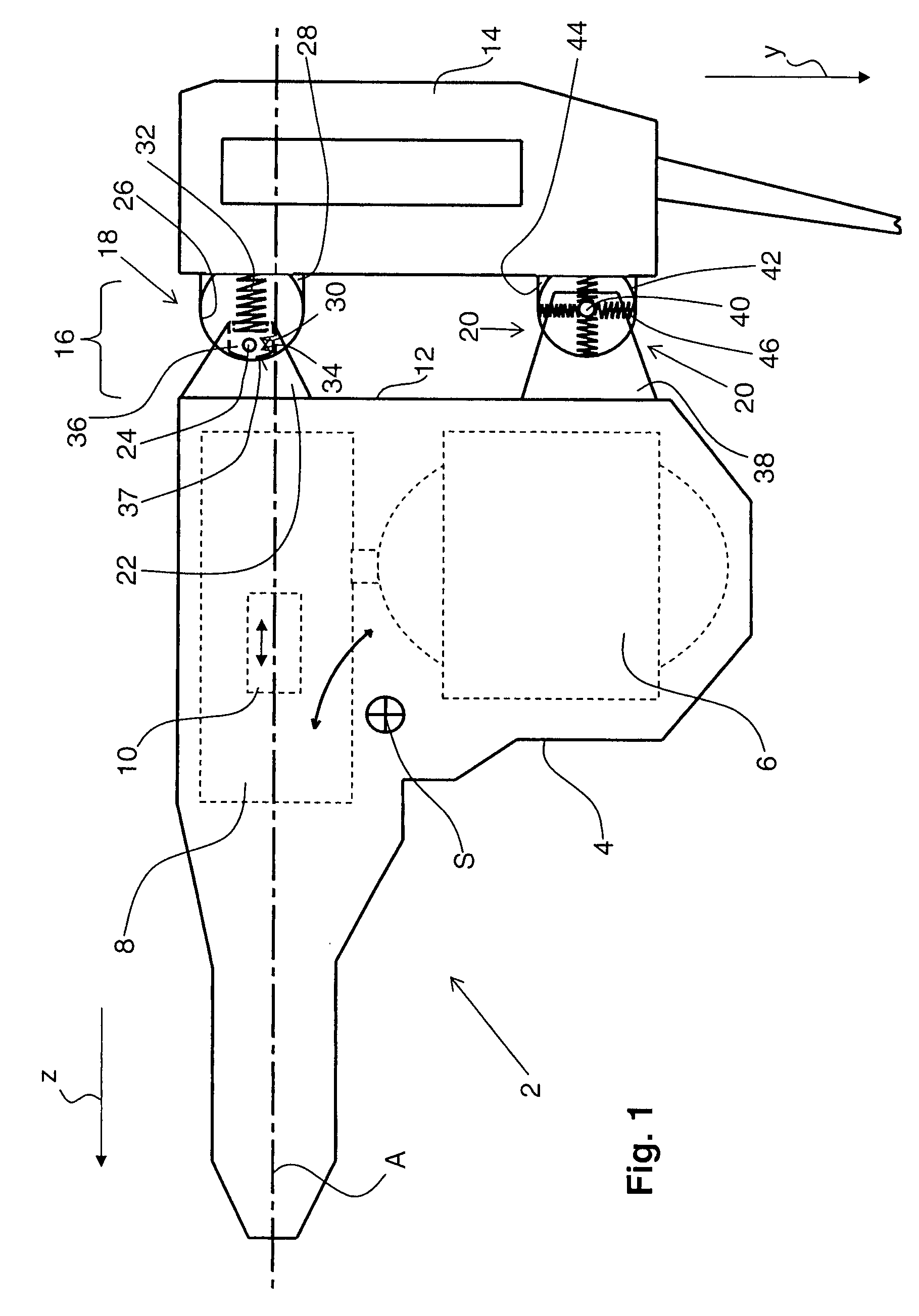

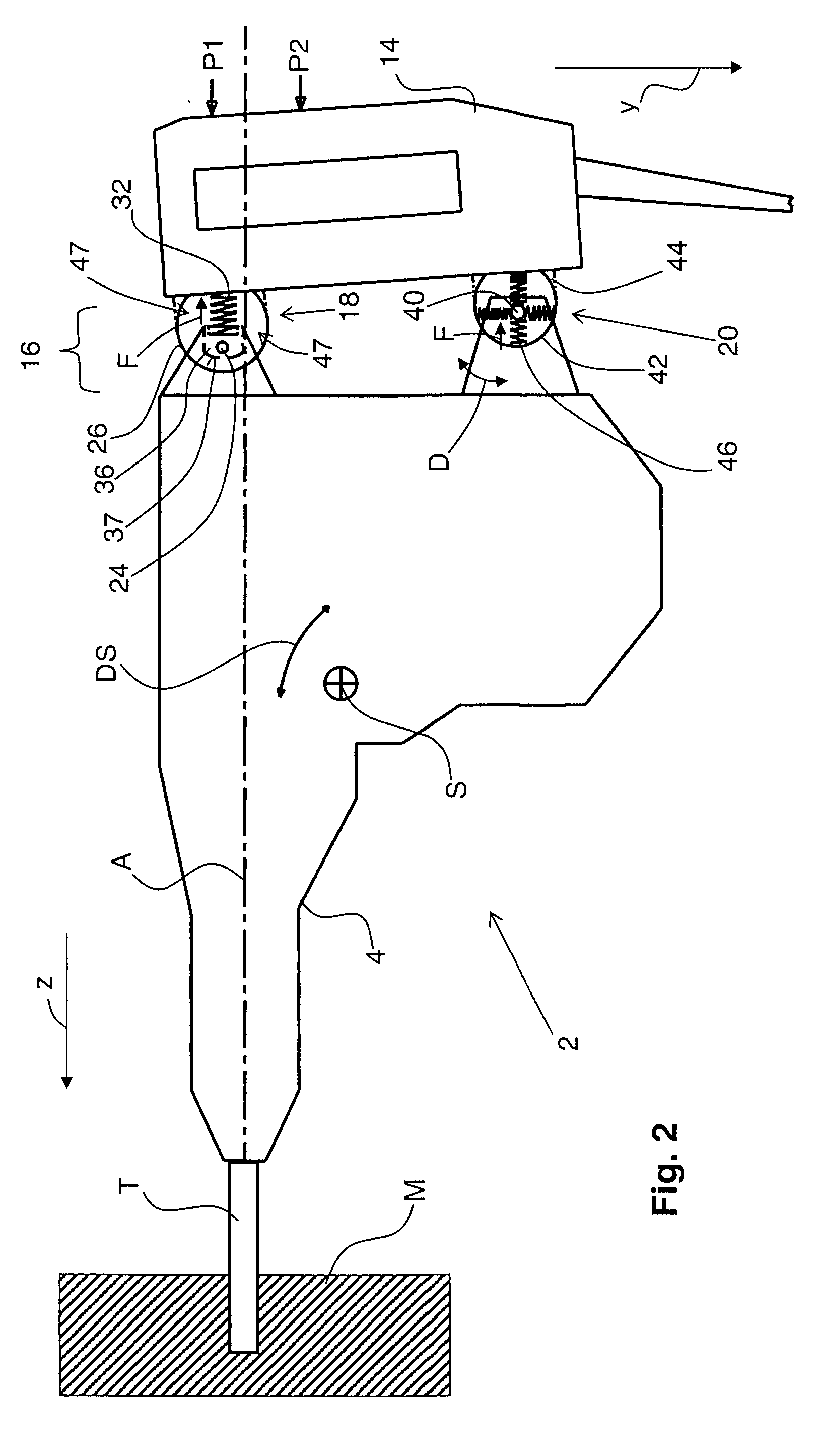

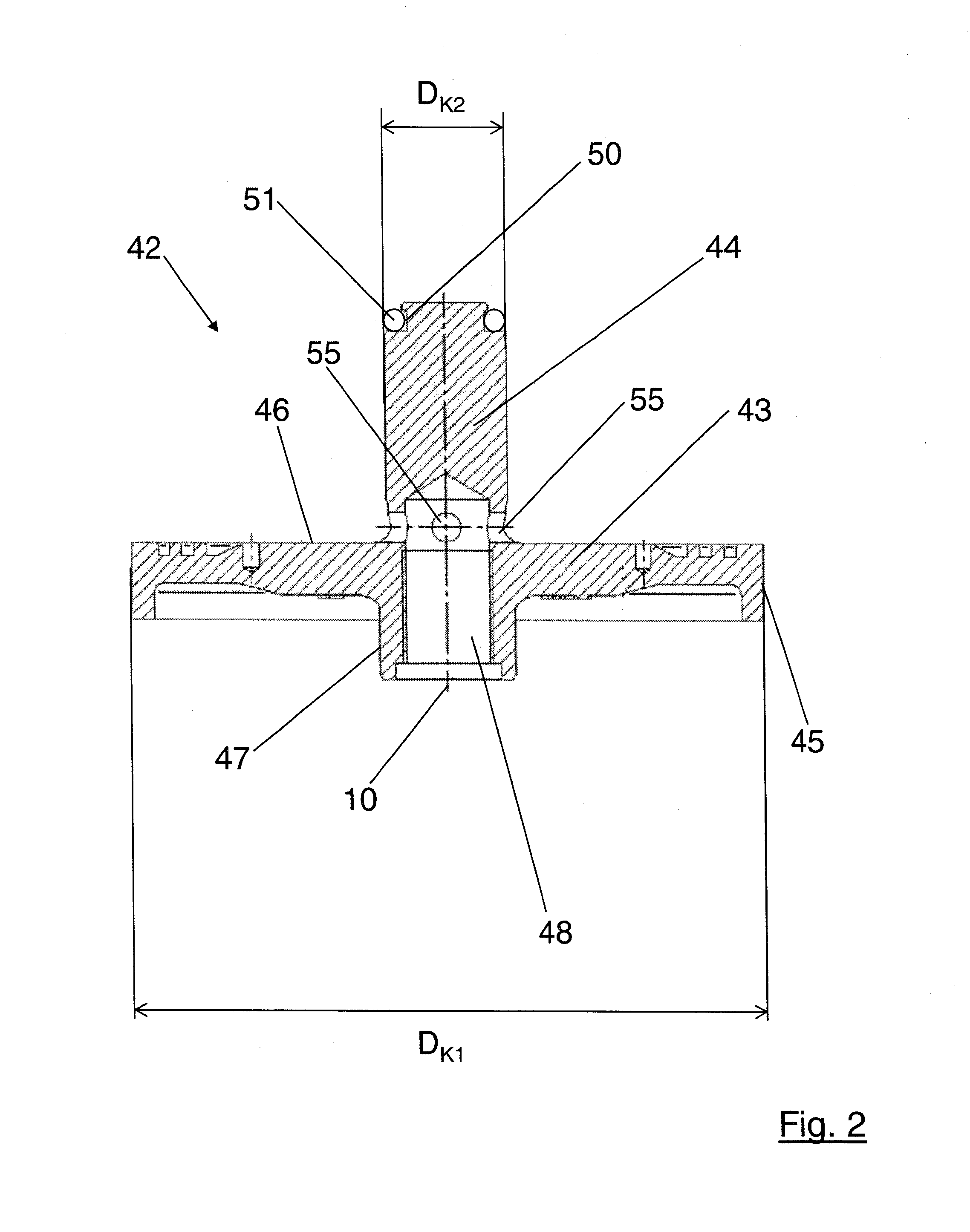

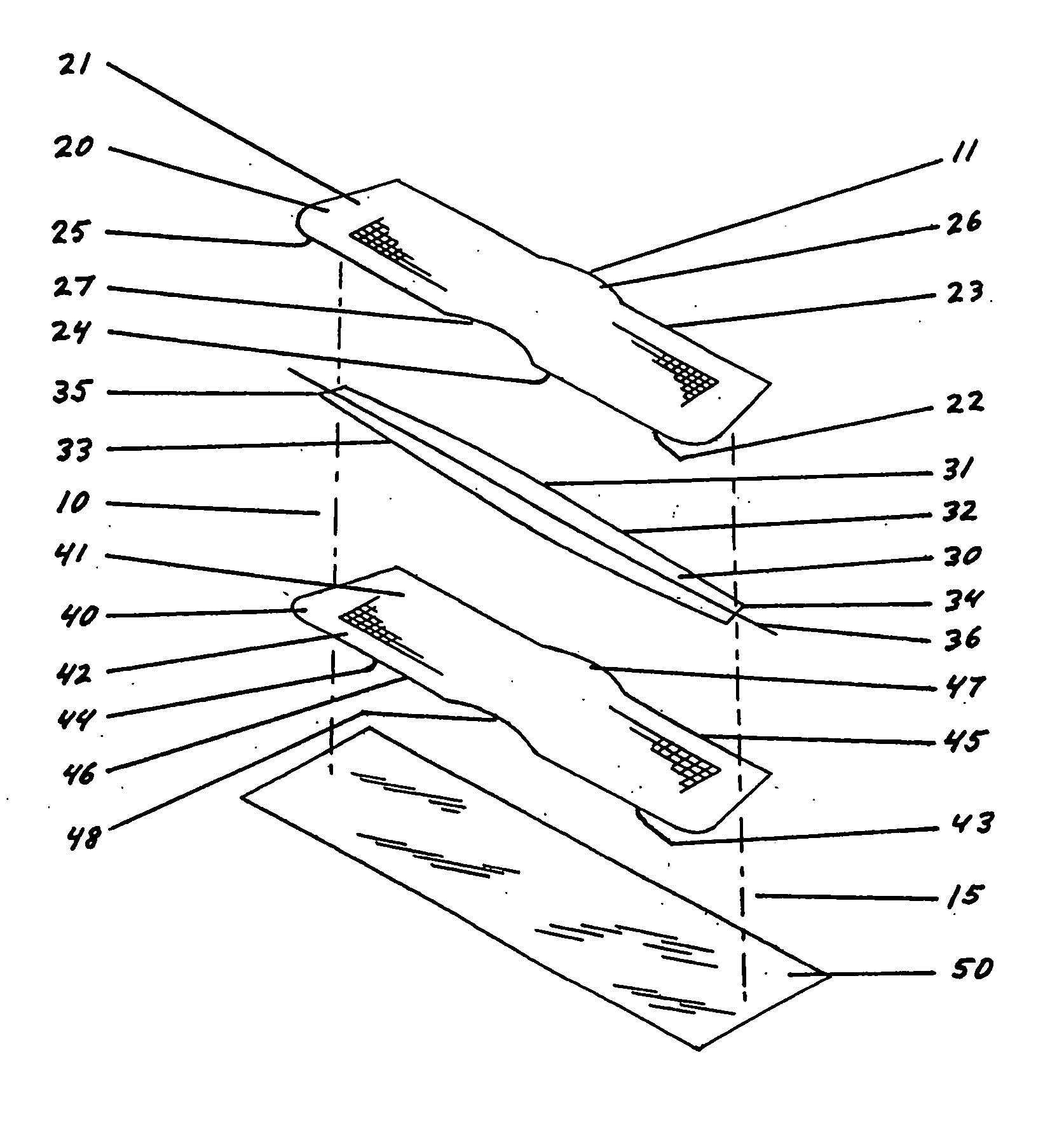

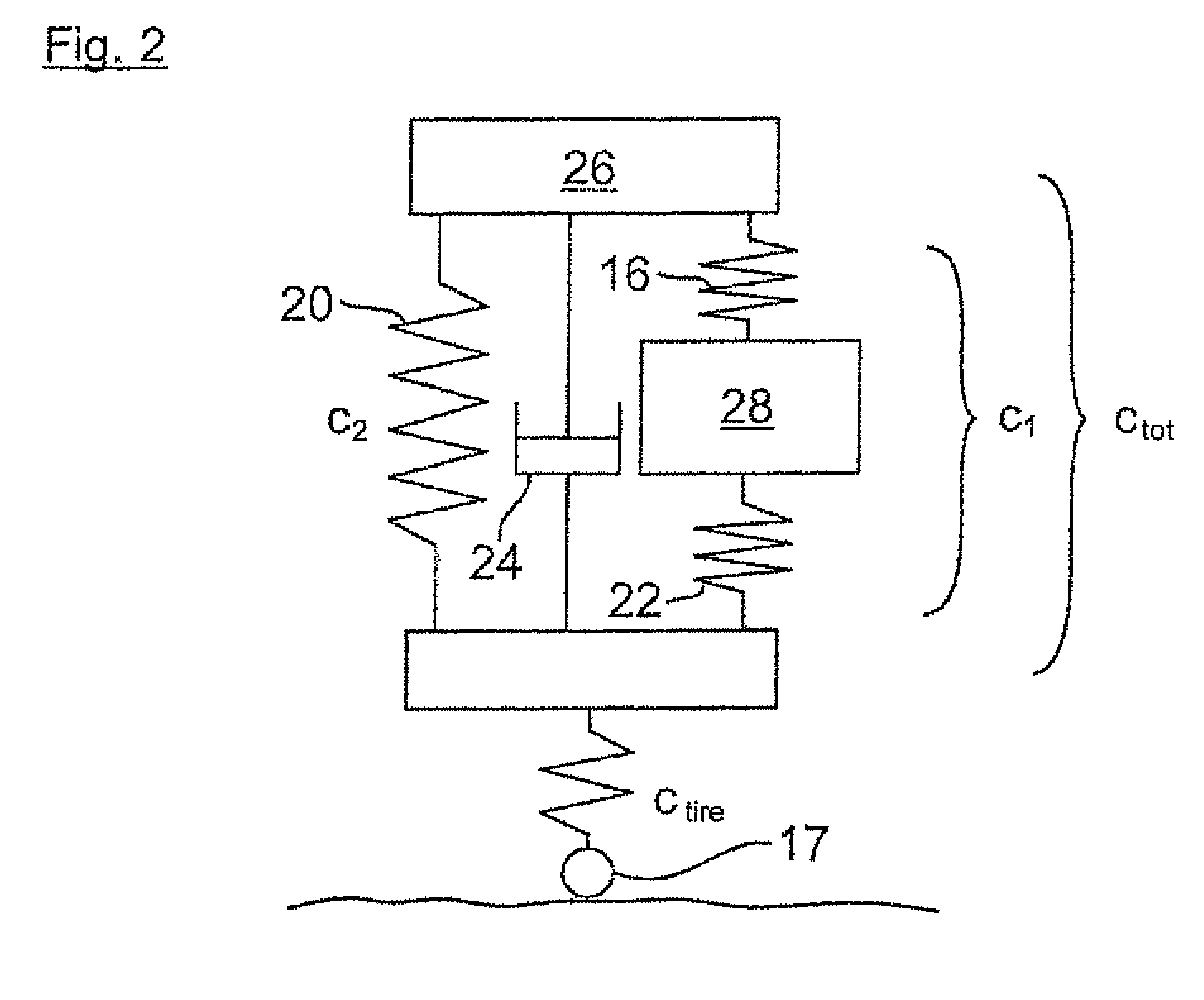

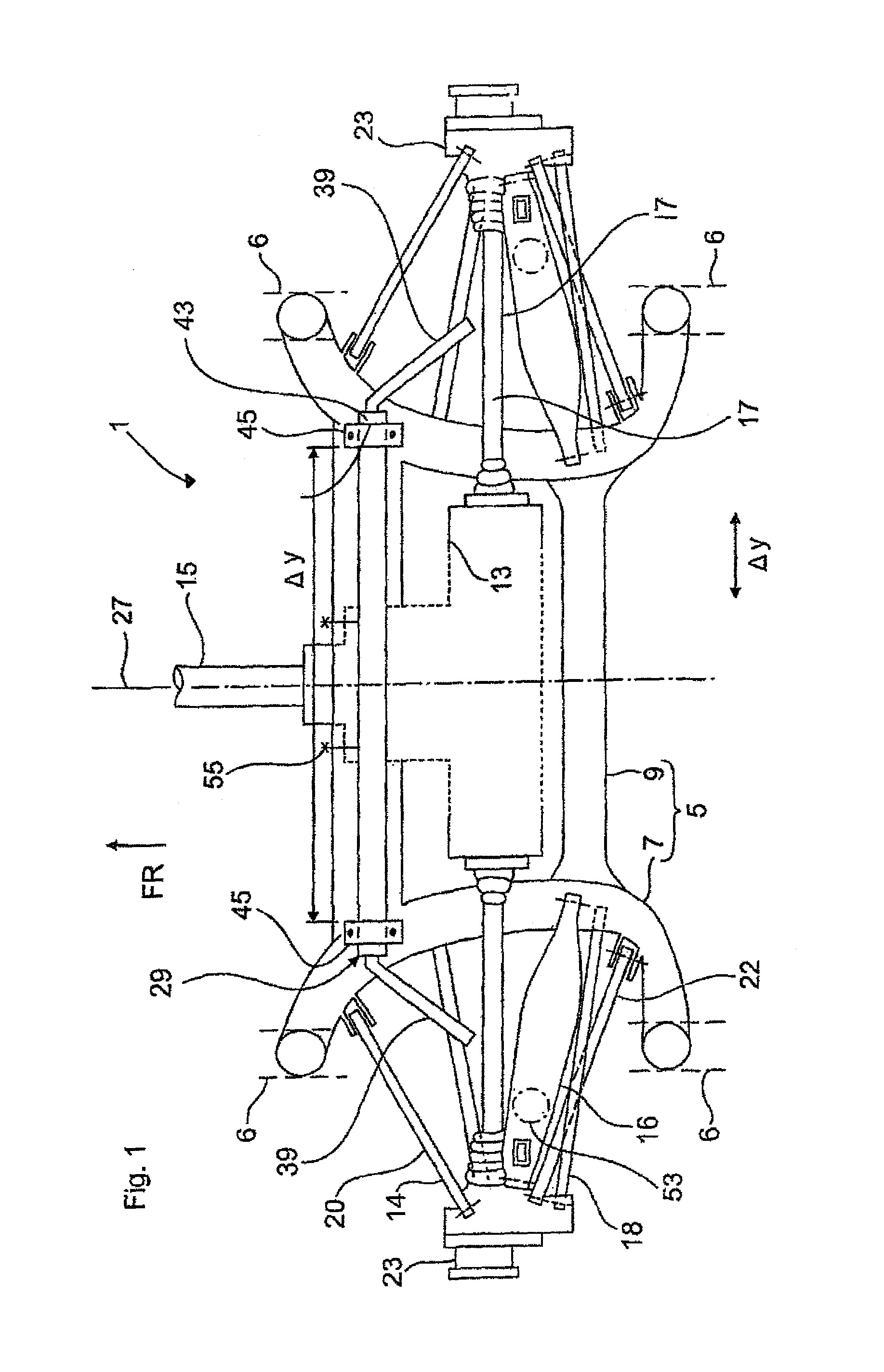

Hand-held power tool with a decoupling device

ActiveUS7610967B2Reduce the spring rateEffective decouplingOperator-supported drilling machinesPortable percussive toolsHand heldPower tool

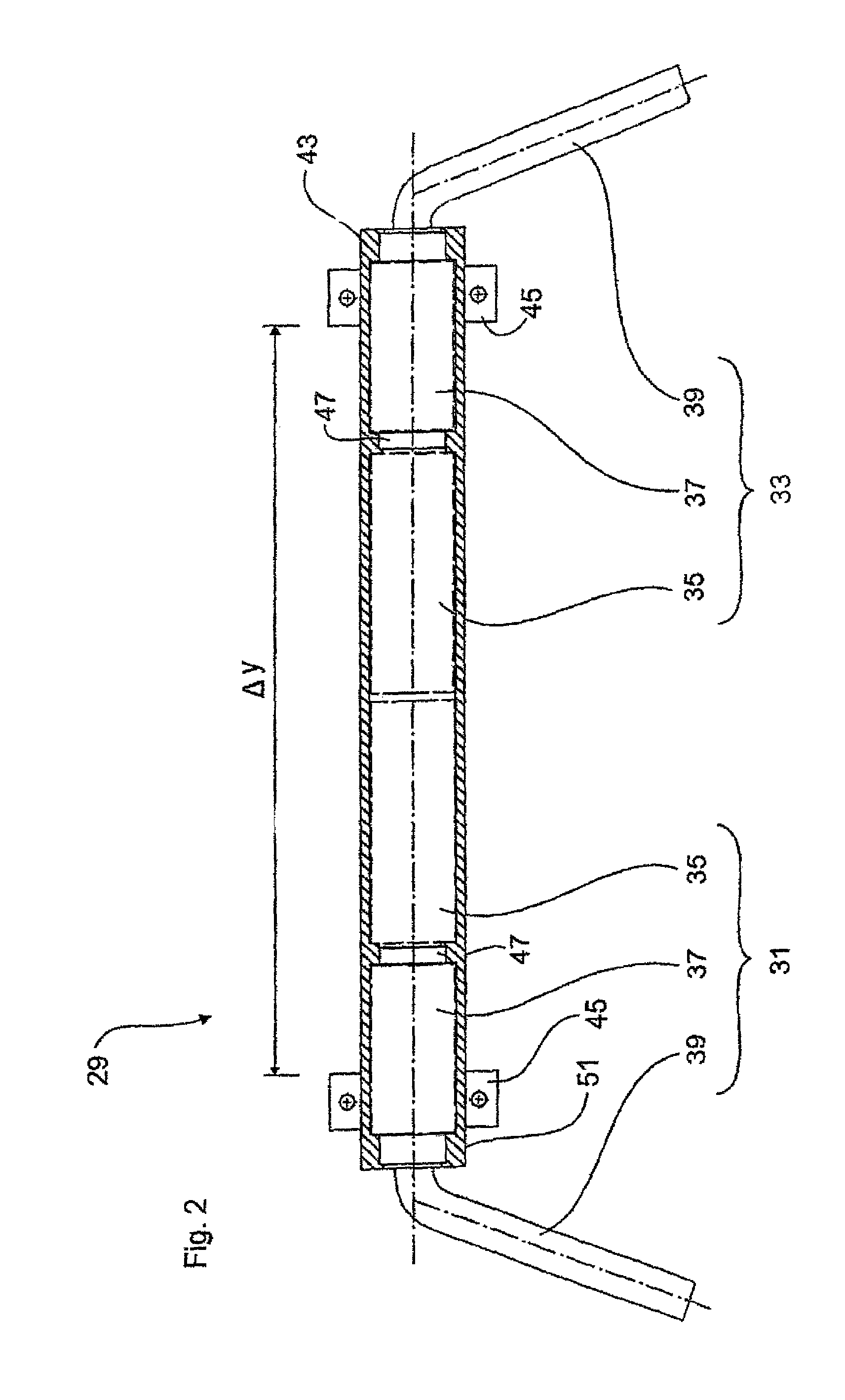

A hand-held power tool includes a spring-mounted decoupling device (16) for supporting a tool handle (14) on the tool housing (4) and having a first spring-mounted support (18) and a second spring-mounted support (20) that is spaced from the operational axis (A) in a second direction (y) perpendicular to the first direction (z) further away than the first spring-mounted support (18) that has a smaller spring stiffness along the second direction (y) than along the first direction (z).

Owner:HILTI AG

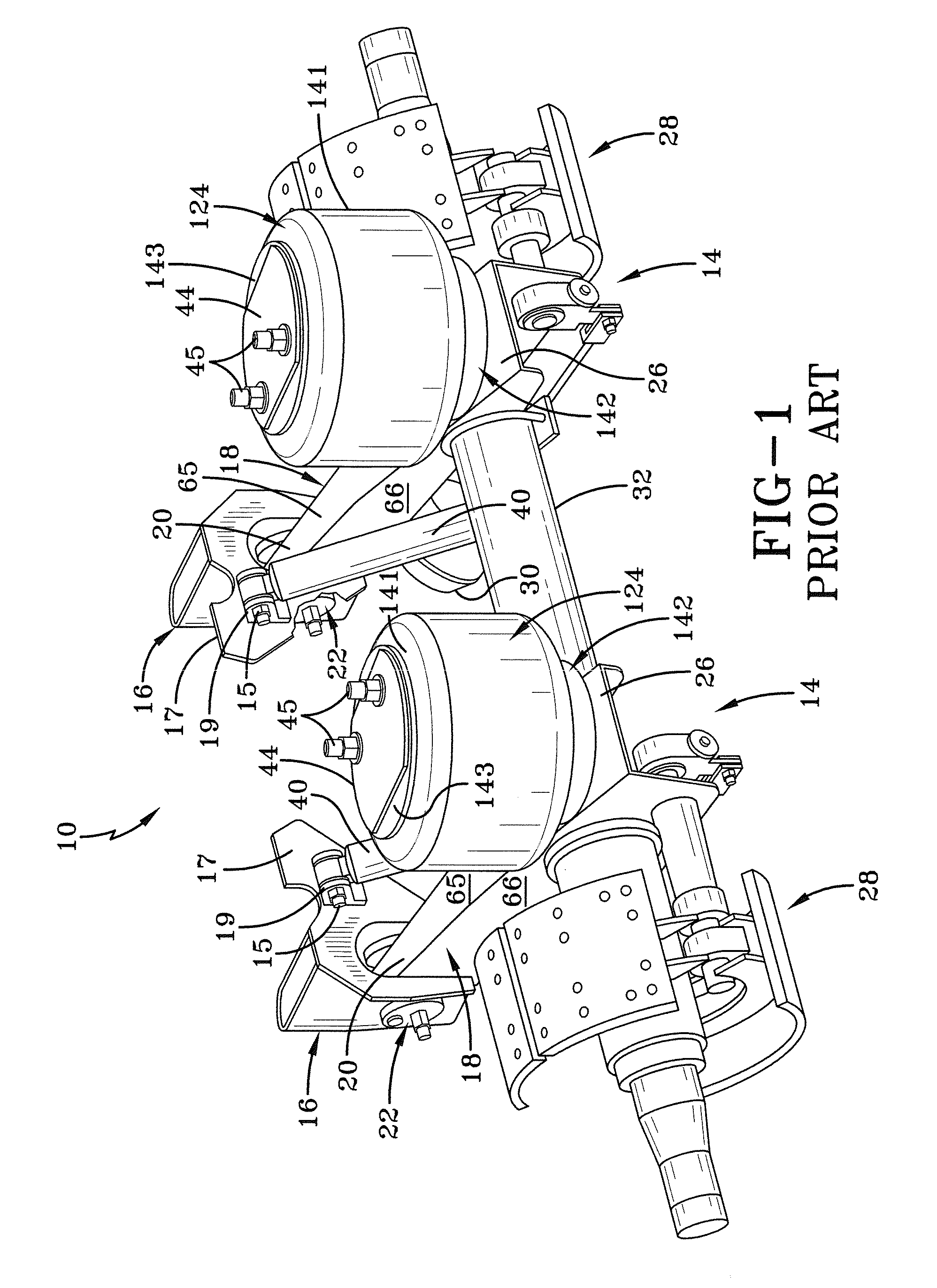

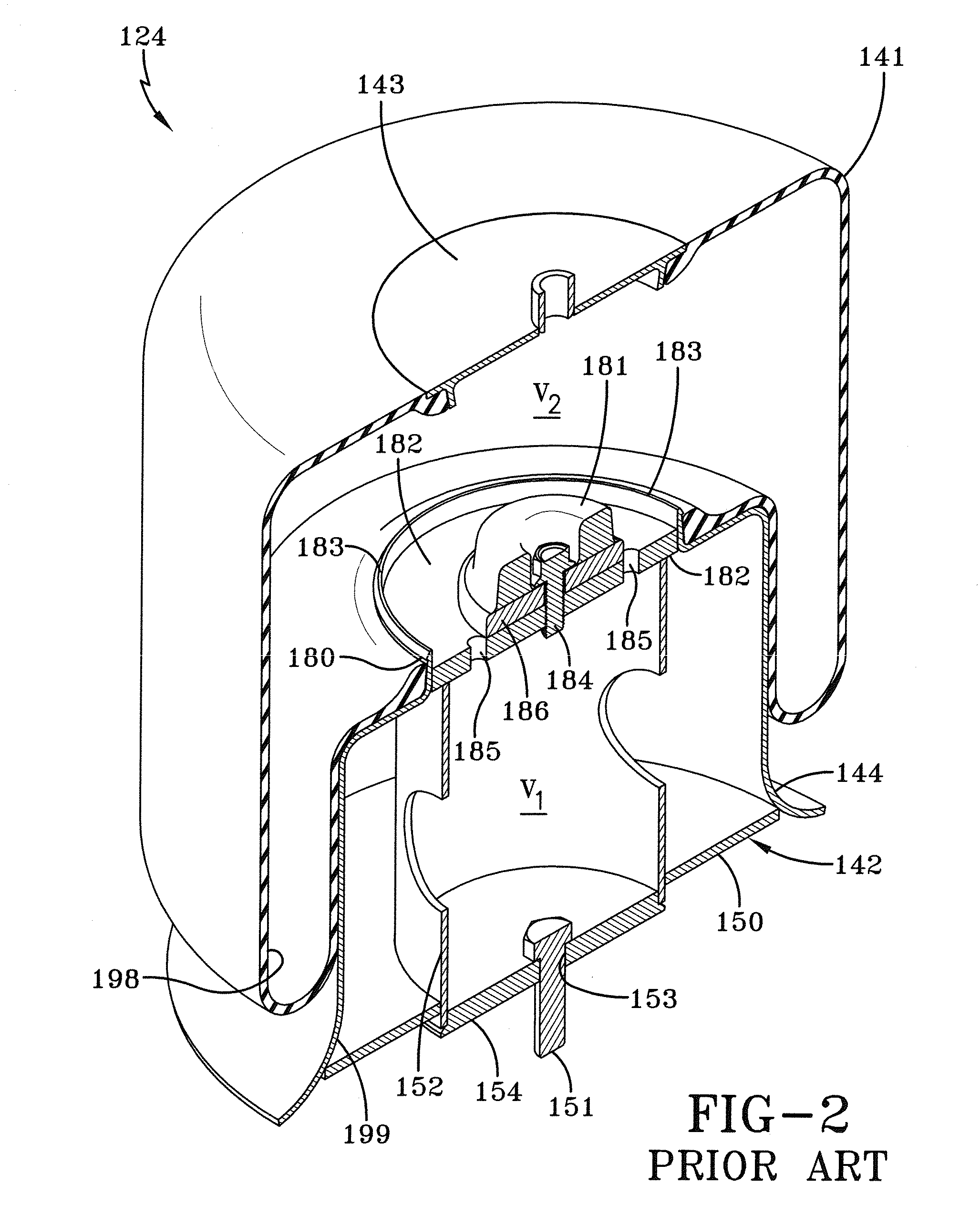

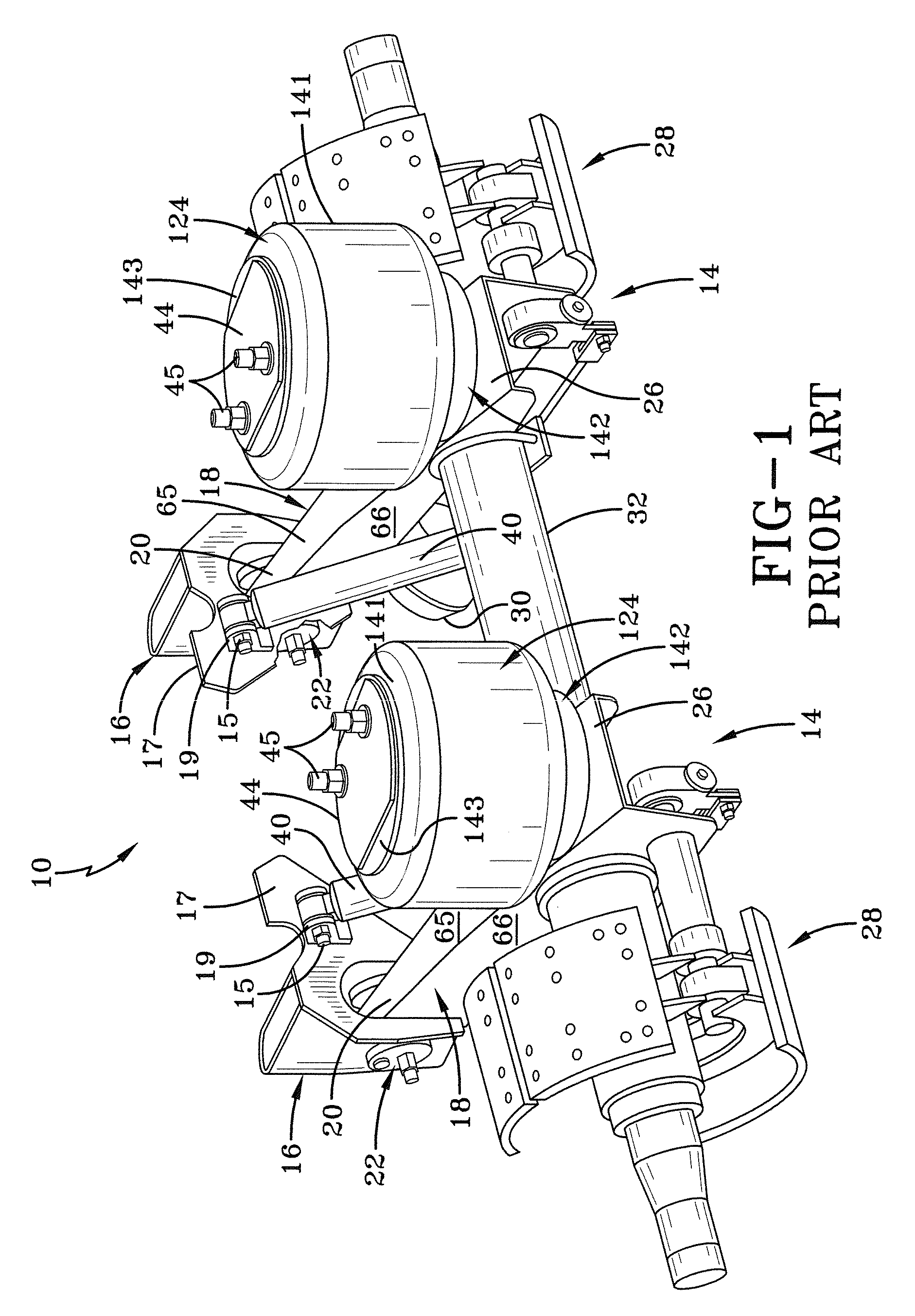

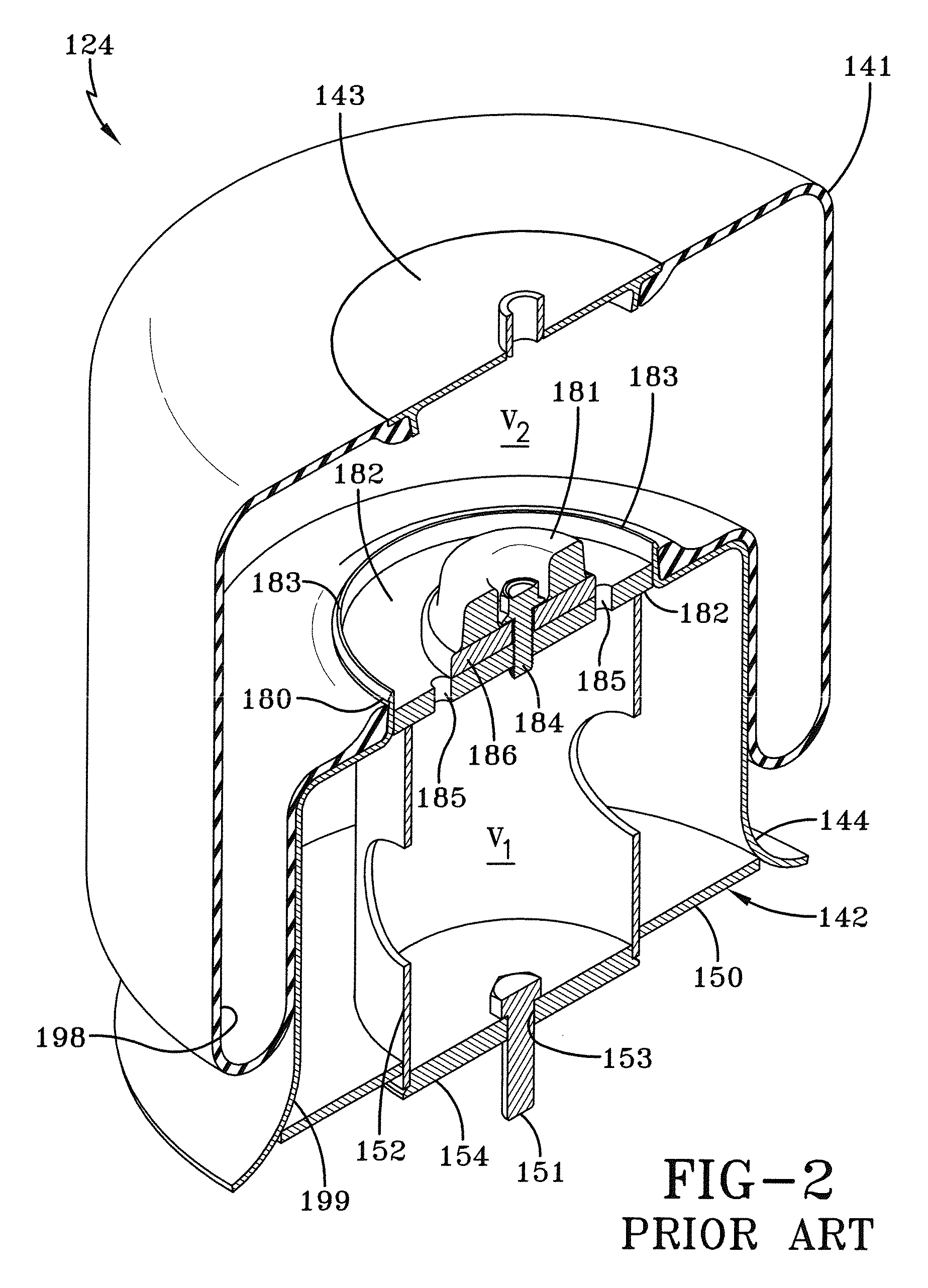

Piston for an air spring of a heavy-duty vehicle

ActiveUS20120291626A1Reduce manufacturing costEasy and efficient to prepareSpringsPlungersAir springEngineering

A piston for an air spring of a heavy-duty vehicle includes a sidewall and a central hub. The sidewall and the central hub are attached to a first bottom plate of the piston. A top plate is removeably attached to a top portion of the sidewall and a top portion of the central hub. A bottom portion of said central hub includes a second bottom plate that is recessed relative to the first bottom plate for attachment to a piston mounting pedestal that is in turn mounted to a beam of a suspension assembly of the heavy-duty vehicle.

Owner:HENDRICKSON USA L L C

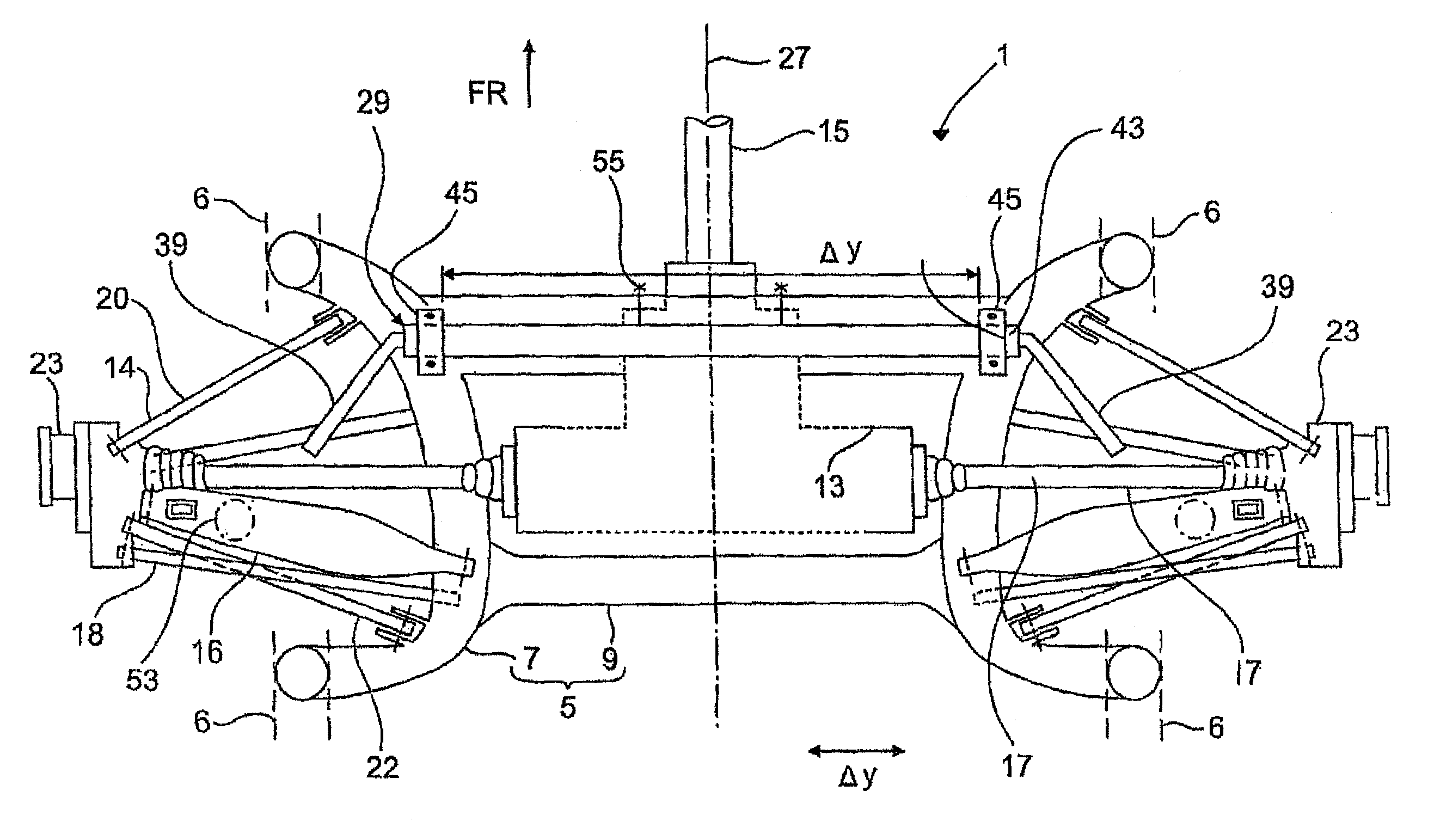

Hand-held power tool with a decoupling device

ActiveUS20080047724A1High spring stiffnessEasy to decoupleOperator-supported drilling machinesPortable percussive toolsHand heldEngineering

A hand-held power tool includes a spring-mounted decoupling device (16) for supporting a tool handle (14) on the tool housing (4) and having a first spring-mounted support (18) and a second spring-mounted support (20) that is spaced from the operational axis (A) in a second direction (y) perpendicular to the first direction (z) further away than the first spring-mounted support (18) that has a smaller spring stiffness along the second direction (y) than along the first direction (z).

Owner:HILTI AG

Muffler hanger

ActiveUS7637472B2Reduce the spring rateIncrease the spring rateExhaust apparatusPipe elementsEngineeringMuffler

A muffler hanger including: a rubber annular portion; a rubber arm constituting an elastic support portion for the muffler; an upper space and a lower space for permitting deformation of the rubber arm; a first mounting hole disposed in a center of the rubber arm in a vehicle left-right direction to extend in a vehicle front-back direction when installed on the vehicle, and attached in a mated condition to a support pin provided on one of a muffler side and a vehicle body side; and a pair of second mounting holes disposed at locations away to right and left sides from the first mounting hole to extend in the front-back direction, and attached in a mated condition to support pins on the other side. The first and second mounting holes are arranged to form a row in the left-right direction, with positional relationships such that when installed on the vehicle the holes overlaps one another as viewed in the left-right direction.

Owner:HONDA MOTOR CO LTD +1

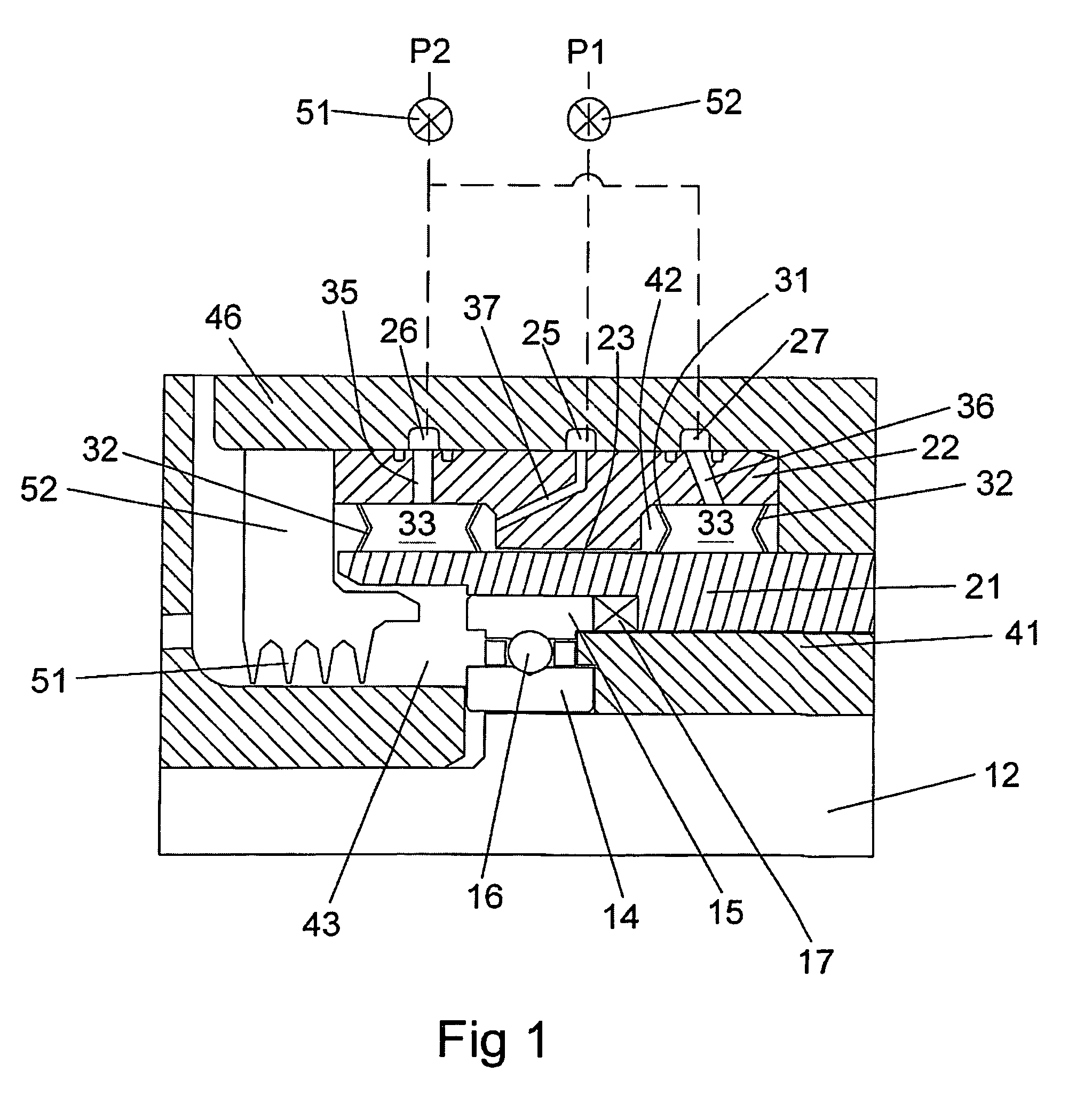

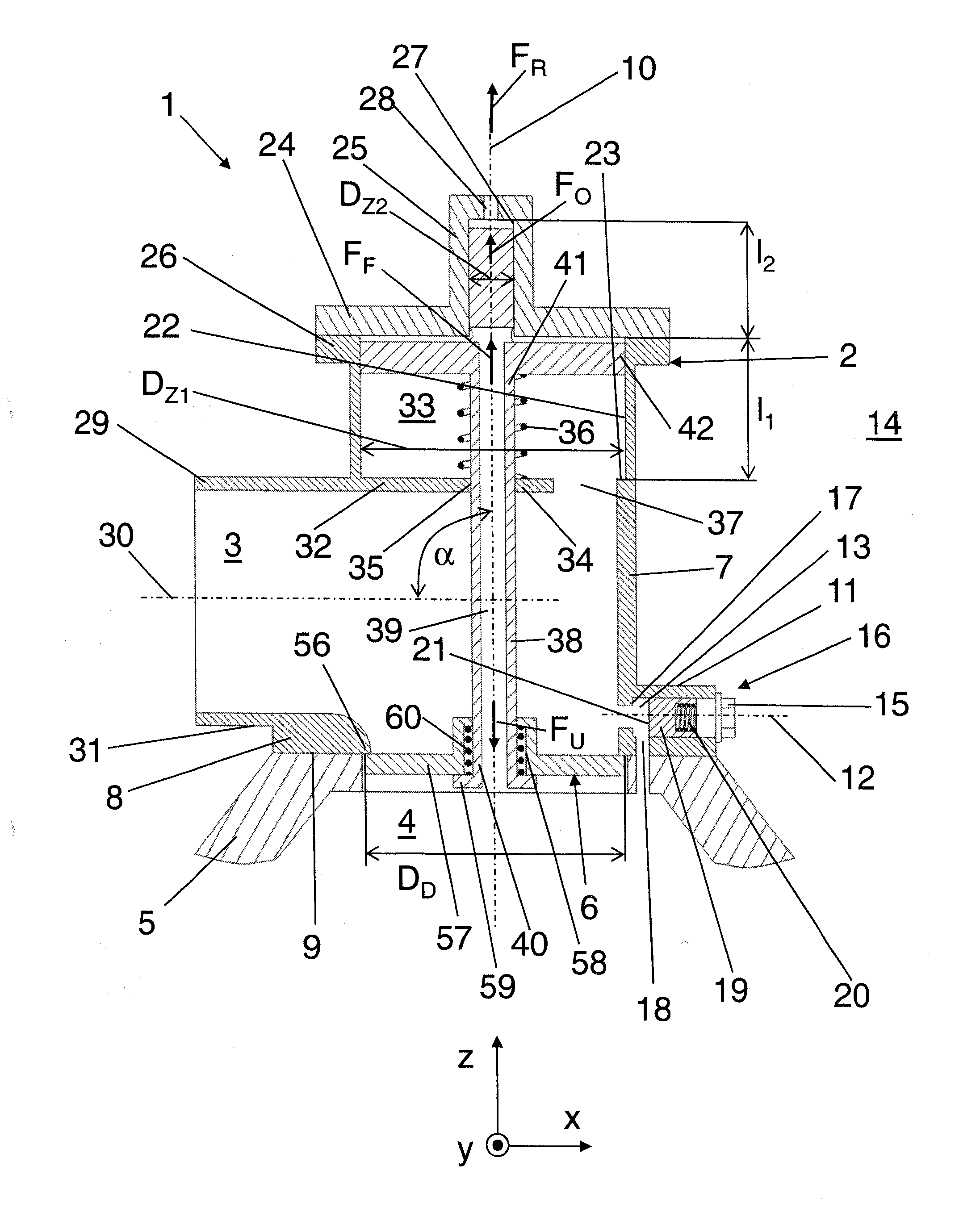

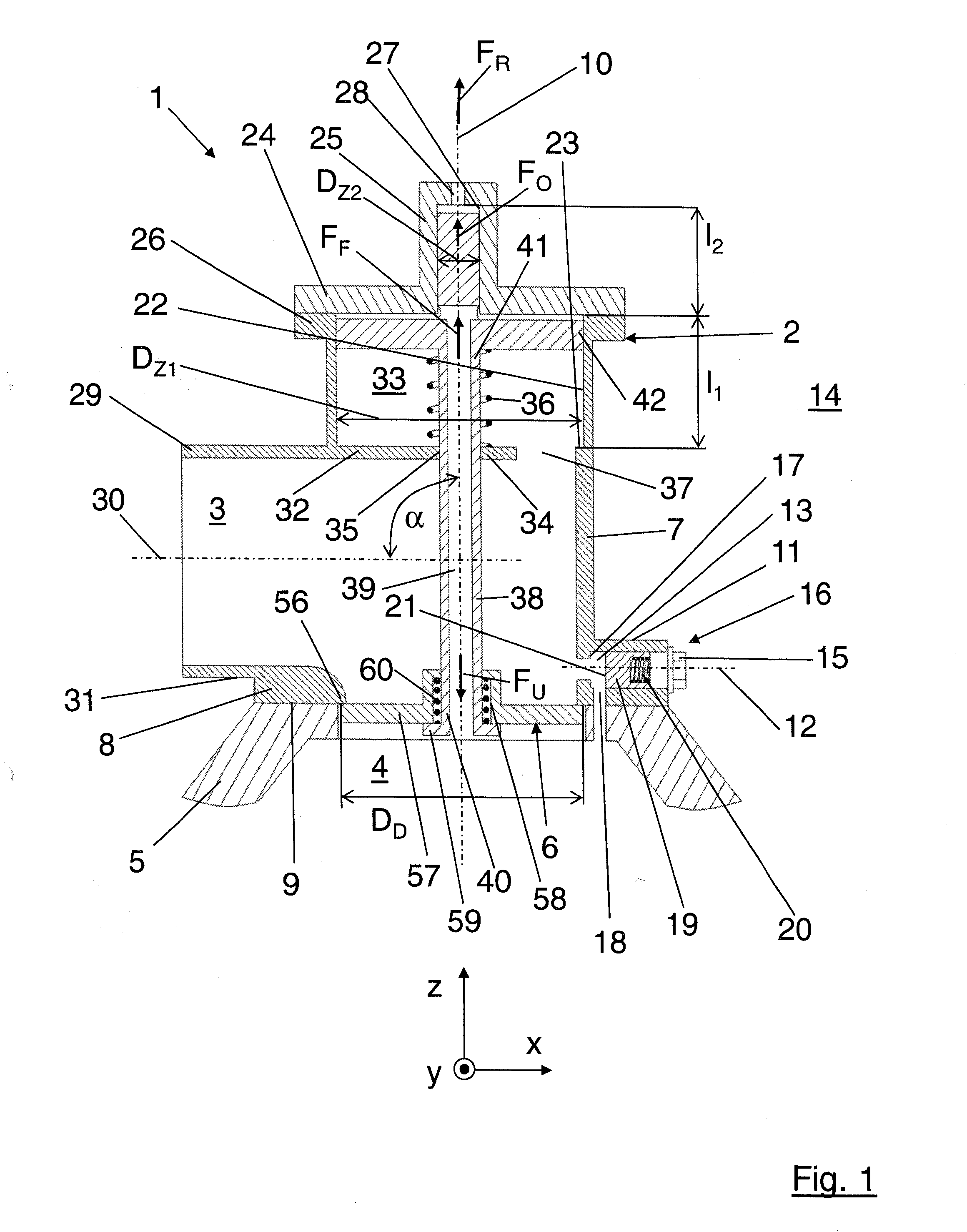

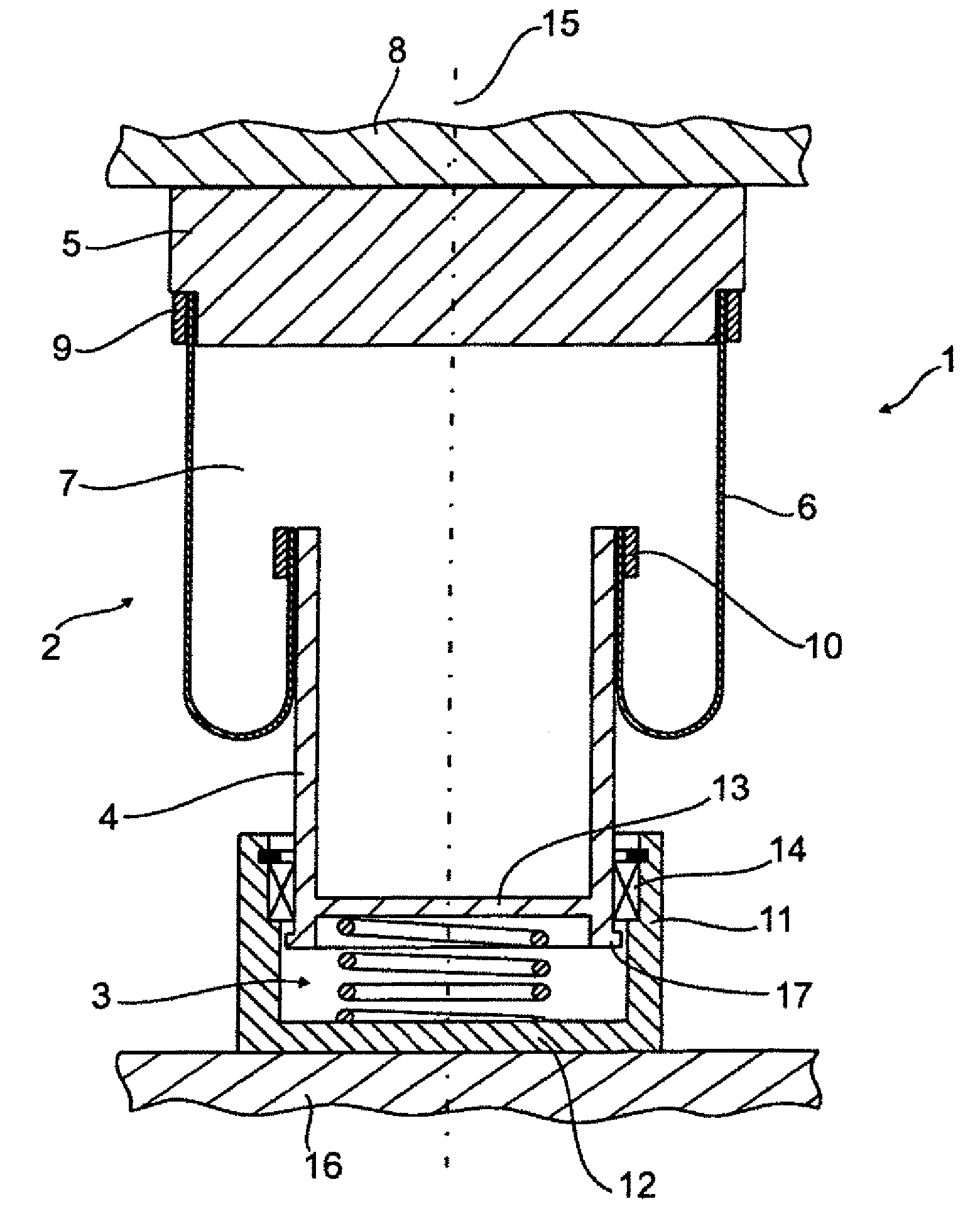

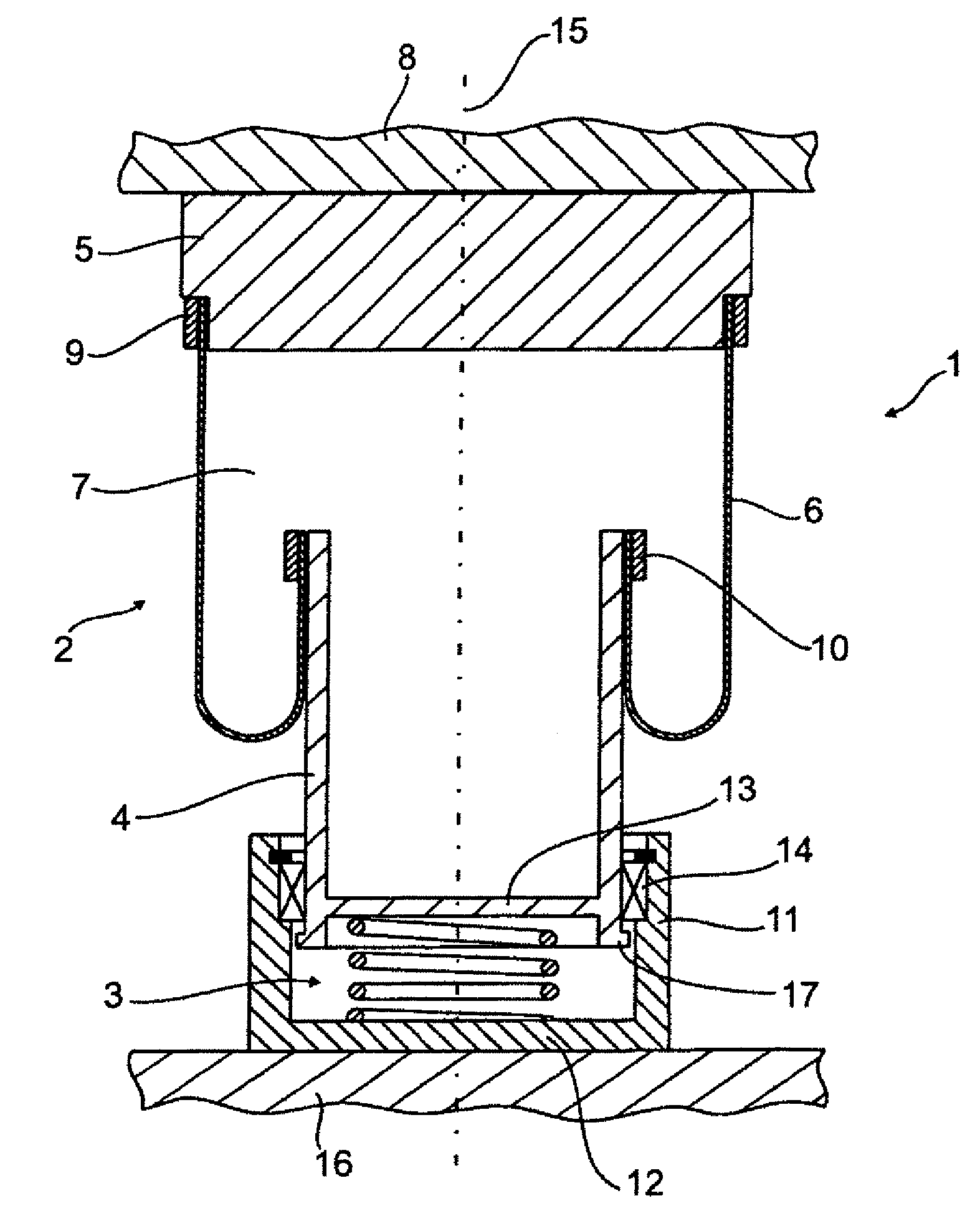

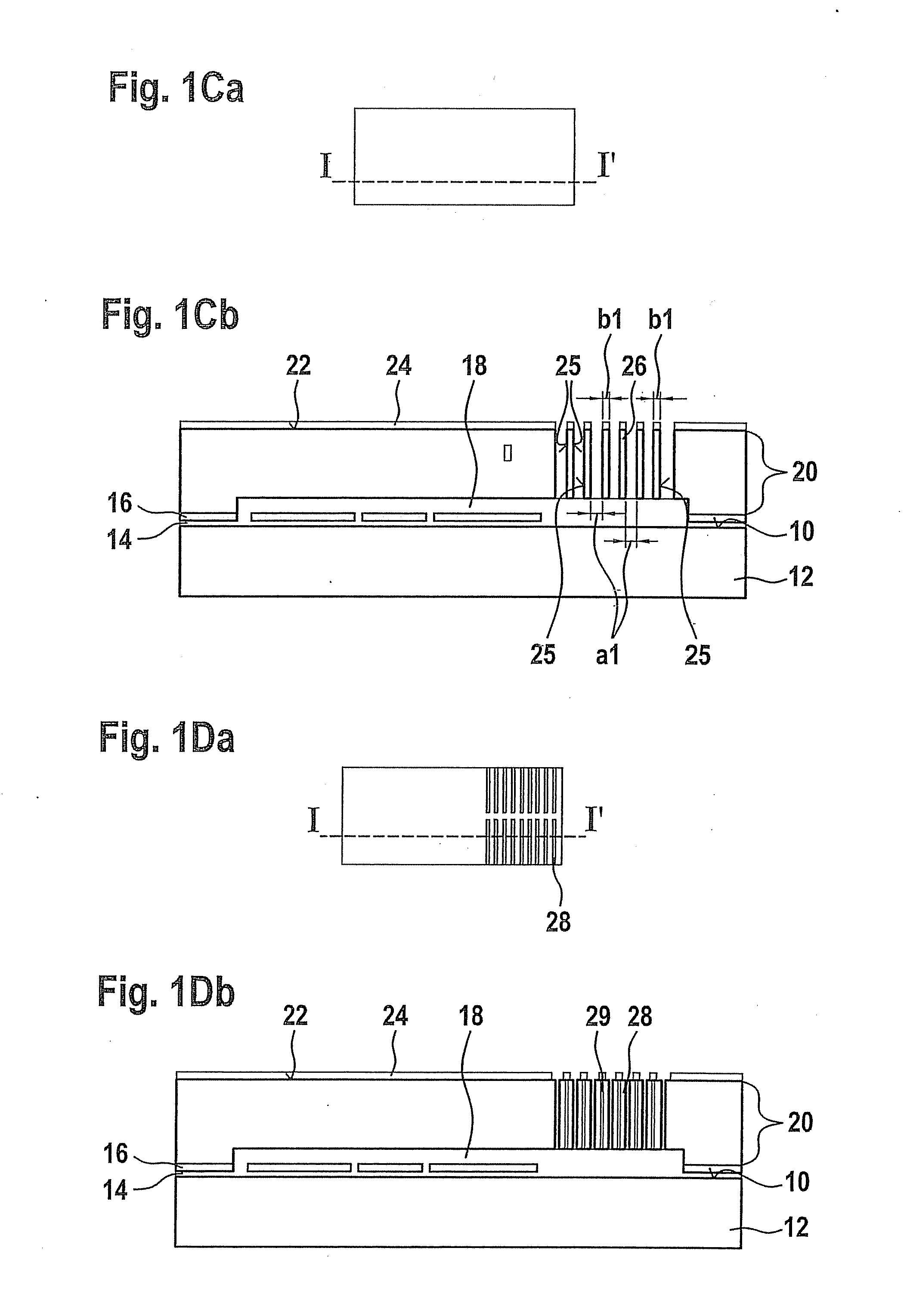

Gas Inlet Valve for a Compressor, Compressor Comprising a Gas Inlet Valve of This Type and Method for Operating a Compressor Comprising a Gas Inlet Valve of This Type

ActiveUS20130136638A1Reliably flowExtended service lifeOscillating piston enginesCheck valvesInlet valveEngineering

A gas inlet valve (1) for a compressor (64), comprising: a housing (2); a valve device (6) arranged between a gas inlet portion (3) and a gas outlet portion (4), a valve body (57) resting against a valve seat (56) in a sealing manner when the valve device (6) is in a closed operating state, and the valve body (57) being lifted from the valve seat (56) when the valve device (6) is in an open operating state; a piston device (42) which comprises a first piston portion (43) and a second piston portion (44) which is different from the first piston portion (43), the first piston portion (43) being displaceably guided in a first cylinder portion (22) of the housing (2) and the second piston portion (44) being displaceably guided in a second cylinder portion (27) of the housing (2) which is different from the first cylinder portion (22); and a piston rod (38) which is displaceably mounted in the housing (2) and mechanically couples the valve body (57) of the valve device (6) to the piston rod (38), a fluid line (39) putting a first cylinder chamber (49) of the first cylinder portion (22) in operative fluid communication with the gas outlet portion (4), it being possible to apply a control pressure to a second cylinder chamber (52) of the second cylinder portion (27) in order to lift the valve body (57) from the valve seat (56). A rotary compressor comprising a gas inlet valve (1) of this type and a method for operating a compressor (64), in particular a rotary compressor, comprising a gas inlet valve (1) of this type.

Owner:KAESER KOMPRESSOREN SE

Nasal strip with variable spring rate

A nasal dilator capable of introducing separating stresses in nasal outer wall tissues has a truss of a single body with a resilient member secured therein and a pair of spaced-apart end surfaces which, when forced toward one another from initial positions to substantially reduce direct spacing therebetween by a spacing reducing force external to said truss, results in restoring forces in the truss tending to return to the original direct spacing between the end surfaces. A resilient member, which is symmetrical with respect to a centerline of the truss that is perpendicular to the long axis of the truss, has a spring rate which continuously diminishes from the centerline to the end surfaces. An adhesive on the end surfaces adhesively engages exposed surfaces of nasal outer wall tissues sufficiently to keep the truss attached to the nasal wall surfaces while subjecting them to the restoring forces.

Owner:INFINITE FINANCIAL SOLUTIONS

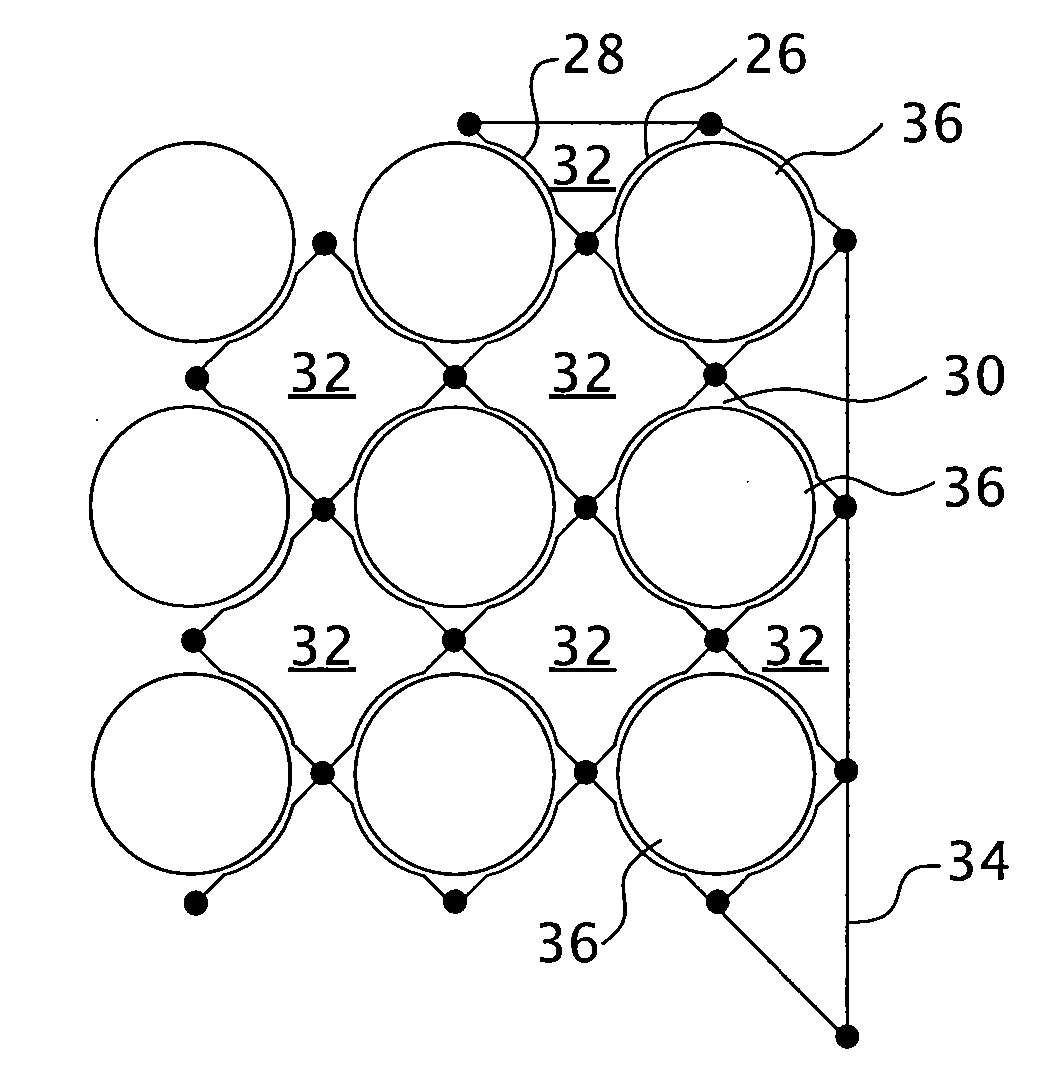

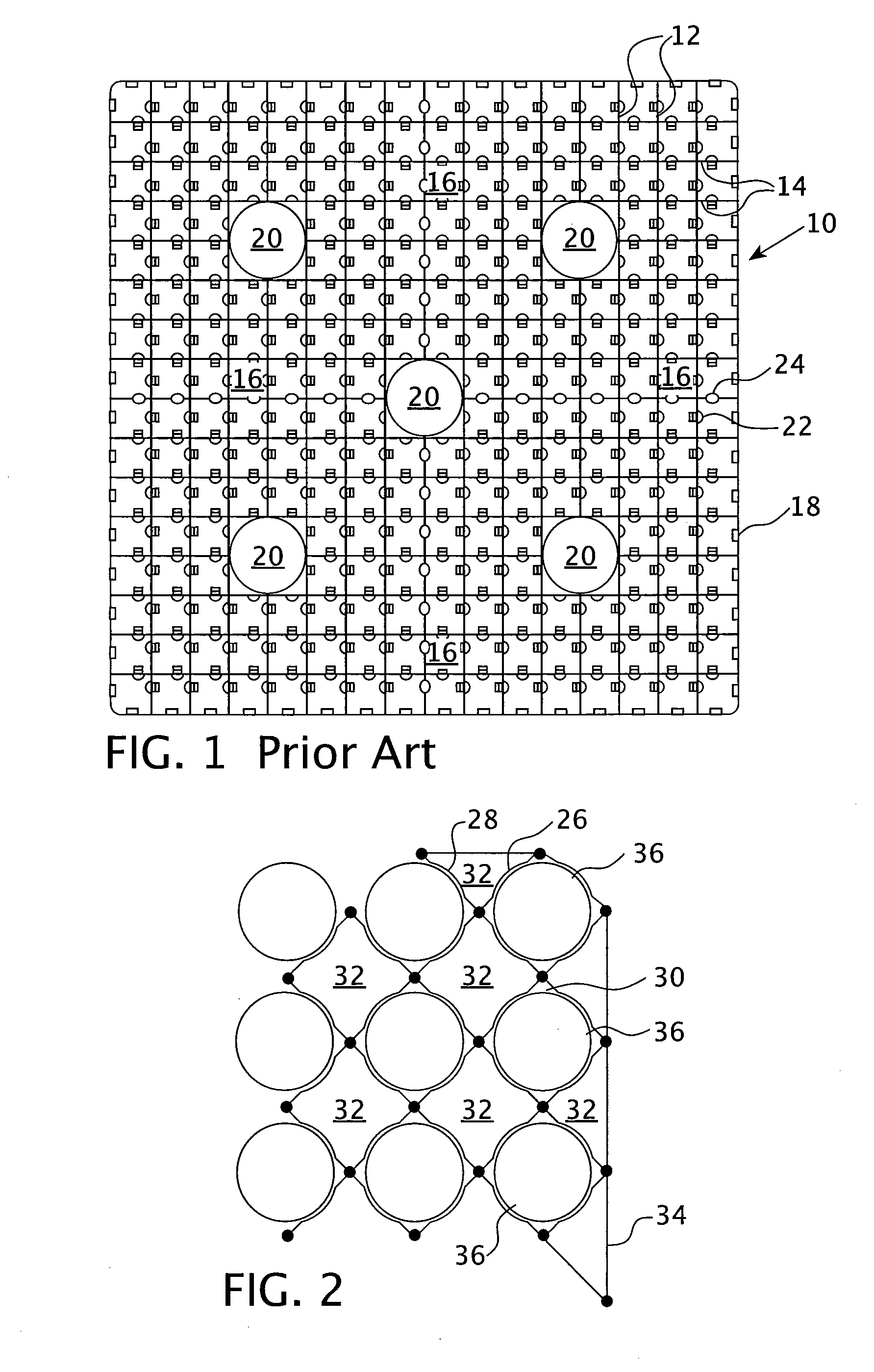

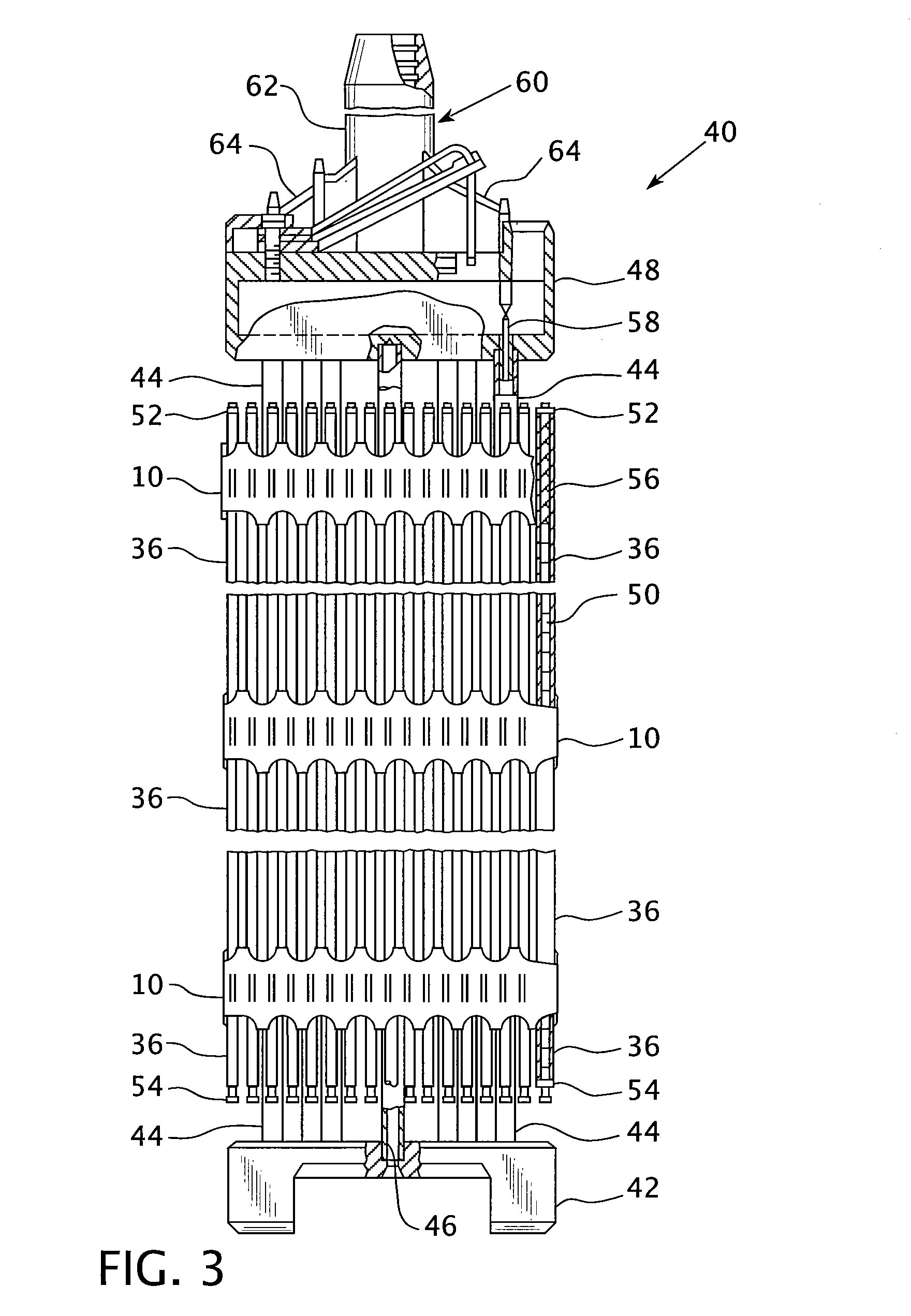

Nuclear fuel assembly with an advanced spacer grid

InactiveUS20080232537A1Reduce the spring rateAppropriate shapeNuclear energy generationFuel element assembliesElectrical batteryDiagonal

An improved nuclear fuel assembly having elongated grid straps curved in a substantially undulating wave pattern along their axial length and interleaved together to form an egg-crate configuration having a plurality of roughly square cells that support fuel rods and guide tube thimbles. The cells that support fuel rods have their outer walls curved outward to increase the contact area around the fuel rod cladding The interior straps are on a diagonal with regard to a peripheral strap and at least one cell adjacent each fuel rod cell is left empty for the unobstructed flow of coolant. Additional coolant mixing devices can be added to the empty cells. The walls of each fuel rod cell are devoid of dimples and, in one embodiment, springs.

Owner:WESTINGHOUSE ELECTRIC CORP

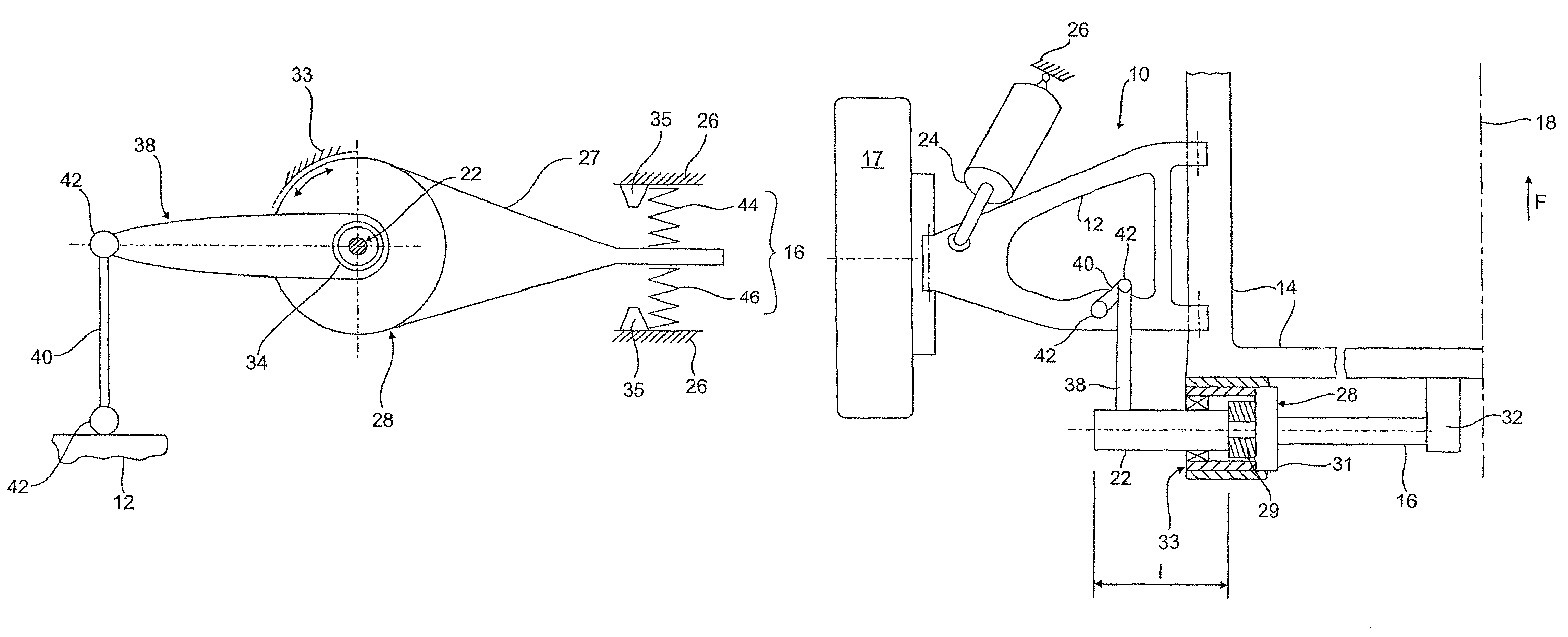

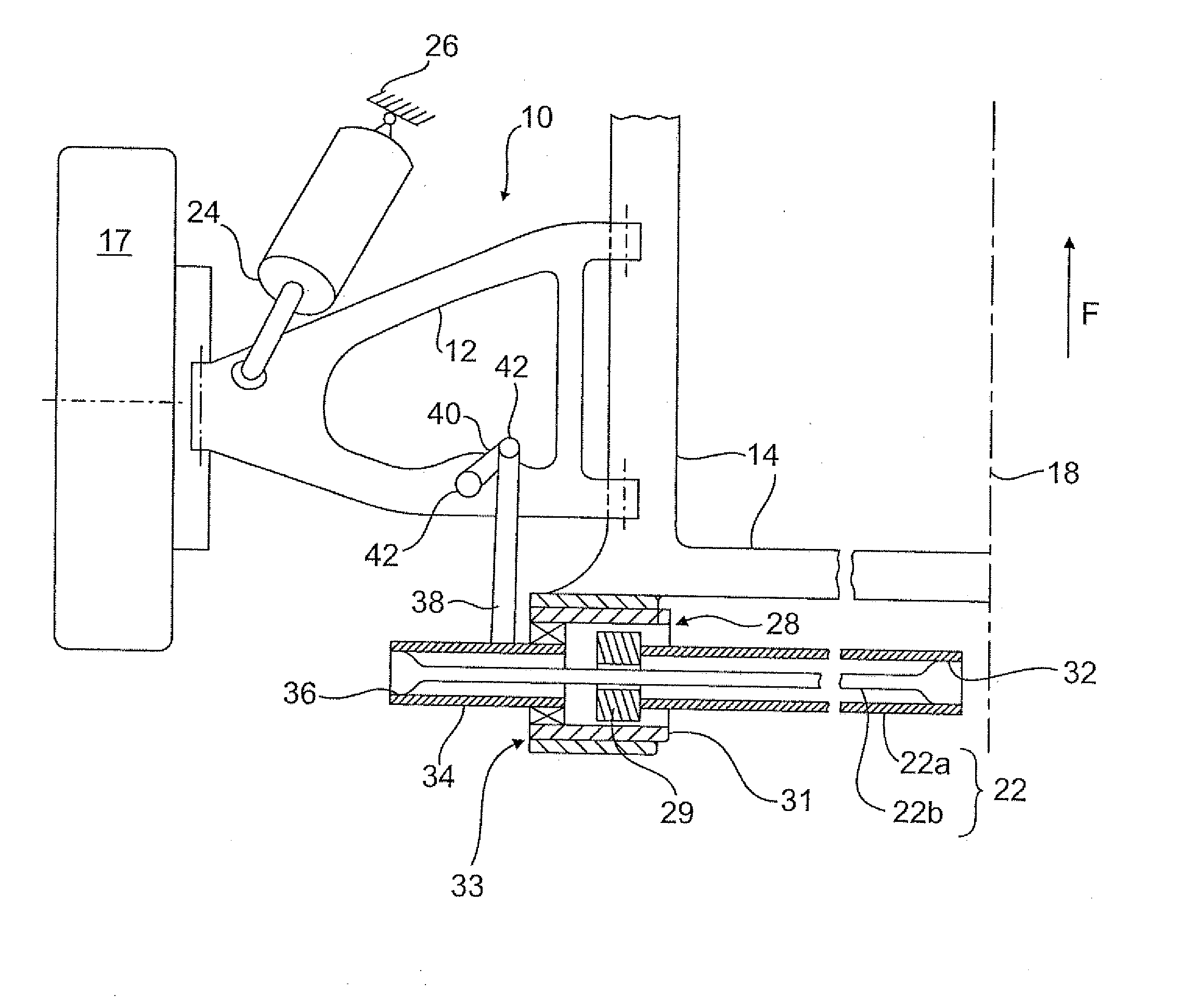

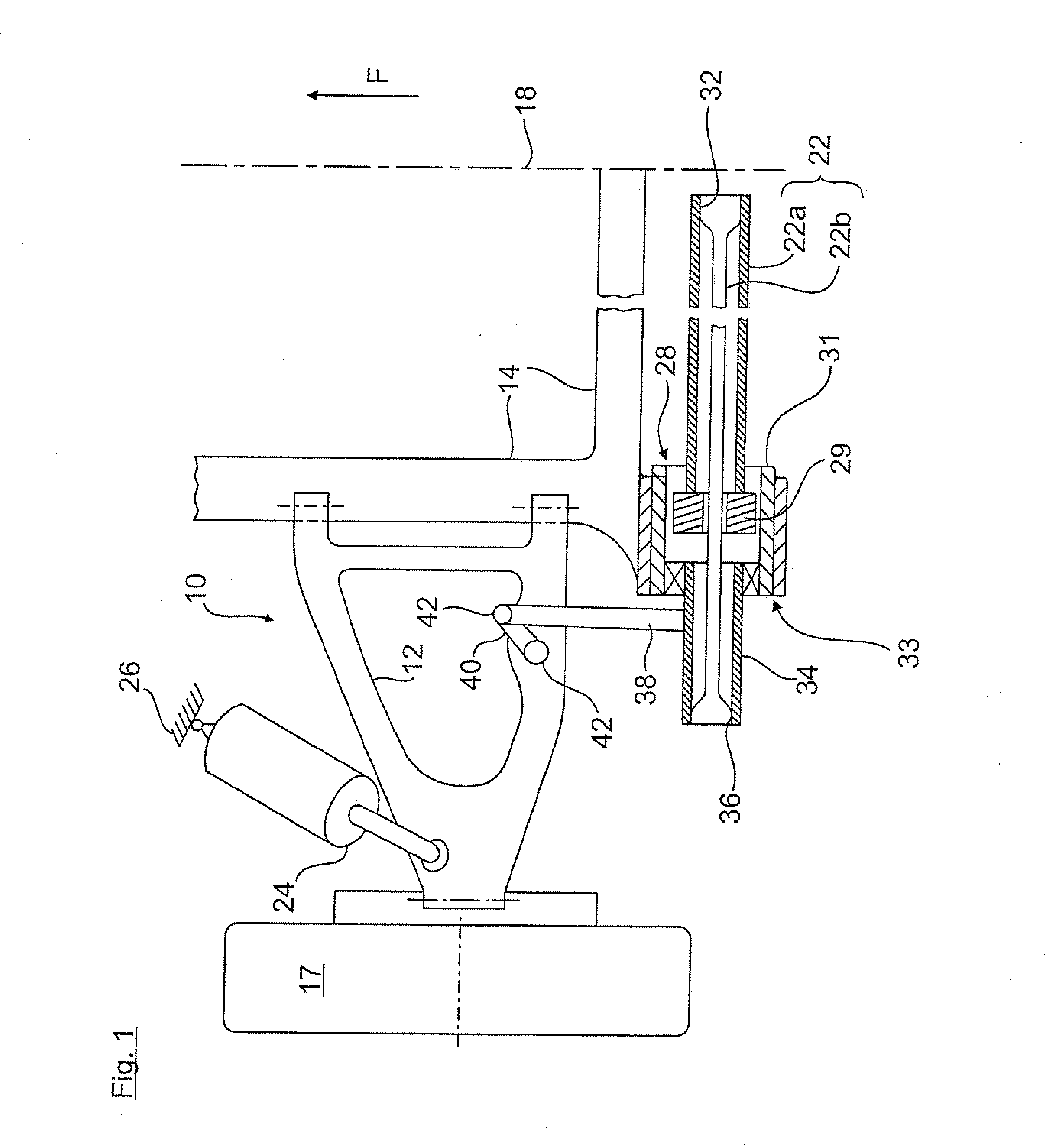

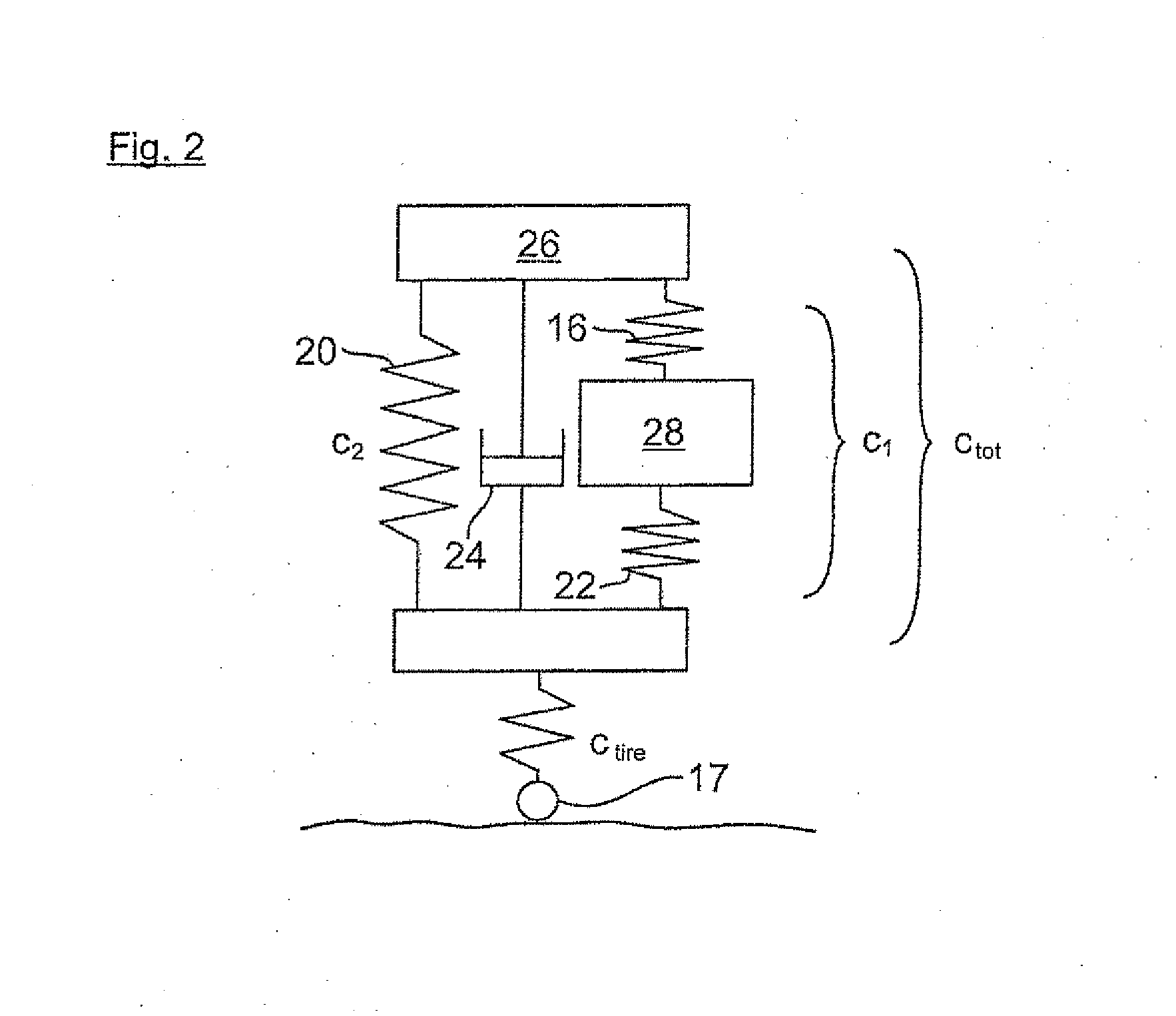

Torsion bar spring arrangement for a wheel suspension of a motor vehicle

InactiveUS9108482B2Reduce the spring rateReduce torsional loadInterconnection systemsResilient suspensionsVehicle frameEngineering

Owner:AUDI AG

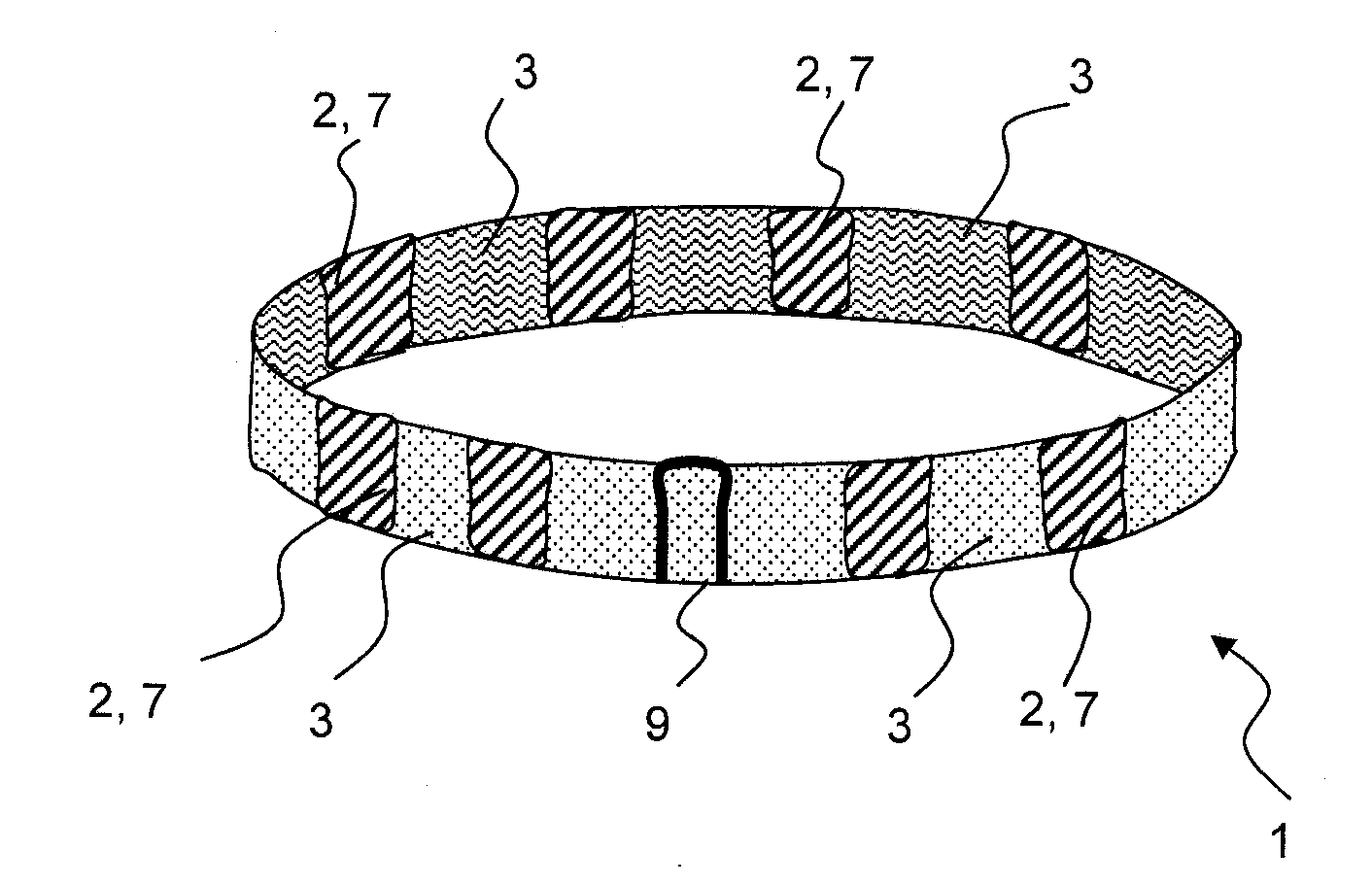

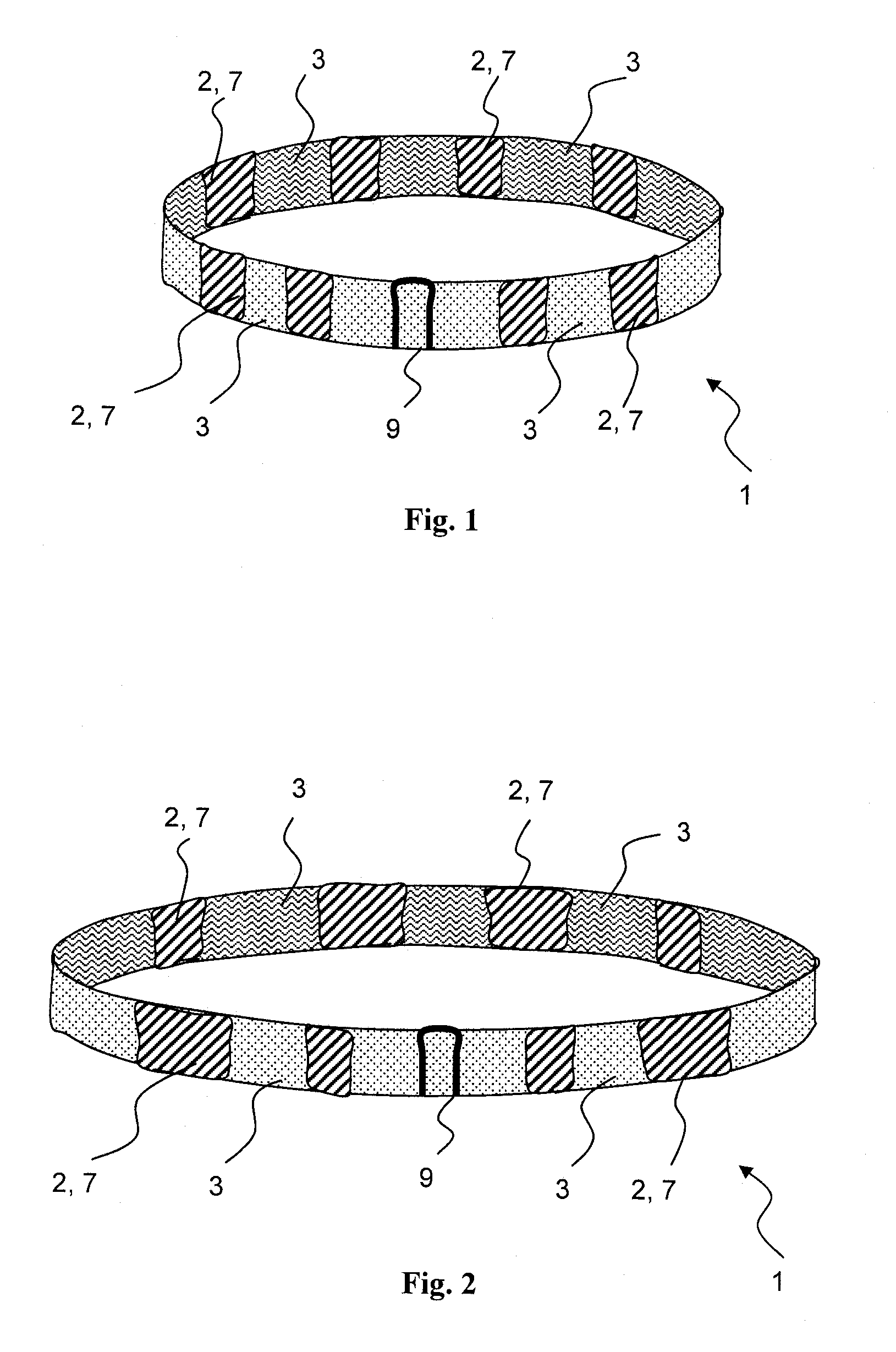

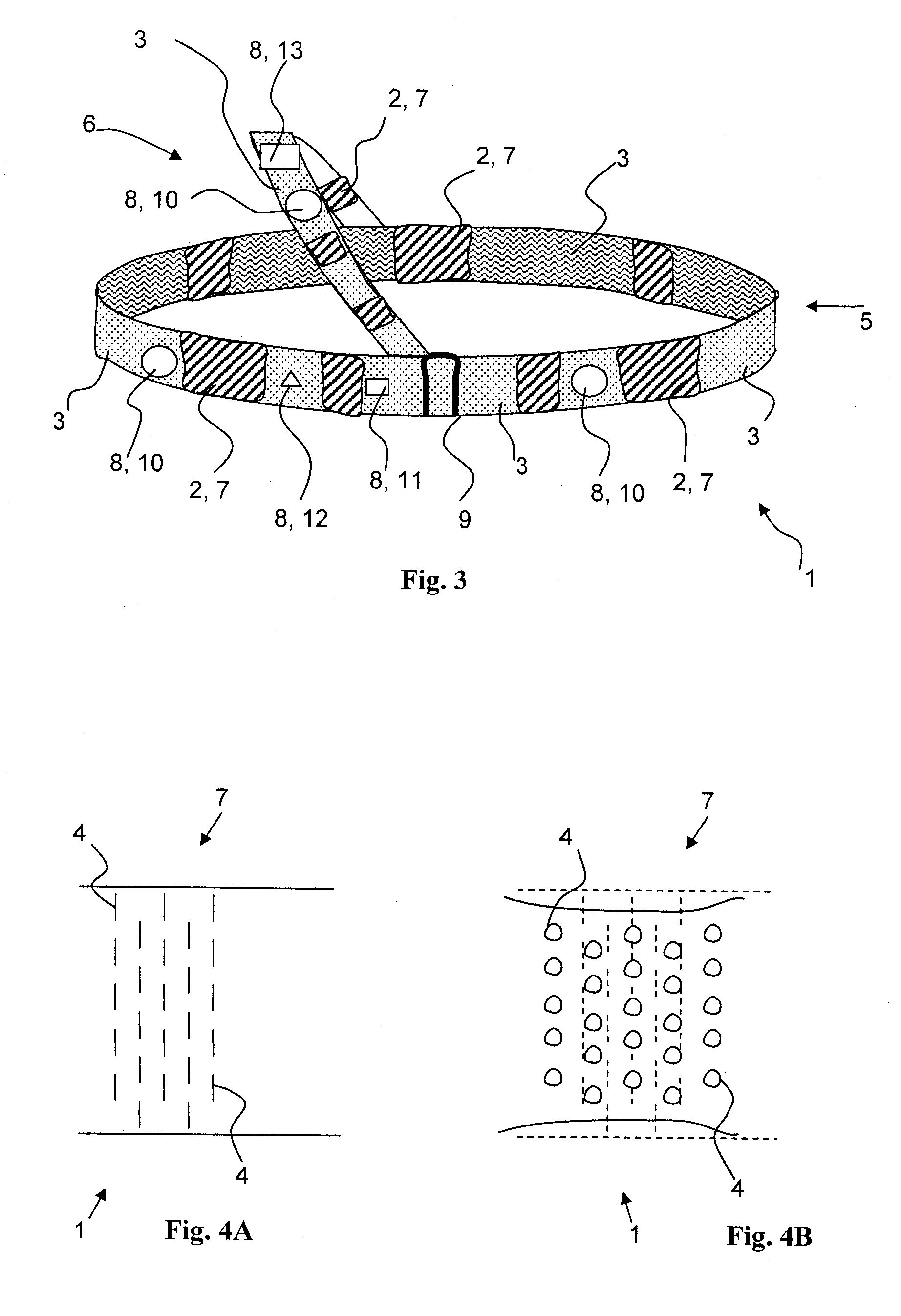

Belt with sensors

InactiveUS20090229039A1Reduce manufacturing costReliable handlingElectrocardiographyShoulder strapEngineeringBody size

A stretchable belt (1) provided for medical purposes for use on the body of a patient has at least one sensor (8) for detecting at least one parameter of the patient's body. An adaptation to different body sizes and motions of the patient is provided without separate length adjusting members being necessary or without the need to stock different belt sizes. Furthermore, the belt is able to be manufactured at a low cost and makes possible simple and reliable handling, even for patients. The belt material (1) has at least one material area (2) with a lower spring rate in the longitudinal extension than at least one material area (3) with a higher spring rate of the belt (1).

Owner:DRAGERWERK AG

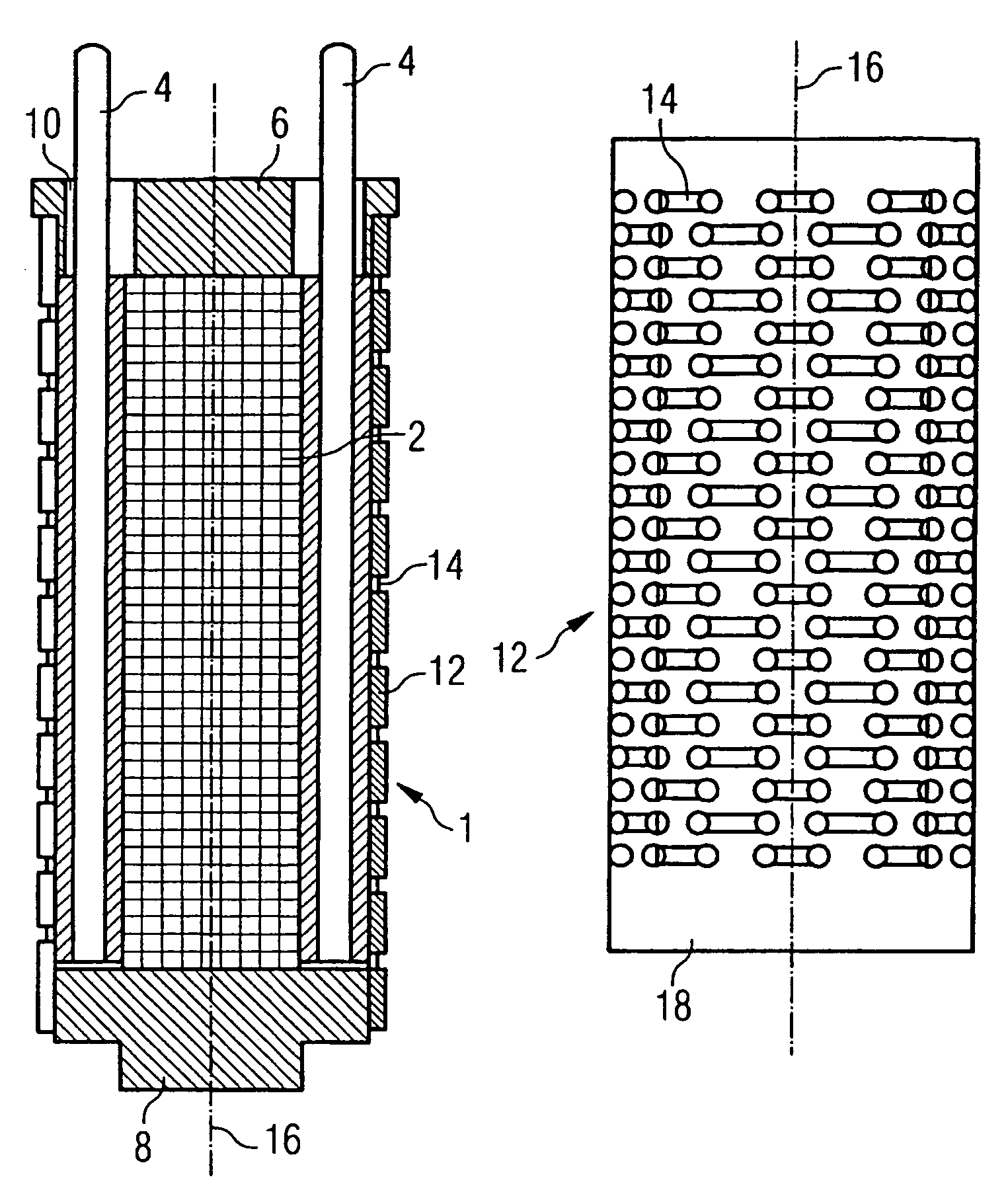

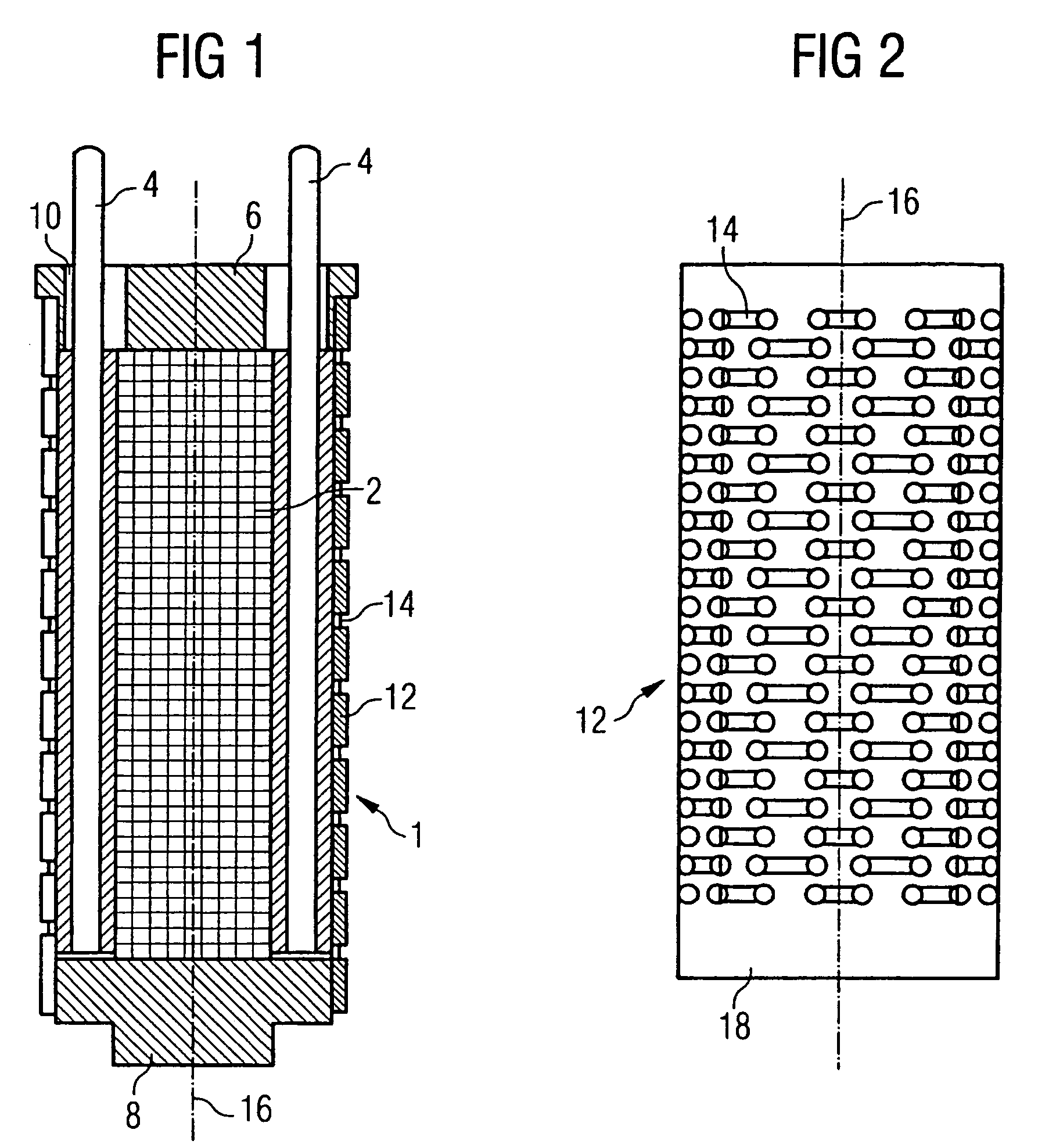

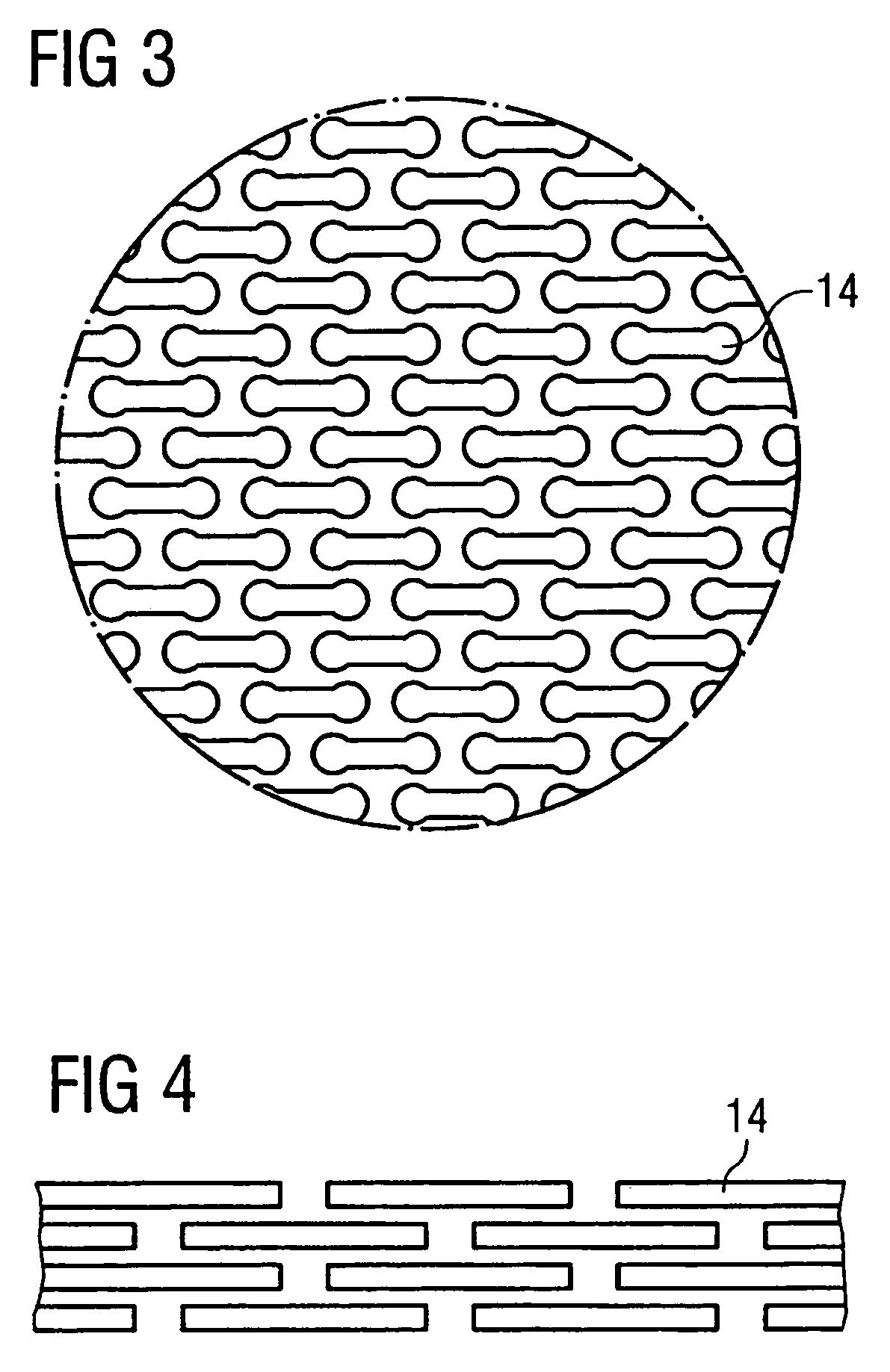

Method for producing a tubular spring and an actuator unit comprising one such tubular spring

InactiveUS7222424B2High strengthReduce the spring ratePiezoelectric/electrostriction/magnetostriction machinesSoldering apparatusPiezoelectric actuatorsLaser cutting

A method for producing a tubular spring (12) in the form of a cylindrical hollow body, especially for pre-tensioning a piezoelectric actuator element (2) of an actuator unit (1) of a fuel injector comprises the step of providing a thin-walled, solid-drawn steel tube with a plurality of regularly arranged longish recesses (14) by means of laser cutting. Thus, an actuator unit (1) comprises a piezoelectric actuator element (2) which is arranged in a thin-walled cylindrical hollow body, wherein the hollow body being elastically embodied and pre-tensioning the actuator element (2). Furthermore, the hollow body is a solid-drawn steel tube which is provided with a plurality of longish recesses (14).

Owner:VITESCO TECH GERMANY GMBH

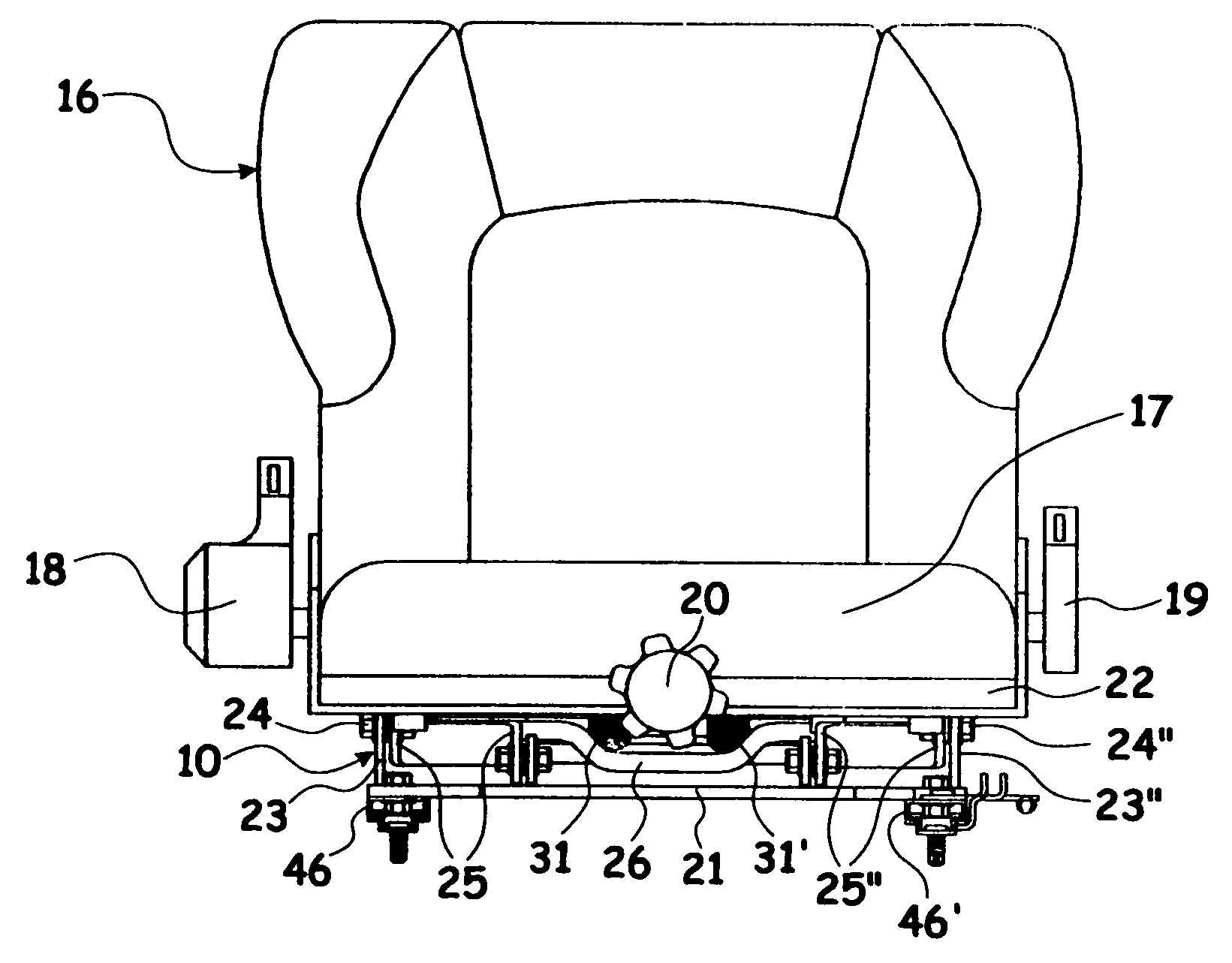

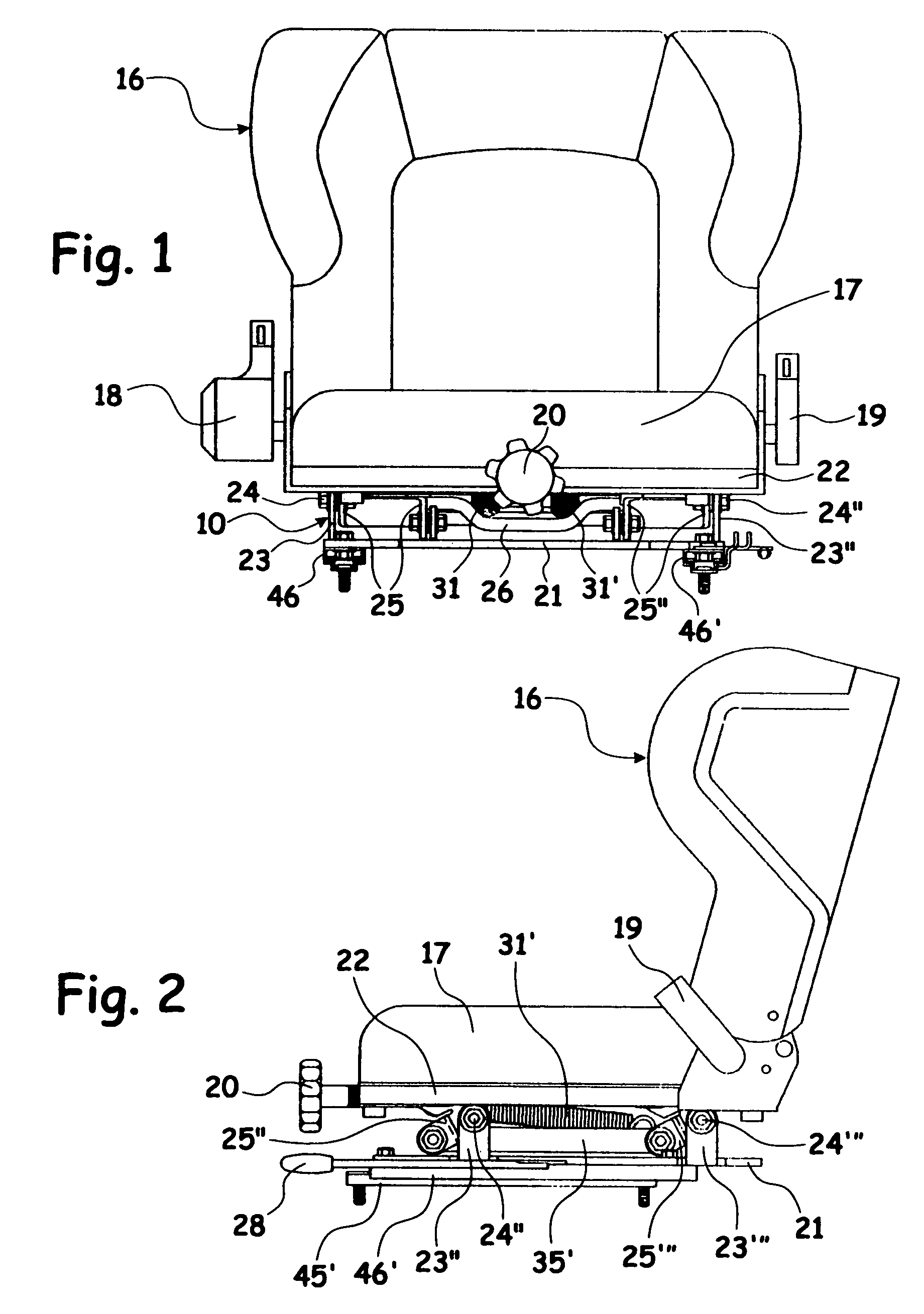

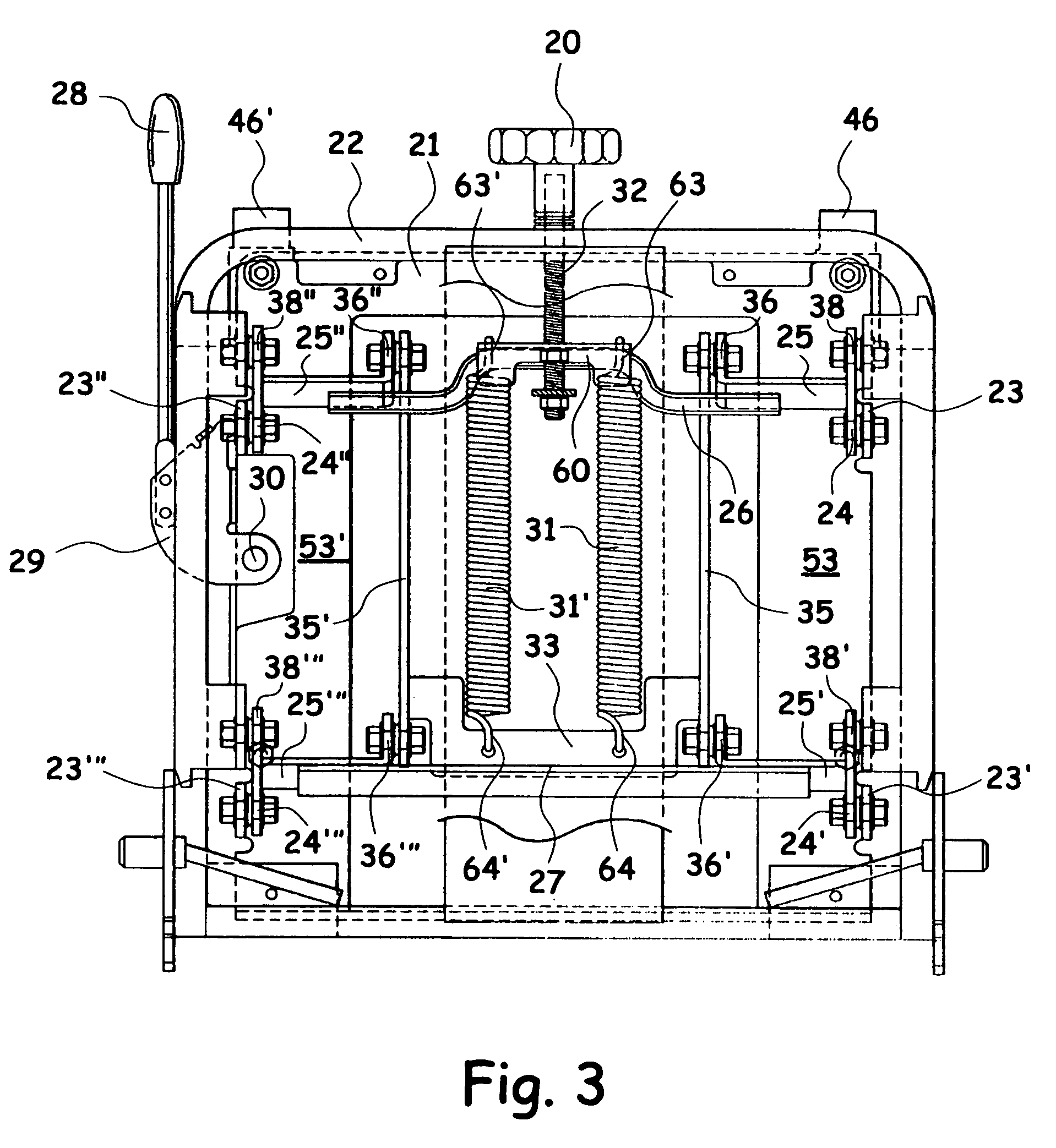

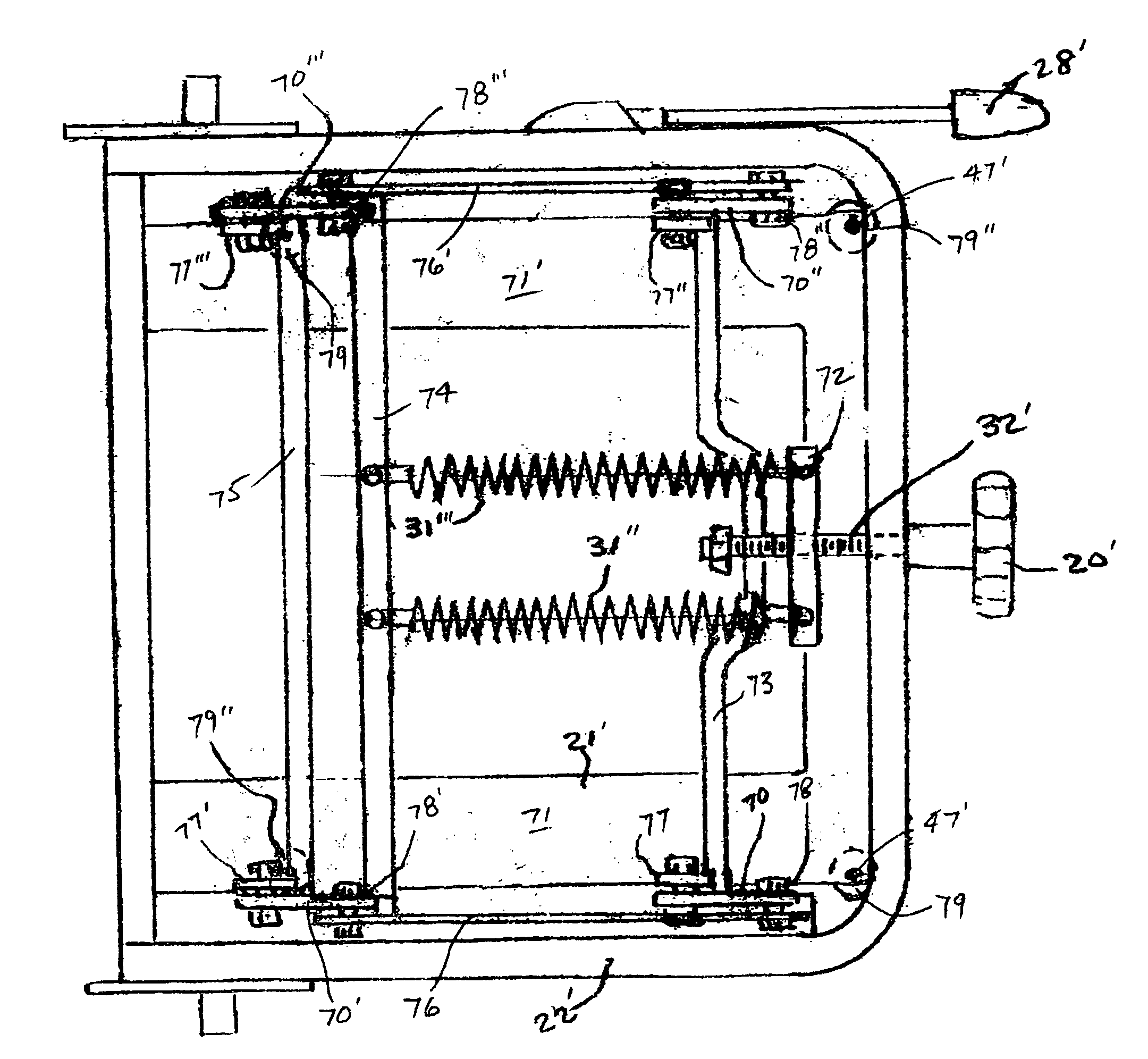

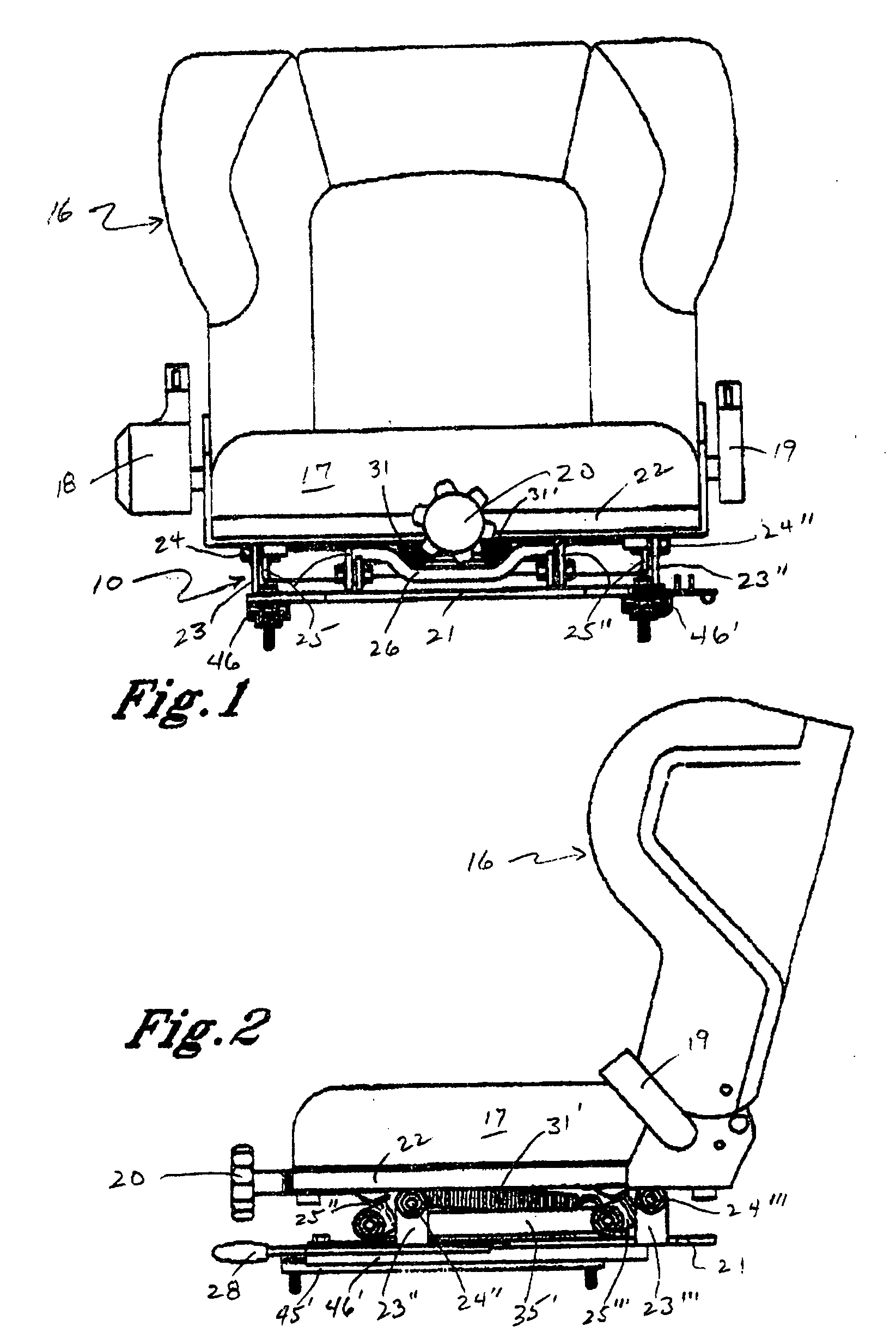

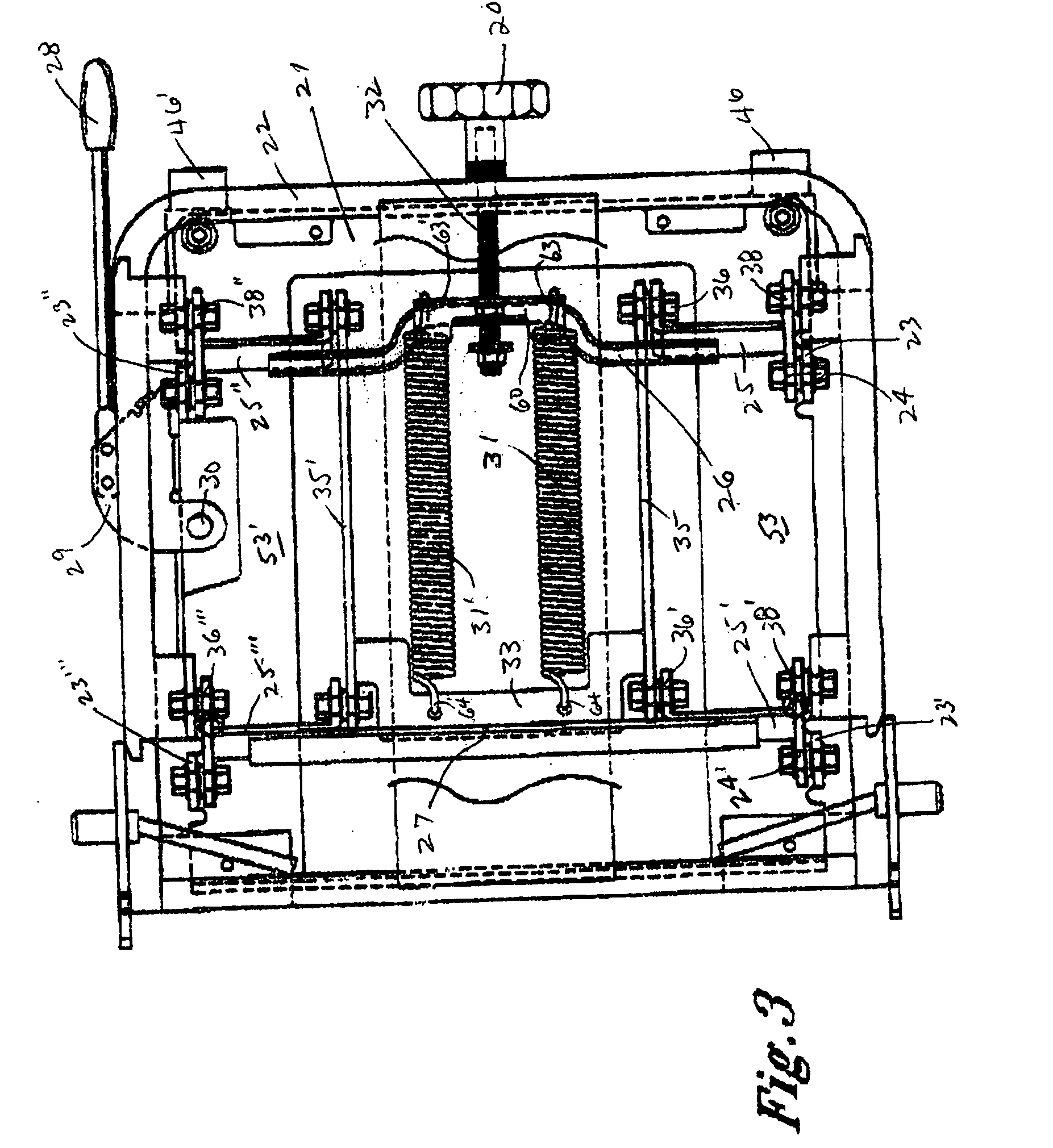

Bellcrank seat suspension apparatus

InactiveUS7571886B2Dampens the jolts of a rough terrainRelieve pressureStoolsStands/trestlesEngineeringCushion

A suspension for a vehicle seat having four bellcranks which guide the seat substantially vertically, oscillate on a central pivot on elevated stationary pivots mounted on a lower frame, with upper arms of the bellcranks pivotally attached to a seat cushion upper frame and the lower arms indirectly attached to adjustable tension springs that are attached to the upper frame; the lower ends with substantial inward offsets so as to rotate downwardly toward the mounting deck of the vehicle while clearing the lower frame and adjustable sliders; the bellcranks being coupled longitudinally and laterally to stay in phase and keep the upper frame level.

Owner:CARTER JOHN W

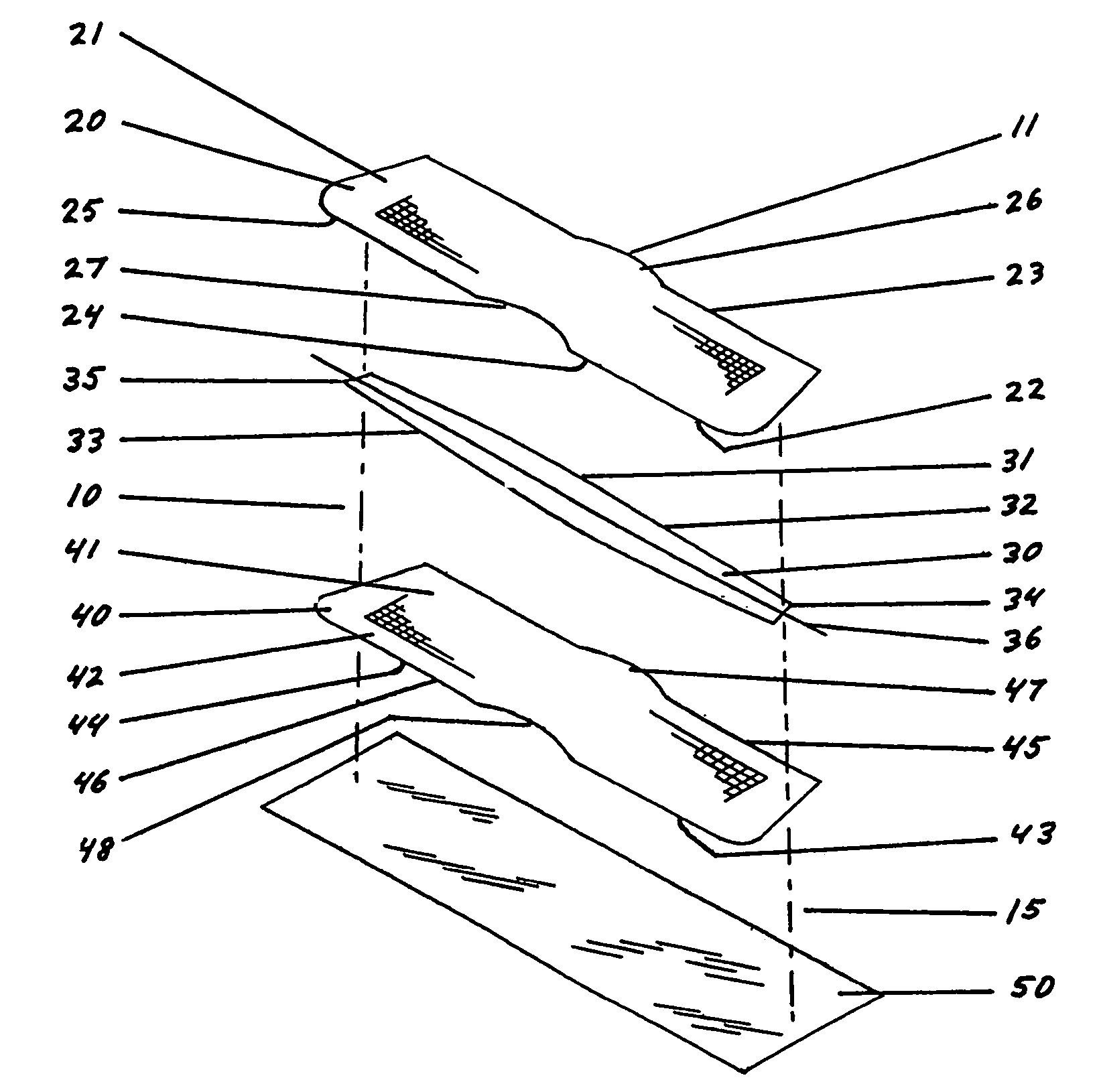

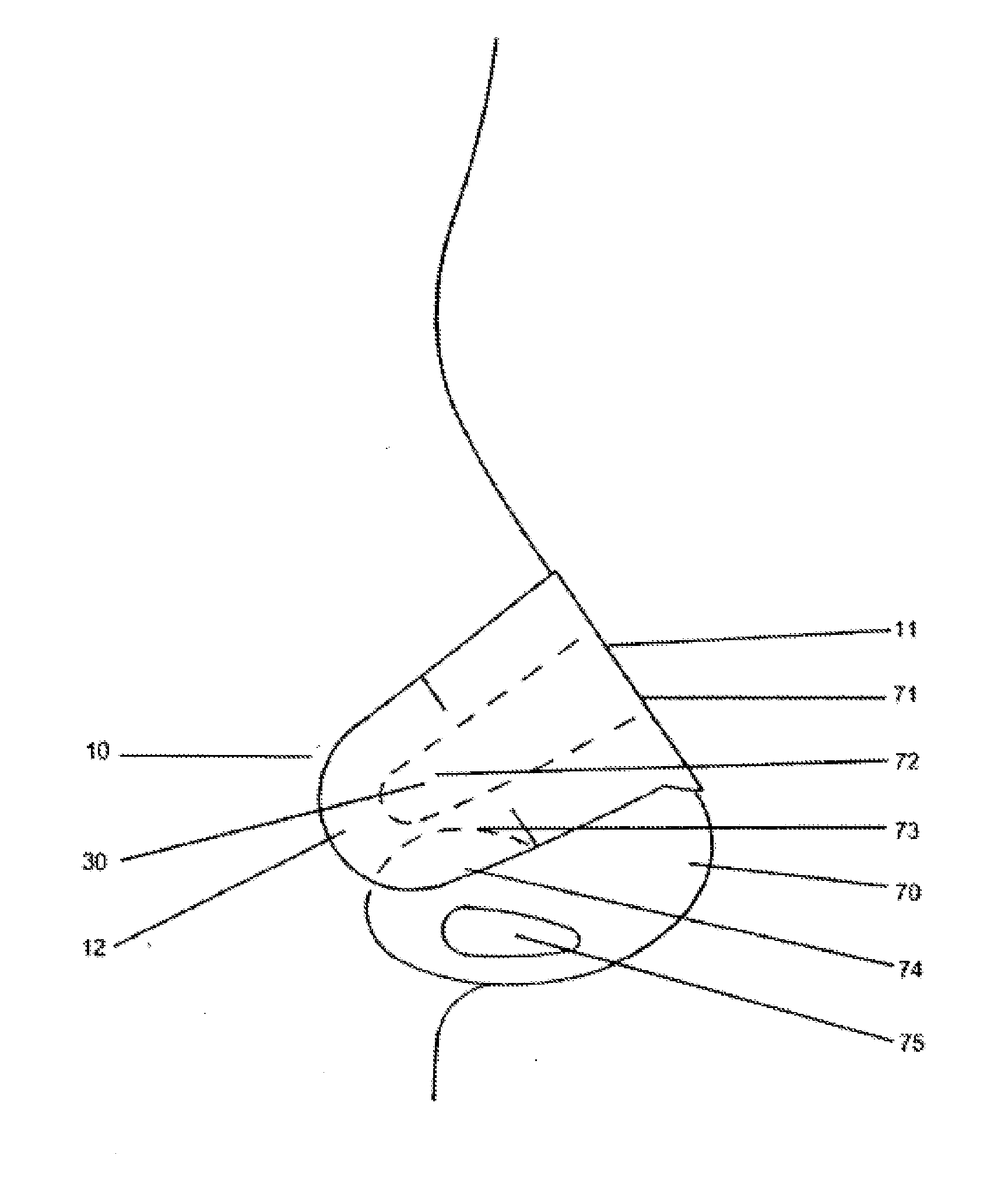

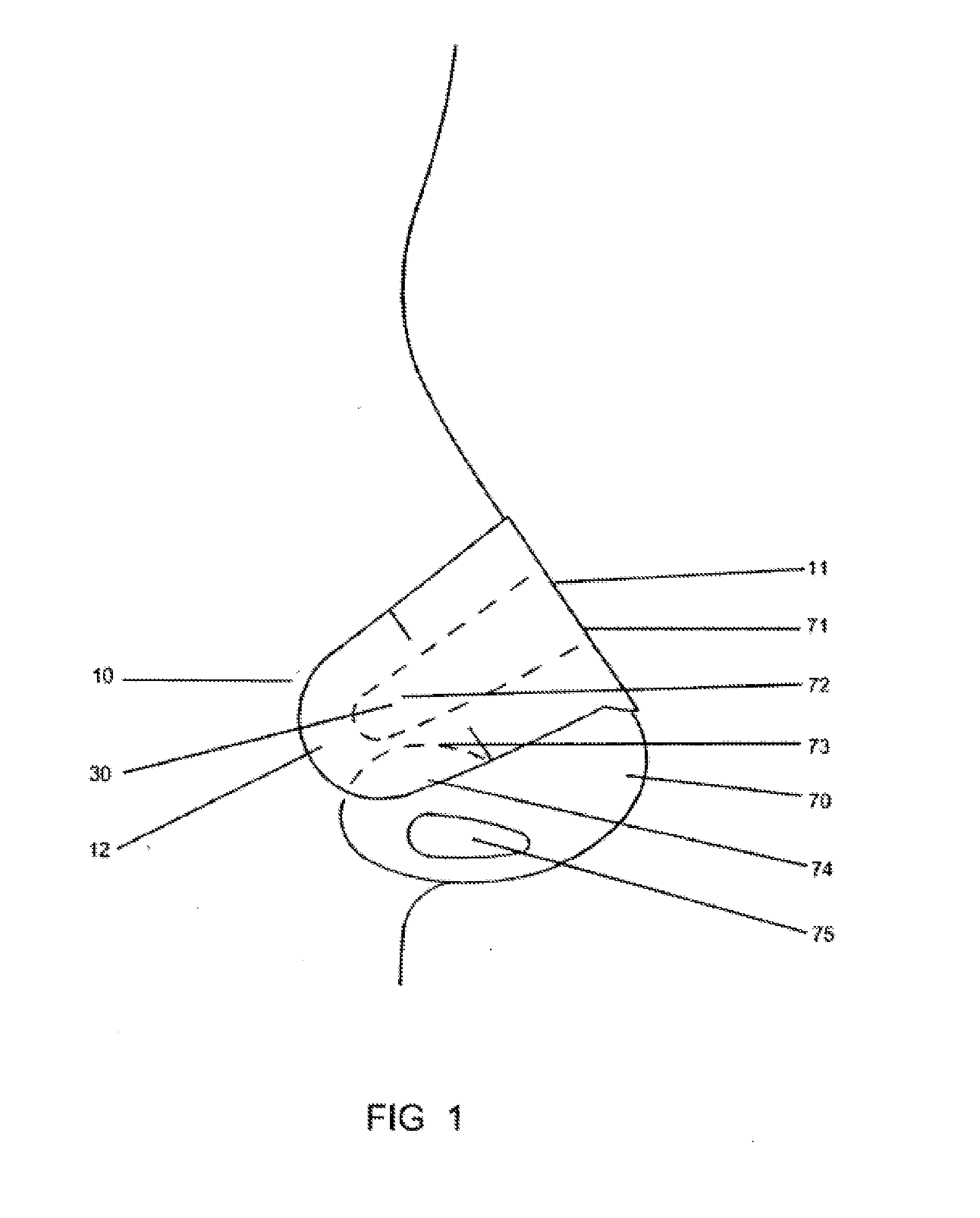

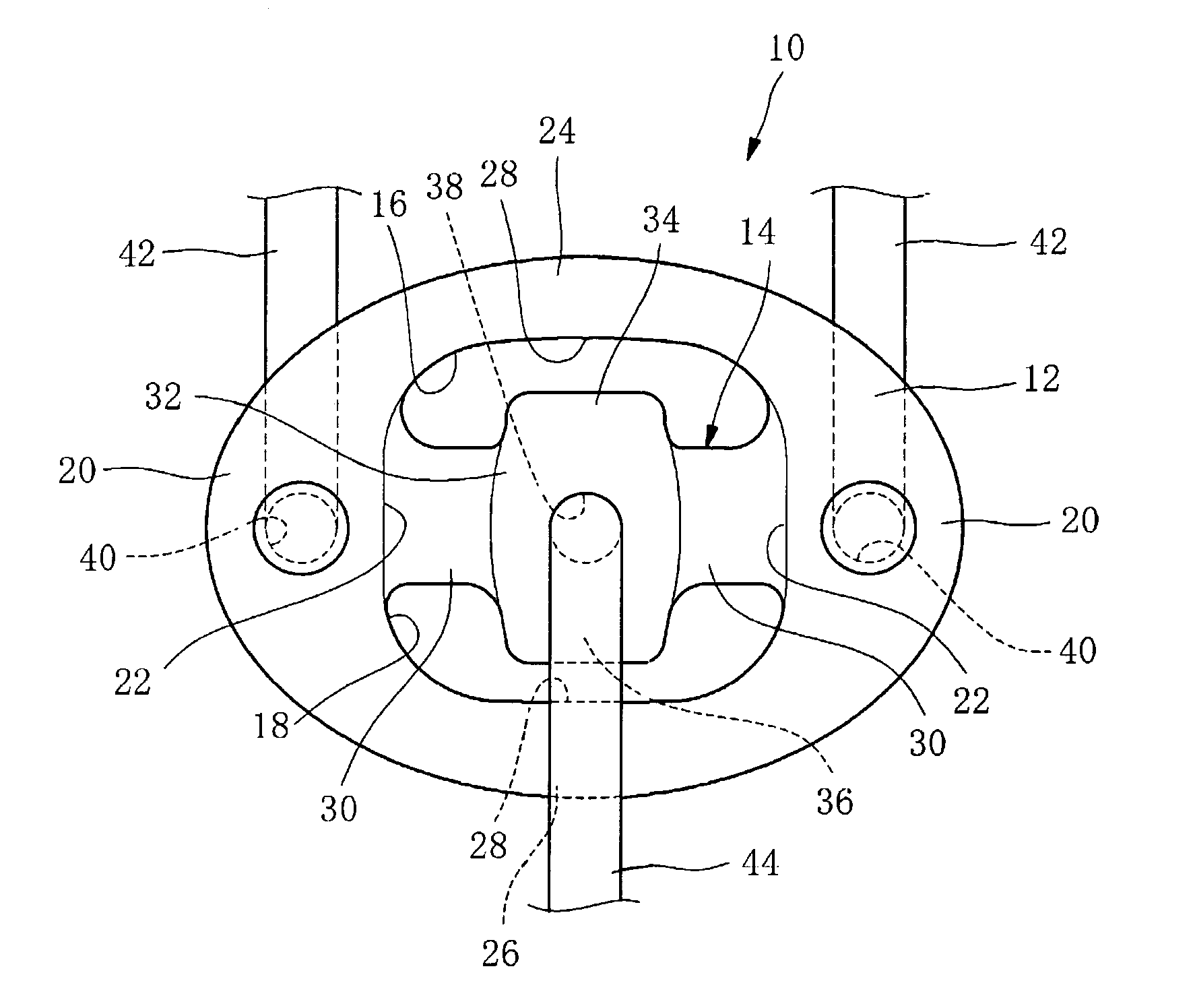

Nasal dilator with cushion layer and variable spring rate

InactiveUS20090020115A1Improve performanceReduce the spring rateRespiratorsBreathing masksNasal cavityLong axis

A nasal dilator capable of introducing separating stresses in nasal outer wall tissues has a resilient member and a pair of spaced-apart end surfaces which can be forced toward one another from an initial flat position of the dilator to thereby substantially reduce the direct spacing therebetween by an external spacing reducing force. This results in restoring forces in the dilator tending to return it to the original direct spacing between the end surfaces. Resilient members, which can be asymmetrical with respect to a centerline of the dilator that is parallel to the long axis of the dilator, have a spring rate which continuously diminishes from the centerline to the end surfaces. The edges of the resilient members are contiguous to the edge of the cushion layer so that adhesive on the cushion layer is at the same level as the bottom surface of the resilient members. An adhesive on the end surfaces adhesively engages exposed surfaces of nasal outer wall tissues sufficiently to keep the dilator attached to the nasal wall surfaces while subjecting them to the restoring forces.

Owner:INFINITE FINANCIAL SOLUTIONS

Torsion bar spring arrangement for a wheel suspension of a motor vehicle

ActiveUS20140232083A1Simple designReduce the spring rateInterconnection systemsResilient suspensionsVehicle frameActuator

A torsion bar spring arrangement for a wheel suspension of a motor vehicle includes an actuator arranged on a vehicle body or on a subframe and constructed to variably pre-tension the torsion bar spring arrangement, a coaxial first torsion bar spring having an output side that is connected by way of an output lever to a wheel suspension element of the wheel suspension, and a housing of the actuator supported on the vehicle body in at least one bearing location for movement in a circumferential direction and resiliently yieldingly supported on the vehicle body in the direction of torsional moments acting on the torsion bar spring by way of at least one spring element.

Owner:AUDI AG

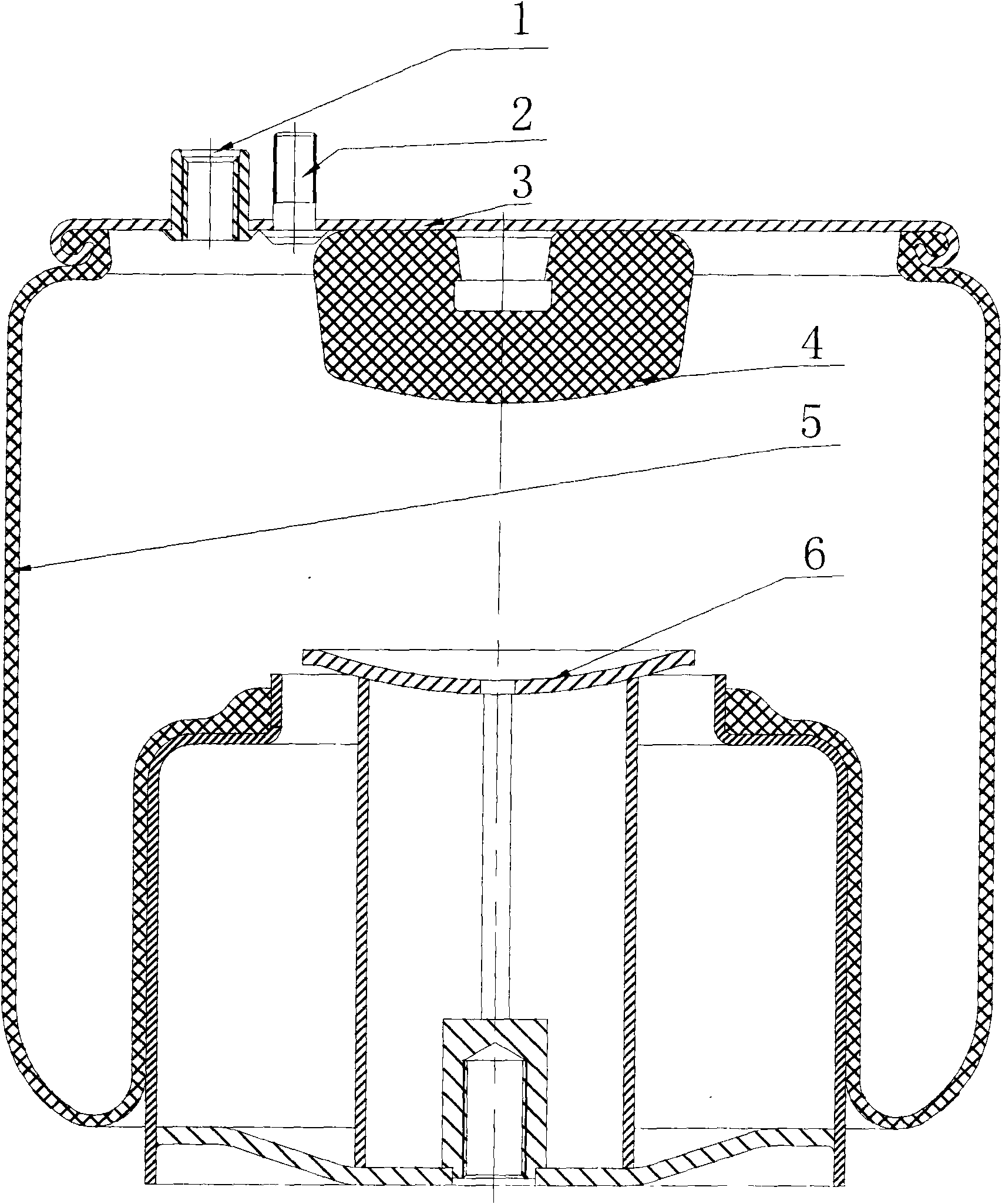

Chassis air spring

InactiveCN101550980AImprove vibration damping effectImprove the shortcomings of high natural frequencyGas based dampersAir springMetallic materials

The invention discloses a chassis air spring, which is characterized in that the bottom end of a capsule is press-mounted with the side wall of a piston, the upper end of the capsule is buckled and connected with an upper cover plate, a gas pipe joint and a locating stud are respectively arranged at one end of the upper cover plate, the gas pipe joint is hollow and communicated with the interior of the capsule, a bulge is arranged in the middle of the bottom end of the upper cover plate, an emergency stopping block is connected with the bulge, the whole piston is made of metal materials and has an integrated structure, and a bolt hole is arranged at the bottom end of the piston. By the above setting, the chassis air spring is lighter than the original steel spring plate and improves the damping effect simultaneously, thus meeting the requirements of the current vehicle technology for light weight and comfort and satisfying the requirements of vehicles for driving on roads with various complicated conditions.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

Muffler hanger

ActiveUS20090001242A1Ensure durabilitySufficient space utilizationExhaust apparatusPipe elementsEngineeringMuffler

A muffler hanger including: a rubber annular portion; a rubber arm constituting an elastic support portion for the muffler; an upper space and a lower space for permitting deformation of the rubber arm; a first mounting hole disposed in a center of the rubber arm in a vehicle left-right direction to extend in a vehicle front-back direction when installed on the vehicle, and attached in a mated condition to a support pin provided on one of a muffler side and a vehicle body side; and a pair of second mounting holes disposed at locations away to right and left sides from the first mounting hole to extend in the front-back direction, and attached in a mated condition to support pins on the other side. The first and second mounting holes are arranged to form a row in the left-right direction, with positional relationships such that when installed on the vehicle the holes overlaps one another as viewed in the left-right direction.

Owner:HONDA MOTOR CO LTD +1

Piston for an air spring of a heavy-duty vehicle

ActiveUS9157529B2Easy and efficient to prepareReduce manufacturing costSpringsBellow pistonsAir springEngineering

A piston for an air spring of a heavy-duty vehicle includes a sidewall and a central hub. The sidewall and the central hub are attached to a first bottom plate of the piston. A top plate is removeably attached to a top portion of the sidewall and a top portion of the central hub. A bottom portion of said central hub includes a second bottom plate that is recessed relative to the first bottom plate for attachment to a piston mounting pedestal that is in turn mounted to a beam of a suspension assembly of the heavy-duty vehicle.

Owner:HENDRICKSON USA L L C

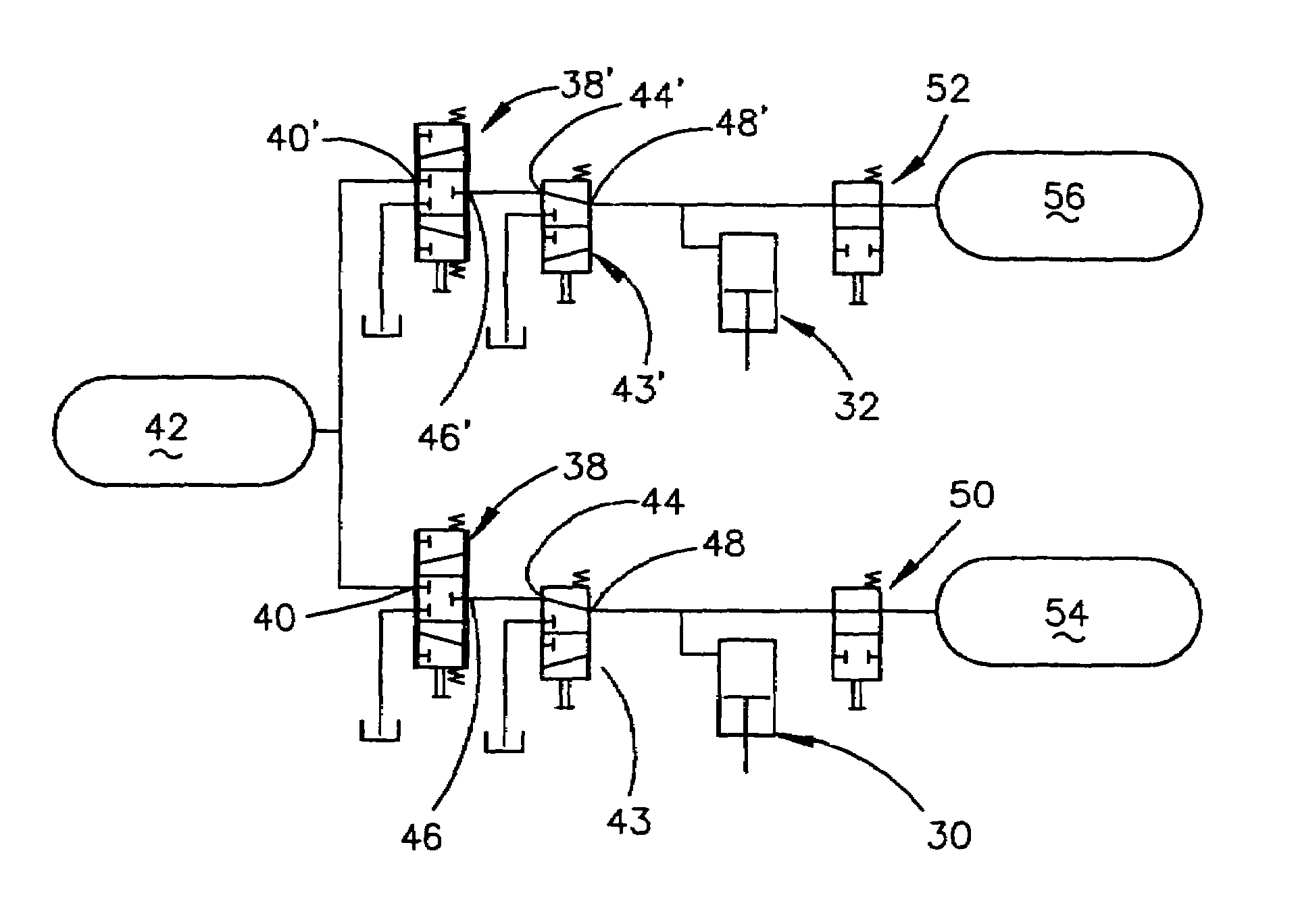

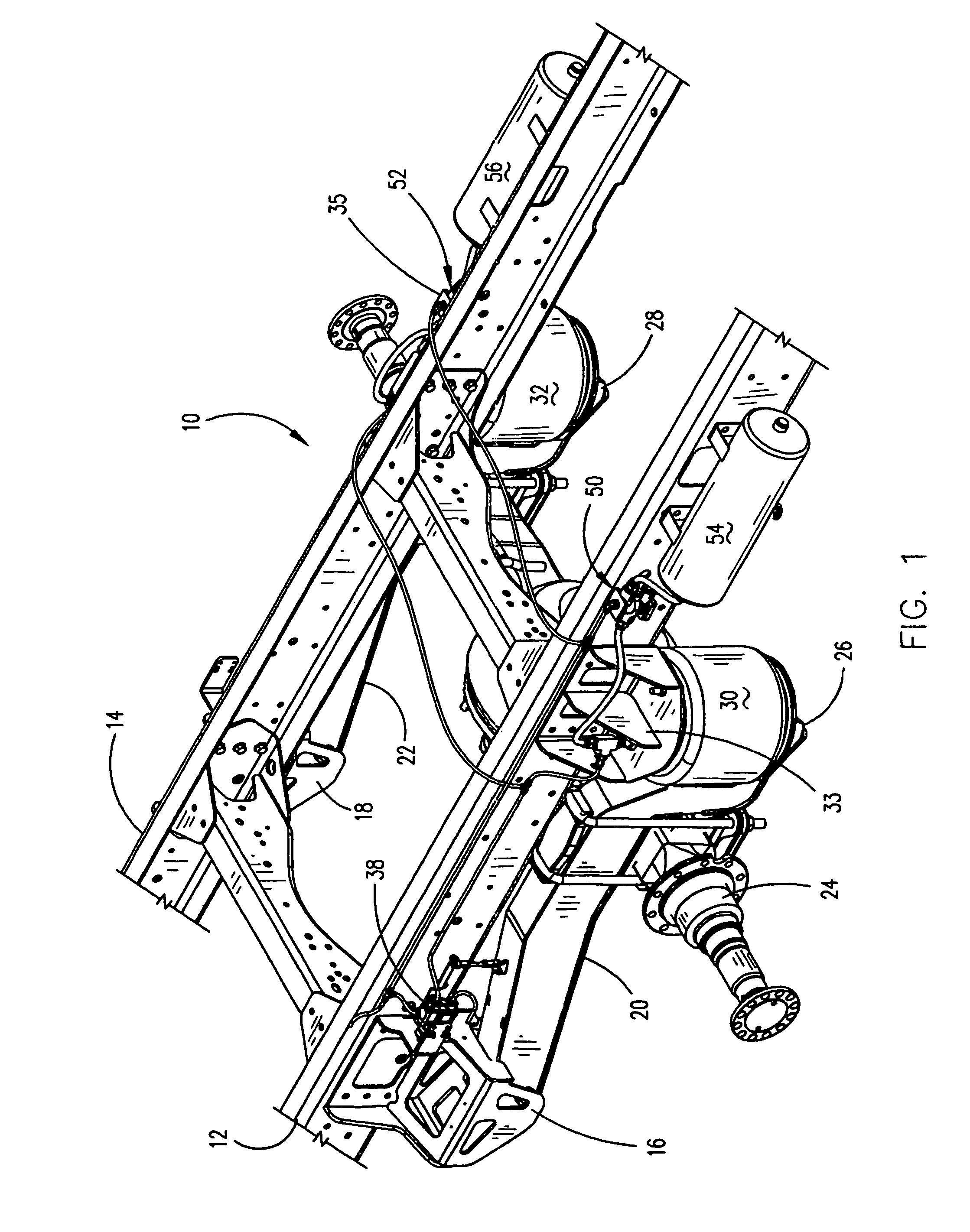

Air suspension system for a vehicle

ActiveUS7416190B2Reduce the spring rateEasy rideVehicle cleaning apparatusLoading/unloading vehicle arrangmentVehicle frameAir spring

An air suspension system for a load bearing vehicle which includes a pair of air springs fluidly connected to a pair of auxiliary air reservoirs and to a main air reservoir. The system includes control valves which permit the air in the air springs to be exhausted therefrom to lower the vehicle frame without exhausting the air from the auxiliary air reservoirs.

Owner:LINK MFG

Bellcrank seat suspension apparatus

A suspension for a vehicle seat having four bellcranks which guide the seat substantially vertically, oscillate on a central pivot on elevated stationary pivots mounted on a lower frame, with upper arms of the bellcranks pivotally attached to a seat cushion upper frame and the lower arms indirectly attached to adjustable tension springs that are attached to the upper frame; the lower ends with substantial inward offsets so as to rotate downwardly toward the mounting deck of the vehicle while clearing the lower frame and adjustable sliders; the bellcranks being coupled longitudinally and laterally to stay in phase and keep the upper frame level.

Owner:CARTER JOHN W

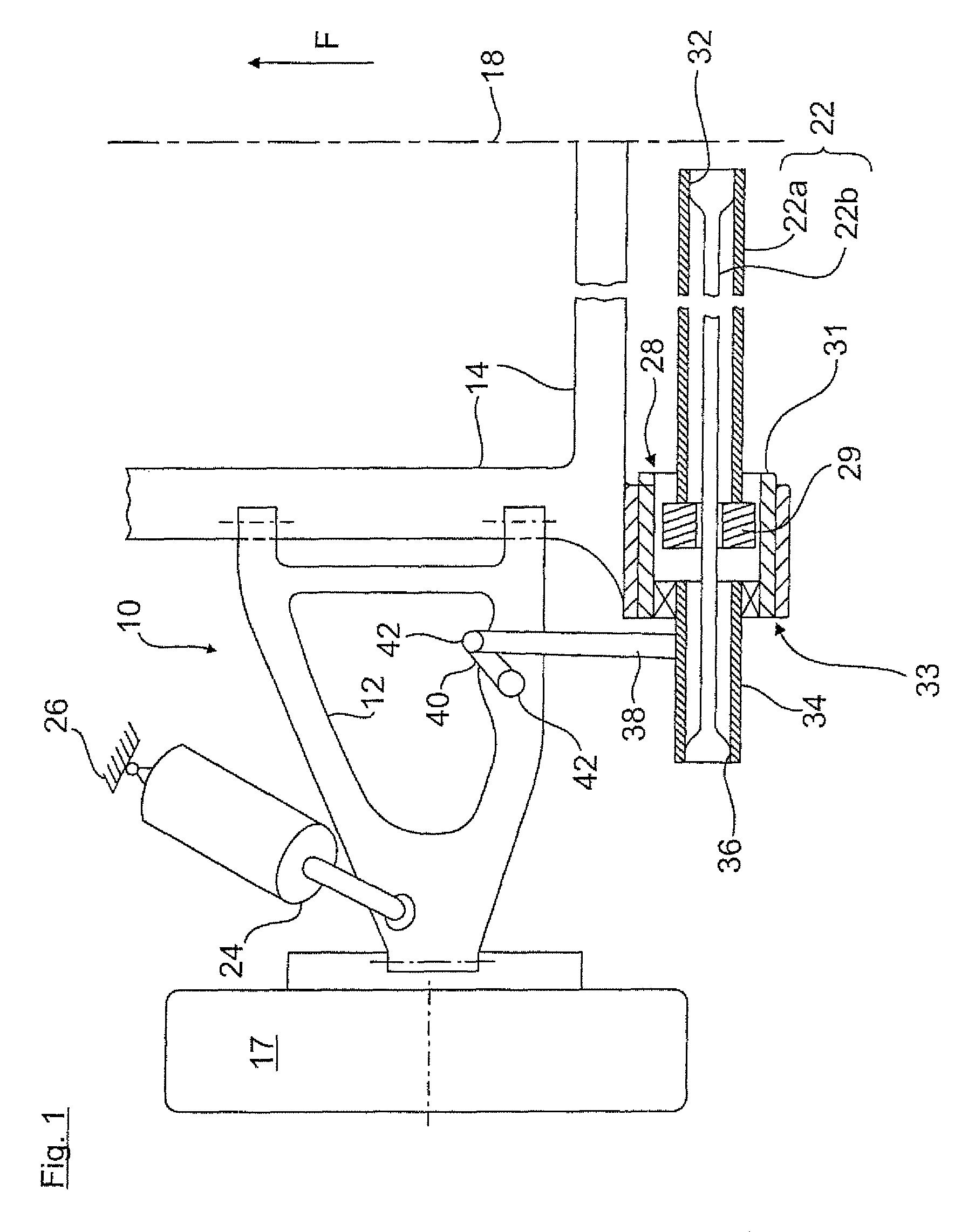

Pneumatic spring device for a motor vehicle

The invention relates to a pneumatic spring device for a motor vehicle, including a rolling piston (4), a pneumatic spring cover (5) axially movable thereto, and an interposed elastomer covering as rolling bellows (6) with a trapped compressible air volume. According to the invention, at least one additional spring element (3) is connected in series to the pneumatic spring (2), with a radial bearing (14) of the rolling piston (4) and / or the pneumatic spring cover (5) being integrated as torsion compensation.

Owner:AUDI AG

Torsion bar system for a vehicle axle of a two track vehicle

ActiveUS9434230B2Less materialLess construction costInterconnection systemsResilient suspensionsRotary actuatorActive suspension

A torsion bar system for a vehicle axle, in particular a rear axle, of a two-track vehicle, includes first and second rotary actuators, each of which is associated with a vehicle side, for an active suspension control. Each rotary actuator has at least one motor / gear unit with which torques can be generated and transmitted as actuating forces onto a wheel suspension element via an output lever. The motor / gear units of both rotary actuators are arranged in a common housing which is rotationally fixed to the vehicle body. The housing has at least two attachment points for bracing the vehicle body, wherein the attachment points are spaced from one another across a bearing distance, and the housing is mounted on the vehicle body in a rigid assembly via said attachment points.

Owner:AUDI AG

Micromechanical component and manufacturing method for a micromechanical component

ActiveUS20120167681A1High reliabilityCost-effectiveAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsHigh densityVolumetric Mass Density

A micromechanical component having a fixing point and a seismic weight, which is connected to the fixing point by at least one spring and is made at least partially out of a first material, the first material being a semiconductor material, the seismic weight being additionally made out of at least one second material, and the second material having a higher density than the first material. In addition, a manufacturing method for a micromechanical component is provided, having the steps of forming a seismic weight at least partially out of a first material, the first material being a semiconductor material, connecting the seismic weight to a fixing point of the micromechanical component, using at least one spring, and forming the seismic weight from the first material and at least one second material, which has a higher density than the first material.

Owner:ROBERT BOSCH GMBH

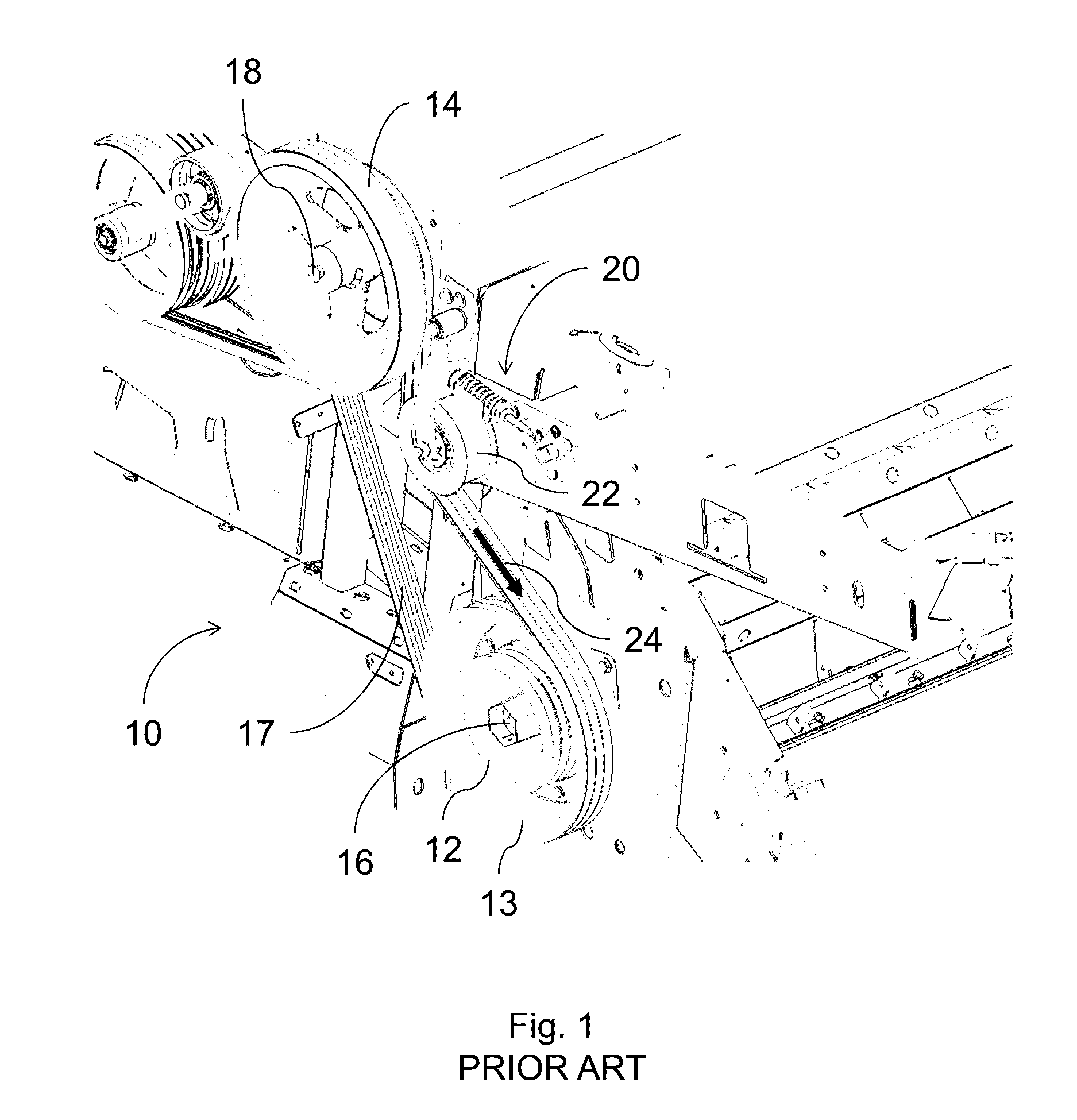

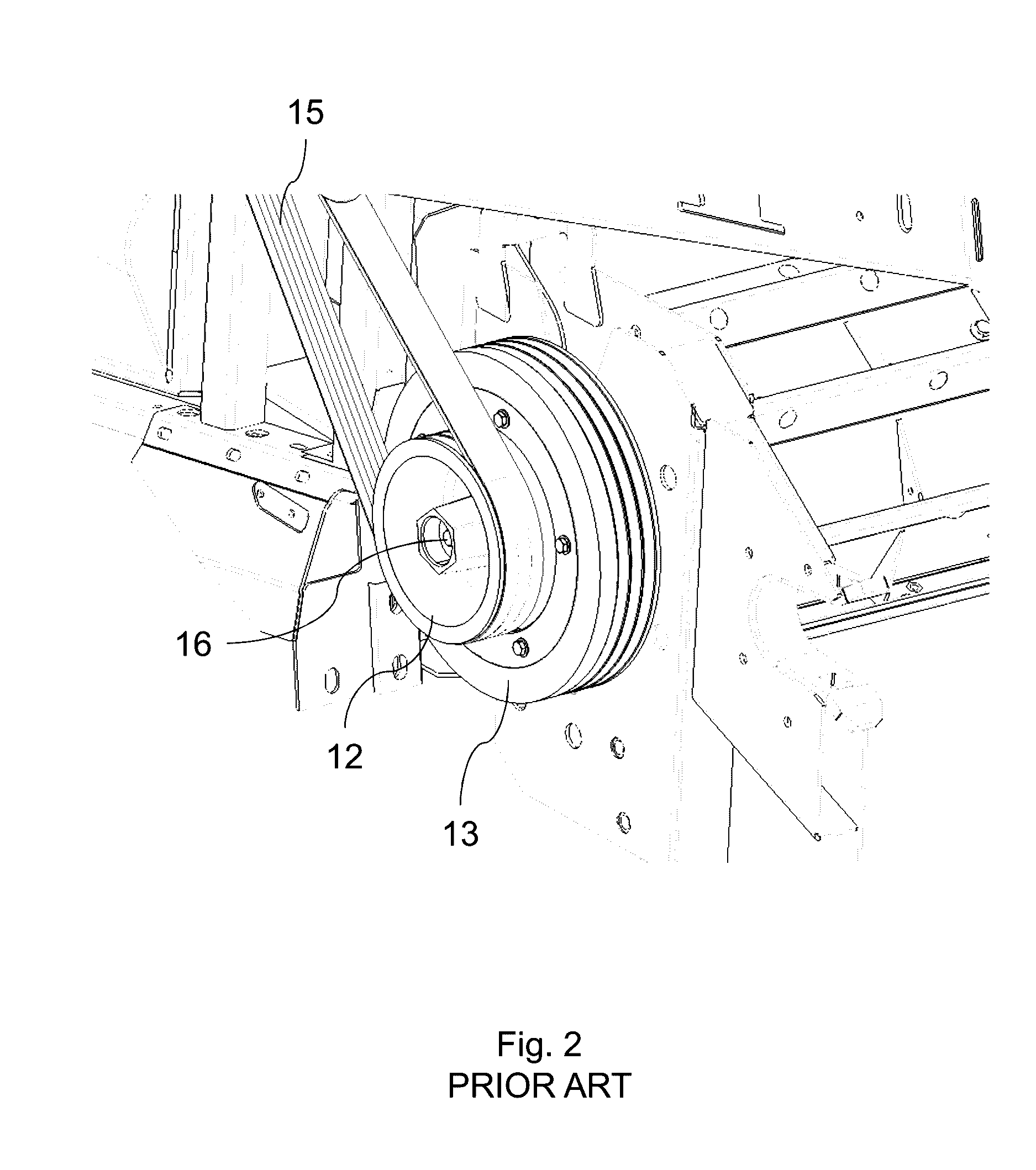

Tension Roller Assembly for a Belt Drive

ActiveUS20170059014A1Easy to carryReduce the risk of injuryHarvestersGearingEngineeringMechanical engineering

A tension roller assembly includes a tension roller, a pivotable support arm, a tension arm, a compression spring, a rod, first and second spring stops, a mounting plate, and an overcenter assembly connected to an end of the tension arm. The overcenter assembly connects the tension arm to the mounting plate. The overcenter assembly is configured to make a pivoting movement over a pivot trajectory between engaged and disengaged positions. The overcenter assembly further has a center position located between the engaged and disengaged positions. The pivot trajectory between the center position and the disengaged position is divided into a tensioned section in which the end stop does not engage the stop surface and the spring exerts a force on the overcenter assembly, and a free-moving section in which the end stop engages the stop surface and the spring does not exert any force on the overcenter assembly.

Owner:BLUE LEAF I P INC

Wheelset to side frame interconnection for a railway car truck

A railway car truck incorporating an interconnection between the side frame and bearing adapter is characterized by a low lateral spring constant relative to the longitudinal spring constant. The interconnection provides a proportional restoring force with minimal internal friction and hysteresis. In embodiments, the interconnection comprises compressed elastomeric members positioned between the thrust lug of the side frame and the bearing adapter in the longitudinal direction and a low friction interface between the roof of the pedestal jaw and the top of the bearing adapter.

Owner:STRATO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com