Patents

Literature

33results about How to "Increase comfort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

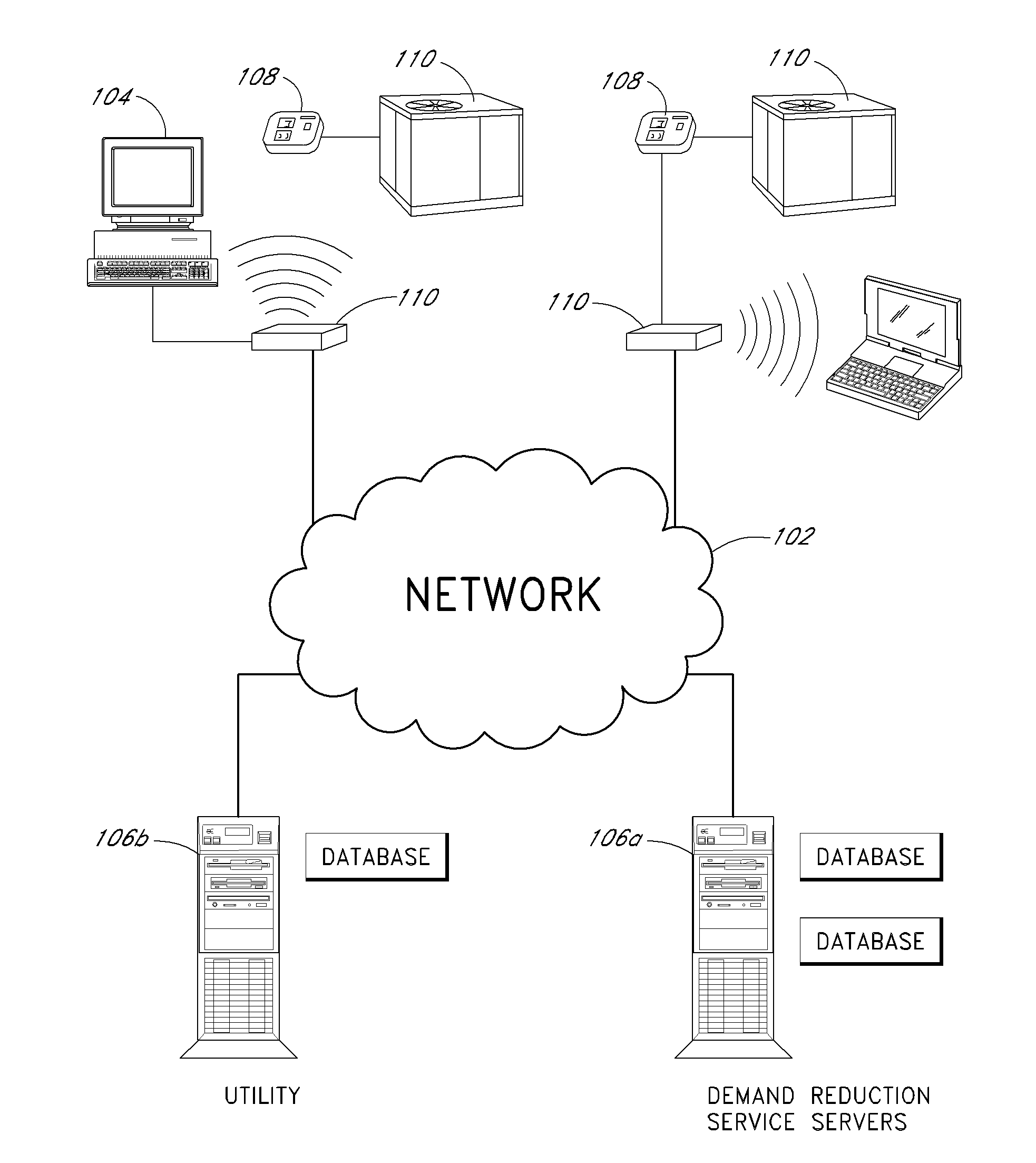

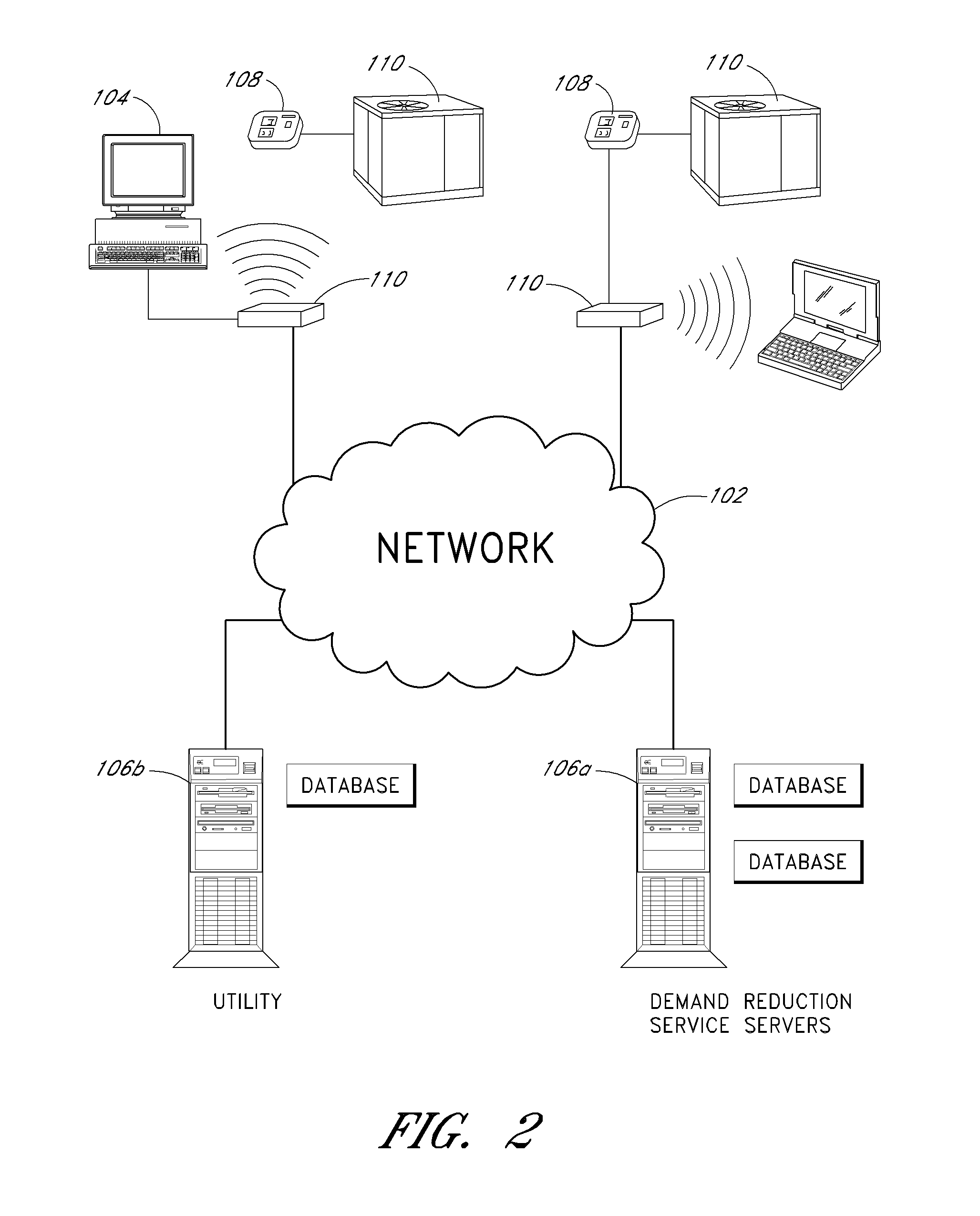

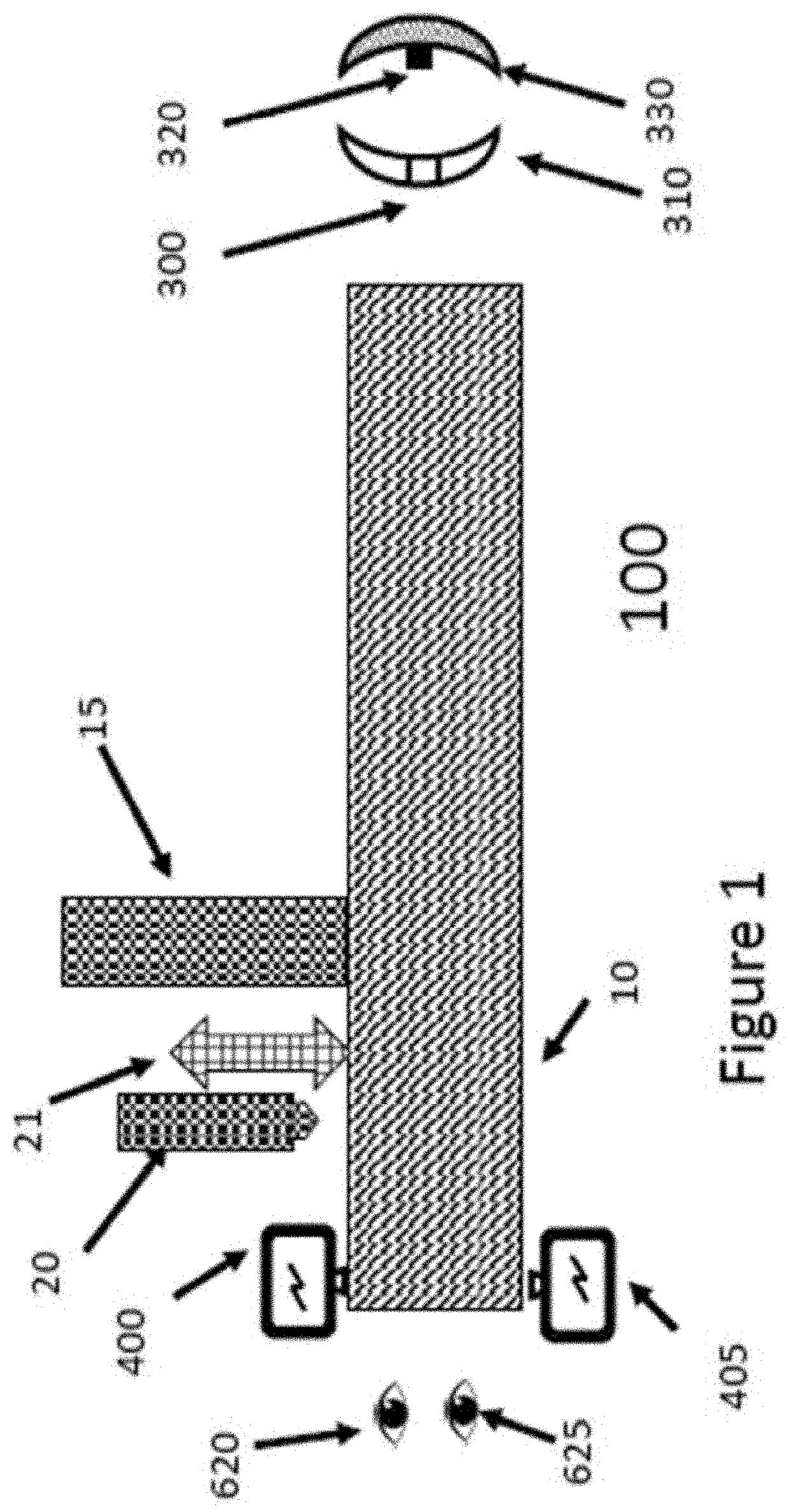

System and method for evaluating changes in the efficiency of an HVAC system

ActiveUS20100070234A1Decrease energy useIncrease comfortTime indicationSpace heating and ventilationHVACTemperature measurement

The invention comprises systems and methods for evaluating changes in the operational efficiency of an HVAC system over time. The climate control system obtains temperature measurements from at least a first location conditioned by the climate system, and status of said HVAC system. One or more processors receives measurements of outside temperatures from at least one source other than said HVAC system and compares said temperature measurements from said first location with expected temperature measurements. The expected temperature measurements are based at least in part upon past temperature measurements.

Owner:ECOFACTOR

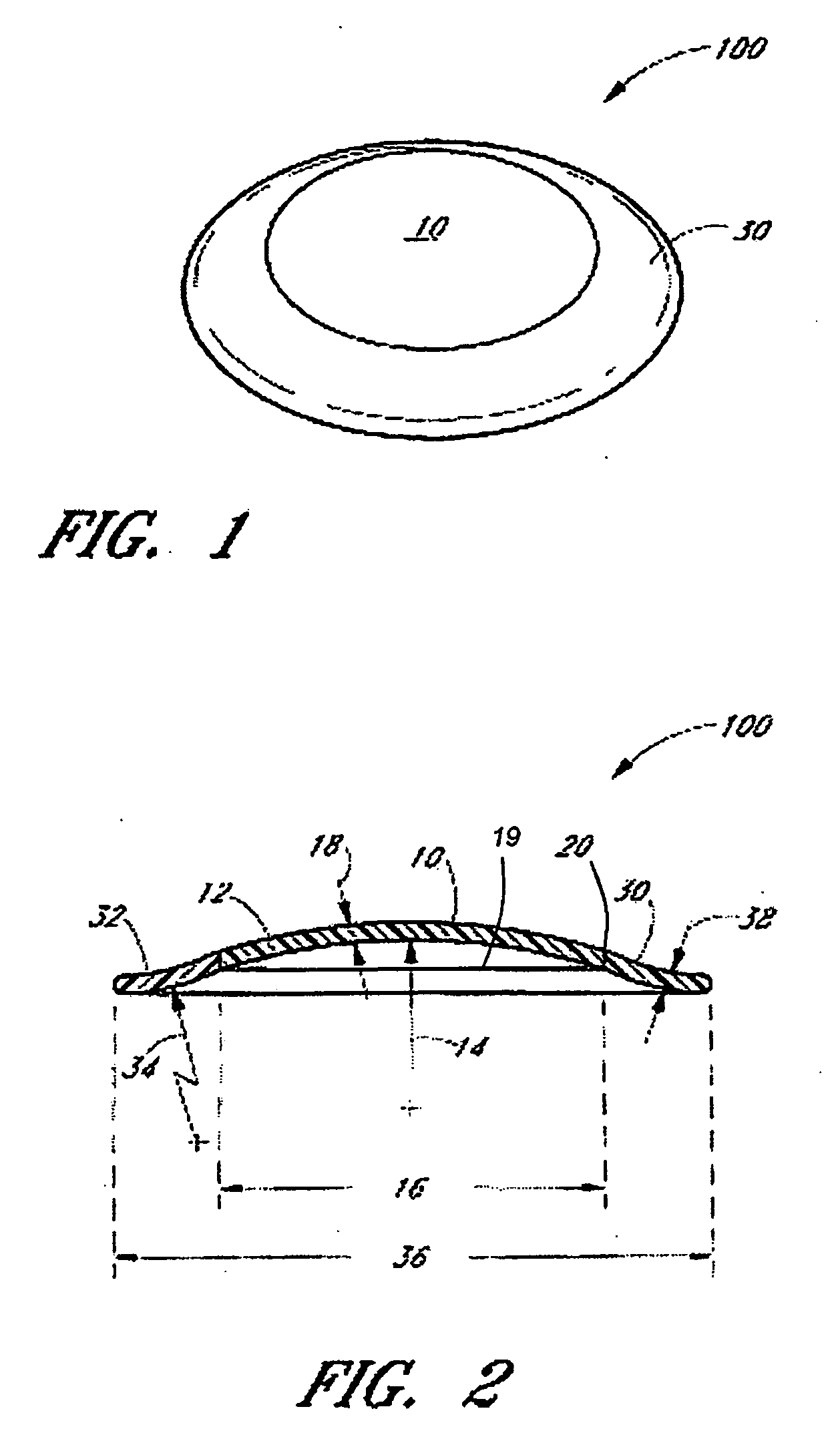

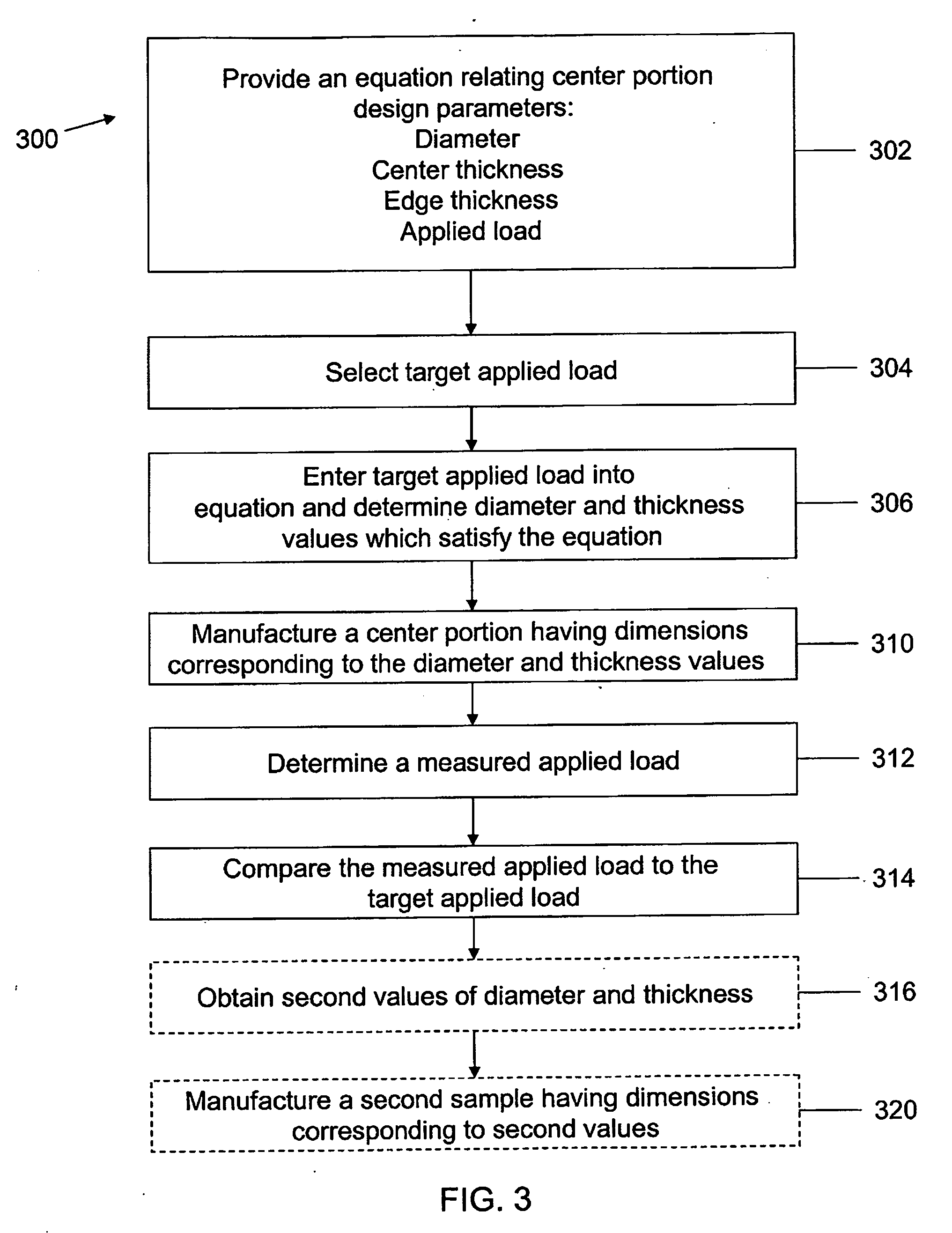

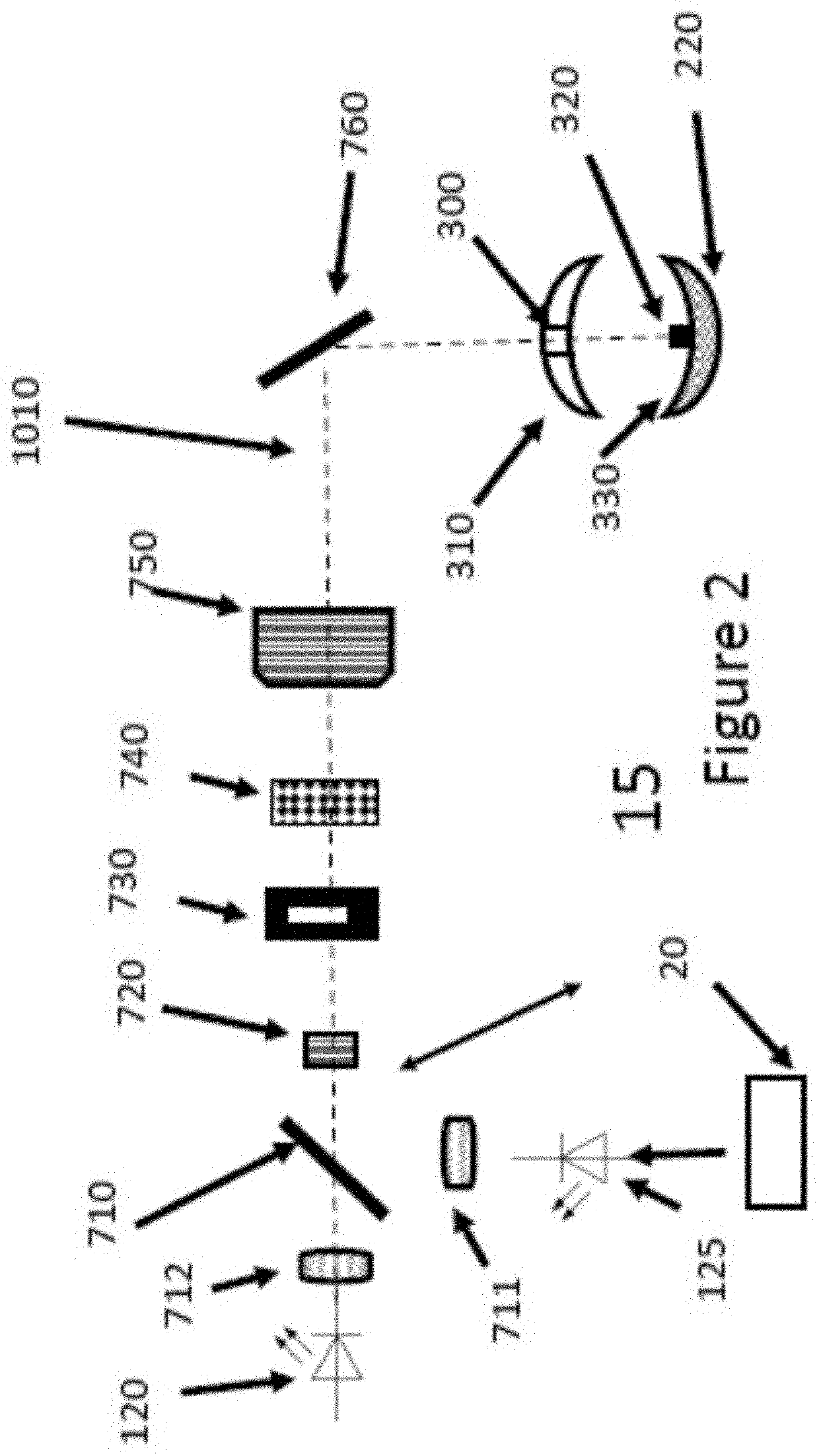

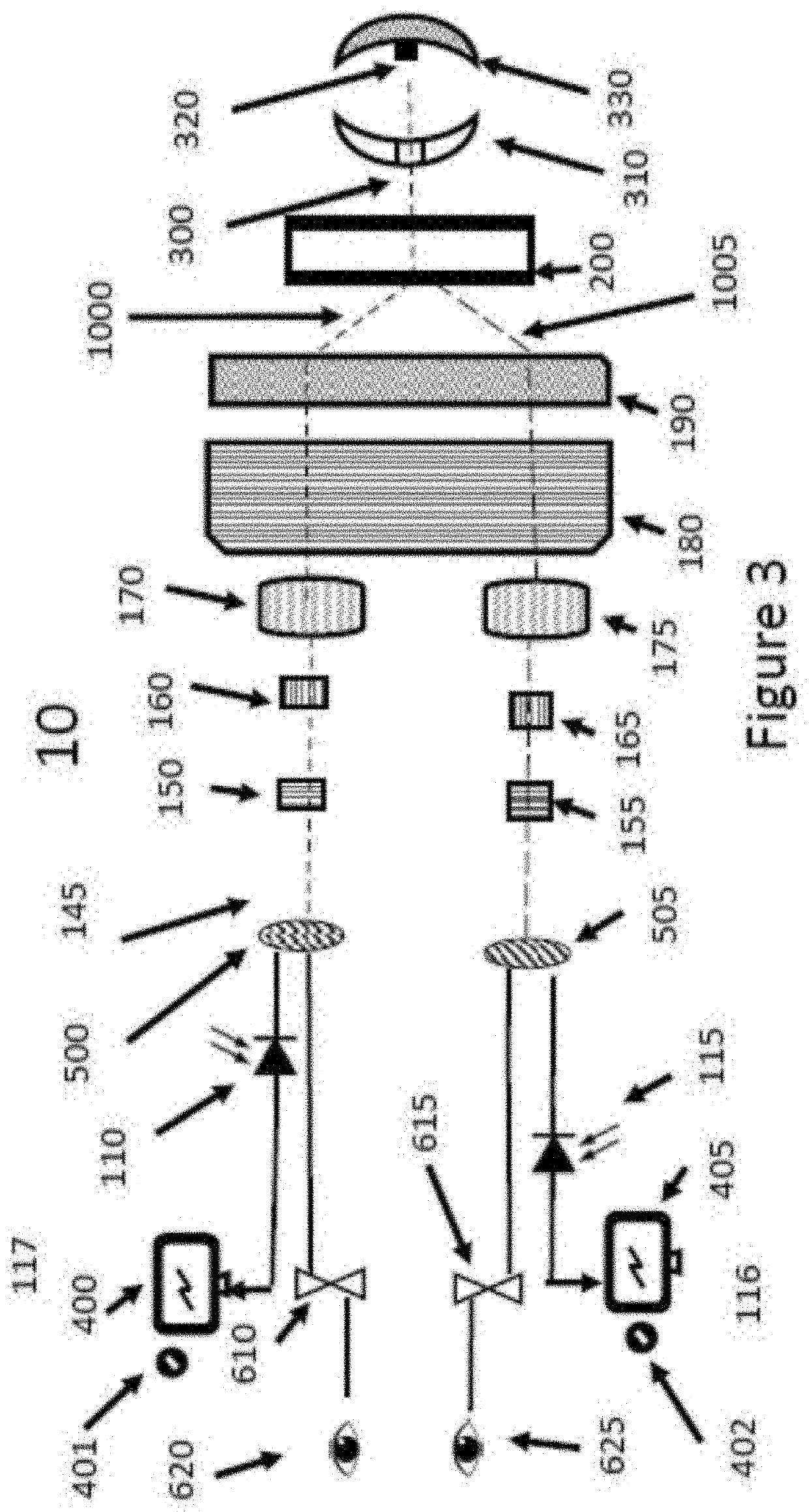

Hybrid contact lens with improved resistance to flexure and method for designing the same

InactiveUS20080074611A1Increase comfortLow degree of flexureEye diagnosticsOptical partsGramEngineering

A hybrid contact lens includes a substantially rigid center portion having a flexural deformation of about 10% at an applied load of at least about 50 grams and a Dk of at least about 30×10−11 (cm2 / sec) (mL O2) / (mL mm Hg). The hybrid contact lens also includes a substantially flexible skirt portion connected to the center portion. A method of designing a hybrid contact lens includes determining the applied load that results in a selected flexural deformation.

Owner:SYNERGEYES

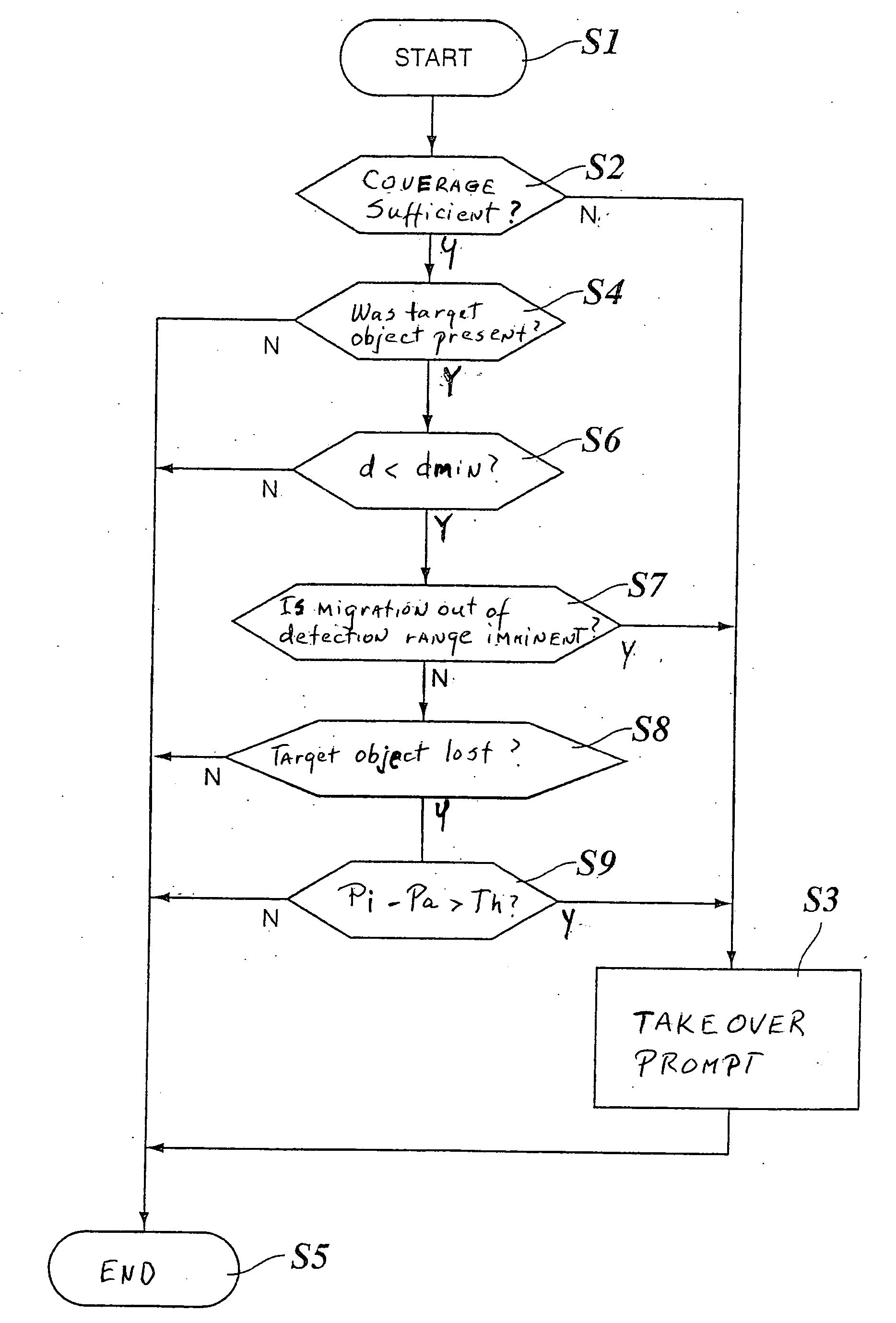

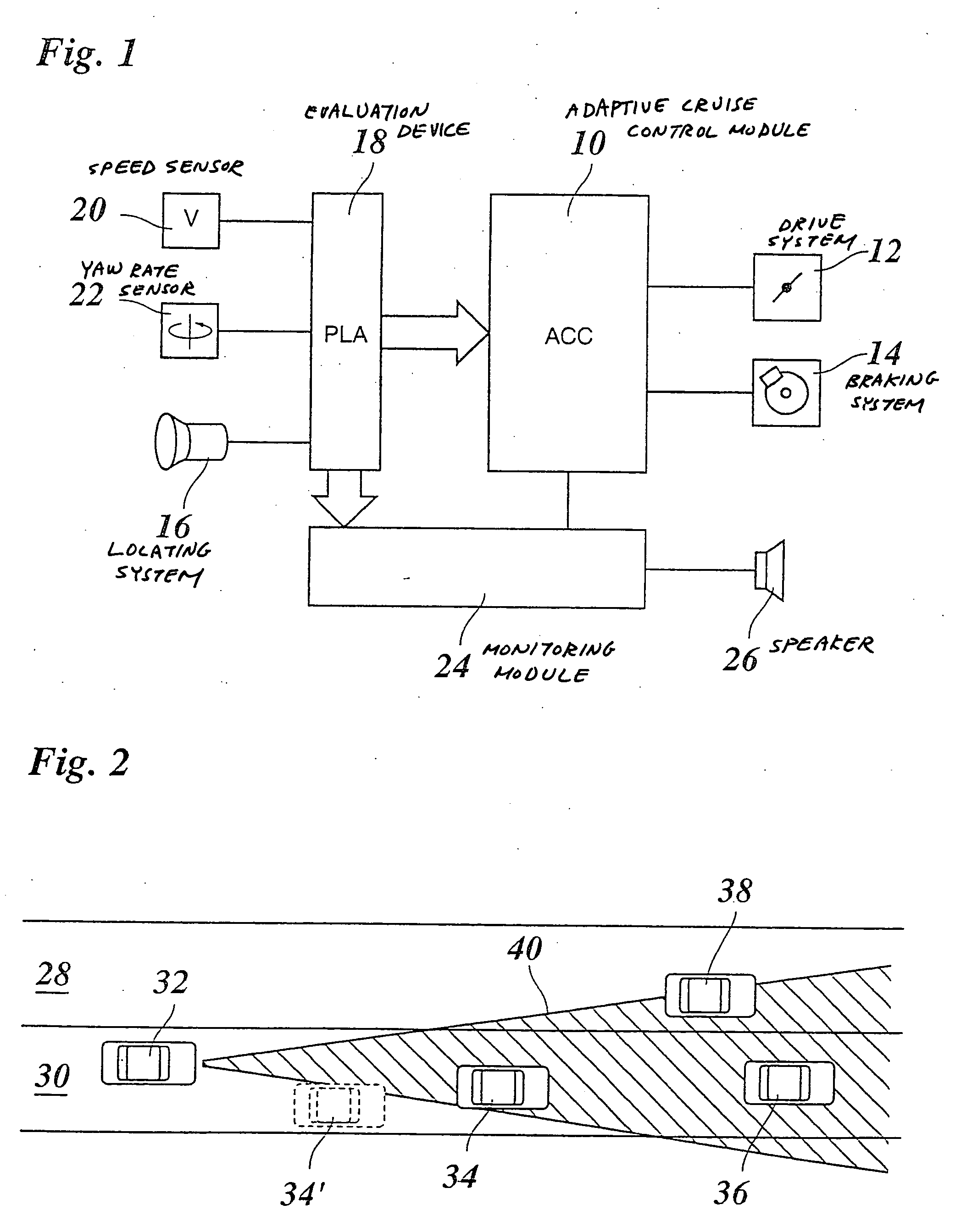

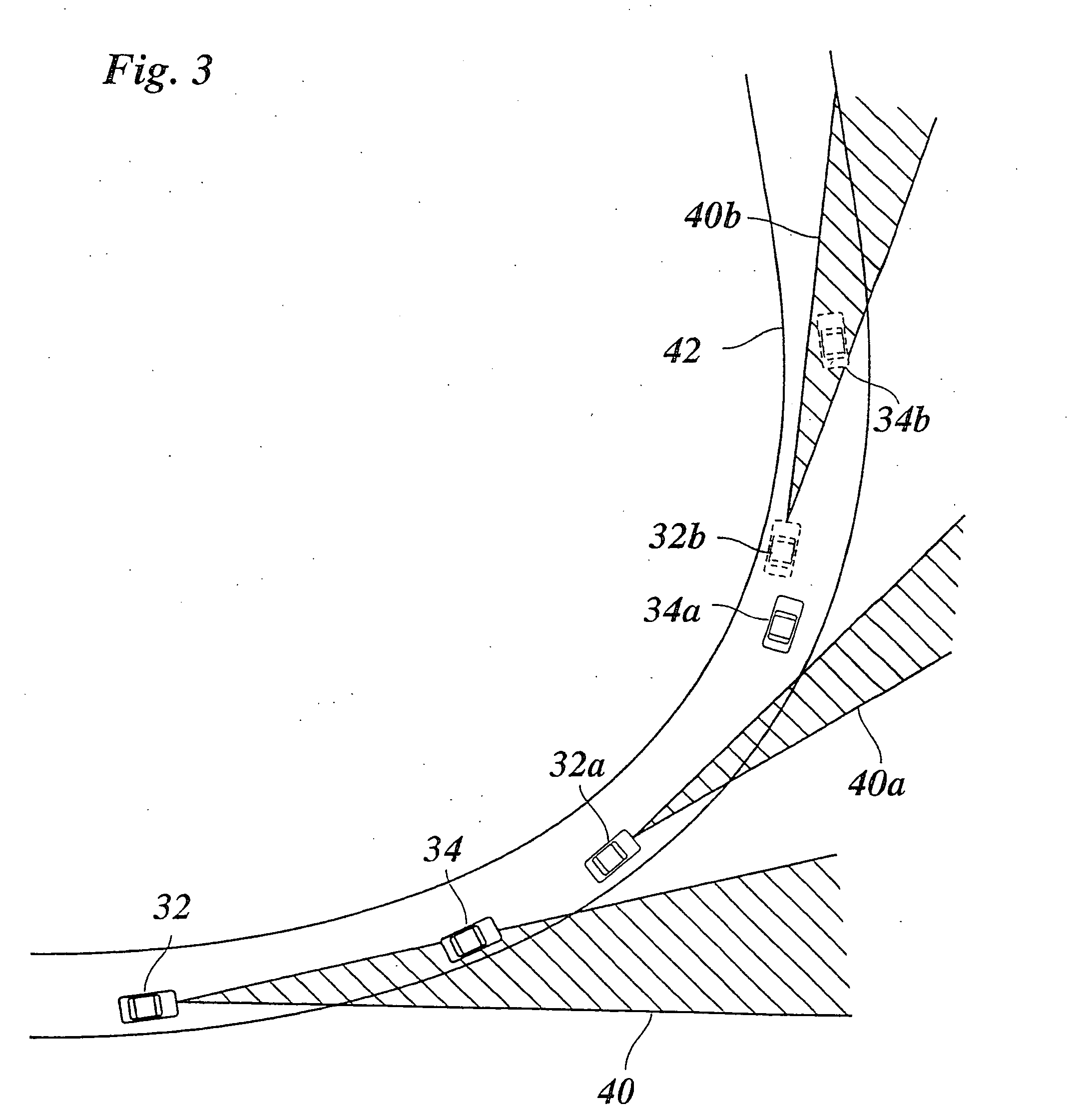

Speed regulator with distance regulating function

InactiveUS20050010351A1Increase comfortIncrease traffic safetyVehicle fittingsDigital data processing detailsClose rangeVelocity controller

A speed controller for motor vehicles is provided, the vehicle having a distance regulating function, a locating system for detecting locating data for objects that are in front of the vehicle, and an evaluation device for determining whether a located object needs to be treated as a relevant target object in the vehicle's lane. The speed controller includes a monitoring module that is designed to detect, by reference to the locating data, a situation in which objects not detected by the locating system are within close range and, in this situation, issue a takeover prompt to the driver.

Owner:ROBERT BOSCH GMBH

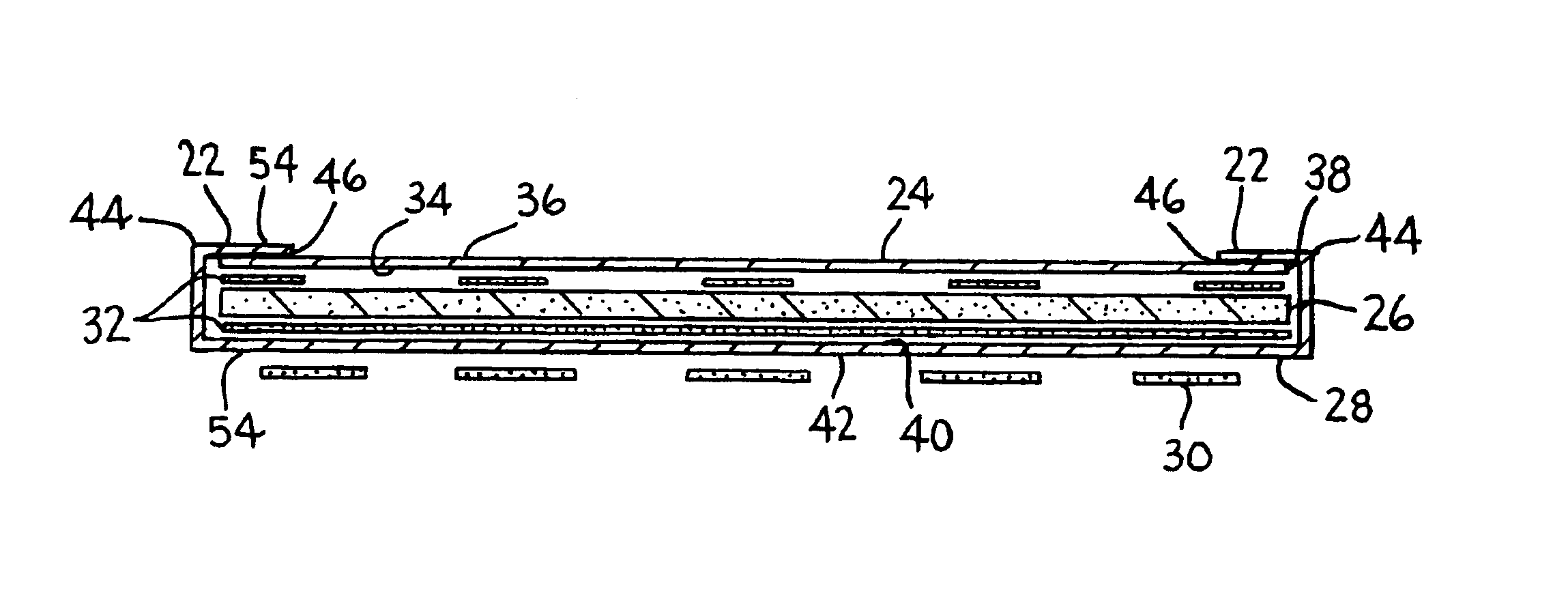

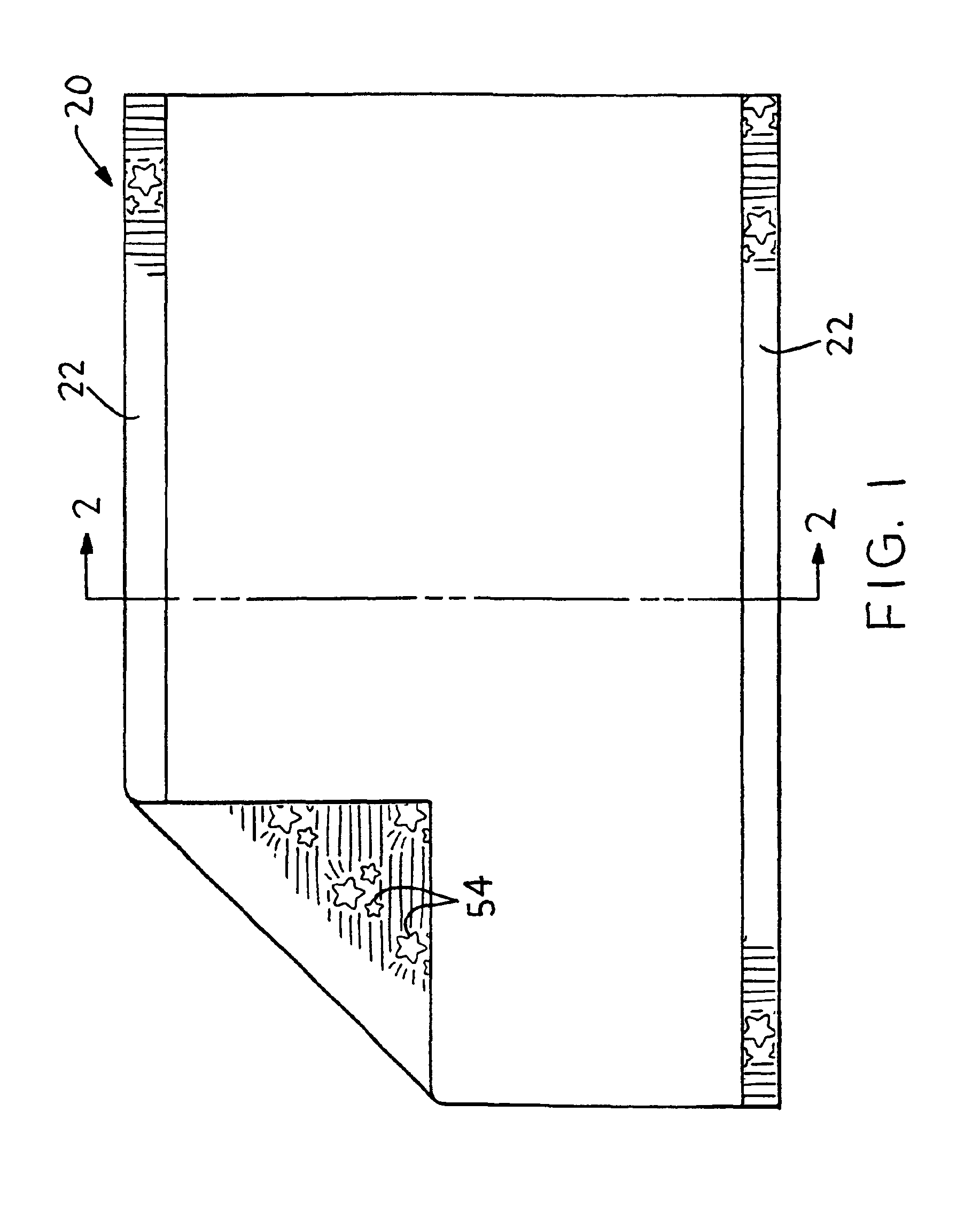

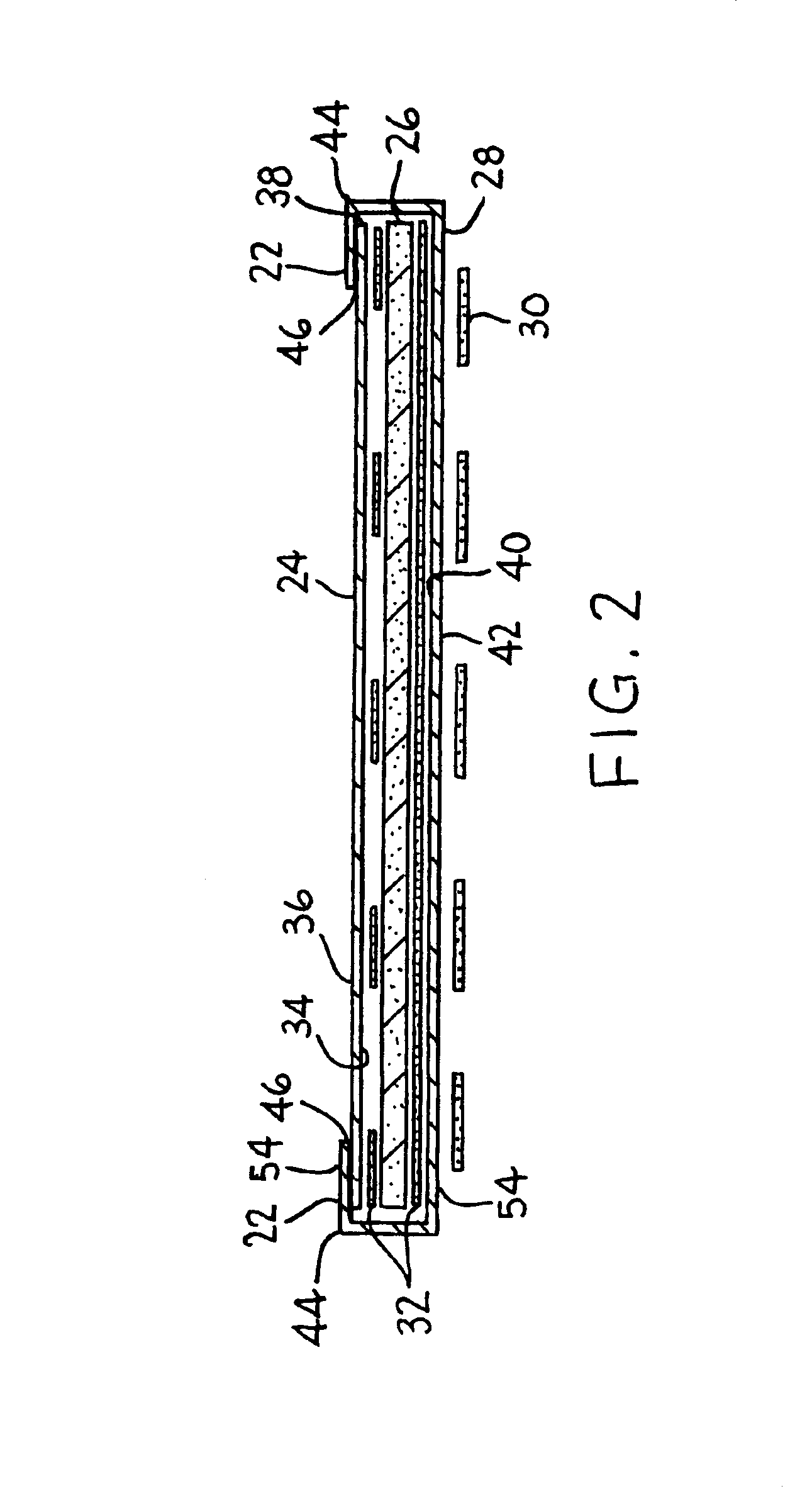

Non-slip absorbent article

InactiveUS6911407B2Increase comfortSufficient breathabilityStuffed mattressesDressing tableAdhesiveEngineering

Disclosed is an absorbent article useful for the following purposes without limitation: as a bed pad, a baby changing pad, a bib, a table cloth, or a painter's drop cloth. The absorbent article includes a vapor-permeable liquid-impermeable bottomsheet having an interior surface and an exterior surface, an absorbent structure positioned adjacent the interior surface, and a non-adhesive skid-resistant coating applied to the exterior surface such that the bottomsheet remains vapor-permeable after application of the coating. The non-adhesive skid resistant coating improves the ability of the absorbent article to remain in position without leaving residue on surfaces while leaving the absorbent article breathable.

Owner:KIMBERLY-CLARK WORLDWIDE INC

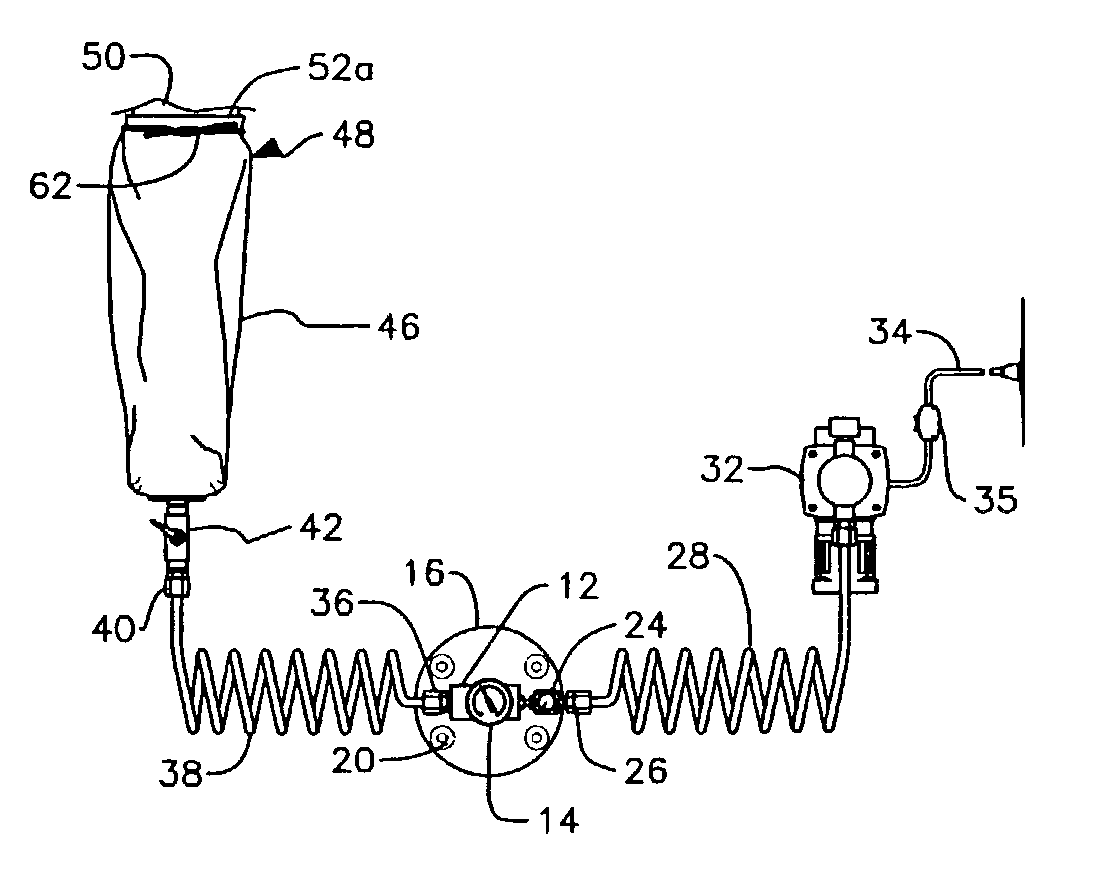

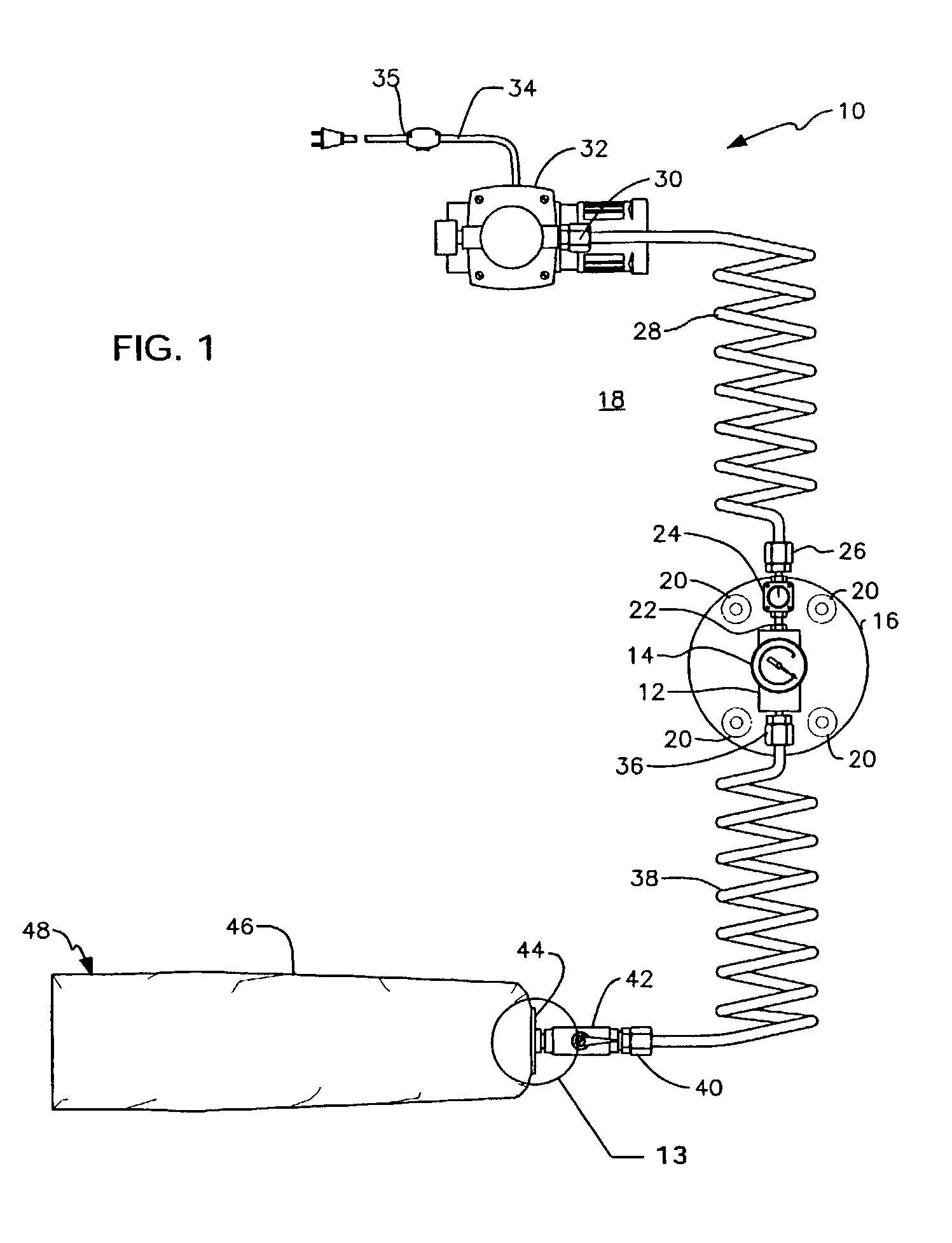

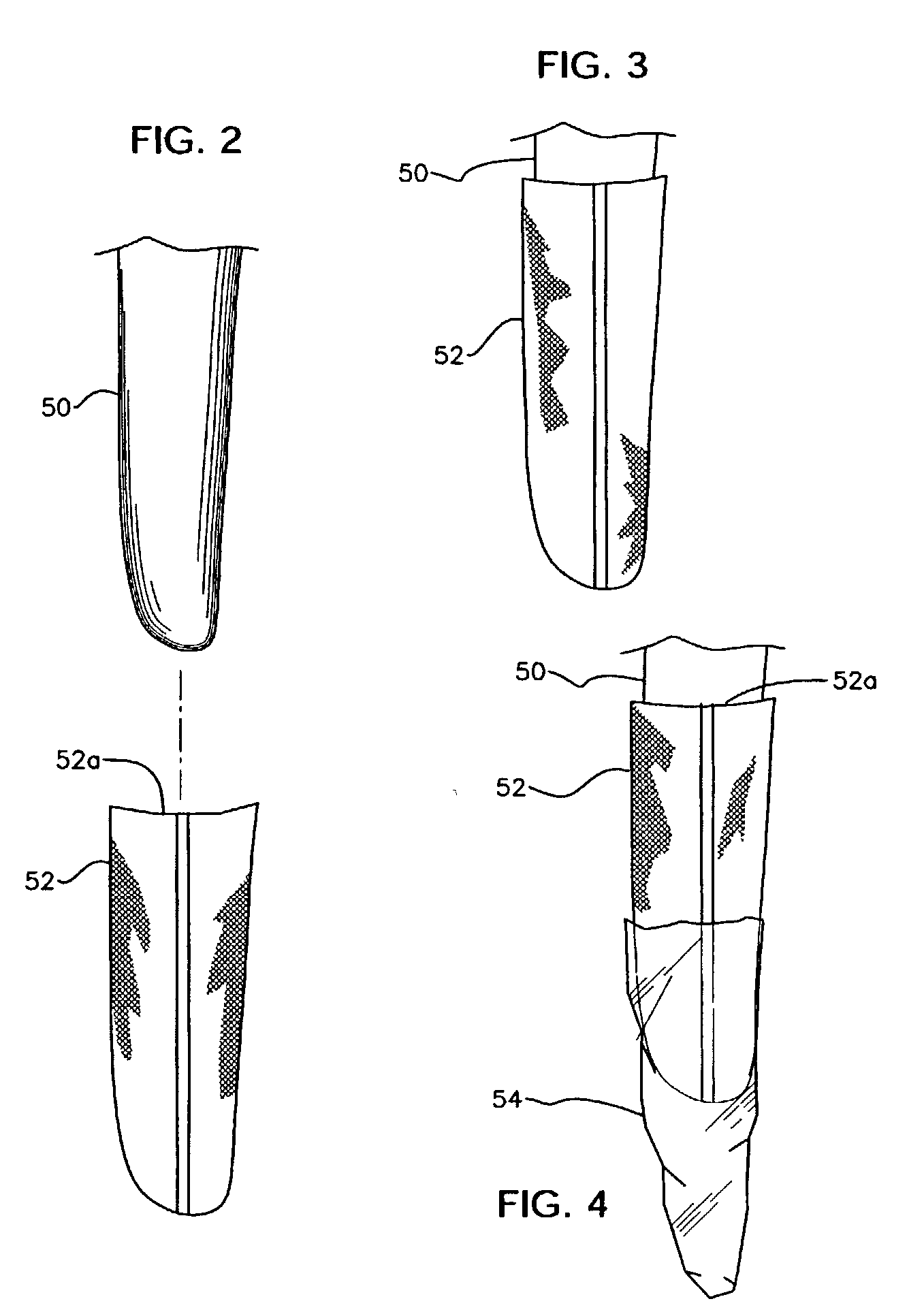

Apparatus for casting a prosthetic socket under vacuum

InactiveUS6991444B1Reduce difficultyIncrease comfortOther chemical processesConfectioneryUrologyBandage

A prosthetic socket is made by wrapping water-soaked plaster bandages around a residual limb or around a prosthetic liner within which is disposed a residual limb, and positioning a vacuum wick in overlying relation to the plaster bandages. The residual limb, prosthetic liner, plaster bandages, and vacuum wick means are then inserted into a vacuum bladder. The vacuum bladder is sealed and a predetermined vacuum is applied internally to the bladder until the plaster hardens into a negative cast. The residual limb is manipulated through the vacuum bladder to modify the geometry of the plaster before the plaster hardens. The negative cast is removed from the residual limb and a positive cast is produced by pouring plaster into the negative cast. A thermoplastic sheet is thermoformed over the positive cast or a carbon-epoxy matrix is laminated over the positive cast. This eliminates reduction and modification of a hard positive cast.

Owner:LAGHI ALDO A

Ankle bolster

InactiveUS7188382B1Increase comfortEasily applyRestraining devicesSofasBolsterPhysical medicine and rehabilitation

This device is made to protect the bony surfaces of a foot from prolonged pressure and ultimate skin breakdown. It consists of a cylinder of dense foam that is fitted to encompass the lower leg of a user from the knee to the ankle. When in place on the leg a of a user lying in bed, it will support the lower leg such that the foot will not be in contact with the firm surface of the bed, thus providing total pressure relief to the foot. The user can also lie in any position, even prone, with out interference from this device.

Owner:TAYLOR ELEANOR L +1

U-shaped float tube with stabilizing frame

InactiveUS20050026520A1Increase comfortSufficient structureLife-buoysSeating furnitureMechanical engineeringWatercraft

A float tube or watercraft comprised of a generally U-shaped inflatable flotation chamber having two generally parallel and laterally disposed leg portions and a rearward portion. The leg portions are preferably formed integrally with the rearward portion. The invention further includes a seating device bridging the two leg portions of the flotation chamber. A stabilizing frame and system for connecting the stabilizing frame to the U-shaped flotation chamber provides support to the opposing legs of the flotation chamber and prevents them from pinching in on the occupant, and also preferably tensions a seat provided between the legs of the floatation chamber. For additional support and / or this preferred tensioning, a rigid and / or adjustable rod, or tube, extends between the opposing legs of the frame. The system for connecting the stabilizing frame comprises preferably a plurality of channel segments, which are fixedly secured to the leg and rearward portions of the flotation chamber. Alternatively, a continuous channel may be used.

Owner:HOWERTON LARRY

Braking Device for Braking a Lift Car

Owner:THYSSENKRUPP ELEVATOR INNOVATION & OPERATIONS GMBH

Method and apparatus for applying a coating to an ophthalmic lens

InactiveUS20050076831A1Increase wettabilityIncrease comfortOptical articlesLiquid/solution decomposition chemical coatingPiezo electricUltrasonic assisted

The invention provide a method for applying a coating to an ophthalmic lens or a mold for making the ophthalmic lens or a medical device other than ophthalmic lens. The method comprises spraying at least one layer of a coating liquid onto an ophthalmic lens using a spraying process selected from the group consisting of an air-assisted atomization and dispensing process, an ultrasonic-assisted atomization and dispensing process, a piezoelectric assisted atomization and dispensing process, an electro-mechanical jet printing process, a piezo-electric jet printing process, a piezo-electric with hydrostatic pressure jet printing process, and a thermal jet printing process. The coating can comprise a property / functionality pattern or a color image or combination of both.

Owner:GILLIARD ALLEN +3

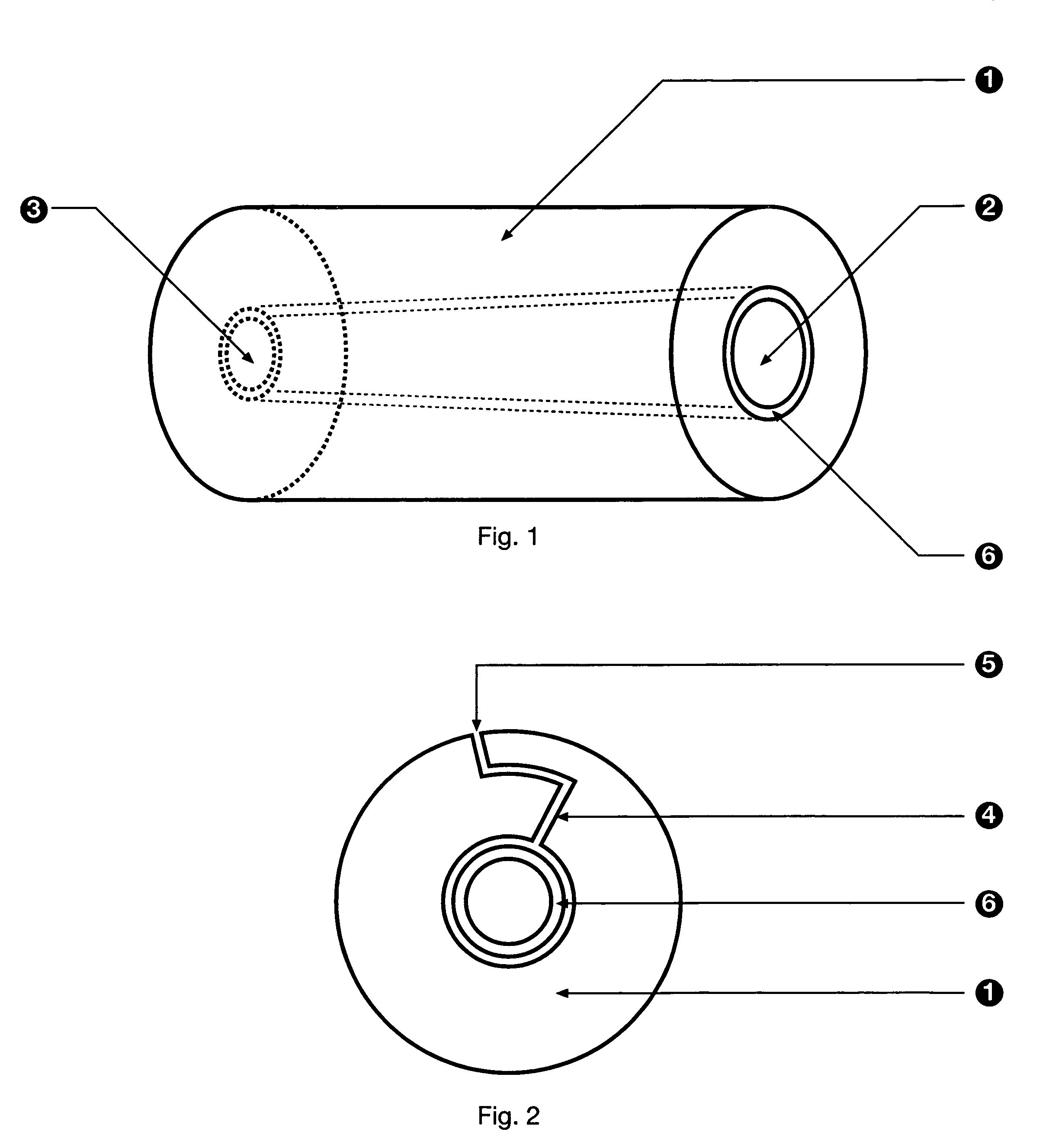

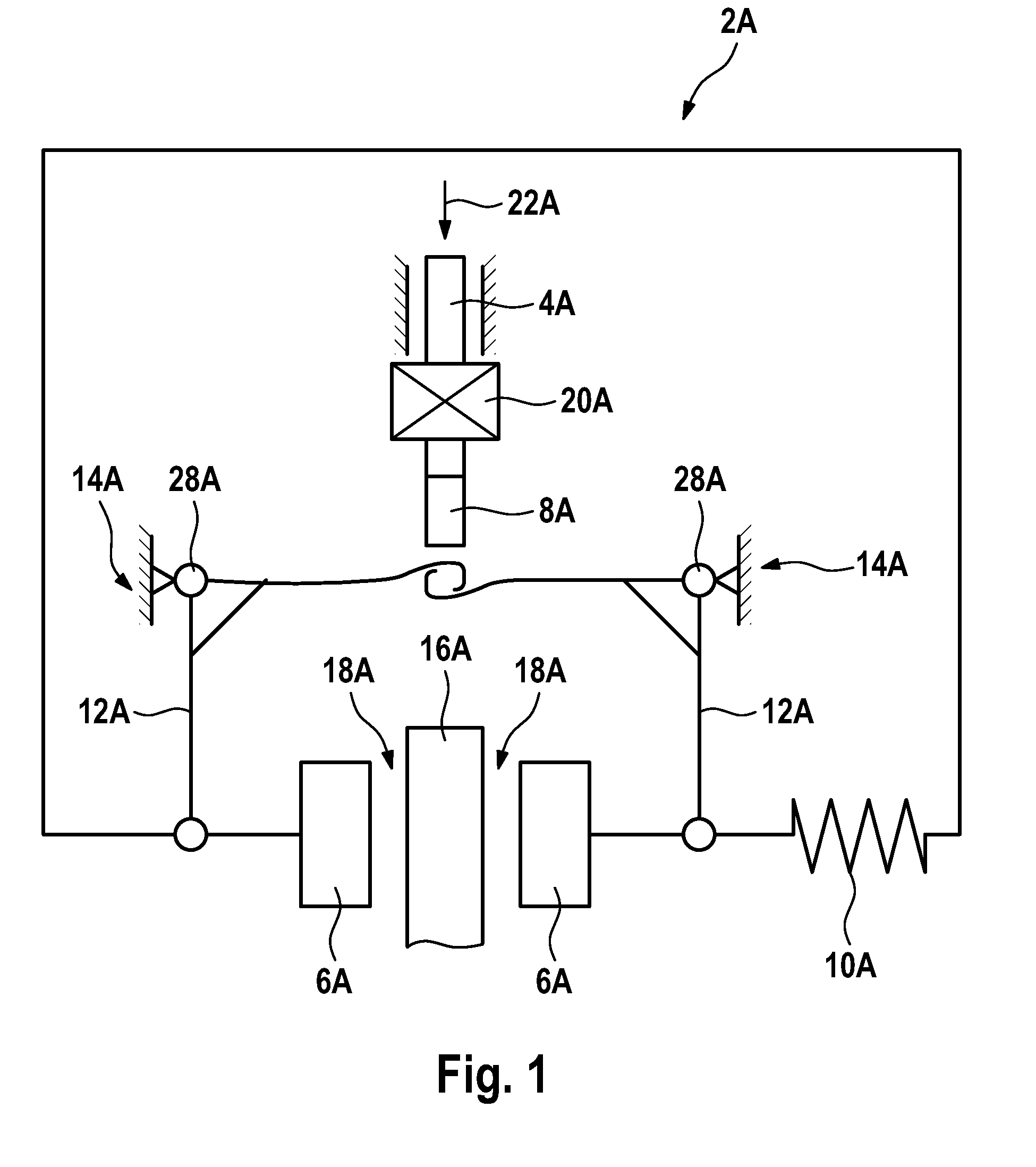

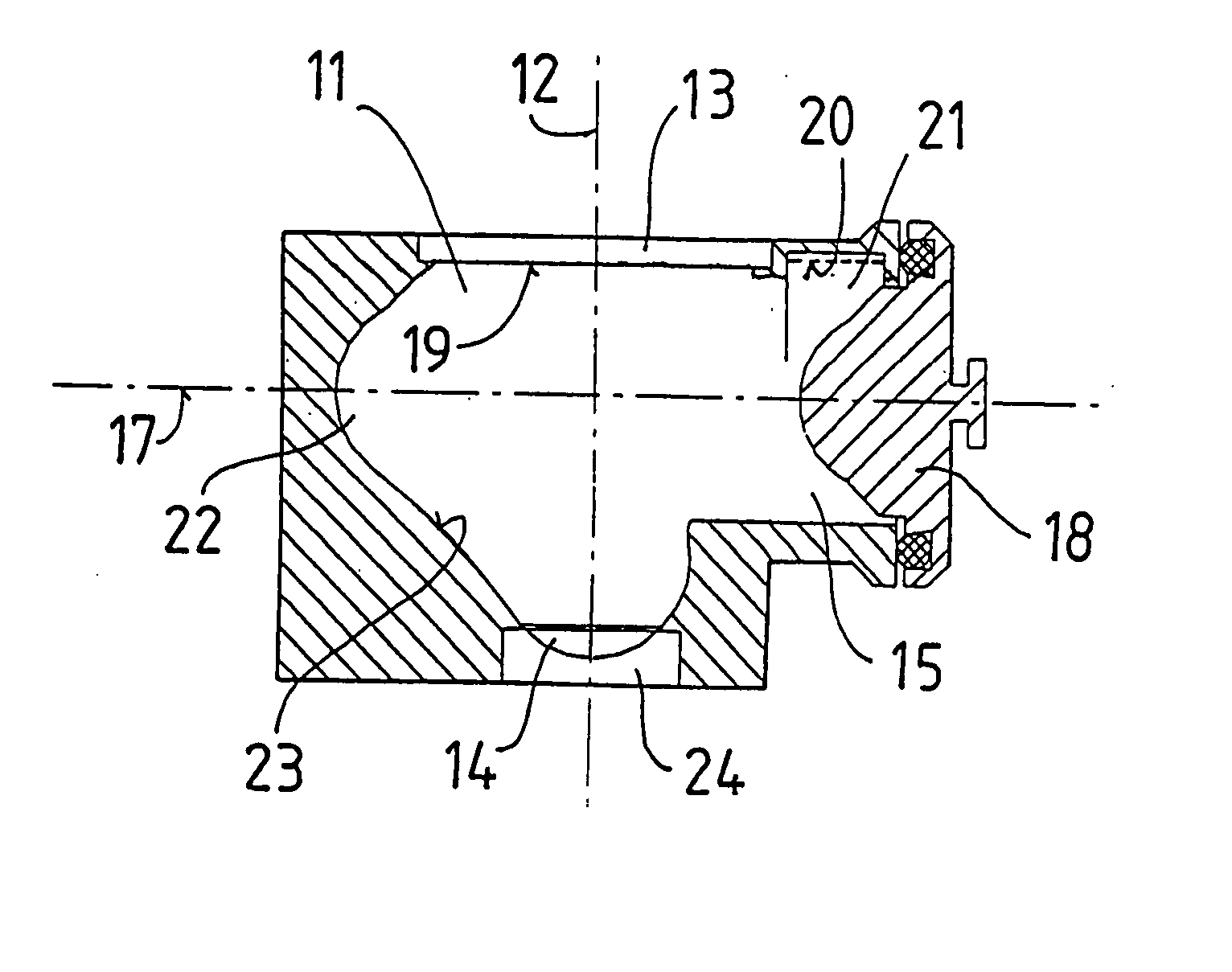

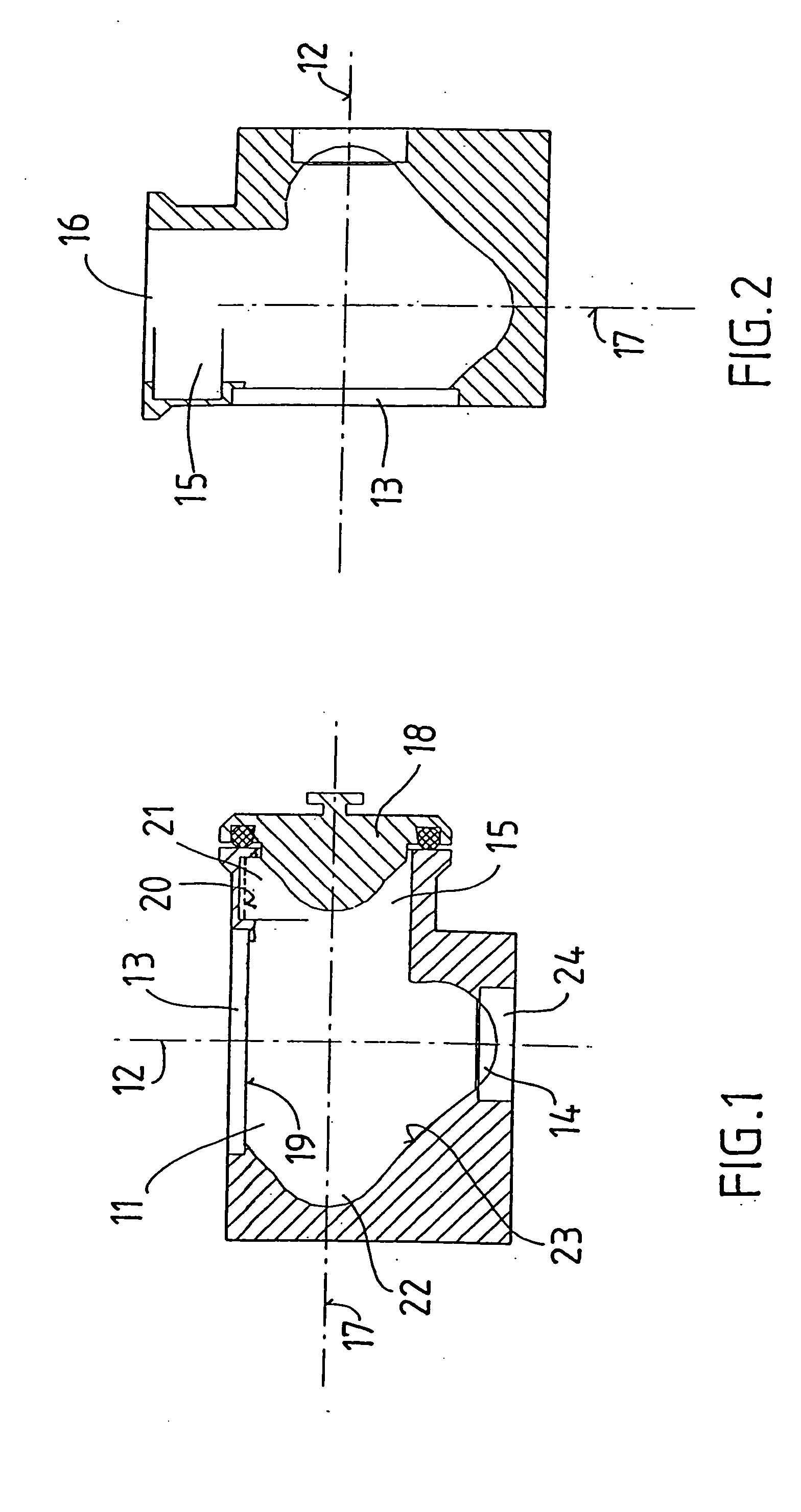

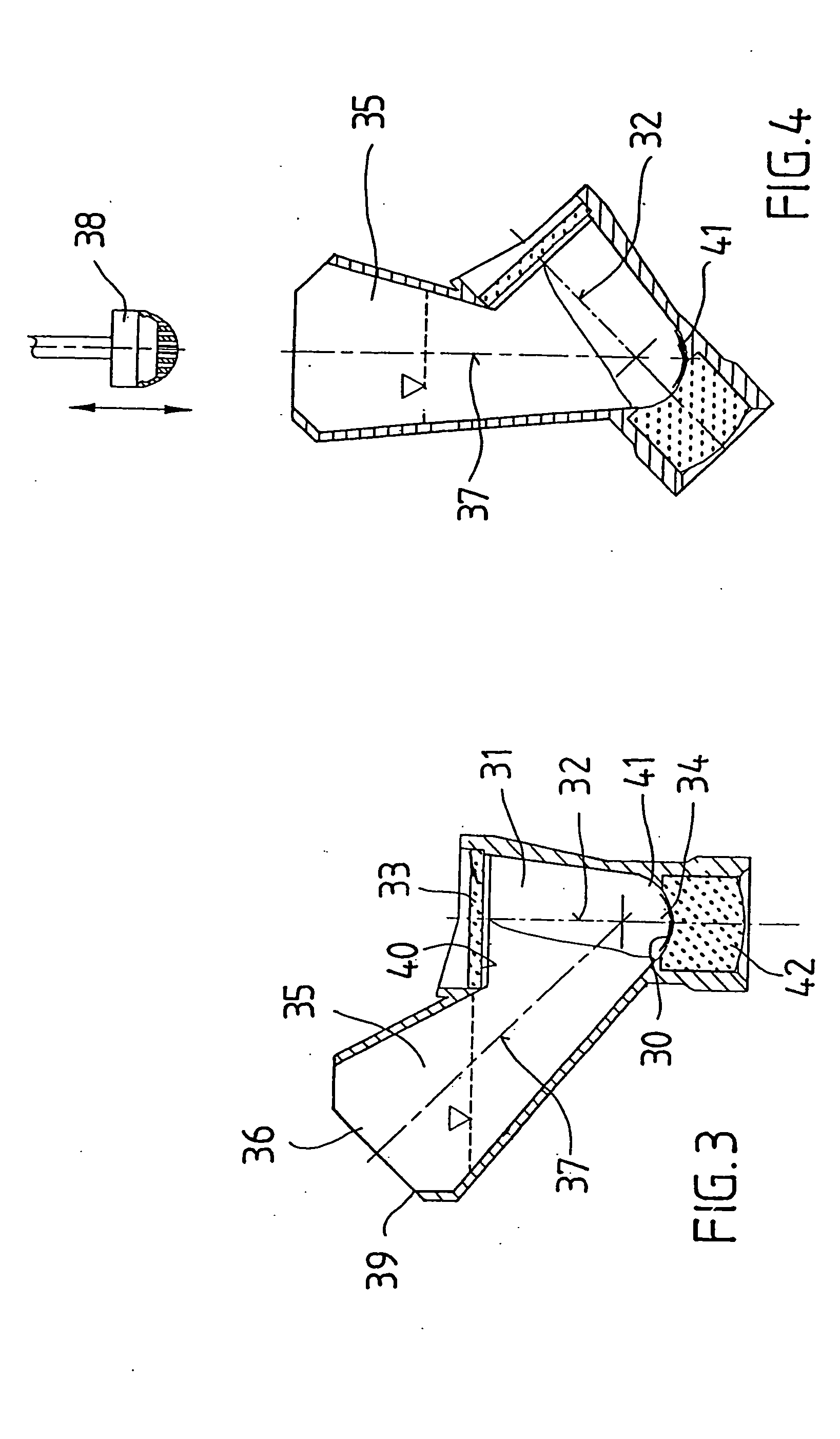

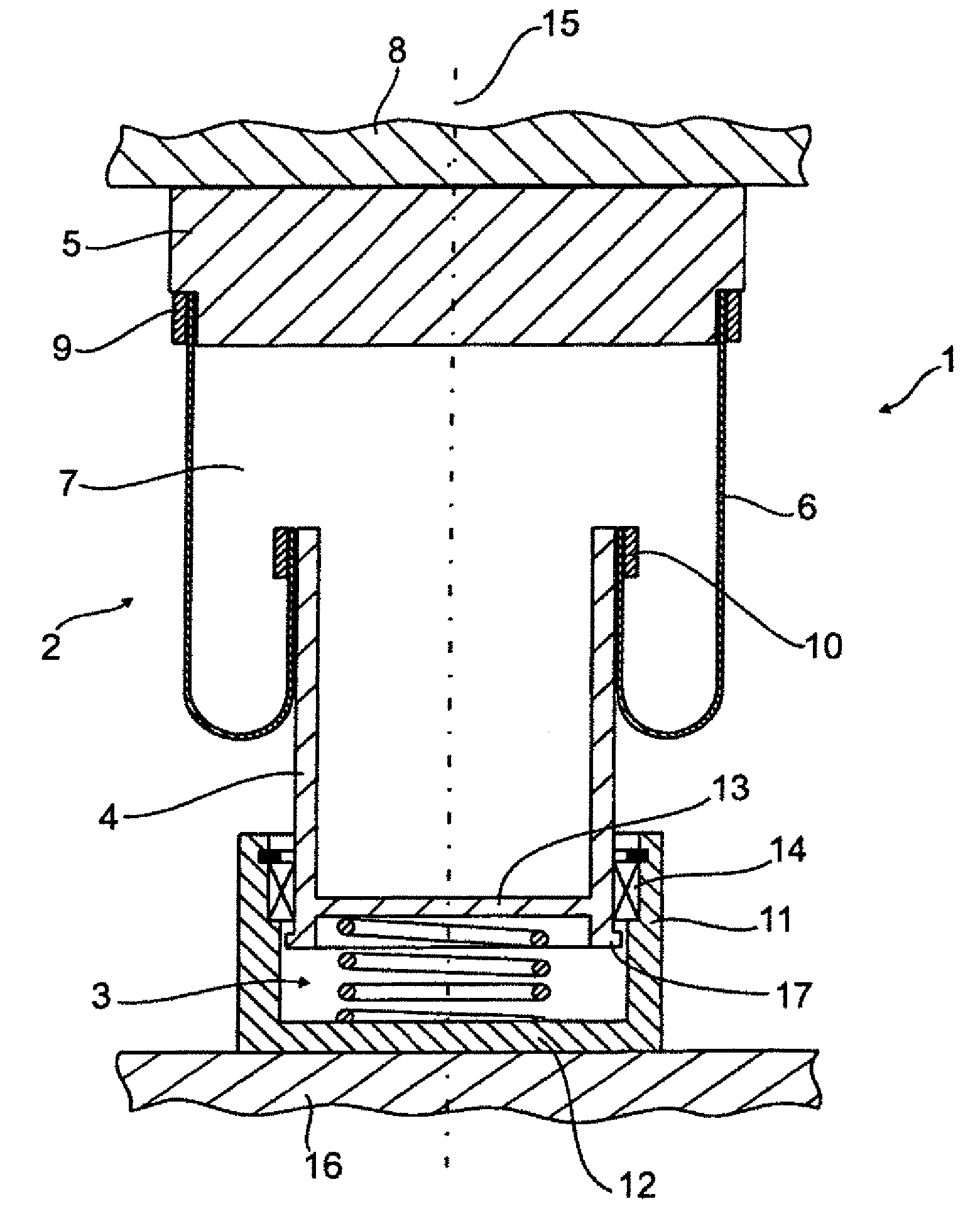

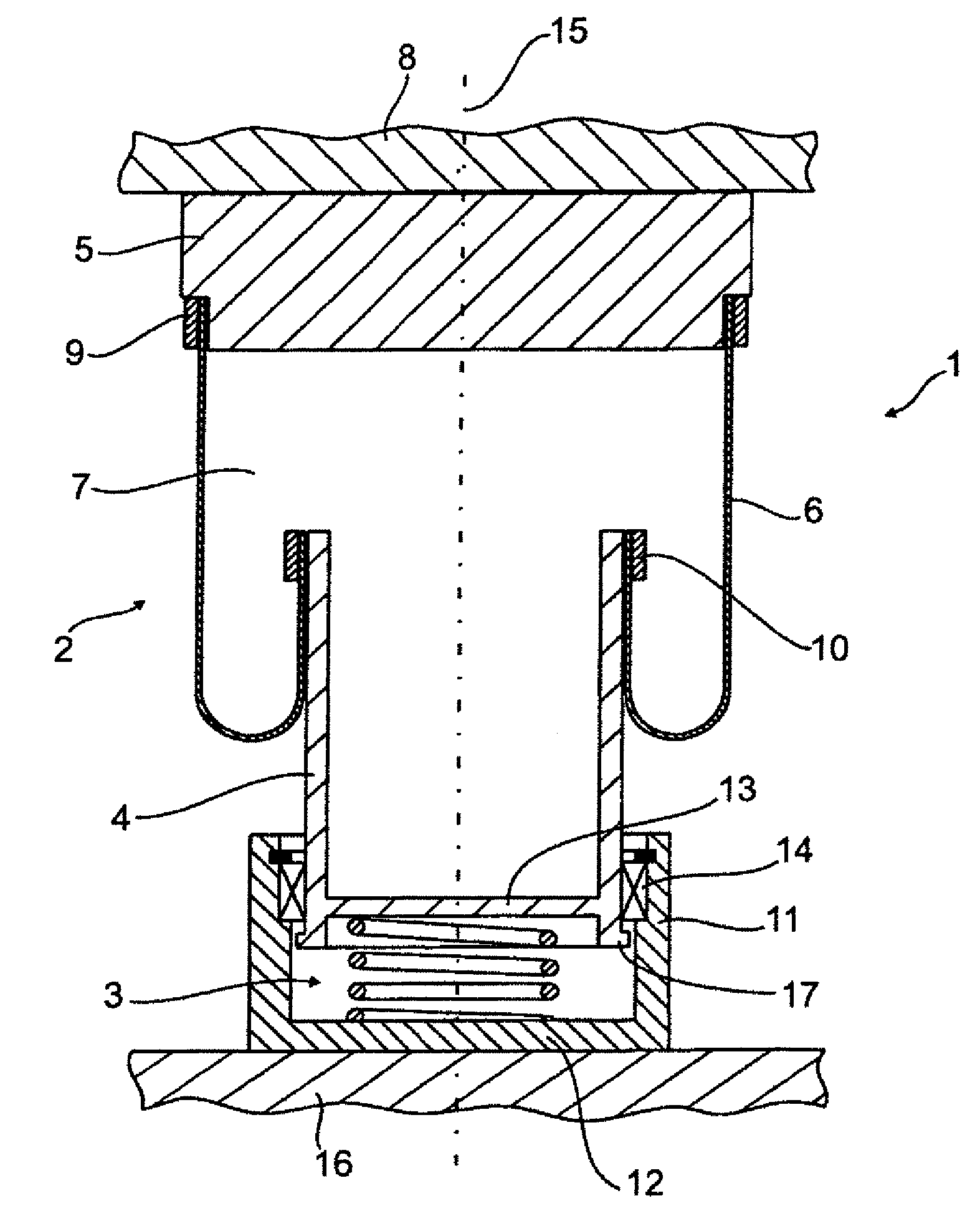

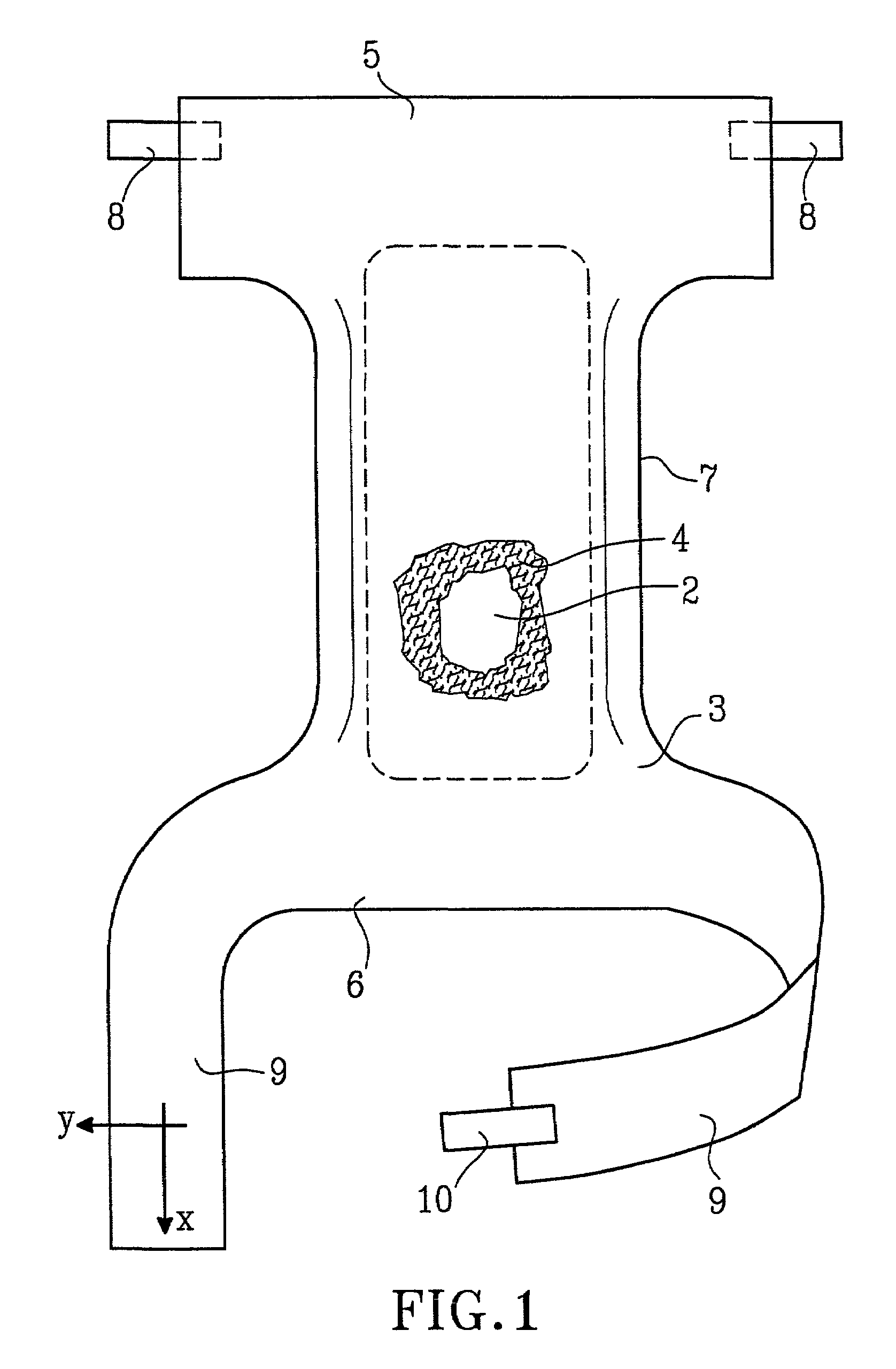

Pneumatic spring device for a motor vehicle

The invention relates to a pneumatic spring device for a motor vehicle, including a rolling piston (4), a pneumatic spring cover (5) axially movable thereto, and an interposed elastomer covering as rolling bellows (6) with a trapped compressible air volume. According to the invention, at least one additional spring element (3) is connected in series to the pneumatic spring (2), with a radial bearing (14) of the rolling piston (4) and / or the pneumatic spring cover (5) being integrated as torsion compensation.

Owner:AUDI AG

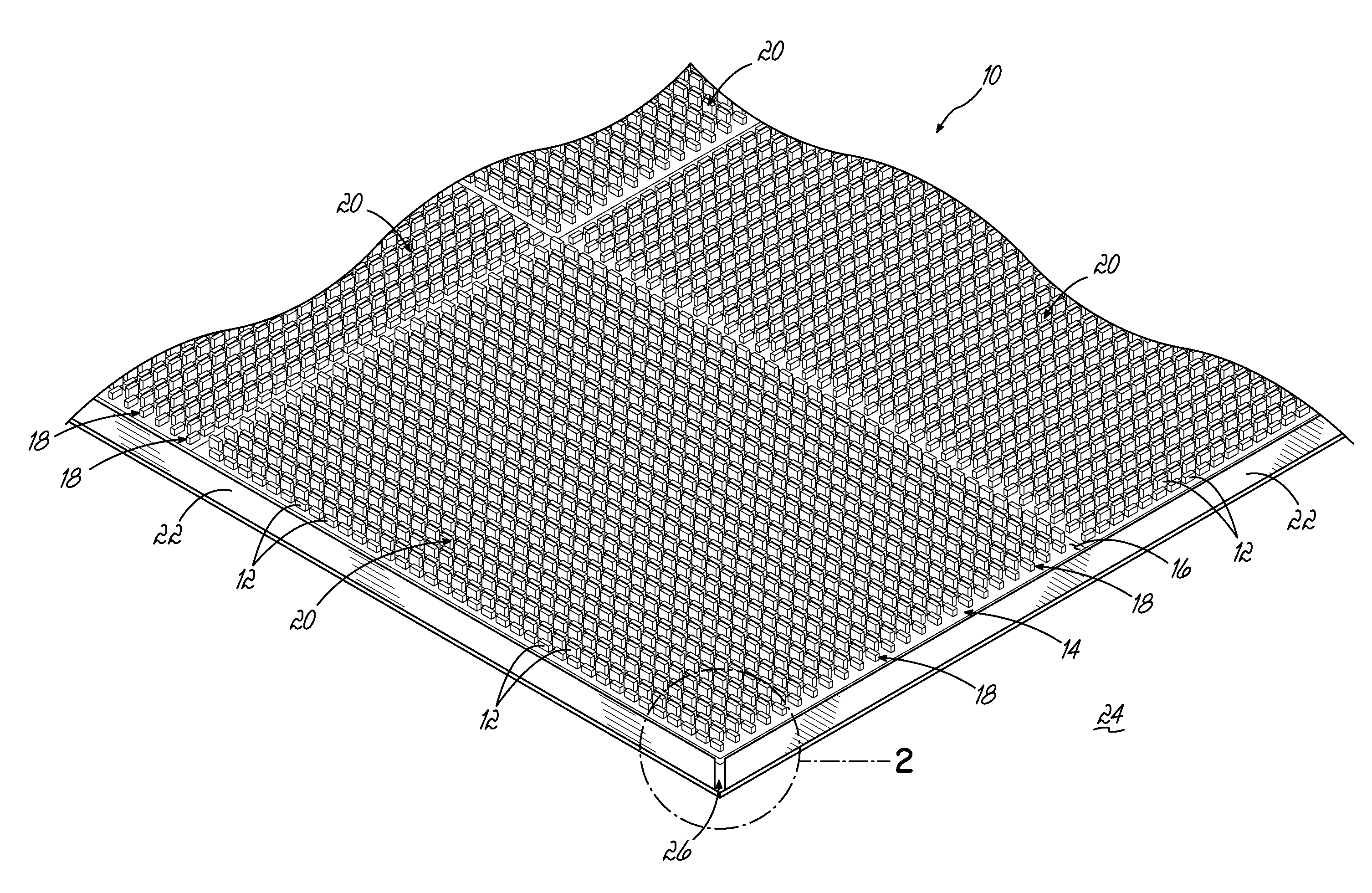

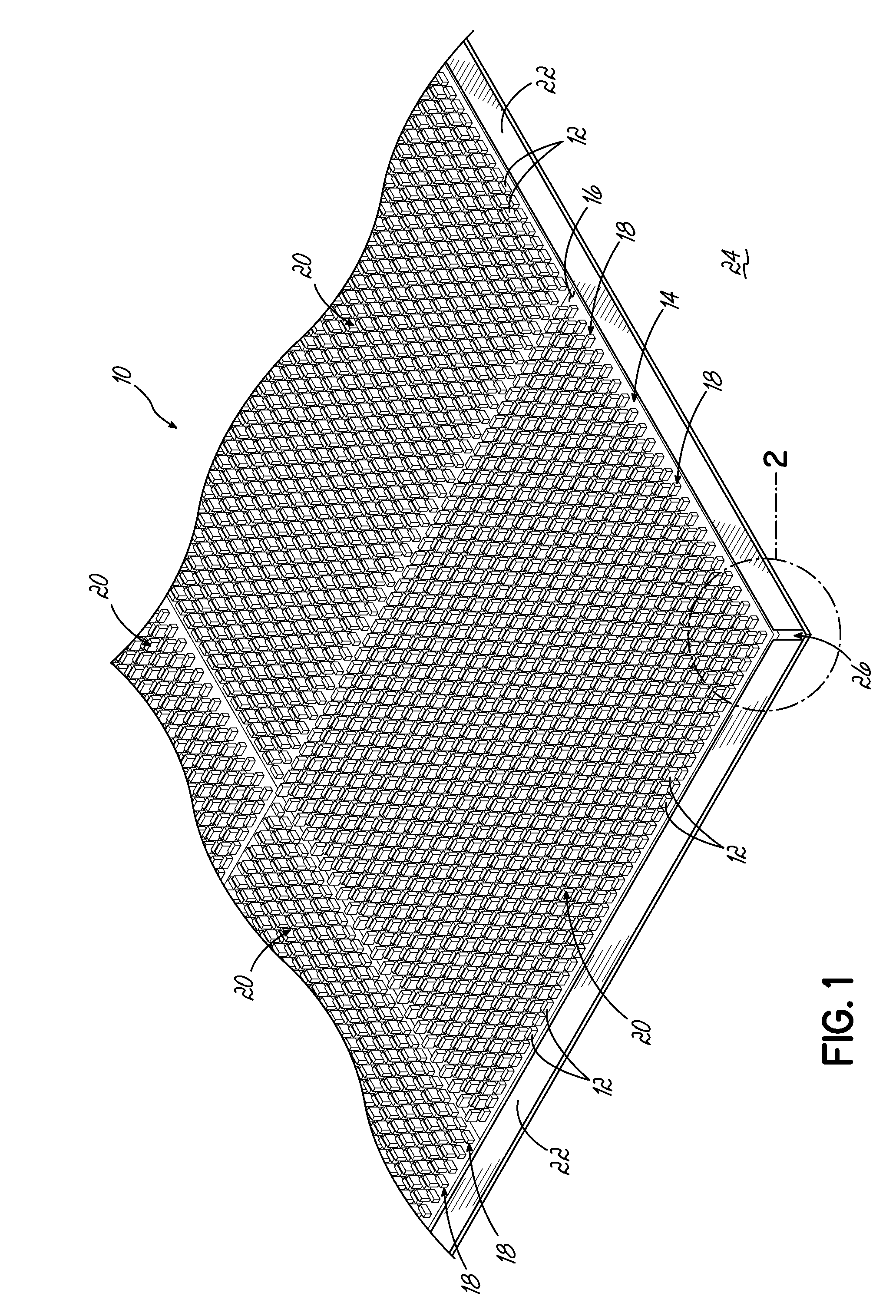

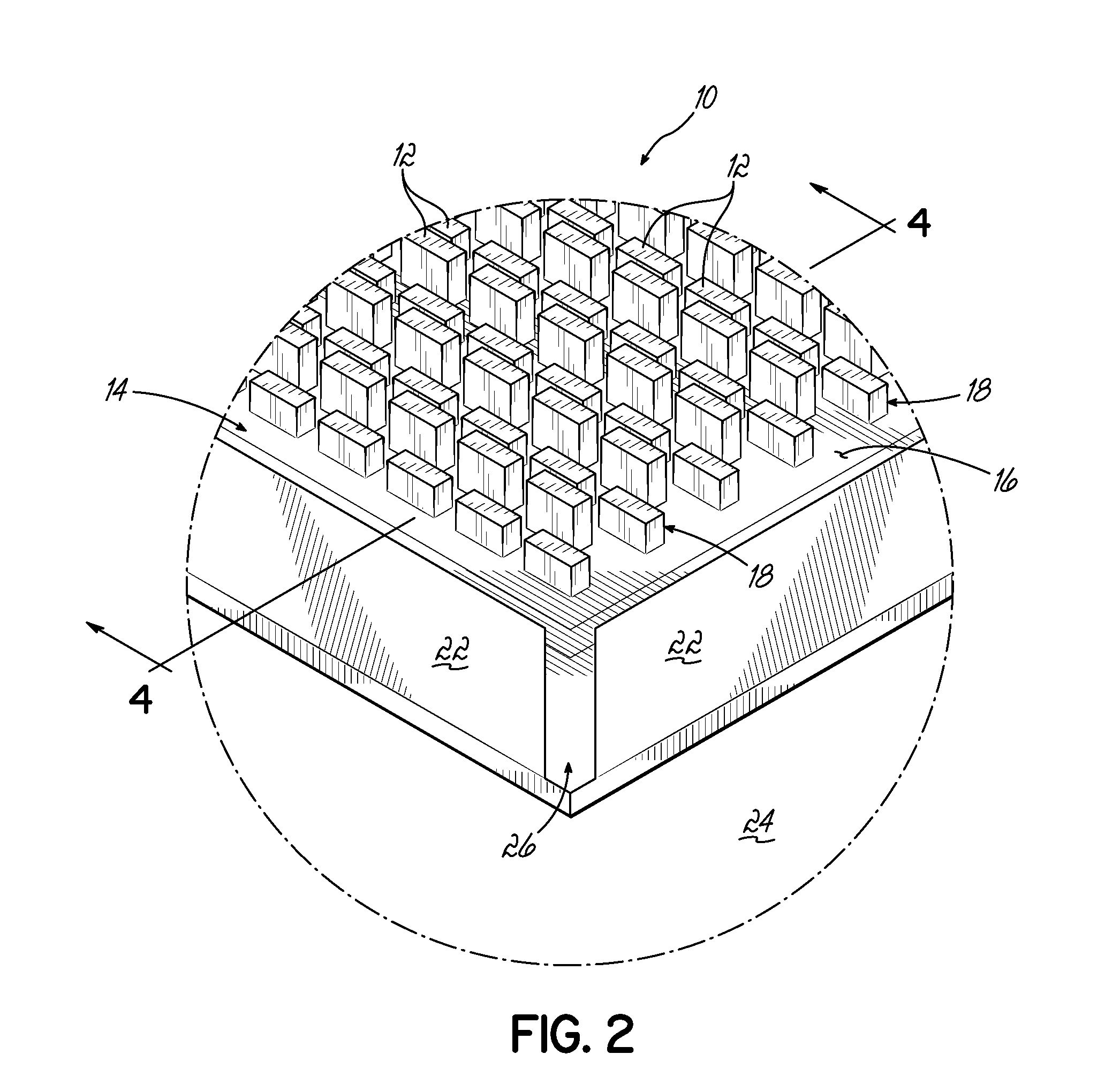

Slip resistant mat with stabilizing projections

ActiveUS20170055749A1Enhance slip-resistanceIncrease comfortThin material handlingFloor carpetsStructural engineeringClassical mechanics

Owner:CINTAS CORP SERVICES INC

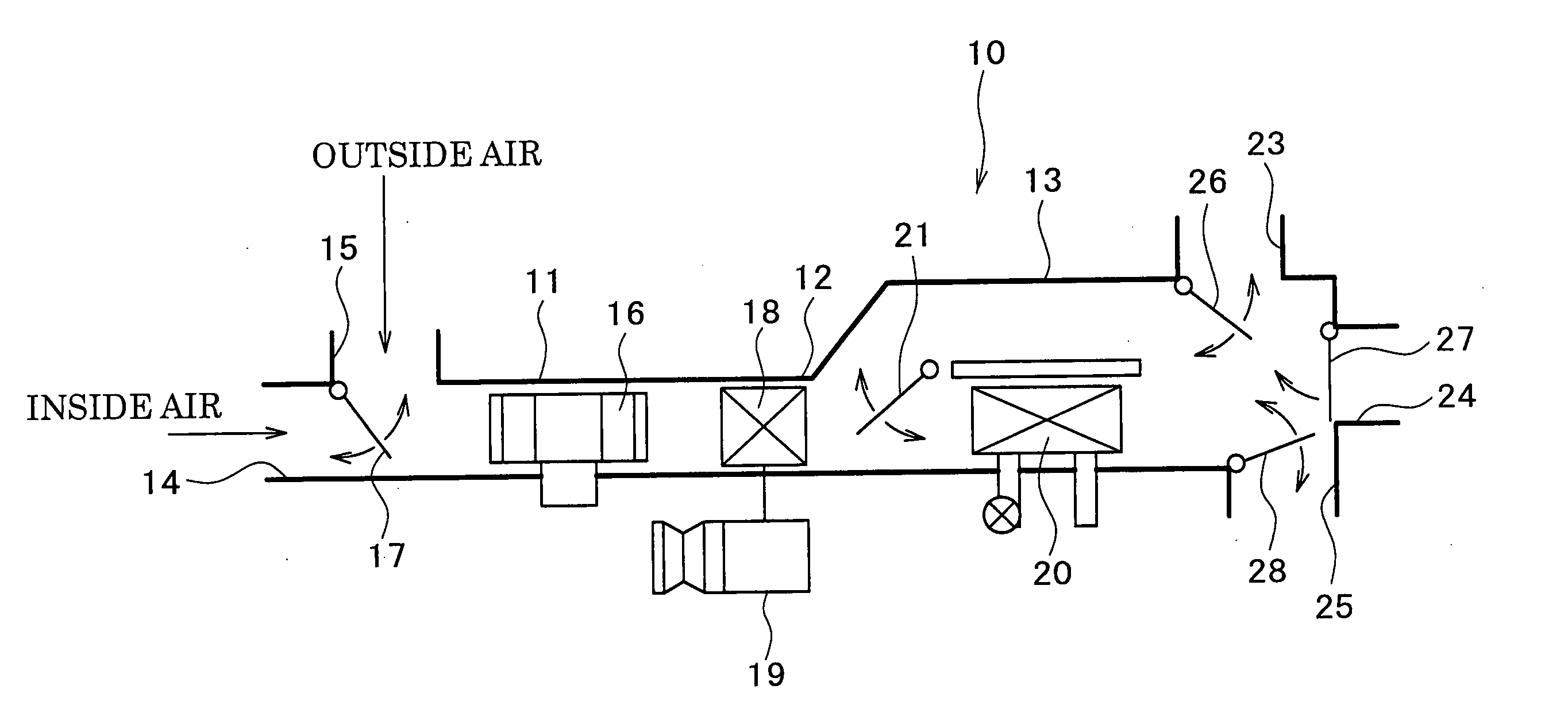

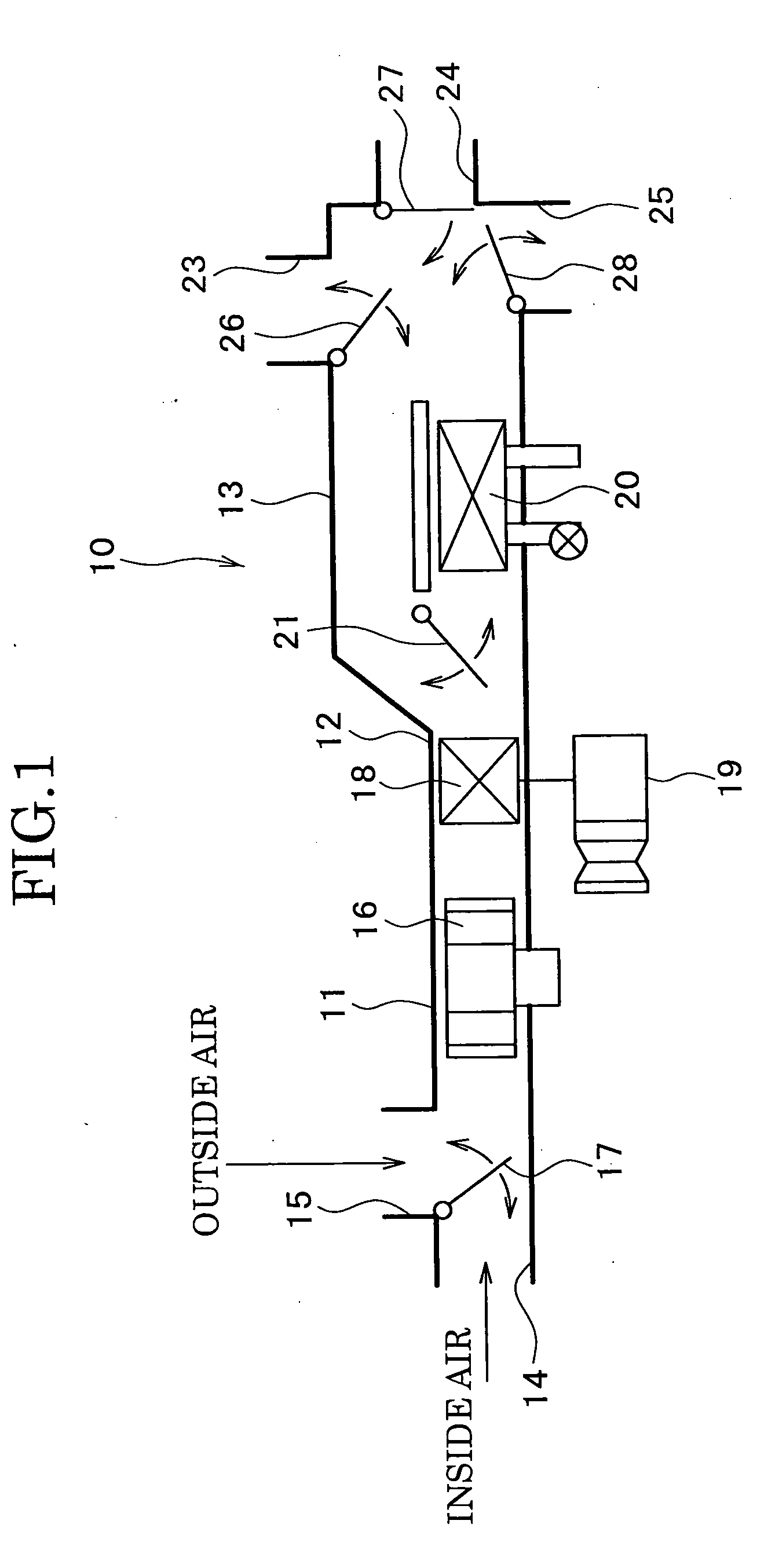

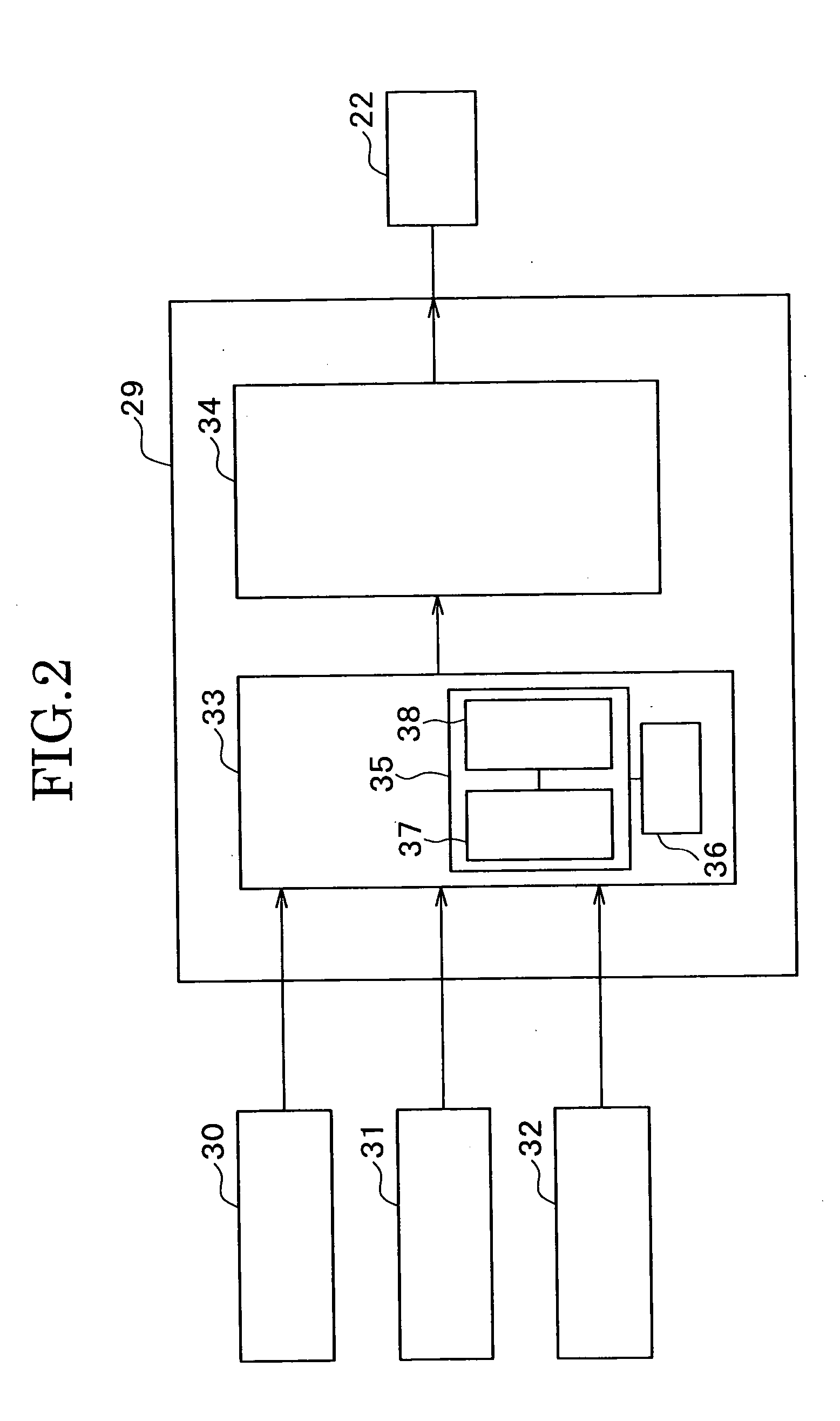

Air-conditioning apparatus for vehicle

InactiveUS20050126773A1Increase comfortImprove comfortAir-treating devicesRailway heating/coolingDriving modeRadiation

An air-conditioning apparatus for a vehicle, in which a temperature in a vehicle interior is automatically adjusted under a stable driving mode in which a difference between the temperature in the vehicle interior and a set temperature is lesser than a predetermined value or a transitional driving mode in which the difference is larger than the predetermined value so that the temperature in the vehicle interior approaches to the set temperature when an amount of solar radiation in the vehicle interior is one of parameters, the apparatus including a detecting device provided in the vehicle interior and configured to detect the amount of solar radiation, and a correcting device for correcting the amount of solar radiation detected by the detecting means to obtain a corrected amount of solar radiation, the corrected amount of solar radiation being used as a parameter of the amount of solar radiation for adjusting the temperature in the vehicle interior, under the stable driving mode.

Owner:CALSONIC KANSEI CORP

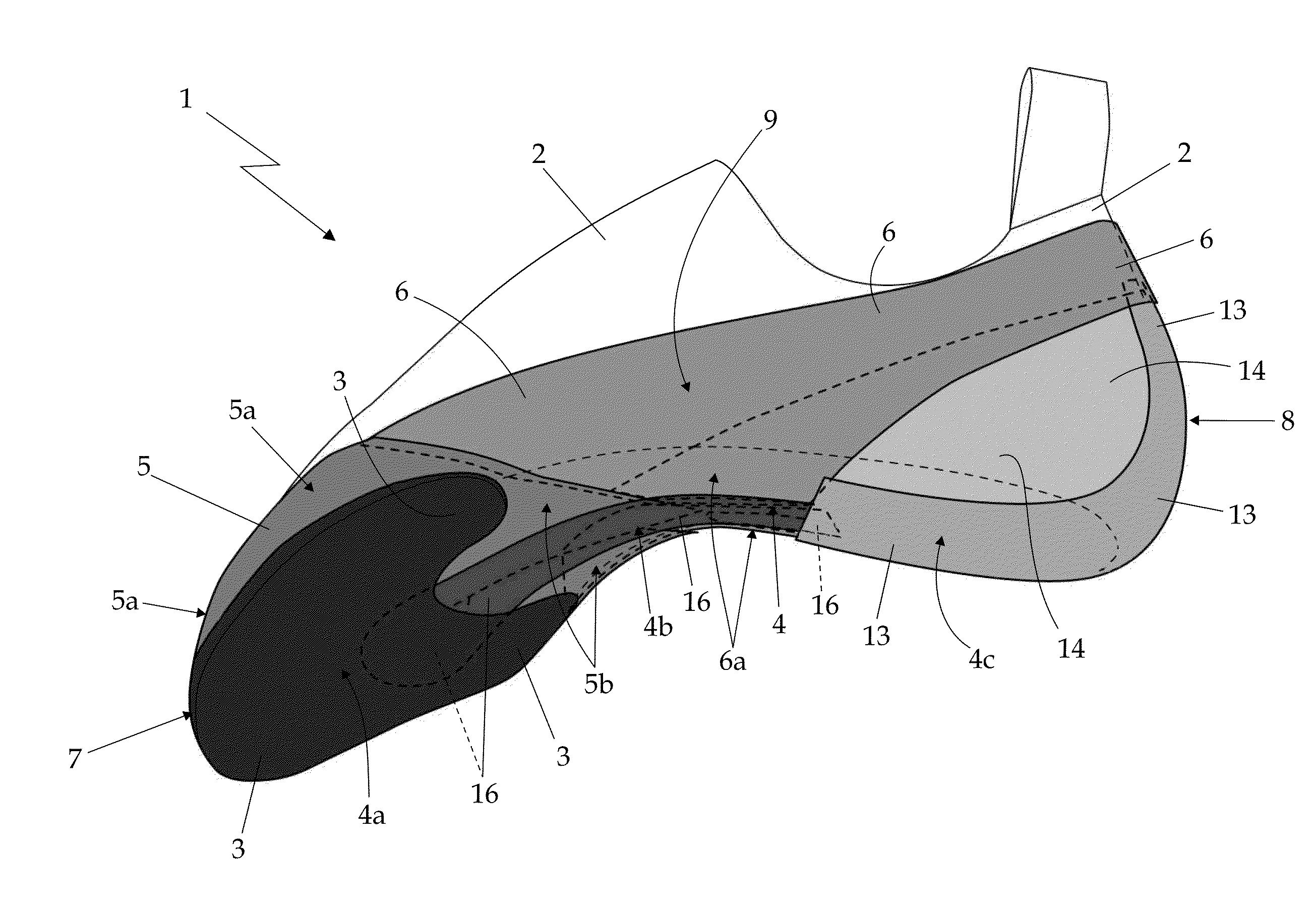

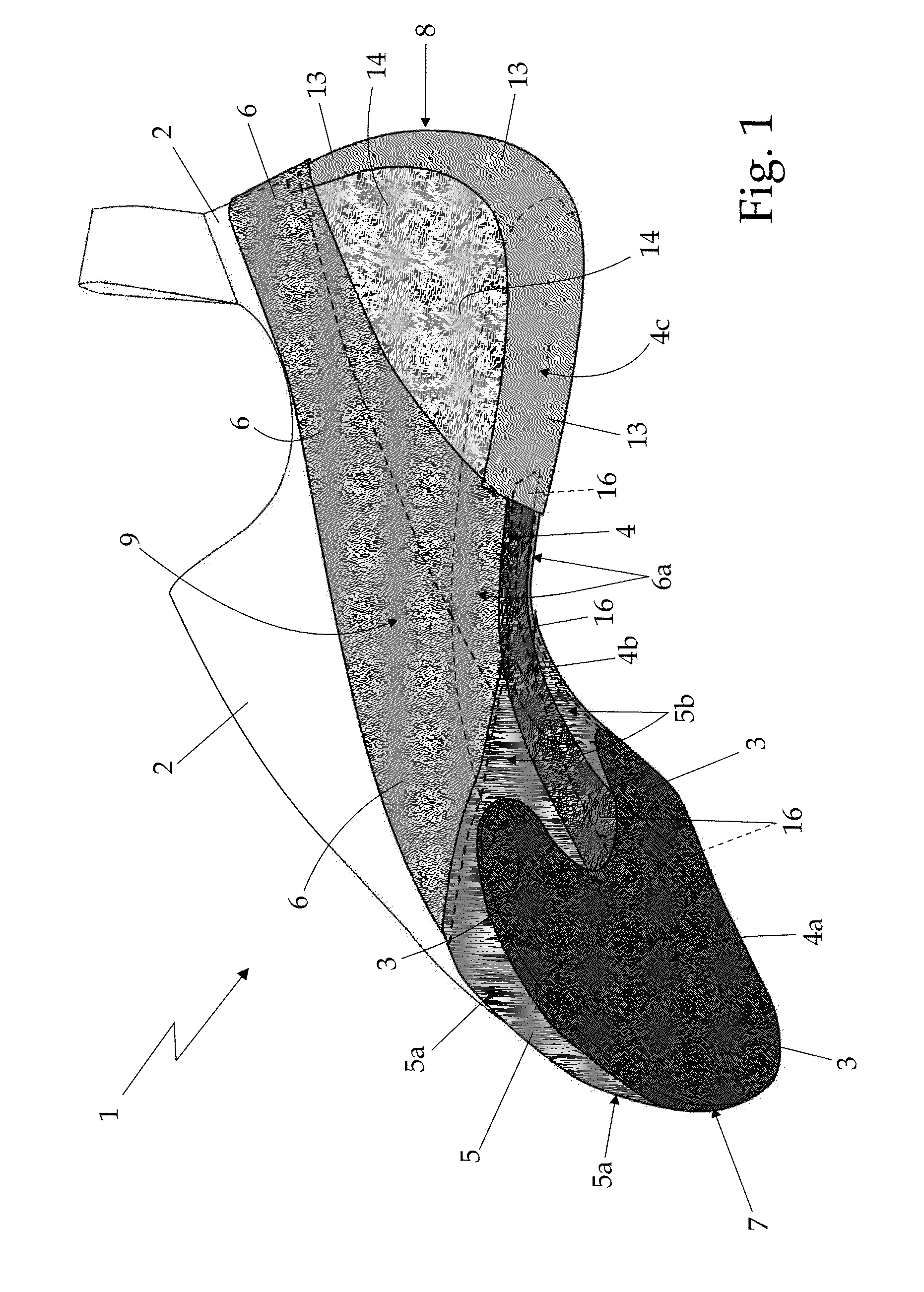

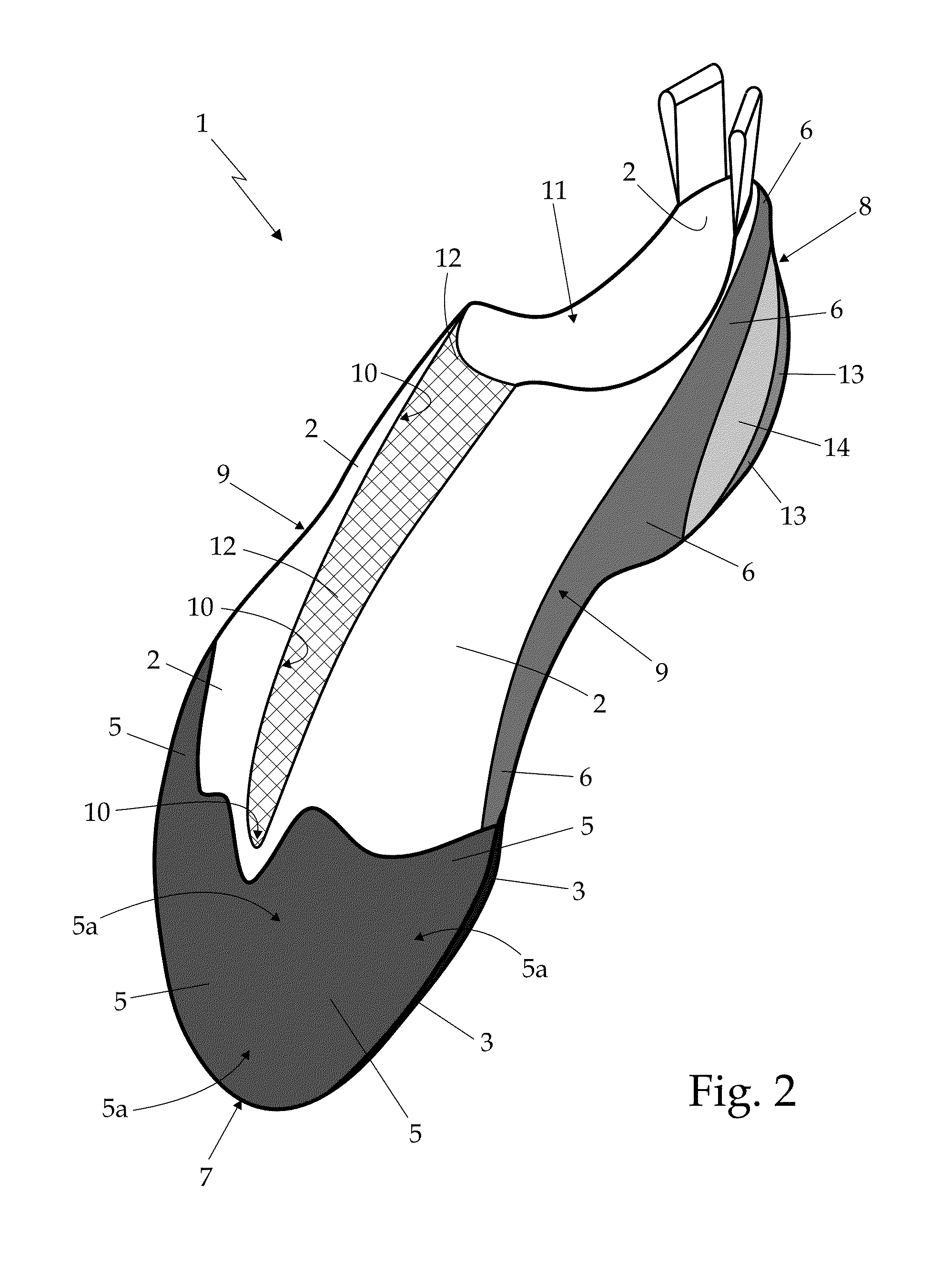

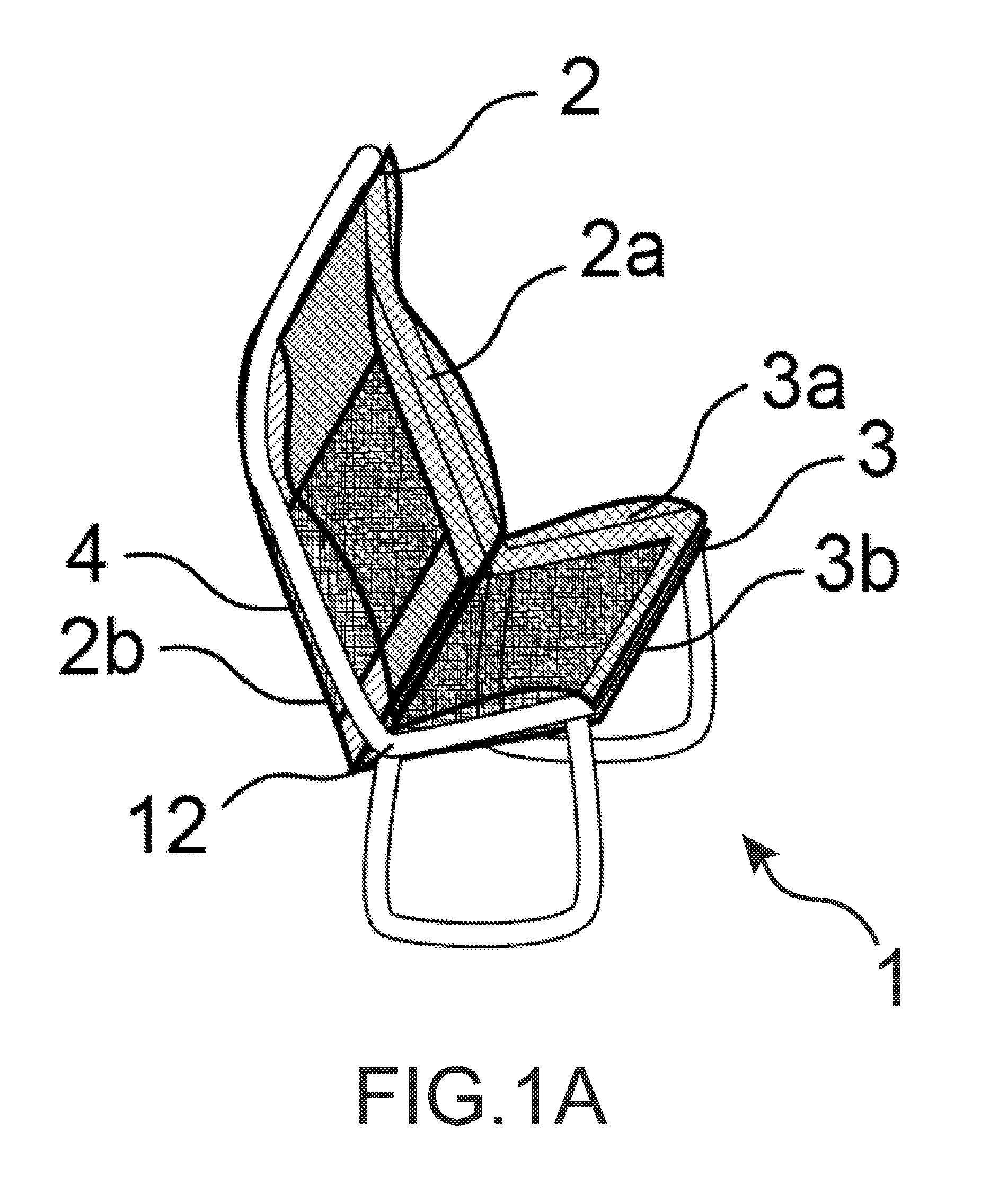

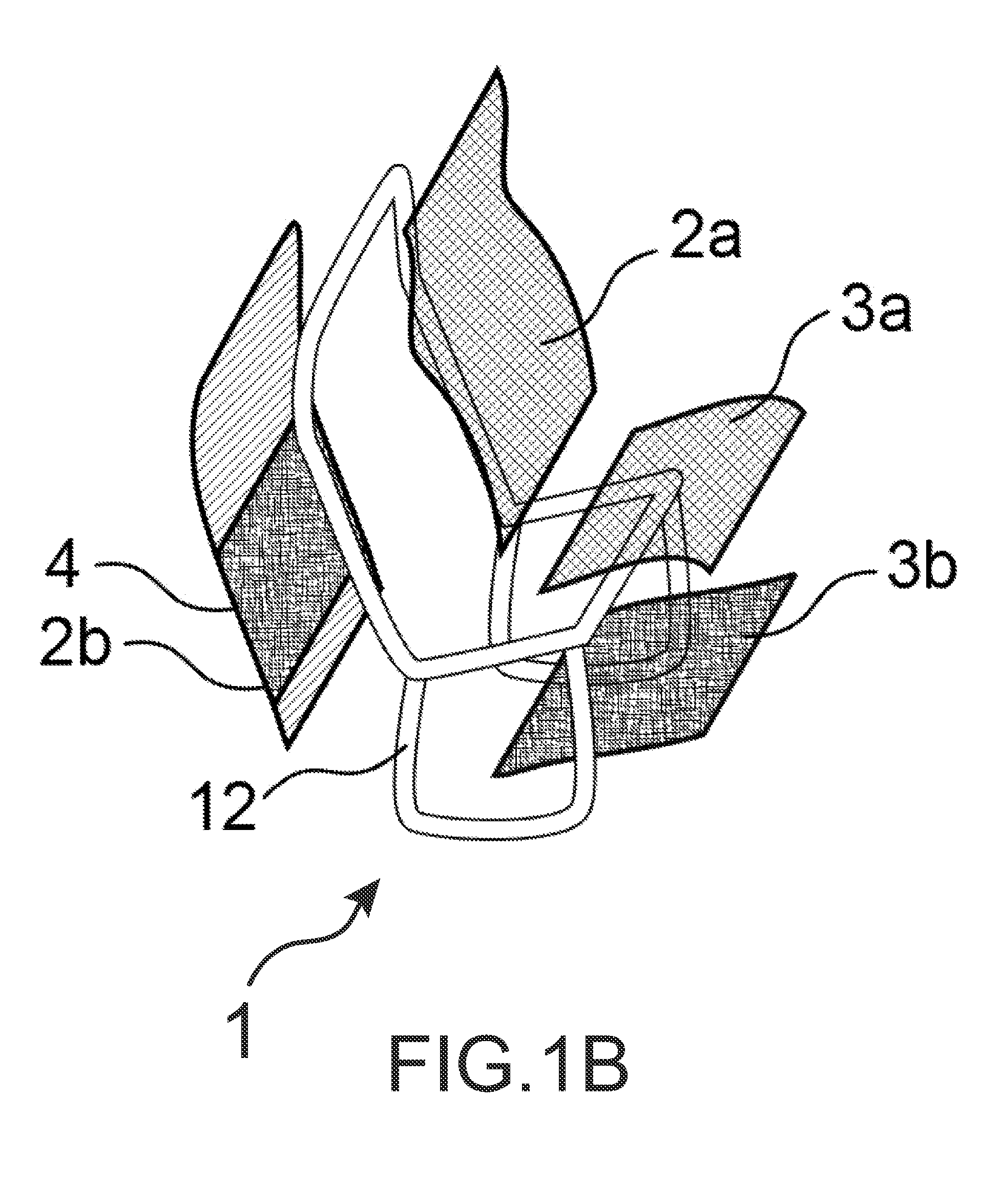

Climbing shoe

Climbing shoe comprising a substantially sock-shaped shoe-upper formed so as to completely cover the foot of the user; a front sole which is fixed on the bottom part of the shoe-upper so as to cover the tarsal-phalangeal region of the sole of the foot; and a elastomeric-material, front tensioning strip which is fixed on the toe of the shoe-upper and is shaped so as to cover the shoe-upper in the area surrounding the tarsal-phalangeal region of the sole of the foot; said front tensioning strip being provided with a middle portion that is shaped so as to cover the toe of the shoe-upper in the area surrounding the tarsal-phalangeal region of the sole of the foot, and with two lateral flaps which prolong on the bottom part of the shoe-upper while converging towards each other up to join to one another at the insole arch region.

Owner:CALZATURIFICIO S C A R P A

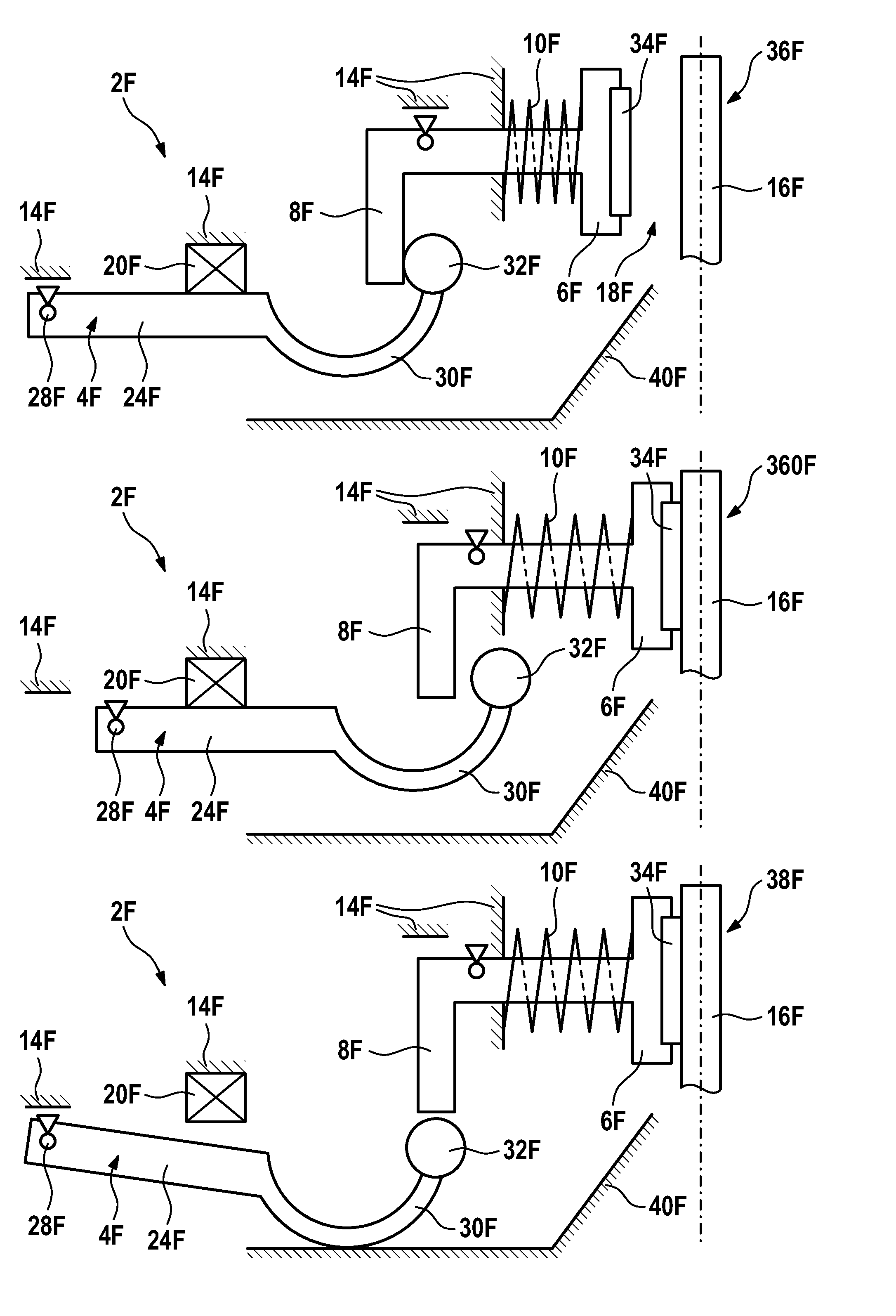

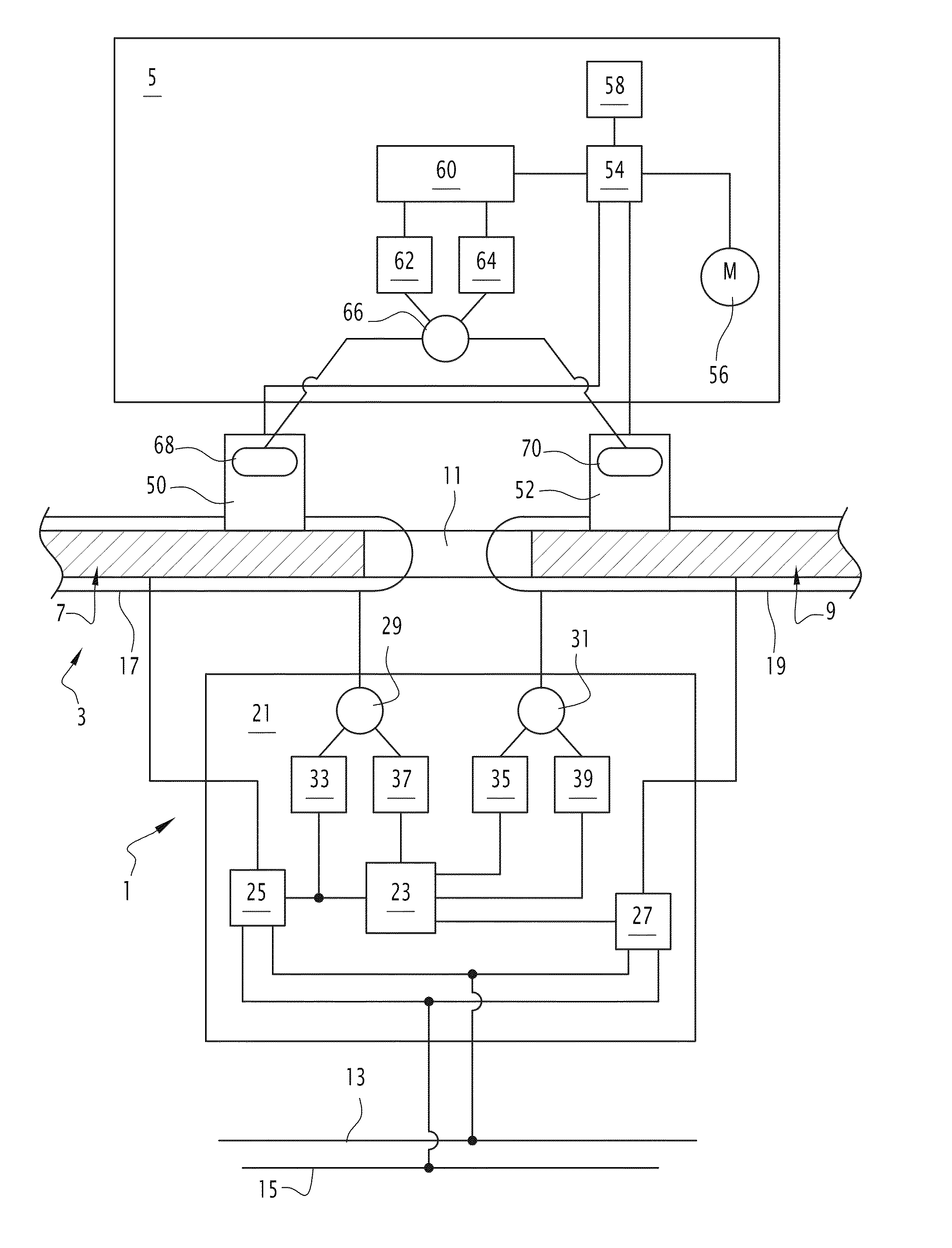

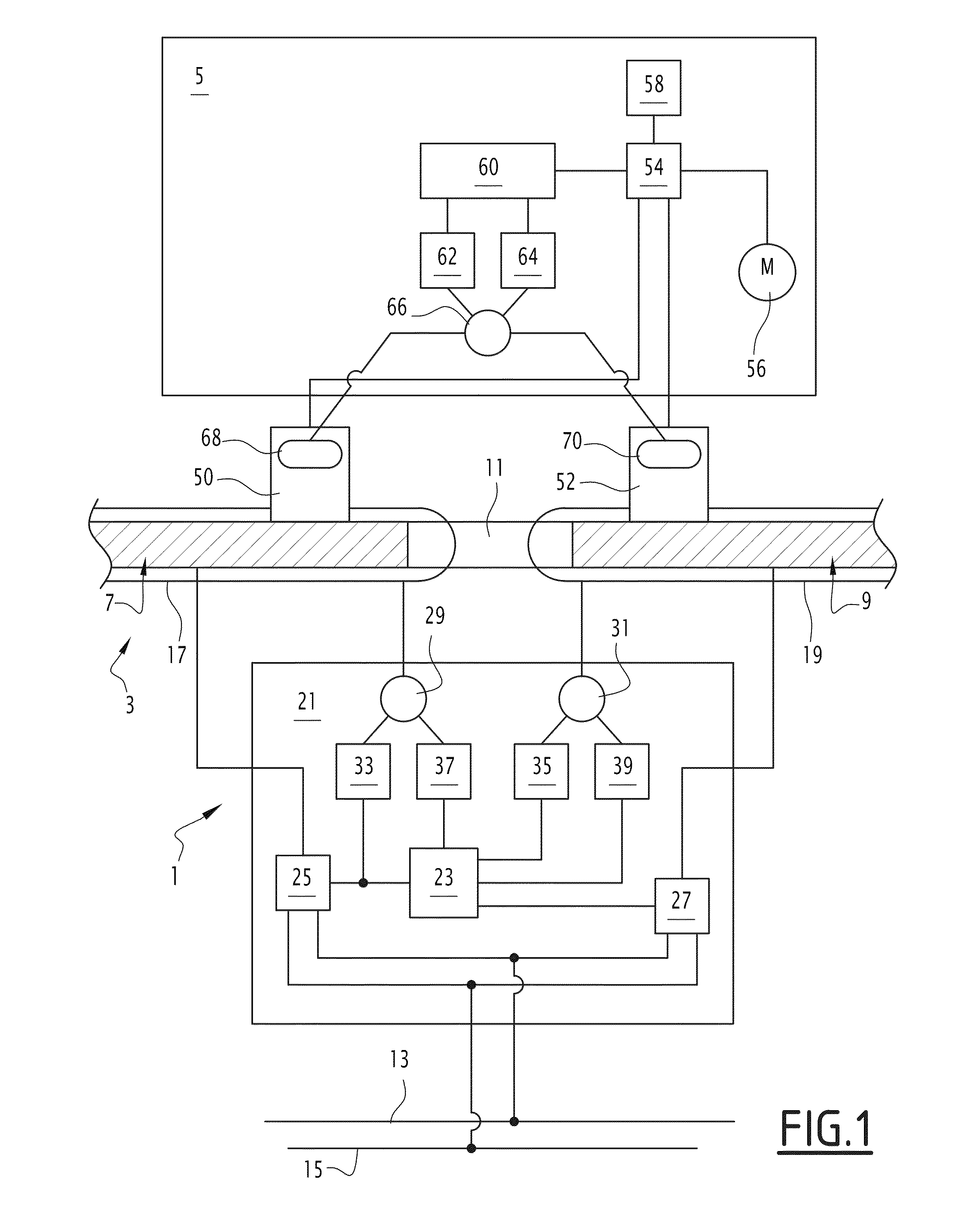

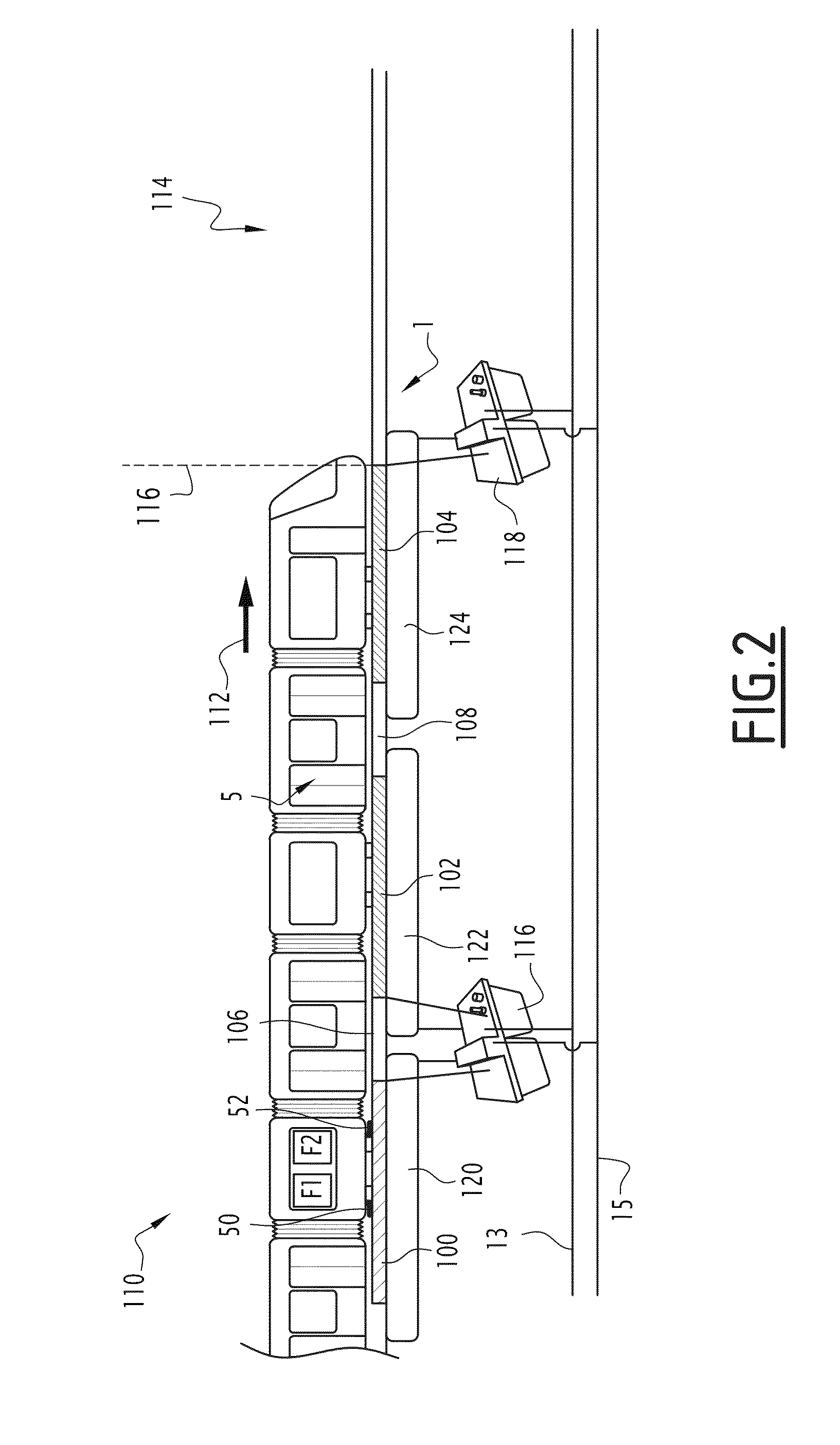

Method for controlling a land transport vehicle, land transport vehicle, ground equipment and transport system

ActiveUS20160068172A1Increase comfortImprove comfortVolume/mass flow measurementPower railsAutomotive engineeringTraction motor

A method for controlling a land transport vehicle traveling on a track, the track including, in a movement direction of the land transport vehicle, a zone with an external power supply adjacent to a zone without an external power supply to be traveled with an onboard power supply device, the zone with an external power supply including an external power supply device on the ground provided with a plurality of power supply segments arranged sequentially in the direction of the track, the land transport vehicle including at least one capture device adapted to be placed in contact with a power supply segment on the one hand and to be electrically connected to at least one traction motor on the other hand, the land transport vehicle further including an onboard power supply device adapted to be electrically connected to the or each traction motor.

Owner:ALSTOM TRANSPORT TECH SAS

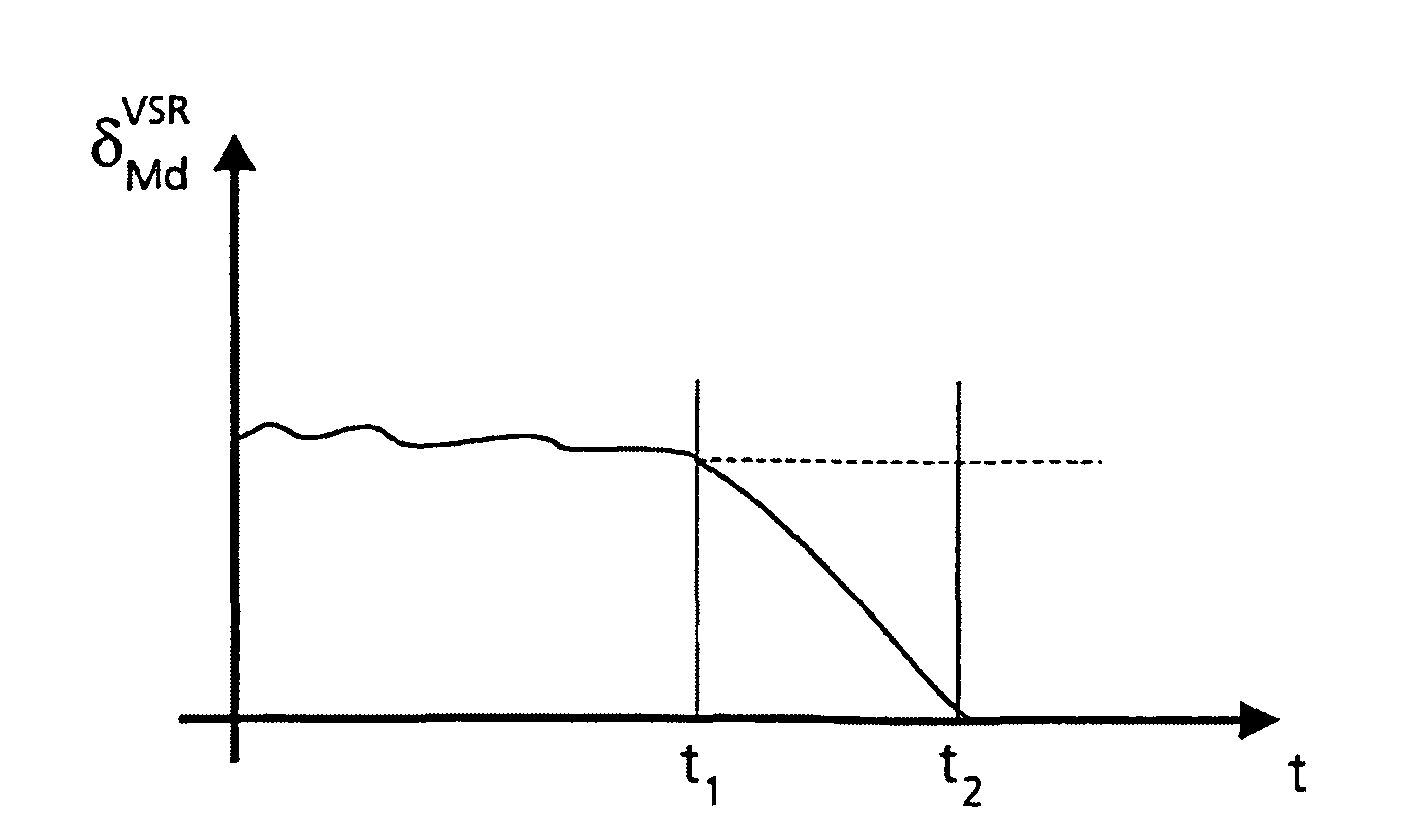

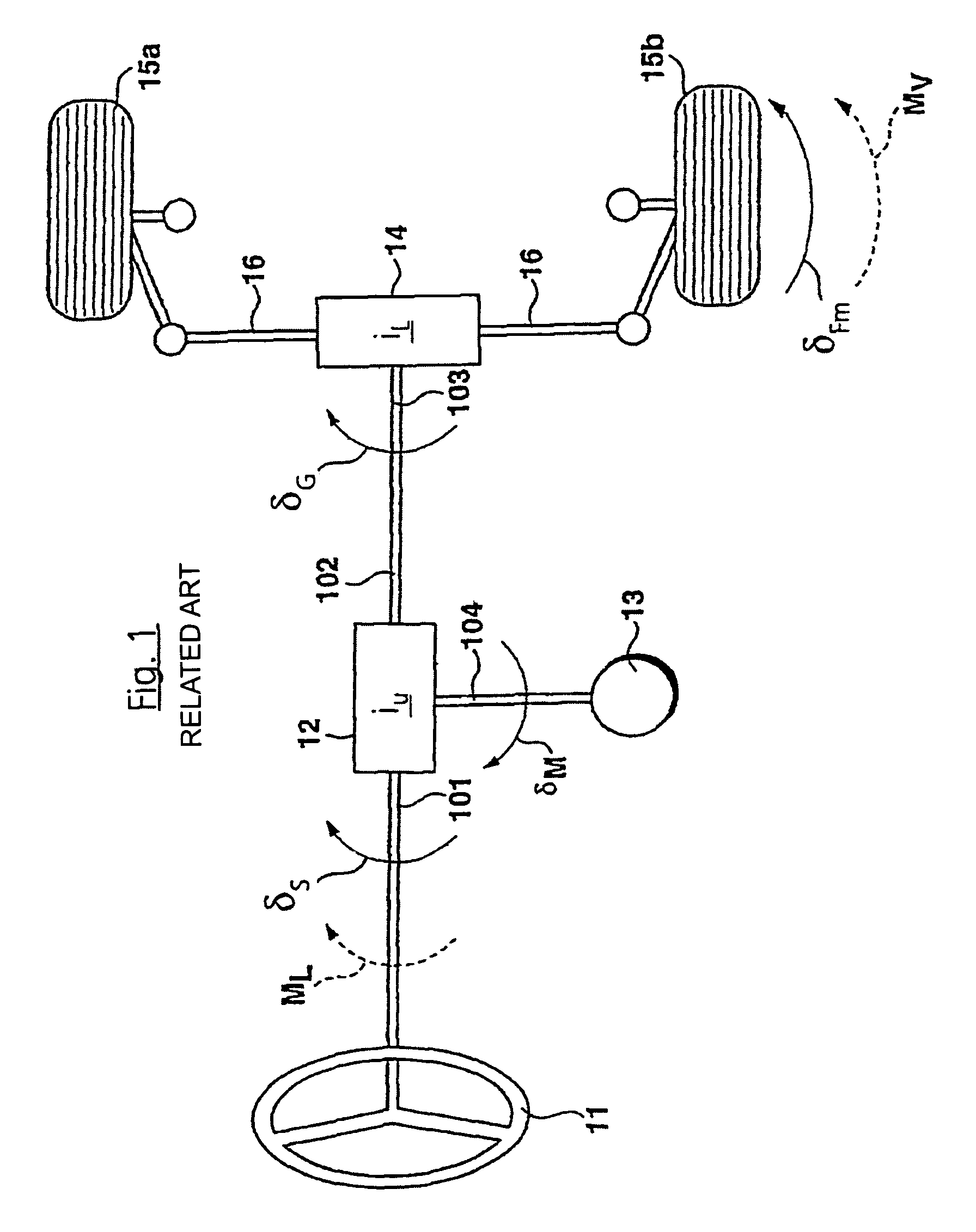

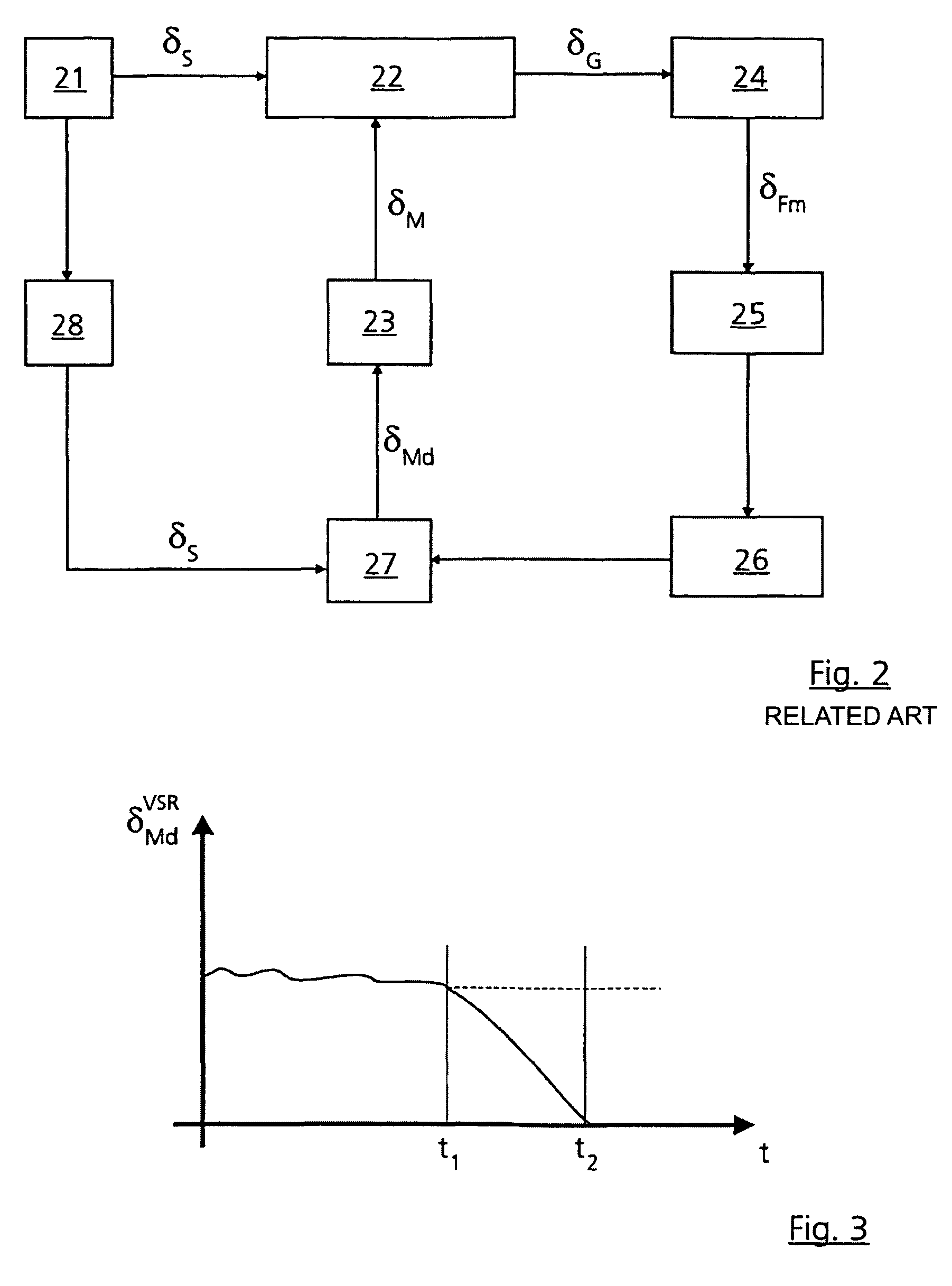

Method for operating a steering system

Method for operating a steering system for a motor vehicle with at least one steerable wheel, a servo drive and a superimposed gear mechanism, the steering movement, initiated by the driver of the vehicle, and the movement for producing the steering movement of the steerable wheel, initiated by the servo drive for realizing useful functions (VSR, LAFN) being superimposed by the superimposed gear mechanism into a pinion angle, the servo drive for initiating the movement being triggered by a control signal (δMd) of a control device. The servo drive is turned back in a controlled manner when a substitute mode of at least one useful function (VSR, LAFN) of the steering system is switched off or on.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING

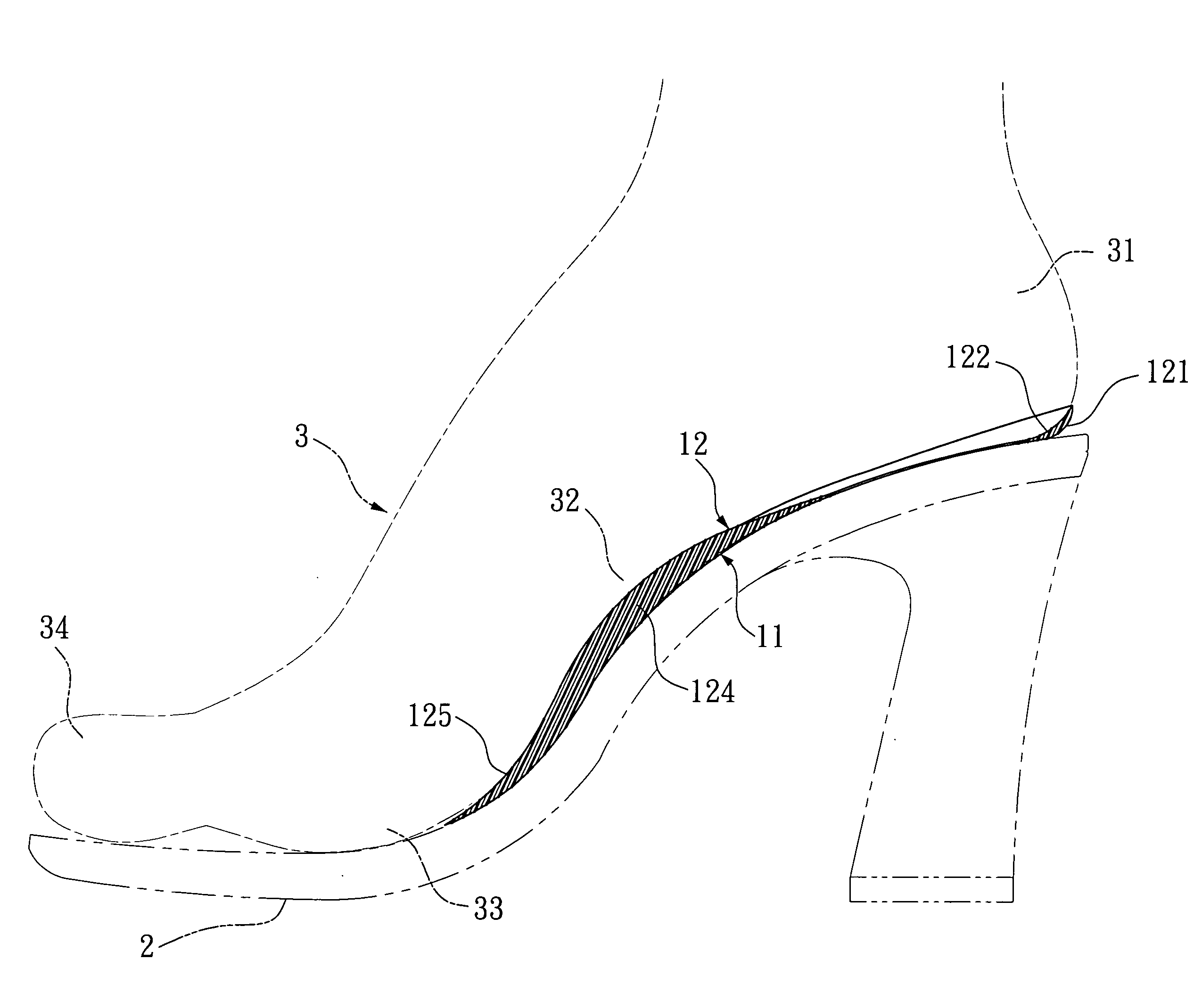

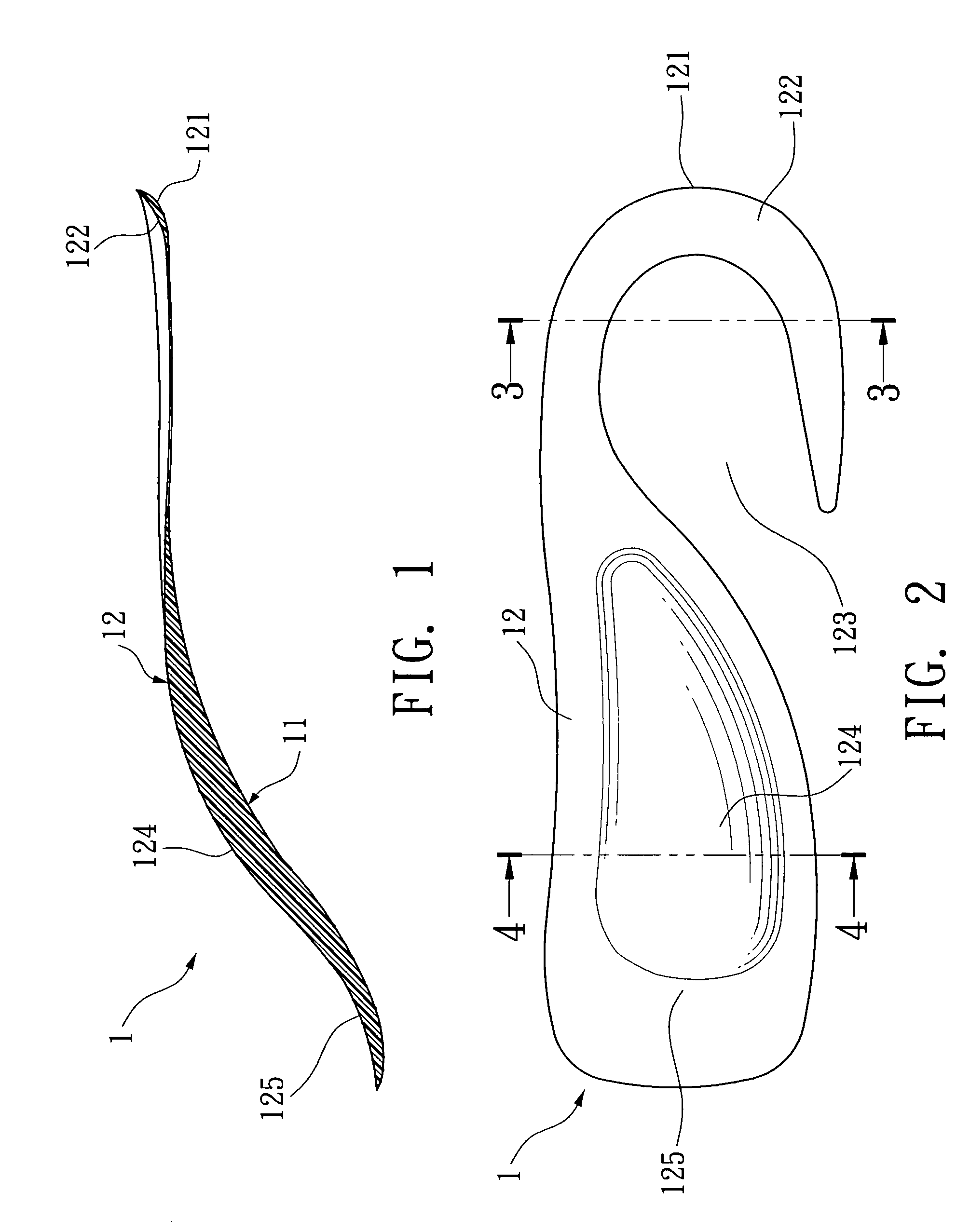

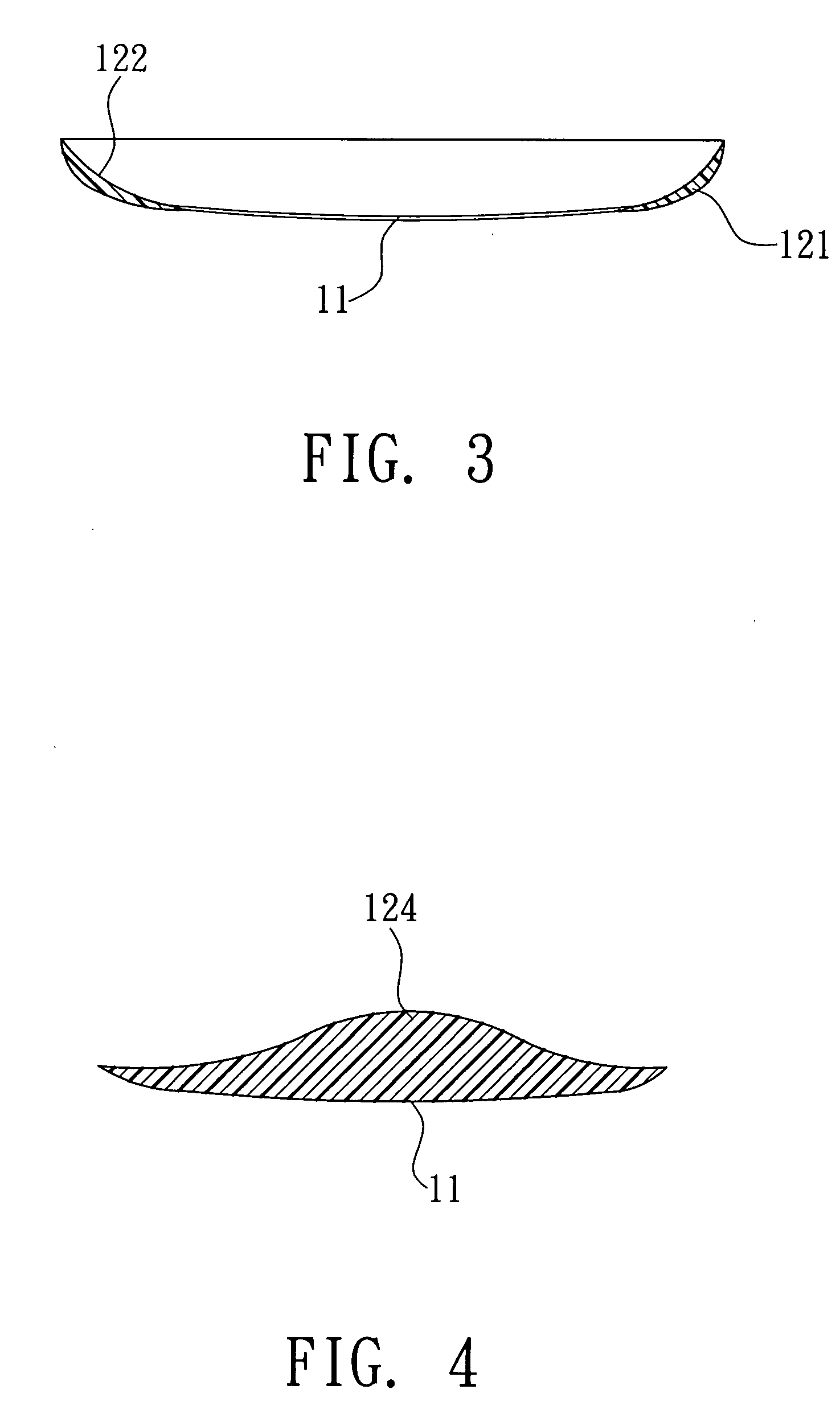

Supporting pad for high heels

A supporting pad for high heels has a heel part, an arc part, and a concave portion on the top surface of its body. Each part is designed according to the curve of the human foot, so as to in close contact with the heel, the foot arc, and the metatarsus between the foot arc and the toes. The bottom surface of the body is also tightly attached to the sole of the high heel. Such a support provides a stable and balanced surface at the bottom of user's feet. This complete support can effectively distribute pressure imposed on the foot and relieve discomfort due to the impacts.

Owner:CHEN WEN LUNG

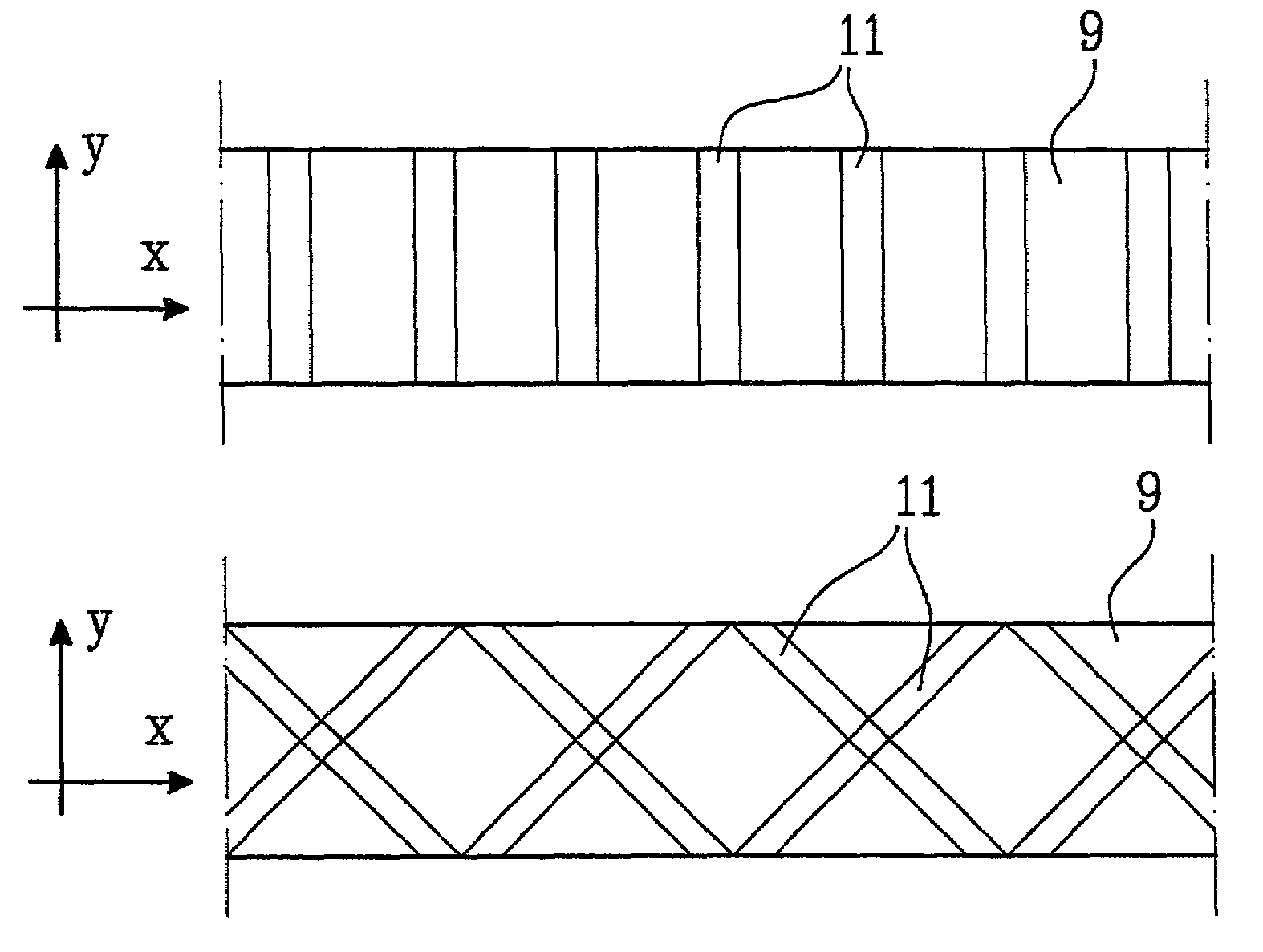

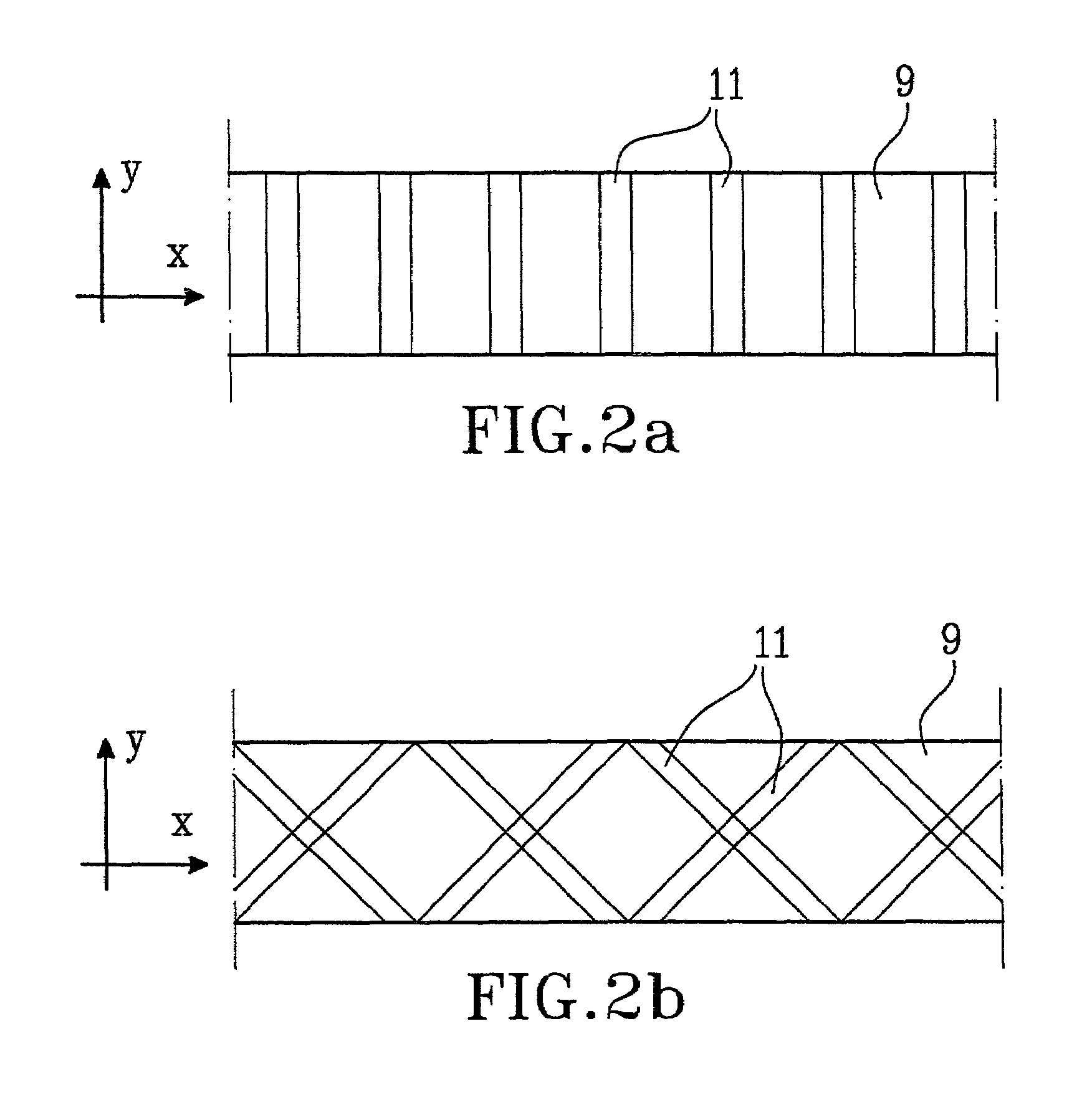

Absorbent article

InactiveUS7008410B2Increase comfortImprove comfortAbsorbent padsBaby linensEngineeringMechanical engineering

Absorbent article such as a diaper and an incontinence guard comprising a pair of belt portions (9) attached to the rear portion (6) alternatively the front portion (5) of the article and which are intended to be fastened together around the waist of the wearer and where said front portion (5) alternatively the rear portion (6) is provided with fastening means (8), intended to be attached to the belt portions (9), in such a way that the article will assume a pantlike shape, where the belt portions (9) form a part of the waist portions of the pant. Said belt portions (9) are provided with stiffening elements (11), being discontinuously arranged in the longitudinal direction (x) of the belt, and whose largest extension substantially being arranged across the longitudinal direction (x) of the belt.

Owner:SCA HYGIENE PROD AB

Gentle and enhanced preservative systems

InactiveUS20050118129A1Excellent preservative effectIncrease comfortBiocideCosmetic preparationsChromatographyContact lens

Owner:BAUSCH & LOMB INC

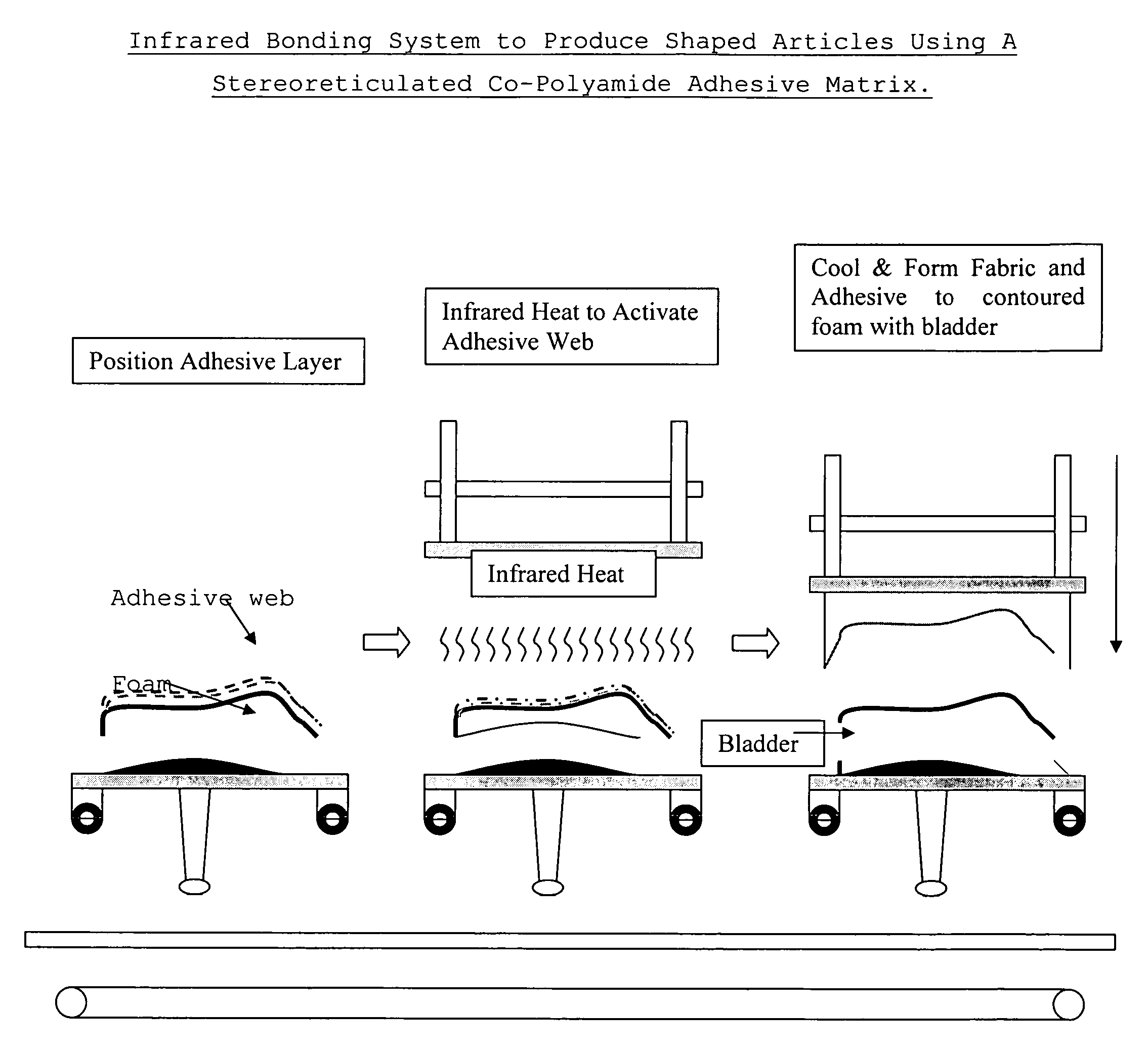

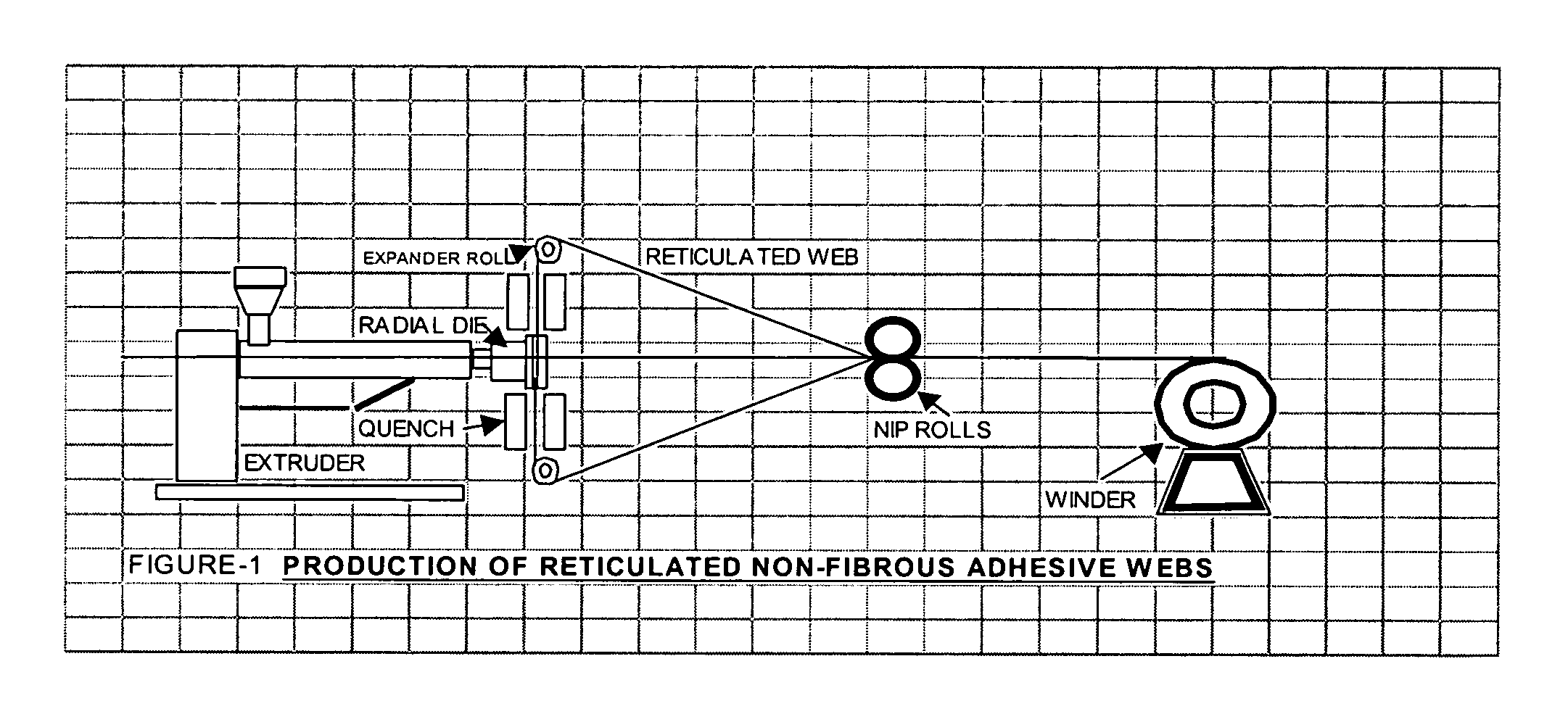

Non-fibrous adhesive matrix and laminate formed therefrom

InactiveUS7803459B2Increase comfortAvoid releaseSynthetic resin layered productsLaminationFiberPolymer

A laminate comprising at least one non-fibrous adhesive layer positioned between a plurality of substrates, the non-fibrous adhesive layer comprising a stereo reticulated, continuous, non-fibrous matrix formed from a polymeric material. A process for producing such a stereo reticulated non-fibrous adhesive matrix comprising: a) blending an adhesive polymer with a blowing agent, b) melting the adhesive polymer / blowing agent blend while passing the molten polymer / blowing agent blend through an extruder to a shaping die and thereby producing a non-fibrous extrudate, c) cooling, drawing and orienting the non-fibrous extrudate, and thereby producing a continuous, stereo reticulated non-fibrous adhesive matrix.

Owner:KEUCHEL HERBERT WILLIE +1

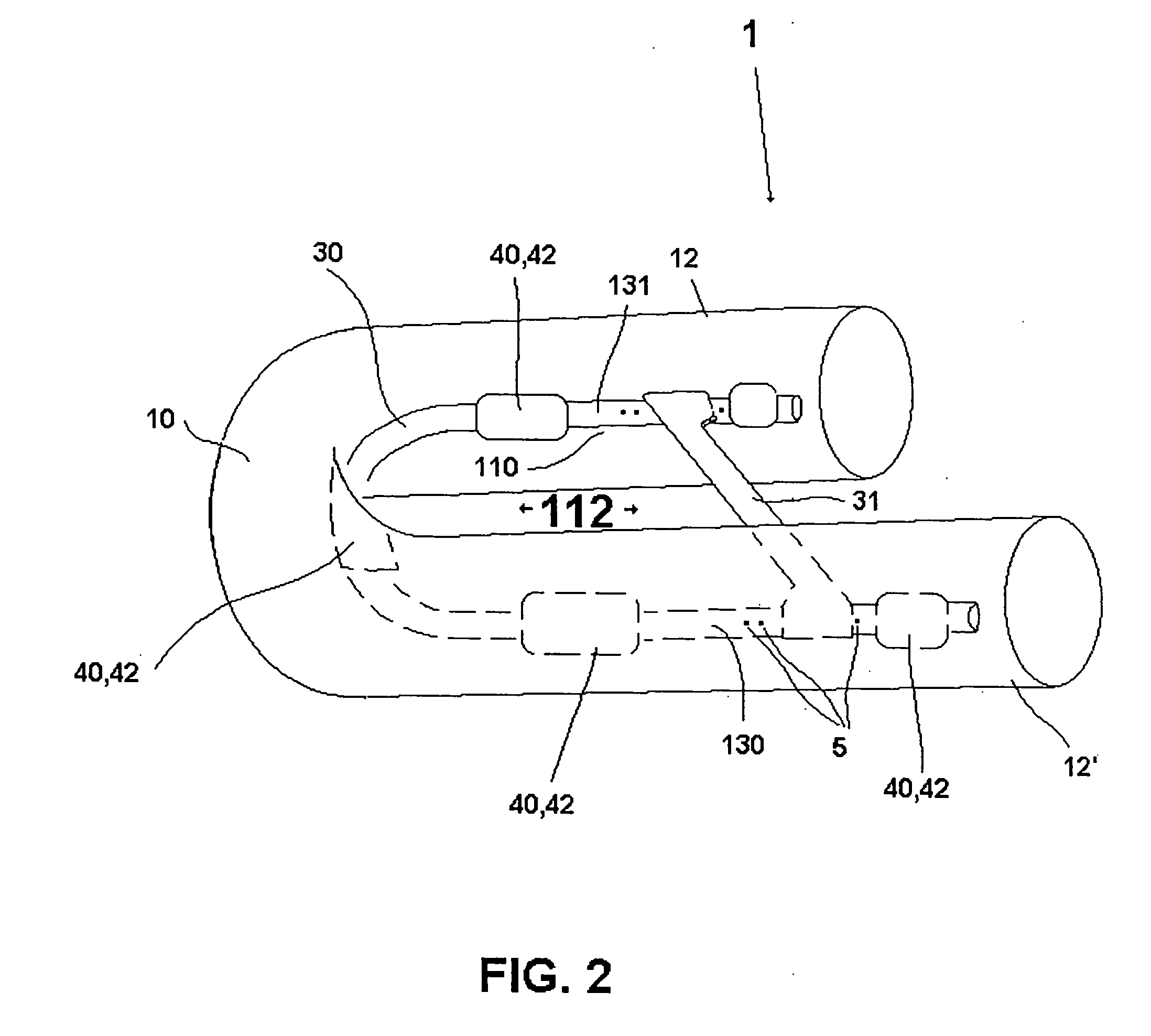

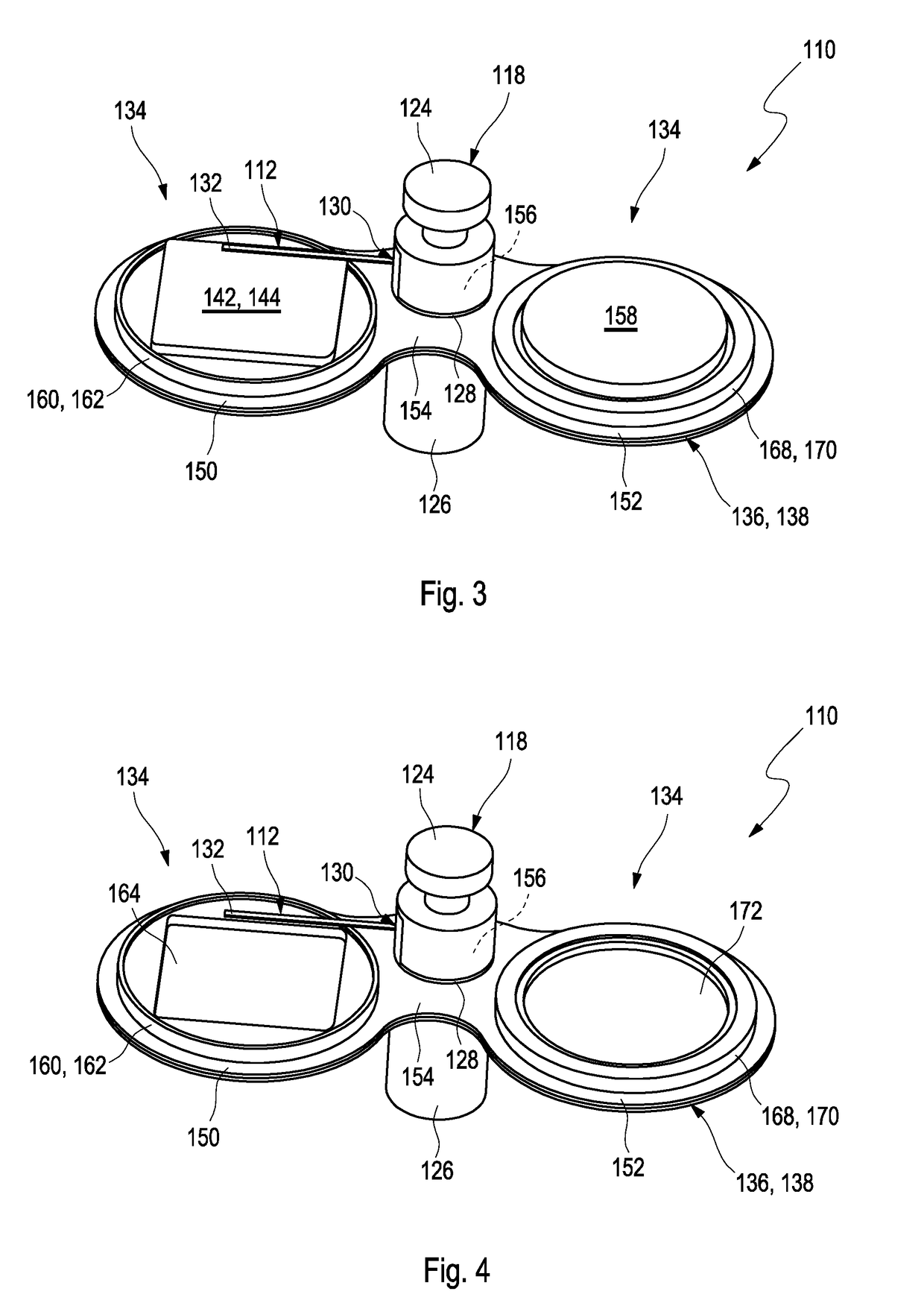

Medical device for detecting at least one analyte in a body fluid

PendingUS20190021636A1Increase comfortSimple mounting and insertionCatheterSensorsElectronicsBody fluid

A medical device for detecting at least one analyte in a body fluid is disclosed. The medical device comprises:at least one analyte sensor having an insertable portion adapted for at least partially being inserted into a body tissue of a user,at least one insertion cannula, wherein the analyte sensor at least partially is placed inside the insertion cannula;at least one housing, wherein the housing comprises at least one sensor compartment, wherein the sensor compartment forms a sealed compartment receiving at least the insertable portion of the analyte sensor, wherein the sealed compartment comprises at least one detachable upper cap and at least one detachable lower cap, wherein the detachable lower cap is configured for detachment before insertion, thereby opening the insertable portion for insertion, wherein the insertion cannula is attached to the detachable upper cap, wherein the detachable upper cap is configured for detachment after insertion, thereby removing the insertion cannula; andat least one electronics unit, wherein the analyte sensor is operably connected to the electronics unit, wherein the electronics unit comprises at least one interconnect device with at least one electronic component attached thereto, wherein the interconnect device fully or partially surrounds the housing.

Owner:ROCHE DIABETES CARE INC

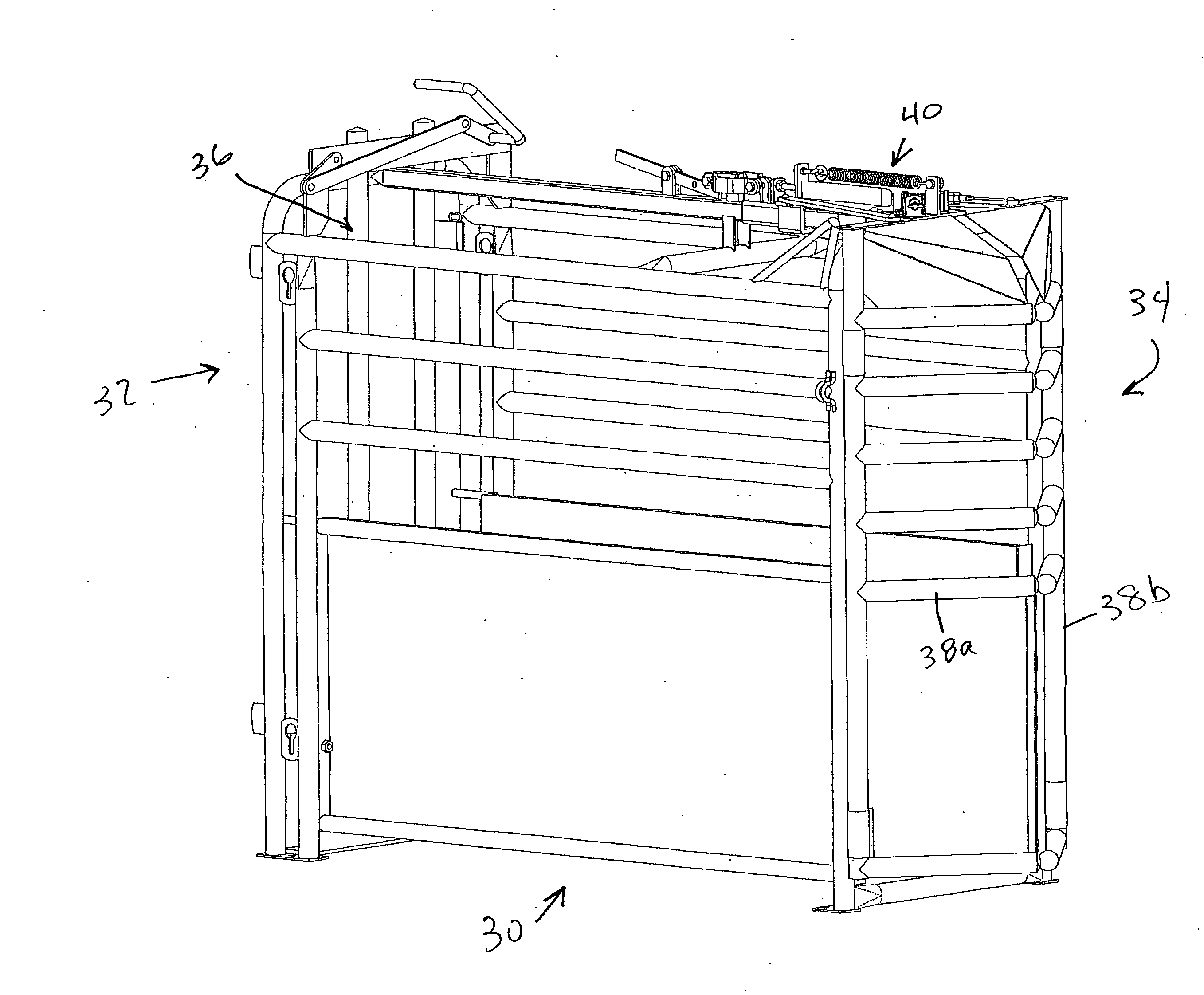

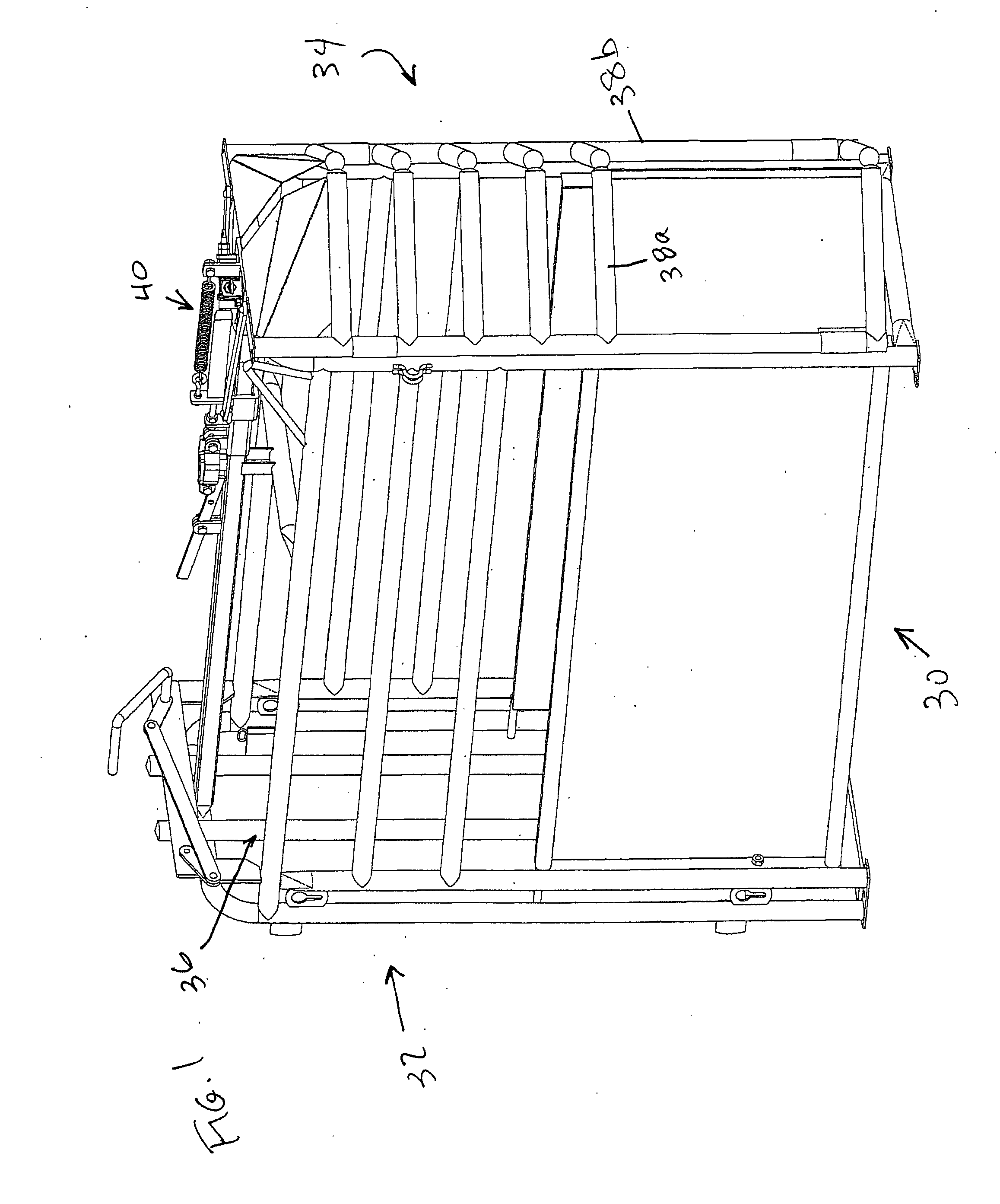

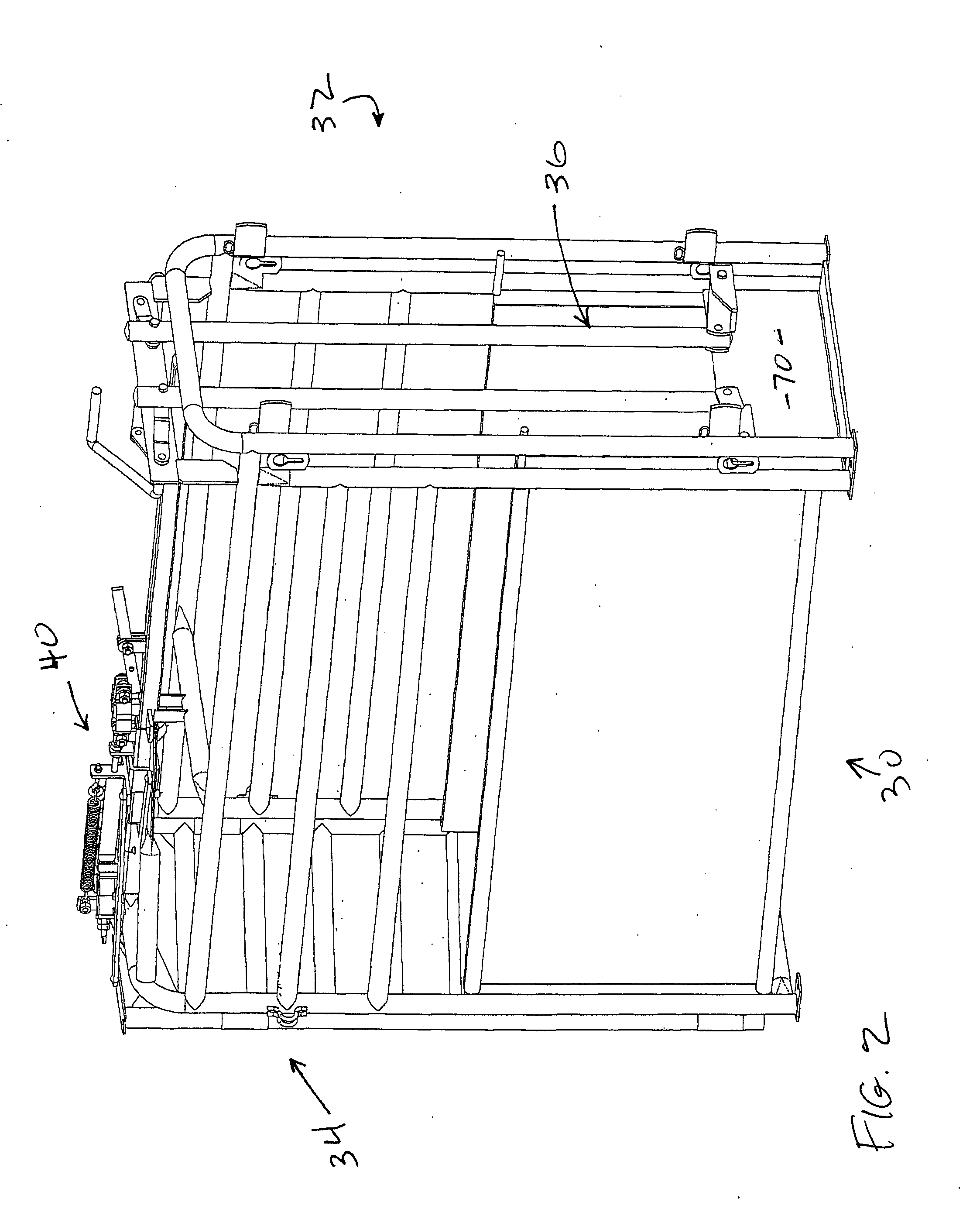

Calf chute tailgate

InactiveUS20100083908A1Increase comfortImproved ease of useRace-coursesAnimal housingEngineeringCattle calf

Owner:PRIEFERT MFG

Vehicle seat comprising an area that is deformable in the event of an impact

ActiveUS20150367943A1Prevent transmissionIncrease comfortVehicle seatsSeating arrangementsLower faceEngineering

A vehicle seat for a passenger, comprising a backrest having a front face directed towards the passenger and a rear face opposite the front face, and a seat part having an upper face directed towards the passenger and a lower face opposite the upper face, wherein the rear face of the backrest and / or the lower face of the seat part comprise(s) at least one area that is deformable in the event of an impact, towards the front face of the backrest and / or towards the upper face of the seat part respectively, and in that the front face and rear face of the backrest, and / or the upper face and lower face of the seat part are located at a distance from each other, at least at said at least one deformable area, so as to define a clearance space, said at least one deformable area of the rear face of the backrest and / or of the lower face of the seat part being configured so as to deform into the clearance space in the event of an impact on the rear face of the backrest and / or the lower face of the seat part, without transmitting the impact to the front face of the backrest and / or the upper face of the seat part respectively.

Owner:EXPLISEAT

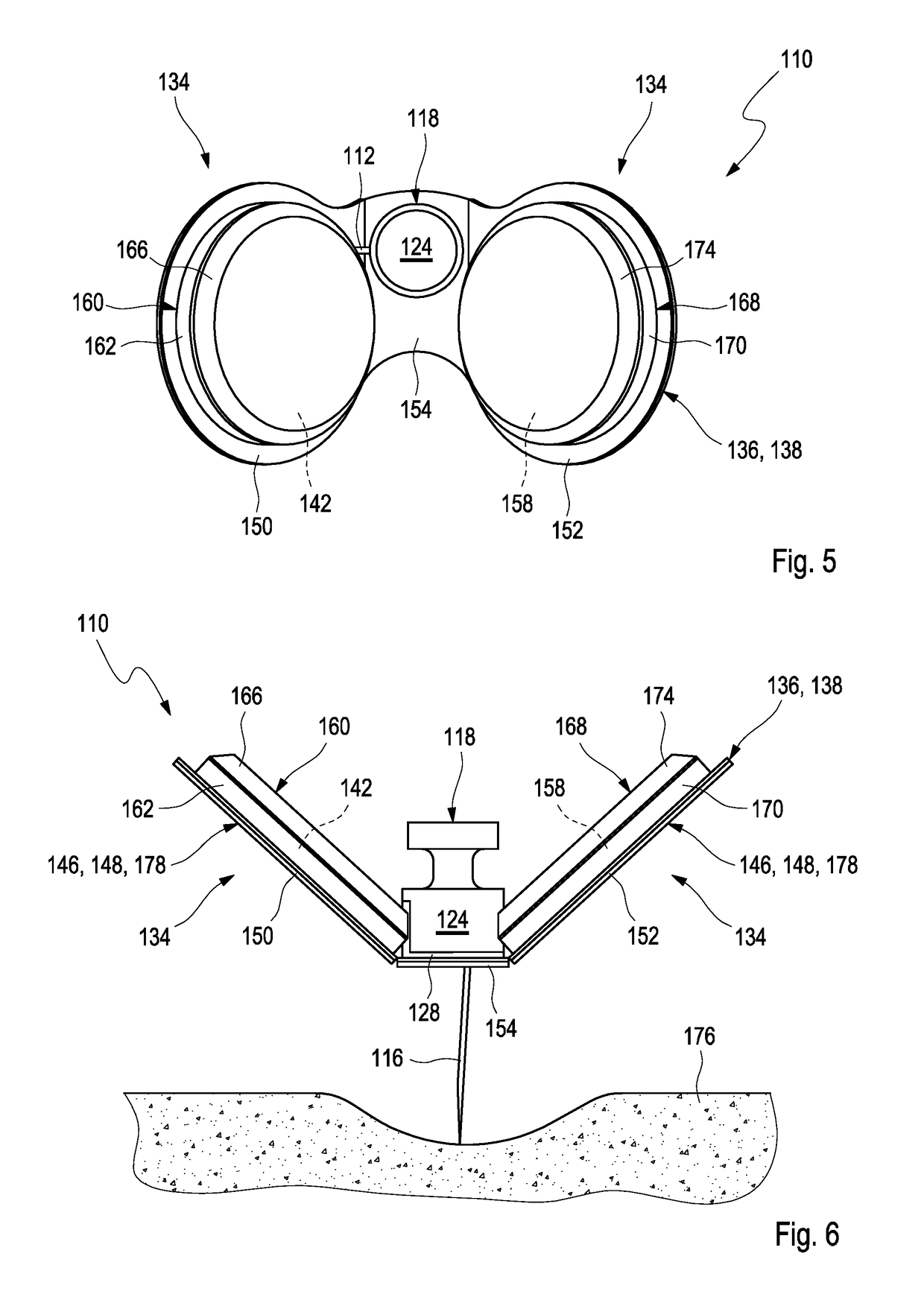

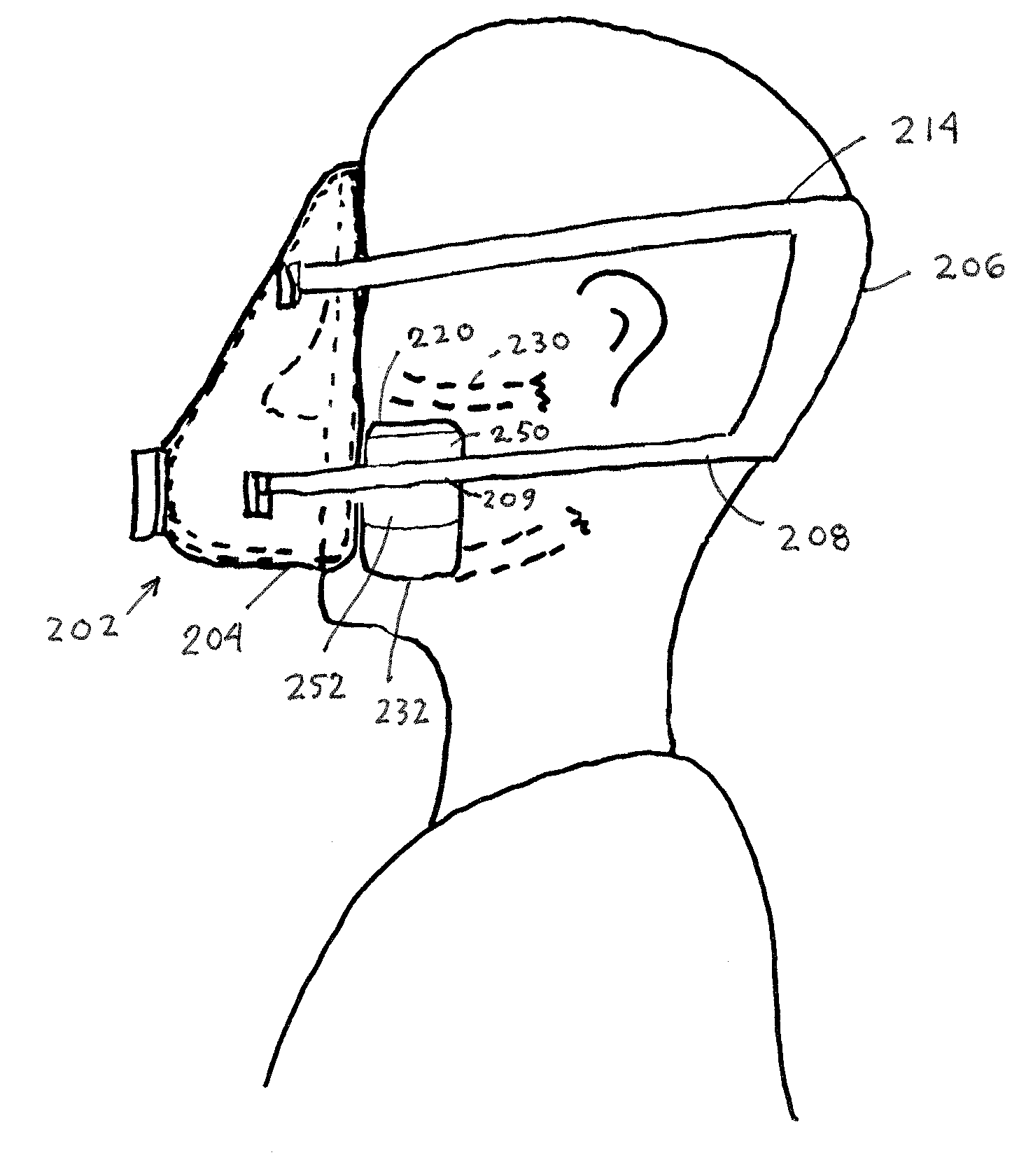

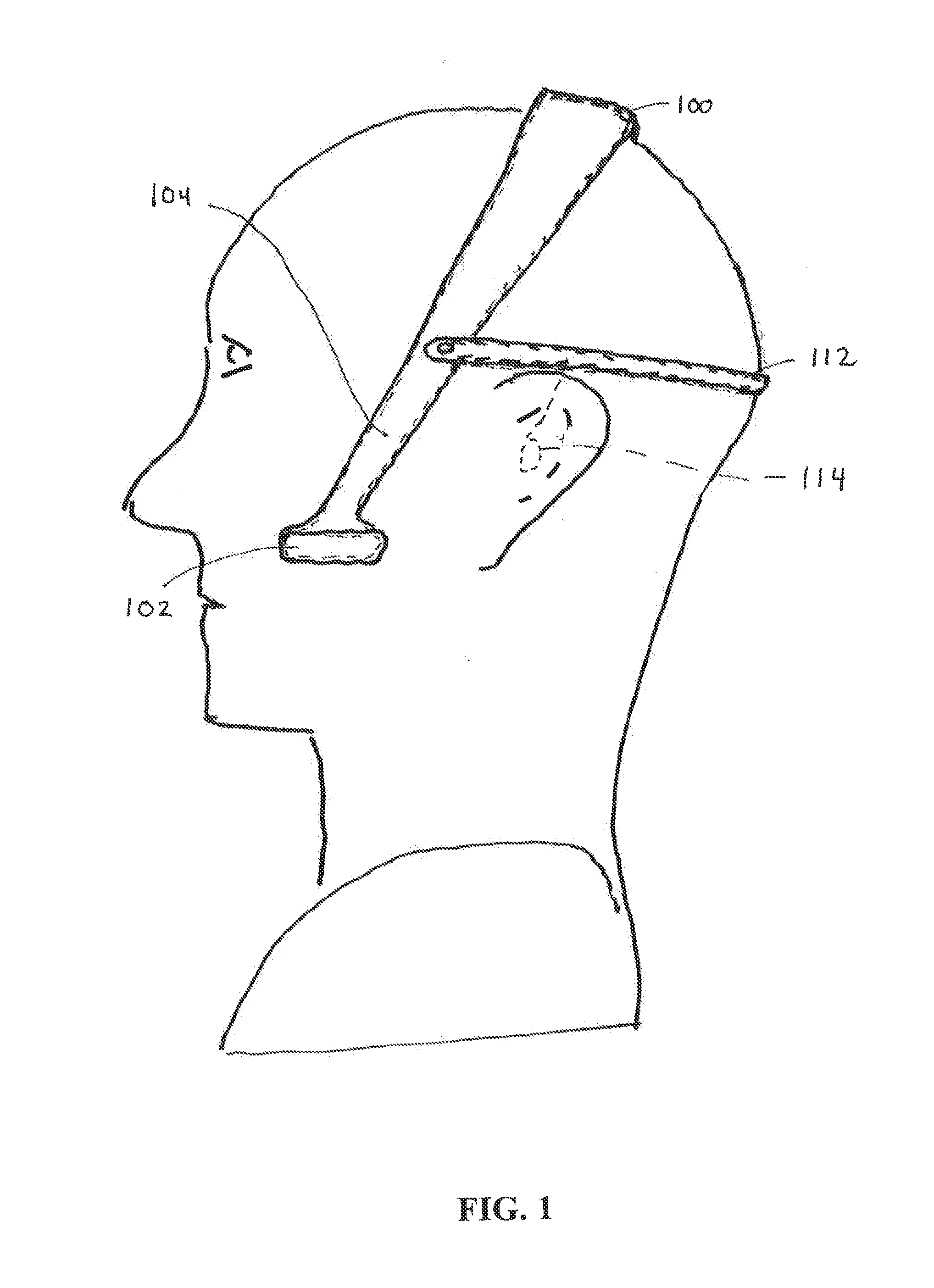

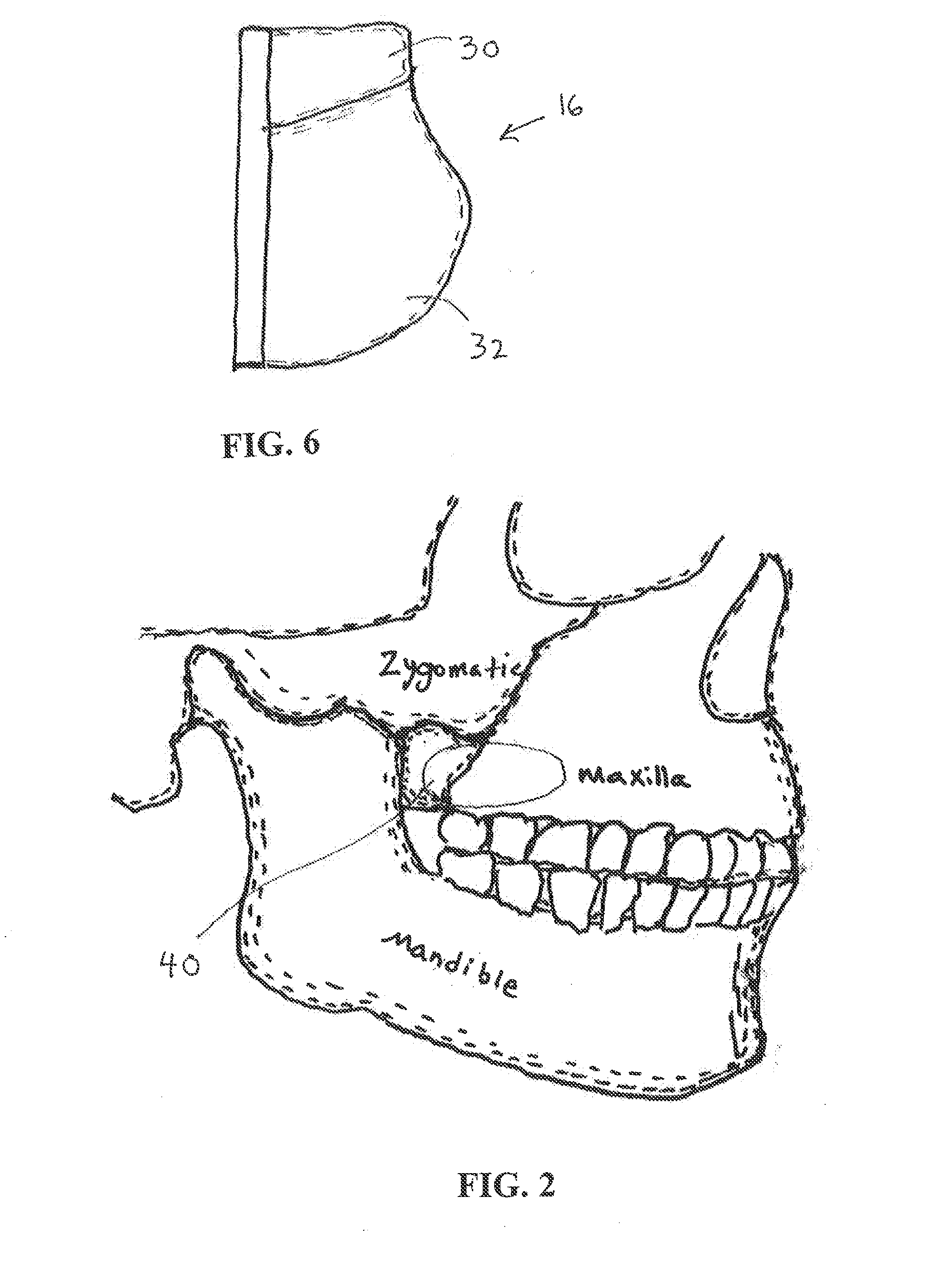

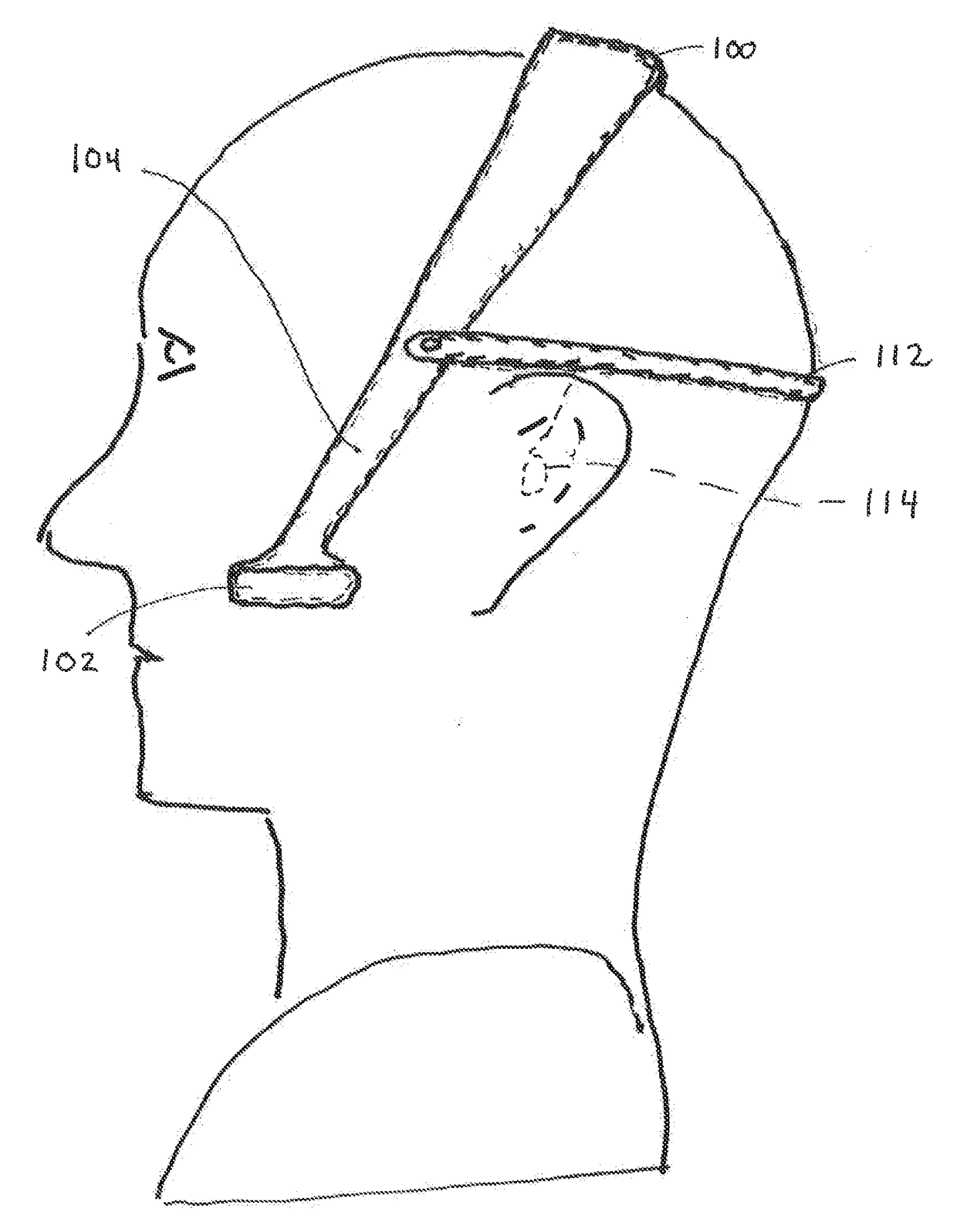

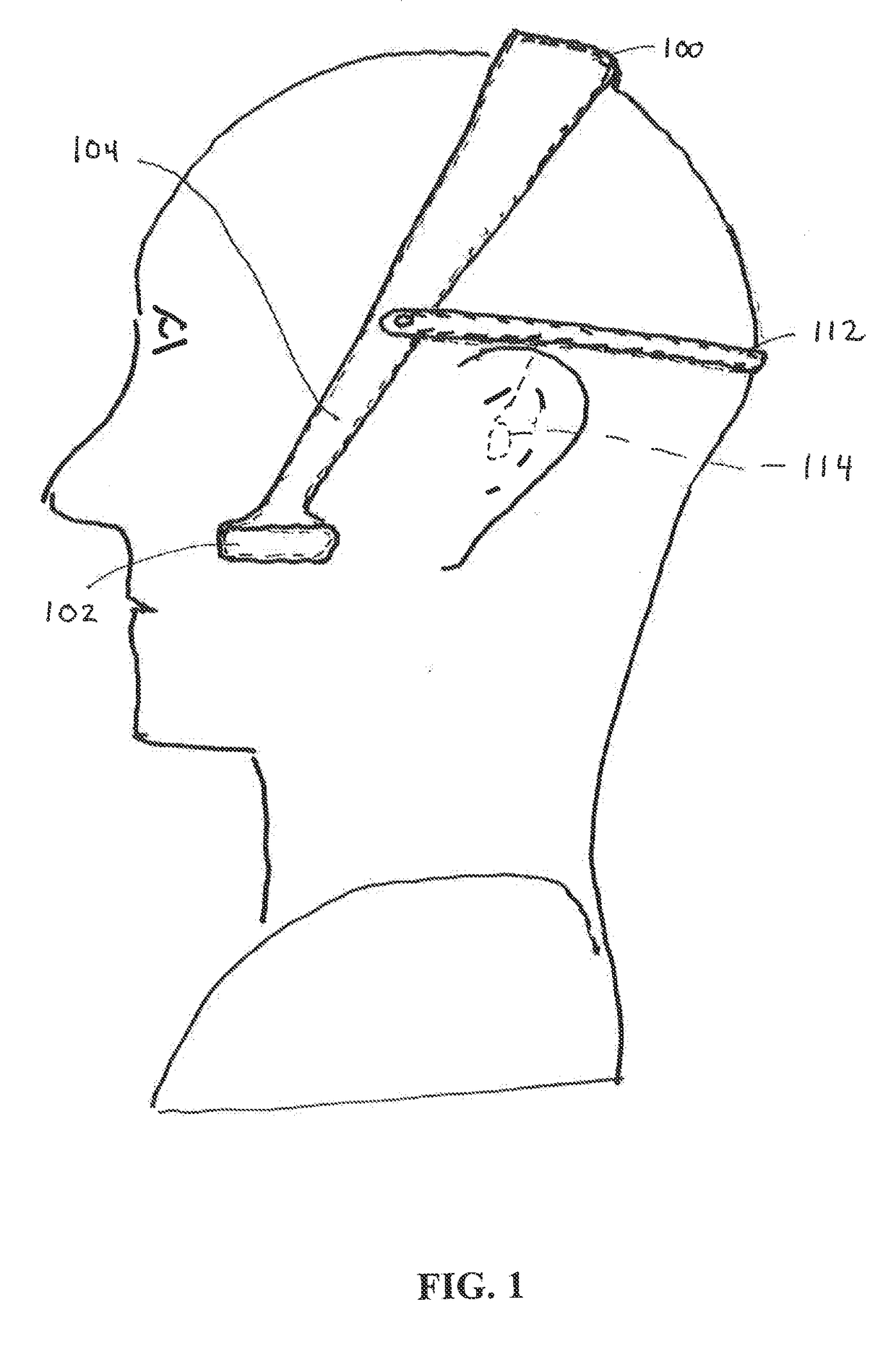

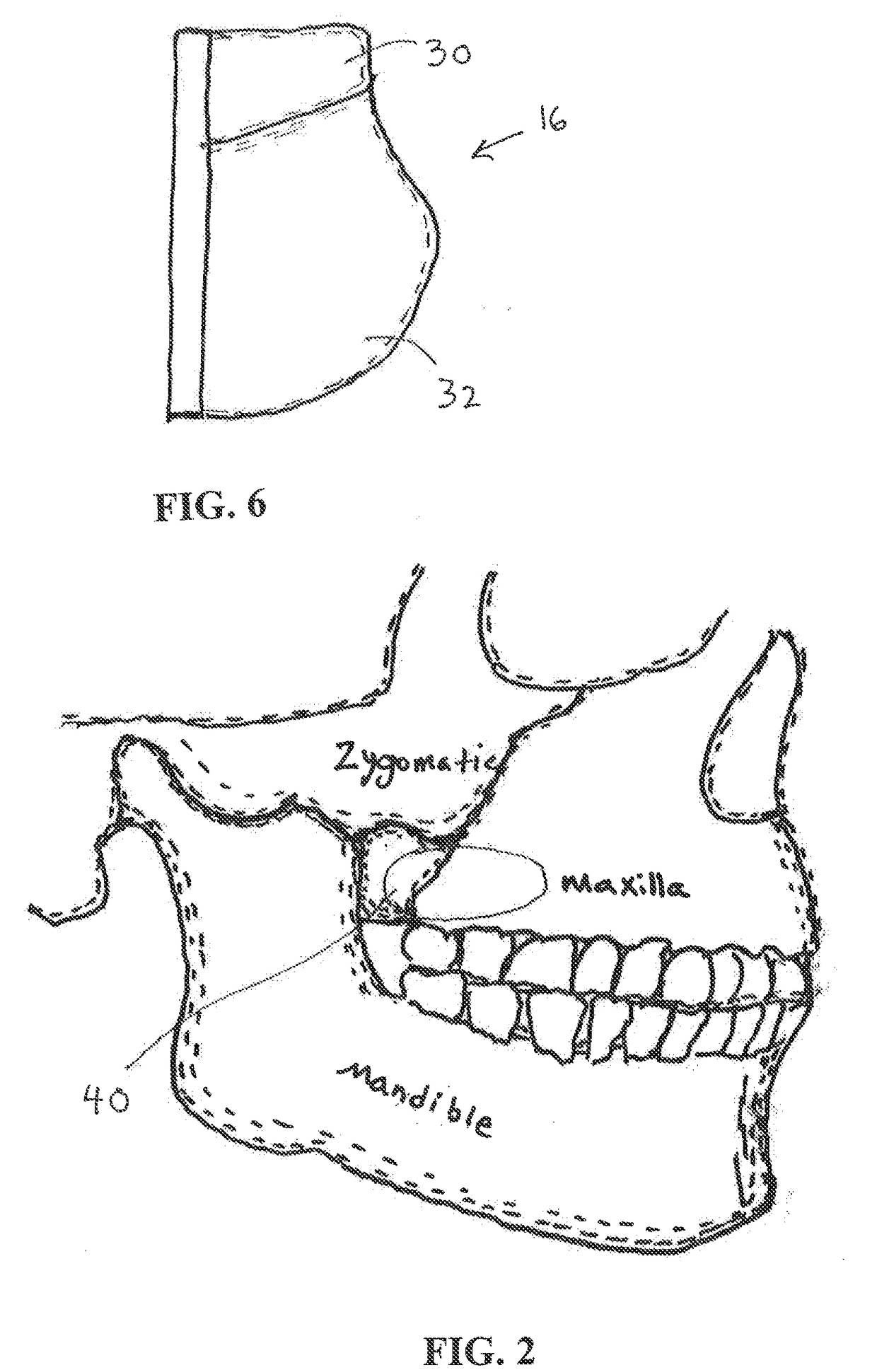

Cheek depressors and method of use

InactiveUS20150122263A1Increase responsivenessIncrease comfortRespiratory masksBreathing masksExhalationDuring expiration

A device and method of use for depressing the cheeks of a user, to limit significant motion of the cheeks and provide for enhanced inhalation and exhalation. The device may be used to enhance respiration during a variety of activities, and is especially beneficial during the use of positive airway pressure (PAP) type medical. devices The device may include a pad adapted to engage a target area of a user's cheek and to maintain cheek tissue against a bone surface during inhalation and exhalation. The device may also include at least one support element coupled to the pad to maintain the pad at the target area during a therapy session.

Owner:VIKEN JAMES P

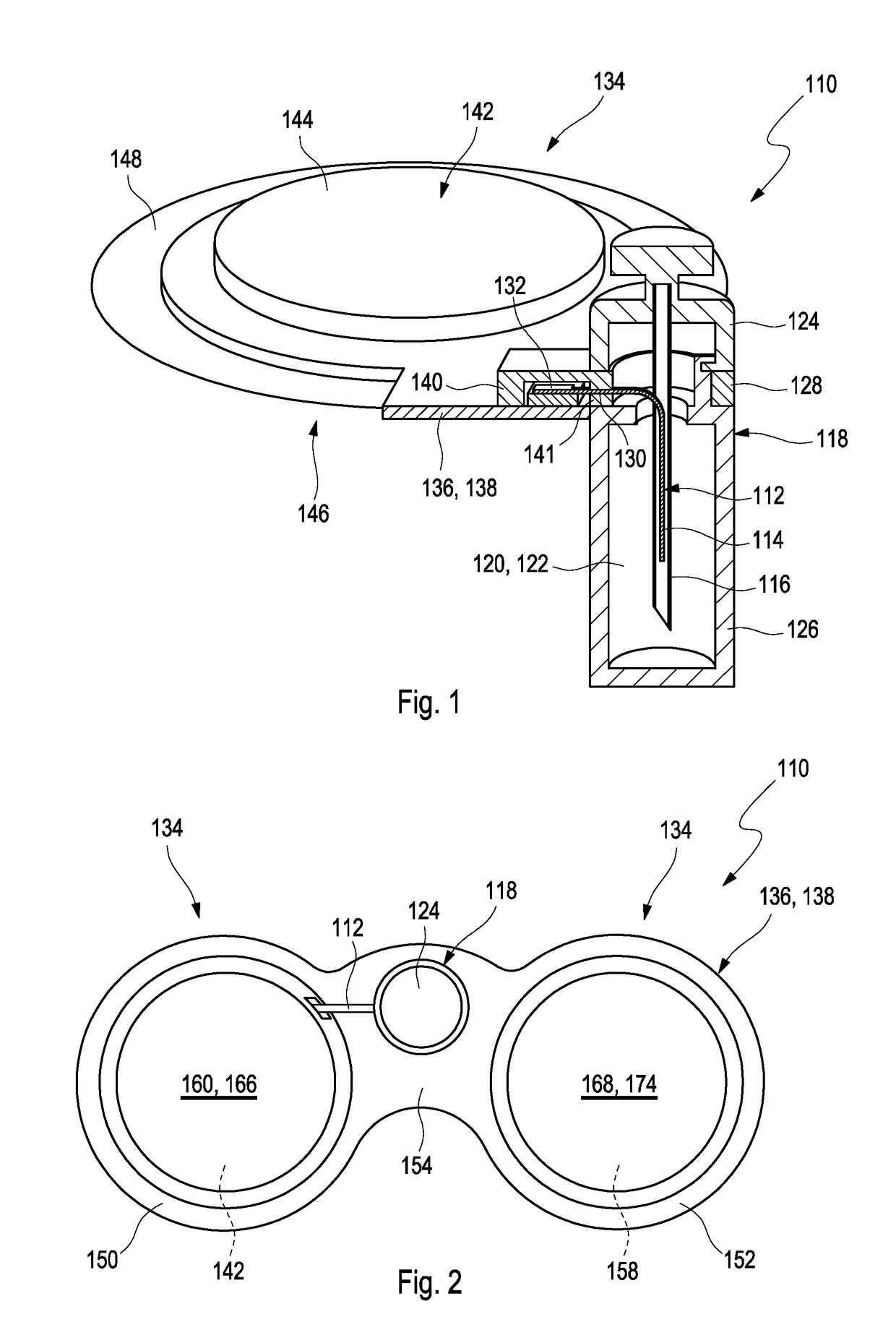

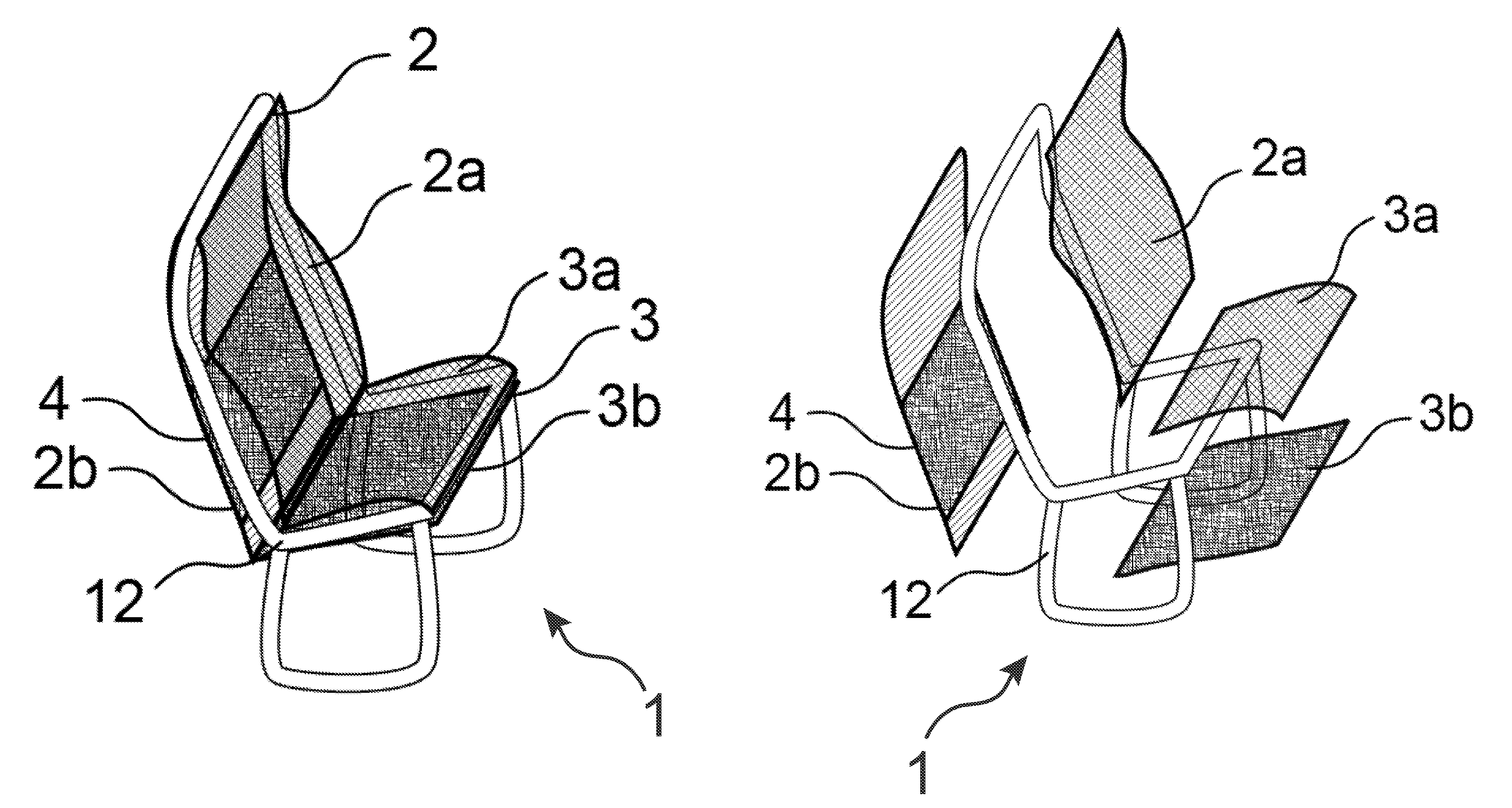

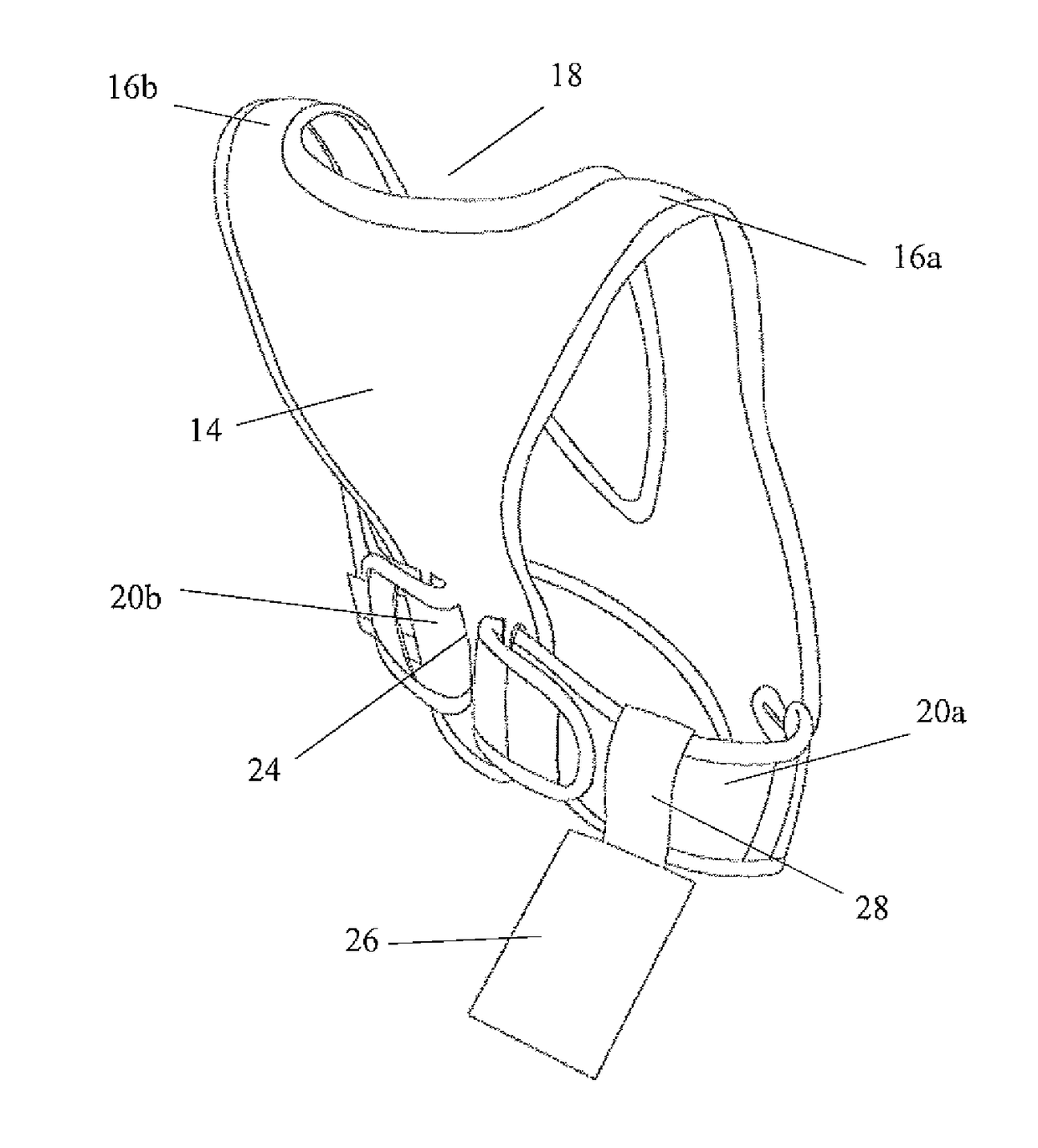

Method and device for nasal dilation by applying force to a target cheek area without mandibular displacement

InactiveUS20170281394A1Increase responsivenessIncrease comfortRespiratorsMedical devicesExhalationDuring expiration

A nasal dilation device and method of use for depressing targeted areas of cheek tissue providing for enhanced inhalation and exhalation via dilation of nasal passageways away from the targeted areas. The device may be used to enhance respiration during a variety of activities, and is especially beneficial during the use of positive airway pressure (PAP) type medical devices. The device may include pads adapted to engage target areas of a user's cheek and to maintain cheek tissue against a bone surface during inhalation and exhalation. The device includes a support element coupled to the pads to maintain the pads at the targeted areas during use.

Owner:VIKEN JAMES P

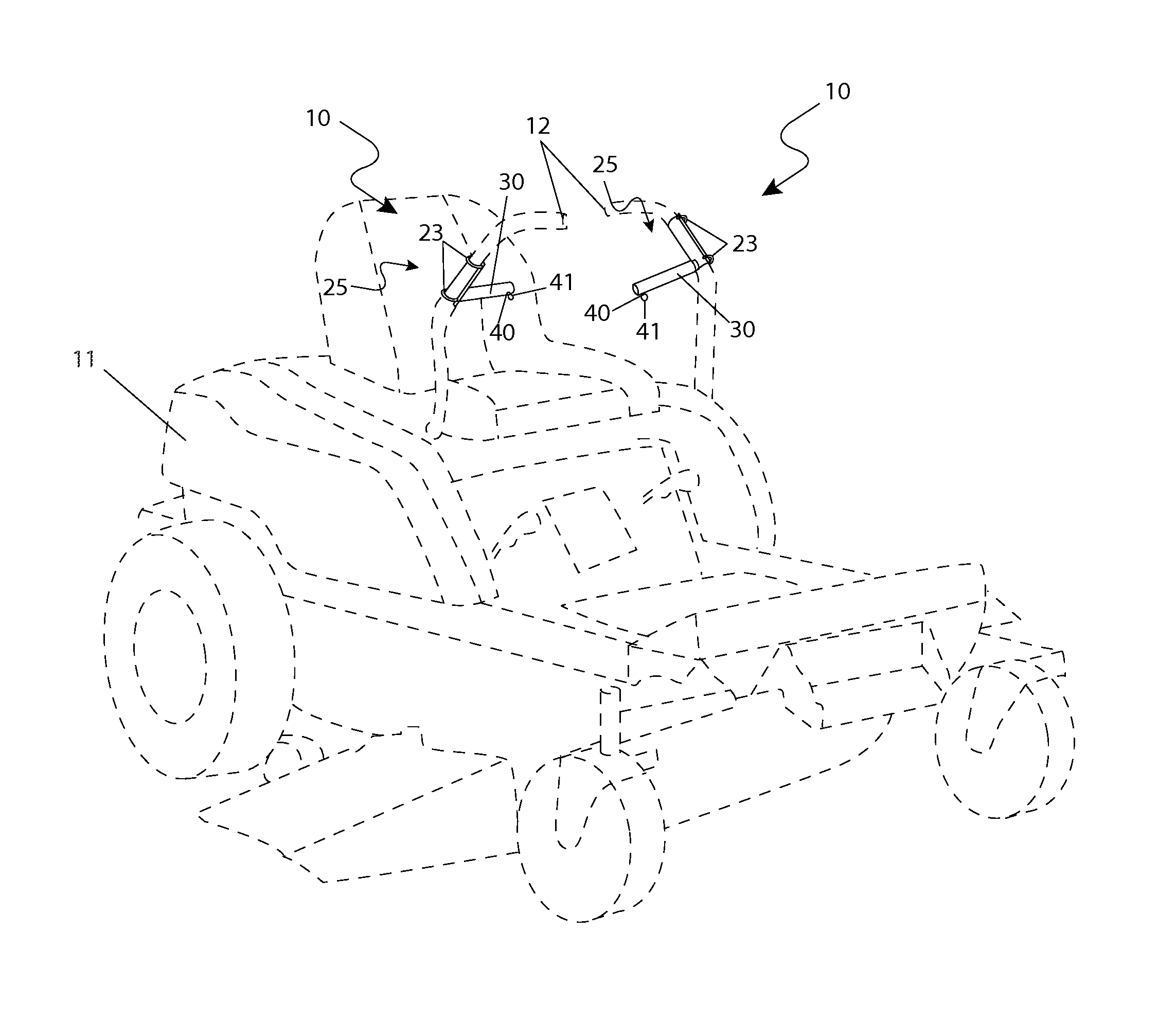

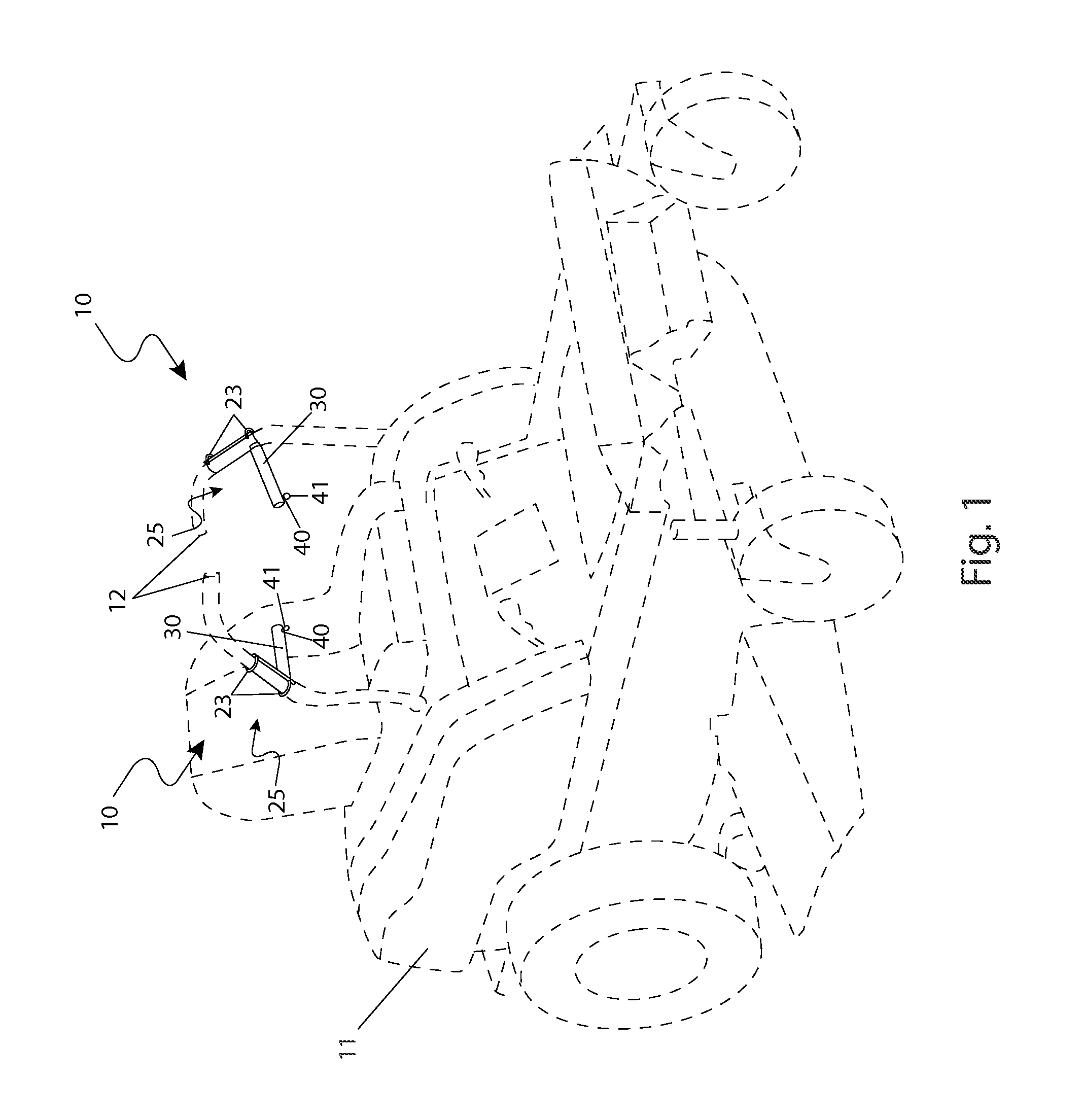

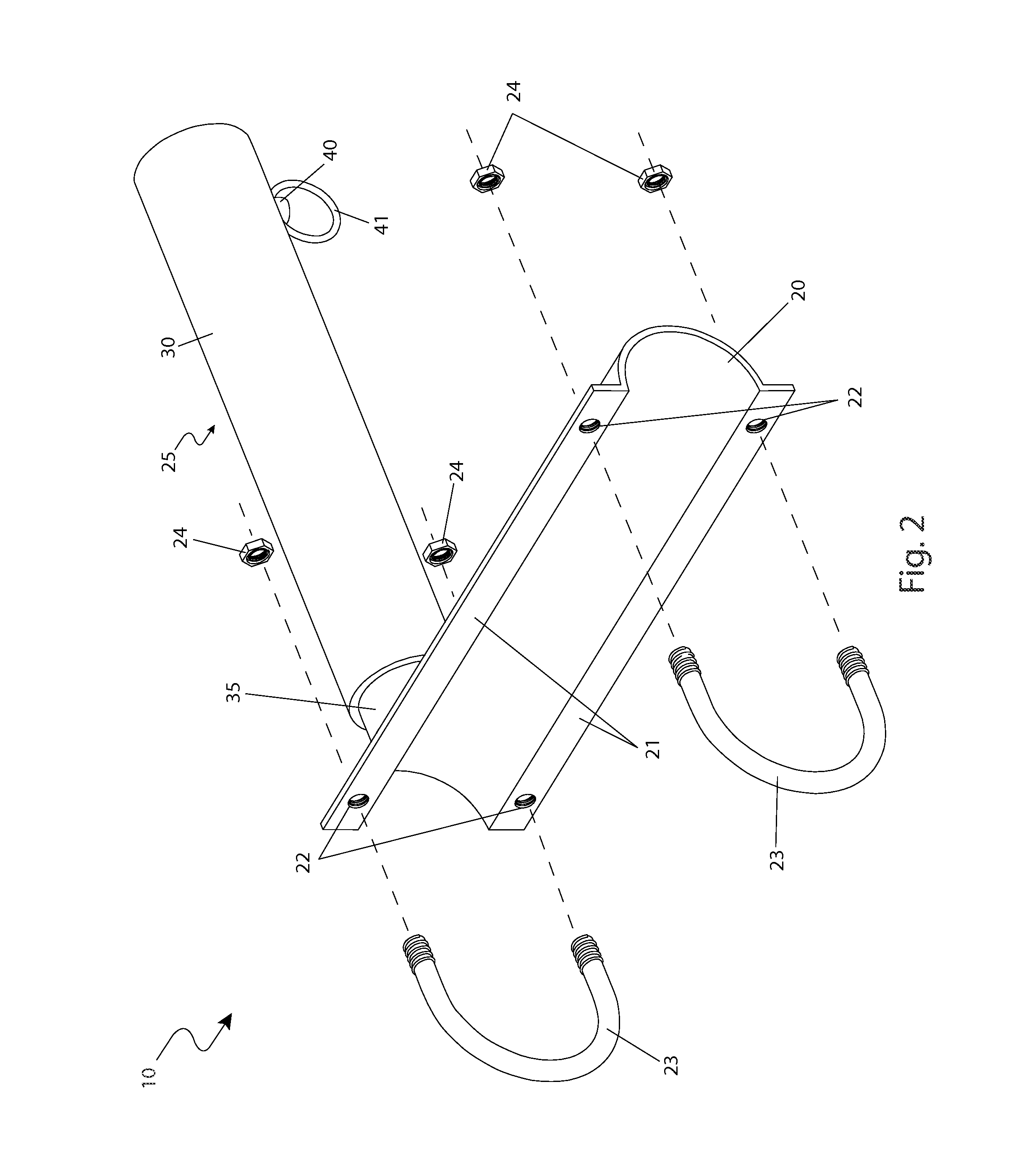

Attachable armrest for a mower steering assembly

An adjustable armrest that attaches to zero-radius turning mowers includes a telescoping armrest and a clamping bracket. The armrest provides a horizontal support for an operator's arm and is covered with a layer of foam padding for comfort. The clamping bracket is attachable to a steering handle at a prescribed location. In this manner, after the operator attaches an adjustable armrest on each of the steering handles the forearms and wrists are supported and the armrests pivot with the steering handles in order to preserve the comfortable supportive functioning of the armrests.

Owner:GUBIN RONALD F

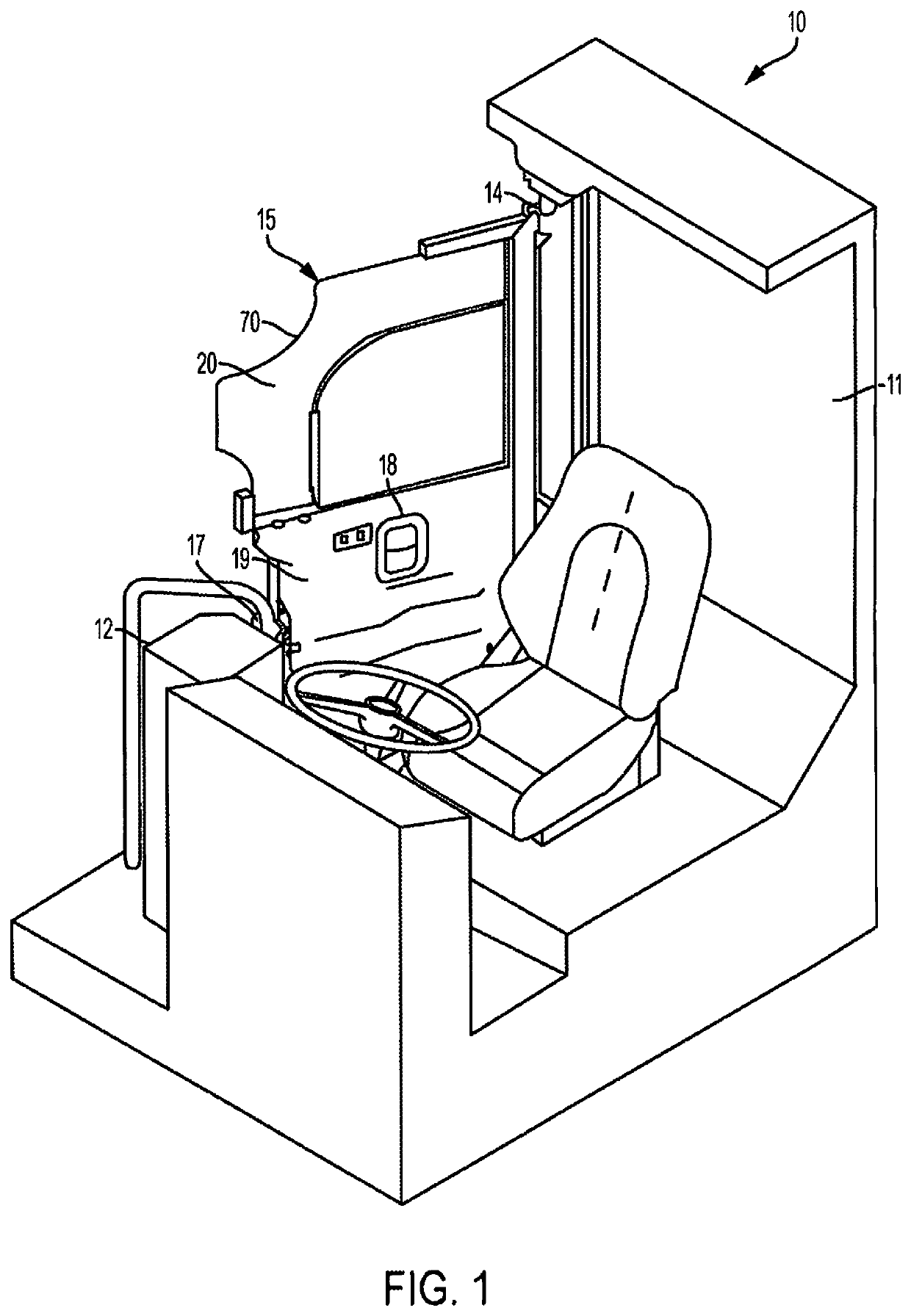

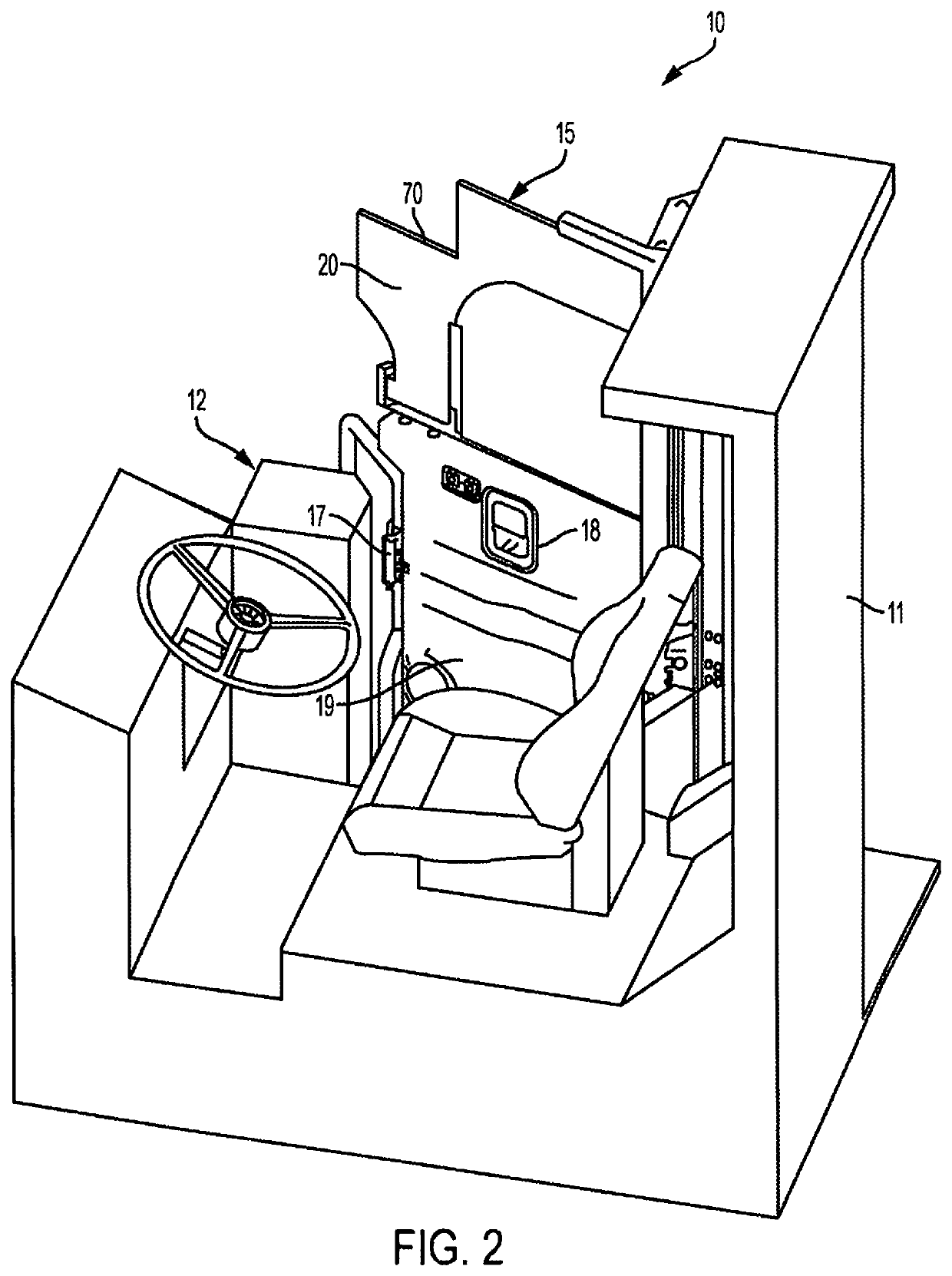

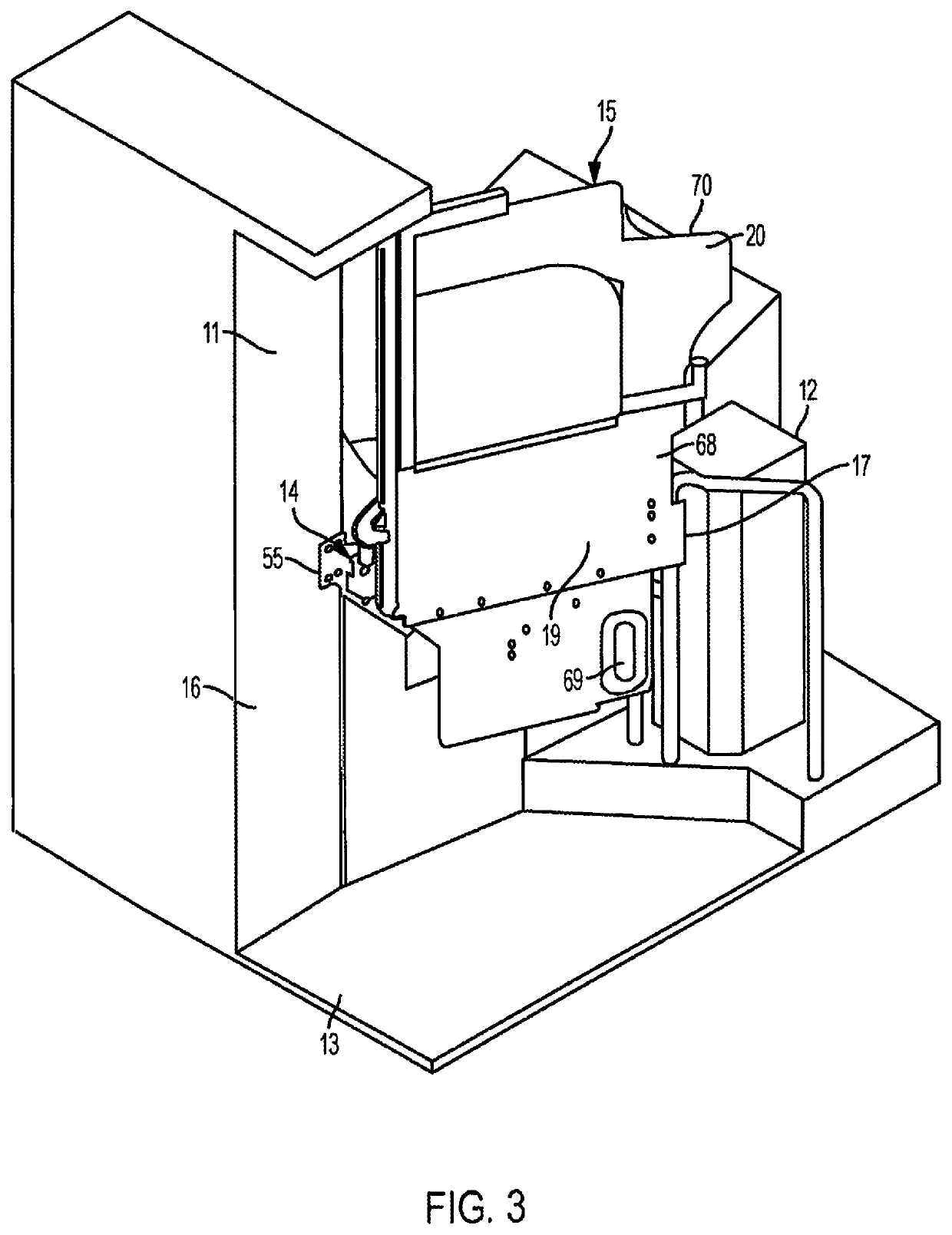

Enclosure for a vehicle system

ActiveUS20200148165A1Reduced distractionIncrease comfortEngine sealsAir-treating devicesPhysicsEngineering

A barrier door for a protective enclosure includes a lower section and an upper section operably coupled with the lower section, and a ventilation system disposed within the lower section. The ventilation system includes one or more blowers and a plenum. The ventilation system is configured to direct air one or more of into or out of the protective enclosure.

Owner:TRANSPORTATION IP HLDG LLC

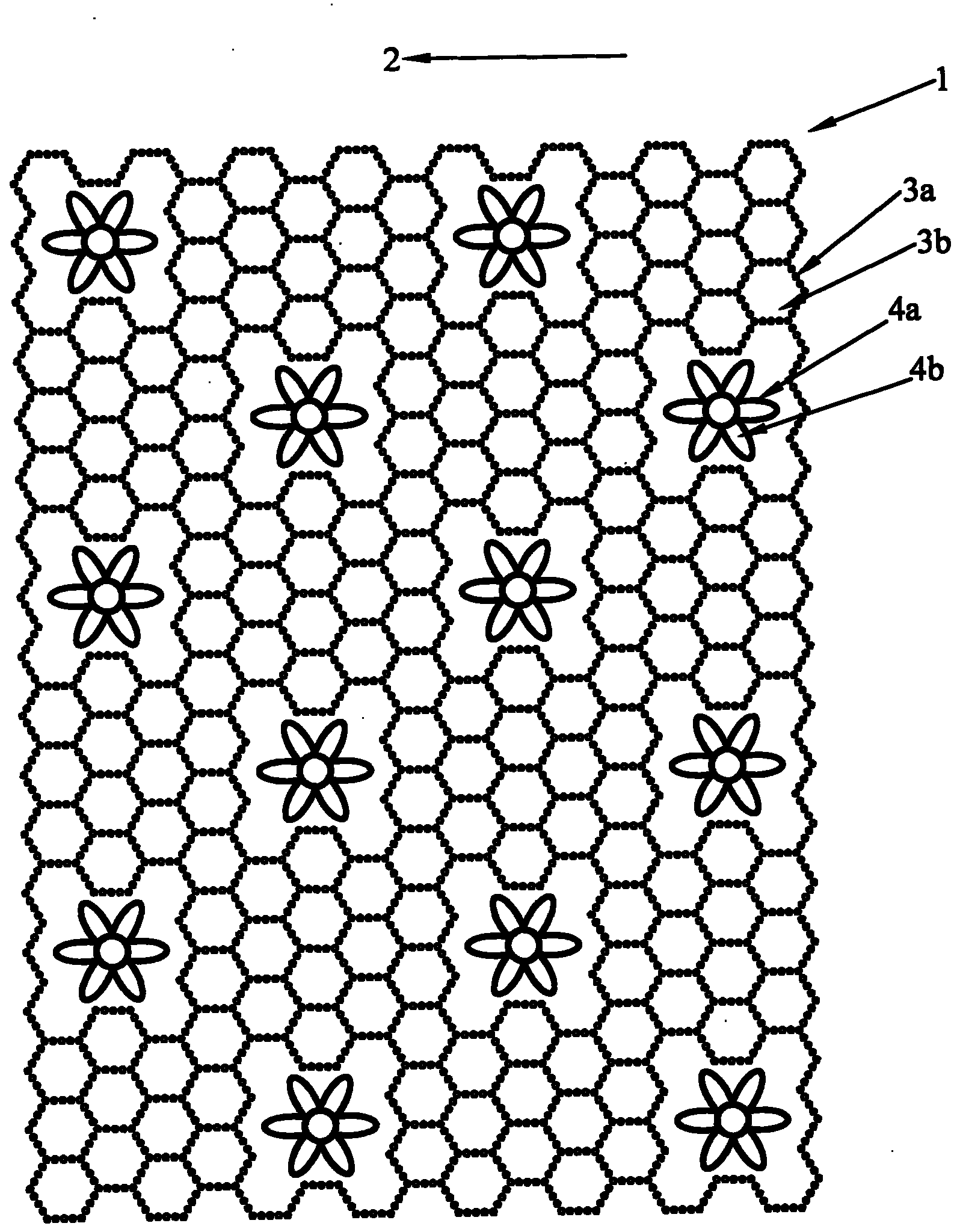

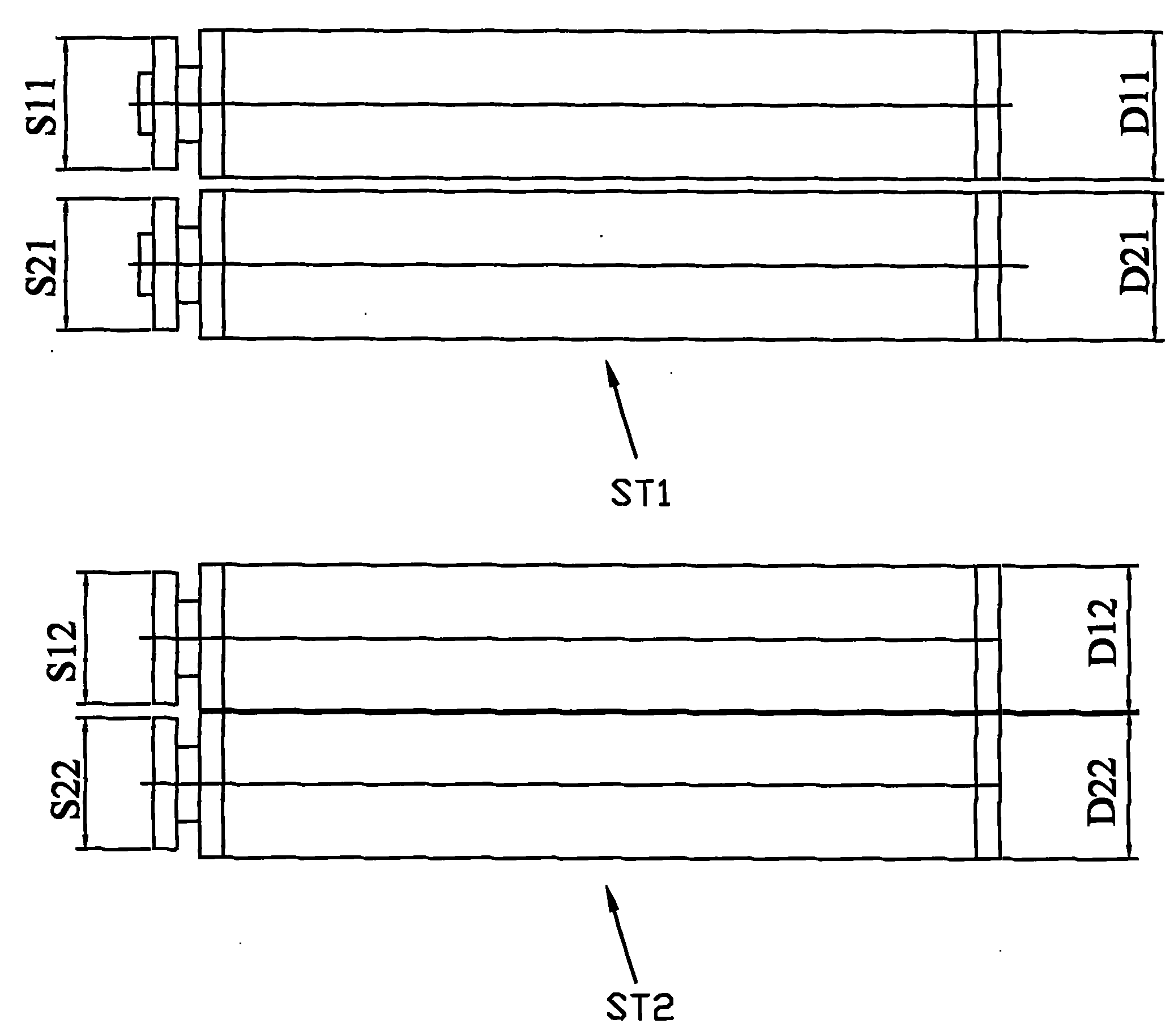

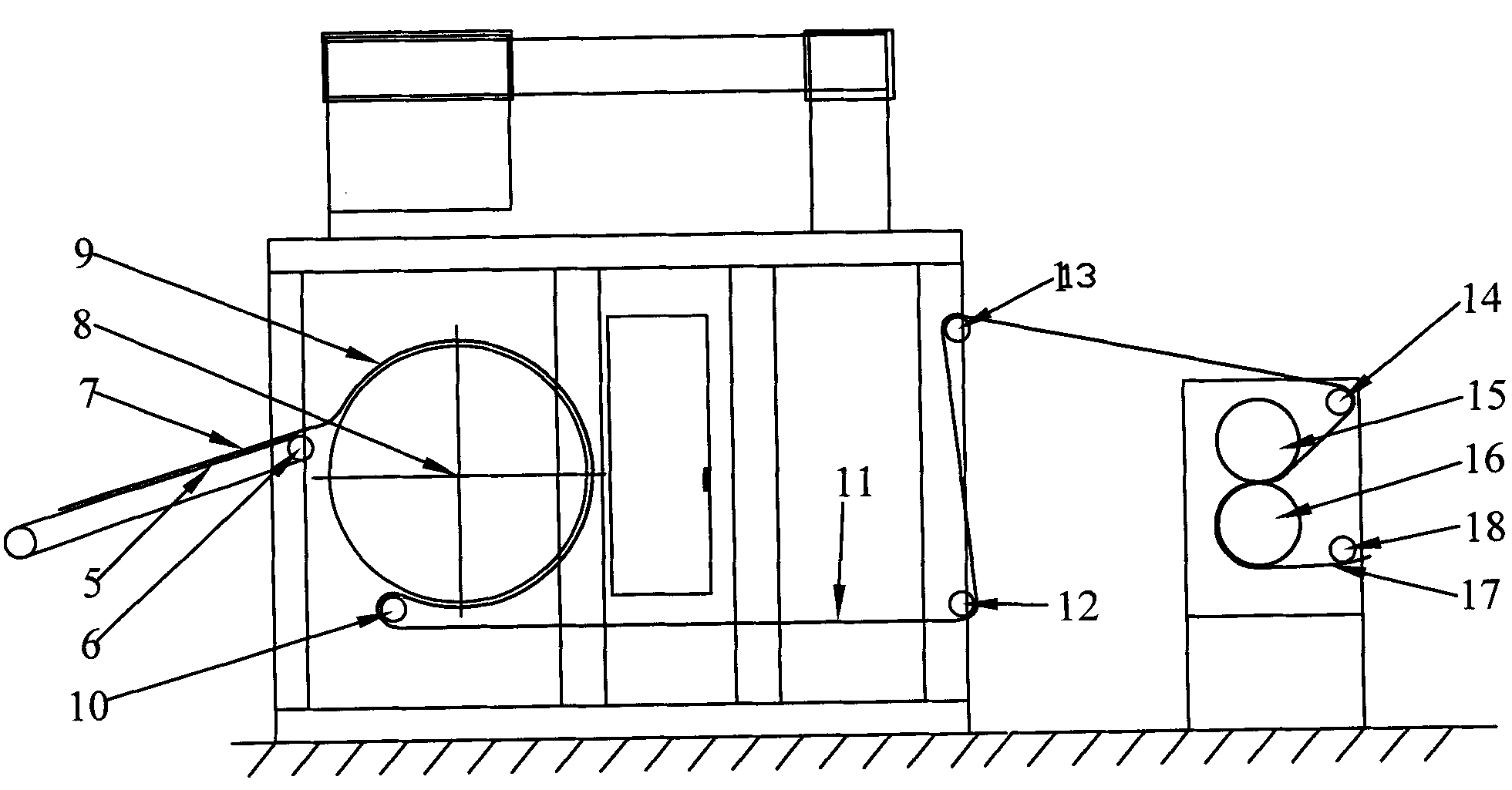

Equipment for producing novel non-woven cloth

ActiveCN101864641AReduce contact areaIncrease comfortPattern makingNon-woven fabricsEngineeringPower transmission

The invention discloses equipment for manufacturing novel non-woven cloth. The equipment comprises a hot rolling mill with an engraving roller. The engraving roller comprises an upper engraving roll and a lower engraving roll which are meshed mutually and a hydraulic device for controlling a relative distance between the upper engraving roll and the lower engraving roll, wherein a convex dot matrix for forming surface sunk parts of the non-woven cloth is engraved on the surface of the upper engraving roll; the hydraulic device is used for controlling movement of the lower engraving roll to realize to regulate the relative distance between the upper engraving roll and the lower engraving roll; the upper engraving roll and the lower engraving roll realize power transmission by transmission gear devices on one side of the upper engraving roll and one side of the lower engraving roll; and the other side of the upper engraving roll is externally connected with a heating device. The equipment can design and change the shape of a pattern according to consumers' requirement and market requirement to make hairiness on the surface of the hot air non-woven cloth greatly reduced and the non-woven cloth have concave-convex feeling, thereby reducing the contact area of a surface layer material and a human body and increasing comfortable feeling of the human body when the non-woven cloth is in use.

Owner:大源无纺新材料(天津)有限公司

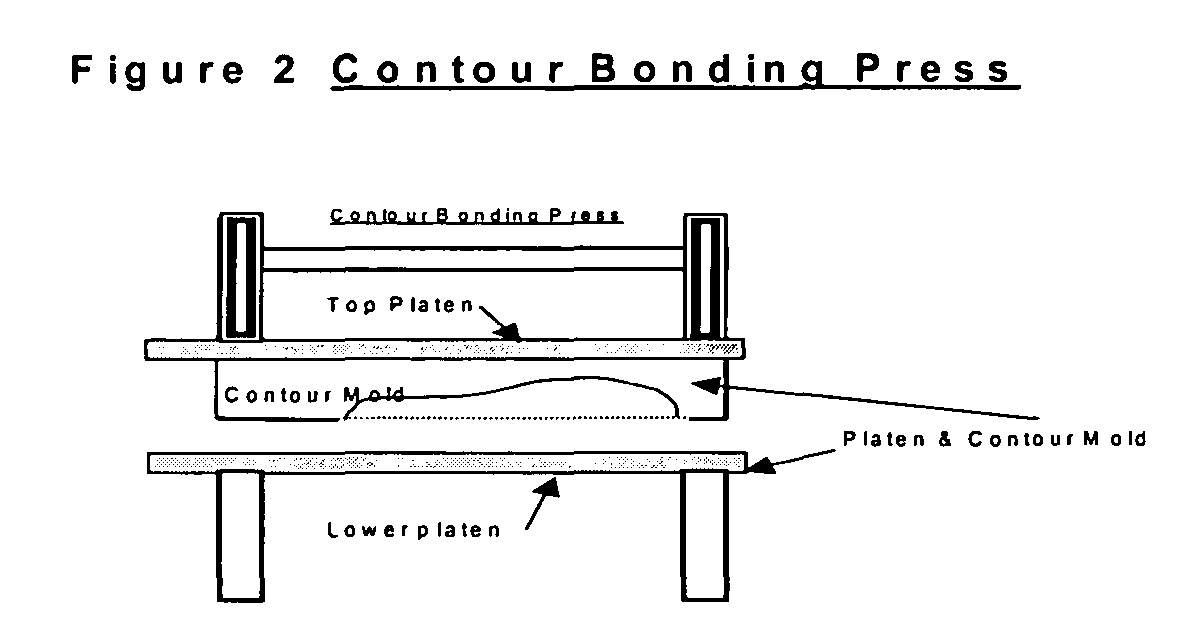

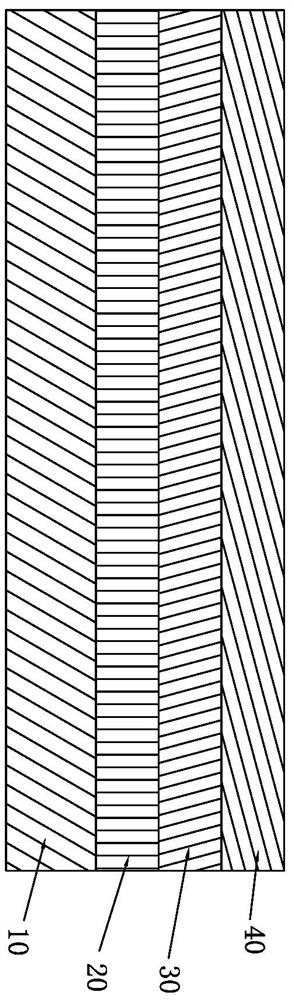

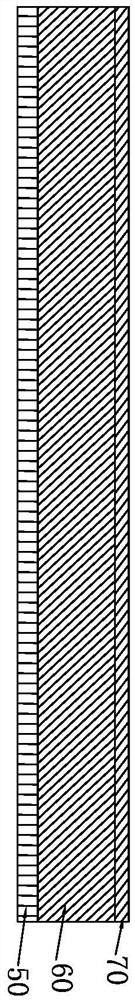

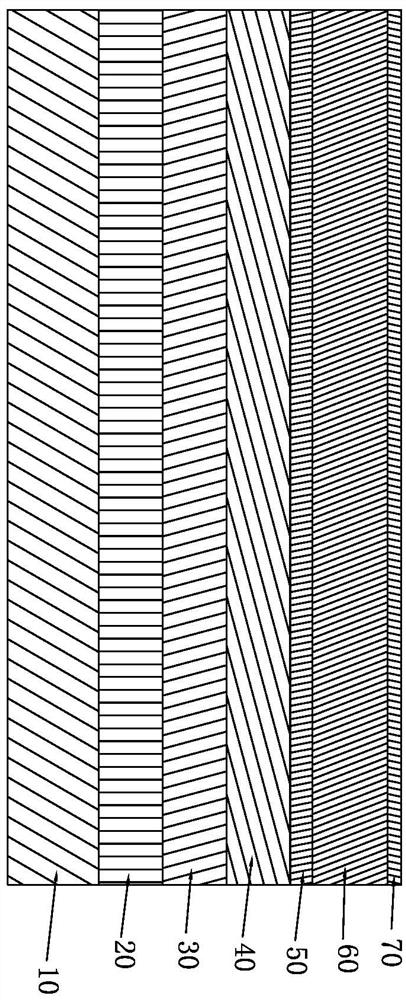

PU (polyurethane) double-layer crystal mirror leather and laminating method thereof

PendingCN114517416AIncrease crystal transparencyIncrease comfortLayered productsTextiles and paperPolymer chemistryOverprinting

The invention discloses PU (Poly Urethane) double-layer crystal mirror leather and a laminating method thereof. The laminating method comprises the following steps: step 1, coating a wet-process PU layer above base cloth; step 2, coating the wet-process PU layer with the dry-process PU grain layer; 3, overprinting a printing layer on the dry-process PU grain layer to obtain a first-stage semi-finished product; 4, coating the mirror release paper with transparent polyurethane elastomer slurry, drying to form a transparent polyurethane elastomer, coating the transparent polyurethane elastomer with polyurethane slurry, and drying the polyurethane slurry to be half-dry to serve as an adhesion layer to obtain a second-stage semi-finished product; 5, injecting an auxiliary agent on the printing layer of the first-stage semi-finished product, and then attaching the adhesion layer of the second-stage semi-finished product; and 6, the bubble row is squeezed out of the outer surface obtained after the first-stage semi-finished product and the second-stage semi-finished product are compounded, then the PU double-layer crystal mirror surface leather is manufactured through attaching, drying and cooling in sequence, and the PU double-layer crystal mirror surface leather has the advantages of being high in crystal feeling, good in permeability and the like mainly through the design of all the steps.

Owner:DONGGUAN SUNGOAL LEATHER

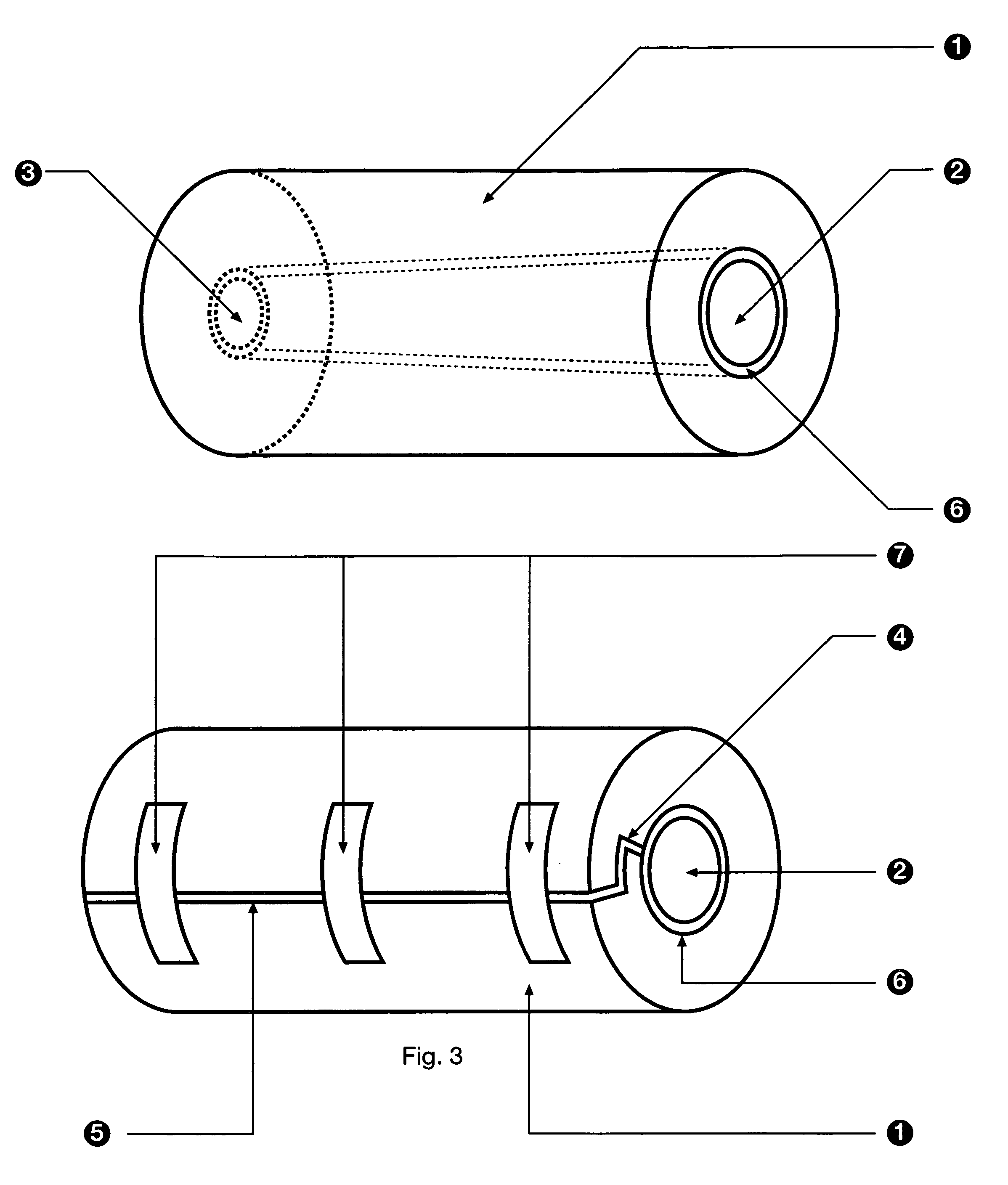

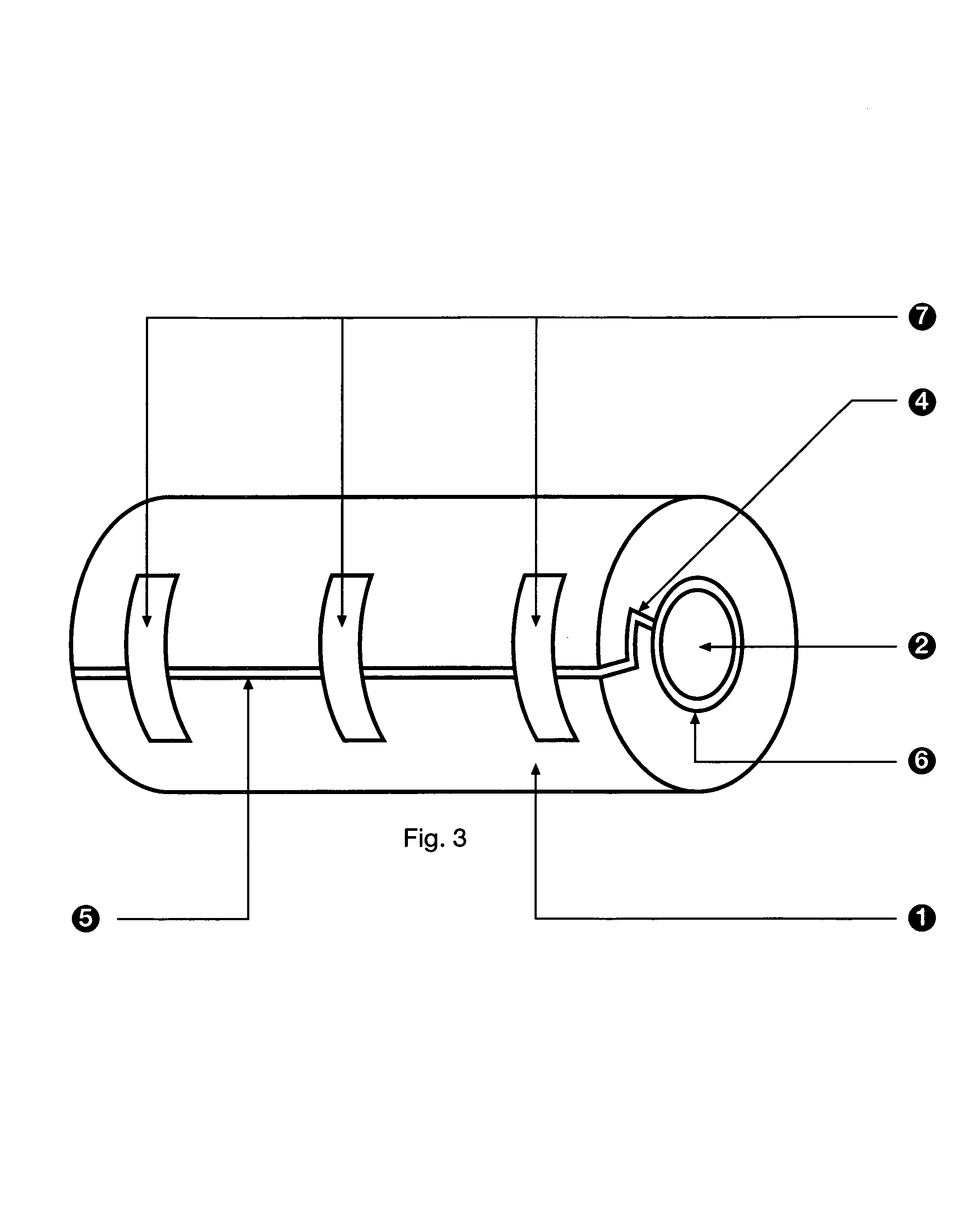

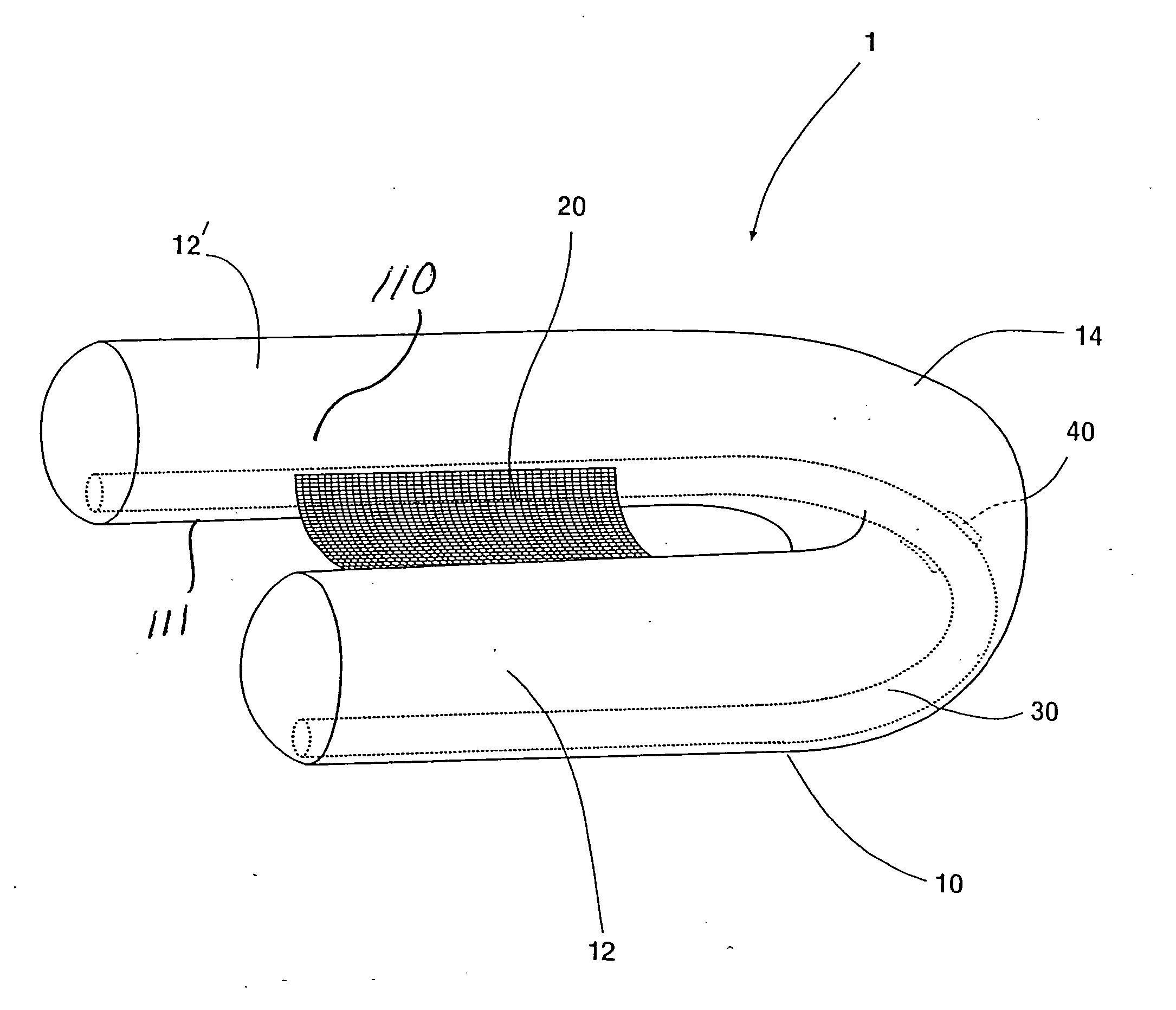

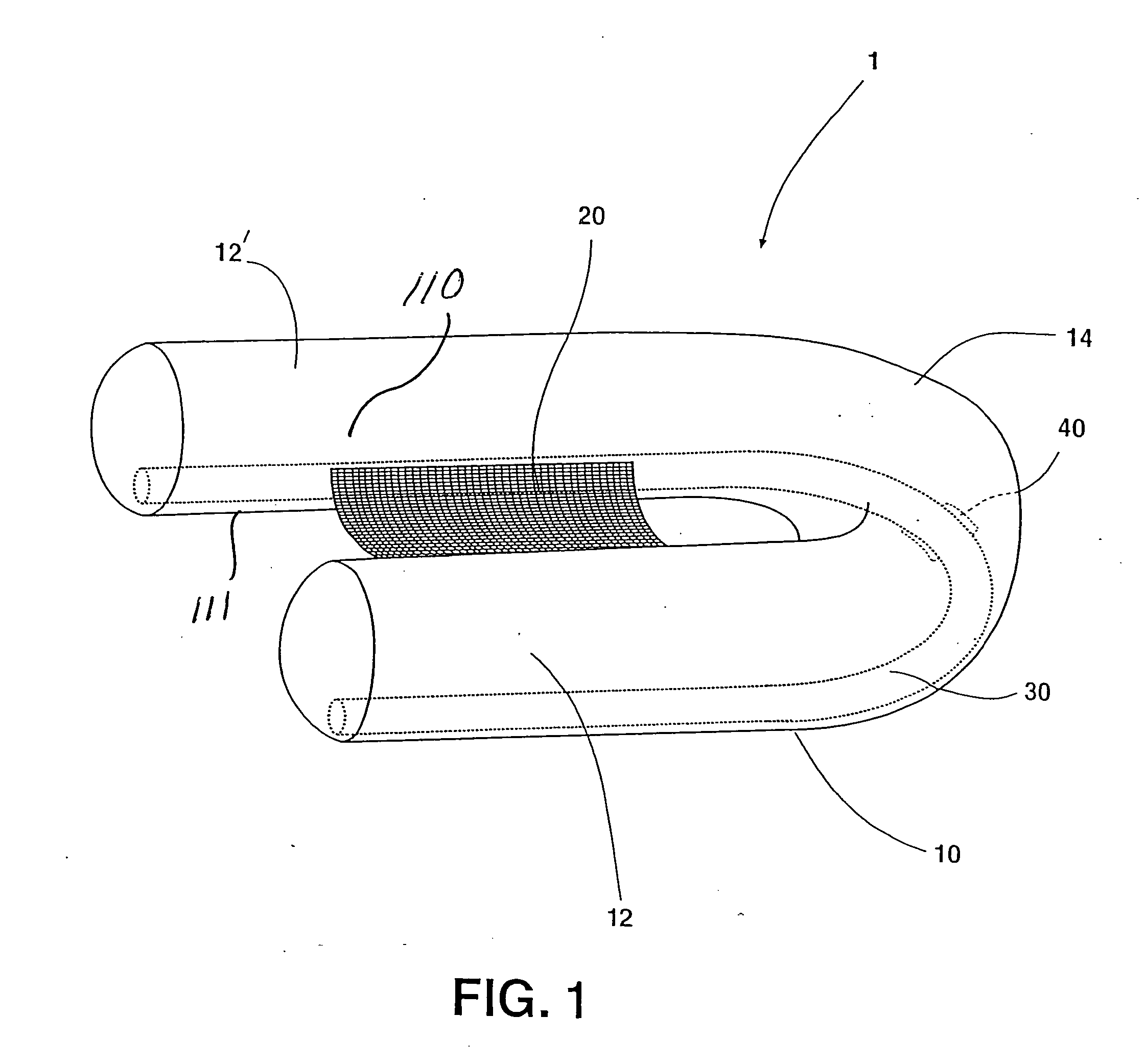

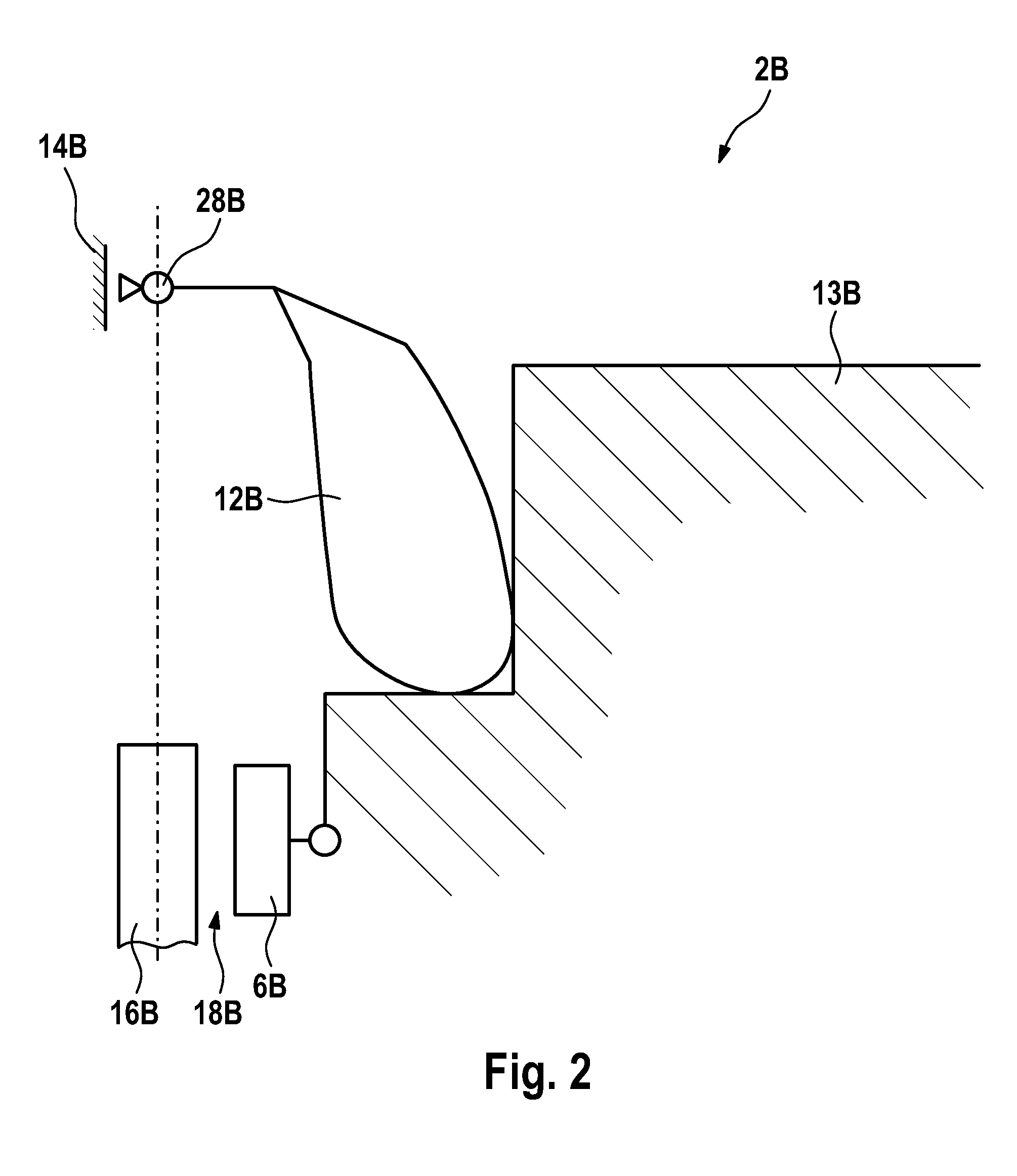

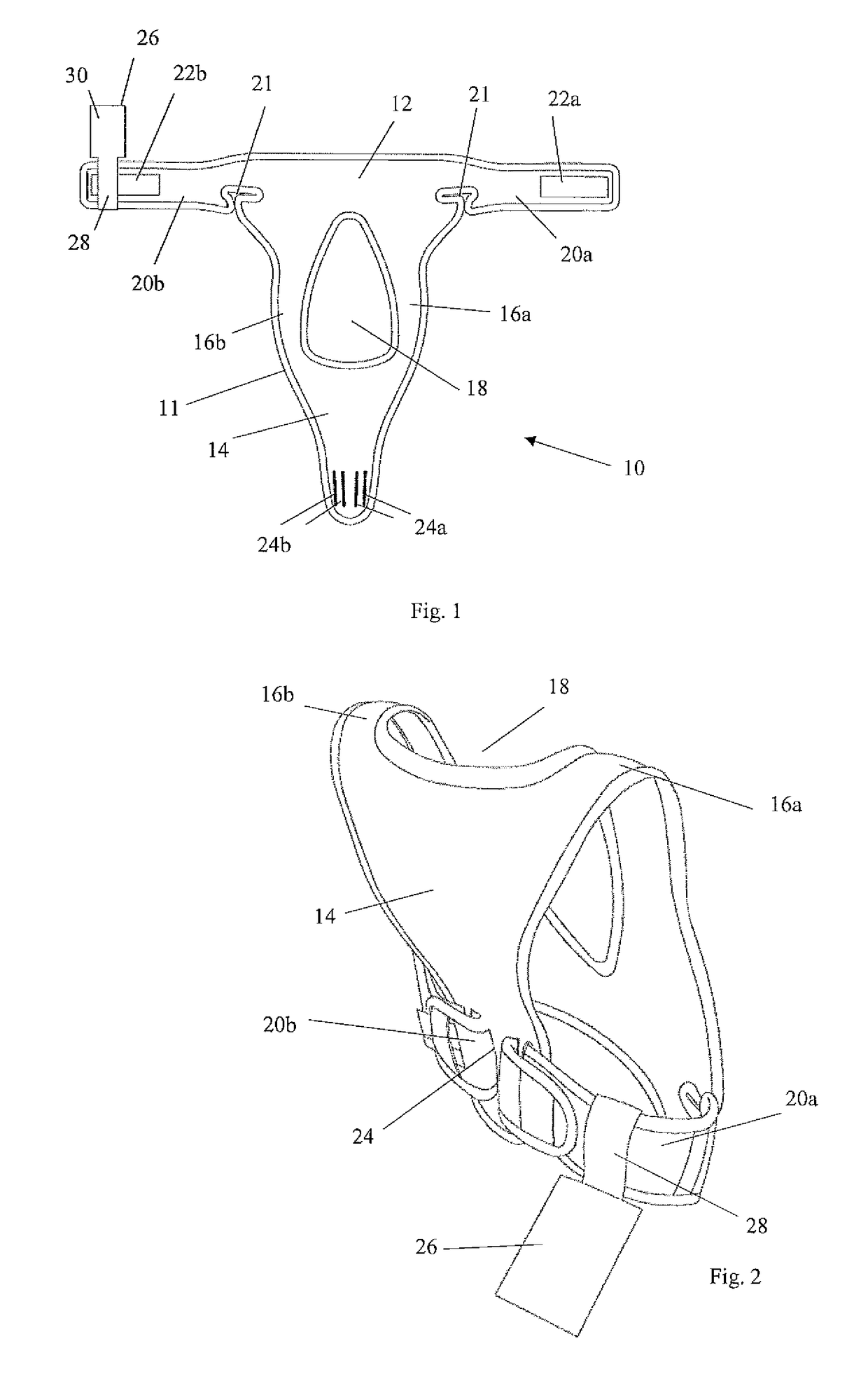

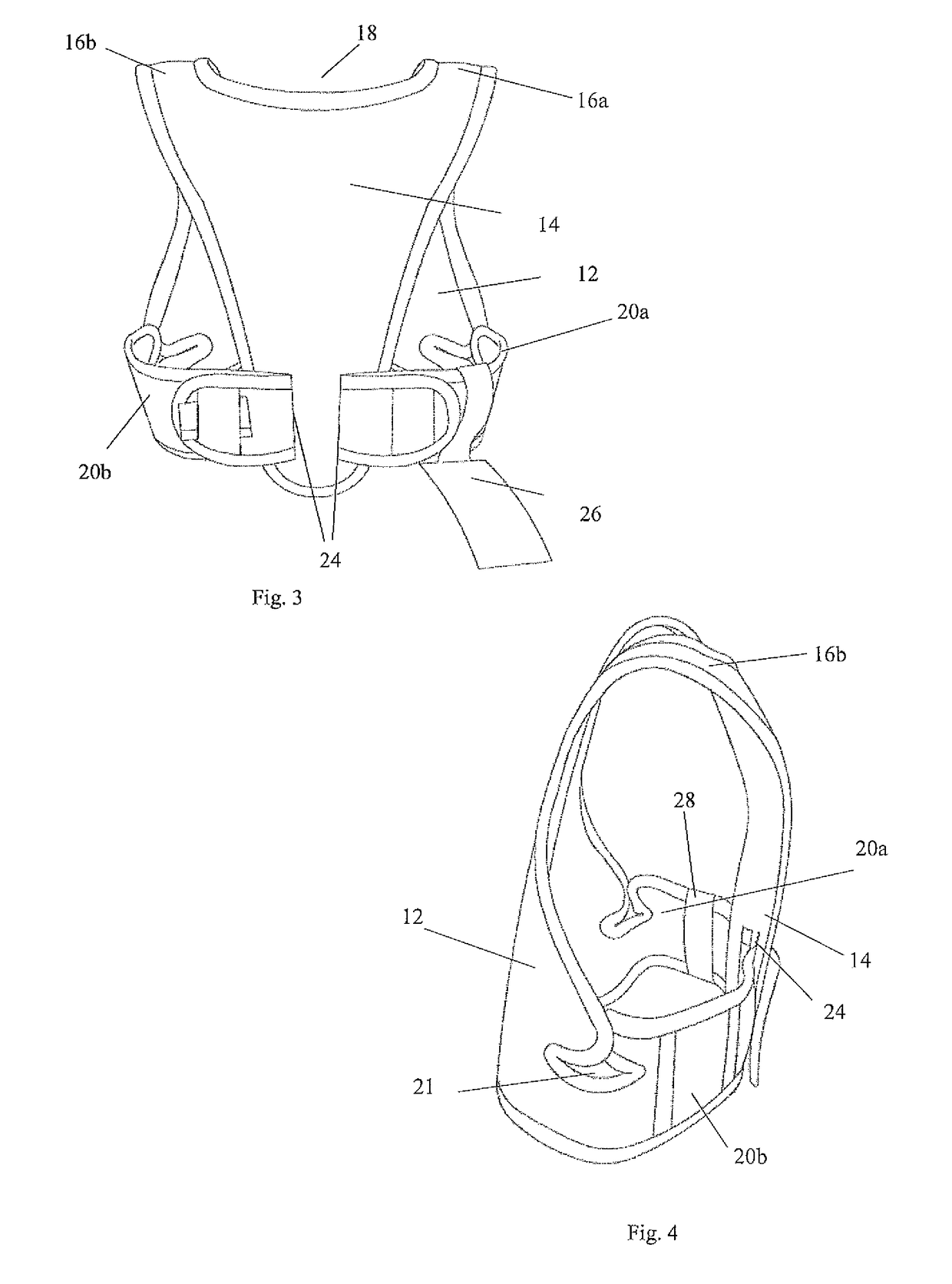

A medical tube storage system

InactiveUS20180229006A1Increase comfortReduce number of partMedical devicesCatheterEngineeringFront panel

A medical tube holder (10) comprising a harness (11) and a pouch (26). The harness comprises a front panel (12) and a back panel (14) with two shoulder straps (16a, 16b) connecting an upper part of the front panel to an upper part of the back panel, with a head aperture (18) between the shoulder straps. The lower part of back panel comprises a first part of a connection mechanism (22) and the lower part of the front panel comprises two laterally extending straps (20a, 20b). The two laterally extending straps form a second part of the connection mechanism and the pouch is connected to one of the laterally extending straps.

Owner:TOOKIE

Digital 3D infrared slit lamp with pupil and retina intensity measurement

ActiveUS20210022607A1Increase comfortGreat responseOthalmoscopesRetinal damageOphthalmology department

Owner:MCWHERTER IAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com