Patents

Literature

76results about How to "Sufficient structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

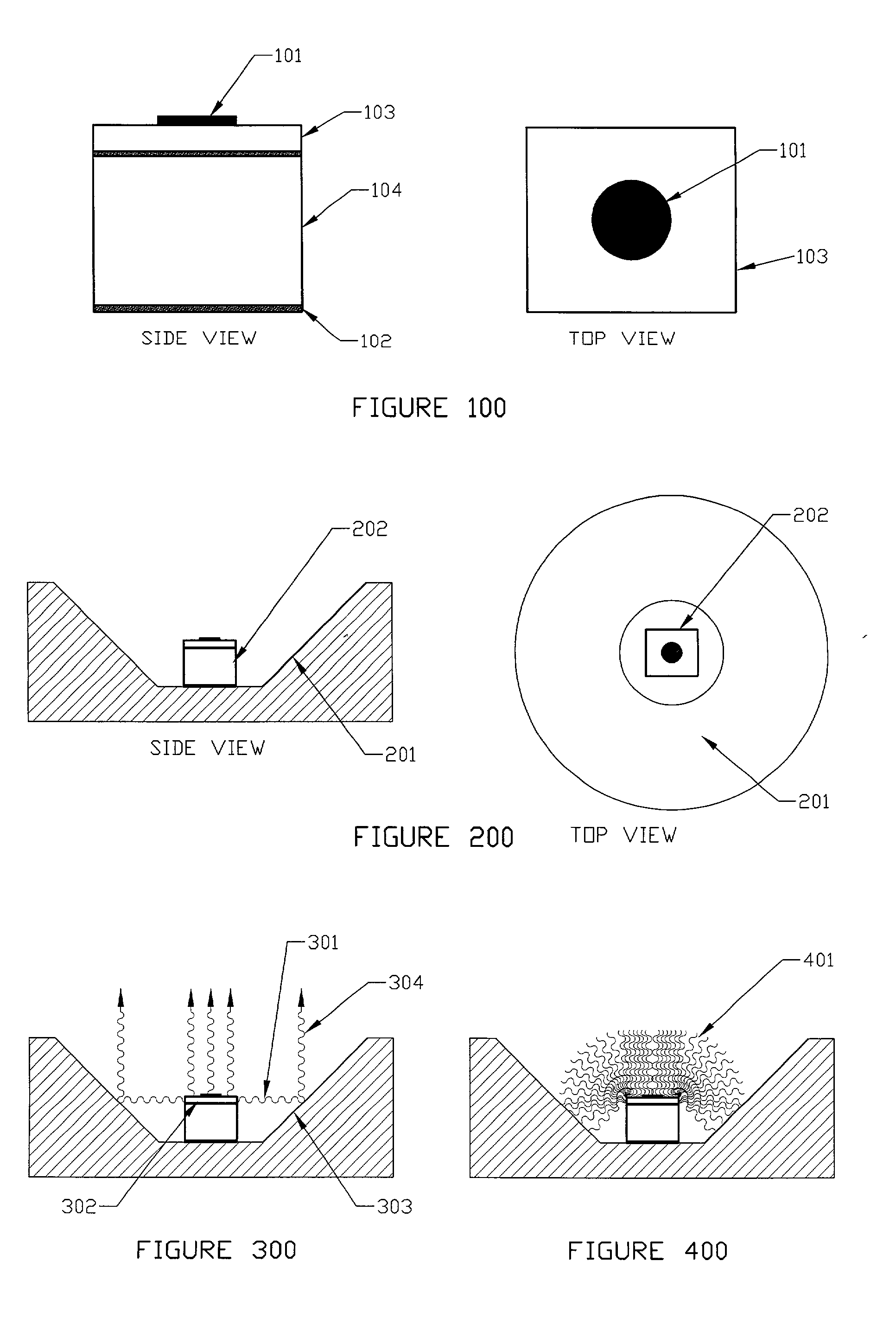

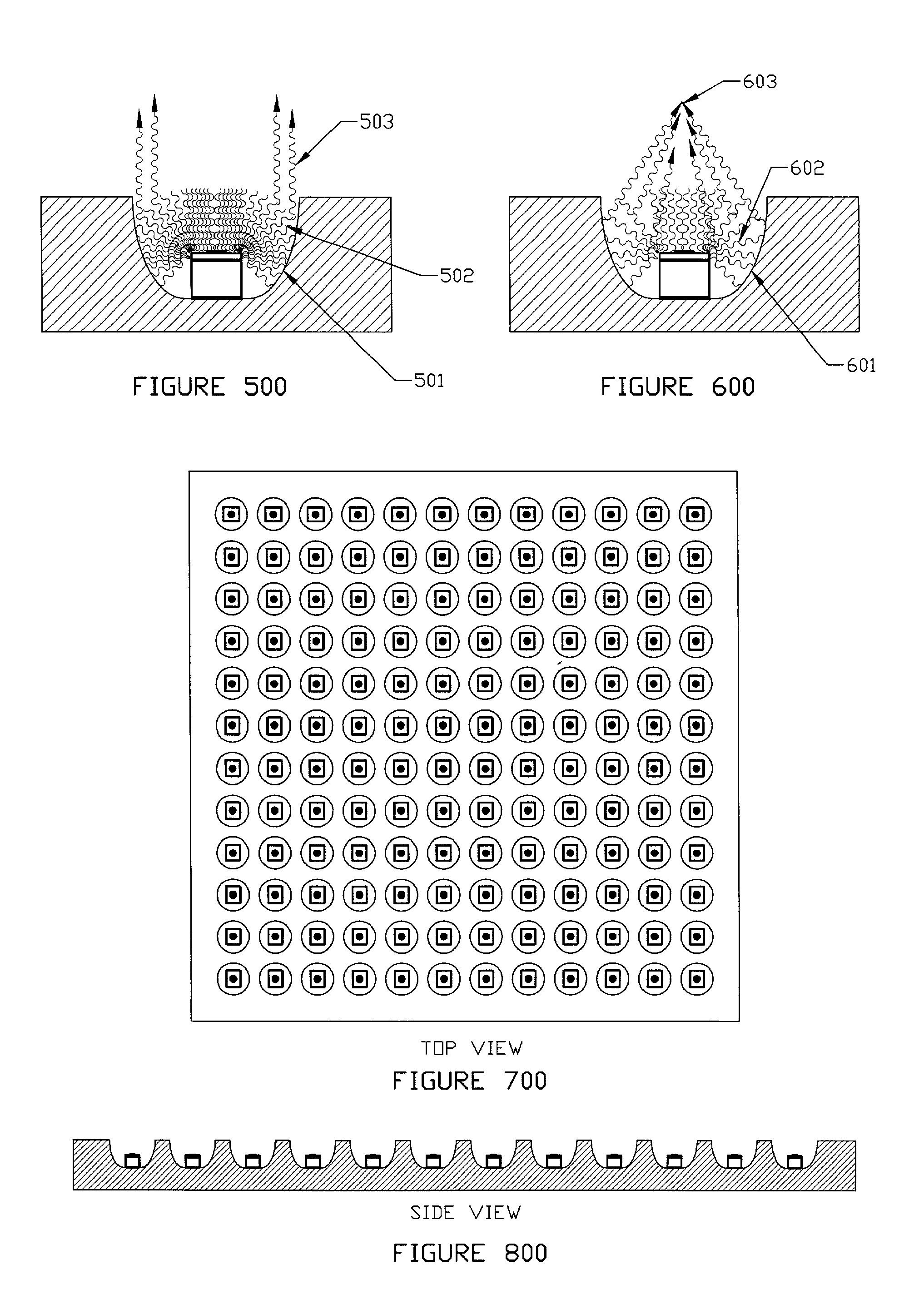

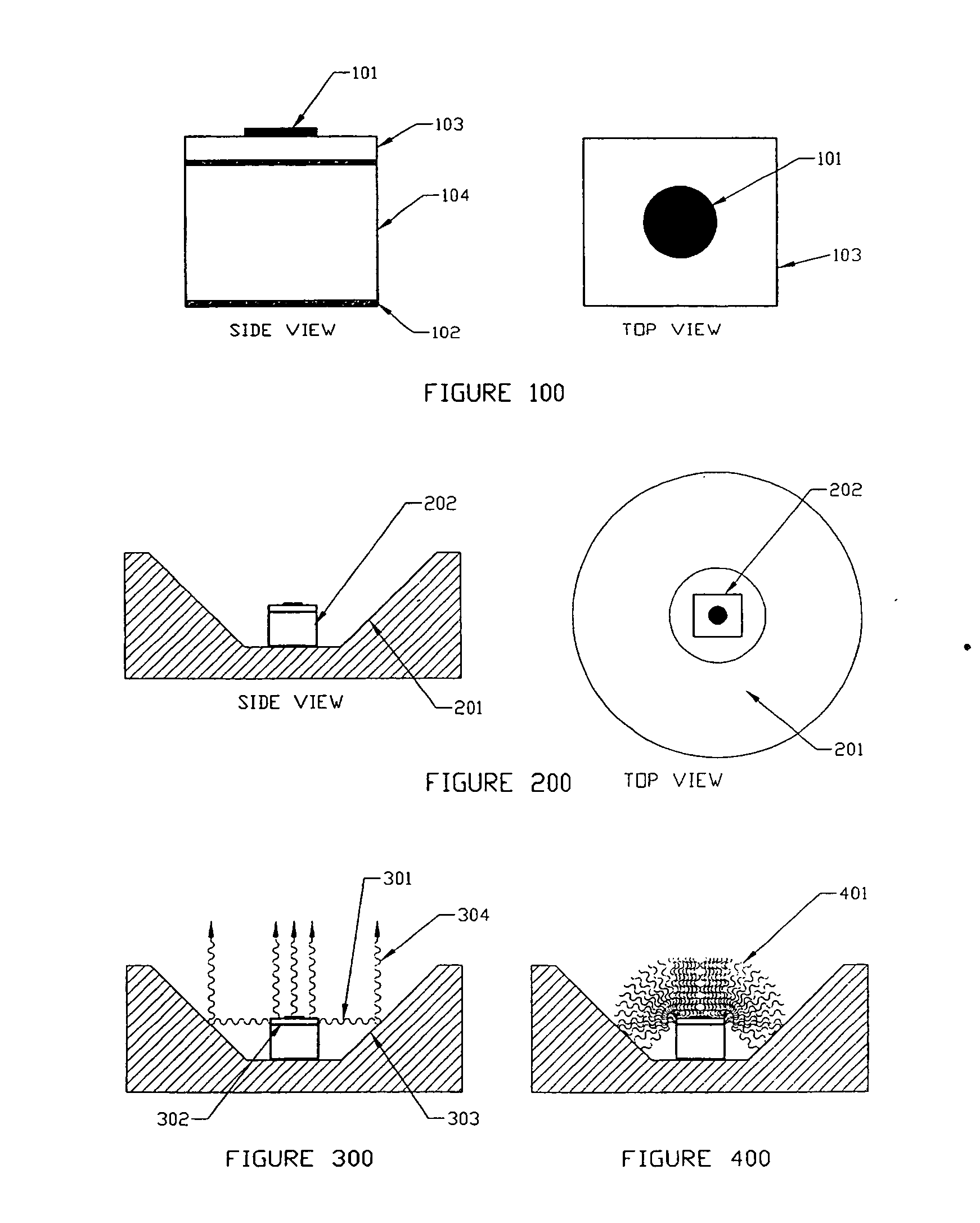

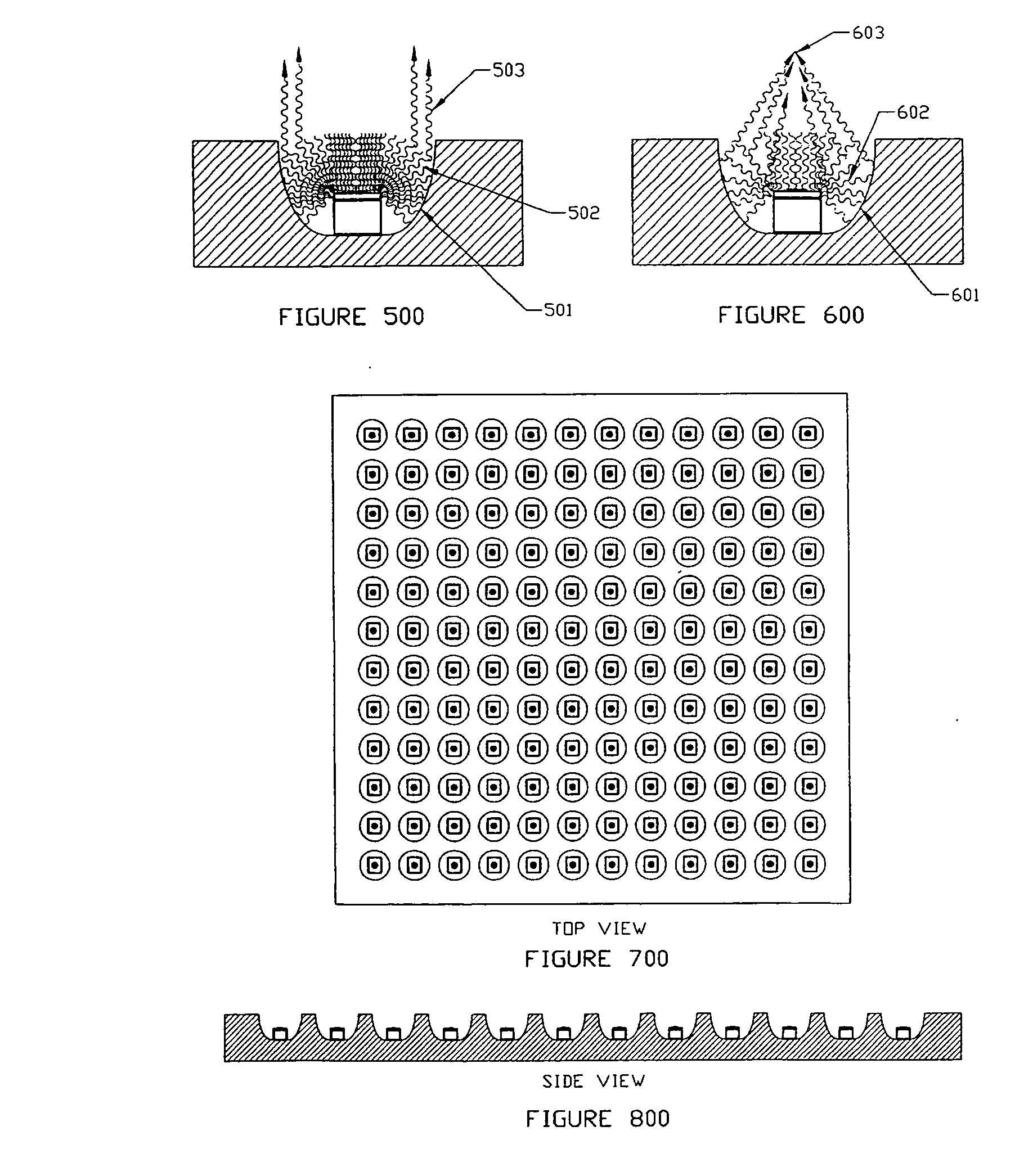

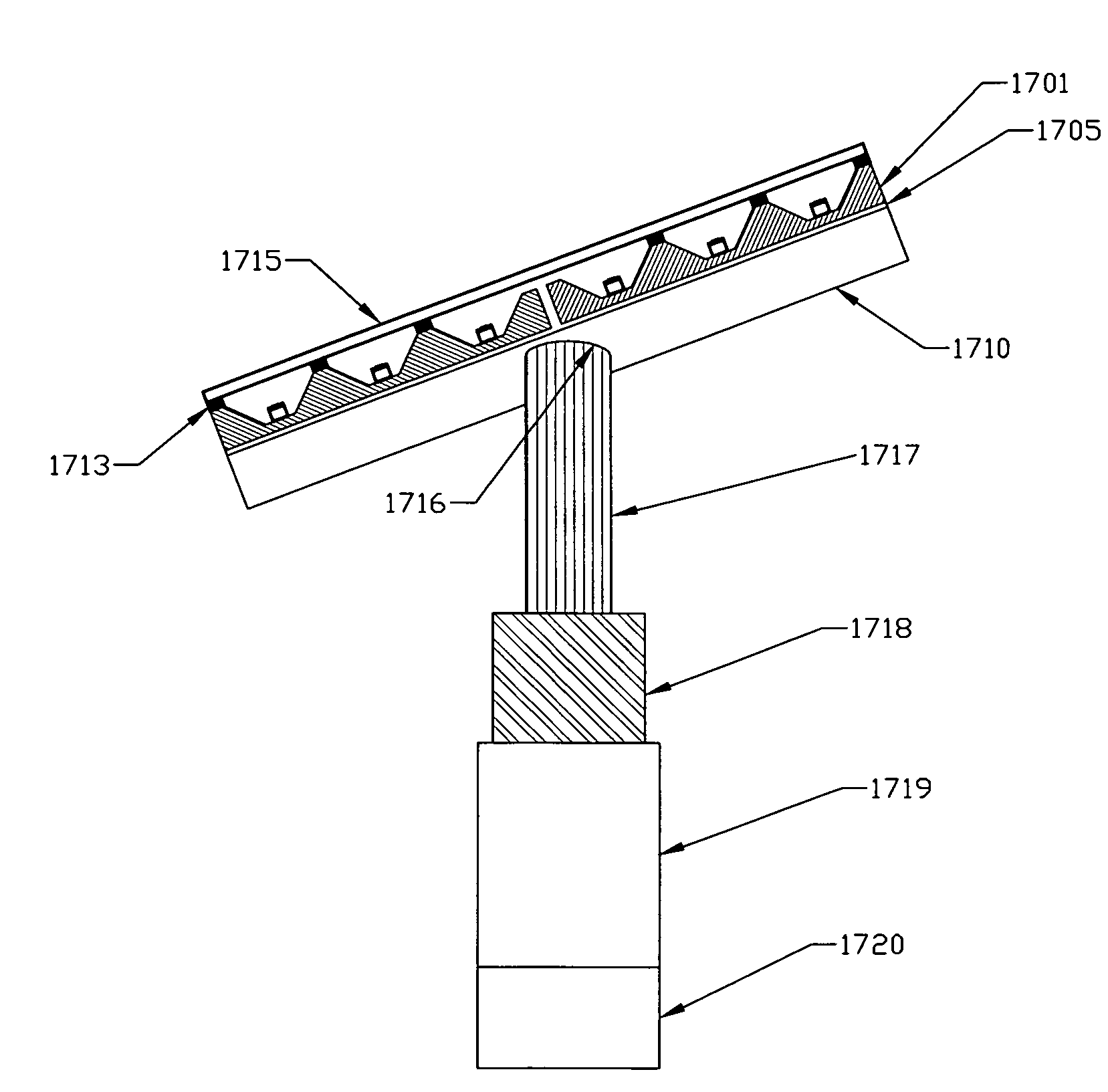

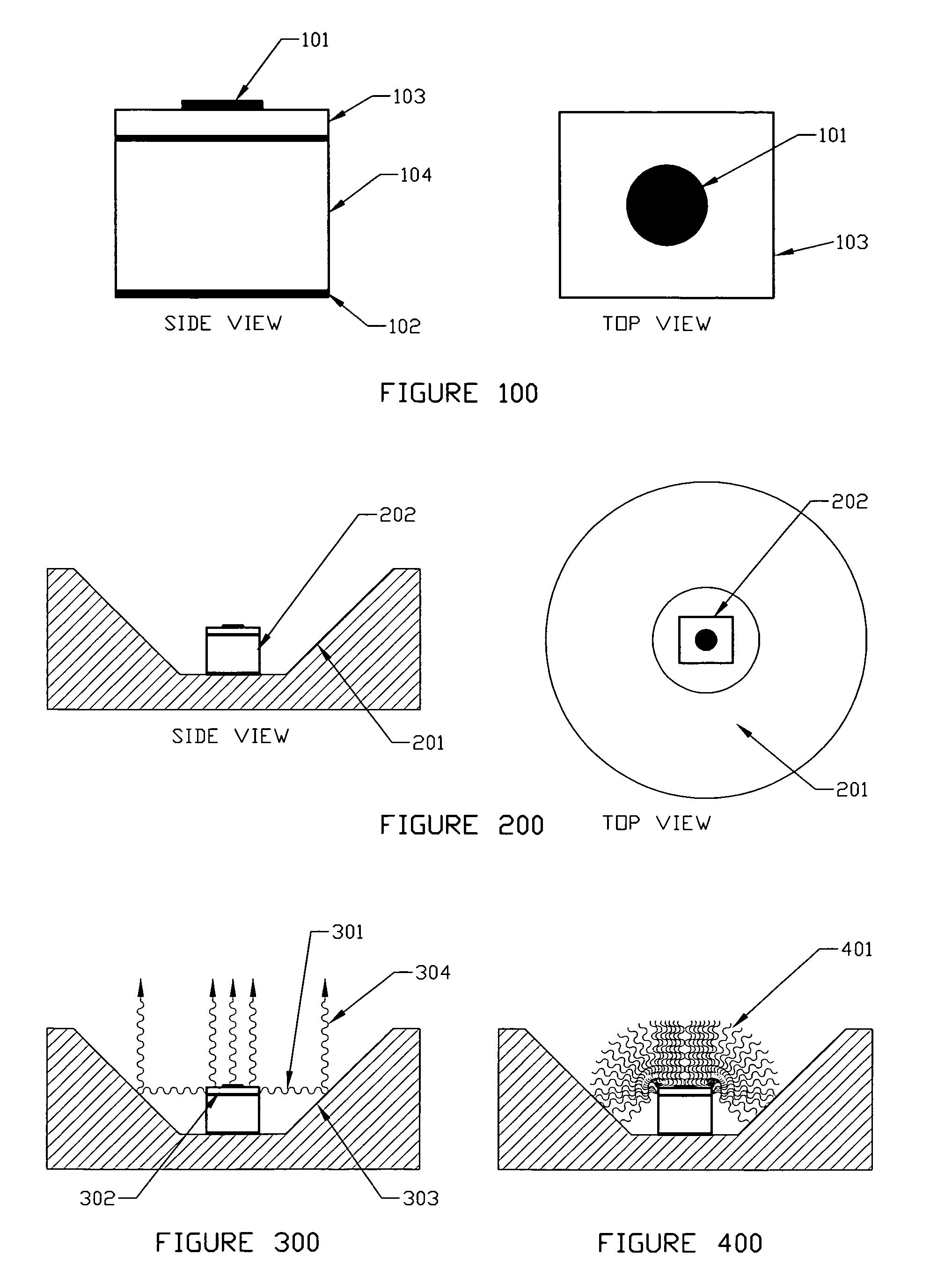

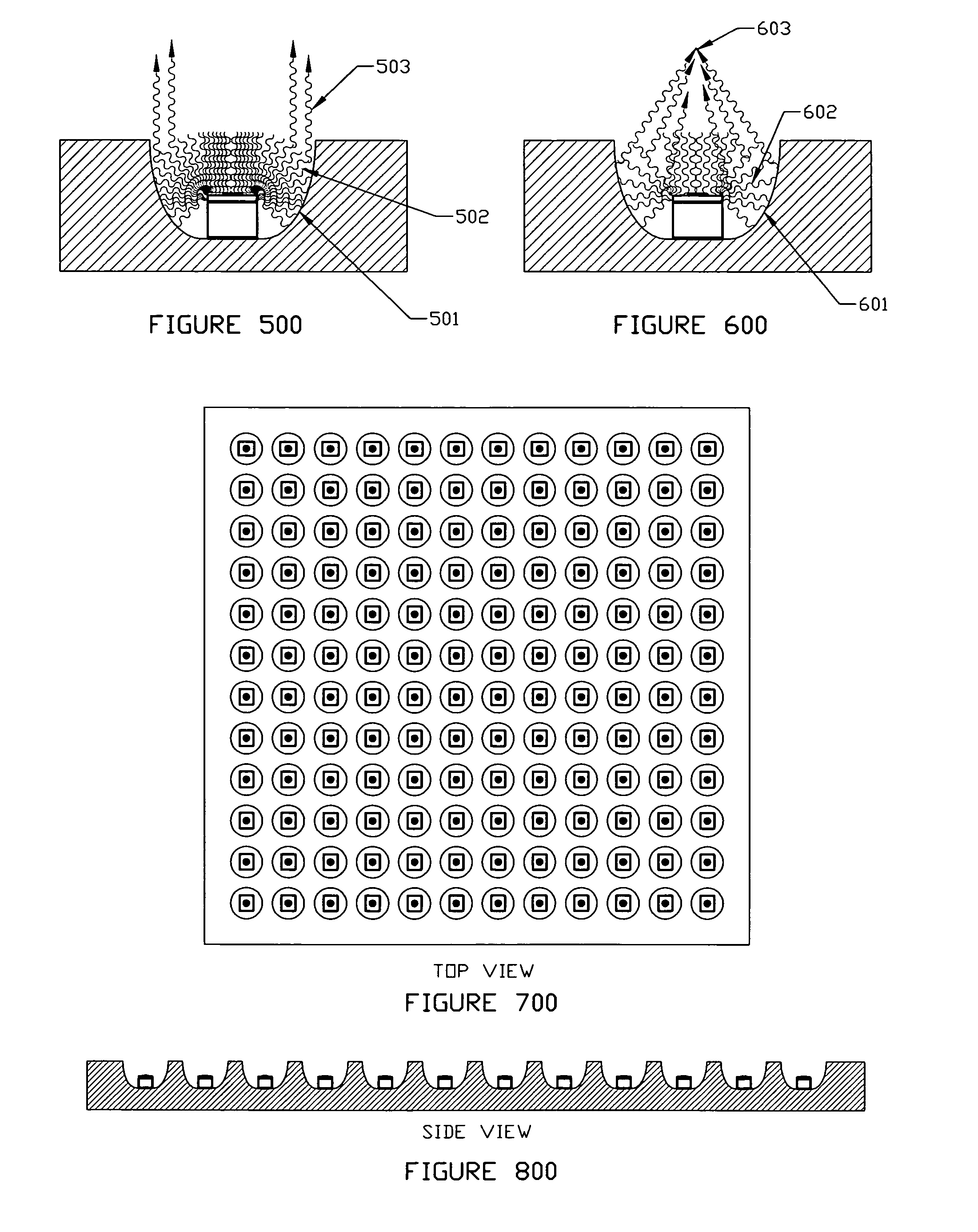

Light emitting diode light source for curing dental composites

InactiveUS20010046652A1Sufficient powerSufficient structurePrinted circuit aspectsSolid-state devicesDental compositeHeat sink

Light Emitting Diode Light Sources for Dental Curing are disclosed. Some embodiments of the invention include structures such as Light Emitting Diode Array(s), heat sink, heat dissipation, heat pipe, and control circuitry are disclosed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

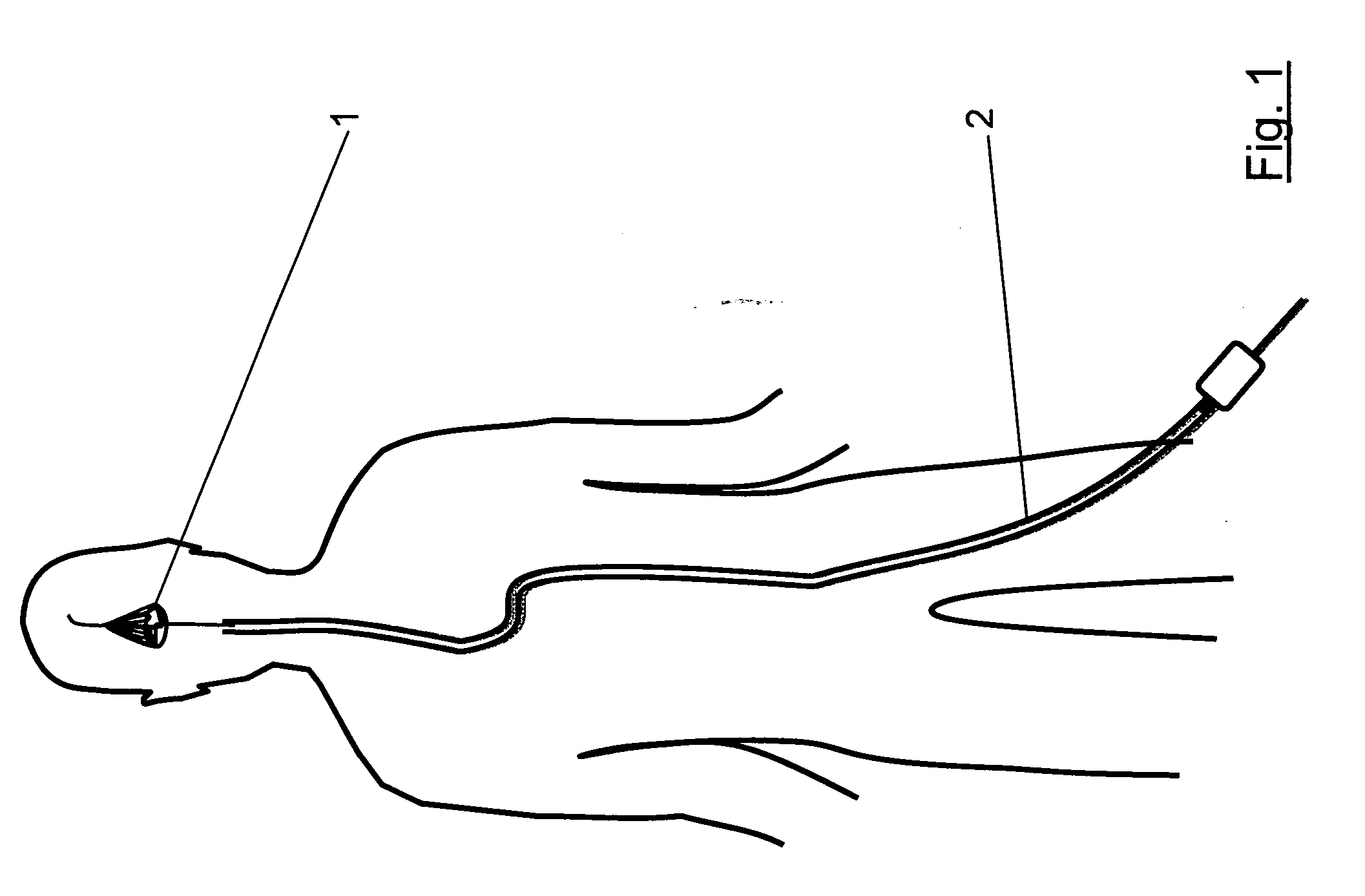

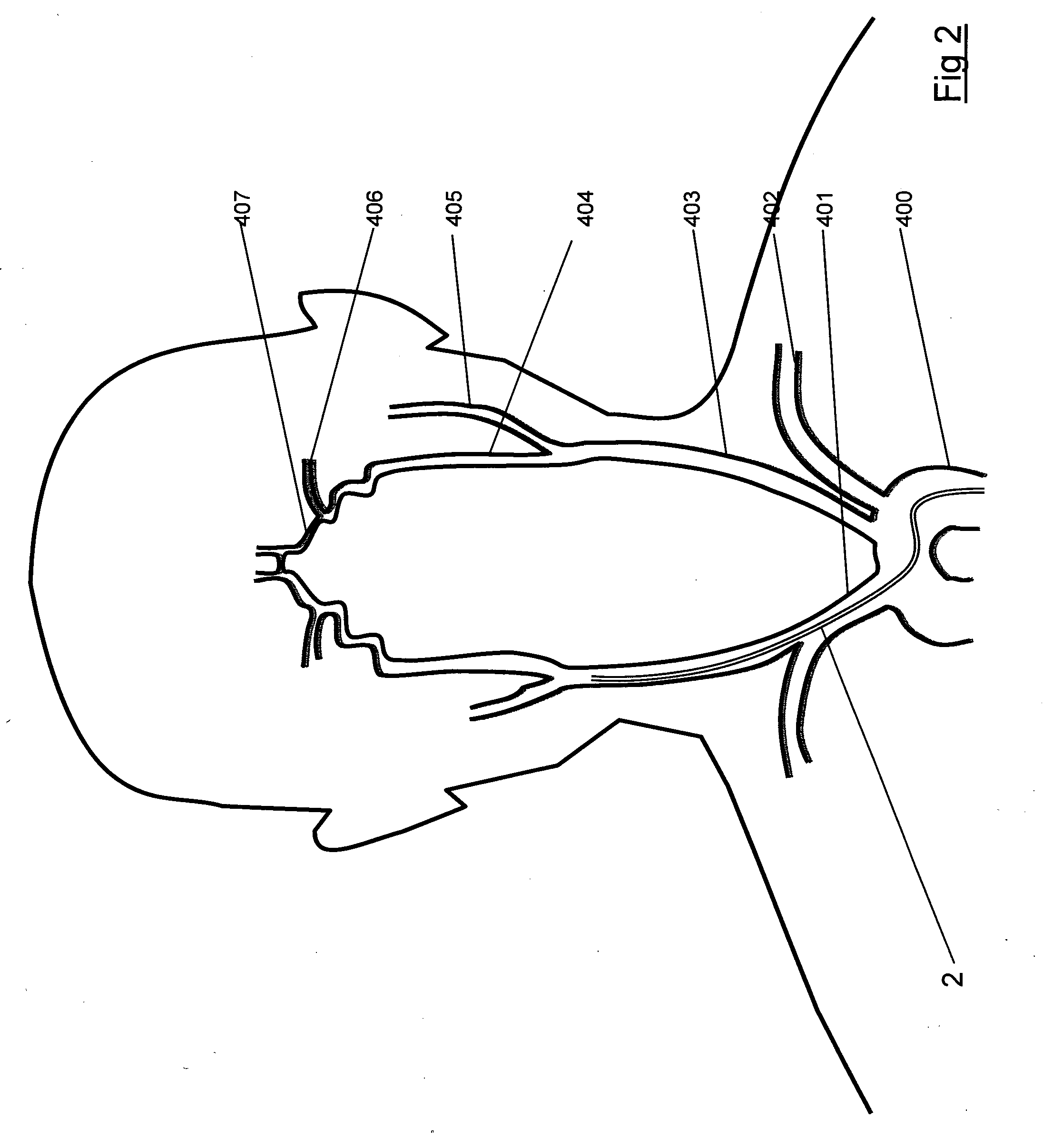

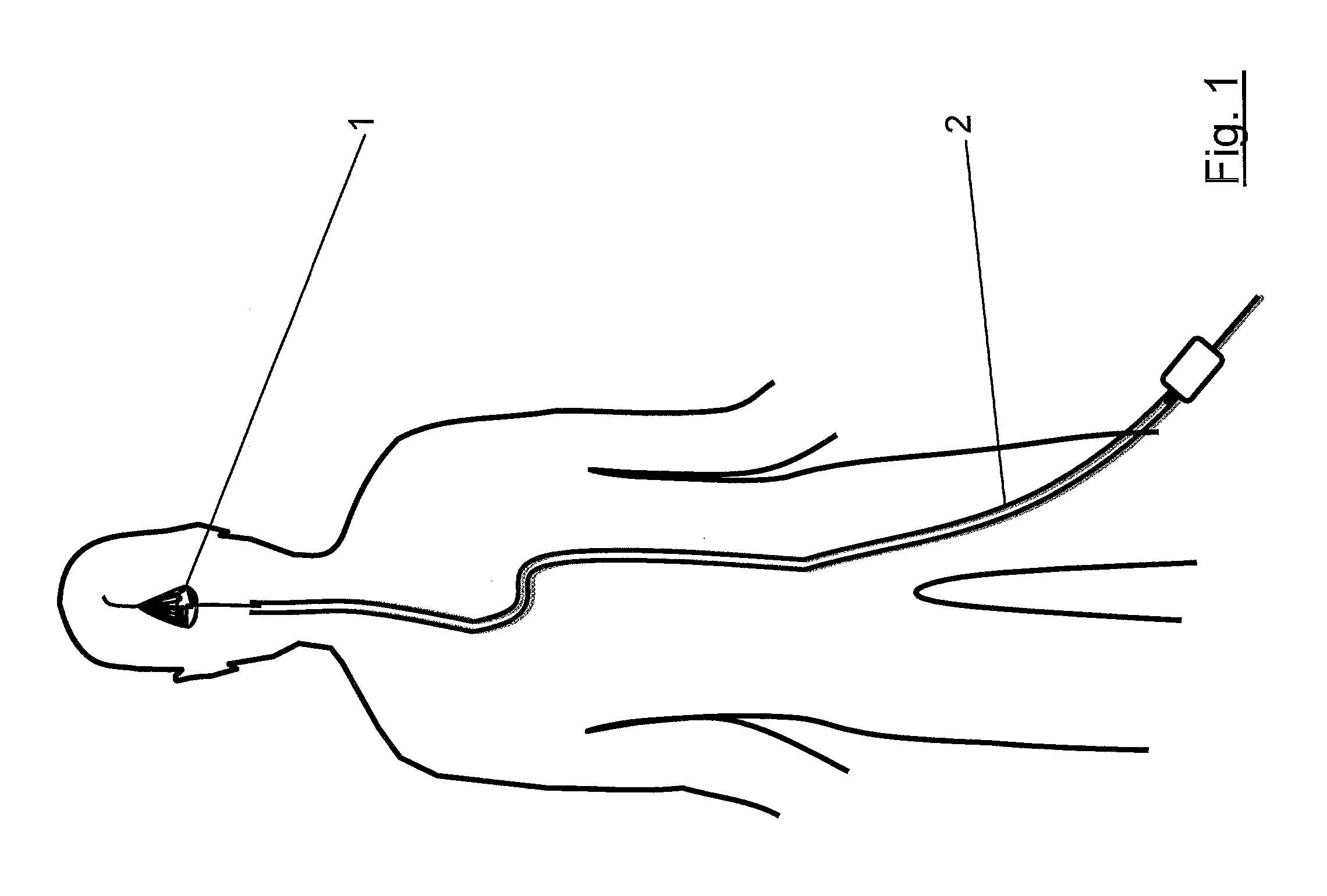

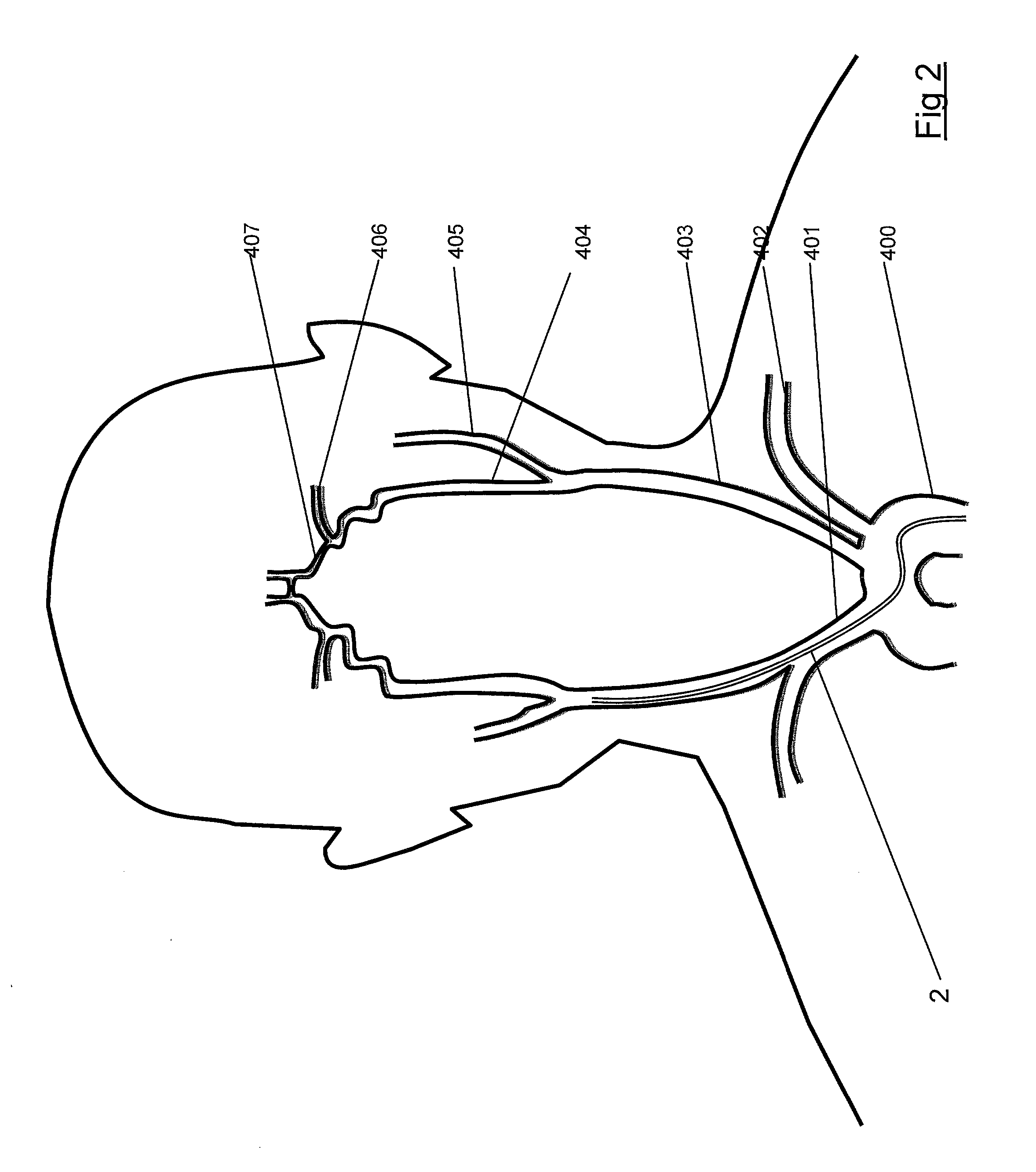

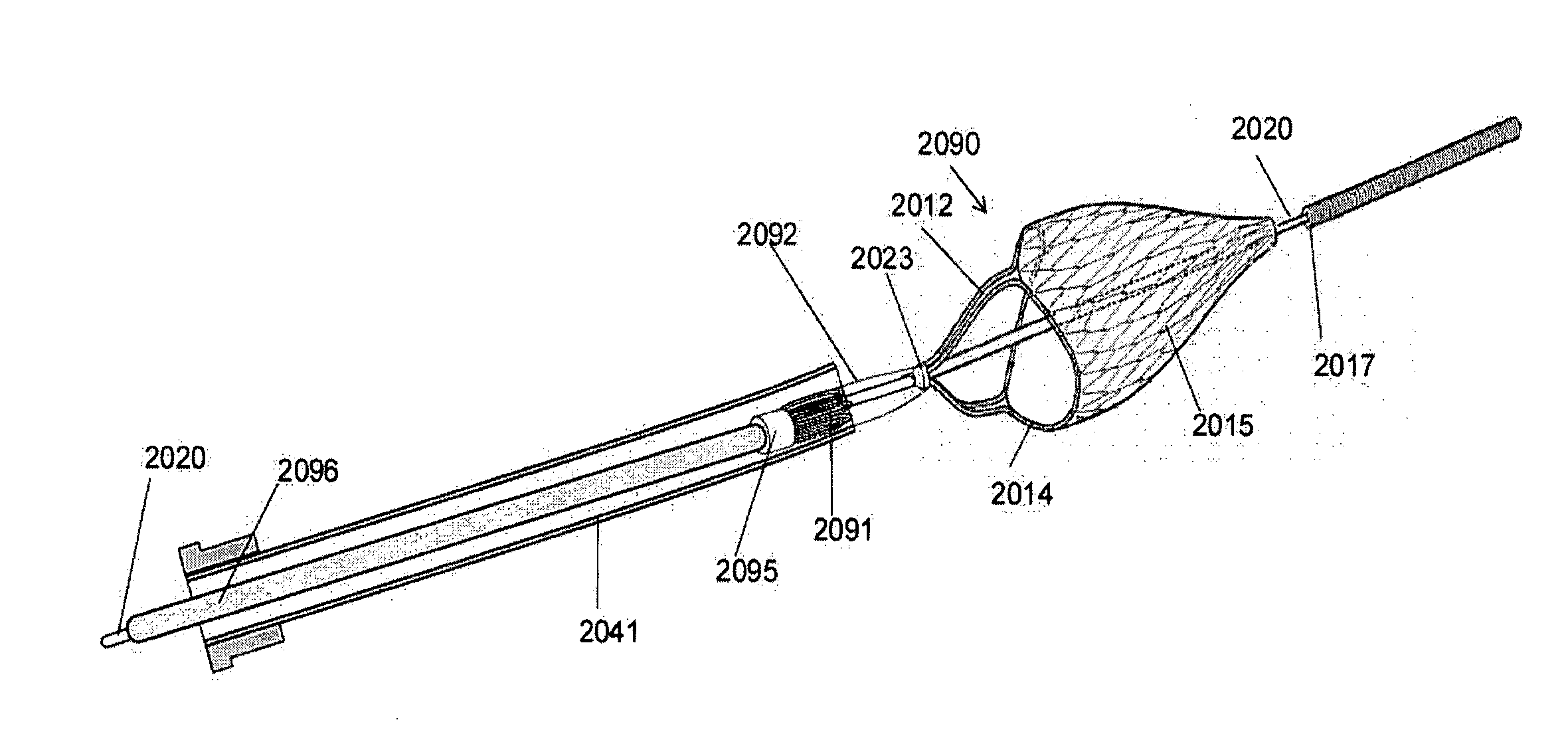

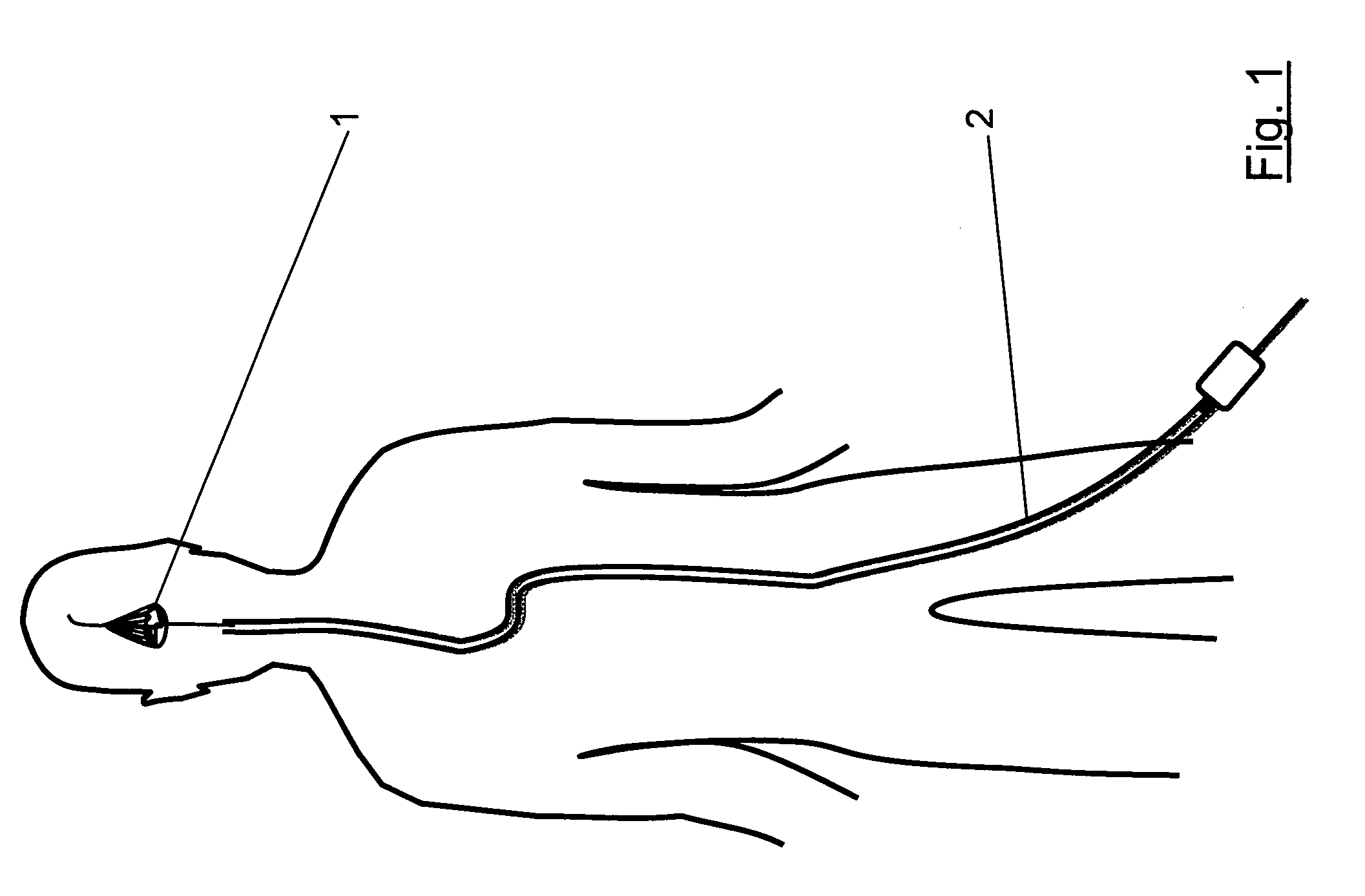

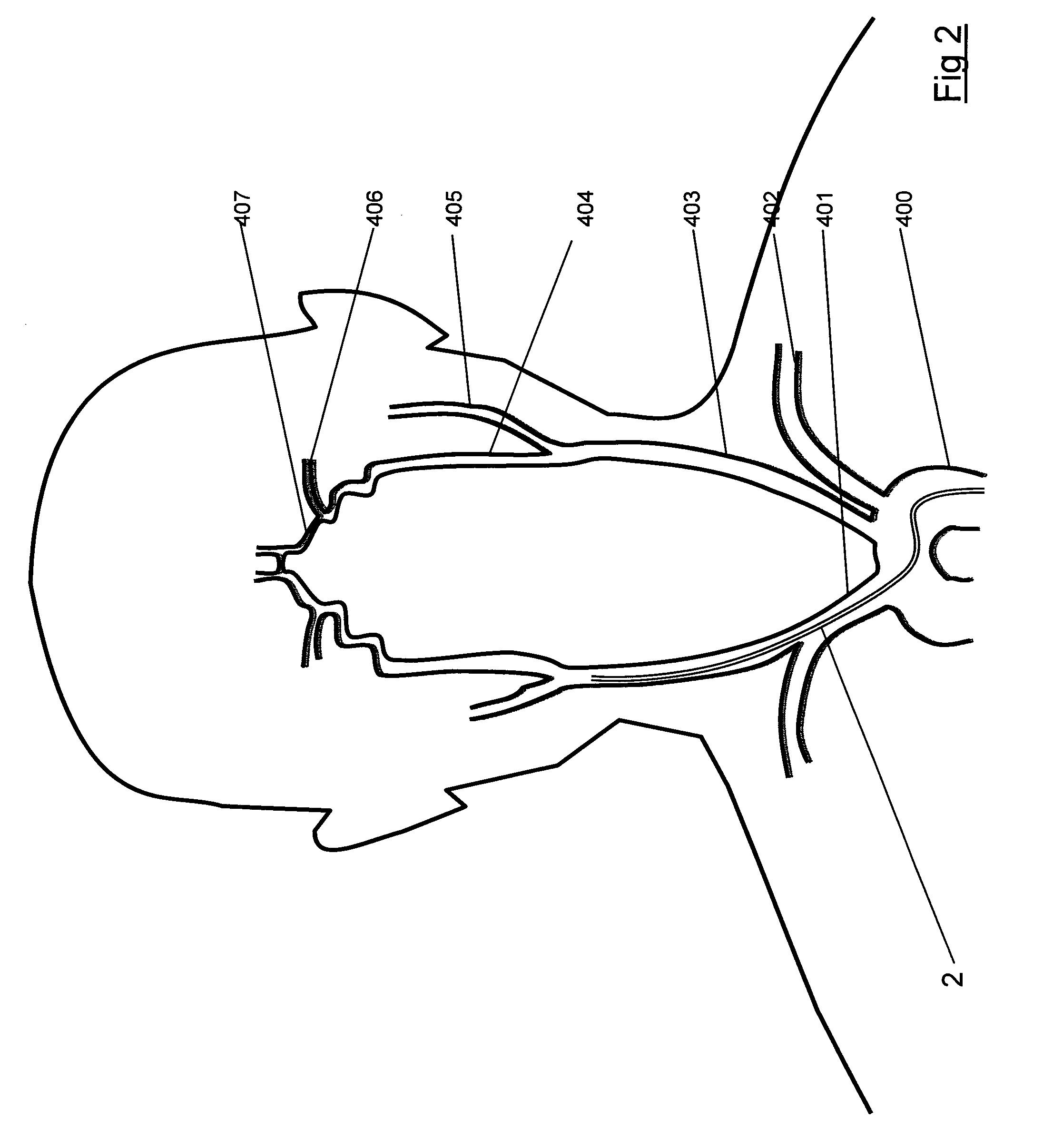

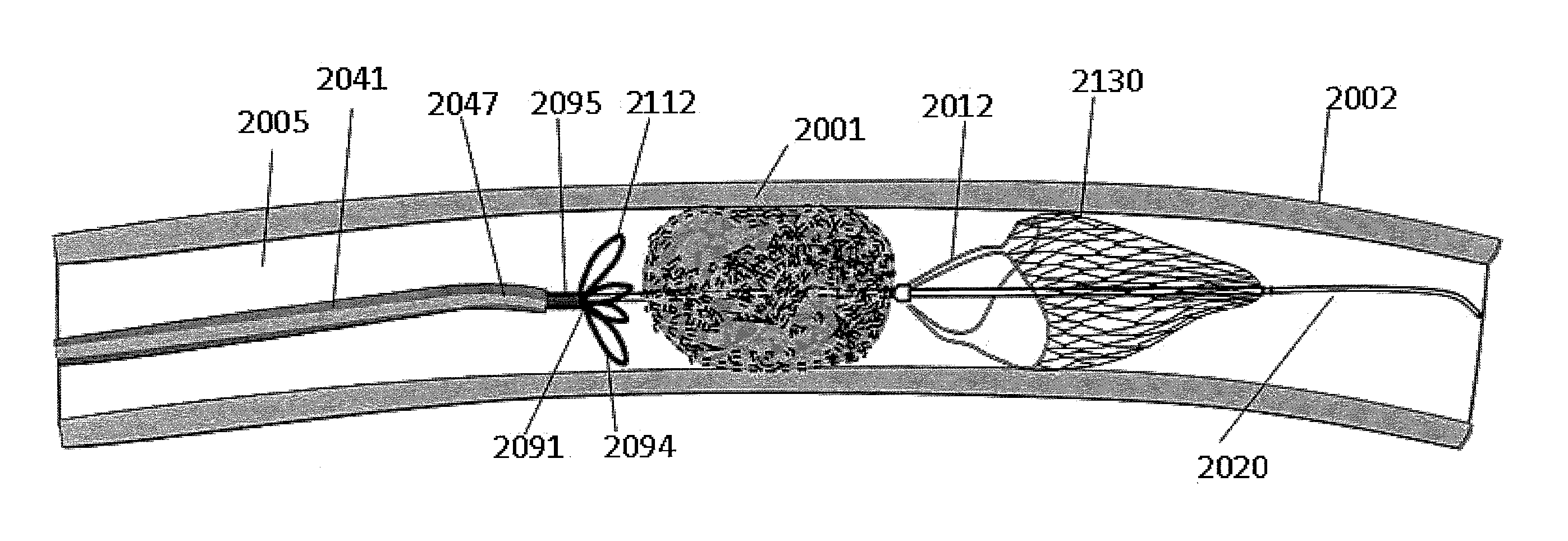

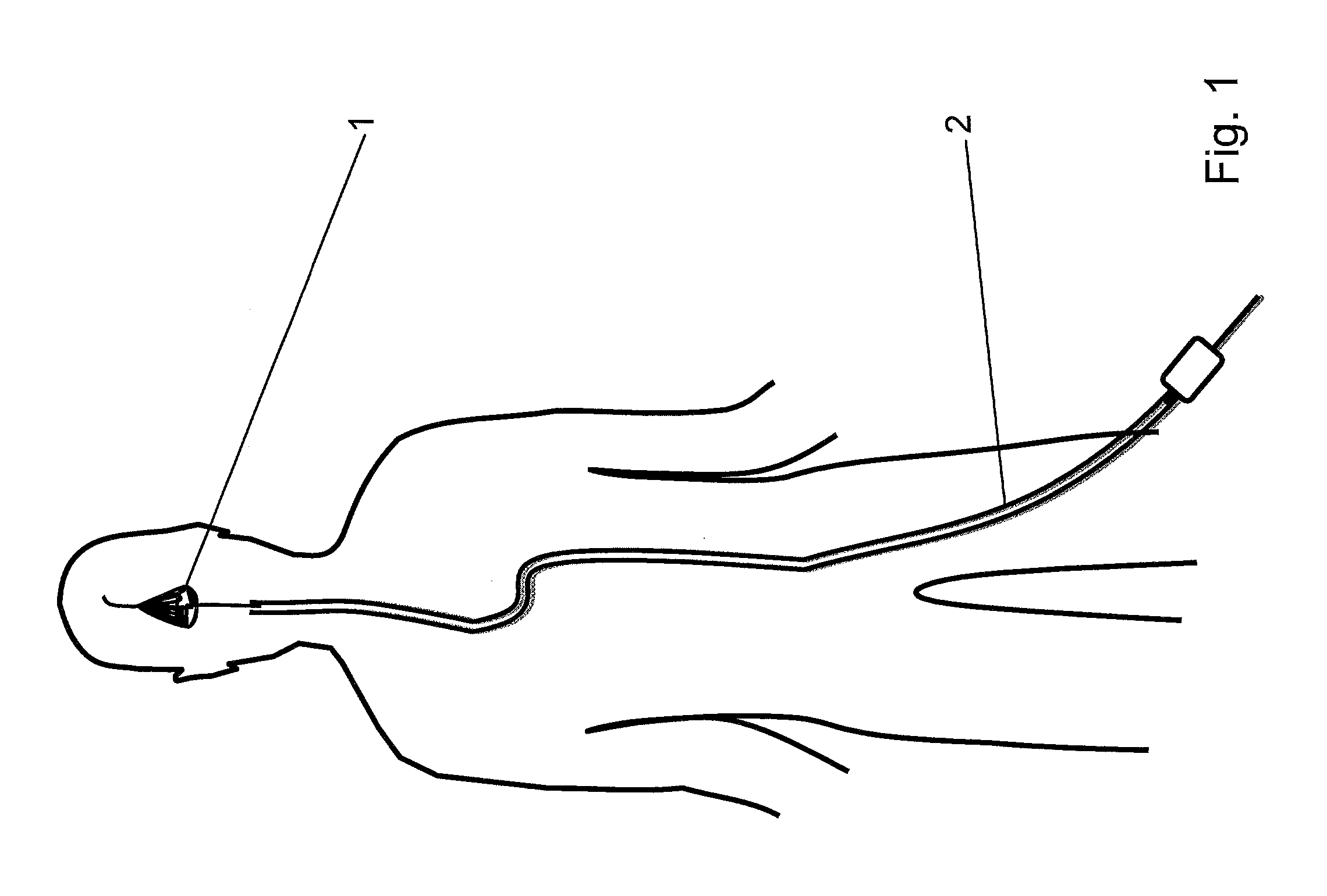

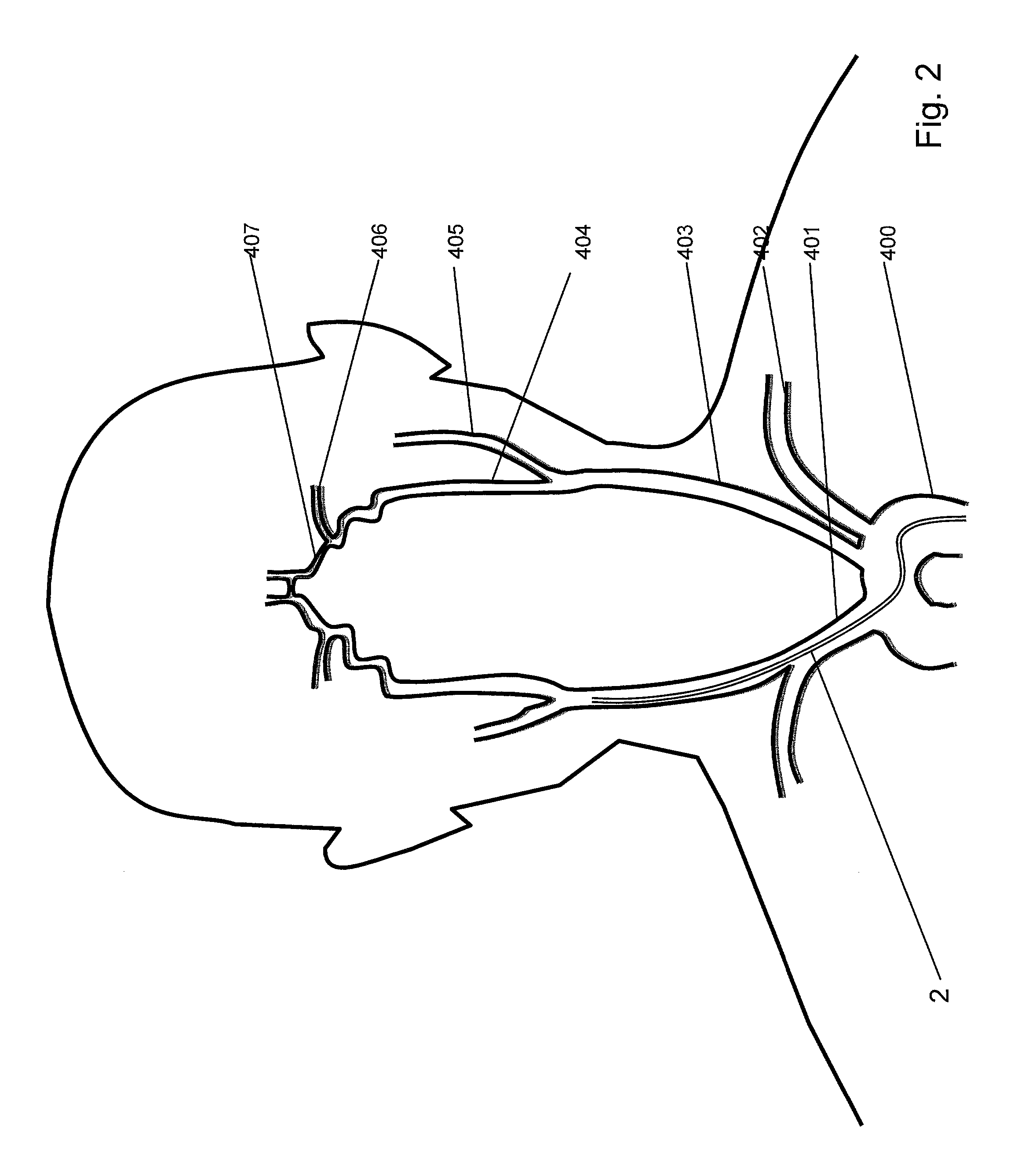

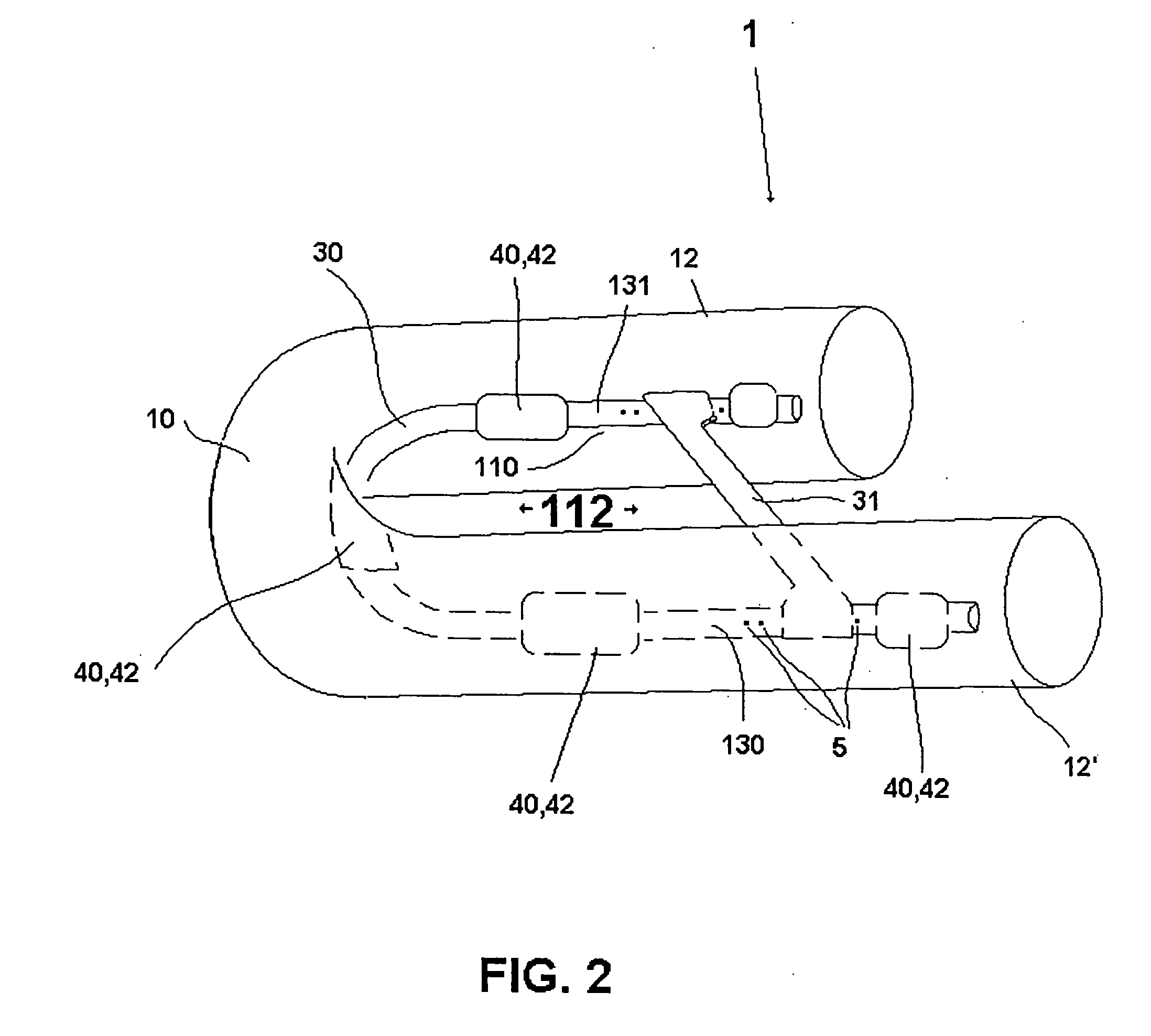

Clot capture systems and associated methods

ActiveUS20110125181A1Sufficient structureAvoid fragmentationSurgeryDilatorsBiomedical engineeringSurgery

A clot capture system for disengaging a clot 2001 from a vessel wall 2002 and removing the clot 2001 from the vessel 202, comprises a clot capture device 2140 for placement on a distal side of a clot 2001. The clot capture device 2140 has a retracted delivery configuration and an expanded deployed configuration. The clot removal device has a proximal support frame 2012, and a distal fibre net 2130. The support frame 2012 has a retracted delivery configuration and an expanded deployed configuration. The proximal support frame 2012 in the expanded configuration defines a proximal inlet mouth for engaging a clot 2001 and a net 2130 for confining the clot 2001. An elongate member facilitates capture and / or withdrawal of a clot 2001 from a vessel 2002. The system also comprises a clot debonding device 2091 for placement on a proximal side of a clot 2001. The clot debonding device 2091 has a retracted delivery configuration and an expanded deployed configuration and comprises a clot engagement element 2112 which defines a distal abutment in the deployed configuration for urging a clot 2001 into the clot cap 2140.

Owner:NEURAVI

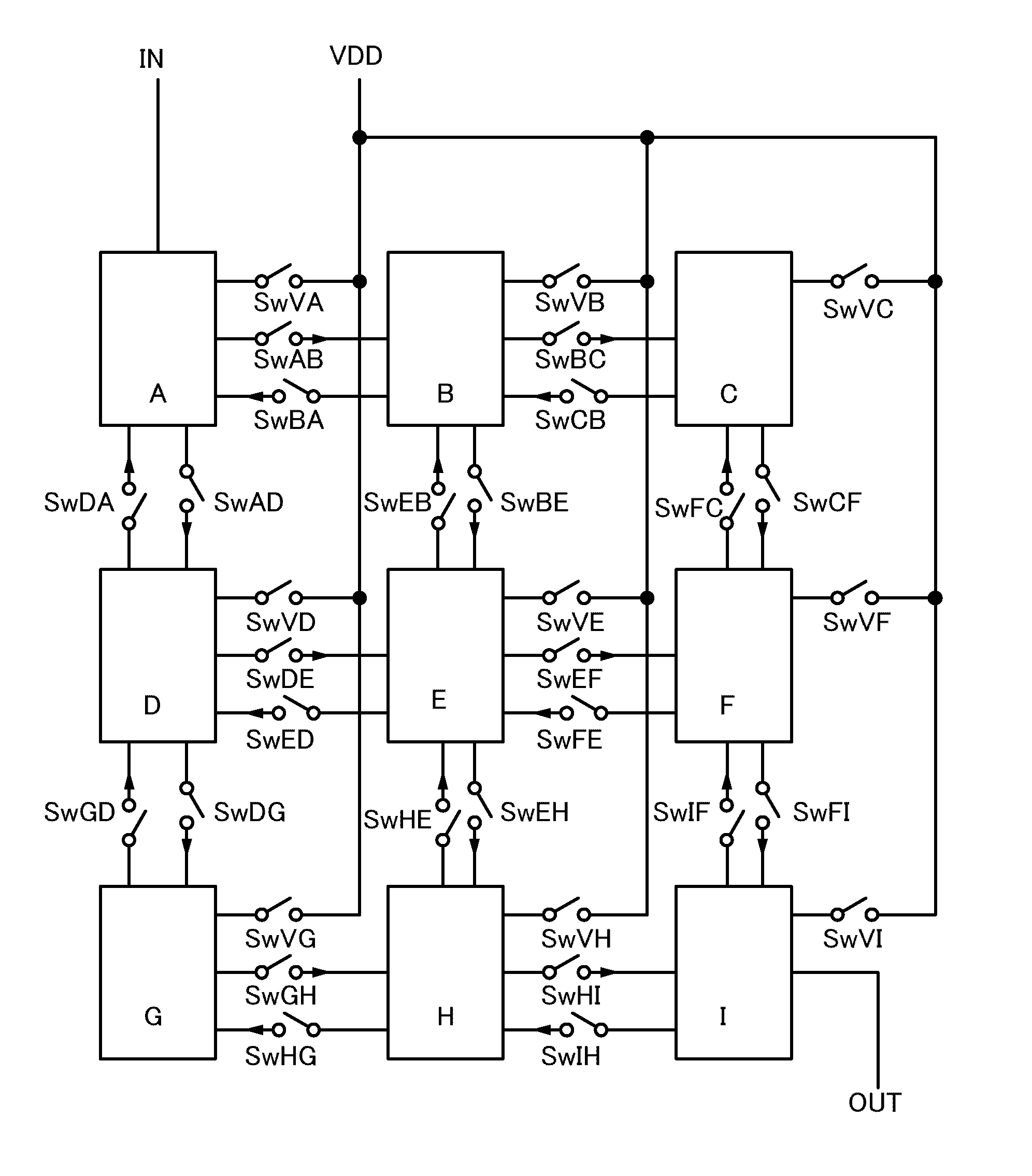

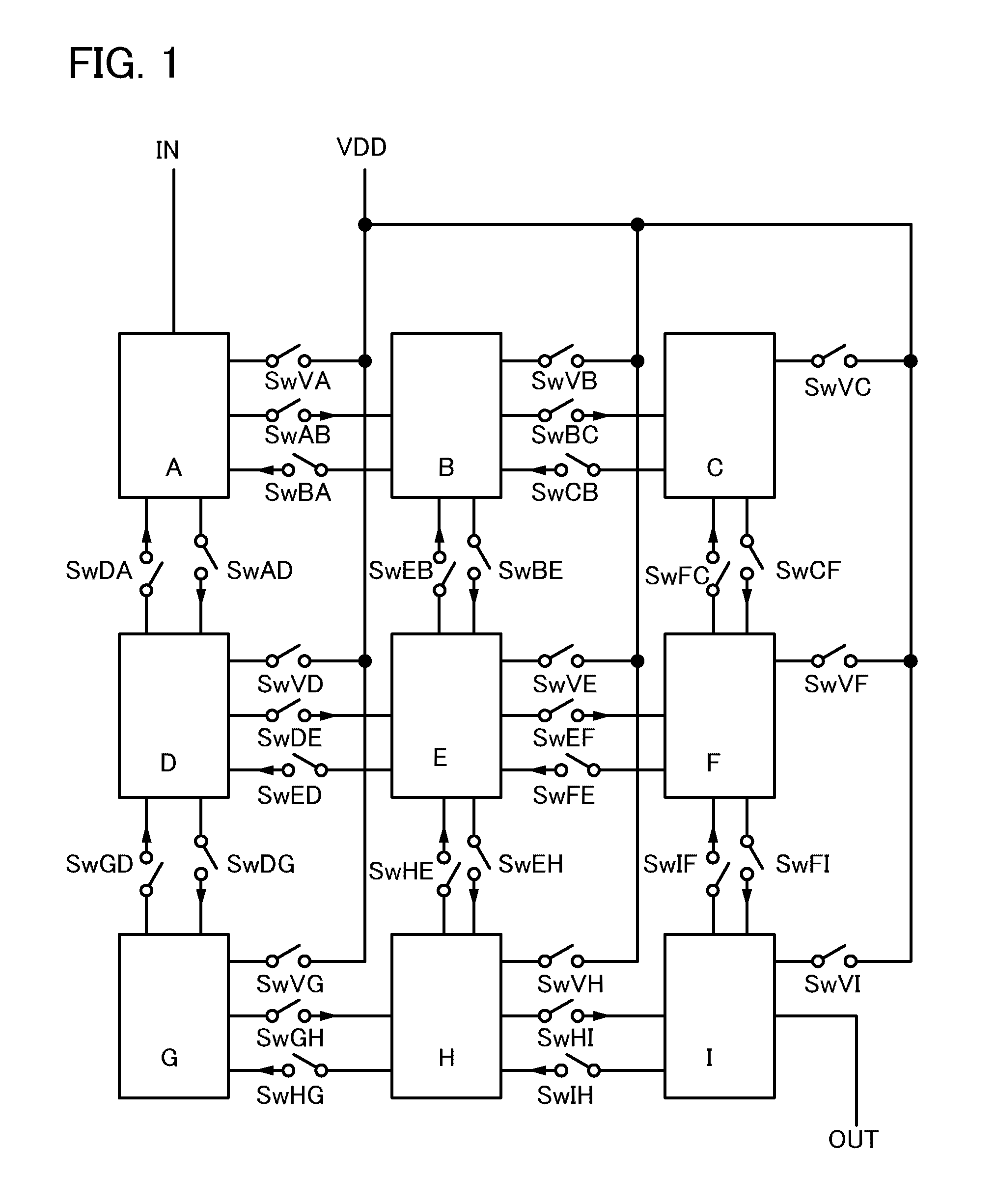

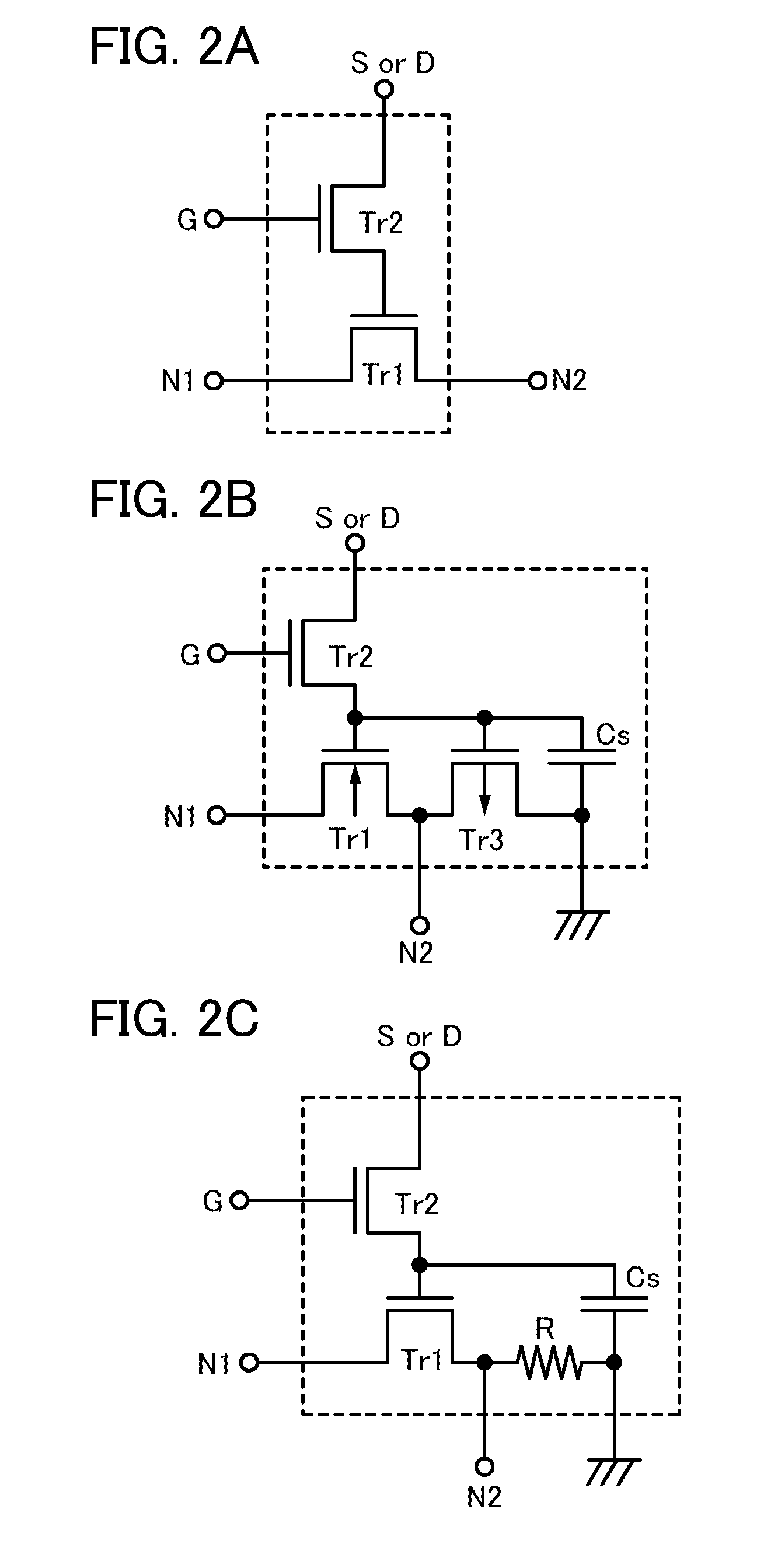

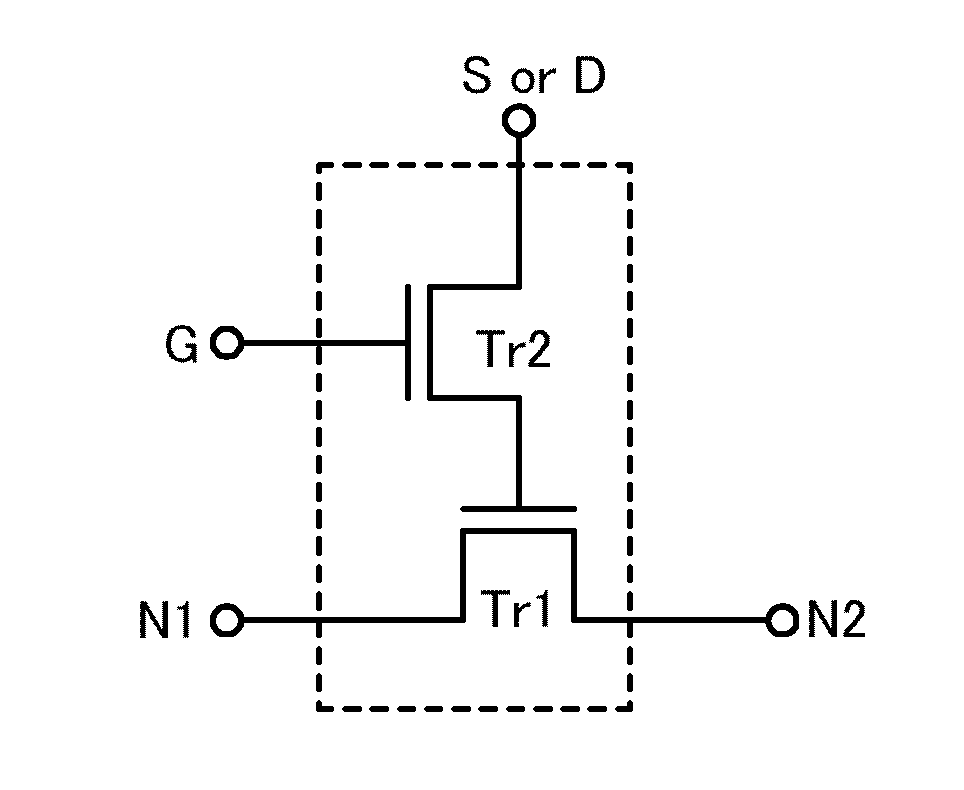

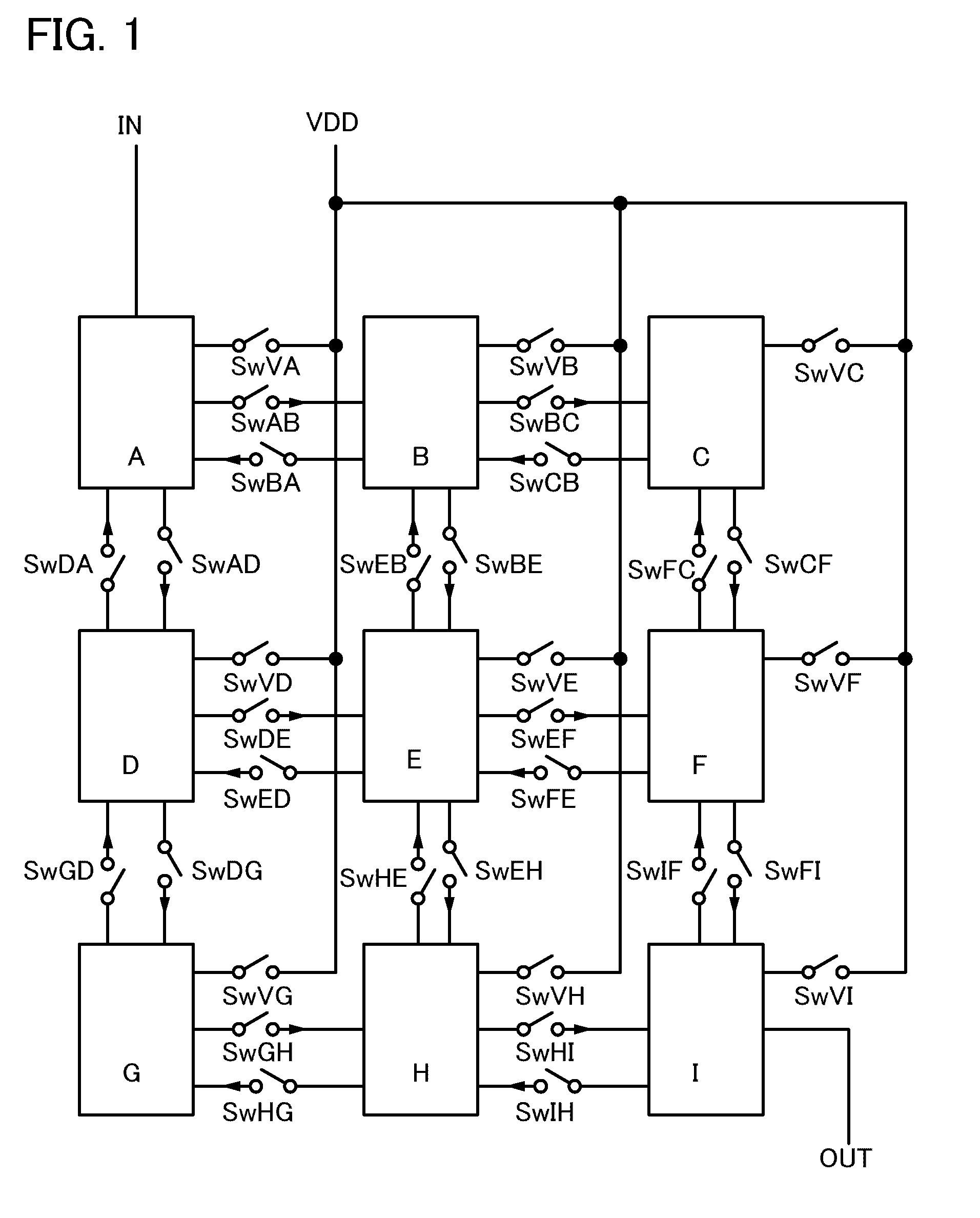

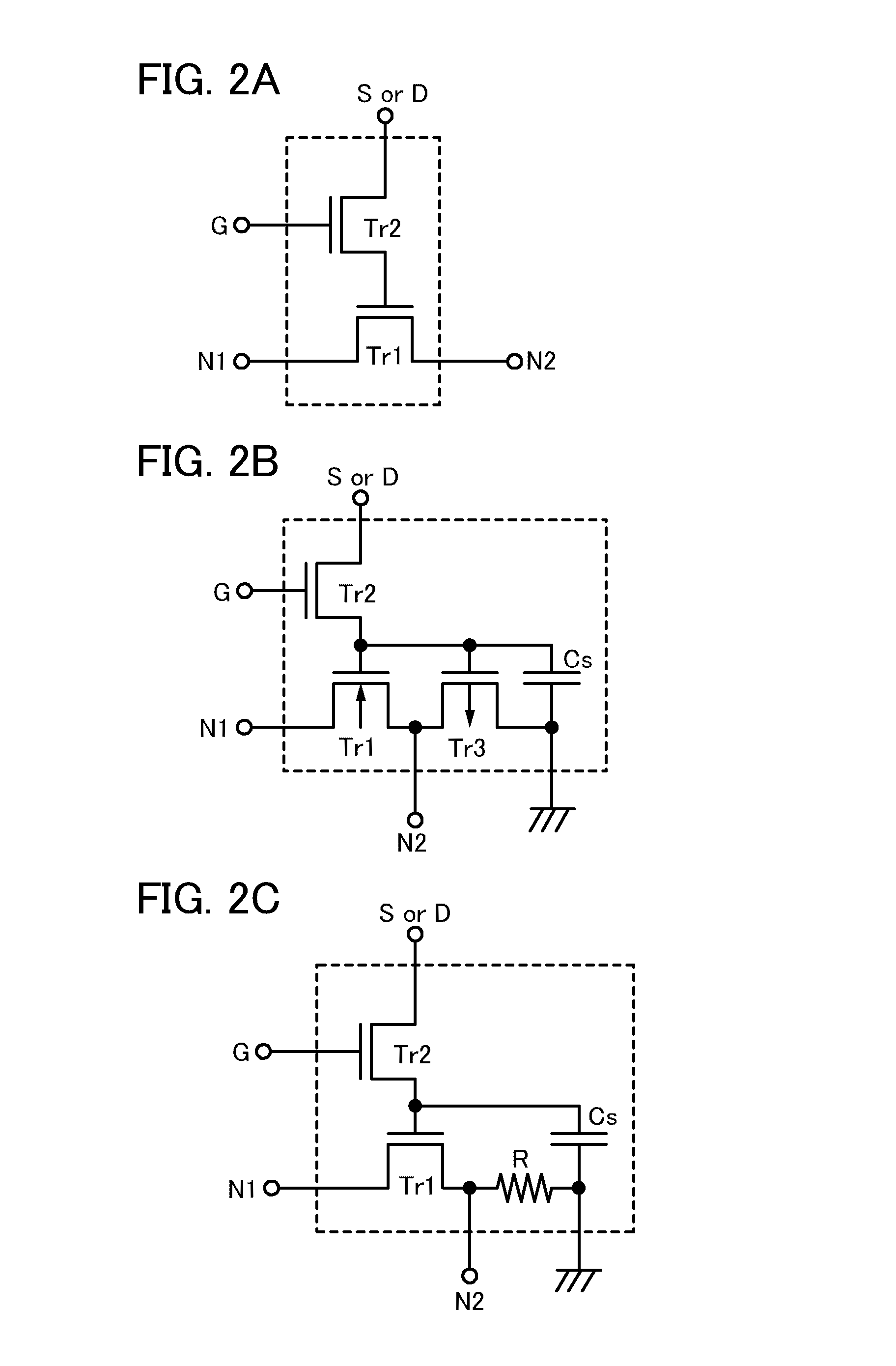

Semiconductor device

ActiveUS20110175646A1Suppress power consumptionPrevent degradationTransistorPower reduction in field effect transistorsProgrammable logic deviceLow leakage

It is an object to provide a semiconductor device in which power consumption can be reduced. It is another object to provide a highly reliable semiconductor device using a programming cell, such as a programmable logic device (PLD). In accordance with a change in a configuration of connections between basic blocks, power supply voltage furnishing to the basic blocks is changed. That is, when the structure of connections between the basic blocks is such that a basic block does not contribute to a circuit, the supply of the power supply voltage to this basic block is stopped. Further, the supply of the power supply voltage to the basic blocks is controlled using a programming cell formed using a field effect transistor whose channel formation region is formed using an oxide semiconductor, the field effect transistor having extremely low off-state current or extremely low leakage current.

Owner:SEMICON ENERGY LAB CO LTD

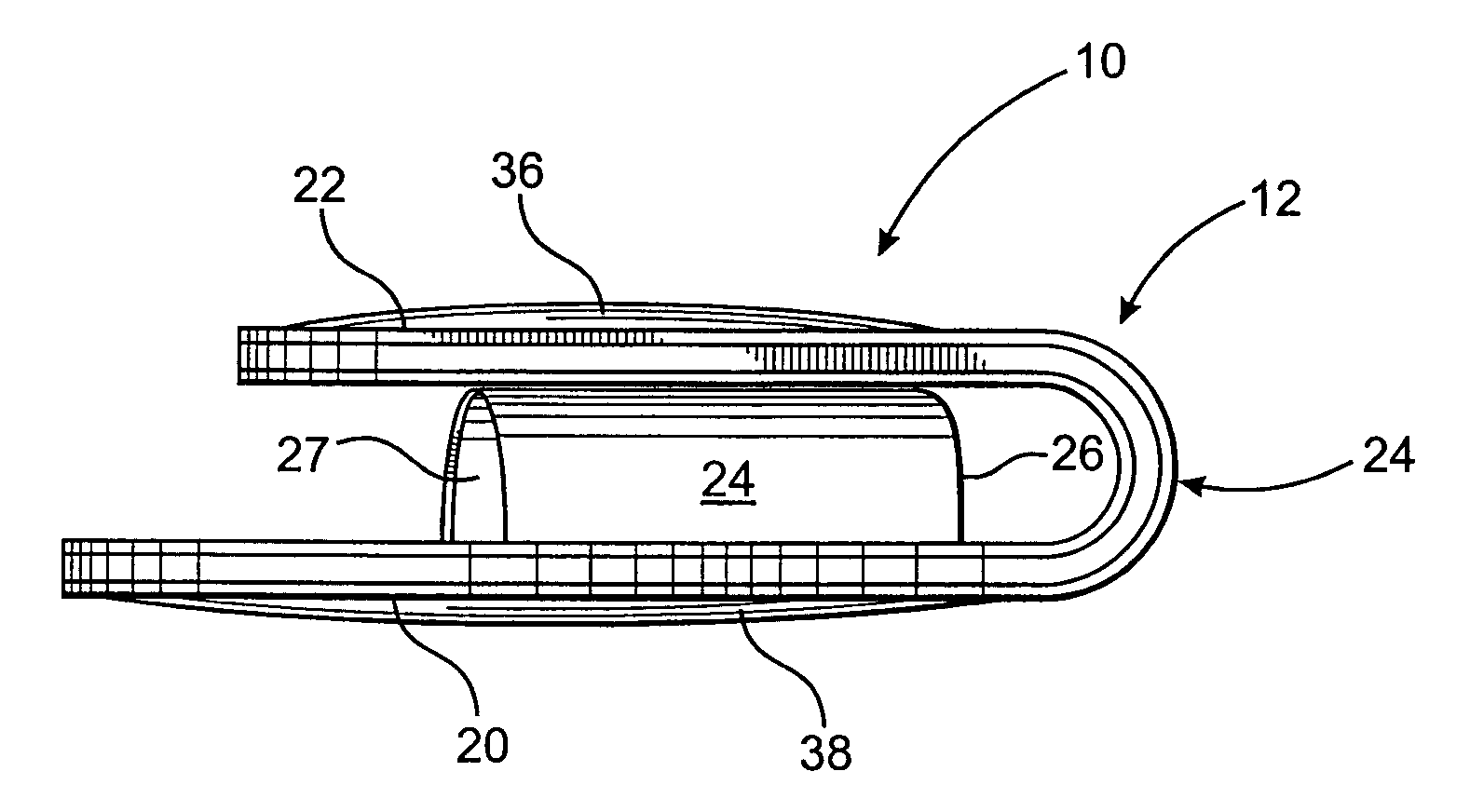

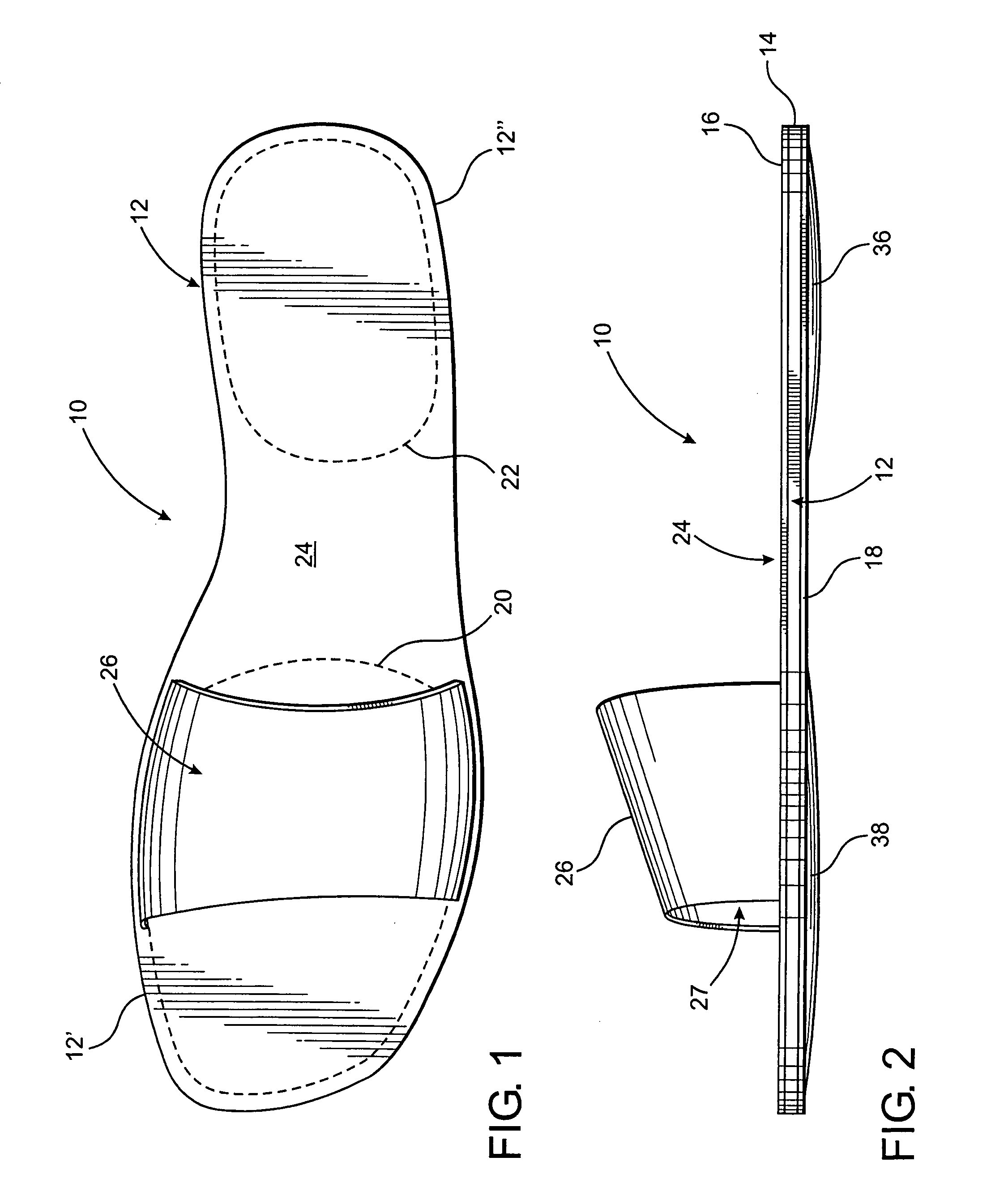

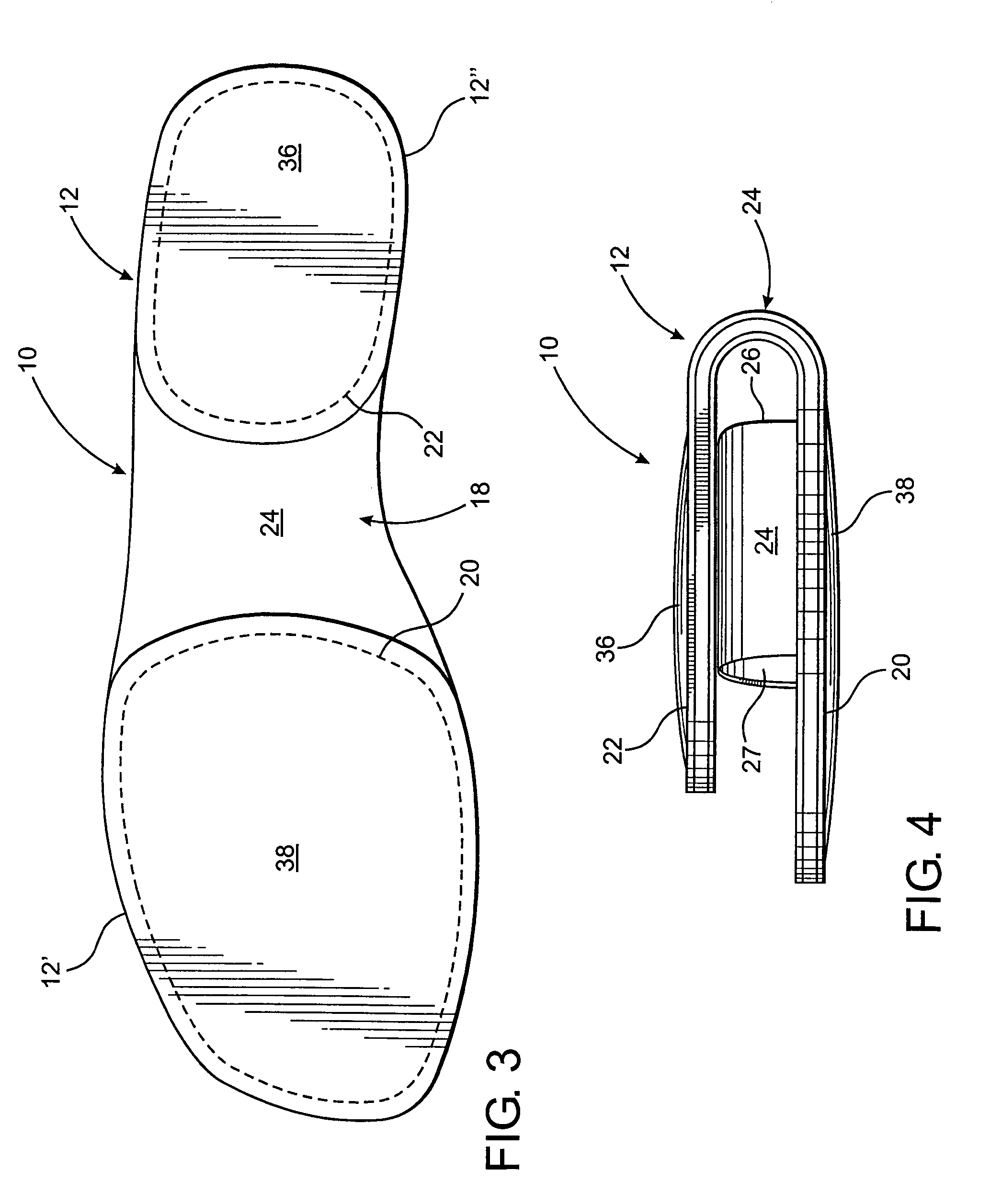

Collapsible footwear

A footwear assembly structured to be collapsible comprising a sole including a front portion and a rear portion movably interconnected by an intermediate segment. An upper extends along at least a portion of the length of the sole, depending upon the style of the footwear, wherein the upper and the sole are preferably structured to define the sandal configuration which may vary in style. The intermediate portion includes sufficient flexibility to significantly reduce the size of the sandal by folding the sole into a stored orientation defined by the front and rear portions disposed in at least partially overlying relation to one another. A pouch-like container is dimensioned and configured to receive and maintain at least a pair of the sandals on the interior thereof, when in the stored orientation.

Owner:LOLA STYLE

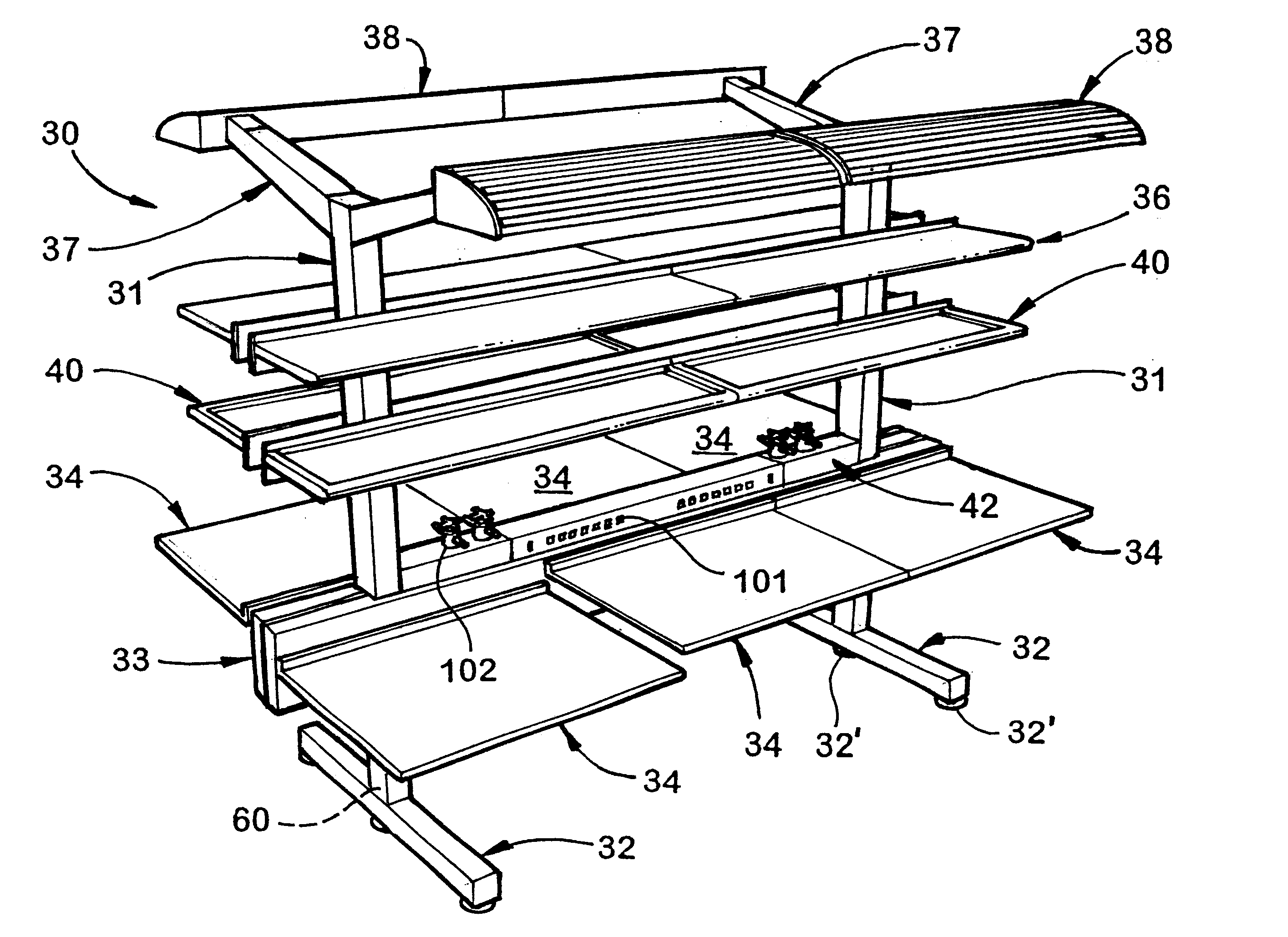

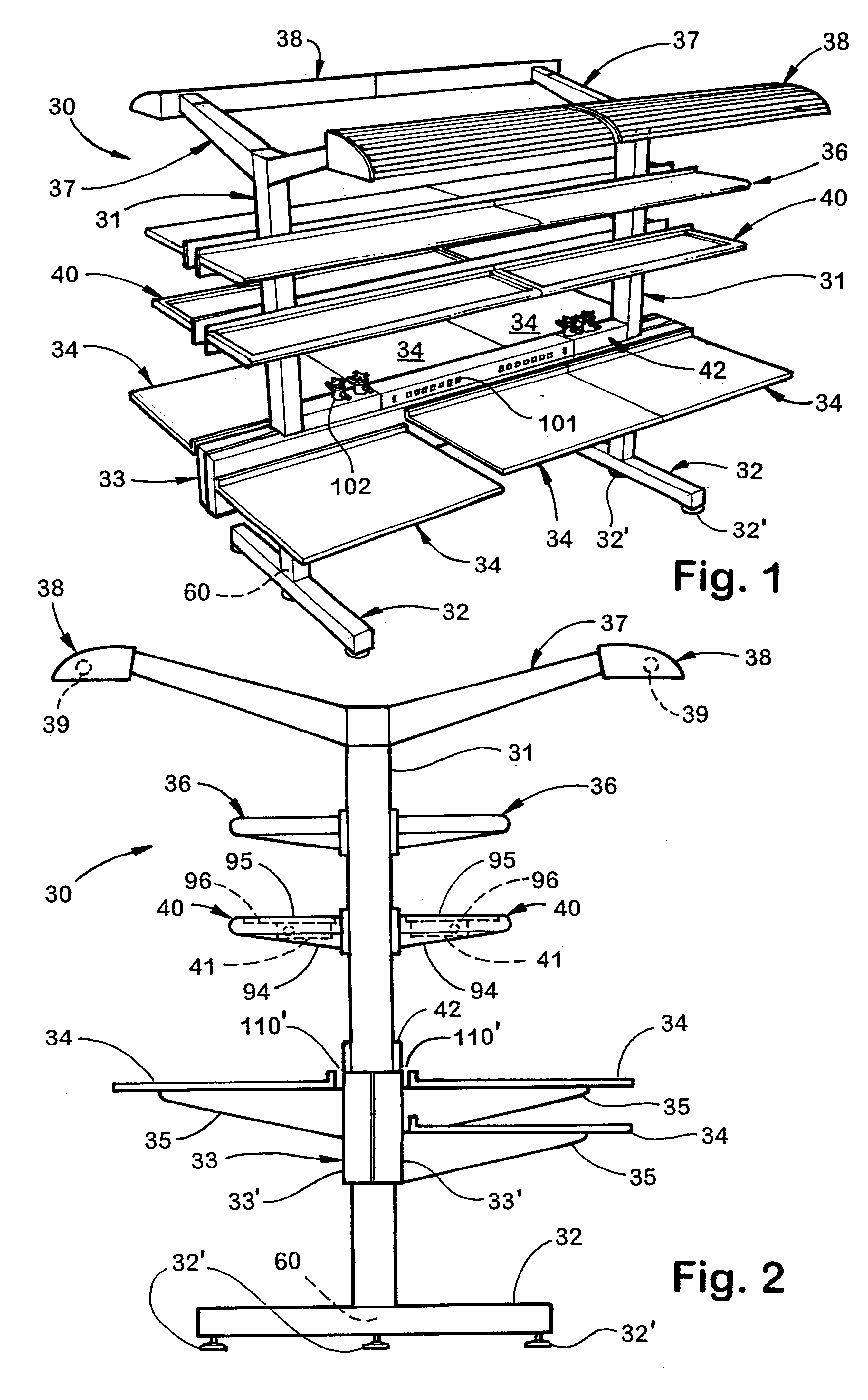

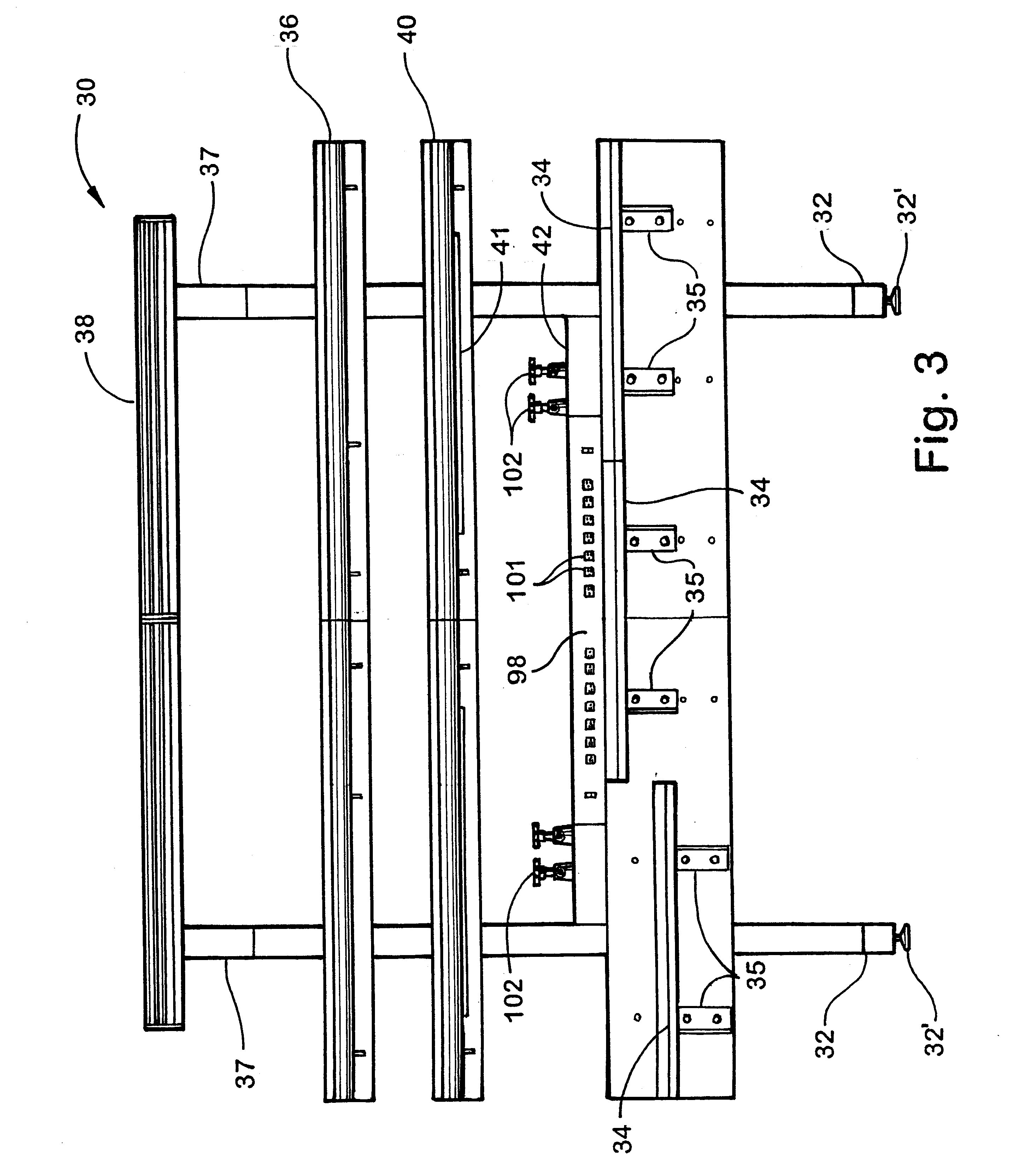

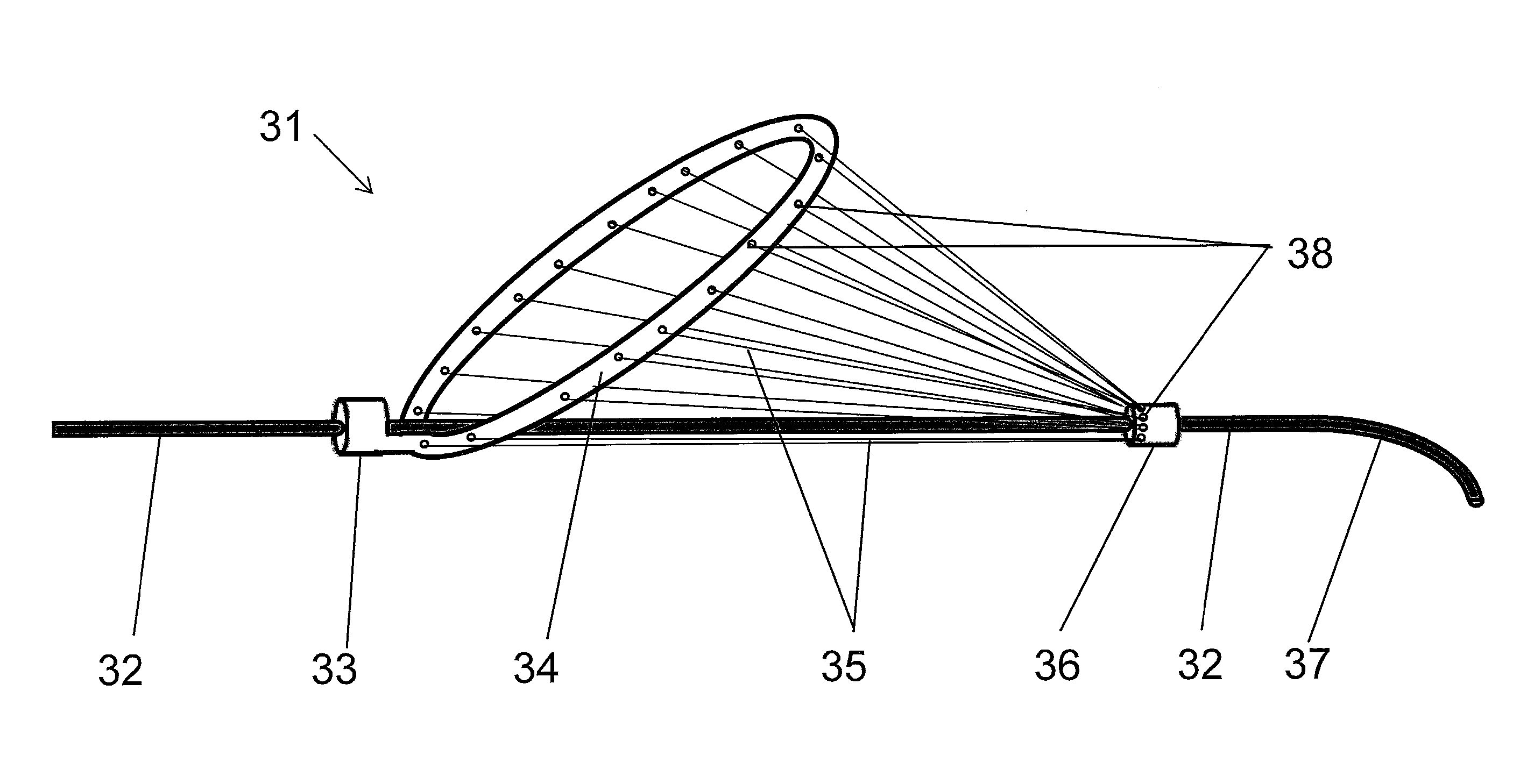

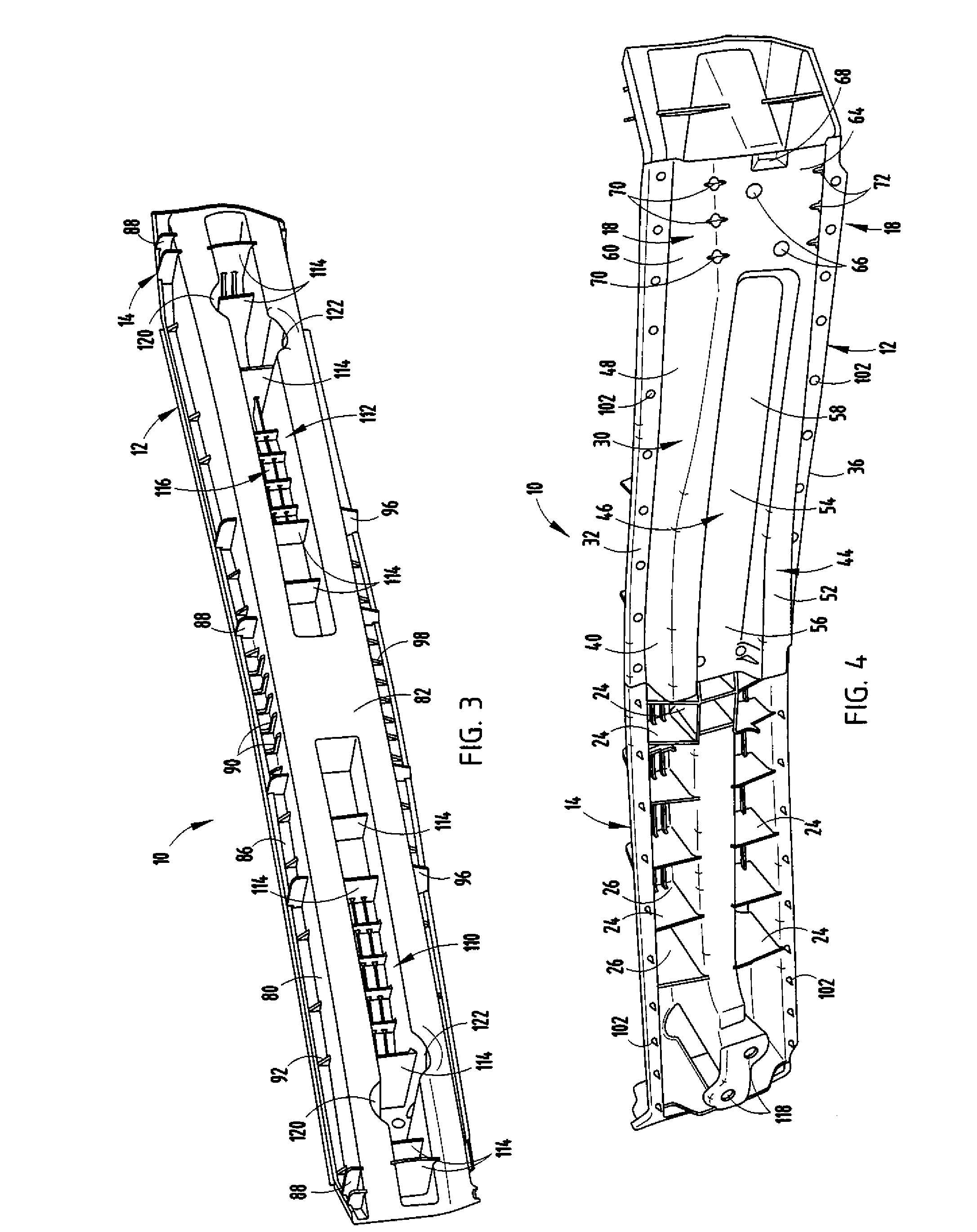

Laboratory furniture unit

A furniture unit is provided specially adapted for use in laboratories. The furniture unit includes a pair of spaced-apart uprights and vibration-dampening legs extending from the uprights for stably supporting the furniture unit on a floor surface. A belt-high structural beam comprising two opposing C-shaped beams is fixedly attached to the uprights to rigidly interconnect the uprights in a spaced relationship. A plurality of worksurfaces is provided, each having a pair of cantilever brackets configured to rigidly connect to a side of the belt-high structural beam and to extend laterally therefrom. The plurality of worksurfaces is separately adjustably supported on the belt-high structural beam for vertical height adjustment, with at least one of the cantilever brackets engaging the belt-high structural beam at a location between the uprights. Shelves are attached between the uprights above the plurality of worksurfaces. Optionally, an accessory panel is mounted between the front and rear shelves for visual shielding and / or for function use, such as a marker board. A Y-shaped lighting support includes a bayonet that telescopingly engages a top of the uprights. A lamp housing structure spans between the lighting supports in a location where a lamp in each lamp housing structure is generally above a front edge of the worksurfaces. A utility distribution beam is mounted between the uprights above the structural beam for communicating utilities, including piped utilities and cabled utilities, to accessible locations along a rear edge of the worksurfaces. The legs include gussets that telescope into the uprights to provide a stable bottom joint.

Owner:STEELCASE INC

Clot capture systems and associated methods

ActiveUS20130144326A1Promote effective engagementEfficient captureSurgeryDilatorsBiomedical engineeringBlood vessel

A clot capture system for disengaging a clot from a vessel wall and removing the clot from the vessel, comprises a clot capture device for placement on a distal side of a clot. The clot capture device has a retracted delivery configuration and an expanded deployed configuration. The clot removal device has a proximal support frame, and a distal fibre net. The support frame has a retracted delivery configuration and an expanded deployed configuration. The proximal support frame in the expanded configuration defines a proximal inlet mouth for engaging a clot and a net for confining the clot. An elongate member facilitates capture and / or withdrawal of a clot from a vessel.

Owner:NEURAVI

Semiconductor device

ActiveUS8547753B2Improve versatilityReduce designPower reduction in field effect transistorsTransistorProgrammable logic deviceHemt circuits

Owner:SEMICON ENERGY LAB CO LTD

Clot capture systems and associated methods

A clot capture system for disengaging a clot 2001 from a vessel wall 2002 and removing the clot 2001 from the vessel 202, includes a clot capture device 2140 for placement on a distal side of a clot 2001. The clot capture device 2140 has a retracted delivery configuration and an expanded deployed configuration. The clot removal device has a proximal support frame 2012, and a distal fiber net 2130. The support frame 2012 has a retracted delivery configuration and an expanded deployed configuration. The proximal support frame 2012 in the expanded configuration defines a proximal inlet mouth for engaging a clot 2001 and a net 2130 for confining the clot 2001. An elongate member facilitates capture and / or withdrawal of a clot 2001 from a vessel 2002. The system also includes a clot debonding device 2091 for placement on a proximal side of a clot 2001. The clot debonding device 2091 has a retracted delivery configuration and an expanded deployed configuration and includes a clot engagement element 2112 which defines a distal abutment in the deployed configuration for urging a clot 2001 into the clot capture device 2140.

Owner:NEURAVI

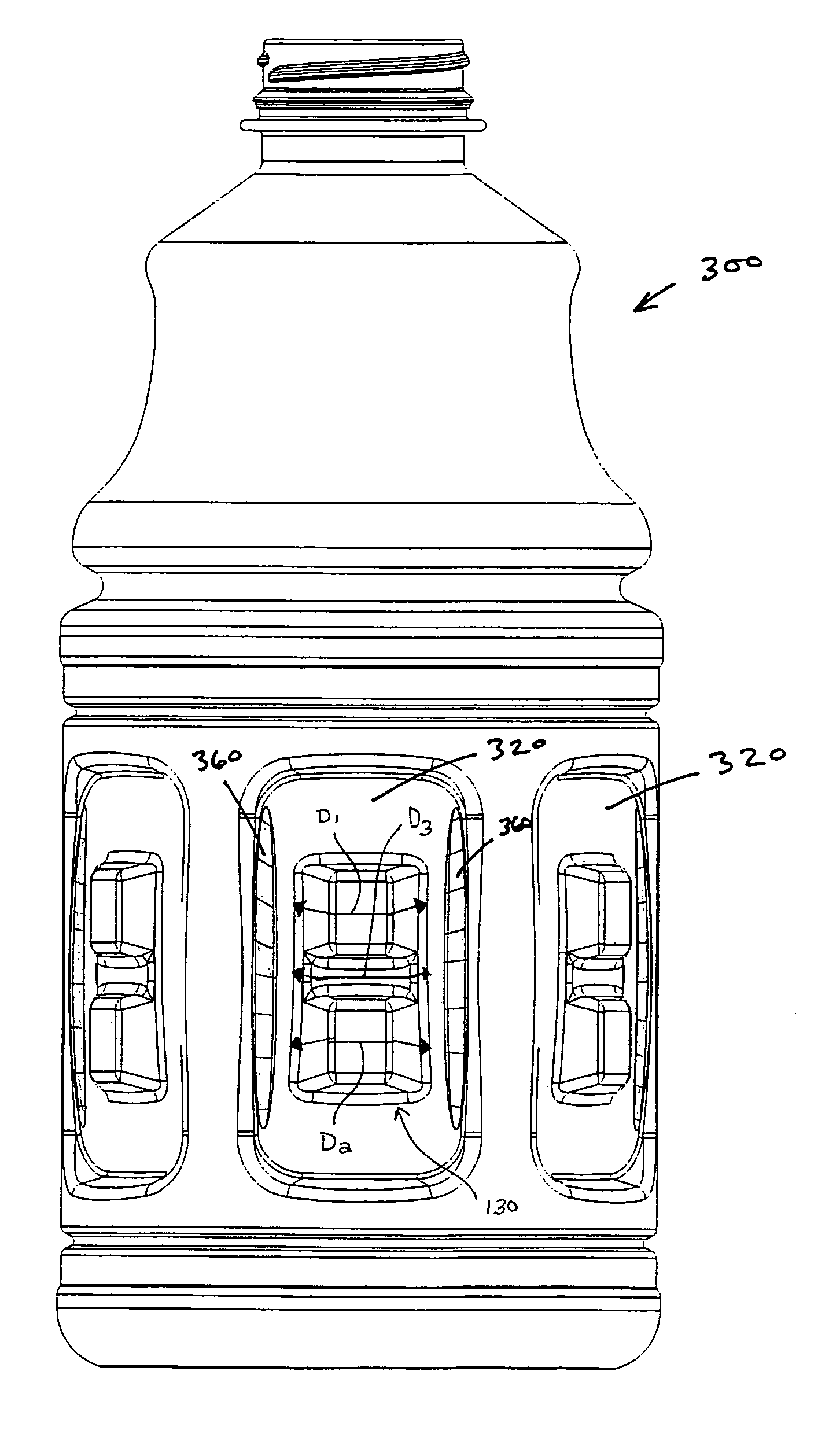

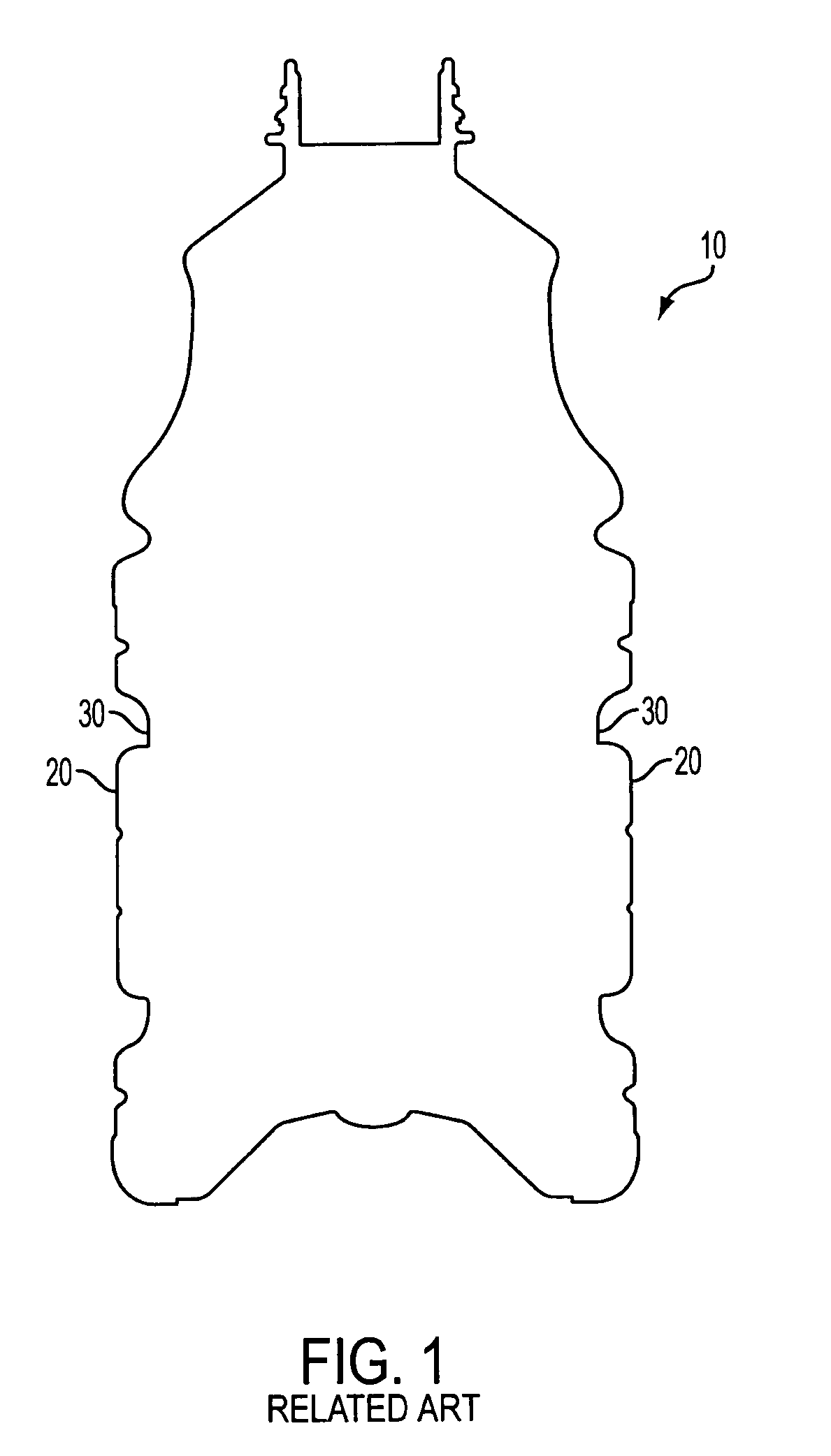

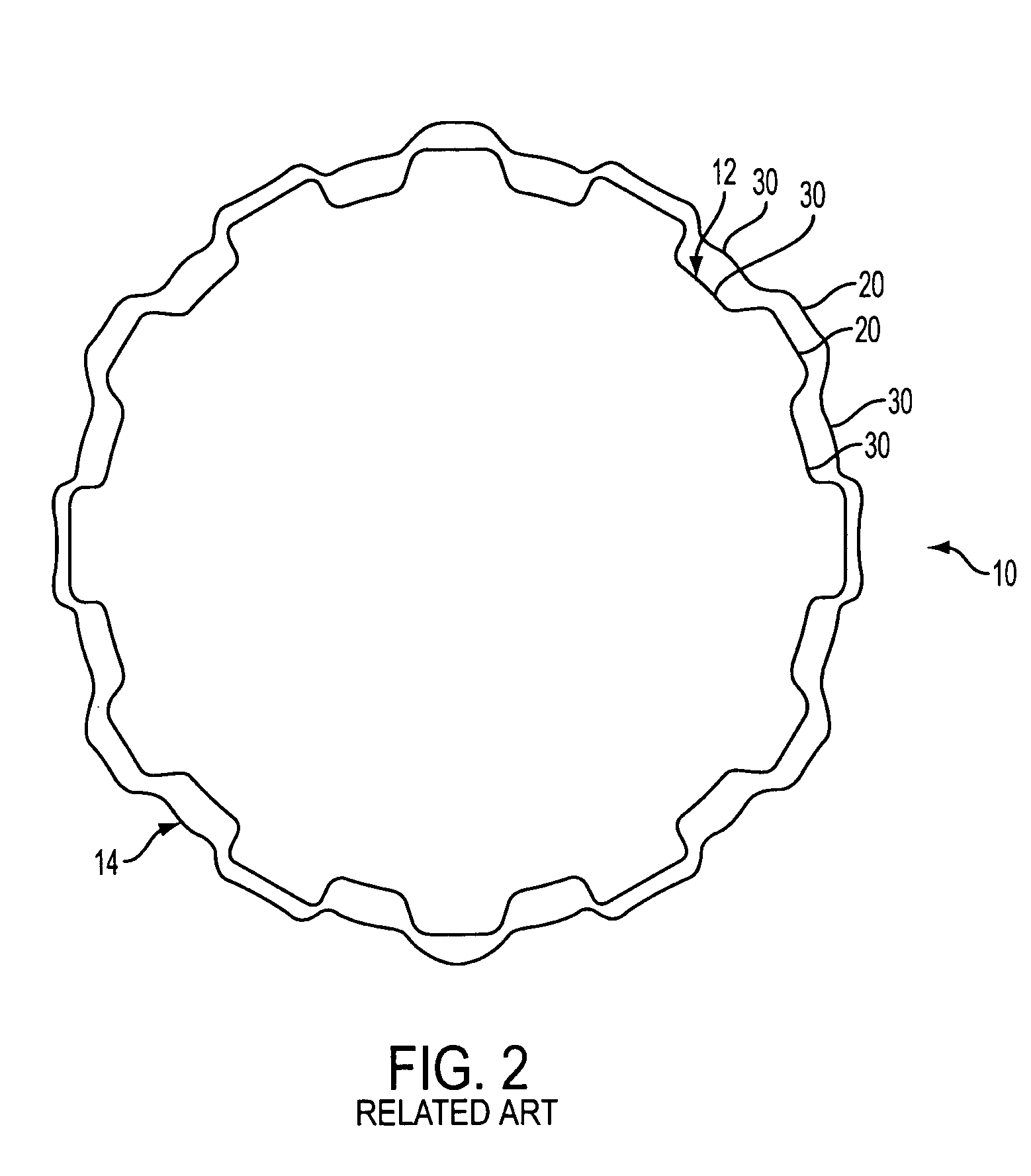

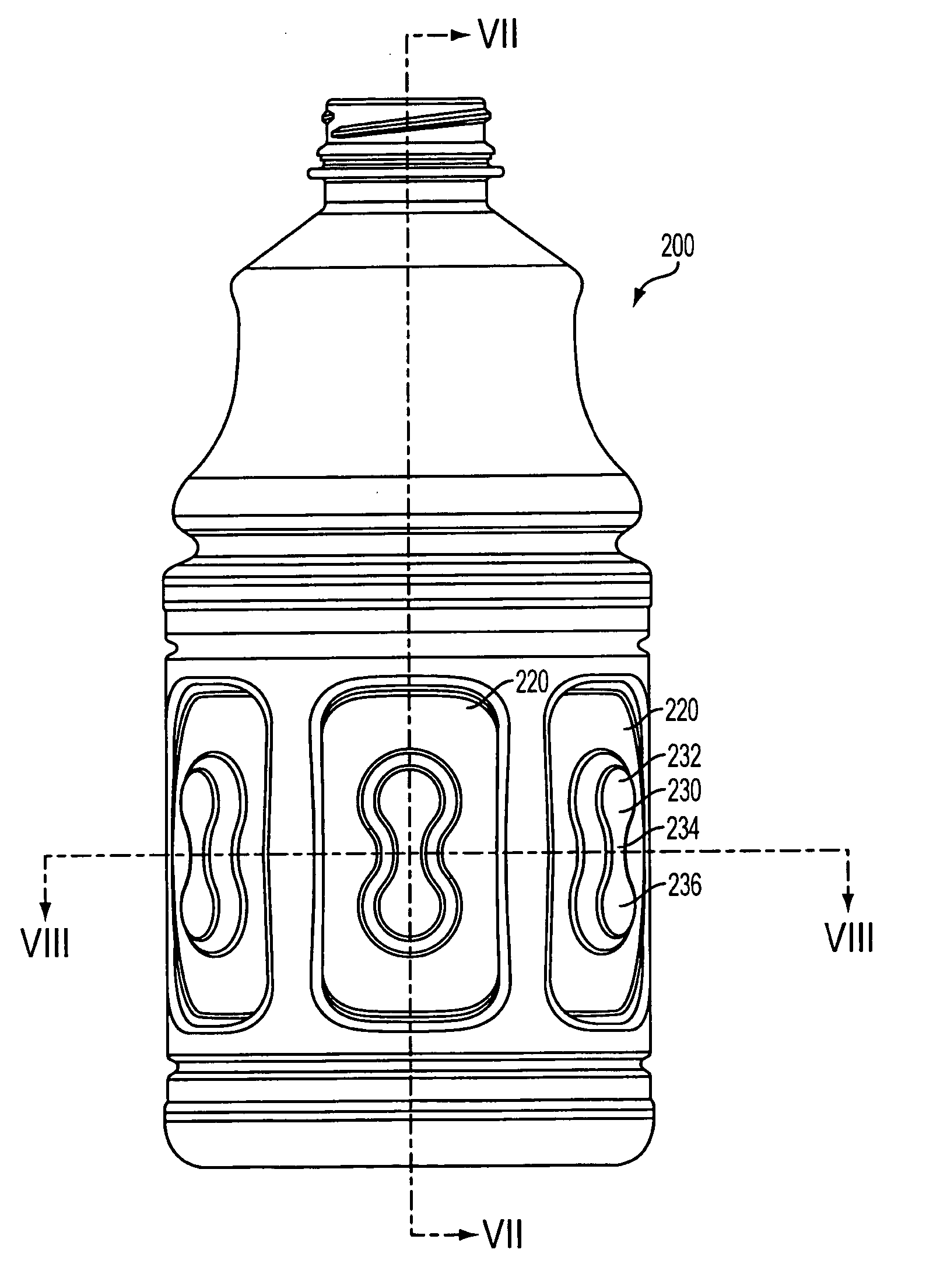

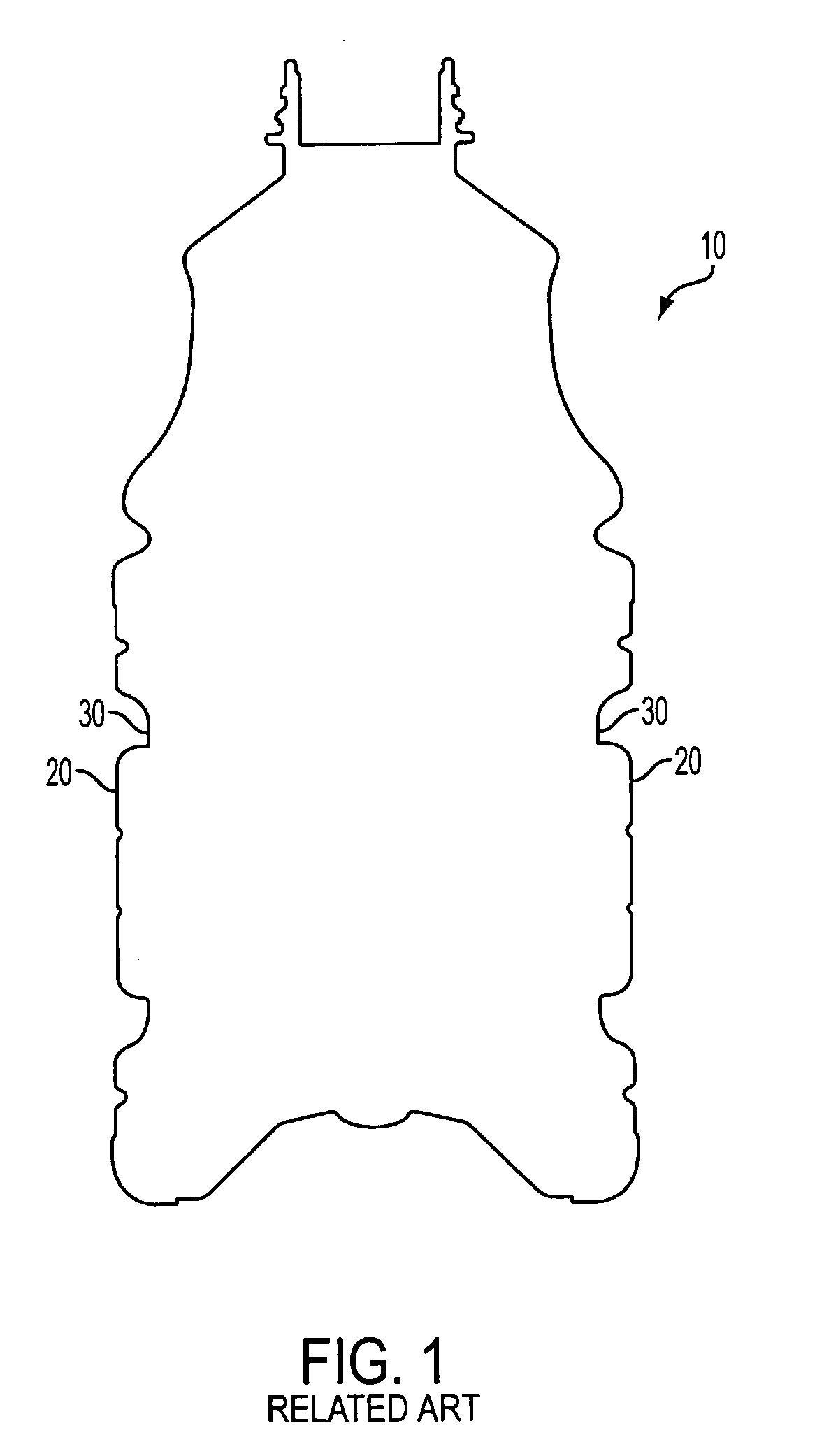

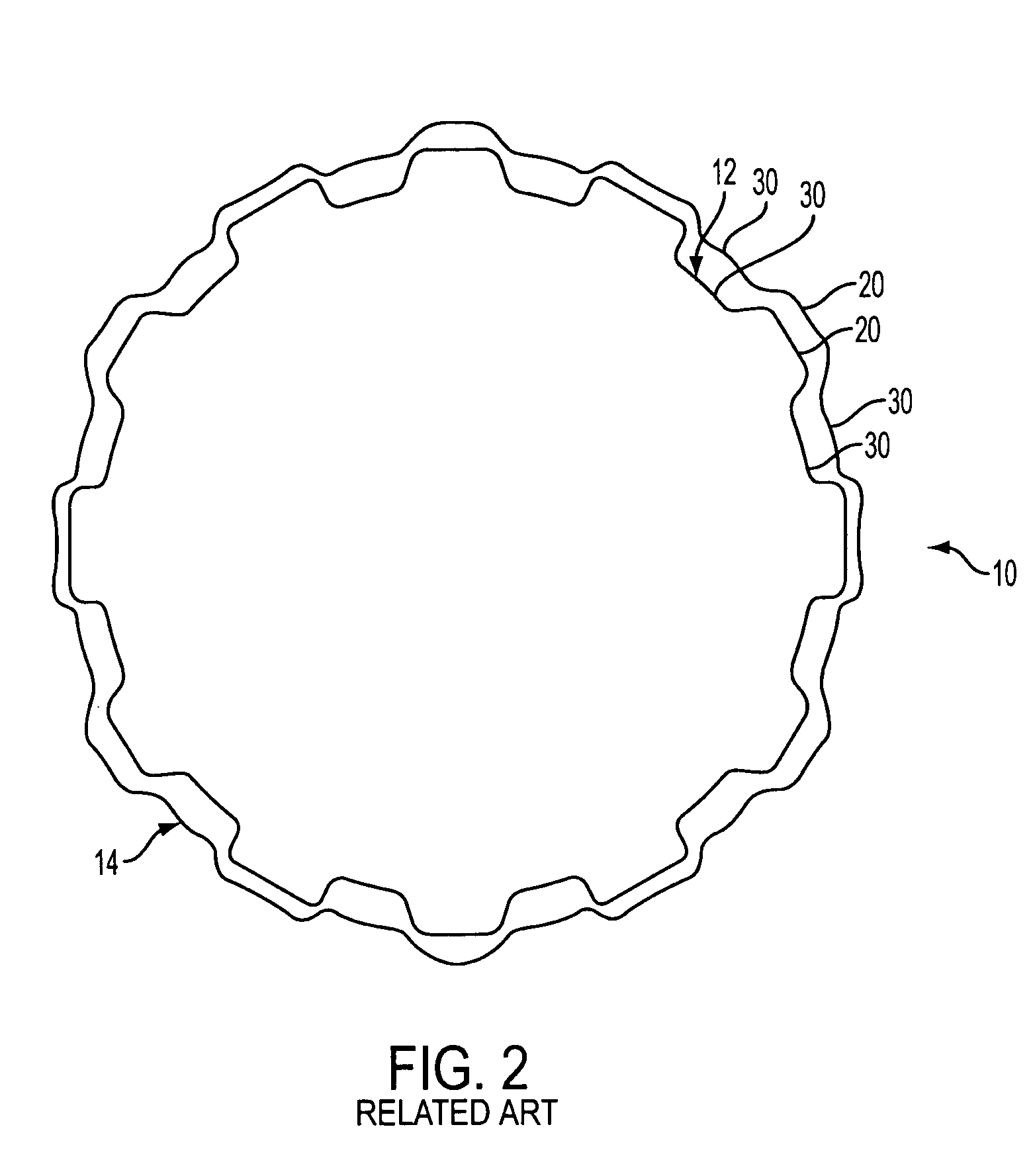

Deformation resistant panels

ActiveUS7334695B2Convenient to accommodateBulging or “barreling” is prevented or diminishedBottlesLarge containersEngineeringMechanical engineering

Owner:GRAHAM PACKAGING CO LP

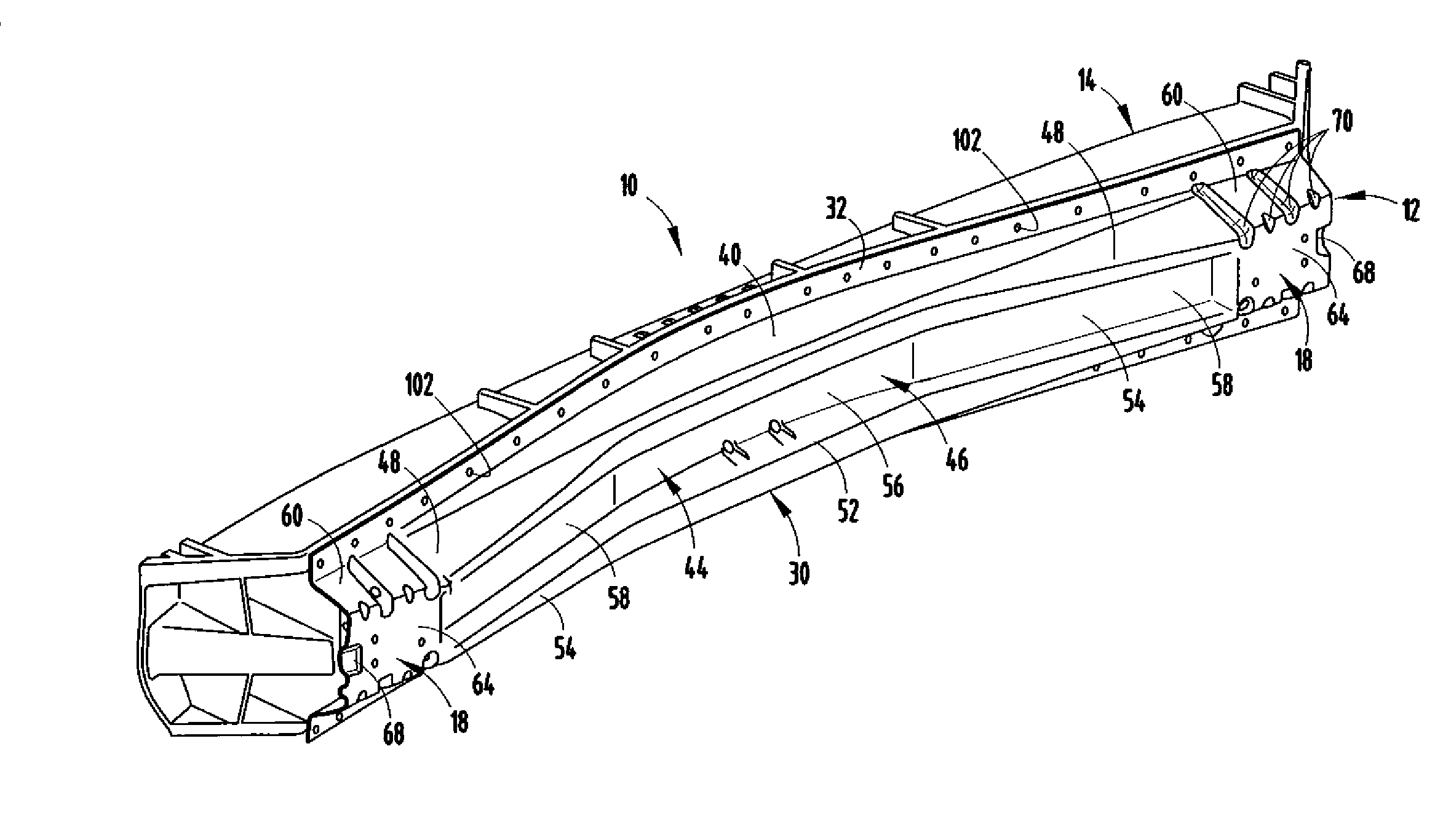

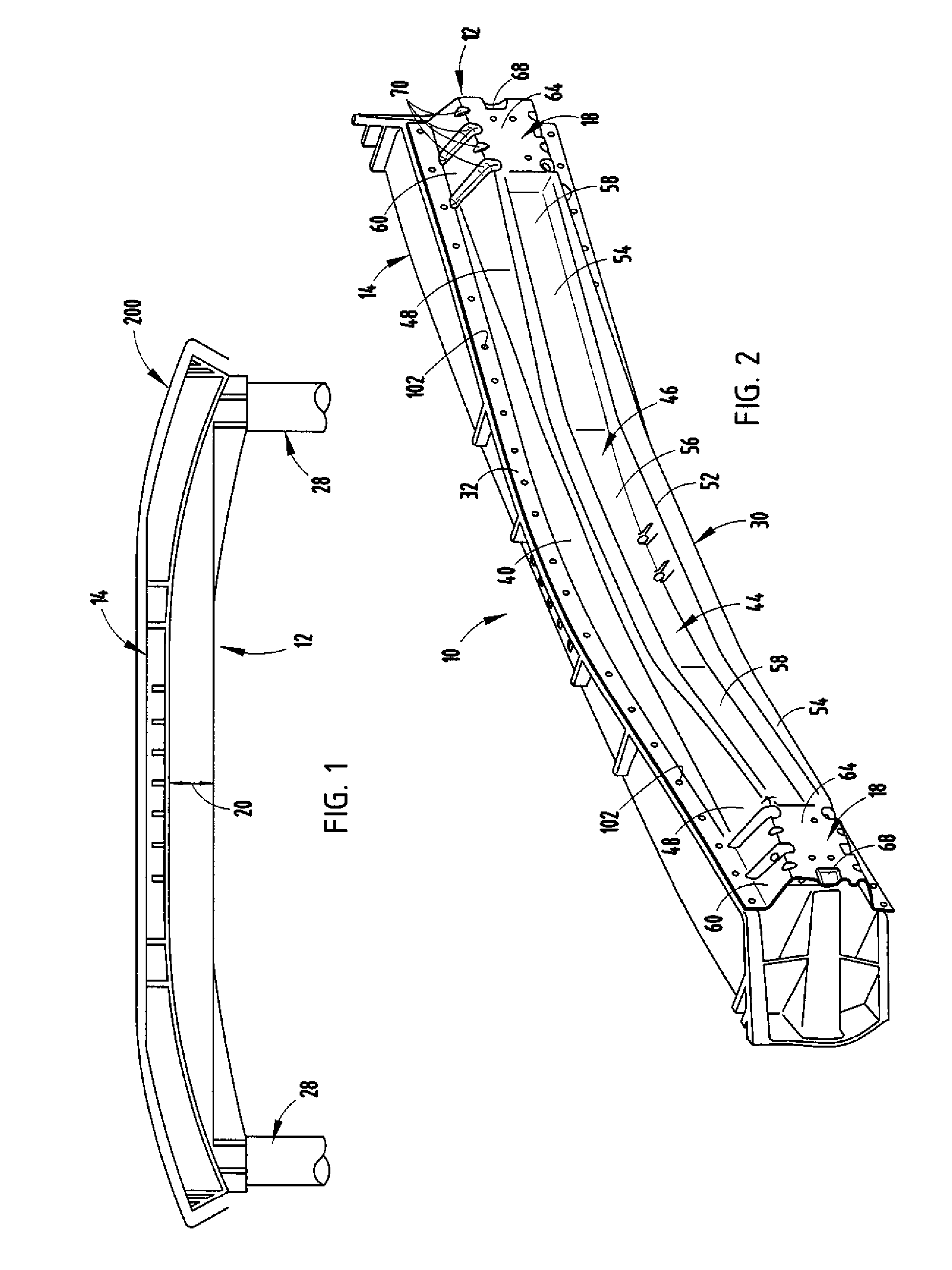

Vehicle bumper beam constructed of metal and plastic

A bumper system for a vehicle comprising a stamped metal component and a second polymeric component fixedly attached to form a beam with particular localized energy absorber characteristics. The metal component is formed from a sheet and has a thickness in a width direction along a majority of the length when in a vehicle-mounted position. The second polymeric component engages a face of the first component and is rigidly attached to the first component in at least several locations along the length to form a structural beam with the first component. The second polymeric component has sufficient structure to form an integral part of the structural beam and interconnected walls extending in the width direction to form energy-absorbing cells at centered and corner locations configured to crush and absorb energy upon a vehicle impact.

Owner:SHAPE CORP

Light emitting diode light source for curing dental composites

InactiveUS20050196720A1Sufficient powerSufficient structureSolid-state devicesDischarge tube main electrodesDental compositeHeat sink

Light Emitting Diode Light Sources for Dental Curing are disclosed. Some embodiments of the invention include structures such as Light Emitting Diode Array(s), heat sink, heat dissipation, heat pipe, and control circuitry are disclosed.

Owner:KONINK PHILIPS ELECTRONICS NV

Clot capture systems and associated methods

A clot capture system for disengaging a clot from a vessel wall and removing the clot from the vessel. The system may include a clot capture device for placement on a distal side of a clot. The clot capture device may have a retracted delivery configuration and an expanded deployed configuration. The clot removal device may have a proximal support frame, and a distal fiber net. The support frame may have a retracted delivery configuration and an expanded deployed configuration. The proximal support frame in the expanded configuration may define a proximal inlet mouth for engaging a clot and a net for confining the clot. An elongate member may facilitate capture and / or withdrawal of a clot from a vessel.

Owner:NEURAVI

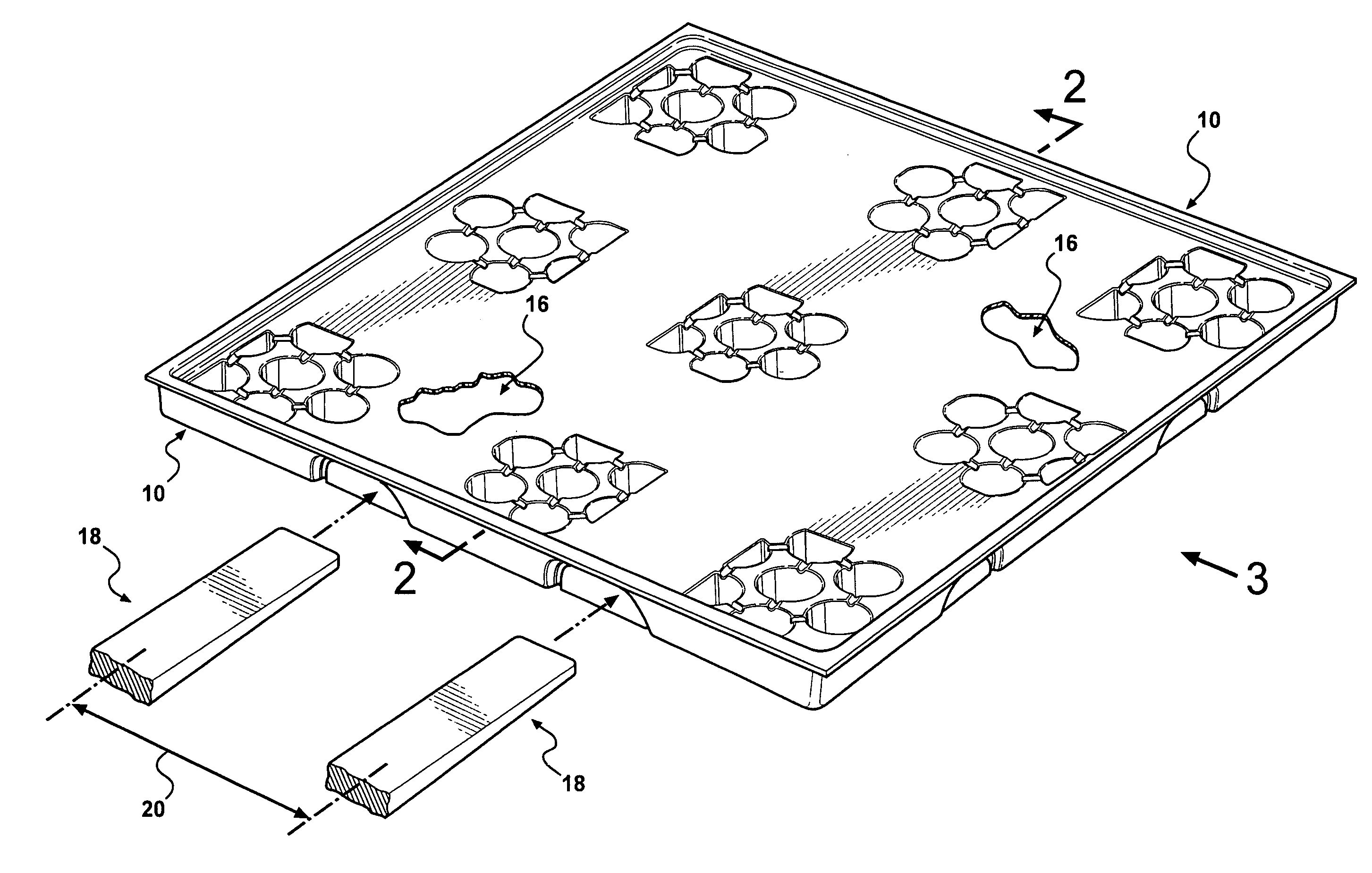

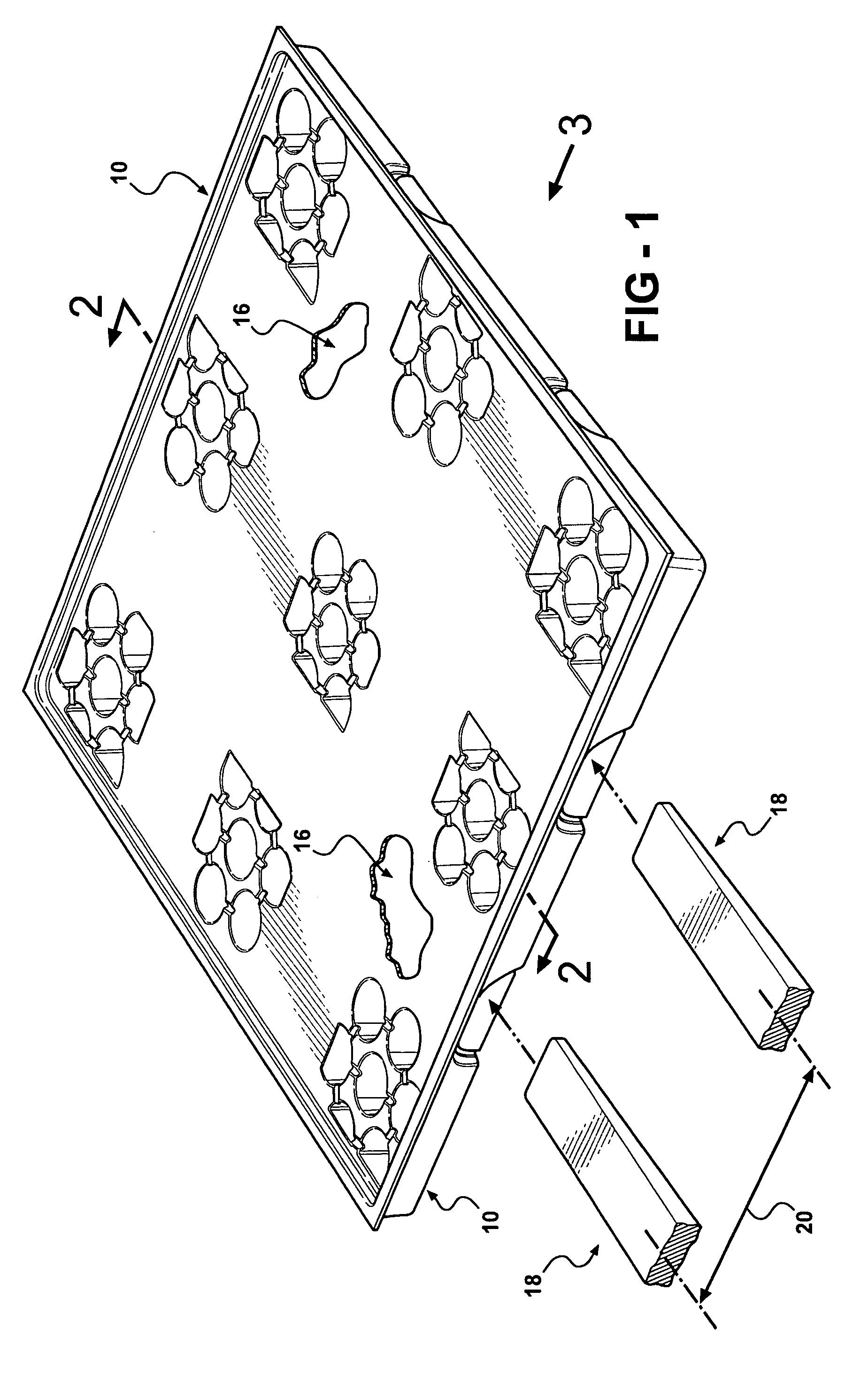

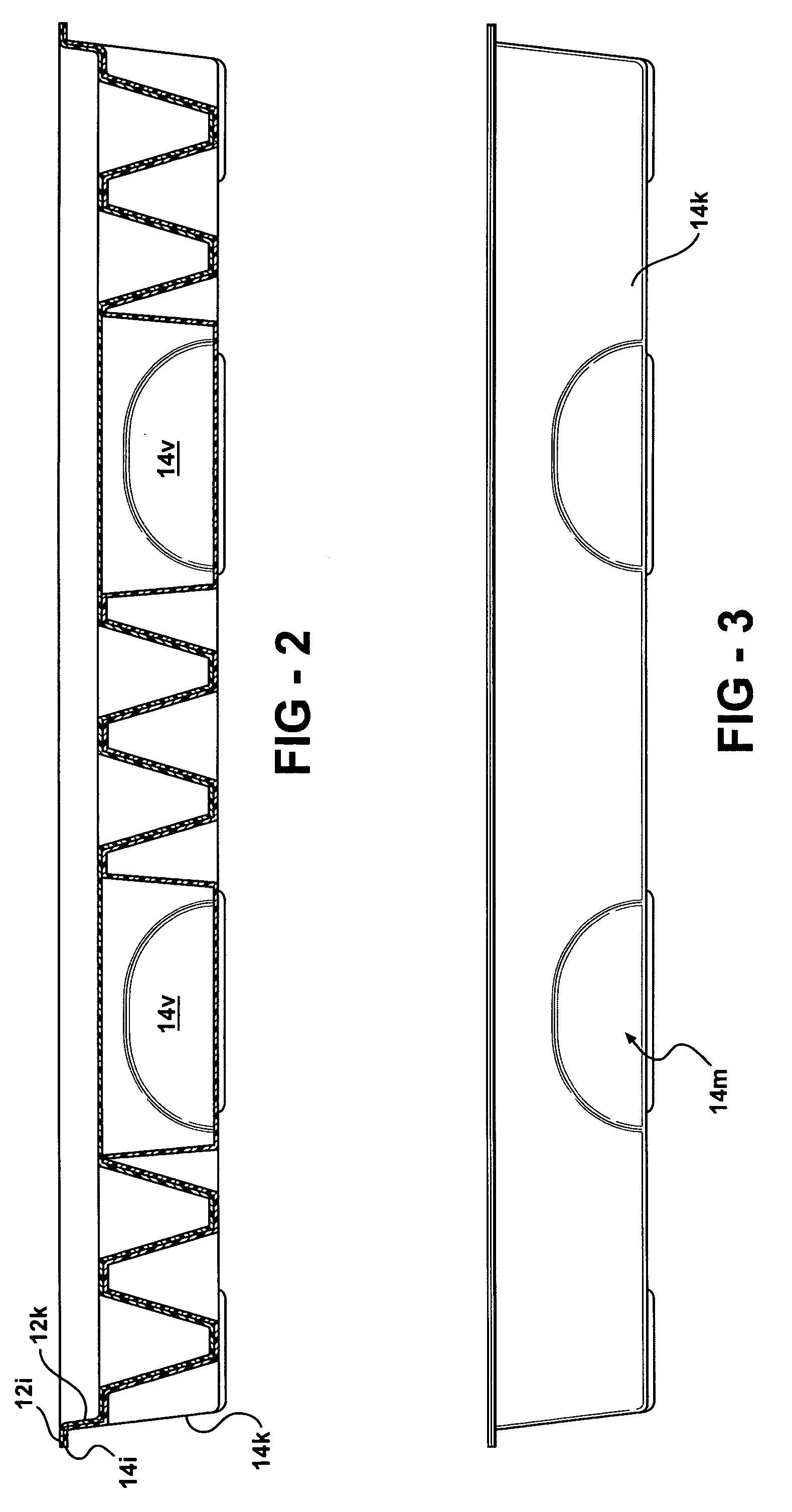

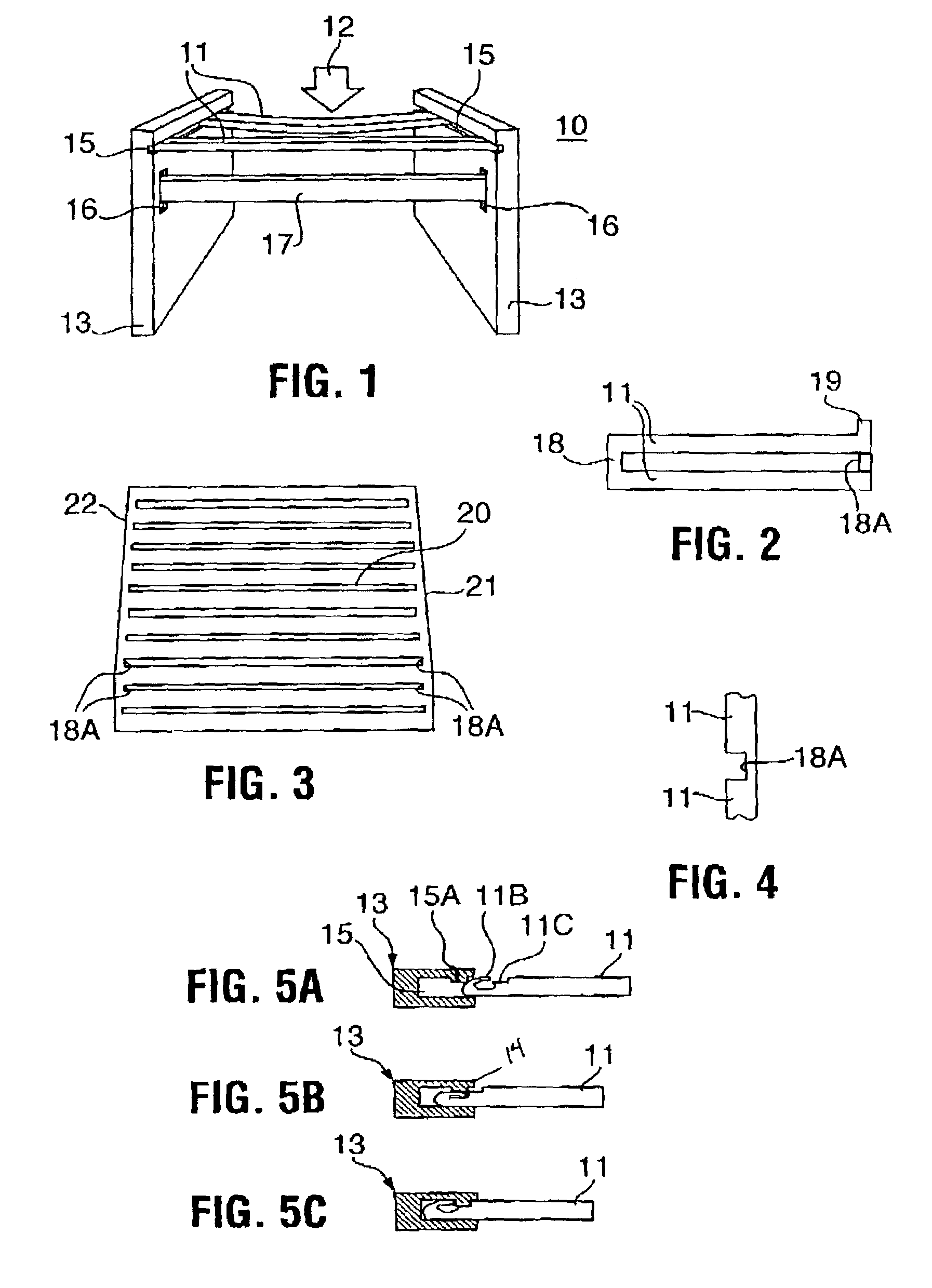

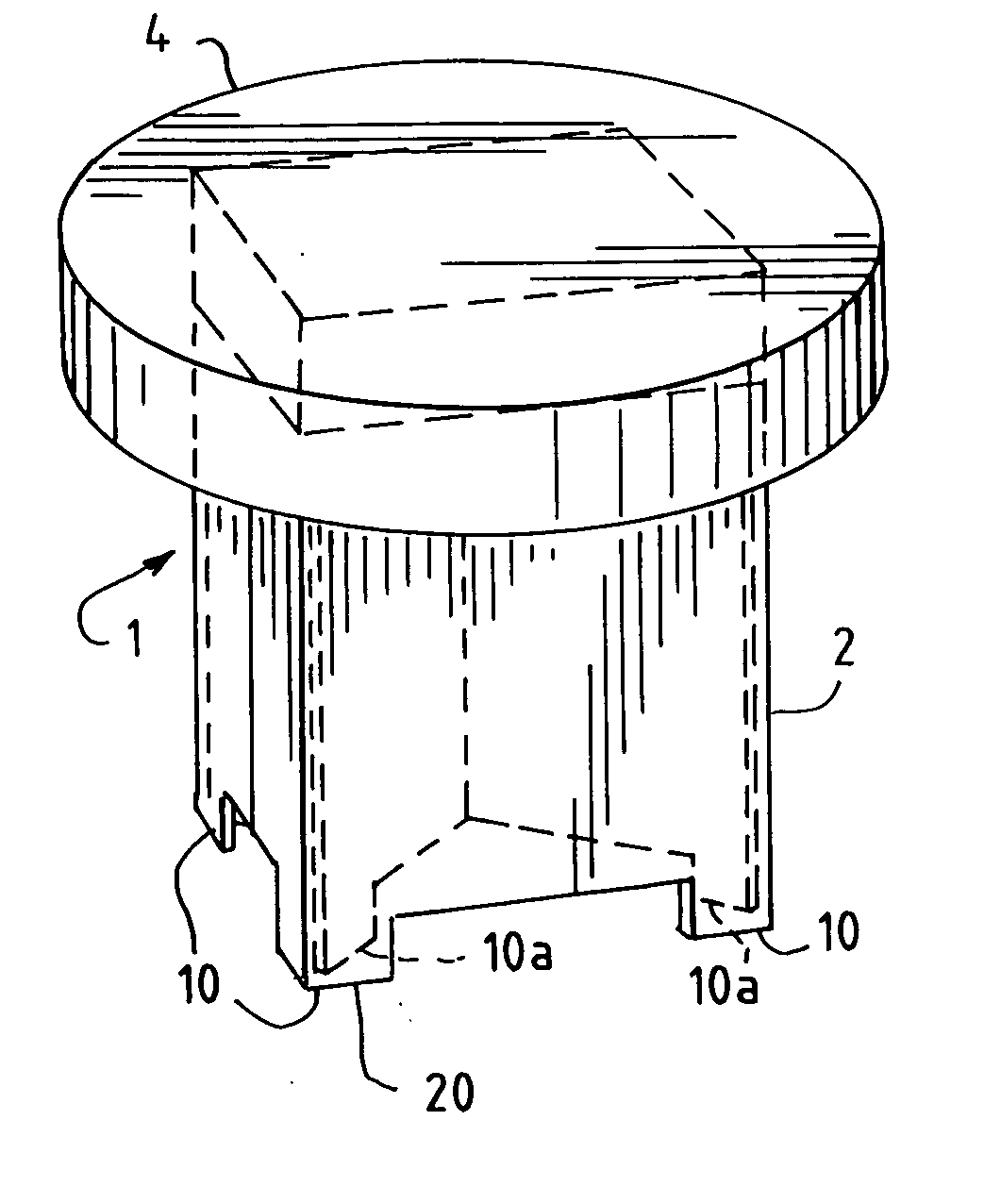

One-way plastic pallet

A thermoformed twin sheet pallet comprising an upper plastic sheet and a lower plastic sheet, the sheets being fused together to form a platform structure and a plurality of leg structures downstanding from the platform structure in spaced relation and defining a plurality of forklift passages therebetween. The leg structures are formed of spaced downstanding leg portions of the upper sheet fused in vertically overlapping relation to spaced upstanding leg portions of the lower sheet, and main body planar portions of the upper sheet between the spaced downstanding leg portions coact with main body planar portions of the lower sheet between the spaced upstanding leg portions to define the forklift passages. The lower sheet further includes an upstanding flange portion extending around the perimeter of the lower sheet and fused to the perimeter of the upper sheet and openings are provided in the flange portion, in alignment with the forklift passages, to provide forklift access to the forklift passages. A flap is provided in each opening which is yieldable to allow entry of a forklift into the opening for access to the respective forklift passage. The downstanding leg portions of the upper sheet comprise clusters of hollow protrusions opening in the upper face of the upper sheet and the upstanding leg portions of the lower sheet comprise clusters of hollow protrusions opening in the lower face of the lower sheet and including sidewalls fused to sidewalls of the downstanding protrusions of the upper sheet.

Owner:SHUERT TECH

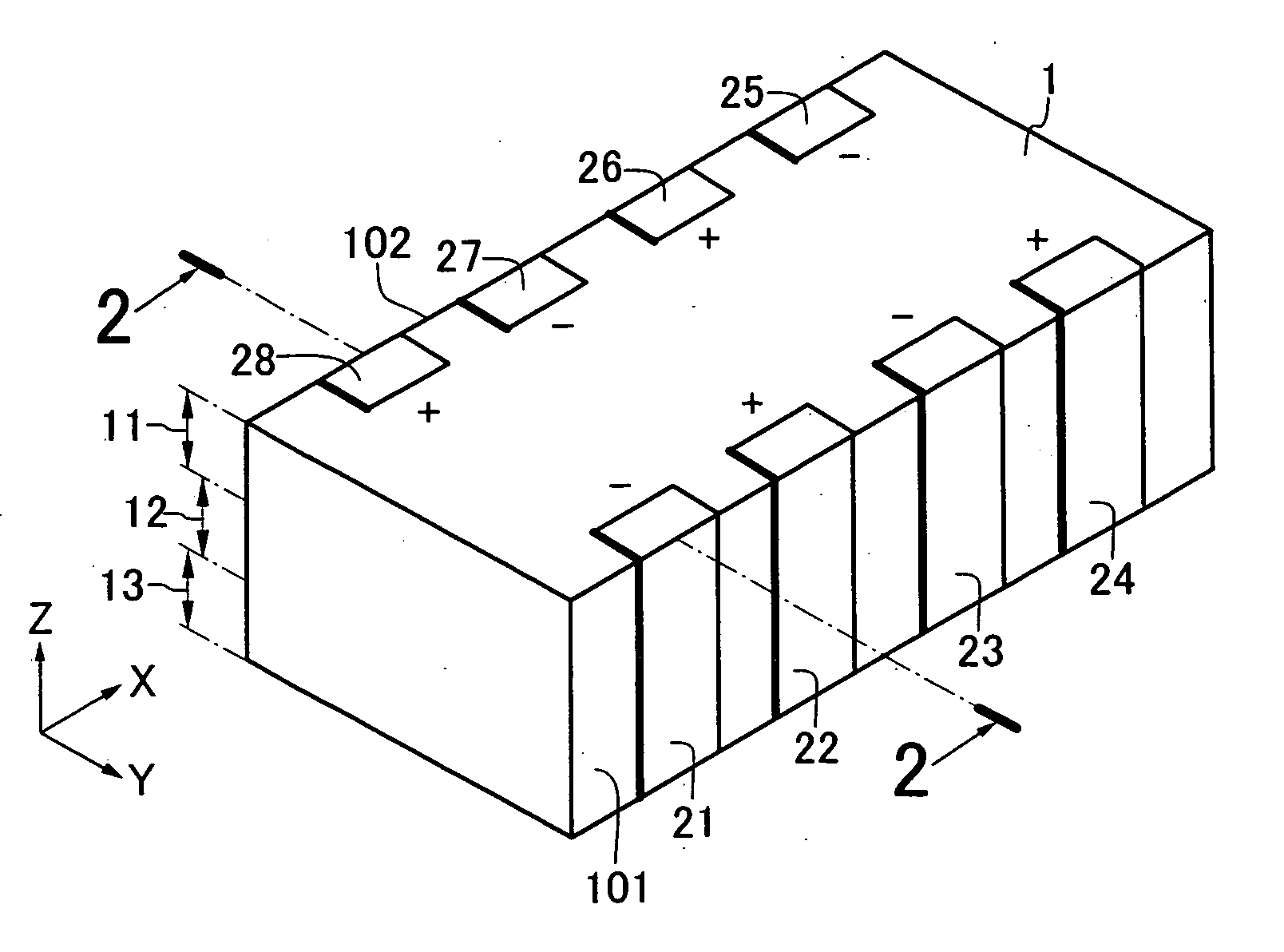

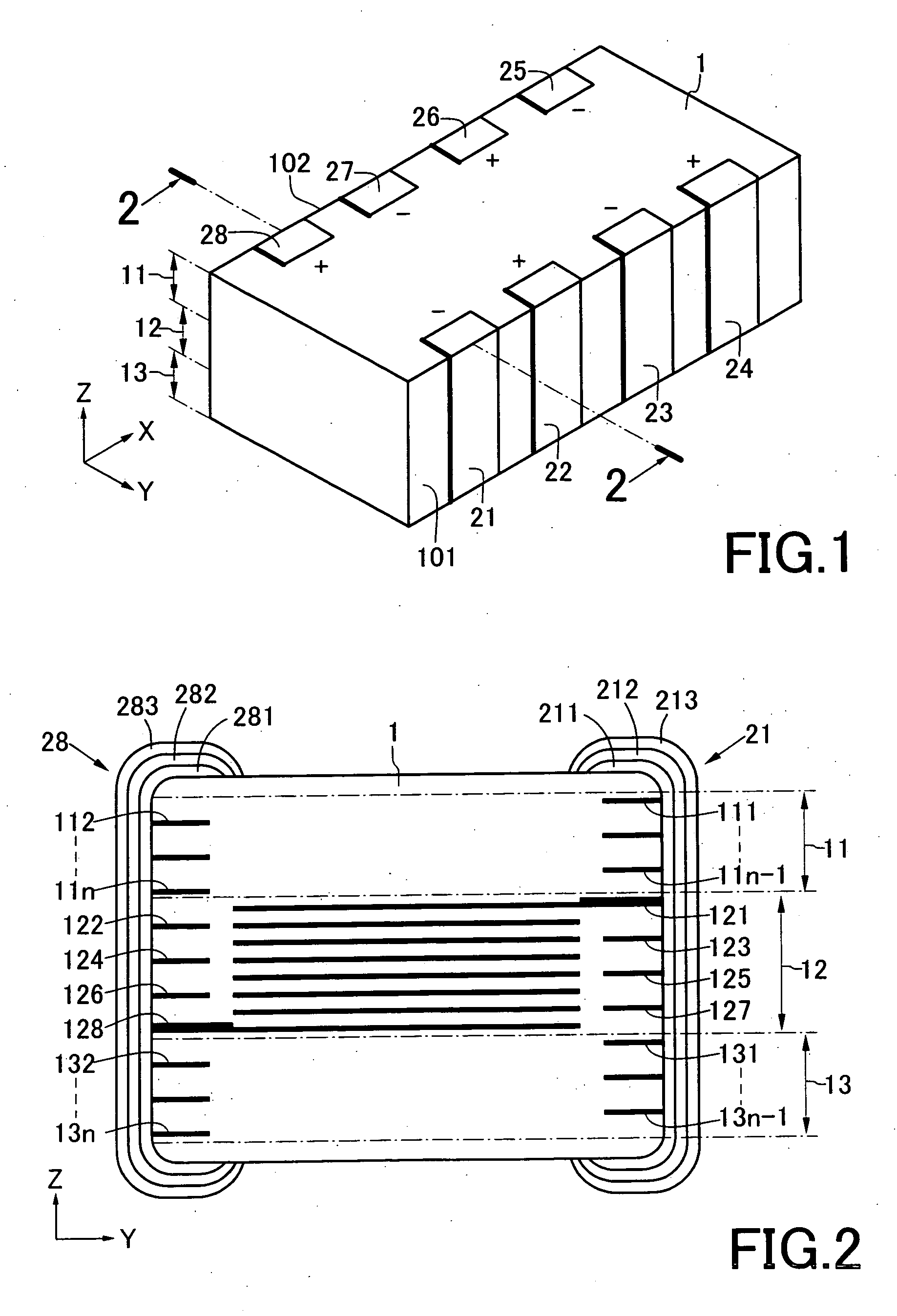

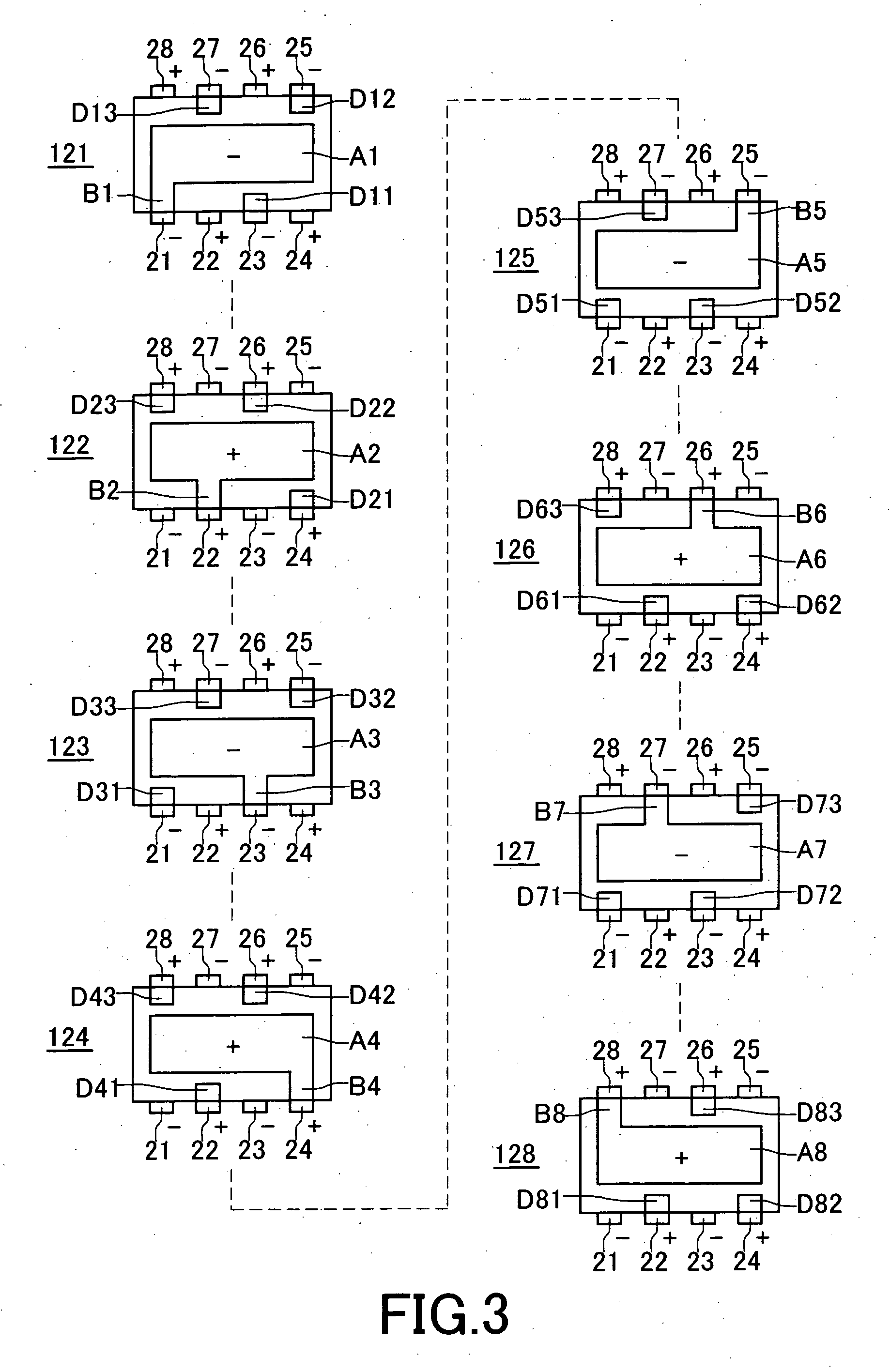

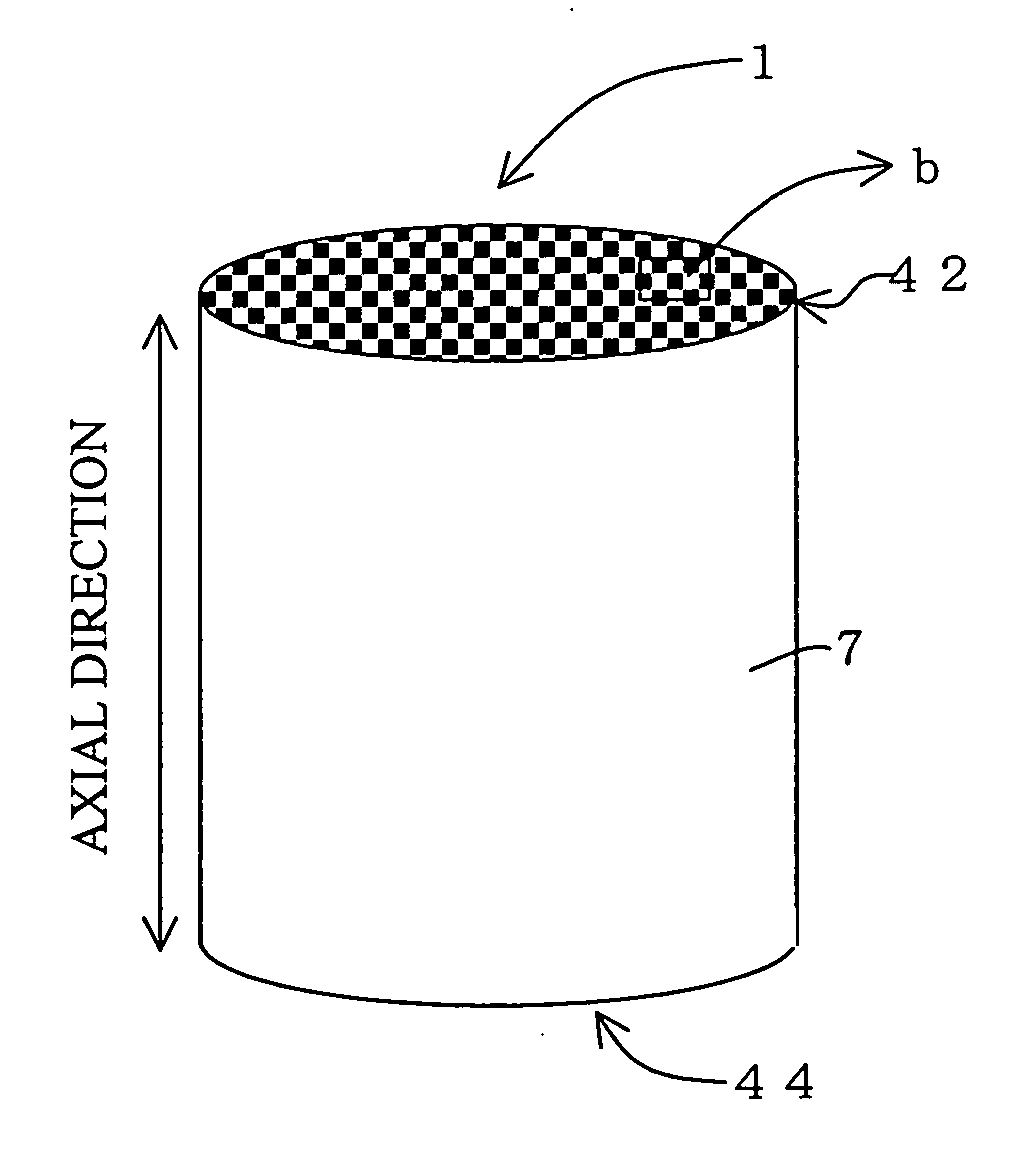

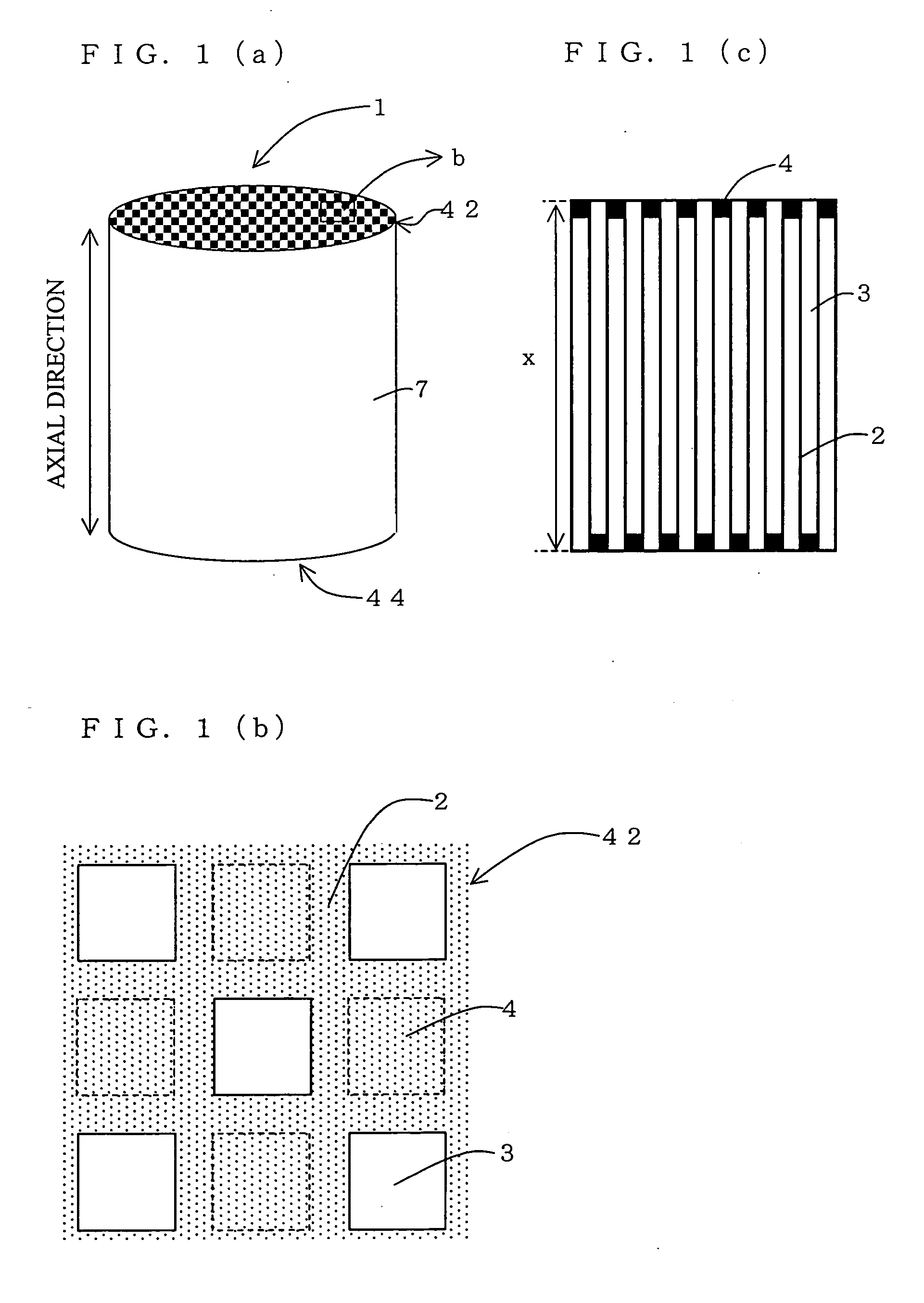

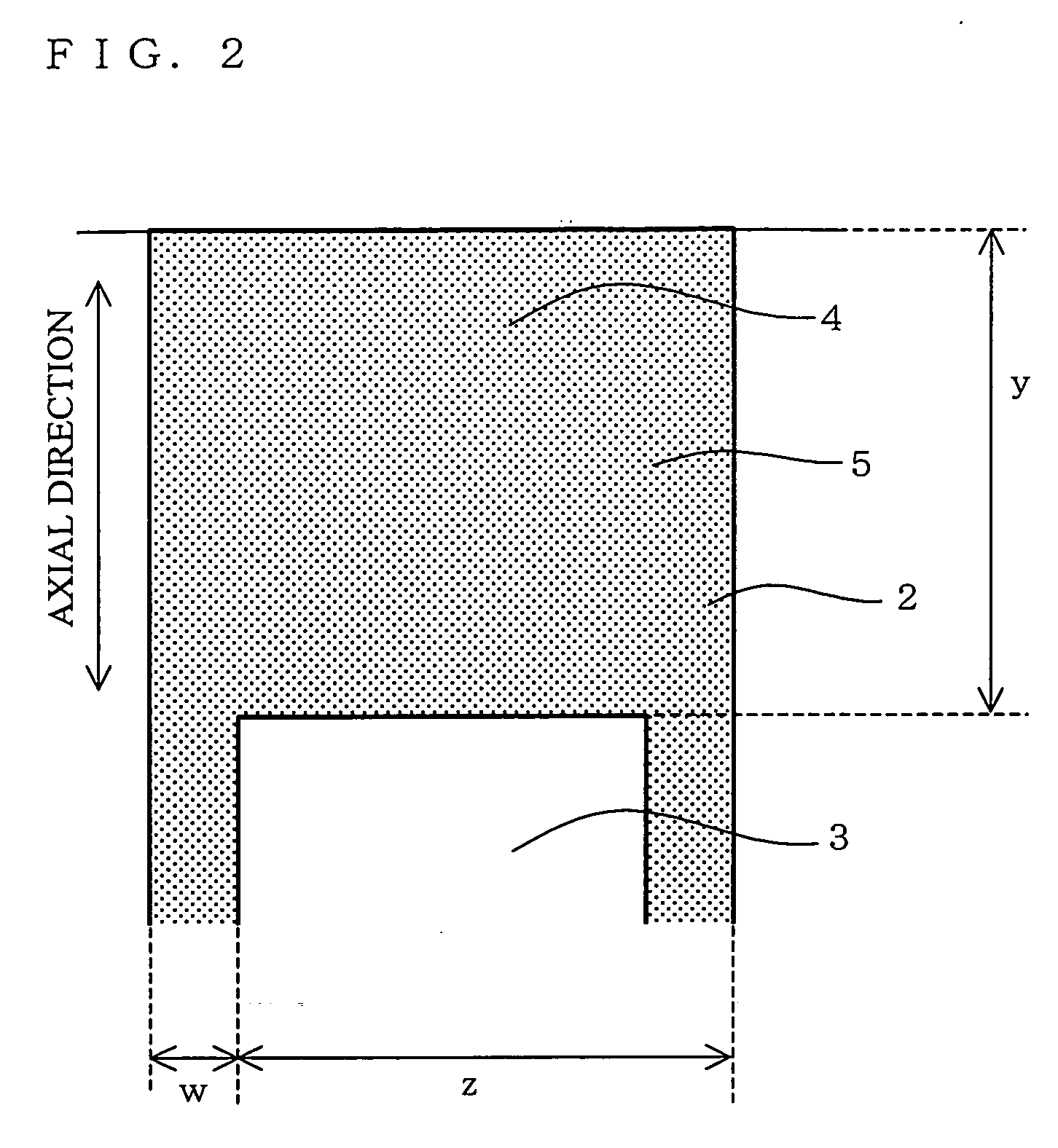

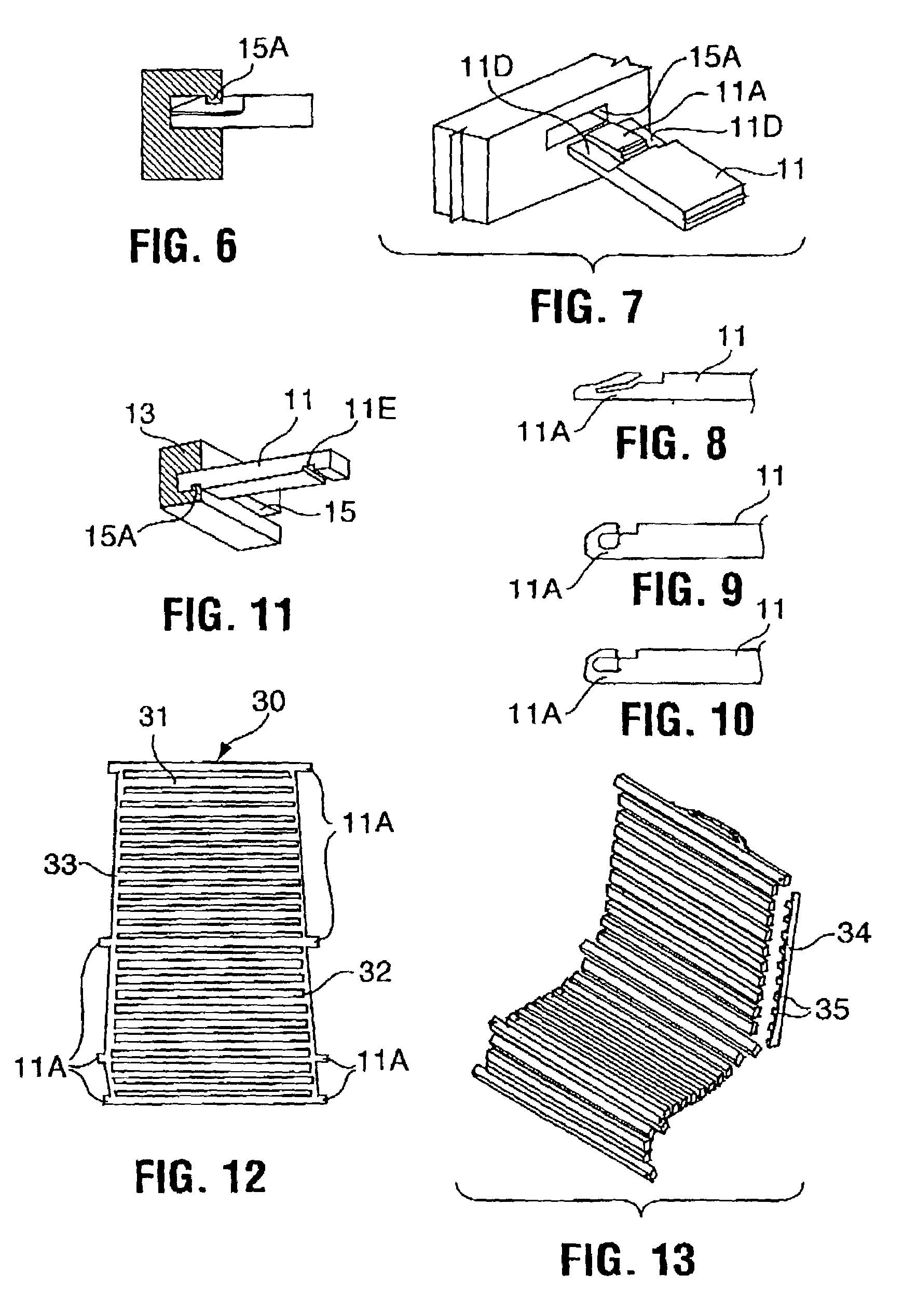

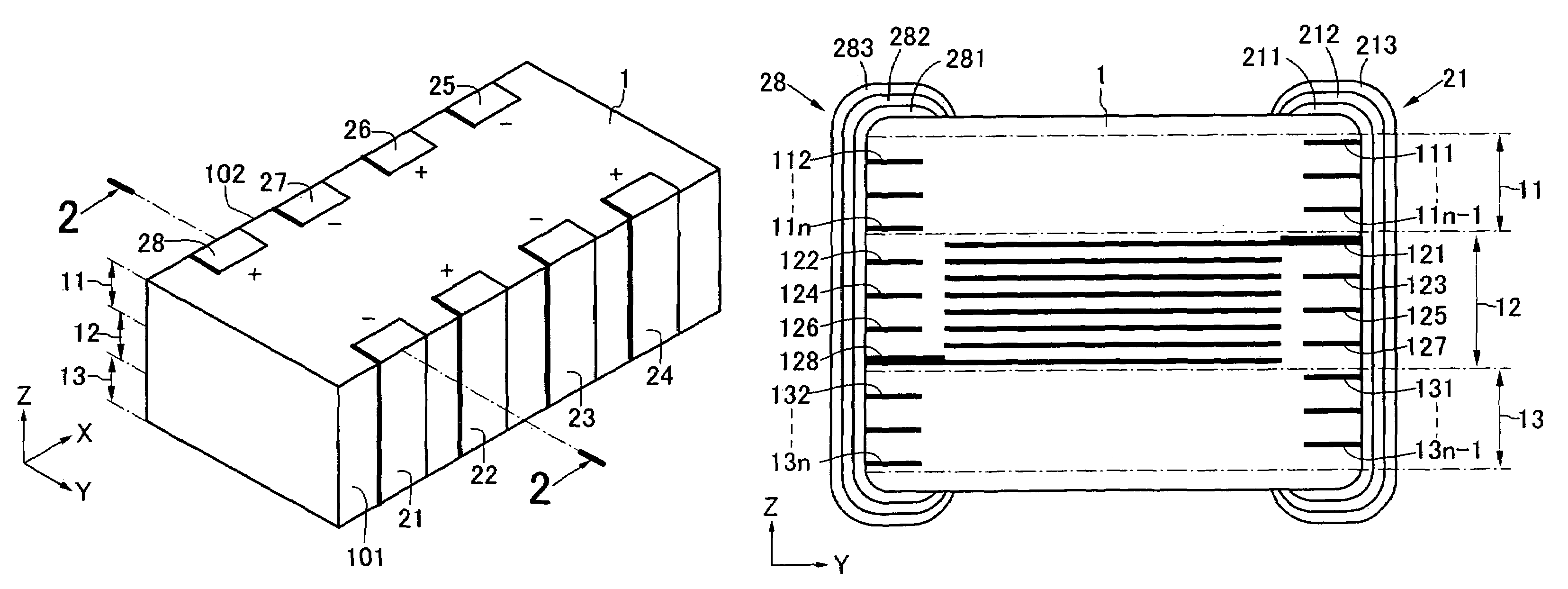

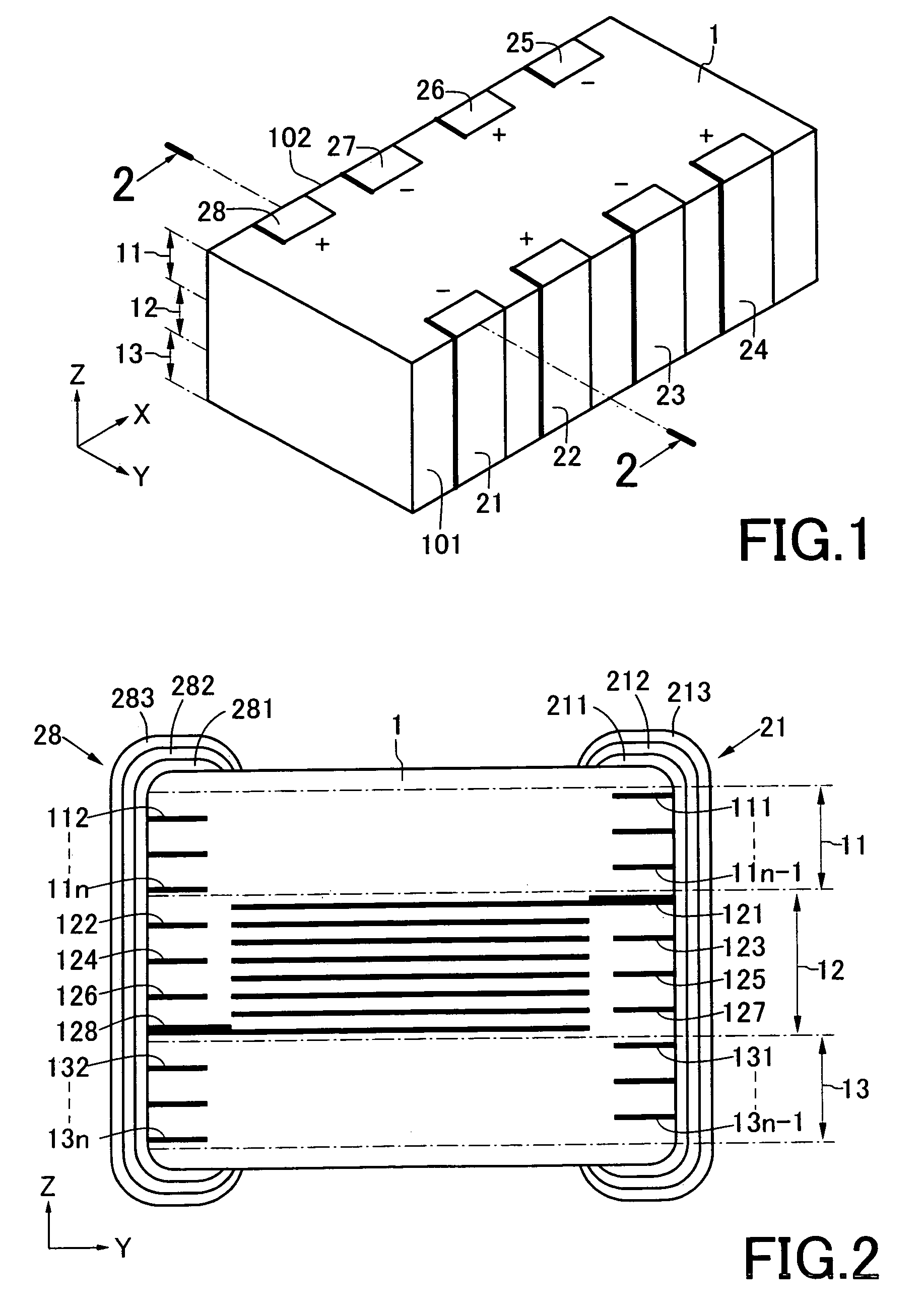

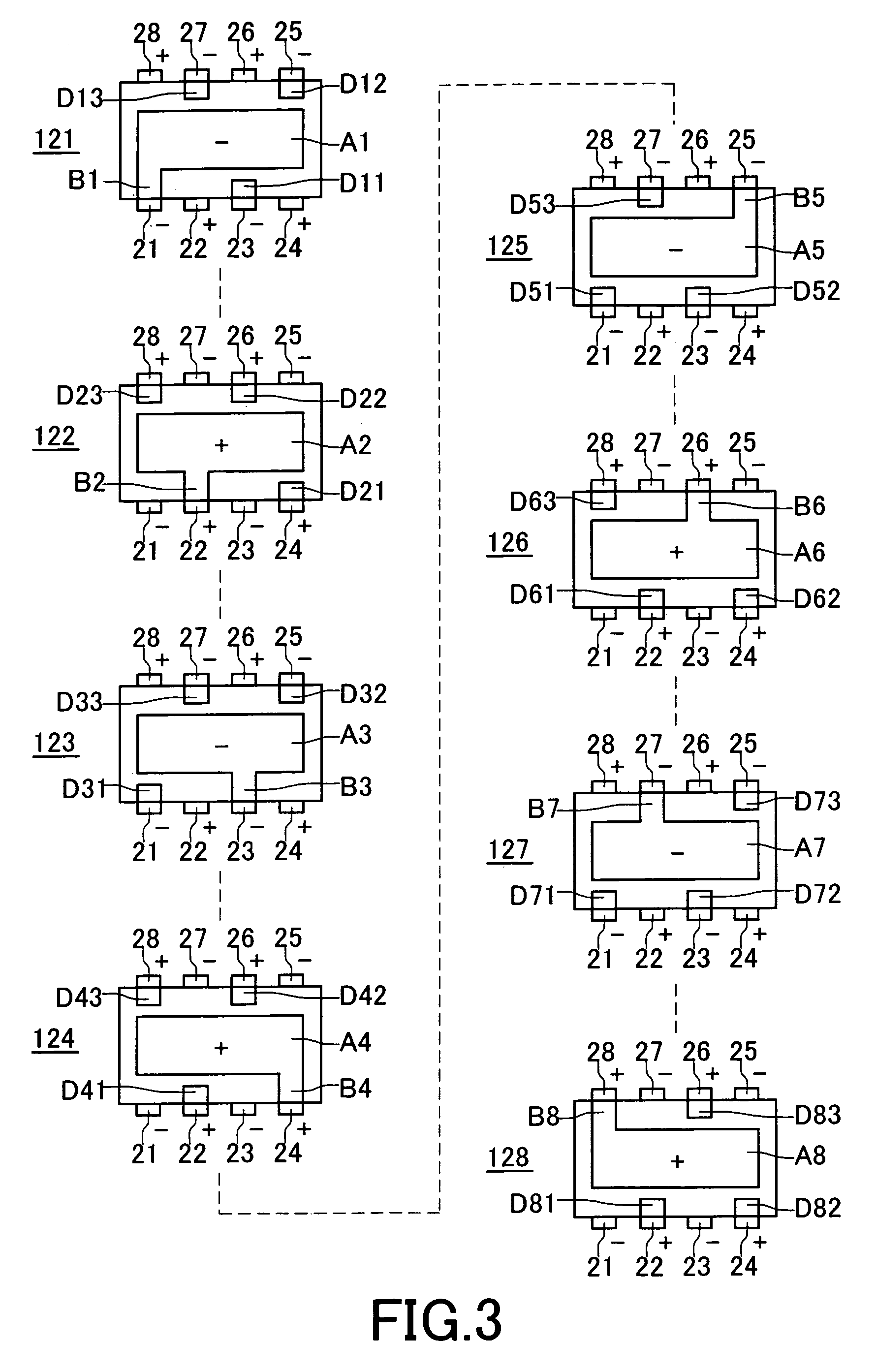

Multi-terminal type laminated capacitor and manufacturing method thereof

ActiveUS20060203420A1Guaranteed adhesionIncreased ESRFixed capacitor electrodesElectric heatingCapacitorMaterials science

Electrode layers 121 to 128 are superimposed in a ceramic porcelain 1 with ceramic layers therebetween. The electrode layers 121 to 128 respectively include internal electrodes A1 to A8 and extraction electrodes B1 to B8. Giving a description on the electrode layer 121, one end of the extraction electrode B1 is connected with the internal electrode A1 in the same layer, and the other end of the same is led onto a side surface of the ceramic porcelain 1. Further, the extraction electrode B1 is formed to be thicker than the internal electrode A1 in the same layer.

Owner:TDK CORPARATION

Light emitting diode light source for curing dental composites

InactiveUS7320593B2Sufficient powerSufficient structurePrinted circuit aspectsSolid-state devicesDental compositeHeat sink

Owner:KONINK PHILIPS ELECTRONICS NV

Sealed honeycomb structure and method of producing the same

ActiveUS20060150598A1High affinitySolve the lack of adhesionCombination devicesAuxillary pretreatmentSolid particleHoneycomb structure

Owner:NGK INSULATORS LTD

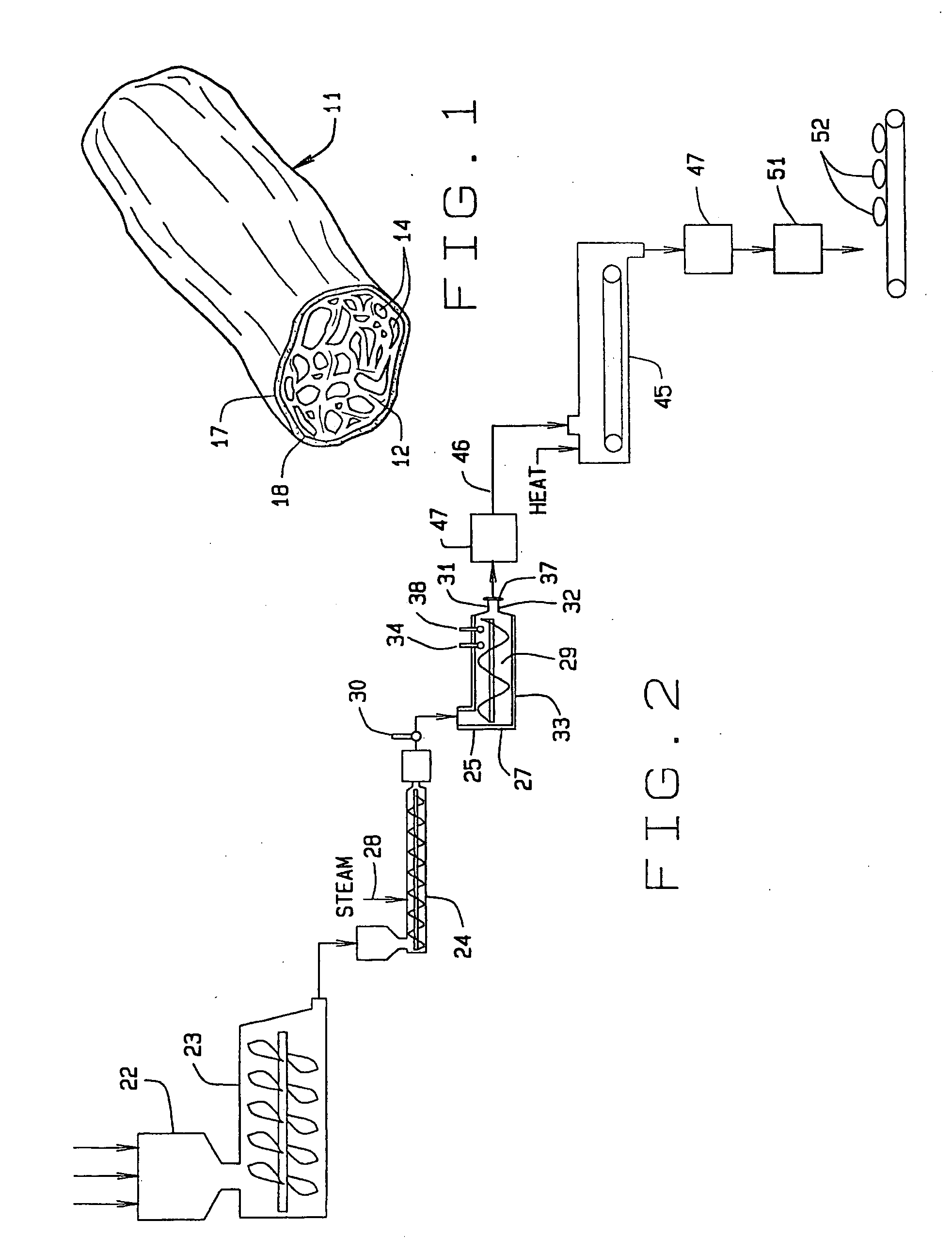

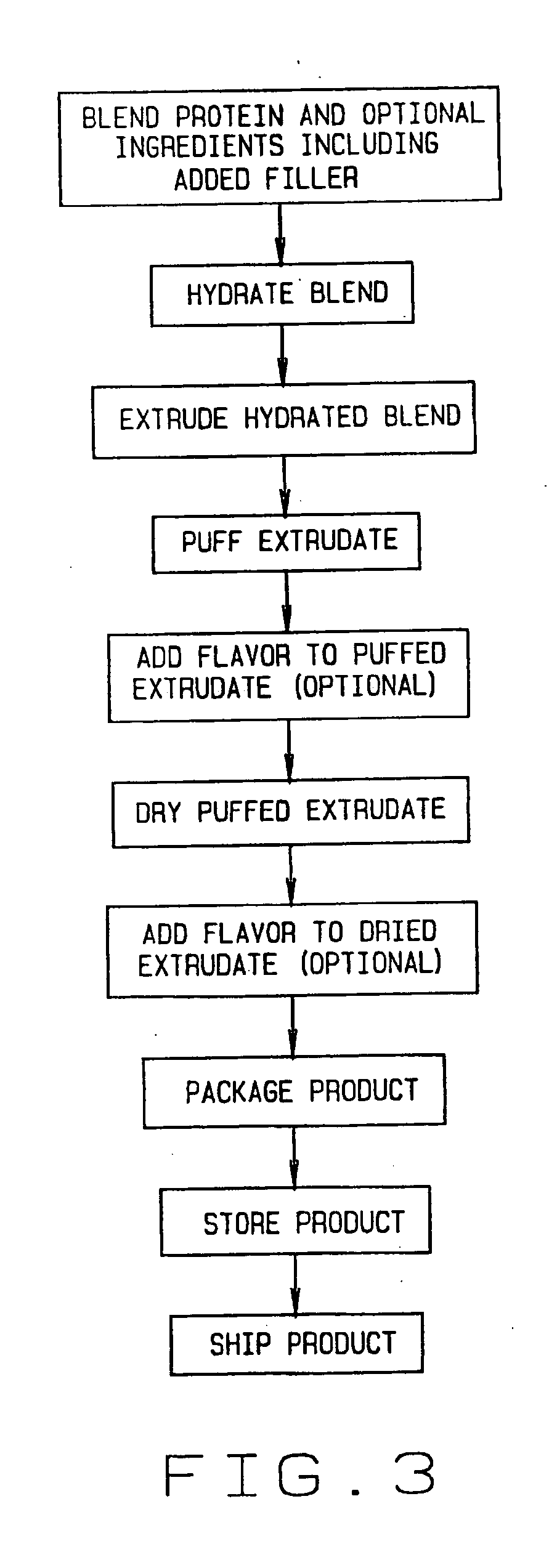

Puffed protein based snack food

InactiveUS20050089623A1Sufficient structureReduced and perceived lack of formationProteins working-up by texturisingFood preservationSnack foodFood flavor

A food product and method are provided. The food product is a crisp expanded proteinacious food product characterized by an absence of objectionable protein fiber formation. The product is puffed to provide a low density while providing a good eating texture. The product may be coated to provide additional flavors and / or nutrients.

Owner:SOLAE LLC +1

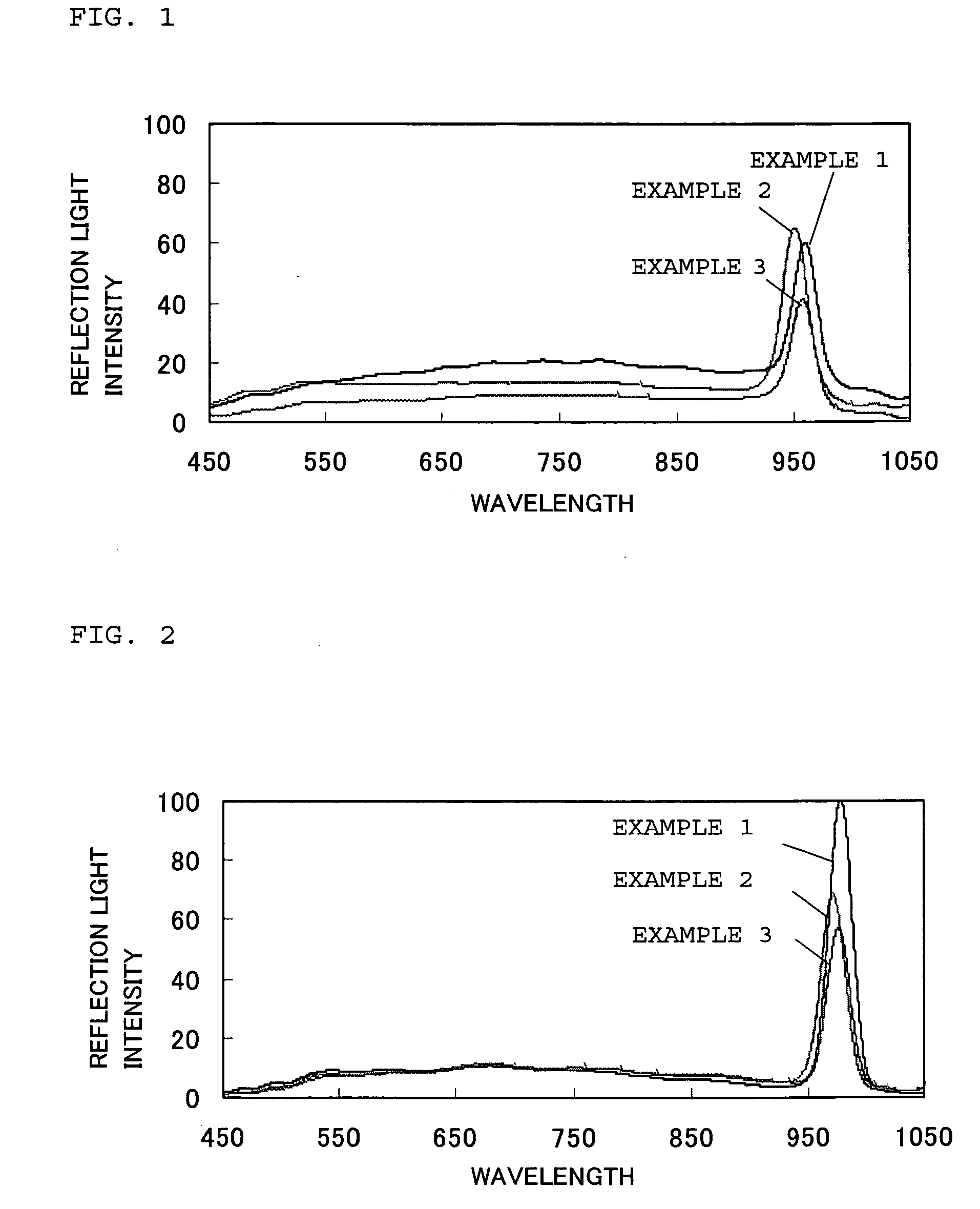

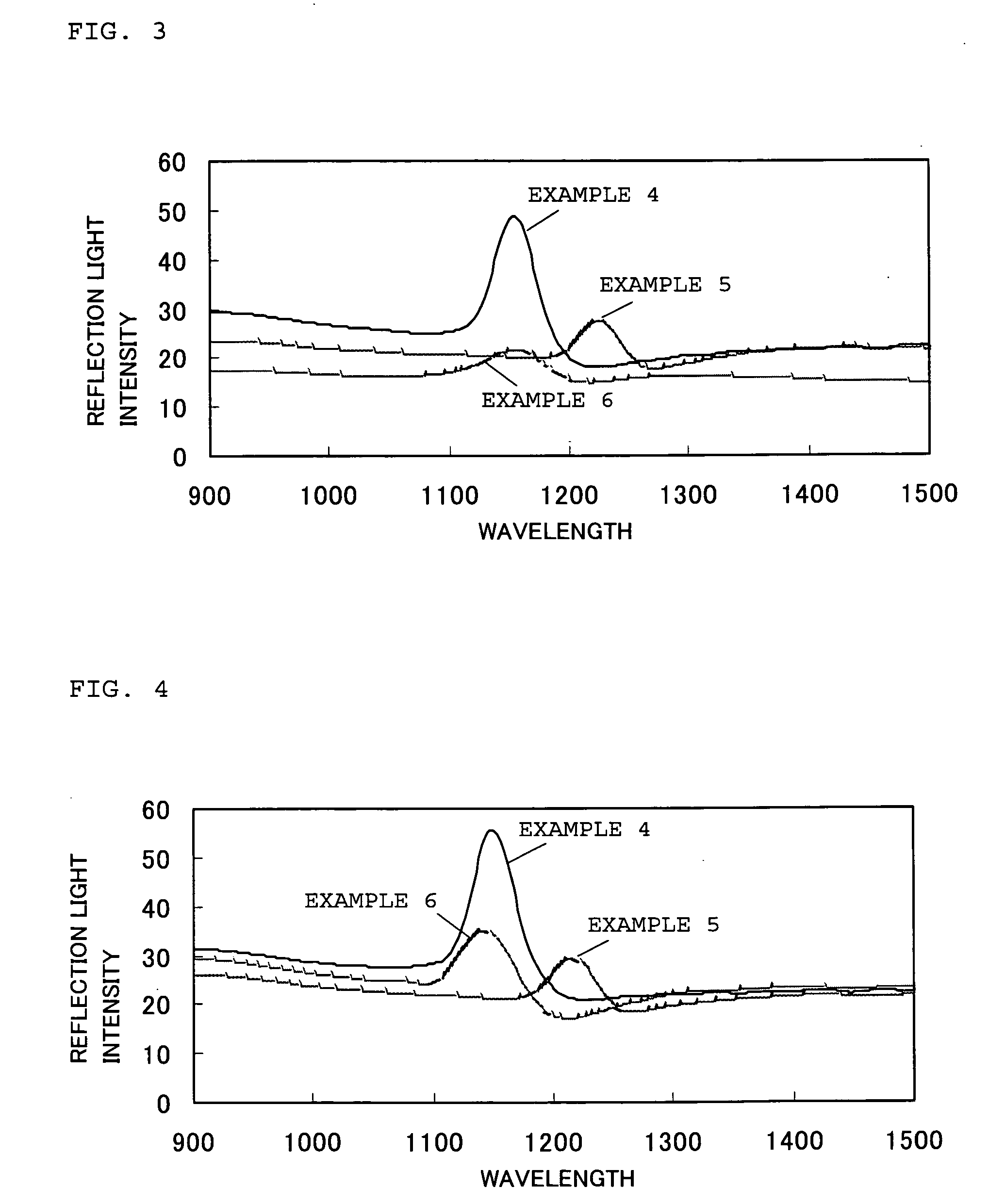

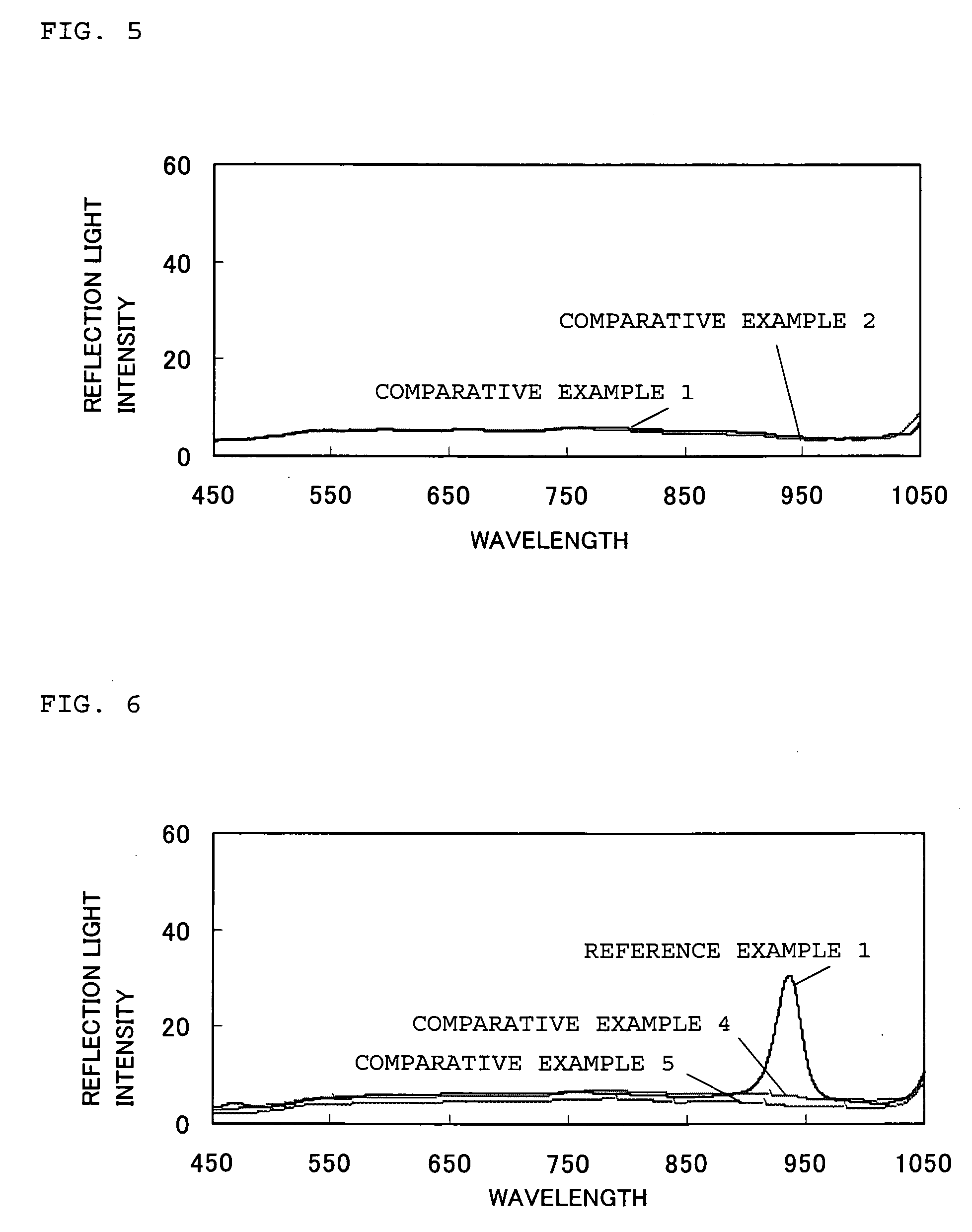

Process for producing colloidal crystals immobilized with a polymer and colloidal crystals immobilized with a polymer

InactiveUS20080305968A1Low degreeEasy to fixPolycrystalline material growthFrom normal temperature solutionsColloidal particleMonomer

A process for producing colloidal crystals immobilized with a polymer, comprising the steps of:preparing a monomer-dispersion in which colloidal crystals having a three-dimensionally ordered array state are formed by adding, to a monomer-containing liquid containing at least one kind of monomers, colloidal particles having an average particle size in a range from 0.01 μm to 10 μm and a degree of monodispersity expressed by a following equation (1) of 20% or below,[Degree of monodispersity (unit: %)]=([Standard deviation of particle size] / [Average particle size])×100 (1)and then by dispersing the colloidal particles so as to arrange the colloidal particles in a three-dimensionally ordered array state at which a reflection spectrum thereof exhibits a reflection peak; andobtaining the colloidal crystals immobilized with a polymer by polymerizing the monomers in the monomer-dispersion.

Owner:TOYOTA CENT RES & DEV LAB INC

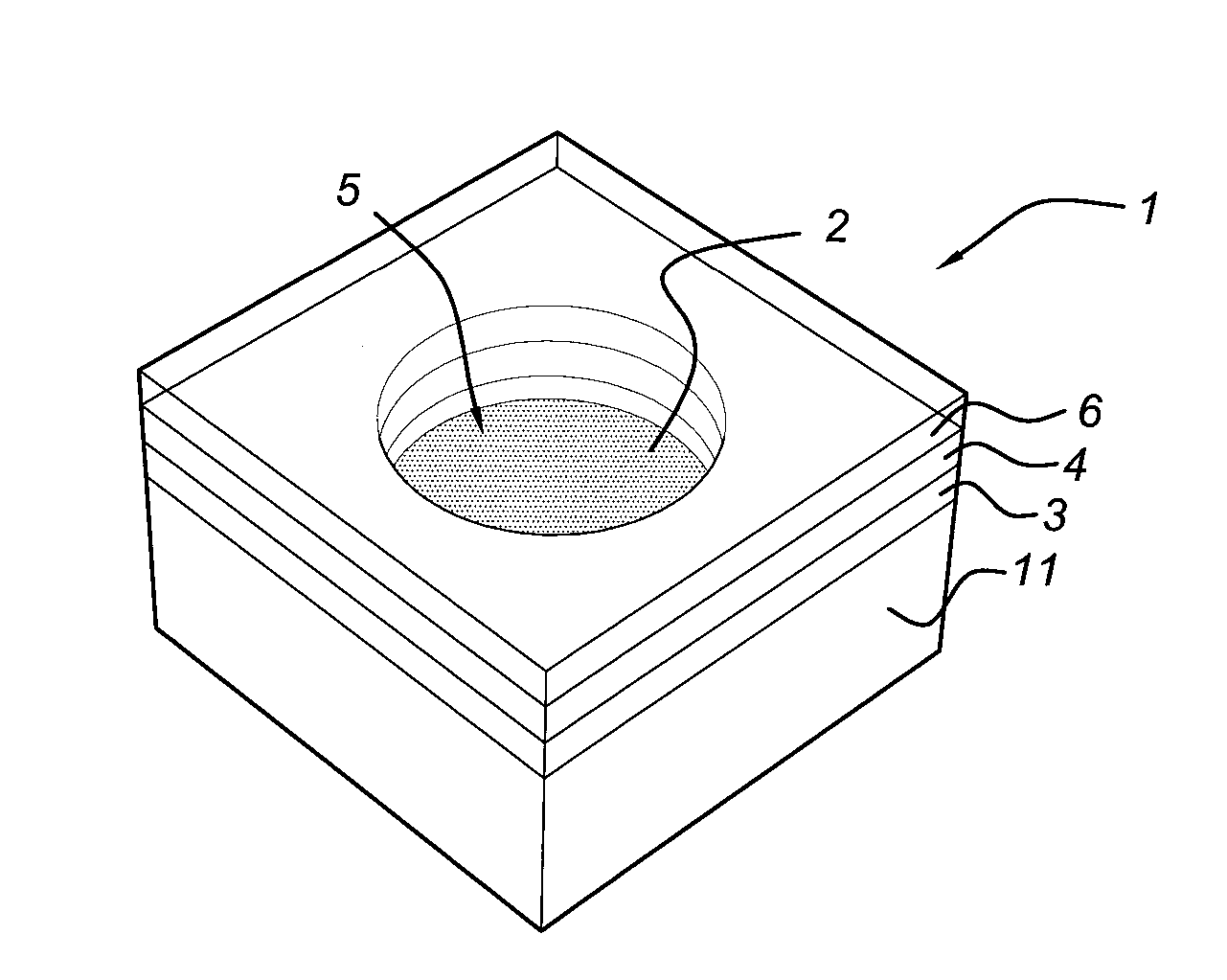

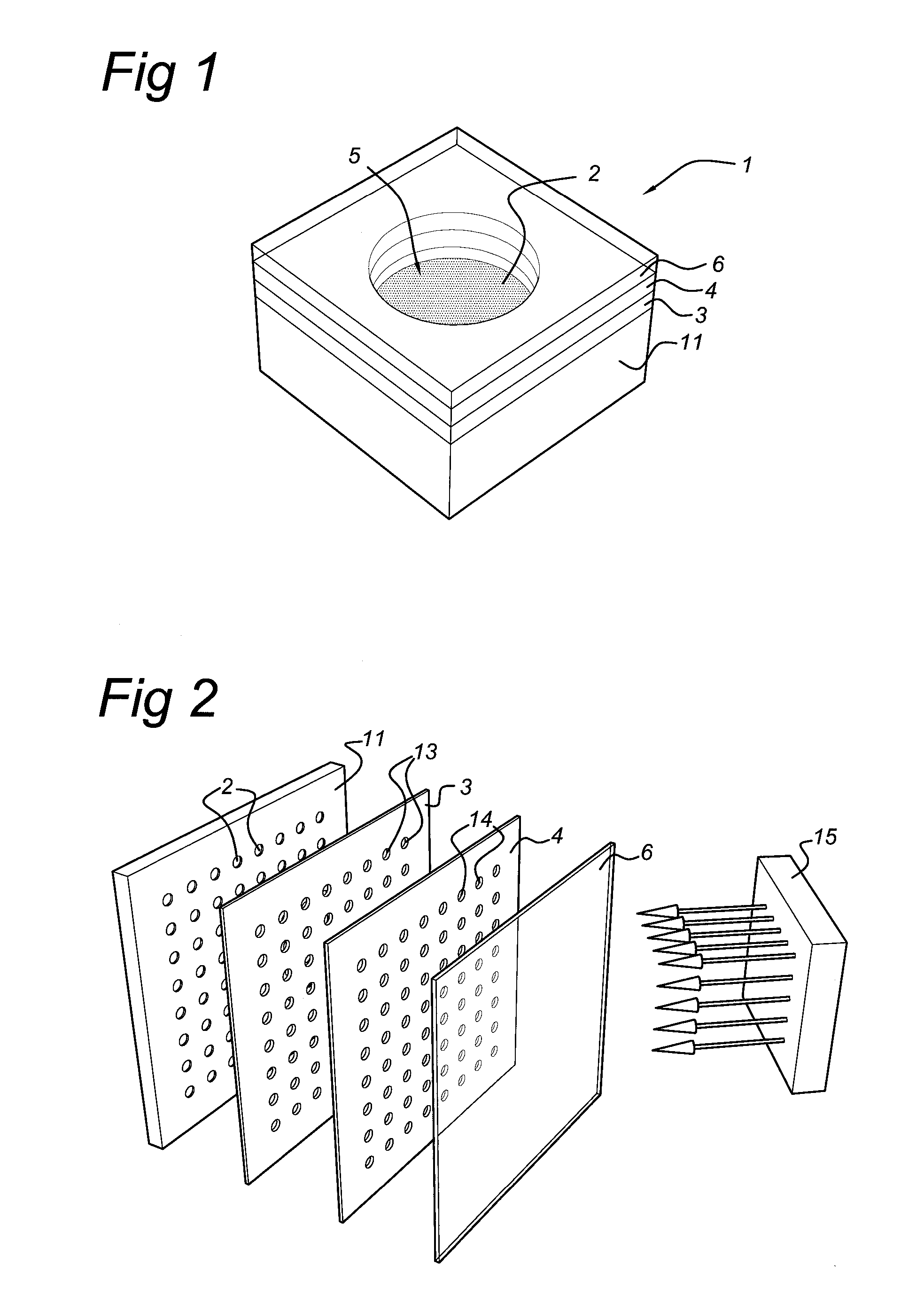

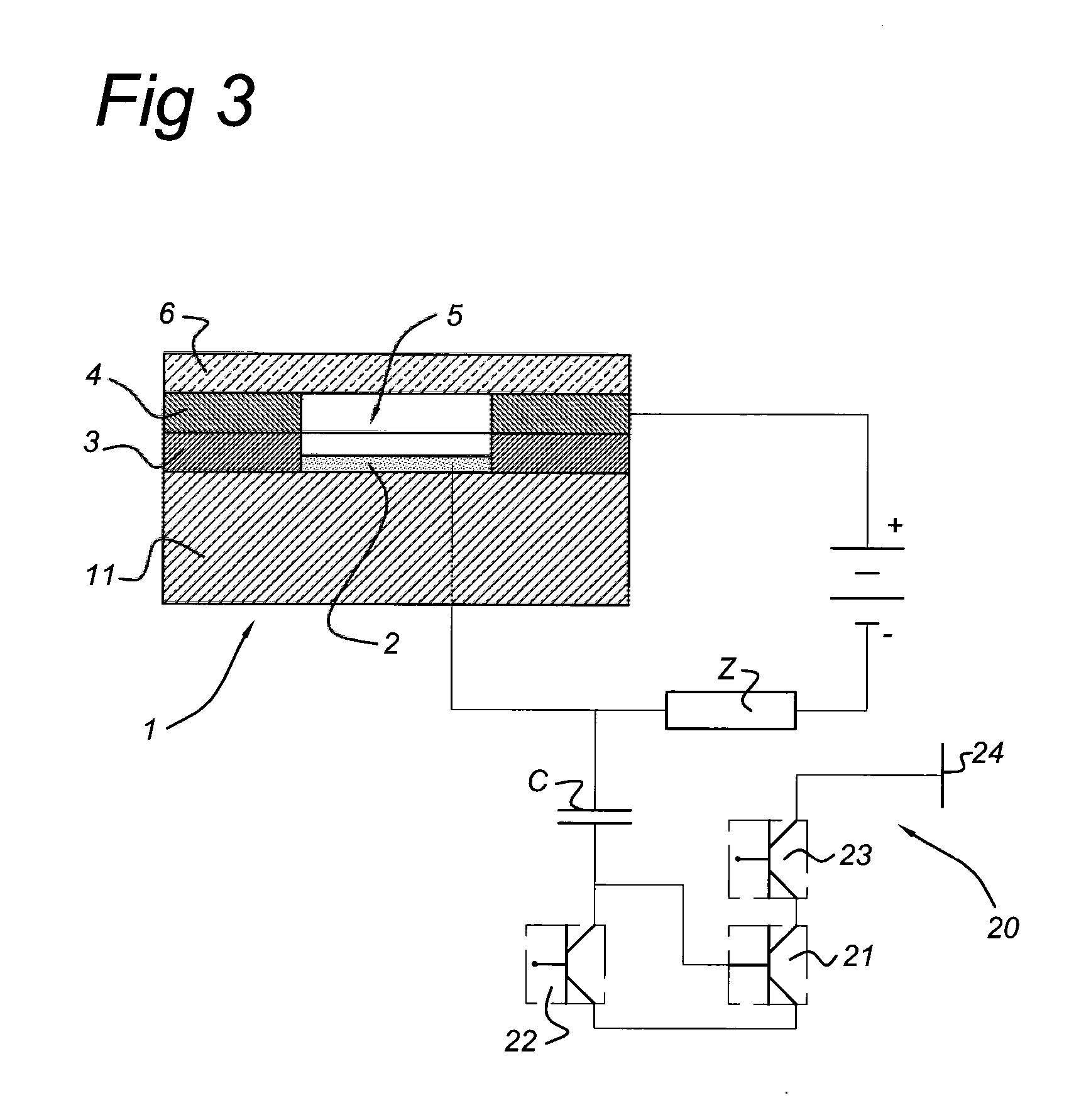

Terahertz radiation detection using micro-plasma

InactiveUS20130256535A1Easy to detectEasy to adjustRadiation pyrometryElectric discharge tubesGas compositionTerahertz radiation

Detector for terahertz radiation with a micro-plasma cell (1) having a cavity (5) including a plasma in operation when applying a DC bias to the micro-plasma cell (1). Furthermore, the detector is provided with read-out electronics (20) connected to the micro-plasma cell (1). The read-out electronics measure changes of an electron density in the plasma in the micro-plasma cell (1) with respect to the DC bias provided electron density. The cavity (5) includes a gas composition near atmospheric pressure or higher, and the gas composition includes a Penning mixture.

Owner:TERAOPTRONICS

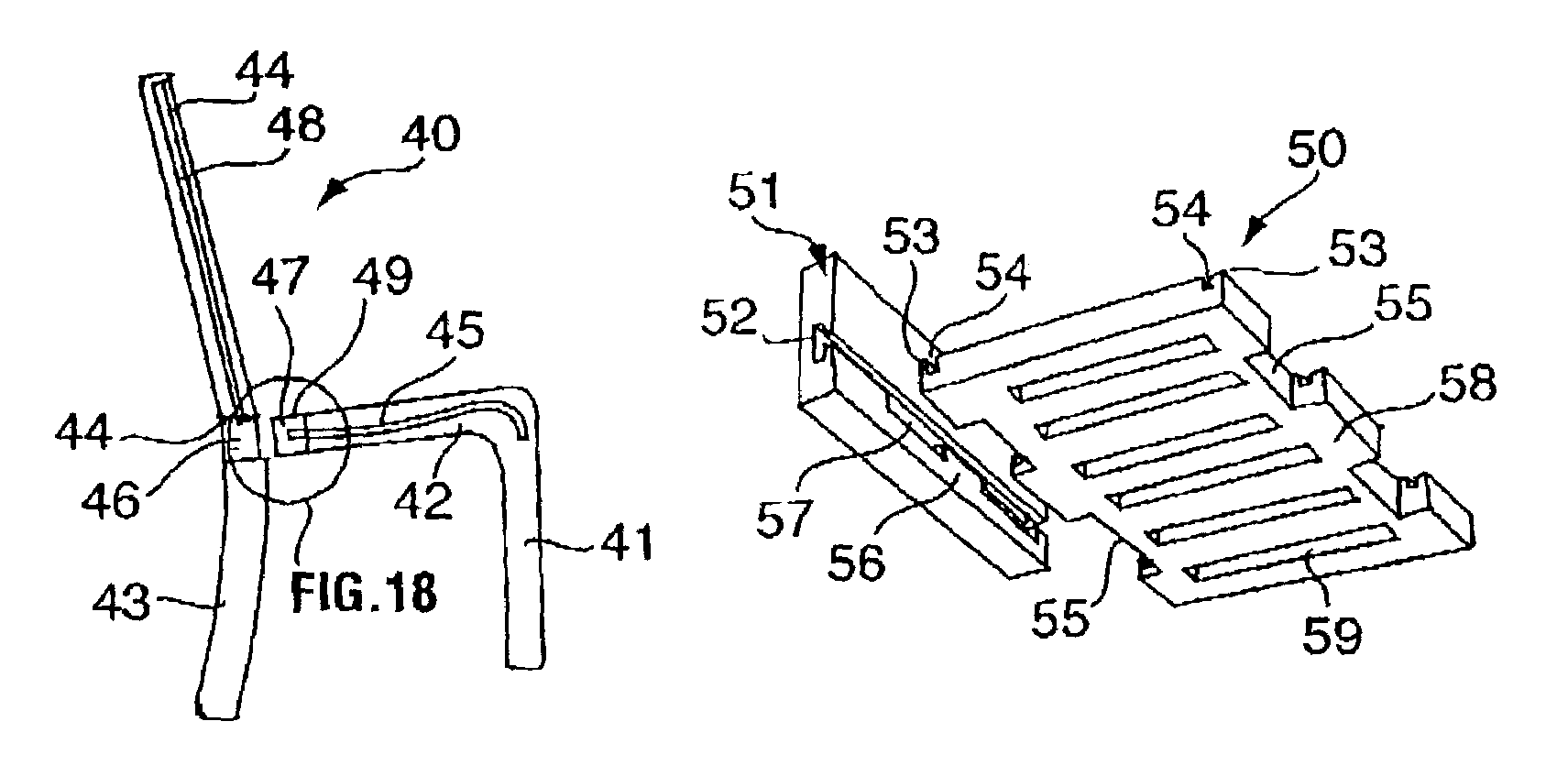

Furniture structure

InactiveUS7066553B2Improve comfortIncreased durabilitySpring mattressesStoolsEngineeringMechanical engineering

Owner:FINCASTLE COUNTY CHAIRWORKS

Deformation resistant panels

ActiveUS20050051509A1Reduce distortionConvenient to accommodateBottlesLarge containersEngineeringMechanical engineering

Owner:GRAHAM PACKAGING CO LP

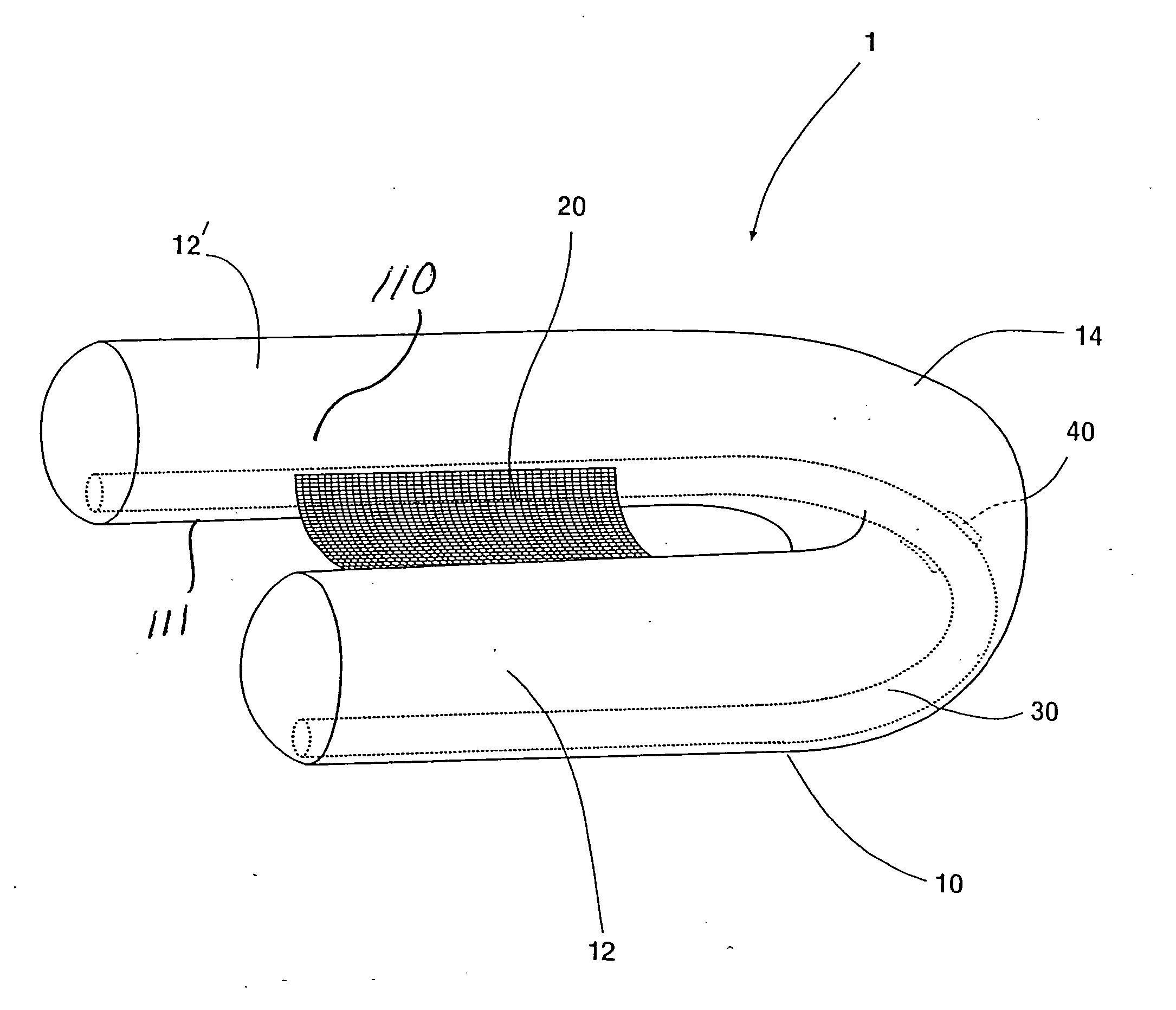

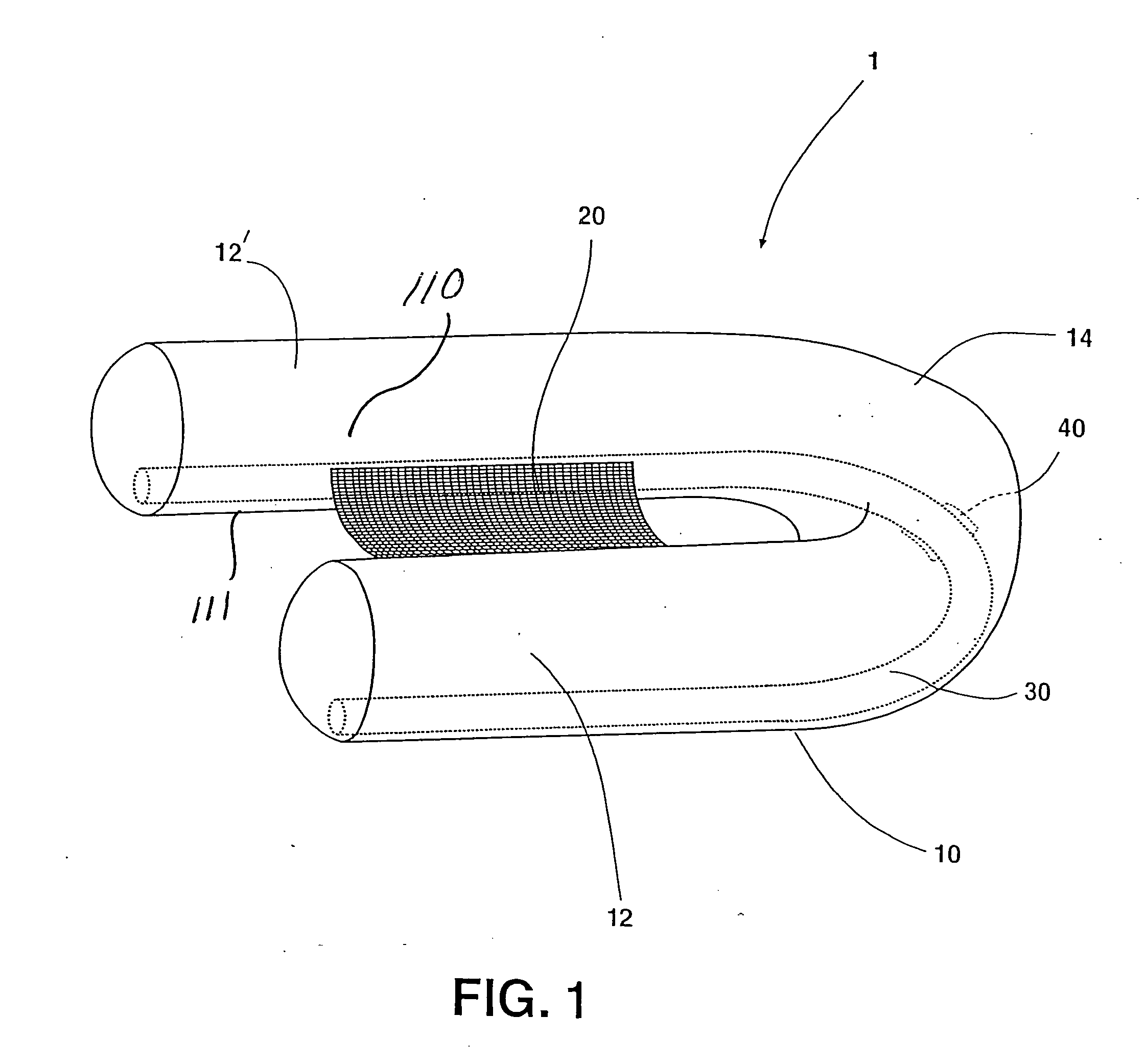

U-shaped float tube with stabilizing frame

InactiveUS20050026520A1Increase comfortSufficient structureLife-buoysSeating furnitureMechanical engineeringWatercraft

A float tube or watercraft comprised of a generally U-shaped inflatable flotation chamber having two generally parallel and laterally disposed leg portions and a rearward portion. The leg portions are preferably formed integrally with the rearward portion. The invention further includes a seating device bridging the two leg portions of the flotation chamber. A stabilizing frame and system for connecting the stabilizing frame to the U-shaped flotation chamber provides support to the opposing legs of the flotation chamber and prevents them from pinching in on the occupant, and also preferably tensions a seat provided between the legs of the floatation chamber. For additional support and / or this preferred tensioning, a rigid and / or adjustable rod, or tube, extends between the opposing legs of the frame. The system for connecting the stabilizing frame comprises preferably a plurality of channel segments, which are fixedly secured to the leg and rearward portions of the flotation chamber. Alternatively, a continuous channel may be used.

Owner:HOWERTON LARRY

Multi-terminal type laminated capacitor

ActiveUS7430105B2Guaranteed adhesionIncreased ESRFixed capacitor electrodesElectric heatingCapacitorMaterials science

Electrode layers 121 to 128 are superimposed in a ceramic porcelain 1 with ceramic layers therebetween. The electrode layers 121 to 128 respectively include internal electrodes A1 to A8 and extraction electrodes B1 to B8. Giving a description on the electrode layer 121, one end of the extraction electrode B1 is connected with the internal electrode A1 in the same layer, and the other end of the same is led onto a side surface of the ceramic porcelain 1. Further, the extraction electrode B1 is formed to be thicker than the internal electrode A1 in the same layer.

Owner:TDK CORPARATION

Frozen microwaveable bakery products

InactiveUS20050136167A1Sufficient structureReduce the amount requiredBakery product refreshing by heating/thawingReady-for-oven doughsBiotechnologyWater activity

A frozen microwaveable bakery product having an open grain structure including from about 40 to about 58% by weight of a cereal grain flour having high protein content. The bakery product has a yeast leavened bread dough matrix including from about 4 to about 8 weight percent of a blend of sweeteners including water activity reducing agents effective to bind water within the bakery product to reduce the amount of free moisture in the bread dough matrix and minimize sublimation of moisture in frozen storage. Preferred embodiments can contain an enrobed portion containing a food or foods. Methods of making the frozen microwaveable bakery products are also disclosed including a step of freezing the products for frozen storage following proofing the products to a rise of about 30 to about 35% of the actual projected leavening capacity.

Owner:FIRST PRODS A MINNESOTA CORP

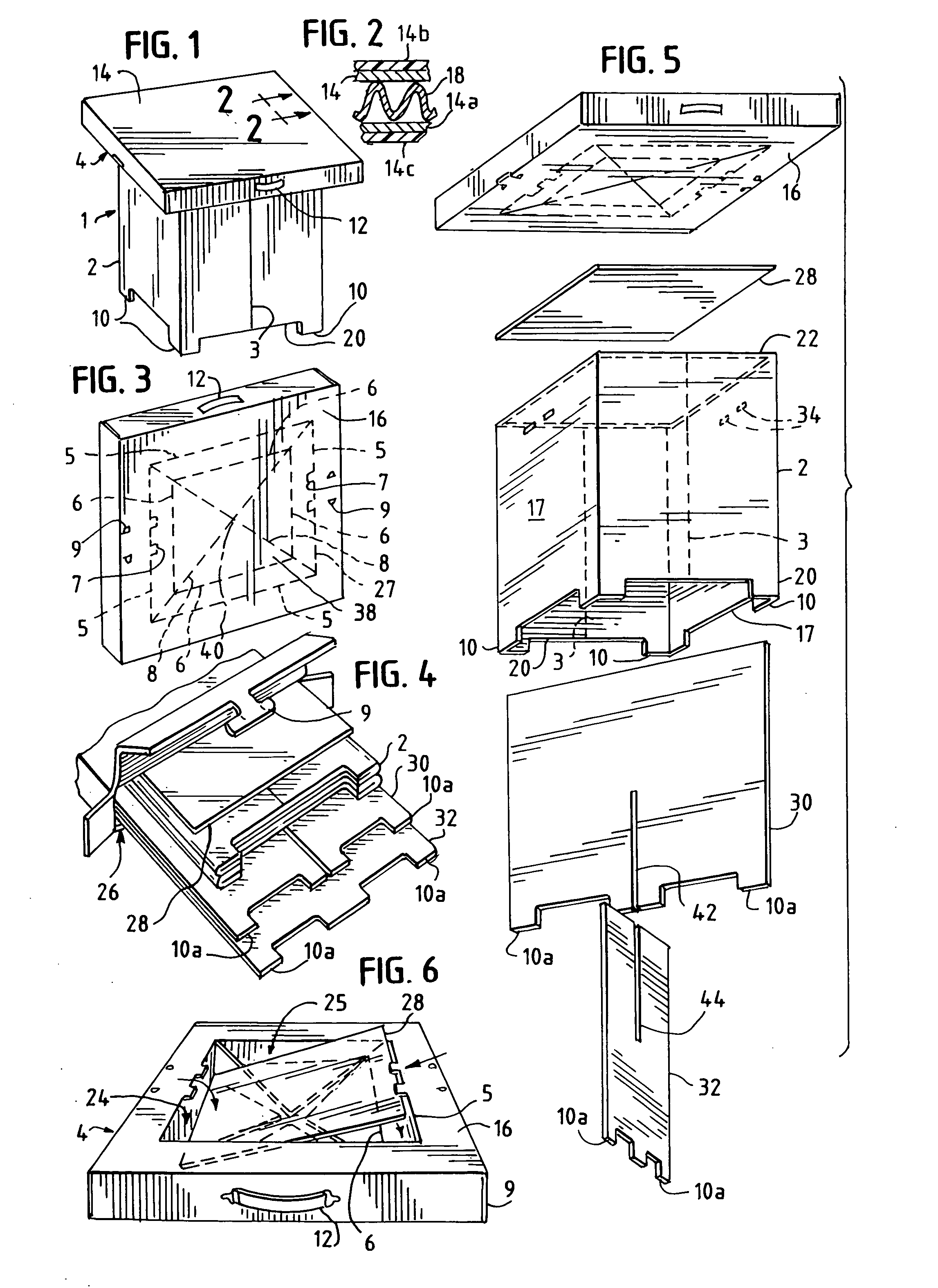

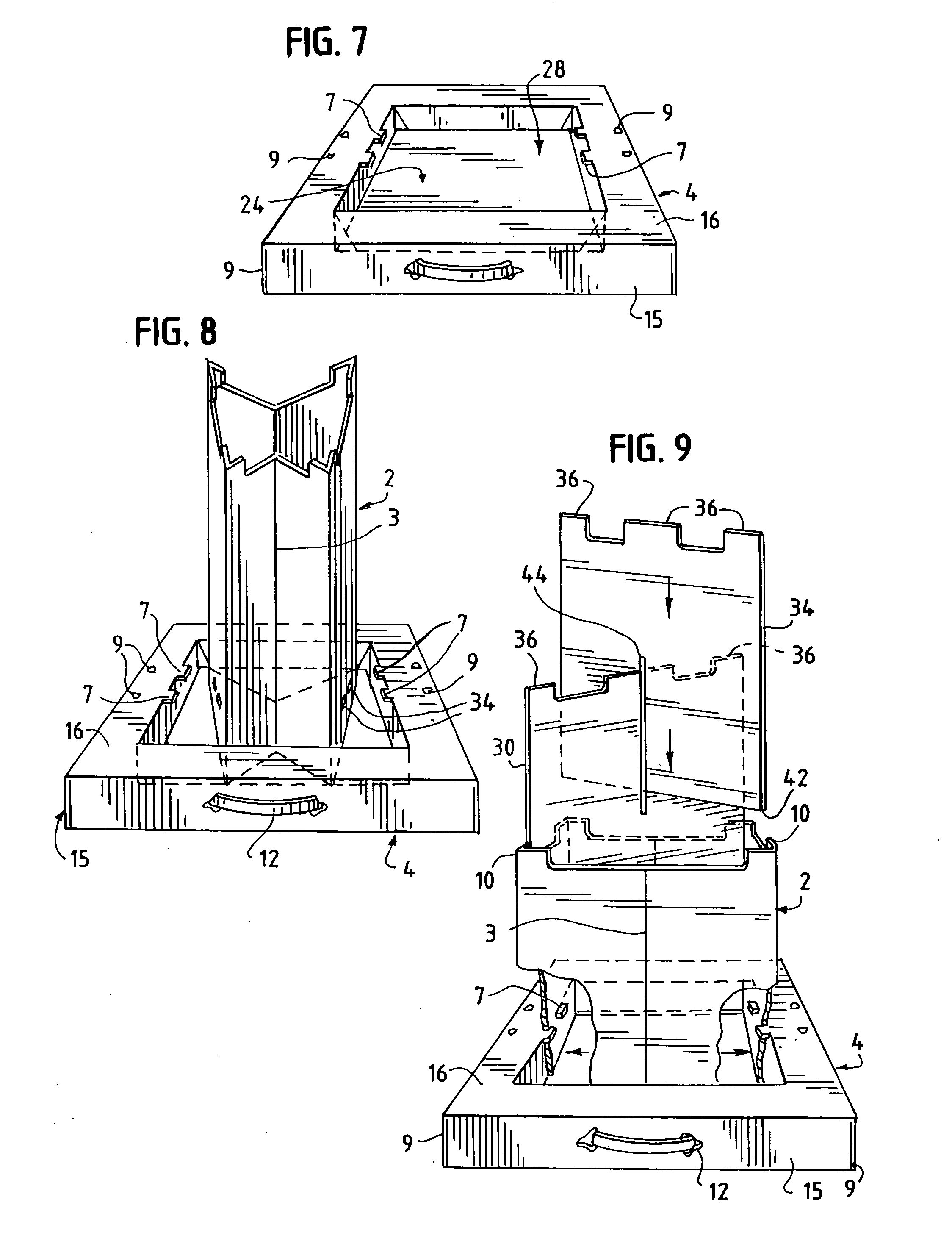

Collapsible table

InactiveUS20050204968A1Reduce effect of waterEffective and stableFoldable tablesStowable tablesEngineeringStructural integrity

An easily transportable collapsible table in which a box with a support structure inside converts to a table top with the support structure as its base. The box provides substantial structural integrity for the table top and it is easily assembled on site. The collapsible table can be disassembled, restored in the box and reused, or disposed of after a single use.

Owner:BUTKUS PATRICIA M +1

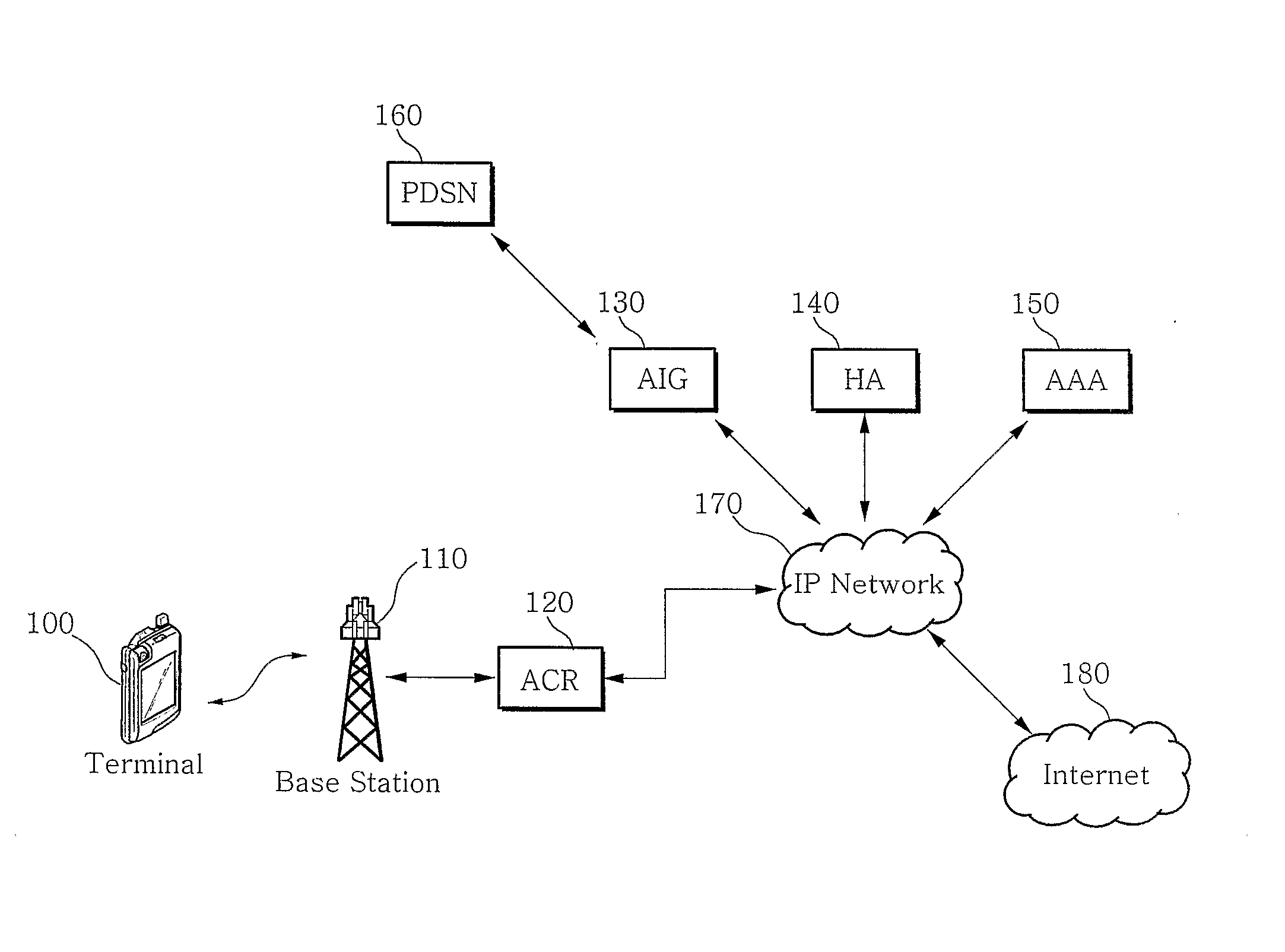

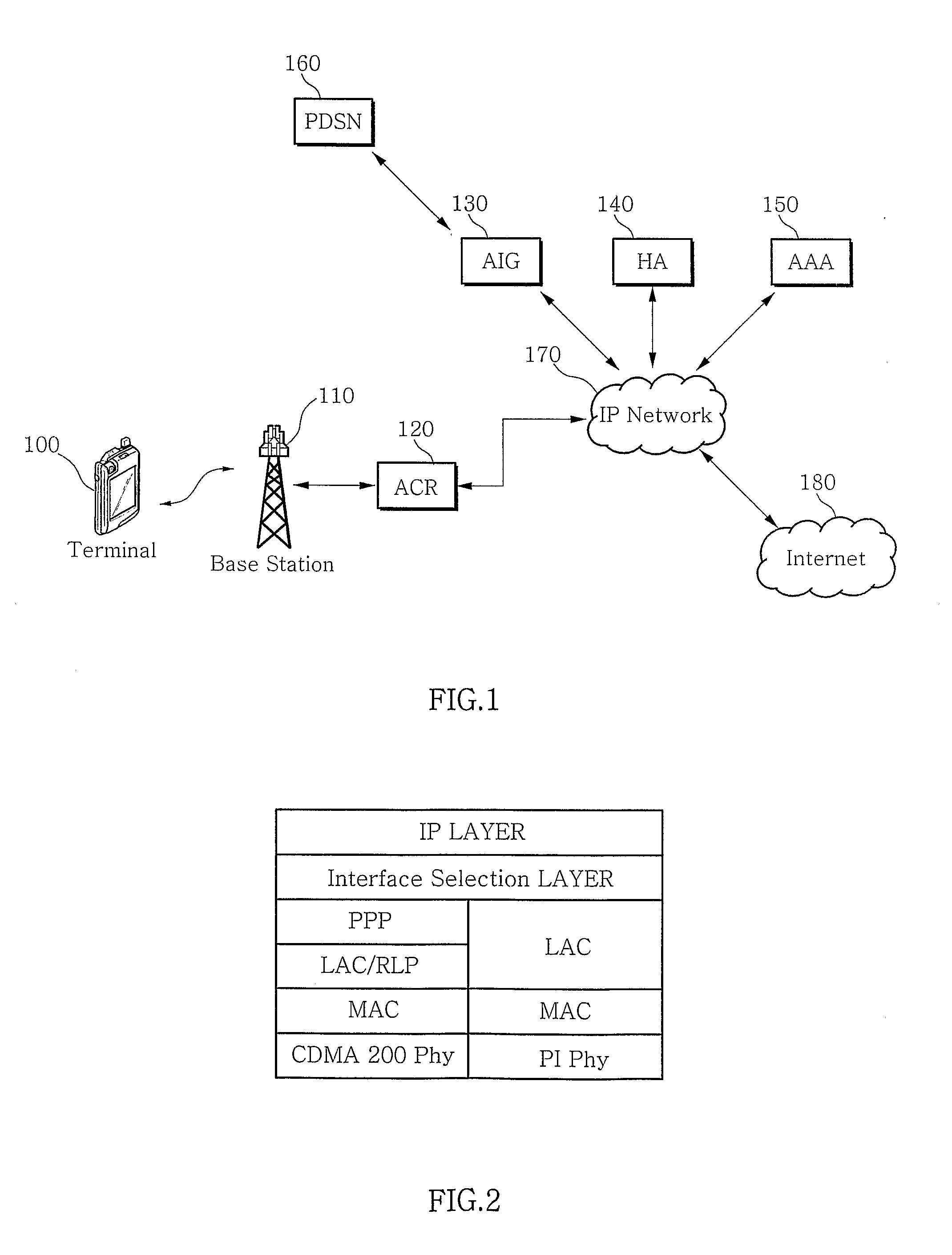

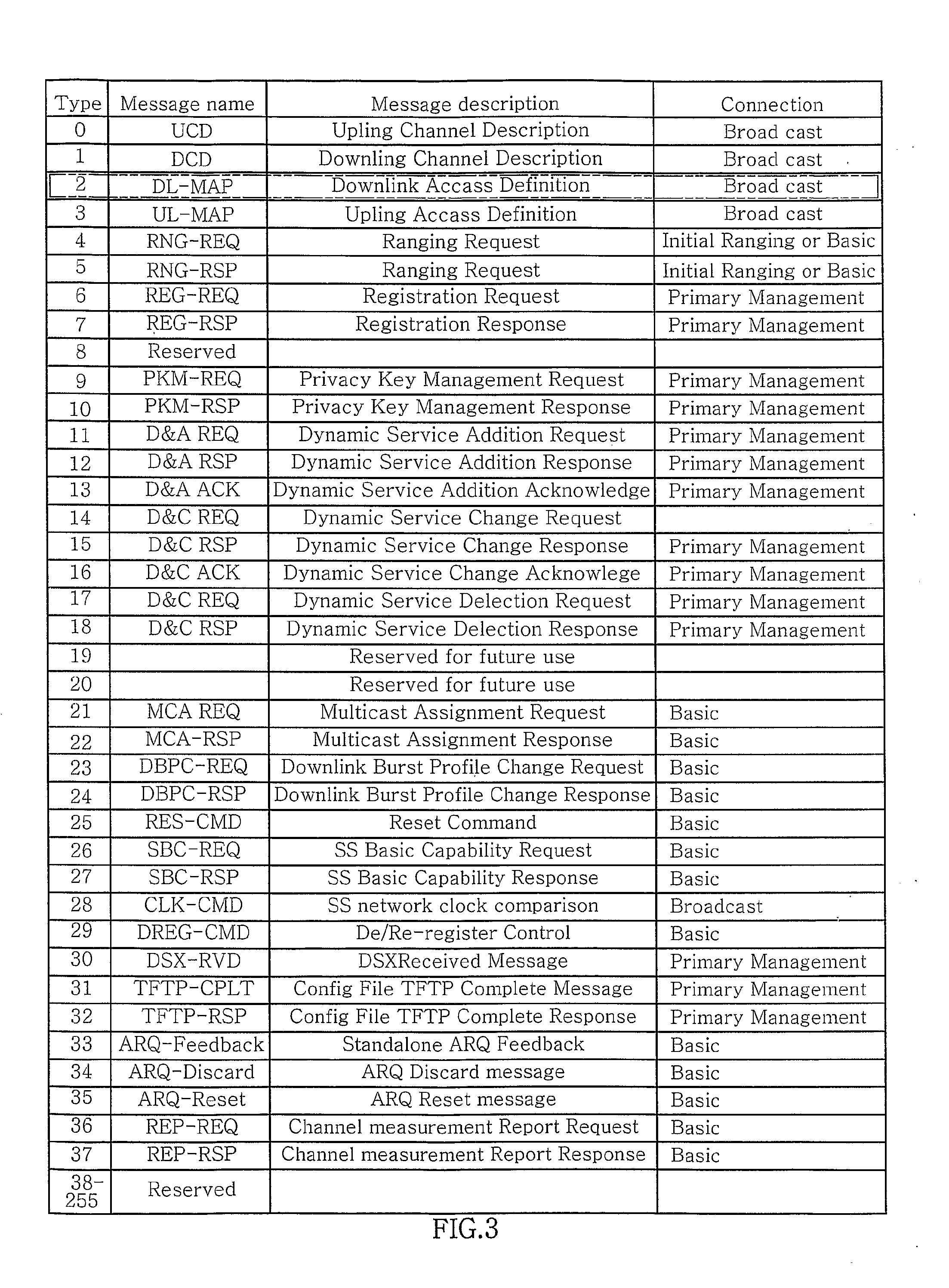

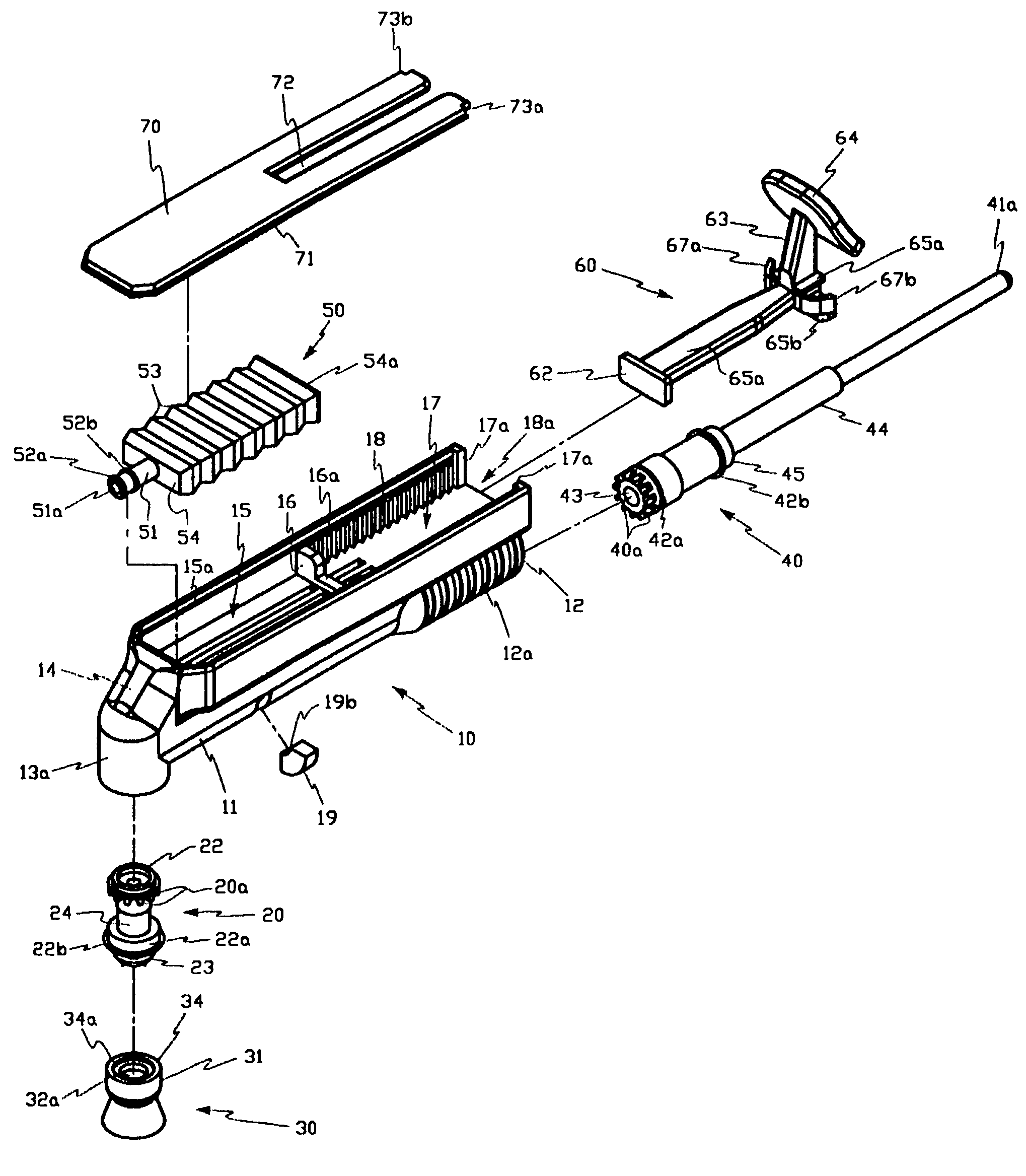

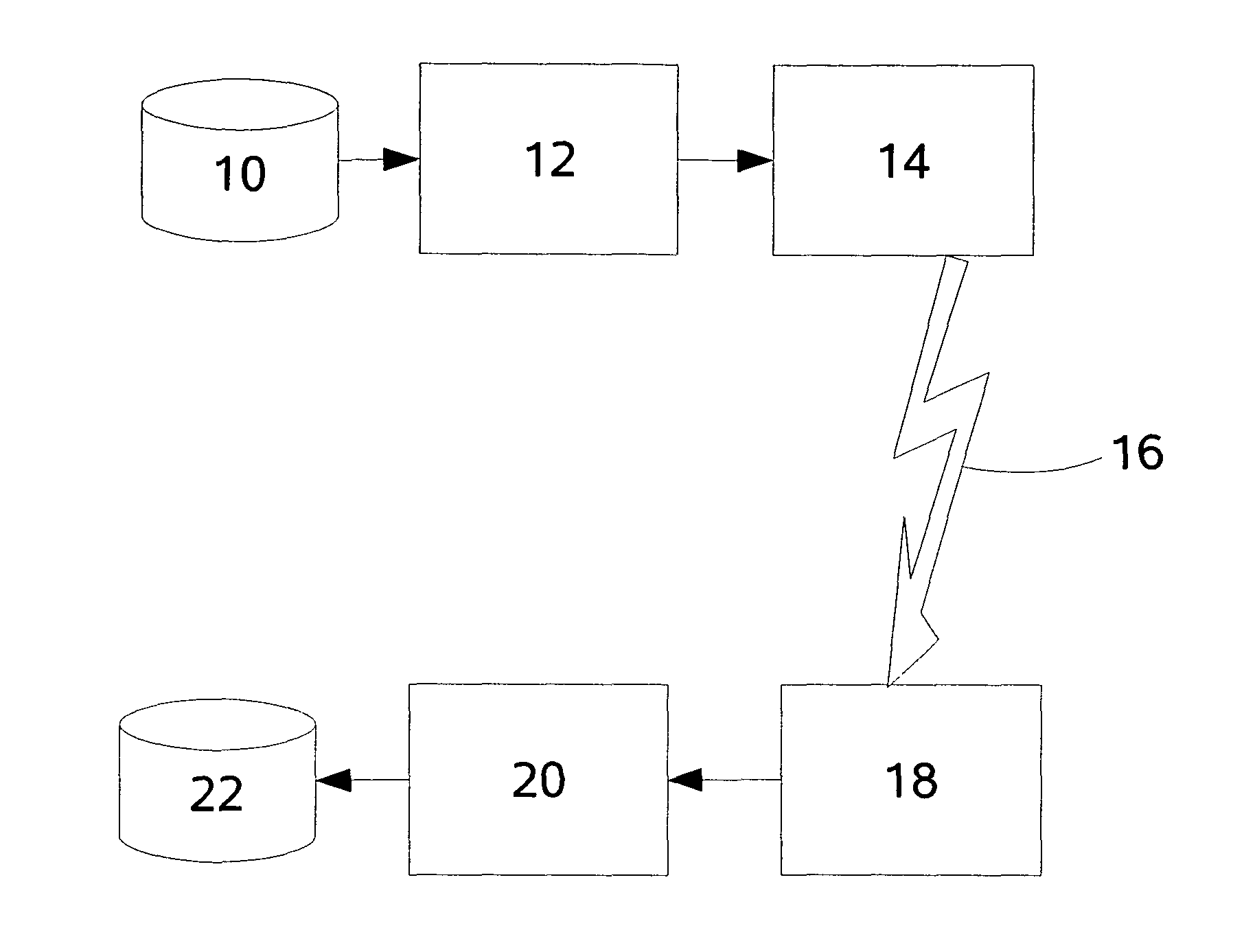

Method And System For Providing Interworking With Portable Internet Network And Other Kinds Of Networks

InactiveUS20080043699A1Sufficient structureAssess restrictionWireless network protocolsAccess networkInternet network

Disclosed is a method for acquiring an Access Network Identification (ANID) of a currently connected portable Internet network when a mobile communication terminal connects to the portable Internet network. The method includes the steps of (a) receiving an MAC management message from a base station when the mobile communication terminal connects to the portable Internet network, (b) extracting a base station identification from the MAC management message, and (c) acquiring the ANID for identifying the network to which the mobile communication terminal has connected from the base station identification. According to the method, access network information of a portable Internet network is transferred to a different type of network when the portable Internet network inter-works with said different type of network, so that network information of a portable Internet system can be acquired

Owner:SK TELECOM CO LTD

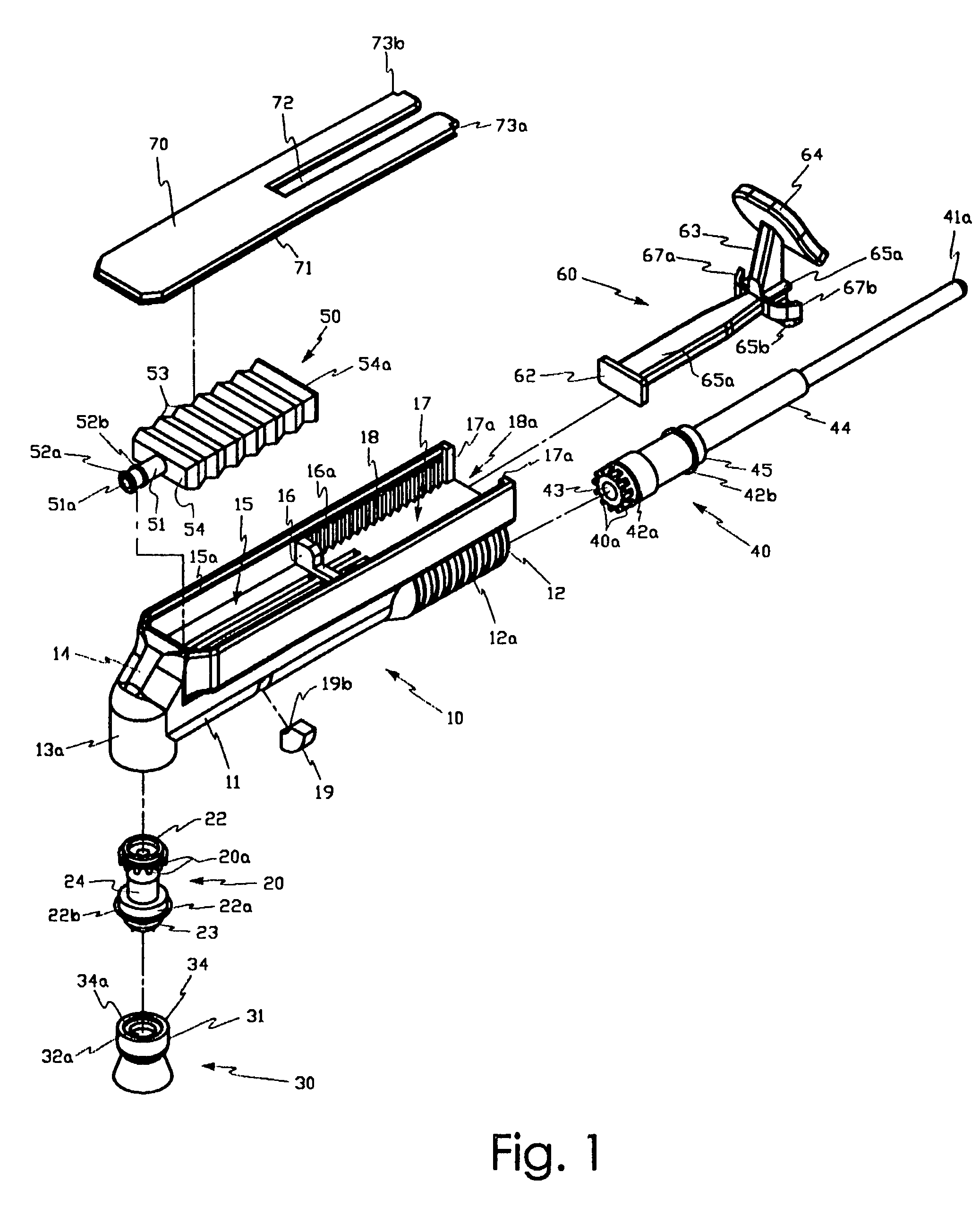

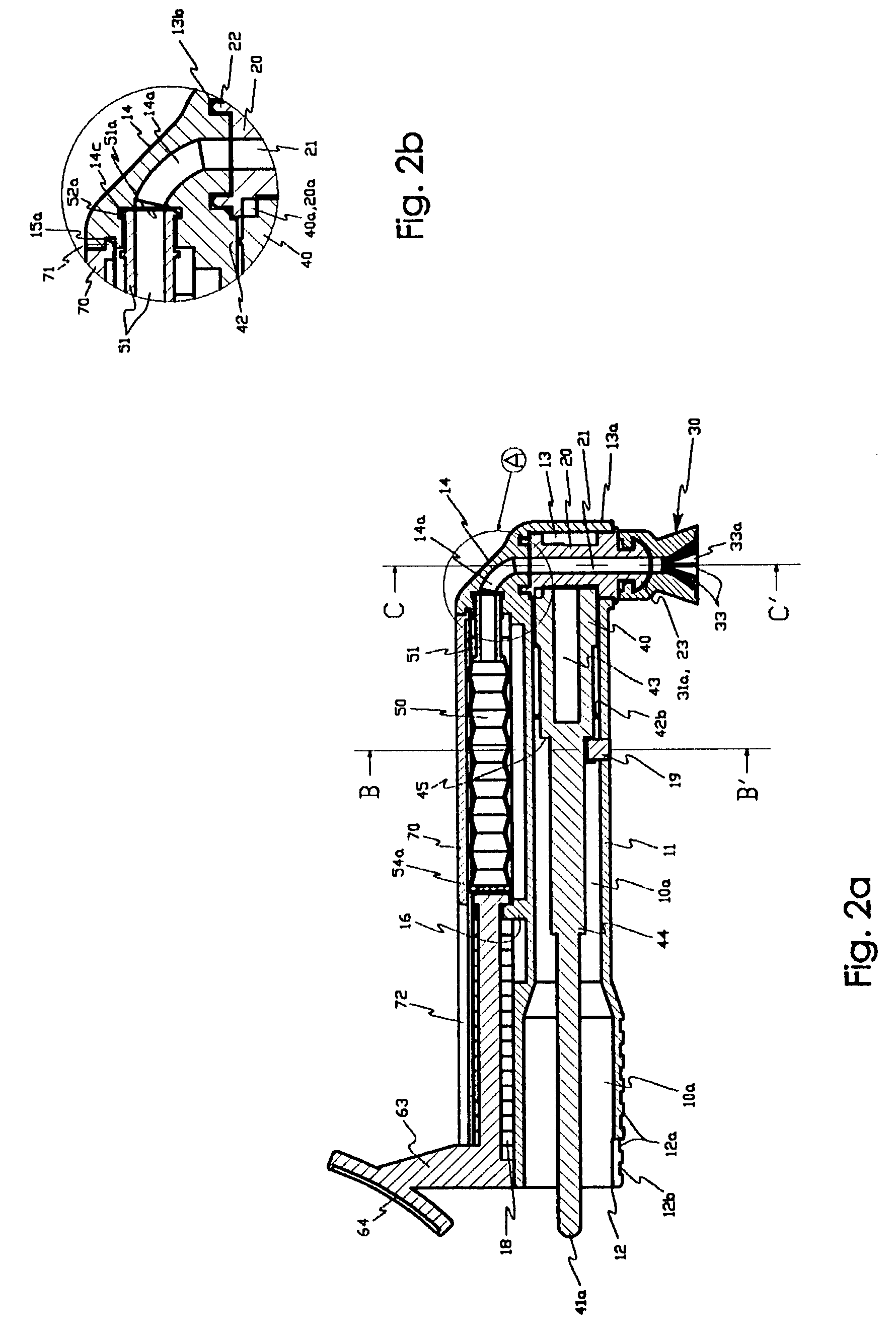

Disposable dental prophylaxis apparatus capable of discharging predetermined amount of dentifrice material therefrom

InactiveUS7510396B2Sufficient structureOptimize quantityTooth pluggers/hammersTeeth fillingFolded formEngineering

The present invention relates to a hand tool used by dental professionals to polish a patient's tooth. The hand tool can be connected to a hand motor used to rotate a wheel cup with a plurality of grinding wings that rub against the patient's tooth as a predetermined amount of dentifrice material is discharged directly on the patient's tooth through a drain hole within the wheel cup. The dentifrice material is discharged from a tube that is assembled in the housing of the hand tool. The tube has a plurality of folds formed on the tube body in such a manner as to be folded by a given distance while being compressed to discharge the dentifrice material therefrom. The tube is compressed by a link with a push button that is guided in the forward direction as it is pushed by a finger.

Owner:LEE KWANG S +1

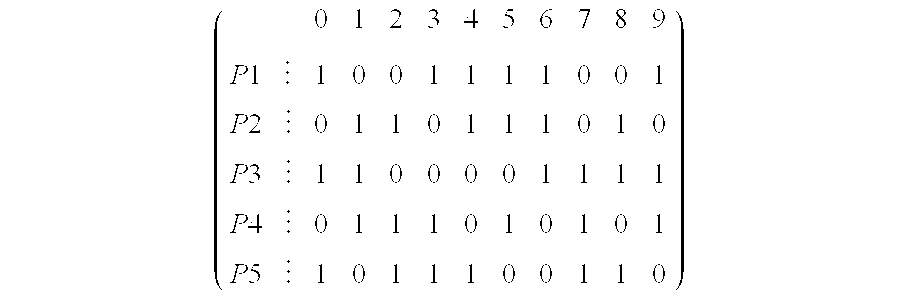

Encoding scheme, and a decoding scheme using a series of LDPC codes based on finite inversive spaces

InactiveUS20100199142A1Wide rangeSimple structureError correction/detection using multiple parity bitsCode conversionAlgorithmParity-check matrix

There is disclosed a method of creating an LDPC code that is defined by a parity-check matrix H. The parity-check matrix H is derived from a (0,1)-geometry which is induced by a finite inversive space. This inversive space has an order q where every circle in the inversive space contains exactly q+1 points, q is preferably even, and most preferably equal to 2. Where the inversive space has a dimension n. Where the (0,1)-geometry is formed as a derived geometric structure based on pencils of degree m≦n in the inversive space. The method includes construction of a binary K by N matrix H labelled by K circles and N pencils of the inversive space, wherein the (i, j)-entry of the matrix is 1 if circle i belongs to pencil j, and 0 otherwise. If the degree of the pencil is given by 2 then the parity-check matrix H needs to be transposed, i.e. HT is used instead of H. A method of transmitting a message, a coder, a decoder and a data transmission system using such codes are also disclosed.

Owner:UNIV COLLEGE DUBLIN NAT UNIV OF IRELAND DUBLIN

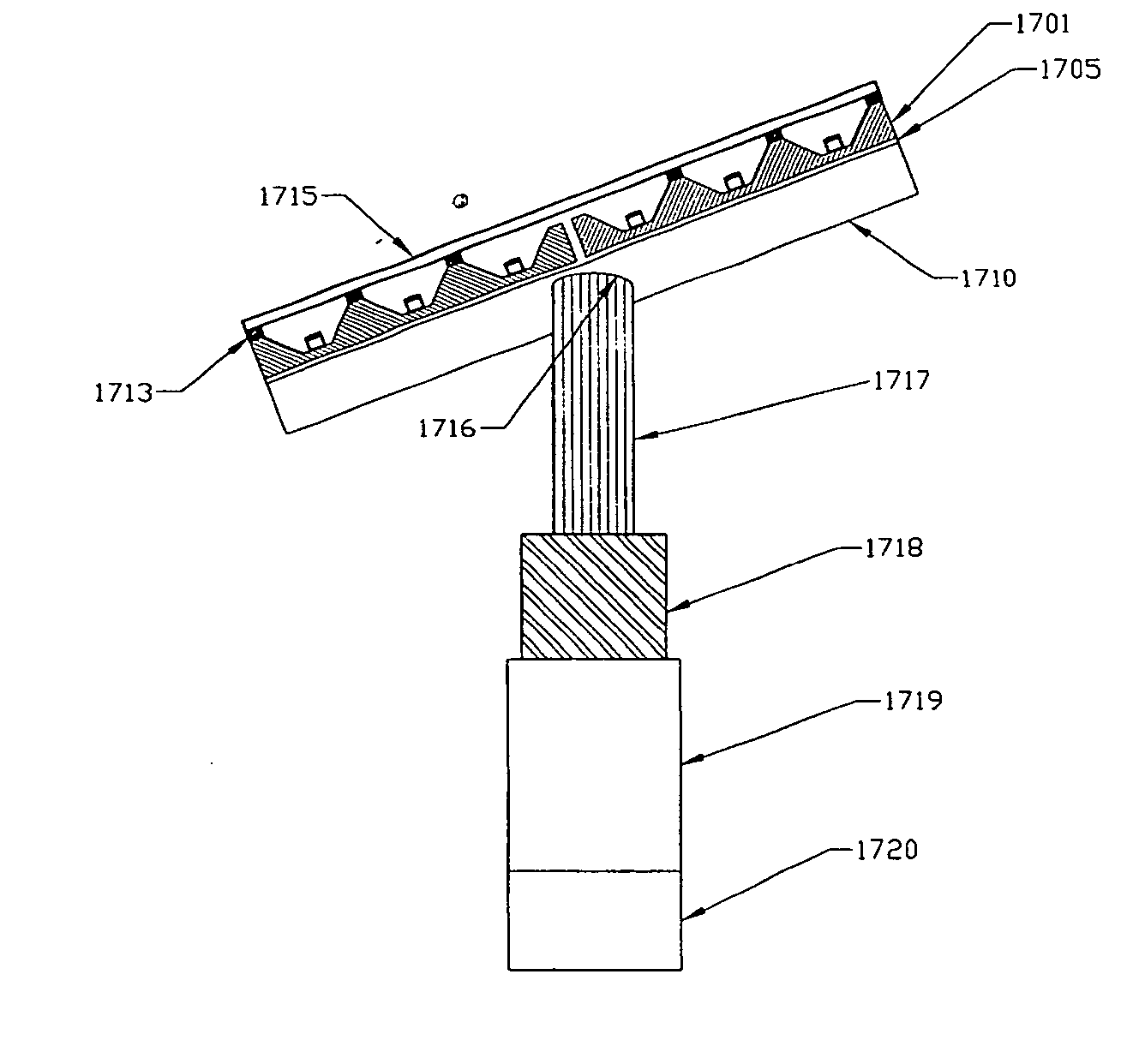

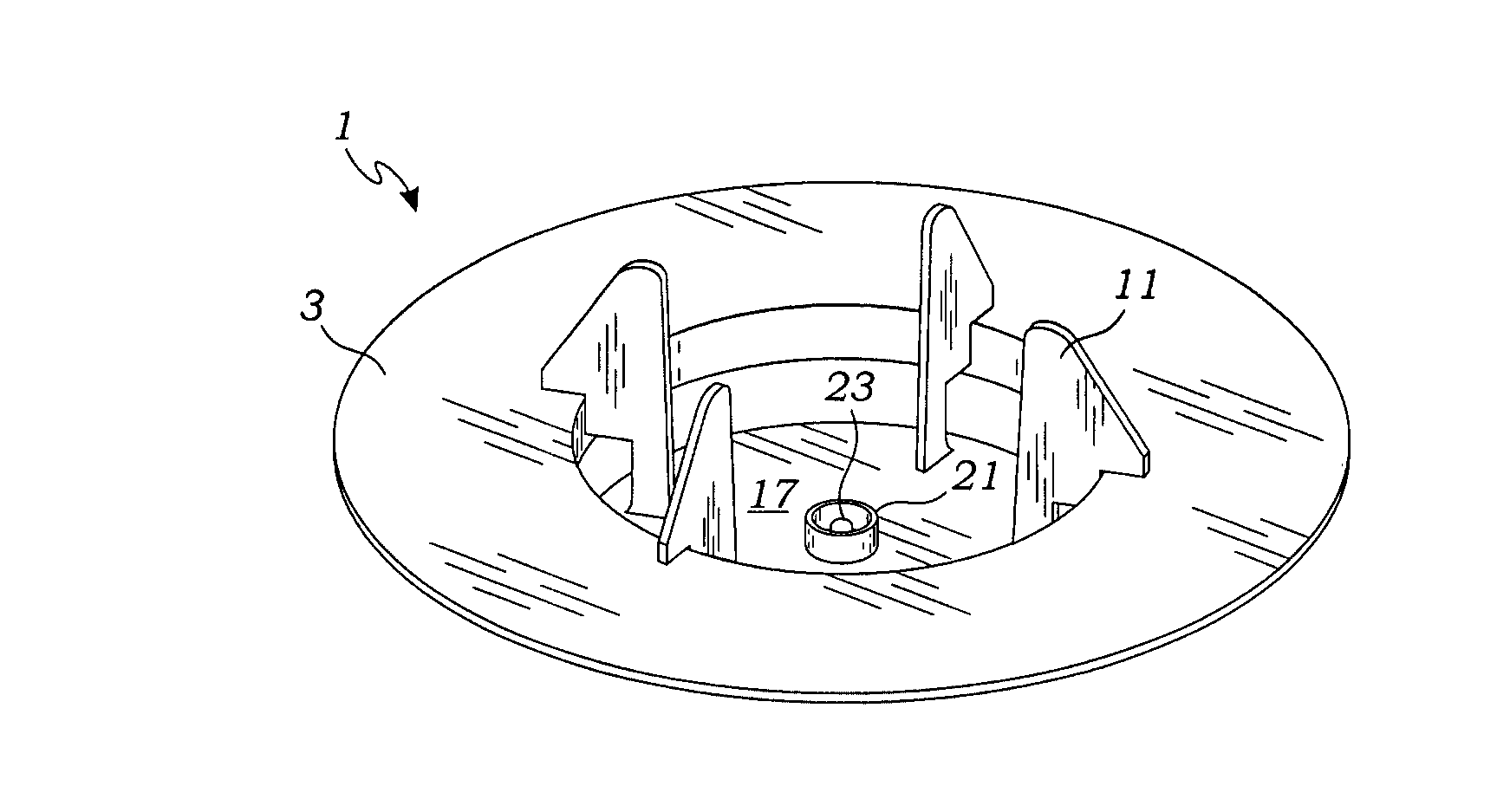

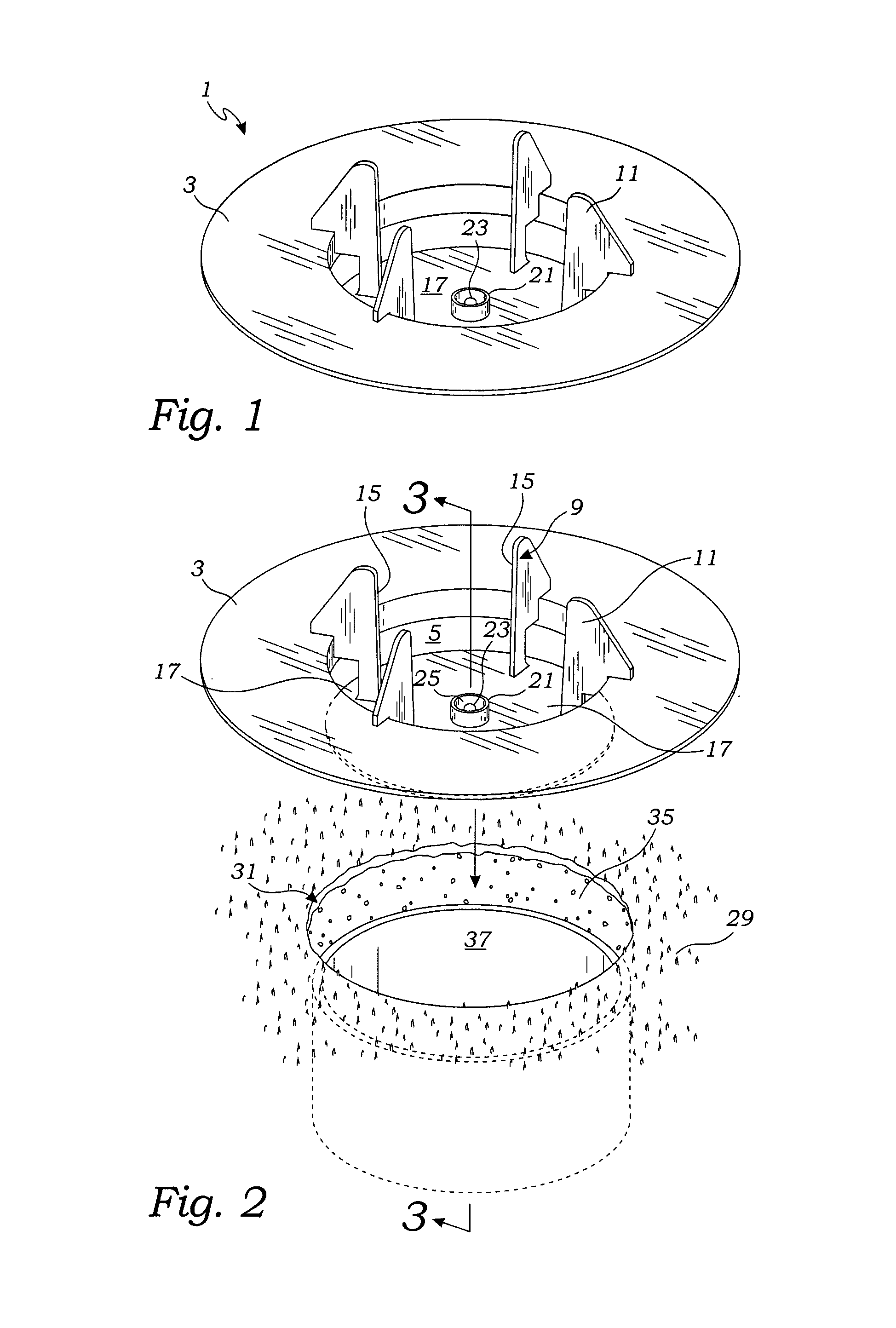

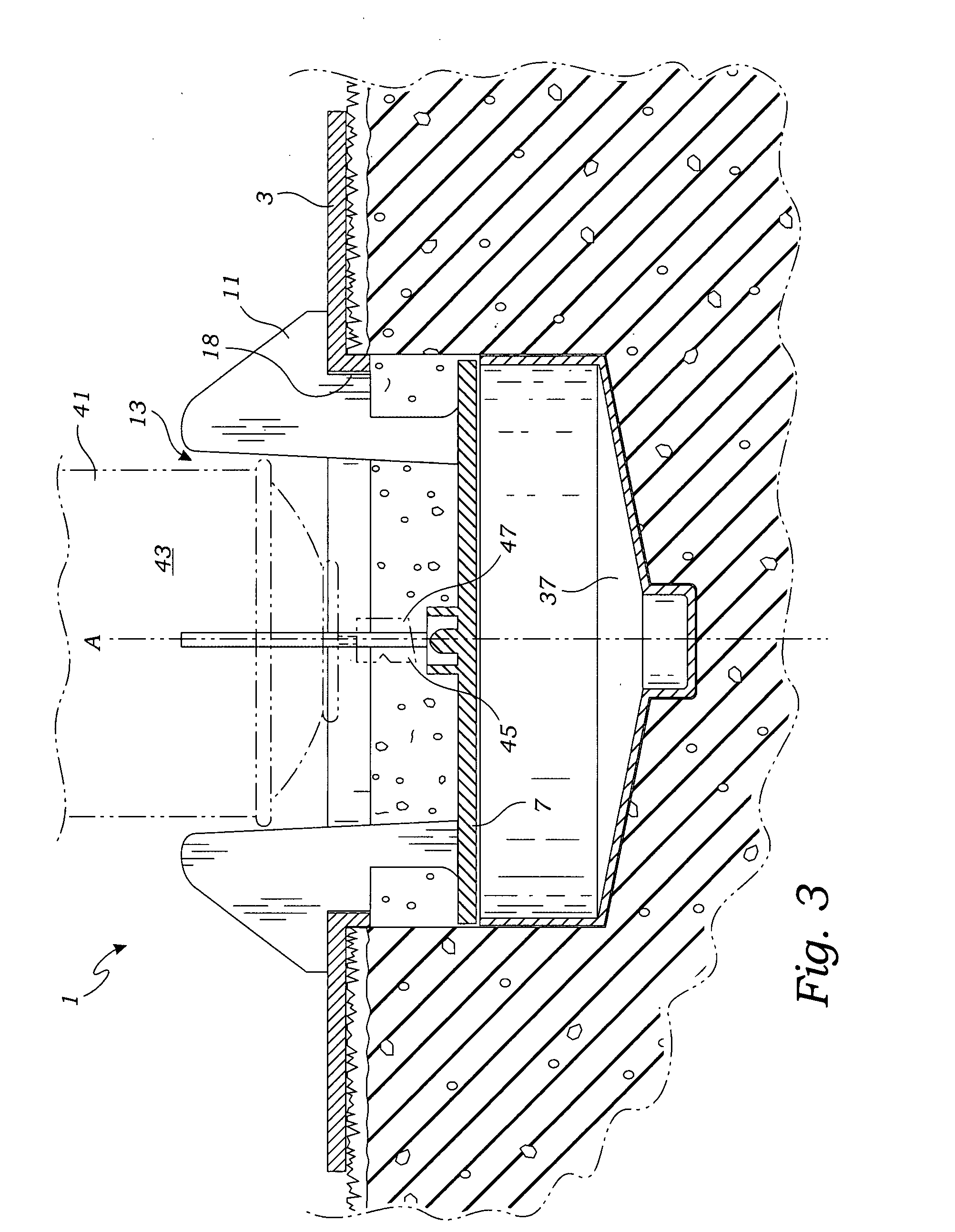

Spray can assembly for painting golf holes

InactiveUS20080296407A1Uniform thicknessSufficient structureFire rescueLiquid spraying apparatusEngineeringGolf Ball

A spray paint can positioning apparatus is provided for painting the interior of a golf hole. The positioning apparatus includes a planar base having a central opening and a plurality of downwardly extending arms forming a receptacle for holding a spray paint can. Each of the arms engage a circular masking plate having a diameter substantially the same as the diameter of a golf hole. A cup having a circular sidewall is formed on the top of the masking plate for receipt of the push button from an inverted spray paint can. Located in the middle of the cup, a projection is positioned to engage and depress the push button of a spray paint can. The cup is sized to prevent lateral movement of the spray can push button and the masking plate provides a uniform width of paint around the interior periphery of a golf hole.

Owner:SCHLEICHER KURT

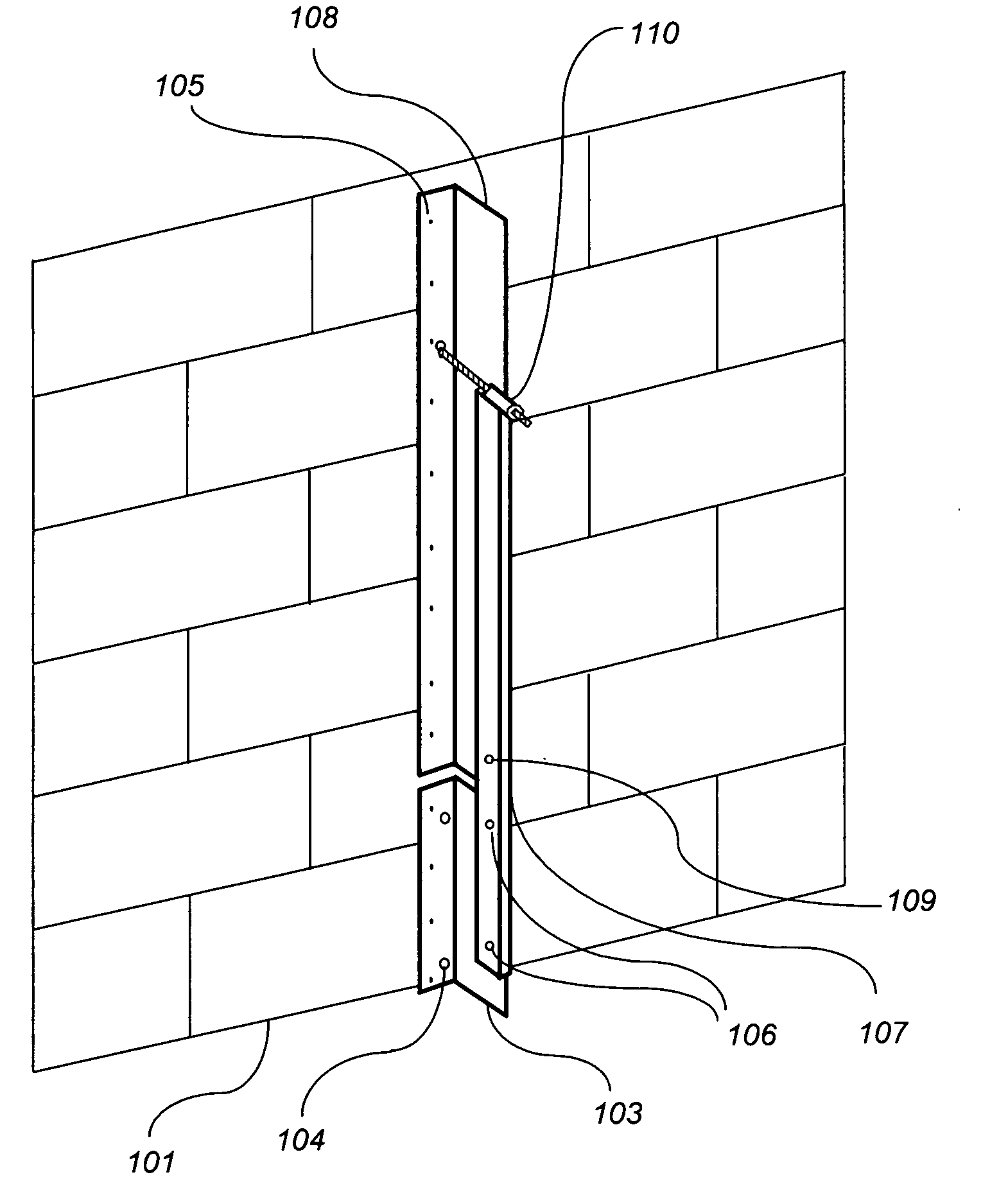

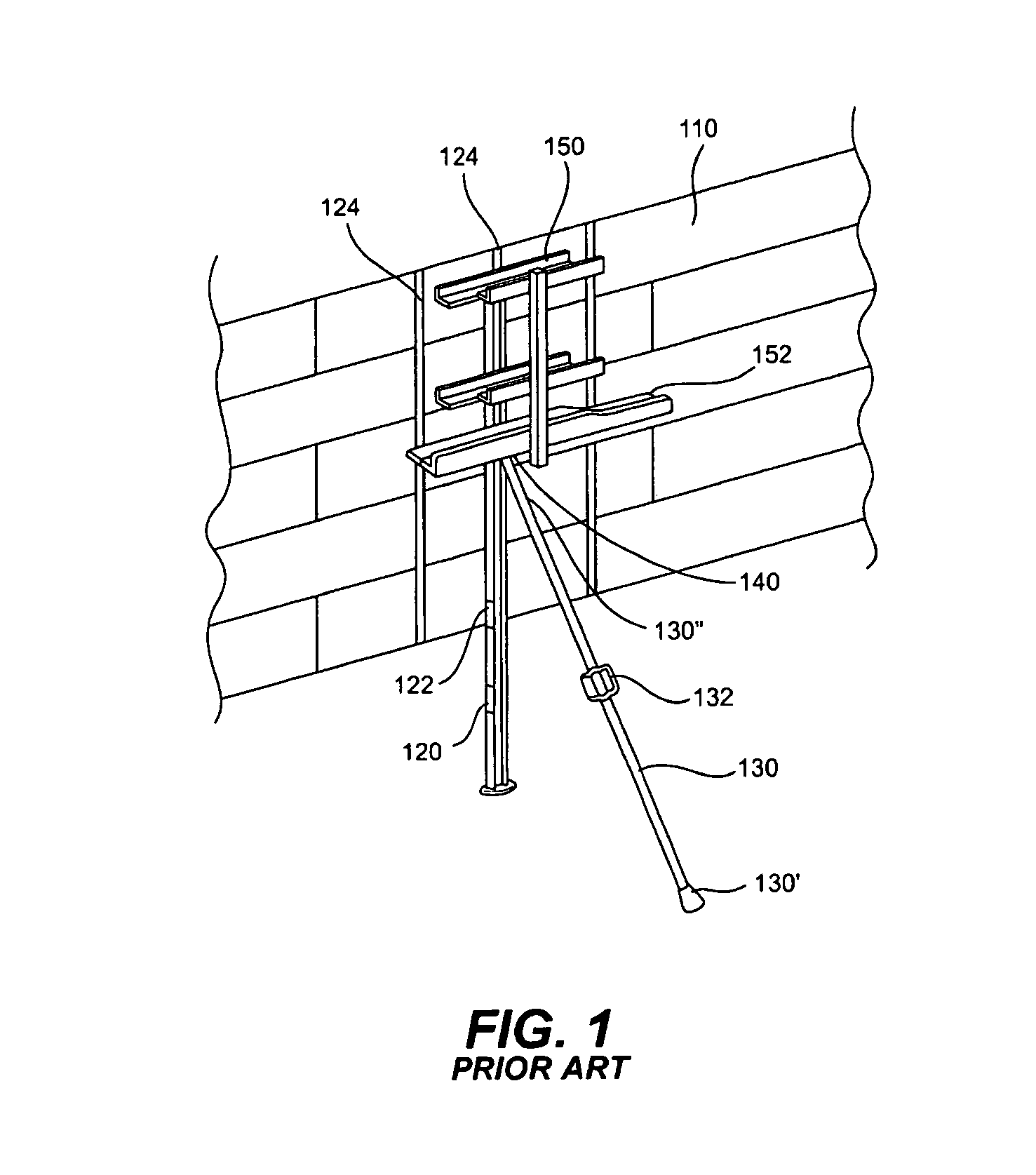

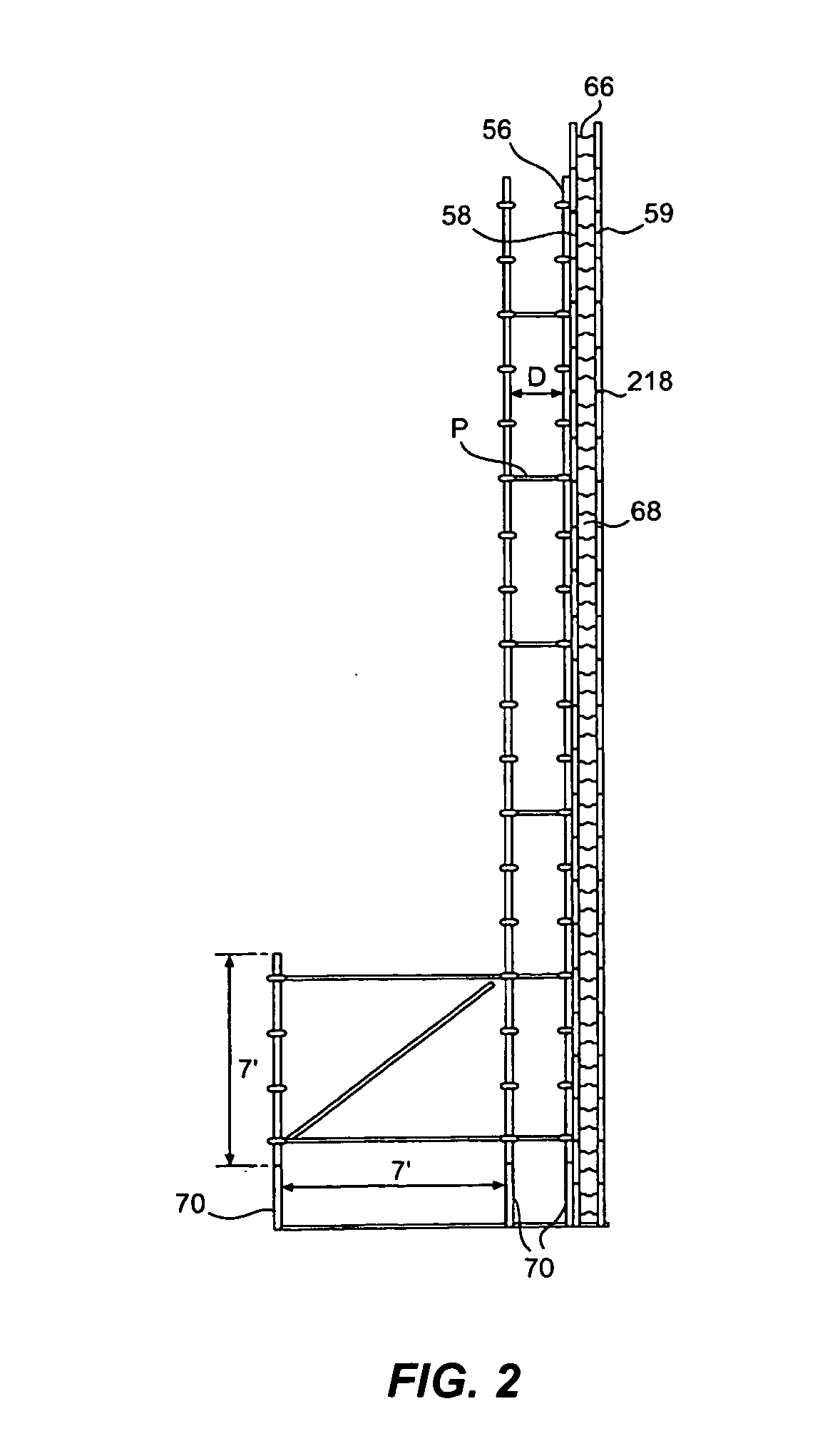

Temporary adjustable support brace

InactiveUS20100037538A1Solve the slow construction speedWork process safetyBuilding material handlingSupport planeLower zone

A system and method for securing an insulated concrete wall to keep the wall straight and plumb during construction, independent of any other bracing structure or scaffolding frame. The system uses the lower previously constructed section of the wall as a secure anchoring base for the continued construction of the wall. The system uses a member that is vertically placed and attached against the insulated form wall with at least one securing extension that passes thru the foam panel and into the cavity of the wall before concrete is placed within the wall cavity. After concrete is placed in the lower section and additional rows of insulated forms are placed on top of the lower wall, a vertical brace is attached to the lower vertical member so that it extends above the lower poured section of the wall. A vertical upper member is then attached to the upper section of the insulated form wall in proper alignment with the vertical brace. A securing adjustment device is attached to the upper member and the brace allowing for the upper section of the formed wall to be properly aligned and plumbed. This system and method is now repeated with the upper section of the formed wall to become the lower section of the formed wall. The system is repeated until the final desired wall height is reached.

Owner:SORICH GEORGE RICHARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com