Puffed protein based snack food

a protein and snack food technology, applied in the field of puff protein based snack food, can solve the problems of high fat intake for consumers, adversely affecting the nutritional value of ingredients, and difficult to achieve nutritious snack foods, etc., and achieves low fat intake, high protein, and sufficient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

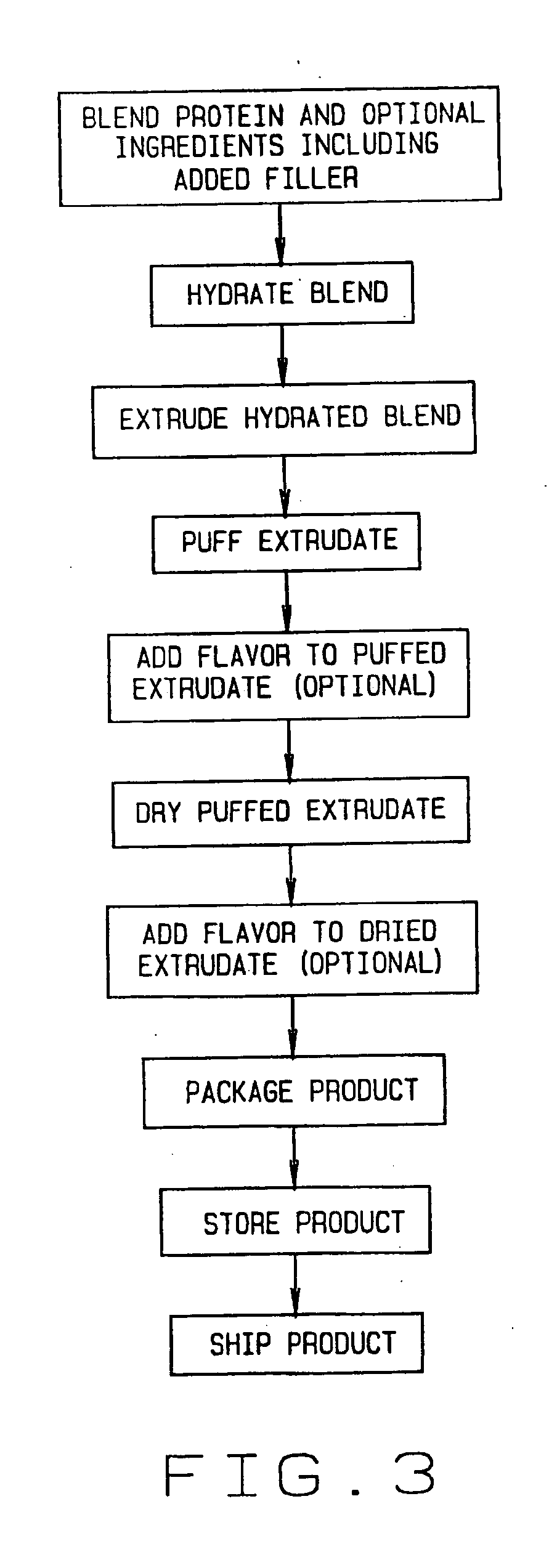

Method used

Image

Examples

Embodiment Construction

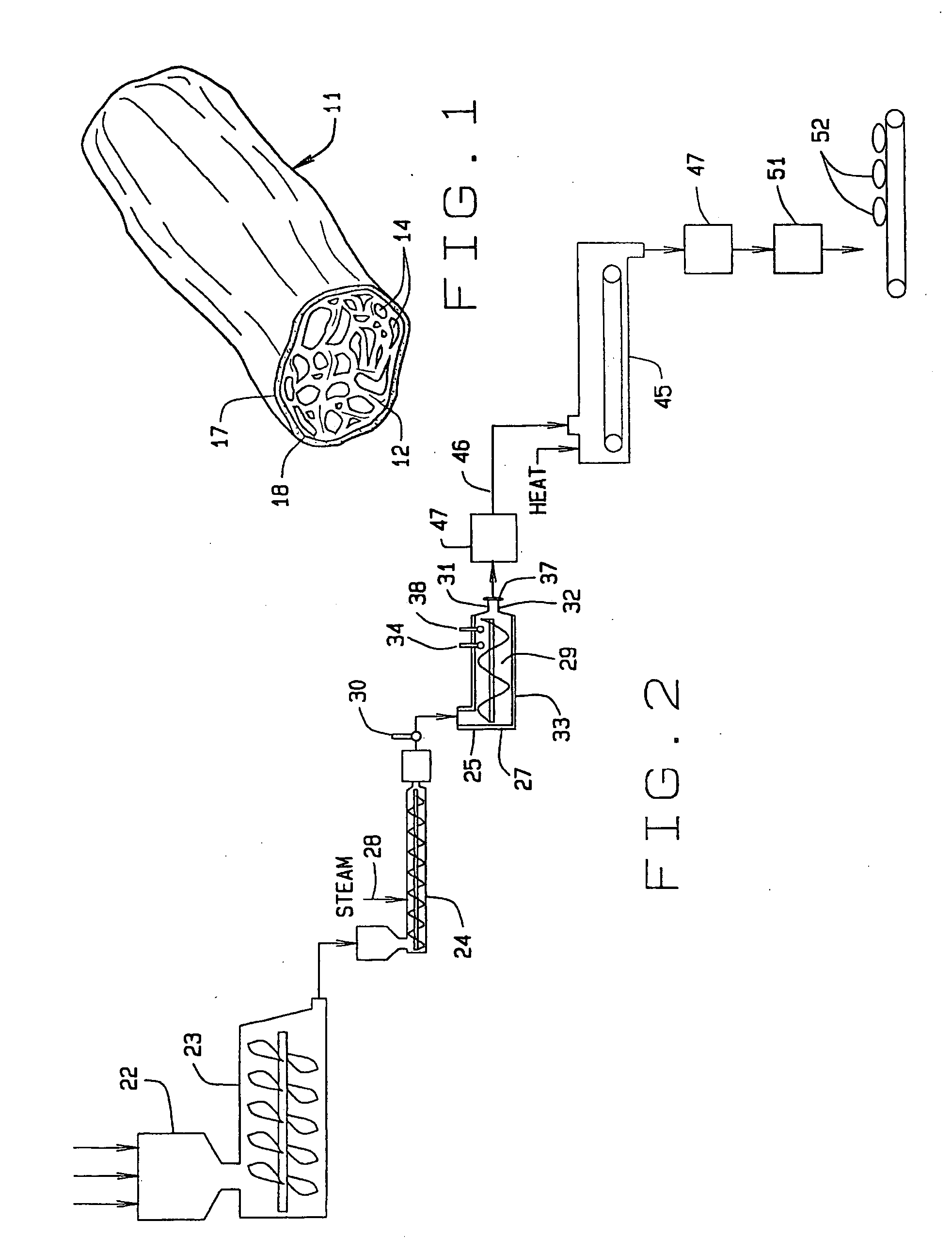

[0014] A puffed food product 11 is formed having a continuous solids matrix 12 of protein, filler (if any) with air spaces 14. The product can contain water as well as a coating 17 that can be applied to the outer surface 18. The formed product is comprised of two major ingredients: protein and water plus filler as an optional ingredient and can have an optional coating 17 and other optional ingredients as described below. In the following description of the products, the percents given are by weight on a dry basis (except for water) unless otherwise specified. Formed product as used herein is that product that is formed by the extrudate including material added only during the extrusion process. Majority solids component consists of the protein and filler (if any).

[0015] The protein component is present by the combined weight of protein, filler (if any) and water in the dried formed product in the amount in the range of between about 25% and about 95% and described in more detail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com