Patents

Literature

906results about How to "Solve the slow construction speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

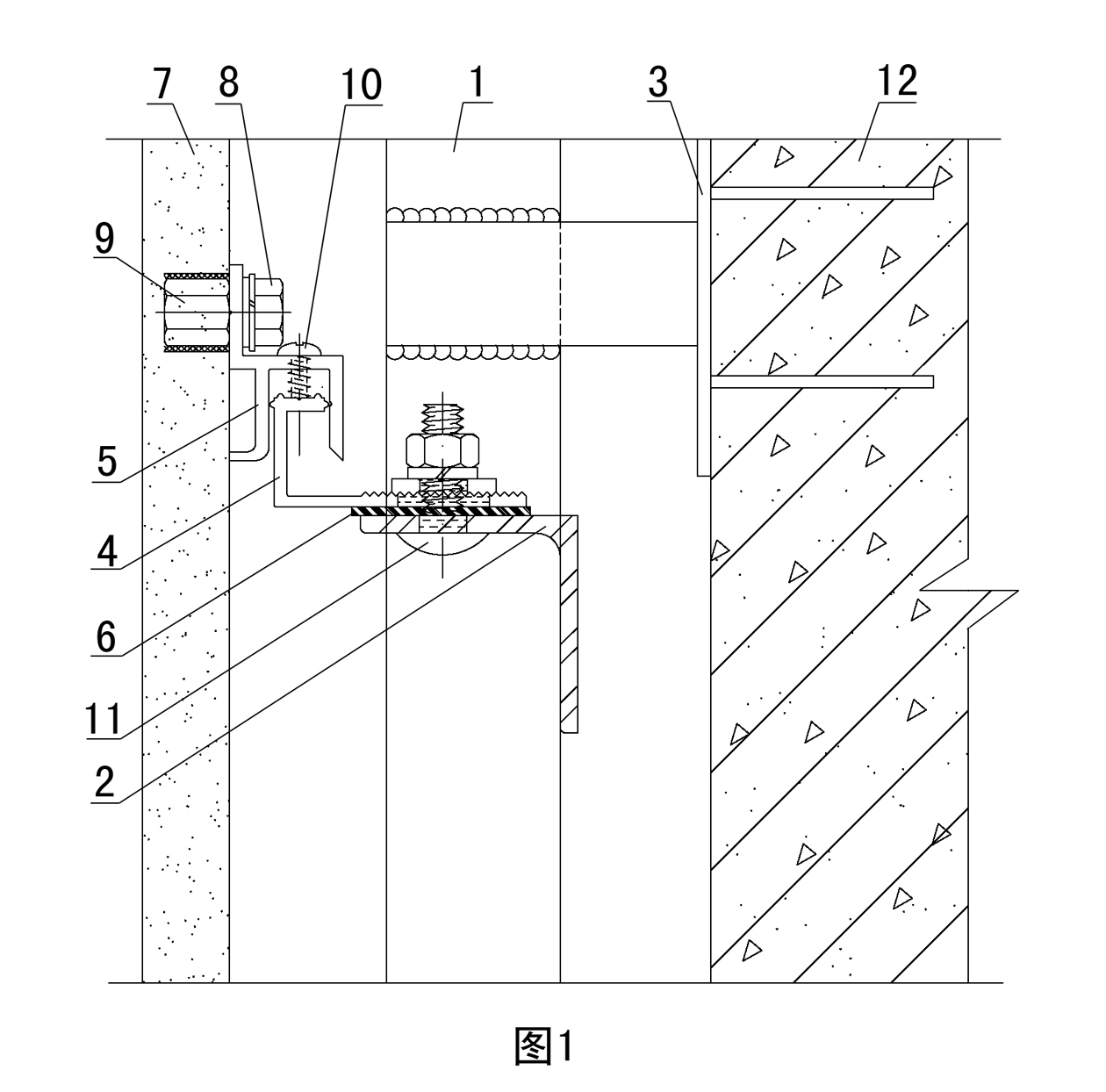

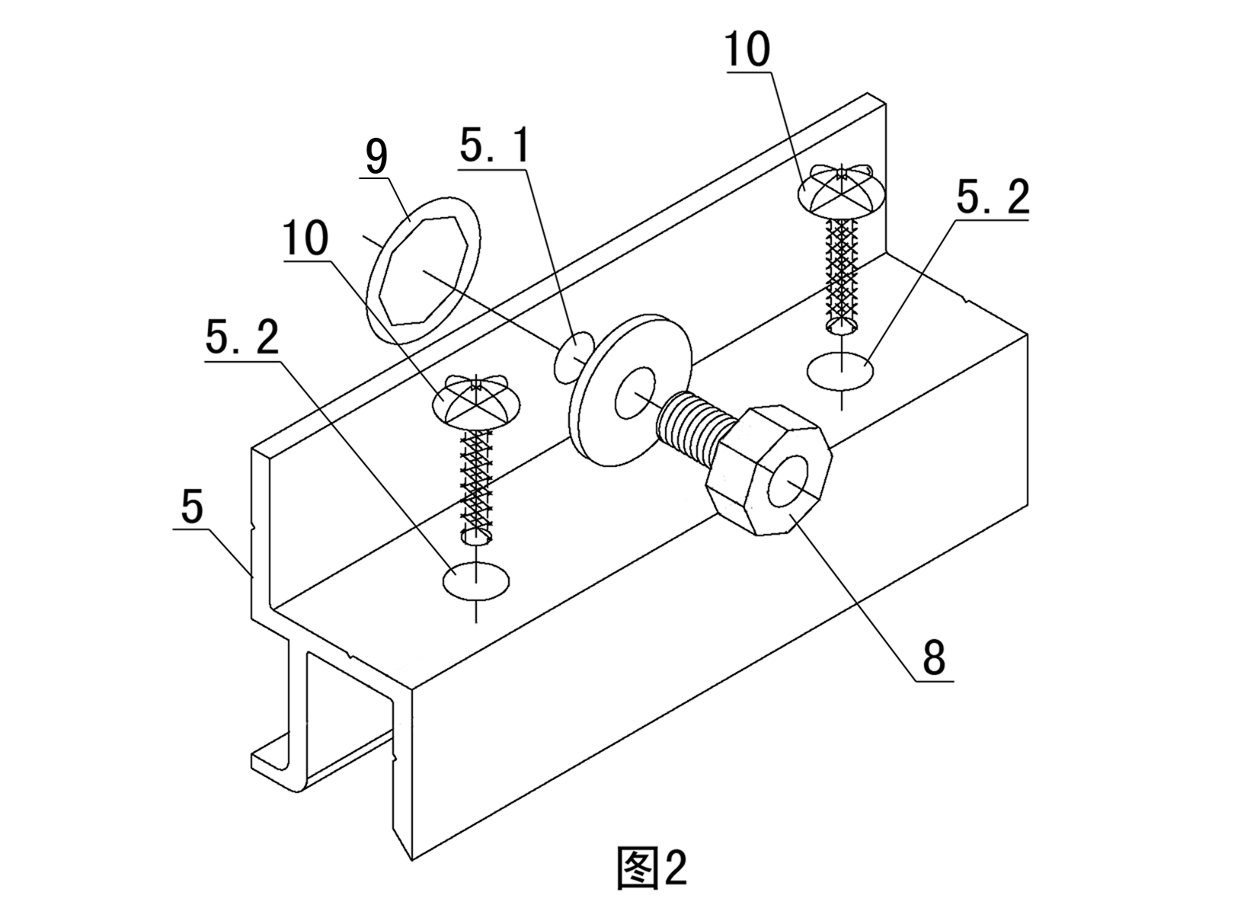

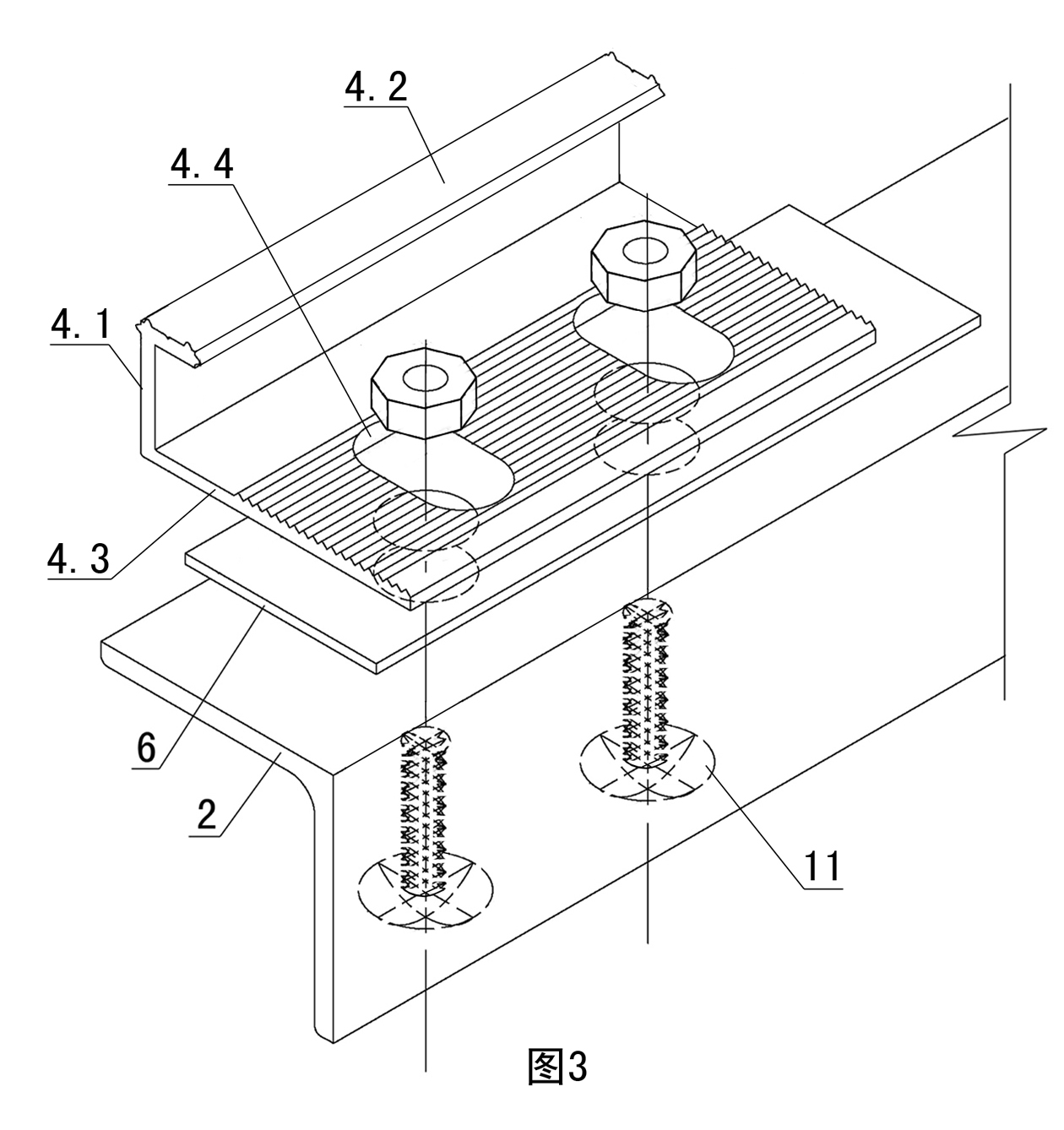

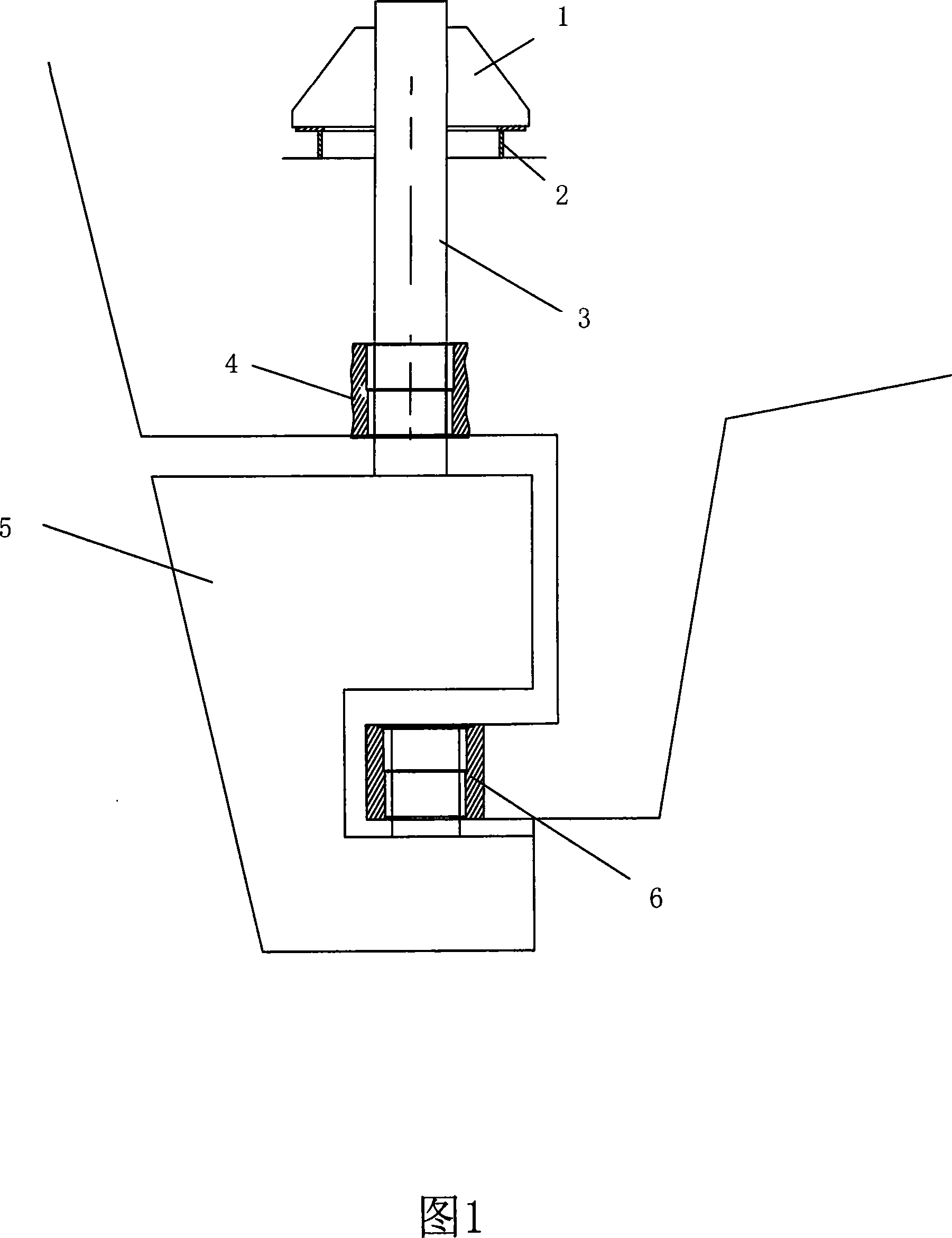

Three-dimensionally adjustable disconnectable curtain wall connecting device and construction method thereof

ActiveCN101956438ASolve the adjustmentSolve the different size of the board seamCovering/liningsWallsVertical deflectionKeel

The invention relates to a three-dimensionally adjustable disconnectable curtain wall connecting device. In the three-dimensionally adjustable disconnectable curtain wall connecting device, the section of a back pendant has a chair shape; a back bolt hole is formed at the back of the chair and is in threaded connection with an embedded nut at the back of each curtain wall plate through a back bolt; the back chair legs have L shapes and are propped against the back of each curtain wall plate; a jackscrew bolt hole is formed on the chair surface and is connected with an adjustable supporting piece of which the upper end is embedded between the front and back chair legs through a jackscrew bolt; the adjustable supporting piece is formed by connecting a supporting plate, a vertical plate and an adjusting plate to be a whole; the supporting plate is in top contact connection with the jackscrew bolt; the thread height of the jackscrew bolt is more than the longitudinally adjusting distance of each curtain wall plate; and a long round hole vertical to the wall body is formed on the adjusting plate. The device solves the problems that the position of each curtain wall plate cannot be adjusted, the plate gaps are different in sizes, the curtain wall plates are staggered with one another and the like so as to guarantee the appearance of the curtain wall and overcomes the defect that the installation of the traditional curtain wall plates completely depends on the control level and the vertical deflection of keels at the same time, so that the construction quality can be controlled easily.

Owner:泛华建设集团有限公司

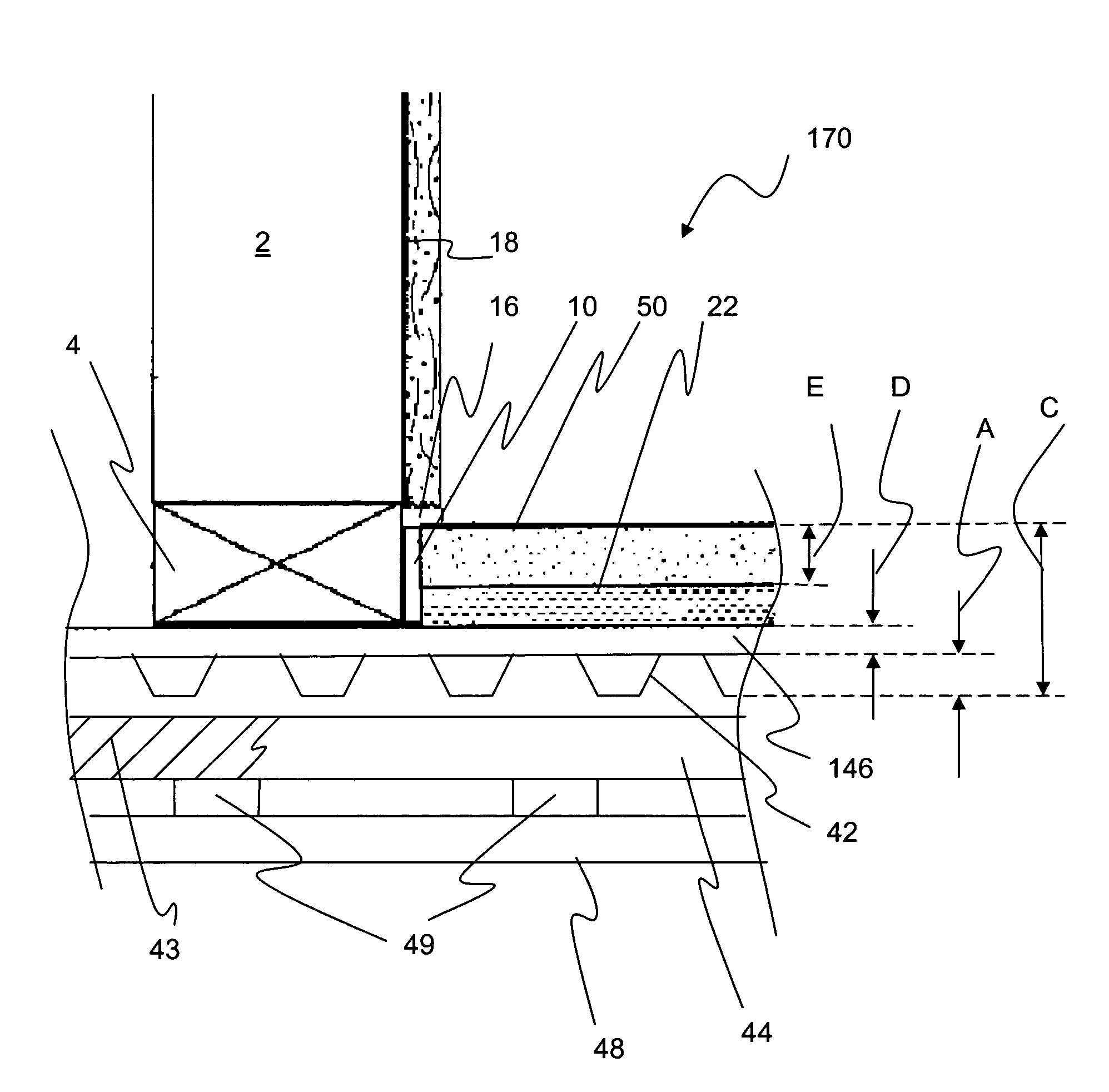

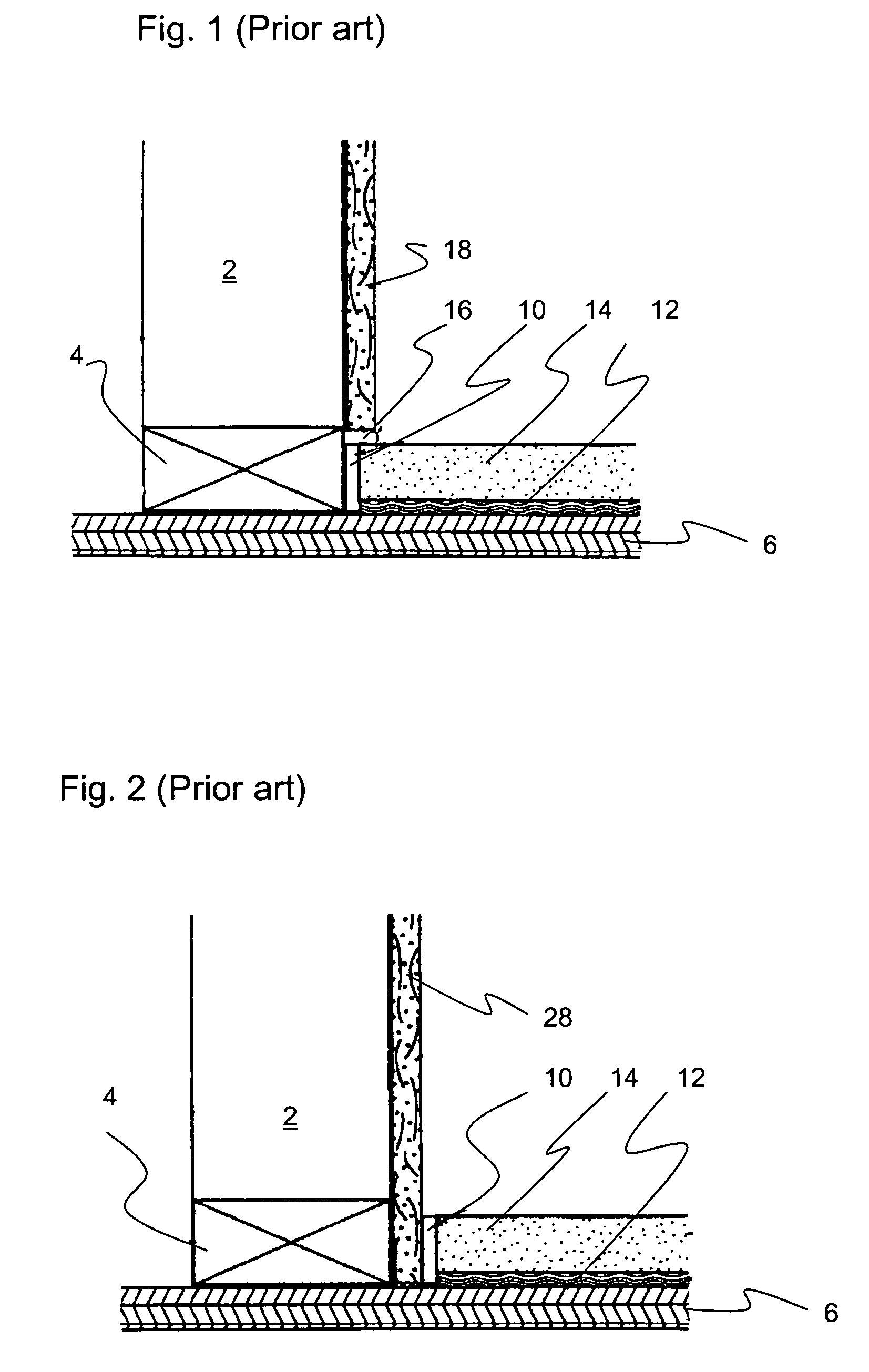

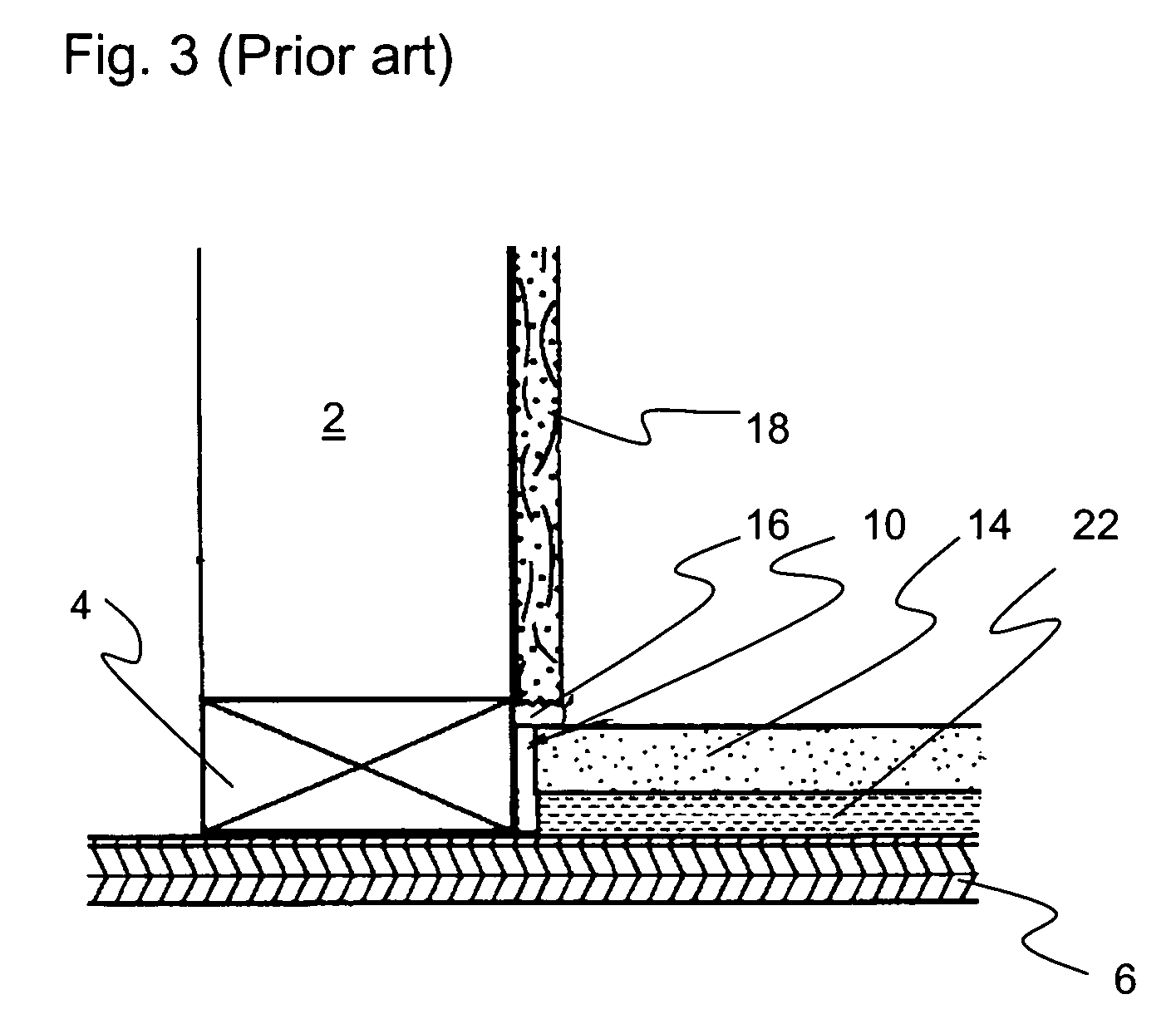

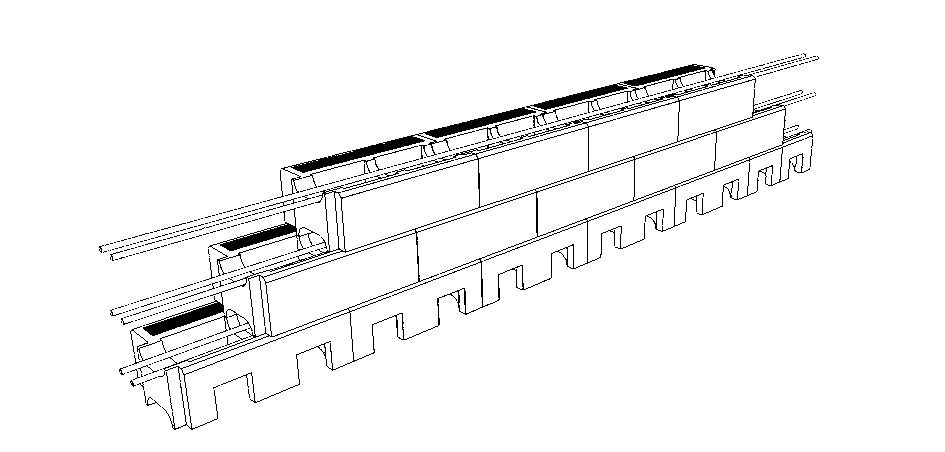

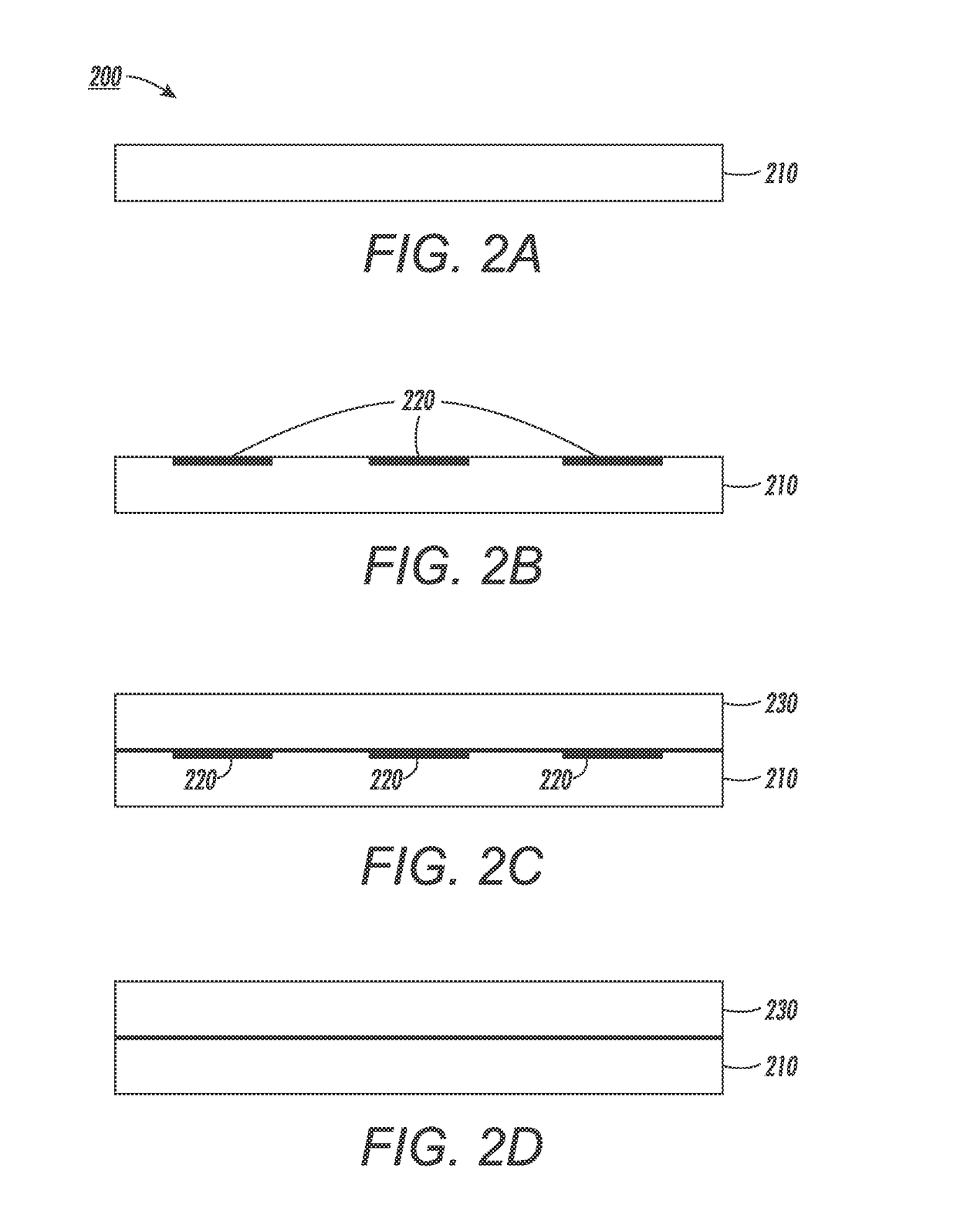

Corrugated steel deck system including acoustic features

ActiveUS7908810B2Solve the slow construction speedReduce laborCeilingsCovering/liningsCarrying capacityEngineering

The present invention relates to a sound rated floor system for inhibiting sound transmission between floors. The system includes a corrugated steel deck; a first layer of cementitious material or board or sheet applied over the corrugated steel deck; a sound insulation mat or board applied over the first layer; a second layer of cementitious material applied over the sound insulation mat or board. The floor system has an IIC rating of at least 25 and the corrugated steel deck provides at least 50 percent of the ultimate load carrying capacity under static and impact loading of the floor system with a floor deflection of at most 1 / 360 of the floor span.

Owner:UNITED STATES GYPSUM CO

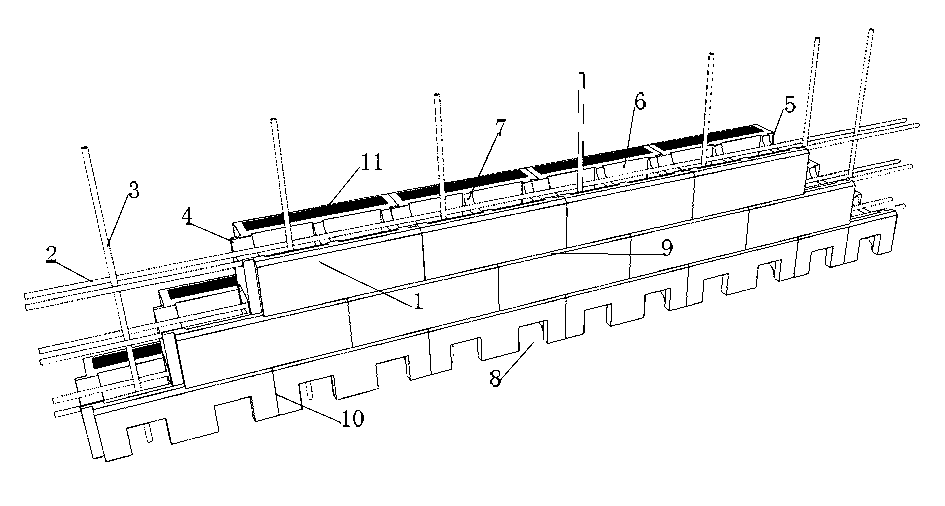

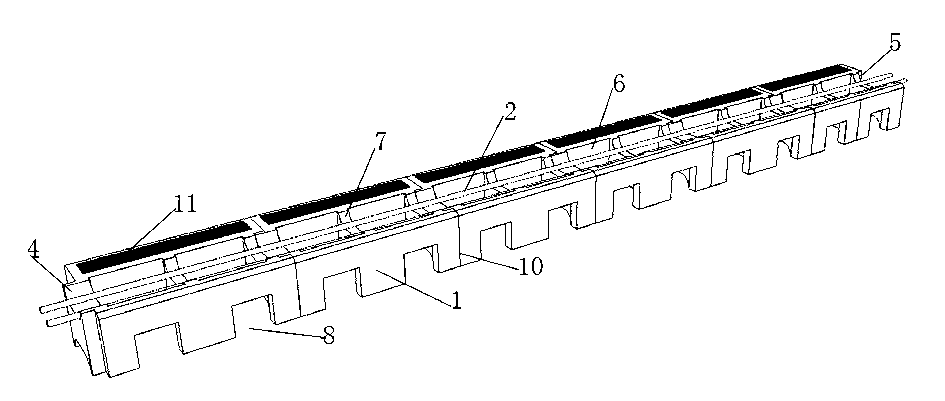

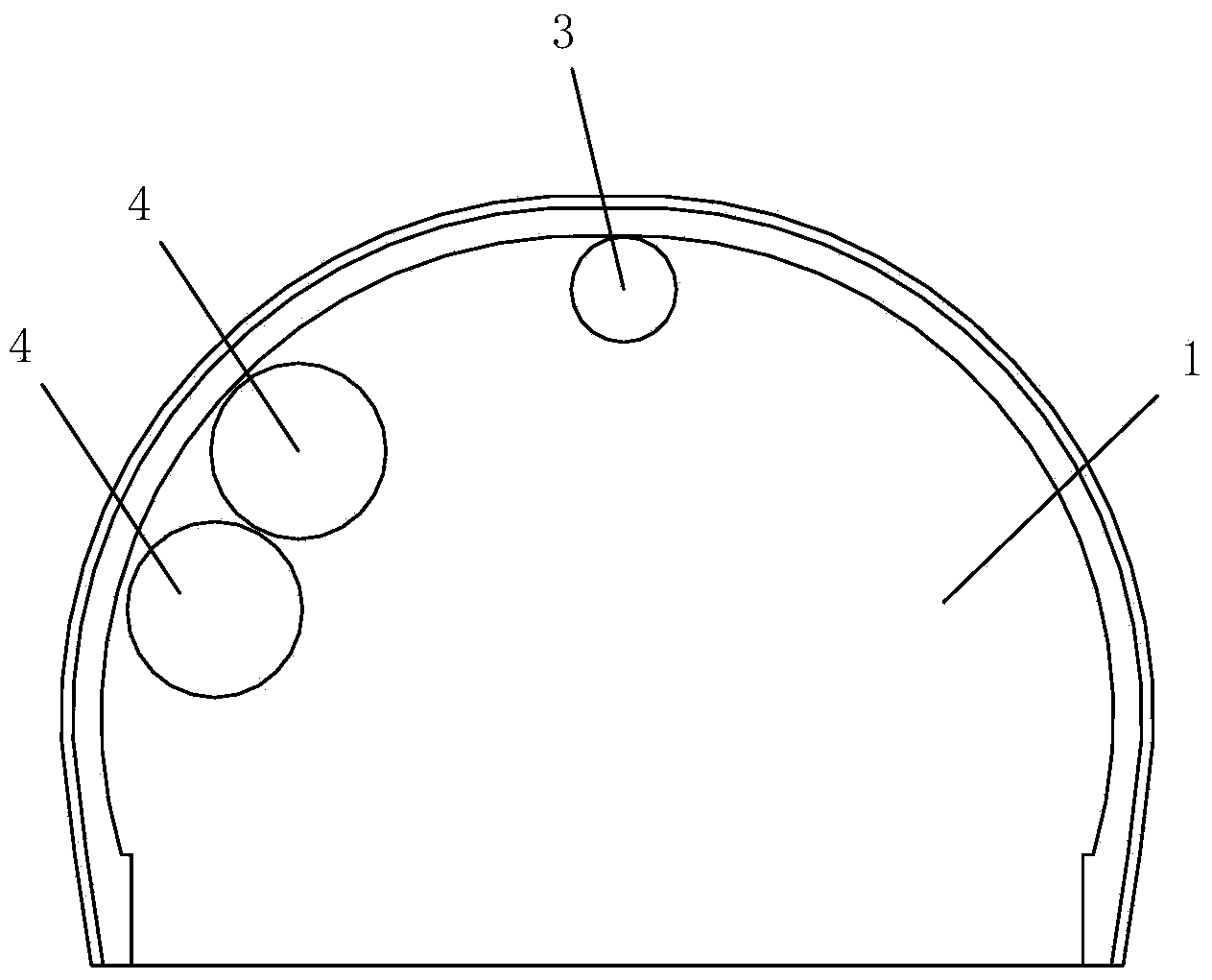

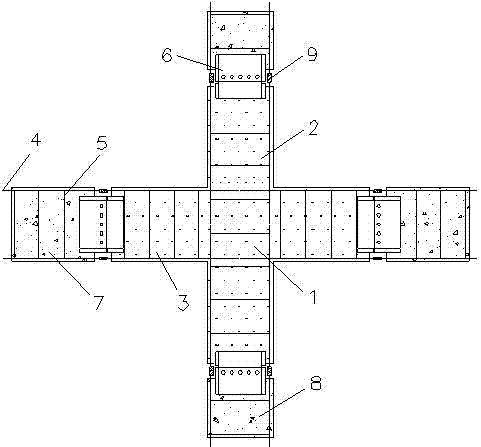

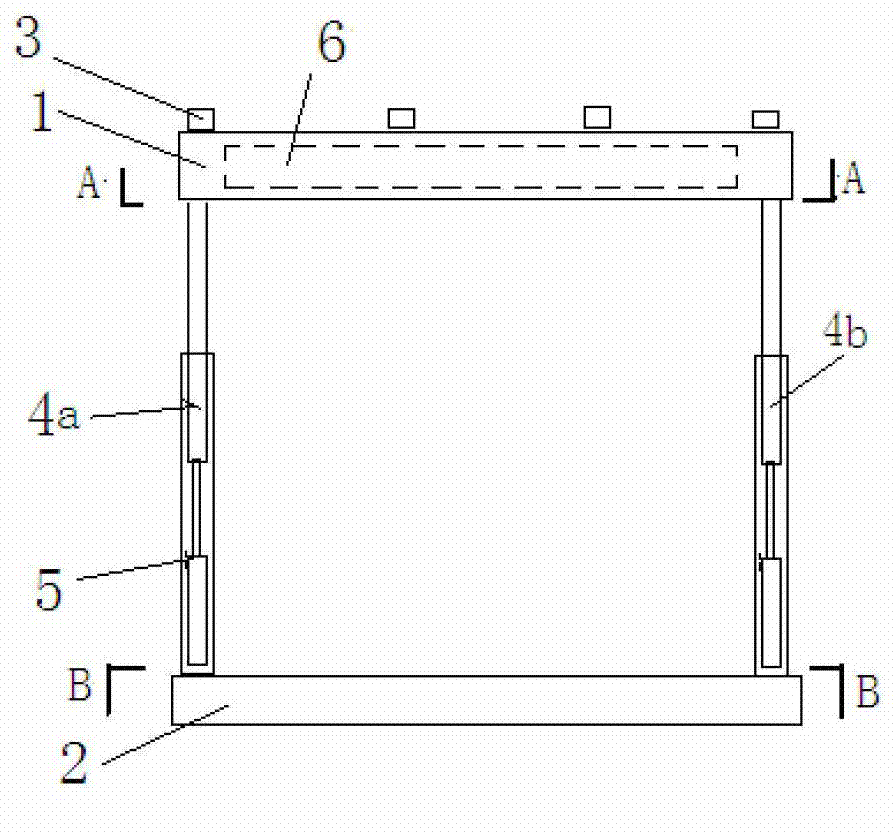

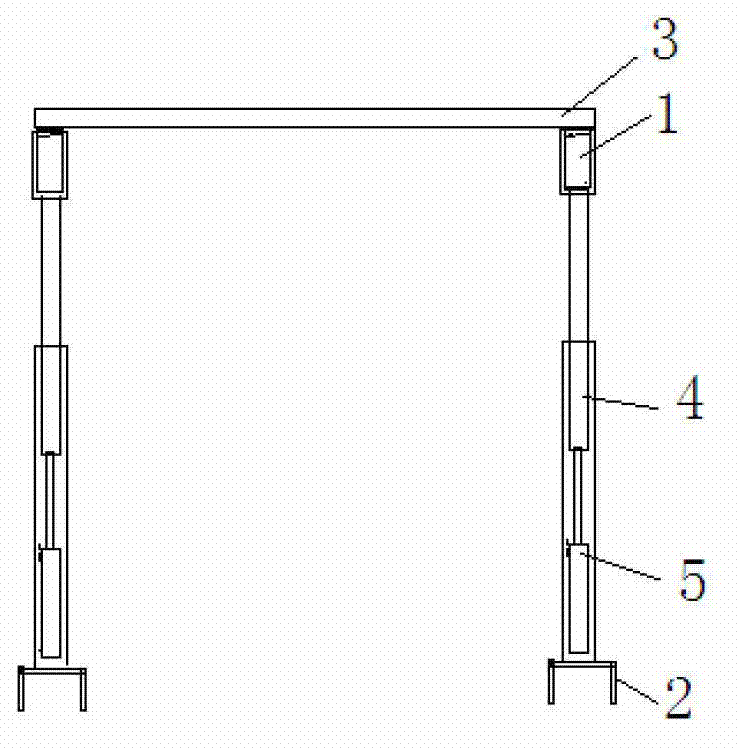

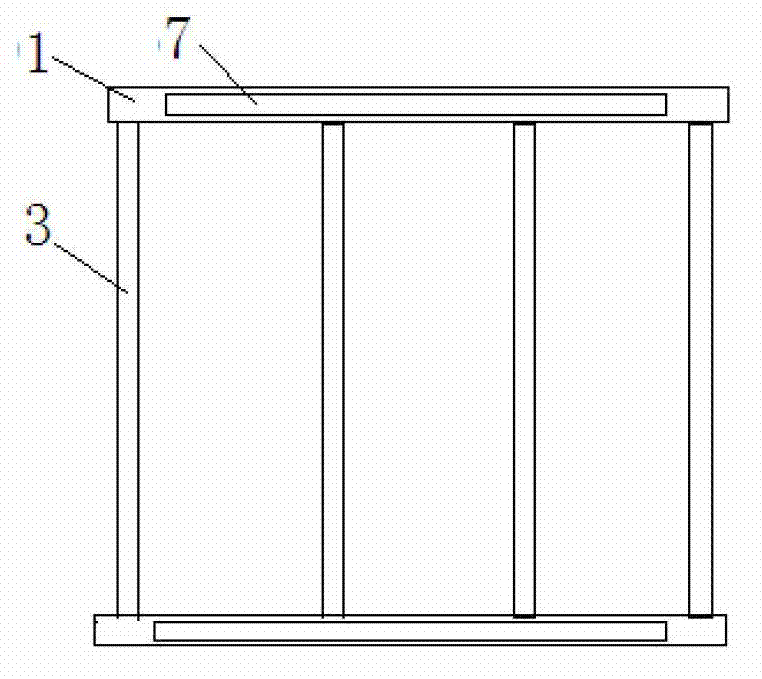

Self-heat-preservation mortar-free block masonry shear wall system and construction method thereof

The invention discloses a self-heat-preservation mortar-free distributed steel block masonry shear wall system and a construction method of the self-heat-preservation mortar-free block masonry shear wall system. A self-heat-preservation mortar-free block masonry shear wall is made of self-heat-preservation mortar-free die clamping blocks (1), horizontal reinforcing bars (2), vertical reinforcing bars (3) and grout concrete. The self-heat-preservation mortar-free die card blocks (1) are connected through rabbets (4) and mortises (5) in a die card mode, and the vertical reinforcing bars (3) are arranged into vertical holes (6) formed by the self-heat-preservation mortar-free die card blocks, and the horizontal reinforcing bars (2) are arranged in horizontal holes (7) formed by the self-heat-preservation mortar-free die clamping blocks (1). The grout concrete is finally poured so as to form the self-heat-preservation mortar-free block masonry shear wall. The construction method of the self-heat-preservation mortar-free block masonry shear wall sequentially comprises the following steps of performing preparatory work, building blocks of the bottommost layer, building blocks of other layers, inserting the bars and pouring the concrete.

Owner:ZHUZHOU BOERMAN TECH DEV

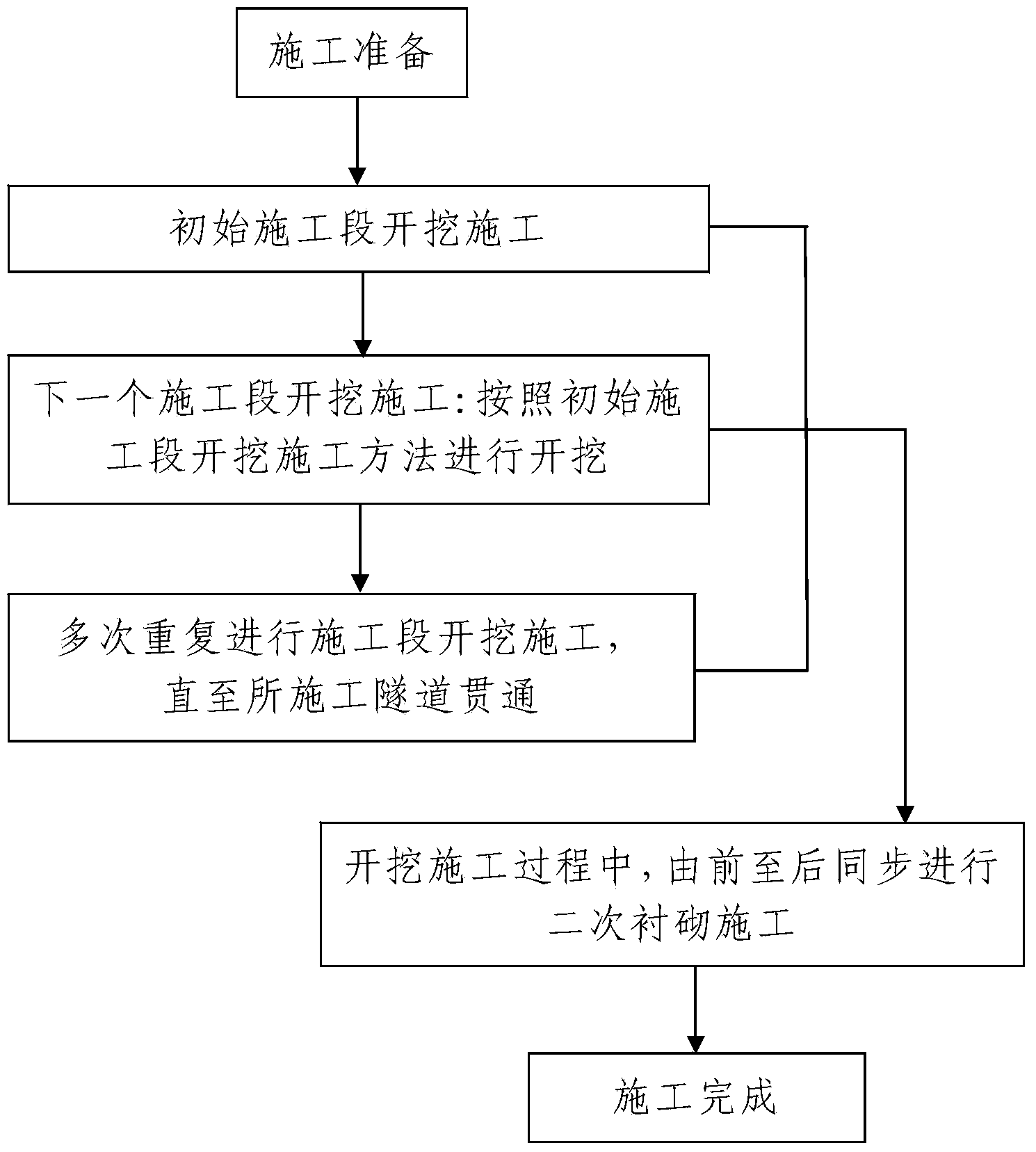

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

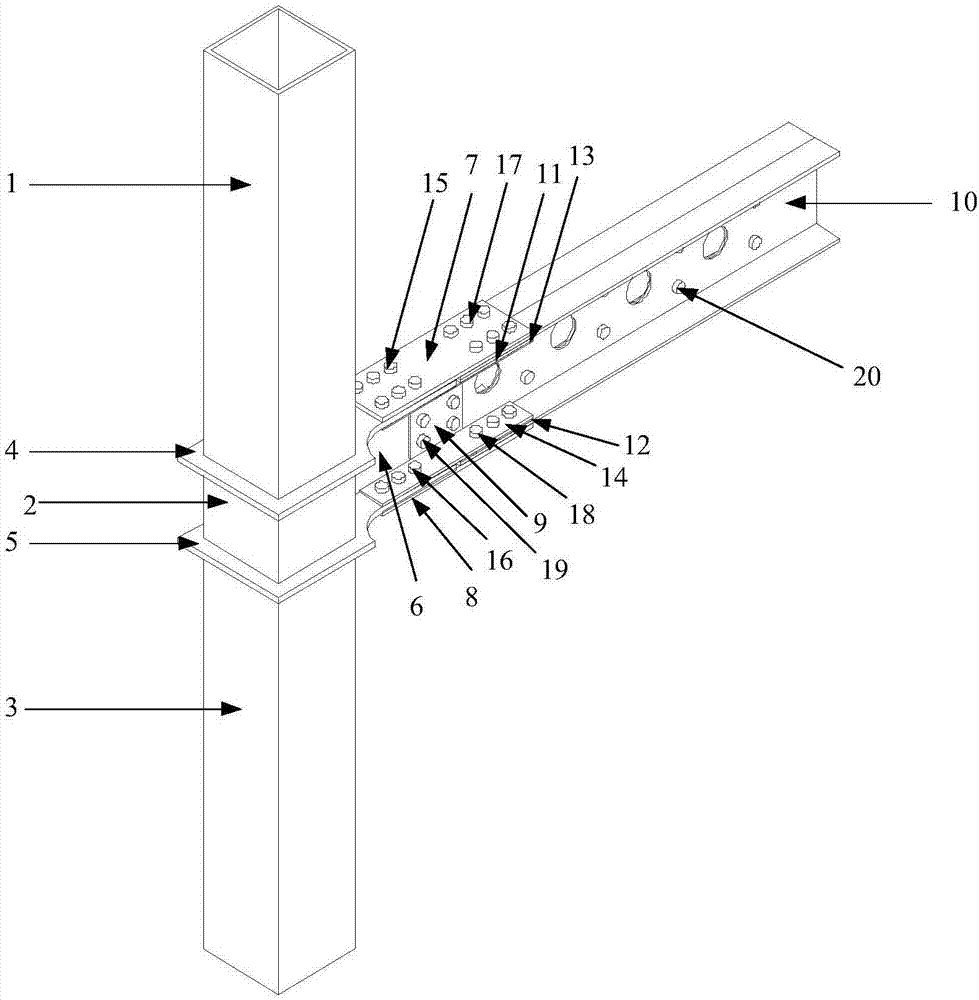

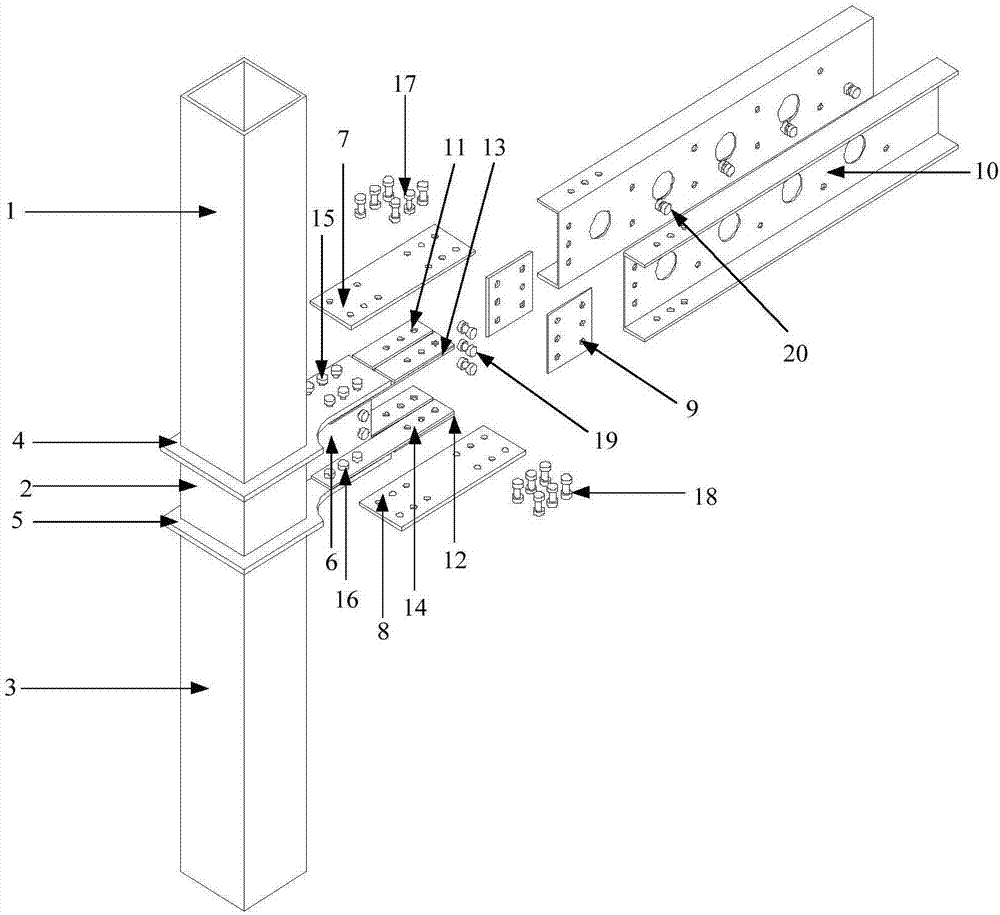

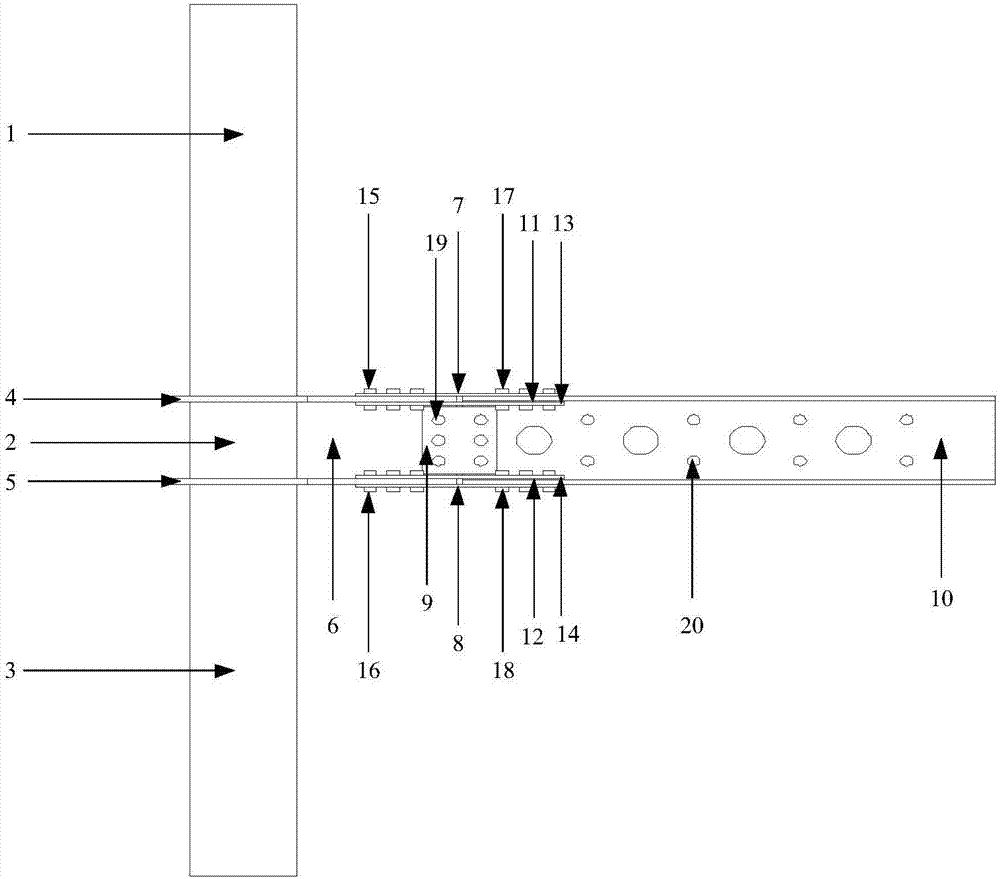

Assembly channel steel punching beam column joint connecting device capable of achieving function recovery

InactiveCN106869325AAvoid complex stress fieldsReduce construction difficultyFloorsFloor slabPunching

The invention relates to an assembly channel steel punching beam column joint connecting device capable of achieving function recovery and belongs to the field of structural engineering. The assembly channel steel punching beam column joint connecting device capable of achieving function recovery is composed of a square steel pipe column with a cantilever beam section, a channel steel punching beam section and a connecting device of the cantilever beam section and the channel punch beam section. All welding parts of the joint connection device are all finished in a factory, so that precision and quality of welds are easier to control. Construction speed is greatly increased and construction quality is greatly improved, and a spatial structure of the channel punch beam section of the channel is conducive to pipeline penetration; the channel steel punching beam and a floor can be assembled and molded in the factory to form modular assembly units. Then all the modular assembly unit and the square steel pipe column with the cantilever beam section achieve assembly connection through the channel steel punching beam. Joints of the connection device can be used for both of beam end reinforcing and cover plate connection weakening. A multi-energy dissipation mechanism can be realized, a plastic hinge is transferred to a cover plate and a connecting plate. The function of structures can be recovered only by replacing the connecting plate after an earthquake.

Owner:BEIJING UNIV OF TECH

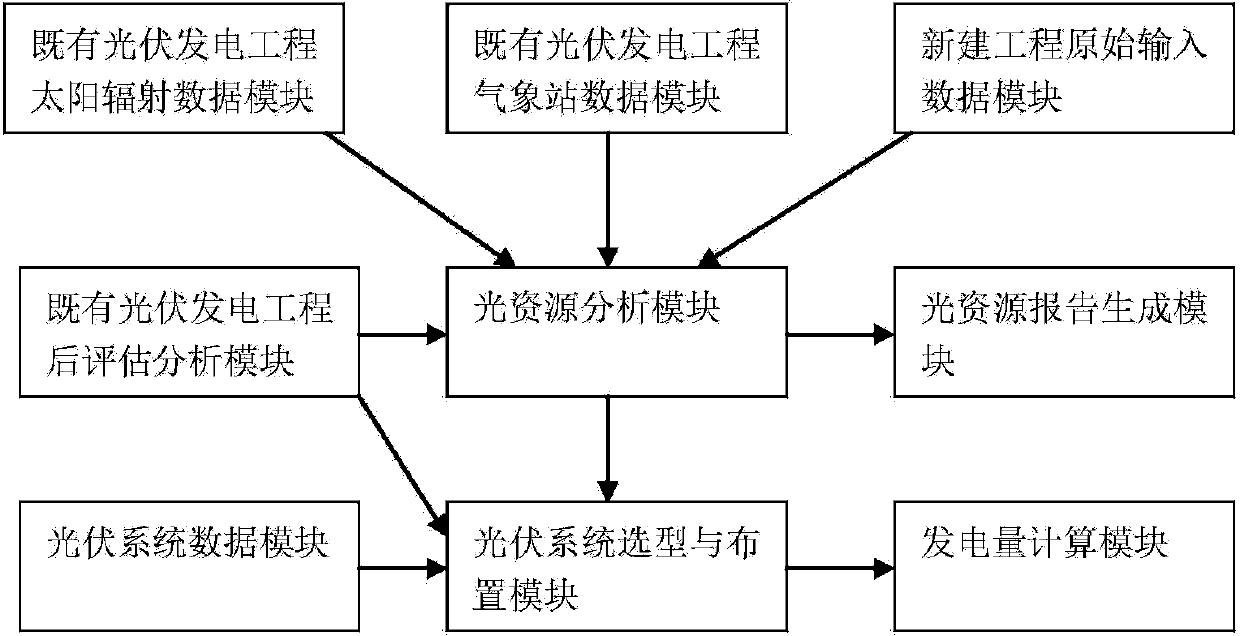

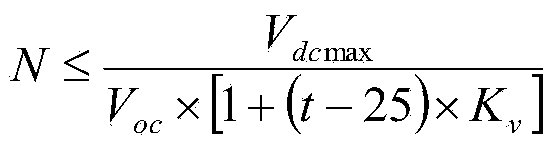

Expert system designed for photovoltaic power station

ActiveCN104182564AShorten the timeImprove the design levelData processing applicationsSystems intergating technologiesComputer modulePhotovoltaic power station

The invention provides an expert system designed for a photovoltaic power station and belongs to the technical field of design of the expert system. The expert system comprises a solar radiation data module of the existing photovoltaic power generation engineering, a meteorological-station data module of the existing photovoltaic power generation engineering, a primary input data module, a light-resource analysis module, a photovoltaic system data module and a photovoltaic system type-selection and arrangement module, wherein the solar radiation data module is used for establishing one or more on-site solar radiation observation station data table of the existing photovoltaic power generation engineering; the meteorological-station data module is used for establishing one or more reference meteorological-station data table of the existing photovoltaic power generation engineering; the primary input data module is used for inputting primary data of a newly-built photovoltaic power generation engineering; the light-resource analysis module is used for generating a solar-energy resource analysis chart; the photovoltaic system data module is used for establishing a photovoltaic-system data table; and the photovoltaic system type-selection and arrangement module is used for type selection of equipment and arrangement of photovoltaic components. The expert system provided by the invention has the advantage that the technical problem that the photovoltaic power station can not be reasonably and accurately designed is solved.

Owner:内蒙古电力勘测设计院有限责任公司

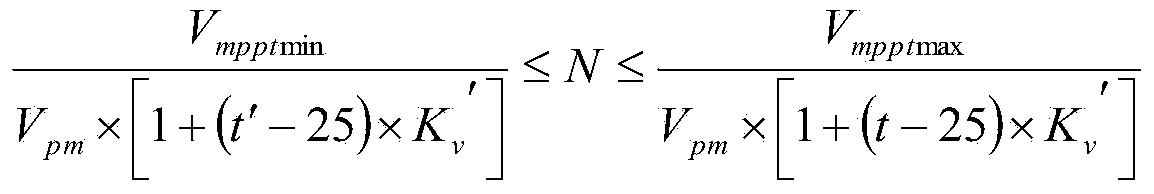

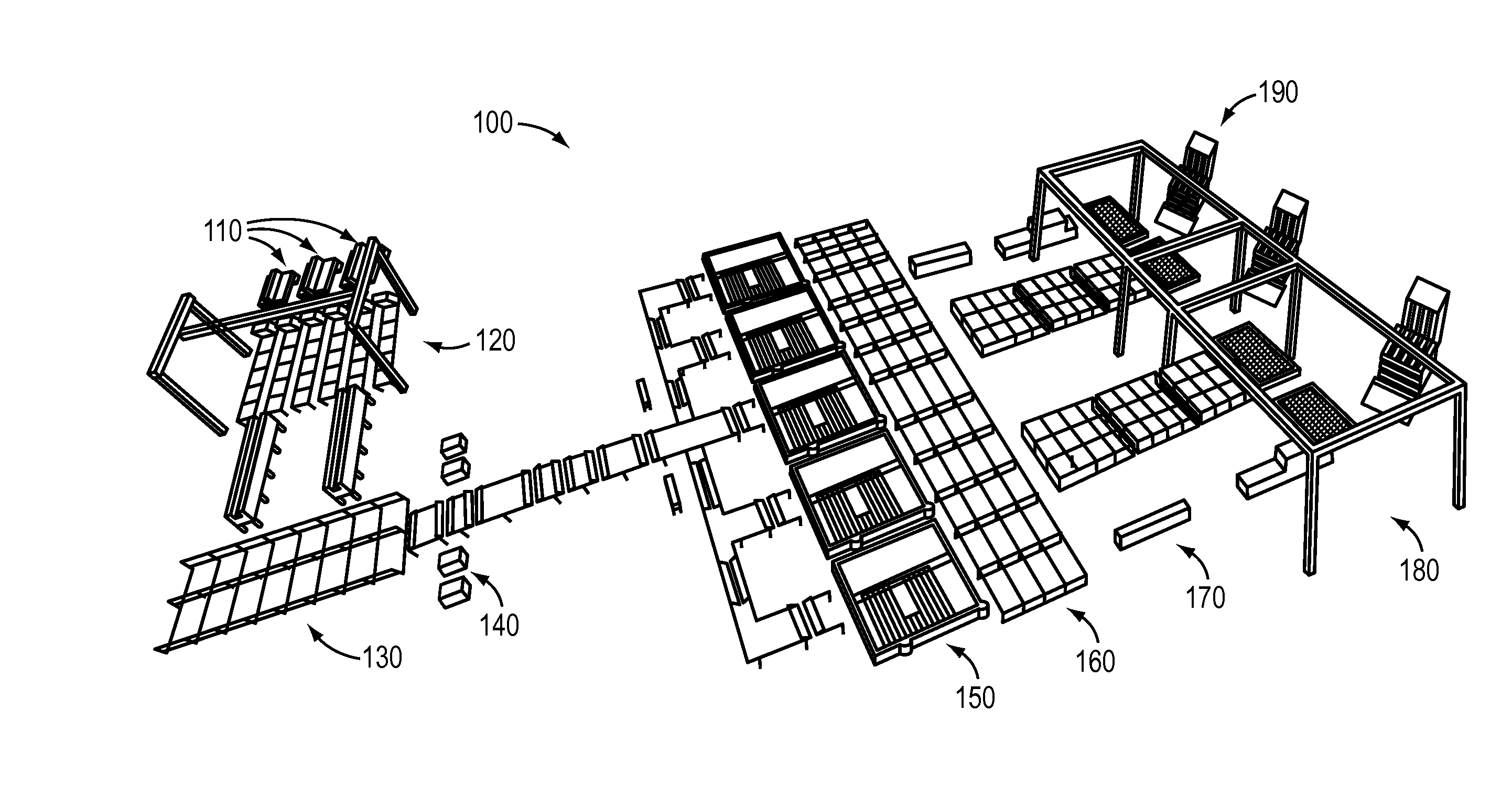

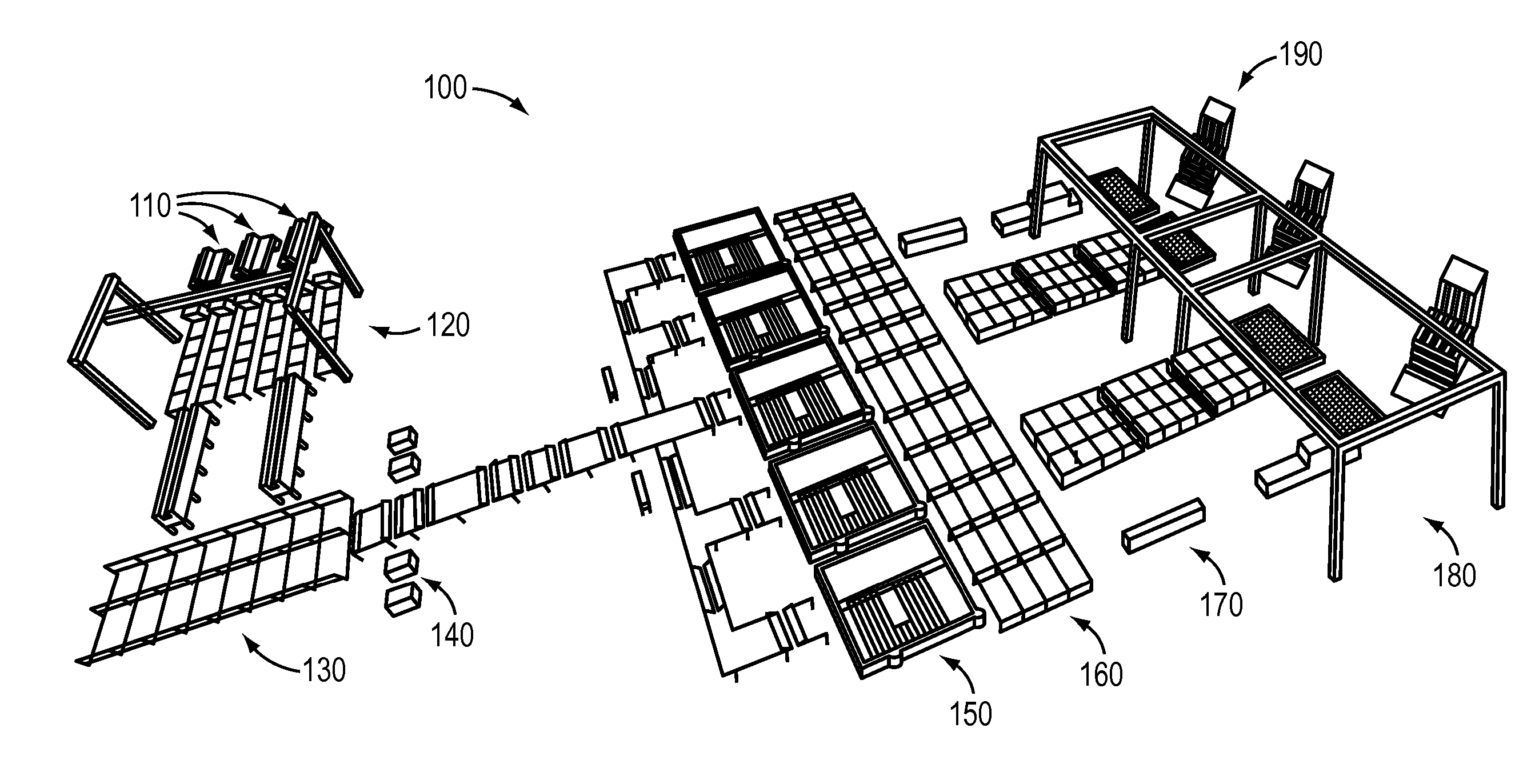

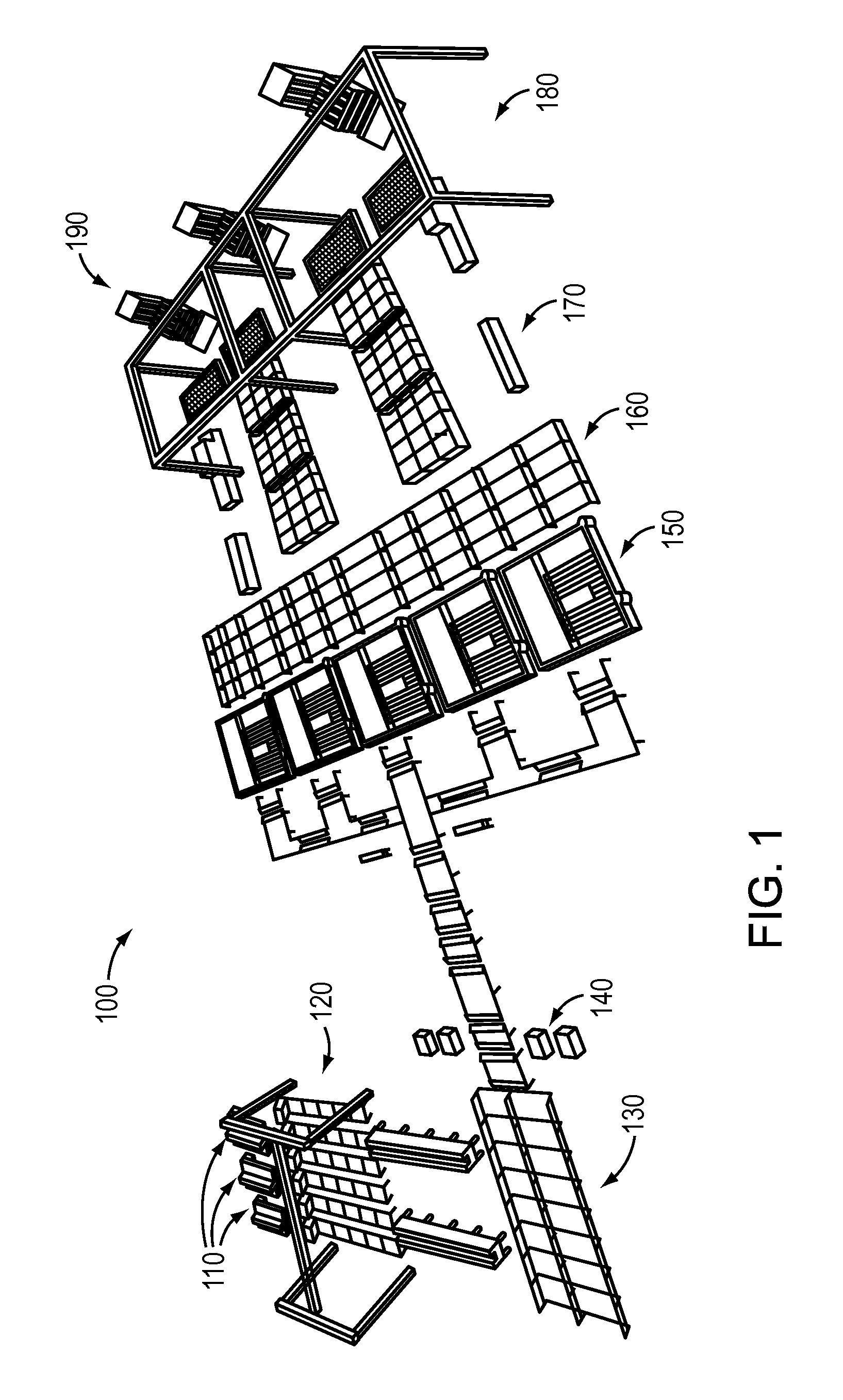

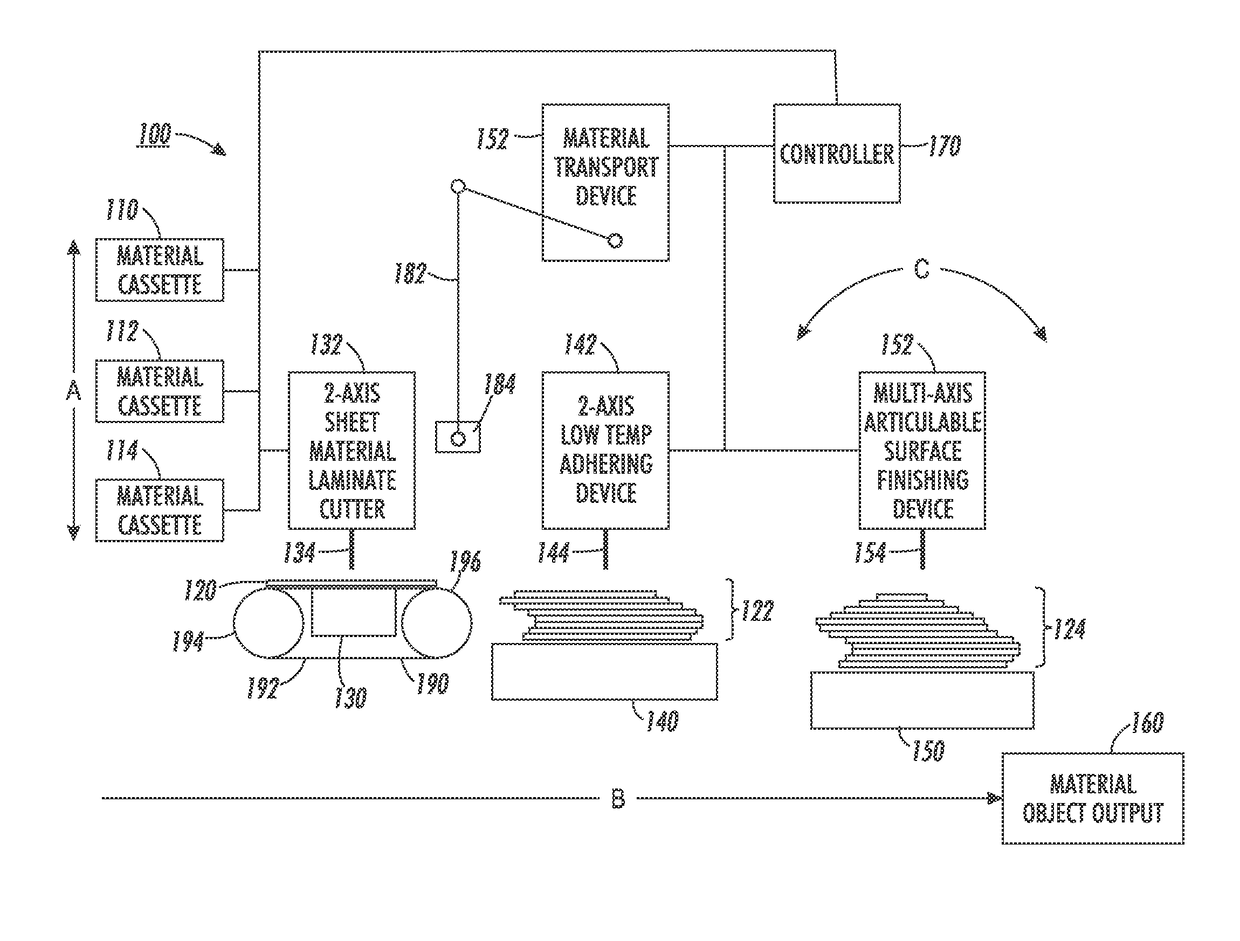

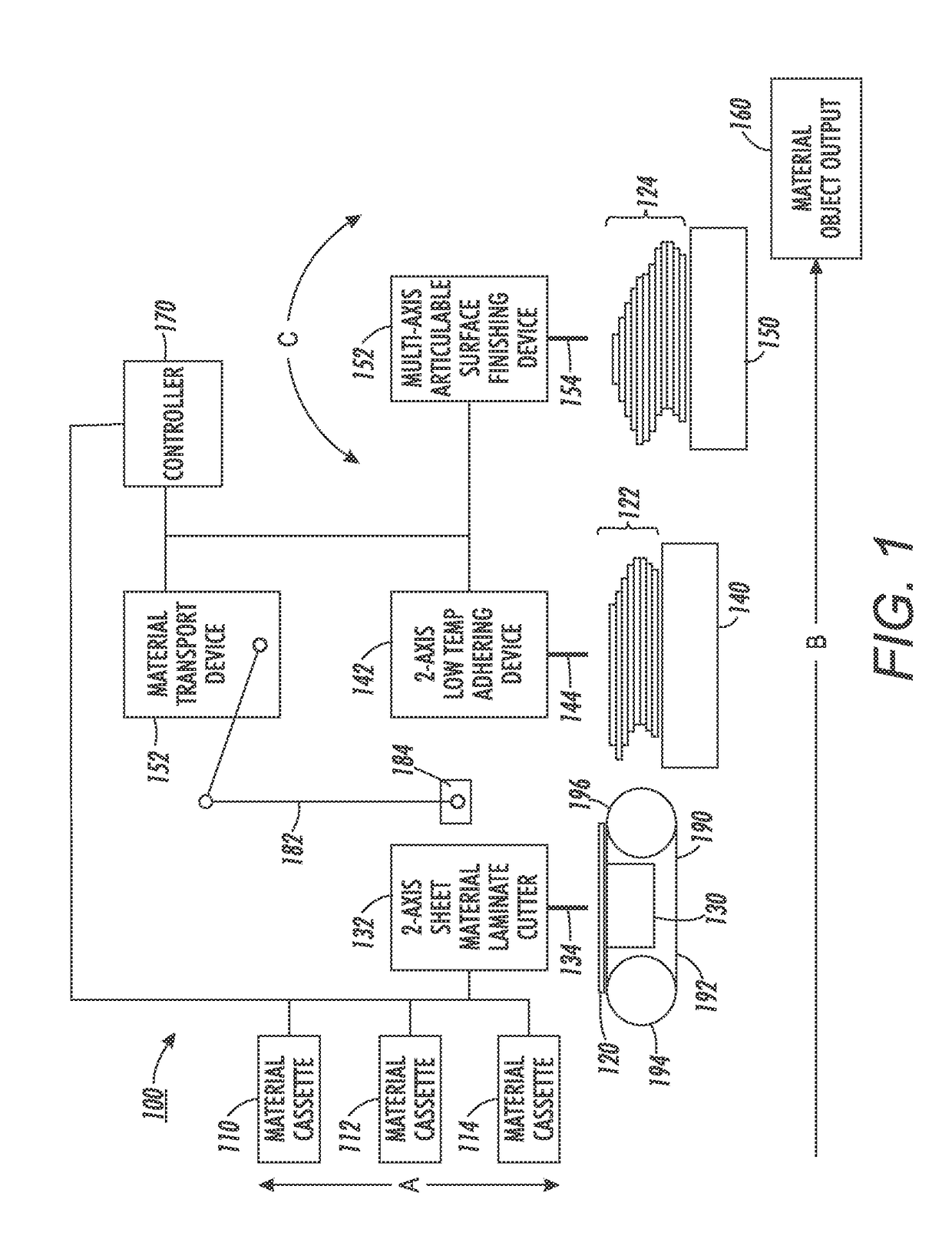

Systems and methods for implementing three dimensional (3D) object, part and component manufacture including locally laser welded laminates

ActiveUS20170144370A1High build rateSolve the slow construction speedAdditive manufacturing apparatus3D object support structuresSurface finishMachining

A system and method are provided for implementing localized and directed laser welding joining techniques in a process of building up laminate layers to form and / or manufacture three-dimensional objects, parts and components (3D objects). A multi-stage 3D object forming scheme is described involving steps of laminate cutting (with lasers or other cutting devices); laminate transport between processing stations (including using one or more of conveyors, robotic pick and place devices and the like); laminate stacking, clamping and adhering through a targeted laser welding technique; and mechanical surface finishing (via CNC machining or other comparable process).

Owner:XEROX CORP

Concrete mixer applied to road construction and provided with vibration puddling and screeding functions

InactiveCN107263714ASimple structureEasy to useRoads maintainenceCement mixing apparatusRoad constructionArchitectural engineering

The invention discloses a concrete mixer for road construction with the function of vibrating and smoothing. The connection cover is connected by bolts, the motor base is fixedly connected to the motor, the output end of the motor is fixedly connected to the driving gear, the upper left side of the driving gear is connected to the first connecting rod in rotation, and the bottom of the first connecting rod is connected to the second connecting rod in rotation. A vibrating pump is fixedly connected to the bottom right side of the body, and a vibrating rod is connected to the lower side of the vibrating pump, and the vibrating rod is fixedly connected to the second connecting rod. Compared with the prior art, the beneficial effects of the present invention are: the present invention is simple in structure, easy to use, and is used for concrete pouring on roads, and simultaneously carries out the functions of concrete mixing, vibrating compaction and smoothing during road construction, which greatly simplifies The process of road construction is simplified, so it can effectively increase the speed of road construction, and it is worth promoting.

Owner:胡沛

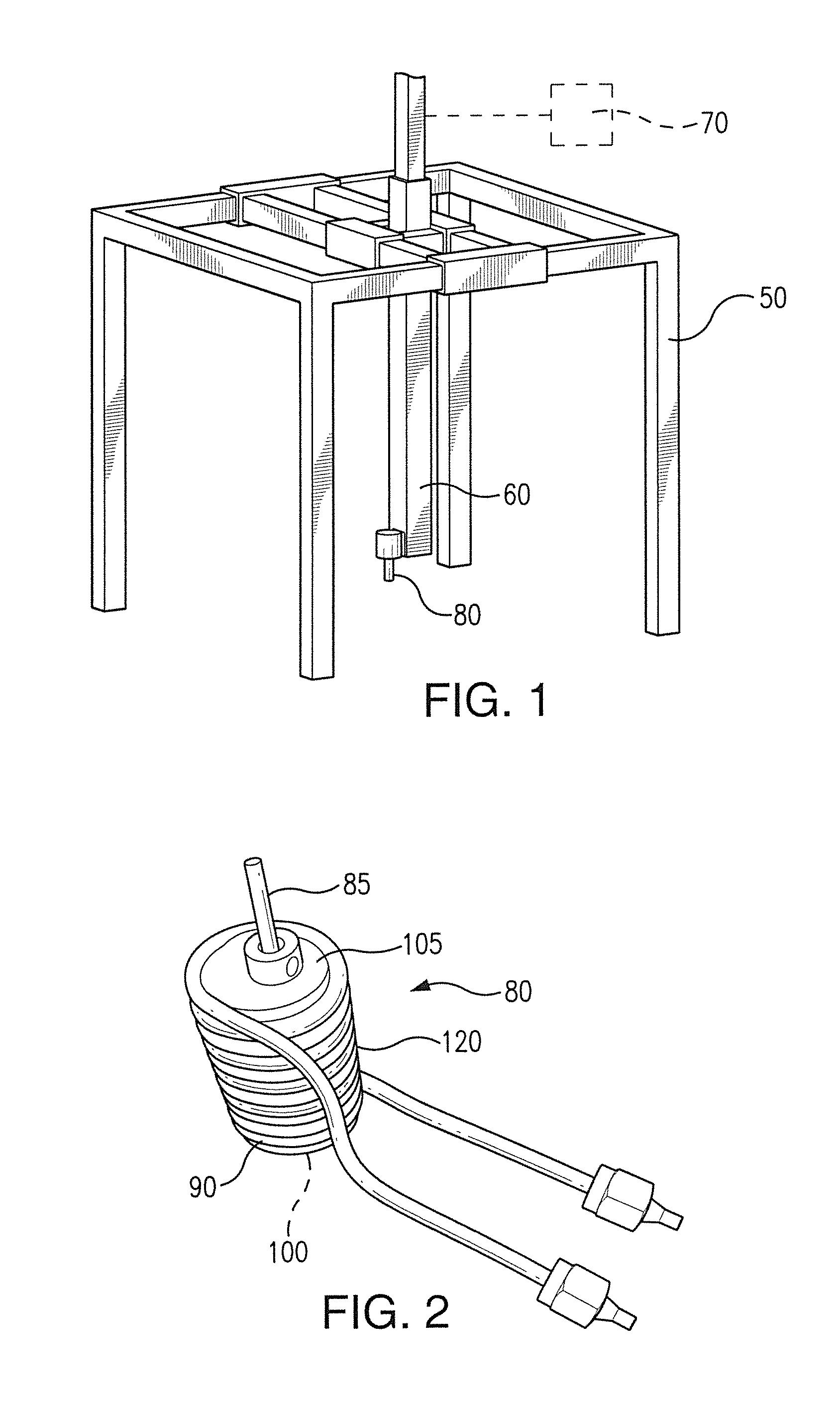

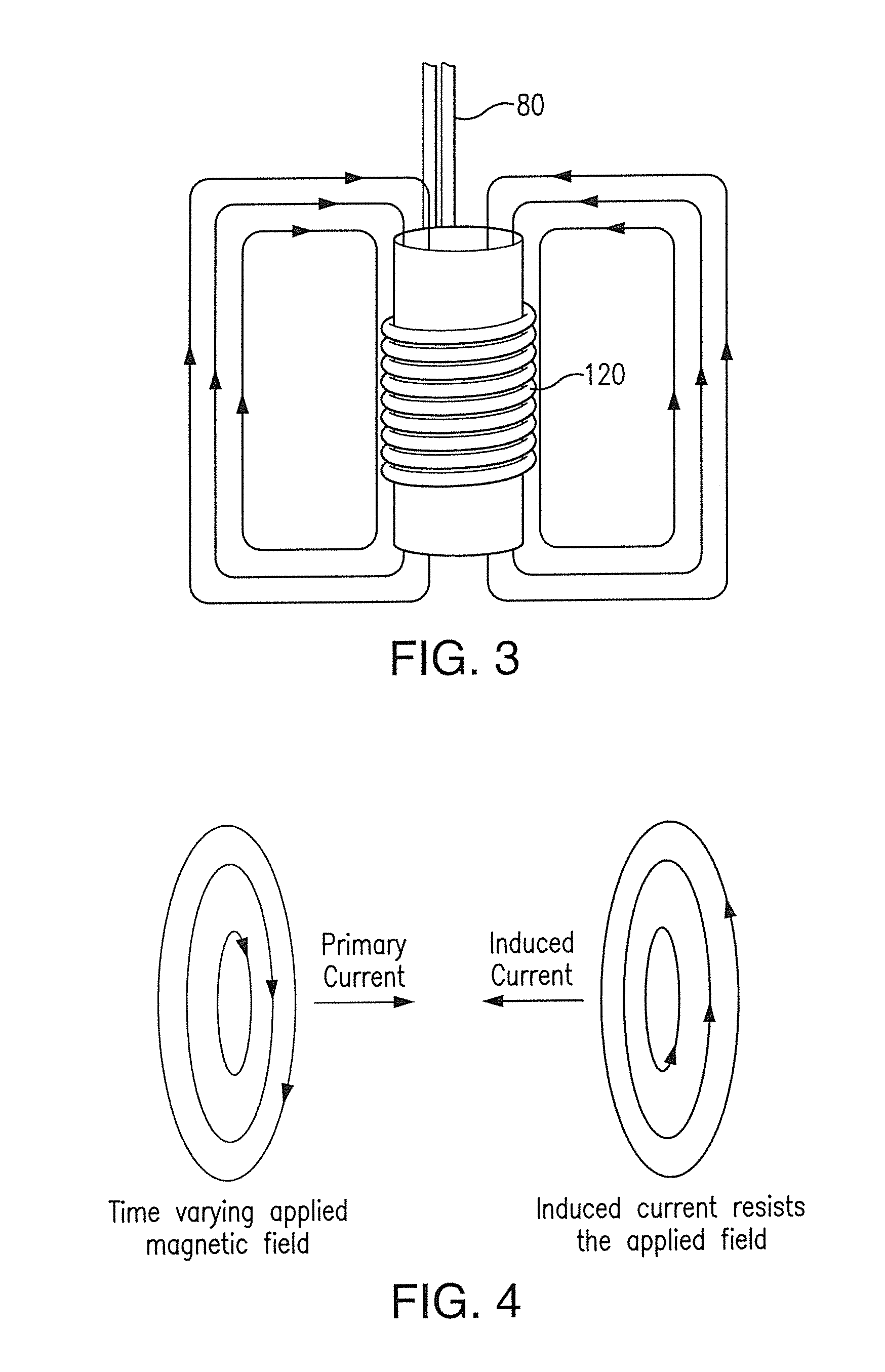

Rapid electro-magnetic heating of nozzle in polymer extrusion based deposition for additive manufacturing

InactiveUS20150183164A1High sensitivityImprove controllabilityAuxillary shaping apparatusAdditive manufacturing with liquidsEngineeringMechanical engineering

A method and apparatus for additive manufacturing that includes a nozzle for extruding a plastic material and a supply of polymeric working material provided to the nozzle, wherein the polymeric working material is magnetically susceptible and / or electrically conductive. A magneto-dynamic heater is provided for producing a time varying, high flux, frequency sweeping, alternating magnetic field in the vicinity of the nozzle to penetrate into and couple the working material to heat the material through at least one of an induced transient magnetic domain and an induced, annular current.

Owner:UT BATTELLE LLC

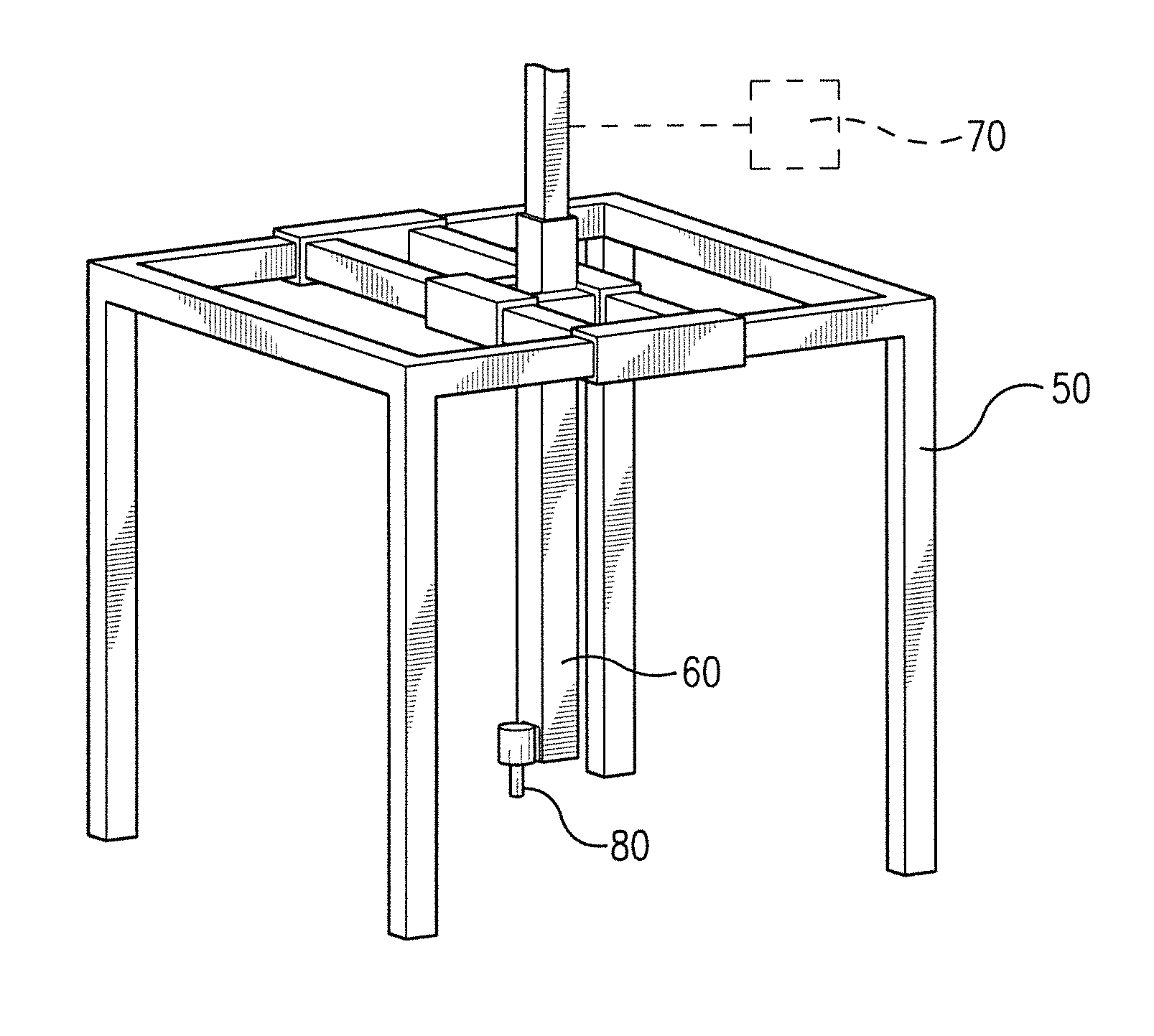

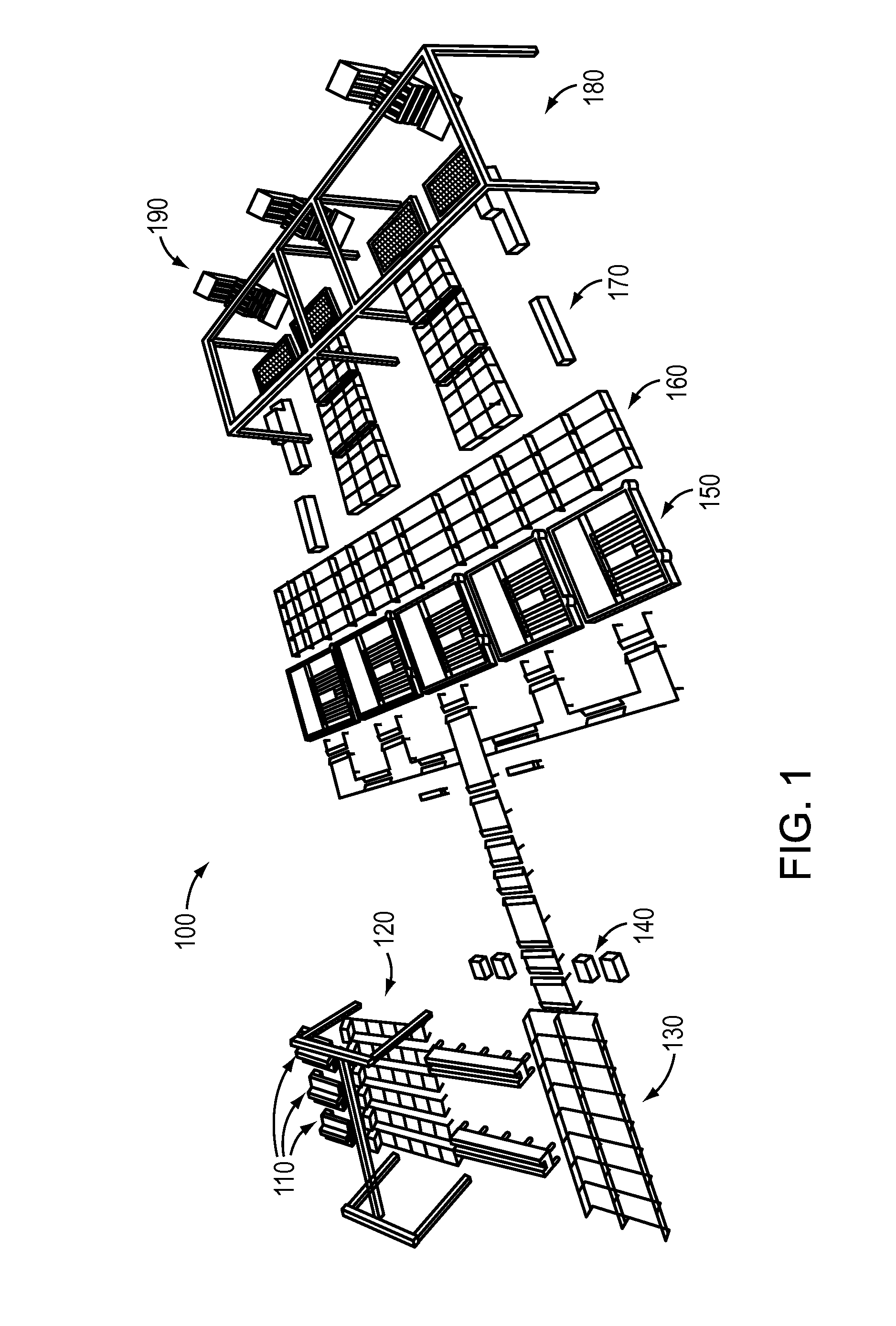

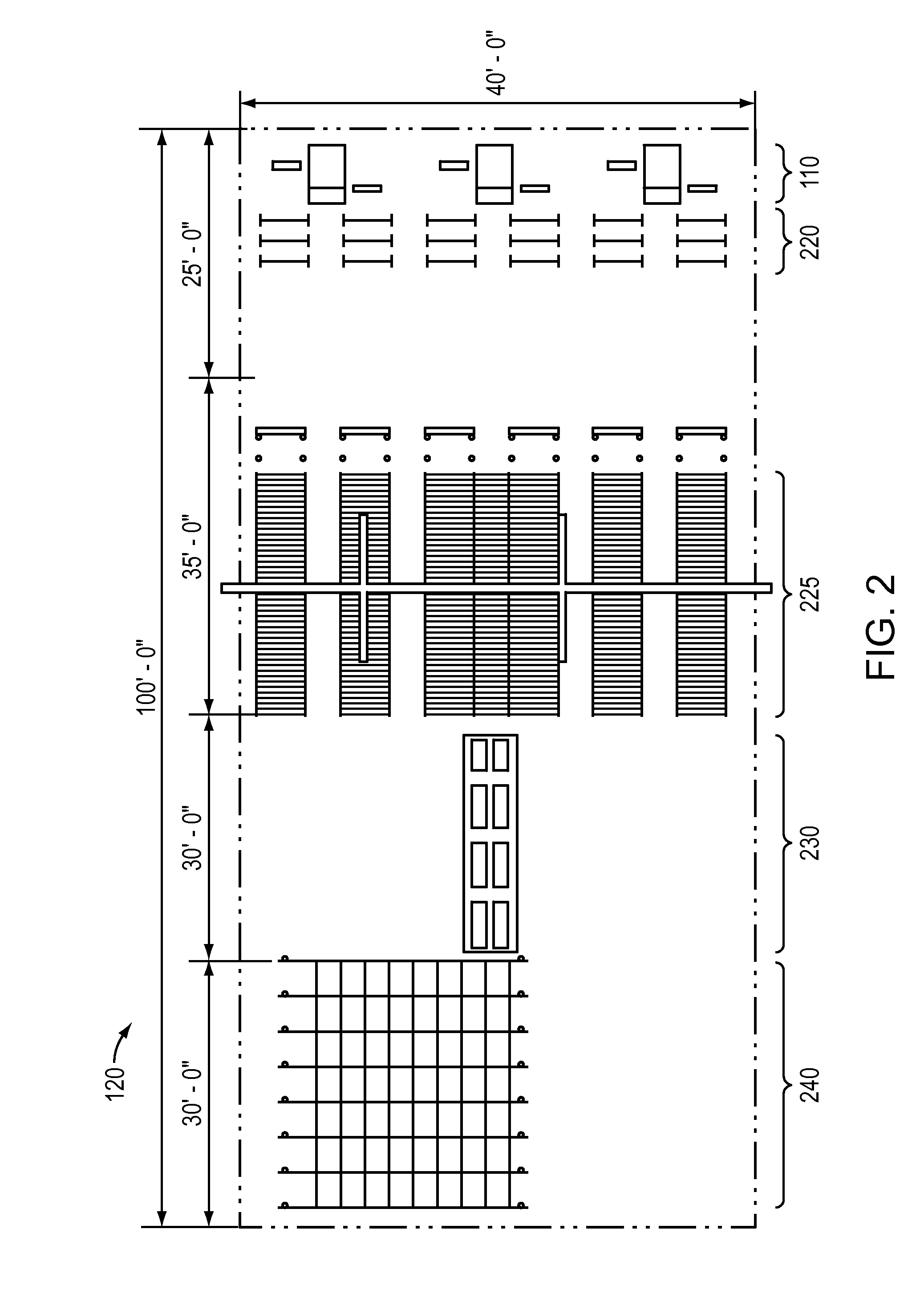

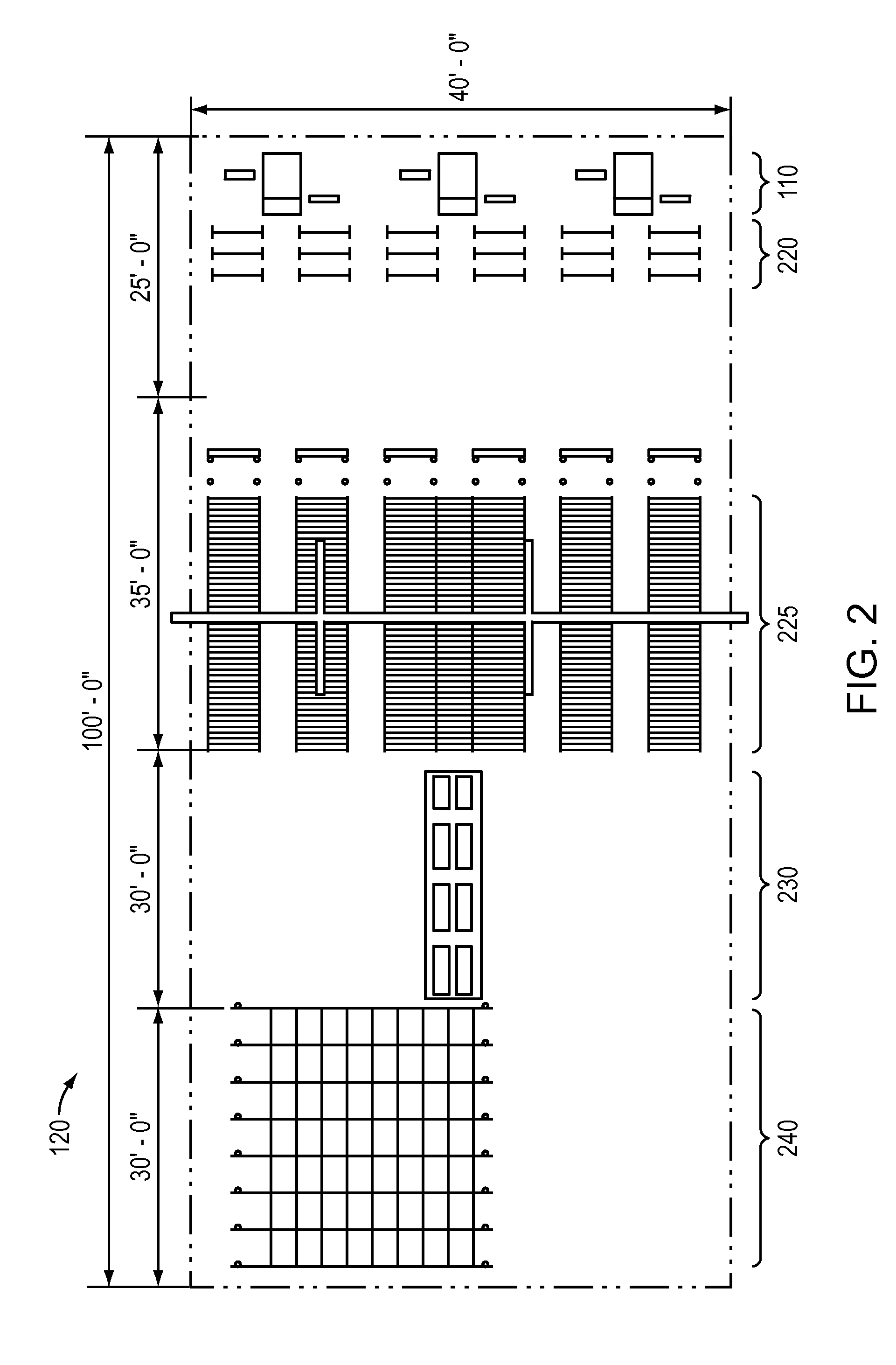

Framing table for building panel assembly

InactiveUS20070256391A1Transport is impairedImprove construction qualityAssembly machinesWire networkCold-formed steelBuilding construction

Owner:GENESISTP INC

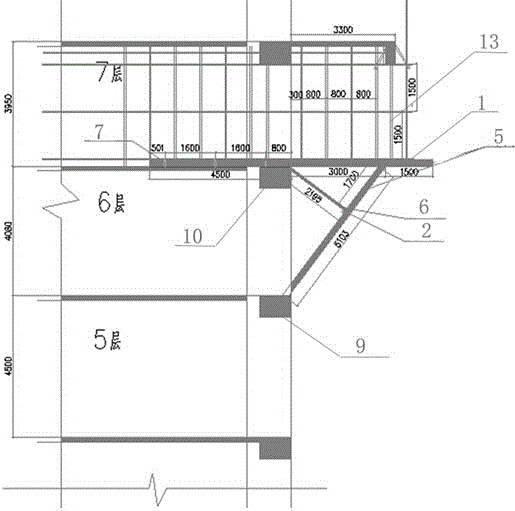

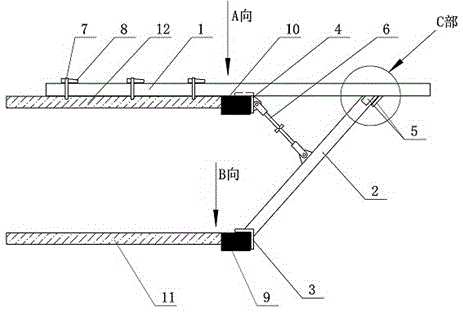

Formwork with high cantilever structure and construction method thereof

ActiveCN105019639ALong cantilever spanImprove overall stability and anti-overturning abilityScaffold accessoriesBuilding support scaffoldsFloor slabStructural element

The invention discloses a formwork with a high cantilever structure and a construction method thereof. The construction method comprises following steps: utilizing angle iron at bottoms fixed at beam corners in a structure with N layers of beams as support points of a braced steel I-beam; welding and fixing top angle iron in middles of a steel I-beam with a cantilever structure; matching and buckling the top angle iron with corners of beams in n+1 layers; welding and fixing a support of the braced steel I-beam at the end portion of the steel I-beam with the cantilever structure or below by closing to the end portion; and pre-burying at least two round steel pressing rings in a floorslab in the N+1 layer during structural construction. Each round steel pressing ring is firmly welded with the steel I-beam with the cantilever structure or plugged and fixed by a wooden wedge. The high cantilever structure is characterized in that positions of cantilever members are high above the ground. The members with cantilever structures are long in cantilever span lengths and great in deflection produced by structural self-weight. The braced steel I-beam and a welding point position of a horizontal steel I-beam cantilever platform can be determined according to cantilever length. An optimal load-carrying position is within the range spacing from the outside of the span edge of the cantilever members.

Owner:HENAN GUOJI CONSTR GRP

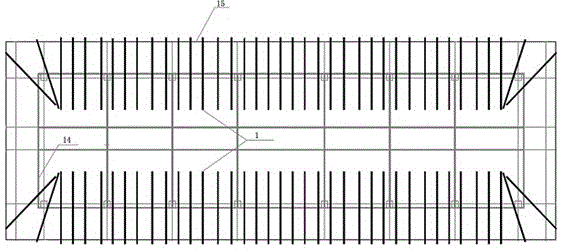

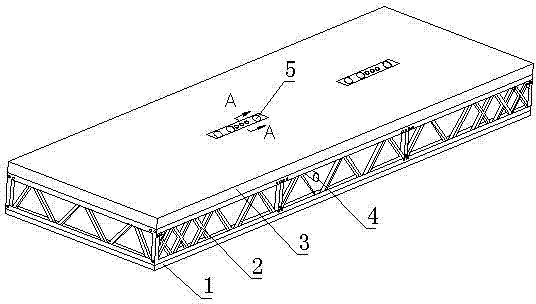

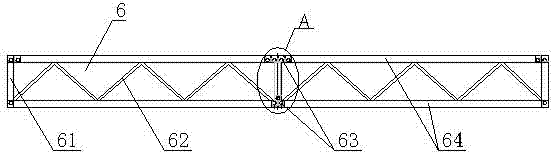

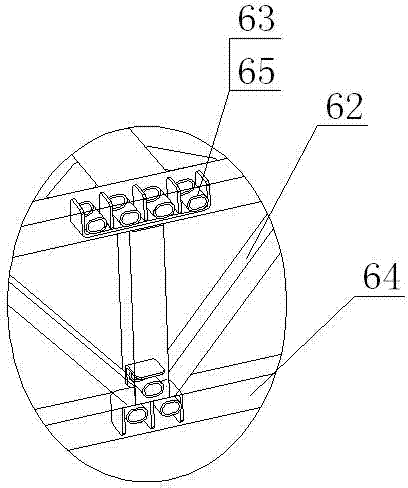

Floor system

ActiveCN103498523AQuality improvementImprove interchangeabilityFloorsFlooring insulationsFloor slabBuilding construction

The invention relates to the technical field of the building technology, in particular to a floor system. The floor system is formed by rectangular frames composed of steel beams. The floor system has the advantages of being reliable in quality, standard in production, high in construction speed, less in rubbish in a construction site and capable of being combined at will and saving materials.

Owner:张跃

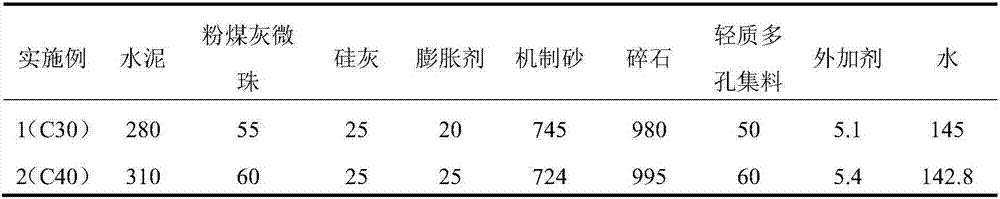

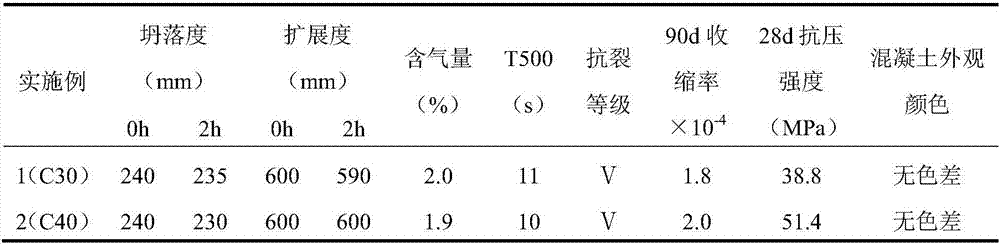

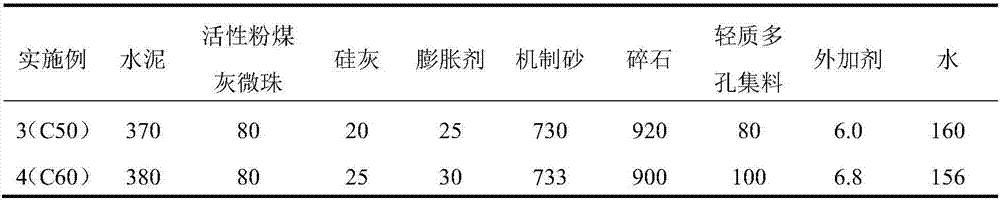

Bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand

The invention discloses a bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand. The bridge self-compaction anti-crack bare concrete is prepared from cement, activated fly ash microbeads, silica fume, an expanding agent, machine-made sand, gravel, a light-weight porous aggregate, a high-performance additive and water. The bridge self-compaction anti-crack bare concrete provided by the invention adopts the high fine powder content machine-made sand to replace common natural river sand, utilizes the activated fly ash microbeads and the silica fume for adjusting the viscosity and the fluidity of the concrete so as to improve the homogeneity of a concrete slurry, and further additive is used for reducing the gas content of the concrete, so that a working performance and a fluidity keeping performance of the concrete are improved; meanwhile, the expanding agent and the light-weight porous aggregate are combined, so that the volume stability and an anti-early-age cracking behavior of the bare concrete can be effectively improved. The self-compaction anti-crack bare concrete obtained through the invention has wide adaptability on different fine powder content machine-made sand, excellent working performance, mechanical property, volume stability performance and anti-cracking ability, uniform appearance and color, and better mirror surface effect.

Owner:WUHAN UNIV OF TECH +2

Fracture rock no-slurry-blocking wall compound grouting construction method

ActiveCN101666234ASave on concrete costsReduce further damageUnderground chambersTunnel liningCement slurryMaterials science

The invention discloses a fracture rock no-slurry-blocking wall compound grouting construction method. The method comprises the following steps: when carrying out grounting, firstly, pressing and injecting pure water cement slurry in an inner hole, closing water glass slurry inlet gate valve, opening the water glass slurry inlet gate valve after the heading face leaks cement slurry and simultaneously pressing and injecting double liquid slurry of cement and water glass; after the heading face does not leak the slurry or the heading face leaks double liquid slurry which is solidified and basically blocks fracturing crack, firstly stopping water-injecting glass, then stopping water-injecting slurry, and opening a pressure-relief gate valve in time. The fracture rock no-slurry-blocking wall compound grouting construction method has the beneficial effects that by normal grouting hole channels and pipelines, the double liquid slurry is pressed to carrying out consolidation to rock bodies near the heading face, simultaneously the double liquid slurry does not block the normal grouting hole channels either, thus achieving the purposes of consolidating the rock bodies near the heading face, then normally grouting single liquid slurry and forming water curtain.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

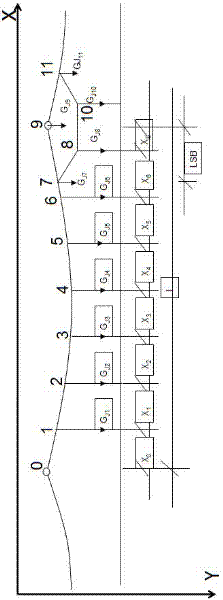

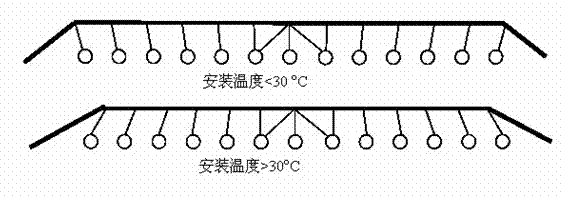

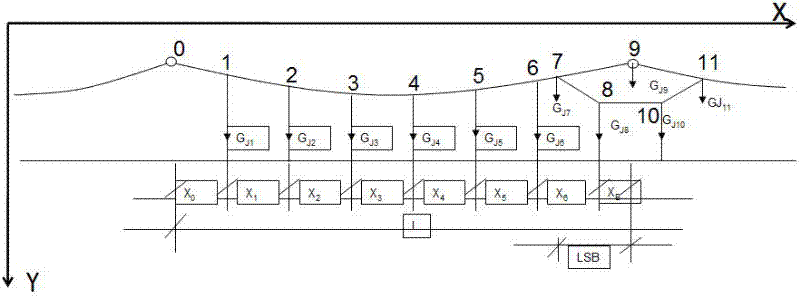

Full-compensation elastic chain hanging construction method for high-speed rail contact network

InactiveCN102381212AGuaranteed accuracyGuaranteed installation qualityTrolley linesContact networkArchitectural engineering

A full-compensation elastic chain hanging construction method for high-speed rail contact network, which comprises a construction preparing process, a construction measuring process, a software calculating process, a precasting process for sling and dropper, a mounting adjusting process for sling and dropper, and an ending process; each process is equipped with uniform and high-quality construction standards, and is assisted by modern construction meanses for satisfying with technical requirements for construction of high-speed rail contact network of 350 km / h; the software calculating process especially can obtain more accurate pre-stowage data of dropper length via a brand new calculating method finding form based on sling net, and then improve elastic chain hanging construction accuracy for high-speed rail contact net of 350 km / h. So the construction method does not only benefit for improving accuracy of sling and droppser calculation, and the construction method but also has high-quality construction standards and modern construction meanses, and is capable of improving quality and speed of construction of high-speed rail contact net of 350 km / h.

Owner:中铁建电气化局集团南方工程有限公司

Information technology process for prefabricated building panel assembly

InactiveUS20070265724A1Improve construction qualitySolve the slow construction speedDigital data processing detailsWire networkCold-formed steelBuilding construction

Owner:GENESISTP INC

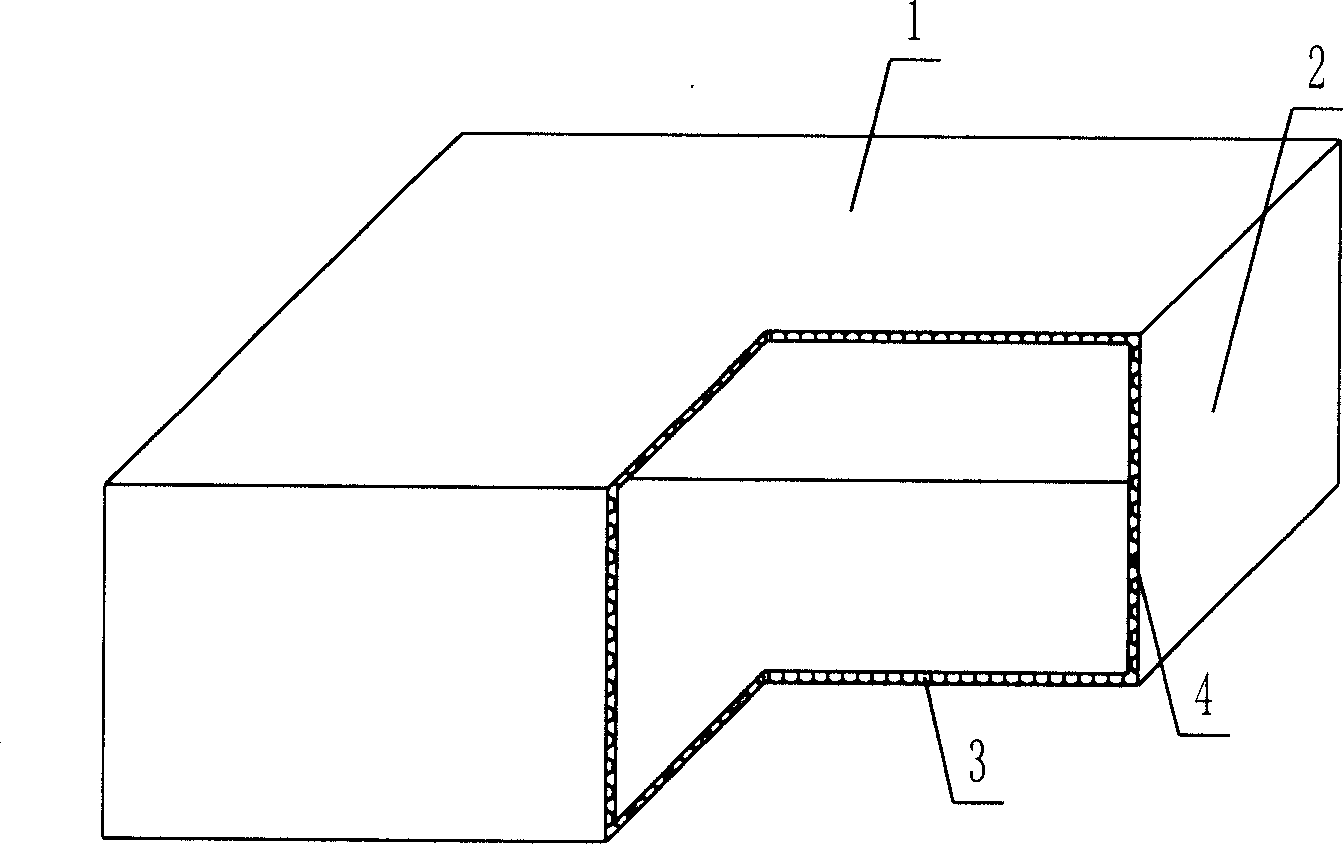

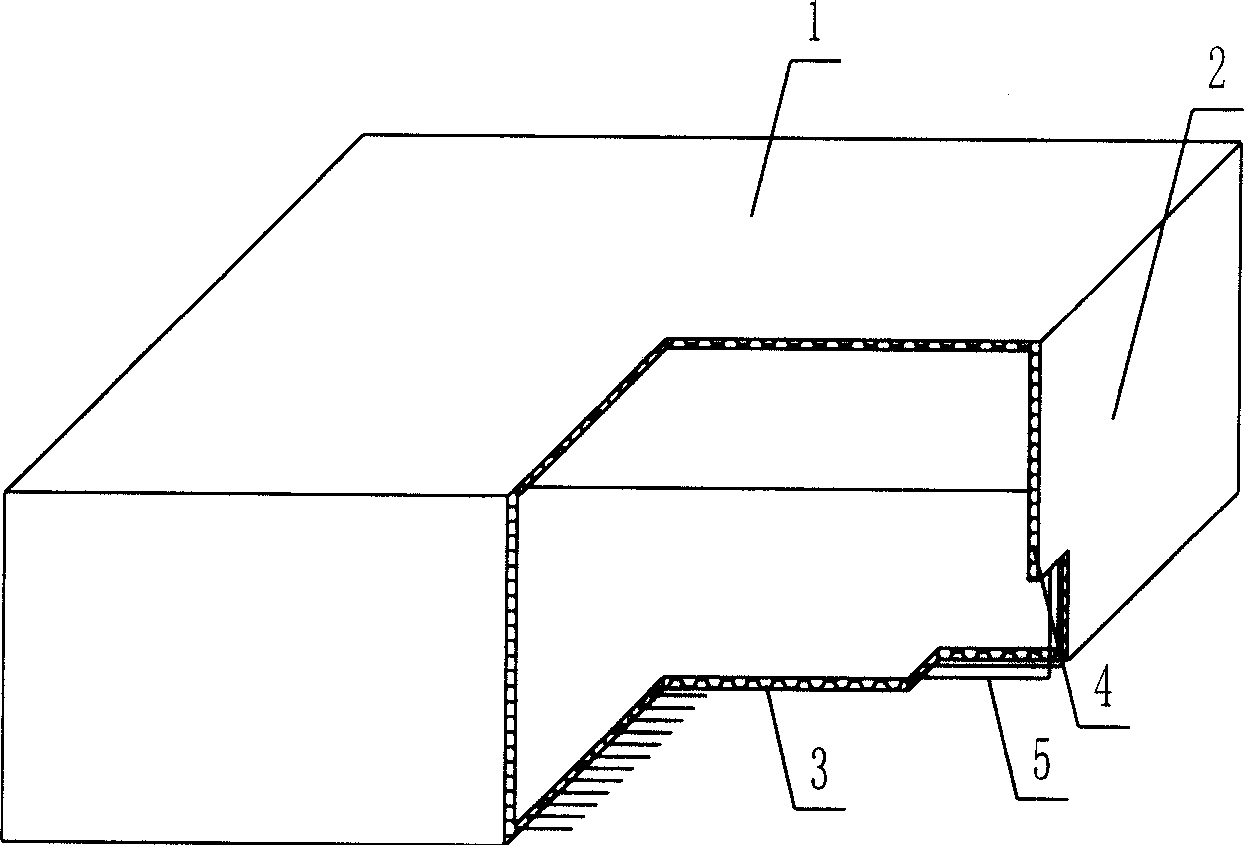

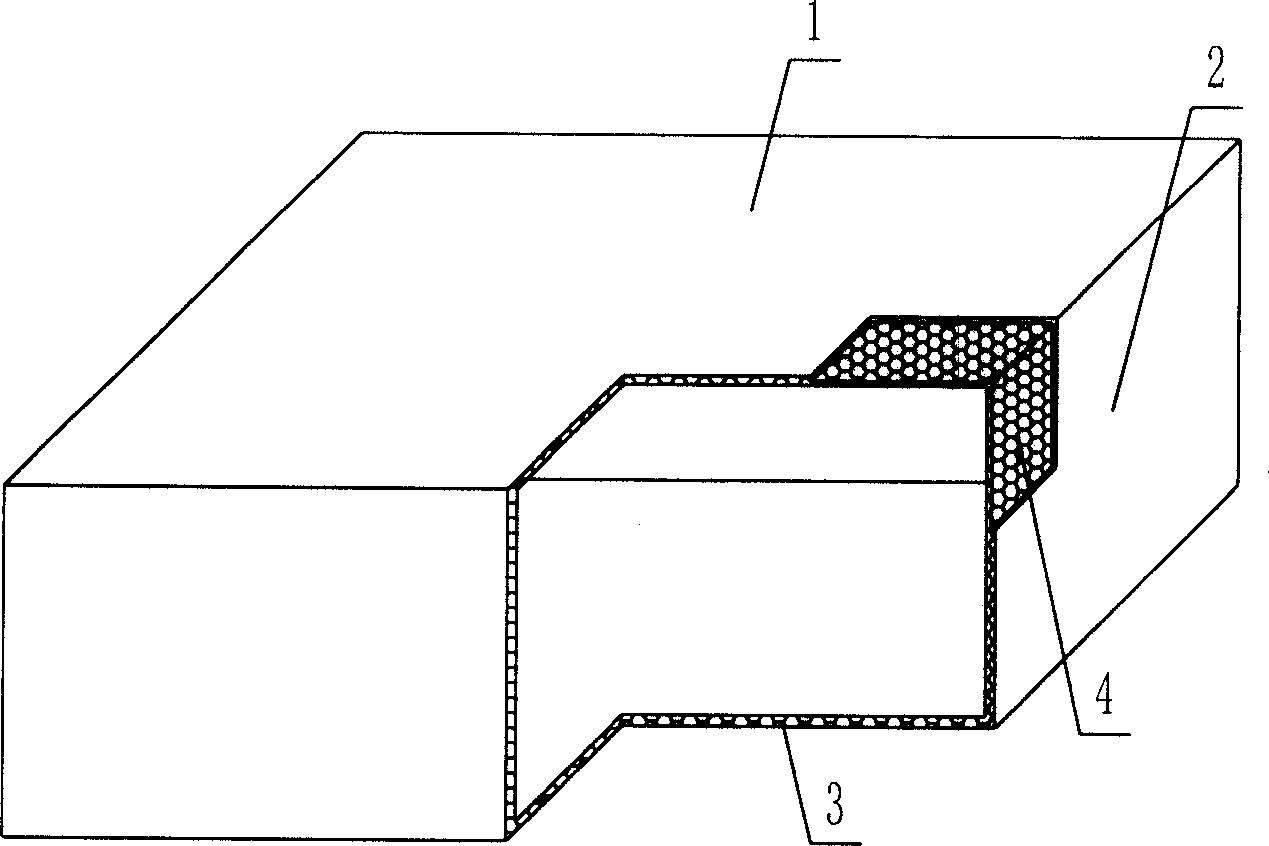

Component of cavity form unit

InactiveCN1598195AReduce installation processImprove construction efficiencyFloorsPre stressEngineering

Owner:湖南邱则有专利战略策划有限公司

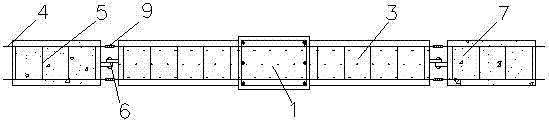

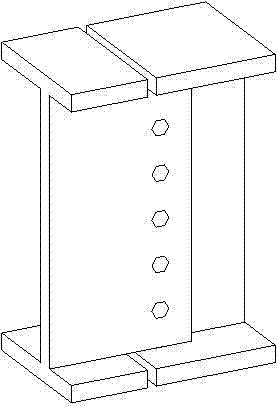

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

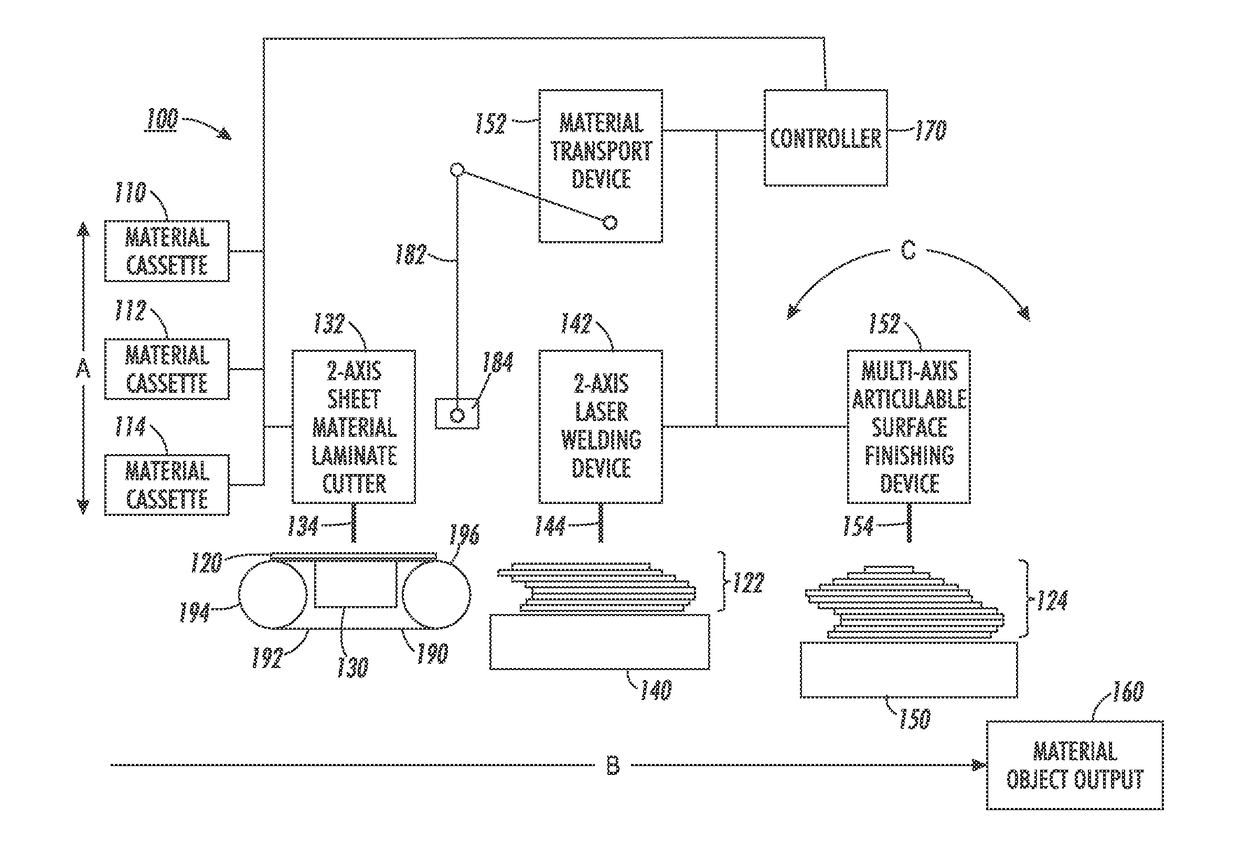

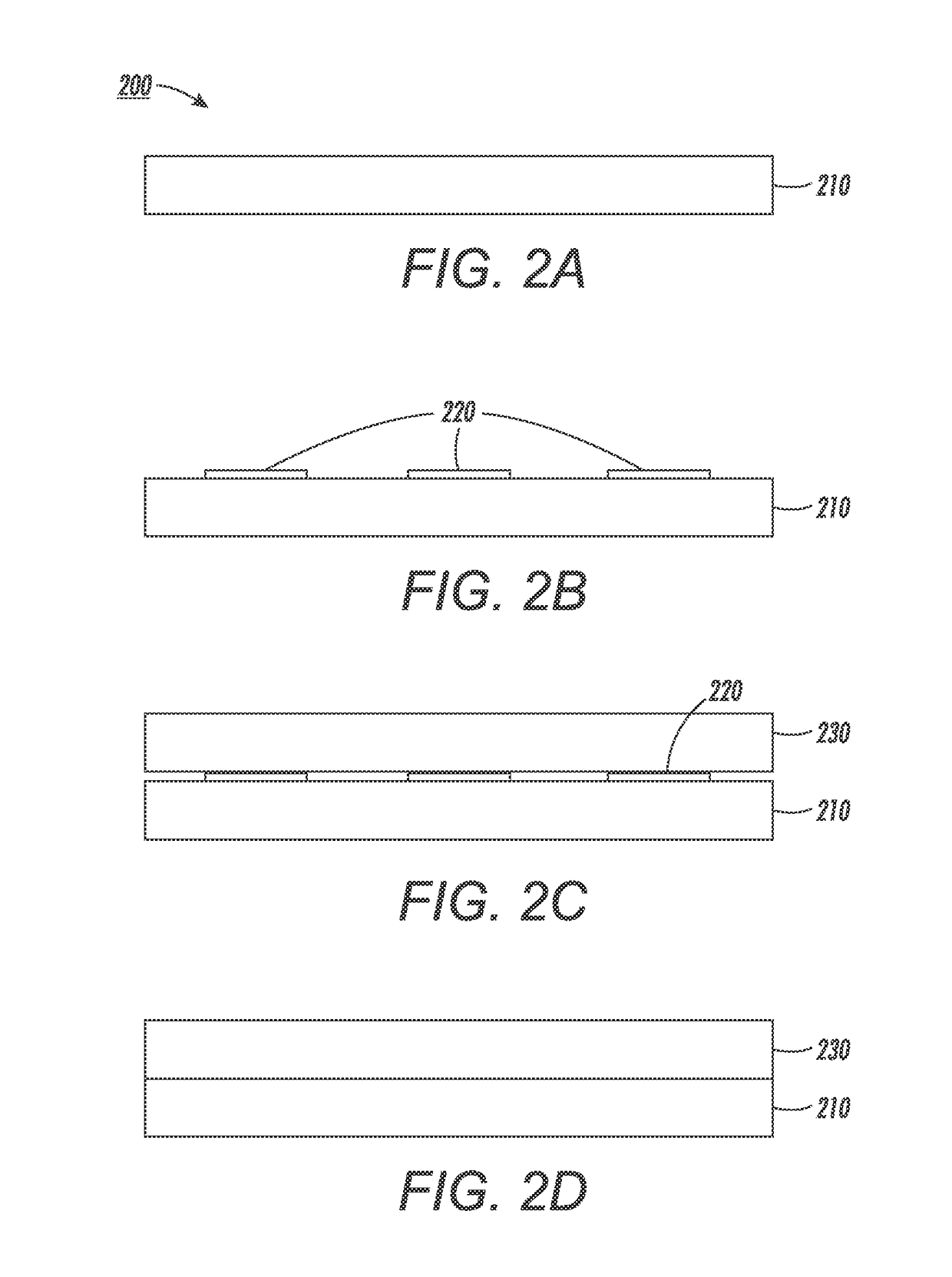

Systems and methods for implementing three dimensional (3D) object, part and component manufacture including displacement/vibration welded or heat staked laminates

ActiveUS20170144426A1High build rateSolve the slow construction speedLamination ancillary operationsLaminationSurface finishingEngineering

A system and method are provided for implementing relatively low temperature joining processes, including displacement / vibration welding techniques and / or heat staking techniques, in a process of building up laminate layers to form and / or manufacture three-dimensional objects, parts and components in additive material (AM) manufacturing systems. A multi-stage 3D object forming scheme is described involving steps of laminate cutting (with lasers or other cutting devices); laminate transport between processing stations (including using one or more of conveyors, robotic pick and place devices and the like); laminate stacking, clamping and adhering through comparatively low temperature welding or other mechanical joining (including displacement / vibration welding or heat staking); and mechanical surface finishing (via CNC machining or other comparable process).

Owner:XEROX CORP

High-gloss real stone lacquer and marble simulation lacquer

The invention discloses a high-gloss stone lacquer and a marble simulation lacquer. The high-gloss stone lacquer is characterized by being prepared from the following raw materials in weight percentage: 20.7%-25.8% of silicone-acrylic emulsion, 4%-6% of HEC (Hydroxy Ethyl Cellulose) solution with the concentration being 2.5%, 0.5%-0.7% of coalescent alcohol ester-12, 0.35%-0.45% of ethylene glycol, 10.4%-15.5% of color sand in 40-80 meshes, 15.55-20.6% of color sand in 80-120 meshes, 36.1%-41.3% of color sand in 120-200 meshes, 0.008%-0.012% of mildew preventive, 0.008%-0.012% of corrosion preventive, 0.008%-0.012% of fungicide, 0.35%-0.45% of moisturizing and polishing agent and 0.5%-0.7% of dye leveler. The high-gloss stone lacquer can be changed into the marble simulation lacquer by adding rock sheets. According to the high-gloss stone lacquer and the marble simulation lacquer, the color is not dark any more, the flower-appearing cannot be caused in construction any more, fast-drying cannot be generated any more, and the high-gloss stone lacquer and the marble simulation lacquer can be subjected to spraying, roller painting and brush coating and are convenient to use.

Owner:尚怀兴

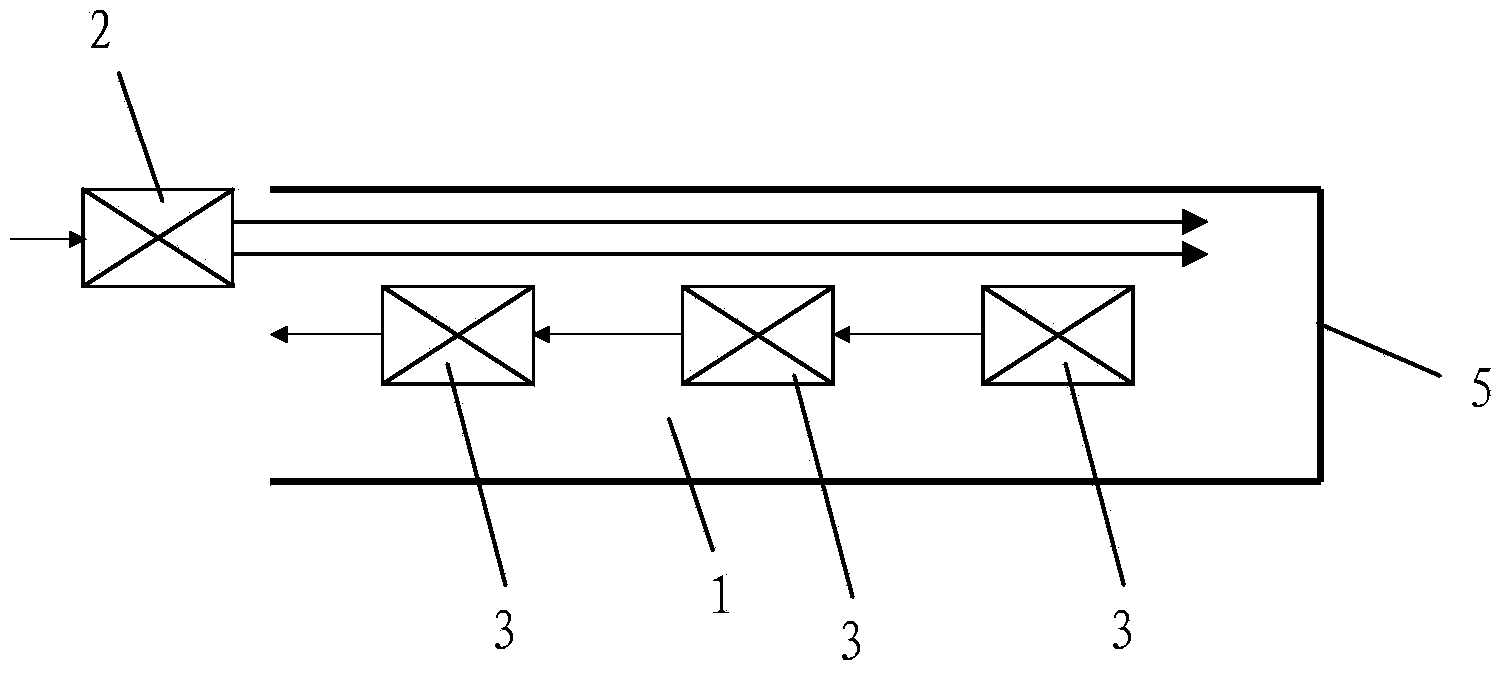

Driving face self-moving temporary support hydraulic support and support method thereof

InactiveCN103089286AImprove support strengthIncrease the support areaMine roof supportsTechnical supportTunnel construction

The invention discloses a driving face self-moving temporary support hydraulic support and a support method thereof. The driving face self-moving temporary support hydraulic support comprises a tetrastyle inner support, a tetrastyle outer support and a hydraulic system. The inner support and the outer support are both made of two transverse top beams, two transverse bottom beams and four elastic stand columns, a plurality of longitudinal beams are arranged on the two transverse top beams to form a top support of a supporting top plate, the tetrastyle inner support is embedded with the outer support to form a pull-draw type combined support, the hydraulic system enables the inner support and the outer support to be capable of lifting and mutually pulling and drawing, and forward movement of the hydraulic support along a working face is achieved. The driving face self-moving temporary support hydraulic support is a novel driving face mechanization temporary support device. The support is a tetrastyle support and can automatically move so that supporting intensity and supporting areas of the temporary support are improved, tunneling construction speed and safety can be substantially improved, and technical supports for rapid and safe tunneling are achieved.

Owner:SHANDONG UNIV OF SCI & TECH

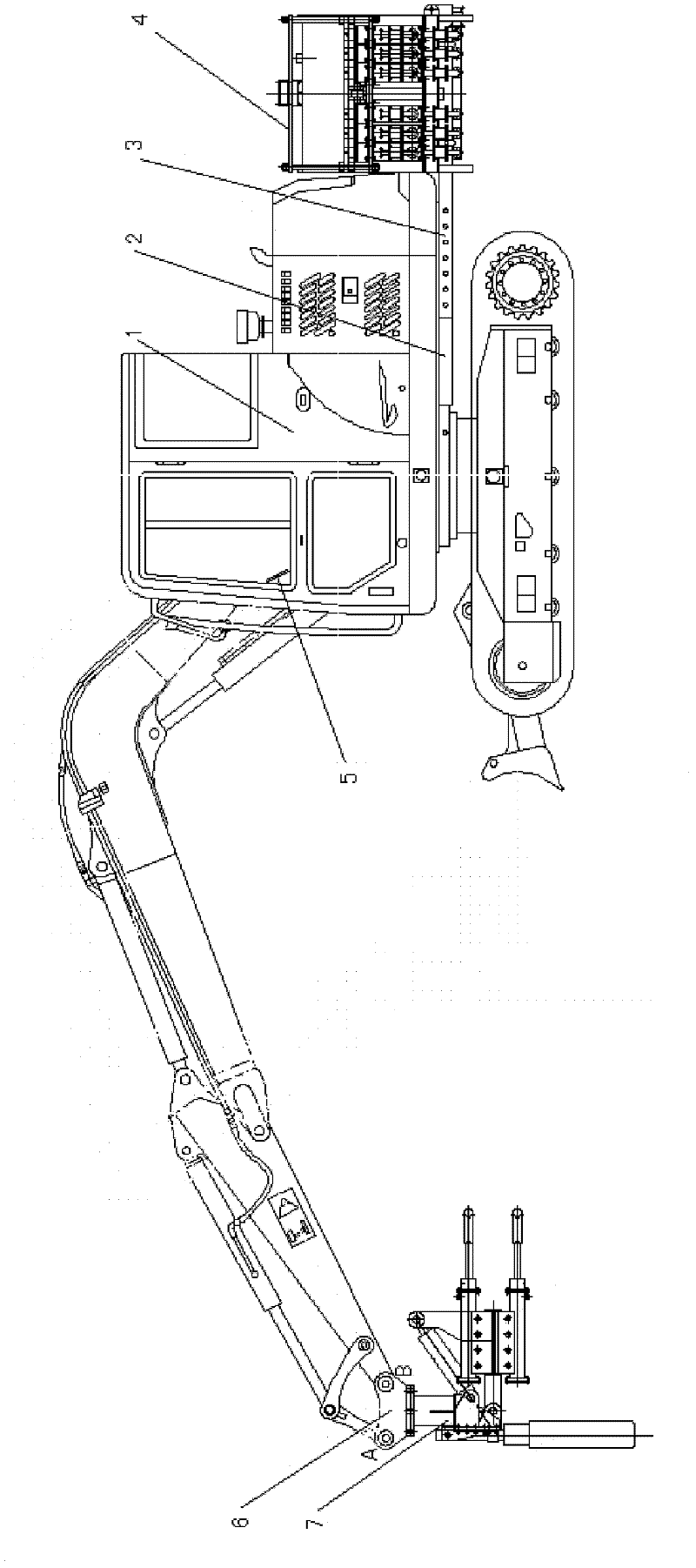

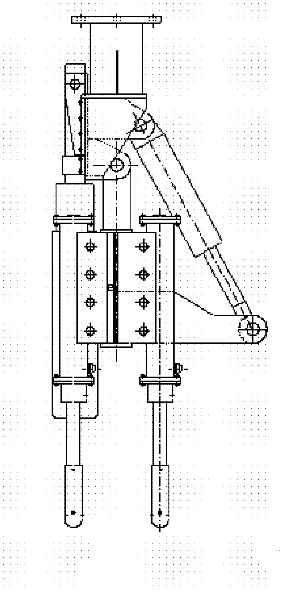

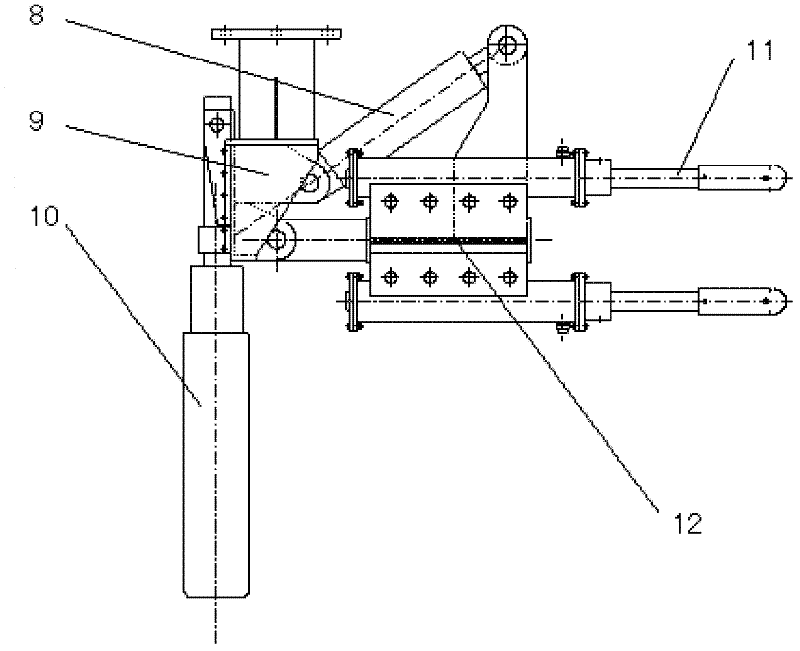

Automatic distorted concrete grouting and vibrating equipment

ActiveCN102505694ARealize free switchingRealize automatic alignmentFoundation engineeringControl systemProgrammable logic controller

The invention discloses automatic distorted concrete grouting and vibrating equipment, which belongs to the technical field of construction and comprises an excavator, a hydraulic system, a slurry supply station, a grouting and vibrating device, a PLC (programmable logic controller) control system and an operation screen. The slurry supply stations is connected with a load-bearing main beam of the excavator via a slurry supply station bracket, the grouting and vibrating device is connected with a four-rod mechanism rocker arm of the excavator by a connecting part via a hinge pin, the PLC control system is located on a rotary worktable of the excavator, and the operation screen is mounted in a driving cab of the excavator. The automatic distorted concrete grouting and vibrating equipment simultaneously has grouting and vibrating functions, can realize free switching between a grouting work state and a vibrating work state, automatic alignment of working devices, accurate control of grouting quantity and the like, is flexible in movement, uniform in grouting, large in vibrating force and simple in operation, increases construction speed and quality, reduces labor intensity of workers, and is applicable to distorted concrete grouting and vibrating construction in various work places.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

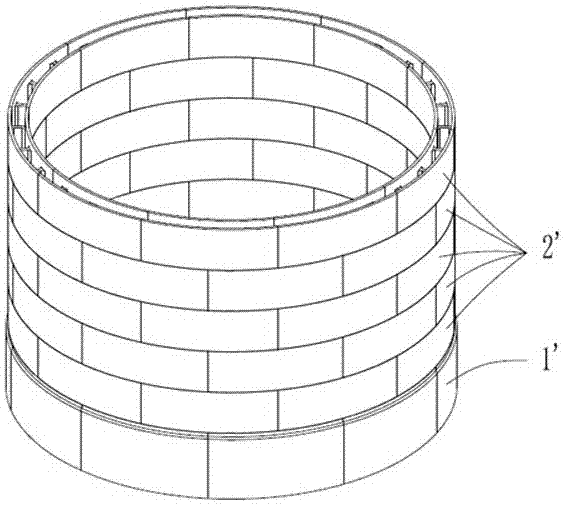

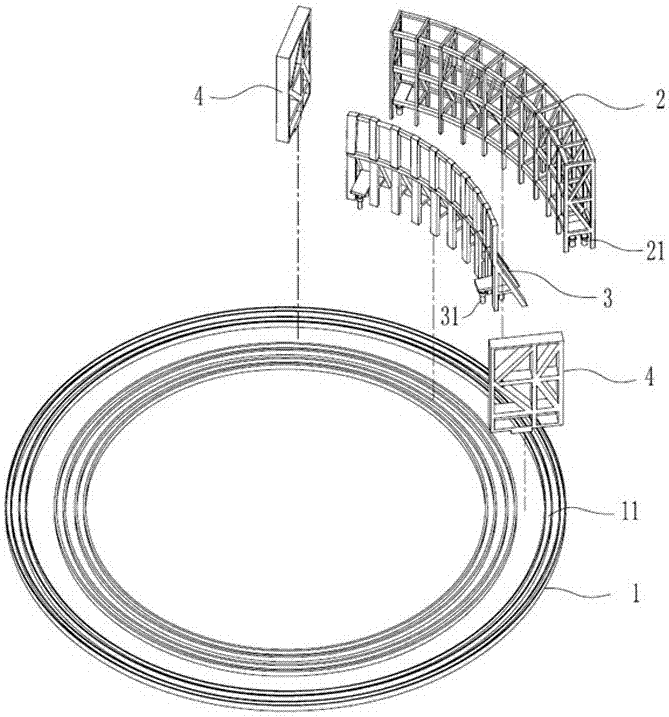

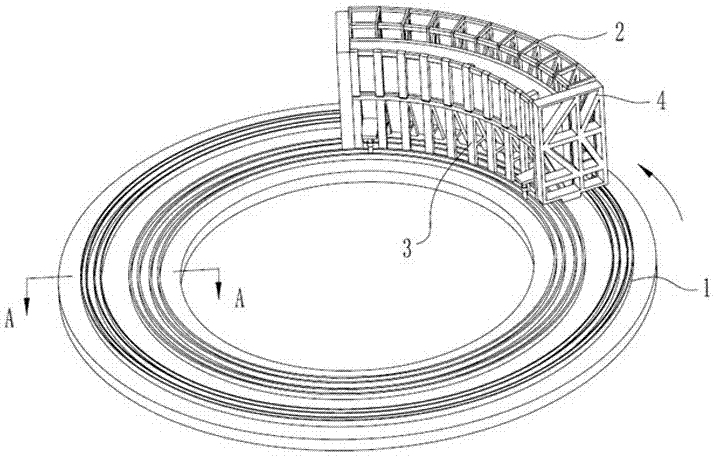

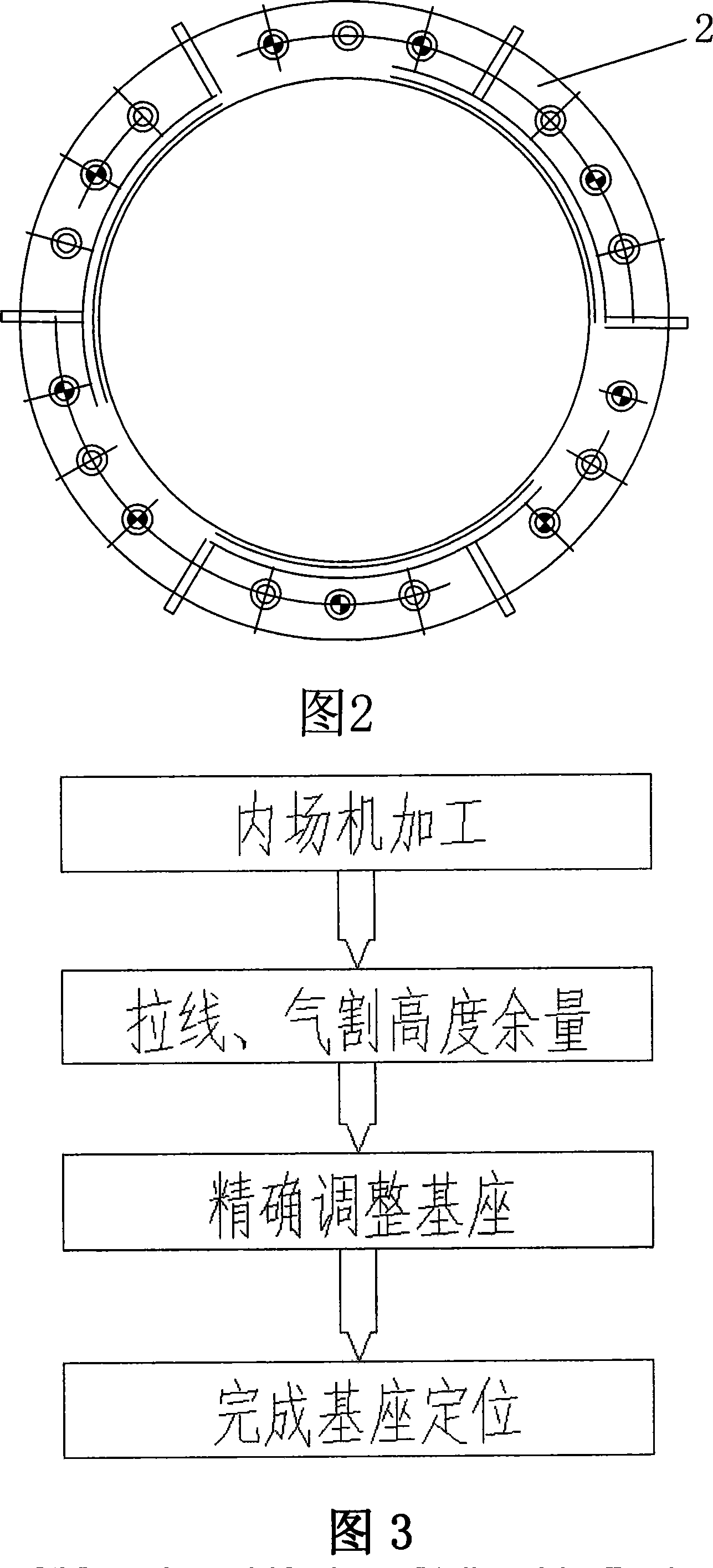

Sliding formwork component and open caisson blade foot layer sliding formwork construction method applying sliding formwork component

PendingCN107575023AGuaranteed vertical accuracyGuaranteed assembly qualityForms/shuttering/falseworksCaissonsSteel barBuilding construction

The invention discloses a sliding formwork component. The sliding formwork component comprises a sliding way, an outer template, an inner template, two side templates and a plurality of connecting fixing pieces. The sliding way is provided with a plurality of sliding grooves for installation of the outer template and the inner template. A plurality of outer stand bars are arranged at the bottom ofthe outer template. The outer stand bars are arranged on the outer side of the sliding way and can be installed and move along the sliding grooves. A plurality of inner stand bars are arranged at thebottom of the inner template. The inner stand bars are arranged on the inner side of the sliding way and can be installed and move along the sliding grooves. The side templates are arranged on the two side edges of the inner template and the two side edges of the outer template and are connected with the inner template and the outer template through the connecting fixing pieces. The invention further discloses an open caisson blade foot layer sliding formwork construction method. The method comprises the steps of field leveling, sliding way installing, steel bar bundling, template installing,concrete pouring, side template dismounting, template sliding and the like. According to the sliding formwork component and the method, the linear vertical perpendicularity after blade foot construction is finished can be ensured, and accordingly the assembling quality of upper-layer open caisson standard segments is guaranteed.

Owner:中铁科建有限公司

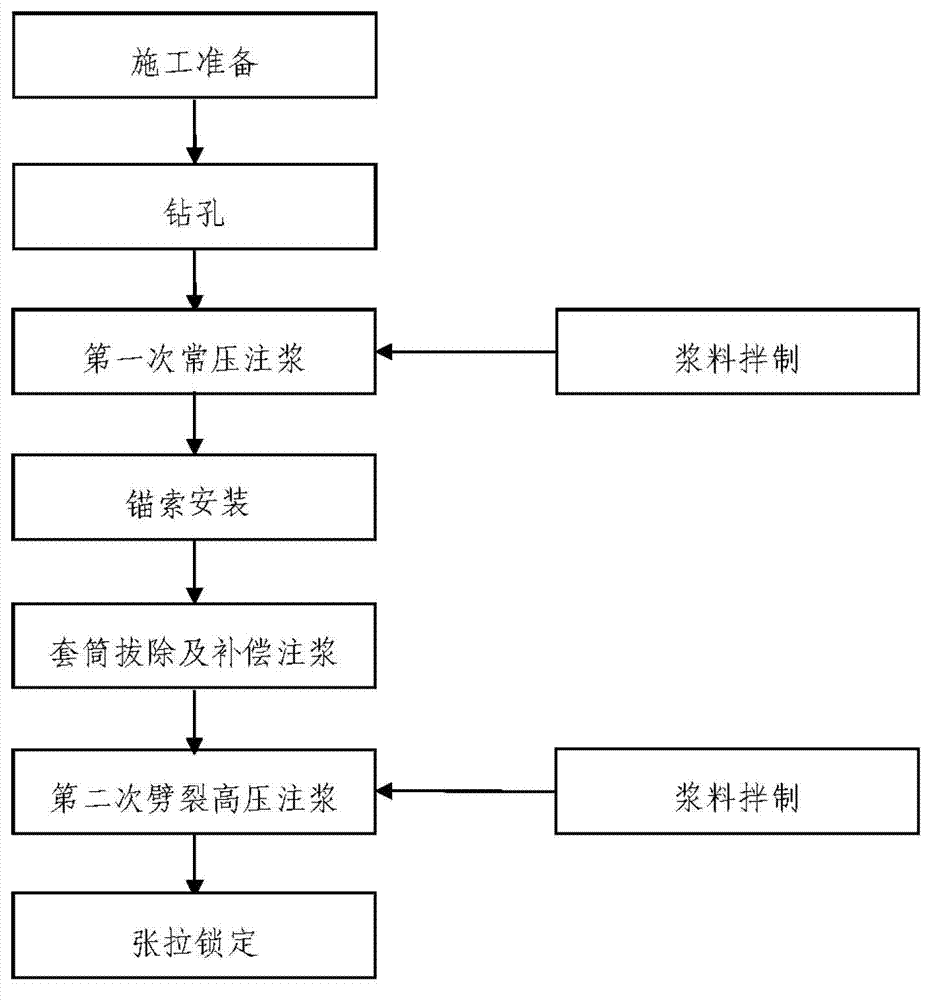

Pre-stressed anchor cable construction method

The invention provides a pre-stressed anchor cable construction method which comprises the following steps that: a hole is drilled under protection of a sleeve and the sleeve support fragile strata at the periphery of the anchor cable hole; after the hole is formed, a first ordinary pressure pouring is conducted so that the sleeve is prevented form sliding in the process that an anchor cable is placed downwards and the anchor cable can be fixed rapidly after being installed; after installation of the anchor cable, the sleeve is removed and compensatory pouring is conducted; and when the intensity of a pouring body formed in the first ordinary pressure pouring reaches a required value, secondarily separating high pressure pouring is conducted so that the anchor cable can be anchored firmly. The pre-stressed anchor cable construction method effectively compensates shortages of ordinary pre-stressed anchoring construction technology, greatly improves pre-stressed anchor cable support effect for the fragile stratum side slopes containing rich ground water, improves project construction speed and increases safety factors of the side slopes.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE

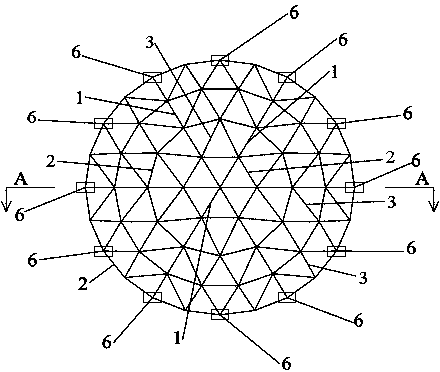

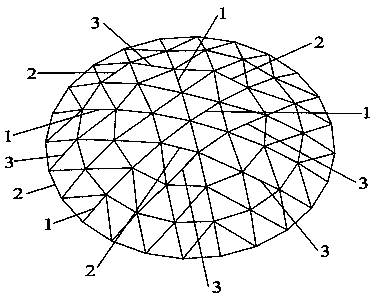

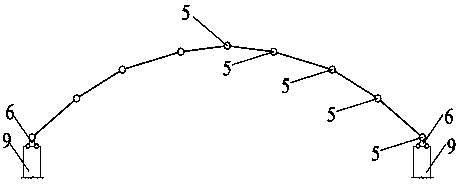

Bamboo-structure single-layer spherical latticed shell and assembling method

InactiveCN103469890ALight weightReduce labor intensityBuilding roofsArched structuresEngineeringStructural stress

The invention relates to a bamboo-structure single-layer spherical latticed shell and an assembling method. The bamboo-structure single-layer spherical latticed shell structurally comprises L bamboo rod pieces, M bamboo connecting pieces and N fixed hinge supports, wherein a single-layer spherical latticed shell main body is formed in a way that two ends of each radial bamboo rod, each weft bamboo rod and each diagonal bamboo rod of the L bamboo rod pieces are connected through the bamboo connecting pieces; the bamboo connecting pieces comprise steel inserting pieces, hollow balls, stiffening steel sheets and bolts; arc-shaped notches are reserved at one ends of the steel inserting pieces and are welded on the hollow balls; bolt holes are reserved at the other ends of the steel inserting pieces, and the bolts are respectively connected to the radial bamboo rods, the weft bamboo rods and the diagonal bamboo rods through the bolt holes; the stiffening steel sheets are welded in connecting positions between the steel inserting pieces and the radial bamboo rods, the weft bamboo rods as well as the diagonal bamboo rods; the upper ends of multiple fixed hinge supports are arranged on the hollow balls of the bamboo connecting pieces which are arranged at the bottom part, and the lower ends of the multiple fixed hinge supports are arranged at the top part of a supporting structure which is arranged at the lower part. The bamboo-structure single-layer spherical latticed shell disclosed by the invention has the advantages that the self weight is light, the construction is convenient, the structural stress is reasonable, the safety is high, the connecting joint is simple and reliable, the maintenance is easy, and environment-friendly effects are realized.

Owner:NANJING FORESTRY UNIV

Locating mounting method for rudder carrier base on ship

The invention relates to a method for positioning and mounting a rudder carrier substrate in a vessel, which includes the following steps: (1) an upper rudder carrier substrate, a rudder stock bearing chock and a rudder pin bearing chock are machined in a workshop. The margin of the upper rudder carrier substrate is retained. (2) the rudder stock bearing chock and the rudder pin bearing chock are arranged on a vessel body and have borings, centers line of the rudder stock bearing chock and the rudder pin bearing chock is made to be the central line of the rudder stock. (3) The upper rudder carrier substrate is roughly positioned on the vessel. The distance between the upper plane of the upper rudder carrier substrate and the upper plane of the rudder pin bearing chock is measured. The margin of the upper rudder carrier substrate is cut. (4) After the distance between the upper plane of the upper rudder carrier substrate and the upper plane of the rudder pin bearing chock is precisely measured, the upper rudder carrier substrate is welded on the deck plane of a steering gear room; (5) the positioning work of the upper rudder carrier substrate is finished through welding. The method for positioning and mounting a rudder carrier substrate in a vessel in the invention transfers the work originally processed on the vessel body to the workshop, thus greatly increasing the precision and efficiency of the machining, reducing the application of great amount of special equipment and increasing the boring efficiency, therefore, the speed of constructing the whole vessel is increased.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

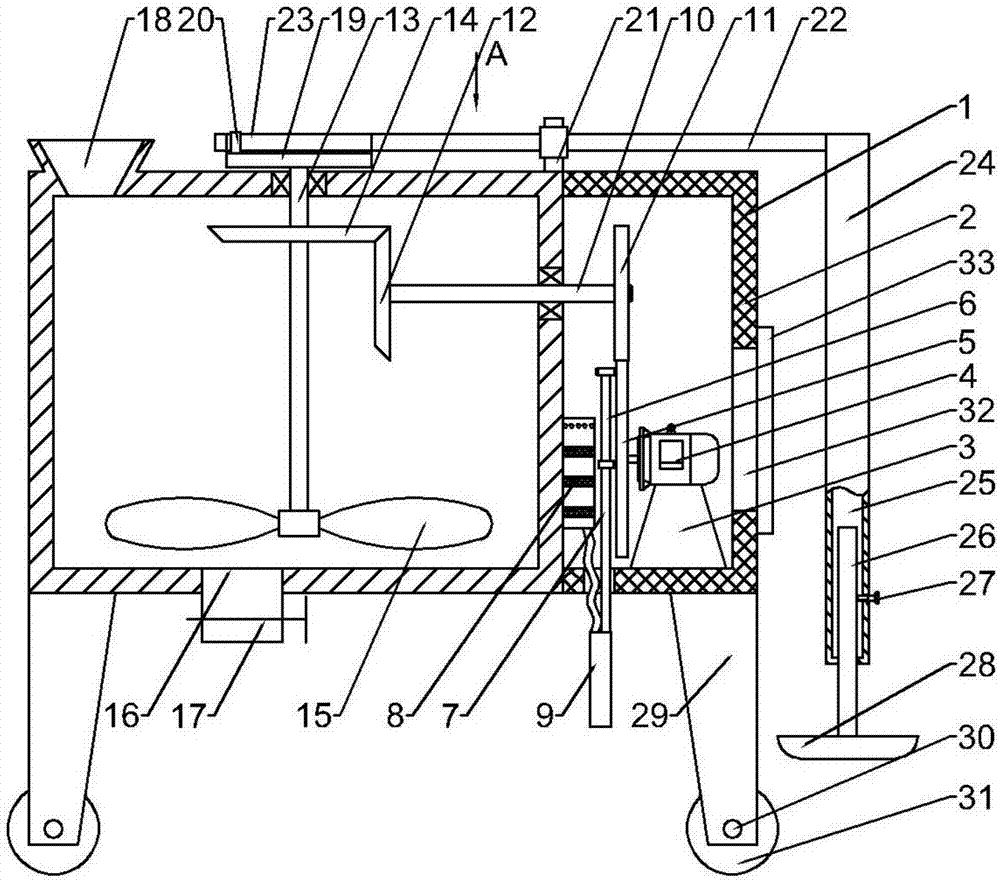

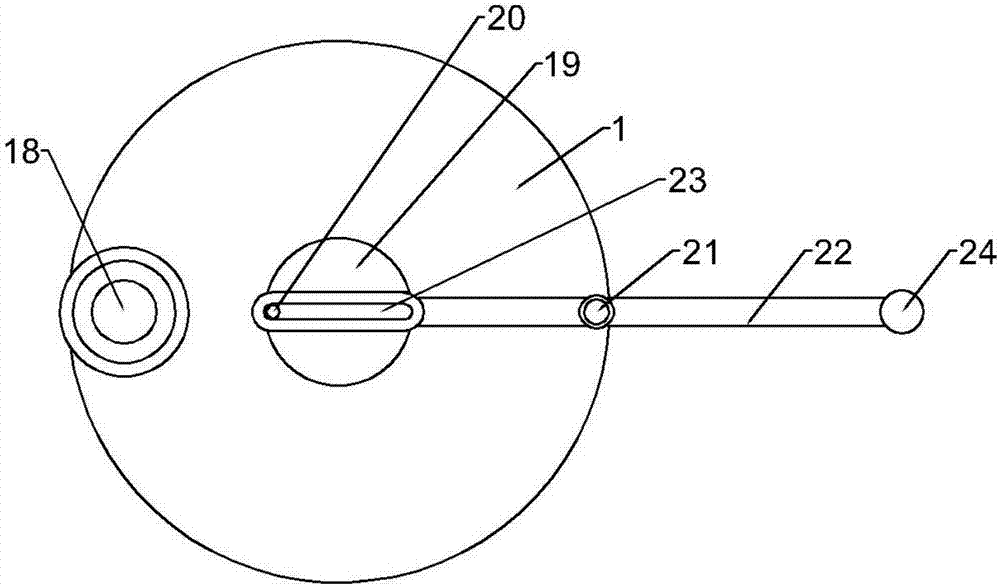

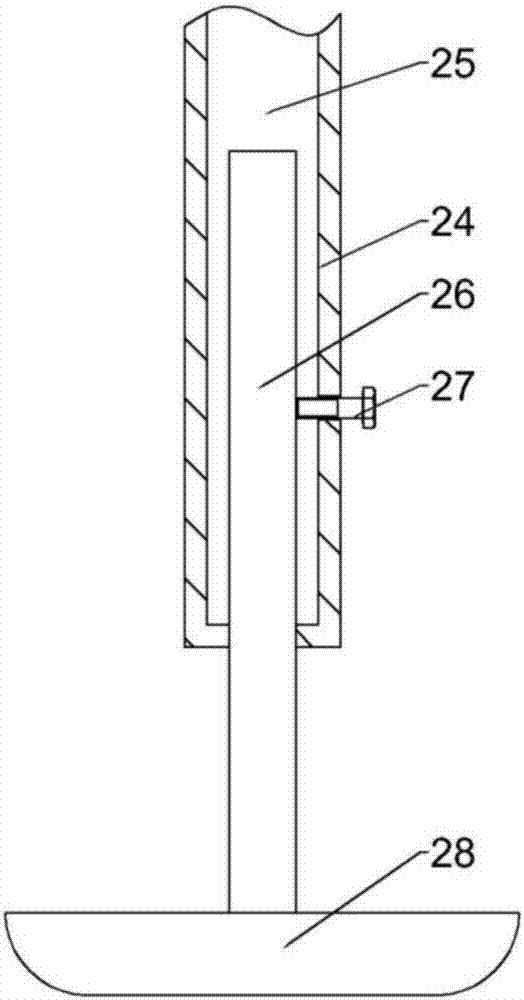

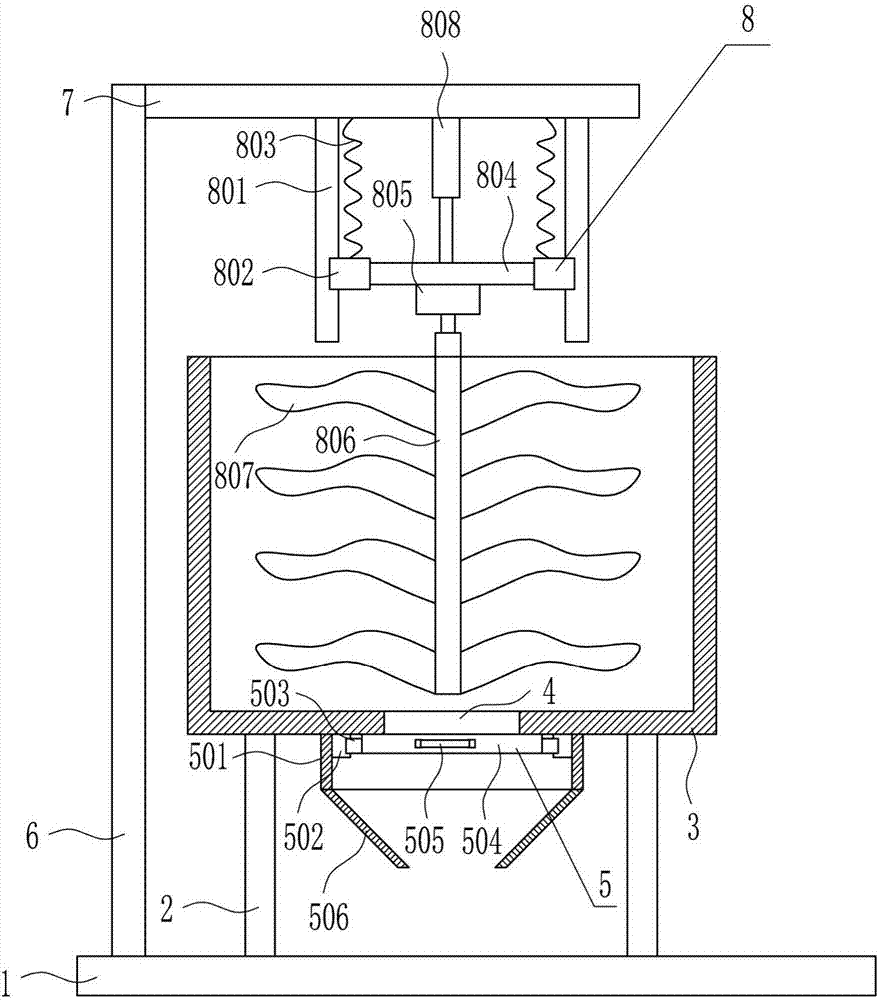

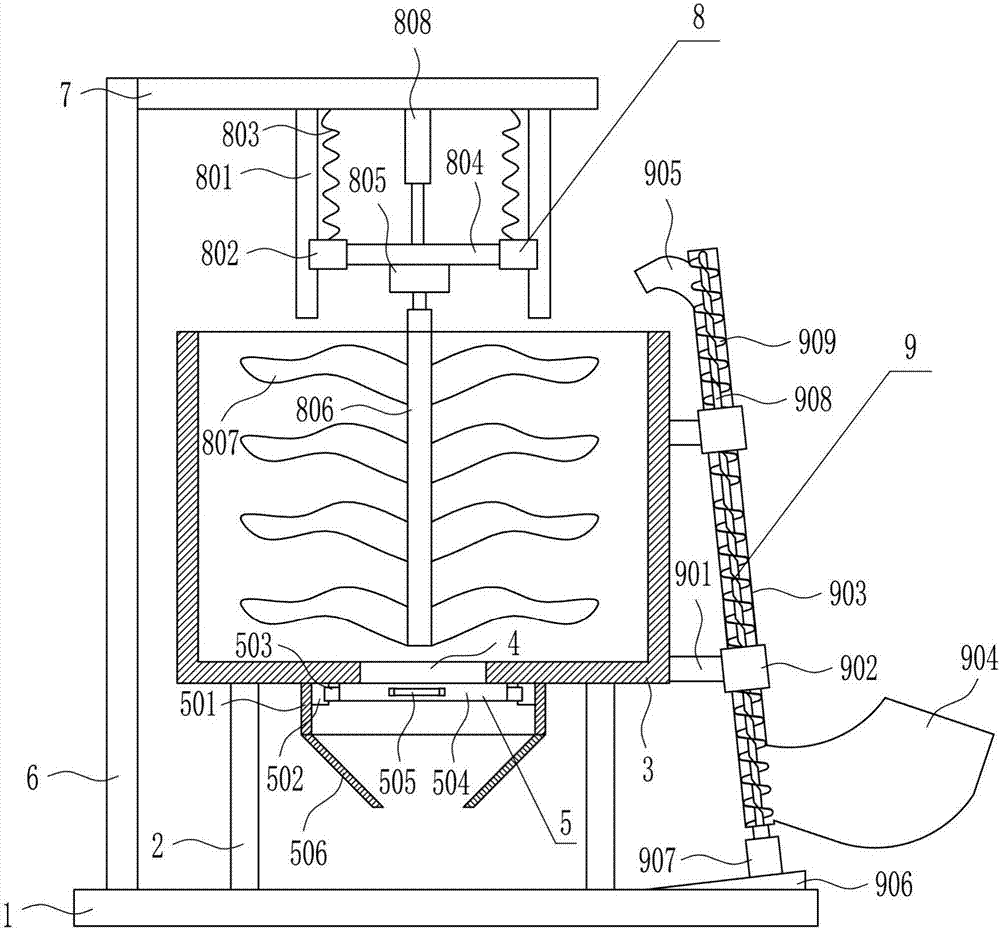

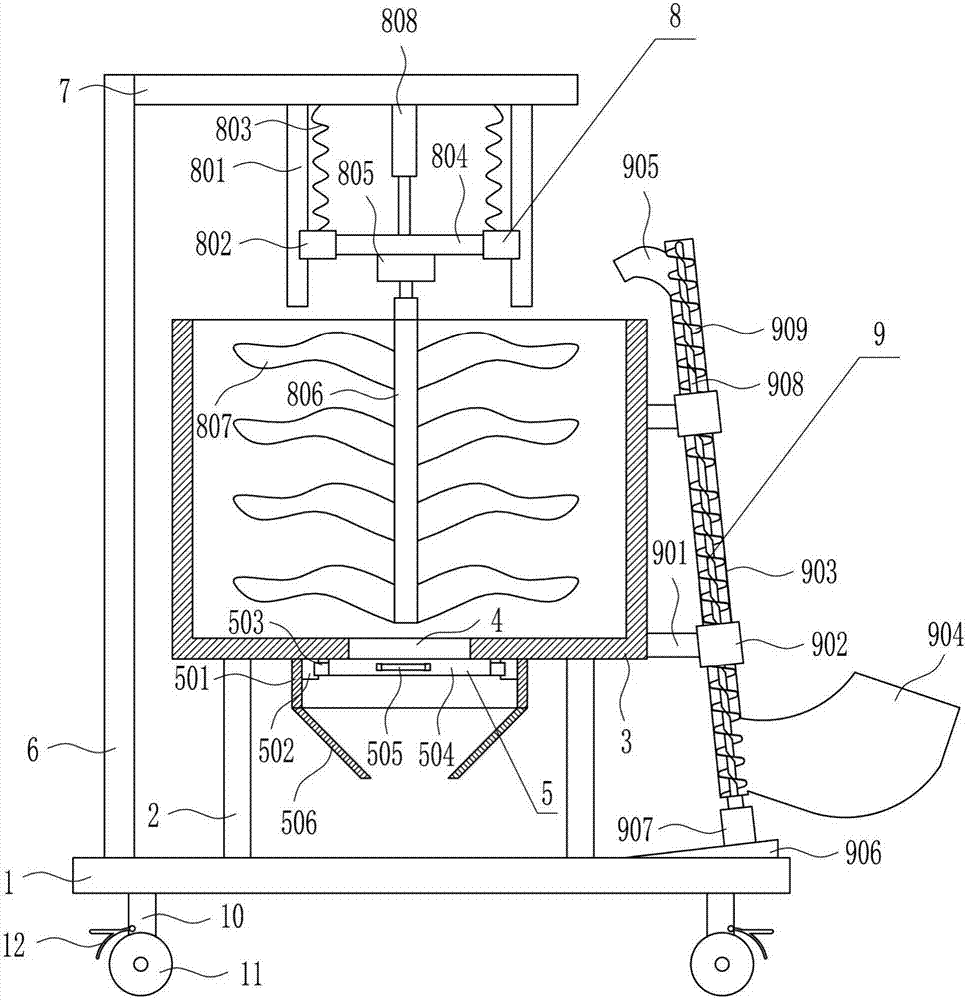

Cement mixing device for land photovoltaic power station construction

InactiveCN107097346ASolve the slow construction speedImprove stirring efficiencyDischarging apparatusCement mixing apparatusPhotovoltaic power stationBilateral symmetry

The invention relates to a device for land photovoltaic power station construction, in particular to a cement mixing device for land photovoltaic power station construction. The cement mixing device for land photovoltaic power station construction can save time and labor, improve mixing efficiency and the mixing effect and increase the construction speed of a photovoltaic power station and is easy to operate. The cement mixing device for land photovoltaic power station construction comprises a base plate and the like. Two supporting plates are arranged at the top of the base plate and are in bilateral symmetry, a mixing tank is connected between the two supporting plates through bolts, and a discharging port is formed in the middle of the bottom of the mixing tank; and a discharging unit is arranged at the part, below the discharging port, of the bottom of the mixing tank, and a vertical plate is connected to the part, on the left side of the mixing tank, of the top of the base plate through bolts. According to the cement mixing device for land photovoltaic power station construction, cement is stirred by means of the method that mixing blades are rotated and vertically moved at the same time.

Owner:王志强

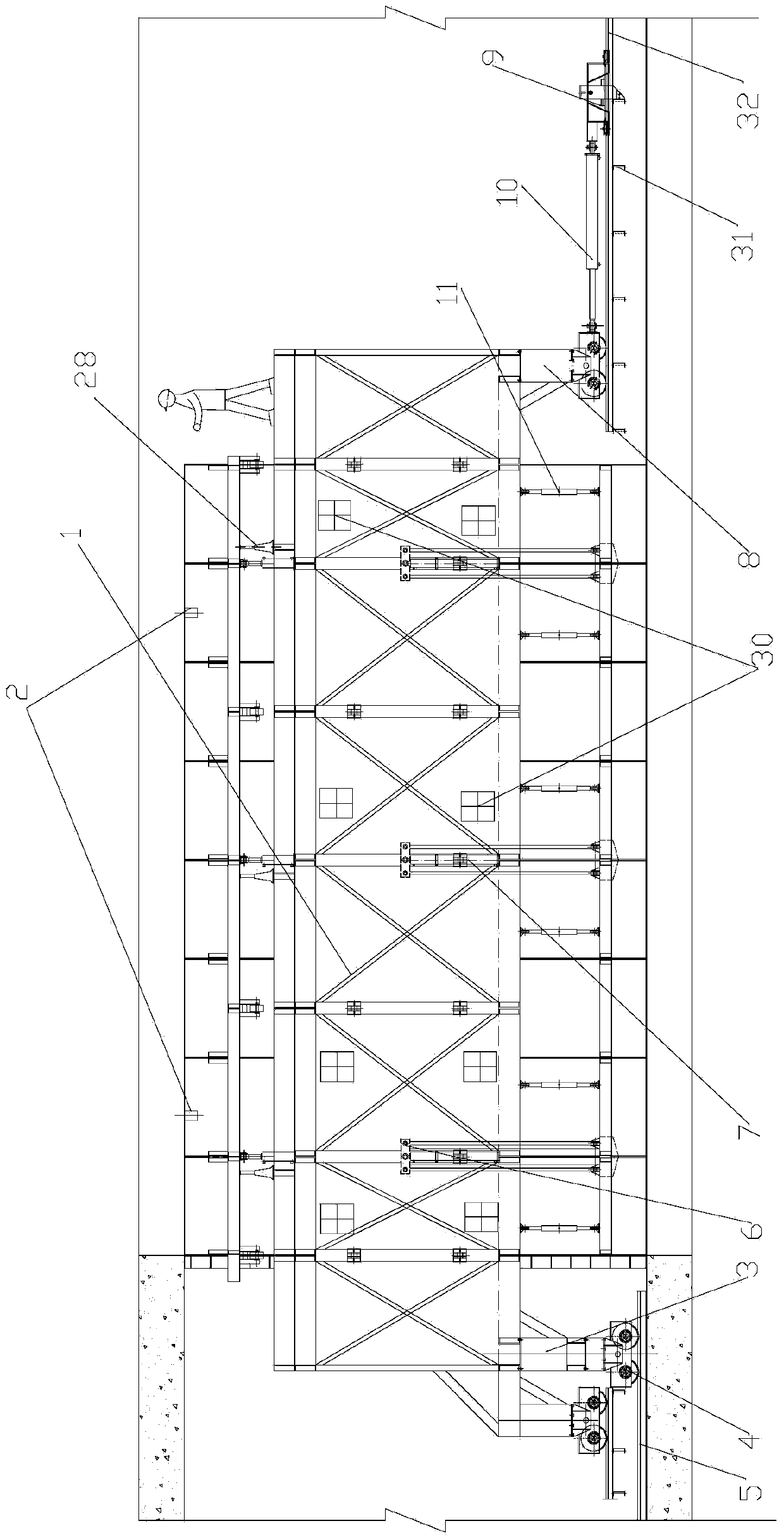

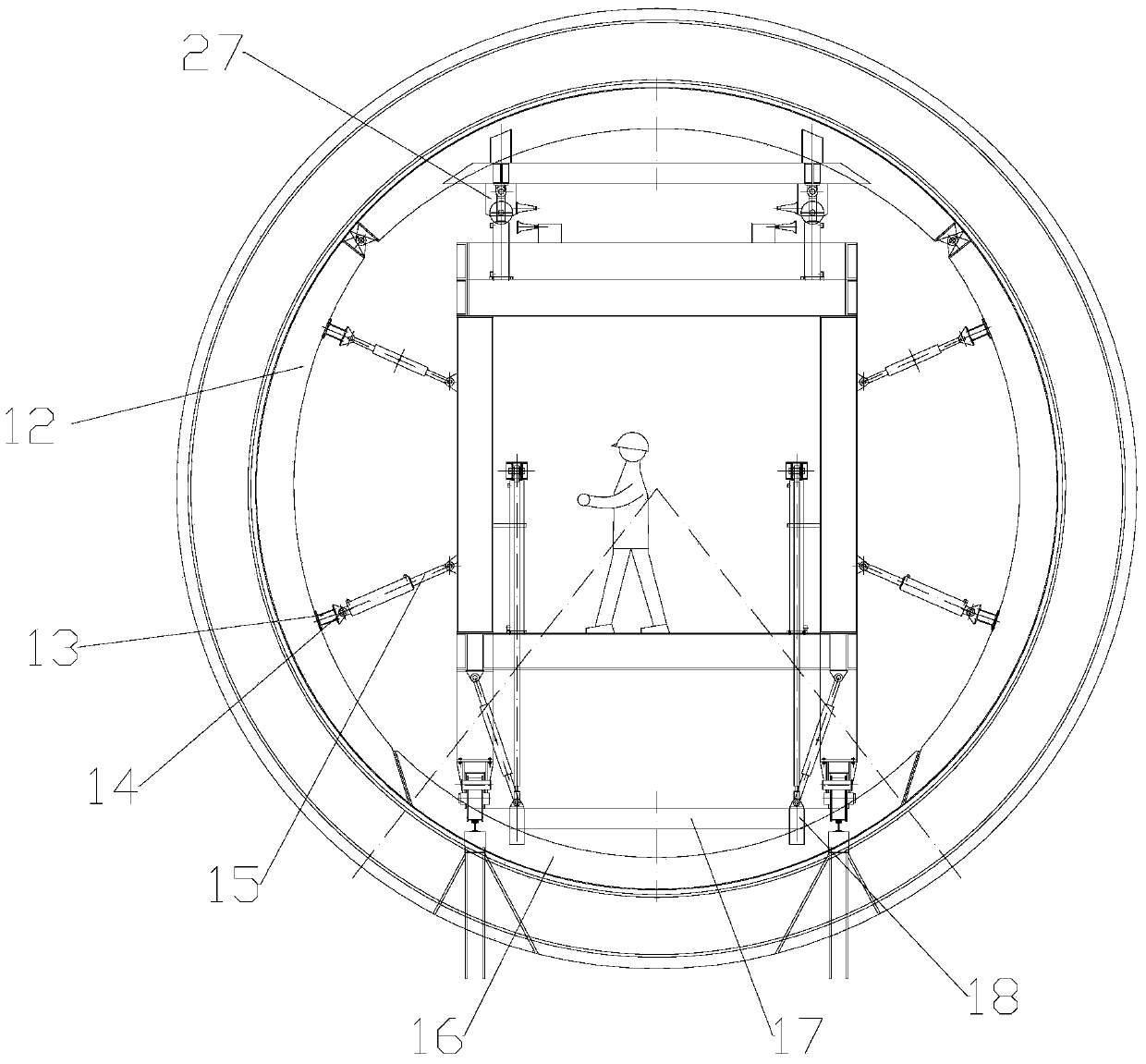

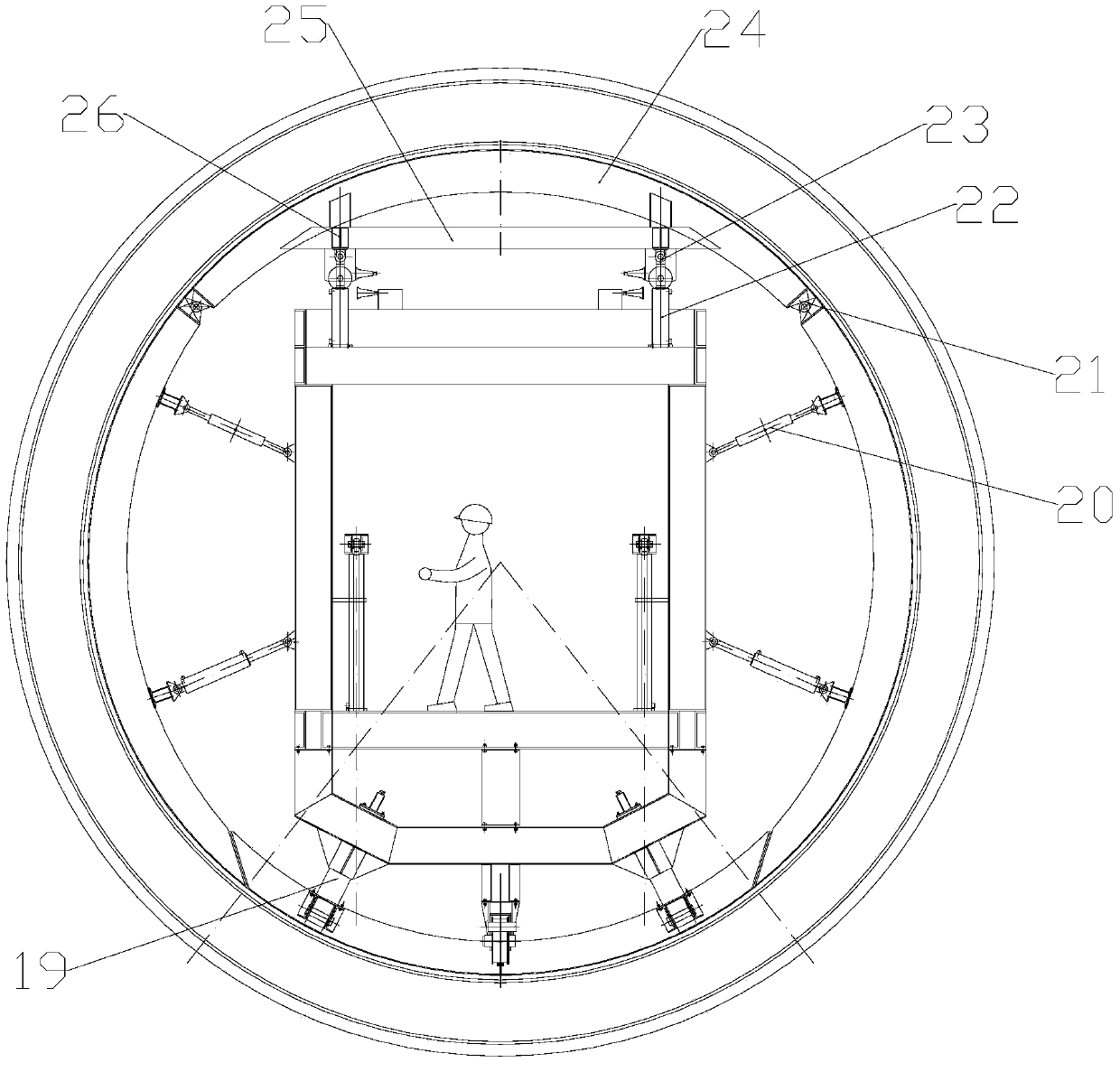

Hydraulic self-moving steel mould trolley and construction method thereof

ActiveCN103437782AFlexible removal locationEasy to moveUnderground chambersTunnel liningHydraulic controlMaterials science

The invention relates to a hydraulic self-moving steel mould trolley and a construction method of the hydraulic self-moving steel mould trolley. The hydraulic self-moving steel mould trolley is used for full-section circular tunnel concrete lining construction. The hydraulic self-moving steel mould trolley comprises a trolley moving device, a trolley structural frame, a steel structure combination formwork and a hydraulic control device, the trolley structural frame is arranged on the trolley moving device, the trolley structural frame is movably connected with the trolley moving device, the steel structure combination formwork is arranged in the trolley structural frame, the steel structure combination formwork is hinged to the trolley structural frame, and the hydraulic control device is used for controlling the hydraulic self-moving type steel mould trolley. The hydraulic self-moving steel mould trolley is simple in structure, convenient to install, strong in adaptability and capable of carrying out demoulding on concrete at the bottom of the tunnel at first and repairing concrete construction defects in time.

Owner:CHINA THREE GORGES CORPORATION +1

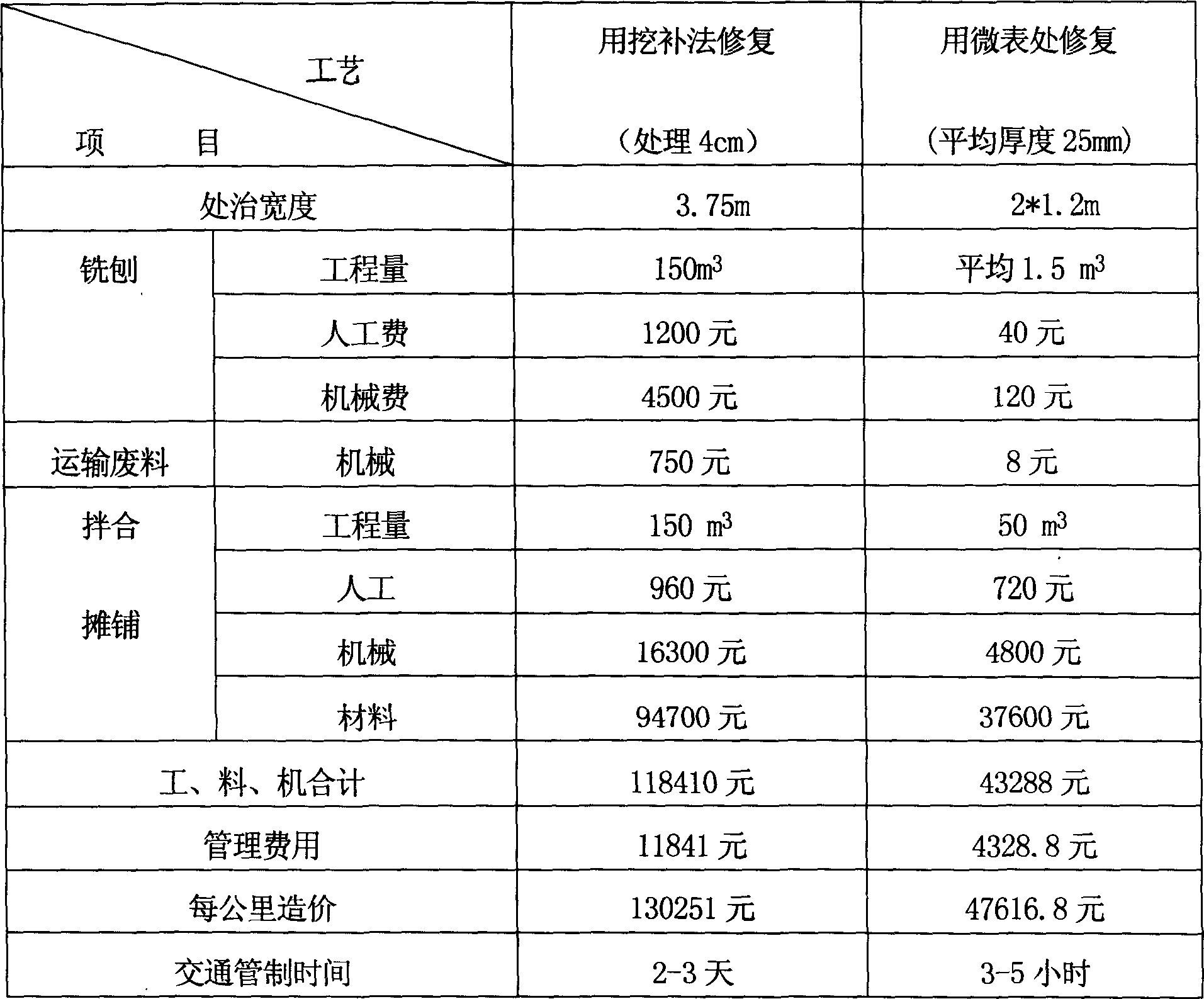

Reconditioning tracks on asphalt pavement by using thin paste mixture of modified emulsified asphalt and construction method thereof

InactiveCN1687526AImprove skid resistanceImprove flatnessIn situ pavingsRoads maintainenceMixed materialsRoad surface

This is a kind of restoring the tracks of the bitumen road surface with the modified emulsified bitumen watery slurry mixed materials and its job practice. Spread single layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 10 - 20 mm depth, and spread double layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 20 - 40 mm depth. The job practice of single layer modified emulsified bitumen watery slurry mixed materials is: close down the traffic, process the original road surface, lay samples, spread, appearance control, joint slots, initial maintenance and quality inspection. Other building steps of the lower layer job practice of the double layer modified emulsified bitumen watery slurry mixed materials are the same as that of single layer, except that the allocated proportion of the single layer modified emulsified bitumen watery slurry mixed materials is different and without quality inspection. The upper layer building steps are: spread, initial maintenance and quality inspection. It has such advantages as high abrading-resistant performance, thin structure layer, long using life, high building speed, fast molding, short building period, fast traffic opening, long building season, low resource waste, no deleterious gas euduction and so on.

Owner:西安高远公路养护技术有限公司

Construction method for going through subway station by double circular shielding

A construction method for passing the dual-circle shield machine the subway station includes such steps as earlier stage preparation, installing movable base, putting the dual-circle shield machine on the base, temporary fixing, installing two 200-ton jacks behind said dual-circle shield machine, welding the back-base to the preburied bottom plate of station, pushing the dual-circle shield machine along with its base forward by 3 m, restoring the jacks, arranging a supporter between jack and back-base, and repeating said steps.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com