Sliding formwork component and open caisson blade foot layer sliding formwork construction method applying sliding formwork component

A construction method and sliding form technology, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, infrastructure engineering, etc., can solve the problem that the solid section of the cutting edge is not easy to handle, the construction period is long, and the noise is easy to disturb the people. and other problems, to achieve the effect of speeding up the construction speed and overall stiffness, saving construction period and labor input, and solving the problem of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

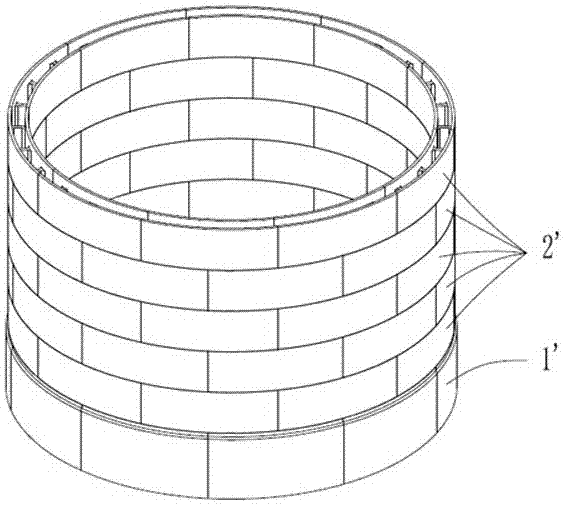

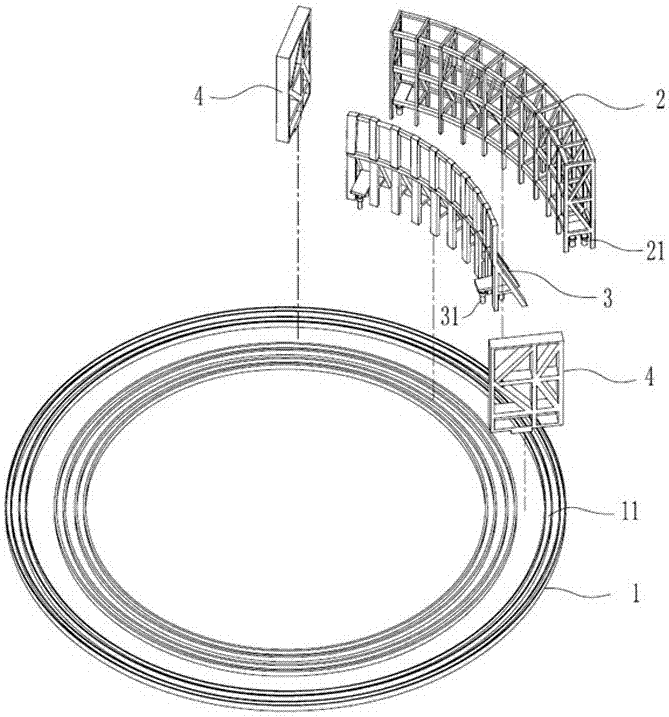

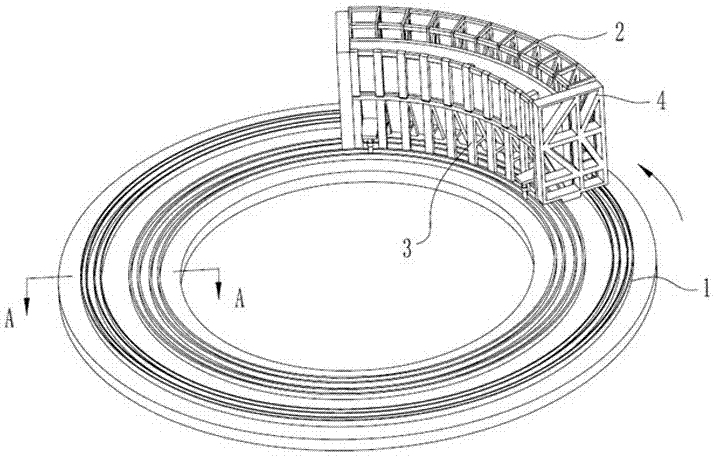

[0039] Such as figure 2 As shown, the present invention discloses a sliding form component, which includes a slideway 1, an outer formwork 2, an inner formwork 3, two side forms 4, an upper tie bar 5, a bottom tie bar 6, and several connecting and fixing pieces.

[0040] A plurality of chutes 11 for the installation of the outer formwork 2 and the inner formwork 3 are arranged on the slideway 1, and the slideway 1 can be formed by assembling a plurality of curved concave-shaped steels.

[0041] In this embodiment, the slideway 1 is a ring-shaped slideway, and an outer ring-shaped chute and an inner ring-shaped chute are arranged on the ring-shaped slideway. The outer formwork 2 and the inner formwork 3 are an arc-shaped structure on the ring. Legs 21, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com