Patents

Literature

172results about How to "High turnover utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

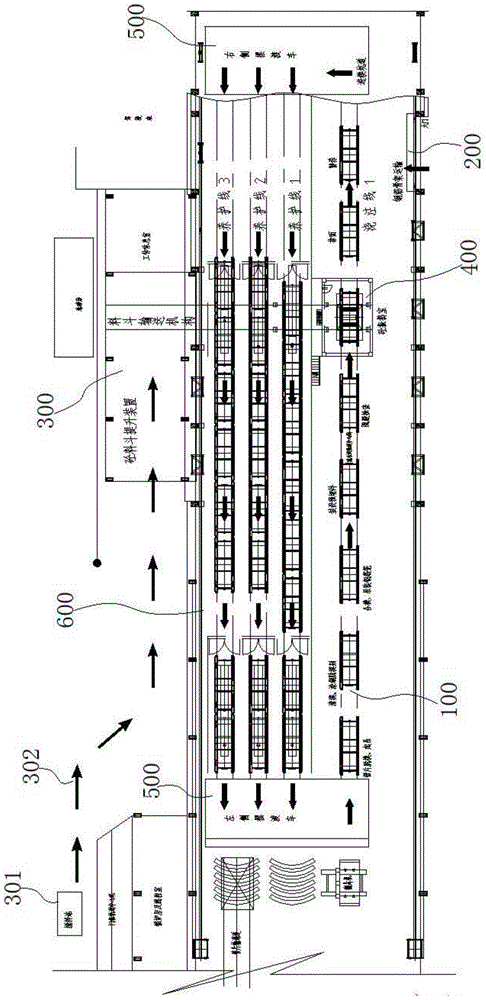

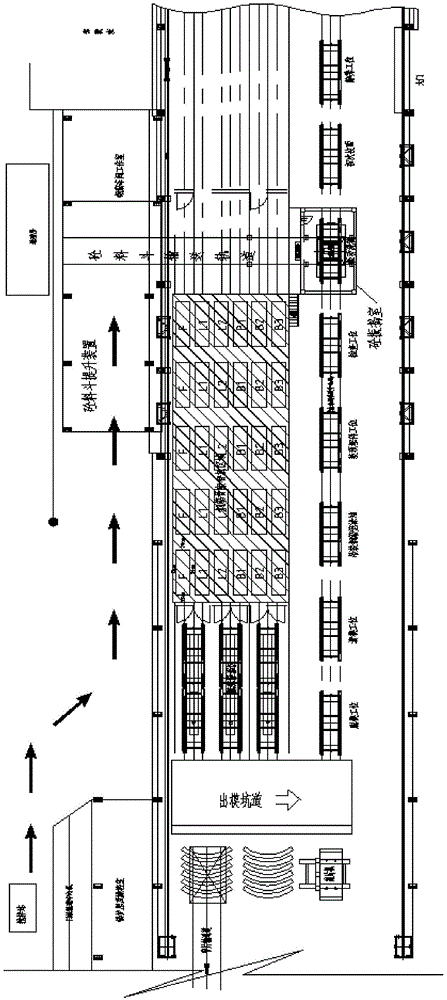

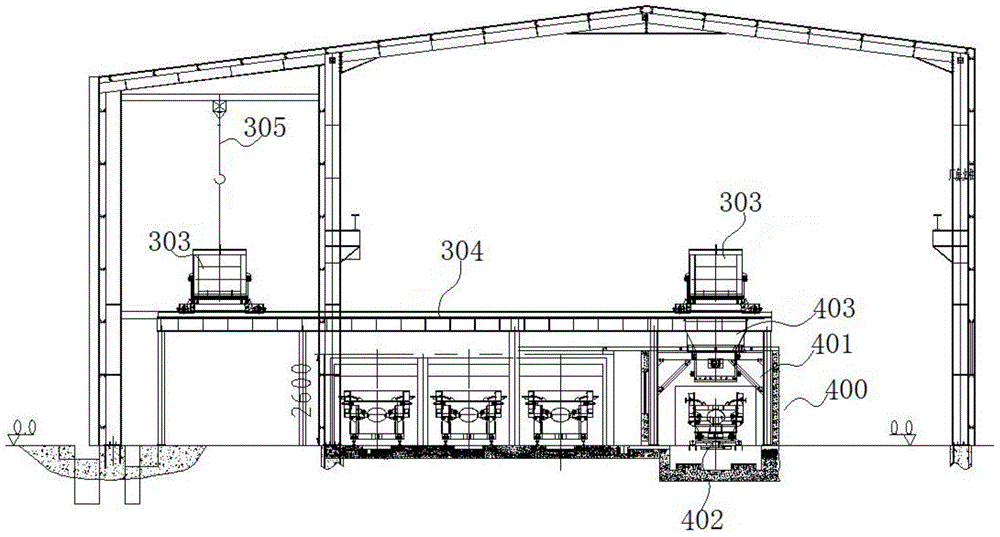

Intelligent flow production line for shield segment prefabrication

ActiveCN105082346AImprove precast production efficiencyReduce labor intensityCeramic shaping plantsProduction lineAutomatic control

The invention discloses an intelligent flow production line for shield segment prefabrication. Mold propelling systems in the production line are arranged on a pouring production line body and curing production line bodies respectively and push segment molds on the production line bodies to move. Transverse moving ferrying systems are matched with the pouring production line body and the curing production line bodies and used for conveying the molds from the pouring production line body to the curing production line bodies or conveying the molds from the curing production line bodies to the pouring production line body. A concrete feeding system is matched with a concrete pouring system and used for conveying concrete to the concrete pouring system. The concrete pouring system is arranged on the pouring production line body and used for completing segment pouring forming. An intelligent steam curing control system is used for conducting steam curing control on segments on the curing production line bodies. A programmable logic controller (PLC) automatic control system coordinates mutual matching among the systems, so that automation of shield segment prefabrication is achieved. The intelligent flow production line is stable in performance, good in reliability, easy to maintain and good in safety performance and meanwhile has the characteristics of being automatic and high in informationization degree and production efficiency.

Owner:CCCC THIRD HARBOR ENG +1

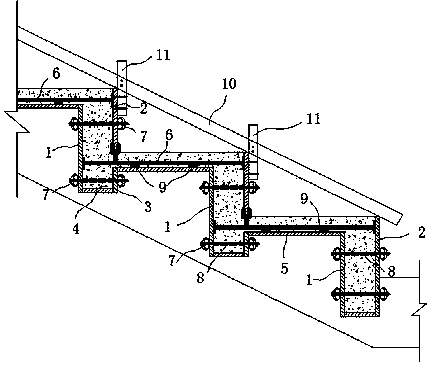

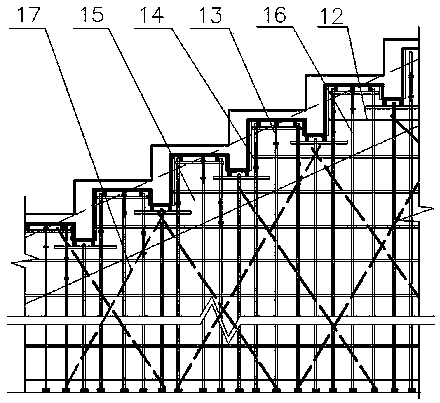

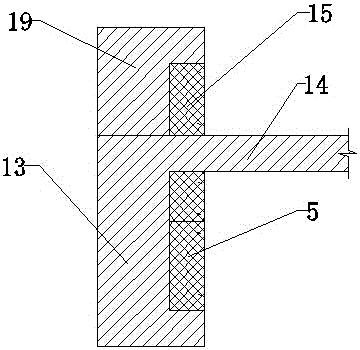

Template structure and method for template support of cast-in-place concrete arc-shaped terrace

ActiveCN103362300AMeet construction requirementsEasy constructionForms/shuttering/falseworksBuilding material handlingShaped beamEngineering

The invention discloses a template structure and a method for template support of a cast-in-place concrete arc-shaped terrace. The template structure comprises a template support frame body and a template fixing system, wherein the template fixing system comprises arc-shaped beam bottom plate templates, seat plate bottom templates, arc-shaped beam outside upper templates, arc-shaped beam outside lower templates and arc-shaped beam inside templates, wherein the arc-shaped beam outside lower templates are positioned below the arc-shaped beam outside upper templates; internal supports are arranged between the arc-shaped beam outside upper templates and the arc-shaped beam inside templates for supporting and enable the arc-shaped beam outside upper templates and the arc-shaped beam inside templates to keep set intervals; split bolts are used for connecting and fixing the arc-shaped beam outside upper templates and the arc-shaped beam inside templates; split bolts are used for connecting and fixing the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the arc-shaped beam bottom plate templates are respectively connected and fixed with the bottom ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the seat plate bottom templates are respectively connected and fixed with the upper ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

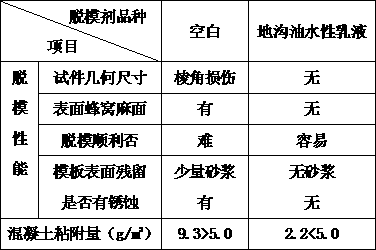

Concrete water-based releasing agent produced by using drainage oil and preparation method thereof

The invention discloses a concrete water-based releasing agent produced by using drainage oil and a preparation method thereof. The releasing agent is prepared from the following raw materials by weight percent: 8%-22.5% of drainage oil, 0.5%-3.6% of a compound emulsifier, 1%-10% of an additive, 1%-3.2% of a stabilizer and 60%-87% of water, wherein the emulsifier is the compound emulsifier comprising an anionic emulsifier and a nonionic emulsifier, the anionic emulsifier comprises one or multiple of stearic acid and sodium dodecylbenzene sulfonate, and the nonionic emulsifier comprises one or multiple of fatty acid polyoxyethylene ether, alkylphenol polyoxyethylene ether, fatty acryl alcohol amine, Span and Tween. After forming a film, the water-based releasing agent plays a role in separation of the concrete and a template. The water-based releasing agent is used for replacing an existing frequently-used emulsification machine oil releasing agent, is odorless and tasteless and has a good using effect; due to the adoption of the releasing agent, the apparent quality of the concrete is improved, and the turnover utilization rate of the template is also increased; and the production cost of the releasing agent is reduced.

Owner:南京友西科技集团股份有限公司

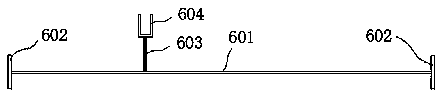

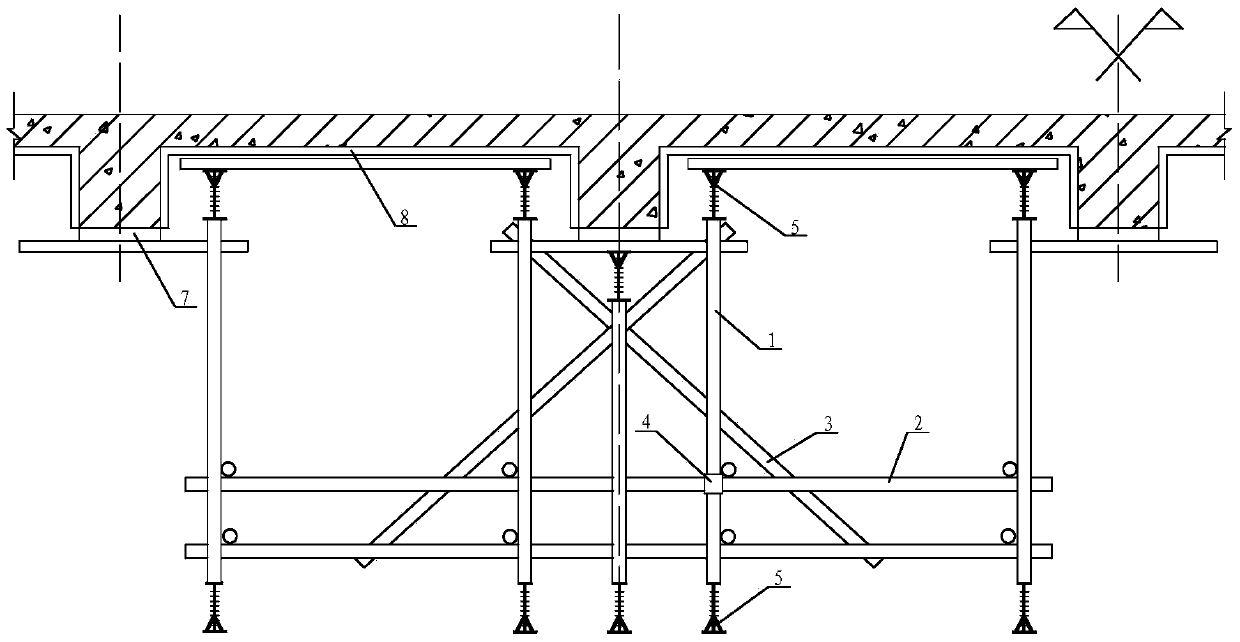

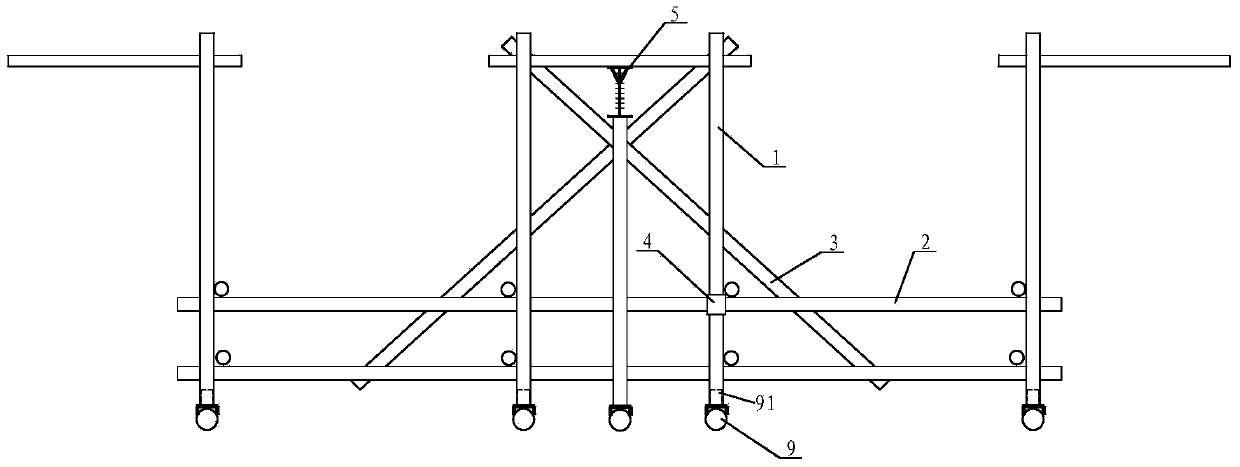

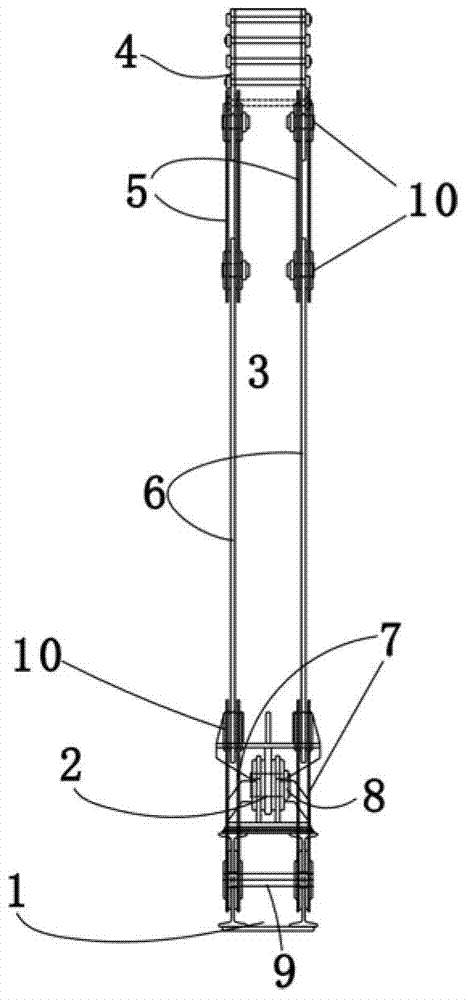

Movable formwork supporting truss and construction method thereof

ActiveCN104196235AHigh turnover utilizationSave manpower and material resourcesForms/shuttering/falseworksShoresMaterial resourcesEngineering

The invention relates to a movable formwork supporting truss and a construction method thereof. The movable supporting truss comprises a supporting rod assembly, a connecting buckle, adjustable supports and universal wheels. The supporting rod assembly is composed of stand rods, horizontal rods and inclined struts, and a truss structure is formed through the connecting buckle. The adjustable supports are placed at the upper ends and the lower ends of the stand rods and used for adjusting the supporting height, and when the adjustable supports on the lower portions of the stand rods are replaced by the universal wheels, the whole truss can move. The construction method comprises the steps of ground leveling, single rod piece assembling, overall truss assembling, overall truss removing, recycling and the like. Compared with the prior art, the movable formwork supporting truss and the construction method thereof have the advantages that the construction efficiency and the material recycling usage rate are increased by two or more times compared with a traditional construction method, labor and material resources are saved, the economical benefits are appreciable, the movable formwork supporting truss is especially suitable for a cross beam structure and the construction occasions with regular and orderly bay sizes and can also be used in a beamless slab construction, wherein the construction occasions include superstores, office buildings, underground garages and other frame structures with post-cast strips.

Owner:CHINA THIRD METALLURGICAL GRP

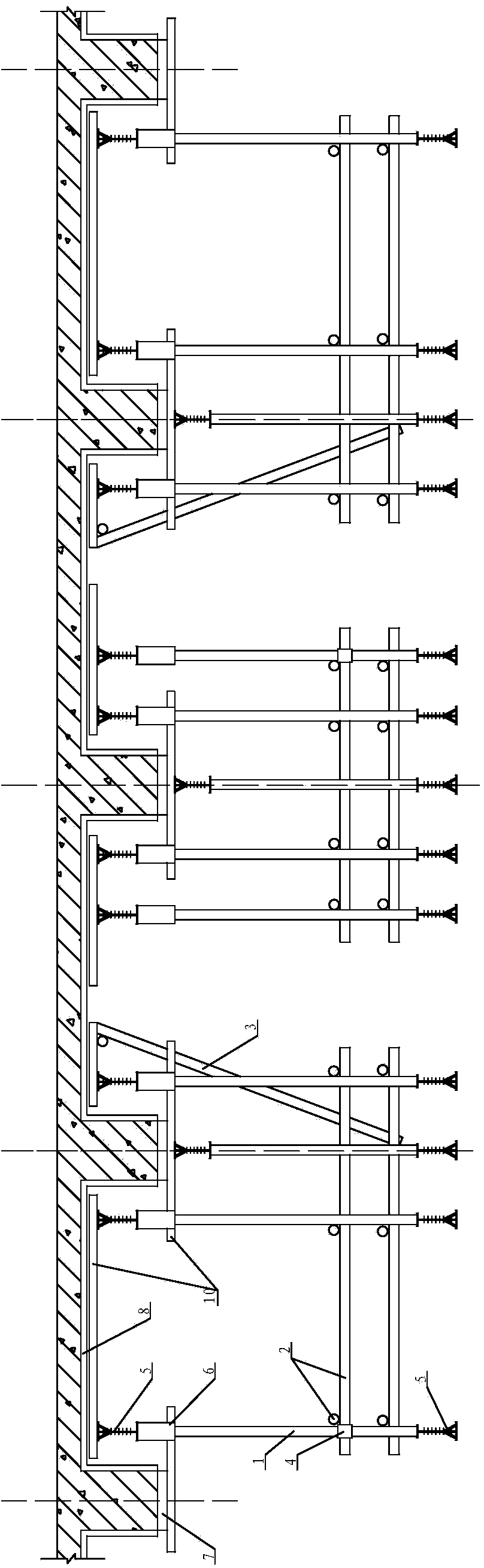

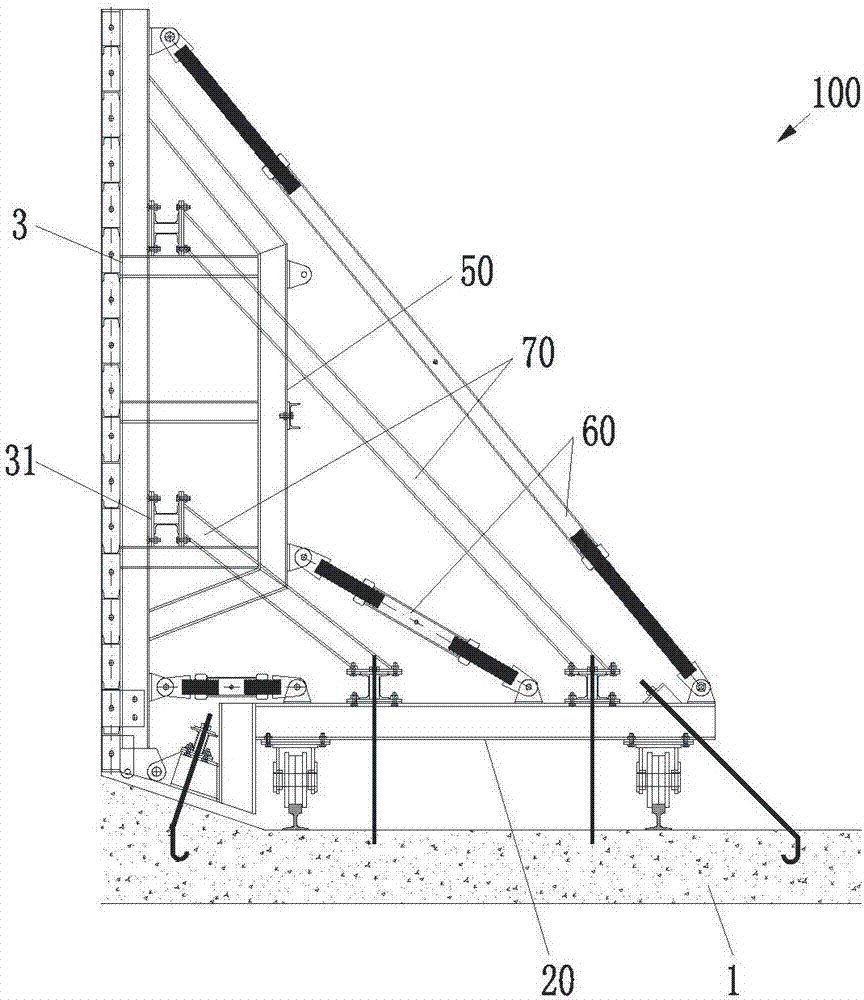

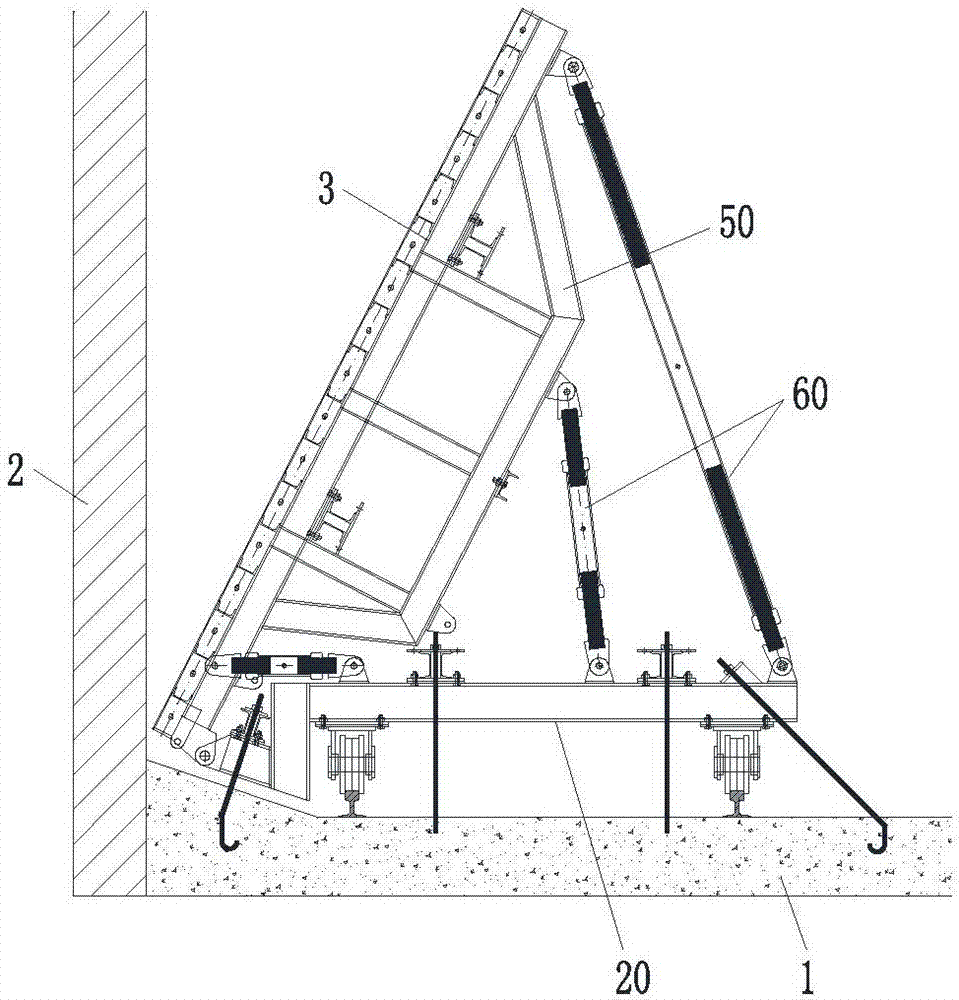

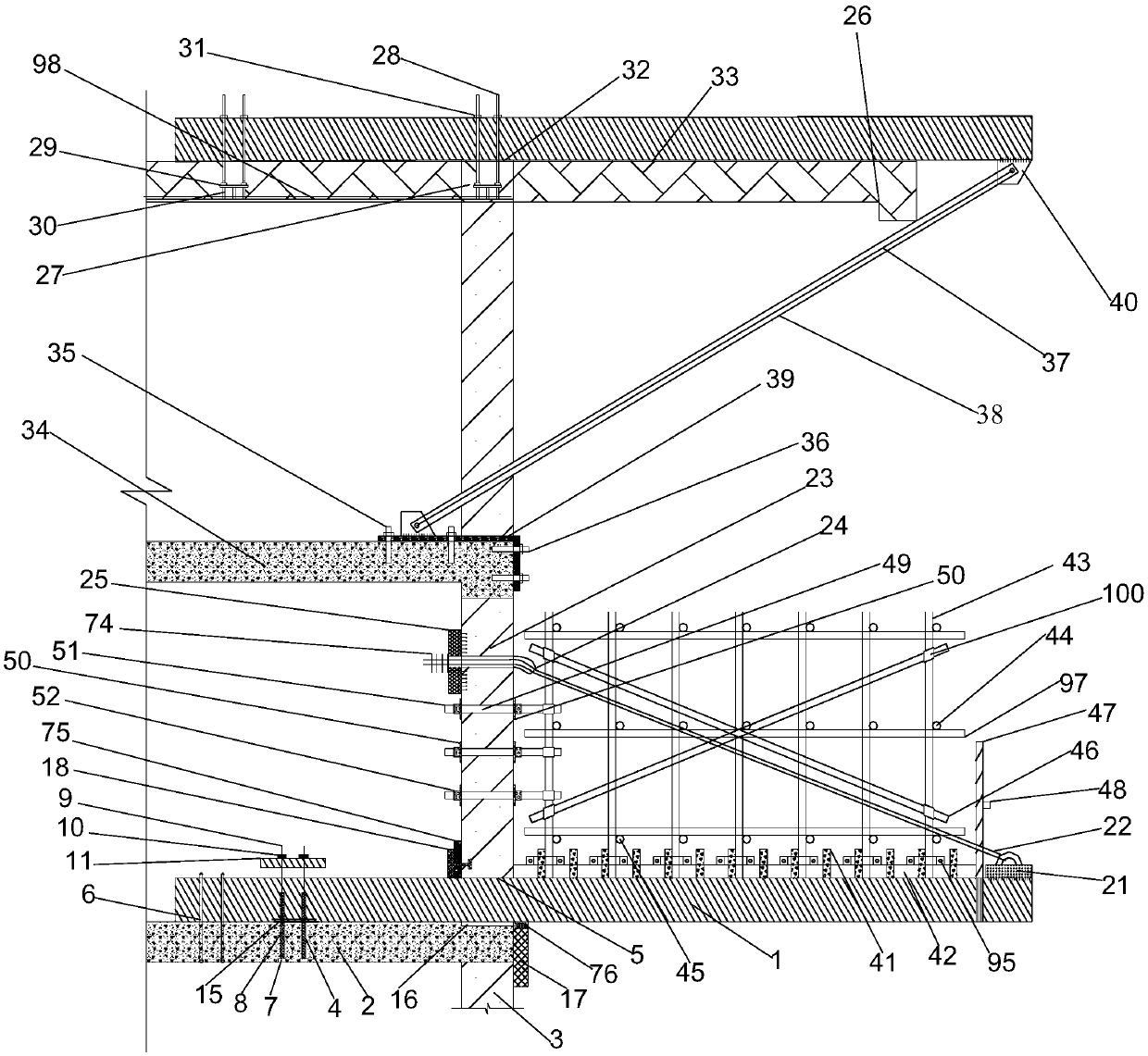

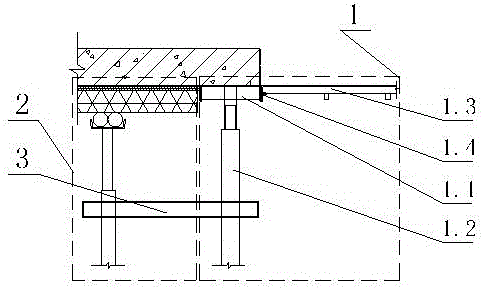

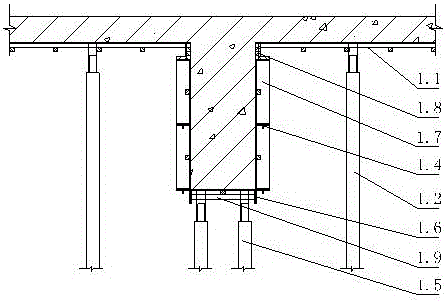

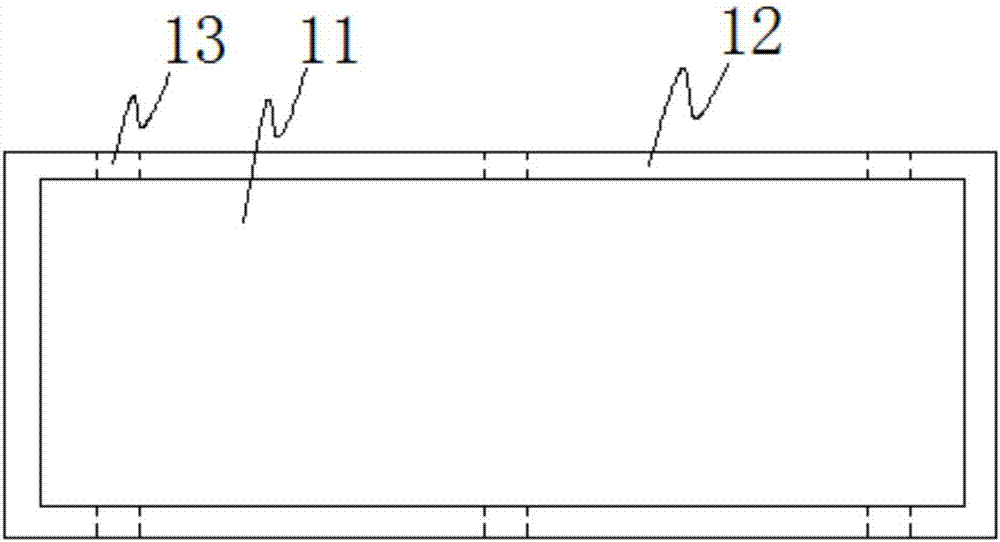

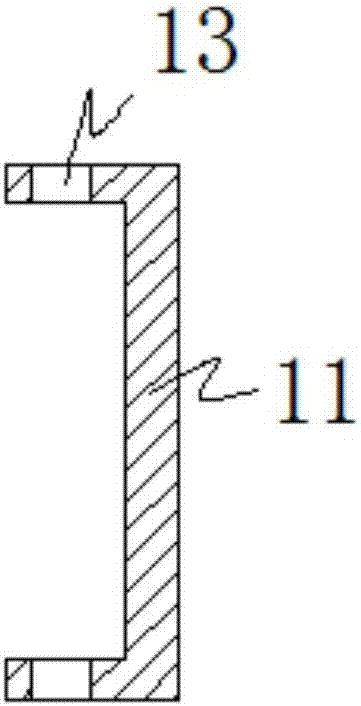

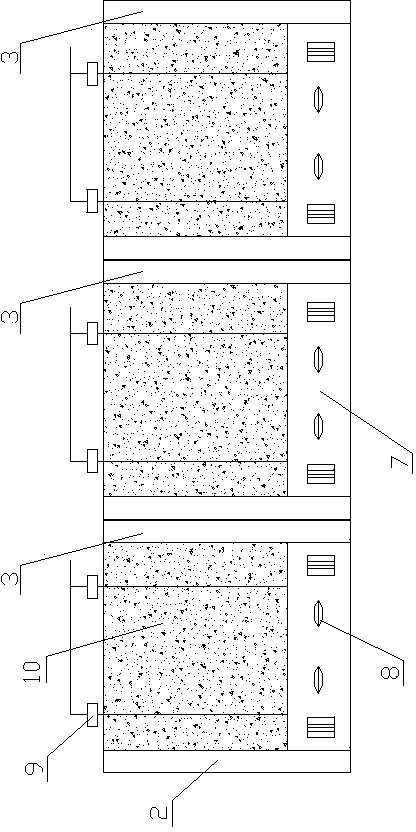

Basement outer wall single-side steel formwork supporting system and construction method thereof

PendingCN107313589AVerticality is easy to controlGuaranteed verticalityAuxillary members of forms/shuttering/falseworksBuilding material handlingSupporting systemArchitectural engineering

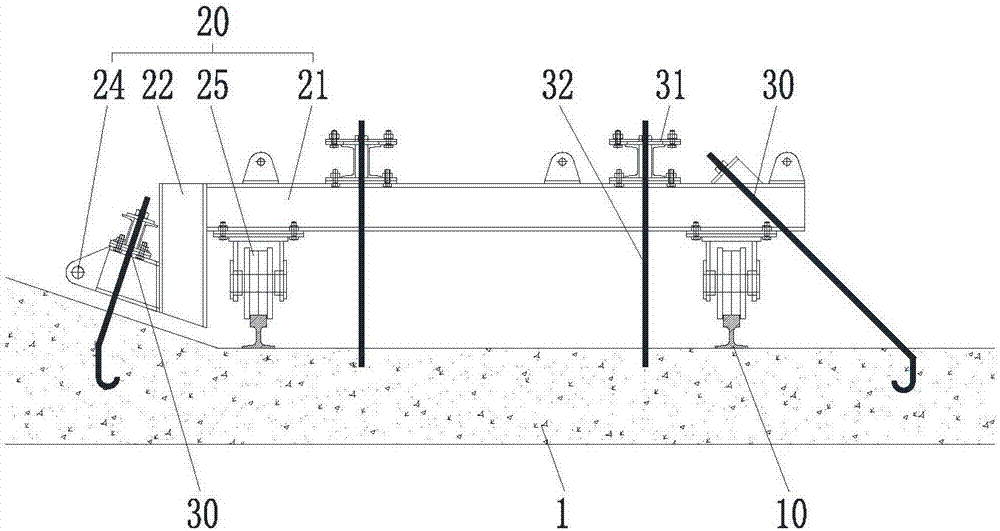

The invention provides a basement outer wall single-side steel formwork supporting system and a construction method thereof, and relates to the technical filed of constructional engineering equipment. Aiming at the problems that the labor intensity of construction personnel is high and formwork supporting work efficiency is low existing in the available supporting system, the basement outer wall single-side steel formwork supporting system and the construction method thereof are provided. The basement outer wall single-side steel formwork supporting system comprises a pair of tracks, bases, and a plurality of supporting trusses, wherein the pair of tracks is laid at a foundation slab and parallel to an outer wall steel formwork, the bases are arranged on the tracks and can slide along the tracks, and the multiple supporting trusses are vertically arranged at intervals and are connected with the outer wall steel formwork; and bottom parts of the supporting trusses are hinged to the bases, and the supporting trusses are detachably connected with top ends of the bases through a plurality of adjusting rod pieces. The construction method comprises the steps that the steel formwork supporting system is spliced and fixed, after outer wall concrete is poured, a ground anchor assembly and a diagonal bracing are disassembled, an adjusting rod piece is retracted, so that the demoulded outer wall steel formwork are made to be supported on the base, and the next working section is started to continue pouring construction of outer wall concrete.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

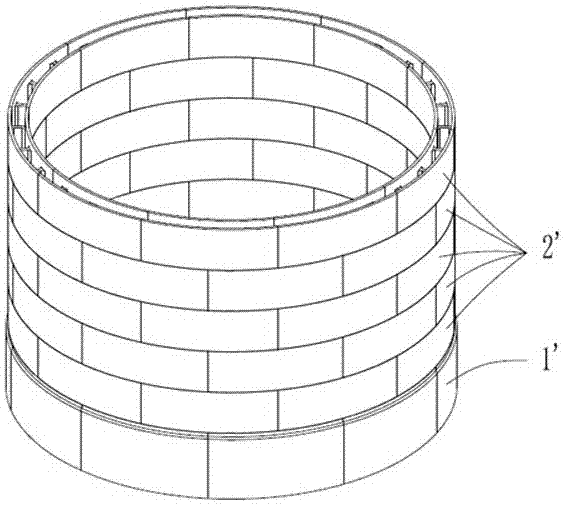

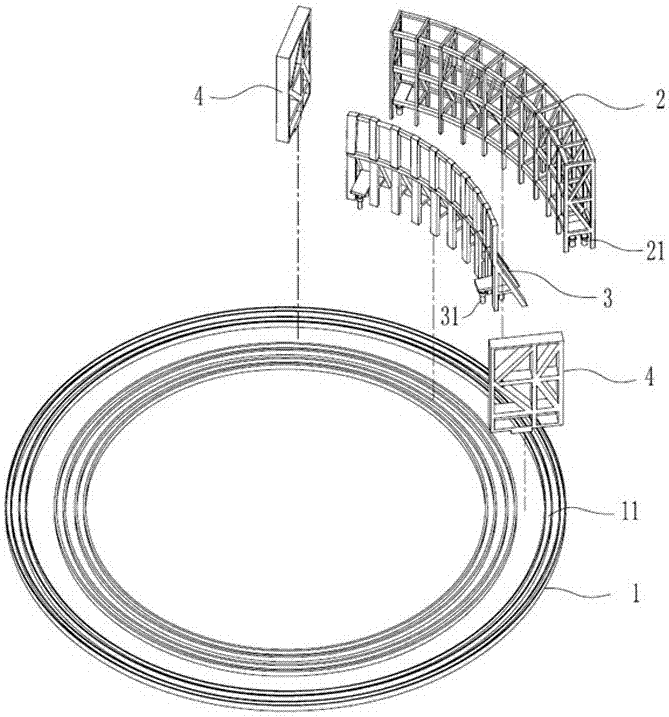

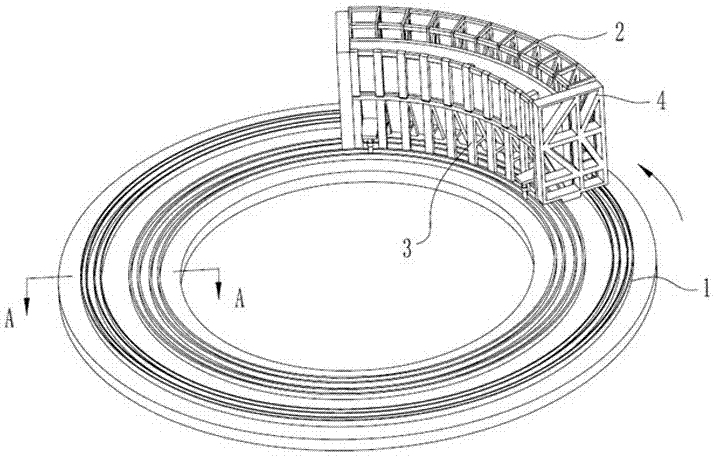

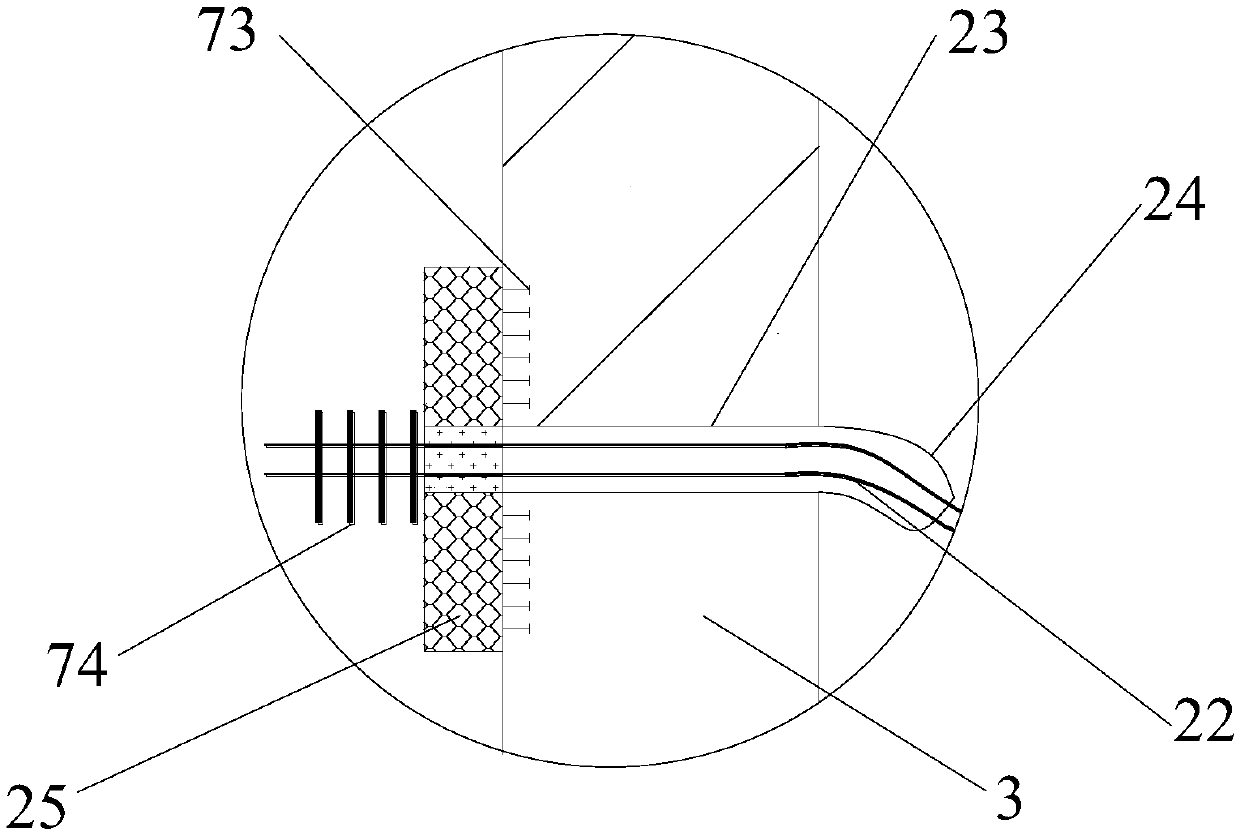

Sliding formwork component and open caisson blade foot layer sliding formwork construction method applying sliding formwork component

PendingCN107575023AGuaranteed vertical accuracyGuaranteed assembly qualityForms/shuttering/falseworksCaissonsSteel barBuilding construction

The invention discloses a sliding formwork component. The sliding formwork component comprises a sliding way, an outer template, an inner template, two side templates and a plurality of connecting fixing pieces. The sliding way is provided with a plurality of sliding grooves for installation of the outer template and the inner template. A plurality of outer stand bars are arranged at the bottom ofthe outer template. The outer stand bars are arranged on the outer side of the sliding way and can be installed and move along the sliding grooves. A plurality of inner stand bars are arranged at thebottom of the inner template. The inner stand bars are arranged on the inner side of the sliding way and can be installed and move along the sliding grooves. The side templates are arranged on the two side edges of the inner template and the two side edges of the outer template and are connected with the inner template and the outer template through the connecting fixing pieces. The invention further discloses an open caisson blade foot layer sliding formwork construction method. The method comprises the steps of field leveling, sliding way installing, steel bar bundling, template installing,concrete pouring, side template dismounting, template sliding and the like. According to the sliding formwork component and the method, the linear vertical perpendicularity after blade foot construction is finished can be ensured, and accordingly the assembling quality of upper-layer open caisson standard segments is guaranteed.

Owner:中铁科建有限公司

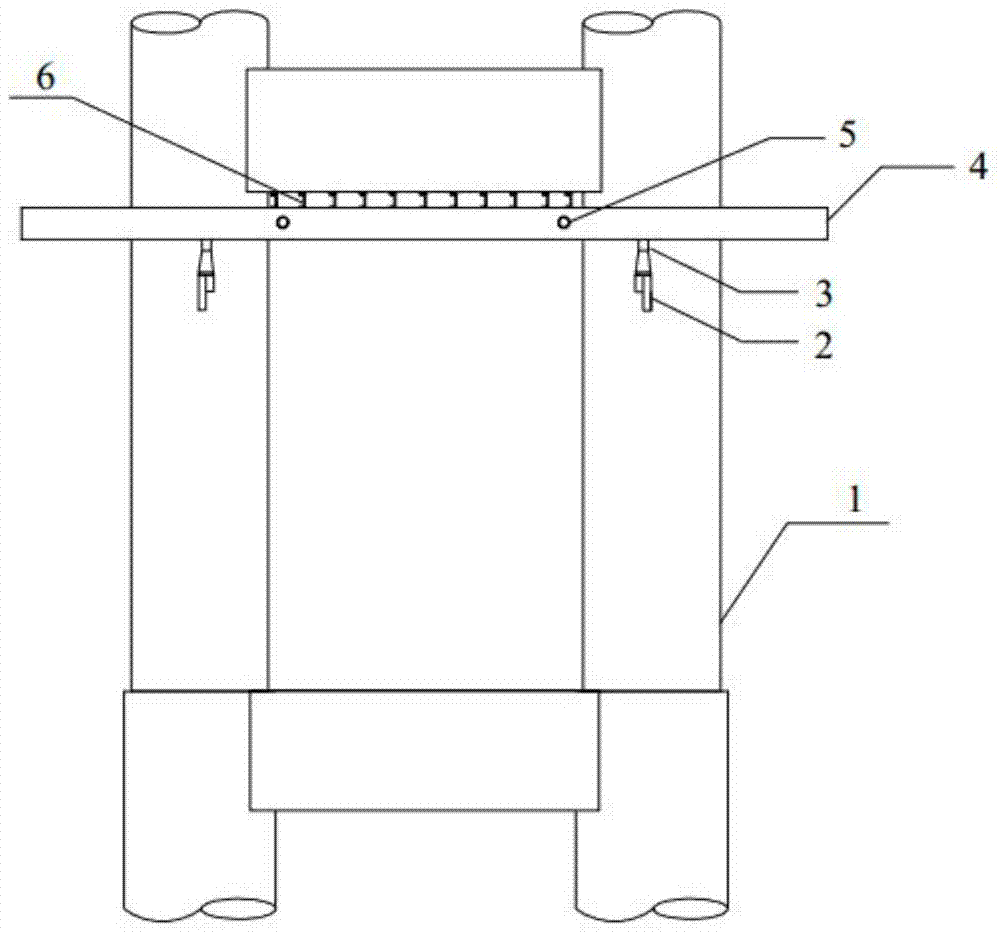

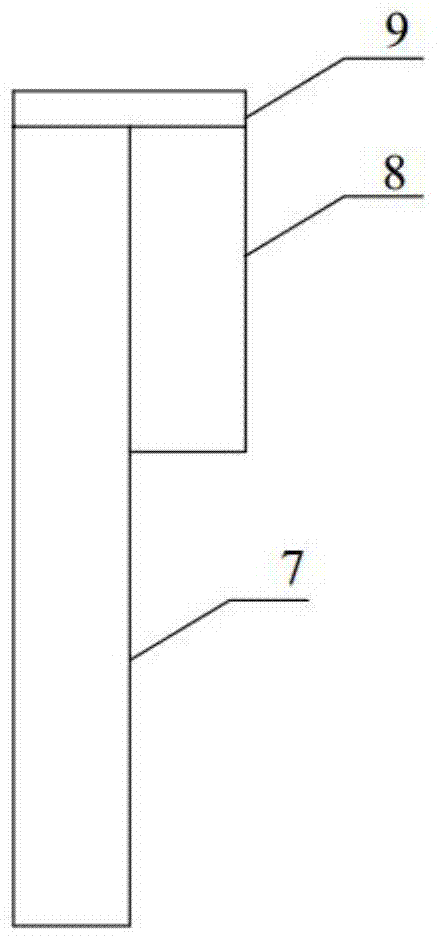

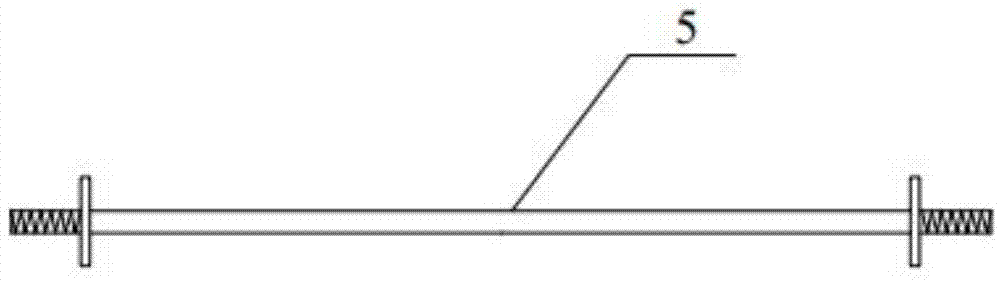

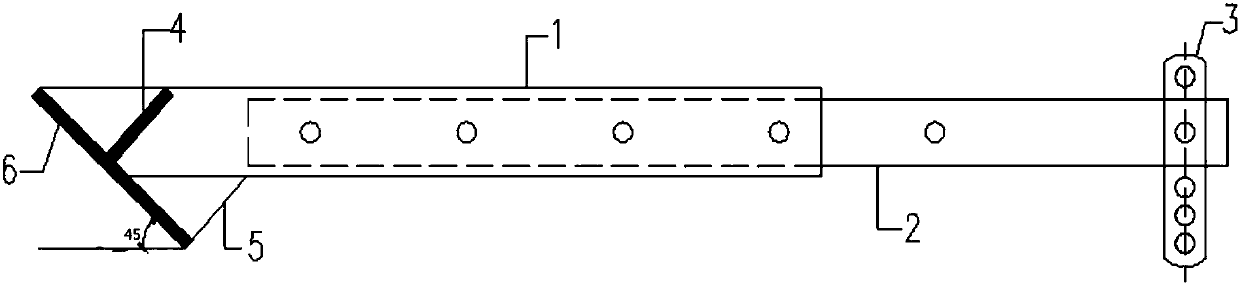

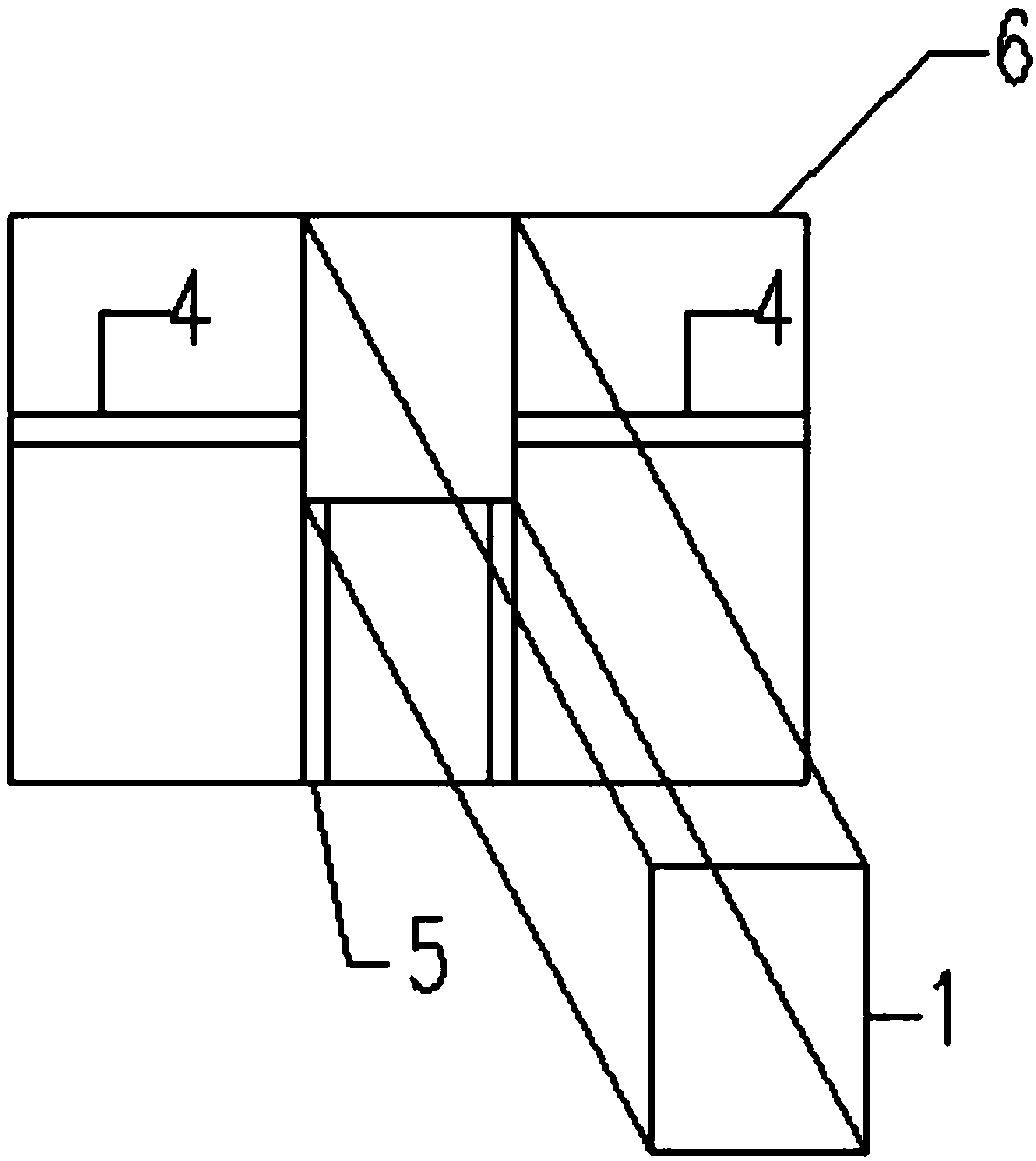

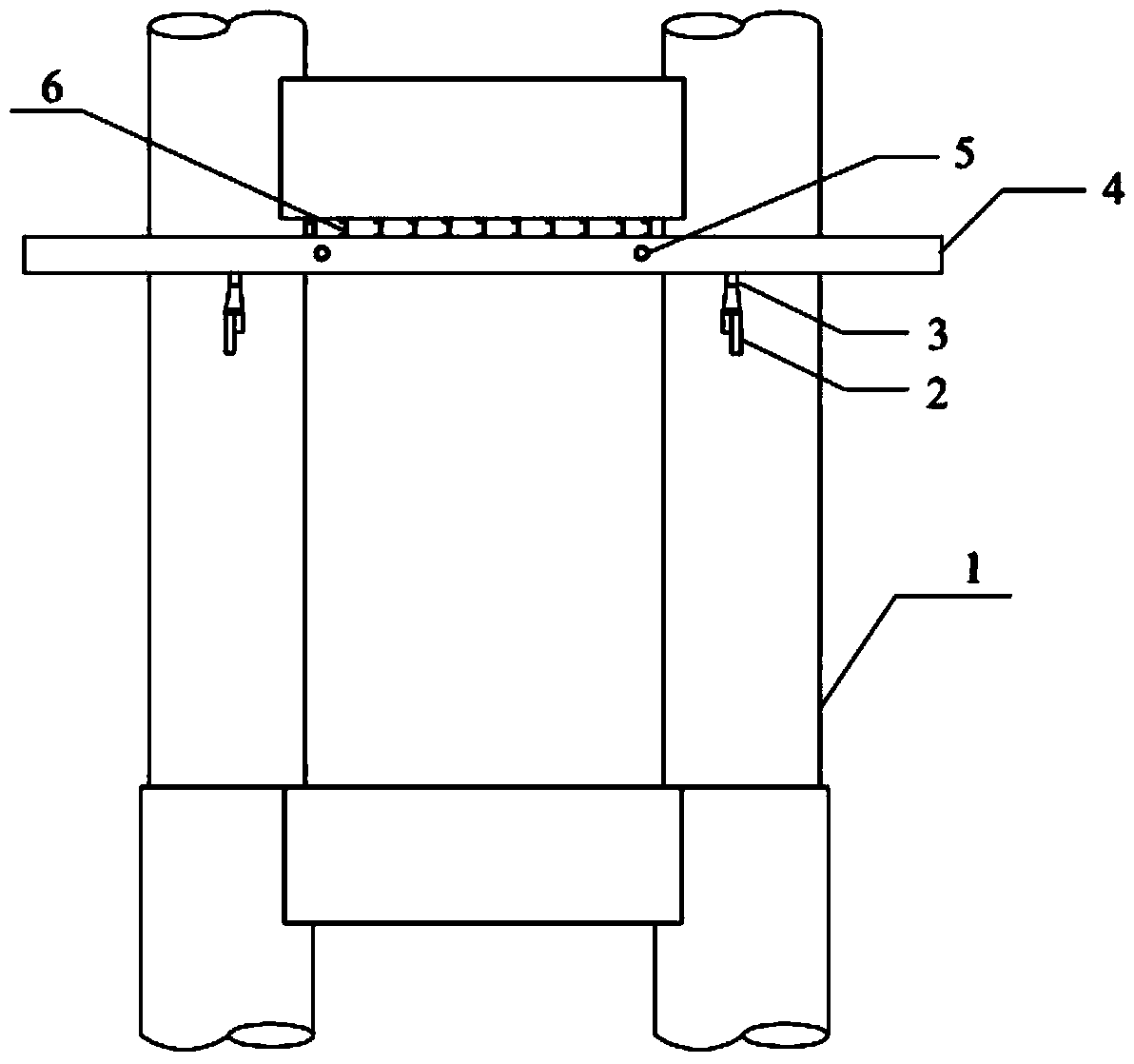

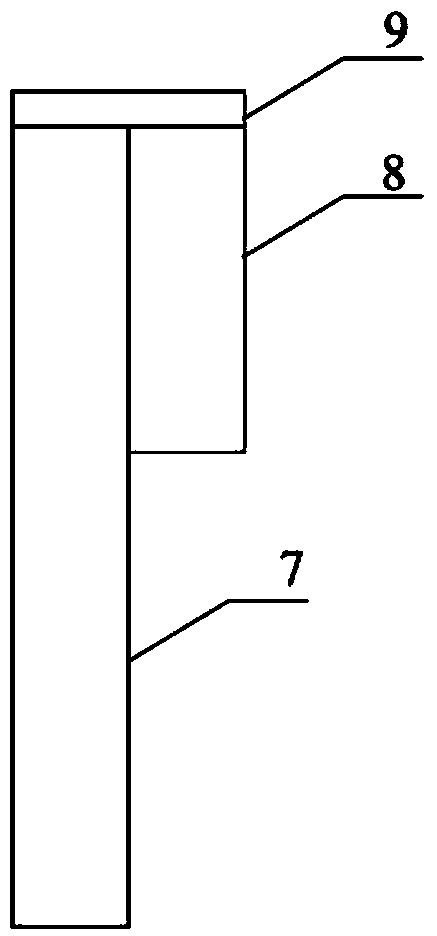

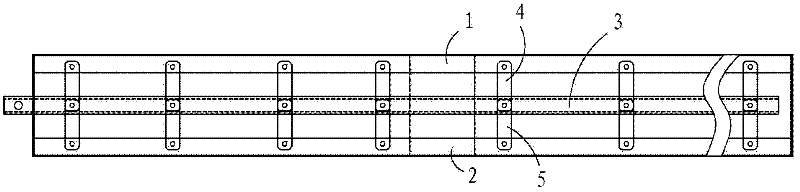

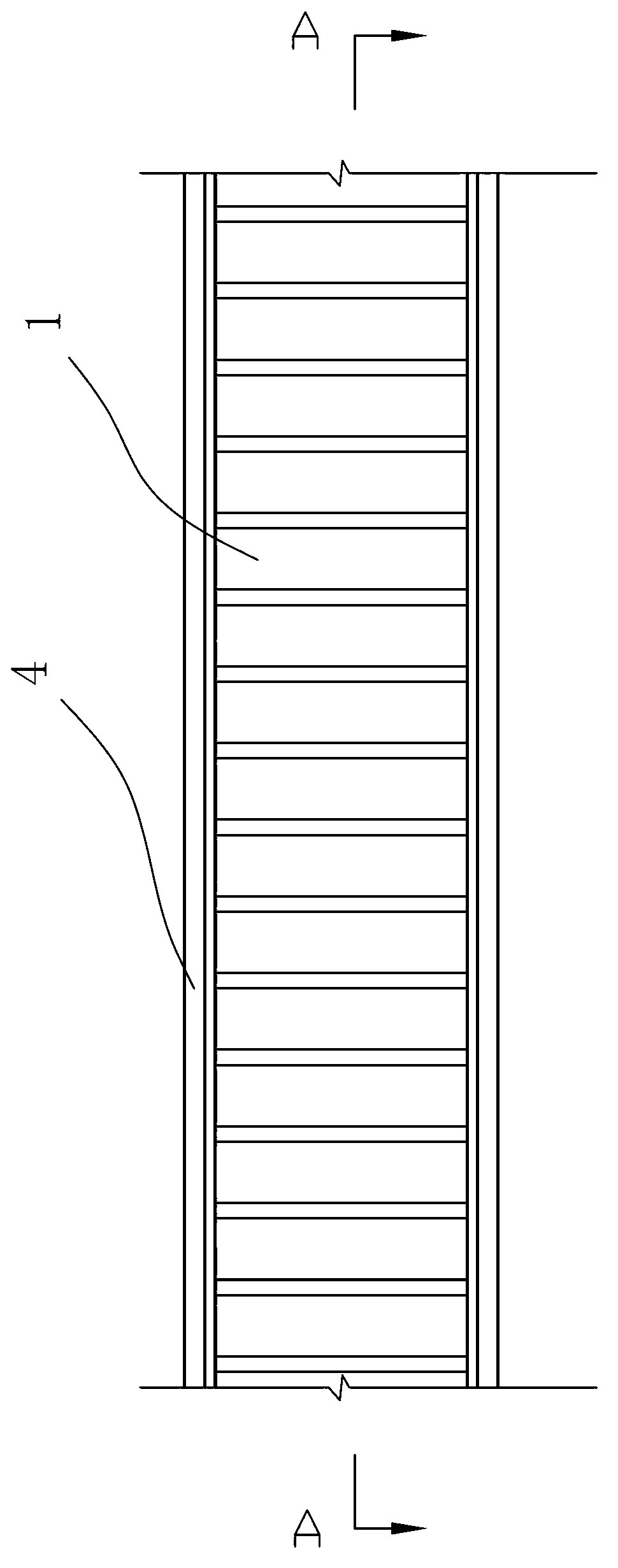

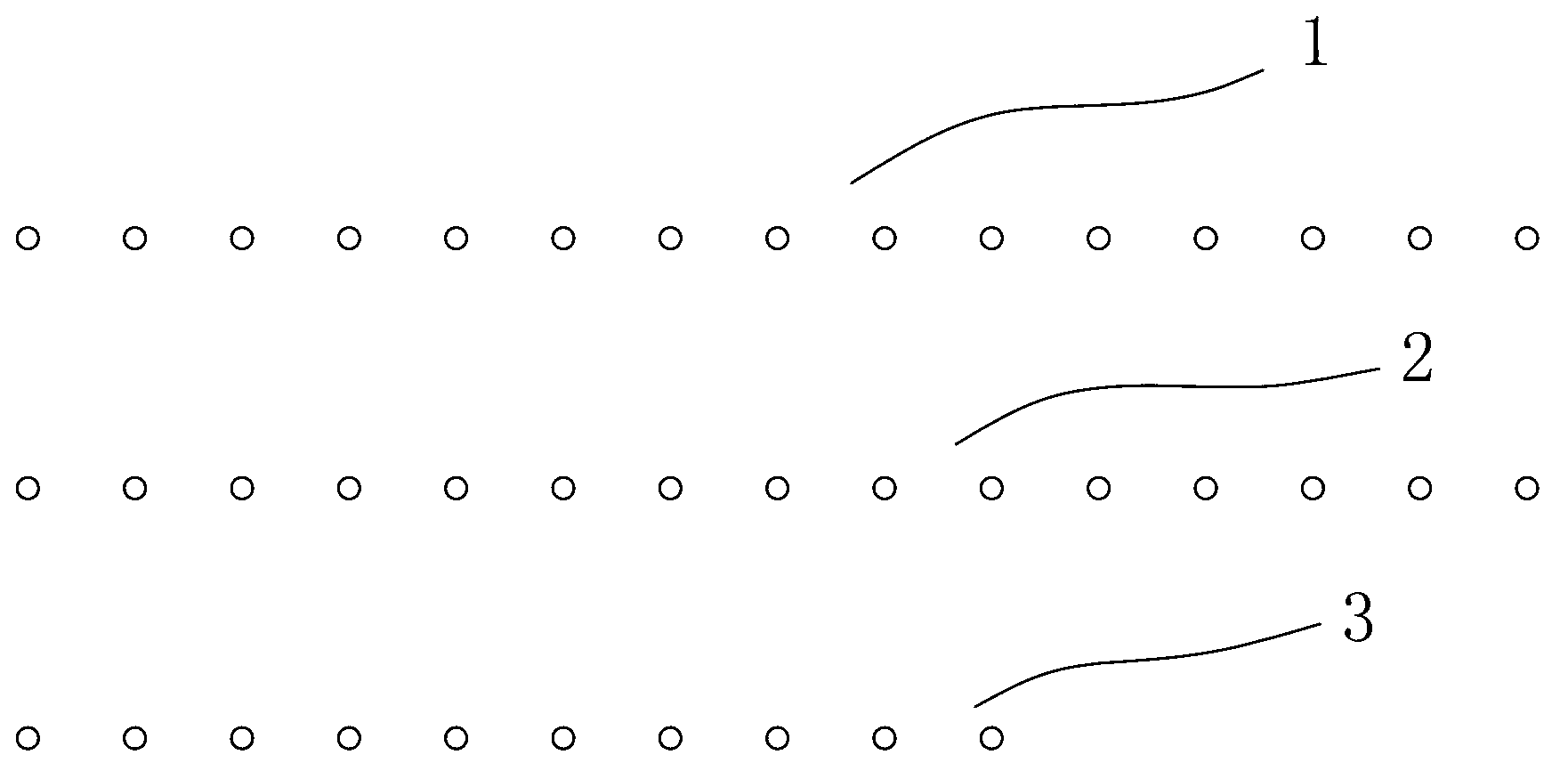

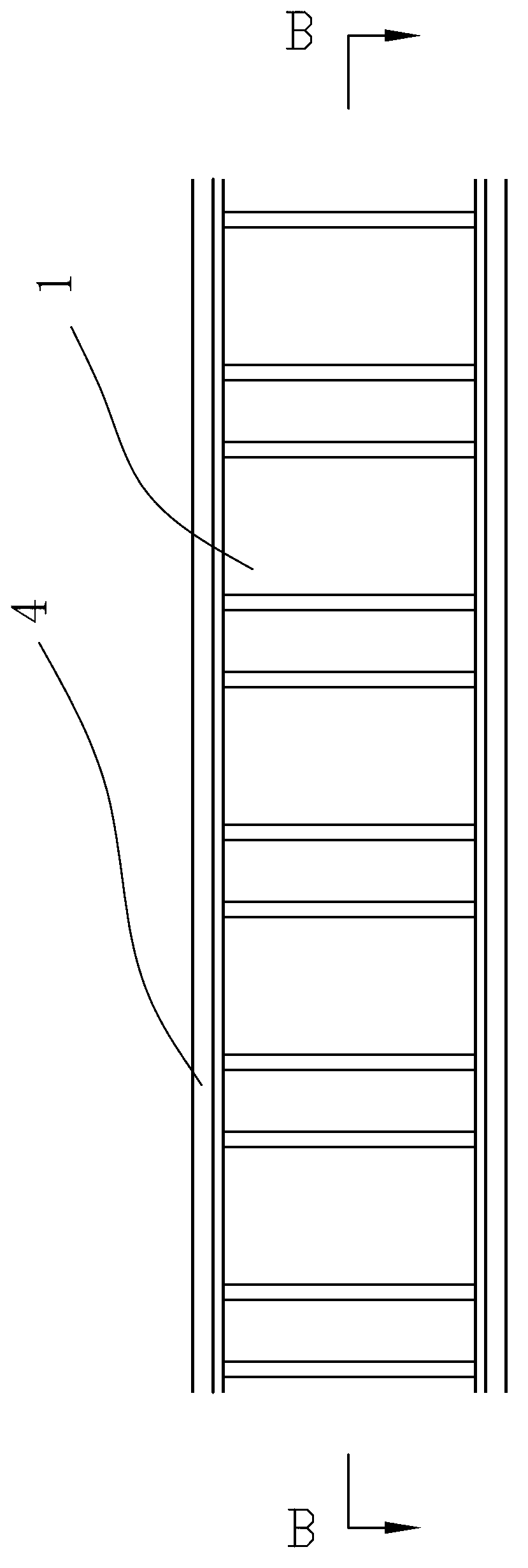

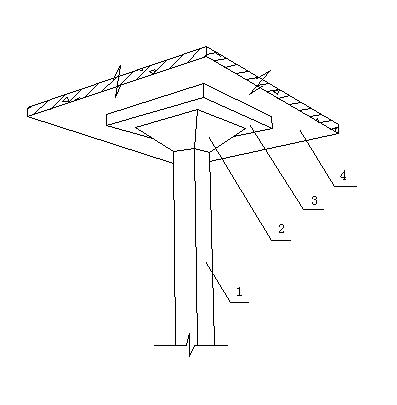

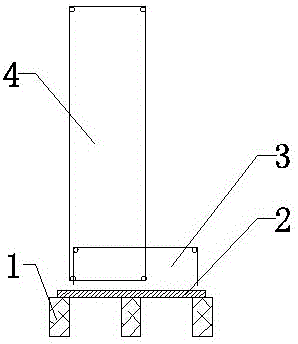

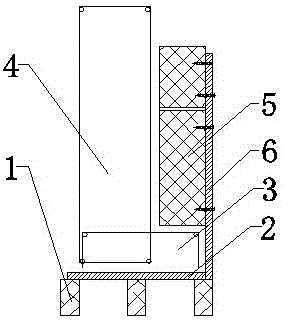

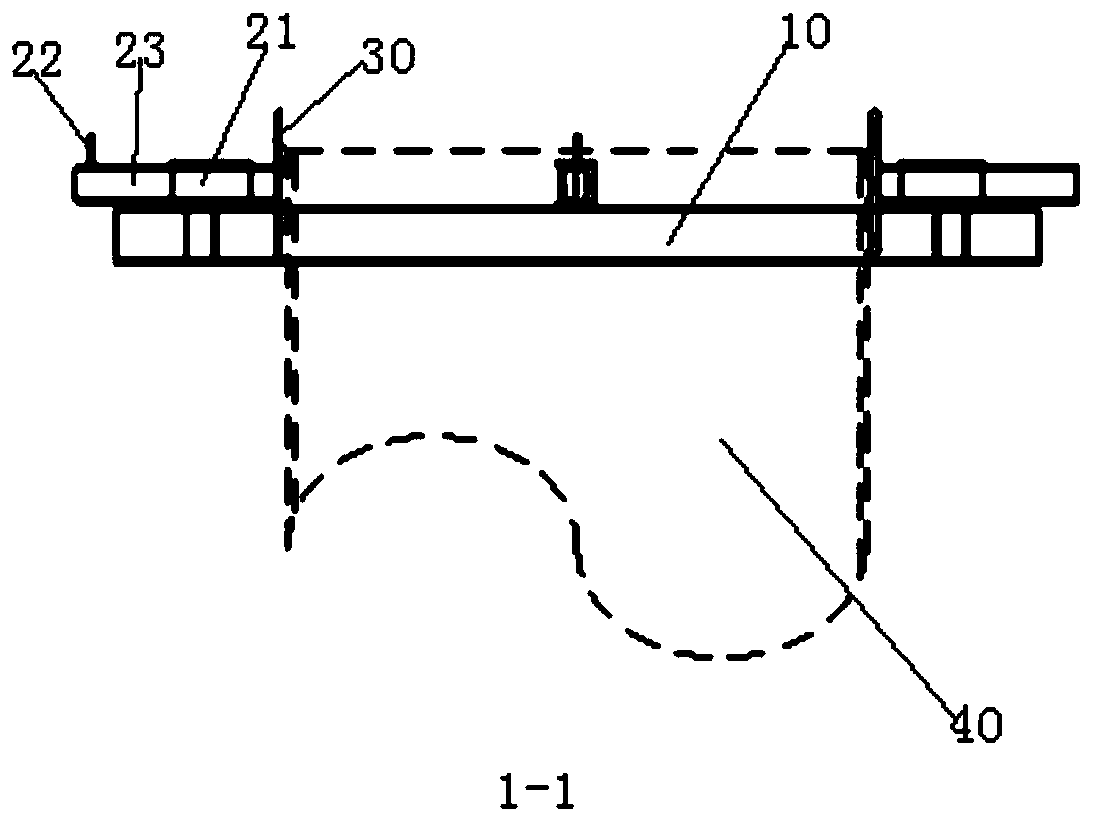

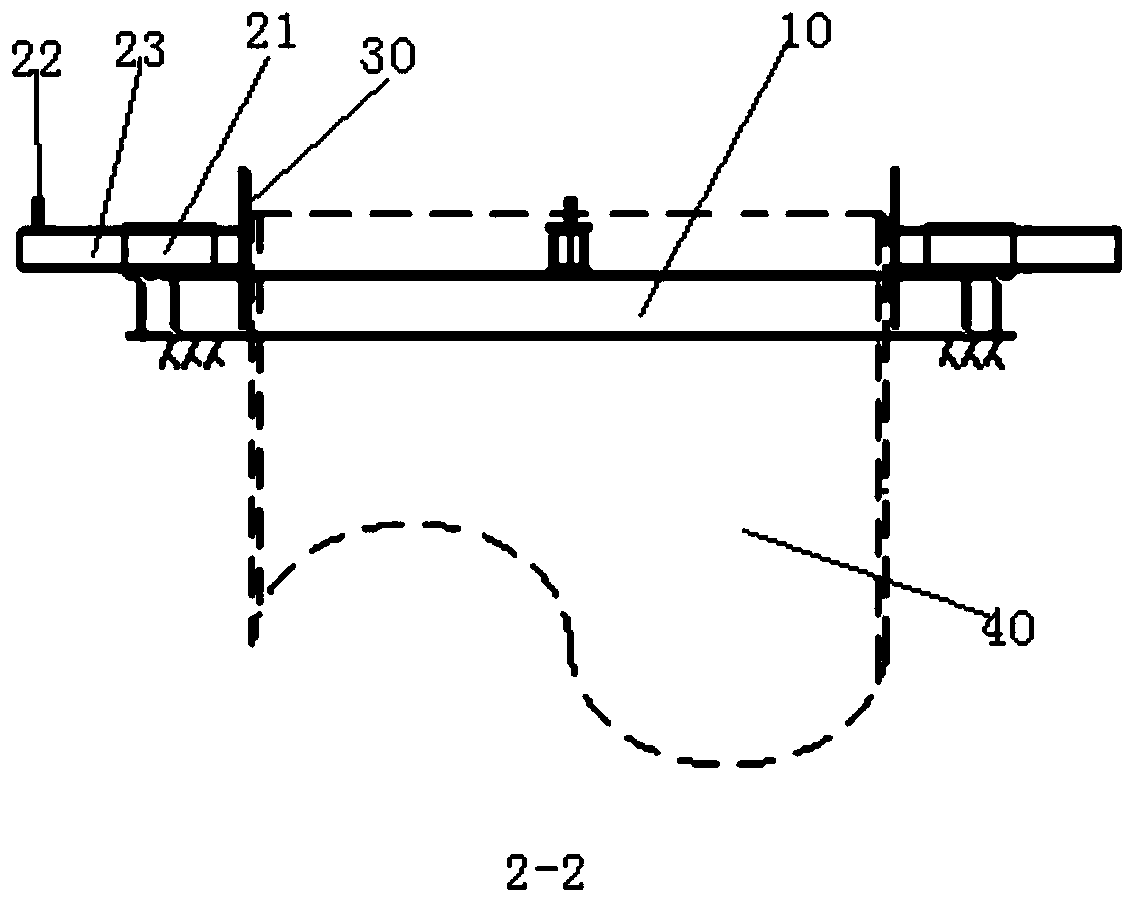

Corbel bracket platform for bridge pier and transverse straining beam synchronous construction and construction method of corbel bracket platform

ActiveCN103882813AMeet the structural stress requirementsUse less materialBridge erection/assemblyCorbelColumn model

The invention discloses a corbel bracket platform for bridge pier and transverse straining beam synchronous construction. The corbel bracket platform is characterized in that the positions, with the equal height, in the middle of semicircular steel molds on the two sides of the upper portion of a pier column model (1) are respectively provided with a corbel (2) in a welding mode, jacks (3) are installed on the corbels (2), I-beams (4) are placed on the jacks (3) in the horizontal direction, the I-beams (4) on the two sides of the pier column model (1) are connected together through pulling rods (5) and fastened on the pier column model (1), and distributive beams (6) are placed between the I-beams (4) at equal intervals. The invention further discloses a construction method of the corbel bracket platform. According to the corbel bracket platform, synchronous construction of a pier column and a transverse straining beam is achieved, the construction cycle period of components below a bridge is shortened, and the bridge construction progress is accelerated. Meanwhile, compared with a traditional construction scheme, the input material cost is low, materials of the platform of the transverse training beam can be completely recycled for coping beam construction, and the circulating utilization rate of the materials is high.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

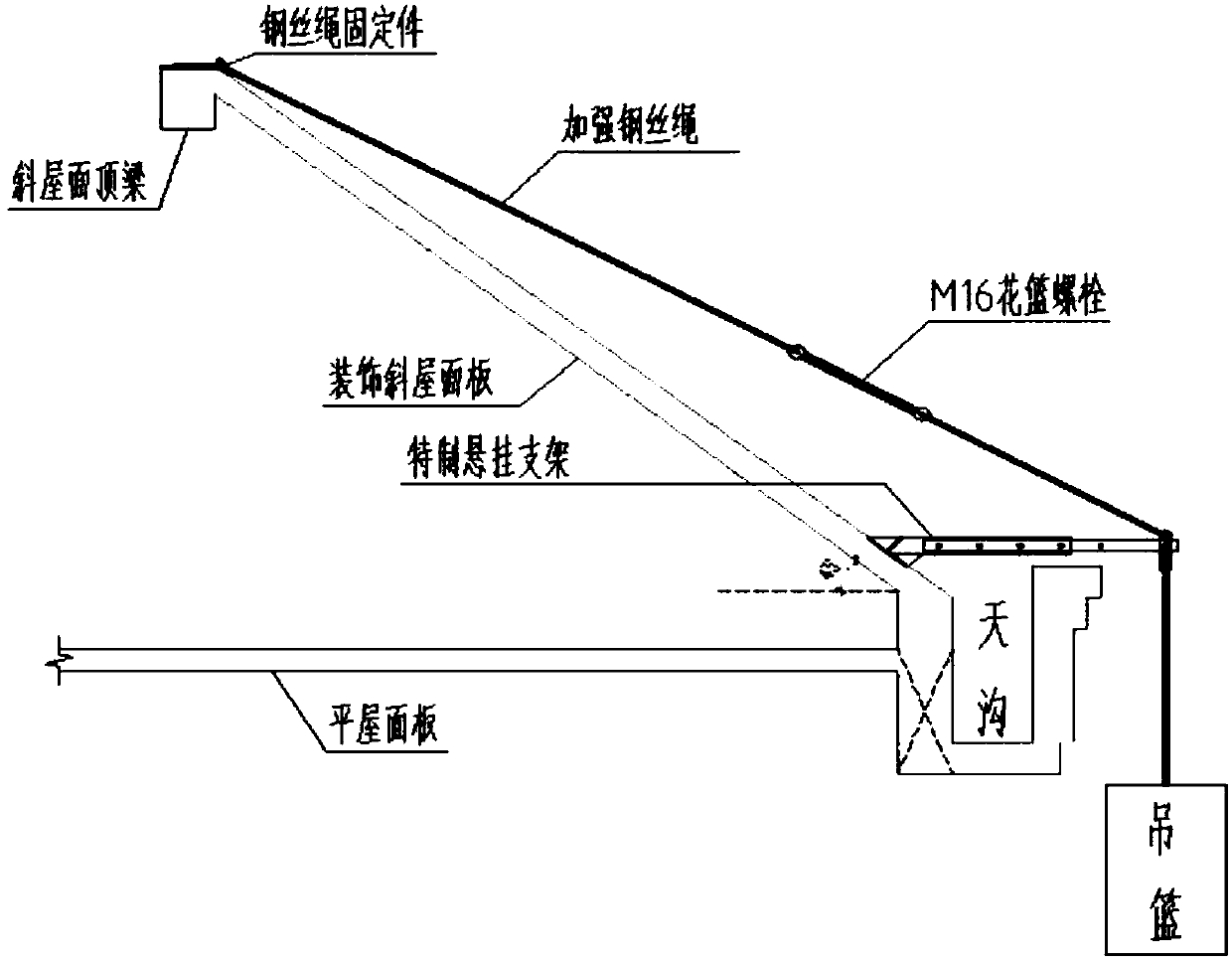

Manufacturing and mounting method of hanging basket suspension support for inclined roof

ActiveCN107558723ASimple structureLow costScaffold accessoriesBuilding support scaffoldsBiochemical engineeringHanging basket

The invention provides a hanging basket suspension support for an inclined roof. The hanging basket suspension support is mounted on a gutter of the inclined roof and used for hoisting a work platform. The hanging basket suspension support is characterized in that the hanging basket suspension support comprises an embedded part, a support body and a hoisting mechanism; the embedded part is arranged on the inclined roof; the support body is arranged on the gutter in a crossing mode and fixedly or detachably mounted on the embedded part; the support body comprises a support main rod and a suspension mechanism; one end of the support main rod is mounted on the embedded part; the other end of the support main rod is detachably provided with the suspension mechanism; and one end of the hoistingmechanism is provided with the work platform, and the other end of the hoisting mechanism is connected with the embedded part through the suspension mechanism. The hanging basket suspension support for the inclined roof has the characteristics of being simple in structure, safe, reliable, convenient to mount and low in cost.

Owner:SHANGHAI TONGJI CONSTR CO LTD

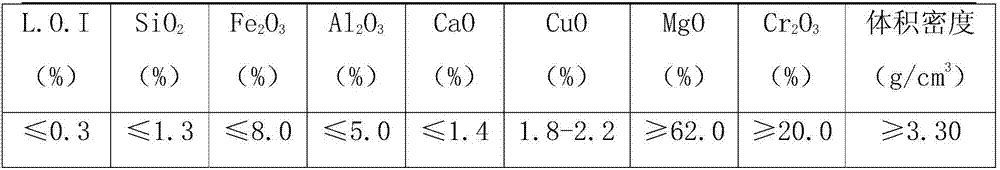

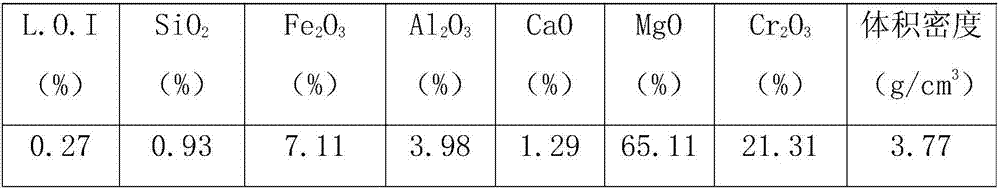

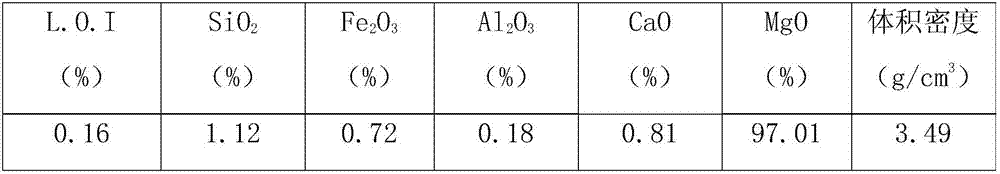

Copper composite high-performance magnesia-chrome brick and manufacturing method thereof

The invention belongs to the technical field of refractory materials, especially refractory materials for nonferrous smelting, and especially relates a copper composite high-performance magnesia-chrome brick and a manufacturing method thereof. The brick comprises 1-10 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 3-5 mm, 10-35 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 1-3 mm, 10-25 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 0.088-1 mm, 1-5 wt% of fused magnesia-chrome sands with the particle size being 3-5 mm, 1-15 wt% of fused magnesia-chrome sands with the particle size being 1-3 mm, 2-13 wt% of fused magnesia-chrome sands with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia-chrome sands with the particle size being not more than 0.088 mm, 1-5 wt% of fused magnesia with the particle size being 3-5 mm, 1-15 wt% of fused magnesia with the particle size being 1-3 mm, 2-13 wt% of fused magnesia with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia with the particle size being not more than 0.088 mm, 2-10 wt% of chromium concentrate with the particle size being not more than 0.088 mm, 1-6 wt% of a composite additive and 3-5 wt% of an (externally added) binder. Magnesia-chrome brick wastes generated by the nonferrous smelting can be fully used reasonably and effectively in the invention.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

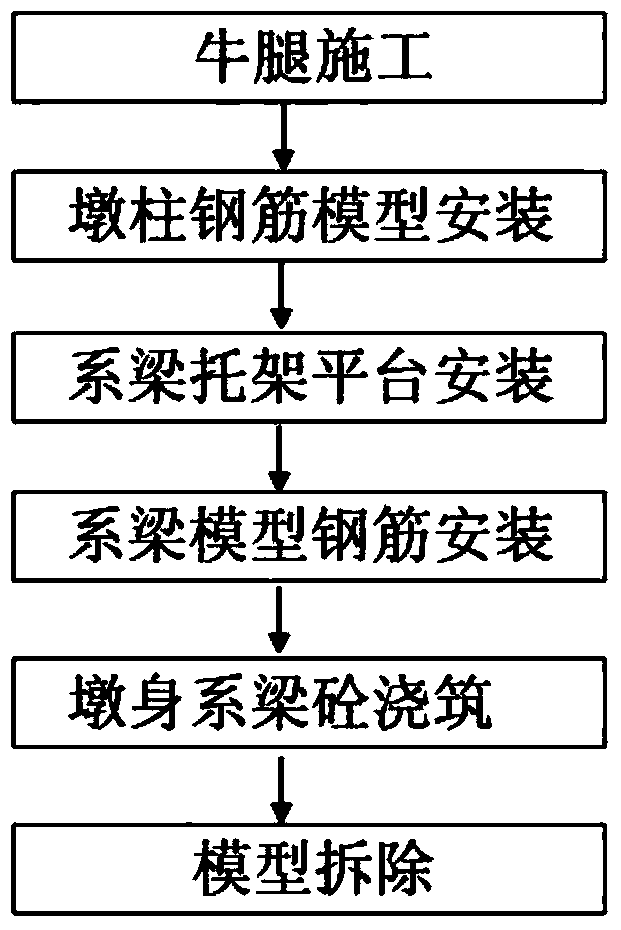

Pier and horizontal tie beam bracket support synchronization construction method

ActiveCN103866697ARealize simultaneous constructionShorten the timeBridge erection/assemblyEngineeringColumn model

The invention discloses a pier and horizontal tie beam bracket support synchronization construction method. A novel bracket support method is used, a bracket is welded to a pier column model, after the pier column model is arranged, a support platform for tie beam construction is arranged on the bracket, and then the following procedures of a tie beam bottom die, a top plate steel rib, a tie beam side die, a pier column, horizontal tie beam concrete and the like are carried out. According to the construction method, synchronization construction of the pier column and a horizontal tie beam is achieved, the construction cycle of parts (the pier column, the horizontal tie beam and the like) below a bridge is shortened, the bridge construction progress is accelerated, the technology is safe and controllable, meanwhile, compared with a traditional construction scheme, operation is easy, and investment cost is low.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

Method for jacking steel casting of bored pile by using jacks

The invention relates to a method for jacking a steel casting of a bored pile by using jacks, which comprises the flowing steps of: placing two smooth sleepers horizontally on the ground on two sides of the jacket steel casting, wherein the two sleepers are vertical to the connecting line of two lifting lugs of the steel casting; (b) placing a jacket on each sleeper; arranging a cross beam on the two jackets; arranging a steel wire rope on the cross beam above each lifting lug, wherein the steel wires pass through the lifting lugs of the steel casting and the two free ends of the steel wire ropes are fixedly jointed; and (c) turning the jackets by two persons at the same time to jack the cross beam up so that the steel casting is pulled up by the cross beam through the steel wire ropes. The invention has the advantages of simple structure, convenient and simple operation, high safety and reliability, no limit by places, fast construction and low cost.

Owner:CHINA FIRST METALLURGICAL GROUP

Closed type cantilever scaffold system and construction method

ActiveCN109629810AGuaranteed to be stable and safeInnovative designScaffold accessoriesBuilding support scaffoldsFalseworkHigh intensity

The invention discloses a closed type cantilever scaffold system and a construction method thereof. The closed type cantilever scaffold system comprises a cantilever steel beam through-wall structure,a cantilever steel beam balcony slab placement structure for containing a balcony slab and manufacturing a cantilever balcony, a closed type cantilever scaffold system for building a scaffold, and anoverhead cantilever formwork protective shed for erecting a protective shed, wherein the cantilever steel beam through-wall structure is used for through-wall fixing construction of a structural steel girder; an anchoring device adopting the cantilever steel beam through-wall structure is convenient to install and flexible to disassemble, the turnover utilization rate can be effectively increased, and an integrated high-intensity embedded U-shaped pull ring and an inclined strut steel tube shaping connecting beam piece are adopted, so that the balcony slab is effectively prevented from beingdamage by crushing, an adjustable vertical rod is adopted for compression joint of a fixing rod and a wall column reinforcing type connecting wall rod, the application range of the scaffold is enlarged, the overhead cantilever formwork dual-layer protective shed is adopted, safety risk in external frame erection is reduced, and safety construction is facilitated.

Owner:浙江恒鸿建设有限公司

Composite enzyme of saccharification and nutrition dedicated to alcohol and fuel ethanol, and application

This invention relates to a special diastatic nutritive complex zyme specially used in alcohol and fuel alcohol including the following components in weight percentage: compound cellulose: 10-20%, pectic enzyme; 3-7%, proteinase: 5-15%, debranching enzyme: 5-15%, phytase: 5-15%, beta-amylase: rest. This invention adds the said diastatic nutritive complex zyme into the being saccharificated materials at one run at the diastatic stage. This invented multizyme reagent compound recipe can replace the beta-amylase in the current technology.

Owner:郭峰

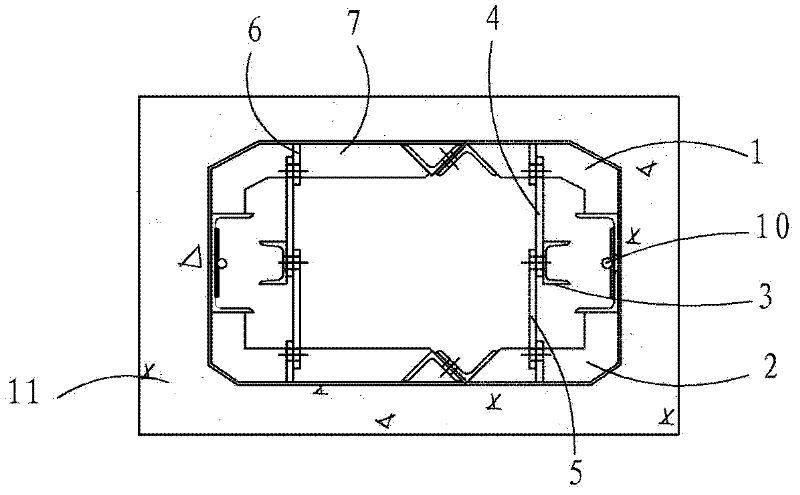

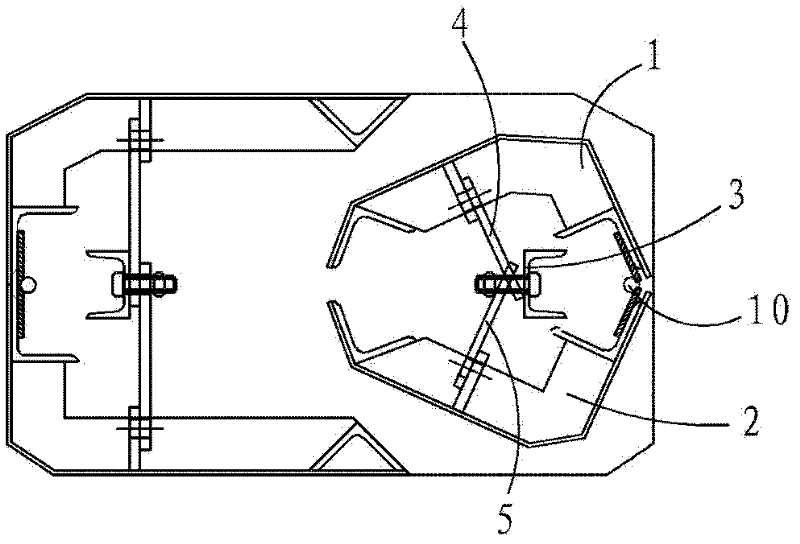

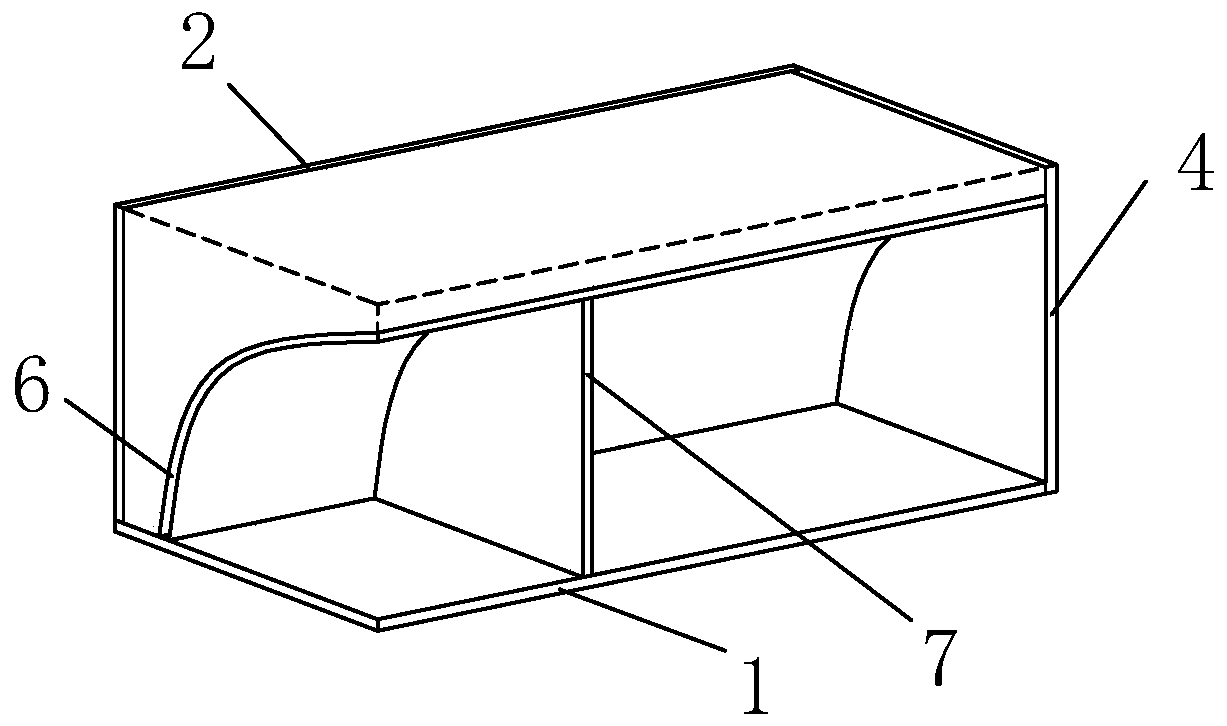

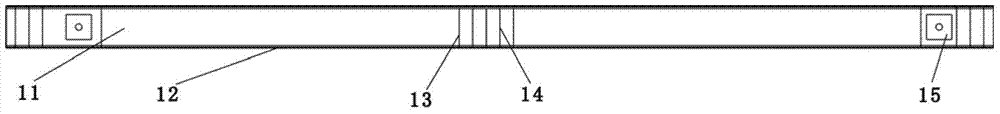

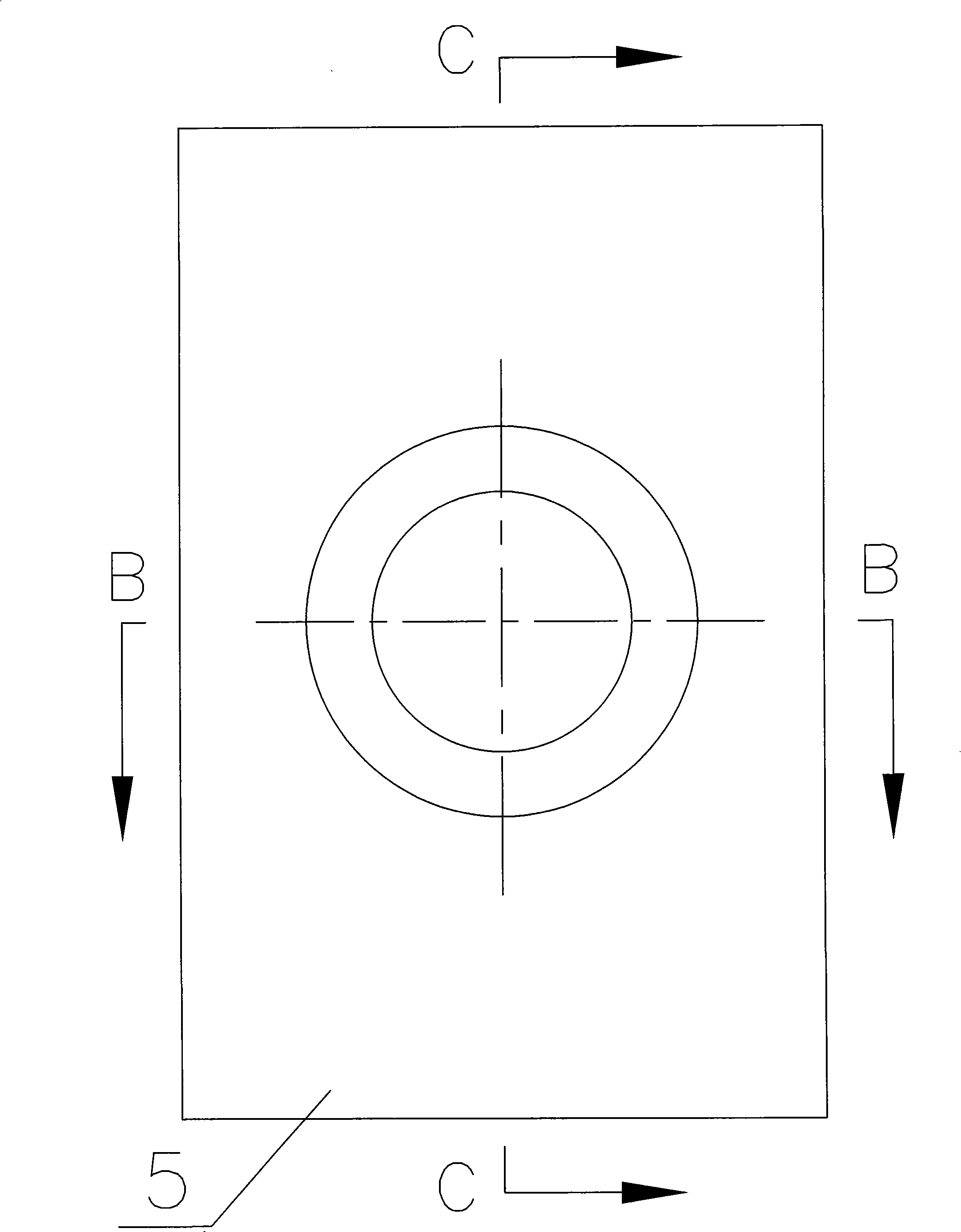

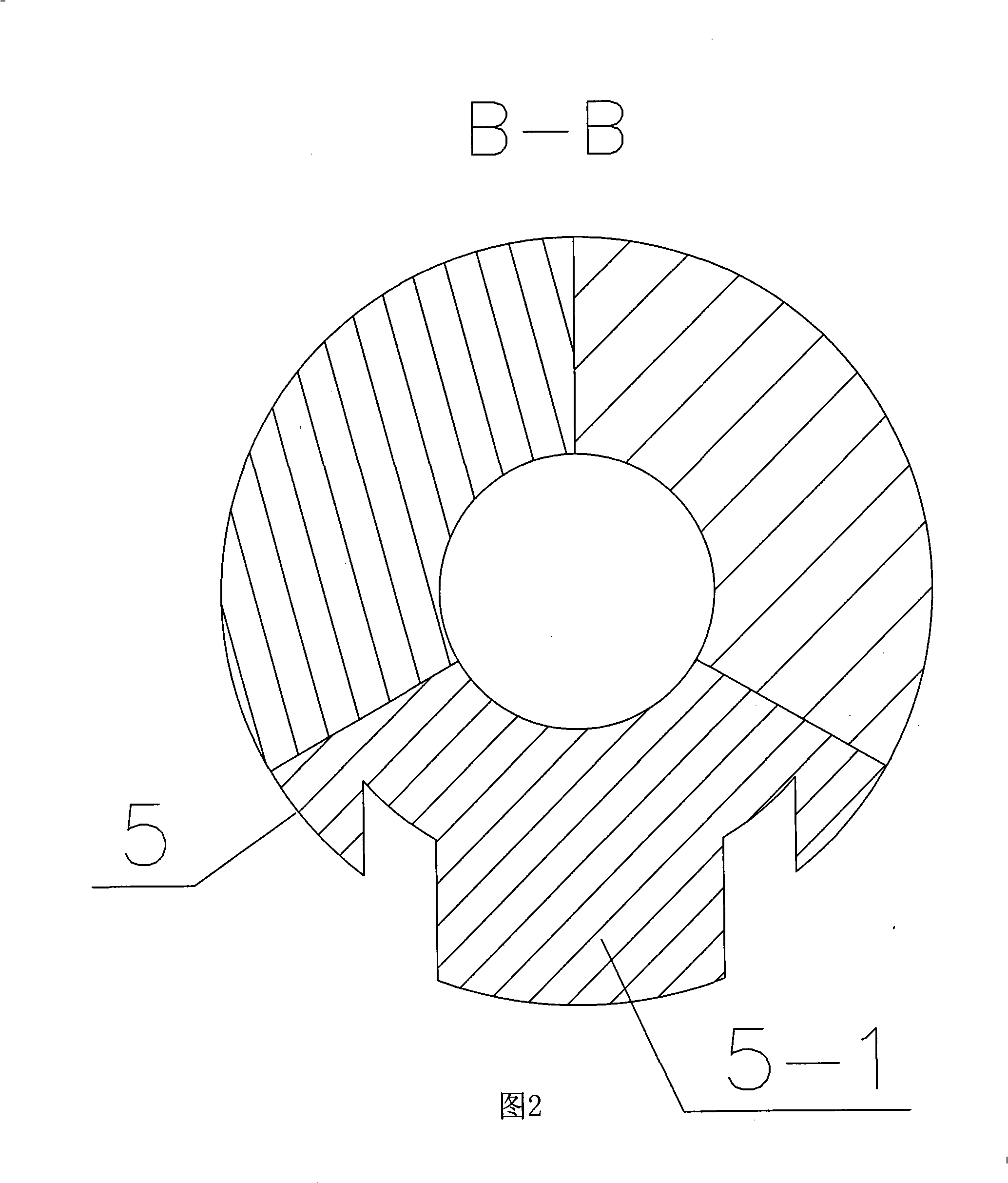

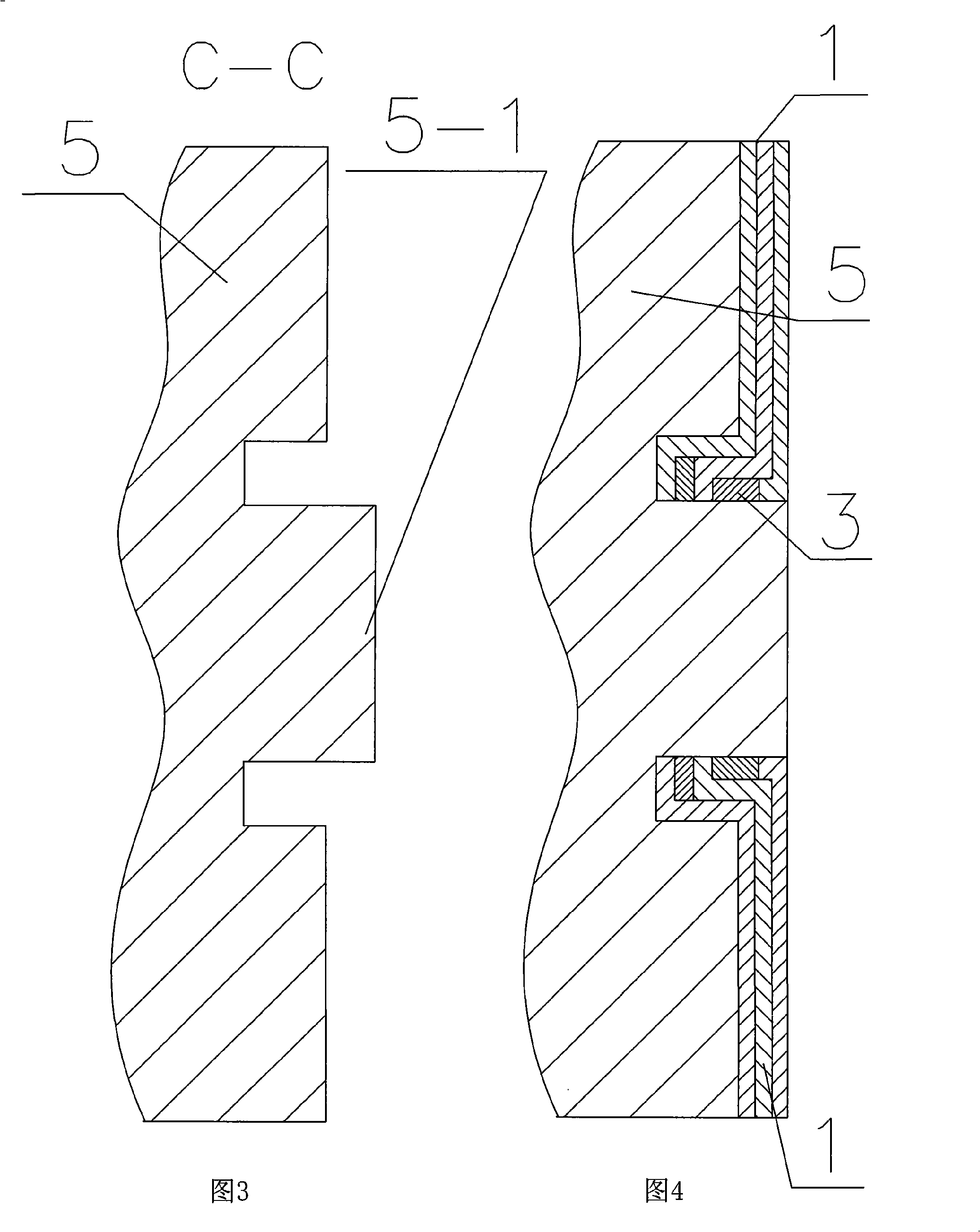

Folding drawing steel internal mould system for prefabricated hollow beam

ActiveCN102398302ANo manual disassemblyImprove ergonomicsCeramic shaping mandrelsCeramic shaping coresMechanical engineeringSteel structures

The invention discloses a folding drawing steel internal mould system for a prefabricated hollow beam, which uses a steel structure and is provided with two semi-mould units with opposite openings at left and right sides on a cross section of the internal mould. The semi-mould unit is formed by an upper unit plate and a lower unit plate which are hinged at the side to form a hinge structure capable of unfolding or folding up and down. In the semi-mould unit, a pull rod is arranged along the length direction of the internal mould. The pull rod is hinged respectively with the upper plate unit at the top plate through a group of upper connecting rods arranged at intervals and hinged with the lower unit plate at the bottom plate through a group of lower connecting rods arranged at intervals. In the invention, the pull rod is drawn so that the internal mould is respectively in unfolding and folding states. The invention does not need to disassemble manually and is particular suitable for prefabricating hollow beams with small sections, and improves the work efficiency greatly.

Owner:THE FOURTH ENG CO LTD OF CTCE GRP

Construction method for dynamic steel supporting system of deep foundation pit

The invention discloses a construction method for a dynamic steel supporting system of a deep foundation pit. The construction method comprises the following steps: constructing a foundation pit space enclosing structure; performing first-layer soil excavation in the foundation pit space enclosing structure, and mounting first-layer steel supports; performing second-layer soil excavation, and mounting second-layer steel supports; performing third-layer soil excavation and mounting third-layer steel supports; and according to the design requirements, dismantling a plurality of steel supports from the first-layer steel supports and / or second-layer steel supports, and synchronously mounting the plurality of steel supports into the third-layer steel supports. Under the premise of ensuring safety, reliability and reasonability in stress of the whole steel support structure, as part of steel supports of the first-layer steel supports and / or the second-layer steel supports are dismantled in advance, and the part of steel supports are synchronously mounted in the third-layer steel supports, turnover usage rate of steel supports is improved, usage amount of steel supports is saved, and engineering construction progress is accelerated. The construction method is applied to the technical field of construction of foundation pits.

Owner:GUANGDONG FOUND ENG GRP CO LTD

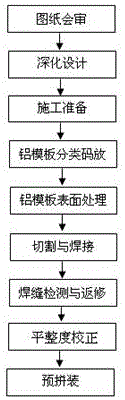

Construction method for reconstruction and turnover use of aluminum alloy templates

ActiveCN106088572ASave materialHigh turnover utilizationBuilding material handlingForming/stuttering elementsPollutionMaterials science

The invention relates to the field of construction, in particular to a method for repeated reconstruction and utilization of an aluminum alloy template system, and provides a construction method for reconstruction and turnover use of aluminum alloy templates. The construction method comprises the following steps: (1) drawing reviewing and detailed design; (2) construction preparation; (3) classified piling up of the aluminum alloy templates; (4) surface treatment of the aluminum alloy templates: the surfaces of the aluminum alloy templates are subjected to shot blasting treatment, and different shot blasting parameters are determined according to classification of pollution degrees of the surfaces of old templates (5) cutting and welding of the aluminum alloy templates; (6) weld detection and repair; (7) correction of flatness of the aluminum alloy templates: the aluminum alloy templates with recess positions are repaired through mechanical correction, and the requirement for the flatness of the aluminum alloy templates can be met; (8) pre-assembly: the aluminum alloy templates processed according to the detailed design drawing are all subjected to 1:1 pre-assembly on a reconstruction site. Deformed and damaged templates are repaired and reconstructed with the method, so that material saving and turnover use of the aluminum alloy templates are realized to the greatest extent.

Owner:DALIAN BRANCH OF CHINA CONSTR EIGHTH ENG DIV CORP

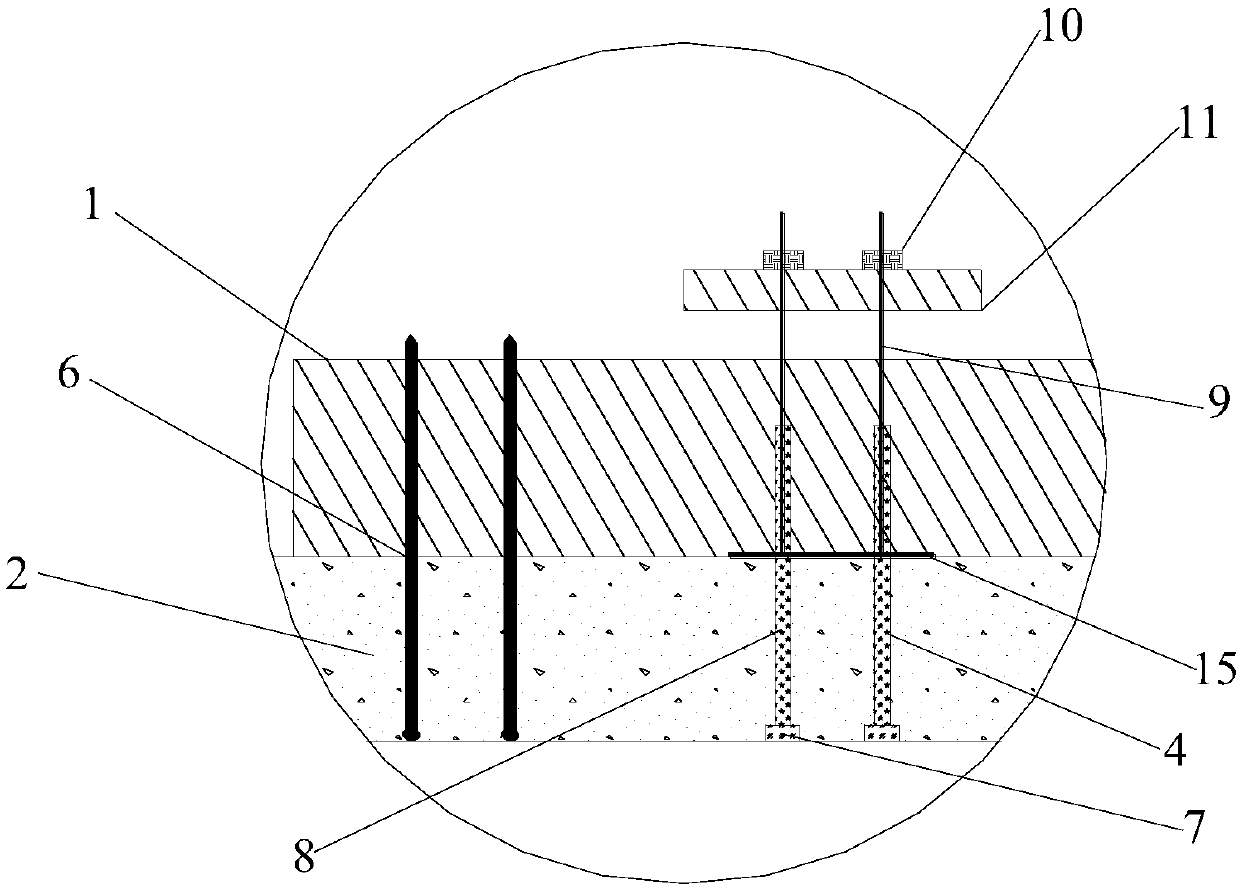

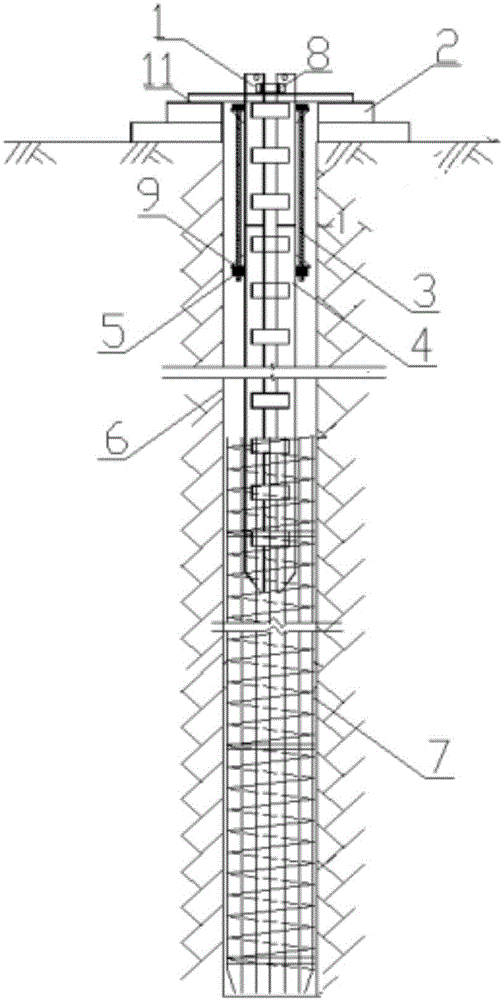

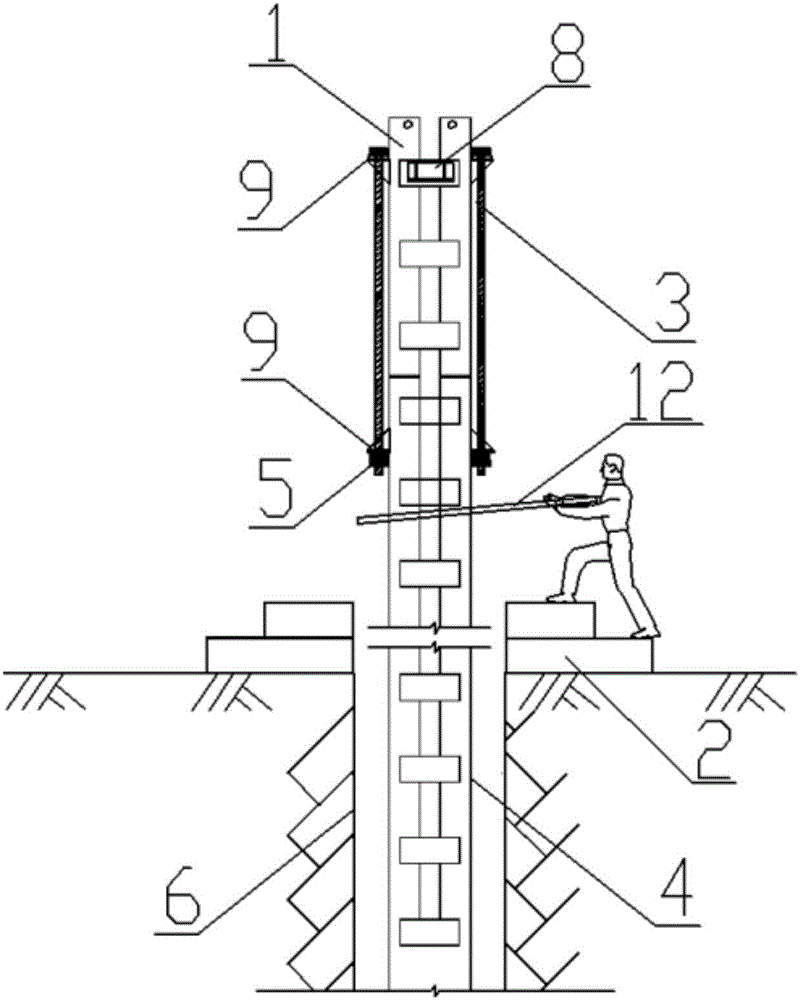

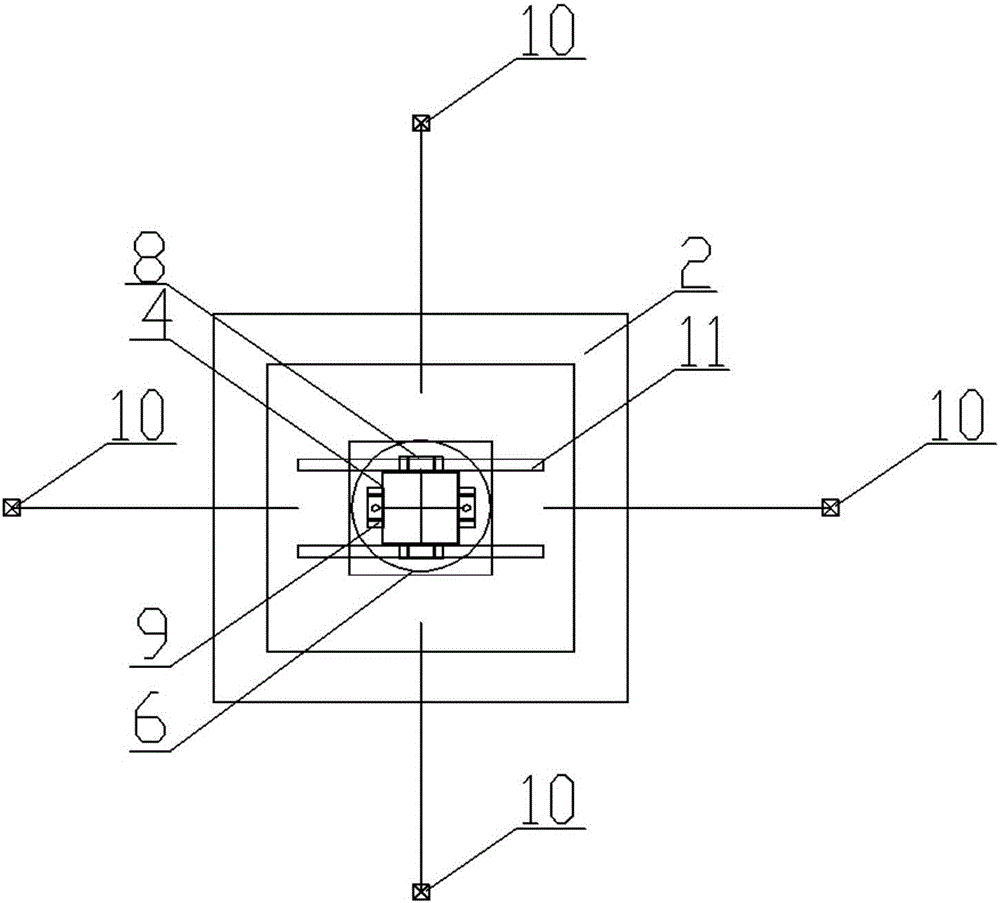

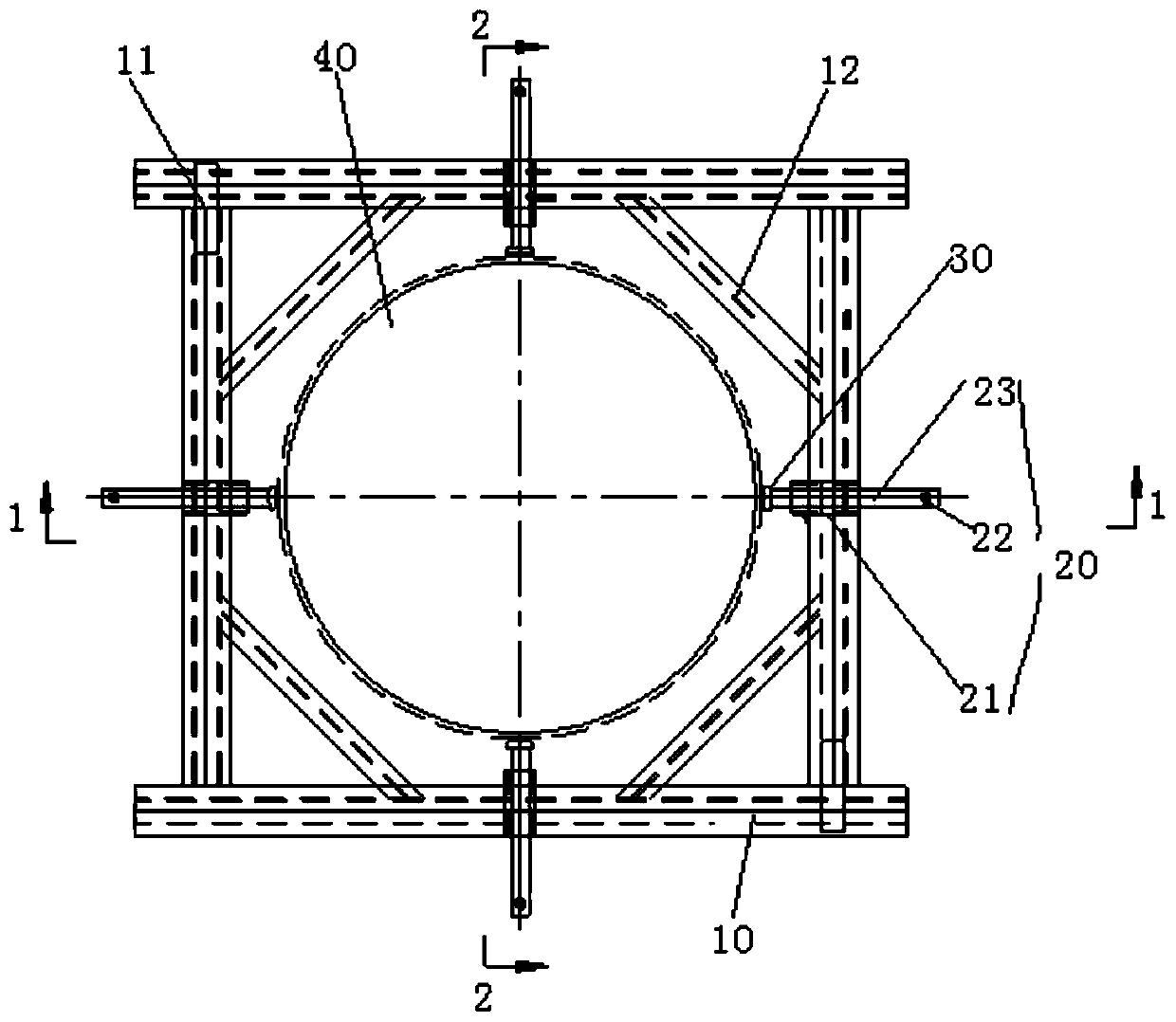

Positioning and steering control system of deep foundation pit bracing vertical lattice column and application method

InactiveCN106759350AControl construction accuracyPrecise control center positionBulkheads/pilesControl systemSteering control

The invention discloses a positioning and steering control system of a deep foundation pit bracing vertical lattice column and an application method. The control system mainly comprises a positioning system, a steering system and an assisting adjusting system, wherein the positioning system comprises a positioning platform, a lattice column, a positioning timber pile, fastening screw rods and lengthening type nuts, the steering system comprises a guiding column, a steel reinforcement cage, a supporting and lifting corbel and a screw rod connecting corbel; the assisting adjusting system comprises a supporting and lifting carrying pole and an adjusting crowbar. The control system is used for placing the positioning platform to the group at the top of a pile opening after a hole is drilled in a pouring pile, enabling the guiding column to penetrate through the hole in the middle of the positioning platform to be inserted into the lattice column and the steel reinforcement cage which are integrally welded by binding eight reinforcing bars, and indirectly adjusting the elevation, the positioning and the steering of the lattice column on the ground through the utilization of meshing between the guiding column and the lattice column and the tight fixing of the fastening screw rods between the guiding column and the lattice column, so that the purpose of accurate control is realized.

Owner:BCEG CIVIL ENG +2

Method for pouring building post-pouring belt and pouring die

ActiveCN106193588ASimple structureEasy to install and removeForms/shuttering/falseworksAluminiumCantilever

The invention discloses a method for pouring a building post-pouring belt and a pouring die. The method comprises the following steps: erecting the pouring die of the post-pouring belt by adopting a wood die system; when pouring the post-pouring belt, erecting the pouring die of the post-pouring belt by adopting an aluminum die system and the wood die system, namely erecting the pouring die of the post-pouring belt by commonly adopting the wood die system and the aluminum die system; in a common erecting process, erecting a pouring die at a cantilever end part of a cantilever beam plate of the post-pouring belt by the aluminum die system; erecting pouring dies of other parts of the post-pouring belt, except the cantilever end part of the cantilever beam plate of the post-pouring belt, by utilizing the wood die system; and after erecting the pouring die of the post-pouring belt through the wood die system and the aluminum die system, pouring the post-pouring belt. The method not only has the advantages of rapidness in construction, convenience for installation and detachment, low loss, high utilization circulation rate and cost saving, but also has the advantages of effectively preventing quality problems including cracking and leakage of the cantilever beam plate of the post-pouring belt and the like from occurring.

Owner:CCFED THE FIRST CONSTR & ENG

Municipal pipeline groove supporting structure and method

ActiveCN107964960AReduce weightEasy constructionClimate change adaptationExcavationsArchitectural engineeringStructure support

The invention provides a municipal pipeline groove supporting structure. The municipal pipeline groove supporting structure is characterized in that the municipal pipeline groove supporting structurecomprises two sets of enclosure plates, a plurality of sets of stand columns and a plurality of sets of truss mechanisms; the two sets of enclosure plates are arranged on the two sides of a foundationditch side by side; each enclosure plate comprises a plurality of sets of spliced enclosure plate units; each enclosure plate unit comprises a rectangular base plate and wing plates symmetrically arranged at the ends of the two sides of the base plate in the length direction, and the two wing plates are provided with a plurality of through holes allowing the stand columns to pass through in an array correspondingly; the stand columns vertically penetrate through the multiple sets of vertical enclosure plate units to be arranged on the two sides of the foundation ditch in an array; and the truss mechanisms are detachably arranged between the adjacent enclosure plate units on the two sides of the foundation ditch.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

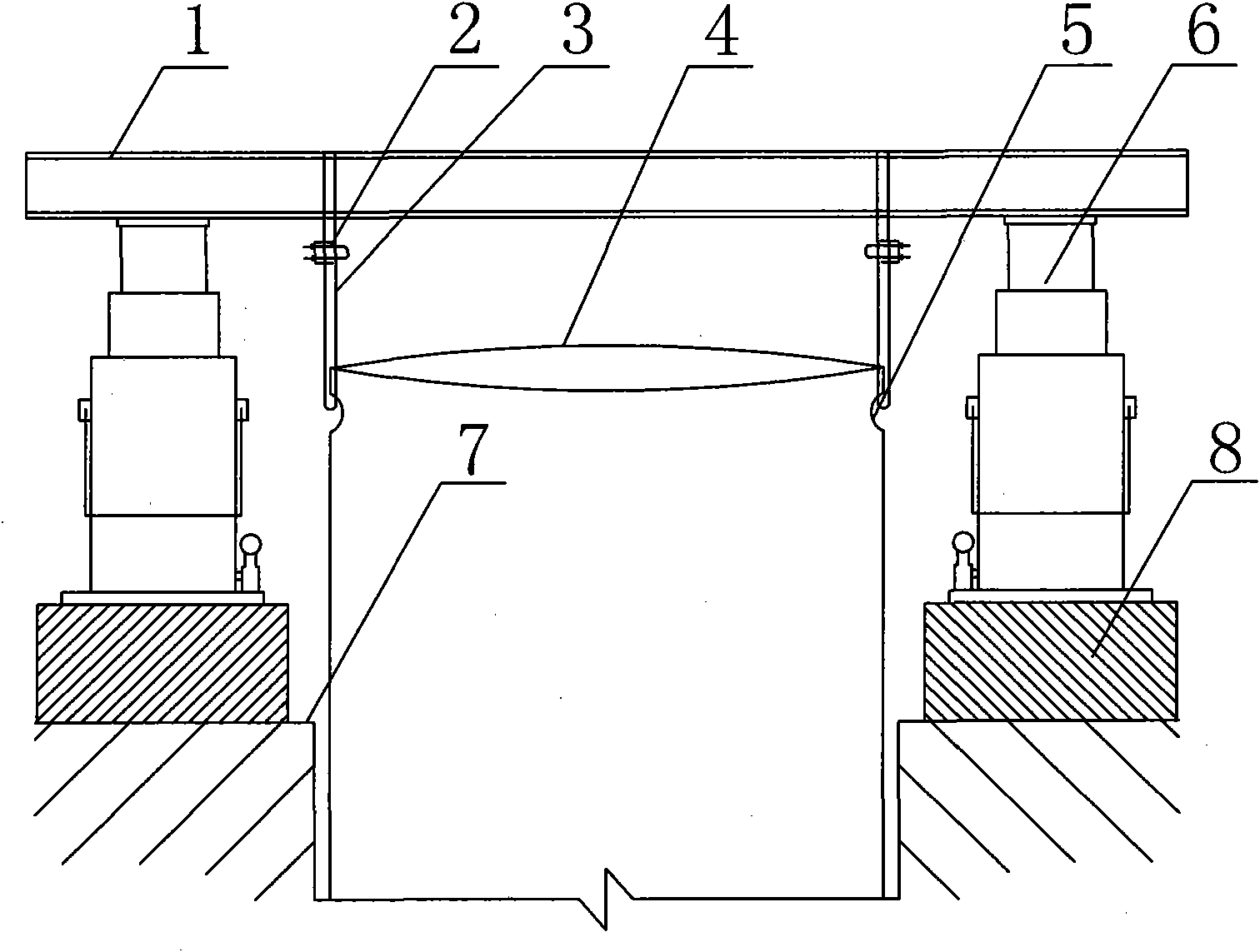

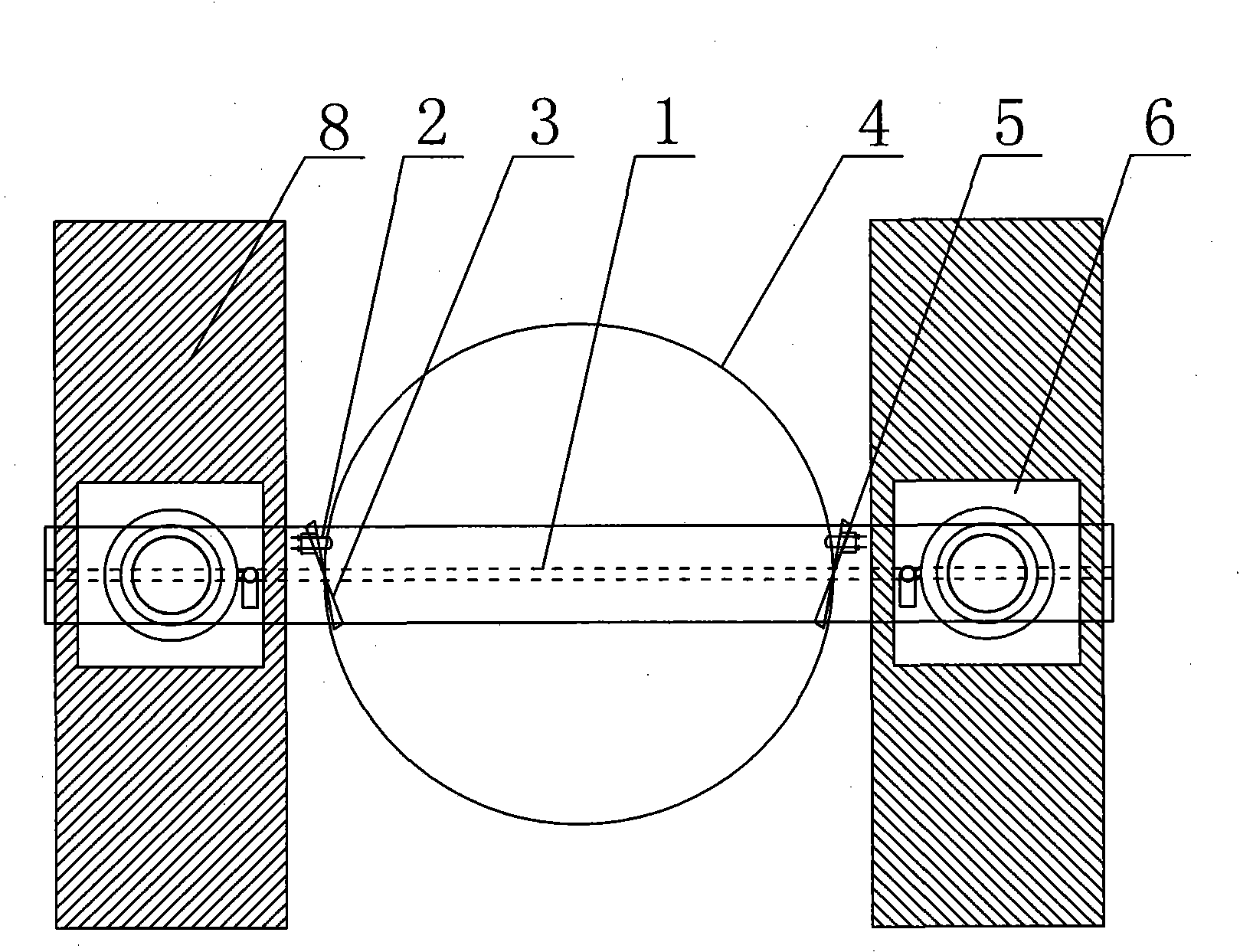

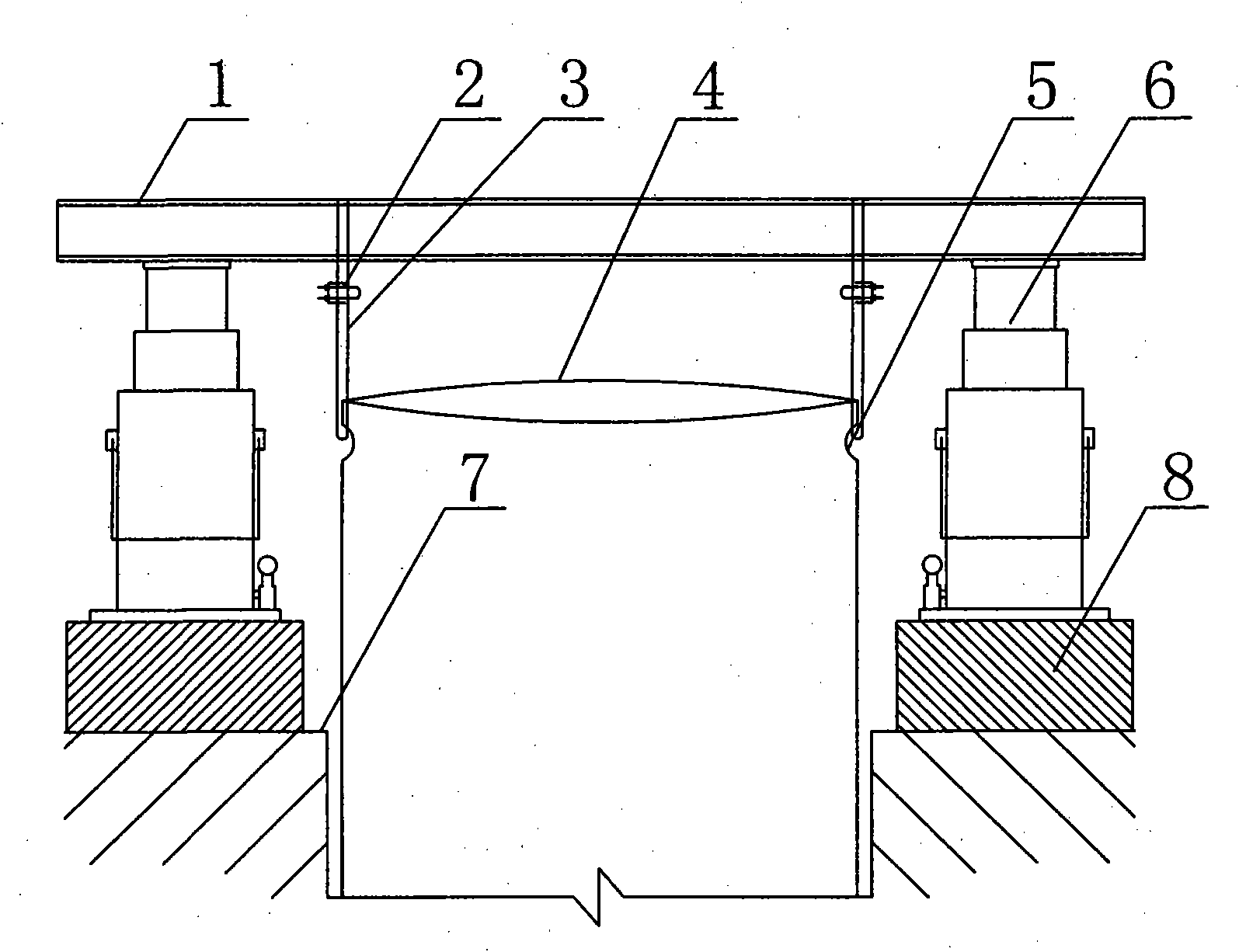

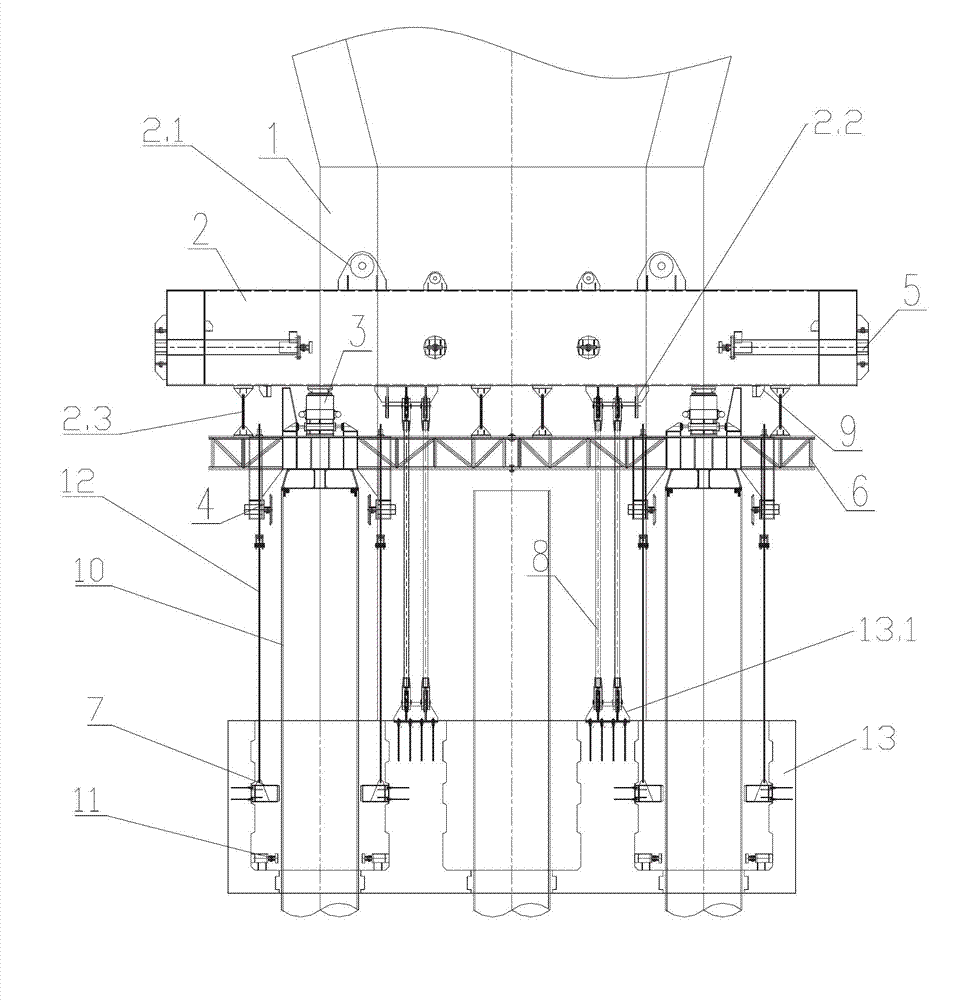

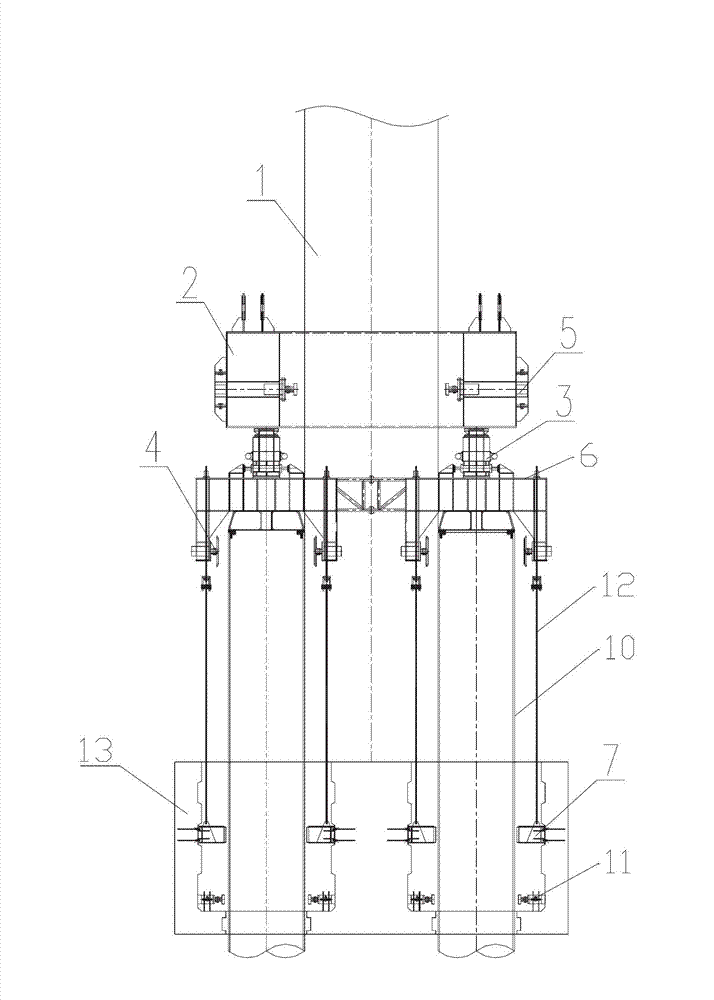

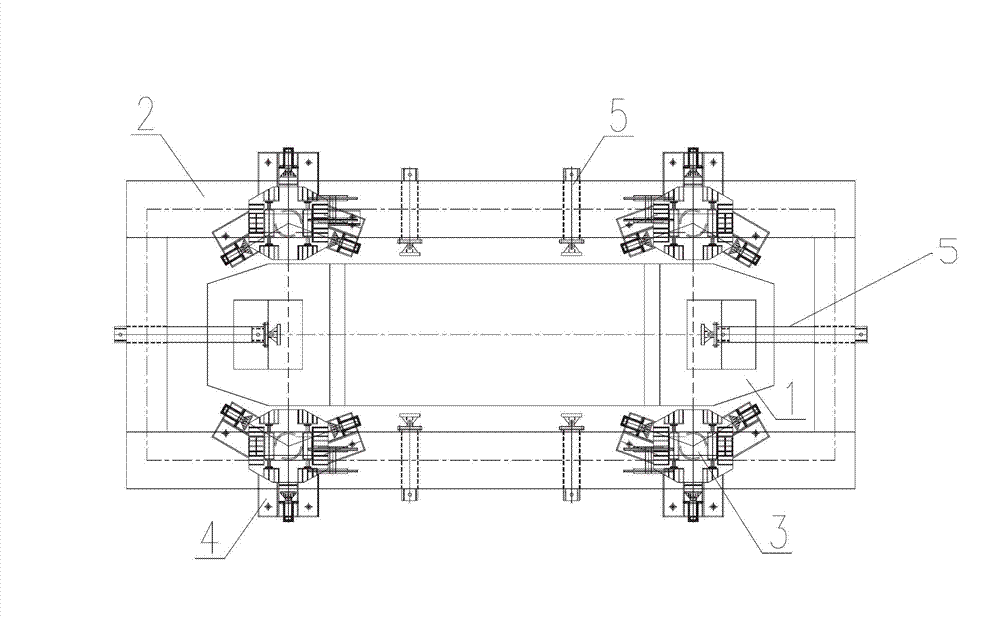

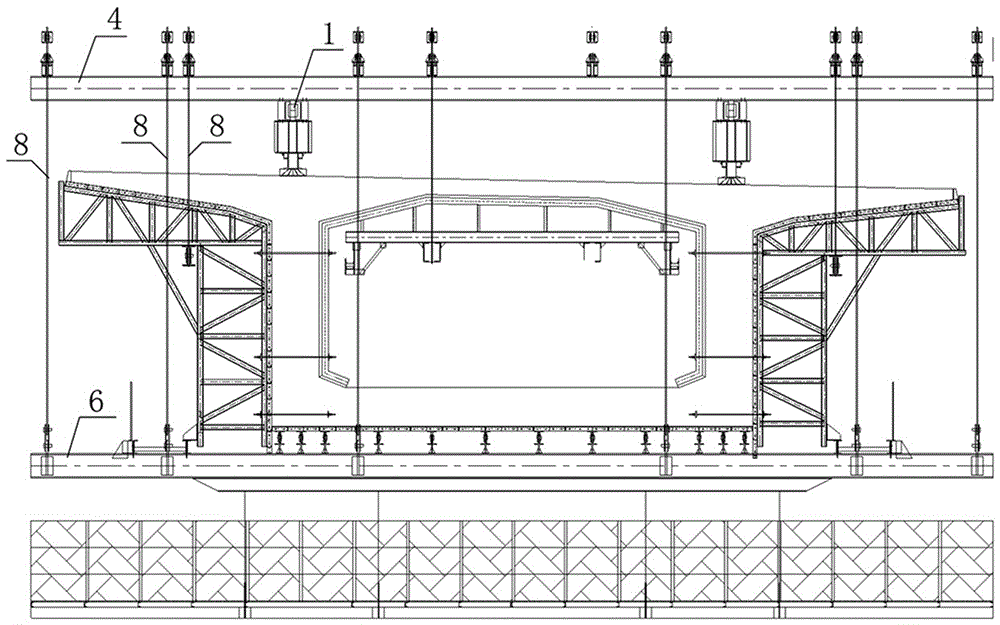

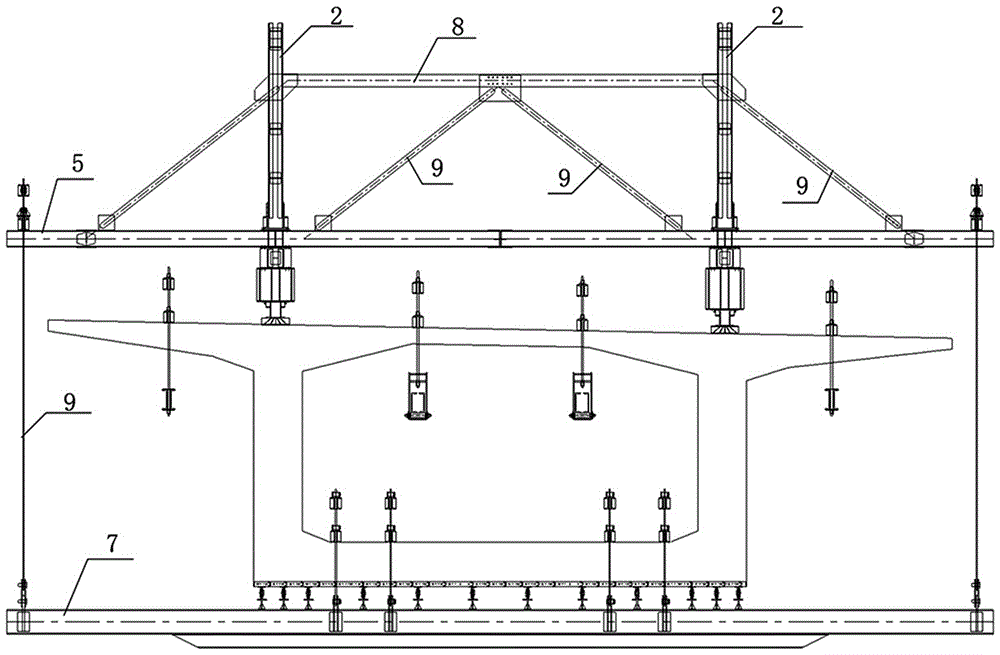

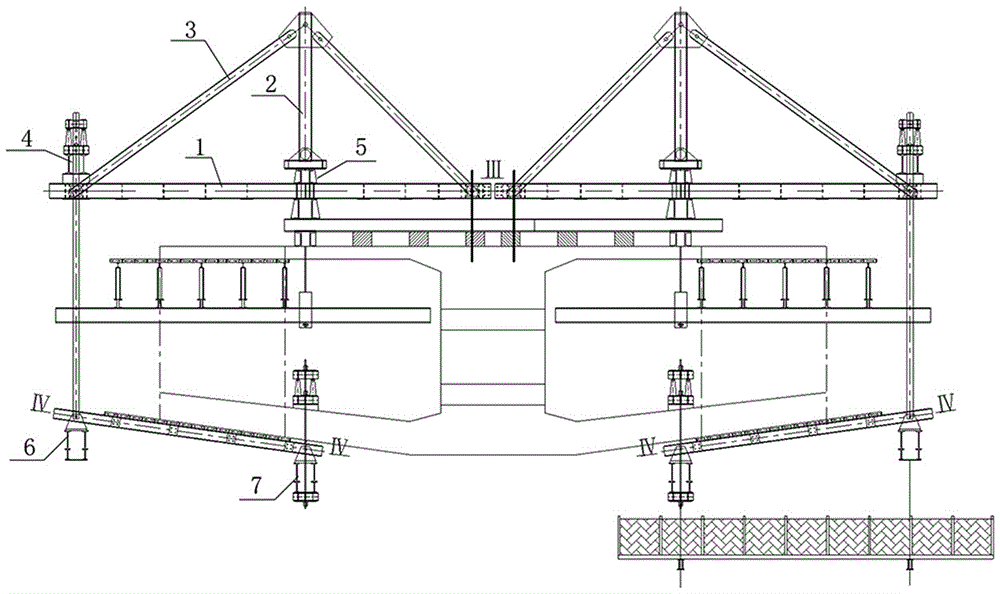

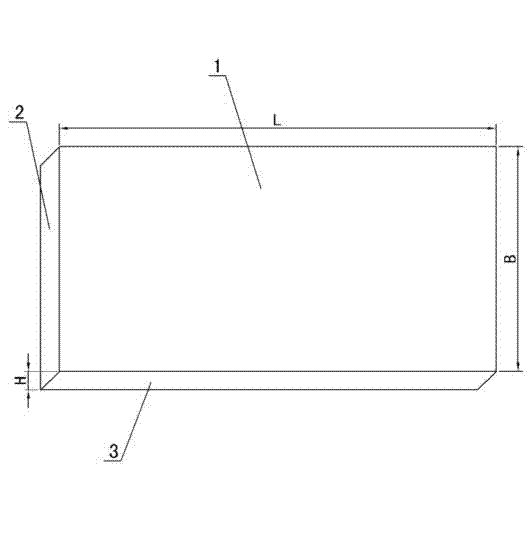

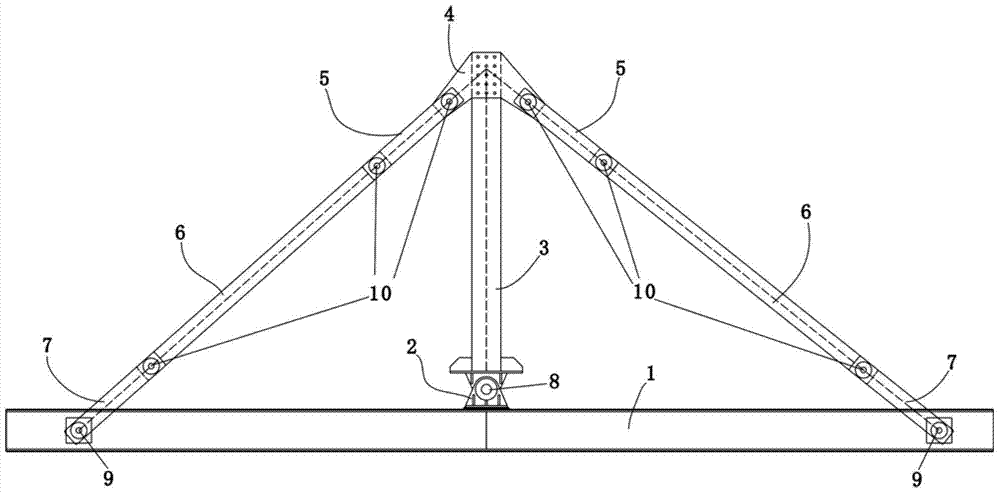

Prefabricated bridge abutment multifunctional lifting system and construction procedure thereof

ActiveCN102852095AHigh turnover utilizationImprove stabilityFoundation engineeringBridge erection/assemblyCushionMultiple function

The invention discloses a prefabricated bridge abutment multifunctional lifting system and a construction procedure thereof. The prefabricated bridge abutment multifunctional lifting system comprises a lifting mechanism for lifting a prefabricated abutment and a position regulating mechanism for regulating the position of the prefabricated abutment in a three-dimensional way, wherein the lifting mechanism is connected with a bearing truss through a flexible lifting rope; the position regulating mechanism is arranged between the bearing truss and the lifting mechanism; the bearing truss is fixed on a steel pipe pile; and the steel pipe pile penetrates into an inner hole of a prefabricated cushion cap. The lifting mechanism and the position regulating mechanism are combined into one, so that lifting and position-regulating continuous construction can be realized, and the turnover utilization ratio of equipment is improved; the bearing truss can bear the position regulating mechanism and a steel pipe pile clasping mechanism in a lifting process and can be used as a connecting truss of the steel pipe pile clasping mechanism in a position-regulating construction; and the steel pipe pile is used as a stable whole, so that the stability of the position-regulating construction is improved.

Owner:CCCC SECOND HARBOR ENG

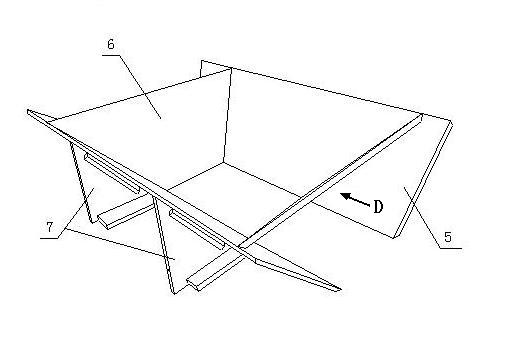

Triangle hanging basket suspended casting device used for overpass bridge construction and construction method thereof

The invention discloses a triangle hanging basket suspended casting device used for overpass bridge construction and a construction method thereof. The triangle hanging basket suspended casting device comprises an anchoring triangular bracket, a bracket platform, a bottom bracket member, a lifting anchoring member, a travelling member and a template system, wherein the anchoring triangular bracket comprises a plurality of triangular supports; one straight edge of the anchoring triangular bracket is used for being anchored on the side surface of a bridge's main pier body through anchor ribs, and the other straight edge of the anchoring triangular bracket horizontally extends forwards in the direction away from the side surface of the bridge's main pier body; the plurality of triangular supports are arranged at intervals in parallel; the anchoring triangular bracket further comprises supporting corbels arranged below the triangular supports and used for jacking and supporting of the bottoms of the triangular supports; the supporting corbels are connected onto the bridge's main pier body through anchor ribs; the bracket support is used for bearing the gravity of other members; the lifting anchoring member is connected with each of the bracket platform and the bottom bracket member; the travelling member is used for the other members to walk thereon; the template system is used for bridge casting. The triangle hanging basket suspended casting device has the advantages of less assembly nodes, definite stressing and high member turnover rate.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

Processing method for renewable waste plastic glass fiber building formwork

InactiveCN102900229AImprove integrityHigh surface hardnessForming/stuttering elementsGlass fiberEngineering

The invention discloses a processing method for a renewable waste plastic glass fiber building formwork. The processing method is characterized by comprising the following steps of: firstly, sorting materials and manually sorting, cleaning and drying different materials; secondly, crushing and drying the sorted materials; thirdly, mixing and blending the crushed materials; fourthly, mixing and granulating; fifthly, conveying the granulated materials to an extruding machine hopper; sixthly, heating and melting; seventhly, casting; eighthly, carrying out compression moulding forming; ninthly, cooling and setting; and tenthly, shearing. The processing method has the advantages of favorable strength, small deformation, high turnout frequency, favorable demoulding effect, 100 percent of recovery of waste plates, environment friendliness and energy saving.

Owner:任聪

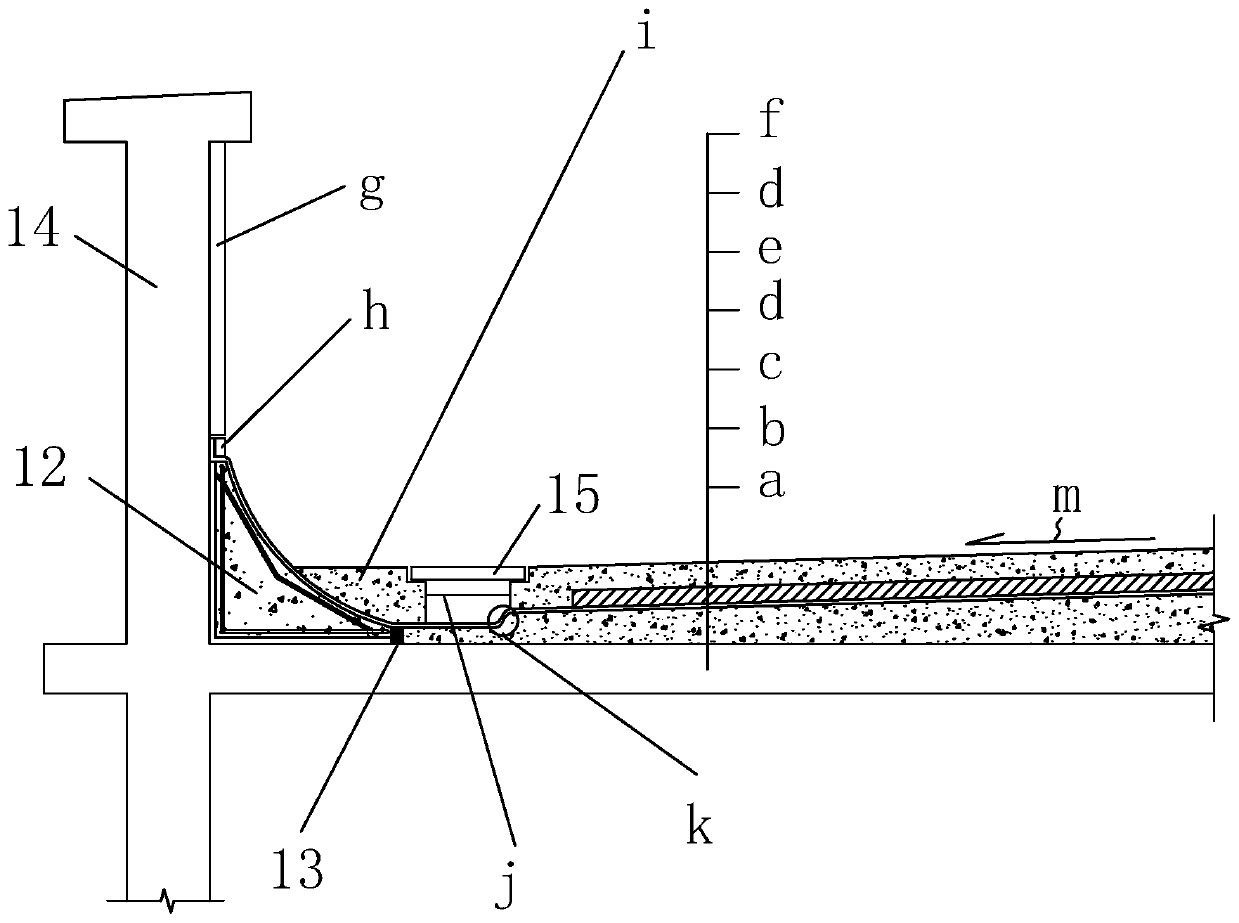

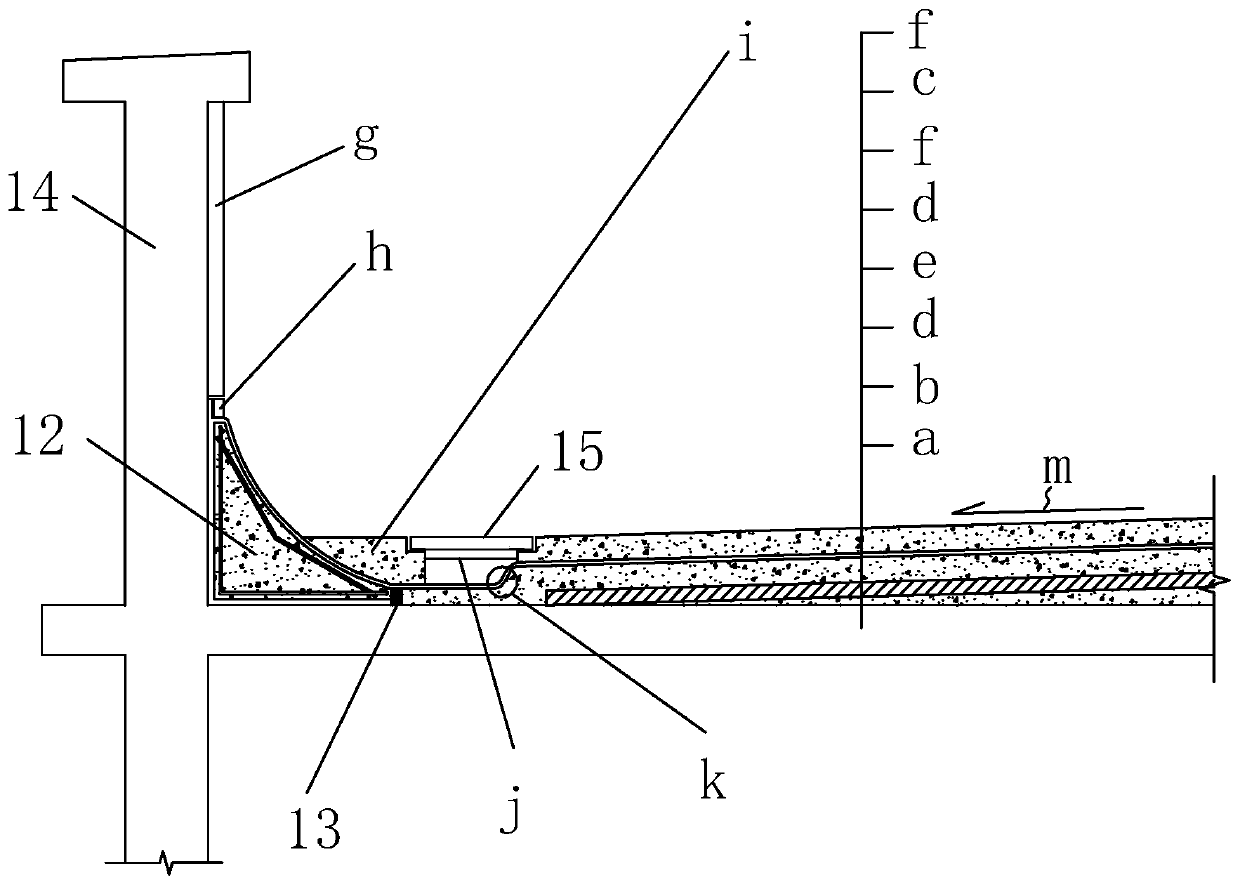

Modular prefabricated concrete circular arc chamfering waterproof system for waterproof paving of roofing coils and construction method of modular prefabricated concrete circular arc chamfering waterproof system

PendingCN110485650AGuaranteed reliabilityGuaranteed durabilityRoof covering insulationsScreedInsulation layer

The invention discloses a modular prefabricated concrete circular arc chamfering waterproof system for waterproof paving of roofing coils. The modular prefabricated concrete circular arc chamfering waterproof system is applied to a corner at a connection position of a roofing parapet and a roofing board. The waterproof system includes a plastering layer arranged on the roofing parapet and a screed-coat, an insulation layer, an isolating layer, a protective layer and a waterproof layer, wherein the screed-coat, the insulation layer, the isolating layer, the protective layer and the waterproof layer are arranged on the construction roofing board; the waterproof system further includes modular prefabricated concrete circular arc chamfering which is paved at the corner at the connection position of the roofing parapet and the roofing board; the prefabricated concrete circular arc chamfering is internally provided with anti-cracking steel bars; a waterproof flashing closure is arranged at the splicing head position of the prefabricated concrete circular arc chamfering and the plastering layer of the parapet; and a gap is reserved at the splicing head position between the prefabricated concrete circular arc chamfering, a gap is further reserved at the splicing head position of the prefabricated concrete circular arc chamfering and the screed-coat, and the gaps are filled with waterproof ointment. The problems of large randomness, difficult shape control and poor molding quality when the circular arc chamfering is made by adopting cement mortar by plasterers are solved.

Owner:广西建工第五建筑工程集团有限公司

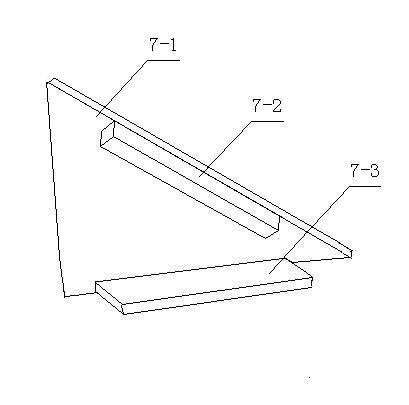

Inclination angle column cap combined wood former in beamless connected upright post

ActiveCN102383595AReduce the workload of planting, cutting and processingReduce limitationsForms/shuttering/falseworksEngineeringPulp and paper industry

The invention relates to an inclination angle column cap combined wood former in a beamless connected upright post, which consists of two trapezoid wood templates and two rectangular wood templates, wherein four peripheries of each trapezoid wood template and upper end surfaces and lower end surfaces of the rectangular wood templates are respectively inclined from the inner side of each plate to the outer side to form a chamfer surface of 45 degrees; the two trapezoid wood templates and the two rectangular wood templates are respectively opposite two by two; each plate is inclined towards theouter side to form an angle of 45 degrees; the two trapezoid wood templates are symmetrically and respectively arranged between the two rectangular wood templates; and two equicrural 45-degree chamfer surfaces are respectively attached to inner side plate surfaces of adjacent rectangular wood template to form an inverted foot pace inclination angle column cap. According to the combined wood former disclosed by the invention, joints between the wood templates as well as between an upper horizontal support plate mould and a lower column body mould are in respectively surface-surface joining relation; a joint between an internal corner and an external corner is compact; the phenomena of concrete mould expansion, mould run and mortar leakage at join parts are avoided; the simpleness in construction is realized; the forming quality of column cap concrete is ensured; the turnover utilization rates of the wood templates are improved; and the construction cost is reduced.

Owner:JIANGSU SHUANGLOU CONSTR GRP

Concrete pouring process for large-angel sloping roof

InactiveCN104018674ASimple cuttingIt should be vibrated and compactedBuilding roofsBuilding material handlingBuilding construction

The invention discloses a concrete pouring process for a large-angel sloping roof, and belongs to the field of building construction. The concrete pouring process comprises the following steps: (1) laying bottom-layer wood formworks of the sloping roof; (2) fixing a plurality of guide rails to the bottom-layer wood formworks from the left ends to the right ends in sequence, wherein the guide rails are arranged from the slope bottom to the slope top and respectively composed of two pieces of U-steel, and the openings of the two pieces of U-steel of each guide rail are opposite; (3) installing steel formworks in the guide rails composed of the U-steel, wherein vibrators are installed on the steel formworks respectively; (4) arranging lifting devices on the portions, above the guide rails, of the roof; (5) pouring concrete into the two pieces of U-steel of each guide rail and starting the vibrators at the same time; (6) after pouring the concrete, starting the lifting devices to drive the steel formworks to slide upwards; (7) after the steel formworks slide upwards, secondary grinding is carried out. By means of the concrete pouring process, the traditional double-layer wood formwork construction process is improved, the concrete is easy to feed, vibrating compaction and formwork thickness control are easy, the surface is flat and does not need to be leveled secondarily, and waste of wood is reduced.

Owner:江苏吴州建工集团有限公司

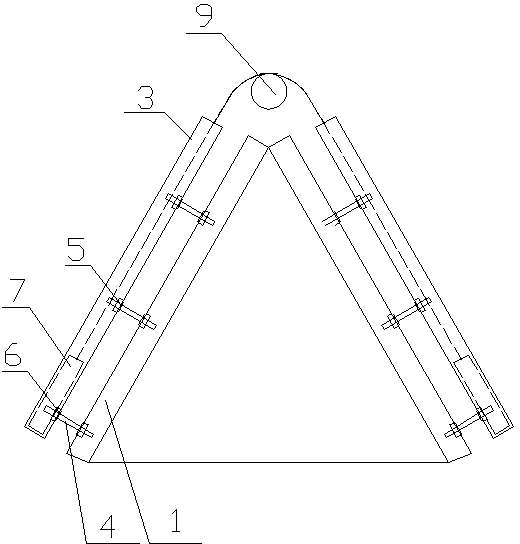

Cantilever construction detachable triangle hanging basket load-bearing primary truss

ActiveCN103696368ASimple structureEasy to assemble and transportBridge erection/assemblyCantileverDead weight

The invention discloses a cantilever construction detachable triangle hanging basket load-bearing primary truss which comprises a girder, an adjustable base, a stand column, a plate-type connecting chapiter and diagonal members. The adjustable base is formed by connecting upper and lower parts through a first hinge pin; the lower part of the adjustable base is connected with the middle part of the girder by intermittent welding; the upper part of the adjustable base is fixedly connected with the lower end of the upright; the upper end of the stand column is connected with the plate-type connecting chapiter by a bolt; both sides of the plate-type connecting chapiter are respectively connected with the diagonal members by second hinge pins; the diagonal members at both sides are symmetrically arranged; the lower ends of the diagonal members are connected to one end of the girder by third hinge pins. The cantilever construction detachable triangle hanging basket load-bearing primary truss disclosed by the invention is formed by utilizing the characteristics of shape steels to carry out machining manufacturing and assembling; not only can the dead weight of a hanging basket be reduced, but also a balance weight is not required; meanwhile, the cantilever construction detachable triangle hanging basket load-bearing primary truss is provided with a small number of components and is convenient to install and transport; the use effect of the hanging basket is ensured; meanwhile, the utilization rate of the components is greatly improved and cost of manufacturing, transportation and the like of equipment is also reduced.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

Opening reinforcement method and reinforcement sheet of fiber reinforcement resin composite material member

The invention discloses an opening reinforcement method and a reinforcement sheet of components of fiber-reinforced resin composites and relates to an opening reinforcement method and a reinforcement sheet used in the method. The invention solves the problems of the present reinforcement method such as difficult quality control, excessive subsequent working procedures, long time of occupying forming molds, and low working efficiency. The main steps of the method are as follows: preparing the reinforcement sheet; laying a fibrous presoaked band and the reinforcement sheet on a core mold for preparing the components of the fiber-strengthening resin composites and compacting fibrous presoaked band and the reinforcement sheet. The reinforcement sheet is annular with the thickness L2 of 2 to 4mm. The implementation of the reinforcement with the method can realize parallel production of a reinforcement section and composite bodies as well as the assembly type production of laying the composites, greatly improve the turnover utilization ratio of the mold, increase work efficiency, shorten the product molding cycle and lower the requirements of application periods of the resin body.

Owner:HARBIN FRP INST

Balcony beam slab inner side filling wall body and main body structure integral casting construction method

ActiveCN105064500AEasy to makeEasy to disassembleBuilding material handlingFalseworkEconomic benefits

The invention relates to a balcony beam slab inner side filling wall body and main body structure integral casting construction method. According to the construction method, the twice structure casting is put forward before the casting step; and a cast filling wall is arranged in grooves formed in the inner side of a beam steel bar and the inner side of a flange steel bar, and is integrally cast with a main body structure. The construction method has the advantages that the manufacturing of a formwork is simple; the reinforcement is convenient; a hollow mold is omitted; the supporting and the dismounting are convenient; building body materials used by a secondary structure are used in advance; the filling wall building work amount of the secondary structure is reduced; meanwhile, the work procedure clearance time is reduced; the integral economic benefits are good; the construction quality is high; the number of times of using a scaffold during the later-stage building is reduced; and the problems of construction quality and construction loss due to aerated concrete block cutting during the later-stage building are avoided.

Owner:中如建工集团有限公司 +1

Guiding and positioning device and method for land large pile foundation permanent steel protecting cylinders

PendingCN110685277AGuaranteed decentralization accuracyImprove decentralization efficiencyBulkheads/pilesArchitectural engineeringMechanical engineering

The invention discloses a guiding and positioning device and method for land large pile foundation permanent steel protecting cylinders, and belongs to the field of architectural construction. The device comprises a positioning frame, positioning modules and limiting plates, wherein four positioning modules are provided; the positioning modules are arranged in the center positions of the side edges of the positioning frame, and can extend; the limiting plates are arranged at the end parts of the positioning modules in directions perpendicular to the length directions of the positioning modules; the limiting plates are arranged near the center of the positioning frame; and the center connecting lines form a circular structure to position and fix placed permanent steel protecting cylinders.The device has the following advantages: when the placing precision of the steel protecting cylinders is guaranteed, temporary structures are few in material and small in occupied land; constructors are convenient to operate; the placing efficiency of the steel protecting cylinder is improved; the transfer usability is high; and the adjustment can be performed according to the sizes of the protecting cylinders to achieve wide application range.

Owner:CHINA RAILWAY JIUJIANG BRIDGE ENG

High-rise building external wall insulation board construction method

InactiveCN107143141AEasy to masterHigh turnover utilizationBuilding material handlingMaterial consumptionArchitectural engineering

The invention discloses a high-rise building external wall insulation board construction method. The method comprises the following steps: being in construction preparation stage, finishing banding a structure steel, deploying a XPS board according to formwork line releasing condition, binding a pad on a wall rib, hoisting the XPS board in position, binding and fixing the XPS board and ribs at outer side the wall, supporting and fixing the formwork, pouring concrete, removing a mold, pulling the bolt outer side and pulling down upwardly to be parallel to the wall surface and repairing the formwork and maintaining the concrete. The high-rise building external wall insulation board construction method has the advantages of being convenient and flexible in construction operation, easy to grasp the construction process, strong in pertinence, improving the working efficiency and shortening the construction period. The Glodon (BIM) software is used to layout in advance for the external wall insulation boards of commercial regions and standard layers, the industrial processing and distributing are carried out combining the design drawing actual size; the leftover bits and pieces are reasonably used, the material consumption is reduced, the production of construction waste is reduced, and the natural environment is protected. The external wall insulation board is bonded firmly with the concrete wall body through a main structure construction method, thus the safety performance is high, and the secondary construction pollution can be reduced; formwork turnover using rate is improved, formwork loss is reduced, and materials are saved; the basket using period is shortened, which plays a role of saving energy; construction basket using period is shortened to reduce the repairing and maintaining costs of equipment.

Owner:SHANGHAI BAOYE GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com