Patents

Literature

1696results about How to "Easy to install and remove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

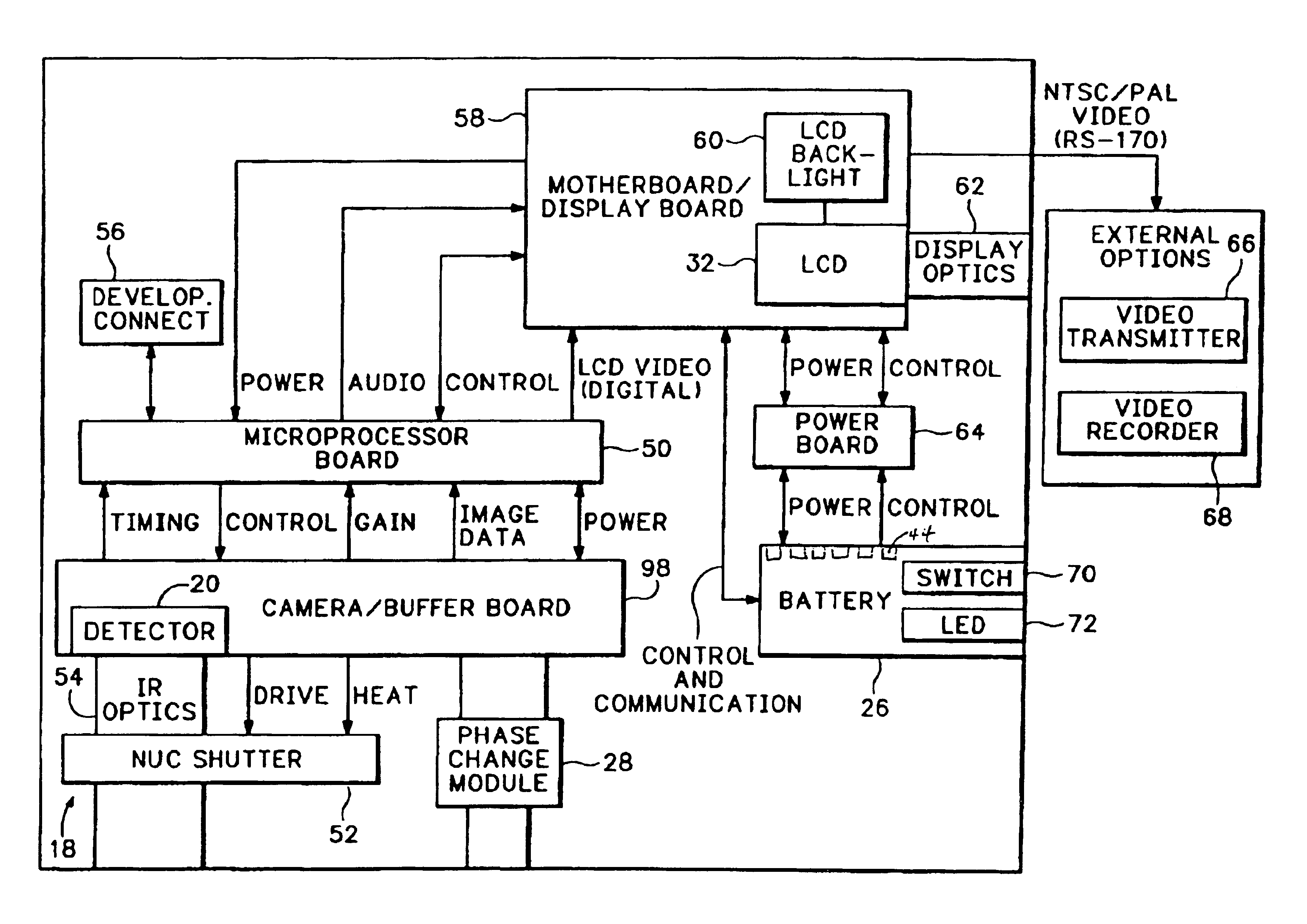

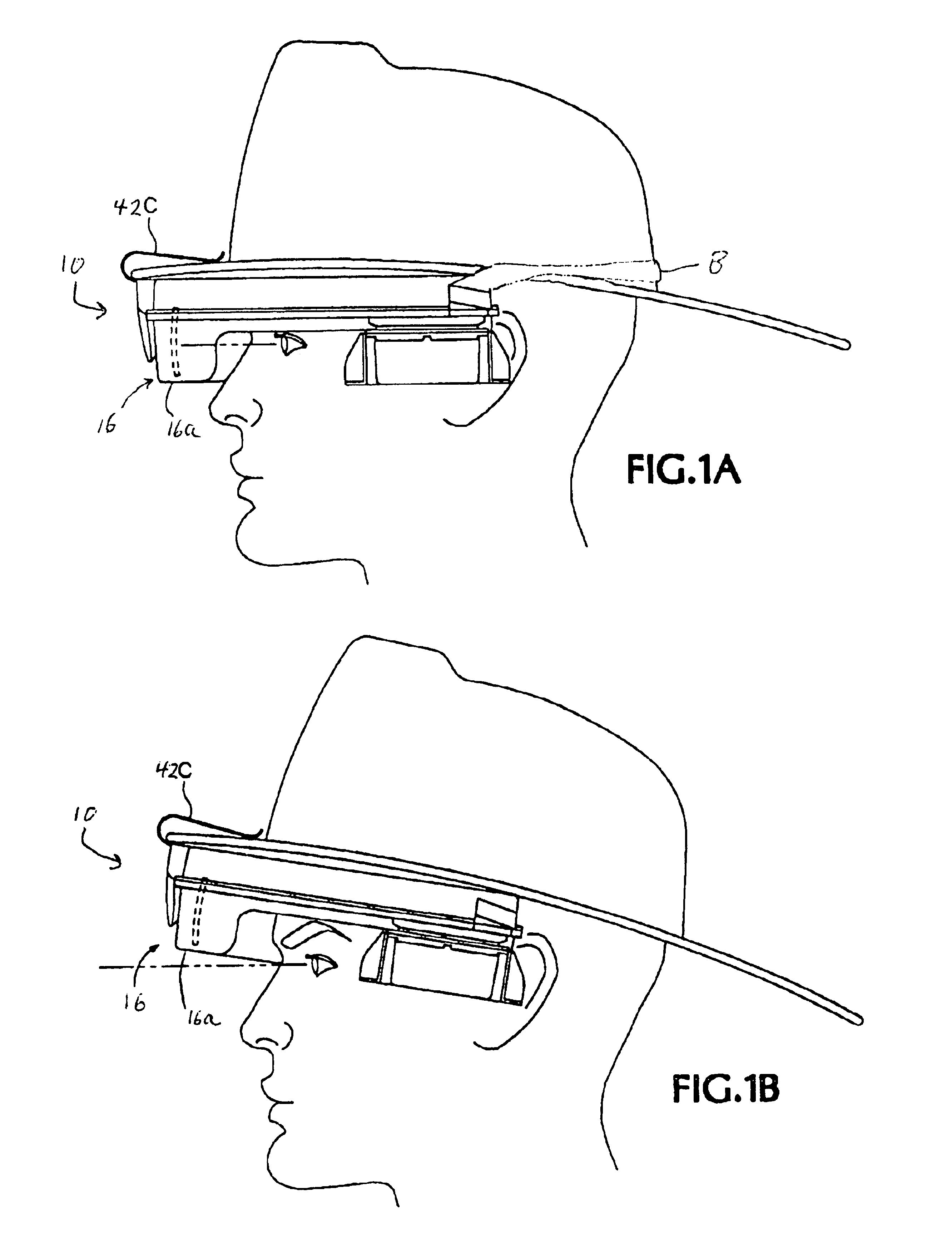

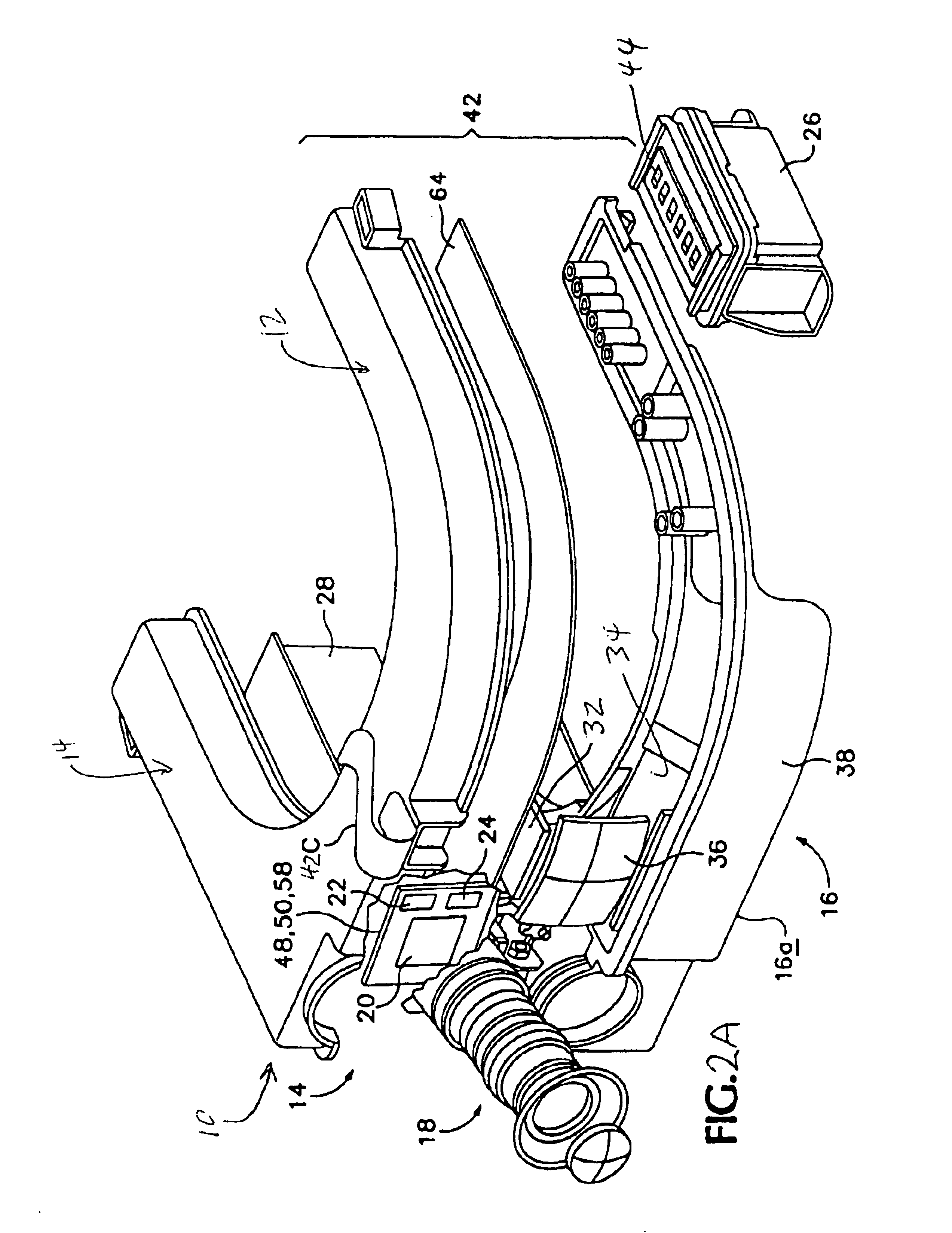

Portable radiometry and imaging apparatus

InactiveUS6849849B1Protection elementEasy to installRadiation pyrometrySolid-state devicesParticulatesEngineering

An infrared (IR) camera and associated electronics including power are integrated into portable, self-contained, vision-enhancement apparatus useful in environments of dense air-borne particulate and thermal extremes such as encountered in fire fighting situations, in accordance with the invention. The IR camera is integral with a self-contained power supply so that the system is portable and requires no umbilical cord or other external connections. The camera includes an imager that is preferably an un-cooled focal plane array, and associated imaging, storing, processing and displaying electronics that are cooled in the extreme thermal environment using an integral plural phase heatsink.

Owner:TELEDYNE FLIR LLC

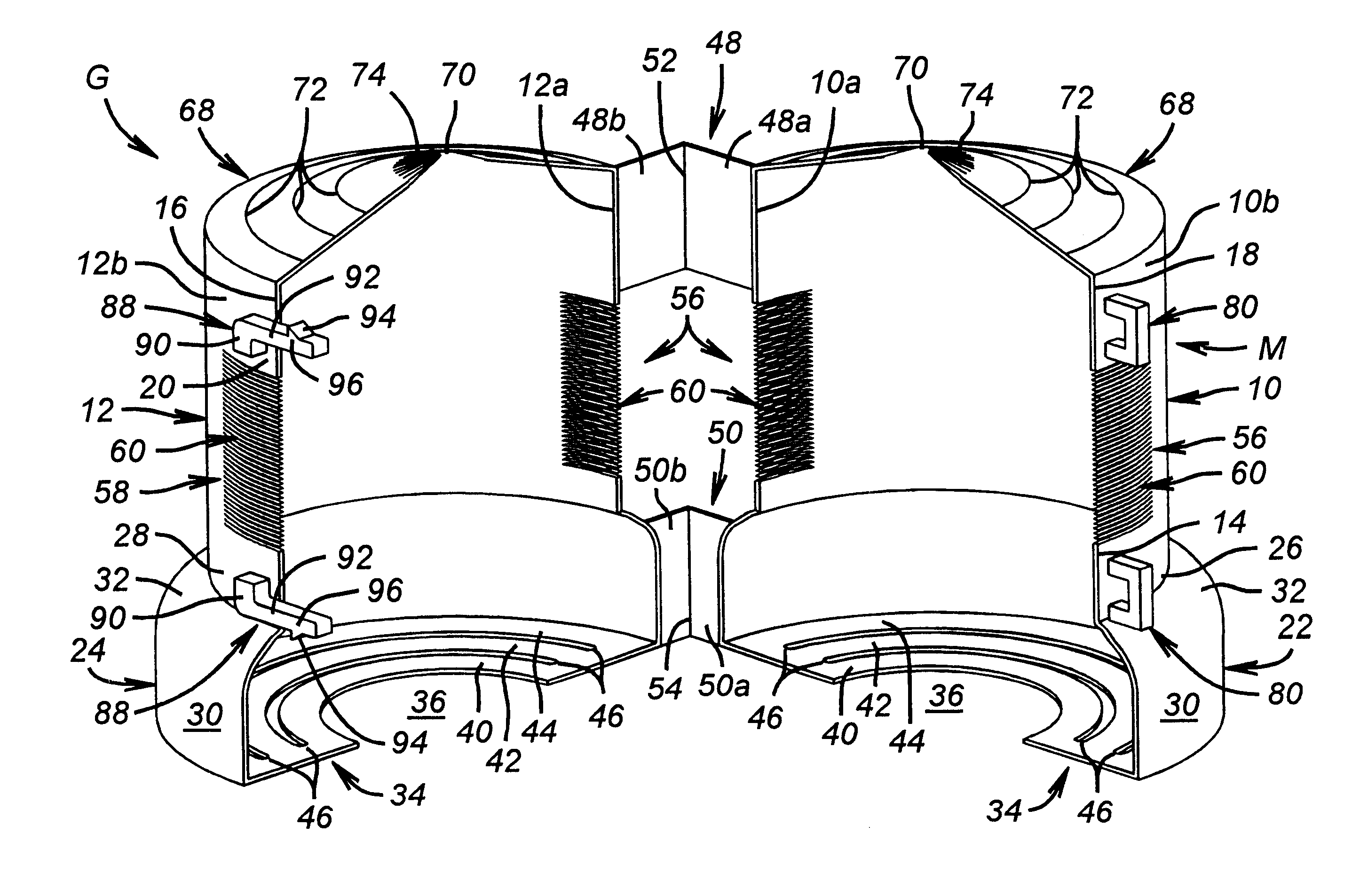

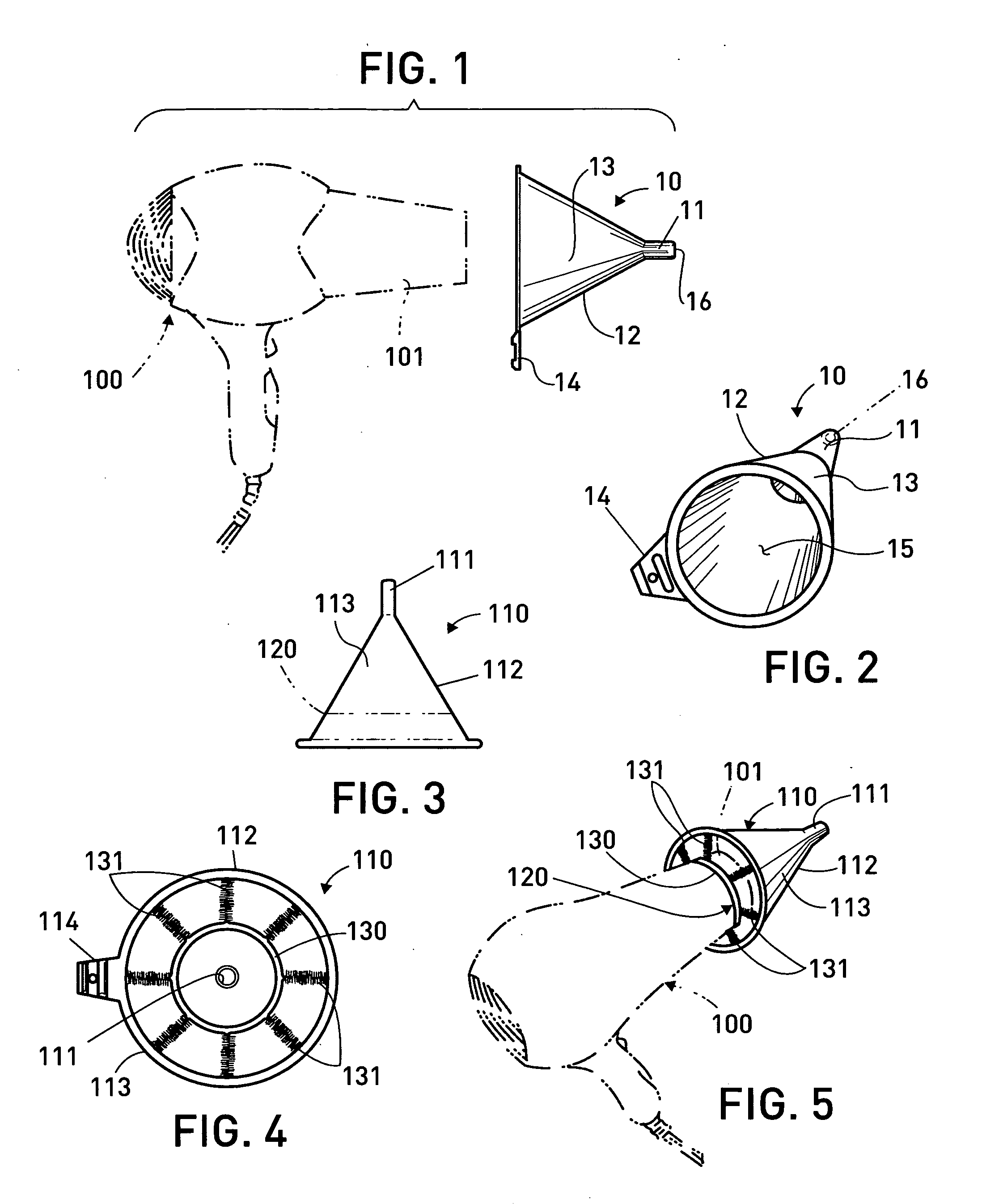

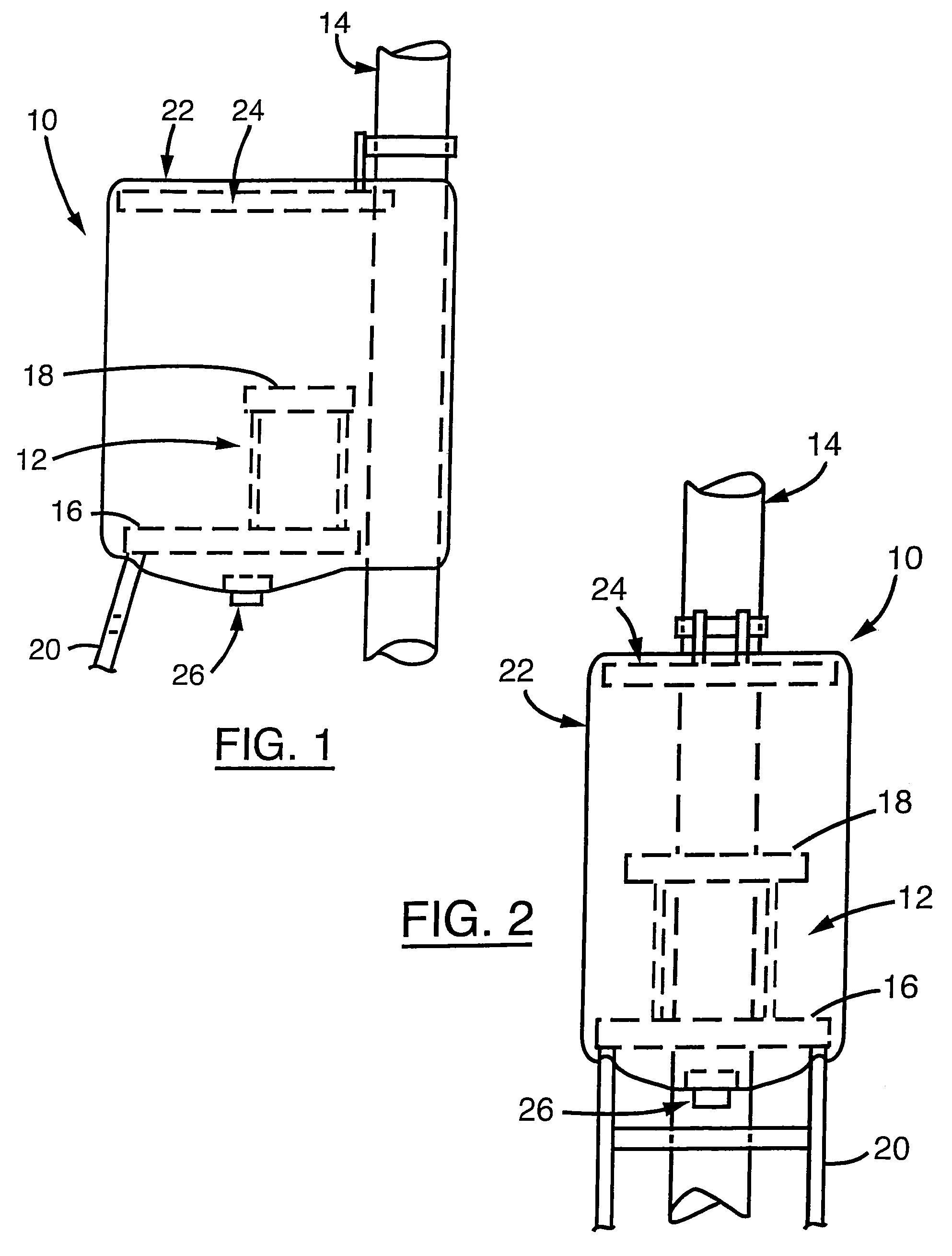

Wildlife guard cover

InactiveUS6291774B1Minimum of effort and timeEasy to install and removeOverhead installationNutsWildlifeField conditions

A wildlife guard for electrical power distribution equipment has two hingedly mounted sections which close together to form a protective cover at the top of an insulator bushing on electrical equipment. The wildlife guard is adapted by its structure to fit a range of bushing sizes and yet provide structural integrity and reliable protection once in place. The wildlife guard also accommodates passage of conductive members such as electrical conductors and sparkgap bars through the cover at locations governed by actual field conditions. The wildlife guard has a cover locking mechanism allowing its easy removal when desired.

Owner:RELIANT ENERGY

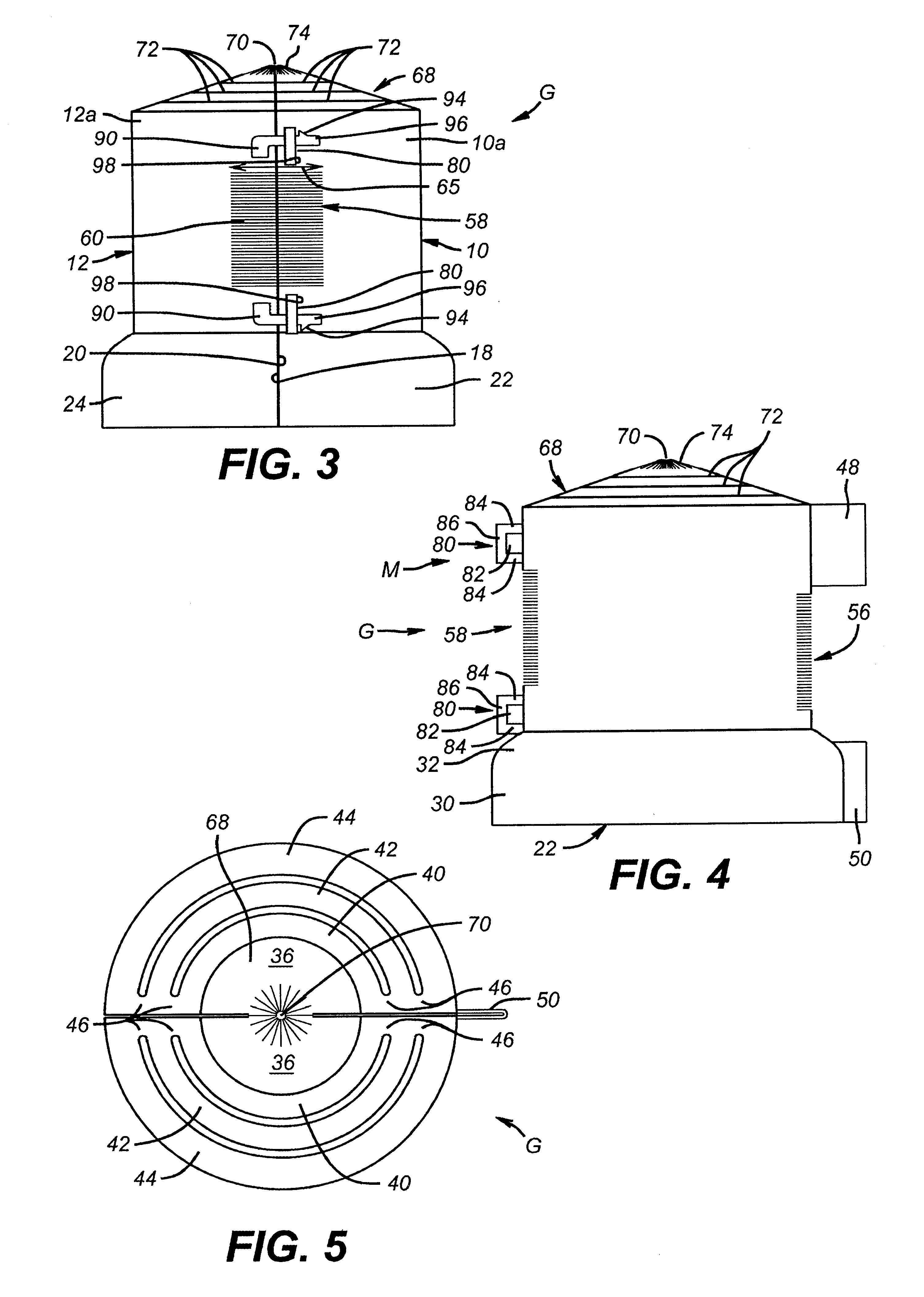

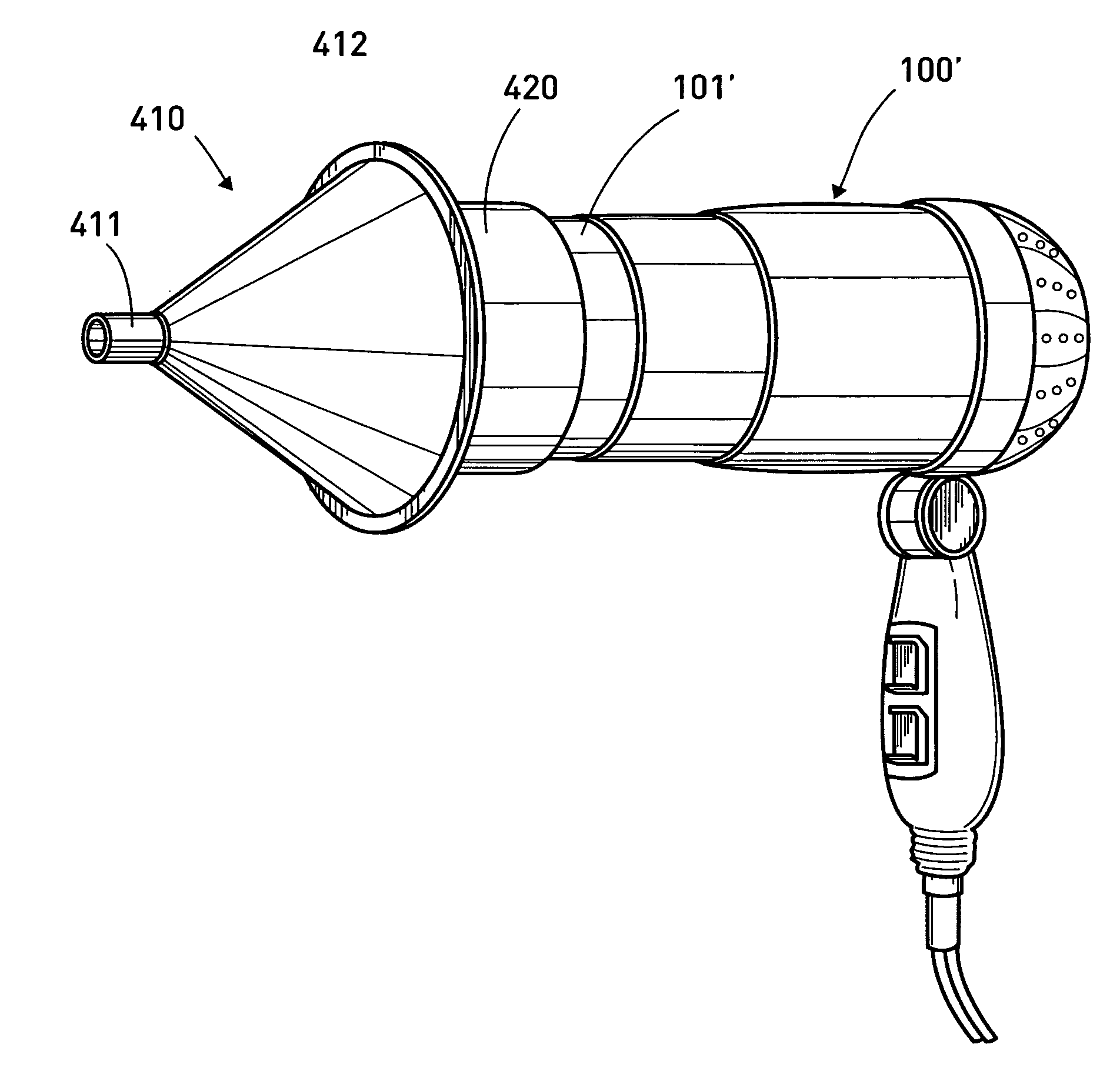

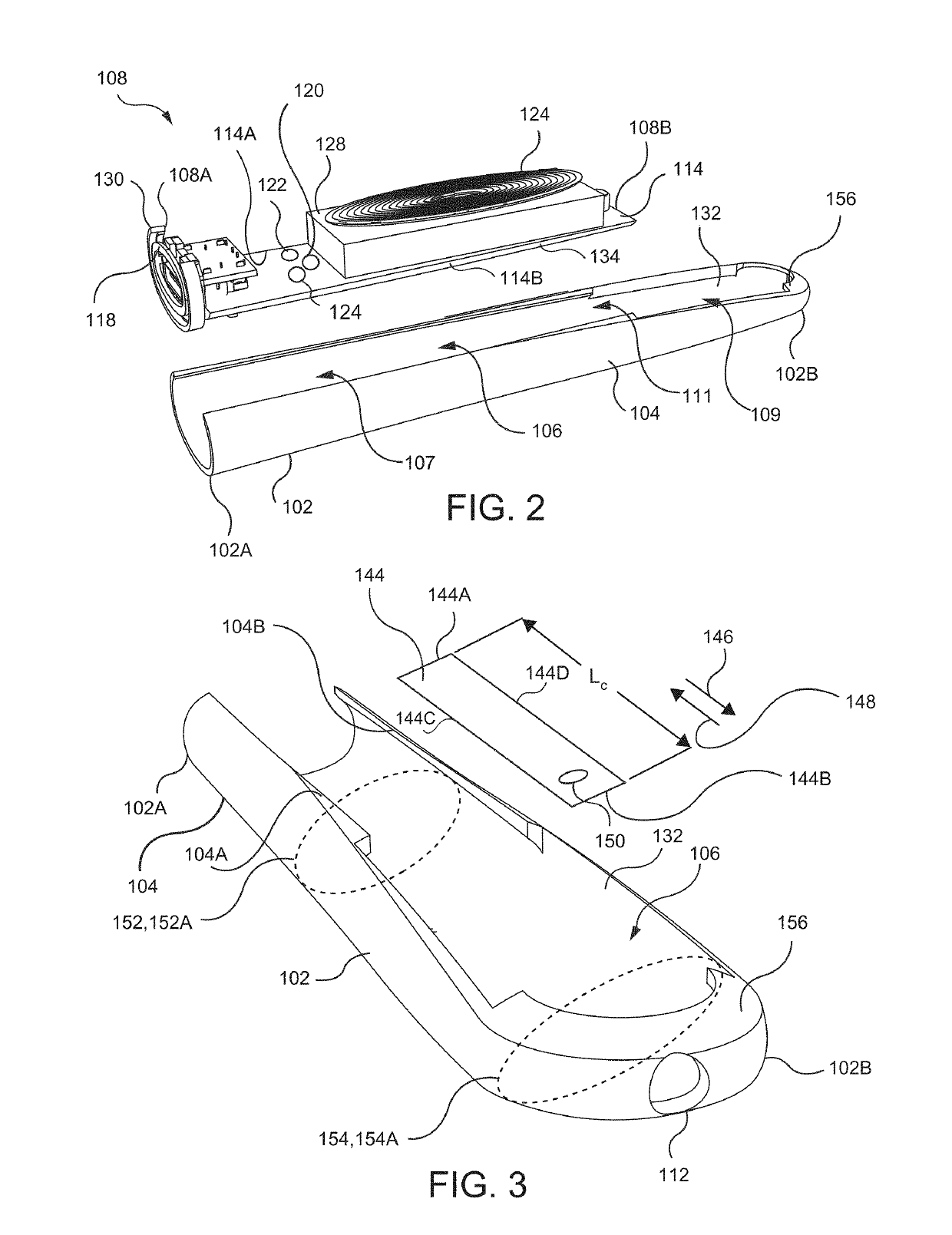

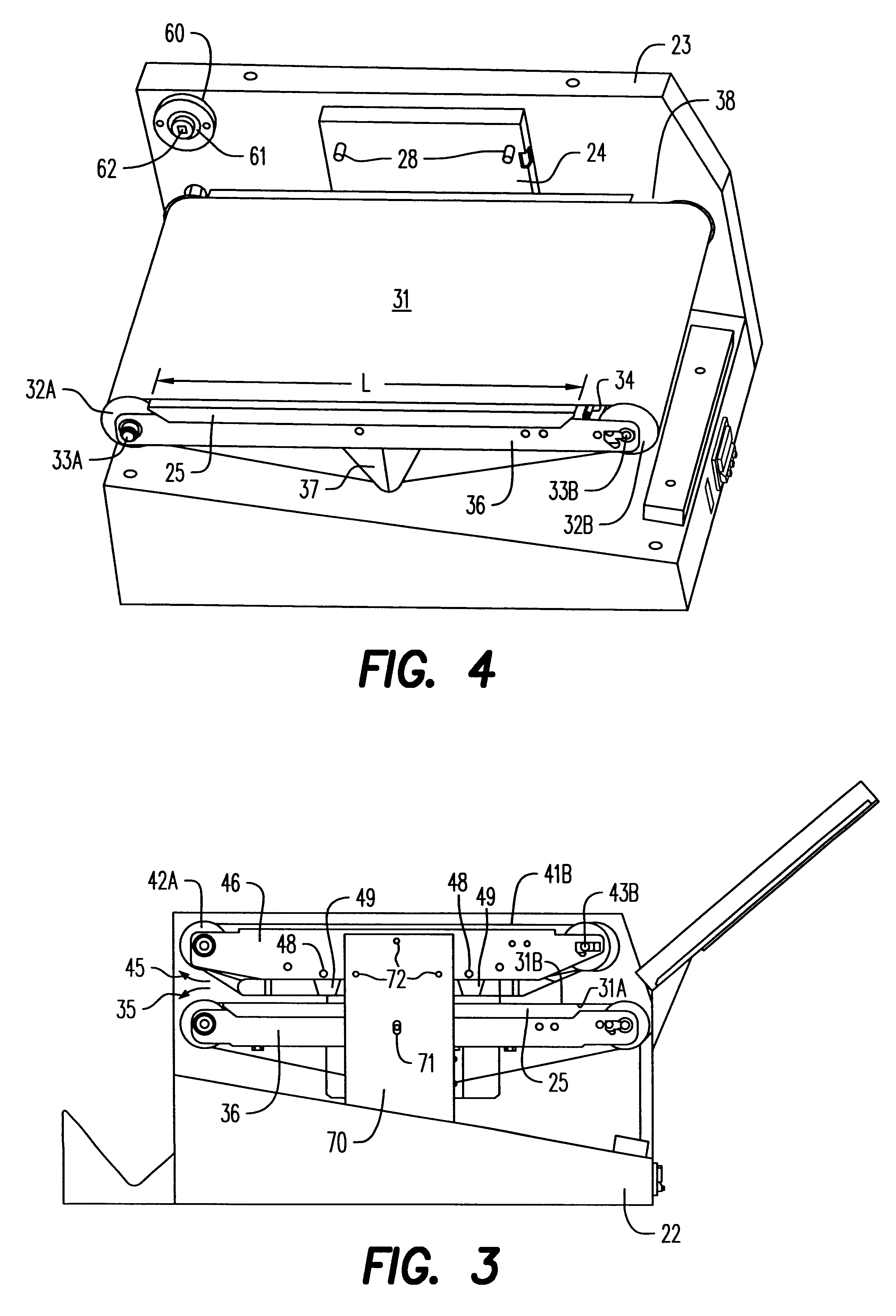

Device, method and system for treatment of sinusitis

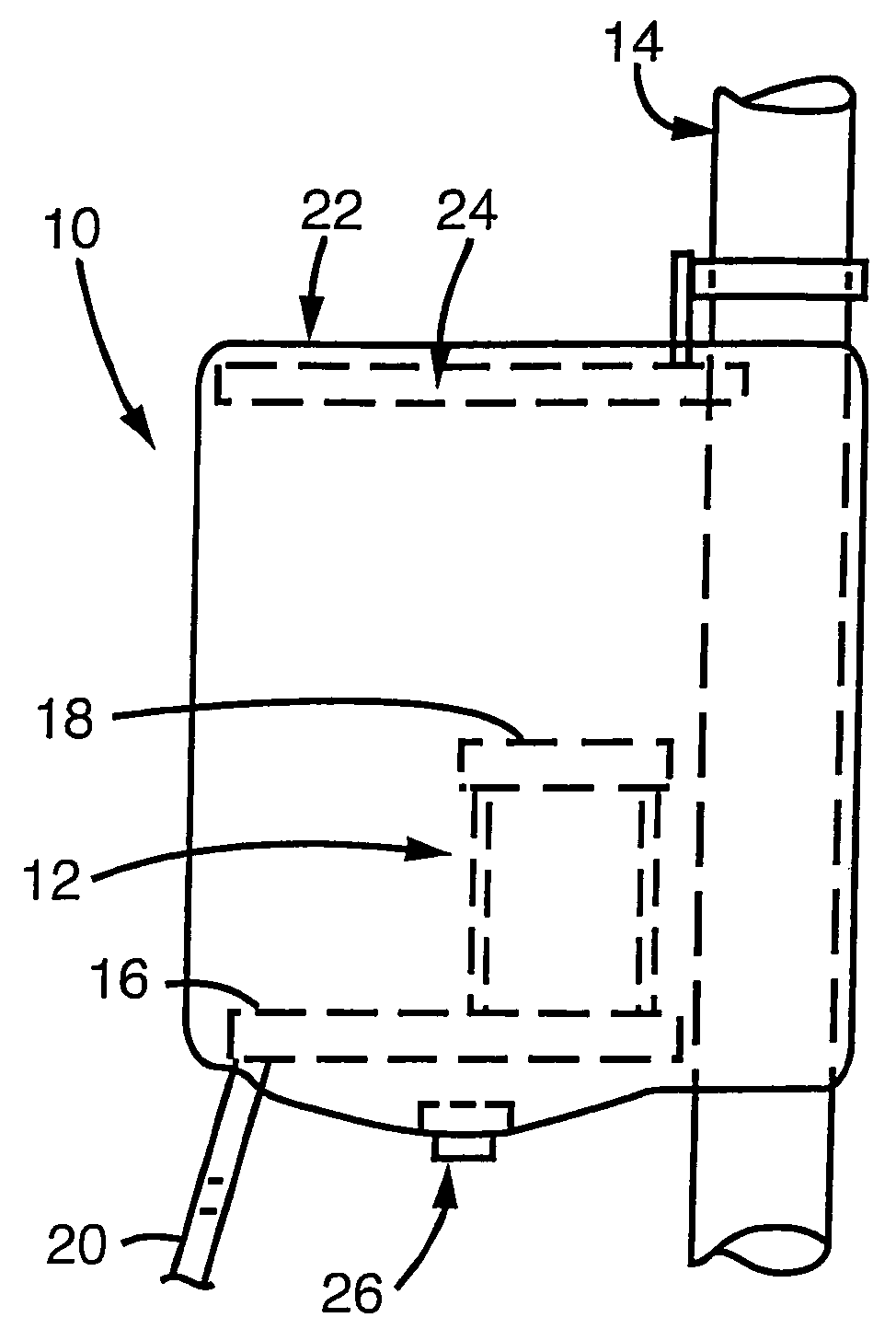

InactiveUS20110307039A1Preventing facilitating treatmentEasy to install and removeTherapeutic coolingTherapeutic heatingNasal passageSinusitis

A device, method and system for facilitating treatment of a sinusitis condition, including a heat source configured to deliver an output of heated air to the nasal passages of an individual, and a delivery component having a space through which the heated air output of the heat source may pass, the delivery component being configured for placement in the individual's nostrils. The system provides a heated air output source and one or more delivery components configured and sized to fit within the nostril of an individual, which may be used to deliver one or more courses of heated air to a user's sinuses through a nostril.

Owner:CORNELL THOMAS H

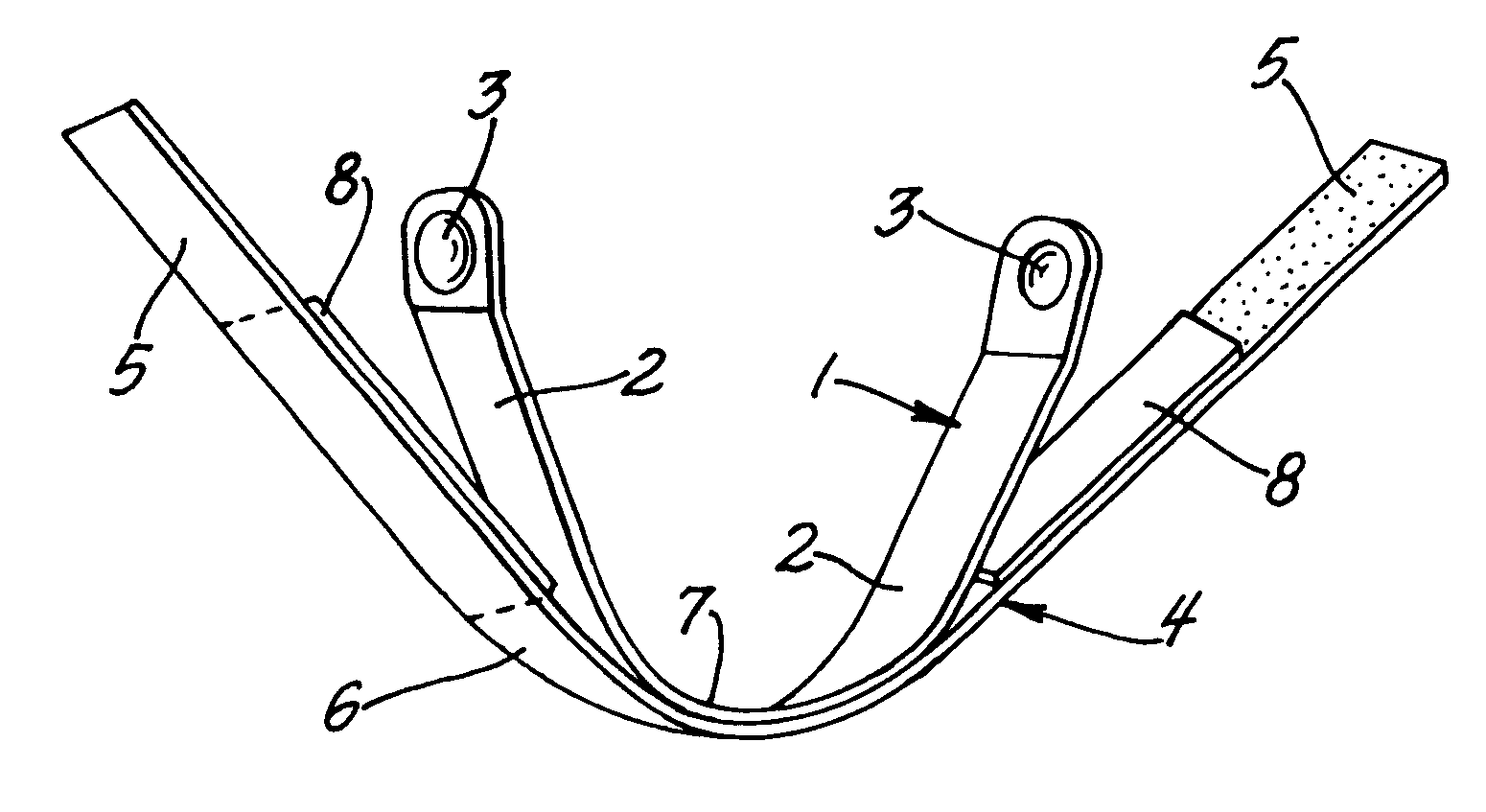

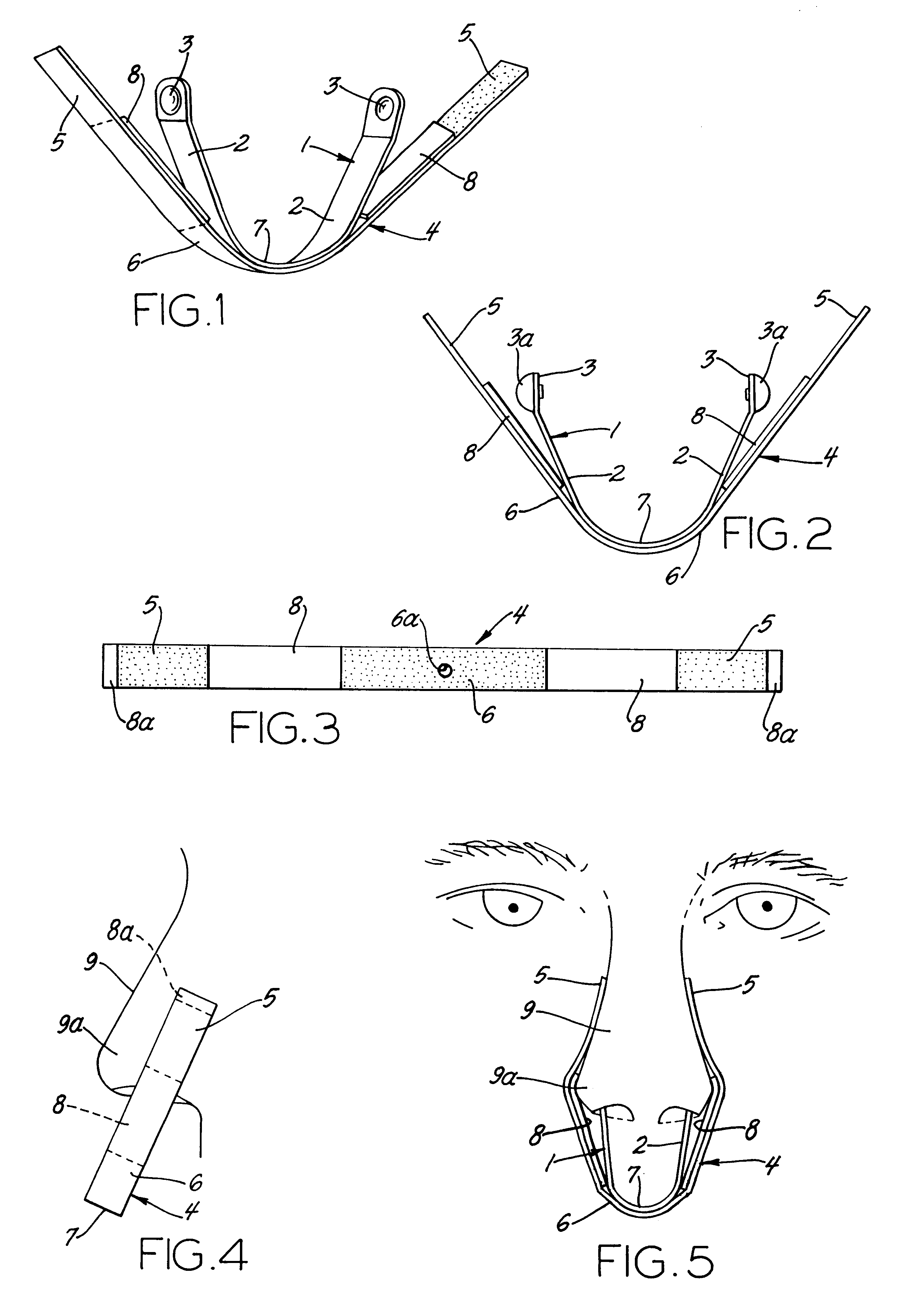

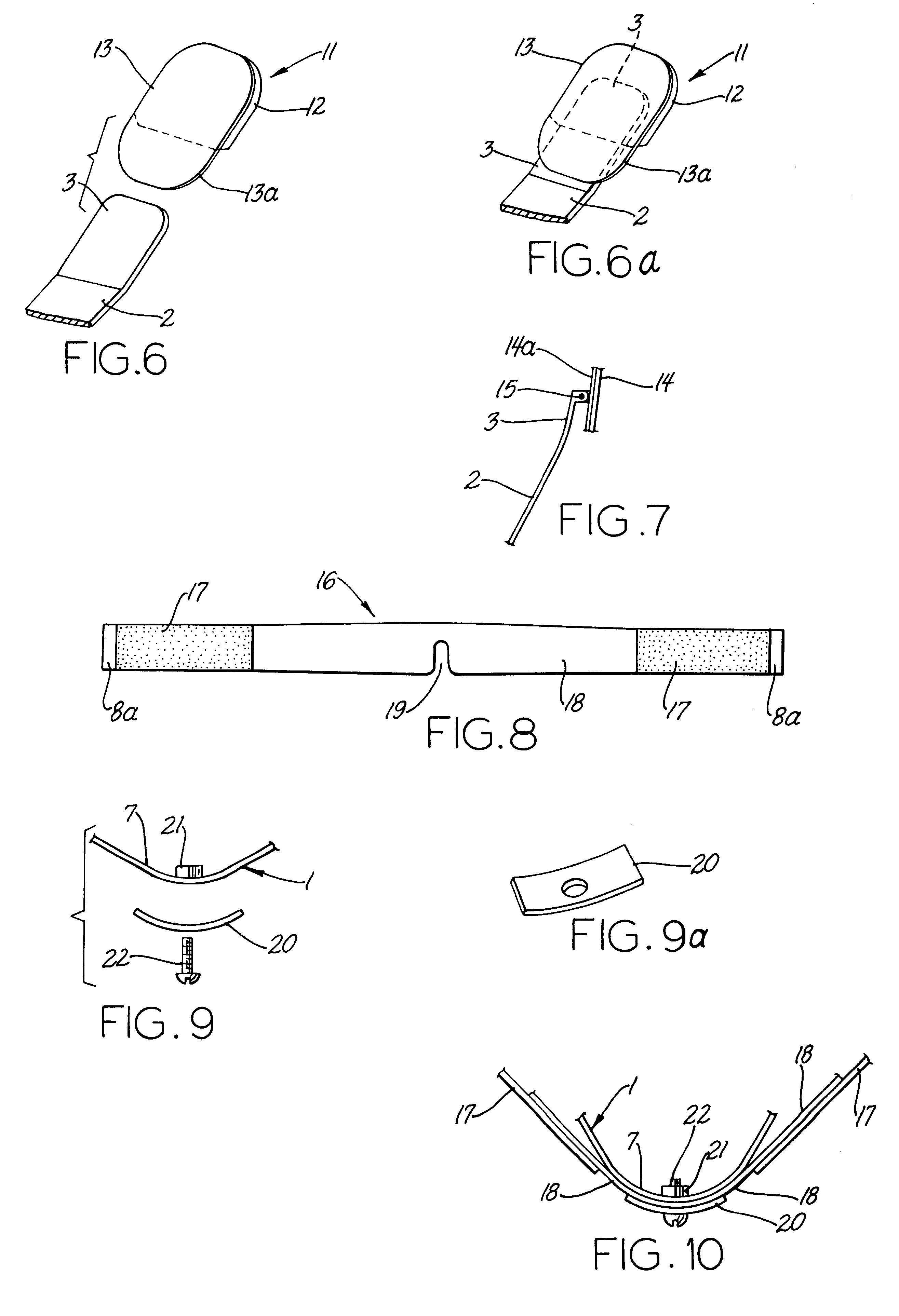

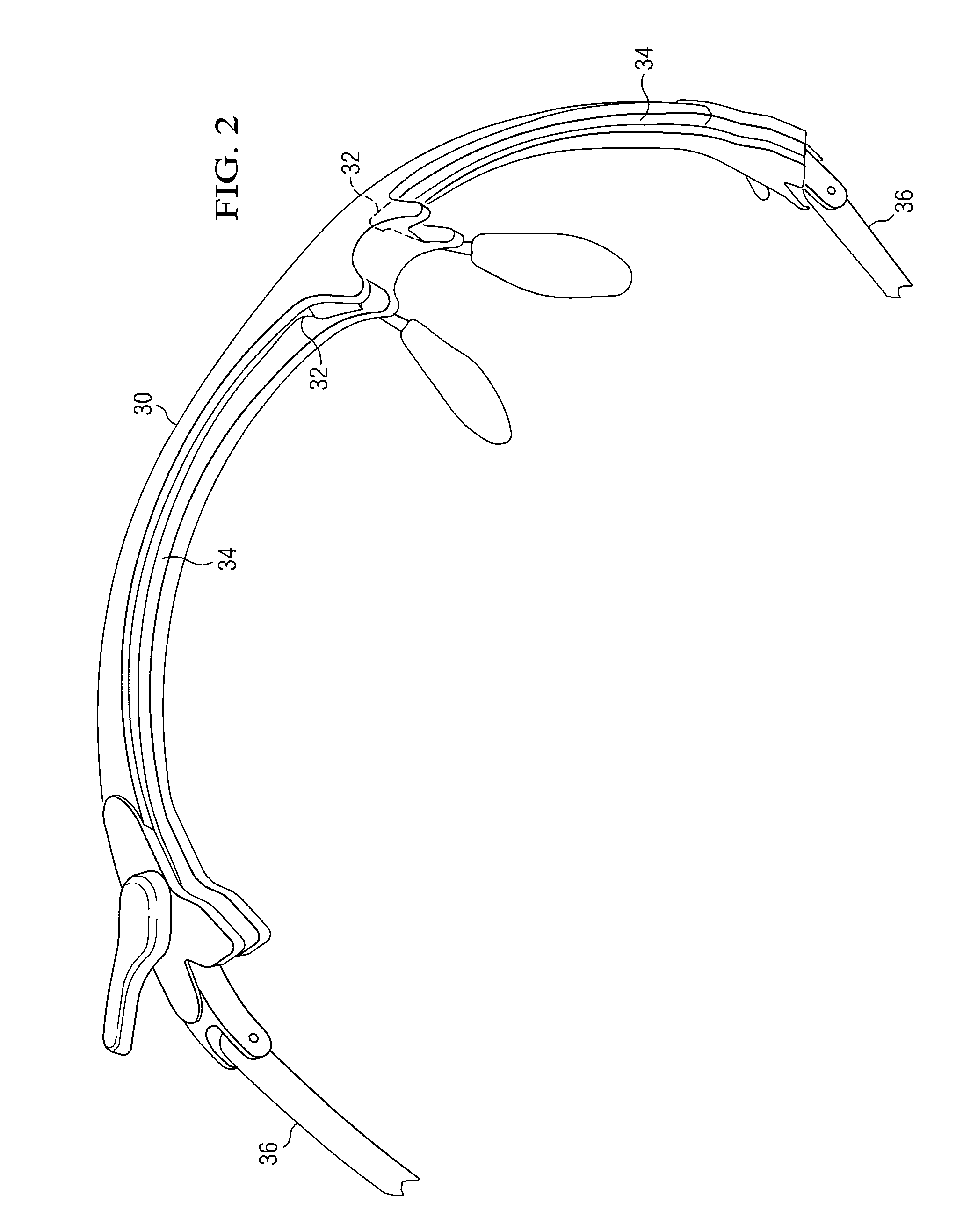

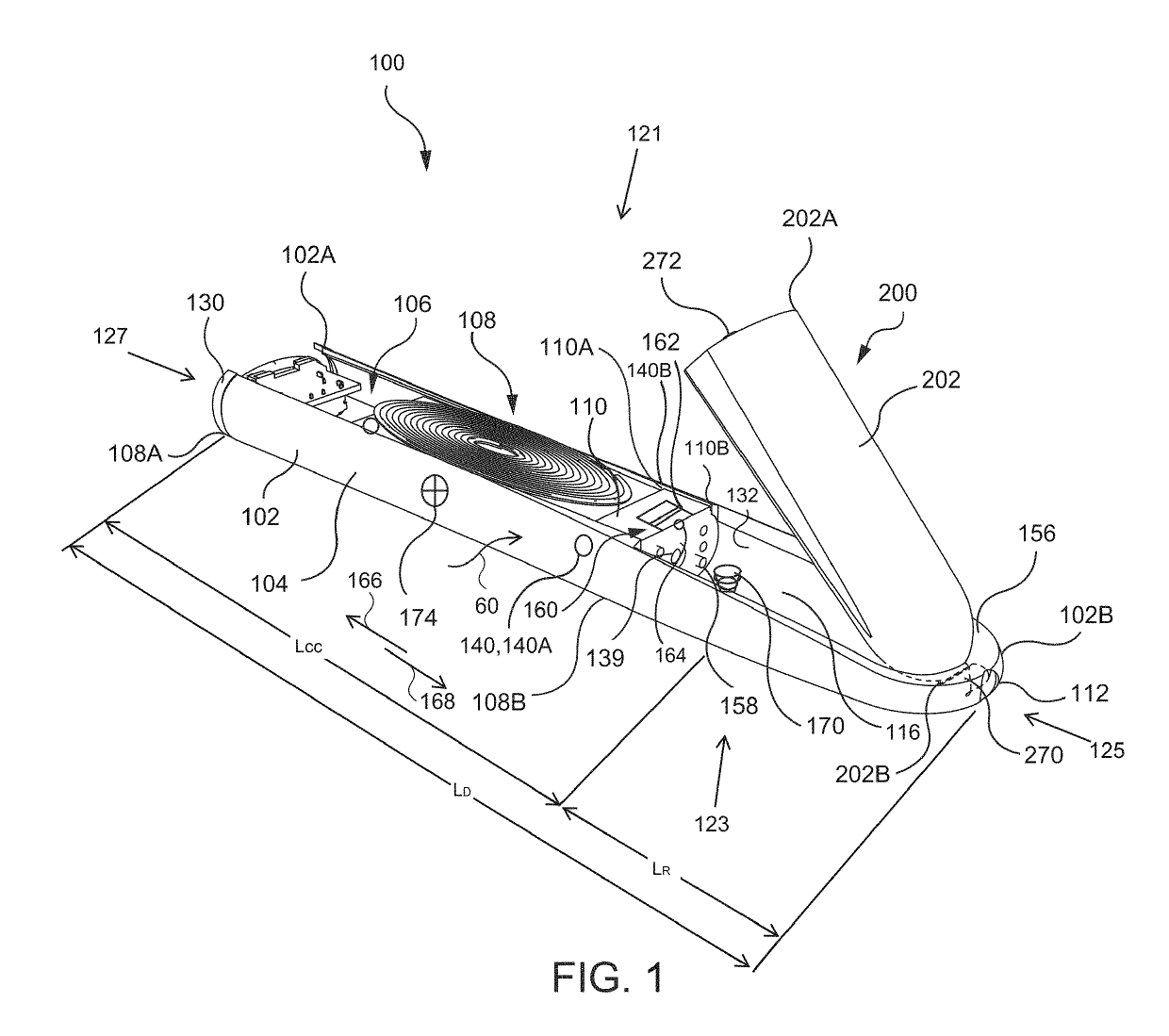

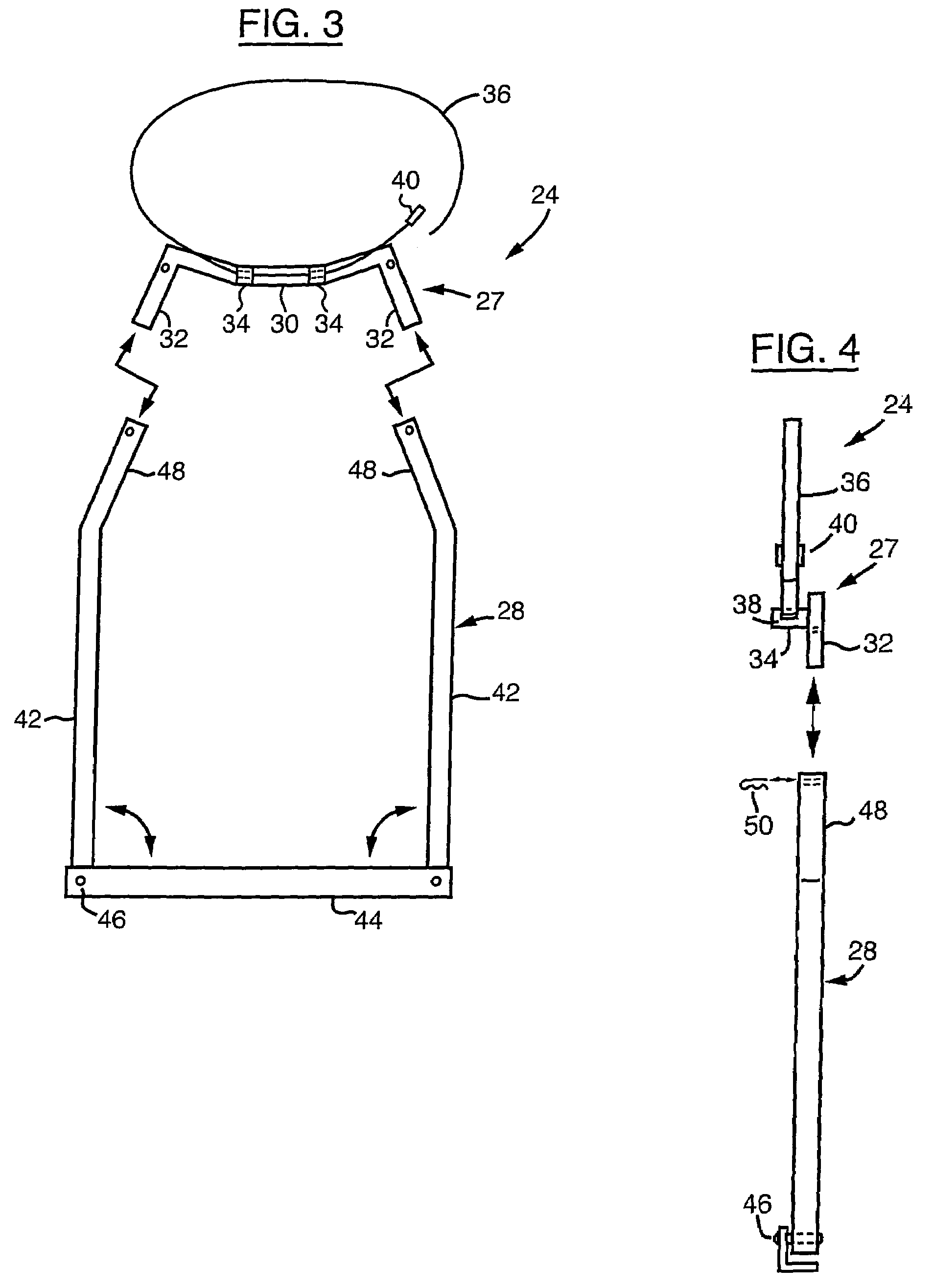

Internal nasal dilator

The anti-snoring invention comprises as internal nasal dilator having a combination of elements constructed and arranged to provide near-normal breathing for the wearer, while preventing the dilator from falling out of the nose, and without annoyance or discomfort for the wearer. To carry out the inventive concept, the internal dilator comprises a combination of several elements. First a V-shaped member, such as a flat spring is provided, with resilient pad means attached at each end thereof. A flexible nasal strip is then attached by the wearer at the central portion (outside bottom) of the V-shaped spring by adhesive means in one form of the invention, or by clamping means in another form; the nasal strip has two adhesive portions at or near the free unattached strip-ends. The spring-ends with the pad means are inserted by the wearer inside the two nostrils so the spring can spread the outer walls of the nose to increase the nasal opening for improved breathing. The adhesive portions at the free strip-ends are then pressed against the outer surfaces of the nose by the wearer to be attached thereto, for retaining the pad means in place inside the nose, so the spring and pad means do not fall out; the soft resilient pad means then prevent discomfort for the wearer. The used nasal strips are replaced daily for good hygiene, and the two pads are replaced once every 20-30 days.

Owner:THORNER ROBERT H

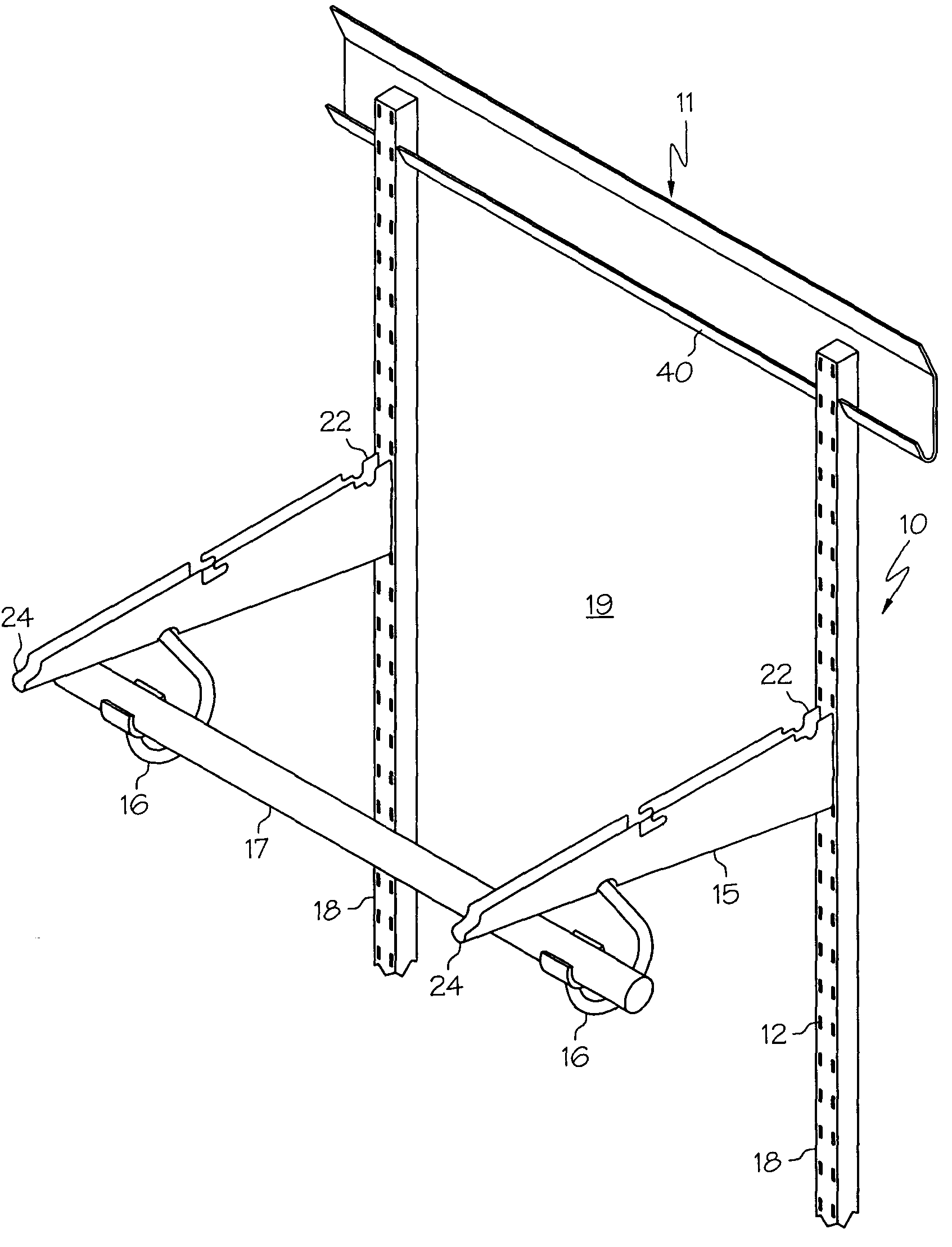

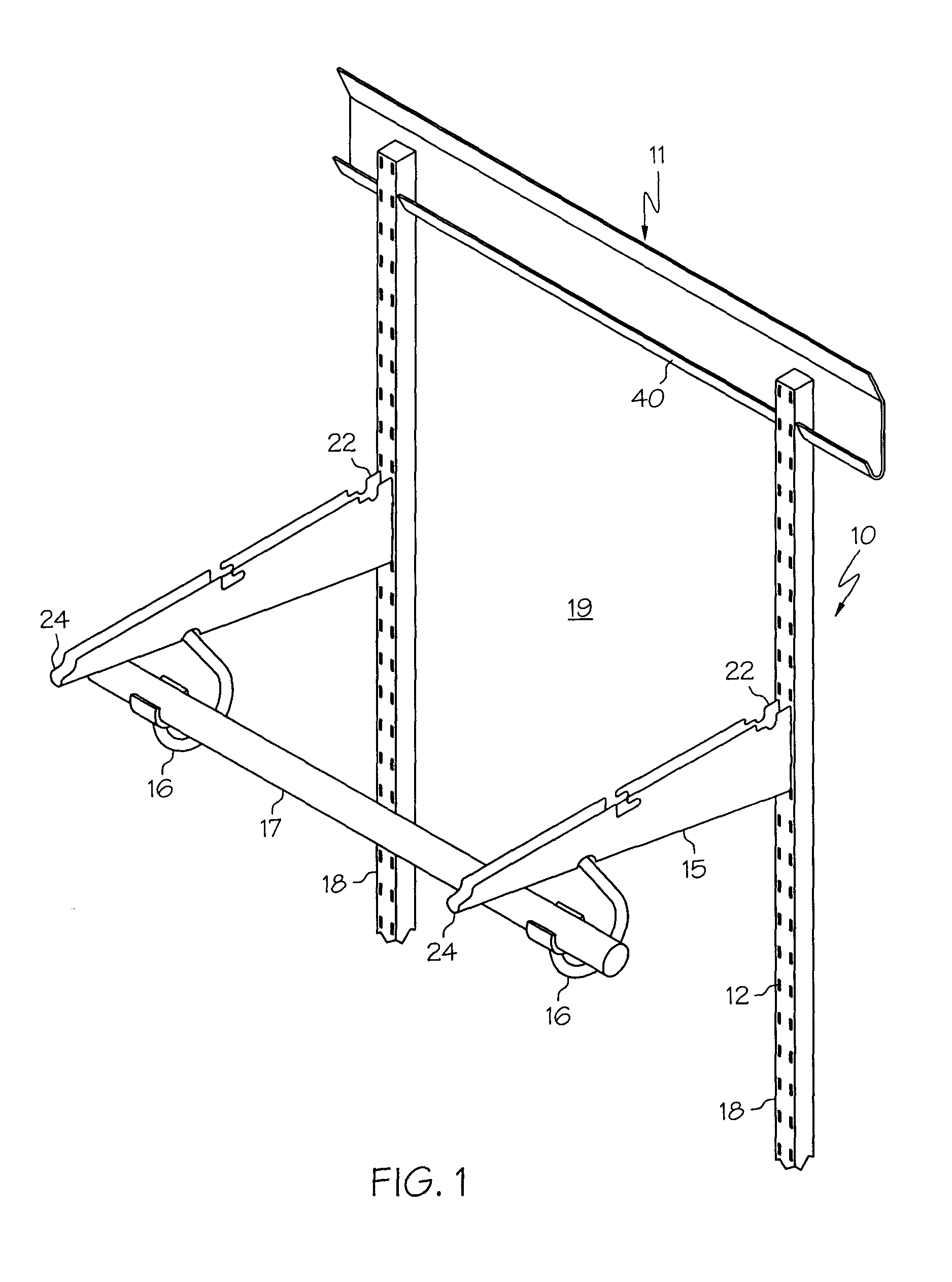

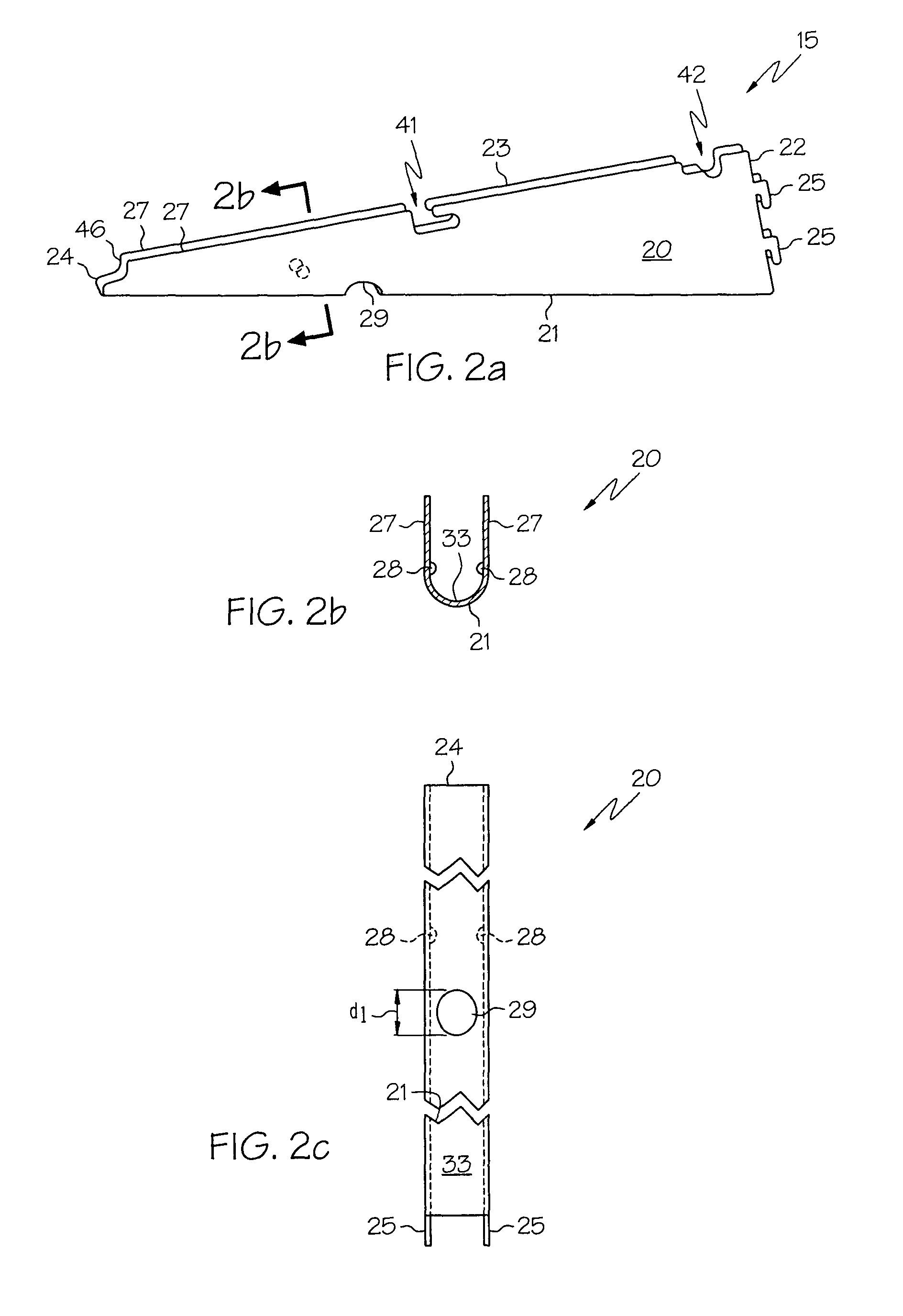

Support assembly for a hanger bar

Owner:SCHULTE

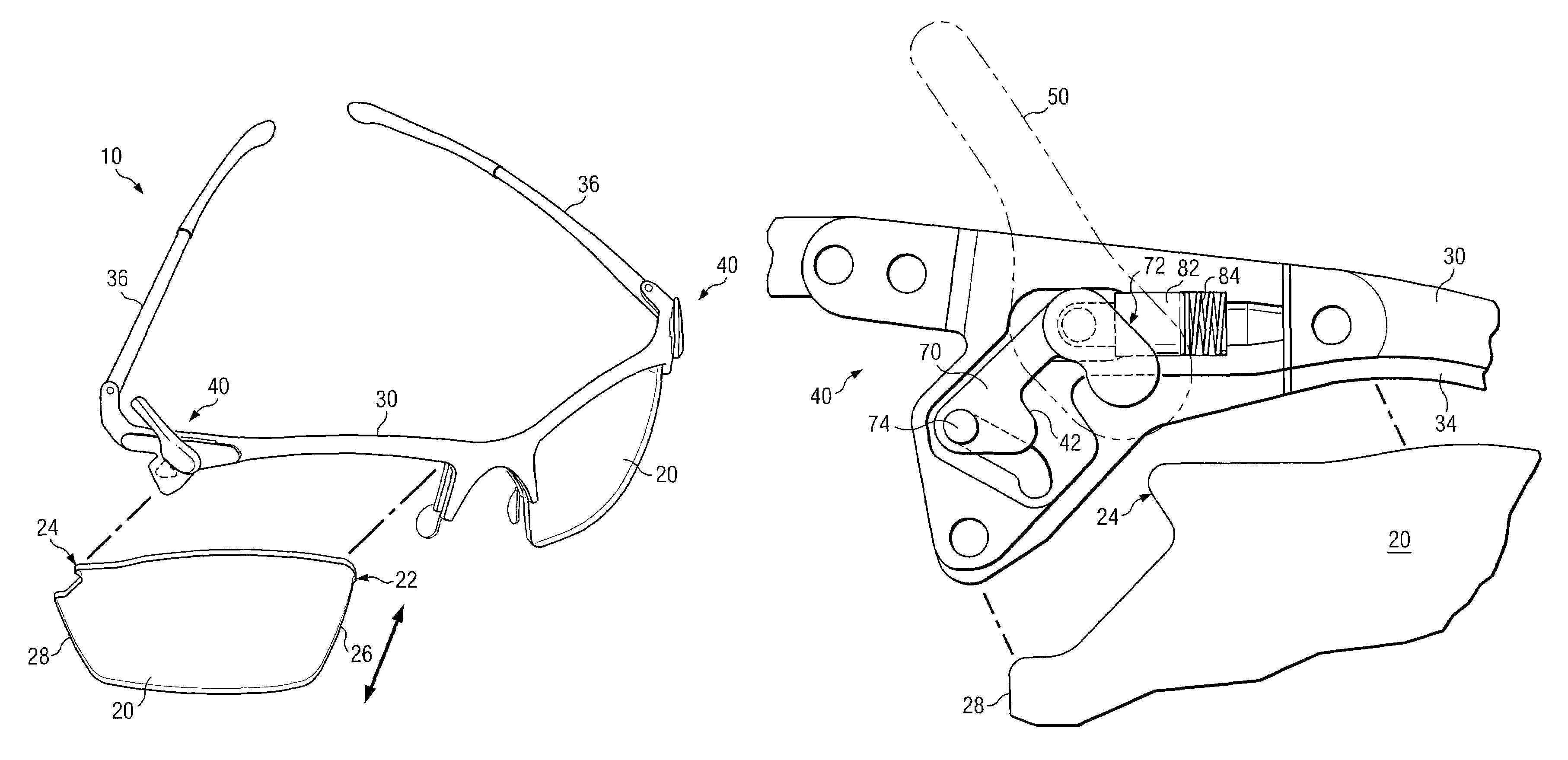

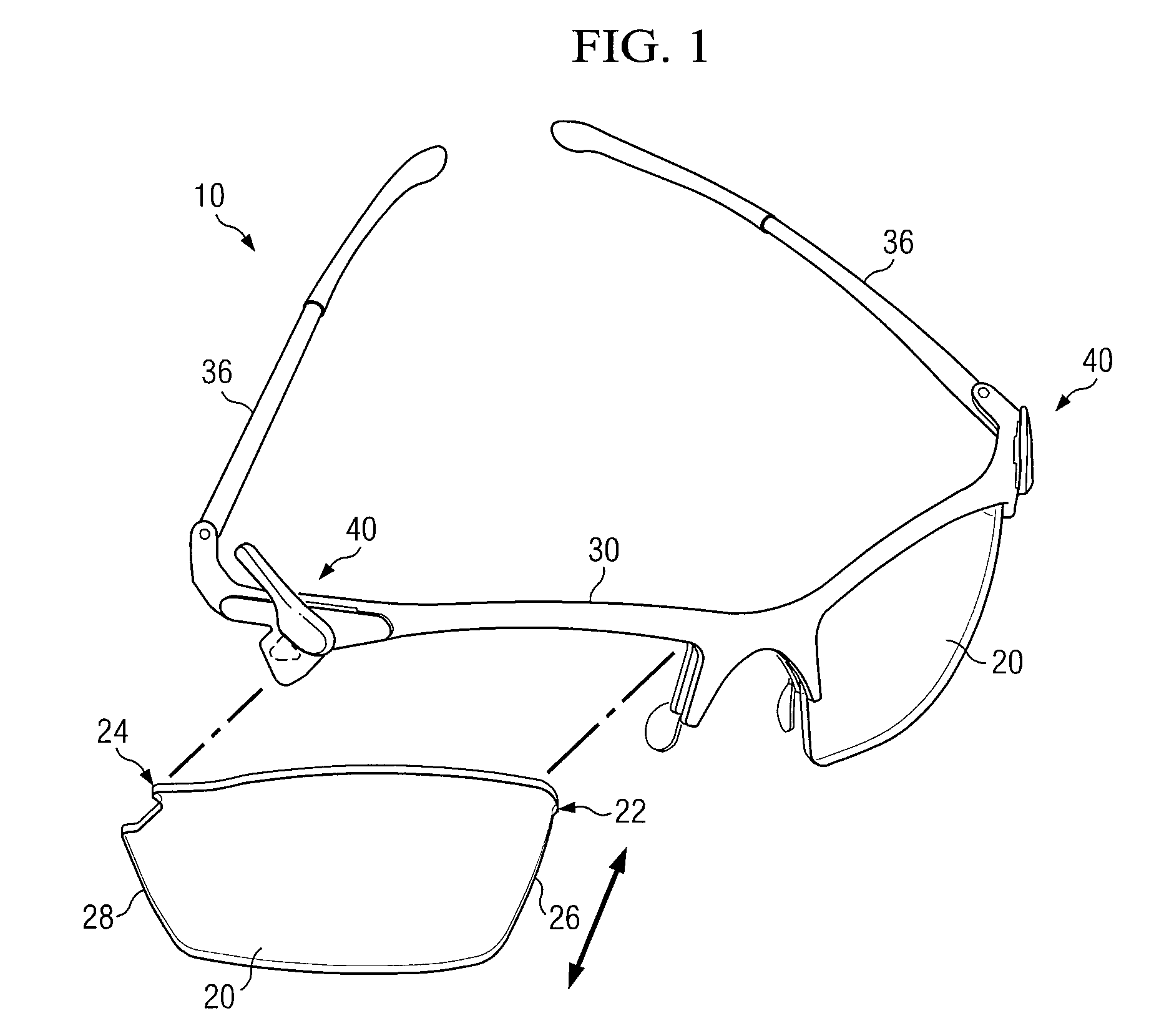

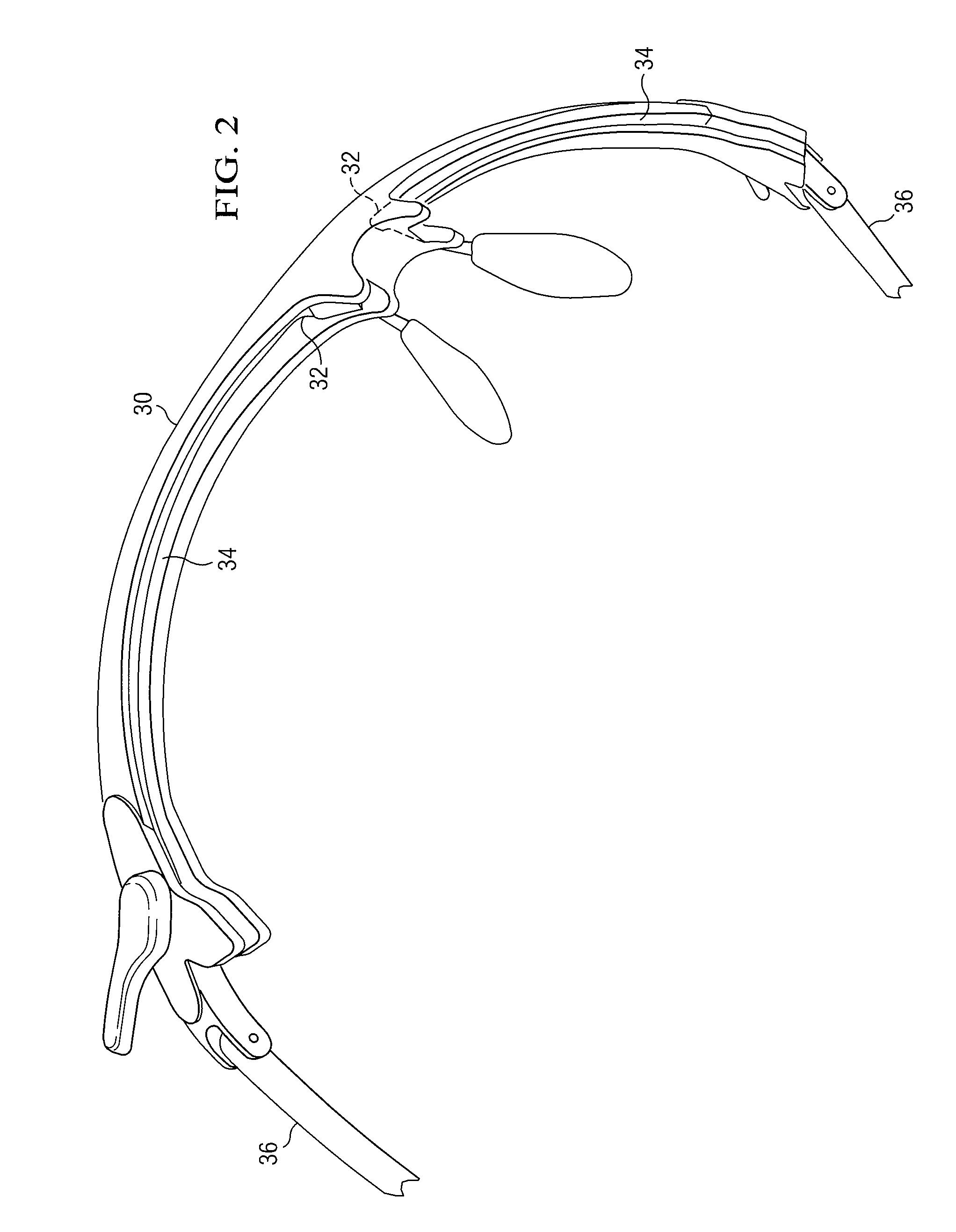

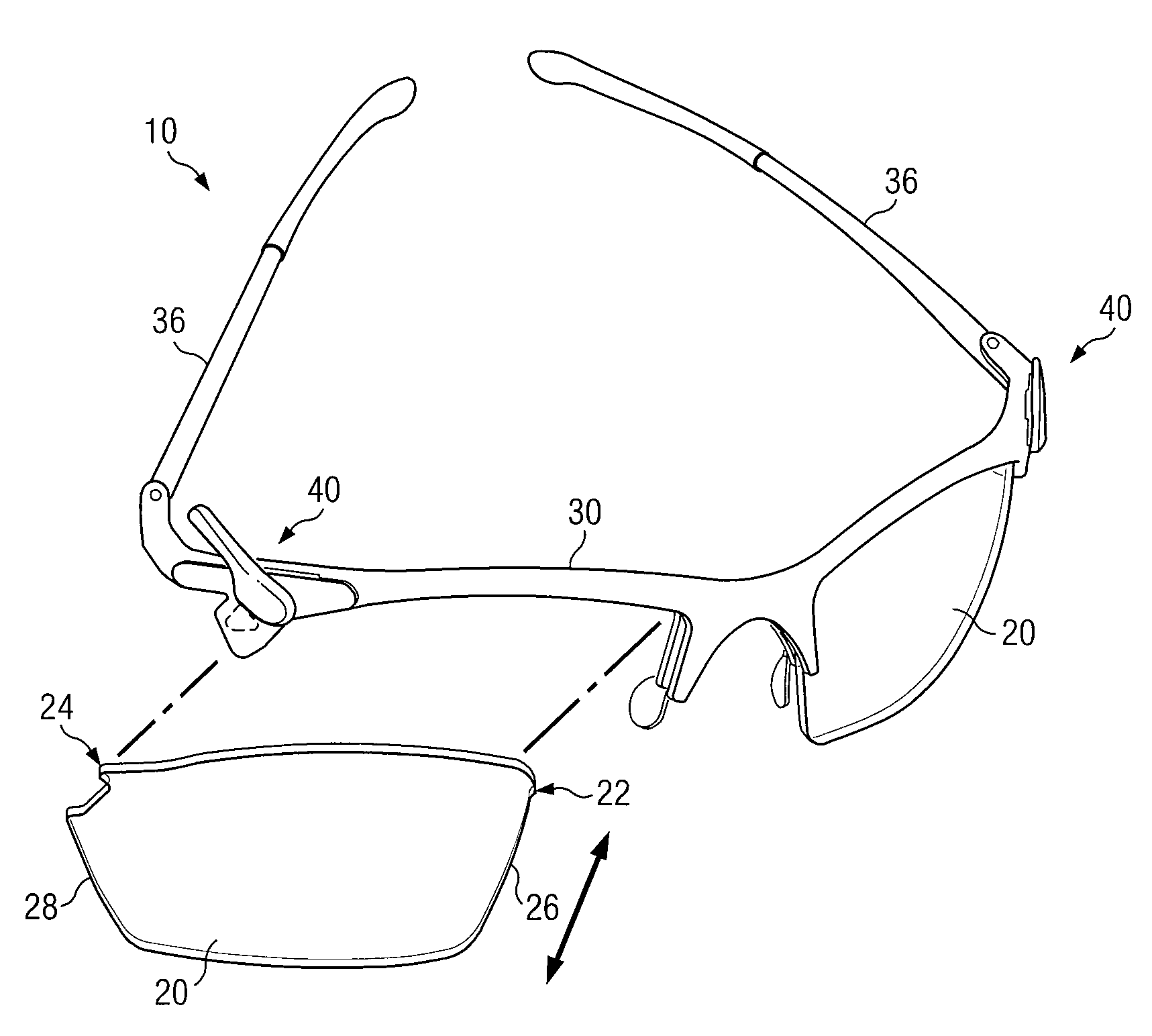

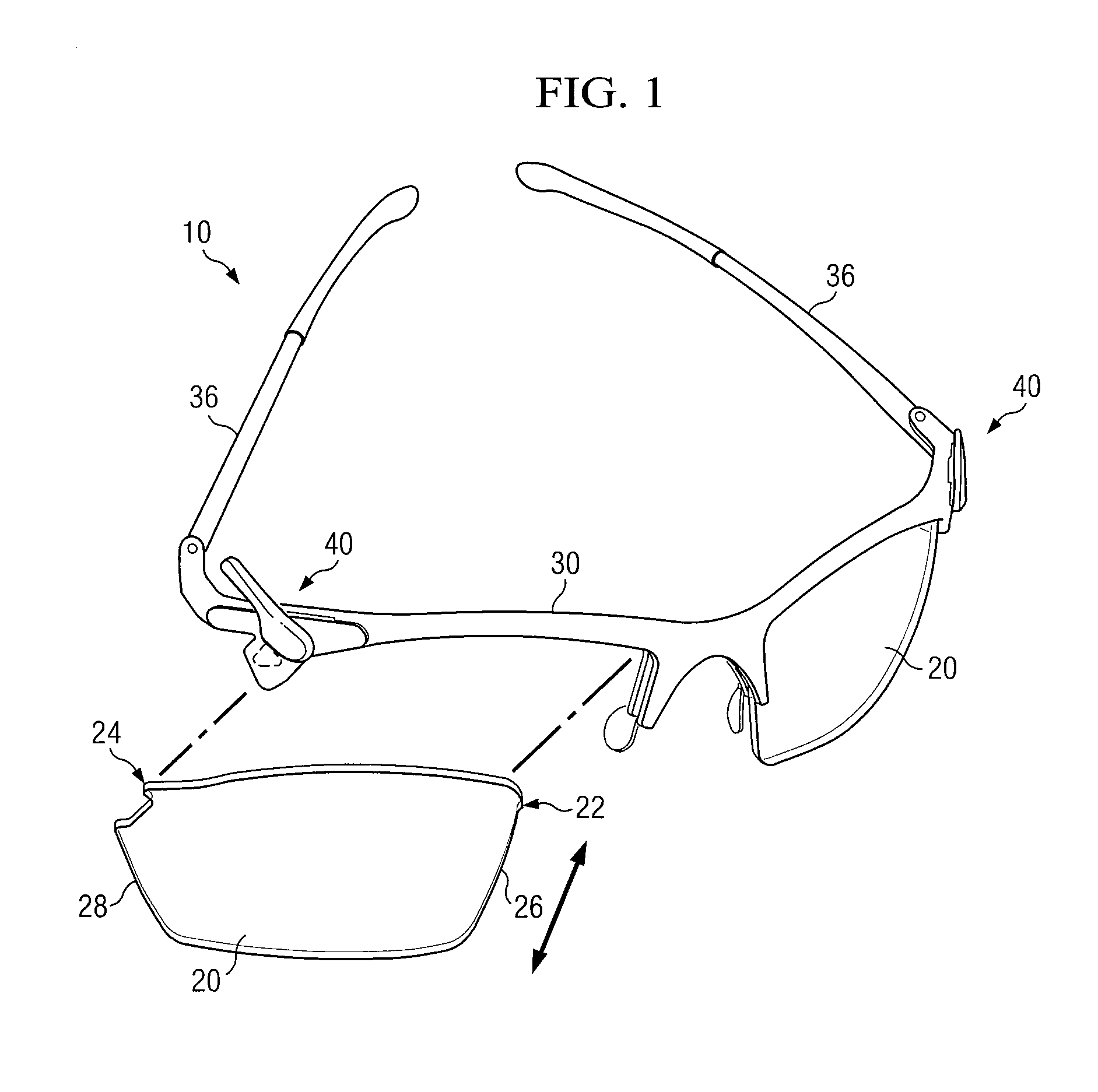

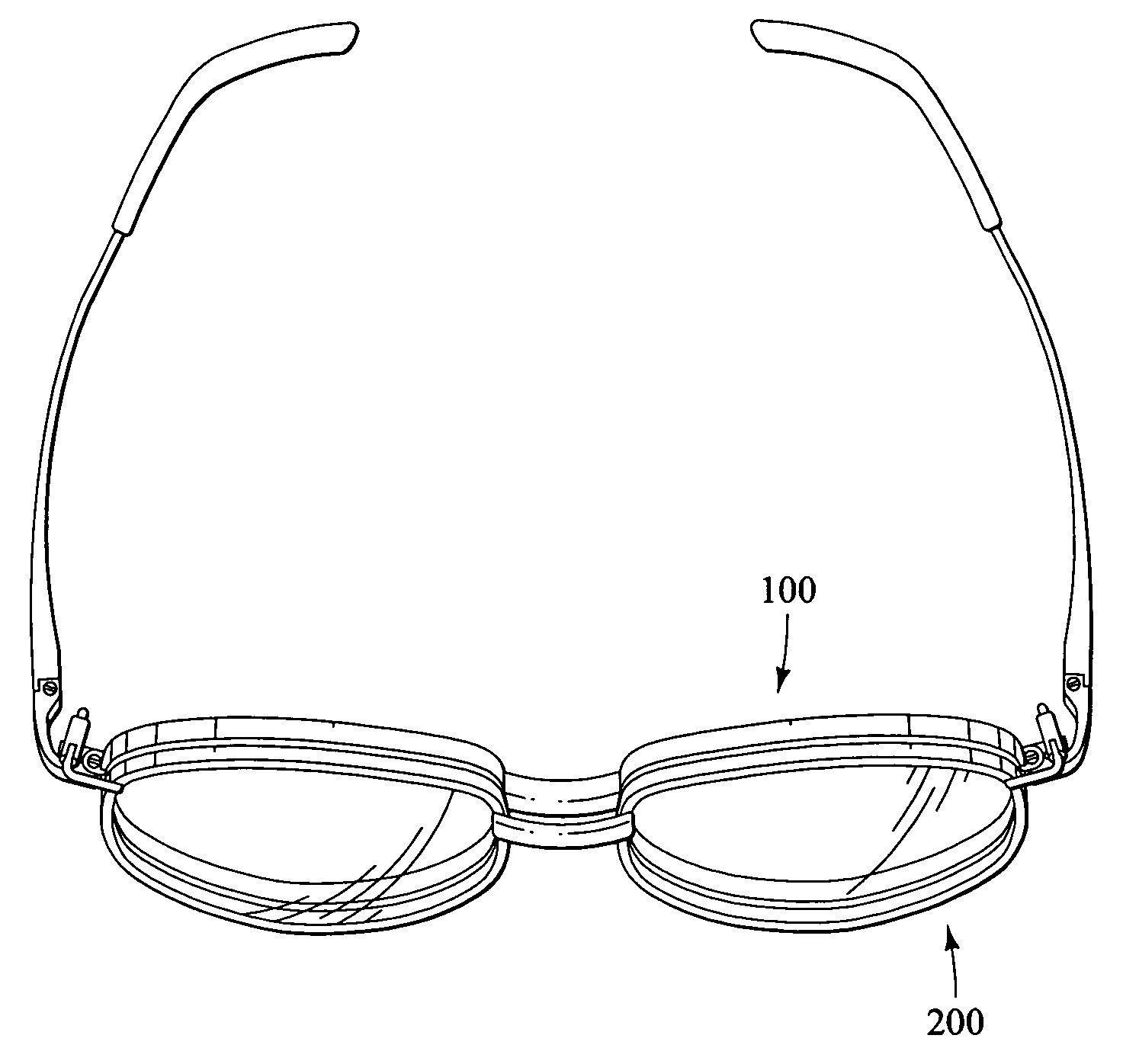

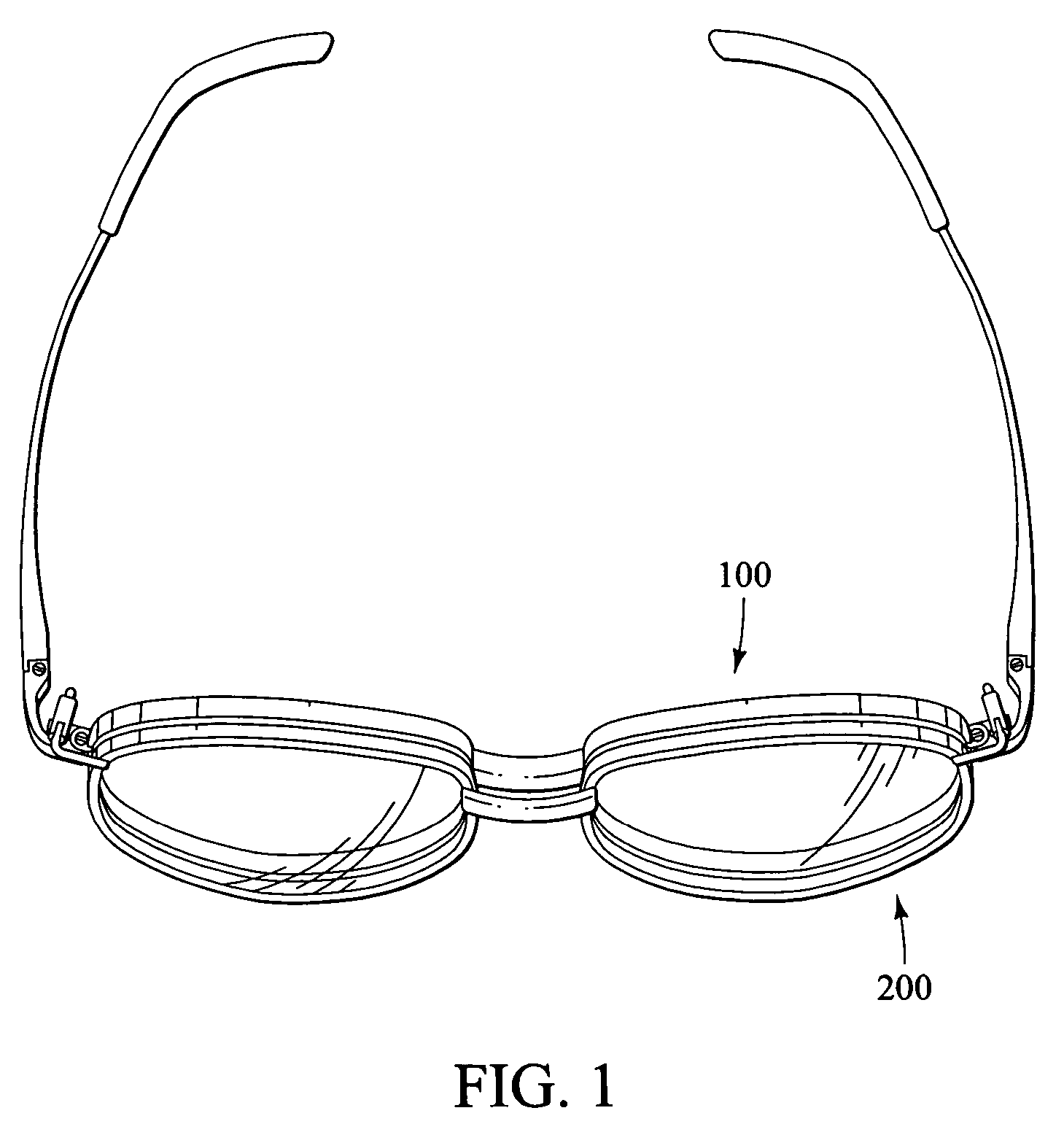

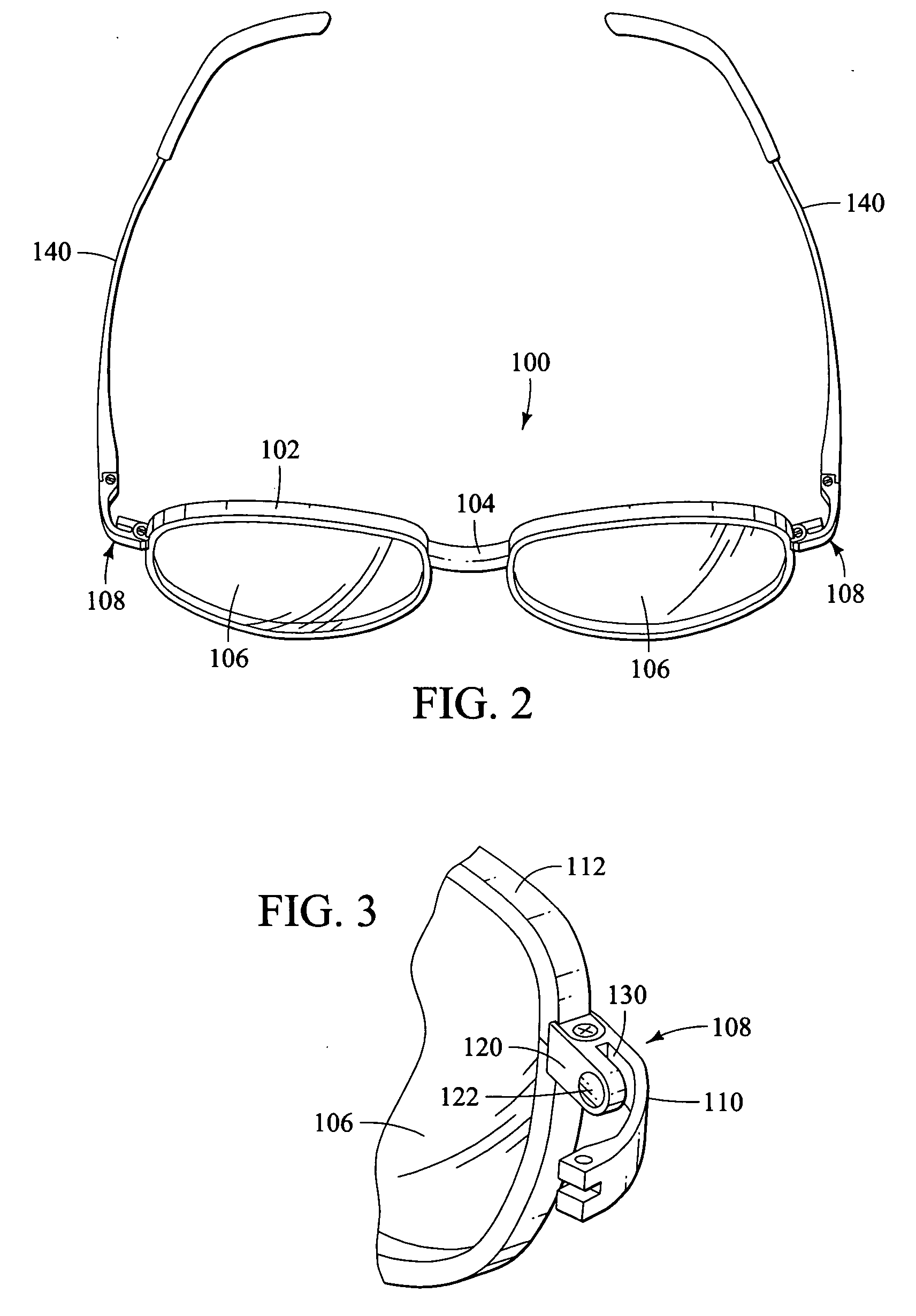

Partially entrapped frame having a removable lens

Owner:BELL SPORTS INC

Partially Entrapped Frame Having a Removable Lens

InactiveUS20080137028A1Eliminates and reduces disadvantageEasy to install and removeLens assembliesCamera lensEngineering

An eyewear system includes a partially entrapped eyewear frame, a lens, and a latching mechanism. The lens is configured to be received into a lens groove of the partially entrapped eyewear frame. The lens includes a first edge with a latch catch and a second edge with a tab configured to be received by a recess of the partially entrapped eyewear frame. The latch mechanism is configured to allow removal of the lens from the partially entrapped eyewear frame and engage the latch catch of the lens to retain the lens in the partially entrapped eyewear frame.

Owner:BELL SPORTS INC

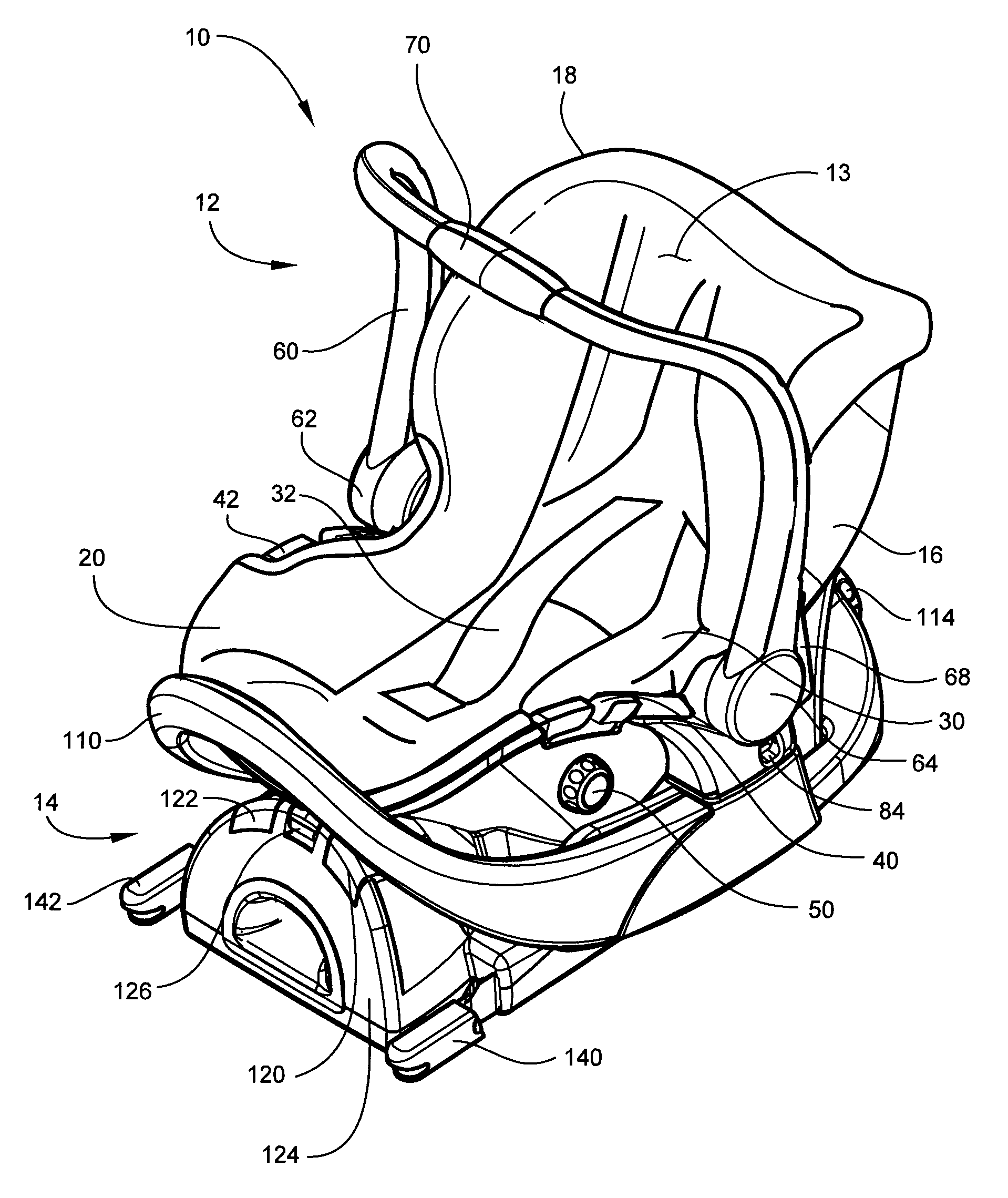

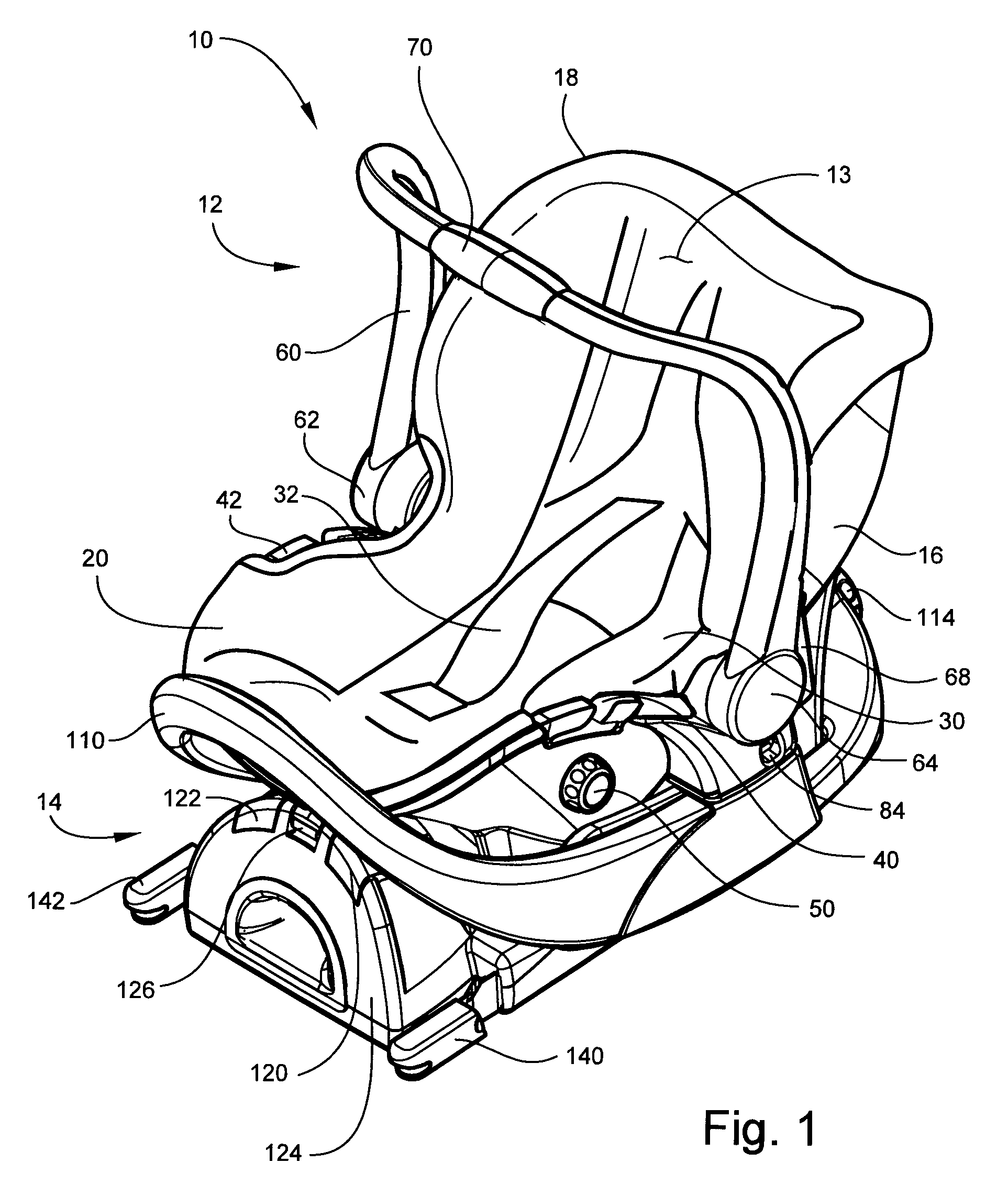

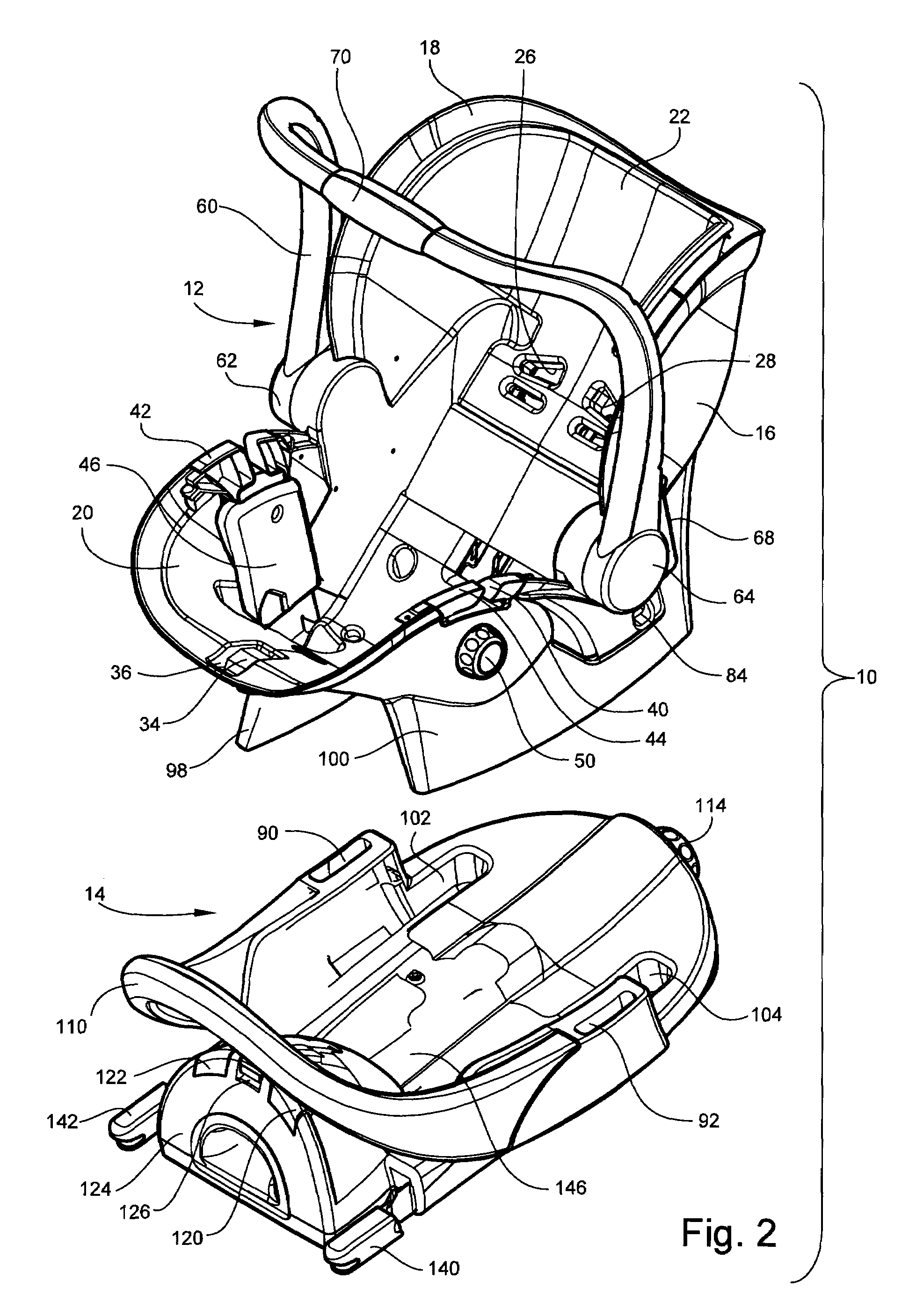

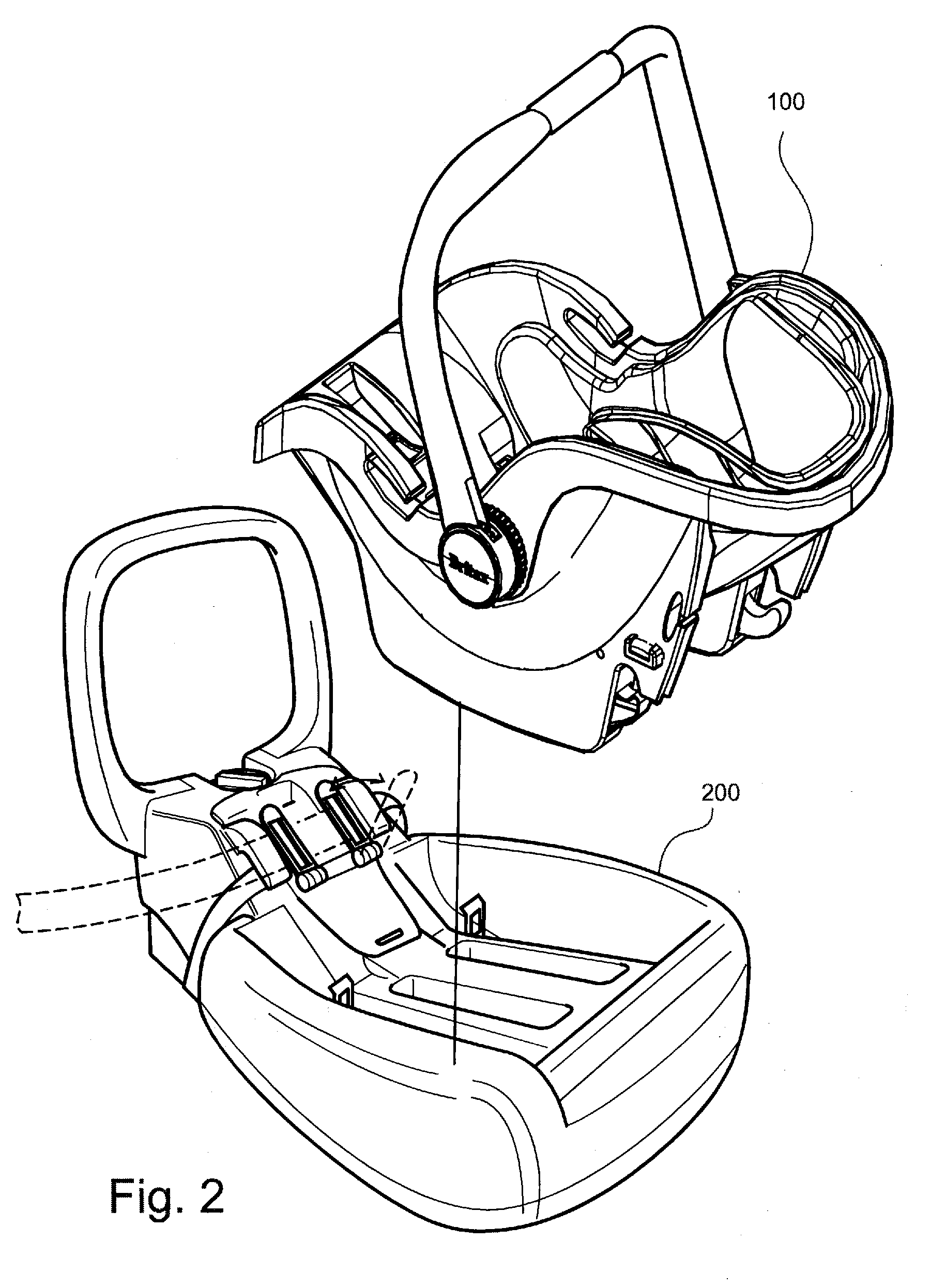

Anti-rebound bar for child safety seat

ActiveUS7488034B2Easy to install and removeEasy to separateVehicle seatsPedestrian/occupant safety arrangementEngineeringMechanical engineering

Owner:BRITAX CHILD SAFETY

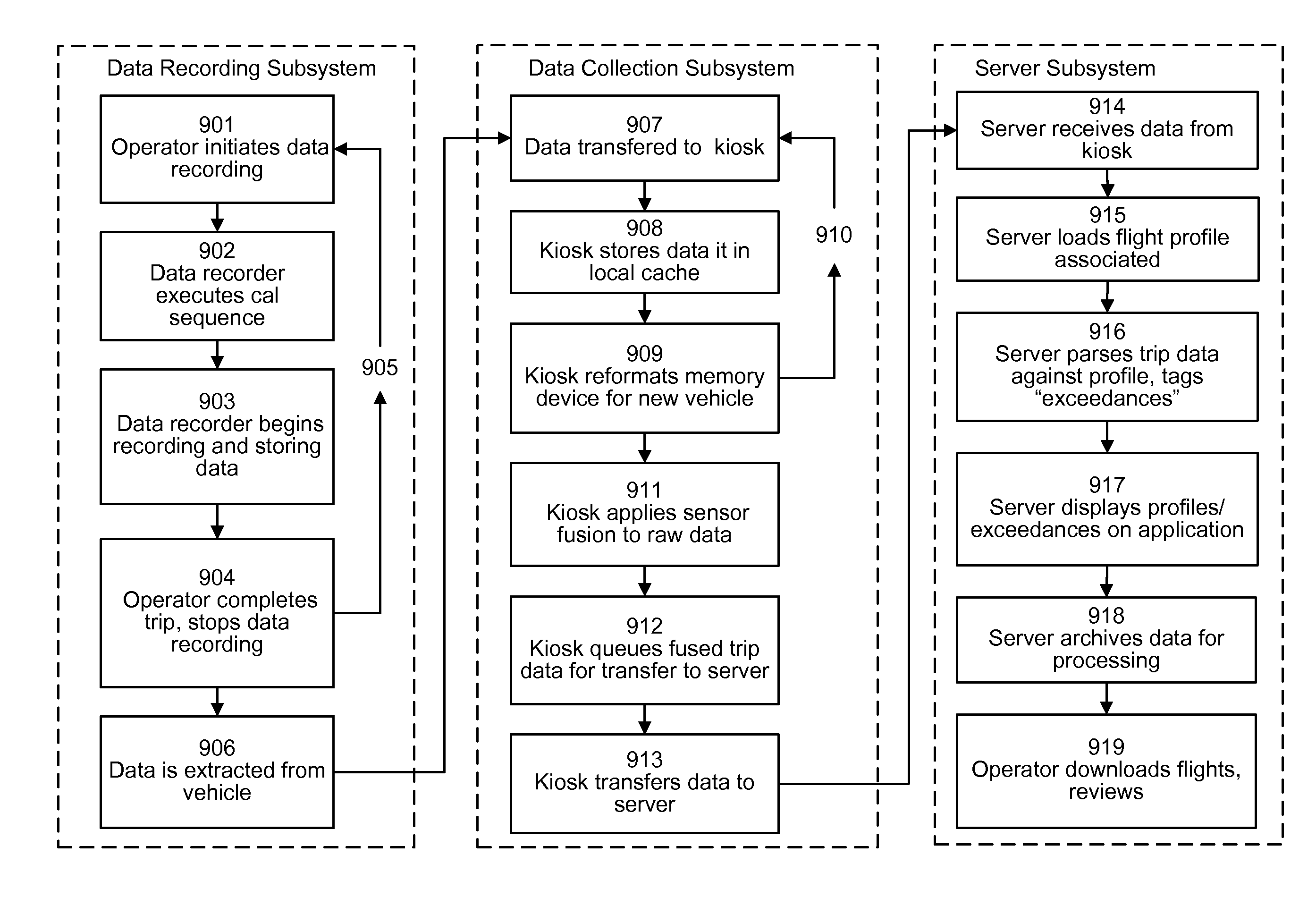

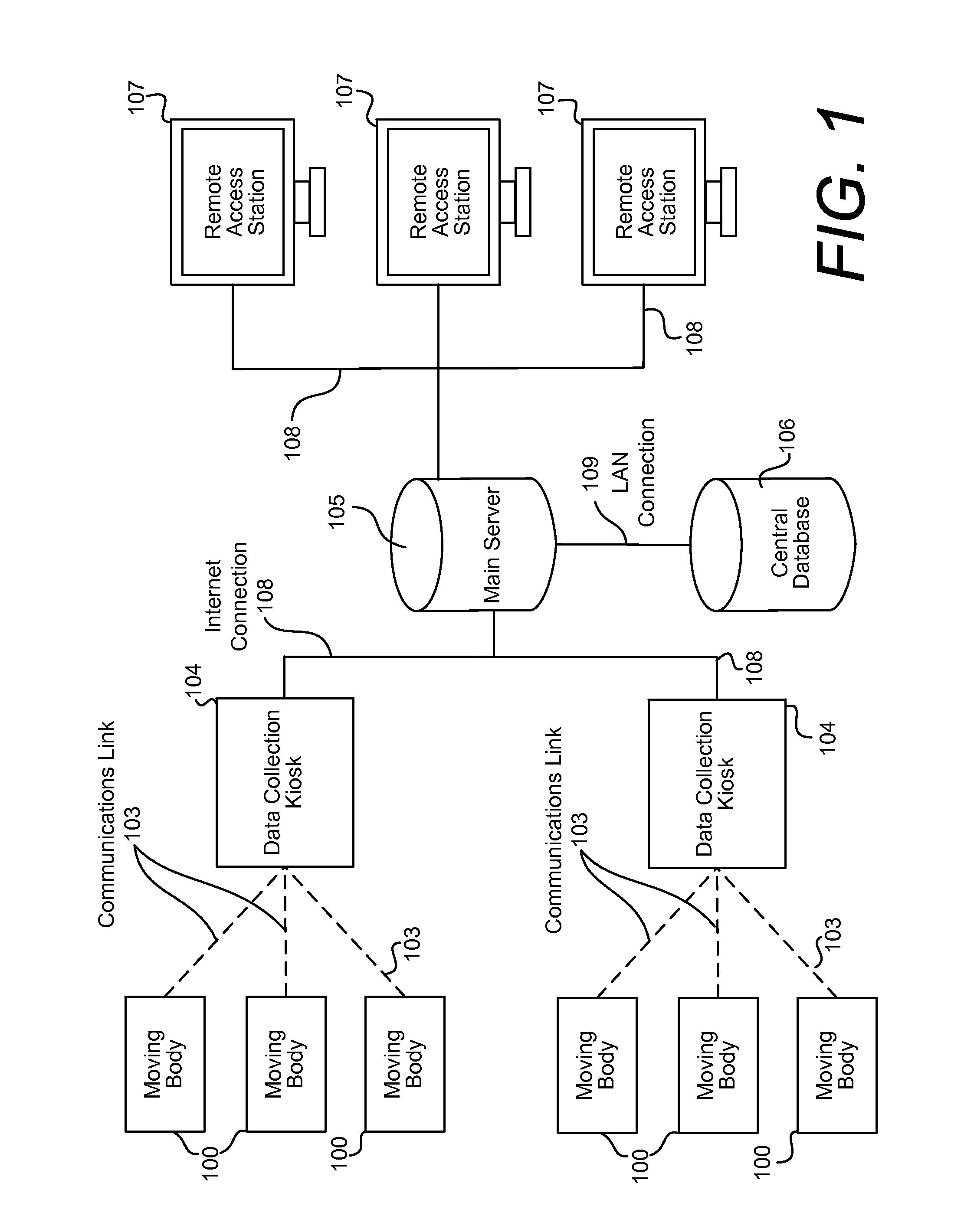

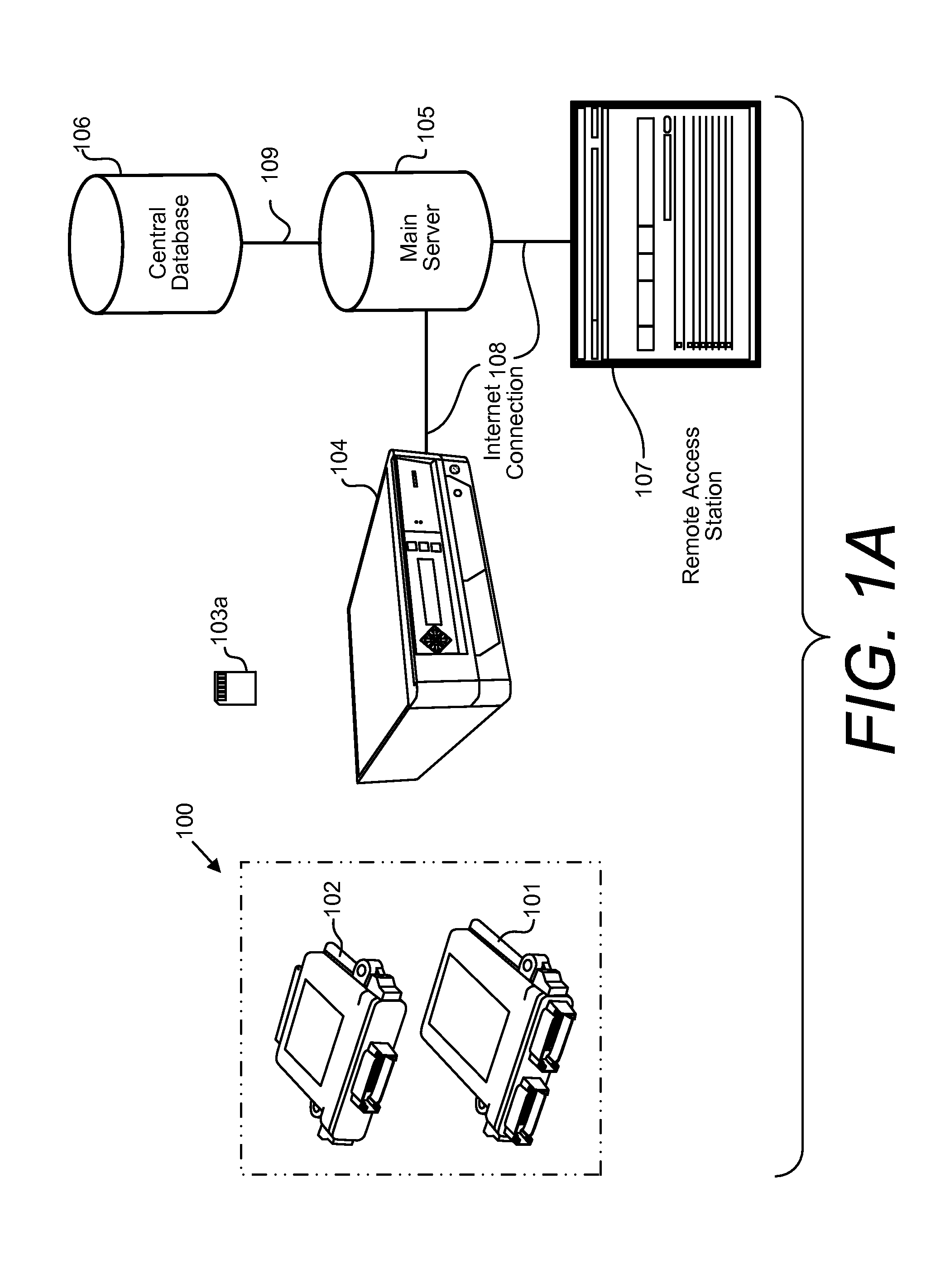

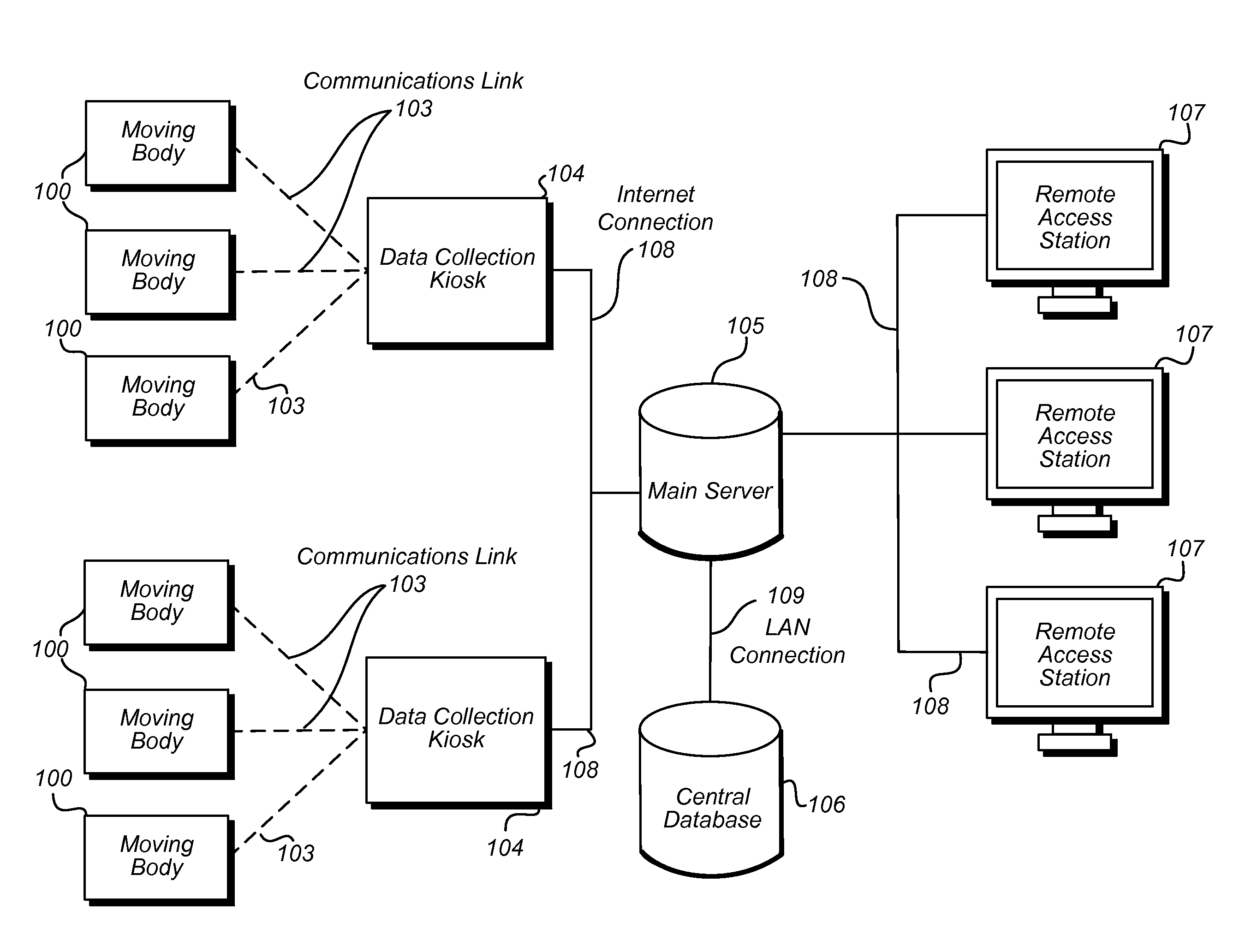

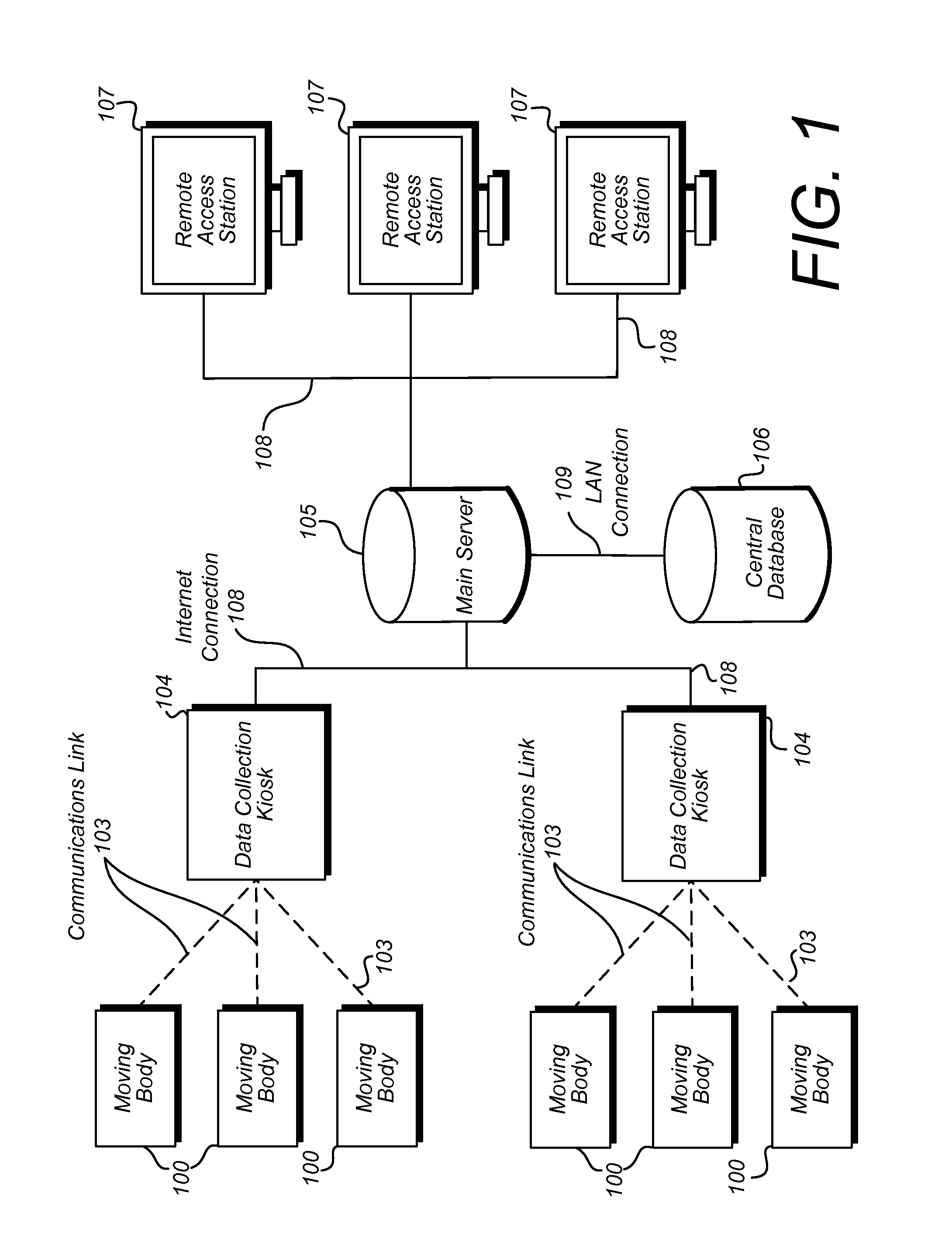

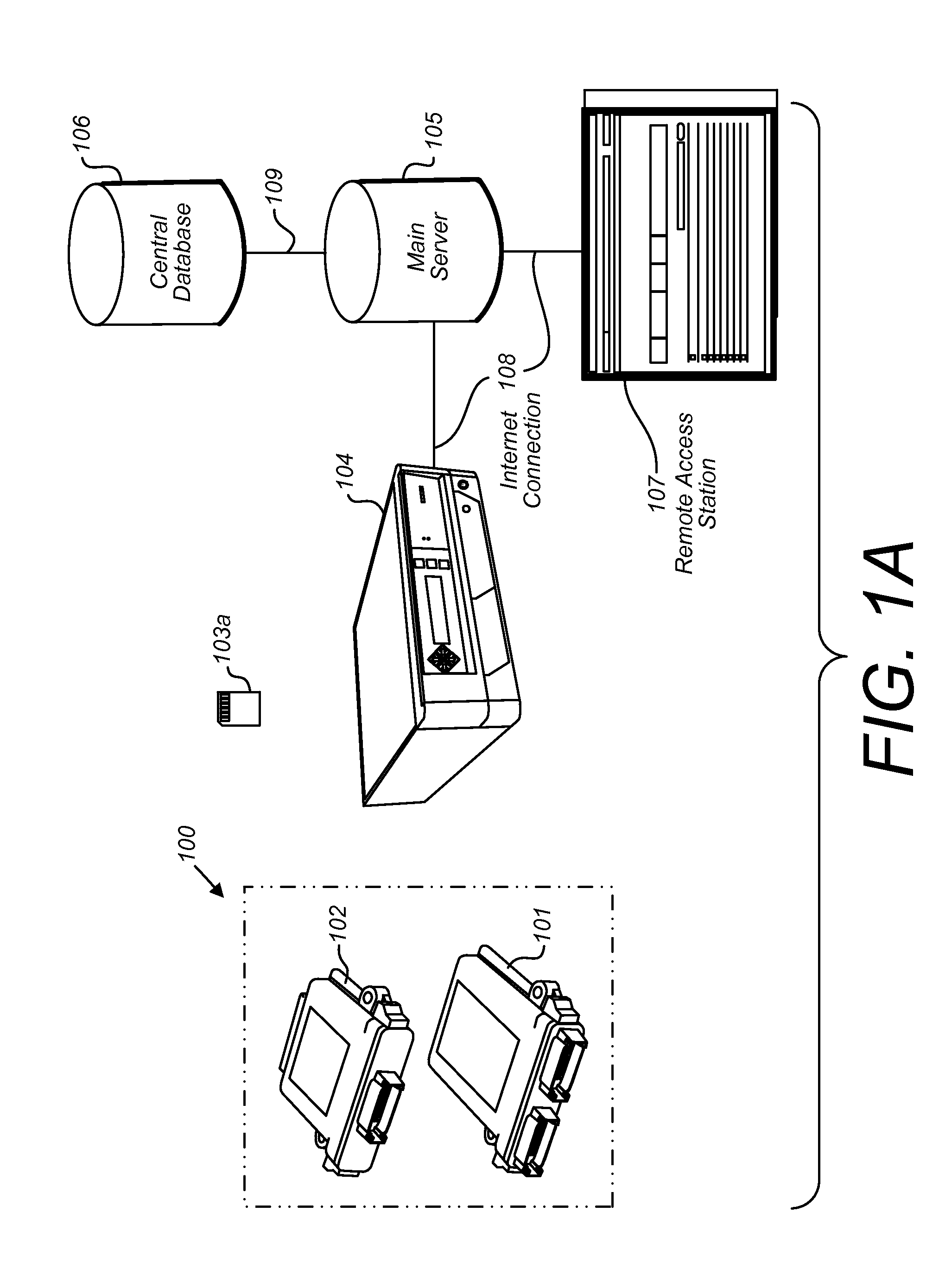

Fleet operations quality management system and automatic multi-generational data caching and recovery

ActiveUS20140081483A1Low costEasy to install and removeAnalogue computers for trafficRegistering/indicating working of vehiclesSystems designData acquisition

A fleet operations quality management system for use with one or more vehicles which includes a data recording unit and separate memory subsystem mounted on each vehicle, a remotely located data collection station to collect, store and pre-process data from multiple vehicles, a centralized data storage and retrieval system designed to accept and assimilate recorded trip data, a web application designed to provide access to and analysis of the recorded trip data, and a graphical software application that can be used to view the recreated trip in a realistic simulated environment. An electronic system comprising a receiver module and a mobile device, whereby the receiver module is capable of receiving data transmissions from a network of ground stations and buffering the data for future use.

Owner:APPAREO SYST

Vaporizer device with removable cartridge and apparatus and method for filling removable cartridge

InactiveUS20190166913A1Easy to moveIncrease inhalationRespiratorsElectric heatingInhalationVaporization

A vaporization device allow users to consume removable cartridges filled with vaporizable material. The vaporizer devices defines a receptacle shaped to receive a cartridge in a snug and compact nesting arrangement. The vaporizer device ensures that the installed cartridges are secured and provide a sealed fluid path. The cartridges have wider fluid conduits facilitating user inhalation. The cartridges also facilitate manufacturing by providing a larger area within which to insert the vaporizable material.

Owner:GSEH HOLISTIC INC

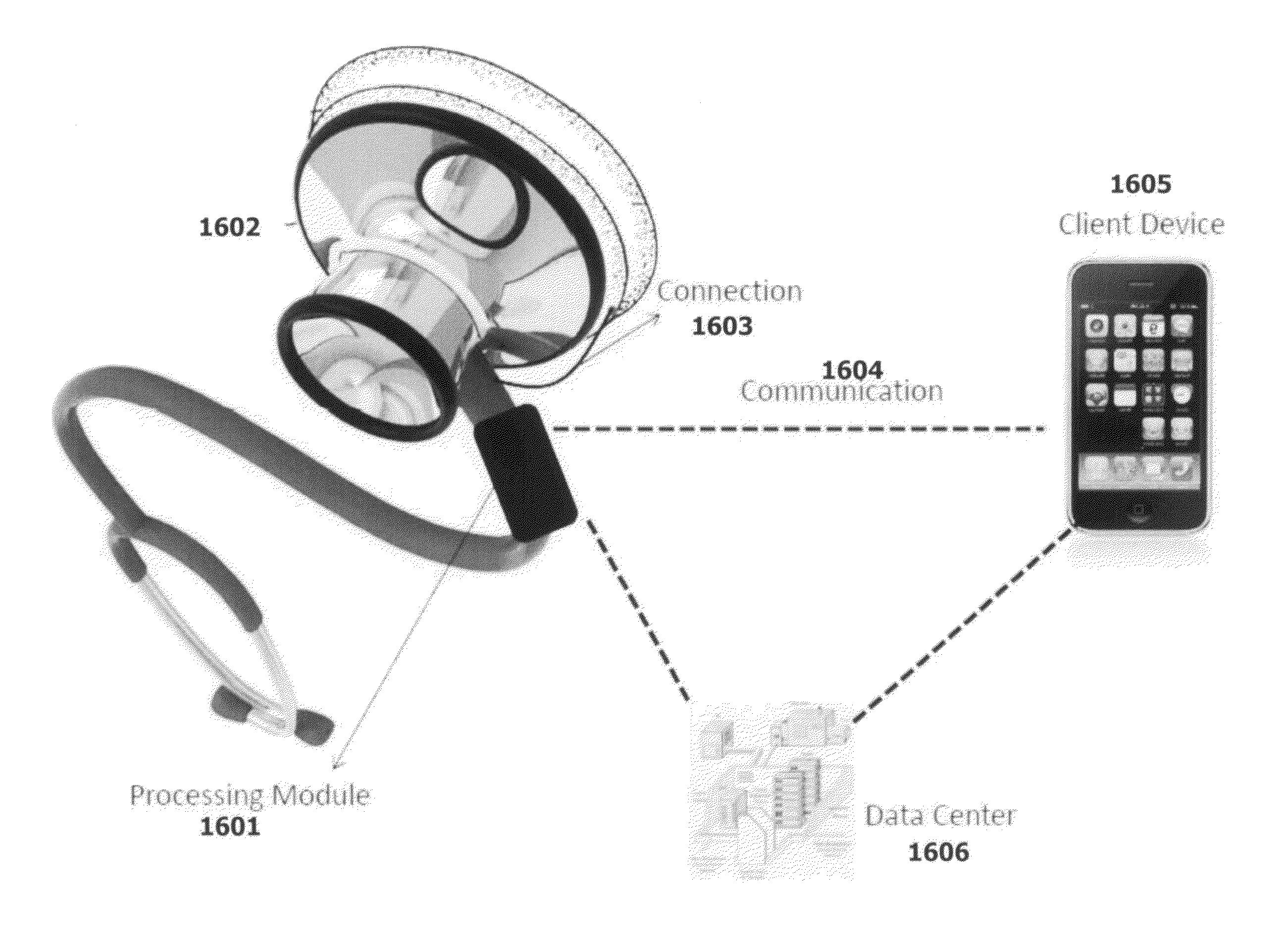

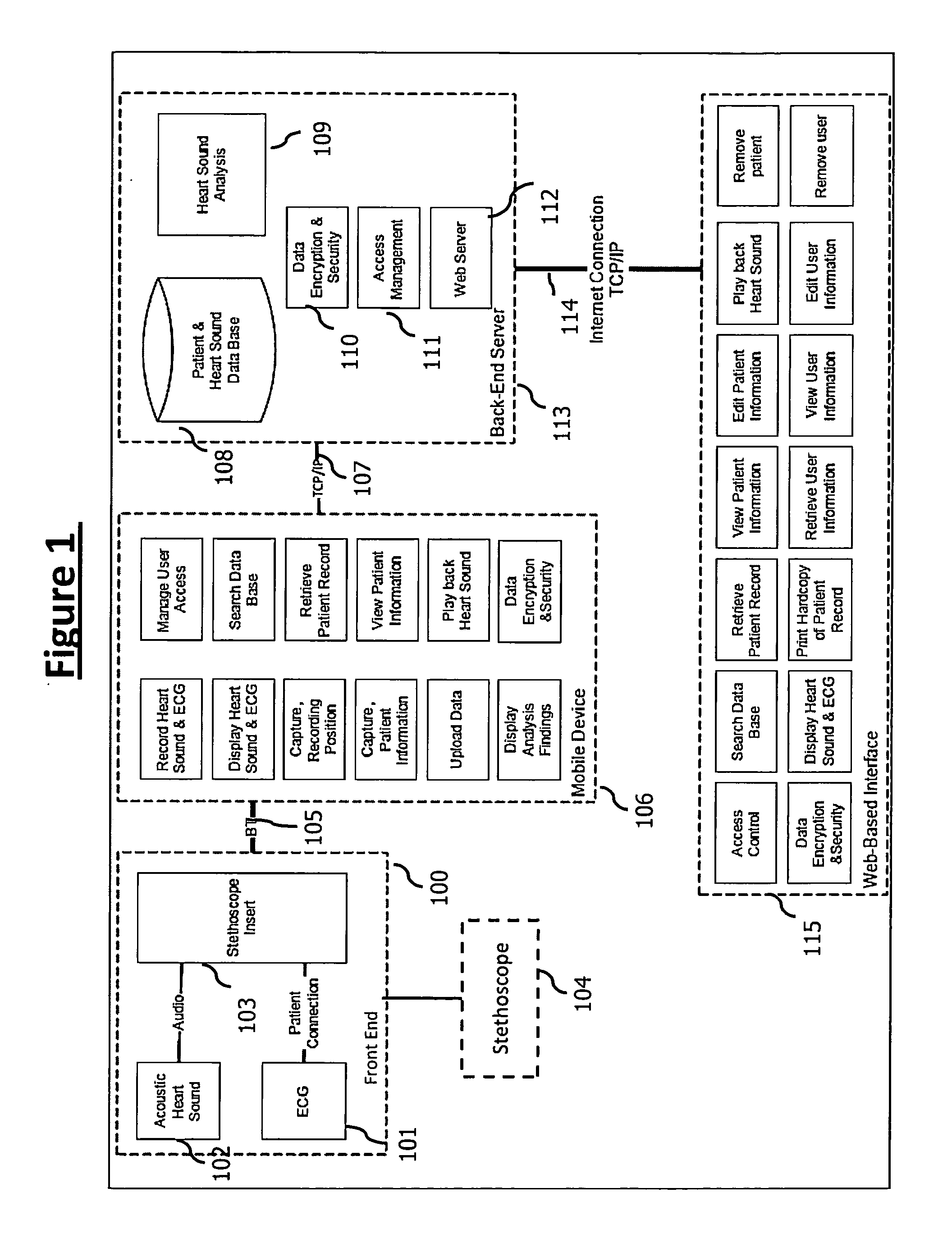

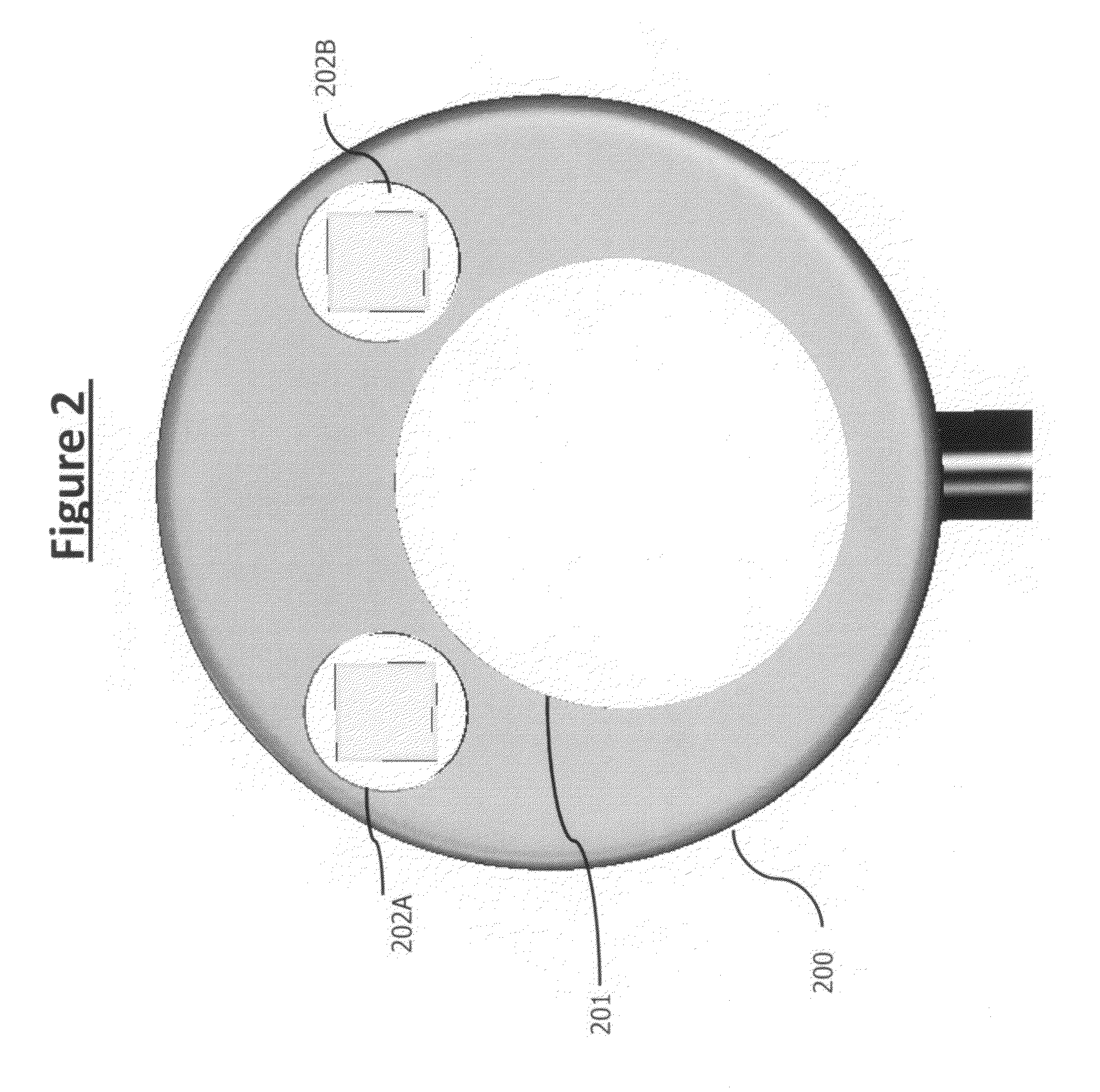

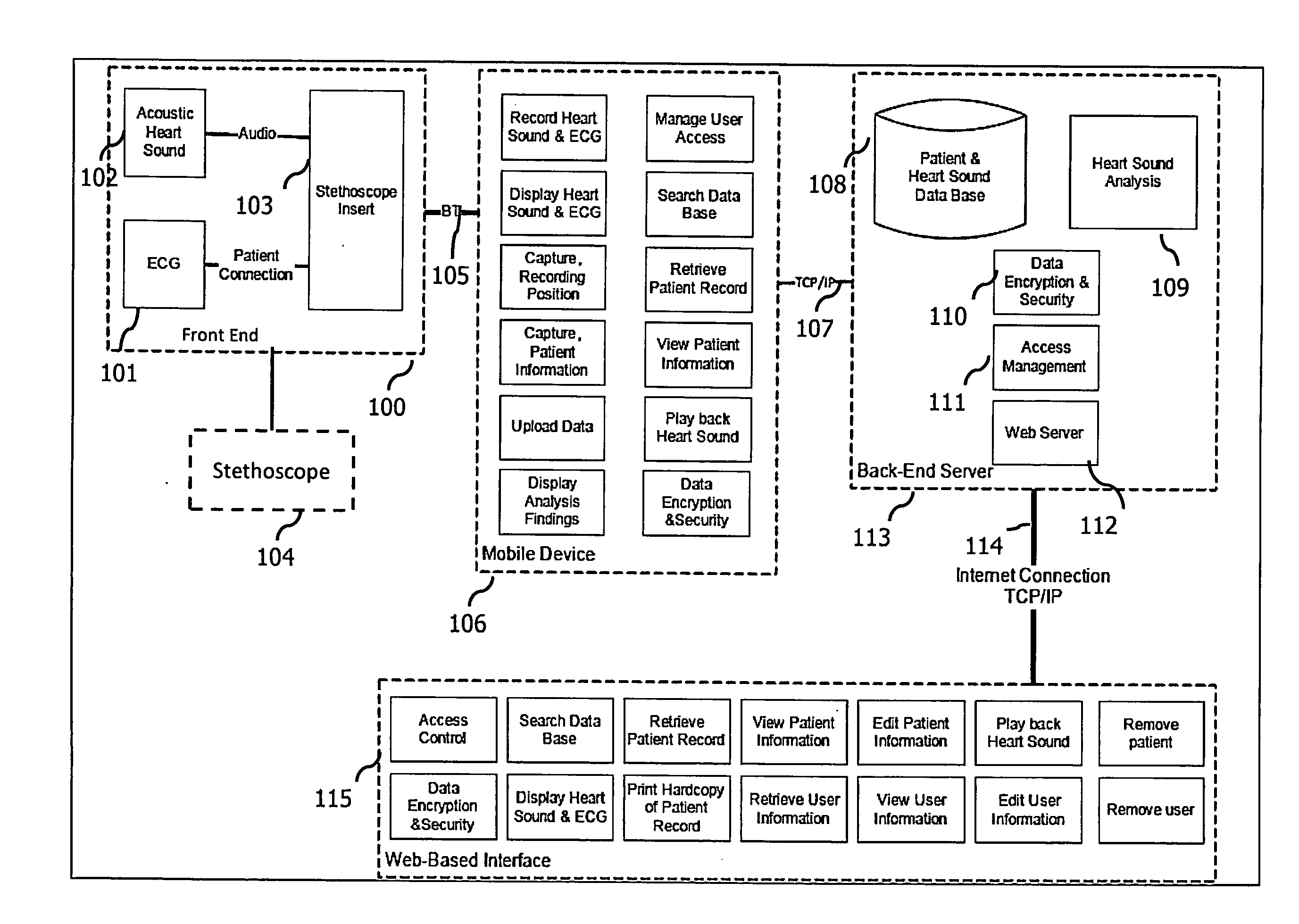

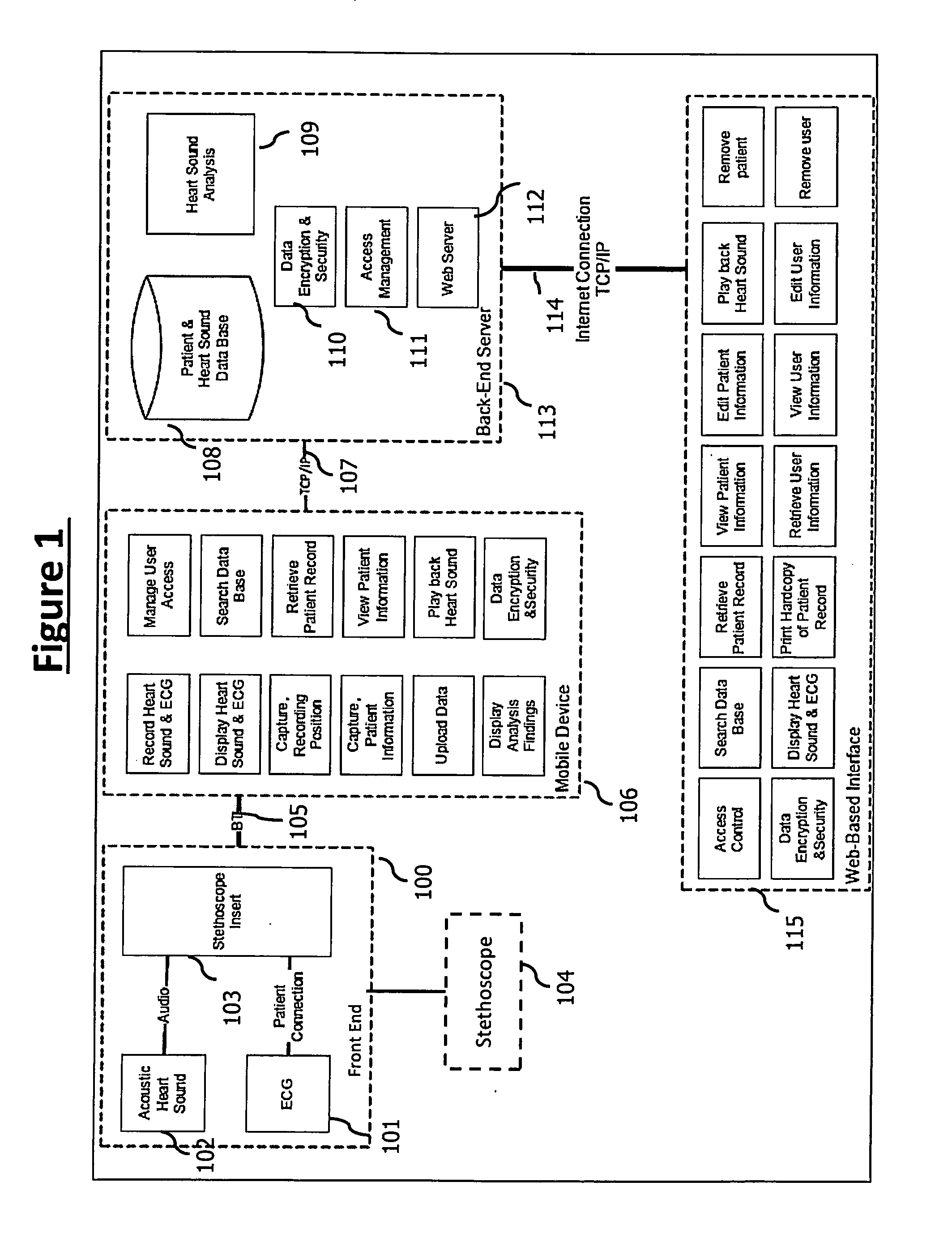

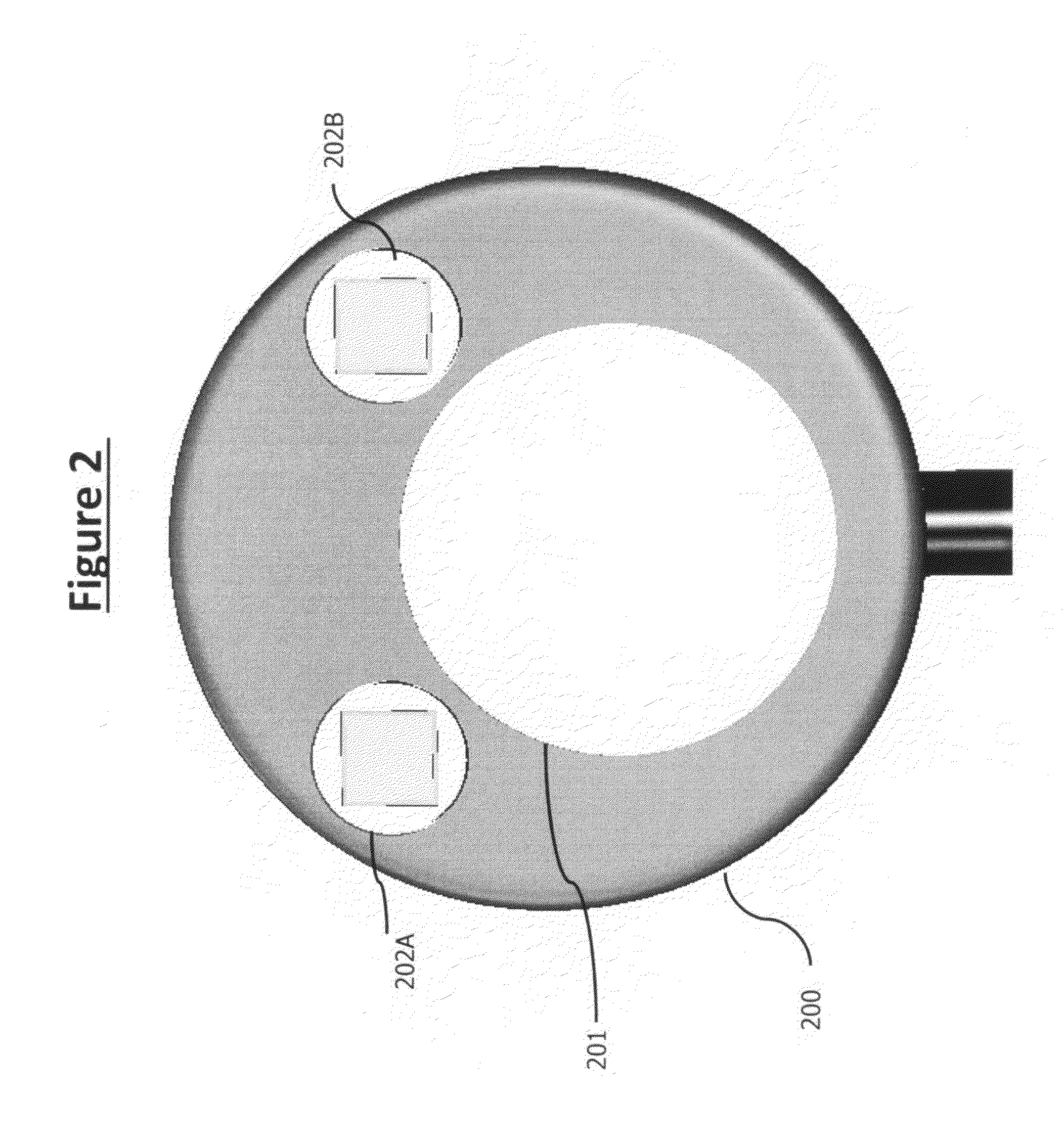

Biometric front-end recorder system

ActiveUS20130116584A1Easy to installEasy to removeElectrocardiographyStethoscopeStethoscopeBiosensor

A stethoscope front-end recorder device (also referred to as Sleeve) for the chest piece of a stethoscope, which is easily installed and removed. The Sleeve covers the circumference of the chest piece of a stethoscope. The Sleeve contains sensors for acquiring biosensor parameters such as electrocardiogram, body temperature, heartbeat, heart rhythm, heart rate variability, heart rate turbulence, heart sounds, respiration, cardiac index and blood flow. The Sleeve has Bluetooth interface communicating with a mobile device with software component, interfacing with a back-end server with the capability to capture, analyze and save patient information.

Owner:RIJUVEN

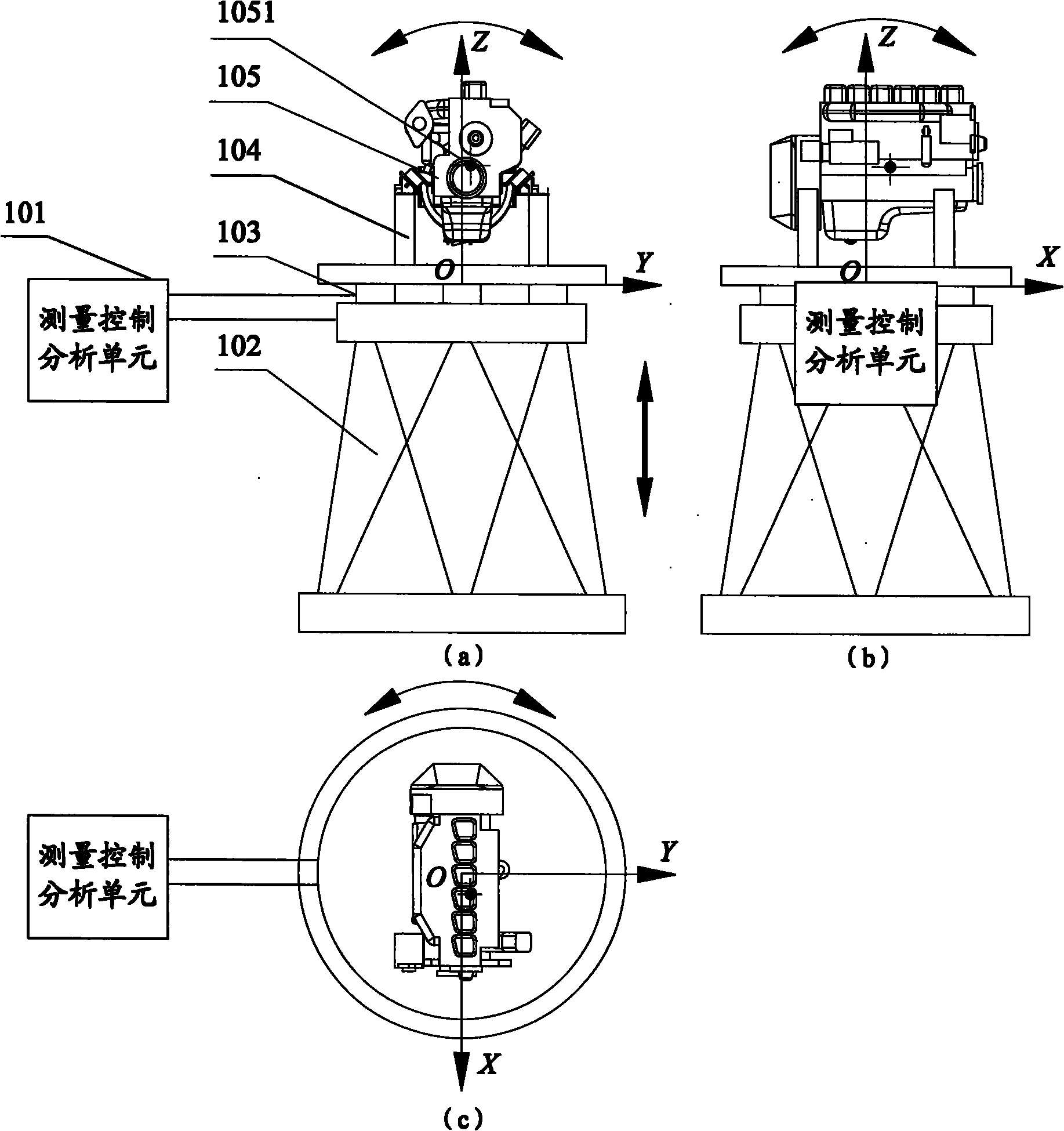

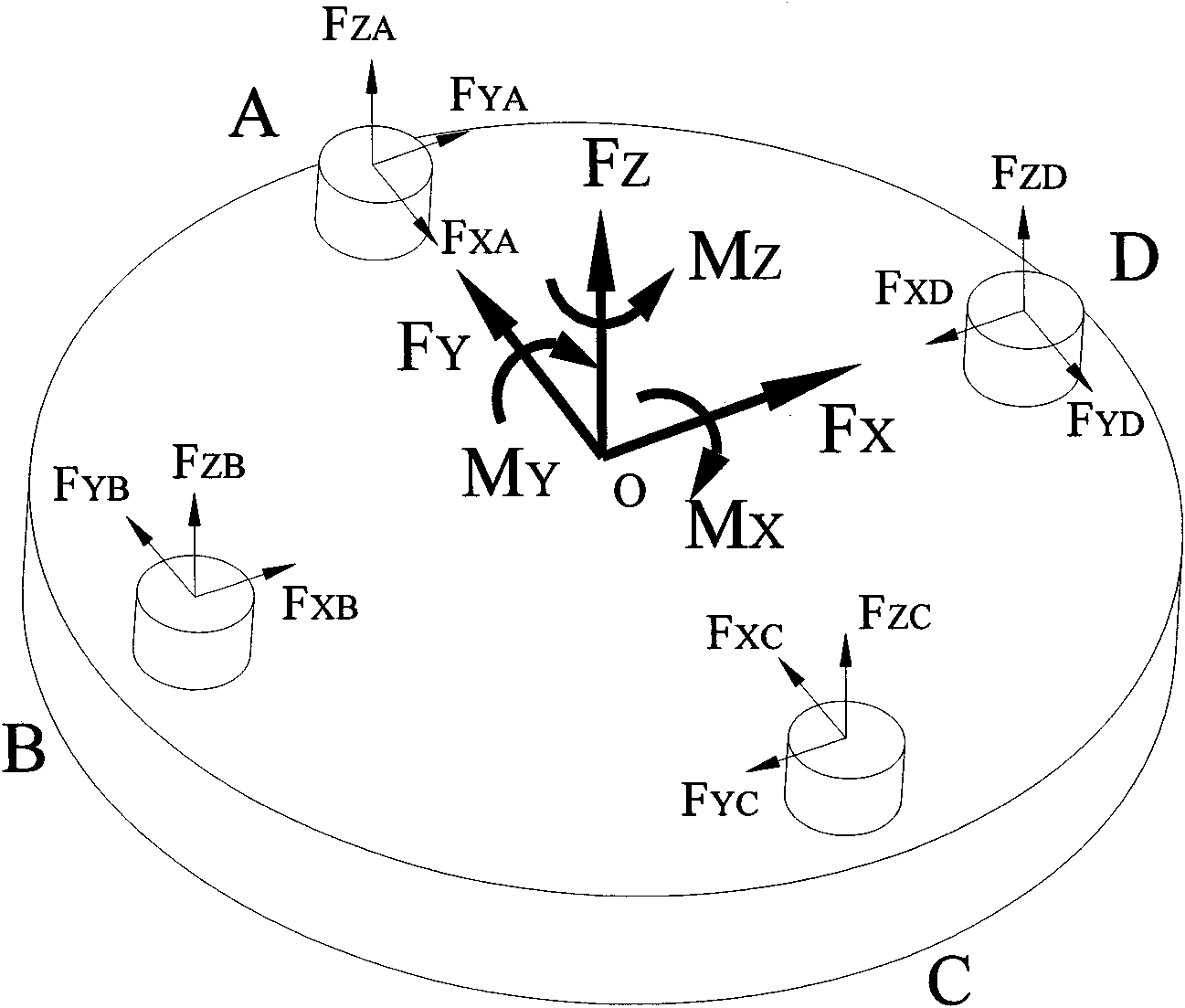

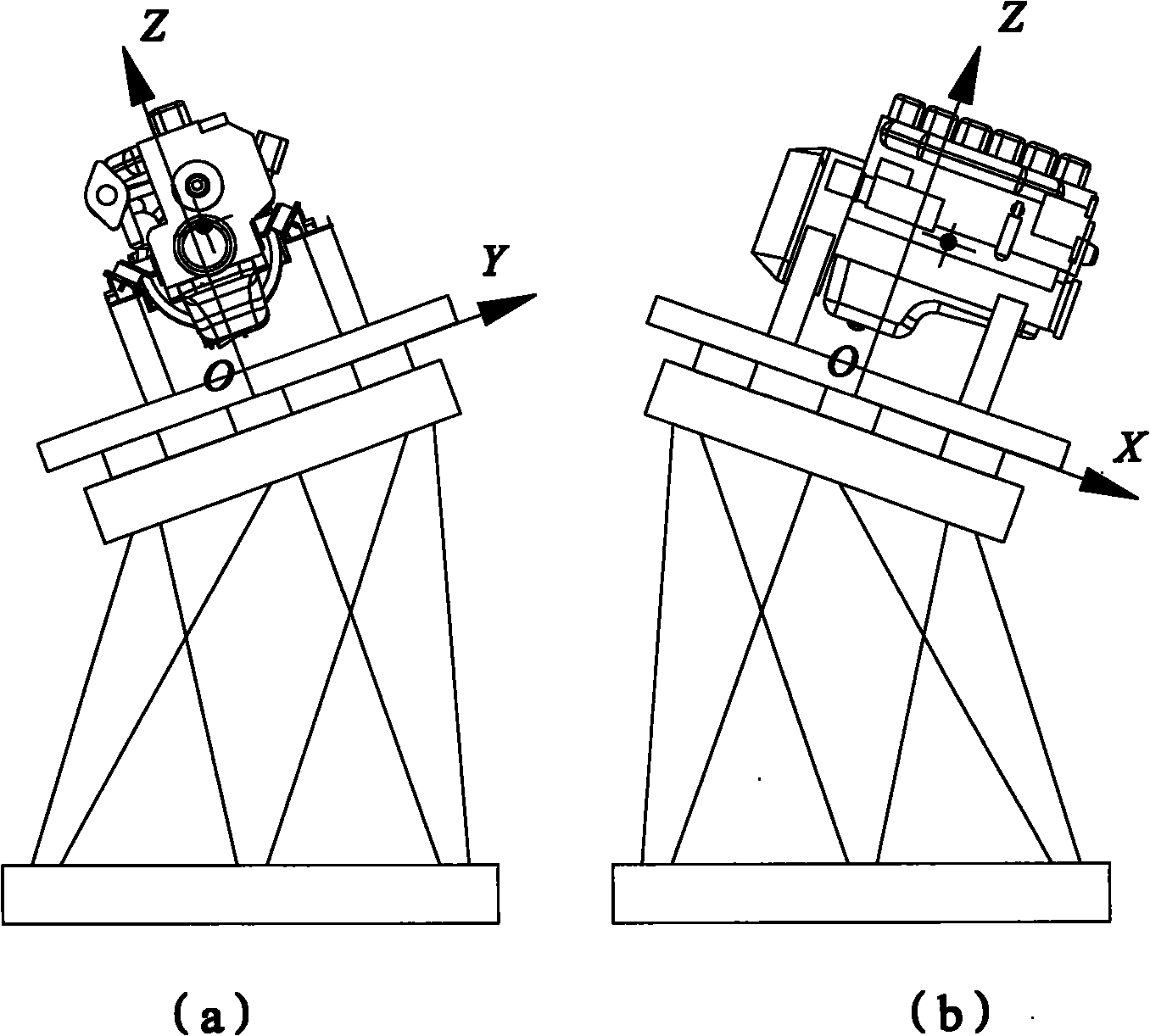

Measuring system and measuring method of mass, center of mass and moment of inertia of rigid body

InactiveCN101793582AEasy to install and removeSimple stepsStatic/dynamic balance measurementAttitude controlMoment of inertiaSix degrees of freedom

The invention provides a measuring system and a measuring method of mass, center of mass and moment of inertia of a rigid body, and the measuring system comprises a measurement control and analysis unit, a six degree-of-freedom motion platform, a six-component force sensor and a mounting platform, wherein the measurement control and analysis unit is used for controlling the attitude or the motion way of the rigid body by sending a motion signal to the six degree-of-freedom motion platform, and analyzing and calculating the mass, the center of mass and the moment of inertia of the measured rigid body according to the motion signal and force and torque sent by the six-component force sensor; the six degree-of-freedom motion platform is used for carrying out motion in the corresponding attitude or the motion way according to the received motion signal; the six-component force sensor is mounted on the six degree-of-freedom motion platform and used for obtaining the force and the torque received by the measured rigid body by acquiring measurement parameters; the mounting platform is fixed on the six-component force sensor and used for mounting the measured rigid body; and the six degree-of-freedom motion platform drives the measured rigid body to carry out the motion through the six-component force sensor and the mounting platform.The measuring system and the measuring method can realize the measurement of the mass, the center of mass and the moment of inertia, and have the advantages of simple steps and small errors.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

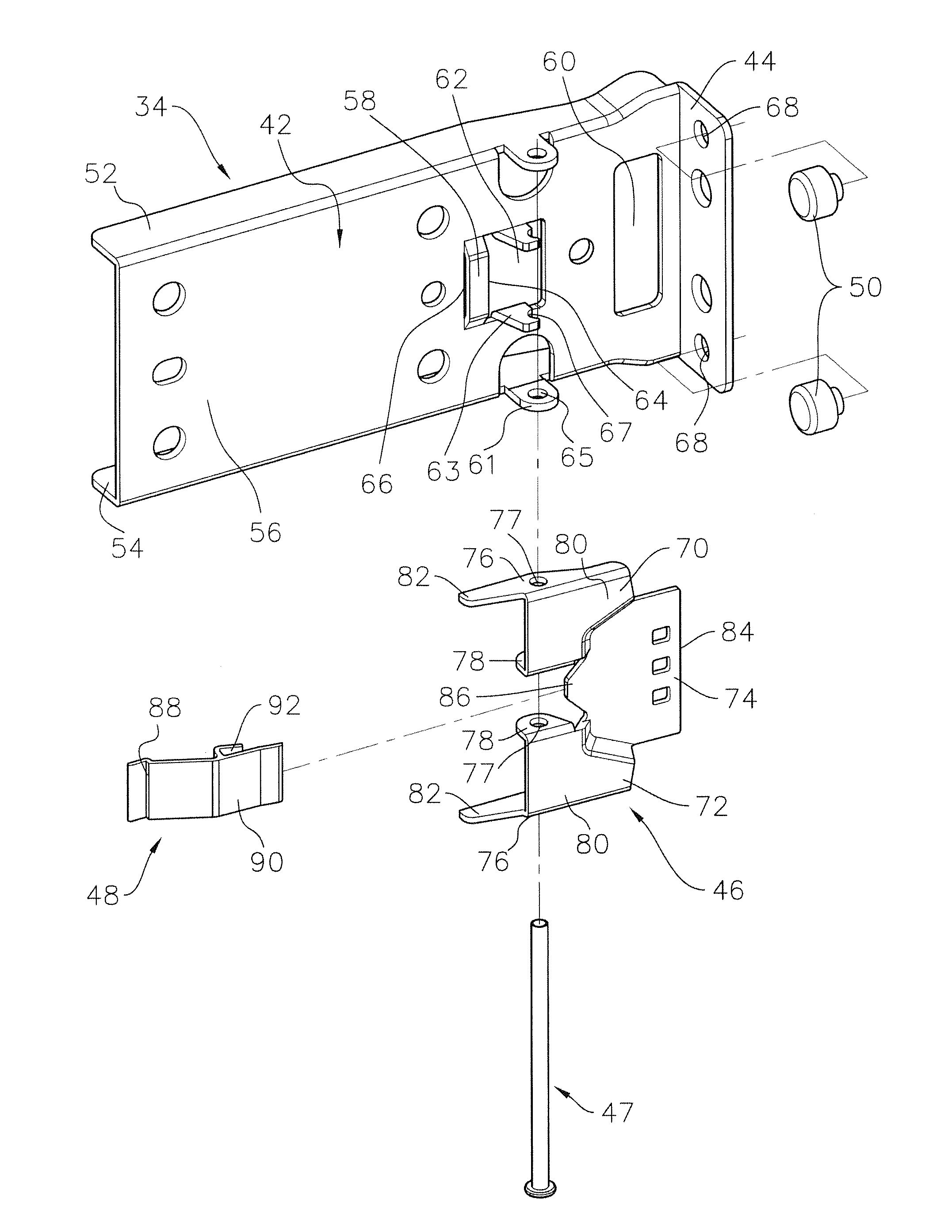

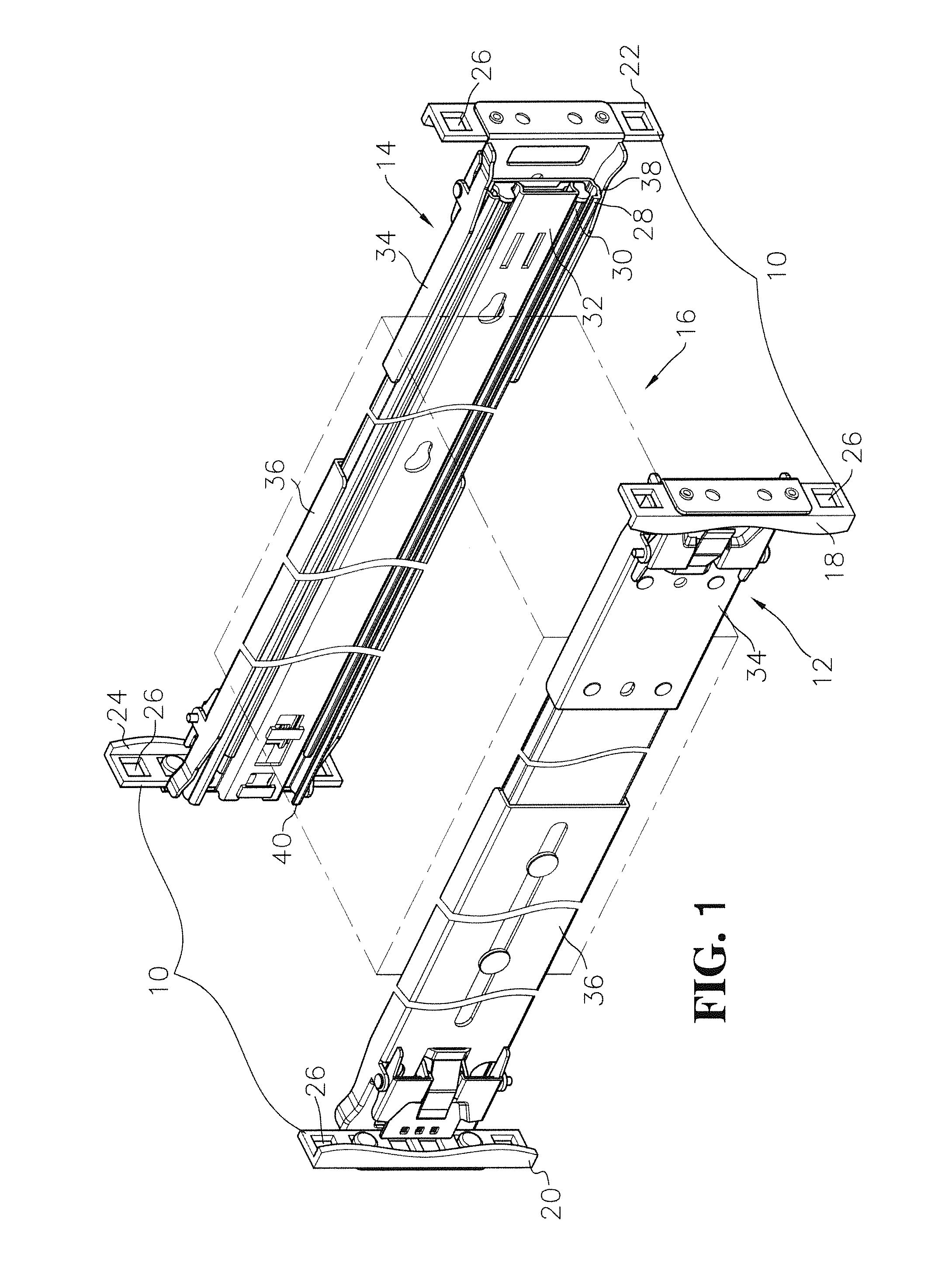

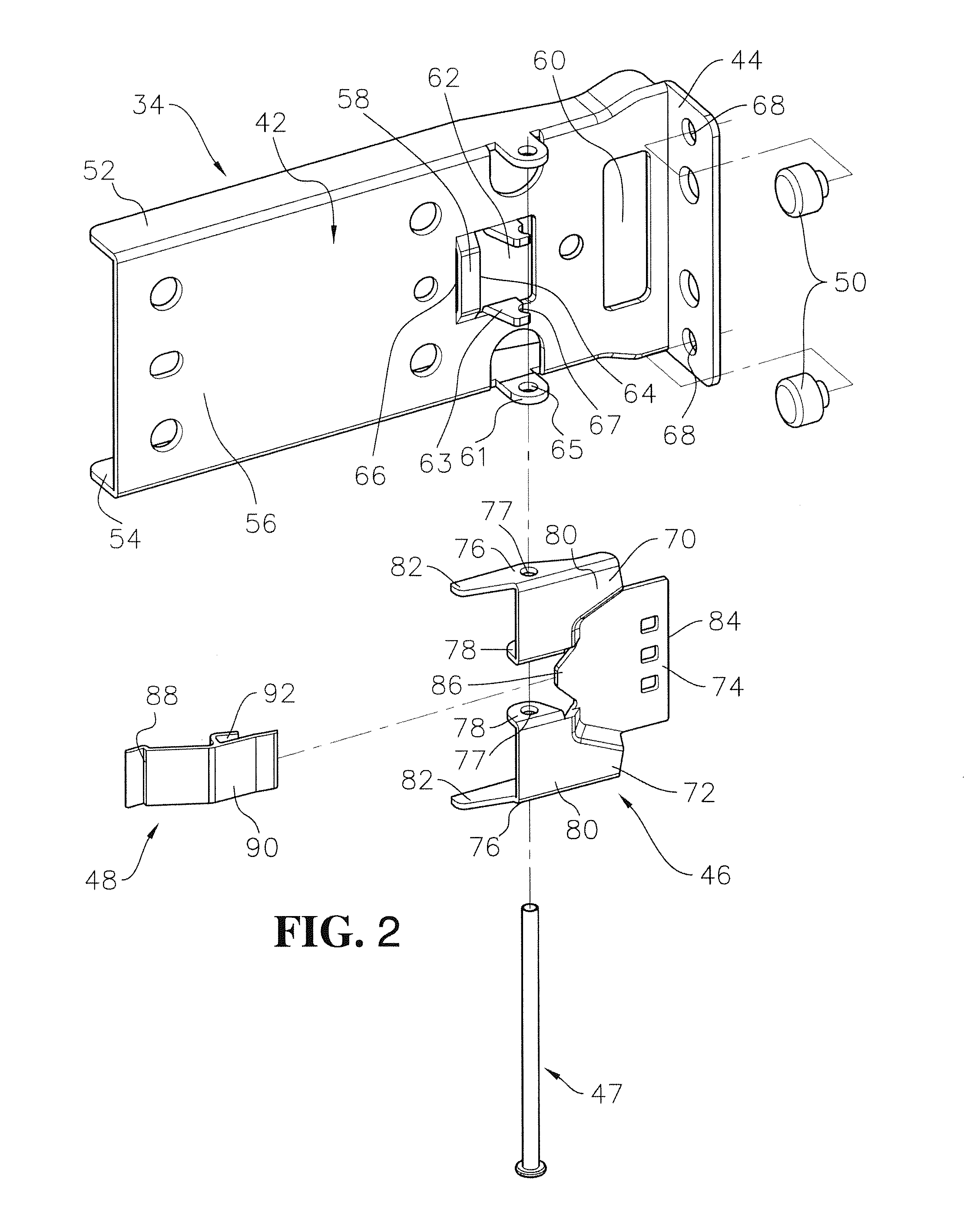

Mounting bracket for slide assembly

ActiveUS20150069196A1Easy to installEasy to removeCandle holdersLighting support devicesEngineeringMechanical engineering

A mounting bracket for a slide assembly includes a side wall, an end wall, at least one installation member, a stop, and a resilient member. The end wall is substantially perpendicular to the side wall. The at least one installation member is connected to the end wall. The stop is pivotably connected to the side wall and includes a first portion and a middle portion which is connected to the first portion. The middle portion has a first end portion. The resilient member provides a force to the stop to position the first end portion of the stop to be located corresponding to the end wall.

Owner:KING SLIDE WORKS CO LTD +1

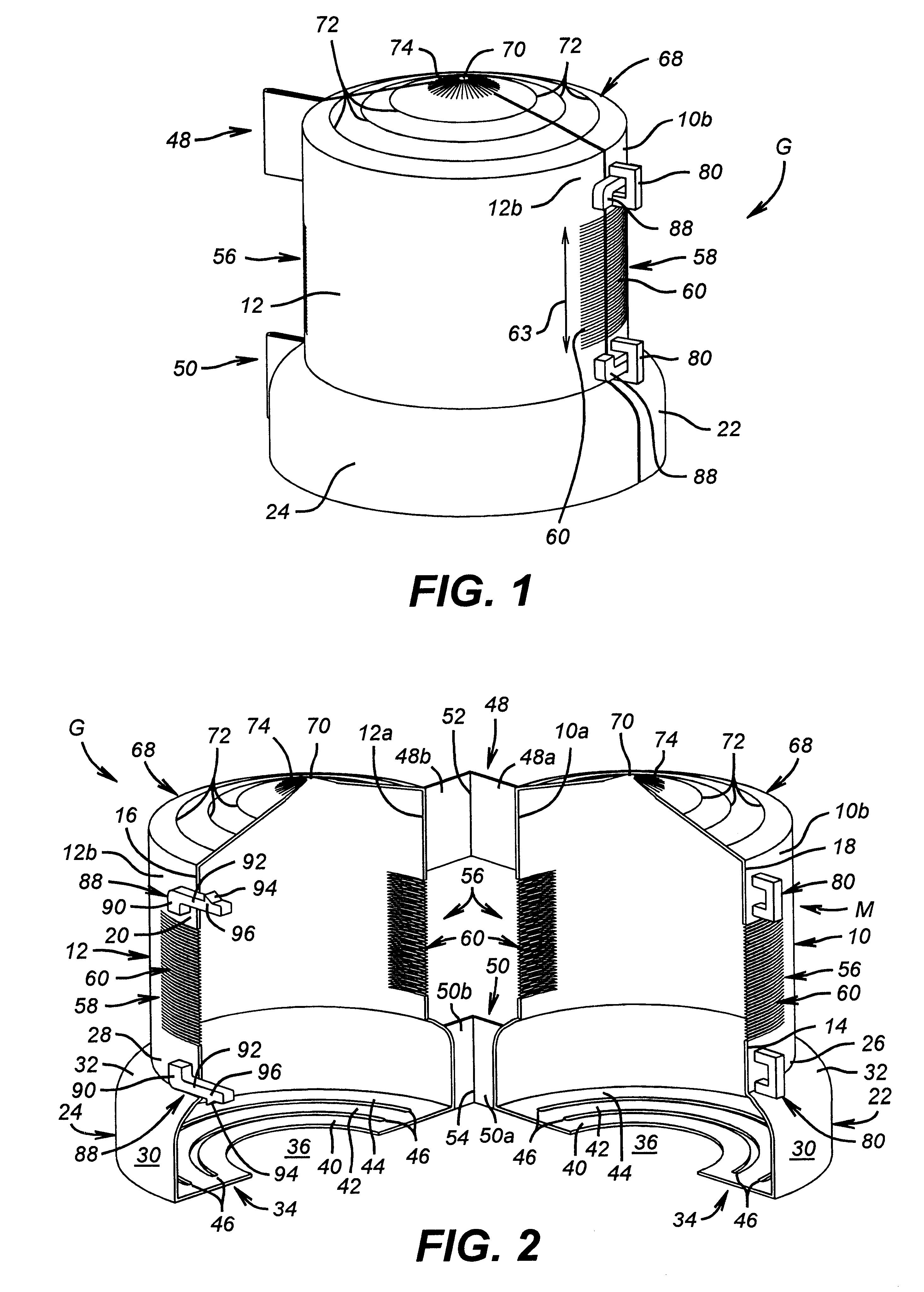

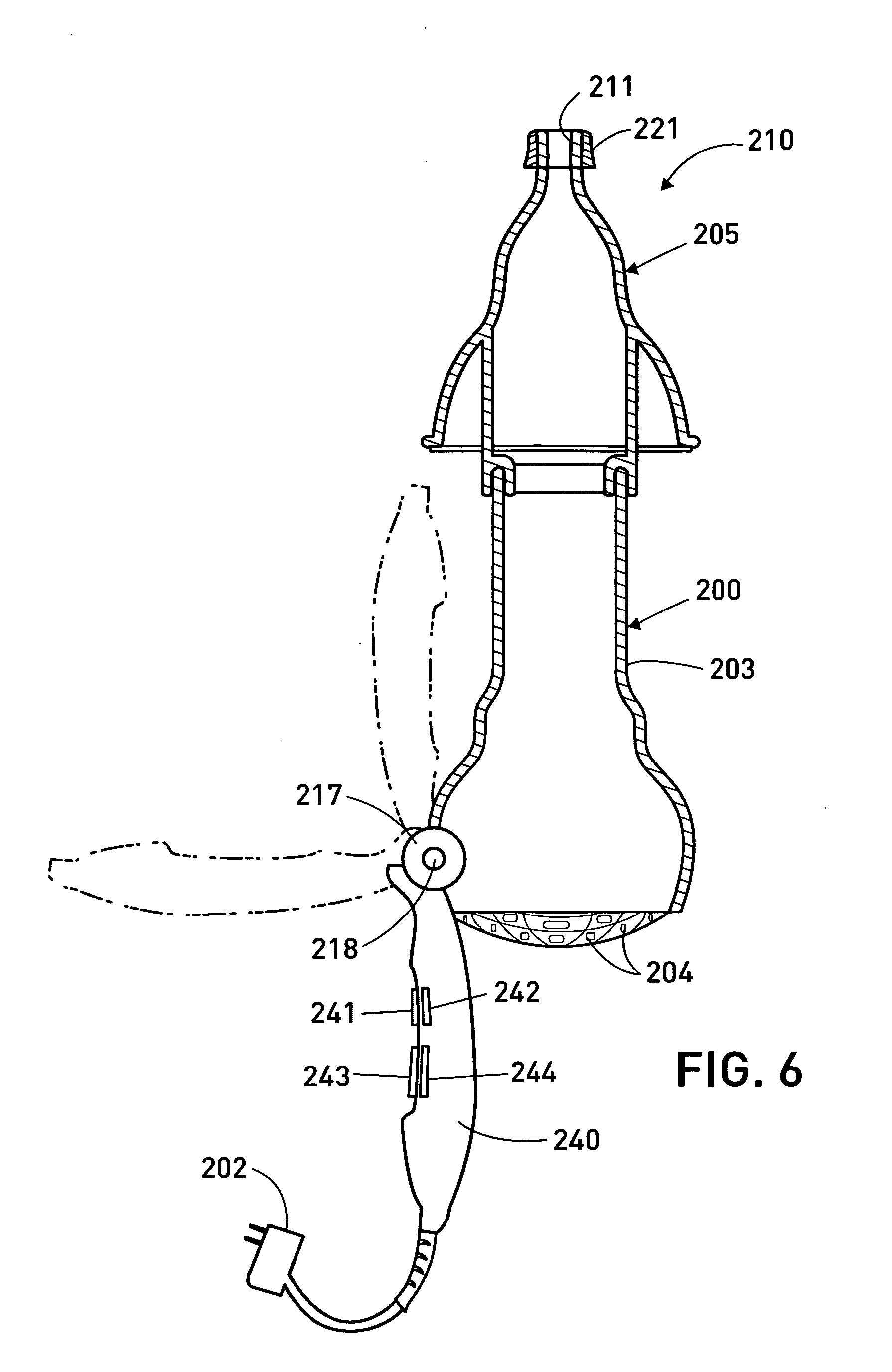

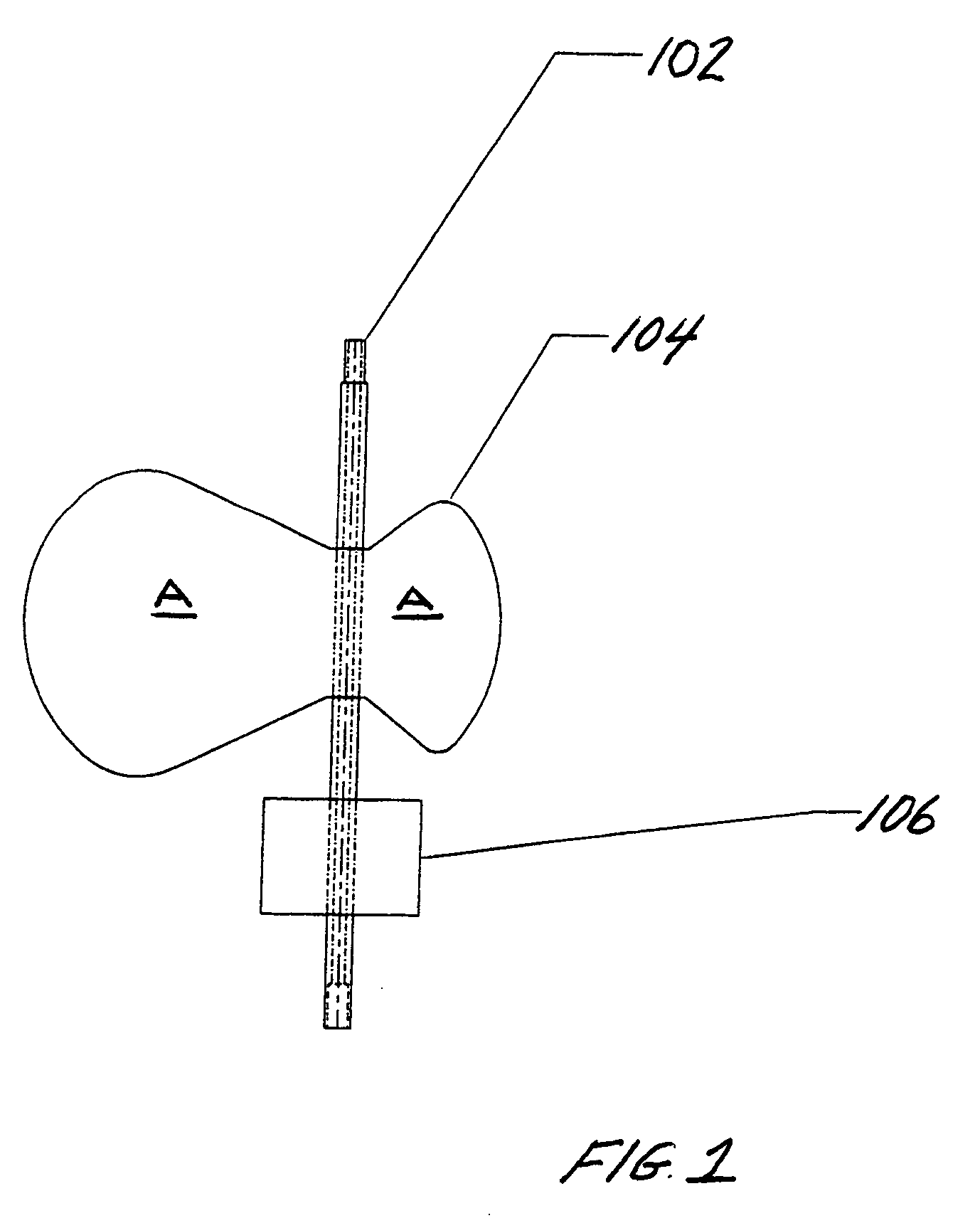

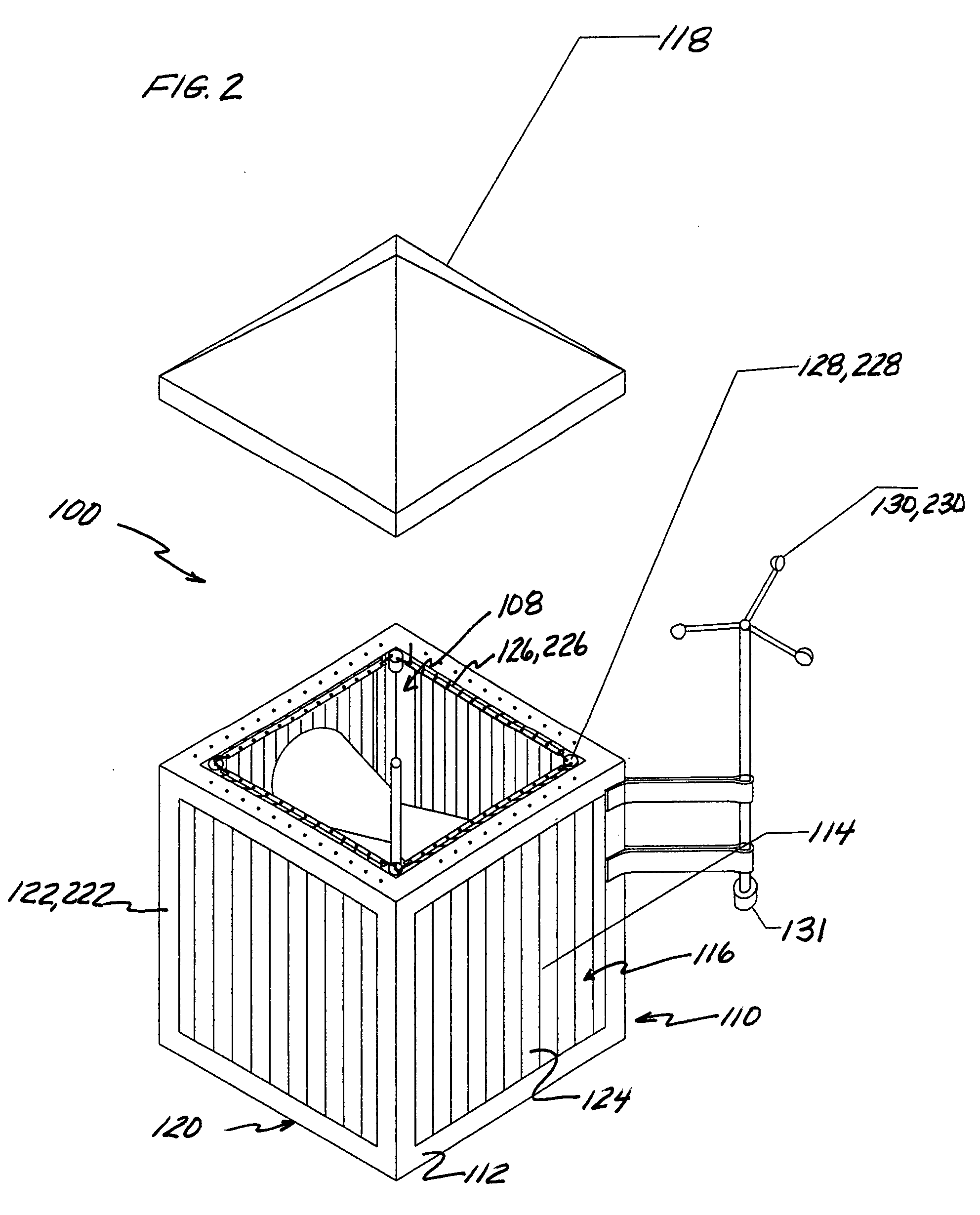

Wind generator system

InactiveUS20070284885A1Increase rotation speedEasy to install and removeWind motor controlWind energy with garvitational potential energyDrive shaftWind force

The present invention is a new and novel wind generator system particularly suitable for small wind applications that harnesses low velocity wind effectively. In a preferred embodiment of the invention, the wind generator system comprises a drive shaft; a plurality of blades attached to the drive shaft and extending radially outwardly therefrom; a generator assembly coupled to the drive shaft and effective for generating electrical power; and a housing having an inner chamber for receiving the plurality of blades and a wind directional apparatus that operates to adjust the speed of the wind and to channel wind along a desired flow pathway towards the plurality of blades.

Owner:STAR SAILOR ENERGY

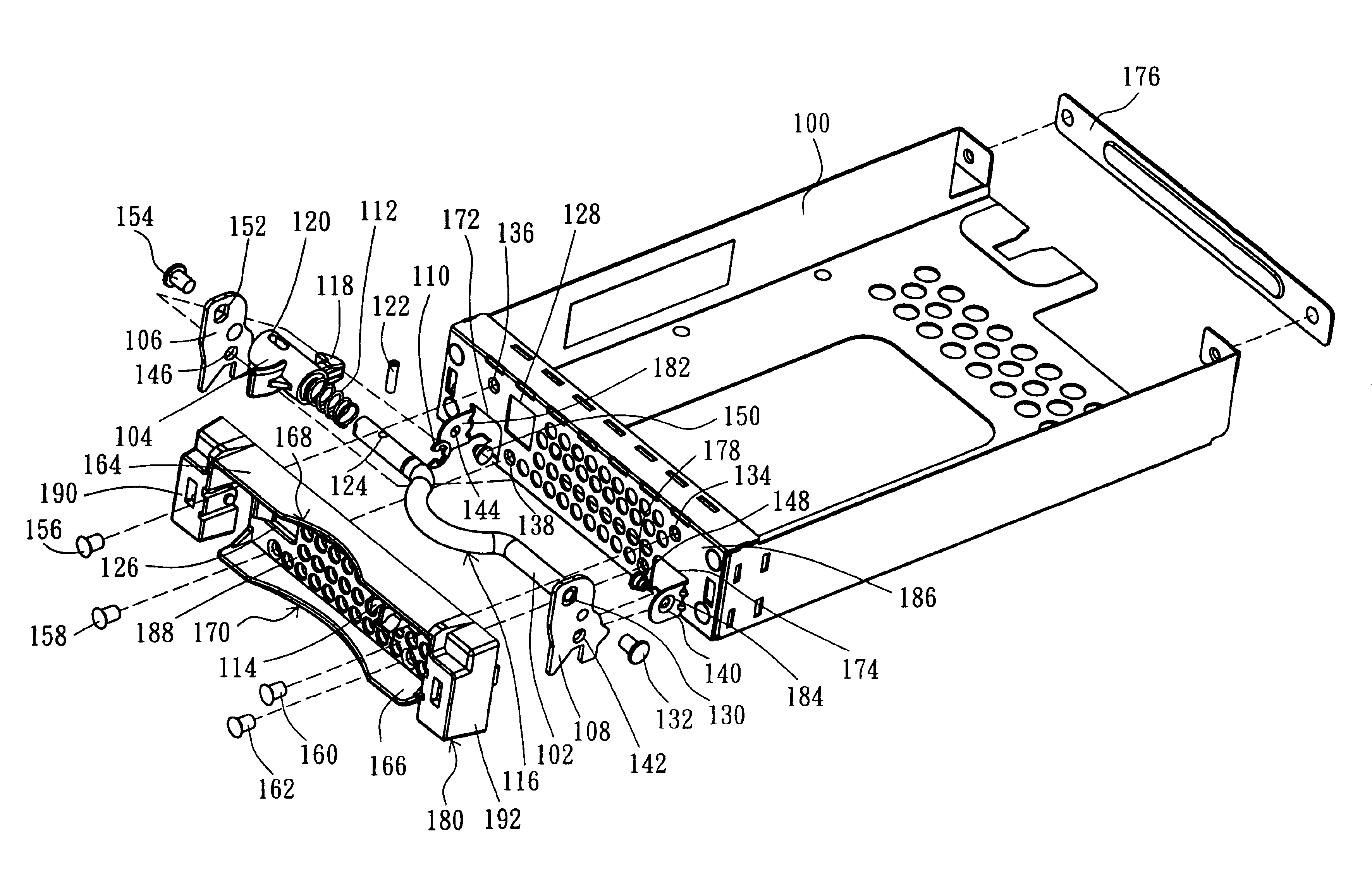

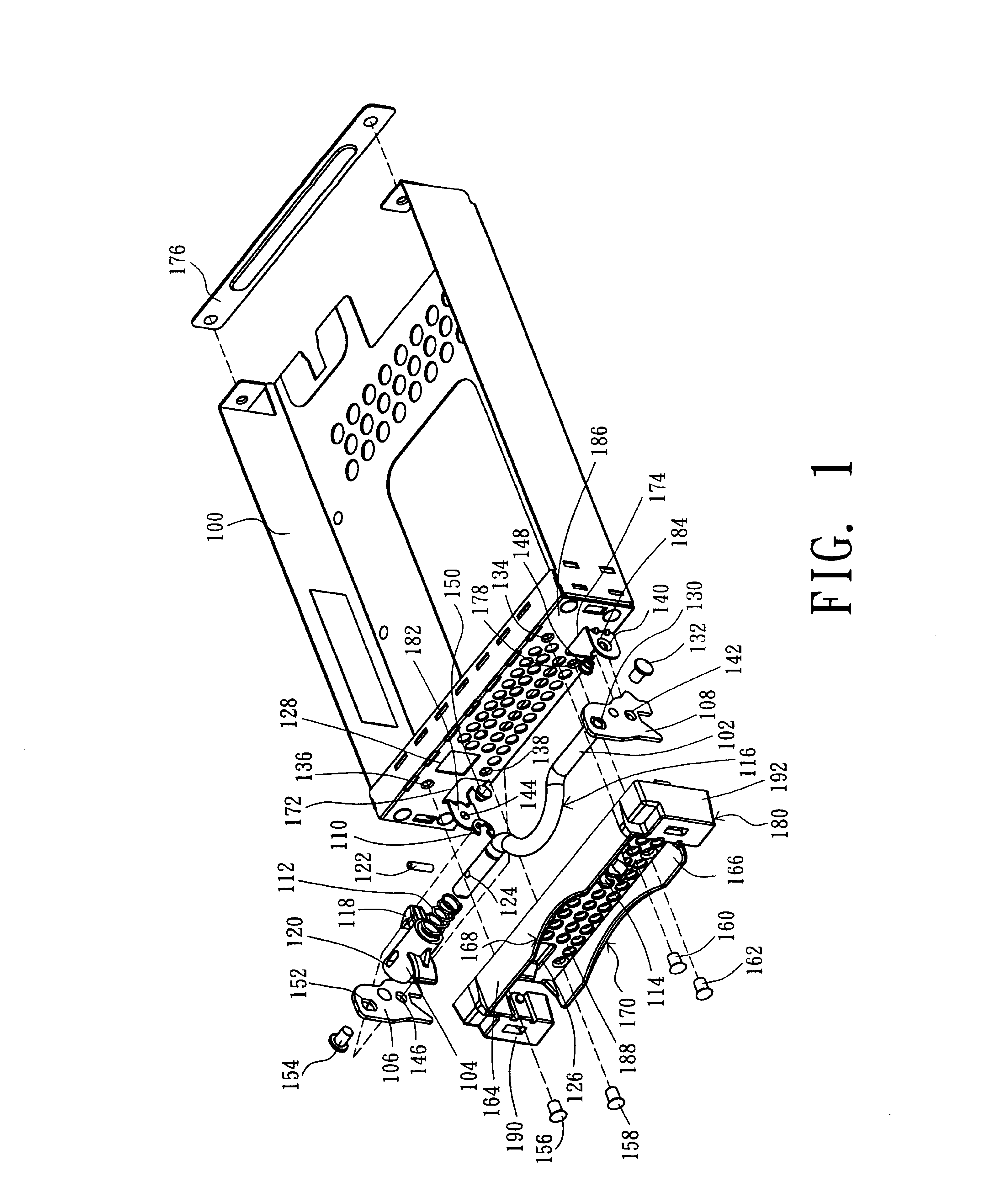

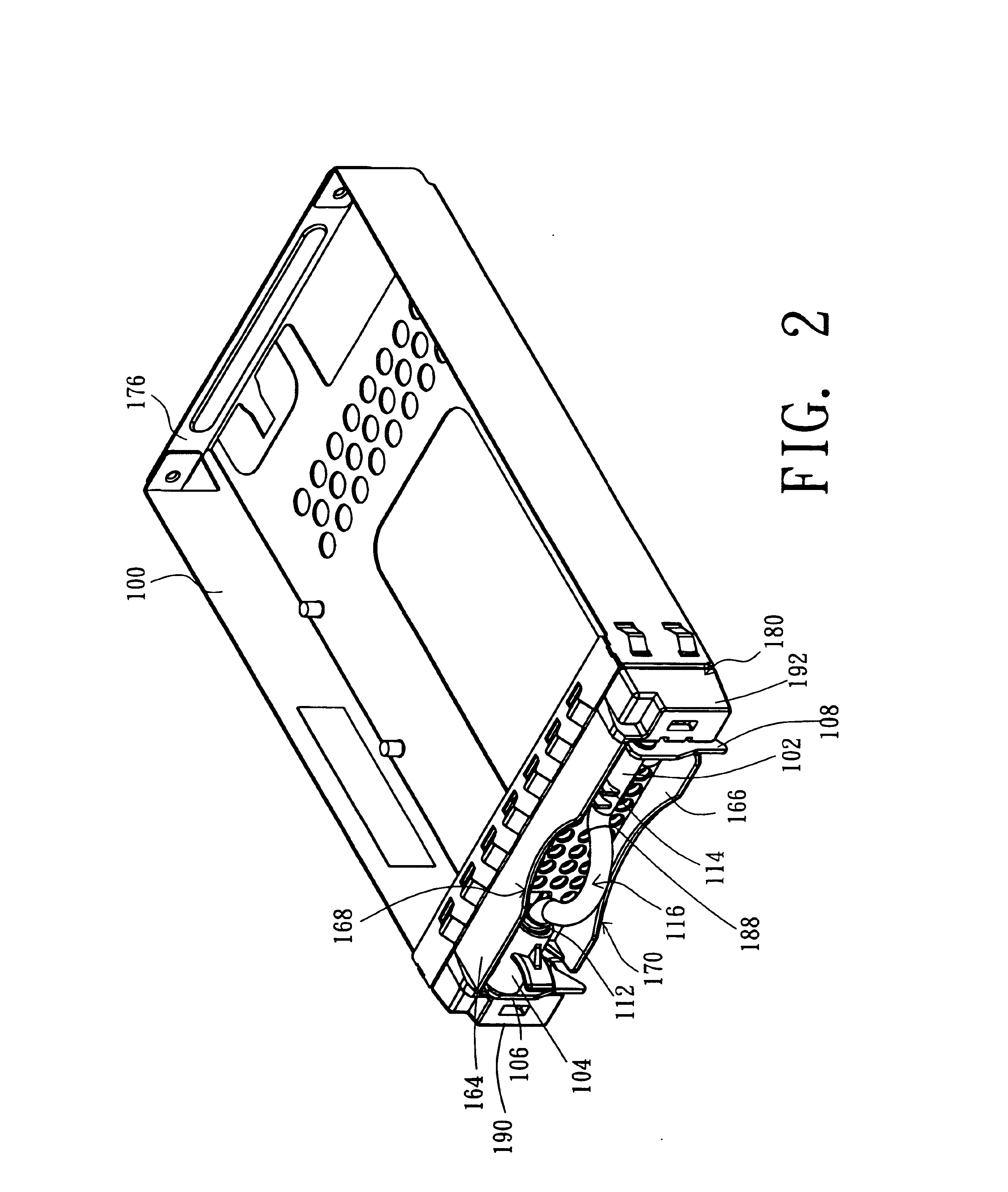

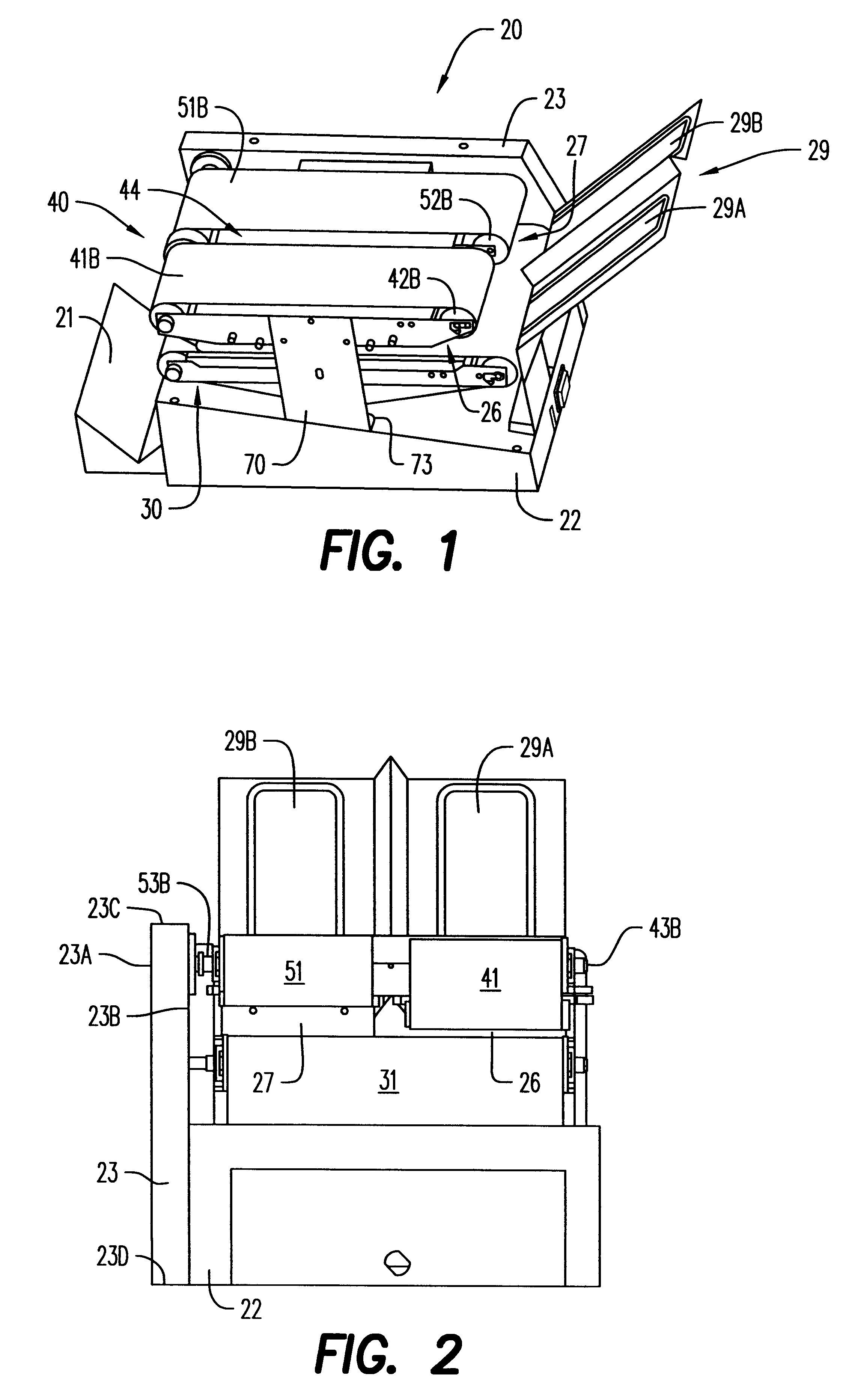

Hard disk drive tray module

ActiveUS6891723B1Easy to disassembleEasy to installDigital data processing detailsCarrier casesHard disc driveEngineering

A hard disk drive (HDD) tray module is disclosed. The hard disk drive tray module comprises a tray, a bezel and a hook device, wherein the bezel is located between the tray and the hook device, and the hook device and the bezel are attached to the tray. The hook device comprises a handle, a latch, a spring, an E ring and two hook plates, wherein the handle is inserted into the spring, the spring is inserted into the latch, and the E ring is installed onto the handle. With the use of the spring and the E ring, the latch can be slid along the handle.

Owner:QUANTA COMPUTER INC

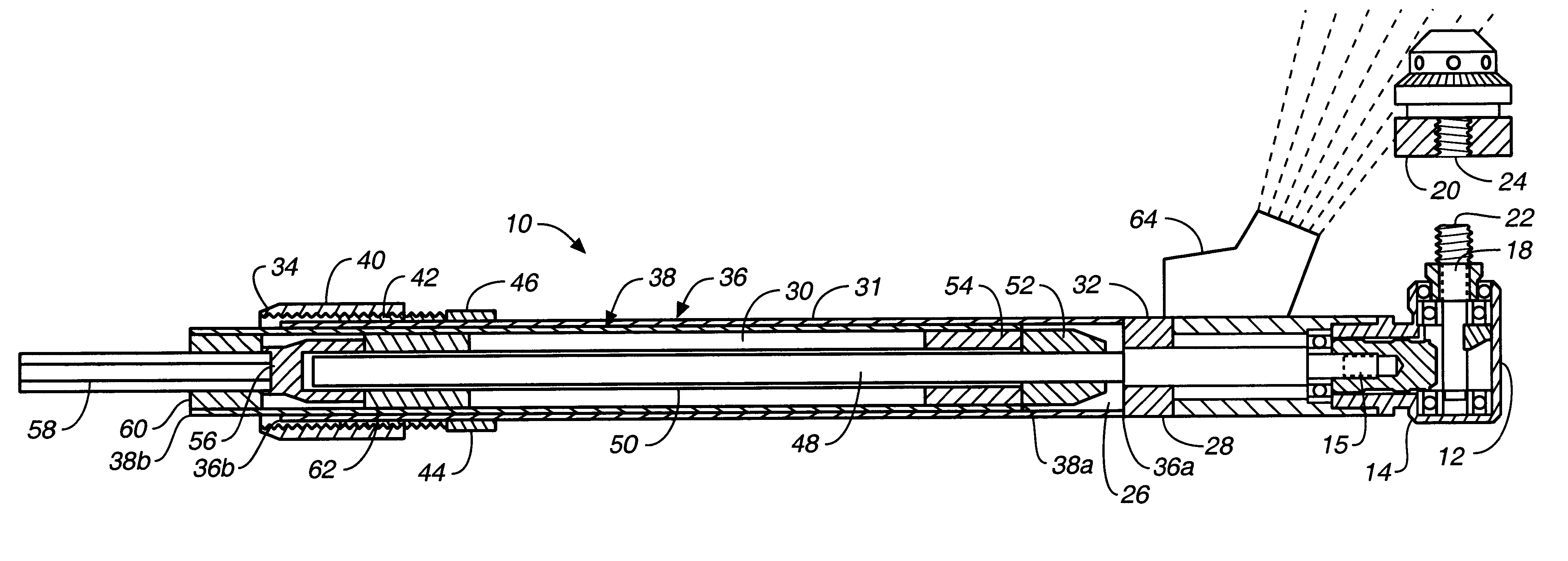

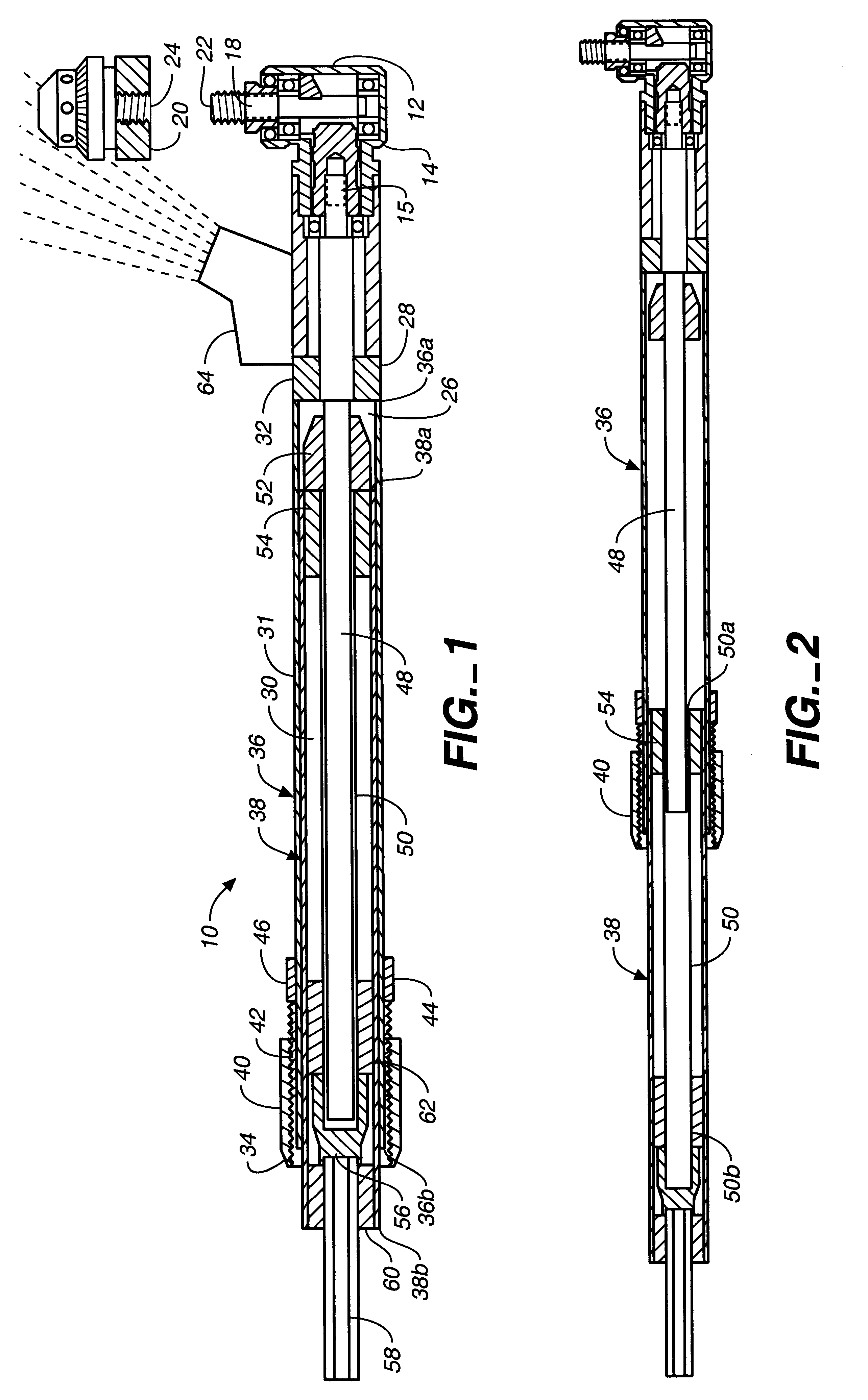

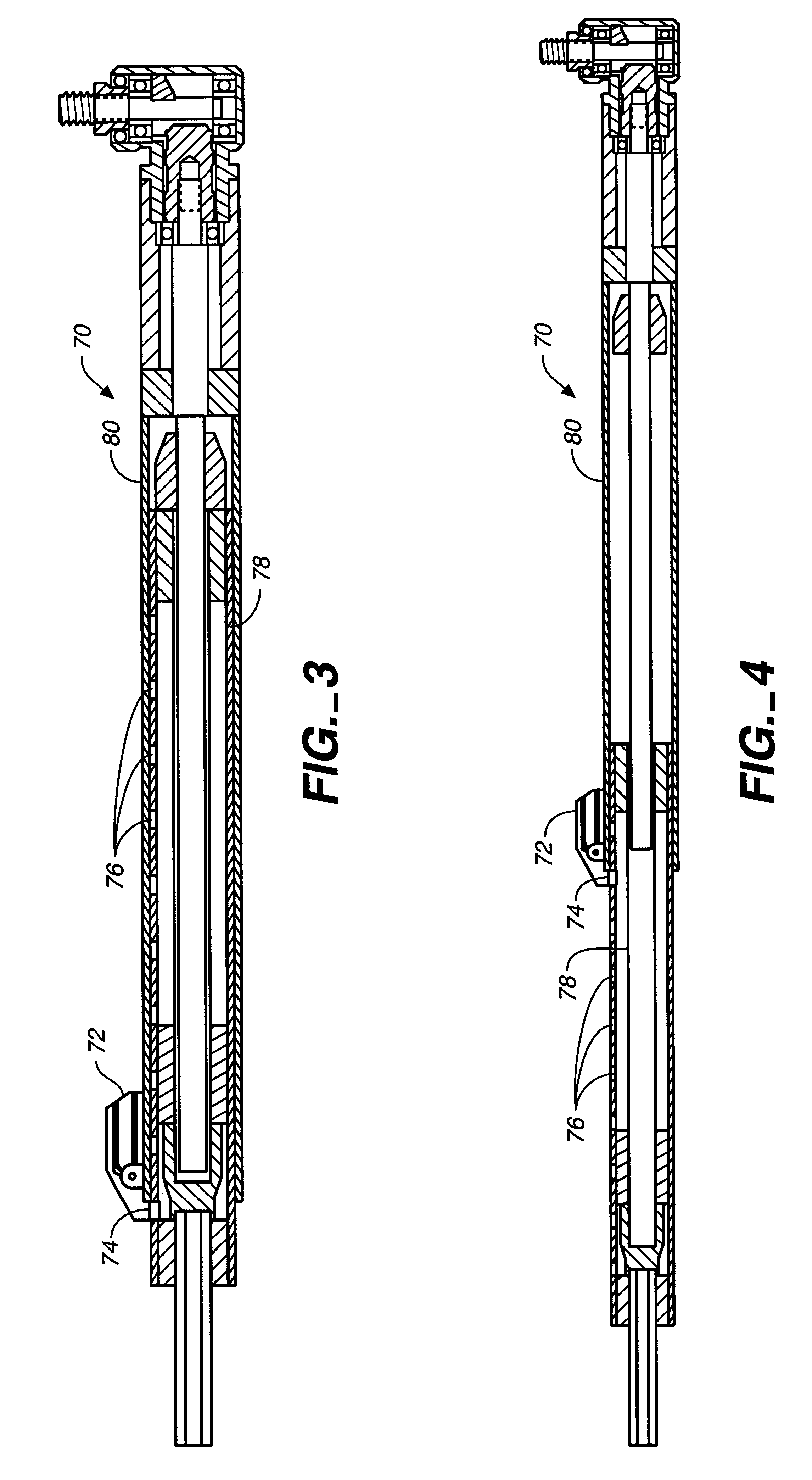

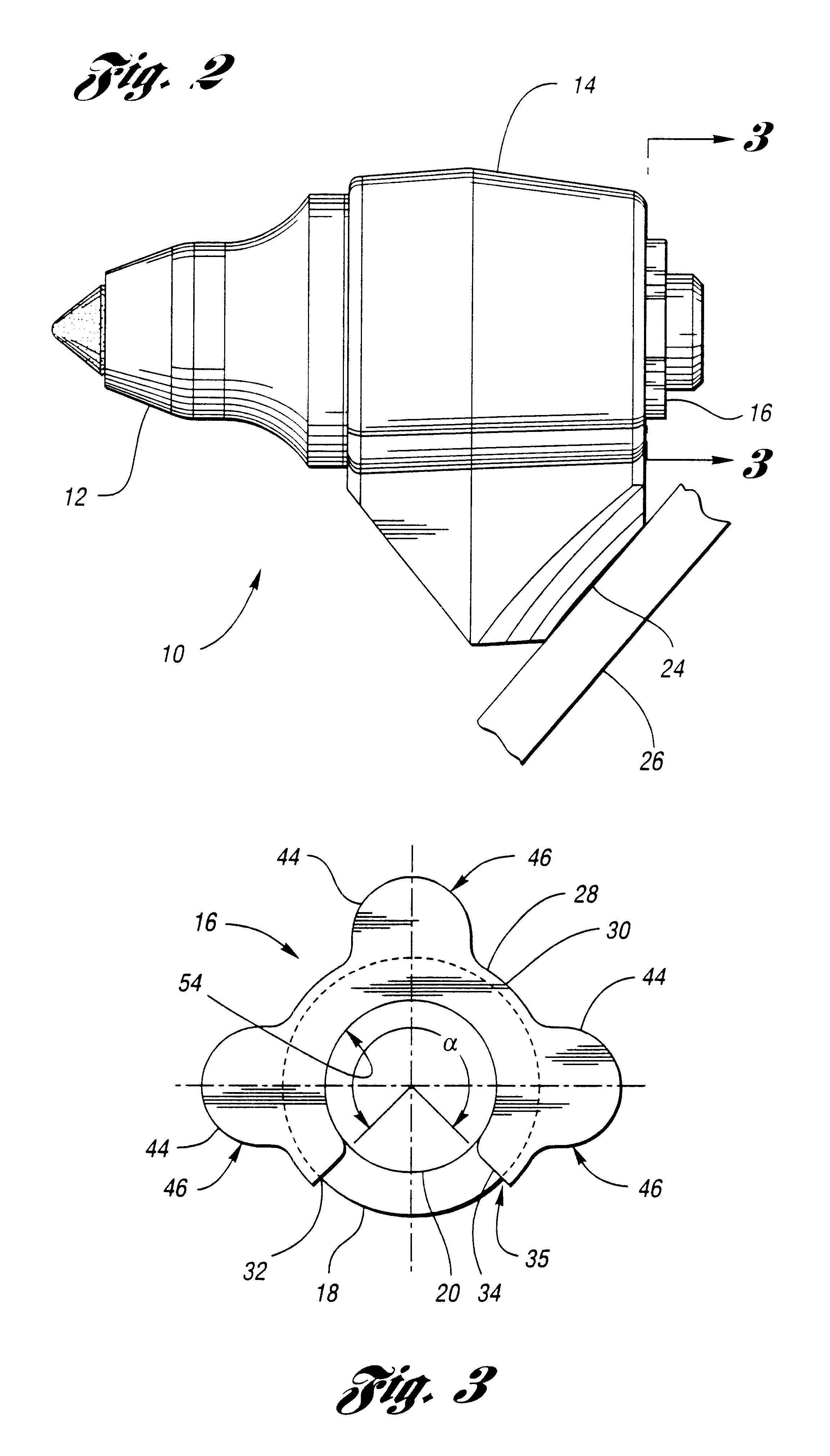

Telescopic pocket door angle drill

InactiveUS6293172B1Easy to install and removeOvercome limitationsMeasurement/indication equipmentsSpannersGear wheelDrive shaft

A pocket door angle drill having a right angle driver with a truly telescopic handle portion that may be extended to reach into confined spaces. The right angle driver has a casing and an internal gear assembly for translating rotary motion from a horizontal drive shaft to a vertical drive shaft. The drill further includes a telescopically extendable primary drive shaft portion that may be operatively connected to a power rotary device, and, optionally, an extension pole having an extension drive shaft for providing access to remote confined spaces.

Owner:SMITH JAMES C

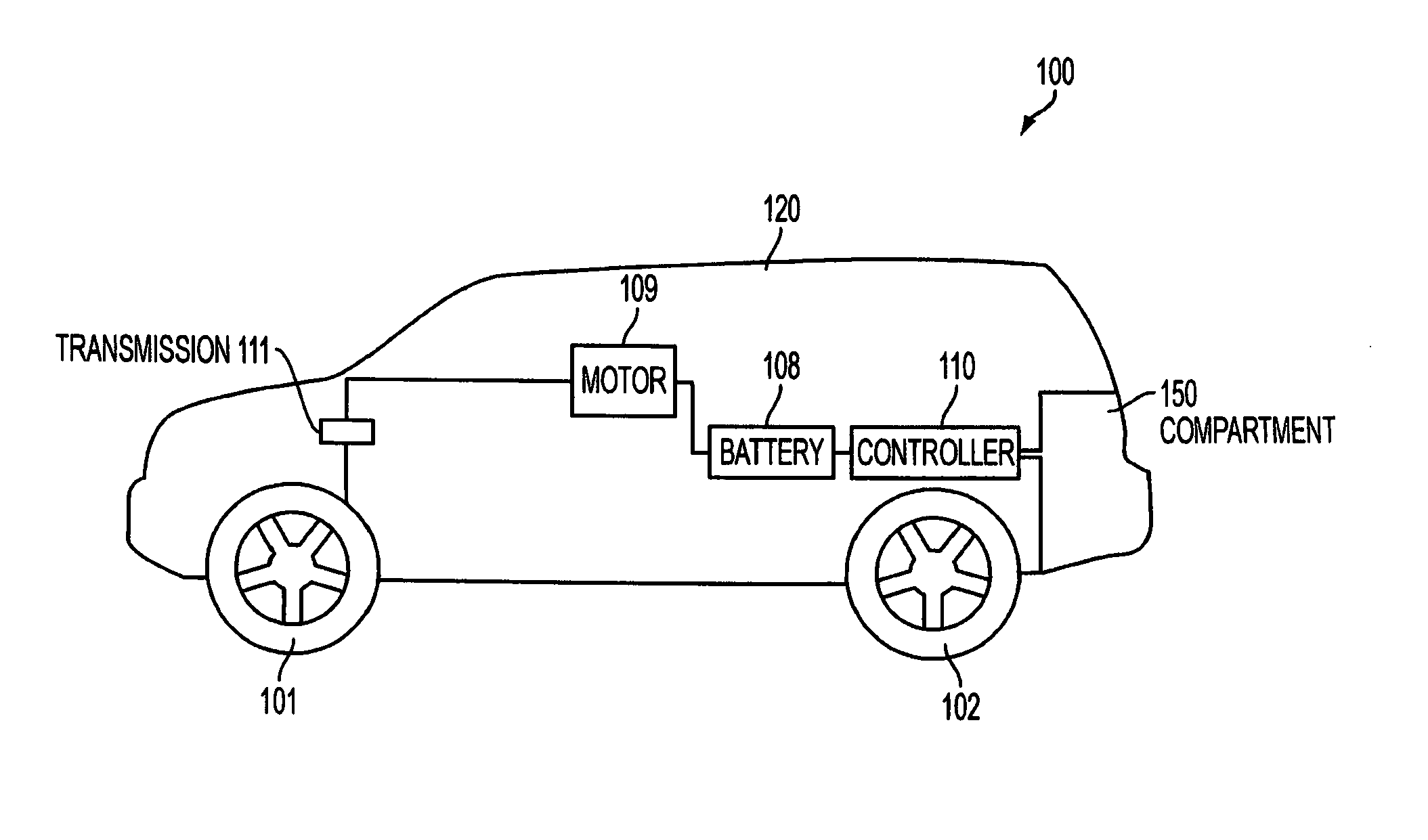

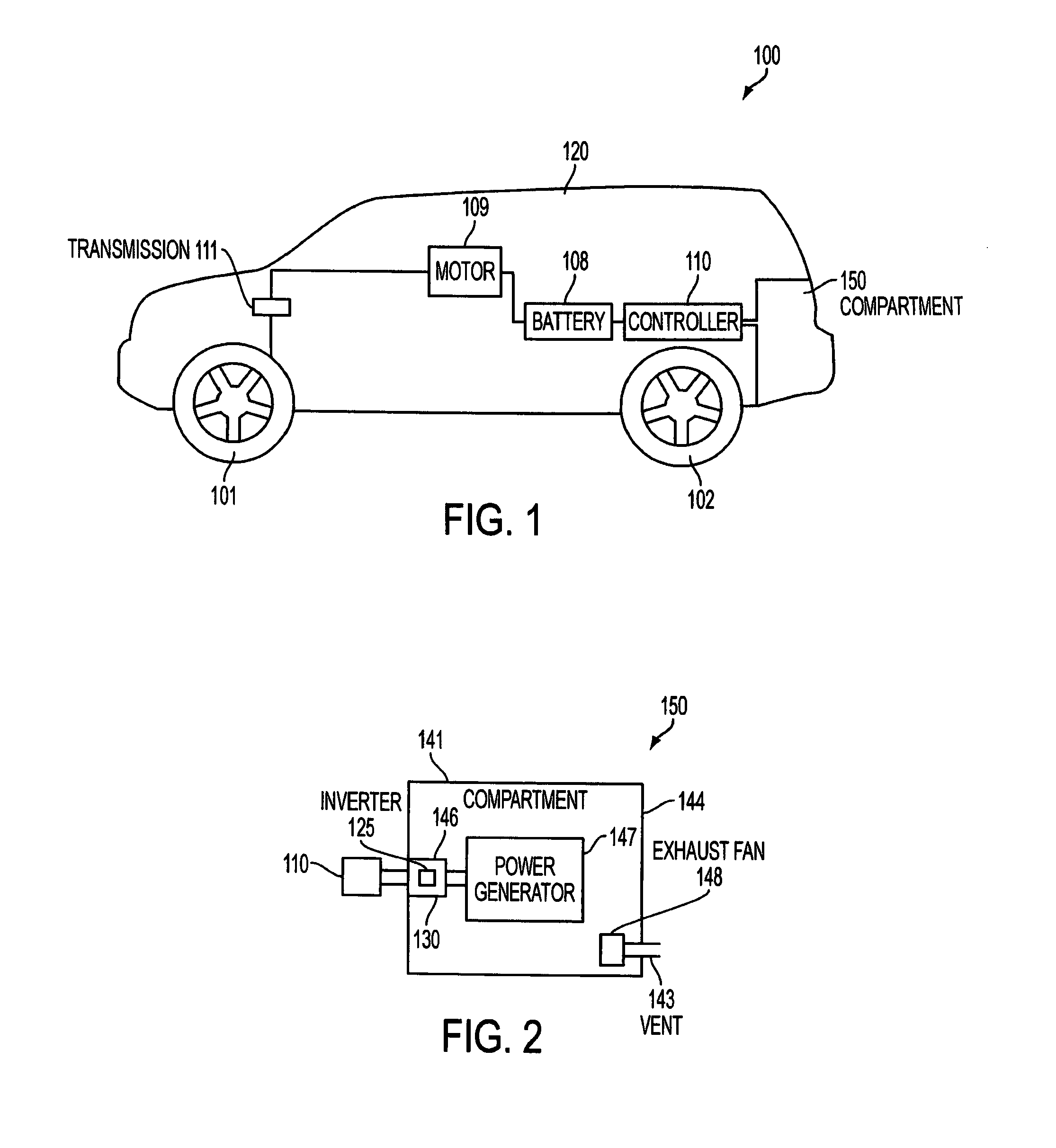

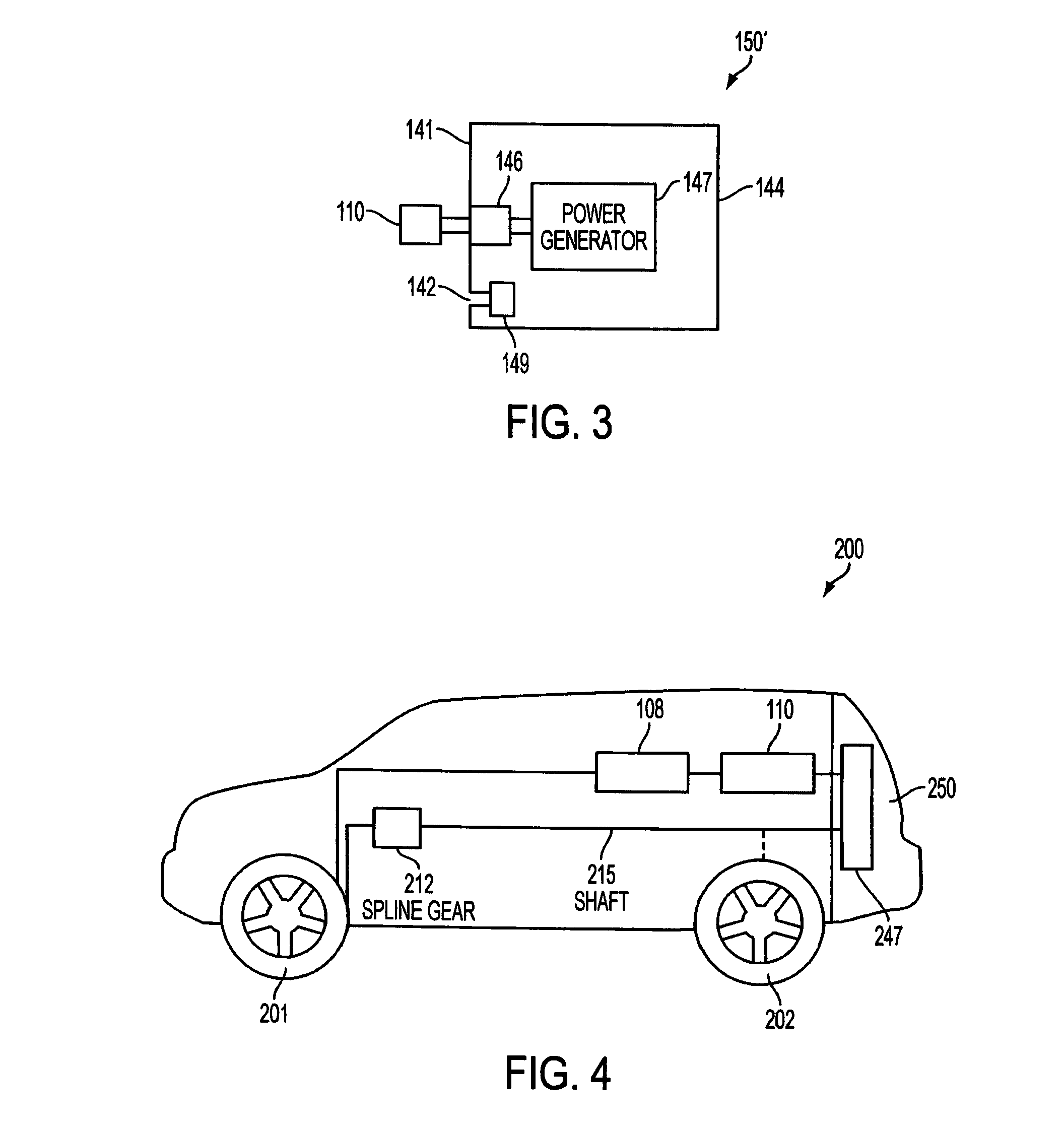

Vehicle with removable auxiliary power system

InactiveUS20110226539A1Increase rangeEasy to install and removeCharging stationsElectric propulsion mountingBattery chargeElectrical battery

An electric and hybrid vehicle configuration with removable auxiliary power supply is disclosed which provides a flexible configuration for, on the one hand, allowing on demand increased range and additional power for accessories and / or increased performance when the auxiliary power supply is easily inserted in the vehicle to charge the battery in an electric vehicle and on the other hand, allowing for weight reduction and increased storage capacity or increased battery capacity when the power supply is removed. In another embodiment, the removable auxiliary power supply may drive the vehicle either separately or in conjunction with the charging of the vehicle main battery to thereby provide a hybrid vehicle configuration.

Owner:HUSS MICHAEL A +1

Ground fleet operations quality management system

ActiveUS20150269790A1Sufficient informationLow costRegistering/indicating working of vehiclesRoad vehicles traffic controlWeb applicationComputer module

A ground fleet operations quality management system for use with one or more vehicles which includes a gateway module mounted on each vehicle, a centralized data server to collect, store and pre-process data from multiple vehicles, and a web application designed to provide access to and analysis of the conditions of the entire fleet of vehicles.

Owner:APPAREO SYST

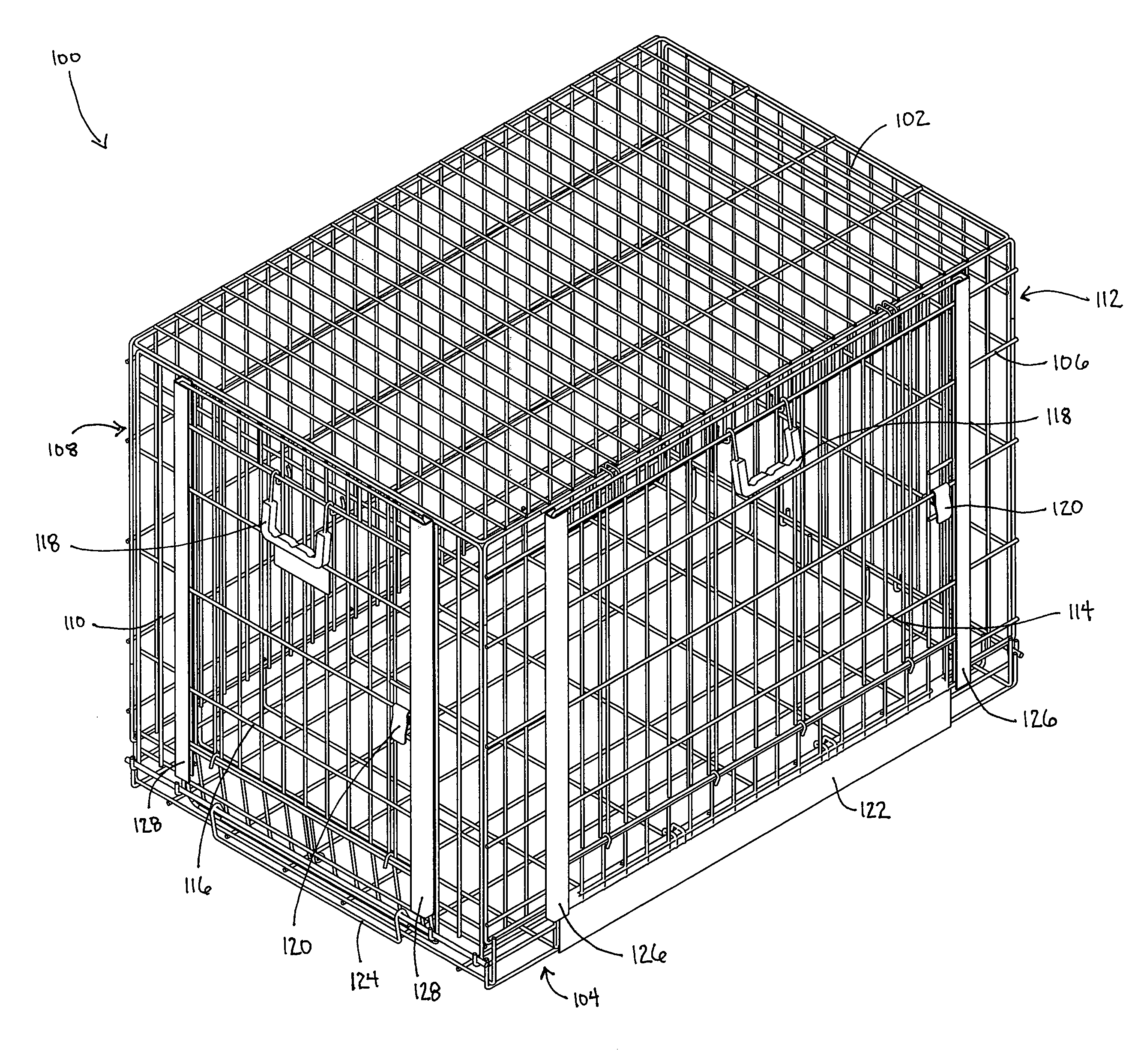

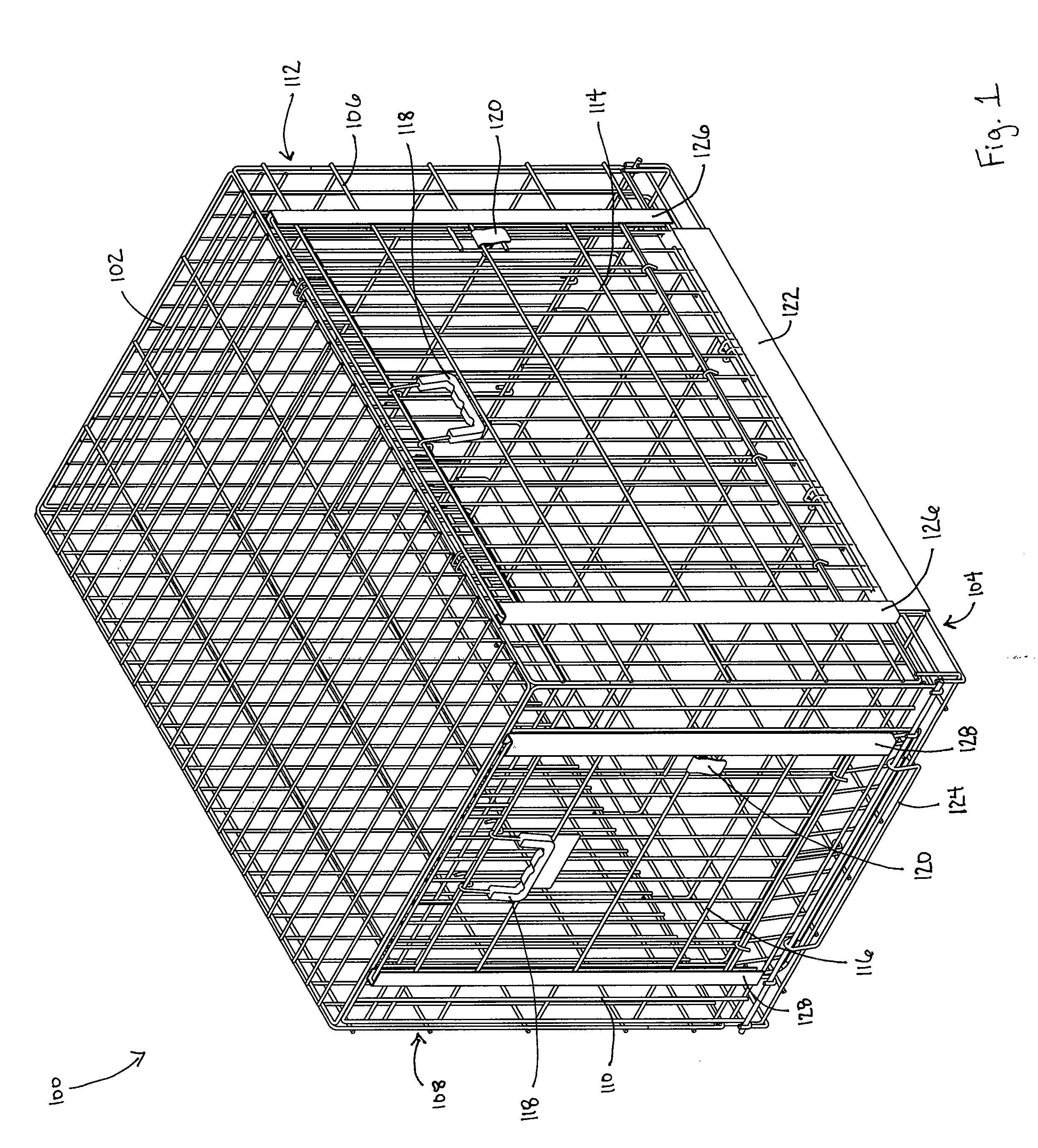

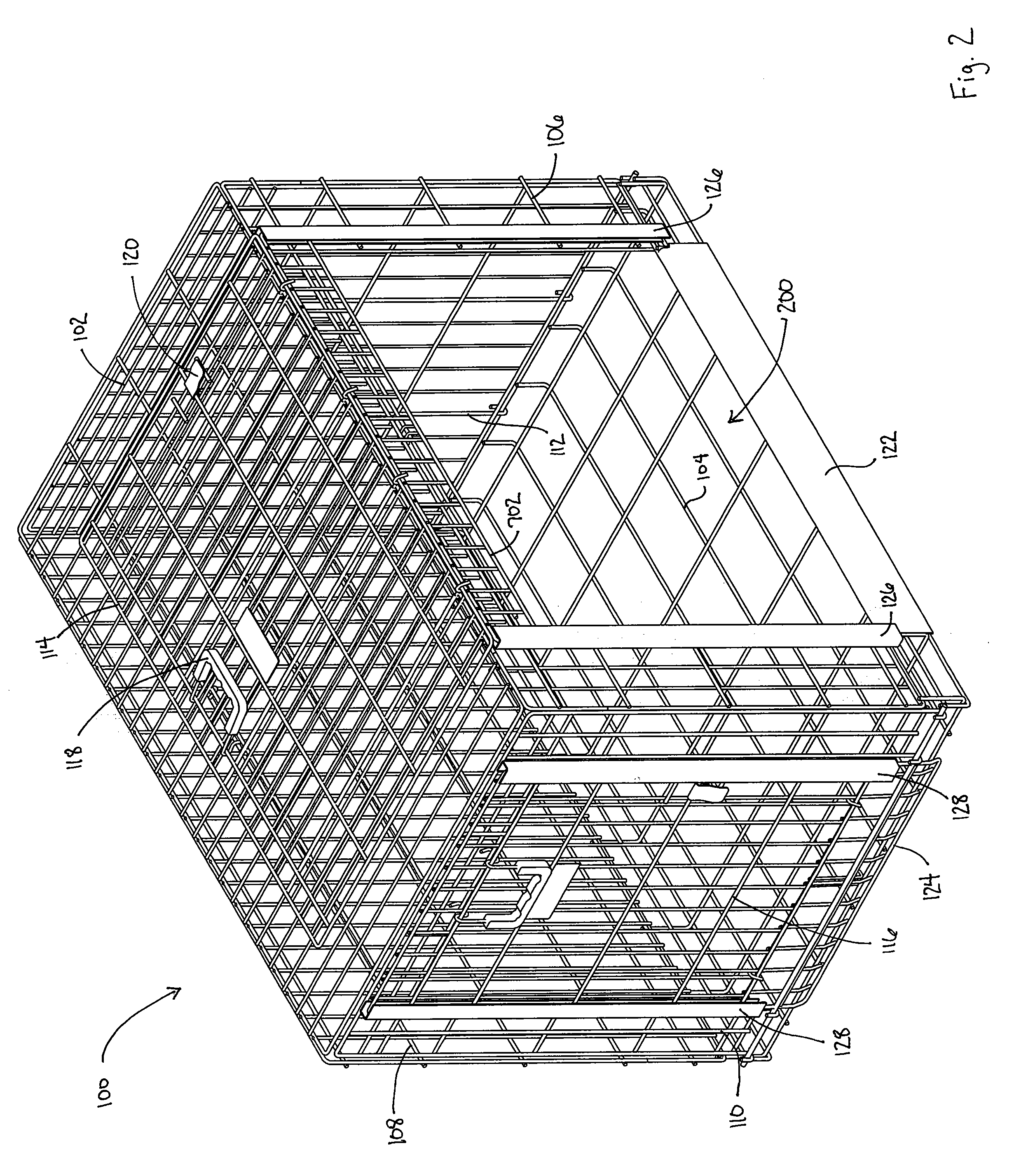

Collapsible Wire Crate And Method Of Assembly

ActiveUS20120186529A1Easy accessReduce the amount requiredAnimal housingMetal working apparatusEngineeringCrate

The present invention provides a wire crate for housing an animal. The wire crate includes a top panel, a bottom panel, a front panel, a back panel, and a pair of side panels oppositely disposed from one another. The crate also includes a front opening defined in the front panel. The front opening is configured to provide access to the interior of the crate. The crate further includes a pair of tracks coupled to each side of the front opening and a door slidably coupled to the pair of tracks. The door slides along the pair of tracks between an open position and a closed position.

Owner:MID WEST METAL PRODS

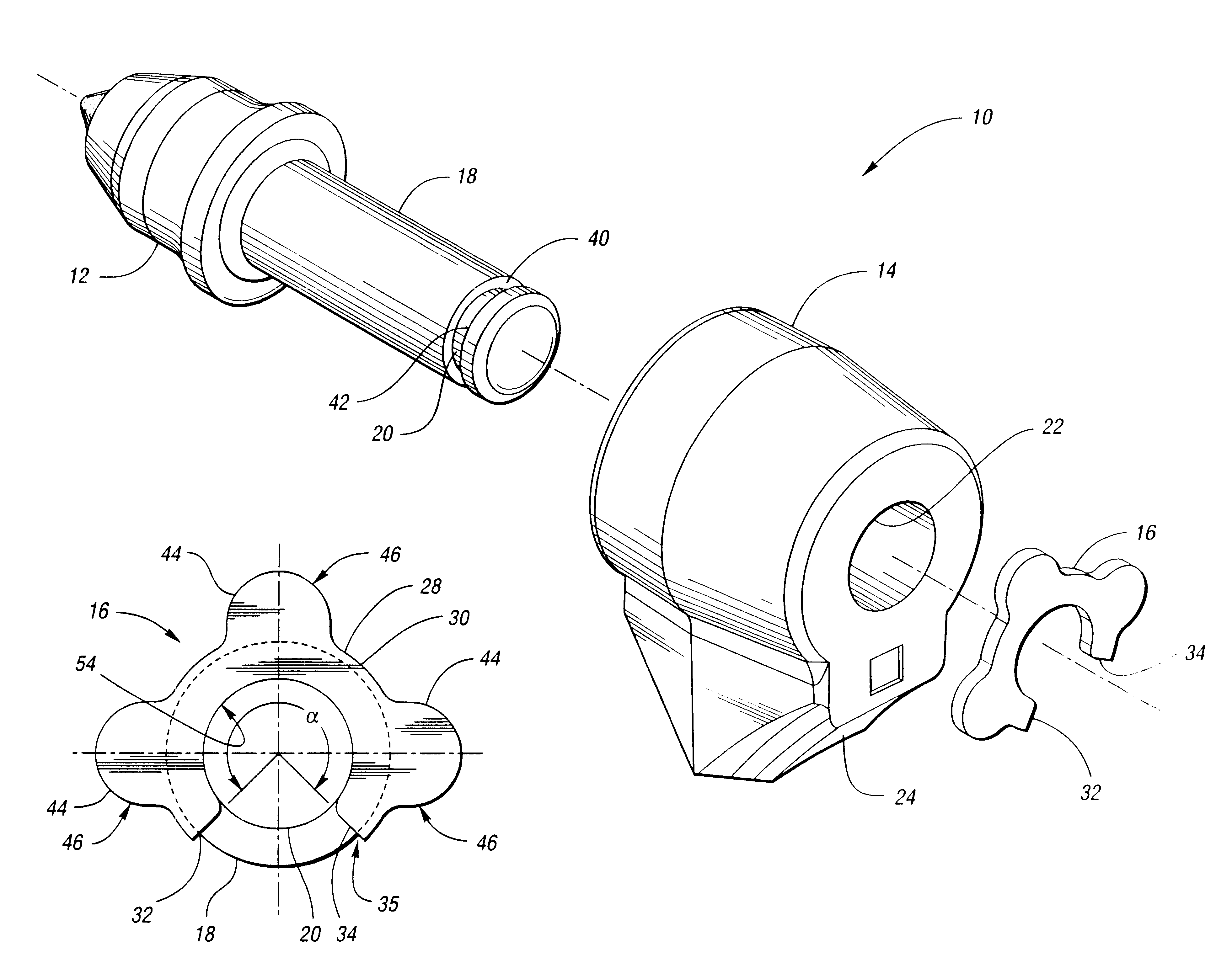

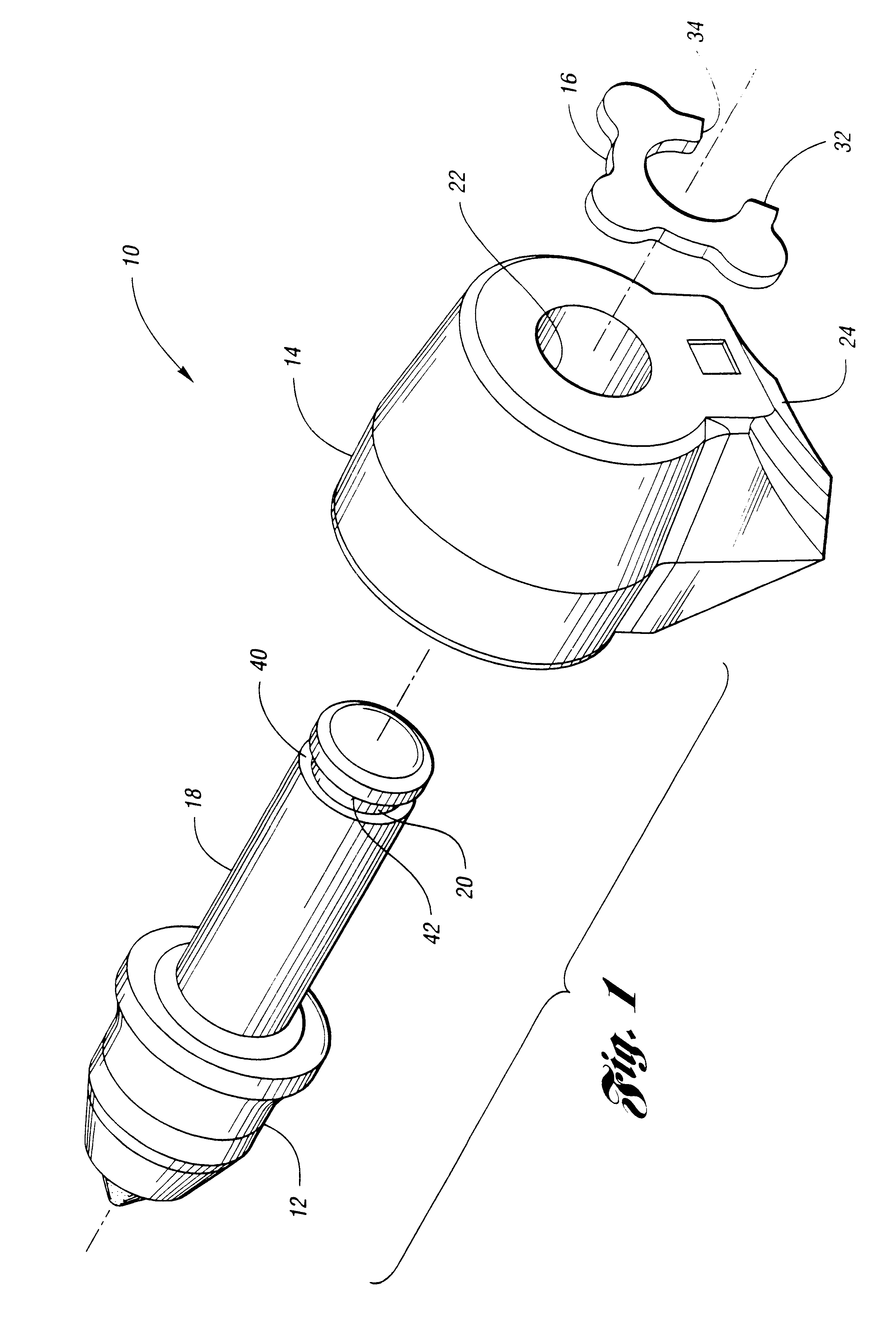

Cutting tool retainer

InactiveUS6428110B1Smooth connectionHigh strengthSnap fastenersSlitting machinesMechanical engineeringShear zone

A retainer, adapted to engage a recess in a cutting tool for securing the cutting tool to a support block, includes a retainer body having a main portion with first and second ends. The main portion defines a continuous shear zone having first and second ends. The retainer body further includes a protruding portion disposed between the ends of the continuous shear zone and spaced away from the ends of the main portion. The protruding portion extends radially from the main portion and is adapted to overlap the support block when the retainer is engaging the recess.

Owner:KENNAMETAL INC

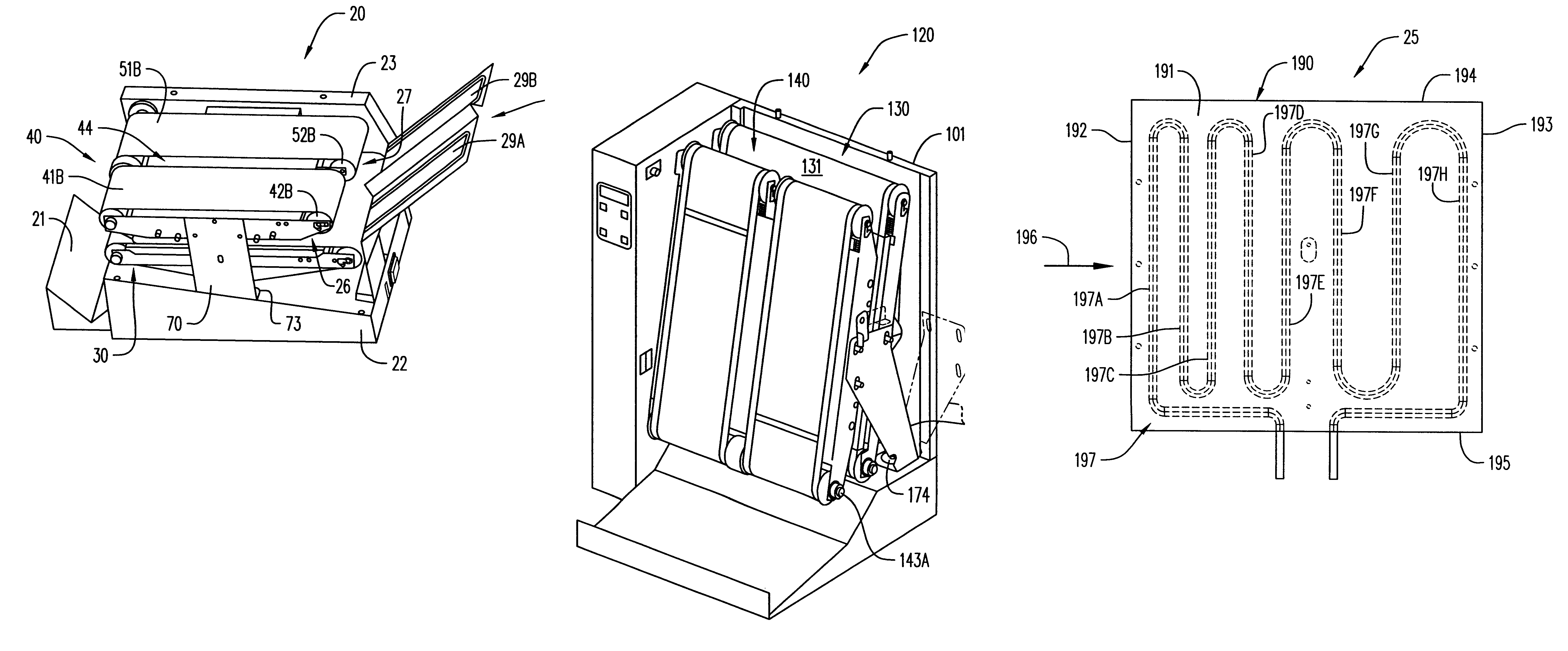

Food cooking apparatus with removable conveyor assembly and serpentine heater providing non-uniform heating

InactiveUS6201218B1Easily and quickly removableEasy accessFood preservationFurnace typesDisfigurementEngineering

Food cooking apparatus comprises two conveyor belts, one of which is heated by a platen to provide a moving cooking surface. Since both belts are movable, they are operable to grip a bun heel or crown and convey it along a cooking path between the two belts without disfigurement of the bun. Also disclosed is a quick connect / disconnect feature that allows quick removal of one of the assemblies for cleaning, maintenance and / or belt replacement. This feature has a bracket member which when released allows the removable assembly to slidably disengage from the frame of the apparatus. The food cooking apparatus includes an electrical heating platen with a coil wound in a serpentine manner and spatially distributed to produce high temperature cooking in the early stage of cooking and lower temperature cooking in the later stages of cooking. The food cooking apparatus also includes a mechanism that responds to manual pushing of the idler roller to shift the idler shaft between a drive position and a belt slack position that allows easy and quick installation or removal of the endless belt.

Owner:FRYMASTER CORPTHE

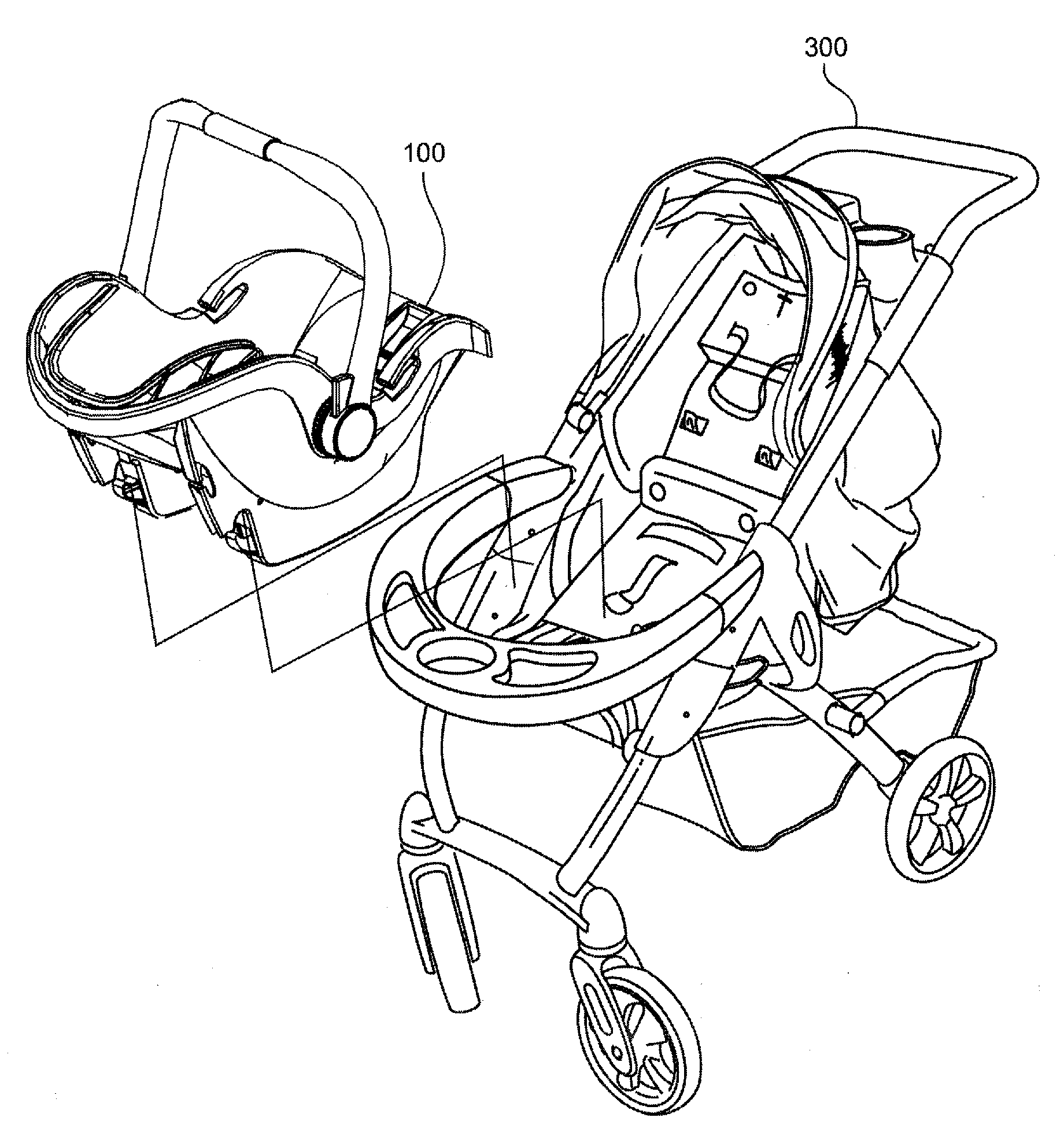

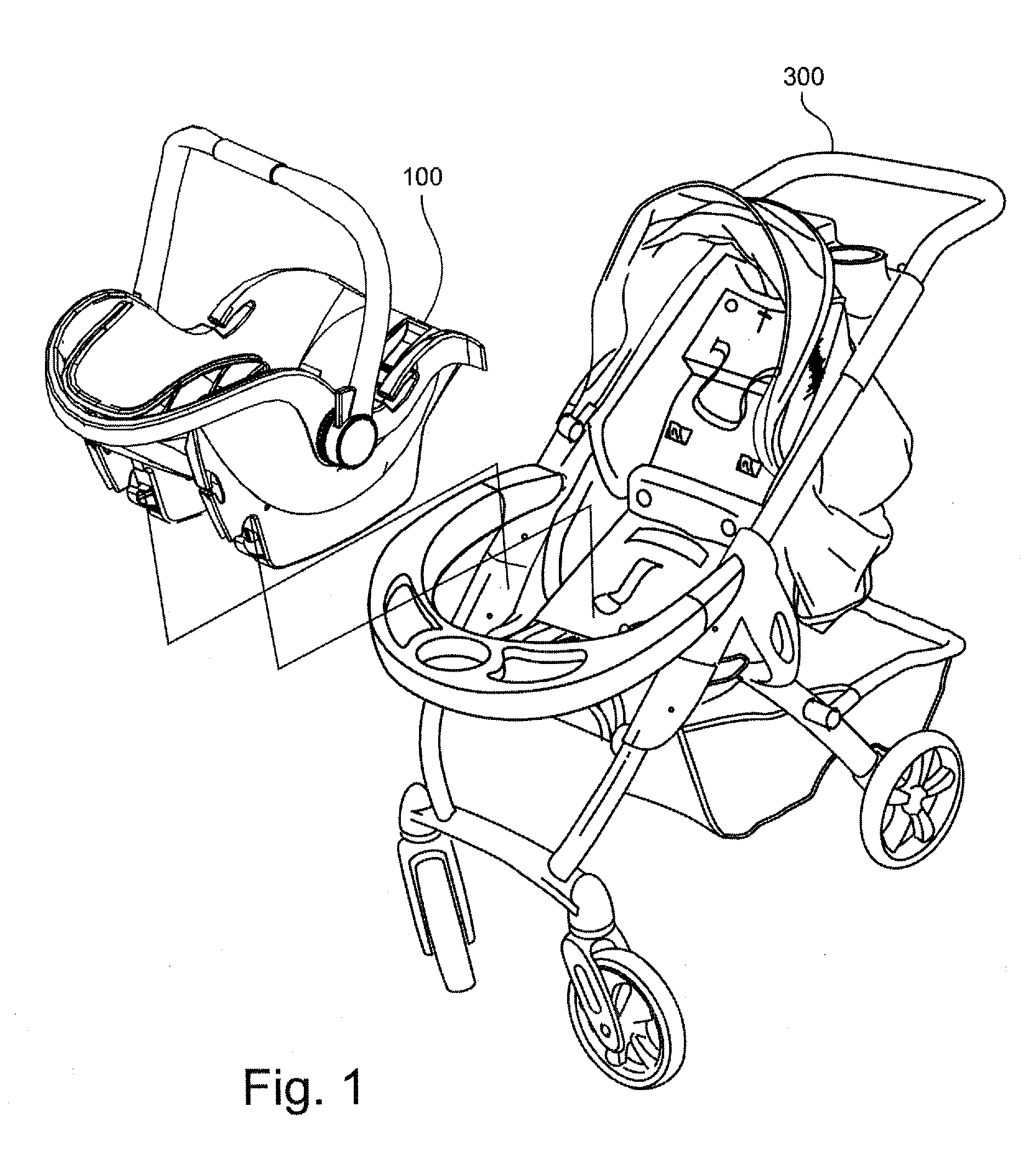

Stroller, child safety seat and child safety system

InactiveUS20090295128A1Wide adaptabilityWide rangeCarriage/perambulator accessoriesVehicle seatsEngineeringMechanical engineering

A stroller including a stroller frame have pivotally connected first, second and third frame elements configured to fold between deployed and collapsed configurations, seat back and bottom portions, a single hand operated frame release mechanism for releasing engagement between the first and second frame elements to collapse the stroller, and a pivoting child tray assembly for releasably locking engagement of the first and second frame elements together.

Owner:BRITAX CHILD SAFETY

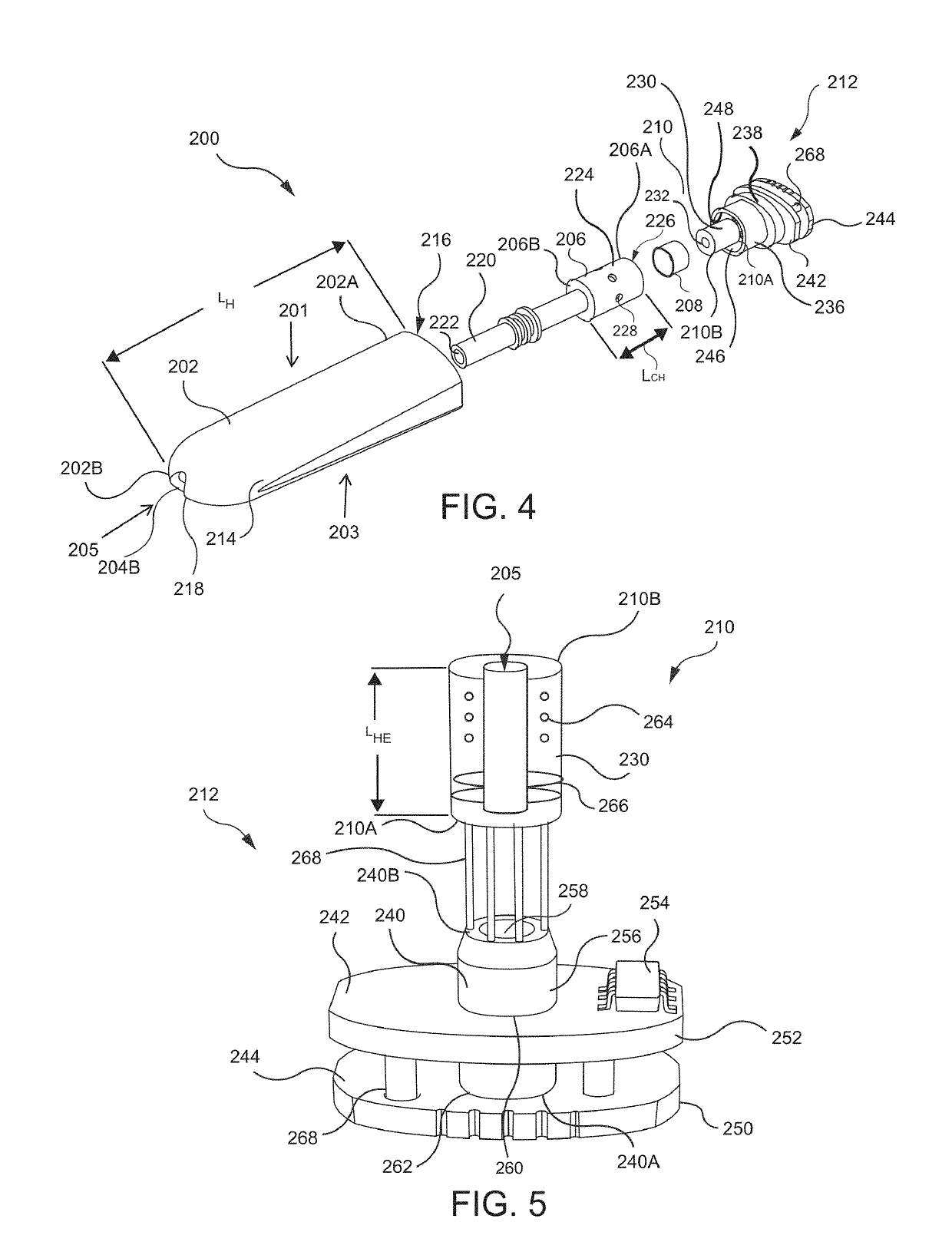

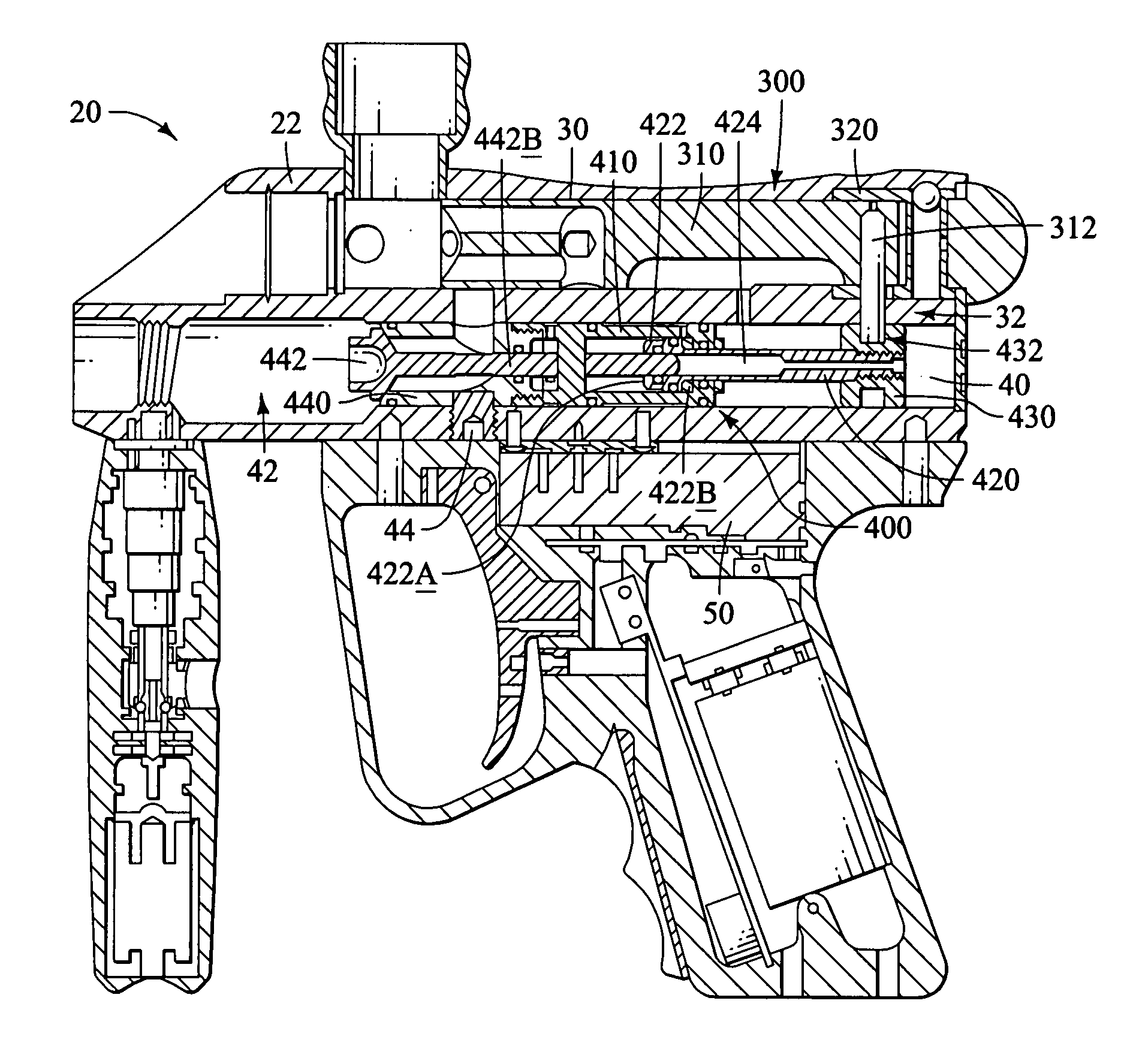

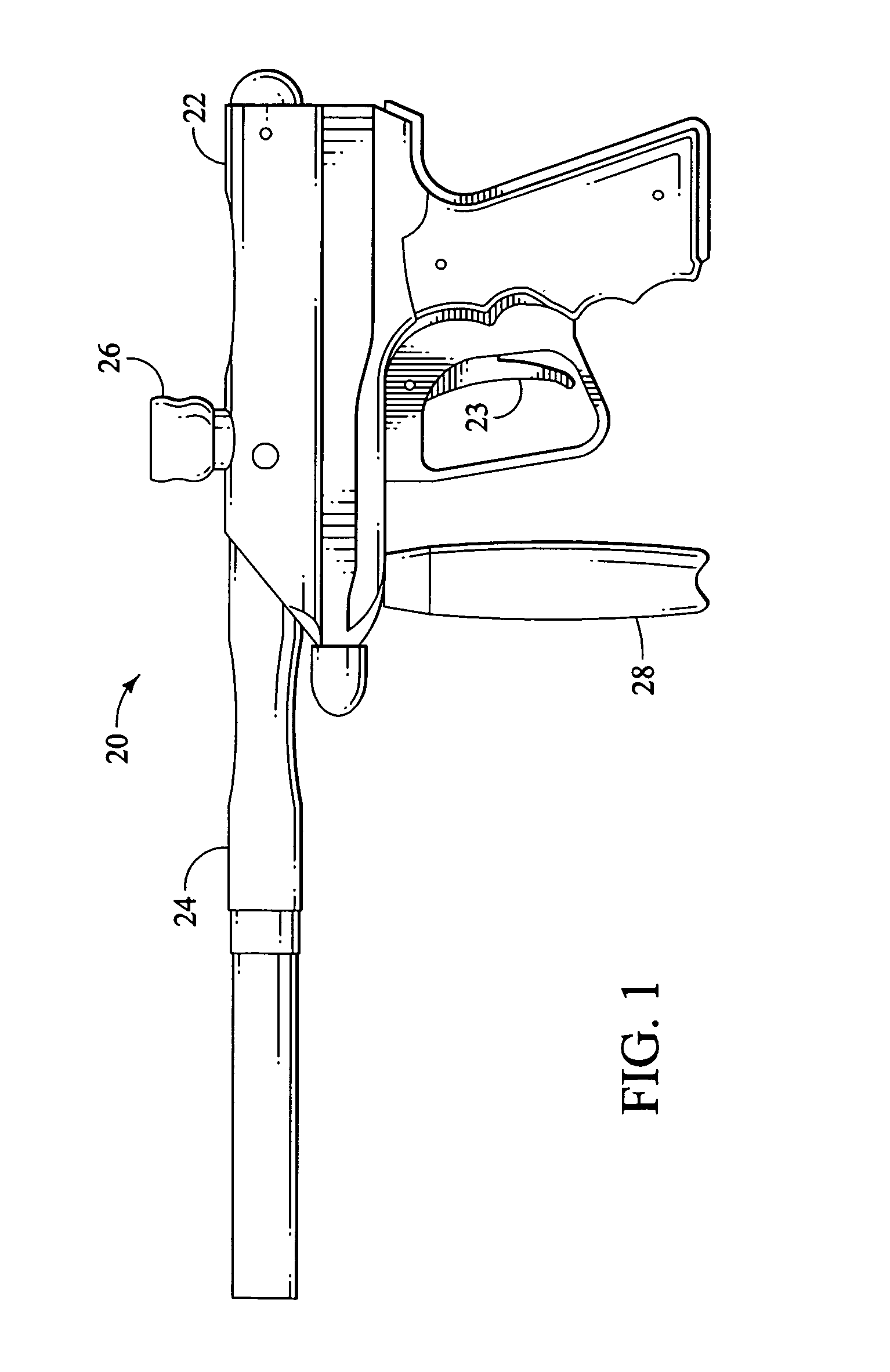

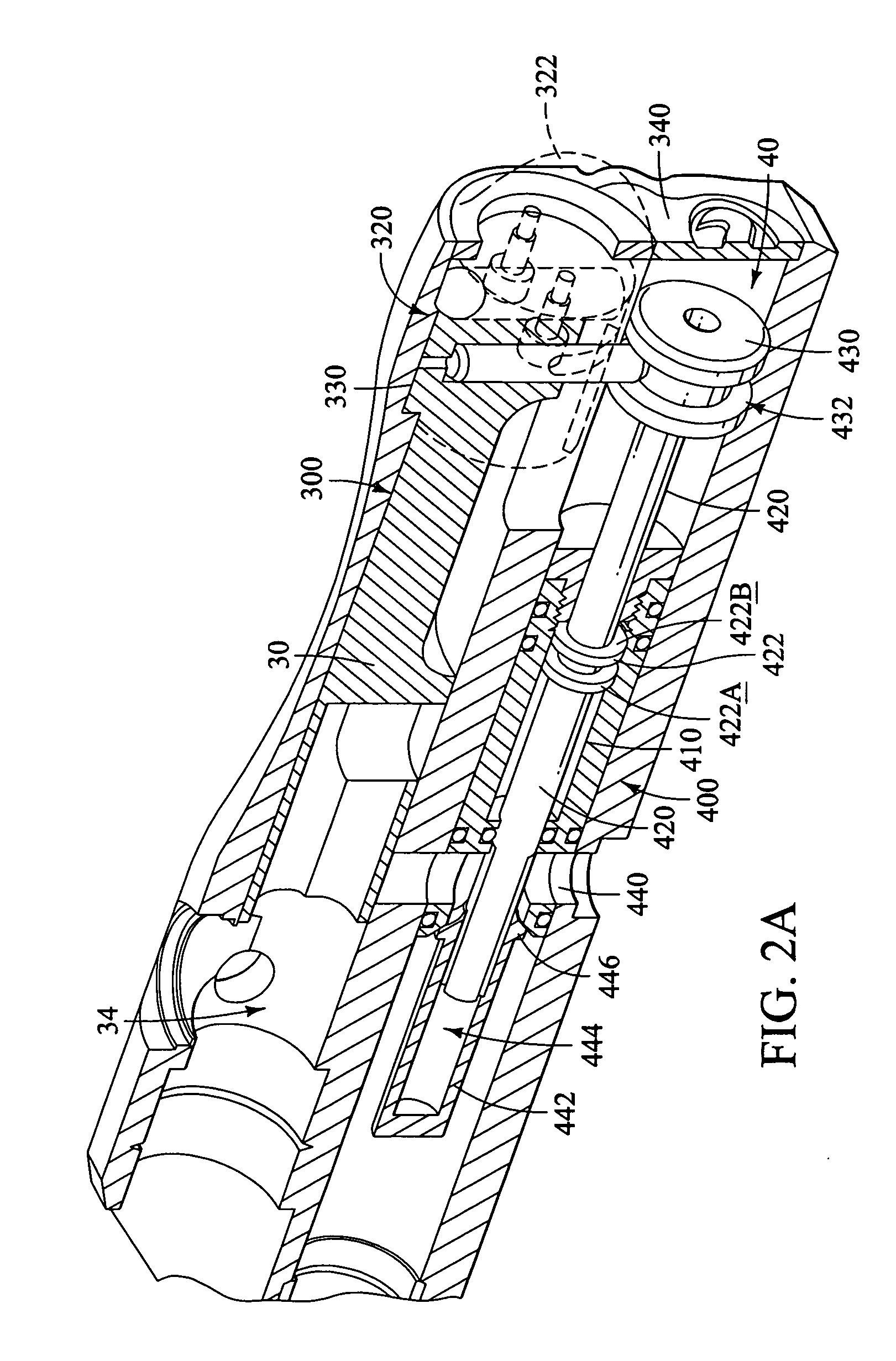

Pneumatic paintball gun and components

An electro-pneumatic paintball gun preferably comprises a bolt assembly and a firing valve assembly that can be readily removed from the paintball gun. A bolt assembly preferably comprises a bolt sleeve. The bolt assembly is preferably removed by turning the bolt sleeve a predetermined rotational distance and then retracting the bolt assembly from a rearward opening in the paintball gun. The firing assembly preferably comprises a pneumatic piston rod and cylinder and a firing valve. A firing mass is preferably arranged on a rearward end of the piston rod. The forward end of the piston rod preferably engages the firing valve. The firing mass can include a groove for receiving a bolt linkage from the bolt assembly.

Owner:KORE OUTDOOR US INC +1

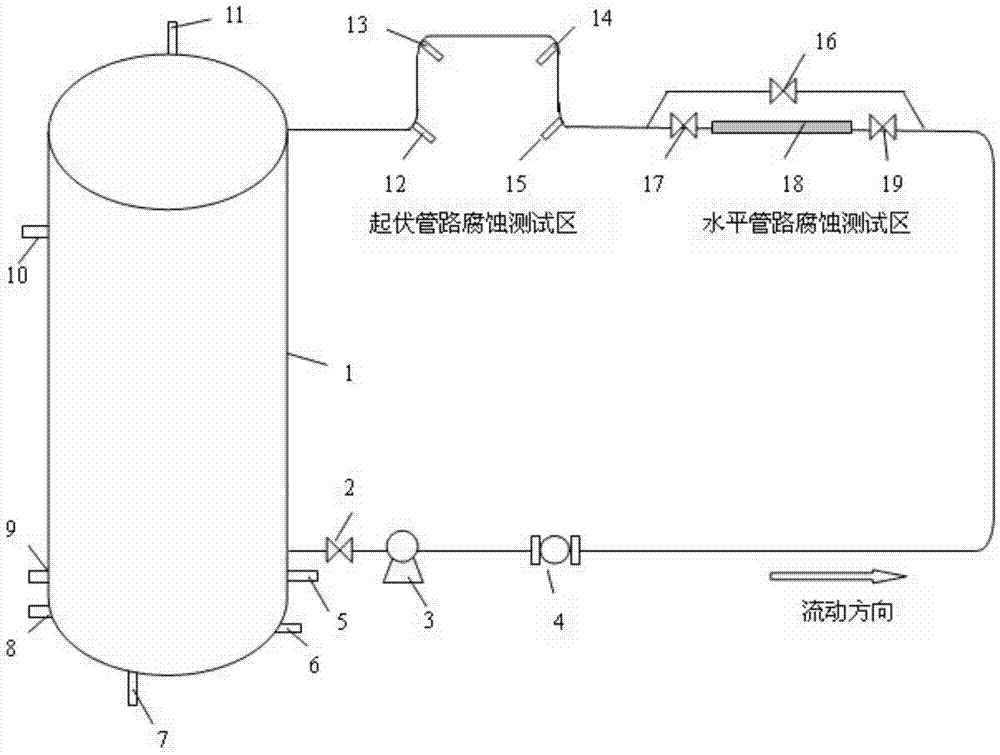

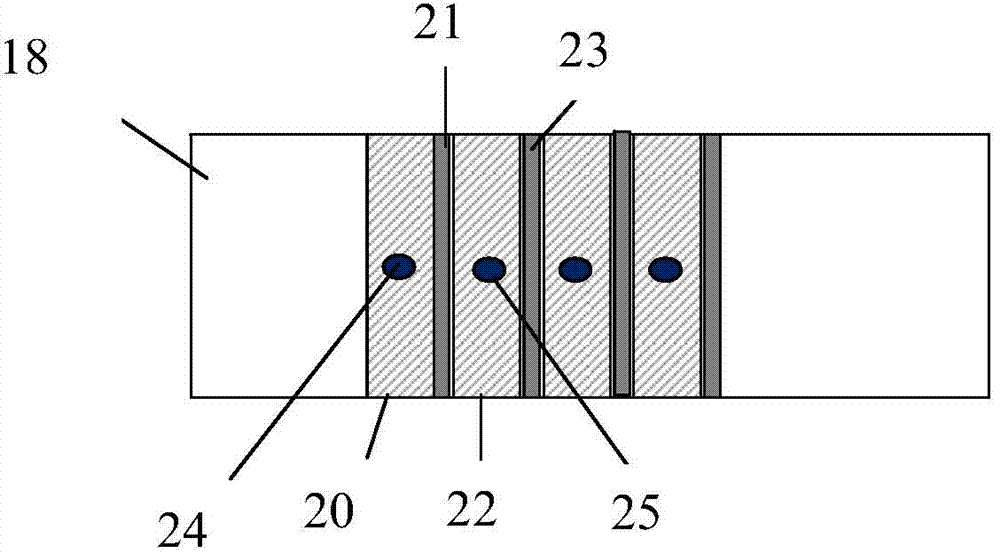

Simulation experimental pipeline device and simulation experimental method of multi-phase fluid erosion and flow states

ActiveCN103926191AAvoid edge effectsEasy to install and removeWeather/light/corrosion resistanceIndustrial siteBall valve

The invention provides a simulation experimental pipeline device of multi-phase fluid erosion and flow states. The simulation experimental pipeline device comprises a pipeline, a bracket, an erosion resistant storage tank, an erosion resistant pump, a ball valve, an electromagnetic flow meter, a resistance probe, a temperature meter, a pH meter and an oxygen dissolving analyzer, wherein the pipeline comprises an waved pipeline erosion test area and a horizontal pipeline erosion test area. The waved pipeline is simulated through the simulation experimental pipeline device with various inclined angles; the change of erosion rates is recorded in real time by virtue of the resistance probe; an annular sample of which the diameter is the same with the inner diameter of the pipeline is adopted in the horizontal pipeline area. A weight loss method and an electrochemical method are used for monitoring the internal erosion of the pipeline, and the flow states and the multi-phase fluid erosion at an industrial site can be truly simulated, so that the technical problem that the flow characteristic and erosion behavior in a flowing pipeline at an industrial site cannot be truly reflected through indoor dynamic erosion simulation is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

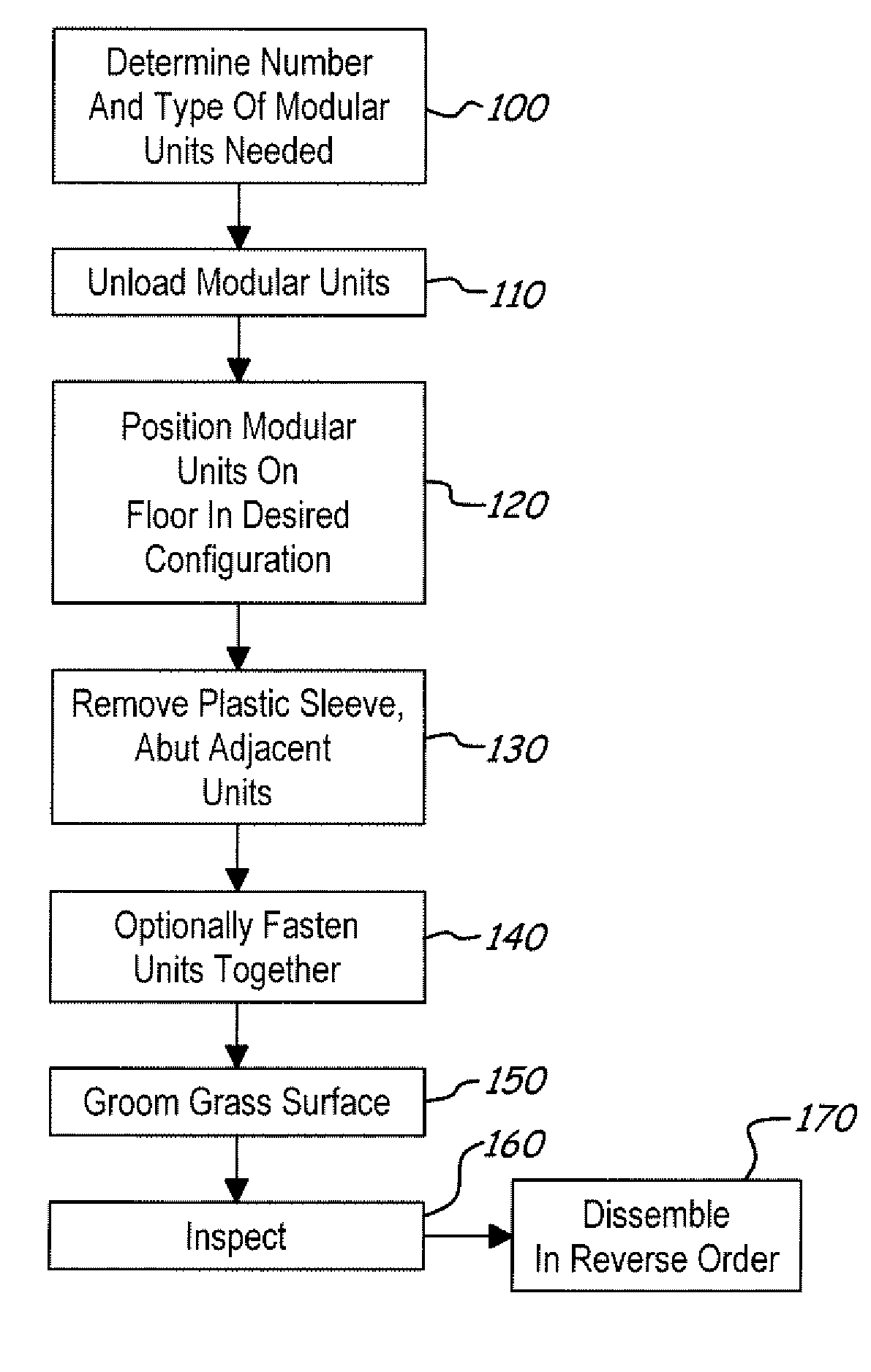

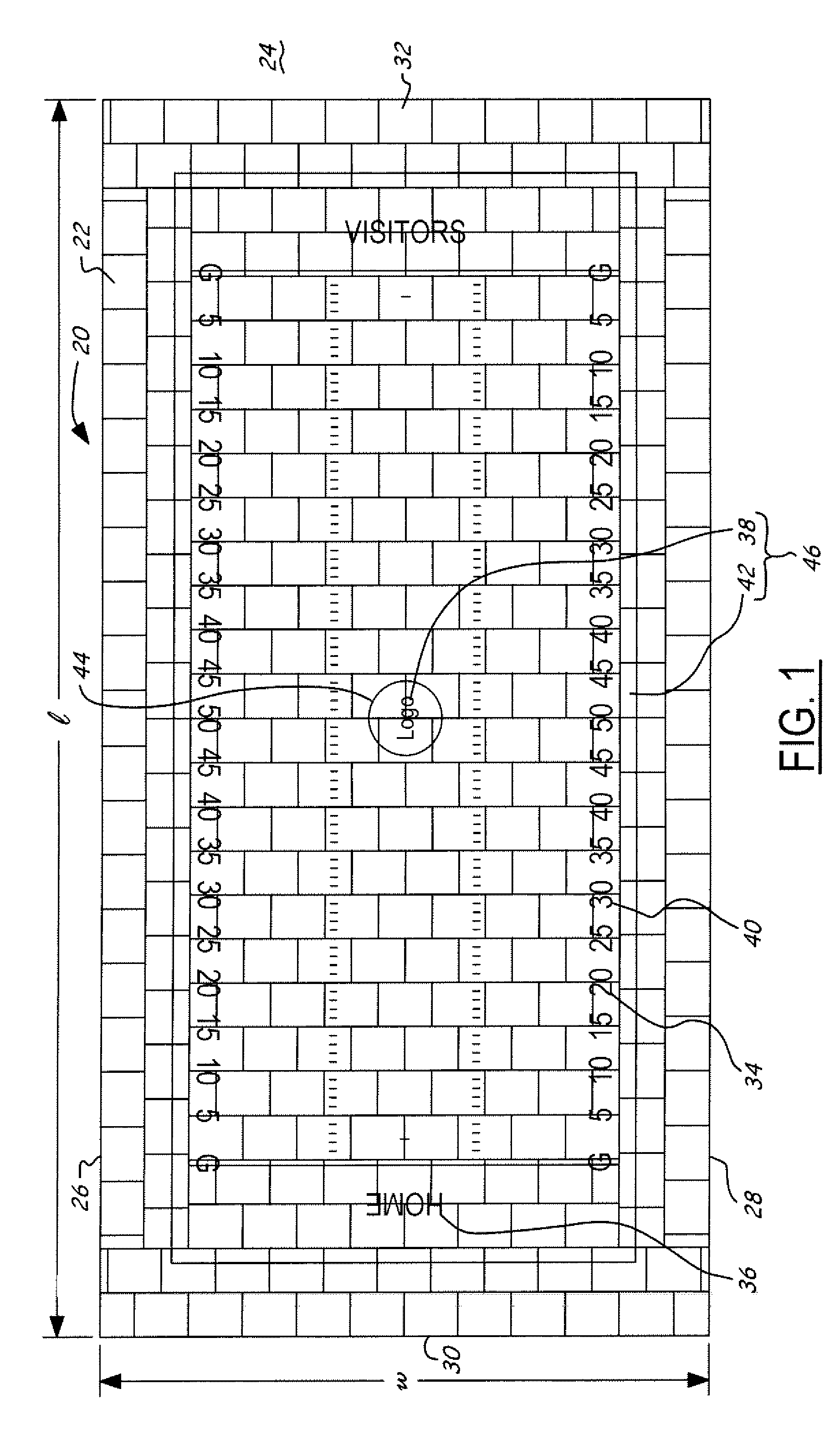

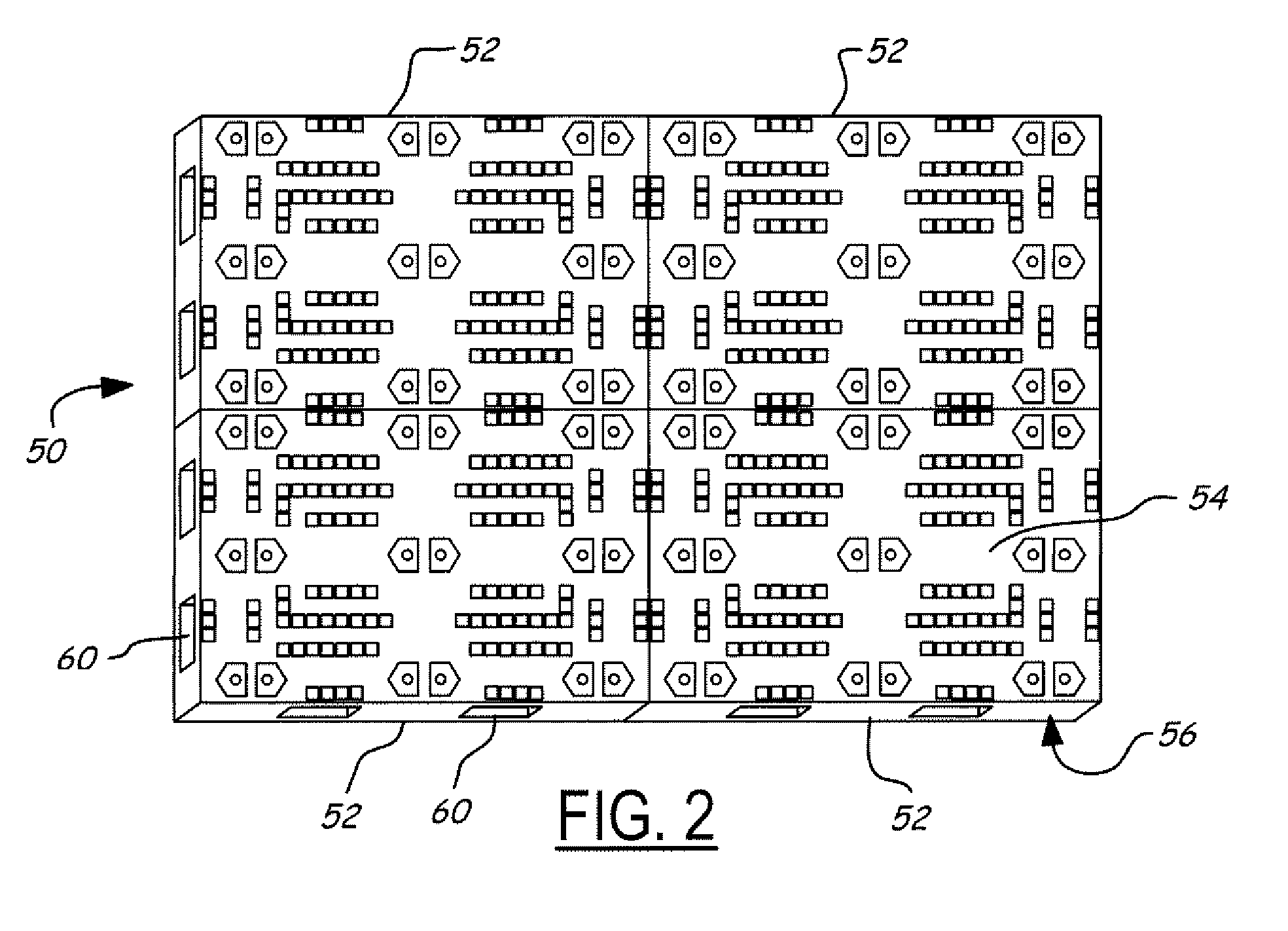

Method for assembling a modular sports field

ActiveUS7155796B2Easy to install and removeEasy to storeDead plant preservationArtificial flowers and garlandsModular unitInfill

A modular synthetic grass playing surface system formed from a plurality of modular units. Each modular unit has a synthetic grass layer placed upon predetermined sized pallets having a pre-installed elastomeric layer. A layer of resilient particle infill is optionally introduced to the top surface of the modular unit. A corrugated plastic sleeve is optionally installed around each formed modular unit while the modular unit is stored and moved. A plurality of modular units are then installed onto a relatively flat surface to form the playing surface in a desired shape and size.

Owner:APT ADVANCED POLYMER TECH CORP

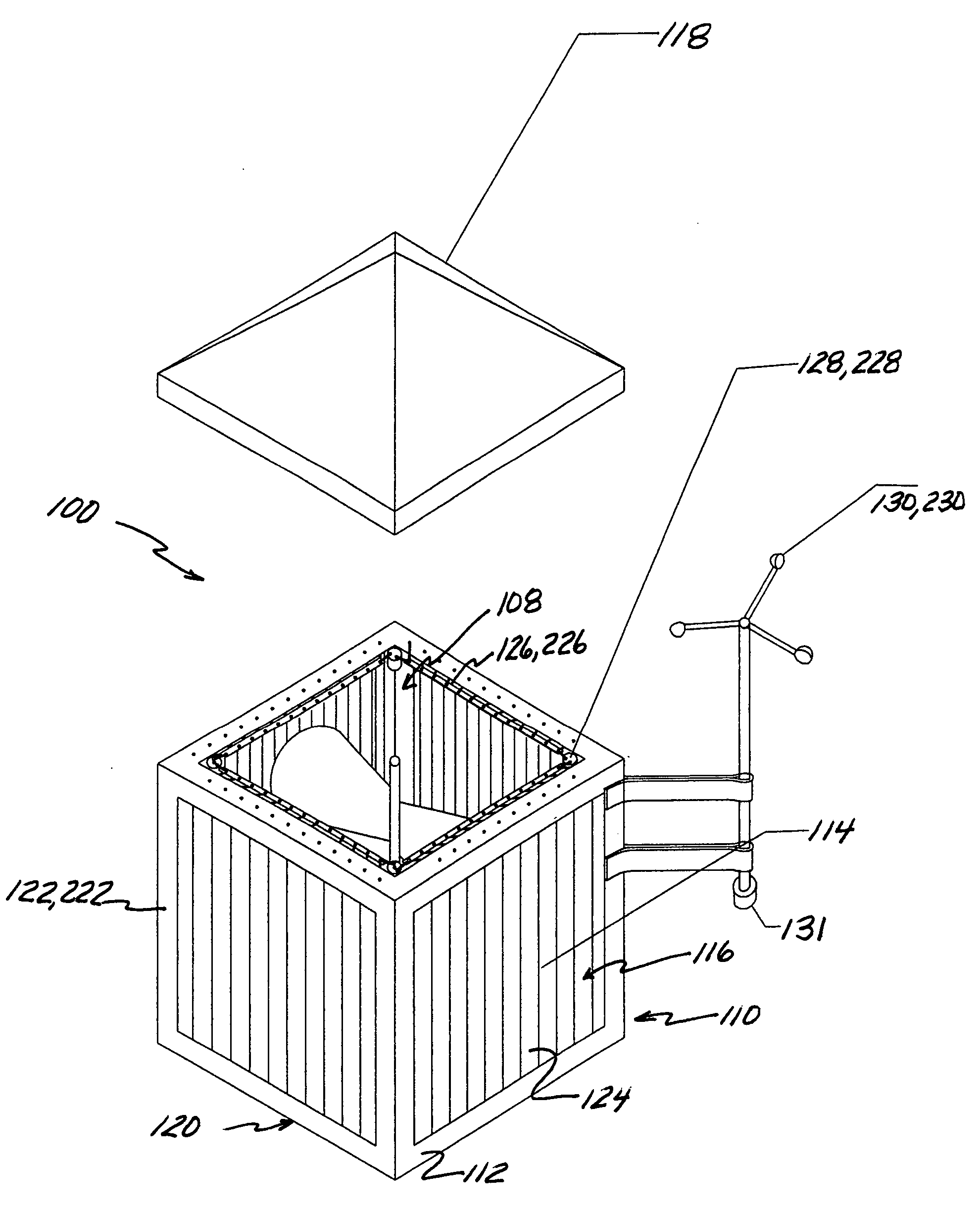

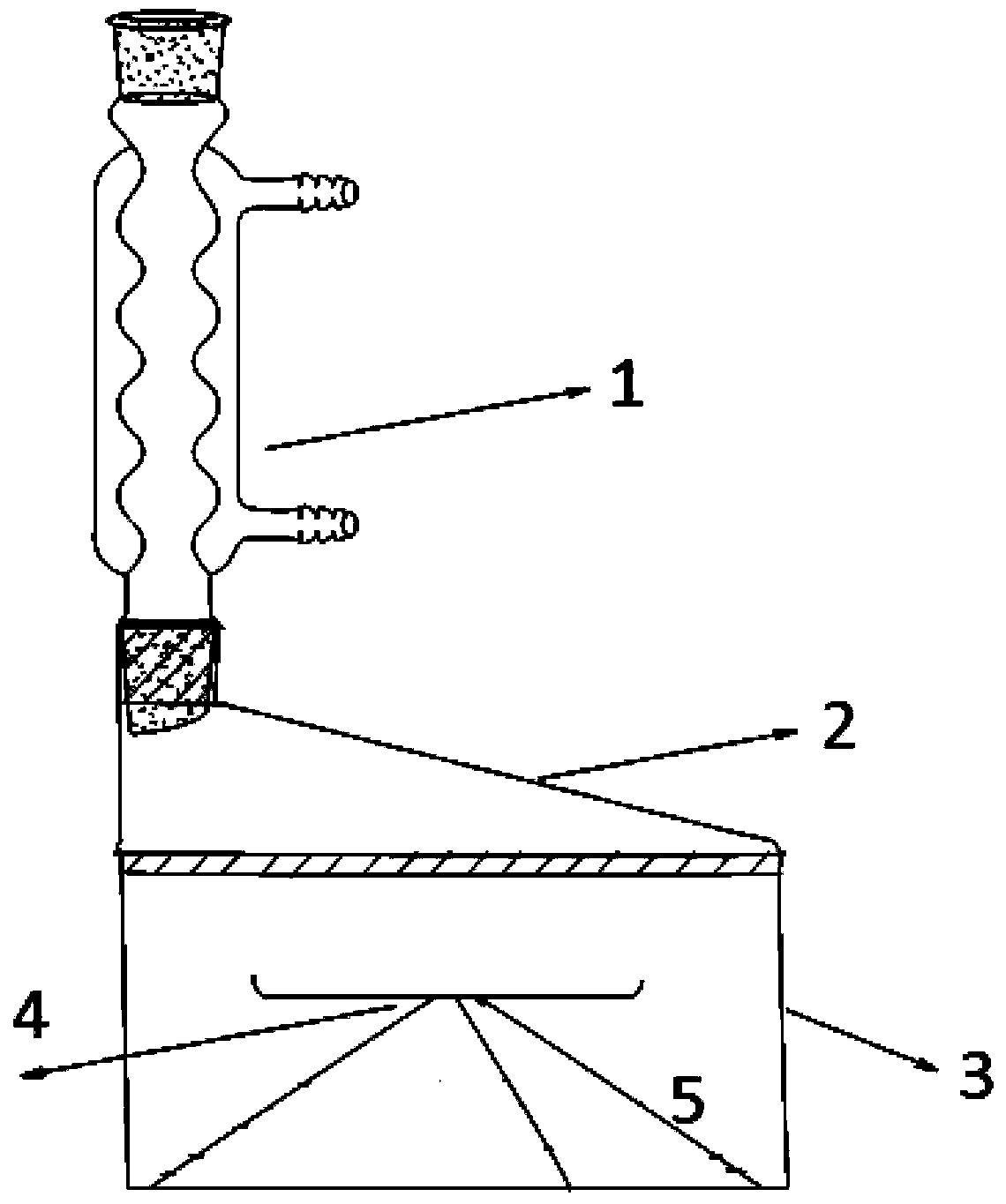

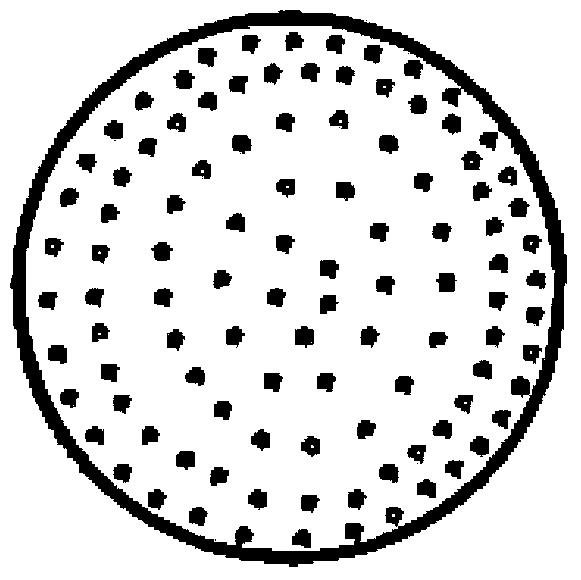

3D (Three Dimensional) printing product surface polishing method and device thereof

The invention relates to a 3D (Three Dimensional) printing product surface polishing method and a device needed by the 3D printing product surface polishing method. The 3D printing product surface polishing method comprises the following steps: putting a 3D printed product into the device with a special design; utilizing a solvent capable of dissolving the product as a chemical polishing agent; heating the solvent to generate steam; and carrying out polishing treatment on the surface of the related product by using the steam. Compared with the prior art, a steam etching technology is adopted; the preparation process is simple and the polishing efficiency is high; the solvent can be recycled and the environment is not polluted, so that an environment-friendly and efficient polishing technology is provided.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Mobile front-end system for comprehensive cardiac diagnosis

ActiveUS20150065814A1Easy to install and removeConnection is requiredUltrasonic/sonic/infrasonic diagnosticsStethoscopeHeart soundsBack end server

A stethoscope front-end recorder device (also referred to as Sleeve) for the chest piece of a stethoscope, which is easily installed and removed. The Sleeve is attached to the chest piece of a stethoscope for comprehensive diagnosis of heart issues. The Sleeve contains sensors for acquiring biosensor parameters such as electrocardiogram, body temperature, heartbeat, heart rhythm, heart rate variability, heart rate turbulence, heart sounds, respiration, cardiac index and blood flow. The Sleeve has Bluetooth interface communicating with a mobile device with software component, interfacing with a back-end server with the capability to capture, analyze and save patient information.

Owner:RIJUVEN

Scent elimination system for hunters

A hunting blind, a blind support, and a filtration unit for use on a tree with or without a tree stand. The blind support preferably includes a bracket for mounting to the tree and a foldable frame for mounting to the bracket. The blind preferably sealingly mounts to the blind support and the tree in a position around the tree stand, and preferably includes a sheet of material segmented into panels for providing access to the tree stand and a good seal around the ladder of ladder tree stands. The filtration unit preferably includes a carbon-activated filter and a fan for drawing air from a top opening of the blind, downward around a hunter in the tree stand, through the filter, and out of the blind.

Owner:VENATICS INC

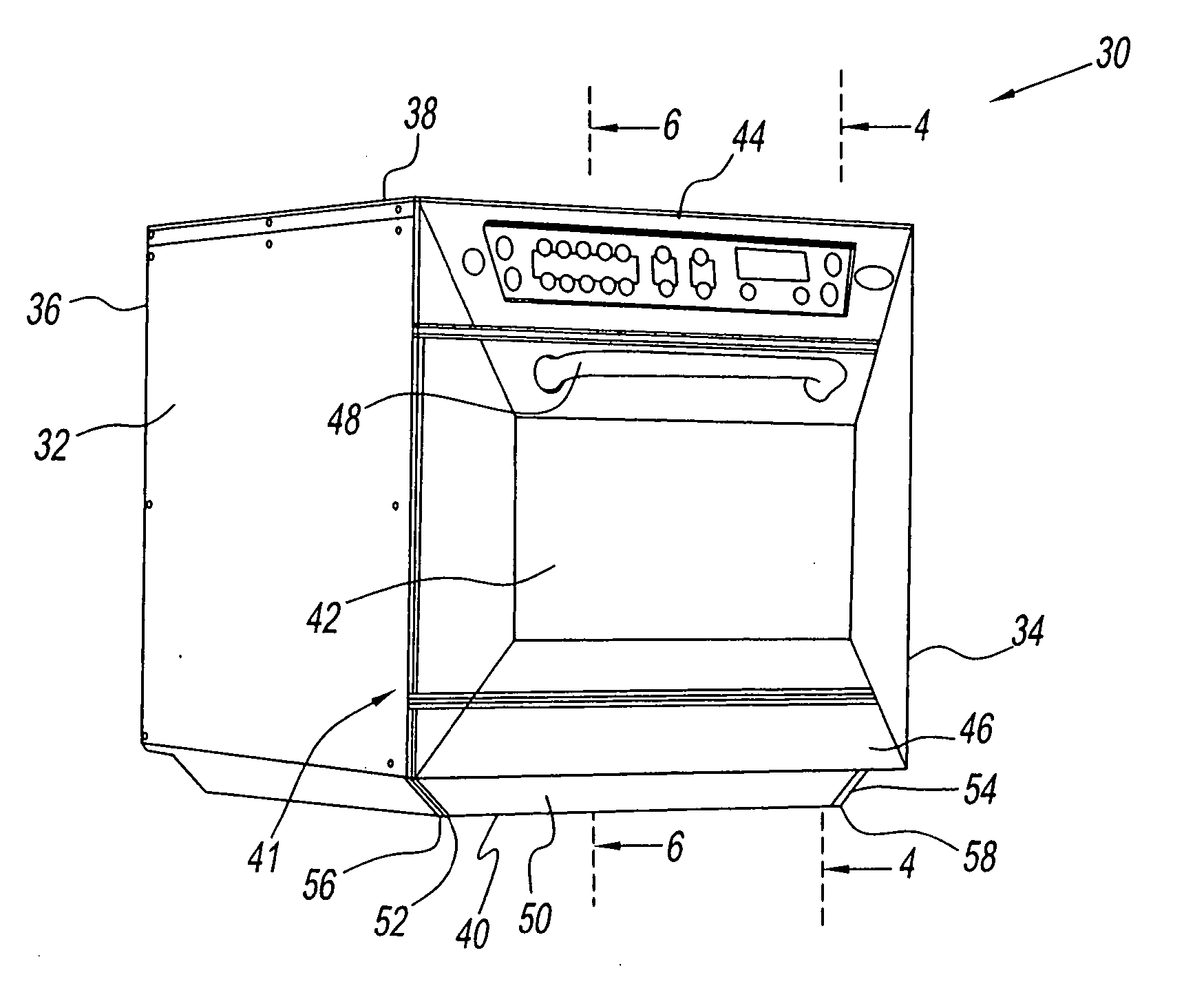

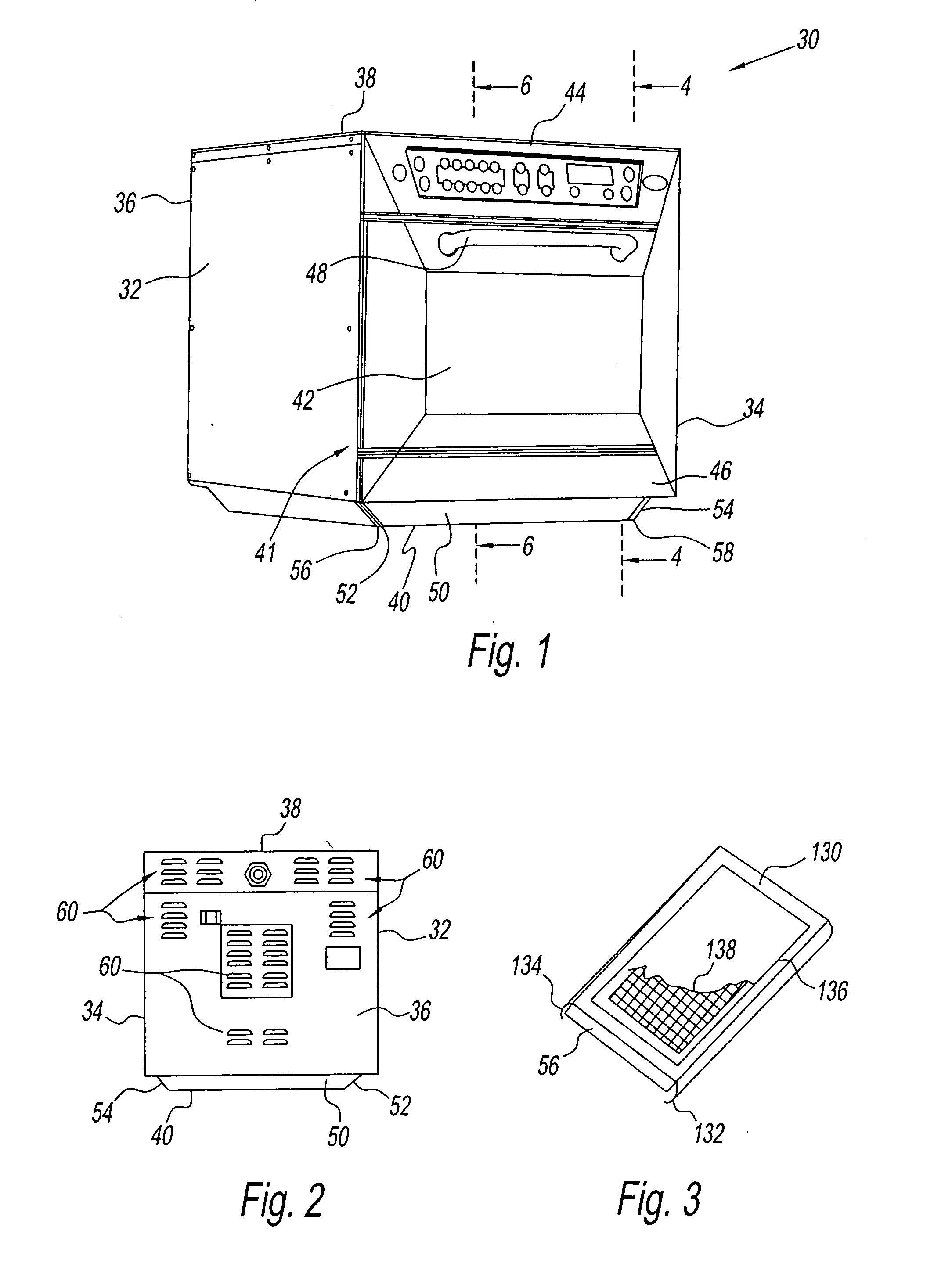

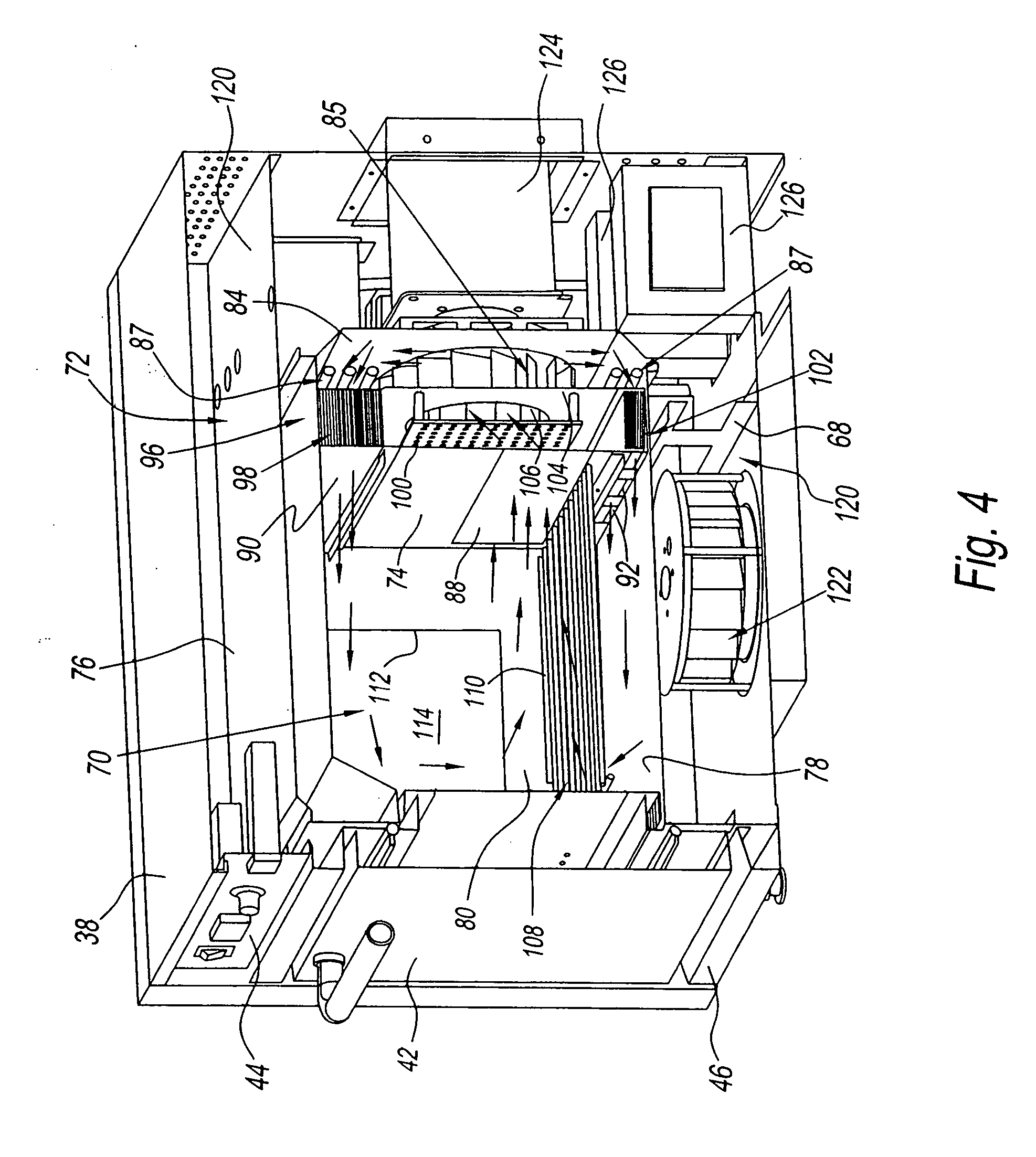

Impingement/convection/microwave oven and method

InactiveUS20070278218A1Easy to install and removeEasy to installBaking ovenMicrowave heatingMicrowave ovenMicrowave electromagnetic radiation

A combination oven that is operable with convection air, impingement air and microwave energy in various combinations thereof. The oven has an oven chamber and a fan box that are located front to back. A fan in the fan box circulates heated air by discharging via openings in a top and a bottom and taking in via an intermediate opening of a baffle plate. Impingement plates are easily installed and removed in the oven chamber to provide impingement air upwardly or downwardly. At least one of the impingement plates is installed and removed by a sliding motion. Microwave energy is provided through the side walls of the oven chamber. Intake ports for cooling air are located in a bevel between the side walls and bottom wall of the oven's outer enclosure so as to allow the oven to be located right next to other structures, such as a wall. An interlock assembly is also provided for the oven door.

Owner:ENODIS

Rotatable and removable auxiliary eyewear system with snap alignment

InactiveUS20050088612A1Accurately alignEasily instal and removeSpectales/gogglesAuxillary optical partsSystem viewLens plate

The present invention discloses a unique and novel system for attaching an auxiliary lens assembly to a primary lens assembly in which the attachment includes two alternative positions, a lowered position and a raised position. In the lower position, the person wearing the eyewear system views through both the primary lenses and auxiliary lenses. In the raised position, the person wearing the eyewear system views only through the primary lenses. As a further option, the auxiliary lens assembly is easily removable from the primary lens assembly, allowing for separate storage of the auxiliary lens assembly when not needed. Slotted extensions on the primary lens frame receive retainers attached to auxiliary extensions on the auxiliary lens assembly. Each auxiliary extension has a rocker pivotally attached to a keyseat. An internal spring urges the rocker into snap alignment with the surfaces of the keyseat.

Owner:ASPEX EYEWEAR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com