3D (Three Dimensional) printing product surface polishing method and device thereof

A 3D printing and surface polishing technology, applied in the field of 3D printing, can solve problems such as inability to use polishing, and achieve the effects of convenient disassembly and installation, high polishing efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

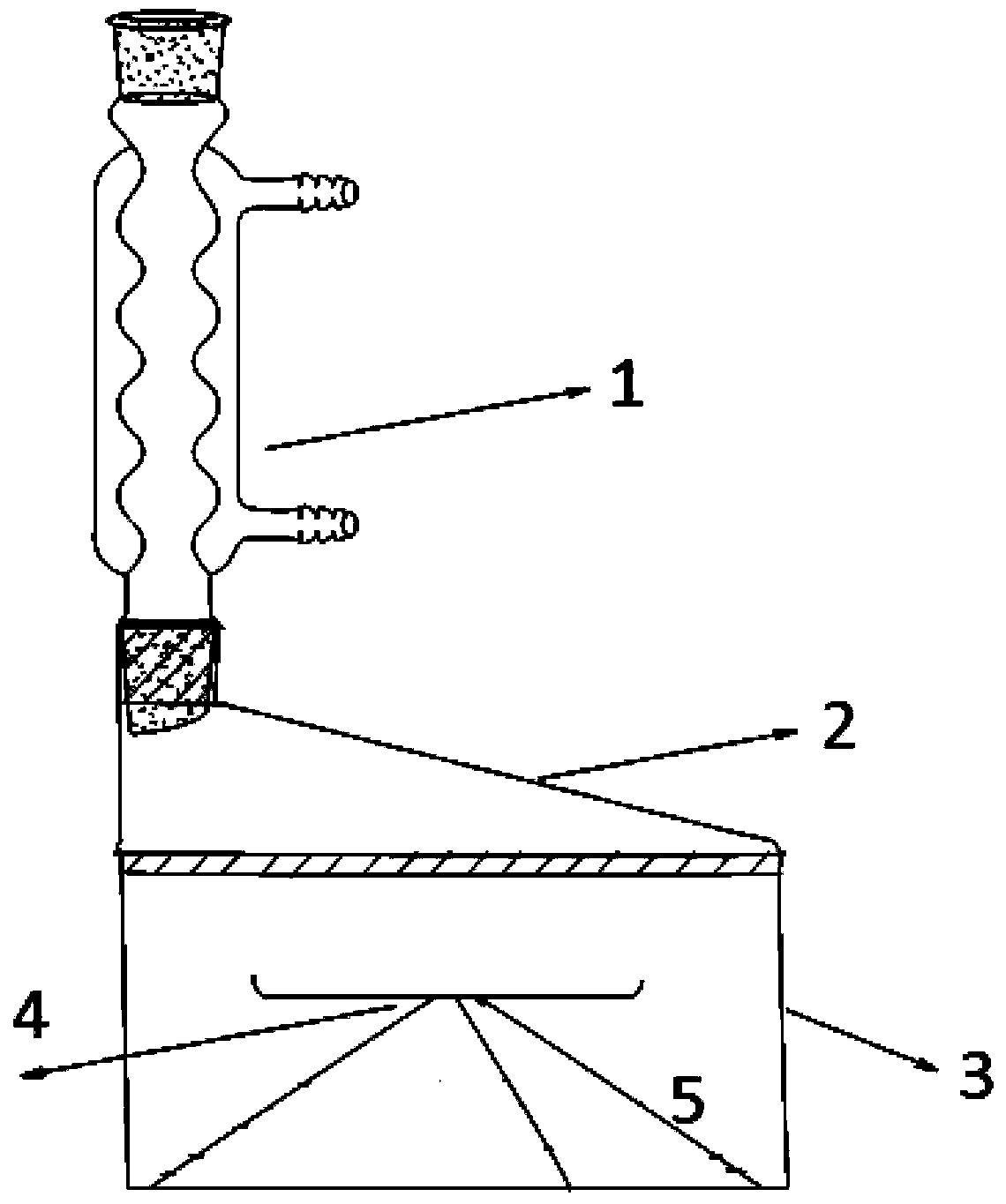

Embodiment 1

[0024] Put the cube printed out with ABS resin on the tray, put the tray into a heatable container, and pour an appropriate amount of acetone solution. The liquid level of the acetone solution should be 2-3cm lower than the tray. Install the tube and pass condensed water. After the device is installed, heat it in a water bath, control the temperature at 56°C, keep it for 1min, stop heating, cool to room temperature, and take it out after the solvent on the sample surface is completely evaporated. After testing, the surface of the cube polished by this method is smooth and free of bubbles, the surface roughness reaches Ra 0.005, and the processing error is less than 0.1 μm.

Embodiment 2

[0028] Put the cylinder printed with PCL resin as the raw material on the tray, put the tray into a heatable container, pour an appropriate amount of mixed solution of chloroform and acetone (1:1 by volume), and the liquid level of the mixed solution should be lower than the tray 2-3cm, install the right-angled triangular interface and the condenser tube in turn, and pass the condensed water. After the installation of the device is completed, heat it in a water bath, control the temperature at 61°C, keep it for 2 minutes, stop heating, cool to room temperature, and wait for the solvent on the surface of the sample After the volatilization is complete, take it out. After testing, the surface of the cube polished by this method is smooth and free of bubbles, the surface roughness reaches Ra 0.005, and the processing error is less than 0.1 μm.

Embodiment 3

[0032] Put the cylinder printed with PLA as the raw material on the tray, put the tray into a heatable container, and pour an appropriate amount of chloroform solution. The liquid level of the chloroform solution should be 2-3cm lower than the tray. Install the tube and pass condensed water. After the device is installed, heat it in a water bath, control the temperature at 61°C, keep it for 1min, stop heating, cool to room temperature, and take it out after the solvent on the sample surface is completely evaporated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com