Patents

Literature

1454 results about "Special design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

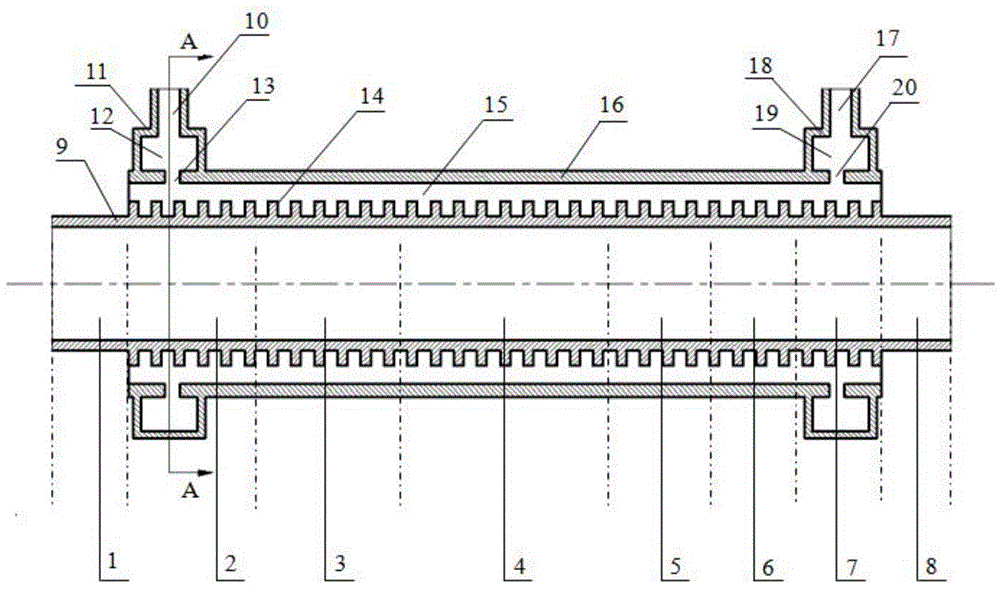

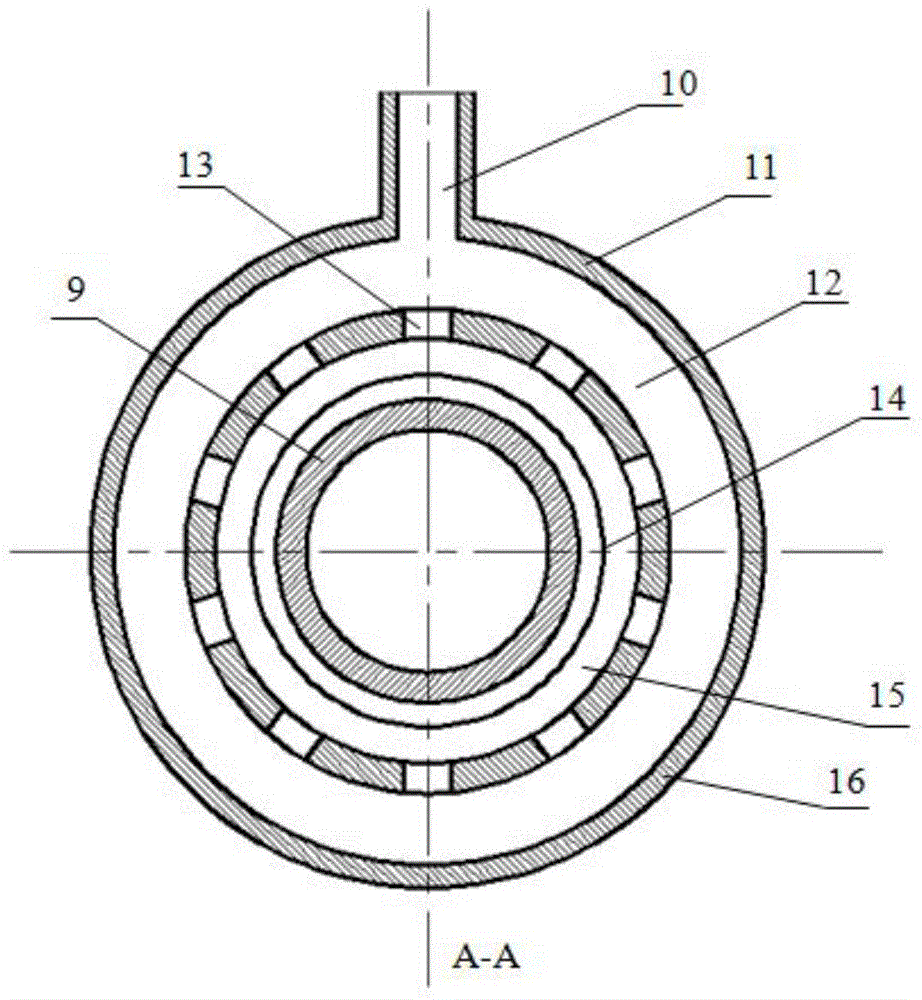

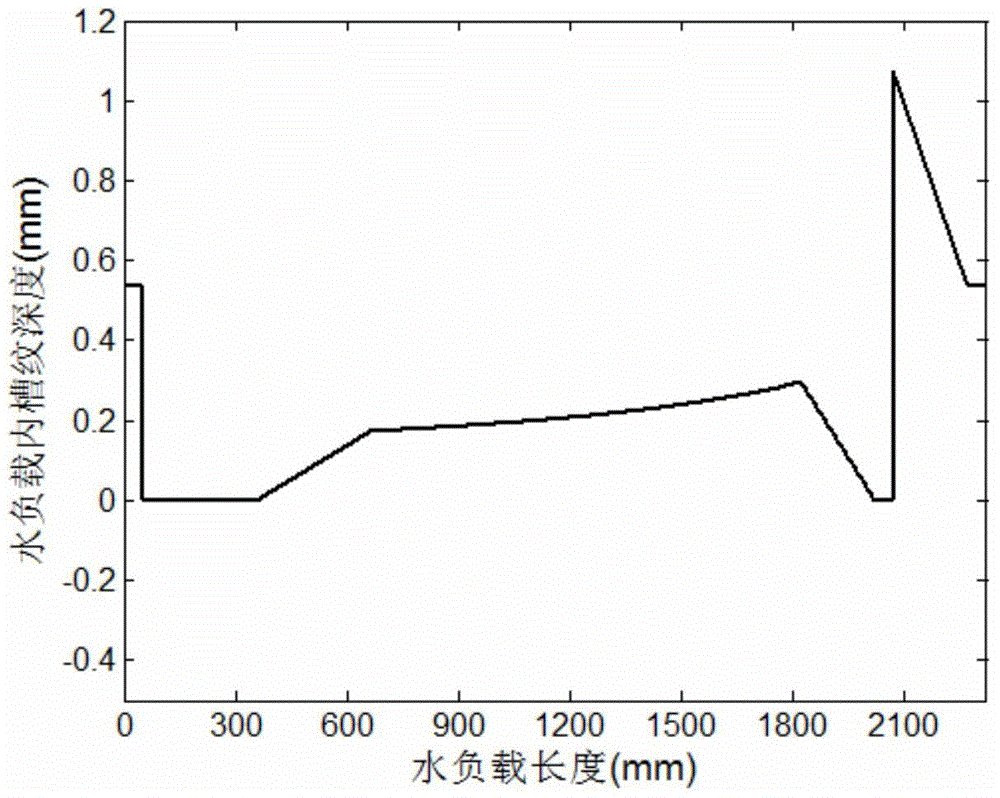

Megawatt corrugated waveguide attenuator

InactiveCN104091987AEnsure consistencyReduce shockWaveguide type devicesUltrasound attenuationSpecial design

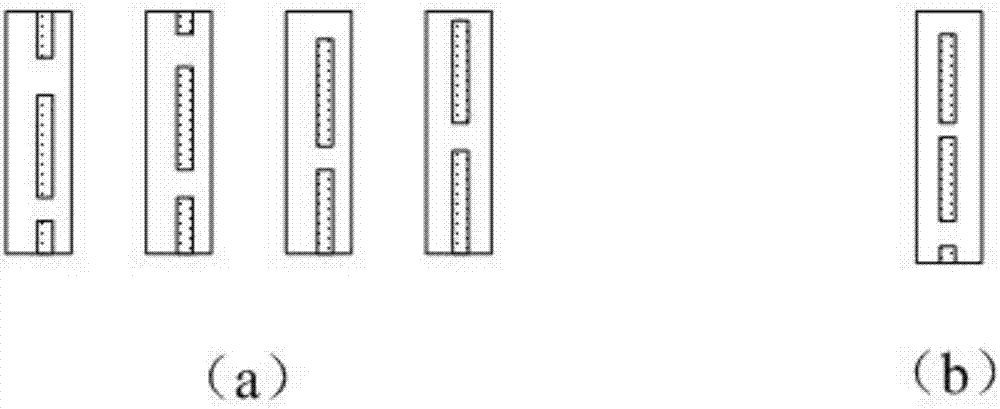

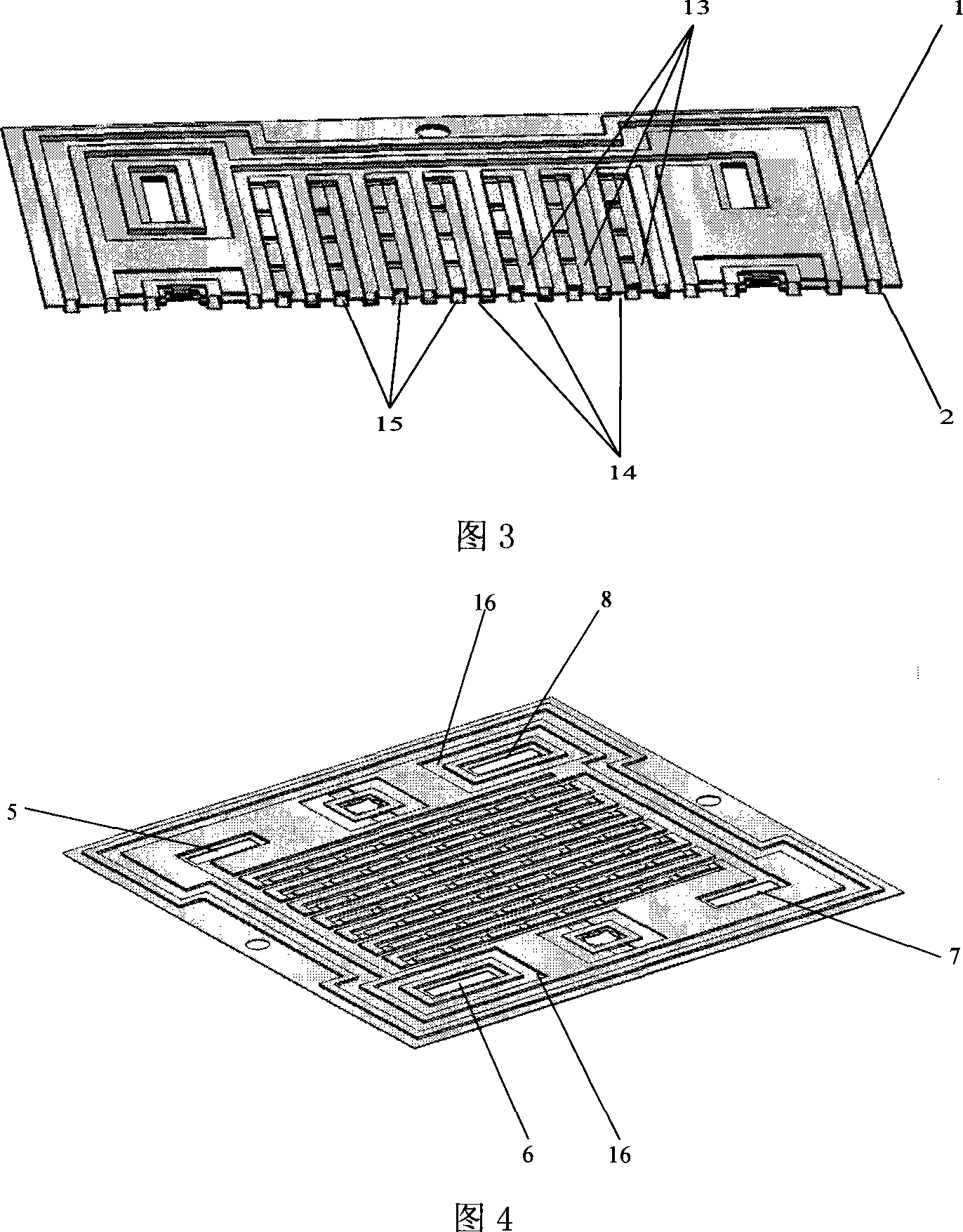

The invention discloses a megawatt corrugated waveguide attenuator. A first standard corrugated waveguide segment, a second smooth waveguide segment, a third mode changing waveguide segment, a fourth main attenuation waveguide segment, a fifth mode changing waveguide segment, a sixth smooth waveguide segment, a seventh mode changing waveguide segment and an eighth standard corrugated waveguide segment are sequentially arranged on a waveguide tube, wherein the first standard corrugated waveguide segment supports HE11 mode transmission, the second smooth waveguide segment achieves conversion from an HE11 mode to a TE11 and TM11 hybrid mode, the third mode changing waveguide segment achieves conversion from the TE11 and TM11 hybrid mode to an EH11 mode, the fourth main attenuation waveguide segment conducts attenuation on power, the fifth mode changing waveguide segment achieves conversion from the EH11 in the surplus power to a TE11 mode, the sixth smooth waveguide segment is used for TE11 mode transmission, the seventh mode changing waveguide segment achieves conversion from the TE11 mode to an HE11 mode, and the eighth standard corrugated waveguide segment supports HE11 mode transmission. According to the megawatt corrugated waveguide attenuator, the uniformity of the power attenuation magnitude per unit length inside the whole main attenuation segment can be achieved due to the design of periodic corrugations; due to the special design of waterways, the impact of high-flow-rate cooling water on waveguide walls can be reduced, and the consistency of the flow rate of the water in the whole water jacket can also be ensured.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

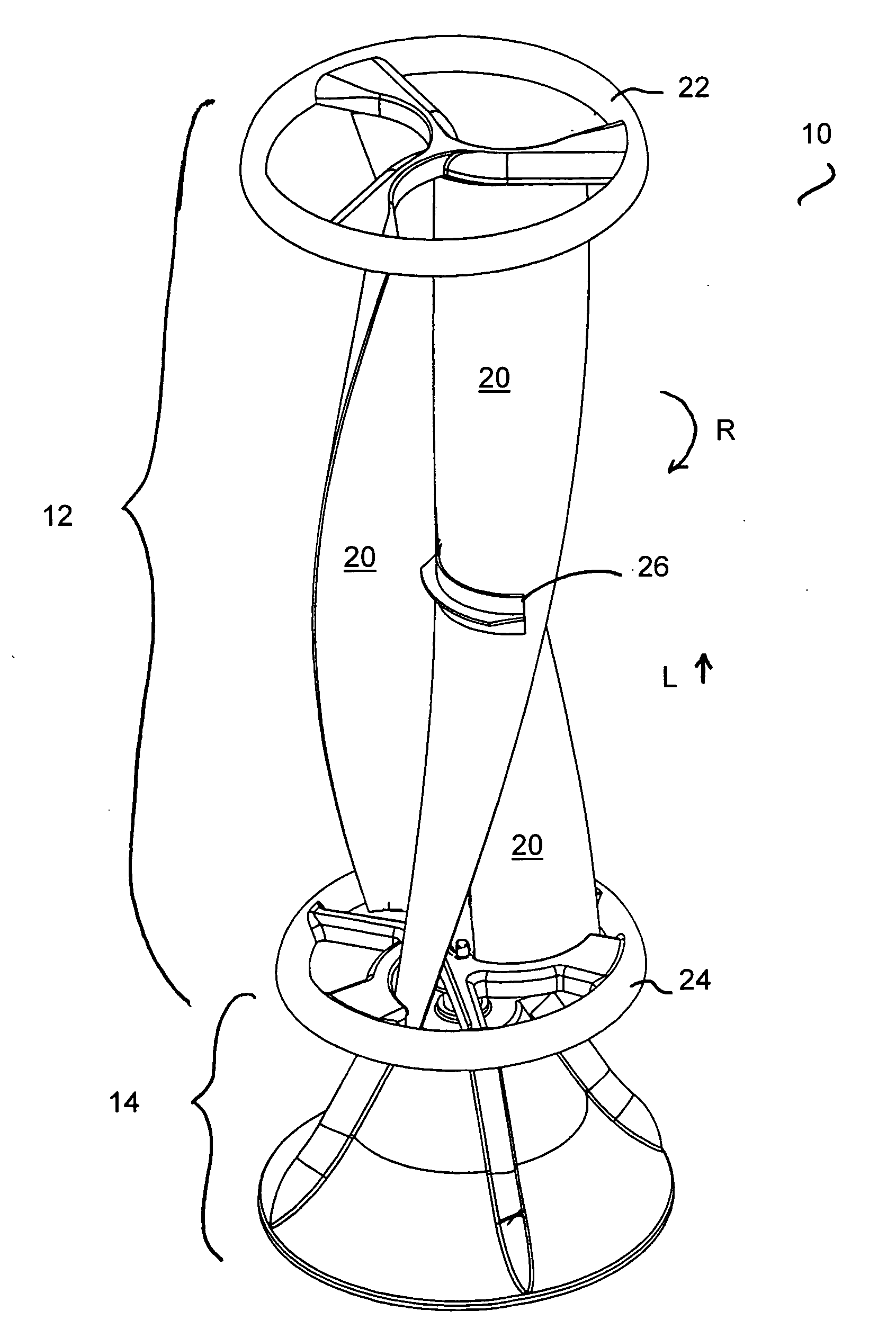

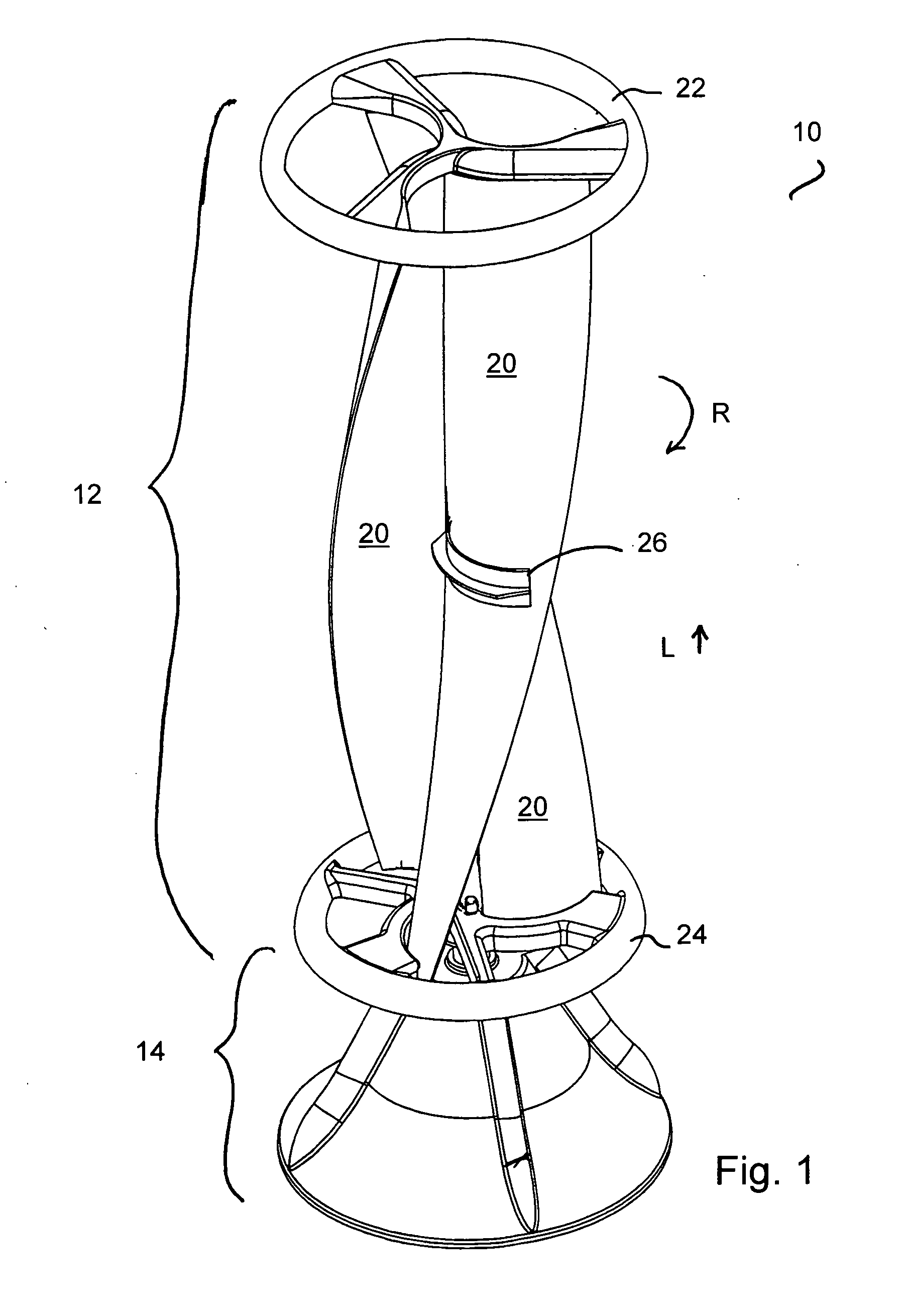

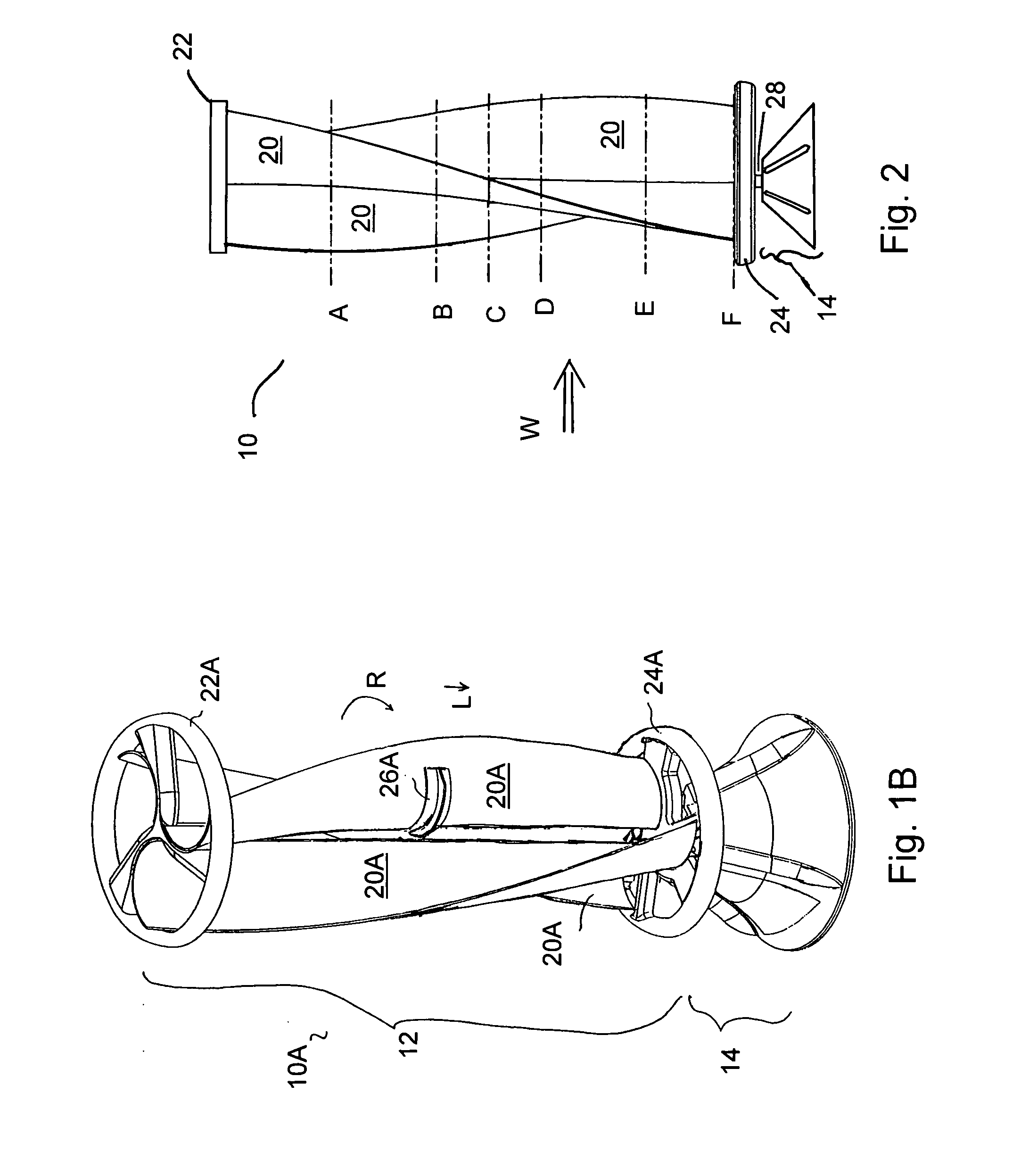

Helical wind turbine

InactiveUS20060257240A1Efficient captureLower resistancePump componentsWind motor controlLinear configurationSpecial design

A vertical axis wind turbine wherein the blades of the rotor section of the wind turbine comprise at least sections wherein the blades have a non-linear configuration in the “z” axis. In a preferred embodiment, the blades of the rotor section have a linear trailing edge with a non-linear, and preferably helical, surface configuration. This particular design allows the blades to provide both a rotational force and a positive or negative lift component. Further, the blades define an open area in the center of the rotor section through which air flow can pass in order to create a vertical vortex of air. As such, a more efficient vertical axis wind turbine provided.

Owner:ARROWIND CORP

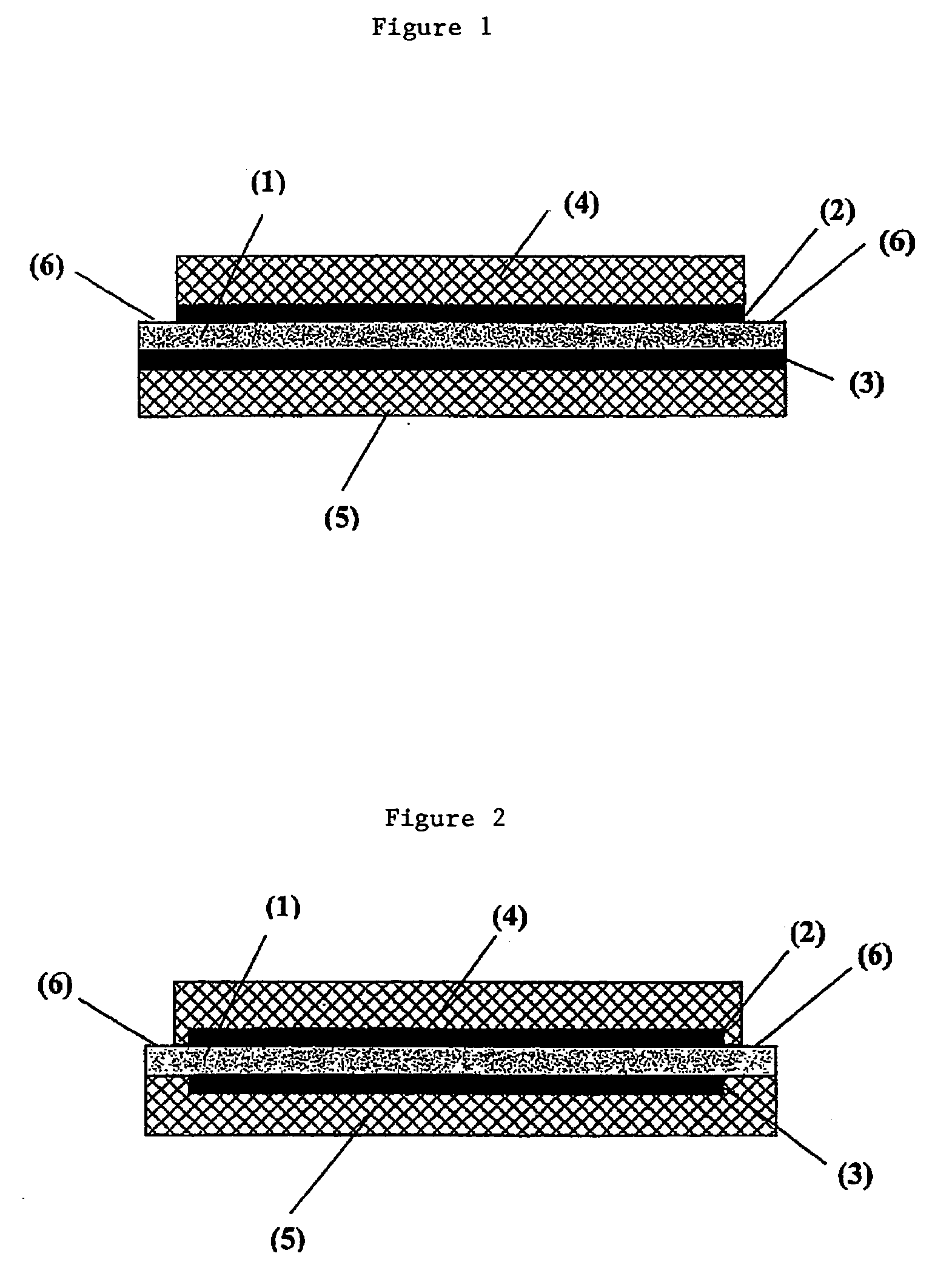

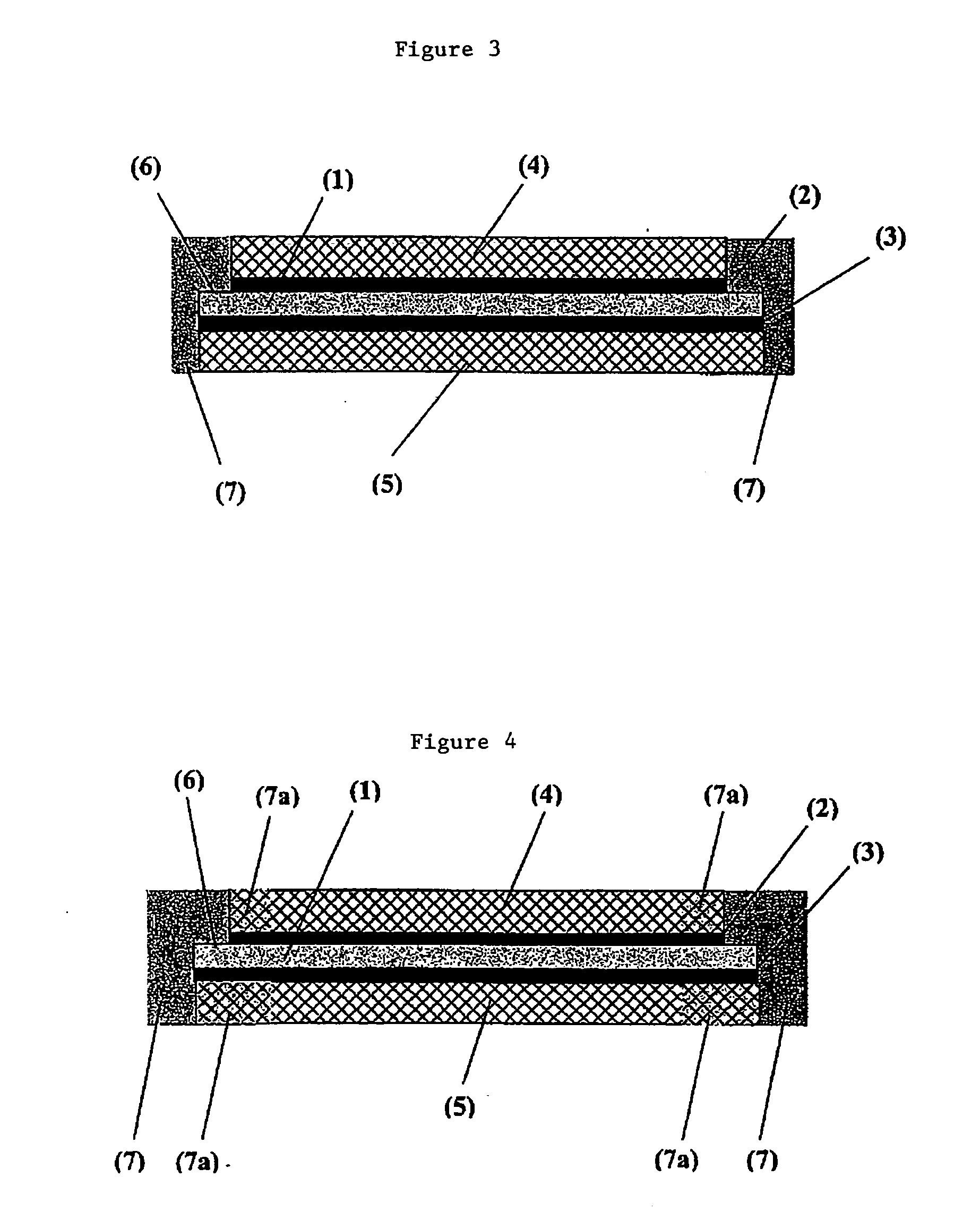

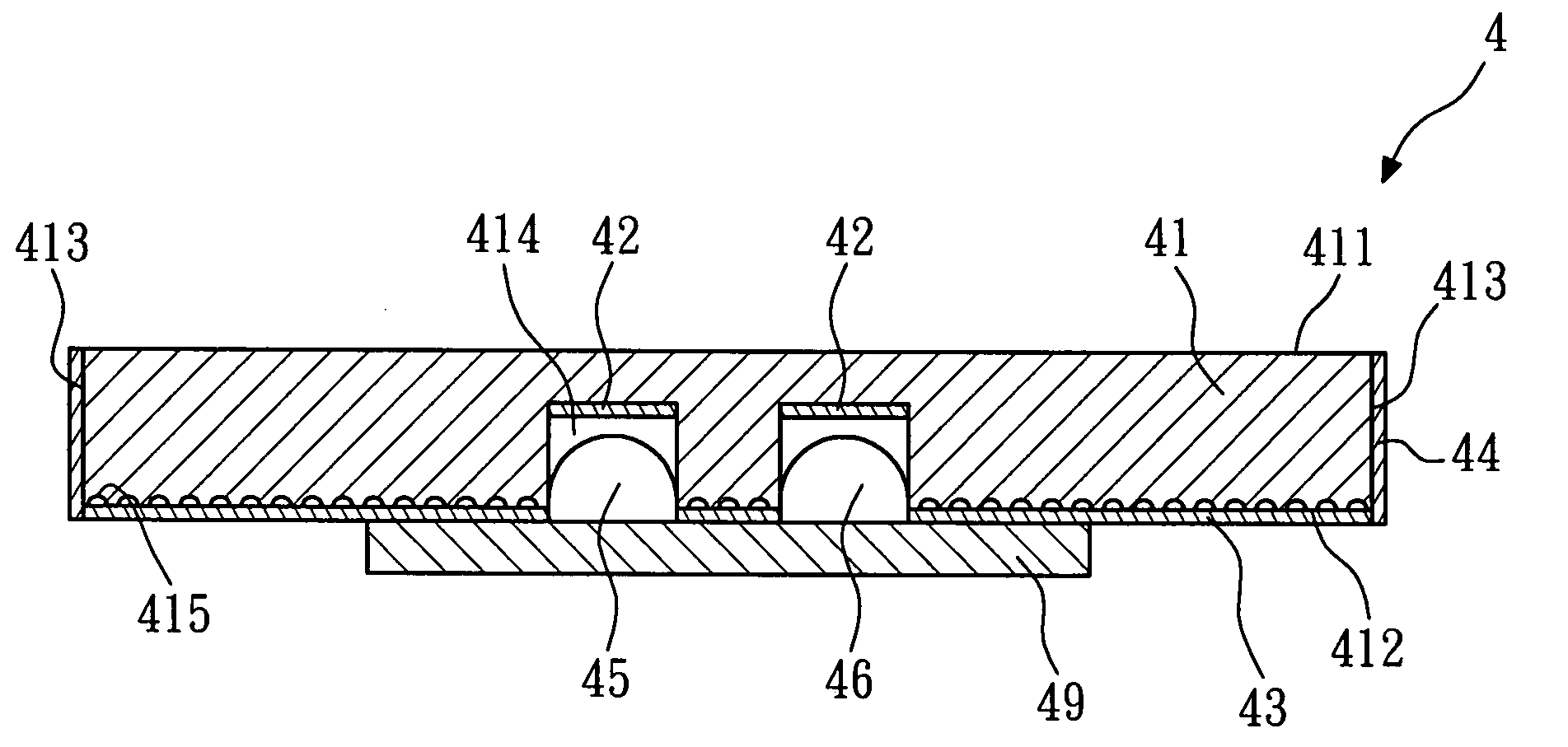

Membrane electrode unit for electrochemical equipment

InactiveUS20050014056A1Good design conceptOvercome disadvantagesCellsFuse device manufactureSpecial designEngineering

The invention concerns a membrane electrode unit (MEU) for electrochemical equipment, especially for membrane fuel cells. The membrane electrode unit has a “semi-coextensive” design and contains an ionically conductive membrane, two catalyst layers, and gas distributor substrates of different sizes on the front and back sides. The first gas distributor substrate has smaller surface dimensions than the ionically conductive membrane, while the second gas distributor substrate has the same area as the ionically conductive membrane. The membrane electrode unit has, because of its special design, a stable structure that can be handled well, and which exhibits advantages for sealing the reactive gases off from each other and in its electrical properties. In particular, the hydrogen penetration current is distinctly reduced. The membrane electrode unit is used in PEM fuel cells, direct methanol fuel cells, electrolyzers, and other electrochemical equipment.

Owner:UMICORE AG & CO KG

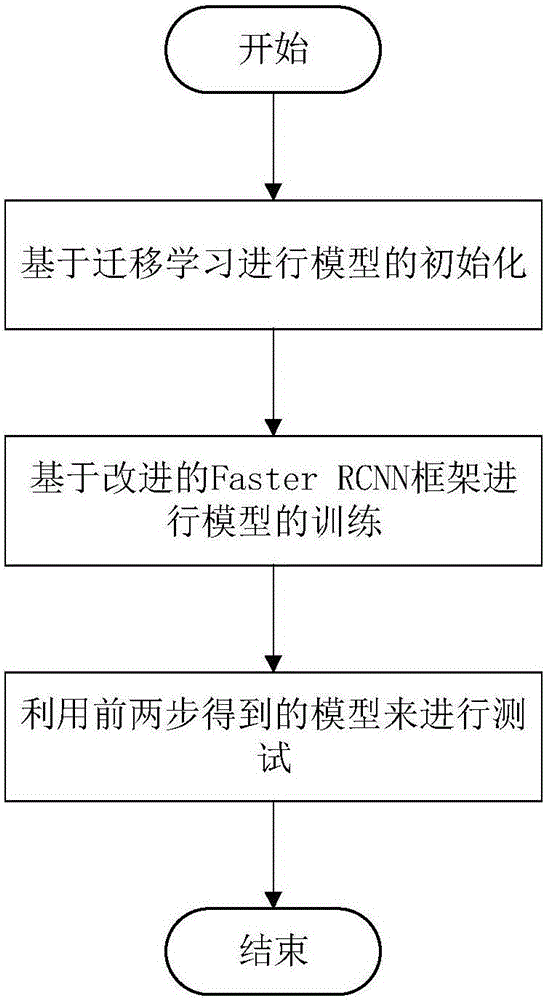

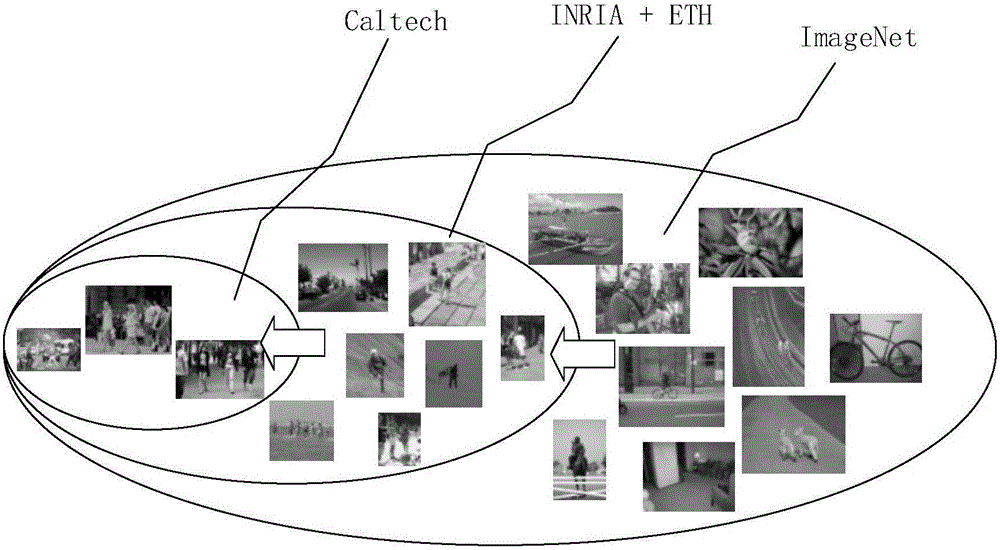

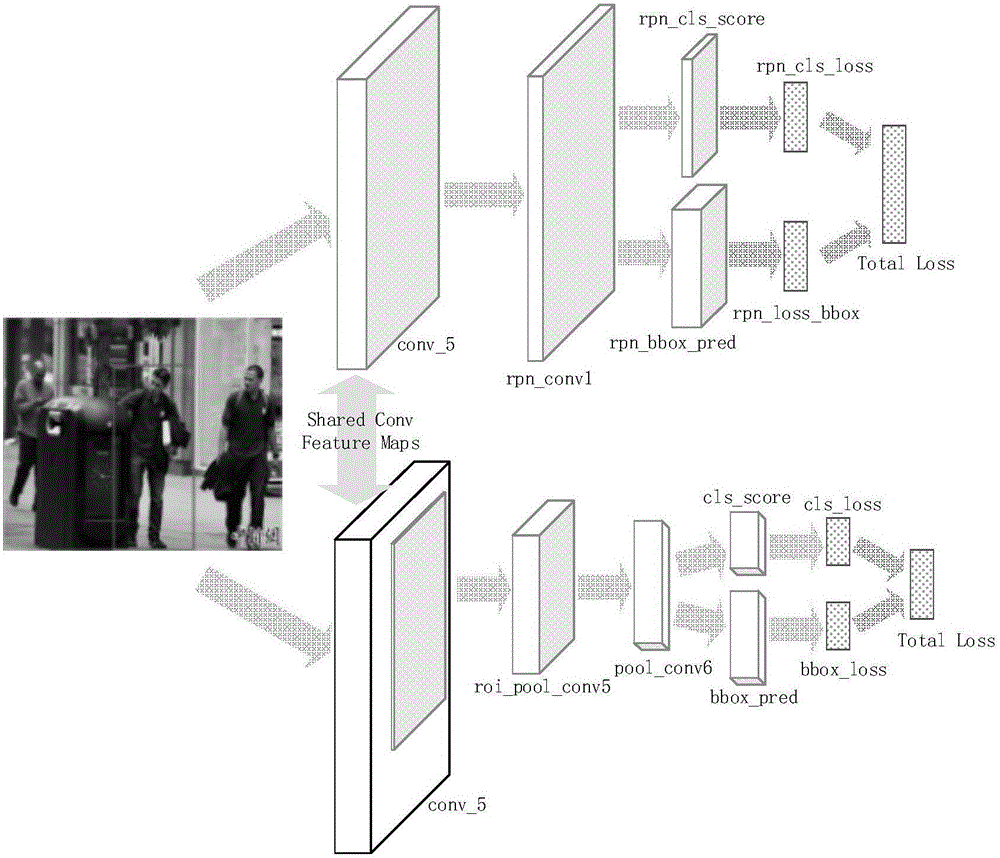

Pedestrian detection method based on deep learning technology

ActiveCN106203506AImprove detection accuracyThe detection process is fastCharacter and pattern recognitionPattern recognitionSpecial design

The invention discloses a pedestrian detection method based on a deep learning technology. The method comprises the steps that firstly, a binary classification model is trained through a step-by-step migration strategy on the basis of transfer learning to initialize final model parameters; secondly, pedestrian detection work is completed by adopting and modifying a currently popular and efficient Faster RCNN frame, and on the basis of the CNN characteristics of the frame, not only can images with any scales be processed, but also the detection speed is high. Compared with the prior art, the method has the advantages that the network does not need to be specially designed, existing available data is fully utilized, a good experiment result still can be achieved by adopting a general network structure, the advantages of a deep convolution network are fully achieved, and the advantages of being simple in design, good in robustness, high in detection accuracy and low in omission ratio are achieved.

Owner:SHANGHAI LINGKE SAFETY GUARD TECH

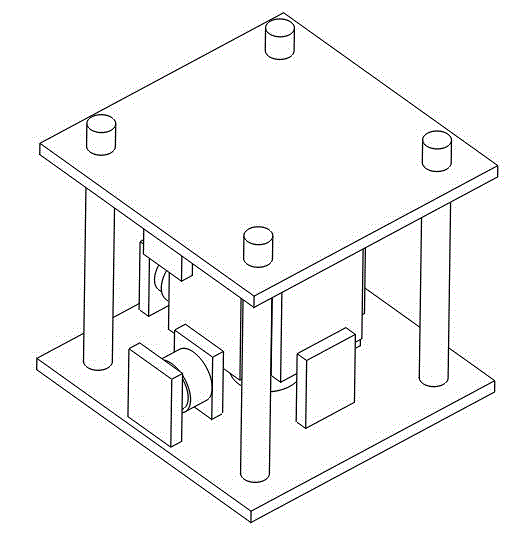

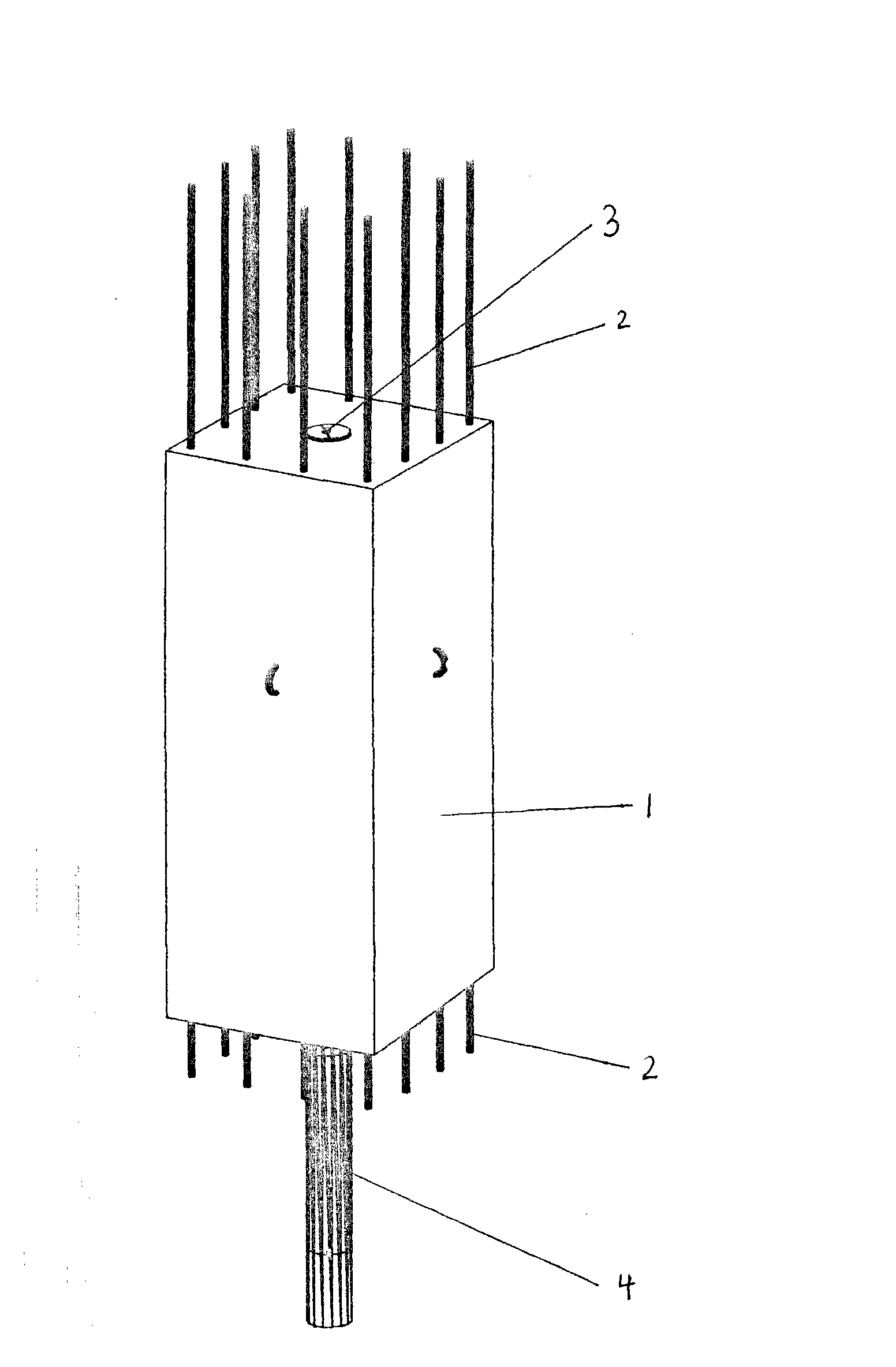

Rock true triaxial test system with CT (Computed Tomography) real-time scanning system and method

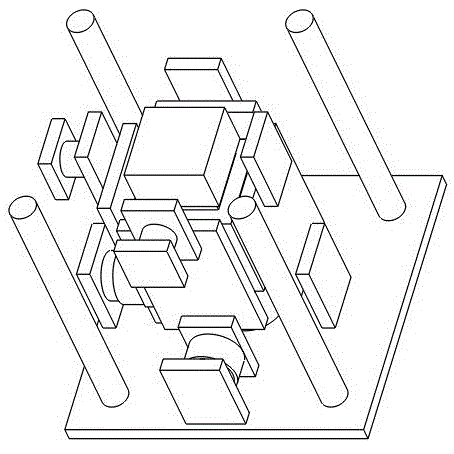

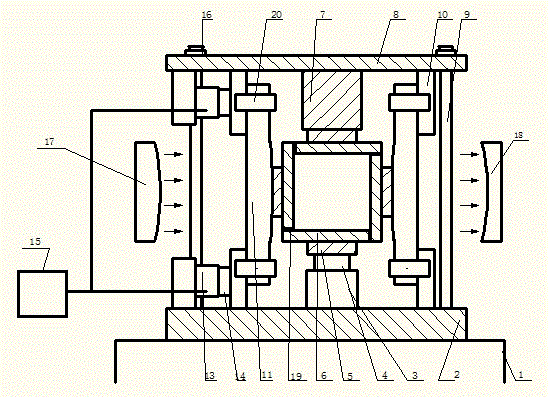

ActiveCN105181471ASolve the problem of not being able to penetrate the traditional true triaxial testing machineReal-time coordinationMaterial strength using tensile/compressive forcesMaterial analysis by transmitting radiationFiberTime extension

The invention relates to a rock true triaxial test system with a CT (Computed Tomography) real-time scanning system and a method. The rock true triaxial test system with the CT real-time scanning system comprises a triaxial pressure box, a triaxial host frame, a loading device and a CT scanning device, wherein the triaxial host frame comprises a bottom plate, a top plate and a stand column supported on the bottom plate; the loading device comprises a reversed force device, a jack and a measuring device; the pressure box, the stand column, and the reversed force device located in a scanning area of the CT scanning device are respectively made of carbon fiber materials. The rock true triaxial test system adopts the horizontal loading device, a carbon fiber force transfer plate and the stand column with special designs for a CT scanning area; solves the difficult problem that an X ray cannot penetrate through a traditional triaxial tester; overcomes the defect that in the traditional test, a rock sample needs to be unloaded and taken down from a true triaxial test bed and is then tested through CT scanning; realizes real-time coordination of rock true triaxial and CT scanning test; has significance on researching real-time extension and evolution law of microfissuring and microvoid in rocks under the triaxial stress state.

Owner:CHINA UNIV OF MINING & TECH

Plasma Centrifuge Heat Engine Beam Fusion Reactor

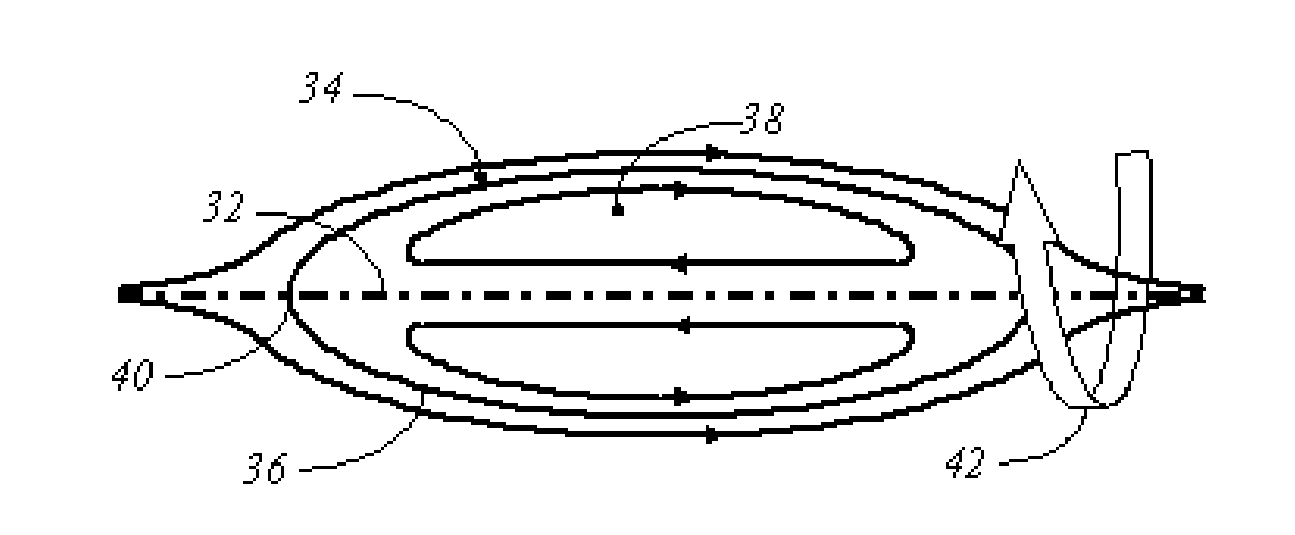

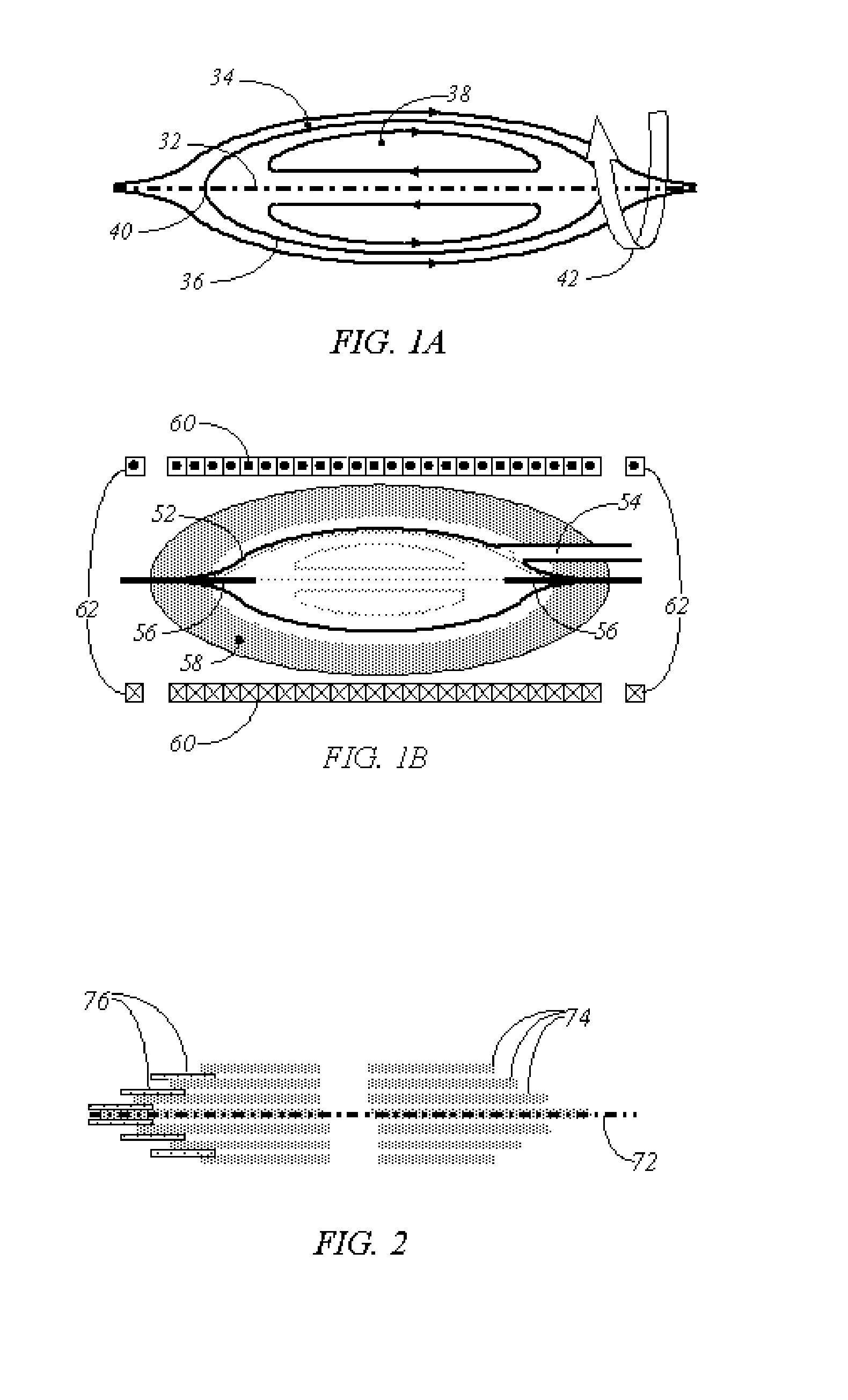

InactiveUS20080226011A1Improve responseReduce the temperatureNuclear energy generationPlasma techniqueField lineNuclear fusion

A system and apparatus for a magnetized plasma nuclear fusion reactor, incorporating special design features which induce a plasma heat engine cycle in a rapidly rotating plasma. The heat engine operates either continuously or by oscillations. A continuous heat engine is formed in the open field outside a field reversed configuration. The oscillatory system operates in synchronism with cyclic acceleration, collision, and deceleration of plasma masses to produce nuclear fusion reactions at an economically useful rate with a relatively small driving power required. A special magnetic field design is combined with applied electrical voltages at the end of the field lines to produce required conditions. Design features allow recovery of large fraction of collision heat which would otherwise be dissipated as a parasitic loss.

Owner:BARNES DANIEL C

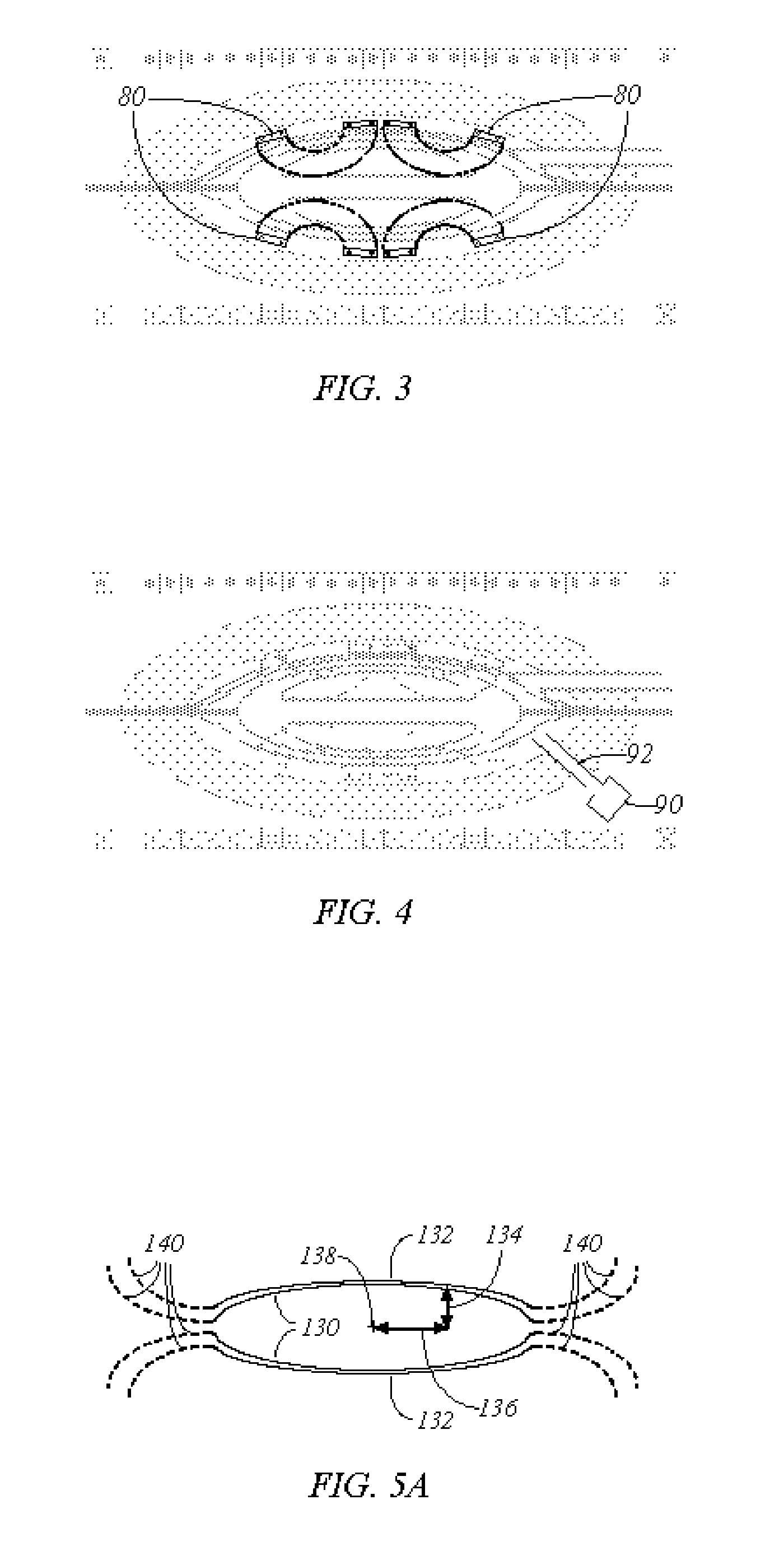

Light mixer and backlight module having the same

ActiveUS20080137335A1Conveniently fabricatedSimple and convenient to maintainNon-electric lightingPoint-like light sourceSpecial designOptoelectronics

A light mixer and a backlight module having the light mixer are provided. The backlight module includes a plurality of light mixers and a diffuser. The light mixers are arranged on a plane in an array. Each light mixer includes a light mixing plate, a plurality of light sources, a plurality of upper reflecting layers, a lower reflecting layer, and a semi-permeable layer. The light mixing plate has an upper surface, a lower surface, a peripheral surface, and a plurality of receiving holes. The light sources are respectively located in the receiving holes. The upper reflecting layers are respectively located right above the light sources. The lower reflecting layer is located on the lower surface of the light mixing plate. The semi-permeable layer wraps the peripheral surface of the light mixing plate. The diffuser is located above the light mixers. Therefore, the fabricating process of the backlight module is relatively simple, the fabricating cost is relatively low, and it is simple and convenient to maintain. Furthermore, the special design of the light mixers enhances the light mixing efficiency and the luminance.

Owner:HKC CORP LTD

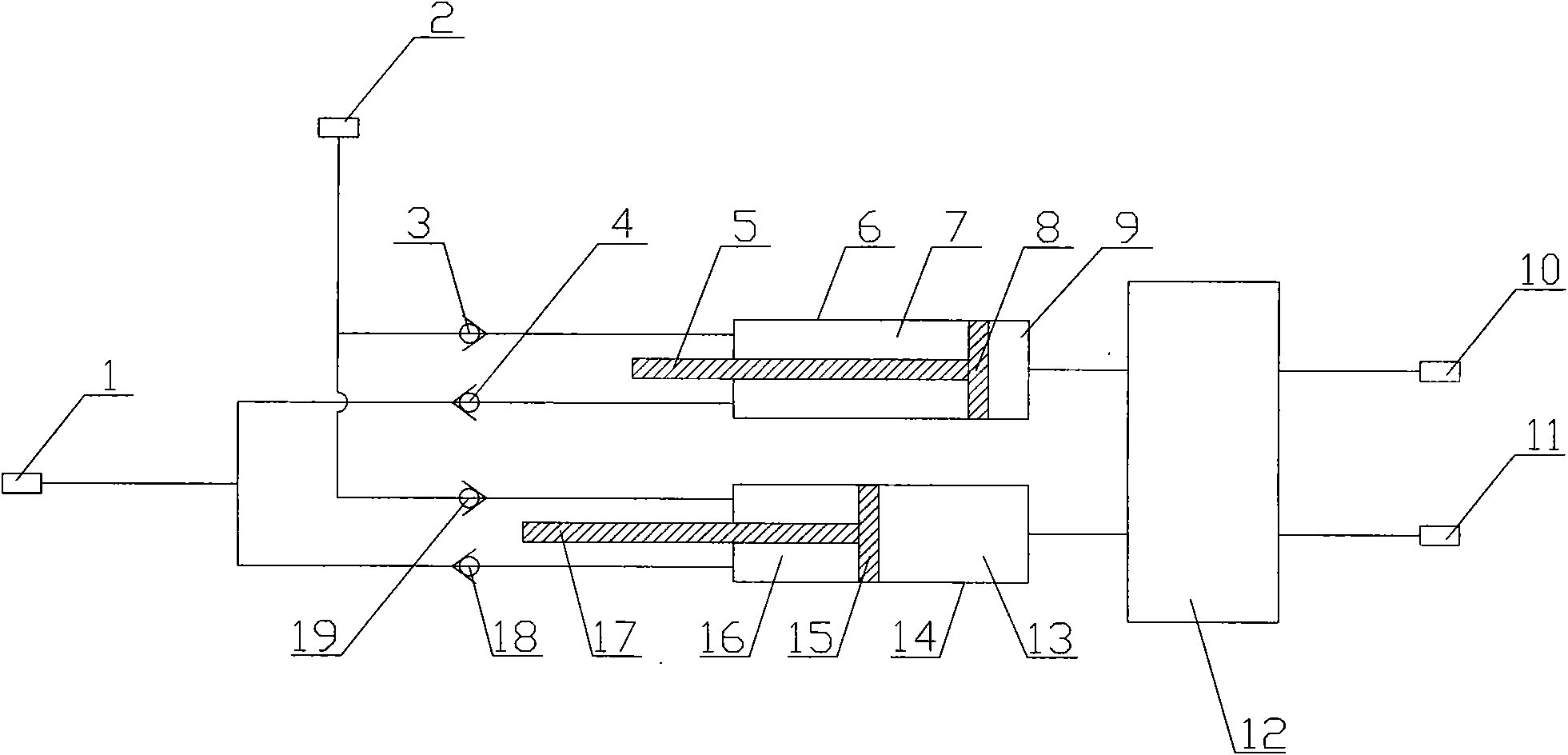

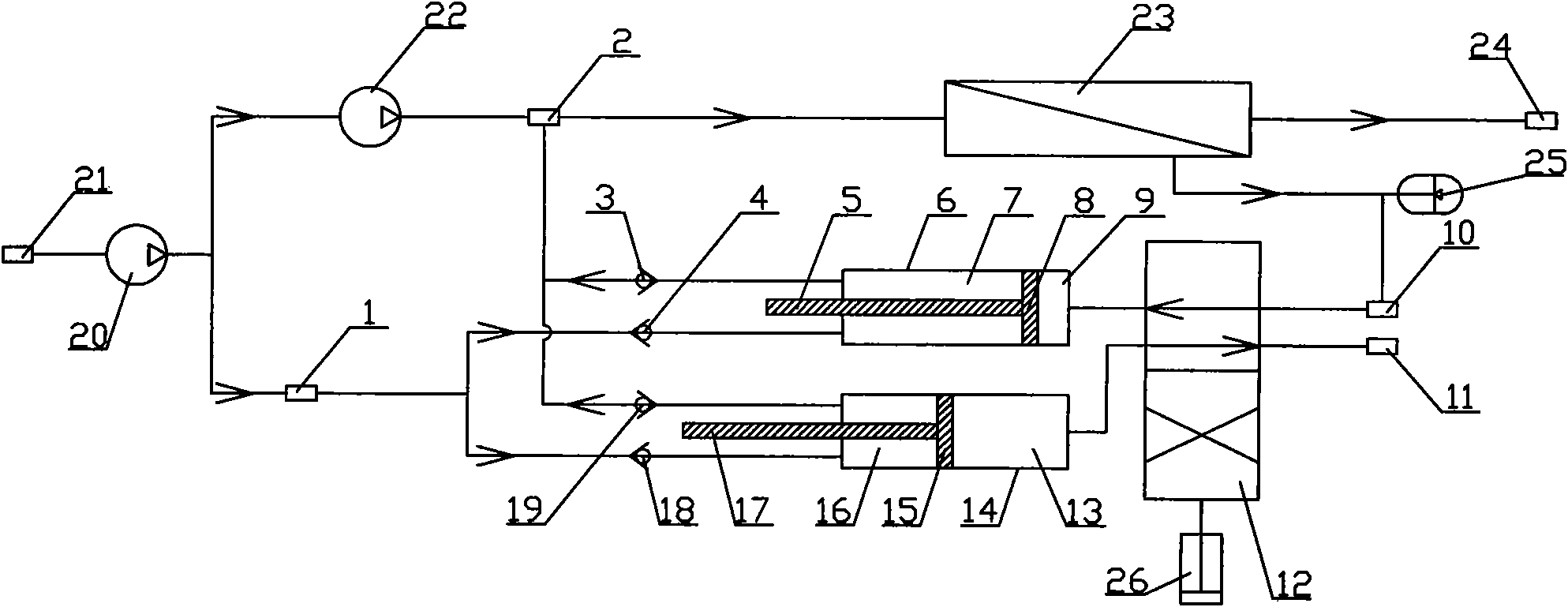

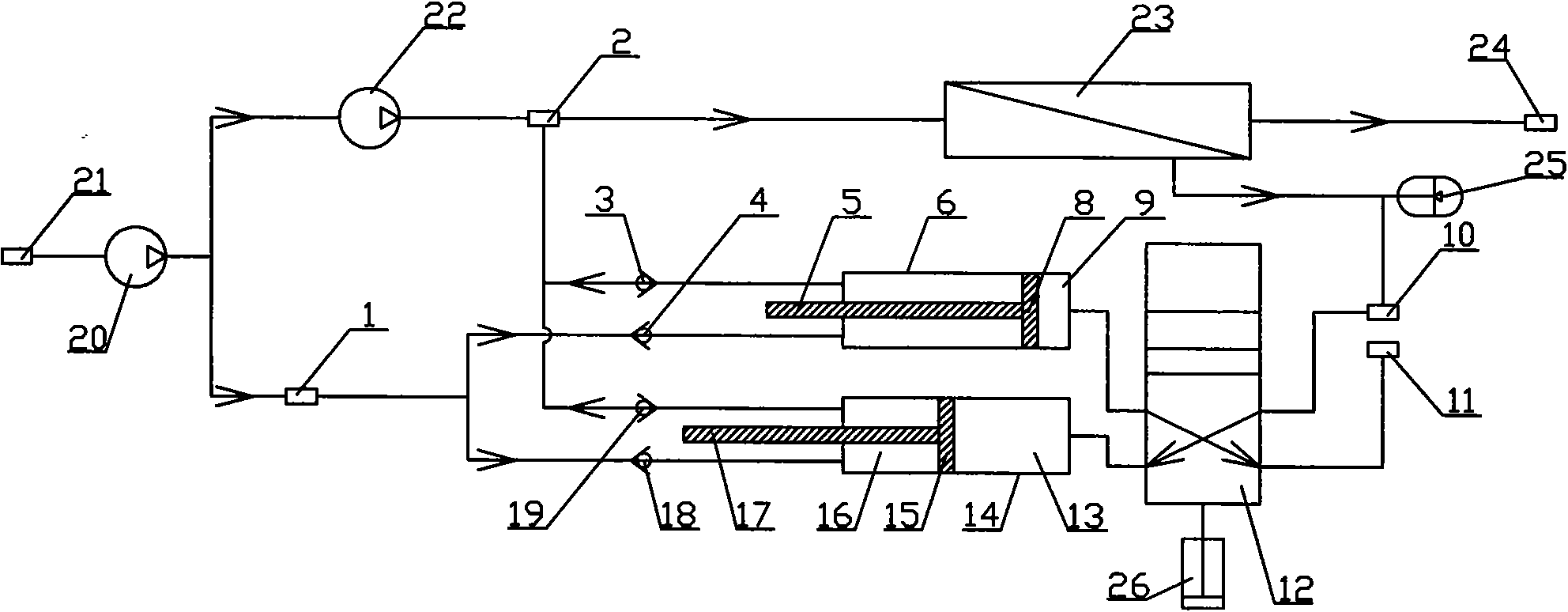

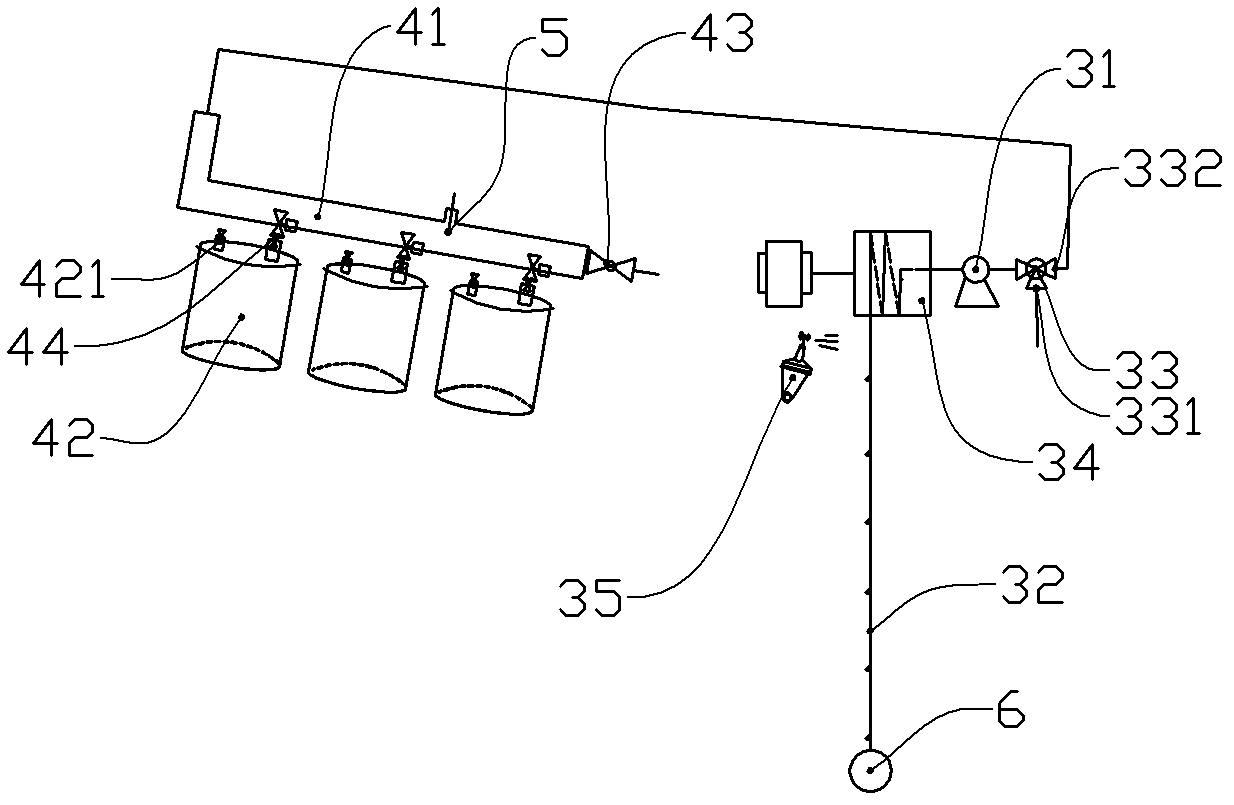

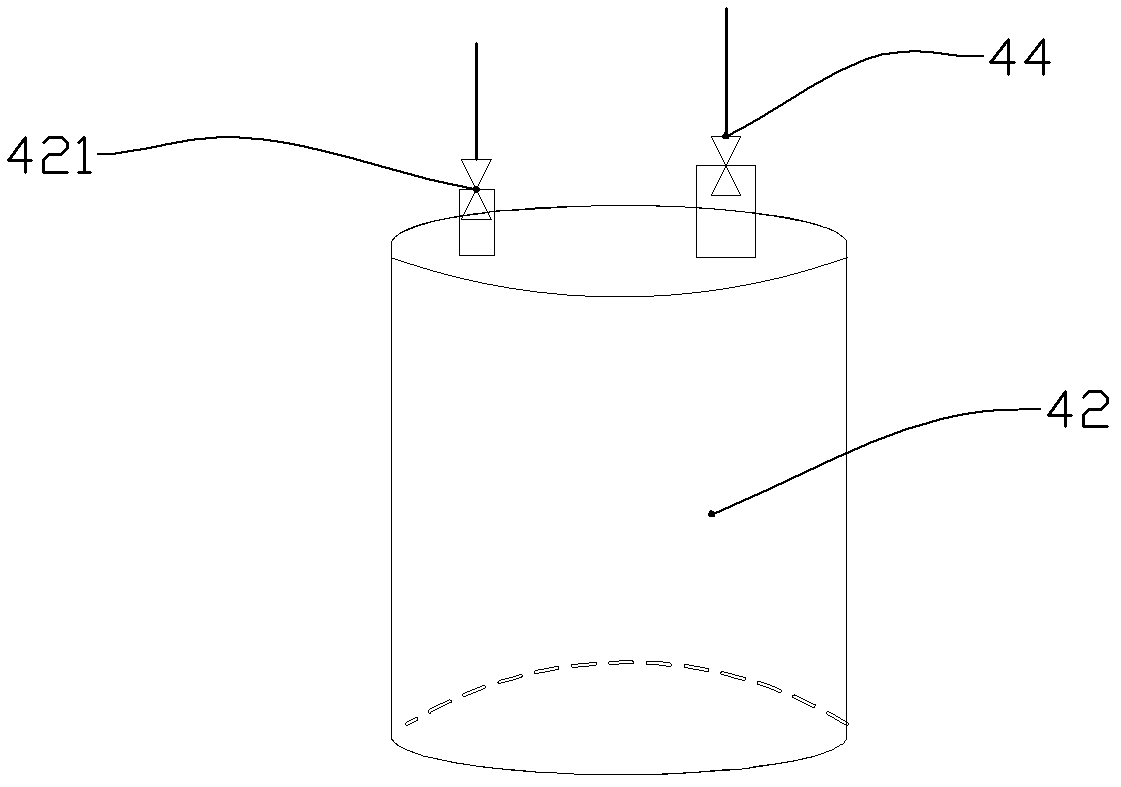

Differential energy recovery device and method for seawater desalination system

InactiveCN101782095AReduce energy consumptionImprove energy conversion efficiencyFluid-pressure actuator componentsSpecial designInlet valve

The invention discloses a differential energy recovery device and a method for a seawater desalination system. The differential energy recovery device comprises two hydraulic cylinders connected in parallel. A piston divides each hydraulic cylinder into two cavities. The piston is fixedly connected with a piston rod. A low-pressure raw water inlet is connected with two left cavities through liquid inlet valves. The left cavities are connected with a high-pressure raw water outlet through liquid drain valves. Two right cavities are connected with reversing valves. The reversing valves are connected with a high-pressure concentrated water inlet and are connected with a low-pressure concentrated drain outlet. The method is that high-pressure concentrated water coming from a reverse osmosis device is enabled to enter the right cavities of the two hydraulic cylinders through the reversing valves, and low-pressure raw water in the left cavities is pushed and pressurized to enter the reverse osmosis device. Since the direct pressurization principle of the hydraulic cylinders is used for the special design, one-time energy conversion is adopted and the pressure of high-pressure seawater after pressure exchange is larger than the pressure of concentrated saline water, the invention has the advantages that the pressurizing pumps are not required for pressurization once more, the energy conversion efficiency is high, the operating cost is saved and the energy consumption of the reverse osmosis system is further reduced.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

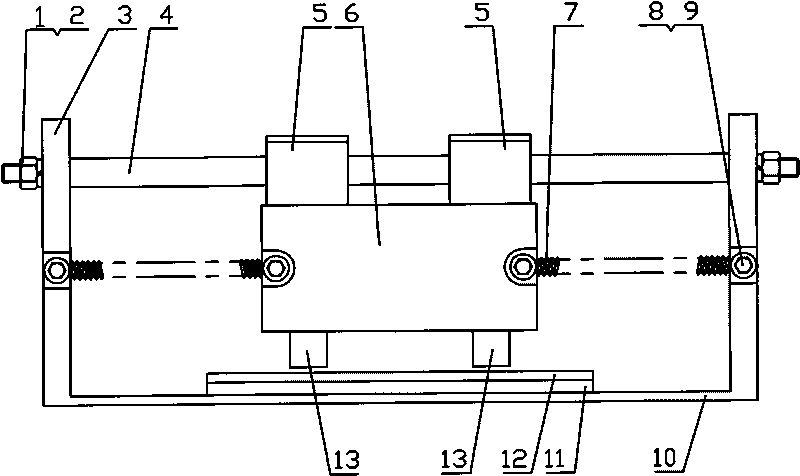

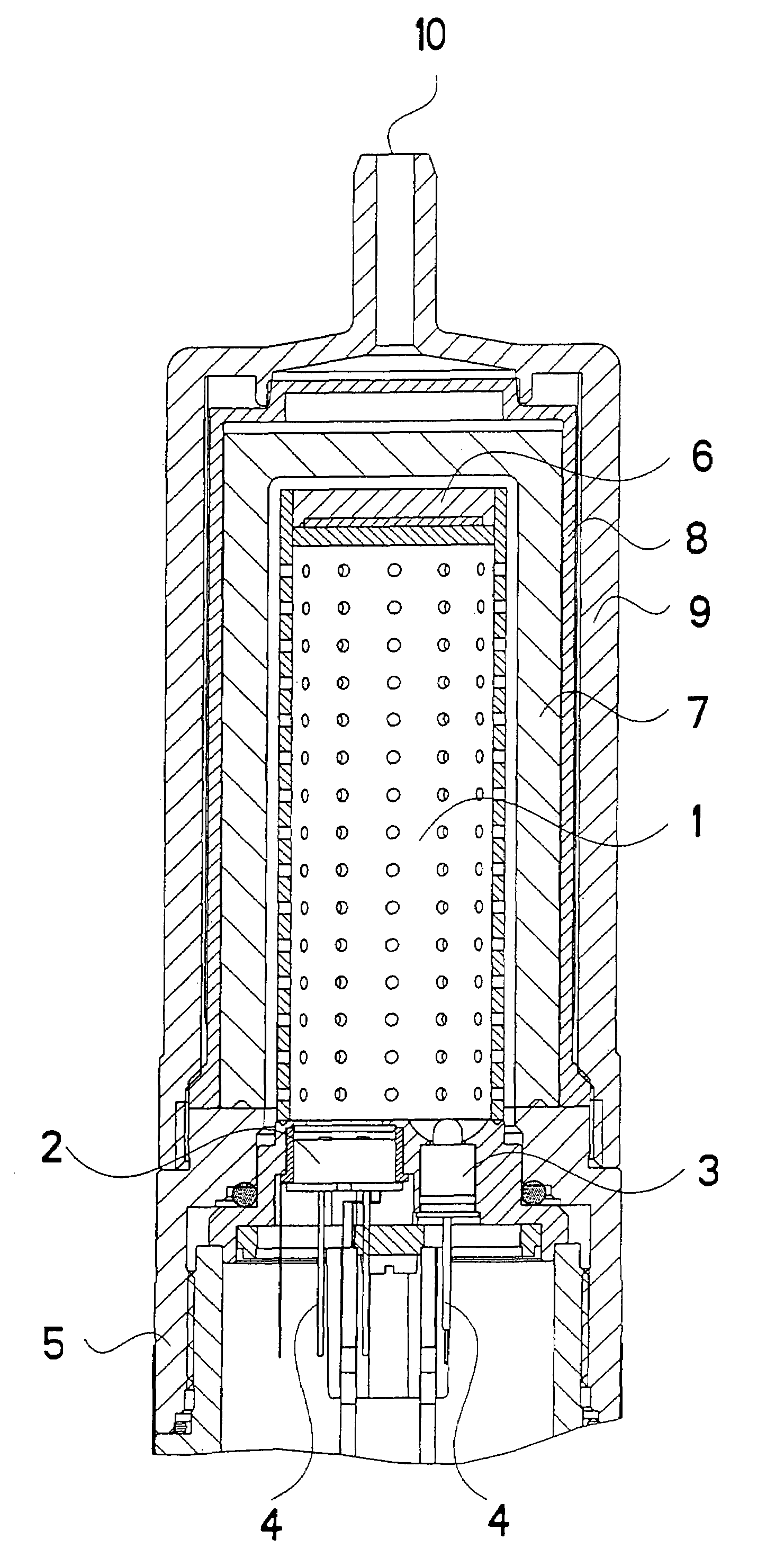

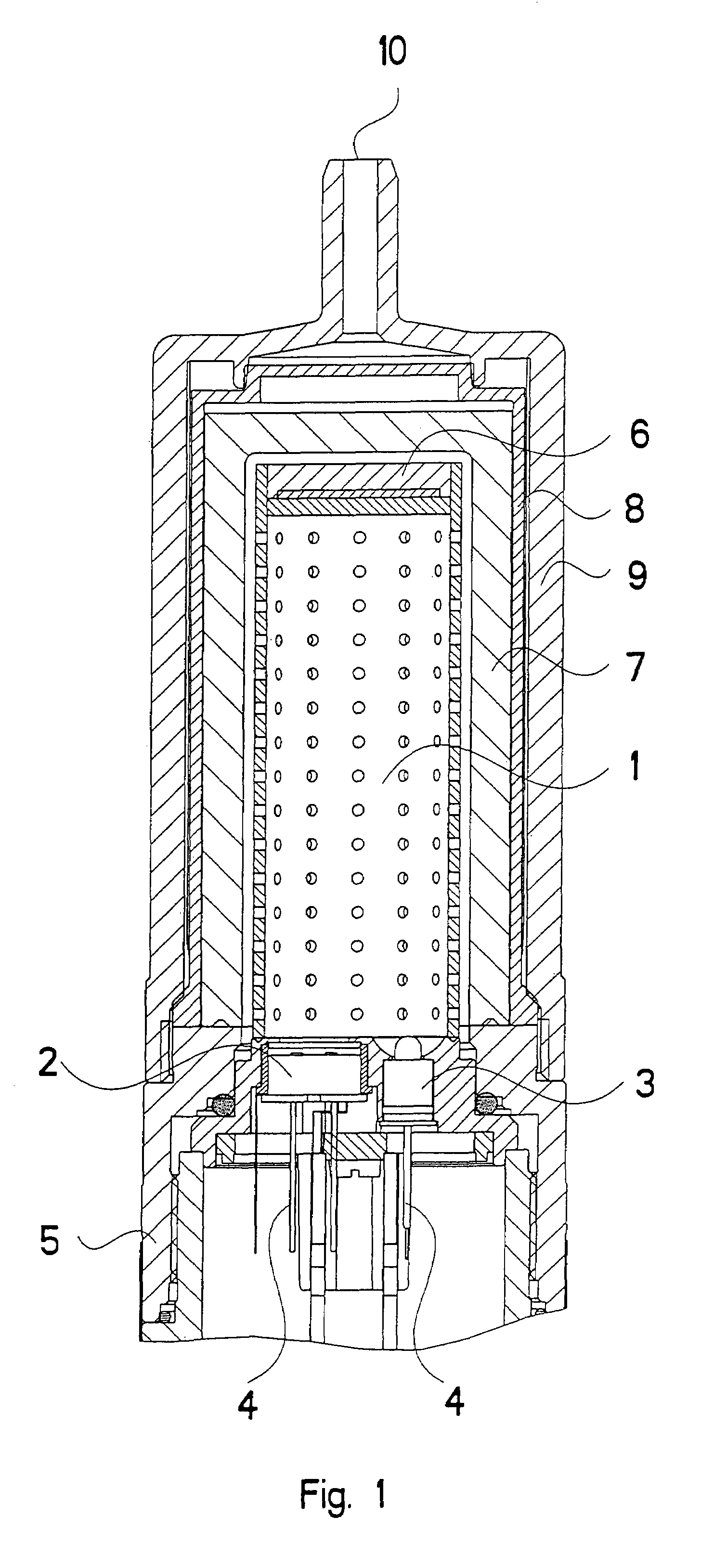

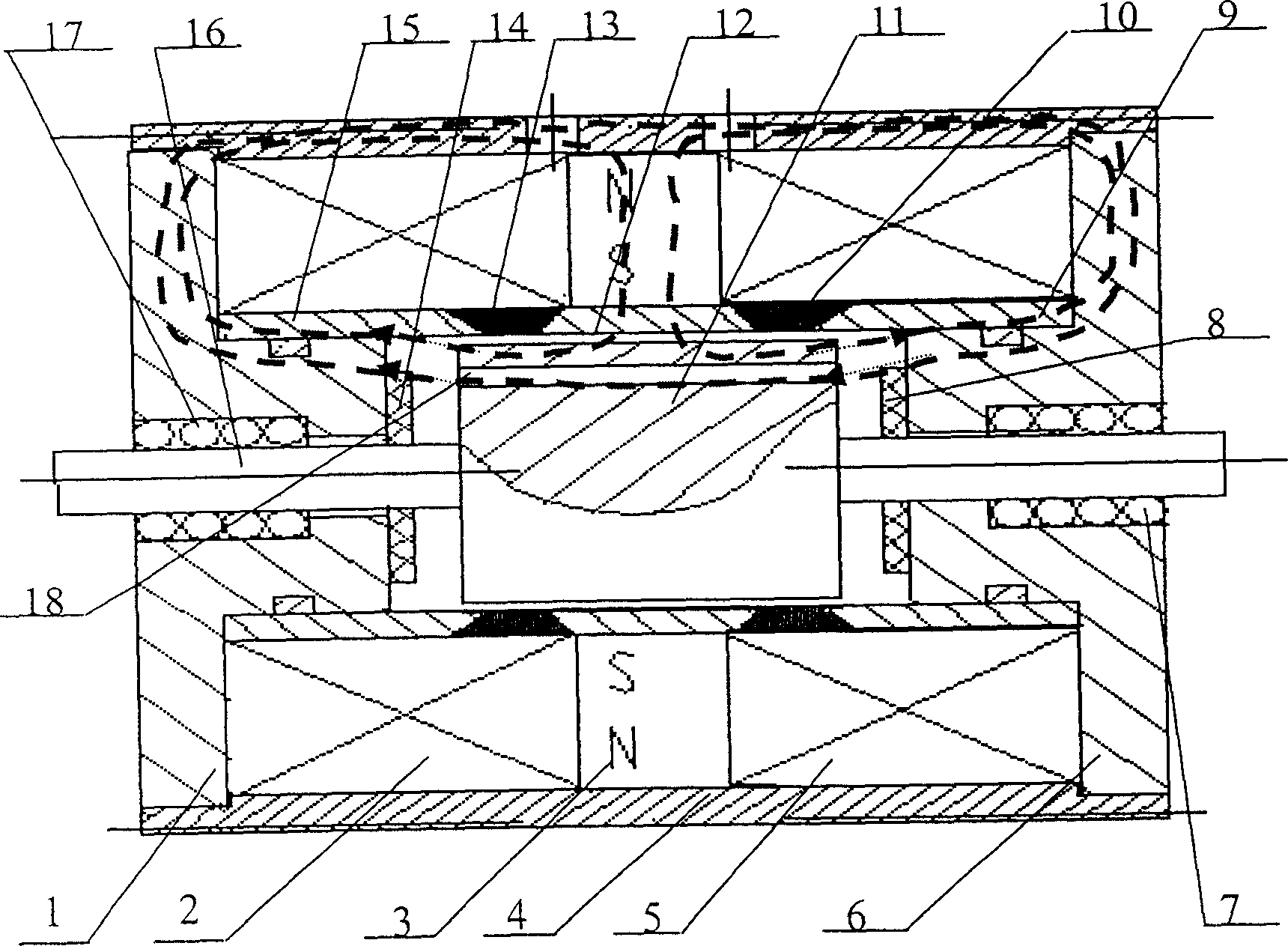

Permanent-magnet type eddy current tuned mass damper

ActiveCN101761146APrecise linear motionStructural damping dropBridge structural detailsTowersStress concentrationElectricity

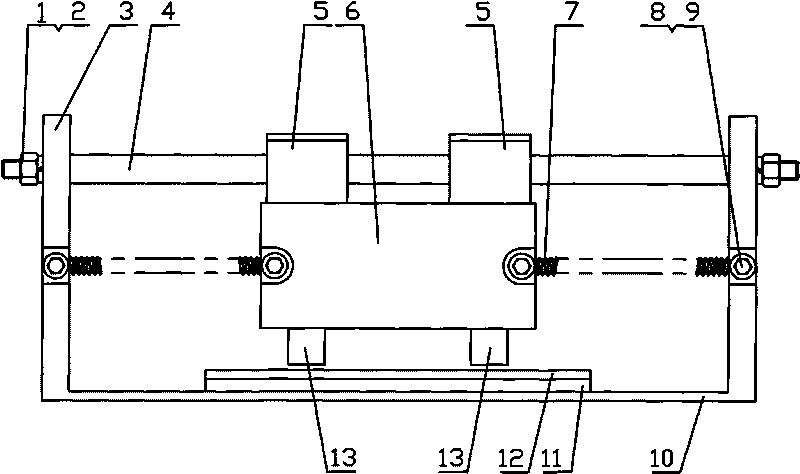

The invention relates to a permanent-magnet type eddy current tuned mass damper which comprises a steel magnetic-conducting baseplate (10), wherein end plates (3) are respectively arranged at two ends of the baseplate (10). The permanent-magnet type eddy current tuned mass damper is characterized by also comprising a circular shaft (4) and a linear bearing seat (5), wherein two ends of the circular shaft (4) are respectively arranged on the corresponding end plates (3), and the linear bearing seat (5) is sleeved on the circular shaft (4) and can slide on the circular shaft (4); the lower part of the bearing seat (5) is connected with a mass block (6), and two ends of the mass block (6) are respectively connected with the corresponding end plates (3) through spiral springs (7); the lower part of the mass block (6) is connected with a permanent magnet (13), and a copper plate (12) is arranged below the permanent magnet (13) and connected with the baseplate (12) through a cushion block (11). By adopting an eddy current damping model with special design, the permanent-magnet type eddy current tuned mass damper realizes the damping adjustability of the damper in a larger range, realizes the complete separation between the system rigidity and the damper, and cancels the mechanical friction energy consumption and stress concentration elements, thereby avoiding the common TMD damage failure.

Owner:湖南省潇振工程科技有限公司 +1

Absorbable / biodegradable composite yarn constructs and applicatons thereof

Absorbable composite medical devices such as surgical meshes and braided sutures, which display two or more absorption / biodegradation and breaking strength retention profiles and exhibit unique properties in different clinical settings, are made using combinations of at least two types of yarns having distinctly different physicochemical and biological properties and incorporate in the subject construct special designs to provide a range of unique properties as clinically useful implants.

Owner:POLY MED

Reduced parallel and pipelined high-order MIMO LMMSE receiver architecture

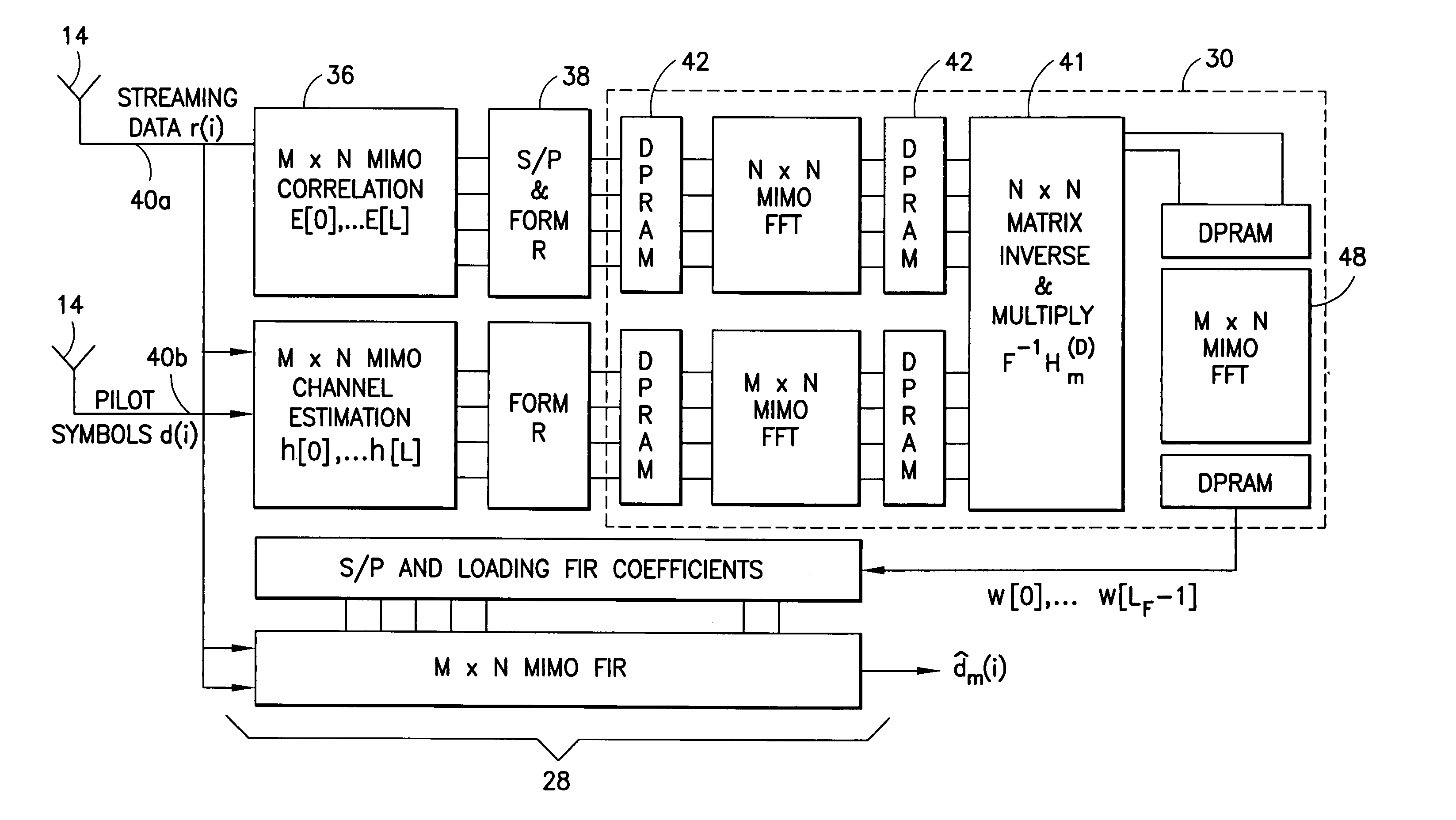

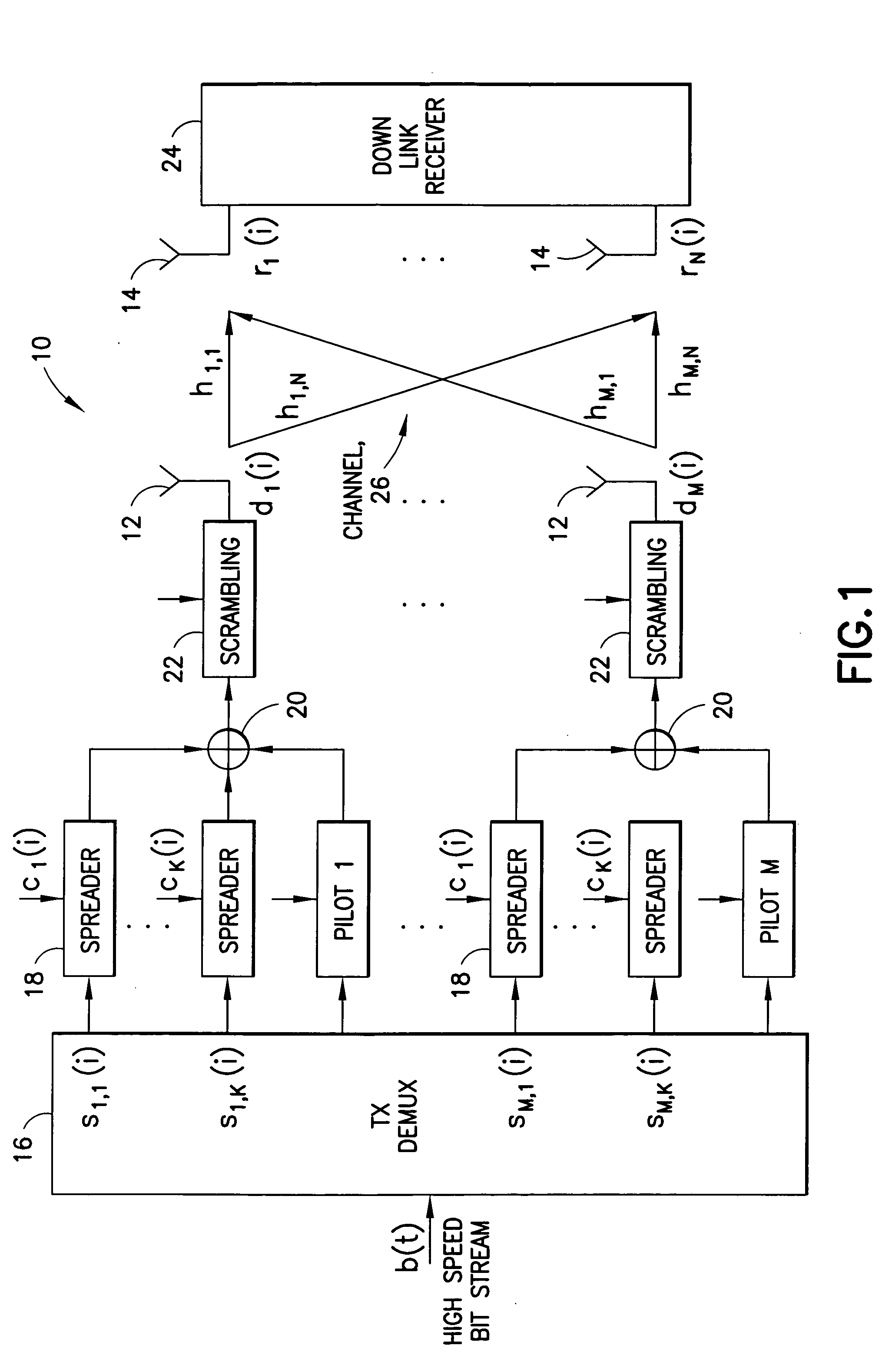

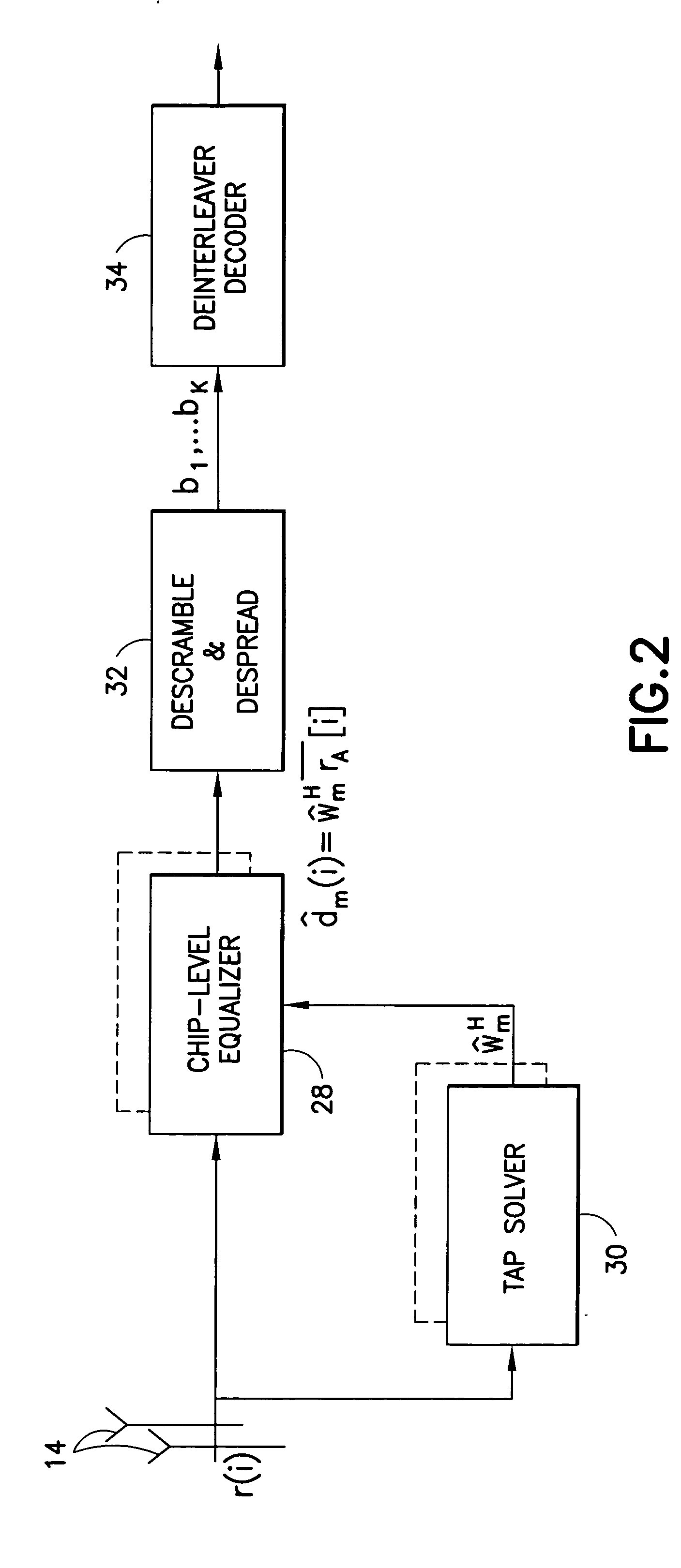

ActiveUS20060109891A1Reduce complexityReduce the numberMultiple-port networksDelay line applicationsFast Fourier transformRound complexity

Disclosed is a LMMSE receiver that restores orthogonality of spreading codes in the downlink channel for a spread spectrum signal received over N receive antennas. The FFT-based chip equalizer tap solver reduces the direct matrix inverse of the prior art to the inverse of some submatrices of size N×N with the dimension of the receive antennas, and most efficiently reduces matrix inverses to no larger than 2×2. Complexity is further reduced over a conventional Fast Fourier Transform approach by Hermitian optimization to the inverse of submatrices and tree pruning. For a receiver with N=4 or N=2 with double oversampling, the resulting 4×4 matrices are partitioned into 2×2 block sub-matrices, inverted, and rebuilt into a 4×4 matrix. Common computations are found and repeated computations are eliminated to improve efficiency. Generic design architecture is derived from the special design blocks to eliminate redundancies in complex operations. Optimally, the architecture is parallel and pipelined.

Owner:VIVO MOBILE COMM CO LTD

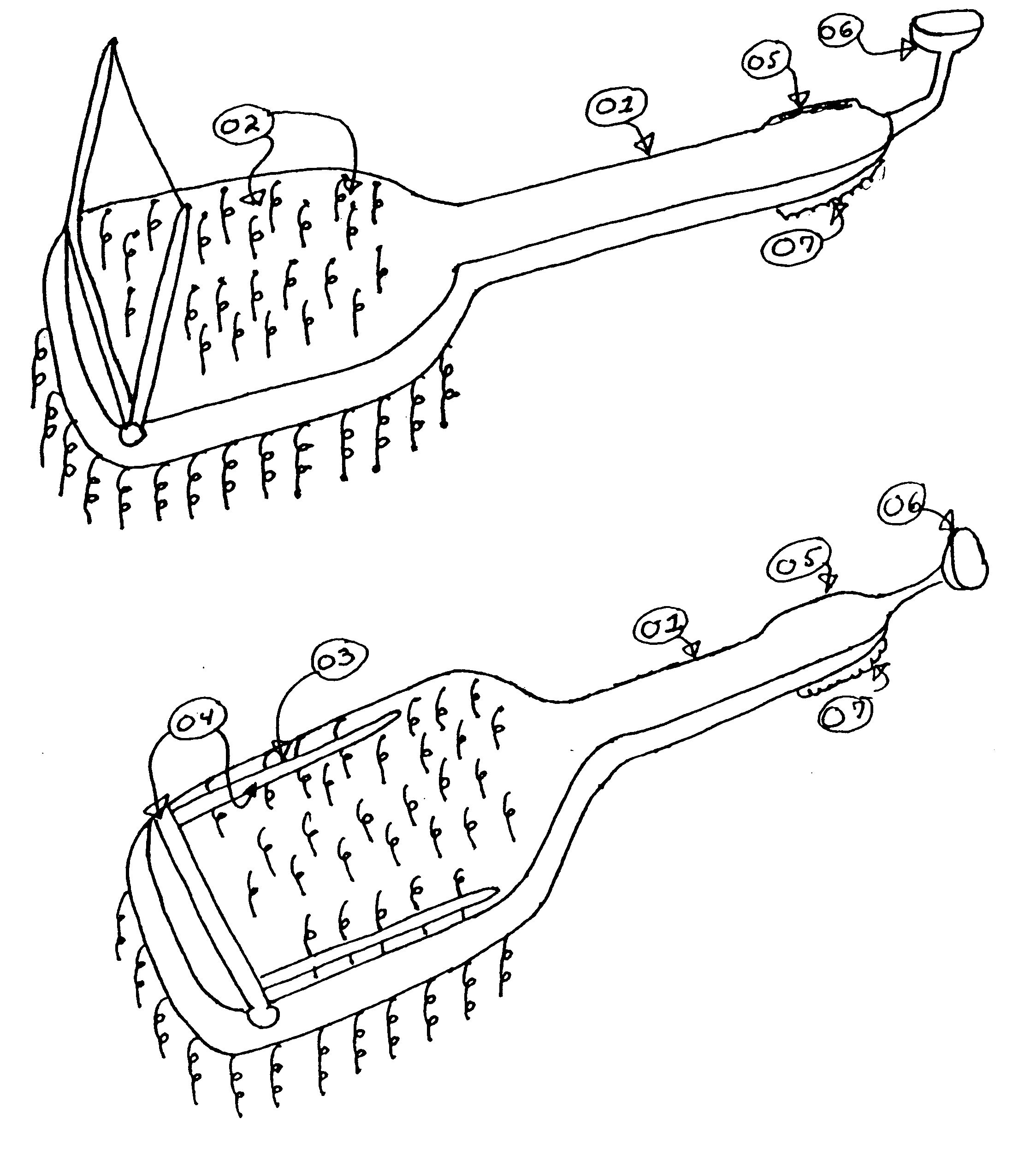

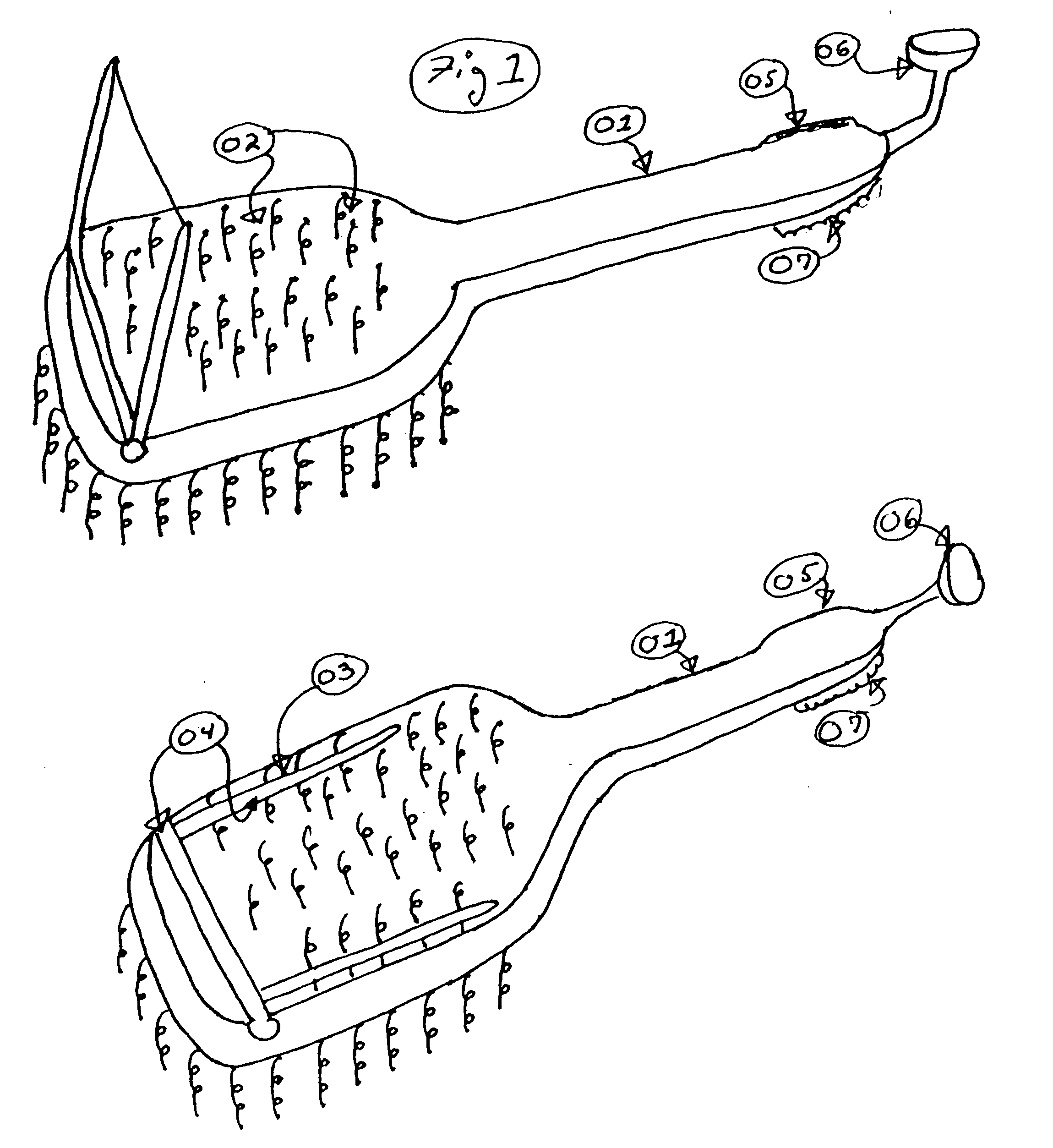

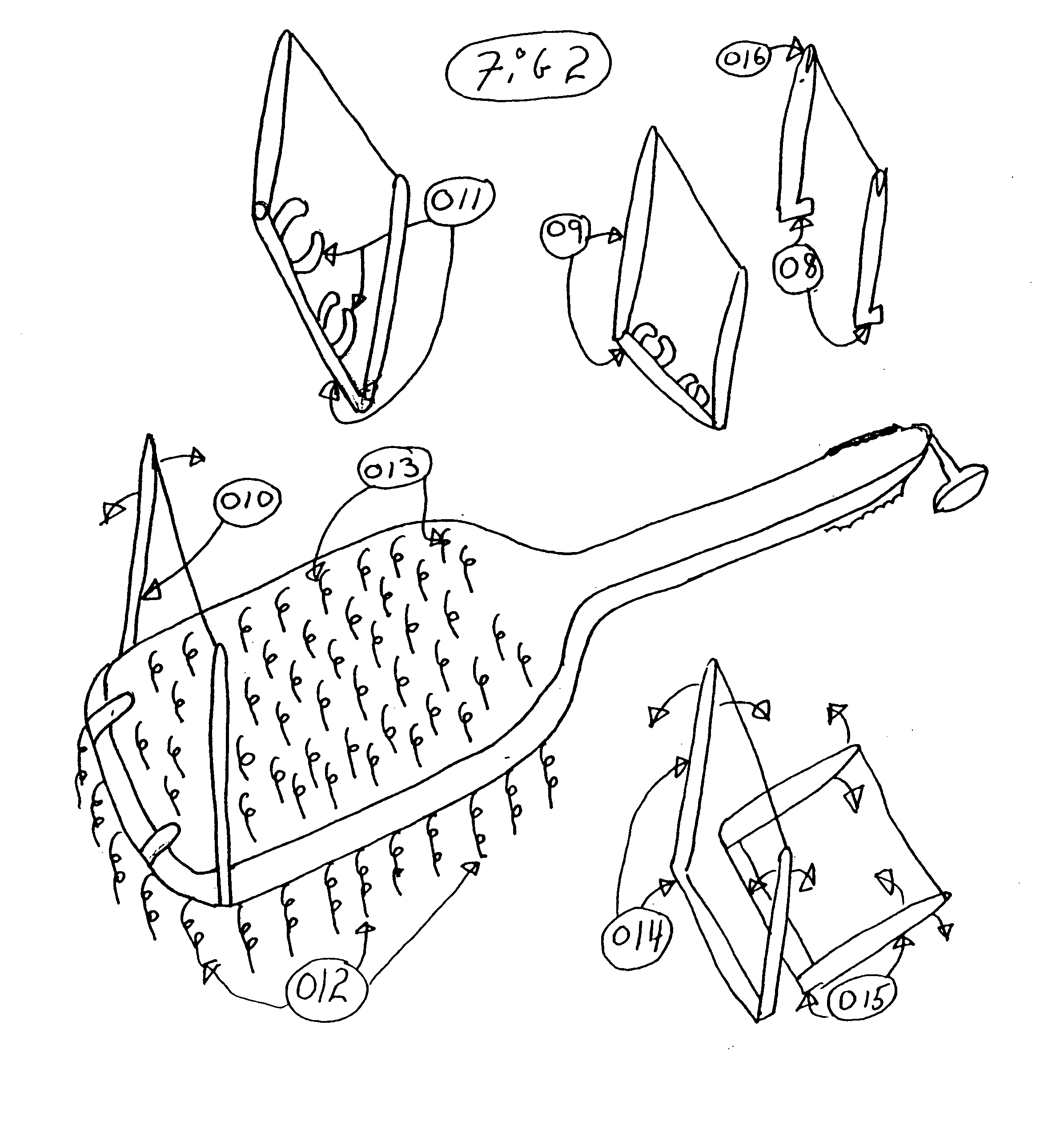

Tooth brush combination

This new and improved tooth brush combination is all one would ever need, the simple design on how and why the rotating flossing head is the only moving part and its simple, to lock in to place when in use and very easy to change when needed, and its location is on the tooth brush bristle head its self, and when not in use the rotating head will simply lay flat down, locks in to place on the tong cleaning section on the back of the tooth brush head, and when brushing your teeth, you will never know that there is a rotating flossing head. And the tooth brush bristle have a special design, with a spring pulling action and little barbs along the bristles that have a natural pulling force so the food and debris are more efficiently pulled from between your teeth and gum area, and all these combinations combined are not by the handle at all, this is the most efficient and friendly germ prevention hygienic tooth brush ever.

Owner:DE MASI SR DOUGLAS D

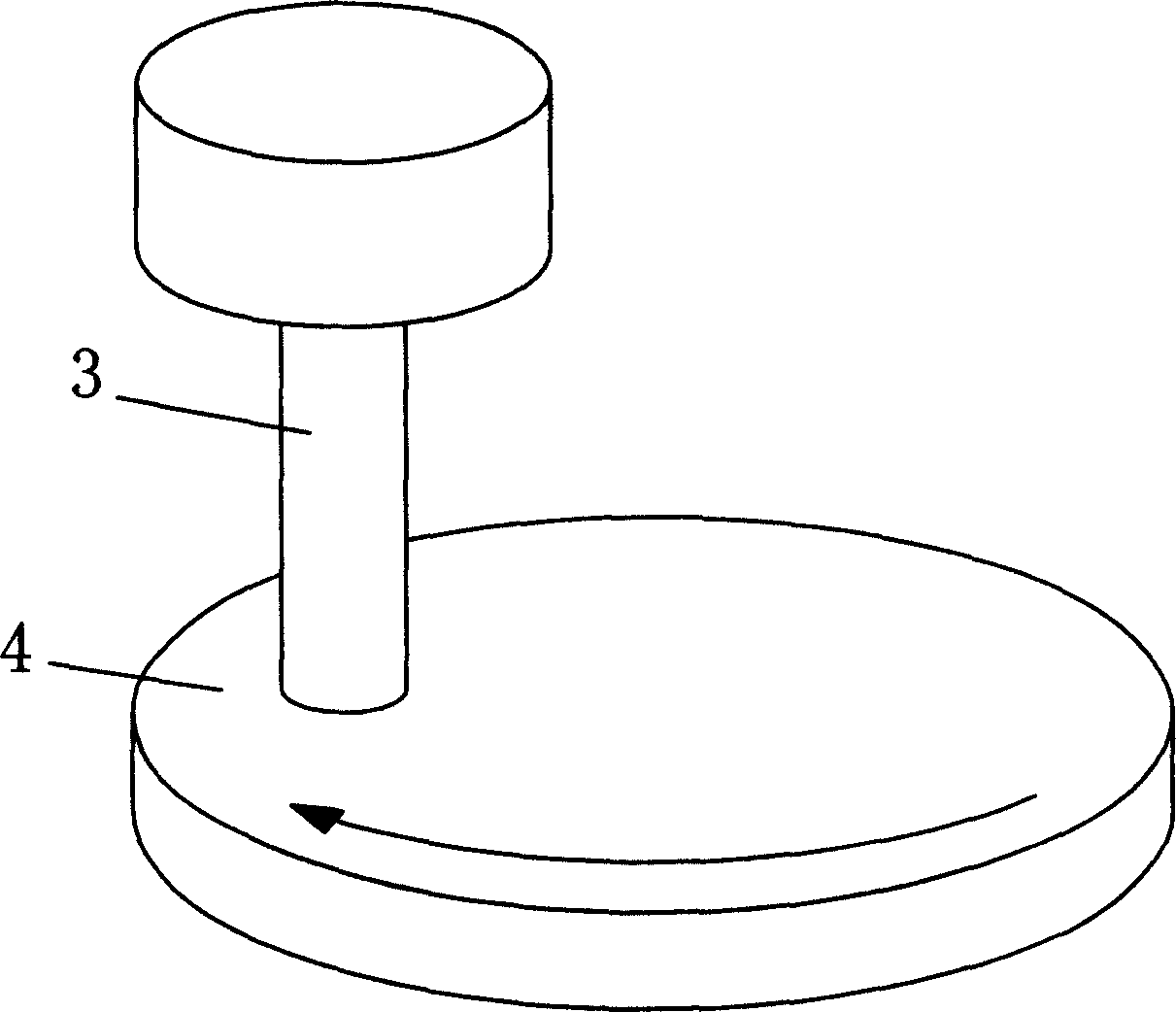

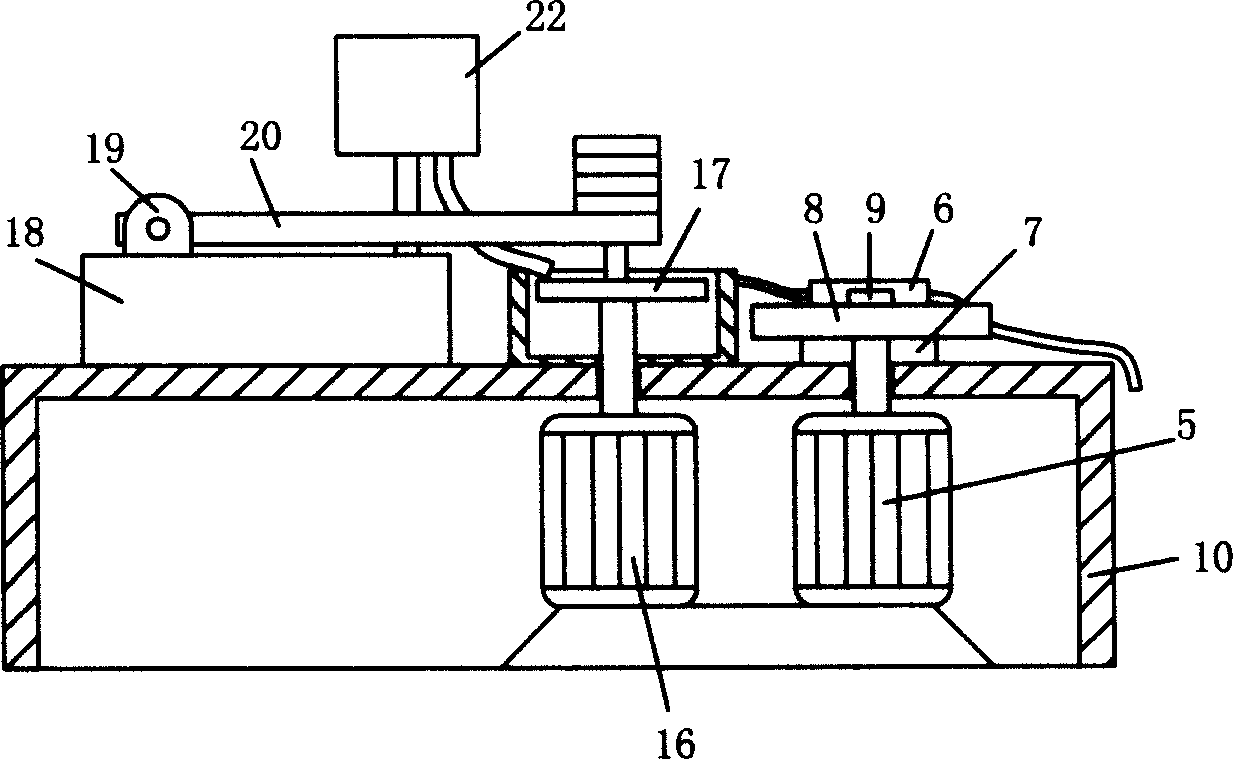

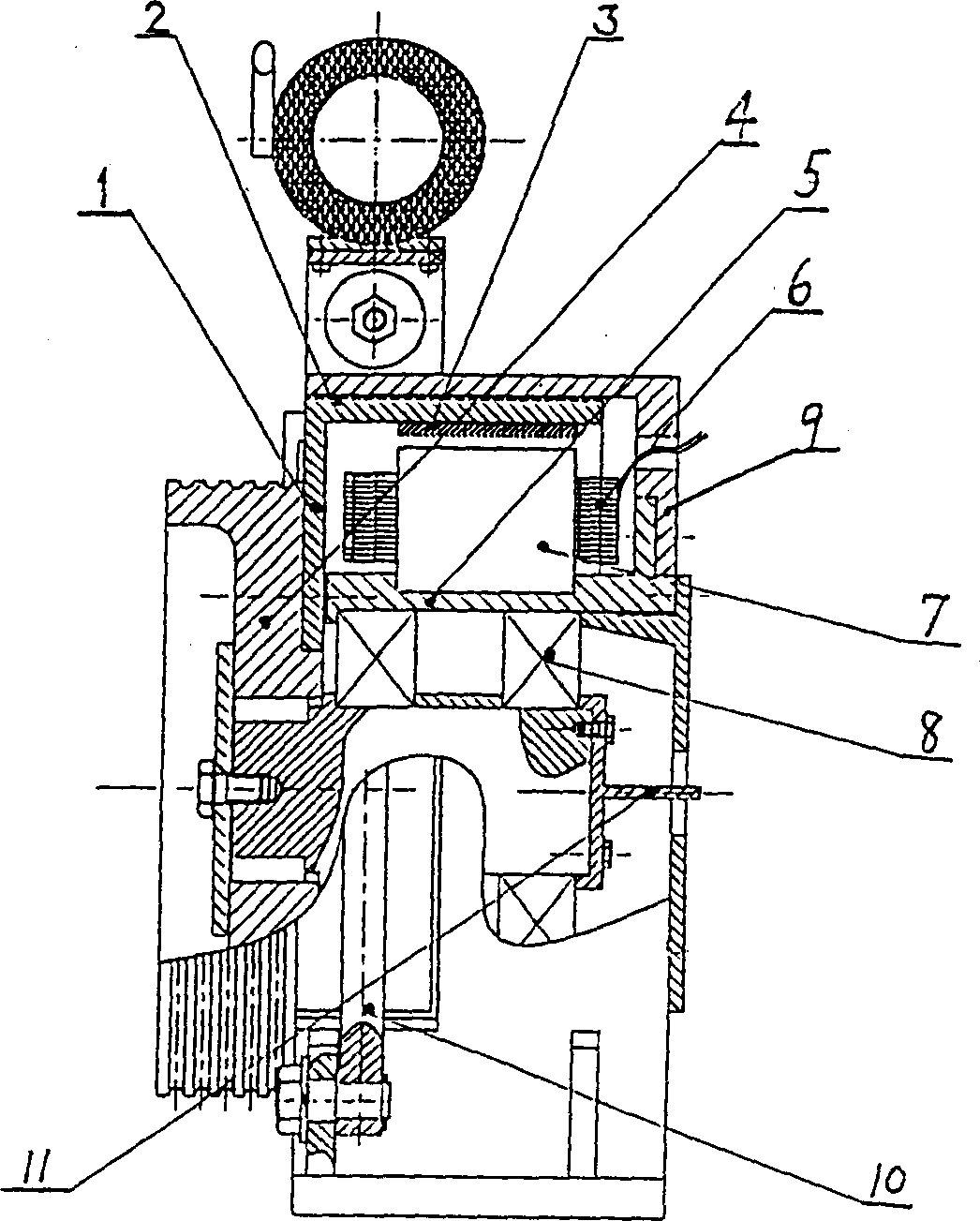

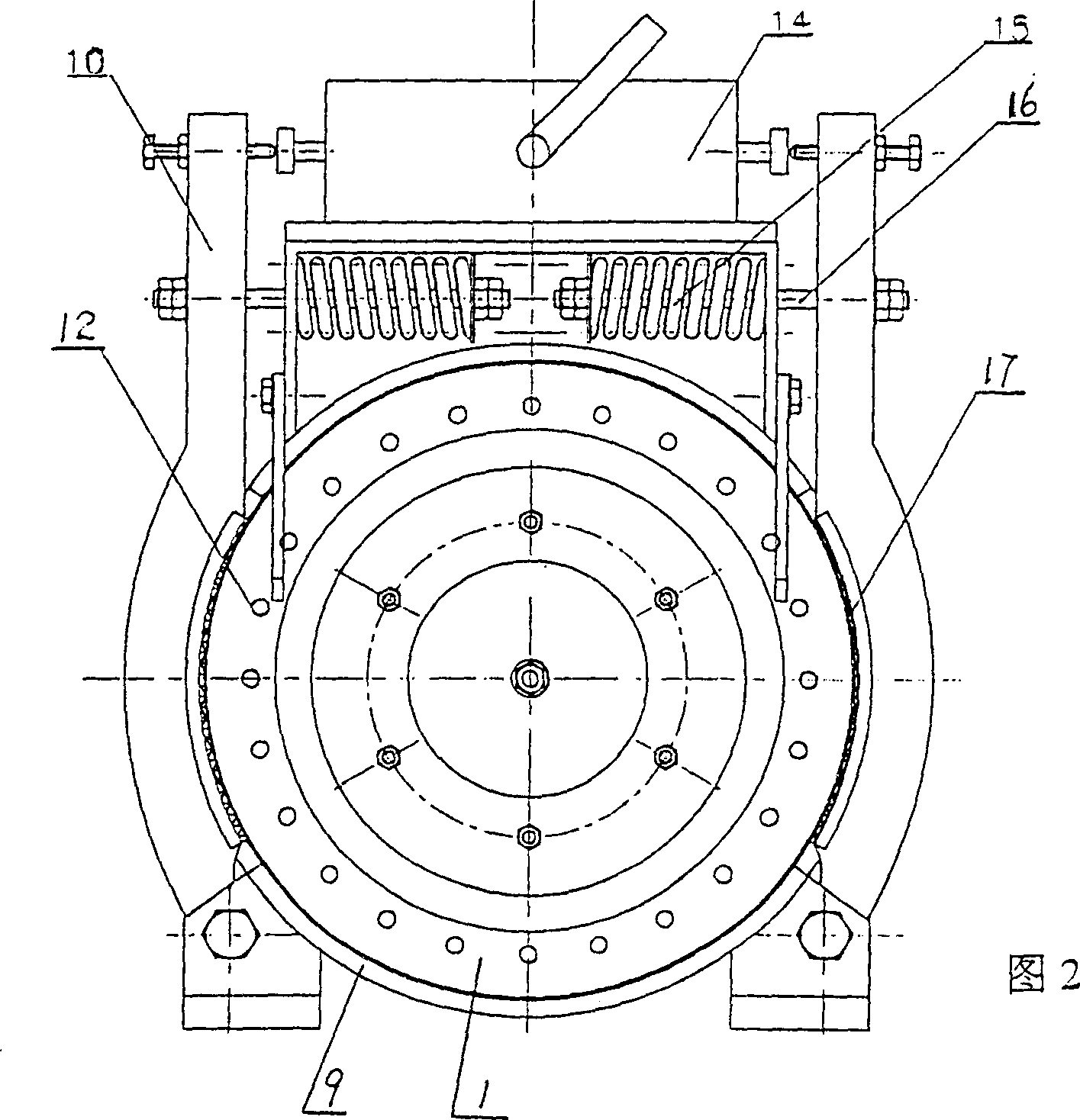

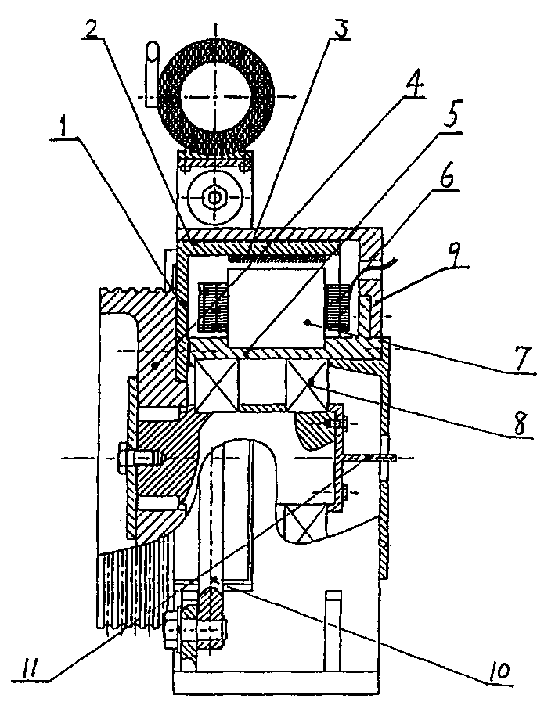

Reciprocal and rotary type incorporated frictional wear test machine

InactiveCN1595100ANo need to disassembleGuaranteed accuracyInvestigating abrasion/wear resistanceCircular discWear testing

This invention discloses two kinds of friction wearing testing machine of integration of reciprocating and rotating, which comprises base socket , reciprocating structure, rotating structure and upper-specimen control device, wherein, the reciprocating structure comprises reciprocating motor, slide block, slide rail, crank, connecting bar; and the rotating structure comprises rotating drive motor and rotating disc; and the upper-specimen control device comprises spring arm, guide rail and slide holder or spring arm , rotating parts and base socket. This invention integrates the reciprocating structure friction wearing machine and rotating friction wearing machine into one structure through special designed base socket and upper-specimen control device and it needn't disassembly specimen and ensures the accuracy of the experience data.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Gas sensor

ActiveUS7406854B2Reduce effortCalibration reducedFuel testingTransmissivity measurementsSpecial designEnvironmental engineering

Owner:DRAGER SAFETY

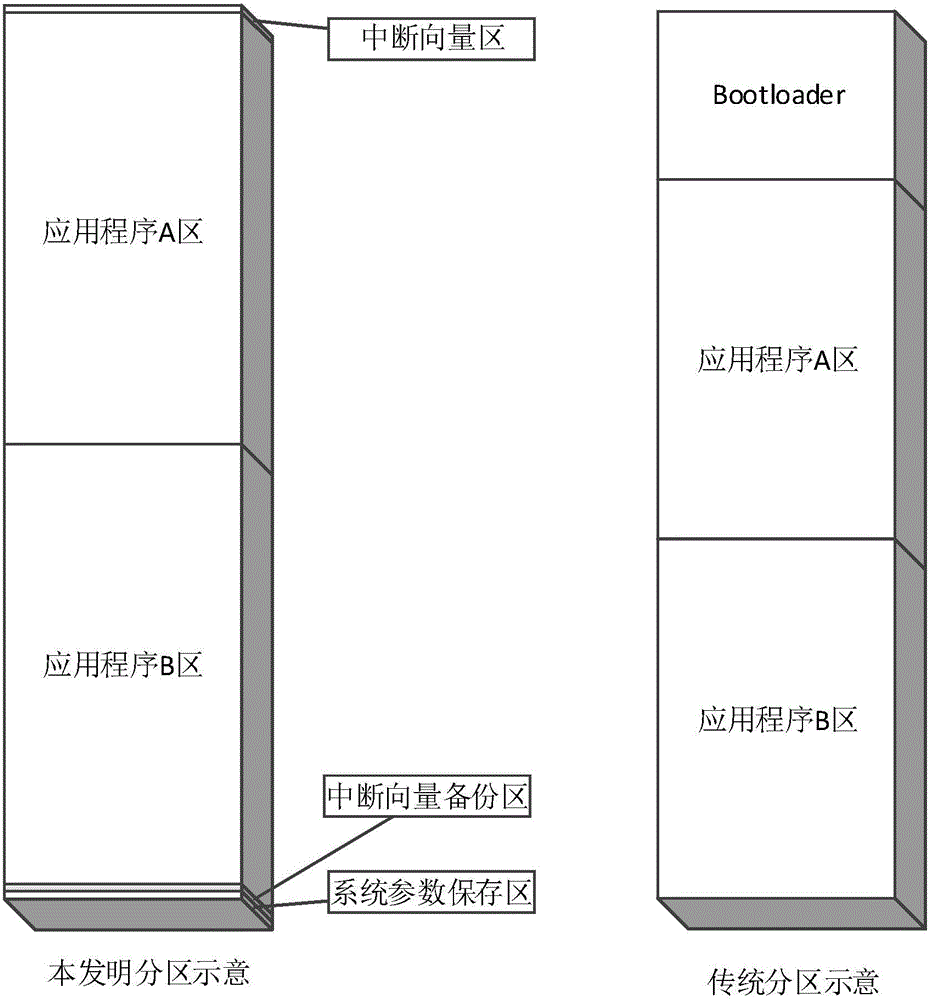

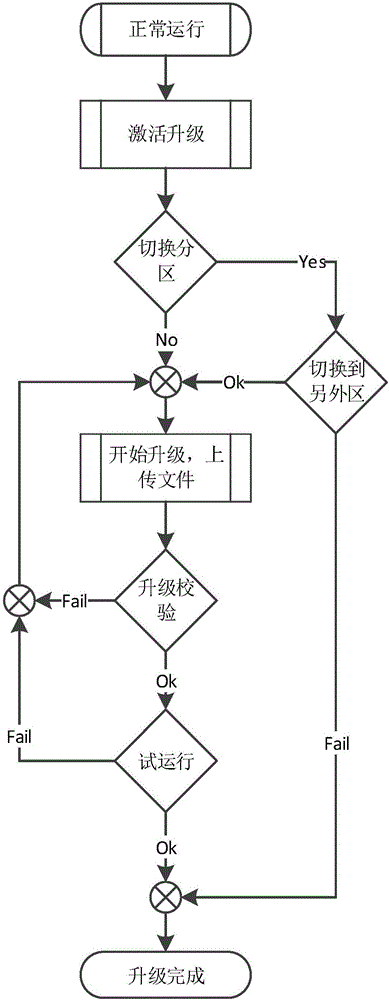

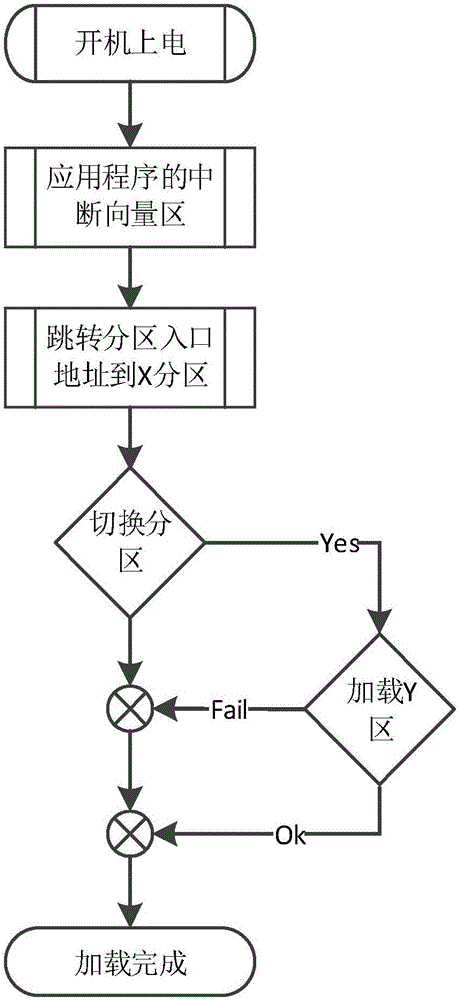

Optical module firmware program online upgrade method supporting version fallback

ActiveCN105912356ASolve the problem of online upgrade without interrupting businessProgram loading/initiatingData switching networksCommunication interfaceOptical Module

The invention relates to an optical module firmware program online upgrade method, comprising the following steps: S1, activating an upgrade identifier, and entering an upgrade mode; S2, receiving upgrade program command parameters; S3, receiving upgrade program data, and writing the upgrade program data into a corresponding application program partition after checking that the upgrade program data is correct; S4, checking the upgrade program data written into the corresponding application program partition, and trial-running the upgrade program after checking that the upgrade program data is correct; and S5, completing application program upgrade, retaining related application program upgrade information according to the result of trial run, and exiting from the upgrade mode. The problem that service is interrupted during online upgrade of an optical module is solved. Moreover, because of special design, the method supports a variety of communication interfaces, firmware with a greater number of codes and a function of firmware version fallback to the version before upgrade, and is applicable to 8051 series MCU online upgrade.

Owner:GUANGXUN SCI & TECH WUHAN

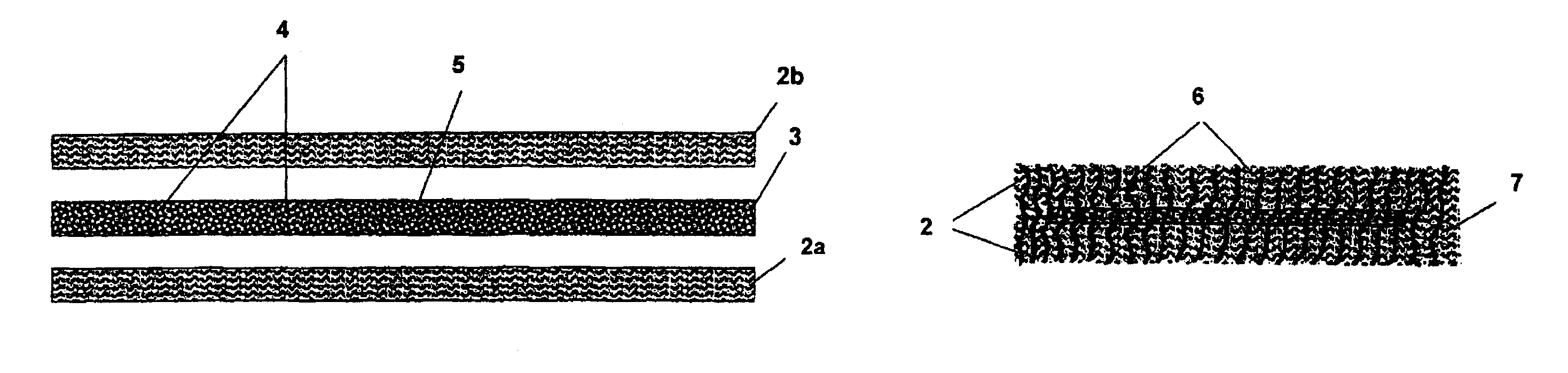

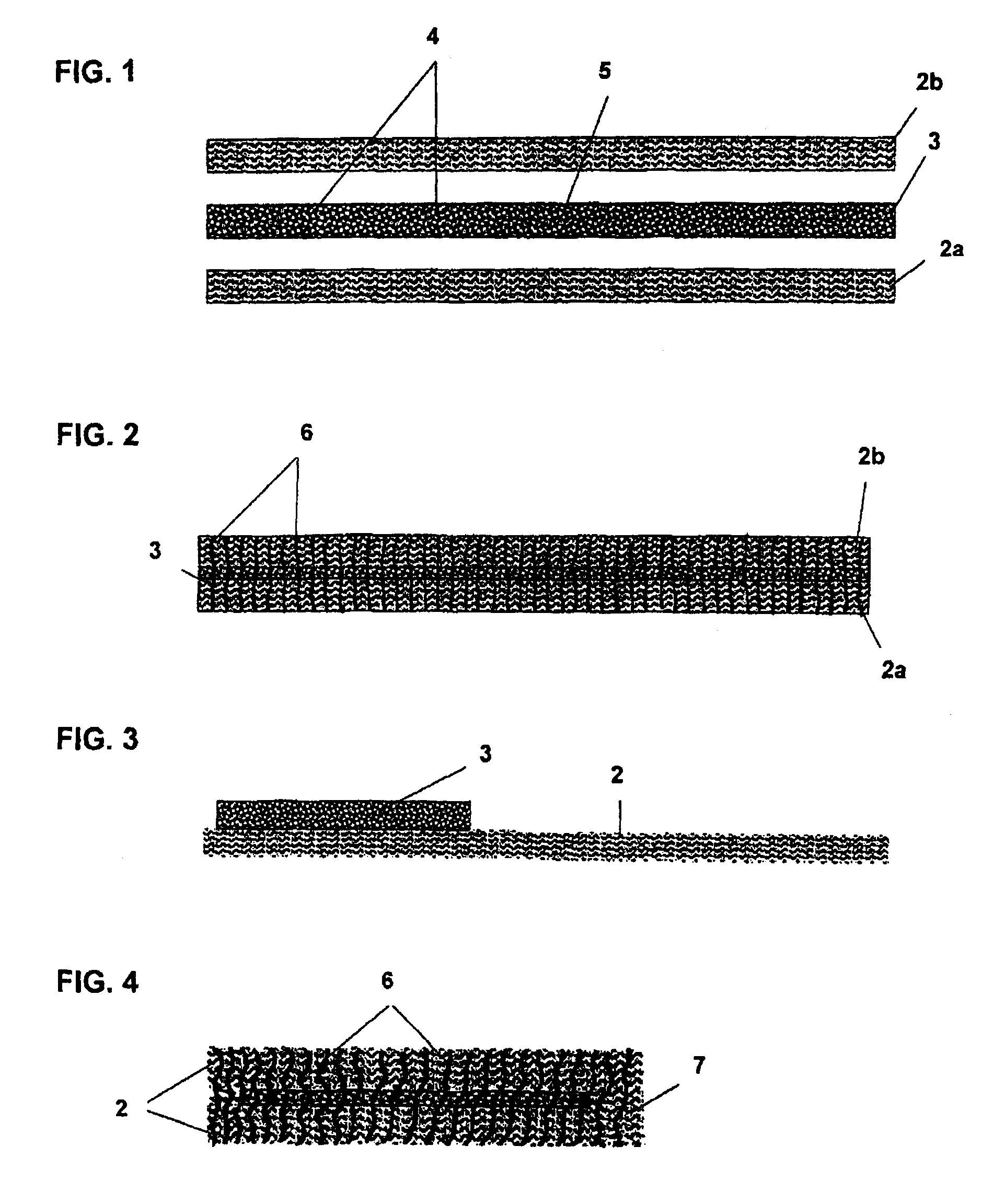

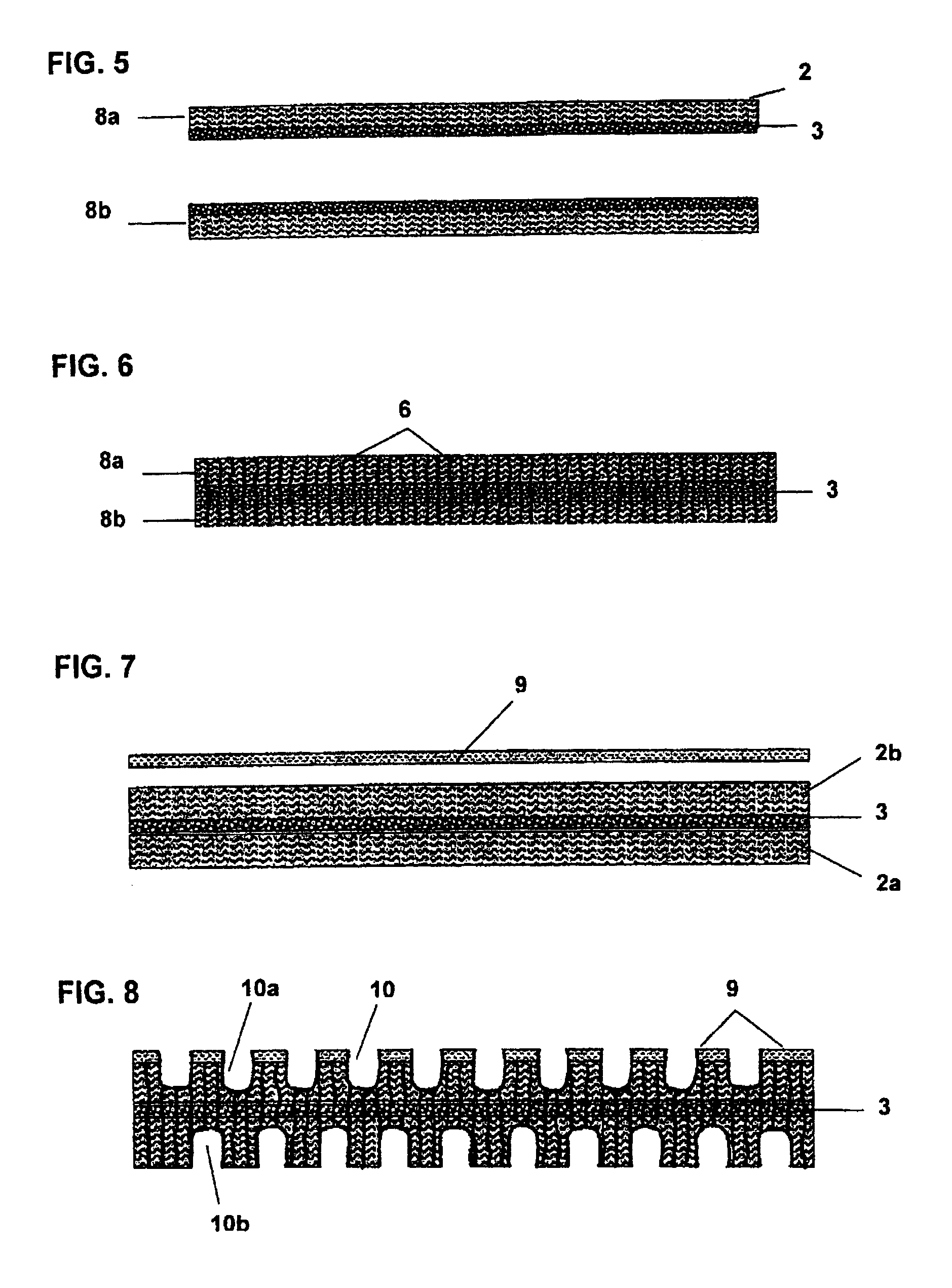

Super absorber polymer felt and method for the production thereof

InactiveUS8844158B2Simple and inexpensive methodAdhesive processesDrying using combination processesSpecial designMaterials science

The invention relates to a felt material comprising at least one felt layer and an absorbing layer, to a method for producing the felt material, and to the use of the felt material in textiles, shoes, technical application or medical applications. The felt material according to the invention has the advantages of conventional felt materials regarding the warming and damping properties and is permeable to air in the dry state. Due to the special design, however, it is waterproof in the wet state and thus it is suitable for sealing many materials. The felt material according to the invention binds more humidity or binds water in a different way than common felt materials.

Owner:IQTEX PATENTVERWALTUNG UG HAFTUNGSBESCHRANKT

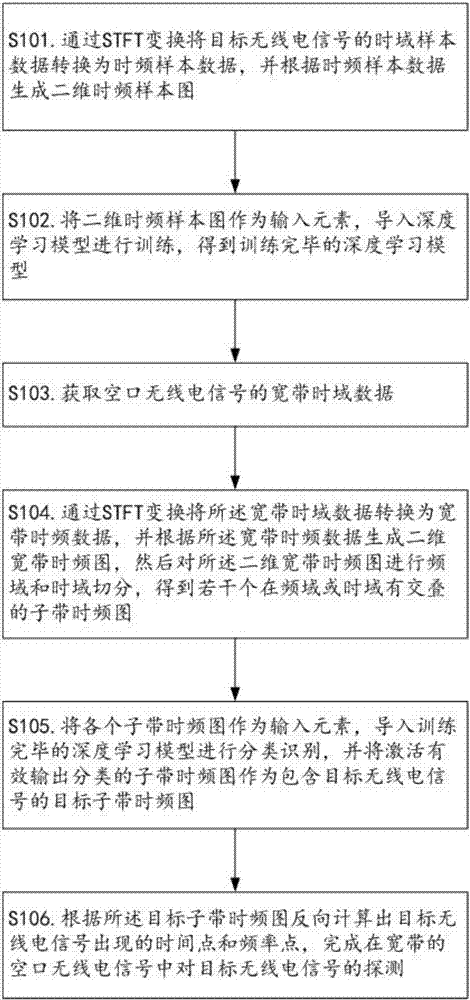

Radio signal identification method based on deep learning model and realization system thereof

ActiveCN107122738AImplement detectionVersatilityCharacter and pattern recognitionNeural architecturesSignal classificationSpecial design

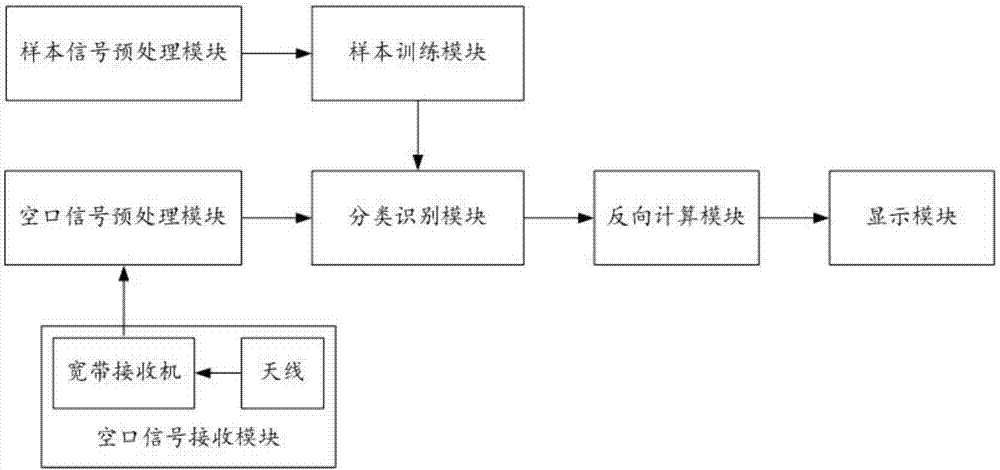

The invention relates to the field of radio signal reconnaissance and discloses a radio signal identification method based on a deep learning model and a realization system thereof. The radio signal identification method realizes signal feature extraction and real-time detection through a machine learning mode, that is, training and classification recognition are carried out on a signal time-frequency graph obtained through STFT by utilizing the deep learning model, so that more signal features can be utilized to be greatest degree, and detection of short burst and weak signals is realized; and meanwhile, the signal detection problem is converted into the image classification identification problem, and signal classification detection is realized through a deep learning method, so that special designs for special signals are not needed, and the method has universality, and facilitates actual promotion and application.

Owner:成都蓝色起源科技有限公司

Atomizer with multiple tobacco extract bottles

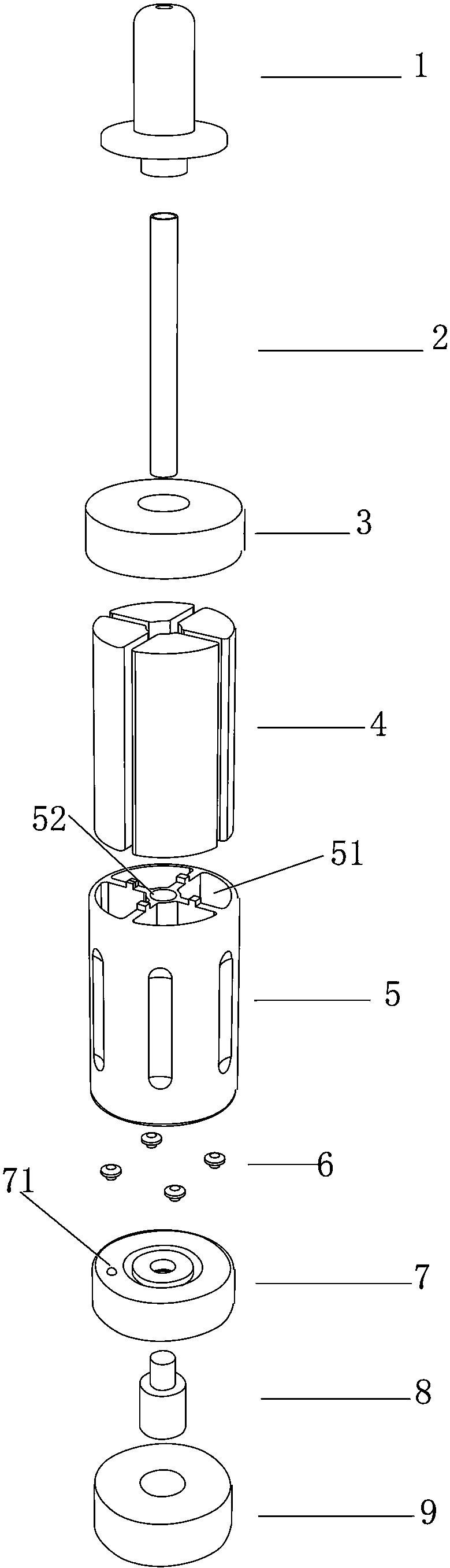

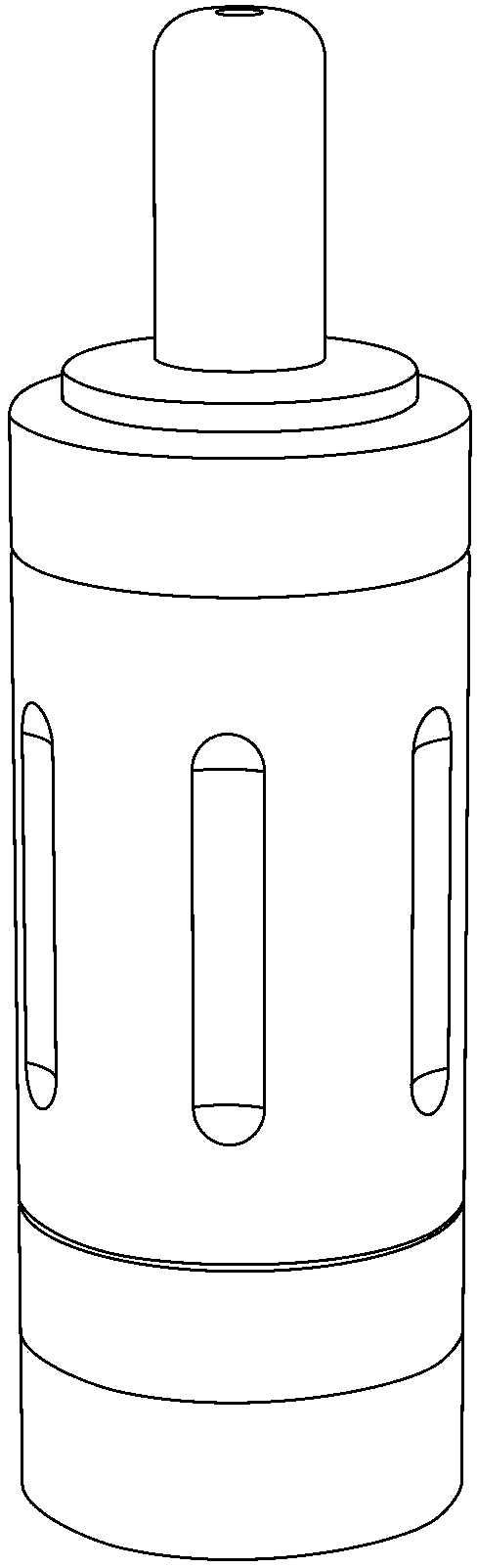

The invention discloses an atomizer with multiple tobacco extract bottles. The atomizer with the multiple tobacco extract bottles comprises a suction nozzle (1), a suction nozzle base (3), a tobacco extract pool (7), an atomizing core (8) and an atomizing core base (9), wherein the suction nozzle (1) is mounted on the suction nozzle base (3), one end of the atomizing core (8) is mounted on the atomizing core base (9), and the other end of the atomizing core (8) is connected with the tobacco extract pool (7). The atomizer with the multiple tobacco extract bottles is characterized by further comprising a rotatable tobacco extract switching assembly, and the independent tobacco extract bottles (4) are arranged in the rotatable tobacco extract switching assembly; the tobacco extract switching assembly is arranged between the suction nozzle base (3) and the tobacco extract pool (7), and the selection of the tobacco extract bottles (4) and the releasing of the corresponding tobacco extract are conducted through the rotation of the tobacco extract switching assembly. According to the atomizer with the multiple tobacco extract bottles, the space of the circular atomizer can be effectively used to the maximum extent, the change of flavor can be achieved fast, when a user needs to change the flavor of the tobacco extract, a sleeve of the tobacco extract bottles of the atomizer can be rotated to achieve the change of the flavor, one flavor can be changed by rotating the sleeve every 90 degrees, and the outflow and the closing of the extract liquid can be ensured through the special designed structure of the bottoms of the tobacco extract bottles.

Owner:HUIZHOU KELVIN TECH

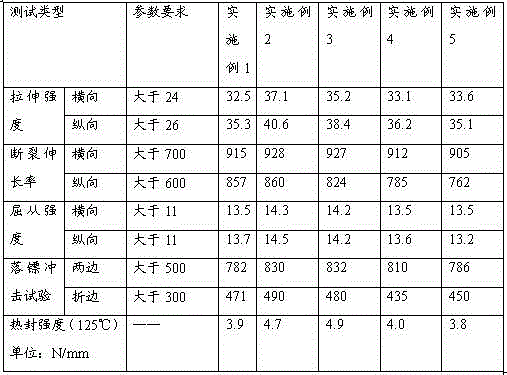

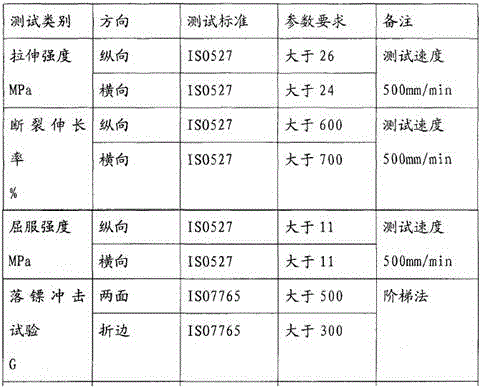

High-temperature-resistant clean type self-adhesive protection film and preparation method thereof

ActiveCN104354414AFilm/foil adhesivesSynthetic resin layered productsLow-density polyethyleneElastomer

The invention discloses a high-temperature-resistant clean type self-adhesive protection film which comprises a self-adhesive layer, a middle layer and a back material layer, wherein the self-adhesive layer and the back material layer are positioned on two sides of the middle layer; the self-adhesive layer consists of 5-20wt% of low-density polyethylene, 55-80wt% of metallocene polypropylene low-density elastomer and 15-30wt% of SEBS; the middle layer consists of 70-85w% of high-density polyethylene and 15-30w% of low-density polyethylene; the back material layer consists of 65-85w% of middle-density polyethylene and 15-35w% of low-density polyethylene; the self-adhesive layer, the middle layer and the back material layer respectively account for 5-20 percent, 60-80 percent and 5-20 percent of the total weight of the protection film; the sum of the weight ratios of the self-adhesive layer, the middle layer and the back material layer is 100 percent. According to the high-temperature-resistant clean type self-adhesive protection film, a composite bottom film comprising the self-adhesive layer, the middle layer and the back material layer is prepared by co-extrusion film blowing; by the special design of all the layers, in particular the self-adhesive layer, the self-adhesive protection film is high in bonding strength, high-temperature-resistant and high in puncturing strength; meanwhile, in a co-extrusion film blowing process, effective combination and the processing stability are guaranteed.

Owner:佛山新长盛塑料薄膜有限公司

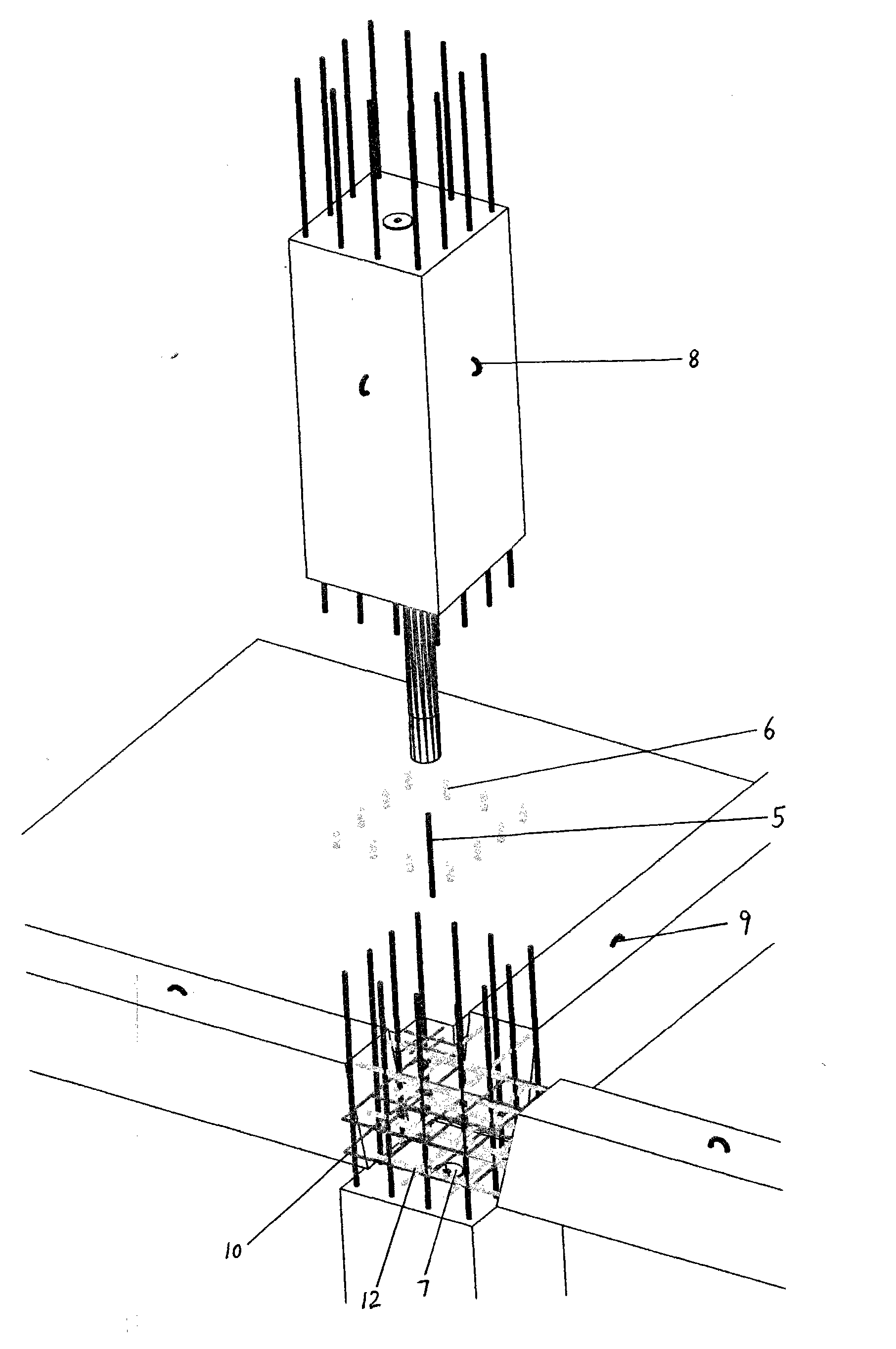

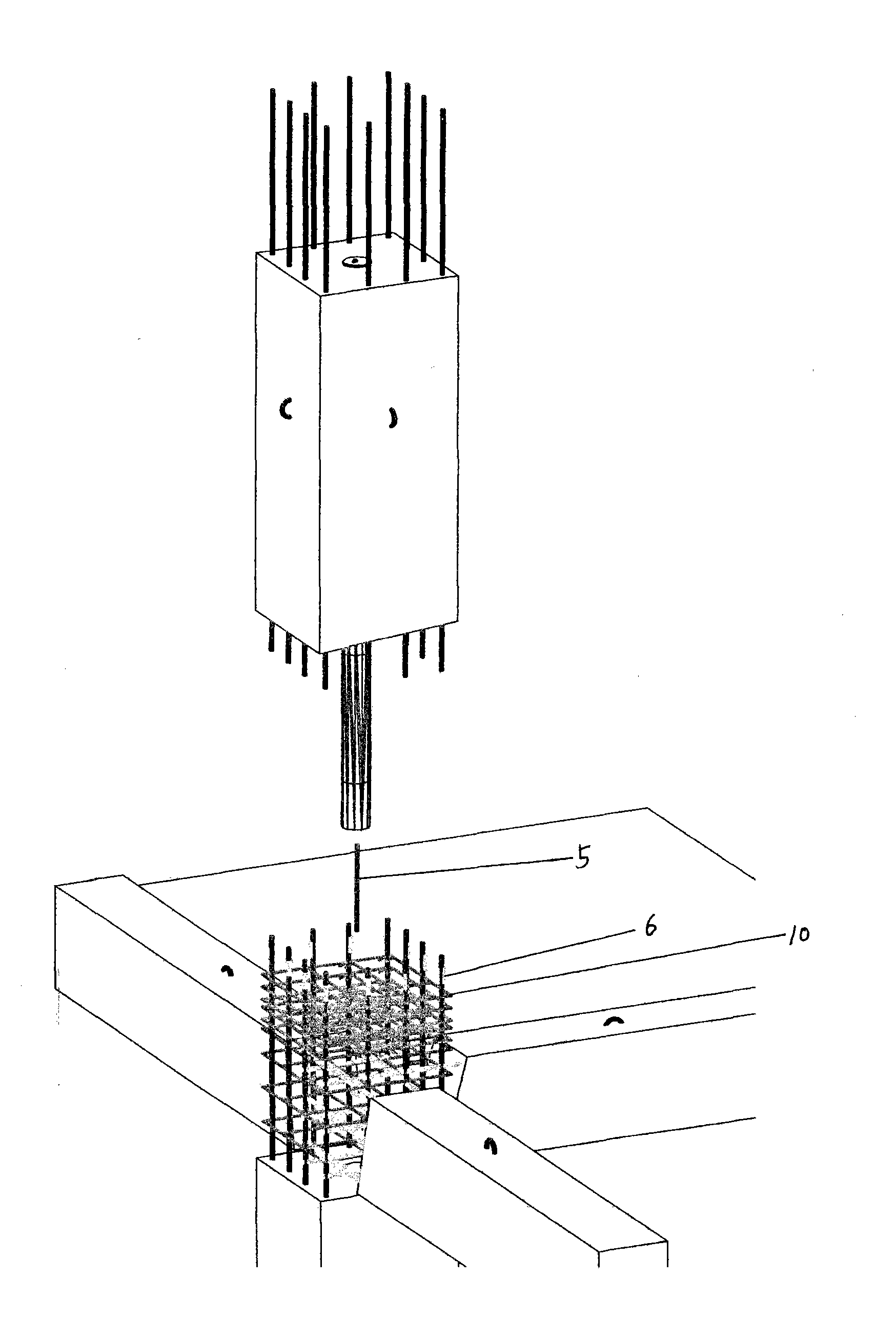

Prefabricated vertical member

The invention provides a prefabricated vertical member (including a pillar and a wall), which mainly comprises a member body and a prefabricated reinforcing bar (the reinforcing bar is the joint name of a principle bar longitudinally arranged along the member body, a vertically-distributed reinforcing bar, a hooping and a tie bar), and the principle bar or the principle bar and the vertically-distributed reinforcing bar stretch out of the upper end surface and the lower end surface of the member body. The prefabricated vertical member is characterized in that a core column is arranged in the middle of the lower end surface of the member body. The invention has the advantages that the installation of the prefabricated vertical member has no conflict with the anchoring of beam steel at a support, so as to meet the code requirement of the structure of cast-in-situ reinforced concrete; the core column is adopted for bearing load, the upper-layer construction operation can be carried out when in the joint concreting; no special design is needed; the connection of the reinforcing bar and the binding of a template are carried out at a floor slab, thereby not only ensuring the safety of workers, but also obviously improving the construction efficiency and the construction quality; the quantity of overhead work can be greatly decreased; the quantity of cast-in-situ concrete can be greatly decreased; and the operation is carried out at the floor slab, therefore, the construction speed is greatly improved.

Owner:管乃彦

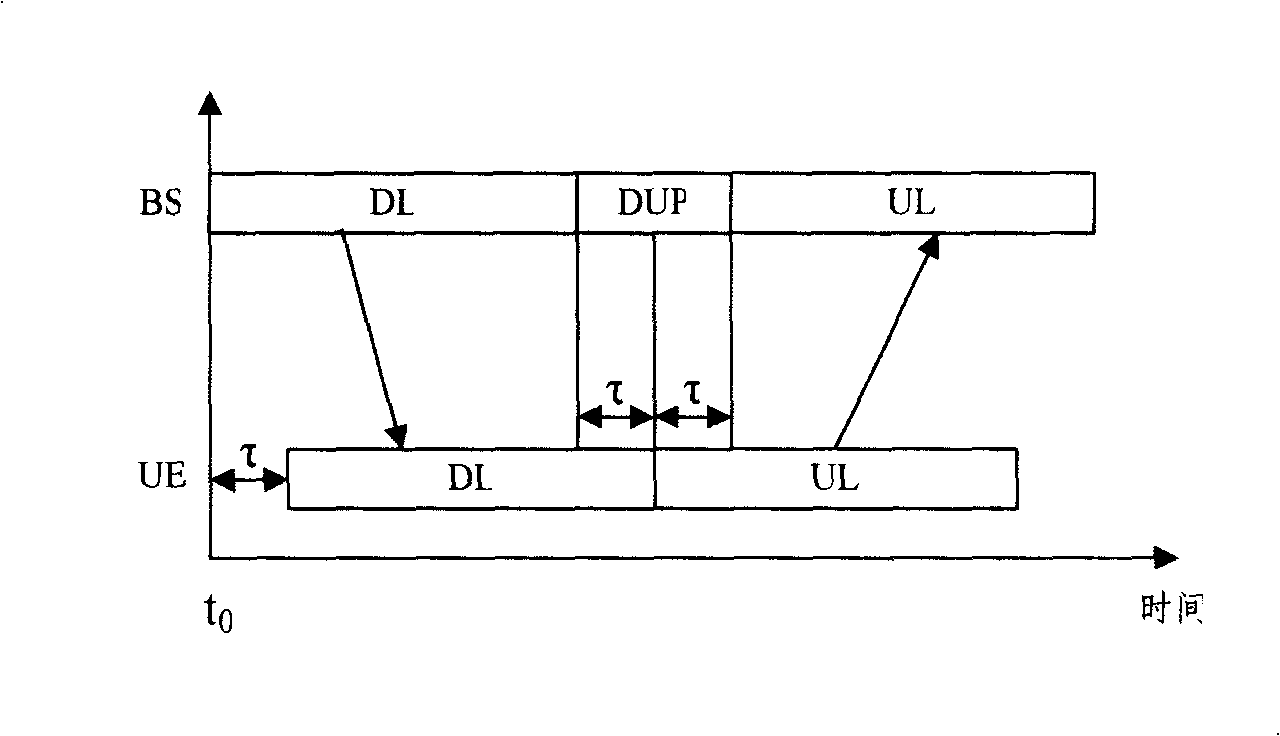

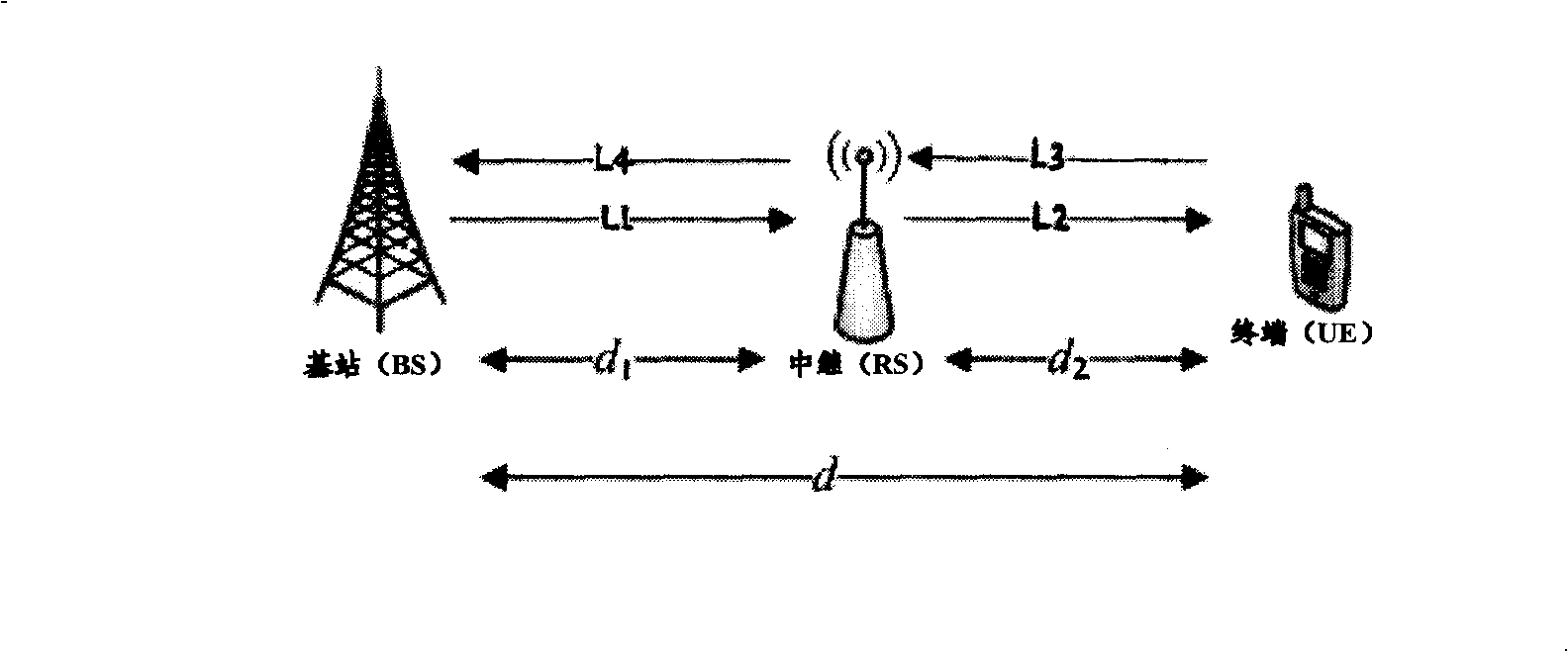

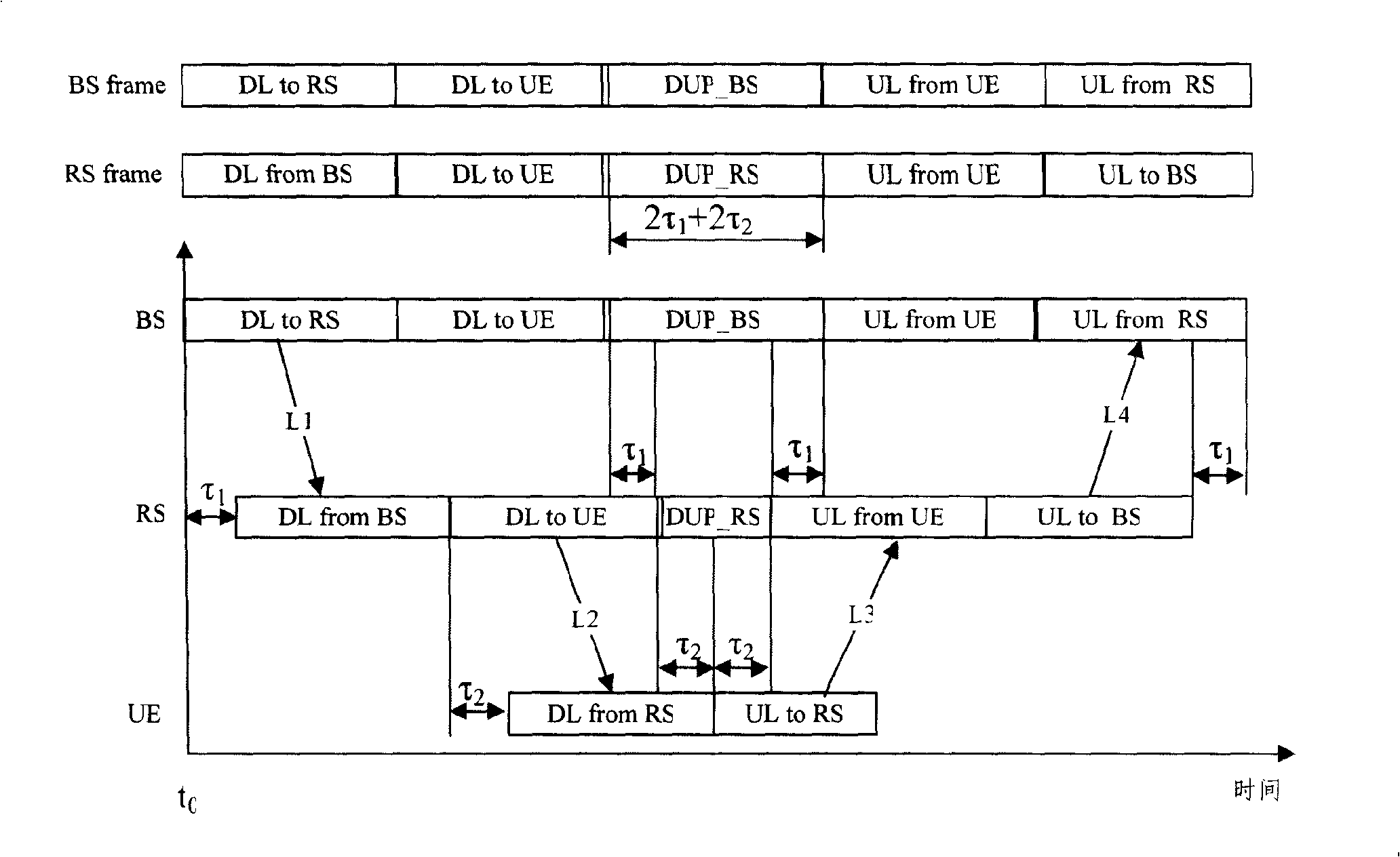

Method and device for preventing relay cellular system from uplink and downlink interference

ActiveCN101262691AMeet the transmissionAvoid uplink and downlink interferenceRadio/inductive link selection arrangementsRadio transmission for post communicationPropagation delayIdle time

The invention relates to a realization method in which a Relay support cellular system can effectively avoid the interference of uplink and downlink, and a device thereof as well as a solution which allows the interference of the uplink and the downlink to be introduced by the system due to coverage expansion. The invention is realized by a special design of a frame structure and the special design comprises a transmission order of four system links in the frame structure which are a downlink relay link L1, a downlink access link L2, an uplink access link L3 and an uplink relay link L4, and a guard space of a transfer point of the uplink and the downlink. When the transmission order of the four links of the frame structure is L1, L2, L3 and L4, a multiplying adjustment is processed on the required guard space of the transfer of the uplink and the downlink simultaneously allowing for path propagation delays between BS and RS as well as between RS and UE, namely offsetting the propagation delay between RS and UE; when the transmission order of the four links of the frame structure is L1, L2, L4 and L3, the guard space of the transfer of the uplink and the downlink only allows for the propagation delay between BS and RS while the propagation delay between RS and UE can be guarded by idle time which is caused by a sending to BS in advance from RS.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Method of desulfurizing and denitrate simultaneously of exhaust gas by micro wave catalysis

The present invention discloses a flue gas purifying method capable of catalyzing flue gas by using microwave and simultaneously making desulfurization and denitration. Said method is characterized by that firstly, the catalyst is placed in a special-designed fixed bed reactor, then the normal-pressure simulated flue gas is introduced to make microwave catalytic desulfurization and denitration reaction. Its desulfurization and denitration efficiency is high, when the space velocity is 8000h-1 and the temperature is 150deg.C, its desulfurization rate can be up to 95% and its denitration rate can be up to 87%, and its catalyst can be regenerated and reused.

Owner:EAST CHINA UNIV OF SCI & TECH

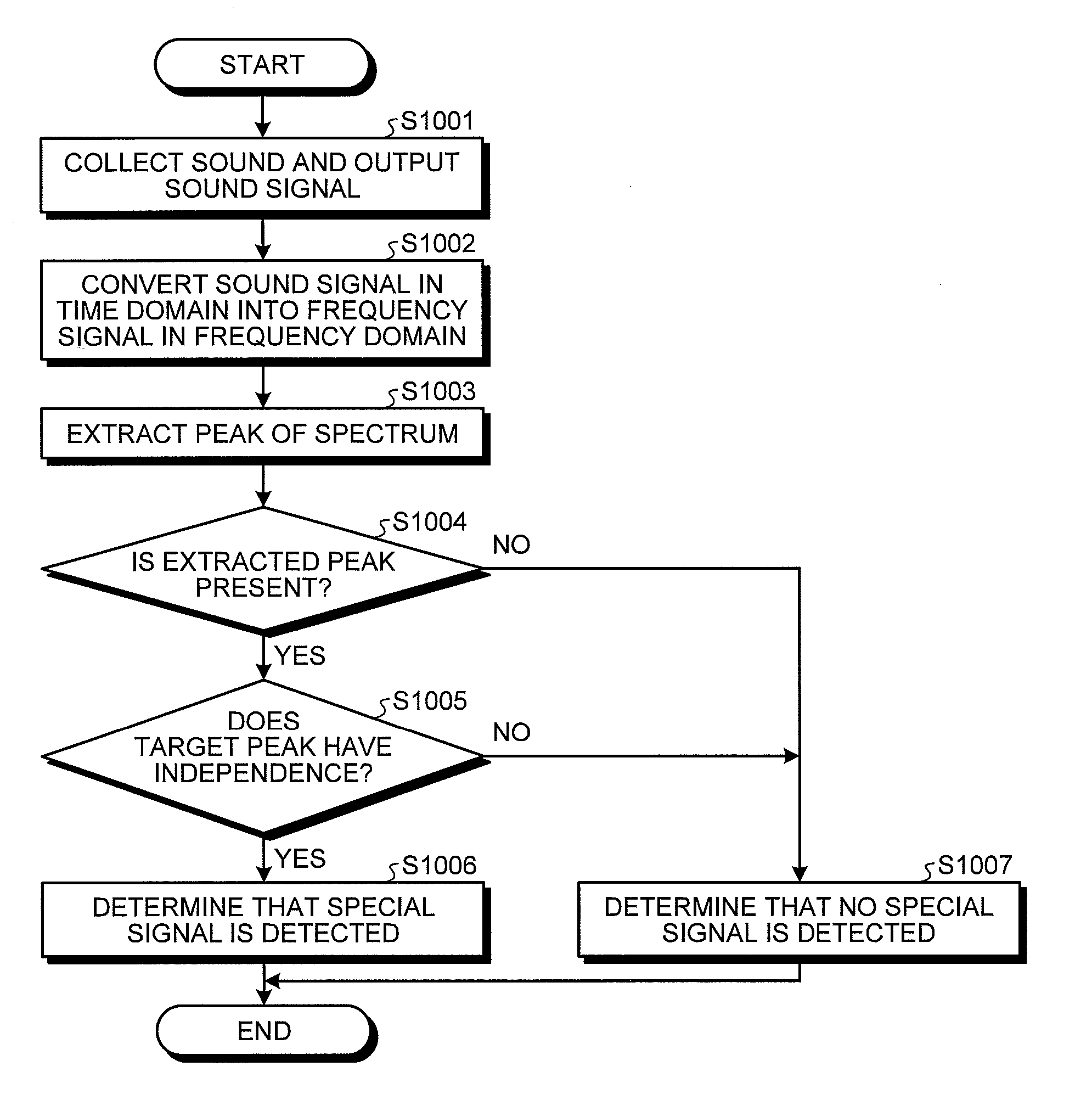

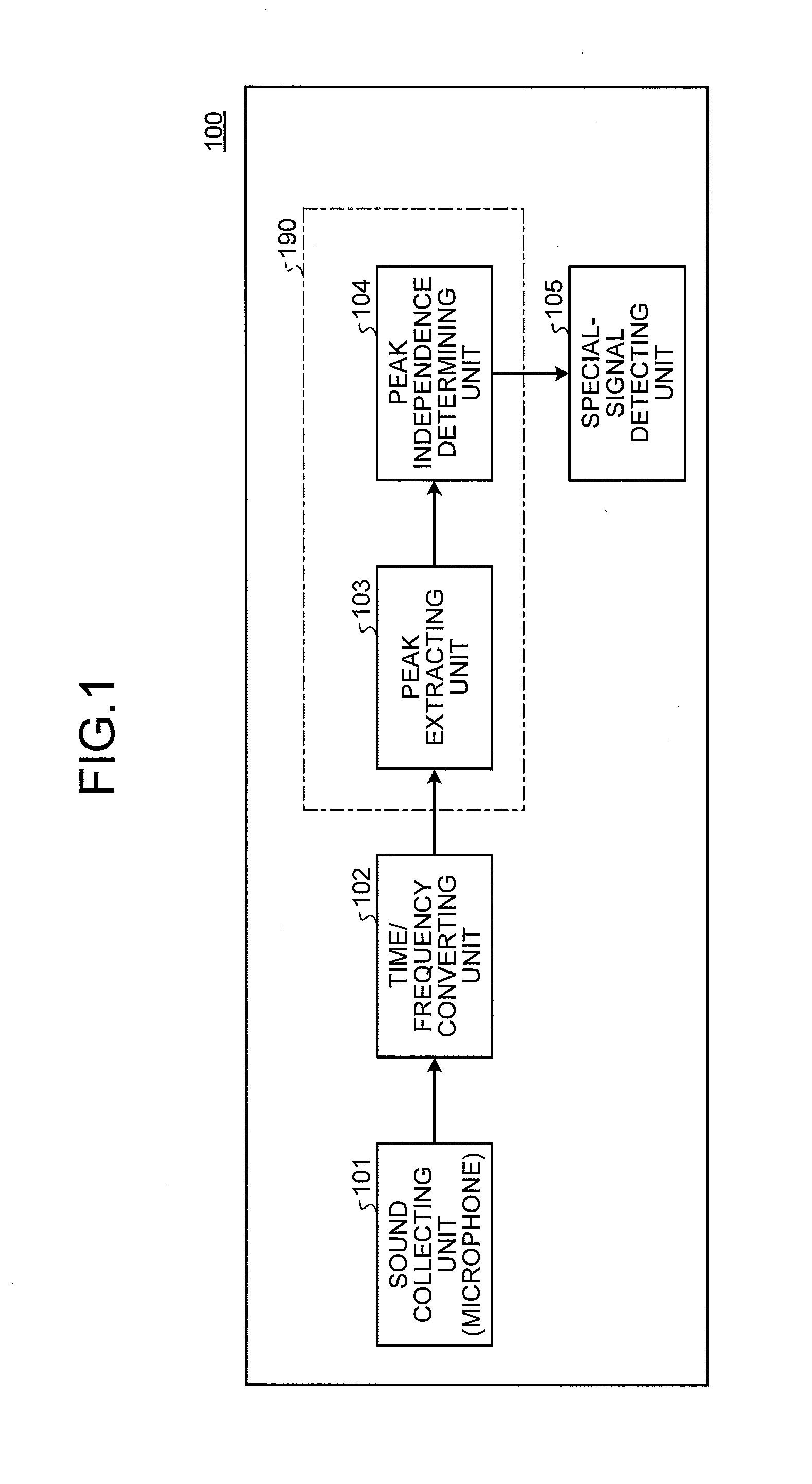

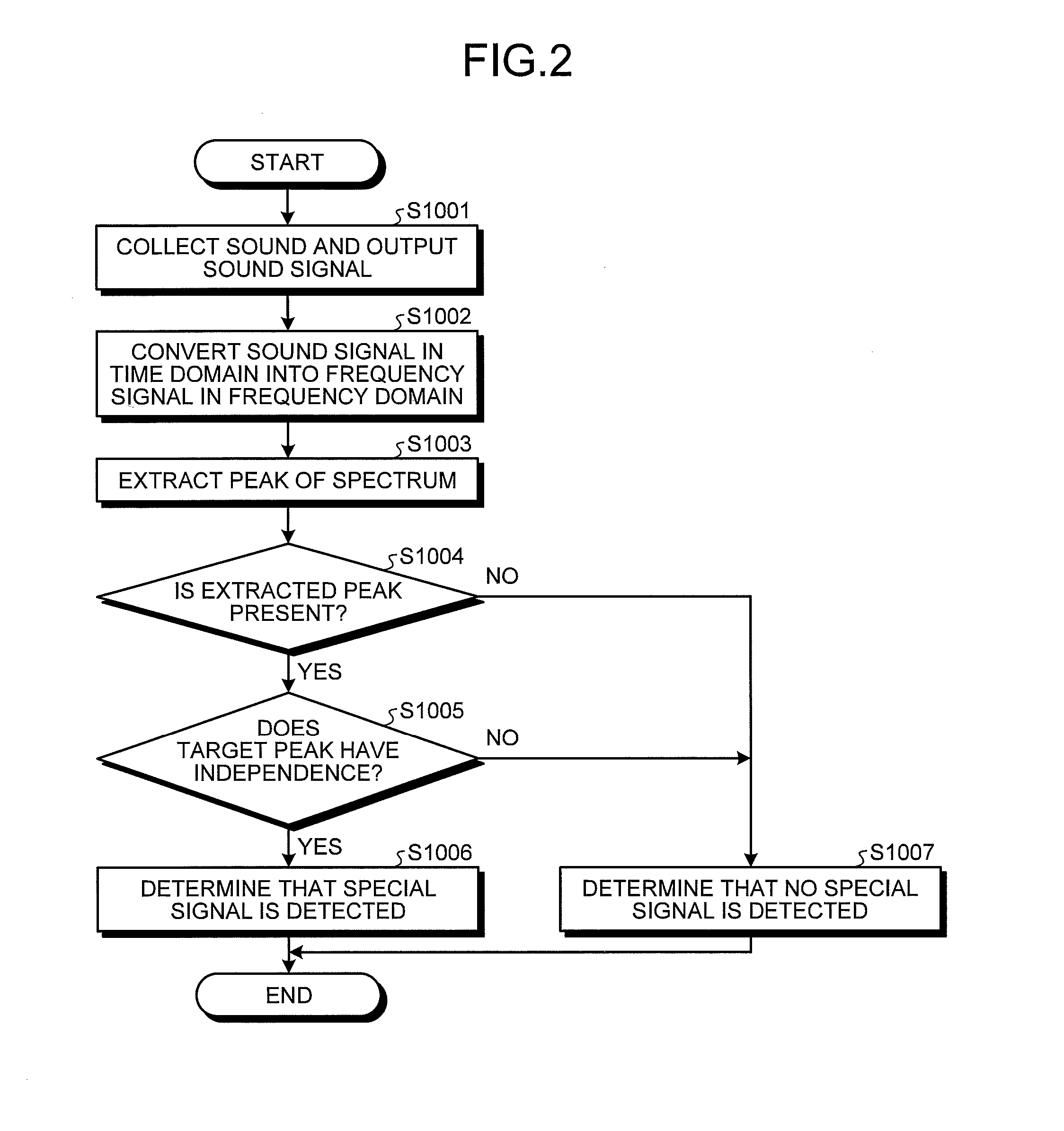

Device and method for suppressing noise signal, device and method for detecting special signal, and device and method for detecting notification sound

Provided is a noise signal suppressing device including: an input unit configured to receive a sound signal; a time / frequency converting unit; an independent peak spectrum extracting unit configured to extract a peak spectrum having independence; a persistence determining unit configured to determine that the peak spectrum having independence persists for a predetermined period or longer; a noise-signal suppressing unit configured to suppress the peak spectrum having independence as the noise signal. The independent peak spectrum extracting unit includes: a first peak extracting unit configured to extract a peak spectrum having higher energy than that of an adjacent frequency signal, and a second peak extracting unit configured to extract a peak spectrum maintaining a frequency interval of equal to or larger than a predetermined value with respect to a peak spectrum adjacent thereto as the peak spectrum having independence.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Thermal treatment wire rod for 2000MPa-grade cable steel wire and production method

ActiveCN107299280AImprove mechanical propertiesImprove uniformityQuenching agentsWire rodSpecial design

The invention provides a thermal treatment wire rod for a 2000MPa-grade cable steel wire and a production method. The thermal treatment wire rod is prepared from the following components in percentage by weight: 0.85 to 1.0 percent of C, 0.80 to 1.5 percent of Si, 0.30 to 0.80 percent of Mn, 0.20 to 0.80 percent of Cr, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.01 to 0.08 percent of Al, and the balance of Fe and inevitable impurities. According to the thermal treatment wire rod for the 2000MPa-grade cable steel wire and the production method disclosed by the invention, through special design of the components, the wire rod is produced through processes of smelting, continuous casting, blank casting and grinding, steel rolling and off-line thermal treatment, and the sorbitizing rate of the wire rod is greater than 95 percent, tissues are homogenized, and quenching tissues such as network carbide and martensite are avoided. After the wire rod is subjected to drawing, zinc (aluminum) plating, and stabilization treatment, the strength of the steel wire is greater than or equal to 2000MPa, so that the wire rod can be used for producing the 2000MPa-grade cable zinc (aluminum) plating steel wire for bridges, and is applied to bridges requiring extra long-span and ultrahigh strength.

Owner:QINGDAO SPECIAL STEEL CO LTD

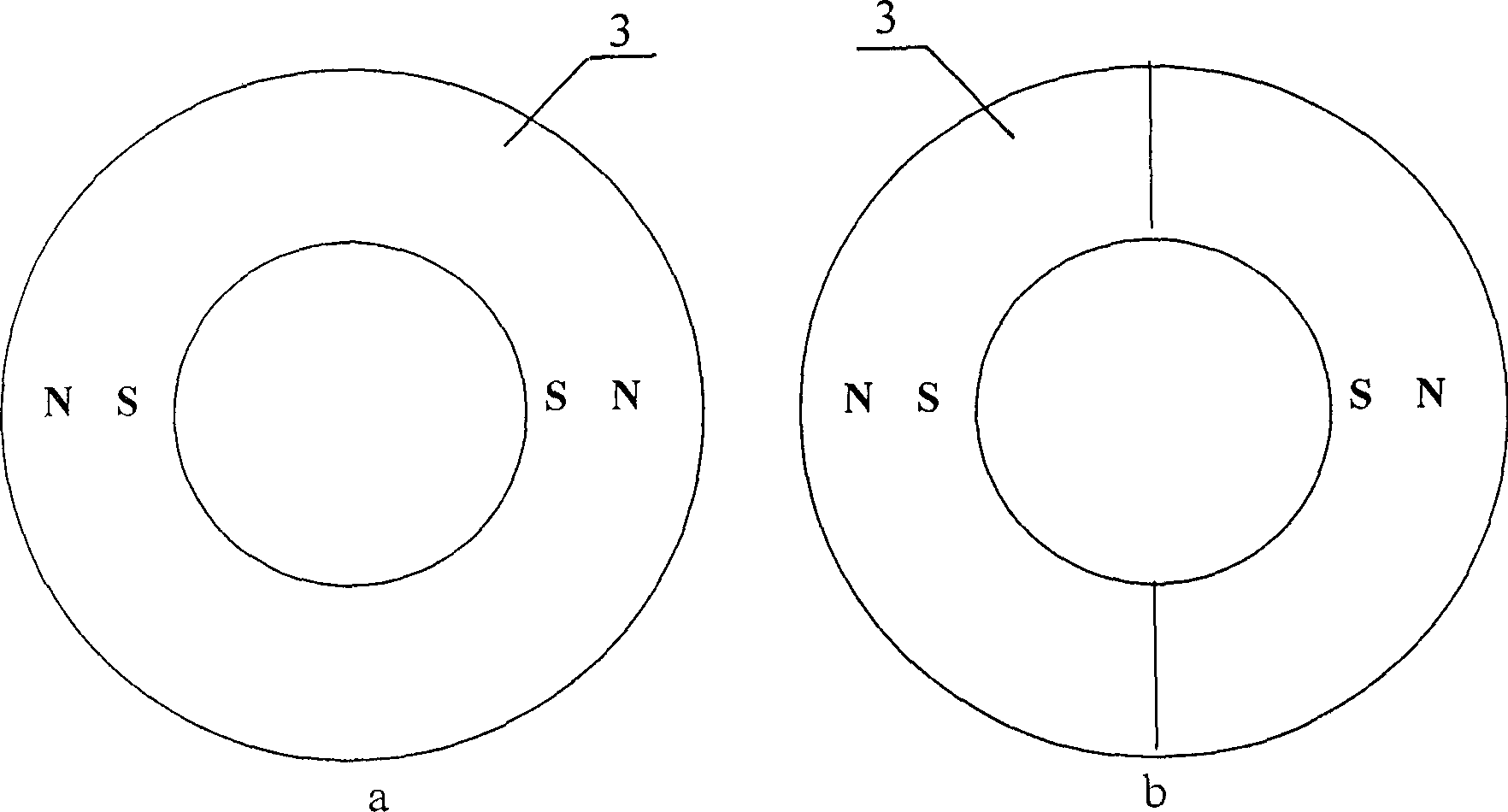

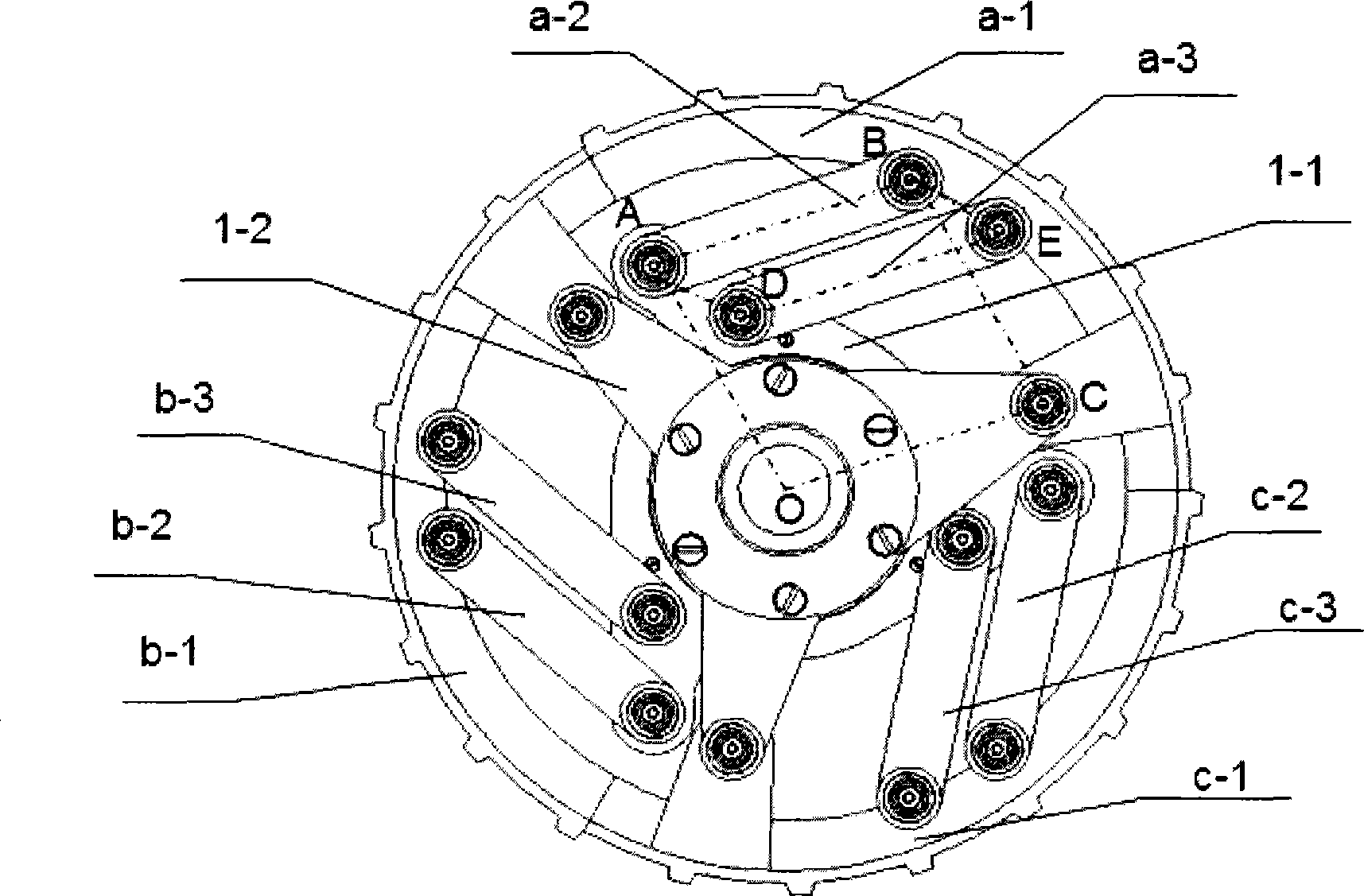

Directly driven synchronous dragger with Nd-Fe-B permanent magnetic rotor

InactiveCN1141775CProtect the endSmooth runningMechanical energy handlingStructural associationSpecial designRing type

In this invention multipole outer rotor structure is used, said out rotor is also used as brake wheel, drag wheel is fit on outer rotor. The special design makes the structure be very compact and can realize direct driving without gear wheel. The special two-layer ring-type stator structure can not only increase working reliability but also improve mfg. process, remarkably. The invention has advantages of lifting steady and flat-layer exact, and two set of brake component is used so as to realize braking and stopping with high reliability.

Owner:SHANGHAI JIAO TONG UNIV +1

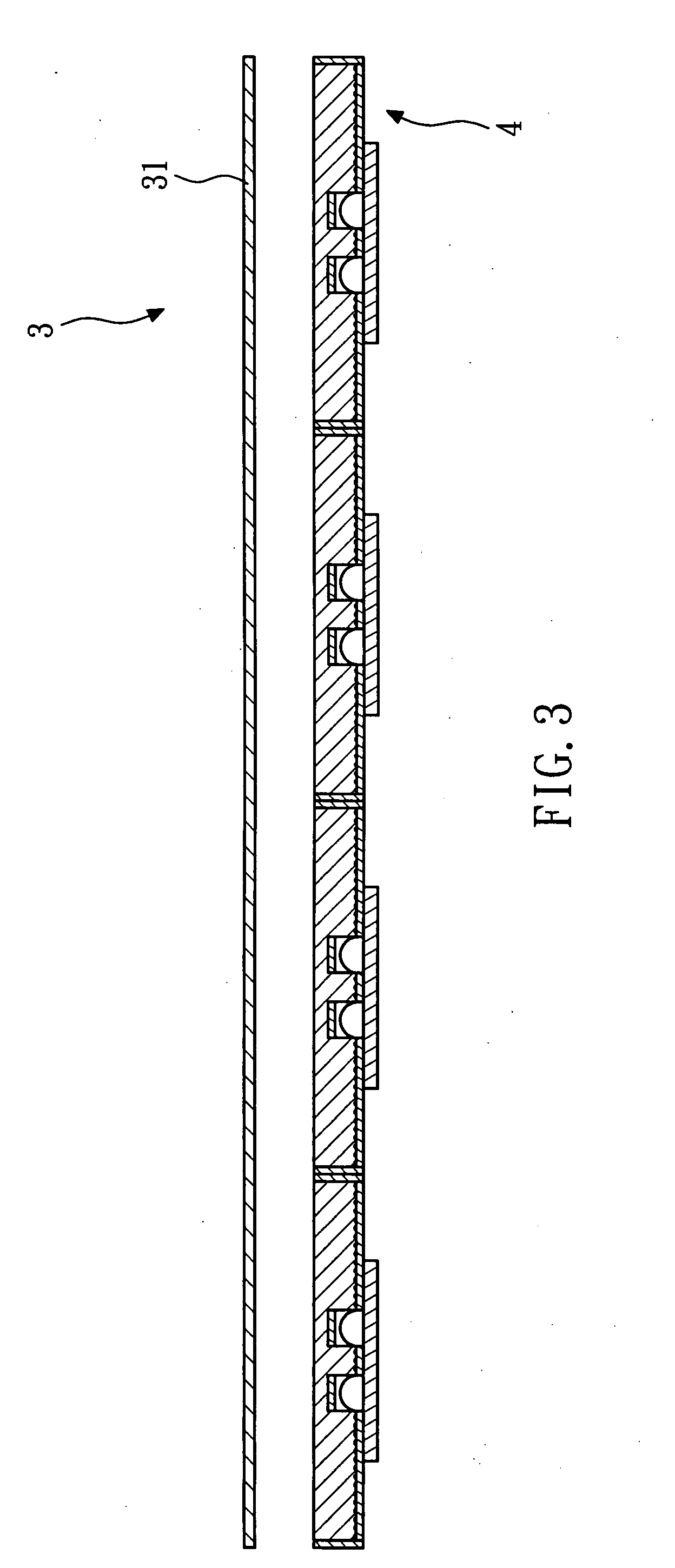

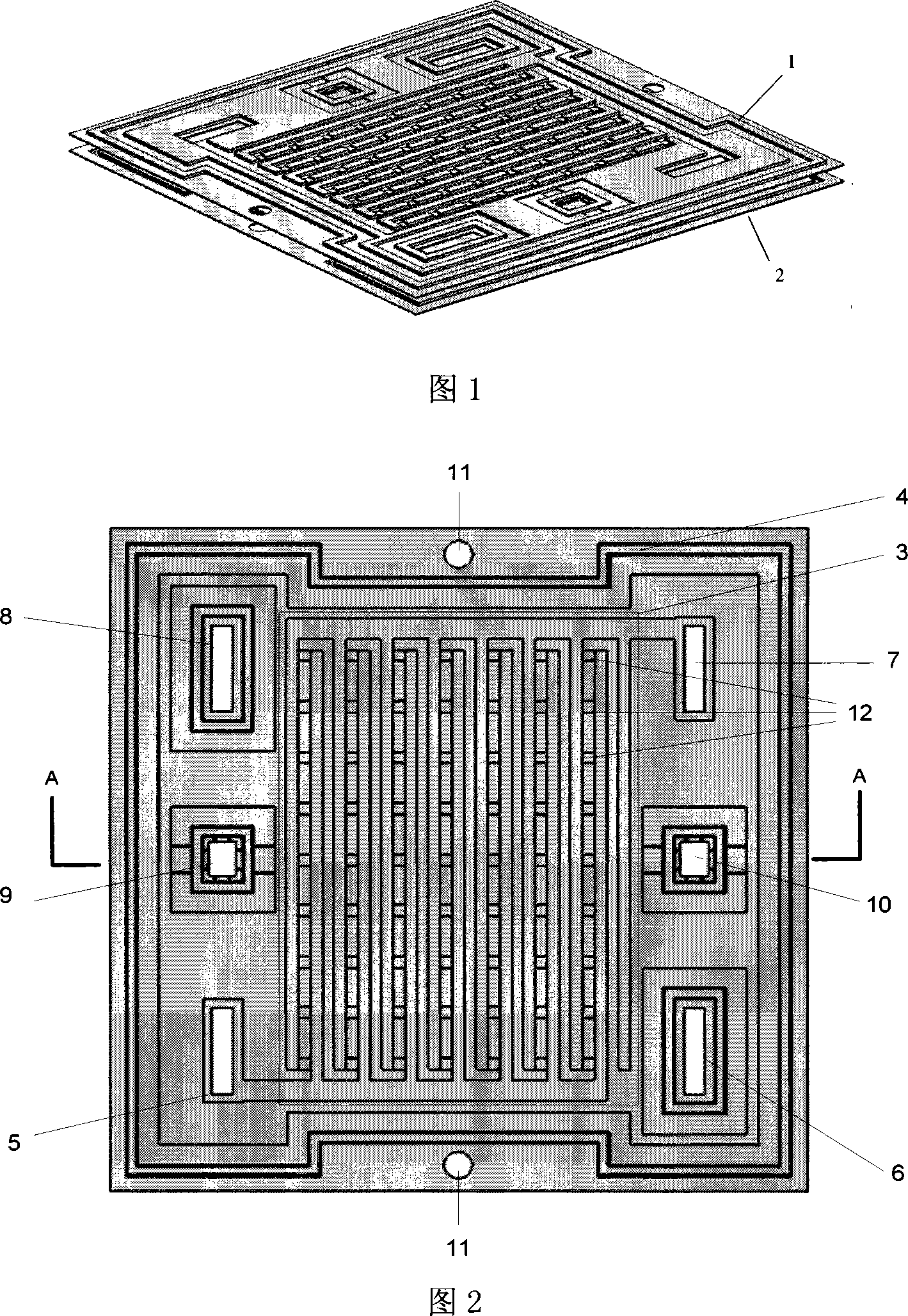

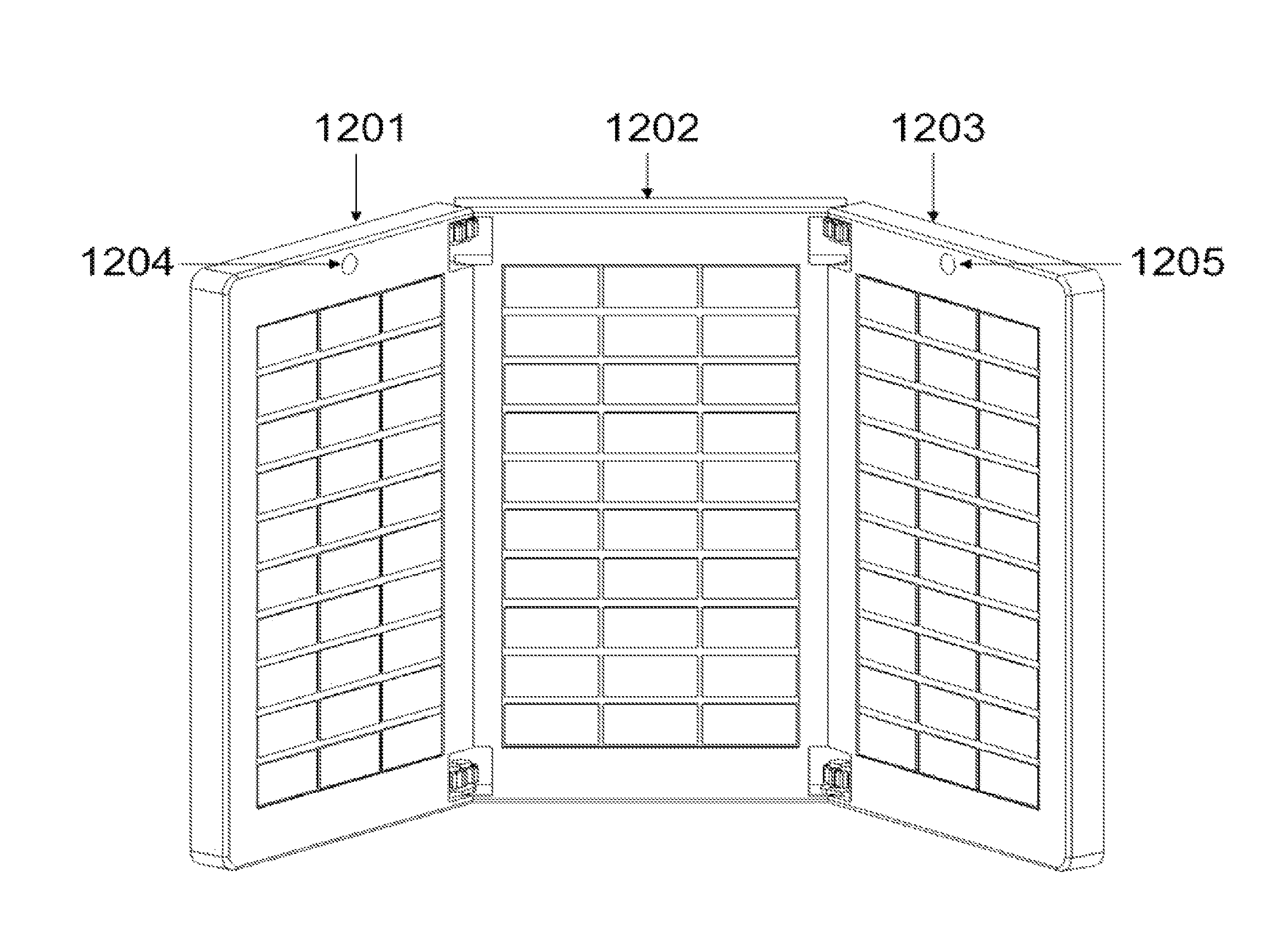

Metal sheet profiled proton exchange membrane fuel cell bipolar plate

ActiveCN101183723AReduce weightReduce usageFinal product manufactureCell electrodesSpecial designProton

The invention relates to a fuel-cell bipolar plate of proton exchange membrane by metal veneer forming, belonging to a fuel cell technical field, comprising two same flow-field veneers. The inventionis characterized in that: the two same flow-field veneers are respectively used as an anode and a cathode, and the two same flow-field veneers are connected together by a peripheral interface and a middle flow-field interface and welded together via symmetrical joint; three inlets and three outlets are arranged on each flow-field veneer and respectively are a fuel gas inlet, a fuel gas outlet, anoxidant inlet, an oxidant outlet, a coolant inlet and a coolant outlet; a plurality of rounded locating holes are respectively arranged at the middle of the two sides. The invention has the advantagesof simpler structure for only two same metal veneers, lower manufacturing cost for only a forming die, using special design of only adding sealing rings to a couple of inlet and outlet to the inletsand the outlets of the reaction gases and reducing use time of the sealing rings.

Owner:上海氢晨新能源科技有限公司

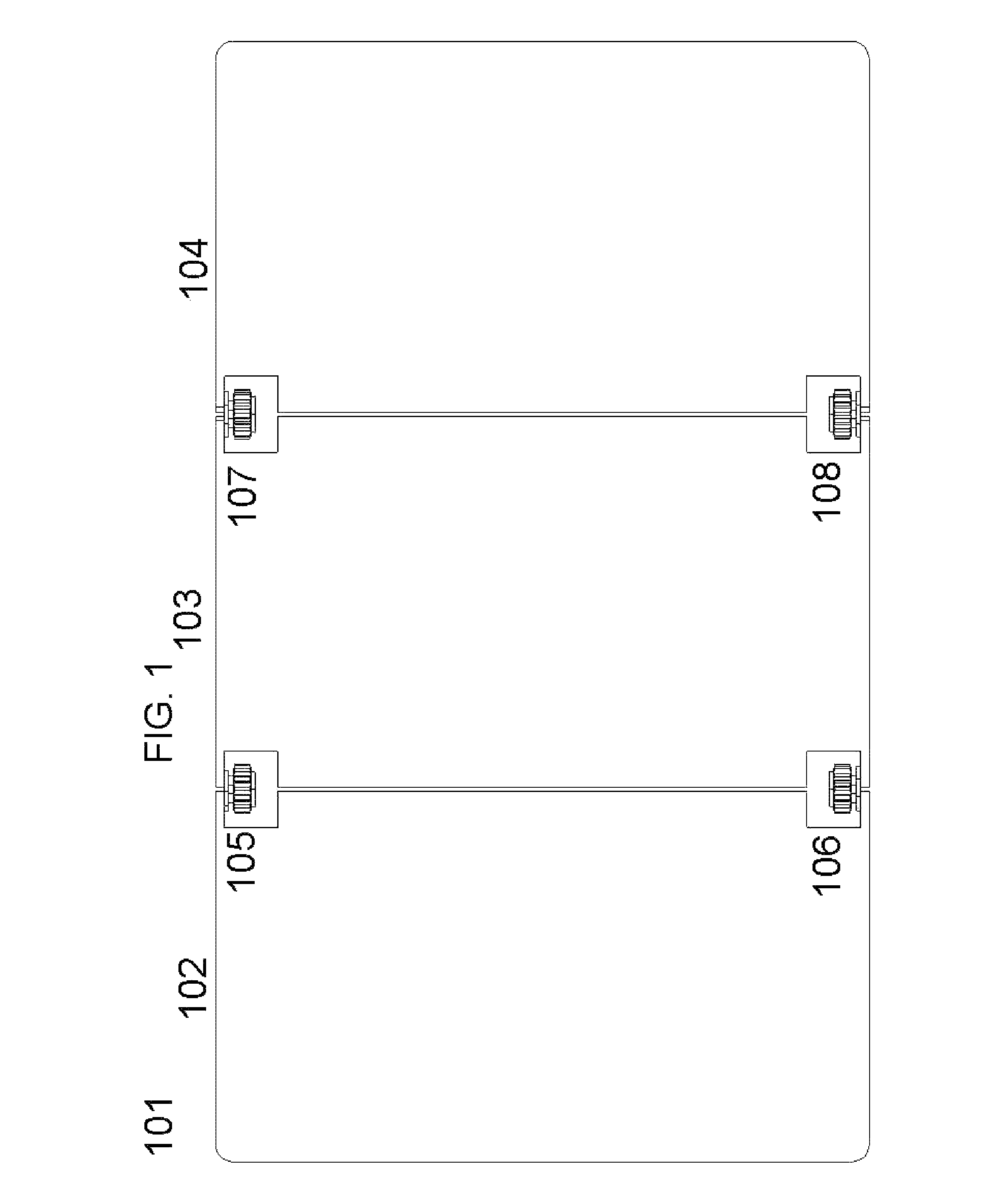

Smartphone-tablet hybrid device

InactiveUS8738101B1Self-charging becomes more realisticDevices with multiple display unitsManual exchangesSpecial designDisplay device

Owner:MAKOR ISSUES & RIGHTS

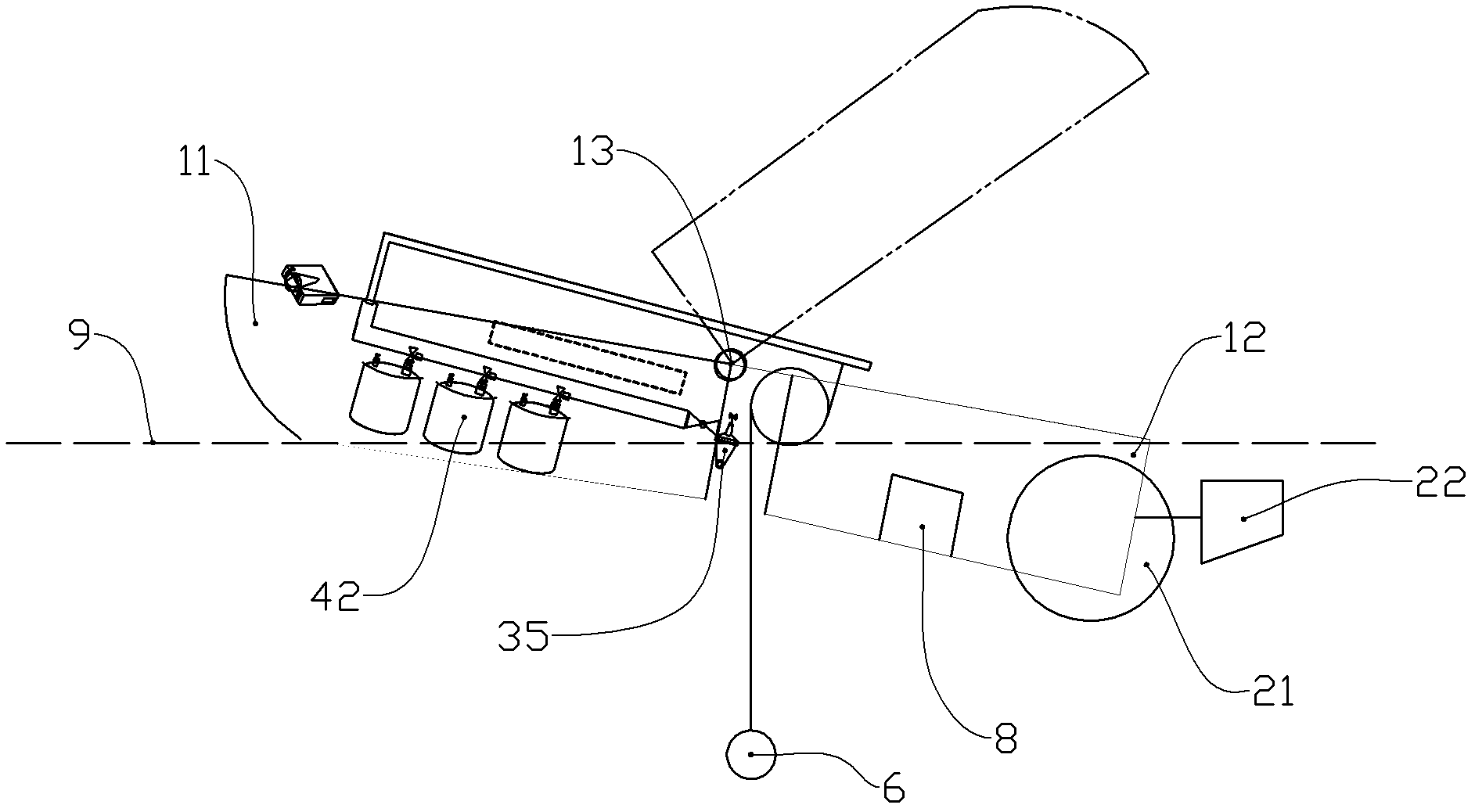

Unmanned water sample sampling boat

ActiveCN102407925AReduce non-conformityImprove securityWithdrawing sample devicesUnderwater equipmentLocking mechanismWater quality

The invention discloses an unmanned water sample sampling boat, which is a water quality sampling device. The boat comprises a boat body; the boat body is formed in a manner that a front cabin is combined with a back cabin; the front and back cabins can be folded and are hinged along with folding and unfolding states; a locking mechanism for keeping the front and back cabins in folding and unfolding states is disposed between the front and back cabins; the weight of the front cabin is smaller than that of the back cabin, so that the boat body forms a certain inclined angle along with the horizontal plane when the boat body is in water; and the boat body is loaded with a power system and a sampling system. Due to special design of foldable boat body, the unmanned water sample sampling boat is convenient to carry and transport; adaptability of the unmanned boat can be effectively improved by special design of inclined boat body and tail wheels of the boat; and a sampling pump is disposed in the cabin, so that disturbance of pump vibration on water body is avoided and sampling of samples is prevented being influenced.

Owner:俞少平 +1

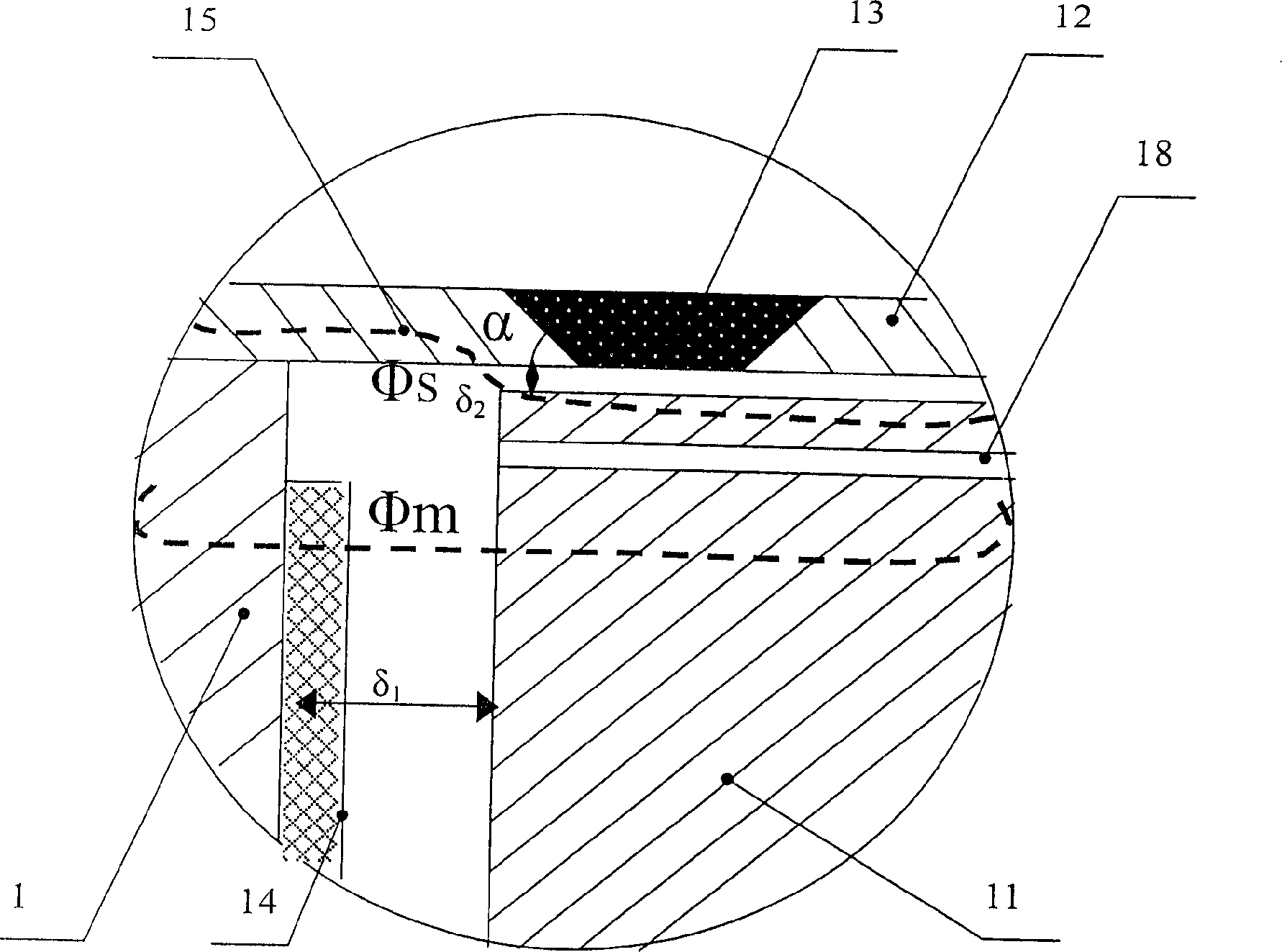

Anti high voltage permanent magnet polarized two-way ratio electromagnet

InactiveCN1588585AReduce energy consumptionLow calorific valueOperating means/releasing devices for valvesElectromagnets with armaturesProportional controlSpecial design

The invention discloses a high voltage resistant permanent magnet polarized two-way proportional electromagnet, belonging to an electromechanical switching mechanism, adopting a special design: using yoke iron and guide sleeve to compose a two-way basin-like pole piece structure, there is permanent magnet mounted in the guide sleeve, there are control coils installed on two sides of the permanent magnet, a polarized magnetic field generated by the permanent magnet is superposed with control magnetic fields generated by the control coils so as to obtain an output force on an armature proportional to input signal, two-way and continuous, thus achieving a good proportional control characteristic; it has low energy consumption, eliminates 'zero'dead zone, has good static and dynamic properties. Therefore, it can be widely applied to proportional valve and servo valve.

Owner:ZHEJIANG UNIV +1

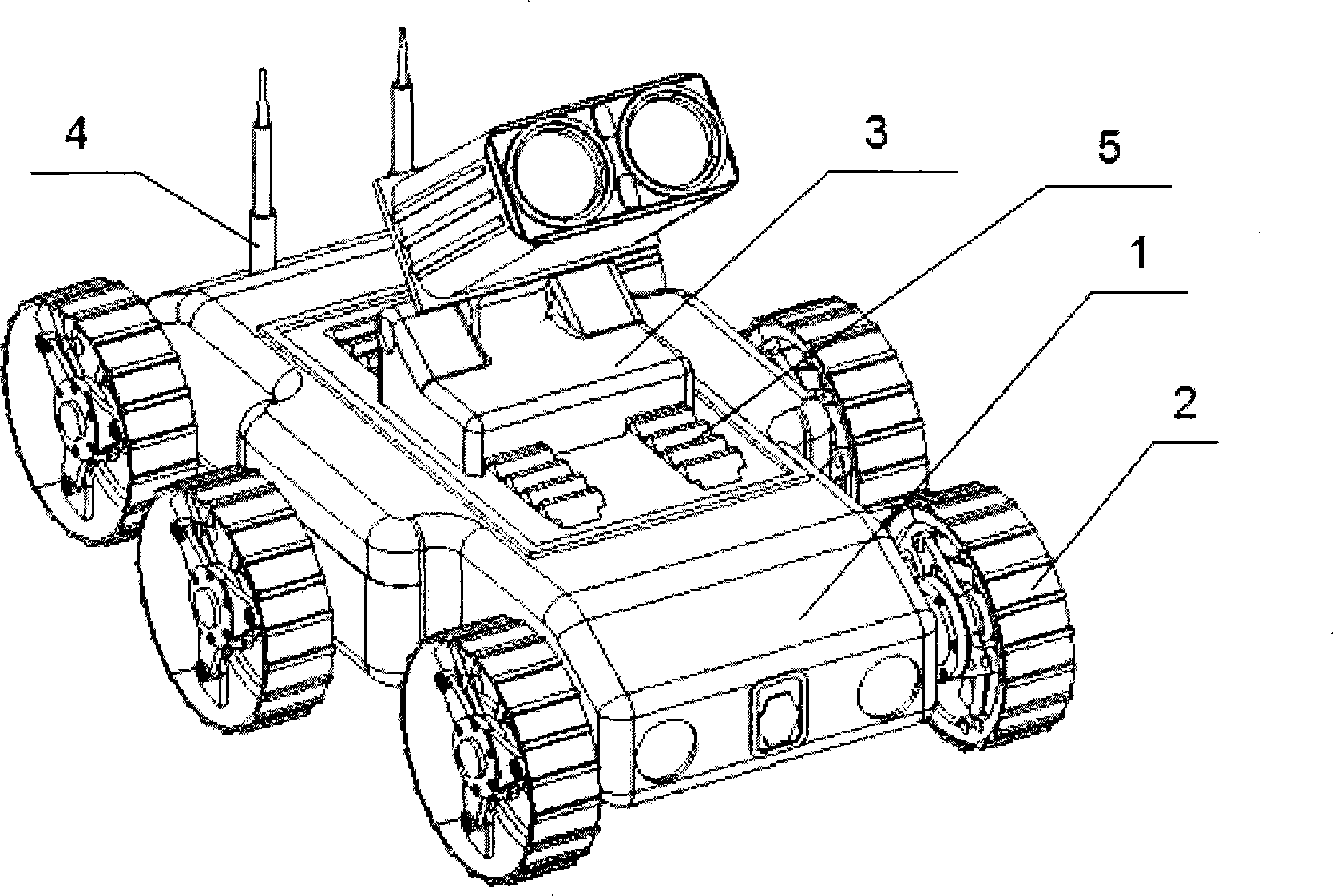

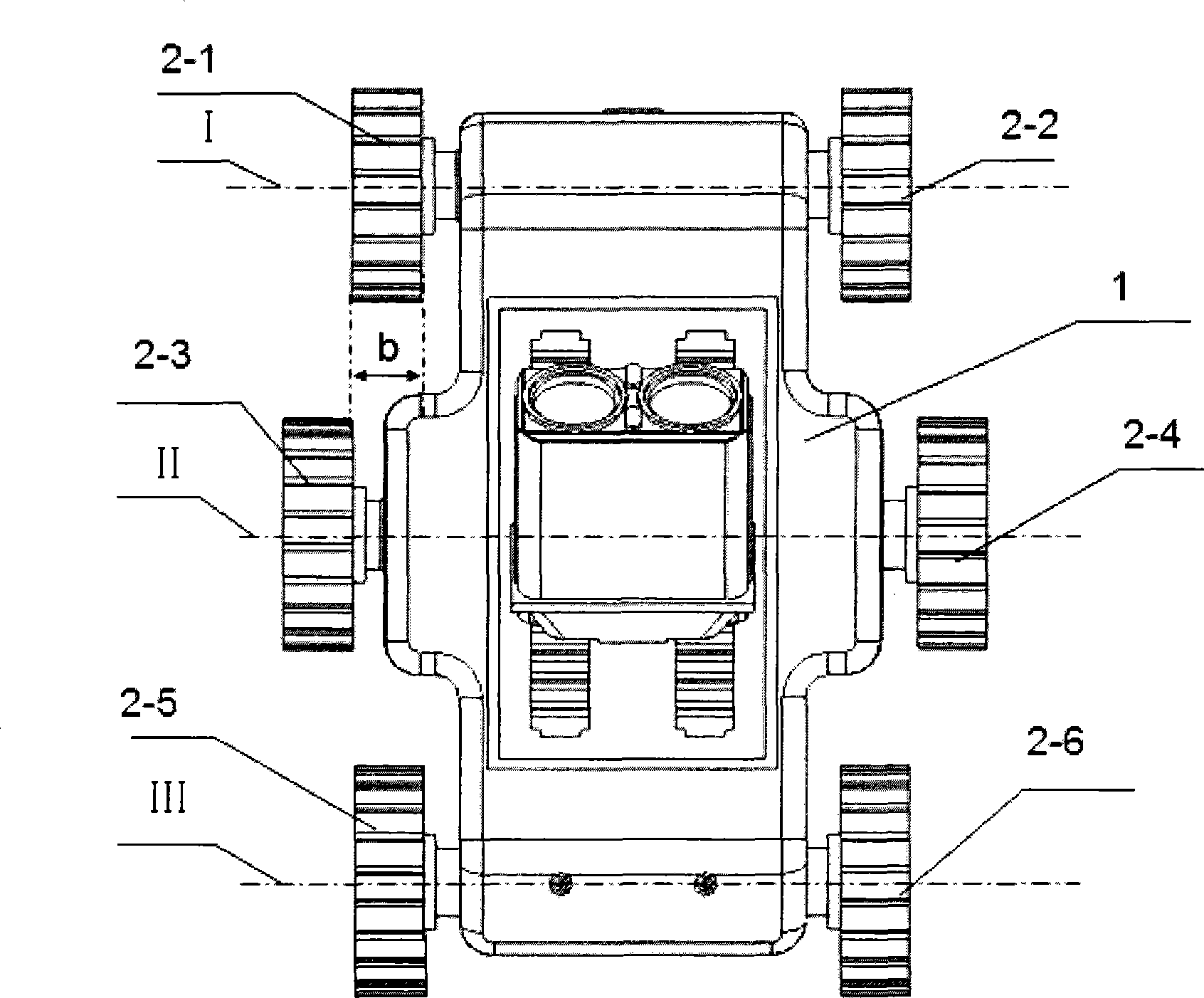

Portable moving device with wheel-leg hybrid advancing function

ActiveCN104249599AAdaptableRealize the compound propulsion function of wheel and footWheelsVehiclesLeg typeTerrain

The invention relates to a portable moving device with a wheel-leg hybrid advancing function and belongs to the technical field of the robot or unmanned ground vehicle. Using a special design of the vehicle wheel structure, the portable moving device of the invention enables the vehicle wheels to unfold to a leg type state and to fold to a wheel type state, so that the wheel-leg hybrid advancing function is realized, thereby giving the device adaptability to complex terrain.

Owner:CHINA NORTH VEHICLE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com