Patents

Literature

2456results about How to "Smooth running" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

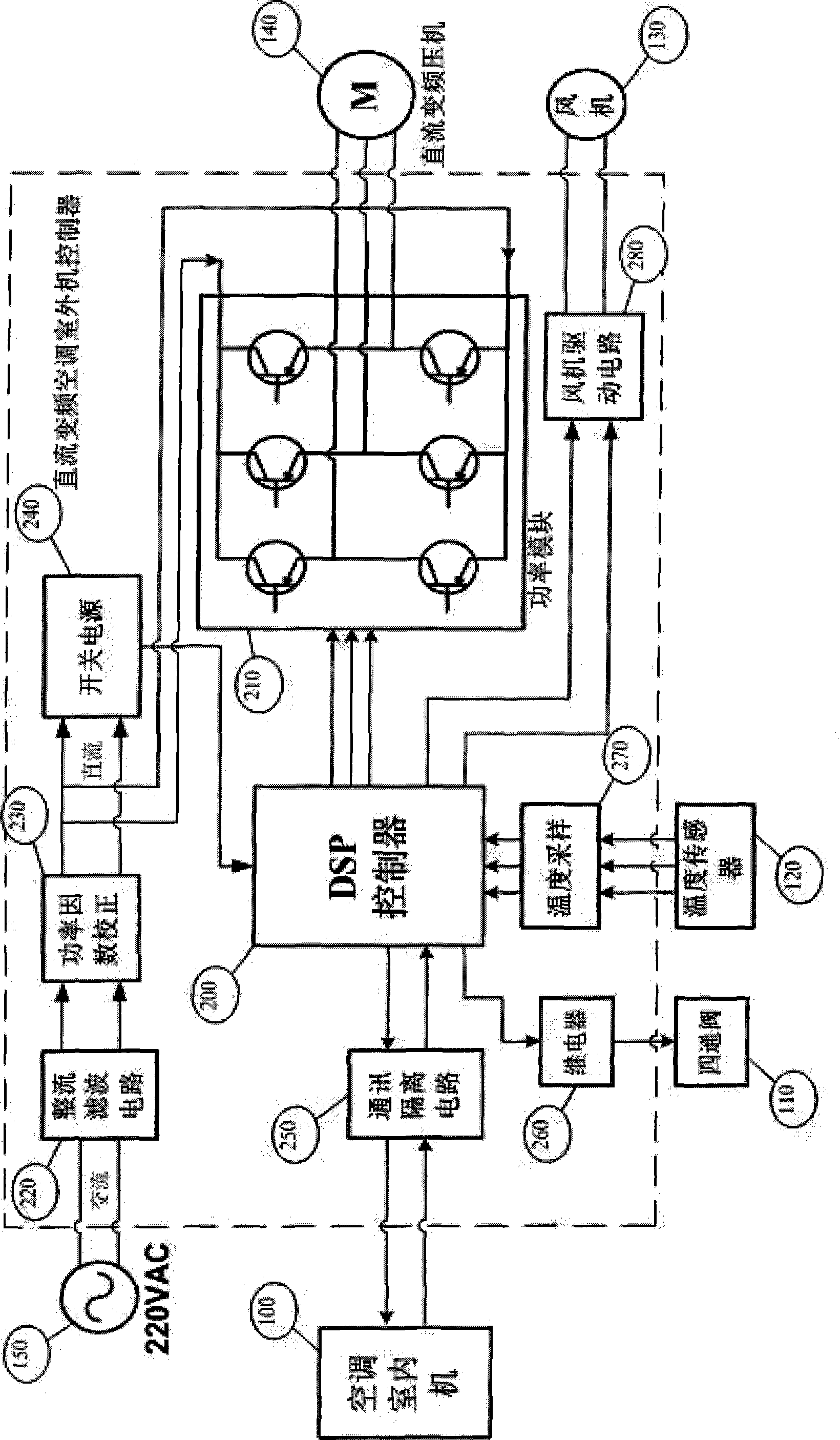

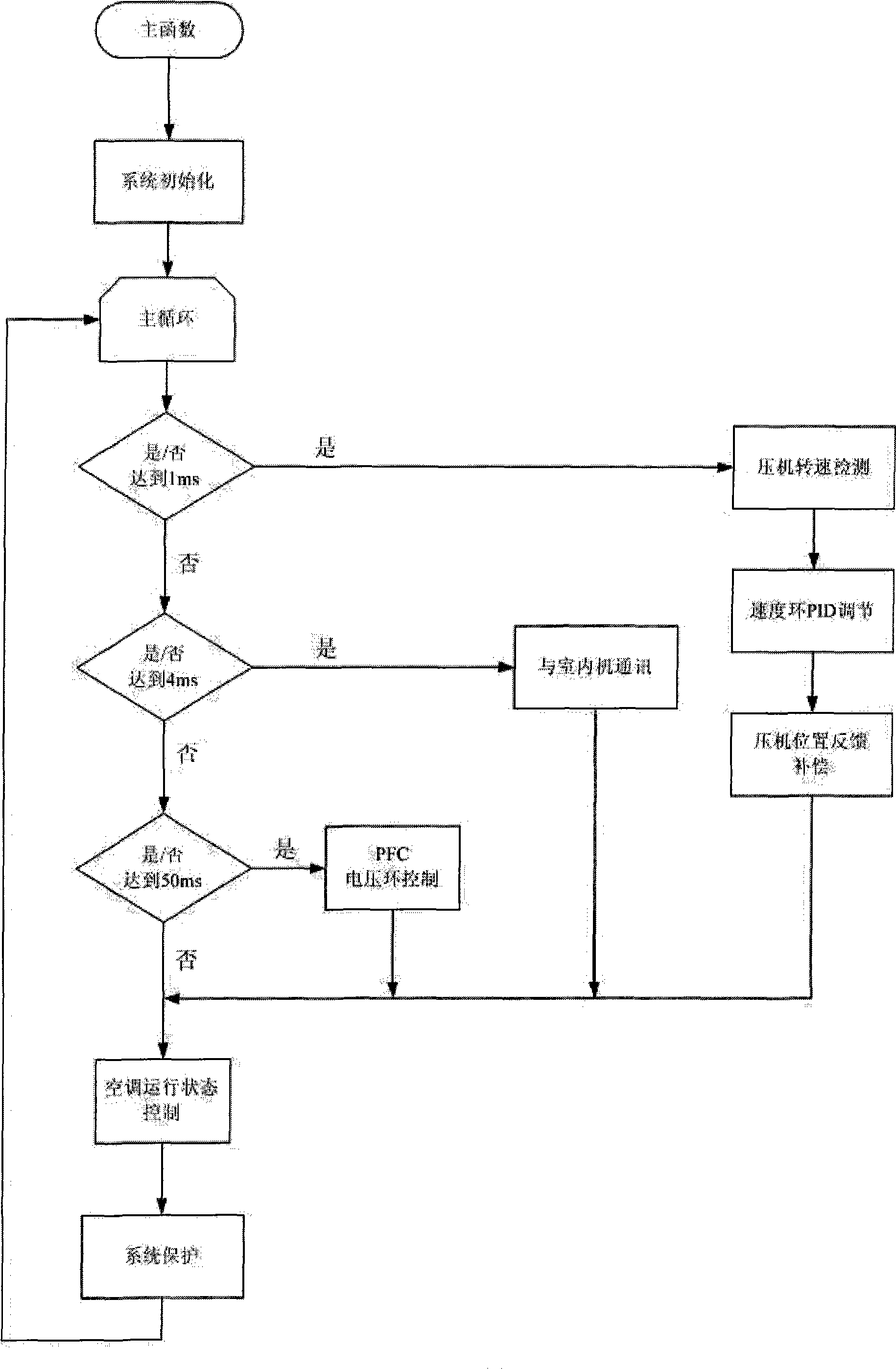

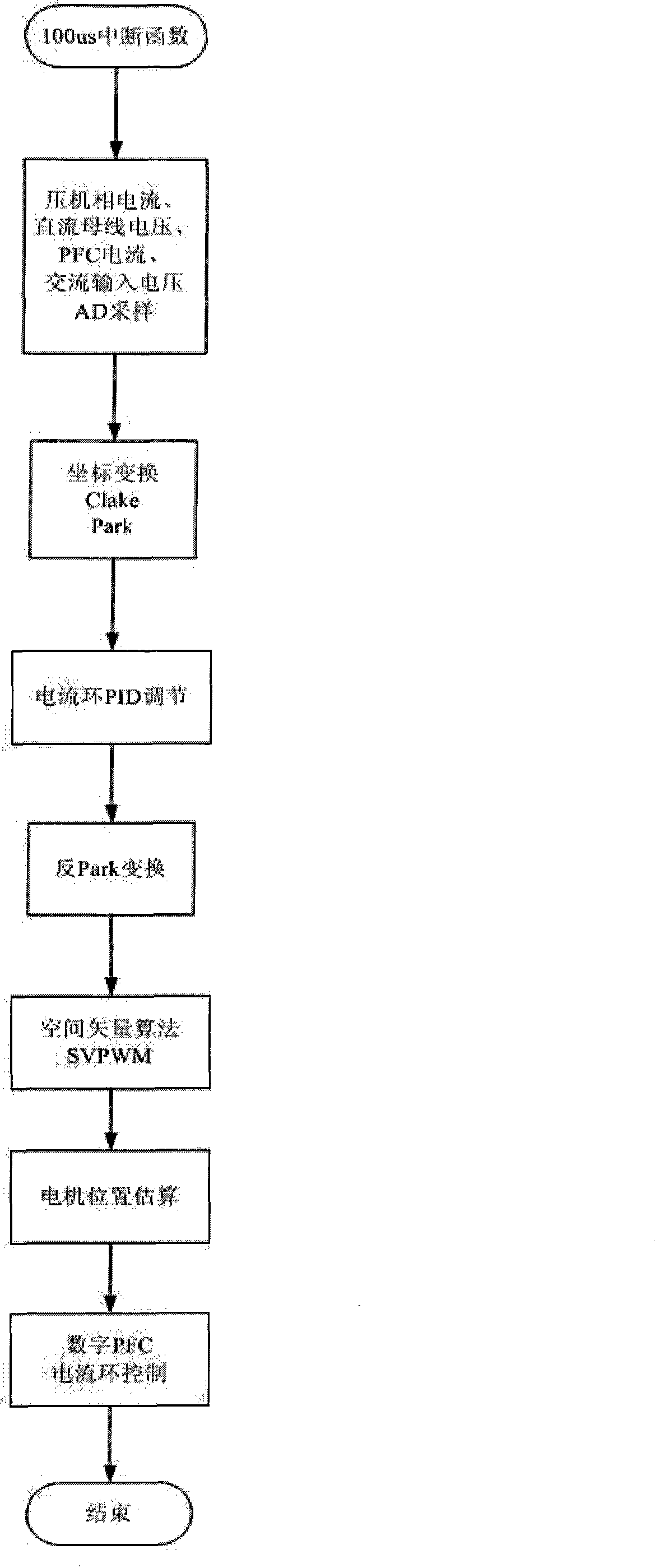

DC frequency converting air-conditioner compressor intelligent controller and control method thereof

ActiveCN101509694AAchieve automatic controlEnables real-time position feedbackSpace heating and ventilation safety systemsLighting and heating apparatusSynchronous motorControl manner

The invention provides an intelligent controller used for a direct current (DC) frequency-conversion air conditioner compressor and a technical proposal of the control method thereof; the hardware proposal comprises a rectifier filter circuit and a power module which are electrically connected sequentially; the rectifier filter circuit (220) is also electrically connected with a single DSP controller used as a core processing unit by a switch power supply (240); the single DSP controller is also respectively and electrically connected with the power module, a communication isolation circuit which is used for communicating with the indoor machine of the air conditioner, a fan driving circuit (280), and a temperature sampling circuit (270); the control method comprises the steps as follows:the control software is embedded in the DSP controller; by a control type of dual close-ring FOC no-sensor magnetic field vector, the current ring at the internal ring realizes the decoupling controlto the driving current of the permanent magnetic synchronous motor of a compressor and indirectly controls the output torque of the motor; the speed ring at the external ring is used for controlling the working frequency of the compressor, thus not only meeting the stable requirement during fixed frequency but also meeting the dynamic response during the frequency conversion; and the control software comprises a primitive recursive function and a main interrupt function.

Owner:宁波德业变频技术有限公司

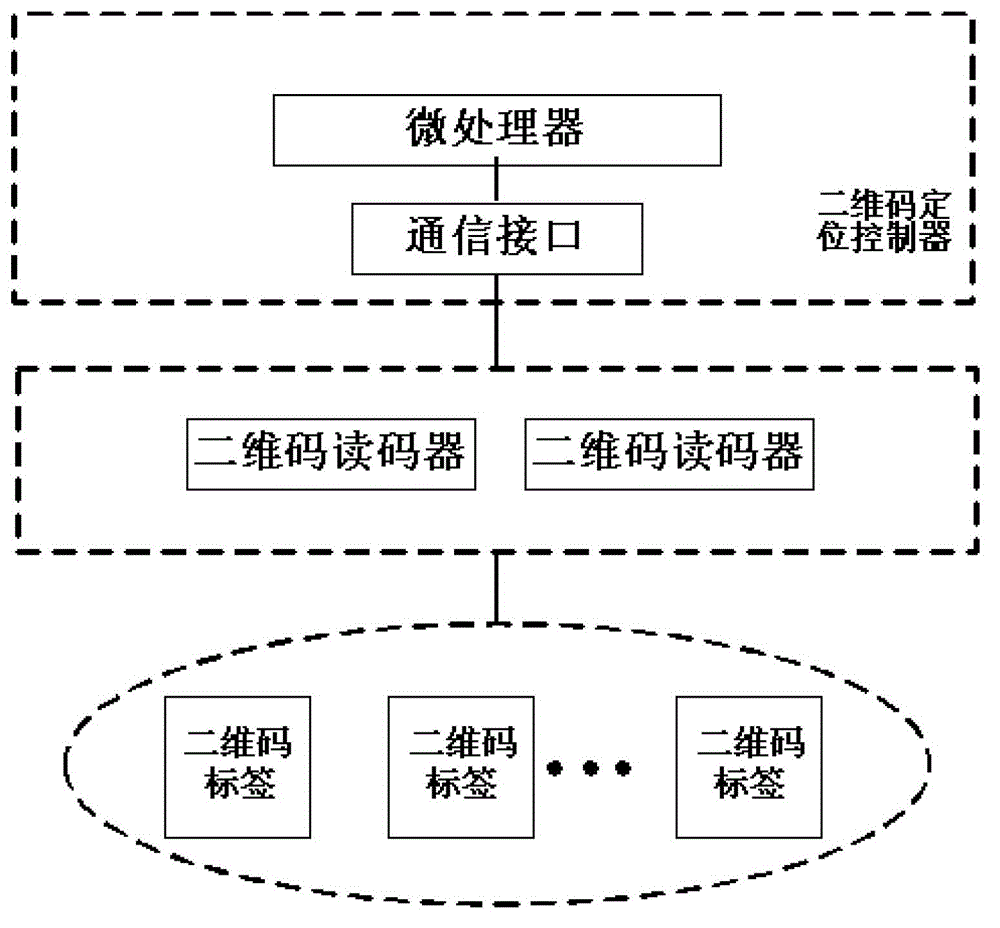

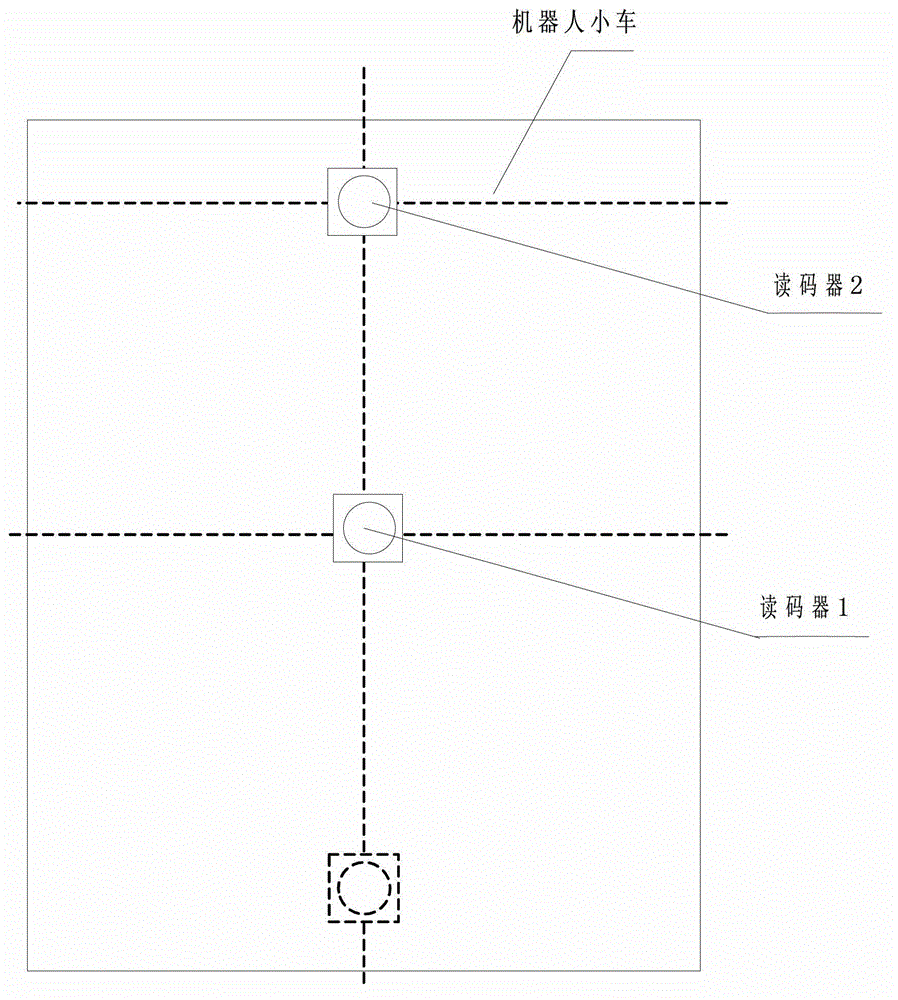

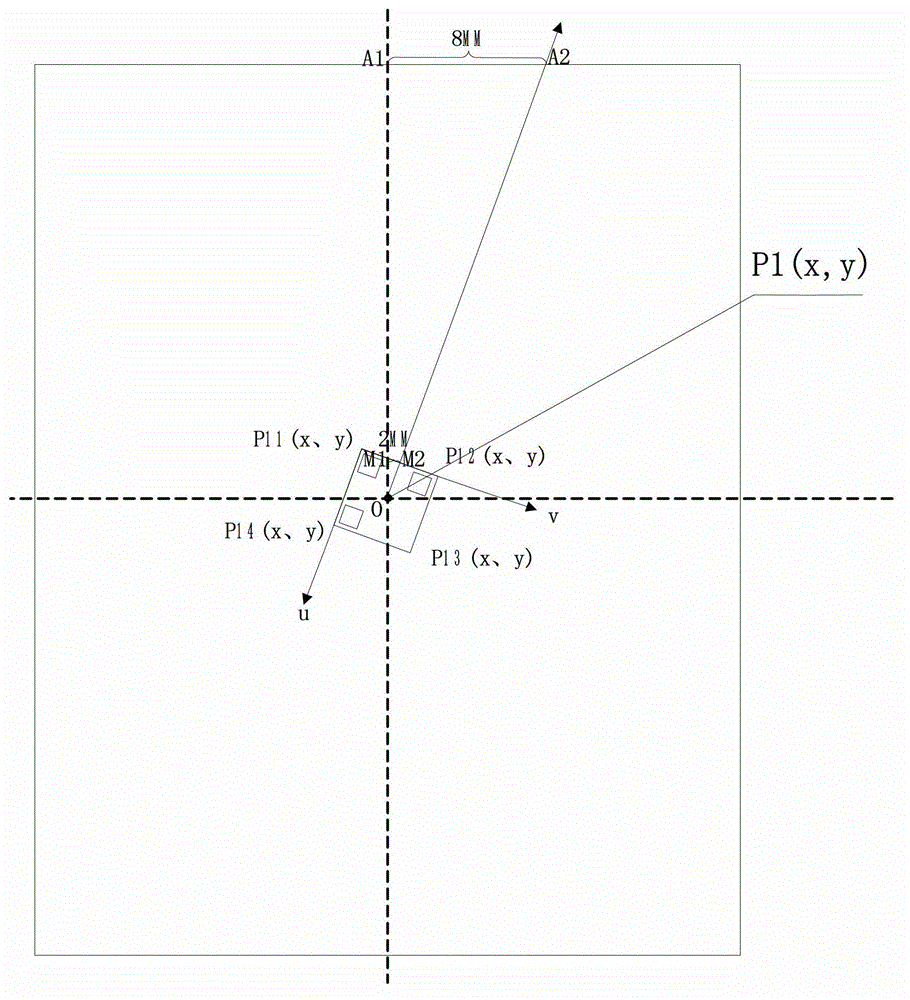

Mobile robot positioning system and method based on a plurality of two-dimensional code readers

InactiveCN102944236ARealize precise positioning functionSmall margin of errorNavigation instrumentsCommunication interfaceComputer vision

The invention relates to a mobile robot positioning system and a method based on the plurality of the two-dimensional code readers. The mobile robot positioning system and the method are characterized in that the positioning system comprises a two-dimensional code positioning controller mounted on a mobile robot trolley, at least two two-dimensional code readers and two-dimensional code tags which are distributed on the ground, the two-dimensional code positioning controller is composed of a microprocessor and a communication interface which is connected with the at least two two-dimensional code readers; and the positioning method includes building three coordinate systems, calculating a deviation angle of the mobile robot trolley in a trolley coordinate system relative to a central point connection line of two two-dimensional codes, calculating a deviation angle of the central point connection line of two two-dimensional codes relative to a world coordinate system and calculating a deviation angle of the mobile robot trolley relative to the world coordinate system to obtain an accurate position of the mobile robot. According to the mobile robot positioning system and the method, the design is reasonable, an accurate positioning function for the mobile robot is achieved, and advantages of high accuracy and stability, implement convenience and the like are provided.

Owner:SHENZHEN PUZHILIANKE ROBOT TECH CO LTD

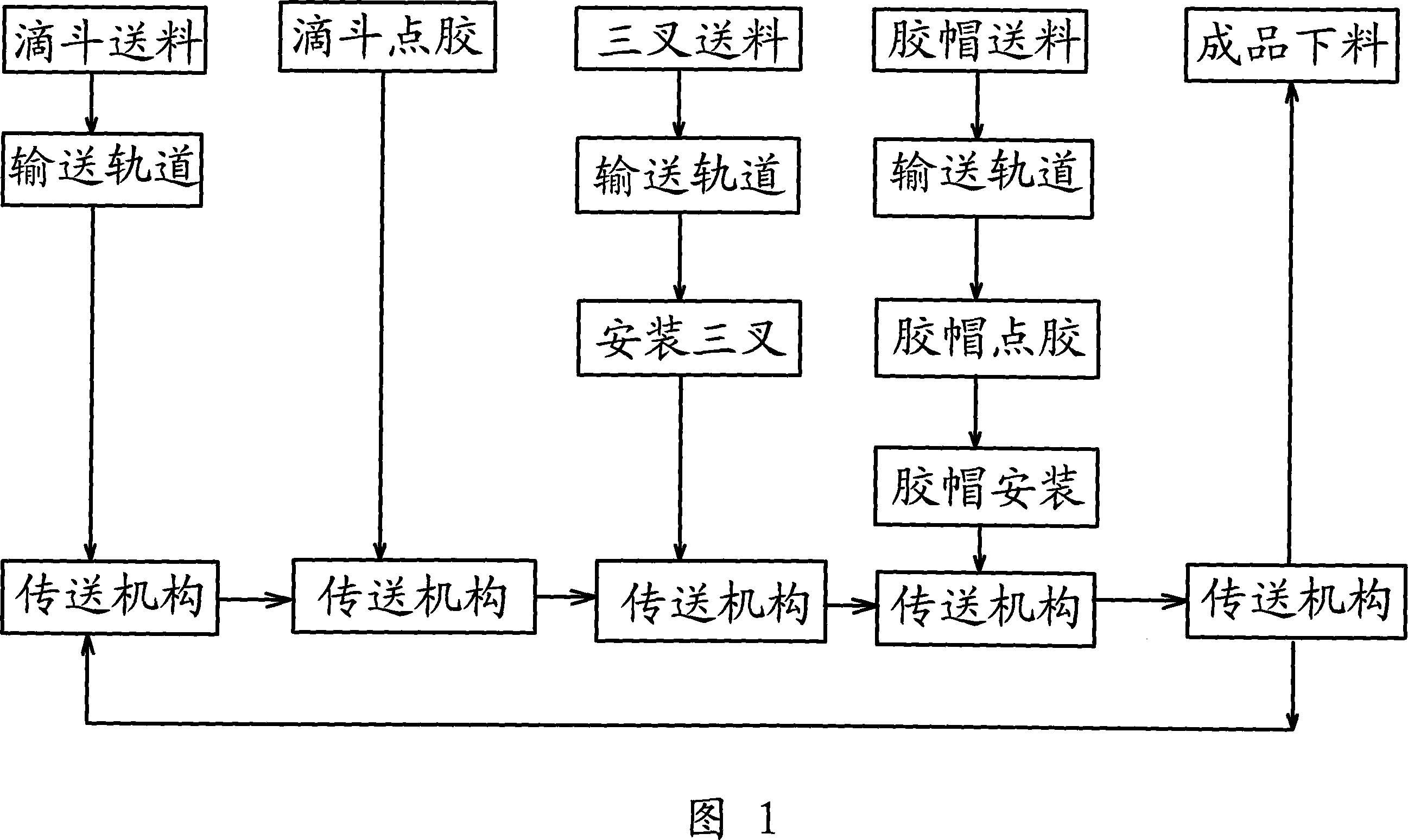

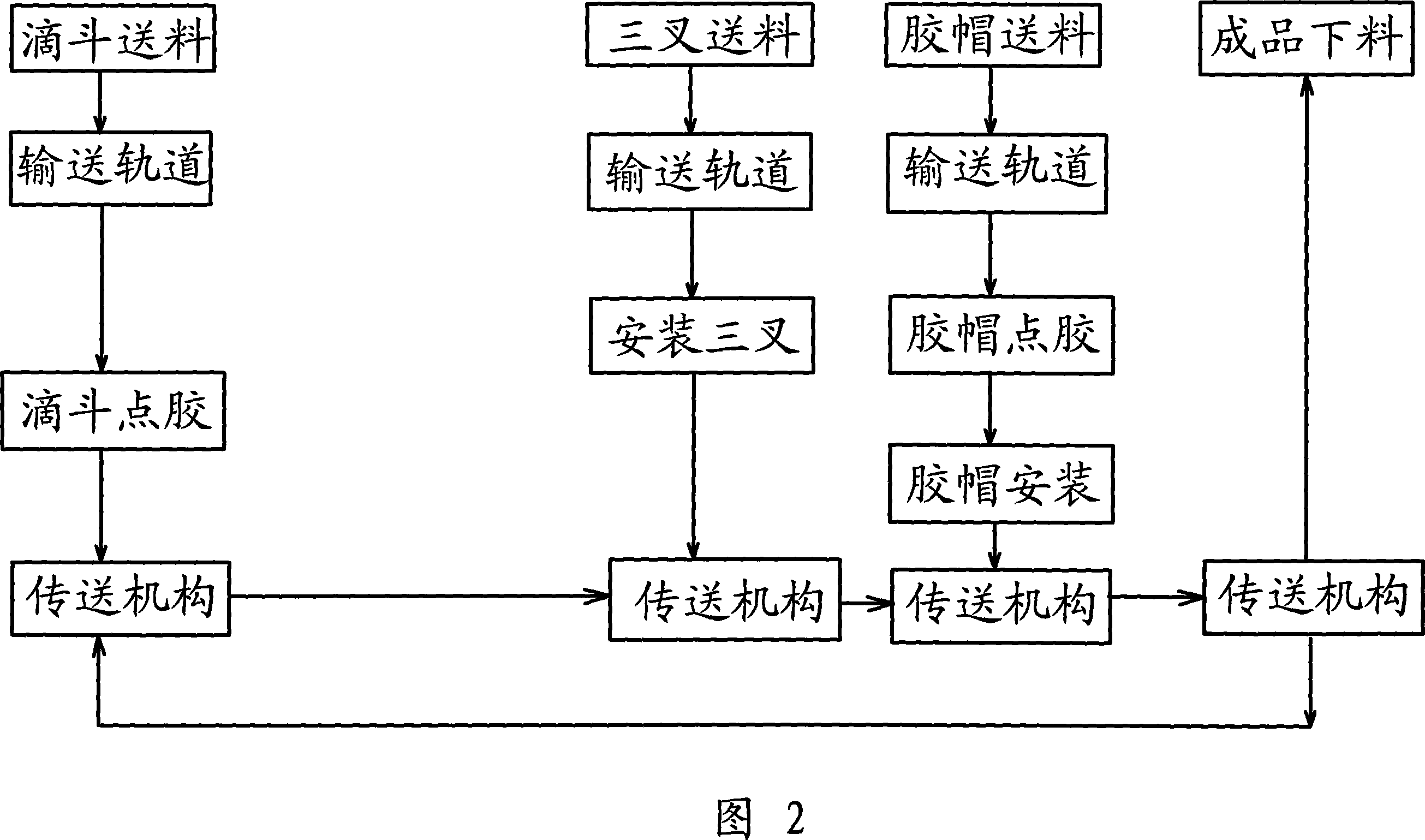

Process and apparatus for assembling infusion unit titrimeter assembly

A technology for automatically assembling the dripping hopper module of perfusion device includes such steps as putting the dripping hoppers, three-way tubes and rubber caps in feeders, arranging them on respective conveying tracks, conveying the dripping hopper in transfer mechanism, fixing, transferring to next workstation, coating adhesive, inserting a three-way tube in it, continuous transferring, installing rubber cap, and releasing the module. Its apparatus is composed of rotary axle, rotary table fixed to said rotary axle, feeders, adhesive applying mechanism and discharger.

Owner:MAIDER MEDICAL IND EQUIP

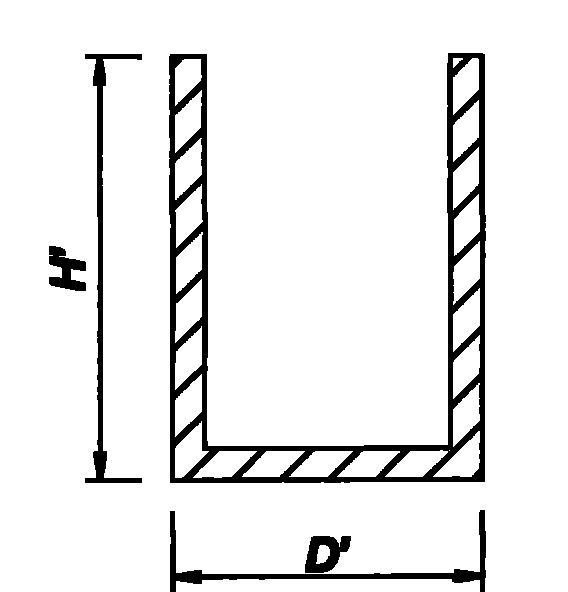

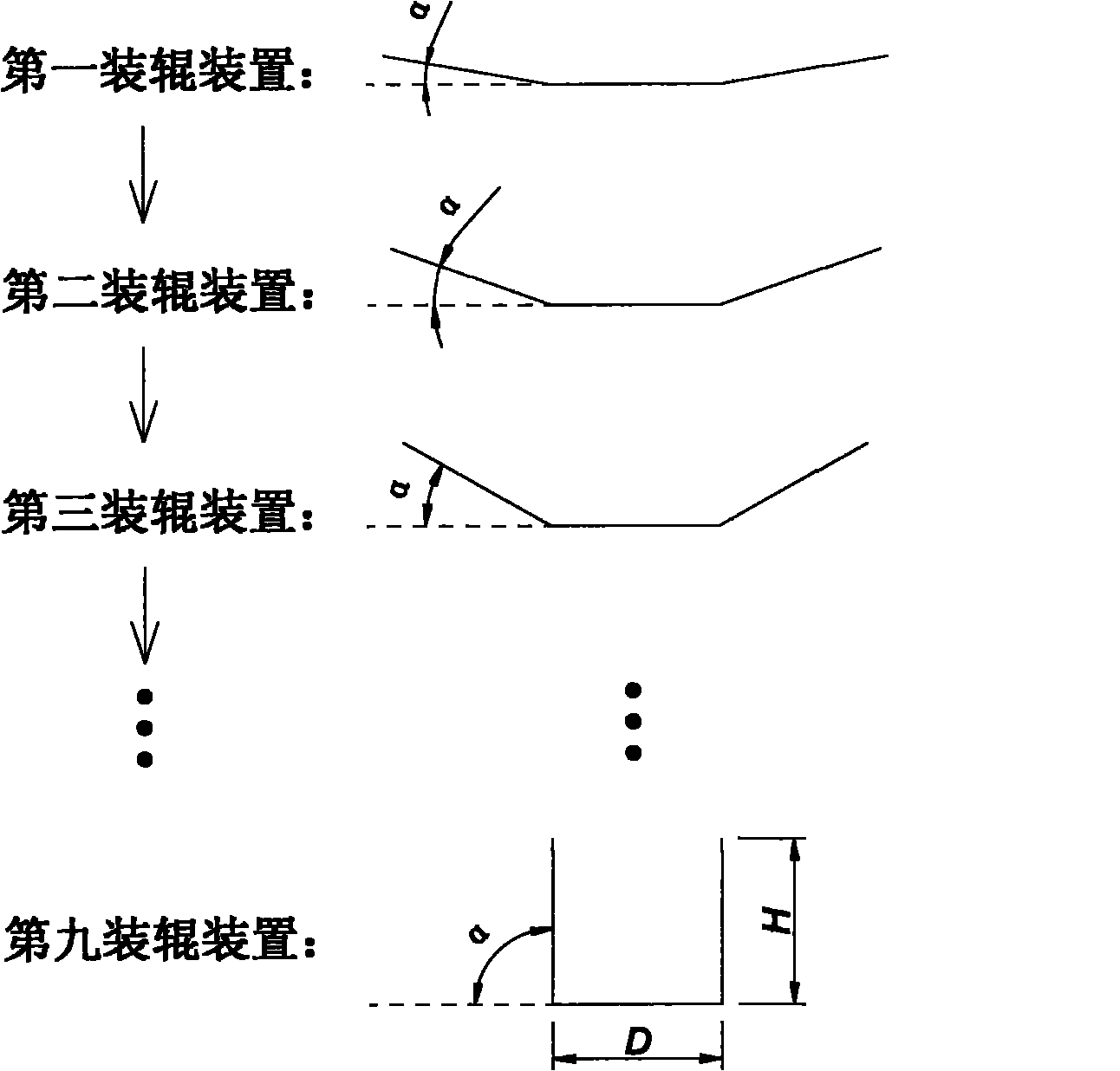

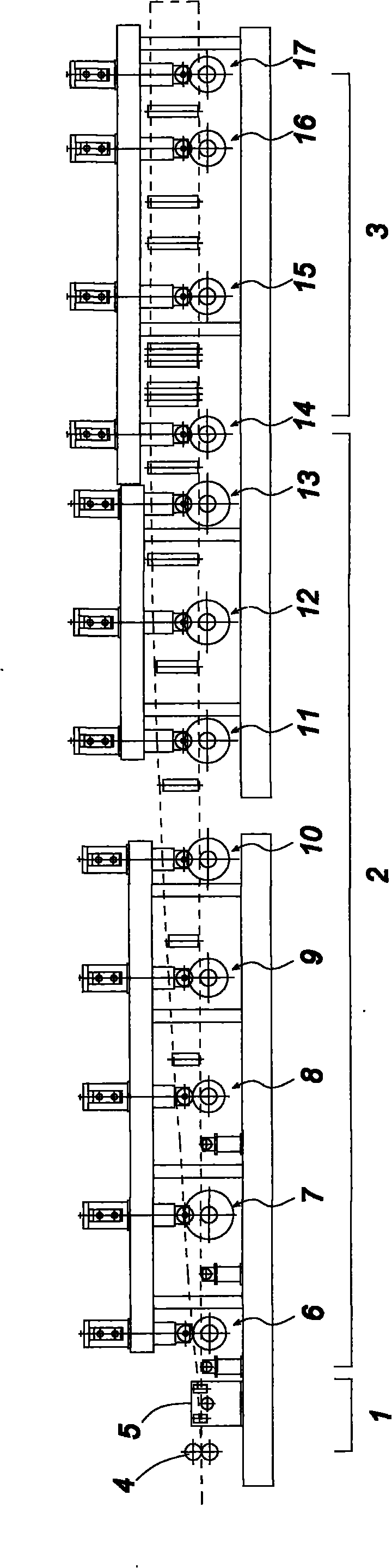

Cold-bending molding technology and production line for producing broad width U-shaped channel steel

The invention provides a cold-bending molding technology and a production line for producing a broad width U-shaped channel steel. The technology comprises the following steps: 1) sheets are pinched synchronously; 2) the sheets pass through a plurality of roll loading devices, the roll loading devices bend both sides of the sheet so as to make both sides of the sheet produce a bending angle alpha, and in the moving direction of the sheet, the rear roll loading device makes the bending angle alpha increased gradually to 90 degrees, so a U-shaped channel steel is initially molded; and 3) the side surface of the U-shaped channel steel initially molded is rectified. With the technology, the flat sheet can be relatively and continuously molded into the integral U-shaped broad width channel steel without welding. The production line of the technology has the advantages of no limit on the total length of the channel steel, high production efficiency, stable production quality, stable operation, low noise and the like.

Owner:山东力丰重型机床有限公司

Nondestructive demolition construction method of reinforced concrete frame beam

A nondestructive demolition construction method of a reinforced concrete frame beam includes: selecting cutting equipment and determining a cutting scheme according to field space conditions and cut component characteristics; designing and mounting a replacement steel beam according to the size of a demolished beam; computing the weight of cut component sub-blocks according to the performance of a chain block, and determining cutting positions and hoisting points; building a supporting frame and an operating frame for demolishing the reinforced concrete beam; measuring setting-out and marking the hoisting points and the cutting positions in field; using a diamond thin-wall drill (hydraulic drill) to drill hoisting holes; penetrating a steel wire rope through the hoisting holes, fixing the steel wire rope on the replacement steel beam, and applying hoisting force in advance; cutting components by the aid of the diamond thin-wall drill according to preset cutting lines; and placing the cut components on the ground by the aid of the chain block and transporting the cut components to a waste treatment plant. The nondestructive demolition construction method of the reinforced concrete frame beam has the advantages that noise is within 40-45dB, water cooling is adopted while powdered scraps are taken away, the method is minimum in labor intensity, construction efficiency is greatly improved, and comprehensive economic benefit is remarkably improved.

Owner:YONGSHENG CONSTR GRP

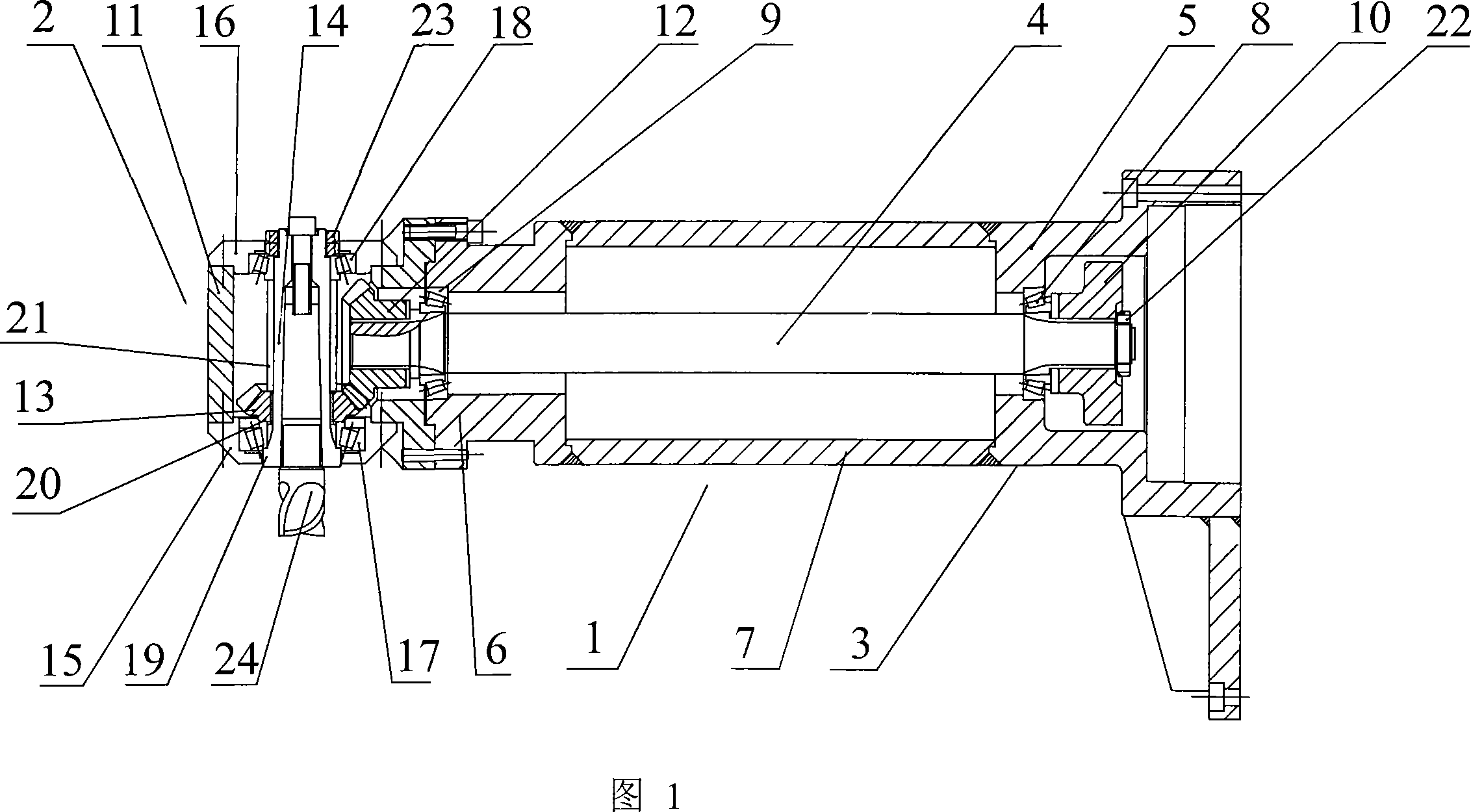

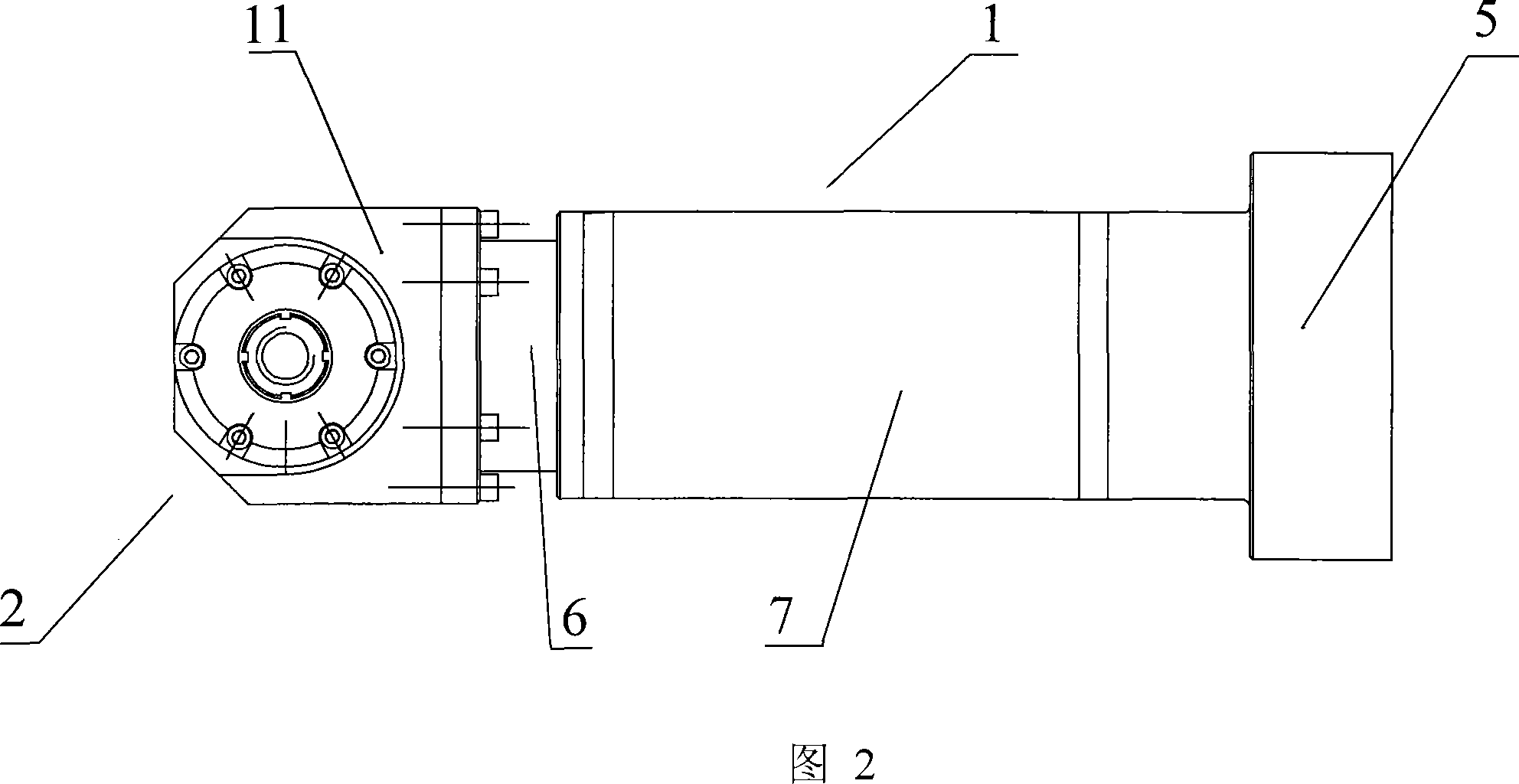

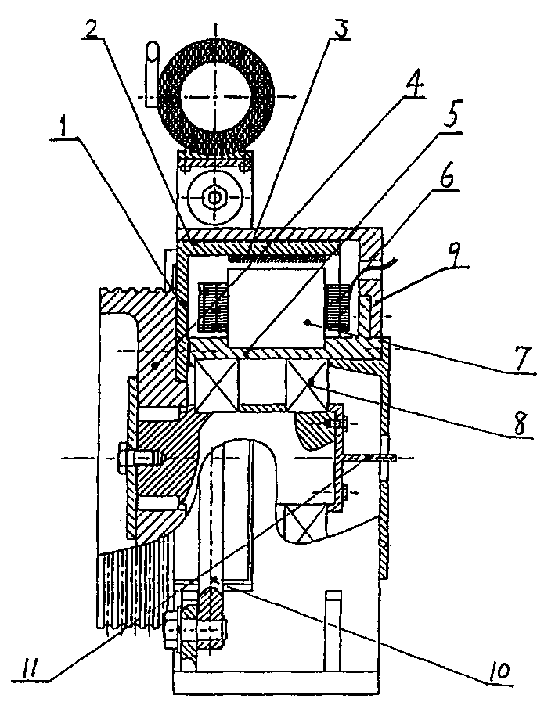

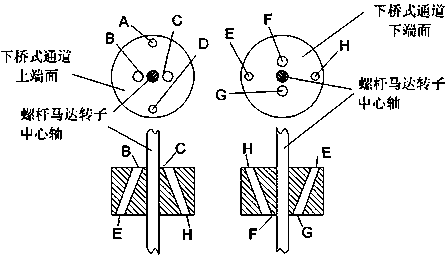

Bevel-gear right-angle milling head

InactiveCN101100035AEasy and accurate installationSmooth runningDriving apparatusMilling cutterGear wheel

The present invention relates to machining fixture, and is especially one kind of milling head for holding milling cutter in numerically controlled machine tool. The rectangular bevel gear milling head includes one driving mechanism and one steering mechanism. The driving mechanism includes one milling head base fixed onto the milling machine and one connecting shaft set inside the base and connected to the milling machine spindle. The steering mechanism includes one milling head casing, two bevel gears to constitute one rectangular gear train, and one milling head spindle. The milling head has capacity of altering the milling cutter rotation direction, capacity of machining inner surface of hole or end parallel to the milling machine spindle, high production efficiency and high machining precision.

Owner:SHANGHAI BLOWER WORKS

Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalyst

ActiveCN103773436AChange processLess investmentHydrotreatment operations starting-upHydrocarbon oil crackingNaphthaEngineering

The invention discloses a start-up method for an ex-situ prevulcanization secondary activity center hydrogenation catalyst. After resistance to air loss of a device is qualified, circulating hydrogen compressor working load is adjusted to 0-20% of a maximum load, the catalyst reacts at a low temperature to release heat; when the bed layer temperature rise to 60-150 DEG C, start-up activation oil is introduced, the circulating hydrogen compressor working load is adjusted to 60-100% of the maximum load for wetting of the catalyst; the start-up activation oil is cycled in a reaction system closed path, the catalyst bed temperature is risen to 180 to 230 DEG C by heat exchange; a proper amount of olefin-enriched naphtha is added into the start-up activation oil, the catalyst bed temperature is risen to 300-380 DEG C to complete start-up activation. The start-up method, in the premise of no influence on the use properties of the secondary activity center hydrogenation catalyst, can better use the catalyst characteristics, reduce the device energy consumption, and reduce the device investment cost, and the start-up process can be simplified.

Owner:CHINA PETROLEUM & CHEM CORP +1

Three-dimensional motion multifunctional washing machine

InactiveCN102212950AAdapt to different needsSmooth runningOther washing machinesWashing machine with receptaclesControl systemEngineering

The invention discloses a three-dimensional motion multifunctional washing machine. The washing machine comprises a shell, a hoisting spring, a bearing hoisting ring, an outer barrel, a drum, a wave wheel, a motor, a control system and a water supply and drainage system. The washing machine is technically characterized in that: the bearing hoisting ring is hung in the shell through the hoisting spring, and the bearing hoisting ring is connected with the outer barrel through left and right support connecting rods; and the drum and the wave wheel are arranged in the outer barrel, the drum and the wave wheel rotate around a longitudinal shaft or a vertical shaft in the outer barrel, and the outer barrel drives the drum, the wave wheel and other components to rotate around a transverse shaft together so as to form three-dimensional motion. The washing machine has multiple washing modes; wave wheel type washing, drum type washing and three-dimensional motion type washing can be selected; wave wheel type washing can also be performed at the same time of drum type washing or three-dimensional motion type washing; the dehydration is uniform balanced drum vertical dehydration in a wave wheel washing state; the functions and the advantages of a wave wheel washing machine and a drum washing machine can be effectively combined, and the defects of the wave wheel washing machine and the drum washing machine are avoided; and as the three-dimensional motion type washing mode is increased, the washing machine has no dead angle and has multiple functions.

Owner:谢海洋

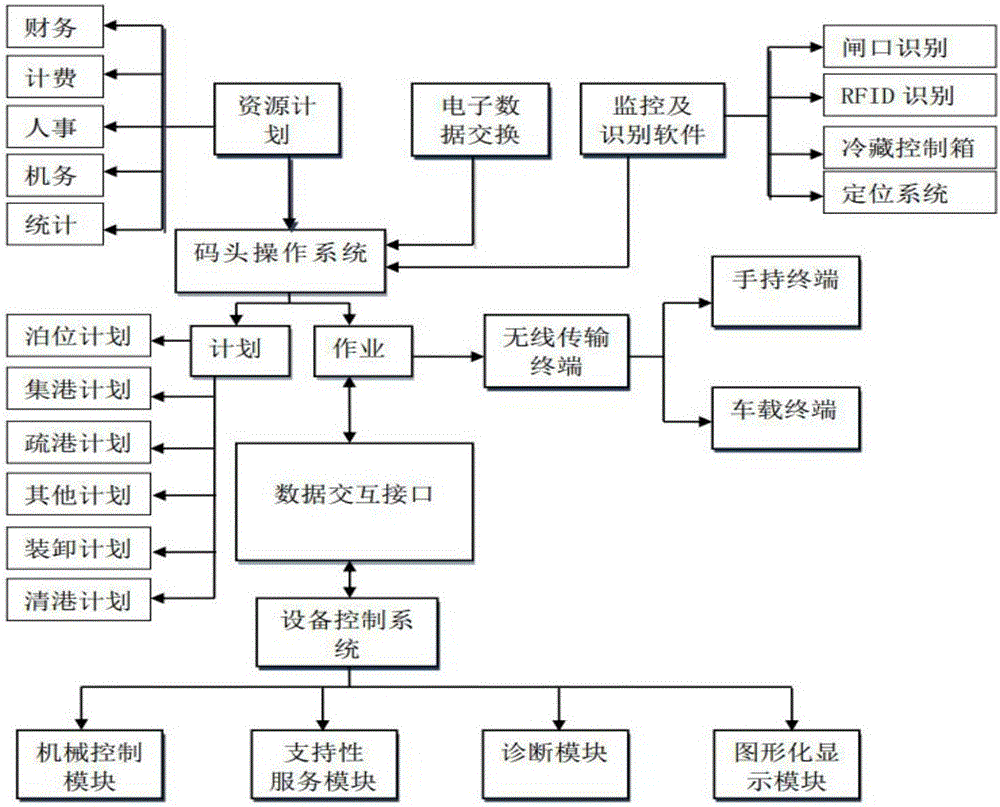

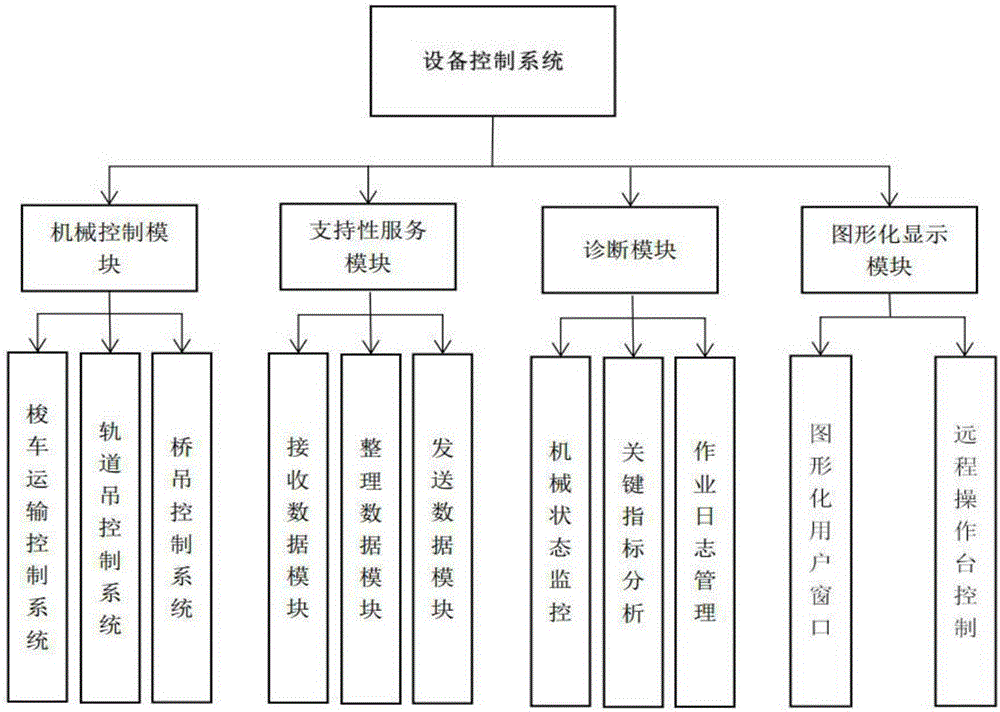

Automatic information management system and method for container terminals

The invention relates to an automatic information management system and method for container terminals, and belongs to the technical field electronic information. The technical scheme is that the system comprises a terminal operation system, an equipment control system and a data interaction interface, wherein the terminal operation system is used for planning and assigning tasks, managing task states, sending instructions to the equipment control system and receiving feedback information; the equipment control system is used for receiving operation information,, driving equipment to execute the instructions, monitoring operation states of the equipment and returning the operation information and the states of the equipment to the terminal operation system; and the terminal operation system and the equipment control system carry out task transmission and processing through the data interaction interface. The system provided by the invention has the beneficial effect that an information management system which is capable of optimizing the structure as far as possible and being simplified in information acquisition, smooth in constructed data and clear in division of work. According to the system and method provided by the invention, a complete solution is provided for the port container loading, unloading and transporting informatization, and the terminal running is smooth, so that the terminal operation efficiency is further enhanced and a lot of labor cost is saved.

Owner:DALIAN UNIV

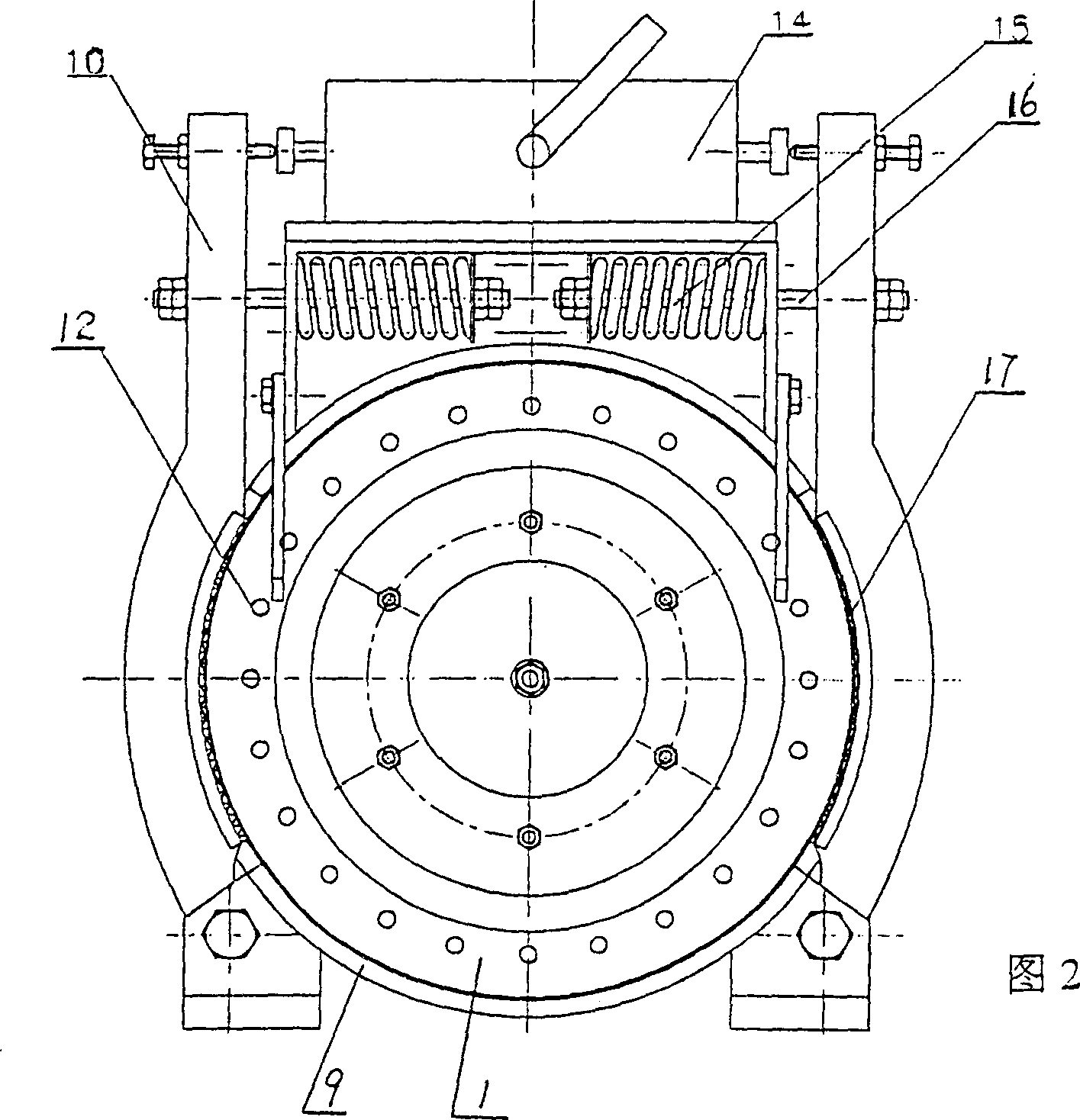

Directly driven synchronous dragger with Nd-Fe-B permanent magnetic rotor

InactiveCN1141775CProtect the endSmooth runningMechanical energy handlingStructural associationSpecial designRing type

In this invention multipole outer rotor structure is used, said out rotor is also used as brake wheel, drag wheel is fit on outer rotor. The special design makes the structure be very compact and can realize direct driving without gear wheel. The special two-layer ring-type stator structure can not only increase working reliability but also improve mfg. process, remarkably. The invention has advantages of lifting steady and flat-layer exact, and two set of brake component is used so as to realize braking and stopping with high reliability.

Owner:SHANGHAI JIAO TONG UNIV +1

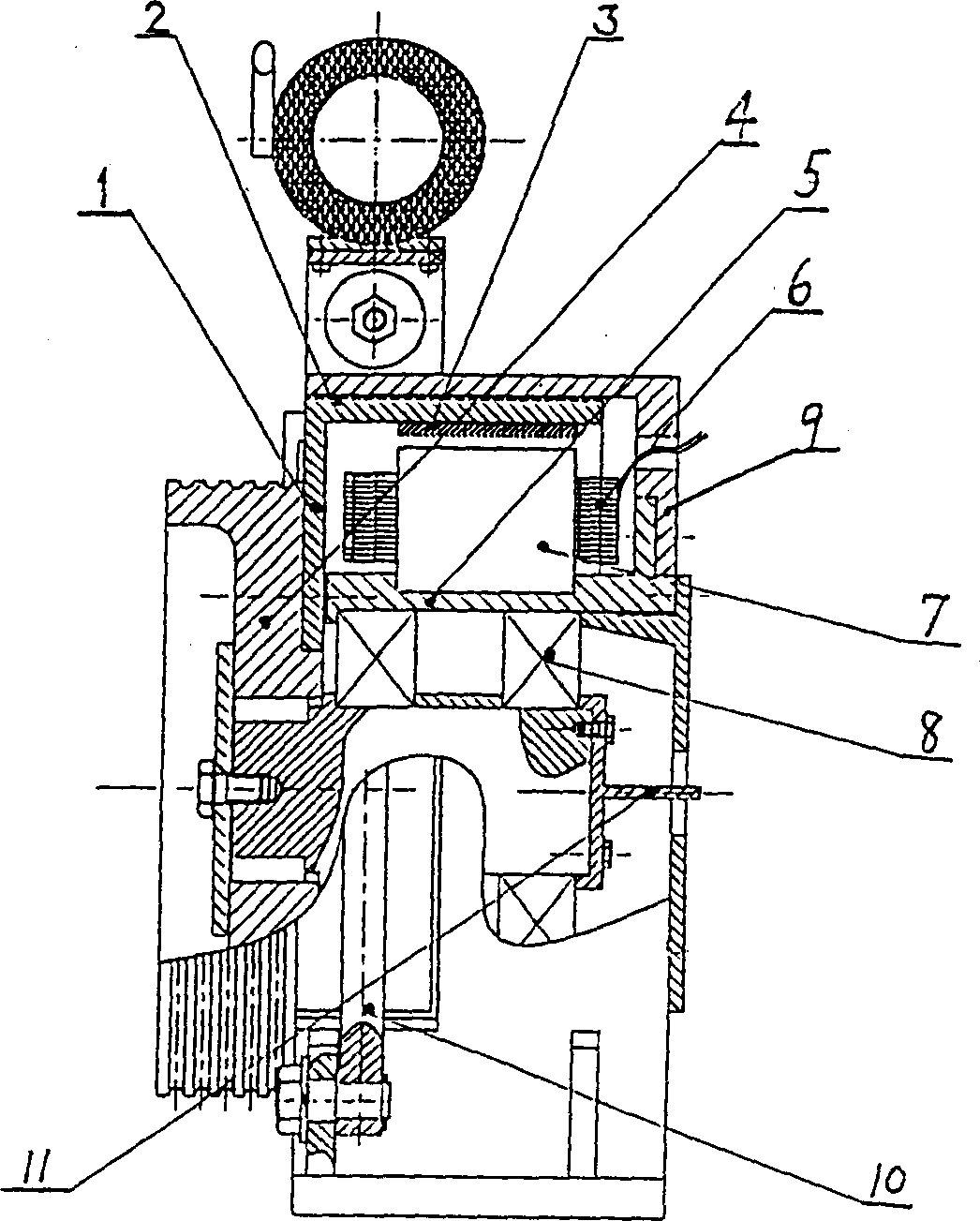

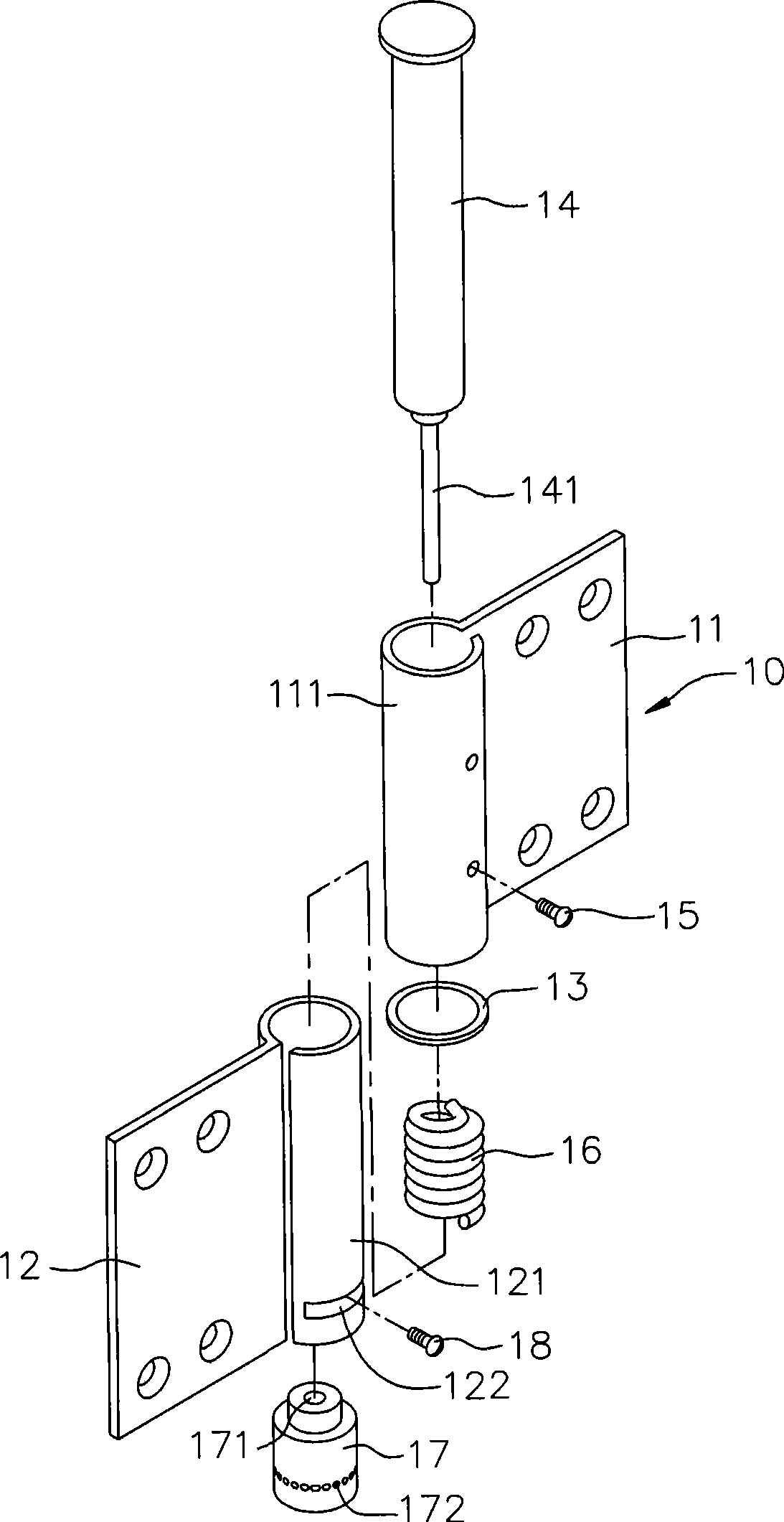

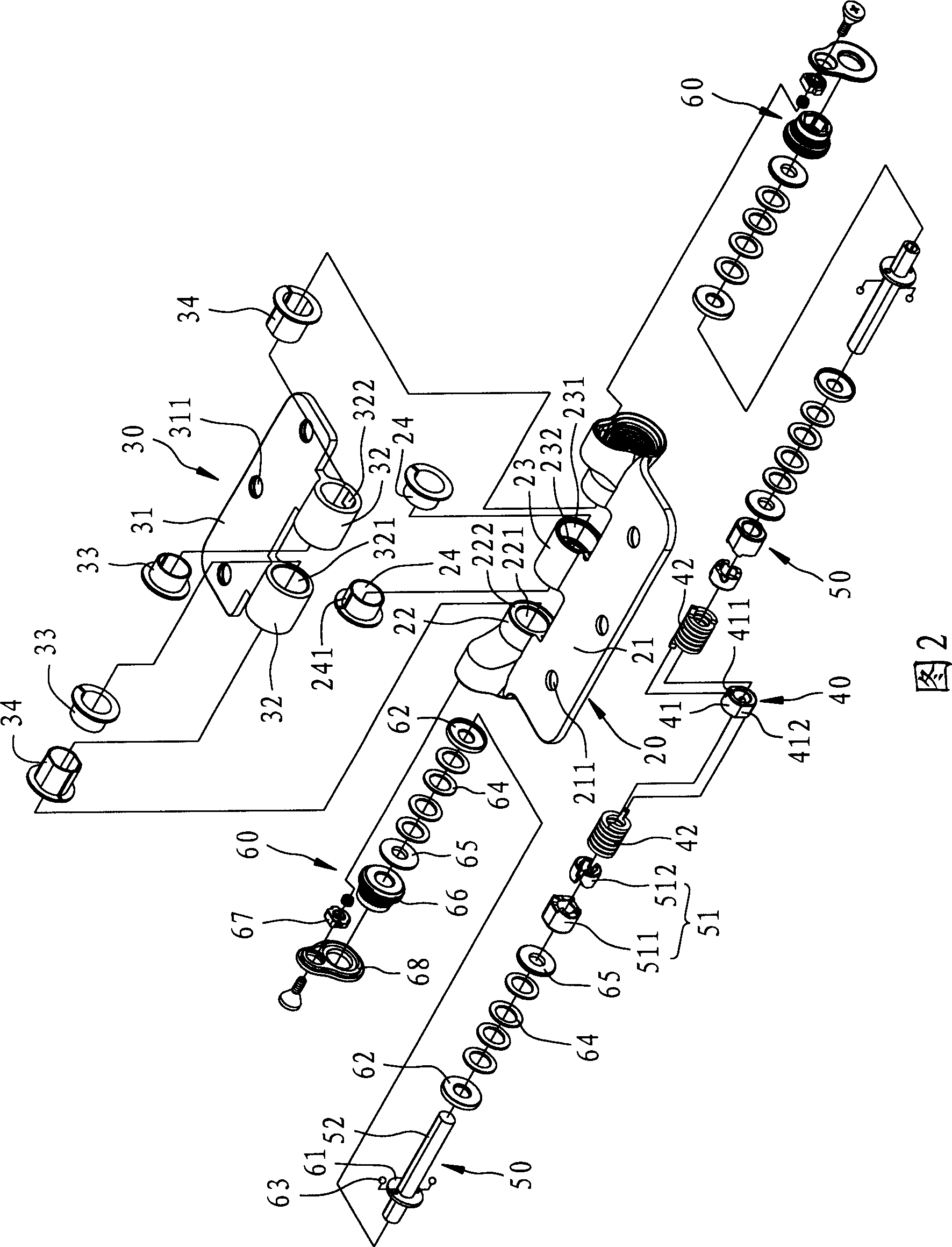

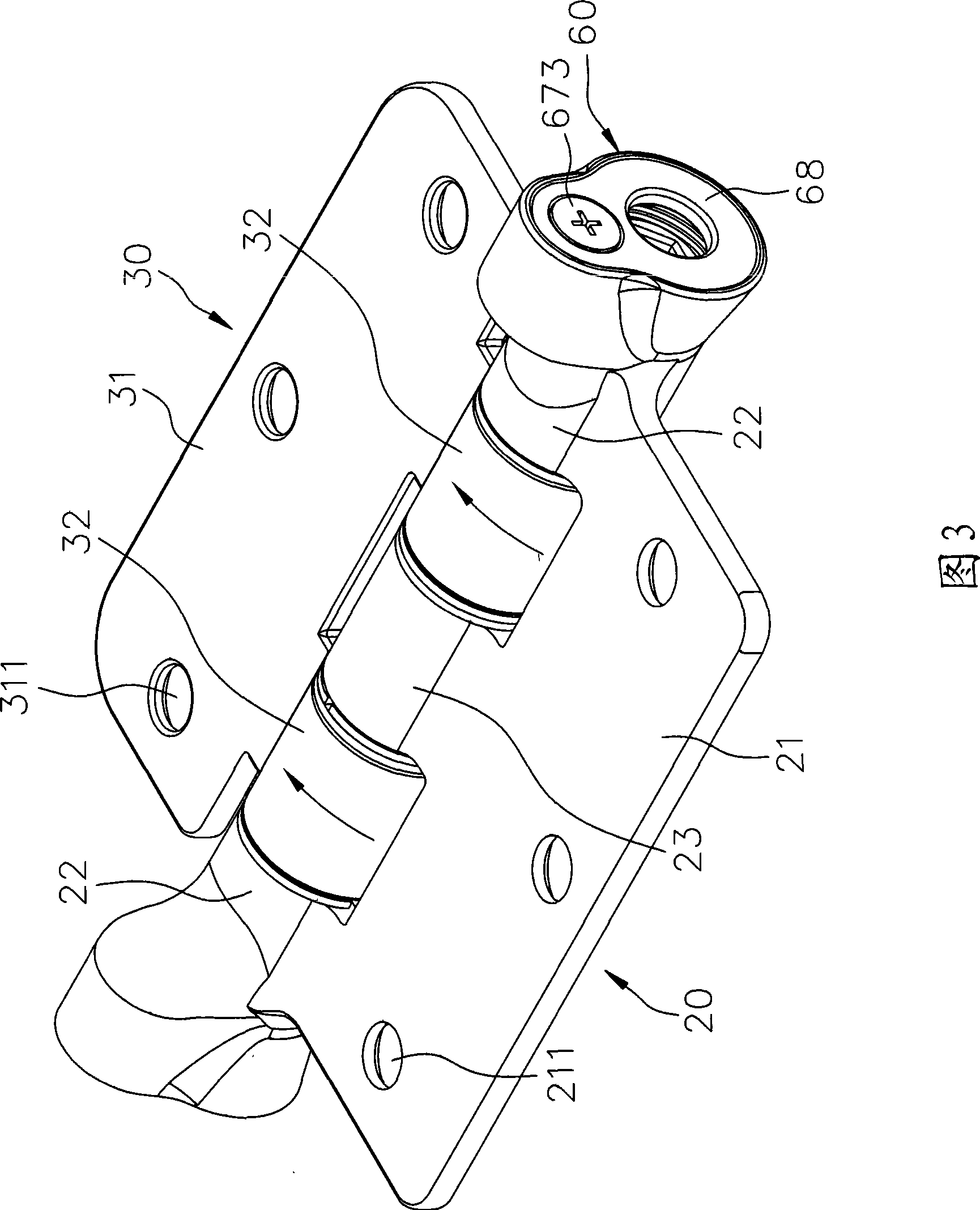

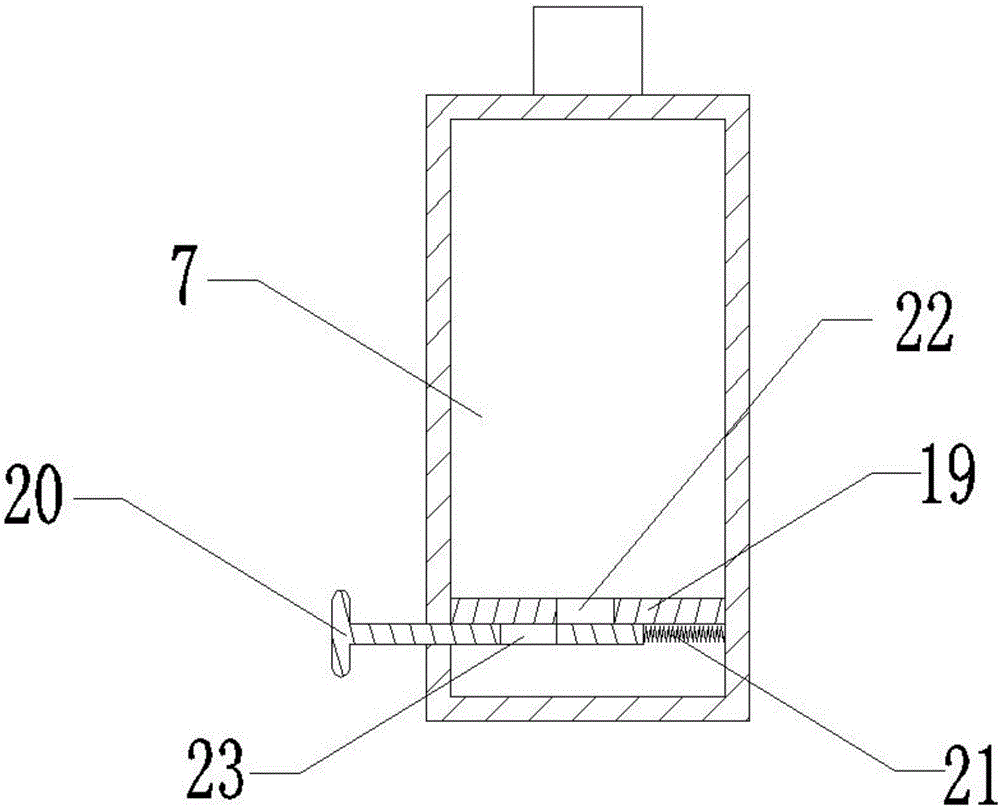

Pivot hinge device with torsion adjustable

The invention relates to a door pivot hinge device capable of adjusting a torque force. The door pivot hinge device comprises a first base plate unit, a second base plate unit, a torque force providing unit, a torque force adjusting unit and a speed adjusting unit. The first base plate unit and the second base plate unit are embedded into each other and can revolve. The torque force providing unit has a torsion spring capable of leading a door sheet to produce a torque force. The torque force adjusting unit has a mandrel and a single cam set, wherein the mandrel can drive the torsion spring through the single cam set so as to adjust the torque force. The speed adjusting unit has a brake disc, a plurality of elastic elements and an adjusting element, wherein the adjusting element can pressthe elastic element so as to adjust the rotation speed. Therefore, the door pivot hinge device has the adjustable torque force, and smooth operation for door opening and closing , and is suitable forhigh load.

Owner:陈 建竹

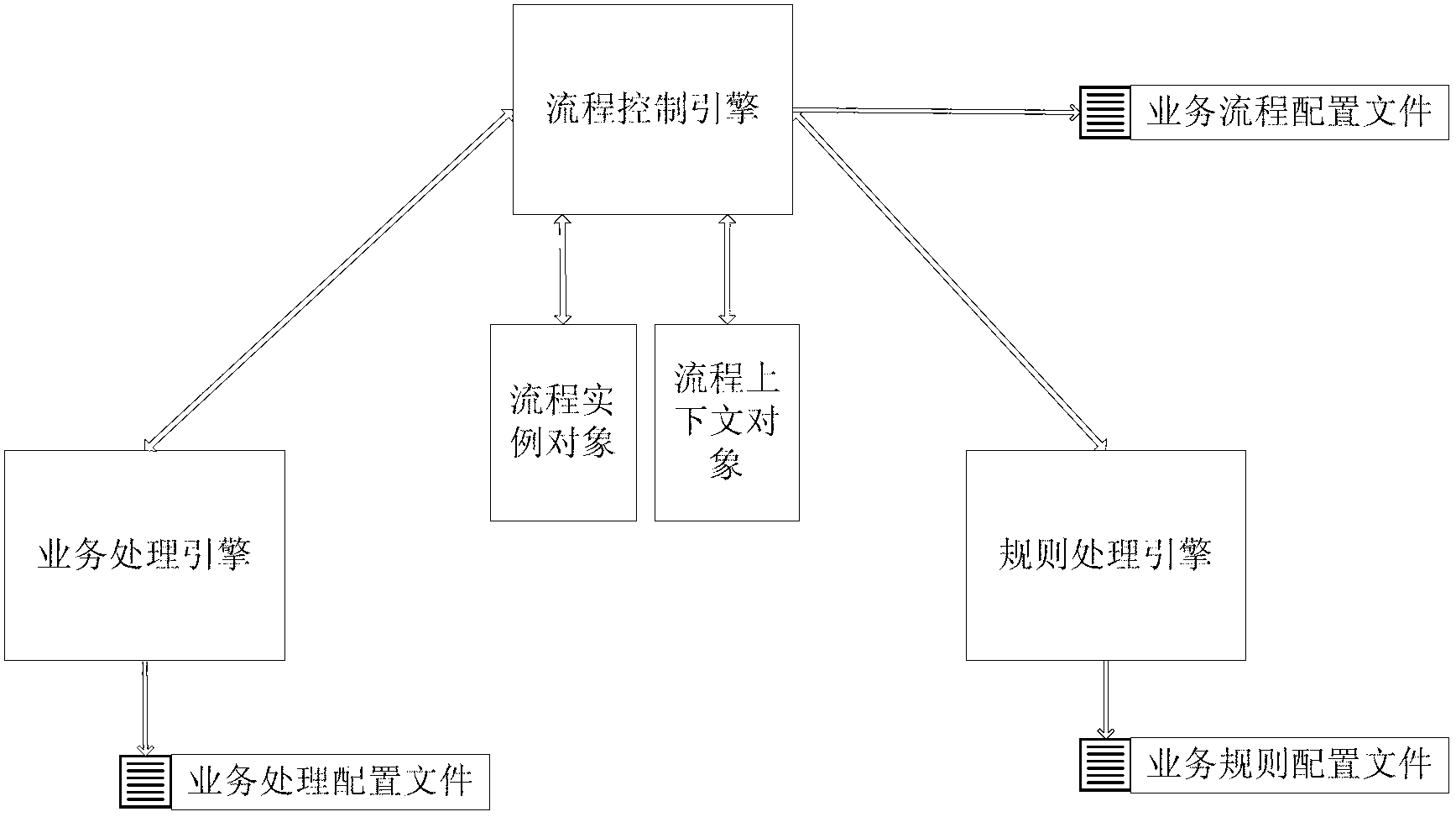

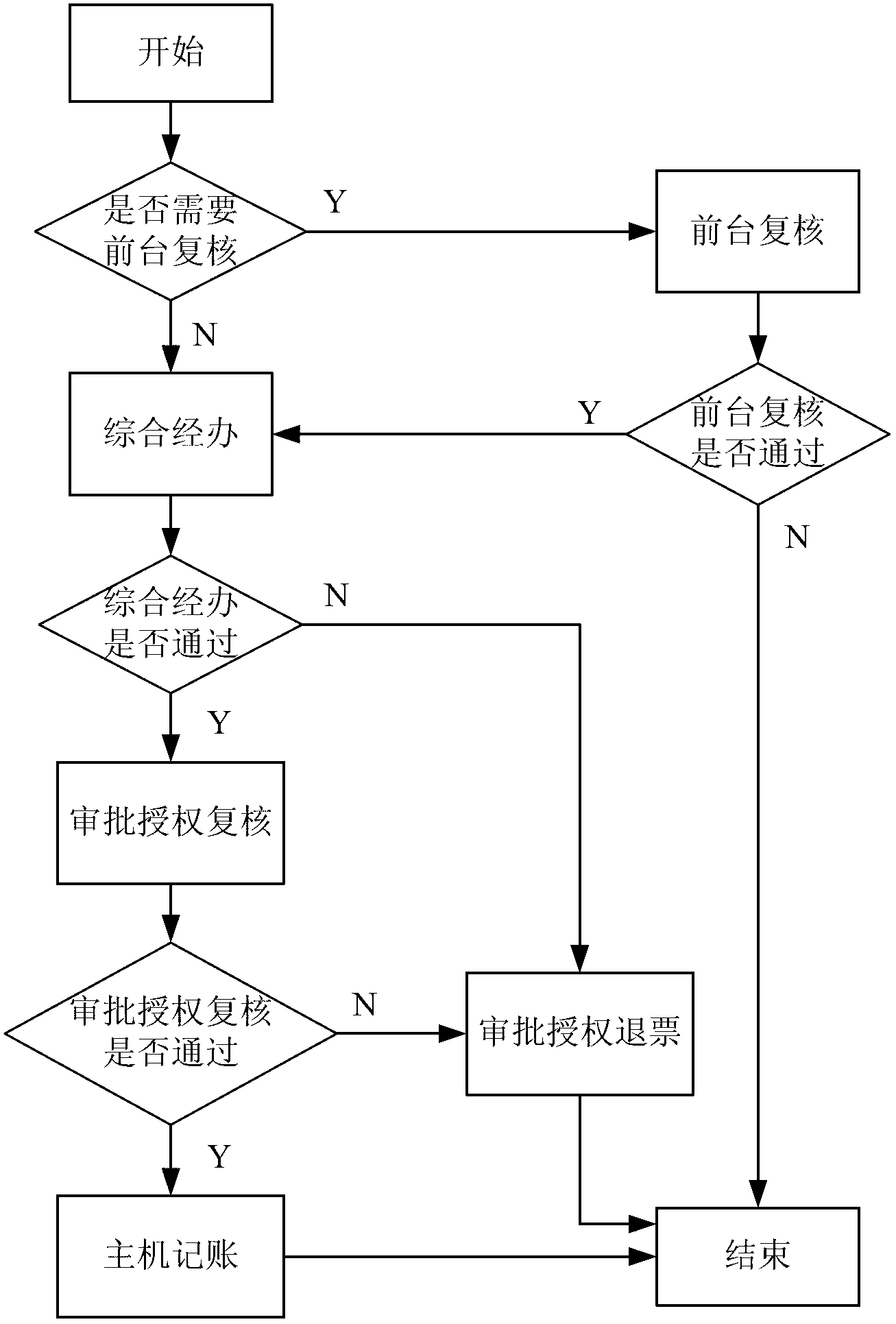

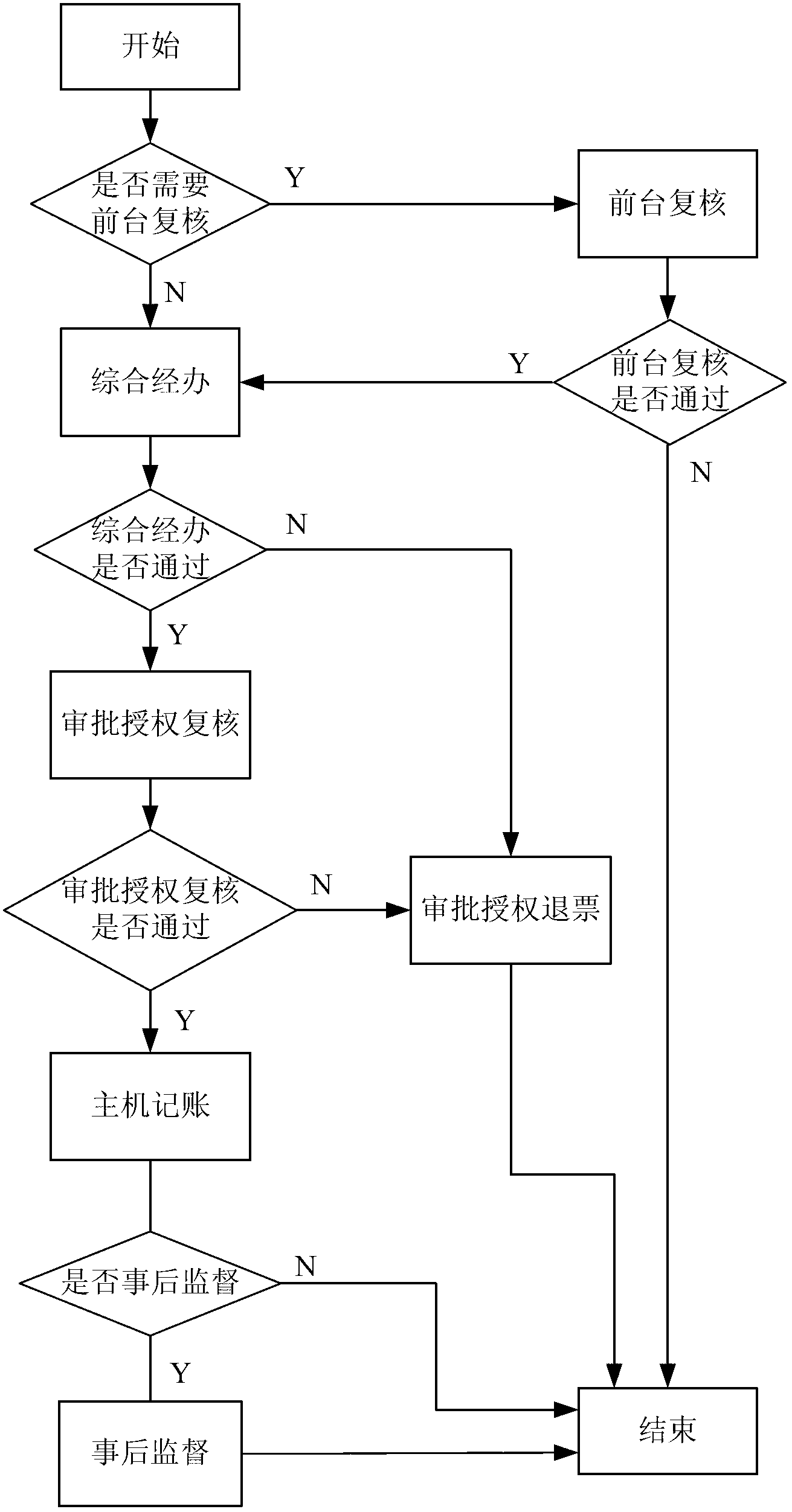

Configuration type business flow system and realization method thereof

ActiveCN102799962AIncrease flexibilityImprove convenienceResourcesSoftware engineeringProcess configuration

The invention relates to a configuration type business flow system and a realization method thereof. A business processing flow is described and defined through three configuration files including a business flow configuration file, a business processing configuration file and a business rule configuration file; a business flow, business processing and a business rule in the business flow are respectively and independently defined through the configuration manner and do not interfere with one another, so as to realize decoupling of the three configuration files, and increase extremely great flexibility and convenience for maintaining and developing a business processing flow; meanwhile, the business processing configuration file is recorded with related information of a processing node and a business link realization module and the business rule configuration file is recorded with related information of a control node and a business rule realizing module, so that an organic relation exists among the three configuration files and a business is ensured to be smoothly operated. According to the configuration type business flow system and the realization method thereof, the developing efficiency can be improved and the flexibility of required changes can be adapted; and meanwhile, the developing period is shortened, and the developing cost and the maintaining cost are reduced.

Owner:南京合荣欣业信息技术有限公司

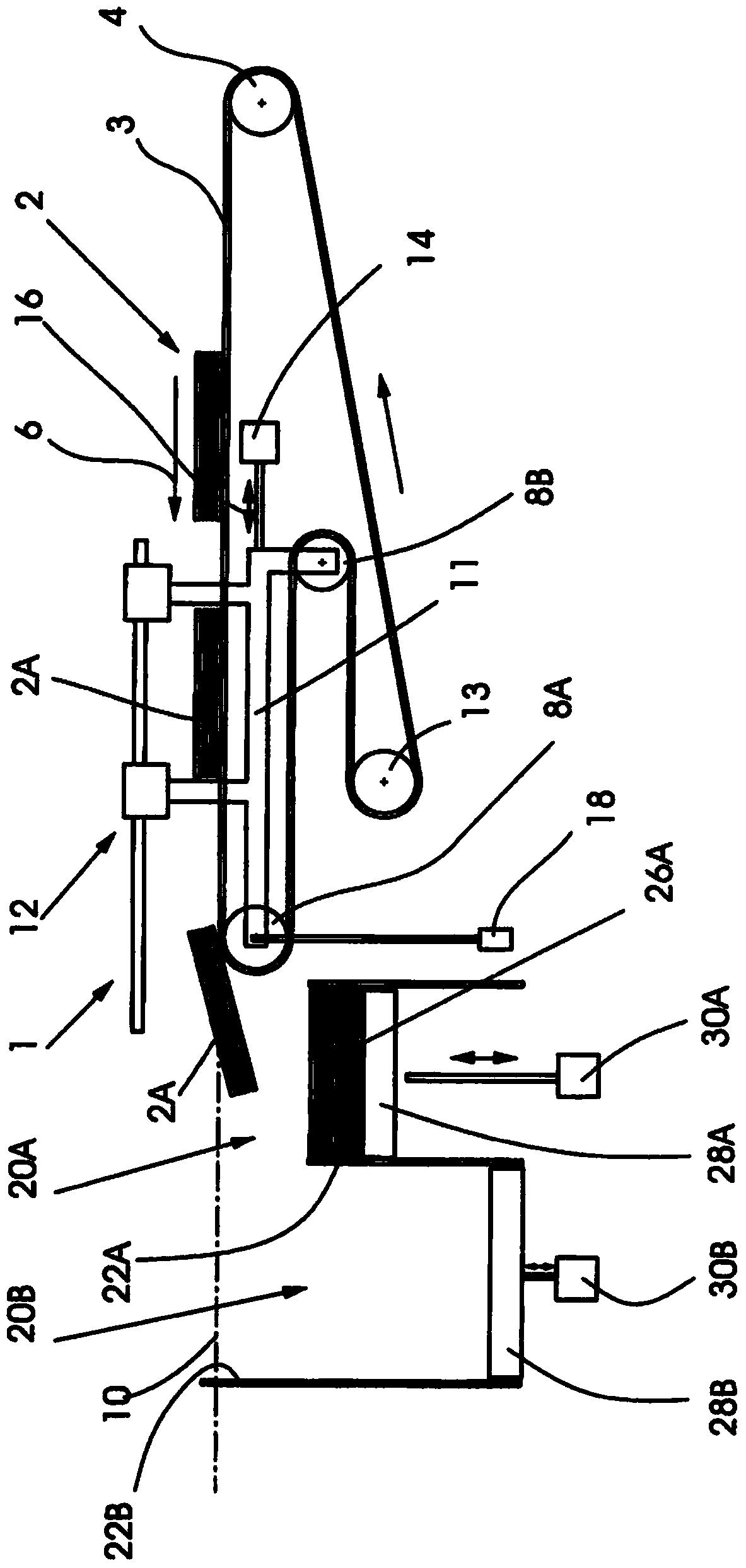

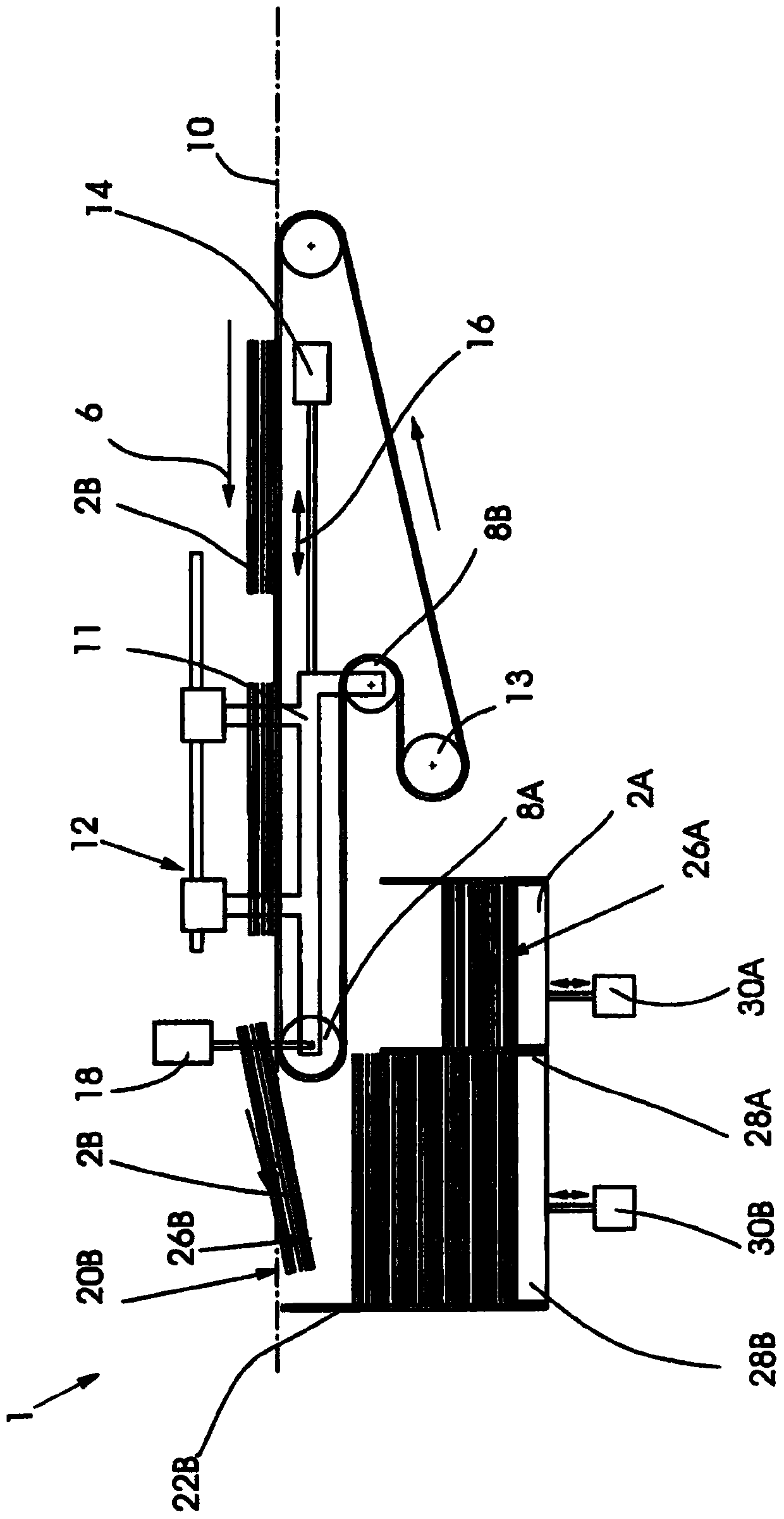

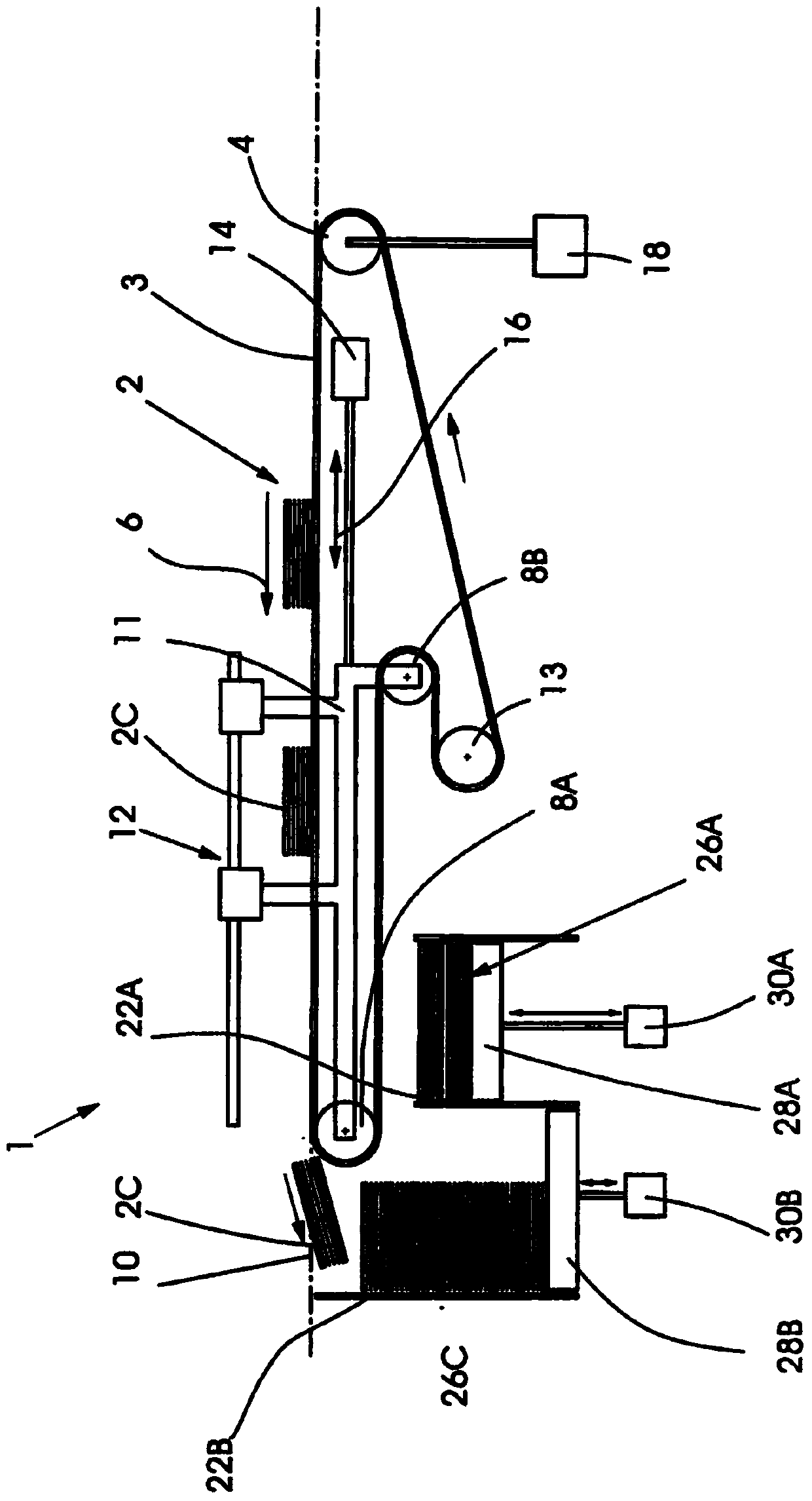

Device for laying out printed products fed in a single product flow into two separate stacks

InactiveCN103991745AIncrease or decrease in thicknessLess quantityConveyorsFunction indicatorsActuatorConveyor belt

The device (1) has an endlessly circulating conveyor belt (3), on which the printed products (2A) are stored, an upper upstream frame-fixed guide roller (4) and an upper downstream movable guide roller (8A) arranged in a horizontal plane with the former guide roller. A third guide roller (8B) is arranged within the latter guide roller. A fourth guide roller (13) is arrranged within the third guide roller. An actuator is raised from a display position into another display position for common movement of the latter and third guide roller parallel to a horizontal plane (10). The printed products with their leading edge advance to a stop arranged above a product receiving chamber for the former stack in the former display position. An independent claim is included for a method for laying or stacking of printed products.

Owner:MULLER MARTINI HLDG

Method for oxidizing asphaltum

InactiveCN1415699AGood dispersionSmall diameterWorking-up pitch/asphalt/bitumen by chemical meansEngineeringTower

A process for oxidizing asphalt includes such steps as dispersing air in the microbubbles mode in asphalt, loading in asphalt oxidizing tower, and oxidizing. Its advantages are high utilization rate of air, high speed, and simple structure of said oxidizing tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

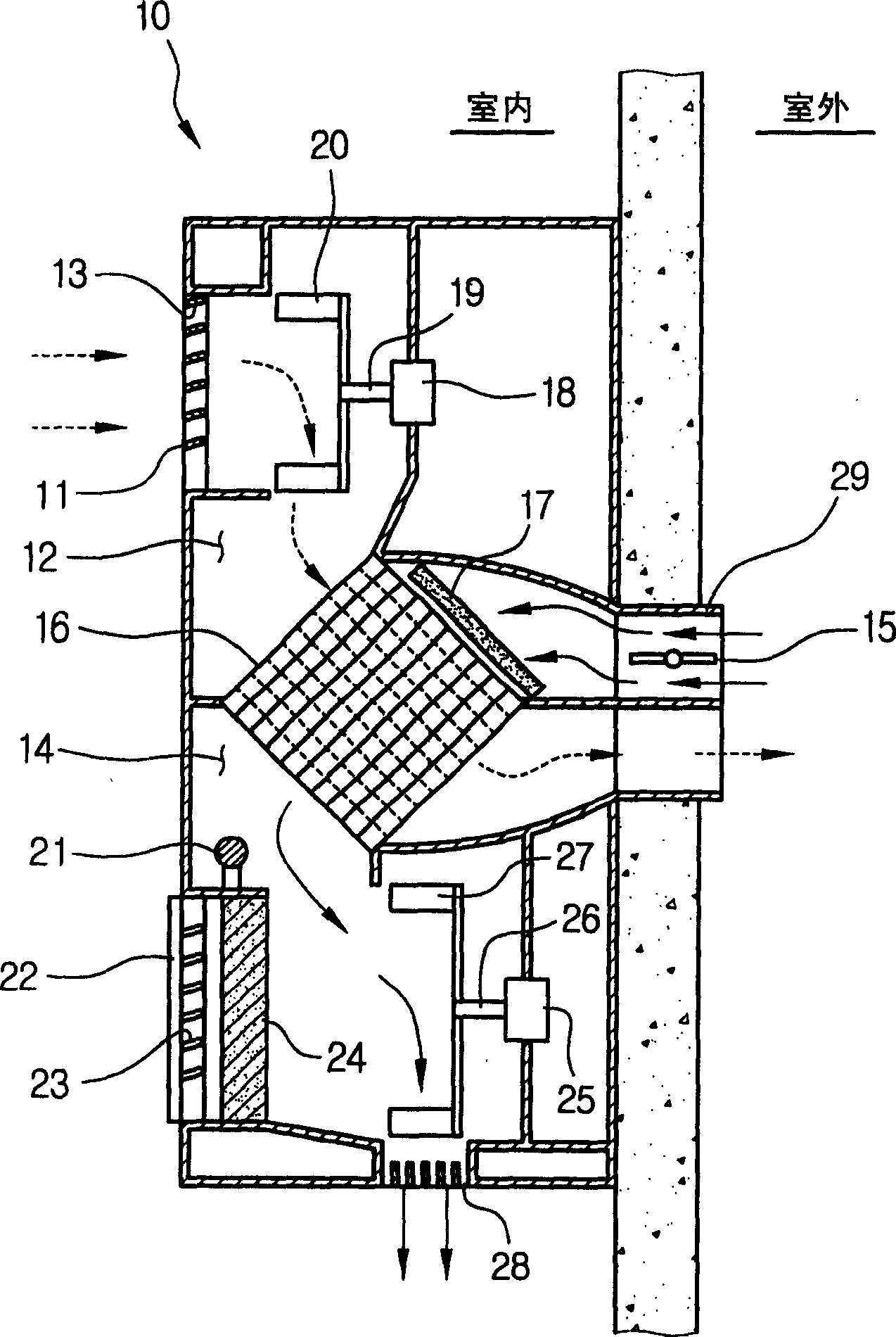

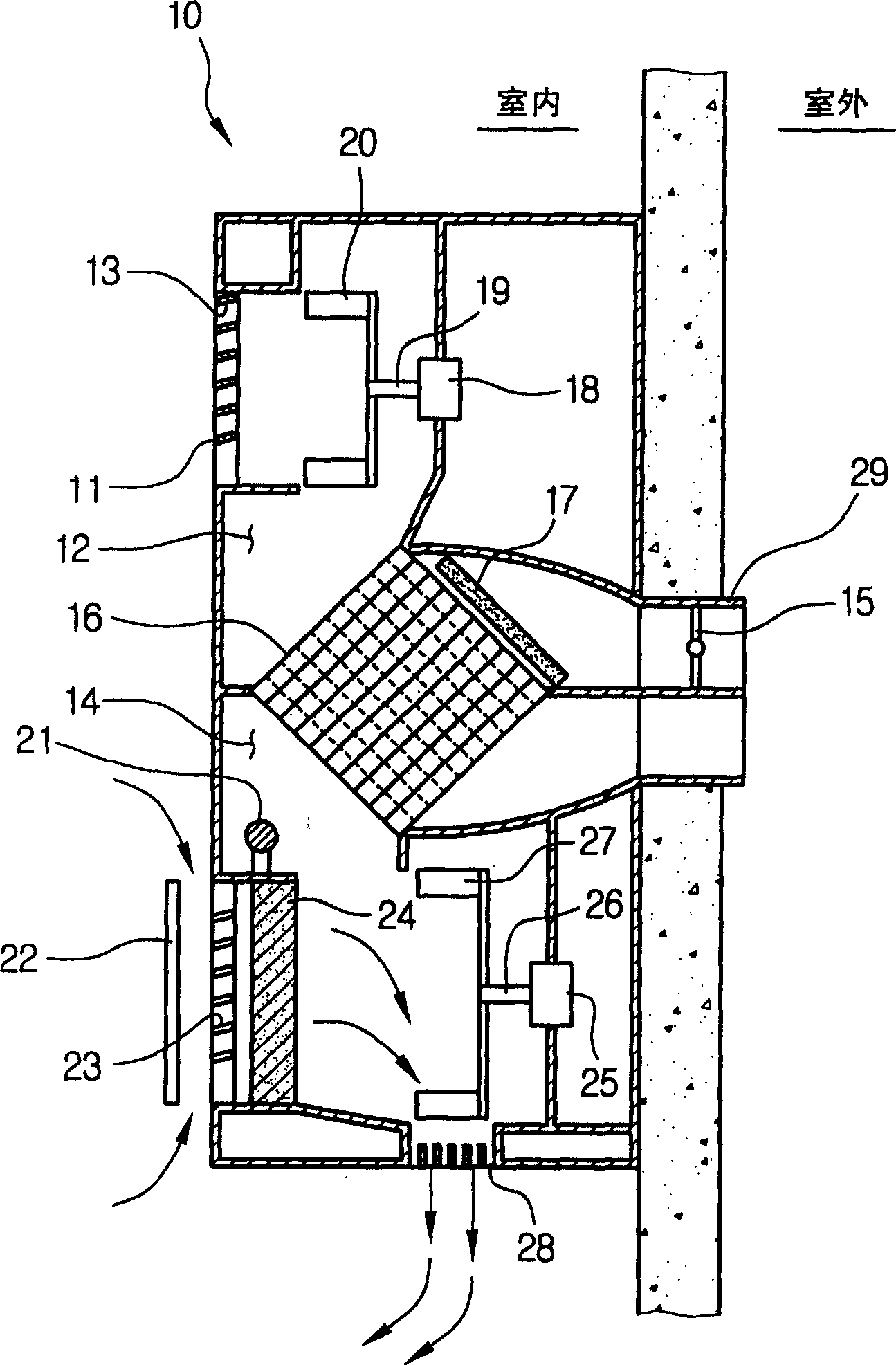

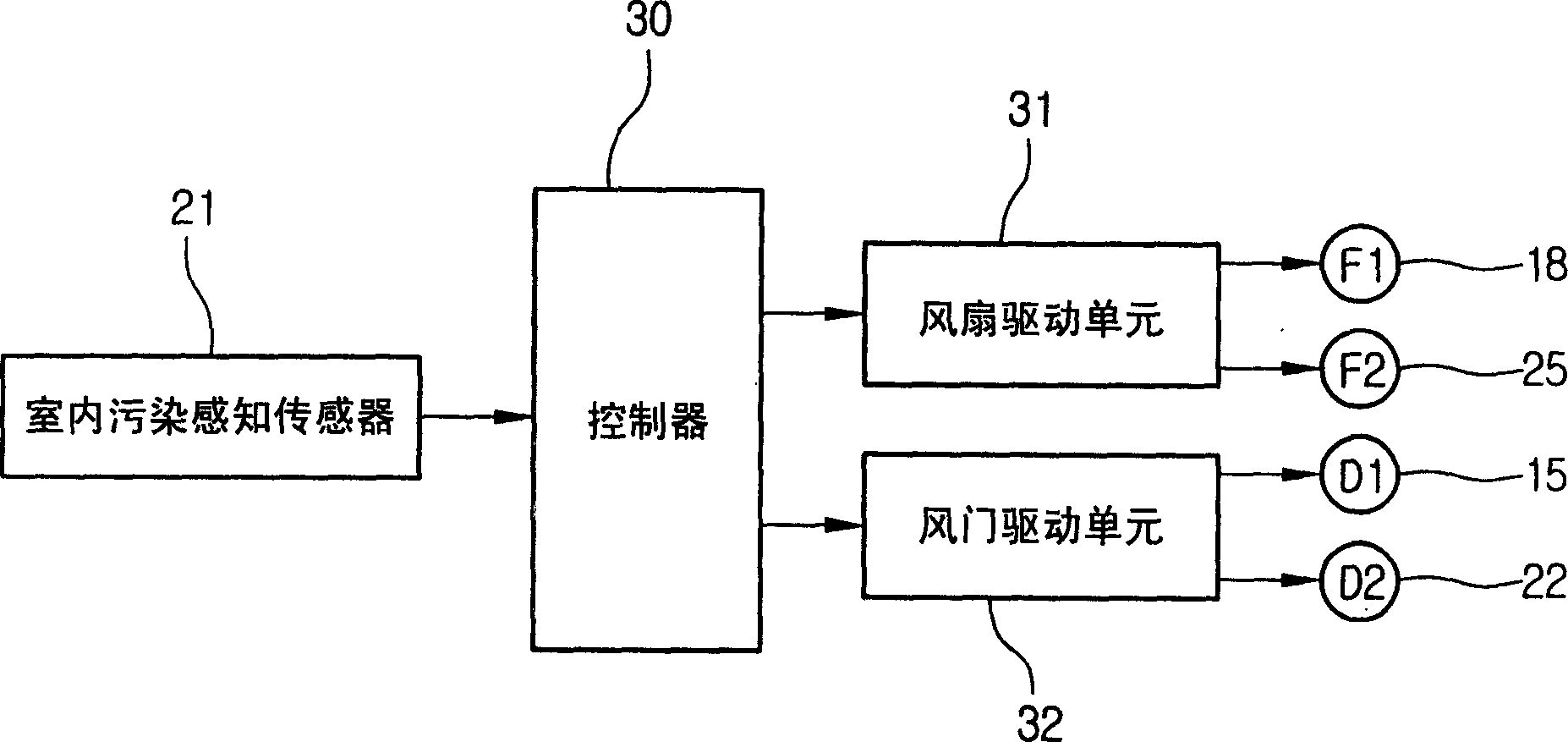

Air purifying system and control method thereof

InactiveCN1576734ASmooth runningReduce power consumptionEnergy recovery in ventilation and heatingMechanical apparatusAir cleaningOperation mode

Provided is an air cleaning system and its control method capable of performing a ventilating operation and an air cleaning operation in accordance with a contamination state of the indoor air. This air cleaning system comprises a ventilating unit, an air cleaning unit, a sensor for detecting the concentration of contamination of the indoor air, and a controller for deciding one of a plurality of operation modes in accordance with the concentration of contamination of the indoor air detected by the sensor, and controlling the ventilating unit and the air cleaning unit in accordance with the decided operation mode.

Owner:SAMSUNG ELECTRONICS CO LTD

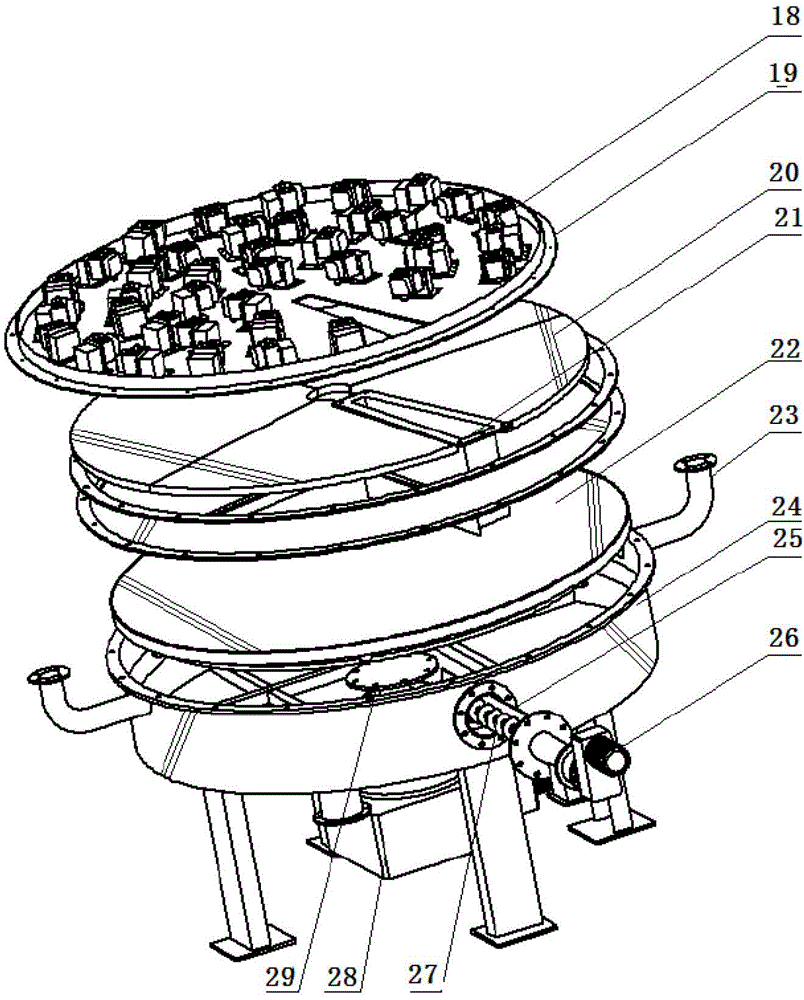

Disc-type microwave continuous splitting device and method for splitting waste rubber

ActiveCN103333709ASmooth runningImprove microwave cracking efficiencyPigmenting treatmentPlastic recyclingMicrowaveWaste rubber

The invention discloses a disc-type microwave continuous splitting device. The disc-type microwave continuous splitting device comprises a feeding assembly, a microwave splitting assembly, a discharging assembly and a control assembly which are sequentially communicated with one another, wherein the microwave splitting assembly comprises a microwave generator, a nonmetal sealing plate, a splitting cavity, a rotating disk and a disk driving motor, the nonmetal sealing plate is used for dividing the splitting cavity into an upper part and a lower part, the rotating disk is arranged at the lower part of the splitting cavity and is matched with the disk driving motor in a driving rotation manner, and the microwave generator is arranged on a circular flange on the splitting cavity. The invention aslo discloses a method for splitting waste rubber by using the splitting device; the disc-type splitting cavity is adopted in the method and is divided into an upper cavity and a lower cavity through the nonmetal sealing plate, so that the microwave splitting efficiency of waste tires is improved; and in order to ensure the stable operation of a disk and prevent the high-temperature deformation, one or a plurality of annular guide rails are arranged on the lower surface of the rotating disk and are used for supporting the rotating disk, so that the rotating disk rotates on a guide rail so as to optimize the splitting effect.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

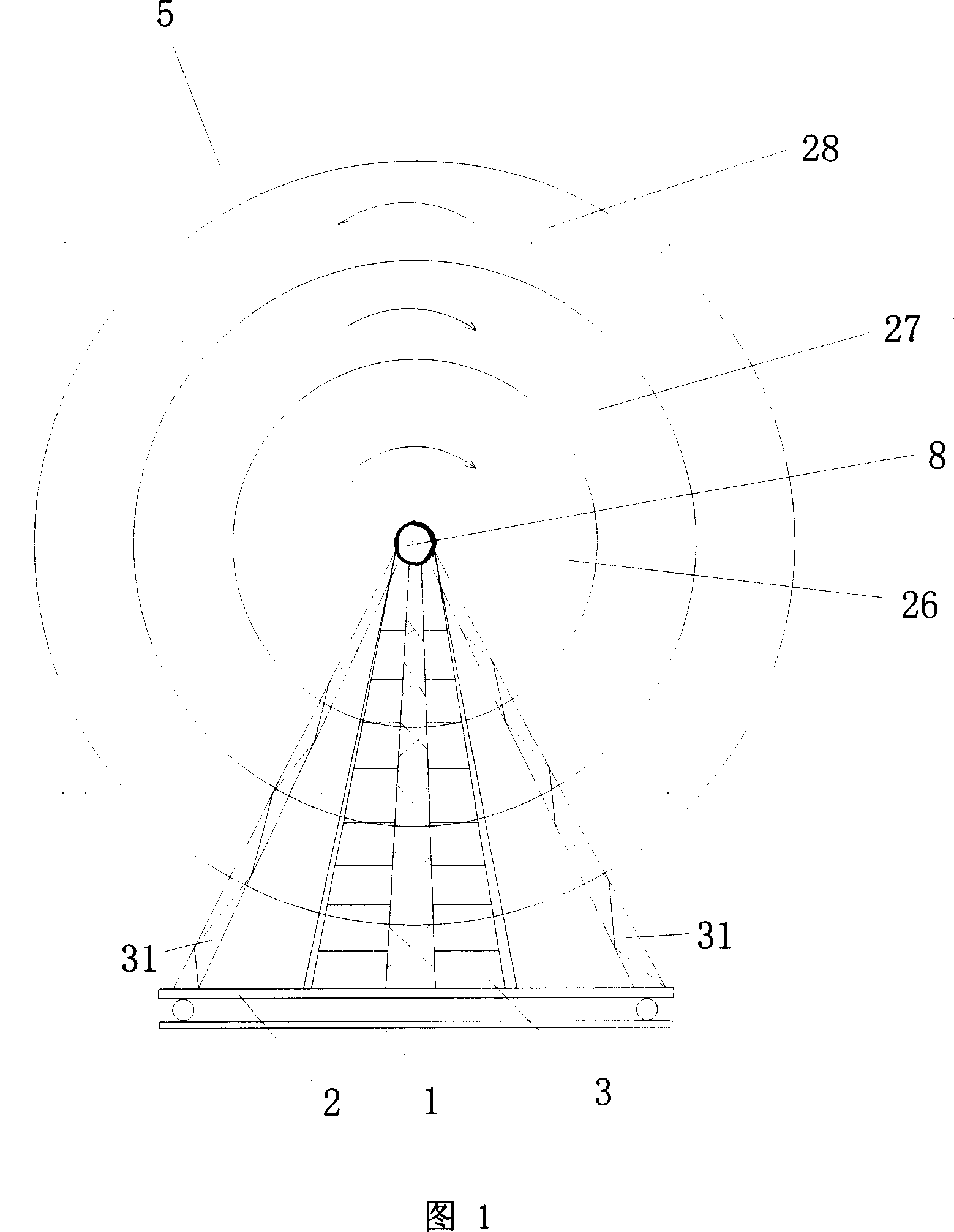

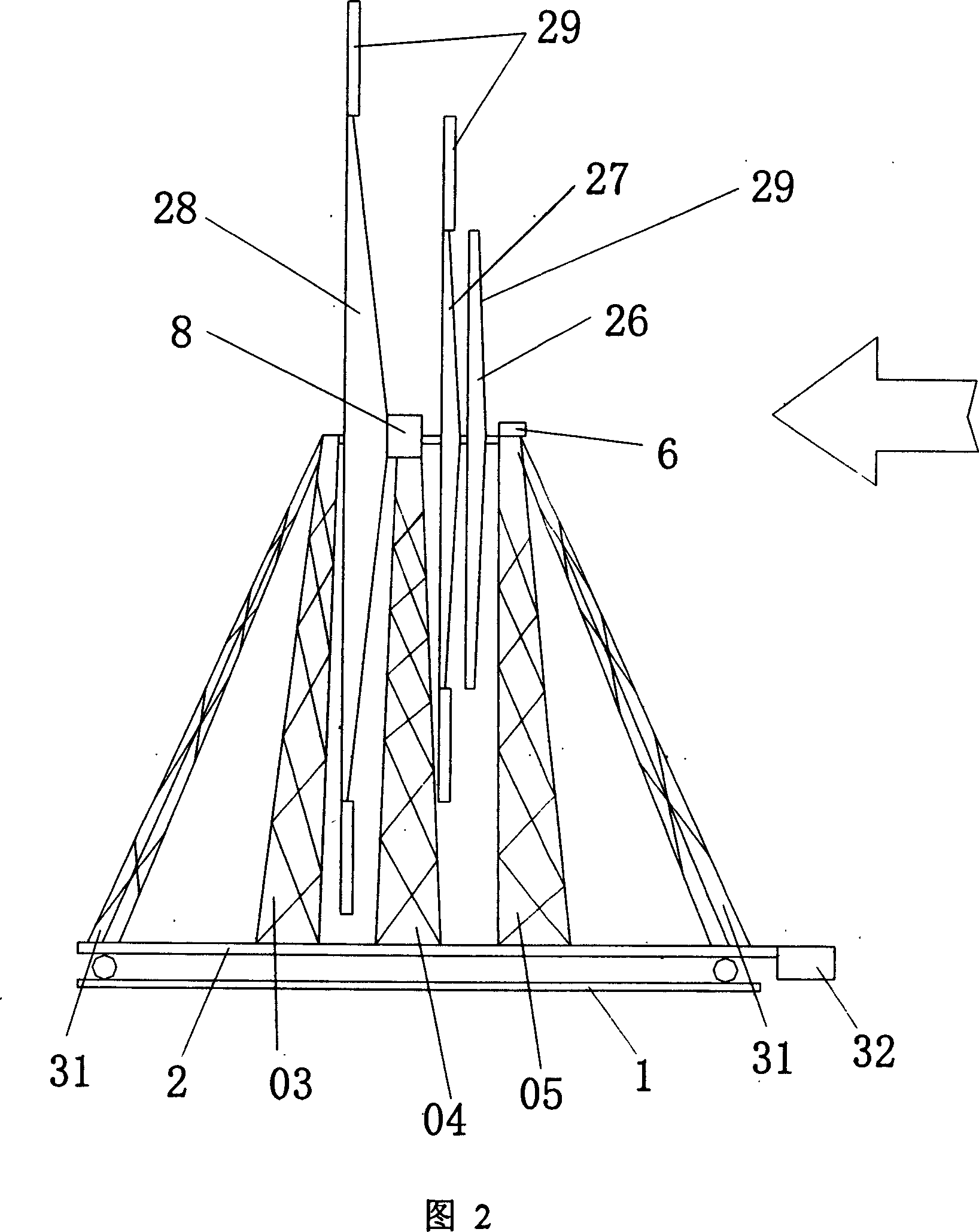

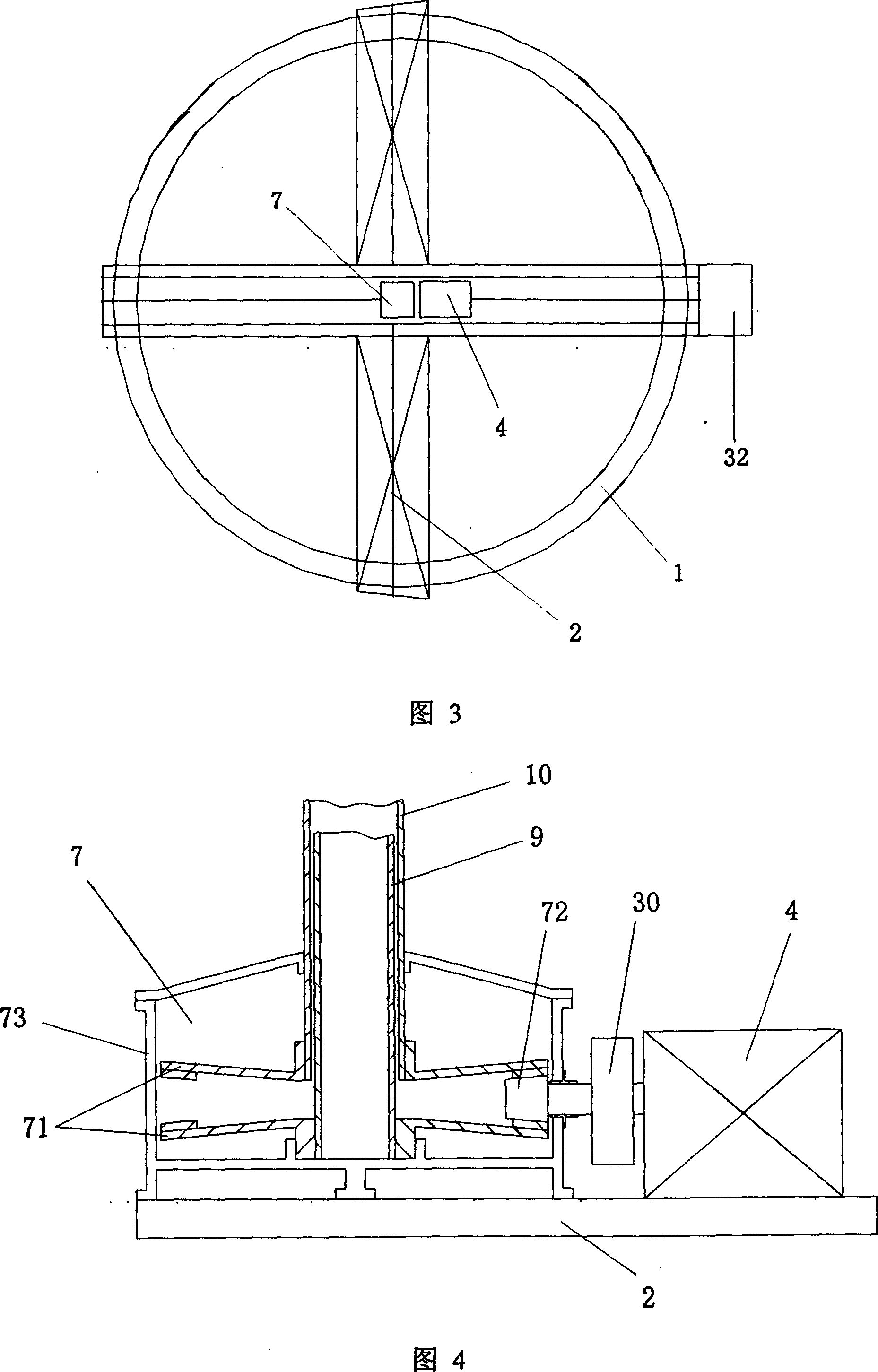

Multistage wind wheel generator with load supporting type frame

ActiveCN101004168AForce balanceIncrease profitWind motor supports/mountsWind motor combinationsWind drivenGear drive

The present invention relates to a load-bearing frame multistage wind-wheel power generator for wind-driven power generation. It is characterized by that it includes the following several portions: a circular stabilized frame connected with ground, a '+' shaped load-bearing rotary frame mounted on the circular stabilized frame by means of rotating device, a supporting frame and a power generator mounted on said '+'-shaped load-bearing rotary frame, first gear box set in the central position of '+'-shaped load-bearing rotary frame, second gear box which is set in the top portion of said supporting fame and is opposite to said first gear box, frame-type multistage wind wheel group with different diameters which is mounted on the supporting frame and symmetrically-arranged gear drive mechanisms.

Owner:深圳市谢振才大风电能源科技有限公司

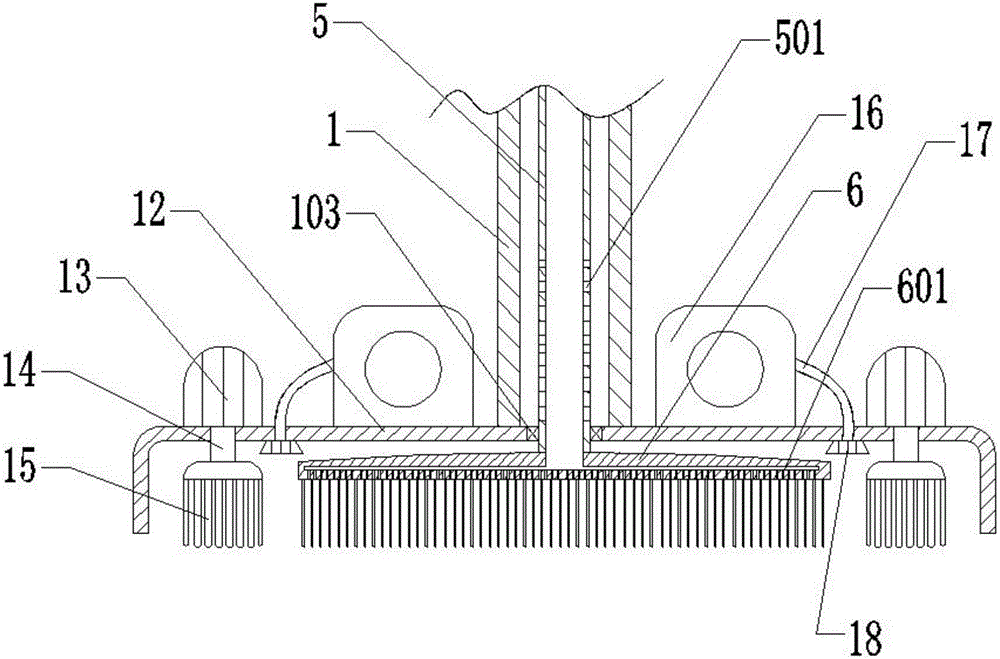

Bathroom electric cleaning device

InactiveCN105919520AAchieve cleaning effectPrevent falls, etc.Carpet cleanersBrush bodiesElectric machineryEngineering

The invention discloses a bathroom electric cleaning device which comprises a long rod, a handle, a storage battery, a motor, a rotating shaft, a hairbrush, a cleaning agent storing box, a water pipe, a corrugated pipe, a connector, a switch button, a protection cover, a second motor, a second rotating shaft, a second hairbrush, a dryer, a pipeline, a drying head, a fixing plate, a sliding plate, a spring, a first filtering hole and a second filtering hole. The bathroom electric cleaning device is simple in structure and powerful in function; the motors when being turned on drive the hairbrushes to clean a floor, so that cleaning by workers is replaced, and labor is reduced; the floor is flushed by a cleaning agent and water while the hairbrushes are in friction with the floor, so that consumption of the cleaning agent and the water is reduced, and cost is saved.

Owner:YANGTZE UNIVERSITY

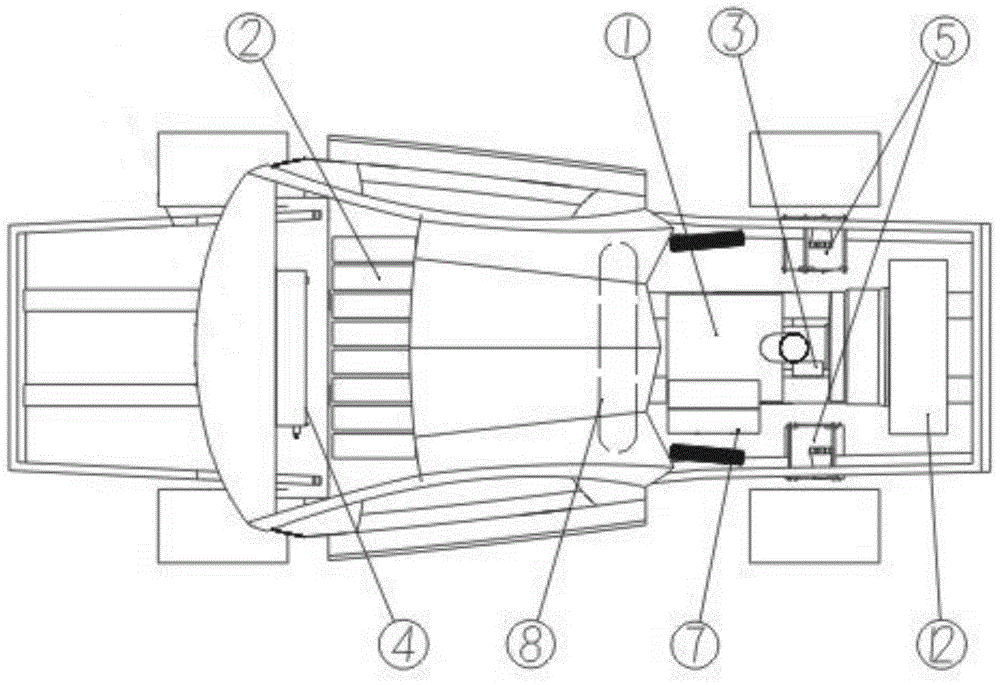

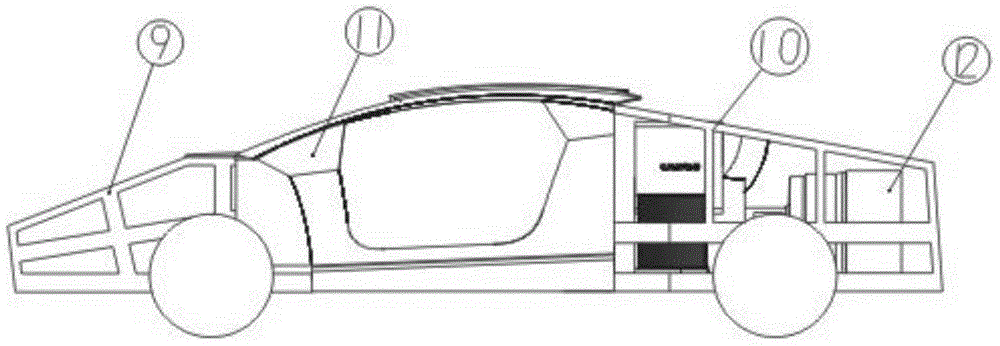

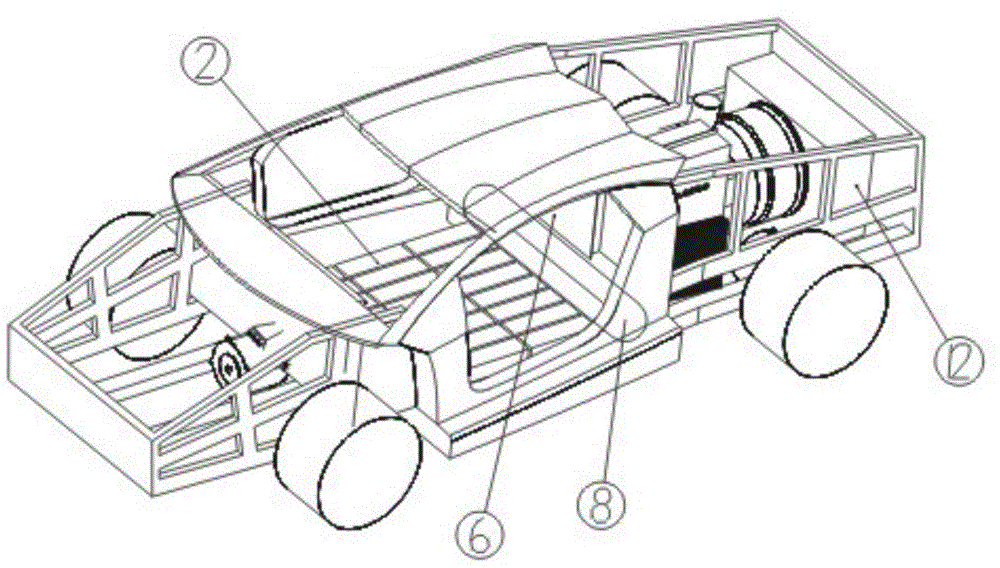

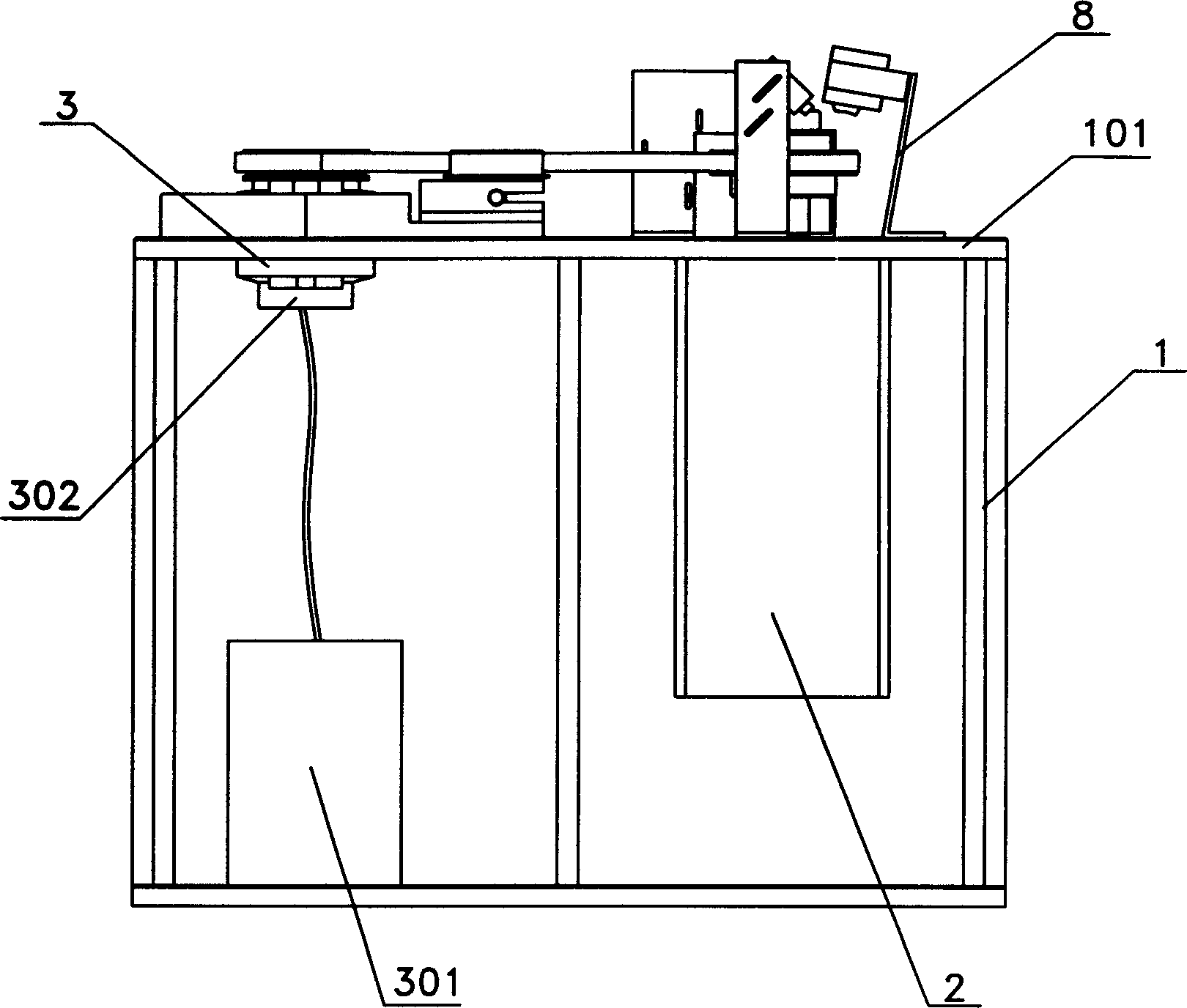

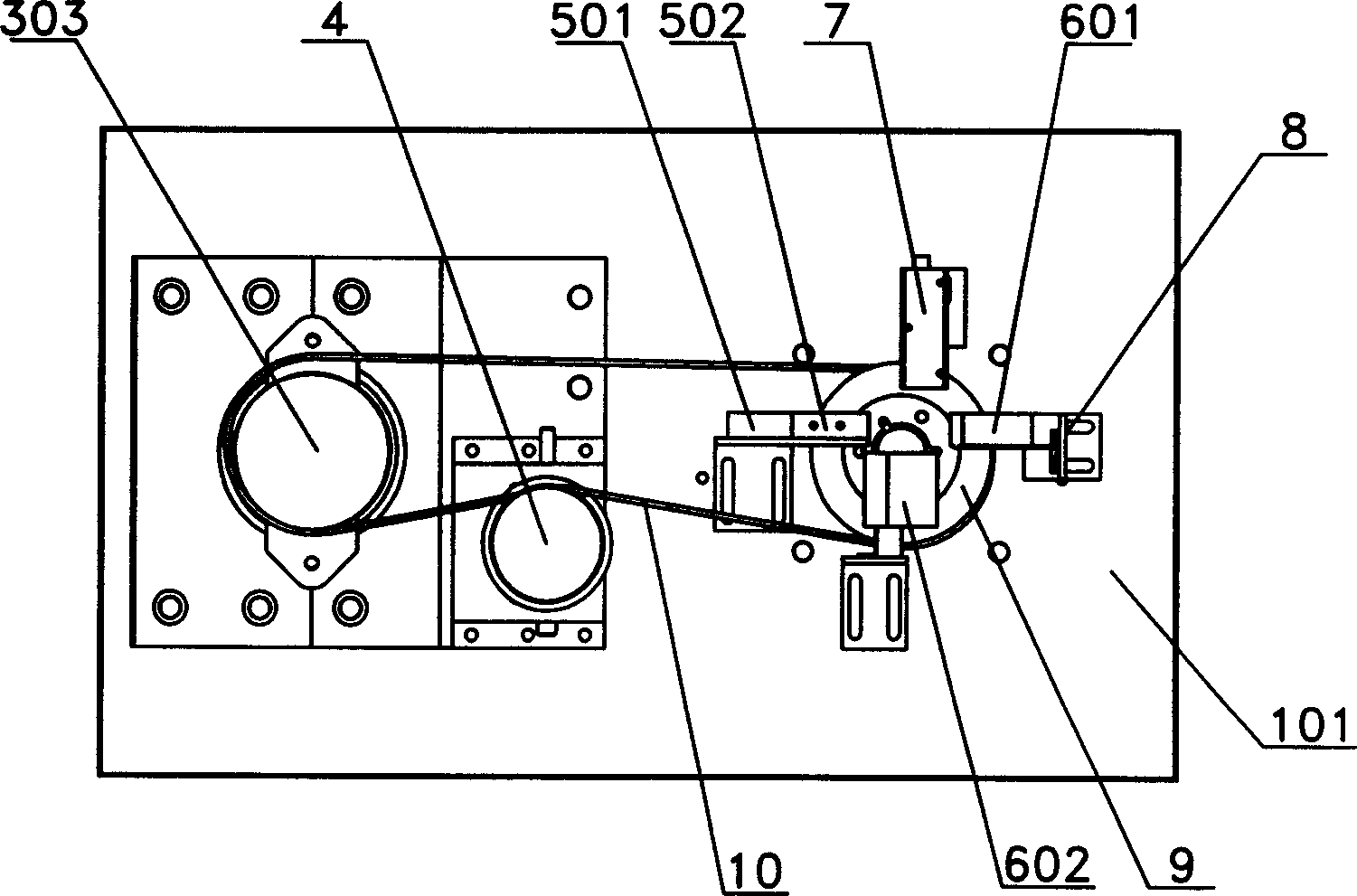

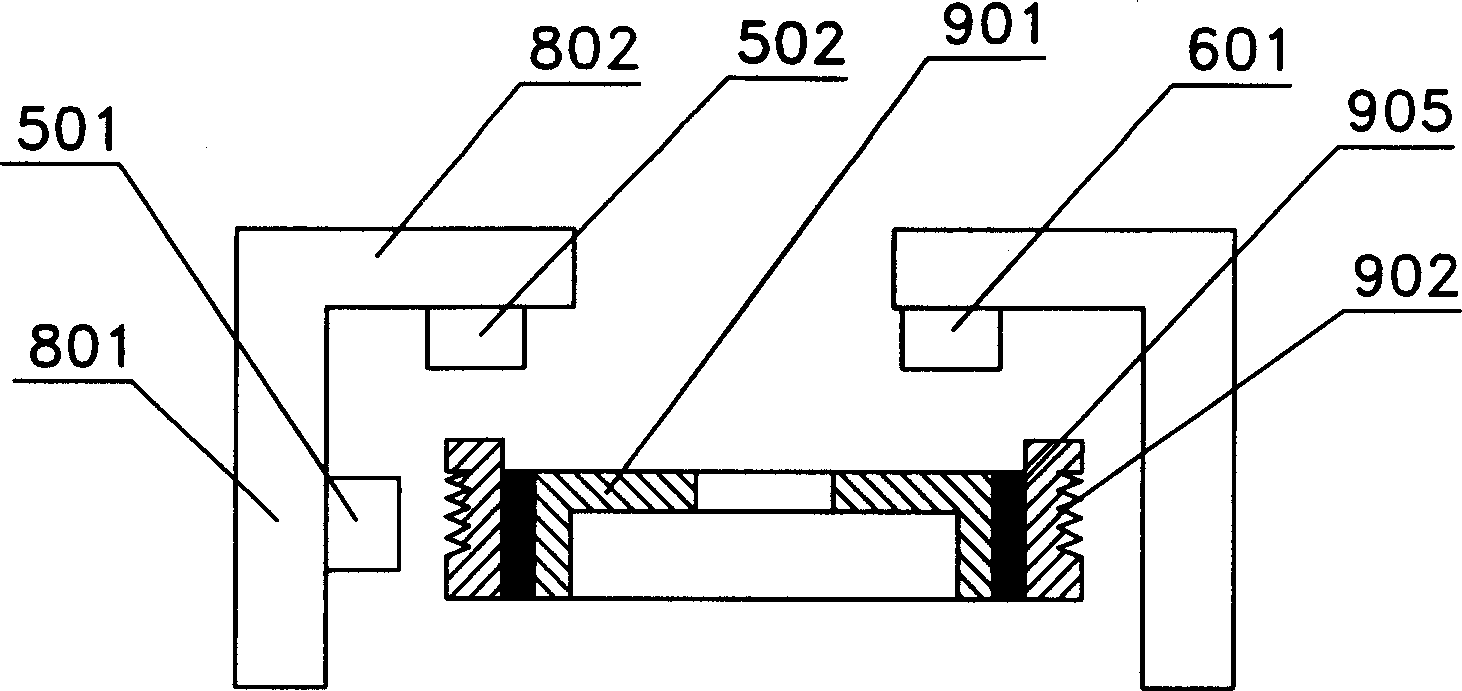

Mid-engine incremental stroke electric vehicle

ActiveCN104802629ASimple structureAvoid pollutionHybrid vehiclesSpeed controllerVehicle frameElectric machine

The invention provides a mid-engine incremental stroke electric vehicle. The electric vehicle comprises a vehicle body, a turbo shaft engine (1), a battery pack (2), a generator (3), a whole vehicle controller (4), a driving motor (5), a gas controller (6), a battery controller (7), a gas holder (8) and a gas inlet tank (12), and is characterized in that the vehicle body comprises a vehicle main body, wherein the bottom structure of the vehicle main body forms a vehicle frame; the turbo shaft engine (1) is distributed between a front axle and a rear axle and is close to the vehicle frame of the rear axle; the axis of the output shaft of the turbo shaft engine (1) is positioned on the symmetry planes of the vehicle body; the air inlet of the turbo shaft engine (1) faces towards the tail of the vehicle; the gas inlet tank (12) is communicated with the air inlet of the turbo shaft engine (1); the gas inlet tank (12) is communicated with a gas inlet grille on a vehicle covering piece. The electric vehicle has the characteristics of high energy conversion efficiency, good operating performance, long driving mileage and high vehicle body structural strength.

Owner:刘慕华

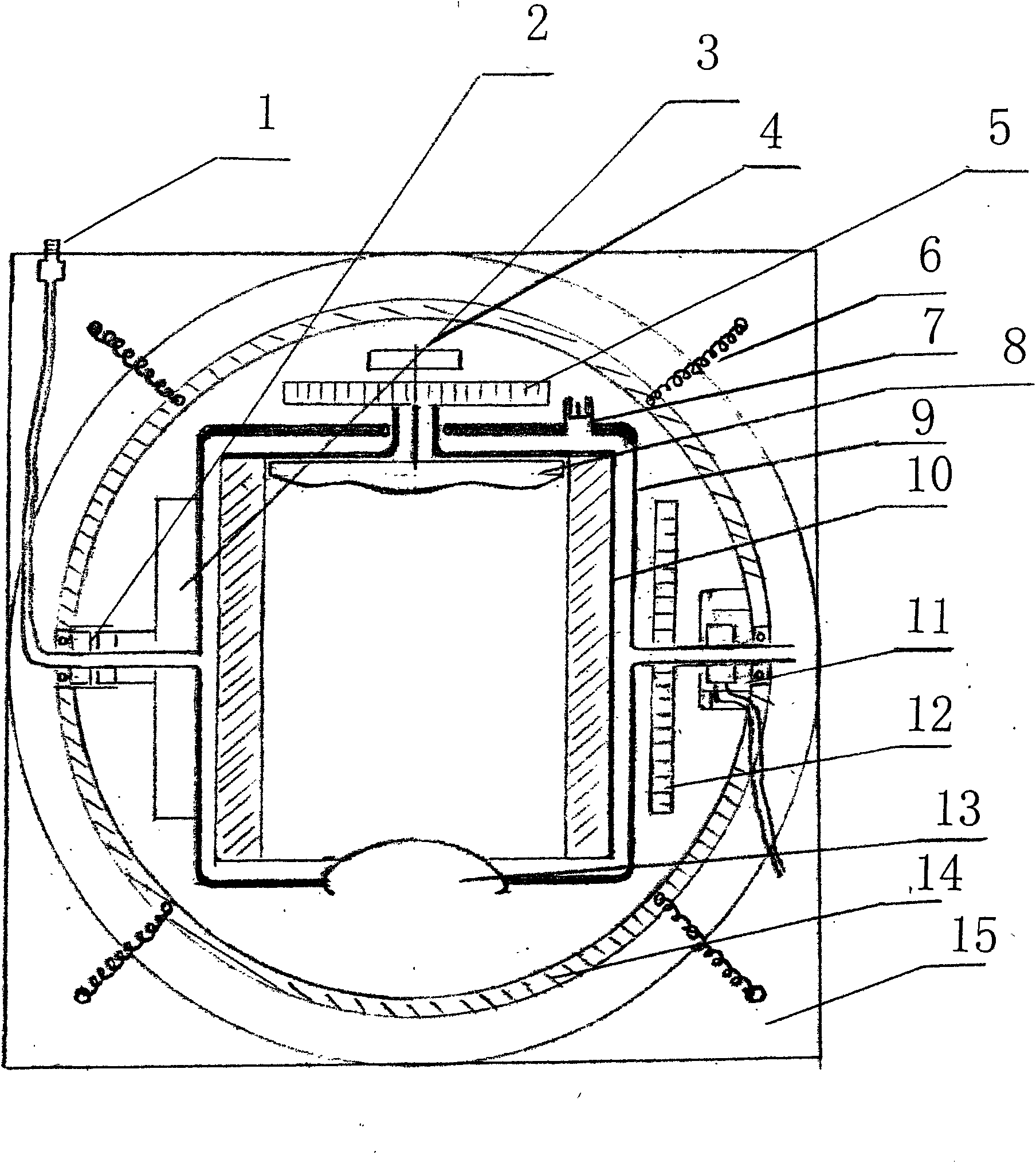

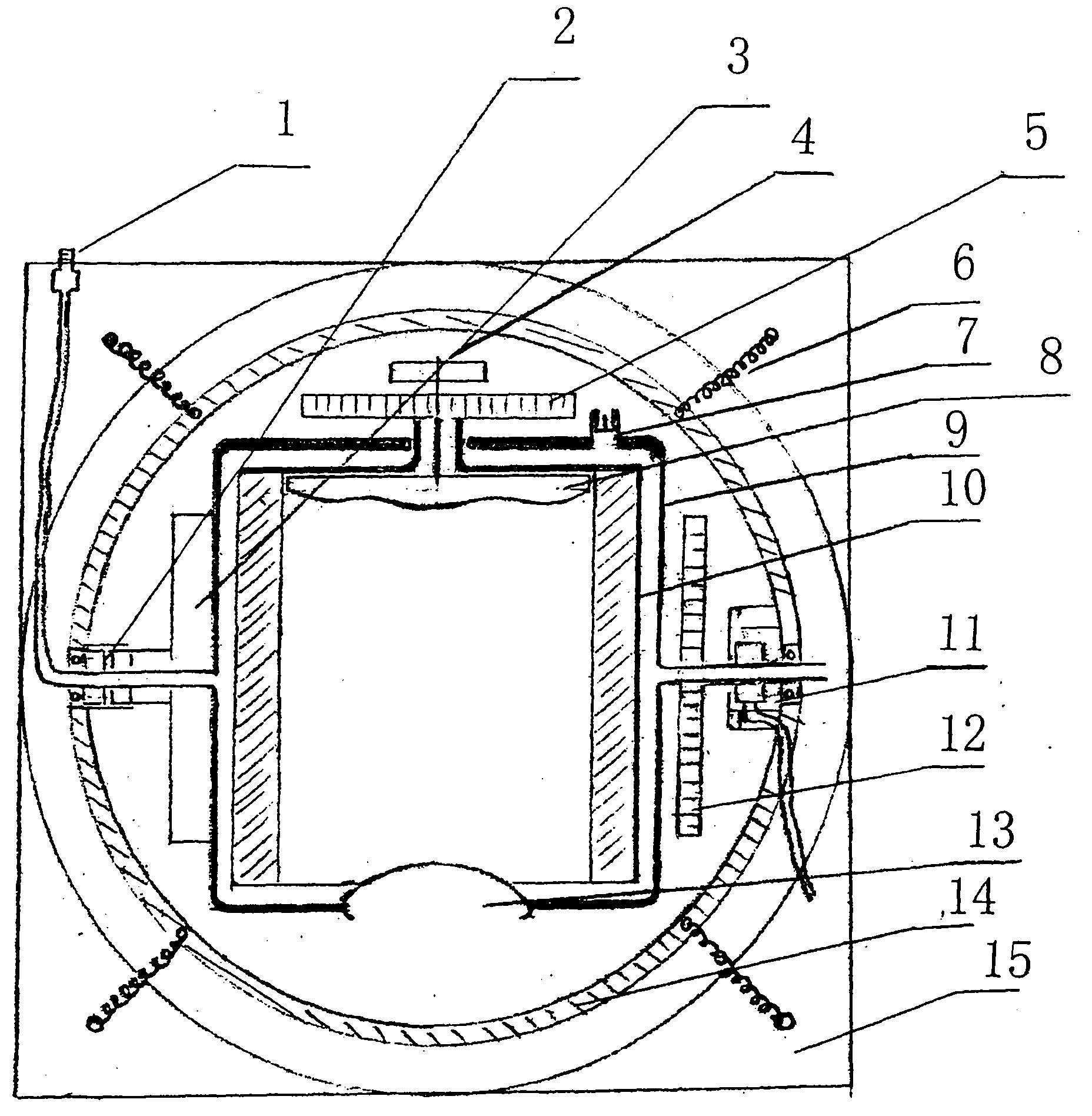

Test-bed for testing performance of vibration damping belt pulley wheel

InactiveCN1601248ASmooth runningImprove running accuracyEngine testingVehicle suspension/damping testingAxial displacementComputerized system

The invention relates to a vibration-damping belt pulley performance test table. It includes table frame, motor and vibration-damping belt pulley to be tested on its motor shaft, load and its belt pulley on its shaft and tension pulley; on the side walls of external ring and internal ring of the vibration-damping belt pulley to be tested the marks are respectively set; and on the table frame the mark sensors for sensing marks, laser displacement sensor for measuring radial displacement of the vibration-damping belt pully and laser displacement sensor for measuring axial displacement of the vibration-damping belt pulley; the output end of every sensor is connected with computer system. Besides, said invention also provides the application and action of said test table.

Owner:WUHAN UNIV OF TECH

No-cylinder-cover double-combustion-chamber horizontal type four-stroke internal combustion engine

InactiveCN103321744AReduce vibrationReduce noiseInternal combustion piston enginesCylinder headsTop dead centerExternal combustion engine

The invention provides a no-cylinder-cover double-combustion-chamber horizontal type four-stroke internal combustion engine which comprises a cylinder body, special-shaped pistons, a crank-link mechanism and a valve seat air distributing system. An air cylinder is arranged inside the cylinder body. Two special-shaped piston heads are arranged inside the air cylinder in a butt joint mode. The special-shaped piston heads are connected with the crank-link mechanism and then connected with the valve seat air distributing system in a gear meshing mode so that the two special-shaped pistons move synchronously in the opposite direction in the air cylinder, and therefore the two special-shaped pistons, the crank-link mechanism and the valve seat air distributing system finish the four-stroke motion together. Moreover, four piston grooves and two piston top inclined faces are arranged in the positions of heat power banks of the special-shaped pistons to avoid opening and closing of a valve of the valve seat air distributing system. When the special-shaped pistons run to the top dead center of a compression stroke, two combustion chambers with the same size are formed in the positions of the gaps of the pistons top inclined faces and the valve. The no-cylinder-cover double-combustion-chamber horizontal type four-stroke internal combustion engine has the advantages of being high in compression ratio, high in rotating speed, stable in operation, large in torque power and long in service life, does not knock easily, saves energy, reduces emission, is green and protects environment.

Owner:张义敏

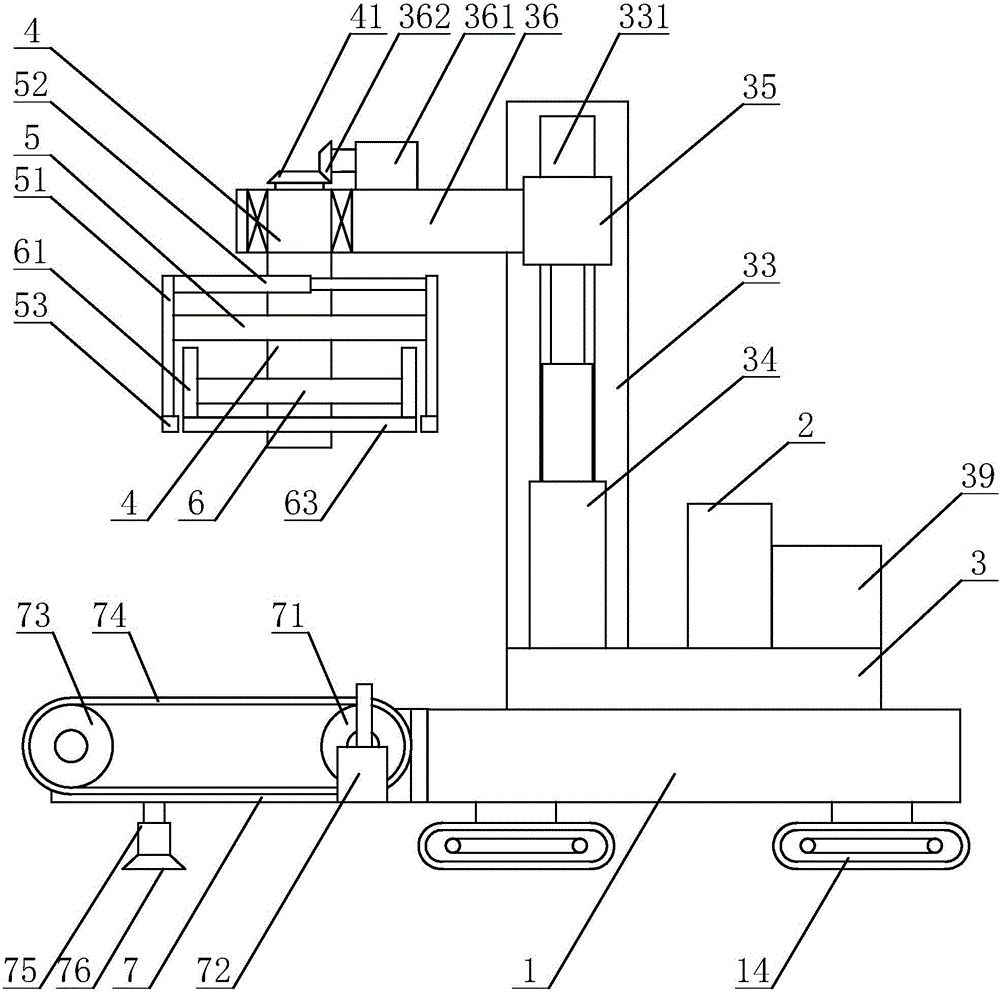

Intelligent brick stacking machine

ActiveCN106429465AMake sure to staggerStack stableStacking articlesConveyor partsBrickAgricultural engineering

The invention discloses an intelligent brick stacking machine and mainly relates to the technical field of building material machinery. The intelligent brick stacking machine comprises a support and a PLC controller, wherein a rotating platform is arranged on the support; a supporting frame and a servo air cylinder are arranged on the rotating platform; a bearing frame is arranged at the upper end of the servo air cylinder; a bearing cross rod is arranged at the front end of the bearing frame; a transmission rod is vertically arranged at the front end of the bearing cross rod; one end, far away from the bearing cross rod, of the transmission rod is connected with a clamping mechanism; the clamping mechanism comprises a transverse clamping part and a longitudinal clamping part; a balancing weight is arranged on the rotating platform. The intelligent brick stacking machine has the beneficial effects that the intelligent brick stacking machine can stack the bricks quickly and efficiently, can increase the working frequency, can move automatically according to the actual stacking requirement and can adjust the placing position of the bricks so as to guarantee the brick stacking stability.

Owner:LUOYANG INST OF SCI & TECH

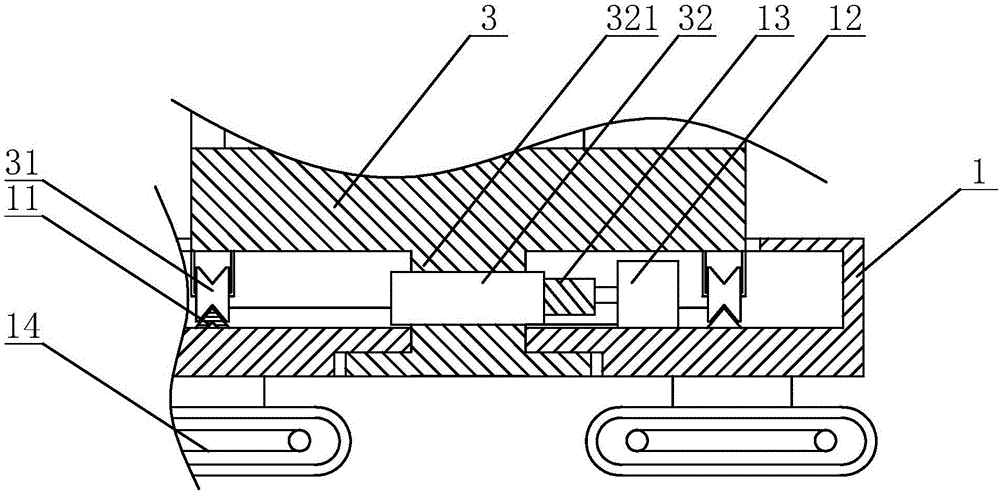

Production method of cold-drawn precision seamless steel pipes

InactiveCN104338777AImprove performanceImprove low temperature impact toughnessAcid washingLubrication

The invention relates to a production method of cold-drawn precision seamless steel pipes. The production method comprises the steps of: heating: pipe blanks are heated in an annular furnace; perforation: the heat pipe blanks are perforated by a perforation machine; annealing: the pipe blanks are annealed; cold rolling: the annealed pipe blanks are leaded into a pipe rolling machine for cold rolling to obtain rolled pipes; stress relieving: the rolled pipes are leaded into a heating furnace for heating to obtain annealed pipe blanks; acid washing treatment: the acid washing is performed for the annealed pipe blanks to remove scales on the surfaces; phosphating treatment: zinc phosphate chemical generation films are formed on the surfaces of the pipe blanks; saponification treatment: such lubrication films as metallic soaps are formed on the films; cold drawing: the cold drawing is performed for the pipe blanks to be cold drawn to obtain cold-drawn pipes; normalization air-cooling treatment; first straightening treatment; induction furnace quenching treatment; box furnace tempering treatment; honing; thermal straightening treatment; and obtaining of the cold-drawn precision seamless steel pipes. The production method obtains the cold-drawn precision seamless steel pipes with high yield strength, high tensile strength, precise sizes and smooth surfaces.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

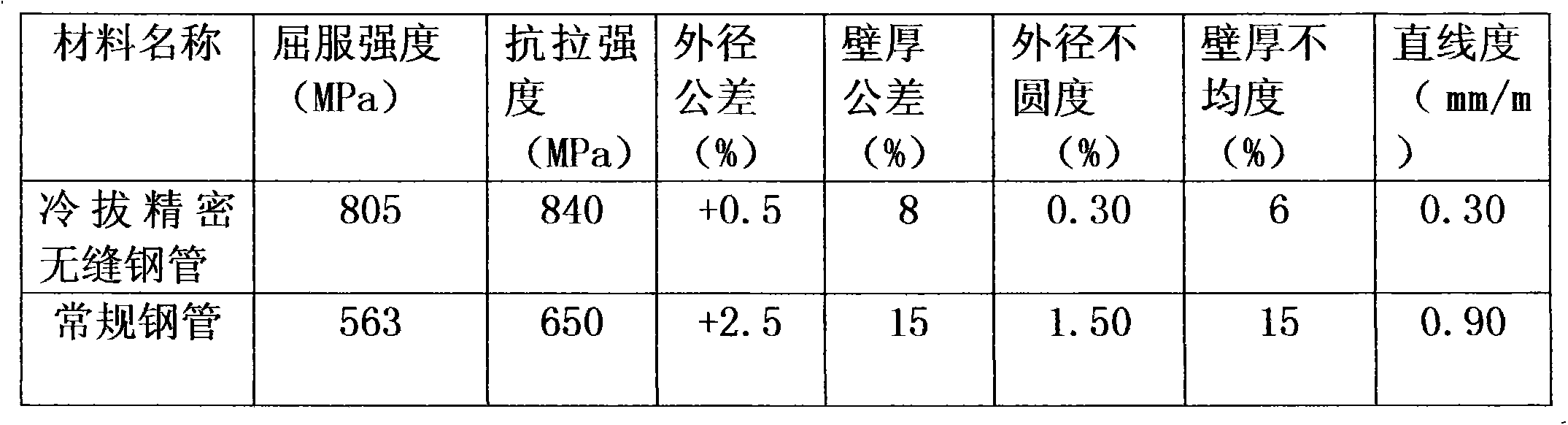

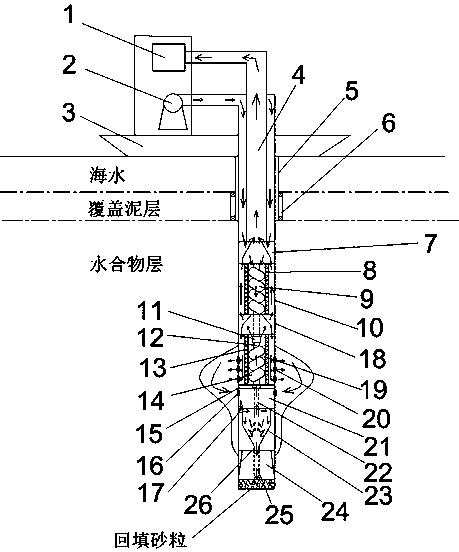

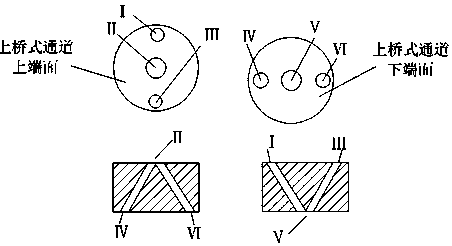

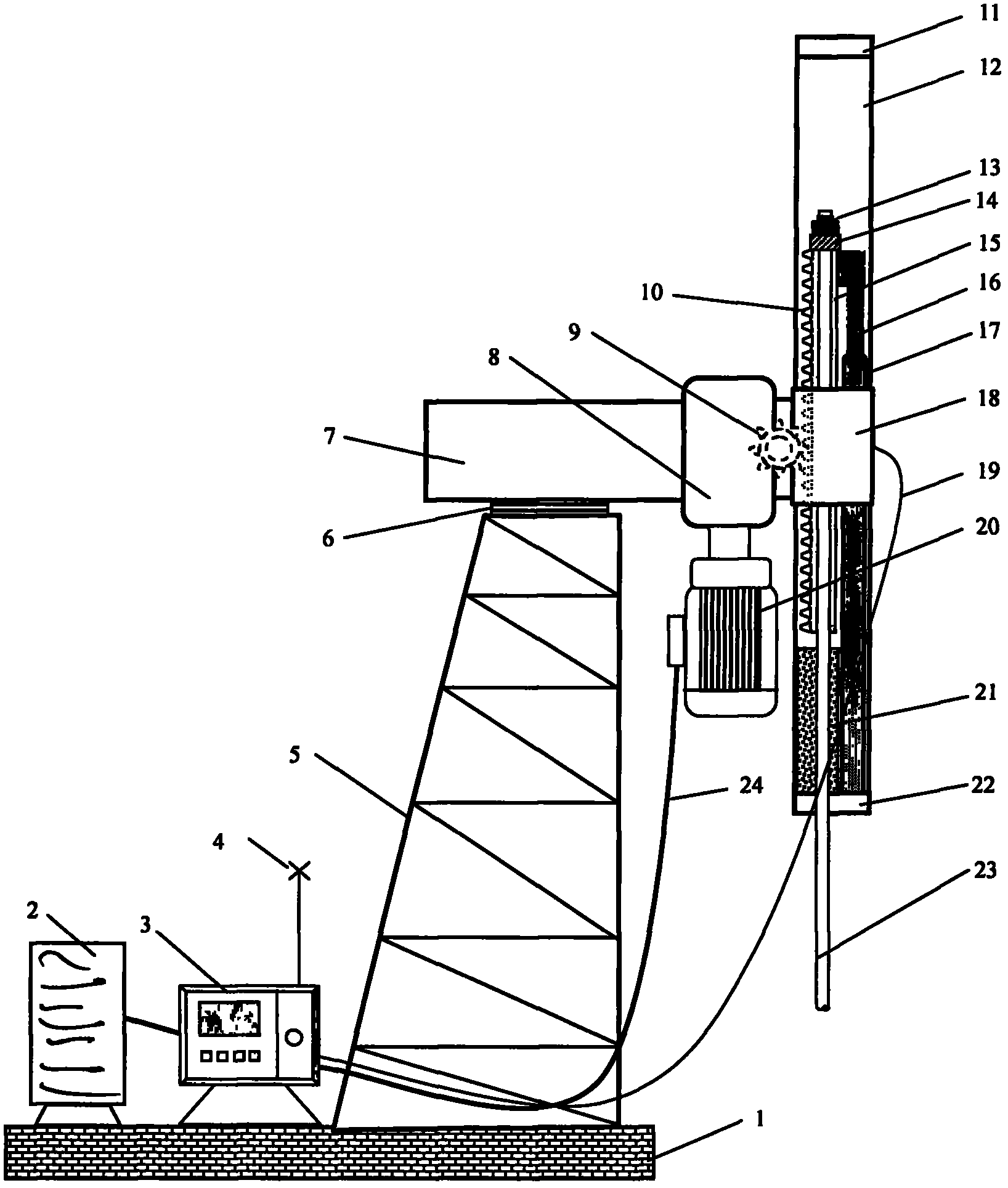

Submarine shallow-layer non-diagenetic natural gas hydrate lifting method and system

The invention discloses a submarine shallow-layer non-diagenetic natural gas hydrate lifting method and a system, which are used for lifting submarine shallow-layer non-diagenetic natural gas hydrate.A pilot hole is drilled by a drill bit, a pressure pump is started after a predetermined position is reached, high-pressure seawater drives a screw motor to rotate, and torque and rotational speed are transmitted to a screw pump by a cardan shaft; jet breaking is started by nozzles, hydrate is collected, secondarily broken and separated by collecting inlets, a secondary breaking device and a separator, separated sand is backfilled, and hydrate slurry is lifted to a solid control system on an offshore platform by the screw pump to undergo post-treatment. The invention has the following advantages: the whole process is simple, and submarine shallow-layer non-diagenetic hydrate can be effectively broken, separated and lifted; the screw pump device has the characteristics of compact structure, small size, high self-sucking capability, stable operation and long service life; and an upper bridge type passage and a lower bridge type passage ingeniously realize the pumping and lifting of seawater and hydrate slurry and save underground space.

Owner:SOUTHWEST PETROLEUM UNIV

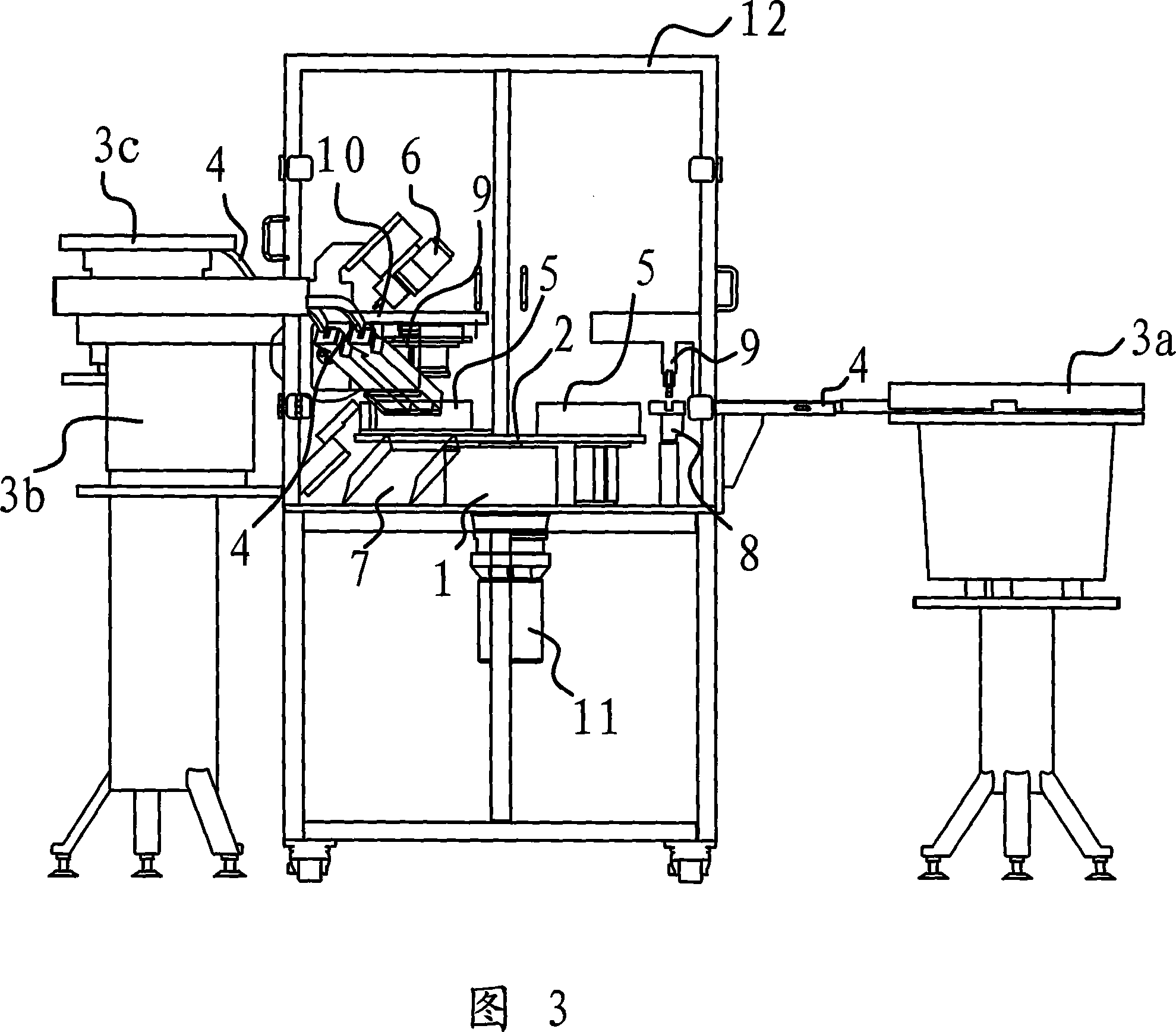

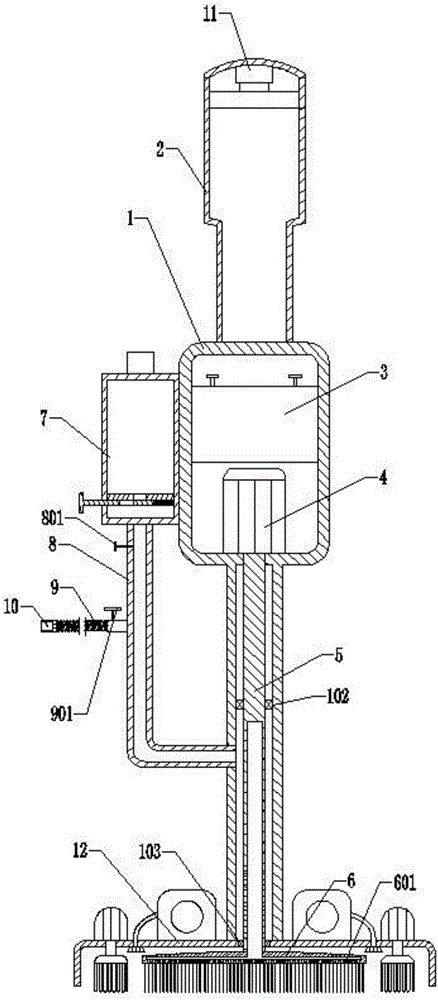

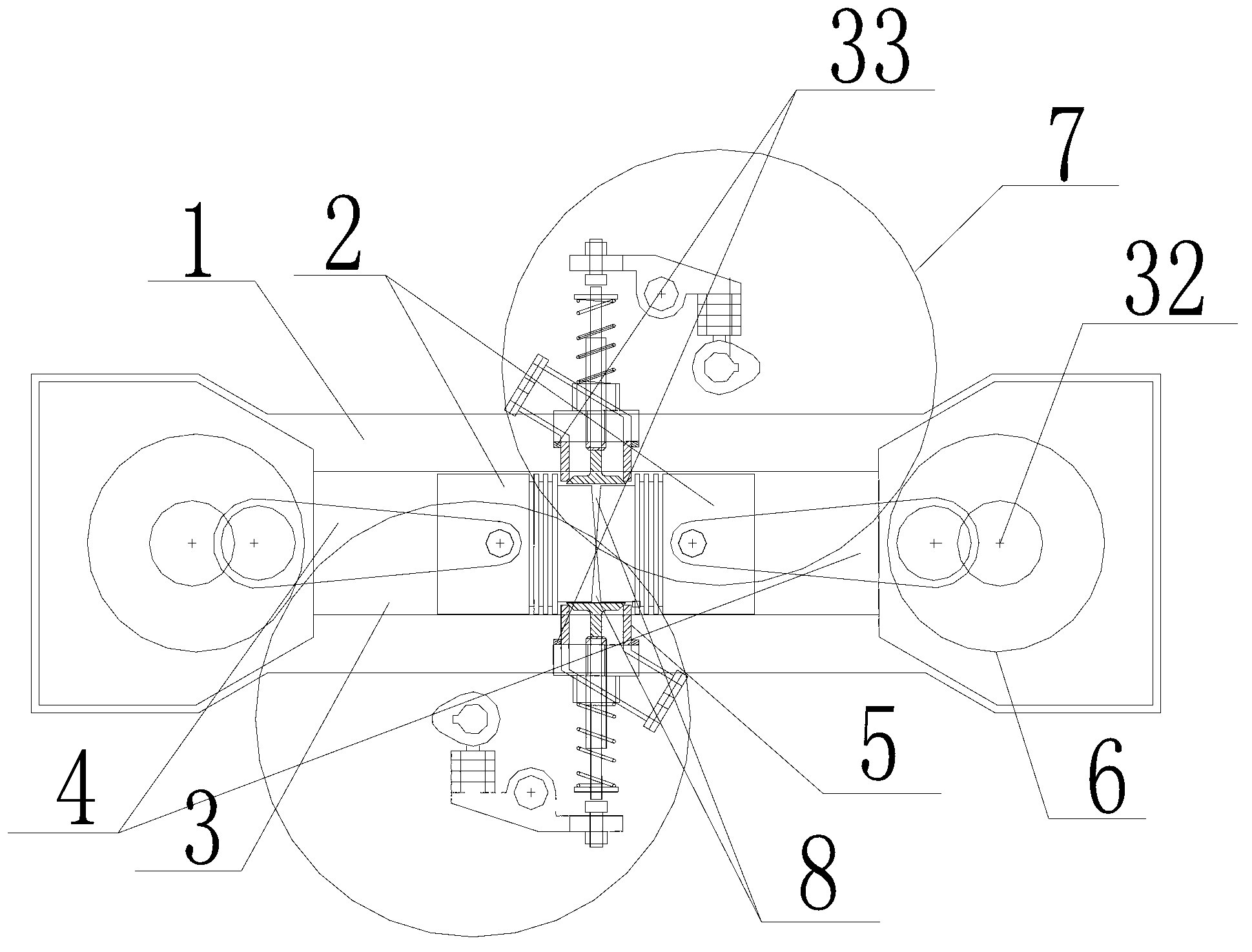

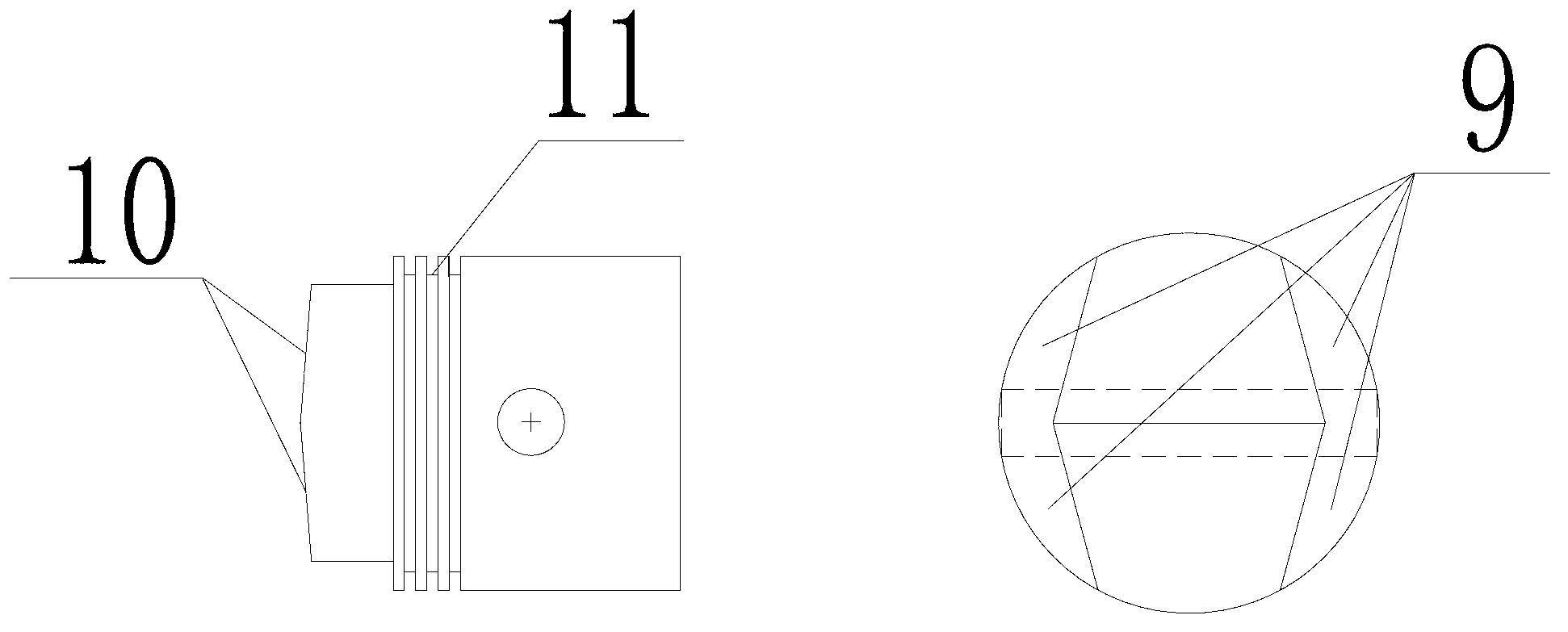

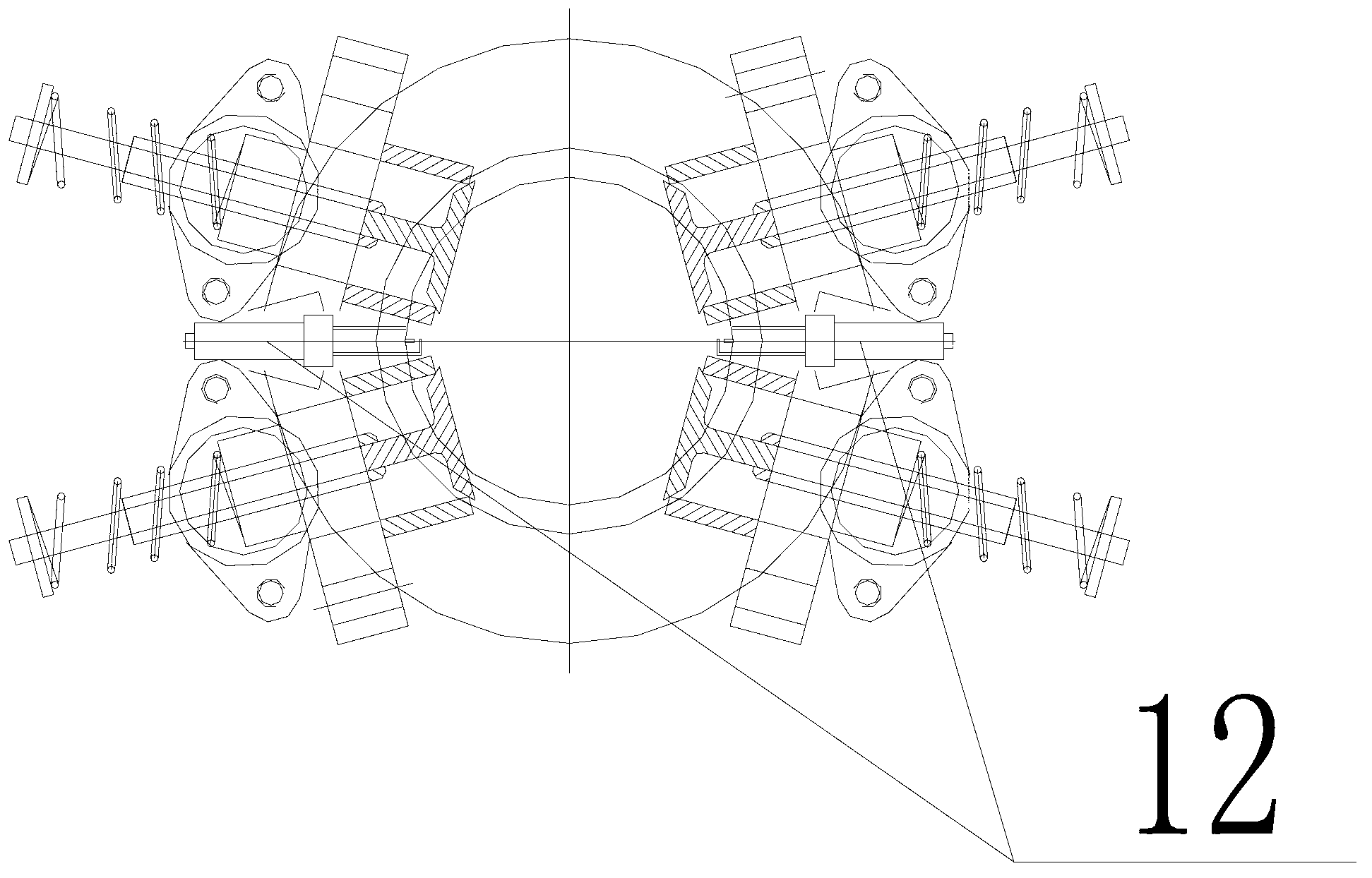

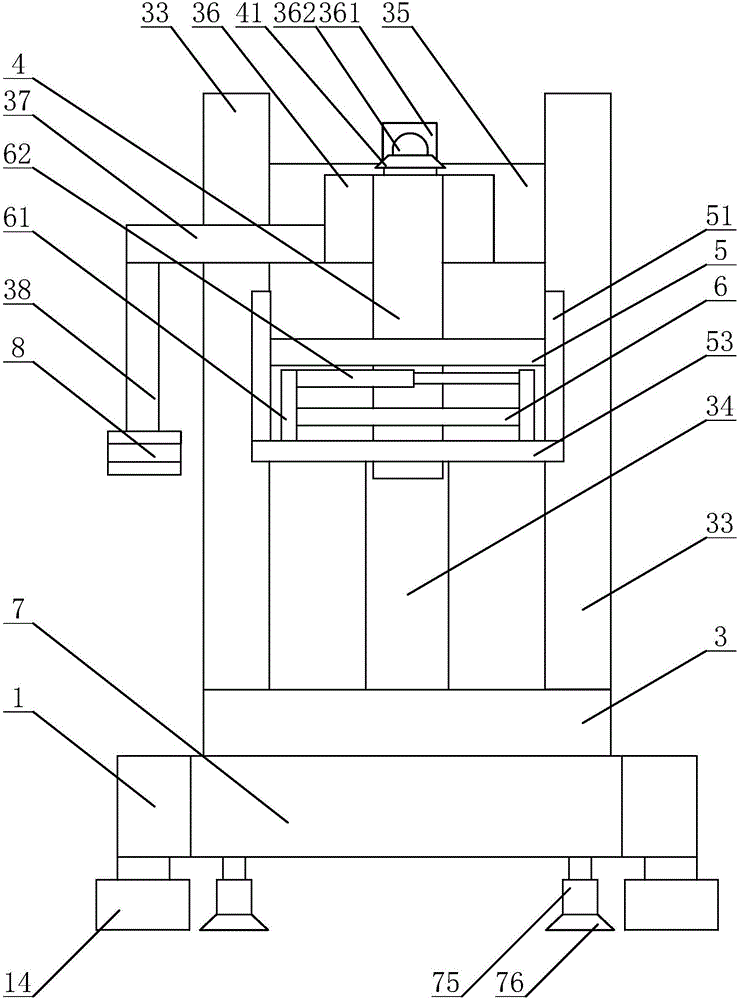

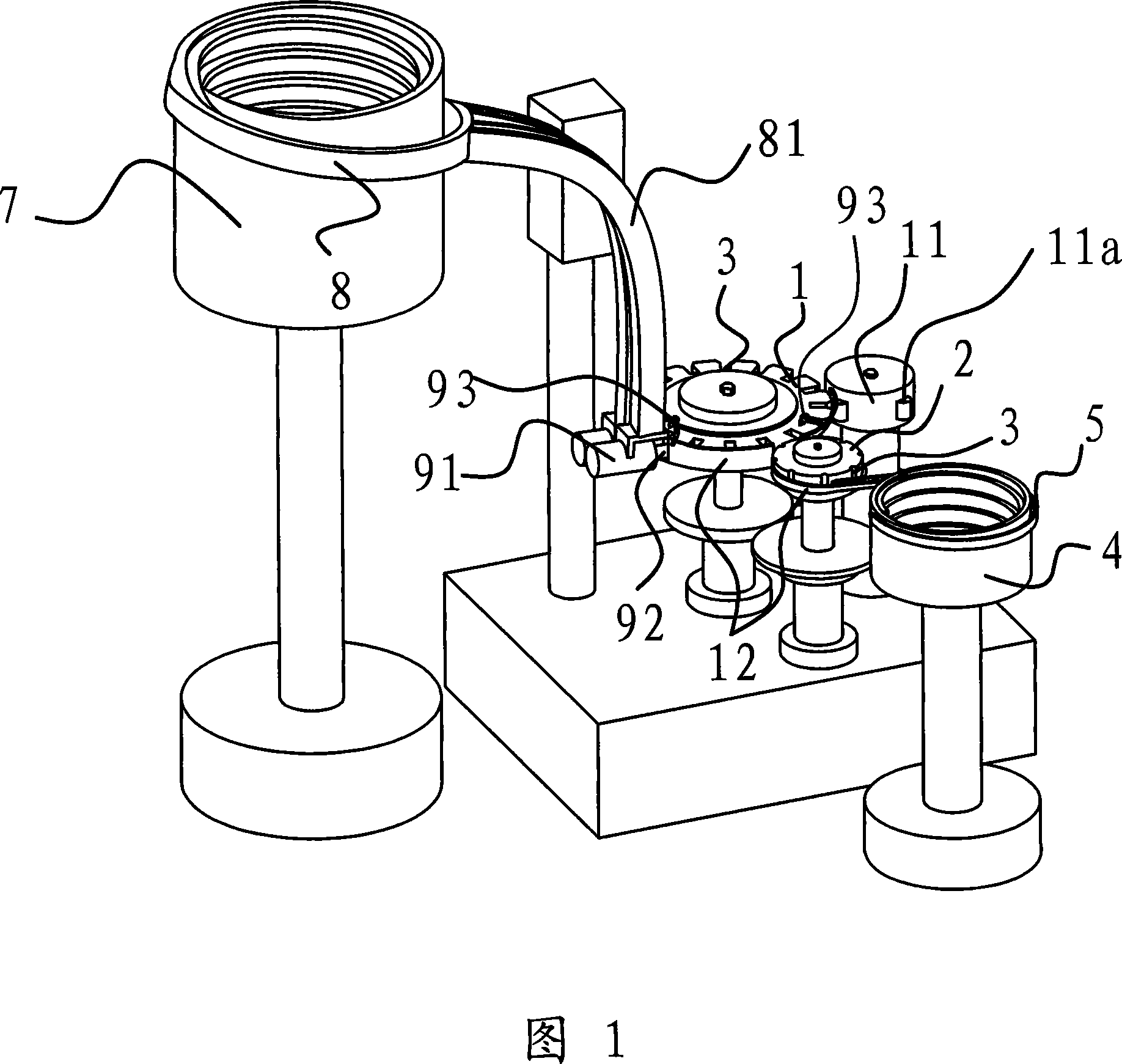

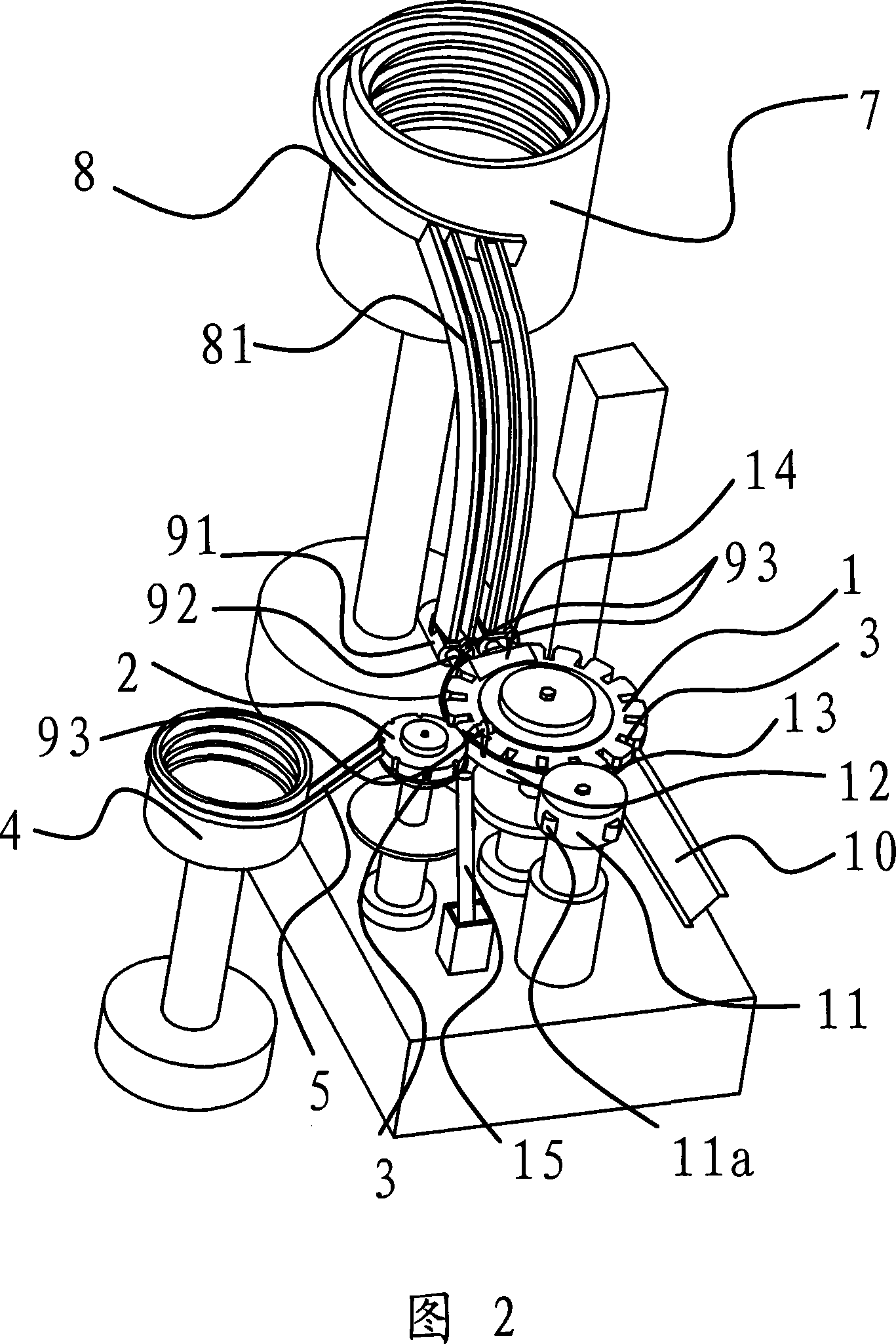

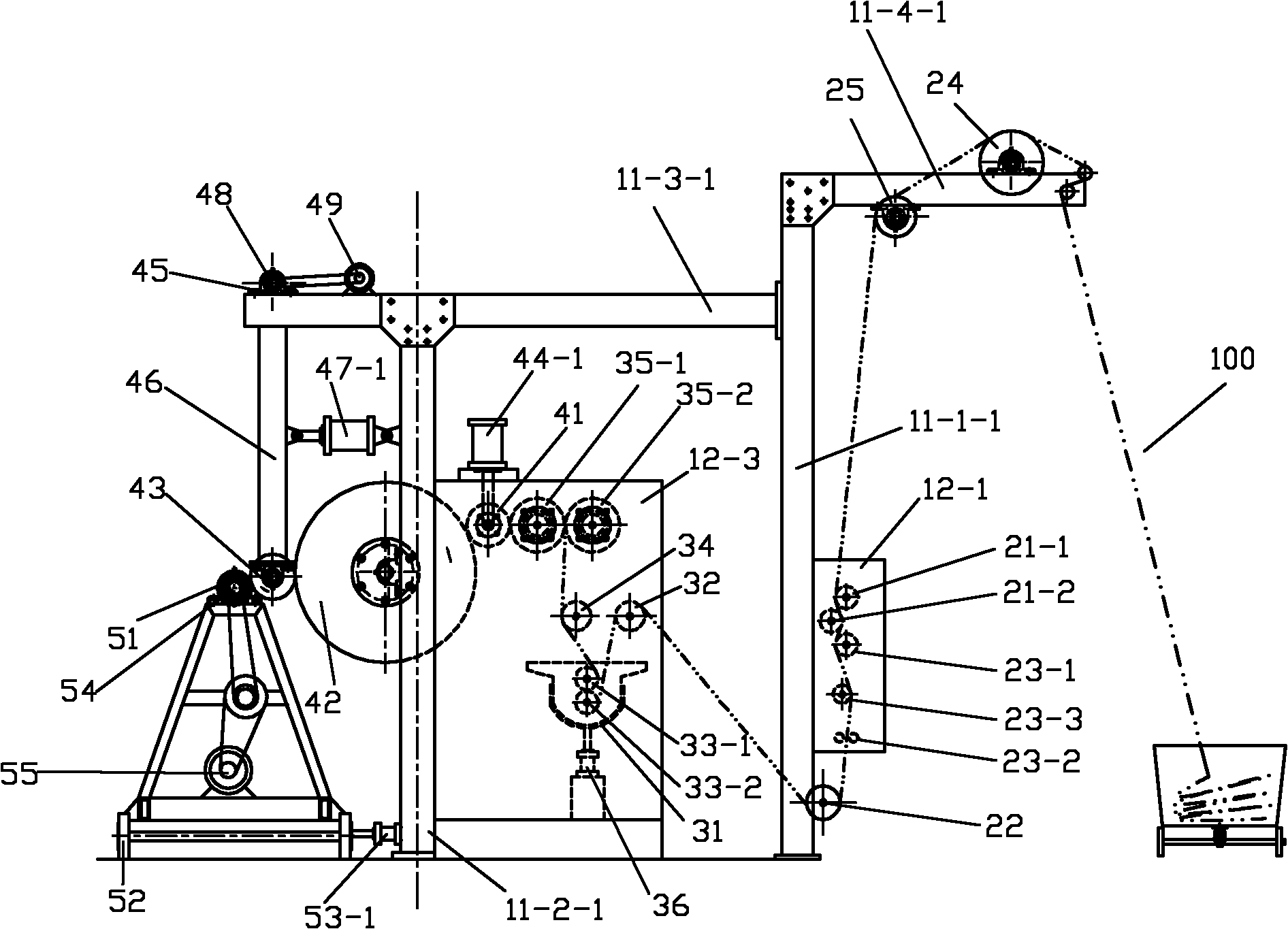

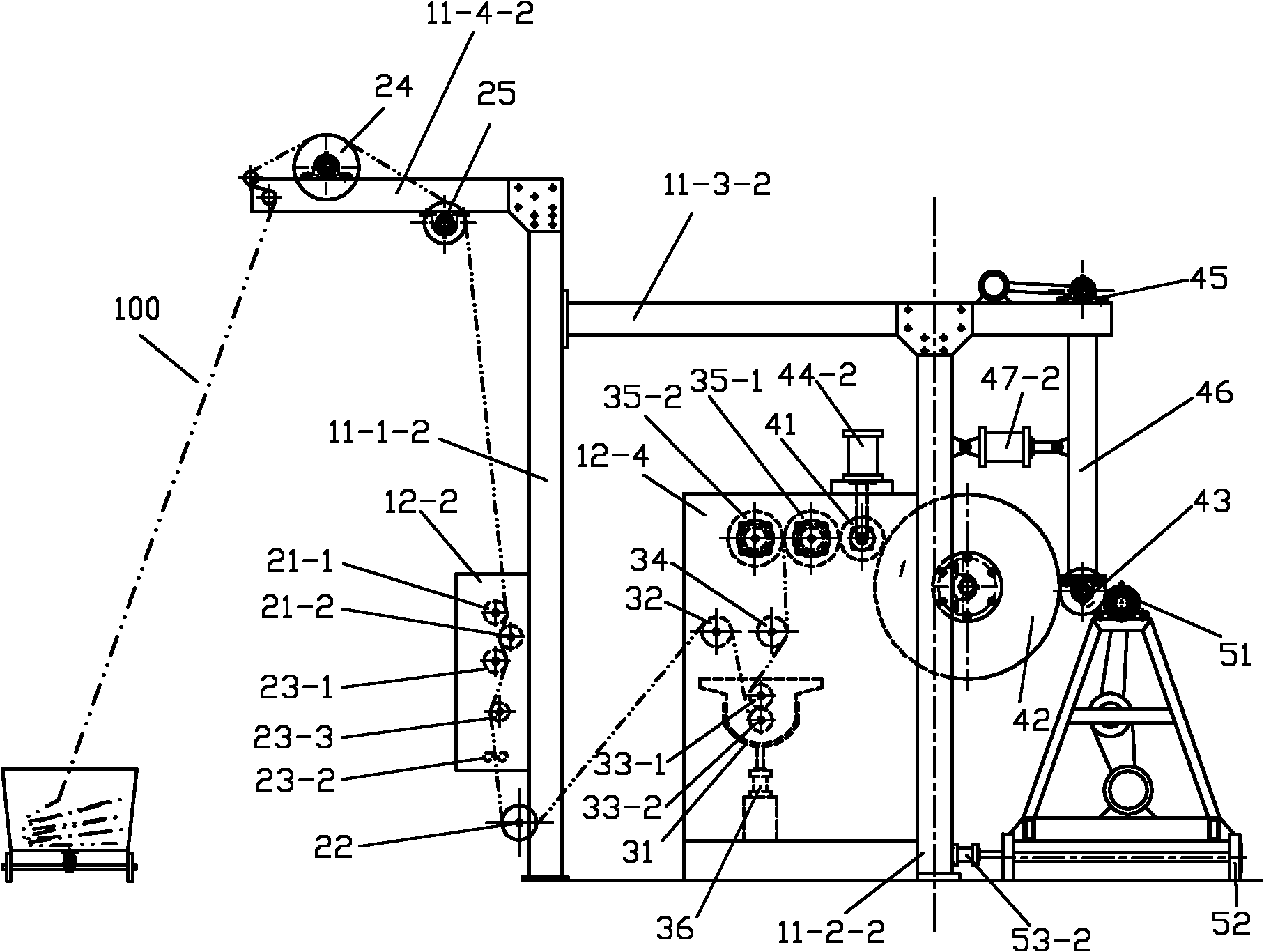

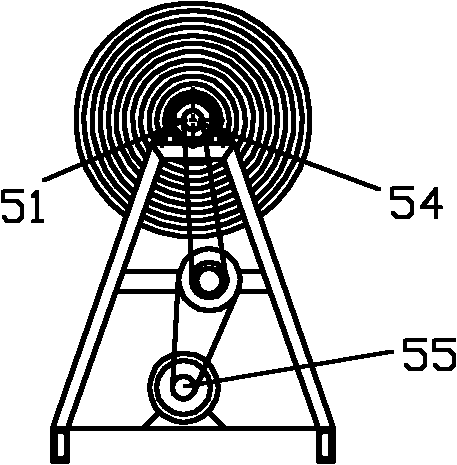

Automatic assembling machine for transfusion regulator

InactiveCN101234469AAssembly automationImprove reliabilityInfusion devicesAssembly machinesKludgeAssembly machine

The invention provides an automatic assembly machine of an infusion regulator, belonging to a mechanical technique field, which solves the problems of low assembling efficiency and low product quality of the existing kludge assembly, and comprises a shell rotary table and a roller rotary table; the edges of each rotary table are respectively provided with notches, and a roller feeder is connected with the shell rotary table by a wheel transportation guide rail; a shell feeder which is arranged on the lateral part of the shell rotary table is connected with the shell rotary table by a shell transportation guide rail, and a shell feed mechanism which is arranged between the discharge hole of the shell transportation guide rail and the shell rotary table comprises a shell feed cylinder which is connected with a shell pusher; a top pressure drum, the edge of which is tangent with the edge of the shell rotary table, is arranged on the lateral side of the shell rotary table, and a jacking block is arranged on the edge of the top pressure drum. The automatic assembly machine of the infusion regulator has the advantages of novel structure, automatic assembly, high assembling efficiency and excellent coordination between the shell and the roller.

Owner:王兴章

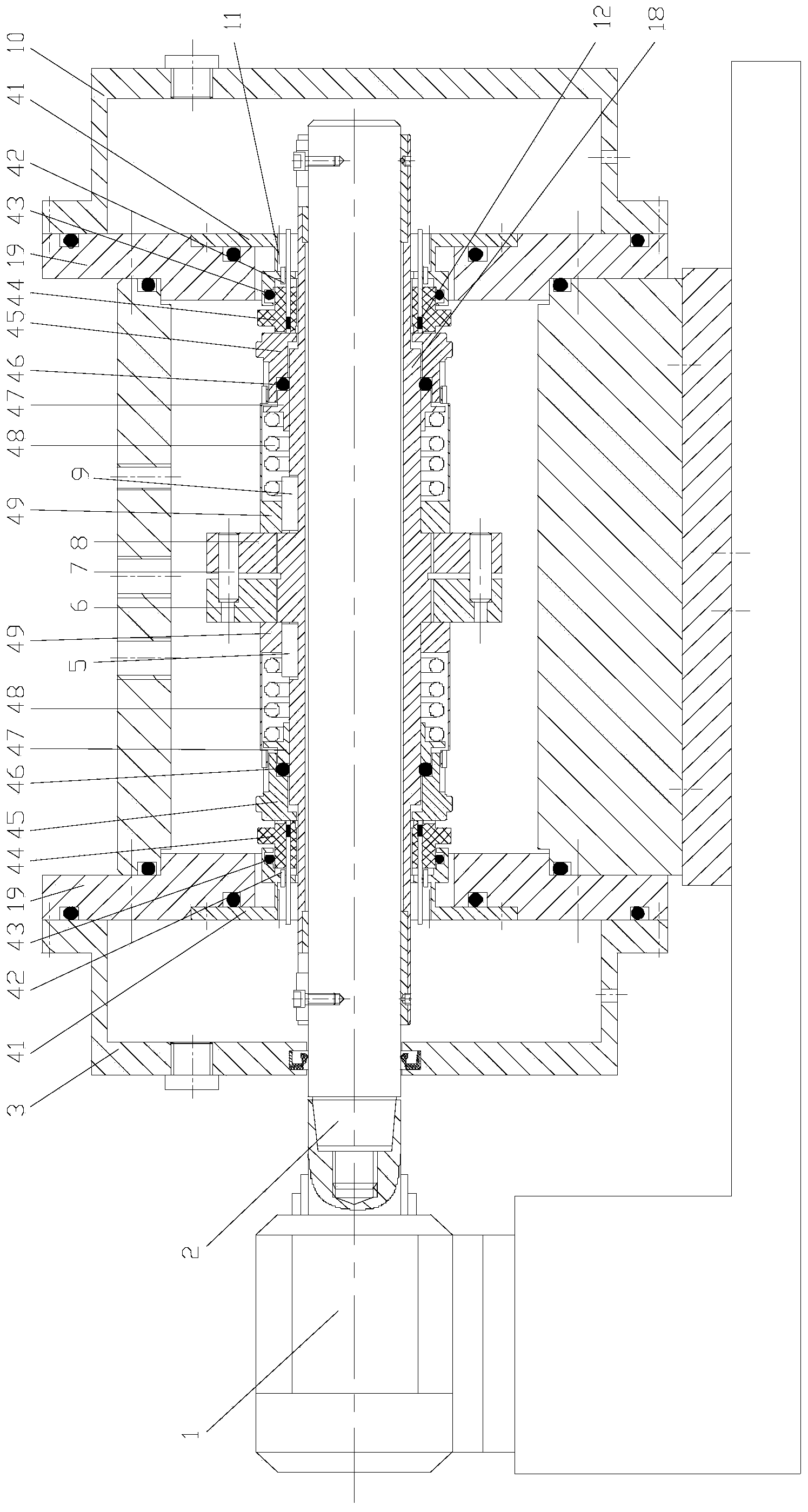

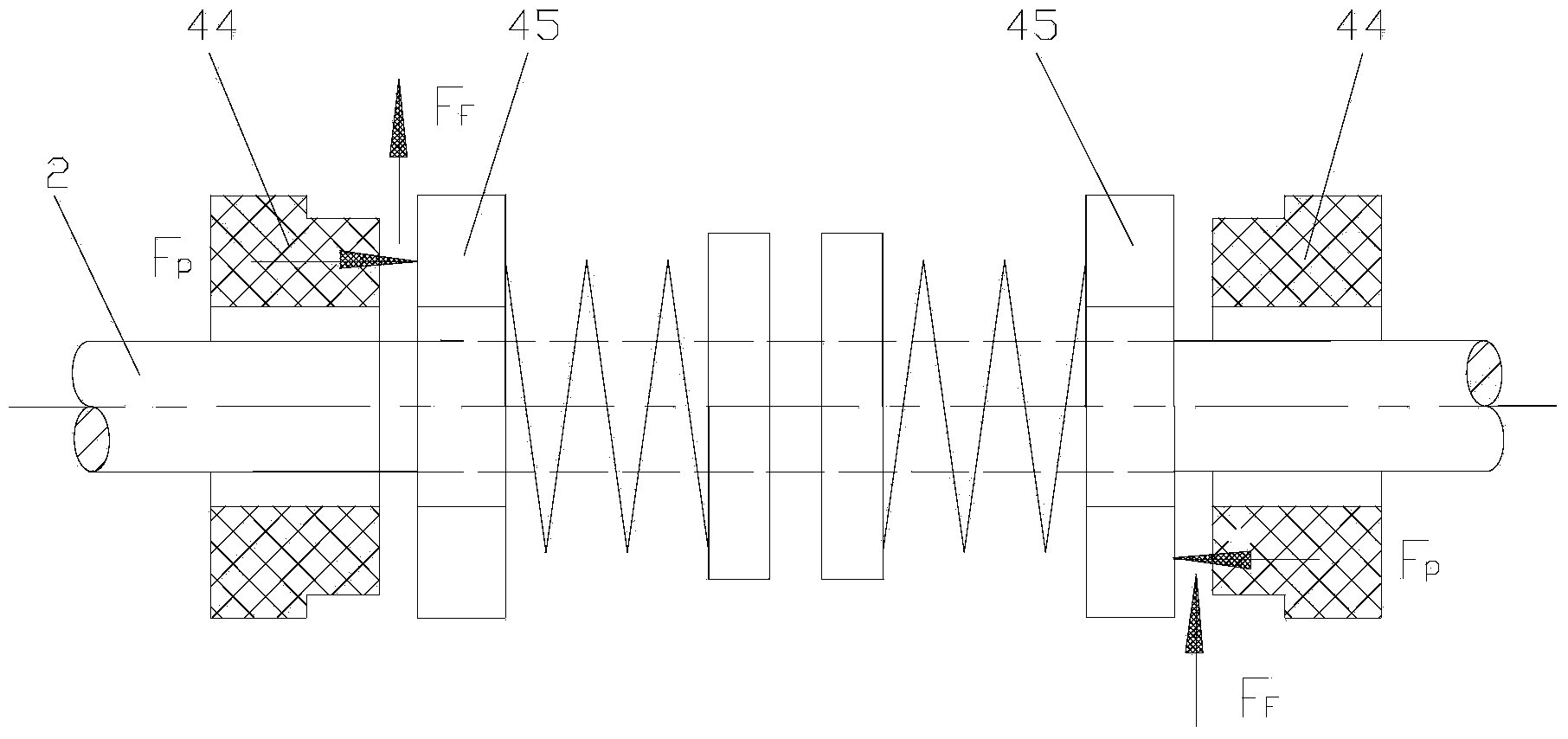

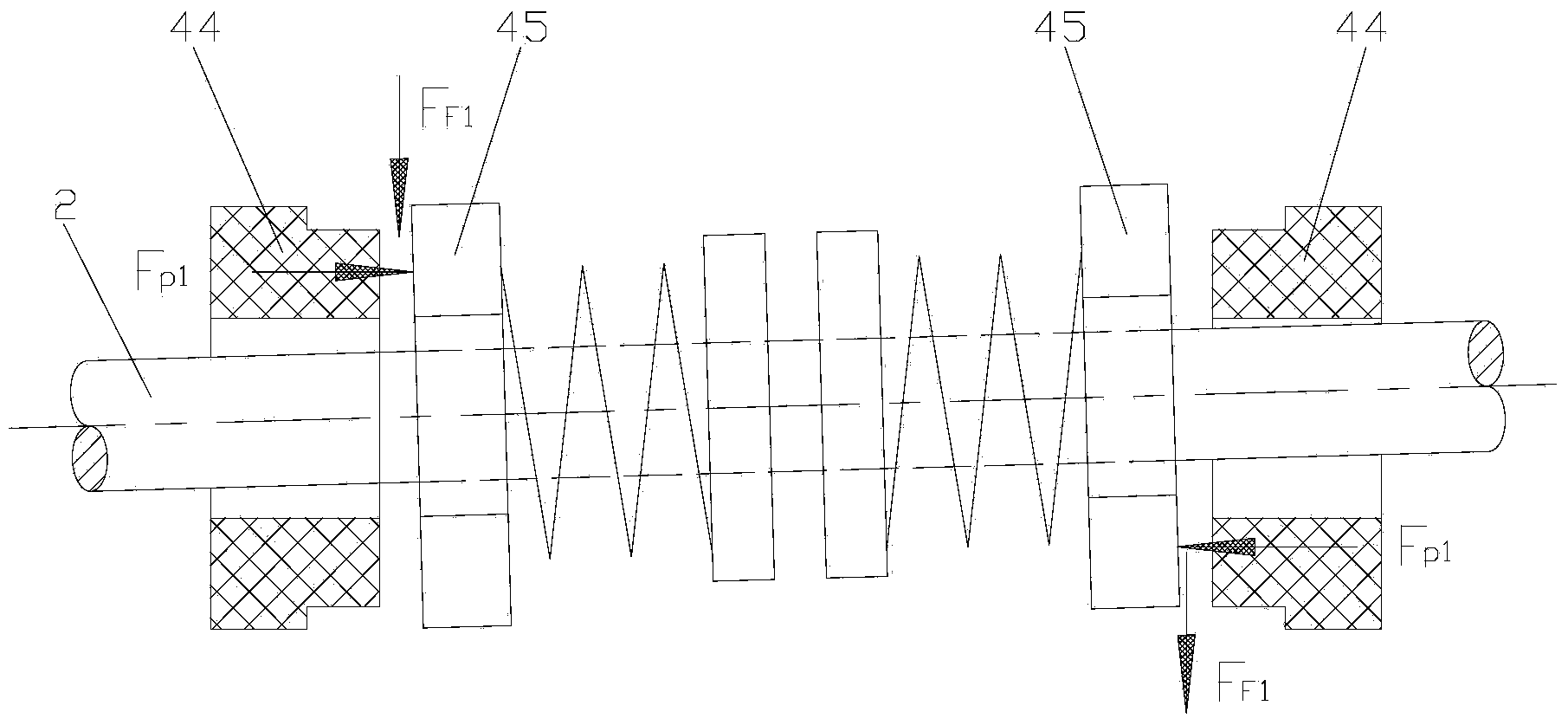

Mechanical sealing property testing device and method for measuring axial force and temperature of sealed end surfaces

ActiveCN104330223AAvoid destructionSimple structureApparatus for force/torque/work measurementPyrometry using electric radation detectorsEngineeringAxial force

The invention discloses a mechanical sealing property testing device. An electric main shaft is connected with a single cantilever working main shaft; floating support of the single cantilever working main shaft is achieved by virtue of the geometric pressure compressing function of a moving ring end surface and a static ring end surface; the edge end of a force measurement sleeve is of a flange structure; an axial force strain piece is arranged on the force measurement sleeve; a shaft sleeve sleeves the single cantilever working main shaft and penetrates through end covers at the left end and right end of a sealing cavity; the shaft sleeve is slidably connected with the single cantilever working main shaft in a sliding manner in the axial direction and in a positioning manner by using an embedding block in the circumferential direction; two sections of threads of which the screw pitches are equal and the spiral lines are in opposite directions are formed in the shaft sleeve; the threads are respectively screwed with a left screw nut and a right screw nut; the back sides of two push rings respectively contact two moving ring bases; the moving ring bases are connected with the shaft sleeve in an sliding manner in the axial direction and in a positioning manner in the circumferential direction; a through hole which is communicated with a sealed end surface is formed inside a static ring; an infrared probe is arranged inside the through hole. Due to the structural design, measurement on property parameters such as large diameter and high rotation speed of mechanical sealing, particularly the measurement on the axial force and the temperature between sealed end surfaces can be achieved.

Owner:NANJING FORESTRY UNIV

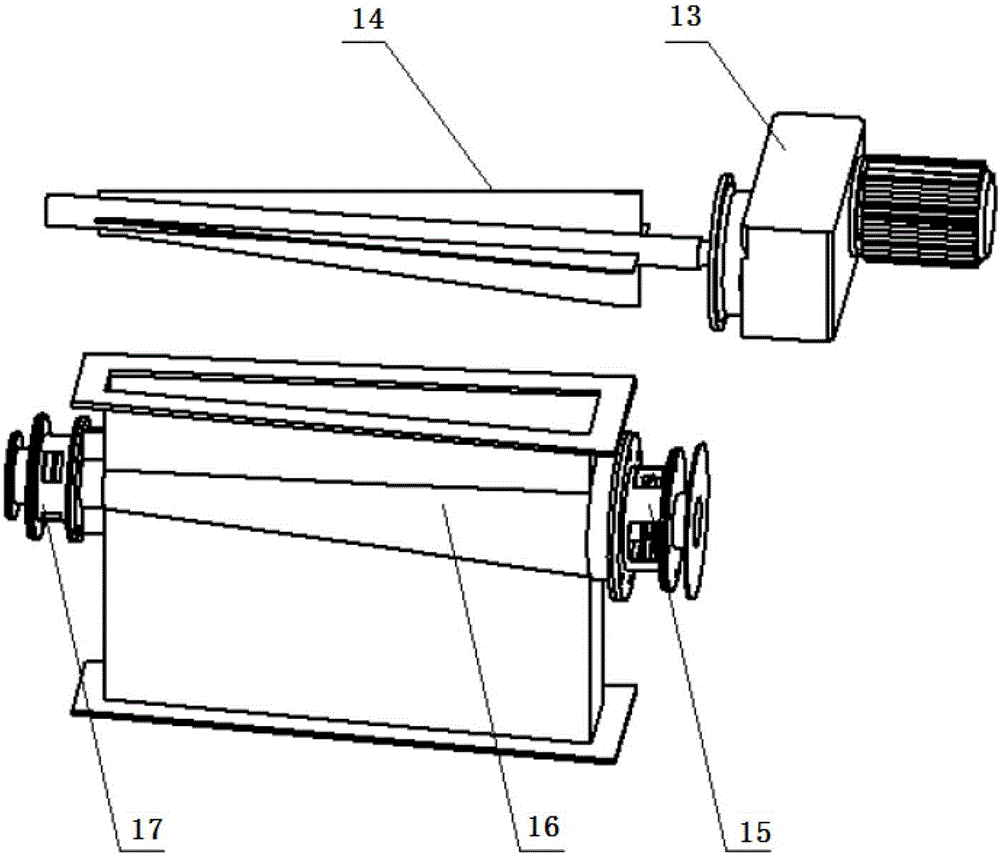

Cold pad-batch dyeing device for open-width knitted fabrics

InactiveCN101818422APrevent deviationAdjustable distanceTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersEngineeringControl circuit

The invention discloses a cold pad-batch dyeing device for open-width knitted fabrics, which comprises a frame, a cloth feeding device and a dyeing padding liquid device, and further comprises a wet supported cloth conveying device, a rollup device and a control circuit. The cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are arranged on the frame one after another; the cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are all provided with mechanical open-width components, and the open-width knitted fabrics are subject to open-width flattening before entering the units described above; the control circuit controls the rotating speed of electric motors in an active manner so that the cloth feeding device, the dyeing padding liquid device, the wet supported cloth conveying device and the rollup device realize the conveyance of the open-width knitted fabrics under bearable tension in a manner of synchronous operation, the open-width knitted fabrics are free from crumpling and curling in the entire treatment process, and eventually, the open-width knitted fabrics are flatly rolled onto a cloth roller in the form of big batch which can be rotatably piled up like woven fabrics, and the dyeing is completed during the rotatable pile-up, which not only reduces various consumptions and saves cost remarkably, but also improves the quality of the knitted fabrics.

Owner:蔡宗义

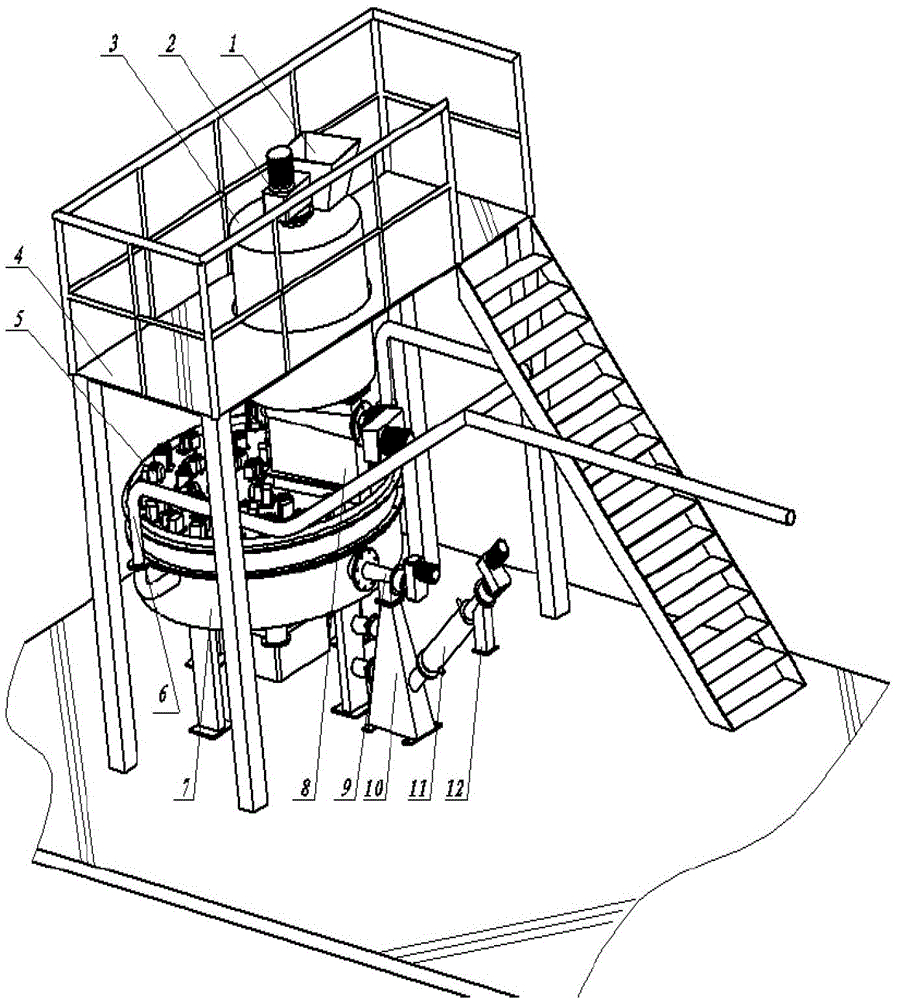

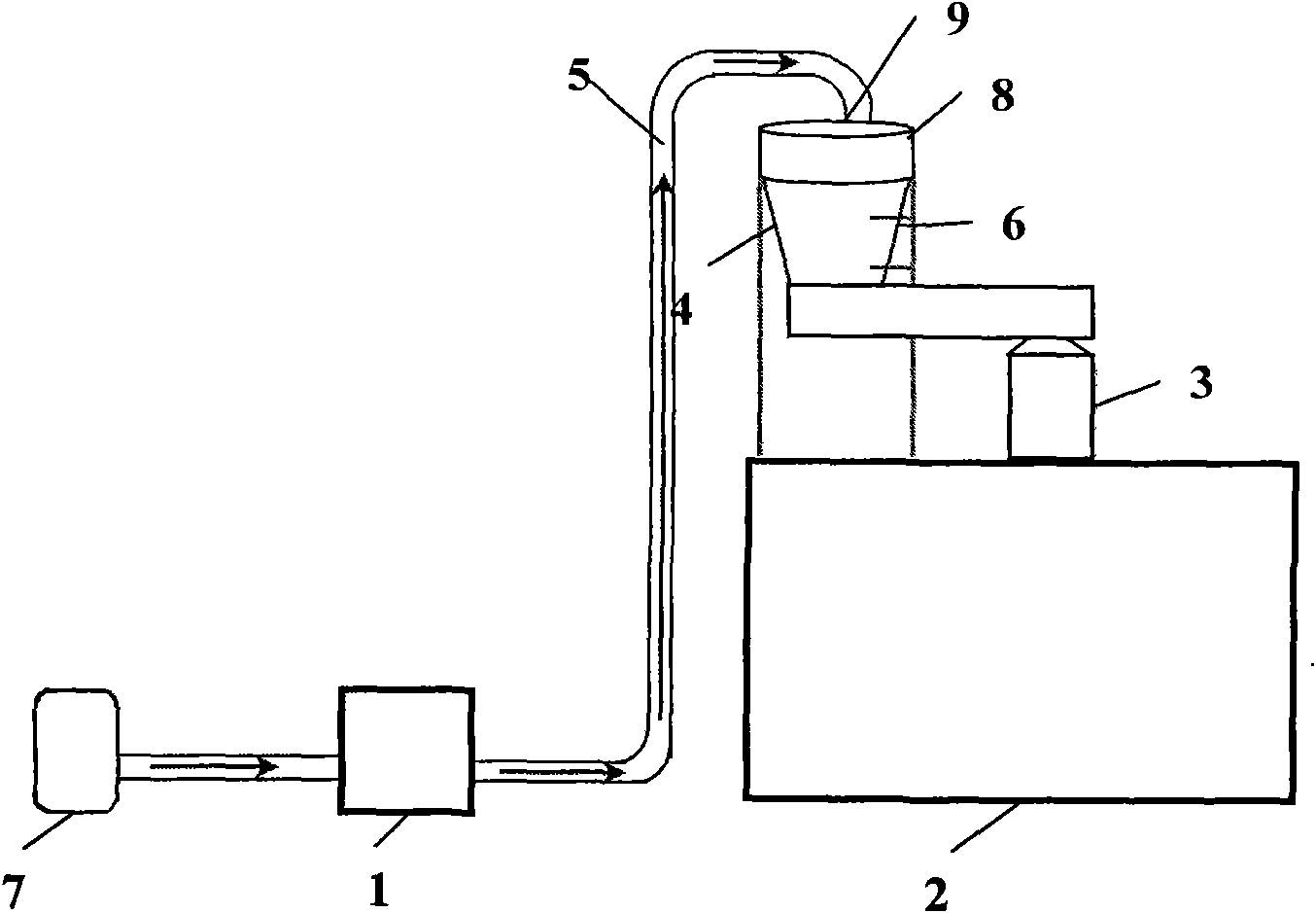

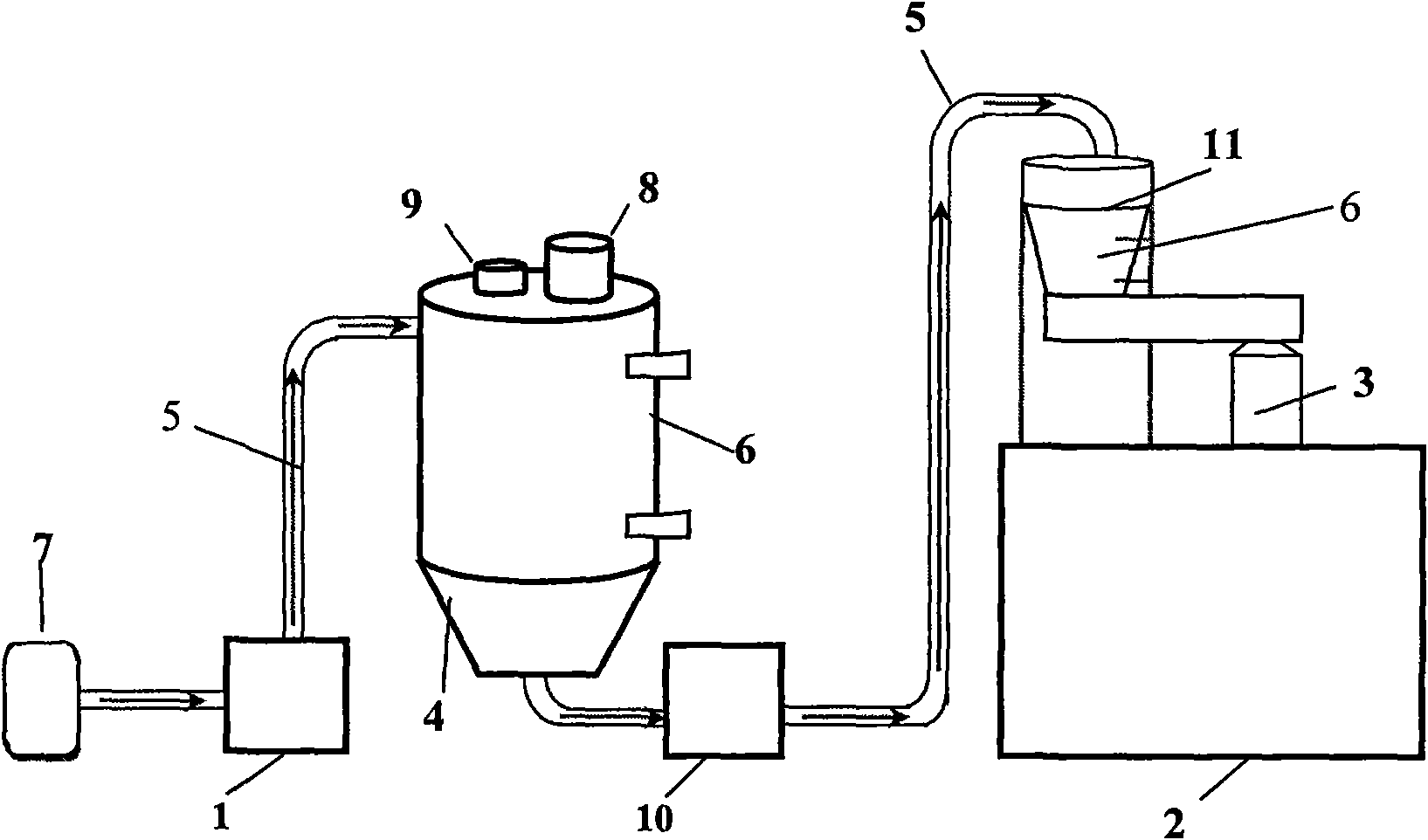

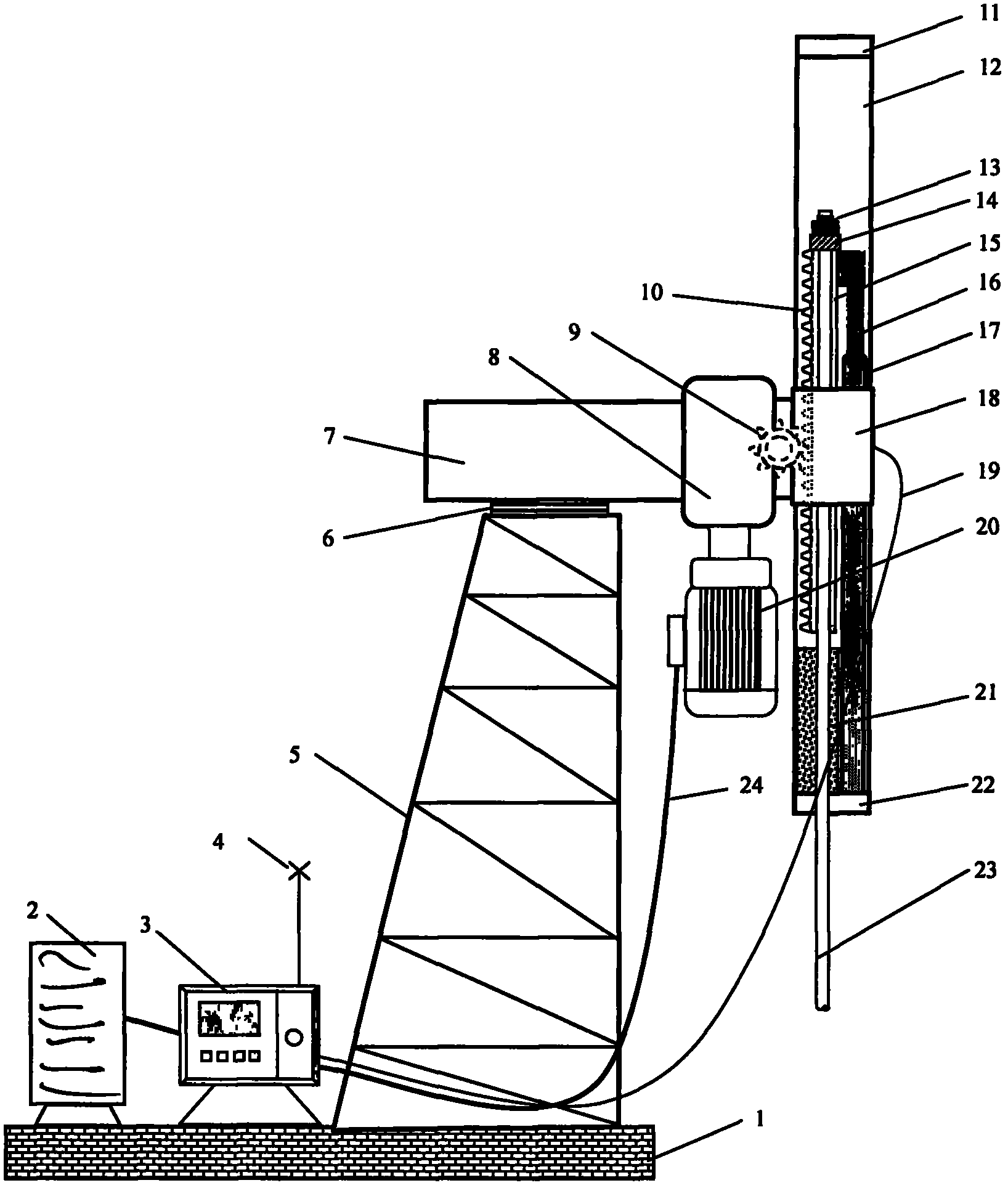

Automatic adding system of powdered activated carbon

InactiveCN101659456AFlexible configurationReduce flyingWater/sewage treatment by sorptionLow noiseActivated carbon

The invention belongs to the technical field of environment protection, and in particular relates to an automatic adding system of powdered activated carbon. The automatic adding system of the powdered activated carbon, which is provided by the invention, comprises a two-stage TJPP serial pneumatic conveyor of the powdered activated carbon, a precise powder feeder, a PHM serial liquid-powder mixer, a storage chamber, a corresponding automatic control system and accessories. Or the automatic adding system of the powdered activated carbon can comprise a one-stage TJPP serial pneumatic conveyor of the powdered activated carbon, a precise powder feeder, a liquid-powder mixer, a corresponding automatic control system and accessories. The automatic adding system of the powdered activated carbonhas simple structure, special design, simple and convenient installation, low noise, economy and rationality, can be widely applied to feedwater treatment and waste water treatment, can relieve the labor intensity of operators and the pollution of the powdered activated carbon to the environment, ensures the adding precision of the powdered activated carbon, and has higher working stability and reliability.

Owner:TONGJI UNIV +1

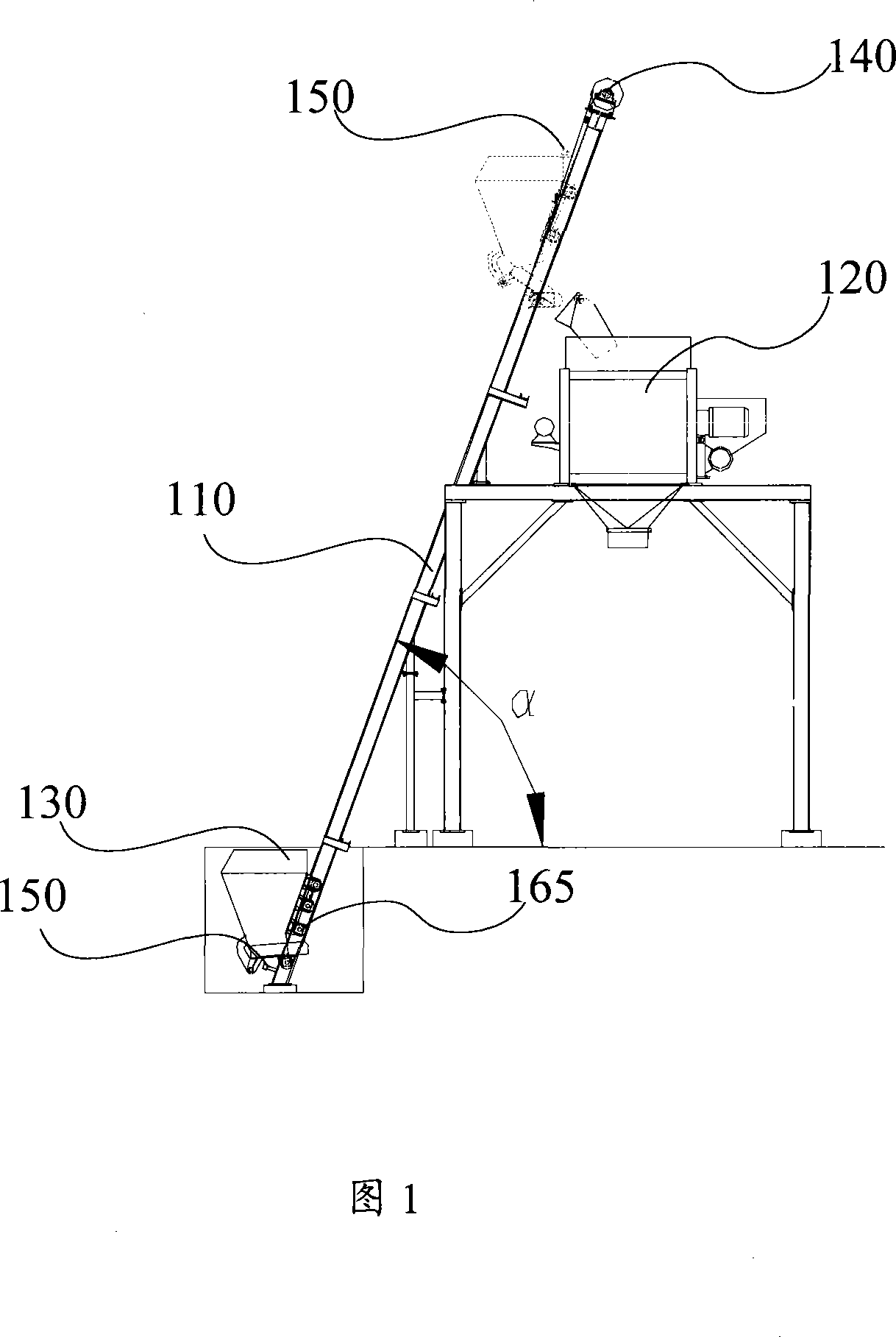

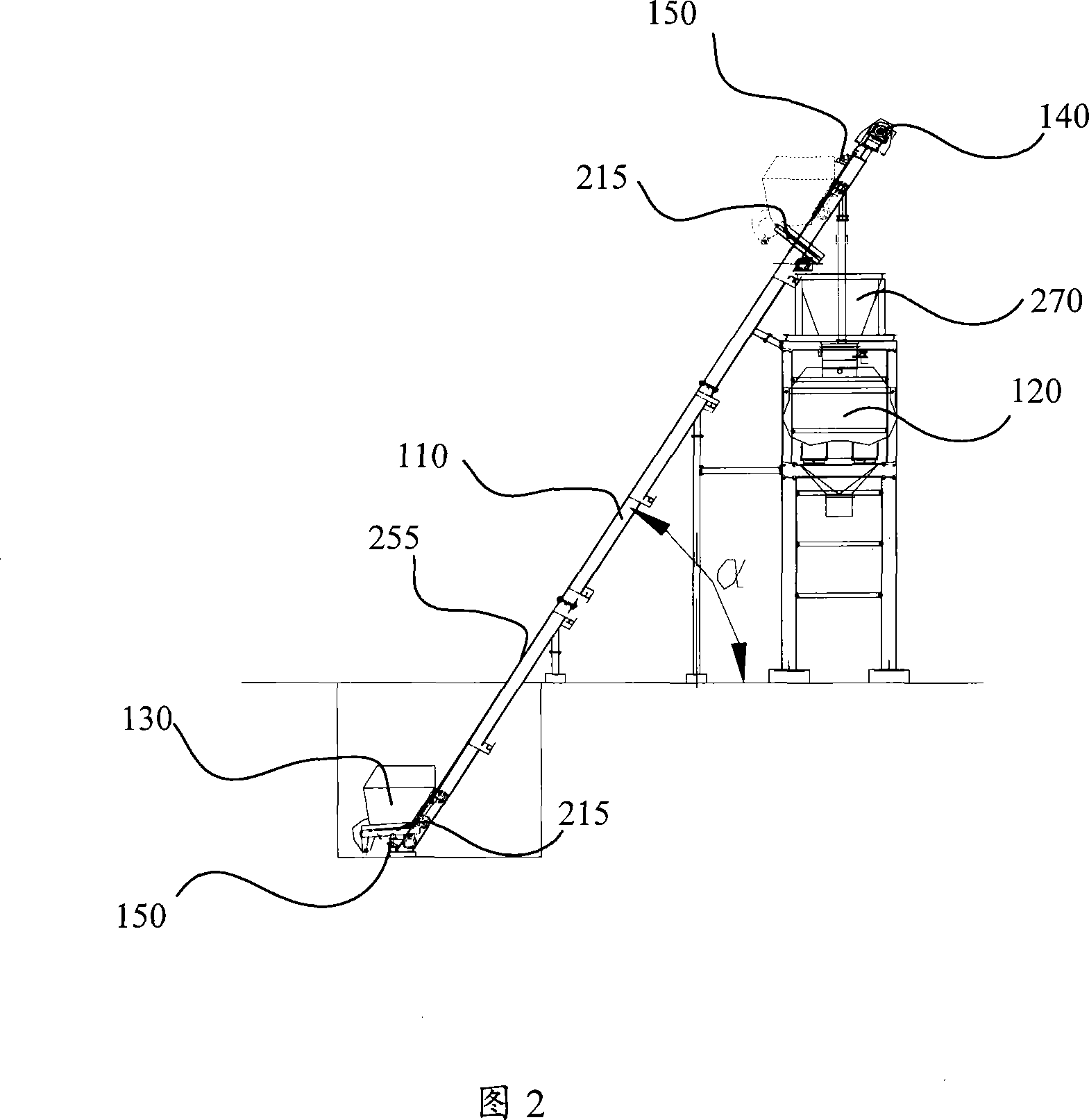

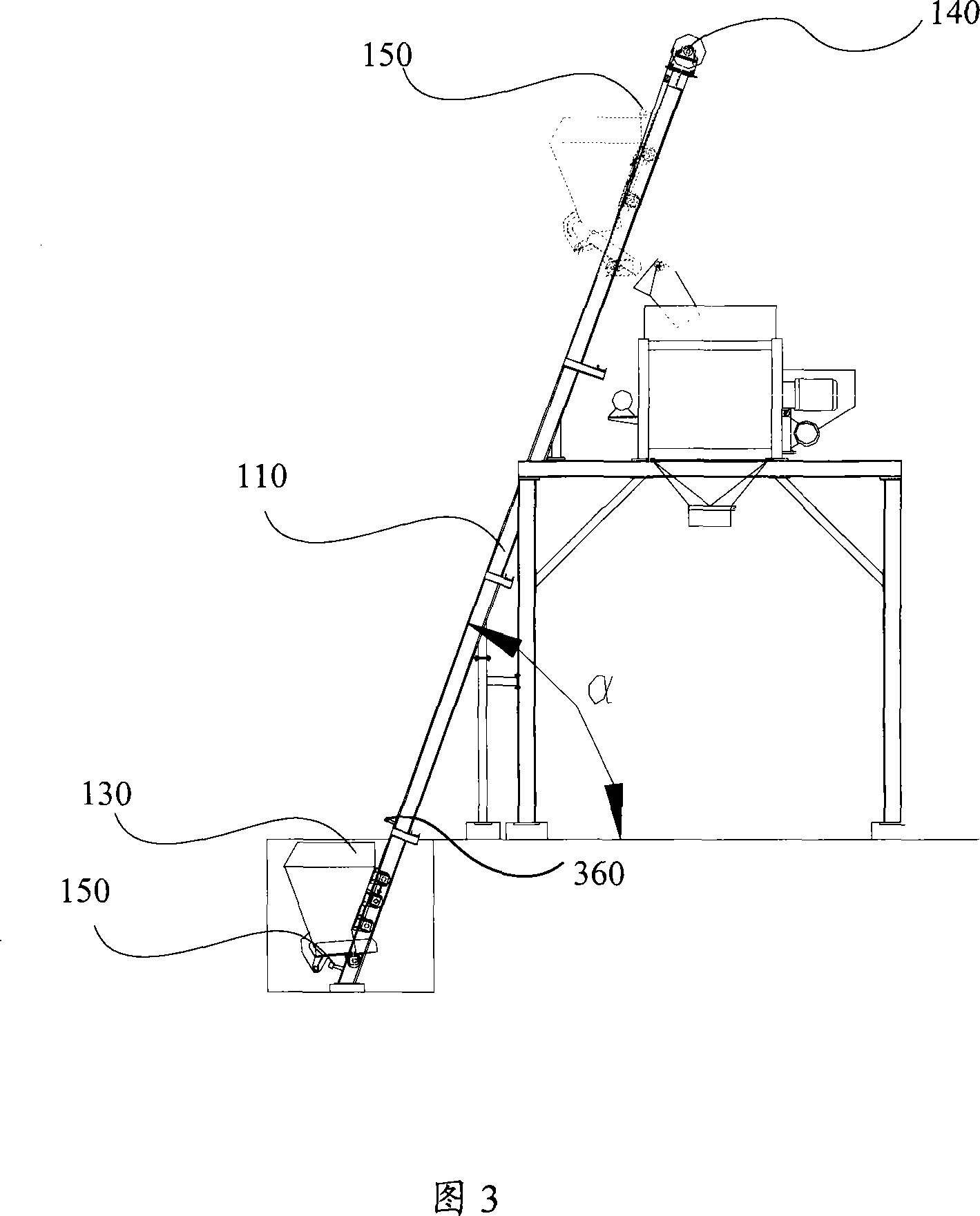

Skeletal material conveyer of concrete station

InactiveCN101219562AReduce the installation angle αReduce loadMixing operation control apparatusConstruction aggregateMaterial storage

The invention discloses an aggregate convey device adopted by a concrete mixing station and comprises a lift rail (110), a lift bucket (130), a hoister (140), a shutdown switch (150) and a mixer. The lift rail (110) is placed aslant; the hoister (140) is at the top end of the lift rail (110) and connected with the lift bucket (130) to drive the lift bucket (130) to slide along the lift rail (110). The convey device also comprises a material storage bucket (270) which is arranged above the mixer (120) and the angle Alfa between the lift rail (110) and the level is less than or equal to 60 degrees. The material storage bucket is added in the invention, which separates the working circulation of a lifter and the mixing circulation and enables the lifter to work continuously and meanwhile, reduces the installation angle of the lift rail and the loading of the hoister, thus improving the reliability of the hoister.

Owner:SANY HEAVY IND CO LTD (CN)

Reciprocating rack linear driving oil pumping unit

InactiveCN102182428ASmooth runningSmall current fluctuationFluid removalMechanical energy handlingEnergy conservationGear transmission

The invention discloses a reciprocating rack linear driving oil pumping unit, which comprises a rack, a walking beam, driving and transmission parts, a unit body part, an air balanced part, an energy storage part and a control part, wherein the rotation of a motor controlled by a controller around a vertical shaft is changed into the rotation of gears around a horizontal shaft by direction changing of a gear transmission box; the gears drive racks in the unit body of the oil pumping unit to perform up-and-down reciprocating linear motion so as to drive a polish rod for oil pumping; and the controller analyzes the operating situation of the oil pumping unit according to a data signal which is measured by a sensor, automatically optimizes and adjusts the stroke and stroke frequency of the oil pumping unit, and can transmit the signal to a production management department for manual remote monitoring control. By adoption of technologies of reciprocating induction motor driving, rack linear driving, real-time monitoring and adjustment, air balance and capacitor energy storage, the reciprocating rack linear driving oil pumping unit is smooth in operation, low in current fluctuation and low in reactive electric quantity loss of the motor, has the advantages of simple mechanism, compact structure, simple and convenient installation, high control, low occupation, light weight, low cost, energy conservation, environmental friendliness and the like, and can be widely applied to low-yield and low-efficiency wells, thickened oil wells and production wells in edge areas.

Owner:钟立国 +6

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com