Patents

Literature

153results about How to "Easy and accurate installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

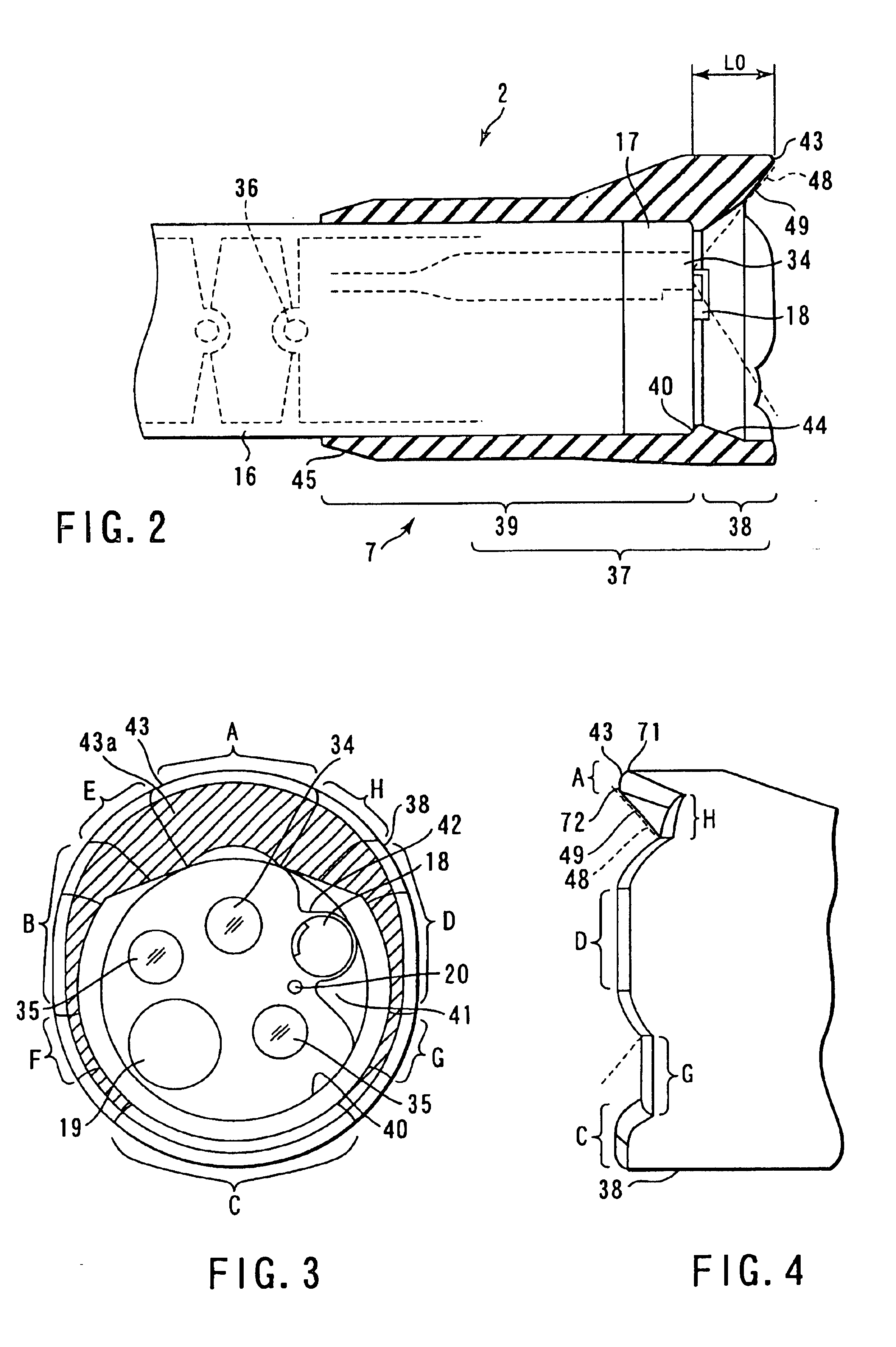

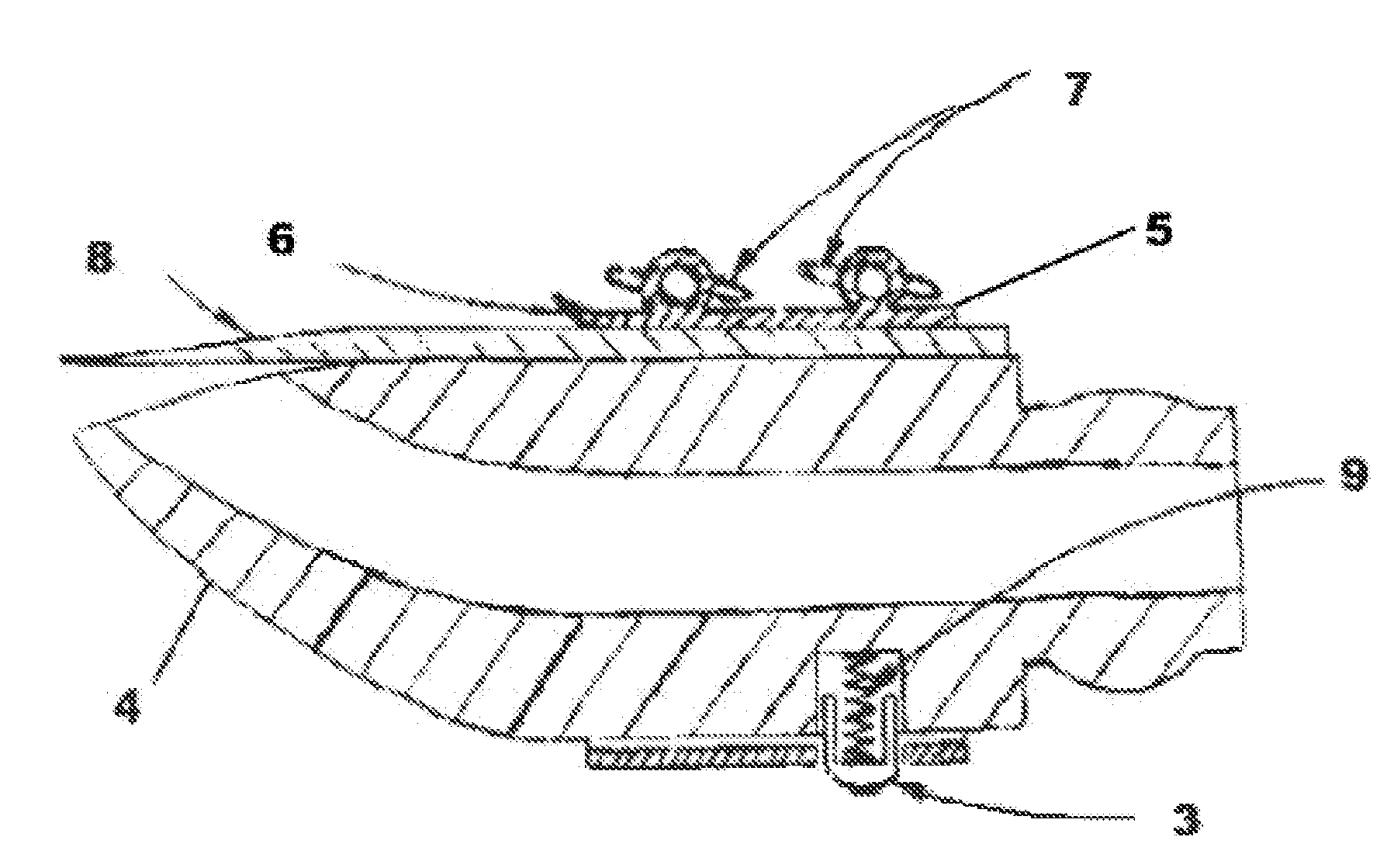

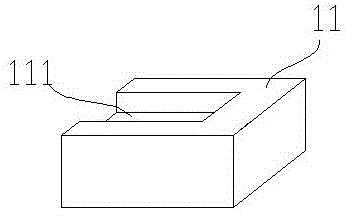

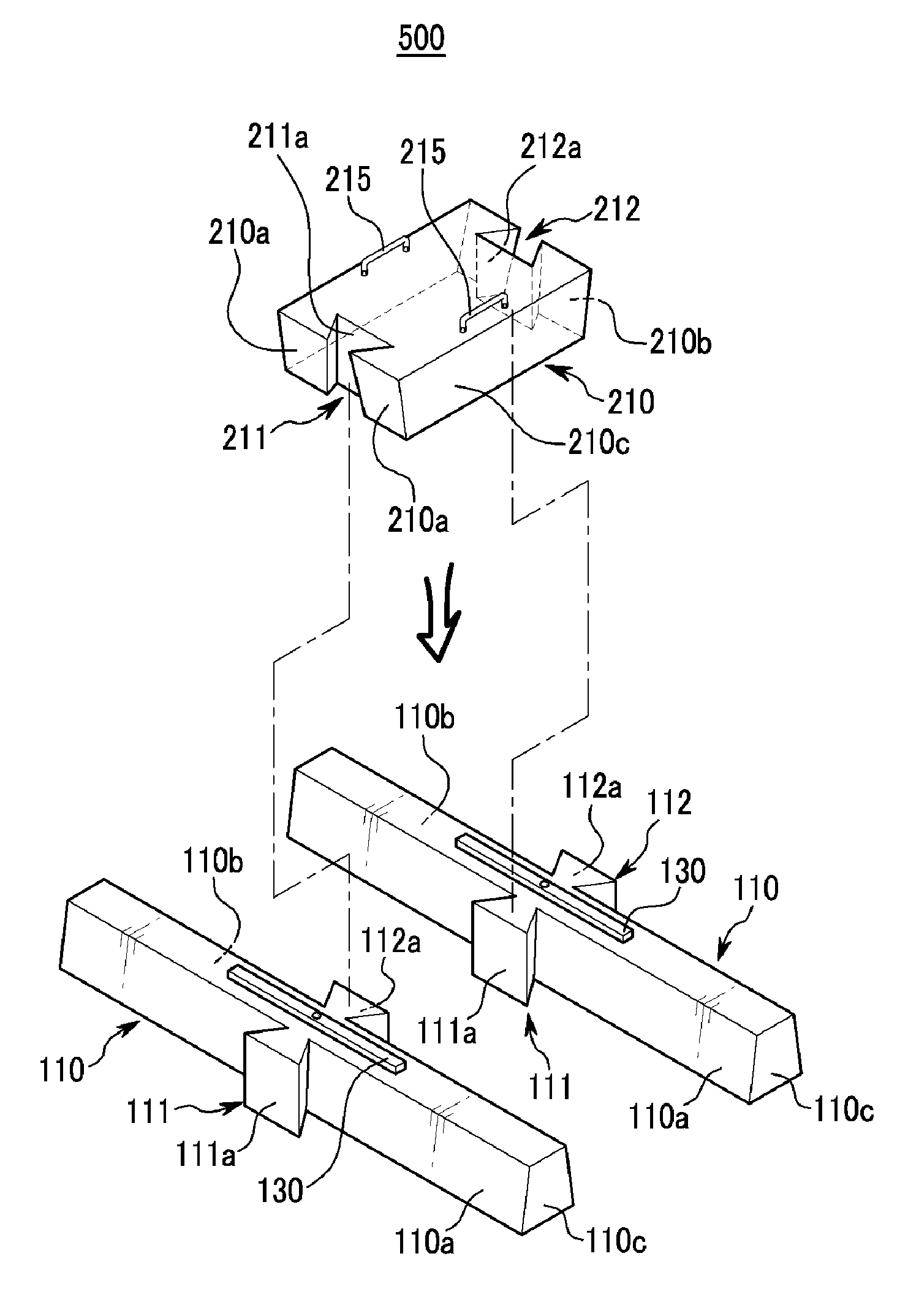

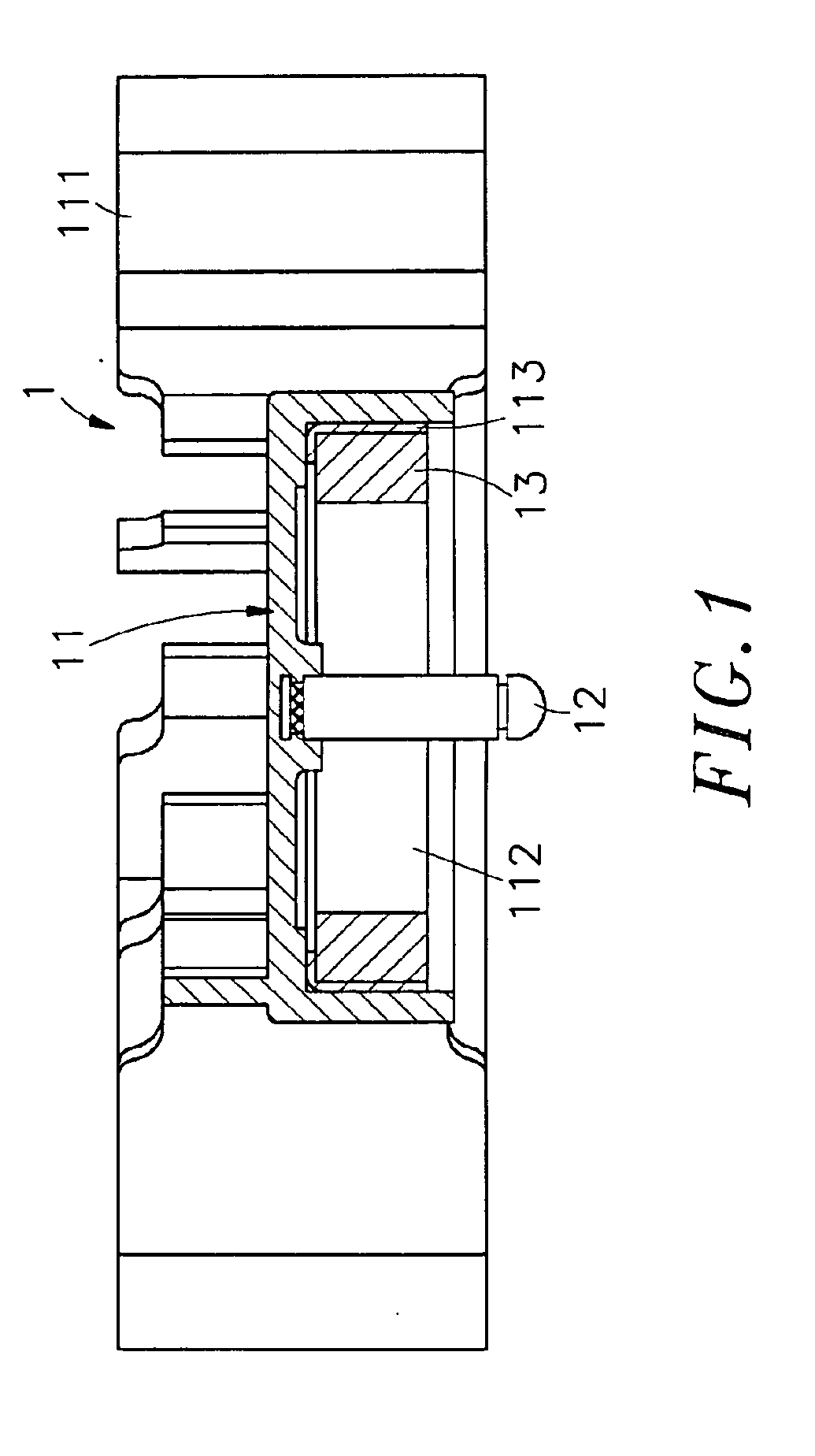

Image sensor module

InactiveUS20050237418A1Easy and accurate installationPrecise positioningTelevision system detailsSolid-state devicesEngineeringImage sensor

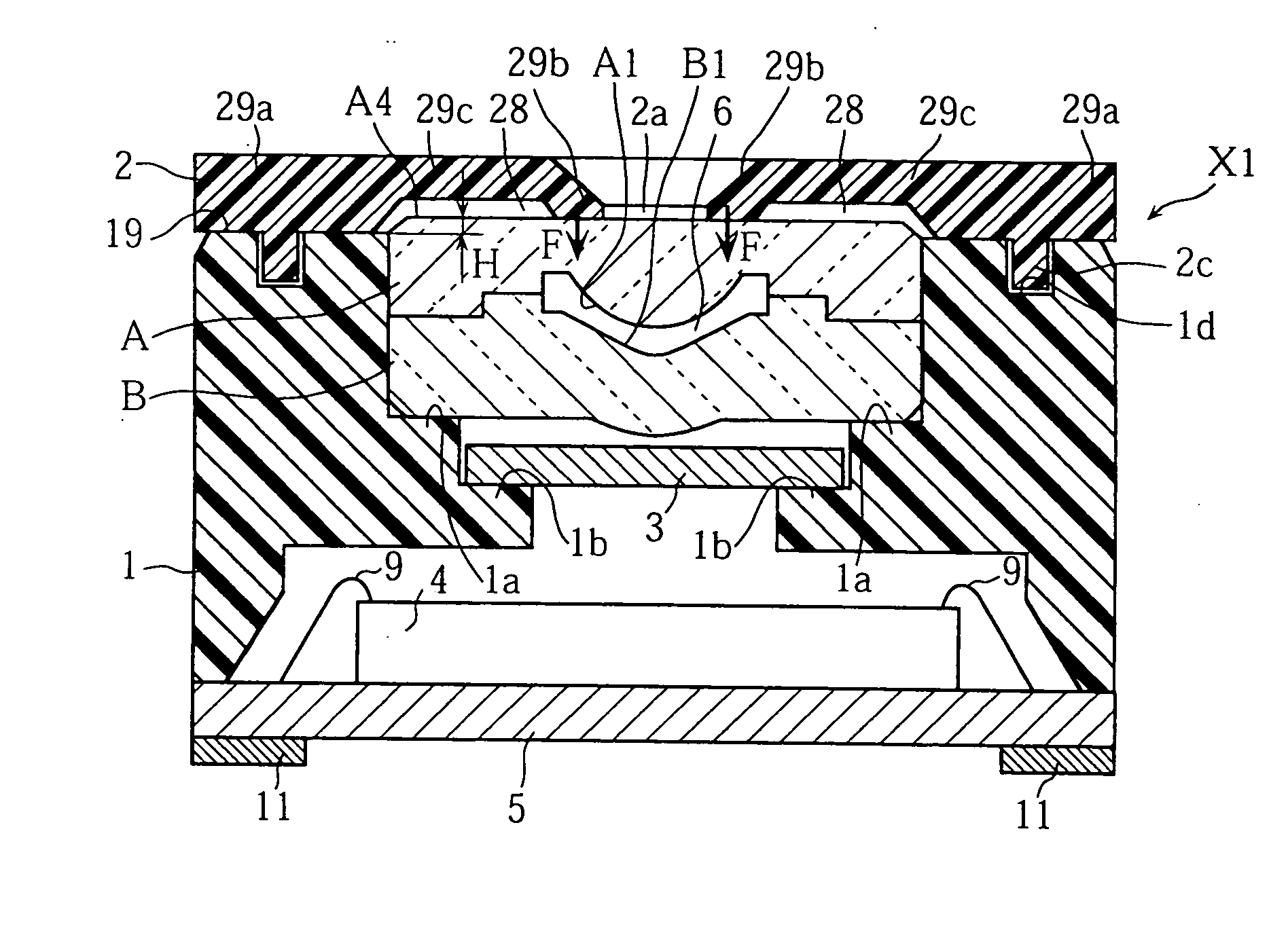

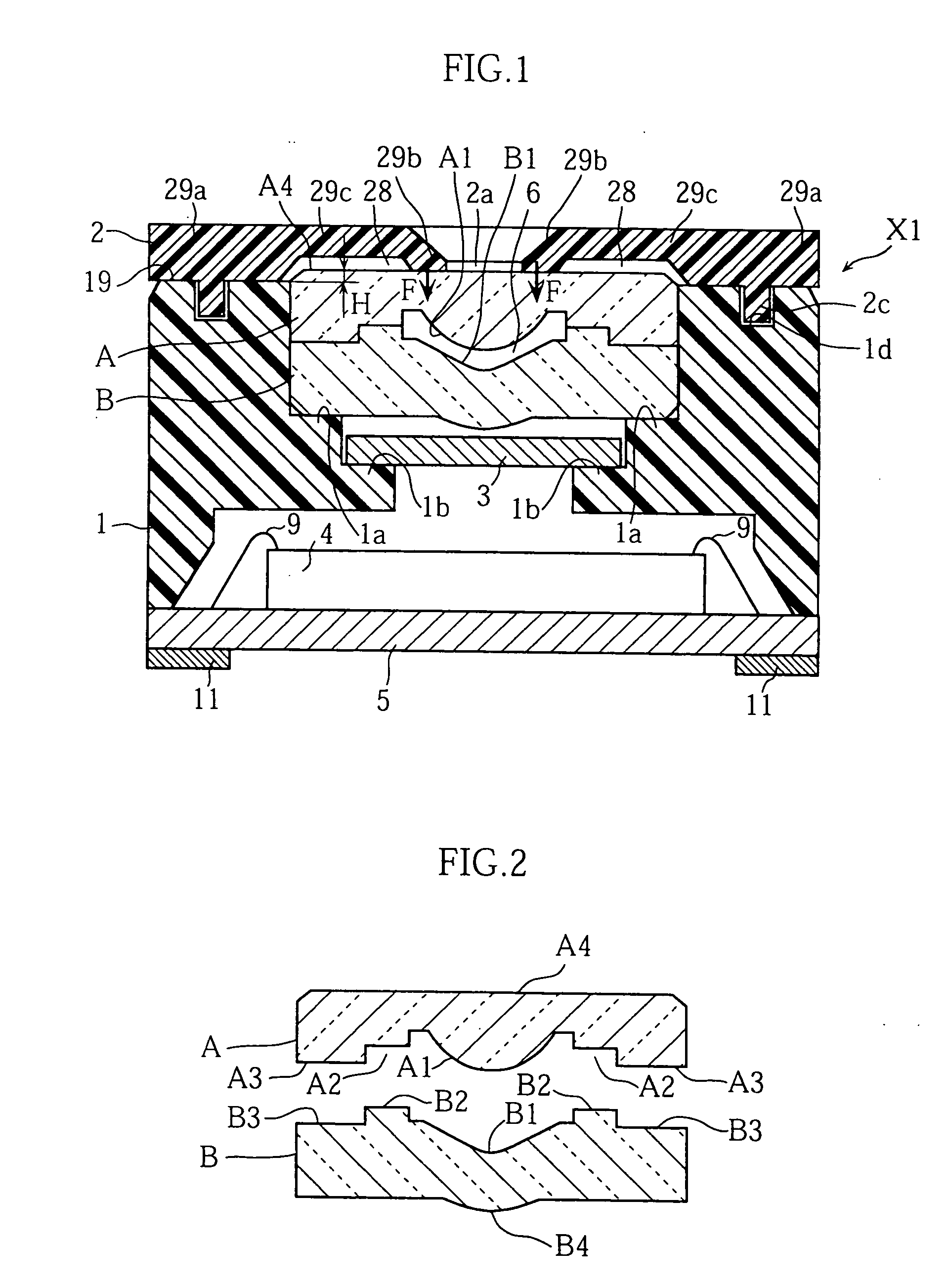

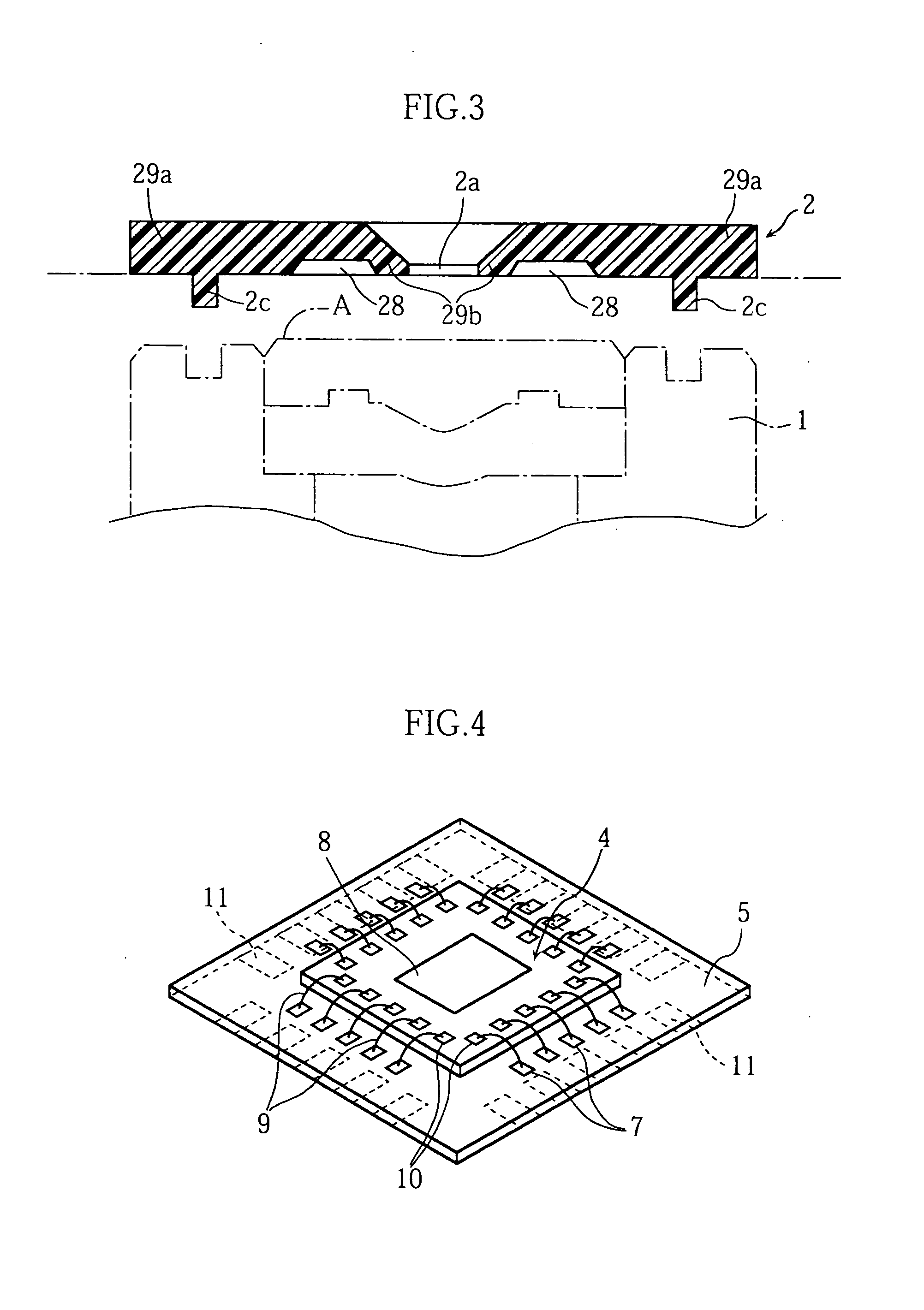

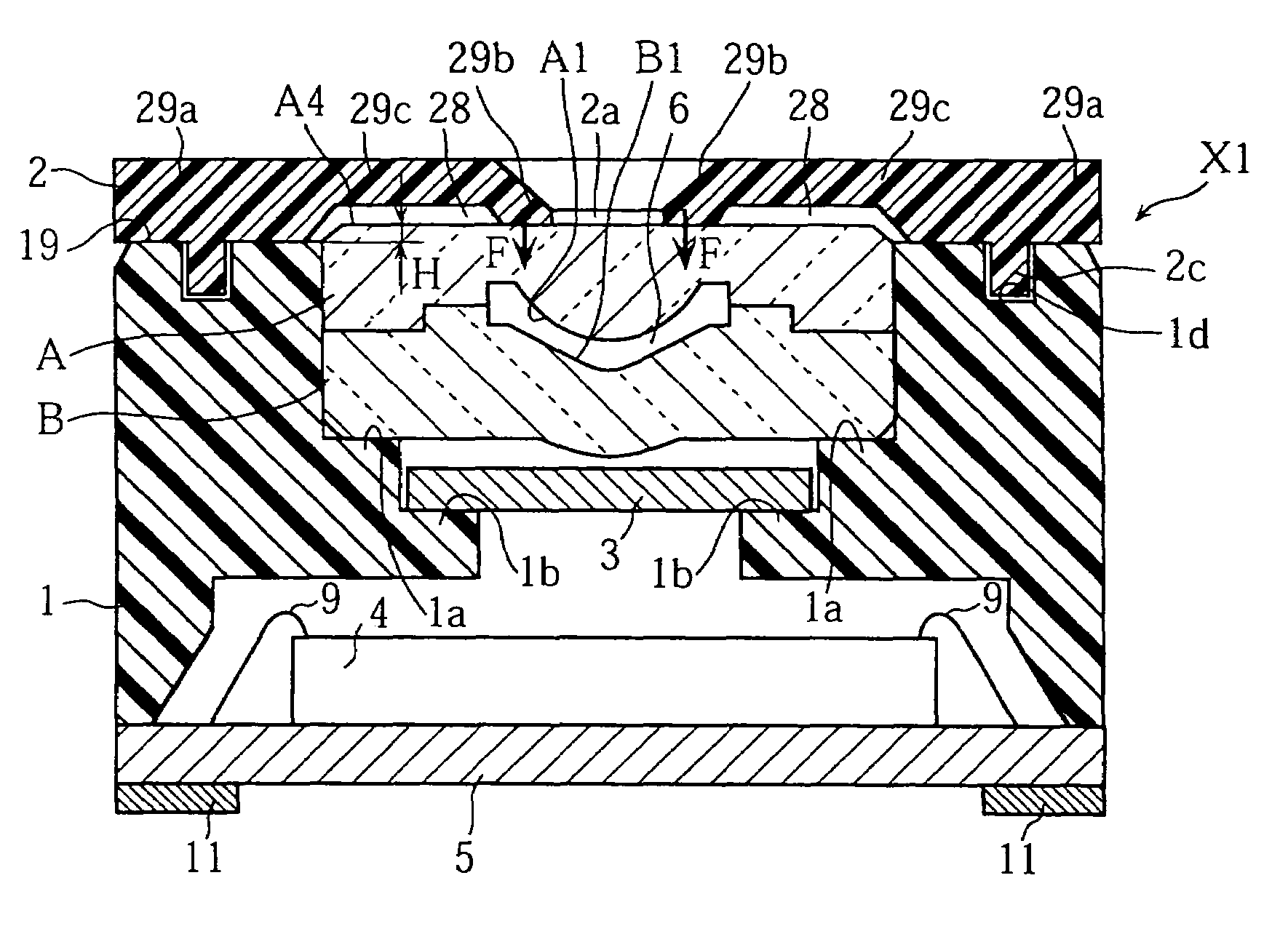

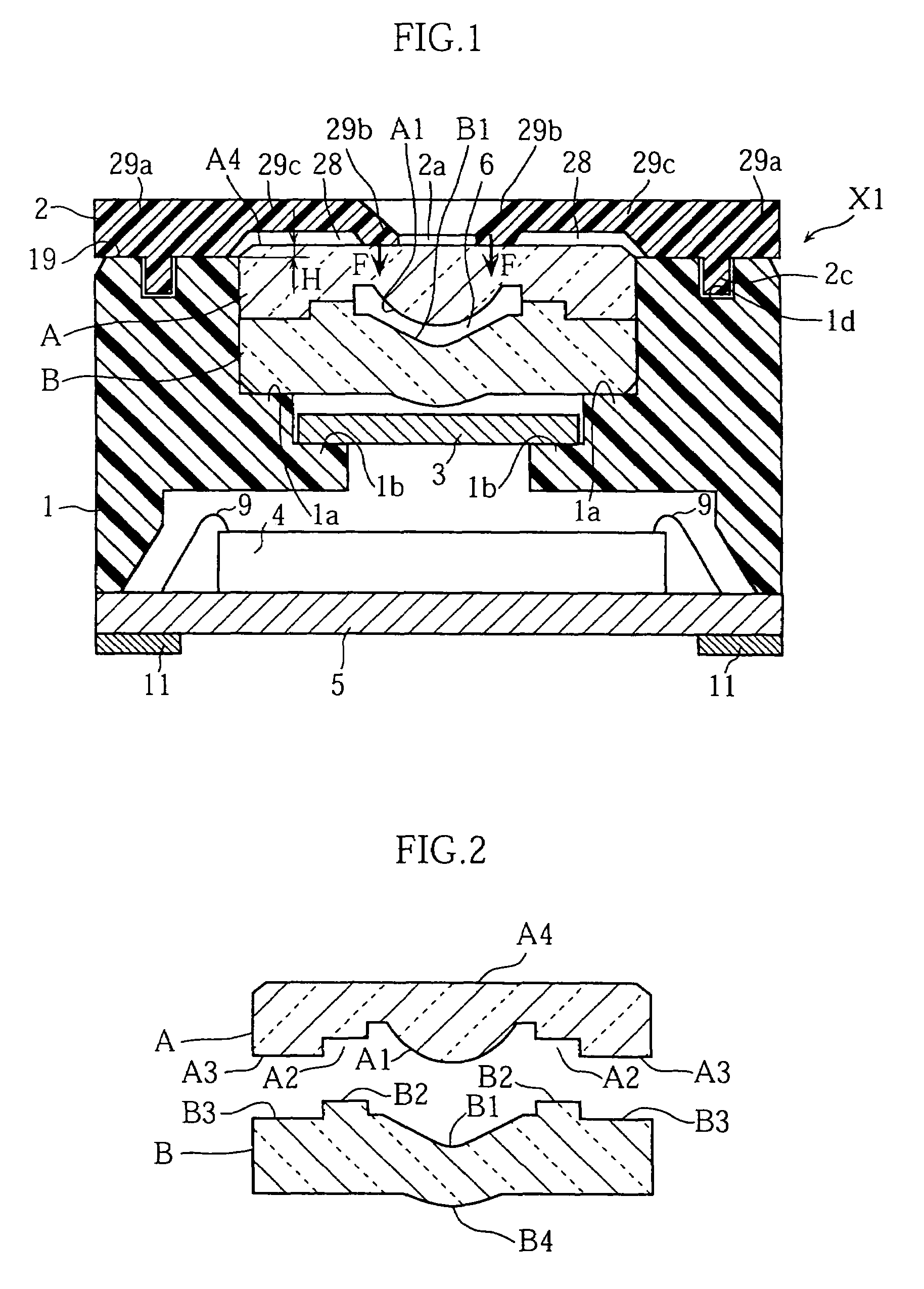

An image sensor module (X1) includes a housing (1), a lens retainer (2), an image sensor chip (4), a substrate (5) and a lens unit (A, B). The housing (1) is formed with a step portion (1a) for fixing the lens unit (A, B). The lens retainer (2) is fixed to the housing (1) and held in contact with the upper face of the lens unit (A, B). The lens unit (A, B) is pressed against the step portion (1a) of the housing (1) by a biasing force of the lens retainer (2).

Owner:ROHM CO LTD

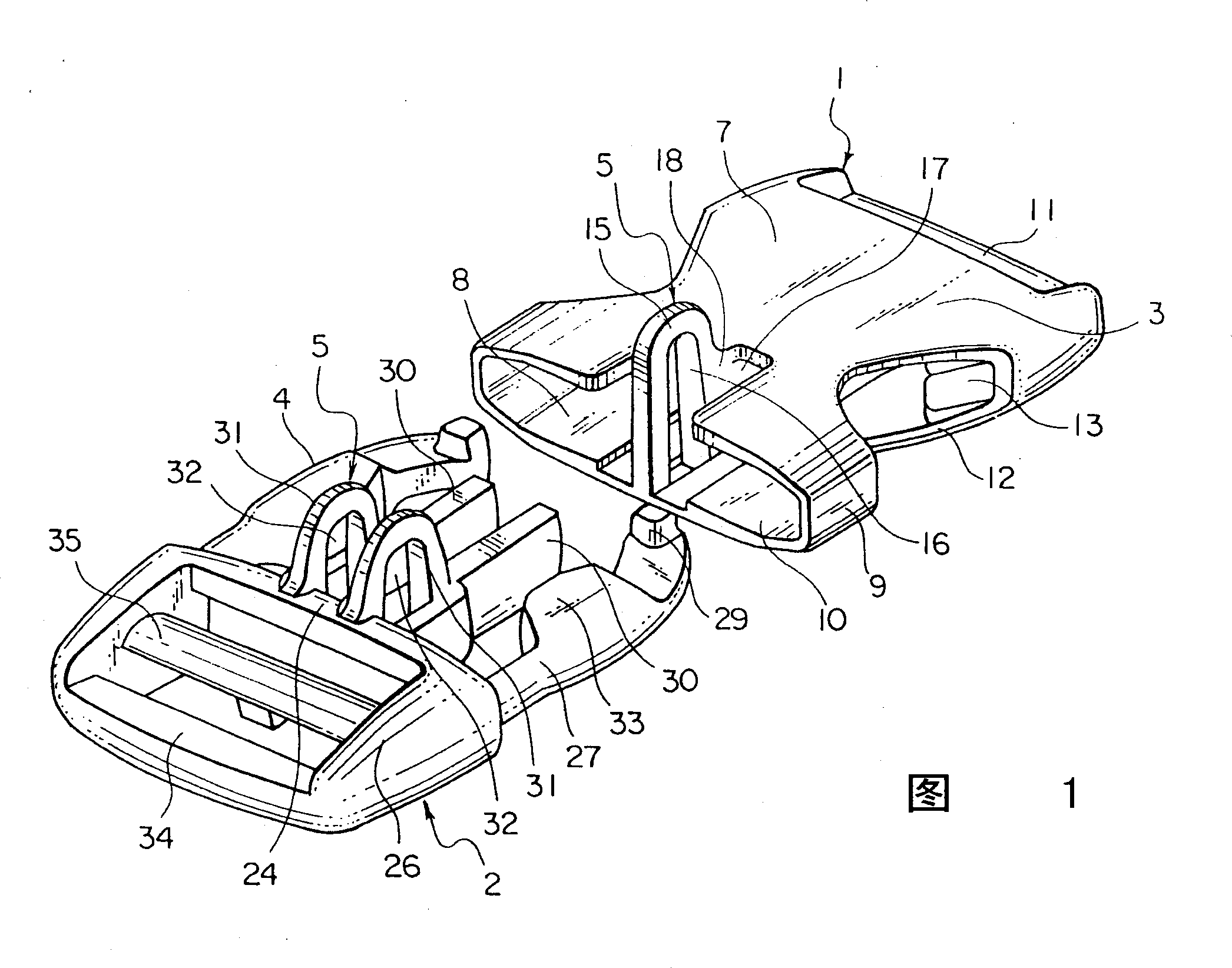

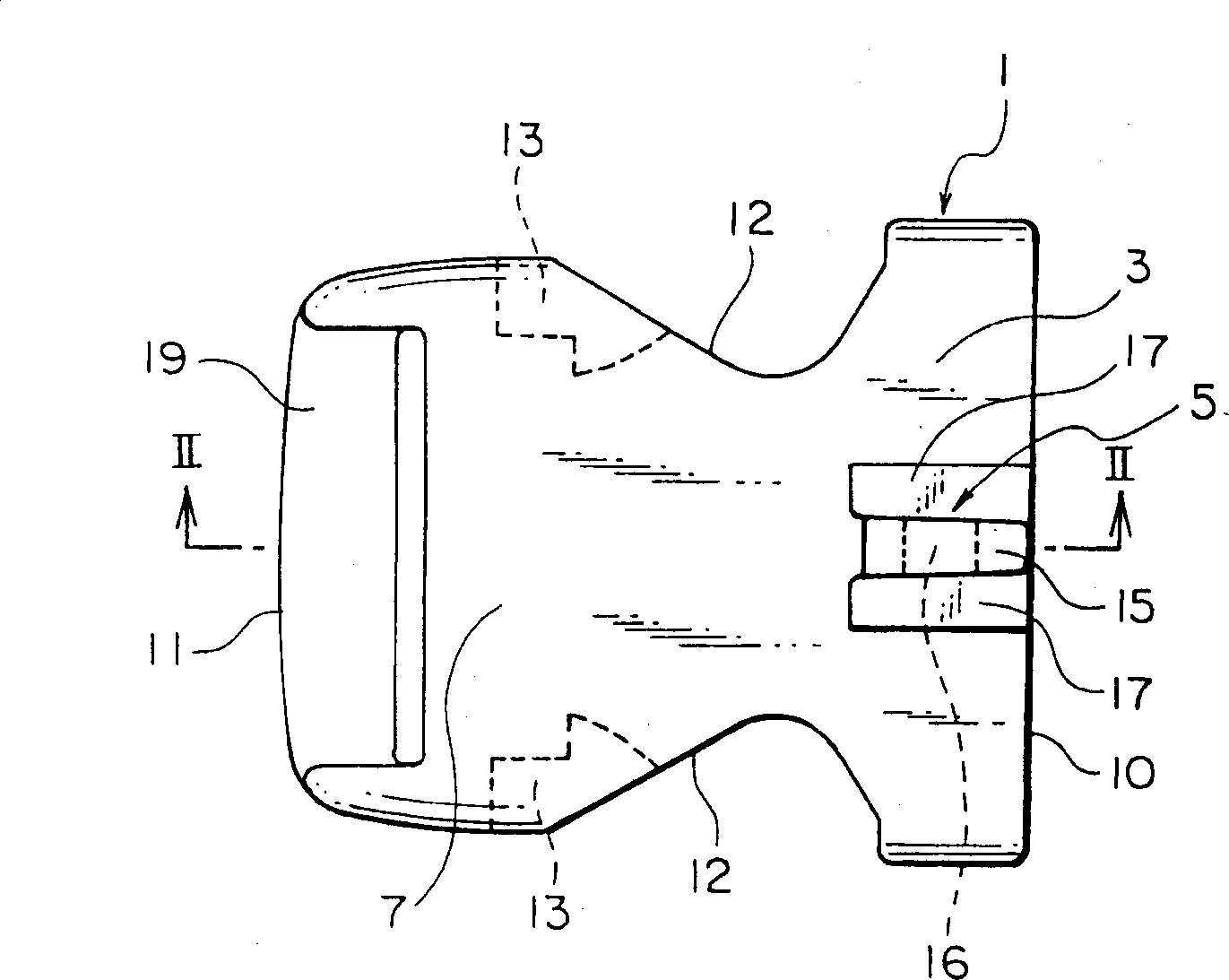

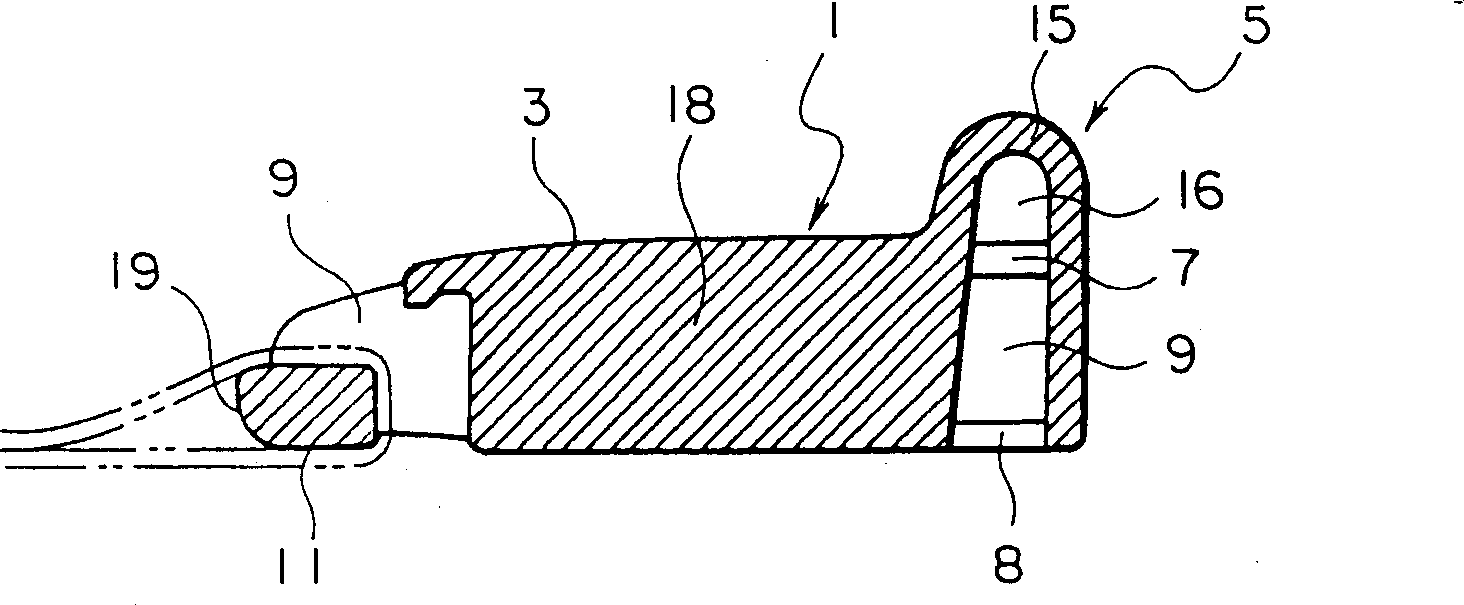

Image sensor module

InactiveUS7391458B2Easy and accurate installationPrecise positioningTelevision system detailsSolid-state devicesEngineeringImage sensor

An image sensor module (X1) includes a housing (1), a lens retainer (2), an image sensor chip (4), a substrate (5) and a lens unit (A, B). The housing (1) is formed with a step portion (1a) for fixing the lens unit (A, B). The lens retainer (2) is fixed to the housing (1) and held in contact with the upper face of the lens unit (A, B). The lens unit (A, B) is pressed against the step portion (1a) of the housing (1) by a biasing force of the lens retainer (2).

Owner:ROHM CO LTD

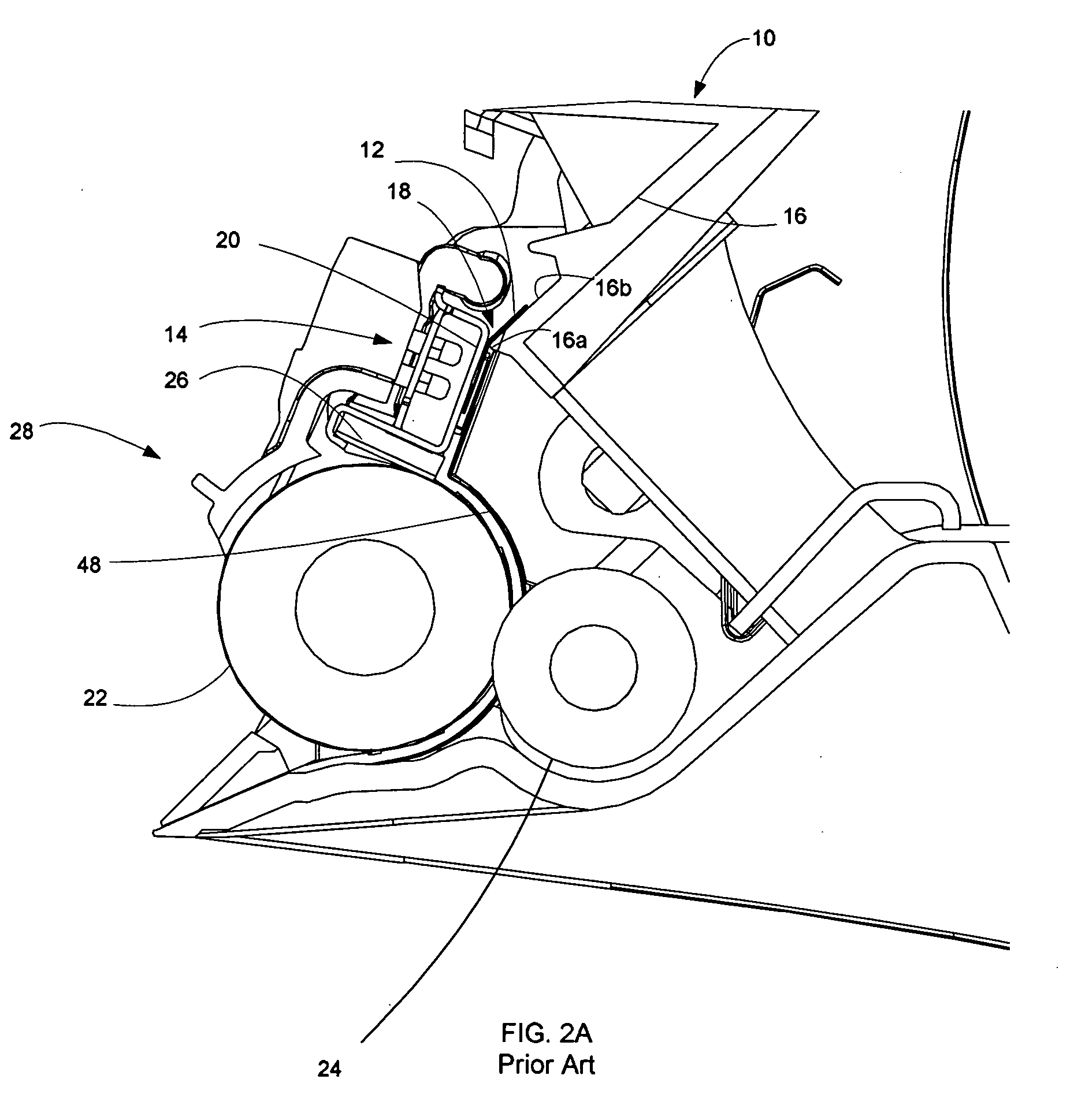

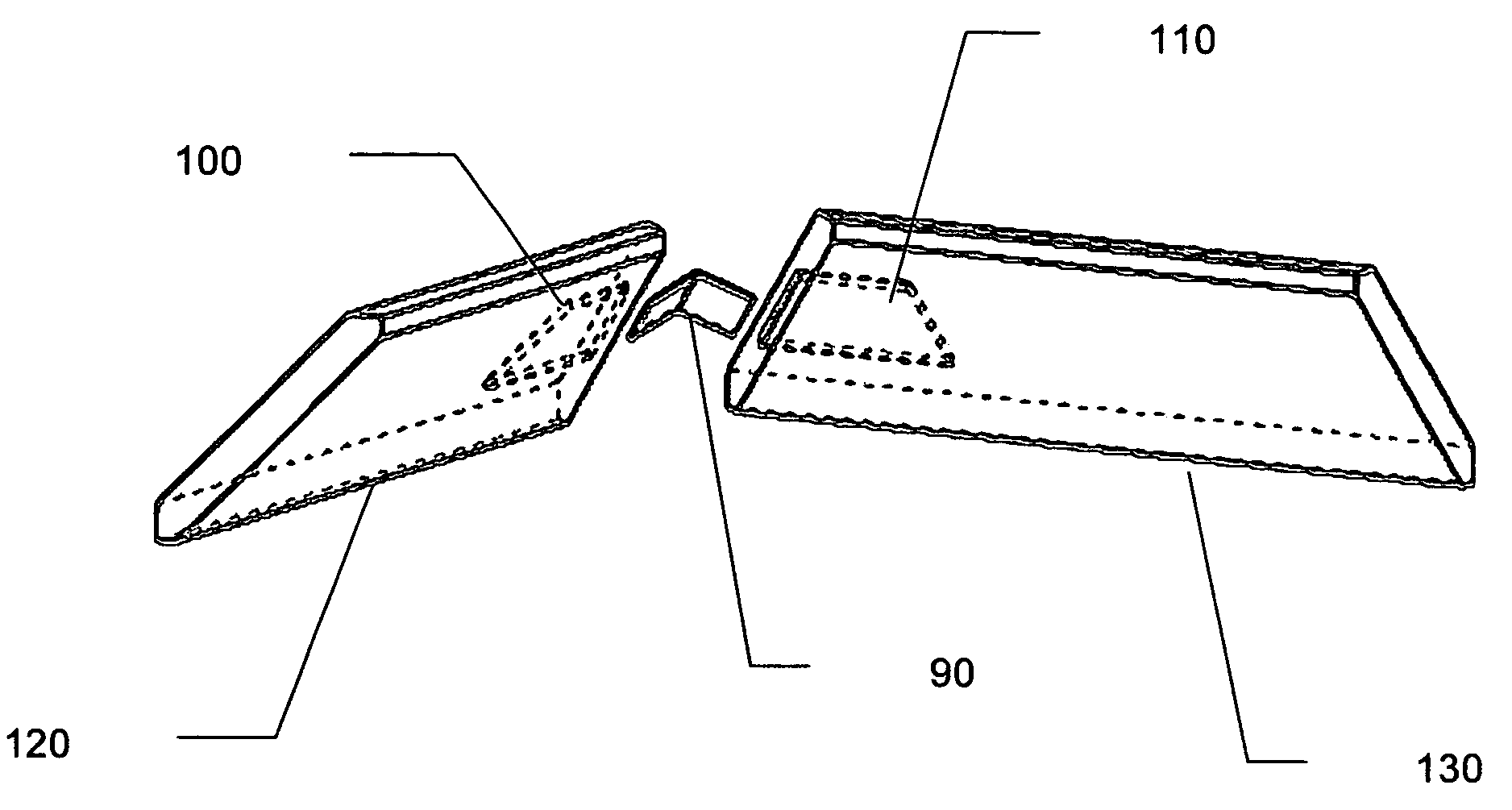

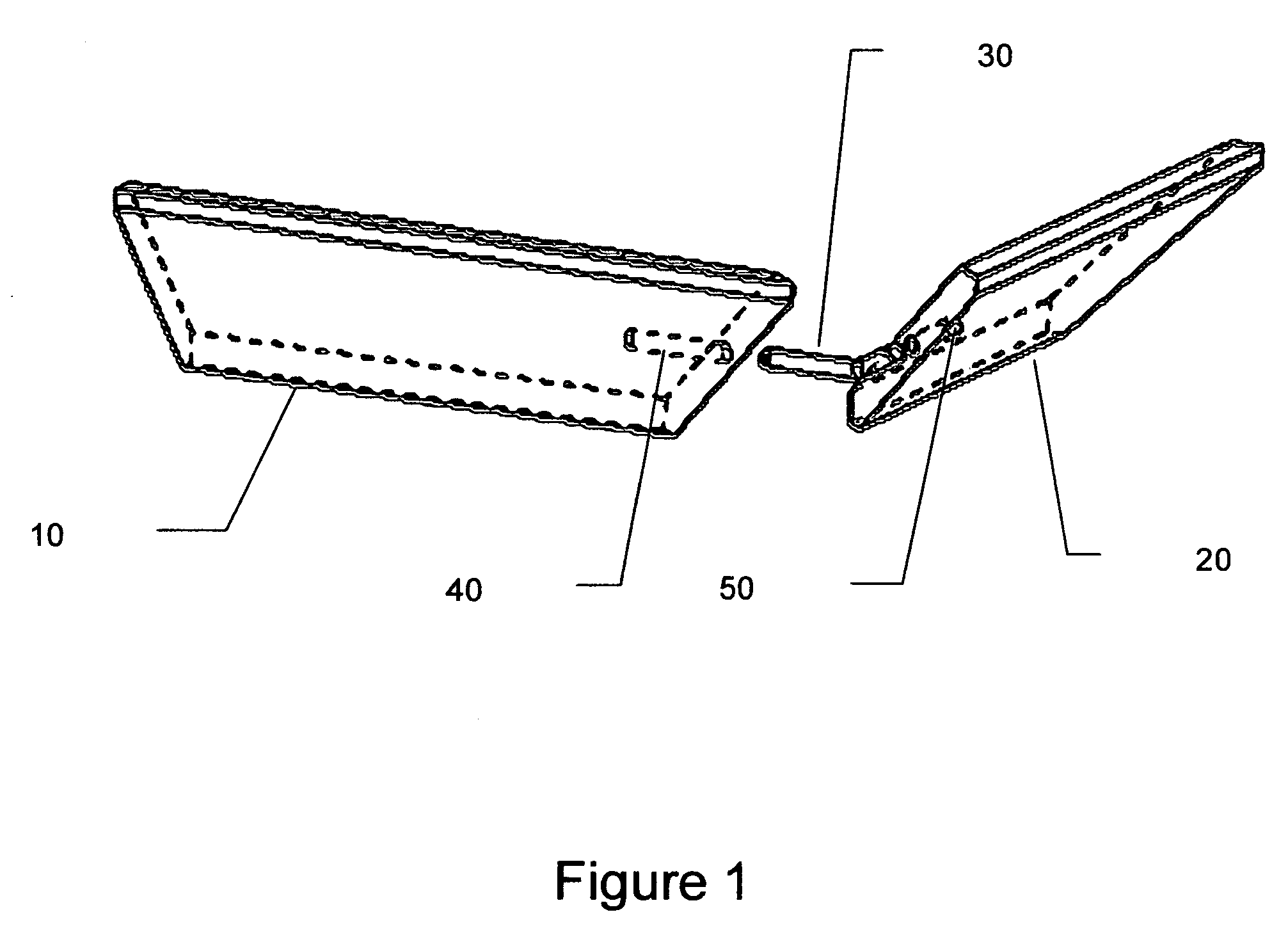

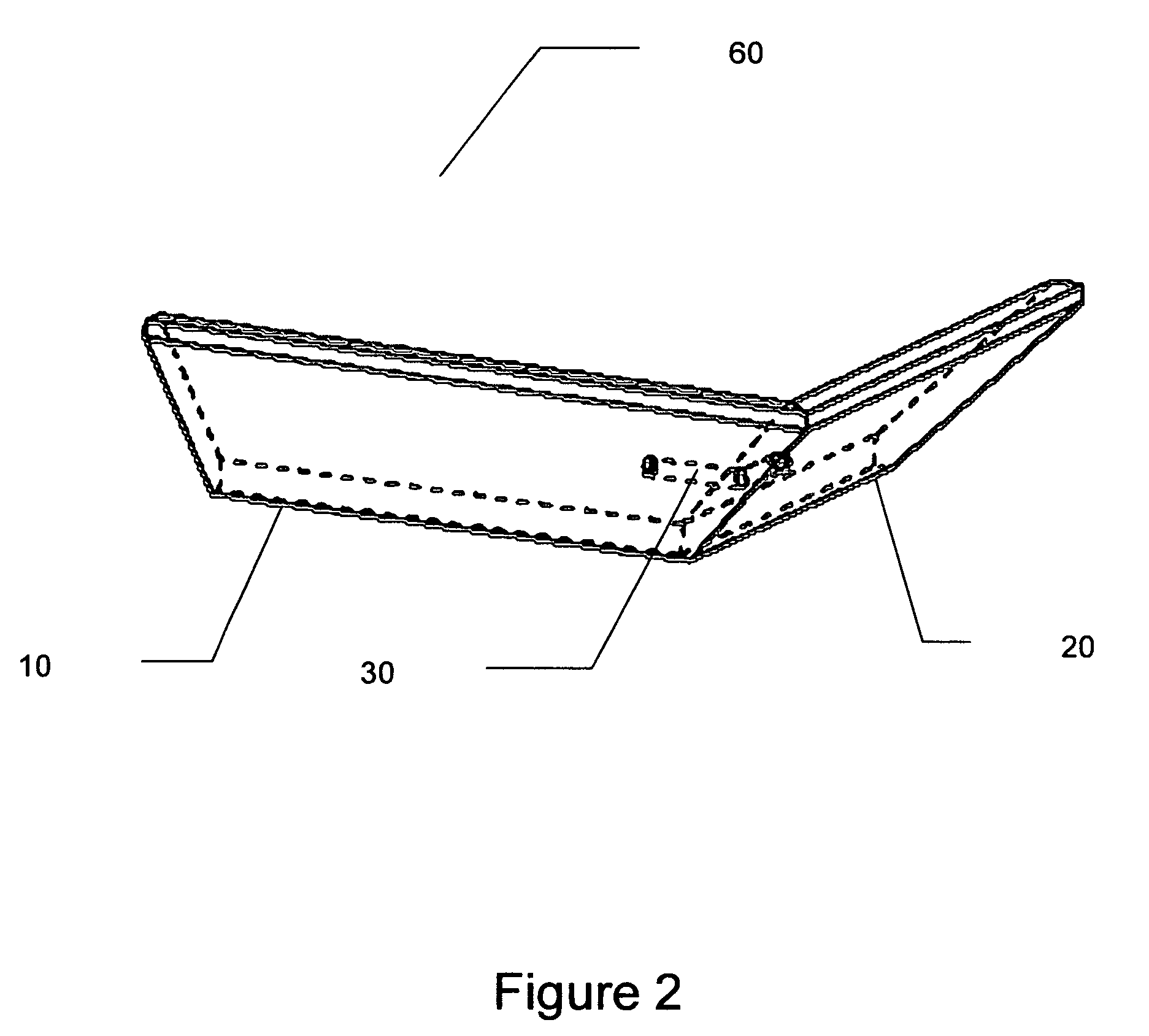

Reinforced Doctor Blade Assembly Seal and Printer Cartridge Employing the Reinforced Seal

ActiveUS20100166452A1Potential for leakageEasy and accurate installationElectrographic process apparatusMultiple edgesEngineering

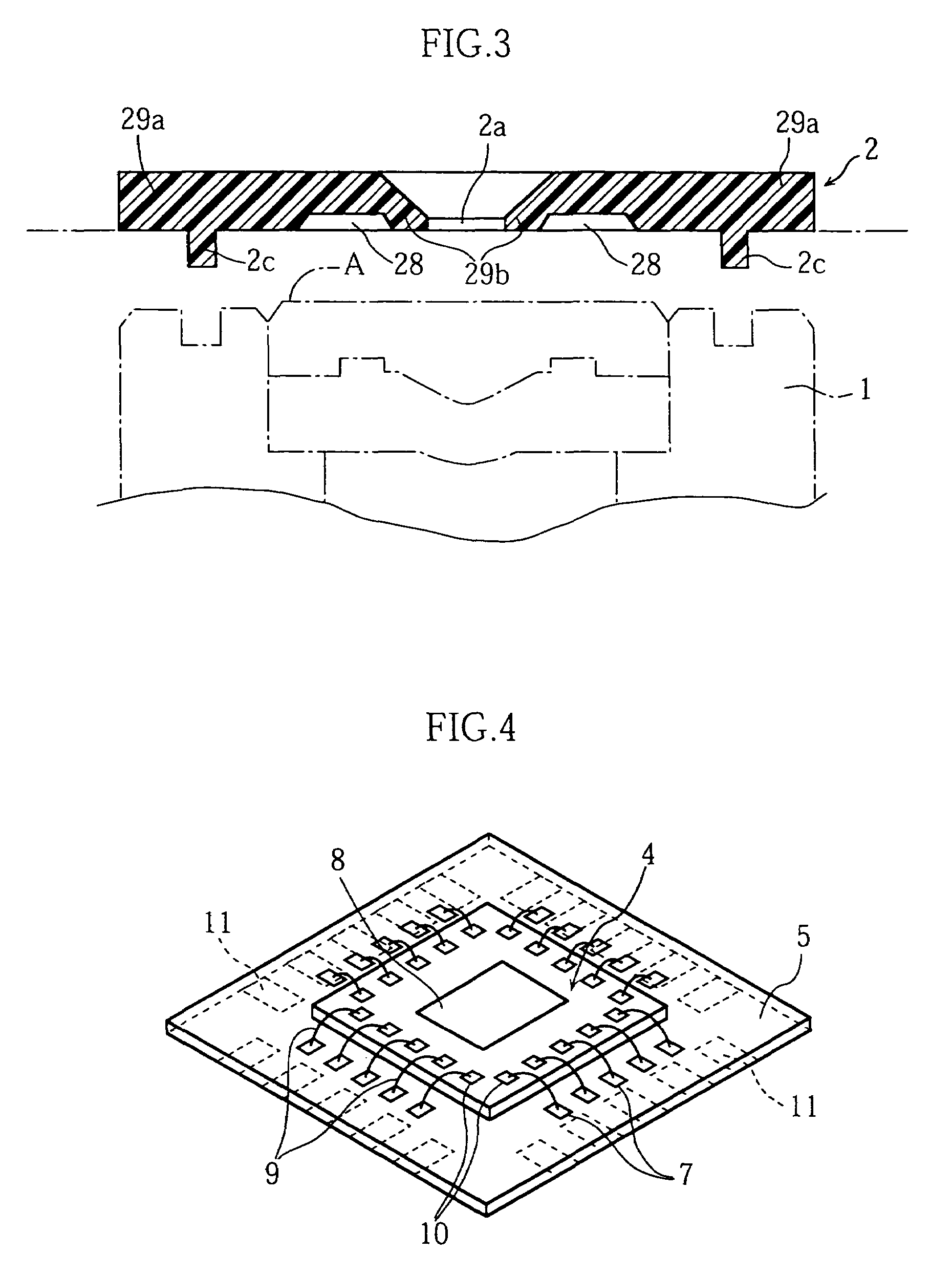

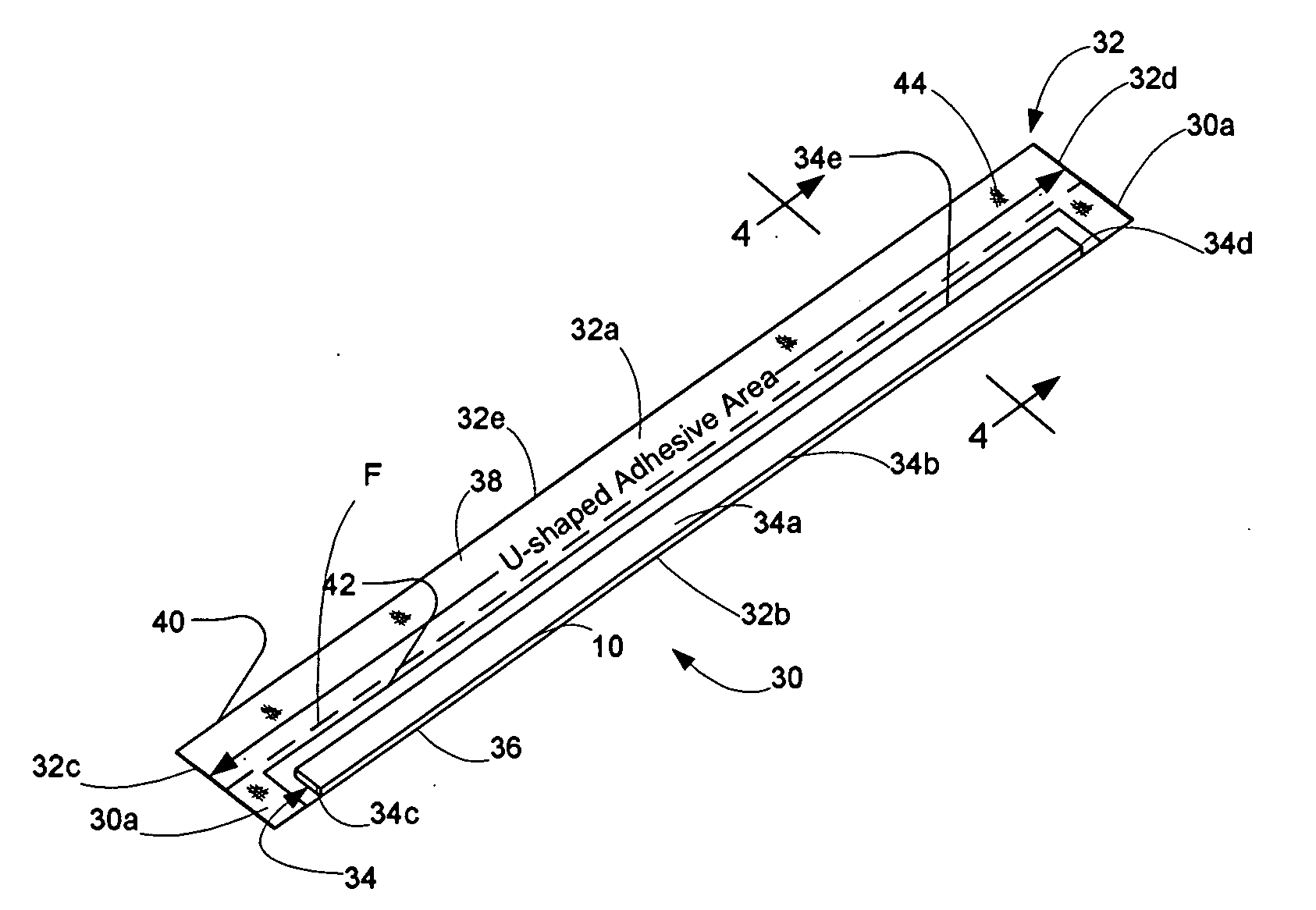

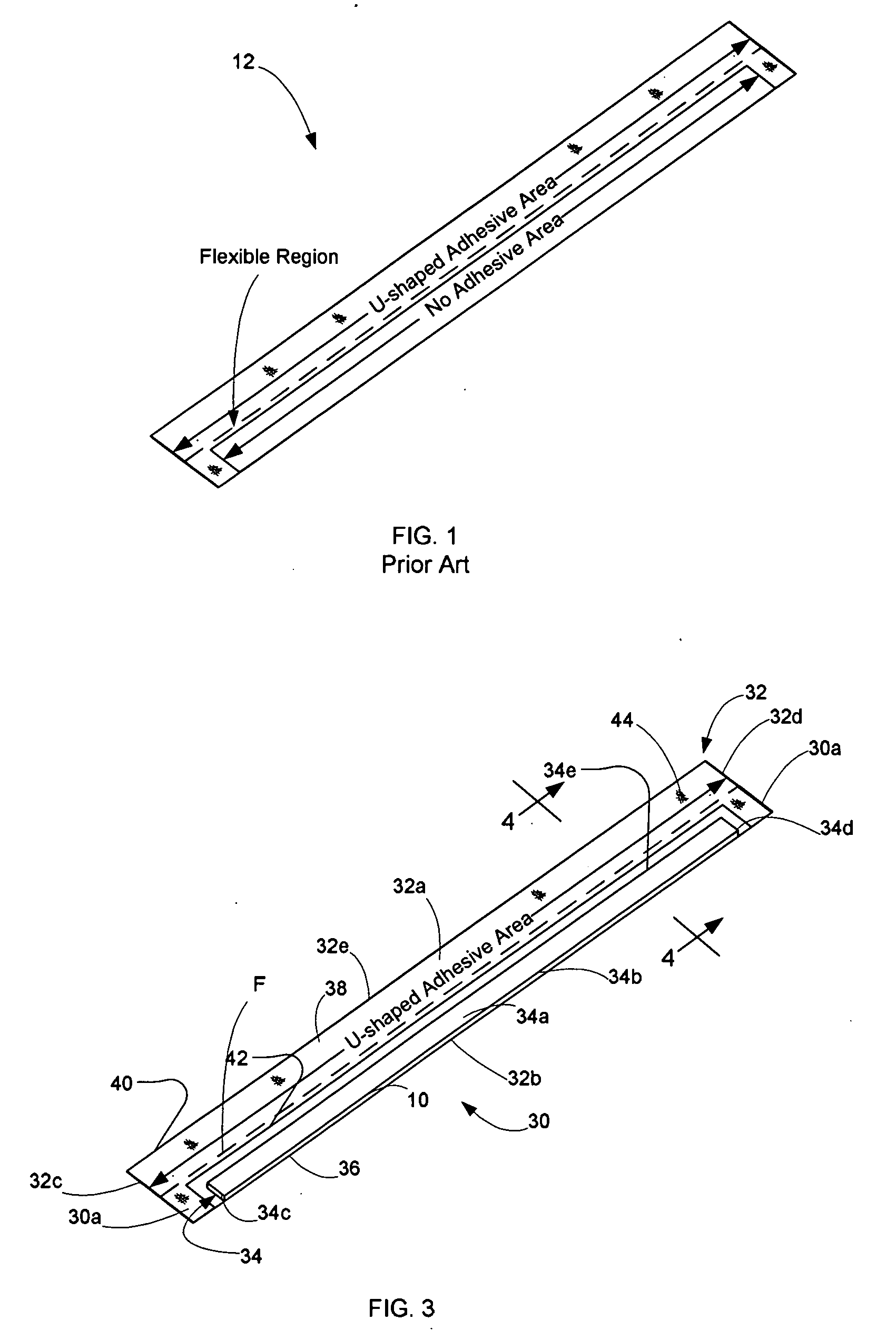

A reinforced doctor blade assembly seal includes a base strip of a flexible plastic film having a thickness, a surface of predetermined area bounded by multiple edges, and a foldable region extending length-wise between one pair of the multiple edges and spaced from and located intermediately between another pair of the multiple edges. The seal also includes a supplemental strip of a flexible plastic film having a thickness and a surface of predetermined area bounded by multiple edges. The supplemental strip is laminated on the base strip offset from and along one side of the foldable region on the base strip such that the base strip has adjacent laminated and non-laminated portions along opposite sides of the foldable region with the laminated portion having a greater thickness than the non-laminated portion. The seal has an attaching mechanism in the form of an adhesive coating on the non-laminated portion of the base strip. The seal is employed in a printer cartridge.

Owner:LEXMARK INT INC

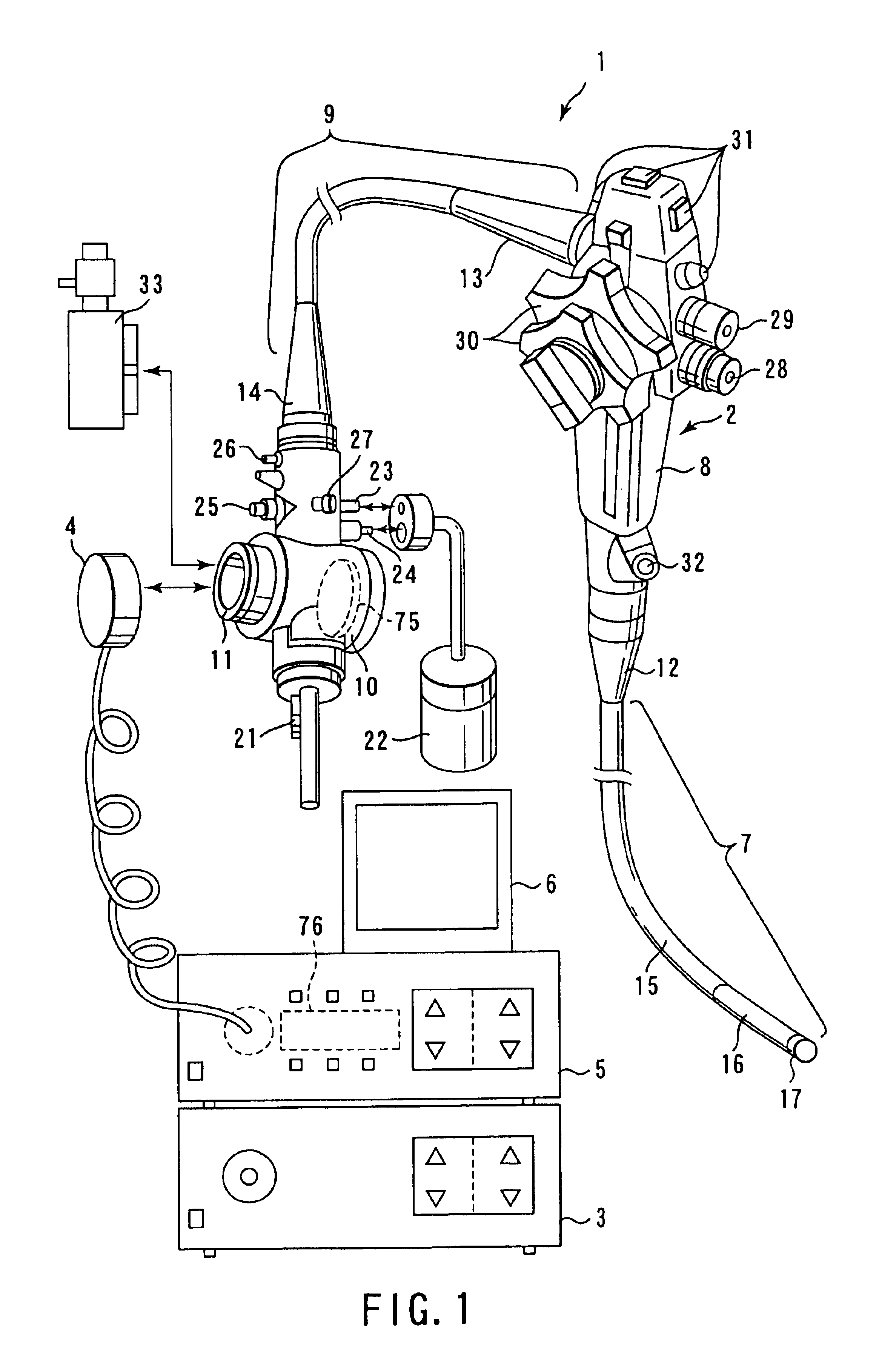

Fitting jig of endoscope hood member

It is provided a hood member fitting jig to mount a hood member on the end section of an inserted section of an endoscope. The hood member fitting jig includes a base section, a first position regulating section provided on the base section to regulate the position of the hood member with respect to the hood member fitting jig, and a second position regulating section provided on the base section to regulate the position of the hood member fitting jig with respect to an end section of the endoscope.

Owner:OLYMPUS CORP

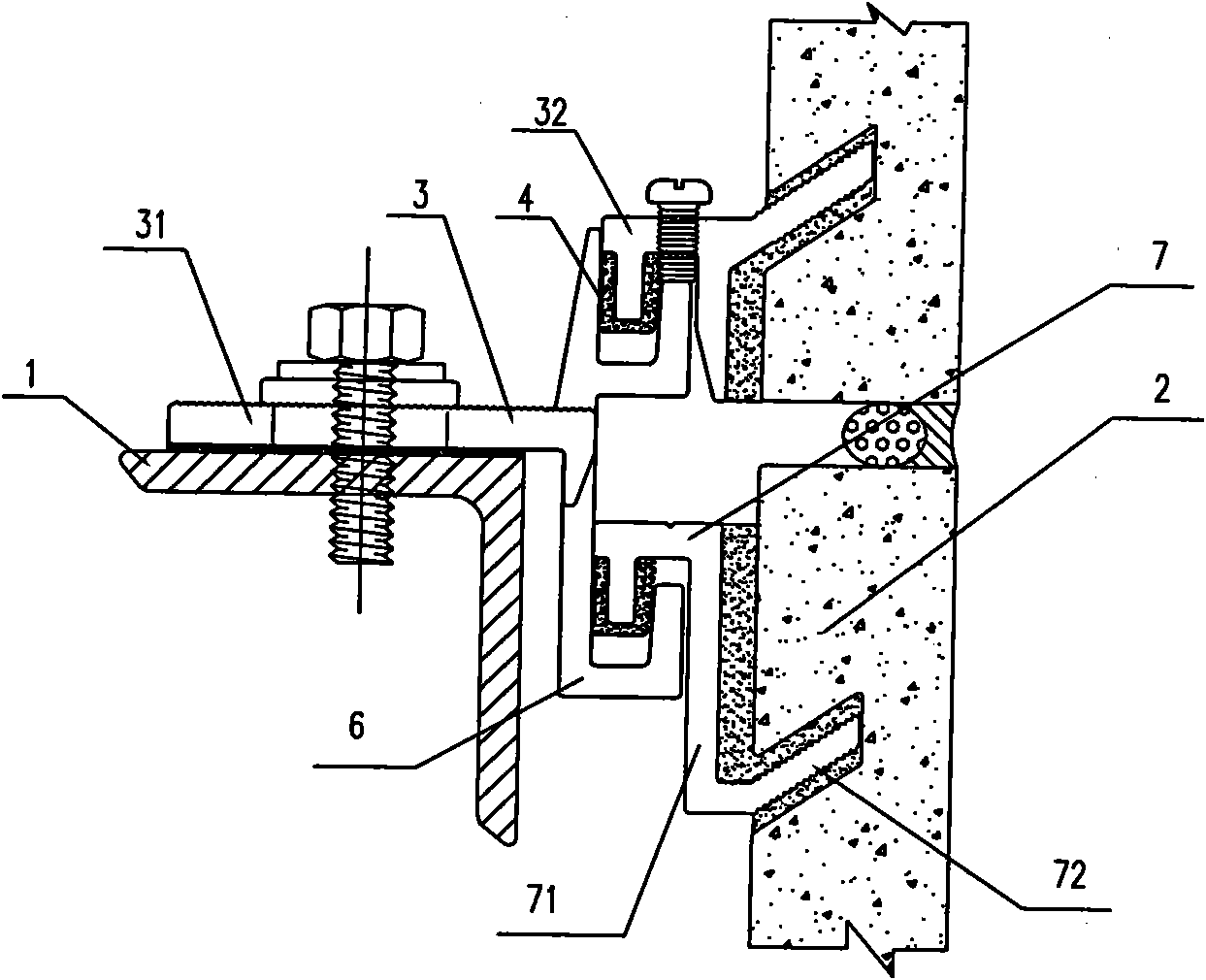

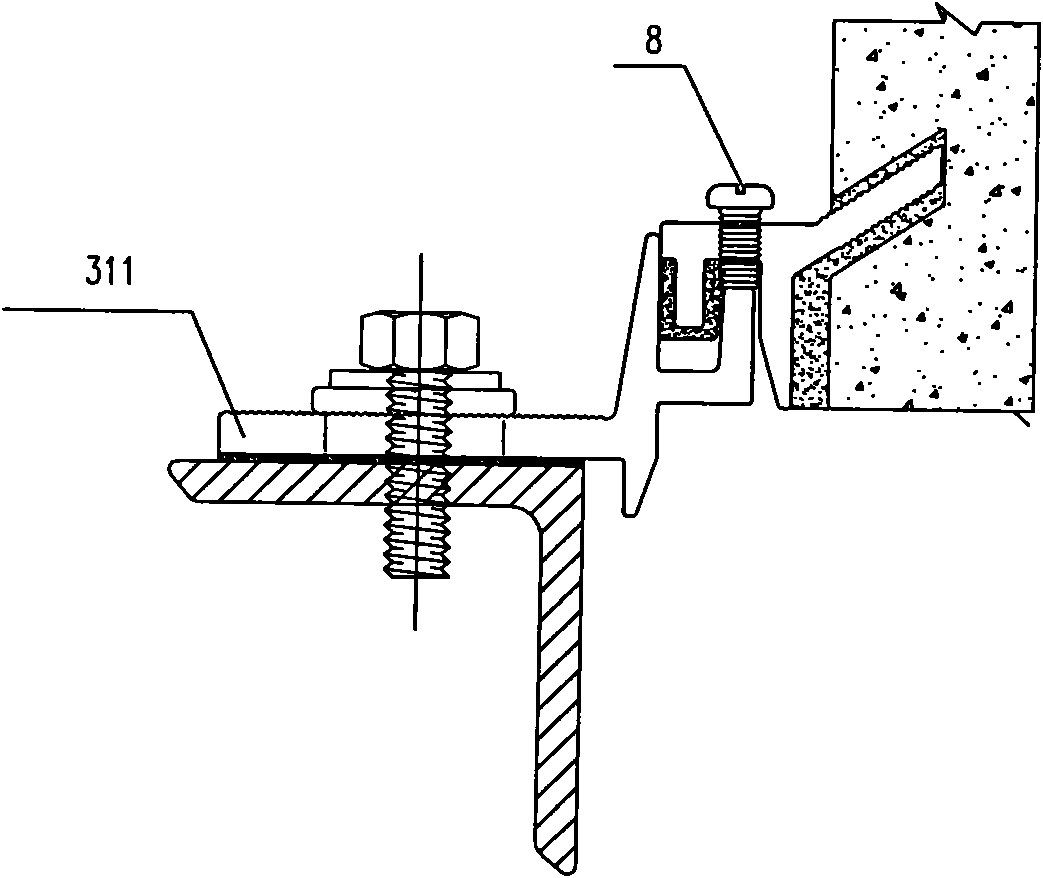

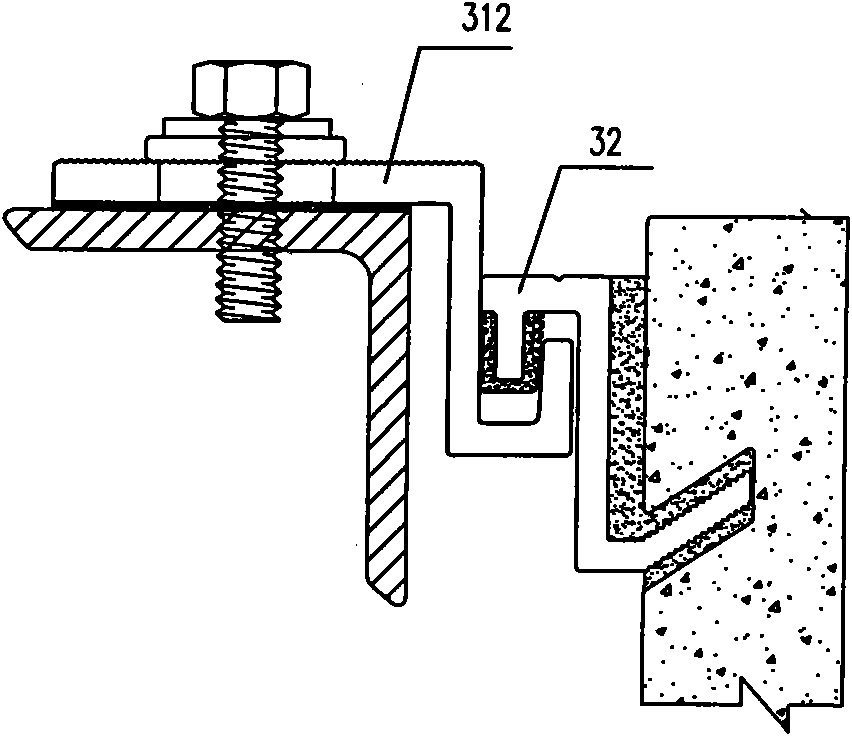

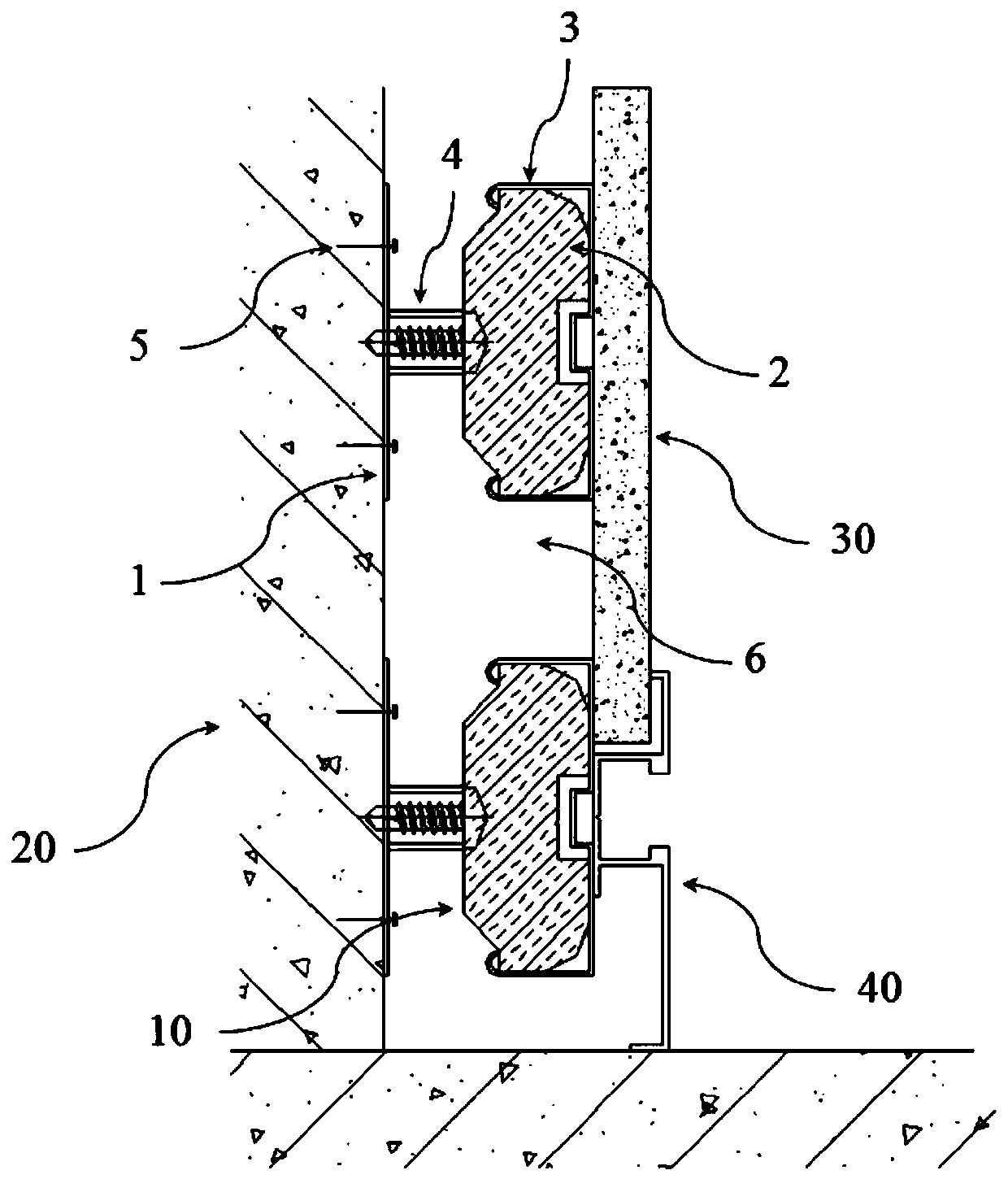

Dry-hanging structure of stone curtain wall

The invention discloses a dry-hanging structure of a stone curtain wall, which comprises a curtain wall frame, a beam, a stone plate and a dry-hanging element fixed between the beam and the stone plate, wherein the dry-hanging element is formed by connecting a hanging seat fixed on the beam and a hanging element fixed on the stone plate; a lateral part of the hanging seat extends outwards to form a hook with an upward hook mouth; and the end part of the hanging element on the stone plate is in hooking fit with the hook. The dry-hanging structure of the stone curtain wall is characterized in that: a joint between the hanging element and the hanging seat is provided with a bolt which is used for adjusting the height deviation of the plate; the hanging seat is provided with a long hole which is used for adjusting length deviation; and the inside of the long hole is provided with a fixing element for fixedly connecting the hanging seat and the beam. The stone plate in the dry-hanging structure of the stone curtain wall can be separately replaced, the installation is convenient and secure, and the cost and the installation charge are saved, thus the dry-hanging structure of the stone curtain wall has good promotion value.

Owner:FANGYUAN CONSTR GRP REAL ESTATE DEVT CO LTD

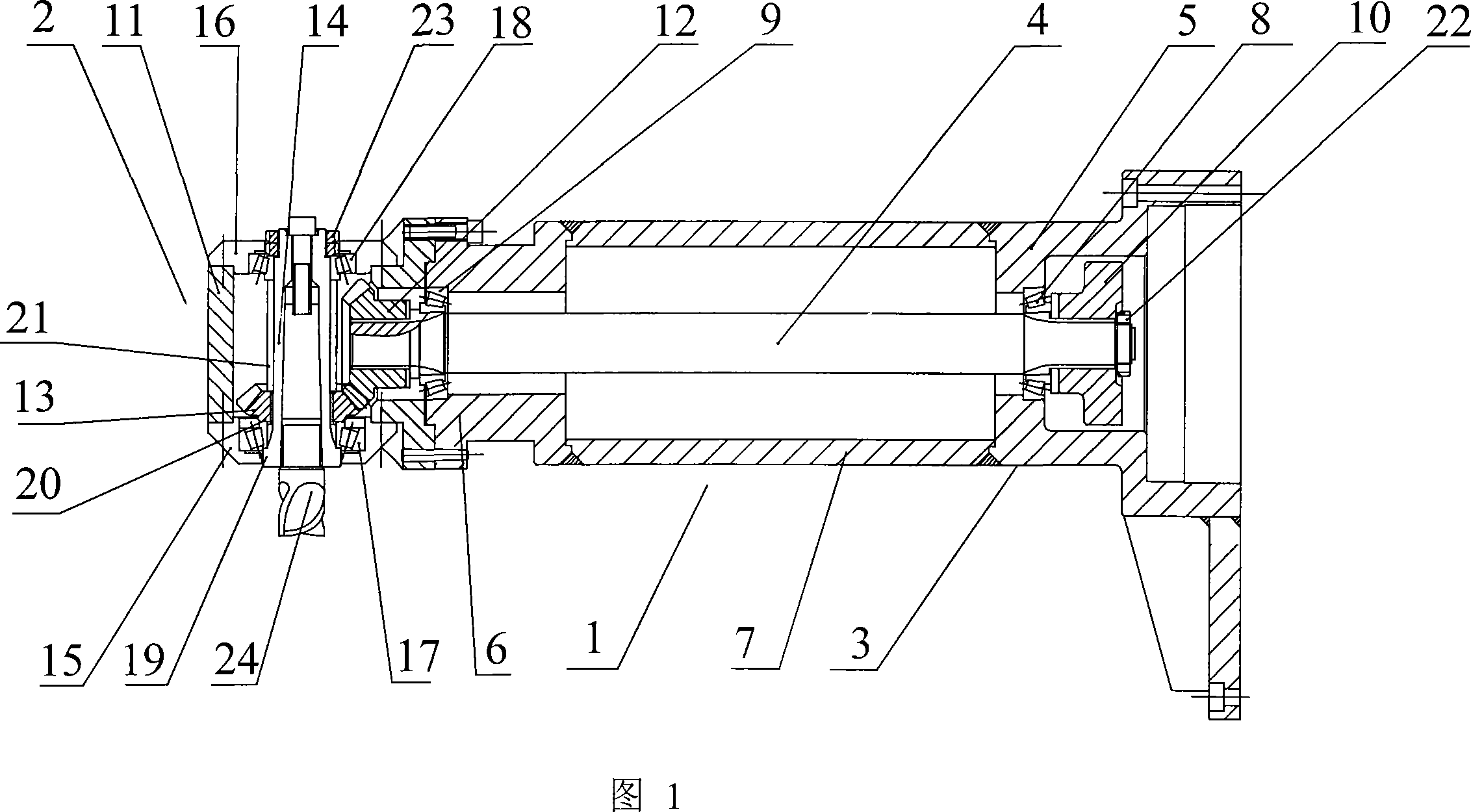

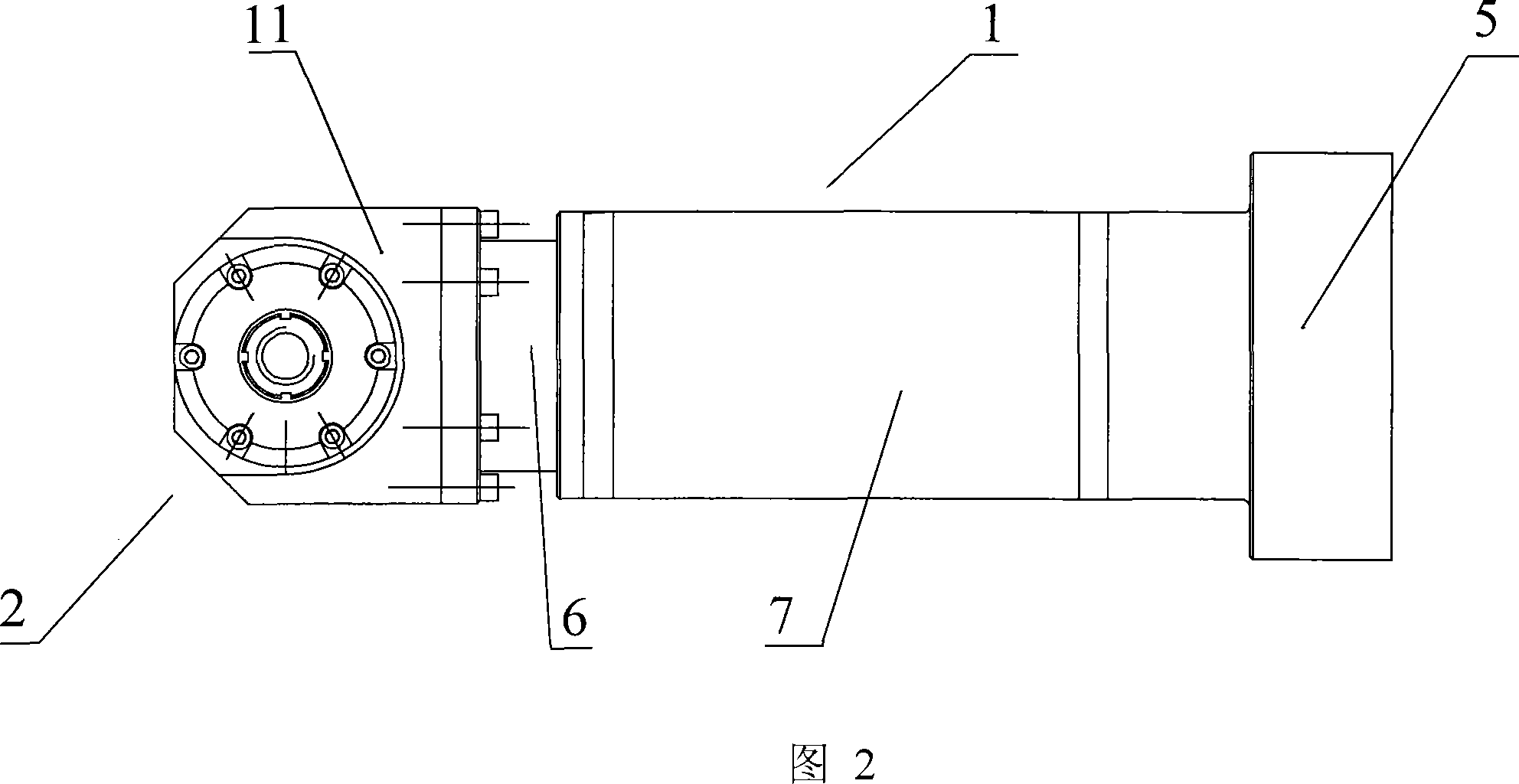

Bevel-gear right-angle milling head

InactiveCN101100035AEasy and accurate installationSmooth runningDriving apparatusMilling cutterGear wheel

The present invention relates to machining fixture, and is especially one kind of milling head for holding milling cutter in numerically controlled machine tool. The rectangular bevel gear milling head includes one driving mechanism and one steering mechanism. The driving mechanism includes one milling head base fixed onto the milling machine and one connecting shaft set inside the base and connected to the milling machine spindle. The steering mechanism includes one milling head casing, two bevel gears to constitute one rectangular gear train, and one milling head spindle. The milling head has capacity of altering the milling cutter rotation direction, capacity of machining inner surface of hole or end parallel to the milling machine spindle, high production efficiency and high machining precision.

Owner:SHANGHAI BLOWER WORKS

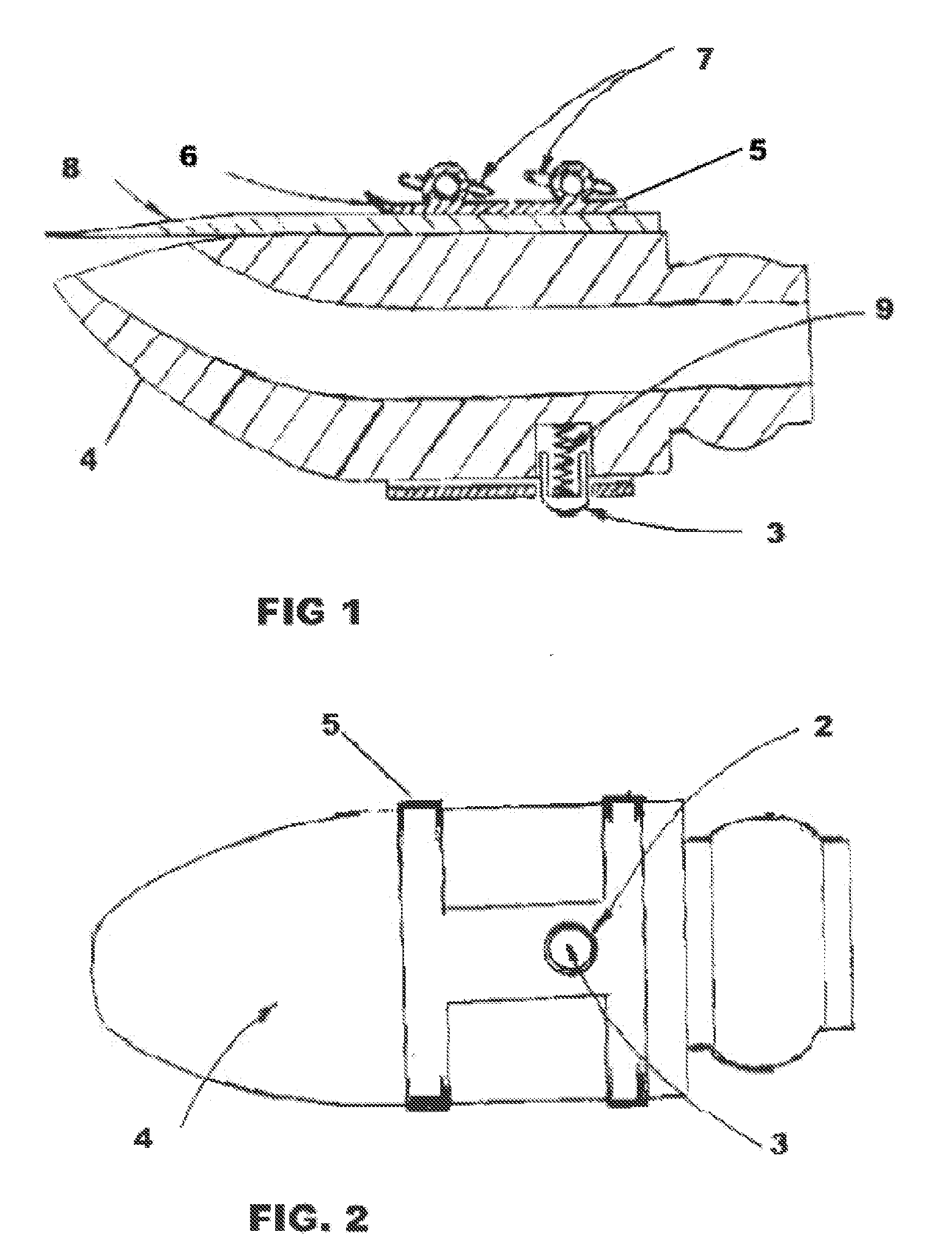

Single reed woodwind musical instrument mouthpiece apparatus and method

InactiveUS20080022839A1Easy and accurate installationEliminate processingWind musical instrumentsMouth pieceOrthodontic ligature

A mouthpiece assembly for a woodwind musical instrument that holds an associated reed includes (1) an elongated mouthpiece body defining an air conduit means extending therethrough for providing a supply of air to facilitate playing of a woodwind musical instrument; (2) a reed placement surface defined on the mouthpiece body adjacent the air conduit dimensioned and configured to receive a reed detachably secured thereagainst; (3) a ligature including a ligature body dimensioned and configured to encircle the mouthpiece body and selectively retain the associated reed in position upon the reed placement surface and (4) a locating body engaging the ligature body and the mouthpiece body to locate the ligature body axially and radially with respect the mouthpiece body. The invention also includes the method for mounting a ligature on a mouthpiece for a woodwind musical instrument that includes the step of providing a locating body engaging the ligature body and the mouthpiece body to locate the ligature body axially and radially with respect the mouthpiece body.

Owner:SULLIVAN GEORGE V

Vial-mounting structure

ActiveUS7832112B2Securely holdEasy and accurate installationIncline measurementEdge surfaceEngineering

Owner:MILWAUKEE ELECTRIC TOOL CORP

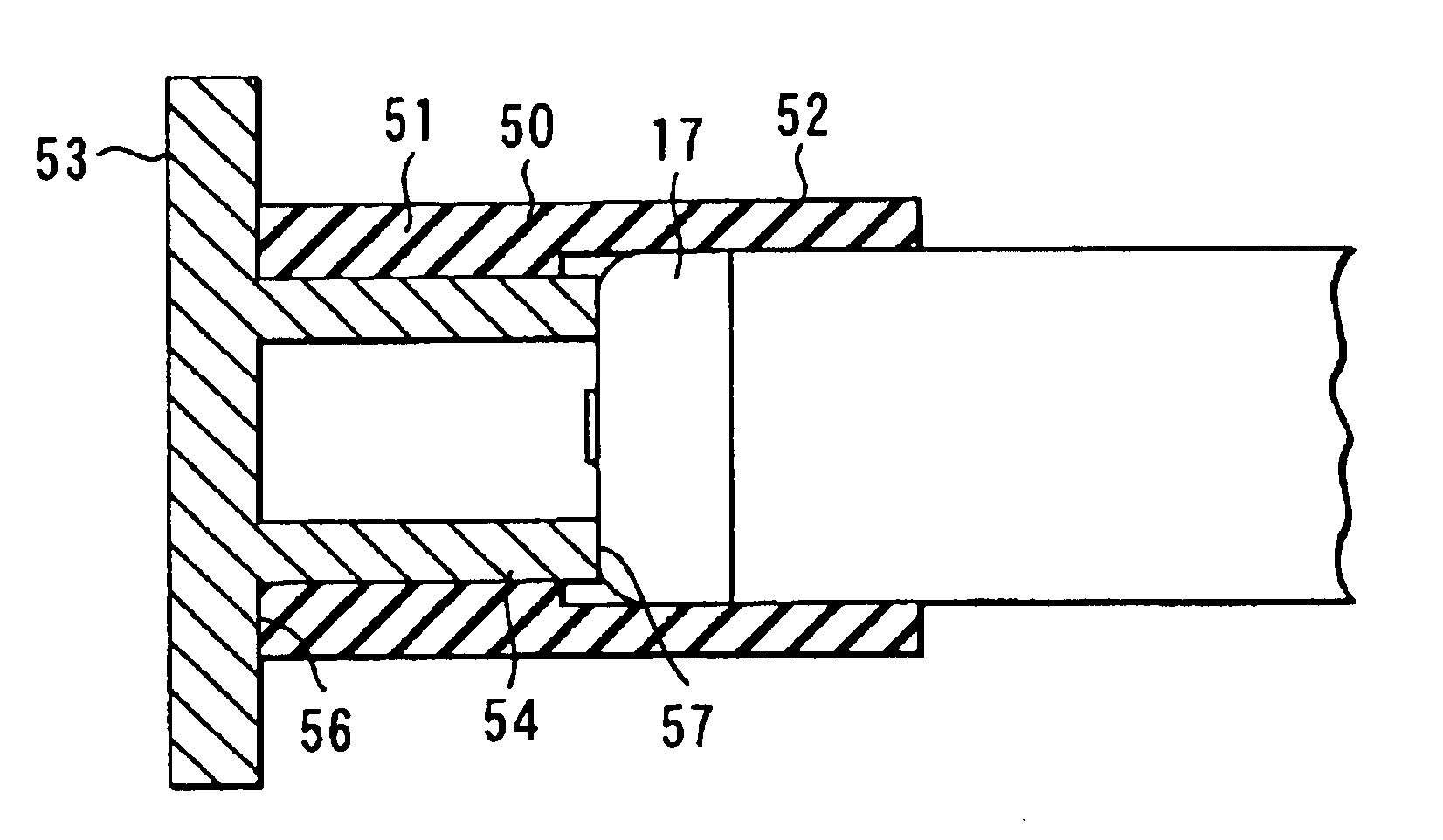

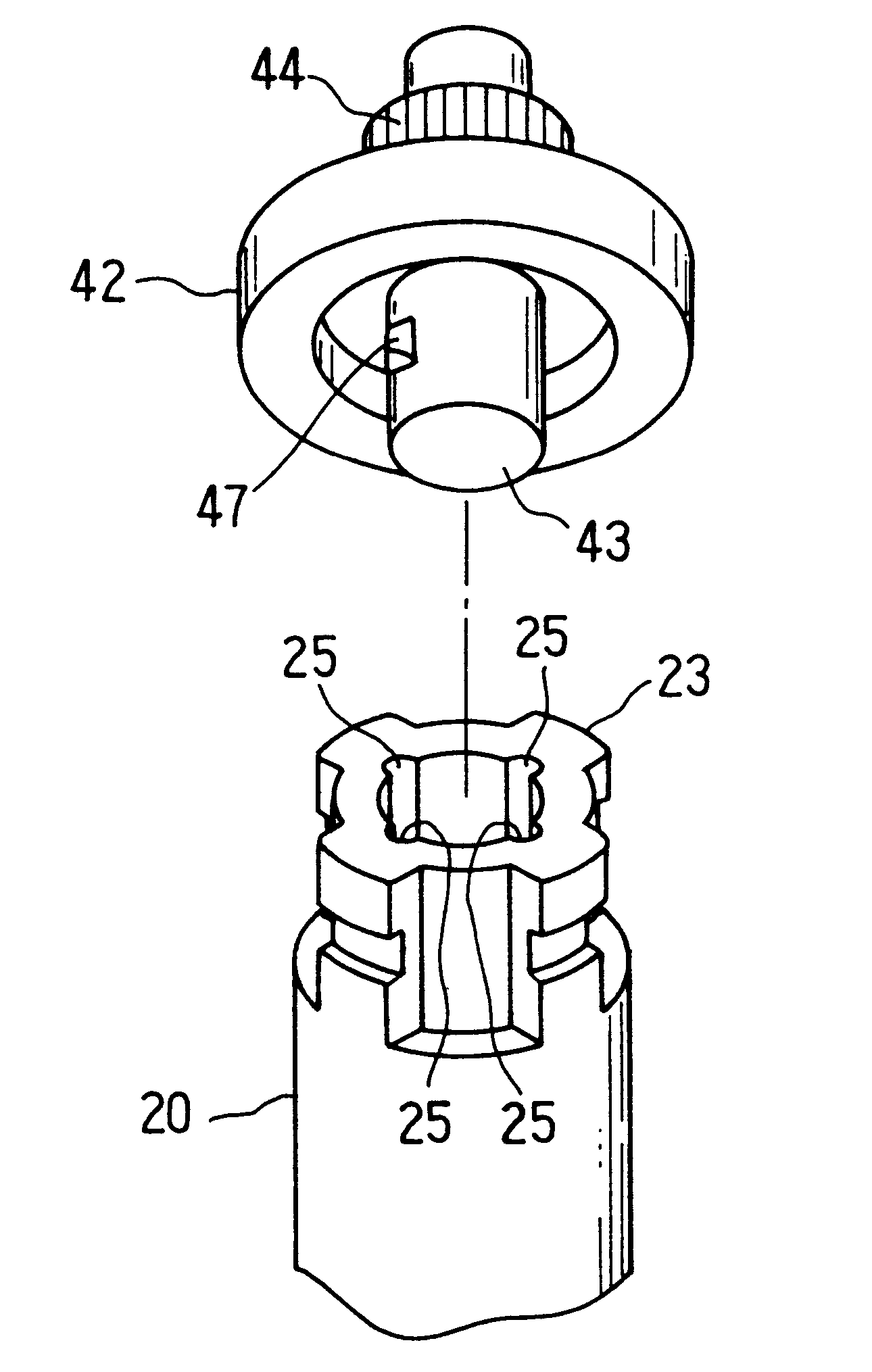

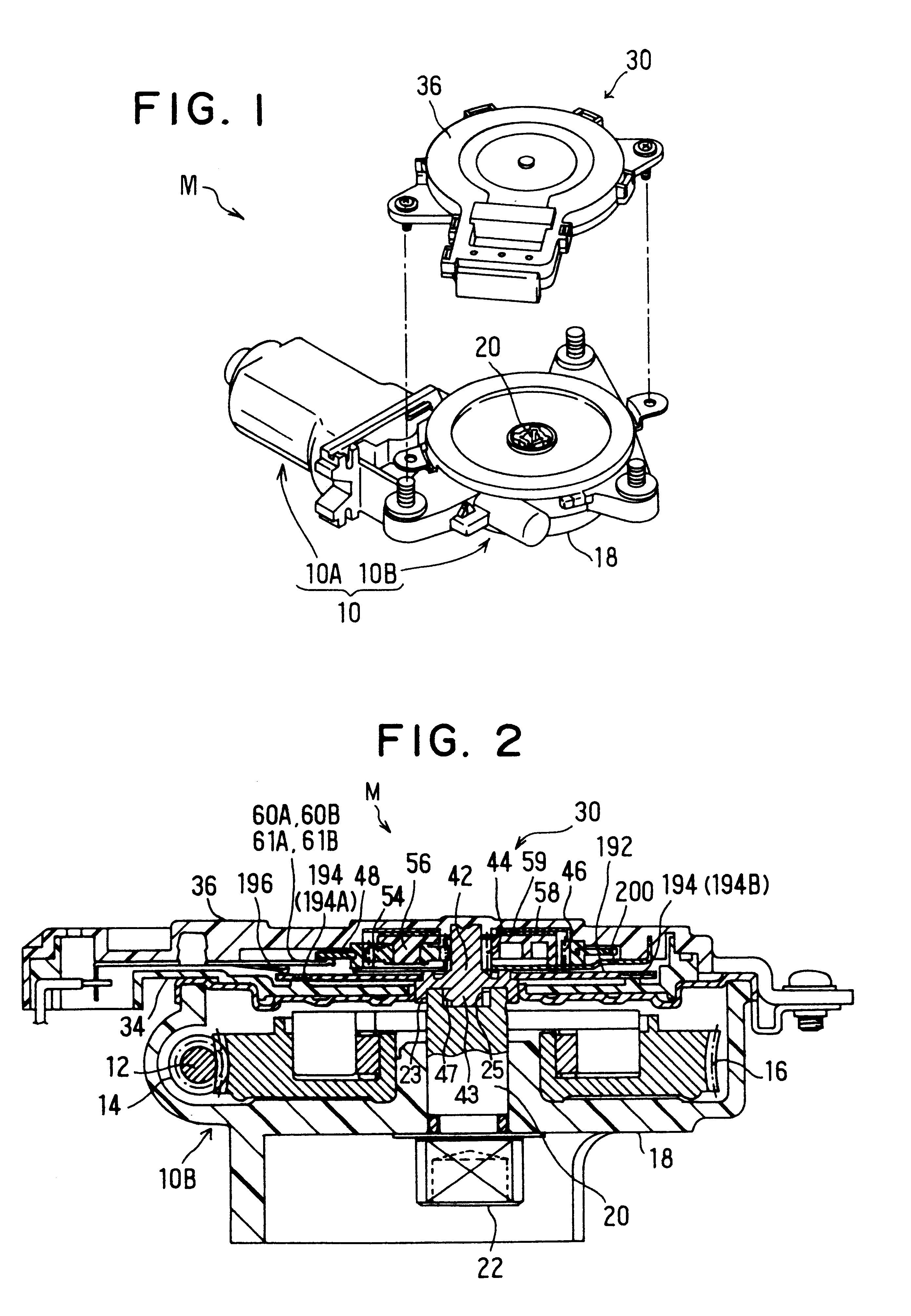

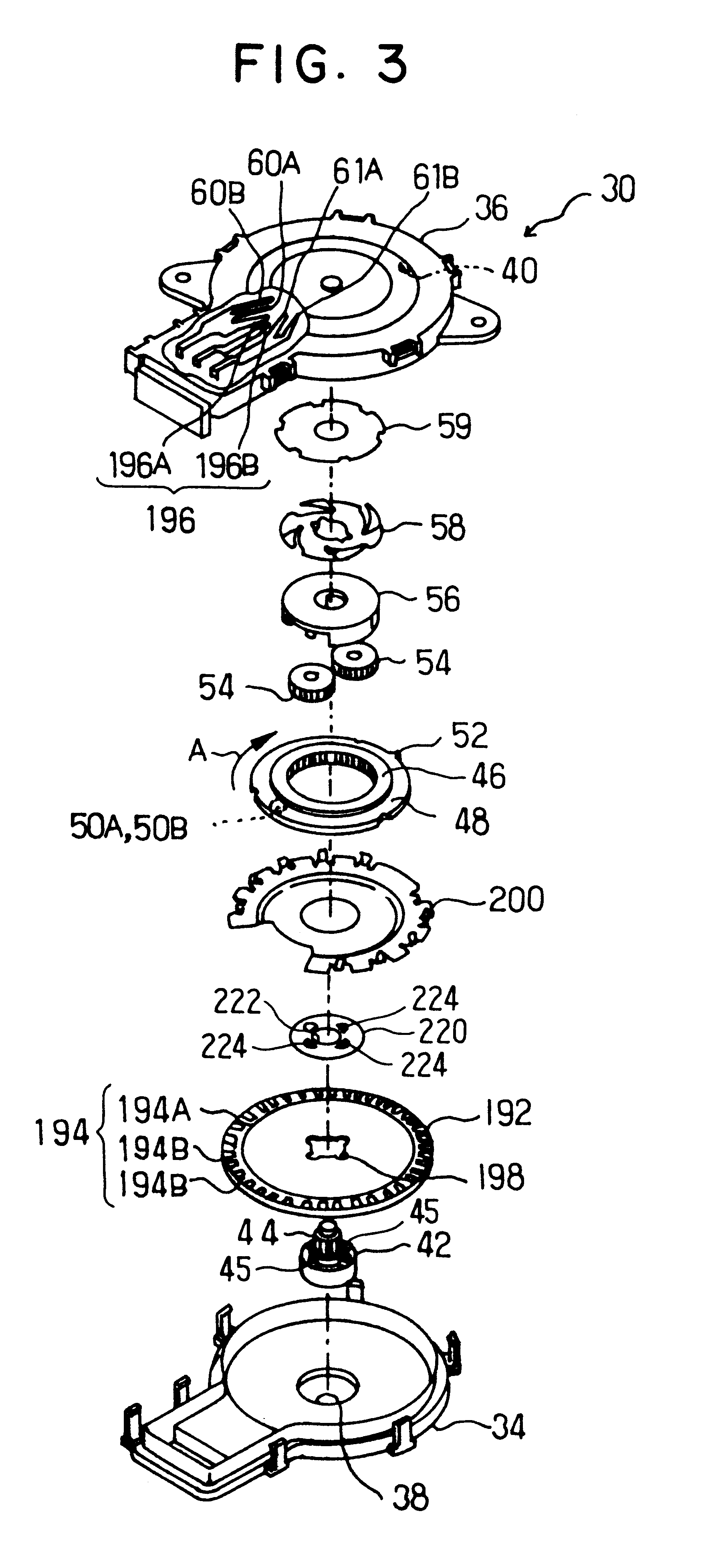

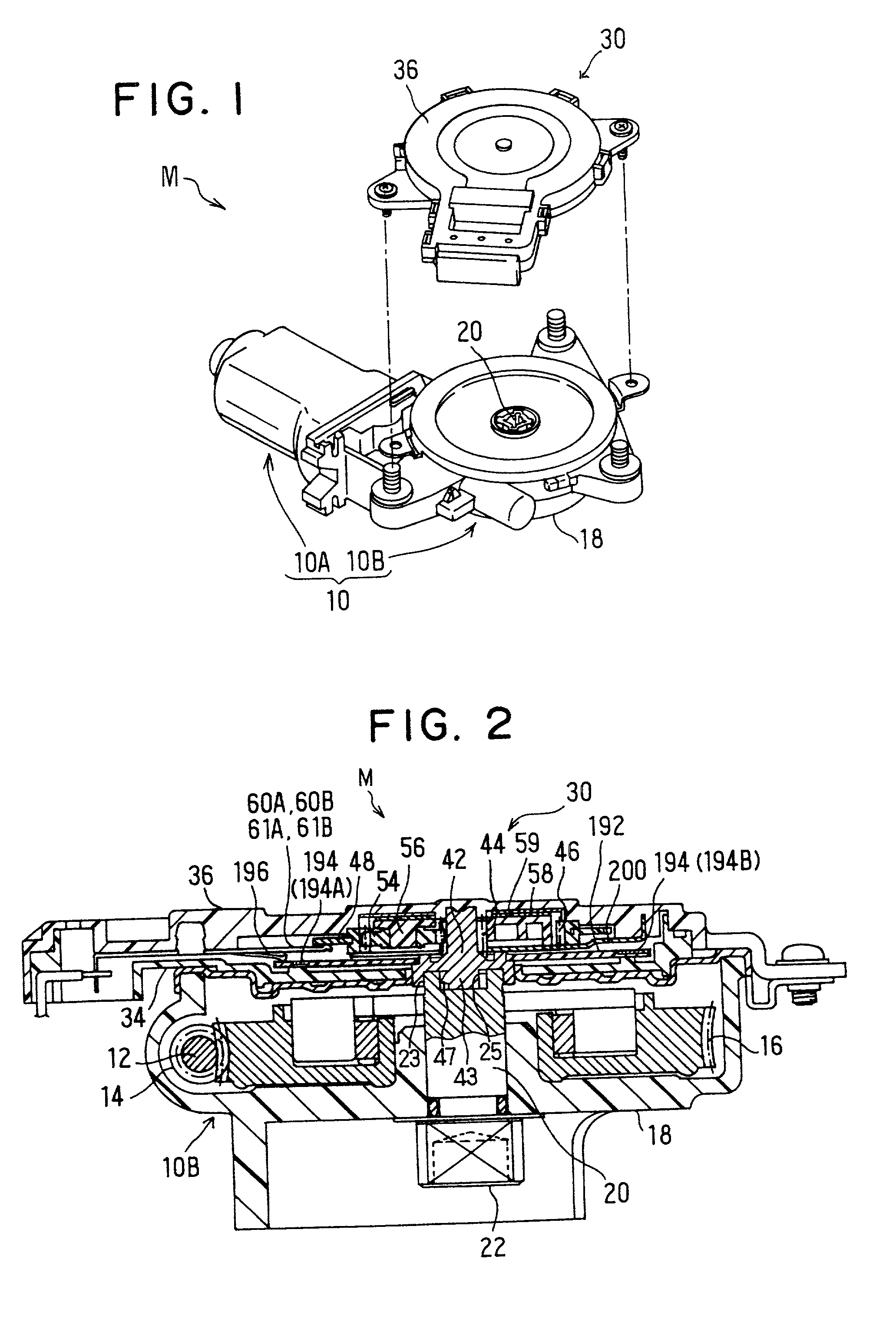

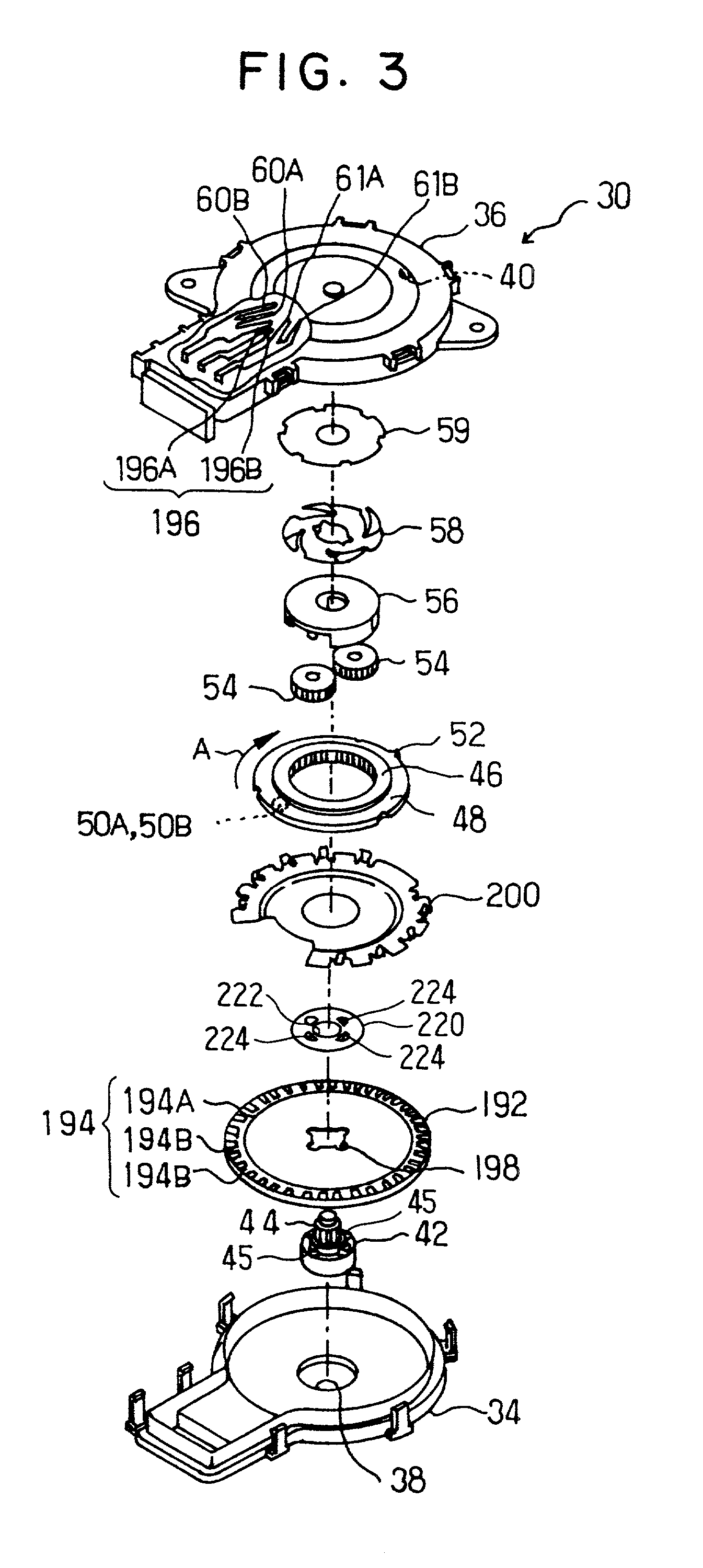

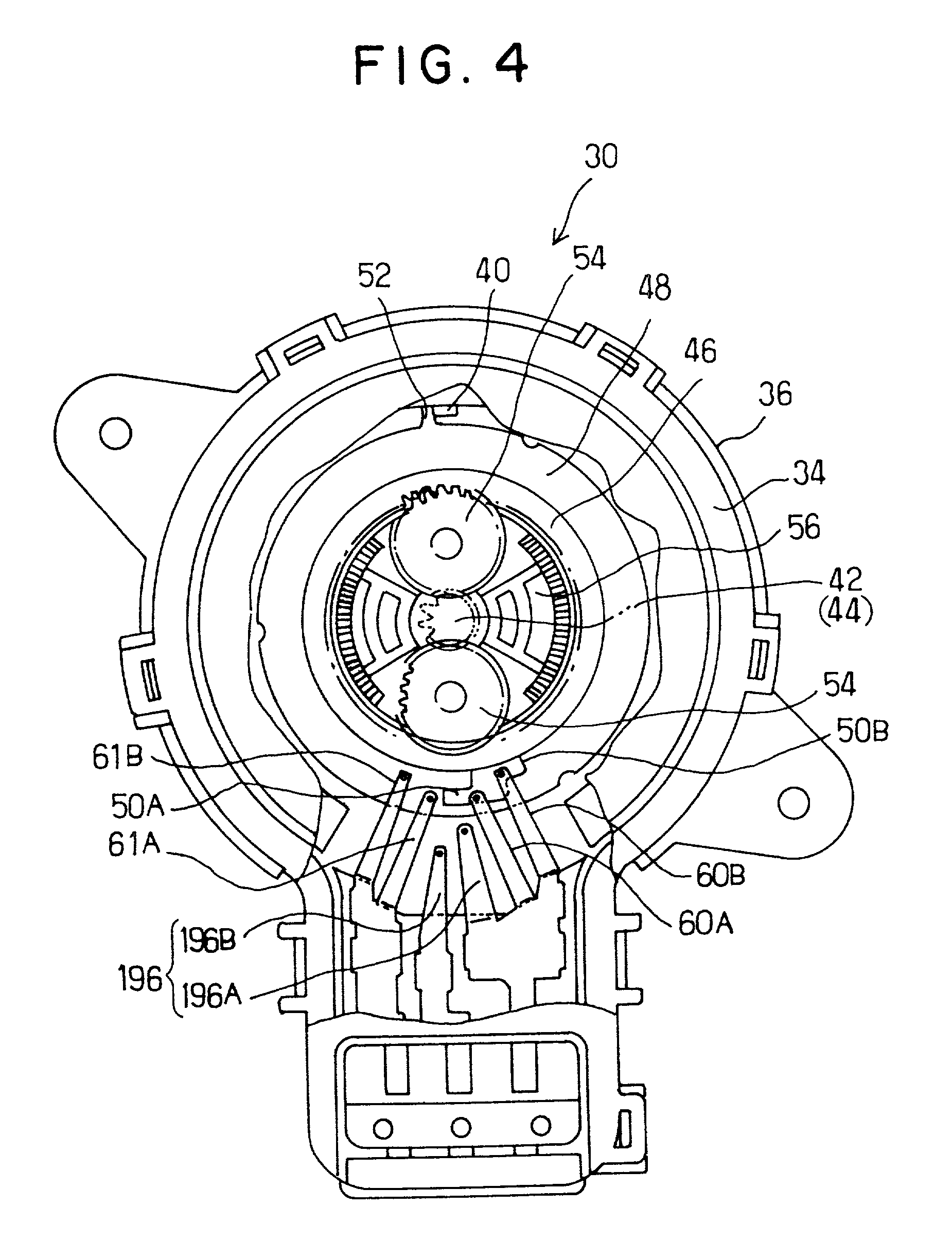

Motor actuator having simplified interfitting connection

InactiveUS6504276B2Readily accurately performedEasy to manufactureSynchronous generatorsYielding couplingMating connectionActuator

In a connection between a motor and a position detector that together constitute a motor actuator, a connection shaft of the position detector is engaged with an outer peripheral surface of a motor output shaft, and a shaft portion of the connection shaft is engaged with an inner peripheral surface of the motor output shaft. Furthermore, radial recesses are provided to be radially outwardly recessed from the inner peripheral surface of the motor output shaft, and one of radial recesses of the motor output shaft engages with a single radial projection of the shaft portion of the connection shaft. Thus, the motor output shaft and the connection shaft are non-rotatably connected with each other, readily accurately.

Owner:ASMO CO LTD

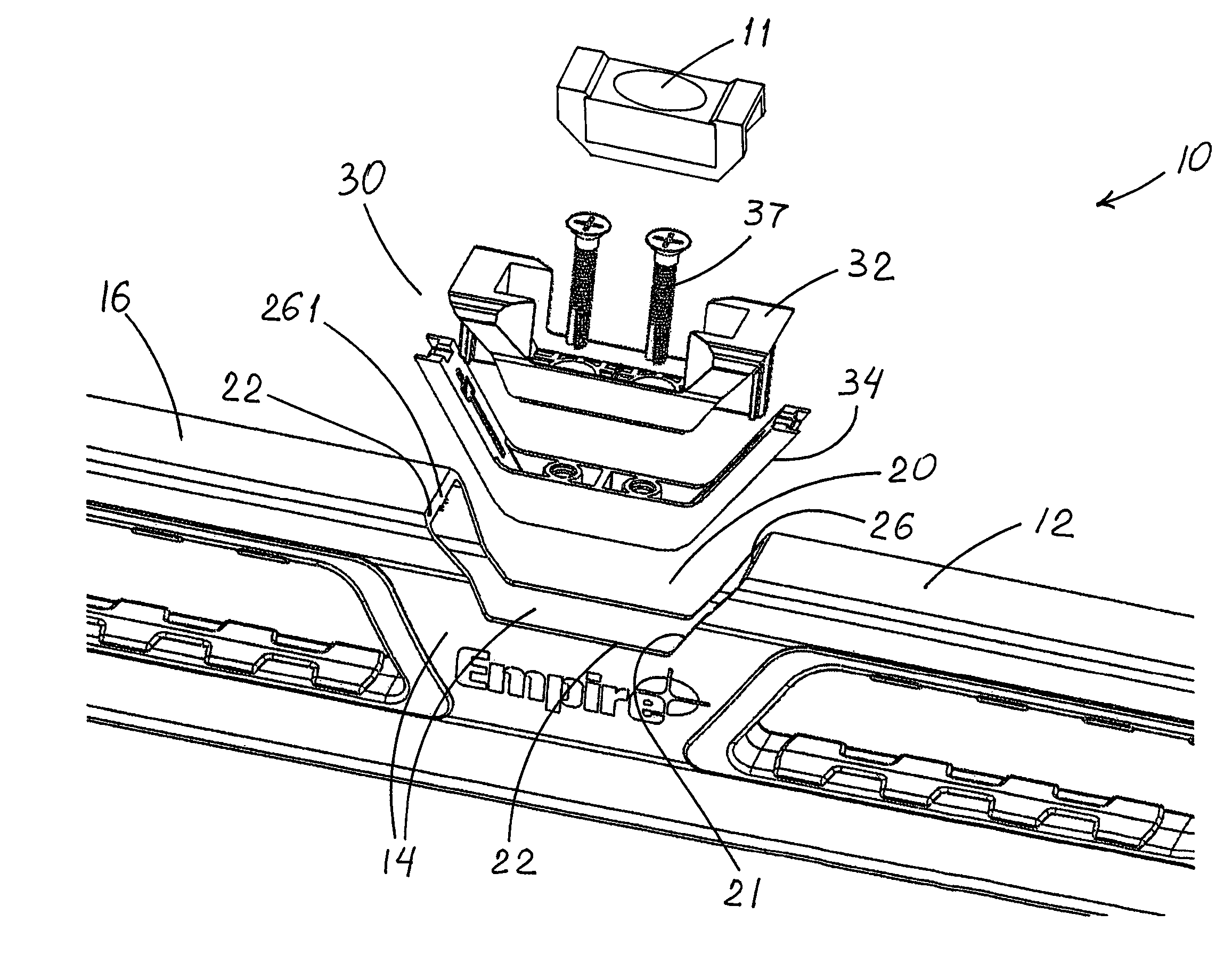

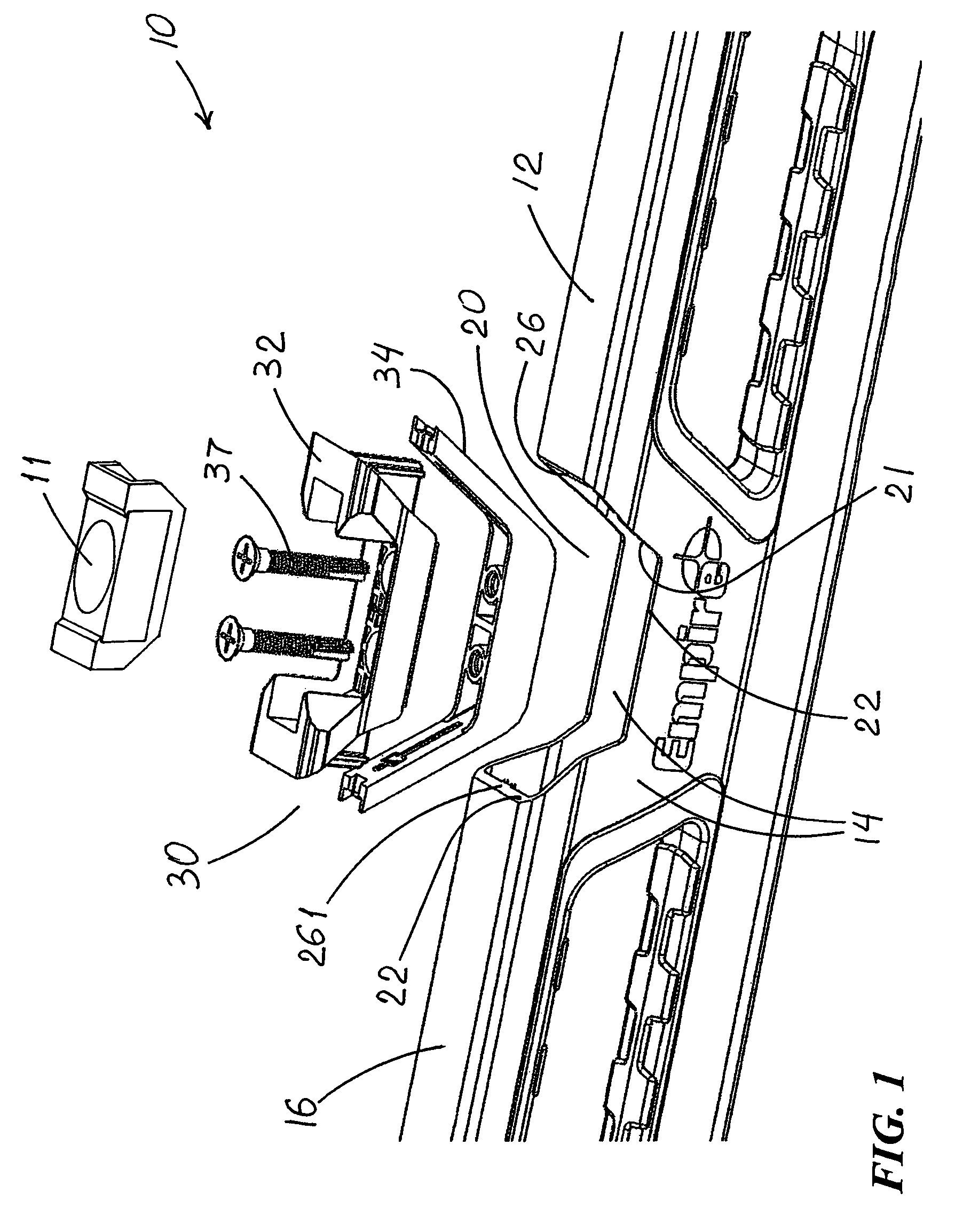

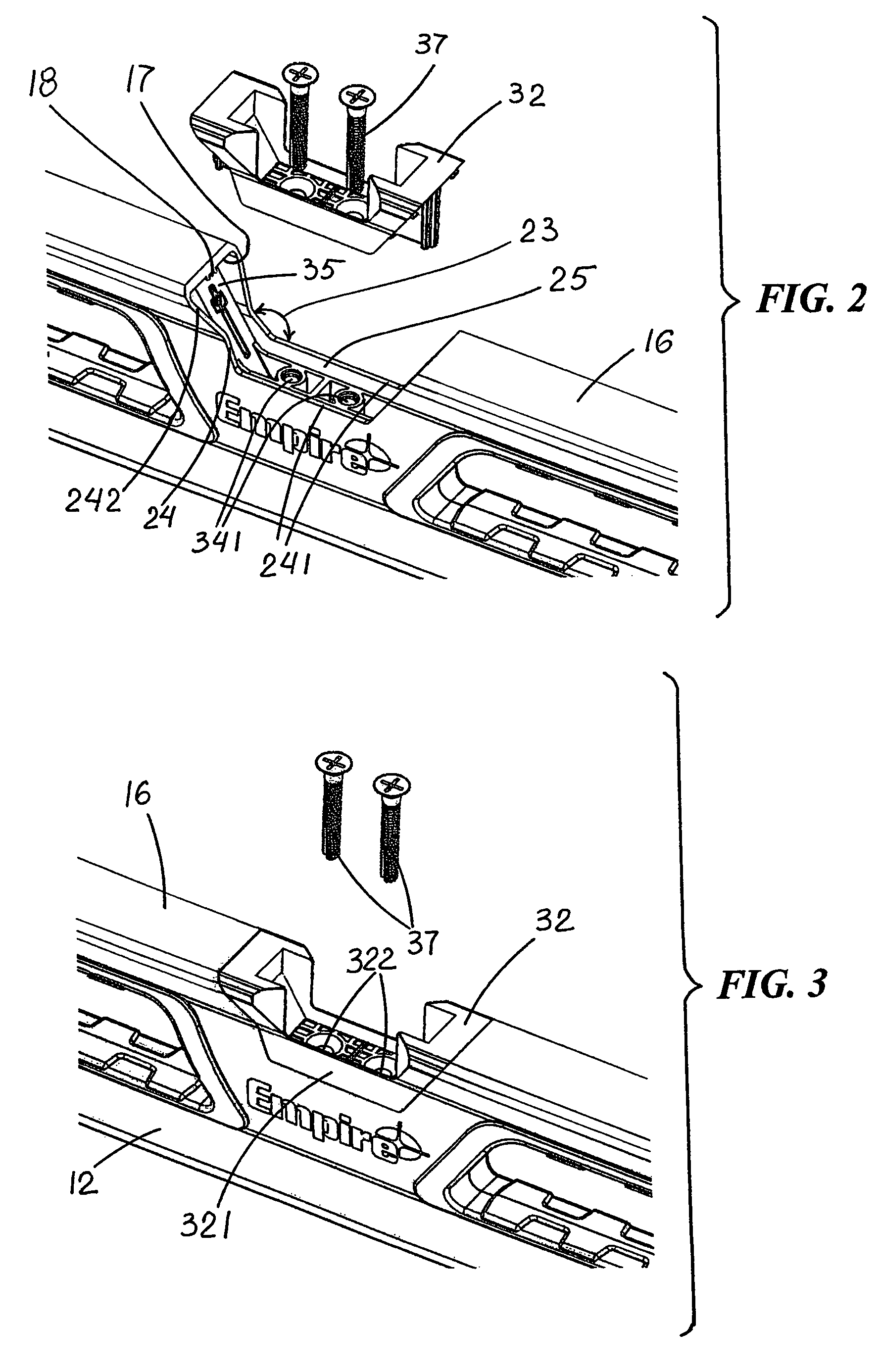

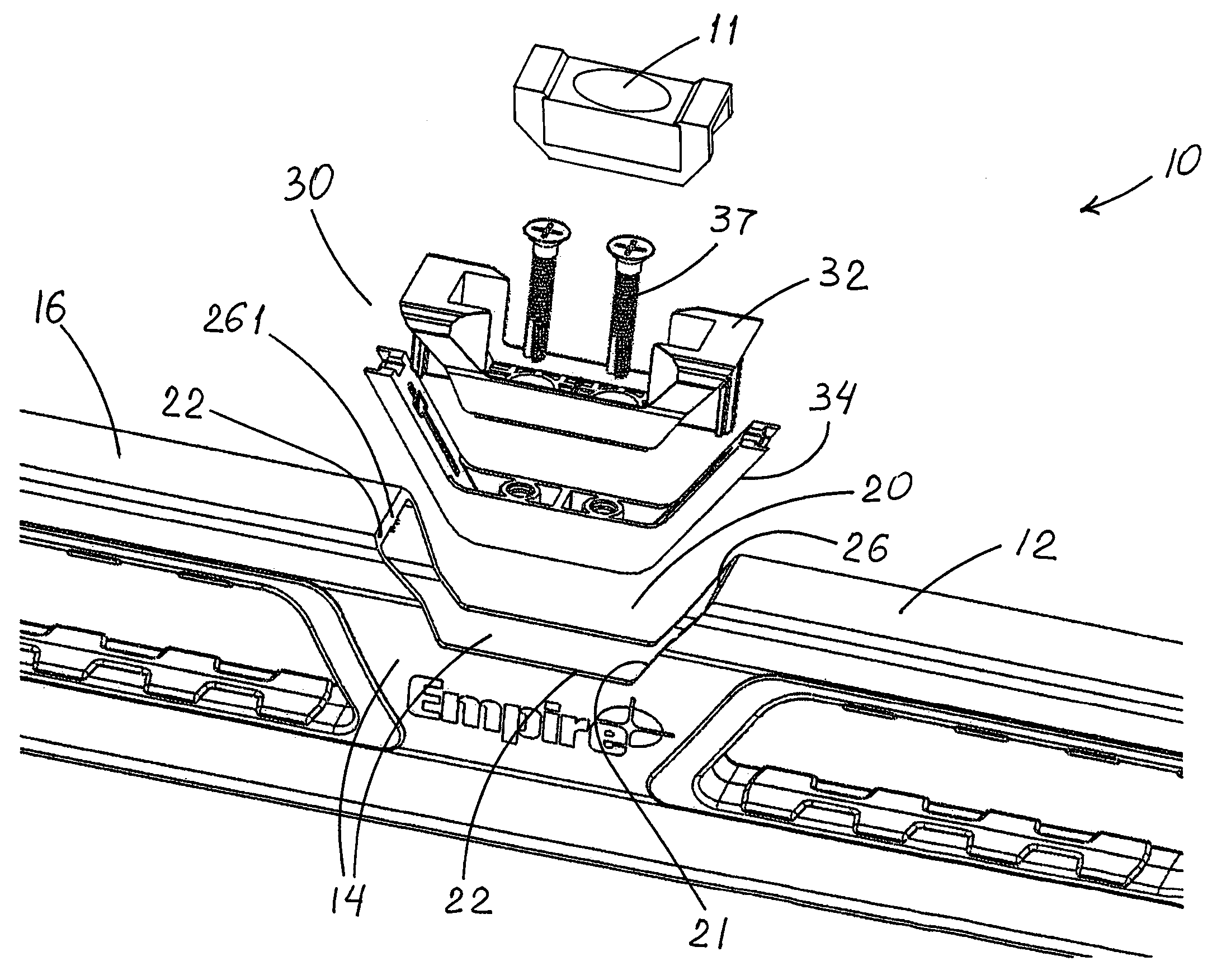

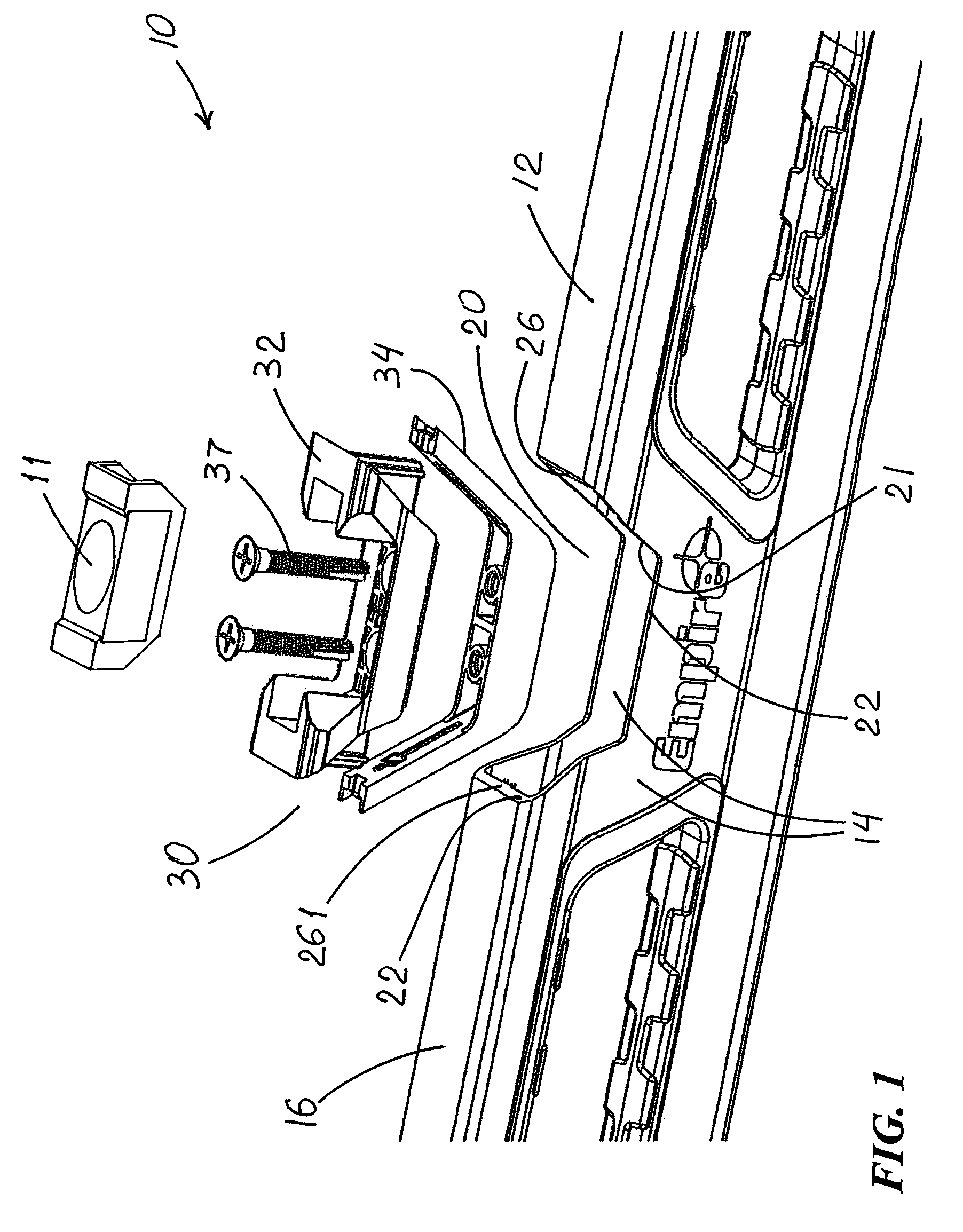

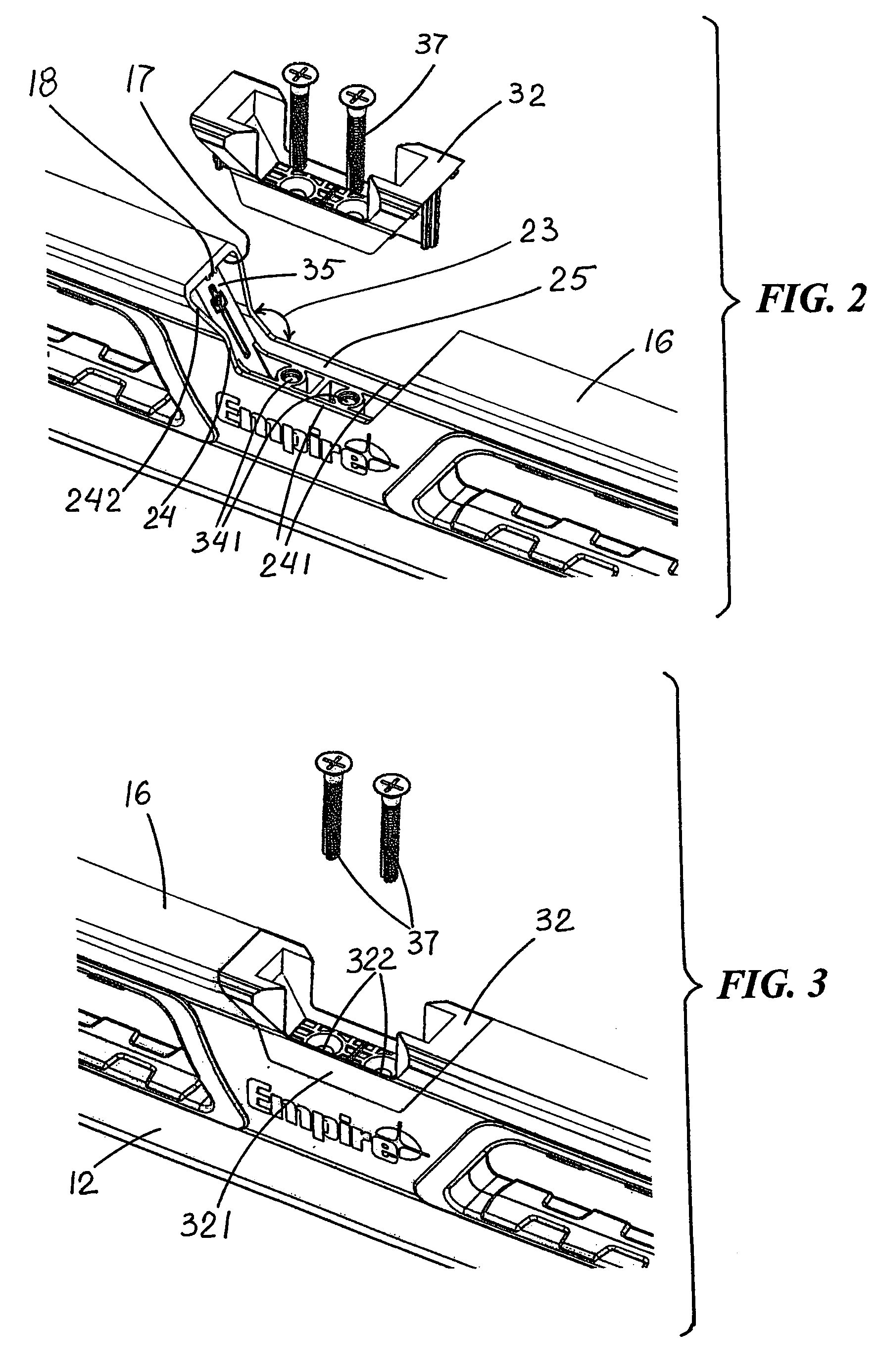

Apparatus and method for facilitating accurate placement and installation of molding

InactiveUS7451576B2Improve accuracyNeed can be easilyScaffold connectionsRoof covering using tiles/slatesEngineeringMechanical engineering

Owner:BARONE JOSEPH

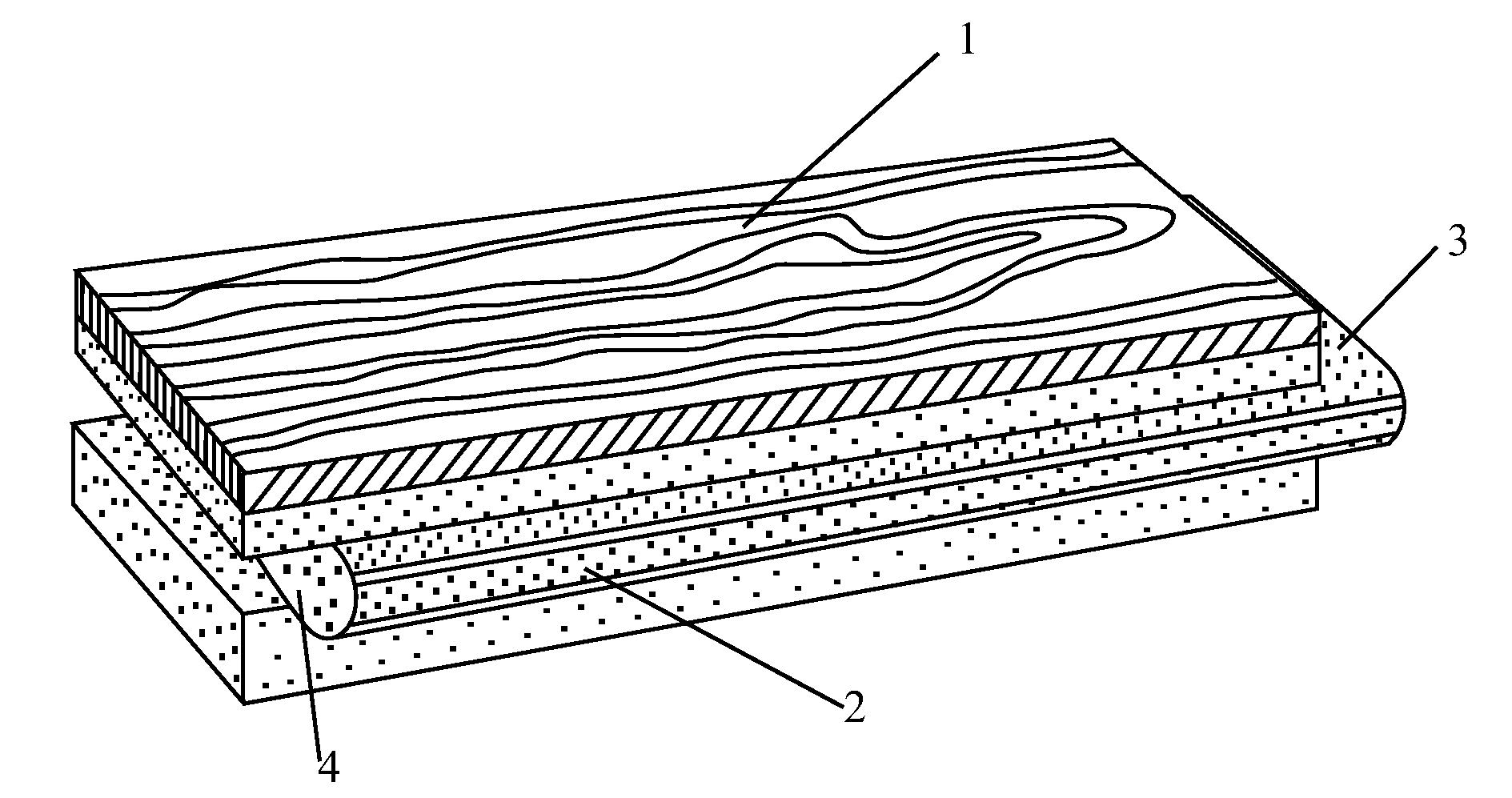

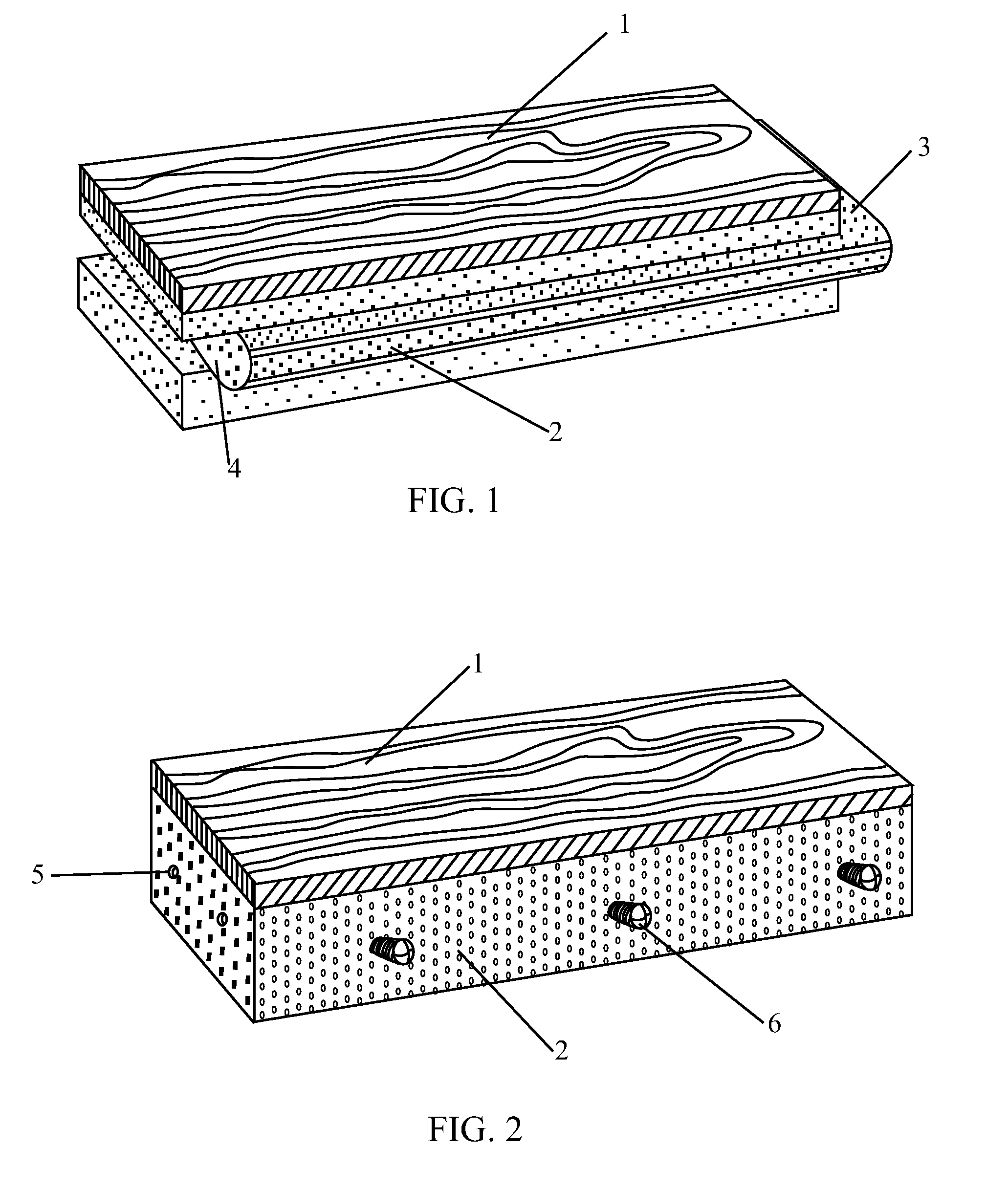

Compound Flooring and Manufacturing Method Thereof

InactiveUS20080261036A1Improve shock absorptionQuality improvementEngine sealsCovering/liningsWood veneerPolyvinyl acetate

The present invention relates to a compound flooring material. The compound flooring such as thermoplastic / wood compound flooring is produced by adhering two layers through adhesive cementing. According to an embodiment, a first sheet is a high quality wood veneer and the second sheet is a low foaming, environment friendly, UPVC board. The sheets are bonded by incorporating a high quality polyvinyl acetate polymer adhesive that contains no formaldehyde, thus providing a strong, safe, odorless product. The UPVC / wood compound flooring has a very low shrinking and swelling rate and is convenient and accurate to install.

Owner:GUANG DONG GUANG YANG HI TECH

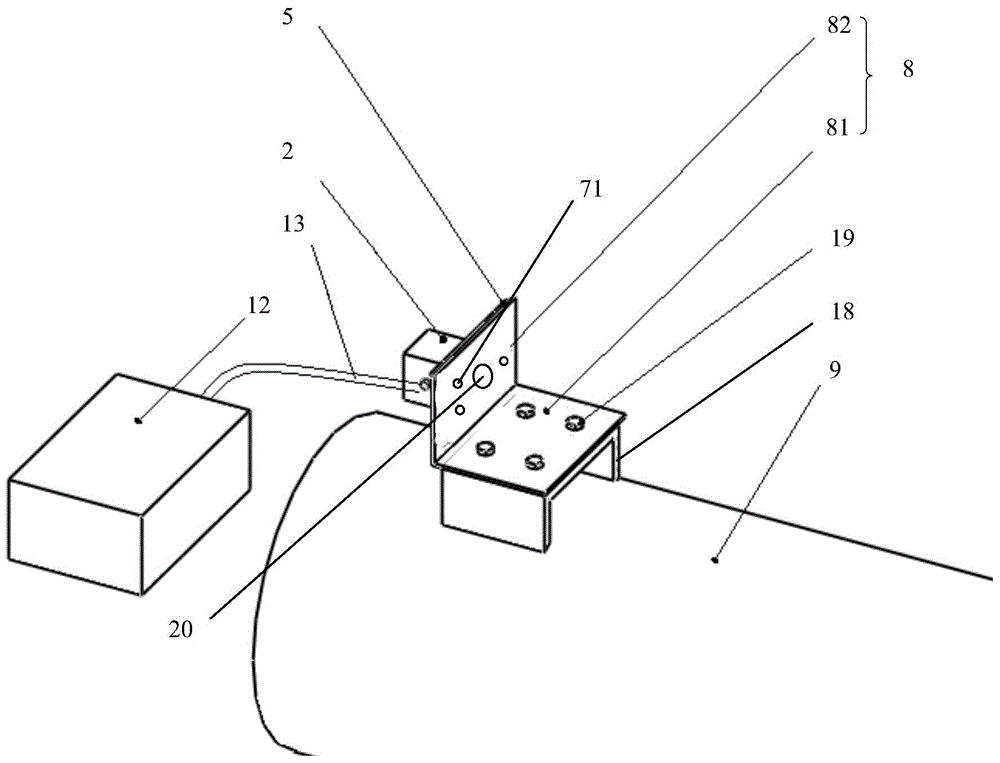

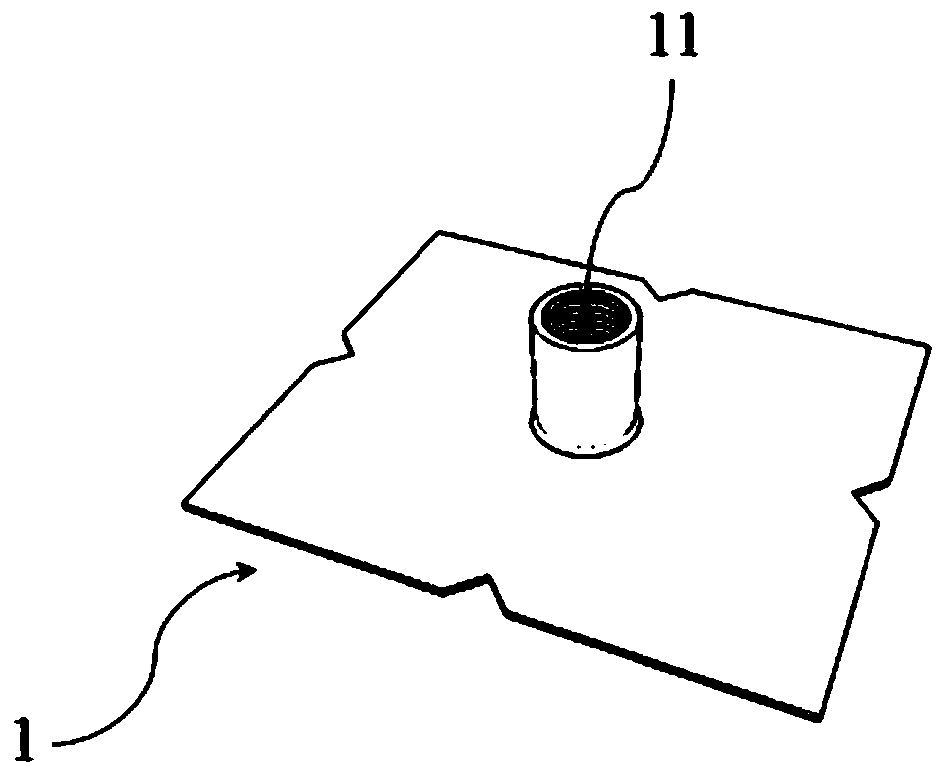

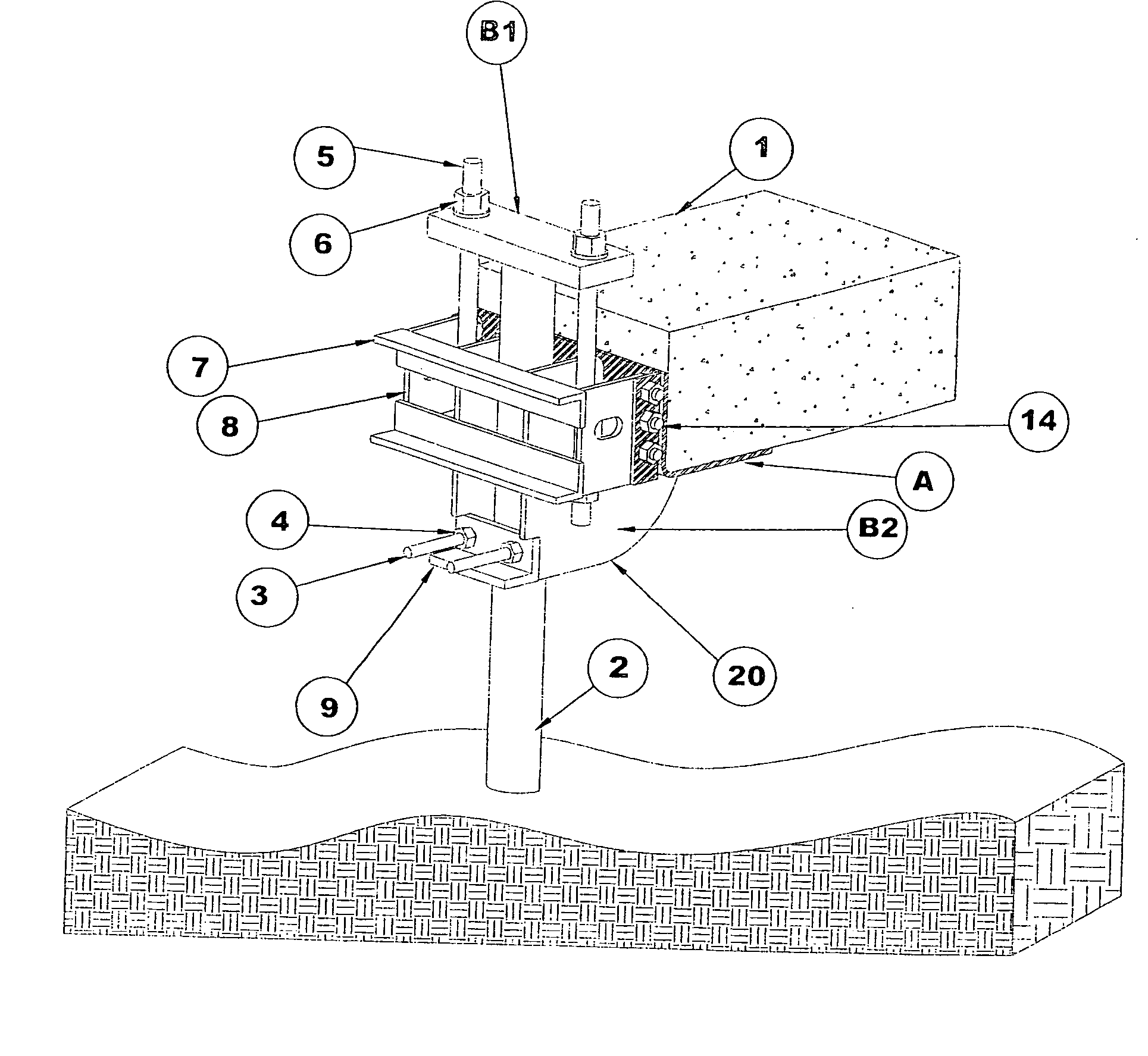

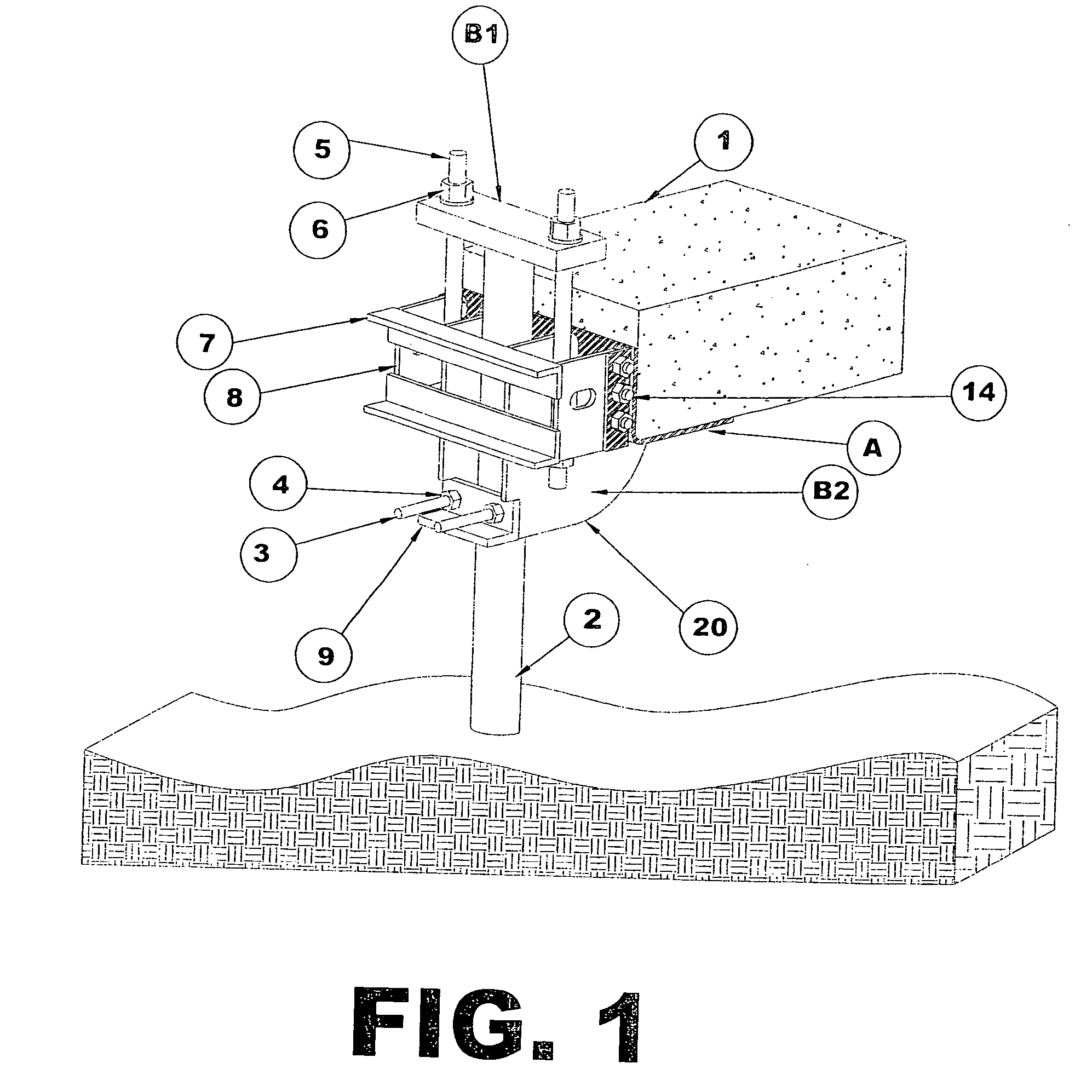

Structure and method for installing perpendicularity sensor on ultralong tubular pillar

ActiveCN104457619AEasy to installEasy and accurate installationUsing optical meansLaser transmitterLaser target

The invention discloses a structure and method for installing a perpendicularity sensor on an ultralong tubular pillar. The structure comprises a laser gradiograph, a coarse adjusting bolt assembly, a fine adjusting bolt assembly, a light target, an installing bottom plate, an adjusting plate and a right-angle bent plate, and the perpendicularity sensor and a laser transmitter are arranged in the laser gradiograph. The perpendicularity sensor can measure the included angle between a measuring datum line and a natural vertical line. The laser of the laser transmitter is parallel to the measuring datum line of the perpendicularity sensor. The position of the adjusting plate is adjusted through the coarse adjusting bolt assembly and the fine adjusting bolt assembly so that when the light target is installed on different datum lines, the position of the laser on the laser target cannot be changed, and the laser transmitted after the laser gradiograph is installed and fixed is parallel to the axis of the tubular pillar. The problem of installing and positioning of the perpendicularity sensor on the ultralong tubular pillar is solved, it is ensured that the laser transmitted by the laser gradiograph is parallel to the axis of the tubular pillar, the measuring precision of the laser gradiograph is guaranteed, and the perpendicularity adjusting construction of the tubular pillar is more convenient and accurate.

Owner:SHANGHAI CONSTRUCTION GROUP

Wall surface leveling assembly and method

The invention belongs to the technical field of building decoration, and particularly relates to a wall surface leveling assembly and method. The wall surface leveling assembly comprises an installation bottom plate, a leveling part and a keel. The installation bottom plate is fixedly installed on a building wall surface, the leveling part is detachably connected with the installation bottom platethrough a leveling bolt, the keel is buckled on the leveling piece, the keel is provided with an installation surface matched and connected with a decorative plate, and the decorative plate is installed on the installation surface. According to the wall surface leveling assembly, the distance between the leveling part and the installation bottom plate is adjusted by adjusting the leveling bolt, so that the plane deviation of the building wall surface can be adjusted to ensure the flatness of the installation surface, rapid and accurate installation of the decorative plate is realized, the wall surface leveling assembly is simple in structure and convenient and accurate to adjust, decoration construction time is shortened, and the installation efficiency of the decorative plate is effectively improved.

Owner:浙江筑加装饰股份有限公司

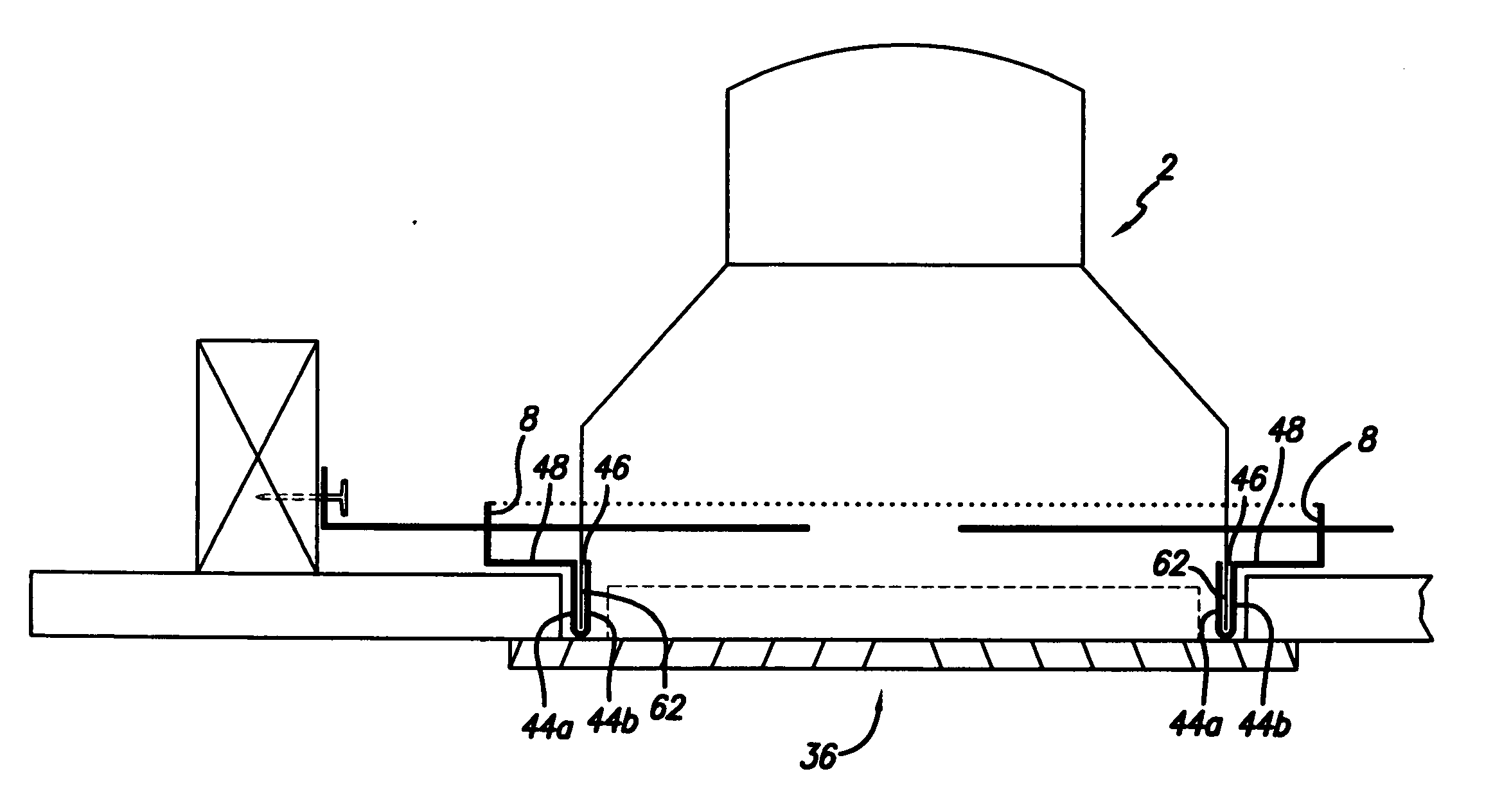

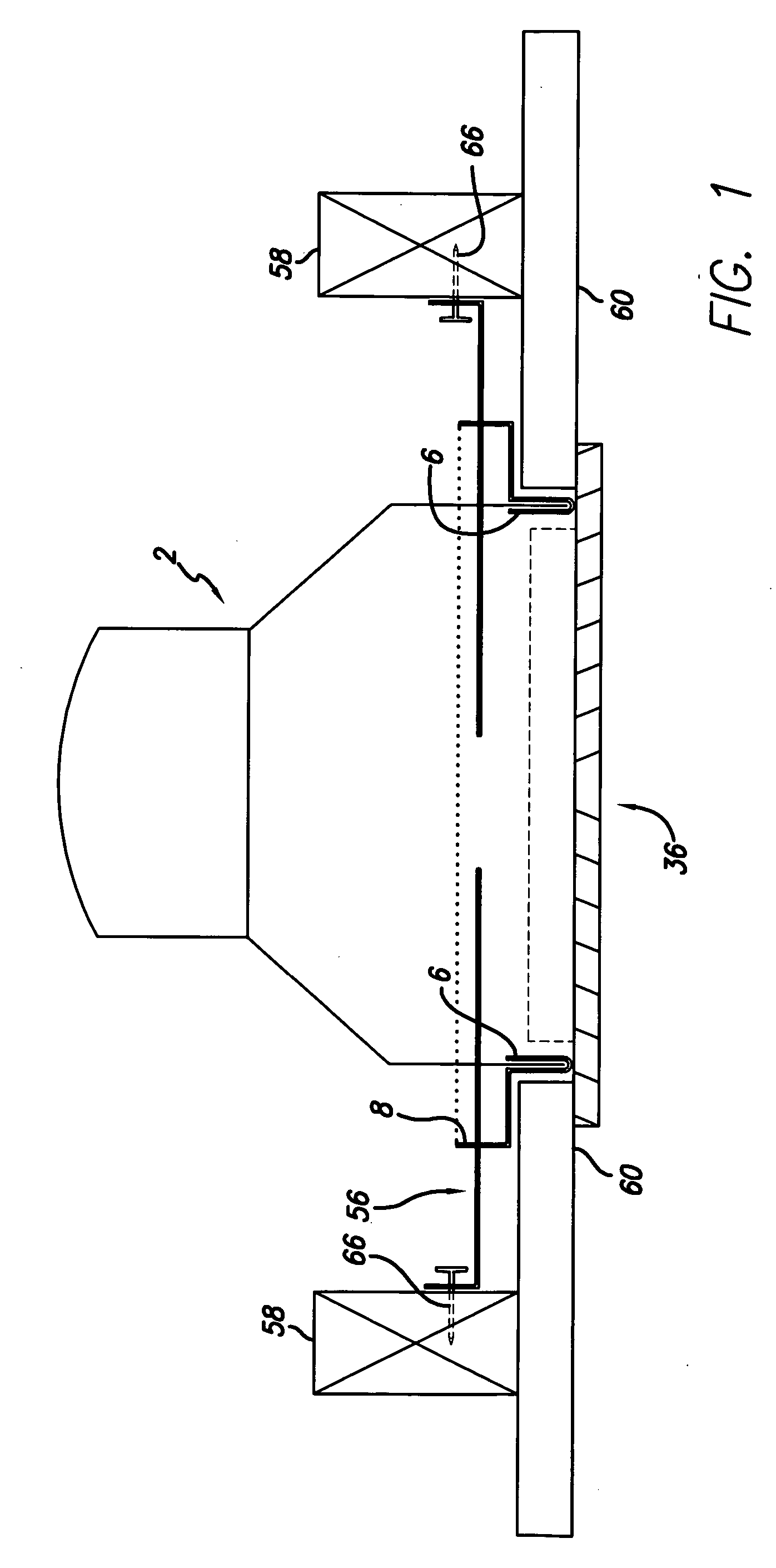

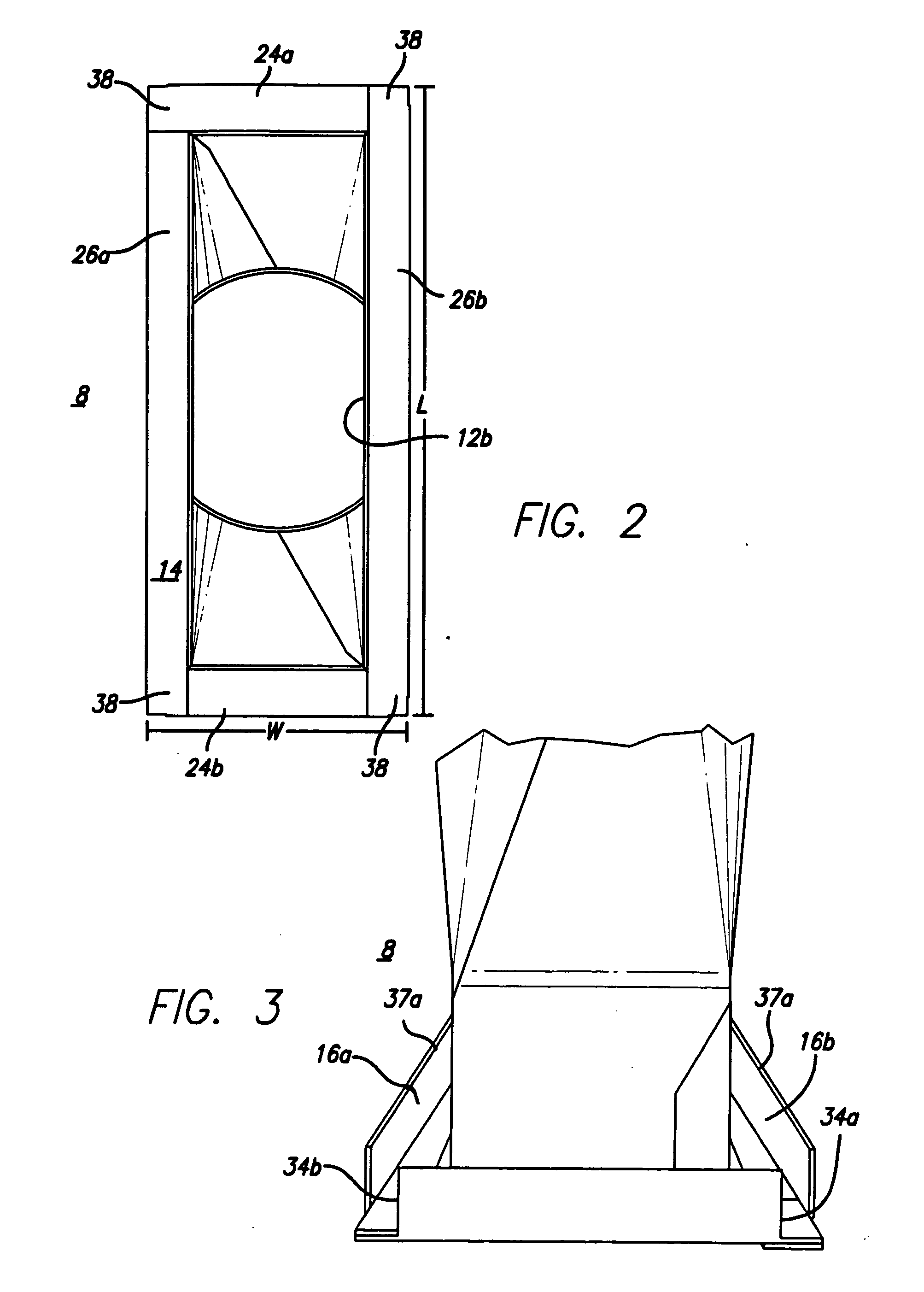

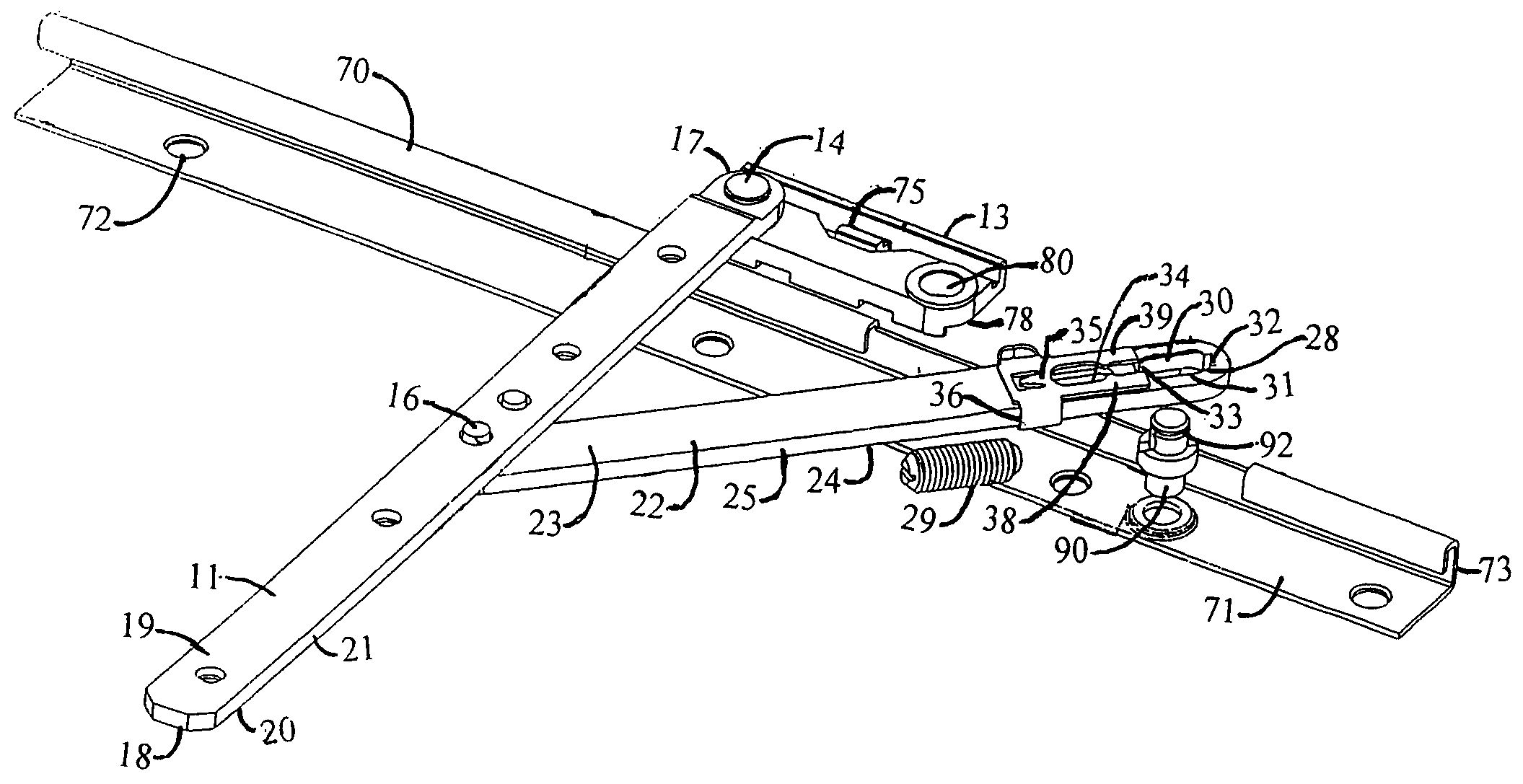

Boot hanger mounting bracket

InactiveUS20040185772A1Minimize risk and damageEfficient compressionDucting arrangementsLighting and heating apparatusEngineeringJoist

The present invention relates to duct systems, registers and ductwork components used with floor or ceiling registers employed in warm air heating, ventilating and air conditioning systems, and specifically to improvements for mounting and installing the components of the duct system, including register boots, mud rings and register grilles, in the walls, floors or ceilings of buildings. The invention includes an adjustable boot hanger mounting bracket assembly comprising a boot hanger frame portion and a support member portion; the ductwork components, which may include a pre-fabricated can-boot / mud ring assembly; a pair of boot hanger arms; and a register grille. The boot hanger mounting bracket assembly is formed of a sturdy yet bendable material so that it can be configured and adjusted on-site. Once configured, the boot hanger mounting bracket assembly is secured to the building structure by securing a pair of boot hanger arms to the ceiling joists, wall studs or other support structure. In this way, the boot hanger mounting bracket, through a direct attachment to the ceiling joist or wall stud, provides a positive inexpensive simple and error free way to mount the duct components.

Owner:APPLIED APPL INT LLC

Motor actuator having simplified interfitting connection

InactiveUS20010011848A1Readily accurately performedEasy to manufactureSynchronous generatorsYielding couplingMating connectionActuator

In a connection between a motor and a position detector that together constitute a motor actuator, a connection shaft of the position detector is engaged with an outer peripheral surface of a motor output shaft, and a shaft portion of the connection shaft is engaged with an inner peripheral surface of the motor output shaft. Furthermore, radial recesses are provided to be radially outwardly recessed from the inner peripheral surface of the motor output shaft, and one of radial recesses of the motor output shaft engages with a single radial projection of the shaft portion of the connection shaft. Thus, the motor output shaft and the connection shaft are non-rotatably connected with each other, readily accurately.

Owner:ASMO CO LTD

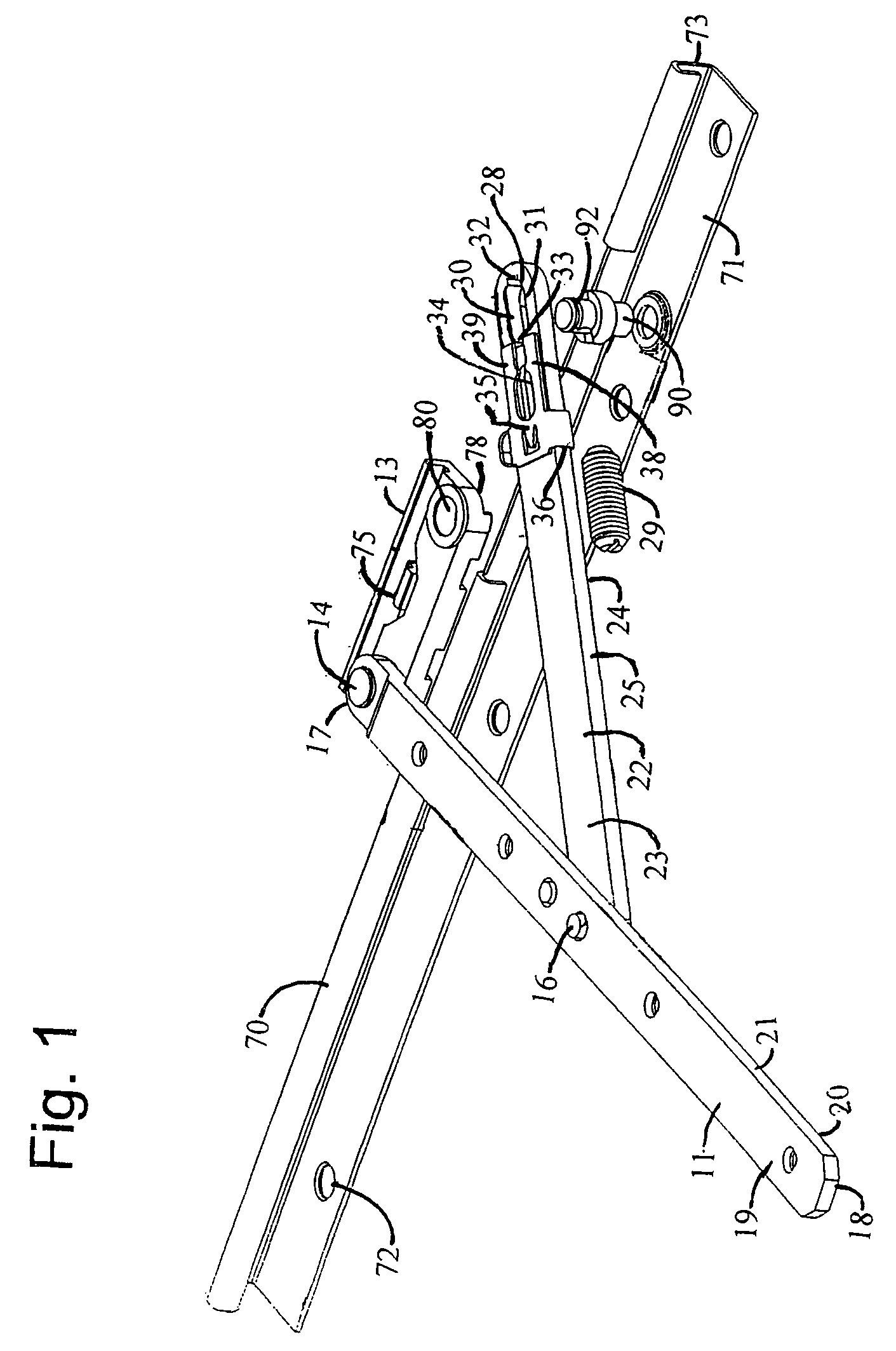

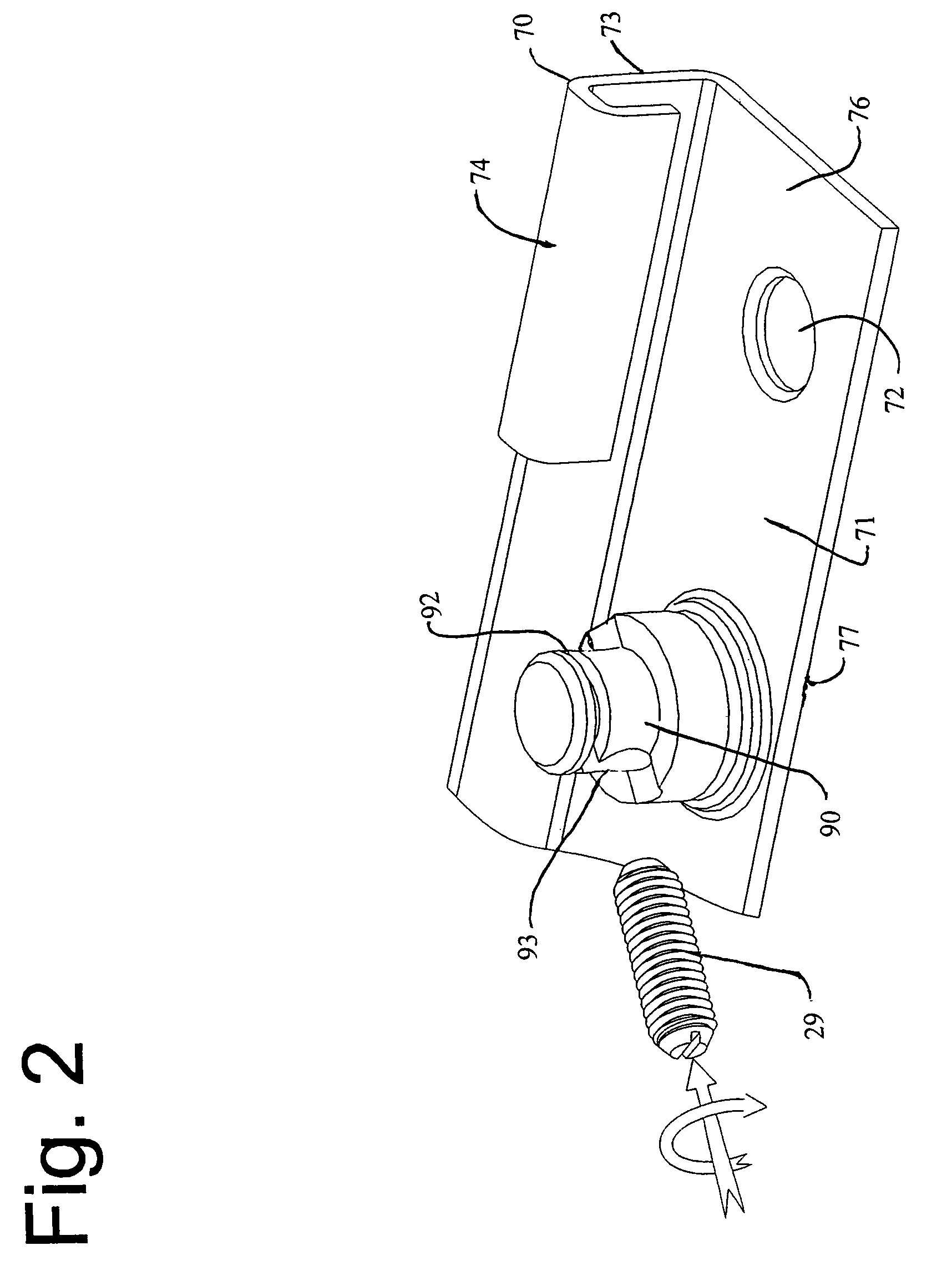

Adjustable window hinge

InactiveUS7900400B2Easy and accurate installationMinimize any loosening of the hinge over the life of the windowHingesWing suspension devicesEngineeringScrew thread

Owner:VISION INDS GROUP

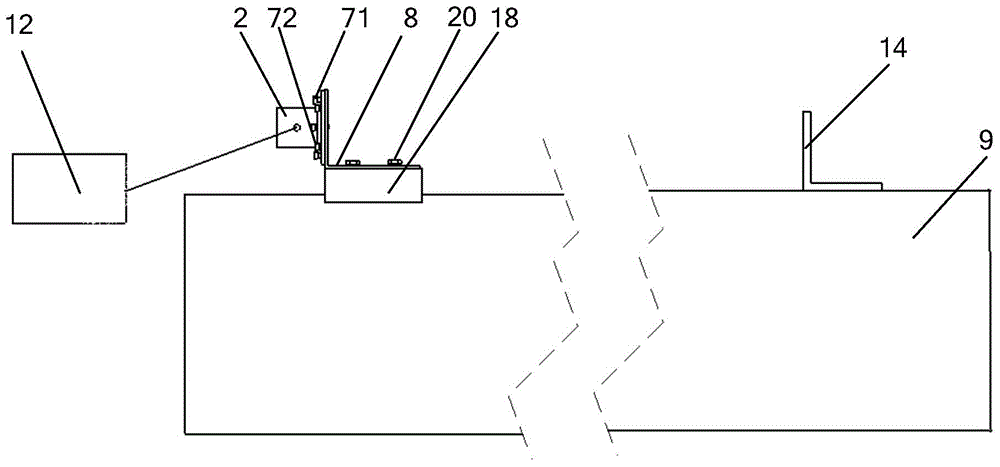

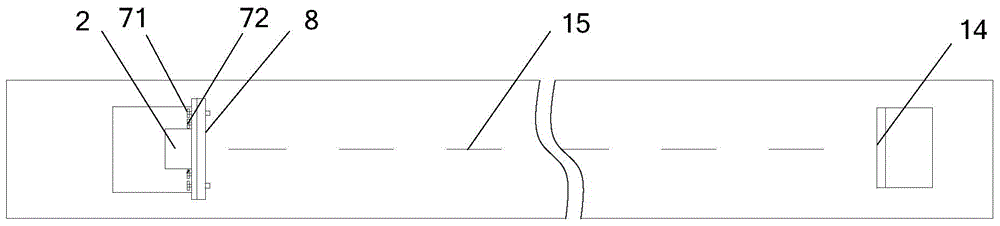

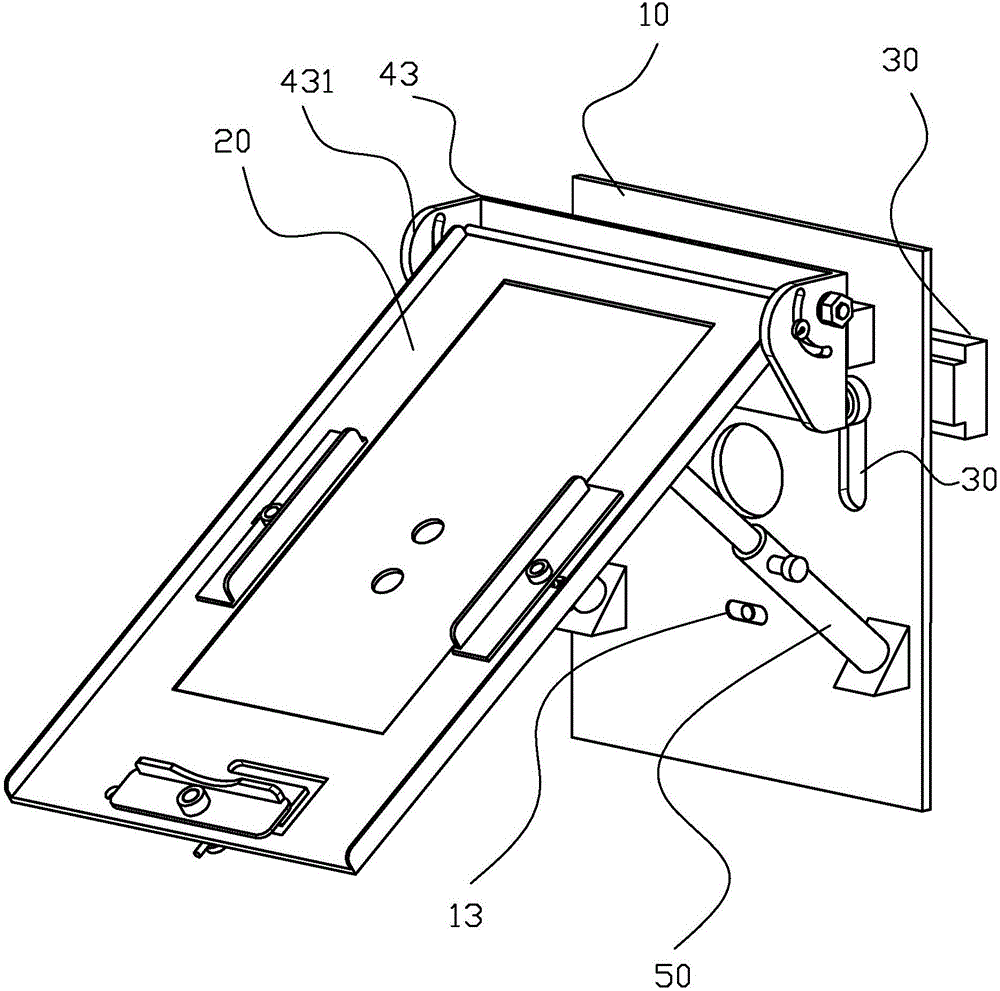

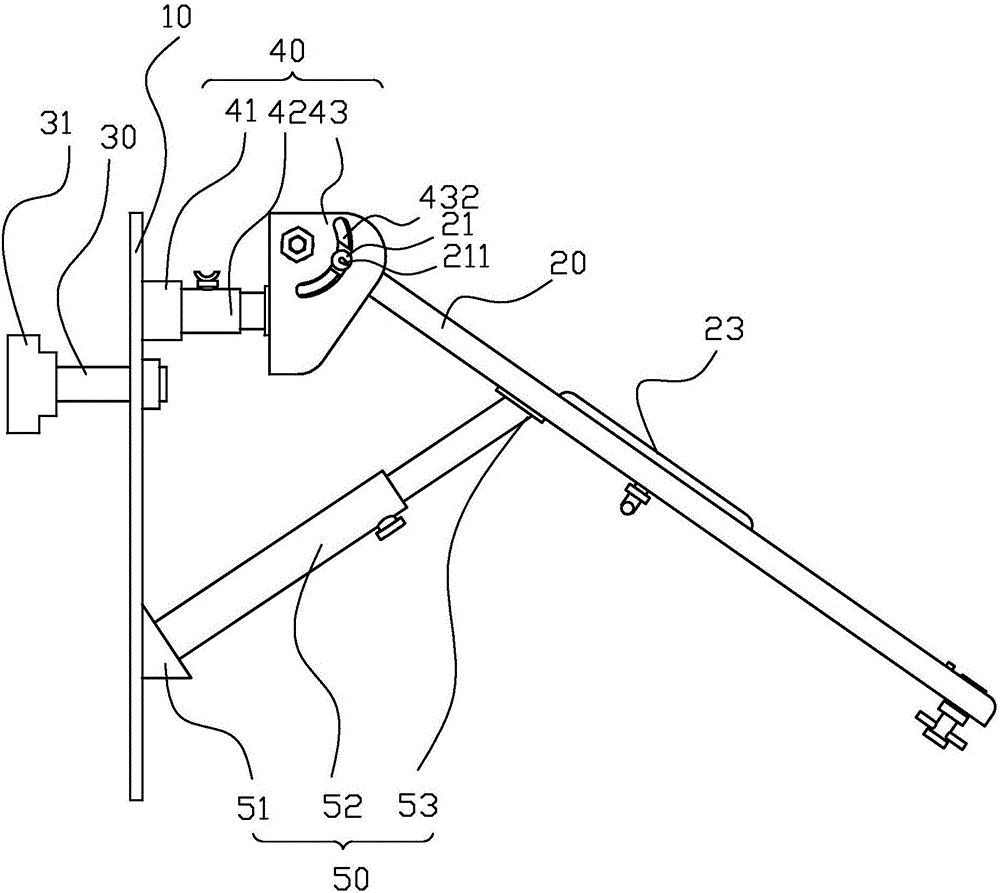

Camera acquiring device for vehicle collision tests

ActiveCN106402616AEasy and accurate installationReduce testing costsStands/trestlesEngineeringCollision test

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD

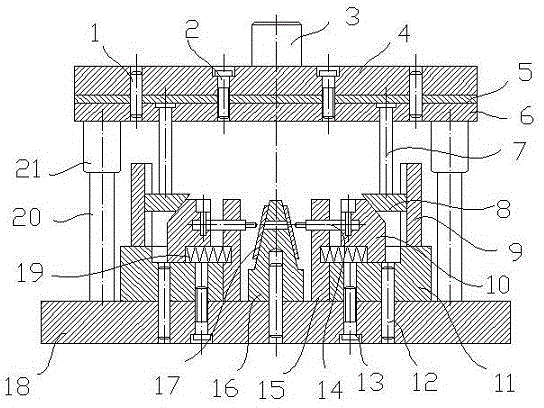

Punching die for truncated-cone-shaped tube

InactiveCN105312406AConvenient and accurate positioningThere is no problem of deformationPerforating toolsPunchingEngineering

The invention discloses a punching die for a truncated-cone-shaped tube. The punching die comprises an upper die seat, a male die, a lower die seat and a female die, wherein two compression bars are symmetrically connected to the left and right sides of the downside of the upper die seat, vertical sliding blocks are connected to the lower ends of the compression bars, the female die is connected to the upside of the lower die seat, supporting seats are respectively arranged at the left and right sides of the female die, the supporting seats are connected onto the lower die seat, the upper sides of the supporting seats are movably connected with horizontal sliding blocks, the punching male die is connected onto the horizontal sliding blocks and is horizontally arranged, supporting plates are arranged between the female die and the supporting seats, and springs are arranged between the supporting plates and the horizontal sliding blocks. The truncated-cone-shaped tube is accurate and convenient to locate, the degree of rotational symmetry of two holes is high, deformation cannot be caused, the quality of product is high, wasting is avoided, and the production cost is reduced.

Owner:徐益红

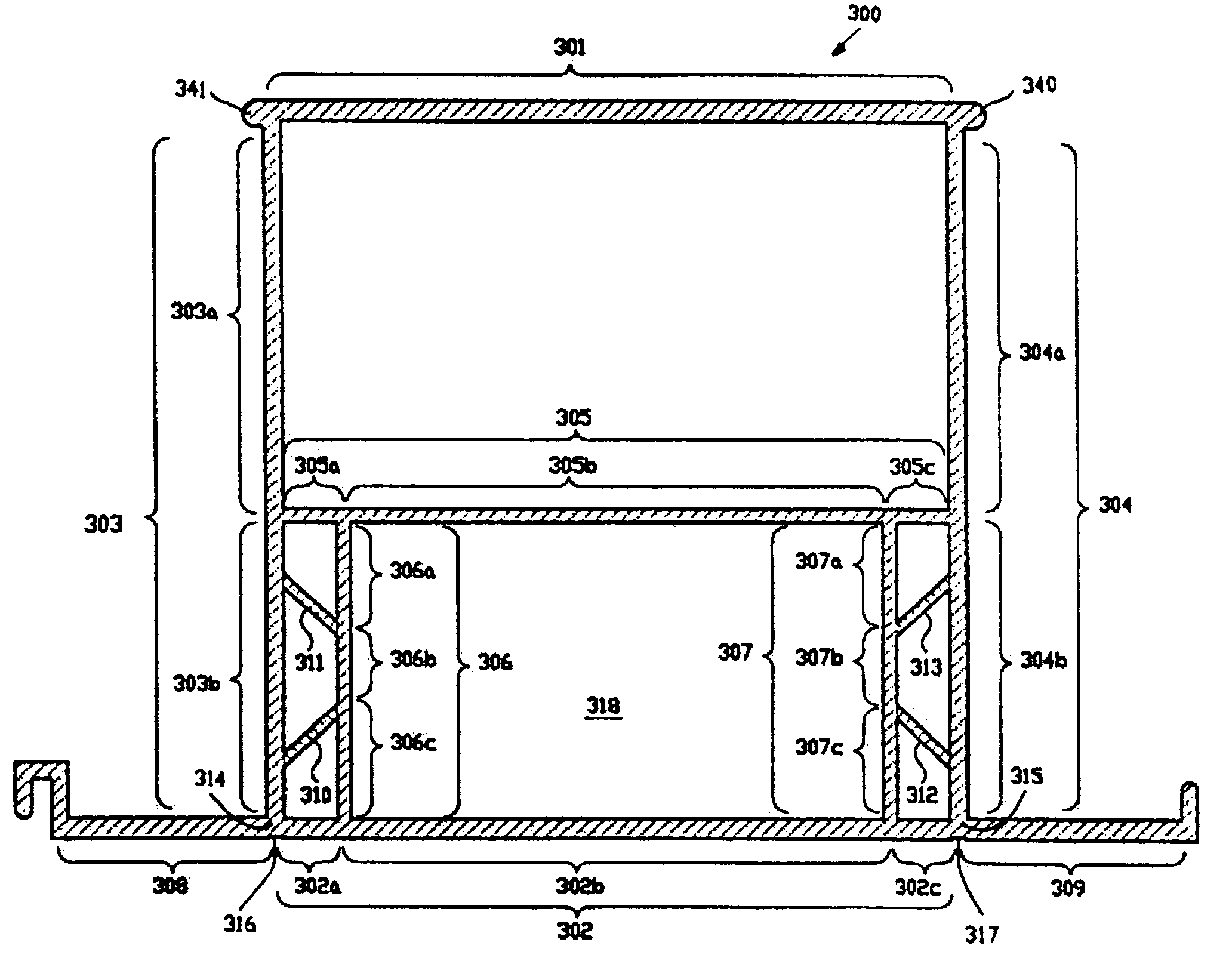

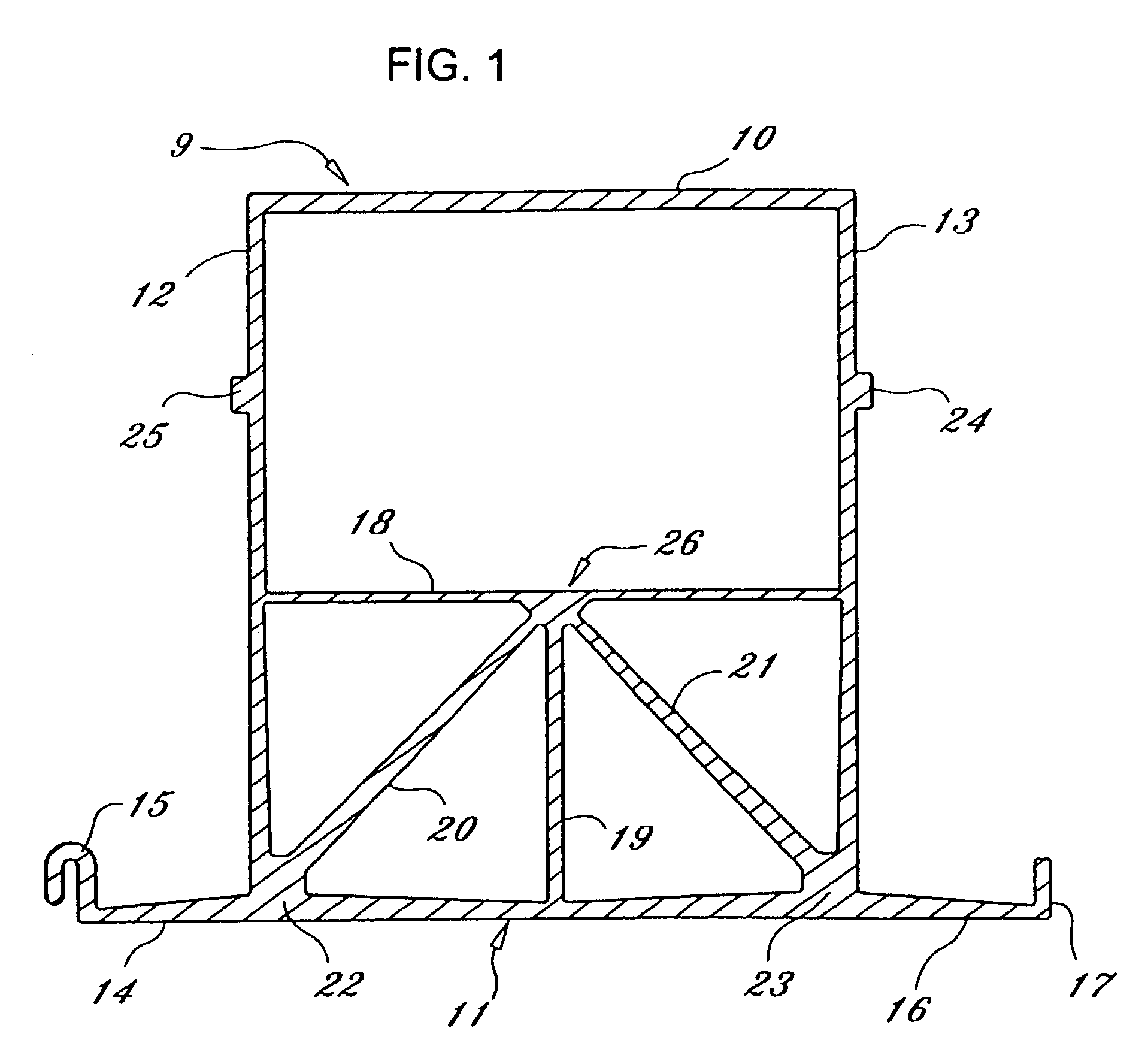

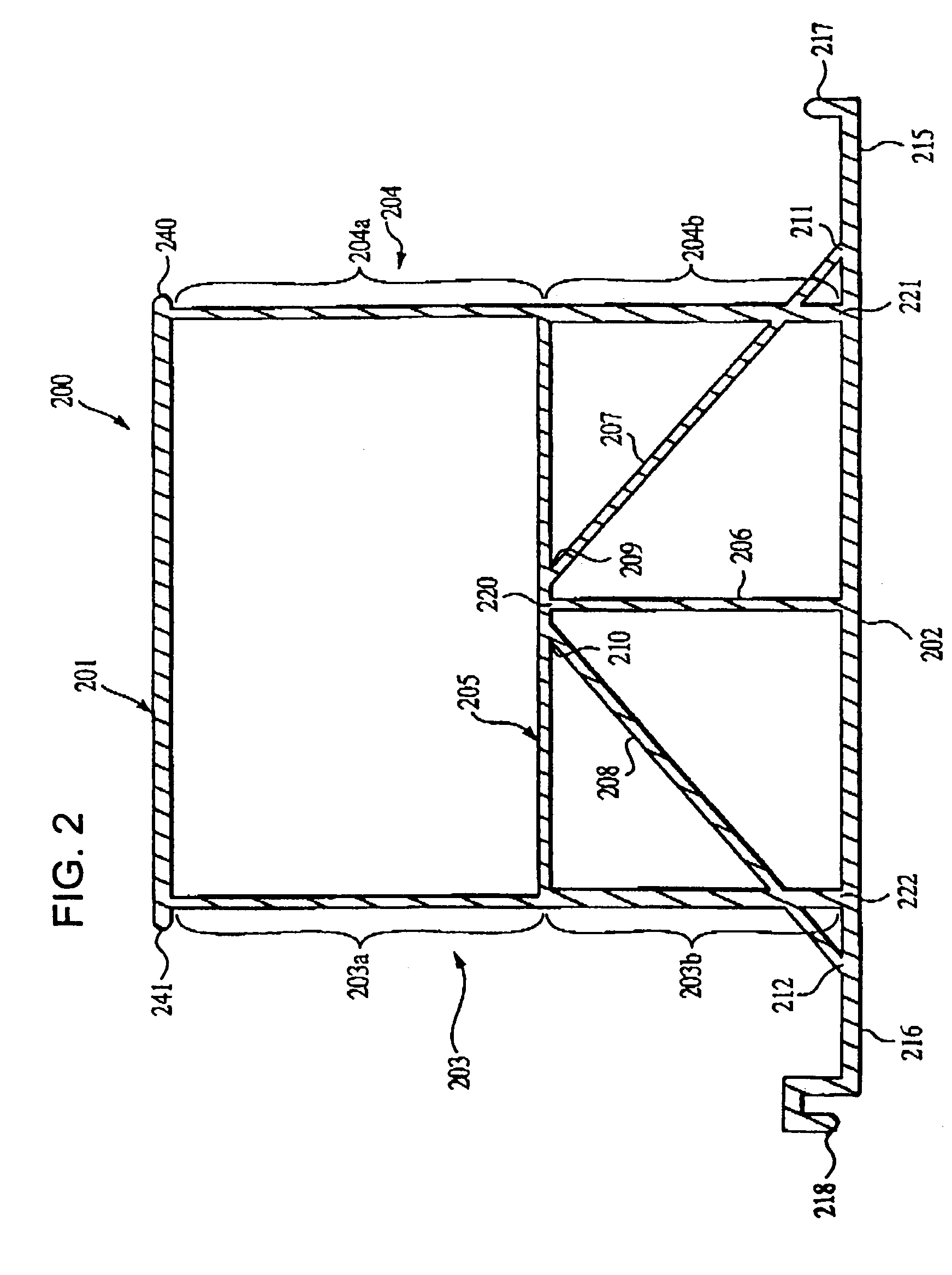

Lightweight building component

A structural member includes side walls, a top wall connecting a top region of the side walls, a bottom wall connecting side wall bottoms and extending beyond the side walls to form wings each having one portion of a connector for connecting members to one another, a span connected to the side walls, and truss configurations each connected to the span and the bottom wall and respectively to one side wall. Side walls, top wall, and span define an upper interior chamber and span, truss configurations, and bottom wall define a lower interior chamber. Each truss configuration has a vertical wall and two intermediate walls. An assembly of members interlock with one another in series by connecting a first portion of the connector with a second portion of another member. These interlocked members form a structure for receiving concrete as a base for a ribbed concrete slab.

Owner:RAY T FORMS

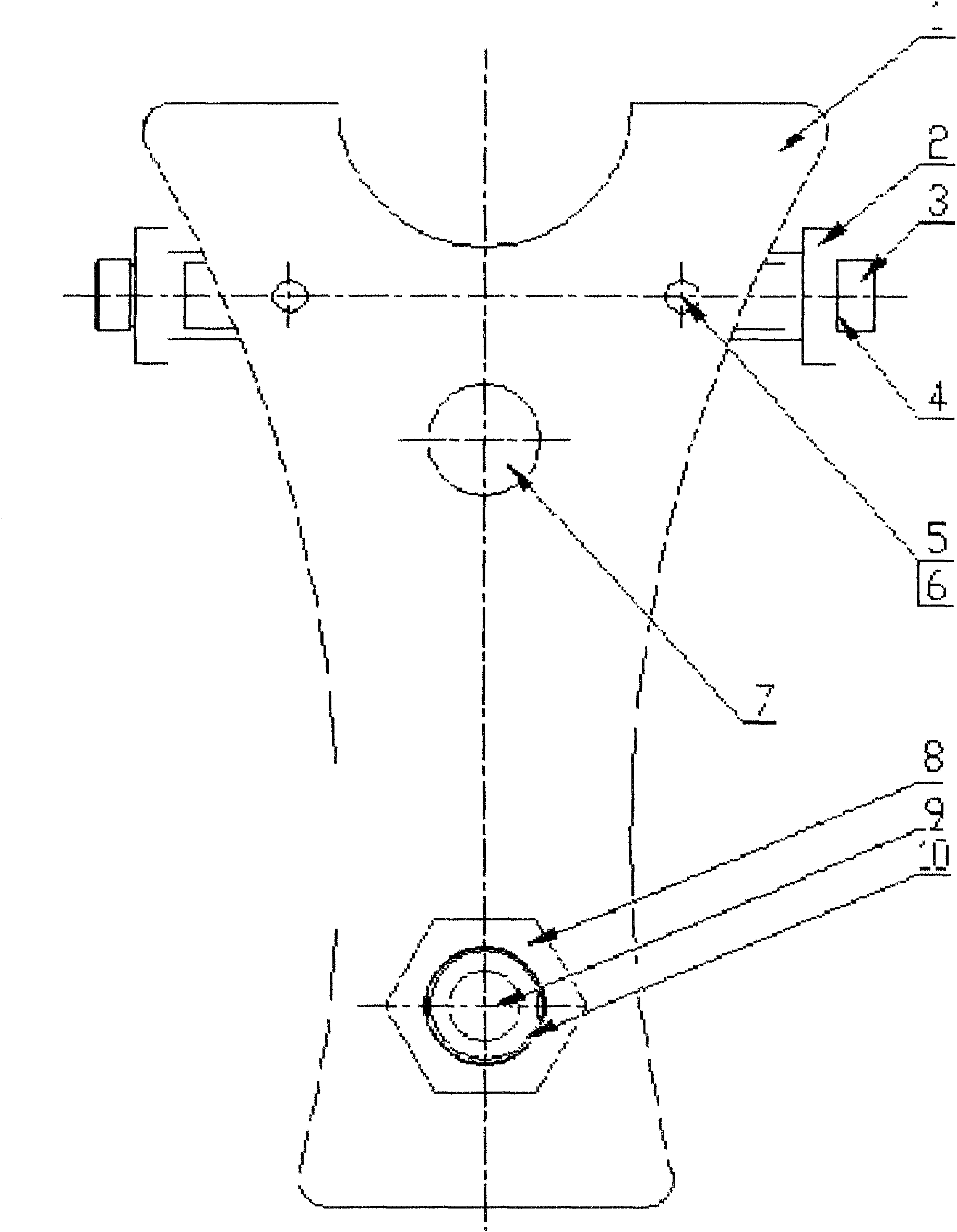

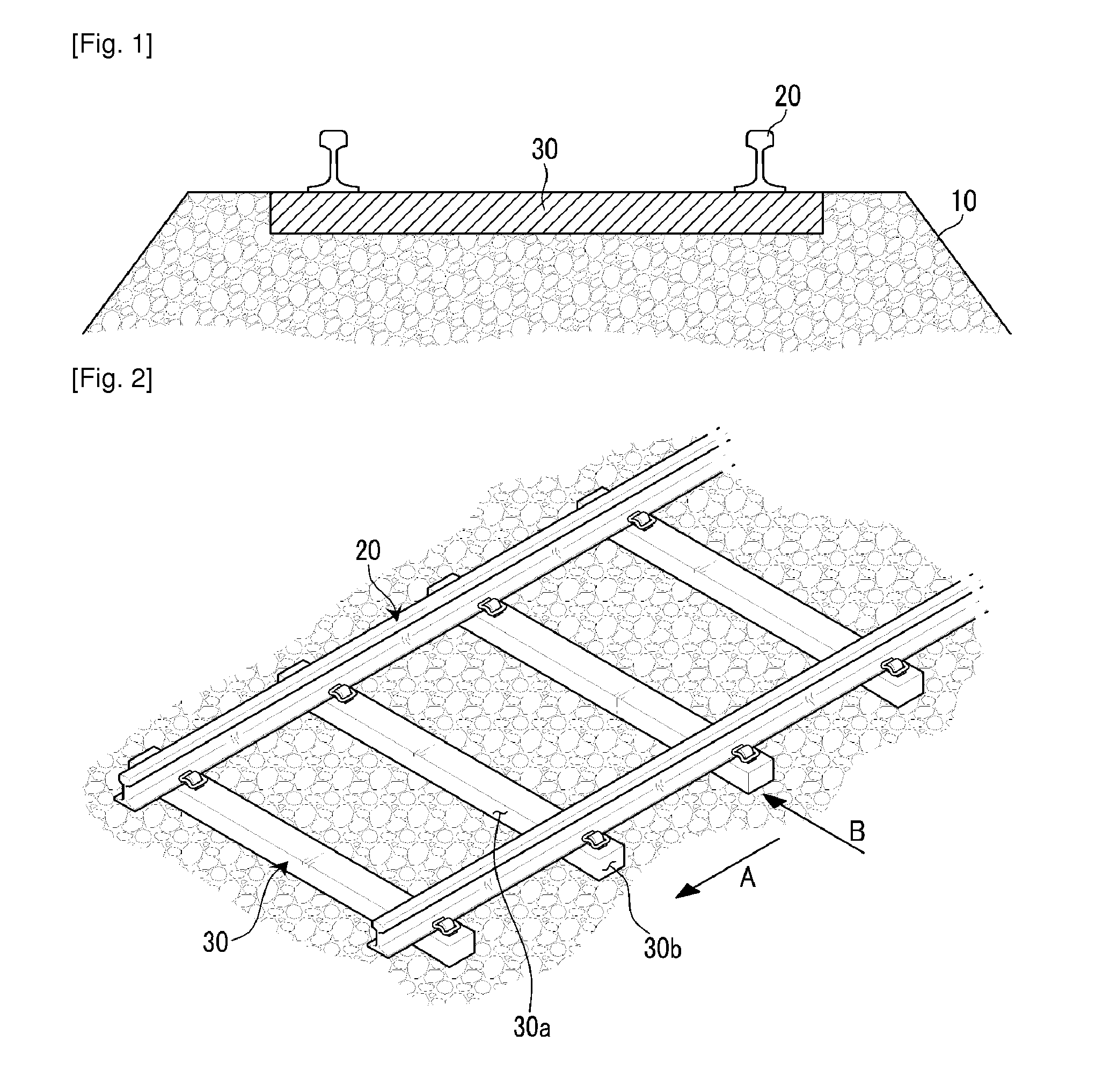

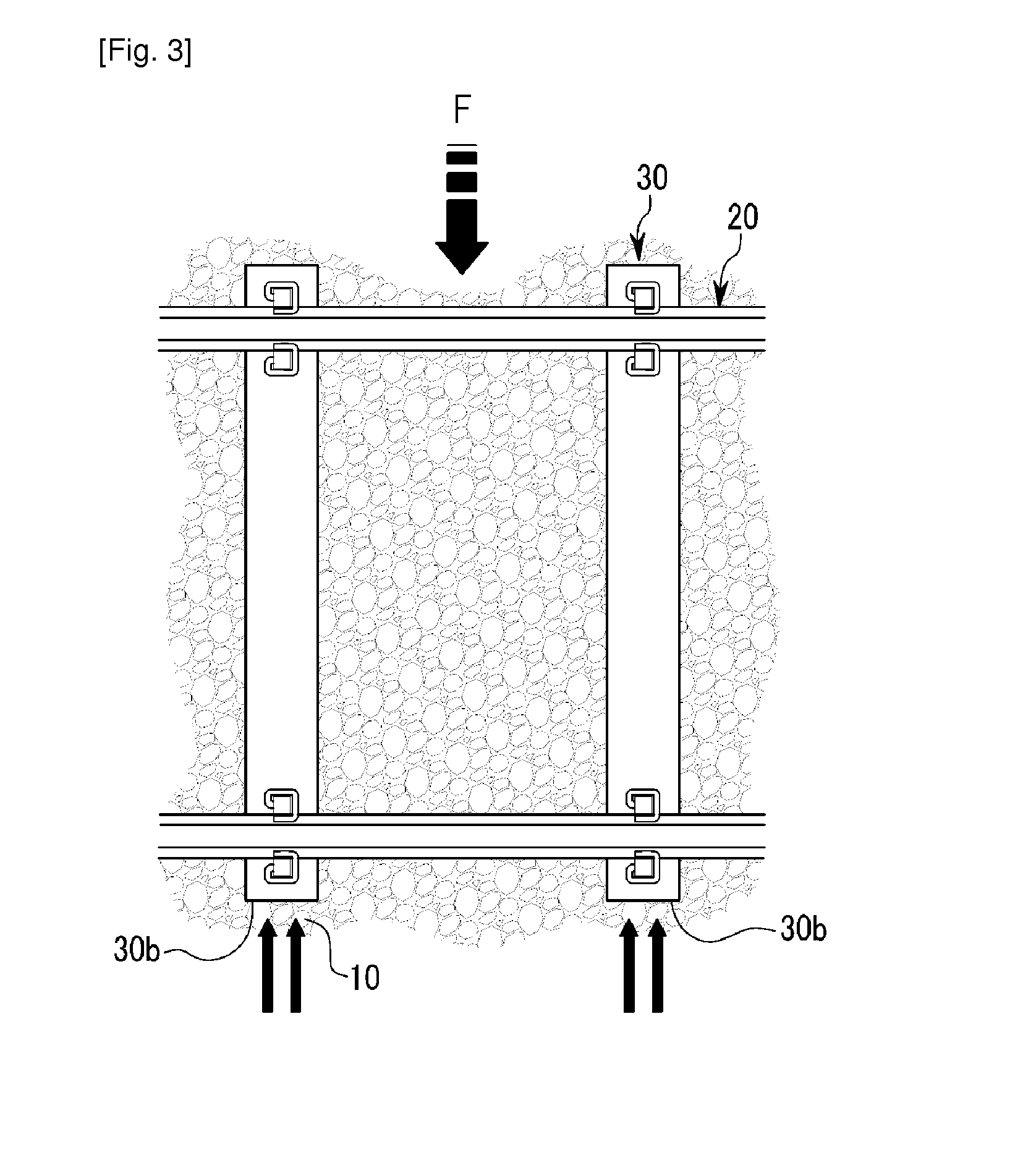

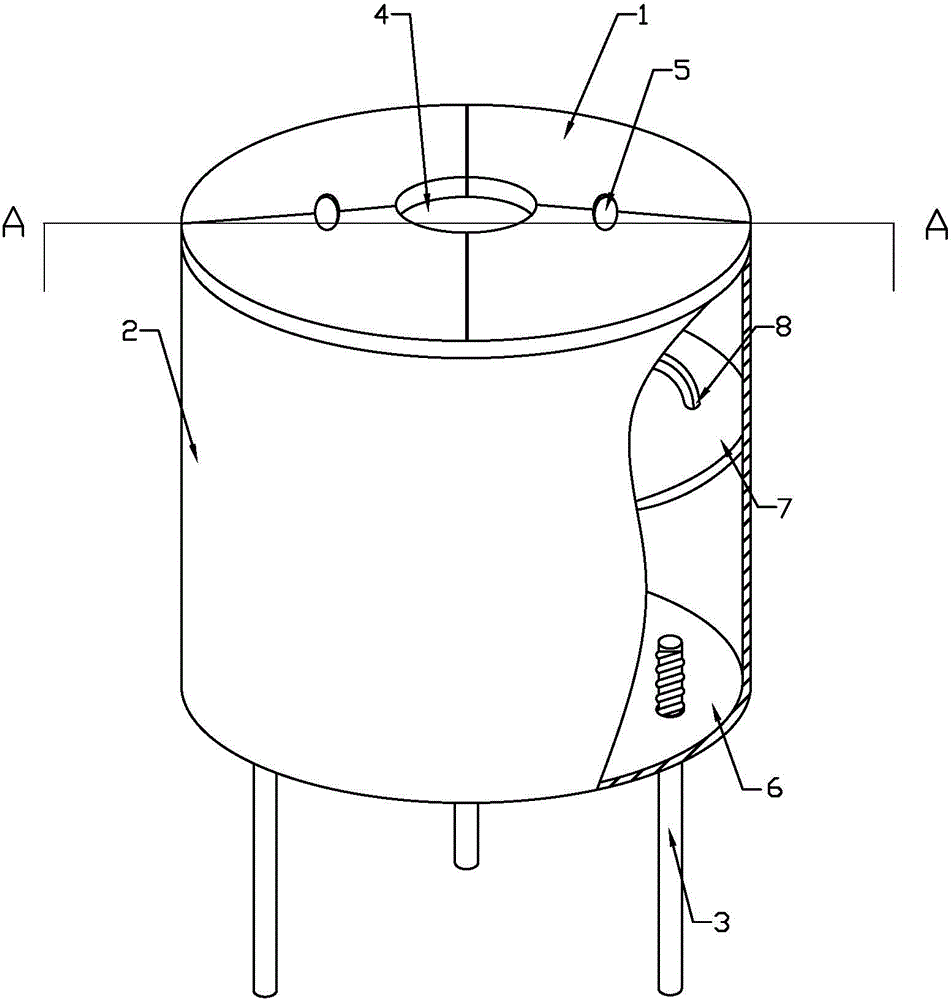

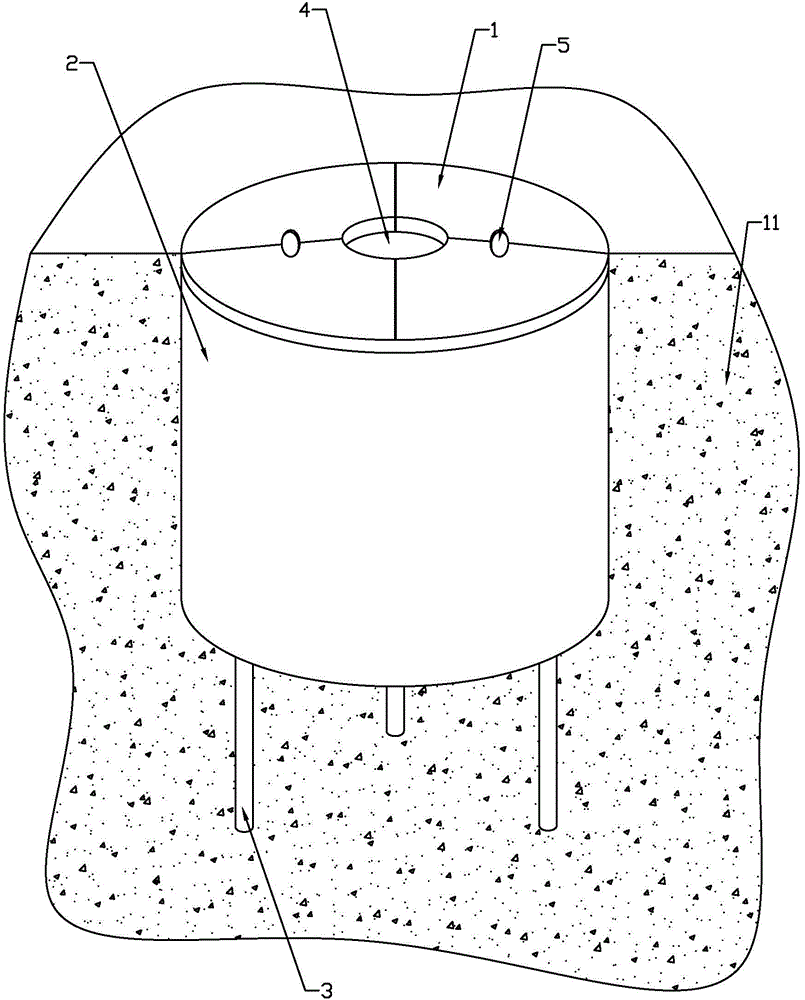

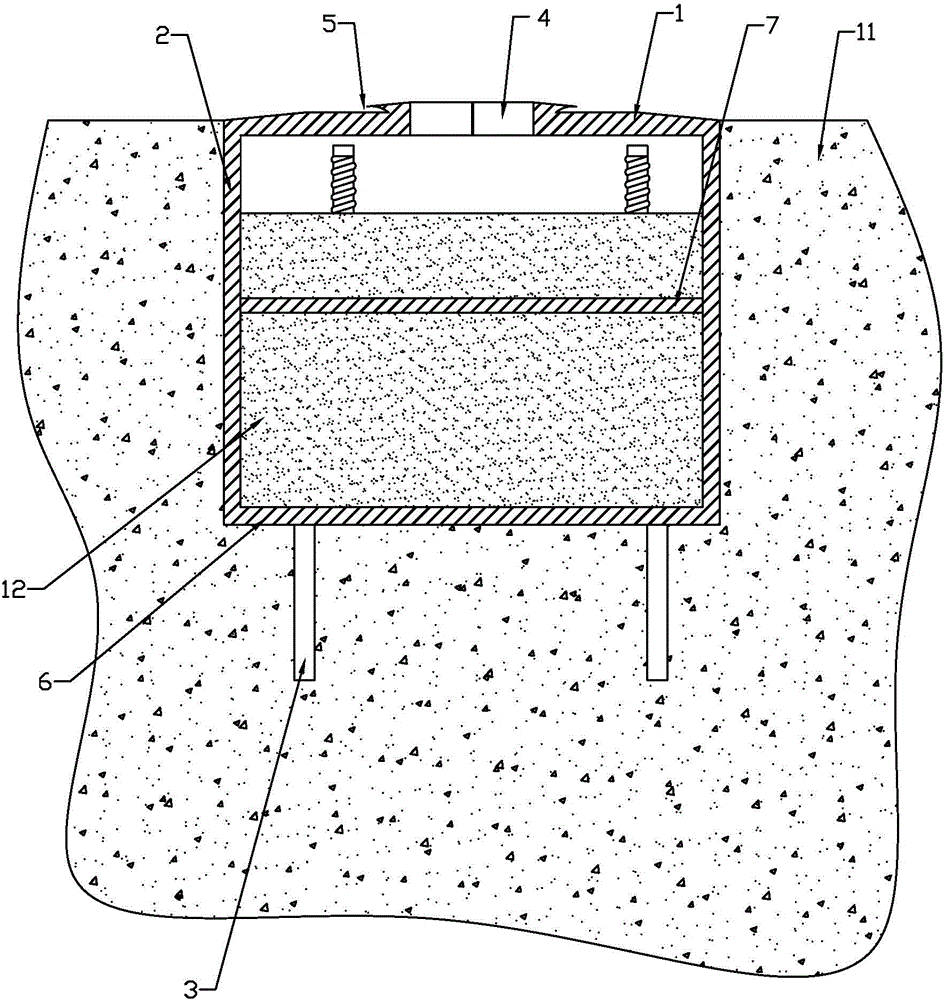

Accurate adjusting frame of high-speed railway ballastless track plate

InactiveCN102733270AGuaranteed vertical placement accuracyEasy and accurate installationRailway track constructionMeasuring apparatusEngineeringCRTS

The invention provides an accurate adjusting frame of a high-speed railway ballastless track plate, which is convenient, accurate and stable to mount, has high precision, and is used for accurate adjusting work of CRTS II and CRTS III ballastless track plates of a high-speed railway. The accurate adjusting frame comprises a rack (1); a pair of through holes (5) is arranged on the rack (1); a connecting line of the centers of the through holes (5) is parallel to the straight-line long edge of the rack (1); bearings (2) are mounted at the two ends of a shaft (3) and are clamped by a clamping spring (4); the shaft (3) is provided with one pair of through holes and is mounted on the rack (1) through a screw rod (6) and the through holes (5); a positioning rod (10) is mounted on the through holes of the rack (1) through a nut (8); a magnet (9) is mounted at the top of the positioning rod (10) and is used for mounting a measuring ball; and the through holes (7) on the rack (1) are used for guaranteeing the vertical placing precision of the frame. According to the accurate adjusting frame of the high-speed railway ballastless track plate, the precise machining precision is controlled so that the rack (1) is horizontal; the vertical distance from the center of the positioning rod (10) to the straight-line long edge of the rack (1) is a fixed value; and after the measuring ball is mounted at the top of the positioning rod, the distance from the spherical center of the measuring ball to the supporting point of the positioning rod (10) is a fixed value. The frame disclosed by the invention has the advantages of small and light frame, convenience and accuracy for installation, good stability, high precision, small influences caused by a temperature and convenience for storage and transportation.

Owner:SHANGHAI I SURVEY SOFTWARE

Vial-Mounting Structure

ActiveUS20100115780A1Easy and accurate installationEasy to assembleIncline measurementEdge surfaceMechanical engineering

A level including an elongate hollow frame with two sidewalls and a topwall extending therebetween, a topnotch defined by the walls which have notch-defining edges including non-vertical surfaces, and a vial within the topnotch. A vial-mounting structure includes a vial-holding member and a locking member movably secured with respect to the vial-holding member. The vial-holding member is configured for resting on the non-vertical notch-edge surfaces. The locking member includes frame-engaging portions which press upwardly against a frame inner surface to pull the vial-holding member downwardly against the non-vertical notch-edge surfaces, thereby securing the vial-holding member to the frame. A method for securing a vial-mounting structure to the level by providing the vial-mounting structure, which includes the vial-holding member, and pulling the vial-holding member downwardly against the non-vertical notch-edge surfaces by a force from inside the frame, thereby securing the vial-holding member to the frame.

Owner:MILWAUKEE ELECTRIC TOOL CORP

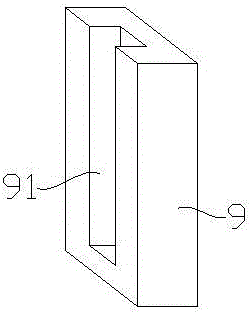

Multiple piece bracket assembly for lifting and supporting a structure

InactiveUS20070065232A1Precise positioningMaintaining bearing area engagementBulkheads/pilesHorizontal axisShallow foundation

An improvement for a bracket assembly of the type used in lifting and supporting a structure or shallow foundation element on a pile is provided. The bracket assembly rests on top of a deep foundation pile positioned adjacent to a structure. The bracket has inside and outside sections, the inside section is a weldment consisting of a bearing member which engages and attaches to the structure or foundation element. The inside section also functions as a guide for installing a pile. The outside section is further divided into upper and lower parts. The lower outside section has a pile guide and a spaced apart U-shaped adjustment bolt that together cradle the pile. The upper outside section caps the pile and attaches to the lower outside section using threadably adjustable rods. The outside section attaches to the inside section thereby fixing the bracket assembly against horizontal translation and rotation about a horizontal axis with respect to the pile.

Owner:FARIES GUY L +2

Apparatus for reinforcing railroad ties

InactiveUS20110155819A1Avoid deformationEasy and accurate installationBallastwayRail fastenersEngineering

Owner:RYU BONG SU

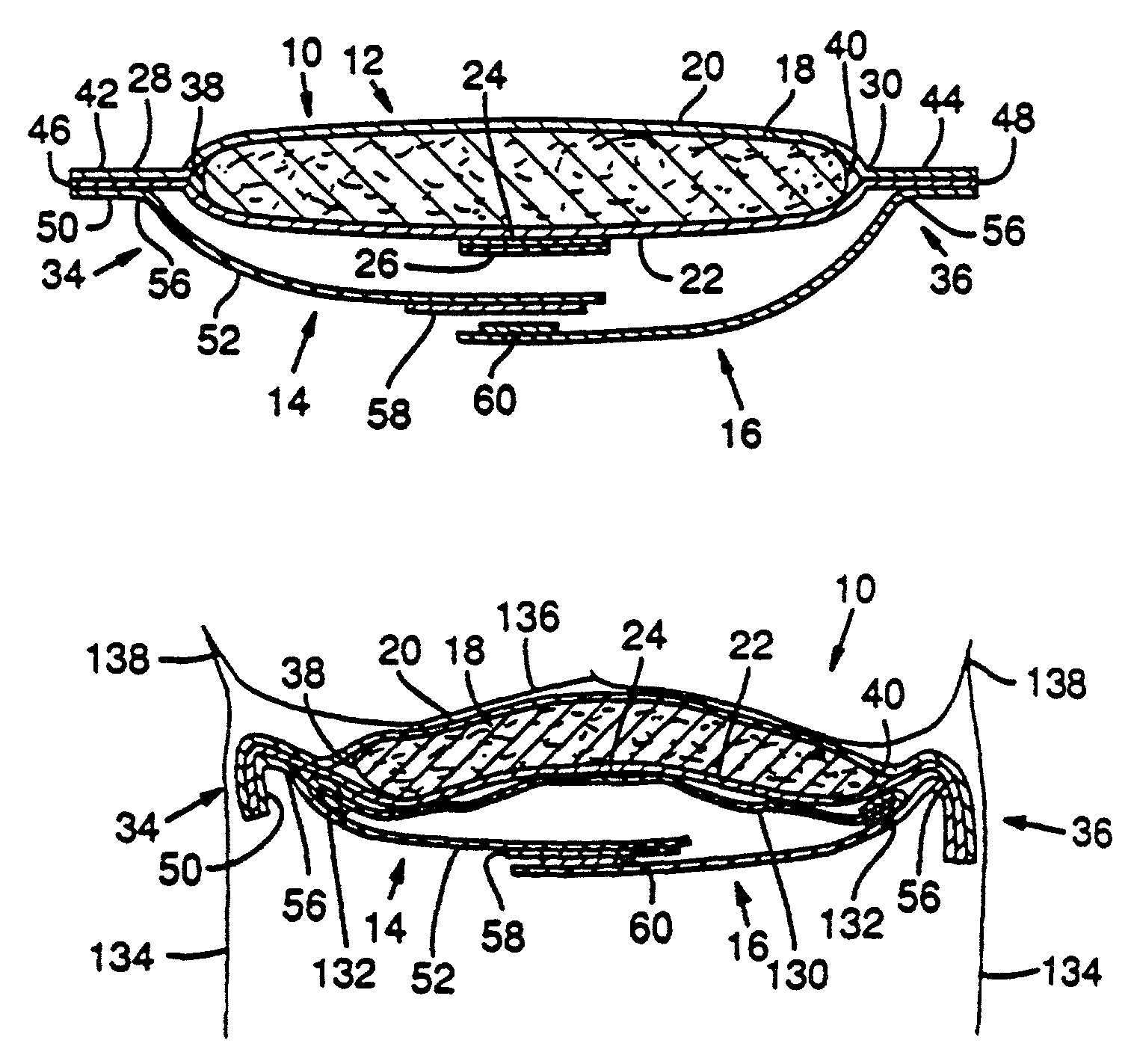

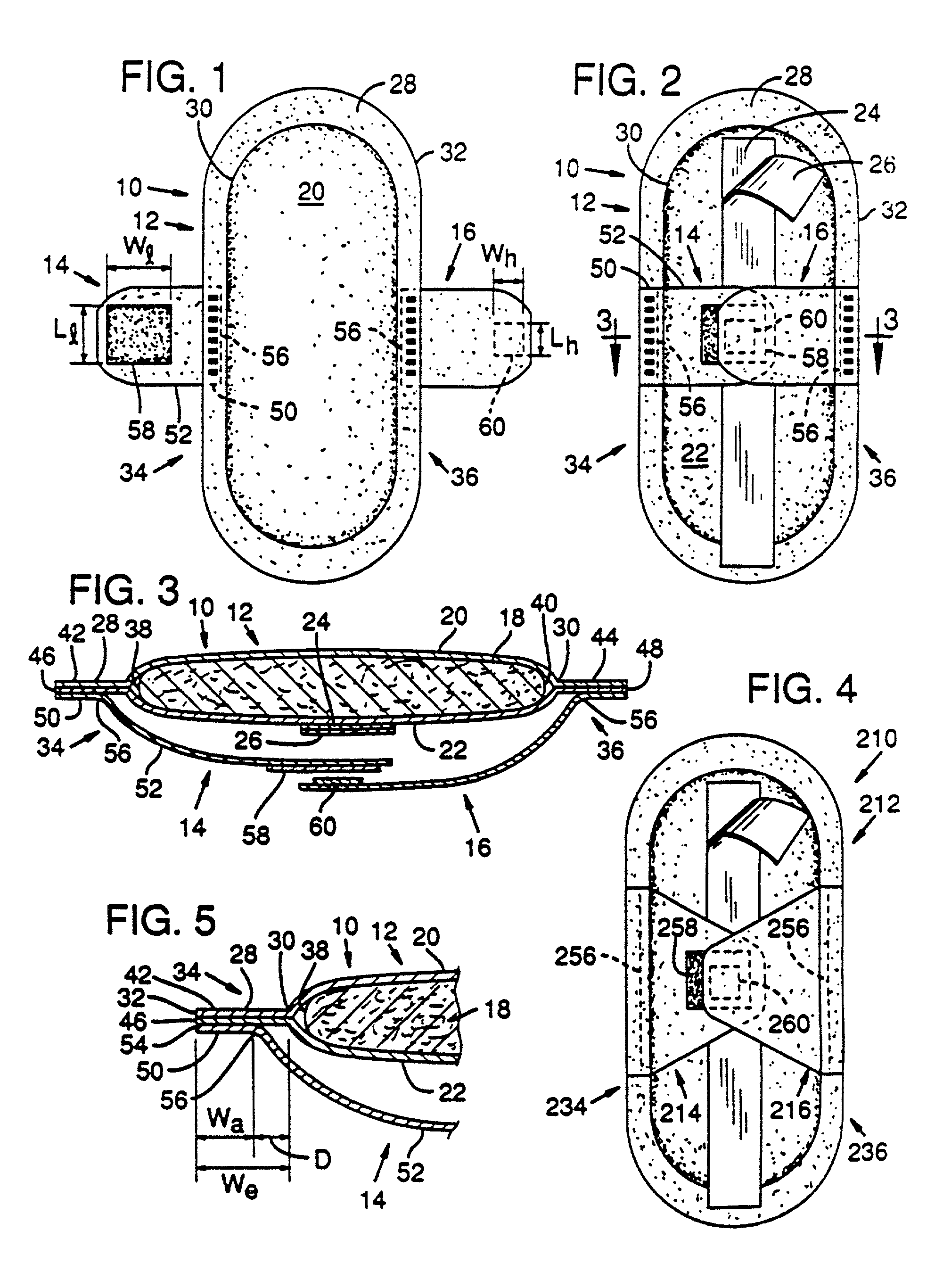

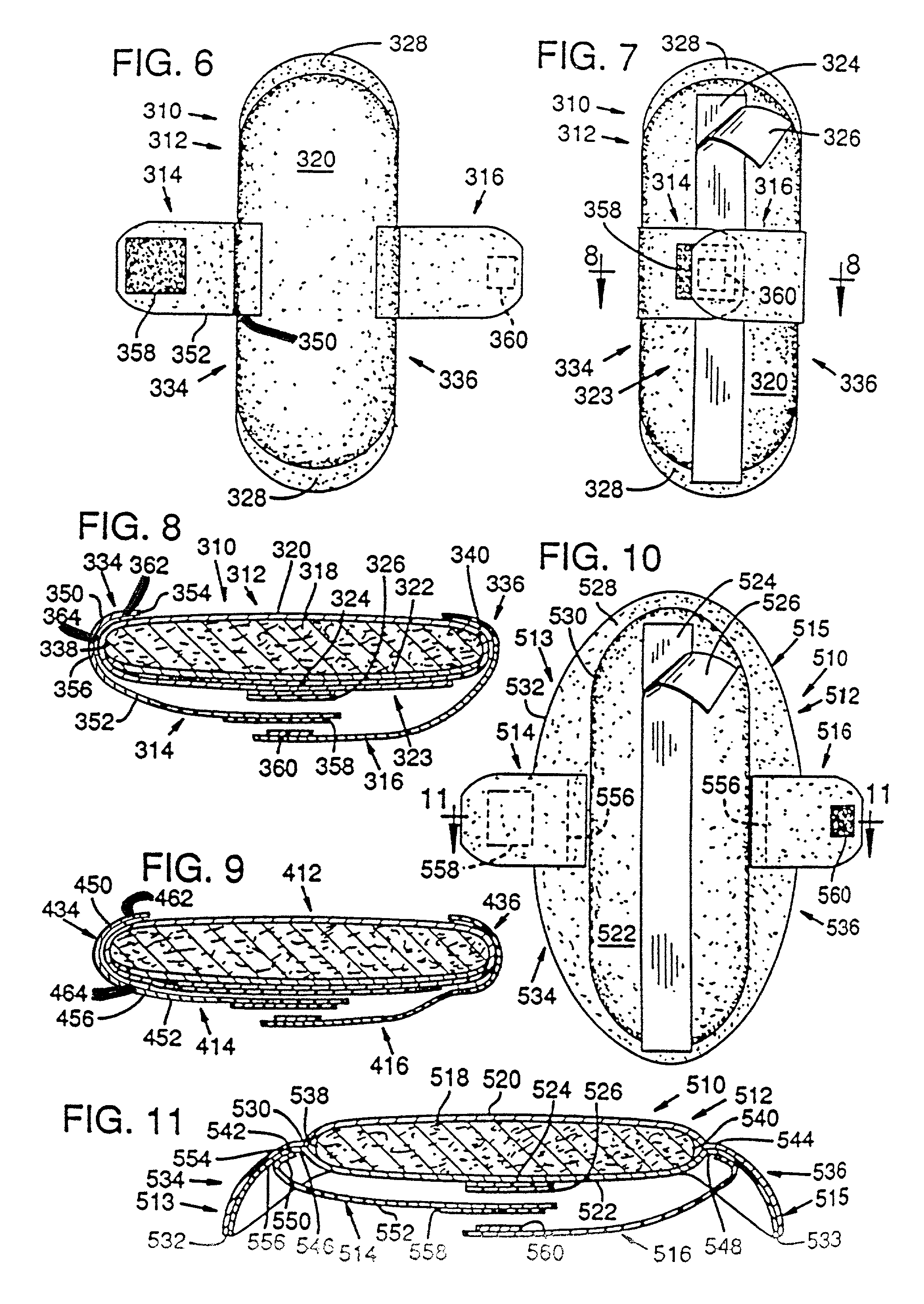

Sanitary napkin with garment attachment panels

InactiveUS7063689B2Avoid foldingEasy and accurate installationSanitary towelsBaby linensEngineeringCrotch

An elongated sanitary napkin has deflectable longitudinal side edges formed by an edge or peripheral seal along the opposite sides of an absorbent. A garment attachment panel is secured to the underside of each side edge. A fixed portion of the panel is bonded flat against the side edge so that a free portion of the panel, extending from the fixed portion, is directed inward and downward. During use, the panels are fastened together beneath an undergarment crotch portion by hook and loop type fastener. Fastener and panels are sized so that when fastened the panels exert a pull on the side edges, controlling their deflection and, for example, preventing them from folding in over the absorbent. The garment attachment panels confine the undergarment crotch portion under the absorbent so that, for example, an elasticized edge of the crotch portion is prevented from pulling up and onto the absorbent.

Owner:KIMBERLY-CLARK WORLDWIDE INC

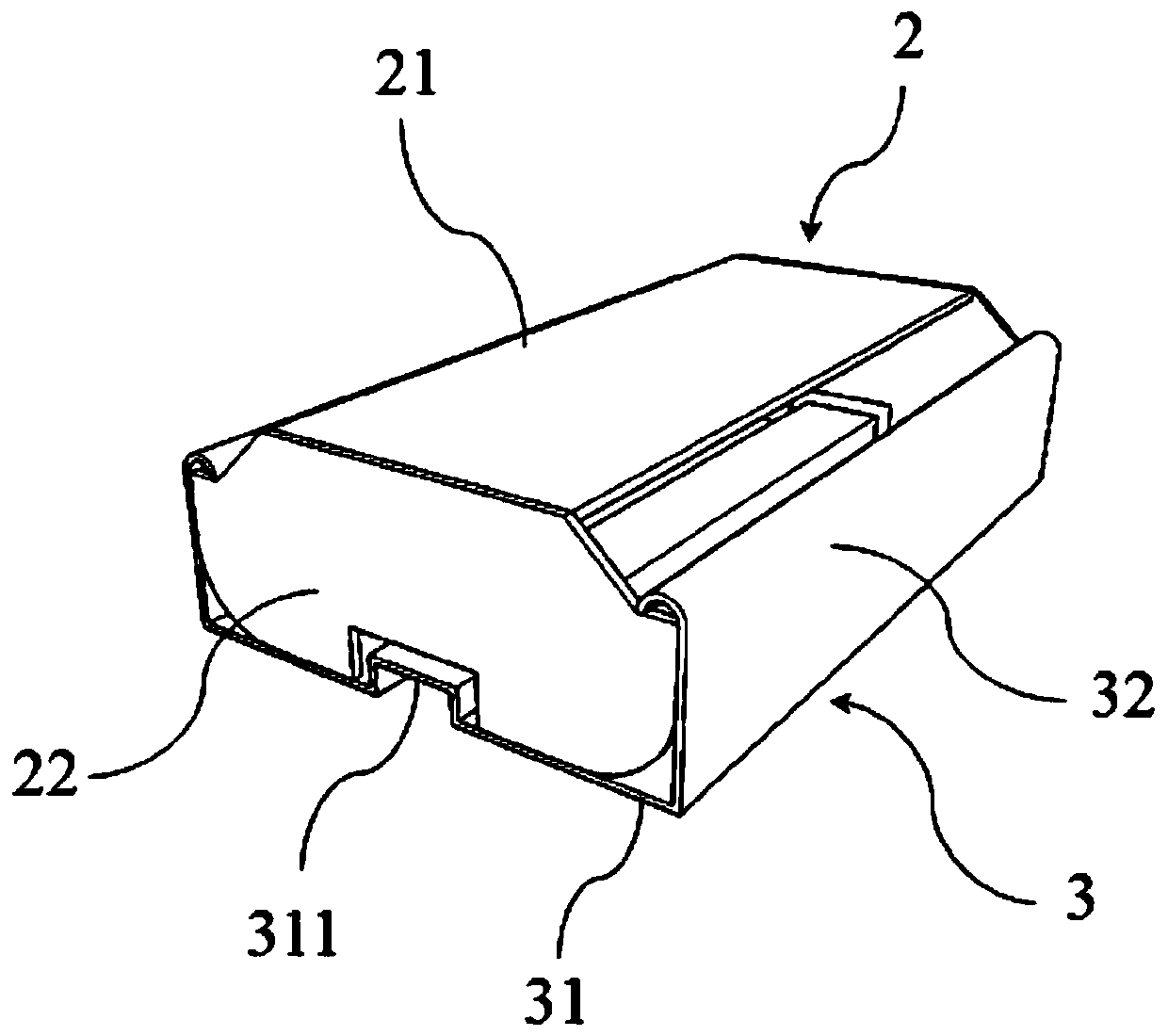

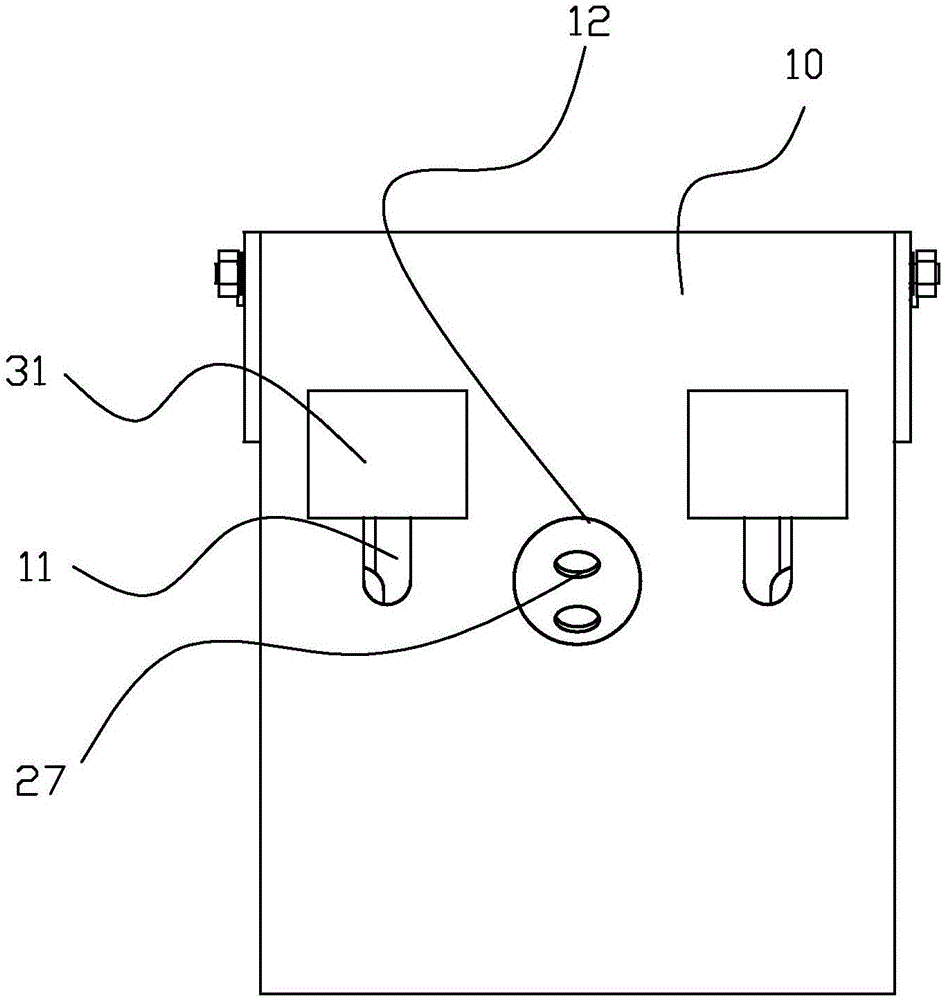

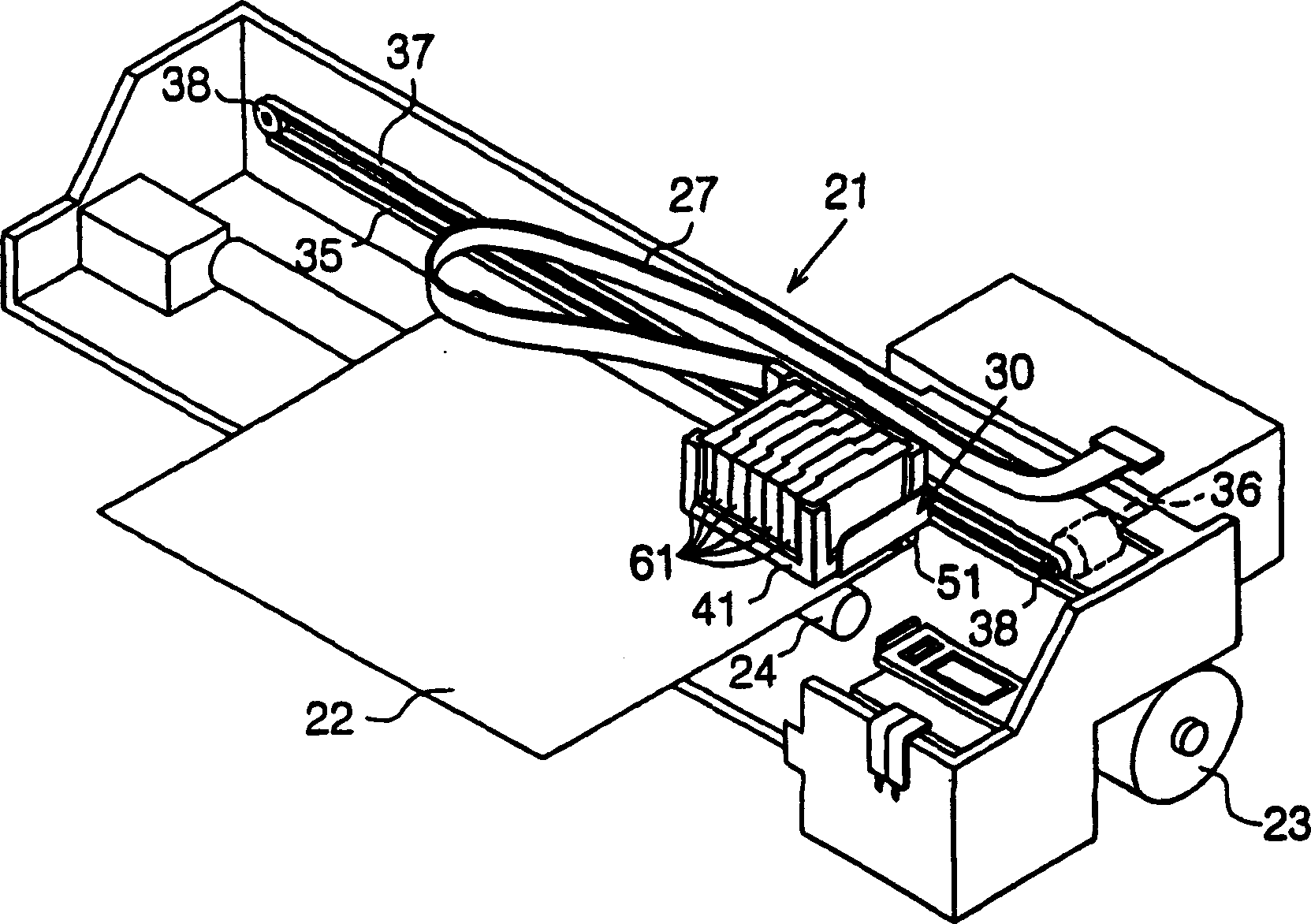

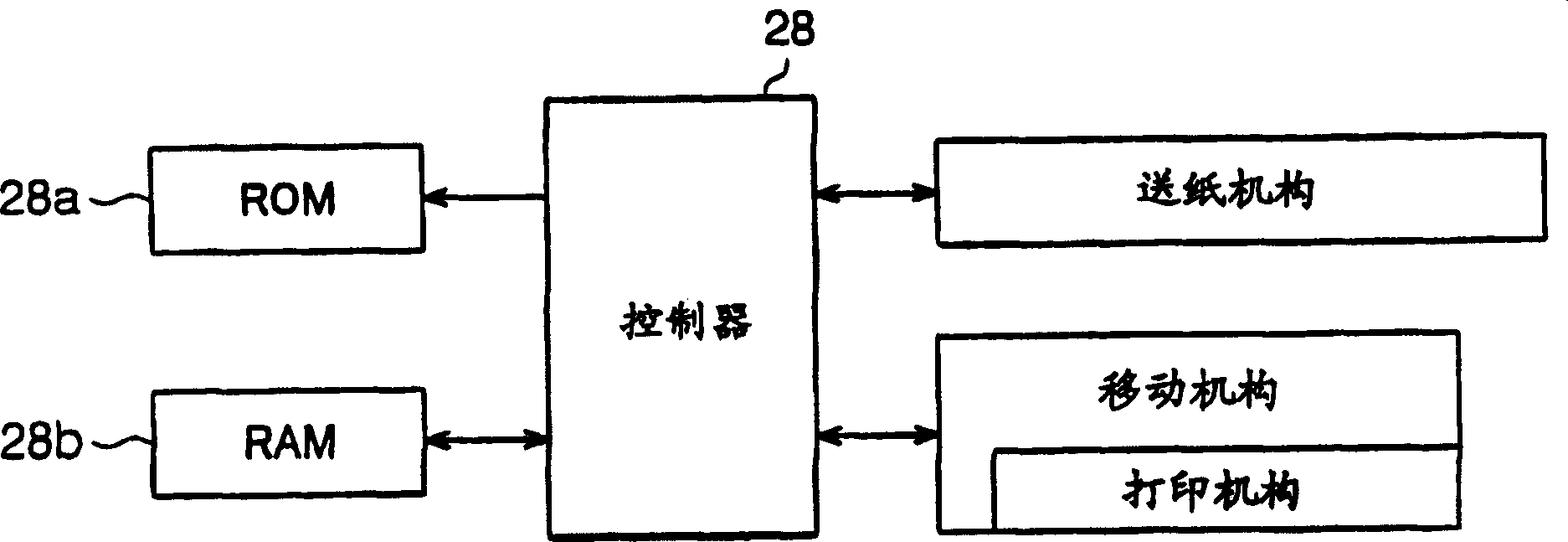

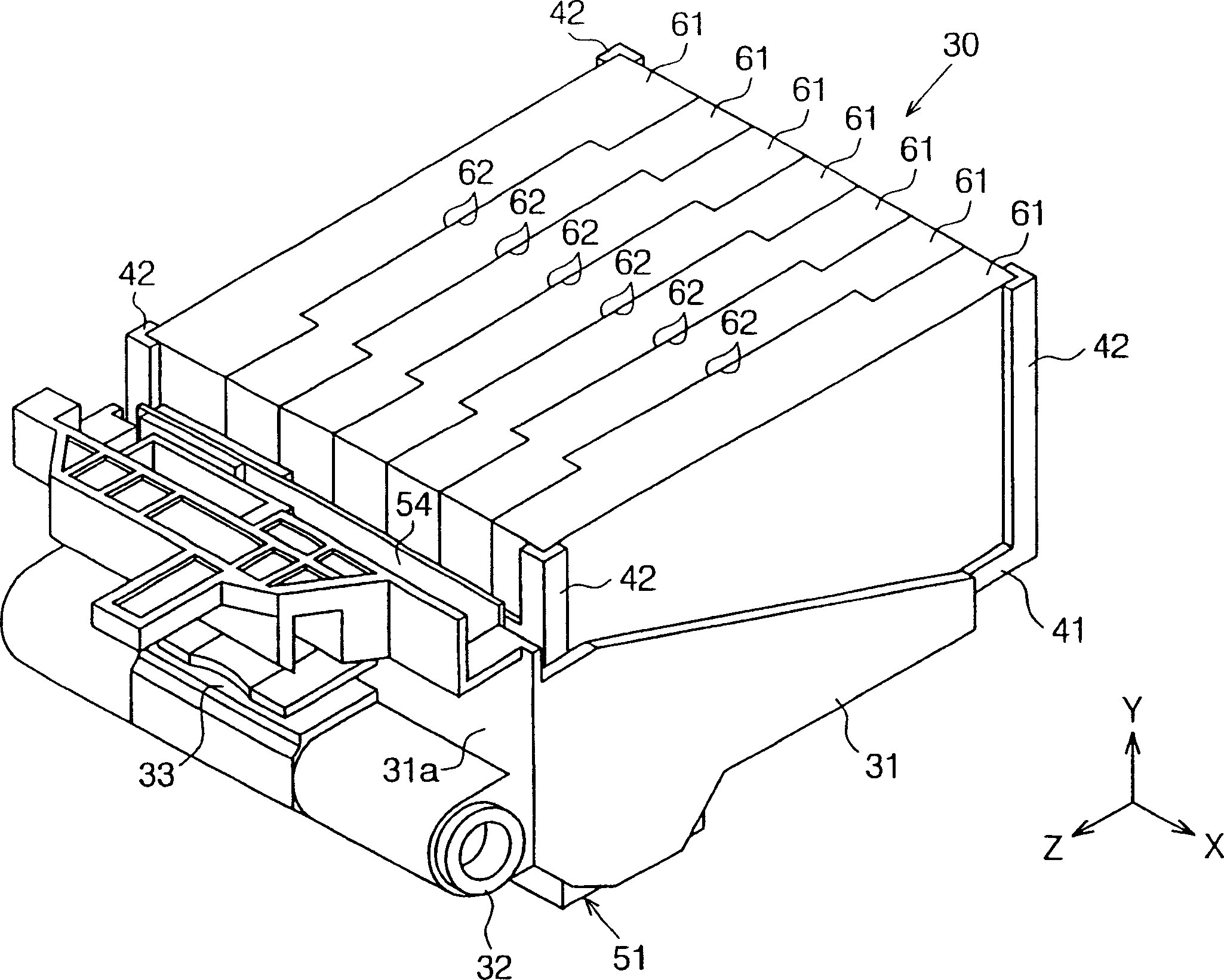

Ink cartridge and inkjet printer

The present invention relates to an ink cartridge used in an inkjet printer, wherein the ink cartridges are detachably attached to a cartridge holder of an inkjet printer and are aligned in parallel. The ink cartridge includes a contact point which is connected to one of the connection elements in the cartridge holders when the ink cartridge is fixed in the cartridge hoder, and the contact point is privided on the outer surface of the ink cartridge and is deviated from the center of the ink cartridges along the array of the ink cartridges.

Owner:SEIKO EPSON CORP

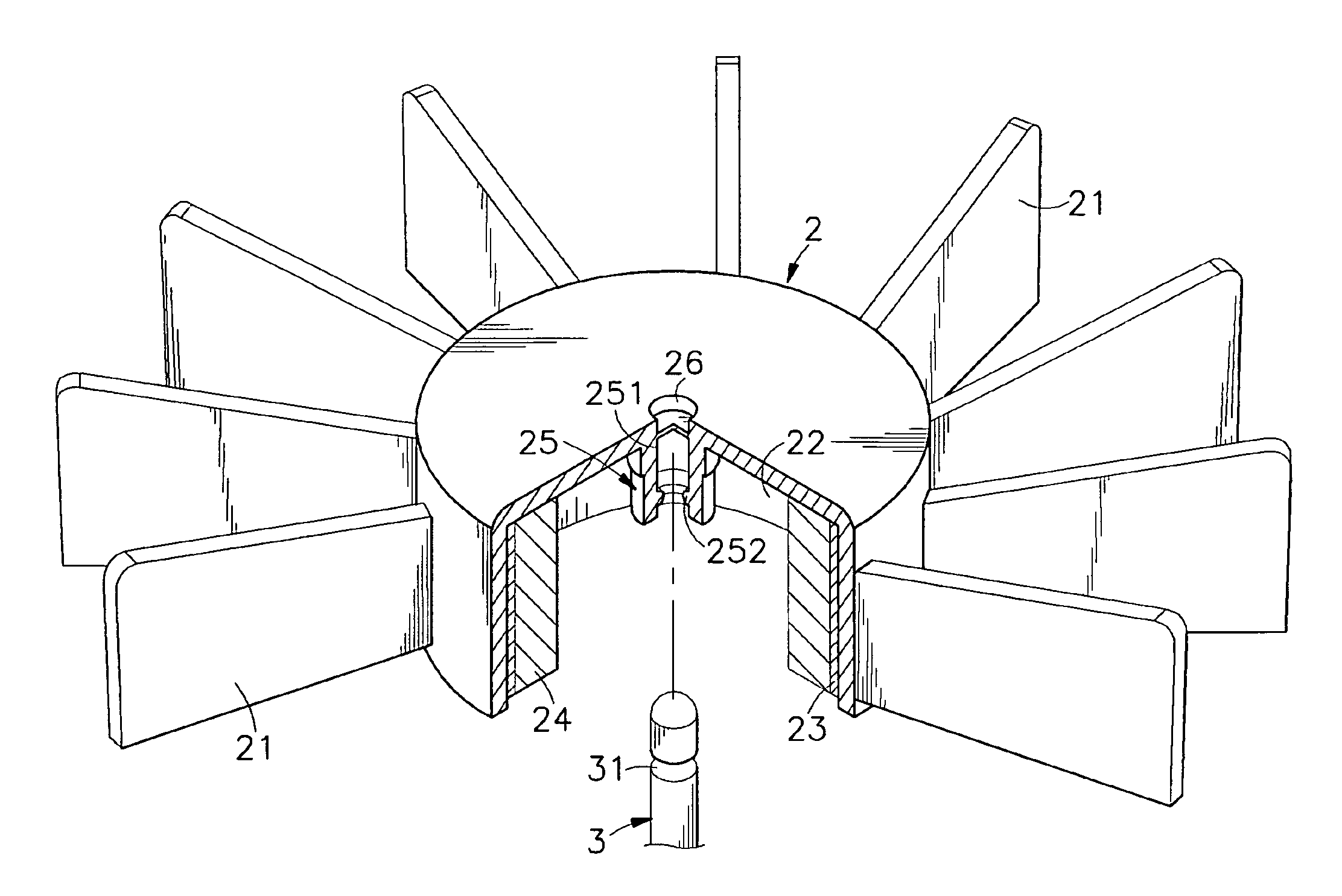

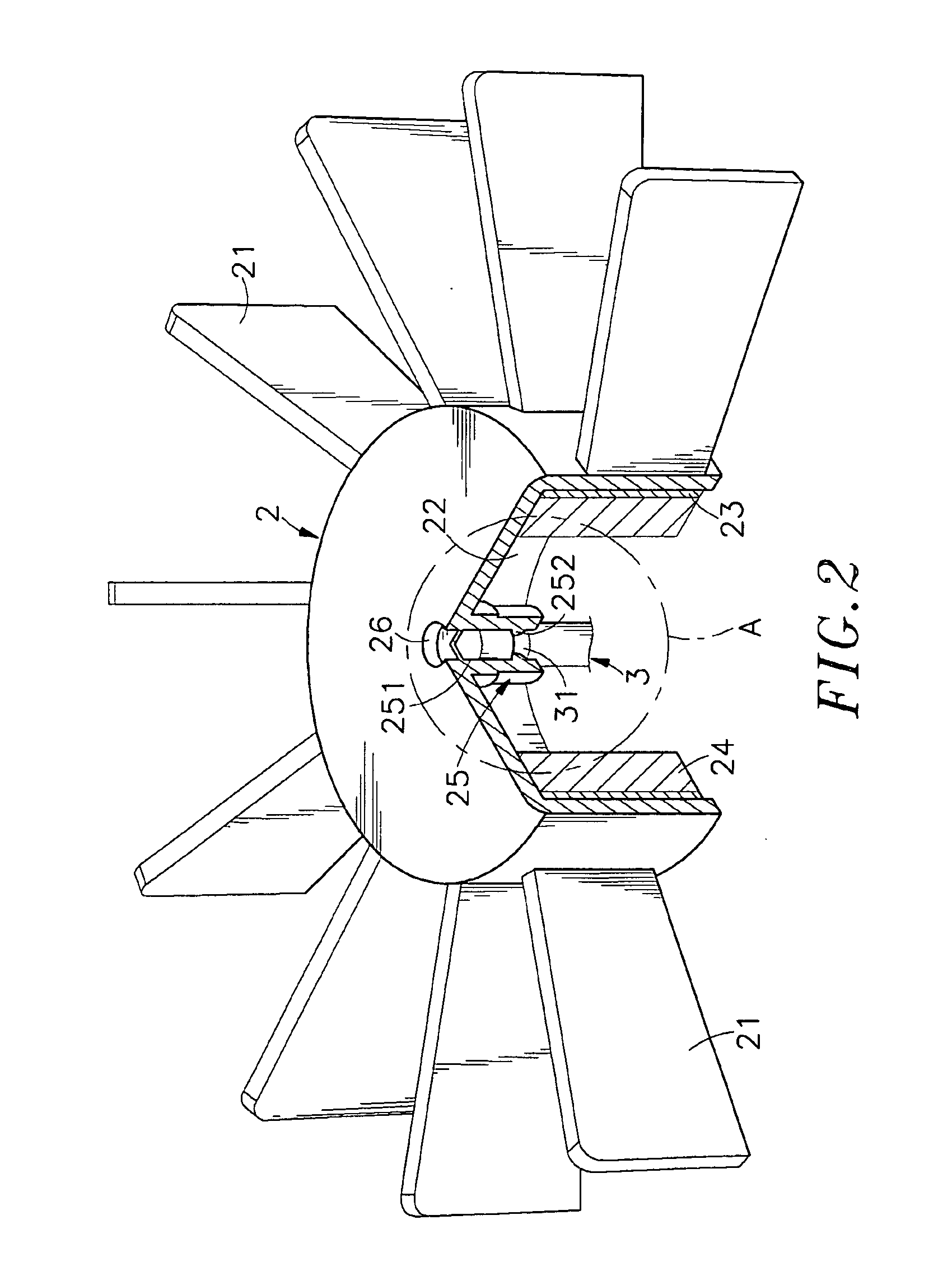

Fan blade assembly

A fan blade assembly includes a fan blade body, which has an axle housing downwardly suspending in a center accommodation open chamber thereof at the center and defining therein an axle hole and an inside annular flange in the axle hole, and a core shaft, which is inserted into the axle hole of the axle housing to support magnetic levitation rotation of the fan blade body and has a coupling groove extending around the periphery thereof and coupled to the inside annular flange of the axle housing with a gap left therebetween.

Owner:HSU TING WEI MR

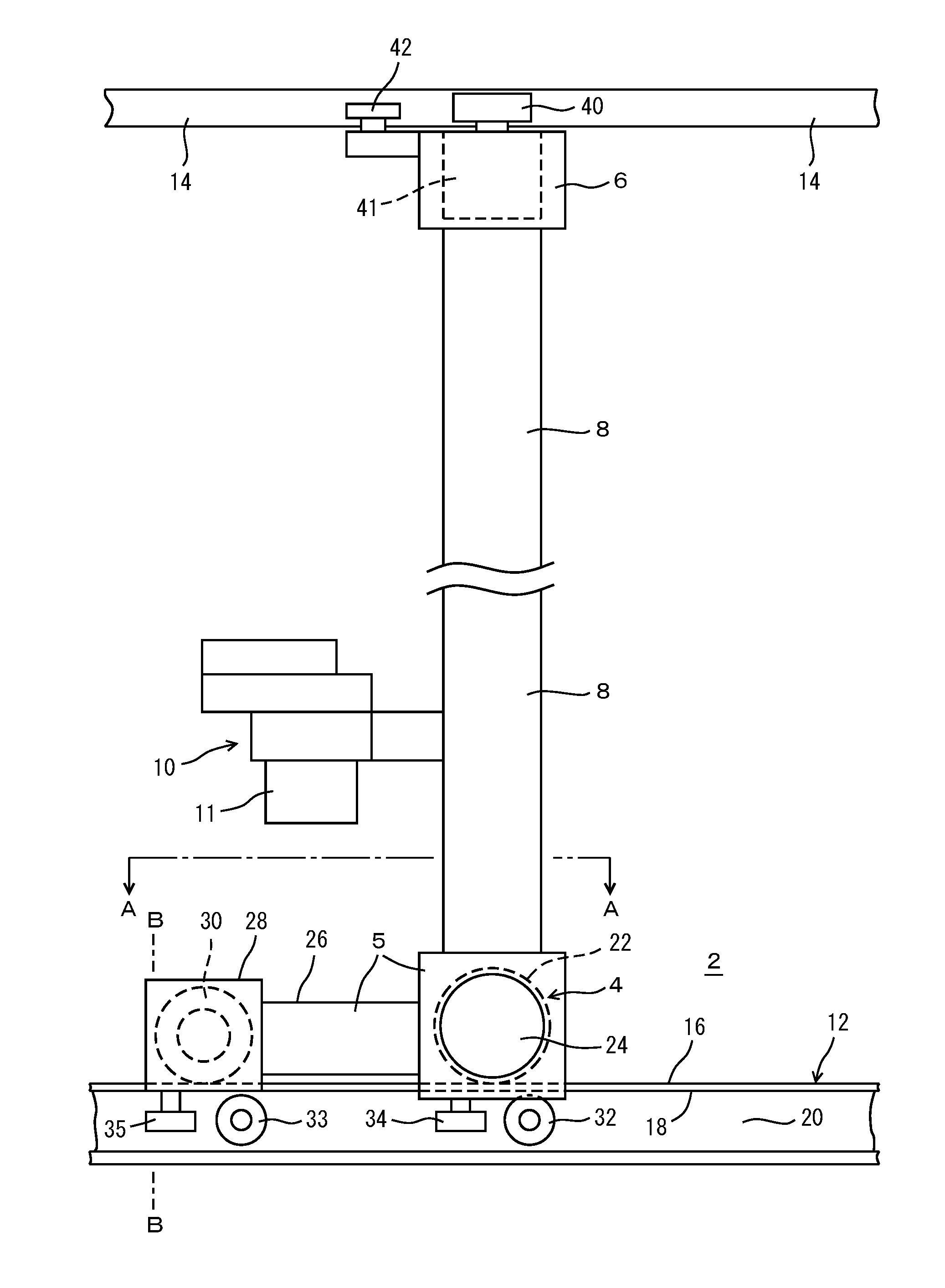

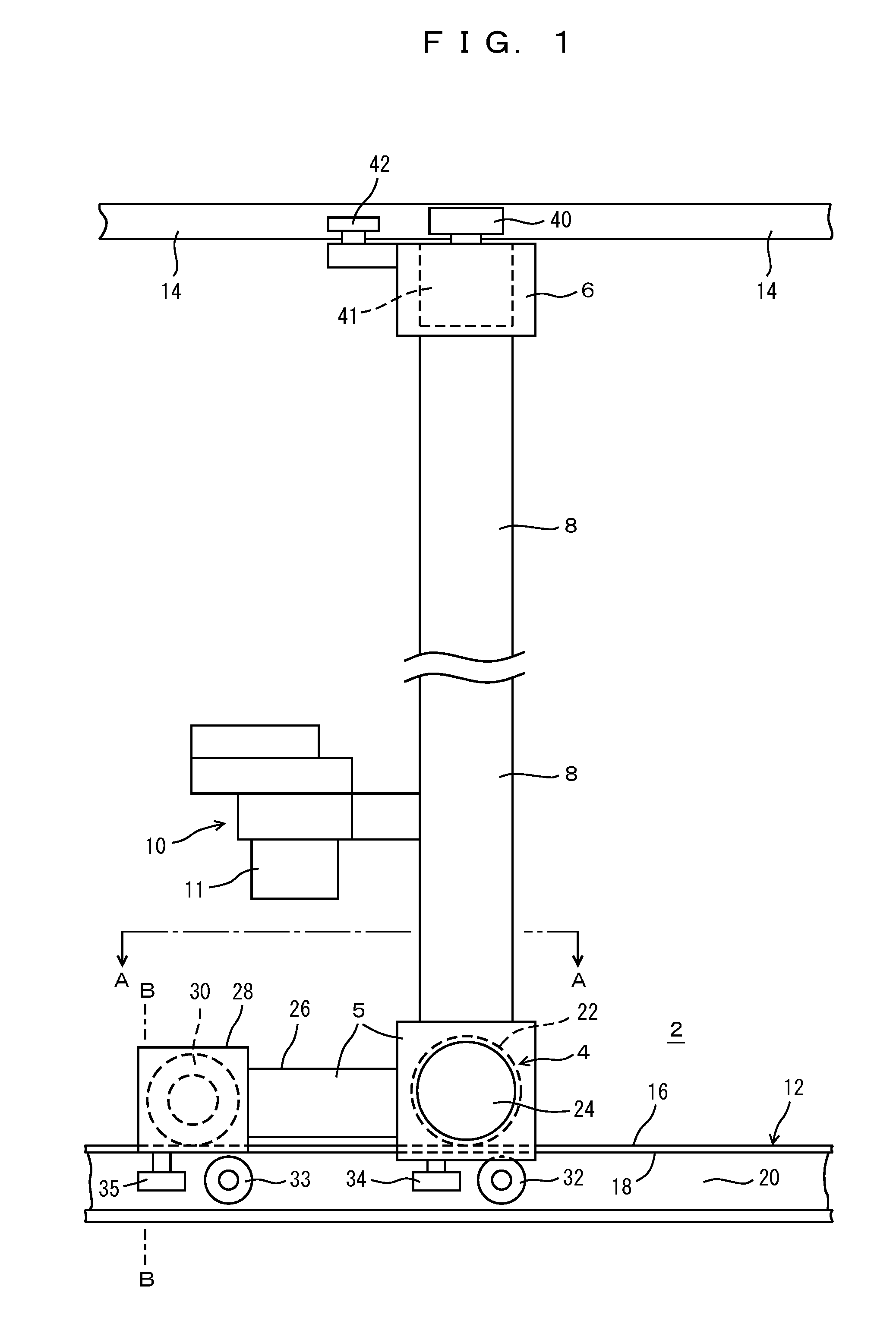

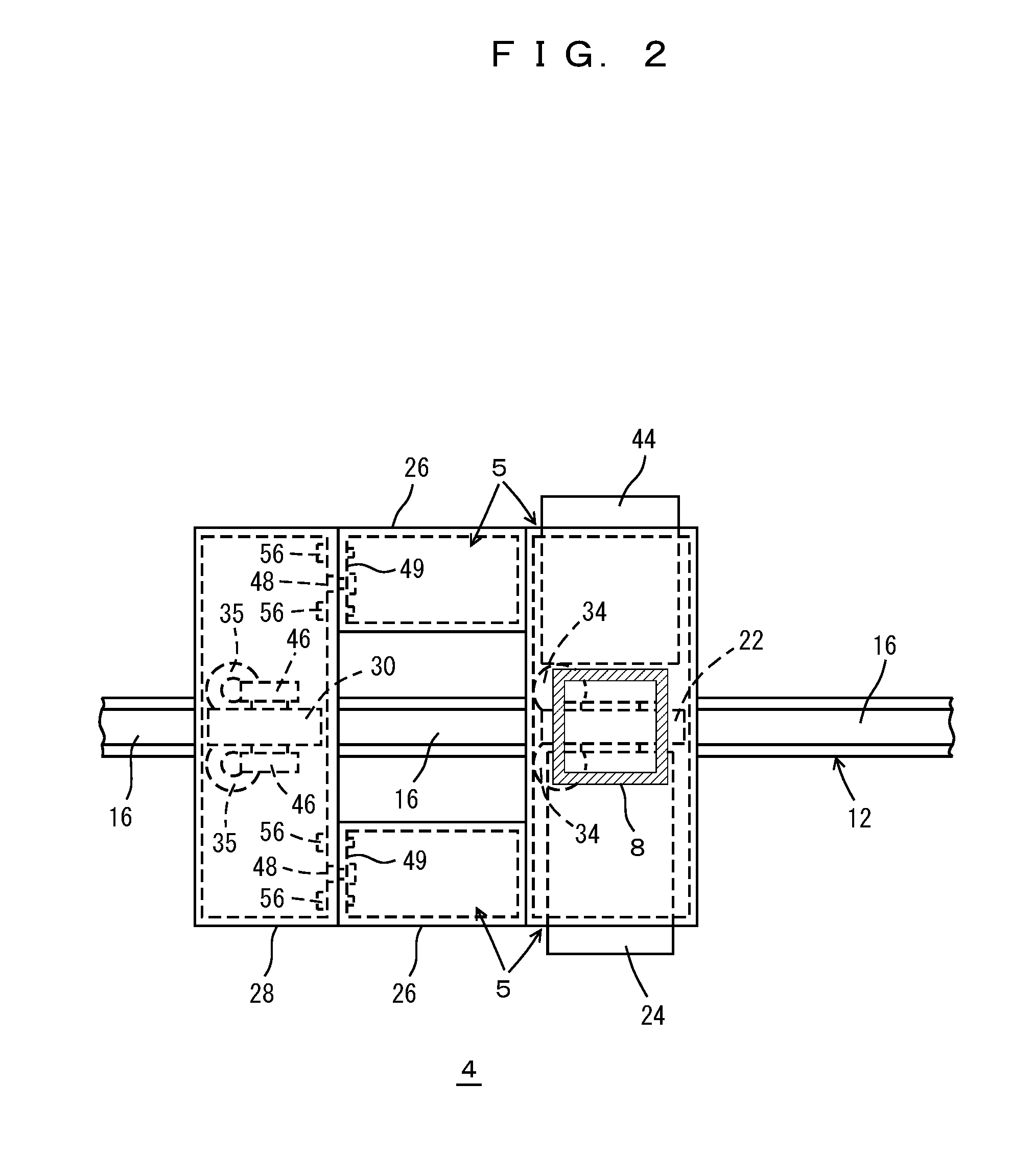

Stacker crane and method for operating same

ActiveUS20150353281A1Improve reliability and durabilityReduce weightLifting devicesBuilding liftsStackerDrive wheel

A stacker crane includes a lower carriage including a lower drive wheel, a lower travel motor, and a support located apart from the lower drive wheel; an upper carriage including an upper drive wheel and an upper travel motor that drives the upper drive wheel; and a mast fixed to the lower carriage, standing upward from the lower carriage and connected to the upper carriage, and including a transfer device capable of moving up and down. A displacement mechanism that raises and lowers the support is provided on the lower carriage between a grounded position supported by a lower rail and a retracted position lifted off the lower rail. The support is lowered to the grounded position when the stacker crane is installed between the lower rail and the upper rail and when the stacker crane is stopped for maintenance, and the support is raised to the retracted position when the stacker crane is operated.

Owner:MURATA MASCH LTD

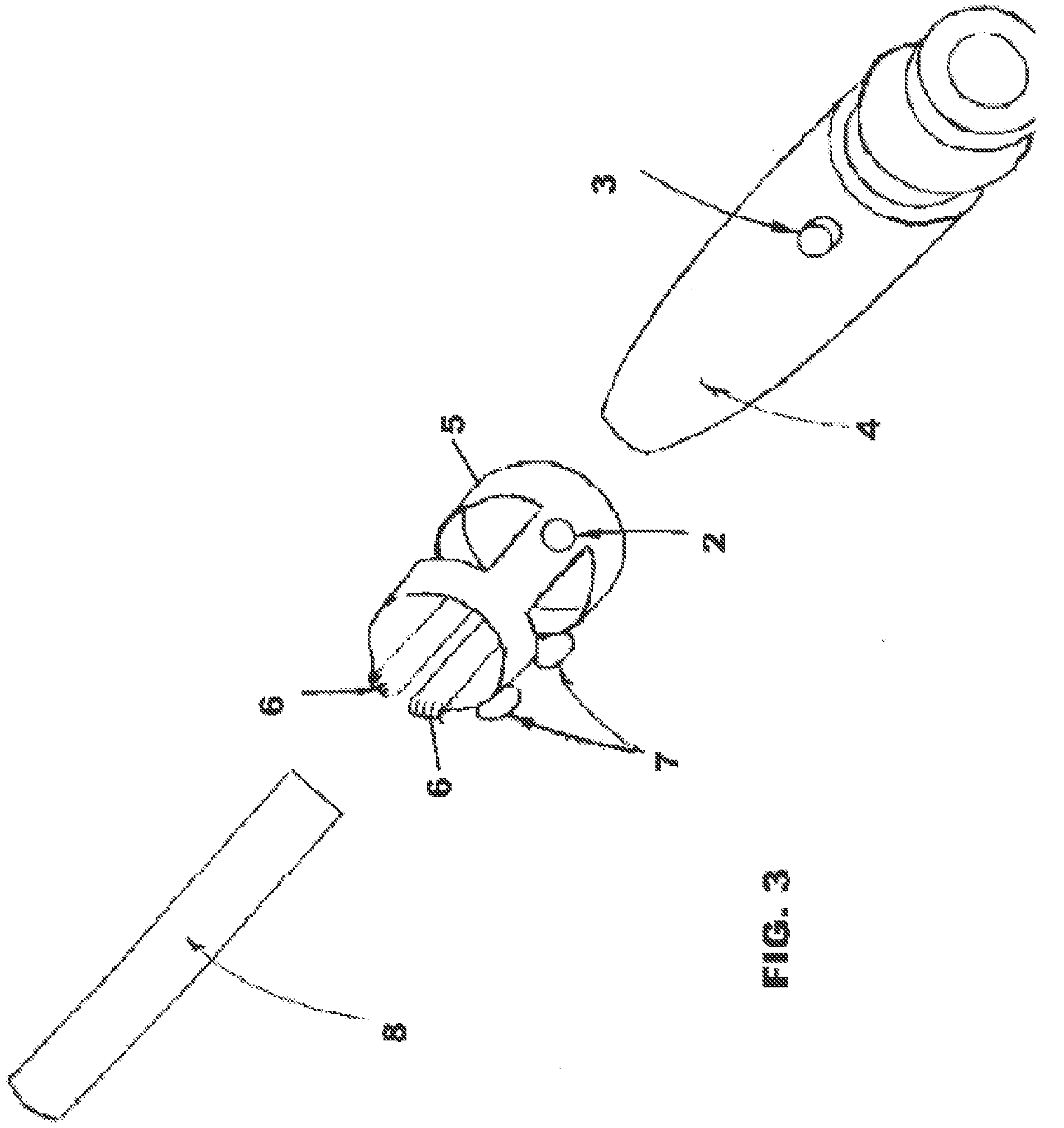

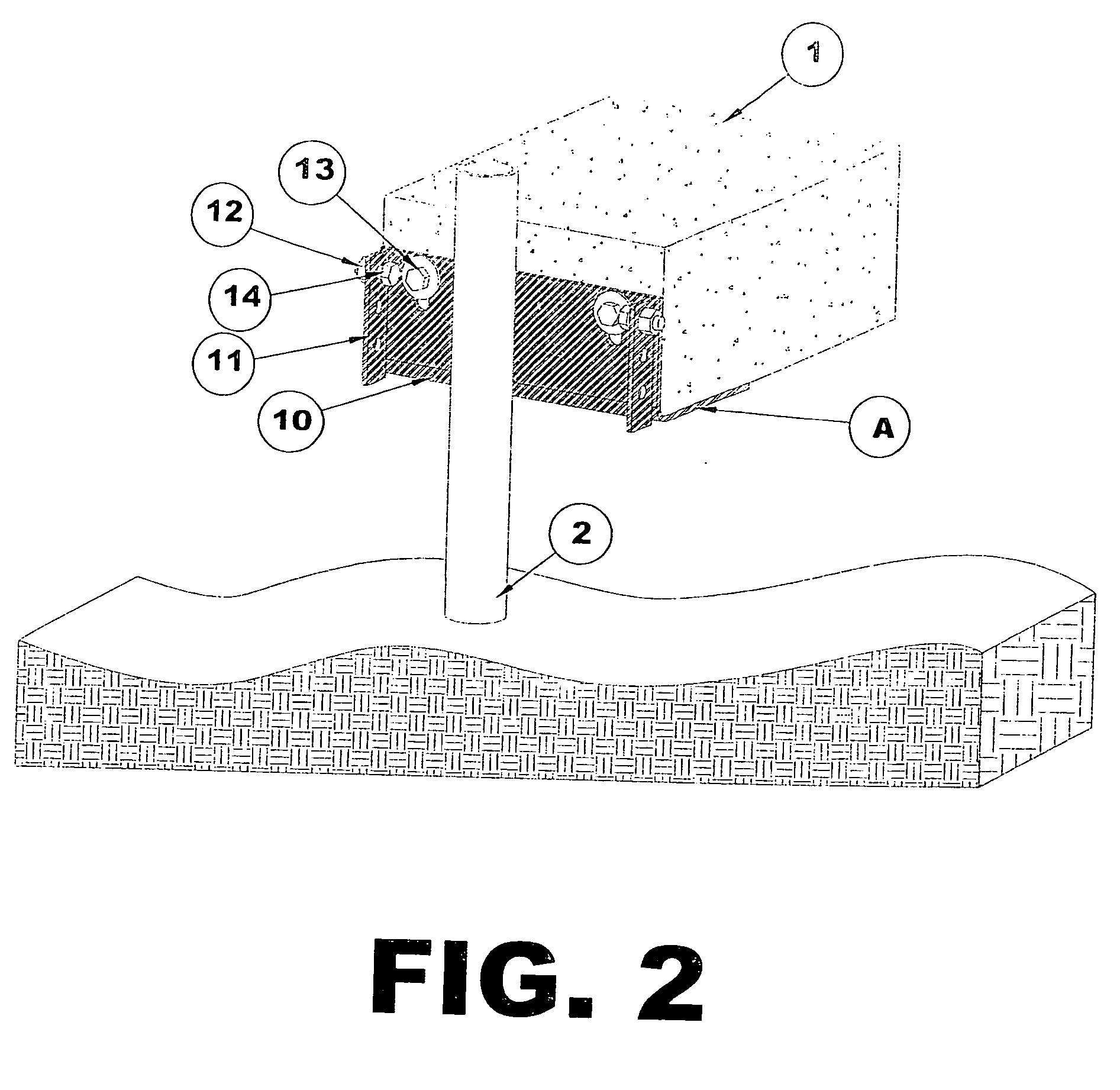

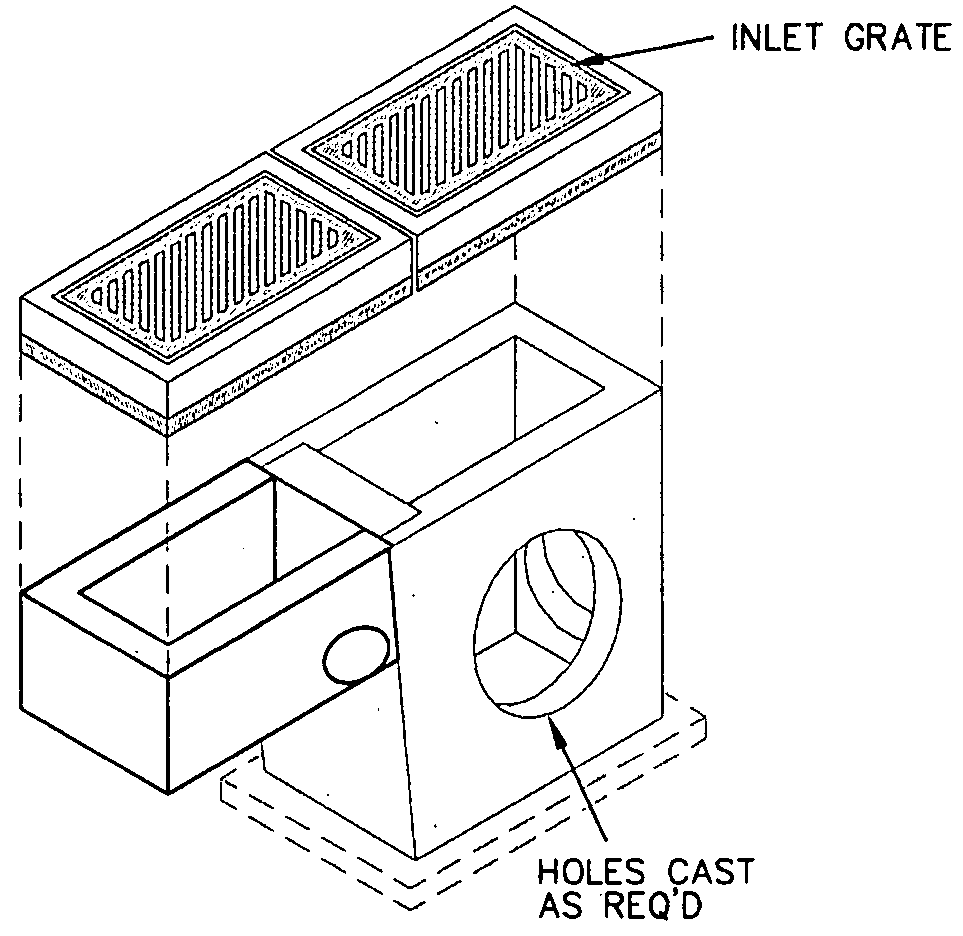

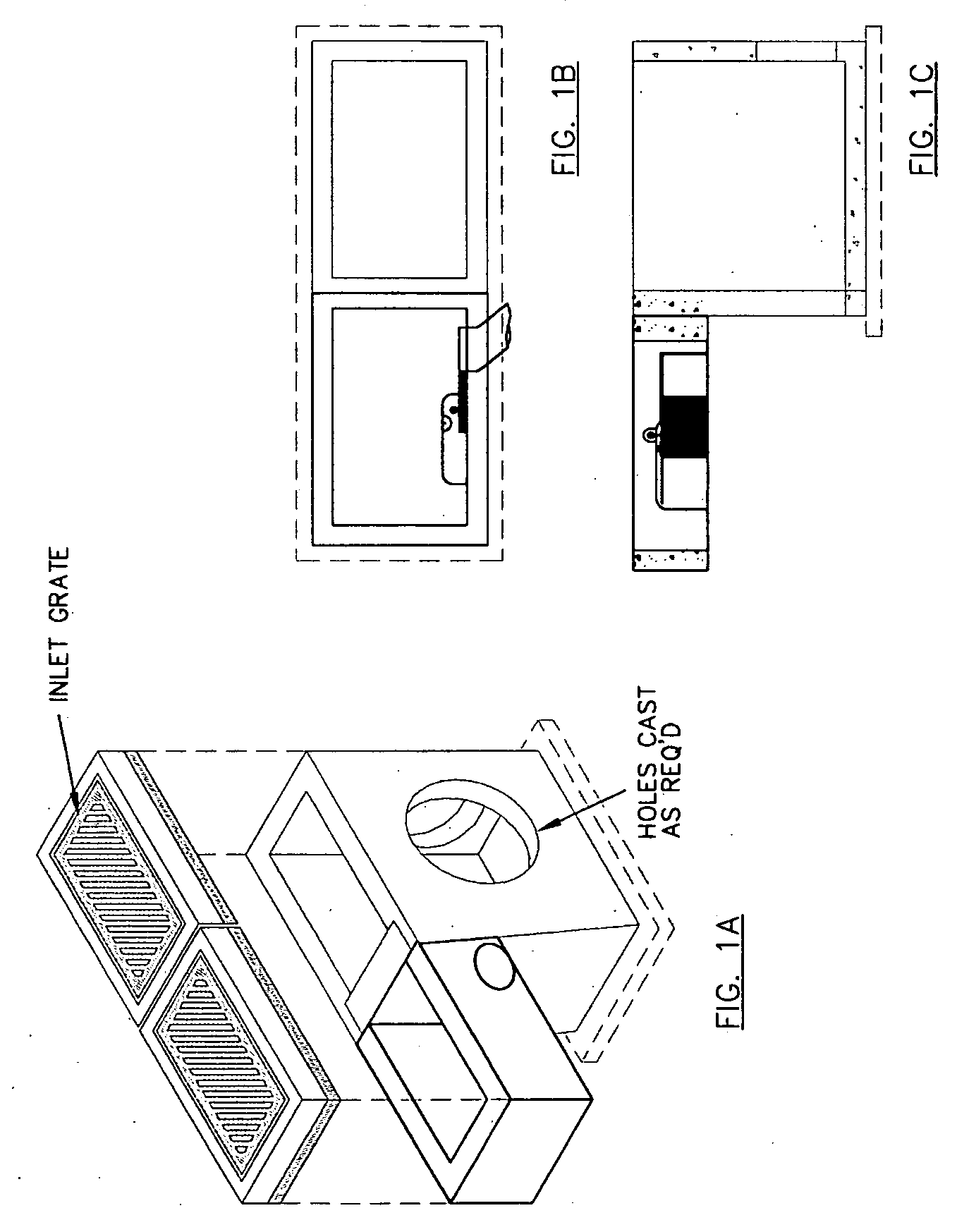

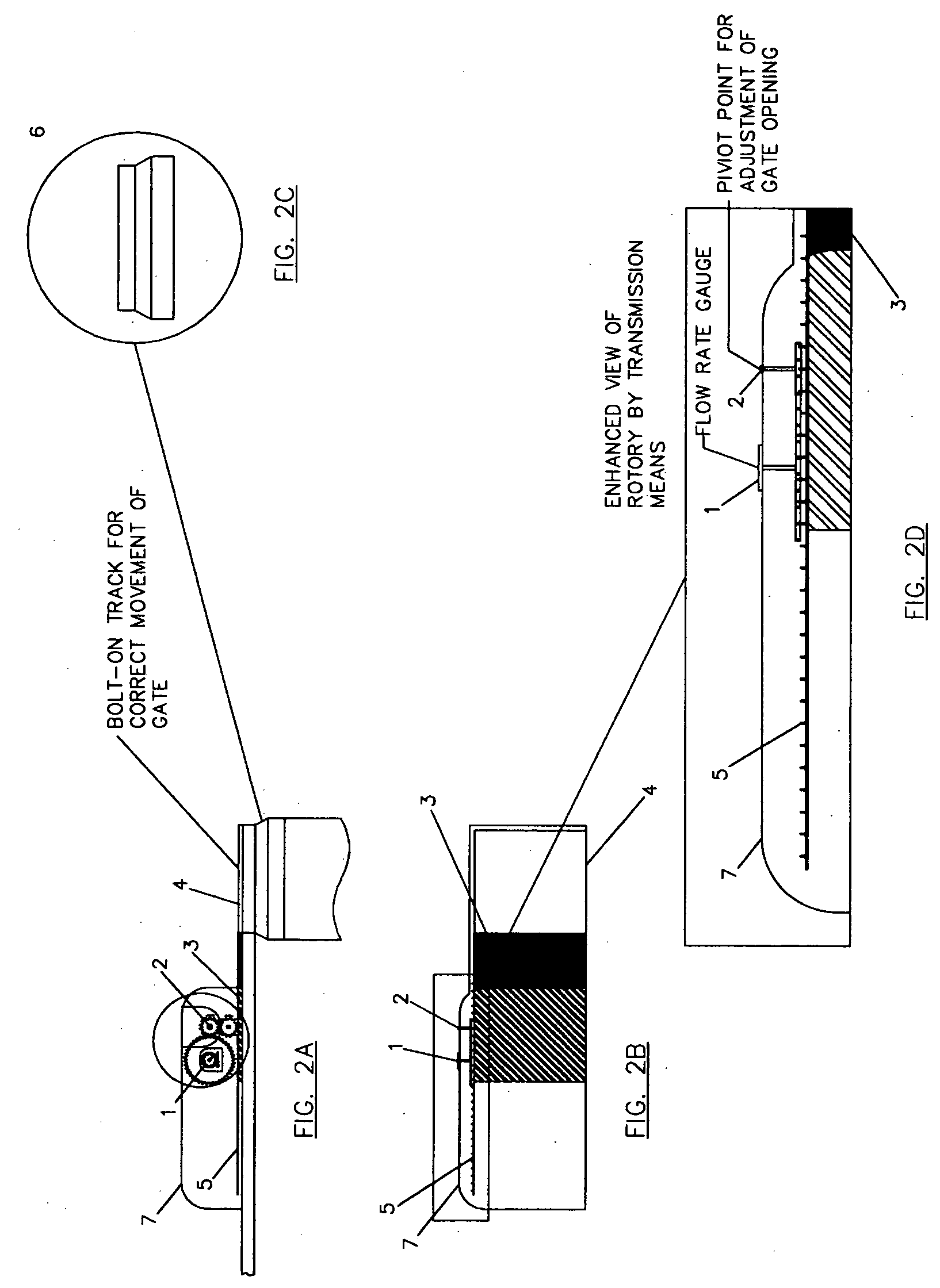

Flow rate calibrated, mechanically adjustable stormwater flow diverter

InactiveUS20090114577A1Easy and accurate installationEasy to adjustSewerage structuresSedimentation separationTraffic volumeWrench

An object of this invention is to provide an improved stormwater diversion device that offers a more precise, easy to install and accurate means for diverting stormwater flow than any of the aforementioned prior art techniques. Referring now to the drawings, a flow rate gauge (1) is displayed on top of the apparatus clearly allows the installer to easily calibrate the device's potential flow rate to fit any particular need / situation without having to change the dimension of the box itself. Quite simply, after the device is fitted to the storm sewer structure, and the structure (e.g. inlet box) is installed in the field; the installer is merely required to use a lug wrench to either accommodate more flow, by turning the adjustment nut (2) counter-clockwise resulting in the movement (opening) of the gate (3) along the track (4) or reduce the allowed flow rate, by turning clockwise resulting in the movement (closure) of the gate (3) along the track (4). While the movement of the gate adjusts the aperture (orifice) size, the gauge (1) will continually allow the installer to observe what flow rate would be achieved depending on the setting of the gate (3). A qualified engineer knowledgeable in hydrological methods would determine the selected flow rate required.

Owner:DUNCAN GREGORY S

Street lamp embedded part installing and positioning device

The invention discloses a street lamp embedded part installing and positioning device which comprises a positioning cover, a positioning body and a positioning support. A round sealing opening matched with a street lamp pole is arranged in the middle of the positioning cover, the two sides of the positioning cover are provided with handles enabling a cover body to be opened conveniently, the positioning body is provided with a bottom plate and a middle plate, the bottom plate is connected with the positioning support, vertical holes used for installing an embedded part are formed in the periphery of the middle plate, a vertical first round hole is formed in the middle of the middle plate, and the cover body is located on the positioning body. The device is simple in structure and low in manufacturing cost, the embedded part can be conveniently installed, and installation accuracy of the embedded part is guaranteed. The embedded part and a street lamp base can be prevented from being blown by wind, shone by the sun and wetted by rain, the embedded part and the street lamp base are not prone to rust, and repair and maintenance are convenient.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Buckle

InactiveCN1377617AEasy and accurate installationPrevent disengagementBucklesEngineeringMechanical engineering

A belt buckle, comprising a containing part (1) and an inserting part (2), the containing part has an insertion opening (10) at one end of a housing (3), and the inserting part has a (3) The buckle is formed with an installation part (5) on at least one of the containing part (1) and the inserting part (2). The mounting part (5) can be equipped with a locking device (50) or a closing device (52) for locking or closing the joint between the containing part (1) and the inserting part (2). A mounting column (15,31) etc. of a through hole (16,32). When the insertion part (4) is inserted into the housing (3), the through holes (16, 32) overlap each other, and a locking rod can be inserted into the through hole (16, 32) to be locked, so that the containing part can be locked accurately and conveniently (1) Engagement with insert (2).

Owner:YKK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com