Dry-hanging structure of stone curtain wall

A stone curtain wall and dry-hanging technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of three-dimensional adjustment of the plate, high cost and installation cost, etc., and achieve the effect of simple structure, accurate and convenient installation, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

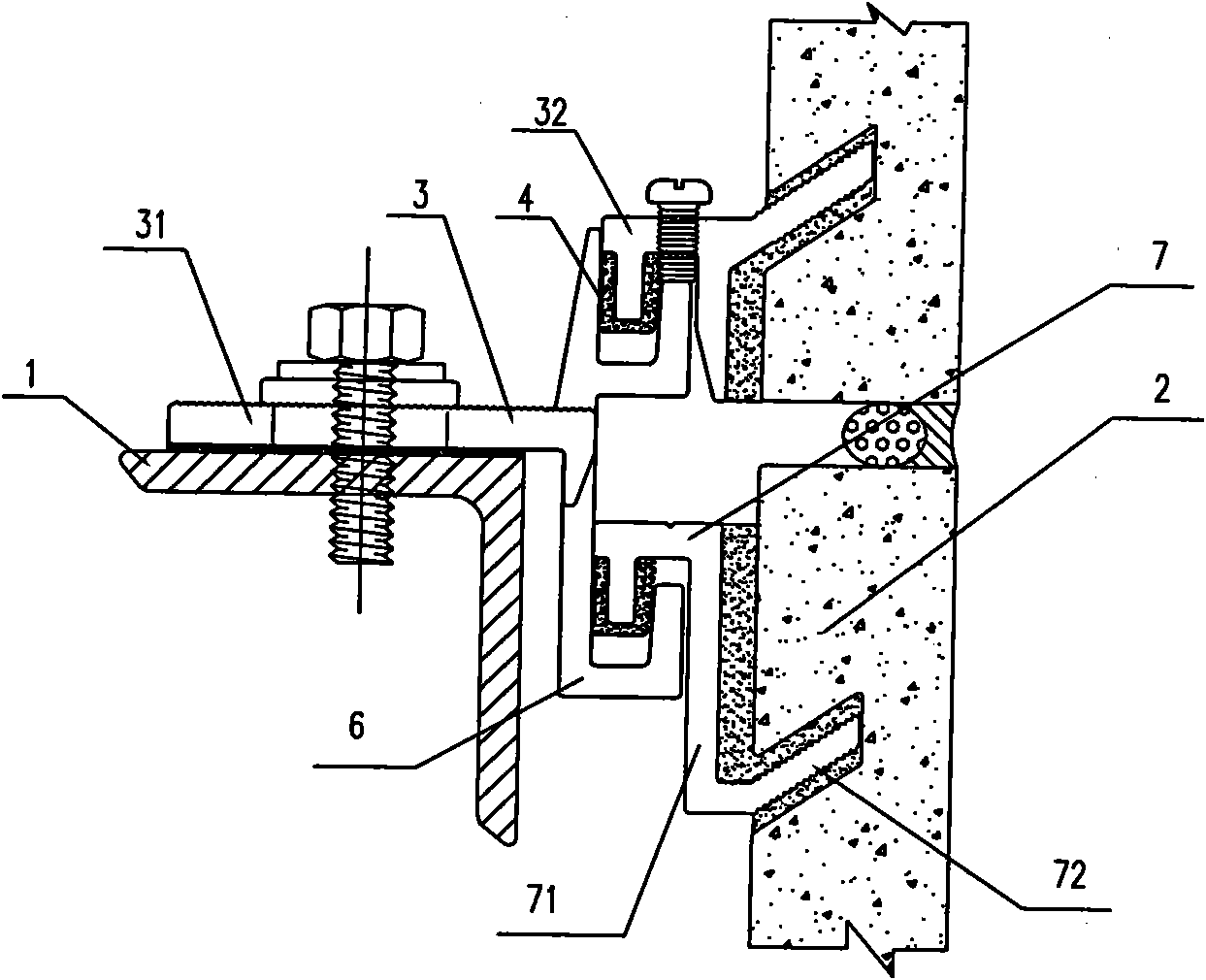

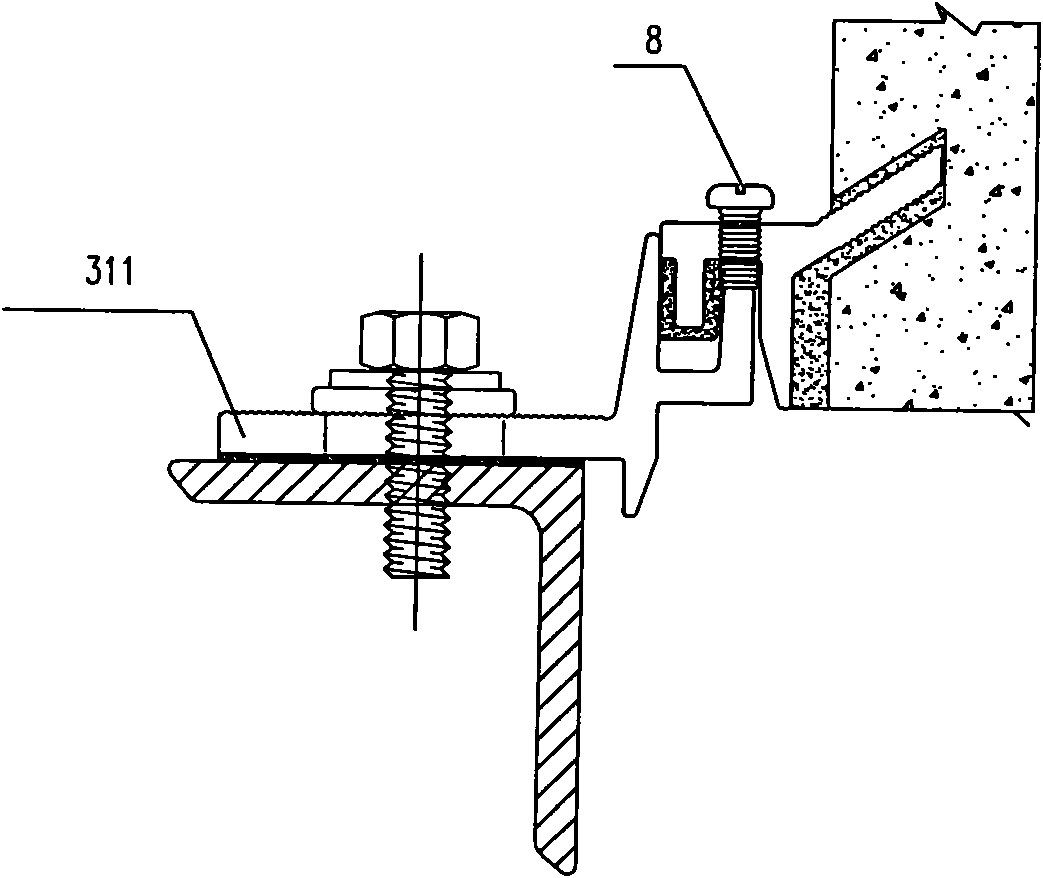

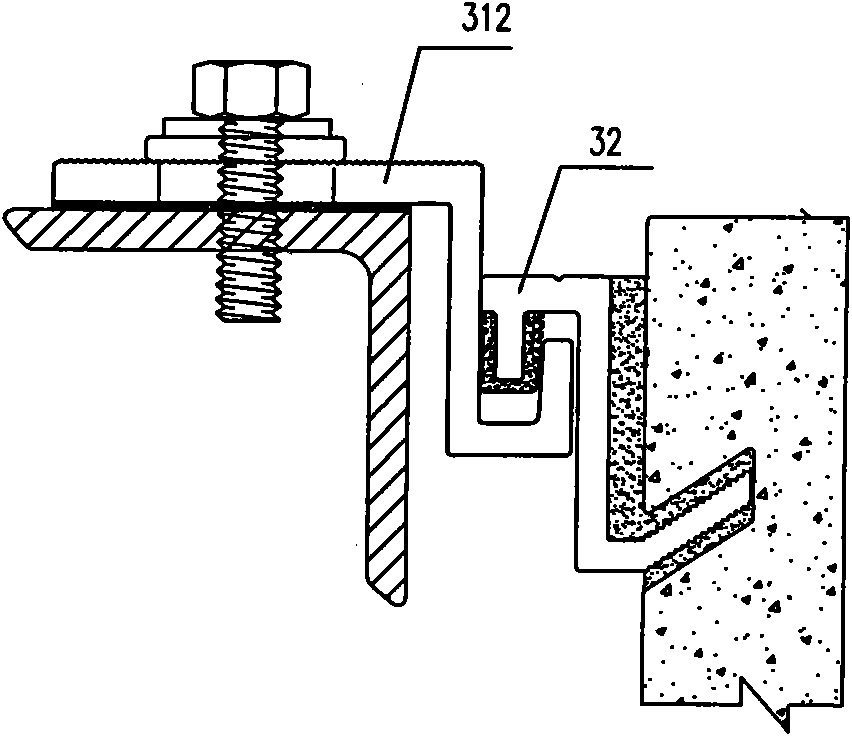

[0029] Such as Figure 1 to Figure 4 As shown, a dry-hanging structure of a stone curtain wall of the present invention comprises a beam 1, a stone plate 2 and a dry-hanging part 3 fixed between the beam 1 and the stone plate 2, and the dry-hanging part 3 consists of a hanging seat fixed on the crossbeam 1 31 and the pendant 32 fixed on the stone plate 2 are connected. The hanger 31 is composed of a split upper hanger 311 and a lower hanger 312. The two hangers are fixed side by side on the same beam, and the lower hanger 312 is located on the upper hanger 311. The outside of the upper hanging seat 311 and the side of the lower hanging seat 312 extend outward to form a hook 6 with a groove in the upward direction of the hook mouth. There is a flexible material 4, and the hanging seat 31 is provided with an elongated bolt hole 5 for adjusting the front and rear deviation of the stone plate. In the embedded groove of hanger hook 6 and hook and cooperate with it. In this embodi...

Embodiment 2

[0031] Such as Figure 5 , Figure 6 and Figure 7 As shown, the difference between this embodiment and the above-mentioned embodiment is that the supporting part connected to the hanging part 7 is a flat plate 9 with a bolt hole on it, and the bolt passes through the hole to fix the hanging part and the stone plate. .

Embodiment 3

[0033] Such as Figure 8 , Figure 9 and Figure 10 As shown, the difference between this embodiment and the above-mentioned two embodiments is that the pendant 32 includes two sets of connection fittings composed of hooks 10 and grooves 11 respectively. The opening of the groove of the connecting fitting is upward, and is connected with the lower end of the stone plate body; the groove opening of the connection fitting located below is downward, and the groove is connected with the upper end of another stone plate body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com